Low-melting-point copolyester and method for preparing same

A technology of copolyester and low melting point, applied in the textile field, can solve the problems of crystallization performance damage, low intrinsic viscosity, easy adhesion, etc., and achieve the effect of good thermal adhesion, good crystallization performance and high intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

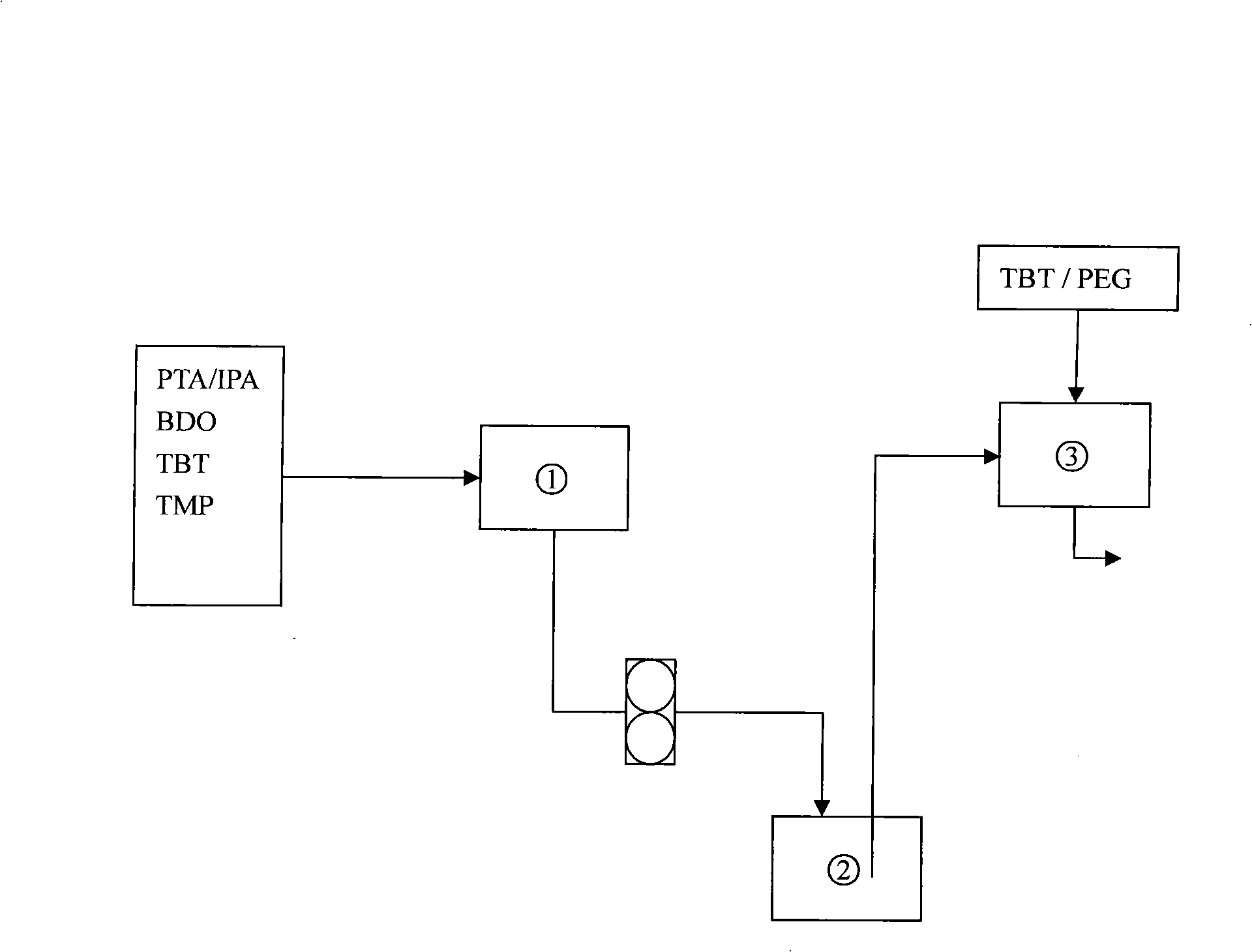

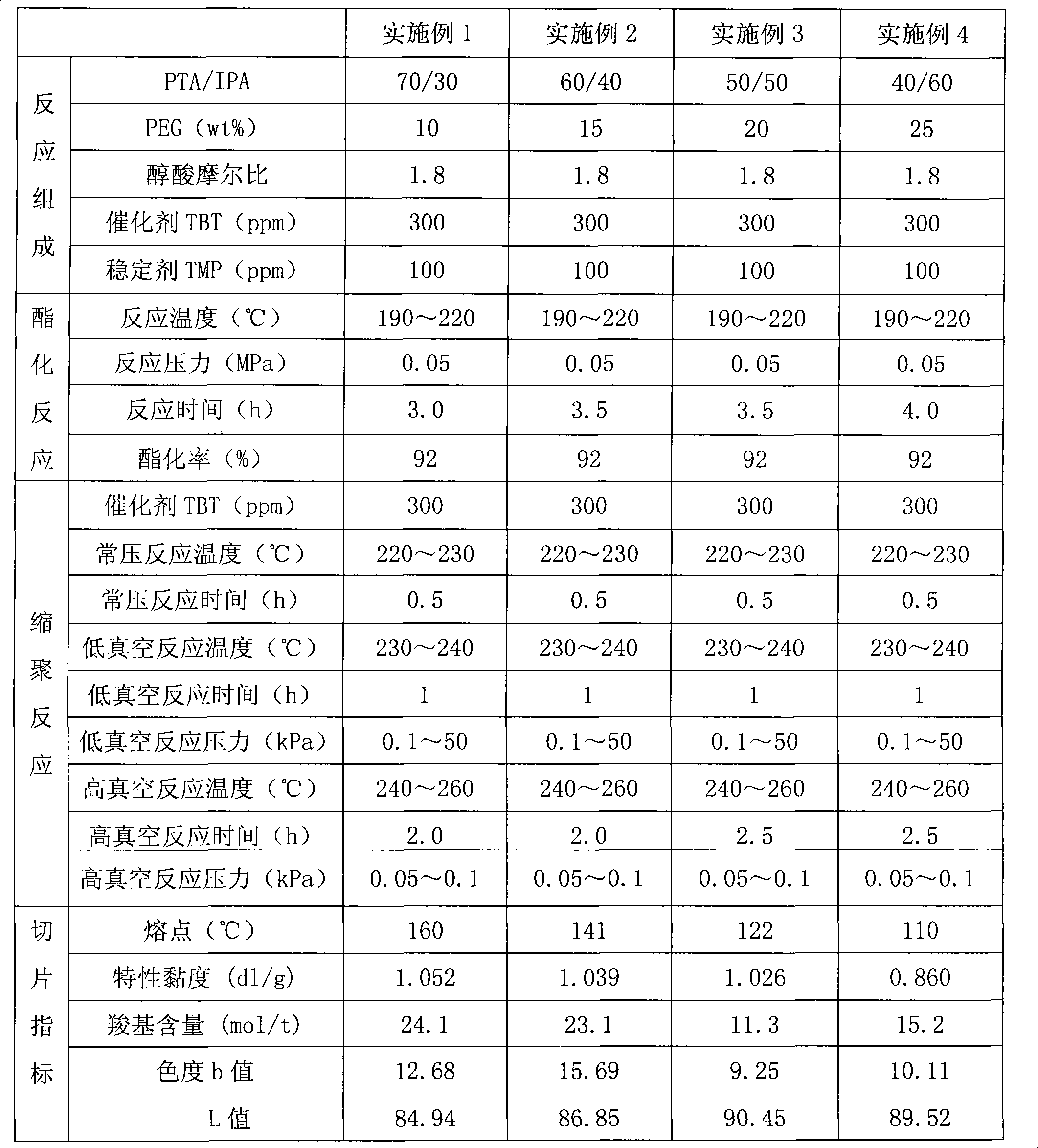

[0022] The present invention will be further described below in conjunction with specific embodiment: the low-melting point copolyester of the present invention forms through esterification reaction and polycondensation reaction with following monomer,

[0023] (a) Terephthalic acid (PTA) and isophthalic acid (IPA);

[0024] (b) 1,4 butanediol (BDO);

[0025] (c) polyethylene glycol 600-6000 (PEG);

[0026] Among them, in component a, the mass ratio of terephthalic acid to isophthalic acid is between 80-20:20-80; in component c, the weight ratio of polyethylene glycol is 1-30% based on a; a and The molar ratio of b is 1:1.5~2.3.

[0027] The low-melting copolyester has an intrinsic viscosity between 0.60-1.20 dL / g and a melting point of 110-160°C.

[0028] A kind of preparation method of low melting point copolyester as mentioned above, this method comprises two stages of esterification reaction and polycondensation reaction:

[0029] The esterification reaction is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com