Patents

Literature

9499 results about "Esterification reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

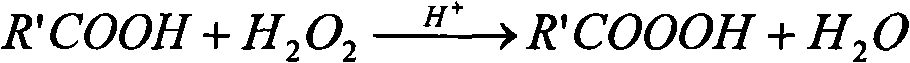

Esterification Definition. Esterification is an equilibrium reaction to form ester mainly from alcohols and carboxylic acids. Esters can also be made from the reactions between acyl chlorides (acid chlorides) and alcohols, and from acid anhydrides and alcohols. Here carboxylic acid and alcohol reacts to form an ester.

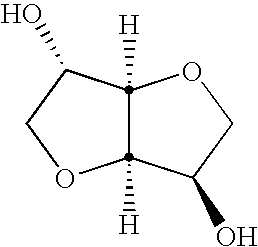

Method for making isosorbide containing polyesters

This invention relates to a process for producing a polyester comprising the steps of:(g) obtaining an aqueous homogenous solution of isosorbide;(h) feeding the aqueous homogenous solution of step (a) into a reactor;(i) feeding one or more glycols and one or more dicarboxylic acids either into the aqueous solution of step (a) or into the reactor of step (b) either prior to, during and / or subsequent to step (b);(j) esterifying the reactor contents at sufficient temperatures and pressures, and optionally in the presence of suitable catalysts, to effect esterification;(k) forming a prepolymer; and(l) polycondensing the prepolymer at sufficient temperatures and pressures in the presence of a suitable catalyst to effect polycondensation to form a polyester.

Owner:EASTMAN CHEM CO

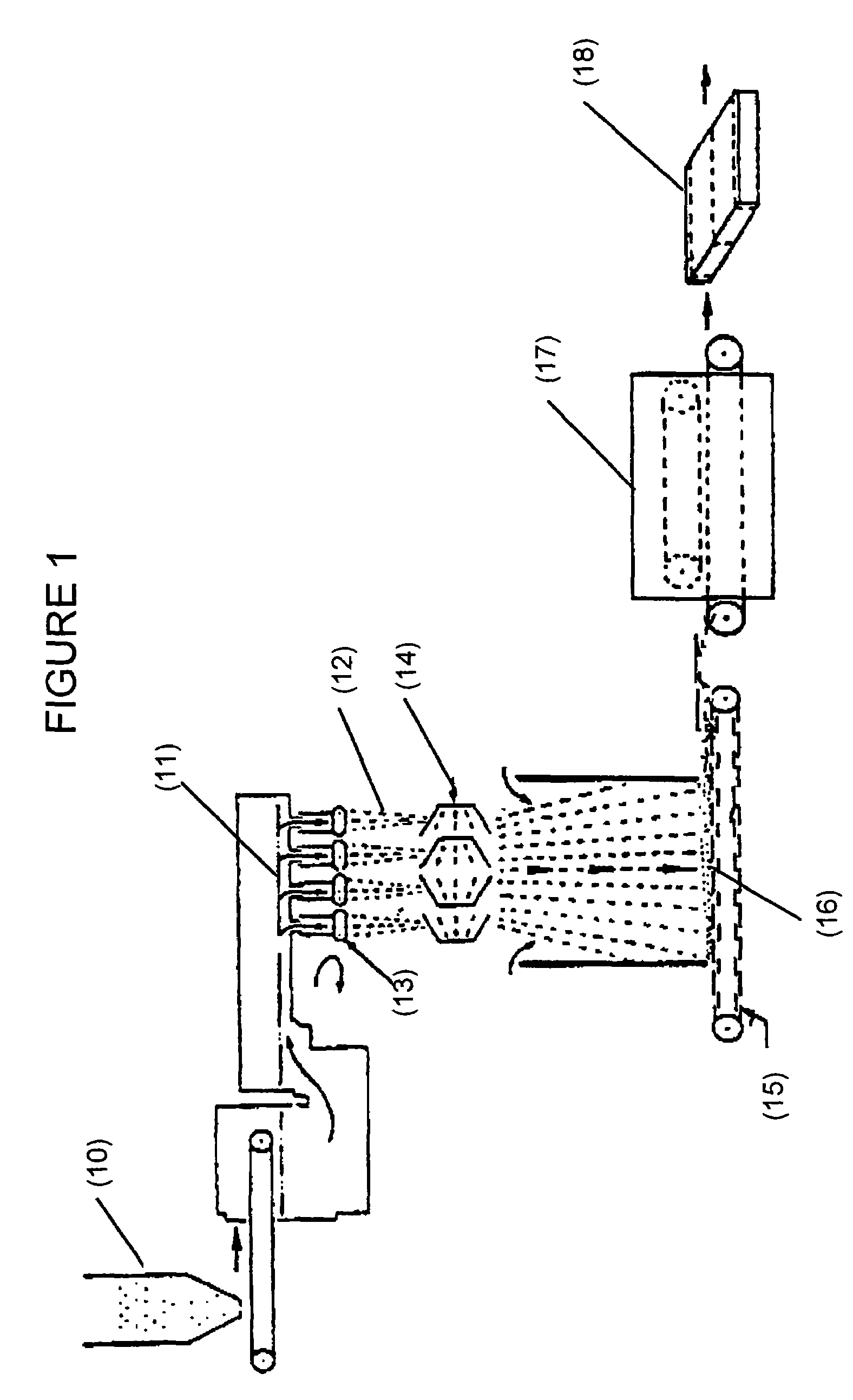

Formaldehyde free binder

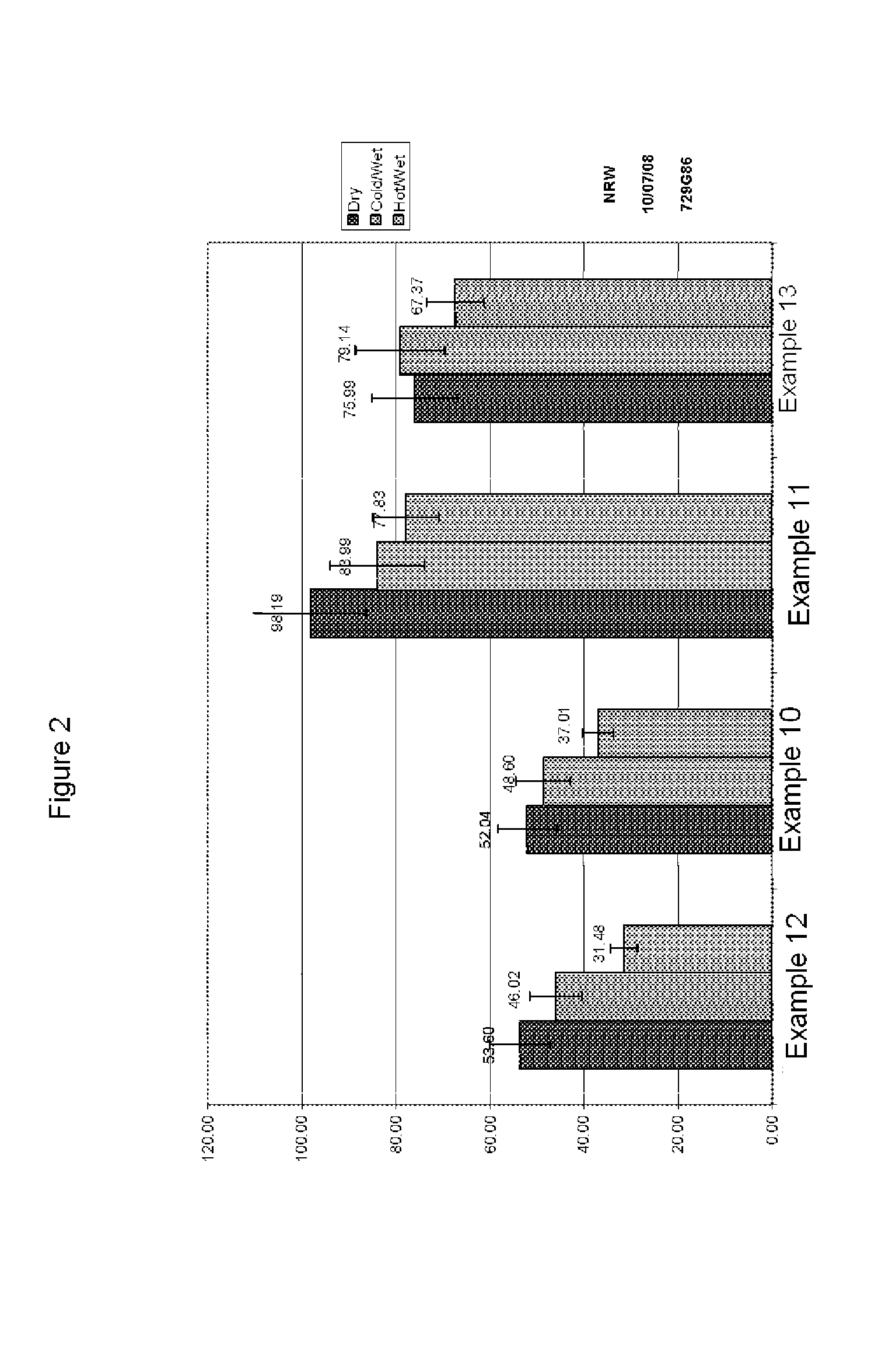

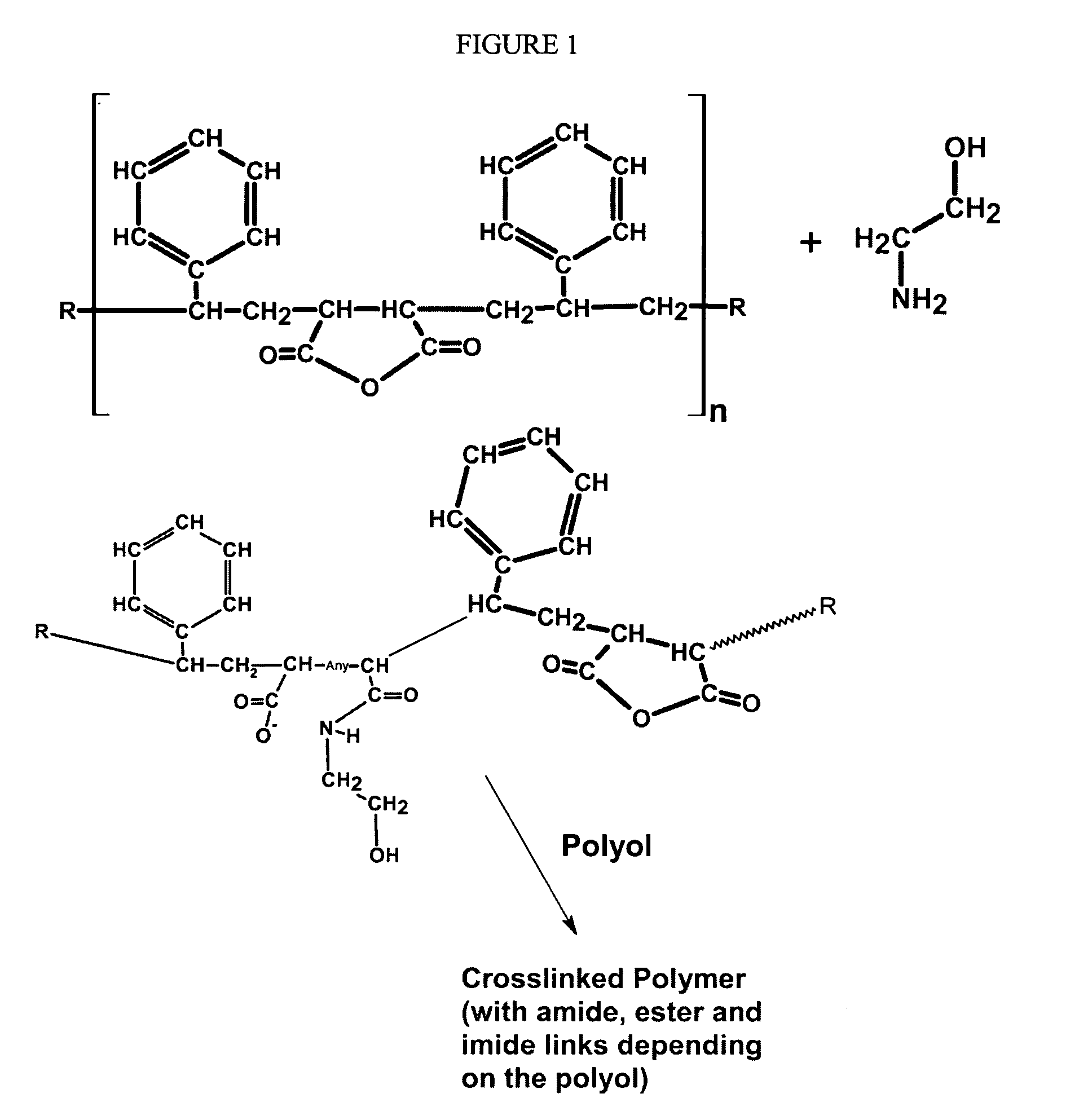

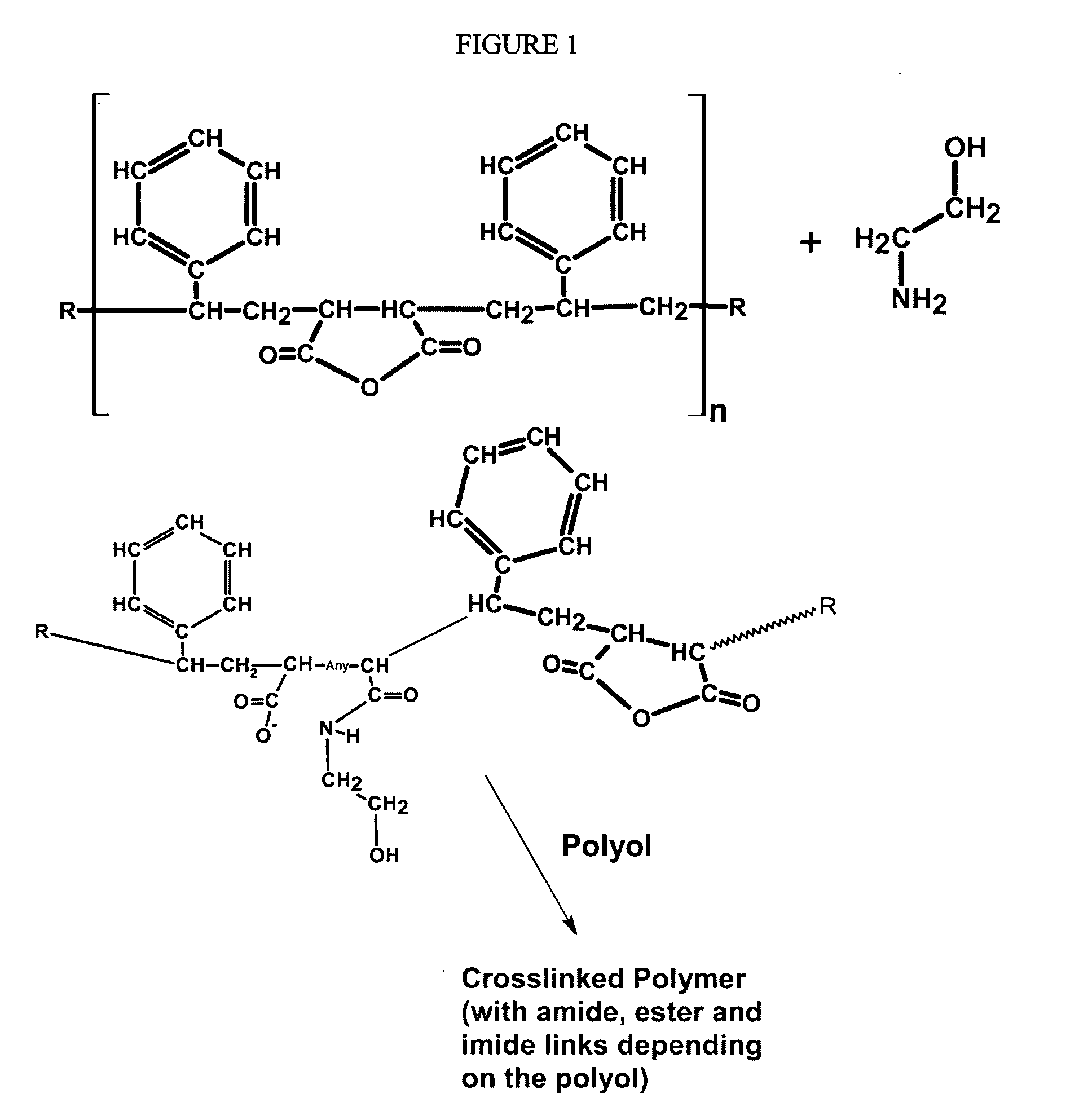

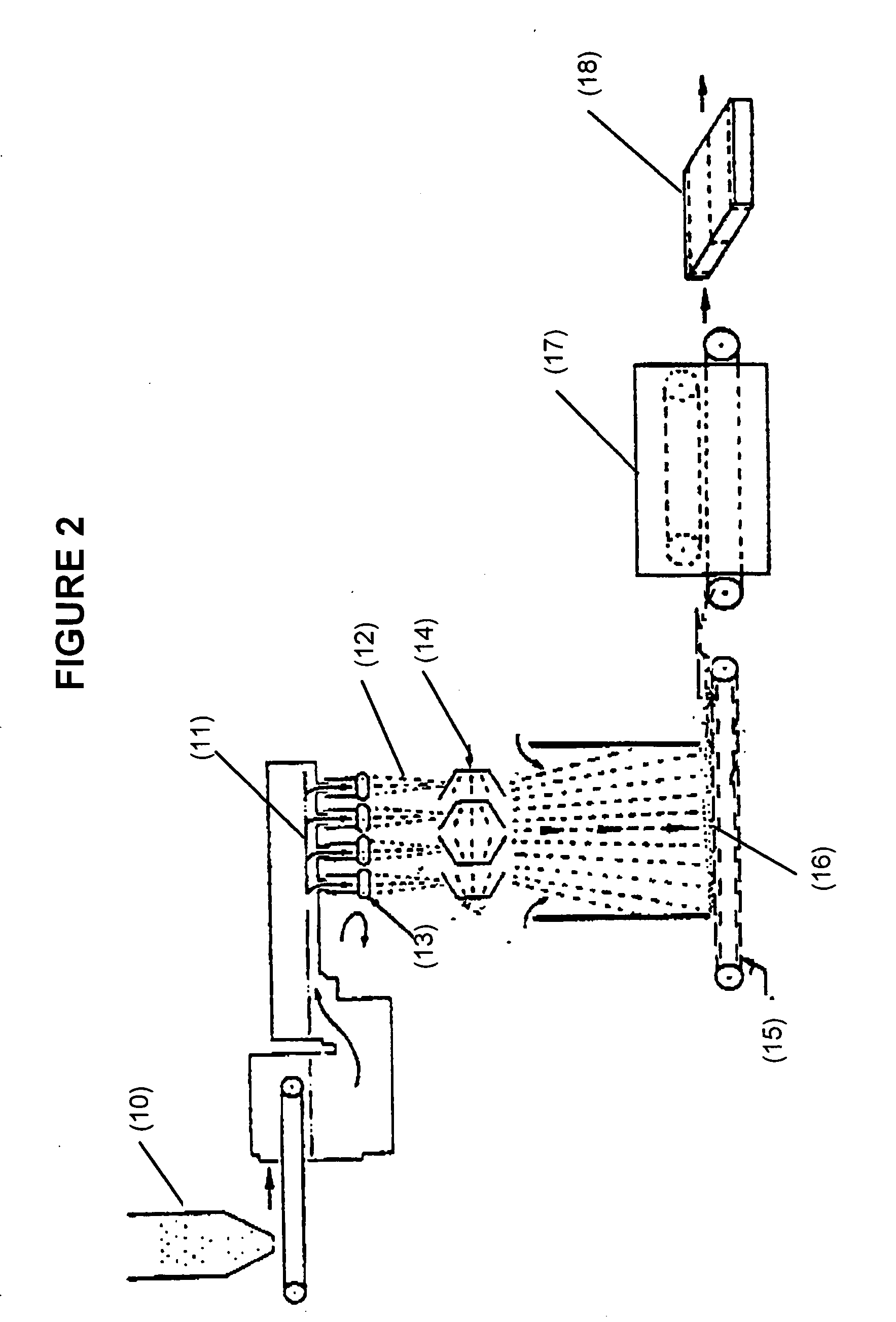

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, an ammine, a primary alkanolamines (preferably monoethanolamine), a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Formaldehyde free binder

An aqueous, formaldehyde-free binder composition comprising a modified copolymer of maleic anhydride and a vinyl aromatic compound such as styrene, the copolymer being modified by reaction with a primary alkanolamine, such as monoethanolamine (MEA), to produce a modified copolymer that is self-curing and cures as a consequence of cross-linking, esterification reactions between pendant carboxyls and hydroxyl groups on the solubilized (hydrolyzed) modified copolymer chains; the invention also relates to the corresponding method of using the binder composition for making fiber products, especially fiberglass insulation.

Owner:GEORGIA PACIFIC CHEM LLC

UV absorbing complex polyester polymers, compositions containing UV absorbing complex polyester polymers, and related methods

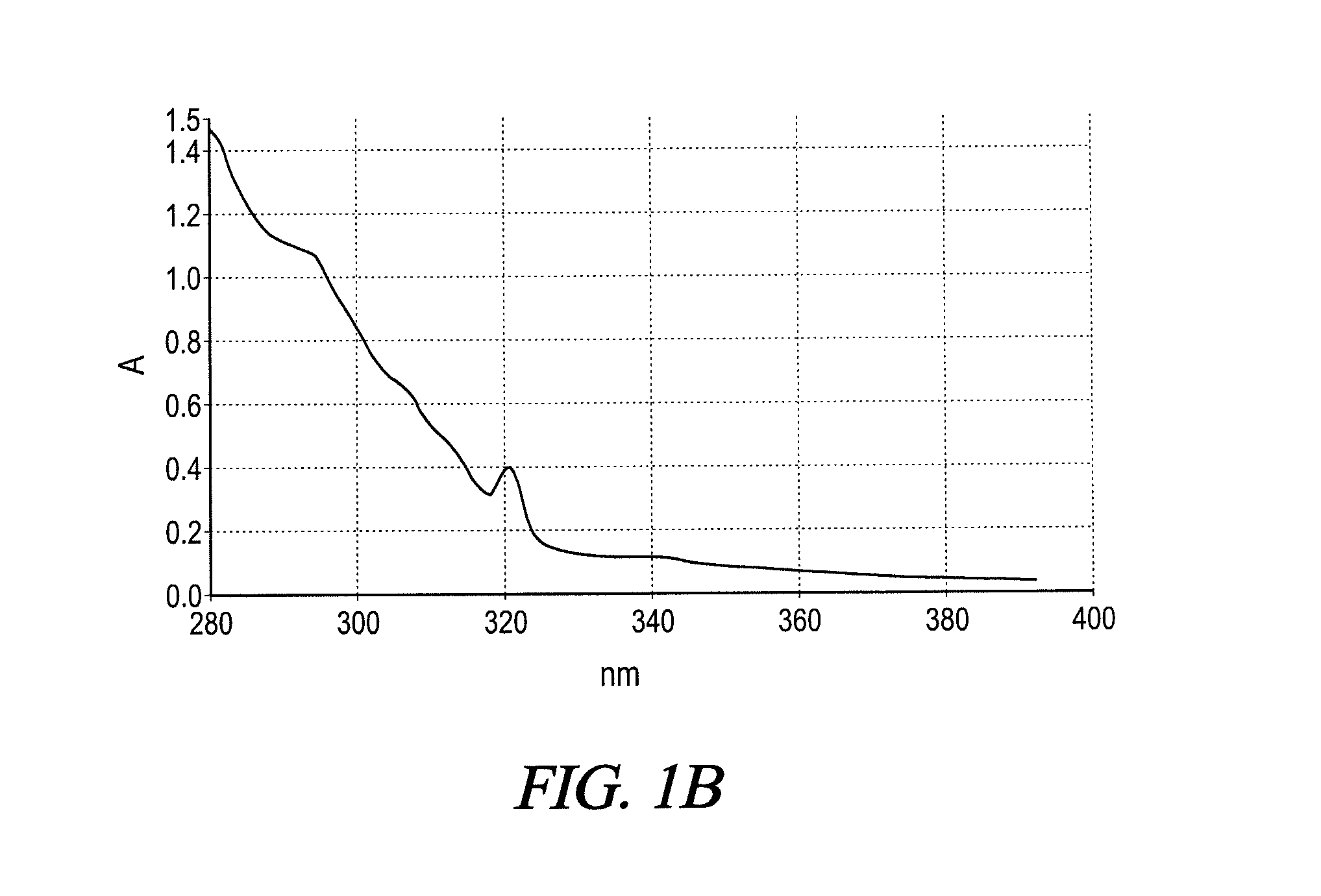

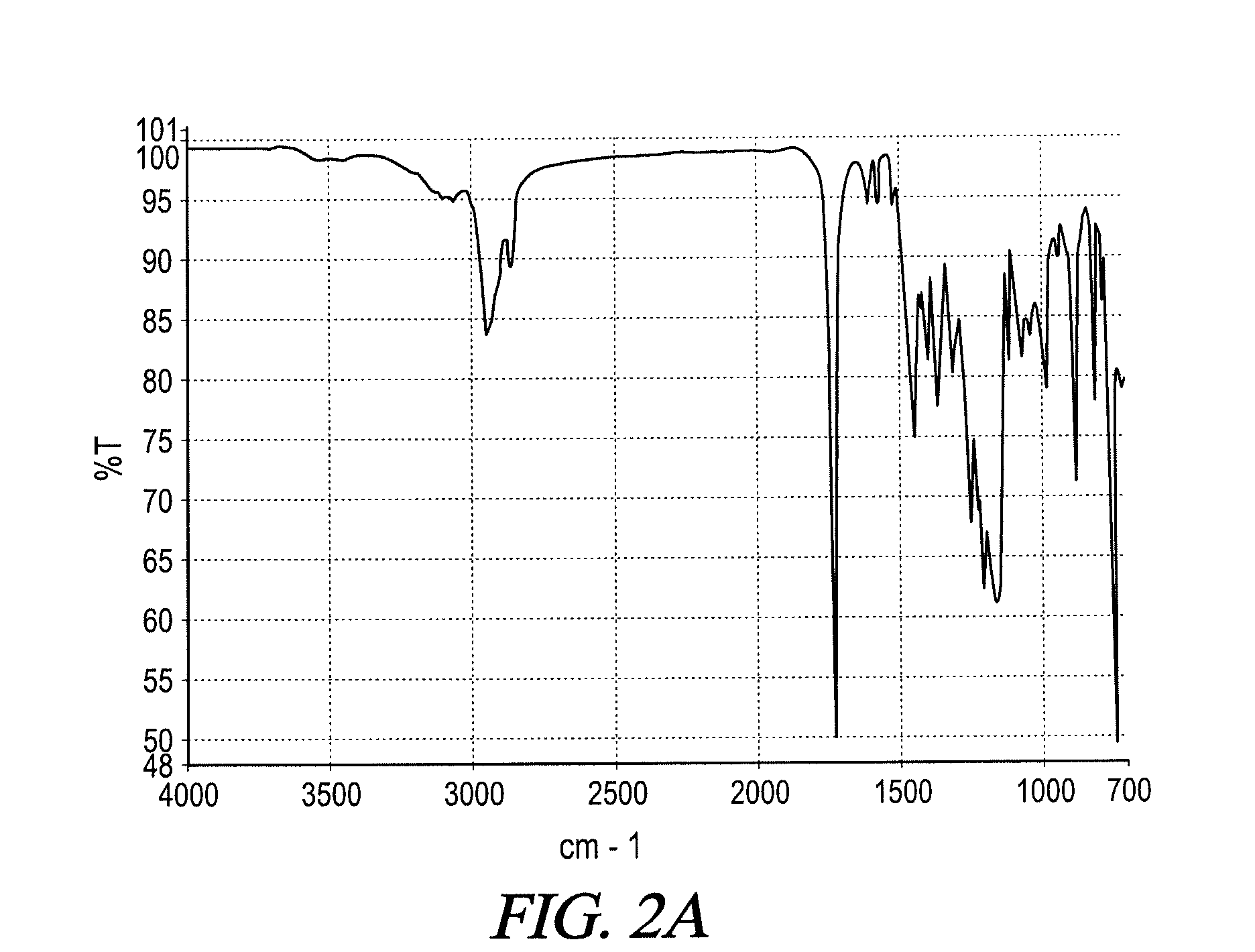

InactiveUS20110104078A1Improve light resistanceImprove protectionAntibacterial agentsCosmetic preparationsPolyesterSide chain

The invention includes an UV absorbing complex polyol polyester polymer that is the product of a reaction scheme that includes: (i) the esterification of a polyol and a dianhydride, wherein the esterification is carried out under conditions that facilitate substantially only anhydride opening, to form a polyester polymer comprising at least two pendant carboxylic groups, and at least two hydroxyl groups; and (ii) the reaction of at least one pendant carboxylic group and at least one terminal hydroxyl group of the polyester polymer with an epoxide having a functional group, wherein the epoxide comprises an UV absorbing moiety.Also included are linear UV absorbing complex polyol polyester polymers represented by Formula (XI):wherein R3 is independently selected from an UV absorbing moiety; R4 and R5 are each independently selected from a hydrocarbon group, and n is an integer of 1 to 1000.A crosslinked UV absorbing complex polyol polyester polymer that is reaction product of a random copolyesterification esterification reaction and / or the esterification product of: a monofunctional carboxylic acid and / or ester that comprises an UV absorbing moiety, at least one of a diol, a polyol, a diacid and / or an ester is also included within the scope of the invention. The resulting polymer has an UV absorbing functionality of greater than 2.0.

Owner:INOLEX INVESTMENT CORP

Formaldehyde free binder

An aqueous, formaldehyde-free binder composition comprising a modified copolymer of maleic anhydride and a vinyl aromatic compound such as styrene, the copolymer being modified by reaction with a primary alkanolamine, such as monoethanolamine (MEA), to produce a modified copolymer that is self-curing and cures as a consequence of cross-linking, esterification reactions between pendant carboxyls and hydroxyl groups on the solubilized (hydrolyzed) modified copolymer chains; the invention also relates to the corresponding method of using the binder composition for making fiber products, especially fiberglass insulation.

Owner:GEORGIA PACIFIC CHEM LLC

Process for preparing 2,3,5,6-Tetrafluoro-para-xylyl alcohol

InactiveCN1458137AOrganic compound preparationHydroxy compound preparationSulfolanePotassium fluoride

The preparation process of 2, 3, 5, 6-tetrafluoro-para-xylyl alcohol with 2, 3, 5, 6-tetrachloro-p-phenyl diformyl chloride as material includes fluorination with potassium fluoride, etc. as fluorination agent, sulfolane, etc. as solvent and calixarene, etc. as catalyst and at 40-230 deg.c; esterification of ester with fatty alcohol or aromatic alcohol as esterifying agent and at 20-120 deg.c; reduction of ester with sodium borohydride, etc. as reductant and sulfolane, etc. as solvent, and at -10 deg.c to 60 deg.c; bromination with HBr acid as brominating agent and dichloromethane as solvent and at 30-160 deg.c; and reduction of bromide with magnesium powder, etc as reductant and fatty alcohol, water, chloride, etc as solvent, and at -10 deg.c to 50 deg.c. The present invention has the advantages of simple process, low production cost, high product yield and purity, and is suitable for industrial production.

Owner:TIANJIN UNIV

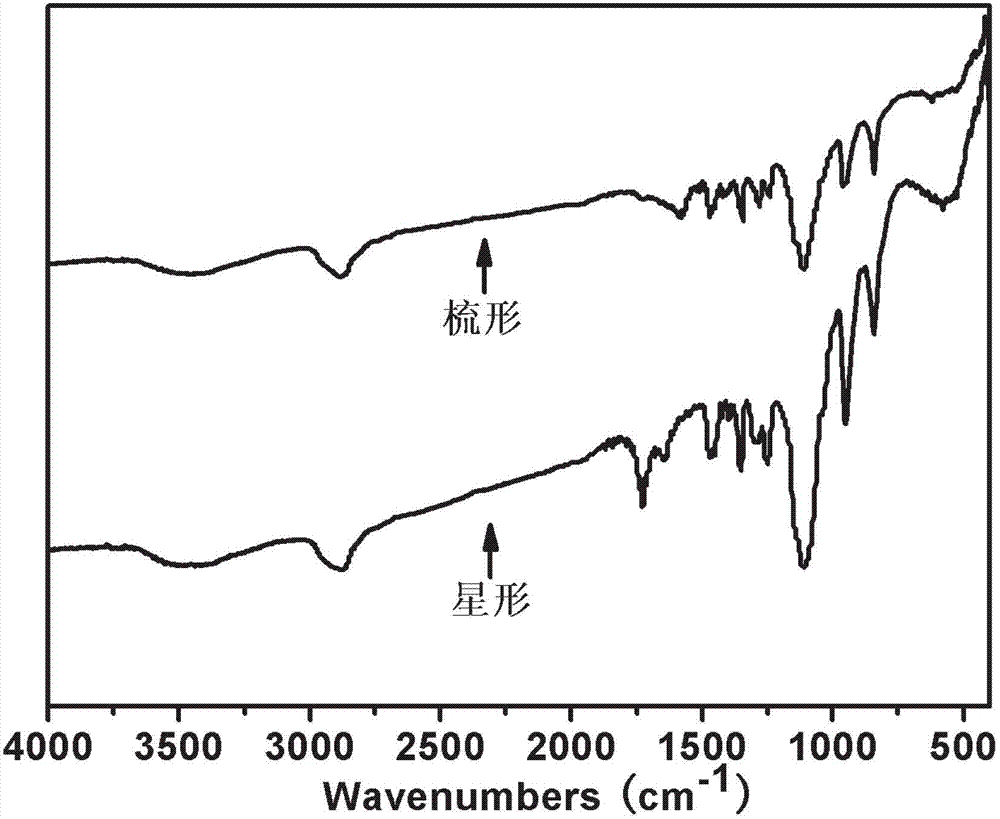

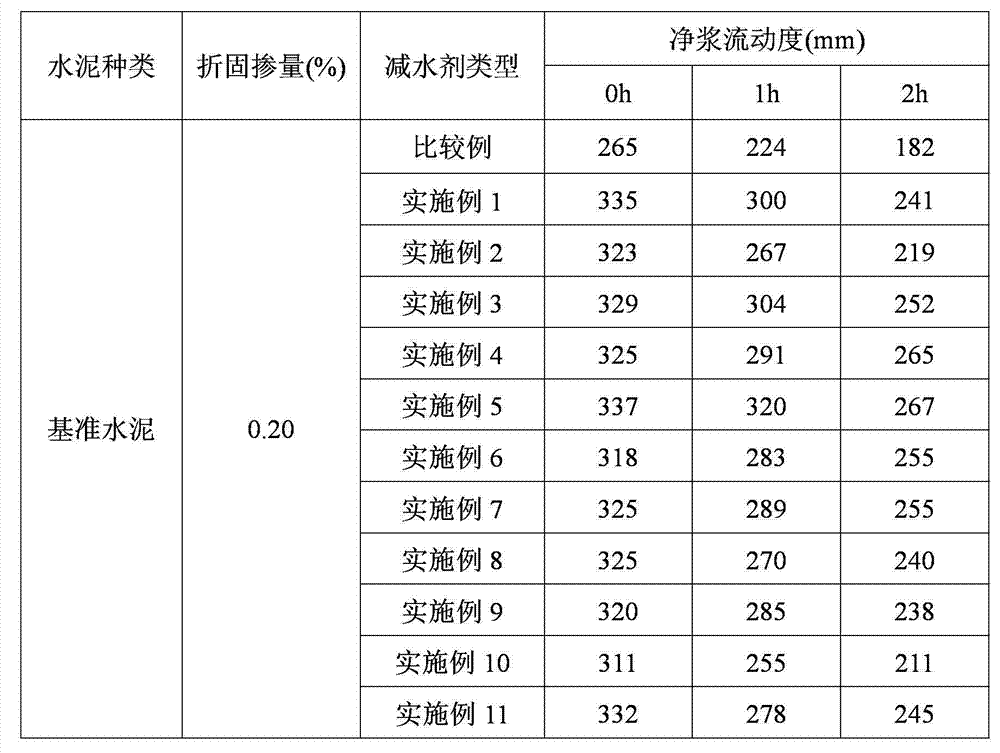

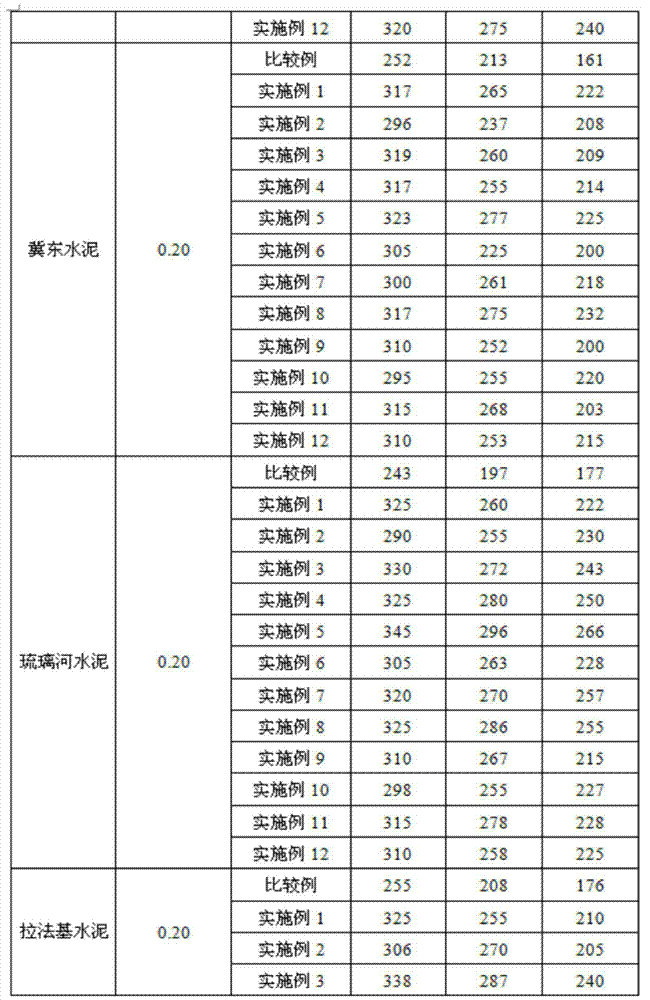

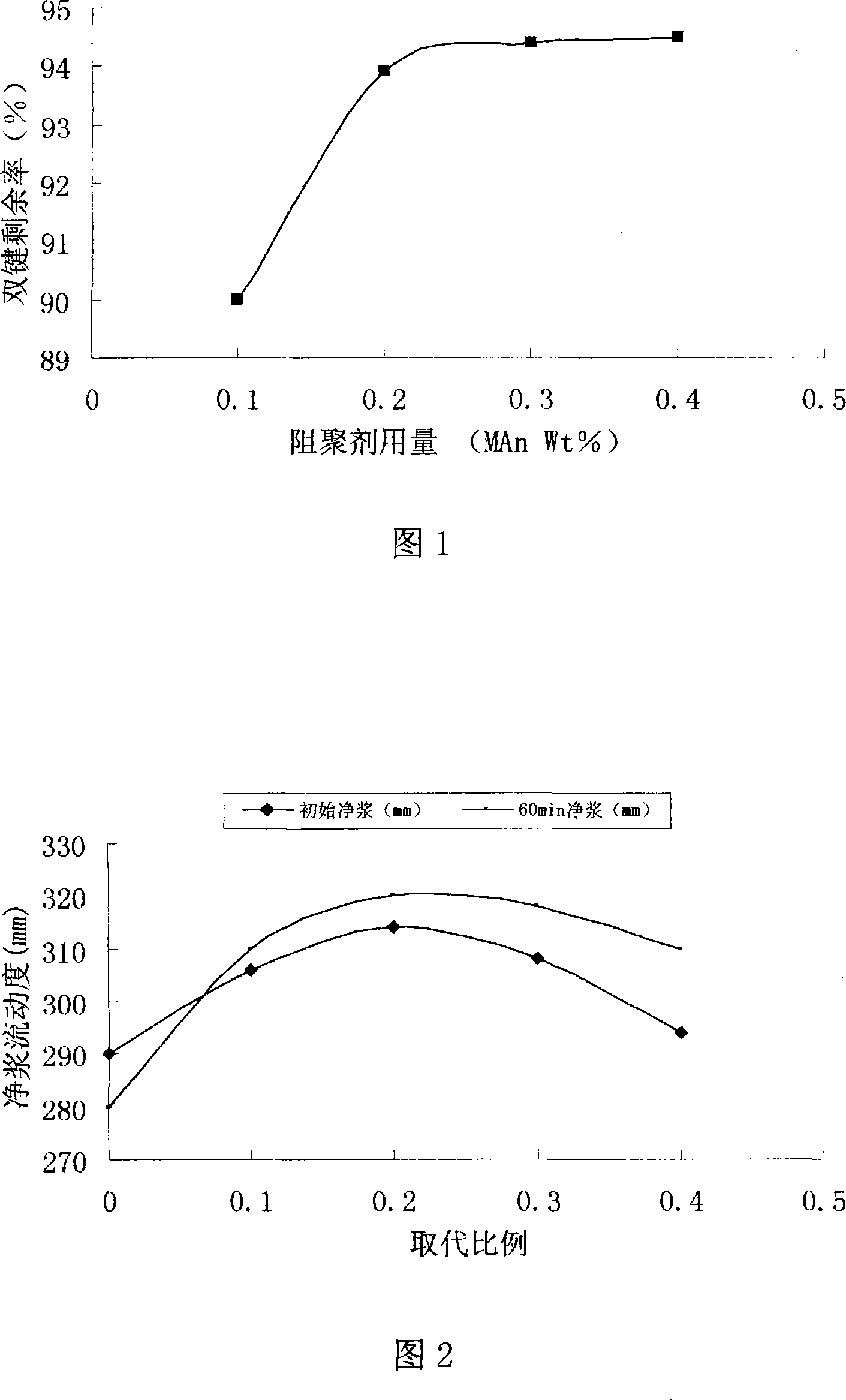

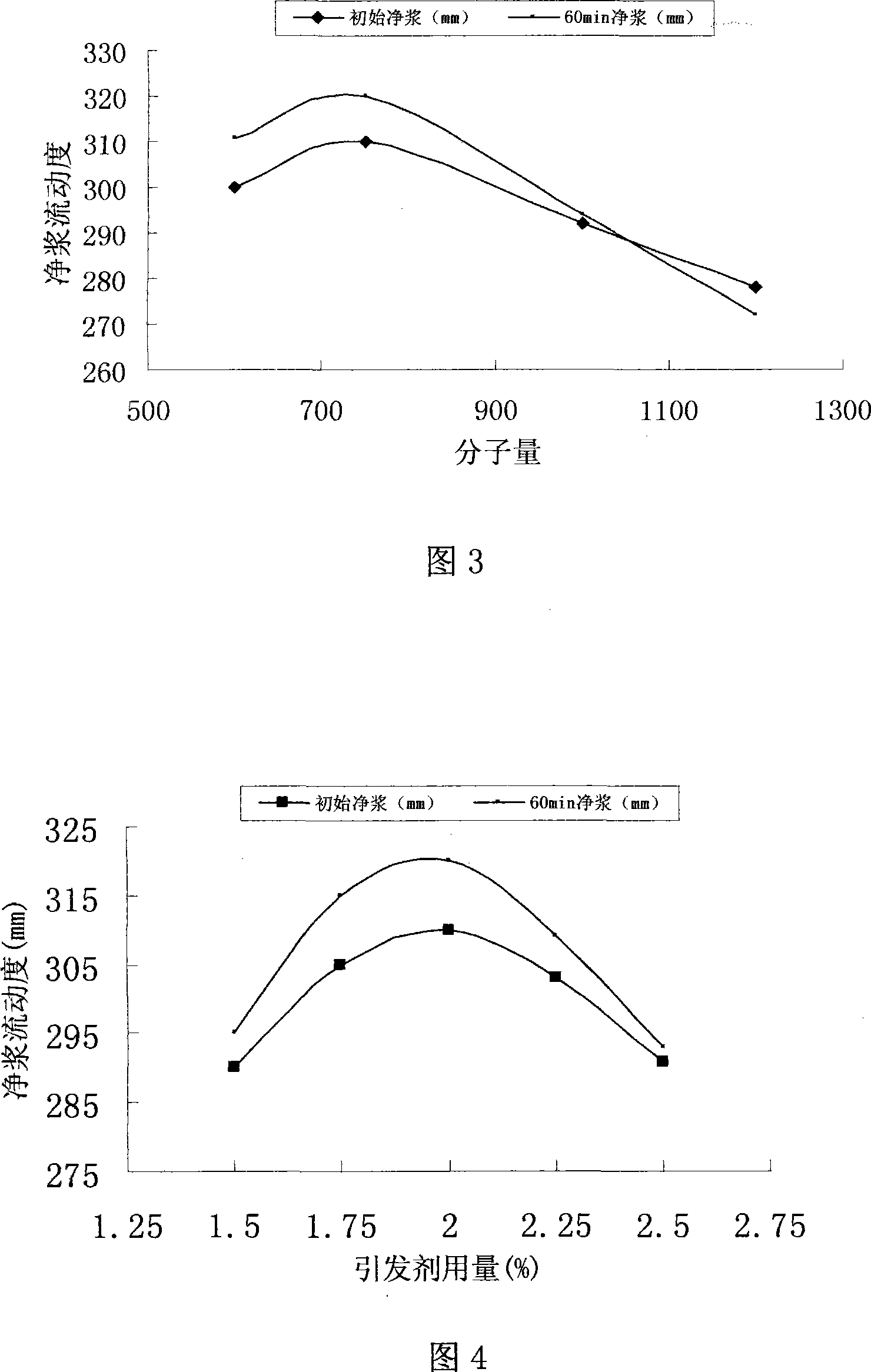

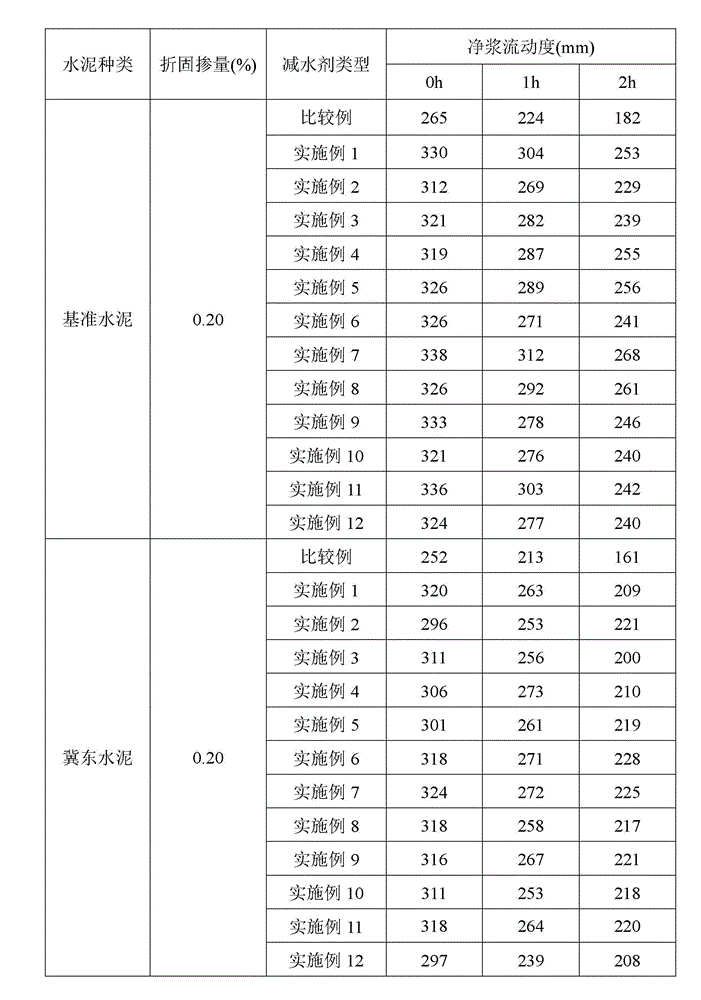

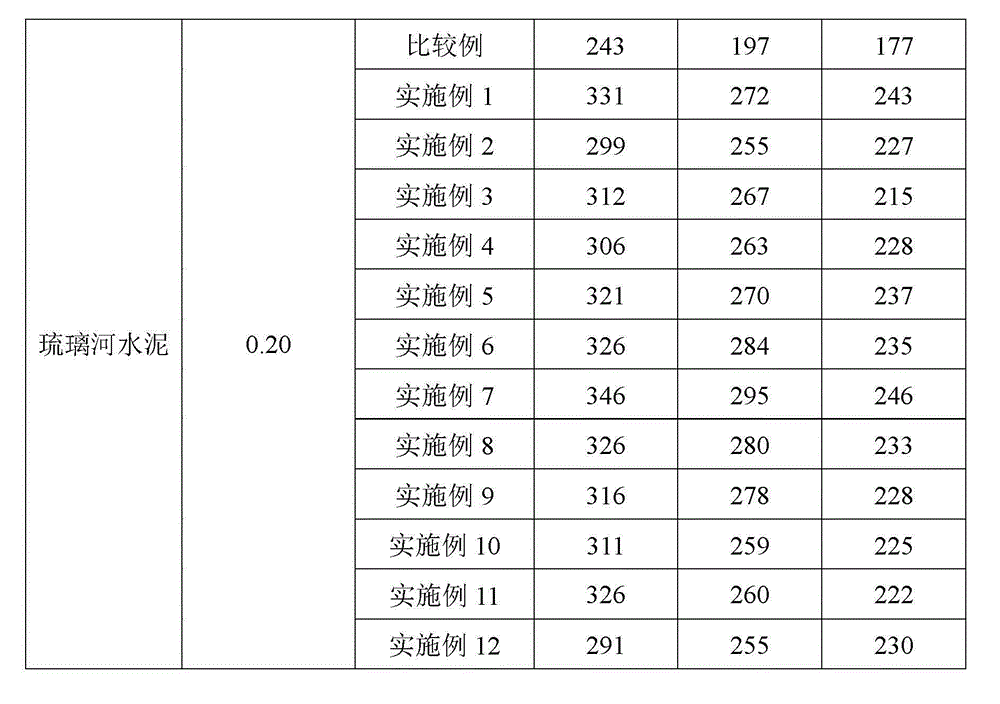

Preparation method of star polycarboxylic acid high-performance water reducing agent

ActiveCN102887979AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesWater reducerPollution

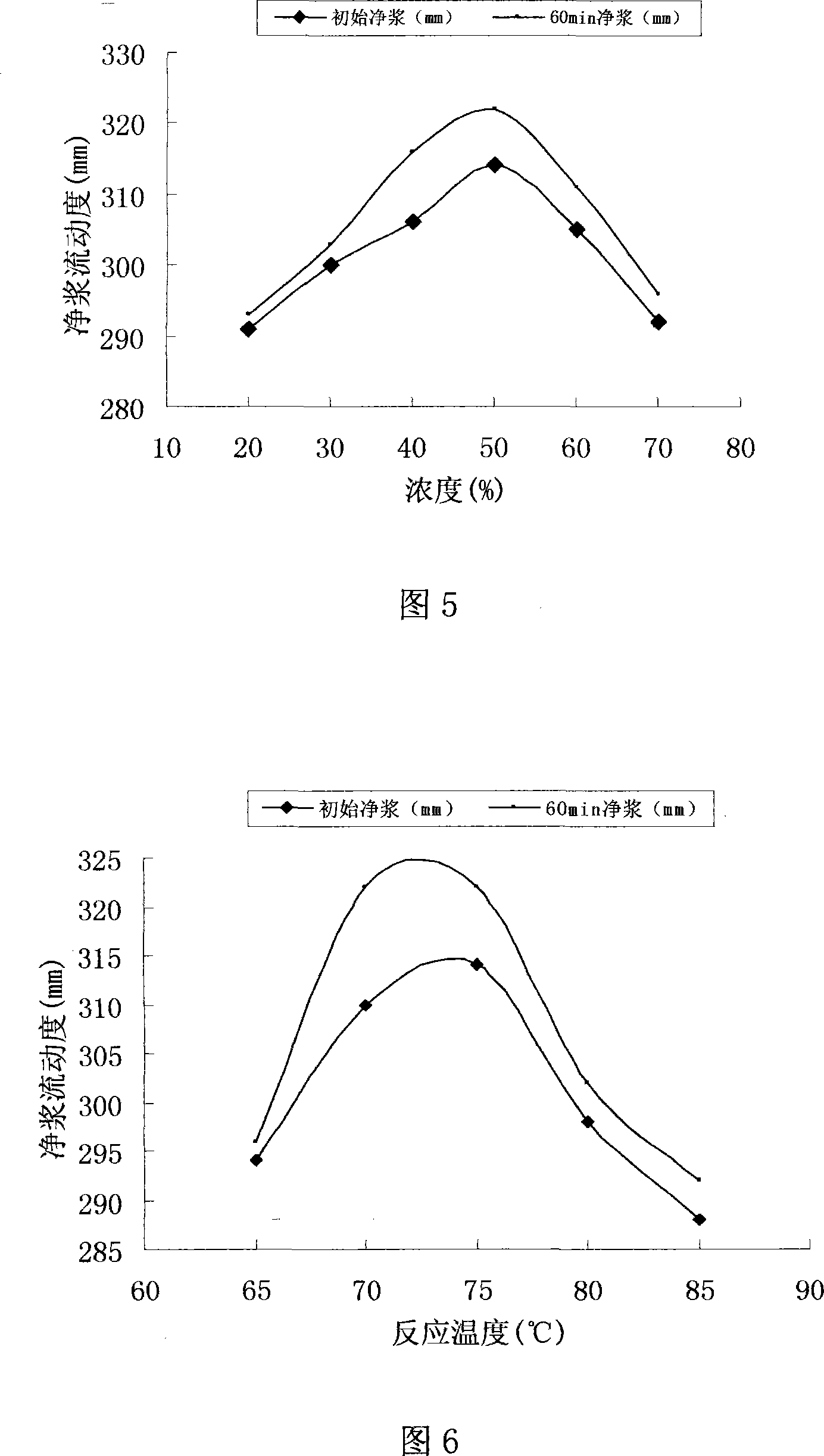

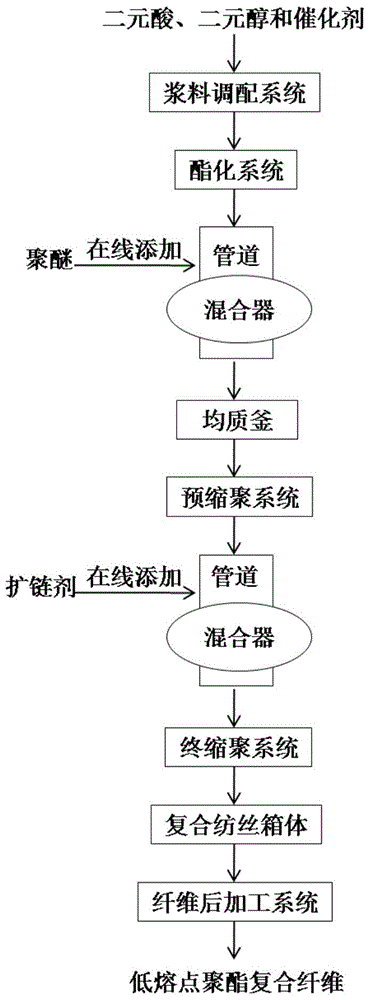

The invention relates to a preparation method of a star polycarboxylic acid high-performance water reducing agent. Polybasic alcohol and (methyl) acrylic acid used as main raw materials for esterification are esterified and polymerized to prepare the star polycarboxylic acid high-performance water reducing agent material: the (methyl) acrylic acid and polybasic alcohol used as reactants are esterified under the action of a catalyst to firstly prepare a star polymerizable active terminal, and free-radical polymerization reaction is carried out with unsaturated polyethenoxy ether, molecular weight regulator and unsaturated carboxylic acid monomer under the action of an initiator to prepare the star polycarboxylic acid high-performance water reducing agent. The invention is easy to control, and has the advantages of high polymerization degree, low cost and no pollution; the esterification reaction is carried out form an active core, and the free-radical polymerization is carried out to generate the chain arm, thereby implementing the polycarboxylic acid high-performance water reducing agent in a star molecular structure; and under the condition of common doping amount and low doping amount, the star polycarboxylic acid high-performance water reducing agent has better cement paste flowability and holding capacity than the traditional linear and comb polycarboxylic acid water reducing agents, and has favorable cement adaptability and concrete application performance.

Owner:GUIZHOU DR SHI TECH

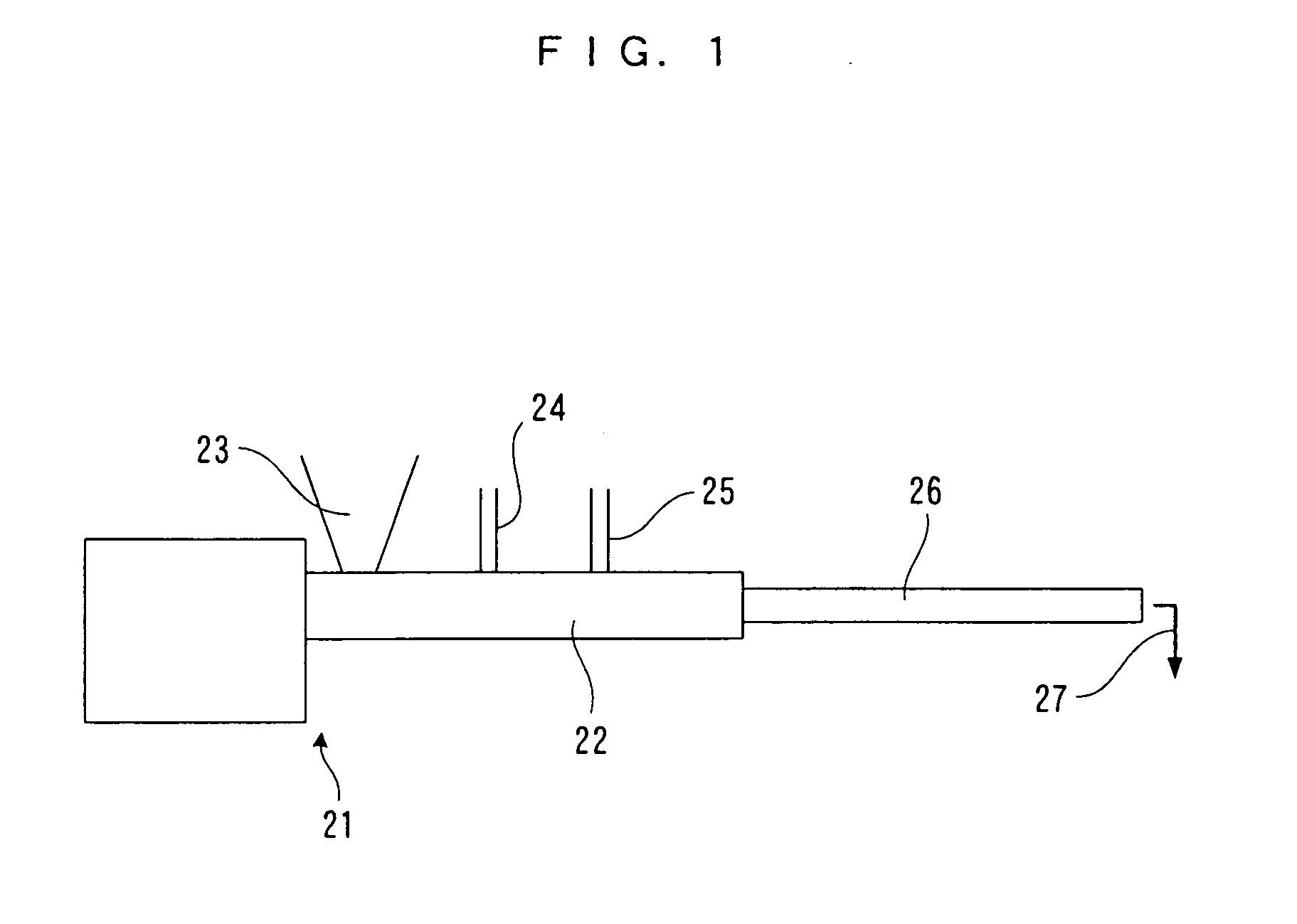

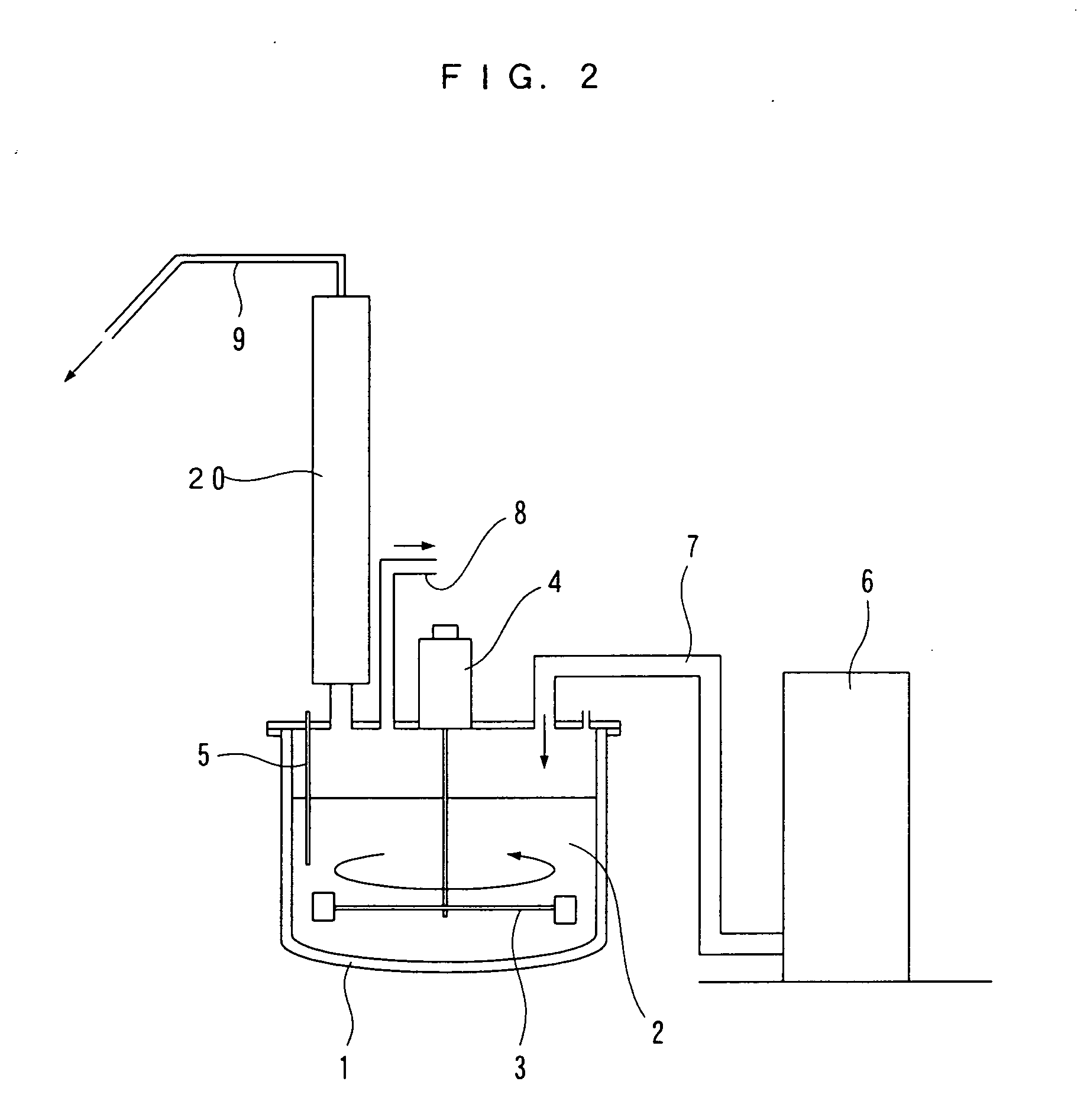

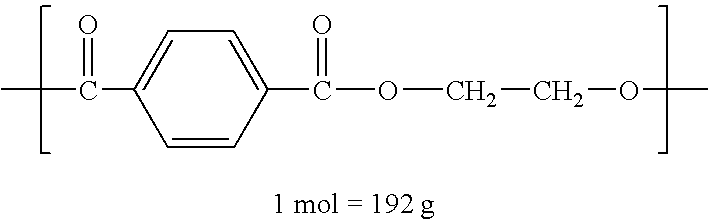

Method of depolymerizing polyethylene terephthalate and process for producing polyester resin

InactiveUS20050096482A1Depolymerization of R-PETShort timePlastic recyclingPreparation by transesterificationPolymer sciencePolyethylene terephthalate

A method of depolymerizing polyethylene terephthalate, and a method of manufacturing a polyester resin. When heating, melting and depolymerizing polyethylene terephthalate to be recycled, the heating, melting and depolymerization reaction of the polyethylene terephthalate to be recycled are carried out all at once using one or a plurality of extruders or using an extruder and a reactor provided at an outlet of the extruder. When manufacturing a polyester resin, the reactants are irradiated with microwaves, thus promoting the heating of the reactants, and promoting the esterification reaction.

Owner:KUBOTA LTD +1

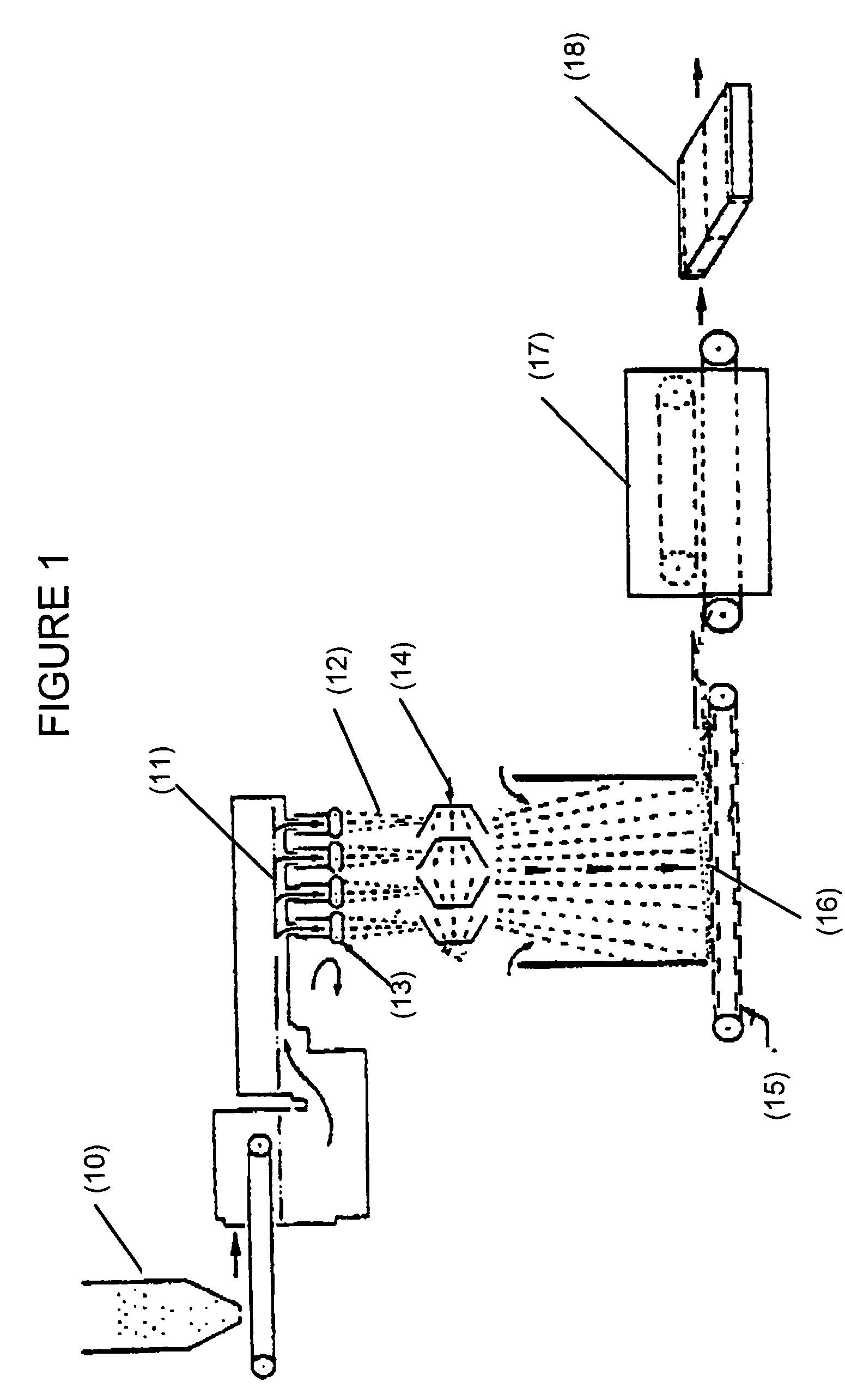

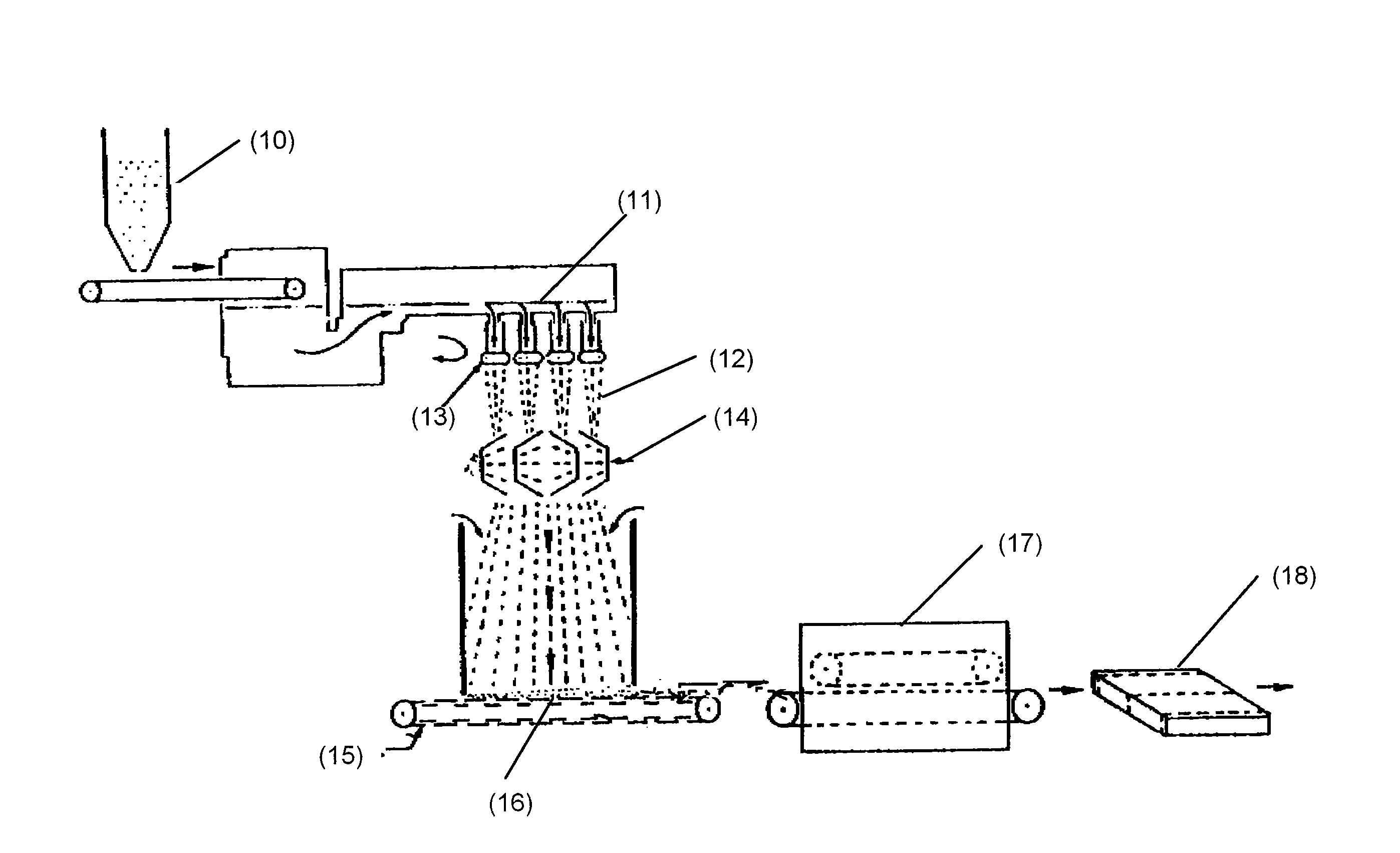

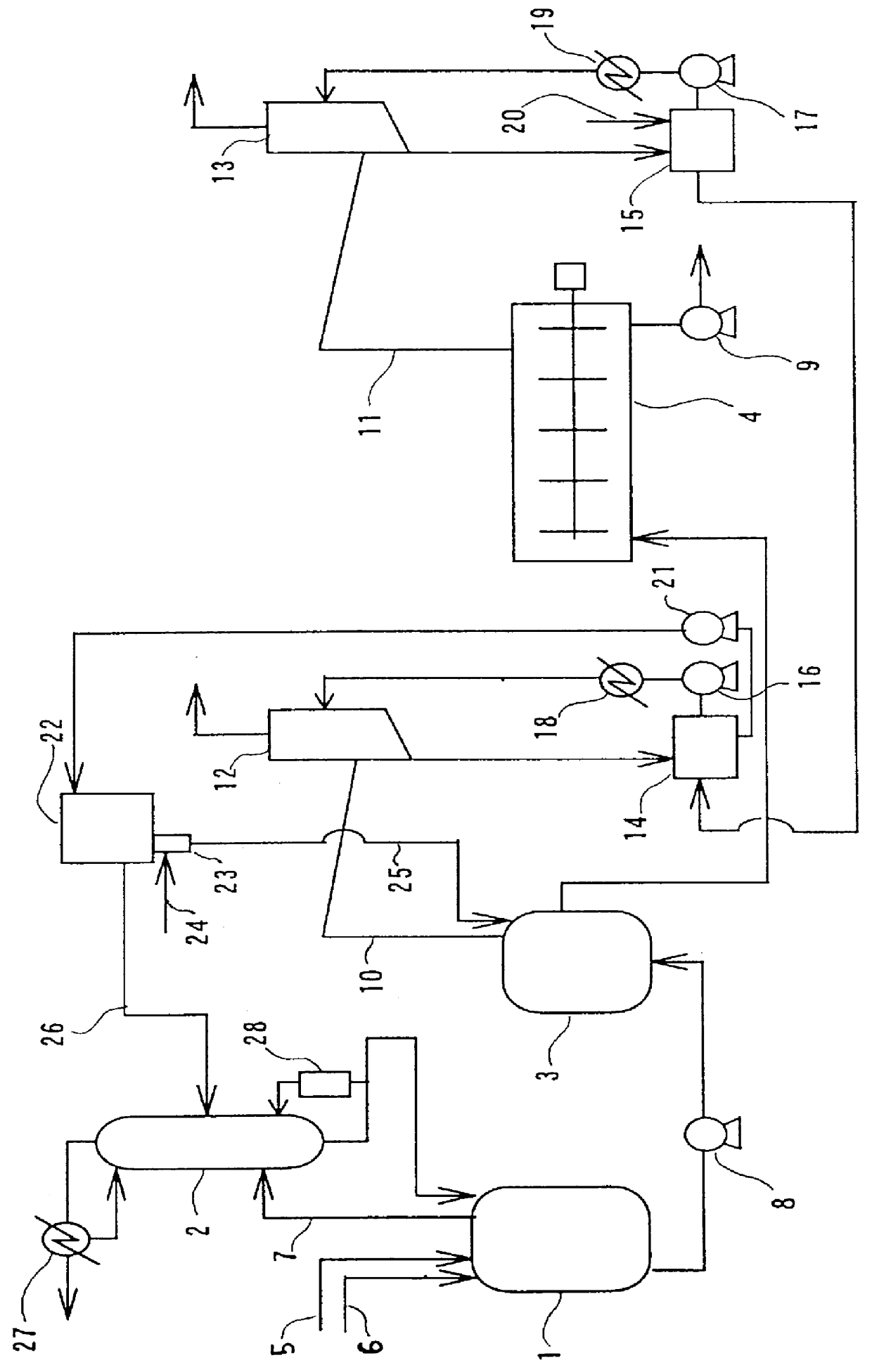

Process for continuously producing polyesters

PCT No. PCT / JP98 / 01977 Sec. 371 Date Dec. 21, 1998 Sec. 102(e) Date Dec. 21, 1998 PCT Filed Apr. 30, 1998 PCT Pub. No. WO98 / 50448 PCT Pub. Date Nov. 12, 1998A method for continuously producing a polyester by continuously melt-polymerizing a raw material consisting of a dicarboxylic acid component composed of mainly an aromatic dicarboxylic acid and containing an alicyclic dicarboxylic acid or an aliphatic dicarboxylic acid, or their ester-forming derivatives with a diol component, characterized in that said diol component as a distillate in the polycondensation reaction, including an adhering material, is condensed, said adhering material is separated centrifugally, and then the residual diol component, after distillation, is supplied to an esterification reaction or an ester interchange reaction.

Owner:TEIJIN LTD

Method for preparing hard polyurethane foam plastics with soybean oil

ActiveCN101314632AImprove water resistanceImprove heat resistancePolyesterFatty acid glycerol esters

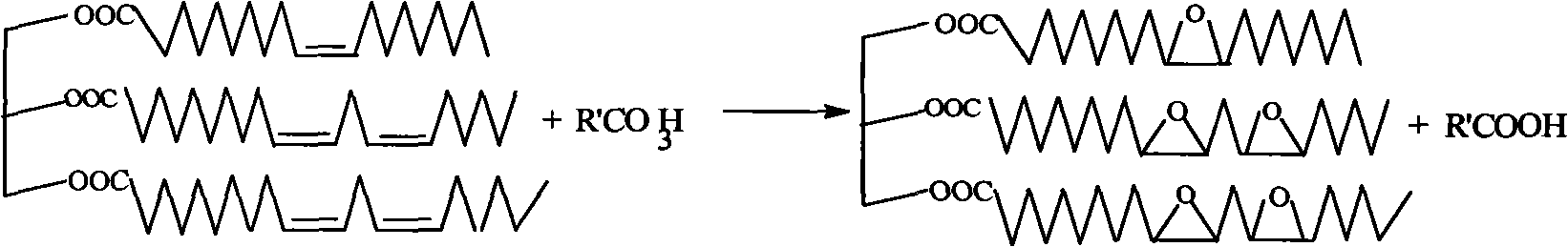

The invention provides a method for preparing hard polyurethane foam plastics from soybean oil. The method comprises the steps as follows: (1) carrying out epoxidation including the sub-steps of subjecting soybean oil and epoxidizing agent to reaction to obtain epoxidized soybean oil; (2) carrying out ring-opening reaction including the sub-steps of subjecting epoxidized soybean oil and nucleophilic reagent of reactive hydrogen to the ring-opening reaction of epoxy chemical bond in the presence of a catalyst to obtain mixed hydroxyl fatty acid glyceride; (3) carrying out alcoholysis and esterification including the sub-steps of adding alcohol, heating for alcoholysis to obtain mixed hydroxyl fatty acid monoester, i.e. soybean oil based polyol, and esterifying with organic acid and acid anhydride to generate polyester polyol; and (4) sequentially adding 80-150 weight parts of isocyanate, 0.3-4 weight parts of triethanolamine and 0.5-4 weight parts of foam stabilizer to 100 weight parts of soybean oil based polyol, intensively stirring, adding 0.5-3 weight parts of distilled water, and uniformly foaming while stirring at the high speed.

Owner:NANTONG HAIERMA TECH CO LTD

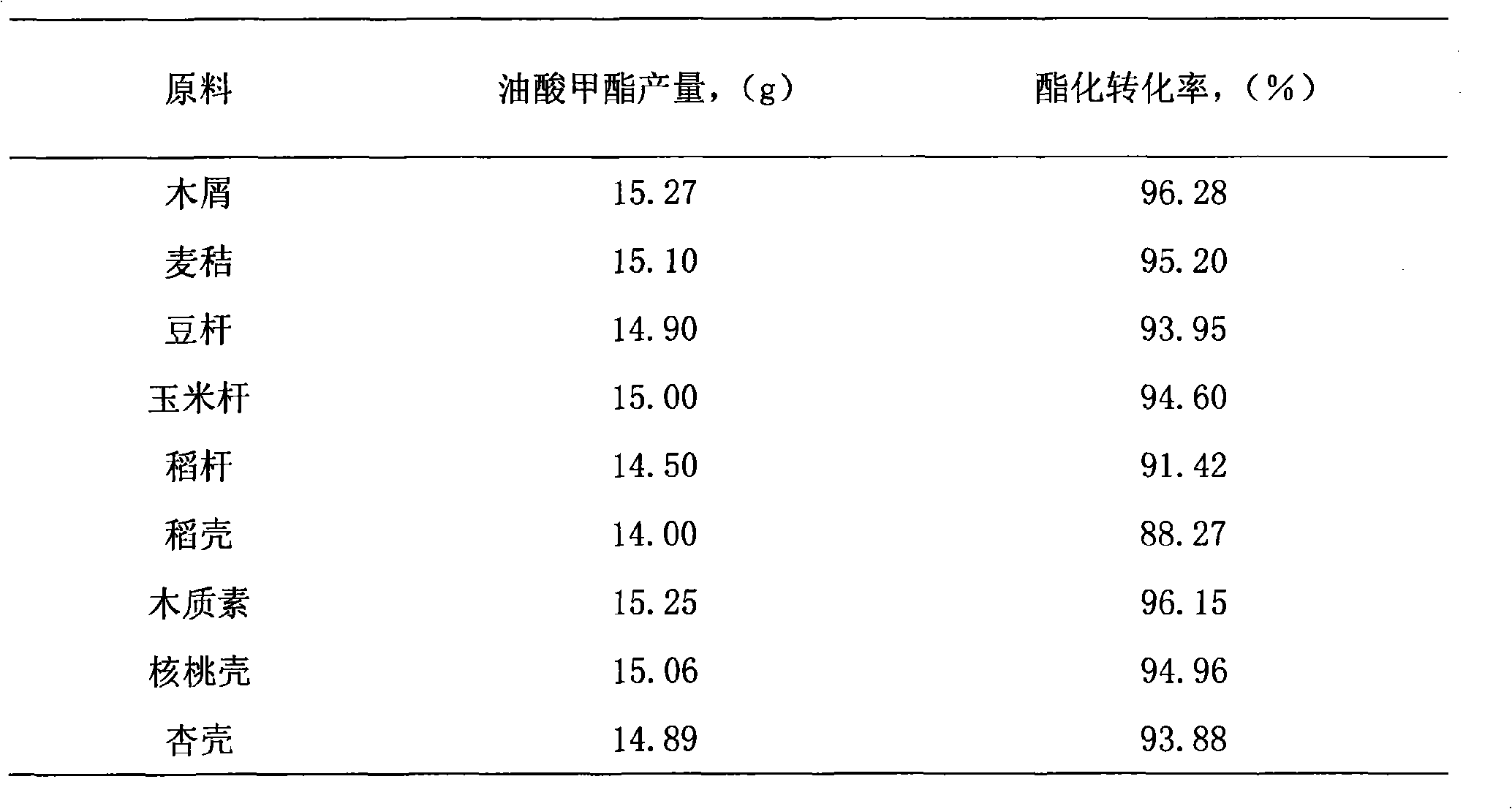

Method for preparing biocarbon solid acid catalyst and biodiesel

InactiveCN101298566AReduce manufacturing costAbundant and renewable resourcesPhysical/chemical process catalystsPreparation by ester-hydroxy reactionBiodieselSolid acid

The invention pertains to the new material technical field, and relates to a method for preparing a carbonaceous solid acid catalyst and biodiesel by taking pure natural biological substances as raw materials. The method is characterized by: taking the pure natural and renewable biological substances as the raw materials; adopting the technical route and method of low-temperature carbonization firstly, oxidation secondly and sulfonation then according to the constituent and structural characteristics to prepare the bio-carbonaceous solid acid catalyst; and adopting a continuous rectification-water separating esterification reaction technology to produce the biodiesel by carrying out the catalytic esterification reaction of a free fatty acid or waste oil and short chain alcohol. The raw materials adopted by the invention are rich in resources, low in price, pure natural and renewable, which pertains to waste utilization; the preparation technology is simple with moderate and controllable reaction conditions; the catalyst has the advantages of high activity, good stability, easy recycling and no corrosion to equipment, which is an really environment-friendly catalyst, thus being applicable to the large scale industrial production of the biodiesel. The method can also be applied to a plurality of organic reactions such as alkylation, hydrolysis and hydration, etc.

Owner:DALIAN UNIV OF TECH

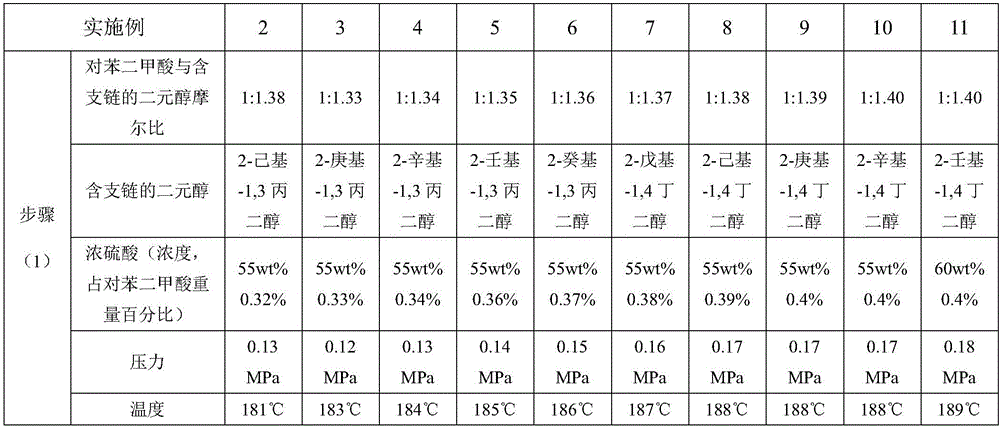

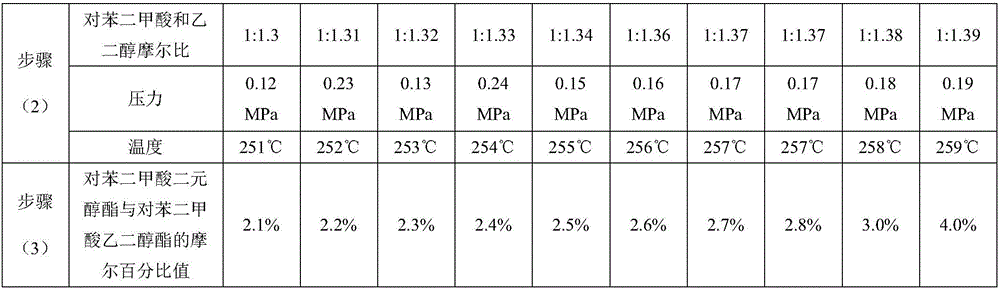

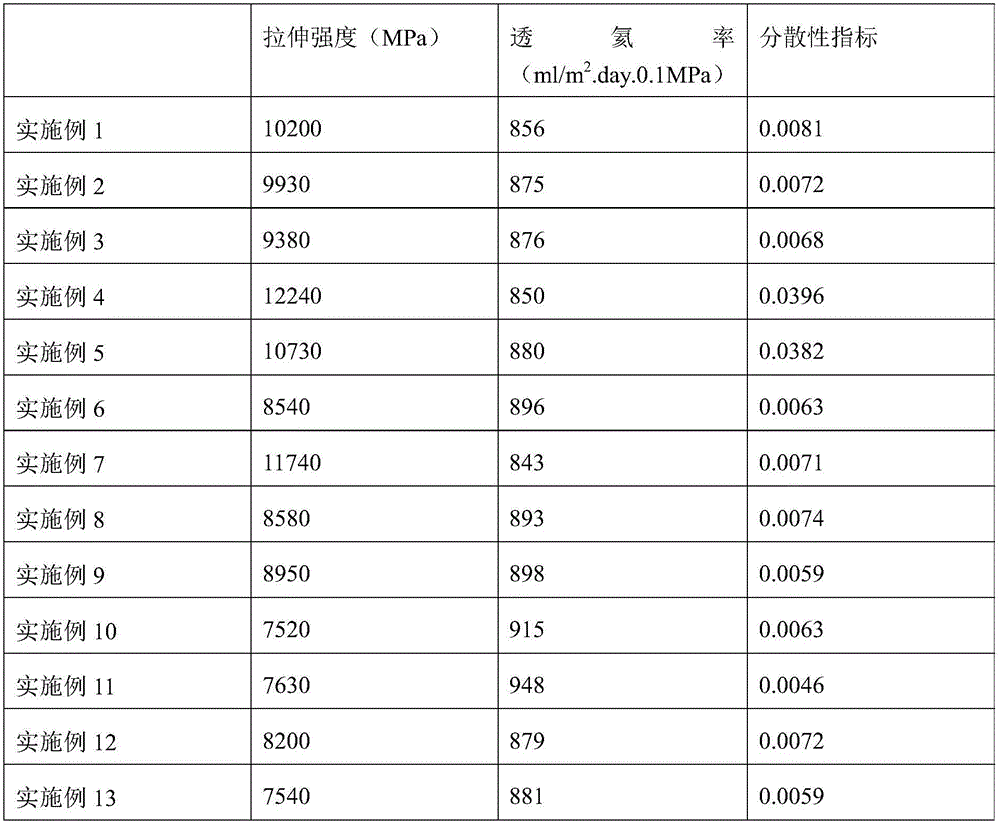

Polyester fibres and preparation method thereof

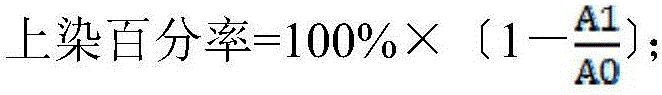

ActiveCN106367835AImprove dyeing effectEasy to processSpinnerette packsMonocomponent copolyesters artificial filamentSlurryLow vacuum

The invention relates to polyester fibres and a preparation method thereof. The raw material of the polyester fibres is modified polyester which consists of a terephthalic acid chain segment, an ethylene glycol chain segment and a branched chain-containing dihydric alcohol chain segment. The preparation method of the polyester fibres comprises the following steps: performing esterification reaction on terephthalic acid and branched chain-containing dihydric alcohol under the catalysis of concentrated sulphuric acid to obtain terephthalic acid dihydric alcohol ester; then, preparing the terephthalic acid and the ethylene glycol into slurry, and performing the esterification reaction on the slurry to obtain the terephthalic acid ethylene glycol ester; finally, stirring and mixing the terephthalic acid dihydric alcohol ester and the terephthalic acid ethylene glycol ester, and performing condensation polymerization in a low vacuum stage and a high vacuum stage under the action of a catalyst and a stabilizing agent to obtain modified polyester; metering, extruding, cooling, oiling, stretching, heat-setting and winding the polyester to prepare the polyester fibres. The increasing amplitude of the spatial gaps of the polyester fibres is much higher than that of branched chain-free polyester fibres at the same temperature, which is beneficial to the degree of micro particles, such as a dye, that enter the polyester; the dyeing rate is improved.

Owner:JIANGSU HENGLI CHEM FIBER

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

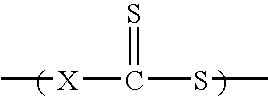

Vinyl-Thiocarbonate and Polyol Containing Block Copolymers

Block copolymers comprising polyols and / or siloxanes and vinyl-thiocarbonate blocks can be made by reacting a thiocarbonate compound such as a dithio- or trithiocarbonate with generally any hydroxyl-terminated polysiloxane via an esterification reaction. The polysiloxane can have a very wide number average molecular weight range and can be chain extended and / or crosslinked as by using a polyisocyanate or a polycarboxylic acid. Desirably, vinyl compounds are then reacted in situ into the thiocarbonate to increase molecular weight thereof. The block copolymers can be used in personal care applications.

Owner:LUBRIZOL ADVANCED MATERIALS INC

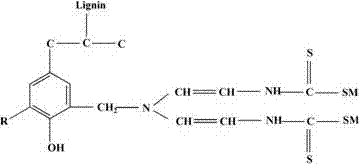

Lignin-based dithiocarbamate heavy metal ion capture agent and preparation method

InactiveCN102784622AReduce manufacturing costThe synthesis method is simpleOther chemical processesWater/sewage treatment by sorptionAminationDithiocarbamate

The invention discloses a preparation method of a lignin-based dithiocarbamate heavy metal ion capture agent. The method comprises the steps of: (1) adding water into lignin and stirring them, adding an alkaline conditioning agent to adjust the pH to 9-11, then adding an oxidizing agent, conducting heating to raise the temperature to 80-90DEG C for reacting for 1-2 hours; (2) adding an amination reagent, maintaining the reaction temperature at 80-90DEG C, then adding formaldehyde to react for 5-6 hours; (3) cooling the solution to room temperature, adjusting the pH value to 10-11, then adding carbon disulfide to perform an esterification reaction for 4-5 hours at 40-45DEG C; and (4) adding a modifier for reacting for 1-2 hours, then carrying out pumping filtration, and then conducting washing 2-3 times with water and absolute ethyl alcohol, thus obtaining a solid product, i.e. the lignin-based dithiocarbamate. The lignin-based dithiocarbamate heavy metal ion capture agent provided in the invention has the advantages of simple preparation process, low production cost, excellent performance, adaptability to treatment of various heavy metal ion polluted wastewater, good stability, and wide applicable range.

Owner:GUANGXI UNIV

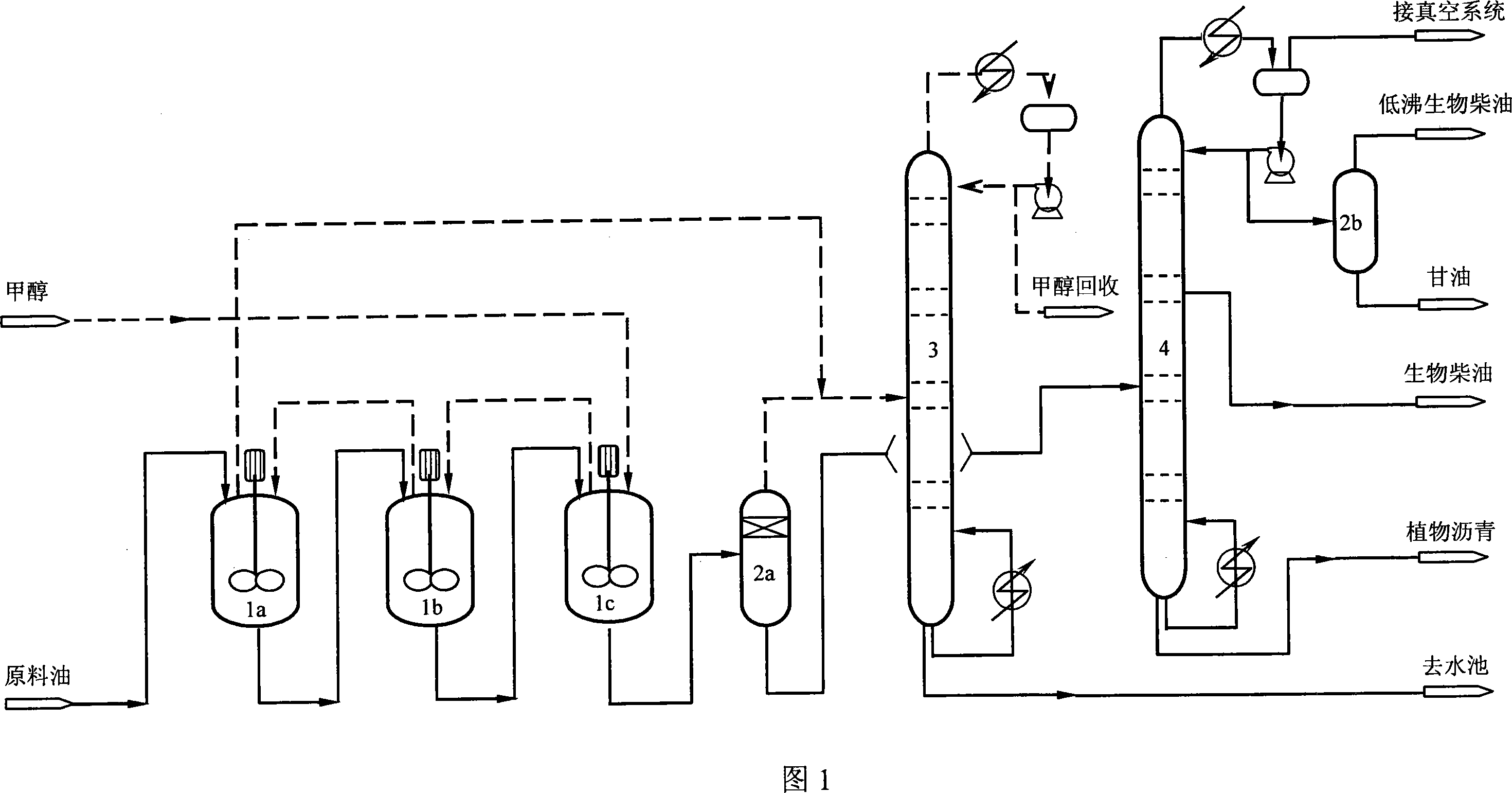

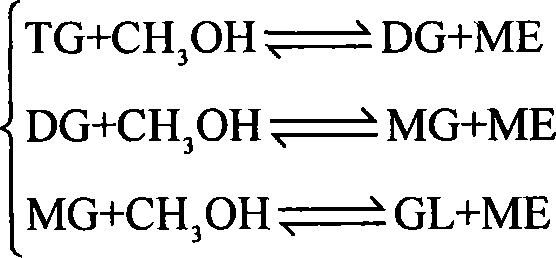

Solid catalysis process of preparing biodiesel oil continuously with high acid value material

InactiveCN101067091AHigh activityLow costPhysical/chemical process catalystsFatty acid esterificationOil and greaseRenewable energy technology

The present invention is solid catalysis process of preparing biodiesel oil continuously with high acid value material, and belongs to the field of grease chemistry and regenerable energy source technology. The process includes following four steps: material pre-treating, reaction, methanol rectifying recovery and vacuum rectification of fatty acid methyl ester; and features the high acid value material, such as acidified oil, waste edible oil, etc. The present invention has the advantages of low material cost, high activity and easy separation of the solid catalyst, high esterification efficiency, high product purity, high yield, less waste, no pollution, etc.

Owner:TSINGHUA UNIV +1

PET-based graphene composite material, preparation method thereof, and aerostat

ActiveCN105820519AGood dispersionImprove barrier propertiesRigid airshipsDimethyl terephthalateIn situ polymerization

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Method for preparing fish oil ethyl ester microcapsule from fish pomace

ActiveCN101940240AHigh purityImprove qualityEdible oils/fatsFood preparationForeign matterNeutral protease

The invention relates to a method for preparing a fish oil ethyl ester microcapsule from fish pomace, which mainly comprises the extraction of fish oil, the preparation of fish fatty acid ethyl ester, the purification of fish oil ethyl ester and the preparation of a fish oil ethyl ester microcapsule, wherein the extraction of fish oil comprising the following steps: eliminating foreign matters from fish viscus, cleaning, mashing, adding pepsin and neutral protease for enzymolysis, then adding anhydrous alcohol, standing to stratify, and centrifuging to obtain the fish oil; the preparation of fish fatty acid ethyl ester comprising the following steps: mixing the fish oil with ethanol, making the mixture to be subject to an esterification reaction under the catalysis of sodium ethylate, vaporizing the ethanol, washing with water, and then centrifuging to obtain the fish oil ethyl ester; in the purification process, supercritical CO2 extraction is adopted, the purified fish oil ethyl ester is a golden yellow transparent liquid, and EPA ethyl ester and DHA ethyl ester contents thereof are more than 50%; and the preparation of a fish oil ethyl ester microcapsule comprises the following steps: mixing sodium alginate, maltodextrin and sodium caseinate, dissolving in water, adding the purified fish oil ethyl ester, and adopting a spray drying method to obtain the powdered fish oil ethyl ester microcapsule which can hide the fishy smell of the fish oil ethyl ester, improve the mouth feel and be beneficial to packaging and storage.

Owner:DALIAN POLYTECHNIC UNIVERSITY

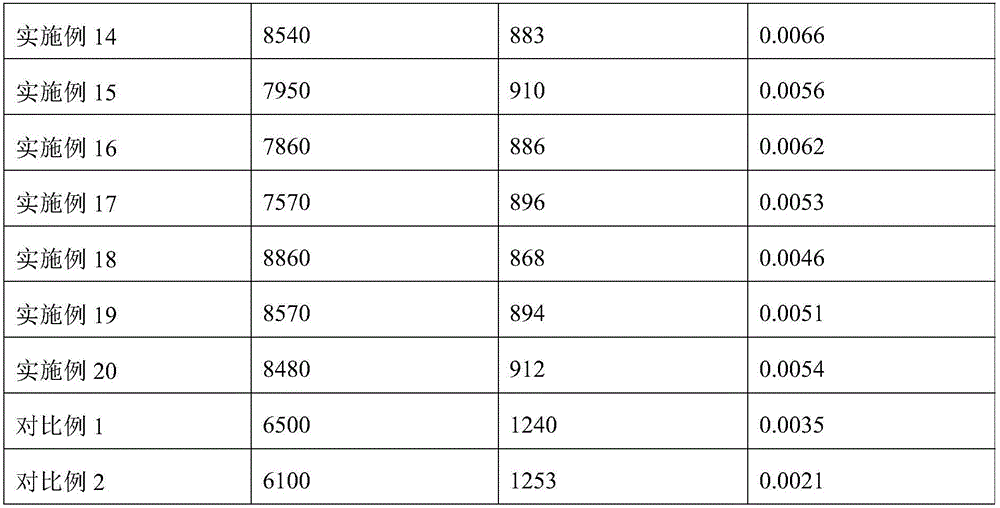

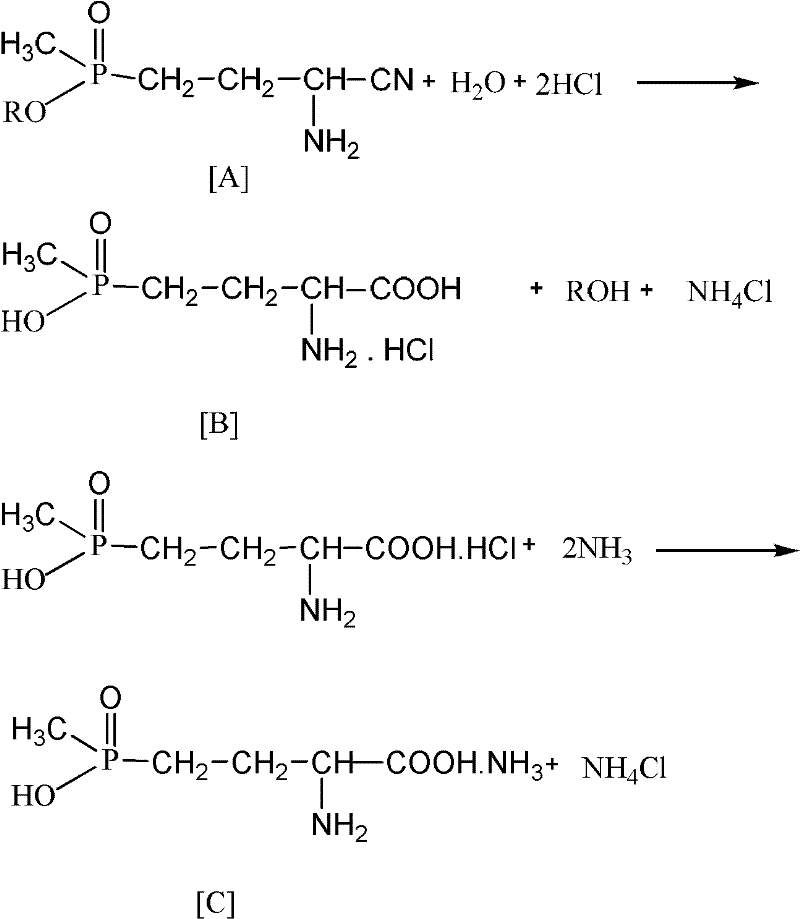

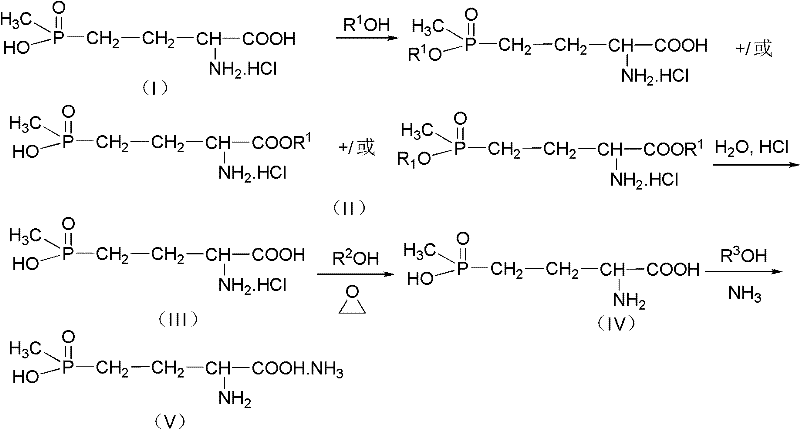

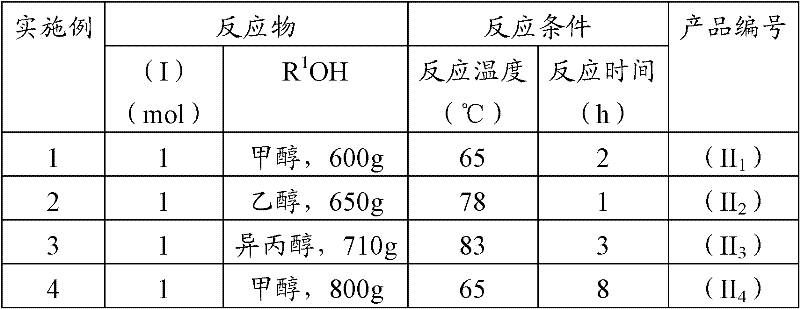

A kind of purification process of glufosinate-ammonium

ActiveCN102268037AThe purification process steps are simpleLow Inorganic Salt ContentGroup 5/15 element organic compoundsEpoxySolvent

The invention discloses a process for purifying glufosinate-ammonium, which comprises: (1) adding glufosinate-ammonium hydrochloride into an alcohol R1OH to perform an esterification reaction, and after the reaction is accomplished, cooling, filtering, removing solvent from filtrate and obtaining ester product of glufosinate-ammonium; (2) adding the ester product of glufosinate-ammonium, which isobtained by step (1), into water solution of hydrochloric acid to perform a hydrolysis reaction, and obtaining glufosinate-ammonium hydrochloride by post treatment; (3) adding the glufosinate-ammonium hydrochloride obtained by the step (2) into an alcohol R2OH, introducing epoxy ethane and obtaining glufosinate-ammonium acid; and (4) adding the glufosinate-ammonium acid obtained by the step (3) into an alcohol R3OH, introducing ammonia gas, and obtaining glufosinate-ammonium after the reaction is finished. In the invention, the process for purifying glufosinate-ammonium comprises simple steps, the inorganic salt content in the obtained glufosinate-ammonium is low, and the purity of the obtained glufosinate-ammonium is high; the process for separating glufosinate-ammonium hydrochloride from HCl by epoxy ethane is more economic than the conventional process which adopts epoxypropane and epoxy chloropropane; and the method is very safe and has a very bright industrialization prospect.

Owner:YONGNONG BIOSCI

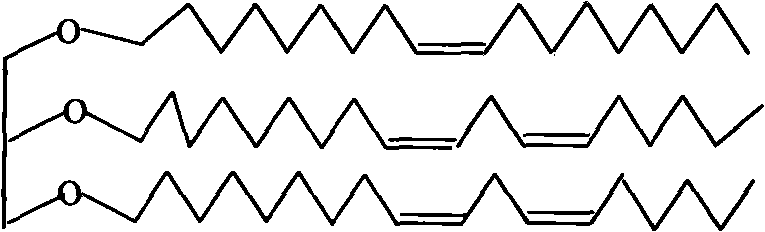

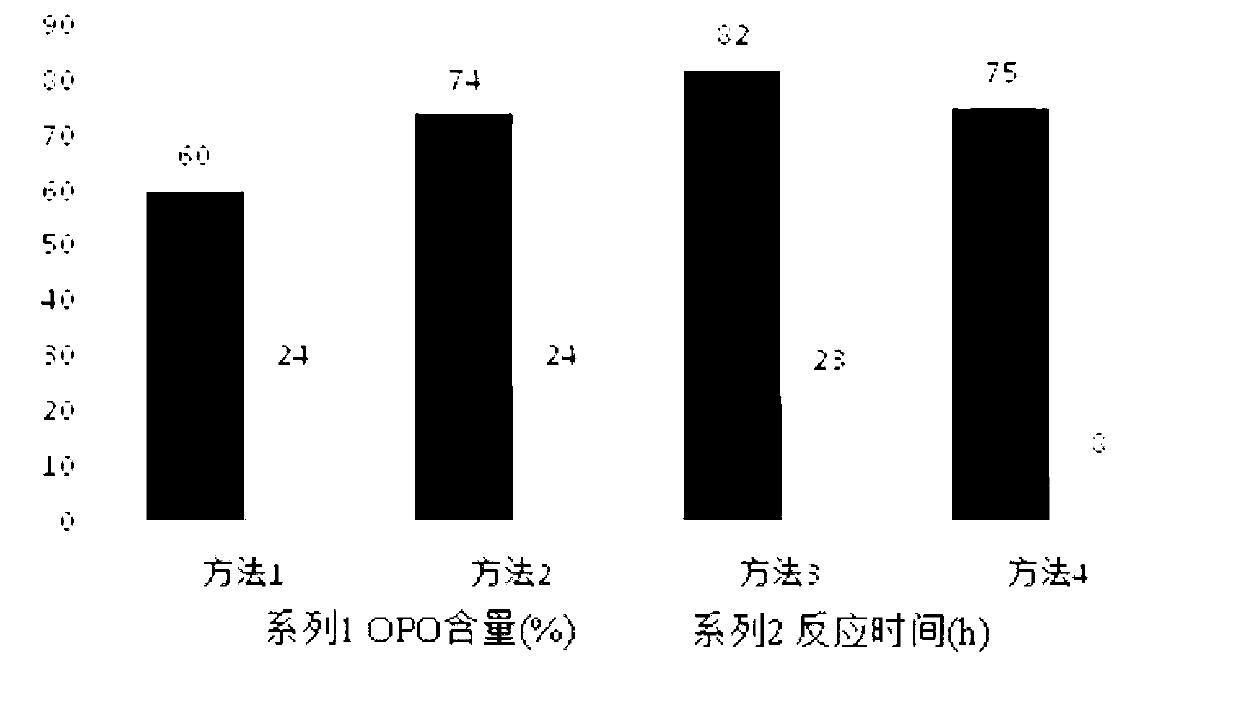

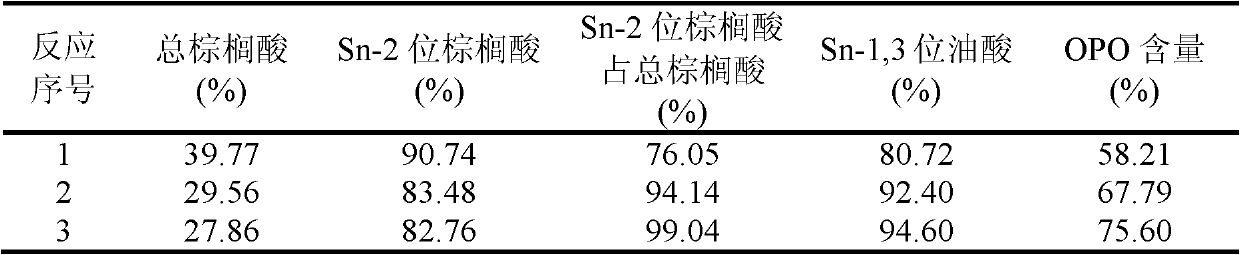

Preparation method of 1,3-dioleoyl-2-palmitoyl triglyceride

ActiveCN102757988AMild process conditionsShort reaction timeFermentationOleic Acid TriglycerideON-glycerol

The invention discloses a preparation method of 1,3-dioleoyl-2-palmitoyl triglyceride, which comprises the following steps: carrying out esterification reaction on glycerol and palmitinic acid under the action of a catalyst to obtain tripalmitin; carrying out ester exchange reaction on the tripalmitin and oleic acid or oleate under the action of 1,3-specific lipase until the ester exchange rate reaches 30-60%, and removing free fatty acids or fatty acid esters in the reaction system; and adding oleic acid or oleate into the reaction system, continuing the reaction until the ester exchange rate reaches 60-90%, and separating and purifying the 1,3-dioleoyl-2-palmitoyl triglyceride from the reaction products. The method disclosed by the invention has the advantages of wide raw material sources, high economy, high safety, mild technological conditions, short reaction time, low energy consumption and low enzyme consumption; and the method can be used for preparing high-yield high-purity 1,3-dioleoyl-2-palmitoyl triglyceride, and can be used as a food nutrient reinforcer for blending infant formula milk powder.

Owner:ZANYU TECH GRP CO LTD

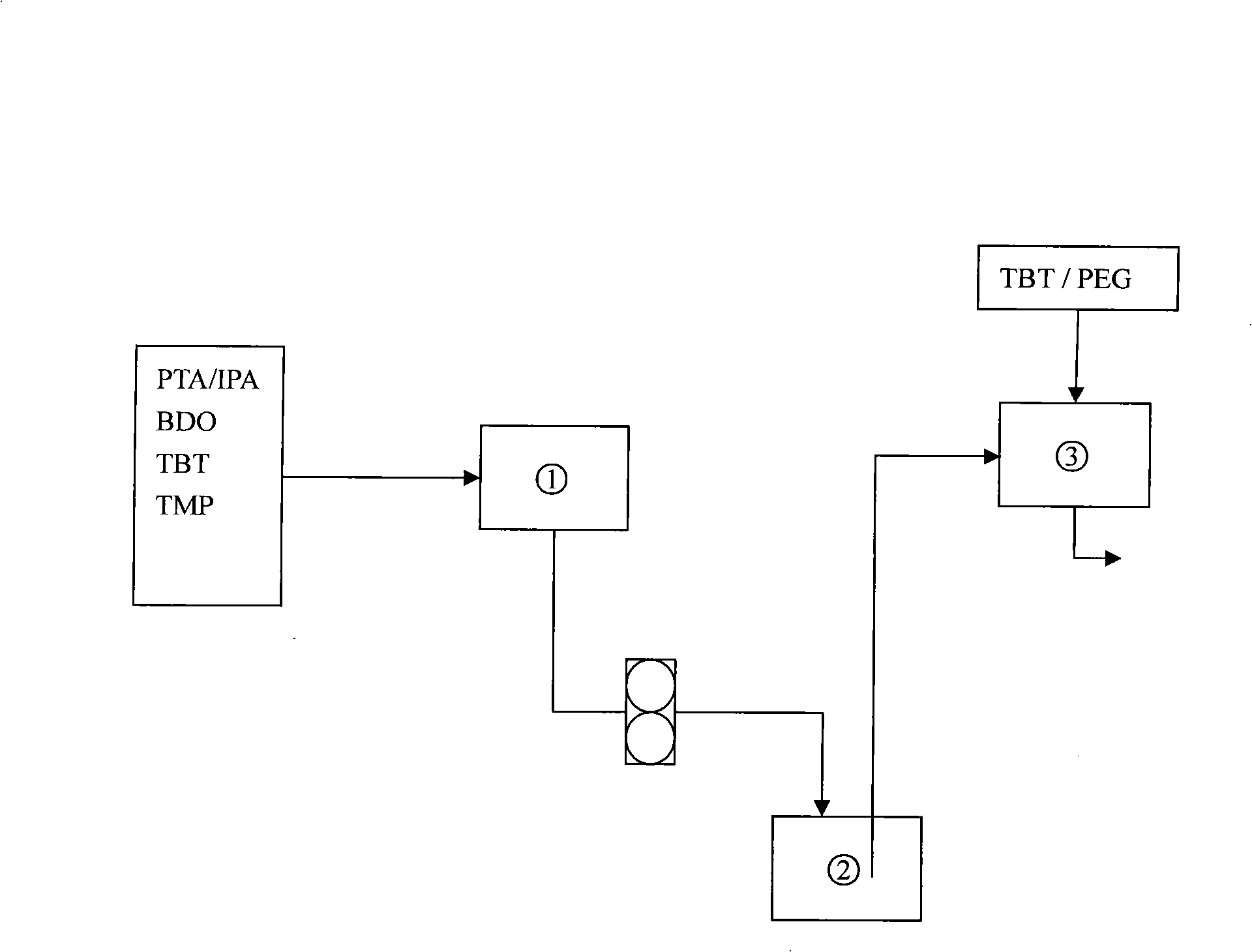

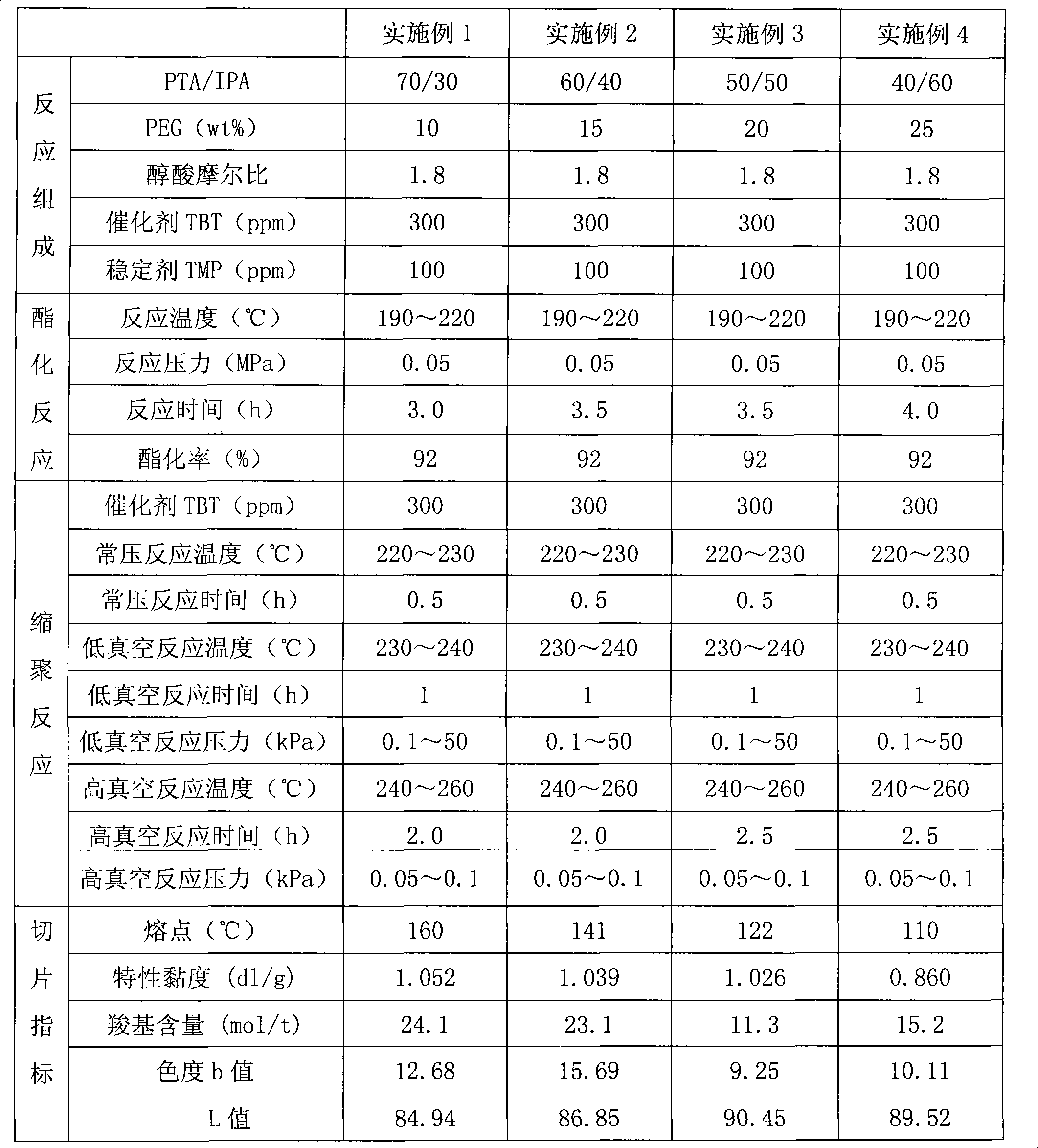

Low-melting-point copolyester and method for preparing same

InactiveCN101338023AIncrease exerciseLow melting pointMonocomponent copolyesters artificial filamentFiberPolymer science

The invention relates to low melting point copolyester and a preparation method thereof. The low melting point copolyester is made from the following monomers followed by the esterification reaction and the polycondensation reaction: (a) terephthalic acid (PTA) and isophthalic acid (IPA), (b) 1, 4- butanediol (BDO) and (c) polyethylene glycol 600 to 6000 (PEG); wherein, in the a component, the feeding mass ratio of the terephthalic acid and the isophthalic acid is between 80 to 20 : 20 to 80; in the c component, the feeding weight ratio of polyethylene glycol is 1 to 30 percent based on the a; the molar ratio of the a and the b is 1:1.5 to 2.3. The preparation method comprises an esterifcation stage and a polycondensation stage. The copolyester has the characteristics of low melting point, good crystallization property, high intrinsic viscosity and difficult adhesion of particles, and is suitable for spinning the filament, the staple fibers and the non-woven fabrics.

Owner:ZHEJIANG SCI-TECH UNIV

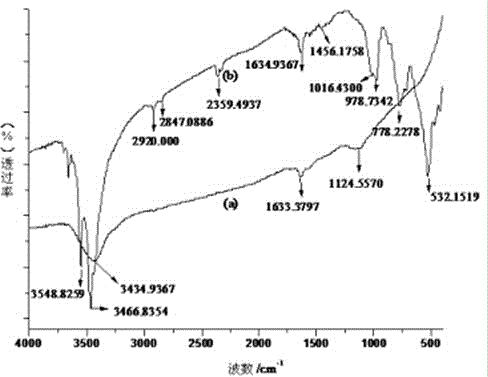

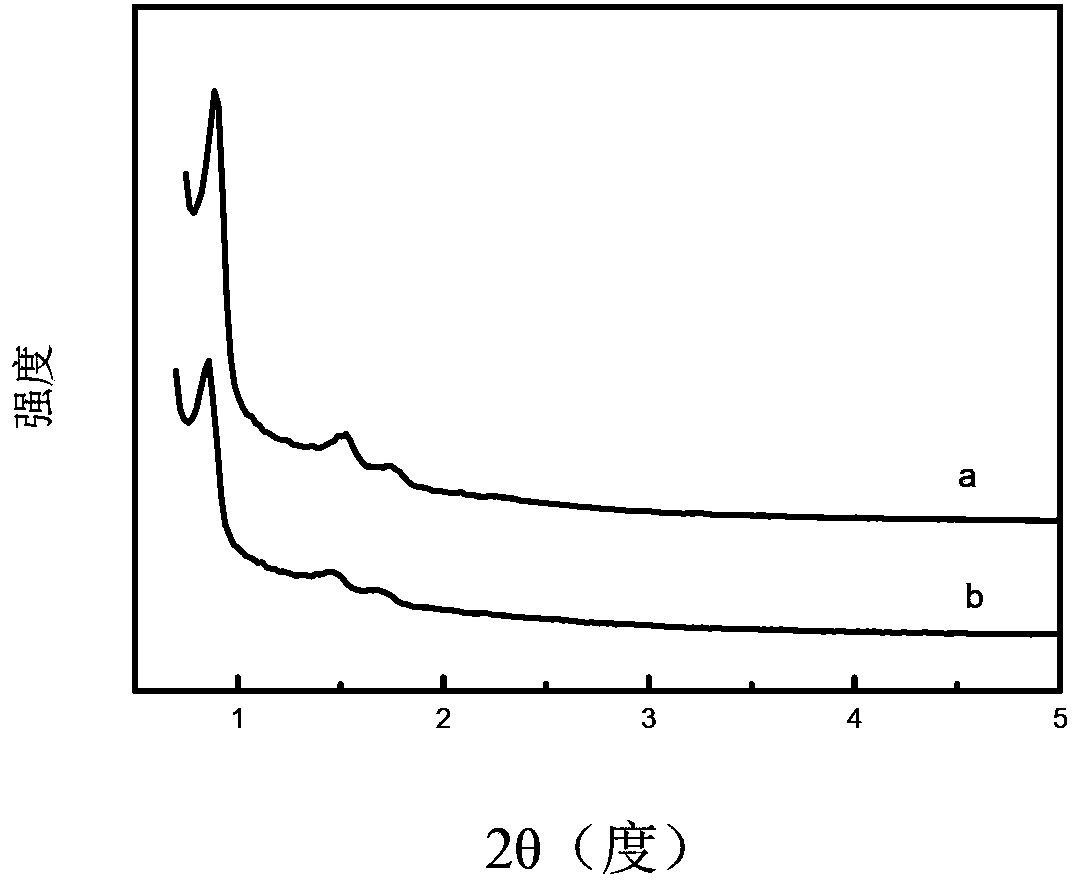

Surface modification method for carbon nano tube

InactiveCN102942810AGood for secondary modificationImprove thermal stabilityPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsPtru catalystModified carbon

The invention provides a surface modification method for a carbon nano tube and belongs to the field of nanotechnology. The method includes step one, uniformly mixing a carbon nano tube which is subjected to acidification by a strong oxidizing acid with a silane coupling agent and deionized water, reacting under a certain condition, filtering, washing, and drying to obtain a primary modified carbon nano tube; step two, uniformly mixing the primary modified carbon nano tube with polyhydric alcohols and a concentrated sulfuric acid, reacting under a certain condition, filtering, washing to neutral, and drying to obtain a secondary modified carbon nano tube; uniformly mixing the secondary modified carbon nano tube with an organic carboxylic acid, an esterification reaction catalyst and N,N-dimethylformamide, reacting under a certain condition by the aid of the protection of inert gases, cooling to the room temperature, filtering, washing, and drying to obtain the surface modification carbon nano tube. When the prepared modified carbon nano tube which is provided with ester groups on the surface is mixed with a polyester resin, the interface-free mixing is achieved, and the heat stability and the mechanical property of the modified polyester resin can be improved.

Owner:TAIYUAN UNIV OF TECH

Preparation method of functional polyester fiber

ActiveCN103789868AAdequate responseHigh apparent viscosityArtificial filament heat treatmentMelt spinning methodsPolymer scienceMoisture absorption

The invention relates to a preparation method of a functional polyester fiber. The preparation method comprises the following steps: performing esterification by stages, wherein dihydric alcohols, polyhydric alcohols and functional inorganic powder are mixed according to a certain mole ratio, in the first esterification stage, acid is slightly excess to ensure that monomers with low capability of participating in esterification reaction in the polyhydric alcohols fully react and are grafted into polyester molecular chains, and in the second esterification stage, the dihydric alcohols are replenished to control the terminal carboxyl group of copolyester. The preparation method has the advantages that polyhydric functional groups can improve the apparent viscosity of a system and play a role in wrapping the introduced functional inorganic powder (such as far infrared ceramic inorganic powder, titanium dioxide powder and zinc oxide antibacterial powder), thus improving the dispersion uniformity of particles; settlement is unlikely to happen in the polymerization process and then functional polyester is prepared through condensation polymerization; the functional polyester fiber is finally prepared by carrying out melt spinning on the prepared polyester, has good moisture absorption property and flexibility and can be widely used for preparing far-infrared moisture absorbing and sweat releasing antistatic and antibacterial fabrics next to the skin.

Owner:JIANGSU HENGZE COMPOSITE MATERIALS TECH

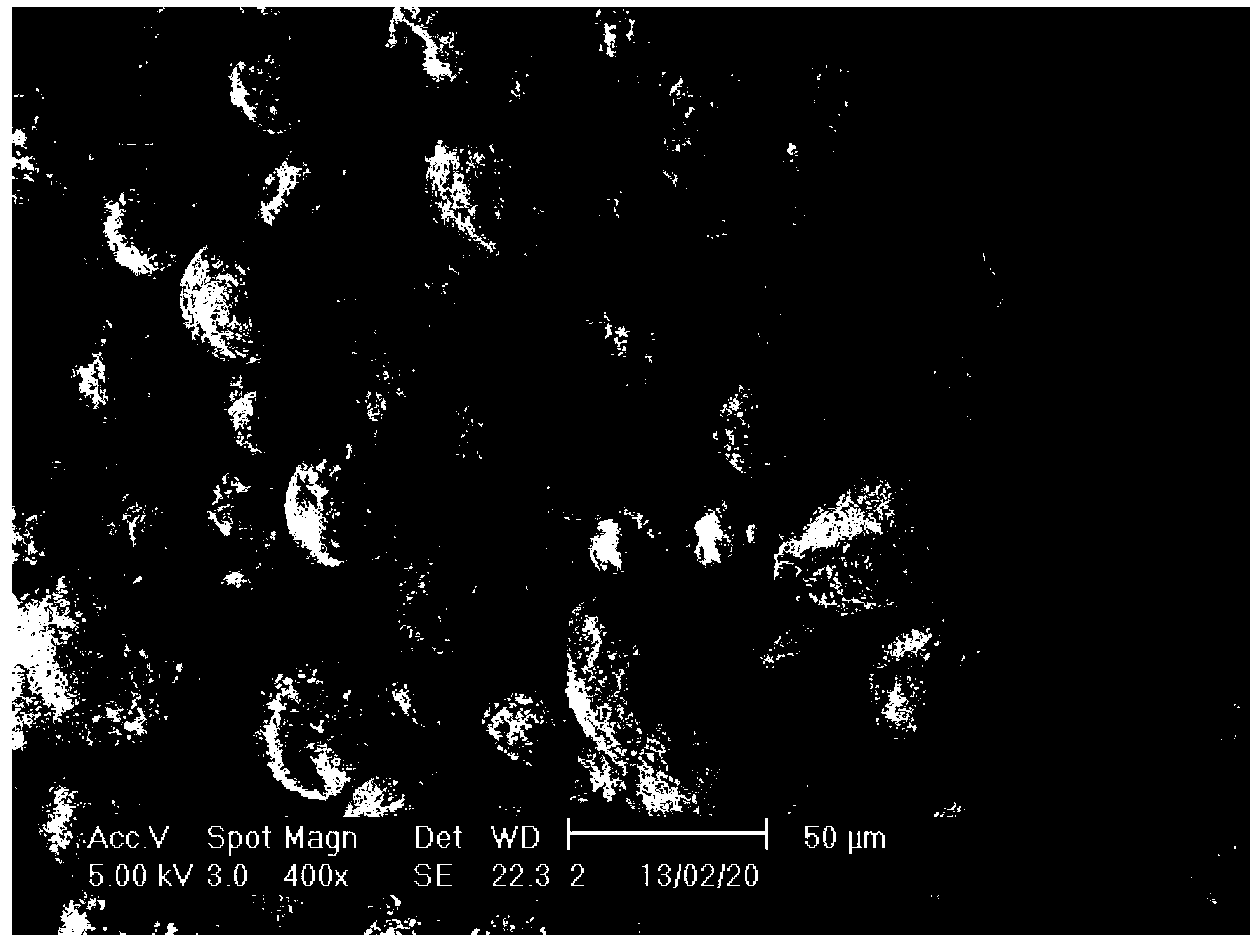

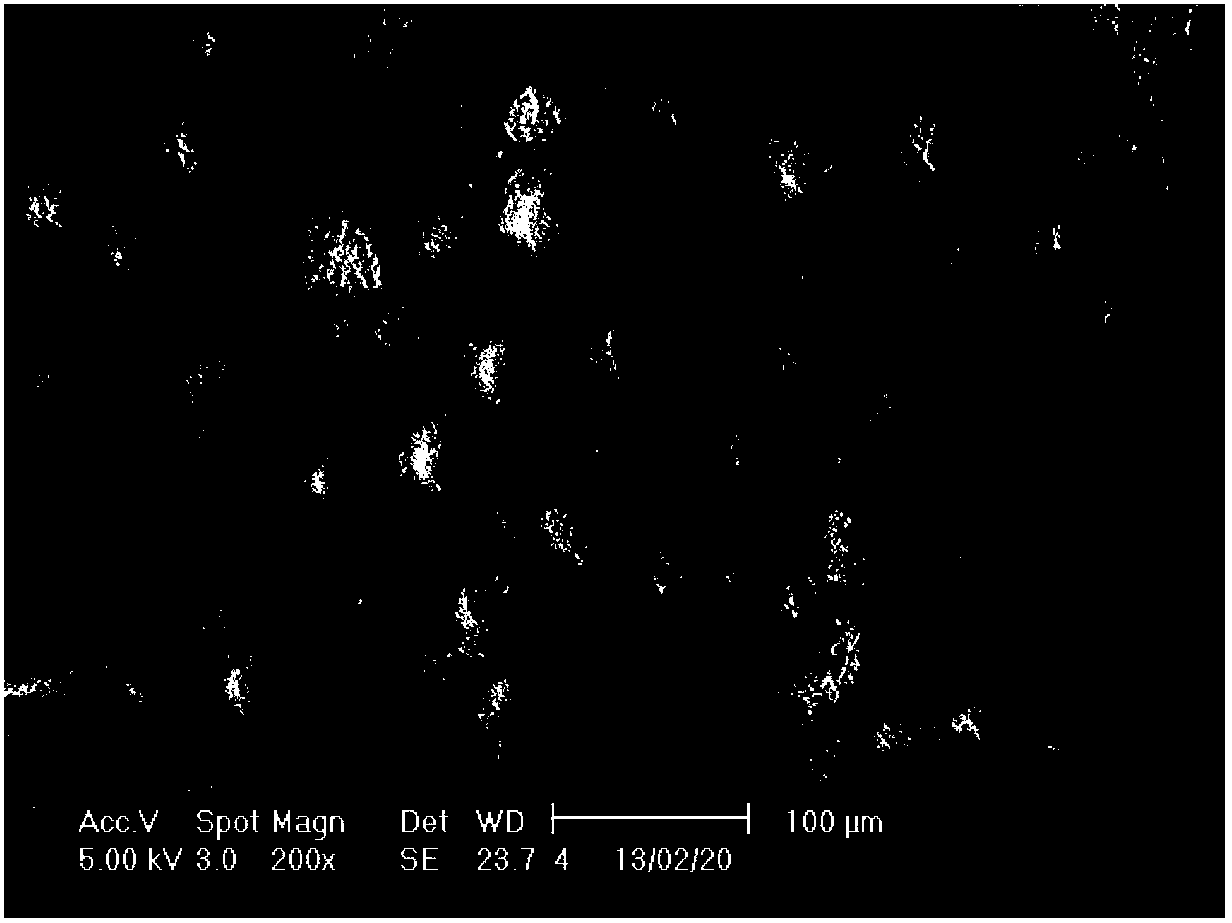

Spherical montmorillonite mesoporous composite carrier, supported catalyst and preparation method and application thereof, and ethyl acetate preparation method

ActiveCN104248985AReduce manufacturing costGood platformCatalyst carriersOrganic compound preparationMolecular sieveAcetic acid

The invention discloses a spherical montmorillonite mesoporous composite carrier and a preparation method thereof, a supported benzenesulfonic acid catalyst and a preparation method thereof, an application of the catalyst in an esterification reaction, and a preparation method of ethyl acetate. The spherical montmorillonite mesoporous composite carrier contains montmorillonite and a mesoporous molecular sieve material, average particle size of the spherical montmorillonite mesoporous composite carrier is 30-60 micrometers, the specific surface area is 150-600 square meters / gram, pore volume is 0.5-1.5 milliliters / gram, aperture distribution is trimodal distribution, most probable apertures corresponding to three peaks are 2-4 nanometers, 5-15 nanometers and 10-40 nanometers respectively. The provided supported benzenesulfonic acid catalyst has the advantages of high catalytic activity and repeated usage.

Owner:CHINA PETROLEUM & CHEM CORP +1

Enzymatic hydrolysis lignin epoxide resin and preparation thereof

The invention provides an enzymolysis lignin epoxy resin and a preparation method thereof. The raw materials include: an enzymolysis lignin-dianhydride prepolymer, a glycidol ether, a catalyst, a curing agent and a filler. The preparation method comprises the following steps that: under the action of the catalyst, an etherification of a hydroxyl group contained in the enzymolysis lignin or a derivative of the enzymolysis lignin and dianhydride is carried to synthesize a prepolymer of enzymolysis lignin-dianhydride; then the prepolymer reacts with the glycidol ether and undergoes etherification and ring closing reaction to obtain an enzymolysis lignin--polyester type epoxy resin. The enzymolysis lignin adopted by the method is natural macromolecular material extracted from the residues which is produced in the preparation of alcohol through the fermentation of wood chips, bamboo and stalk, thereby not only effectively utilizing biological resources, but also replacing petrochemical raw materials. The enzymolysis lignin epoxy resin which can be used as a modifier for engineering materials, adhesives, paints and macromolecular materials has a broad application prospect.

Owner:重庆辉泰化工销售有限公司

Formula of sustained release type polycarboxylic acid series high-performance dehydragent and method for manufacturing same

The invention proposes a compounding formula and manufacture method of a sustained release-type polyocarboxy acid high performance water reducing agent. The compounding formula comprises esterification reaction formula and copolymerization reaction formula. The invention combines the esterification reaction and copolymerization reaction into one to carry on after the improvement of the craftwork. The invention utilizing non-solvent esterification method achieves the esterification reaction in the lower temperature (75 DEG C) through using the compound catalyst. Compared with the two steps, the invention has better application performance. The invention synthesizes sustained release-type polyocarboxy acid high performance water reducing agent through the adjustment of the reaction condition and the kind and type of components in each reaction. The product is suitable for the concrete with high request to the control of the slump.

Owner:重庆建研科之杰新材料有限公司

Method for producing epoxy plasticizer dirty oil and vegetable and animal waste oil

A method for producing epoxy plasticizer from refused animal and vegetable oil is carried out by adding refused oil 97-99.8wt% and porous carrier solid acid 0.2-3wt% into reactor, inducing into gas-phase methanol at 95-130degree, agitating for 1-4hrs, esterification reacting, separating out solid acid, adding liquid 70-80wt%, methanol 15-25wt% and solid alkali catalyst 1-5wt% into reactor, agitating at 50-65degree and normal pressure for 0.5-2hrs, separating out to obtain aliphatic acid methoxy-carbonyl, adding hydrogen peroxide 25-5wt%, methane acid 2.5-10wt% and sodium tripolyphosphate 0-1wt% into aliphatic acid methoxy-carbonyl 55-70wt%, agitating for 8-10hrs at 60+-5degree, reacting, separating out acid water, neutralizing, washing and dewatering to obtain the final product. It's simple, cheap and has less consumption.

Owner:江苏悦达卡特新能源有限公司

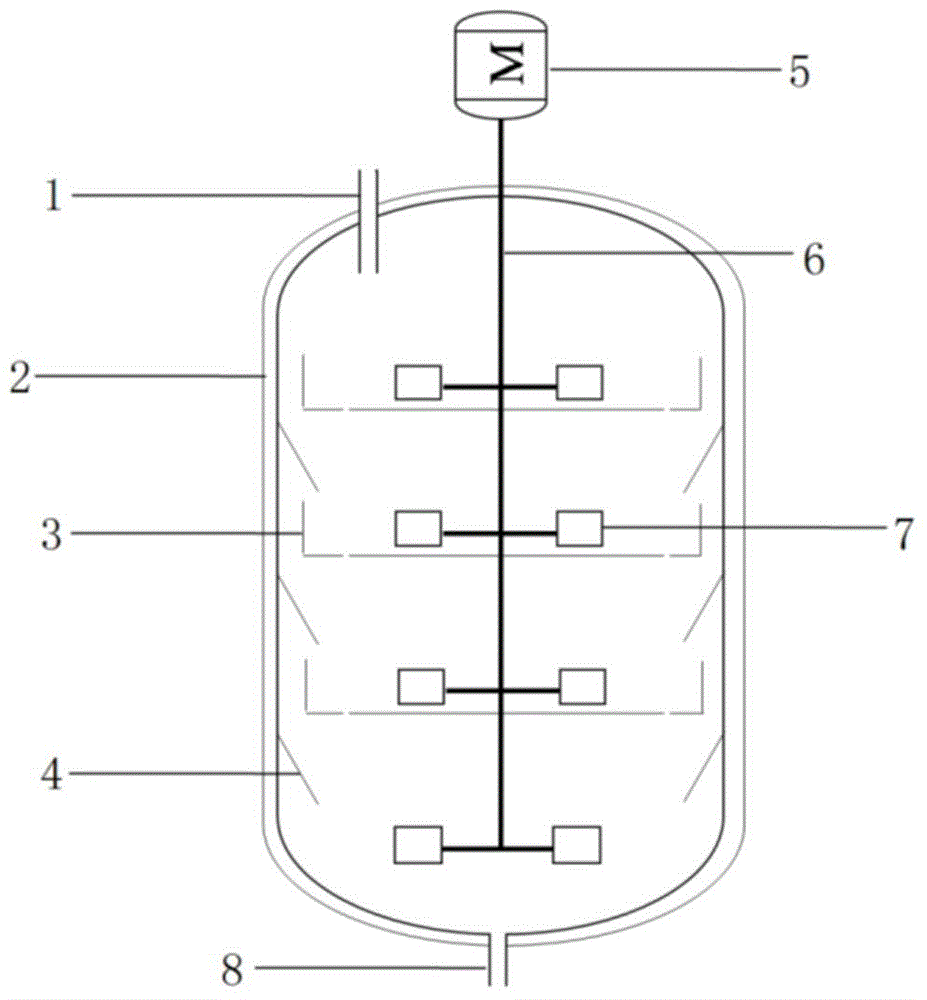

Method for preparing low-melting-point polyester composite fiber by adopting continuous polymerization and melt direct-spinning

ActiveCN105063797AImprove thermal stabilitySuppress thermal degradation side reactionsArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsOligomerTransesterification

The invention relates to a method for preparing a modified copolyester composite fiber, in particular to a method for preparing a low-melting-point polyester composite fiber by adopting continuous polymerization and melt direct-spinning. The method comprises the following steps: slurry is prepared from raw materials in proportion and added continuously into an esterification system for an esterification reaction, an obtained oligomer is uniformly mixed with polyether, the mixture enters a homogenizing kettle for transesterification and pre-polycondensation, a product is uniformly mixed with a chain extender for final polycondensation, and an obtained low-melting-point polyester melt and a common polyester melt enter a composite spinning assembly to prepare the low-melting-point polyester composite fiber which comprises a common polyester core layer and a low-melting-point polyester cortex layer. The method has the advantages as follows: a side reaction of thermal degradation of polyether components is inhibited effectively, and the color and spinnability of the low-melting-point polyester melt are improved; the problem of poor performance of composite spinning of the low-melting-point polyester on the cortex layer and the common polyester on the core layer due to large dynamic viscosity difference of the melt is solved, and the composite fiber is well formed; the production efficiency of the low-melting-point polyester composite fiber is improved.

Owner:CHINESE TEXTILE ACAD

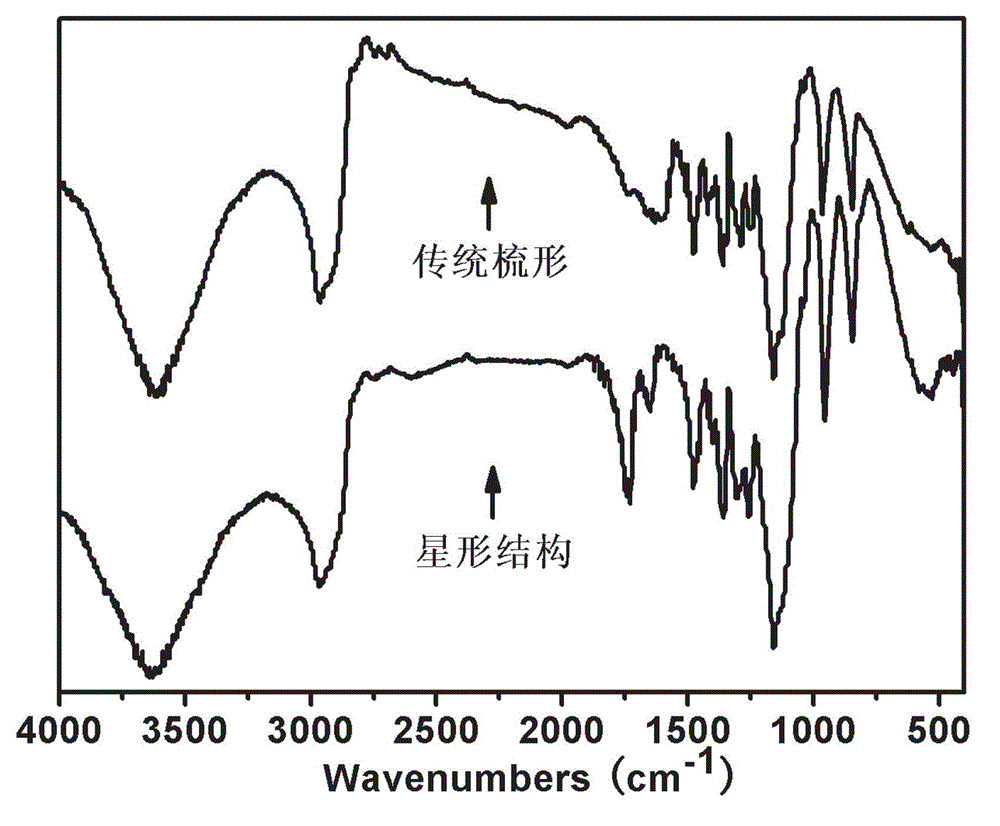

Synthesis method of polycarboxylic acid high-performance water reducing agent of star-like structure

ActiveCN102911322AExtended Dionon Design-Structure-PropertyExpanding the theoretical connotation of the design-structure-performance of moleculesSynthesis methodsPolyethylene glycol

The invention discloses a synthesis method of a polycarboxylic acid high-performance water reducing agent of a star-like structure, belonging to the field of a water reducing agent. According to the synthesis method, polybasic alcohol, (methyl) acrylic acid, a polyethylene glycol compound and the like are used as esterification raw materials, and the polycarboxylic acid high-performance water reducing agent of the star-like structure is prepared through a sequential esterification and polymerization method, i.e., the (methyl) acrylic acid and the polybasic alcohol are used as reactants, a star-like polymerizable active end is prepared through esterification reaction under the action of a catalyst, and then the polycarboxylic acid high-performance water reducing agent is prepared from the star-like polymerizable active end and esterification macromolecule, a molecular weight regulator and an unsaturated carboxylic acid monomer under the action of an initiator through free radical polymerization reaction. The synthesis method has the advantages of simplicity, easiness in control, high polymerization degree, low cost, no pollution, capability of realizing the polycarboxylic acid high-performance water reducing agent of the star-like structure connected with a plurality of polycarboxylic acid molecules, and more superior cement paste fluidity and holding capacity, good cement adaptability and concrete application performance compared with the conventional linear and comb-shaped polycarboxylic acid water reducing agent in the case of normal and low added amount.

Owner:GUIZHOU DR SHI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com