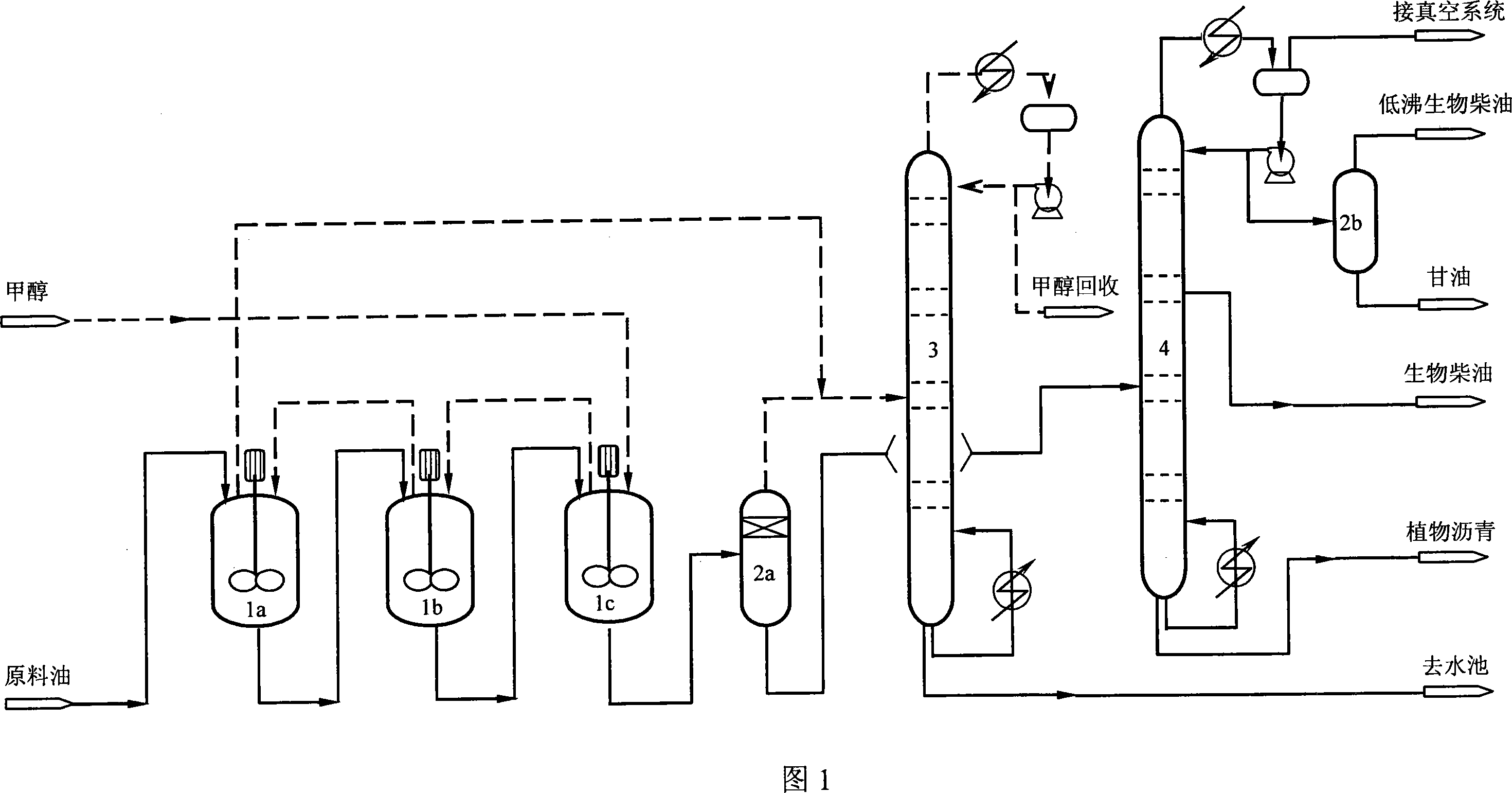

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

A technology for biodiesel and raw oil, which is applied in the petroleum industry, biological raw materials, biofuels, etc., can solve the problems of long process flow, increase production cost, waste acid wastewater pollution, etc., achieve high purity, reduce raw material cost, and yield Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

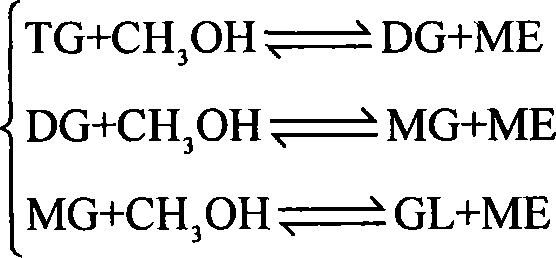

[0043] Embodiment one laboratory small-scale intermittent operation

[0044] 90g cottonseed oil (acid value 10mgKOH / g), 34ml methanol and 18g MgO-Al 2 o 3 The catalyst is added into the reactor, that is, the mass ratio of the amount of methanol to the raw oil is 0.3, and the amount of the catalyst is 20 wt% of the raw oil in the reactor. The temperature of the autoclave was maintained at 230° C., the pressure was 2.5 MPa, and the reaction was carried out at a stirring speed of 300 r / min for 6 h. After the reaction, the lower oil phase product was vacuum distilled (at a pressure of 0.1 kPa to 0.5 kPa) to obtain 86.1 g of fractions at 180 to 210° C., that is, the yield of biodiesel was 95.6%.

Embodiment 2

[0045] Embodiment two laboratory small-scale semi-continuous operation

[0046] 1000g corn sour oil (acid value 80mgKOH / g, composition: 40% fatty acid, 45% triglyceride, 0.40% water, 14.6% other) was added to the reactor, and 60g ZrO was added at the same time 2 -SO 4 2- Catalyst (6wt%), reaction temperature 160°C, pressure 1.5MPa. Under the condition of ensuring the above pressure, methanol was continuously fed in at a rate of 8.5ml / min, and was continuously discharged in the form of gas phase. The reaction process was kept for 2.5 hours, and the final mass ratio of methanol feed to acidified oil was 1. The product obtained by the reaction was first atmospherically distilled to remove methanol and water, and then vacuum distilled to obtain 802 g of crude biodiesel (most fatty acid methyl esters, a small amount of glycerol and unreacted fatty acids), that is, the yield was 80.2%. Vacuum distillation conditions: vacuum degree -0.097MPa~-0.098MPa, that is, the pressure is 2.5...

Embodiment 3

[0047] Embodiment three laboratory small-scale semi-continuous operation

[0048] Add 1000g cottonseed oil acidified oil and oleic acid mixed oil (acid value 200mgKOH / g, composition: 95% fatty acid, 4% triglyceride, 0.40% water, 0.6% other) into the reactor, and add 10g TiO 2 -SO 4 2- Catalyst (1wt%), reaction temperature 150°C, pressure 0.8MPa. Under the condition of ensuring the above pressure, the liquid phase methanol is heated and vaporized at a speed of 40ml / min, then continuously fed in and discharged continuously, and reacted for 1 hour. The product obtained by the reaction was firstly distilled to remove methanol and water under normal pressure, and then vacuum distilled to obtain 875 g of biodiesel, that is, the yield was 87.5%. Vacuum distillation conditions: vacuum degree -0.095MPa~-0.096MPa, that is, the pressure is 4kPa~5Pa, and the fraction at 210~250℃ is taken. During the whole semi-continuous operation process, 57.4g of water was taken out by methanol, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com