Patents

Literature

6837 results about "Edible oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycerol Feedstock Utilization for Oil-Based Fuel Manufacturing

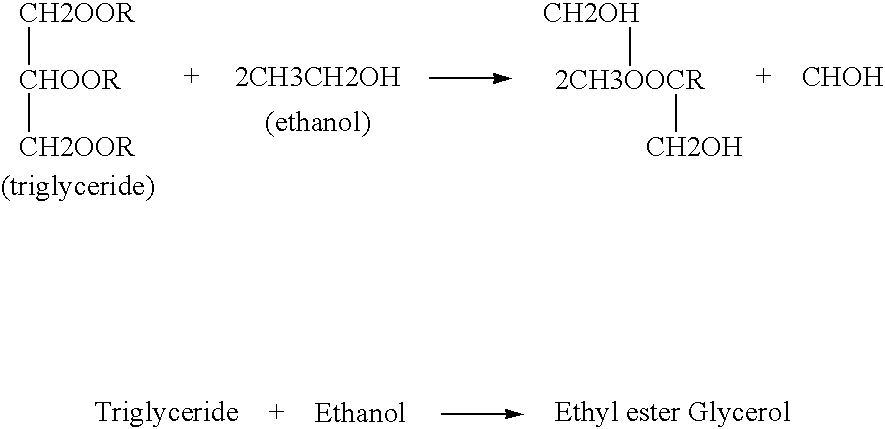

InactiveUS20090004715A1Bioreactor/fermenter combinationsFatty acid chemical modificationMicroorganismTransesterification

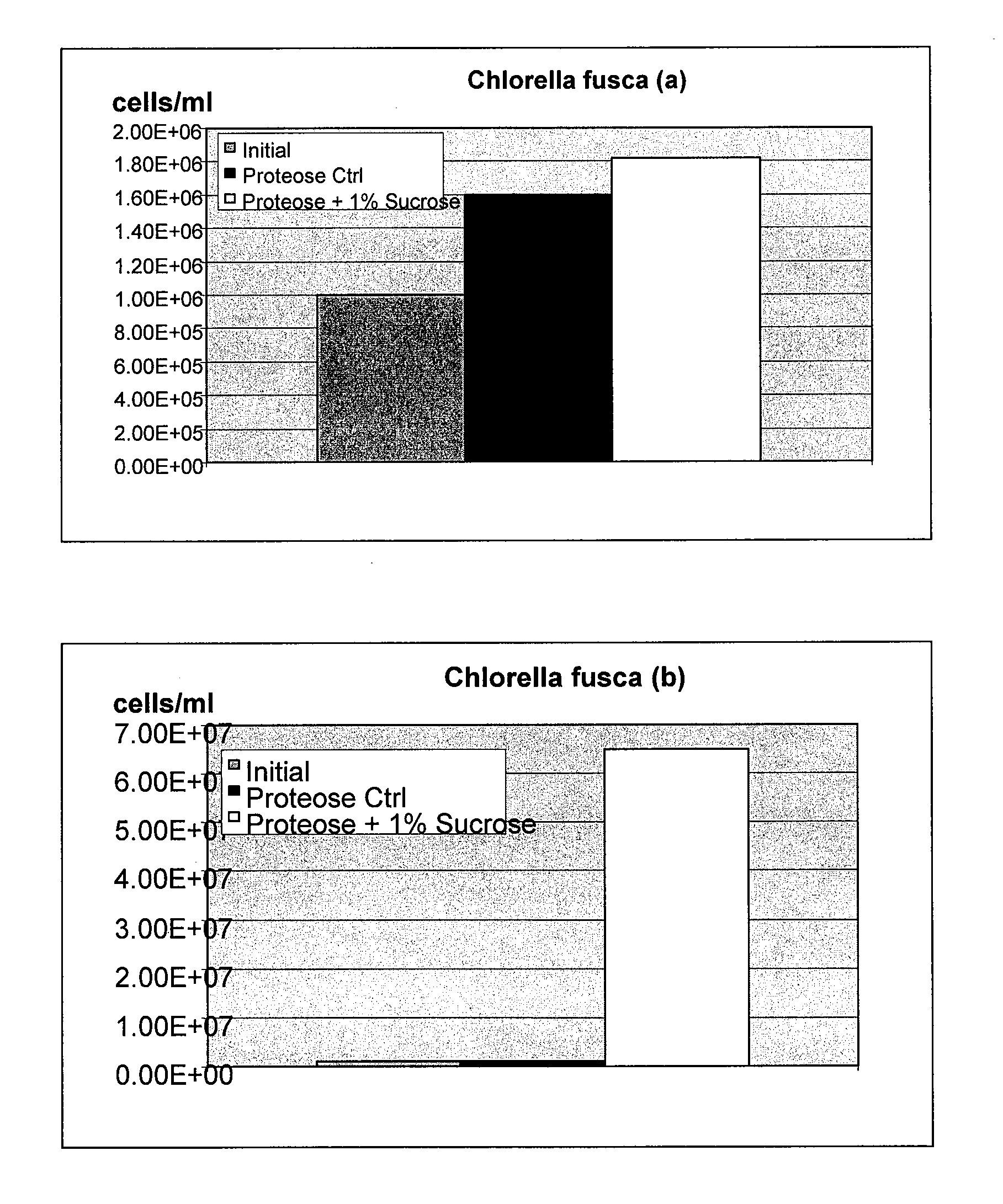

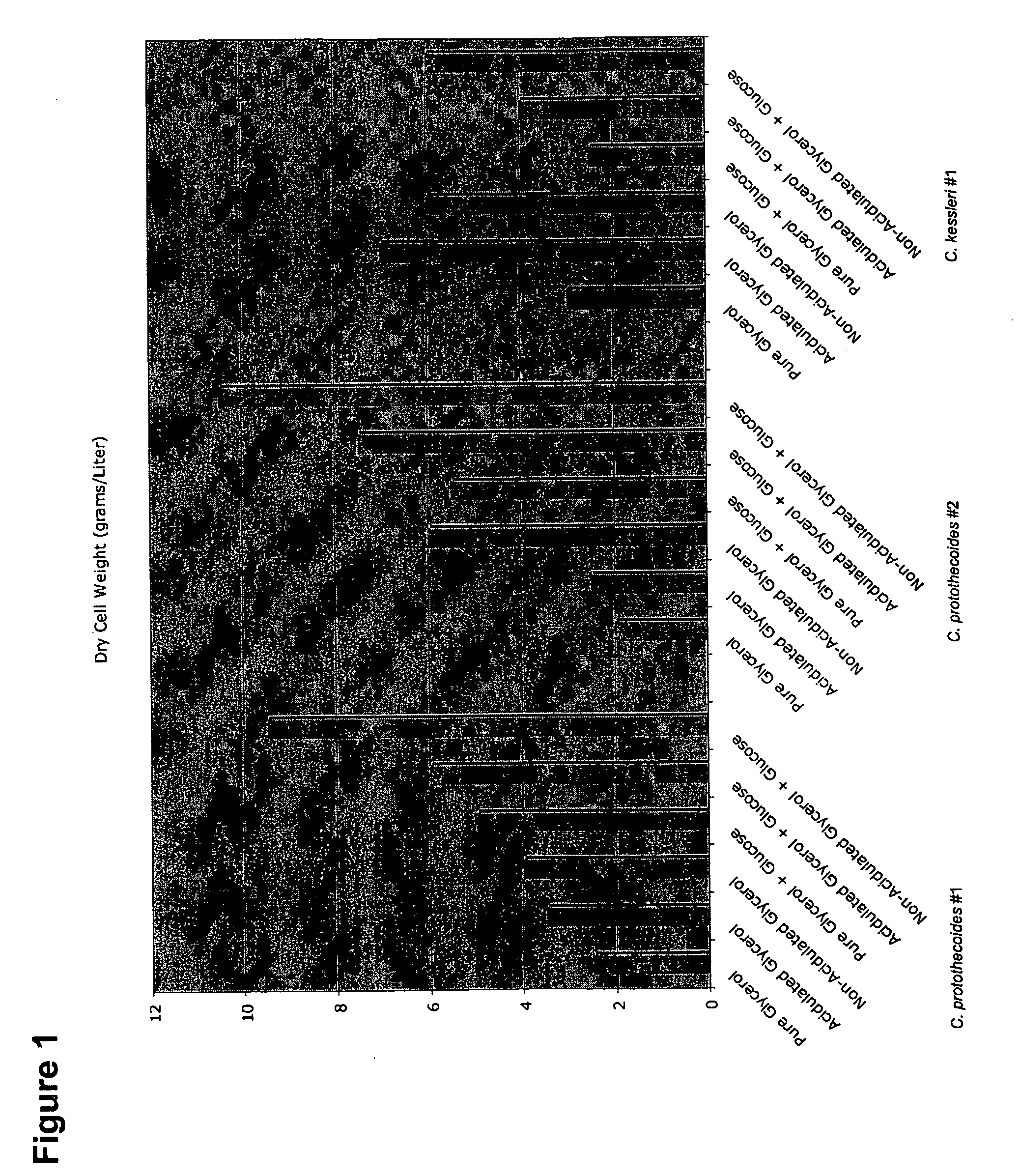

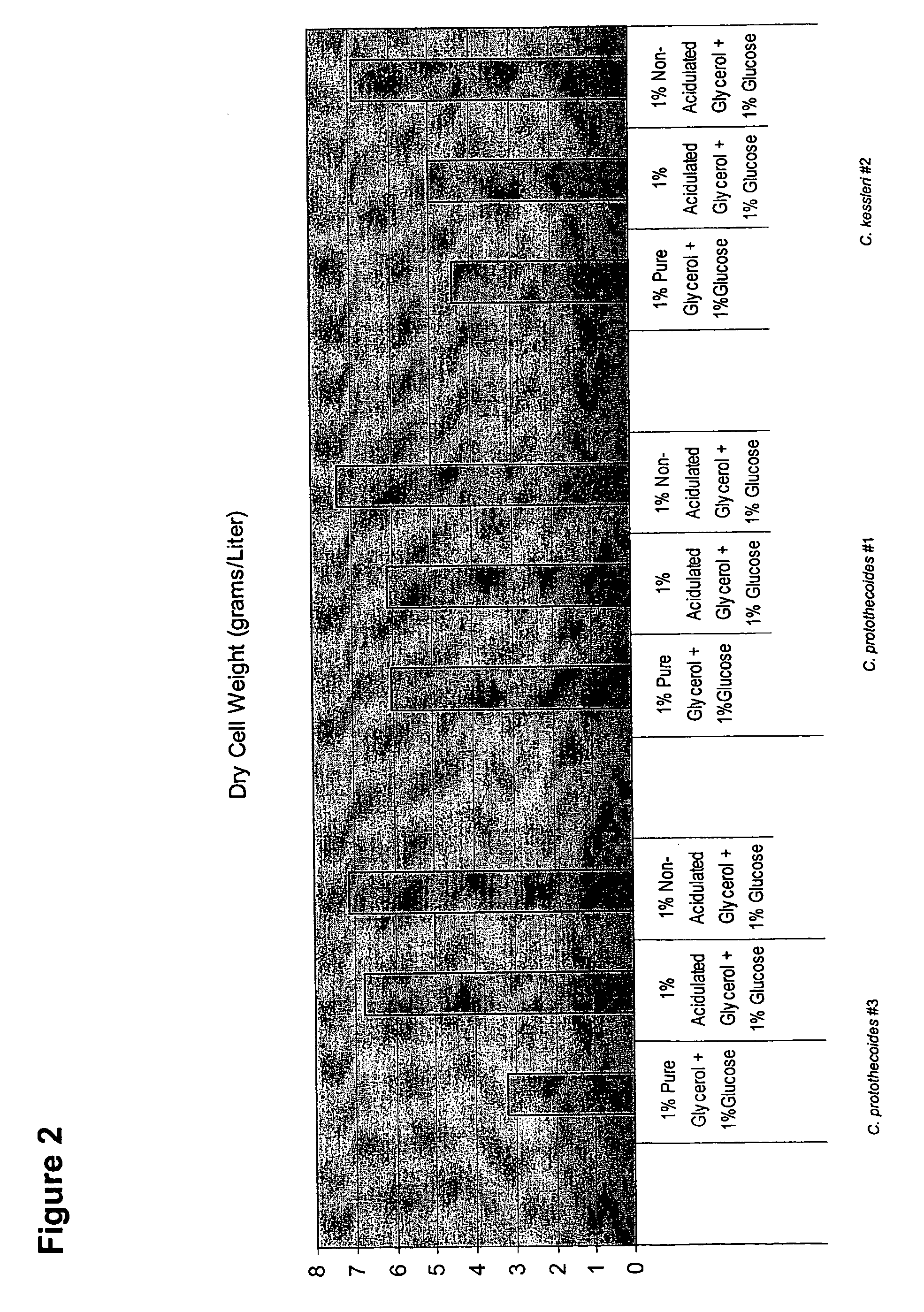

The invention provides methods of manufacturing biodiesel and other oil-based compounds using glycerol and combinations of glycerol and other feedstocks as an energy source in fermentation of oil-bearing microorganisms. Methods disclosed herein include processes for manufacturing high nutrition edible oils from non-food feedstock materials such as waste products from industrial waste transesterification processes. Also included are methods of increasing oil yields by temporally separating glycerol and other feedstocks during cultivation processes. Also provided herein are oil-bearing microbes containing exogenous oil production genes and methods of cultivating such microbes on glycerol and other feedstocks.

Owner:TERRAVIA HLDG INC

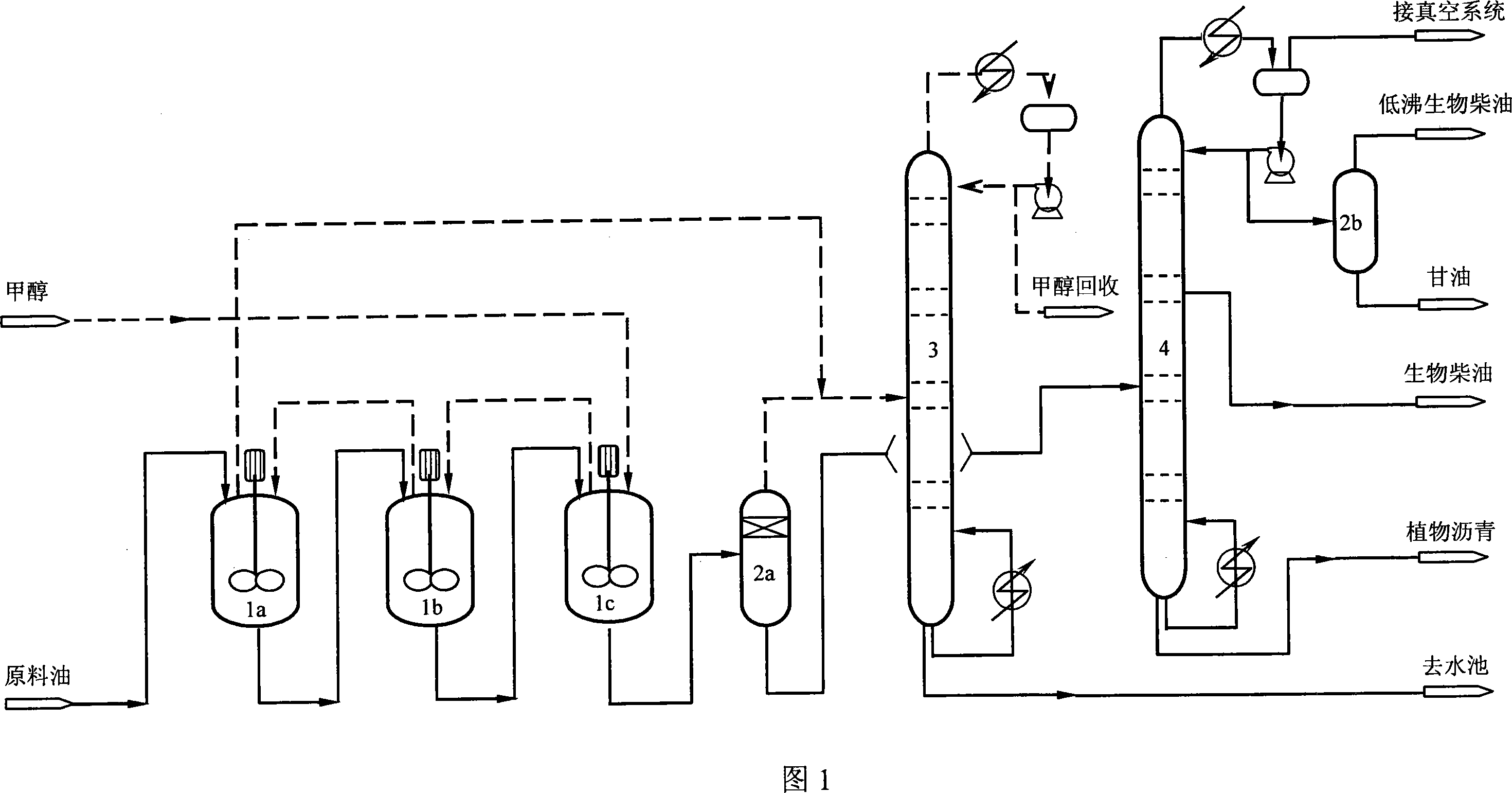

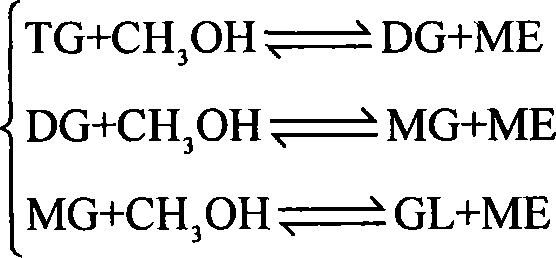

Process for supercritical preparation of biologic diesel oil

InactiveCN1594504AReduce pollutionRaw materials are easy to getBiofuelsLiquid hydrocarbon mixture productionBiodieselPhase splitting

The invention discloses a process for supercritical preparation of biologic diesel oil by using animal or plant oil, waste edible oil, oiling crop seeds as raw material through the steps of filtering, dewatering, esterification, ester interchange, filtering, steaming methanol and phase-splitting.

Owner:WUHAN CHEM COLLEGE

Edible Oil and Processes for Its Production from Microalgae

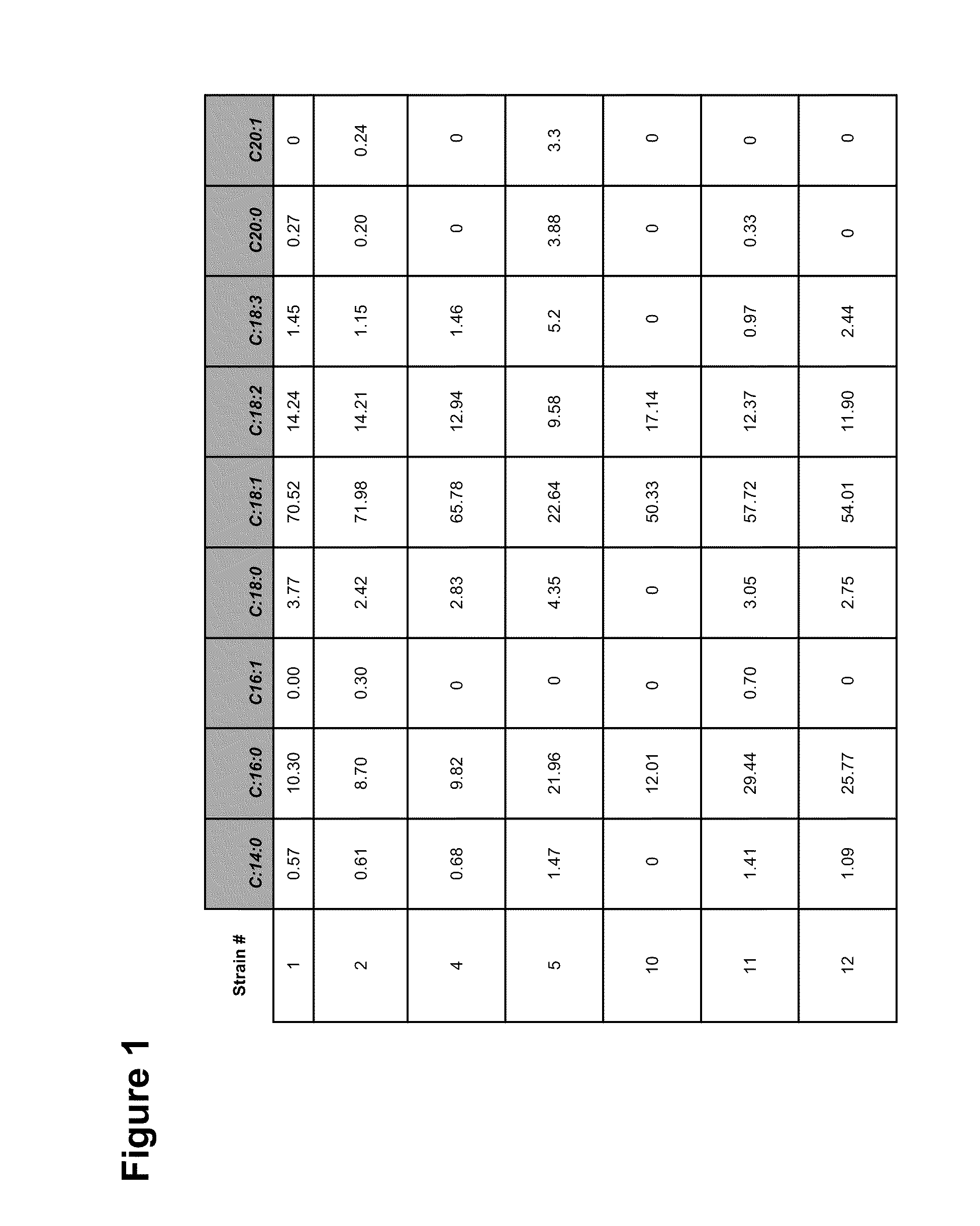

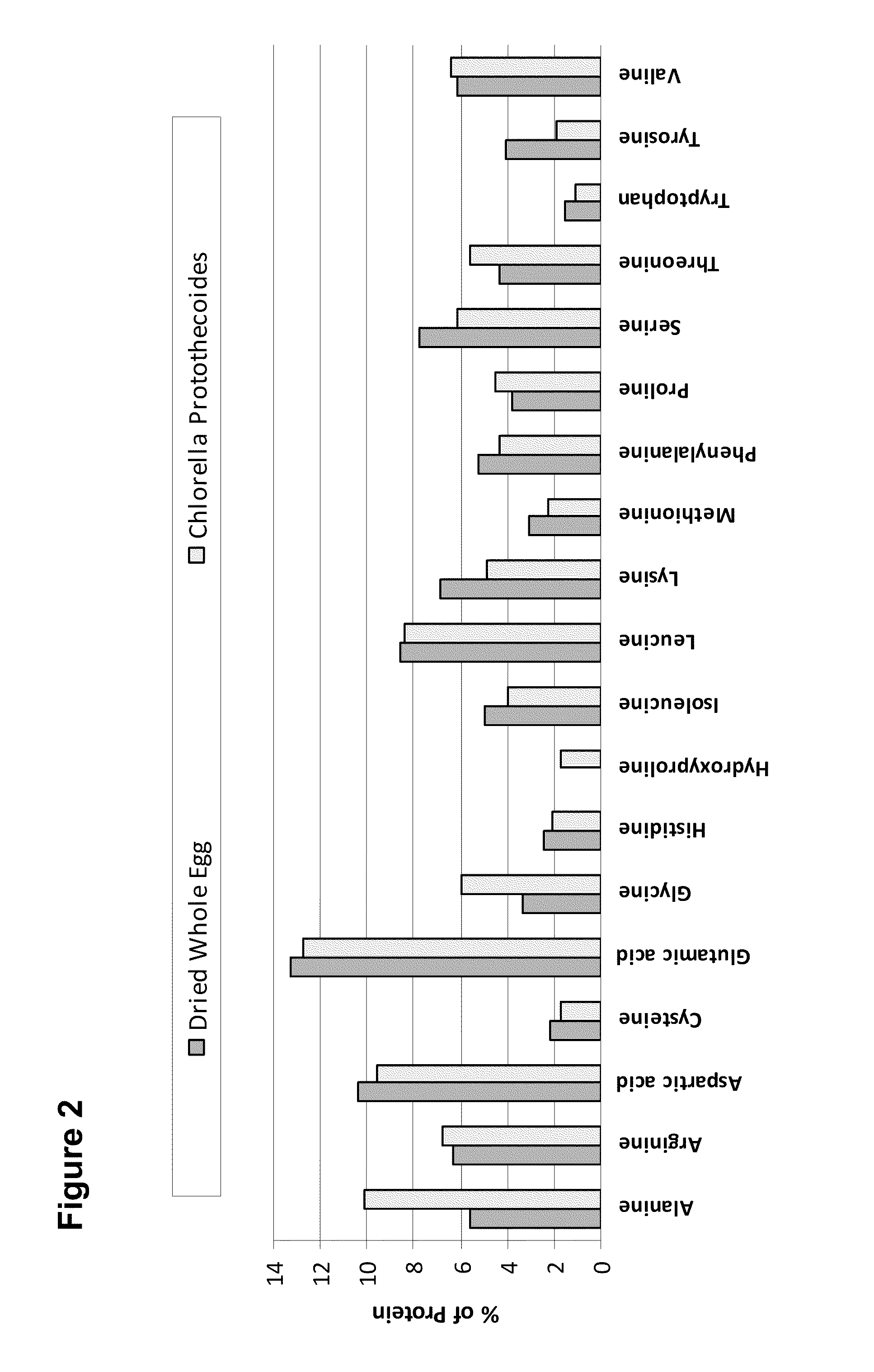

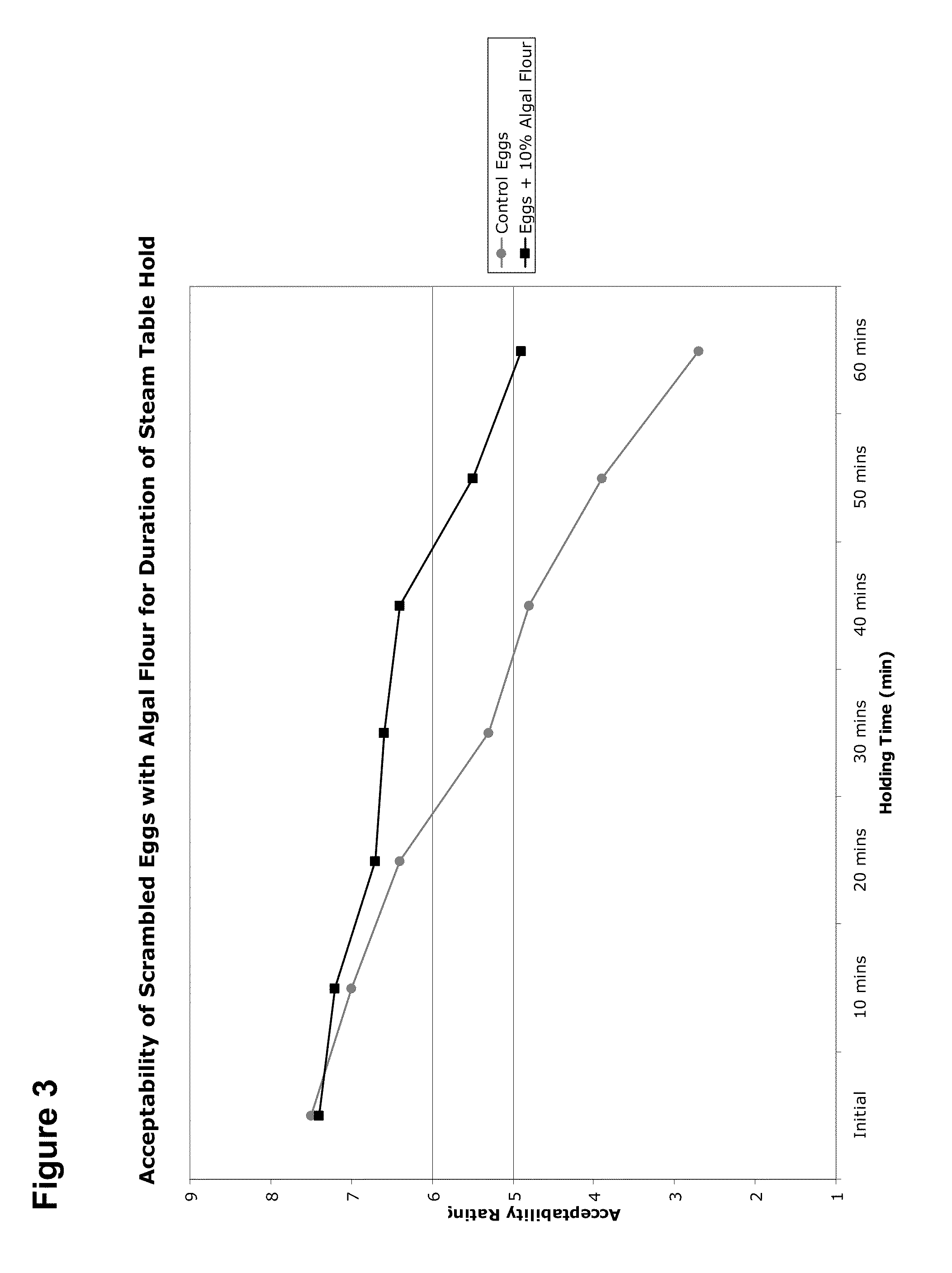

InactiveUS20100303957A1Simple preparation conditionsFatty acid hydrogenationReady-for-oven doughsCelluloseBiotechnology

Novel triglyceride oils are provided for human consumption. Traditionally, agricultural materials such as canola, soybean, and olives have been the sources of edible oils, and such materials are limited by the geography in which these crops can be cultivated. Oils of the invention can be manufactured from edible and inedible heterotrophic fermentation feedstocks, including corn starch, sugar cane, glycerol, and depolymerized cellulose that are purpose-grown or byproducts of existing agricultural processes from an extremely broad diversity of geographic regions. The food oils disclosed herein are low in saturates, high in monounsaturates, and can be manufactured in reduced pigment form through the use of pigment-reduced microalgae strains. The food oils disclosed herein can be manufactured through the use of a variety of different types of oil-producing microalgae.

Owner:TERRAVIA HLDG INC

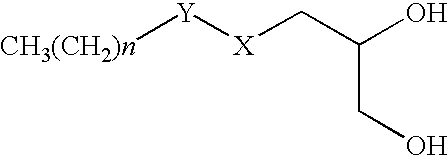

Food spreads

The present invention is of a food spread containing a mixture of at least one edible oil of natural or synthetic origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, nut oils, walnut oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil, palm oil, sesame oil, wheatgerm oil, jojoba oil or corn oil. More preferably an oil such as avocado oil, fish oil, palm oil or olive oil is used and most preferably the oil is olive oil and fish oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The oil is present preferably in an amount of from about 85 to about 98 percent and most preferably in an amount of from about 93 to about 96 percent. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

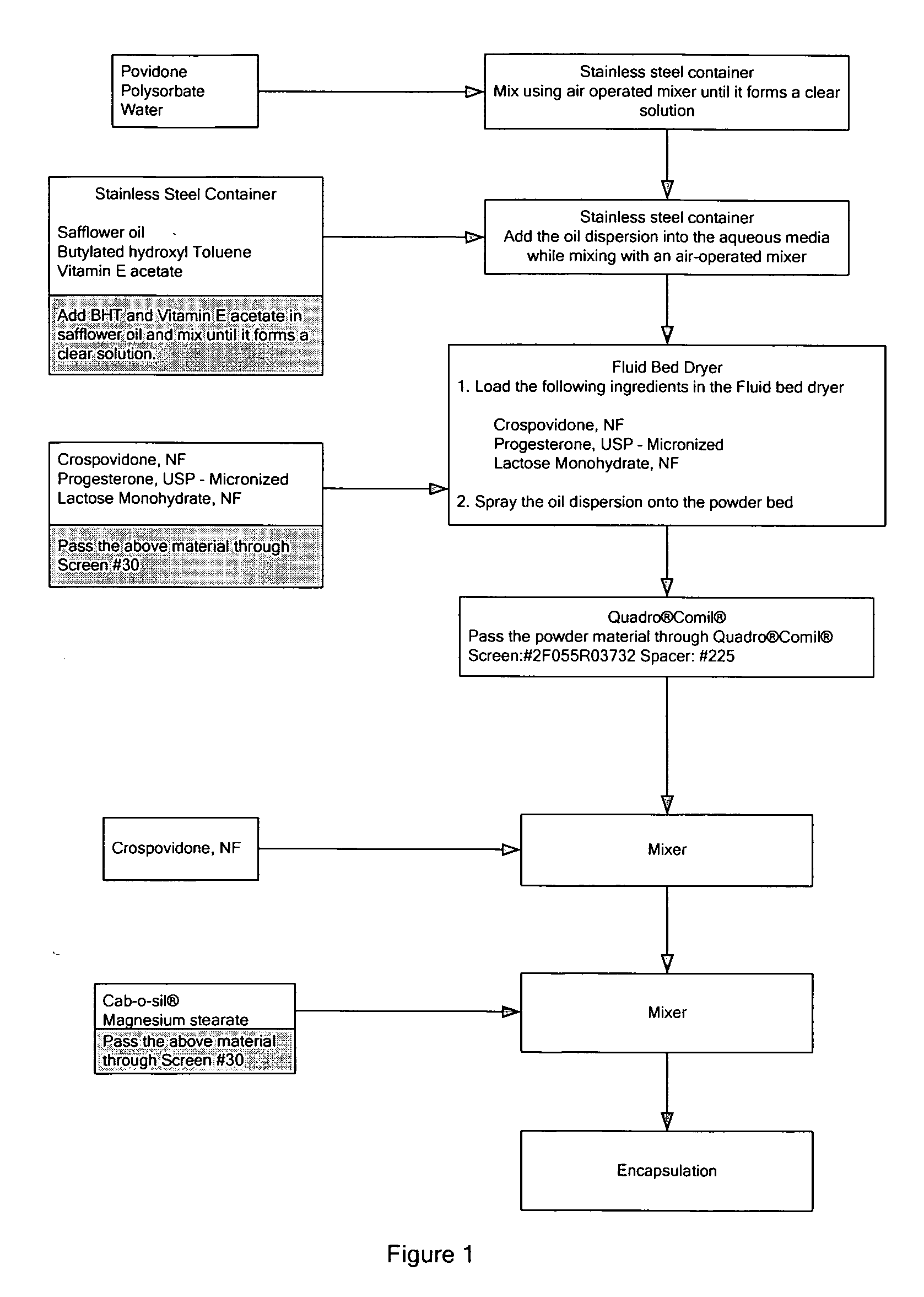

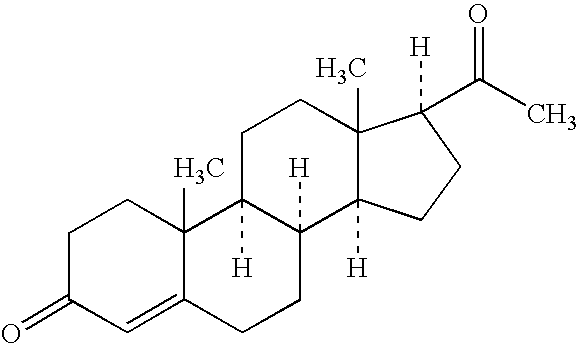

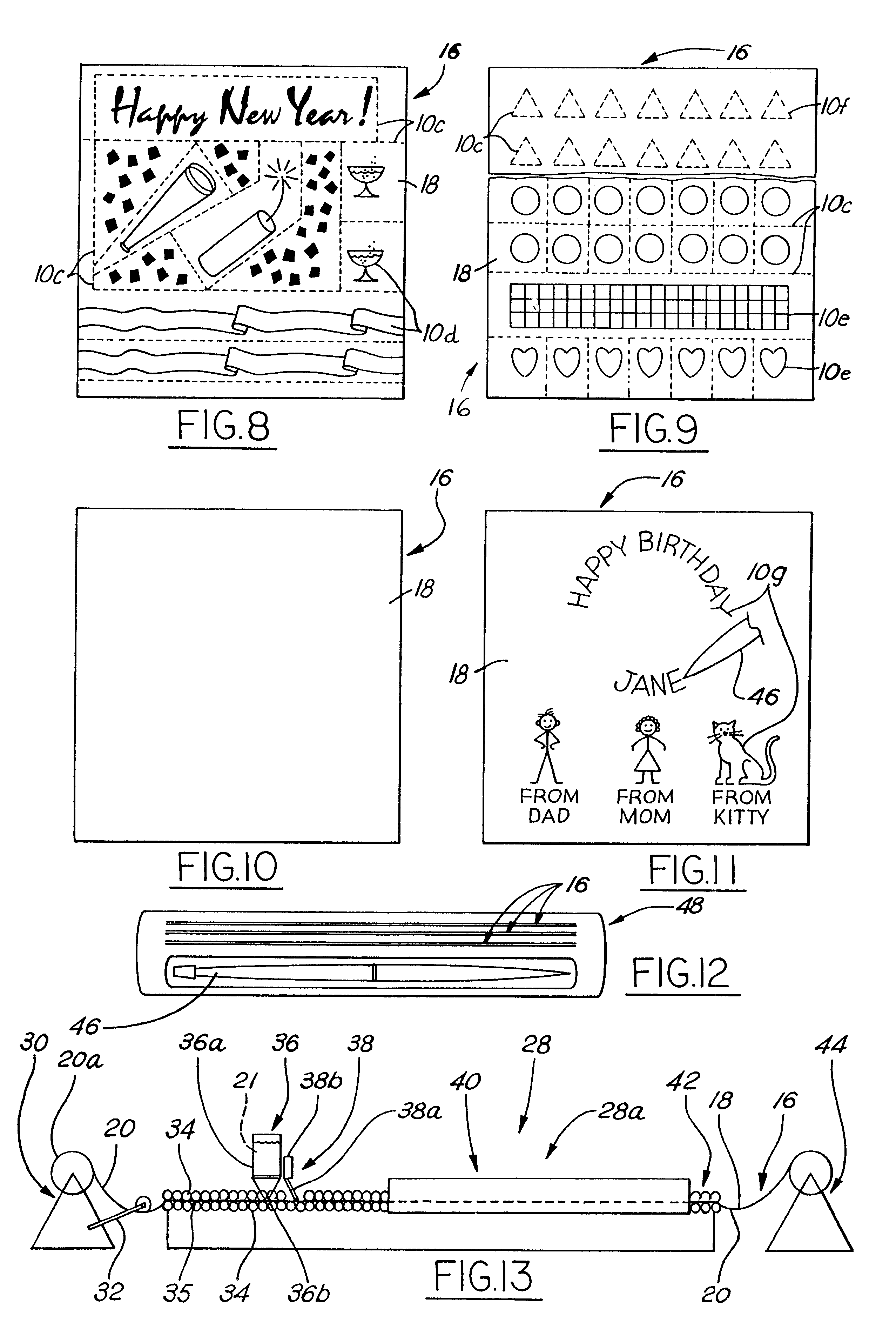

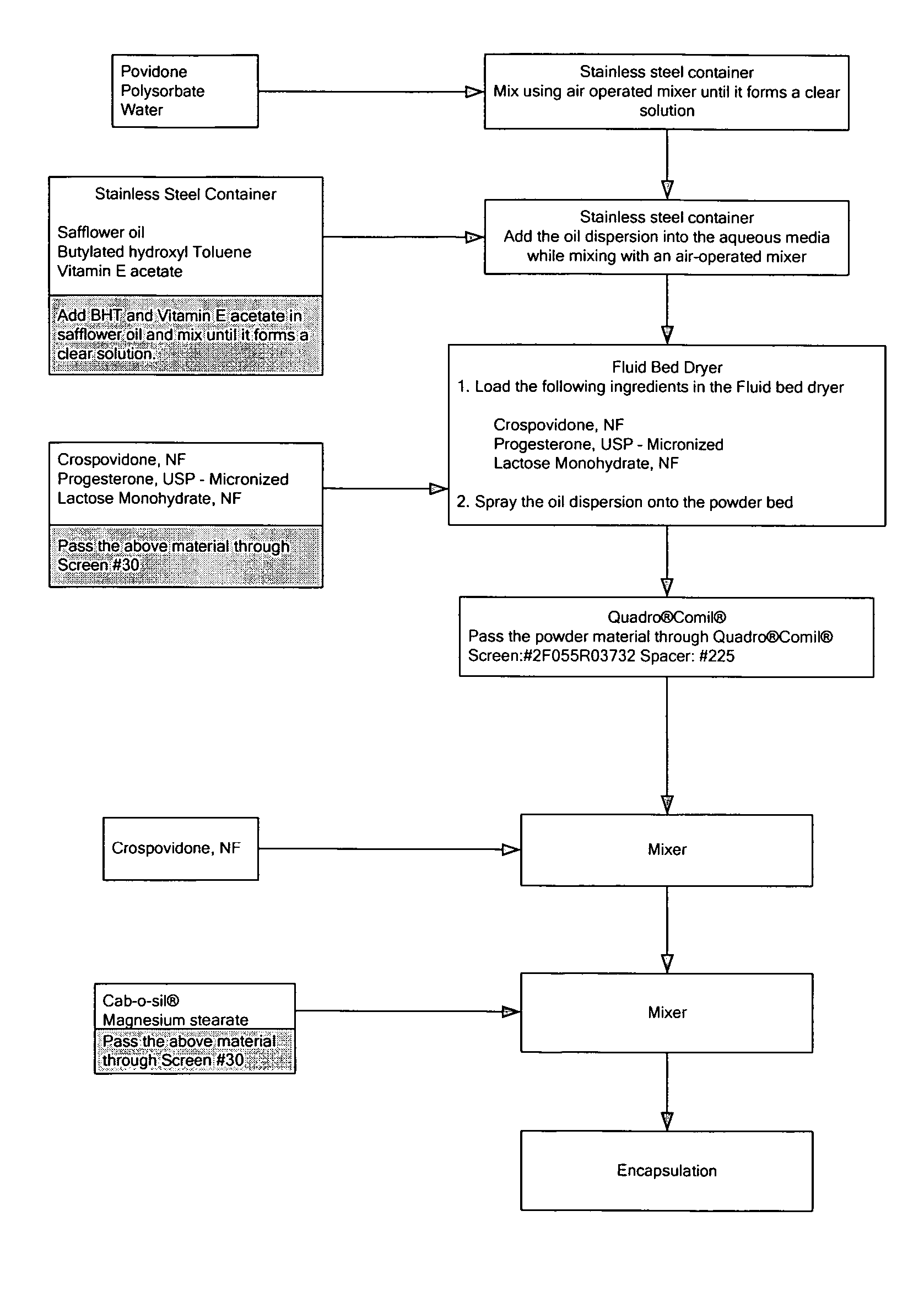

Oral dosage forms comprising progesterone and methods of making and using the same

InactiveUS20060275360A1Stable absorption profileOrganic active ingredientsCapsule deliveryProgesteronesEdible oil

The present invention relates to an oral pharmaceutical dosage form comprising micronized progesterone, an edible oil, a disintegrant, and a hydrophilic excipient. Particularly, the invention relates to a pharmaceutical dosage form wherein the dosage form is in a powder form and is contained in a pharmaceutically acceptable capsule. The present invention is also directed toward methods of making the dosage form, methods of using the dosage form, and kits comprising the dosage form.

Owner:TEVA WOMENS HEALTH

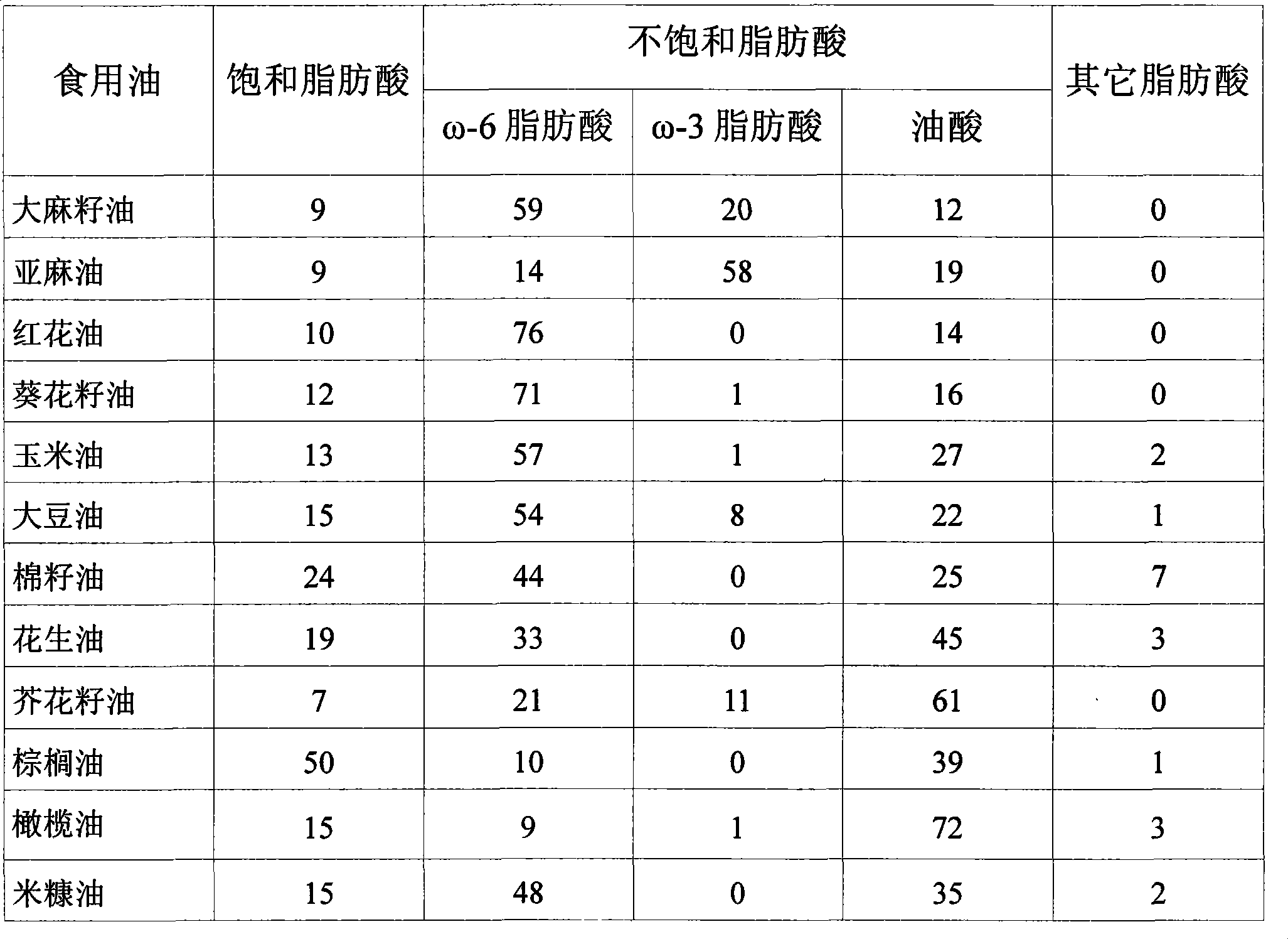

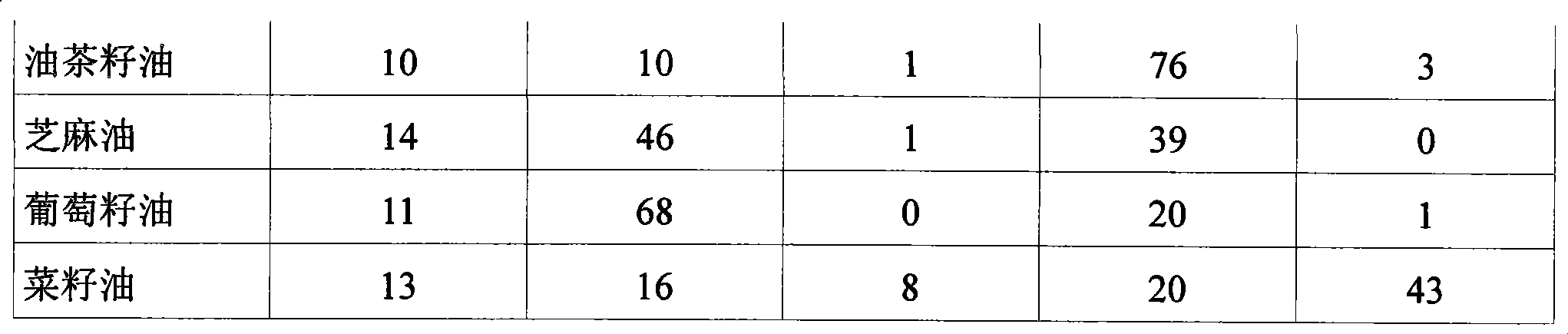

Edible nourishing oil with balanced fatty acid rate

The invention relates to edible nutritious oil which is characterized in that the contents of saturated fatty acid, oleic acid, linoleic acid and linolenic acid are respectively 8 to 16 percent, 42 to 56 percent, 13 to 23 percent and 13 to 30 percent of total fatty acid. With the proposal of eating less saturated fatty acid and linoleic acid and more oleic acid and linolenic acid from the international alimentology community, the edible oil is designed based on the particular reference that the ratio of the linoleic acid to the linolenic acid is close to 1 to 1 in the meal of human beings and people in Crete, Greece 100 years ago. The edible oil which has more balanced ratio between the fatty acid is quite suitable for human beings and has very important effects on reducing human beings fatness, hypertension, high blood fat, cardiovascular and cranial vascular diseases and cancers and reinforcing intelligence development. In addition, the edible oil has high quality and low price.

Owner:罗红宇

Method and composition for repairing and promoting regeneration of mucosal tissue in the gastrointestinal tract

InactiveUS6685971B2Restore physiological structure and functionPromote general health of whole bodyBiocideAerosol deliveryDiseaseAdditive ingredient

The present invention provides novel compositions and methods for protecting and promoting cell growth and restoring physiological structure and function to mucosal tissue of the body, especially mucosa in the gastrointestinal tract. The composition can be used as a pharmaceutical or nutraceutical to treat a gastrointestinal disorder or to promote general health of an animal, preferably a human. The composition is in an oral dosage form and comprises edible oil homogenized with a sterol compound at a concentration of at least 0.5% by weight and edible wax at a concentration ranging from 3% to 30% by weight. The composition can also be used to deliver other active ingredients to the gastrointestinal tract for treating various diseases.

Owner:XU RONGXIANG

Production of biodiesel from combination of corn (maize) and other feed stocks

InactiveUS20070099278A1Increase Biodiesel production outputStable year round productionFatty oils/acids recovery from wasteOrganic compound preparationProcess systemsSodium Bentonite

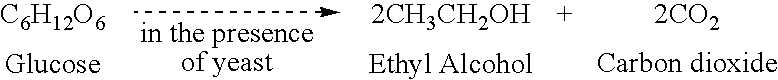

A method and system to produce biodiesel from a combination of corn (maize) and other agro feedstock may be simarouba, mahua, rice, pongamia etc. Germ is separated (either by wet process or dry process) from corn, crude corn oil extracted from germ and corn starch milk / slurry is heated and cooked in jet cooker to about 105 degree Celsius, enzymes added to convert starch into fermentable sugars in liquification and saccharification process and rapidly cooled down to about 30 degree Celsius. Simarouba fruits syrup, mahua syrup is mixed with corn starch milk (after saccharification). When yeast is added the fermentation takes place for about 72 hours. Thereafter the fermented wash is distilled to produce ethanol. Water consumed in dry process is very less compared to traditional wet process system. Corn oil and mixture of other oils is fed into transesterification (reaction) vessels where ethanol with catalyst, usually sodium hydroxide is added and reaction takes place for about a period of 2-8 hours. Crude biodiesel and crude glycerin as by-products is produced. Excess ethanol removed by distillation process. Crude biodiesel washed with warm water to remove residual soaps or unused catalyst, dried and biodiesel stored for commercial use. Oil extracted from spent bleach mud (used sodium bentonite), a waste product of edible oil refineries may also be utilized for economical production of biodiesel in combination of corn oil and ethanol.

Owner:AARE PALANISWAMY RAMASWAMY

Environmentally friendly ink cleaning preparation

InactiveUS6284720B1Less quantityEasy to cleanAnionic surface-active compoundsChemical paints/ink removersHuman healthSolvent

A solvent that is biodegradable, provides effective solvency for a broad range of tasks and is generally benign to human health is disclosed. This solvent is a mixture of a lactate ester and an edible oil ester that has a closed cup flash point at or above 59° C., and can include other non-halogenated solvents and surfactants.

Owner:VERTEC BIOSOLVENTS

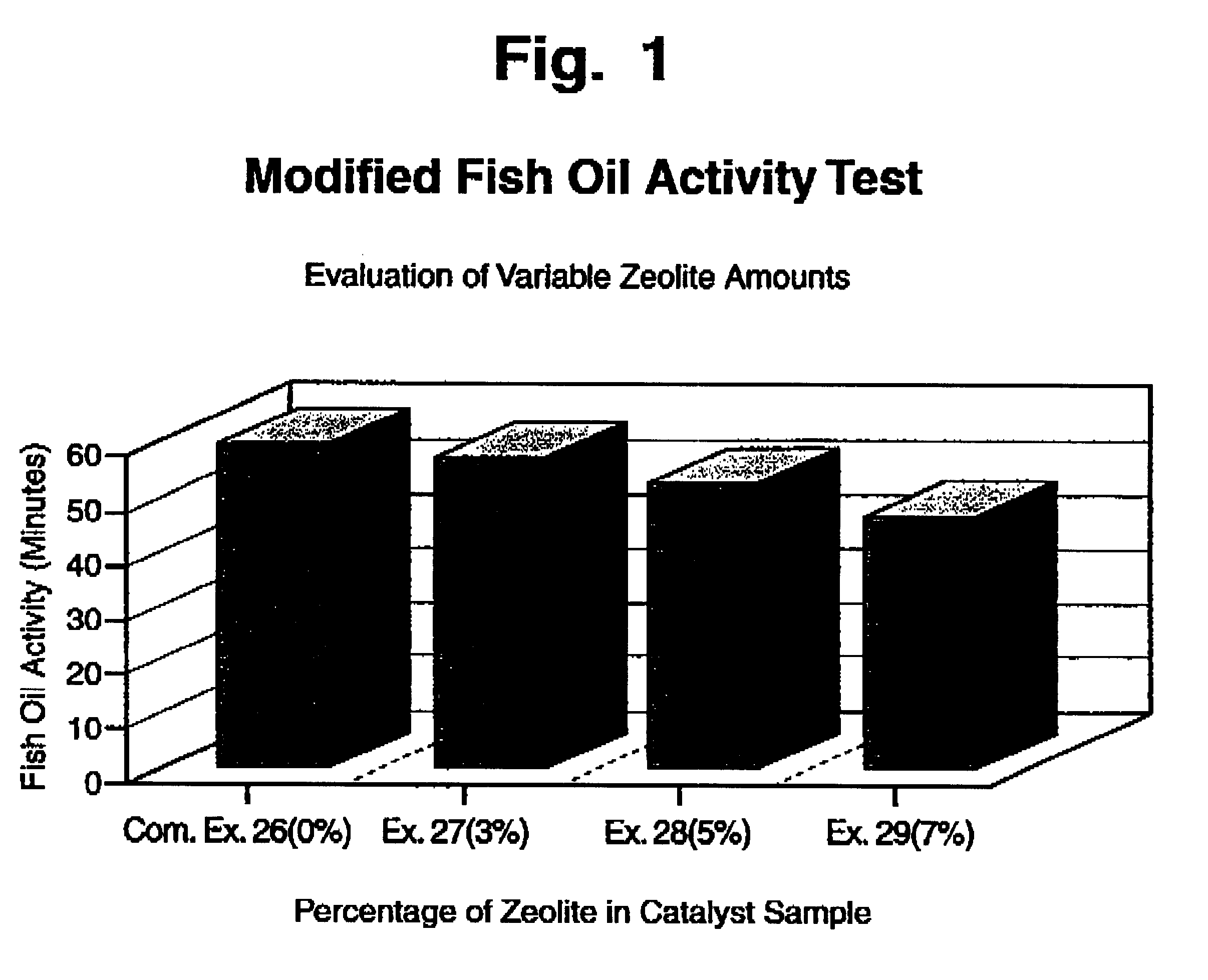

Combination sulphur adsorbent and hydrogenation catalyst for edible oils

An improved catalyst for edible oil hydrogenation produced by the incorporation of a sulphur adsorbing zeolite with a supported nickel hydrogenation catalyst. The zeolite is a cation-exchanged form of low silica faujasite with a silica to alumina ratio from about 1.8 to 2.1. The hydrogenation catalyst is a supported nickel catalyst. The zeolite is incorporated into the stabilization media with the reduced hydrogenation catalyst to form a physical blend of sulphur adsorbing zeolite and reduced nickel hydrogenation catalyst in a stabilization medium.

Owner:UNITED CATALYSTS INC

Dietary supplements and prepared foods containing triglyceride-recrystallized non-esterified phytosterols

ActiveUS7575768B2Reduce fat oxidationReduce probabilityVitamin food ingredientsFatty substance preservation using additivesFood additiveDietary supplement

A nutritional supplement, prepared food product, or direct food additive for ingestion by mammals, and methods for preparing such products, are provided. Products of the invention comprise an oxidation-resistant fat-based composition substantially free of exogenous solubilizing and dispersing agents for phytosterols. The fat-based composition includes greater than 25% and less than 75% by weight of one or more triglyceride-based edible oil or fat, and greater than 25% and less than 75% by weight of one or more non-esterified phytosterols. The fat-based composition, when exposed to air, contains a reduced amount of oxidative by-products compared to a similar fat-based composition lacking non-esterified phytosterols. Also provided are methods for reducing plasma cholesterol in mammals, and methods for protecting plasma lipoproteins and cholesterol from oxidation by ingestion of products of the invention.

Owner:BRANDEIS UNIV

Fish paste product and processing method thereof

The invention provides a fish paste product and a processing method thereof. The fish paste product is prepared by adding 0-3 percent of sauce, 25-60 percent of edible oil, 0-35 percent of nut type and bean type powdered particles, 0-15 percent of fruit and vegetable powdered particles, 0-30 percent of reorganized plant protein particles or filaments, 0-25 percent of medicine-food component powder, 0-15 percent of a nutrient improvement component, 0.1-5 percent of a product quality modifier, 0-10 percent of raw ginger or ginger juice, 0-5 percent of monosodium glutamate, 0-1 percent of I+G, 0-3 percent of sesames or sesame powder, 0.05-3 percent of salt, 0-5 percent of cooking wine, 0-6 percent of vinegar, 0-5 percent of white granulated sugar and 0.1-25 percent of spicy to 30-70 percent of fish meat silks or dried fish meat floss or fish meat particles serving as a raw material according to the weight percentage, mixing the materials, then frying or stewing in a sauce frying pan or a jacketed pan for 10-60 minutes, bottling, canning or bagging the fish paste, heating and sterilizing under the condition of the temperature of 80-145 DEG C, and performing cooling, cleaning and blow-drying in sequence. The fish paste product prepared by the processing method is rich in nutrition, tastes delicious, is convenient to carry and eat and is favored by customers.

Owner:刘良忠

Trans fat replacement system and method of making a baked good with a trans fat replacement system

The invention provides a trans fat replacement system that is a stable and shelf storable mixture of an edible oil and an expanded, low-density carbohydrate for use in preparing baked goods having a reduced trans fat content. Depending upon formulation and processing, the mixture can have a consistency ranging from generally granular to an almost paste-like consistency. The trans fat replacement system consists of at least one edible oil and an expanded, low-density carbohydrate having a bulk density less than about 0.4 g / cc. The trans fat replacement system can be used to reduce or eliminate the amounts of traditional fats used to make baked goods. In one representative formulation, the trans fat replacement system can take the form of a generally, paste-like mixture that is suitable for spreading and is especially useful for the preparation of laminated dough products such as biscuits and croissants.

Owner:GENERAL MILLS INC

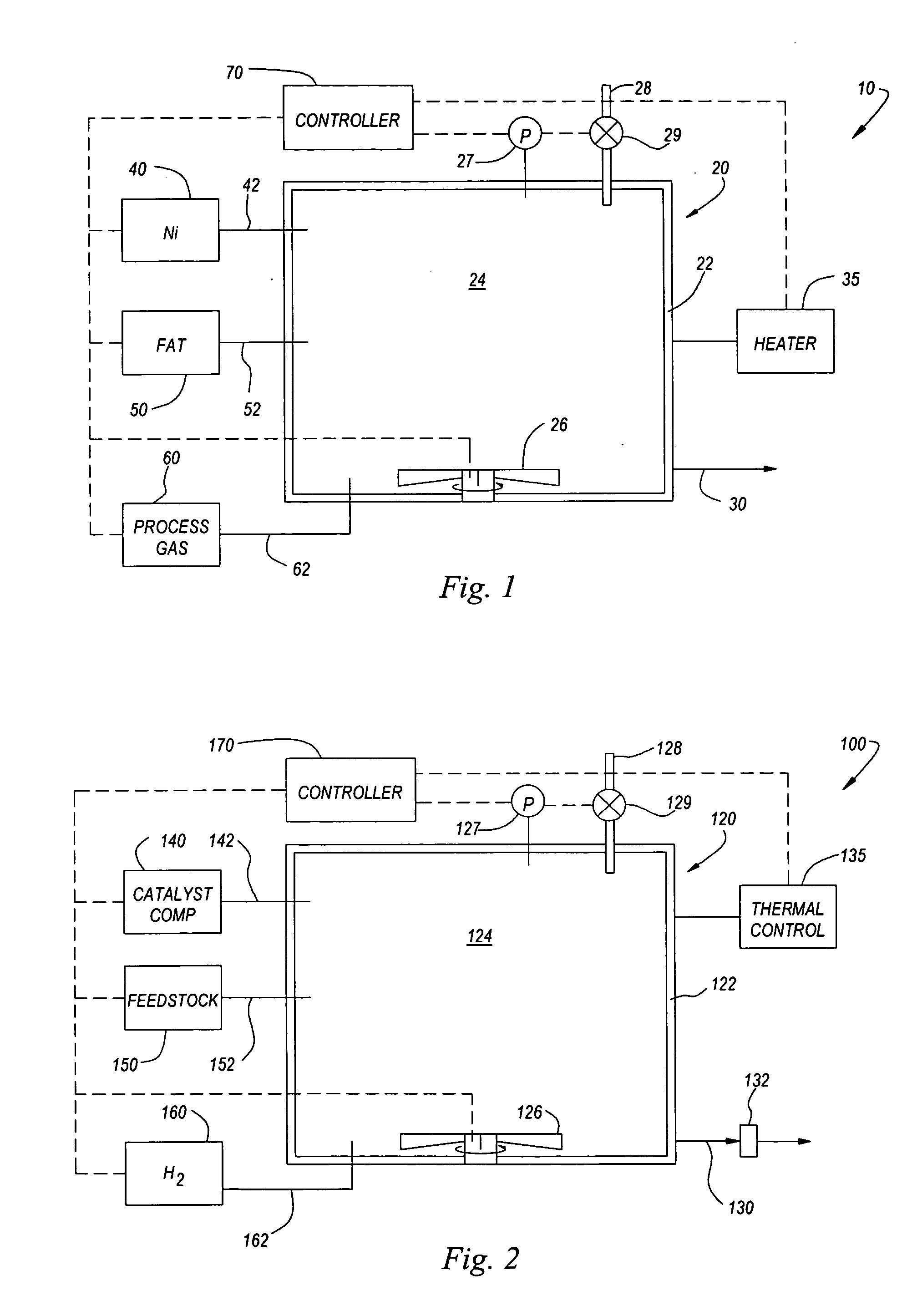

Low trans-fatty acid fat compositions; low-temperature hydrogenation, e.g., of edible oils

InactiveUS20050027136A1Fatty acid hydrogenationOrganic compound preparationPartial hydrogenationHydrogenation reaction

The present disclosure provides low trans-fatty acid fat compositions, methods of hydrogenating unsaturated feedstocks (e.g., oils), and hydrogenation catalyst compositions. One exemplary method involves producing an activated catalyst composition by heating a nickel-based catalyst to a first temperature of at least about 100° C. in the presence of hydrogen and a fat component. An unsaturated feedstock may be contacted with the activated catalyst composition and hydrogenated by sustaining a hydrogenation reaction at a second temperature of no greater than about 70° C. Some specific implementations of the invention permit the production of partially hydrogenated seed oils with low trans-fatty acid contents.

Owner:CARGILL INC

Healthy food spreads

InactiveUS6117476AGreat degree of solidityUnlimited shelf lifeEdible oils/fats with aqeous phaseFood borneMonoglyceride

The present invention is of a food spread containing a mixture of an edible oil of natural origin and a monoglyceride. The oil is preferably one or more of the oils from the group of olive oil, avocado oil, canola oil, soybean oil, sunflower oil, peanut oil, safflower oil, cottonseed oil, coconut oil, rice bran oil, mustardseed oil, camelina oil, chia oil, flaxseed oil, perilla oil, fish oil or corn oil. More preferably an oil such as avocado oil or olive oil is used and most preferably the oil is olive oil. The monoglycerides used are preferably derivatives of oleic, or palmitic acid. The ratio of oil to monoglyceride is preferably from about 9 to about 1 to from about 49 to about 1 and most preferably from about 15 to about 1 to from about 24 to about 1. The more monoglyceride used, the greater the degree of solidity of the food spread at room temperature. It is therefore possible to produce a desired degree of solidity, by changing the proportion of monoglyceride.

Owner:DR EGER OLIVE OIL PROD IND

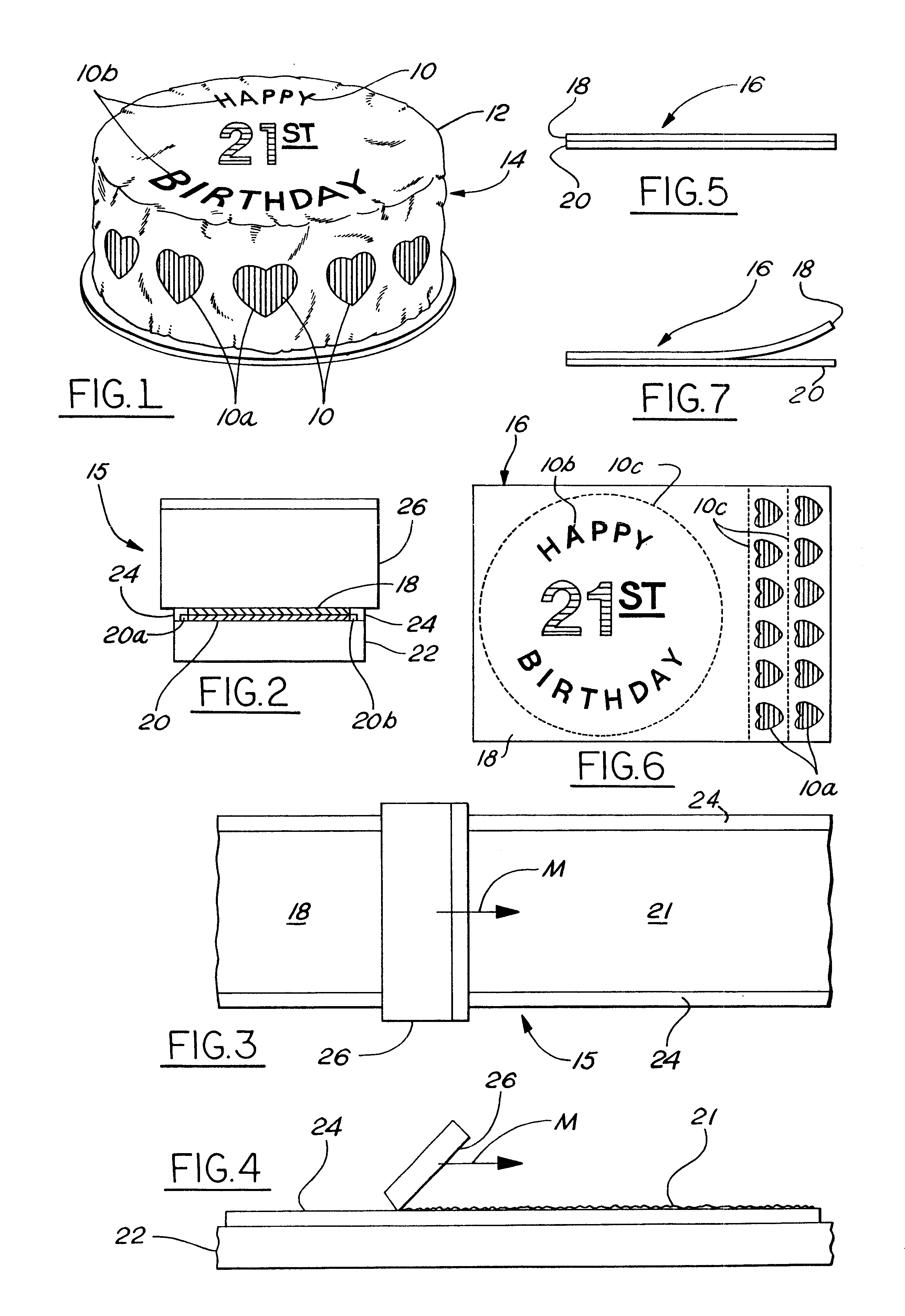

Method of making and using an edible film for decorating foodstuffs

An edible film and method of making and using same for decorating foodstuffs, in particular baked goods, wherein anyone can easily, inexpensively and artistically decorate foodstuffs. The edible film according to the present invention is composed of an edible polymer film which is preferably releasably mounted upon a flexible substrate to provide a reinforced edible film. The edible film is peelably released from the substrate to provide decorations for the foodstuff. The edible film may be decoratively prepared into predetermined decorations prior to distribution, which may include being pre-printed, pre-cut, colored, or being of pre-selected opacity and sheen. Alternatively, the edible film may be distributed in a not yet finalized decoration form, wherein finalization is left up to the user.

Owner:DECOPAC INC

Oral dosage forms comprising progesterone and methods of making and using the same

InactiveUS8663681B2Stable absorption profileBiocideOrganic active ingredientsProgesteronesEdible oil

Owner:TEVA WOMENS HEALTH

Edible mixed oil

ActiveCN101422200AReduce chronic diseaseEdible oils/fatsFood preparationVegetable oilOMEGA-3 POLYUNSATURATED FATTY ACIDS

The invention relates to an edible blend oil, which aims at solving the problem of the improper ratio between Omega-6 polyunsaturated fatty acid and Omega-3 polyunsaturated fatty acid in the current single plant edible oil and provides an edible plant blend oil with the ratio between Omega-6 polyunsaturated fatty acid and Omega-3 polyunsaturated fatty acid being the best, meeting the health need of Chinese residents and simultaneously being capable of controlling the amount and stability of saturated fatty acids. The technical keys are as follows: the edible blend oil is prepared with a hemp seed oil and another edible plant oil or other edible plant oils according to weight percentage; wherein, the hemp seed oil is 8 to 85 and the edible plant oil is 15 to 92; and the other edible plant oil can be as follows: grape seed oil, olive oil, camellia oil, rice bran oil, safflower oil, canola oil, sunflower oil, corn oil, linseed oil, sesame oil, rapeseed oil, soybean oil, peanut oil and other edible plant oils. The content of the saturated fatty acids does not exceed 15 percent and the ratio between Omega-6 and Omega-3 is 4-6:1.

Owner:淮安市淮安区综合检验检测中心

Cold water soluble creamer

A powdered creamer which made up of agglomerated creamer particles. The creamer particles are each made up of a sweetener, a water-dispersible or water-soluble protein and an edible oil having a bland flavor and a melting point below 10° C. The powdered creamer is soluble in cold water.

Owner:NESTEC SA

Mushroom sauce and preparation method thereof

The invention relates to the technical field of deep processing of mushroom, in particular to a mushroom sauce and a preparation method of the mushroom sauce. The invention aims to solve the problem that current homemade mushroom is poor in taste, and provides the mushroom sauce with unique flavor. The mushroom sauce comprises the following components in parts by weight: 10-15 parts of edible oil, 50-60 parts of mushroom, 5-6 parts of sweet soybean paste, 5-6 parts of fermented soya beans, 5-6 parts of bean sauce, 3-7 parts of carrot, 1-3 parts of onion, 0.1-0.3 parts of sesame, 1-3 parts of table salt, 2-4 parts of white sugar, 0.5-1 parts of monosodium glutamate and 0.8-1 parts of spice. The mushroom sauce is mellow, concentrated, and oil but not greasy, pliable and tough, spicy but not dry, fresh and tasty, and has flickering bakery spices flavor, unique spicy flavor. The mushroom sauce is a tasty food which is low in salt, healthy and convenient and light but thin in flavor.

Owner:山西沐风农林开发有限公司

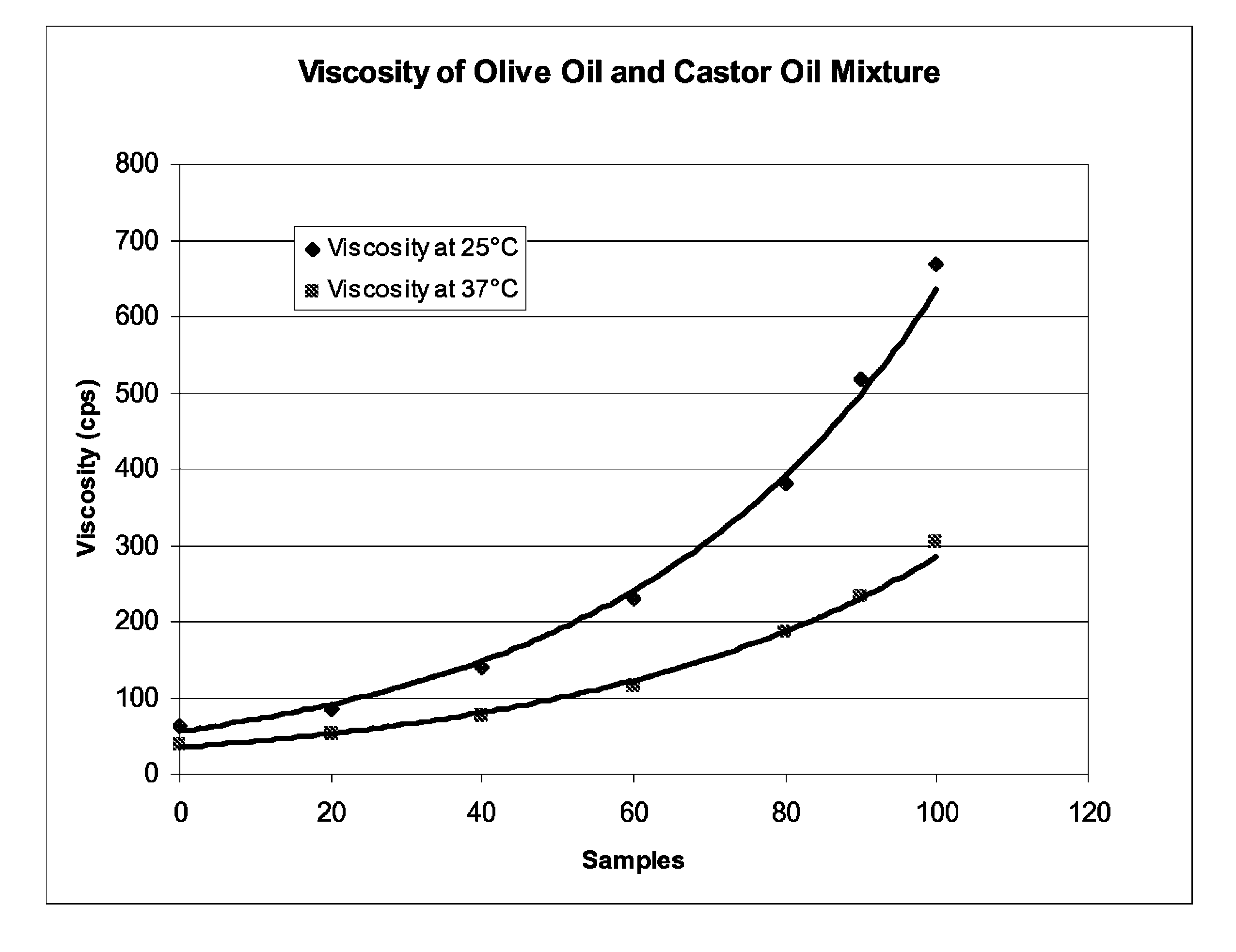

Thickened oil compositions of edible oil

InactiveUS20030099747A1Simple processAntibacterial agentsOrganic active ingredientsLong chain fatty acidChemical composition

Thickened, preferably thixotropic oil compositions are disclosed comprised of high proportions of edible oils, in particular unsaturated oils, and edible solidifying agents, in particular long chain fatty acids and / or long chain fatty alcohols, for use in the preparation of edible foods and medicinal / therapeutic products. Further disclosed are methods for the production of the thickened, thixotropic oil compositions, edible food and medicinal / therapeutic products containing same and methods of their production and consumption.

Owner:THIXO

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

Oil-Based Processed Flavor With Cooked Note and Process for Producing the Same

InactiveUS20090092732A1Favorable effectStrong impactButter manufactureFood preparationFood flavorCooked food

A material to be extracted and an edible fat are introduced into an extractor equipped with a device for collecting stream and gases, such as a condenser. The contents are heated, and the resultant extract is cooled. The distillate collected with the condenser during heating is returned to the extractor. Alternatively, the distillate is further extracted with an edible oil and / or fat and the extract obtained by the distillate extraction with the oil and / or fat is returned to the extractor. Thus, an oil-based processed flavor with a cooked note is produced. This oil-based processed flavor with a cooked note is added to or incorporated in a food or beverage as it is or, if necessary, after having been diluted, emulsified, powdered, or otherwise treated.

Owner:TAKASAGO INTERNATIONAL CORPORATION

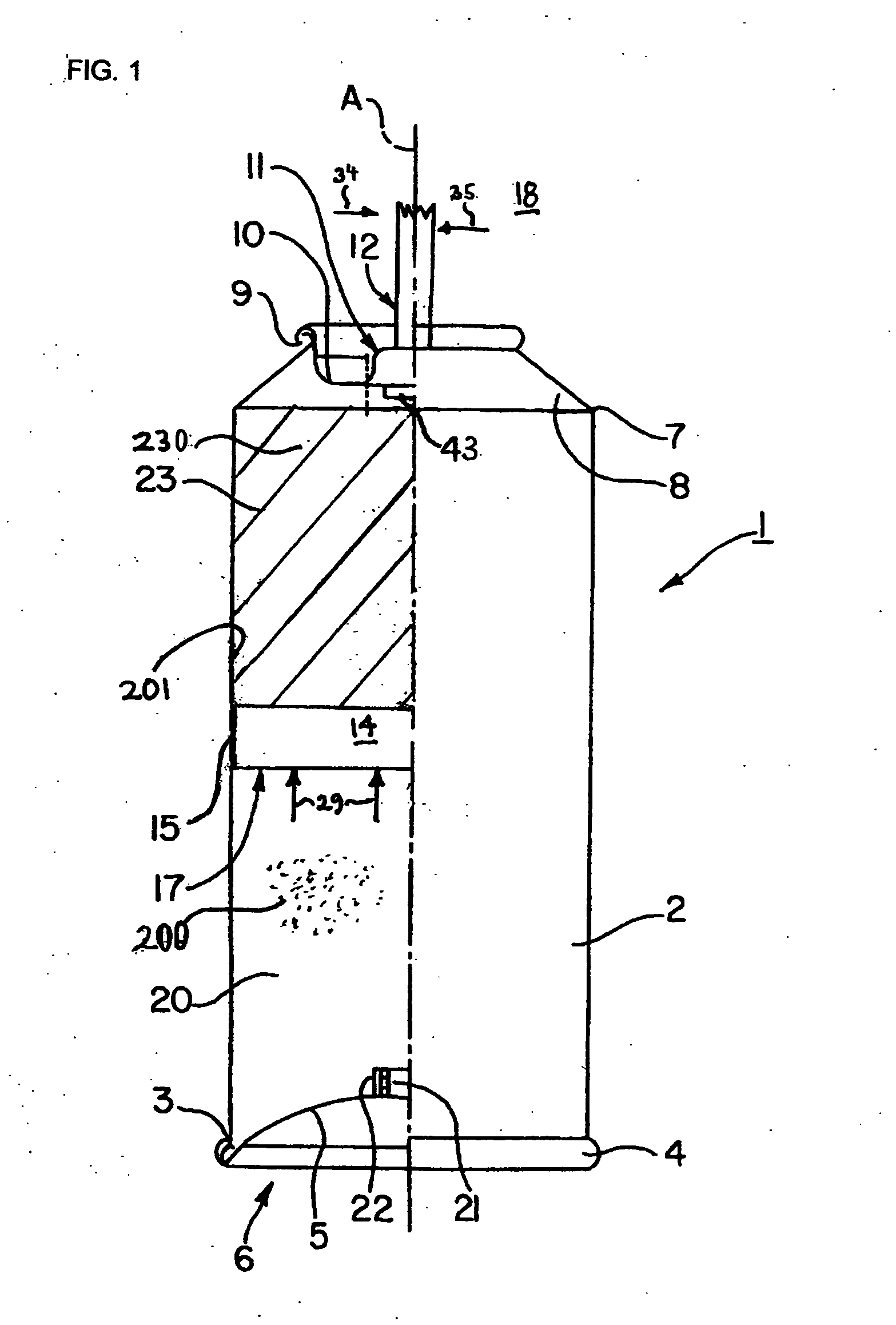

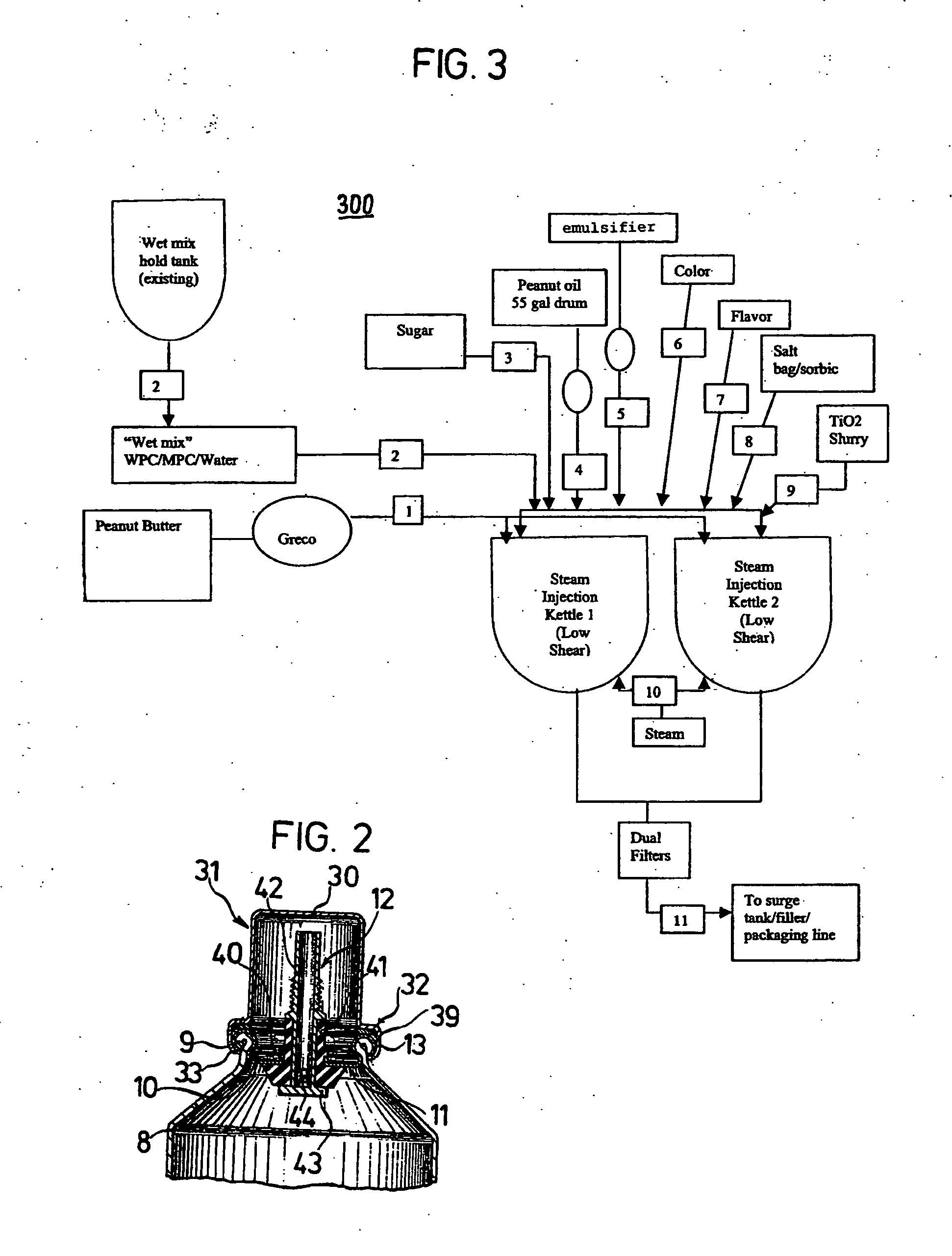

Edible spread composition and packaged product

An edible spread composition comprises a homogenous mixture of plant fiber-containing material, edible oil, water, and an effective amount of an emulsifier that prevents separation of oil from the plant fiber and other mixture solids that otherwise occurs in its absence when the edible spread composition is discharged while held under pressure. The edible spread composition may be, for instance, a peanut butter spread composition or a chocolate spread composition. There also is a packaged spread product comprising the edible spread composition that is held inside a pressurized container and dispensed without experiencing oil separation.

Owner:KRAFT FOODS GRP BRANDS LLC

Health care food containing natural astaxanthin

InactiveCN101053409AImprove antioxidant capacityImprove immunityFood shapingFood preparationSide effectPropolis

The patent relates to health foods containing natural astaxanthin, which is made into liquid capsule containing natural astaxanthin with natural astaxanthin oil, edible oil and fat and natural antioxidant as raw materials by conventional processing; or which is made into power capsule or tables containing natural astaxanthin with natural astaxanthin, natural antioxidant and other health food as raw materials by conventional processing. In comparison with present technology, the advantage of the invention includes, (1) the health food provided in present patent takes natural astaxanthin as main raw material, has the strongest antioxidant, capable of improving human immunity and anti-aging and ranking first in terms of health foods containing natural antioxidant; (2) the health food is made from pure natural materials and without any compound materials and side-effect; (3) the natural astaxanthin of health food coordinately used with shark cartilage, glucosamine hydrochloride, chitosan, propolis and paclitaxel etc as function material, which is capable of enhancing astaxanthin function; (4) adding antioxidant of natural tea-pigment and tea polyphenols is capable of avoiding oxidation of astaxanthin, thus prolonging shelf life more than one year.

Owner:汪昔奇 +1

Method for abstracting tea seed oil from camellia oleifera seed

InactiveCN101096612AReduce the number of operationsQuality controllableEnzymesFatty-oils/fats productionCamellia oleiferaSlurry

The invention discloses an extracting method of tea seed oil from tea seed, which comprises the following steps: adopting tea seed core as raw material; grinding to add water to stir into slurry; adding amylase or / and cellulose enzyme to enzymolyze; separating to obtain the product. The invention improves the oil-out rate more than traditional extracting method, which remains more non-oil nourishing element.

Owner:HUNAN AGRICULTURAL UNIV

Artificial tears and therapeutic uses

Owner:ALLERGAN INC

Oil composition of conjugated linoleic acid

InactiveUS20070218183A1Reduce consumptionGood compatibilityFatty acid esterificationFood ingredientsPhytosterol estersEdible oil

A novel oil composition comprises an interesterified structured lipid component, the component being an interesterifcation reaction product of an amount of a medium chain triglyceride, an amount of a long chain domestic oil, and an amount of a conjugated linoleic acid material. The structured lipid component can be used in edible oil compositions. The oil compositions advantageously can contain an amount of a phytosterol ester component, up to about 12 weight percent of the total composition. The oil compositions disclosed herein have good stability and also have other properties useful for an edible oil composition.

Owner:BUNGE OILS INC

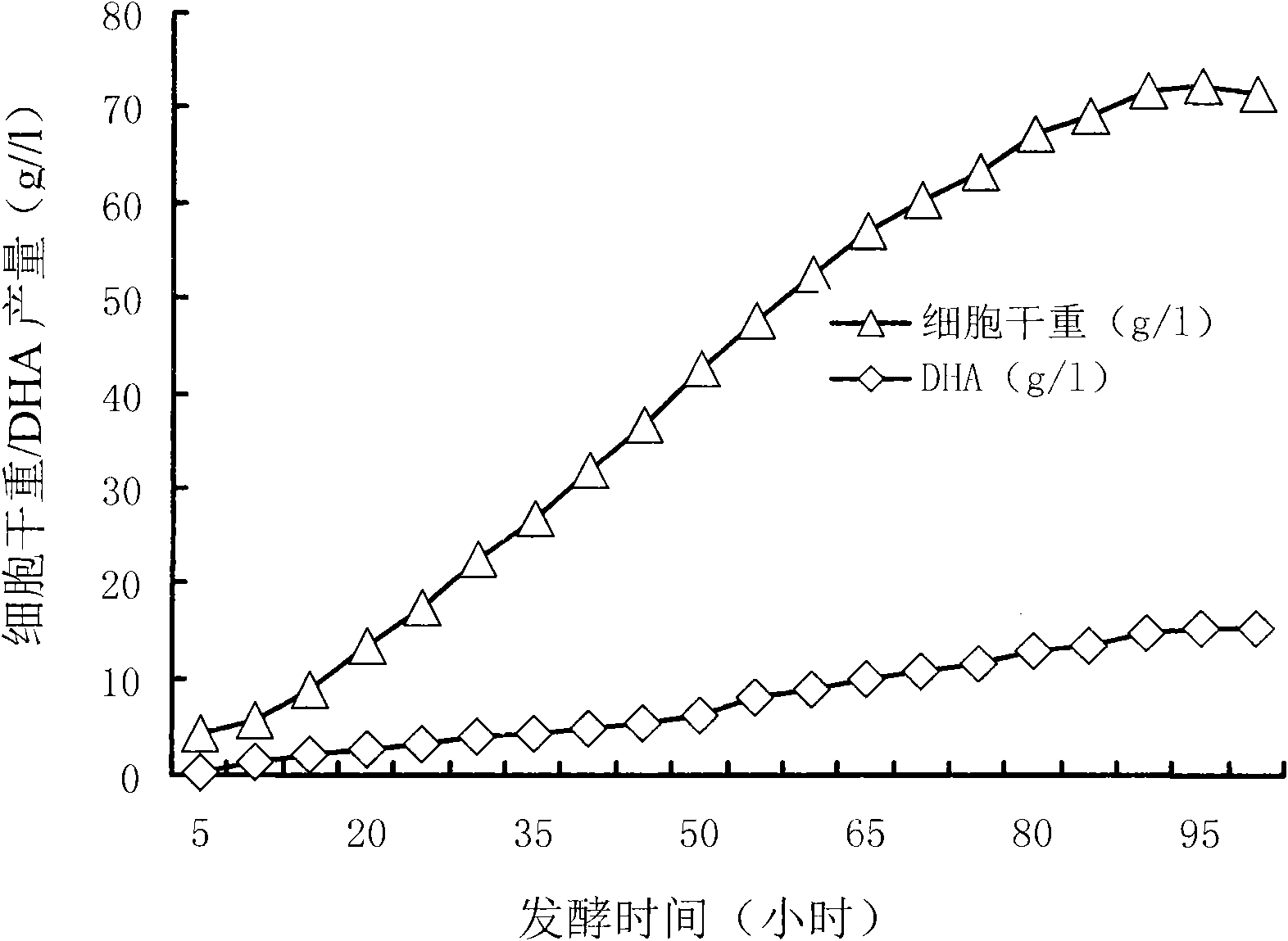

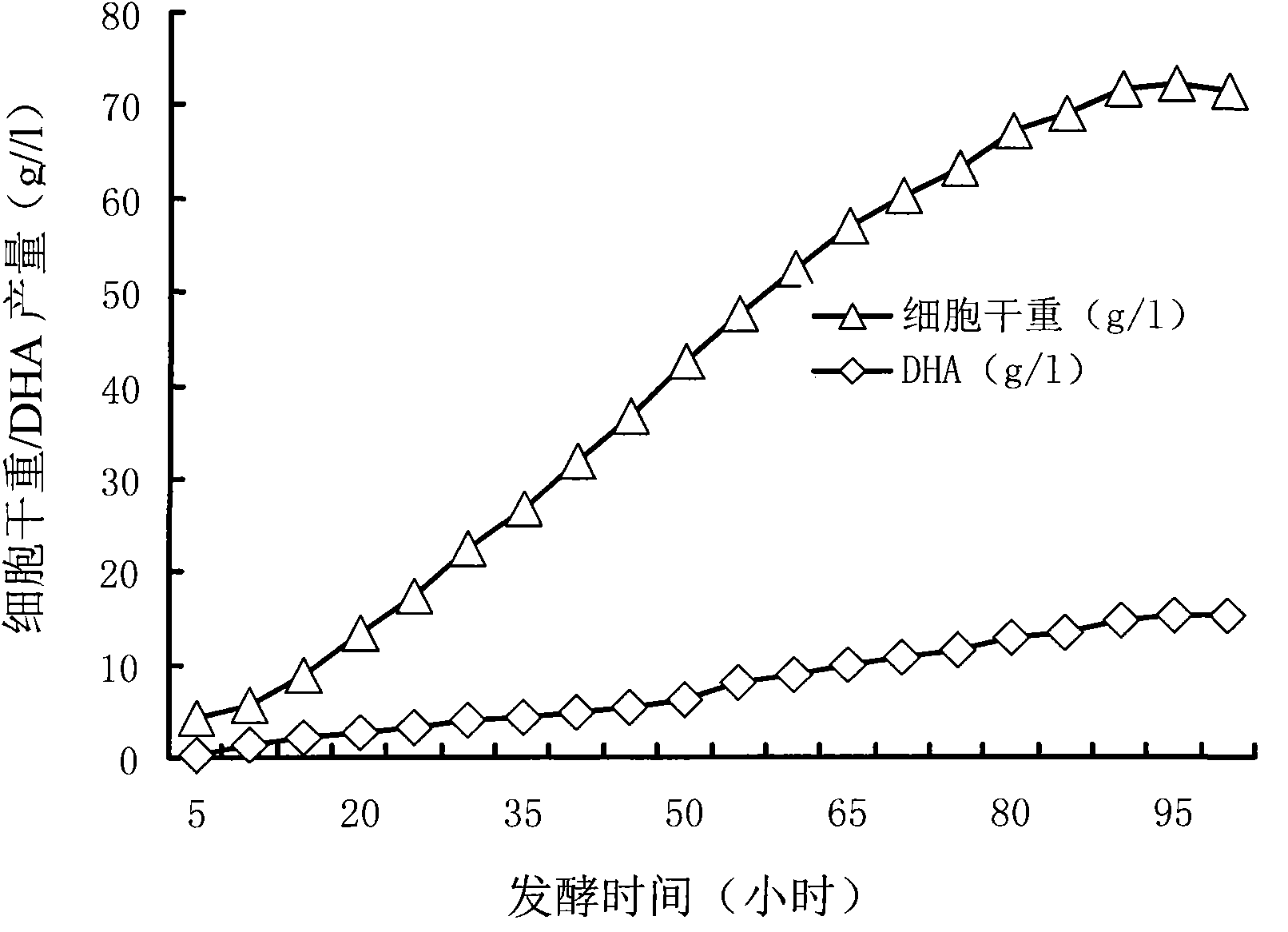

Schizochytrium LX0809 (marine fungus) and industrial application thereof

InactiveCN101892160AEasy to separateEasy to purifyFungiFatty acid esterificationFood additiveSchizochytrium

The invention provides schizochytrium LX0809 (marine fungus), which has a high docosahexaenoic acid (DHA) production capability. The schizochytrium LX0809 of the invention was separated from the corroded soil collected from the red beach in Zhaoquanhe Town, Dawa County, Liaoning Province and was preserved in China General Microbiological Culture Collection Center with a preservation number CGMCC No.3535 on December 23th, 2009. When the schizochytrium LX0809 is used for fermenting supplementary food, the dry cell weight of the fermentation liquor can reach 72.5 g / L, and the DHA content can reach 15.3g / L. LX 0809 thallus cells and extracts thereof can be used as food additives for edible oil, dairy products, grain products and the like and can be used as a feed additive for aquaculture and livestock culture and the like. Saturated triglycercide in the thallus cells can be used to produce biodiesel through catalytic transesterification.

Owner:吉林省希玛生物科技有限公司

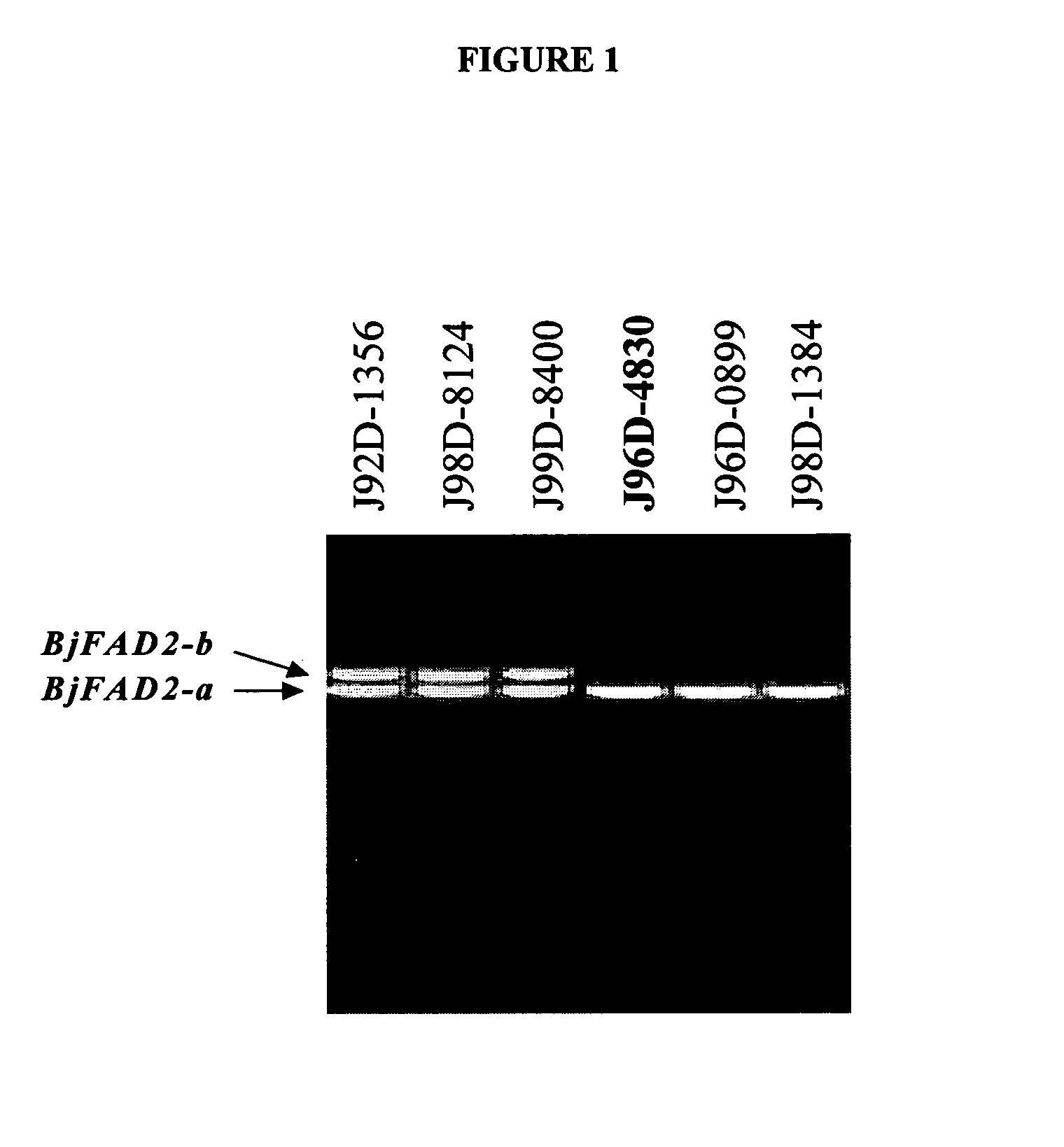

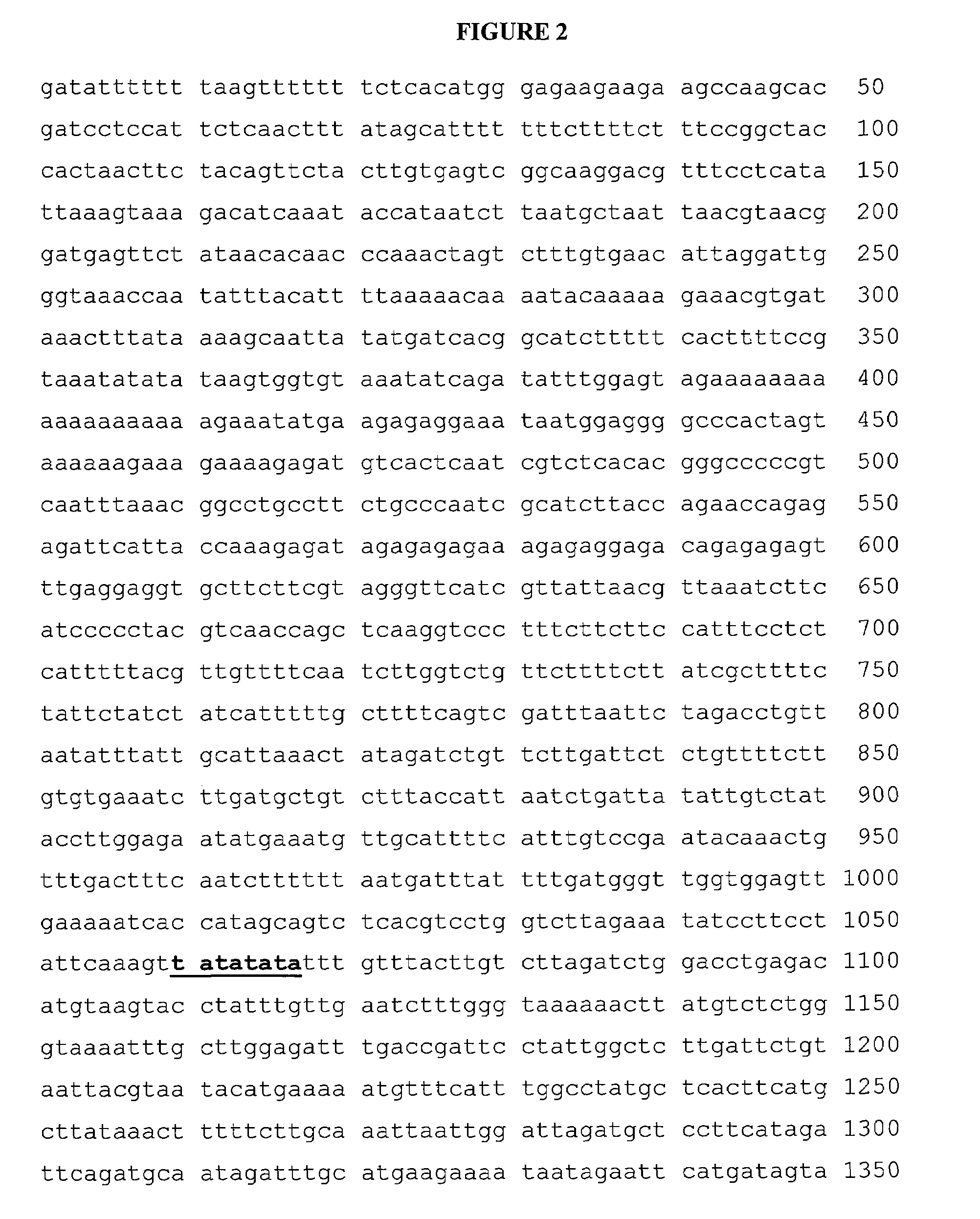

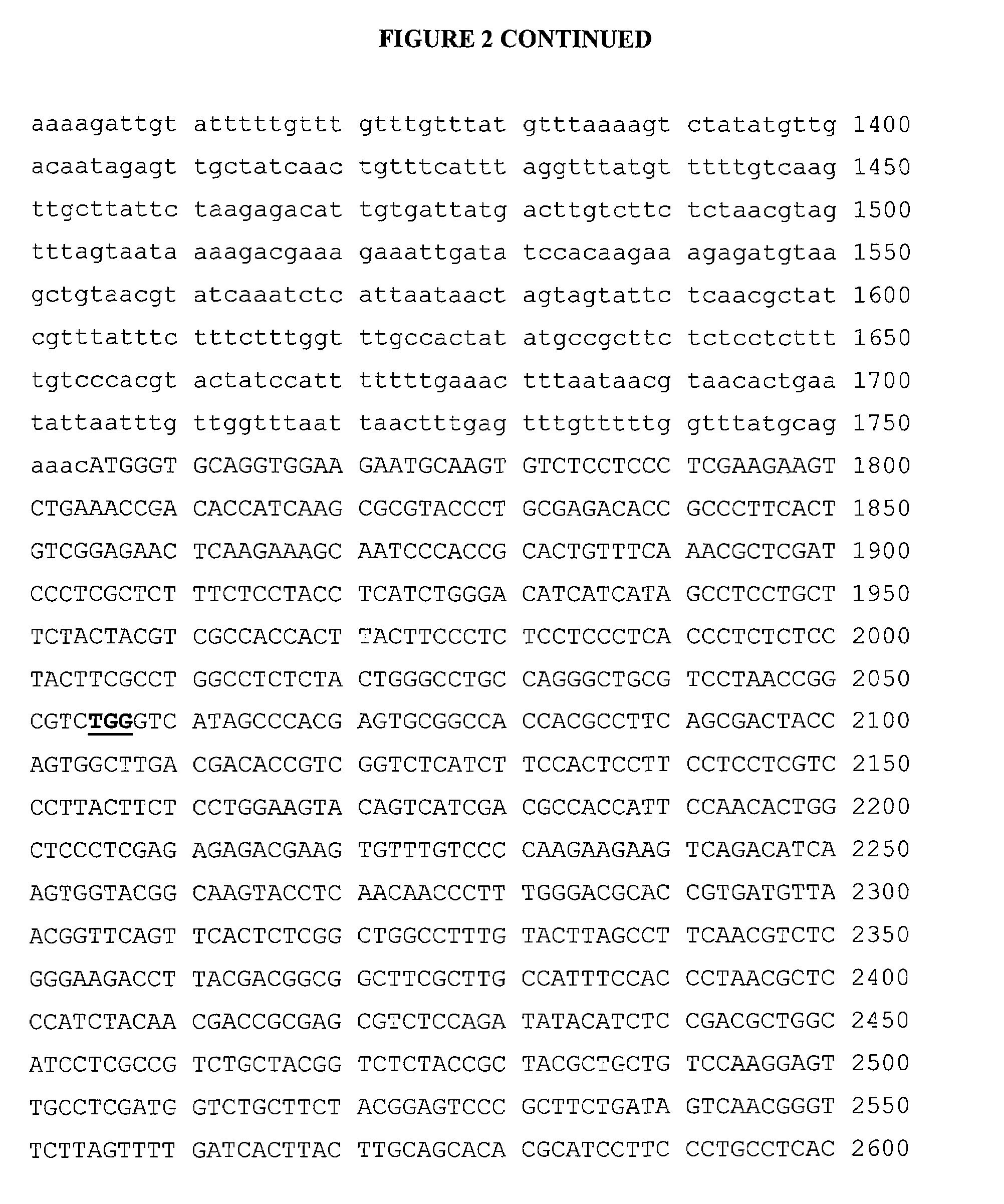

High oleic acid Brassica juncea

In various aspects, the invention provides Brassica juncea plants, seeds, cells, nucleic acid sequences and oils. Edible oil derived from plants of the invention may have significantly higher oleic acid content than other B. juncea plants. In one embodiment, the B. juncea line MJ02-086-3 contains a mutant allele MJ02-086-3 / BjFAD2-a at the BjFAD2-a gene locus, having a premature stop codon, so that there are no functional copies of the FAD2 gene in MJ02-086-3 plants. Seeds from MJ02-086-3 plants may for example yield an oil having oleic acid content of greater than about 70% by weight.

Owner:SASKATCHEWAN WHEAT POOL +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com