Patents

Literature

1992 results about "Intrinsic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intrinsic viscosity [η] is a measure of a solute's contribution to the viscosity η of a solution. It should not be confused with inherent viscosity, which is the ratio of the natural logarithm of the relative viscosity to the mass concentration of the polymer. Intrinsic viscosity is defined as [η]=limϕ→₀(η-η₀)/η₀ϕ where η₀ is the viscosity in the absence of the solute, η is (dynamic or kinematic) viscosity of the solution and ϕ is the volume fraction of the solute in the solution.

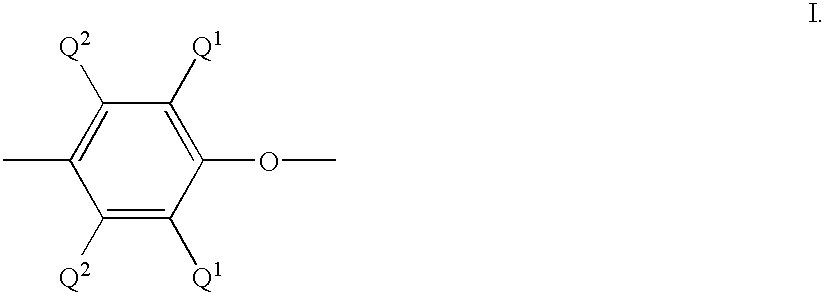

High flow polyphenylene ether formulations

A high flow polyphenylene ether resin composition with improved HDT values and flame retardance comprising a blend of at least two polyphenylene ether resins, a first resin having an intrinsic viscosity of at least 0.3 dl / g, and a second resin having an intrinsic viscosity of less than 0.25 dl / g and preferably having a particle size of at least about 100 mum. The composition preferably contains less than 30 wt % of the low viscosity polyphenylene ether based on the weight of the total composition. Fiber reinforced and flame retarded compositions also exhibit high HDT values.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Polypropylene resin composition and use thereof

A polypropylene resin composition exibiting a high melt tension and superior moldability, which can be molded efficiently by a high-speed molding into scarcely deformable larger molded articles of better appearance with high stiffness and which comprises polypropylene as a main component and has the following characteristic features 1) to 4), namely,1) that a melt flow rate (MFR, determined at 230° C. under a load of 2.16 kg) is in the range of 0.01 to 5 g / 10 min.,2) that a content of a high molecular weight polypropylene exhibiting an intrinsic viscosity [eta], determined at 135° C. in decalin, of 8-13 dl / g is in the range of 15 to 50% by weight,3) that a gel areal density in number is 3,000 / 450 cm2 or less and4) that a molecular weight distribution determined by gel permeation chromatography (GPC) is 6-20, as expressed by Mw / Mn, and is 3.5 or higher, as expressed by Mz / Mw.

Owner:PRIME POLYMER CO LTD

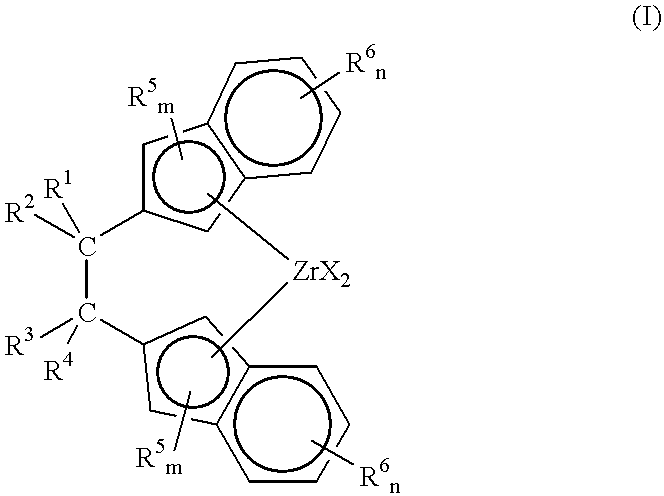

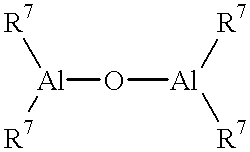

Multi-stage process for the polymerization of olefins

A multi-stage process for preparing ethylene (co)polymers having broad molecular weight distributions is disclosed, said process comprising:(A) a first polymerization stage in which, in the presence of a Ti or V catalyst, a first ethylene polymer is prepared;(B) a treatment stage in which the catalyst used in the first stage is deactivated and in which a bridged bis-2-indenyl zirconocene is supported on the ethylene polymer produced in stage (A), optionally in the presence of a suitable cocatalyst; and(C) a second polymerization stage in which ethylene is polymerized in the presence of the product obtained from stage (B).Furthermore, polyethylene obtainable by the above process is disclosed, having intrinsic viscosity ranging from 0.5 to 6 dl / g, Mw / Mn>8 and cold xylene solubility<1.2% wt.

Owner:MONTELL TECH CO BV

Polypropylene resin composition and injection-molded article thereof

A polypropylene resin composition, which is light weighing, has very high values for the stiffness and heat resistance and is superior in the scratch-proof property with better moldability upon molding and which can be injection-molded into formed articles without occurrence of cracking, comprising 5-25% by weight of a higher molecular weight polypropylene (A) having an intrinsic viscosity [eta], determined in decalin at 135° C., in the range from 6 to 11 dl / g and 95-75% by weight of a lower molecular weight polypropylene (B) having an intrinsic viscosity [eta], determined in decalin at 135° C., in the range from 0.6 to 1.6 dl / g, wherein the said resin composition has the following charactristic features <<1>> and <<2>>, namely,<<1>> an isotactic pentad fraction (mmmm-fraction), determined by 13C-NMR, of at least 96.5% and<<2>> a molecular weight distribution value expressed by Mw / Mn (weight-average molecular weight / number-average molecular weight), determined by gel permeation chromatography (GPC), of at least 8.

Owner:PRIME POLYMER CO LTD

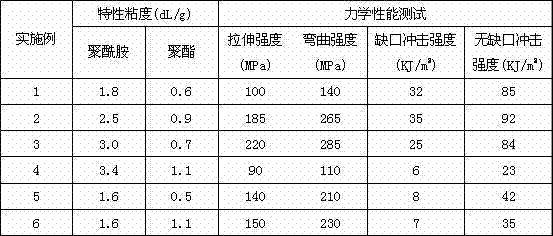

Glass fiber reinforced polyamide/polyester alloy and preparation method thereof

The invention discloses a glass fiber reinforced polyamide / polyester alloy and a preparation method thereof. The glass fiber reinforced polyamide / polyester alloy consists of the following components in percentage by weight: (A) 99-30 percent of resin component and (B) 70-1 percent of glass fiber, wherein the resin component (A) consists of the following components in percentage by weight: (1) 97-1 percent of polyamide of which the intrinsic viscosity is 1.8-3.0 dL / g, (2) 97-1 percent of polyester of which the intrinsic viscosity is 0.6-0.9 dL / g, (3) 1-20 percent of compatilizer and (4) 1 percent of other aids. The preparation method comprises the following steps of: weighing the materials with an electronic metering scale; feeding the materials into a dual-screw extruder respectively; and melting and mixing together to obtain a high-strength and high-toughness glass fiber reinforced polyamide / polyester alloy. The method is simple, and the performance of the obtained polyamide / polyester alloy is higher than that of a glass fiber reinforced nylon material.

Owner:KINGFA SCI & TECH CO LTD +1

Stiff polypropylene composition with excellent elongation at break

Polypropylene composition comprising (a) a high melt strength polypropylene having a melt flow rate MFR 2 (230 °C) of equal or below 15 g / l 0min and a branching index g' of below 1.0, (b) a first heterophasic propylene copolymer comprising €¢ a polypropylene having a melt flow rate MFR 2 (230 °C) in the range of 50 to 500 g / 10min and an elastomeric propylene copolymer having a propylene content in the range of 50 to 80 wt.-% and €¢ an intrinsic viscosity (IV) of equal or more than 2.5 dl / g, (c) a second heterophasic propylene copolymer comprising €¢ a random propylene copolymer having a melt flow rate MFR 2 (230 °C) in the range of 1 to 40 g / 10min, a branching index g' of 1.0, and a comonomer content of more than 0.5 wt.-%,and €¢ an elastomeric propylene copolymer having a propylene content in the range of 50 to 80 wt.-%, and an intrinsic viscosity (IV) of equal or below 2.4 dl / g, (d) a polyethylene plastomer having an ethylene content of at least 50 wt.-%, and (e) a mineral filler (F).

Owner:BOREALIS AG

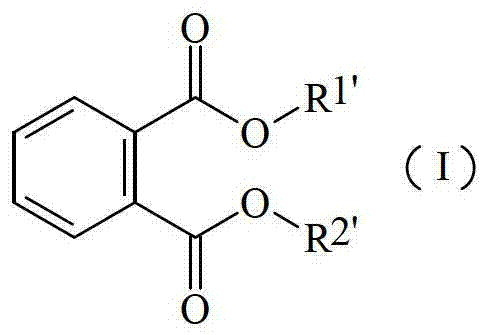

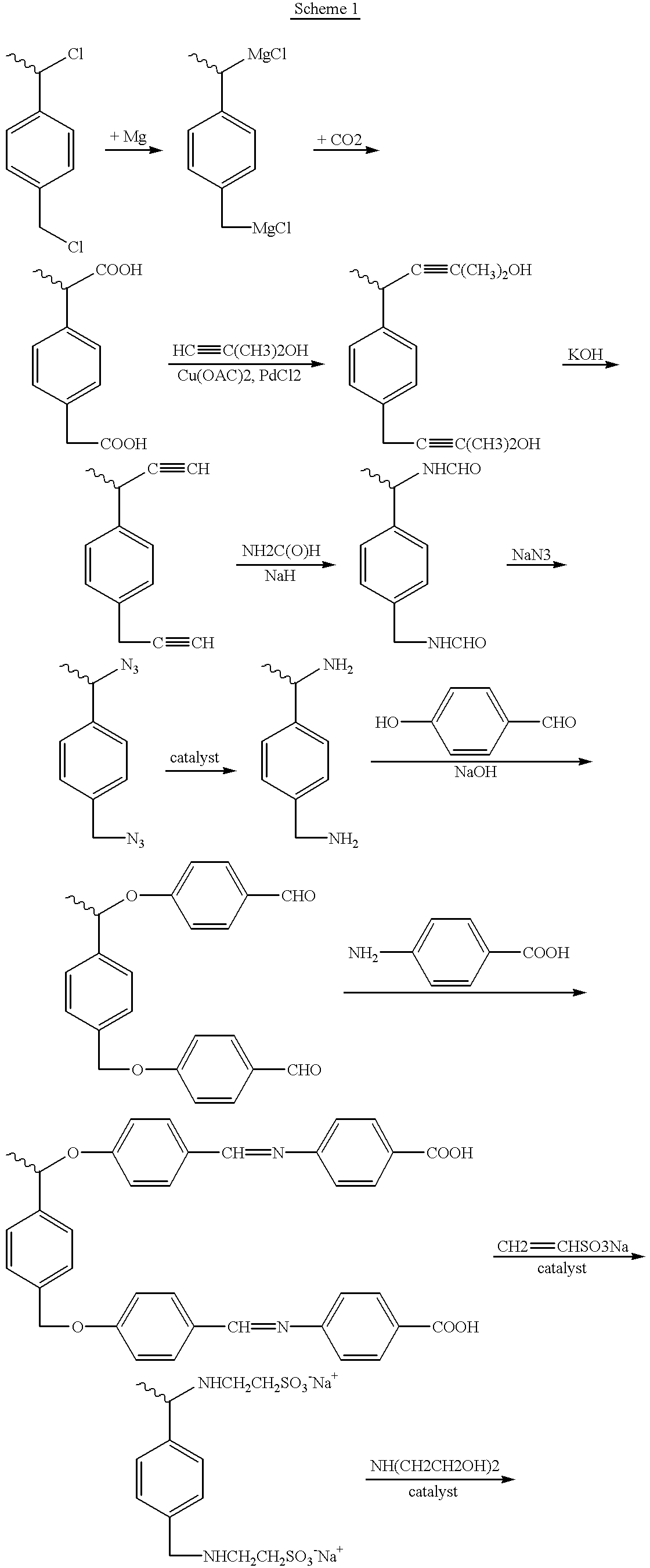

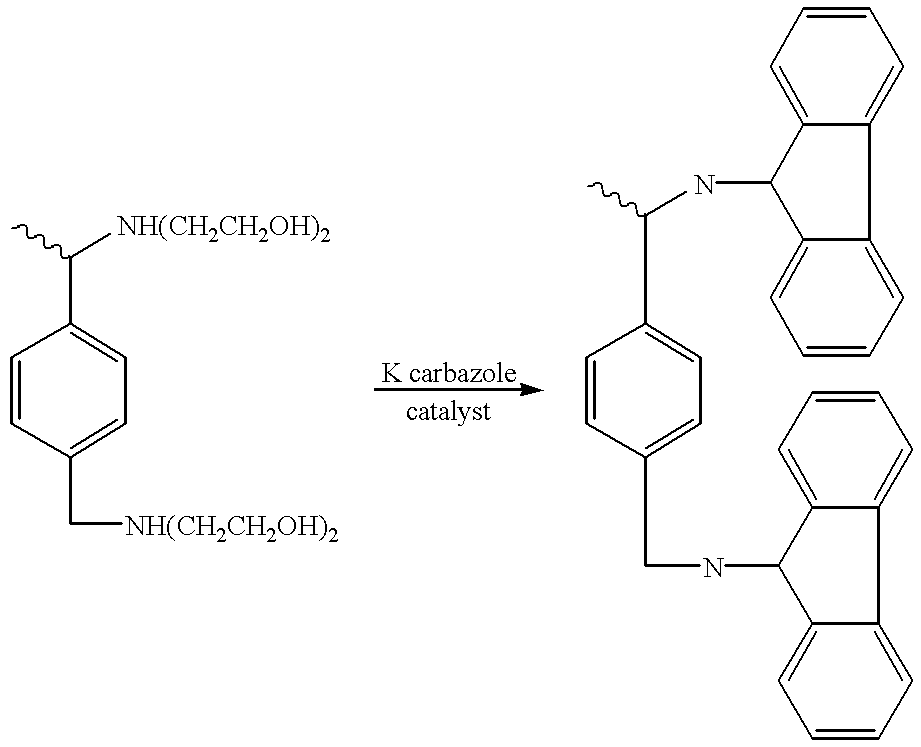

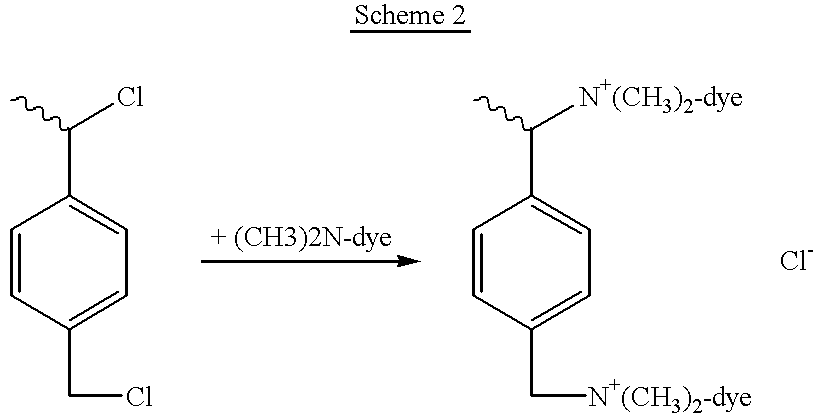

Vinyl hyperbranched polymer with photographically useful end groups

InactiveUS6252025B1Photoprinting processesMulticolor photographic processingDendrimerPolymer science

Photographically useful materials are disclosed comprising a hyperbranched polymer segment and multiple pendant photographically useful groups. Such materials may be prepared by forming an active hyperbranched polymer segment with multiple functionalized end group sites, and reacting the active hyperbranched polymer segment with an active compound comprising a photographically useful group to form a hyperbranched polymer ended with photographically useful groups. The hyperbranched segment may comprise any kind of polymer segment with hyperbranched architecture, and the active end groups may comprise any kind of reactive site. The active hyperbranched polymer may comprise any kind of other functional groups which are located in either backbone or the ends. The hyperbranched polymers containing photographically useful groups obtained in accordance with the invention are particularly advantageous in that they enable polymer structures comprising components exhibiting different photographically useful properties, while maintaining relatively low intrinsic viscosities compared to non-hyperbranched polymers containing photographically useful groups of similar chemical compositions. Additionally, the hyperbranched polymers are advantageous with respect to dendrimer type polymers in that a wide variety of hyperbranched polymer compositions may be synthesized in accordance with commercially acceptable processes.

Owner:EASTMAN KODAK CO

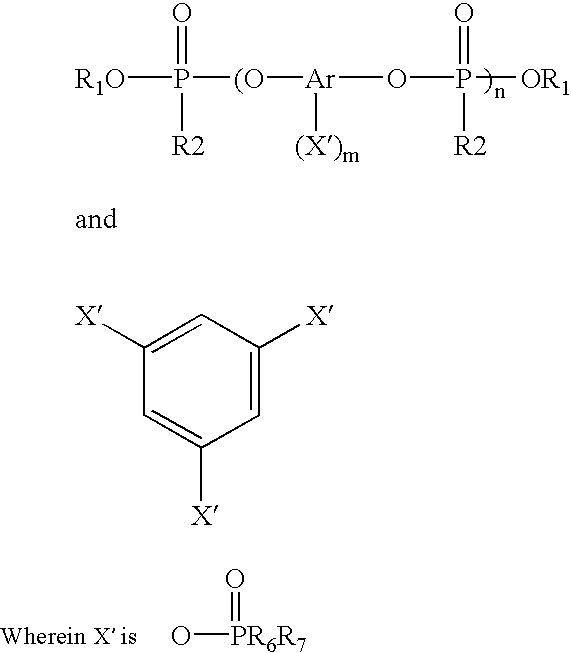

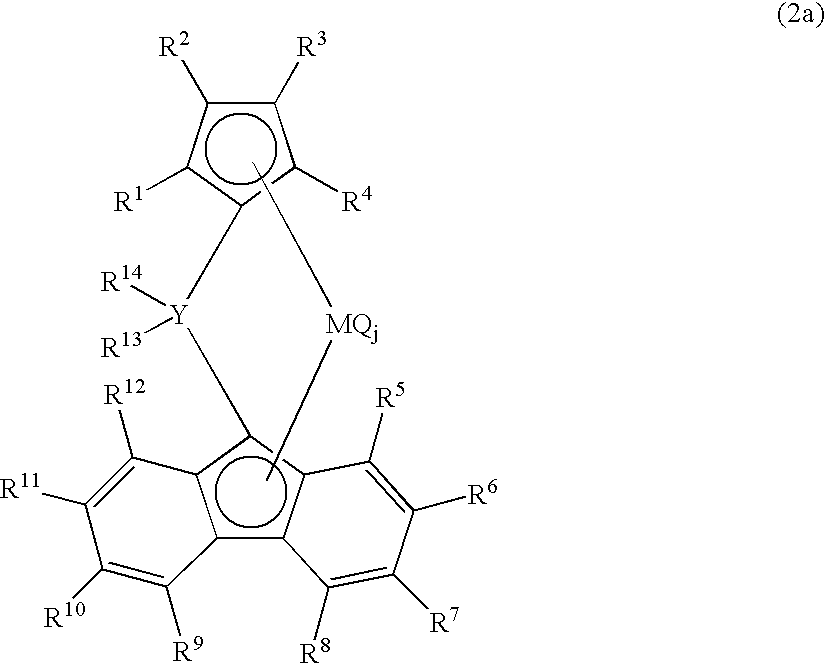

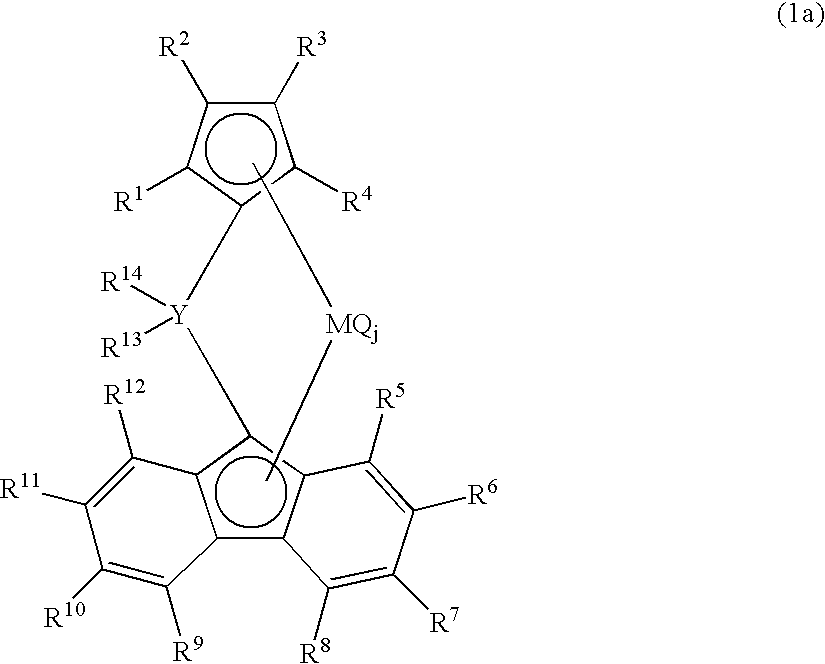

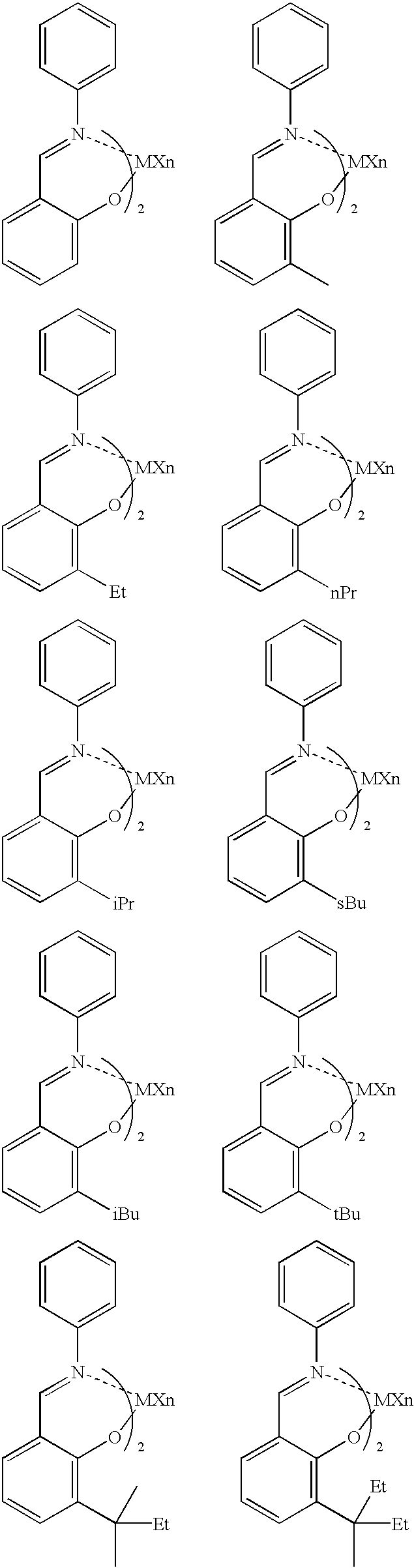

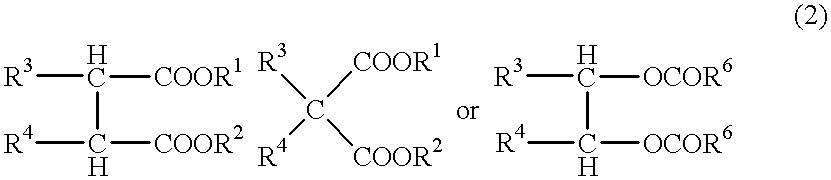

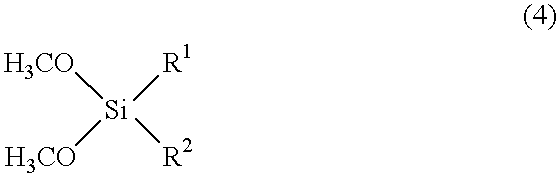

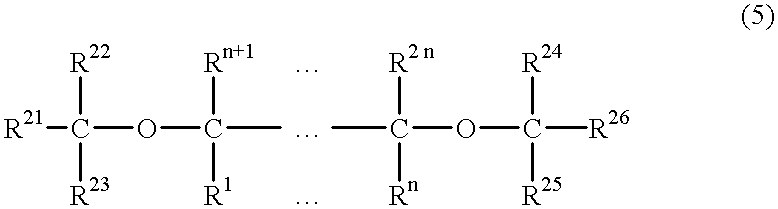

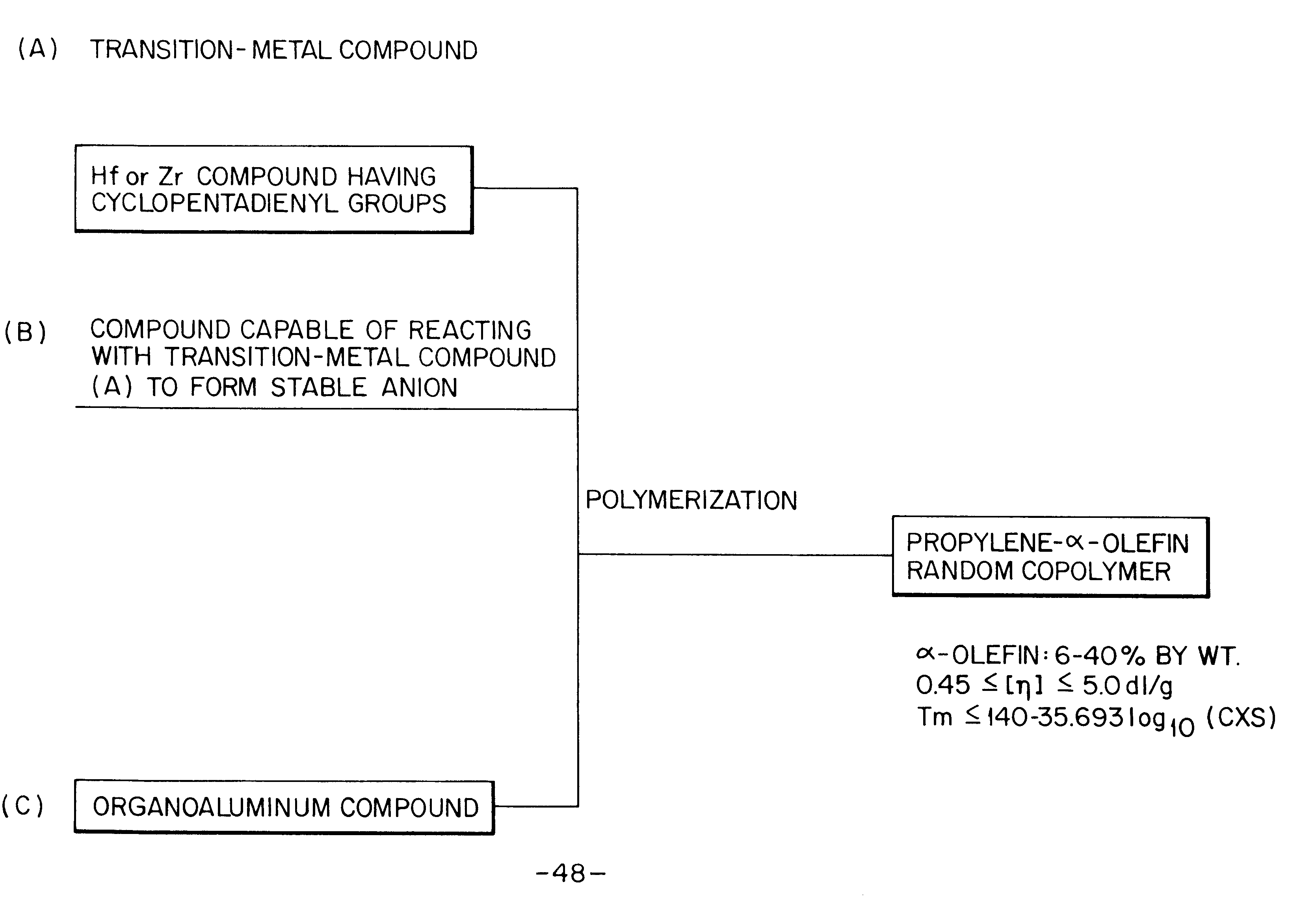

Propylene copolymer, polypropylene composition, and uses thereof, transition metal compounds and catalyst for olefin polymerization

ActiveUS20060276607A1Good molding effectHigh transparencyDomestic articlesThin material handlingPolypropyleneIntrinsic viscosity

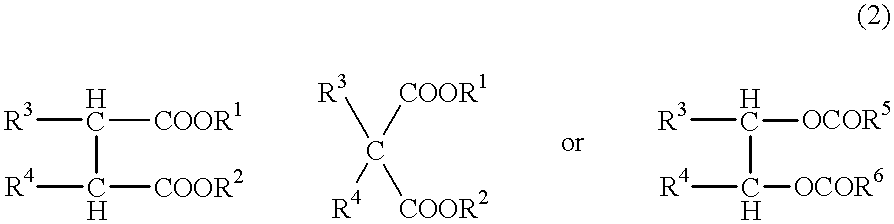

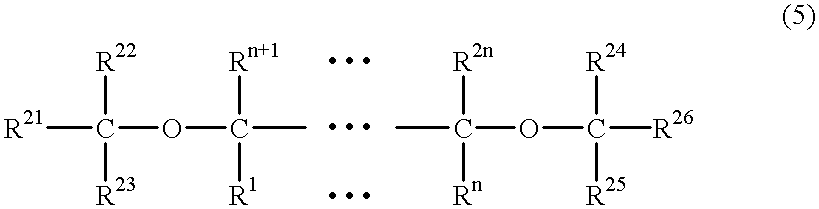

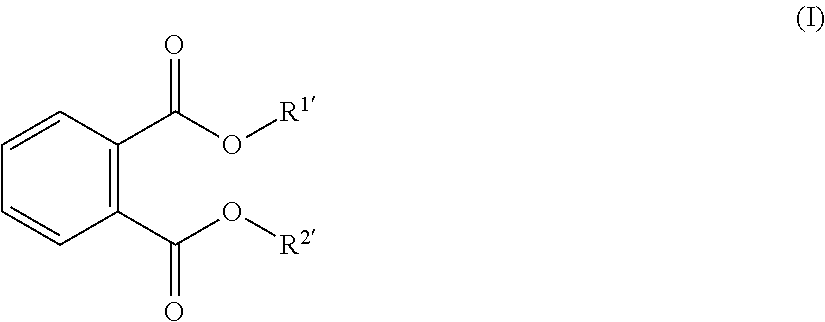

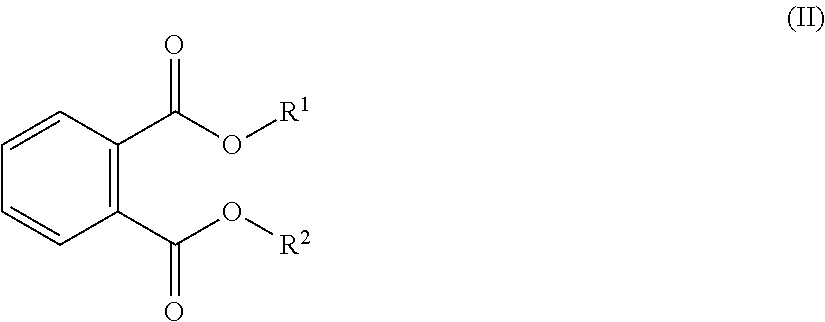

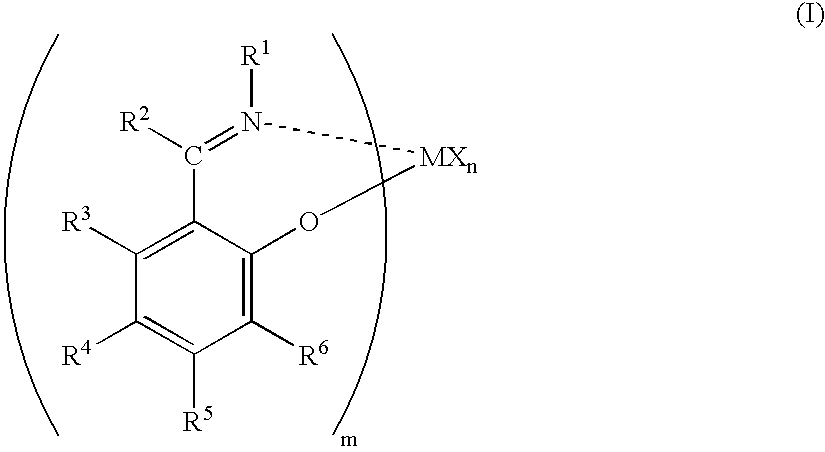

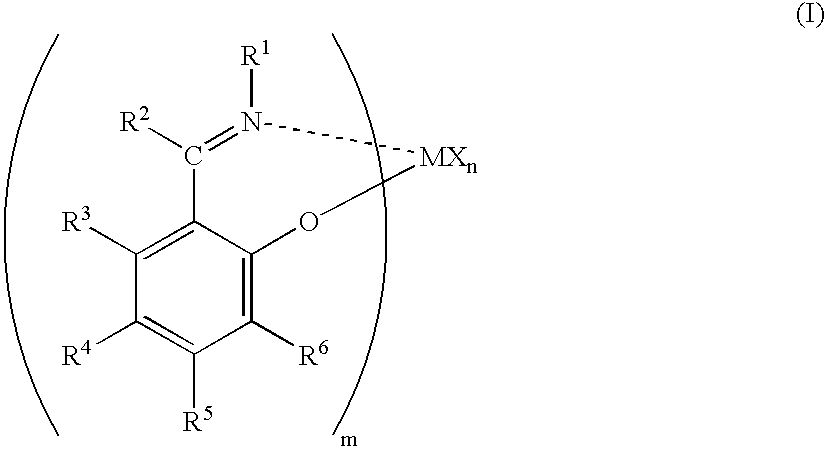

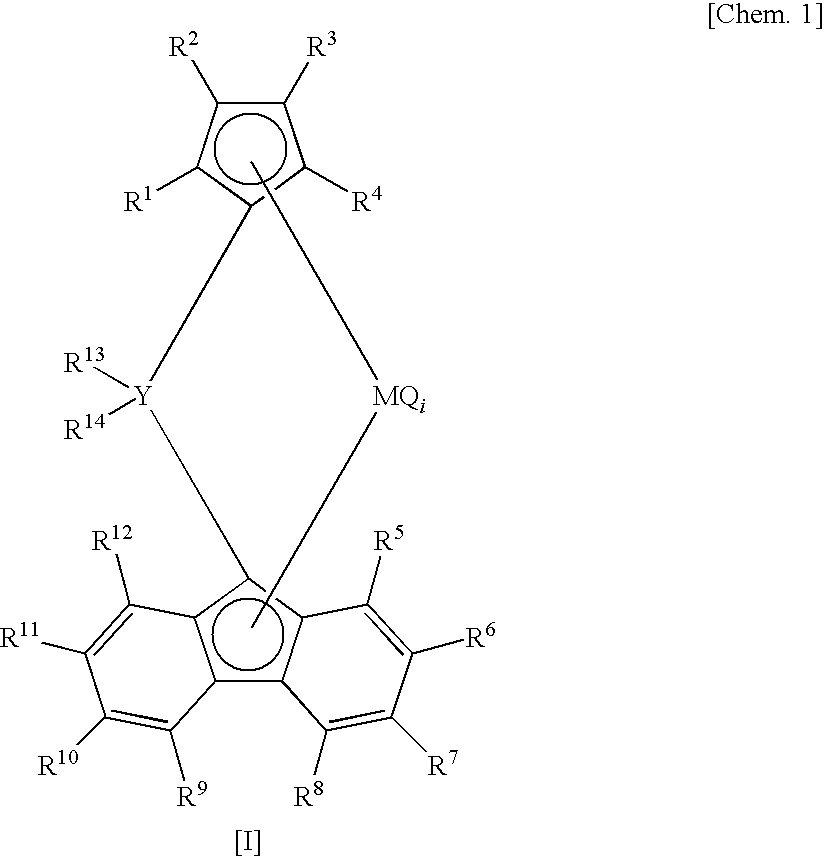

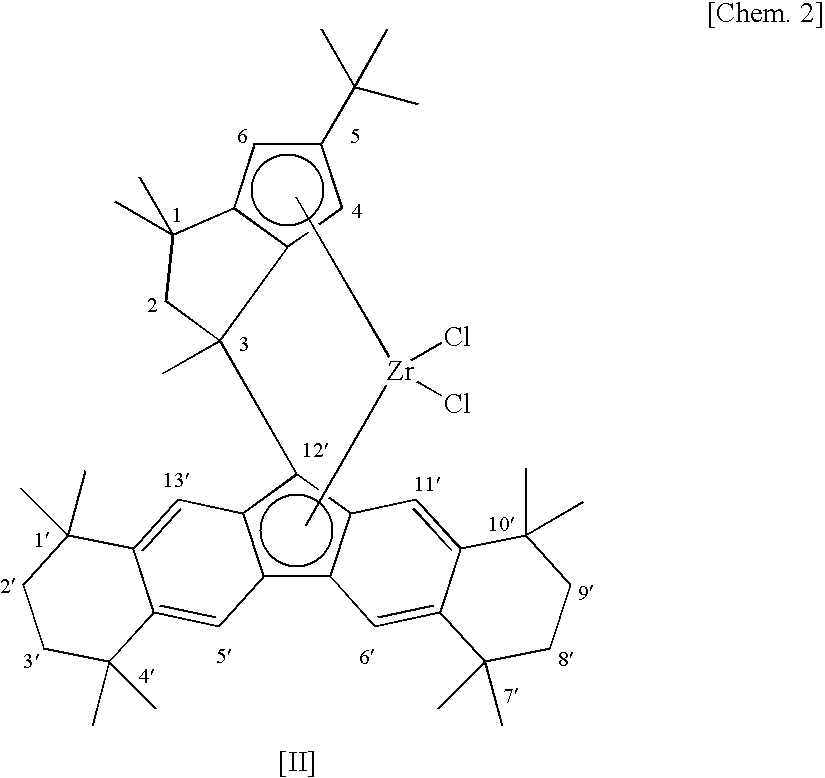

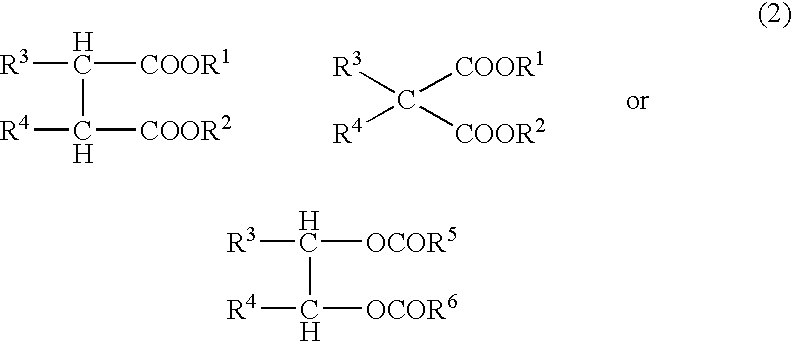

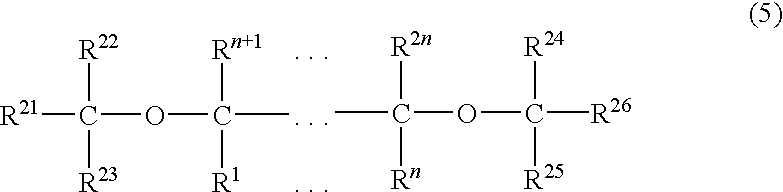

The present invention provides a propylene / 1-butene random copolymer (PBR) having excellent flexibility, impact resistance, heat resistance and low-temperature heat-seal properties, a polypropylene composition containg the copolymer, a sheet, film or stretched film comprising the composition and a composite film having a layer of the composition. The propylene / 1-butene random copolymer contains 60 to 90 mol % of propylene units and 10 to 40 mol % of 1-butene units and has a triad isotacticity of not less than 85% and not more than 97.5%, a molecular weight distribution (Mw / Mn) of from 1 to 3, an intrinsic viscosity of from 0.1 to 12 dl / g, a melting point (Tm) of from 40 to 120° C., and satisfies the following relation 146 exp(−0.022M)≧Tm≧125 exp(−0.032M) wherein Tm represents a melting point and M (mol %) represents a content of 1-butene constituent units. The invention, further, provides a transition metal compound useful as an olefin polymerization catalyst and an olefin polymerization catalyst containing the transition metal compound. The transition metal compound is represented by the following formula (2a): wherein each of R1 and R3 is hydrogen, R2 and R4 are selected from a hydrocarbon group and silicon-containing group, R5 to R13 are selected from hydrogen, a hydrocarbon group and silicon-containing group, and adjacent substituent groups R5 to R12 may be linked to form a ring. R14 is an aryl group, and R13 and R14 may be linked to form a ring. M is a Group 4 transition metal, Y is a carbon atom, Q is halogen, etc, and j is an integer of 1 to 4.

Owner:MITSUI CHEM INC

Flexible poly(arylene ether) composition and articles thereof

A thermoplastic composition comprises poly(arylene ether) having an initial intrinsic viscosity greater than 0.25 dl / g as measured in chloroform at 25° C.; a polyolefin having a melt temperature greater than or equal to 120° C. and a melt flow rate of 0.3 to 15; a first block copolymer having a aryl alkylene content greater than or equal to 50 weight percent based on the total weight of the first block copolymer; a second block copolymer having an aryl alkylene content less than 50 weight percent based on the total weight of the second block copolymer; and a flame retardant, wherein the poly(arylene ether) is present in an amount greater than the amount of polyolefin. The composition is useful in the production of covered wire.

Owner:SHPP GLOBAL TECH BV

Polyester and process for preparing polyester

Owner:MITSUI CHEM INC

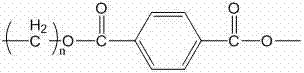

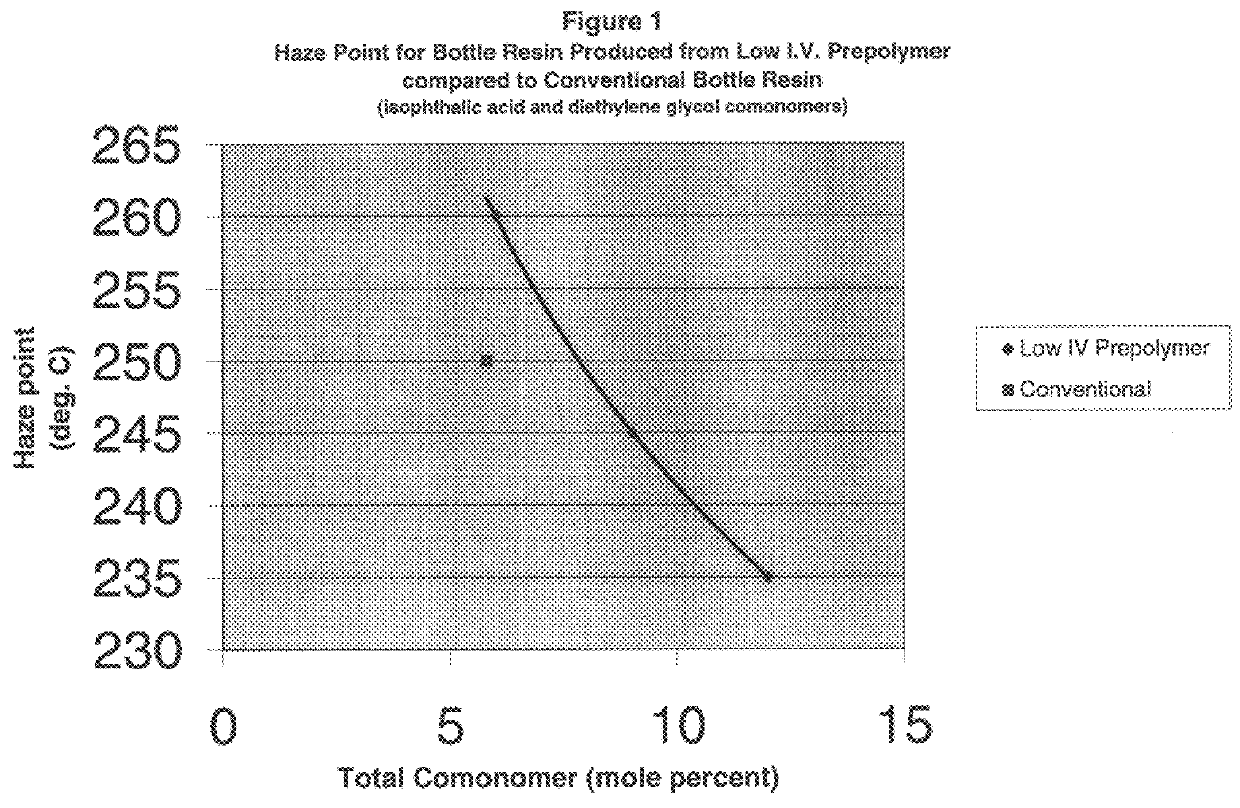

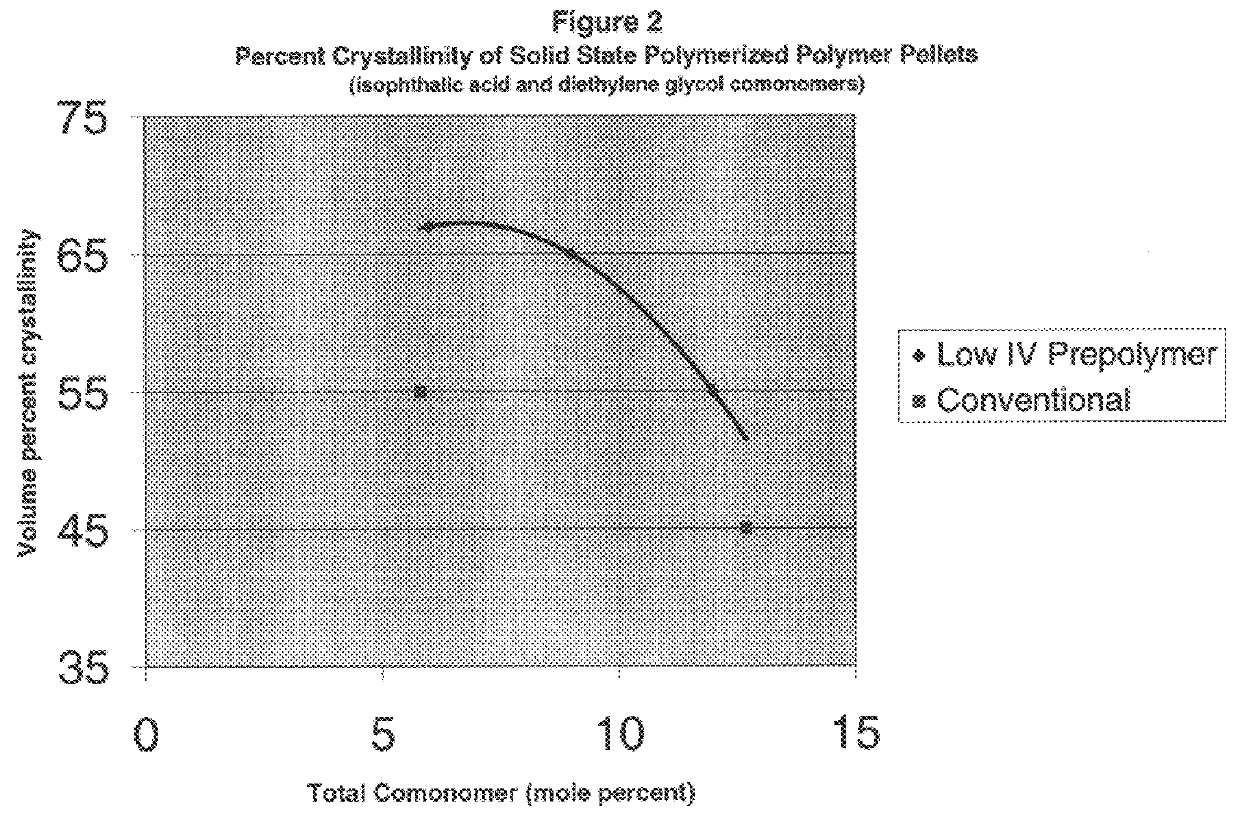

Method of preparing modified polyester bottle resins

InactiveUS6284866B1Low haze pointLess heatBottlesSynthetic resin layered productsDimethyl terephthalatePolyethylene terephthalate

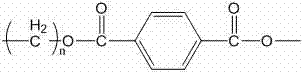

The present invention is a method of preparing a high molecular weight copolyester bottle resin that has excellent melt processing characteristics. The method includes the steps of reacting a diacid or diester component and a diol component to form modified polyethylene terephthalate, wherein diol component is present in excess of stoichiometric proportions. Together, the diacid or diester component and the diol component must include at least 7 percent comonomer. The remainder of the diacid component is terephthalic acid or dimethyl terephthalate and the remainder of the diol component is ethylene glycol. The modified polyethylene terephthalate is copolymerized in the melt phase to an intrinsic viscosity of between about 0.25 dl / g and 0.40 dl / g to thereby form a copolyester prepolymer. Thereafter the copolyester prepolymer is polymerized in the solid phase to form a high molecular weight bottle resin that has an intrinsic viscosity of at least about 0.70 dl / g, and a solid phase density of less than 1.413 g / cc.

Owner:WELLMAN INC

Tough composition for food applications

Heterophasic polypropylene composition comprising:—a polypropylene matrix (M) and—an elastomeric copolymer (E) being dispersed in the matrix (M), wherein the elastomeric copolymer (E) comprises units derived from—propylene and—ethylene and / or C4 to C20 α-olefin, and wherein further,—the intrinsic viscosity of the xylene cold soluble fraction (XCS) of the heterophasic polypropylene composition is above 2.1 dl / g measured according to ISO 1628-1 (at 135° C. in decaline) and / or—Mz / Mw of the xylene cold soluble fraction (XCS) of the heterophasic polypropylene composition is more than 2.6, preferably 2.7, wherein the Mz is the z-average molecular weight measured according to ISO 16014-4:2003 and Mw is the weight average molecular weight measured according to ISO 16014-4:2003.

Owner:BOREALIS AG

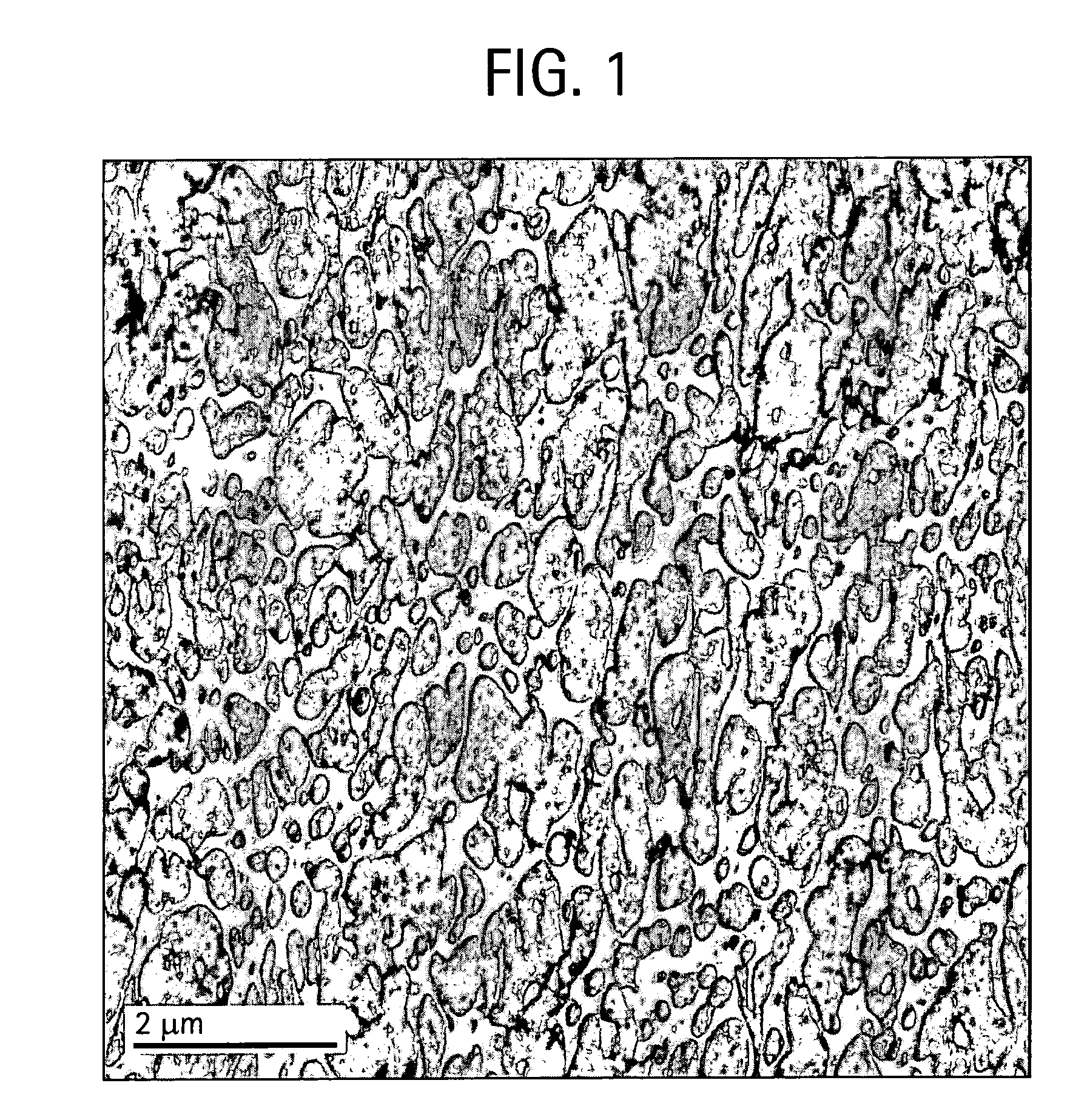

Ethylene copolymer and process for producing the same, resin composition containing the copolymer, and uses of these

InactiveUS6462136B1High tear strengthUniform processElectric/magnetic detectionAcoustic wave reradiationPolymer scienceActivation energy

The present invention is intended to provide an ethylene copolymer having excellent mechanical properties and moldability, a process for preparing the copolymer, a resin composition containing the copolymer and uses thereof. The ethylene copolymer has the following properties: the copolymer comprises 90 to 99% by mol of ethylene constituent units and 1 to 60% by mol of C3-20 alpha-olefin constituent units; the ratio (Mz / Mw) of a Z average molecular weight (Mz) to a weight-average molecular weight (Mw), each molecular weight being measured by GPC, is in the range of 10 to 30, and said ratio (Mz / Mw) and the ratio (Mw / Mn) of a weight-average molecular weight (Mw) to a number-average molecular weight (Mn), each molecular weight being measured by GPC, satisfy the relation (Mz / Mw)>(Mw / Mn); the intrinsic viscosity is in the range of 0.5 to 9 dl / g; the ratio (n*0.01 / n*8) of a melt viscosity (eta*0.01) at a shear rate of 0.01 rad / sec, as measured at 190° C., to a melt viscosity (eta*8) at a shear rate of 8 rad / sec, as measured at 190° C., and the intrinsic viscosity (eta) satisfy the relation (eta*0.01 / eta*8)>=0.893x(eta)+1.0; and the absolute value of an activation energy (Ea) of a shift factor of melt viscoelasticity is not more than 4x104 J / mol.K.

Owner:MITSUI CHEM INC

High-temperature resistant semi-aromatic nylon and its preparation method

ActiveCN102477219AOvercome the disadvantages of high viscosity, poor fluidity and difficult dischargeHigh viscosityPresent methodPolymer science

The invention relates to semi-aromatic high-temperature resistant nylon and its preparation method. The preparation method provided by the invention comprises the following steps of: by weight, adding 75-95 parts of nylon salt, 0.2-0.8 part of an end-capping reagent, 0.1-0.6 part of a catalyst, 0.5-1 part of an antioxidant, 0.1-0.5 part of a lubricant and 30-50 parts of deionized water into a stirred polymerization autoclave, synthesizing a high-temperature resistant nylon prepolymer in a high-pressure stirred tank reactor, and carrying out melting extrusion on the prepolymer through a double screw extruder twice. According to the invention, devolatilization efficiency is raised, tackifying time is shortened, and simultaneously the high-viscosity polymer in the reaction vessel can be smoothly discharged. By different extrusion temperatures, high-temperature degradation of the prepolymer is prevented. Intrinsic viscosity of the high-temperature resistant nylon prepared by the method is higher than that of a polymer prepared by a present method. Therefore, the obtained nylon in the invention has better mechanical properties.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Polypropylene resin composition and injection-molded article

InactiveUS6320009B1Increasing the isotactic pentad proportionImprove machinabilityPolymer scienceHeat resistance

The present invention provides a polypropylene-based resin composition which is light weighing, has a very high values of stiffness and heat resistance, exhibits superior scratchproof property and is superior in the processibility with better flowability upon molding thereof, especially that can favorably be used for injection molding. The polypropylene-based resin composition according to the present invention is constituted predominantly of polypropylene and has the following characteristic features A and B:A: a melt flow rate (MFR), determined at 230° C. under a load of 2.16 kg, in the range of 5-50 g / 10 min. andB: a content of a high molecular weight polypropylene having an intrinsic viscosity [eta] of 9-13 dl / g in the range of 15-30% by weight.

Owner:MITSUI CHEM INC

Thermoformed poly-4-hydroxybutyrate medical implants

ActiveUS20150056131A1In-vivo radioactive preparationsSurgical adhesivesPolymer scienceEthylene Homopolymers

Methods to produce thermoforms from P4HB homopolymer and blends thereof have been developed. These thermoforms are produced from films and sheets including P4HB, wherein the intrinsic viscosity of the P4HB is less than 3.5 dl / g, but greater than 0.35 dl / g, and the thermoforms are produced at a temperature equal to or greater than the softening point of P4HB, and more preferably at a temperature higher than the melting point of P4HB. A preferred embodiment includes a P4HB thermoform wherein a film or sheet including a P4HB polymer is thermoformed at a temperature between its melting point and 150° C. In a particularly preferred embodiment the thermoform is a laminate made from a P4HB film and a P4HB mesh.

Owner:TEPHA INC

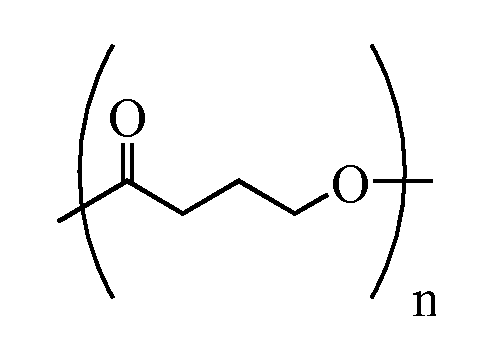

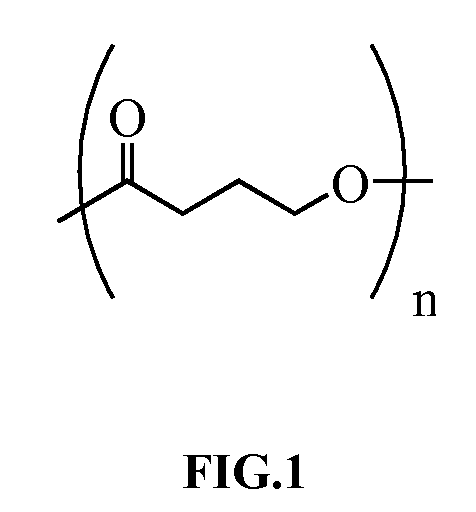

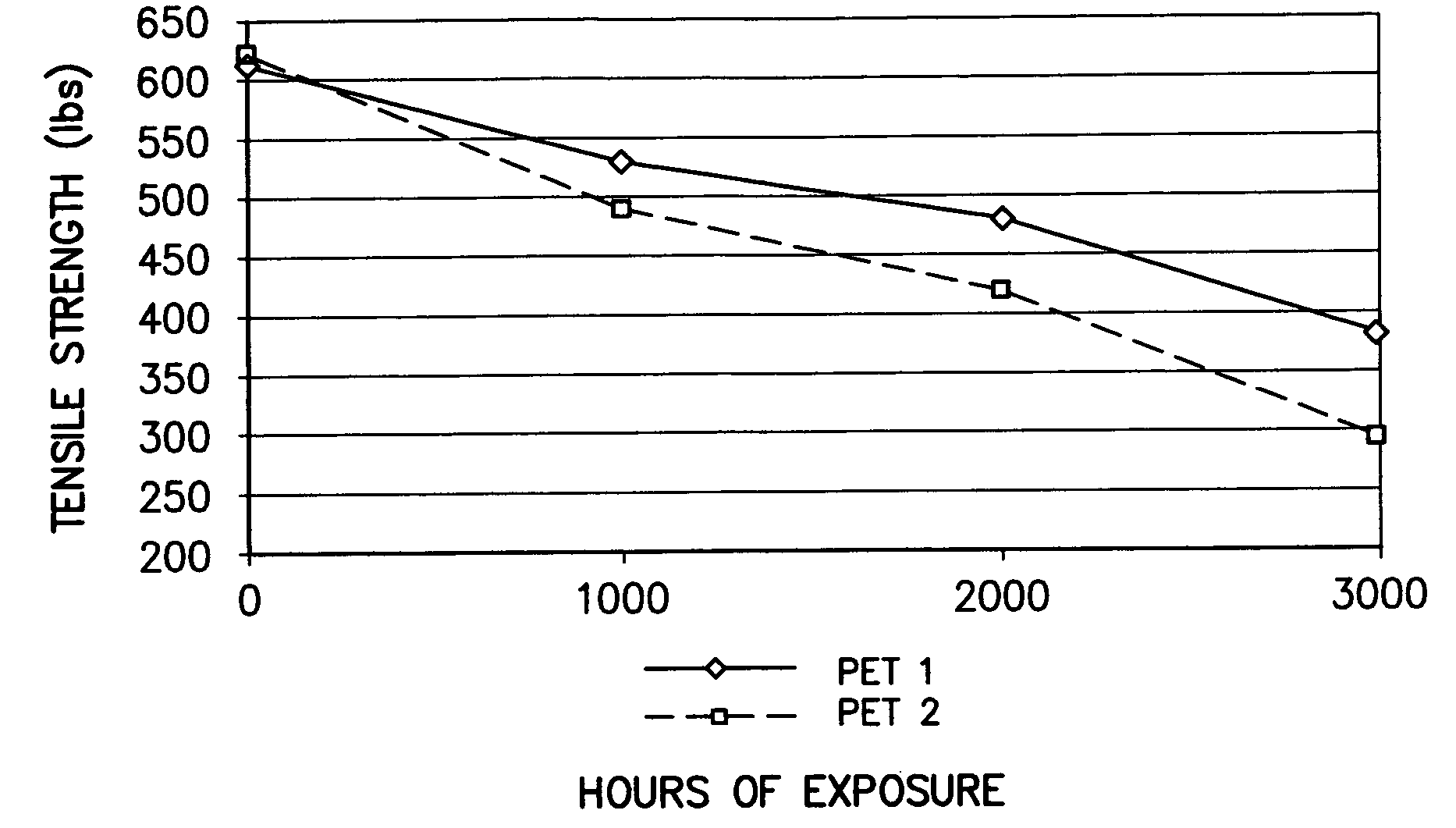

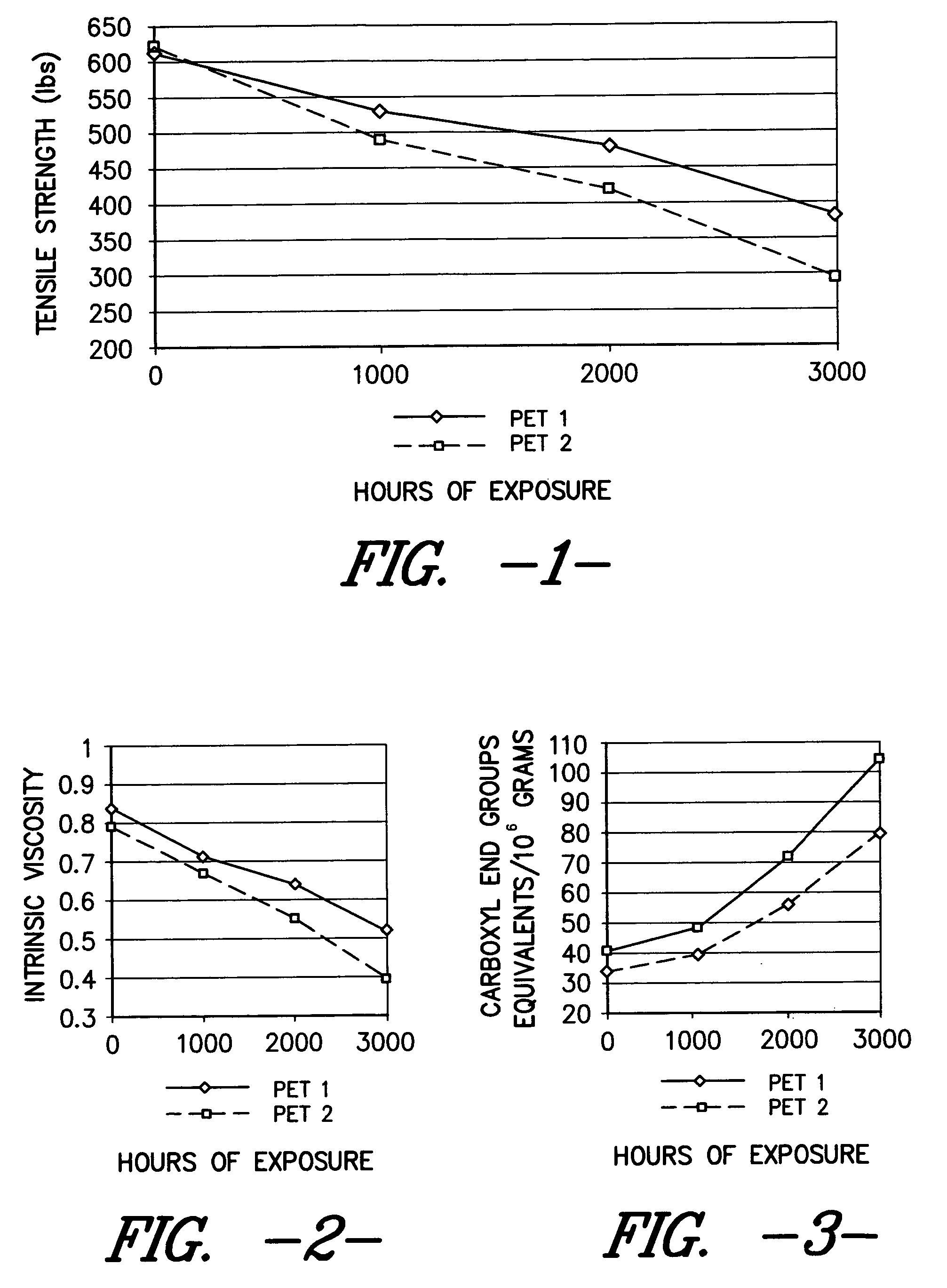

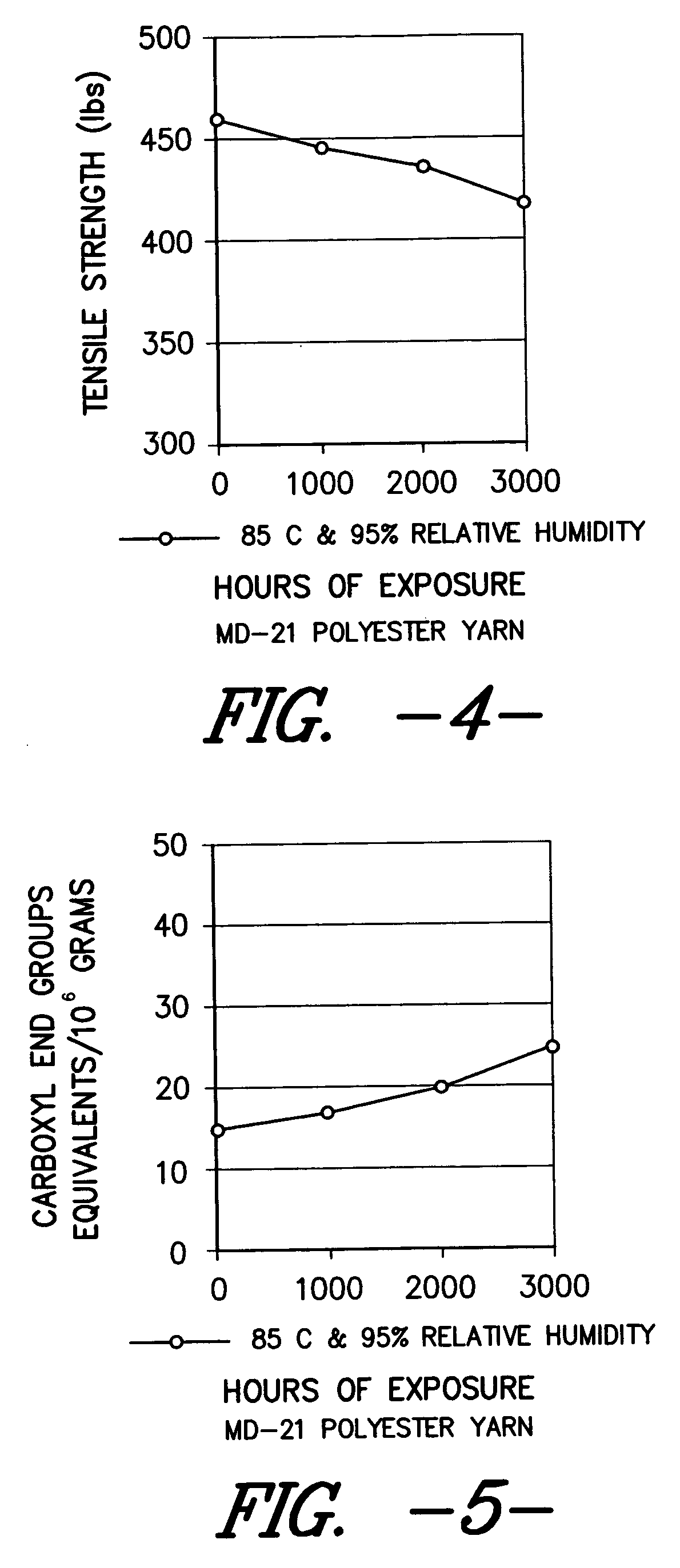

Polyester yarn and airbags employing certain polyester yarn

Airbag cushions manufactured from polyester yarn having certain levels of intrinsic viscosity (IV) and certain specific carboxyl end group (“CEG”) levels perform unexpectedly well in high temperature and high humidity environments for airbag cushion applications. This specification identifies certain polyester yarns and characteristics of such polyester yams that are necessary to achieve unexpectedly good performance in such high humidity and high temperature applications. A polymeric polyester yarn for airbags, said yarn having a high degree of tenacity even after a long period of exposure to high temperature and high humidity conditions is disclosed. In one aspect of the invention, a polyester yarn having CEG of less than about 60 equivalents / 106 gram, and more preferably less than about 30 equivalents / 106 grams, is particularly useful. In another embodiment, a polyester yarn having an IV value of at least about 0.6 performs exhibits superior properties.

Owner:MILLIKEN & CO

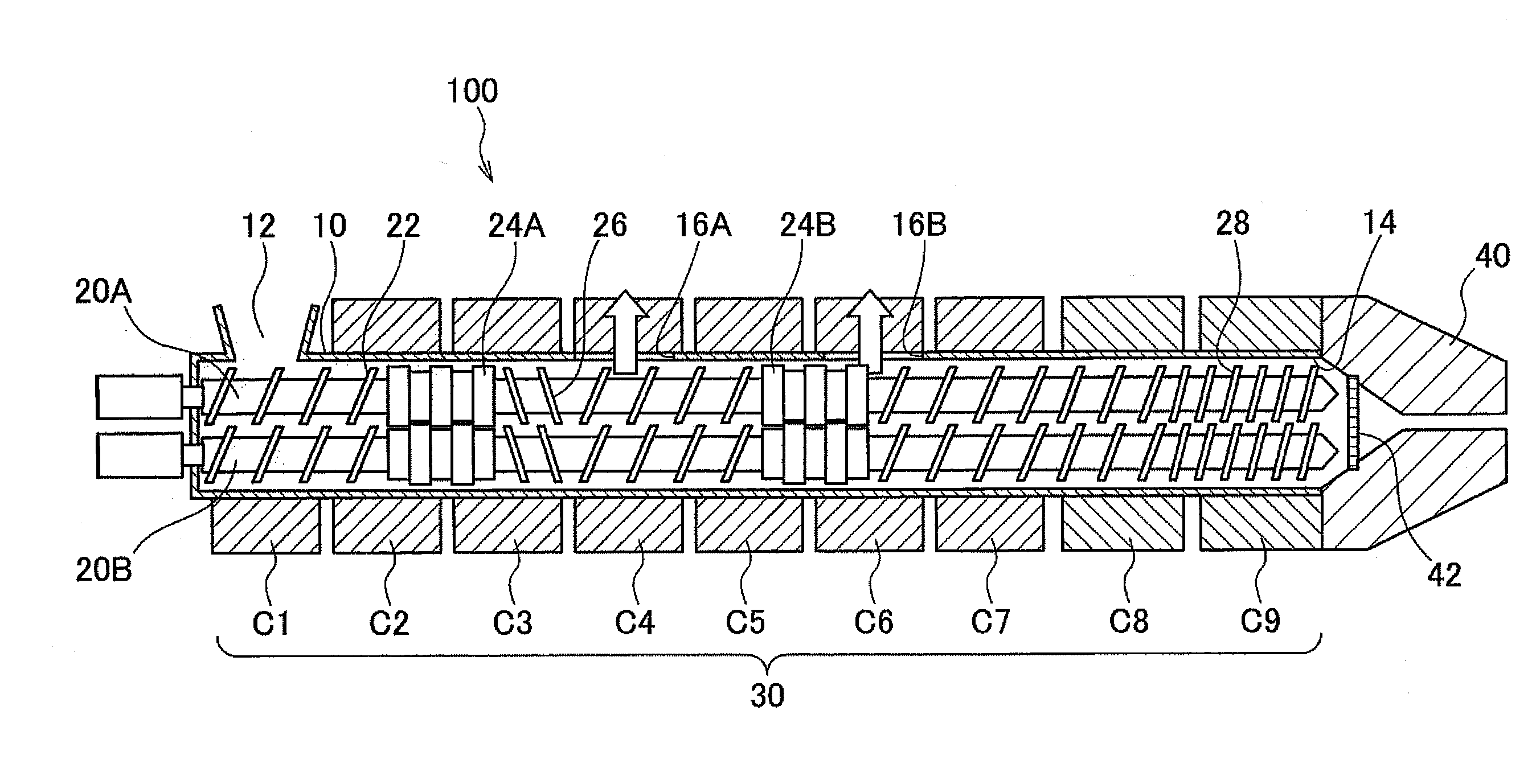

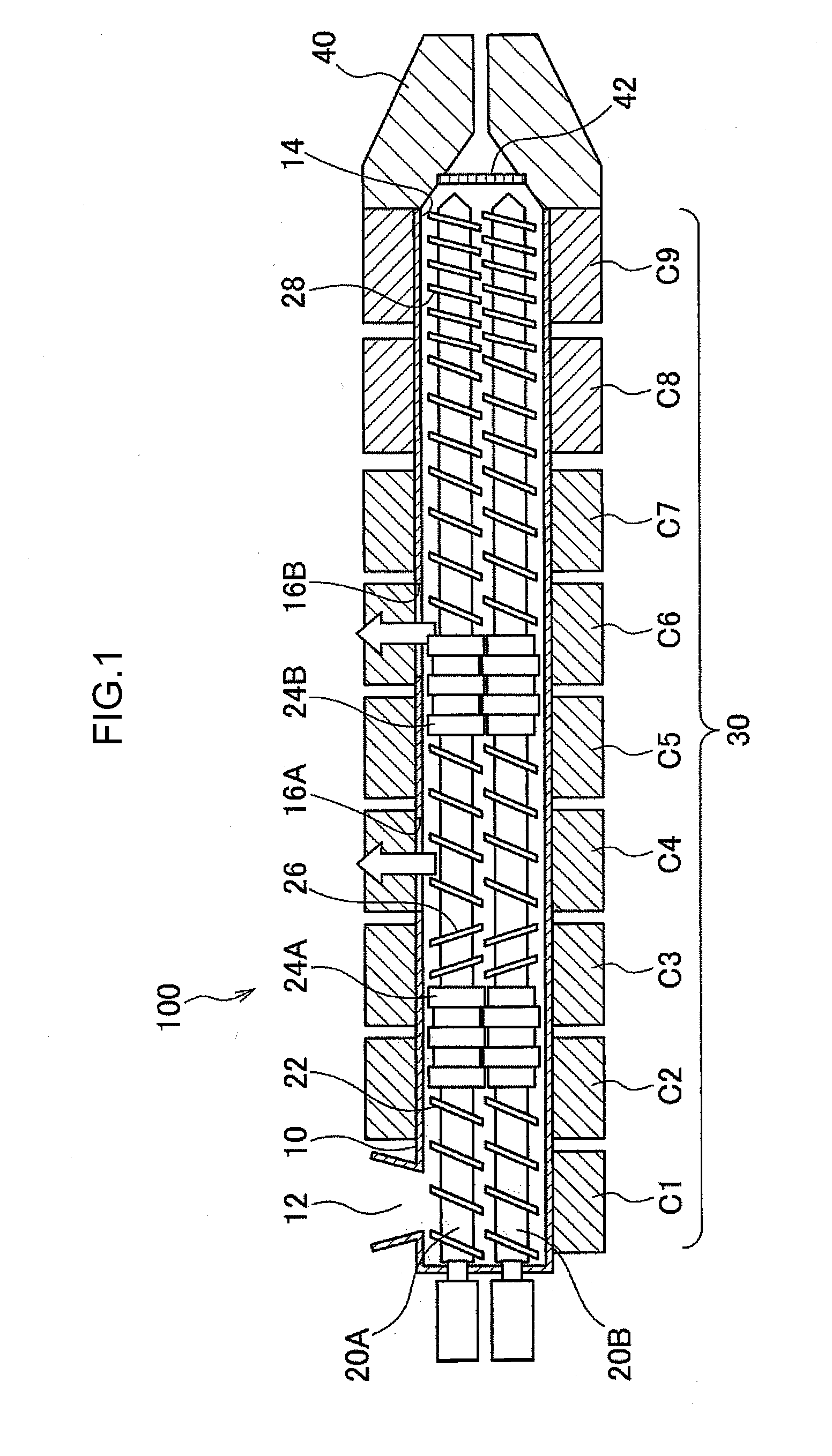

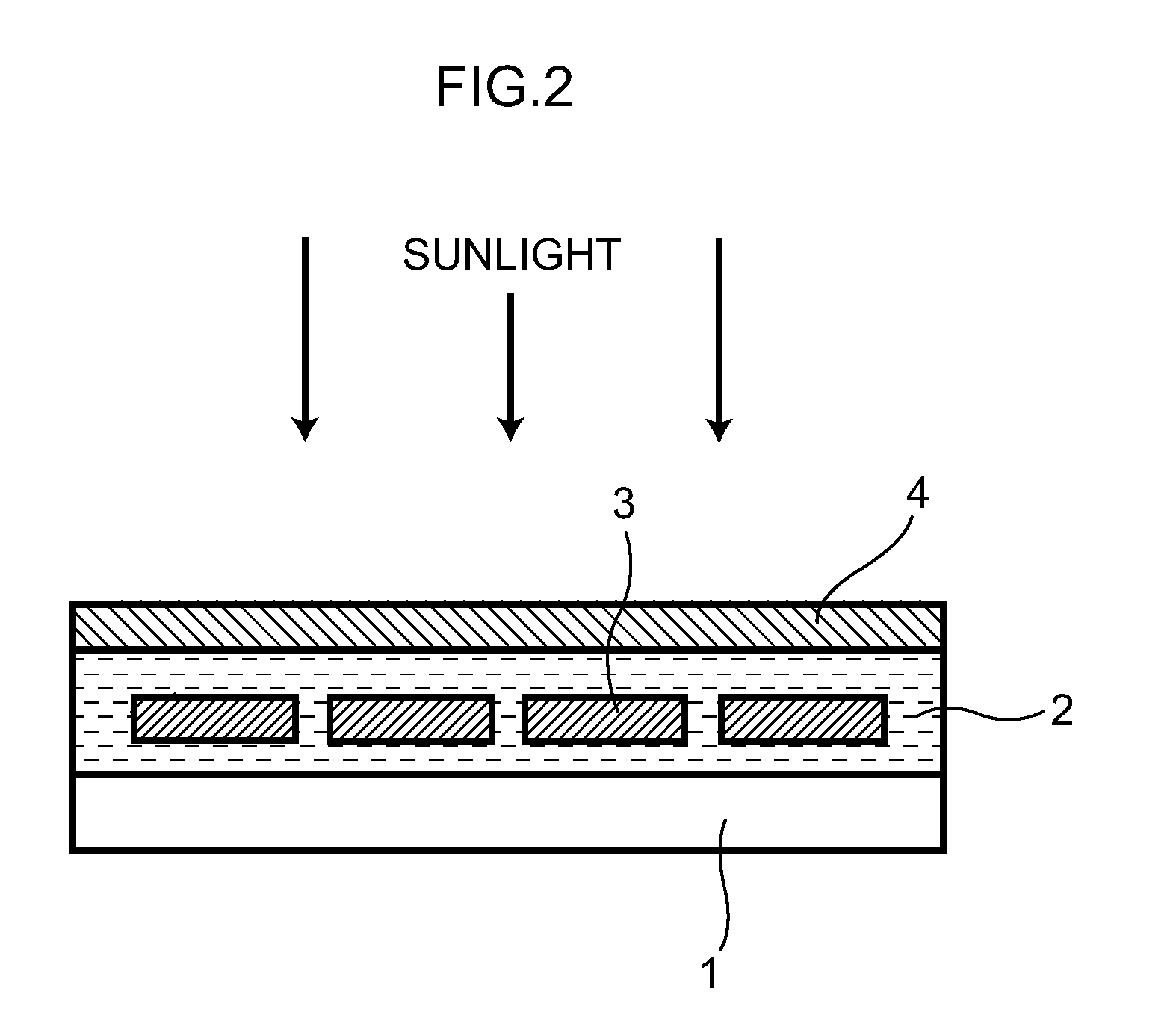

Polyester film, method for producing the same, back sheet for solar cells, and solar cell module

InactiveUS20120070615A1Not impairing effectImprove productivityLayered productsTraffic signalsShear rateEngineering

Provided is a method for producing a polyester film, including: subjecting a polyester raw material resin, which contains a titanium compound and has an intrinsic viscosity of from 0.71 to 1.00, to melt extrusion using a twin-screw extruder which includes a cylinder; two screws disposed inside the cylinder; and a kneading disk unit disposed in at least a portion of a region extending from a 10%-position to a 65%-position of screw length with respect to an upstream end of the screws in a resin extrusion direction as a starting point, at a maximum shear rate generated inside the twin-screw extruder of from 10 sec−1 to 2000 sec−1;forming an unstretched film by cooling and solidifying the melt extruded polyester resin on a cast roll; subjecting the unstretched film to biaxial stretching in a longitudinal direction and a lateral direction; and heat fixing the stretched film formed by biaxial stretching.

Owner:FUJIFILM CORP

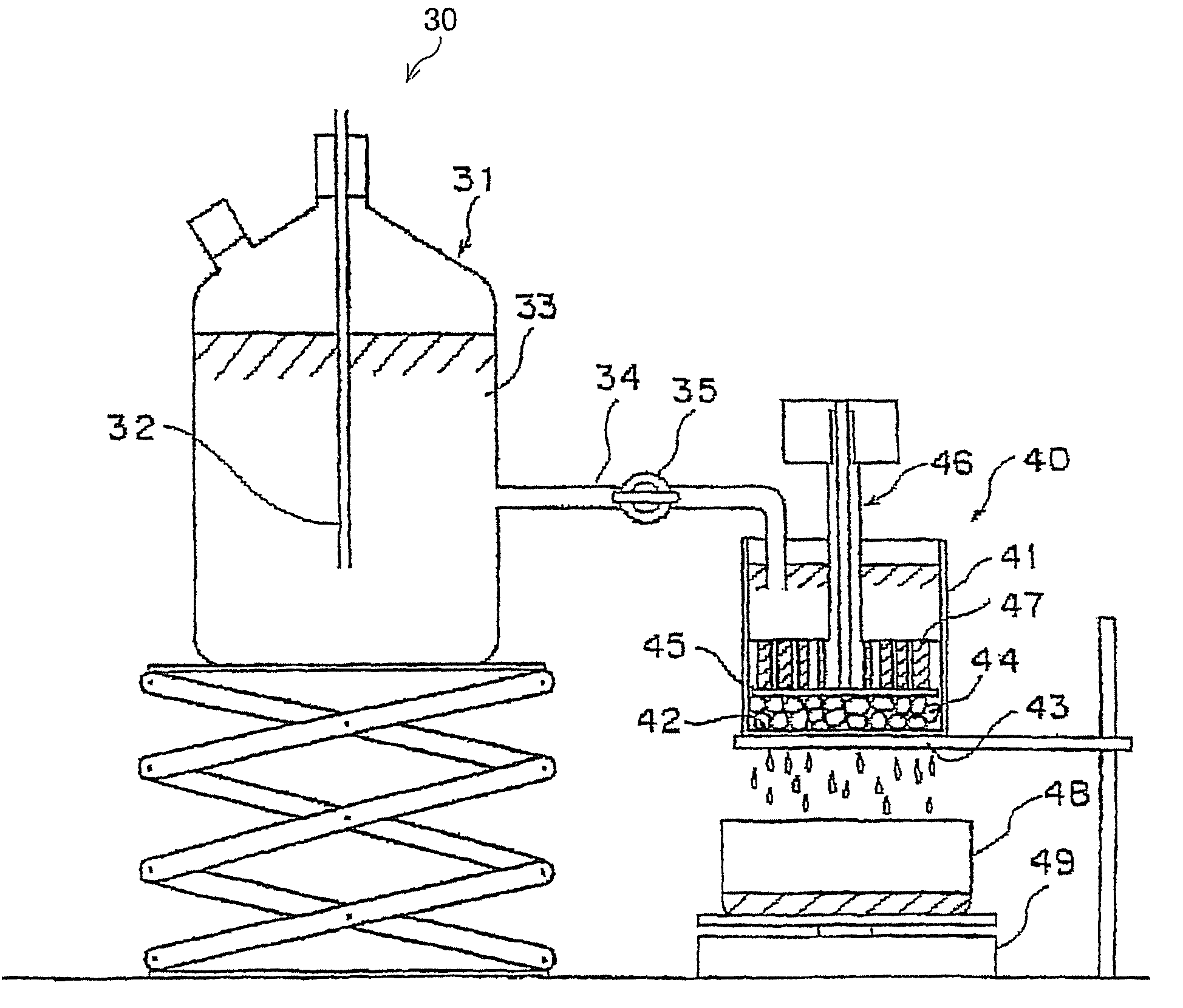

Water absorbing resin with improved internal structure and manufacturing method therefor

ActiveUS8383746B2Simple internal structureConvenient timeAbsorbent padsThin material handlingAfter treatmentPolymer science

According to the present invention, the manufacturing method for the water absorbing resin involves the step of polymerizing a water-soluble unsaturated monomer, 0.06 of 5 mol % of which is composed of an internal crosslinking agent; and the step of drying a water-containing gel which has a thermally decomposing radical initiator content index of 40 to 100 at 100 to 250° C. The water absorbing resin of the present invention contains a water-soluble unsaturated monomer as a repeat unit for a major chain, 90 mol % of the monomer being composed of an acrylic acid and / or salt thereof, the resin having an internal crosslinking structure and exhibiting a weight-average molecular weight Mw of 360,000 to 1,000,000 daltons and an intrinsic viscosity IV of 2.1 to 6.0 dL / g where the weight-average molecular weight Mw and the intrinsic viscosity IV are measured after treatment under set 2 of hydrolysis conditions.

Owner:NIPPON SHOKUBAI CO LTD

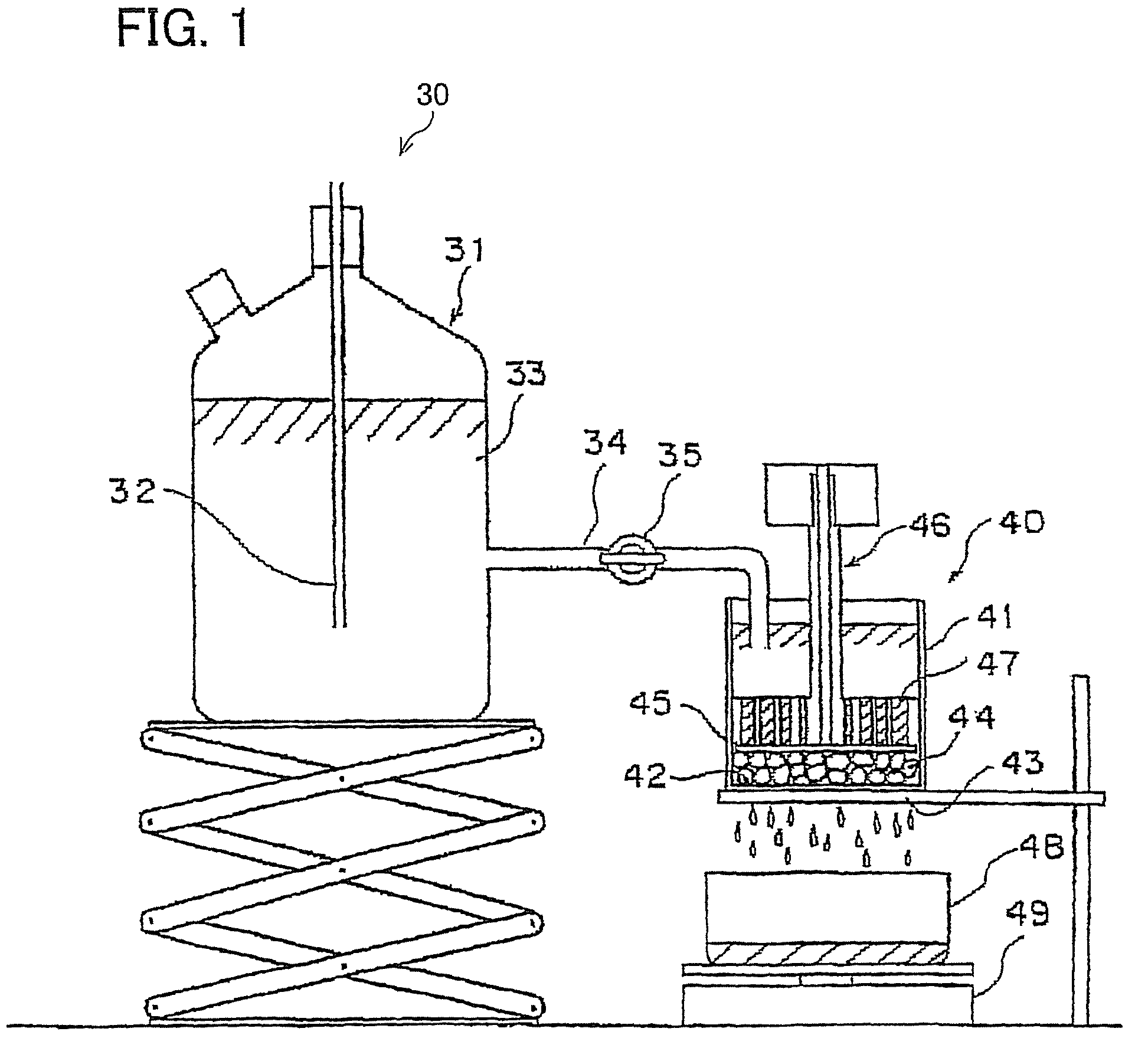

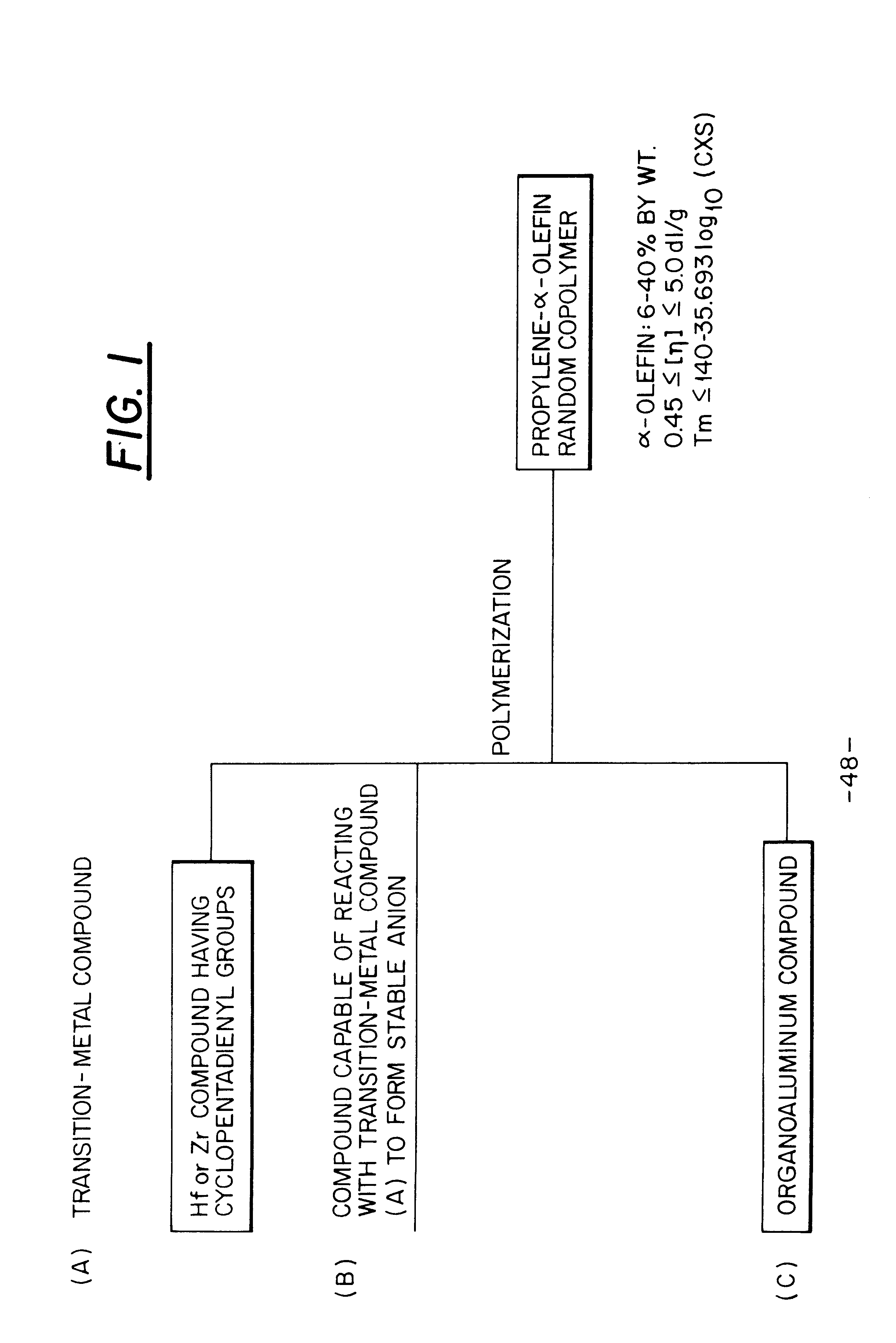

Propylene random copolymer and film laminate thereof

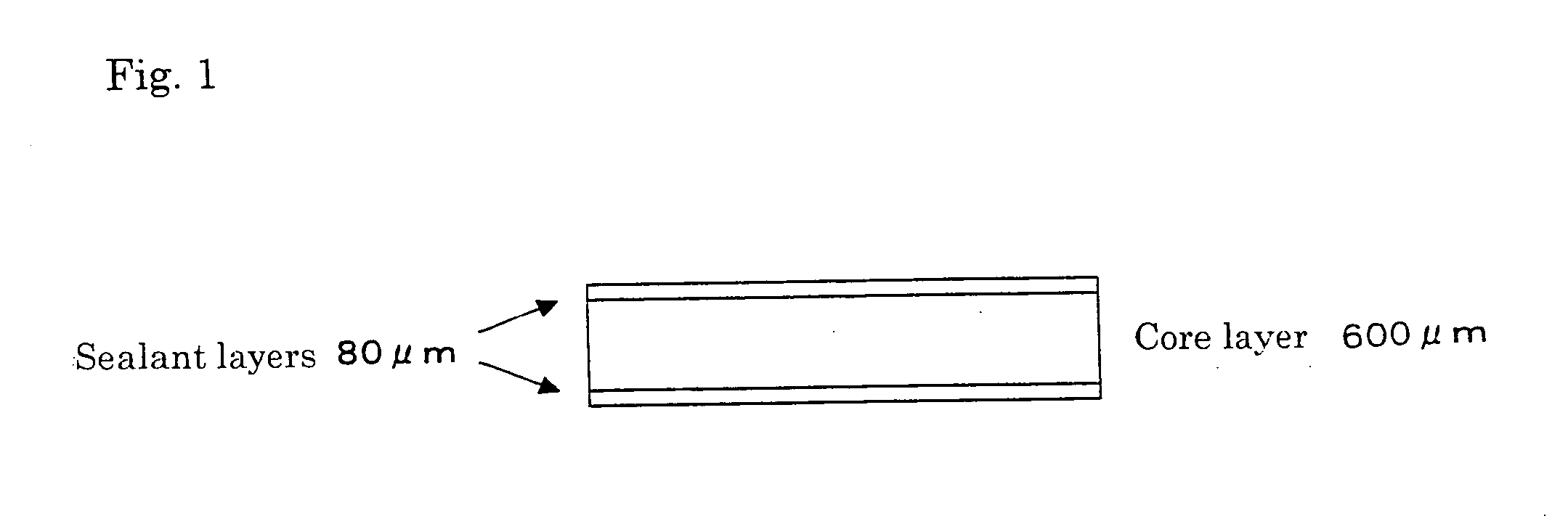

InactiveUS6214952B1Excellent blocking resistanceHigh transparencySynthetic resin layered productsThin material handlingElectricityTetralin

A propylene random copolymer and a film laminate thereof is described having excellent blocking resistance and transparency and substantially maintaining favorable low-temperature heat-sealing properties after corona discharge treatment. The propylene random copolymer of the invention includes a propylene component and an alpha-olefin component having 4 to 10 carbon atoms, wherein the content of the alpha-olefin component is in the range of about 6% to about 40% by weight, the intrinsic viscosity [eta] measured in tetralin at 135° C. is not lower than about 0.45 dl / g and not higher than about 5.0 dl / g, and the melting point (Tm) measured by a differential scanning calorimeter and the content of 20° C. xylene soluble fraction (CSX) fulfill a relationship of

Owner:SUMITOMO CHEM CO LTD

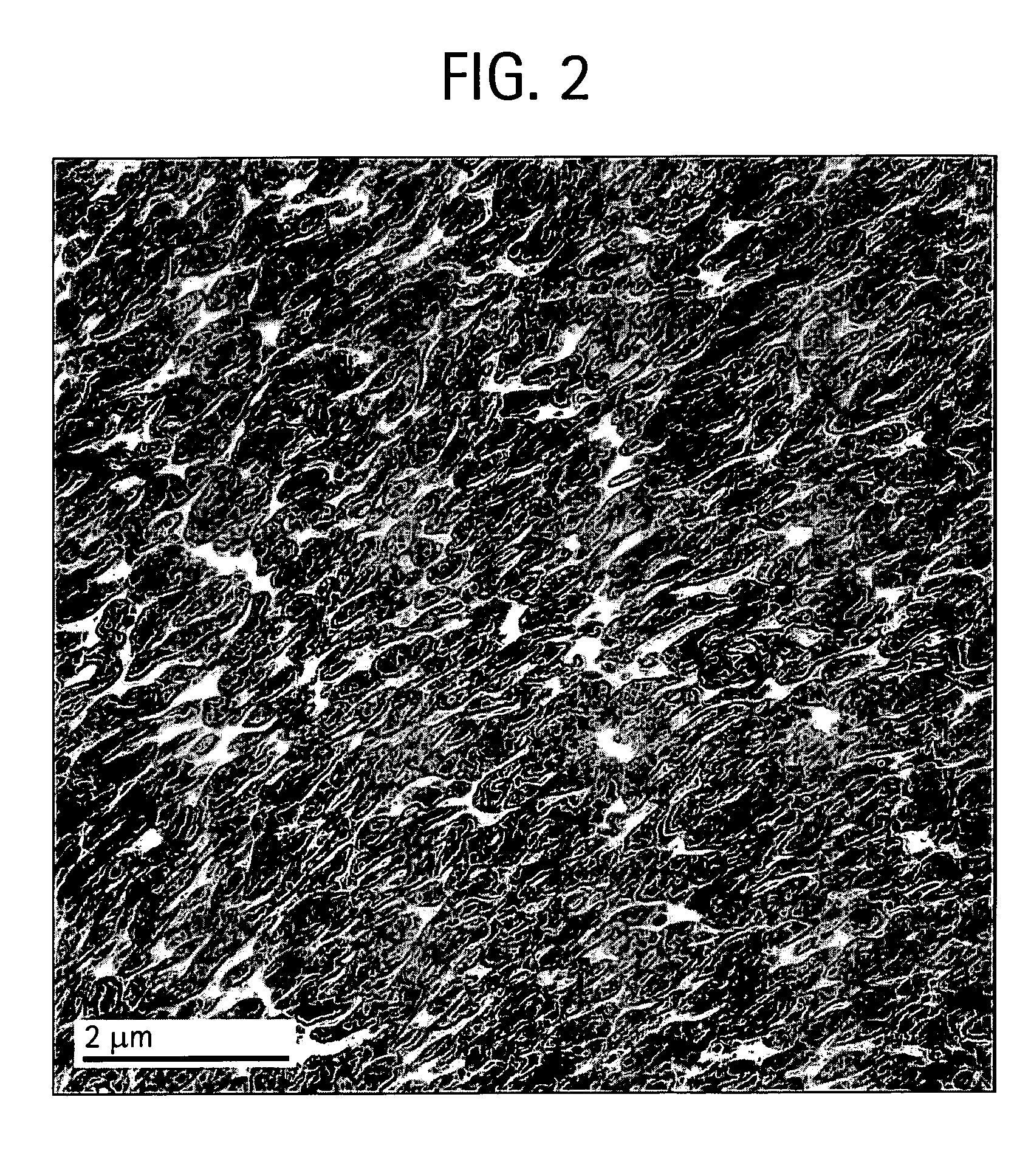

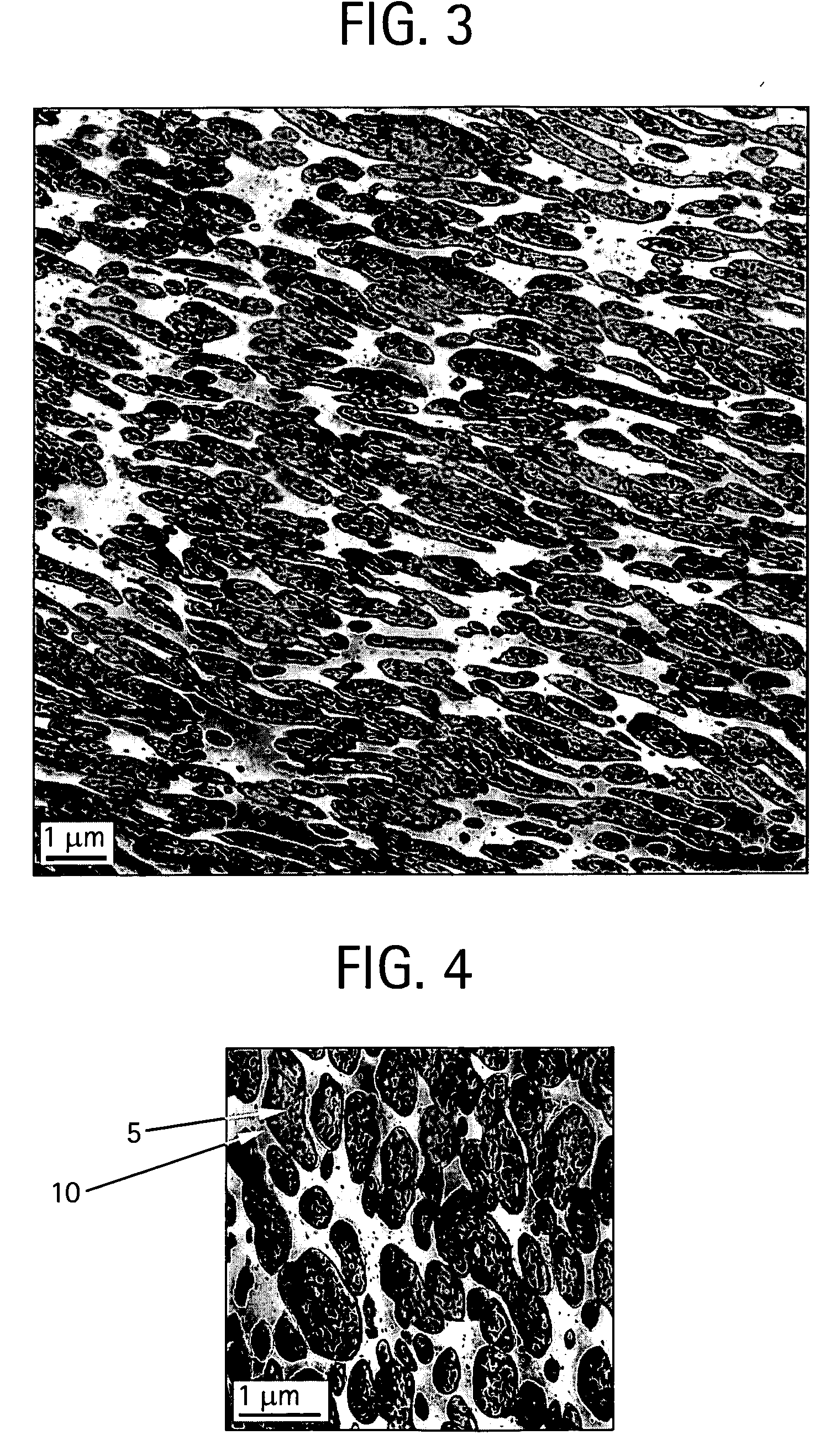

Composite fiber structure and method for producing the same

ActiveUS7387976B2Good flexibilityIncrease elasticityLamination ancillary operationsLaminationElastomerPolyester

A web containing comprising side-by-side or eccentric core / shell conjugate short fibers A, which contain two kinds of polyester different from each other in intrinsic viscosity, and elastic conjugate fibers B, which contain a thermoplastic elastomer having a melting point lower by 40° C. or more than the two kinds of polyester, and a nonelastic polyester, with at least the thermoplastic elastomer being exposed on a surface of the fibers, is subjected to a heat treatment at a temperature equal to or higher than the melting point of the thermoplastic elastomer, so as to obtain a polyester elastic fiber structure, and then polyester woven or knitted fabrics are laminated adhered on both surfaces of the polyester elastic fiber structure with a polyester adhesive, followed by heat molding into a curved shape by a molding process depending on necessity, so as to obtain a composite fiber structure.

Owner:TEIJIN FRONTIER CO LTD

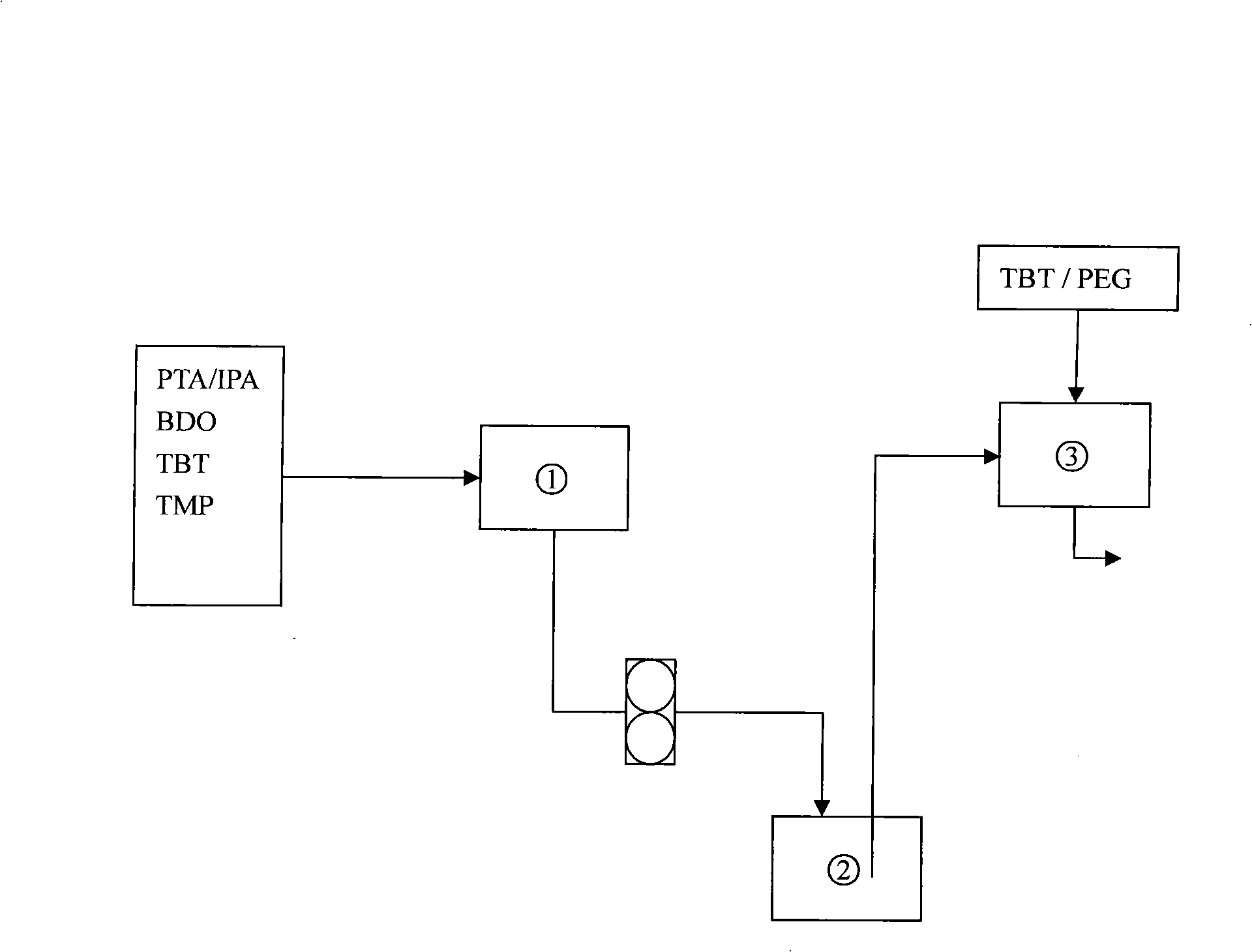

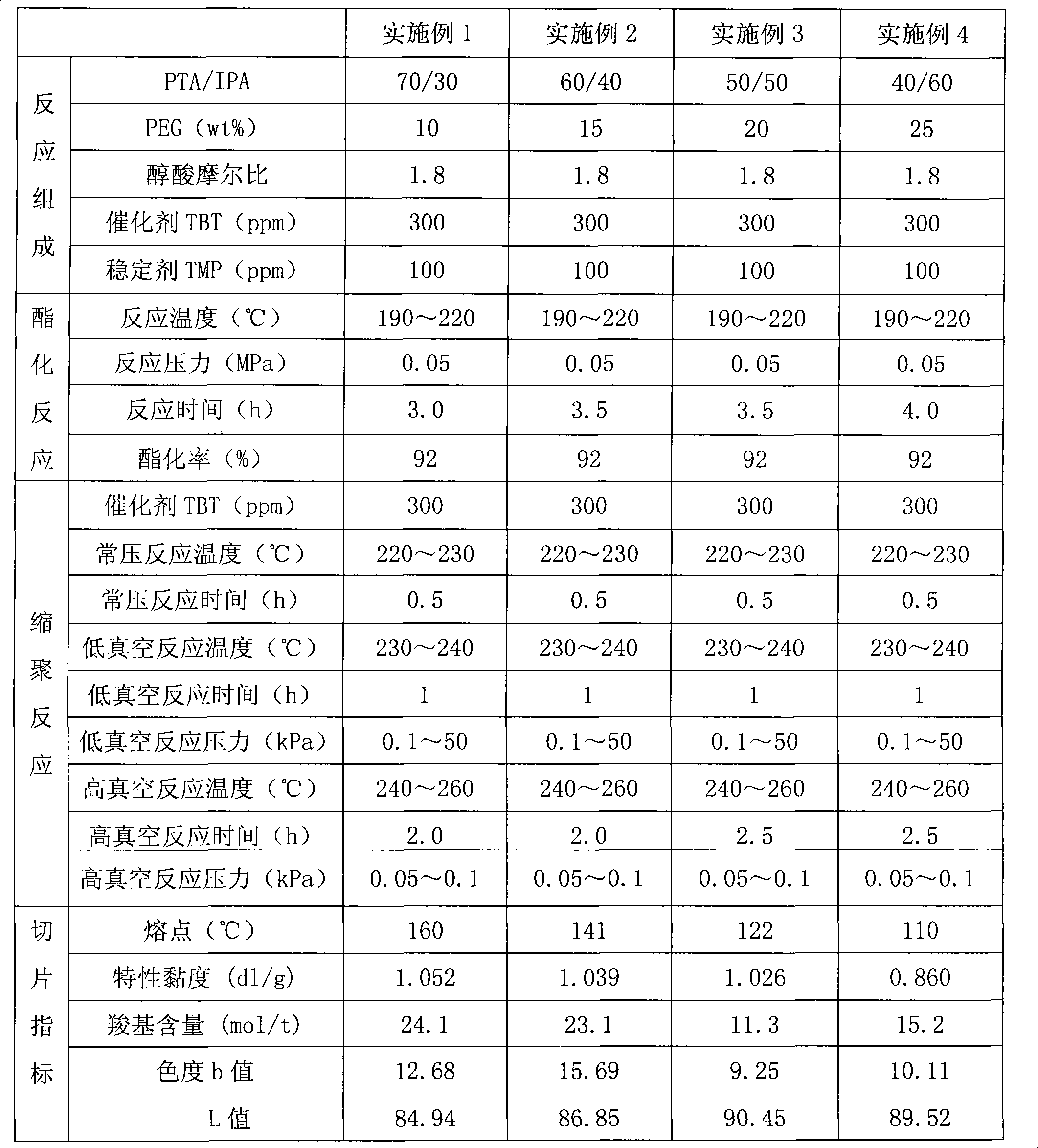

Low-melting-point copolyester and method for preparing same

InactiveCN101338023AIncrease exerciseLow melting pointMonocomponent copolyesters artificial filamentFiberPolymer science

The invention relates to low melting point copolyester and a preparation method thereof. The low melting point copolyester is made from the following monomers followed by the esterification reaction and the polycondensation reaction: (a) terephthalic acid (PTA) and isophthalic acid (IPA), (b) 1, 4- butanediol (BDO) and (c) polyethylene glycol 600 to 6000 (PEG); wherein, in the a component, the feeding mass ratio of the terephthalic acid and the isophthalic acid is between 80 to 20 : 20 to 80; in the c component, the feeding weight ratio of polyethylene glycol is 1 to 30 percent based on the a; the molar ratio of the a and the b is 1:1.5 to 2.3. The preparation method comprises an esterifcation stage and a polycondensation stage. The copolyester has the characteristics of low melting point, good crystallization property, high intrinsic viscosity and difficult adhesion of particles, and is suitable for spinning the filament, the staple fibers and the non-woven fabrics.

Owner:ZHEJIANG SCI-TECH UNIV

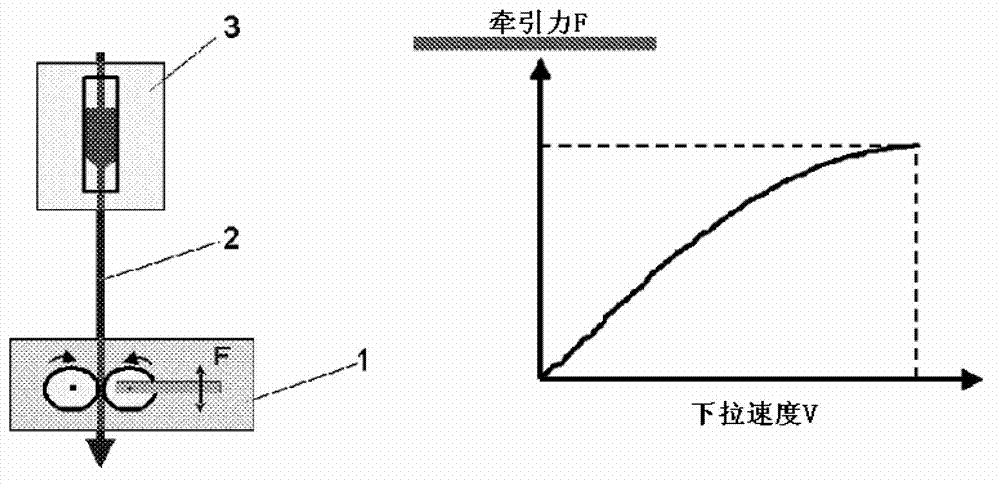

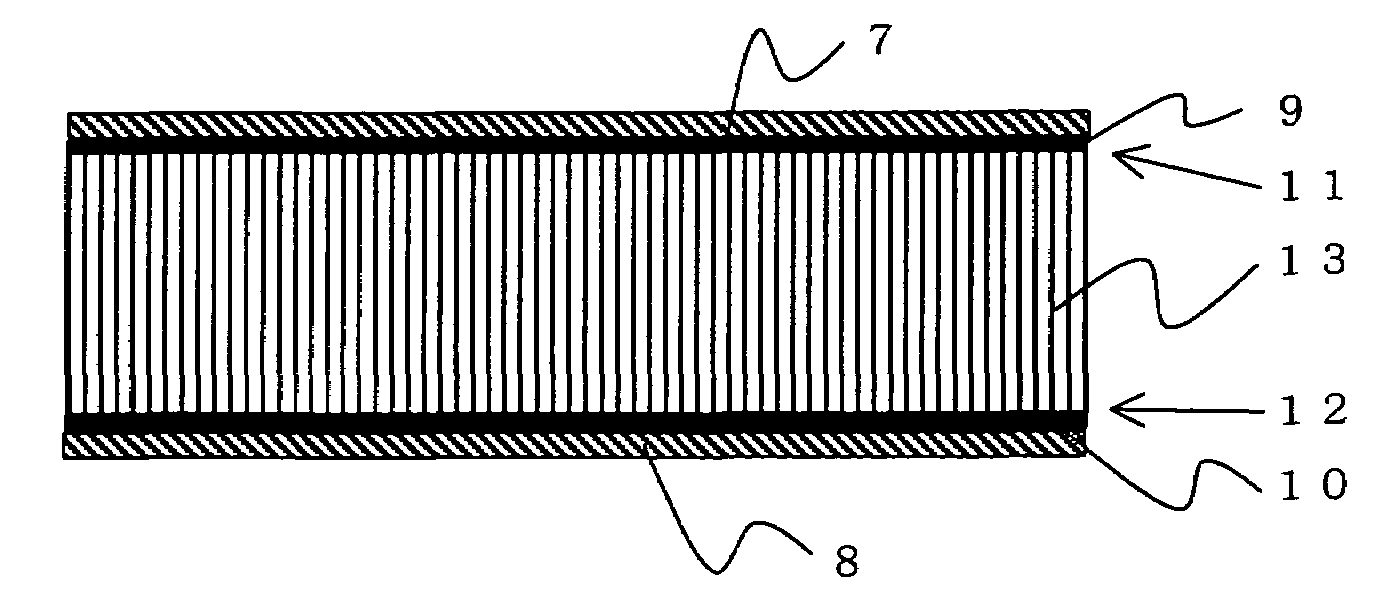

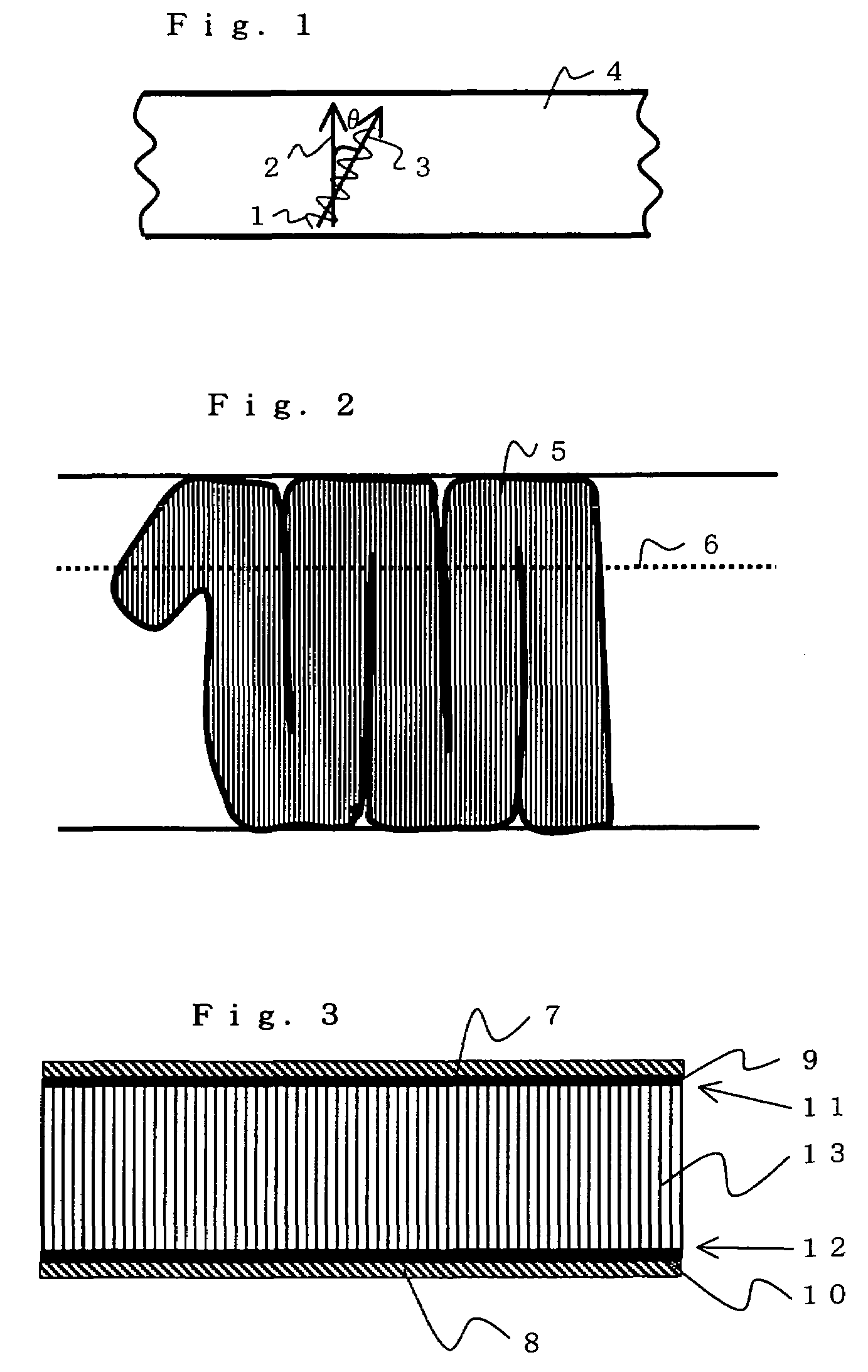

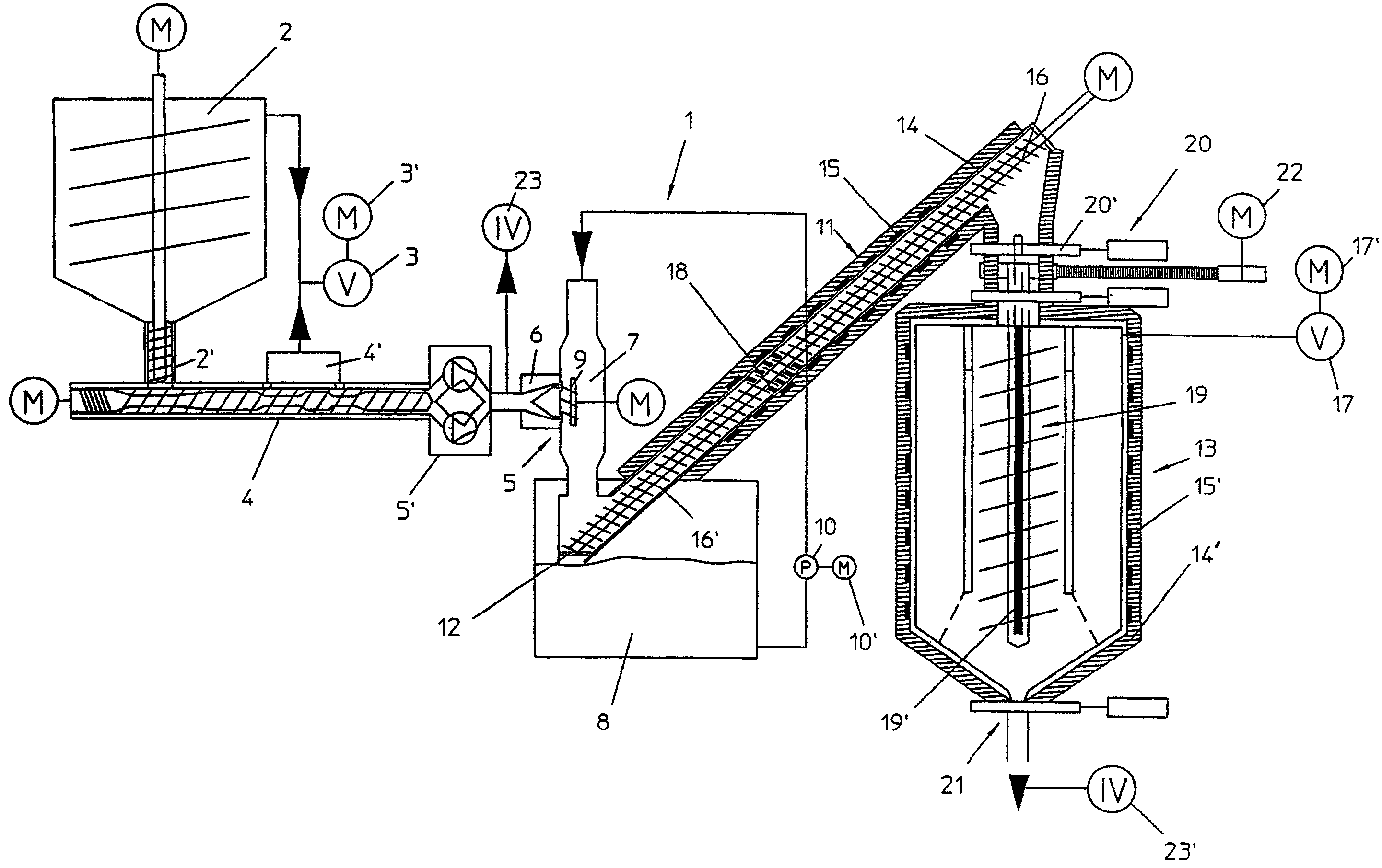

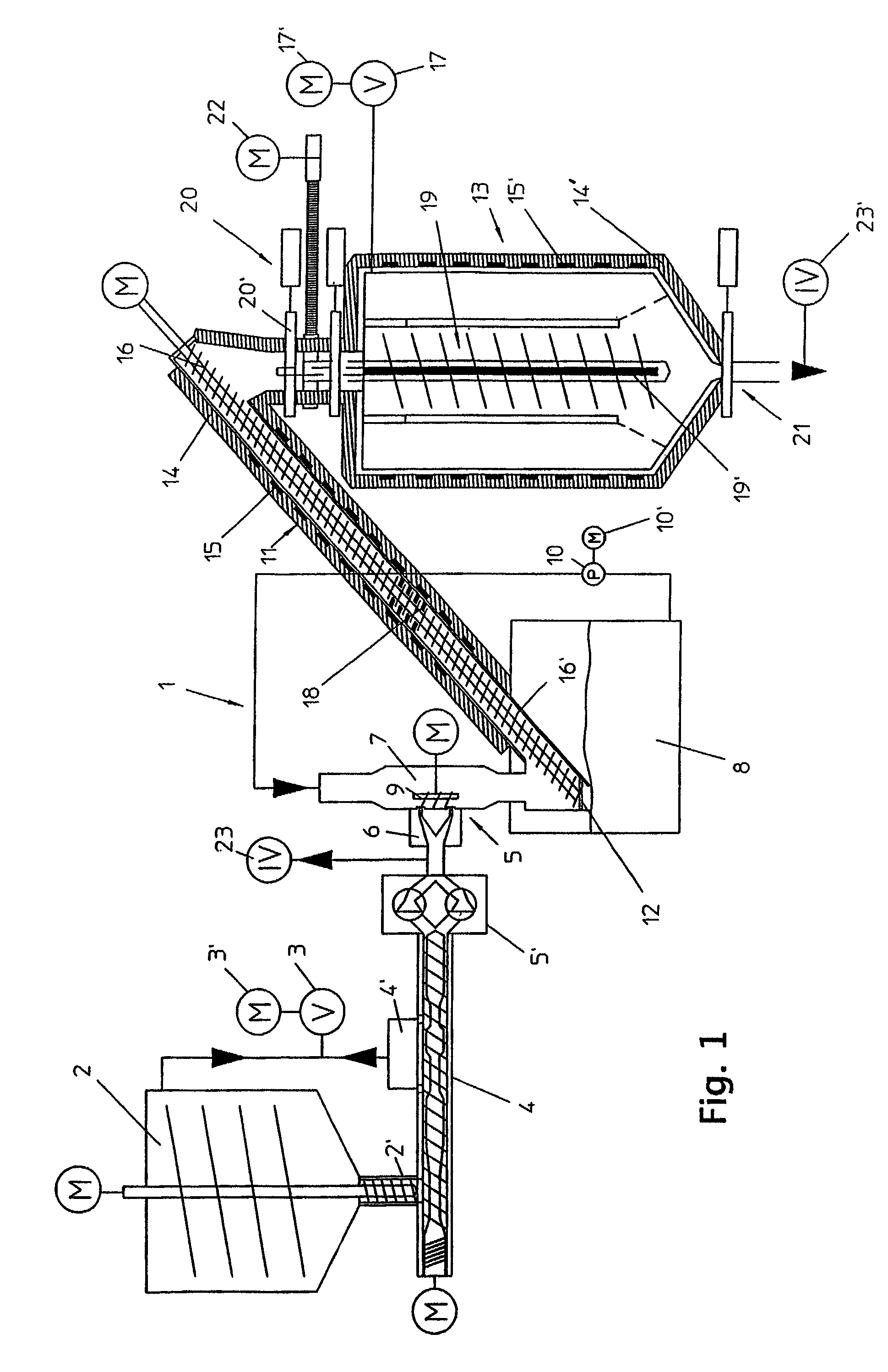

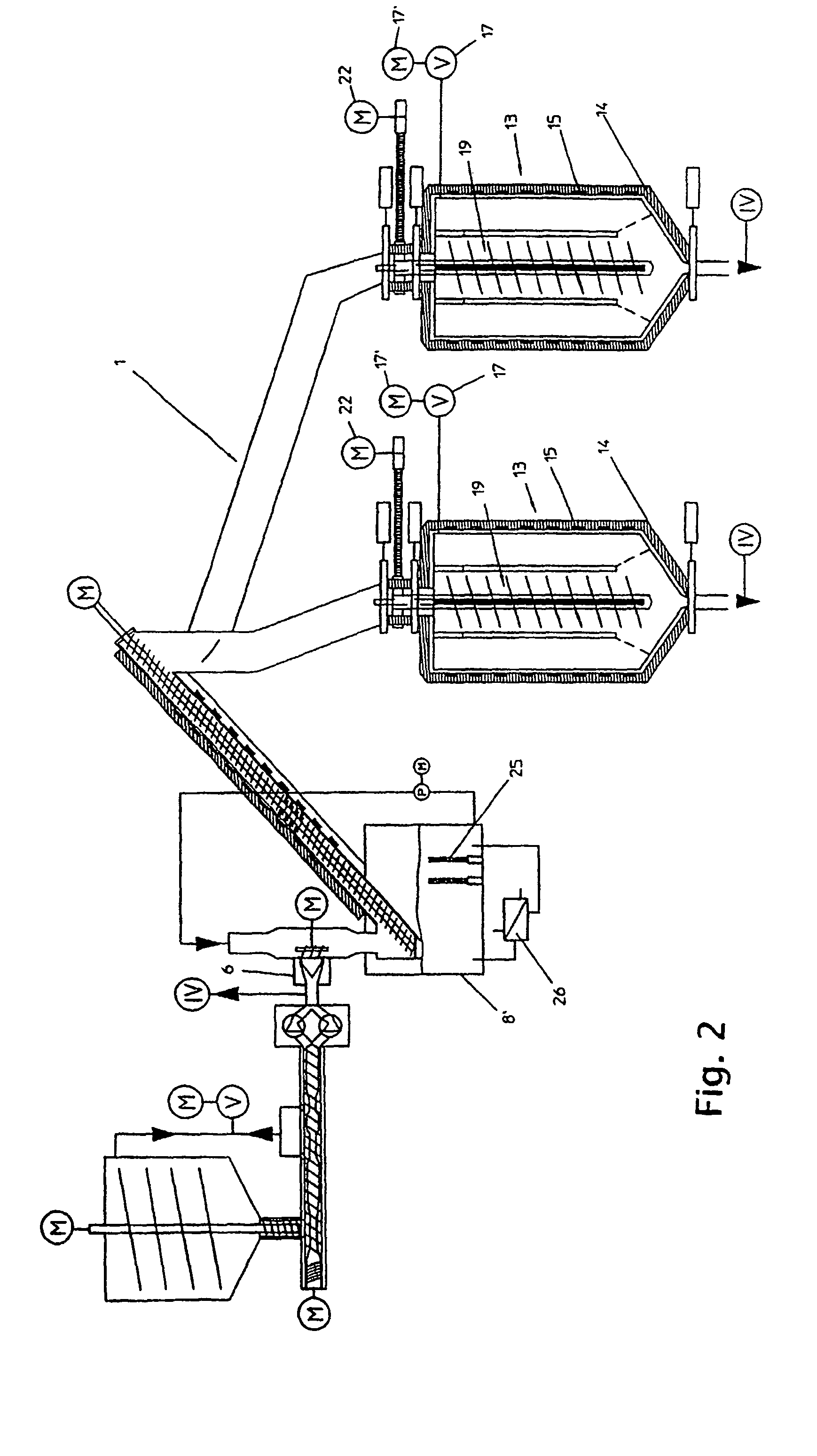

Method and apparatus for increasing an intrinsic viscosity of polyester

A method of increasing the intrinsic viscosity of polyester by means of solid state polymerization, wherein a polyester plastics melt is granulated and after granulation is conveyed into a thermal treatment container (13) for thermal treatment therein, the granules being produced slightly below their melting temperature and being fed into the thermal treatment container (13) immediately after granulation so as to utilize the residual heat in the granules, as well as an arrangement for increasing the intrinsic viscosity of polyester by means of solid state polymerization with a granulating and a thermal treatment unit, with an unheated, thermally insulated container (13) or a container (13) having wall heating means (15) being provided as the thermal treatment unit, which is directly connected to the granulating unit via a conveying device (11, 36, 37).

Owner:FELLINGER MARKUS

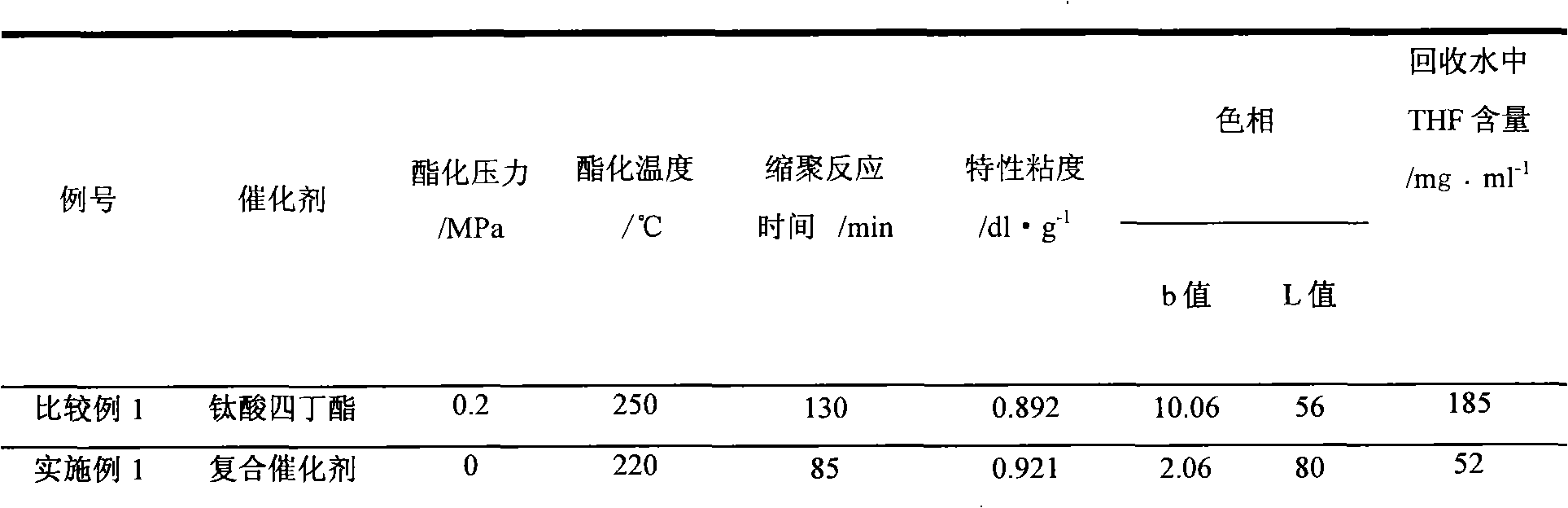

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out at normal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in the fields of various soft package plastic products.

Owner:PETROCHINA CO LTD

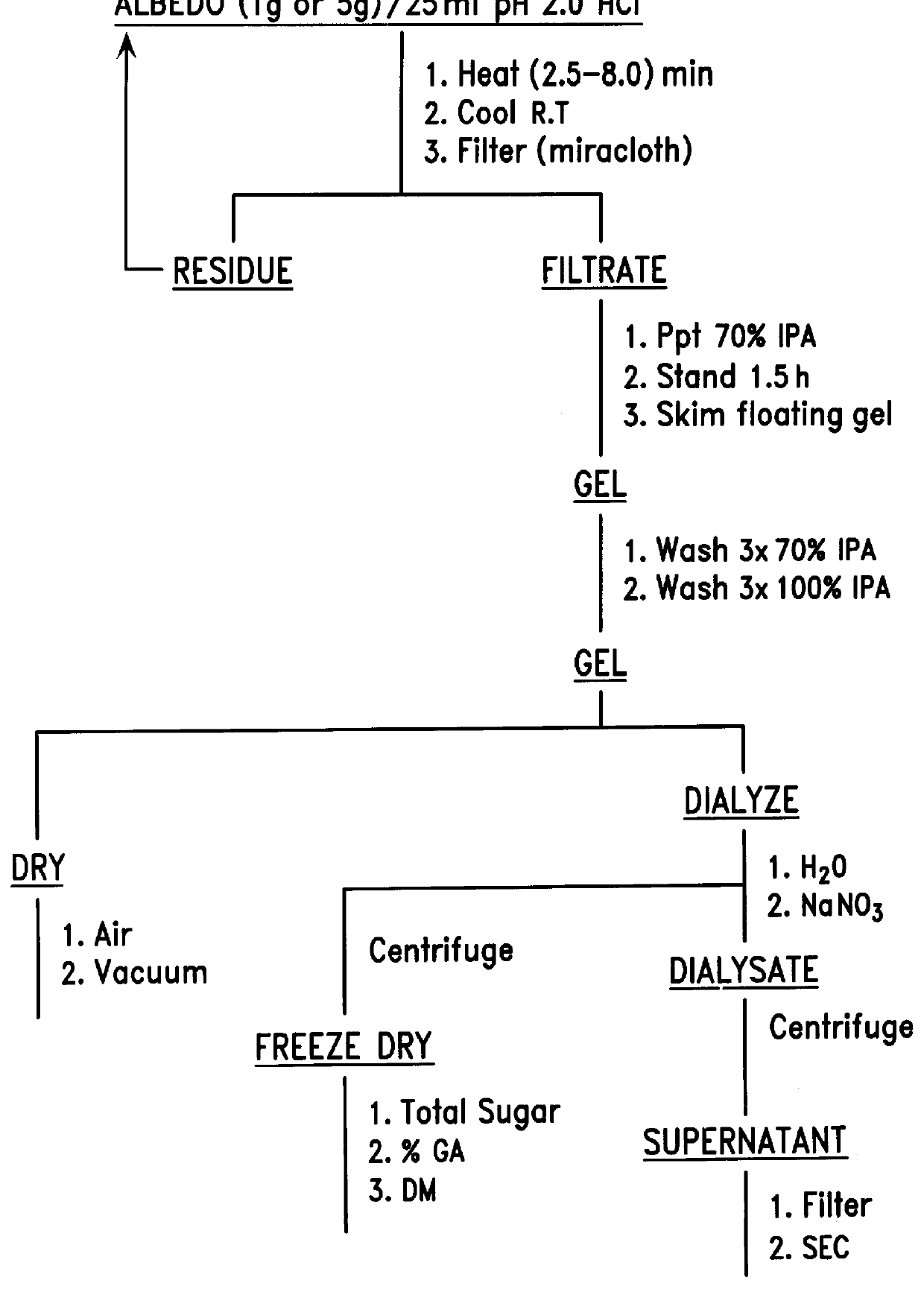

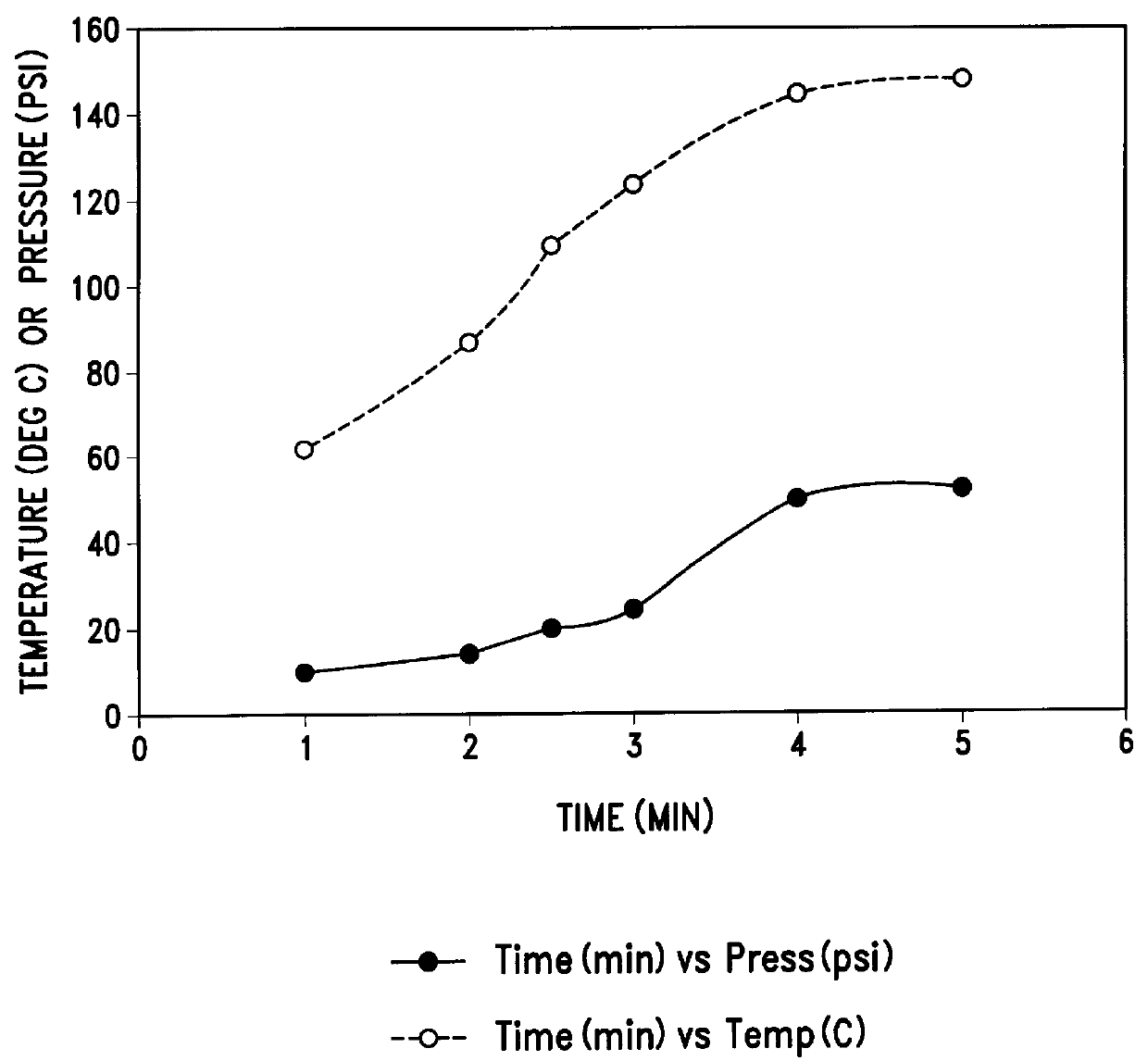

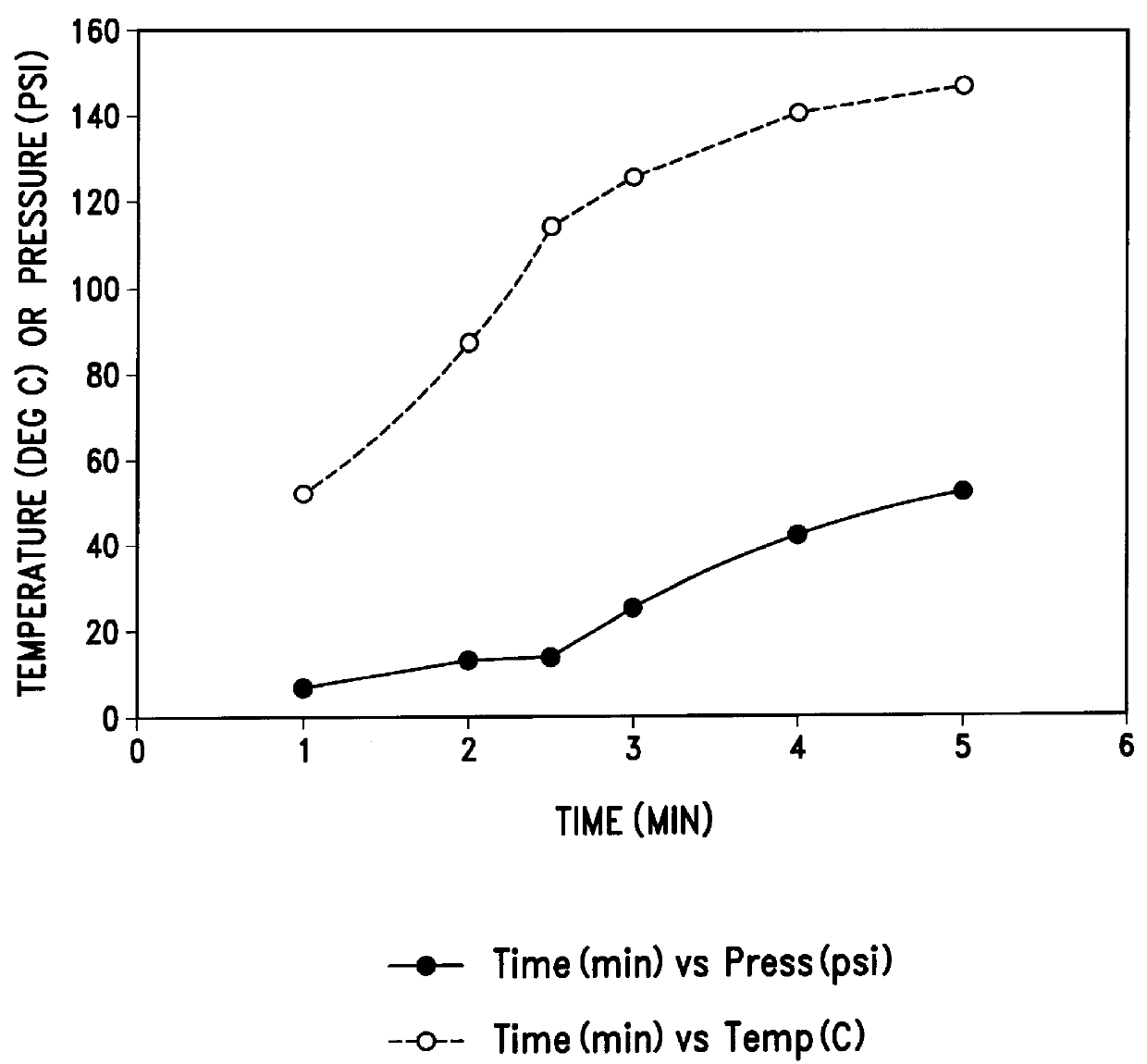

Extraction of pectin by microwave heating under pressure

High-quality pectins may be extracted from pectin-containing plant materials with microwave energy under pressure. The pectins are characterized by increased molecular weight, size and intrinsic viscosity when compared to pectin extracted by conventional heating techniques.

Owner:US SEC AGRI

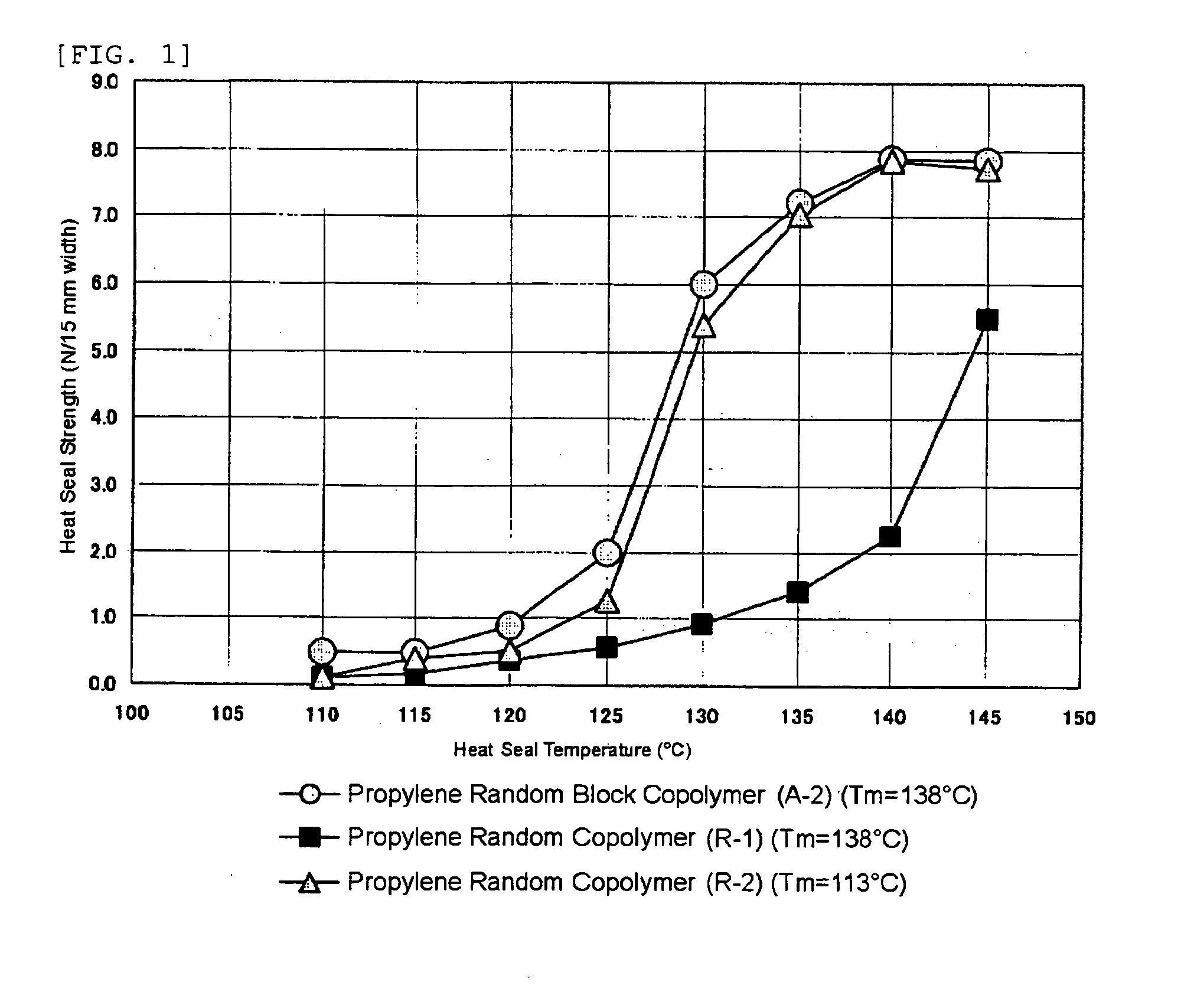

Propylene Random Block Copolymer, Resin Composition Containing the Copolymer and Molded Article Made Thereof

The invention provides a propylene random block copolymer (A) that has a melt flow rate from 0.1 to 100 g / 10 min and a melting point from 100 to 155° C. and includes 90 to 60% by weight of a portion insoluble (Dinsol) in n-decane at room temperature and 10 to 40% by weight of a portion soluble (Dsol) in n-decane at room temperature, wherein the Dinsol satisfies the following requirements (1) through (3) and the Dsol satisfies the following requirements (4) through (6). The invention further provides molded articles such as sheets, films, injection molded articles, hollow molded articles, injection blow molded articles and fibers, which are formed of the propylene random block copolymer (A) or a propylene resin composition containing the propylene random block copolymer (A). (1) The molecular weight distribution (Mw / Mn) obtained by GPC of the Dinsol is from 1.0 to 3.5, (2) the content of skeletons derived from ethylene in the Dinsol is from 0.5 to 13% by mole, (3) the total amount of 2,1- and 1,3-propylene units in the Dinsol is 0.2% by mole or less, (4) the molecular weight distribution (Mw / Mn) obtained by GPC of the Dsol is from 1.0 to 3.5, (5) the intrinsic viscosity [η] in decalin at 135° C. of the Dsol is from 1.5 to 4 dl / g and (6) the content of skeletons derived from ethylene in the Dsol is from 15 to 35% by mole.

Owner:MITSUI CHEM INC +1

Resin composition based on crystalline polypropylene

The present invention provides a resin composition based on crystalline polypropylene which includes: (a) 3-65% by weight of a component soluble in paraxylene of 23° C., (b) 35-97% by weight of a component soluble in paraxylene of 135° C. and insoluble in paraxylene of 23° C., and (c) 0-30% by weight of a compoent insoluble in paraxylene of 135° C. The component (a) soluble in paraxylene of 23° C. is composed substantially of an elastomeric constituent (a1) having a content of styrene or its derivative in the range of 0-35% by weight and an intrinsic viscosity (n) in the range of 0.1-5 dl / g, the component (b) soluble is paraxylene of 135° C. and insoluble in paraxylene of 23° C. is composed substantially of a crystalline polyproylene constituent (b1) having an isotactic pentad proportion (mmmm) of 97% or higher, a molecular weight distribution (Mw / Mn) of 6 or higher and a molecular weight distribution (Mz / Mw) of 6 or higher and the component (c) insoluble in paraxylene of 135° C. is composed substantially of a filler (c1).

Owner:MITSUI CHEM INC

Magnetic recording medium

InactiveUS20060083954A1InhibitionImprove heat resistanceMagnetic materials for record carriersRecord information storageRefractive indexNon magnetic

A magnetic recording medium comprising a non-magnetic support and at least one magnetic layer containing a ferromagnetic powder and a binder, wherein the non-magnetic support has an intrinsic viscosity of from 0.46 to 0.58 dl / g and a refractive index in a direction of a depth within a range from 1.490 to 1.500.

Owner:FUJIFILM HLDG CORP +1

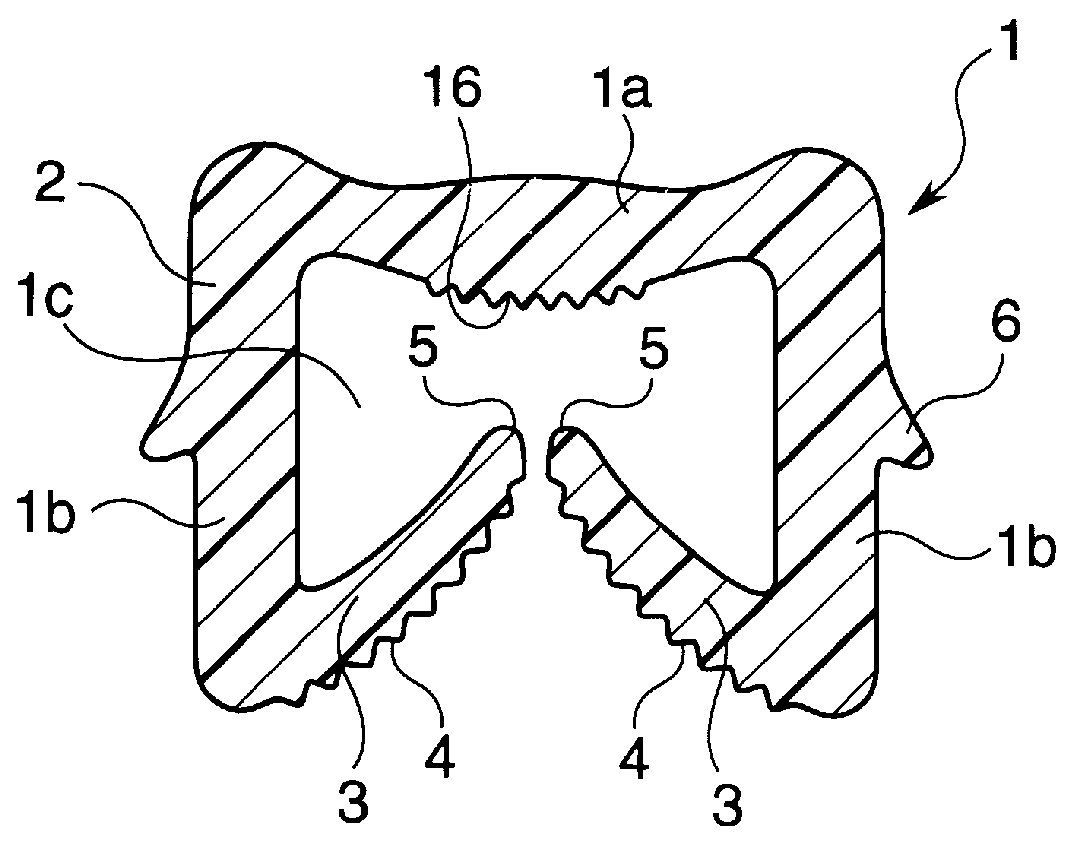

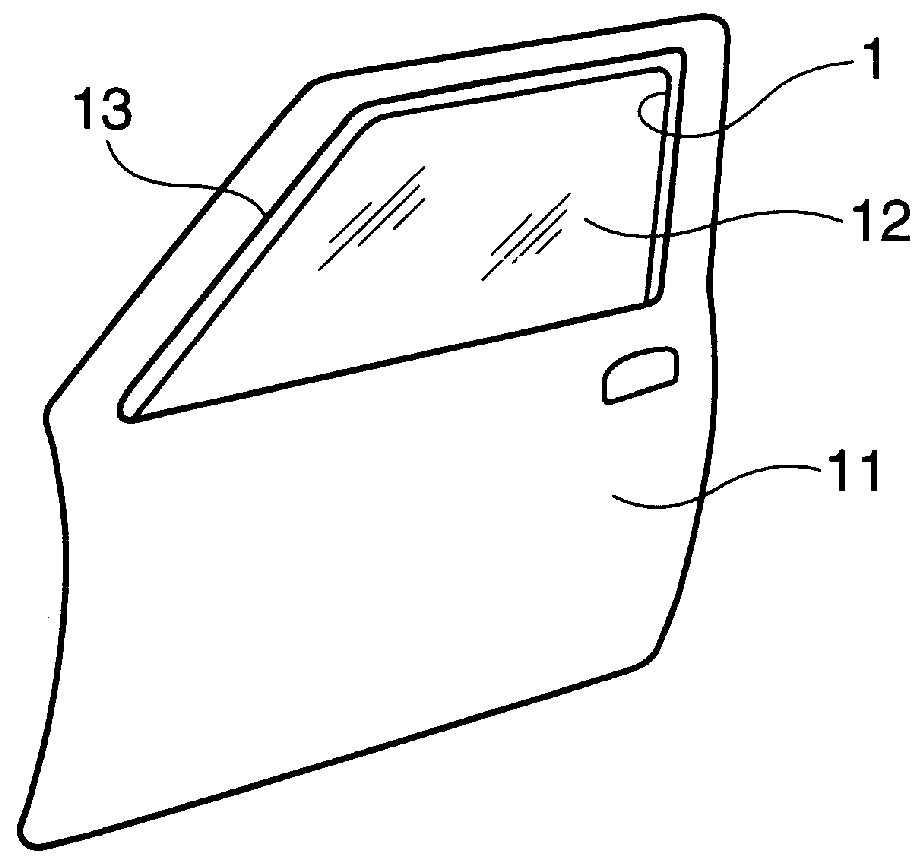

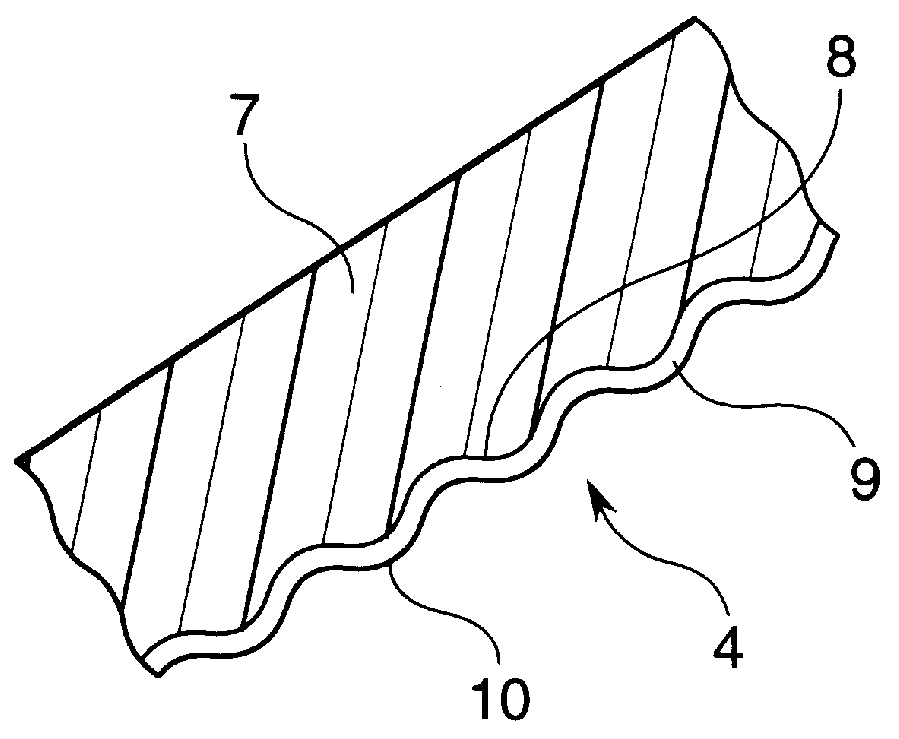

Glass run channel

InactiveUS6146739AReduce the number of stepsIncreased durabilityWindowsEngine sealsElastomerPolymer science

A glass run channel comprising a glass run channel body composed of a bottom wall and side walls extending from two opposite edges of the bottom wall, the glass run channel body having a substantially U-shaped section and provided with a groove, and tonguelike draining parts protruding from vicinities of distal edges of the side walls toward the bottom wall of the glass run channel body so as to become proximate to each other. Each of the tonguelike draining parts has a window glass contact part composed of a surface to be brought into contact with a window glass, which comprises a layer of a thermoplastic elastomer and a layer of an ultrahigh molecular weight polyolefin composition. The layer of ultrahigh molecular weight polyolefin composition is arranged so as to contact a window glass. The ultrahigh molecular weight polyolefin composition comprises at least a polyolefin (composition) having a specified intrinsic viscosity and an olefinic thermoplastic elastomer. The glass run channel is excellent in the durability, tight contactability with a window glass exhibited when the window glass is held closed and supple slide exhibited when a window glass is closed or opened and, even when twisted or bent, is free from a creasing of the ultrahigh molecular weight polyolefin composition layer.

Owner:MITSUI CHEM INC

Aqueous resin dispersion composition

InactiveUS6359030B1Excellent hot water resistanceMaintain good propertiesCoatingsKetone solventsMethyl ethyl ketone peroxide

An aqueous-dispersing composition of synthetic resin (A) having an intrinsic viscosity "eta" of from 0.3 to 2.0 measured at 35° C. in a methyl ethyl ketone solvent or a mixture of that aqueous dispersion and an aqueous dispersion of synthetic resin (B) having an intrinsic viscosity "eta" of not less than 0.6 which is larger by 0.3 or more than the intrinsic viscosity "eta" of the synthetic resin (A) when the intrinsic viscosity is measured at 35° C. in a methyl ethyl ketone solvent. The aqueous-dispersing composition and the mixture have improved film forming property and can give a coating film being excellent in chemical resistance, water resistance, mechanical properties and further hot water resistance.

Owner:DAIKIN IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com