Patents

Literature

388results about How to "Good hue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of polybutylene terephthalate/adipate butanediol copolyester

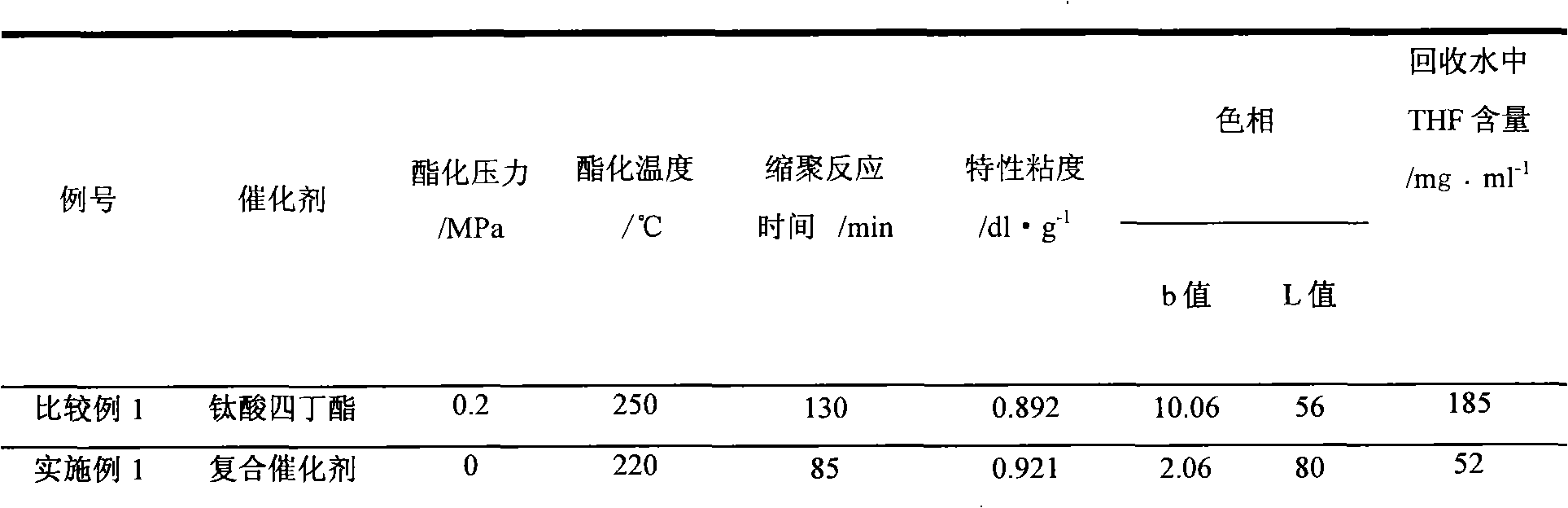

The invention relates to a preparation method of polybutylene terephthalate / adipate butanediol copolyester, which utilizes a titanium compound and an antimony compound as the composite catalyst, the mole ratio of terephthalic acid to adipate is 3:7-8:2, the ratio of the total mole of the terephthalic acid and the adipate to the mole of 1,4-butanediol is 1:1.0-1.8, esterification is carried out at normal pressure and the temperature of 150-220 DEG C, the pressure is reduced to high vacuum 10-150 Pa for the reaction, the final temperature for the reaction is 265-280 DEG C, and inert gas is utilized to recover the pressure to be normal to obtain the copolyester. The reaction time is shortened, the production amount of tetrahydrofuran is small, the intrinsic viscosity of copolyester chips is 0.90-1.32 dL / g, the hue b value of the product is between 0 and 8, the L value is between 68 and 85, and the product of the polybutylene terephthalate / adipate butanediol copolyester can be used in the fields of various soft package plastic products.

Owner:PETROCHINA CO LTD

Ink set, ink cartridge, ink jet printer and recording method

ActiveUS20040050291A1Excellent in handleabilityExcellent in odorMonoazo dyesMeasurement apparatus componentsComputer printingImage recording

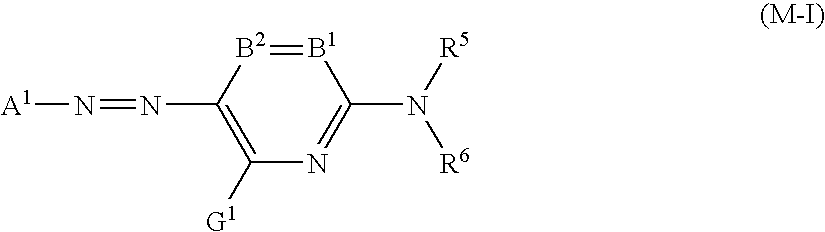

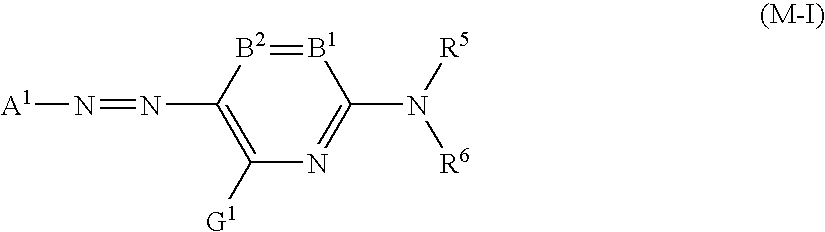

The ink set of the present invention provides a high ejection stability, gives an image having an excellent hue, light-resistance and waterproofness and improves the image preservability under severe conditions in ink jet recording, in which the ink set comprising a plurality of inks different in hues, wherein the plurality of inks includes a yellow ink containing a coloring agent that is a dye having: a lambdamax of from 390 nm to 470 nm; an I(lambdamax+70 nm) / I(lambdamax) ratio of not greater than 0.4, in which I(lambdamax) is the absorbance at lambdamax and I(lambdamax+70 nm) is the absorbance at (lambdamax+70 nm); and a forced fading rate constant of not greater than 5.0x10<-2 >[hour<-1>], an ink cartridge having the ink set received therein, an ink jet printer comprising the ink cartridge mounted therein and an image recording method.

Owner:FUJIFILM HLDG CORP +1

Method for preparing uvioresistant polyester by nanometer titania generated in situ

InactiveCN1552765AReduce the rate of hydrolysisGood hueArtifical filament manufactureNanometreTitanium dioxide

A process for in-situ preparing UV-resistant polyester by use of TiO2 nanoparticles includes such steps as synthesizing the hydrolysis speed controllable glycol salt of Ti, organic stabilizing it, dispersing it in diol, and polymerizing (or copolymerizing) with polyester and other monomers. Its advantage is high UV shielding effect.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of titanium series catalyst for polyester

The invention discloses a preparing method of titanium-system catalyst of polyester, which is characterized by the following: reacting titanic acid ester and 2-hydroxy carboxylic compound and organic phosphonic acid compound; making the product react with at least one phosphorus compound of phosphoric acid, phosphorous acid, hypophosphorous acid, phosphate ester or phosphite ester; fitting for polyester industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

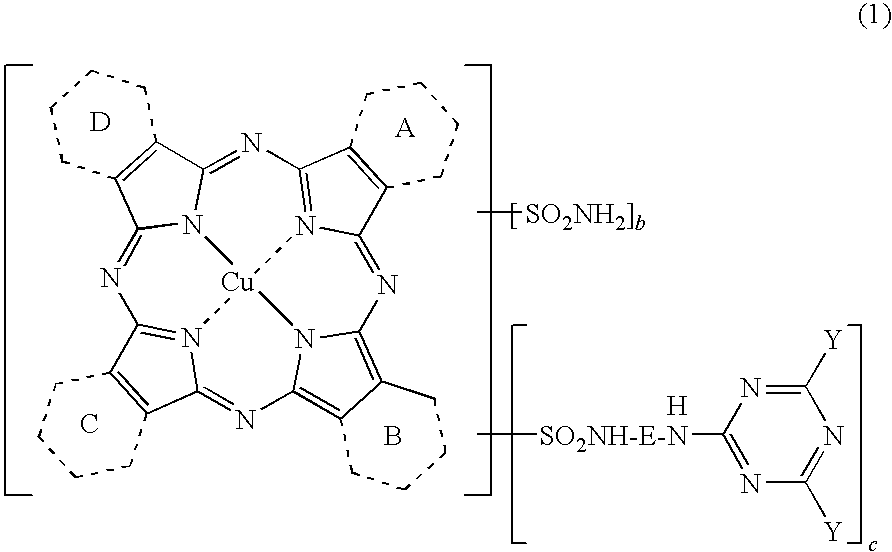

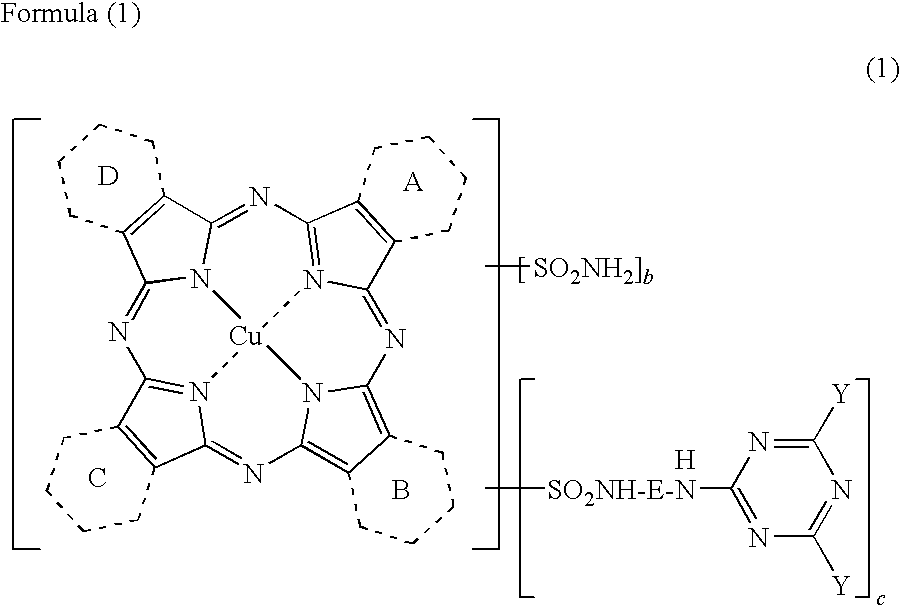

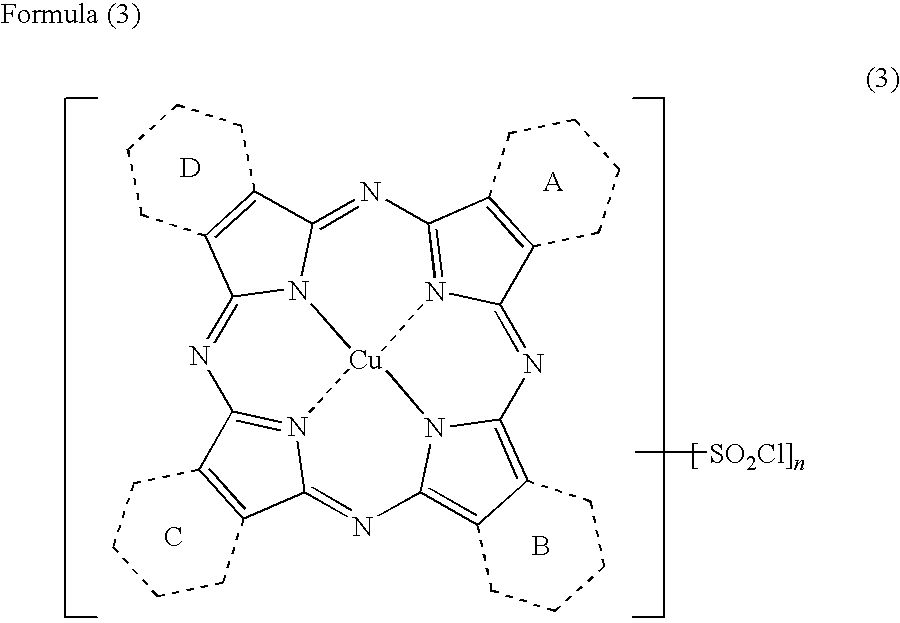

Porphyrazine coloring matter, ink, ink set, and colored product

ActiveUS7854797B2Excellent toneGood light fastnessOrganic chemistryMeasurement apparatus componentsPorphyrazineNitrogen

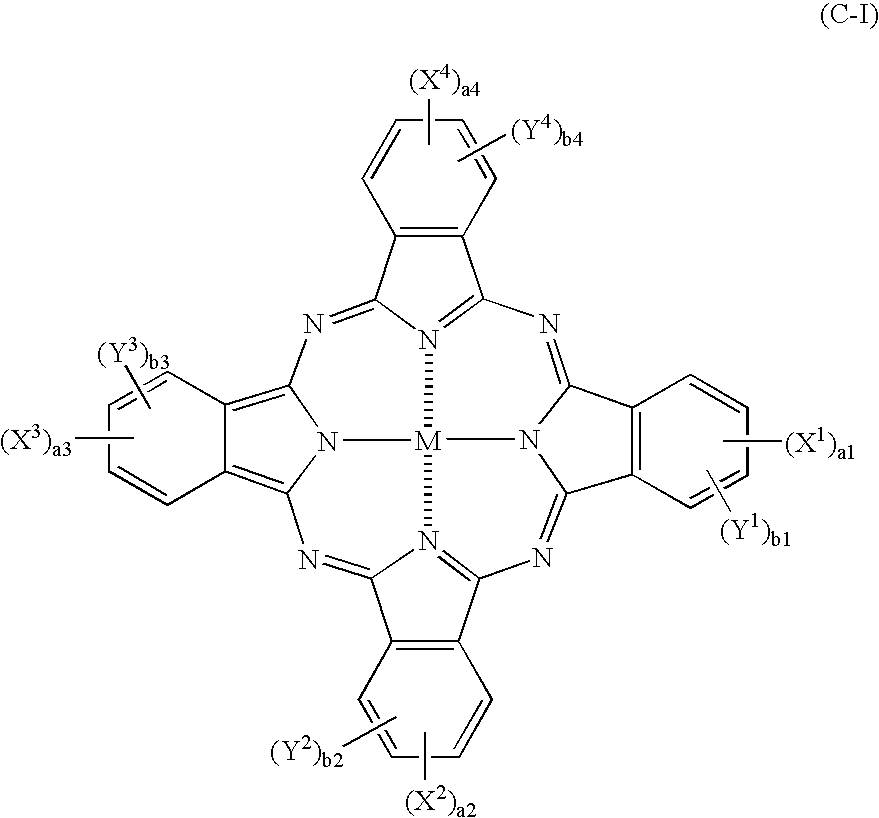

The present invention relates to a porphyrazine coloring matter represented by the following formula (1) or a salt thereof;wherein, each of the rings A to D independently represents a benzene ring or a 6-membered nitrogen-containing heteroaromatic ring, at least one or more thereof is a benzene ring, at least one of the rest is a nitrogen-containing heteroaromatic ring, E represents alkylene, X is an anilino group having a substituent and the like, Y represents an amino group; a hydroxy group; a mono- or di-alkylamino group or a nitrogen-containing heterocyclic group which may have a substituent, excepting for the combination in which Y is an amino group or a hydroxy group and X is a substituted anilino group, b is 0 to 2.9, c is 0.1 to 3, and the sum of b and c is 1 to 3. According to the present invention, a porphyrazine coloring matter suitable for inkjet recording which has a good hue as a cyan ink, is excellent in light fastness, ozone fastness and moisture fastness, and causes no bronze phenomenon can be provided.

Owner:NIPPON KAYAKU CO LTD

Aromatic polycarbonate resin composition and process for producing the same

InactiveCN101023134AImprove flame retardant performancePrevent molten drippingIon contentIon chromatography

A process of manufacturing the resin compositon and a method of preventing the melt dripping during combustion of the resin composition. The flame retardancy of the above aromatic polycarbonate resin composition comprising the fluorine-containing organic metal salt compound is improved. An aromatic polycarbonate resin composition containing a fluorinated organometal salt compound. The resin composition has improved flame retardancy. The resin composition comprises (1) 100 parts by weight of an aromatic polycarbonate resin (ingredient (A)), (2) 0.005-0.6 parts by weight of a fluorinated organometal salt (ingredient (B)) having a fluoride ion content as measured by ion chromatography of 0.2-20 ppm by weight, and (3) at least one ingredient selected from the group consisting of a flame retardant (ingredient (C)), fatty acid ester (ingredient (D)), ultraviolet absorber (ingredient (E)), polytetrafluoroethylene having fibril-forming ability (ingredient (F)), filler (ingredient (G)), silicate mineral (ingredient (H)), and titanium dioxide pigment (ingredient (I)). Also provided is a method of preventing a resin composition from melting / dripping upon combustion.

Owner:TEIJIN LTD

Process for in-situ quiclely preparing crystalline polyester using nano silicon dioxide

The present invention relates to composite material preparing technology. The production process of nano composite silica / polyester material includes the following steps: coating nano silica as crystallizing nucleartor with organic matter for surface modification to make it capable of distribute well in ethylene glycol as one monomer for polyester; high temperature pre-treating compounded nano silica / ethylene glycol slurry to make nano silica possess average size smaller than 100 nm; and polymerization or copolymerization between nano silica / ethylene glycol slurry and other monomer for polyester inside reactor to obtain in-situ nano composite silica / polyester material. The composite material with 1 wt% of nanometer silica contained has non-isothermal crystallization melting peak temperature raised to 213.4 deg.c and 4-8 times raised isothermal crystallization rate at 185-200 deg.c.

Owner:SHANGHAI JIAO TONG UNIV

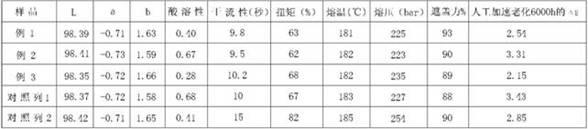

Reinforced greasy-dirt-resistant high-gloss polypropylene composite material and preparation method thereof

ActiveCN104744818ALower surface free energyGood oil resistancePolypropylene compositesPolymer science

The invention provides a reinforced greasy-dirt-resistant high-gloss polypropylene composite material and a preparation method thereof. The reinforced greasy-dirt-resistant high-gloss polypropylene composite material is prepared form the following components in parts by weight: 60-80 parts of PP resin, 10-15 parts of superfine precipitated barium sulfate, 6-10 parts of reinforced magnesium sulfate whiskers, 2-5 parts of fluoride, 0.2-0.4 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 0.5-1 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the reinforced greasy-dirt-resistant high-gloss polypropylene composite material prepared by the method disclosed by the invention, the surface polarity of the material is changed and the greasy dirt resistance of the material is improved; meanwhile, the composite material meets the European Union Regulation (EC) No.1935 / 2004 of related food contact materials, and has the characteristics of being high in gloss, low in after shrinkage, high in rigidity, and the like. The material is applied to a housing of a kitchen appliance, so that the surface of the kitchen appliance has capacity of resisting greasy dirt and self-cleaning capacity, and the self-cleaning anti-greasy-dirt environmental requirements of modern kitchen appliance are met.

Owner:ORINKO NEW MATERIAL CO LTD

Method for preparing special titanium dioxide pigment for plastic sectional materials by chlorination method

ActiveCN102070921APrevent chalkingGood weather resistancePigment treatment with organosilicon compoundsPigment physical treatmentPhosphateSlurry

The invention provides a method for preparing special titanium dioxide pigment for plastic sectional materials by a chlorination method, which comprises the following steps that: the chlorination method is adopted for preparing titanium dioxide primary products into slurry, and the pH value of the slurry is regulated to 4.0 to 5.0; phosphate dispersing agents are added; grinding treatment is carried out, then, grinding media is removed, and the temperature is raised; water-soluble silicate solution is added, the pH value of the slurry is maintained between 3.5 and 4.5, amorphous silicon oxide is formed, curing is carried out, and a first covering layer is formed; the pH value of the slurry is regulated to 6.0 to 7.0, curing is carried out, and a second covering layer is formed; aluminum salt solution is added, the pH value is controlled between 7.0 and 9.0, curing is carried out, a third covering layer is formed, the pH value of the slurry is regulated to 6.0 to 7.0, and curing is carried out; the slurry is washed by de-ionized water until the conductivity of filter cake is higher than 15000 ohm*cm, and then, drying and air powder treatment are carried out; modified polysiloxane is added in the air powder process, and a fourth organic covering layer is formed; and materials are recovered through a bag filter. The titanium dioxide pigment prepared by the method provided by the invention has the advantages of high weatherability, high shielding capability, high non-transparency and excellent processing performance in the field of plastic sectional materials.

Owner:中信钛业股份有限公司

Hydrogenation catalyst for preparing dicyclopentadiene hydrogenated petroleum resin

A hydrogenation catalyst for preparing dicyclopentadiene hydrogenant petroleum resin by dicyclopentadiene petroleum resin. The active components of the resin are Pd and Pt. The contents of Pd and Pt are 0.1í½ 1.0wtúÑ and 0.05í½0.5wtúÑ, respectively. The carrier of the catalyst is ª†-Al2O3, the specific surface are is 150í½250m2 / g, the volume is 0.5í½0.9ml / g. Hydrogenant resin prepared from dicyclopentadiene petroleum resin through the catalyst has a lowered content of unsaturated hydrocarbon bonds, and the color of the resin is improved to water-white.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Preparation method of hydrogenated C9 petroleum resin

The invention relates to a preparation method of hydrogenated C9 petroleum resin, which is characterized by comprising the following steps of: (1) preparation of supported noble metal hydrogenated catalyst: preparing by using a coating method, selecting noble metal palladium and platinum and transition metal cobalt or nickel as metal active components, preparing a spherical alumina supporter, then coating the active components of palladium and platinum and transition metal on the alumina supporter, and activating to obtain a hydrogenated catalyst; (2) selective hydrogenation: desulfurizing and denitrifying; (3) high pressure hydrogenation reaction: controlling the weight ratio of resin to solvent to ensure that the concentration of resin is 20-40% by weight, taking chain-like or annular saturated hydrocarbon or aromatic hydrocarbon or hydrocarbon mixture as a solvent, and taking a supported noble metal hydrogenated catalyst as a catalyst, wherein the temperature of the high pressure hydrogenation reaction is 250-350 DEG C, the pressure is 8.0-20.0 MPa and the liquid volume space velocity is 0.5-2h<-1>. The properties of the final product hydrogenated C9 petroleum resin are as follows: Gardner is not more than 1, and the softening point is not smaller than 100 DEG C.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for preparing titanium series catalyst

The invention relates to a titanium catalyst, mainly aiming to solve the problems of the diol compound of the titanium as a catalyst in the former technology, which has the problems of the low solubility in the ethylene glycol and the poor polyester color difference. The invention uses the technical proposal with the reaction between the titanium compound and diol and the reaction between the product of the precious reaction and the IA metal compound in the periodic table of elements to produce the titanium catalyst to solve the problems well; the invention can be used in the industrial production of the polyester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyester resin, molded object thereof, and processes for producing the same

InactiveCN101068848AGood formabilityImprove featuresThin material handlingHollow articlesPolymer sciencePolyethylene terephthalate

The present invention relates to a polyester resin, molded object thereof, and processes for producing the same. The invention provides polyethylene terephthalate resin which is obtained by melt polymerization at a reduced pressure or in an inert gas atmosphere and has the following properties (A) to (F): (A) the intrinsic viscosity [eta] is 0.4-2.5 dL / g; (B) the content of carboxy groups present at polymer ends is 30 meq / kg or lower; (C) the acetaldehyde content is 10 ppm or lower; (D) a hexafluoroisopropanol solution of the resin, when analyzed by the transmission method, has a hue which has an L value of 99 or larger and a b value of 0.4 or smaller; (E) the Mw / Mn is 1.8-2.3; and (F)the cyclic trimer content is 5 wt.% or lower.

Owner:ASAHI KASEI CHEM CORP

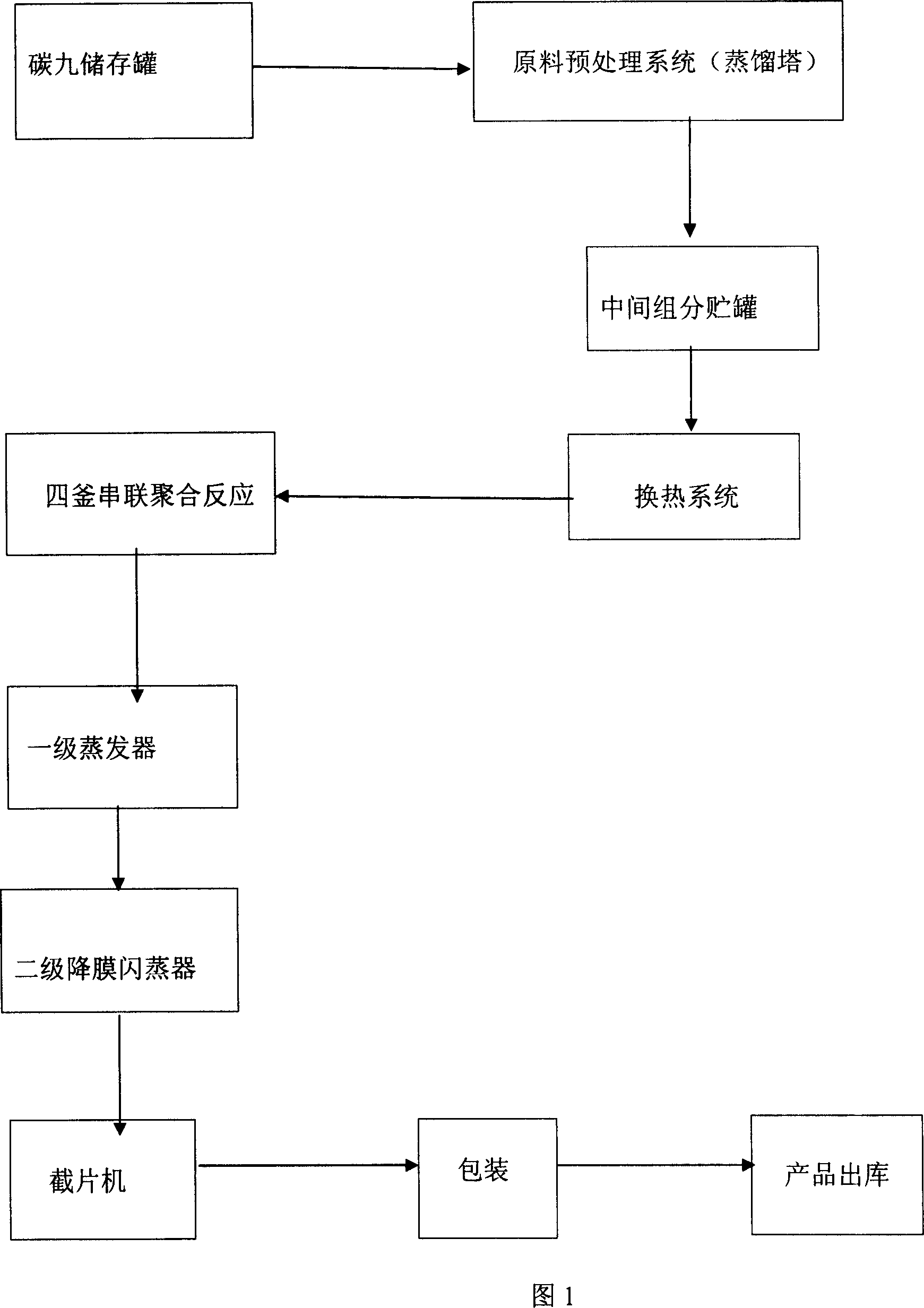

Technique for producing petroleum resin of carbon - 9 through continuous hot polymerization in cascade connected multiple kettles

This invention relates to a method for producing light color C9 petroleum resin by continuous heat polymerization in multiple kettles in series. The method comprises: (1) pre-treating C9 raw materials; (2) performing heat polymerization in multiple kettles in series for 20-30 h; (3) sending the polymerization products into a primary evaporator, then sending into a secondary film-falling flash evaporator to remove the solvent, slicing, and cooling to obtain the final product. The method adopts negative pressure distillation to purify the raw materials. Heat polymerization in multiple kettles in series can effectively lower the energy consumption. Besides, secondary film-falling flash evaporator is adopted to remove the solvent, thus the solvent removal efficiency is increased and the resin appearance is improved.

Owner:东营市神州化工有限公司

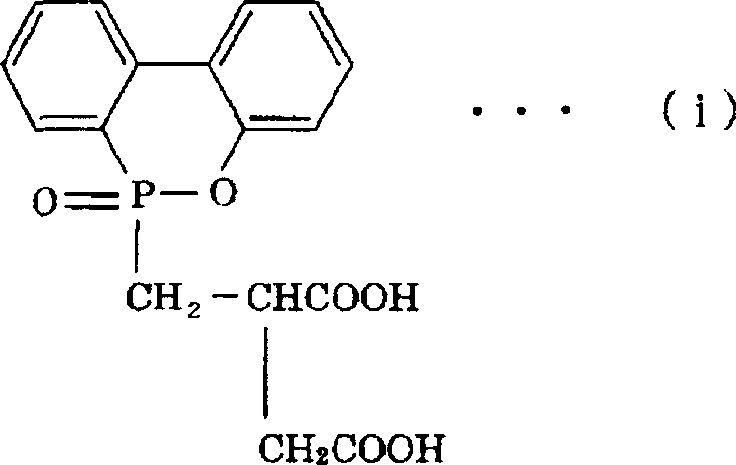

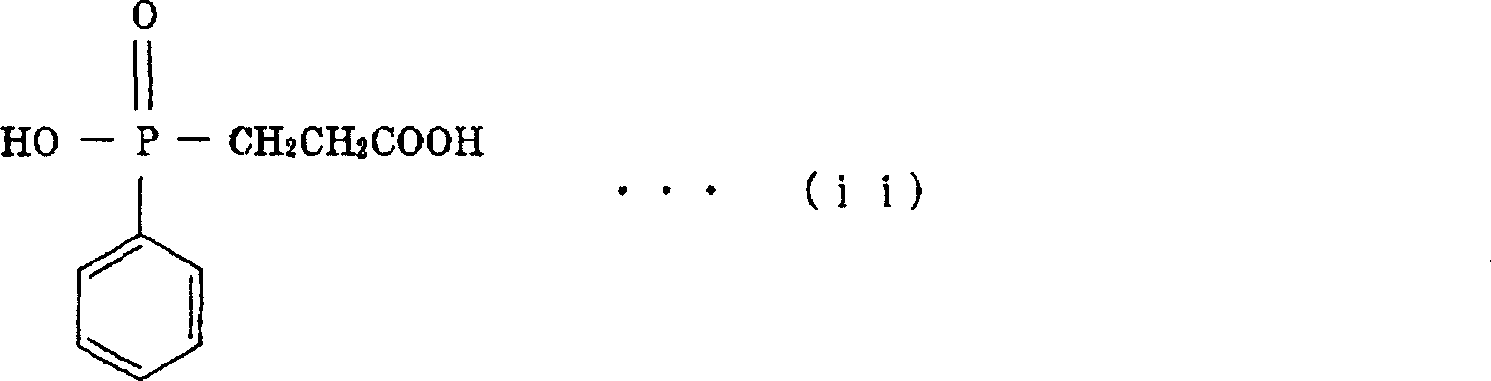

Flame-retardant polyester and process for producing the same

The invention relates to easily obtain a polyester having excellent mechanical properties, a satisfactory hue, and a high degree of flame retardancy. The flame-retardant polyester is a polyester comprising ethylene terephthalate units as the main structural units and a phosphorus compound copolymerized or incorporated therein or is a resin composition comprising polyesters including that polyester. The flame-retardant polyester is characterized in that a polycarboxylic acid and / or polyol having three or more functional groups capable of forming an ester bond is contained in the polyester in a total amount of 0.05-2.00 mol (per 200 mol of the sum of the dicarboxylic acid ingredient and the diol ingredient), that a specific phosphorus compound having a functional group capable of forming an ester bond is contained in the polyester in an amount of 5,000-50,000 ppm of the polyester in terms of phosphorus amount, and that the polyester pellet obtained has a b value of -5 to 20, an L value of 35 or larger, and a melt viscosity at 280 DEG C of 1,000-20,000 dPas.

Owner:TOYOBO CO LTD +1

Semi-aromatic polyamide and low wastewater discharge preparation thereof

The invention relates to a semi-aromatic polyamide and a preparation method producing low wastewater discharge. The semi-aromatic polyamide is prepared by the following steps: adding aromatic dicarboxylic acid, aliphatic diamine containing 4-14 carbon atoms and wastewater produced in a last prepolymerization process to a pressure pan for a prepolymerization reaction; and then further performing a tackification reaction on the prepolymer to obtain the semi-aromatic polyamide. In the preparation method, the wastewater produced in the polymerization process is recycled, which greatly reduces wastewater discharge; and raw materials in the wastewater are recovered effectively, which improves the utilization ratio of the raw materials; meanwhile, the diamine in the wastewater supplements the diamine which runs off along with the water during the prepolymerization process, which ensures balance of mol ratio of monomer dicarboxylic acid and monomer diamine.

Owner:KINGFA SCI & TECH CO LTD +1

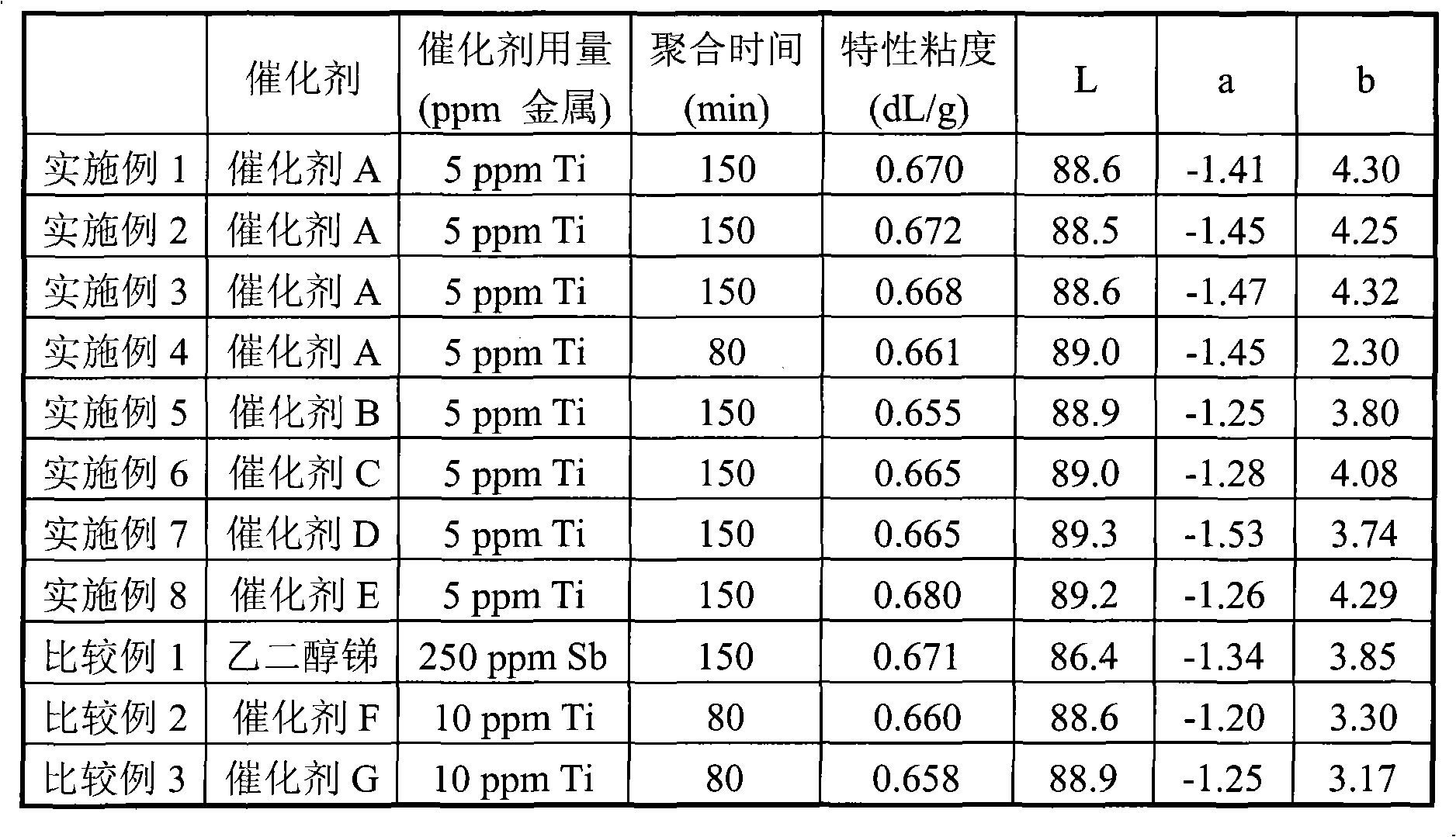

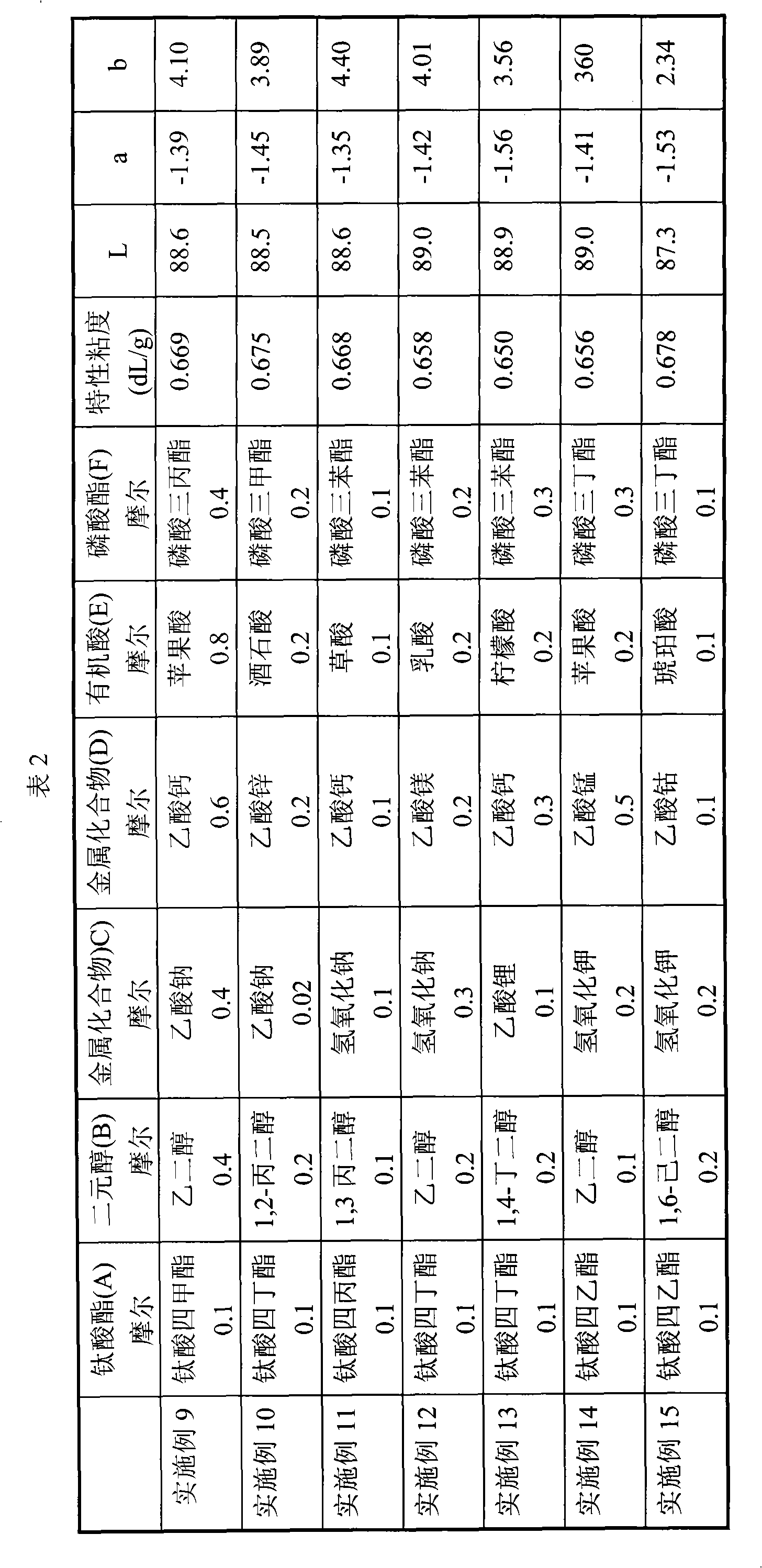

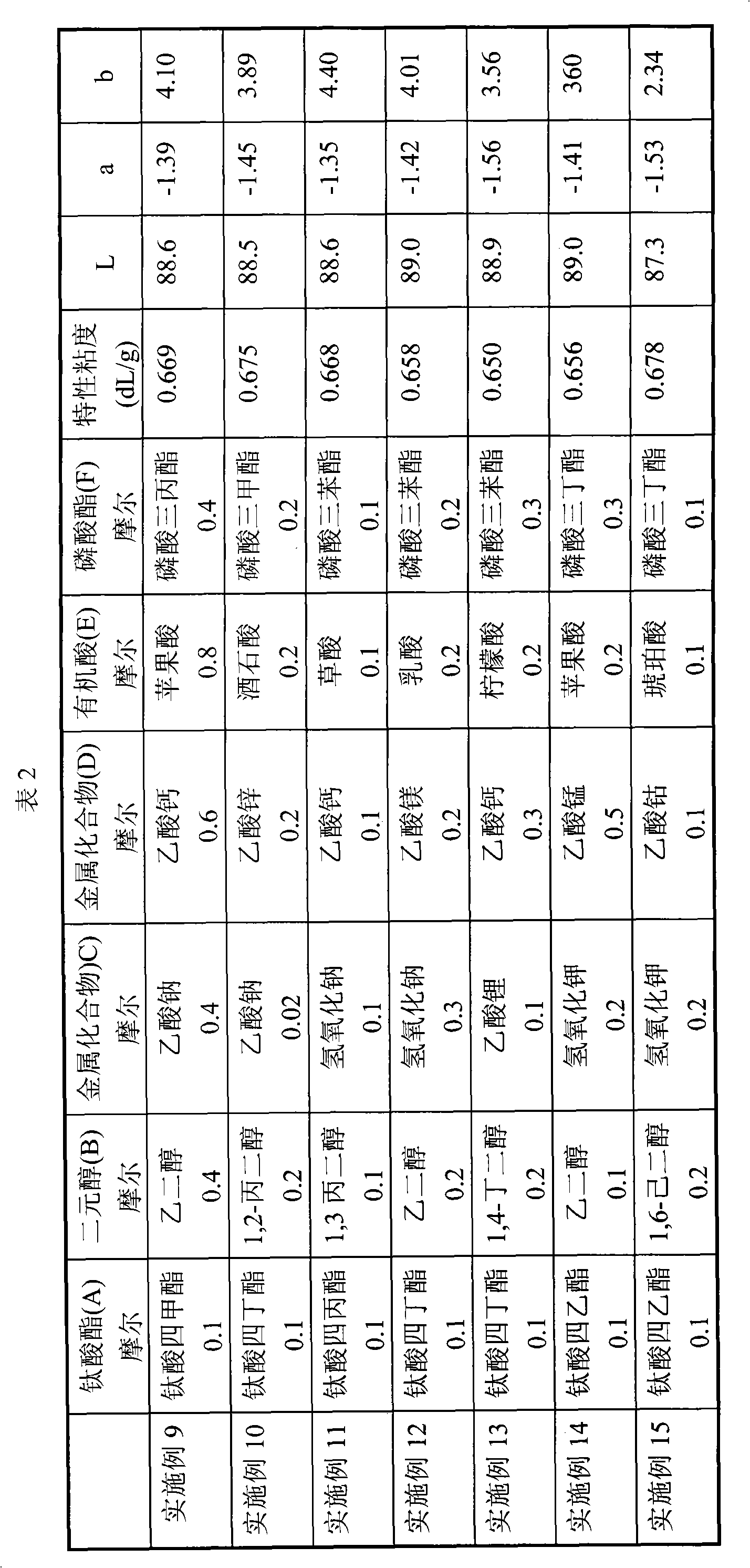

Titanium polyester catalyst for preparing polyester

The invention relates to a titanium polyester catalyst for preparing polyester, which mainly solves the problems of the low storage stability and easy color changing under illumination of a liquid-state titanium polyester catalyst and the low stability and poor hue of the prepared polyester in the conventional technology. The titanium polyester catalyst for preparing the polyester adopted in the invention comprises a reaction product prepared from the following raw materials at the reaction temperature of between 0 and 200 DEG C for 0.5 to 10 hours: (A) a titanium compound having the following general formula: Ti(OR)4, wherein R is selected from alkyl having 1 to 10 carbon atoms; (B) dihydric alcohol having 2 to 10 carbon atoms; (C) at least one metal compound of IA selected from a periodic table of elements; (D) at least one metal compound selected from IIA, IB, IIB, VIIB and VIII in the periodic table of the elements; (E) at least one aliphatic organic acid selected from organic acids; and (F) at least one phosphate compound selected from a phosphorus compound. The technical scheme solves the problems well and can be used in the industrial production of the polyester.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of polyester

The invention relates to a preparation method of polyester, mainly solving the problems of poor storing stability and easy changing of the colour of the liquid titanium-based polyester catalyst, and poor heat stability and bad hue of the polyester prepared in the prior art. According to the invention, dicarboxylic acids and dihydric alcohols are used as raw materials, and the raw materials are subjected to the esterification reaction to prepare a prepolymer with the presence of the titanium-based polyester catalyst under the reaction temperature of 230 to 280 DEG C and the reaction pressure of normal pressure to 0.5 MPa, and then the prepolymer is subjected to the polycondensation reaction to prepare the product of polyester under the reaction temperature of 250 to 320 DEG C and the vacuum condition with the reaction pressure less than 150 Pa. The technical scheme of the invention solves the problems preferably, and the preparation method can be used in the industrial production of polyester.

Owner:CHINA PETROLEUM & CHEM CORP +1

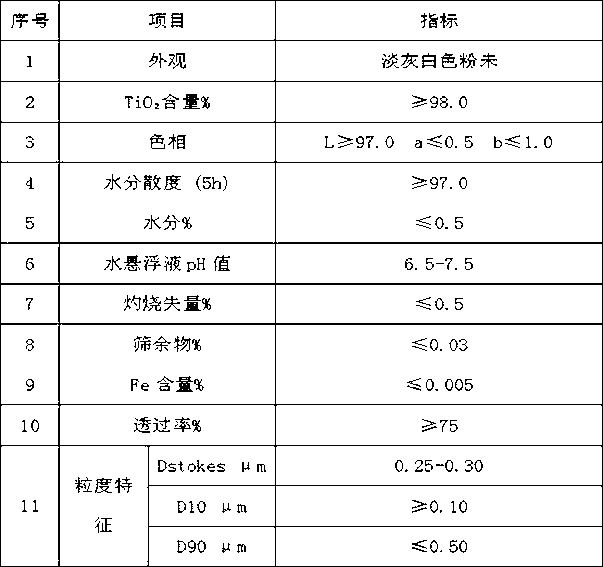

Method for preparing titanium dioxide for delustering chemical fibers

The invention belongs to the field of fine chemical engineering, and particularly relates to a method for preparing titanium dioxide for delustering chemical fibers. The method comprises the following technological flows: slurry making, iron-removal filtering, wet grinding, diluting, iron-removal filtering, grading, surface treatment, washing settling, atomized drying, grinding and packaging. The method provided by the invention has the advantageous effects as follows: 1, the prepared products have controllable particle sizes and stable dispersity; 2, the impurity removal effect is good; 3, the removal effect of soluble slats is good; and 4, the product quality is guaranteed.

Owner:JIAXING GAOSHENG NEW MATERIAL TECH

Polycarbonate resin composition for thin optical component, and thin optical component

ActiveUS20160122533A1High light transmittanceImprove the immunityGroup 5/15 element organic compoundsSynthetic resin layered productsEtherHue

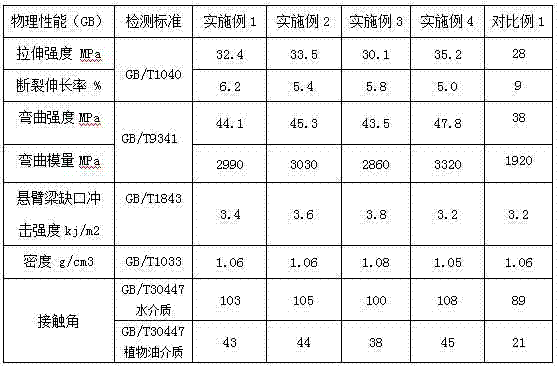

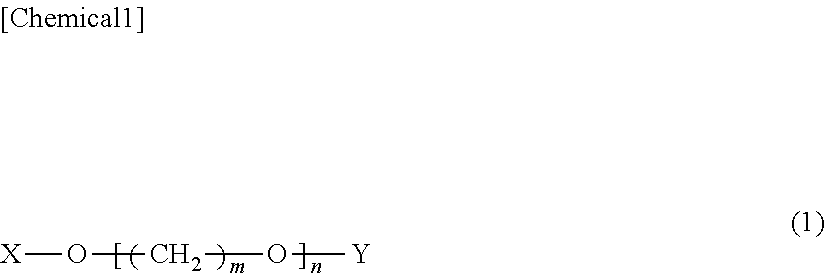

A polycarbonate resin composition for a thin optical component is provided, which has a high transmittance and a good hue and an excellent resistance to thermal discoloration, and a thin optical component is also provided. The polycarbonate resin composition for a thin optical component comprising, per 100 mass parts of a polycarbonate resin (A), 0.1 to 2 mass parts of a polyalkylene ether glycol compound (B) represented by general formula (1) and 0.005 to 0.5 mass parts of a phosphorus stabilizer (C).

Owner:MITSUBISHI ENG PLASTICS CORP

Refining method of titanium dioxide by-product ferrous sulphate

The invention provides a refining method of titanium dioxide by-product ferrous sulphate. The method comprises: (1) preparing a ferrous sulfate heptahydrate solution by using the titanium dioxide by-product ferrous sulphate; (2) adjusting a pH value of the solution to 1-2.5, and performing titanium hydrolysis of the titanium dioxide by-product ferrous sulphate; (3) adding iron powder or iron sheets into the ferrous sulfate heptahydrate solution after the titanium hydrolysis, reducing Fe<3+> in the solution, adjusting a pH value of the solution to 6.0-6.5, and performing a magnesium, manganese and zinc precipitation treatment for the titanium dioxide by-product ferrous sulphate; and (4) adding a flocculating agent into the above solution, stirring, standing, settling and filtering to obtain the refined ferrous sulphate solution. The method can effectively remove impurities such as titanium, magnesium, zinc, manganese and other ions in the titanium dioxide by-product ferrous sulphate, and obtain the high-purity refined ferrous sulphate.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Titanium series catalyst

The present invention is one technological scheme of titanium catalyst of the reaction resultant of titanium compound, diol and metal compound. The titanium catalyst of the present invention is superior to available similar catalyst, which has poor dissolubility in ethylene glycol and poor hue of the prepared polyester. The titanium catalyst is applied in industrial production of polyester.

Owner:CHINA PETROLEUM & CHEM CORP +1

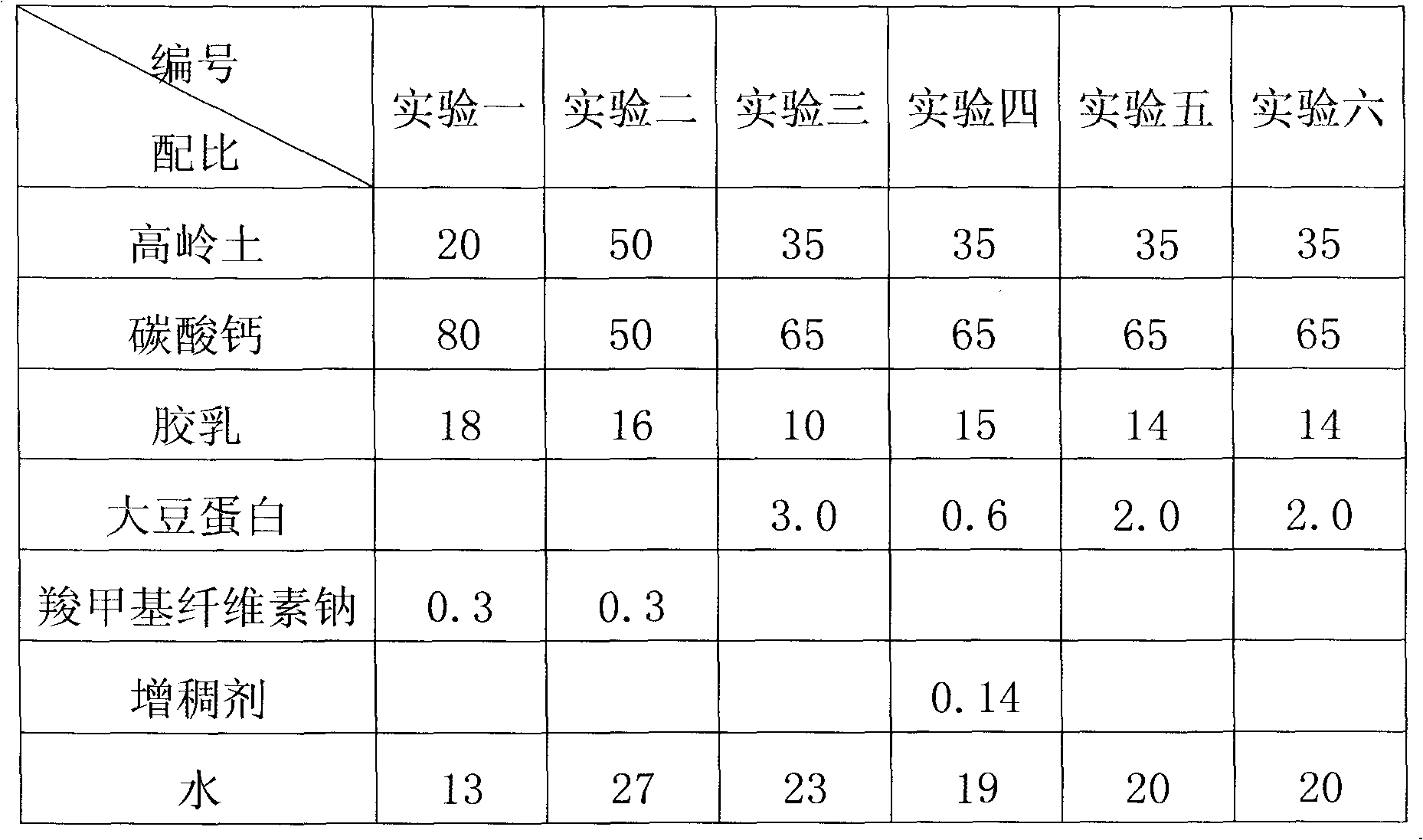

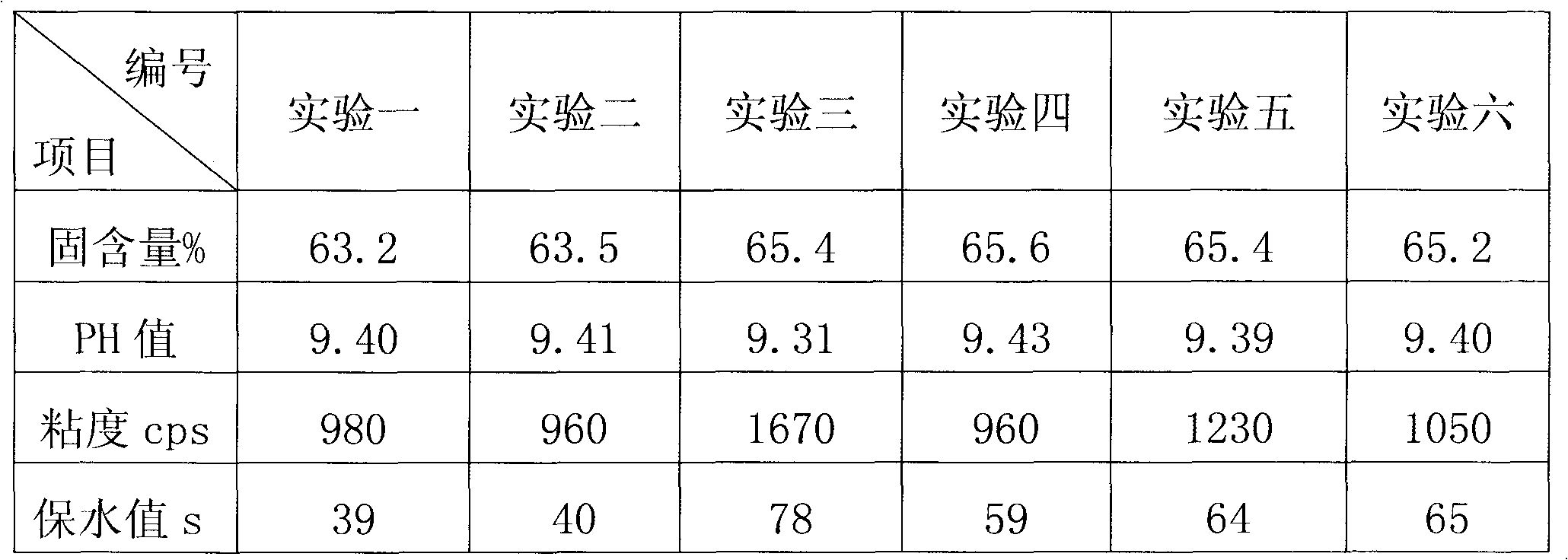

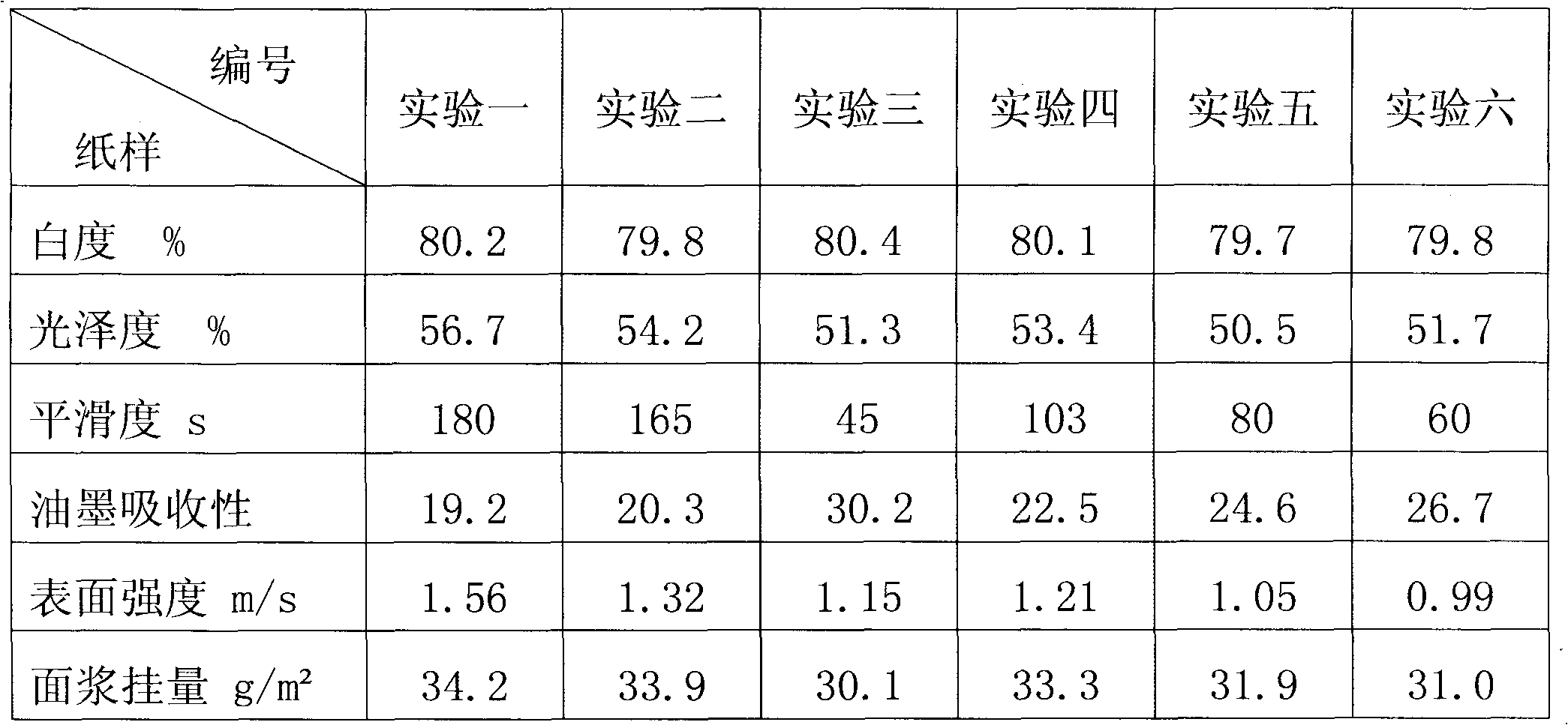

Top coating for coating layer of double-sided coating white board as well as preparation method and application thereof

The invention discloses a top coating for a coating layer of a double-sided coating white board as well as a preparation method and application thereof. As the top coating, the double-sided coating white board after being applied and coated by a coating machine not only is suitable for high-grade printing but also is suitable for vacuum forming. The top coating comprises the following components in parts by mass: 20 to 50 parts of kaolin, 50 to 80 parts of calcium carbonate, 10 to 18 parts of latex and 25 to 35 parts of water. The top coating also contains the components of a dispersant, a lubricant, a water repellent agent, a bactericide, a pH regulator and a functional assistant of 0.6 to 3.0 parts by mass of PC4200 soybean protein. By adding the functional assistant, the closure property of the coating layer can be opened, the covering property of the coating is enhanced, the use quantity of wood pulp is reduced, the smoothness of finished paper is lowered, and the infiltration of vacuum forming oil is benefited. The coating is applied and coated on a paperboard by the coating machine, can enable the paperboard to have favorable printing ink acceptance, improves the covering property of a paper face greatly and has lower smoothness and roughness and favorable printing adaptability.

Owner:YUANTONG PAPER SHANDONG

Method for preparing uvioresistant polyester by nanometer titania generated in situ

InactiveCN1300246CSolve reunionReduce dispersionArtifical filament manufactureEngineering plasticUltraviolet

A process for in-situ preparing UV-resistant polyester by use of TiO2 nanoparticles includes such steps as synthesizing the hydrolysis speed controllable glycol salt of Ti, organic stabilizing it, dispersing it in diol, and polymerizing (or copolymerizing) with polyester and other monomers. Its advantage is high UV shielding effect.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing dicyclopentadiene hydrogenated petroleum resin

ActiveCN102558444AGood dispersionLarge specific surface areaCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsBromine numberHydrogen

The invention relates to a method for preparing dicyclopentadiene hydrogenated petroleum resin. Dicyclopentadiene petroleum resin is used as a raw material and hydrogenated under the action of a catalyst to prepare the dicyclopentadiene hydrogenated petroleum resin, wherein the weight ratio of the dicyclopentadiene petroleum resin to the catalyst is 100: (3-6), the hydrogenating temperature is 170 to 215 DEG C, the pressure of the reaction hydrogen is 3.0 to 5.5MPa, and the reaction time is 4 to 8 hours; a silicon-aluminum composite oxide is used as a carrier in the catalyst, the active ingredient of the catalyst is Pd, the weight of the Pd is 0.1 to 1.0 percent of the weight of the catalyst, the specific surface of the catalyst is 350 to 420 m<2> / g, and the pore volume is 0.6 to 0.7ml / g;and according to the dicyclopentadiene hydrogenated petroleum resin product prepared by the method, the bromine number is less than or equal to 2.0gBr / 100g, the chromaticity (Gardner) is less than orequal to 1, and the softening point is 110 to 120 DEG C.

Owner:PETROCHINA CO LTD

Preparation method of polyphenylene sulfide

The invention relates to the field of high molecular material synthesis, in particular to a preparation method of polyphenylene sulfide. The preparation method comprises the following steps of: adding Na2S.9H2O, N-methyl pyrrolidone and a reaction assistant into a polymerization kettle, supplying nitrogen to replace air, then heating to 180 DEG C for dehydration at a dehydration rate of 80-95%, adding an N-methylpyrrolidine solution containing p-dichlorobenzene into a dehydrated system in Step (1) for reaction for 3-8h at 190-230 DEG C, after the reaction finishes, obtaining a size mixture, filtering the size mixture, adding a filter cake into boiled pure water, stirring, washing, and performing 90Hz ultrasonic treatment for 15-30min, repeatedly washing for 2-3 times, and obtaining PPS (polyphenylene sulfide) resin after drying. The method has the advantageous effects that the product hue can be obviously improved since sodium thiosulfate is added, even a water content of the system is higher (the dehydration rate is 80%) and the reaction temperature is higher, and the ultrasonic washing can effectively remove inorganic salt impurities included due to macromolecular chain bending and winding in a reaction process.

Owner:CHONGQING JUSHI NEW MATERIAL TECH CO LTD

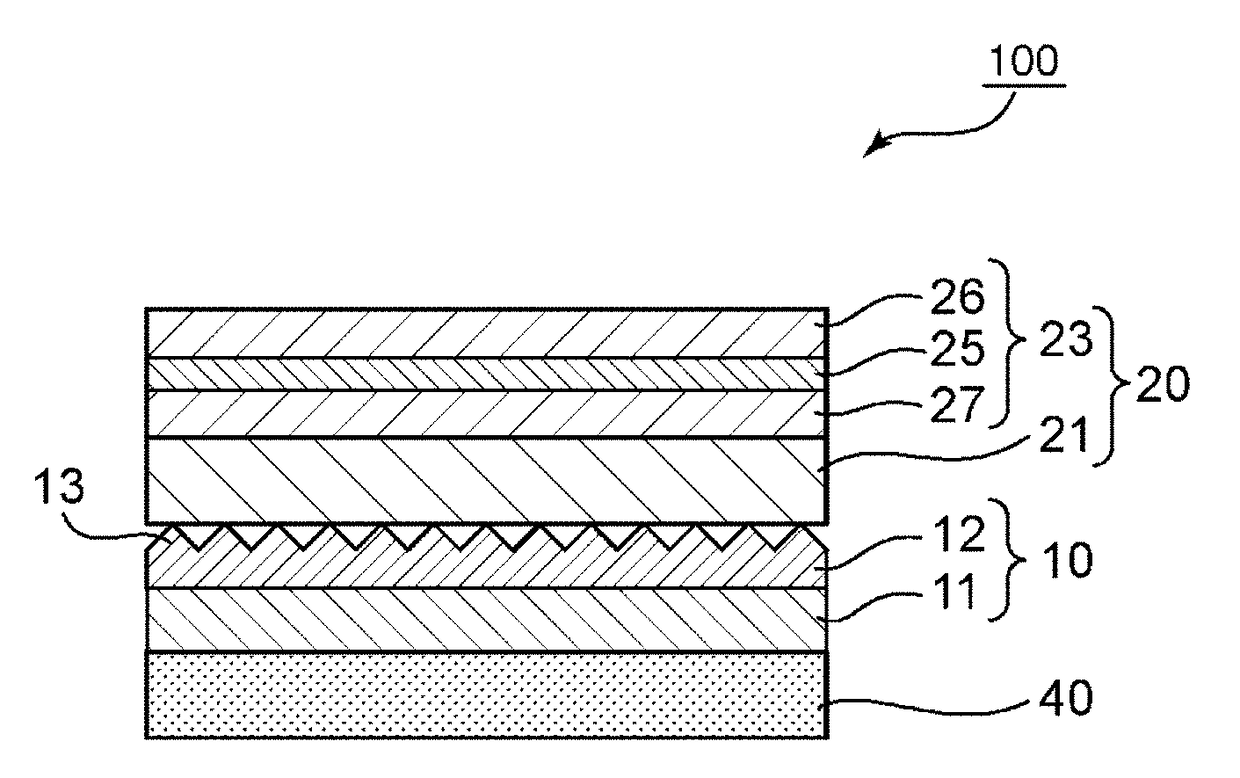

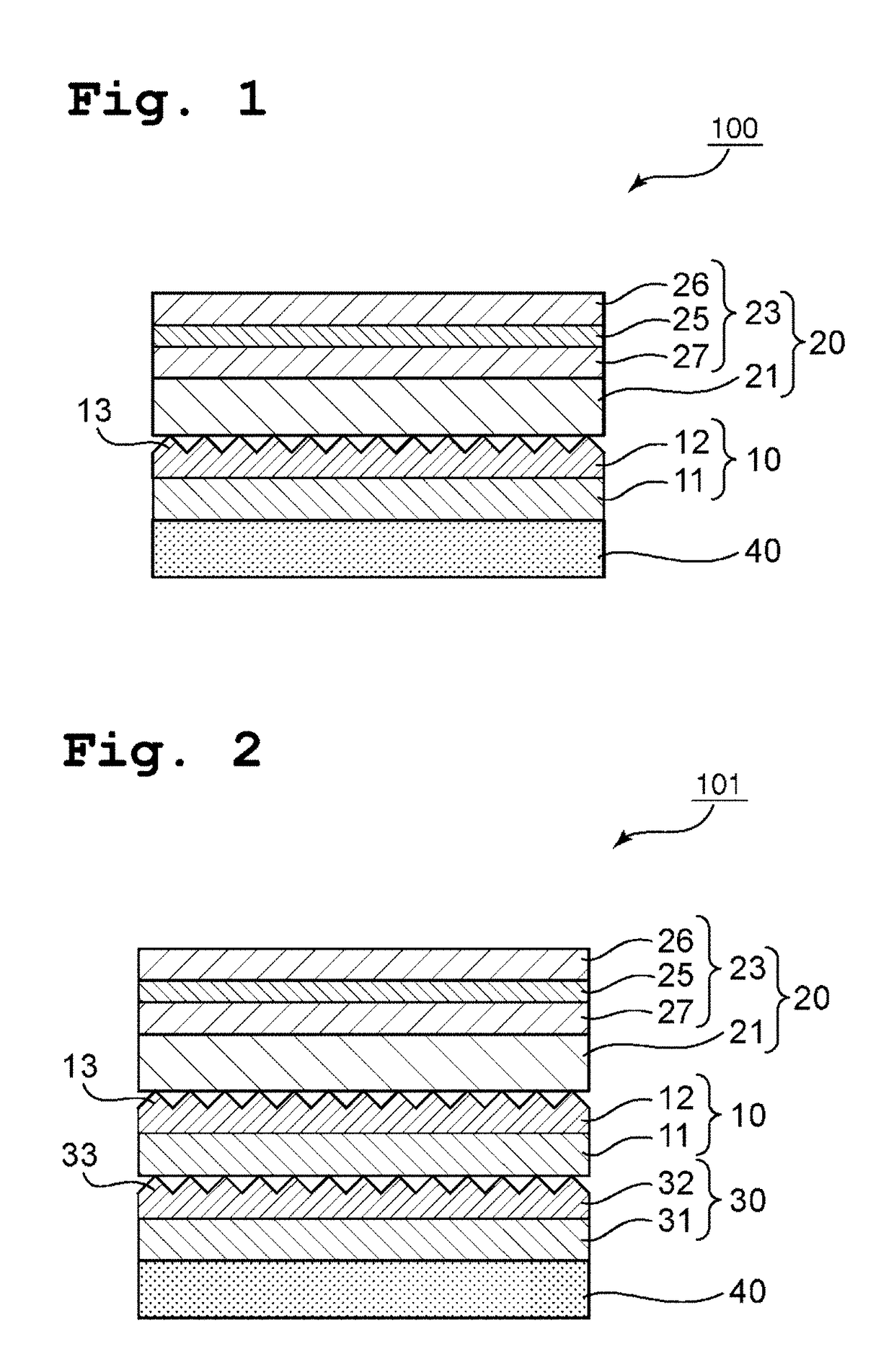

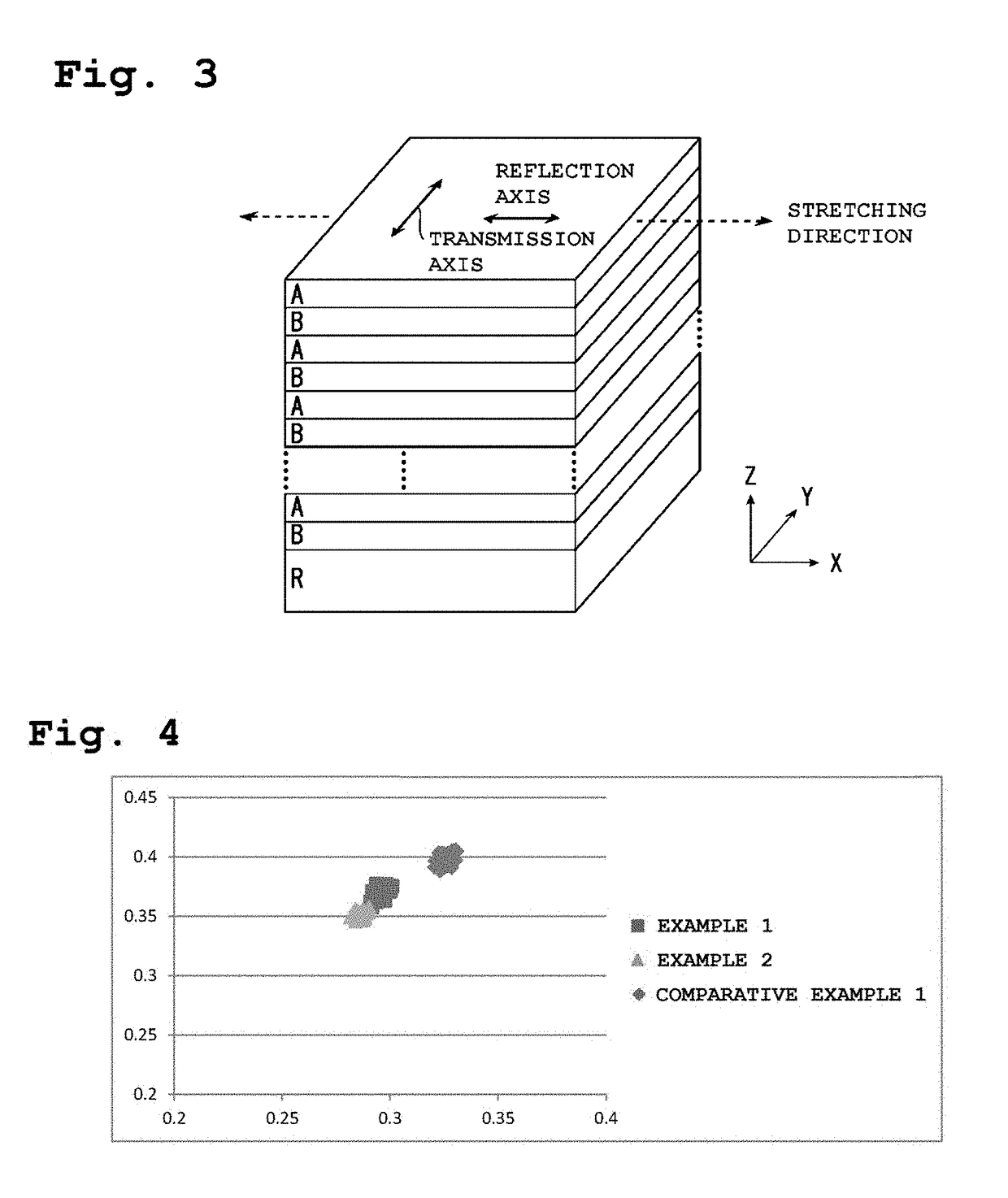

Optical member, and polarizing plate set and liquid crystal display device that use said optical member

ActiveUS20180252968A1Excellent mechanical strengthGood hueMechanical apparatusOptical filtersPolarizerLiquid-crystal display

Provided is an optical member that can achieve a liquid crystal display apparatus that is excellent in mechanical strength, has an excellent hue, and shows little change in hue dependent on a viewing angle. The optical member includes a prism sheet and an optically functional element that are integrated with each other. The prism sheet has: a first main surface, which is flat; and a second main surface, on which a plurality of unit prisms each having a columnar shape convex toward an opposite side to the first main surface are arrayed. Convex portions formed by the plurality of unit prisms on the second main surface of the prism sheet are bonded to one main surface of the optically functional element.

Owner:NITTO DENKO CORP

Process for producing polyester

The invention relates to a manufacturing method of a polyester, which mainly solves the problems that dihydric alcohol compounds of titanium have poor solubility in glycol and the manufactured polyester has poor hue with the prior art. The manufacturing method takes dicarboxylic acids and alkylidene diols as raw materials, carries out an esterification reaction on conditions of a titanium-including catalyst, temperature of 230 DEG C to 280 DEG C and reaction pressure of the normal pressure to 0.5MPa to obtain a prepolymer; and then a condensation polymerization is carried out to obtain a product of polyester; the technical proposal that the product from the reaction of titanium compound, dihydroxy alcohol and at least one metallic compound selected from the IA column in the periodic table of (chemical) elements is used as the catalyst for the reaction of dicarboxylic acids and alkylidene diols can solve the problem and be used in the industrialized production of polyester.

Owner:CHINA PETROLEUM & CHEM CORP +1

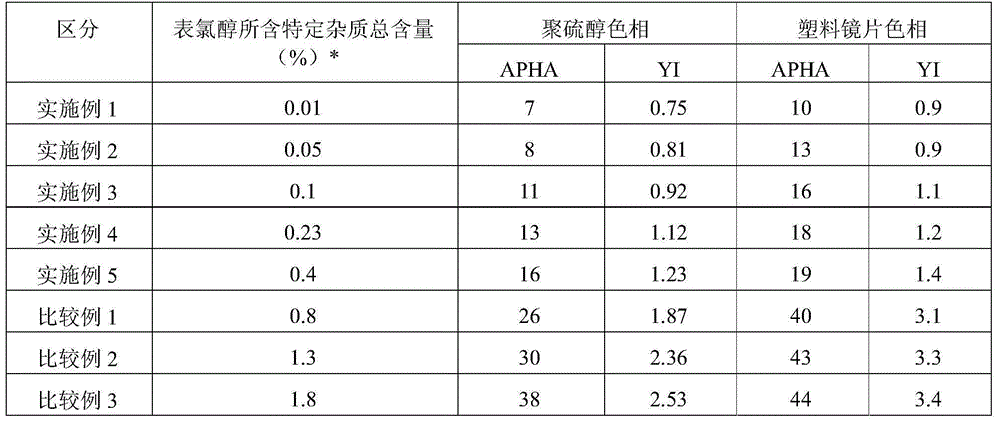

Method for producing polythiol compound for optical materials and composition comprising same for optical materials

ActiveCN104066716AInhibit coloringLow yellownessThiol preparationSulfide preparationChemical compound2-Mercaptoethanol

The present invention relates to a polythiol compound for optical materials exhibiting desirable characteristics from a coloring perspective, a composition comprising same for optical materials, and a method for producing optical materials. The present invention provides a method for producing a polythiol compound for optical materials which reacts epichlorohydrin compound having total impurities content of less than 0.5 wt% and 2-Mercaptoethanol. The present invention allows obtaining a polythiol compound exhibiting suppressed coloration, and by using same, allows obtaining a urethane group exhibiting suppressed coloration, low yellowness and good coloring. The polythiol compound according to the present invention can be used in the production of a variety of optical materials such as a urethane group, and optical lenses having good coloring, obtained by means of the present invention, can replace existing lenses and be widely used in diverse fields, particularly as lenses for glasses, polarized lights and cameras.

Owner:MITSUI CHEM INC

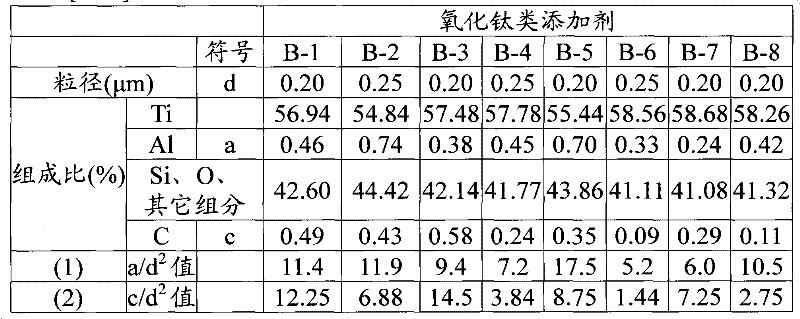

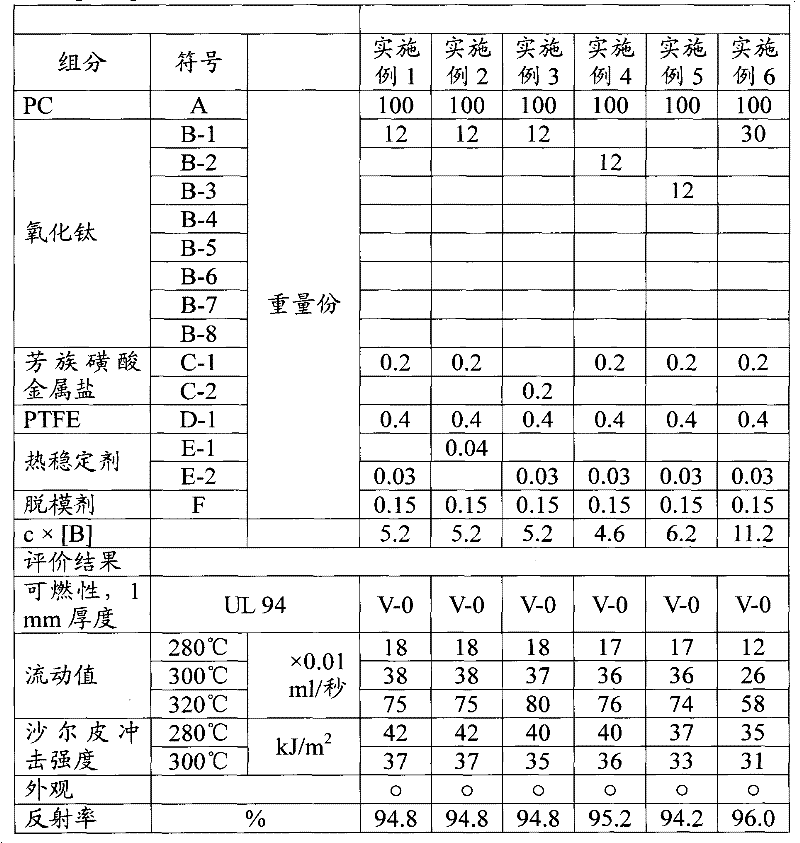

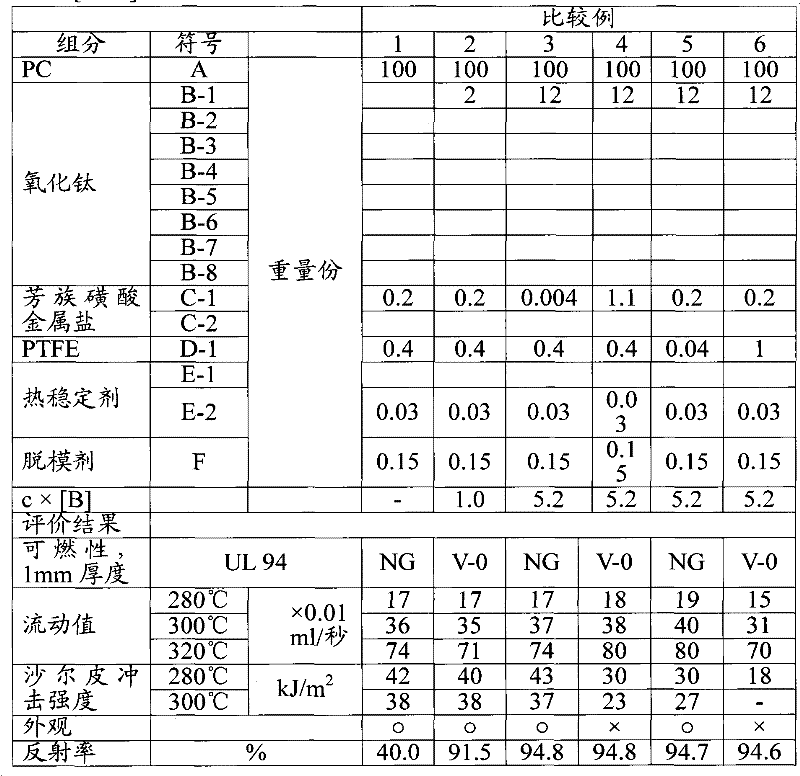

Aromatic polycarbonate resin composition, process for producing resin composition, and molded article

Disclosed is an aromatic polycarbonate composition having excellent thermal stability, excellent flame retardancy and excellent light reflectivity. Also disclosed is a light-reflecting member comprising a molded resin article produced from the aromatic polycarbonate composition. The aromatic polycarbonate resin composition is characterized by comprising 100 parts by mass of an aromatic polycarbonate resin (A), 3 to 30 parts by mass of a titanium oxide additive (B) having a surface treated with alumina and an organosiloxane, 0.05 to 0.9 part by mass of an aromatic sulfonic acid metal salt (C) and 0.01 to 1.5 parts by mass of polytetrafluoroethylene (D), wherein the content (a) (% by mass) of aluminum in the titanium oxide additive (B), the carbon content (c) (% by mass) and the average particle diameter (d) ([mu]m) of titanium oxide meet the requirements represented by formulae (1); and (2). Formula (1): 6.5 = (a / d2) = 15 Formula (2): 5 = (c / d2) = 25.

Owner:MITSUBISHI ENG PLASTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com