Patents

Literature

8394 results about "Corrosion prevention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion prevention is used in industries to maintain the safety, reliability and effectiveness of materials. It also helps in reducing the expensive replacement processes required when corrosion occurs.

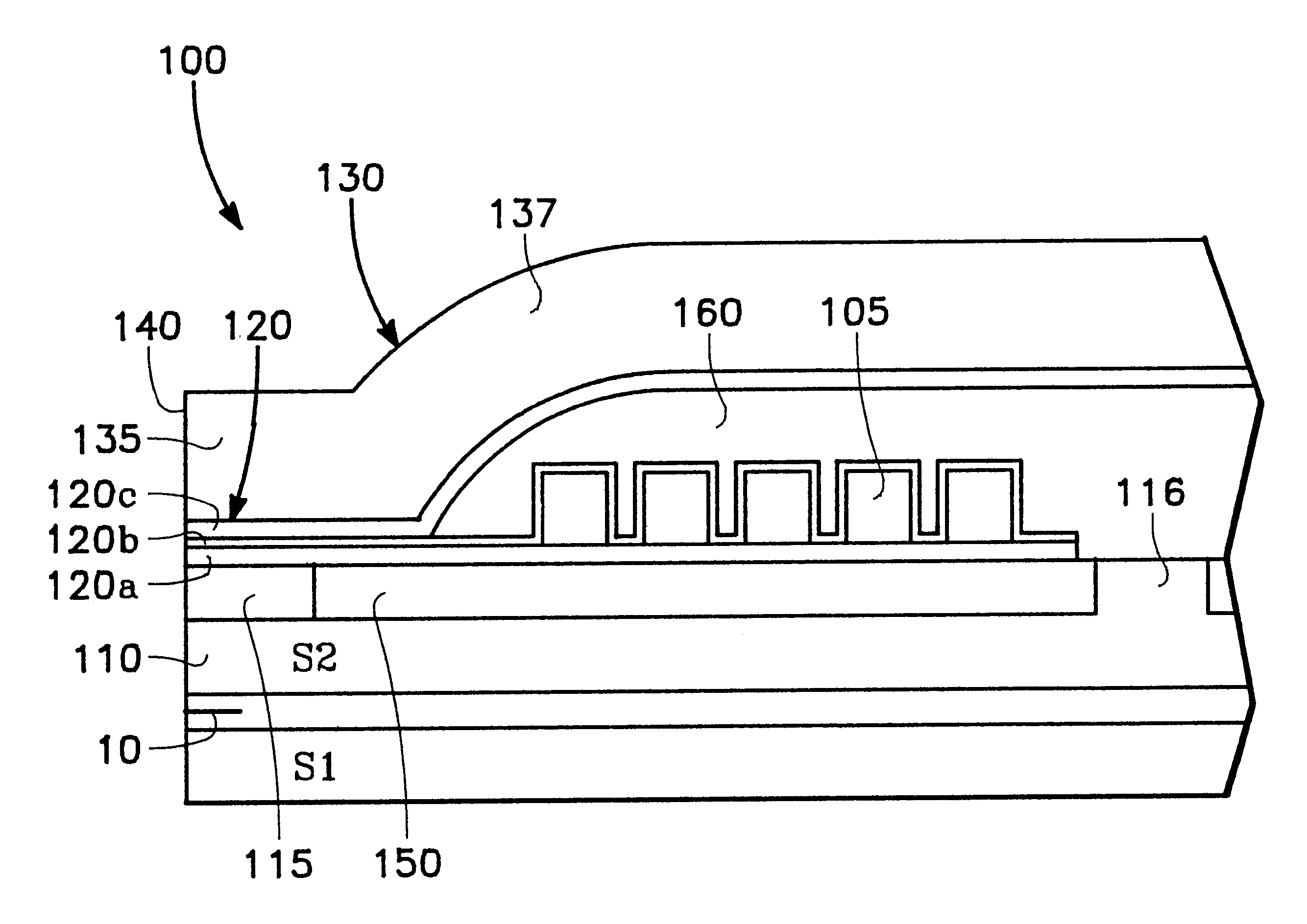

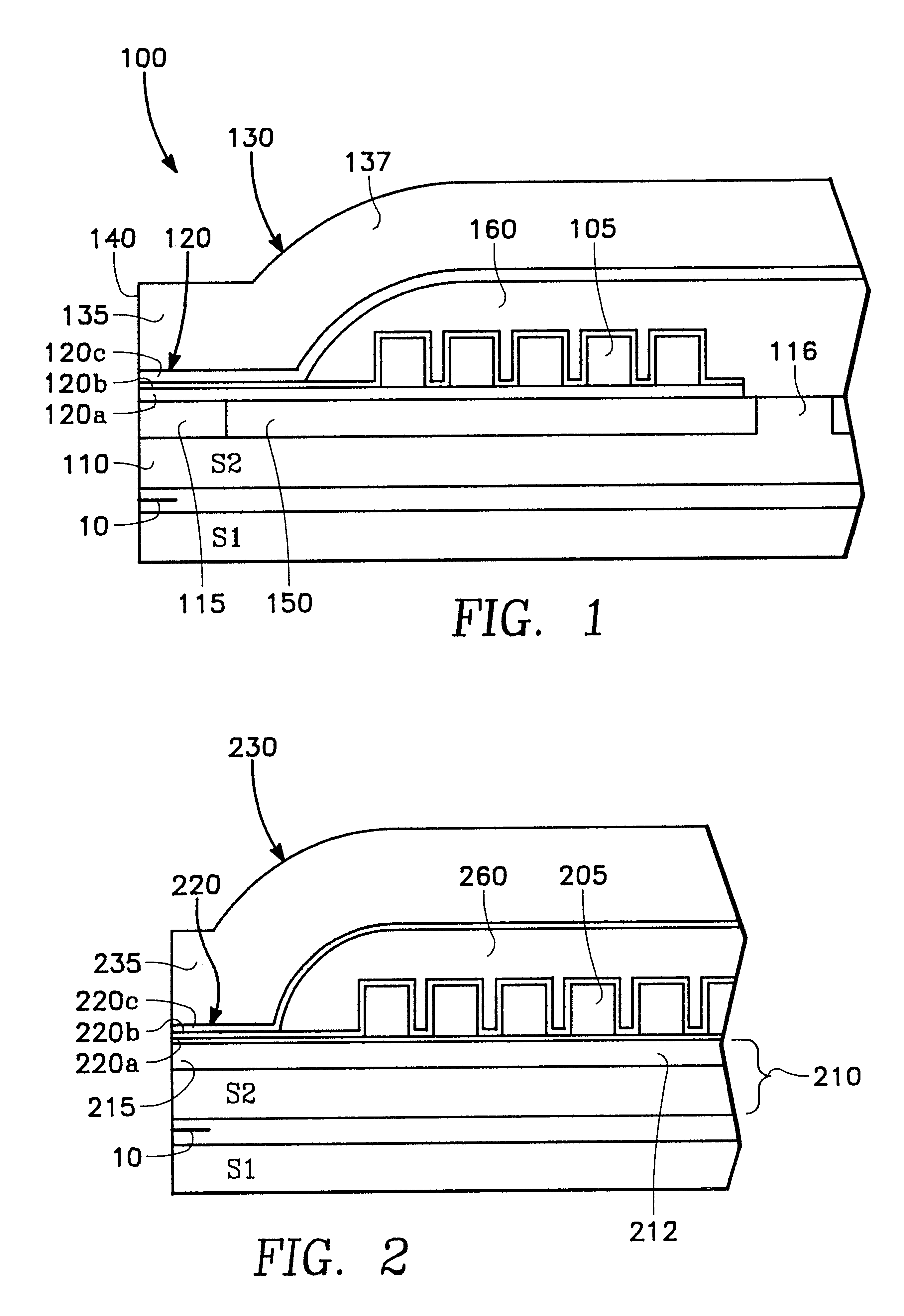

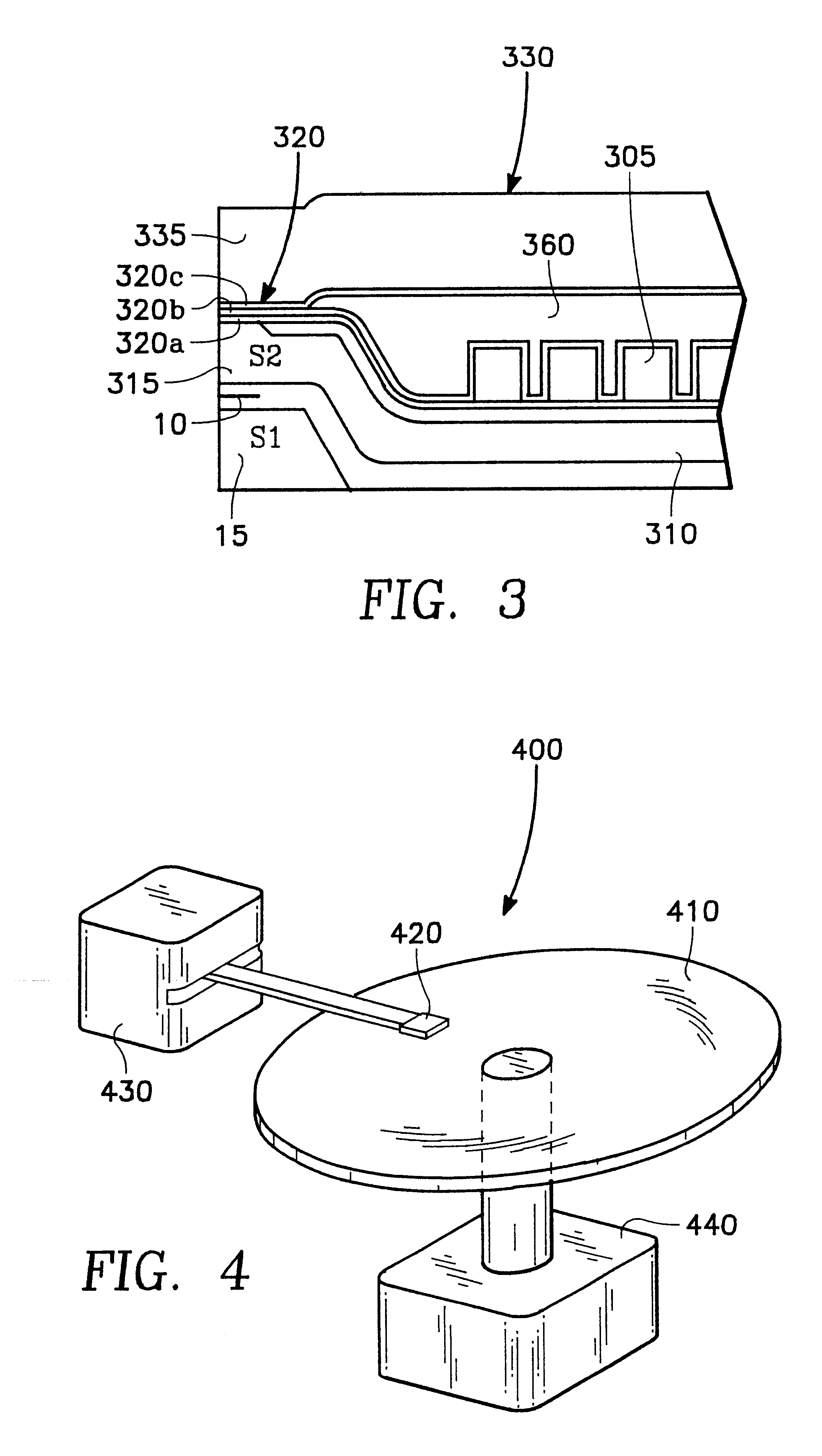

Thin film writer with multiplayer write gap

InactiveUS6724569B1Easy to controlControl performanceConstruction of head windingsManufacture head surfaceElectrical conductorLower pole

Embodiments in accordance with the thin film write head of the present invention have a lower pole structure, an upper pole structure, and a multilayer write gap extending from an air bearing surface between the upper and lower pole structures. In preferred embodiments, the write gap comprises at least two of: (a) a first layer covering a lower pole tip portion of the lower pole structure, (b) a second layer covering turns of a semiconductor winding, or (c) a third layer covering a winding insulation stack. In more preferred embodiments, the write gap is formed of the first, the second, and the third write gap layers. An advantage of a write head with a multilayer write gap is that it allows better control of write gap thickness. As such, loss of write gap thickness can be compensated for by deposition of the second write gap layers, or by deposition of the third write gap layer. Some embodiments have one or more additional advantages in providing increased corrosion prevention, improving the integrity of conductor insulation, and / or improving the top pole magnetic material characteristics.

Owner:WESTERN DIGITAL TECH INC

Corrosion protective cleaning agent for tin-plated steel

InactiveUS6060122ASignificant positive effectGood effectOther chemical processesPretreated surfacesTitaniumNonionic surfactant

PCT No. PCT / EP96 / 01137 Sec. 371 Date Sep. 24, 1997 Sec. 102(e) Date Sep. 24, 1997 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 30558 PCT Pub. Date Oct. 3, 1996The invention concerns an aqueous corrosion-protective cleaning solution for tin-plated steel, in particular for tin-plated steel cans, the solution containing complex fluorides of the elements boron, titanium, zirconium, and hafnium; non-ionic surfactants; and corrosion inhibitors and having a pH within the range from 3 to 6. The invention also concerns an aqueous concentrate for preparing the solution by dilution with water and a method of cleaning tin-plated cans using the solution.

Owner:HENKEL KGAA

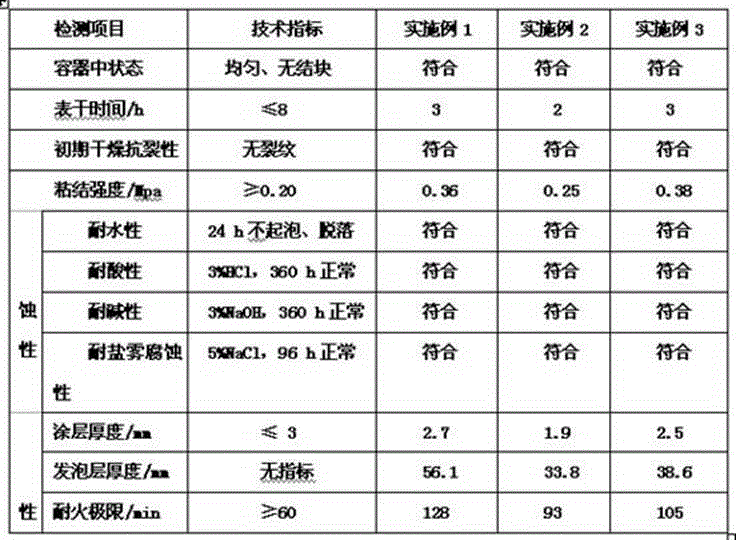

Aqueous fire-proof corrosion-proof paint for steel structure and preparation method thereof

ActiveCN104130638ATaking into account fire resistanceCompatible with anti-corrosionFireproof paintsAnti-corrosive paintsPtru catalystFoaming agent

The invention discloses aqueous fire-proof corrosion-proof paint for a steel structure and a preparation method thereof, and belongs to the technical field of paint. The aqueous fire-proof corrosion-proof paint comprises, by mass, 20-45% of a composite emulsion, 12-25% of a charring catalyst, 6-12% of a foaming agent, 8-17% of a charring agent, 5-10% of a fire retardant, 1-5% of layered double hydroxide, 8-18% of an corrosion-proof filling material, 4-12% of a strengthening filling material, 1-5% of modified nano-powder, 0.5-6% of an assistant and 10-30% of water. Through use of the composite modified emulsion as a base material, coating flame resistance, corrosion resistance and decorativeness are obtained and coating defects caused by a single emulsion as a base material are overcome. Through use of a small amount of the nano-powder, the coating is compact because of filling effects of the nano-powder, the coating corrosion caused by O2, H2O and Cl <-> is avoided, good fire-proof and corrosion-proof effects are obtained under the condition of a small addition amount and a cost is reduced. The aqueous fire-proof corrosion-proof paint has the characteristics of green environmental protection and simple preparation processes.

Owner:山东七维新材料有限公司

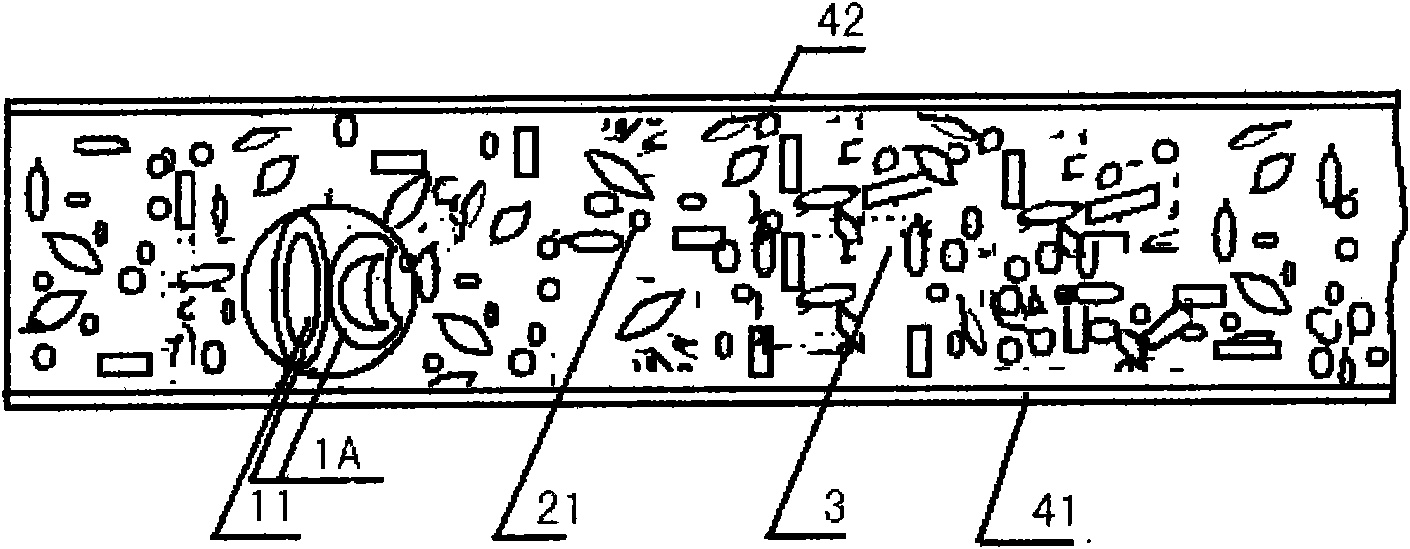

Environment-friendly light heat-insulating material and manufacturing method thereof

The invention relates to an environment-friendly light heat-insulating material for fireproof doors and buildings, and a manufacturing method thereof. The manufacturing method is characterized by comprising the following steps of: pretreating plant hollow core bodies and / or flexible porous fillers by using a water glass adhesive; mixing with inorganic fire-resistant hollow particles; and performing mould pressing, shaping and drying to obtain the environment-friendly light heat-insulating material. The hollow core bodies and the flexible porous fillers are arranged multidirectionally; one layer of water glass adhesive is arranged at least on the surfaces of the hollow core bodies and the flexible porous fillers; and discontinuous holes are reserved between the hollow core bodies and / or the flexible porous fillers and the inorganic fire-resistant hollow particles. Preferably, the hollow core bodies are rice husks and straw sections; and the flexible porous fillers are foam and fibers. Renewable plant resources and recovered foam and fiber waste are adopted, so the environment-friendly light heat-insulating material is energy-saving and environment-friendly; and a large number of sealed holes are formed among the material particles through the penetration and coating of the modified water glass adhesive, and a heat-insulating hydrophobic corrosion-resistant multi-effect protective layer is provided, so the environment-friendly light heat-insulating material has good fireproof, heat-insulating and heat-preserving effects, high weather resistance, combined rigidity and toughness, low density and low cost.

Owner:重庆恒宏致嘉全过程建设项目管理有限公司

Valve body surface protection treatment process

InactiveCN108103483AReduce rustReduce corrosionLiquid/solution decomposition chemical coatingImpurityHeat treated

The invention provides a surface protection process used for long-time corrosion prevention and rust prevention. The process comprises the following process flow: sandblasting: performing surface blasting of brown steel shot on a valve body after heat treatment; pretreatment: cleaning to remove impurities such as oil stains, oxides, or water scales on the surface of the valve body by utilizing analkaline cleaning liquid; cleaning: rinsing chemical substances remaining on the surface of the valve body with clean water; plating solution preparation: preparing a plating solution according to a ratio of 5% to 14% of phosphorus content; preheating: putting the valve body in hot water to be preheated so that the temperature of a workpiece is close to the temperature of the plating solution; plating: putting the preheated workpiece into the plating solution for plating; treatment after plating: after the plating is completed, cleaning, air drying and storing the workpiece sequentially withinone hour. The surface protection process provided by the invention can delay the premature rust and corrosion of the valve body in the use process, and prolong the service life of the valve body to 20 to 30 hours.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

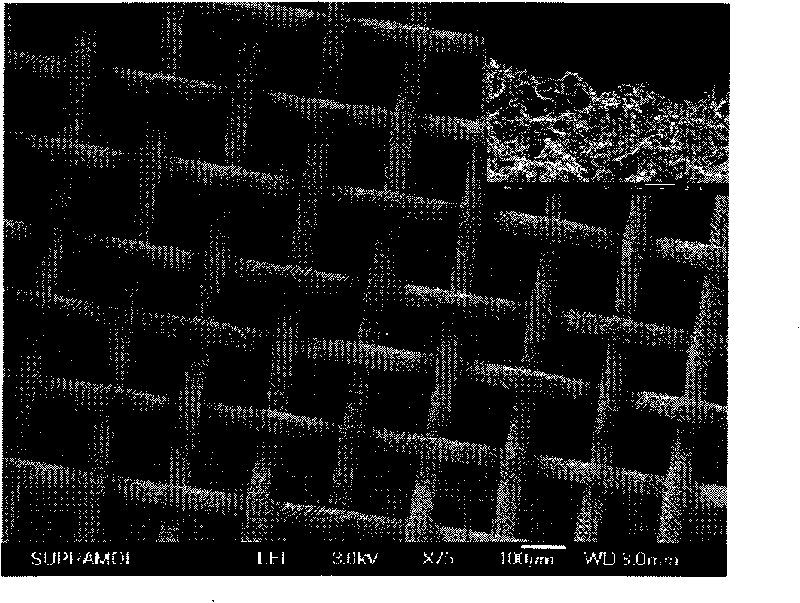

Method for preparing metal mesh for oil-water separation

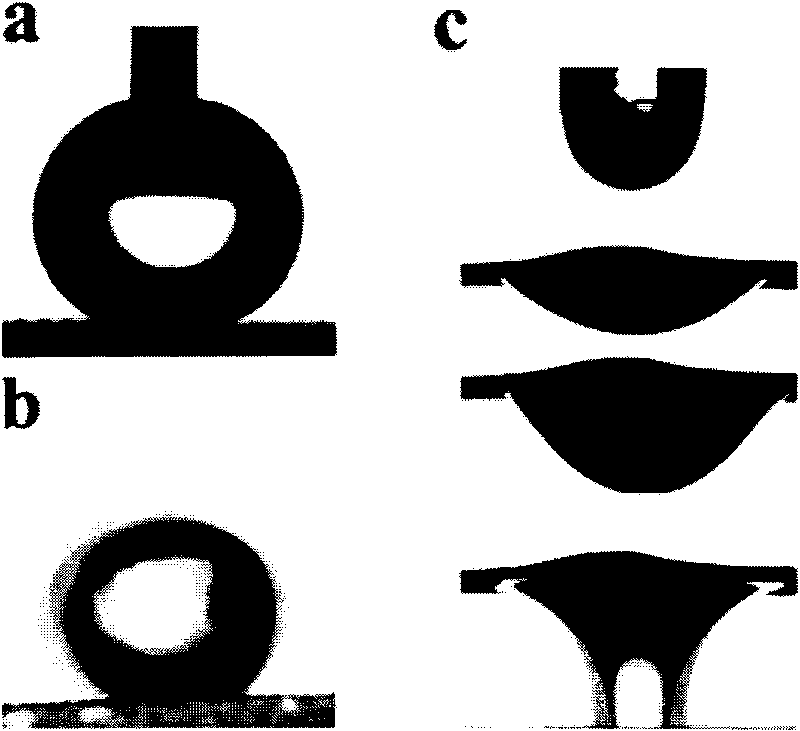

InactiveCN101708384AAchieve the purpose of separationAcid resistantFiltration separationLiquid separationChemical industryNanoscopic scale

The invention belongs to the technical field of chemistry and chemical industry and functional materials, and relates to a method for preparing a metal mesh which has special wetting properties and is used for oil-water separation. The method adopts simple wet-method chemical etching technology, nano-scale microscopic bulges are prepared on the surface of a metal mesh with micron-grade pore diameters, and then a compound which does not contain fluorine and has low surface energy is modified on the surfaces of the microscopic bulges. For the surface of the prepared material, a contact angle of a water drop is more than 150 degrees, and a contact angle of oil is close to 0 degree. Due to the specific wetting properties, the material can allow the oil to pass through the metal mesh smoothly, but the water cannot permeate through the metal mesh completely, so that the property of effectively separating oil-water mixtures is realized. Particularly, the specific wetting properties of the surface of the material can keep stable in acid solution, alkali solution and salt solution, and thus the functional metal mesh can be excellently applied in aspects of metal corrosion prevention and the like. A mesh membrane does not contain the fluorine, and has the advantages of simple preparation method, high permeability of pore space and good oil-water separation effect, and corrosion resistance.

Owner:JILIN UNIV

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

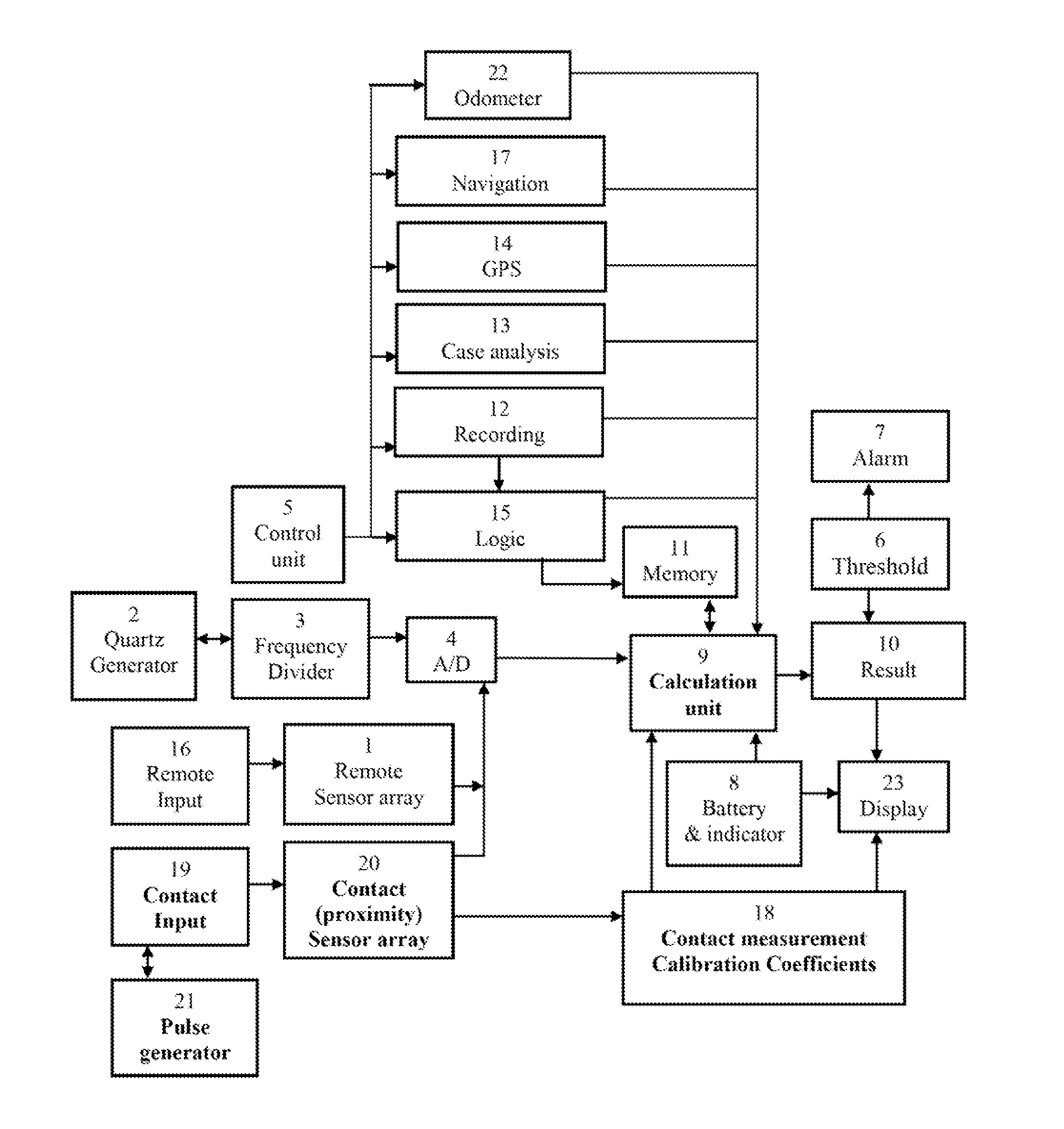

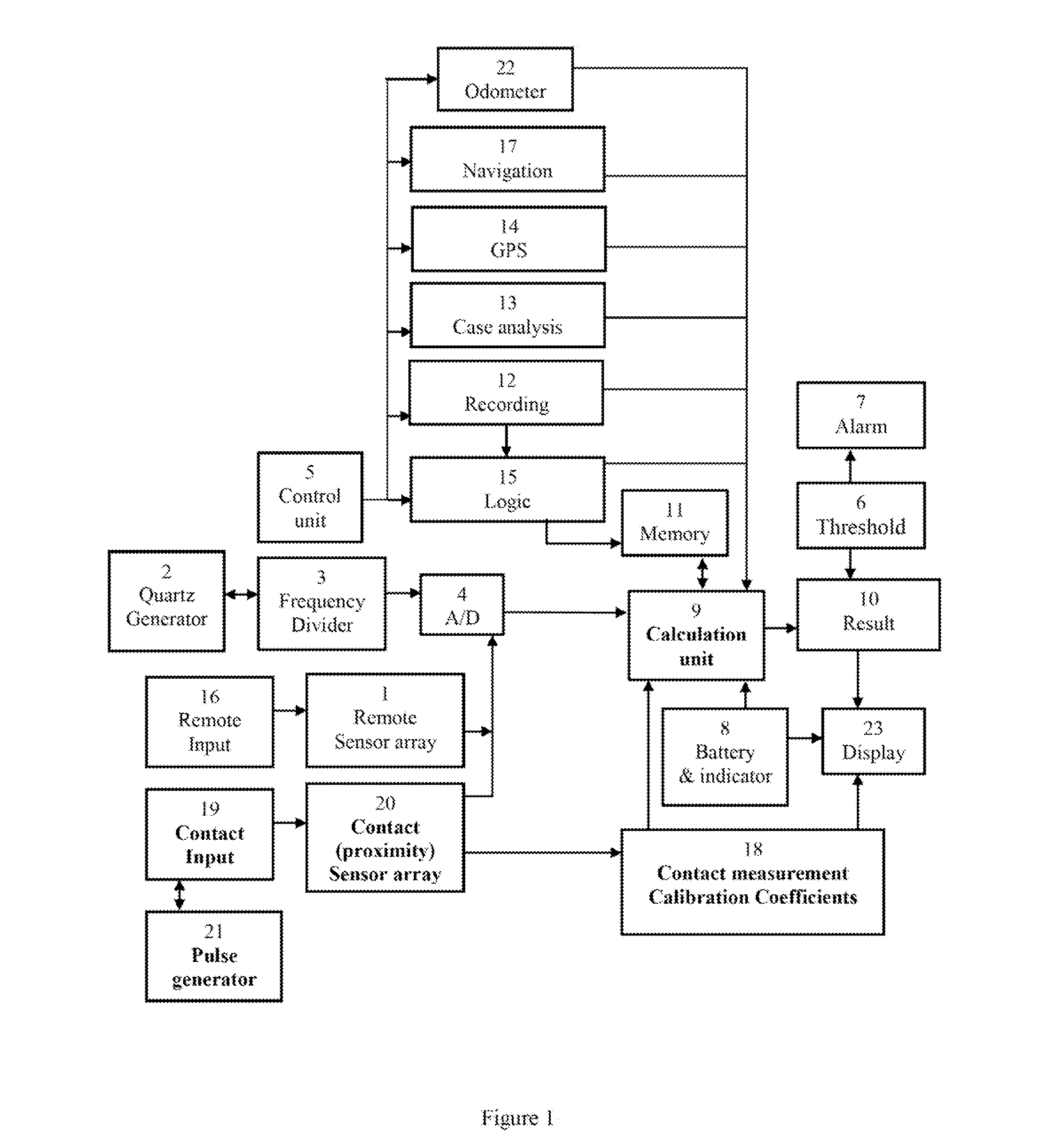

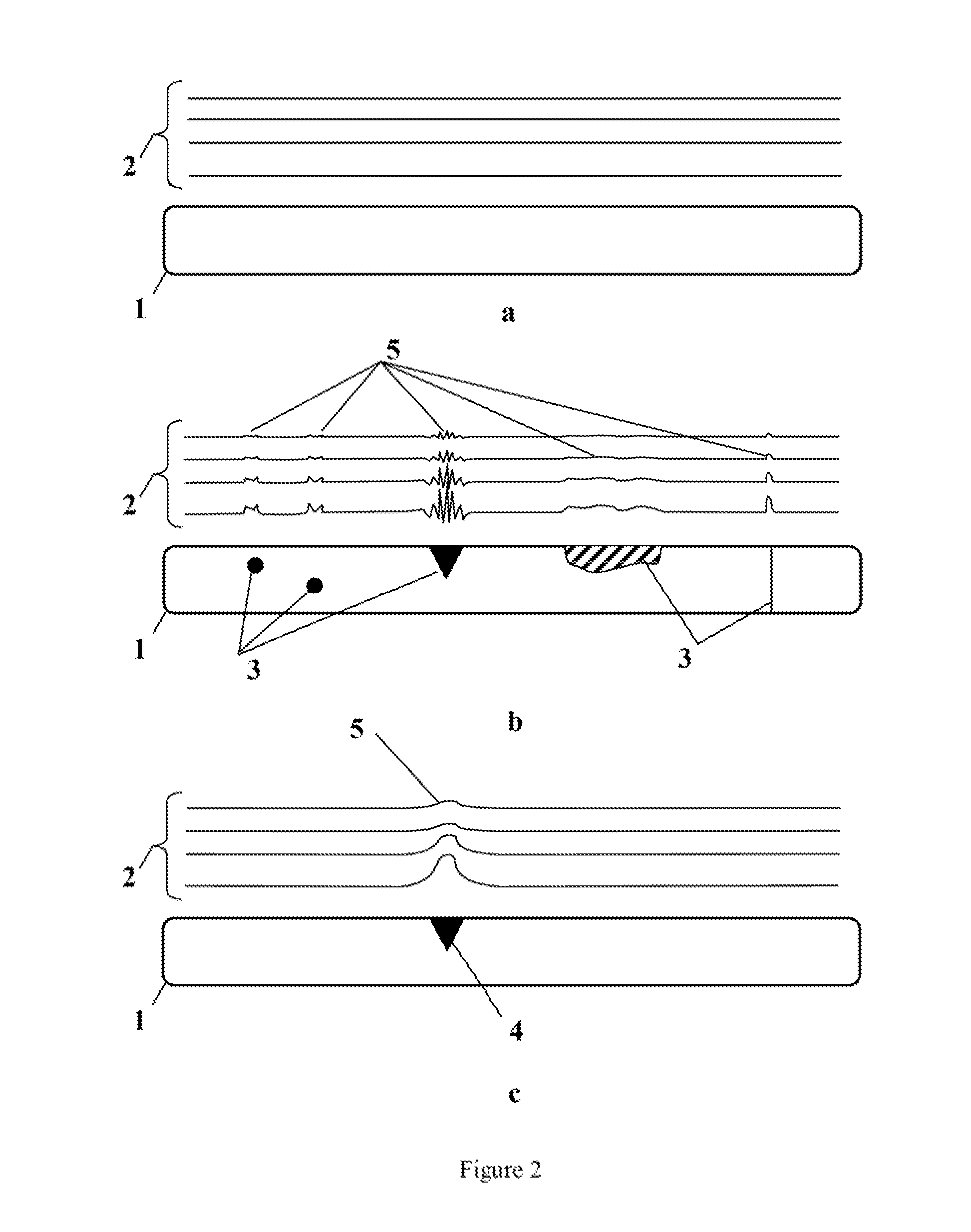

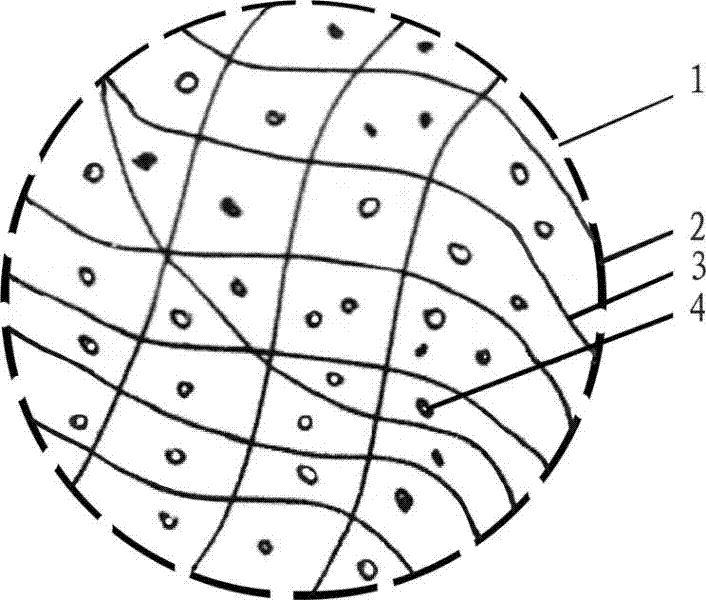

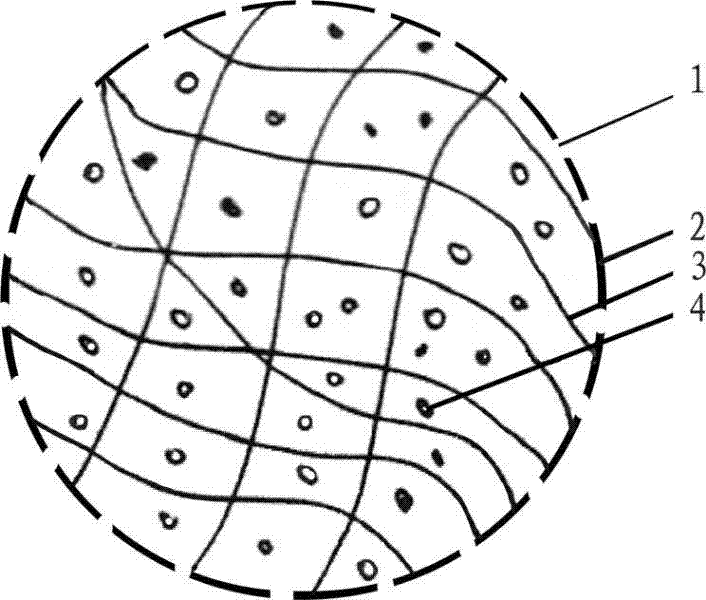

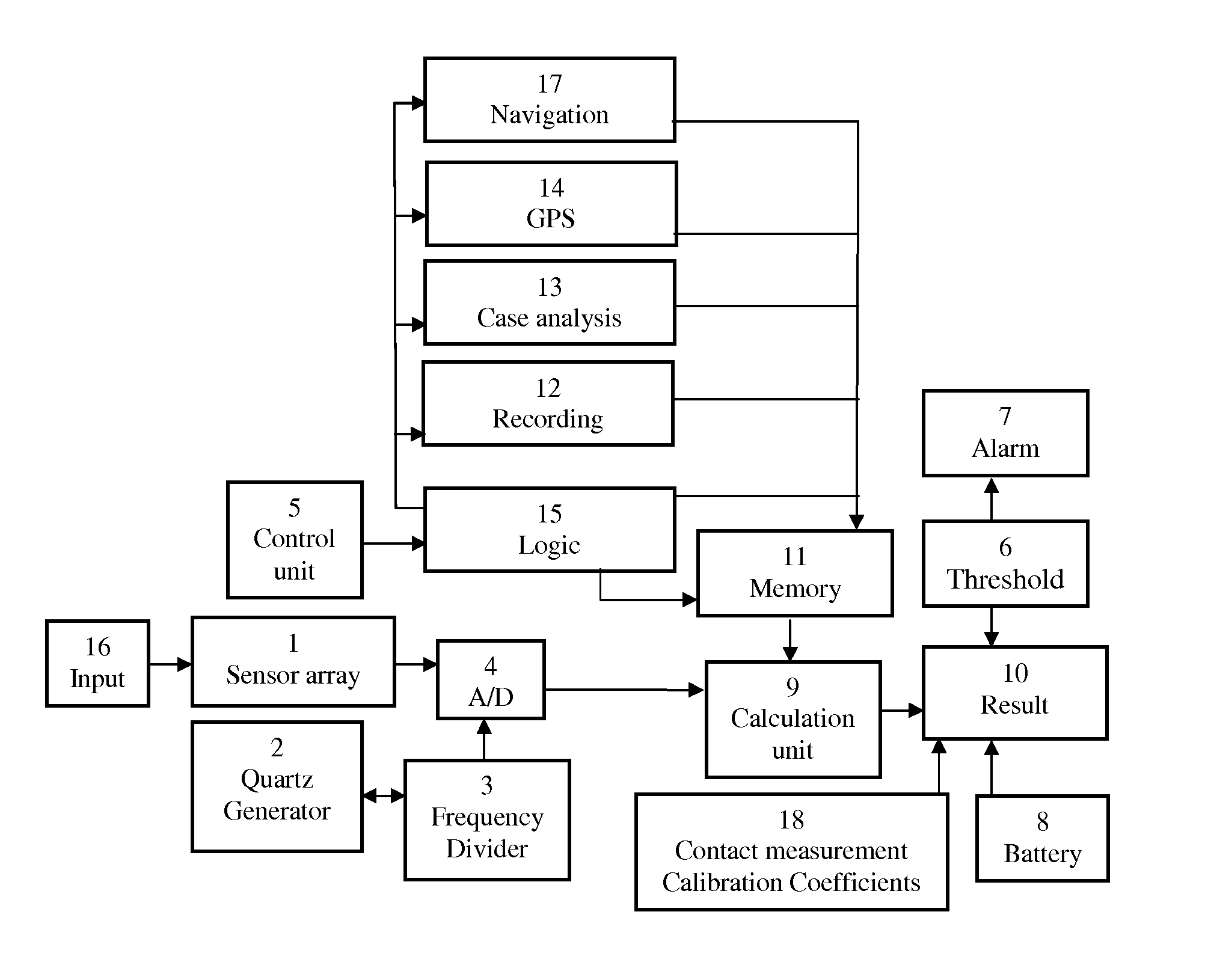

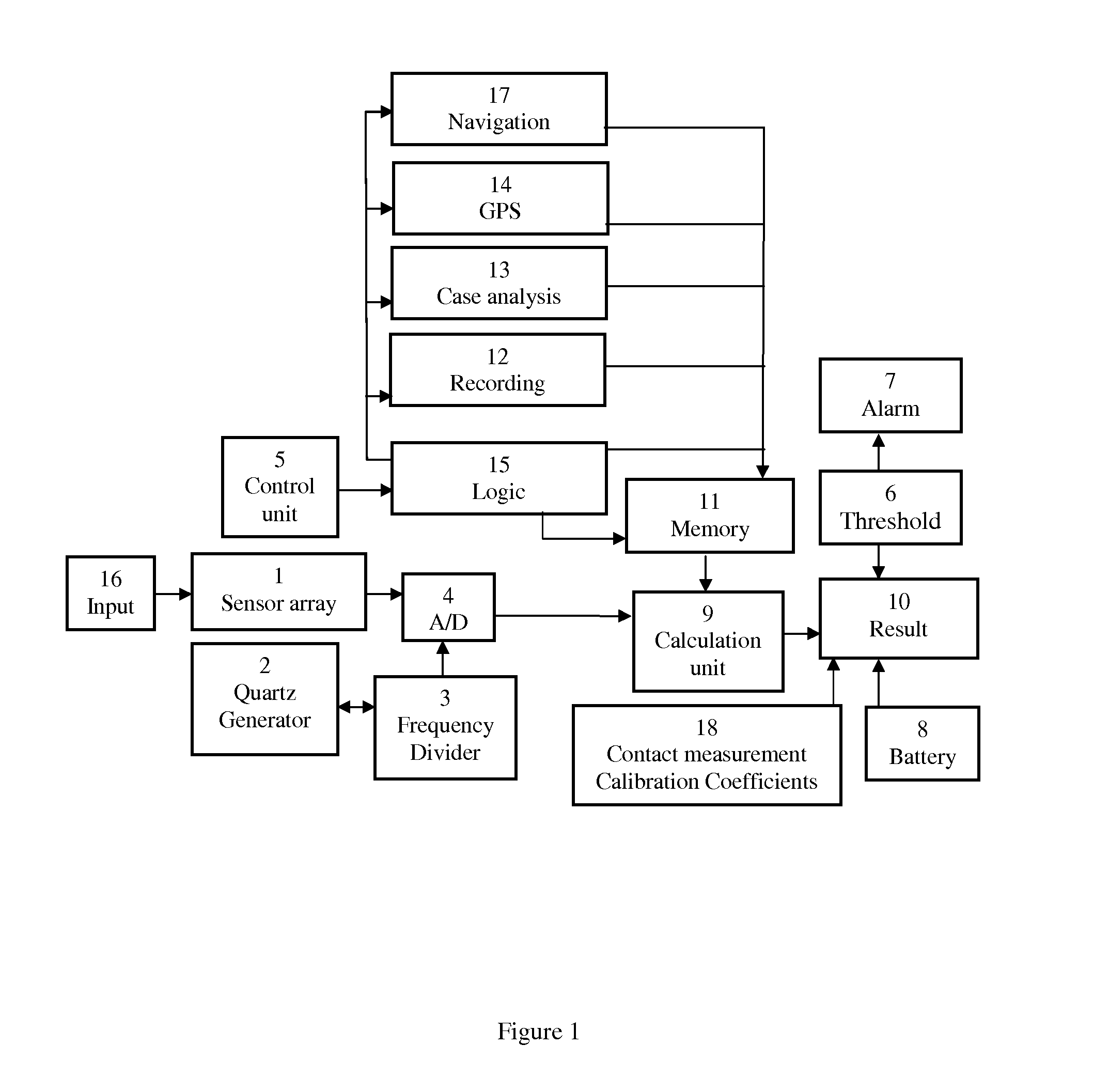

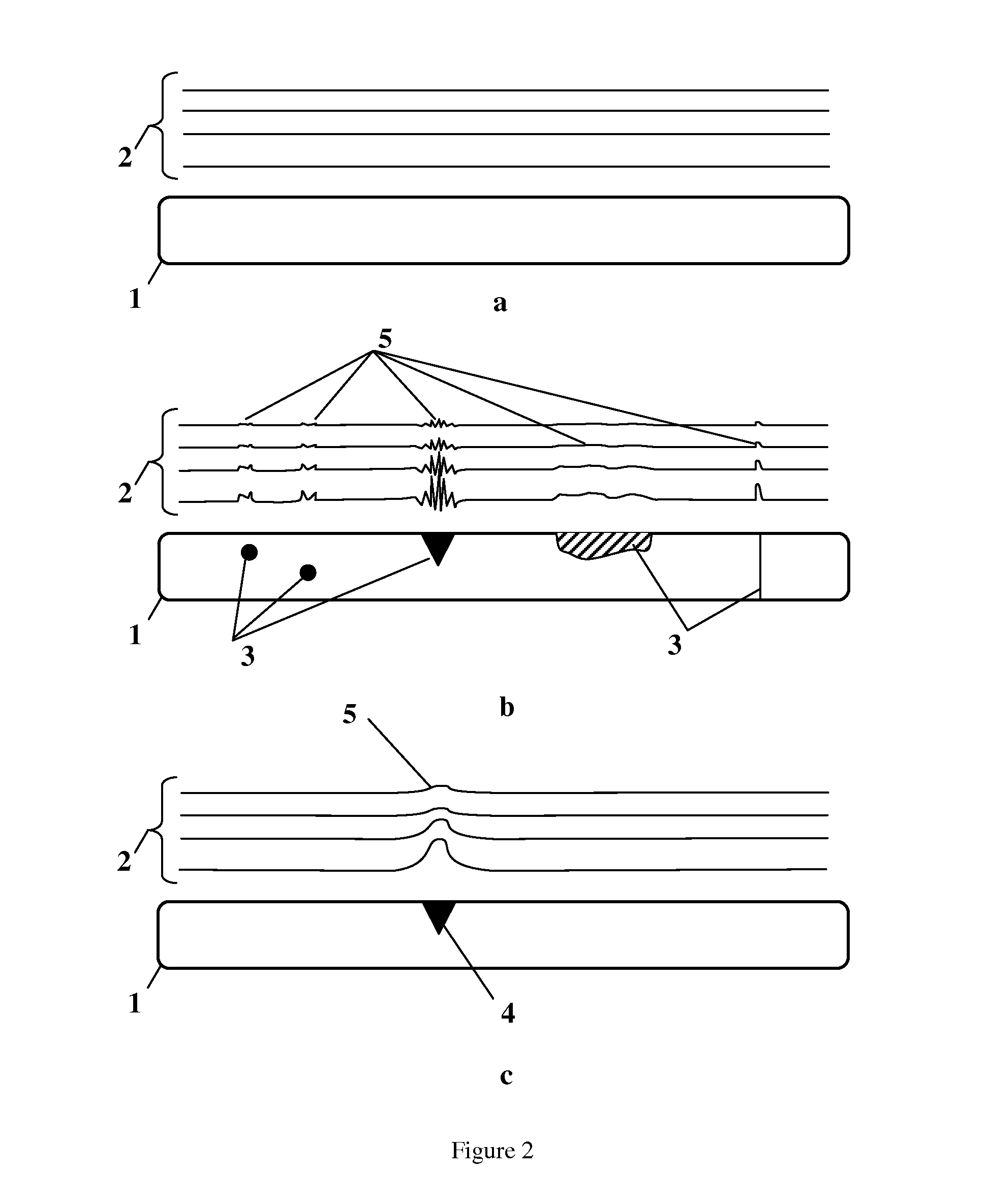

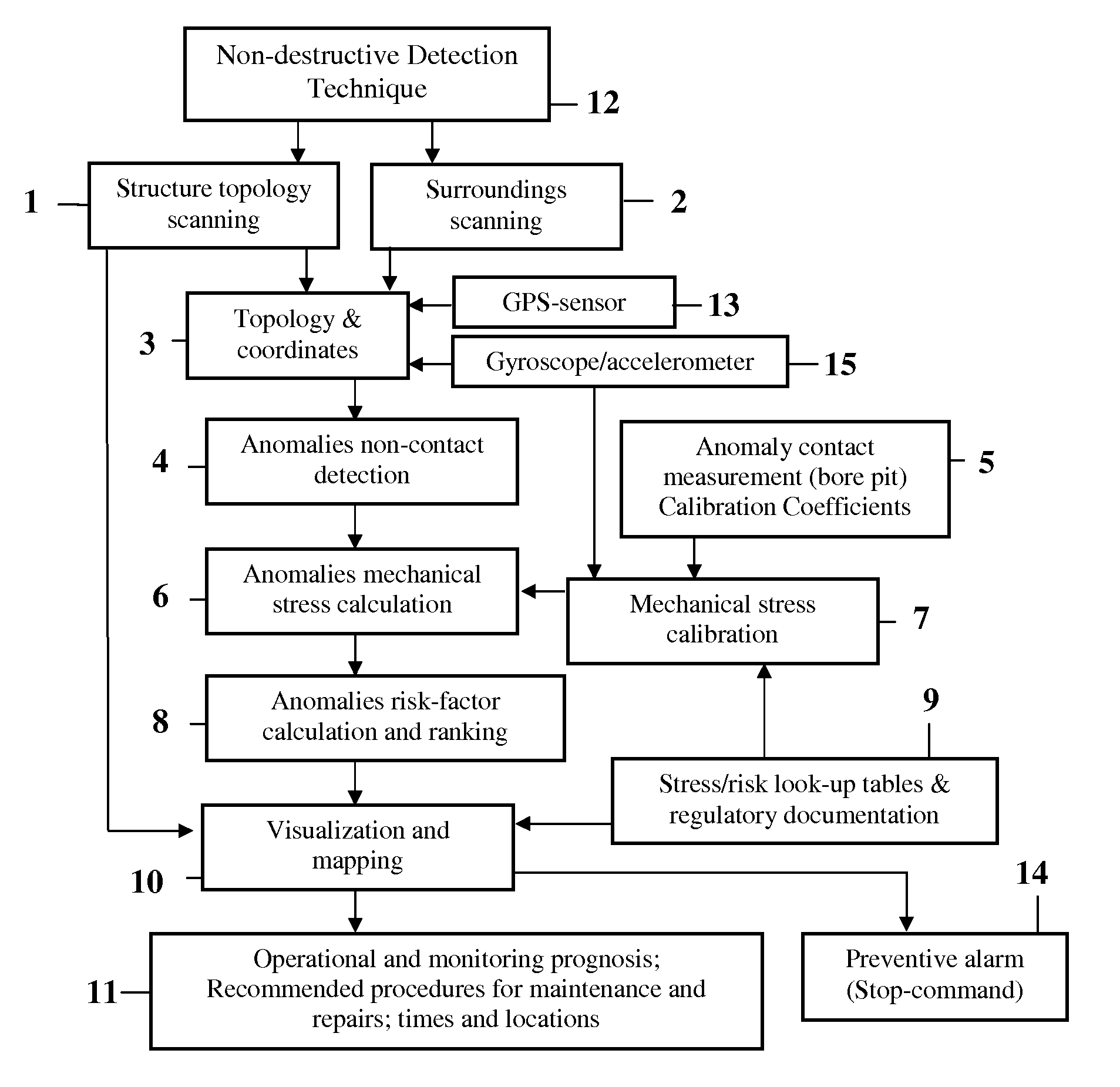

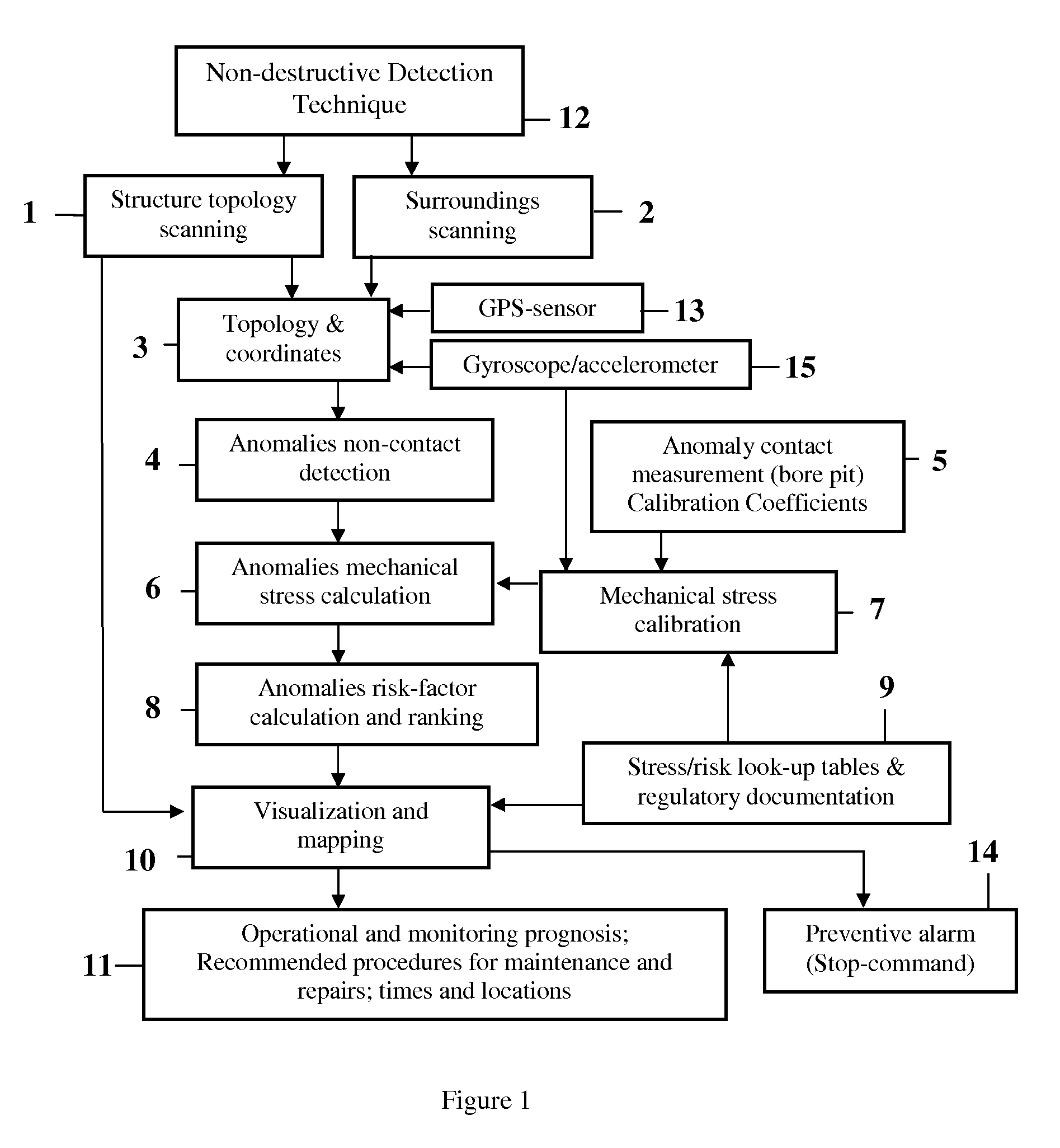

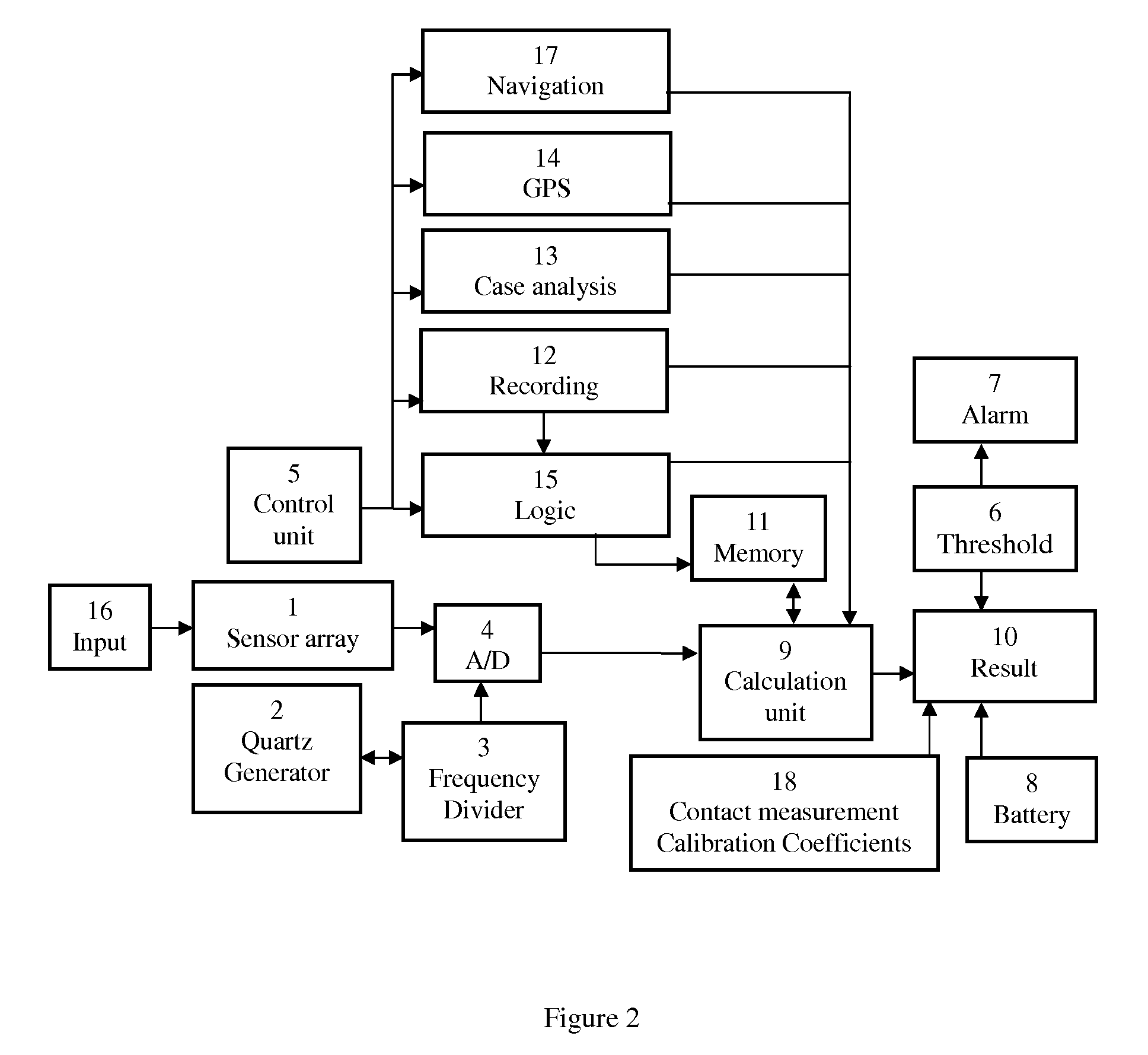

Apparatus and method for metallic constructions assessment

ActiveUS20140368191A1Improve accuracyEnsure qualitySusceptibility measurementsMaterial magnetic variablesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device includes registration means that optimized for use with metallic structures of various types, shapes and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs. etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

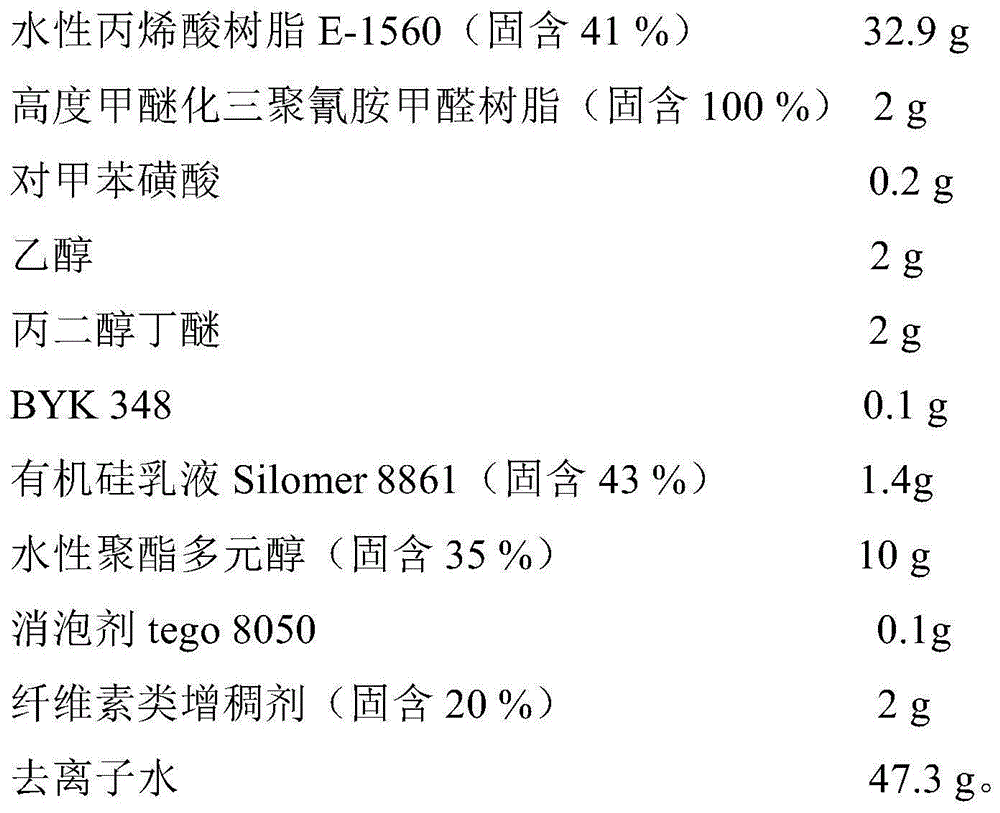

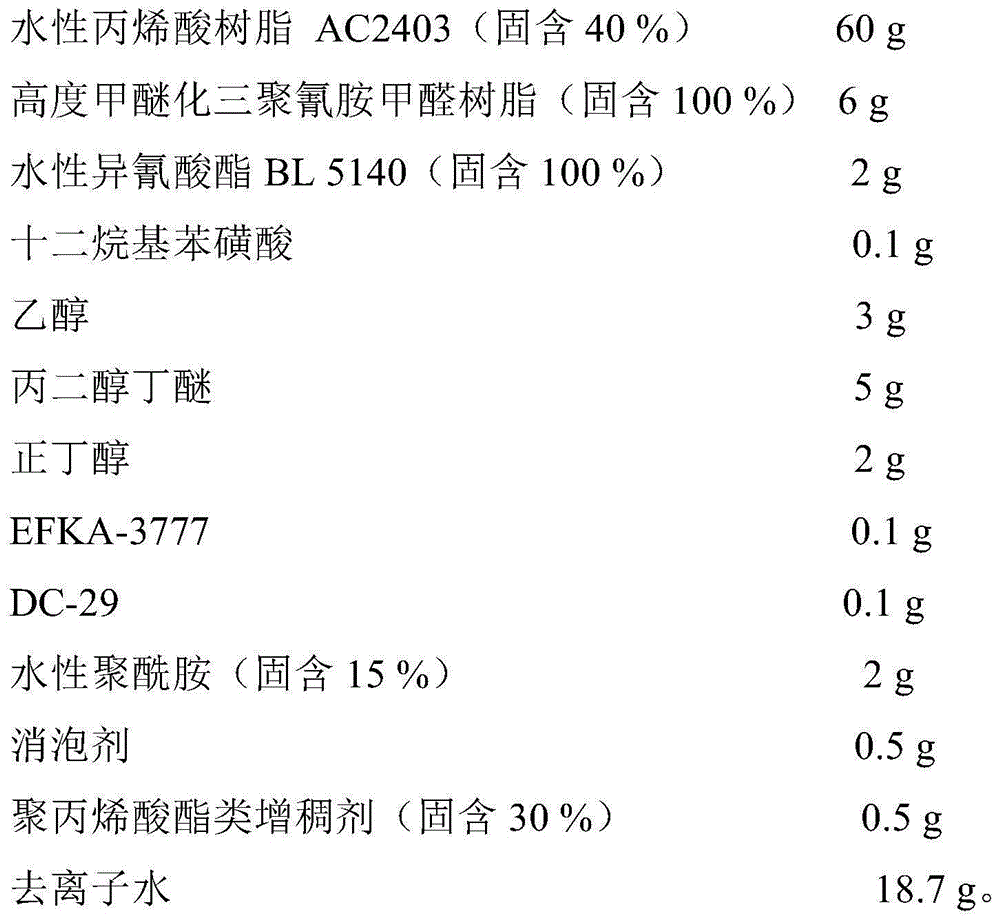

Water-based primer-topcoat braking paint and preparation method thereof

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

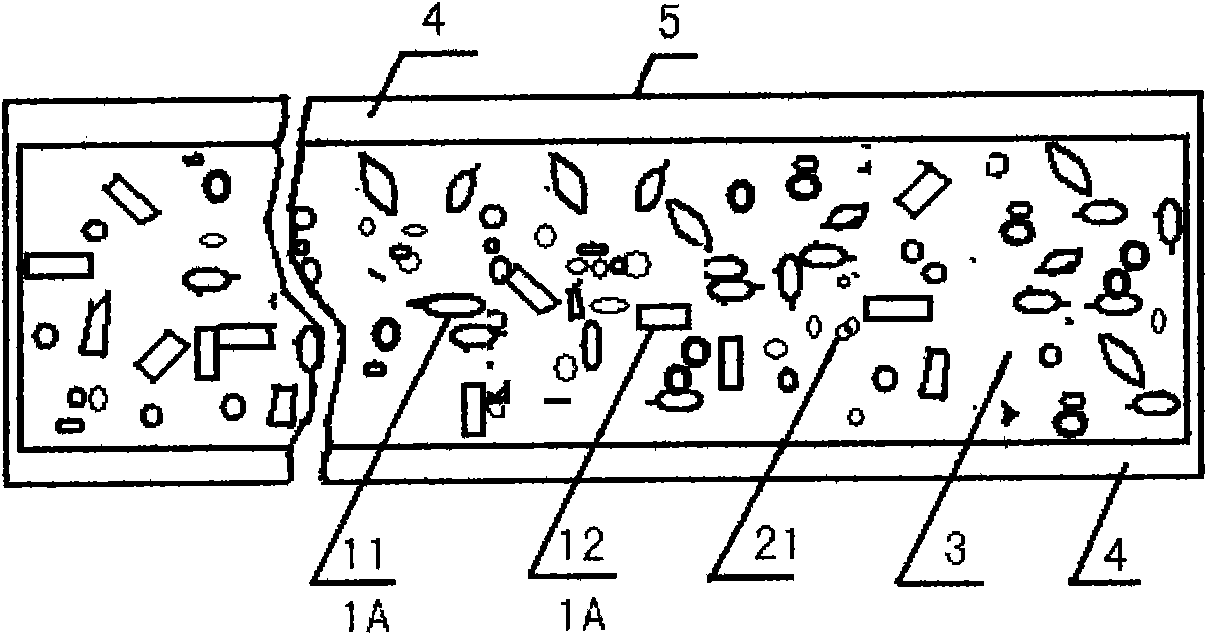

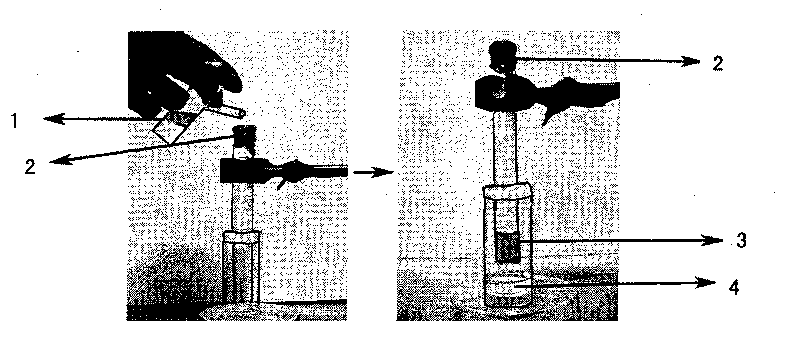

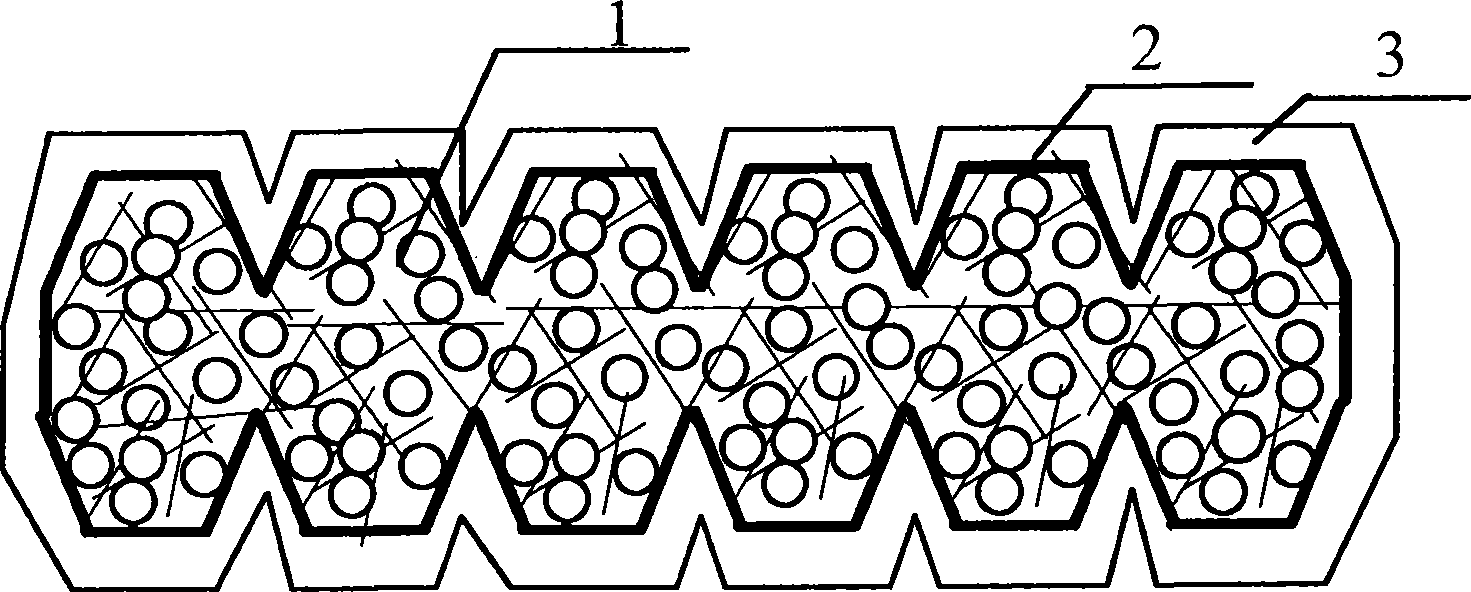

Controlled releasing microcapsule for scale prevention, wax prevention or viscosity reduction of oil well

InactiveCN102250604AAchieve slow releaseAchieve long-term effectiveDrilling compositionBorehole/well accessoriesPetrochemicalComponents of crude oil

The invention relates to the technical field of petrochemical engineering, in particular to a controlled releasing microcapsule for scale prevention, wax prevention or viscosity reduction of an oil well. The invention discloses a solid controlled releasing microcapsule for scale and corrosion prevention in the production process of crude oil and wax prevention or viscosity reduction in the production process of the crude oil as well as a preparation method thereof. Filler comprising an inorganic framework and agent components is arranged in a macromolecule composite membrane. The controlled releasing microcapsule has a stable structure comprising an inside inorganic framework support and an outer-layer macromolecular composite membrane wrapping film, can be used for realizing the slow release of the agent and achieving the aim of maintaining the agent effective for a long term as well as the functions of corrosion inhibition and dispersion. With proper volume and density, the controlled releasing microcapsule can be prevented from being taken away by an extraction solution and can be added through a sleeve; and the controlled releasing microcapsule is simple in process and is strong in maneuverability. According to the controlled releasing microcapsule, volatile matters and harmful components which do harm to the human health are avoided; various components can be basically and slowly dissolved; the labor intensity of workers is reduced; and one-time agent addition can ensure stable operation for 30-90 days.

Owner:门正国

Concrete base sound absorption material for road sound screen and method of manufacturing the same

The invention relates to a cement-matrix sound-absorption material used in road noise barriers and a preparation method thereof; the sound-absorption material is a noise barrier material which can be used in airports, high-speed railways, expressways, urban viaducts, subways and light rails; the components and weight ratios are as follows: 15.4 to 62.3 percent of Portland cement, 0.1 to 15.7 percent of mineral admixture, 18.9 to 79.9 percent of lightweight porous aggregate, 0.013 to 0.078 percent of foaming agents, 0.1 to 0.7 percent of water reducing agent and 0.4 to 2.6 percent of fiber. The sound-absorption material and the preparation method thereof have the advantages of large sound absorption coefficient, high strength, good anti-impact performance, excellent durability, fire resistance, moisture resistance, anti-corrosion and self-clean function; at the same time, the sound-absorption material is wide in sources of raw materials, convenient in preparation and processing, suitable for large-scale production, low in cost, environment-friendly and good in decorativeness.

Owner:SOUTHEAST UNIV +1

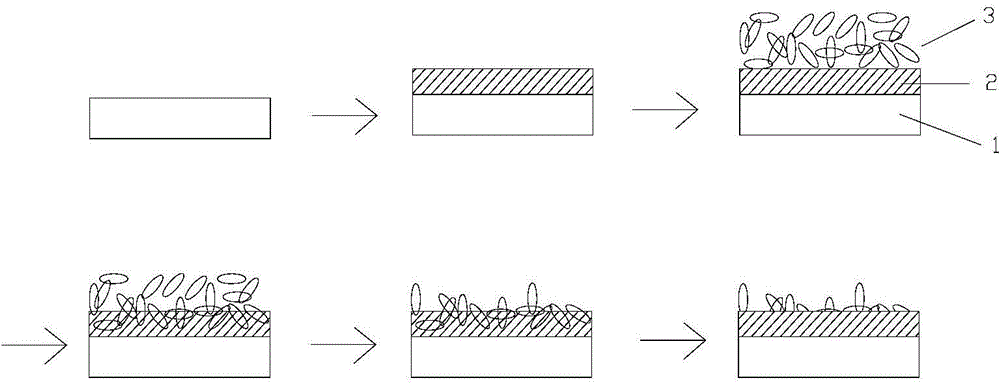

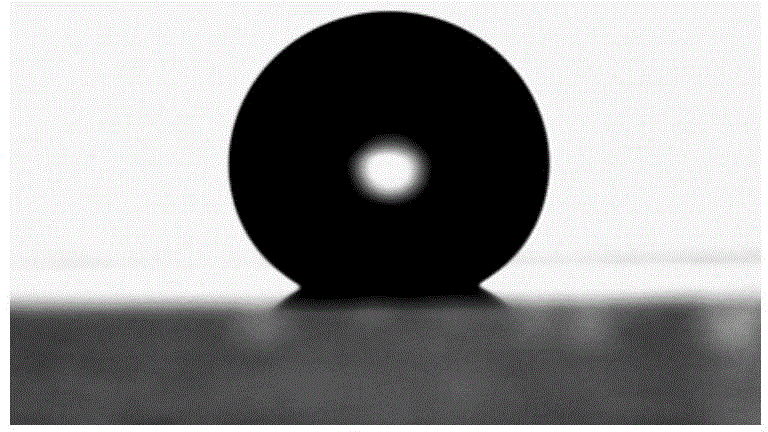

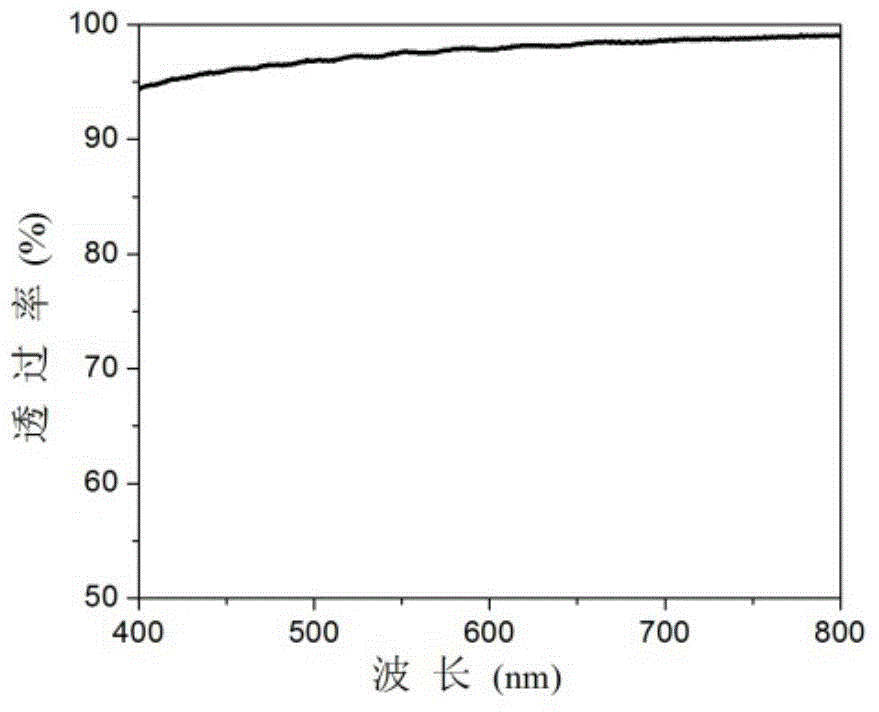

Transparent wear-resistant super-hydrophobic coating material, preparation method and coating process thereof

ActiveCN104910776ASuperhydrophobicHigh transparencyPretreated surfacesPolyurea/polyurethane coatingsWear resistantCement board

The present invention relates to a transparent wear-resistant super-hydrophobic coating material, a preparation method and a coating process thereof. The transparent wear-resistant super-hydrophobic coating material comprises a nanometer material dispersion liquid and an adhesion material dispersion liquid. According to the present invention, during the preparation, a nanometer material and a volatile solvent are mixed and dispersed to prepare the nanometer material dispersion liquid, and the adhesion material and the good solvent thereof are mixed and dispersed to prepare the adhesion material dispersion liquid; during the coating, the substrate surface is cleaned, the adhesion material dispersion liquid is coated to form the adhesion layer, the nanometer material dispersion liquid is coated after drying, the partial nanometer material is embedded into the adhesion layer through heating, pressurization and other ways, and finally the unstably-binding nanoparticles are removed by using scraping or adhesive tape adhesion to obtain the super-hydrophobic coating, wherein the coating has characteristics of good transparency, strong binding force, and wear resistance; and the super-hydrophobic coating material of the present invention can be used for the surfaces of a variety of materials such as metals, plastics, glass, cement boards and the like so as to achieve functions of water resistance, stain resistance, corrosion resistance, self-cleaning, dew resistance, icing resistance, and the like.

Owner:王舒

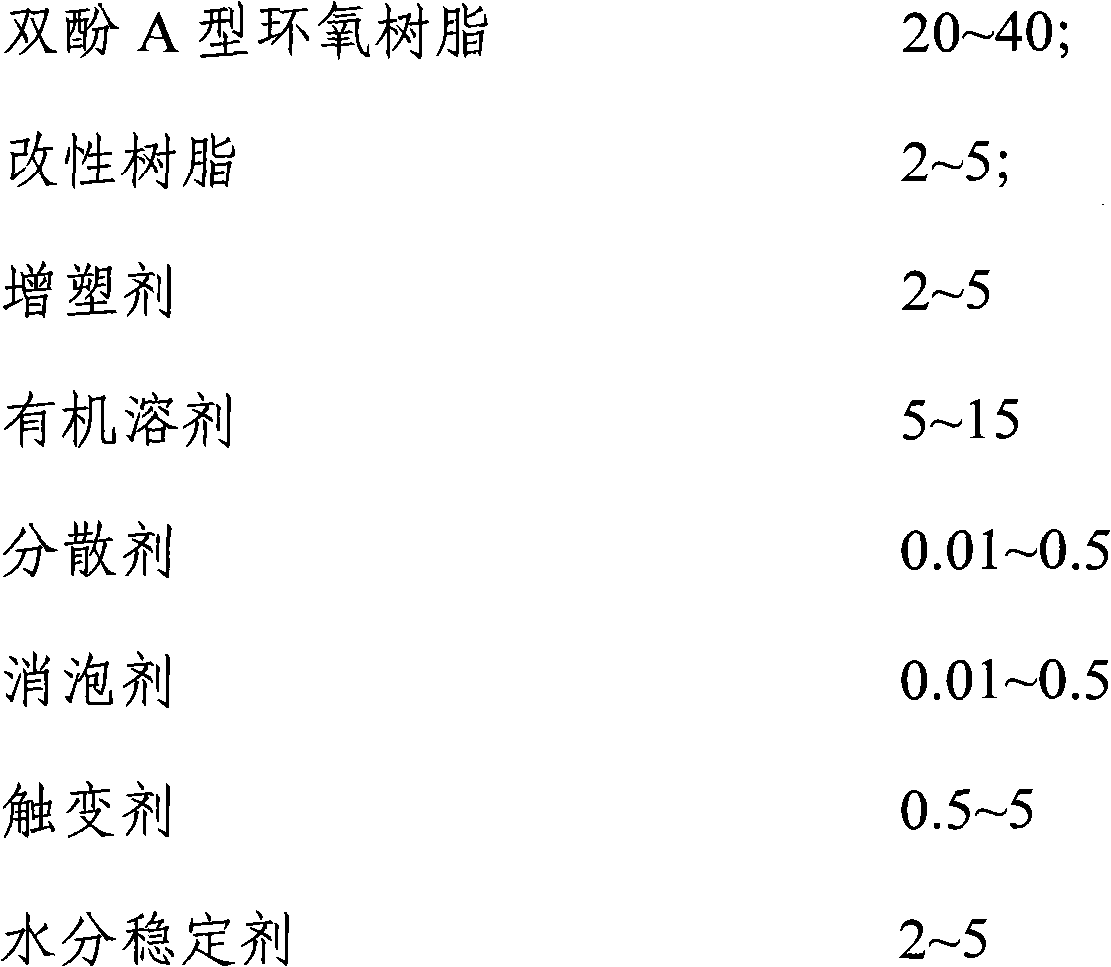

Epoxy coating and preparation method and application thereof

ActiveCN102618148AImprove the shortcomings of hard and easy to crack and poor flexibilityHigh mechanical strengthRosin coatingsAnti-corrosive paintsResin coatingPolyurethane coating

The invention provides a novel epoxy coating and a preparation method thereof. The coating not only has excellent corrosion resistance, but also has excellent compatibility with a base material or a lower coating film, particularly an epoxy coating, a polyurethane coating, a fluorocarbon coating or an alkyd resin coating. The epoxy coating comprises a main paint and a curing agent, wherein the main paint contains bisphenol A epoxy resin and modifying resin for modifying the bisphenol A epoxy resin; and the curing agent contains polyamino amide and cardanol modified phenolic amine.

Owner:北京红狮科技发展有限公司

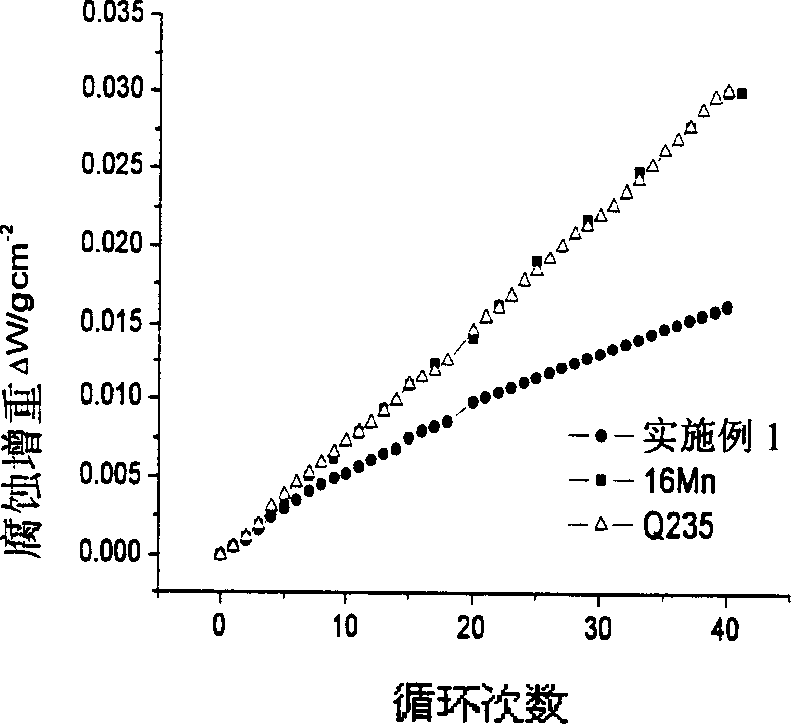

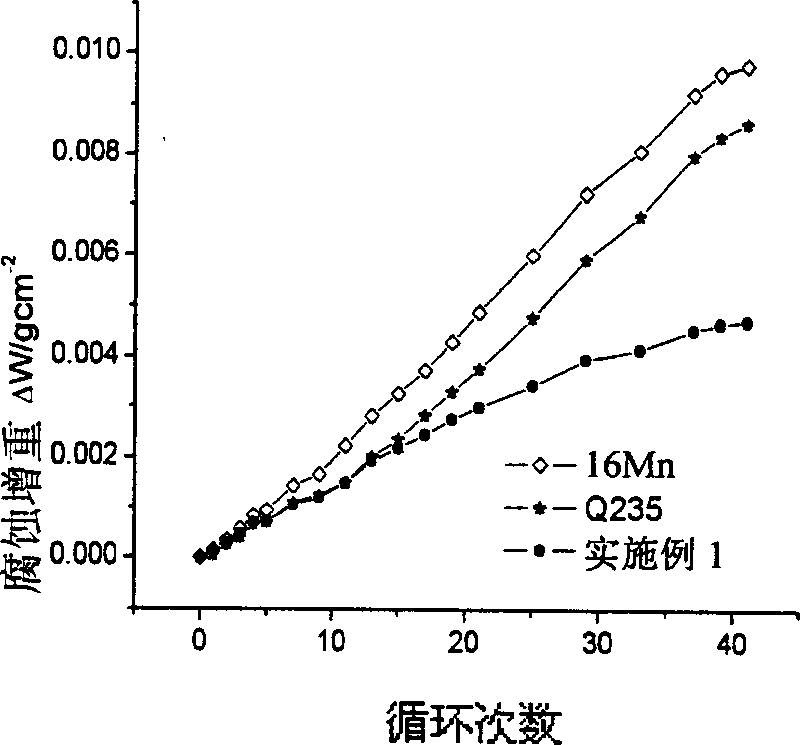

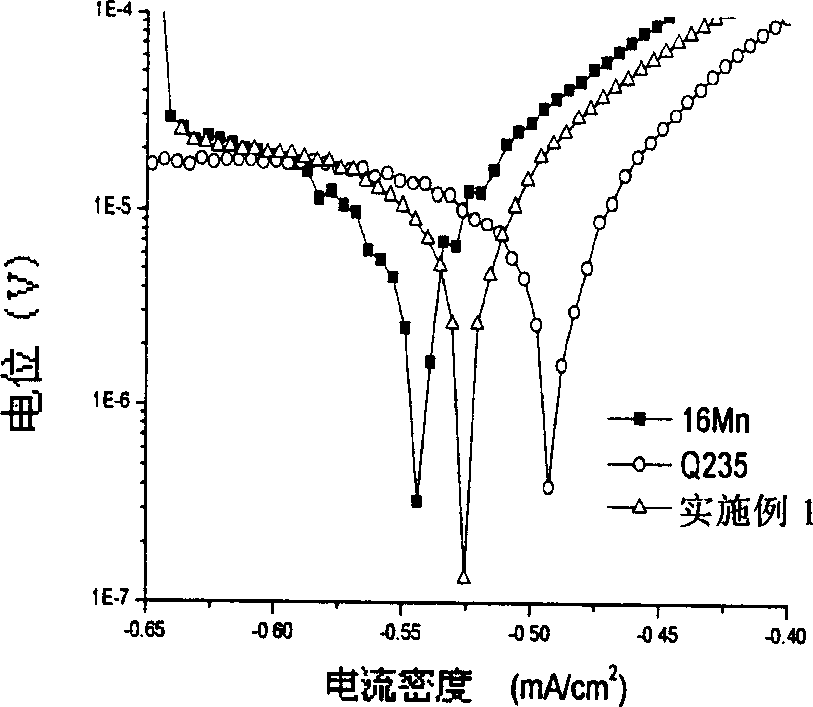

Economy type weathering-resistant steel

The invention relates to economic air corrosion prevention low-alloy carbon constructional steel in the field of low-alloy constructional steel. It is mainly used in the steel structure which is used in air such as railroad, carriage, bridge and tower and so on. The alloying component and the percentage by weight of the weather fastness steel is as following: C: 0.12-0.21, Si: 0.2-2.0, Mn: 0.7-2.0, S <=0.036, P<=0.034, Cu: 0.10-0.40, Al<0.2, and other iron and impurity elements.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Inorganic heat-insulating dry powder mortar

The invention relates to inorganic heat-insulating dry powder mortar, which comprises the following components in percentage by weight: 30 to 95 percent of inorganic gelled material, 5 to 70 percent of lightweight aggregate and 0 to 10 percent of additive, wherein the inorganic gelled material comprises 75 to 90 weight percent of desulfuration gypsum and 10 to 25 weight percent of cement; the lightweight aggregate is hydrophobic expanded perlite or vitrified micro bubbles or a mixture of the hydrophobic expanded perlite and the vitrified micro bubbles; and the additive comprises a composite retarder, a water retention agent, a thickening agent, a cementing compound and a reinforcing agent. The inorganic heat-insulating dry powder mortar can replace cement mortar and mixed mortar, is applied to non-humid wall surfaces such as the inner side of an outer wall, a separating wall, an inner partition wall, a ceiling and the like, has the characteristics of heat preservation, heat insulation, crack resistance, fire prevention, ageing resistance, environmental protection, biological bite corrosion prevention and the like, and can improve the heat-preserving and heat-insulating performanceof wall bodies.

Owner:谢日清

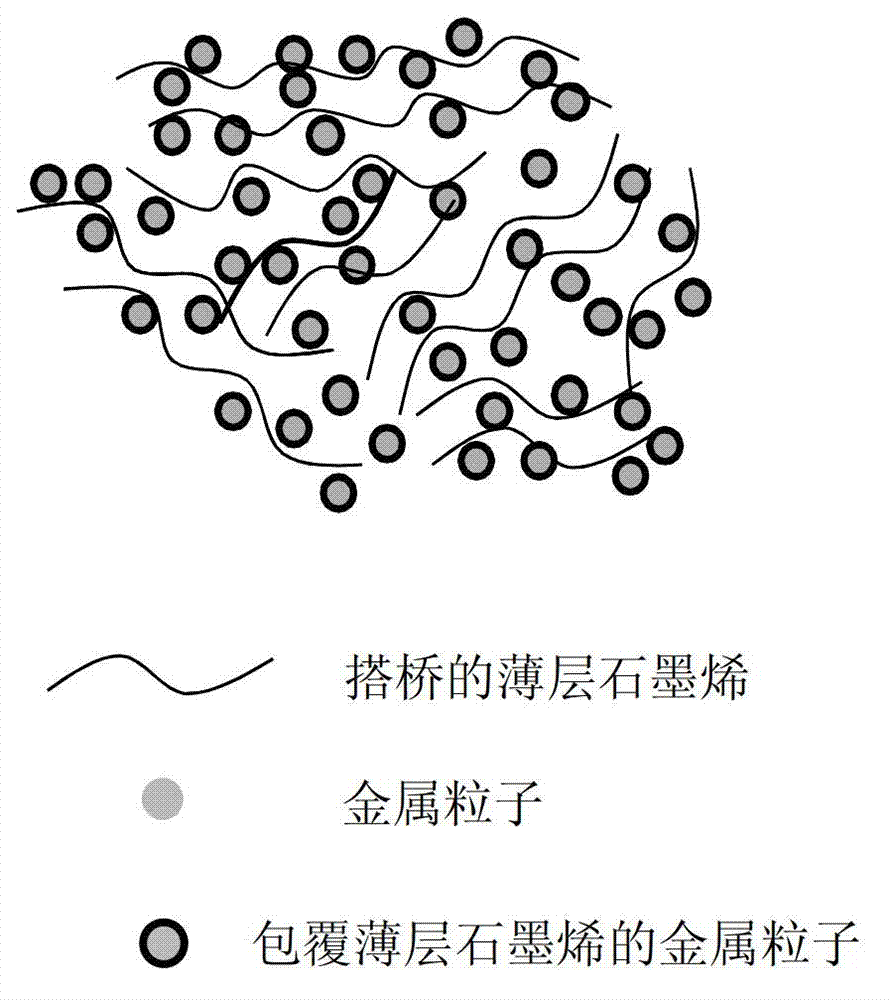

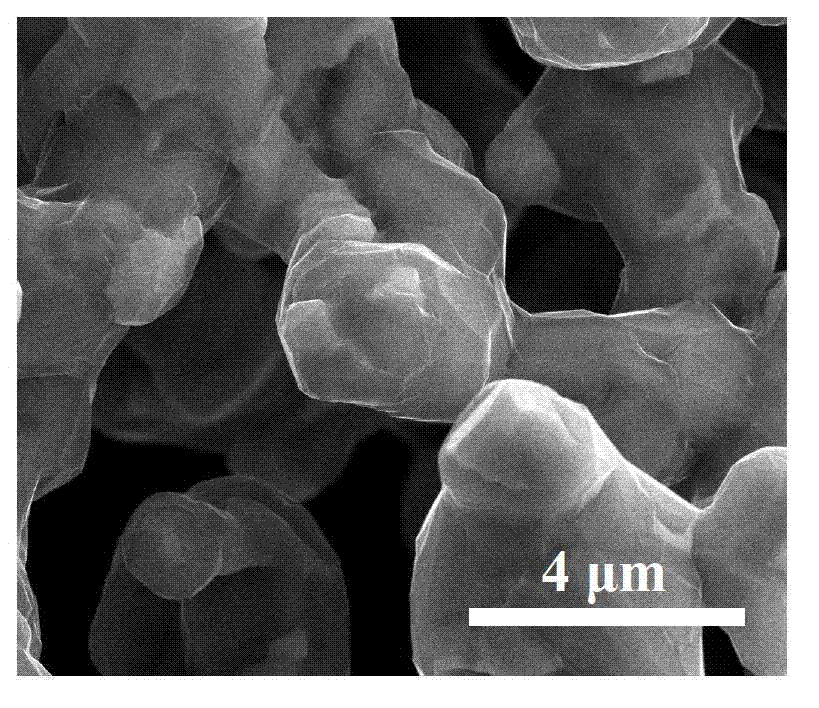

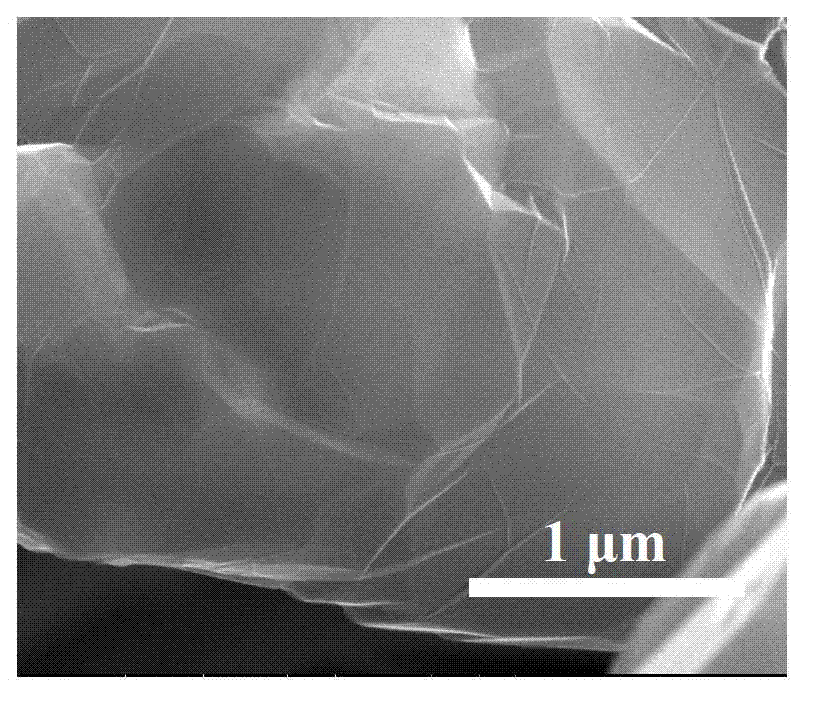

Material adopting thin graphene and metal powder composite structure, preparation method and application thereof

ActiveCN103192072AImprove antioxidant capacityImprove corrosion resistanceCarbon compoundsGas phaseSlurry

The invention discloses a material adopting a thin graphene and metal powder composite structure, a preparation method and an application thereof. The material adopting the composite structure comprises metal powder bridged by and coated with thin graphene. The preparation technology of the material comprises the steps as follows: mixing transition metal powder or reduced transition metal powder with the thin graphene, and growing the thin graphene on the surface of the transition metal powder through CVD (chemical vapor deposition) and coating the surface of the transition metal powder with the thin graphene, so as to obtain the metal powder bridged by and coated with the thin graphene; or growing the thin graphene on the surface of the transition metal powder through the CVD, and then compositing the metal powder with the thin graphene to obtain a target product. The invention has the advantages that the technology is simple; the oxidation resistance and the corrosion prevention of the metal powder can be enhanced, meanwhile, the metal powder has good heat conduction, antistatic and electromagnetic shielding properties, the service life of the metal powder can be prolonged, and the cost can be reduced; and besides, the material has a wide application prospect in antistatic performance, thermal management, heat conduction and radiation, electromagnetic shielding, catalysts, sintering activators, electro-conduction slurry, batteries, cemented carbide and the like.

Owner:苏州格瑞丰纳米科技有限公司

Apparatus for the non-contact metallic constructions assessment

ActiveUS8542127B1The result is accurate and reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesElectrical measurementsHeavy equipmentHeavy duty

A device and method for discovering, identification and monitoring of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The technique is specifically optimized for extended, not-accessible underground and underwater metallic structures quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the technique implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

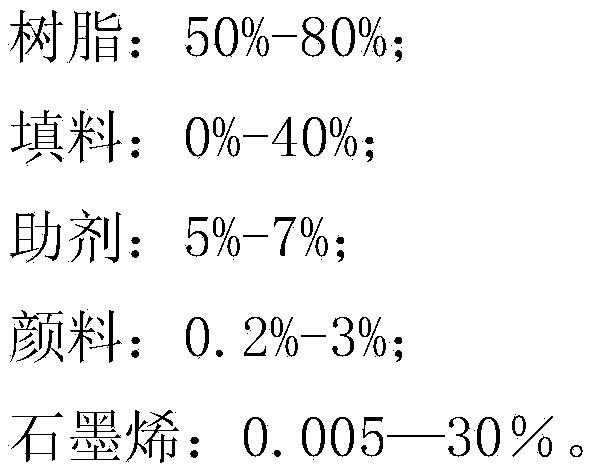

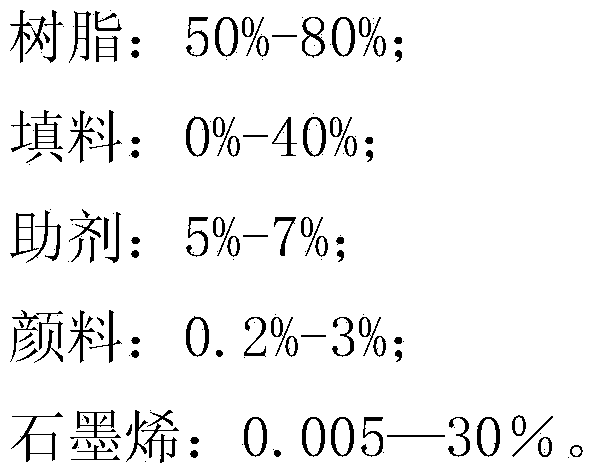

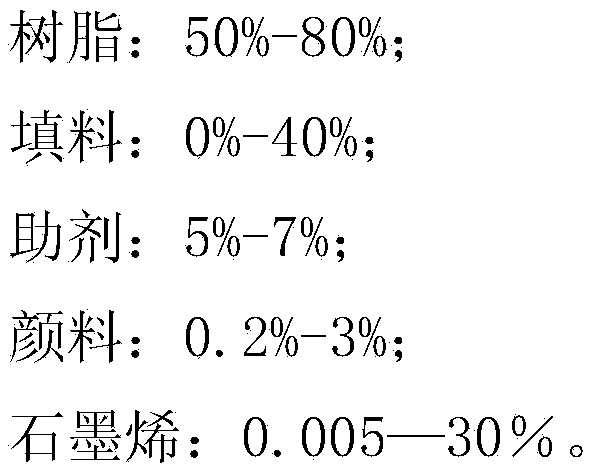

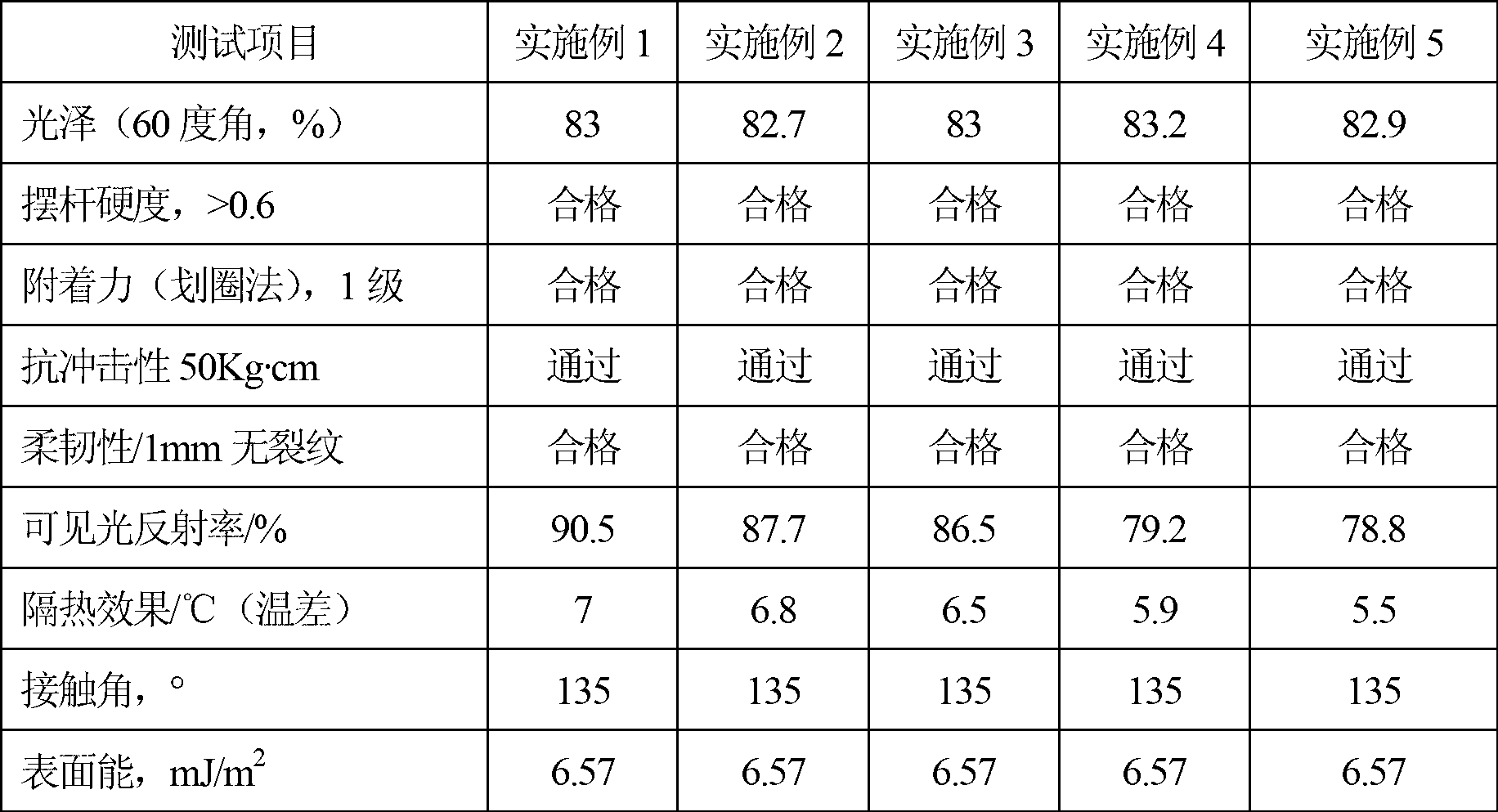

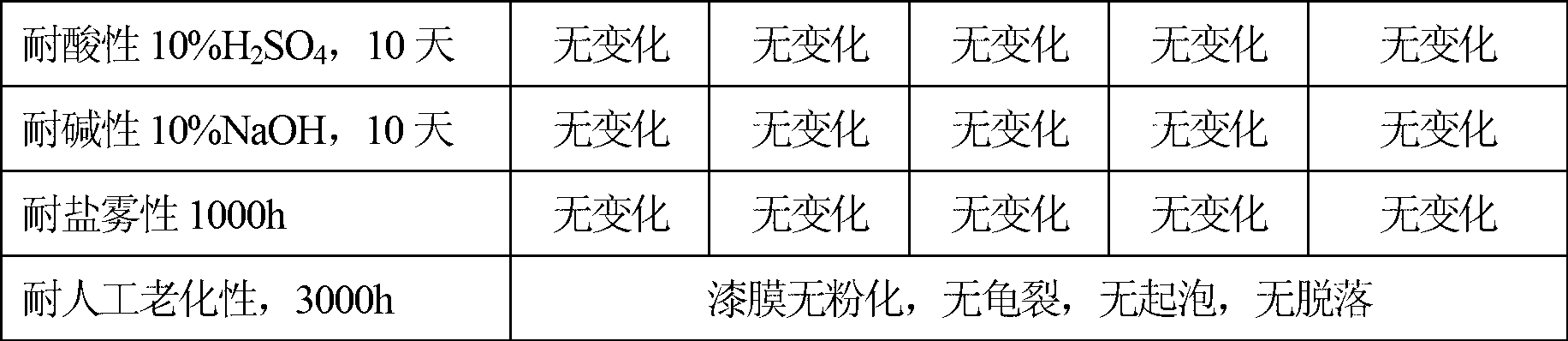

Graphene-modified resin powder coating and production process thereof

InactiveCN104194585AIncrease profitReduce pollutionFireproof paintsPolyurea/polyurethane coatingsWeather resistanceGraphene

The invention relates to graphene-modified resin powder coating and a production process thereof. The graphene-modified resin powder coating comprises the following components in percentage by weight: 50-80 percent of resin, 0-40 percent of filler, 5-7 percent of an auxiliary agent, 0.2-3 percent of pigment and 0.005-30 percent of graphene. According to the graphene-modified resin powder coating provided by the invention, a proper amount of graphene is added in the traditional resin powder coating, so that the mechanical property, the conductivity, thermal conductivity, flame resistance, corrosion resistance and weather resistance of the resin powder coating are greatly improved; the graphene-modified resin powder coating has a broad market prospect.

Owner:周诚

Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

ActiveCN103013241AImprove reflectivityImprove anti-corrosion performanceReflecting/signal paintsCross-linkInfrared

The invention relates to a fluorocarbon nanometer solar heat-insulation reflective paint, a preparation method thereof and a using method thereof. The paint can be used for roofs and glass curtain walls of the building industry, offshore drilling platforms, oil tanks and petroleum pipelines of the petroleum industry, the surfaces of cars and trains of the transportation industry, hulls and decks of the ship-building industry, and the tanks and warships of the weapon and aerospace industry. The fluorocarbon nanometer solar heat-insulation reflective paint comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 40%-70% of fluorocarbon resin, 1%-10% of nanometer TiO2 concentrated slurry, 10%-30% of infrared-ray reflective pigment, 3%-10% of hollow micro beads, 1%-5% of auxiliaries and 10%-20% of organic solvent; and the component B is cross-linking agent. The preparation method for the fluorocarbon nanometer solar heat-insulation reflective paint comprises the following steps: 1) preparing, dispersing and grinding the materials of the component A in proportion until the fineness is lower than 30 microns; and 2) mixing and curing the component A and the component B to prepare the fluorocarbon nanometer solar heat-insulation reflective paint. The fluorocarbon nanometer solar heat-insulation reflective paint provided by the invention is suitable for normal-temperature drying or low-temperature baking and drying; moreover, a coating film formed by the paint has the characteristics such as high reflectivity, a good heat-insulation effect, high corrosion prevention, high weather resistance, high self-cleanness, low friction and the like.

Owner:大连佳秀百隆新材料股份有限公司

Epoxy graphene heavy corrosion-resistant coating, and preparation method and application thereof

InactiveCN107739566APlay a physical anti-corrosion effectAct as electrochemical anticorrosionAnti-corrosive paintsEpoxy resin coatingsEpoxyChemical products

The invention relates to the field of corrosion-resistant coating, in particular to epoxy graphene heavy corrosion-resistant coating and a preparation method thereof. The epoxy graphene heavy corrosion-resistant coating mainly comprises the following components in percentage by weight: 0.1 to 5 percent of a graphene material, 30 to 60 percent of epoxy resin, 30 to 50 percent of a pigment filler, 0.1 to 10 percent of a dispersing agent, 0.1 to 5 percent of a coating aid and 8 to 30 percent of a solvent. The components of the coating provided by the invention have synergistic effect, grinding, ultrasonic dispersion and grinding are conducted step by step, the graphene powder is added step by step, the graphene is dispersed uniformly, excellent barrier property and excellent electric conductivity of a nano-sheet layer structure of the graphene on the chemical products are exerted completely, and the corrosion resistance of the epoxy resin heavy corrosion-resistant coating is improved andenhanced, so that the super long-lasting corrosion-resistant effect is achieved and the coating of the prepared coating is thin. The preparation method provided by the invention is simple and practical, and the prepared coating has excellent performance.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Metallic constructions integrity assessment and maintenance planning method

ActiveUS8447532B1Easy maintenancePromote repairPlug gaugesForce measurement by measuring magnetic property varationMaintenance planningHeavy duty

A method for metallic structure maintenance is disclosed. The method includes a magneto-graphic / Magnetic Tomography technique to identify stress-related defects. The method is specifically optimized for extended, non-accessible underground and underwater metallic structures in providing quality control, emergency alarms as well as timeline planning for structural repairs and maintenance work. Examples of the method implementation include pipes for oil and gas industry, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships reservoirs, etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

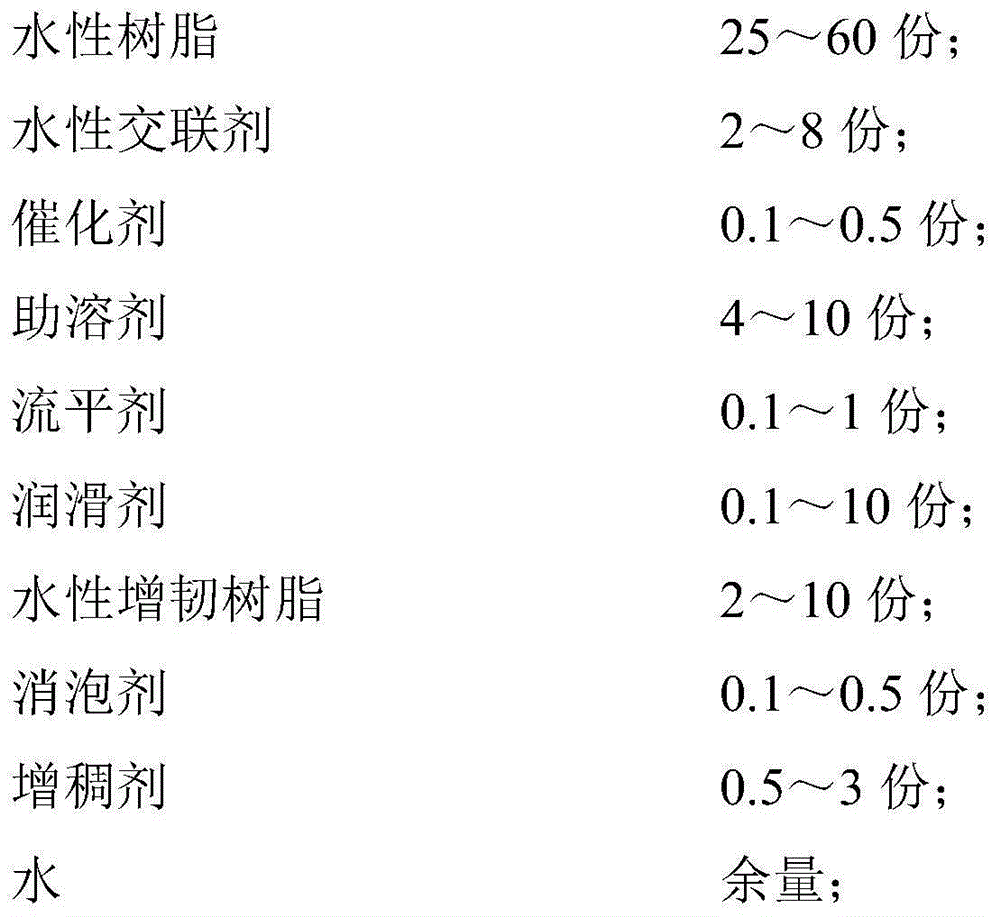

Water-based high-corrosion-resistance coating with excellent stamping performance and preparing method and application of water-based high-corrosion-resistance coating

ActiveCN105038464AEmission reductionReduce pollutionPretreated surfacesAnti-corrosive paintsWater basedMicrometer

The invention belongs to the technical field of surface corrosion prevention and discloses a water-based high-corrosion-resistance coating with excellent stamping performance and a preparing method and application of the water-based high-corrosion-resistance coating. The coating comprises, by mass, 25-60 parts of water-based resin, 2-8 parts of water-based cross-linking agent, 0.1-0.5 part of catalyst, 4-10 parts of cosolvent, 0.1-1 part of flatting agent, 0.1-10 parts of lubricating agent, 2-10 parts of water-based toughening resin, 0.1-0.5 part of defoaming agent, 0.5-3 parts of thickening agent and the balance water, and the total mass parts of the components are 100 parts. According to the water-based high-corrosion-resistance coating, the water-base resin serves as film forming matter, so that good construction performance is achieved, curing is quick, super corrosion resistance can be obtained when the thickness of the coating is 2-5 micrometers, the performance of resisting neutral salt mist is longer than 2,000 hours, resistance to acid salt mist is longer than 500 h, the corrosion grade can reach 9.8 or higher, and the salt mist resisting performance of the coating is maintained unchanged after stamping or bending is carried out.

Owner:GUANGZHOU HUMAN CHEM

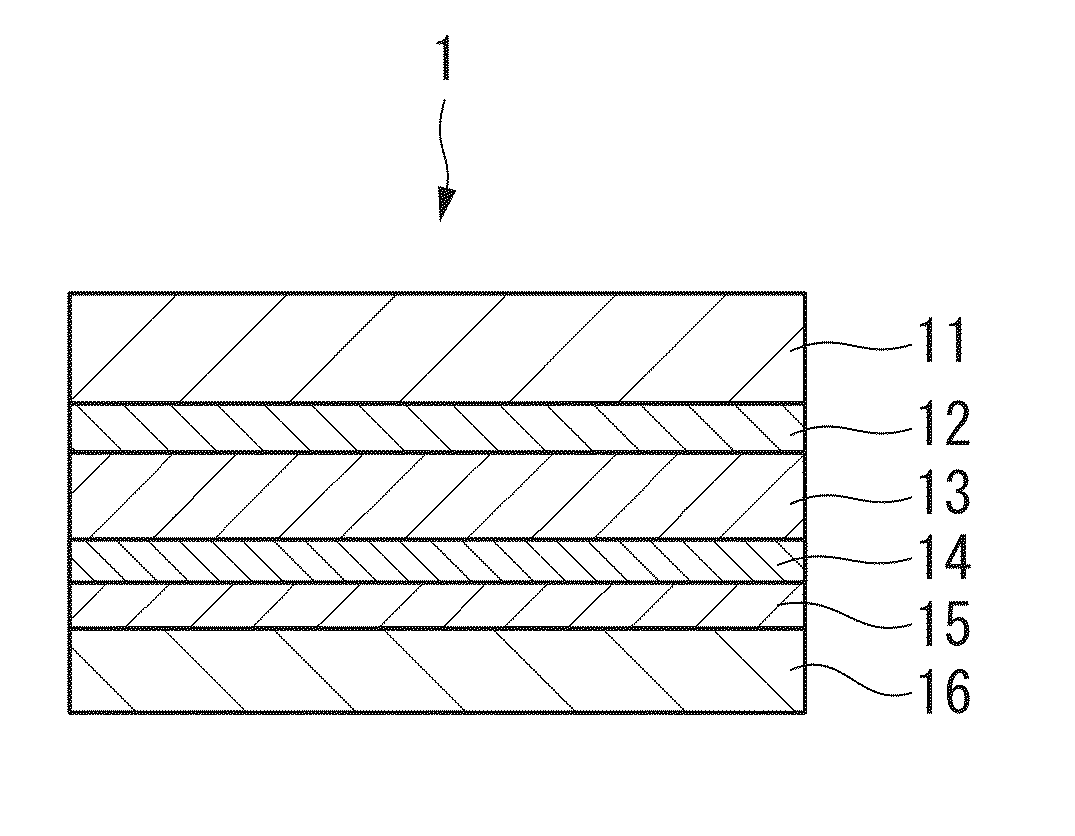

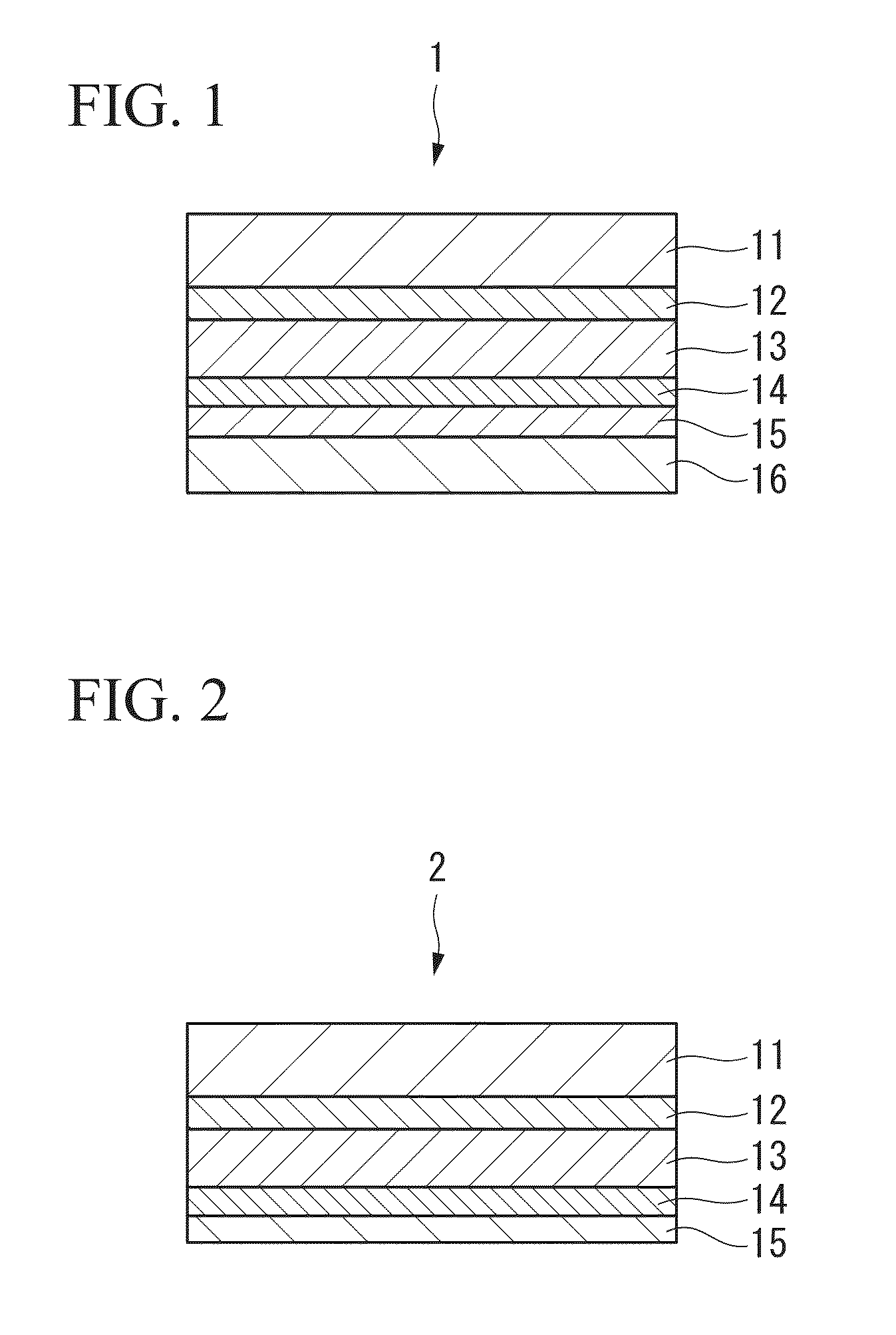

Lithium ion battery exterior material

ActiveUS20130209868A1Improve pressure resistanceImprove moisture resistanceSynthetic resin layered productsSpecific condition cell workingElastomerPolyolefin

A lithium ion battery exterior material, includes: a base material layer, and a sequentially laminated adhesive layer, aluminum foil layer provided with a corrosion prevention treated layer, and an adhesive resin layer on one surface of the base material layer; wherein, the adhesive resin layer contains an acid-modified polyolefin resin and a miscible elastomer dispersed in the acid-modified polyolefin at a dispersed phase size of 1 nm to less than 1 μm.

Owner:TOPPAN PRINTING CO LTD

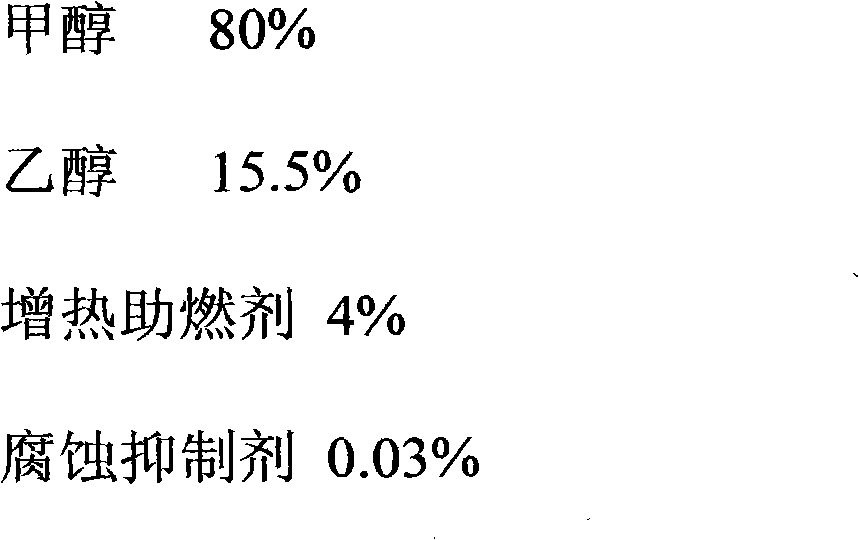

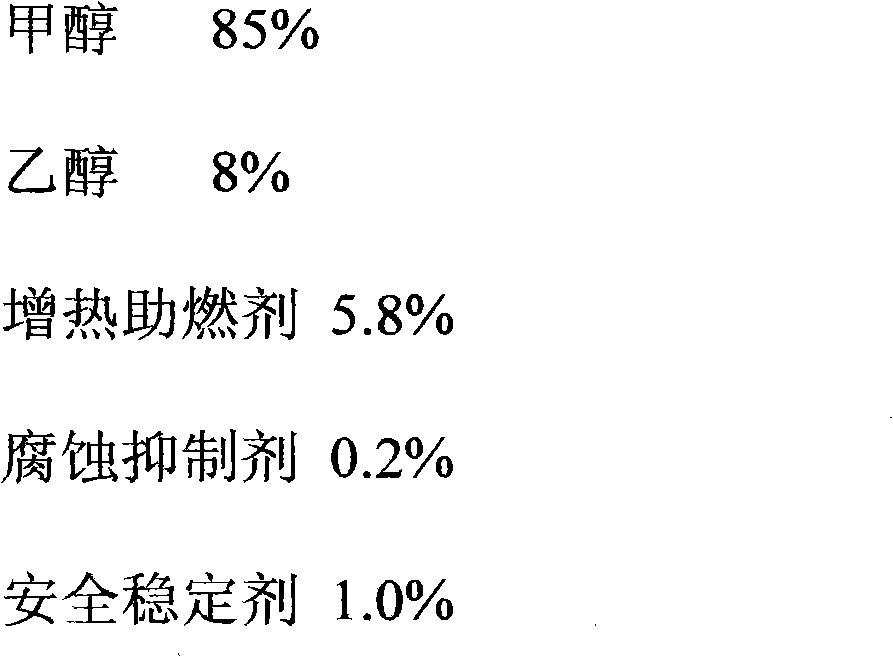

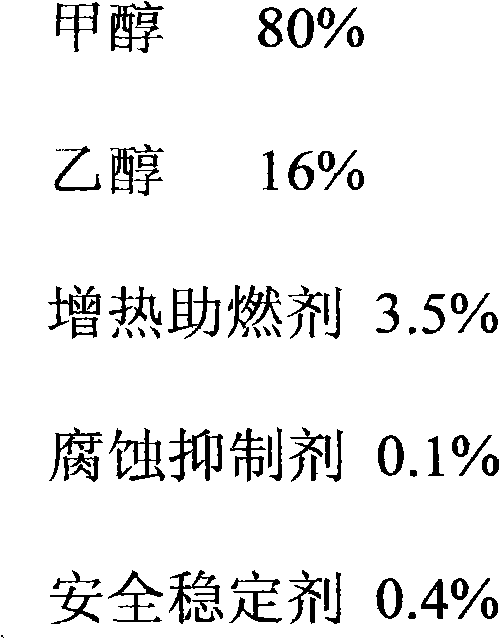

Novel high-heat anticorrosive biomass alcohol-based fuel

The invention relates to a novel high-heat anticorrosive biomass alcohol-based fuel, and relates to the field of environment protection. The alcohol-based fuel is prepared with main combustion agents of methanol and ethanol and auxiliary materials of alcohol-based fuel additives. The fuel is prepared from 60-90% of methanol, 10-30% of ethanol, 2-8% of a combustion-enhancing heat-gain agent, 0.01-0.2% of a corrosion inhibitor, and 0.1-1% of a safe stabilizer. The fuel provided by the invention has the advantages of high heat value, easy ignition, stable combustion, corrosion resistance, no air resistance, explosion-proof safety, clean property and no odor, low emission, low cost, energy saving, and environment friendliness. The heat value can be increased to 6500-7000 kcal / kg, and a central flame temperature can reach 1200-1300 DEG C. The fuel provided by the invention can be used in fields such as stoves, boilers, industrial furnaces, and the like.

Owner:QIQIHAR NORTH KUN SYNTHETIC POLYMER MATERIALS

Aerogel core material capsule, paint prepared from same and preparation method of paint

InactiveCN105363396AAvoid destructionHigh surface area for strong adsorptionCoatingsMicroballoon preparationThermal insulationFilm-forming agent

The invention relates to an aerogel core material capsule, paint prepared from the same and a preparation method of the paint, in particular to the paint which is prepared by conducting encapsulation on aerogel particles through a suspension coating method and adding a film forming agent, reinforcement powder, function powder and an additive with the capsule, with aerogel particles as the core material, as the main thermal insulation component, and has the nanometer porous structure. Encapsulation is conducted on aerogel particles through the suspension coating method, it is avoided that water or other reagents permeate aerogel nano-pore particles to generate capillary force and damage porous structures, and therefore the paint of the complete nano-pore structure is prepared. The prepared paint has excellent thermal insulation performance and is easy to operate, low in production cost, green, environmentally friendly, safe, capable of being applied to thermal insulation and corrosion prevention of devices such as hearths, pipelines, valves and storage tanks in the fields of aviation and military, metallurgy forging, petroleum refining, electric power, ships and the like, and also capable of being used for heat preservation and thermal insulation in the field of construction.

Owner:浙江圣润纳米科技有限公司

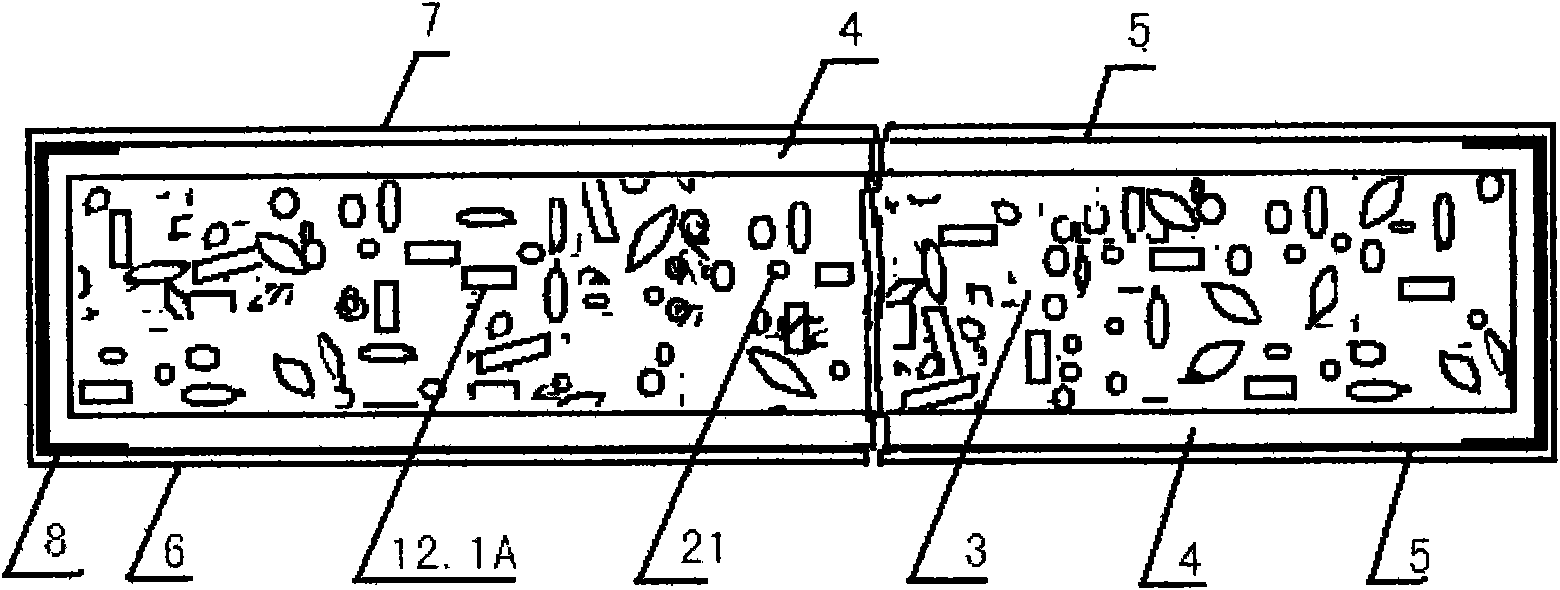

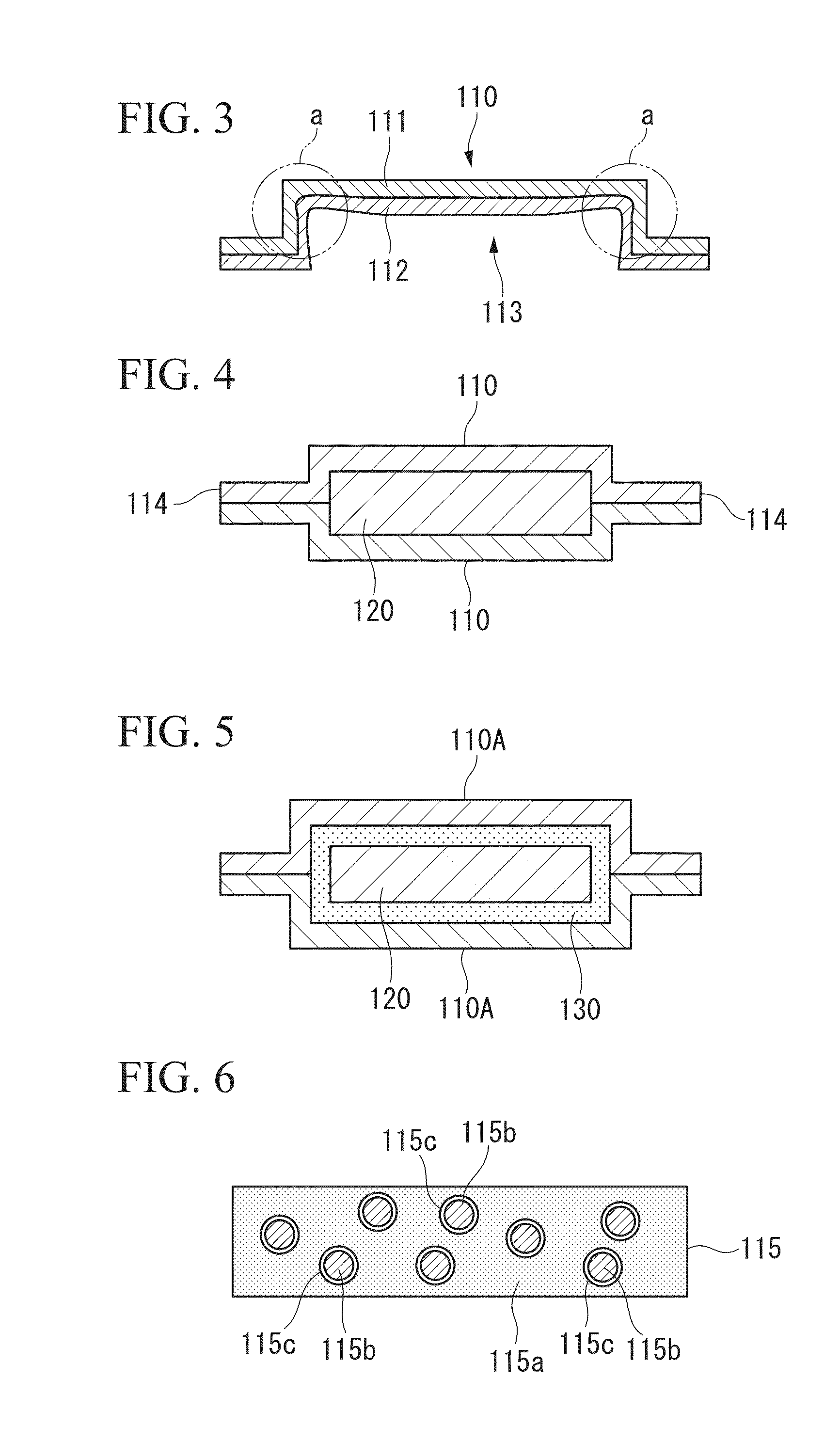

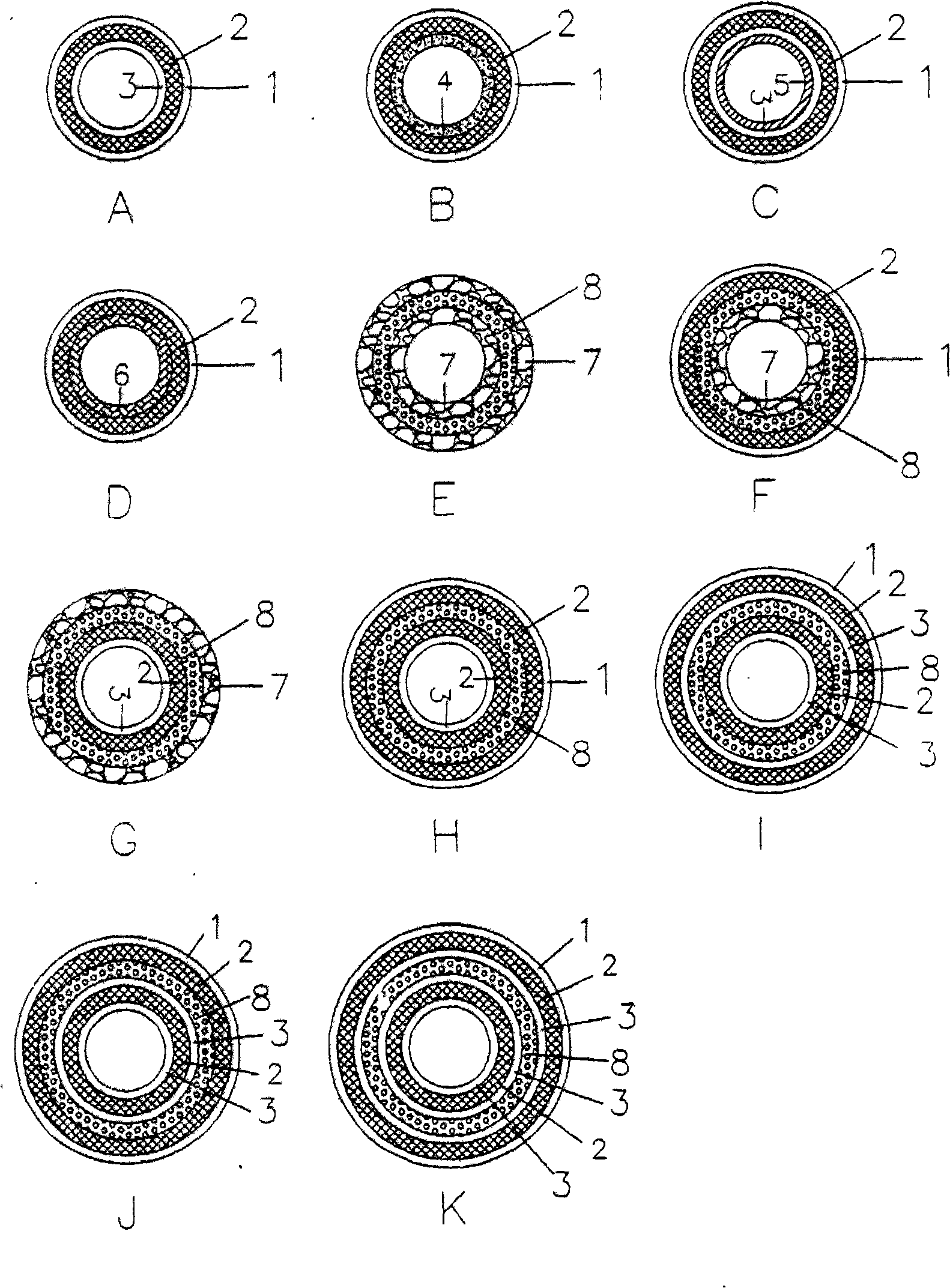

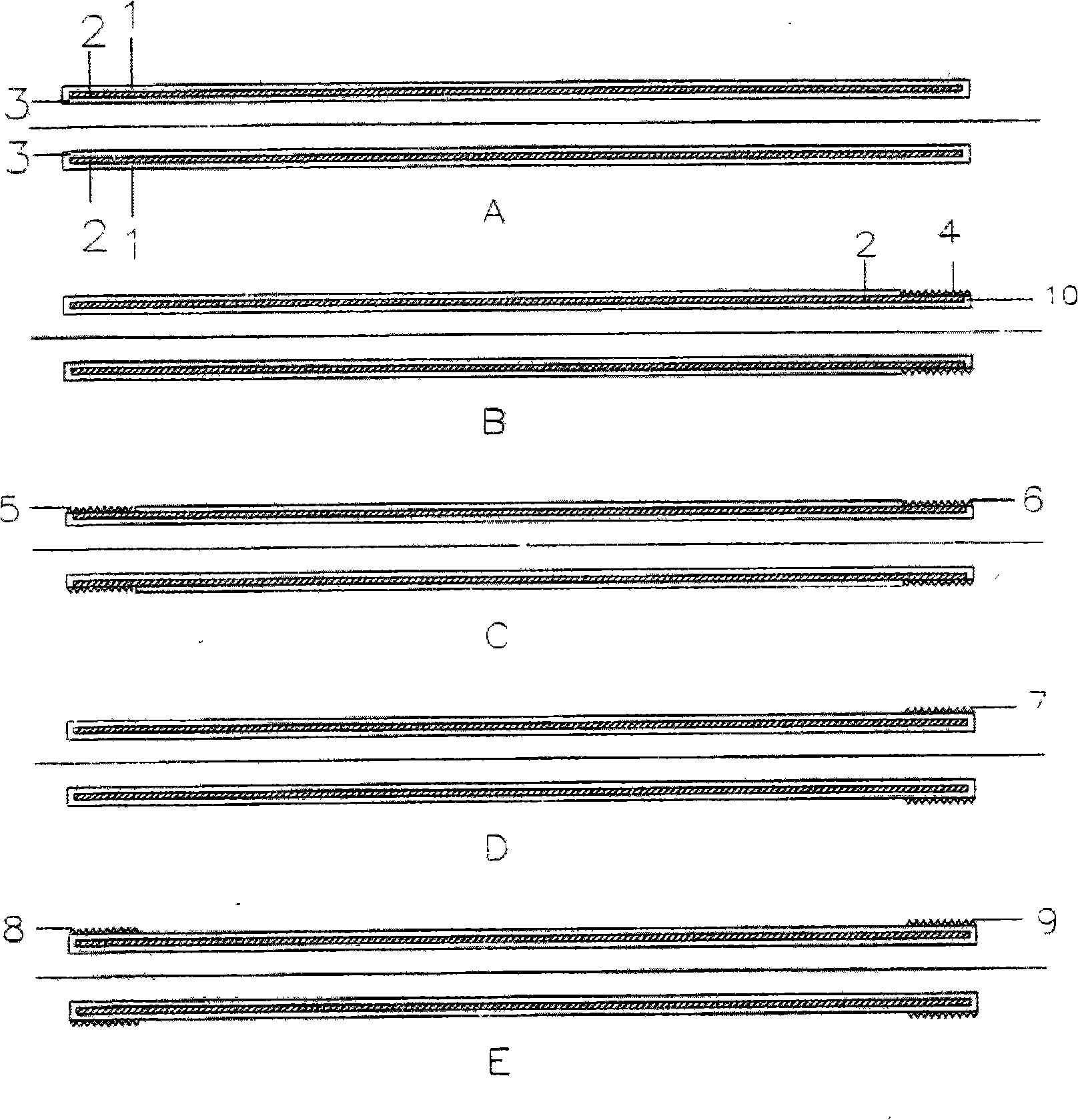

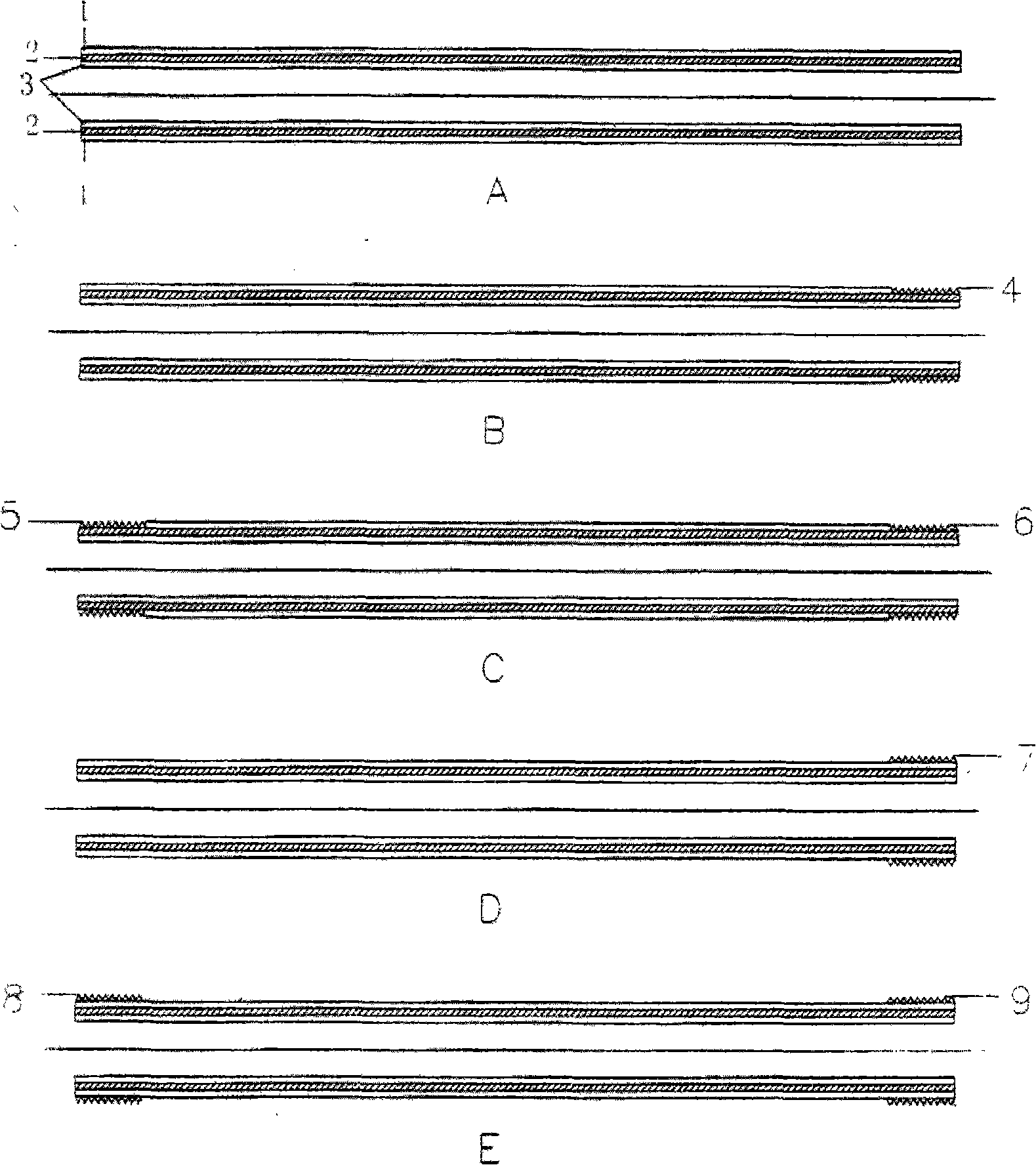

Multilayered structure and multifunction pipeline and connecting device

The invention relates to a multilayered structure and multifunction pipeline and a connecting device, solving the disadvantages of poor corrosion resistance, poor crushing resistance, poor heat-insulating property, no shapely appearance, high production cost, single structure, and the like of the existing pipelines. The pipeline comprises a corrosion resistance layer, a crushing resistance layer, a heat-insulating layer and a bacteria resistance layer, and can be of the types of single corrosion resistance and crushing resistance, bacteria resistance, corrosion resistance and crushing resistance and heat-insulating, corrosion resistance and crushing resistance. The invention has the advantages of favorable corrosion resistance, high crushing resistance, favorable heat-insulating property, bacteria resistance, simple installation and connection, reduced production and installation cost, diversified structural type of pipeline and connecting device, and the like. The pipeline can be used for drinking water supply projects, drainage engineering, oil transportation, corrosive liquid transportation, high temperature liquid and gas transportation, etc.

Owner:韦鸿雁

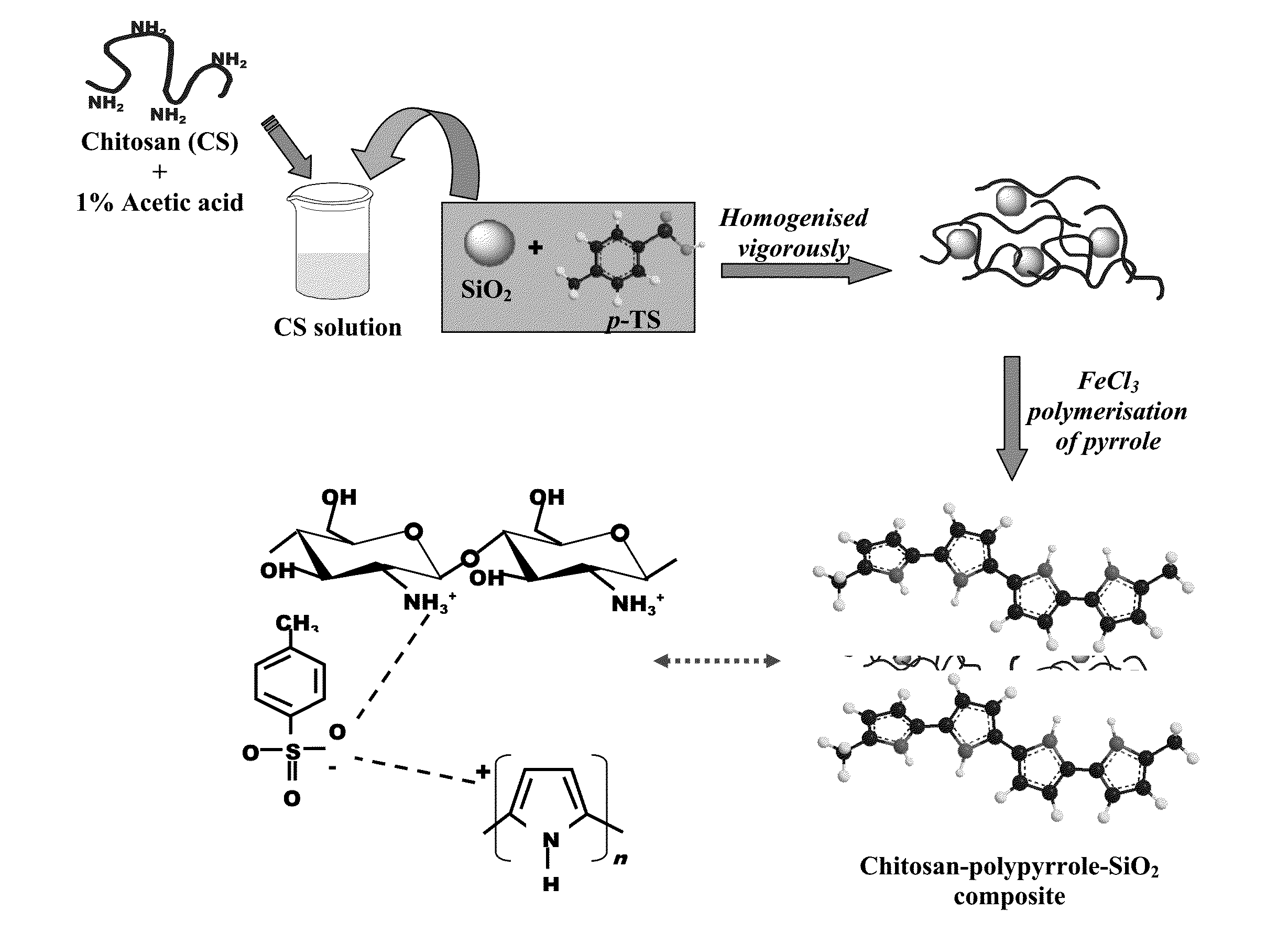

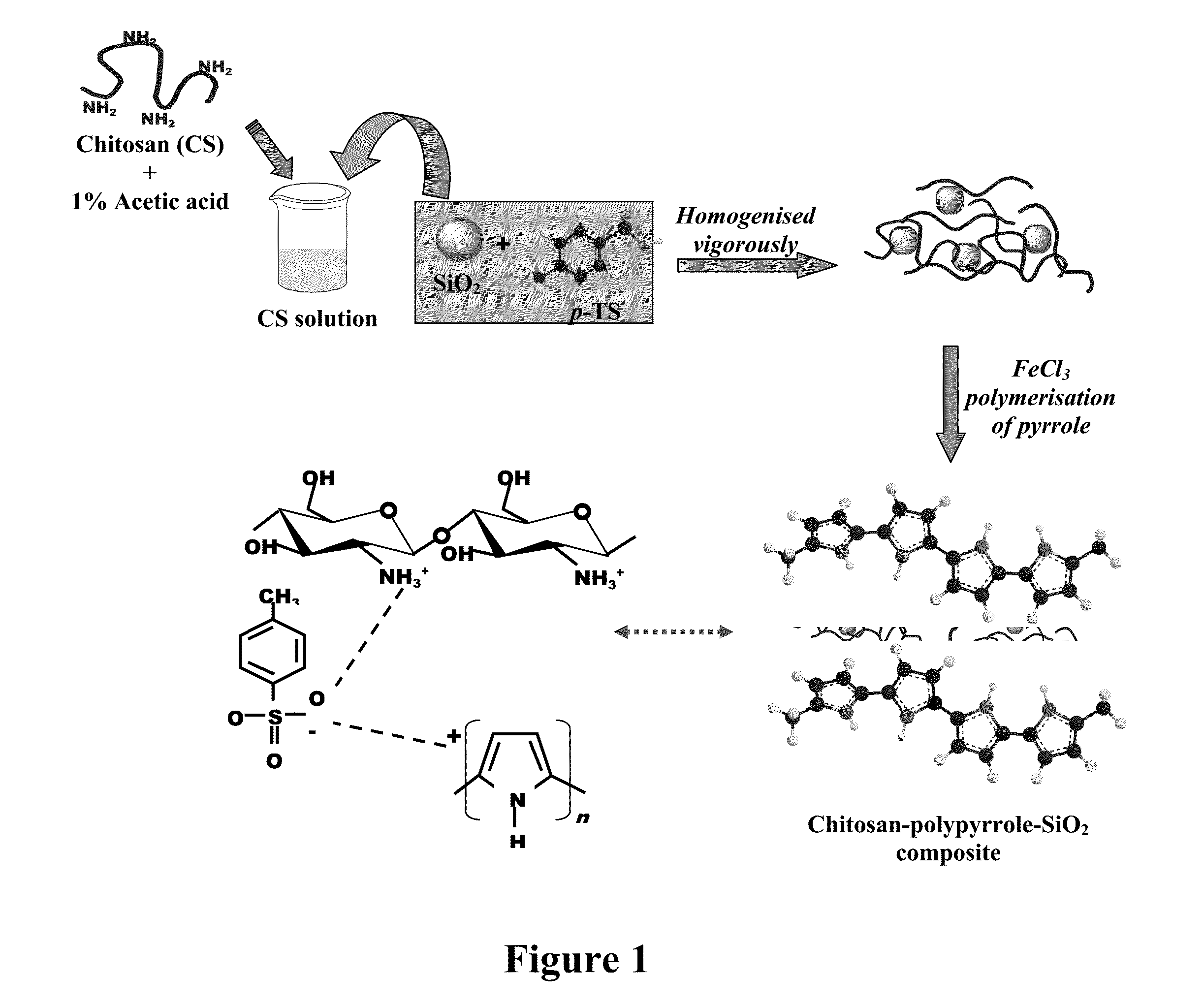

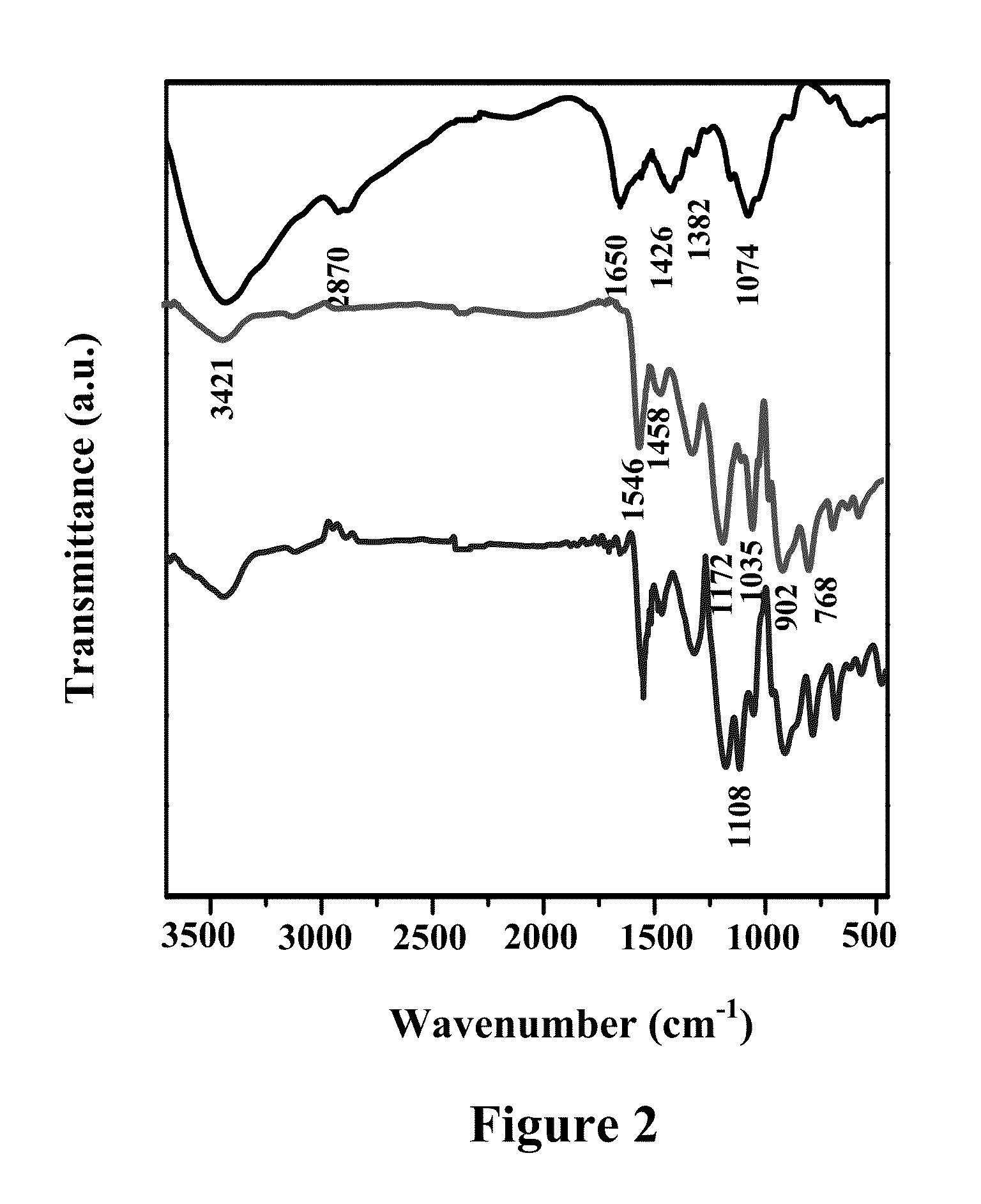

Self healing anti corrosive coatings and a process for the preparation thereof

ActiveUS20150184304A1Improve corrosion resistanceInhibited DiffusionConductive materialAnti-corrosive paintsSelf-healingEpoxy

The present invention provides self-healing anti corrosive coatings comprising composites of conducting polymers, chitosan and silica particles along with epoxy useful for corrosion prevention under highly corrosive medium like 3.5% NaCl. Tafel plots exhibits significantly high corrosion protection efficiency (99.99%) for the epoxy coatings with 2.0 wt % loading of chitosan-polymer composite. The weight loss measurements and salt spray test results clearly exhibit superior corrosion resistance offered by coatings with chitosan-polymer composite. The synergistic interaction between chitosan and polypyrrole in the composite is expected to improve the corrosion resistance properties of the coatings. The SiO2 particles present in the composite reinforce the integrity of the coating under corrosive conditions.

Owner:COUNCIL OF SCI & IND RES

Fire-retardant paint with steel structure

ActiveCN101857756AExtend fire resistance timeImprove fire resistanceFireproof paintsPolyurea/polyurethane coatingsPhosphoric acidComposite substrate

The invention relates to fire-retardant paint with a steel structure, which is prepared from the following raw materials proportioning by weight: 45 to 60 of composite substrate resin, 6 to 8 of melamine, 6 to 8 of pentaerythritol, 16 to 20 of ammonium polyphosphate, 4 to 10 of expansible graphite, 2 to 5 of nano magnesium hydroxide, 1 to 3 of zinc phosphate, 1 to 3 of zinc borate, 2 to 5 of aluminum hydroxide, 3 to 5 of aluminum polyphosphate, 6 to 9 of titanium dioxide, 0.5 to 0.8 of flatting agent and 15 to 20 of acetone. The paint has excellent capabilities of fire prevention and corrosion prevention.

Owner:INNER MONGOLIA XINGTAI CONSTRAL GRP CO LTD

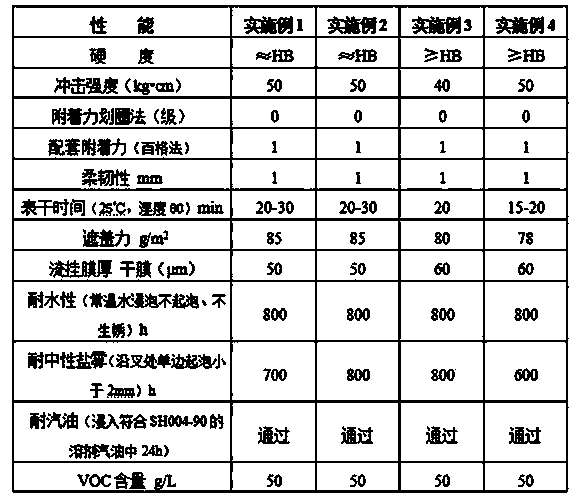

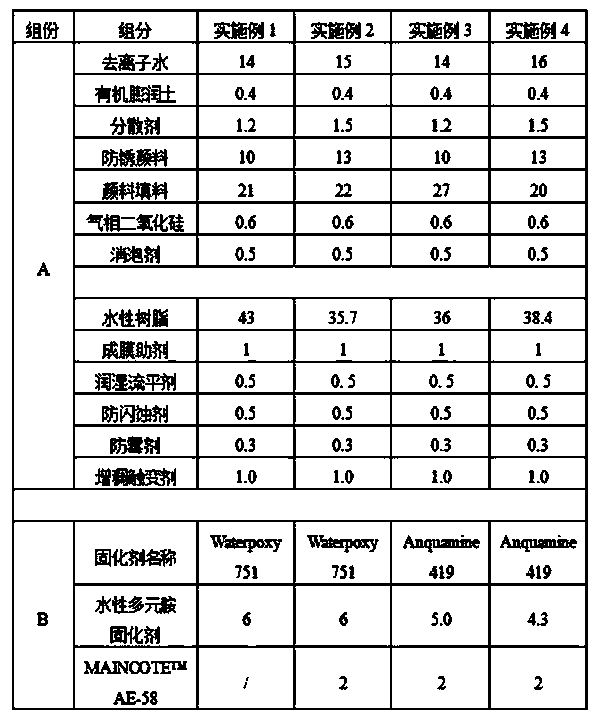

Room-temperature-curable aqueous anticorrosion primer used for coating external surface of construction crane and preparation method of primer

ActiveCN103436136AIntensity rises fastShort construction intervalAnti-corrosive paintsPolyurea/polyurethane coatingsAntifoam agentCorrosion resistant

The invention discloses a room-temperature-curable aqueous anticorrosion primer used for coating the external surface of a construction crane. The primer comprises the following components by weight: 35-45% of an aqueous resin, 5-8% of a curing agent, 1-3% of a dispersant, 5-12% of an antirust pigment, 20-35% of a pigment filling material, 1-2% of an anti-settling agent, 0.5-1% of a wetting agent, 0.5-1% of a thixotropic agent, 0.5-1% of an antifoaming agent, 0.1-0.8% of a flash etching inhibitor, 0.1-0.8% of a mildew inhibitor, 1-3% of a film-forming auxiliary agent and 10-20% of deionized water. The invention also discloses a preparation method of the aqueous anticorrosion primer. The aqueous anticorrosion primer has a room-temperature-curable paint film, is energy-saving and environment friendly, and can satisfy safe production requirements of enterprises; the primer is high in solidity, low in viscosity, convenient for construction; and the coating of the primer has good corrosion resistance and water proofness, and the comprehensive properties of the coating reach performance indexes of same-type oiliness products.

Owner:GUANGZHOU KINTE IND +1

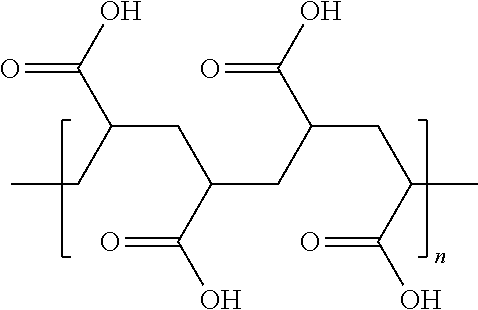

High molecular weight polyacrylates for aluminum protection in warewash applications

ActiveUS20120053104A1Achieve protectionReduce corrosionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEthylene HomopolymersAlloy

A warewashing detergent composition is provided for use for in cleaning of alkaline sensitive metals such as aluminum or aluminum containing alloys. The compositions include alternatives to sodium tripolyphosphate and / or other phosphorous containing raw materials, while retaining cleaning performance and corrosion prevention. According to the invention, high molecular weight polyacrylates (polyacrylic acid homopolymers) with a molecular weight of at least about 5000 are used as corrosion inhibitors and can be included for aluminum protection in a number of different detergent compositions.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com