Electric arc spraying method

A technology of arc spraying and sandblasting, which is applied in the direction of coating, fusion spraying, metal material coating process, etc. It can solve the problems that metal wires are easy to be stained with oil, dust, uneven arc spraying layer, and reduce the effect of arc spraying, etc. , to achieve the effect of eliminating residual thermal stress, uniform and compact coating, and smooth outer surface of workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

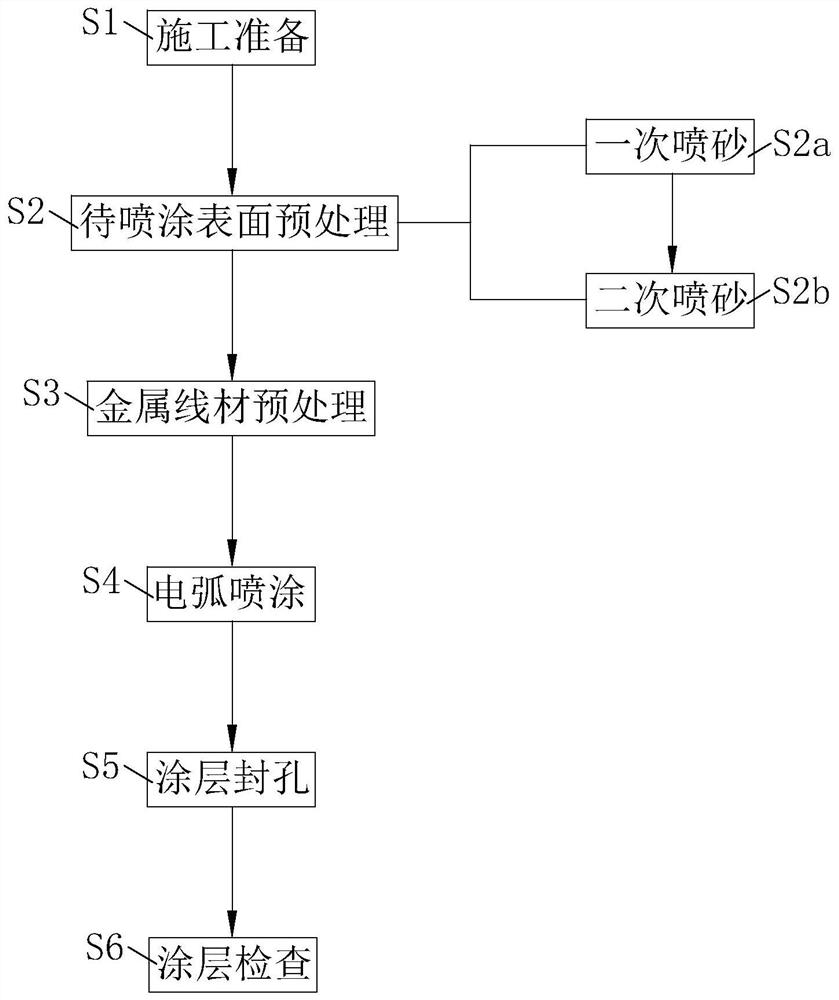

[0041] refer to figure 1 , is a kind of electric arc spraying method disclosed by the present invention, comprises the following steps:

[0042] S1: Construction preparation, remove dust and impurities on the surface of the workpiece, and conduct all-round quality inspection on the parts where the workpiece is sprayed;

[0043] S2: Pretreatment of the surface to be sprayed, using pneumatically controlled sandblasting equipment to perform sandblasting on the surface of the workpiece, so that the roughness of the workpiece reaches 90-120um;

[0044] S3: pretreatment of metal wire rods, cleaning the metal wire rods with a rust remover, straightening the metal wire rods through a straightening machine after cleaning and drying, and polishing the metal wire rods to make the surface smooth after straightening;

[0045] S4: Arc spraying, connect the air compressor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com