Pure physical squeezing technology for sunflower seed oil

A sunflower kernel, pure physical technology, applied in the field of sunflower kernel oil pure kernel physical pressing technology, can solve the problems of dirty production environment in the workshop, reduce oil health care effect, poor quality, etc., achieve the goal of avoiding chemical pollution of oil products and improving yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

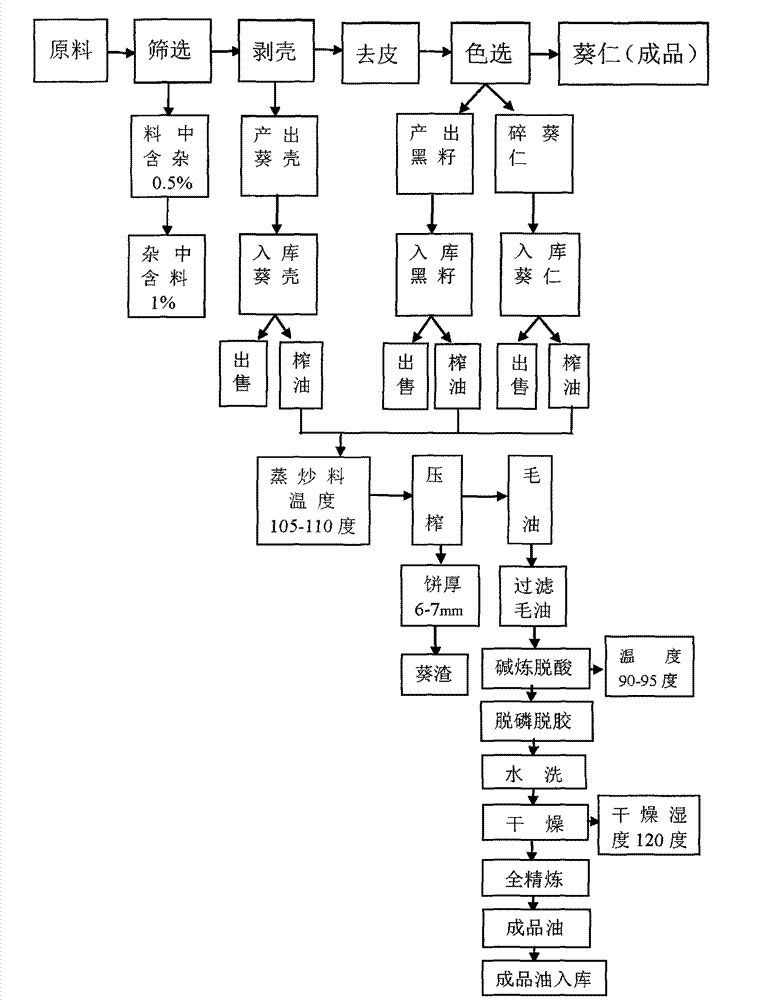

[0024] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the drawings and specific embodiments.

[0025] like figure 1 As shown, the steps that the sunflower kernel oil pure physical pressing process proposed by the present invention comprises are:

[0026] Material selection and shelling: the sunflower seeds after harvest are screened to remove impurities. After the impurities are removed, the shell of the sunflower seeds is peeled off, and the shell is separated from the sunflower kernels to obtain pure sunflower kernels; the sunflower seeds are completely shelled, Pure kernel to oil can completely avoid the above problems. The use of pure sunflower kernels for pressing can improve the quality of oil products, make the color of the oil lighter, increase the processing capacity of the subsequent equipment, and basi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com