Patents

Literature

799results about How to "Achieve the purpose of separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

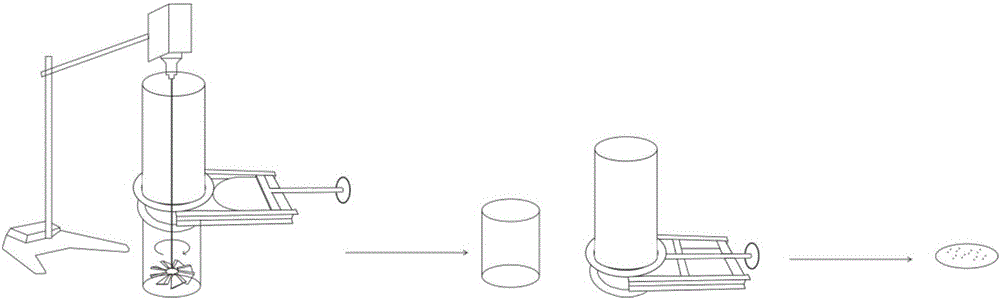

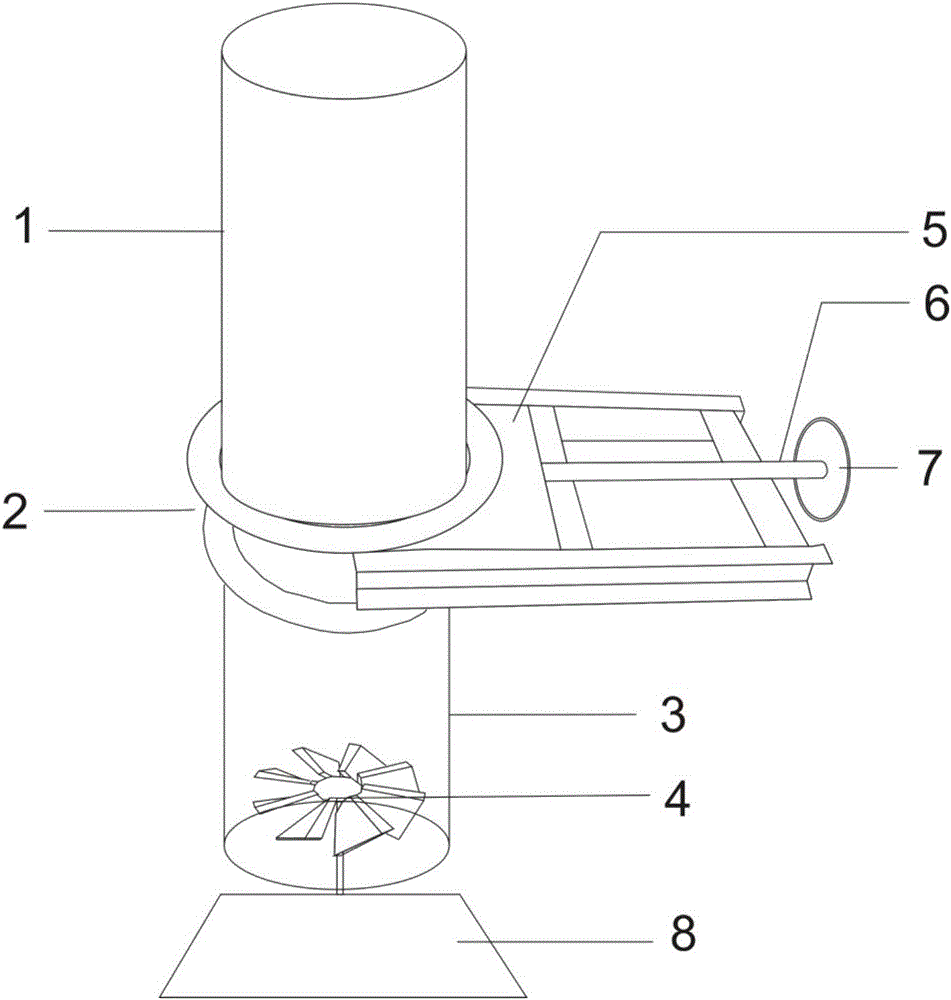

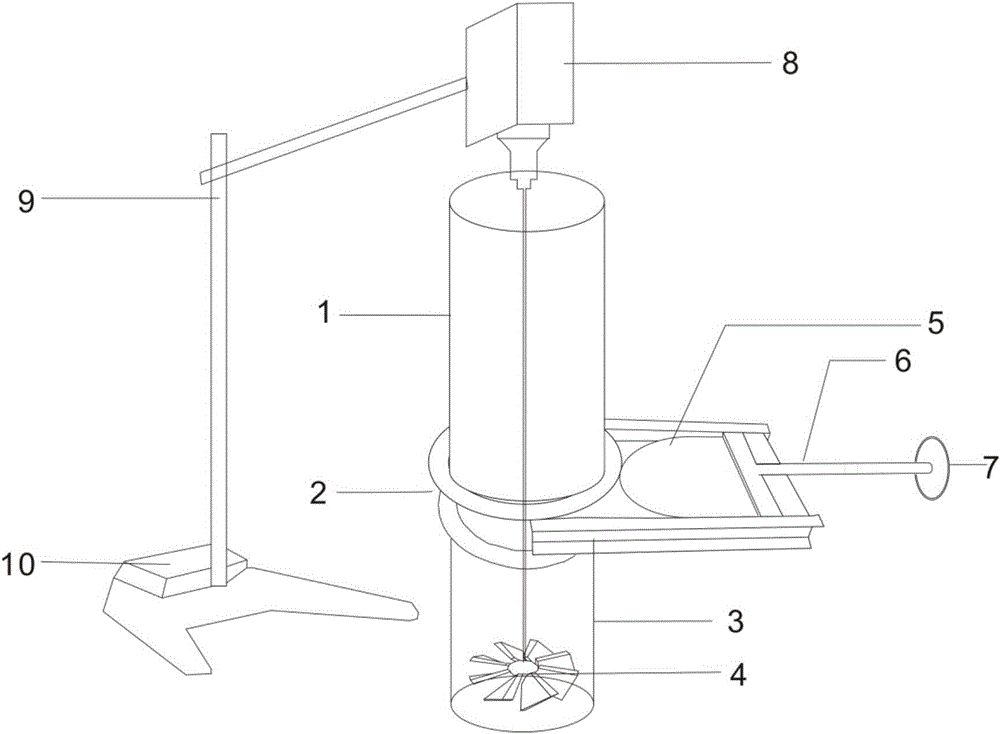

Micro-plastic separation method and device

ActiveCN106363835AImprove separation efficiencyShort processing timeSemi-permeable membranesPlastic recyclingFreeze-dryingVolumetric Mass Density

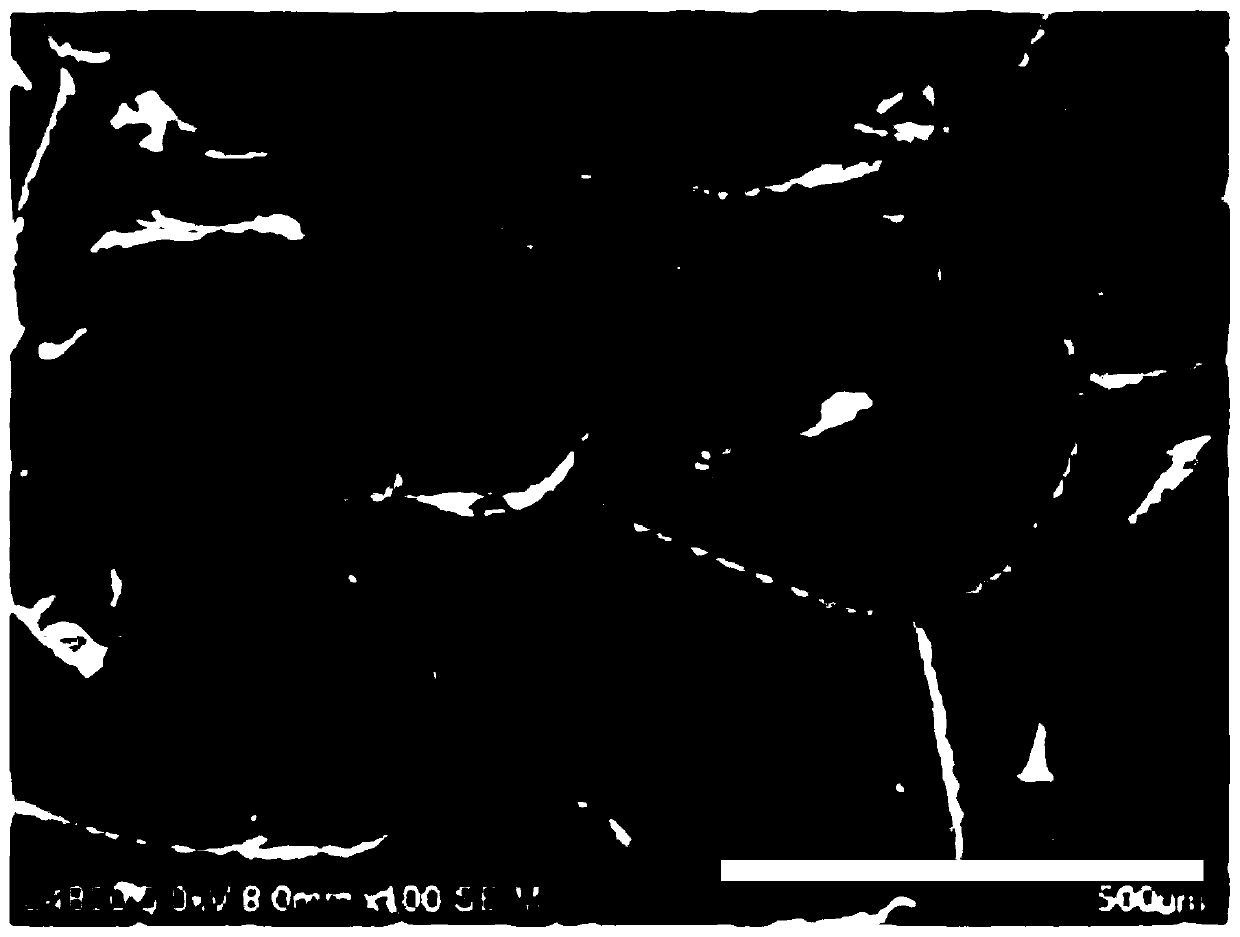

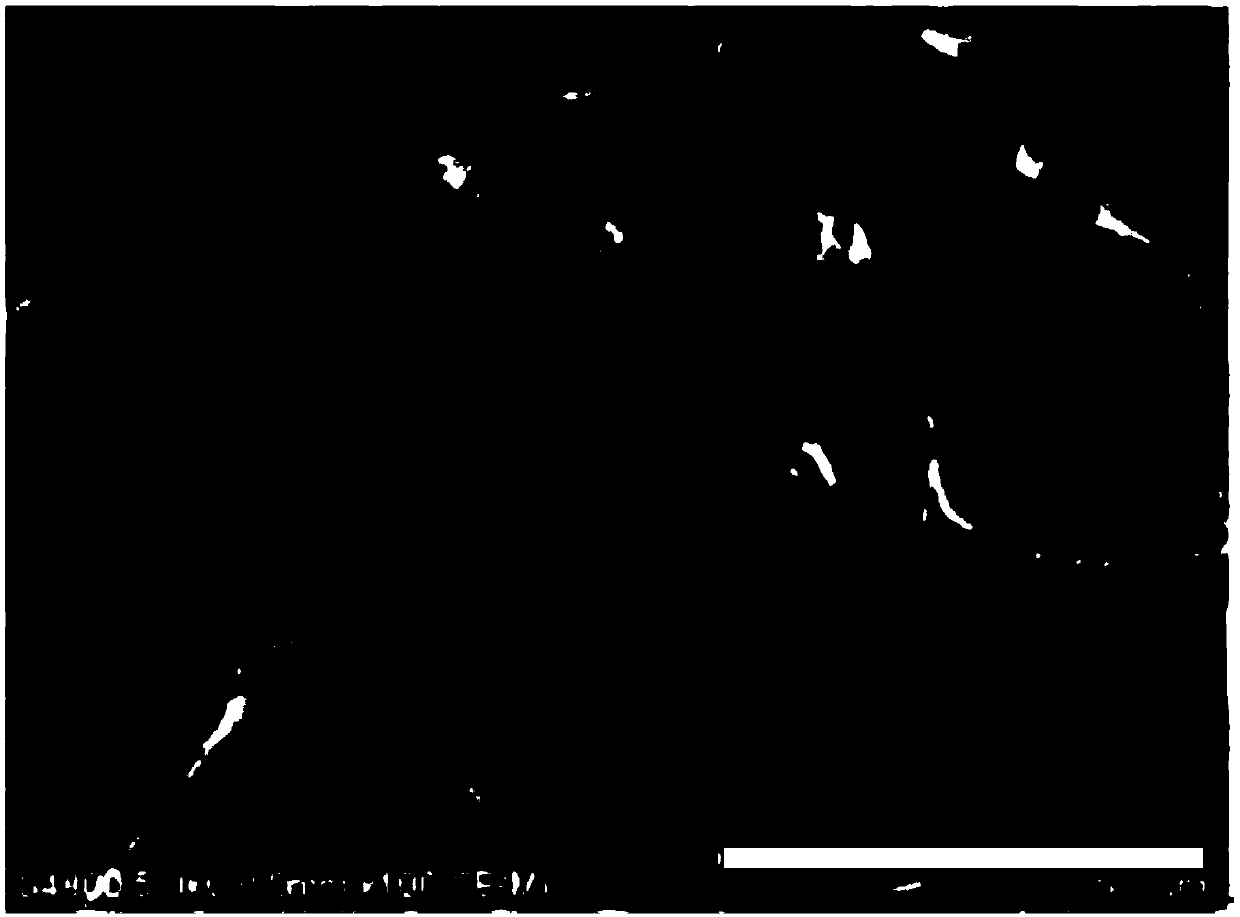

The invention belongs to the technical field of solid waste treatment and relates to a micro-plastic separation method and device. The micro-plastic separation method comprises the steps that (1) settlings of field natural water are collected; (2) the settlings of the field natural water is subjected to low-temperature drying and freeze-drying, and samples to be treated are obtained; (3) after a density solution is added into the samples to be treated, sufficient stirring is conducted until the samples to be treated are completely suspended in the density solution, and a non-sediment layer and a sediment layer are formed from top to bottom after still standing; and (4) the non-sediment layer is extracted and passes through a filter film, liquid passing through the filter film is repeatedly used, and objects isolated by the filter film include but limited to micro-plastic particles in the settlings of the field natural water. The provided micro-plastic pollutant separation method and device are capable of rapidly and effectively separating and extracting the micro-plastic particles in settlings of water such as rivers and lakes.

Owner:INST OF AQUATIC LIFE ACAD SINICA

Method for producing the red pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415665AProlong hydrolysis timeReduce manufacturing costPigmenting treatmentAmmonium sulfateFertilizer

A process for preparing iron oxide red pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining heptahydrated ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

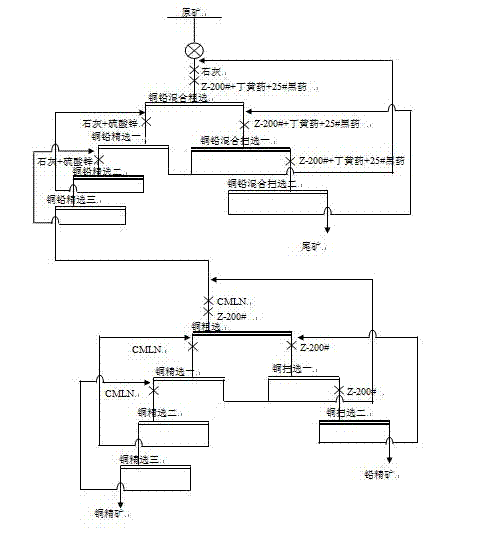

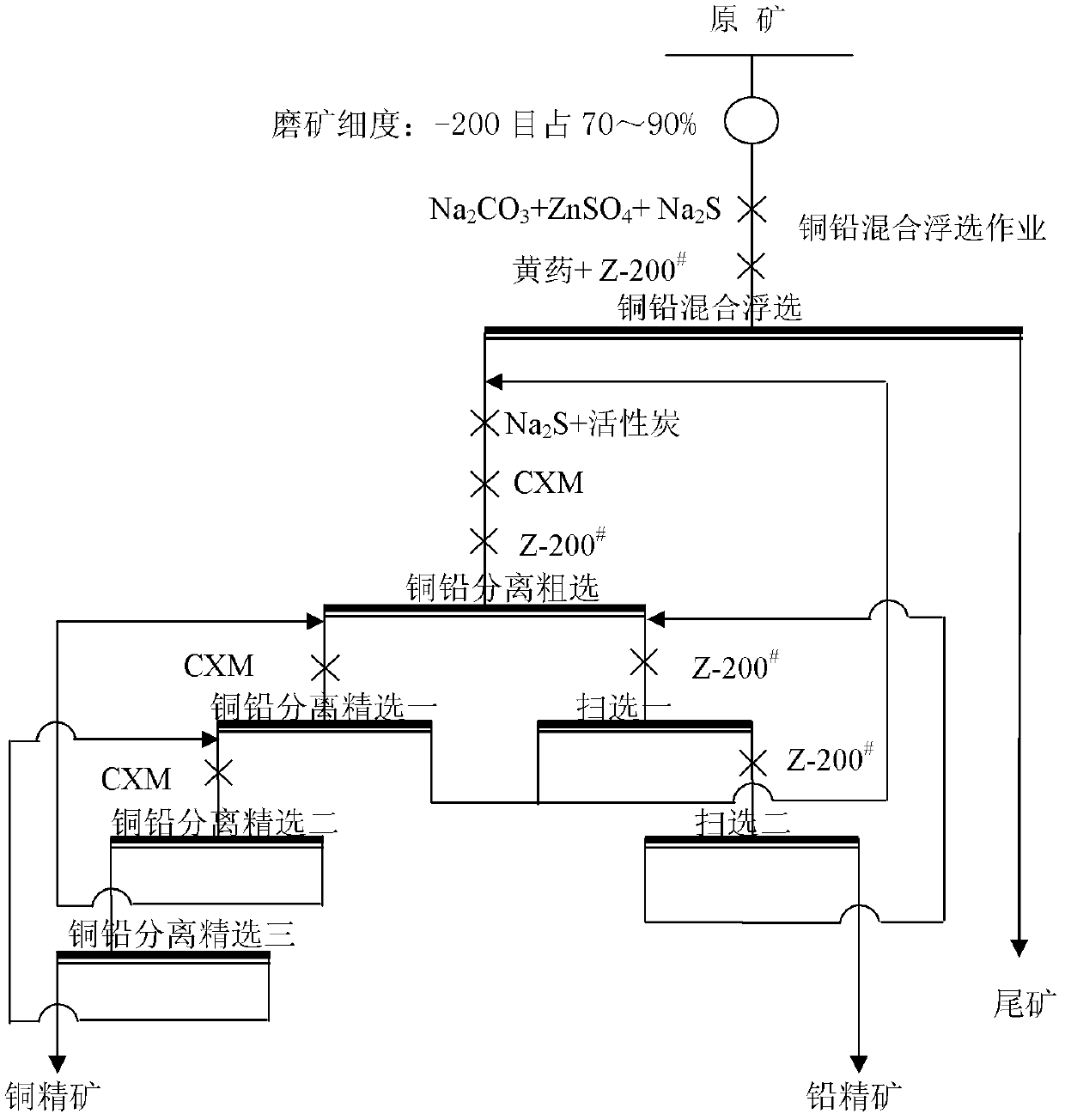

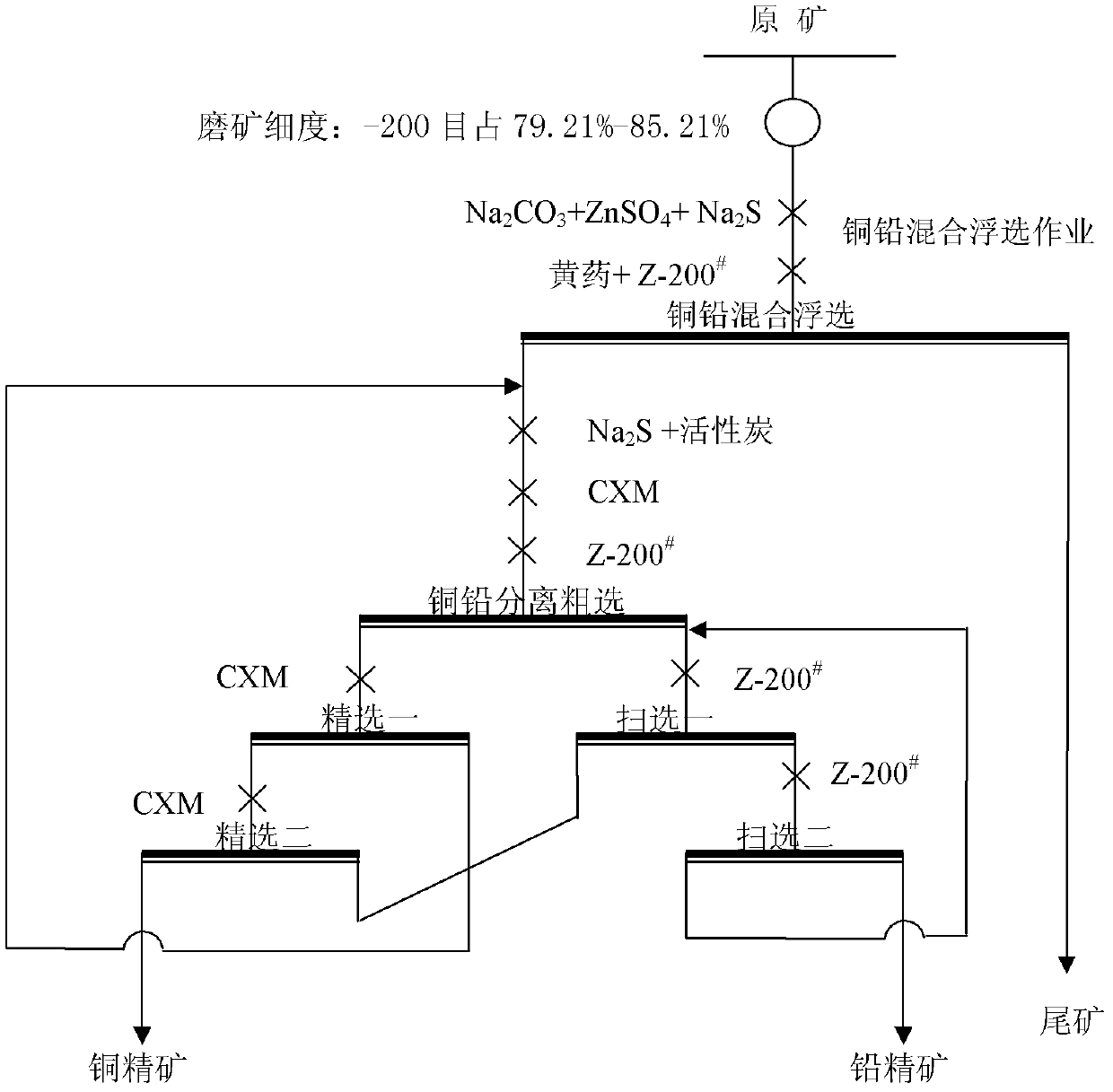

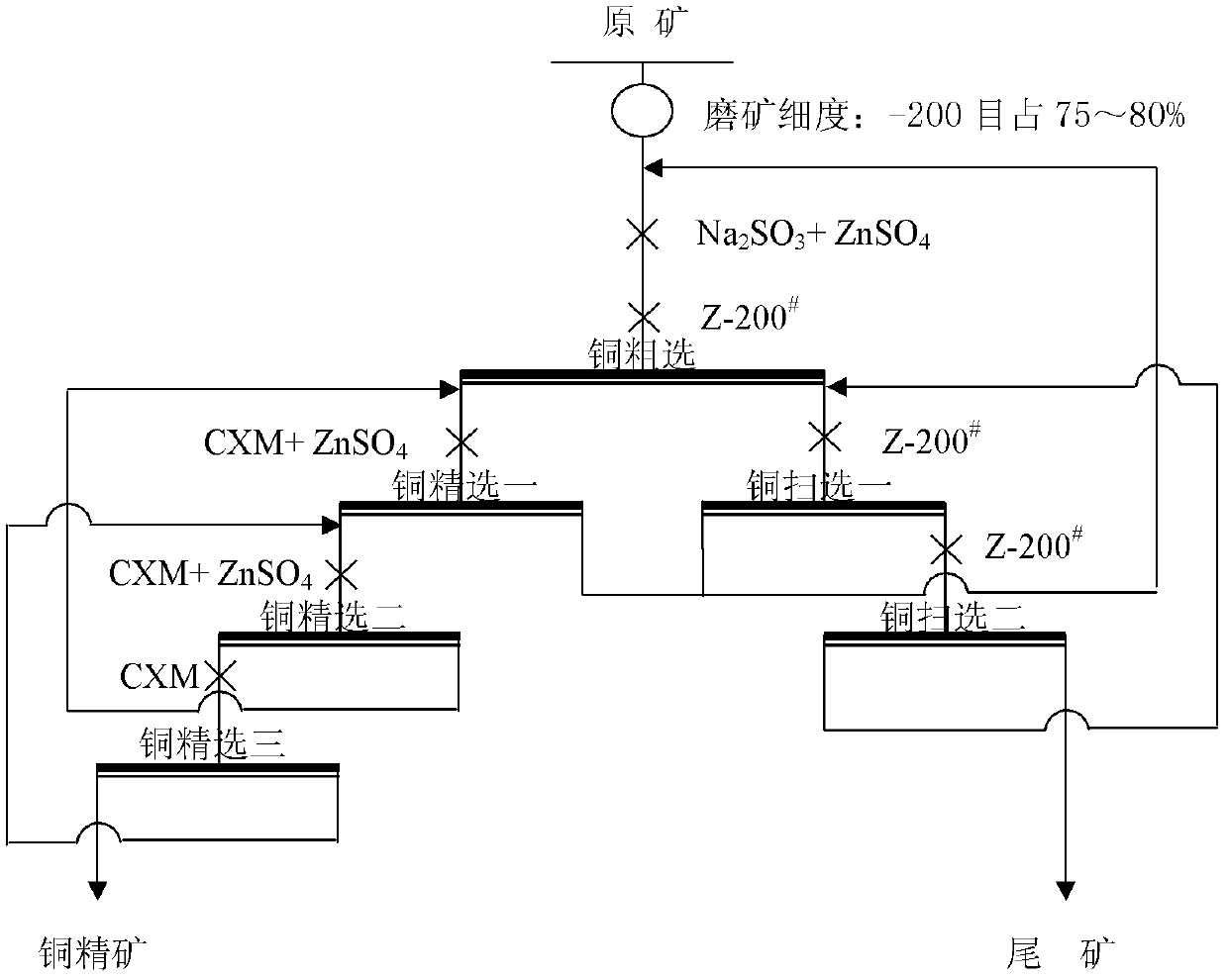

Separation method of copper-lead sulfide minerals

The invention discloses a separation method of copper-lead sulfide minerals and belongs to the field of mineral separation. According to the method, the copper-lead sulfide minerals are used as raw materials. The separation method includes steps that raw ores are milled; copper and lead mixed rough concentrate is obtained by means of a flotation method, lime and zinc sulfate which serve as inhibitors are added to the copper and lead mixed rough concentrate for concentration to obtain copper and lead mixed concentrate, CMLM (starch phosphate: sodium carboxymethyl starch=(2-4):1) is added to the copper and lead mixed concentrate, the CMLM is used as an inhibitor of lead minerals, and Z-200# is used as a flotation collecting agent of copper minerals for performing copper-lead separation. The CMLM which is used as an inhibitor of lead sulfide minerals has the advantages of being good in selectivity, high in inhibiting ability, small in using amount and convenient to add, activated carbon reagent removal or mechanical concentration reagent removal is not required during the process of copper-lead separation, the operating procedure is simple, problems of environmental pollution brought by traditional dichromate methods and cyanide methods and high costs are solved, and the floating separation method for separating the copper-lead sulfide minerals is simple, convenient, efficient and environment-friendly.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Copper-lead separation flotation inhibitor and applications thereof

The invention belongs to the field of complicated copper-lead-zinc sulphide ore beneficiation separation and provides a copper-lead separation flotation inhibitor and applications thereof. The copper-lead separation flotation inhibitor is formed by mixing polymeric ferric sulfate solution with a mass concentration of 5.0%-6.0% and glycerin solution with a mass concentration of 0.8%-1.2%, wherein the mass ratio of the polymeric ferric sulfate solution to the glycerin solution is 1:1-4. Addition of the inhibitor in copper-lead separation operation can remarkably improve copper and lead concentrate qualities, evidently lower mutual containing of copper and lead, and improve flotation recovery rate of copper and lead minerals. The copper-lead separation flotation inhibitor and the applications thereof have the advantages that the copper-lead separation flotation inhibitor is environment-friendly, efficient in sorting, low in reagent cost, easy to operate and the like and applicable to the complicated copper-lead-zinc sulphide ore beneficiation separation.

Owner:HUNAN RES INST FOR NONFERROUS METALS

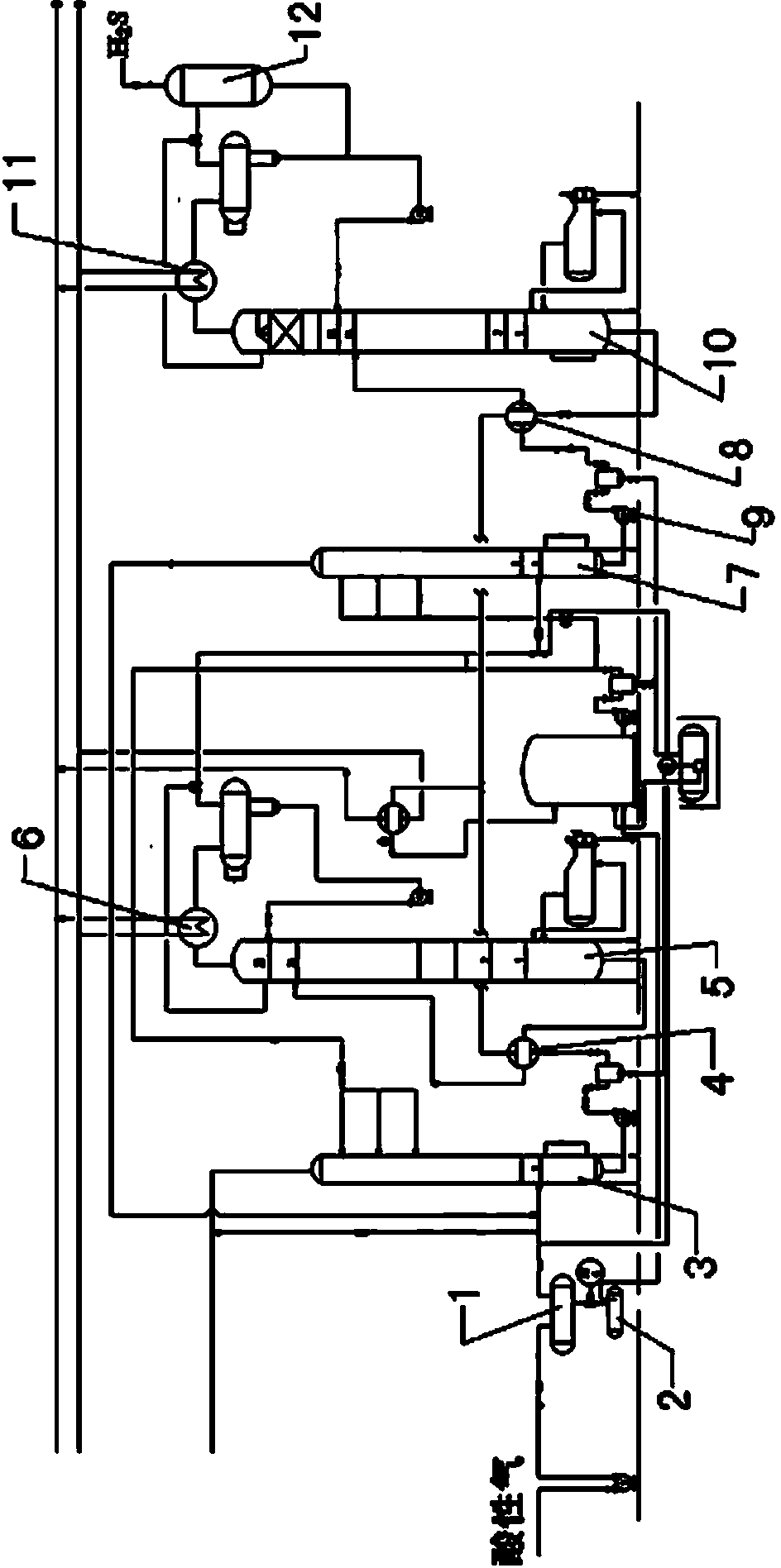

Separation technology of hydrogen sulfide and carbon dioxide in acid gas of oil refinery

InactiveCN103446849AHigh selectivityImprove stabilityHydrogen sulfidesDispersed particle separationSeparation technologyGas phase

The invention relates to a separation technology of hydrogen sulfide and carbon dioxide in acid gas of an oil refinery. According to the technical scheme, the separation technology comprises the following processing steps that the acid gas of the oil refinery flows through an acid gas separating tank and an acid water separating tank and then enters a first absorbing column; the acid gas at the bottom part of the first absorbing column is in contact with barren liquor from the upper part of the column, thus hydrogen sulfide in the acid gas can be fully absorbed to generate rich liquor; the rich liquor and barren liquor enter a first-grade rich-barren heat exchanger to exchange the heat and then enter a first regenerating column to regenerate; H2S gas generated at the top of a second regenerating column is condensed through a second condenser and then flows into a separating tank; a separated liquid phase is used for backflow in the top of the regenerating column; and a gas phase, namely, H2S gas, is used as sodium hydrosulfide to prepare some of raw materials. The separation technology has the beneficial effects that a methyldiethanolamine extracting agent at a concentration of 50% is selected; and compared with other extracting agents, the methyldiethanolamine extracting agent has relatively high selectivity and stability, causes a very little loss, and is low in energy consumption of devices.

Owner:SHANDONG KENLI PETROCHEM GRP

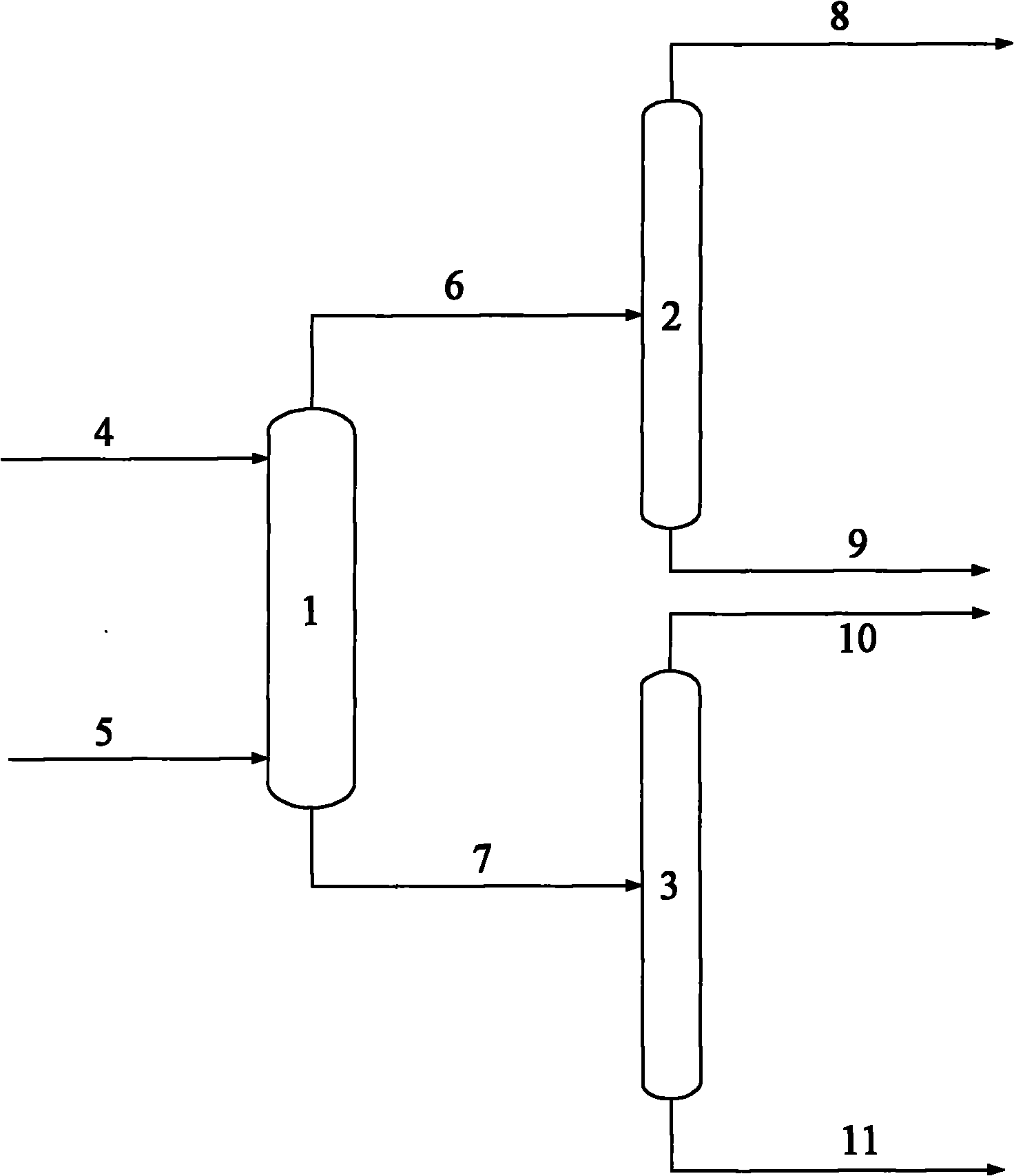

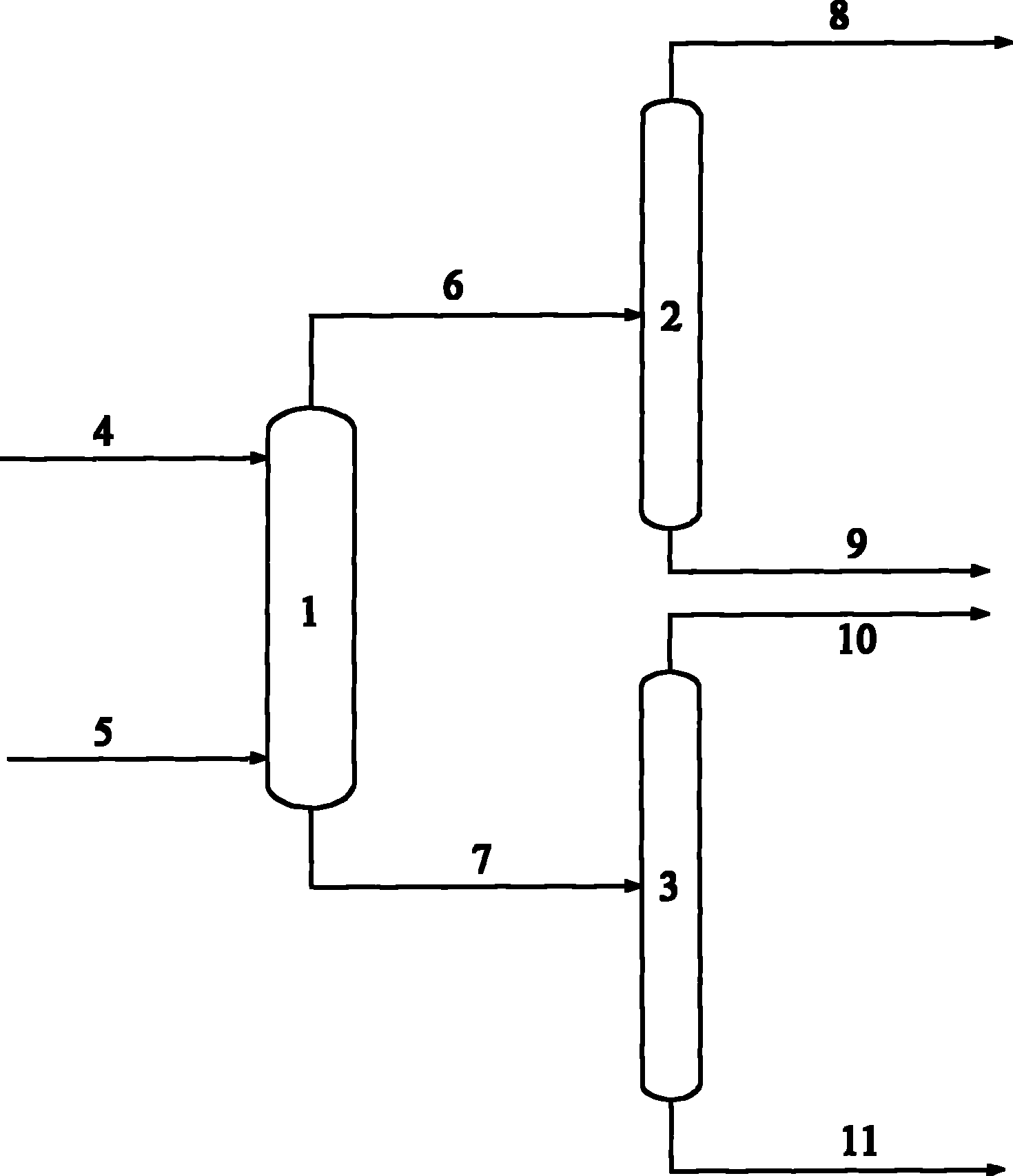

Separation method for glycol, propylene glycol and butylene glycol

ActiveCN102372600AReduce separation energy consumptionEasy to separateOrganic compound preparationHydroxy compound separation/purificationHigh energyPropylene glycol

The invention relates to a separation method for glycol, propylene glycol and butylene glycol and mainly aims to solve the problem of high energy consumption in separation of glycol, propylene glycol and butylene glycol by using azeotropic rectification in the prior art. The invention comprises the following sequential steps that: a raw material containing glycol, propylene glycol and butylene glycol and an extractant enter into an extraction tower (1) respectively from the top and the bottom of the extraction tower, an extractant material flow I containing butylene glycol is obtained at tower top, and glycol material flow II containing propylene glycol is obtained at tower bottom; the material flow I enters into the central part of an extractant recovery tower (2), the recovered extractant is obtained at tower top, and an extractant solution containing butylene glycol is obtained at tower bottom; the material flow I enters into the central part of a glycol treating tower (3), a solution containing propylene glycol and the extractant is obtained at tower top, and the product of glycol is obtained at tower bottom. The method provided in the invention enables the above-mentioned problem to be well overcome and can be used in industrial production for separation of glycol, propylene glycol and butylene glycol.

Owner:CHINA PETROLEUM & CHEM CORP +1

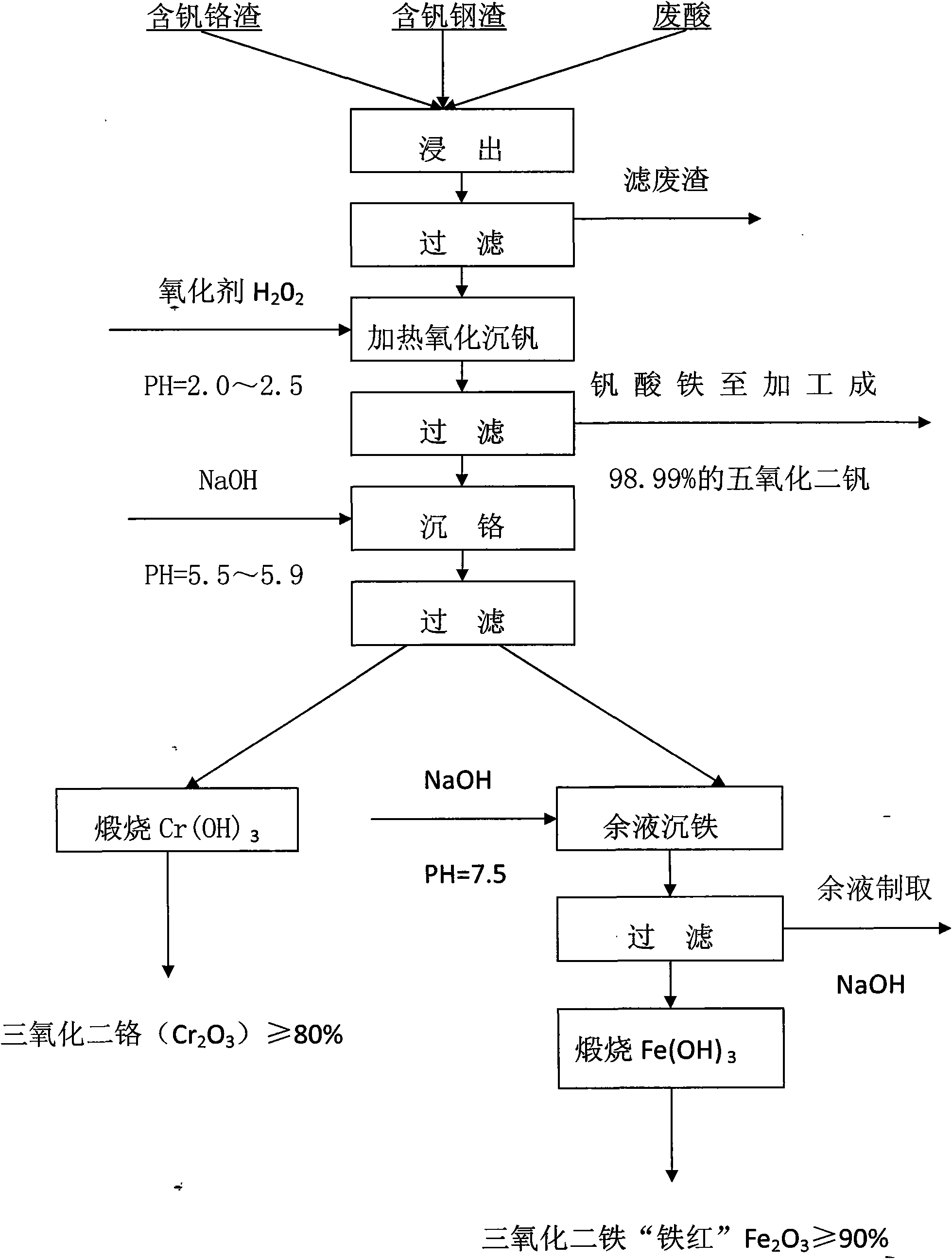

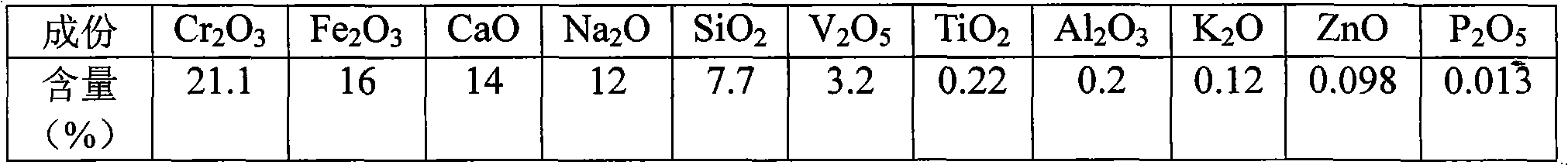

Process for extracting vanadium and chromium from chromic slag by using waste acid of titanium powder plant

InactiveCN101979683AFiltration process goes wellAchieve the purpose of separationProcess efficiency improvementChromium(III) hydroxideSlag

The invention discloses a method for separating and extracting vanadium and chromium. The method comprises the following steps of: (1) producing chromium fine sand (Cr2O3) of which the content is over 80 percent and ferric vandate of which the content is over 20 percent from two waste materials by taking waste acid of a titanium powder plant as a leaching agent and vanadium-chromium slag (containing 2.5 to 4.5 percent of vanadium and 14 to 25 percent of chromium) as a raw material; (2) putting the vanadium-chromium slag into the waste acid to allow the chromium and the vanadium in the slag to form chromium sulfate and vanadyl sulfate which can be dissolved in water very easily, wherein the leaching time is about 6 hours; (3) adding a certain amount of steel making steel slag during leaching to fulfill the aim of generating a great deal of calcium sulfate when a great deal of calcium oxide meets the acid during filtration, and wrapping, adsorbing or and stopping 'silica gel' formed by silicon dioxide in the chromium slag by the calcium sulfate which is used as a filter medium to ensure that the filtration is performed smoothly; (4) adjusting the pH value of the filtrate to be 2.5 by using sodium hydroxide, and then adding an oxidant and oxydol to ensure that the chromium in the solution is oxidized to be hexavalent, the iron is oxidized to be trivalent, and the vanadium is oxidized to be pentavalent; (5) heating the leaching solution to the temperature of between 70 and 90 DEG C to ensure that the vanadium and the iron is combined together to generate water-fast 'ferric vandate', wherein the time for thermal precipitation is about one hour, and the vanadium residual in the solution is not more than 0.4 g / L; (6) adding sodium hydroxide into the solution of which the ferric vandate is filtered out, and fully stirring the mixture until the pH value of the solution is between 5.5 and 5.9 to ensure that the chromium in the solution is completely converted into chromium.

Owner:PANZHIHUA SHUOSHENG IND & TRADING

Method for producing the yellow pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415666AHigh recovery rateAchieve the purpose of separationPigmenting treatmentFerric oxide yellowTitanium oxide

A process for preparing iron oxide yield pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

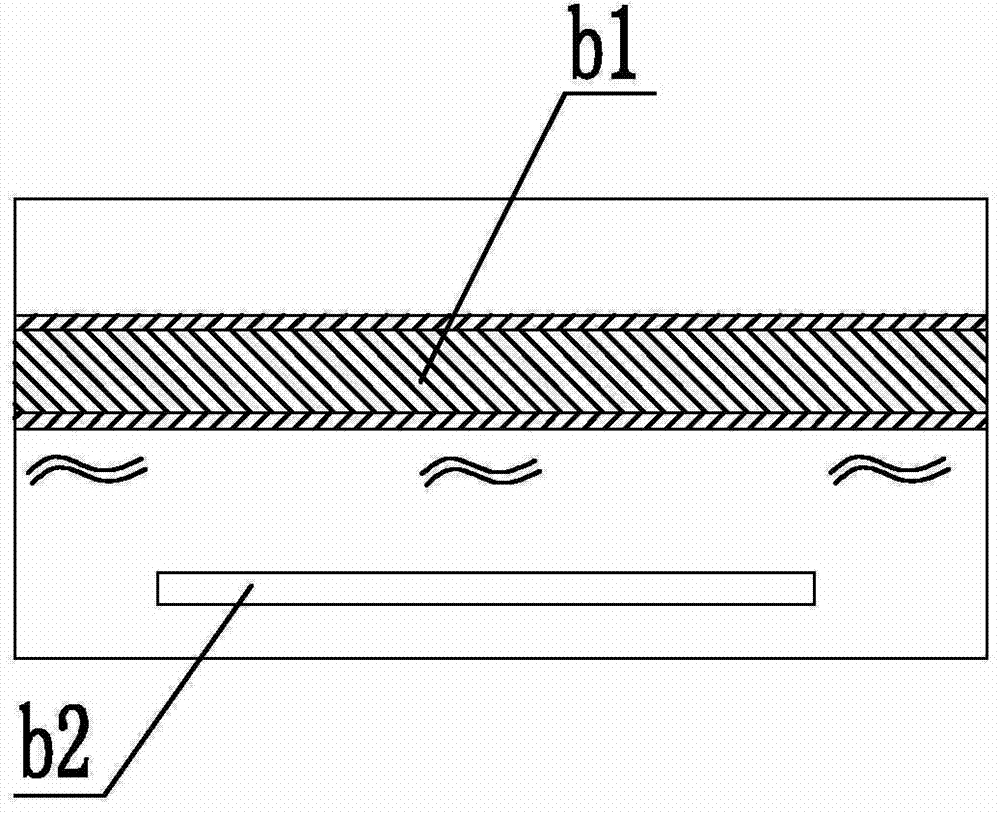

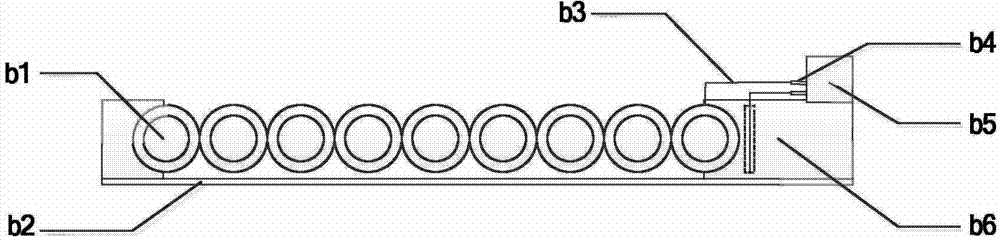

Ultrasonic separation device for fine particles

InactiveCN104722106AAchieve the purpose of separationImprove processing efficiencyWater/sewage treatment with mechanical oscillationsSedimentation separationUltrasonic sensorMechanics

The invention relates to an ultrasonic separation device for fine particles. The ultrasonic separation device is characterized in that a water inlet is formed in the top of a dynamic separation chamber, and a particle outlet and a water outlet are sequentially formed in the bottom of one end, opposite to the water inlet, of the dynamic separation chamber; a reflection plate is horizontally arranged at the front end of the particle outlet; a first ultrasonic transducer is arranged at the position, directly facing the reflection plate, on the top of the dynamic separation chamber; a second ultrasonic transducer is arranged at the water outlet of the dynamic separation chamber; an acoustic panel is arranged at the position, directly facing the second ultrasonic transducer, at the water inlet of the dynamic separation chamber. According to the ultrasonic separation device, by virtue of a low-frequency standing wave and high-frequency traveling wave combination method, the processing time is greatly shortened, the equipment cost is greatly lowered, the whole structure is compact, the fine particles, even a very limited number of fine particles in a flow field can be separated, furthermore, the separation time is short, and the separation effect is good.

Owner:SHAANXI NORMAL UNIV

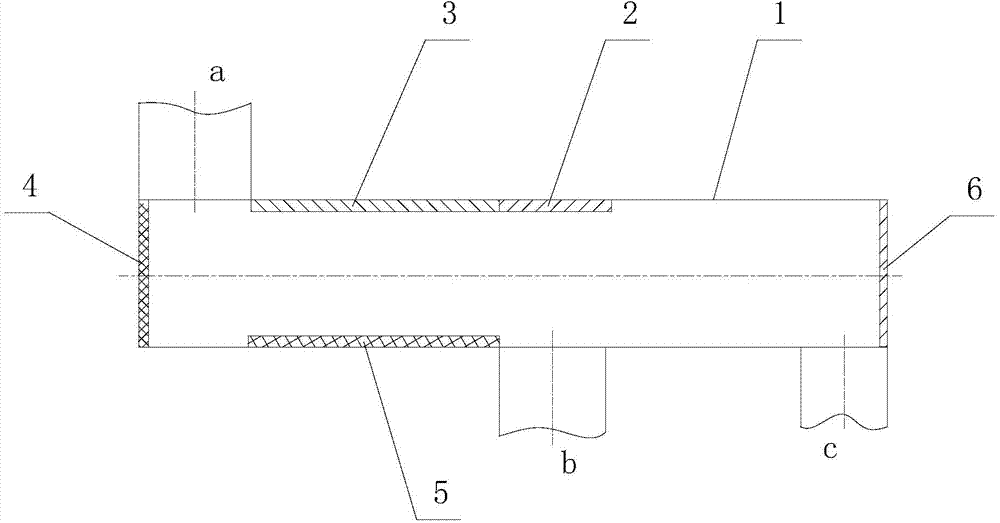

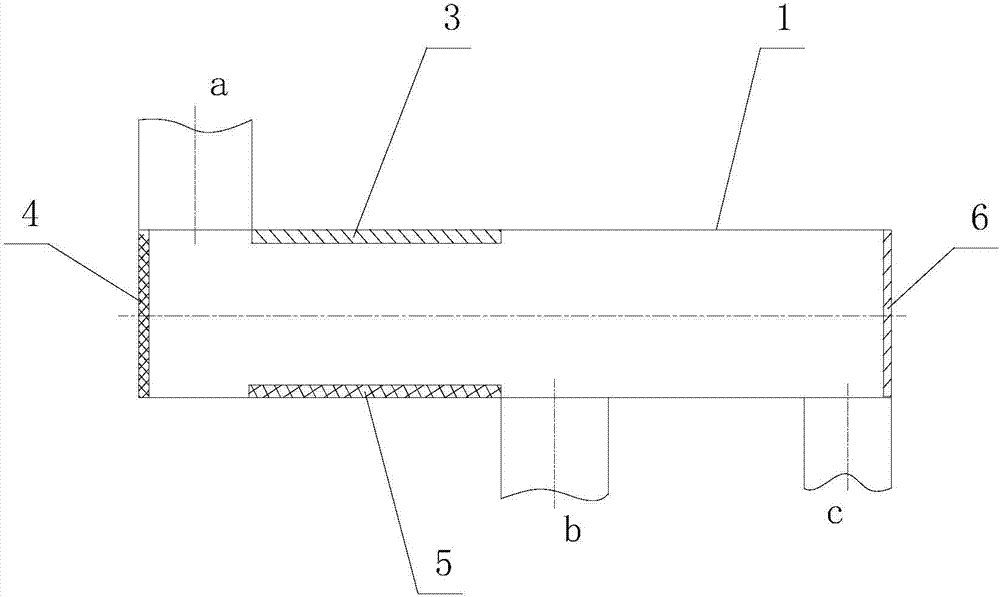

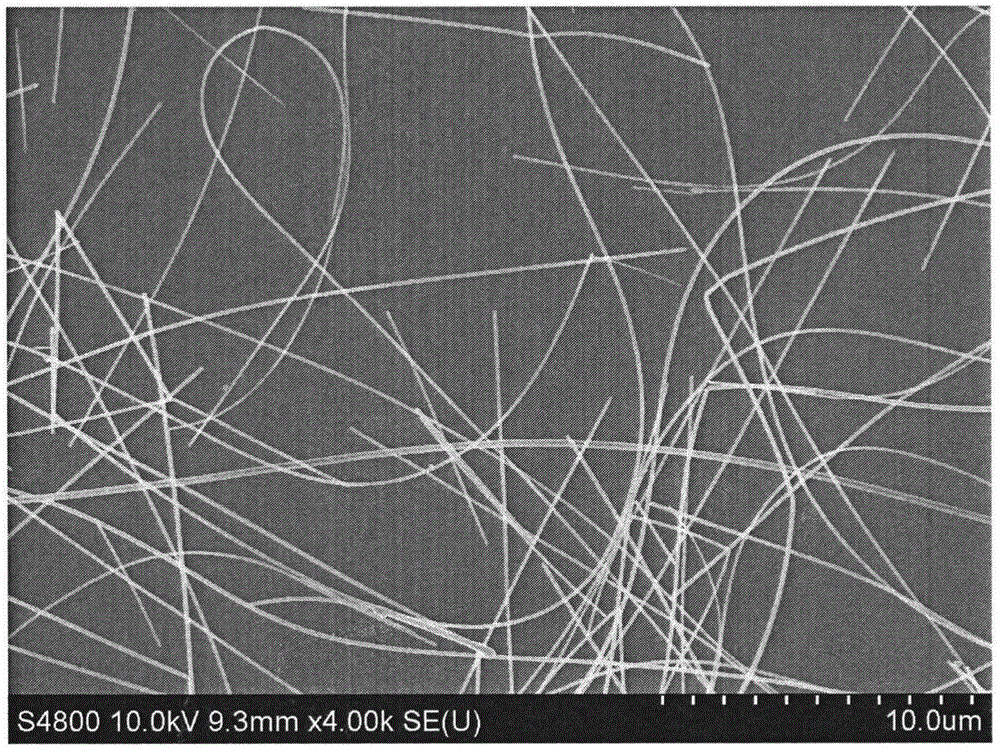

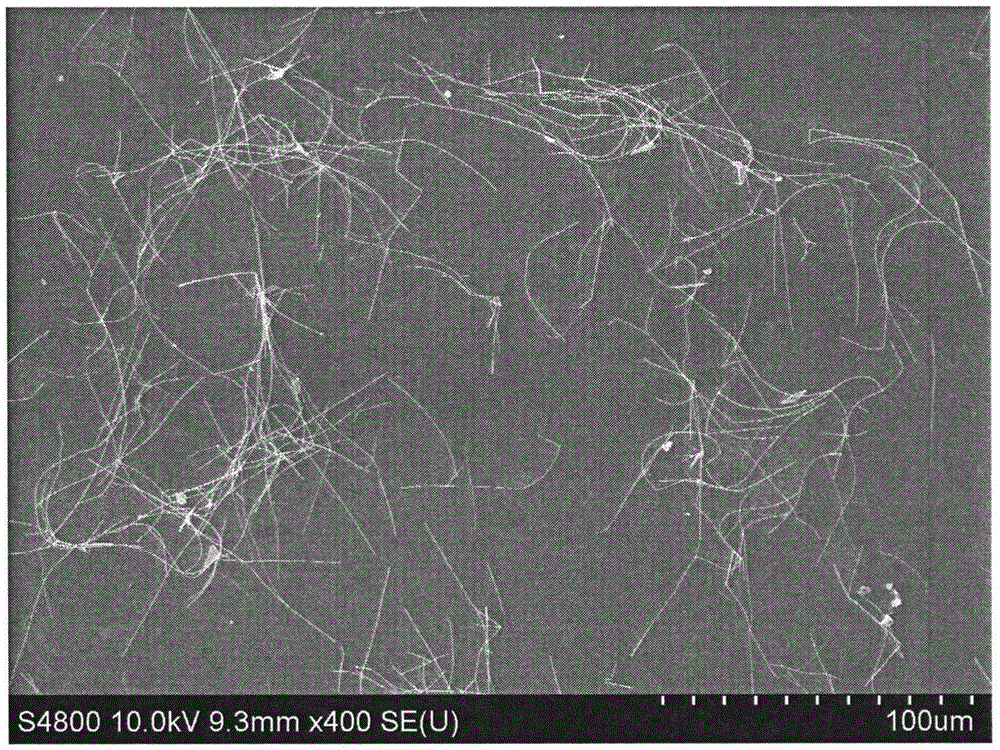

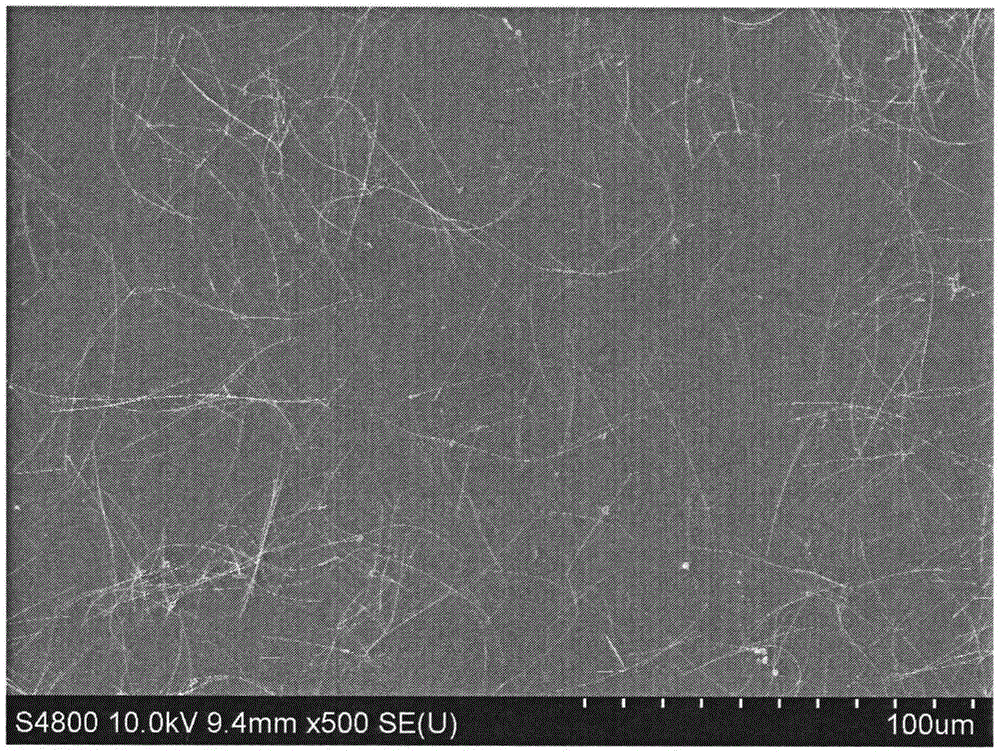

Method for preparing silver nanowires

InactiveCN105537622AEasy to operateAvoid the effects of reactionsNanotechnologyPolymerPhotochemistry

The invention discloses a method for preparing silver nanowires. Under protection of inert gas, a polymer polyhydric alcohol solution and a silver salt and halide polyhydric alcohol solution are sequentially added into a premixing container and are stirred to be completely dissolved, and mixed liquor is transferred to a reaction device which is preheated to 100-180 DEG C to react for 2-5 h; acetone with the volume being 5-9 times that of prepared silver nanowire mother liquor is added into the prepared silver nanowire mother liquor, natural settling is conducted for 10-30 min after acute vibration, supernatant is moved away, sediment is reserved, and the process is repeated 2-3 times; ethyl alcohol with the volume being 5-9 times that of the mother liquor is added into the sediment, centrifugal separation is carried out, supernatant is moved away, sediment is reserved, and the process is repeated 2-3 times; and obtained silver nanowires are stored in the ethyl alcohol in a scattered mode. The preparation method is one-pot, operation is simple, and stability and repeatability are good; stirring is not needed in the reaction process during preparation, and silver wire particles are few; the material adding speed does not need to be strictly controlled in the preparing process, and large-scale production is facilitated; separation and purification are carried out through natural settling of the acetone and then centrifugal sedimentation of the ethyl alcohol, so that the separation efficiency is higher.

Owner:嘉兴禾浦光电科技有限公司

Natural perfume refining fluid suitable for cigarette fluid of electronic cigarettes and cigarette fluid and preparation method thereof

ActiveCN105029681ARemove ingredients that are unfavorable to smoking tasteEfficient removalTobacco treatmentSolubilityLiquid smoke

The invention discloses natural perfume refining fluid suitable for cigarette fluid of electronic cigarettes and cigarette fluid and a preparation method thereof, and belongs to the technical field of cigarette fluid of electronic cigarettes. Separation and impurity removal are performed on natural perfume such as extract, tincture and absolute oil through a macroporous adsorption resin column chromatography technology, high-boiling-point components such as monosaccharide and disaccharide and macromolecular components such as protein, polysaccharide and pectin in the natural perfume are simultaneously and effectively removed according to the differences of polarities and molecular sizes of all the components in the mixture, the components unfavorable for the smoking mouthfeel of the electronic cigarettes are removed, and the problem that charring flavor is generated due to the fact that the substances are deposited on heating wires is solved; meanwhile, the solubleness of the natural perfume in propylene glycol and glycerinum is improved, therefore, the cigarette fluid of the electronic cigarettes becomes clear and bright, the emission performance of perfume is significantly improved, the sweet greasy feeling is reduced, and the sensory effect is significantly improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

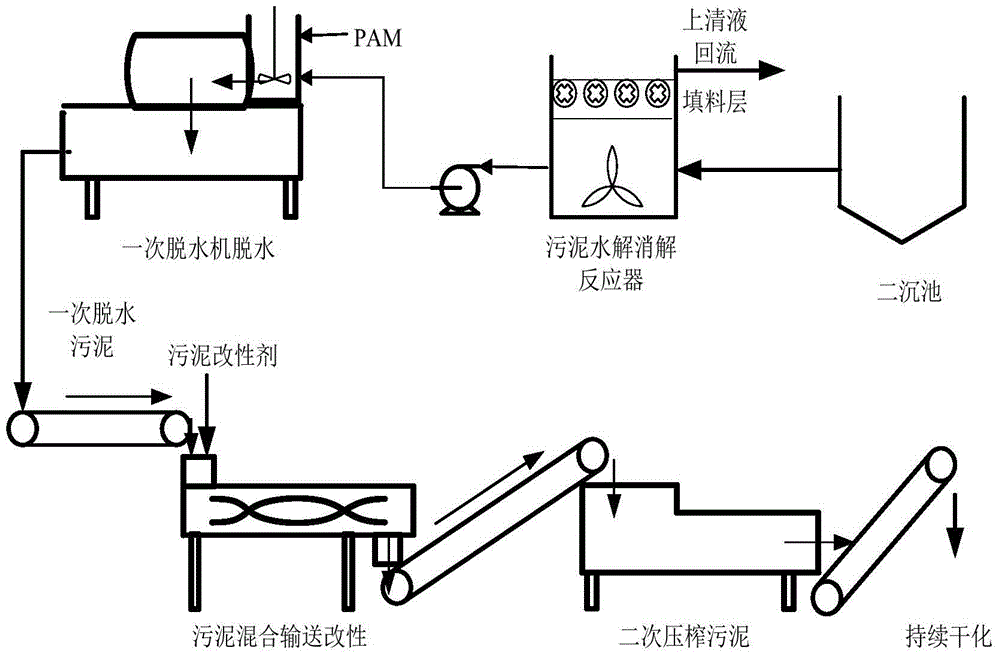

Sludge reduction and desiccation combination method

ActiveCN103951146AAchieve the purpose of separationSolve problemsSludge treatment by de-watering/drying/thickeningSludge processingSludgeResource utilization

The invention relates to a sludge reduction and desiccation combination method. Sludge with a moisture content of 99% in a secondary sedimentation tank is inputted into a sludge hydrolysis digestion reactor internally provided with a filler layer, in the reaction conditions of full stirring, sludge floc cell wall is broken for sludge liquefaction to realize sludge and water separation, an acidizing fluid discharging from the top of the filler layer flows back to flooding water of a sewage plant for carbon source recycling, the sludge reduction rate can reach 20-60%; after first dehydration, the reduced sludge is modified for cell wall disruption, and then is dehydrated by secondary pressing, and finally the moisture content of the sludge is reduced to 20%-30% by continuous desiccation reaction. According to the method, the sludge output can be reduced from the source, the sludge desiccation treatment cost can be saved, the sludge after desiccation treatment is not easy to rot and is good in stabilizing effect, and the method can be widely used in the treatment and disposal of residual sludge in the sewage plant, and finally realizes the reduction and resource utilization of the residual sludge.

Owner:SHANGHAI SHENYAO ENVIRONMENTAL PROTECTION ENG +1

Text template generating method

InactiveCN103353863AAvoid wastingAchieve separationNatural language data processingSpecial data processing applicationsNatural language processingCollision detection

The invention relates to a text template generating method. In the text template generating method, an XML (Extensive Makeup Language) language is used for describing characteristics of a text style so as to achieve the separation of the text style from a text content; through the implementation of a collision detection technology, the free space of an irregular image is sufficiently utilized, the effects which cannot be achieved by many traditional text styles are achieved, and the layout of a text is more user-friendly; because of a cross-platform transmission characteristic of the XML language, more text styles can be chosen by a user, thus improving the reading experience of the user. The text template generating method is applicable to e-books, blogs, e-mails, multimedia messages, instant chats and other application environments.

Owner:徐华

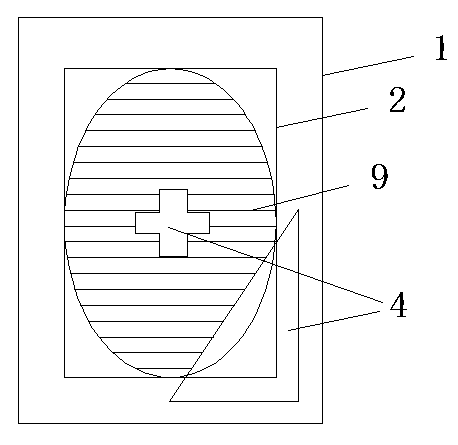

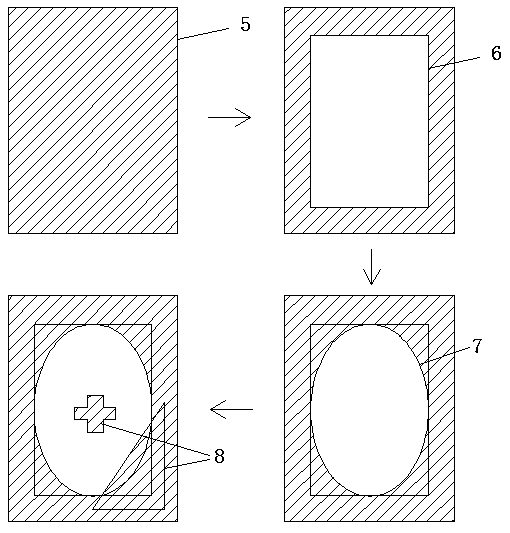

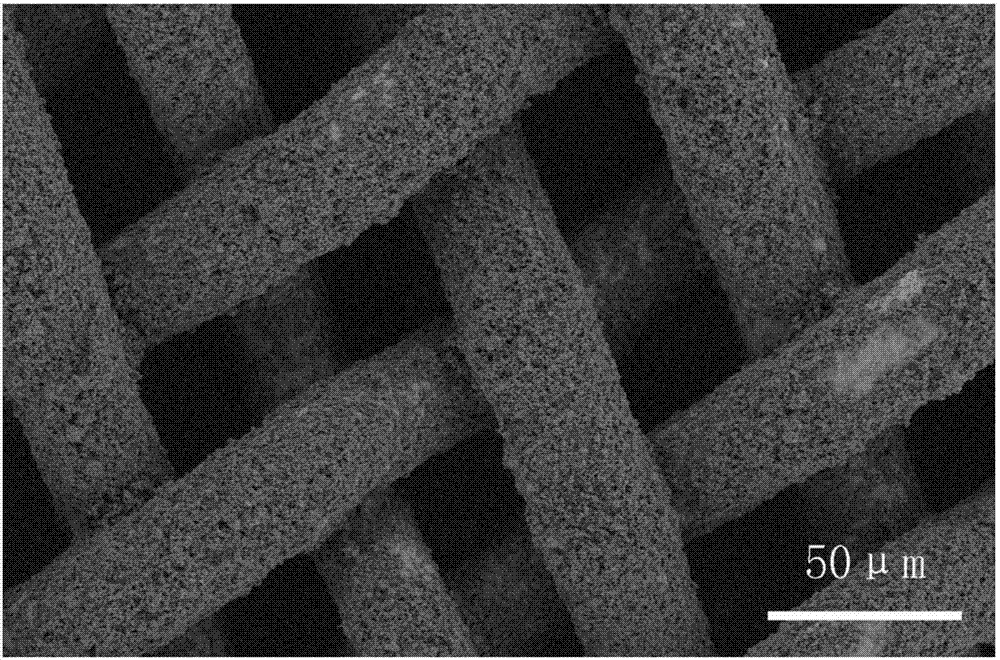

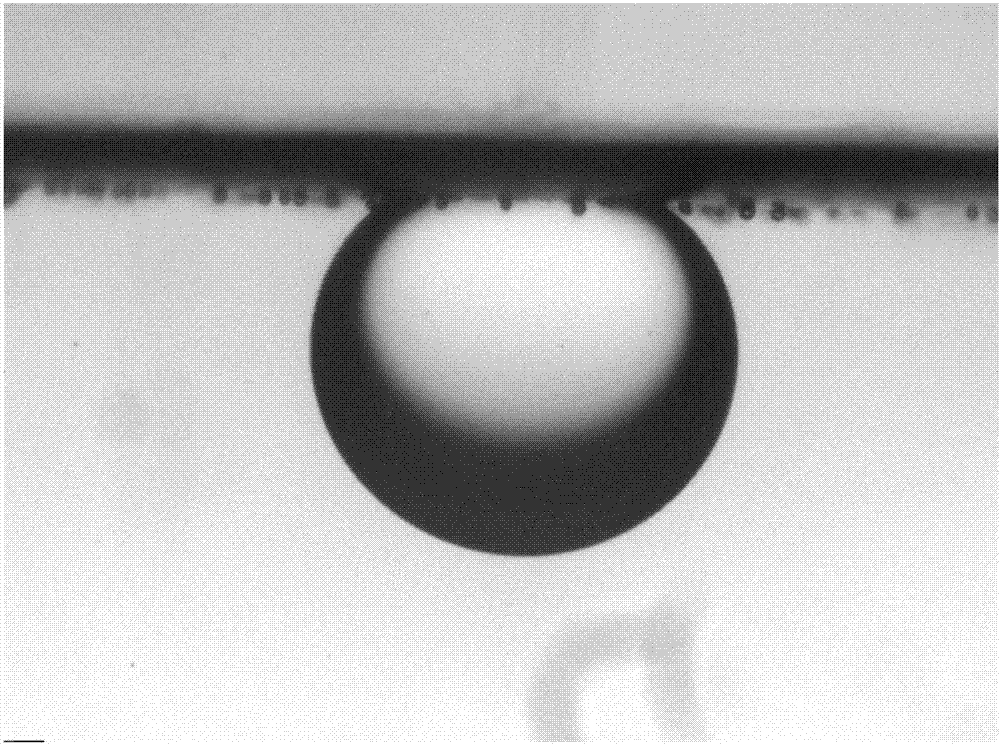

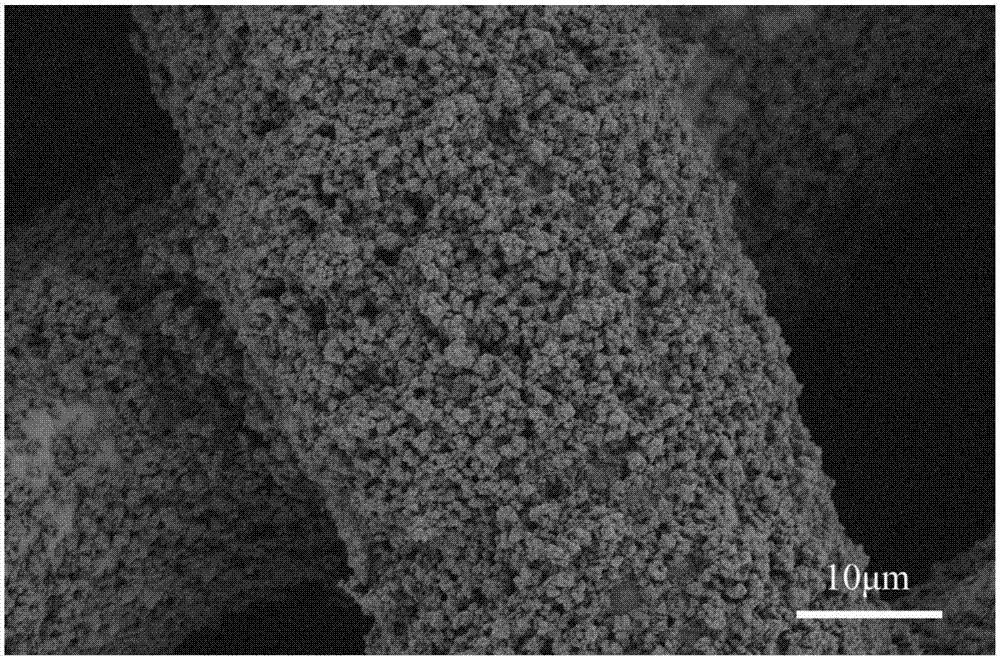

Preparation method of oil-water separation mesh film with super-hydrophilicity and super-lipophobicity

InactiveCN107080975AAchieve the purpose of separationIncrease water fluxFatty/oily/floating substances removal devicesLiquid separationAdhesiveOil water

The invention discloses a preparation method of an oil-water separation mesh film with super-hydrophilicity and super-lipophobicity. The method comprises the steps that a metal net with the mesh size being 400-2,000 is adopted as a substrate, a cold spraying method is adopted, net wires of the metal net are coated with hydrophilic materials in a spraying mode, the hydrophilic materials are one or more of zinc oxide, silicon dioxide, calcium carbonate and titanium dioxide, and the grain size range is 5-200 nanometers; finally sintering is performed under the temperature of 300-750 DEG C for 60-240 min, and the oil-water separation mesh film with super-hydrophilicity and super-lipophobicity is obtained. The metal net does not need to be modified, the binding force is improved with no adhesive, no secondary pollution is generated, cleaning is easy, and the mesh film can be repeatedly used.

Owner:HEBEI UNIV OF TECH

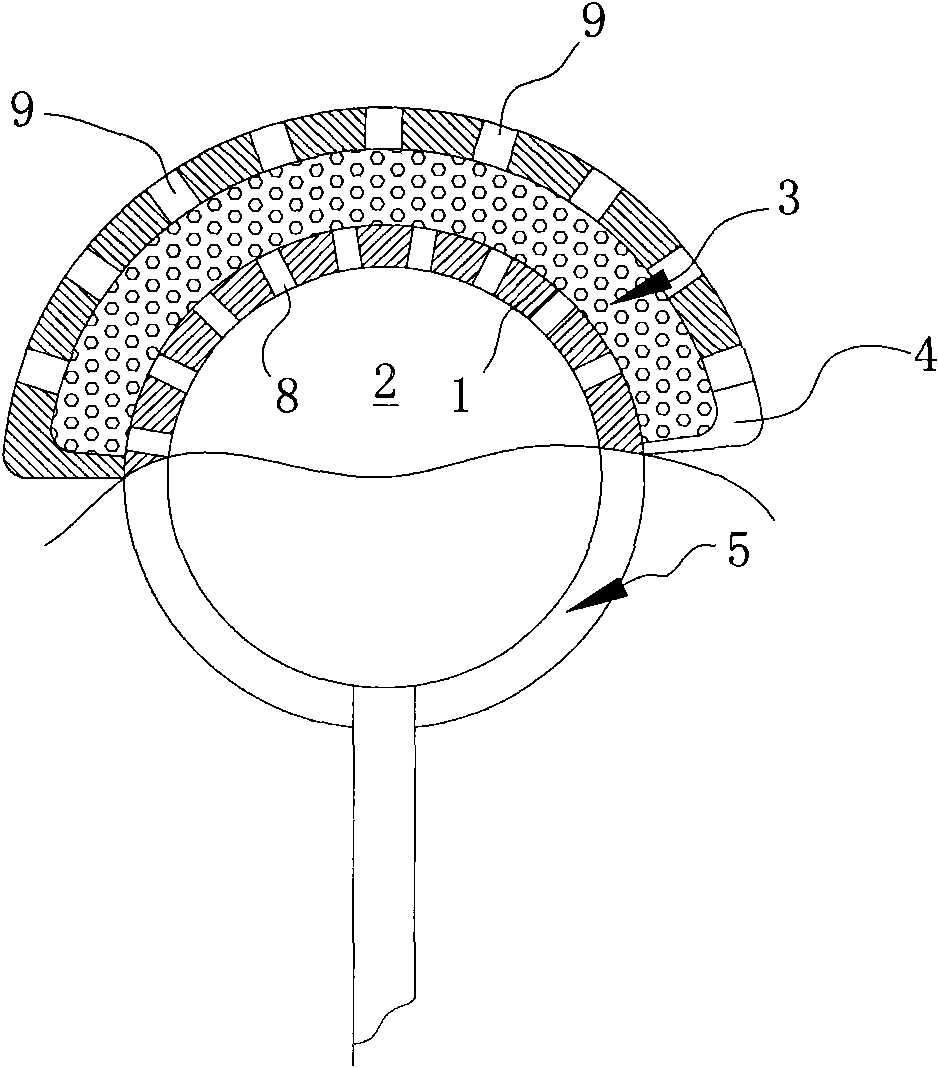

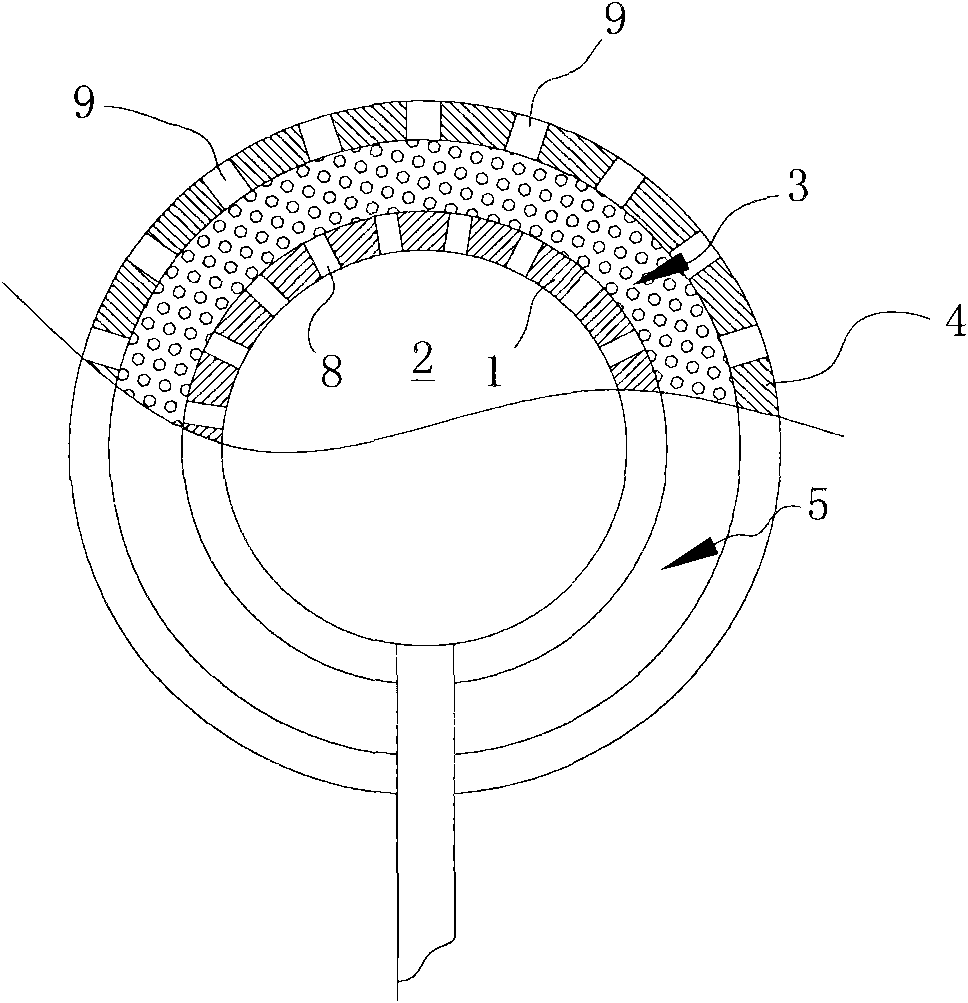

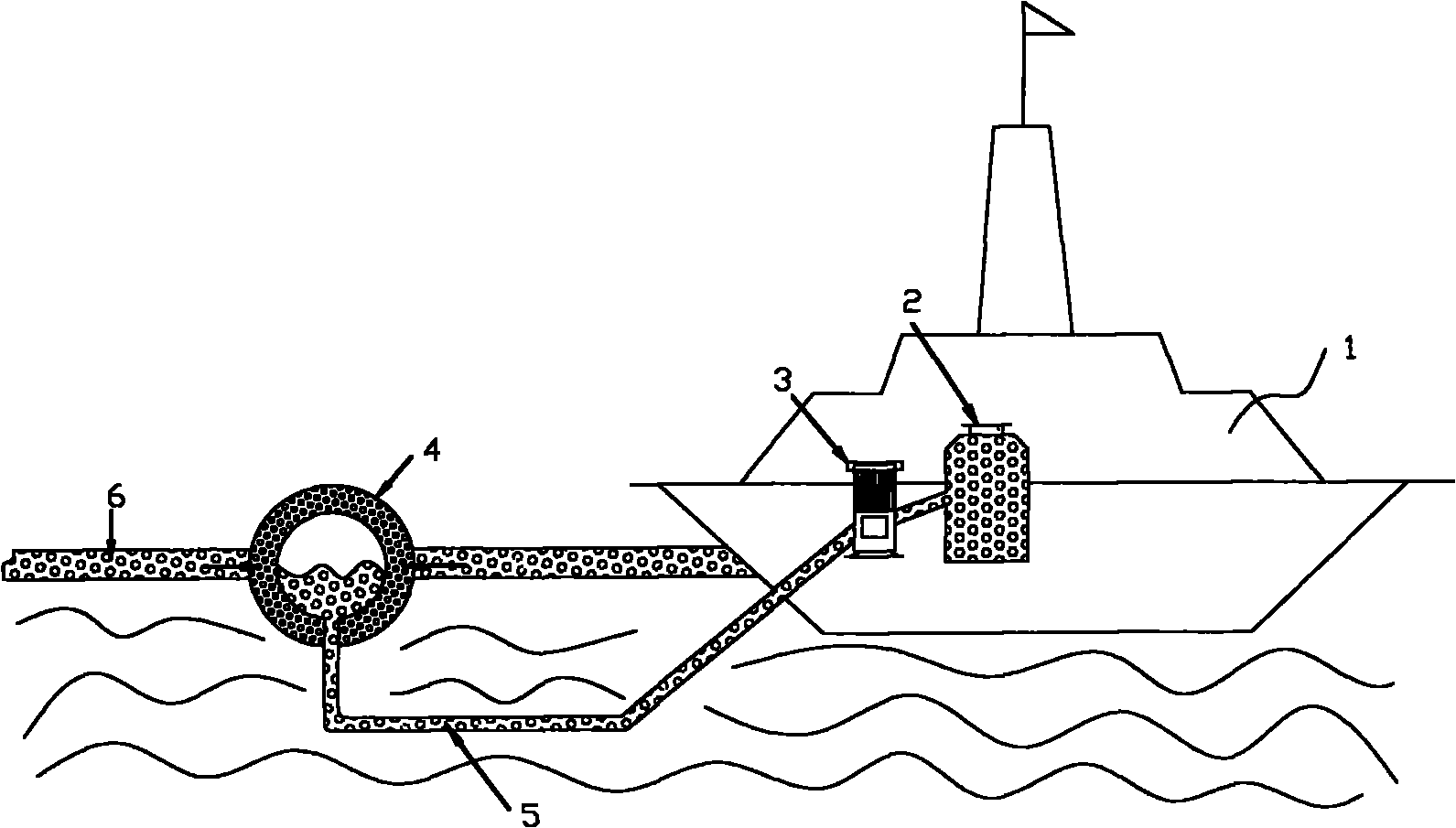

Method for collecting floating oil on water surface

ActiveCN102464381AIncreased oil slick collection efficiencyImprove collection efficiencyFatty/oily/floating substances removal devicesLiquid separationOil waterMarine engineering

The invention provides a method for collecting floating oil on a water surface. In the method, an oil-water separation device is provided, wherein the device comprises an oil collecting cavity (2) defined by a wall (1), at least partial surface of the wall (1) is covered with a porous oleophylic hydrophobic layer (3), the part of the wall (1), covered with the porous oleophylic hydrophobic layer (3), allows water and oil to pass through, the device also comprises a fixing layer (4) which is covered on the surface or above the porous oleophylic hydrophobic layer (3) and is used for limiting the flowing of the porous oleophylic hydrophobic layer, and the fixing layer (4) allows the water and the oil to pass through, the hole diameter of the porous oleophylic hydrophobic layer (3) is 300 to 850mu, and the porosity is 10 to 40%; the oil-water separation device is placed on the water surface with the floating oil such that the at least partial surface of the fixing layer (4), which is covered on the surface or above the porous oleophylic hydrophobic layer (3) and is used for limiting the flowing of the porous oleophylic hydrophobic layer, is in contact with the water surface with the floating oil; and then the floating oil in the oil collecting cavity is collected. By means of the method provided by the invention, a large area of floating oil on the sea can be effectively collectedand the efficiency of collecting the floating oil is remarkably improved.

Owner:北京仁创日升石油开采技术有限公司

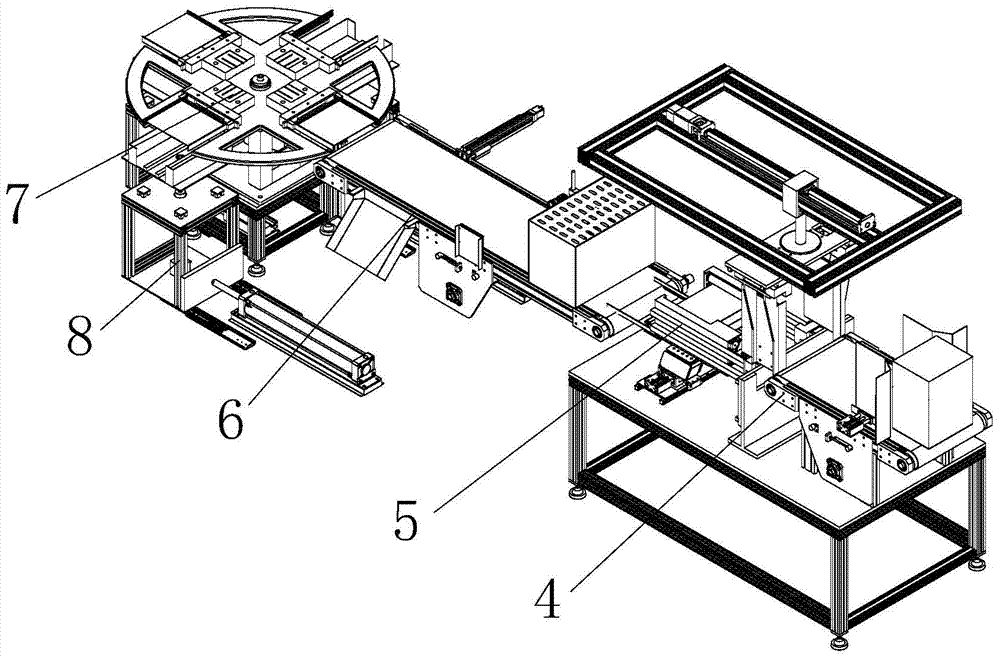

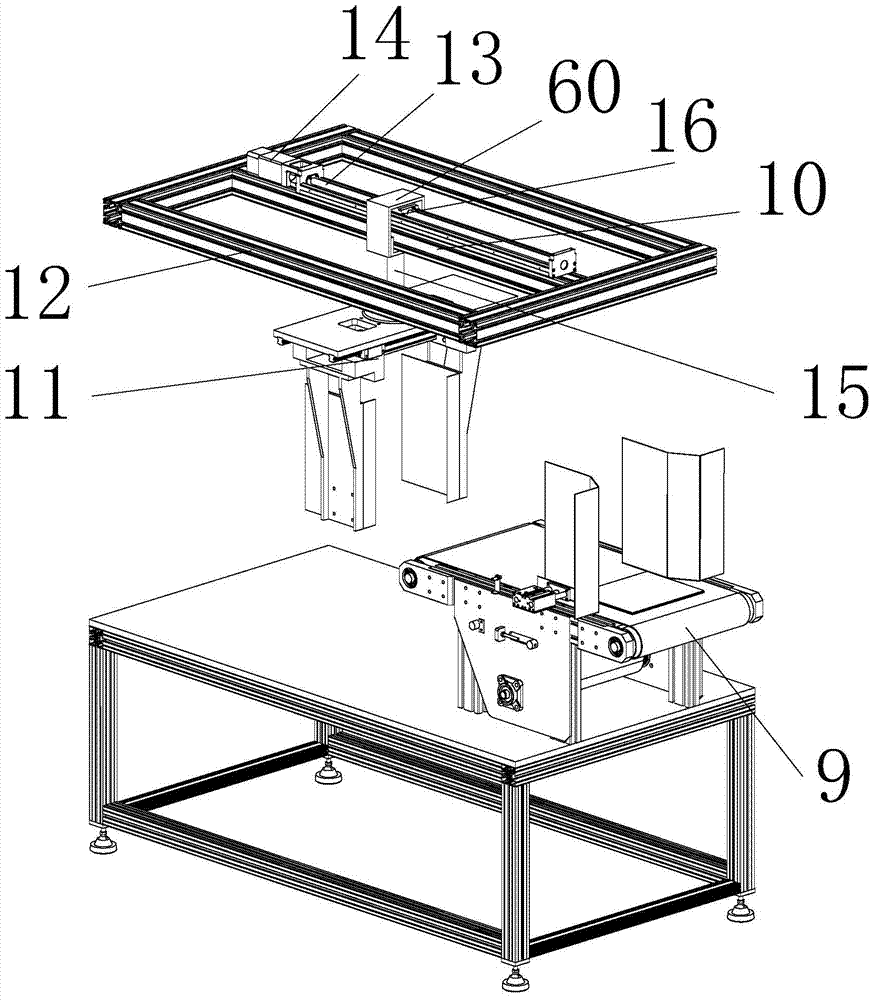

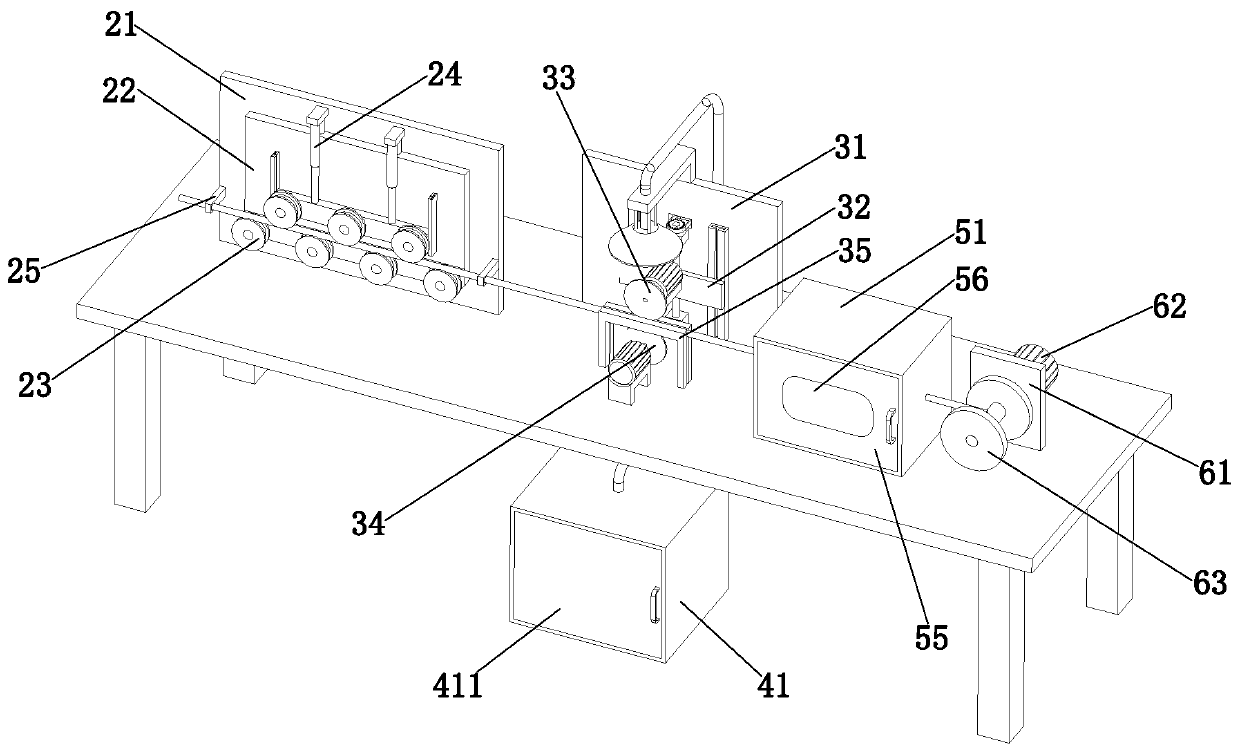

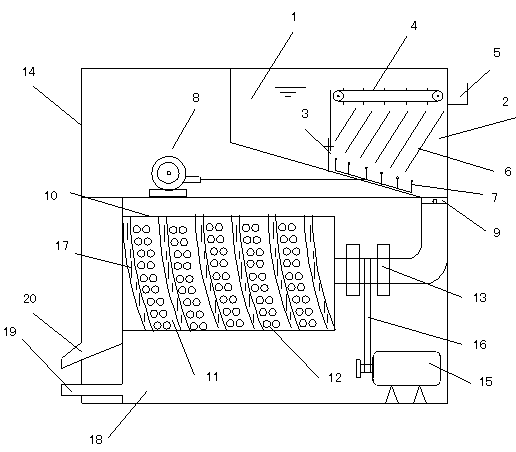

PCB (printed circuit board) automatic sorting machine based on machine vision

ActiveCN104841647ASolve the problem that the PCB board with holes cannot be separatedSolve collection problemsSortingMachine visionTransfer mechanism

The invention discloses a PCB (printed circuit board) automatic sorting machine based on machine vision. The PCB automatic sorting machine comprises a machine case (1), wherein a feeding opening (2) and a waste material outlet (3) are formed in the machine case (1); a feeding mechanism (4), a rolling separation mechanism (5), a waste material removing mechanism (6), a turntable removing mechanism (7) and a stacking transfer mechanism (8) which are in sequential connection are arranged in the machine case (1); the feeding mechanism (4) is connected with the feeding opening (2); the waste material removing mechanism (6) is connected with the waste material outlet (3). The PCB automatic sorting machine can be applicable to PCBs in various specifications, and has the advantages of high automation degree, high recognition efficiency and high sorting speed.

Owner:NORTHEASTERN UNIV

Glufosinate separation and purification method

ActiveCN104860988ASlow flowFast flowGroup 5/15 element organic compoundsPurification methodsCentrifugation

The invention belongs to the field of pesticide production and particularly relates to a glufosinate separation and purification method. According to the method, the separation and purification is started when a glufosinate hydrochloride reaction solution in the steps of distilling the glufosinate hydrochloride reaction solution under reduced pressure to remove dilute hydrochloric acid, adding ammonia water to adjust the pH to maximally produce ammonium chloride, distilling under reduced pressure to remove water, adding a flotation solvent for dispersion, placing the material into a chute at specific temperature and speed, performing flotation separation according to the difference in the proportion of a principal component and subsidiary salt, removing the solvent, dissolving the material in aqueous methanol to remove trace ammonium chloride, filling ammonia gas to adjust the pH value to 8, performing centrifugation and drying to obtain a final product. The glufosinate separation and purification method uses a flotation method for separating the principal component glufosinate and an intermediate of the principal component from the subsidiary salt ammonium chloride and the aqueous methanol for purification and is high in yield, good in purity, simple in process, low in cost and is suitable for industrial production.

Owner:石家庄瑞凯化工有限公司

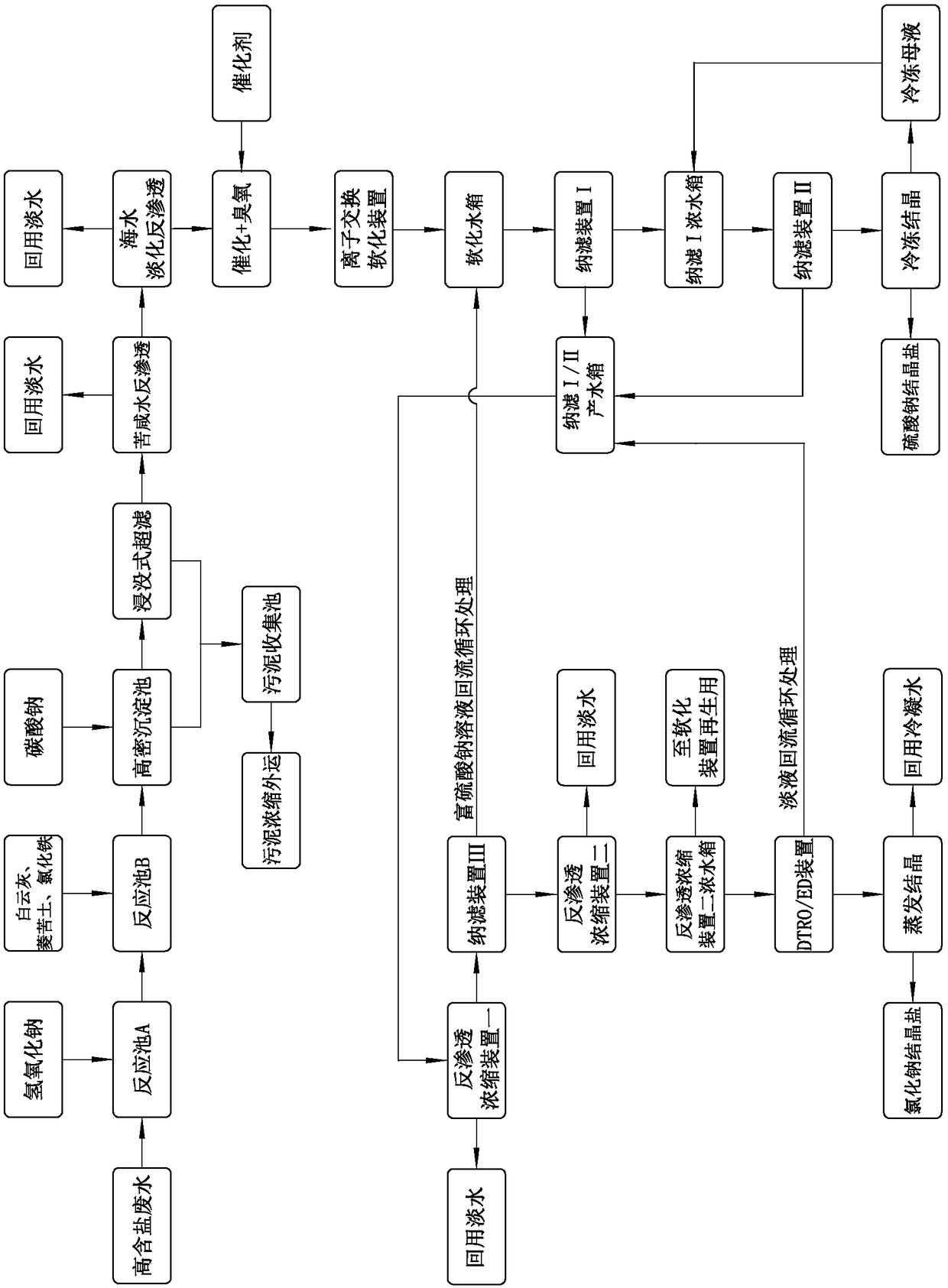

Zero discharge process for high-salt wastewater discharged from titanium dioxide production

ActiveCN108529802AAvoidance of foulingAvoid foulingGeneral water supply conservationWater softeningUltrafiltrationCatalytic oxidation

The invention relates to a zero discharge process for high-salt wastewater discharged from titanium dioxide production, and the steps are as follows: high-salt wastewater, removal of silicon by a magnesium agent, medicinal agent softening, high-density precipitation, immersion-type ultrafiltration, brackish water reverse osmosis membrane concentration, seawater desalination reverse osmosis membrane concentration, reduction of COD by catalytic oxidation, ion exchange softening, multi-stage nanofiltration salt separation, high pressure reverse osmosis membrane concentration, DTRO / ED electrodialysis concentration, and evaporation crystallization / freezing crystallization. The zero discharge process adopts corresponding treatment processes separately, realizes for the first time the zero discharge of the high-salt wastewater of titanium dioxide by a detailed control technology of each specific process in the system, ensures the normal and smooth operation of the system, and recovers a largeamount of fresh water resources and industrial salts. The purpose of resource recycling of the titanium dioxide production wastewater is realized, and on the basis of creating of certain economic benefits, significant environmental and social benefits are reflected.

Owner:SHANDONG YUXIN ENVIRONMENTAL SCI & TECH

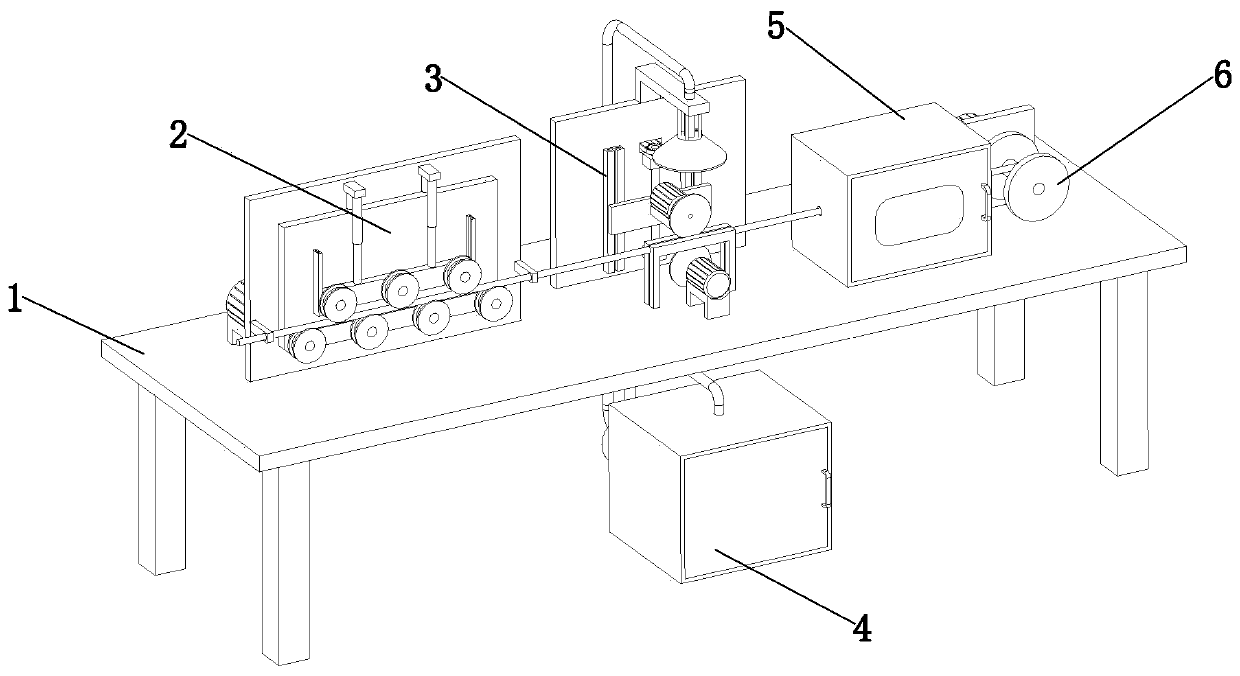

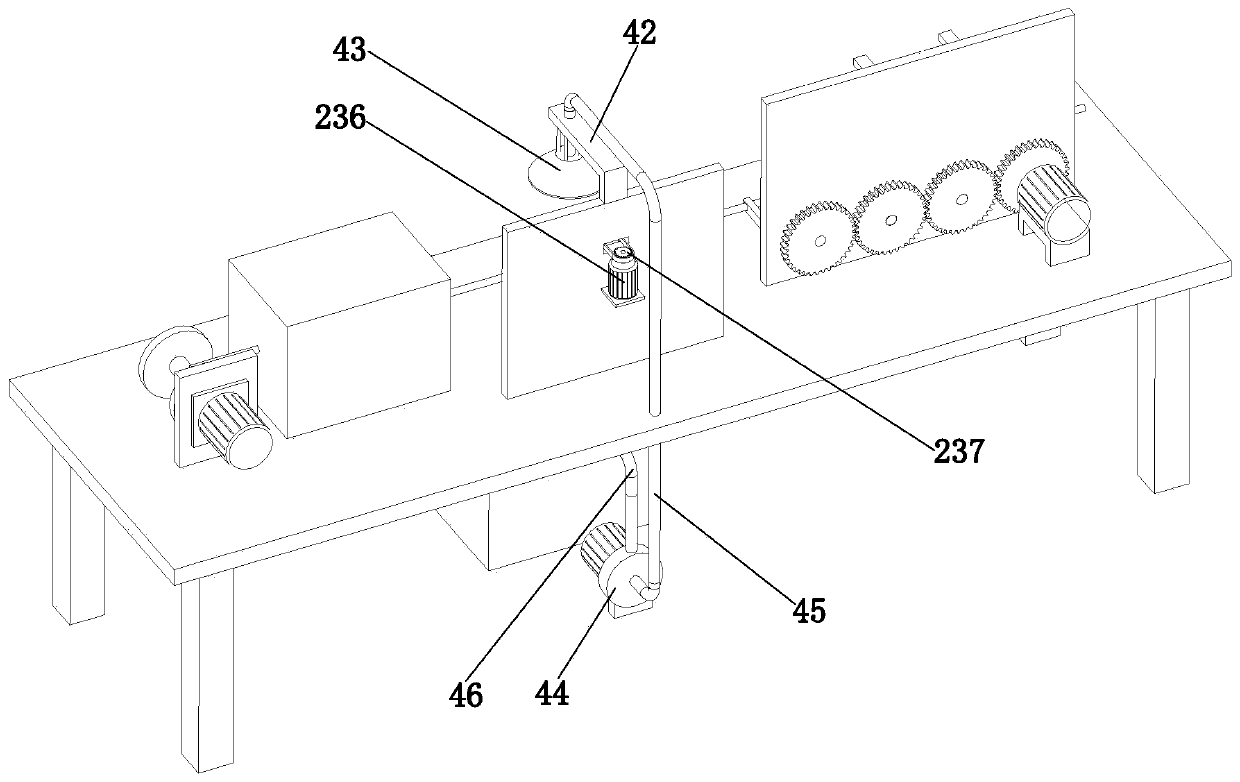

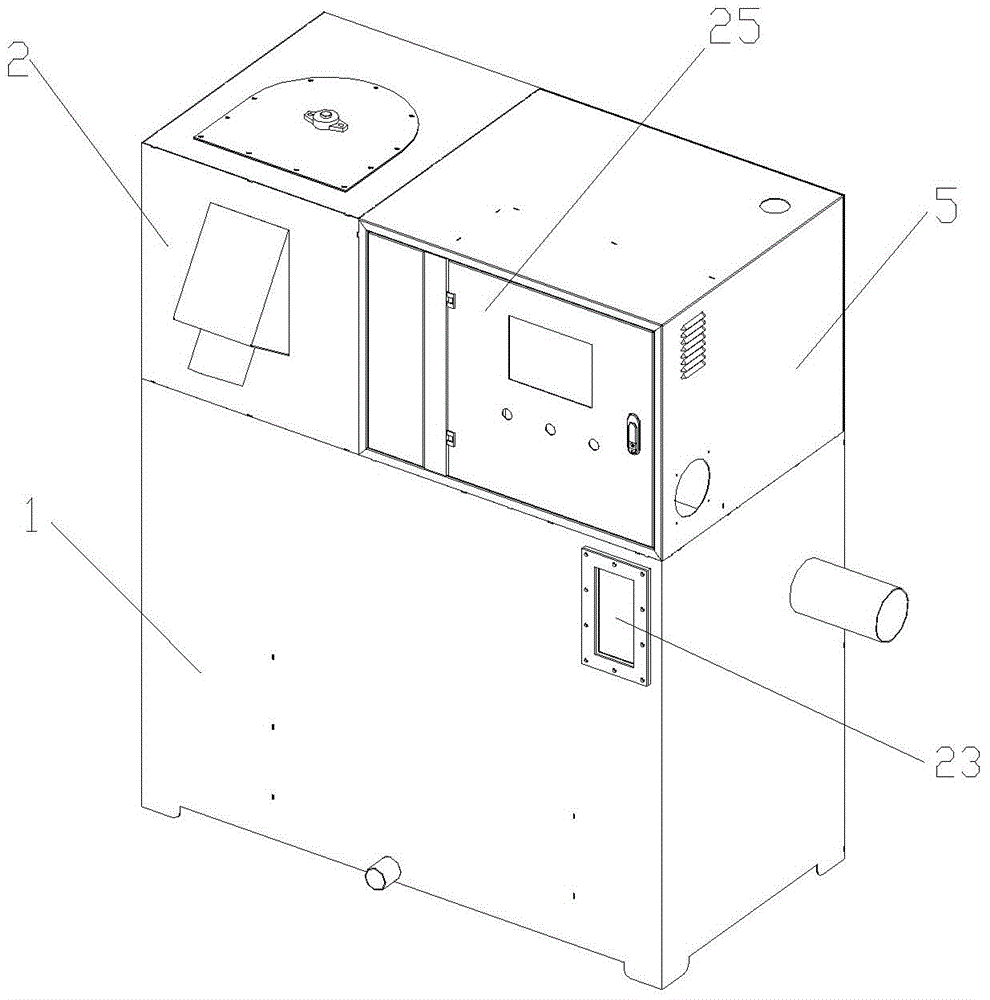

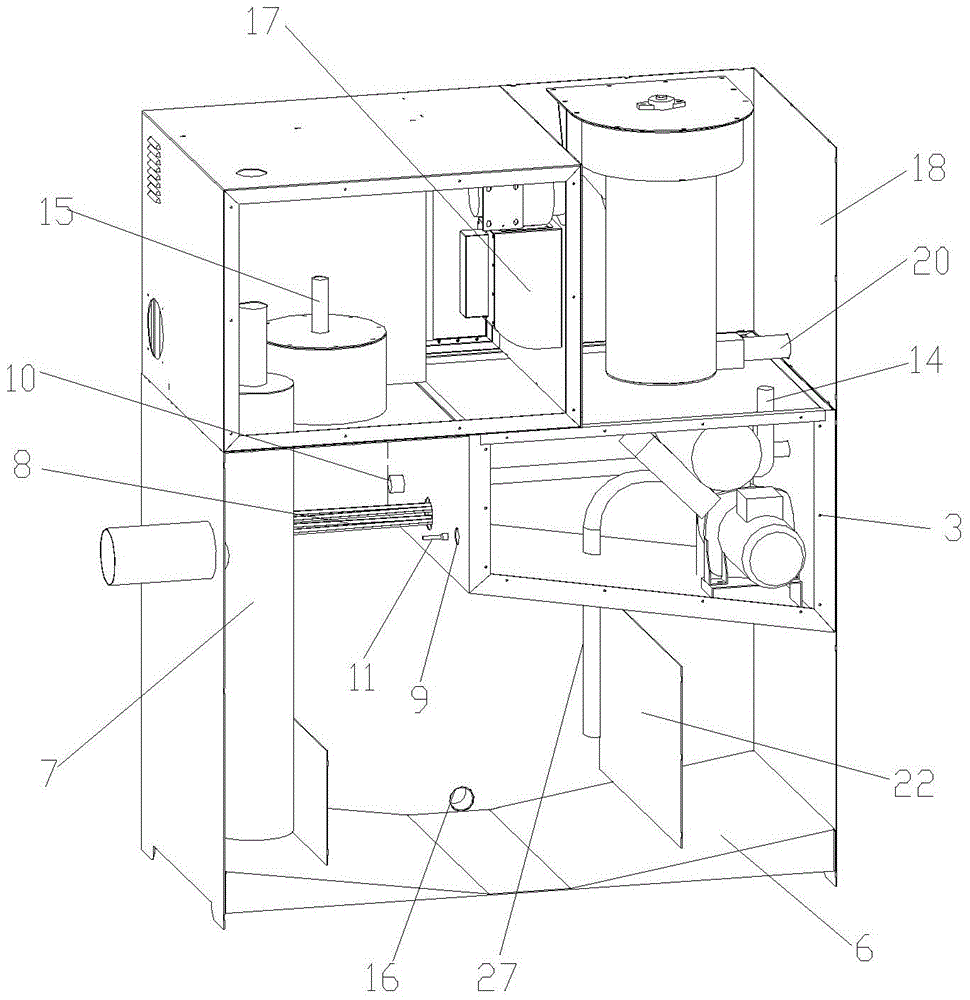

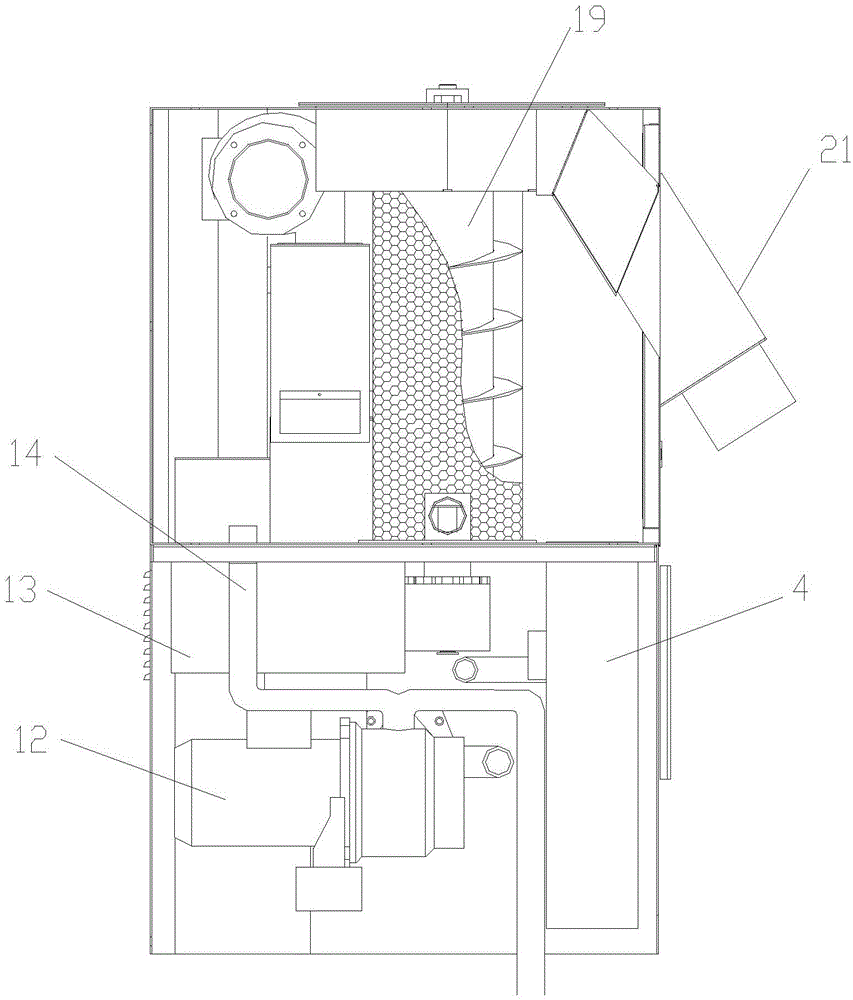

Winding recovery device of power cable

ActiveCN109920610AReach winding recoveryAchieve the purpose of separationBasic electric elementsElectronic waste recyclingPower cableEngineering

The invention relates to a winding recovery device of a power cable, and belongs to the technical field of electric power cable recovery. The winding recovery device comprises a workbench, a conveyingassembly, a sheath-cutting assembly, a cleaning assembly, a peeling assembly and a recovery assembly, wherein the conveying assembly, the sheath-cutting assembly, the peeling assembly and the recovery assembly are sequentially arranged on the workbench from left to right; the cleaning assembly is arranged below the workbench, and one end of the cleaning assembly extends to the sheath-cutting assembly; the conveying assembly comprises a first mounting plate, a bearing plate, a driving part, a pressing part and two limiting plates, wherein the first mounting plate is vertically arranged on theworkbench; the bearing plate is fixedly connected with the front end face of the first mounting plate; and the driving part and the pressing part are arranged on the first mounting plate and the bearing plate. According to the cable, the sheath-cutting assembly is used for cutting an insulating sheath of the cable; and the peeling assembly separates the insulating sheath and metal wires of the cable; and the recovery assembly is used for winding and recovering the metal wires.

Owner:ANQING NORMAL UNIV

Oil-water separation machine

ActiveCN104150626AAchieve the purpose of separationAchieve the final effectMultistage water/sewage treatmentSewageOil water

The invention discloses an oil-water separation machine which comprises an electric cabinet, a solid-liquid separation device, a sewage pipe and an oil-water separation device, wherein the electric cabinet is connected with the oil-water separation device; the solid-liquid separation device is communicated with the oil-water separation device by virtue of the sewage pipe; the oil-water separation device comprises a sewage tank, as well as a water outlet pipe and an oil outlet pipe which are fixed in the sewage tank; a water inlet of the water outlet pipe extends into the bottom of the sewage tank, and the height of a water outlet of the water outlet pipe is not lower than the vertical height of the oil outlet pipe; an emptying pipe is further arranged at the top of the sewage tank. By virtue of the mode, the invention provides an oil-water separation machine. According to the oil-water separation machine, a floating oil layer floating on the surface of a water surface can be drained in accordance with the principle that oil and water are different in specific gravity, so as to realize the separation purpose of oil and water.

Owner:SUZHOU MEISHENG ENVIRONMENTAL PROTECTION TECH

Method for chemically separating bastnaesite and urdite from mixed rare earth concentrate

InactiveCN102051477AReduce pollutionAchieve the purpose of separationProcess efficiency improvementRare-earth elementHydrometallurgy

The invention relates to a method for chemically separating bastnaesite and urdite from a mixed rare earth concentrate, belonging to the technical field of rare earth hydrometallurgy. In the invention, the mixed rare earth concentrate (bastnaesite / urdite mixed rare earth ores) from Baotou is separated into a single bastnaesite concentrate and a urdite concentrate, and fluorions can be converted into a complex by using a complexing method, so that the complex can enter a solution to destroy the bastnaesite. The method provided by the invention comprises the following steps: adding bastnaesite / urdite mixed ores into water, pulping, and adding a complexing agent solution and an inorganic acid solution to decompose the bastnaesite, so that the dissolved bastnaesite enters the solution, thereby separating the bastnaesite from the urdite. The method provided by the invention is simple, has the advantages of low production cost and low pollution, develops a new way for further extracting rare earth elements from bastnaesite and urdite, and can be used as a method for extracting rare earth elements from single bastnaesite or other bastnaesite / urdite mixed rare earth ores.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

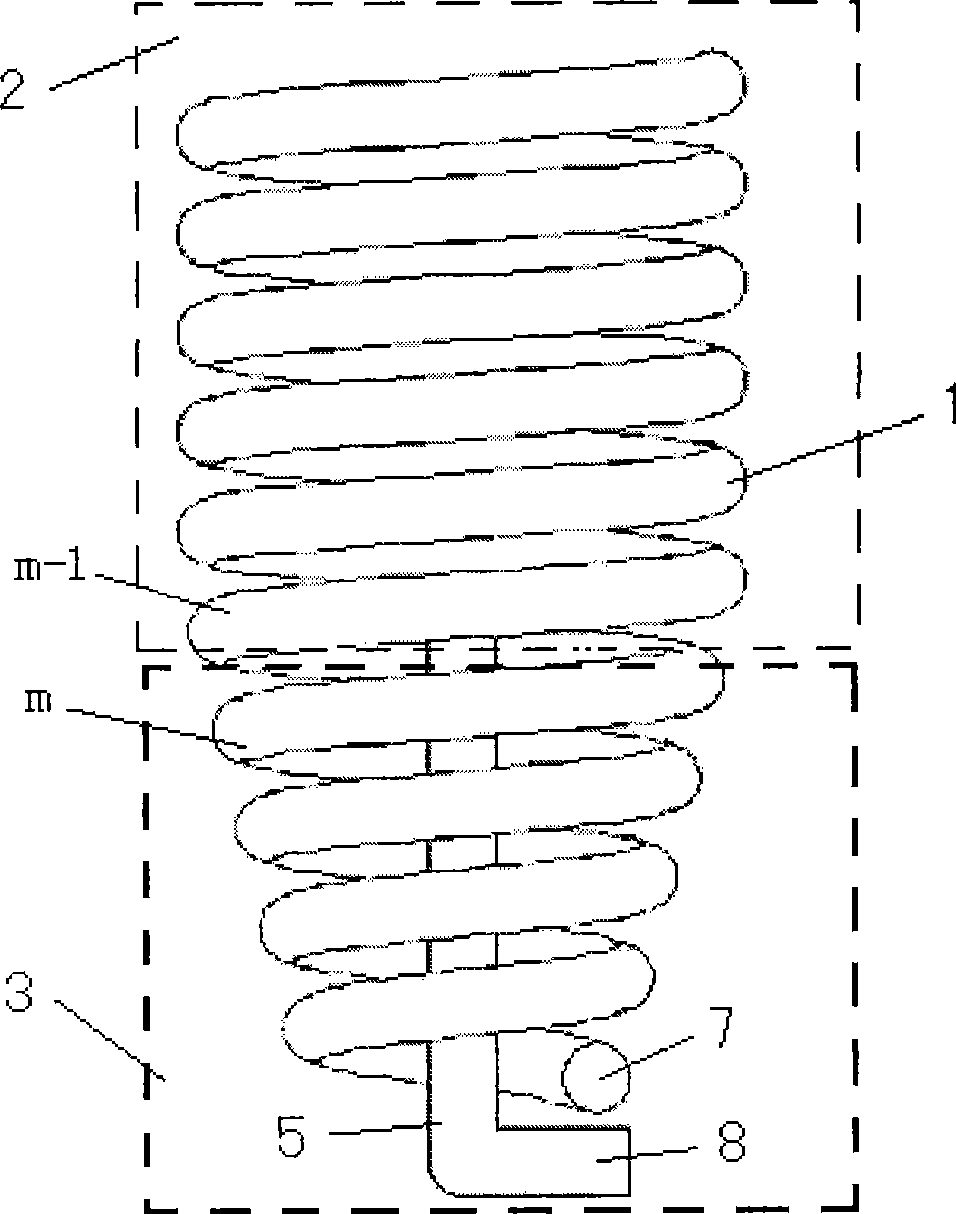

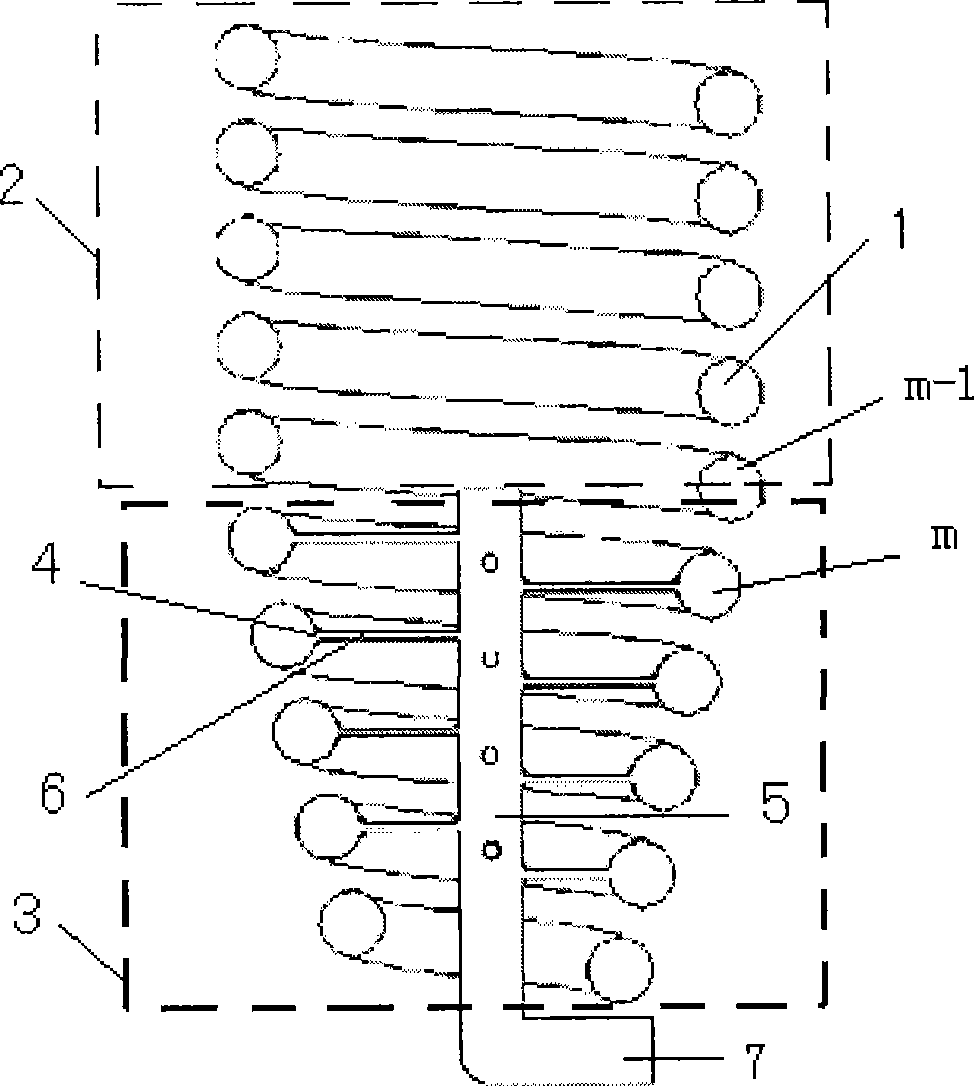

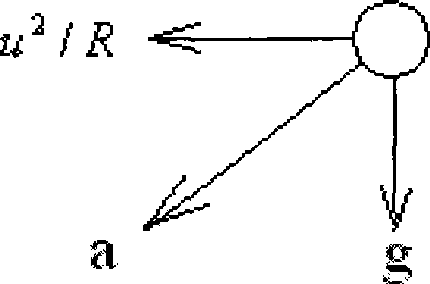

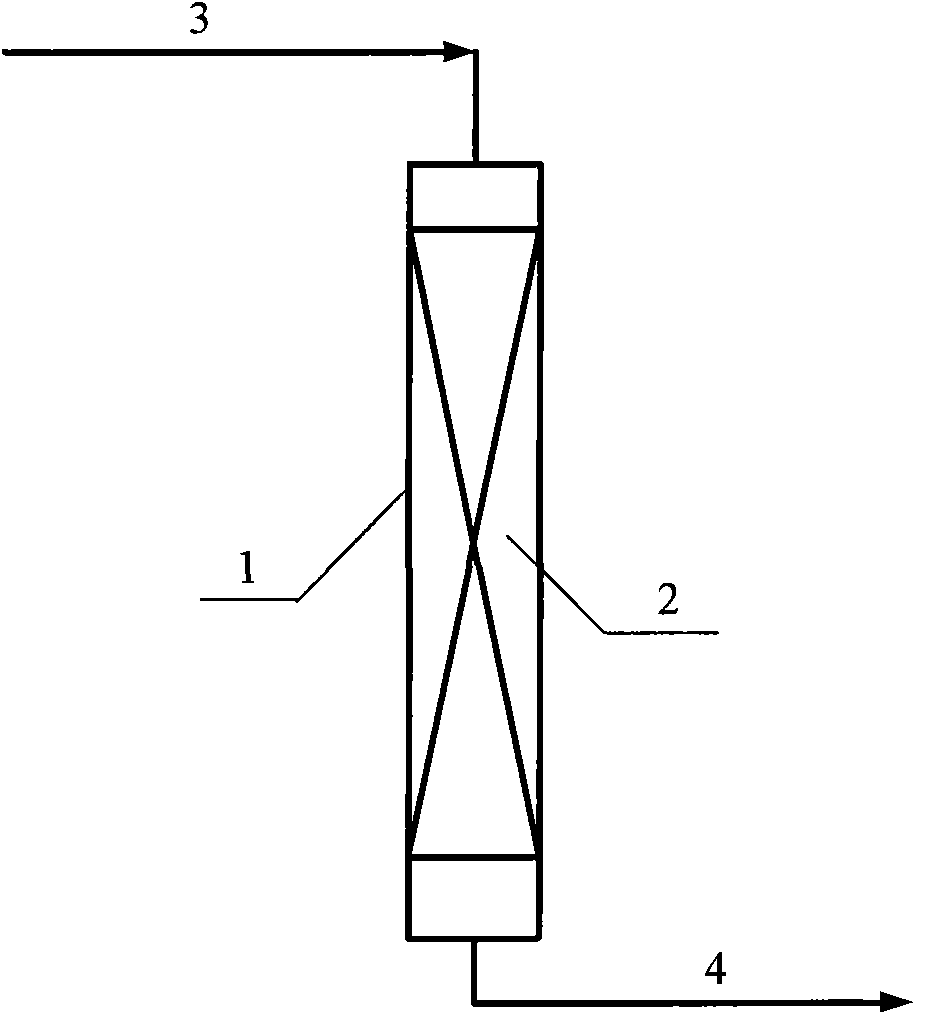

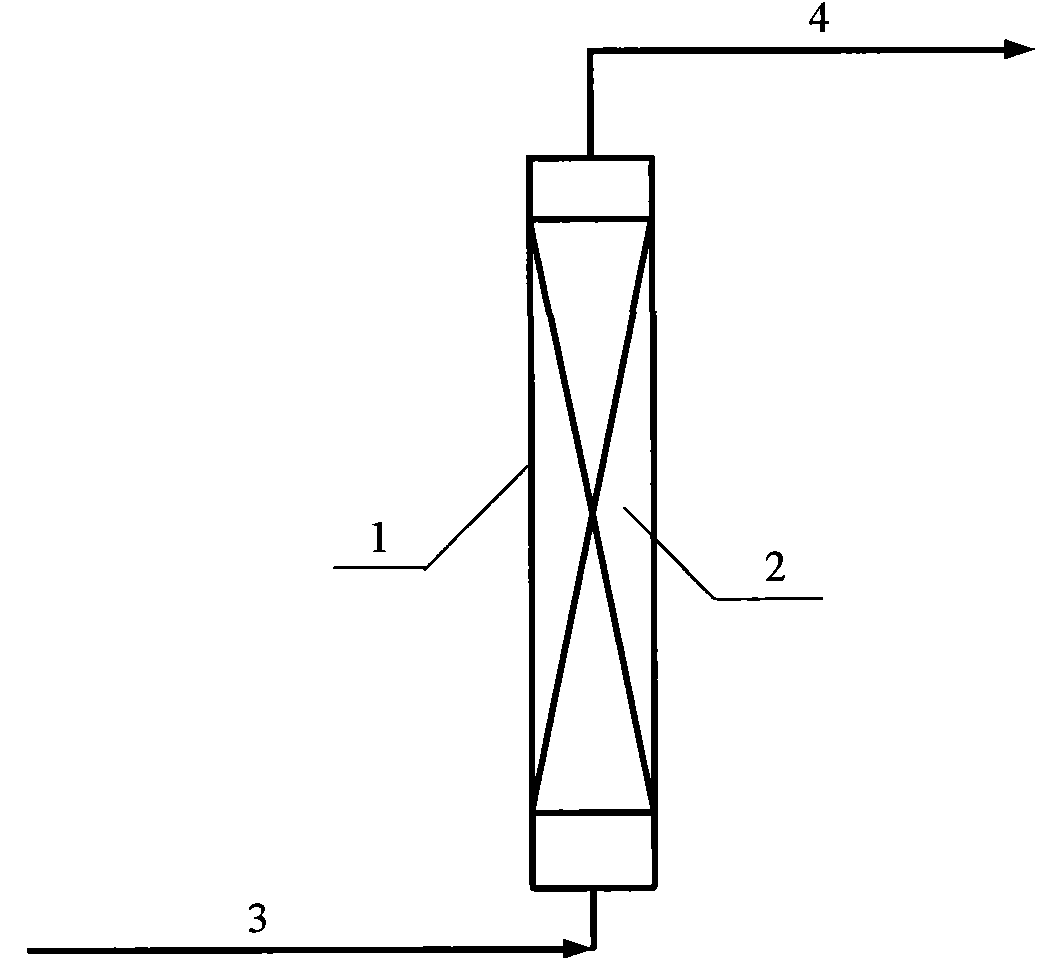

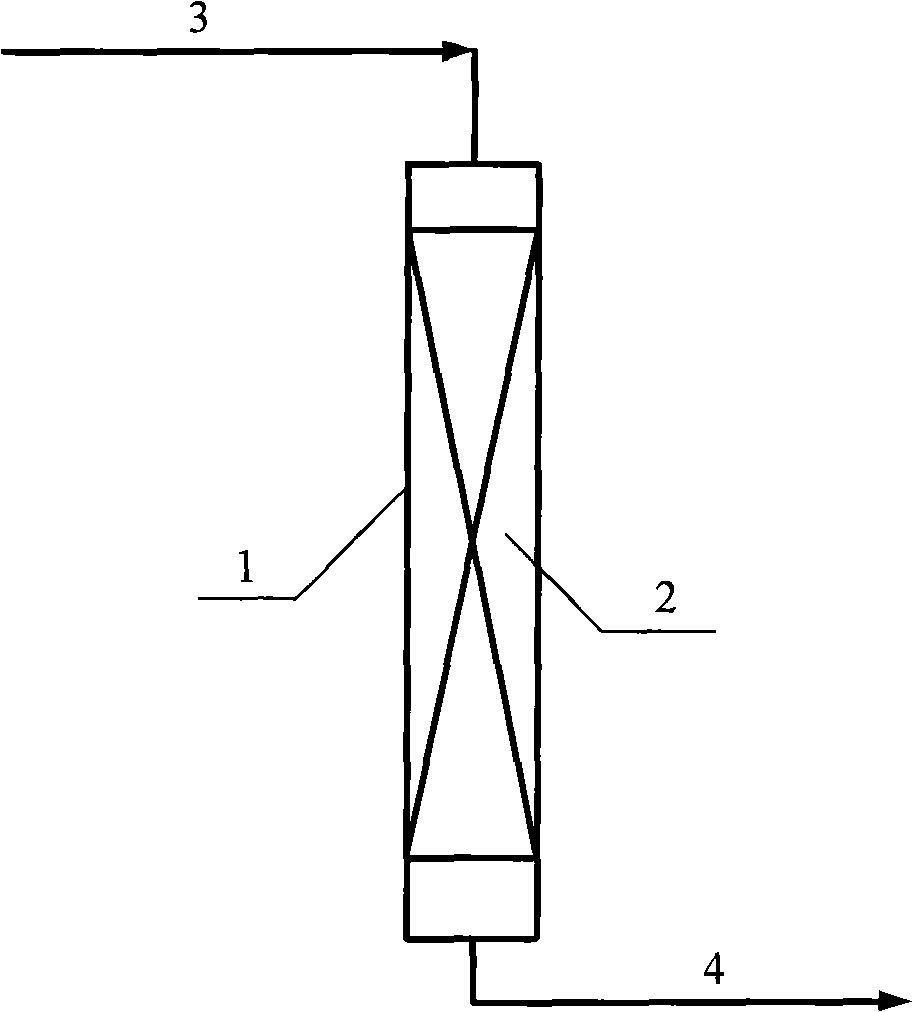

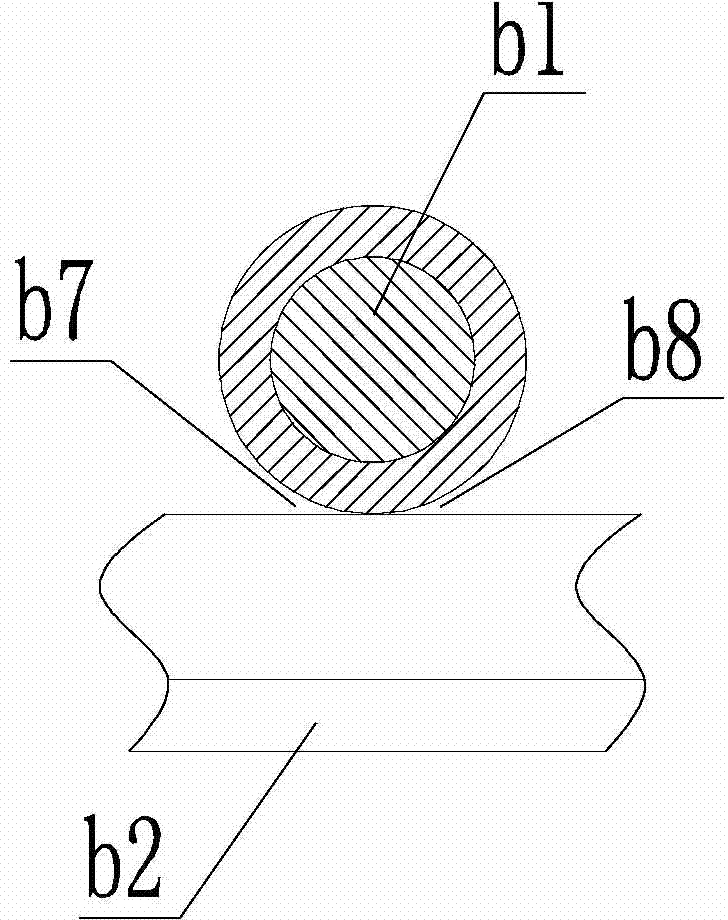

Method and device for separating oil and water

InactiveCN101518696AAchieving a state of separationAchieve the purpose of separationLiquid separationEngineeringDensity difference

The invention relates to a method and a device for separating oil and water. The method comprises the following steps: a spiral pipe is divided into an upper pipe with the equal turning radius and a lower pipe with the variable turning radius, the upper pipe and the lower pipe are communicated in an integrative mode, the lower pipe is designed into a reversed cone shape, the inner side of the pipe wall of the lower pipe is provided with a plurality of holes at intervals, the center of the lower pipe is provided with an oil collecting pipe which is connected with the corresponding holes through a plurality of connecting pipes, water-phase liquid with larger density moves outside the pipe wall of the lower pipe by using the density difference between oil and water and centrifugal force generated by the spiral flow of oil-water mixed liquid in the spiral pipe, oil-phase liquid collects towards the inner side of the pipe wall of the lower pipe under the pressure function of the water-phrase liquid, meanwhile, the turning radius of the lower pipe is gradually reduced, under the condition that the flow speed of the oil-water mixed liquid is gradually reduced, the centrifugal acceleration is stably maintained, and the separated water-phrase liquid and oil-phrase liquid respectively flow out through a water-phrase liquid outlet arranged at the bottom of the lower pipe and an oil-phrase liquid outlet arranged at the bottom of the oil collecting pipe. The invention can be widely used for various oil-gas field separating systems.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Preparation method of oil-water separation omentum with underwater ultra oleophobicity

InactiveCN107080976AAchieve the purpose of separationIncrease roughnessFatty/oily/floating substances removal devicesLiquid separationFiberCrosslinked polymers

The invention relates to a preparation method of an oil-water separation omentum with underwater ultra oleophobicity. The method comprises the steps that by using a woven fiber net of 400-2000 mesh as the substrate, and combining the inorganic nano particles with hydrogel, the surface roughness of the hydrogel is improved to enhance the surface hydrophilicity of the omentum; by using the method of photo polymerization, the meshes of the woven fiber net are coated with a hydrogel coating layer which has a nanocomposite structure and is formed with cross-linked polymer and inorganic nanoparticles, and then the oil-water separation omentum with underwater ultra oleophobicity is obtained. The oil-water separation omentum prepared by the method has the advantages of a large water flux, a fast speed of oil-water separation, and no need to modify the woven fiber net.

Owner:HEBEI UNIV OF TECH

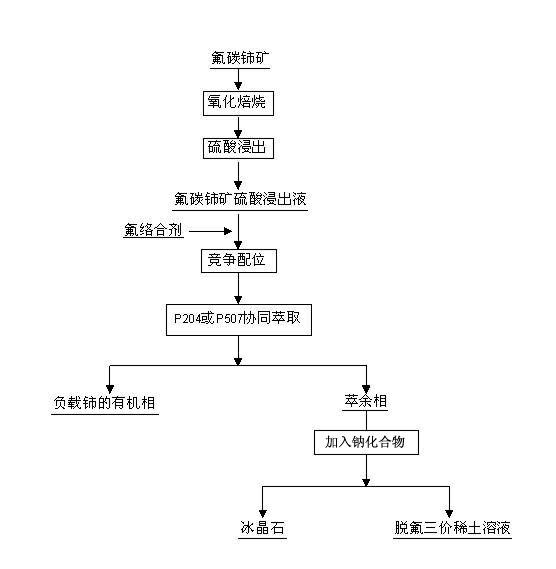

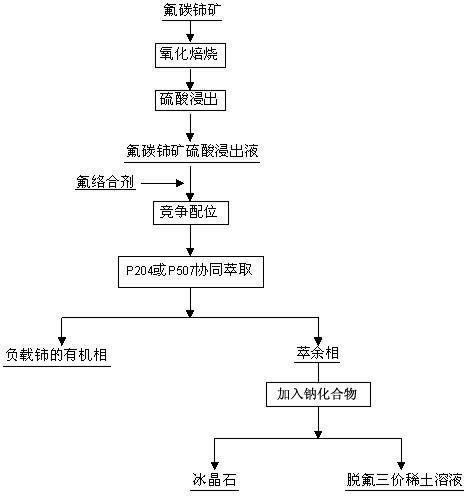

Method used for separating rare earth from bastnaesite sulphuric acid leach solution and preparing ice stone

InactiveCN102653823AAchieve the purpose of separationGood coordination abilityAluminium fluoridesProcess efficiency improvementPregnant leach solutionCerium

The invention belongs to the technical field of rare earth hydrometallurgy, and specifically relates to a method used for separating rare earth from a bastnaesite sulphuric acid leach solution and preparing an ice stone. The method comprises the following steps of: adding aluminium salt as a fluorine complexing agent in a bastnaesite sulphuric acid leach solution, mixing an extraction agent and a diluting agent to obtain an organic phase, mixing the organic phase and the bastnaesite sulphuric acid leach solution according to the volume ratio of (1-10):1, vibrating for 5-60 minutes, and splitting phase after standing for 10-60 minutes; and obtaining the organic phase of loading cerium and an extractive surplus phase containing fluorine and trivalence rare earth, adding a sodium compound in the extractive surplus phase, adjusting pH to 2-5, obtaining Na3AlF6 precipitation, namely the ice stone, carrying out solid-liquid separation, and obtaining the trivalence rare earth solution after defluorination. Compared with the prior art, the method provided by the invention reduces the generation of three wastes containing fluorine due to fluorine recovery, greatly lightens the environmental pollution from a flow, can carry out reclamation utilization on fluorine in a water phase, and reduces the waste of a fluorine resource.

Owner:NORTHEASTERN UNIV LIAONING

Method for separating glycol from butanediol

InactiveCN102372598AReduce energy consumptionAchieve the purpose of separationHydroxy compound separation/purificationMolecular sieveHigh energy

The invention relates to a method for separating glycol from butanediol. By the method, the problems of a complex process and high energy consumption during the separation of the glycol and the butanediol by azeotropic rectification and particularly high separation energy consumption due to low content of the butanediol in a mixture at present are mainly solved. In the method, a glycol solution with less than or equal to 3 percent of butanediol contacts an adsorption column filled with an adsorbent, the butanediol is adsorbed by resin, raffinate is the glycol, and the adsorbent is selected from at least one of nonfunctional resin or a molecular sieve. Through the technical scheme, the problems are better solved. The method can be used for the industrial production of separating the glycol from the butanediol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oil-water slag separation device for kitchen garbage

InactiveCN103382058AImprove collection efficiencyReduce oilWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesSlagResource utilization

The invention discloses an oil-water slag separation device for kitchen garbage. The separation device comprises a feeding box, an oil-water separator and a solid-liquid separation rotary drum; a material outlet of the feeding box is communicated with a material inlet of the oil-water separator, and a material outlet of the oil-water separator is communicated with a material inlet of the solid-liquid separation rotary drum; the upper part of the oil-water separator is provided with an oil scraping collector, the middle part of the oil-water separator is provided with inclined plates, the bottom part of the oil-water separator is provided with aerator pipes, and each inclined plate is inclined in the reverse material flow direction; the inner wall of the solid-liquid separation rotary drum is provided with a conveying screw, and the side wall of the solid-liquid separation rotary drum is provided with sieve holes. The oil-water slag separation device for the kitchen garbage has the characteristics of simple structure, convenient operation, small power consumption, short treatment cycle, high degree of automation and the like, can effectively dewater the kitchen garbage, simultaneously separates out oil and water, and meets the needs of further treatment and utilization; and the oil-water slag separation device for the kitchen garbage can significantly decrease the oil content and the water ratio of solid matters, shortens the treatment cycle in a greater degree, and is more conducive to subsequent resource utilization.

Owner:NANJING WONDUX ENVIRONMENTAL PROTECTION TECH CO LTD

Super-hydrophobic oleophilic sponge material and preparing method and oil-water separation application thereof

InactiveCN109621923AImprove hydrophobic propertiesLow priceOther chemical processesAlkali metal oxides/hydroxidesOil waterLong chain

The invention discloses a super-hydrophobic oleophilic sponge material and a preparing method and oil-water separation application thereof, and belongs to the preparation of high-performance oil-waterseparation composites. The preparing method includes the steps of cleaning a sponge to remove impurities, putting the sponge in roughening liquid for surface roughening treatment, and adding a fattyacid solution for hydrophobic modification treatment to obtain the super-hydrophobic oleophilic sponge material. The super-hydrophobic oleophilic sponge material is a sponge material obtained after anon-polarity long-chain alkane group conducts hydrophobic modification on the surface of a substrate with a polyurethane or melamine sponge as the substrate. The preparing process is simple, the priceis low, and the oil absorption performance is excellent and stable. The material can be widely applied for leaking oil recovery, oil-containing wastewater treatment and oil-water mixture separation;the super-hydrophobic oleophilic sponge material solves the problem that an oil-water separation porous material is low in mechanical strength, low in separation efficiency, poor in repeatability andthe like in the current stage.

Owner:SHENYANG JIANZHU UNIVERSITY

1-butylene dimerization in ion solution and method for producing c8 and c12 olefin by dimerization

InactiveCN1418856AWill not polluteAchieve the purpose of separationHydrocarbons from unsaturated hydrocarbon additionNickel saltHigh pressure

The method for producing C8 and C12 olefine by means of dimerization and trimerization in ion liquid and by using 1-butylene includes the following steps: in a high-pressure still adding 1-butyl-3-methyl imidazole chlorine 3.05-4.95g, nickel salt 0.3399-0.5238g, aluminium trichloride 3.3347-5.4019 g in turn, then cooling to -6 deg.C, pouring 60 ml of liquid 1-butylene and 1.7-2.75 g of monochloro-diethyl aluminium, controlling temp. at 30-50 deg.C, controlling reaction time at 5 min-4 hr., cooling to -6 deg.c, and automatically demixing the product and catalyst, finally determining by GC-MS, its reaction conversion rate can be up to 80-95% and selectivity of dimerization is 78-92%.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC +1

Glow discharge plasma water treatment method and device

ActiveCN103754994AEasy to handleImprove processing efficiencyWater/sewage treatment using germicide/oligodynamic-processElectricityWastewater

The invention discloses a glow discharge plasma water treatment method comprising the following steps: after to-be-treated wastewater is subjected to mechanical treatment, water surface electrodes having the same potential are placed on the wastewater surface, the water surface electrodes are each cylindrical in shape, an insulating medium externally wraps the water surface electrodes, and the water surface electrodes are connected to a positive electrode or a negative electrode of a power source; an underwater electrode connected to the positive electrode or the negative electrode of the power source is placed in the wastewater, and is an exposed conductive material; the water surface electrodes are directly contacted with the wastewater, and a gap is formed between the outer surface of each water surface electrode and the water surface; after the power supply is switched on and an initial discharge voltage is reached, glow discharge is generated in the gaps, plasma and active particles are generated, and the wastewater is deep treated by utilizing the plasma and the active particles. The invention also provides a corresponding plasma water treatment device aiming at the plasma water treatment method. The method and the device are suitable for various water treatment, besides, can remove microbes and bacteria in the wastewater, and can remove peculiar smell radiated by the wastewater.

Owner:BEIJING RUIYUDA TECH

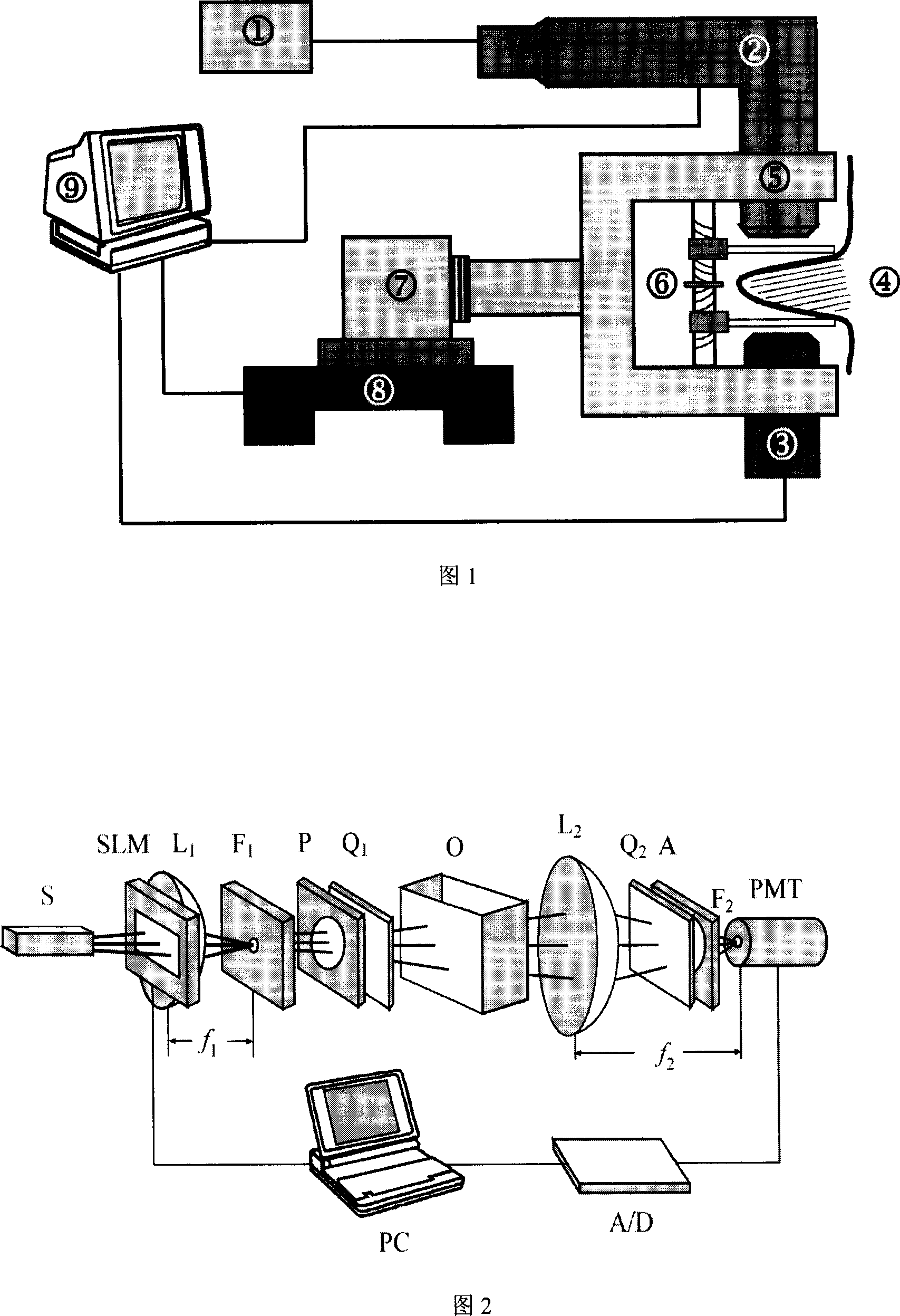

3-D high-definition mammary gland imager

InactiveCN101015446AAccurate reconstructionReduce volumeSurgeryDiagnostic recording/measuringDiseaseMammary gland structure

The invention discloses a three-dimensional high-definition mammary gland imager in the biological medical imaging domain, which is characterized by the following: judging pathologic position and degree of mammary gland tissue according to optical parameter according to grey, tissue structure and size semi-quantitatively or qualitatively; adopting infrared (600-900nm) as light source; modulating space of irradiated light through coded aperture without harmful detecting; forming digital infrared optical scanning hologram; utilizing digital decoded technique to extract the information of galactophore tissue; displaying three-dimensional high-definition image.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com