Patents

Literature

184 results about "Pressure function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure as a function of altitude. Gases and liquids exert pressure on the surfaces of solids that are immersed in them, simply the force of the atoms bouncing off of the solid surface. The pressure gets lower as you climb higher in the atmosphere. As we ascend, we decrease the amount of fluid that is above us, decreasing the pressure that we feel.

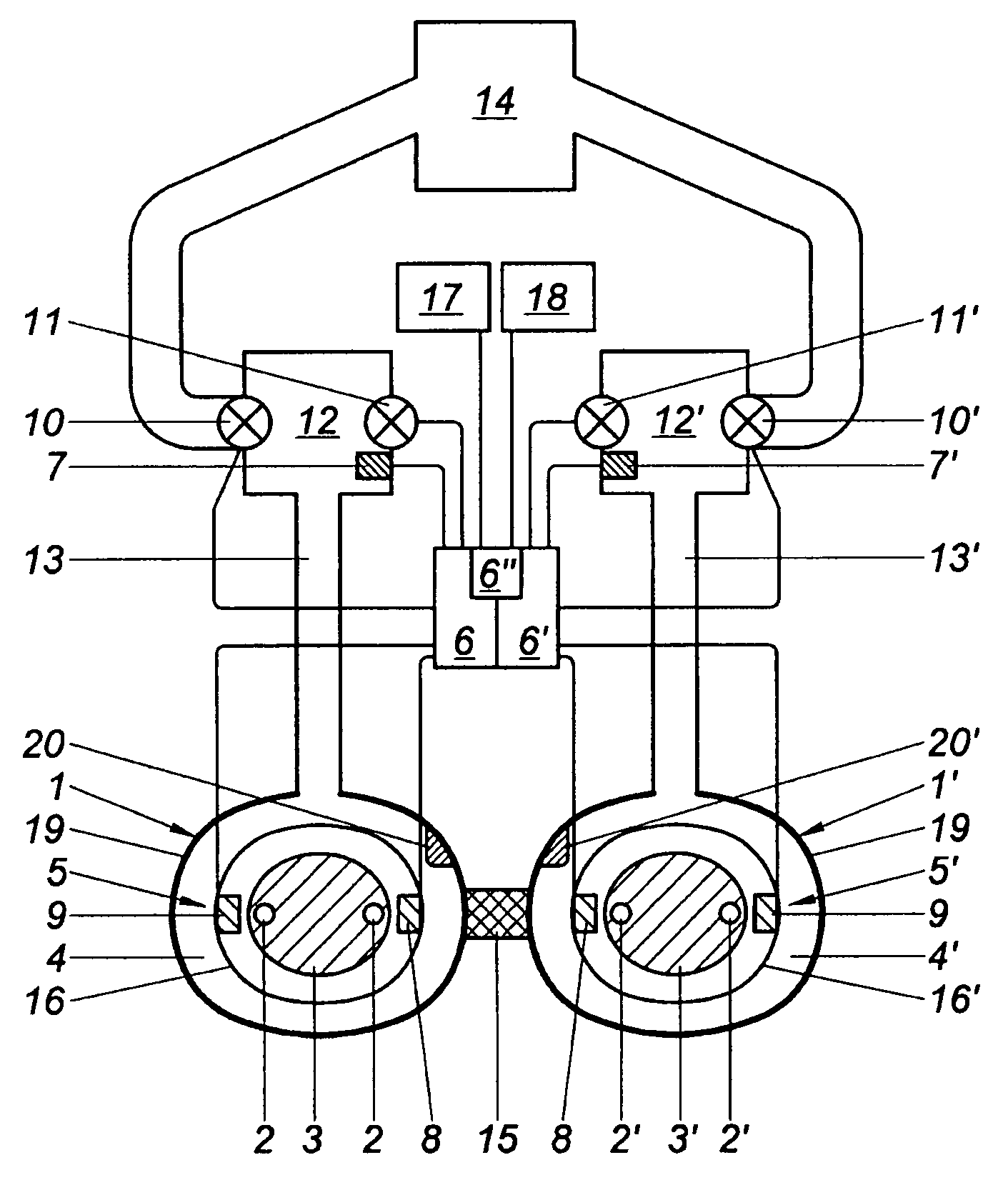

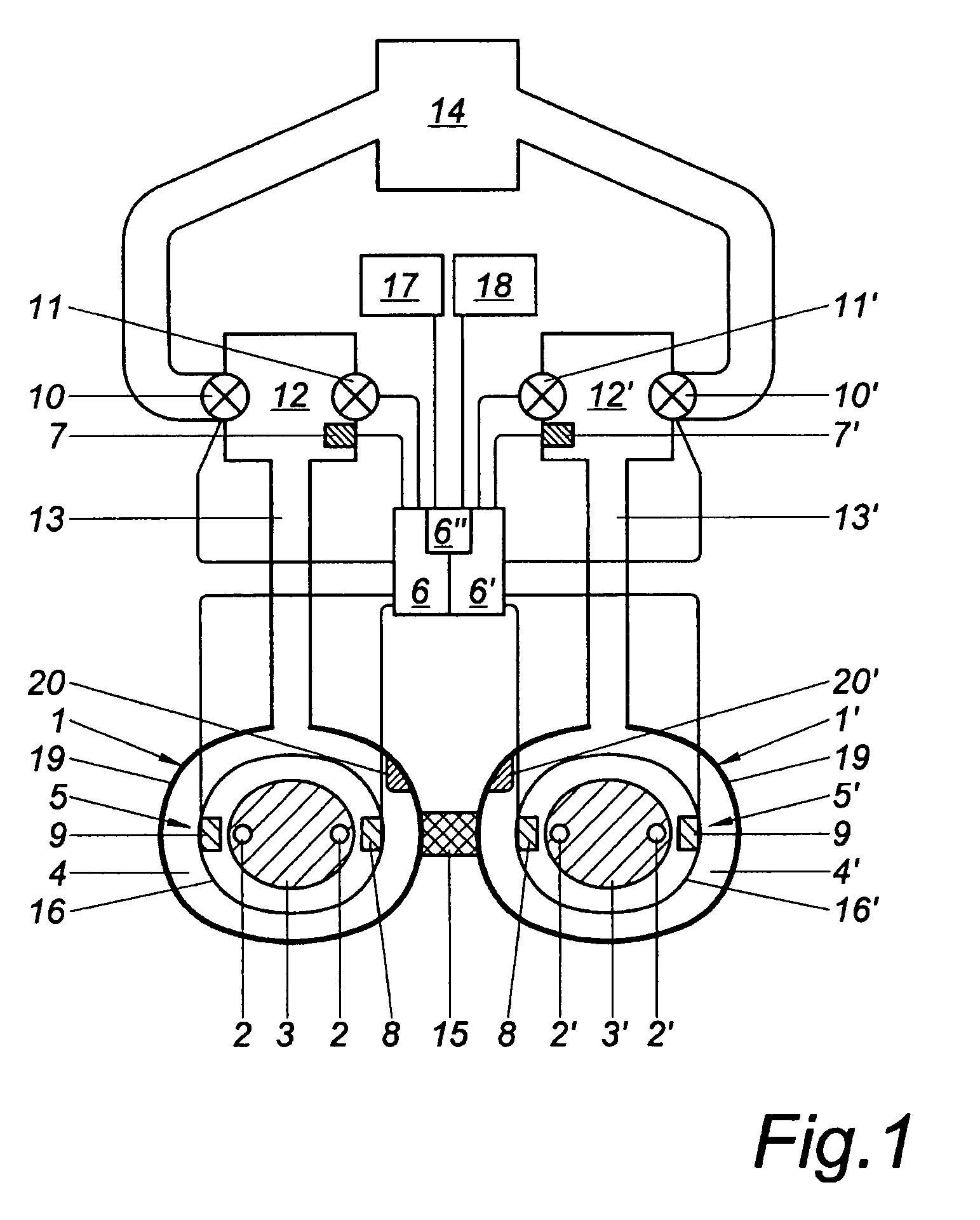

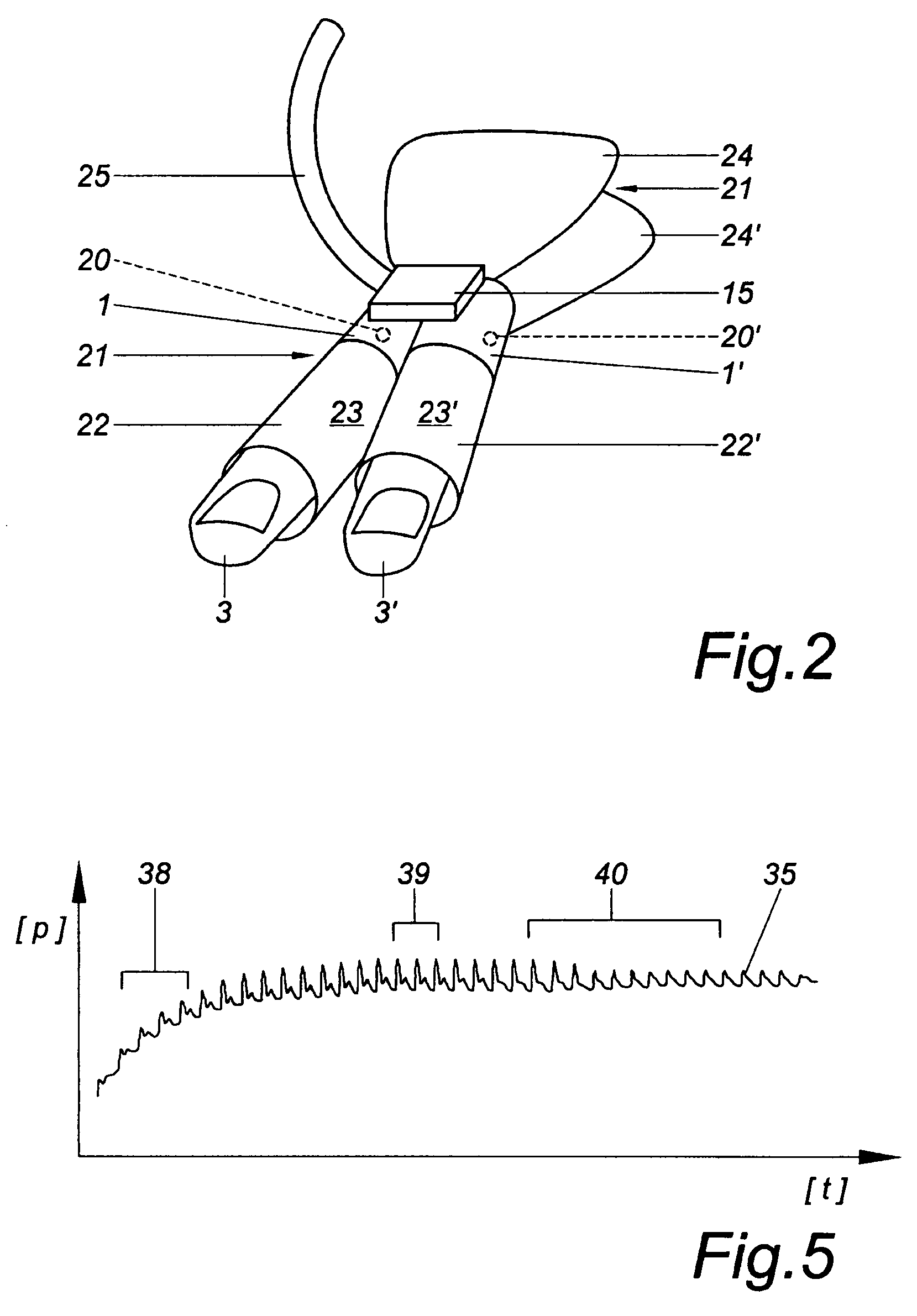

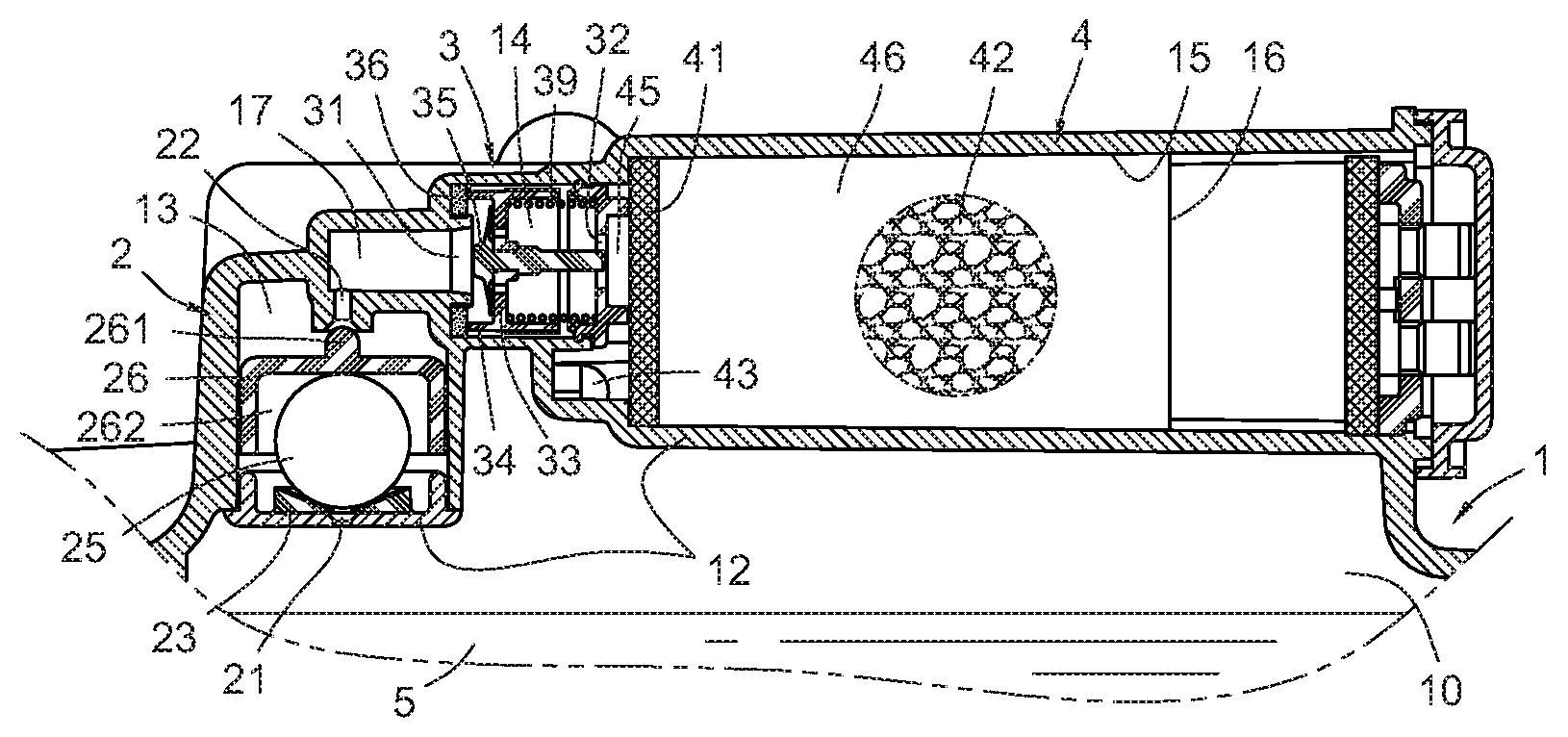

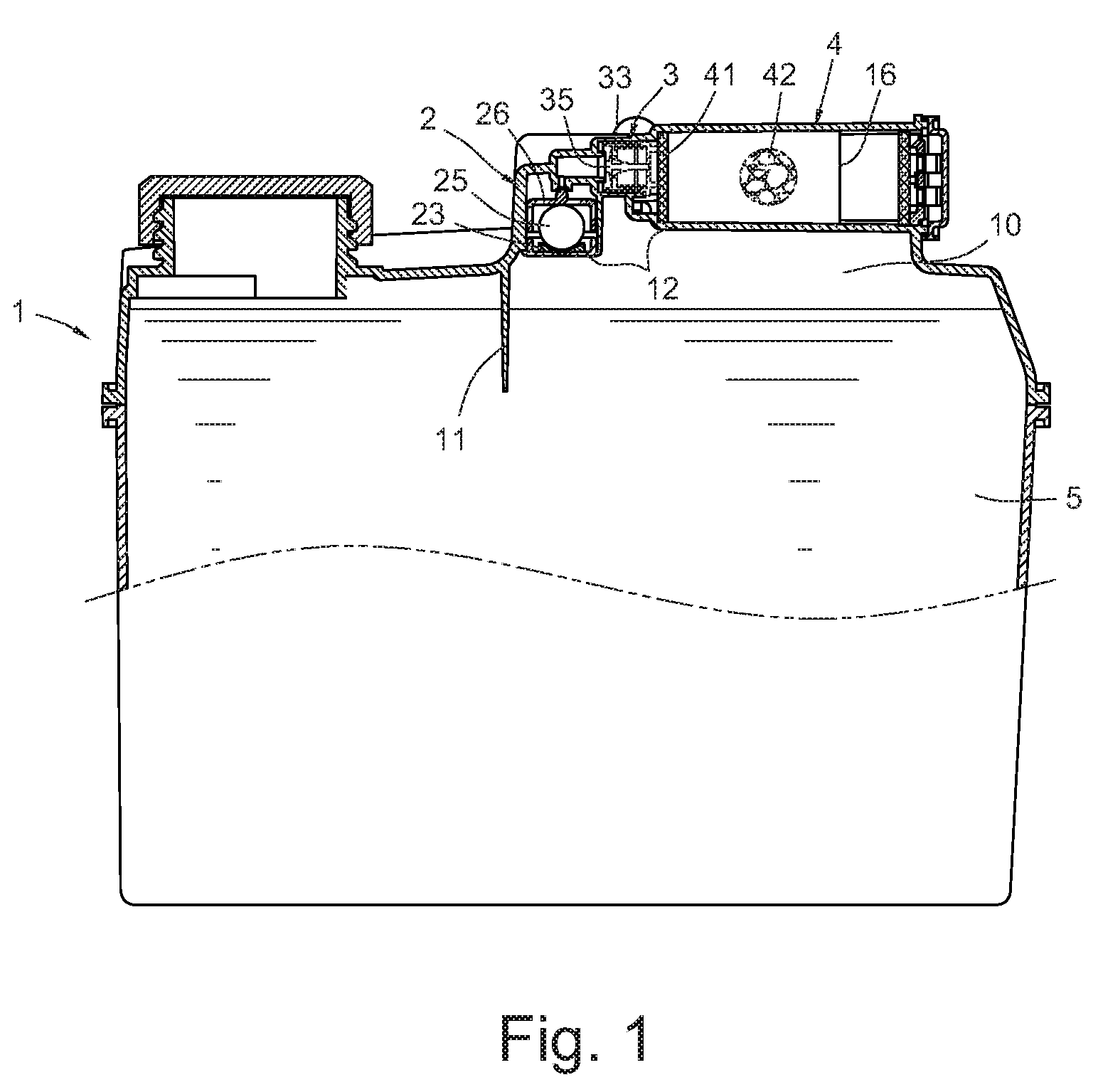

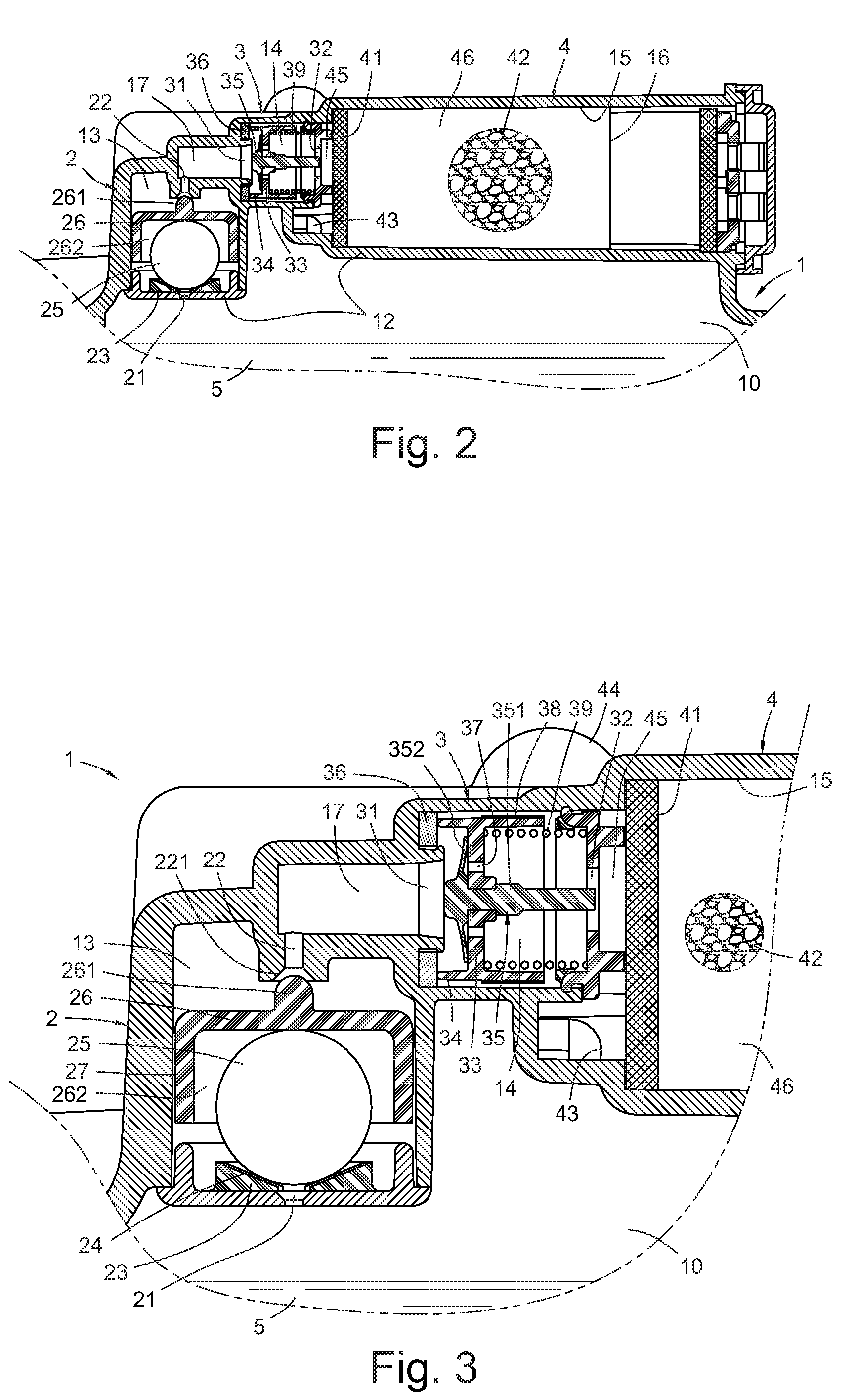

Device and method for the continuous non-invasive measurement of blood pressure

A method for the continuous non-invasive measurement of blood pressure includes at least one first pressure cuff and one second pressure cuff of comparable or identical size, each cuff including an inflatable pressure measuring chamber applicable to a first and a second body part or region containing an artery. The first pressure cuff has a first plethysmographic sensor connected to a regulating and control device used to regulate the pressure in a first pressure measuring chamber by means of a measuring signal of the plethysmographic sensor. The first pressure measuring chamber is connected to a pressure sensor in order to obtain a pressure measuring signal. The second pressure measuring chamber is a reference pressure chamber that can be regulated at the same time as the first pressure measuring chamber, independently therefrom, and can be regulated by the regulating and control device according to a pre-determinable pressure function.

Owner:CNSYST MEDIZINTECHN

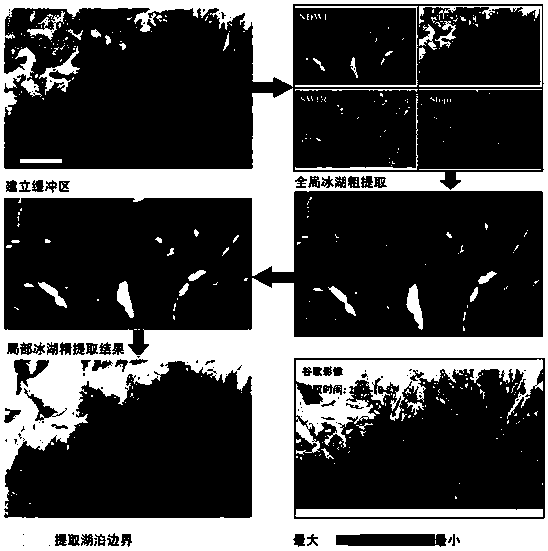

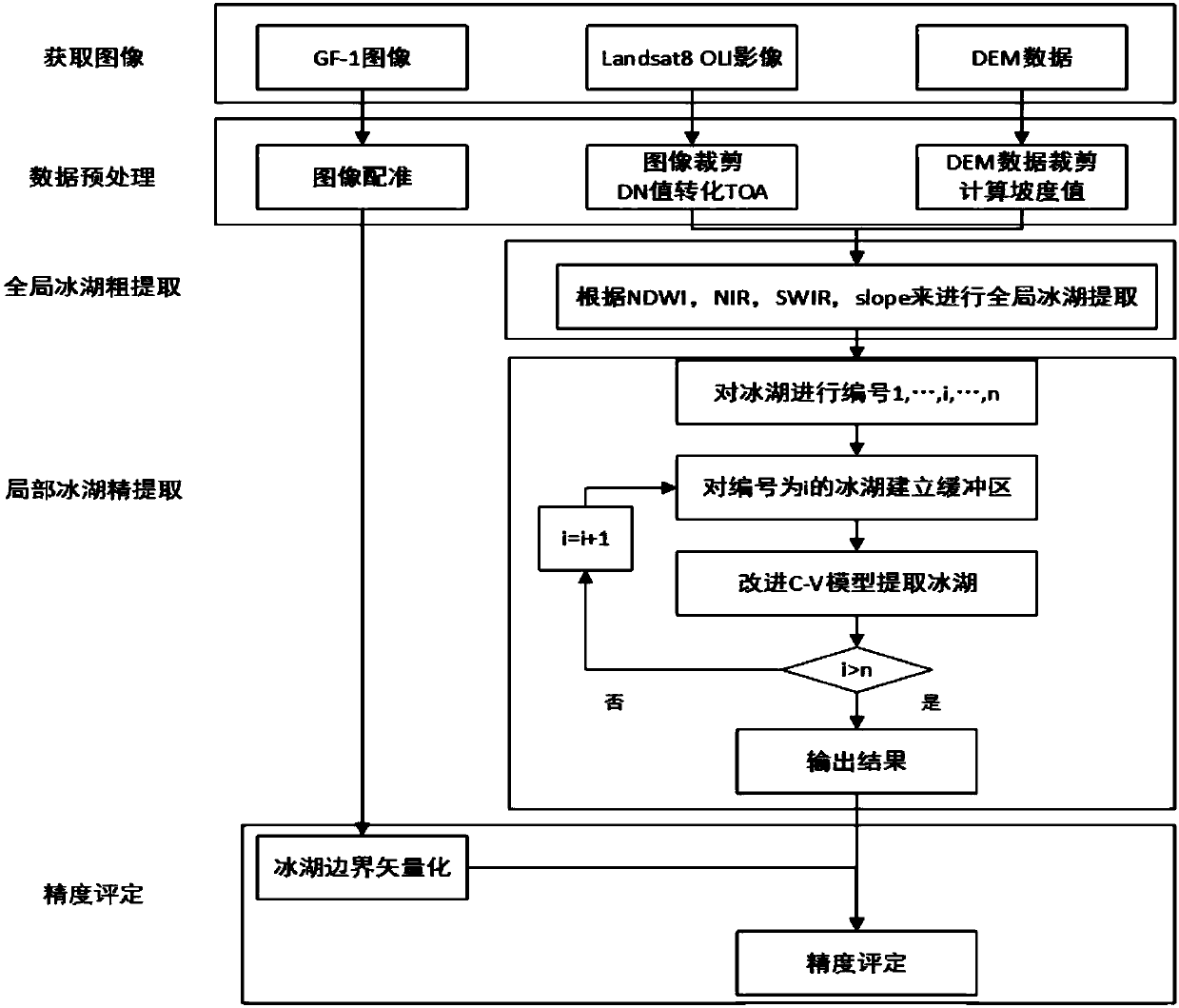

Method for extracting glacial lakes in highland area based on remote sensing satellite image

ActiveCN107730527AAccurate extractionEasy extractionImage enhancementImage analysisPressure functionNear infrared reflectance

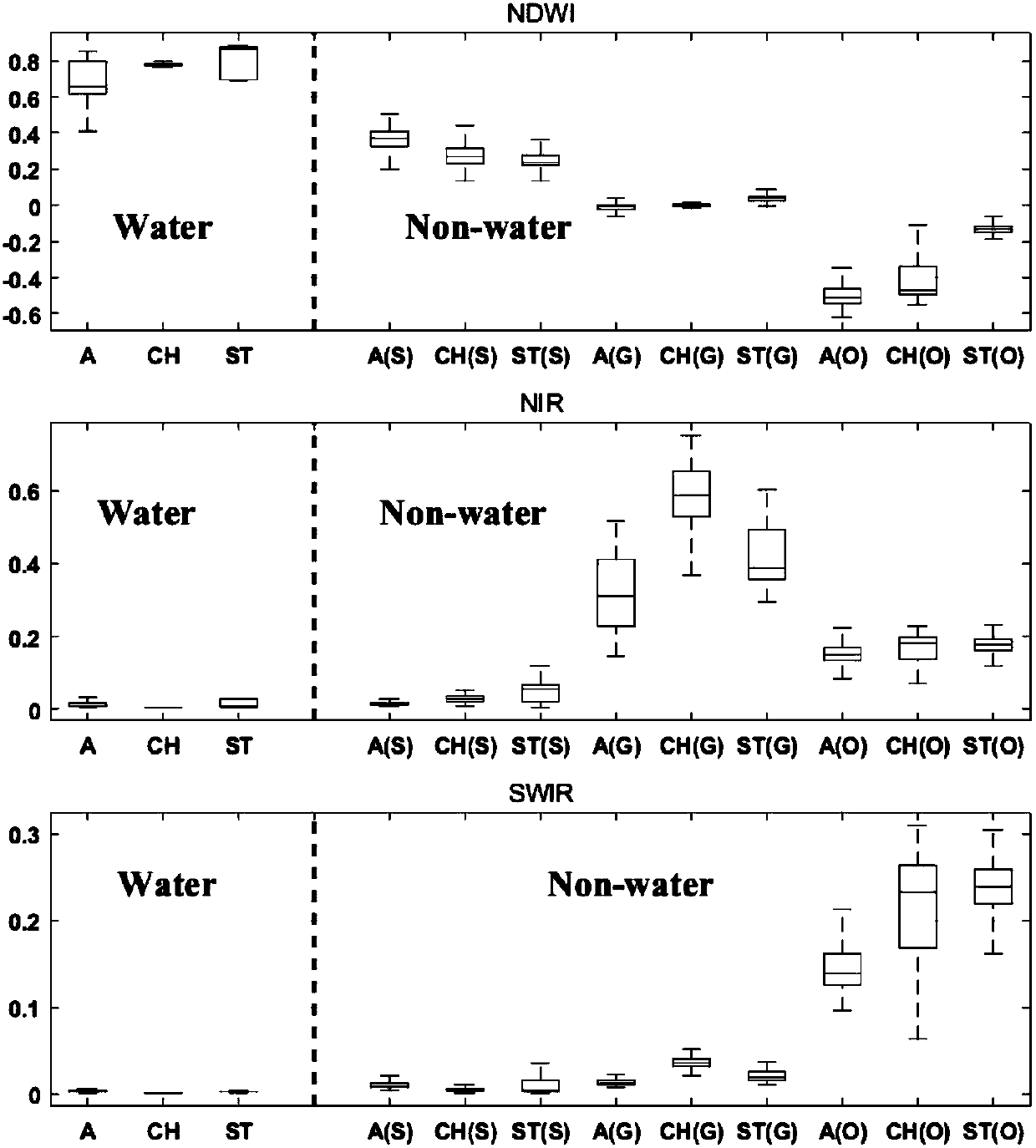

The invention discloses a method for extracting glacial lakes in a highland area based on a remote sensing satellite image. The method comprises the steps of (1) obtaining the remote sensing satelliteimage and DEM data and carrying out pre-processing on the remote sensing satellite image and the DEM data, (2) carrying out global glacial lake crude extraction which comprises a step of obtaining anormalized different water index (NDWI) value of a whole region according to pre-processed remote sensing satellite image, combining a near infrared reflectance (NIR) value and a short wave infraredreflectance (SWIR) value, setting threshold values of NDWI, NIR and SWIR for the whole image, and eliminating the influences of glaciers and other ground features and a step of generating a slope mapof the area by using pre-processed DEM data, setting a slope threshold value and removing the effect of a hill shadow, and roughly extracting all glacial lakes and mixed backgrounds, and (3) carryingout local glacial lake fine extraction which comprises the steps of introducing a C-V model of a symbolic pressure function to accurately extract the glacial lakes one by one based on a result of glacial lake crude extraction. According to the extraction method of the invention, various factors affecting the extraction of the glacial lakes can be effectively removed, accurate extraction is achieved, and the method also has a good extraction result for smaller glacial lakes in the image.

Owner:INST OF REMOTE SENSING & DIGITAL EARTH CHINESE ACADEMY OF SCI

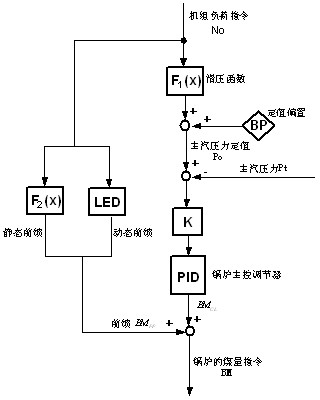

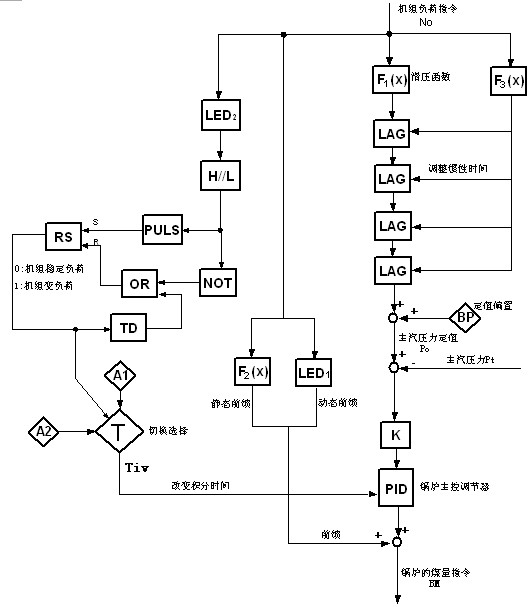

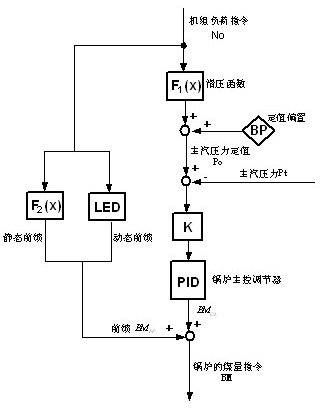

Control method for preventing excessive adjustment of coal feed for boiler in process of varying load

InactiveCN102607055AReduce integral actionReduce overshootFuel supply regulationSteam pressurePressure function

The invention discloses a control method for preventing excessive adjustment of coal feed for a boiler in the process of varying load, which is characterized in that a set value of main stem pressure obtained via a sliding pressure function is subjected to inertial filtering by four variable parameter inertial procedures, the change of the set value of the main steam pressure within a varying load starting period of a unit is delayed, the deviation between the set value of the main steam pressure and actual steam pressure within the starting period is reduced, and accordingly the excessive adjustment of coal feed for the boiler in the process of varying load is lessened, and influence of main steam pressure fluctuation on stability of the whole unit is prevented. By the control method, operational stability of the unit can be improved effectively.

Owner:SOUTHEAST UNIV

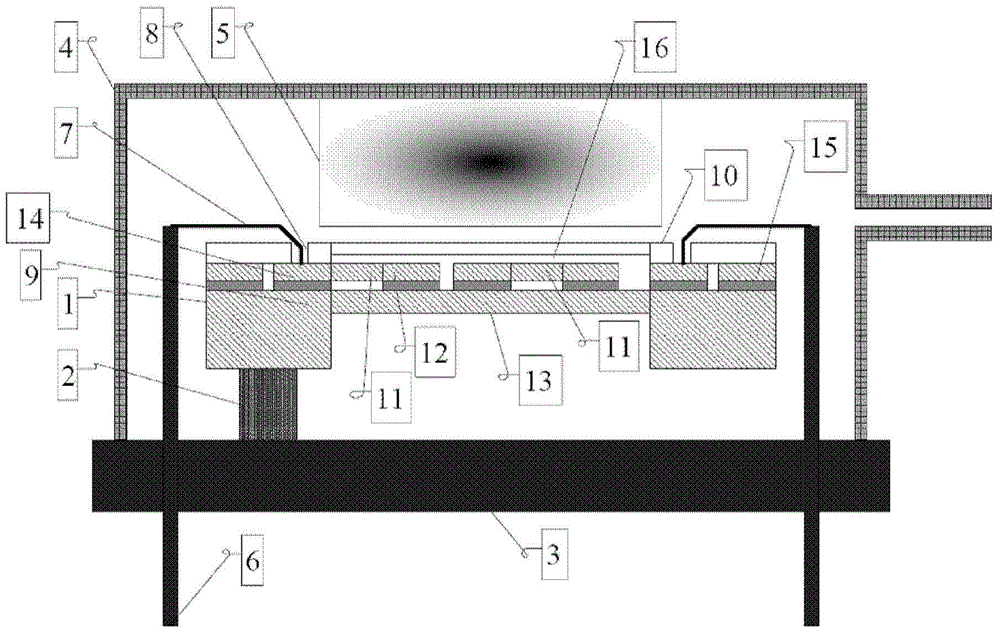

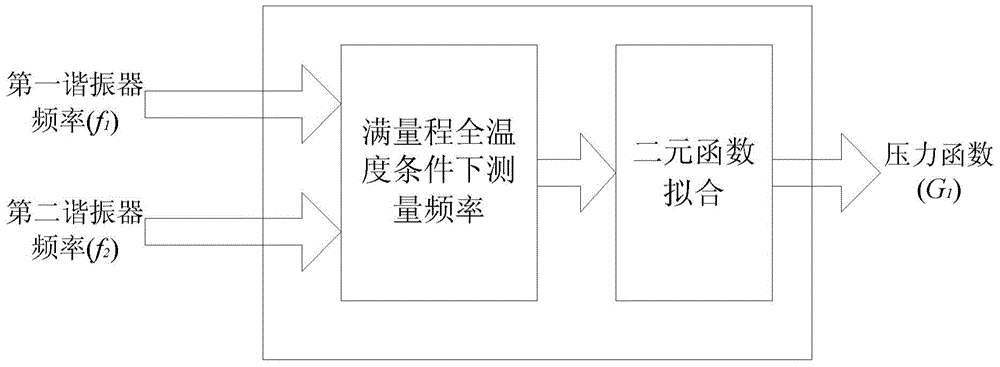

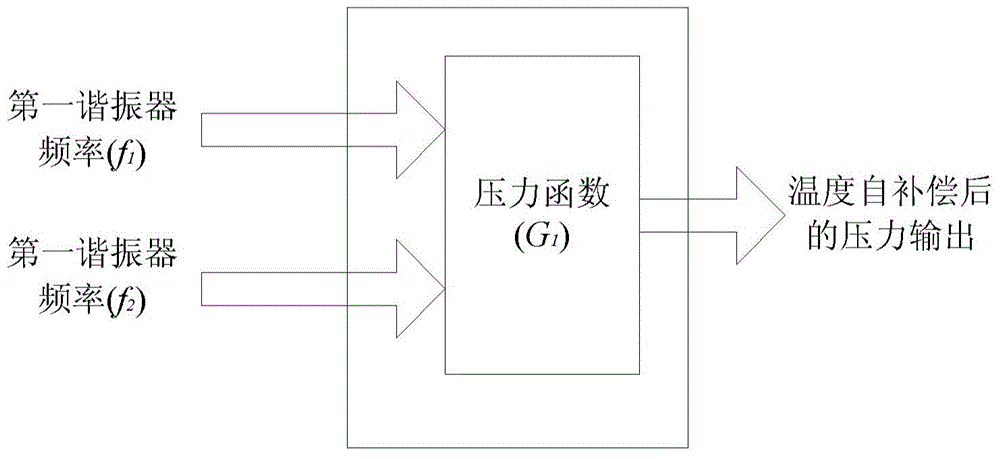

Temperature self-compensating method and measuring mode for double-resonator pressure sensor

ActiveCN104535251AOvercoming Inaccurate Temperature MeasurementsHigh compensation accuracyFluid pressure measurement by electric/magnetic elementsPressure functionResonance

The invention provides a temperature self-compensating method and a measuring mode for a double-resonator pressure sensor. The temperature self-compensating method includes the steps that m temperature calibration points are selected within a preset temperature range; n pressure calibration points are selected within a preset pressure range; frequencies of two resonators are measured at all the temperature calibration points and all the pressure calibration points respectively, the frequencies f1 of the first resonator and the frequencies f2 of the second resonator are obtained through testing, and m*n sets of calibration data are obtained in total; by means of the m*n sets of calibration data, a binary function fitting method is used for obtaining an expression of the pressure function G1 of the double-resonator pressure sensor, and the expression is p=G1(f1,f2). The frequencies of the two resonance beams are measured for temperature self-compensating, an external temperature sensitive element is not needed, the problem that temperature measurement is inaccurate because distribution of a temperature field is indeterminate can be solved, and the compensation accuracy can be improved.

Owner:山东中科思尔科技有限公司

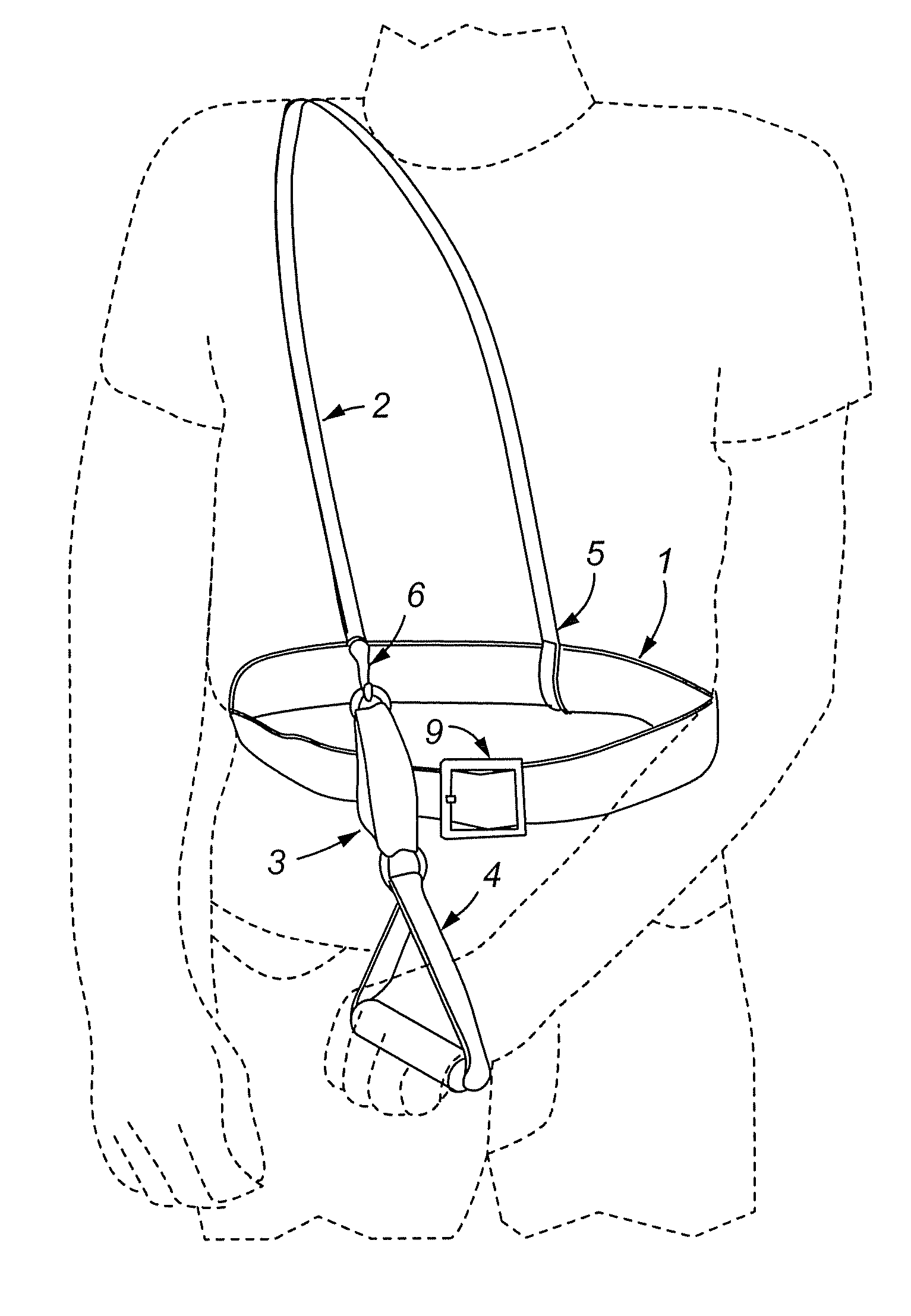

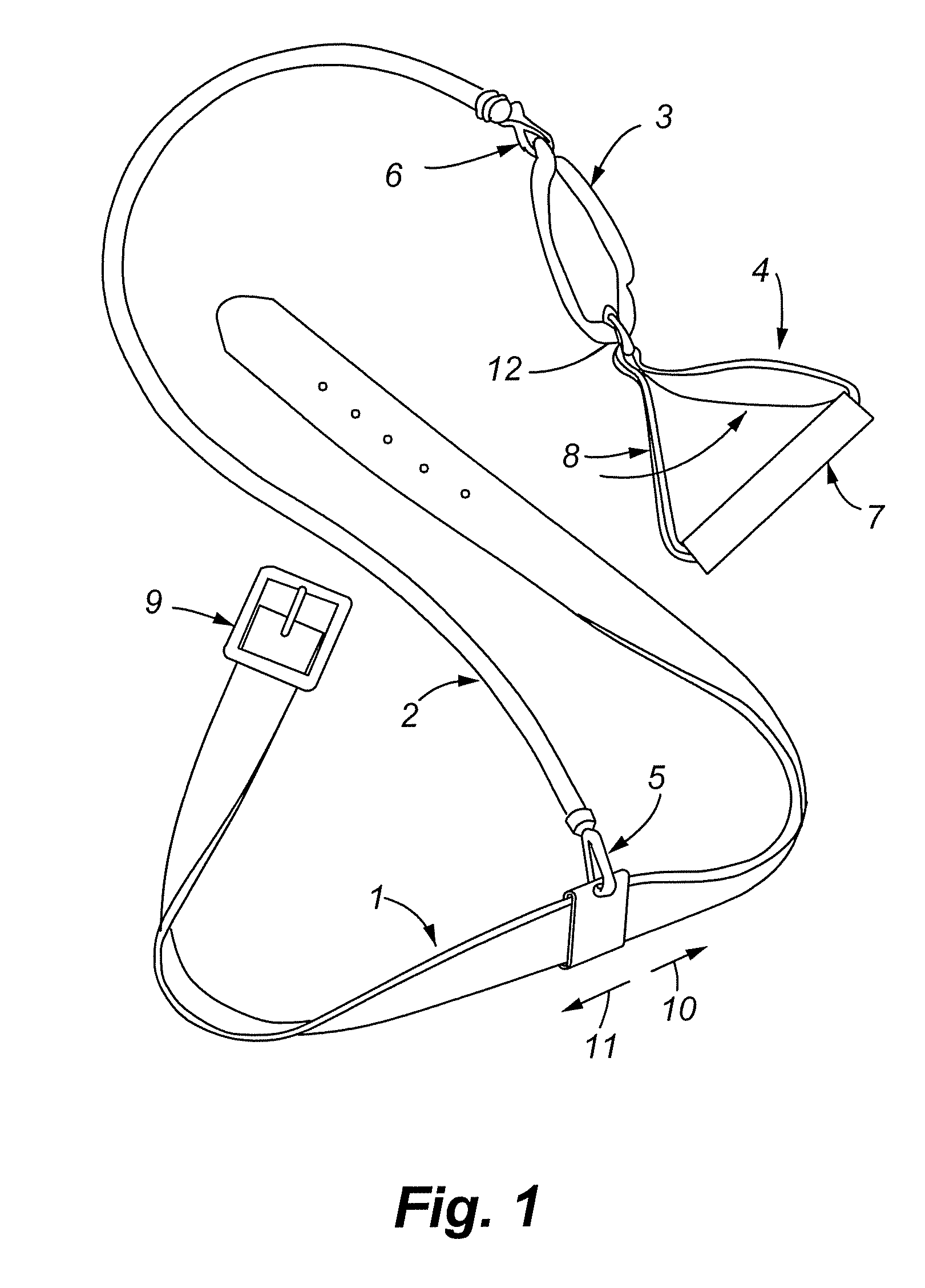

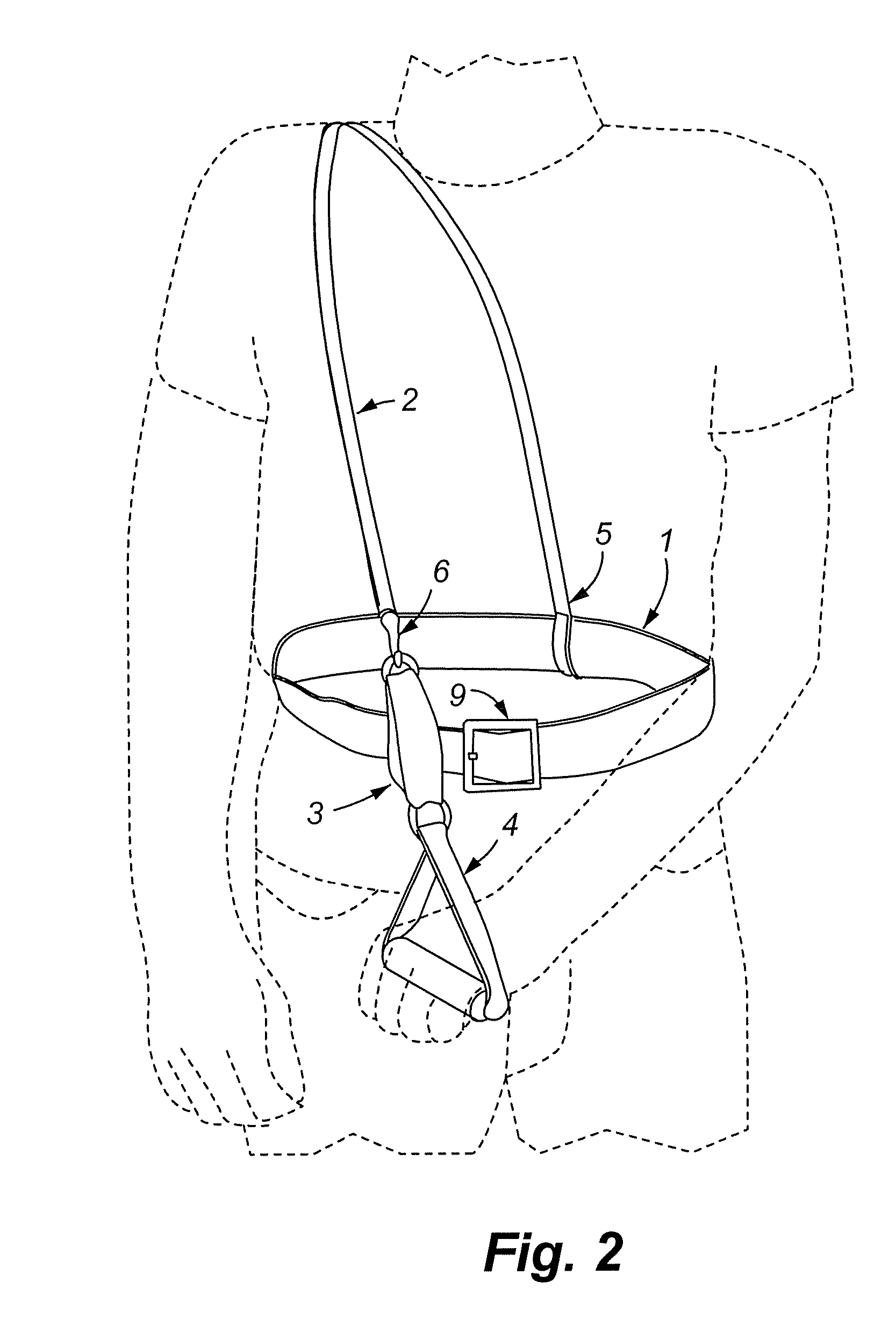

Adjustable shoulder orthotic

InactiveUS20070129657A1More freedom of motionControl unwanted verticalRestraining devicesNon-surgical orthopedic devicesPressure functionBlood flow

The invention is a shoulder orthotic that provides therapeutic functional support to an injured upper limb and eliminates the weighted pressure of limb support from the injured side of the body. The functional and supportive contributions are achieved by a shoulder suspension strap that is attached to a torso belt and then laid over an unaffected shoulder where the end of a limb is suspended. The passive and active incorporation of the injured limb with the device provides relief of subluxation in the joints, allows the patient to control contraction and relaxation of limb muscles and may be adjusted to alleviate restricted blood flow in the injured limb, all of which facilitate recovery of the injured limb.

Owner:FISHER RANDALL

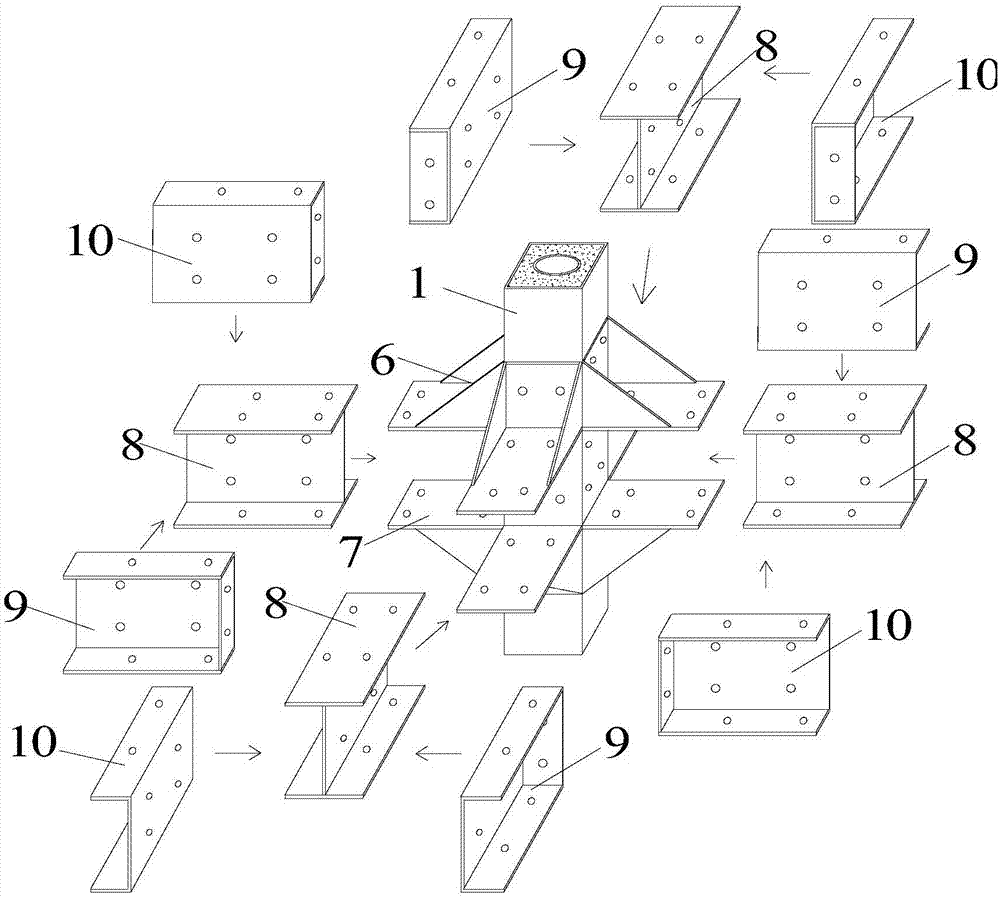

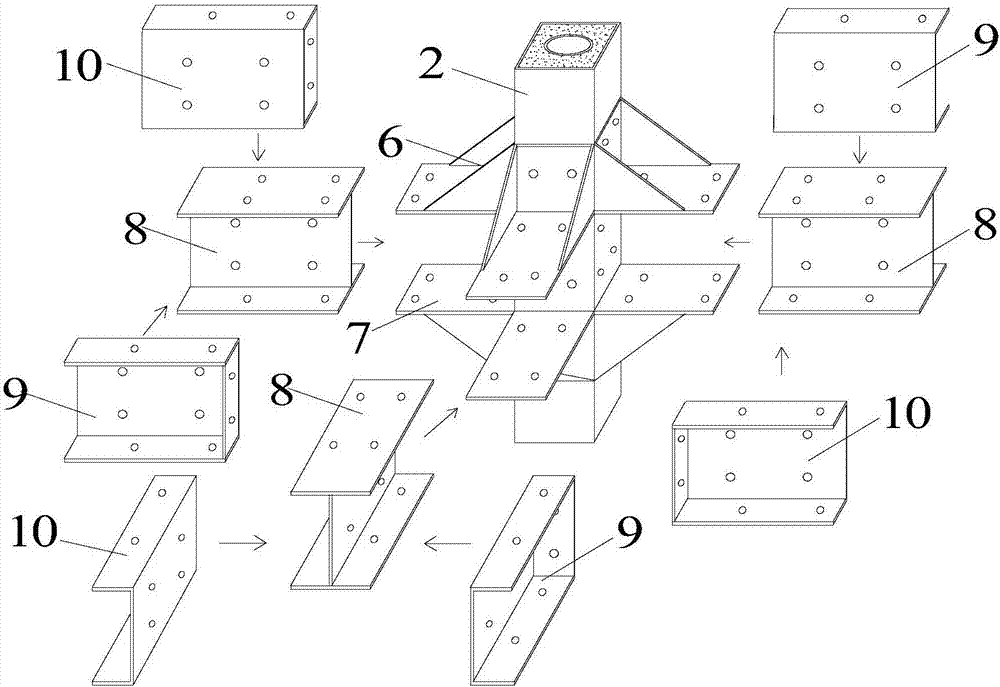

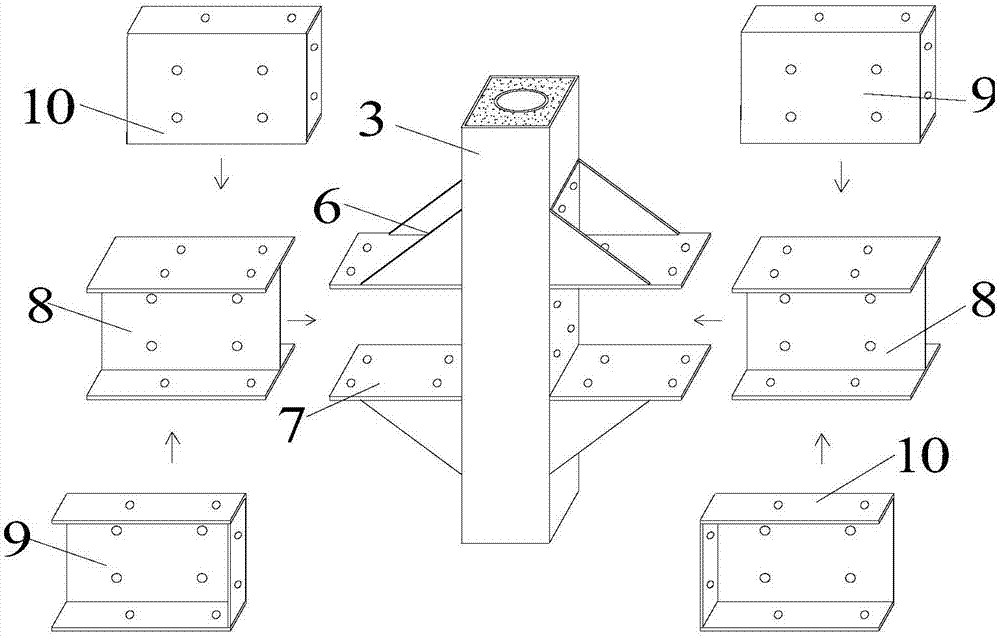

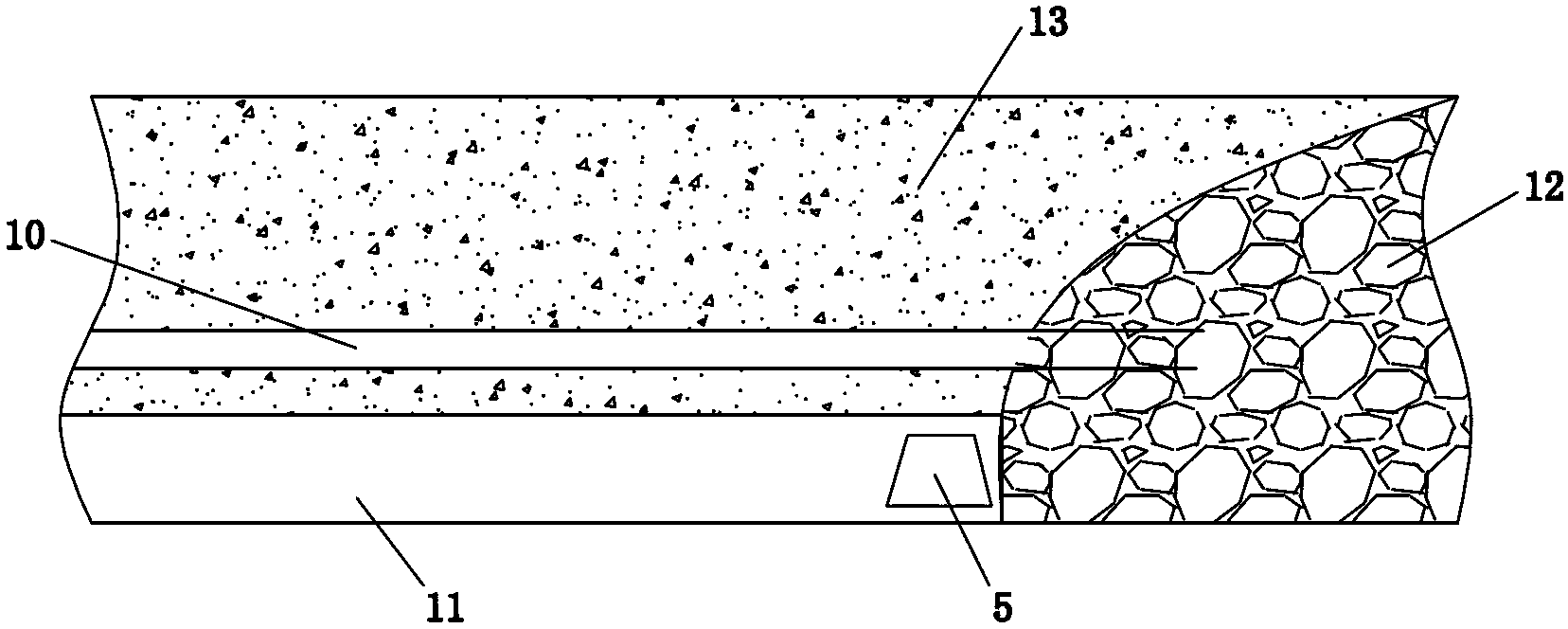

Constraint type assembly compound concrete filled-steel tubular column and steel beam joints provided with reinforcing blocks

InactiveCN107237401AReduce construction difficultyReduce construction workloadBuilding constructionsBolted jointPressure function

The invention discloses constraint type assembly compound concrete-filled steel tubular column and steel beam joints provided with reinforcing blocks. The constraint type assembly compound concrete-filled steel tubular column and steel beam joints provided with the reinforcing blocks fall into crossed joints, T-shaped joints, straight joints and L-shaped joints. Each joint comprises a compound concrete-filled steel tubular column, a first beam end connector, a second beam end connector, the first reinforcing block and the second reinforcing block, wherein the first beam end connector and the second beam end connector are each formed by welding a beam end cover board, a beam end connection board and two beam end reinforcing ribs, a second bolt hole is formed in the beam end connection cover board, a first bolt hole is formed in the beam end connection board, the first reinforcing block and the second reinforcing block are each formed by welding a piece of channel steel and a reinforcing block connection board, second bolt holes are formed in two sides of the channel steel, and a third bolt hole is formed in the other side of the channel steel. All the joints are connected through bolts completely, traditional stud welded connection is abandoned, construction and installation are convenient, the constraint pressure function is formed for concrete in the columns, and the joints can be detached and replaced.

Owner:CHANGAN UNIV

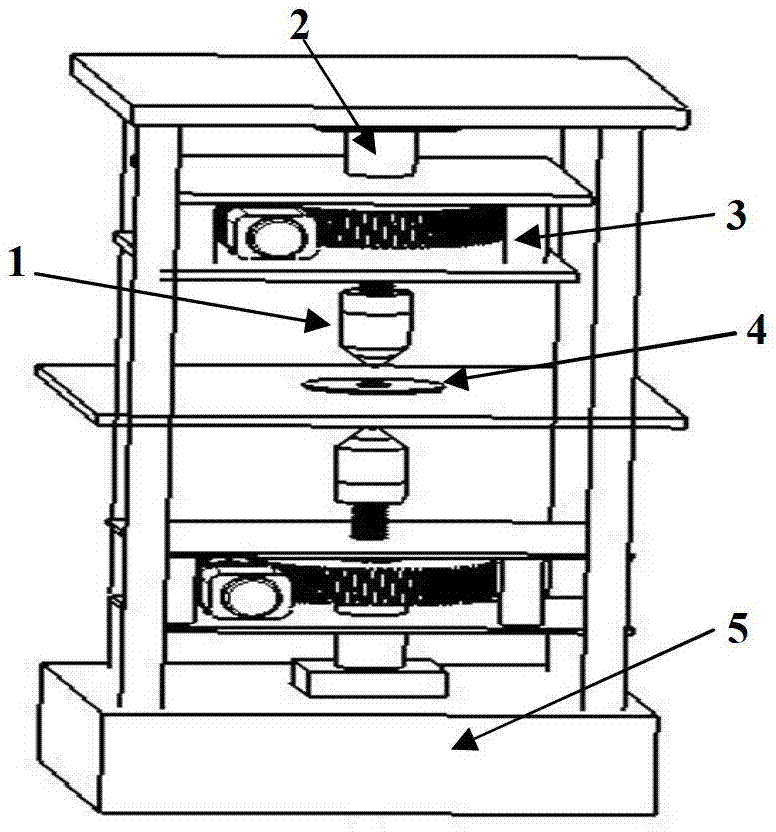

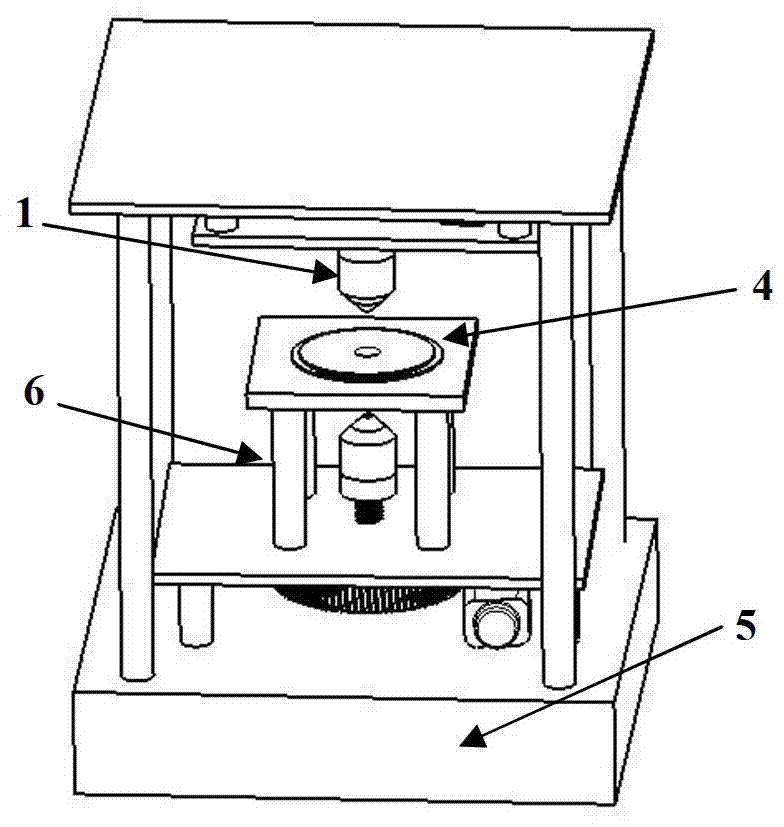

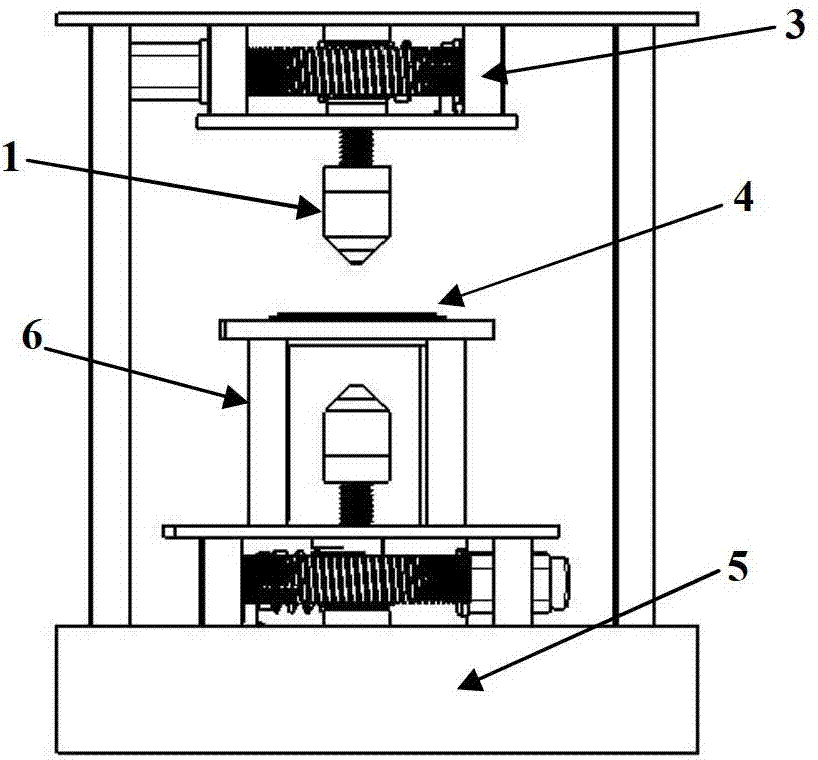

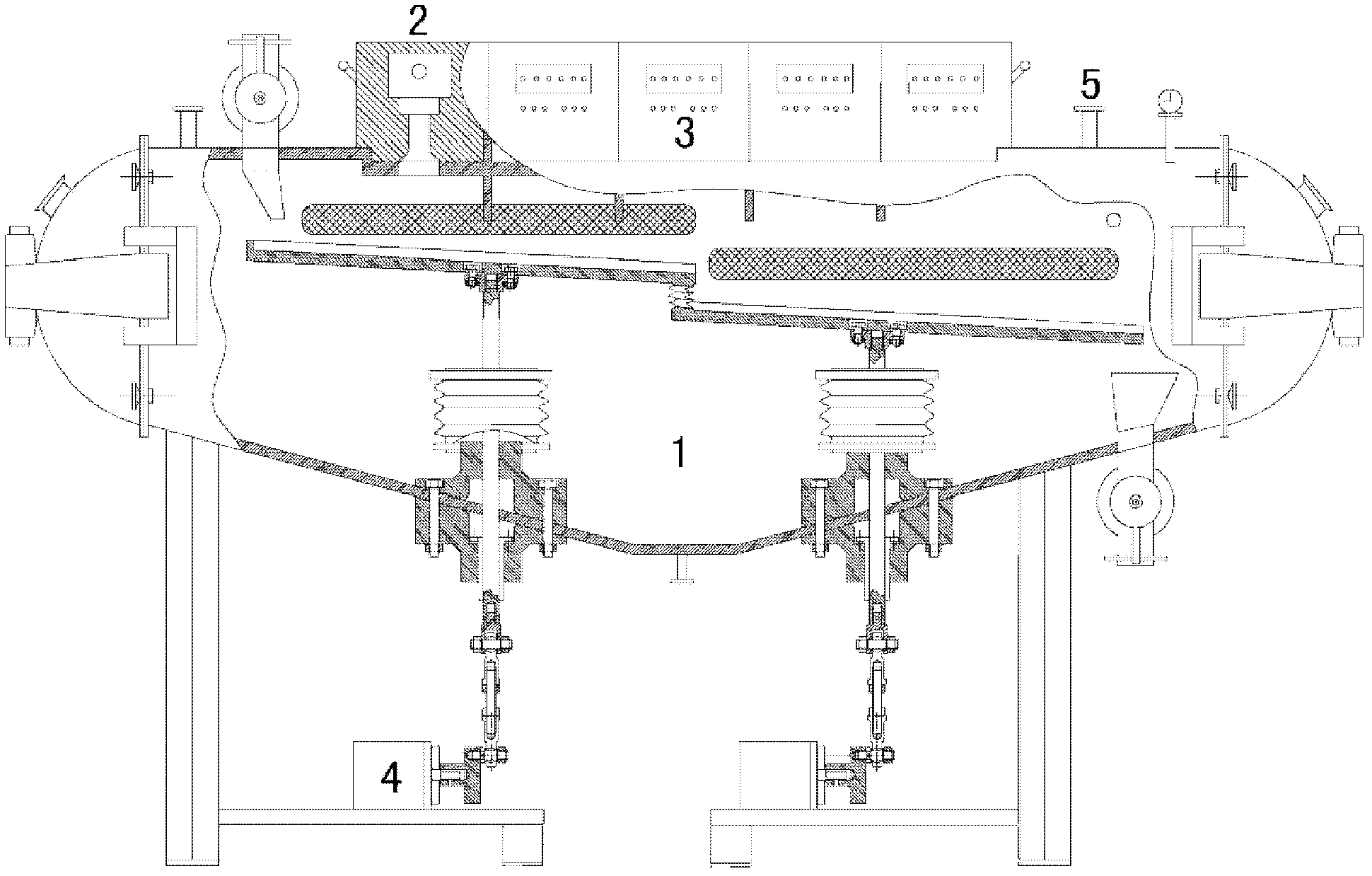

Vertical and rotating combined pressure type multi-anvil press

InactiveCN103028348AAchieve synthesisSolve puzzles that don't have spin press functionalityUltra-high pressure processesPressure functionPressure transmission

The invention discloses a vertical and rotating combined pressure type multi-anvil press, and belongs to the field of high-pressure physics. Anvil faces of an ejector anvil device of the press are arranged oppositely and coaxially; a lateral support device is arranged in the middle of the ejector anvil device; a pressure device is arranged coaxially at the rear end of the ejector anvil device, and used for applying vertical, rotating or simultaneous pressure on the ejector anvil device; the ejector anvil device consists of anvil heads, pretightening steel rings and cushion blocks; the lateral support device is in an integral or split structure, and is positioned in the center of an axis of the ejector anvil device and fixed on a rack; a cooling device consists of a water through ring and a water tank, and is used for heat dissipation of the press; and a control system is used for controlling a movement track of the ejector anvil device of the multi-anvil press to achieve that a sample in a pressure transmission medium block obtains high pressure. The multi-anvil press can achieve that the sample in the pressure transmission medium block obtains very high atmospheric pressure, so that the problem that the existing high-pressure device does not have a rotating pressure function is solved, and a material is synthesized under the action of a high shear force.

Owner:JILIN UNIV

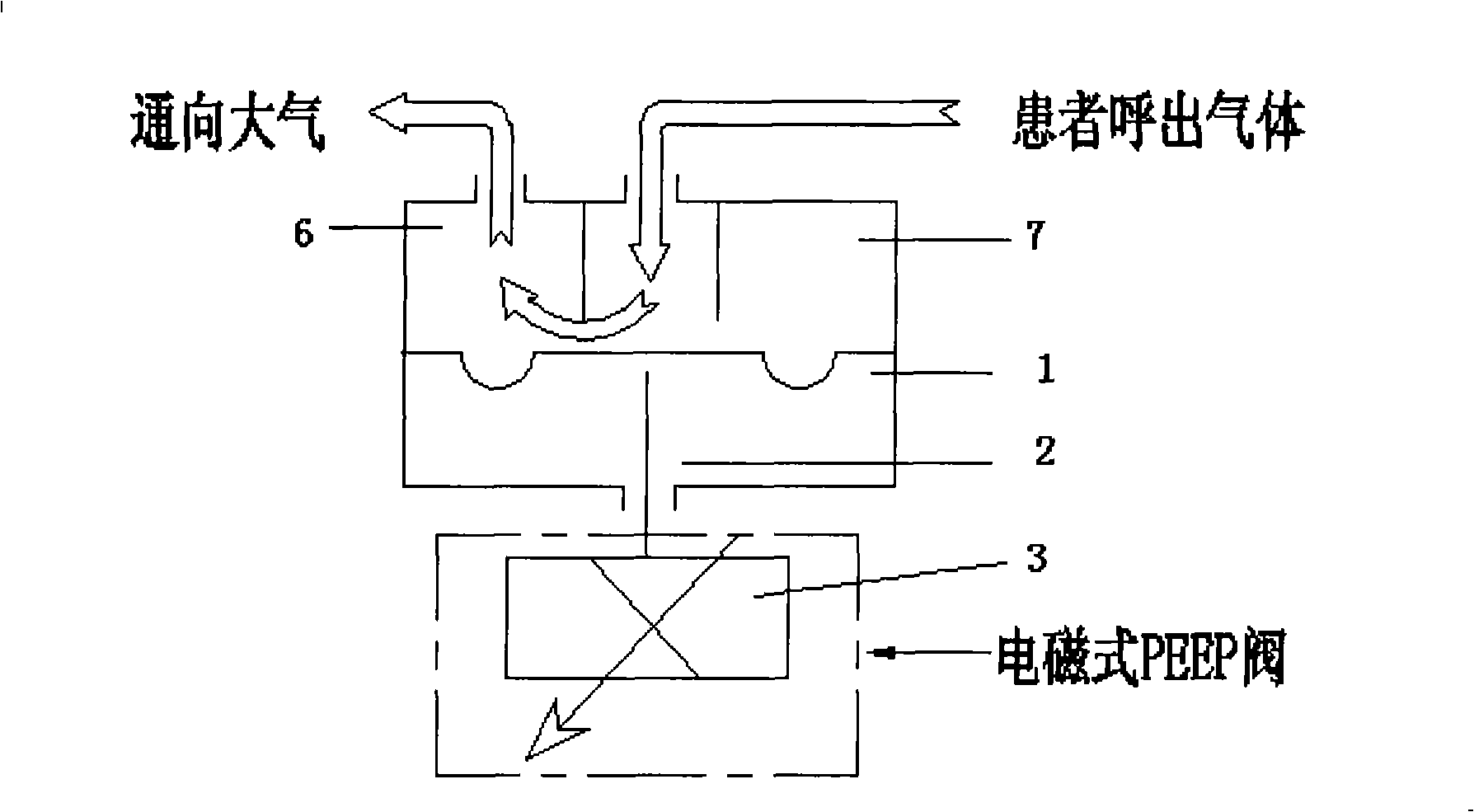

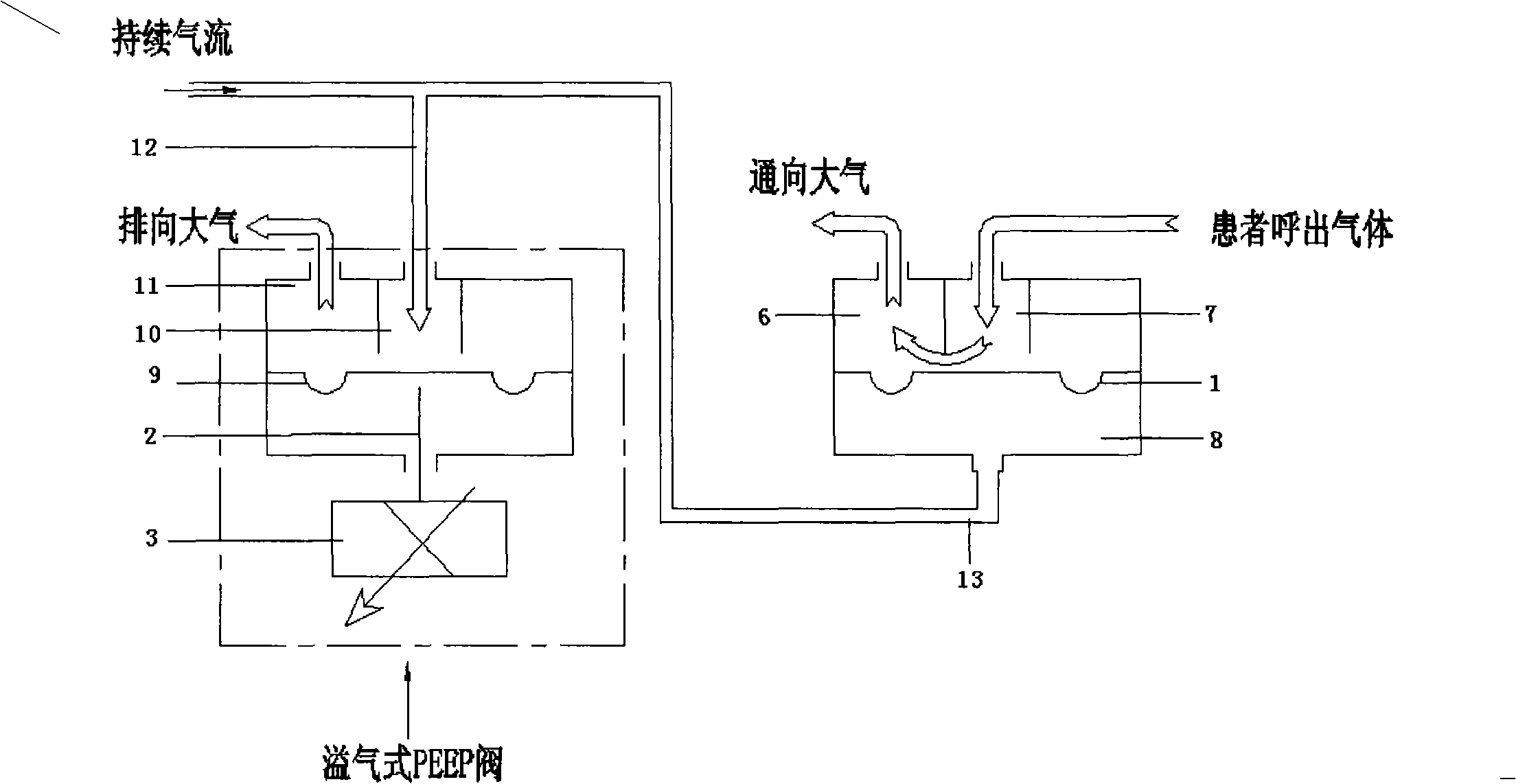

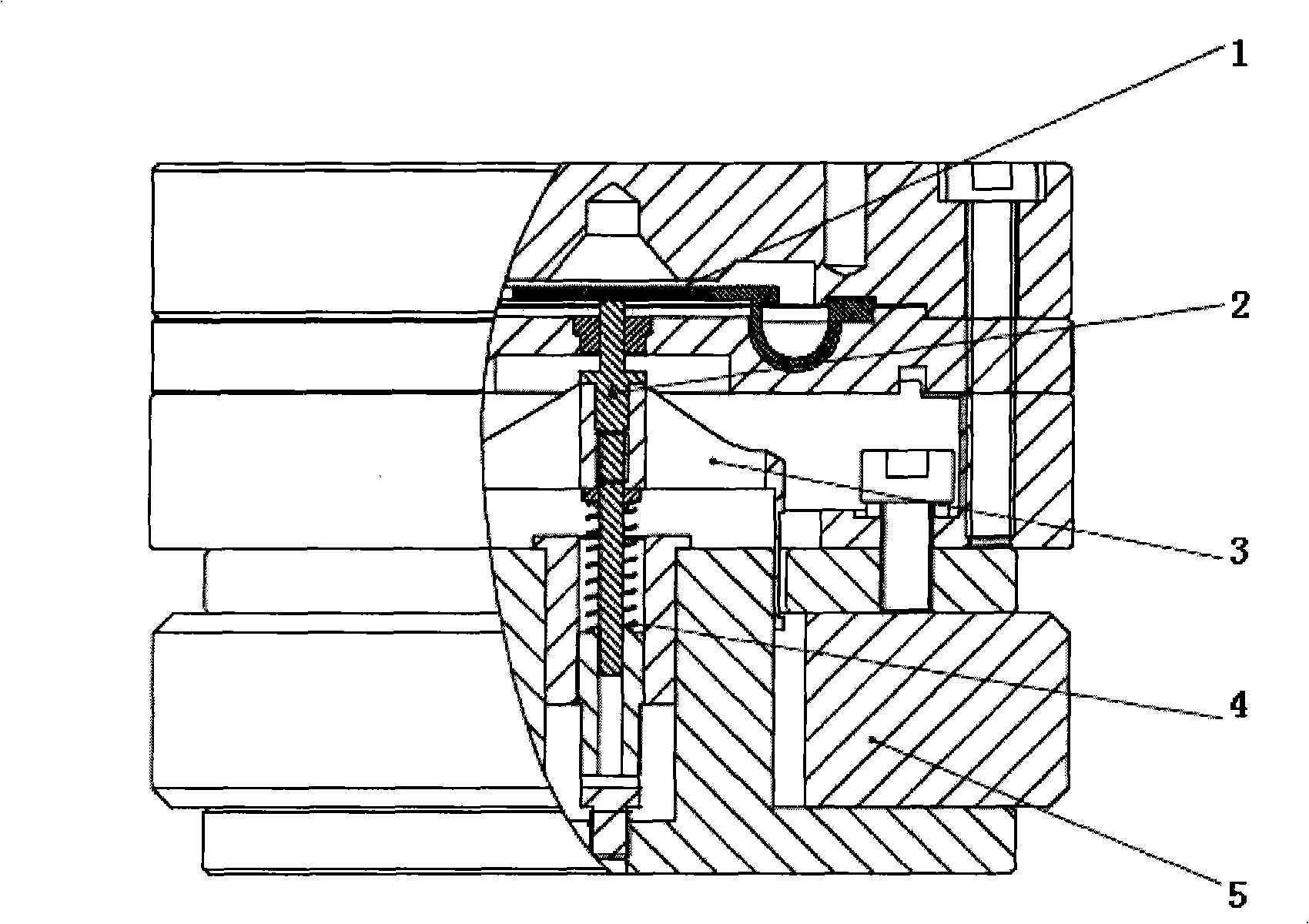

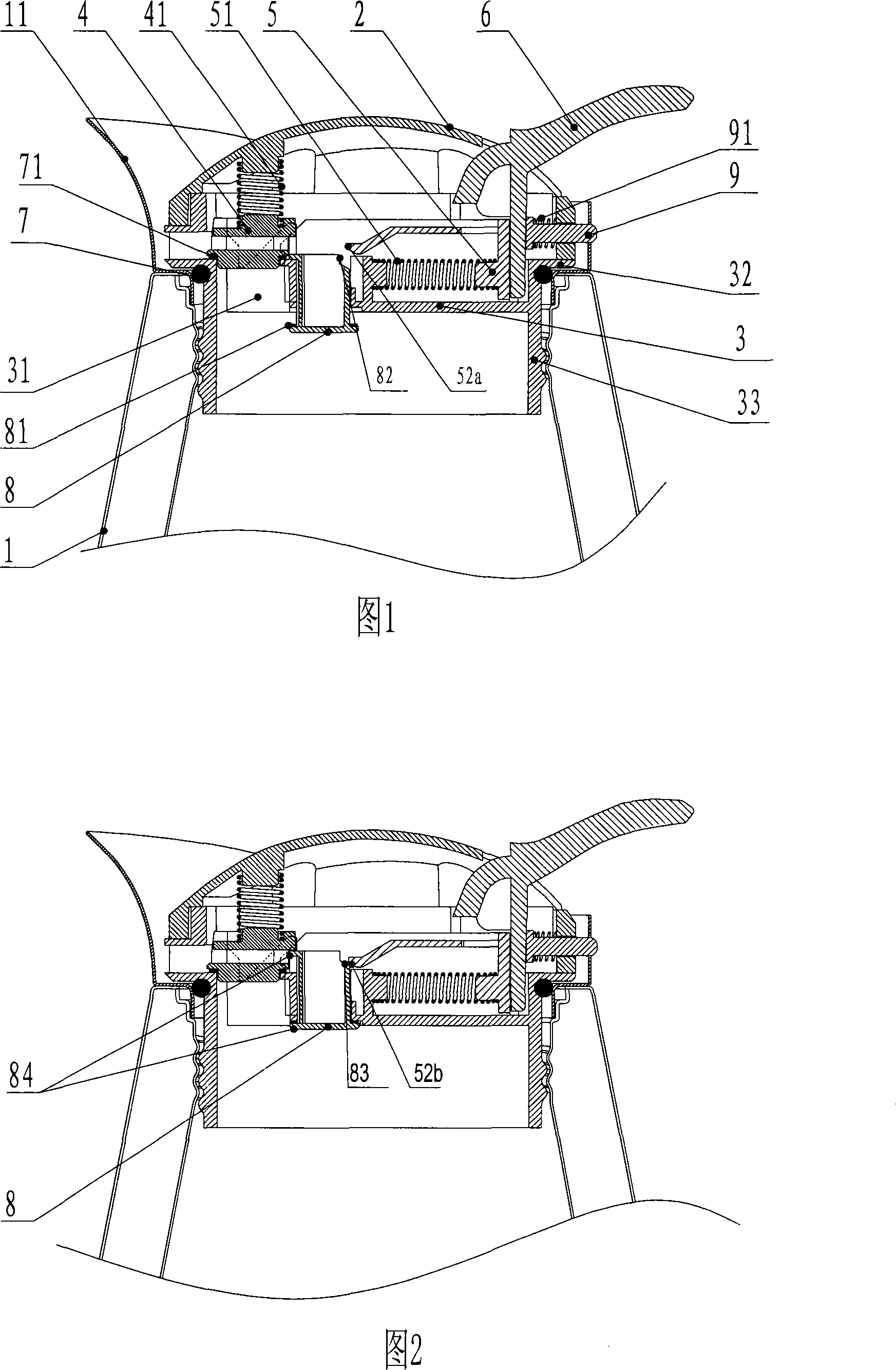

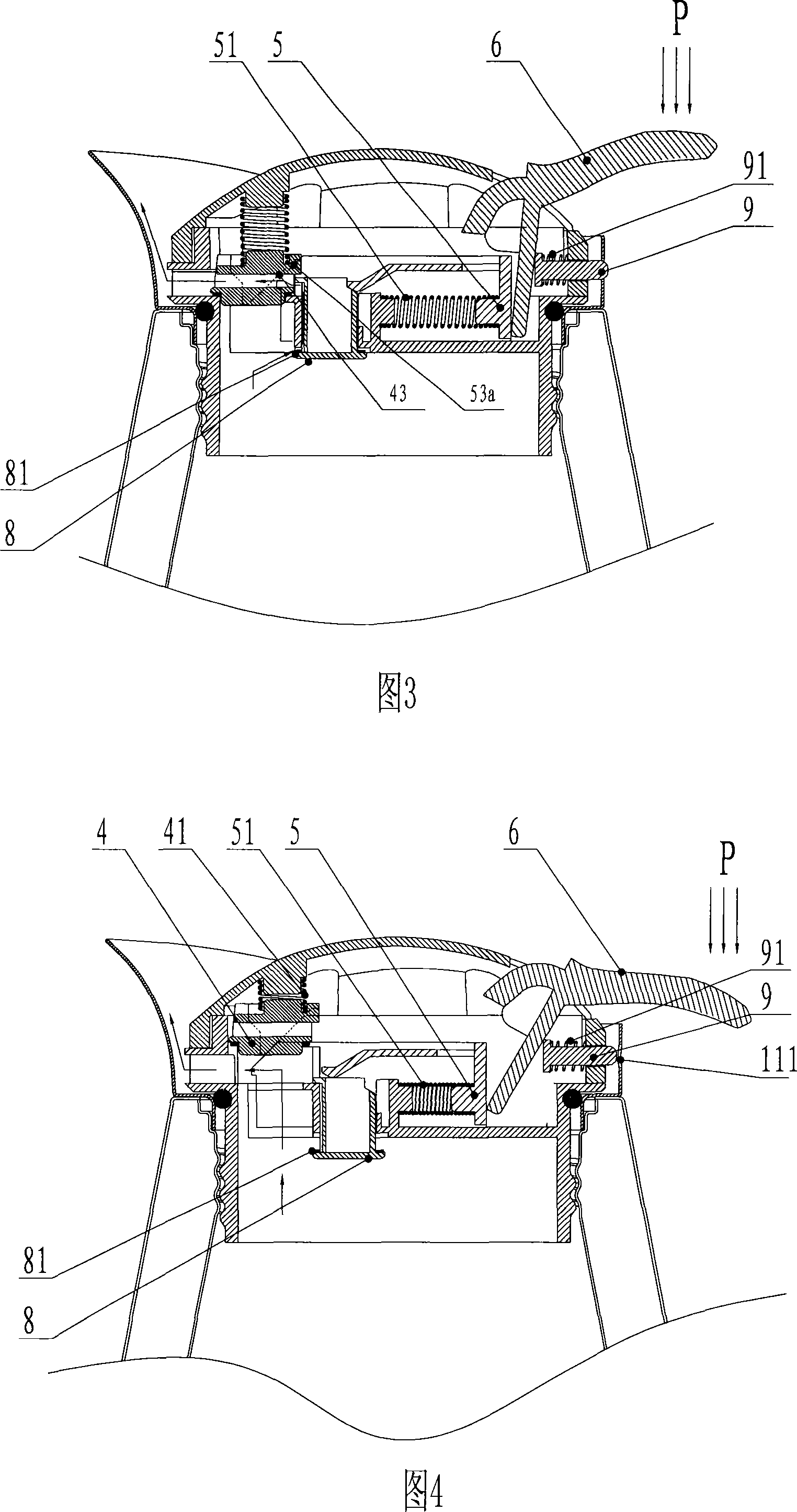

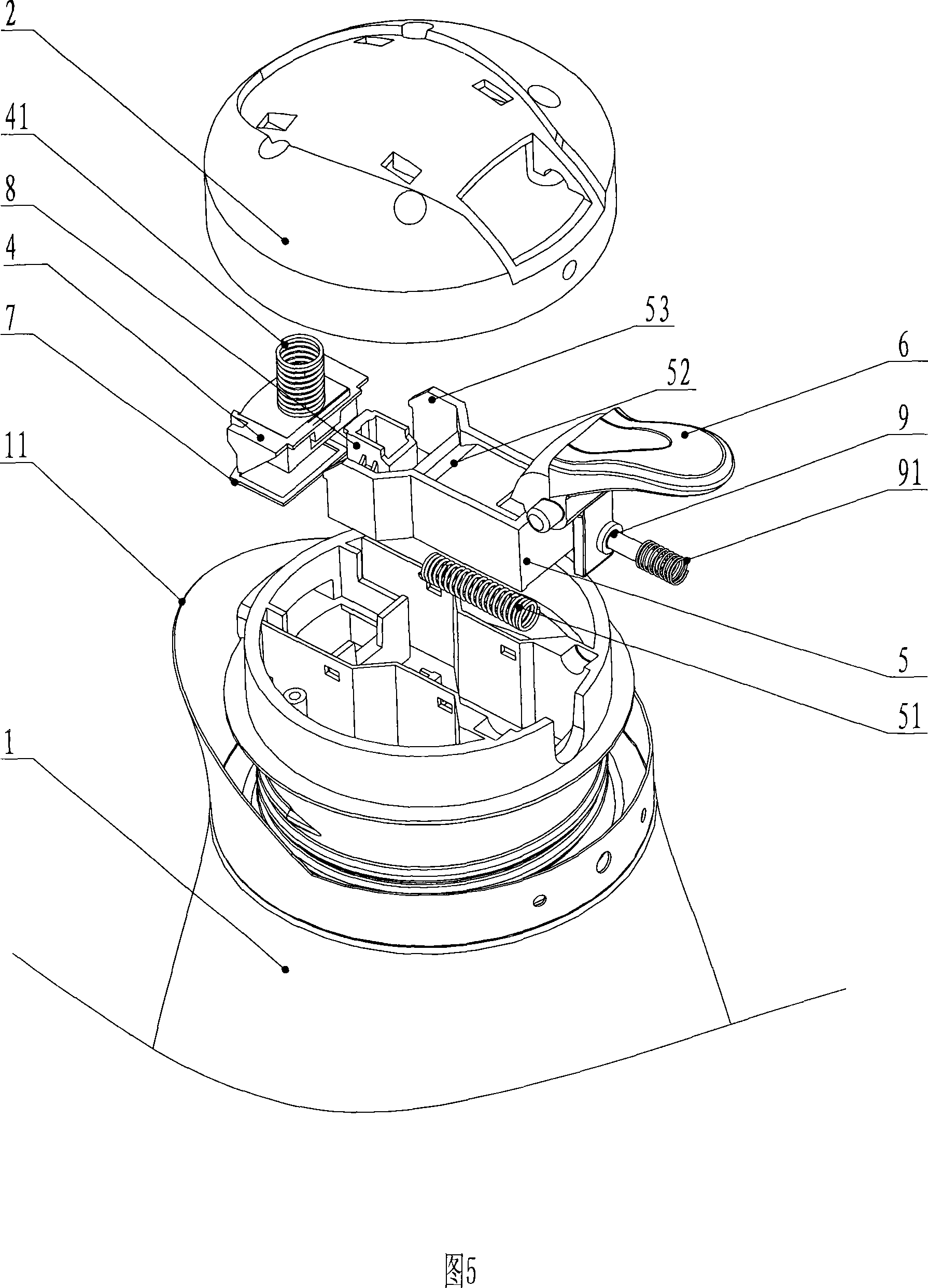

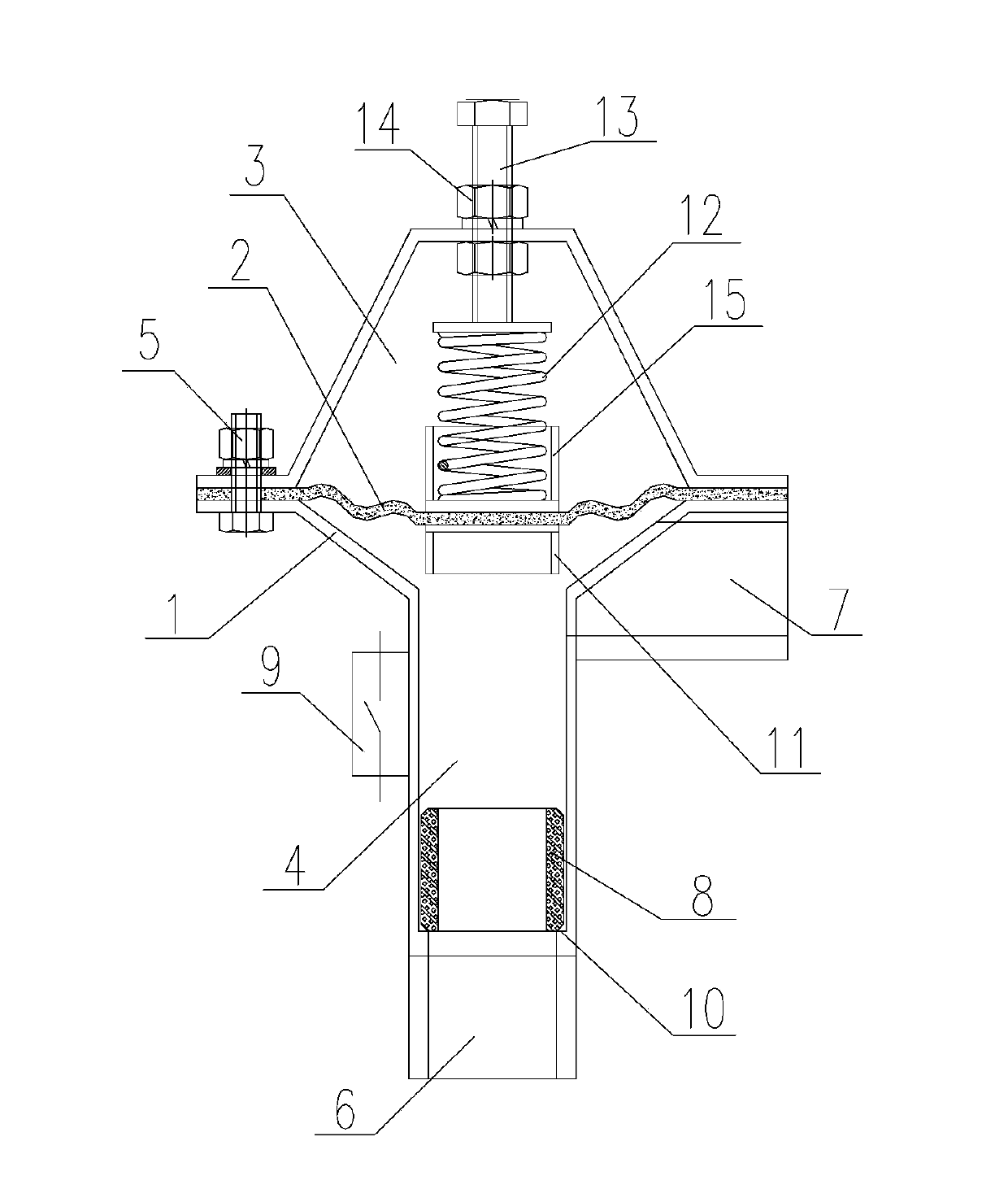

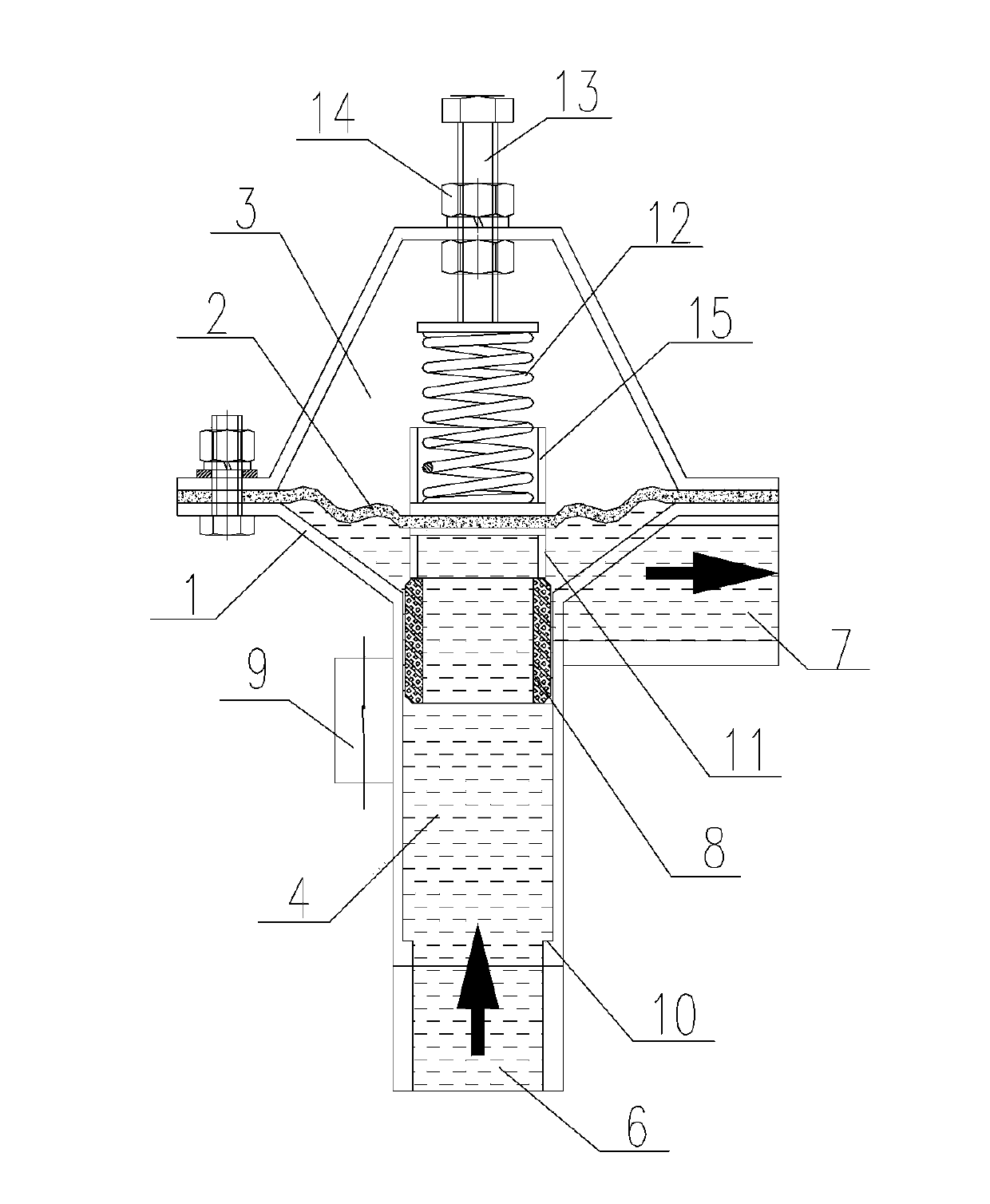

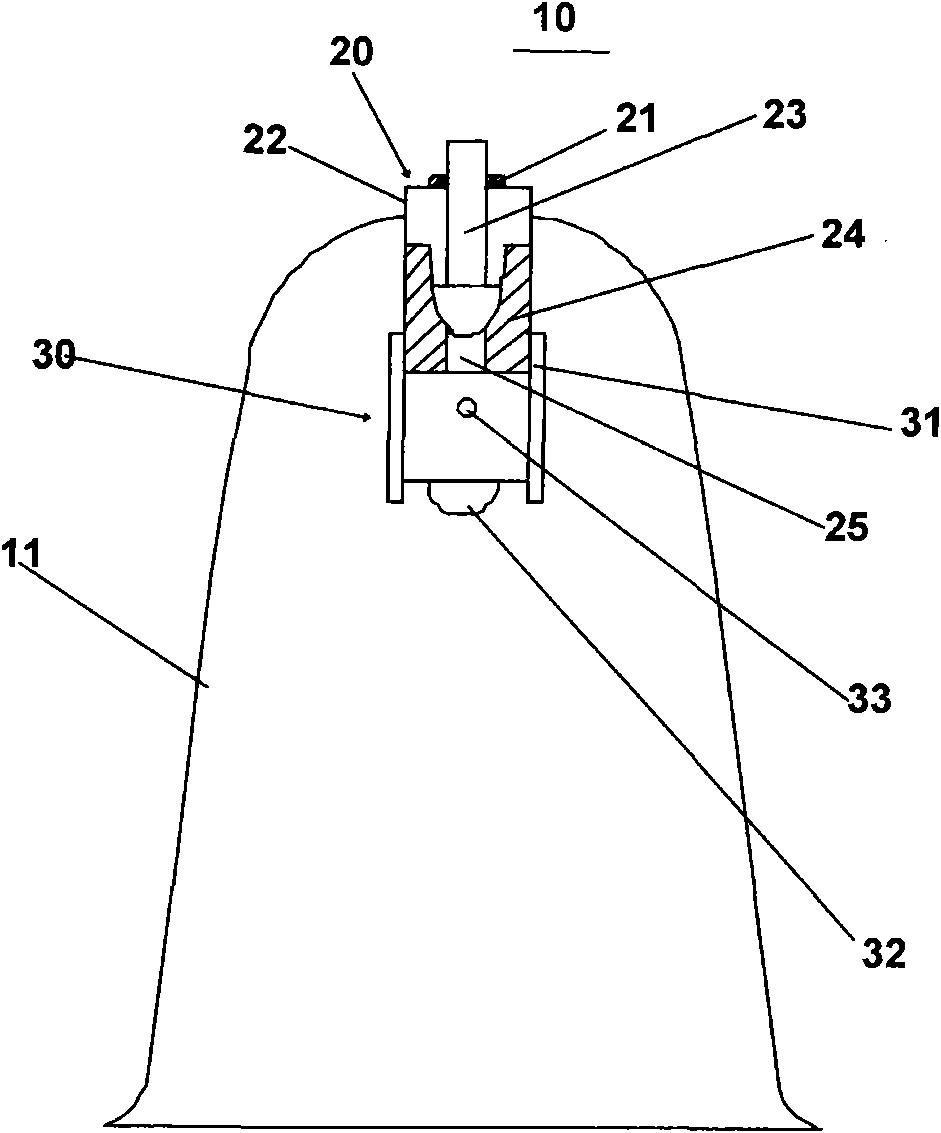

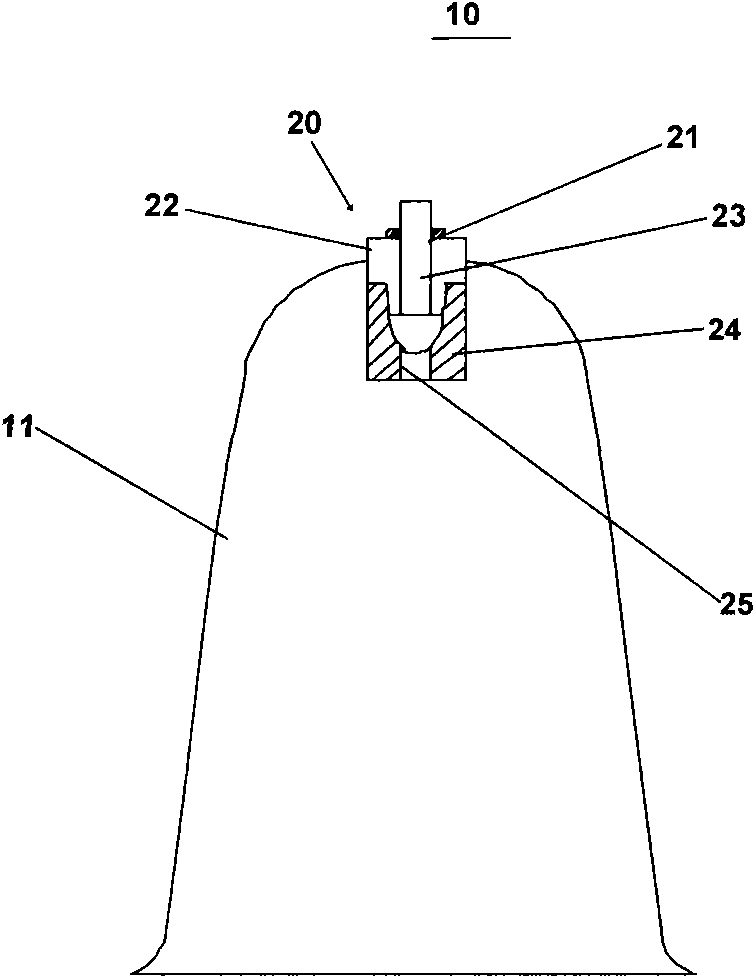

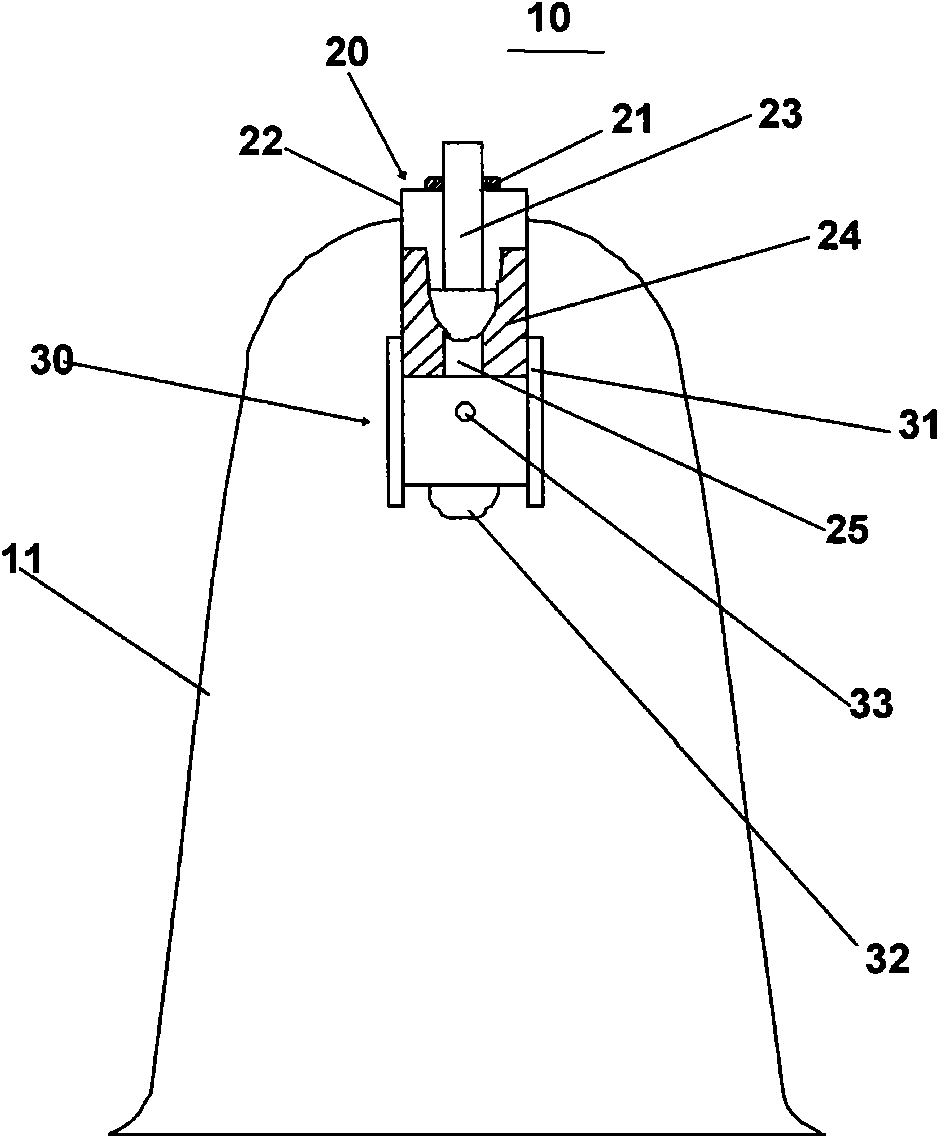

Device and method for controlling expiratory valve

InactiveCN101310792ALower work of breathingImprove ventilation comfortRespiratorsPressure functionExpiratory valve

The invention provides a device and a method for controlling an exhalation valve, the device for controlling the exhalation valve comprises: a film disk (9); an electromagnetic valve which is positioned at first side of the film disk (9); a first exhaust chamber (11) and an air inlet chamber (10), which are positioned at second side of the film disk (9), and the film disk (9) can selectively block off the air inlet chamber (10) and a channel between the first exhaust chamber (11) and the air inlet chamber (10) by a valve rod (2) of the electromagnetic valve. The method for controlling the exhalation valve comprises that: the electromagnetic valve is controlled to lead the film disk (9) to move towards the direction of an electromagnet under the input pressure function of the air inlet chamber (10); the input air flow of the air inlet chamber (10) is exhausted from the first exhaust chamber (11) from an air flow channel; the air flow is controlled to be directly flowed into an air containing chamber of the exhalation valve, thus pushing an exhalation valve body of the exhalation valve to block off an exhalation chamber of the exhalation valve. The device has fast response time and high control precision.

Owner:BEIJING AEONMED

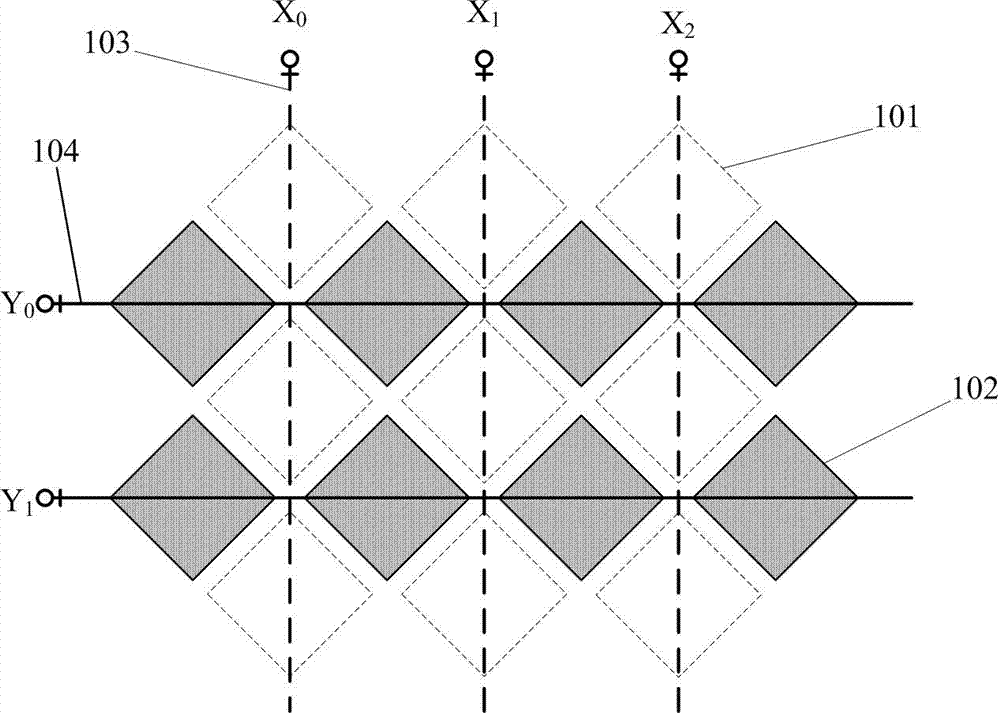

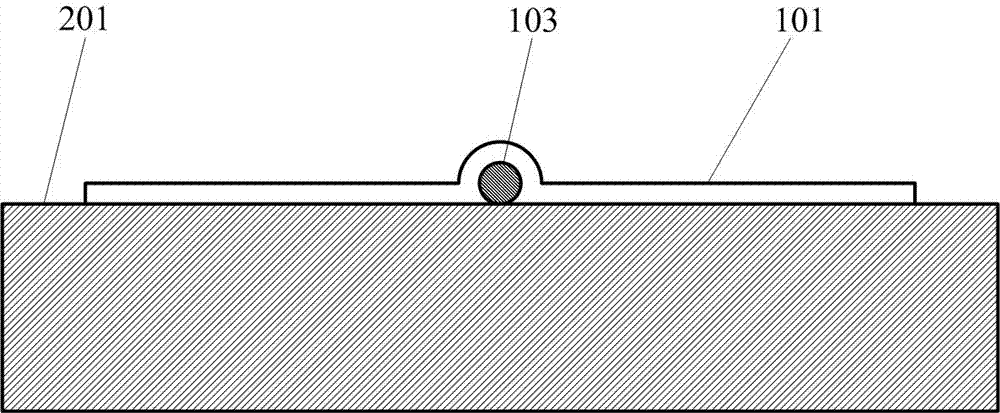

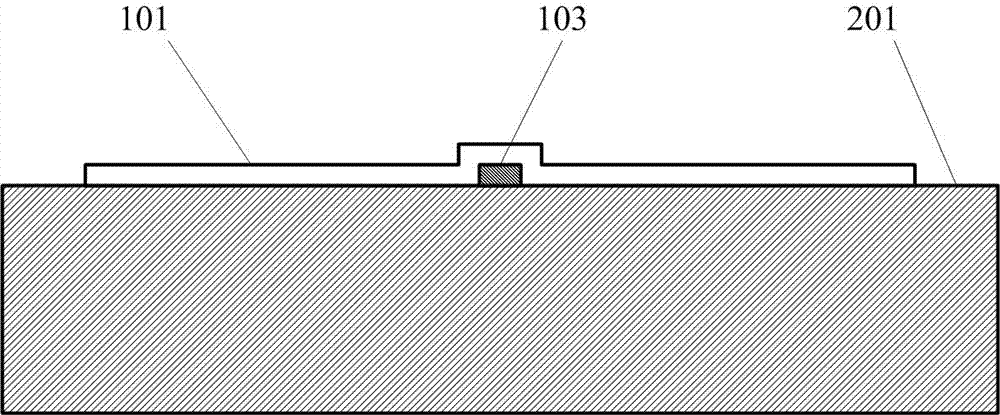

Two-dimensional touch control sensor of combined structure

InactiveCN104298406AHigh sensitivityReduce eddy current lossDigital data processing detailsInput/output processes for data processingHandwritingCapacitance

A two-dimensional touch control sensor of a combined structure comprises a plurality of sets of transparent electrodes which are attached to a substrate as patterns in the X and Y directions and are made of transparent conductive films, and at least one fine metal wire electrically connecting the same set of electrodes is attached to the substrate. In order to avoid affecting the vision, the equivalent diameter of the fine metal wire should be smaller than 30 micrometers. The fine metal wire is further used for forming a coil, the electrodes are made of the transparent films with high sheet resistance, and then the two-dimensional touch control sensor can be expanded to be used for detecting electromagnetic signals of a handwriting pen and used for handwriting input detecting needing higher accuracy and including a pressure function. The fine metal wire is used as a signal channel so that the two-dimensional touch control sensor can be applied to a large capacitance touch screen. The electrodes are made of the films with higher transparency and sheet resistance, the power consumption of a display panel can be reduced, and the influences of a touch panel on the vision are minimized.

Owner:刘中华

A heavy pressure jug

InactiveCN101156749ASimple structureEasy to assembleWater-boiling vesselsPressure functionExhaust valve

The invention relates to a high pressure kettle which comprises a kettle body component, a kettle cover component connected with the kettle body component in a disassemble way, and a discharge valve arranged on the kettle cover component, wherein, the kettle cover component is provided with an exhaust passage which is communicated with environment and the inside of the kettle body, under an air pressure function, an exhaust valve of the exhaust passage is sealed, and a water out control device controlling the startup of the exhaust valve and the discharge valve are controlled in sequence. The water out control device comprises a valve push rod and a button which is interacted with the valve push rod, after pressing the button, the valve push rod firstly pushes the exhaust valve to move, to ensure that the exhaust valve drains off the high pressure in the kettle, an then the valve push rod only can continuously push the valve to realize backwater, therefore, before the backwater of the high pressure kettle of the invention, the steaming high pressure inside the kettle can be taken off, thereby preventing the boiling water in the kettle from being spouted to scald a human body, therefore, the usage is more convenient and safer. The structure of the high pressure kettle of the invention is simple, the assembly is easy, and therefore, the manufacture cost is lower.

Owner:MIDEA GRP CO LTD

High-position inclined E-type ventilation system of coal face

InactiveCN103075173AIncrease the leakage sinkReduce air leakageTunnel/mines ventillationGas removalPressure functionAir volume

The invention relates to a ventilation system, of which the gas of an upper corner and a ventilation roadway is ultra-limit on a coal face, in particular to a high-position inclined E-type ventilation system of the coal face, and belongs to the technical field of coal mine safety equipment. A gas discharging high-position tunnel is formed between the ventilation roadway and an intake airway closed to a coal seam upper rock layer of the ventilation roadway, so as to form the high-position inclined E-type ventilation system with one intake airway and two ventilation roadways; the gas of a goaf can be restrained from pouring out to the upper corner and the ventilation roadway through adjusting the air quantity and air pressure of the ventilation roadway and the gas discharging high-position tunnel; and the gas of the goaf can be introduced to migrate to a gas special tunnel. The system uses a high-position tail tunnel, so that air leak congruence of the goaf is increased, and the gas accumulation of a U-type ventilation system is changed; and under the negative pressure of the ventilation system and / or the auxiliary extraction negative pressure functions, a high-position inclined E-type work face air power system is formed, so that the gas accumulation problem of the upper corner on the work face can be effectively solved.

Owner:JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

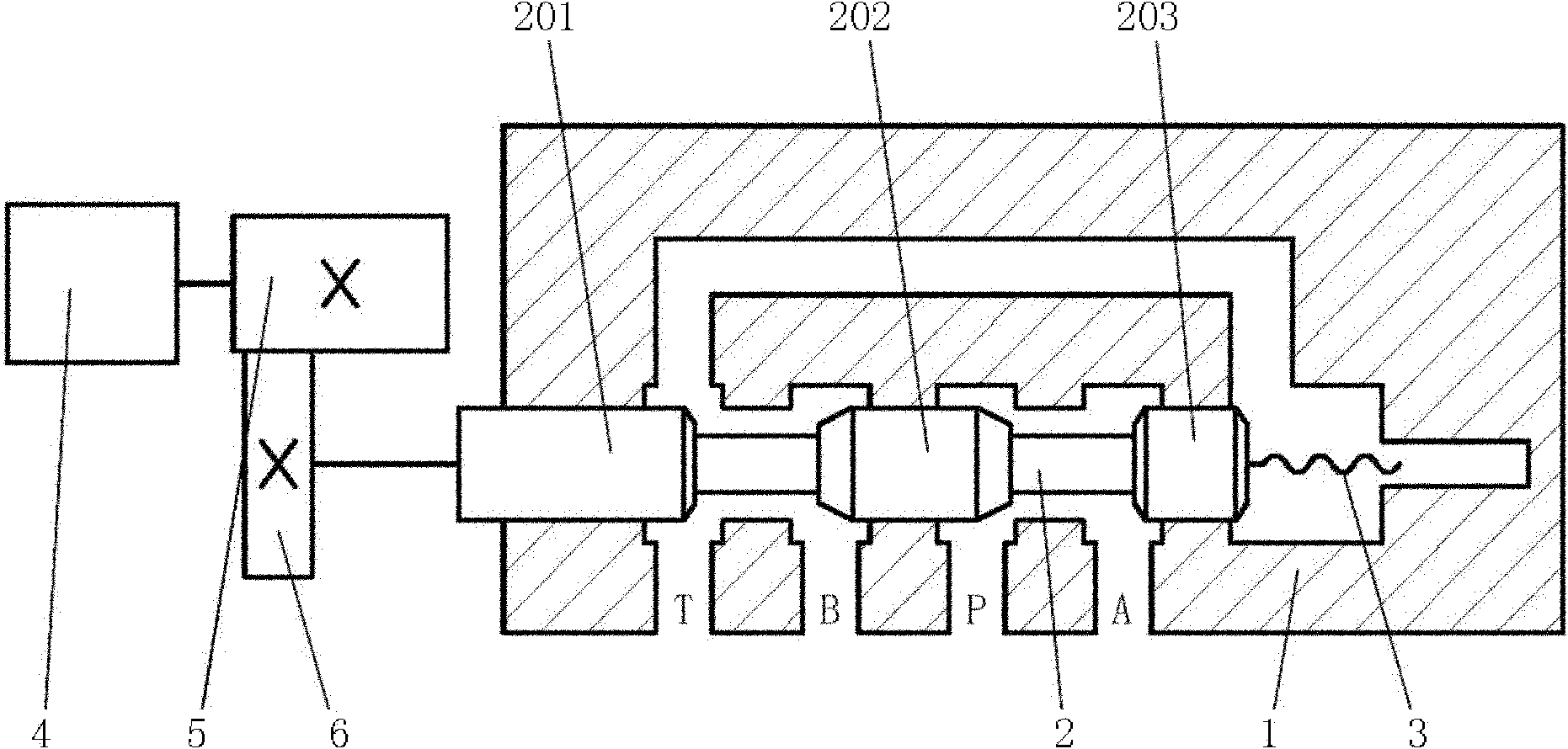

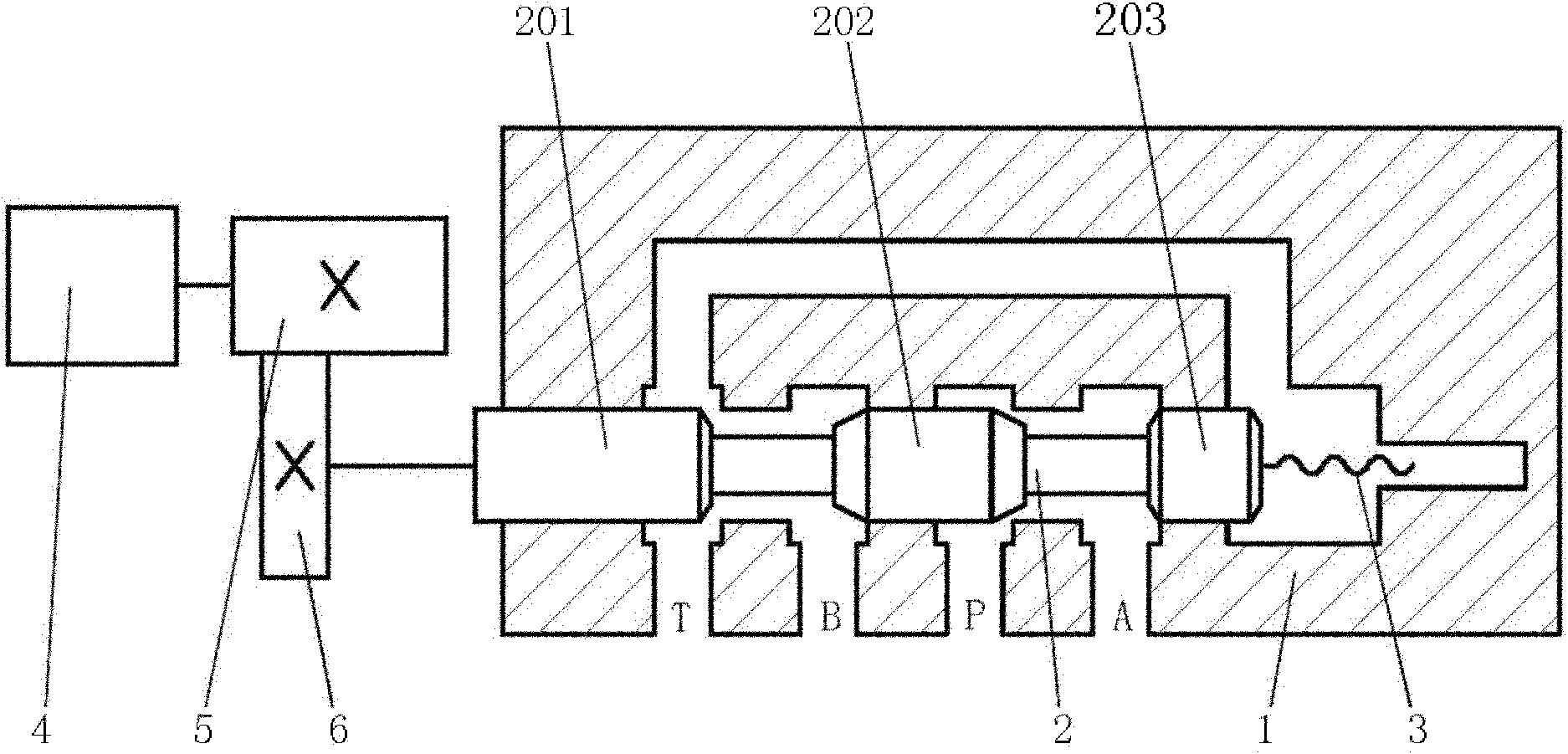

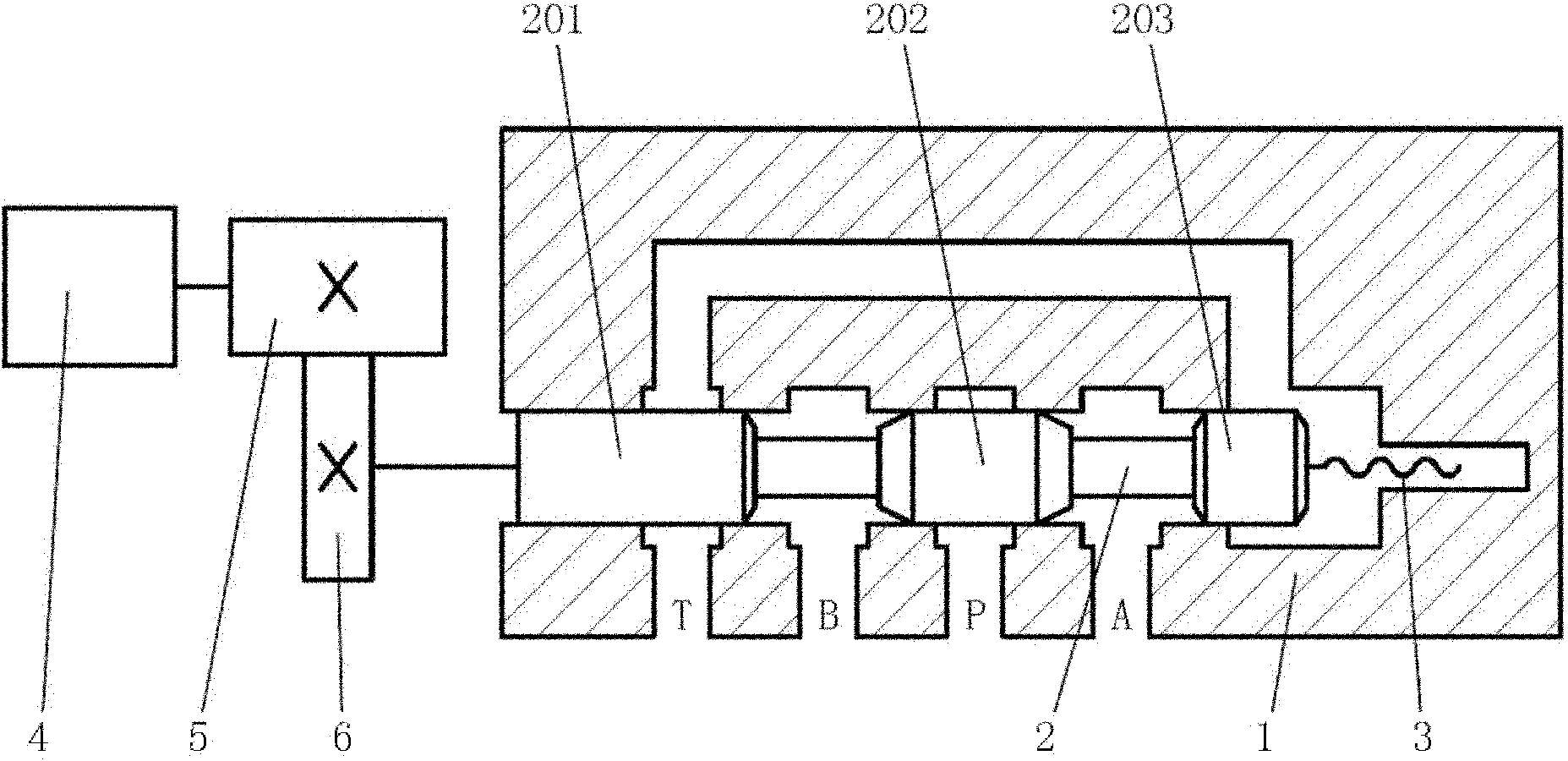

Numerical control proportioning hydraulic directional control valve

The invention discloses a numerical control proportioning hydraulic directional control valve. Aiming at the defect that the existing hydraulic directional control valve does not have functions of accurately controlling flow and pressure, the invention provides a numerical control proportioning hydraulic directional control valve which can accurately control valve opening so as to accurately control flow and pressure when switching to certain working oil paths for supplying oil. The numerical control proportioning hydraulic directional control valve comprises a valve body, a valve core, a numerical control motor and a transmission mechanism, wherein the valve body is provided with an oil inlet duct, a first working oil duct, a second working oil duct and an oil return duct, and the oil inlet duct, the first working oil duct, the second working oil duct and the oil return duct on the valve body are communicated with the valve cavity of the valve body; the valve core is provided with three mate shafts and is arranged in the valve cavity in the valve body; the mate shafts on the valve core are tightly matched with the inner wall of the valve cavity of the valve body; the transmission mechanism is composed of a driving gear and a driven gear; the output shaft of the numerical control motor is connected with the driving gear; the driven gear is connected with one end of the valve core; and the driving gear and the driven gear are meshed to form a pair of gear pair.

Owner:许新跃

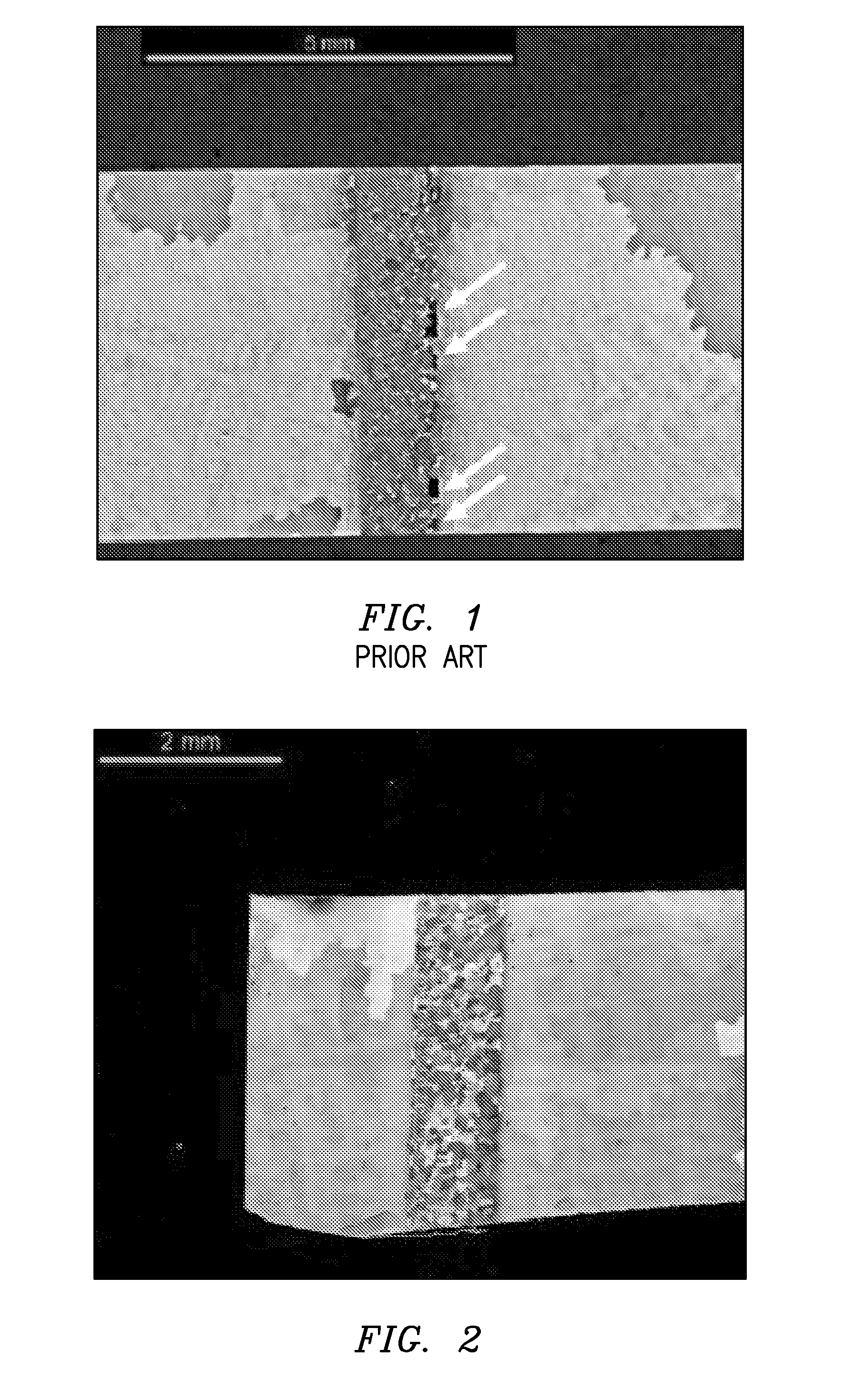

Superalloy component braze repair with isostatic solution treatment

A method of braze repair for a superalloy material component. Following a brazing operation on the superalloy material, the component is subjected to an isostatic solution treatment, followed by a rapid cool down to ambient temperature under pressure The conditions of the isostatic solution treatment combined with the cool down at pressure function to both reduce porosity in the component and to solution treat the superalloy material, thereby optimizing superalloy properties without reintroducing porosity in the braze.

Owner:SIEMENS ENERGY INC

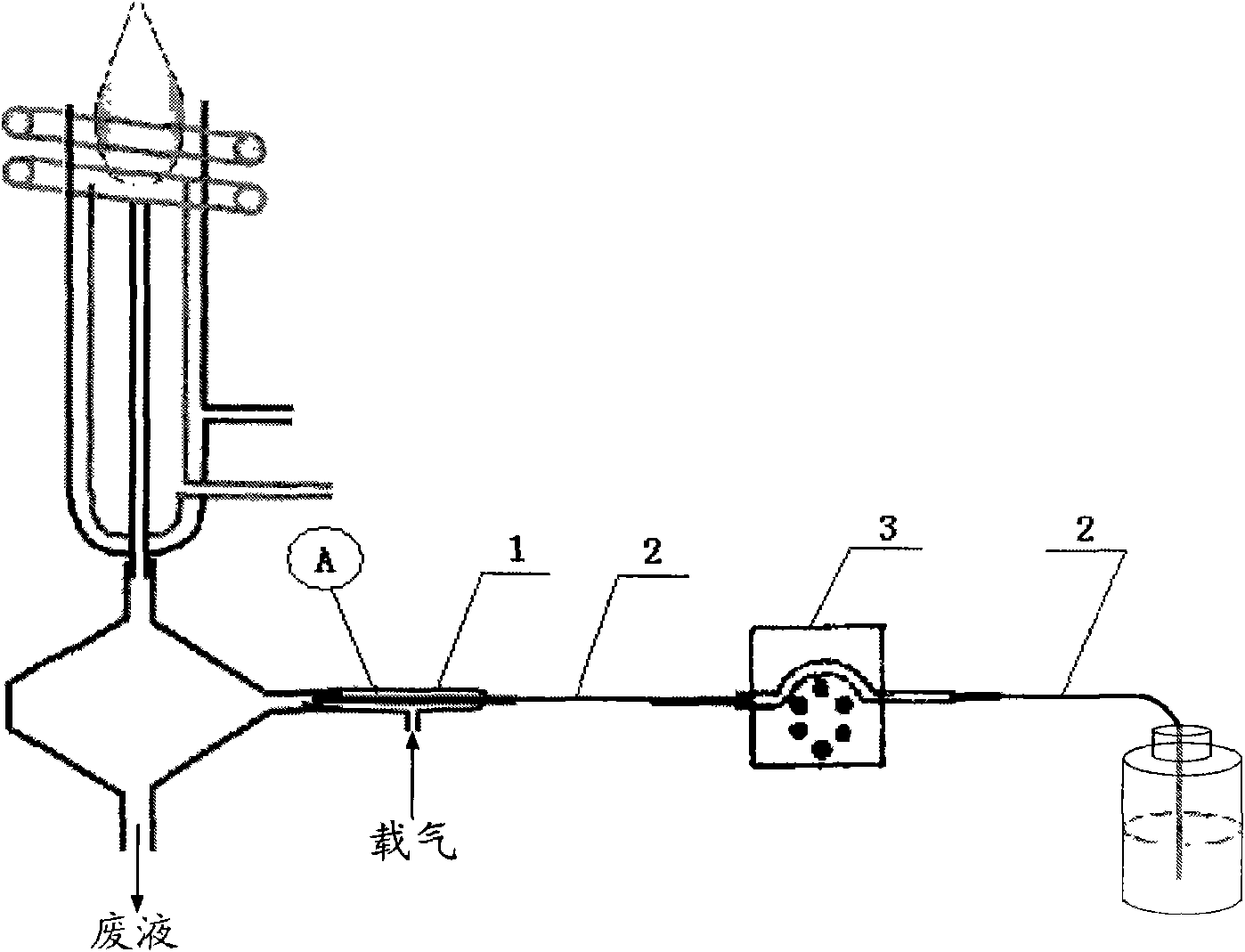

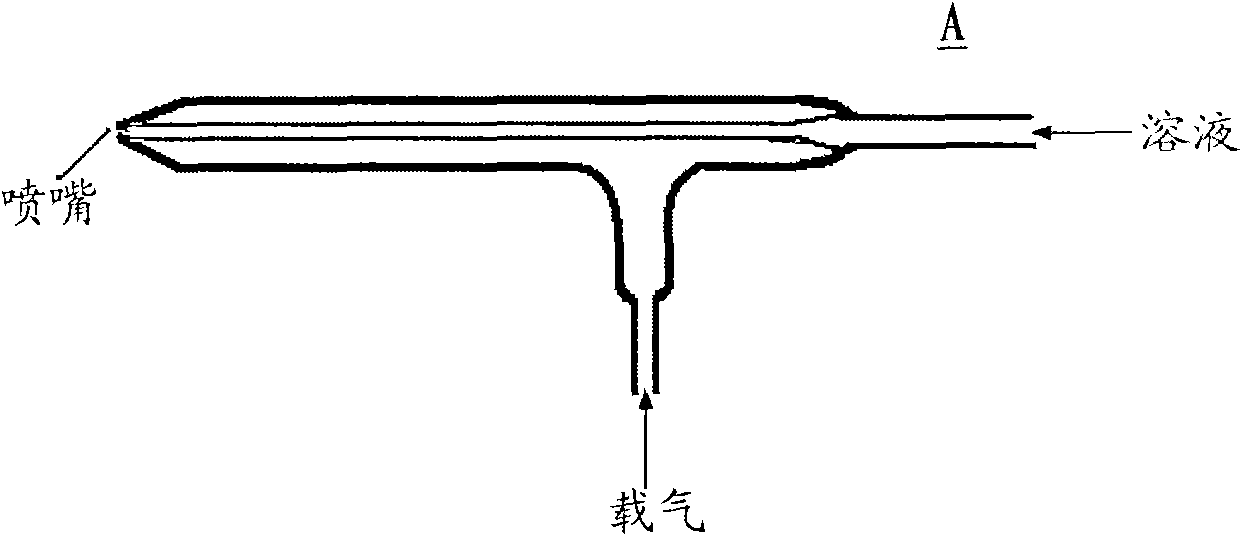

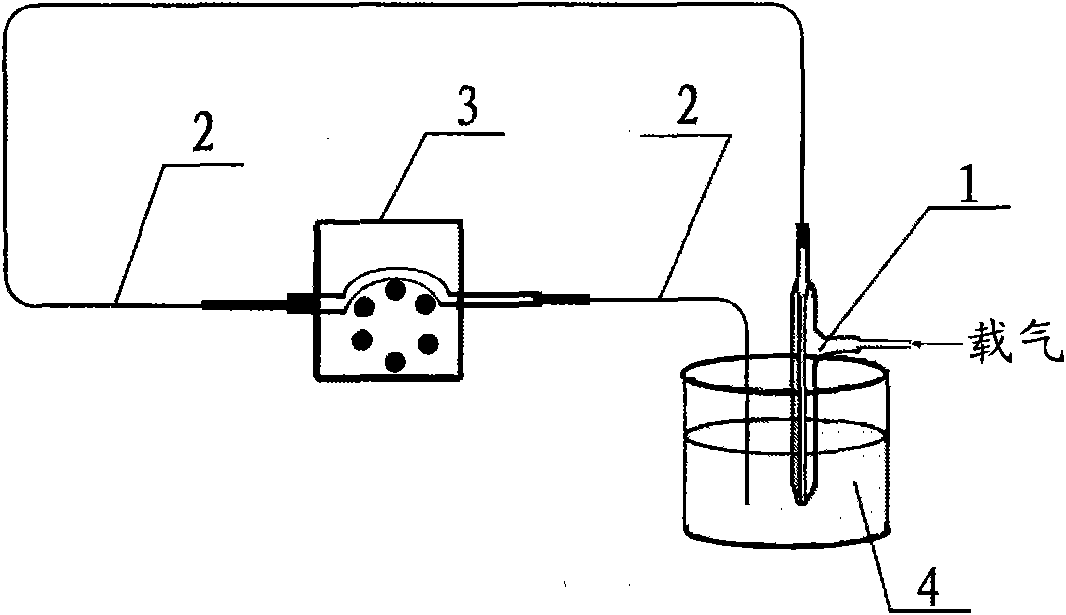

Method for removing obstruction of atomizer

InactiveCN101602037ASimple and quick to implementOperational securitySpraying apparatusPressure functionAtomizer nozzle

The invention discloses two methods of removing obstruction of a concentric atomizer, one of which comprises using a cleaning solution to remove obstruction in the atomizer, putting one end of a nozzle of the atomizer into the cleaning solution, blowing atomizing flow into the atomizer, so as to enable the cleaning solution to pass through a sampling capillary tube at high speed under negative pressure function produced by high speed gas flow and spray from the nozzle of the atomizer, thereby brushing and cleaning the obstruction in the atomizer at high speed; the other comprises using atomizing gas flow for back flushing of obstruction in the atomizer, plugging the gas flow channel of the atomizer, connecting one end of the nozzle of the atomizer with an atomizing gas flow pipeline, using high speed gas flow for back flushing of the sampling capillary tube from the nozzle end of the atomizer, so as to brush and clean the obstruction in the atomizer at high speed. In the case of maintaining original connection state of the atomizer unchanged, the invention meets the requirement of removing obstruction in the atomizer, reduces the frequency of replacing the atomizer as a result of blocking damage, and greatly reduces the production cost.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

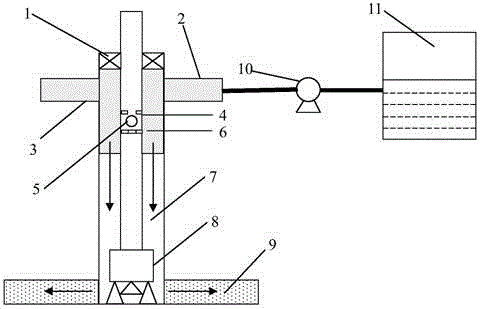

Determination method of well killing occasion of pressing-back method for gas well

ActiveCN105756660AEliminates the risk of pressure exceeding the maximum allowable wellhead pressureReduced risk of pressure exceeding the maximum allowable wellhead pressureSurveyWell killBottom hole pressure

The invention discloses a determination method of a well killing occasion of a pressing-back method for a gas well. The determination method of the well killing occasion of the pressing-back method for the gas well comprises the following steps of collecting the physical property parameters of a stratigraphic rock and a fluid through geological logging and the data of an adjoining well; drawing an IPR (Inflow Performance Relationship) curve of the gas well by a formula through the collected data; drawing an OPR (Outflow Performance Relationship) curve of a relationship between a pit shaft gas yield and bottom hole pressure; drawing the IPR curve and the OPR curve in the same coordinate system; calculating an allowable maximum well shut-in time; calculating a wellhead pressure function when the well killing is started at some moment after well shut-in; solving wellhead maximum pressure; judging latest time when the well killing is started. The method is applicable to the conditions that the circulating well killing cannot be carried out due to the well blowout of the gas well and the pressing-back method is adopted to carry out the well killing; the latest well killing time that the well is successfully killed by using the pressing-back method after the well shut-in can be calculated; therefore, the risk that wellhead pressure generated in a well killing process exceeds maximum allowable wellhead pressure can be removed; the theoretical guidance is provided for the success of the well killing. The method is uncomplicated in calculation process, simpler in operation technique, and suitable for field use.

Owner:CHINA PETROCHEMICAL CORP +3

Fuel Tank having Functions of Adjusting Press Produced by Fuel Volatilizing and Preventing Fuel Overflowing

InactiveUS20080251139A1Preventing fuel overflowingIncrease capacityNon-fuel substance addition to fuelEqualizing valvesVacuum pressurePressure function

A fuel tank includes a canister and a fuel control valve arranged in an expanding room. The canister has two guiding pipes communicated respectively with an entrance of an engine and environment. The fuel control valve is communicated with the expanding room. A double-lane valve is arranged between the canister and the fuel control valve. The double-lane valve has an entrance communicated with the fuel control valve, an exit communicated with the canister, a first valve and a second valve arranged between the entrance and the exit. The second valve withstands a spring and is arranged on the first valve. The first valve can detect an expending press produced by volatilized fuel gas to control whether the fuel gas enter into the entrance of the engine. The second valve can detects a vacuum press of the fuel tank to control whether air enter into the fuel tank.

Owner:SENTEC E&E CO LTD

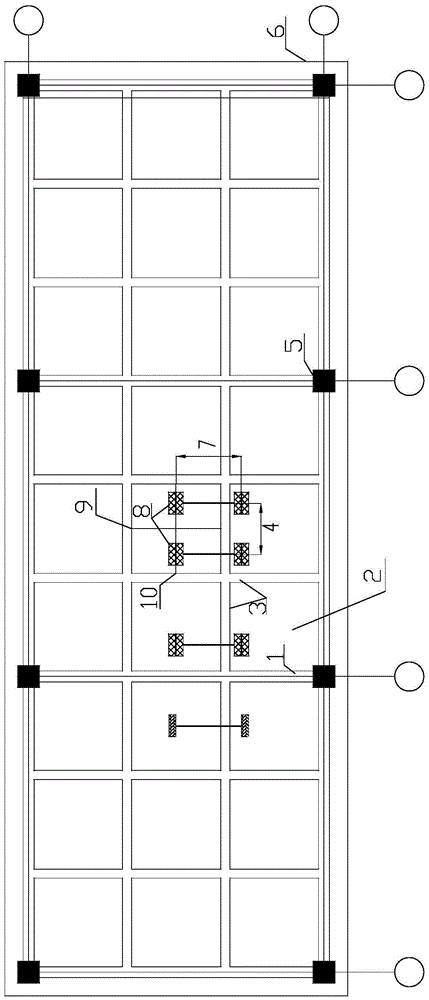

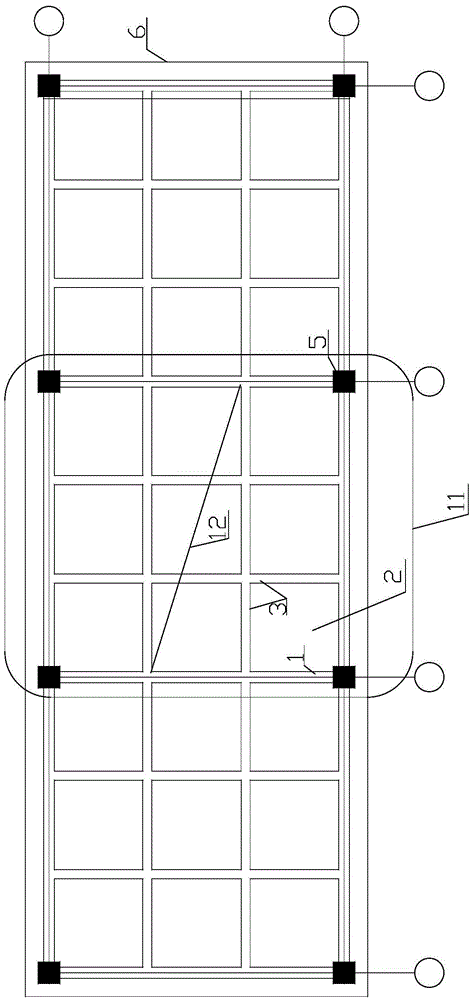

Garage roof bearing capacity calculation and construction method under engineering vehicle load effect

ActiveCN105625764AAvoid double bad luckImprove construction efficiencyFloorsParkingsPressure functionBuilding design

The invention belongs to the building design and construction technology crossing field, and particularly relates to a garage roof bearing capacity calculation and construction method under the engineering vehicle load effect. The method is characterized by adopting the following steps of (1) confirming an underground garage roof bearing capacity checking calculation object; (2) checking and calculating the bearing capacity of a cast-in-place slab; (3) punching-resistance checking and calculating the cast-in-place slab; (4) checking and calculating the bearing capacity of a framed beam and a secondary beam; (5) selecting an engineering vehicle; (6) confirming a driving path of the engineering vehicle. According to the garage roof bearing capacity calculation and construction method under the engineering vehicle load effect provided by the invention, the bearing capacity checking calculation is carried out on the underground garage roof according to the most unfavourable condition of the engineering vehicle wheel-pressure function without considering the working condition of the accidental load and earthquake action. Under the condition of ensuring the structure safety, a building material transportation vehicle directly arrives at the destination from the garage roof, so that the secondary transportation of main building construction materials is avoided, the construction period is greatly shortened, the construction comprehensive cost is greatly saved, and the green construction requirements of high efficiency and energy conservation are met.

Owner:SHANDONG WANXIN CONSTR

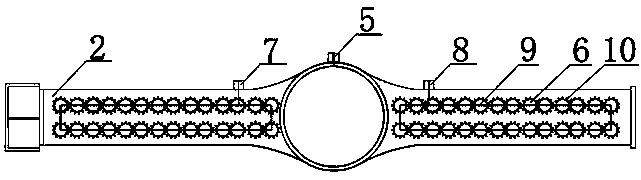

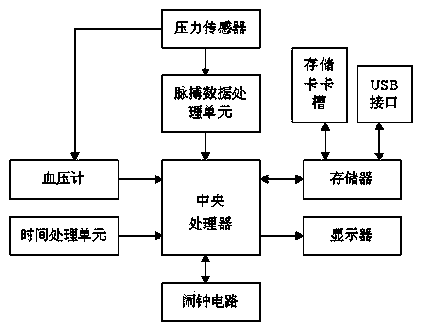

Massage watch with pulse and blood-pressure testing function

ActiveCN103645630AEasy to observeEasy to remindElectrotherapyRoller massageKey pressingSphygmomanometer

The invention discloses a massage watch with a pulse and blood-pressure testing function. The message watch includes a dial (1) and a watchband (2), wherein the two ends of the dial (2) are fixedly connected with the watchband (2). The massage watch is characterized in that the surface of the dial (1) is provided with a display (3); a sphygmomanometer (4) is arranged at a position at one side of the display, next to the dial (1); one side of the dial (1) is provided with a USB interface, a storage-card groove and a button (5); the back of the watchband (2) is provided with a pressure sensor used for testing pulses; the pressure sensor is arranged at a position of the watchband (2), corresponding to a wrist artery; and the back of the watchband (2) is provided with a plurality of massage devices. The massage watch with the pulse and blood-pressure testing function integrates a plurality of functions of a blood testing system, pulse measurement and therapeutic massage and the like into a whole and the watch dial is provided with the storage-card groove and the USB interface so that a storage card can be inserted directly or data can be output through the USB interface and thus long-time observation of pulse and blood-pressure conditions of a wearer is facilitated.

Owner:安徽格太信控科技有限公司

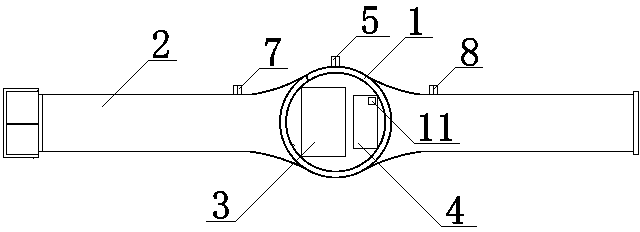

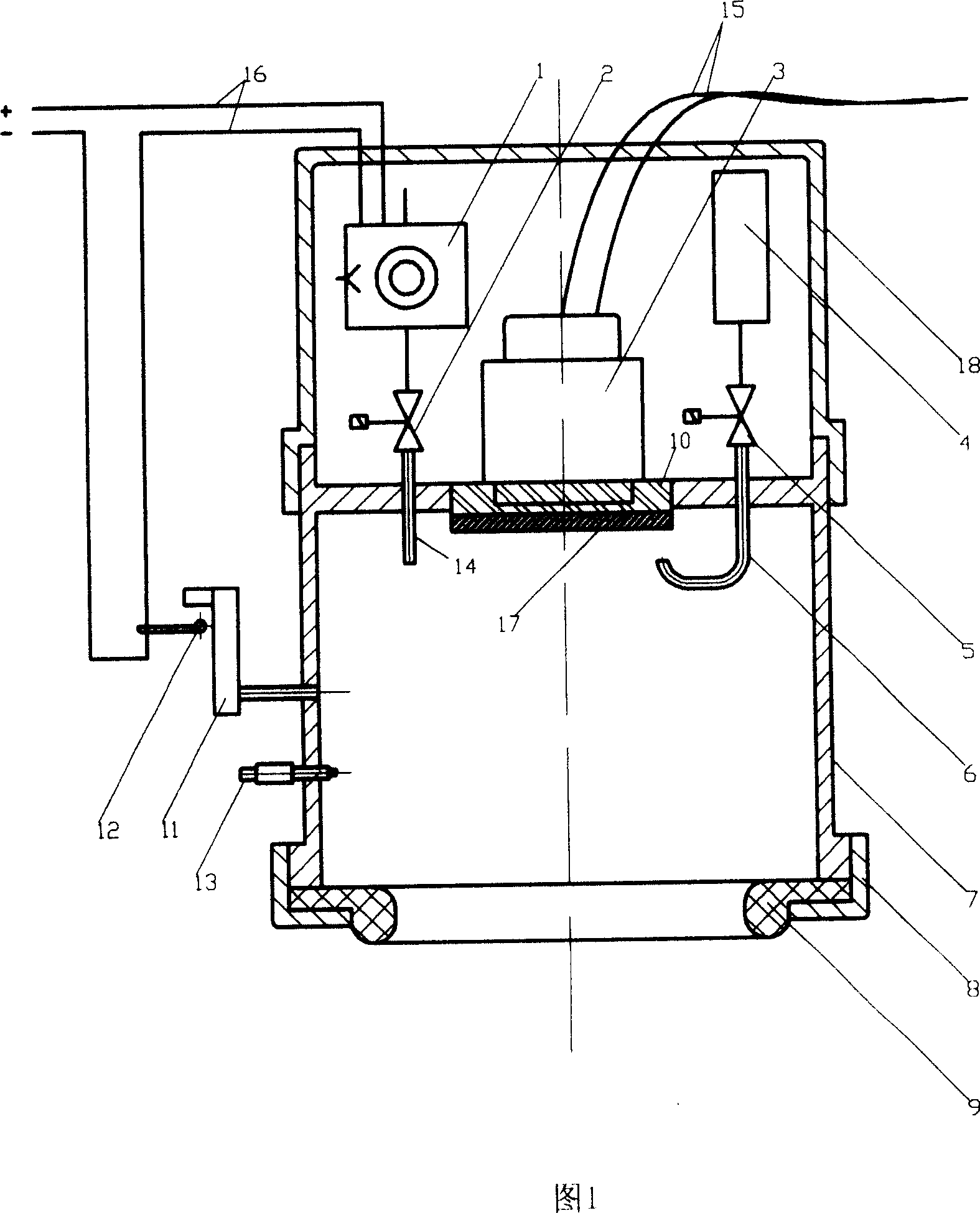

Automatic water pump control device

ActiveCN103629096AEasy to controlSimple structurePump controlPositive-displacement liquid enginesAutomatic controlPressure function

The invention relates to an automatic water pump control device which comprises a shell body, wherein a water inlet and a water outlet are formed in the shell body, the interior of the shell body is divided into an upper containing cavity and a lower containing cavity through a membrane, the upper containing cavity is separated from the lower containing cavity, the lower containing cavity is communicated with the water inlet and the water outlet, a magnetic floater is arranged in the lower containing cavity, a corresponding magnetic-sensing switch is arranged on the outer wall of the shell body, a pressure adjusting device is arranged in the upper containing cavity, and the pressure adjusting device is connected with the membrane. The automatic water pump control device is simple in structure, high in integration degree, small in occupied space, easy and convenient to control, and capable of achieving water lack protection and automatic starting and stopping of a water pump by means of a set of magnetic floater and magnetic-sensing switch. The arrangement of the membrane enables the pressure of the water outlet to be maintained. Meanwhile, the automatic water pump control device is a non-contact type device, electrically-controlled devices and detection parts are not in contact with water, and therefore the device is more reliable.

Owner:CRRC QINGDAO SIFANG CO LTD

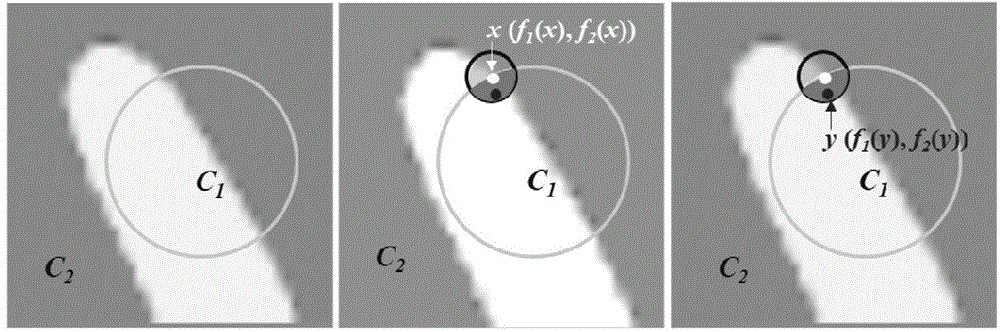

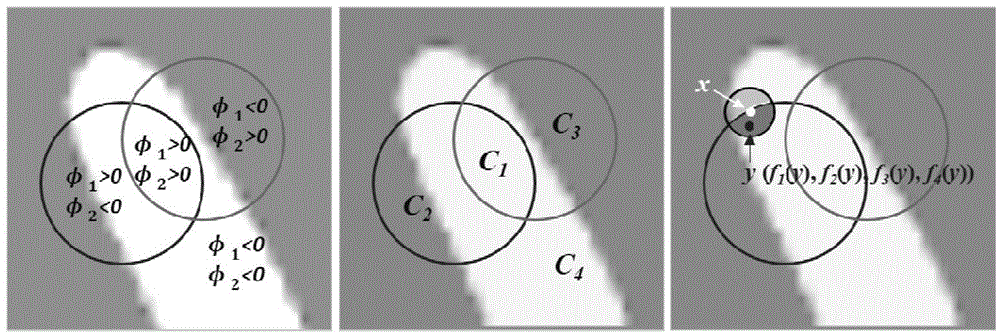

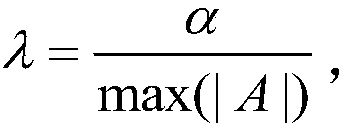

MR image segmentation and displacement field correction method based on geodesic models of local and global areas

ActiveCN105654450ALimit grayscale non-uniformityFlexible choiceImage enhancementImage analysisPressure functionImaging analysis

The invention belongs to the field of MR image segmentation and application, and relates to an MR image segmentation and displacement field correction method based on geodesic models of local and global areas. Based on the critical importance of MR image segmentation in medical image analysis, even more difficult segmentation caused by MR image grayscale non-uniformity and grayscale non-uniformity caused by noise and displacement field, global and local information of images extracted based on global and local symbol pressure functions are used to process images of grayscale non-uniformity; a displacement field correction item is added to the local symbol pressure function to perform MR image segmentation and displacement field correction simultaneously so as to overcome grayscale non-uniformity caused by the displacement field; and the models are expanded from a two-item level set to a four-item level set to realize accurate segmentation of gray matter, white matter and cerebrospinal fluid of a brain MR image. The method is applied to synthetic images and MR images, and the segmentation results show that the method is of significant accuracy and efficiency.

Owner:FUDAN UNIV

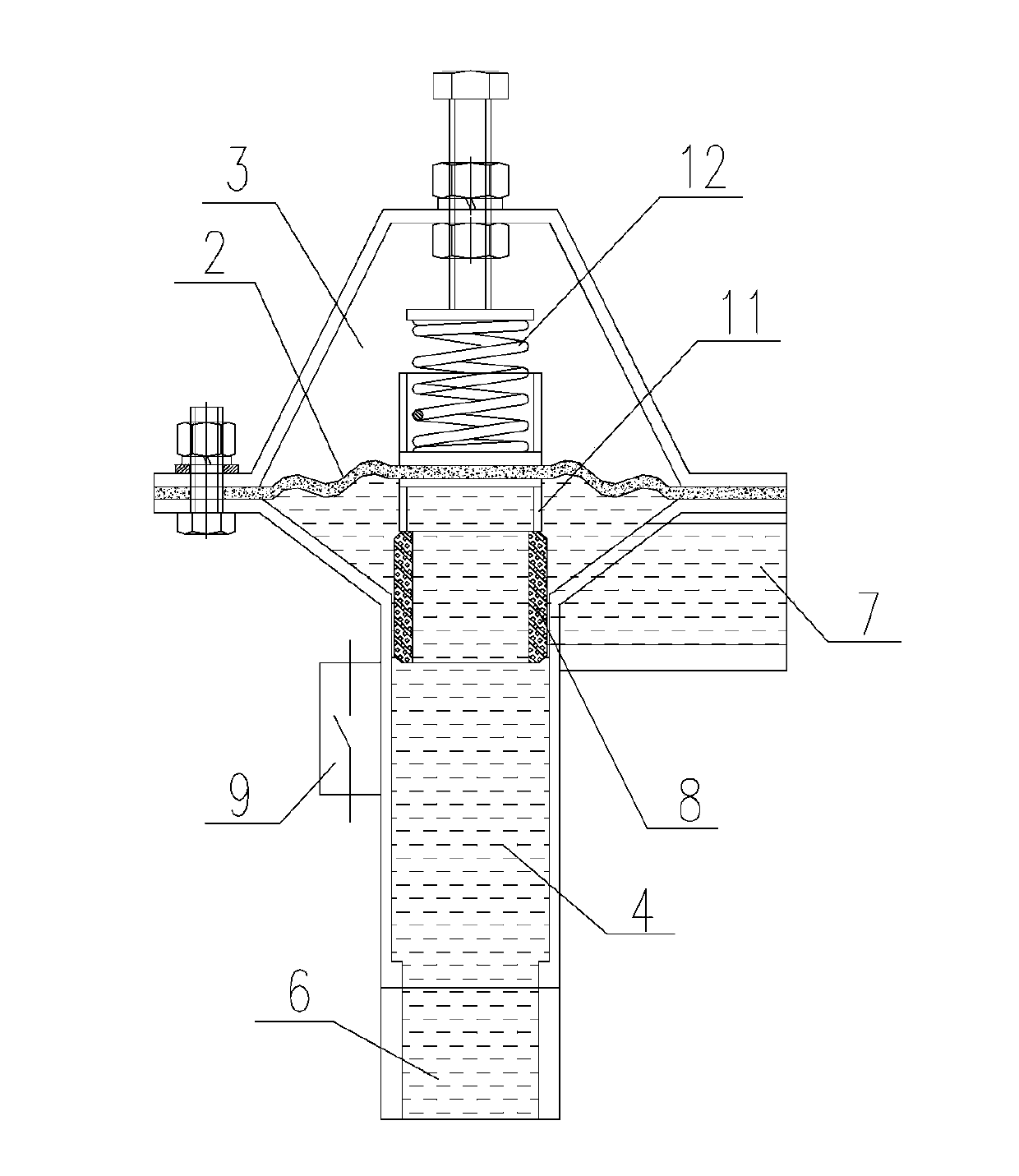

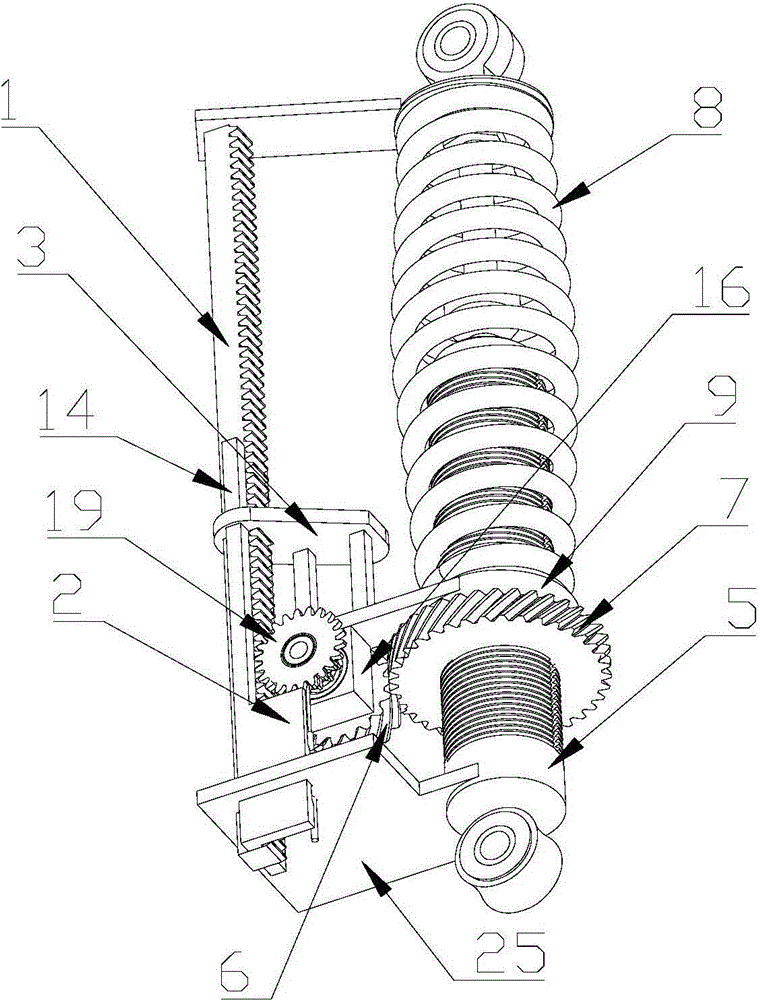

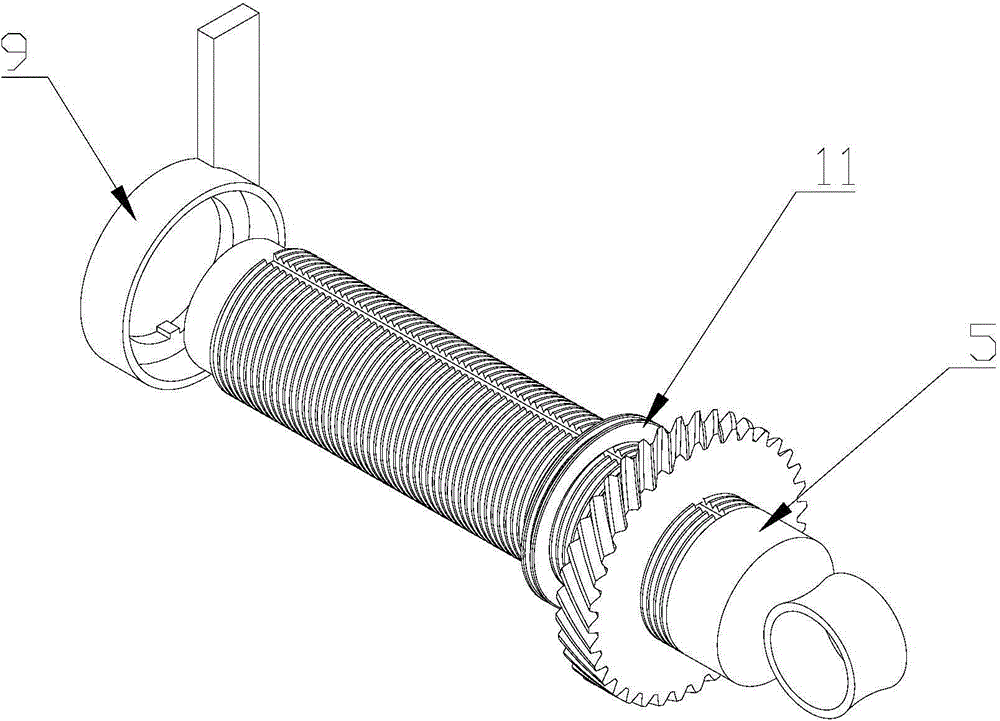

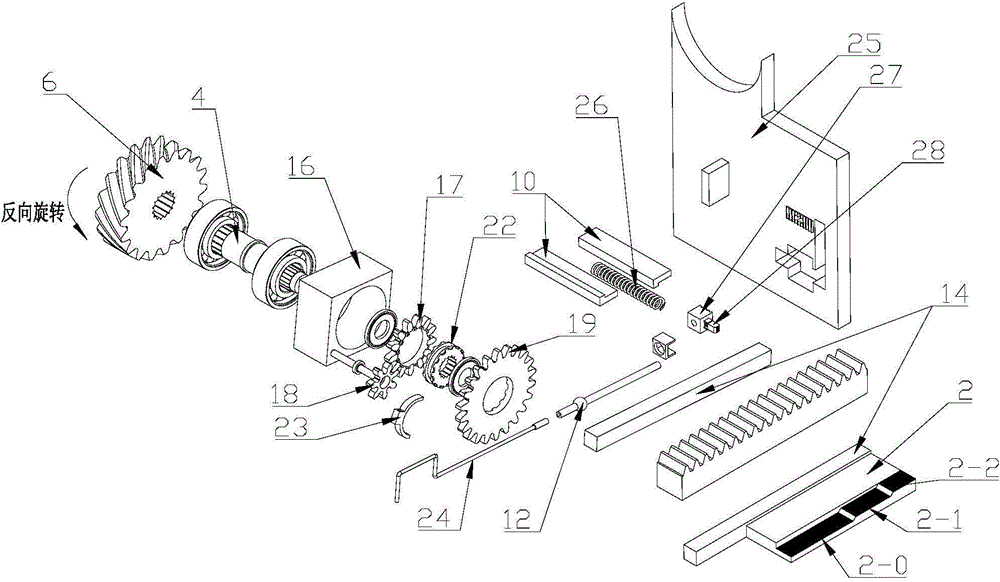

Shock absorber with intelligent automatic pre-pressure adjusting function

ActiveCN104879430AReduce the modulus of elasticityMeet comfort requirementsSpringsShock absorbersPressure functionEngineering

The invention relates to a shock absorber with the intelligent automatic pre-pressure adjusting function. The shock absorber comprises a damping rod and a damping spring. A first telescopic portion of the damping rod is provided with a lifting seat and an adjusting gear. The adjusting gear drives the lifting seat to rise and fall to adjust the pre-pressure of the damping spring. An adjusting device comprises a main rack, a gear plate, a gear shifting mechanism and a gear shifting transmission mechanism. The gear shifting transmission mechanism is provided with three gears, namely the forward gear for driving the adjusting gear to fall, the neutral gear not driving the adjusting gear and the reverse gear for driving the adjusting gear to rise. The gear shifting transmission mechanism is located in different gears through gear shifting motion of a gear shifting driving lever, and when a gear shifting switch is located in the upshift position, the gear shifting transmission mechanism is in the reverse gear state; when the gear shifting switch is located in the downshift position, the gear shifting switch drives the gear shifting driving lever to make the gear shifting transmission mechanism located in the forward gear state. The shock absorber has the advantages that the pre-pressure can be automatically adjusted according to loads, and the comfort requirements under different load conditions are met.

Owner:常州舒安智能机器人有限公司

Vacuum suction cup

InactiveCN101810890AImprove securityAvoid discomfortTherapeutic coolingTherapeutic heatingElectricityPressure function

The invention provides a vacuum suction cup. The vacuum suction cup comprises a cup body, a one-way valve and a high-power light-emitting diode device, wherein the high-power light-emitting diode device is accommodated in the cup body, comprises a bracket, a high-power light-emitting diode and an air hole and is jointed at the bottom end of the one-way valve through the bracket; the air hole is a through hole formed on the side wall of the bracket; and a first end and a second end of the high-power light-emitting diode are electrically connected with a power supply through leads to form a high-power light-emitting diode circuit. Since the high-power light-emitting diode serving as a heat source is further arranged in the vacuum suction cup, the vacuum suction cup can provide a warming function while providing a negative pressure function. Therefore, the function of the suction cup is effectively brought into play and the vacuum cup is safe and easy to use.

Owner:王卫东

Active contour image segmentation method and device based on improved SPF

ActiveCN108460781ARealize adaptive adjustmentSolve the segmentation problemImage analysisPattern recognitionPressure function

The invention relates to the field of image segmentation, and particularly relates to an active contour image segmentation method and device based on improved SPF. According to the method, firstly, asign pressure function is redefined based on the global information of the image, and then a local image fitting LIF model is introduced, finally, a weight function model is established based on imagelocal and global information, the self-adaptive adjustment of the weights between the local information items and the global information items is achieved, and a new level set evolutionary equation is obtained. According to the method, the problem that the gray non-uniform image cannot be accurately segmented by only utilizing the image global information is solved, and the defect that a model based on the image local information is sensitive to noise and initial contour is overcome. The method is simple in calculation and high in convergence speed, and can effectively solve the problem of segmentation of multi-target and gray non-uniform images, and meanwhile, the robustness for the initial contour and the noise is relatively high.

Owner:HENAN NORMAL UNIV

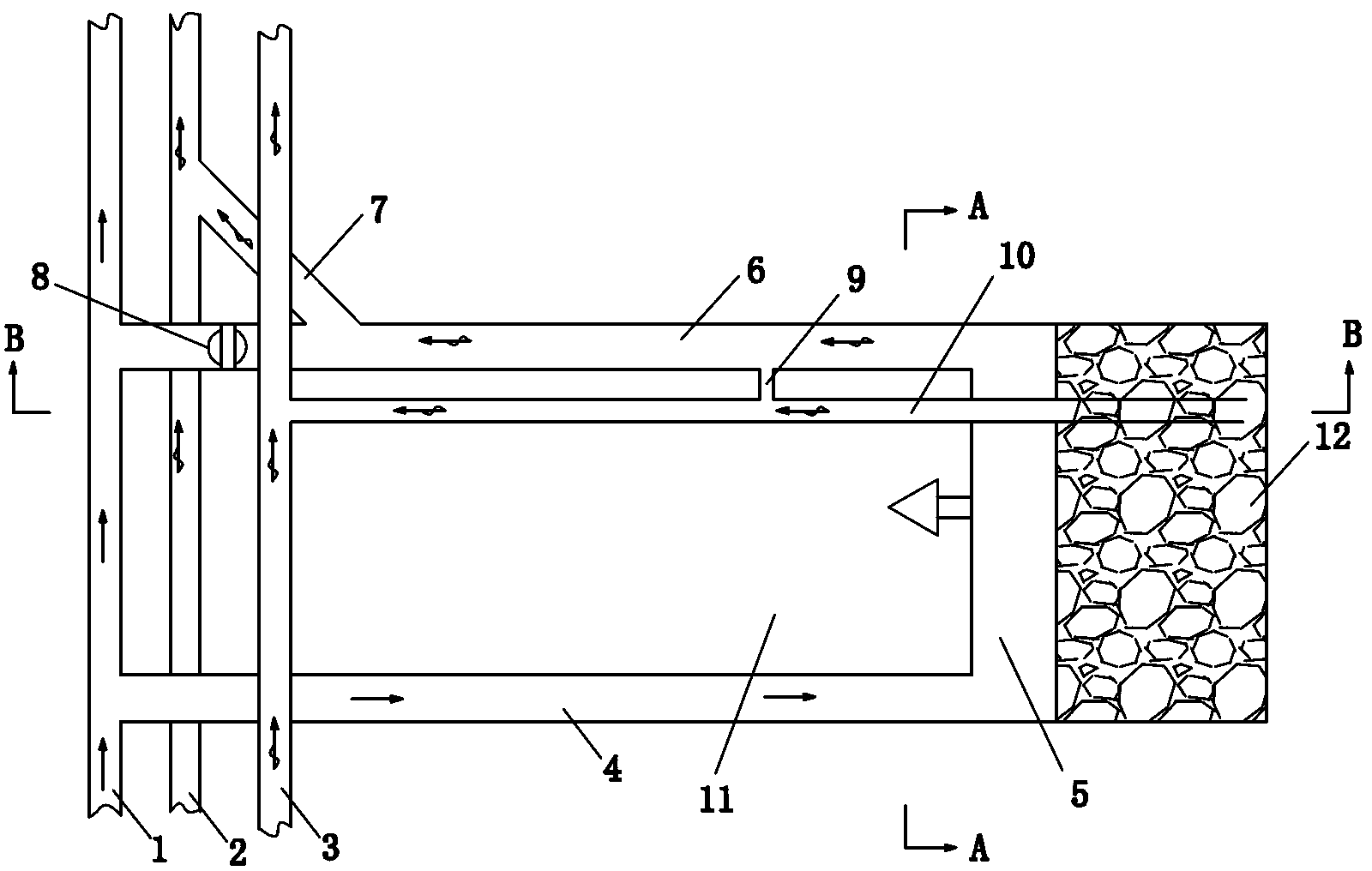

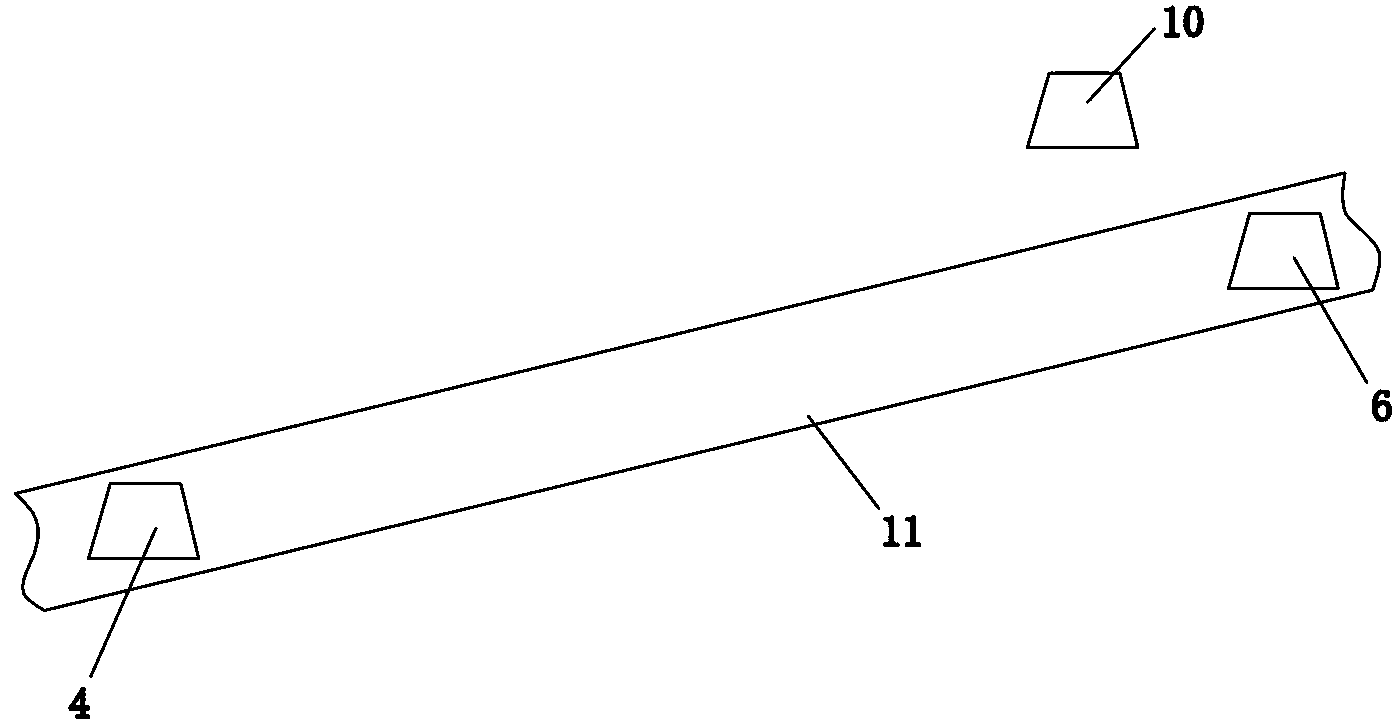

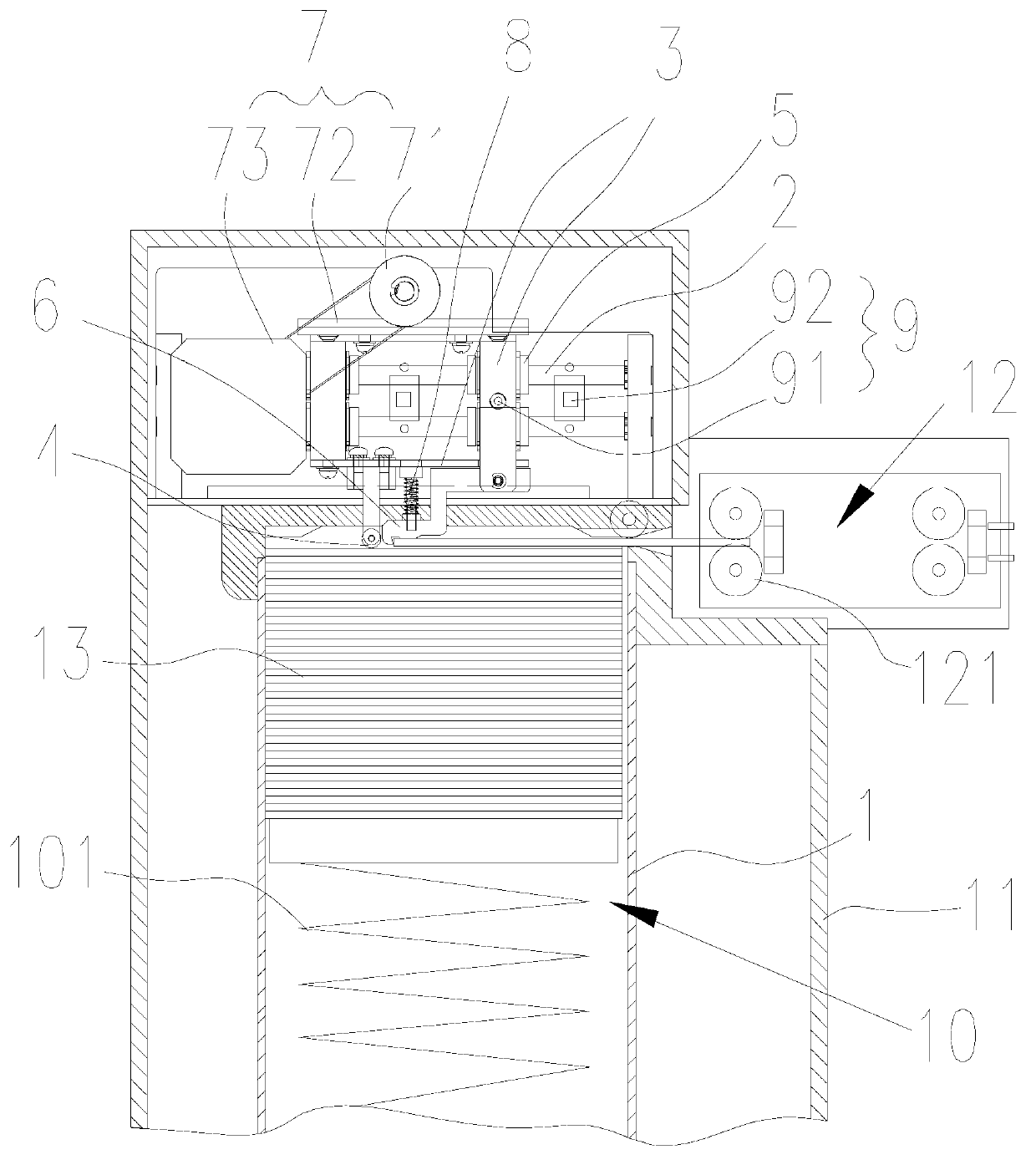

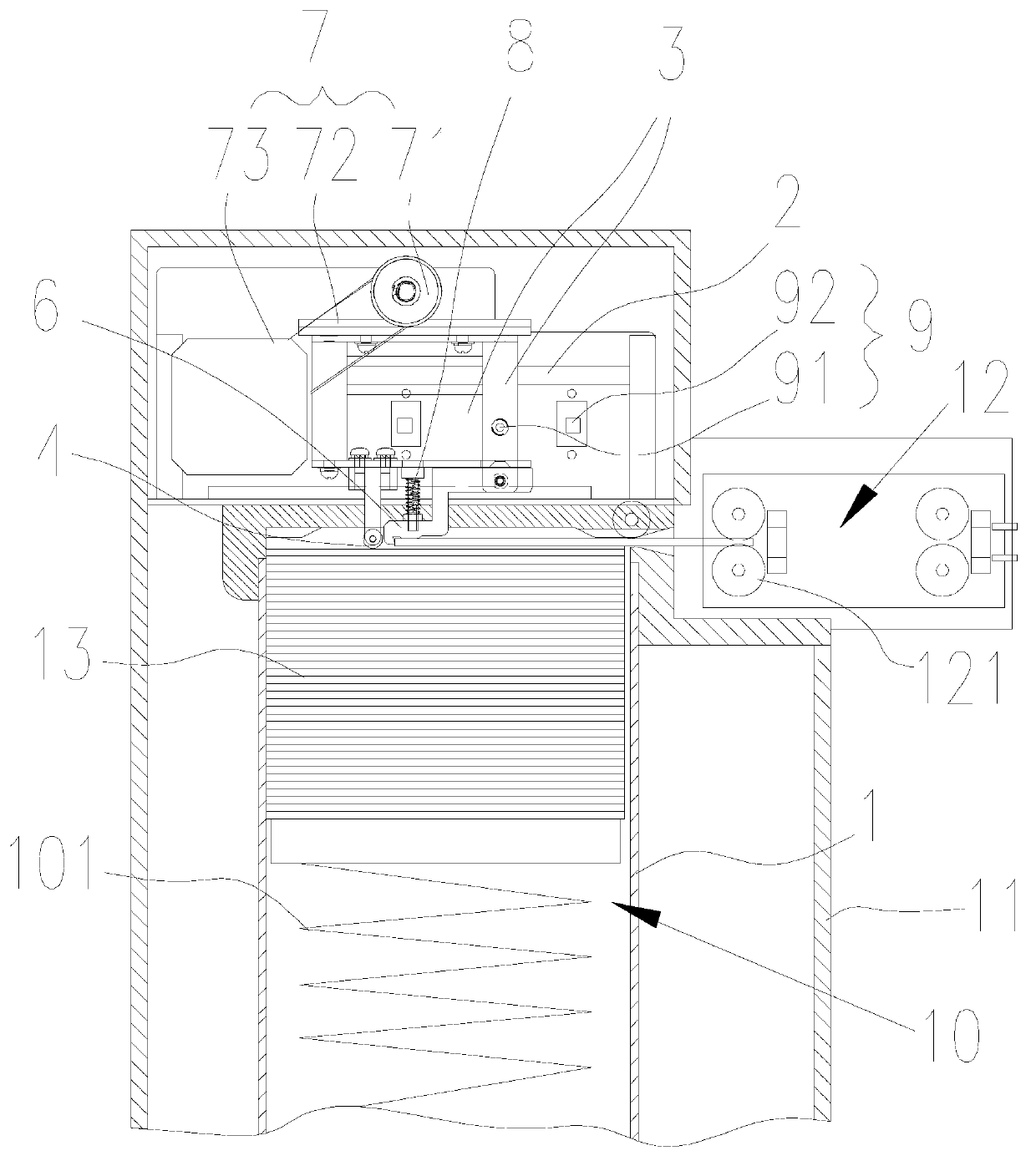

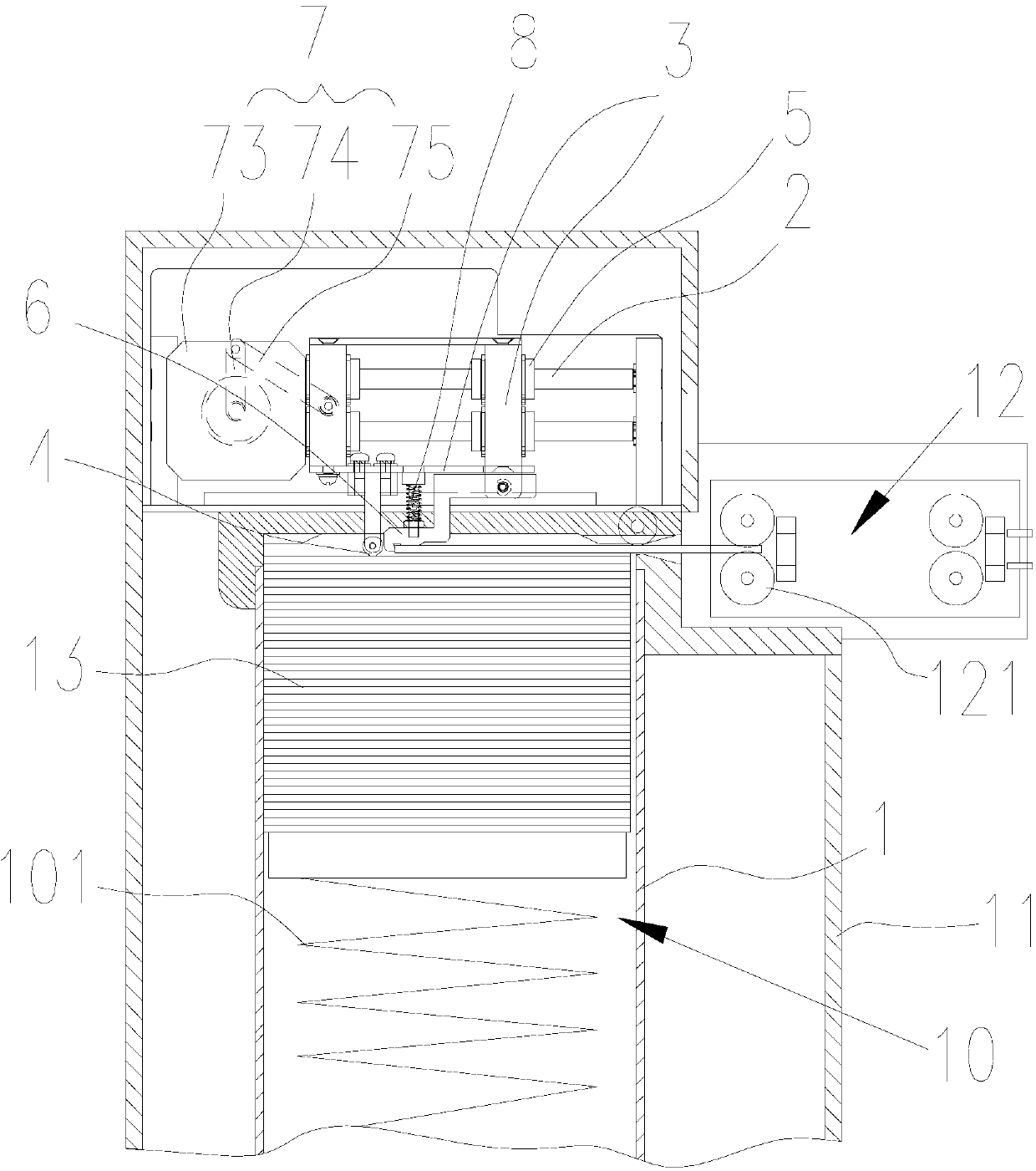

Card-poking mechanism with pressuring function and card sender using the same

InactiveCN103136801AImprove distributionDial the card accuratelyTicket-issuing apparatusPressure functionReciprocating motion

The invention discloses a card-poking mechanism with a pressuring function. The card-poking mechanism with the pressuring function comprises a guide rail, a sliding block and a straight reciprocating motion mechanism, wherein the guide rail, the sliding block and the straight reciprocating motion mechanism are all installed on a case of the card sender. The straight reciprocating motion mechanism drives the sliding block to move straightly in a reciprocating mode in the guide rail. A pressure wheel used for pressuring a second card in a card storage case of the card sender and a card hook used for poking a first card in the card storage case of a card sender are arranged on the sliding block, wherein the pressure wheel is connected on the sliding block in a rotatable mode and is placed at the back of the poking direction of the card hook. The horizontal plane which the bottommost portion of the pressure wheel is located in is lower than the horizontal plane which the bottommost portion of the card hook is located in, so that a gap between the first card and the second card is formed. The invention further discloses the card sender using the card-poking mechanism with the pressuring function. By pressuring the second card to form the gap between the first card and the second card, the card-poking mechanism with the pressuring function and the card sender using the card-poking mechanism enable the poking of the card to be accurate and in place.

Owner:GUANGDONG ELECTRONICS TECH RES INST

Moxibustion dry cup comprising drug administration system

InactiveCN1919365AMoxibustion temperature controllableNo pollution in the processMedical devicesCupping glassesPressure functionAgricultural engineering

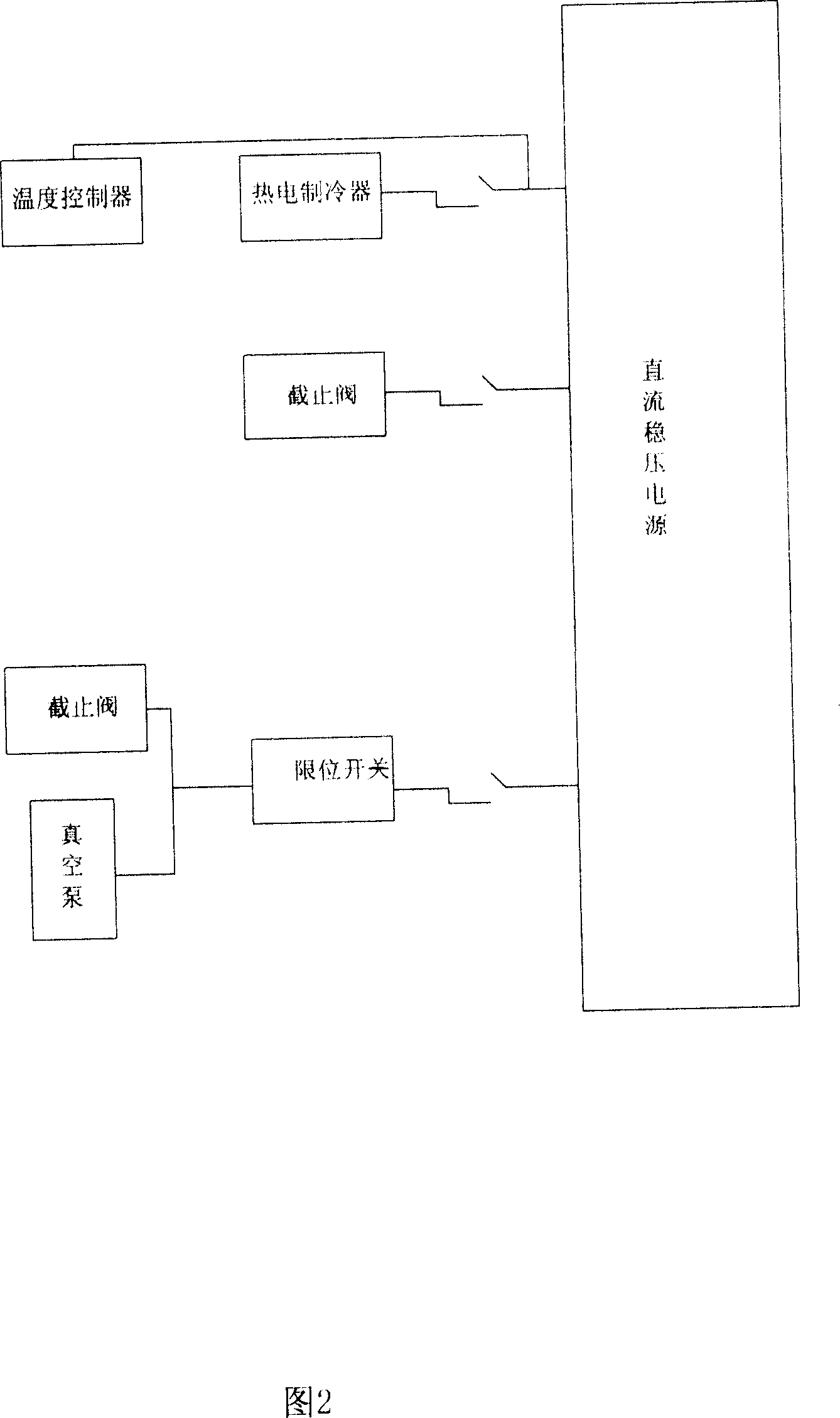

The invention discloses an acupuncture dry cup of drug-supplying system, which comprises the following parts: oilless vacuum pump, air shutter cut-off valve, airtightness terminal, soup tank, soup-closing cutoff valve, injection pipe, dry cup tank, silica gel coil, heat-exchanging board, corrugation pipe, limit switch, extracting pipe, thermoelectric refrigerator, temperature sensor, temperature controller and DC stabilizer, wherein the dry cup is extracted into negative pressure through oilless vacuum pump, which possesses constant negative pressure function, the thermoelectric refrigerator heats and assists acupuncture, which controls drug quantity effectively.

Owner:邓梁

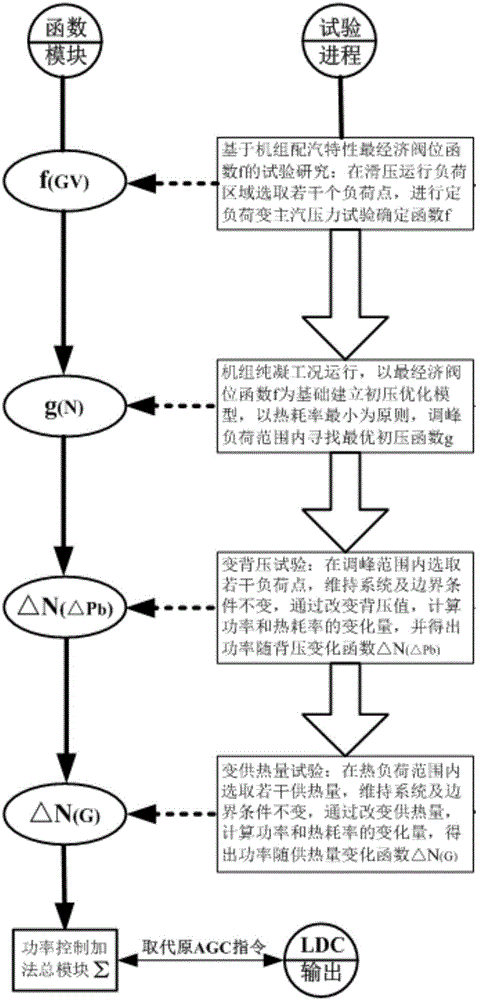

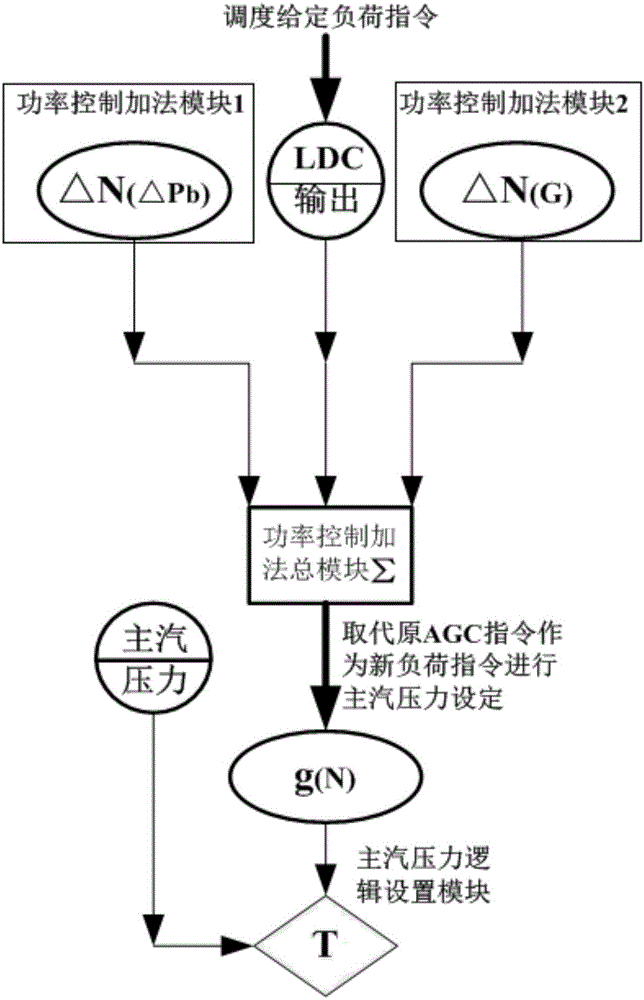

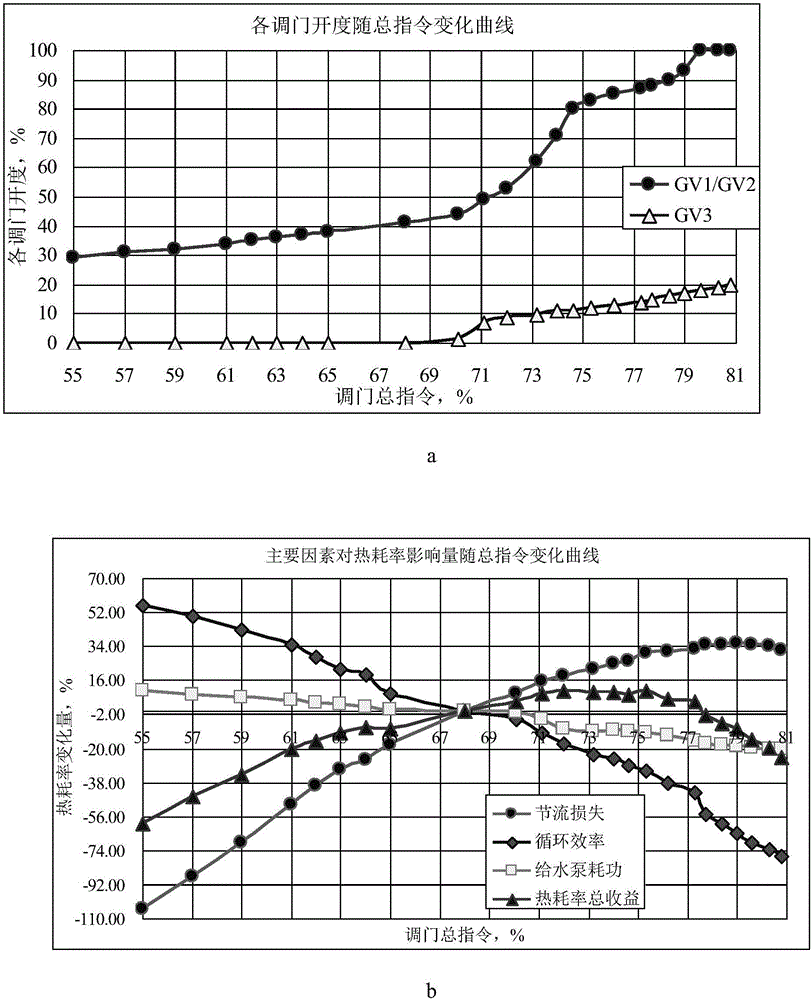

Automatic control method for achieving optimal initial-pressure operation of heat-supply units

ActiveCN106765520ALow investment costConsiderable economyLighting and heating apparatusSpace heating and ventilation detailsEnvironmental resistanceAutomatic control

The invention discloses an automatic control method for achieving optimal initial-pressure operation of heat-supply units. By modifying a coordinated control system, the method achieves optimal initial-pressure automatic control operation of heat-supply units under all operating conditions; according to the automatic control method, by real-time back pressures and real-time heat supplying, power variations corresponding to a standard operating condition are calculated and then subjected to addition operation with load commands, and after that, the operated power variations are used as new load commands of optimal initial-pressure functions, and initial-pressure values corresponding to the new load commands are calculated and output again. The method can achieve optimal initial-pressure automatic control operation of heat-supply units under all operating conditions. At the external conditions of spontaneous environment-temperature variations and requirement changes of heat consumers, the method can ensure that the units maintain operating around economic efficiency points. Because only the testing cost of field performance is involved, the method is low in investment cost, brings extremely considerable economic and environmental protection benefits to heat supply, industrial heat supply and units with both heat supply and industrial heat supply, and has a wide popularization effect.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

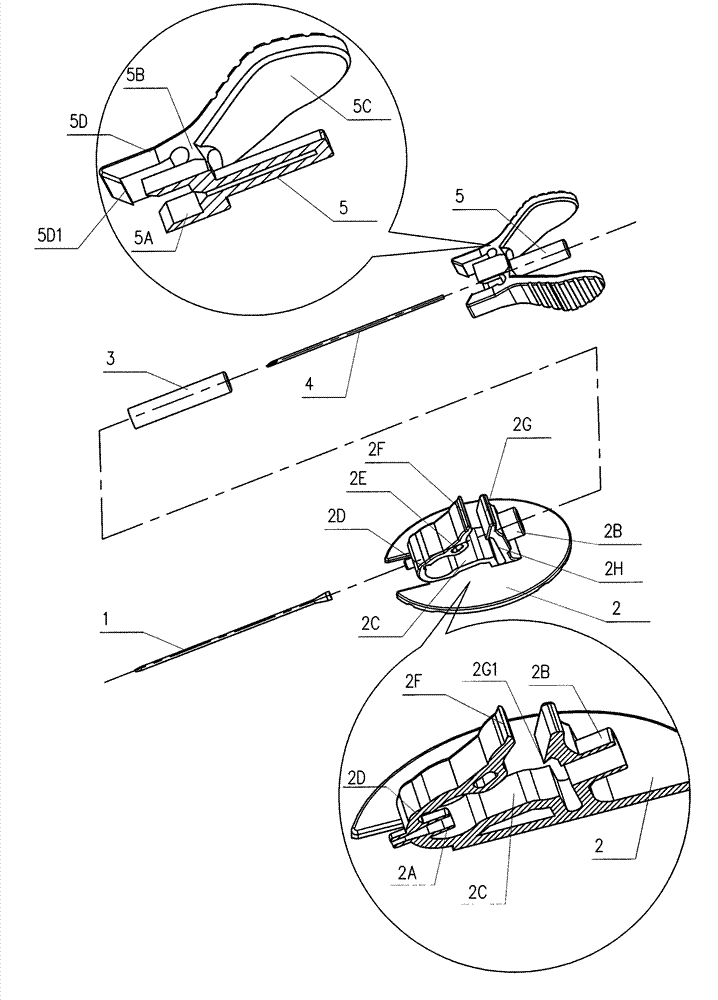

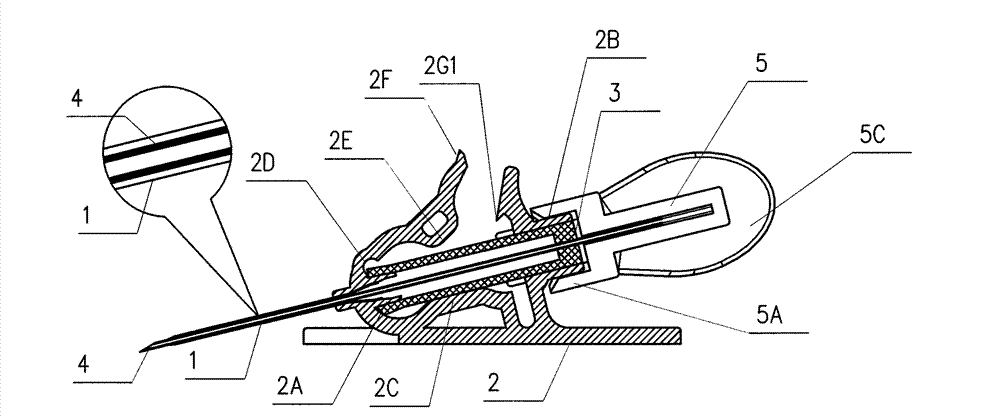

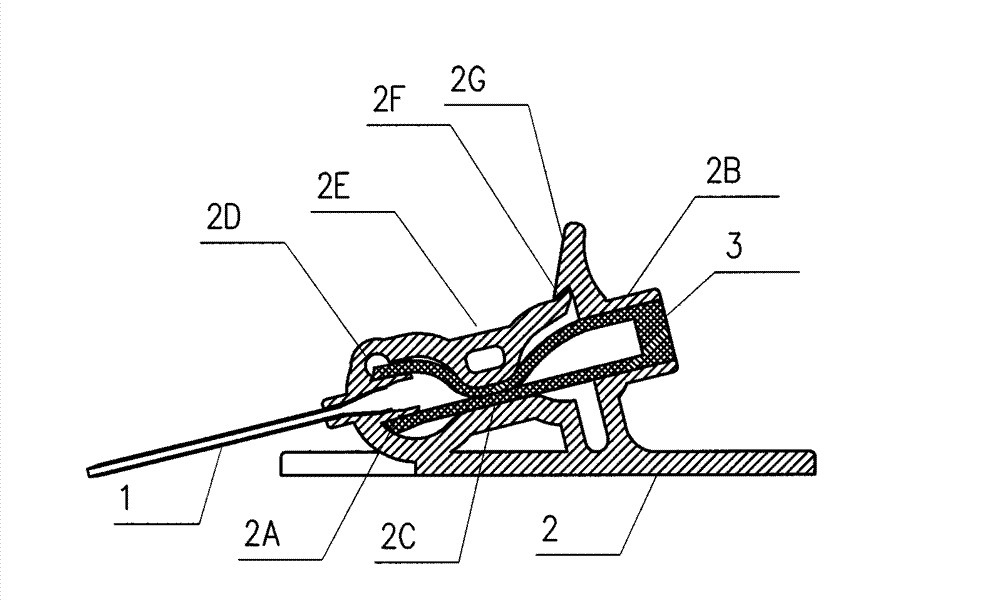

Sack clamp venous indwelling needle with dual-pressure function

The invention provides a sack clamp venous indwelling needle with dual-pressure function, which comprises an indwelling hose, an indwelling hose seat, a sack tube cap, a puncture needle tube and a puncture needle tube seat. The venous indwelling needle is characterized in that after infusion is completed and a connecting steel needle is removed, the indwelling hose seat is clamped by pressing the upper wall on the indwelling hose seat, so that the sac tube cap is flattened and deformed by extrusion of the roof and the pressure plate on the indwelling hose seat, and forms positive pressure in accordance with the direction of infusion; when the next infusion is started, the clamping state on the indwelling hose seat is opened, and negative pressure opposite to the direction of infusion is generated when the sac tube cap is restored by means of the characteristics of the sac tube cap; and the space variation generated by flattening and deformation of the sac tube cap is more than the internal space volume of the indwelling hose, and more than the volume of the connecting steel needle. Therefore, non-heparin tube sealing can be realized by utilizing the positive pressure, and whether the indwelling hose is plugged or not can be verified by utilizing the negative pressure.

Owner:张亚根

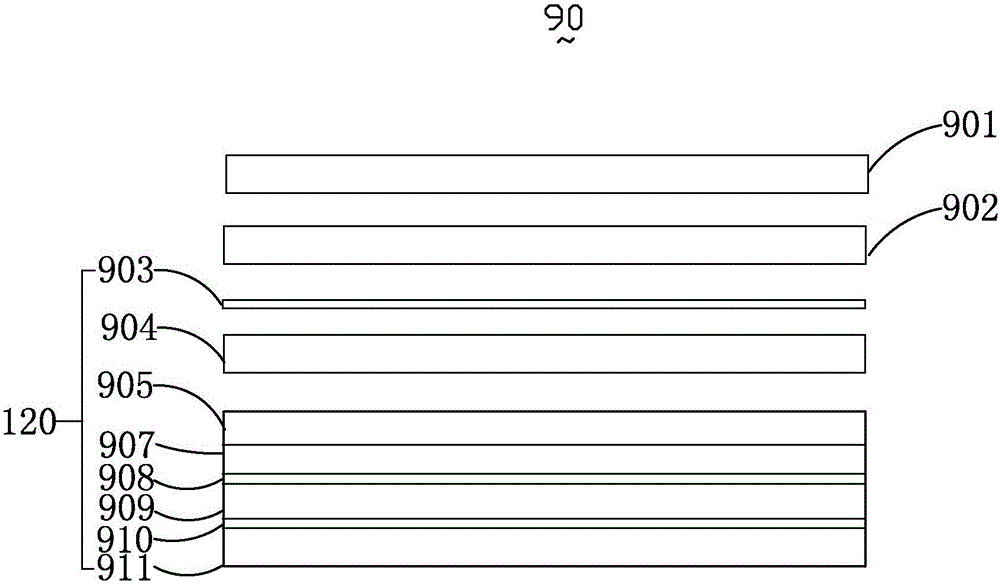

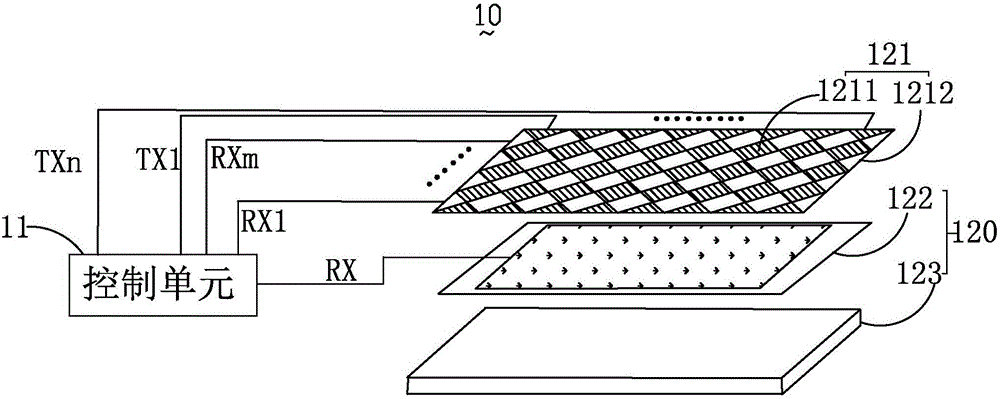

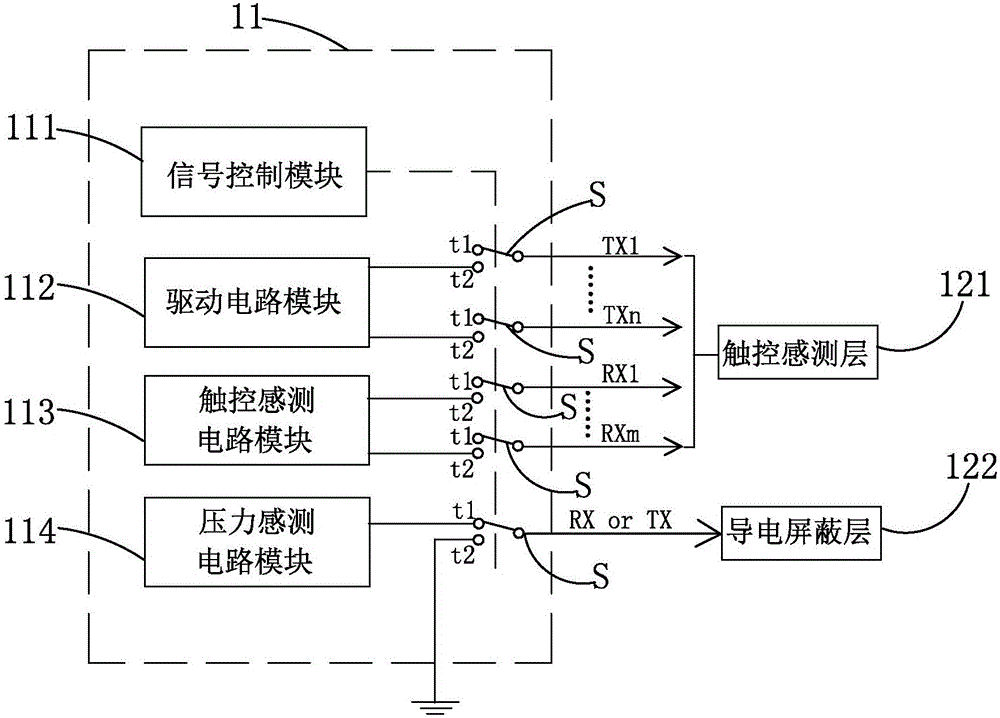

Touch display system with pressure sensing function

ActiveCN106383607ASimple structureLow costInput/output processes for data processingPressure functionTouch Senses

The invention provides a touch display system with a pressure sensing function. The touch display system comprises a touch sensing layer and a display module, wherein the display module further comprises a conductive shielding layer; the touch sensing layer is arranged on the display module and insulated from the conductive shielding layer; and the conductive shielding layer is used for providing the pressure sensing function at a first time sequence and is used for providing a ground connection for the display module at a second time sequence. By adopting the touch display system with the pressure sensing function, provided by the invention, the pressure sensing function can be realized in the touch display system without arranging a pressure sensing layer, so that the pressure sensing structure can be simplified and the cost can be reduced.

Owner:TPK UNIVERSAL SOLUTIONS

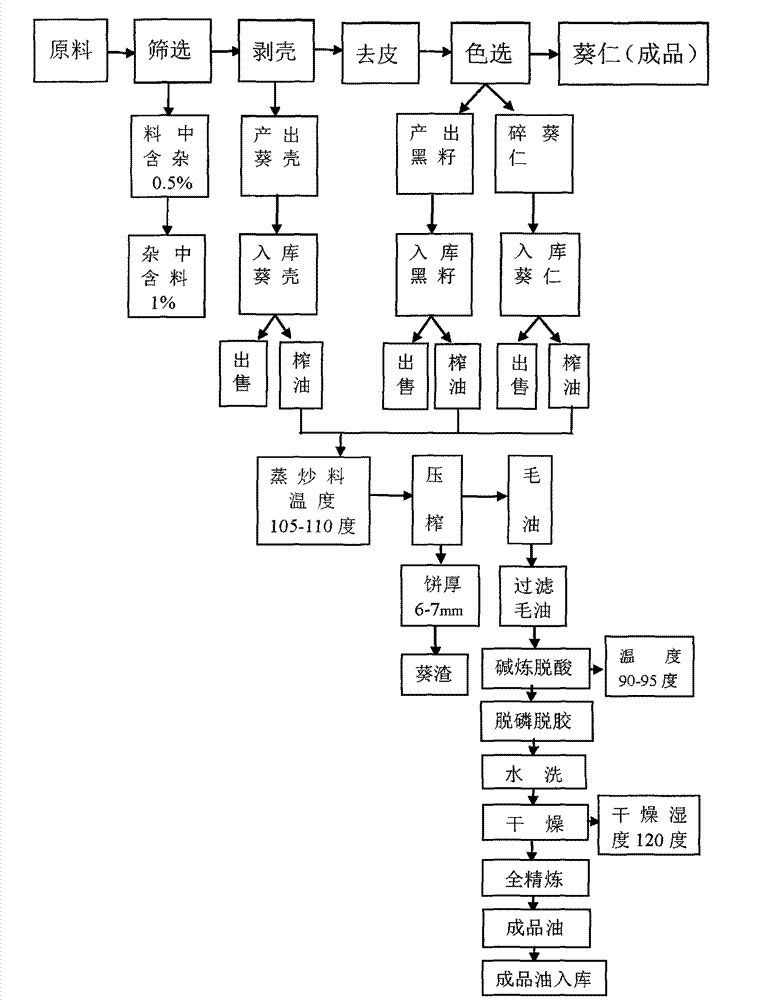

Pure physical squeezing technology for sunflower seed oil

InactiveCN102899159AHigh yieldAvoid the problem of chemical contamination of oilFatty-oils/fats refiningFatty-oils/fats productionOil and greasePressure function

The invention provides a pure physical squeezing technology for sunflower seed oil. The pure physical squeezing technology comprises the steps of: 1) selecting materials and husking, screening the harvested the sunflower seeds, removing the impurities in the sunflower seeds, husking the shells of the sunflower seeds after the impurities are removed, separating the shells from the sunflower seeds to obtain the pure sunflower seeds; 2) roasting: roasting the sunflower seeds; 3) squeezing: squeezing the roasted sunflower seeds, squeezing oil drops under the pressure function, and separating out the sunflower seed meal obtain the crude oil; and 4) washing and dewatering: precipitating the crude oil, washing and drying the precipitated crude oil mixed with water to obtain the food grade sunflower seed oil. The pure physical squeezing technology adopts the pure sunflower seeds to physically squeeze the oil, the nutrients in the oil materials are extremely preserved in the finished product grease, and simultaneously, a chemical solvent is not utilized in the whole production process, and a problem of chemically polluting the oil product is avoided by not adding a chemical preservative and an antioxidant in the production process, the safety and the nutrition of the product is guaranteed radically and the yield of the refined oil products is increased.

Owner:QITAI BOFENG WEIYE

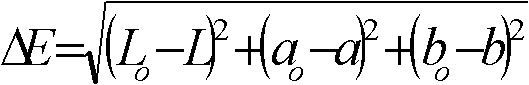

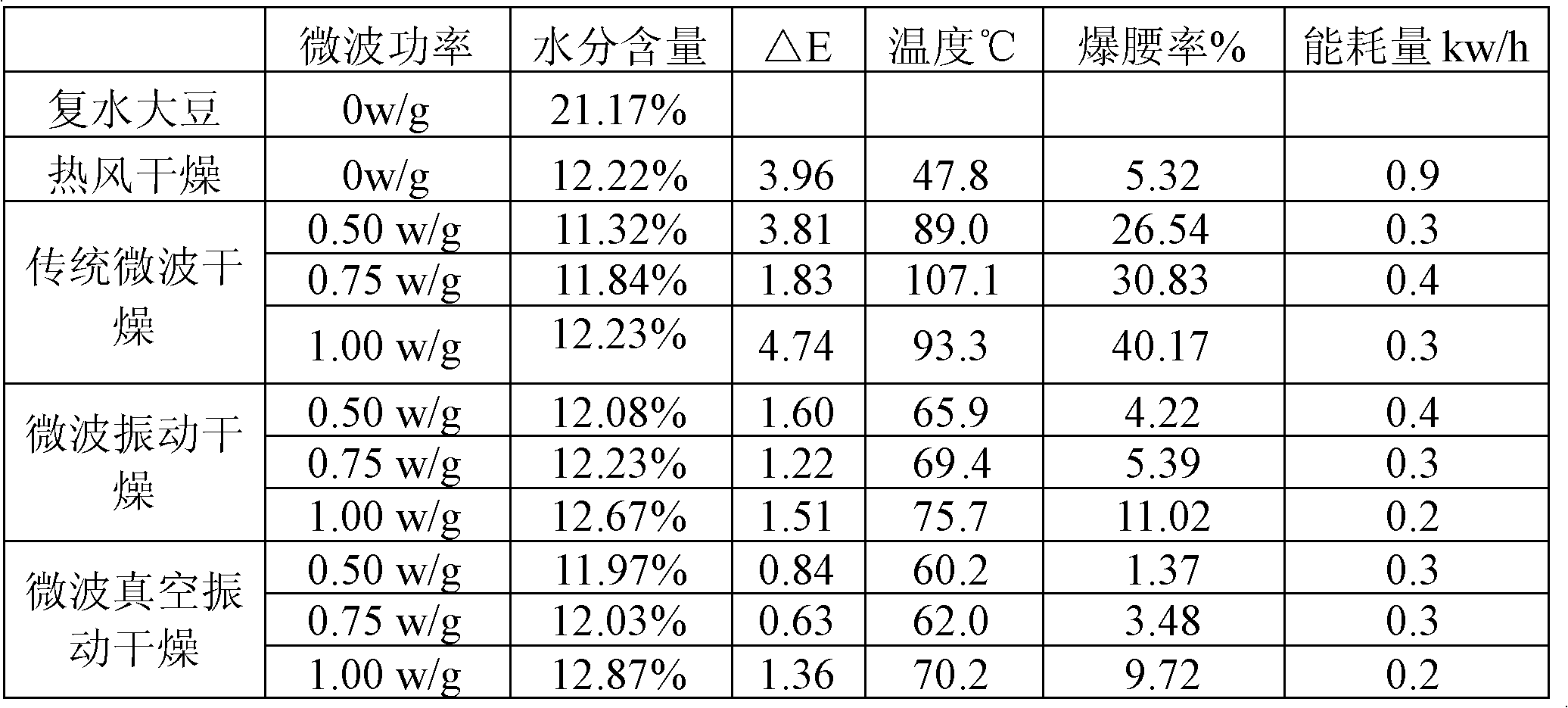

Vacuum microwave vibration drying method with low energy consumption and low percent cracked rice for granular food-borne material

ActiveCN102626135ADry evenlyReduce waist burst rateSeed preservation by dryingVibration amplitudePressure function

The invention relates to a vacuum microwave vibration drying method with low energy consumption and low percent cracked rice for a granular food-borne material. The vacuum microwave vibration drying method comprises the steps of: filling grains subjected to a pre-treatment into a vacuum tank; vacuumizing to below -0.065 Mpa, wherein a microwave output power is 0.5 w / g-1.0 w / g, a vibration frequency is 350 r / min-550 r / min, and a vibration amplitude is -2 cm to 2 cm; and reducing moisture content of the material from 20%-25% to less than 13% after 12 min to 30 min. According to the invention, the vacuum microwave vibration drying method is adopted to fully make use of the advantage of a fast microwave drying speed and a vacuum low-temperature drying superiority to reduce a boiling point of water in the material through a negative pressure function for one aspect, thereby shortening a drying time and reducing drying energy consumption, and change the position of the material in a microwave field in real time through a vibration function for the other aspect, thereby improving uniformity of microwave energy absorption, reducing percent cracked rice and improving drying quality. The vacuum microwave vibration drying method, disclosed by the invention, can reduce the energy consumption by 70% when compared with the traditional hot air drying method, and can reduce the percent cracked rice by 60% when compared with a microwave vibration drying method.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com