Patents

Literature

302results about How to "Lower surface free energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

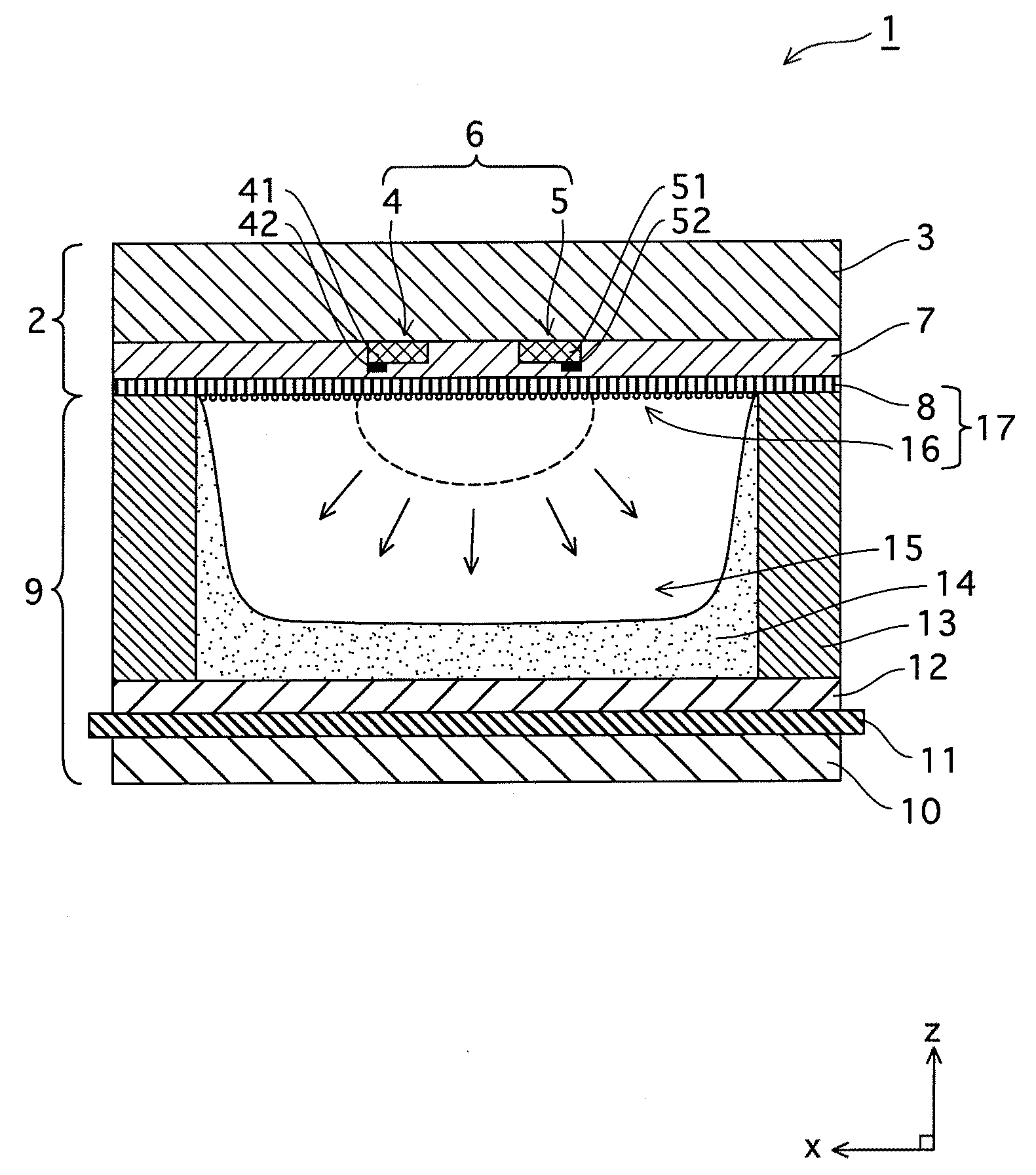

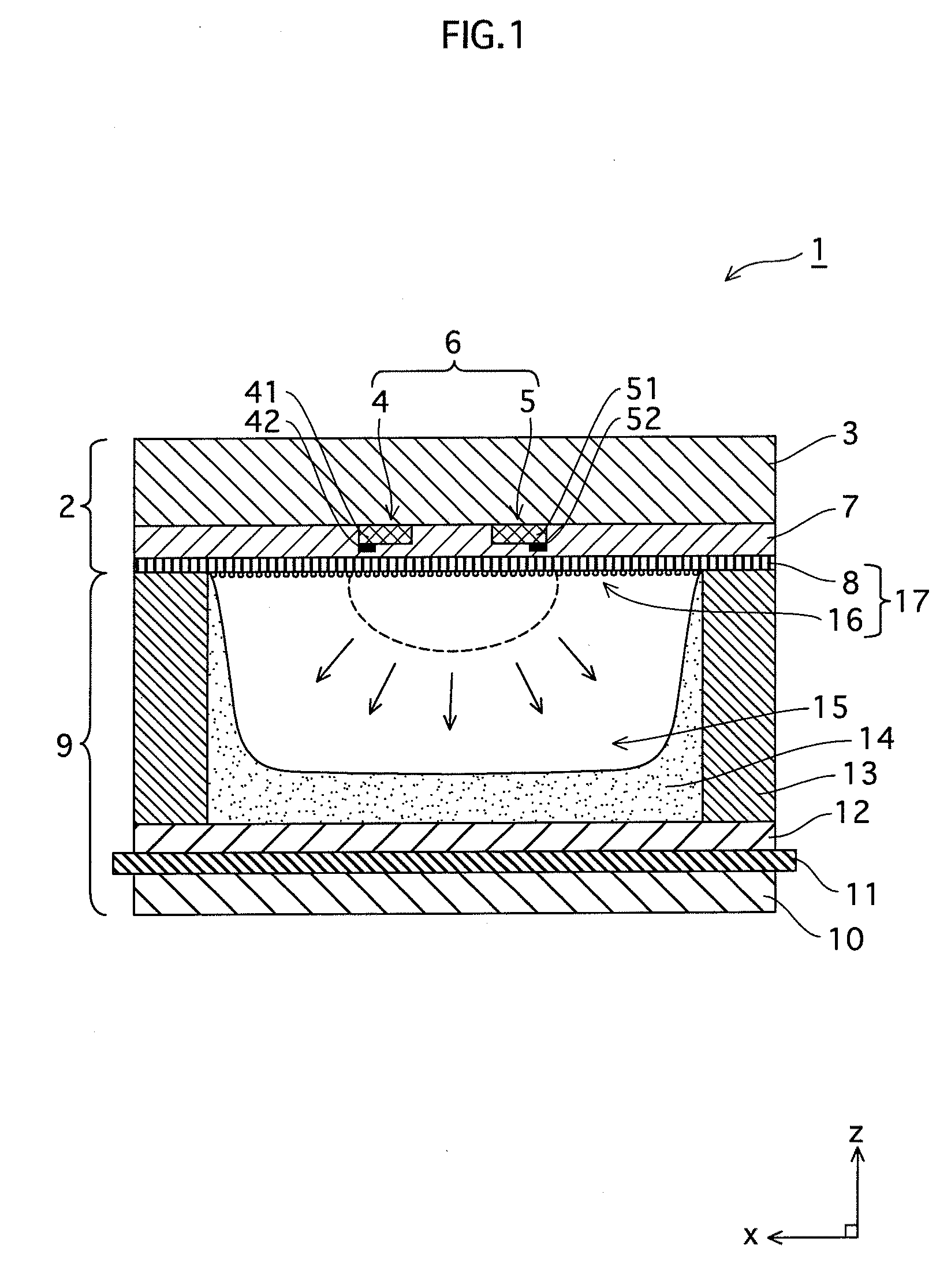

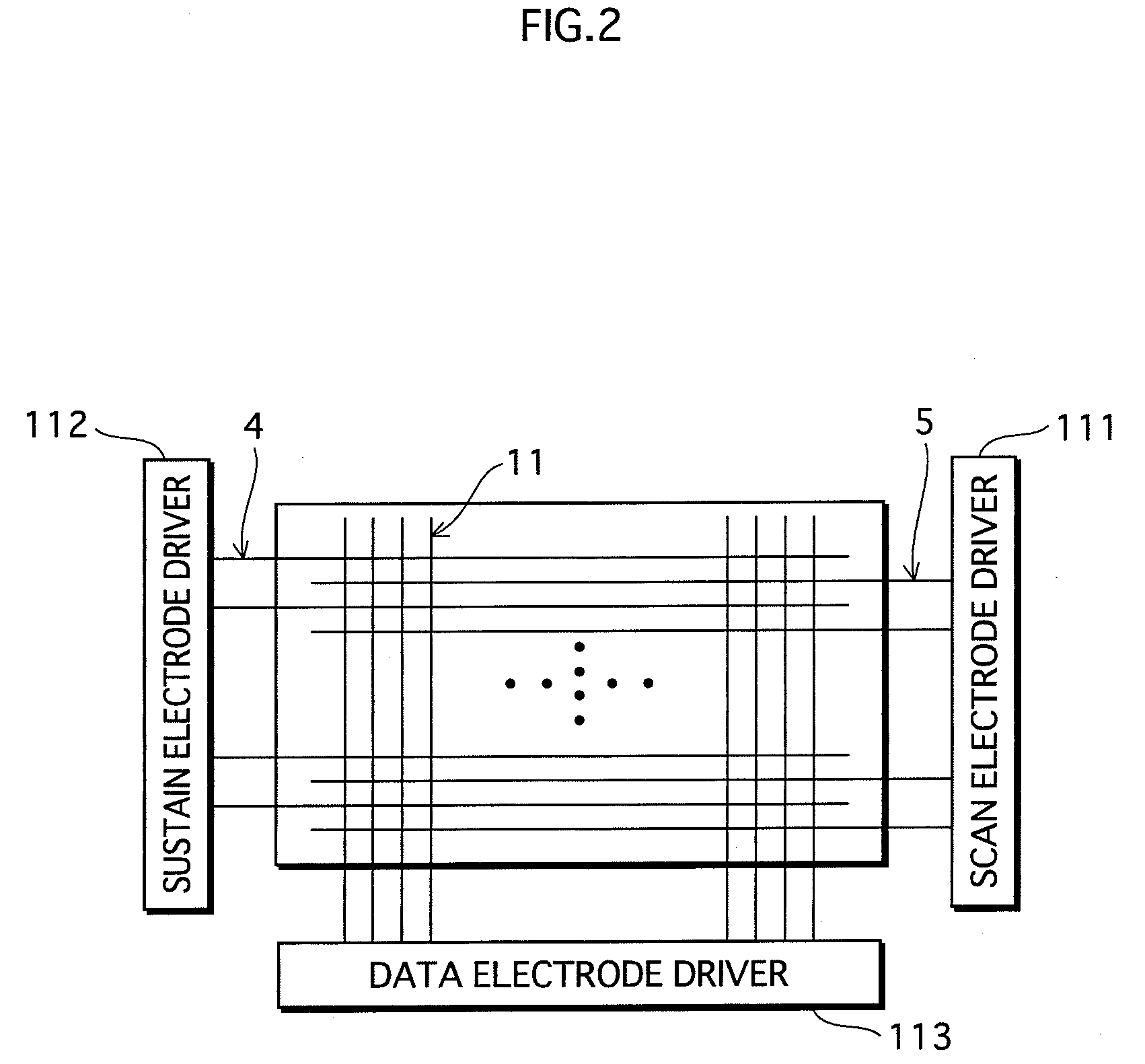

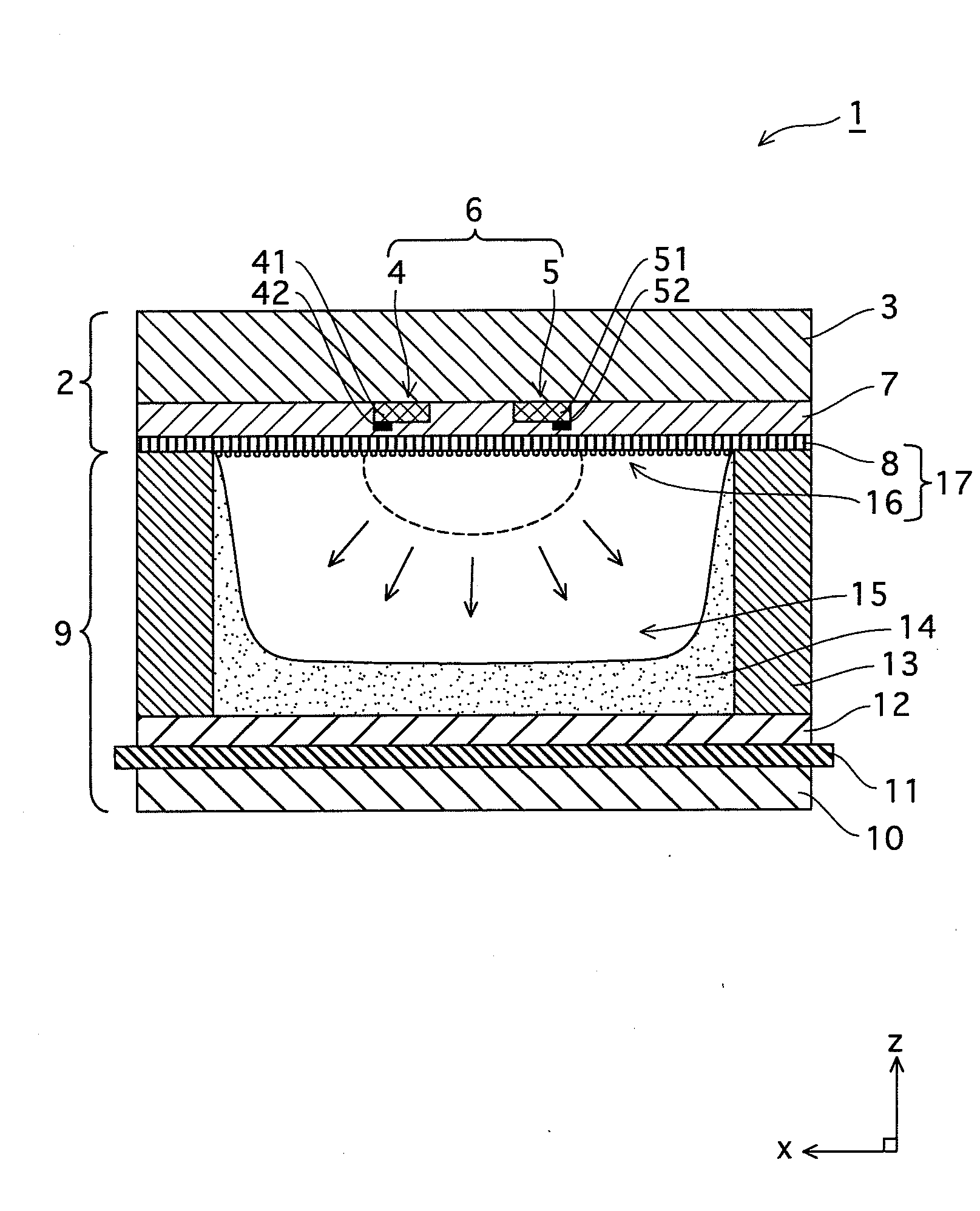

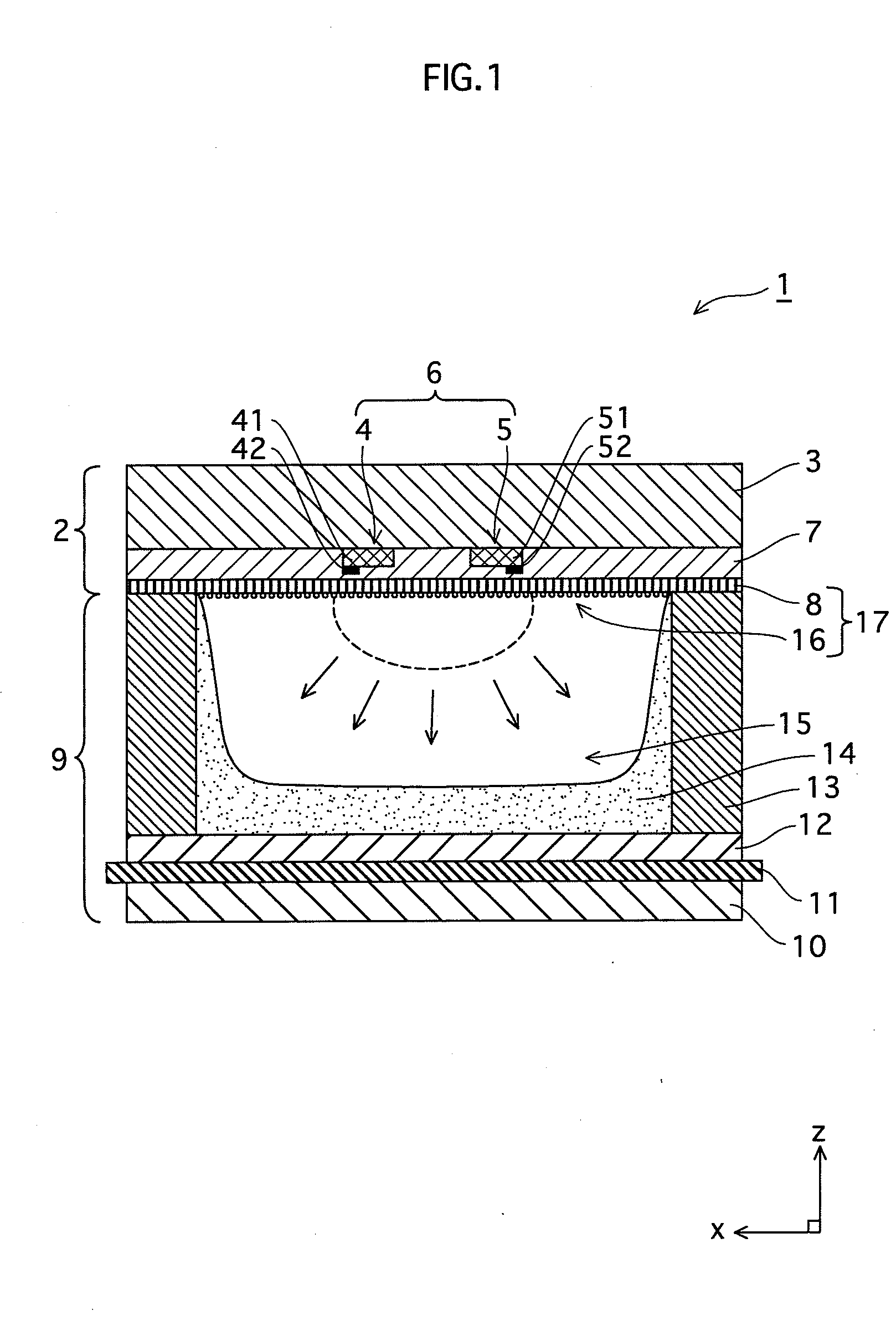

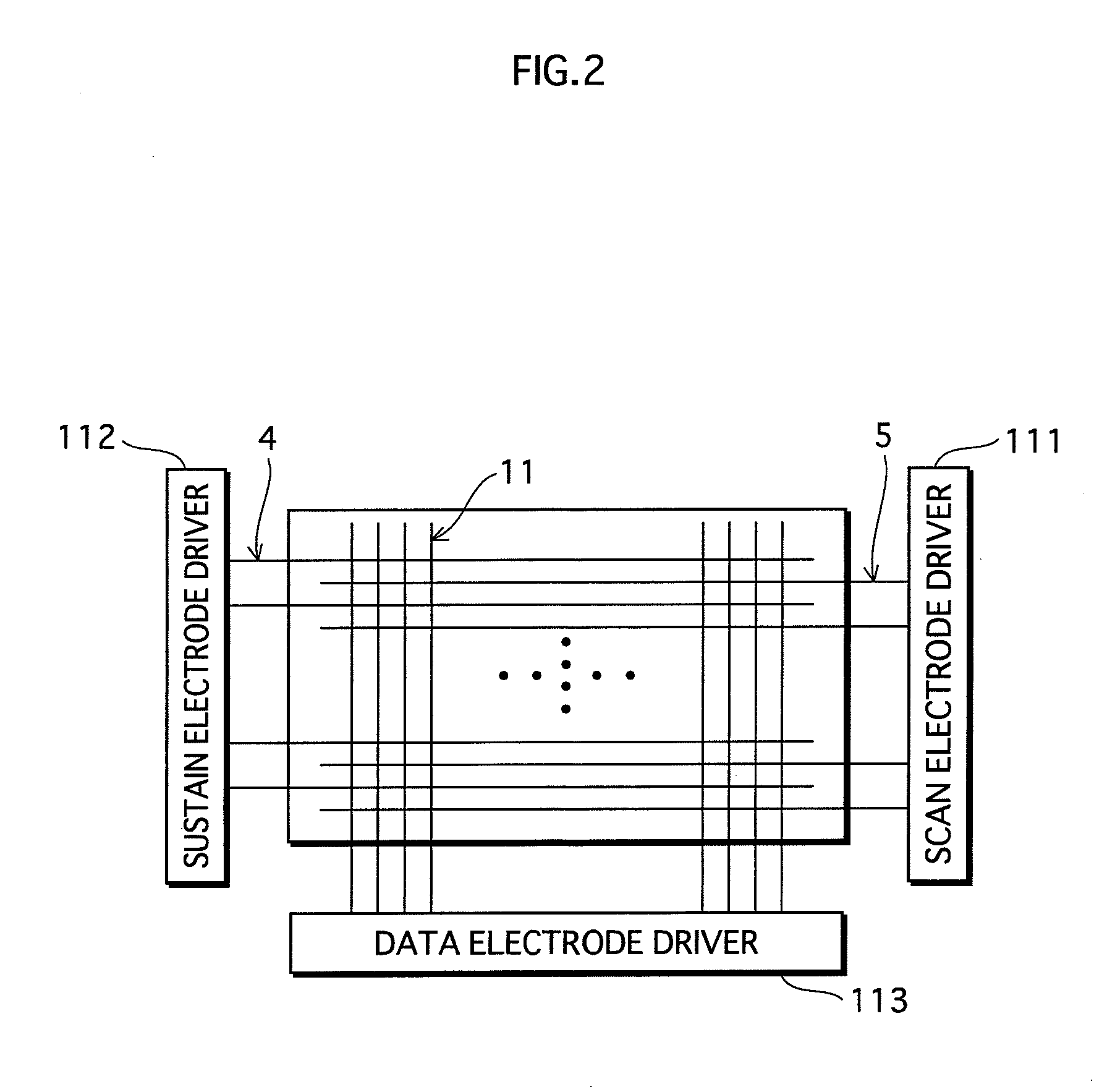

Plasma display panel and method for manufacturing the same

ActiveUS20090140652A1Large secondary electron emission coefficientLaunch evenlyTube/lamp screens manufactureAddress electrodesLow voltagePlasma display

“Discharge delay” and “dependence of discharge delay on temperatures” are solved by improving a protective layer, thus a PDP can be driven at a low voltage. Furthermore, the PDP can display excellent images by suppressing “dependence of discharge delay on space charges.” Liquid-phase magnesium alkoxide (Mg (OR)2) or acetylacetone magnesium ate whose purity is 99.95% or more is prepared, and is hydrolyzed by adding a small amount of acids to the solution. Thus, a gel of magnesium hydroxide that is a magnesium oxide precursor is formed. Burning the gel in atmosphere at 700° C. or more produces powder containing MgO particles 16a-16d having the NaCl crystal structure with (100) and (111) crystal faces or with (100), (110) and (111) crystal faces. By pasting the powder on a dielectric layer 7 or a surface layer 8, the MgO powder 16 is formed so as to serve as the protective layer.

Owner:PANASONIC CORP

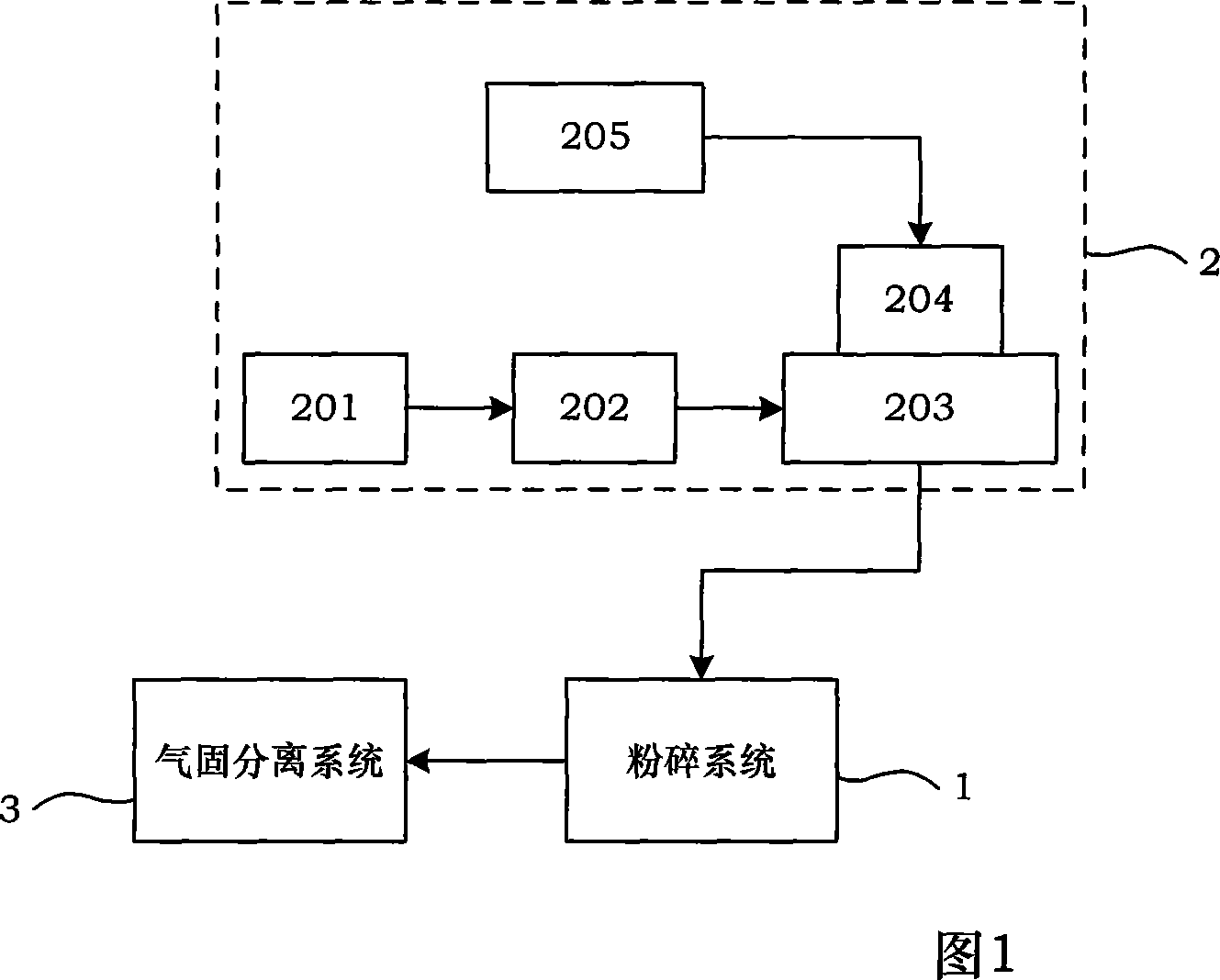

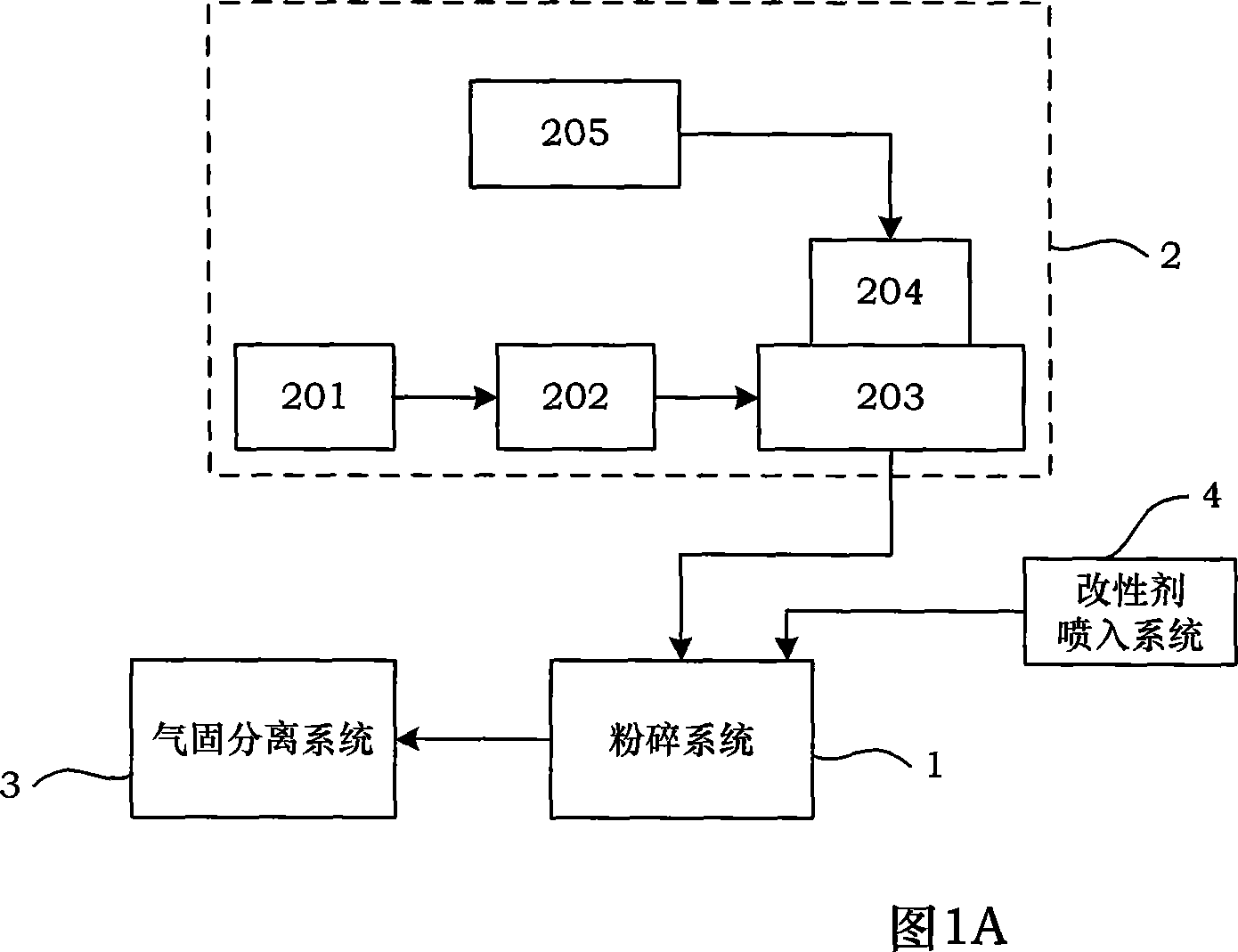

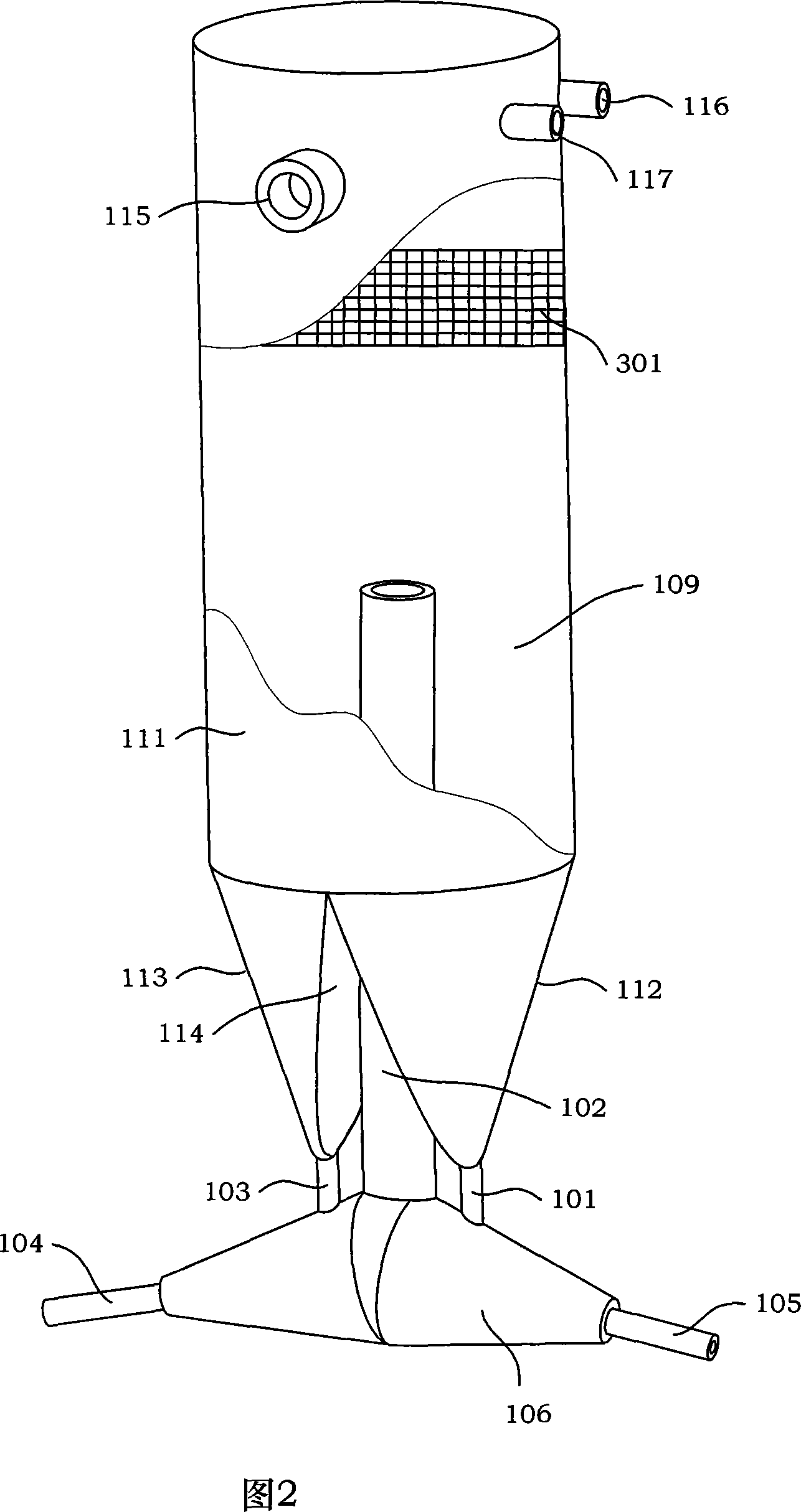

Technique and equipment for preparing Nano granules in high purity by using method of comminution by gas stream

InactiveCN101049580AEasy accessGood for collision smashingDispersed particle filtrationGrain treatmentsNanoparticleEngineering

An apparatus for preparing high-purity nanoparticles by airflow pulverizing method is composed of an air source system, a pulverizing system consisting of left and right reflux pipes and flow-up pipe to form a circulating loop of material, and air-solid separating system. Its process features that the raw material is carried by two supersonic jets for mutual and cyclic collision to obtain nanoparticles.

Owner:BEIHANG UNIV

Sol-gel method for preparing micro/nano titanium dioxide and lyophobic film thereof on metal surfaces

InactiveCN102553813AImprove corrosion resistanceLower surface free energySpecial surfacesCoatingsFree energiesSilanes

The invention discloses a sol-gel method for preparing micro / nano titanium dioxide and lyophobic film thereof on metal surfaces, which includes the following steps of (a) pretreating metal substrates; (b) preparing micro / nano TiO2 films on surfaces of the metal substrates which are pretreated; and (c) preparing (heptadecafluoro-1,1,2,2-tetradecyl) triisopropoxysilane-silicon dioxide lyophobic films on the micro / nano TiO2 films on the surfaces of the metal substrates. The sol-gel method has the advantages of high operability, simplicity in processing and equipment and easiness in industrialization. Besides, the titanium dioxide films are used as transitional layers so that corrosion of acid sol to the metal substrates during the process of directly coating the silane lyophobic films is avoided, wettability to silane sol is enhanced, and uniform and compact lyophobic films are prepared finally. Meanwhile, defects such as cracking and the like can be reduced by means of multiple coating processes, corrosion resistance performance of the films is improved, surface free energy of the films is decreased by lyophobic treatment, and dirt settled on the films is reduced.

Owner:TIANJIN UNIV

Plasma display panel and method for manufacturing the same

InactiveUS20090146566A1Increase dependenceLarge secondary electron emission coefficientTube/lamp screens manufactureAddress electrodesLow voltageSpace charge

“Discharge delay” and “dependence of discharge delay on temperatures” are solved by improving a protective layer, thus a PDP can be driven at a low voltage. Furthermore, the PDP can display excellent images by suppressing “dependence of discharge delay on space charges.” Liquid-phase magnesium alkoxide (Mg(OR)2) or acetylacetone magnesium ate whose purity is 99.95% or more is prepared, and is hydrolyzed by adding a small amount of acids to the solution. Thus, a gel of magnesium hydroxide that is a magnesium oxide precursor is formed. Burning the gel in atmosphere at 700° C. or more produces powder containing MgO particles 16a-16d having the NaCl crystal structure with (100) and (111) crystal faces or with (100), (110) and (111) crystal faces. By pasting the powder on a dielectric layer 7 or a surface layer 8, the MgO powder 16 is formed so as to serve as the protective layer.

Owner:PANASONIC CORP

Method for improving bonding strength of hard alloy and diamond coating

ActiveCN104746030AAvoid the problem of interfacial stressHigh bonding strengthVacuum evaporation coatingSputtering coatingShielding gasGlow plasma

The invention relates to a method for improving the bonding strength of a hard alloy and a diamond coating. The method is realized by the technical scheme that by adopting a double glow plasma surface alloying technology, taking a metal carbide forming element material or a composite material of metal carbide forming elements as a target, inert gases as protecting gases, as well as carbon-containing gases as precursors, a diffusion barrier layer is prepared on the surface layer of the hard alloy, and then the diamond coating is deposited on the hard alloy surface on which the diffusion barrier layer is prepared by using a chemical vapor deposition method. By the use of the diffusion barrier layer prepared by the method disclosed by the invention, the diffusion of Co element to the surface layer of the hard alloy can be effectively stopped, the damage to a hard alloy matrix due to a surface Co removing treatment method is avoided, and the interface stress problem introduced by a transition layer applying method due to new interface addition can be avoided, so that the bonding strength between the diamond coating and the hard alloy matrix can be greatly improved.

Owner:TAIYUAN UNIV OF TECH

Preparation method of super-hydrophobic, super-oleophobic and high transparency triple-function coating film

InactiveCN103965673AExcellent superhydrophobic propertiesFrost resistantCoatingsCoated membraneSolar battery

The invention discloses a preparation method of a super-hydrophobic, super-oleophobic and high transparency triple-function coating film, belongs to the field of novel materials, and particularly belongs to the field of self-cleaning optical materials. The method comprises the steps of firstly assembling large-grained SiO2 nano particles on a glass substrate, so as to form the lower layer of the fine structure of a functional coating layer, simultaneously adding pore-foaming agent, so as to adjust and control space filling factors, then assembling upper layer fluoride SiO2 nano fine particles, and constructing a two-stage uneven surface coating layer with a suspension structure and super-hydrophobic, super-oleophobic high and transparency functions. The functional film has frost prevention, fog prevention, pollution prevention, bacteriostasis and self-cleaning properties, also has excellent translucency, can effectively prevent properties of optical elements, photoelectron elements, solar batteries and laser systems from being influenced by environment in severe environment, greatly expands the application range of the equipment, guarantees the operational reliability, and prolongs the service life, thereby greatly improving the practical values of the equipment.

Owner:JIANGNAN UNIV +1

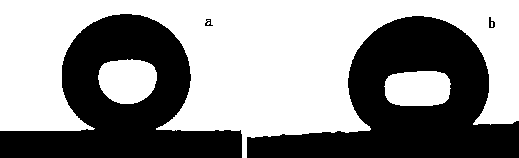

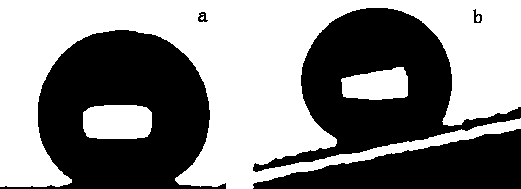

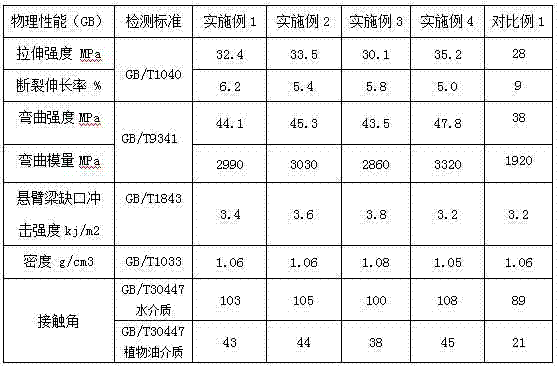

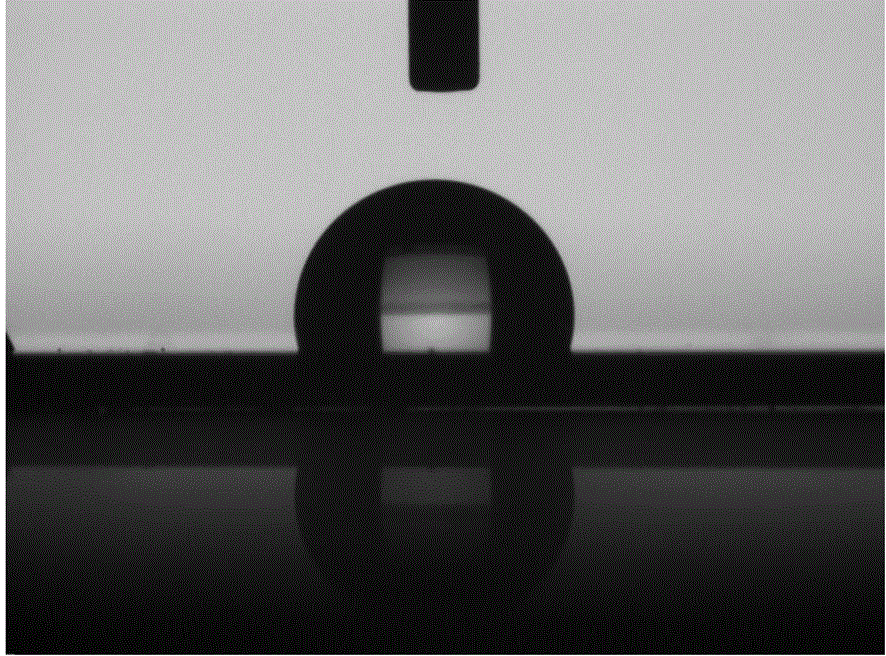

Reinforced greasy-dirt-resistant high-gloss polypropylene composite material and preparation method thereof

ActiveCN104744818ALower surface free energyGood oil resistancePolypropylene compositesPolymer science

The invention provides a reinforced greasy-dirt-resistant high-gloss polypropylene composite material and a preparation method thereof. The reinforced greasy-dirt-resistant high-gloss polypropylene composite material is prepared form the following components in parts by weight: 60-80 parts of PP resin, 10-15 parts of superfine precipitated barium sulfate, 6-10 parts of reinforced magnesium sulfate whiskers, 2-5 parts of fluoride, 0.2-0.4 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 0.5-1 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the reinforced greasy-dirt-resistant high-gloss polypropylene composite material prepared by the method disclosed by the invention, the surface polarity of the material is changed and the greasy dirt resistance of the material is improved; meanwhile, the composite material meets the European Union Regulation (EC) No.1935 / 2004 of related food contact materials, and has the characteristics of being high in gloss, low in after shrinkage, high in rigidity, and the like. The material is applied to a housing of a kitchen appliance, so that the surface of the kitchen appliance has capacity of resisting greasy dirt and self-cleaning capacity, and the self-cleaning anti-greasy-dirt environmental requirements of modern kitchen appliance are met.

Owner:ORINKO NEW MATERIAL CO LTD

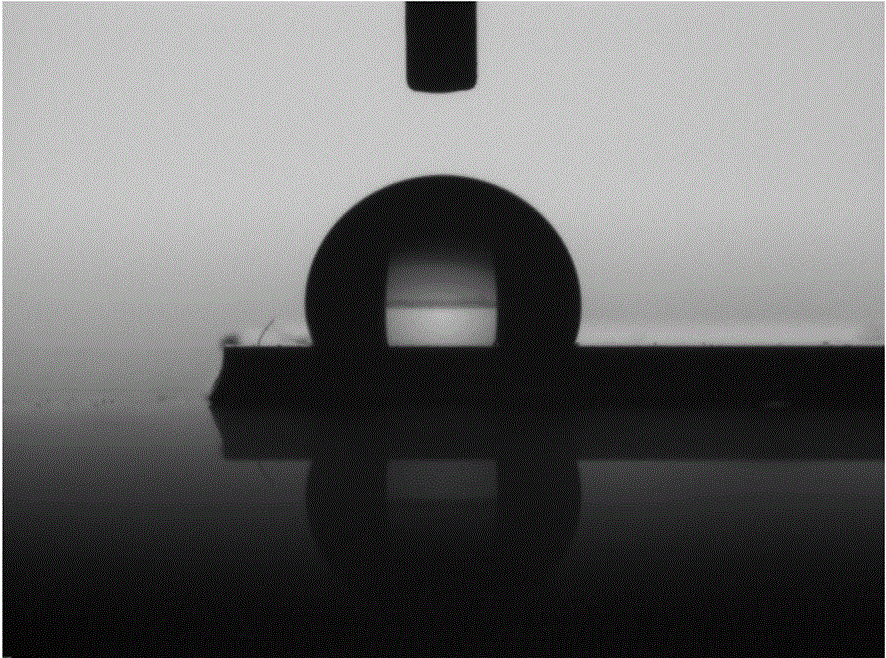

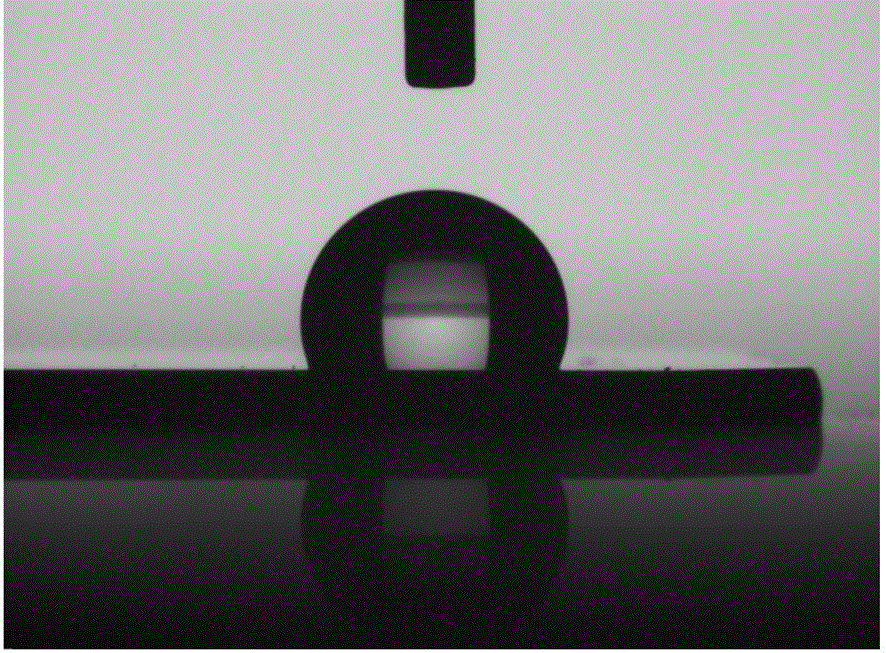

Fluorinated polyurethane and preparation method thereof

ActiveCN106674473AEasy to storeEasy to migrateAntifouling/underwater paintsPaints with biocidesDiolFluorine containing

The invention discloses fluorinated polyurethane and a preparation method thereof. The fluorinated polyurethane is prepared through the steps: fluoroalkyl-containing polyether glycol and diisocyanate perform addition polymerization reaction, a tin catalyst is utilized to catalyze, a chain extender is utilized to extend a chain, and an amino silane coupling agent is added to seal ends. A product contains a fluorine-containing polyether block, the fluorine content is high, fluoroalkyl on a polyether lateral group is prone to generating microphase separation and surface migration, polyurethane surface energy is low, and the fluorinated polyurethane is easy to store and cure as the silane coupling agent is utilized to seal the ends. A water contact angle of a coating prepared from the fluorinated polyurethane is higher than 110 degrees, and the coating has excellent water repellency.

Owner:UPCHEM CHINA

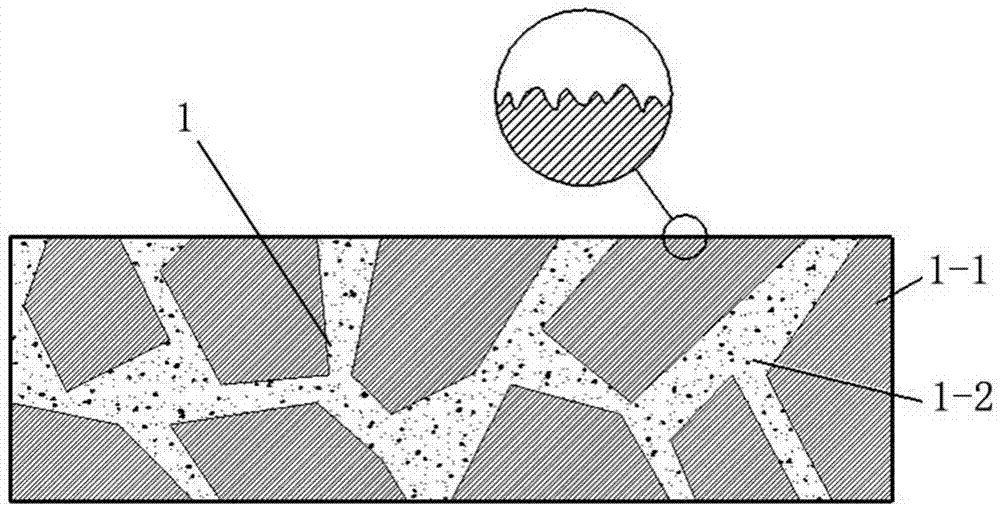

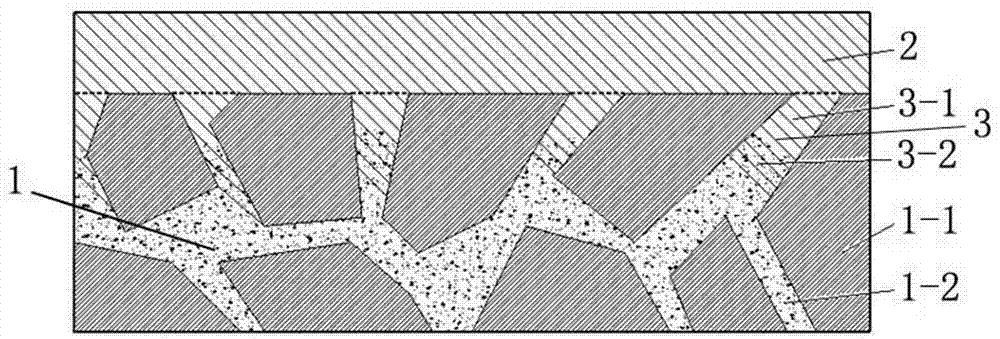

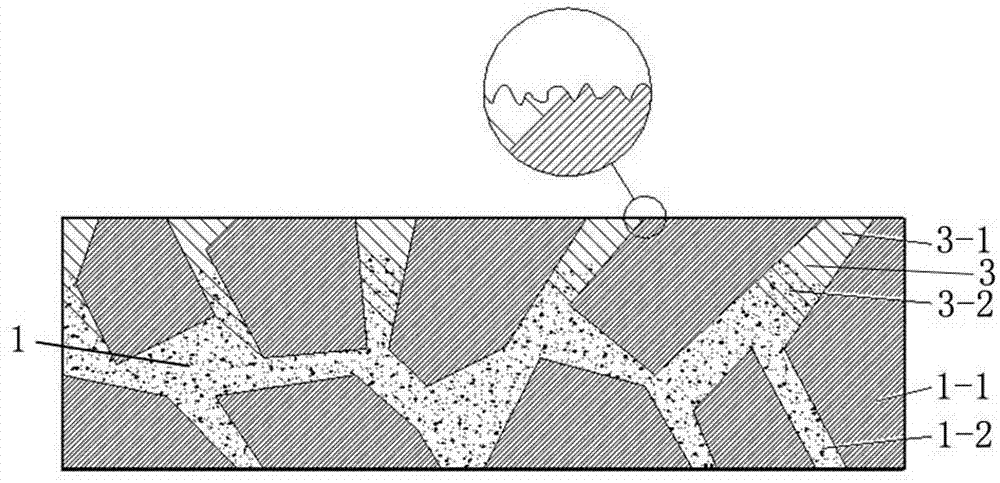

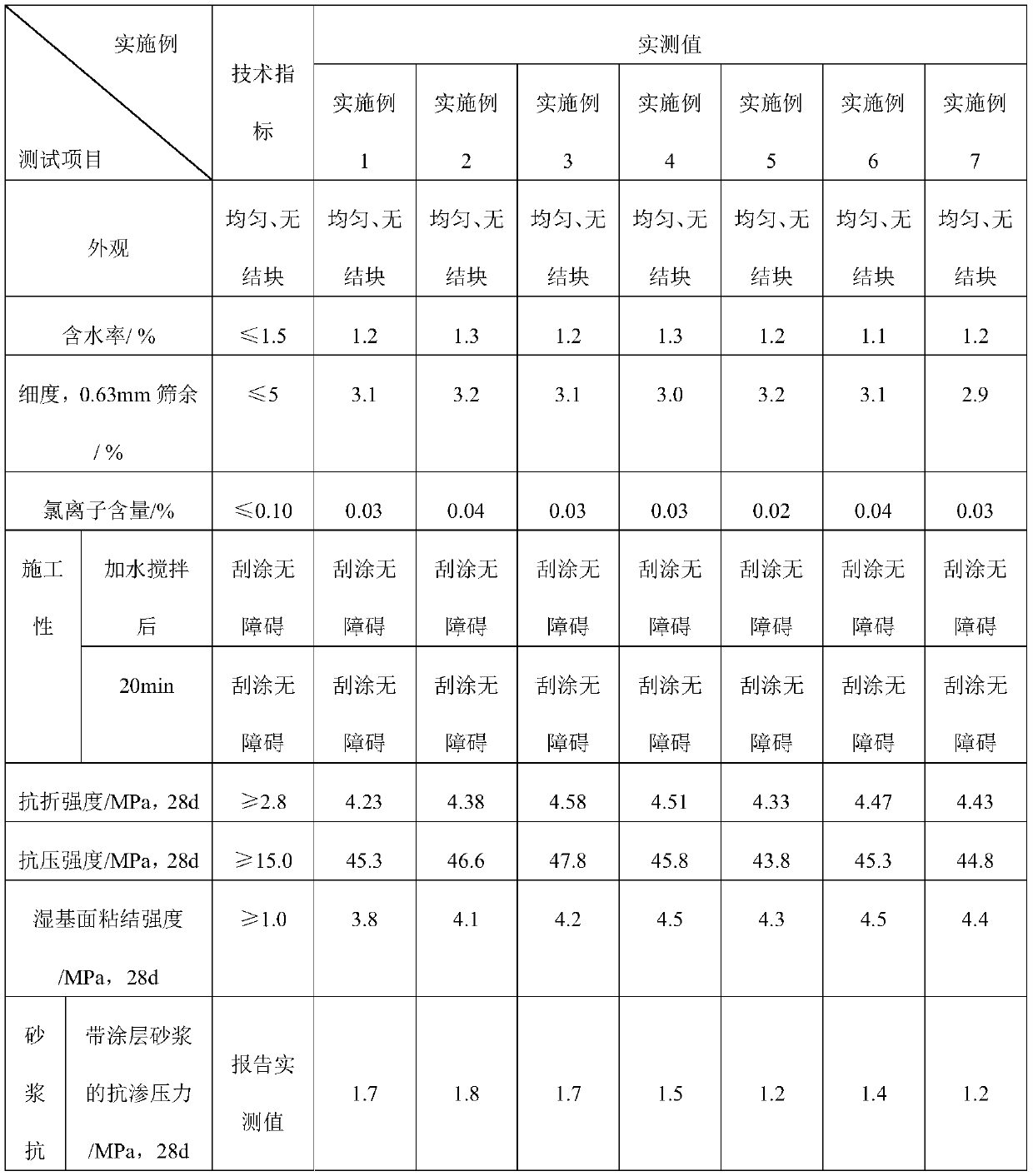

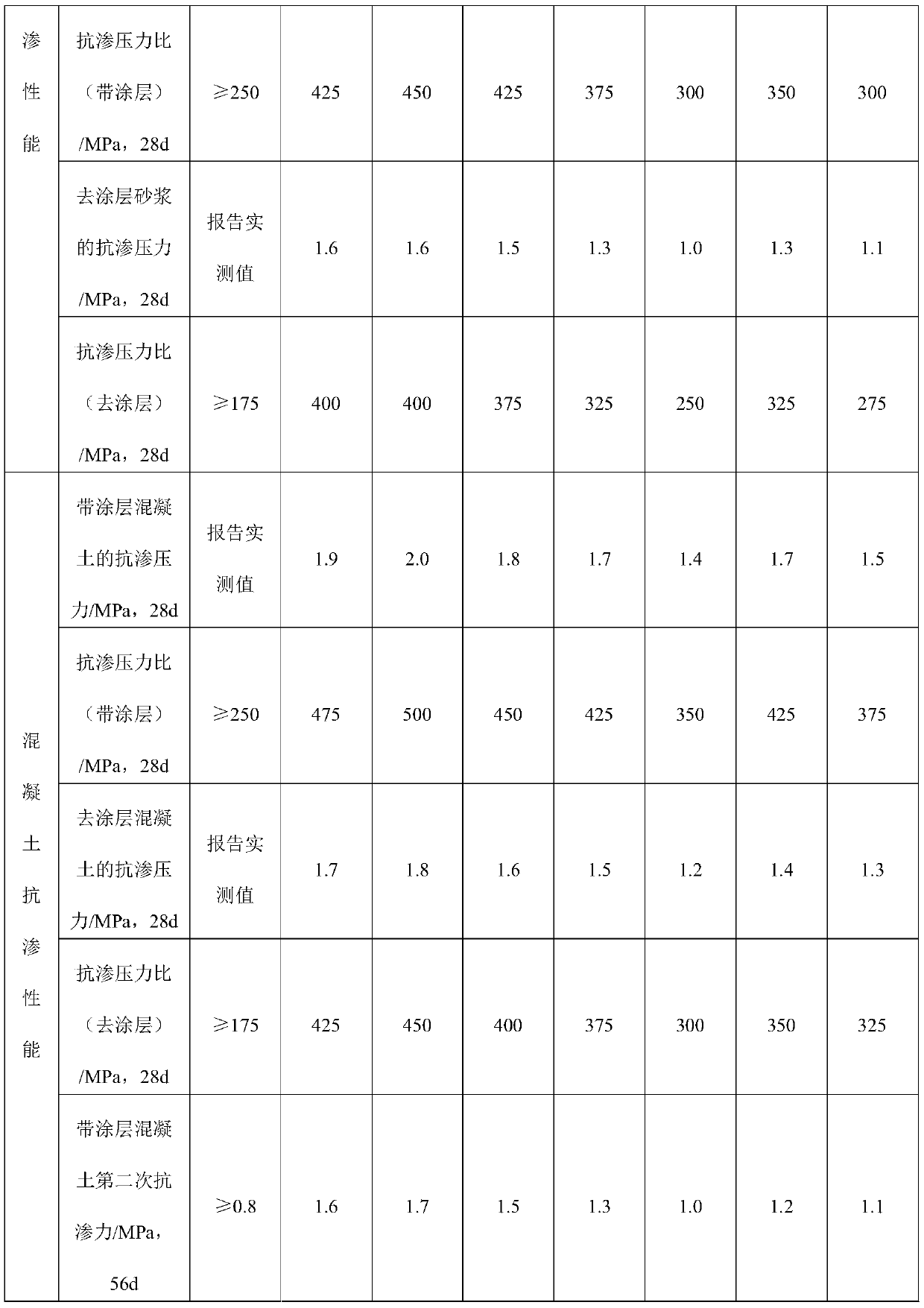

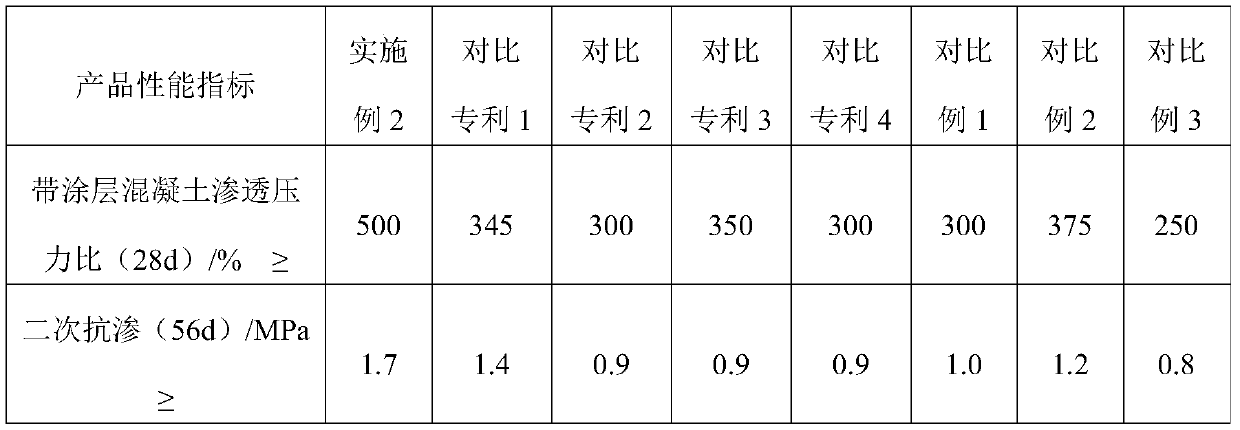

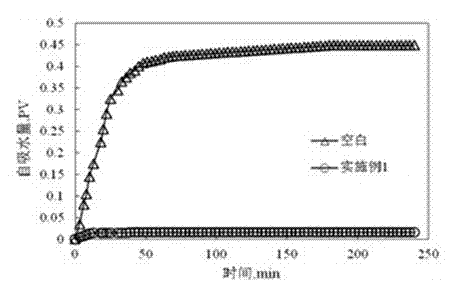

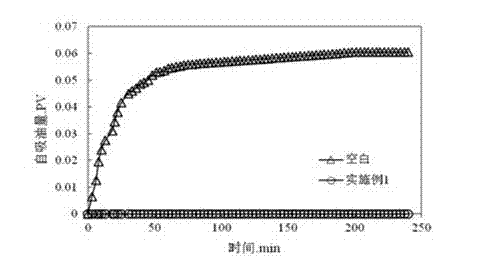

Cement-based capillary crystalline waterproof material based on nanosilicon-based material and preparation method and application thereof

The invention relates to a cement-based capillary crystalline waterproof material based on a nanosilicon-based material and a preparation method and application thereof. The waterproof material is prepared from, by weight, 45-65 parts of cement, 14-32 parts of quartz sand, 5-10 parts of a retarder, 0.1-0.4 part of the nanosilicon-based material, 2-9 parts of a crystal precipitant, 0.5-5 parts of asurfactant, 0.5-2 parts of a complexing agent, 1-5 parts of a calcium ion compensation agent, 0.5-2 parts of a water reducing agent and 0.2-2 parts of cellulose ether. Compared with the prior art, the cement-based capillary crystalline waterproof material is suitable for repairing pores and cracks inside cement, when a cement-based material has the cracks of which the diameters are small than 0.4mm, insoluble sediment is generated in the cracks of the cement-based material in the presence of water to fill and seal the cracks of the cement-based material, and thus self-repairing of the cracksof the cement-based material is achieved.

Owner:上海凯顿百森建筑工程有限公司

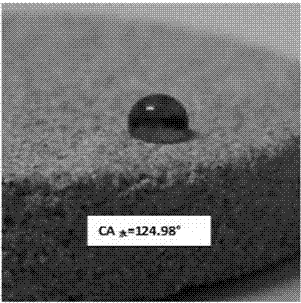

Novel anti-pollution flashover coating for ultra and super high voltage insulator

ActiveCN105086820AReduce the temperaturePrevent escapeFireproof paintsAntifouling/underwater paintsSolventSurface-active agents

The invention belongs to the technical field of functional coatings and particularly relates to a novel anti-pollution flashover coating for an ultra and super high voltage insulator. The novel anti-pollution flashover coating comprises, by mass, 40%-50% of room temperature vulcanized silicone rubber, 5%-10% of titanate coupling agent, 2%-6% of composite fire retardant, 5%-12% of modified composite reinforcing agent, 2%-4% of nano TiO2, 0.5%-1% of surface active agent, 1%-5% ofhexamethyldisilazane, 0.2%-0.5% of antifoaming agent, 0.3%-0.6% of catalyst, 0.3%-0.6% of cross-linking agent and the balance solvent. The prepared anti-pollution flashover coating is sprayed on the surface of the cleaned ceramic insulator, and the coating can be used after being naturally cured for 96 hours under the condition of 25 DEG C+ / -2 DEG C and 40%-70% of RH. According to the anti-pollution flashover coating, after the sprayed anti-pollution flashover coating is completely cured, the contact angle is not smaller than 135 degrees.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

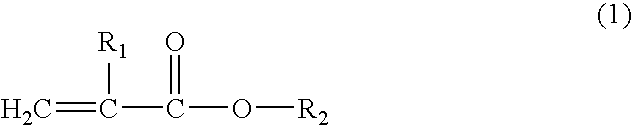

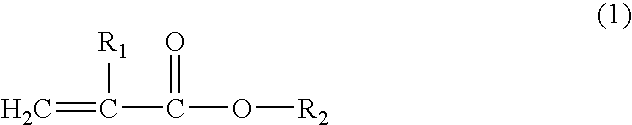

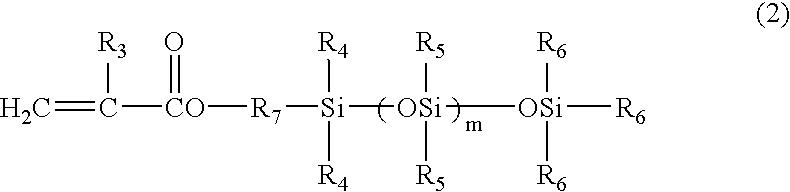

Resin composition for electrophotographic photoconductor and electrophotographic photoconductor using the same

InactiveUS20090087761A1Abrasion resistance is excellentImprove wear resistanceElectrographic process apparatusCorona dischargePolycarbonateBisphenol-A-polycarbonate

The present invention provides a resin composition for an electrophotographic photoconductor having excellent image stability and abrasion resistance which comprises a polycarbonate resin and a polysiloxane group-containing A-B type block copolymer consisting of a polysiloxane group-containing copolymer segment-A formed by a vinyl monomer represented by the general formula (1) and a polysiloxane group-containing monomer and a polymer segment-B formed by a vinyl monomer represented by the general formula (1), wherein the content of said polysiloxane group-containing monomer is 10 to 85% by weight based upon said polysiloxane group-containing A-B type block copolymer, and the content of said polysiloxane group-containing A-B type block copolymer is 0.03 to 3 parts by weight based upon 100 parts by weight of said polycarbonate resin.(In the formula (1), R1 represents a hydrogen atom or a methyl group. R2 represents a hydrogen atom, an alkyl group having 1 to 18 carbon atoms, or a hydroxyalkyl group having 2 or 3 carbon atoms.)

Owner:MITSUBISHI GAS CHEM CO INC

Water-based fluorine-containing polyurethane paint and preparation method thereof

InactiveCN102977762AHigh hardnessHigh glossPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a water-based fluorine-containing polyurethane paint and a preparation method thereof. The water-based fluorine-containing polyurethane paint comprises the following raw materials in parts by weight: 5-8 parts of BayhydurXP2655, 60-70 parts of water-based hydroxy fluorine-containing polyurethane resin, 0.05-0.1 part of leveling agent, 1-10 parts of wetting agent, 1-3 parts of thickening agent, 0.2-1 part of defoaming agent, 2-5 parts of film-forming assistant, 0.02-1.0 part of catalyst A and 20-40 parts of deionized water. After being coated, the water-based fluorine-containing polyurethane paint has high film coating hardness, high gloss and high water contact angle, so that the water-based fluorine-containing polyurethane paint can be used in the traditional application fields of the conventional solvent polyurethane paint, such as the high-performance technical fields of automobiles, woodware, industrial maintenance, plastics, wind-driven generator vanes, solar cells and the like.

Owner:佛山市顺德区金冠涂料集团有限公司

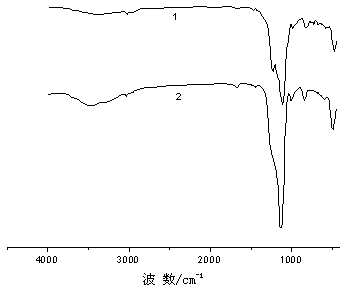

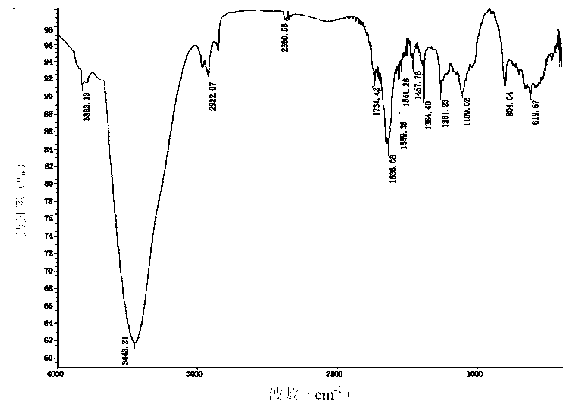

Anti-water-blocking agent for drilling fluid and preparation method thereof

ActiveCN102887974AGood weather resistanceImprove performanceDrilling compositionGas phaseWater block

The invention relates to an anti-water-blocking agent for drilling fluid and a preparation method thereof. The anti-water-blocking agent is a polymer containing a butyl acrylate (BA) monomer, a methyl methacrylate (MMA) monomer, a methacrylic acid (MAA) monomer, an acrylamide (AM) monomer and a 2-(perfluorohexyl)ethyl methacrylate (G06B) monomer, wherein the mol percent of a is 35.8-36.5%, the mol percent of b is 27.0-30.5%, the mol percent of c is 7.5-9.0% and the mol percent of d is 7.5-9.0%. According to the invention, the anti-water-blocking agent effectively reduces filtrate surface tension and oil-water interfacial tension, improves gas-phase relative permeability, has a good invading fluid draining effect and is beneficial to driving away resident fluid in near wellbore formations in a draining manner so as to better relieve the water blocking effect. The preparation method of the anti-water-blocking agent is safe and economic and has a high conversion rate; and a batch feeding method is used, so that the requirements for low dosage and high performance are met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Repairing liquid of lead-acid storage battery

InactiveCN102709612AHigh viscosityImprove system stabilityLead-acid accumulatorsSecondary cells servicing/maintenanceIonSodium polyacrylate

The invention discloses a repairing liquid of a lead-acid storage battery, which is prepared through the following steps: preparing materials according to the following formula (weight percent): 90-94.5% of de-ionized water, 2.5-4.0% of nano silicon nitride powder, 0.5-1.0% of poly N-vinyl pyrrolidone, 0.5-1.0% of polyethylene glycol, 0.5-1.0% of relative low molecular sodium polyacrylate dispersing agent, 0.5-1.0% of polyvinyl alcohol, 0.5-1.0% of polyethylene amide, 0.5-1.0% of preservative; placing the materials in a glass or enamel heating kettle, heating up to 80-85 DEG, preserving temperature to obtain a semitransparent solution so as to obtain the repairing liquid. The repairing liquid can effectively dissolve and remove the lead sulfate crystal on a battery polar plate, recovers the function of the polar plate, repairs the failed lead-acid storage battery, and forms a protecting film on the surface of the battery polar plate, so that the battery polar plate does not crystallize the lead sulfate, and the service life of the battery is prolonged.

Owner:HEFEI JIALIAN ACCUMULATOR TECH

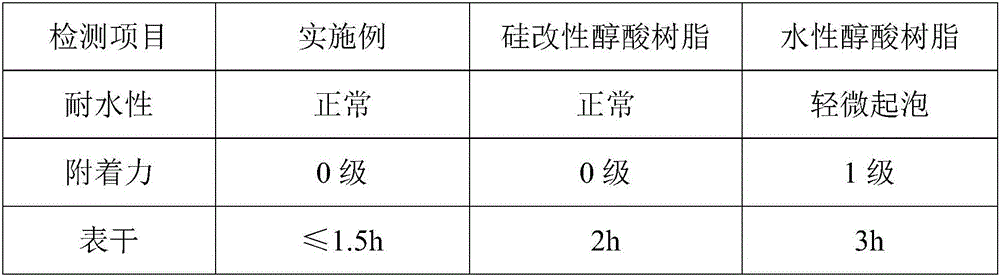

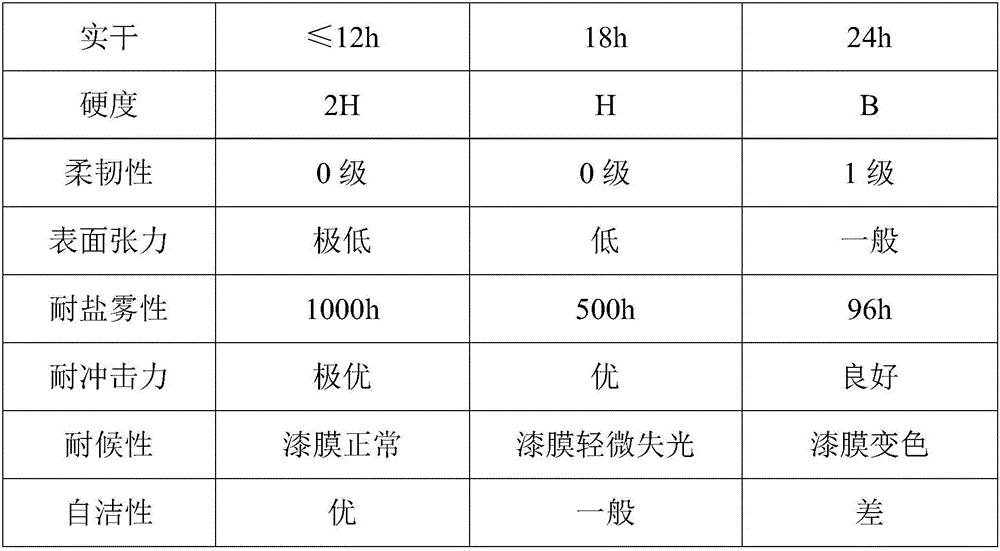

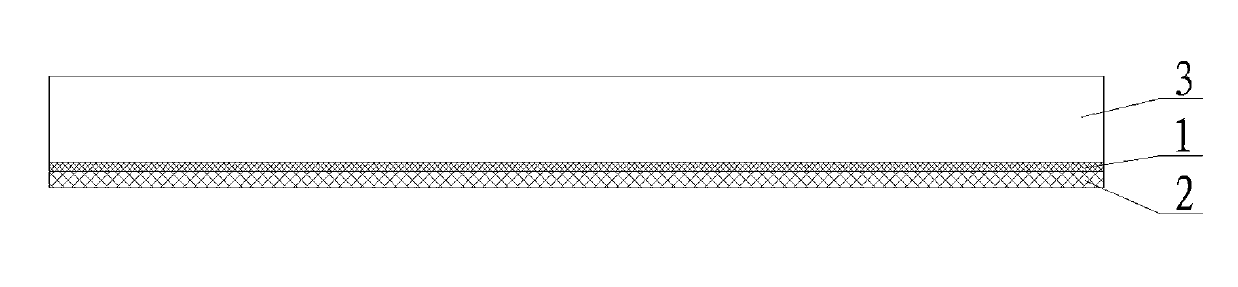

Fluorine-silicon modified waterborne alkyd resin and preparing method thereof

ActiveCN106117449AWith shielding protectionImprove thermal stabilityAntifouling/underwater paintsPaints with biocidesAcid anhydride formationStain

The invention relates to a fluorine-silicon modified waterborne alkyd resin and a preparing method thereof. The fluorine-silicon modified waterborne alkyd resin is prepared from vegetable oil fatty acid, organic acid anhydride, polyol, fluorinated allyl monomers, isocyanate, hydroxyl-terminated organic silicon, acrylic monomers and deionized water. Single-component waterborne paint, double-component waterborne paint and room-temperature curing paint can be blended with the fluorine-silicon modified waterborne alkyd resin prepared through the method. The prepared fluorine-silicon modified waterborne alkyd resin has the performance such as high adhesion, stain resistance, high hardness, water resistance, durability, hydrophobicity and self-cleaning performance, and can be widely applied to waterborne wood paint, waterborne industrial paint, waterborne anti-fouling paint, waterborne corrosion resistance paint, waterborne special engineering paint such as radar dome materials, wind power generation, nuclear power and vessel paint and the like.

Owner:湖南大禹防水建材科技有限公司

Anti-sticking coating

ActiveCN103103470ALower surface free energyReduce surface tensionMolten spray coatingMetal layered productsChromium carbideTungsten

The invention discloses an anti-sticking coating. The anti-sticking coating comprises a bottom layer and a surface layer, wherein the bottom layer is used for binding a blank piece with the surface layer and positioned between the surface of the blank piece and the surface layer, the surface layer is positioned on the bottom layer, the surface layer comprises a powder matrix and a hard phase mixed in the powder matrix, the power matrix mainly comprises ferrum, nickel and chromium; and the hard phase comprises tungsten carbide, chromium carbide and the like. The anti-sticking coating adopts a structure that the coating is formed by combining the powder matrix taking ferrum, nickel and chromium as main substances and manganese, molybdenum, boron, silicon and cobalt as secondary substances, with the hard phase of large particle ceramic or metal ceramic such as tungsten carbide, chromium carbide with the size of larger than 5mu m, so that the surface free energy on the surface of the coating and the surface tension of the coating can be obviously reduced, the compatibility of plastic or other macromolecular material blank pieces with the coating can be reduced, the sticking possibility of the two can be greatly decreased, in addition, the coating can keep higher hardness at a high temperature, and overcome the defects that paint of Telfon and the like is not wear-resistant and easy to deform at a high temperature.

Owner:GUANGDONG YUEKE NEW MATERIALS TECH CO LTD

Super-hydrophobic super-oleophobic anti-reflection glass surface layer and preparation method thereof

The invention discloses a super-hydrophobic super-oleophobic anti-reflection glass surface layer and a preparation method thereof, which belong to the field of novel materials and particularly belong to the field of self-cleaning optical materials. The preparation method comprises the following steps: firstly, etching the surface of a glass body by CF3 / O2 plasma to construct a submicron coarse structure; secondly, chemically bonding a SiO2 nano porous layer; adjusting the space packing factor by means of adding a pore-foaming agent so as to construct a double-stage coarse glass surface with a suspended structure; and finally fluoridizing for modification so as to reduce surface free energy. The obtained glass surface layer achieves super-hydrophobic and super-oleophobic self-cleaning standards and has excellent light transmission. As the lower layer submicron structure in a micro-nano composite structure required by super-amphiphobic performance is directly constructed from the glass body and then a nano porous layer is chemically bonded, so that the double-layer loose structure in the prior art is avoided and the mechanical strength of the surface layer is enhanced greatly; the glass surface is high in stability and excellent in durability, thereby having significant practical application value.

Owner:JIANGNAN UNIV

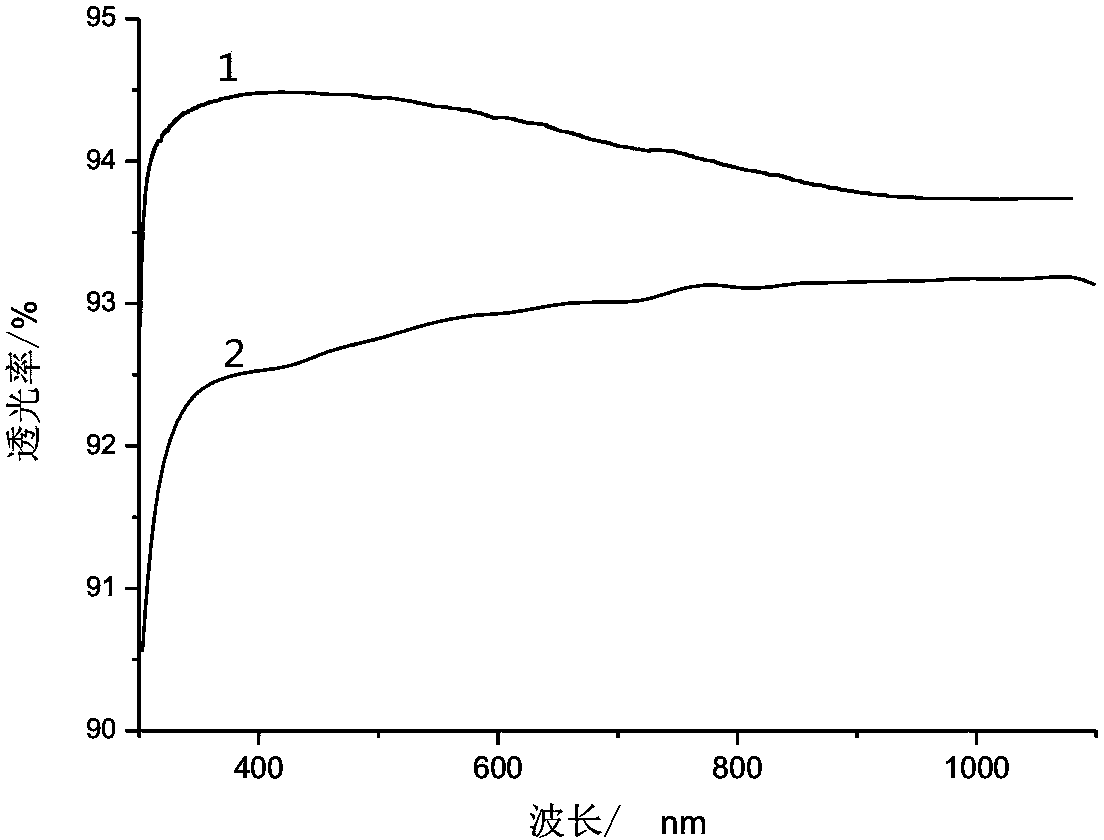

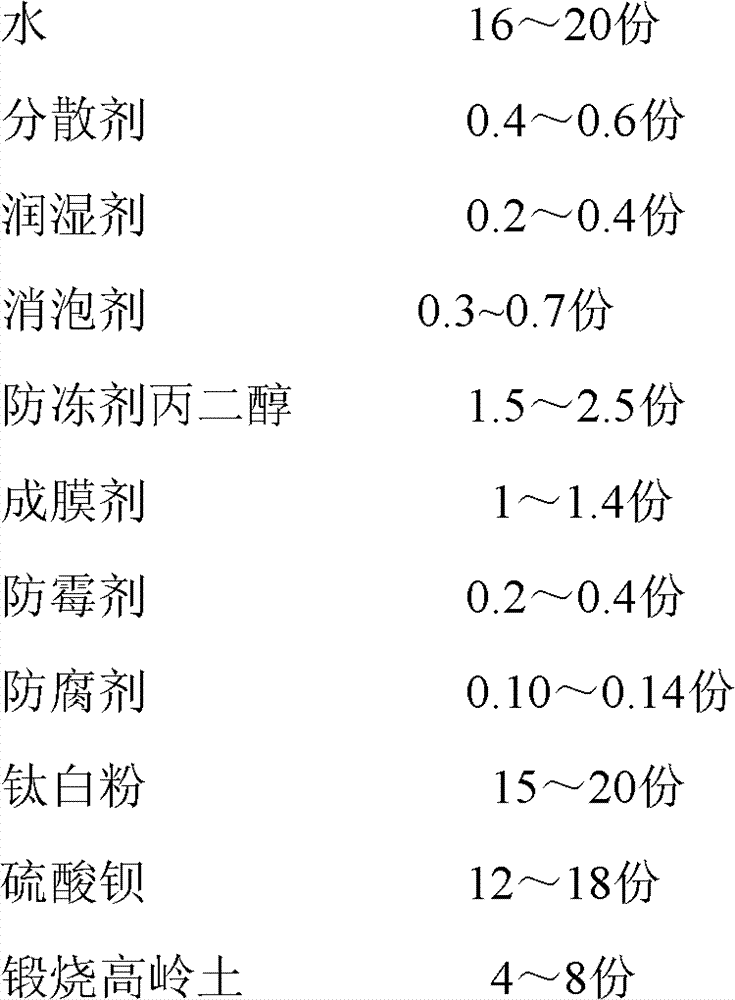

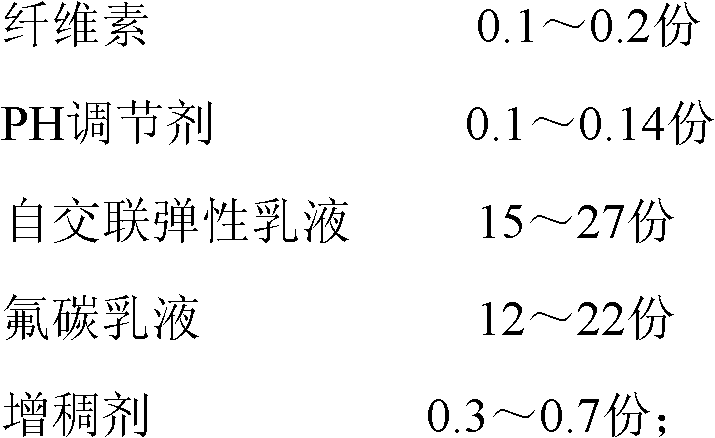

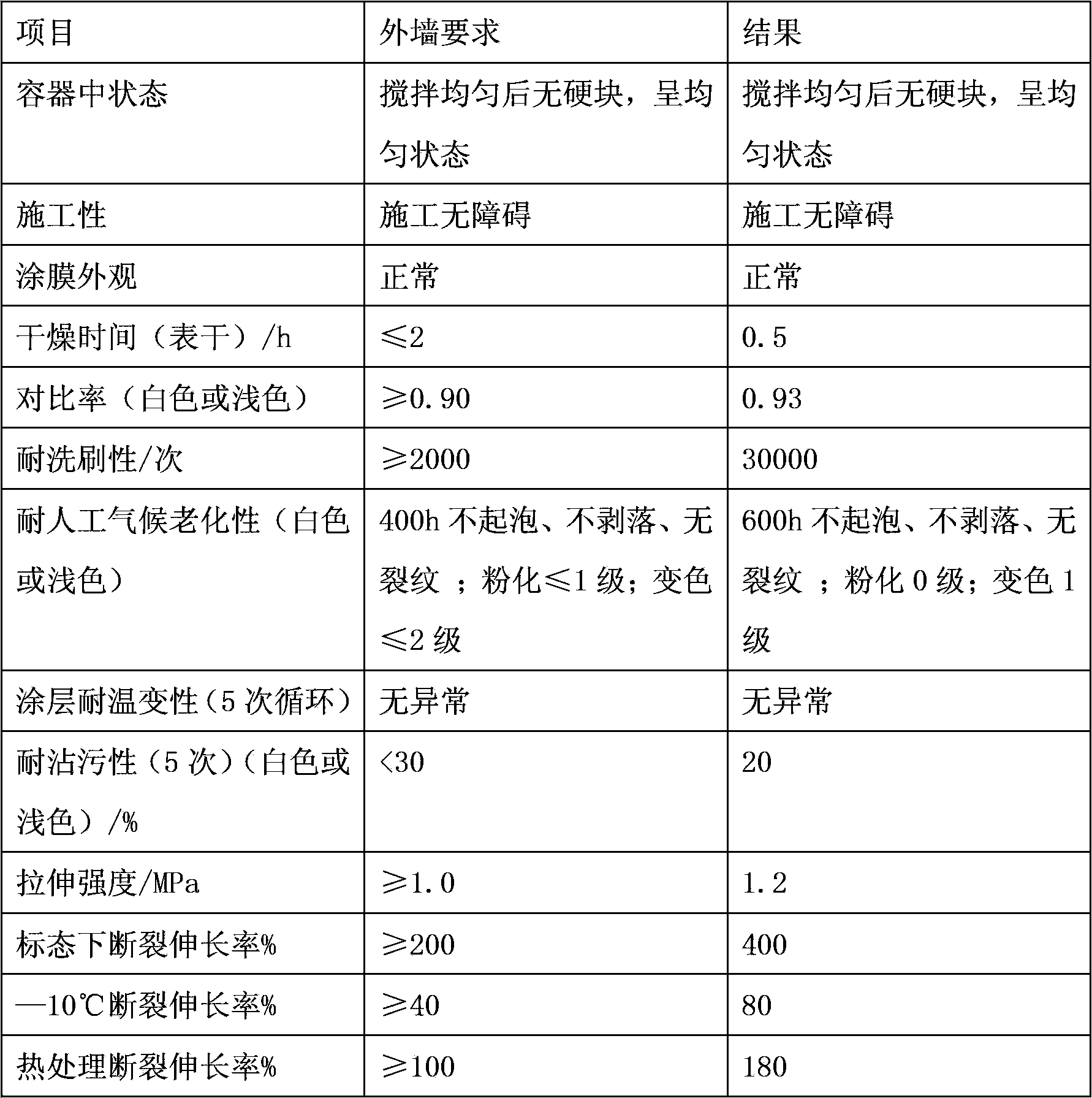

Elastic antifouling aqueous fluorocarbon exterior wall paint

ActiveCN103113796ALower surface free energyGood oil repellencyAnti-corrosive paintsEmulsion paintsEmulsionFree energies

The invention provides an elastic antifouling aqueous fluorocarbon exterior wall paint. The paint comprises the following components, by weight, 16-20 parts of water, 15-27 parts of a self-crosslinking elastic acrylic emulsion, 12-22 parts of an aqueous fluorocarbon emulsion, 15-20 parts of titanium dioxide, 12-18 parts of barium sulfate, 4-8 parts of calcined kaolin and 1-1.4 parts of a film forming agent. In the invention, the self-crosslinking elastic acrylic emulsion is treated as a main base material to reach an anti-crack requirement, and the aqueous fluorocarbon emulsion having a good compatibility is matched for modifying to make a paint film having low surface free energy and a good lipophobic property in order to make the formed film compact, so the paint film cannot be polluted by blots, and can be easily cleaned after the blot pollution; and rutile and titanium dioxide are simultaneously combined to improve the weather ability, the chemicals (acid rain, salts and the like) corrosion resistance of the film, so the film has good color and light maintenance properties, thereby the elastic antifouling aqueous fluorocarbon exterior wall paint is a new high-performance elastic antifouling aqueous fluorocarbon exterior wall paint.

Owner:珠海展辰新材料股份有限公司

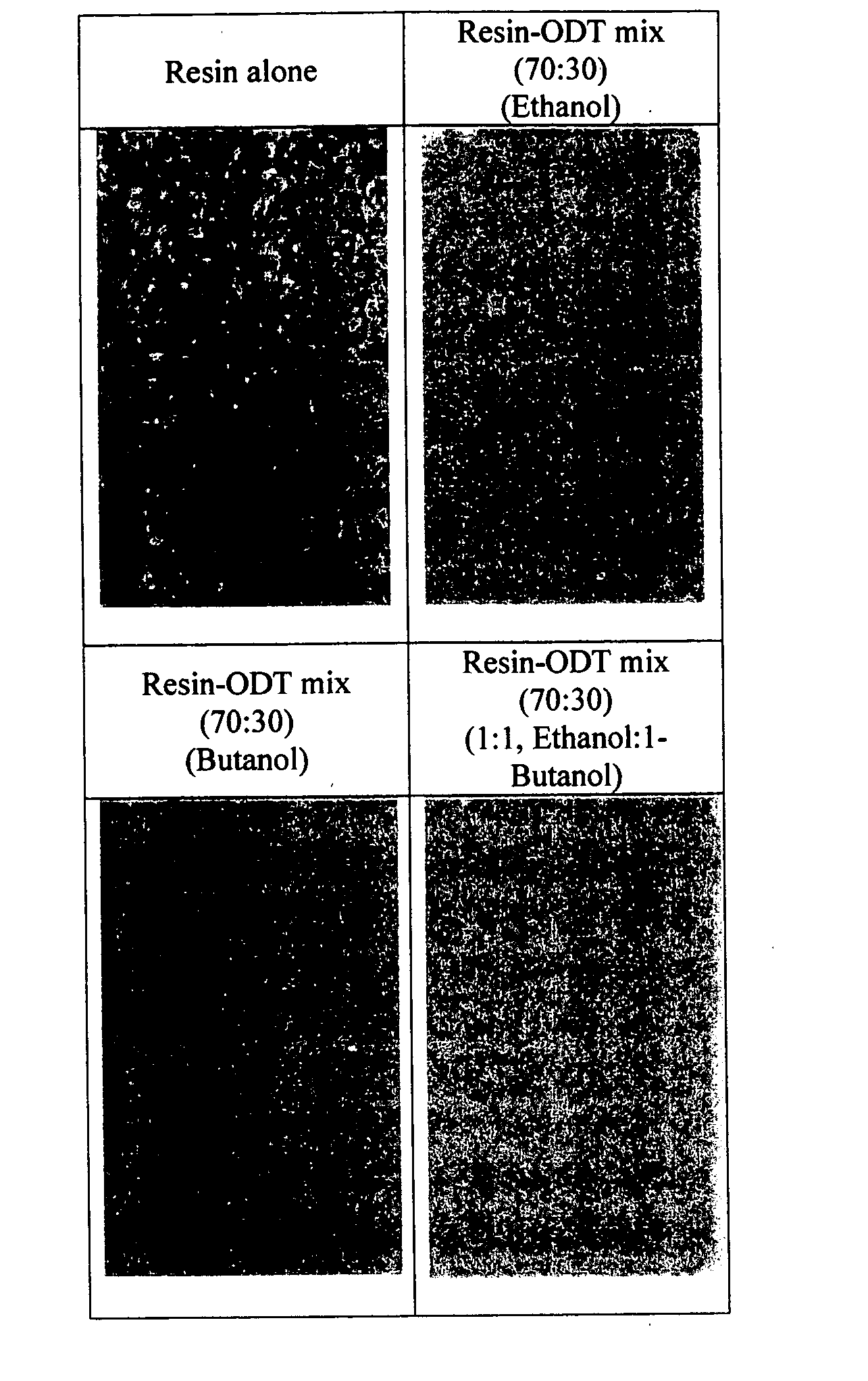

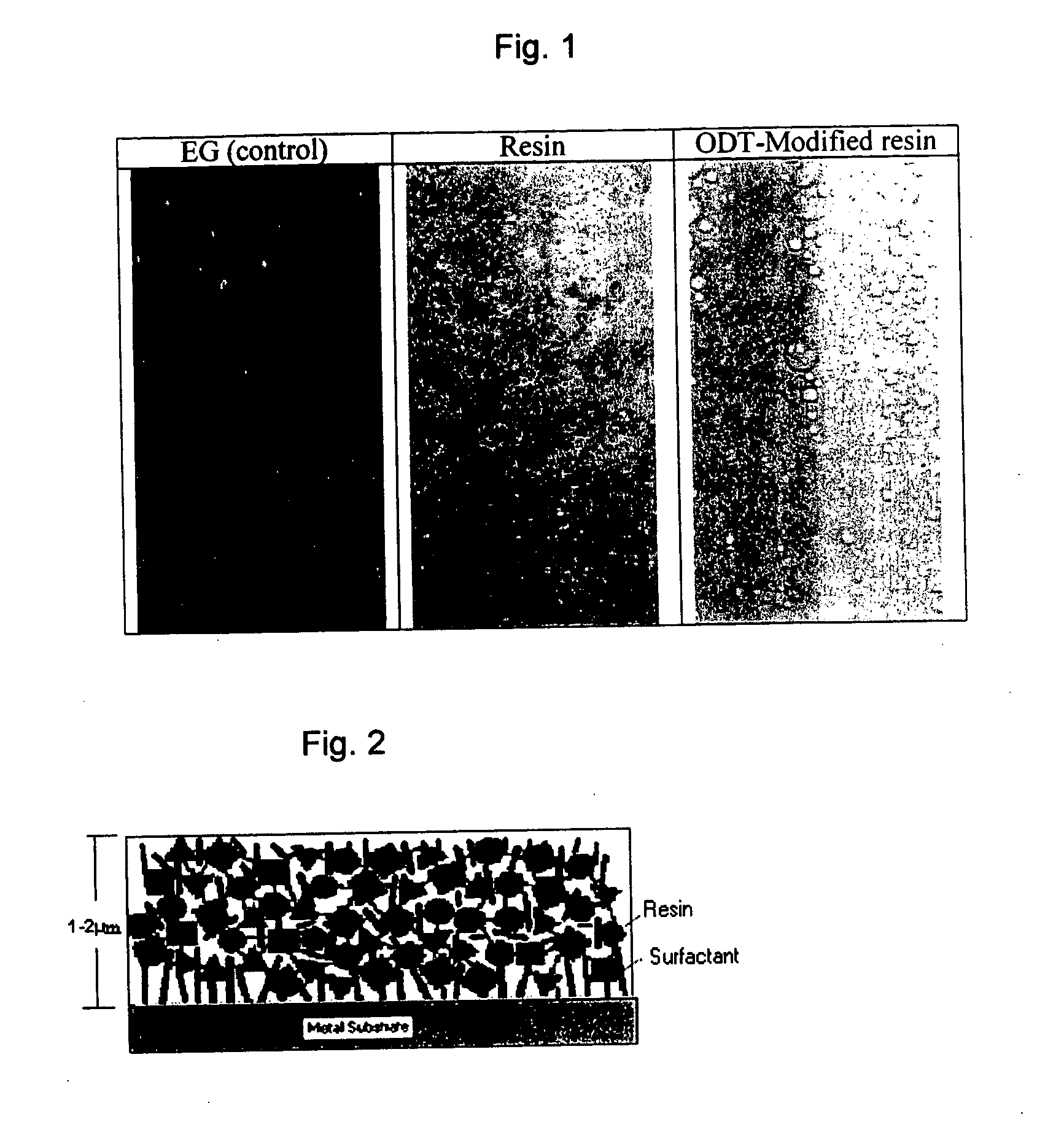

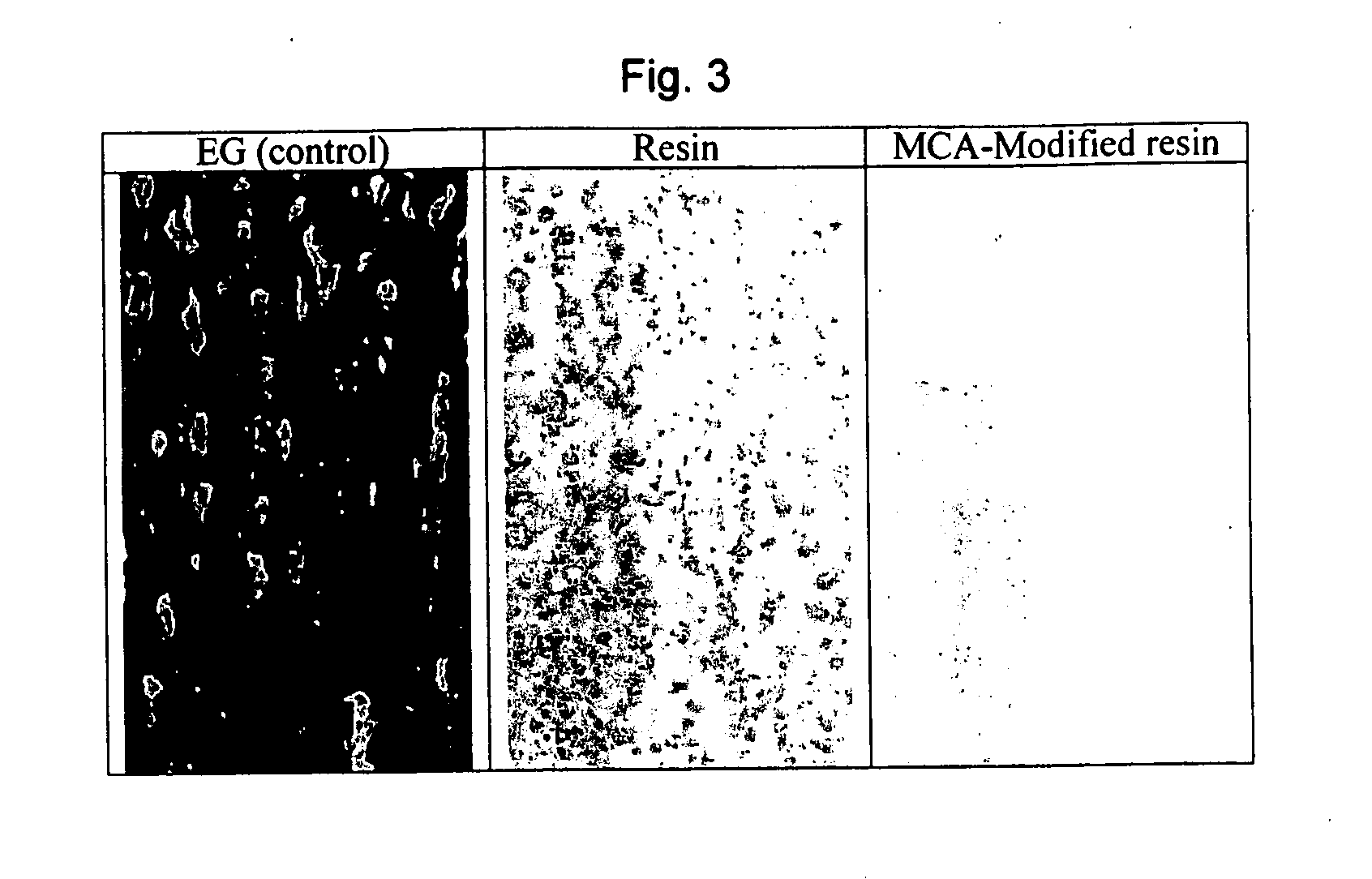

Method of improving the performance of organic coatings for corrosion resistance

InactiveUS20050183793A1Simple processExemption stepsLiquid surface applicatorsAnti-corrosive paintsAlkaneThiol

This invention pertains to a method of modifying polymeric coating materials by adding organosulfur compounds, so that the metallic substrates coated with the modified polymeric materials become more resistant to corrosion. The organosufur compounds are alkane thiols with a general formula R(CH2)nSH, where R represents H, NH2, HOOC, and HO groups and n is in the range of 10 to 21. The reagents are designed to increase the adhesion between the polymeric coating materials and the metallic substrates, which may be conducive to increased corrosion resistance.

Owner:POHANG IRON & STEEL CO LTD

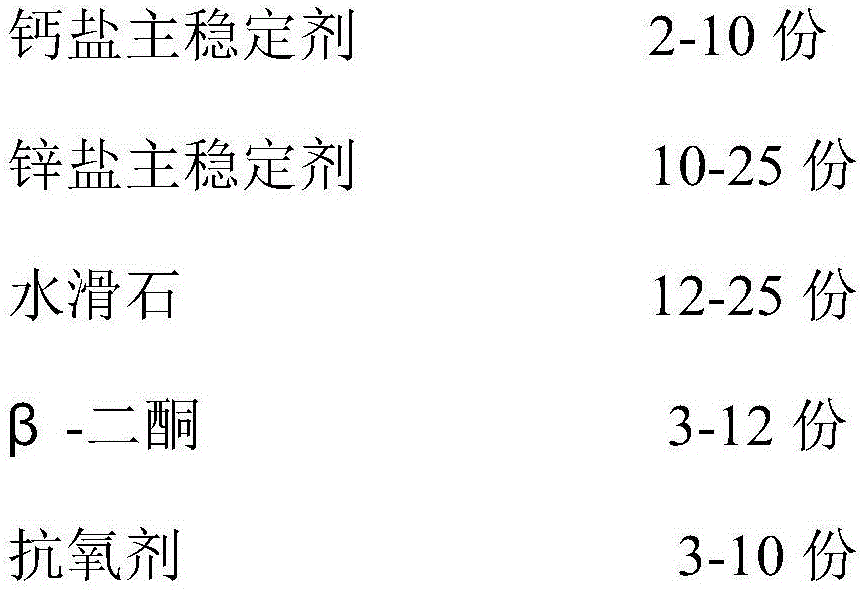

Transparent phenol-free pasty heat stabilizer and preparing method thereof

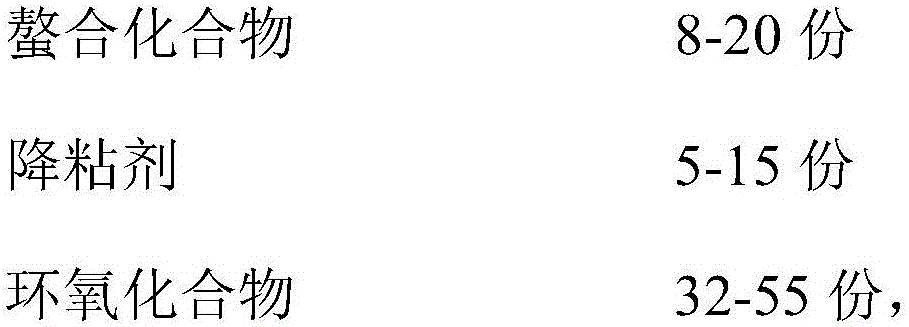

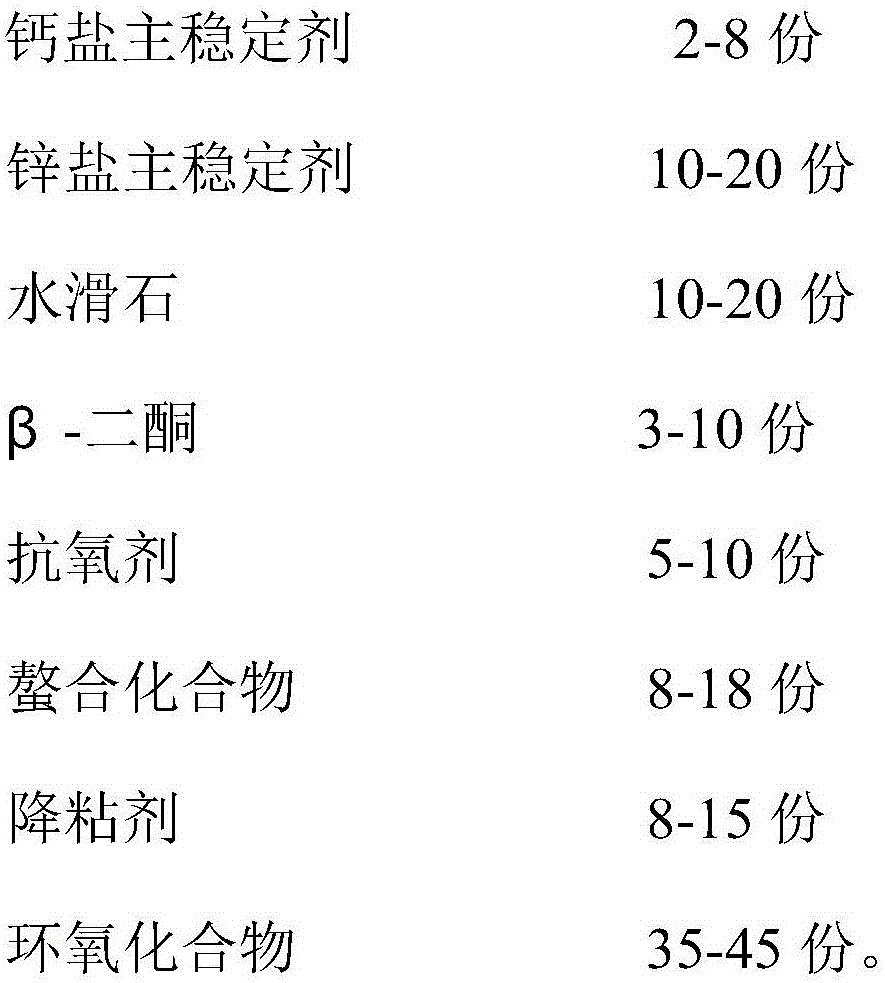

The invention relates to the technical field of heat stabilizers, in particular to a transparent phenol-free environment-friendly pasty heat stabilizer and a preparing method thereof. The pasty heat stabilizer is prepared from, by weight, 2-10 parts of calcium salt main stabilizer, 10-25 parts of zinc salt main stabilizer, 12-25 parts of hydrotalcite, 3-12 parts of beta-diketone, 3-10 parts of antioxidant, 8-20 parts of chelation compound, 5-15 parts of viscosity reducer and 32-55 parts of epoxy compound. The pasty heat stabilizer completely meets the phenol-free environment-friendly requirement, transparency and later-stage heat resistance are high, and the prepared product is free of red stain for a long time, high in dispersion mobility and free of lamination; besides, processing range is wide, and the pasty heat stabilizer is suitable for flexible, semi-rigid and high-transparency PVC extrusion and injection molding, and paste resin plastic processing.

Owner:DONGGUAN SUNVO NEW MATERIAL CO LTD

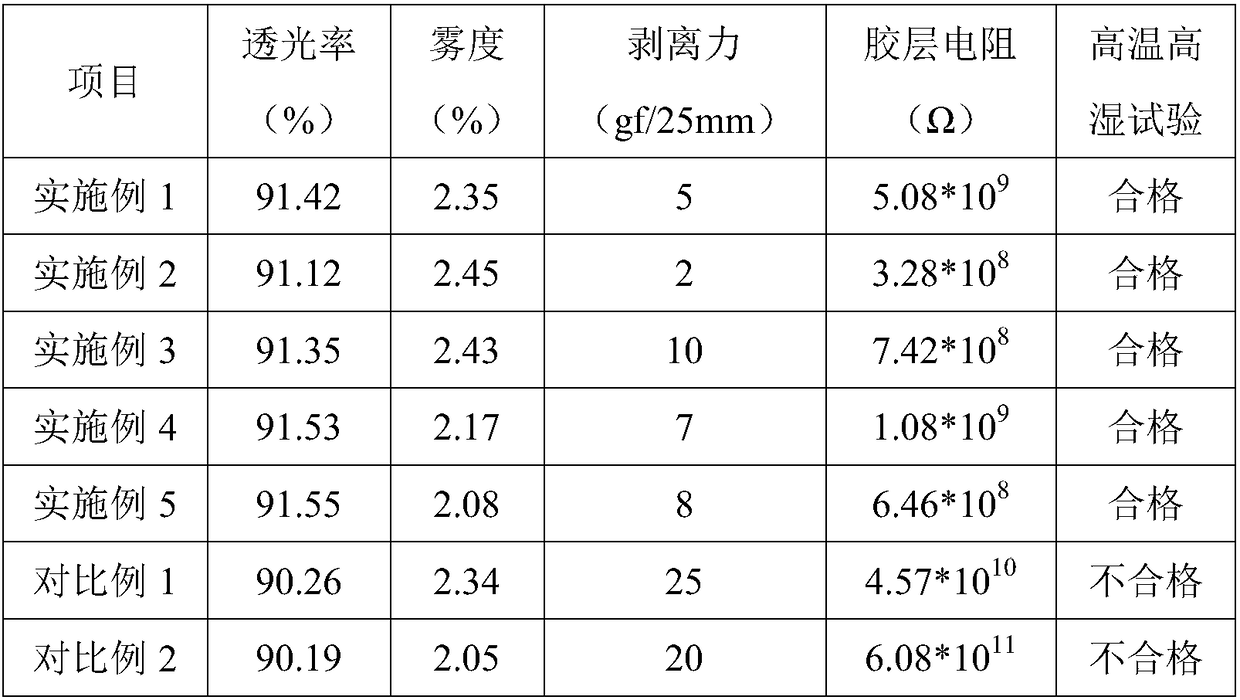

Preparation method of pressure sensitive adhesive for polaroid protection film and protection film thereof

InactiveCN108384476ASave glue dispensing processLow costNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyesterTectorial membrane

The invention discloses a preparation method of a pressure sensitive adhesive for a polaroid protection film and a protection film thereof. The pressure sensitive adhesive is prepared from the following raw materials in parts by weight: 10 to 40 weight parts of soft monomers, 5 to 15 weight parts of hard monomers, 2 to 6 weight parts of fluorine containing acrylate monomers, 0.8 to 3 weight partsof crosslinking monomers, 0.8 to 2 weight parts of vinylsilane, 0.5 to 2 weight parts of anti-static agents, 0.5 to 1.5 weight parts of initiators and 80 to 190 weight parts of solvents. The pressuresensitive adhesive can be directly covered on the surface of a polyester film; the additional addition of the curing agents and the anti-static agents is not needed; the adhesive layer resistance is 1010 ohm or less; the anti-static performance is realized. When the polaroid protection film adhesive layer is pasted on the surface of a polaroid, after the high-temperature and high-humidity tests for 500h, the protection film and the polaroid are tightly attached; no bubble bulges exist; no adhesive is remained when the protection film is torn away; defects such as hard shadow do not exist.

Owner:昆山乐凯锦富光电科技有限公司 +1

Ship corrosion preventing method

InactiveCN104525458ALower surface free energyReduce coefficient of frictionPretreated surfacesAnti-corrosive paintsSand blastingPre treatment

The invention discloses a ship corrosion preventing method. The ship corrosion preventing method comprises the following steps of steel plate surface pre-treatment, base material sanding treatment, weld joint and other structure defect repair sand blasting, priming paint coating, strengthening paint spraying, finishing paint spraying and follow-up maintenance. According to the ship corrosion preventing method, steel plate surface pre-treatment is performed before coating, an epoxy anticorrosive coating is sprayed on the position with high rust-proof requirement, and whole spraying is performed after spraying; during whole spraying, corrosion resistant polyurethane serves as film forming matter, a coating for a framework formed by sheet metal flakes does not contain precious metal and toxic components and is a novel environment-friendly coating, flakes are formed and distributed on the material surface, multiple layers of flakes are horizontally arranged in an overlapped mode, a path for a corrosive medium to permeate into a base material is prolonged, and the corrosion preventing performance of the coating is improved. The ship corrosion preventing method is short in technological process, and produced ships have excellent rust, corrosion and fouling preventing performance.

Owner:QINGDAO WUWEI THERMAL INSULATION MATERIAL

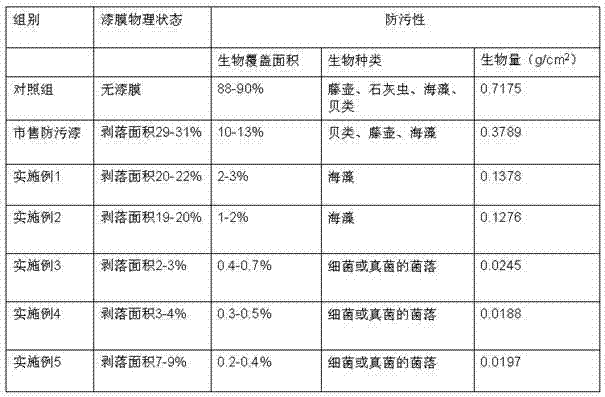

Bionic marine antifouling paint

ActiveCN103694754AStrong inhibition of adhesionPrevent adhesionAntifouling/underwater paintsPaints with biocidesSodium BentonitePolymer science

The invention discloses a bionic marine antifouling paint which comprises the following raw materials in parts by weight: 30-45 parts of fluorinated acrylic ester, 20-35 parts of silicone rubber, 2-10 parts of biological antifouling agent, 15-25 parts of filler, 0.5-1 part of organic bentonite, 0.5-1 part of polyethylene wax and 2-7 parts of propylene glycol. According to the bionic marine antifouling paint disclosed by the invention, P-cinnamate sulfate in the biological antifouling agent has a remarkably strong attachment inhibiting effect on marine bacteria and barnacle; homarine can prevent attachment of marine benthic diatom and barnacle; diterpene formamide has a function of inhibiting barnacle and shellfish larvae; the rubber silicon material and fluorinated acrylic ester material have extremely low surface free energy, low friction coefficient, high hydrophobicity and high contamination release performance, so that attachments are not easily attached or are insecurely attached.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Preparation method of aqueous fluorine-modified phosphorus-containing acrylate emulsion

InactiveCN103833888AWith fine grainFlash corrosion resistantFibre treatmentCoatingsEnvironmental resistanceFunctional monomer

The invention discloses a preparation method of an aqueous fluorine-modified phosphorus-containing acrylate emulsion. The preparation method comprises the steps of firstly preparing a pre-emulsion, then preparing a seed emulsion, and carrying out emulsion polymerization, so as to obtain the milky-white and slightly-blue aqueous fluorine-modified phosphorus-containing acrylate emulsion. According to the preparation method, a phosphate emulsifier is taken as an anionic emulsifier, meanwhile, phosphate is added as a functional monomer, phosphate groups are intruded into the emulsion, so that the emulsion has the characteristics of fine granularity and flash rusting resistance, and a coating has high adhesive force and certain salt water resistance; by adding a fluorine-containing modified monomer having good effects in the reduction of surface free energy and the improvement of surface dewatering and oleophobic performance, the water resistance of the coating of the emulsion is enhanced, and the pollution resistance of the coating of the emulsion is improved; meanwhile, the utilized fluorine-containing modified monomer is a fluorine-containing acrylic monomer, so that the problems of environment friendliness and biological harm of a long-fluorocarbon-chain compound are avoided, and the prepared emulsion is environmental friendly; the utilized nonionic emulsifier does not contain APEO (alkylphenol ethoxylate) and is environmental friendly.

Owner:西安佳龙油漆新技术发展有限公司

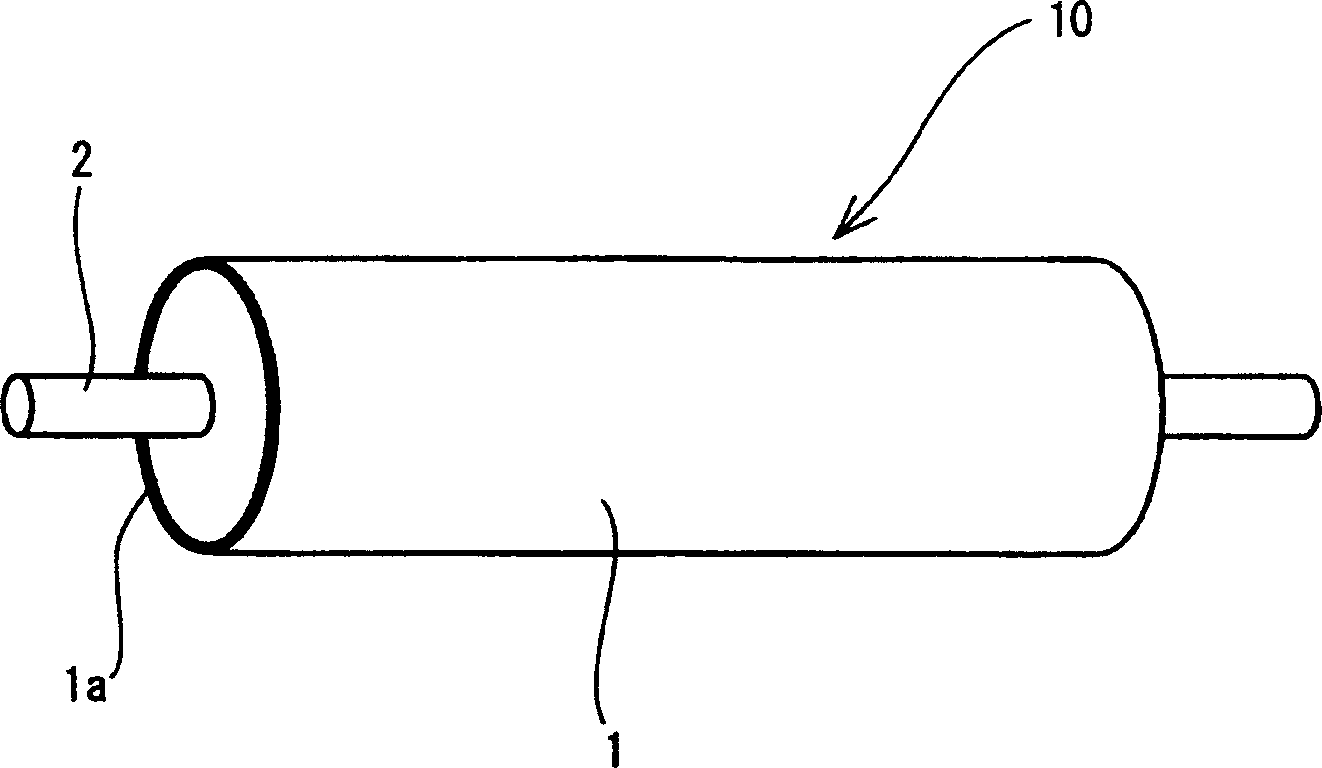

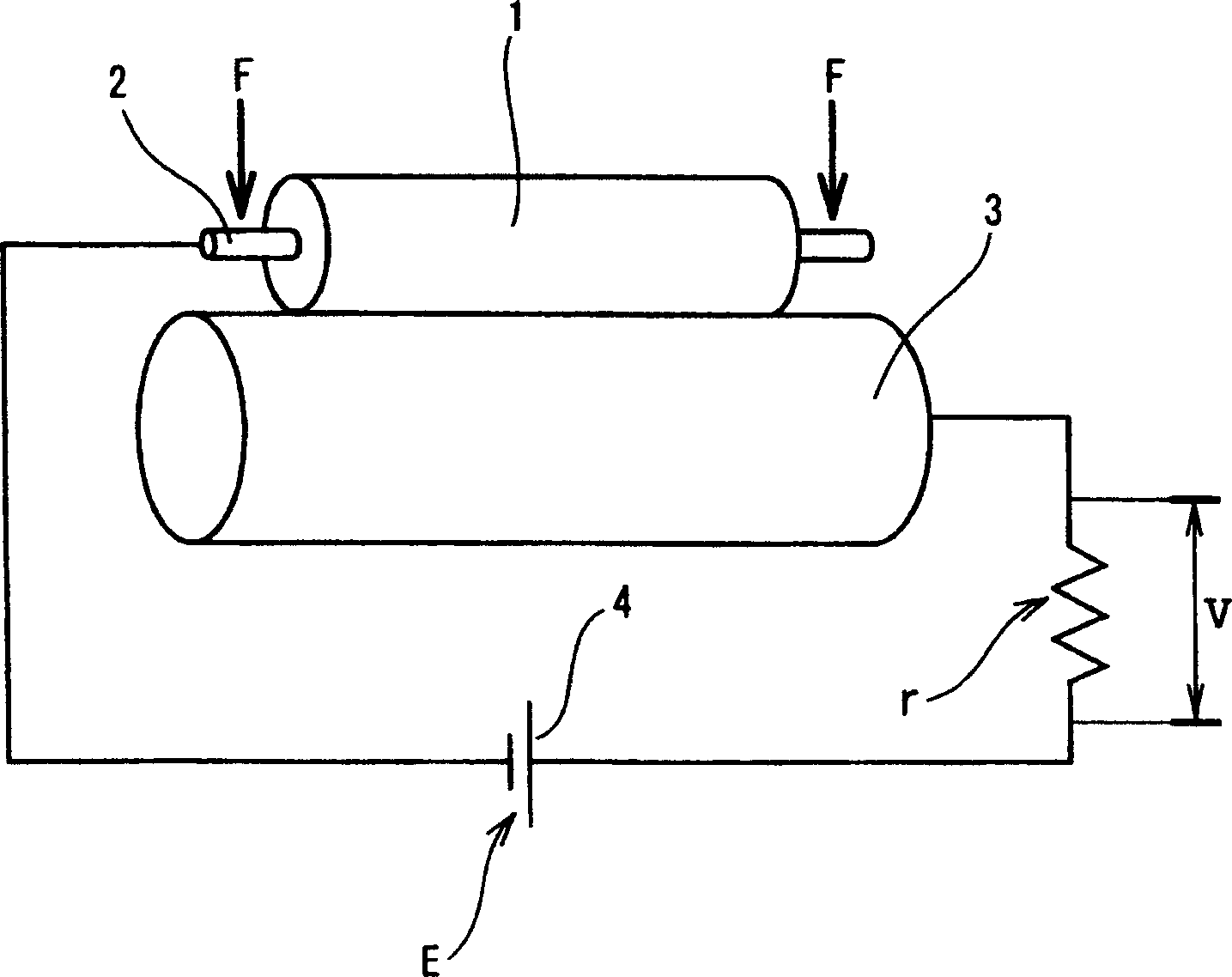

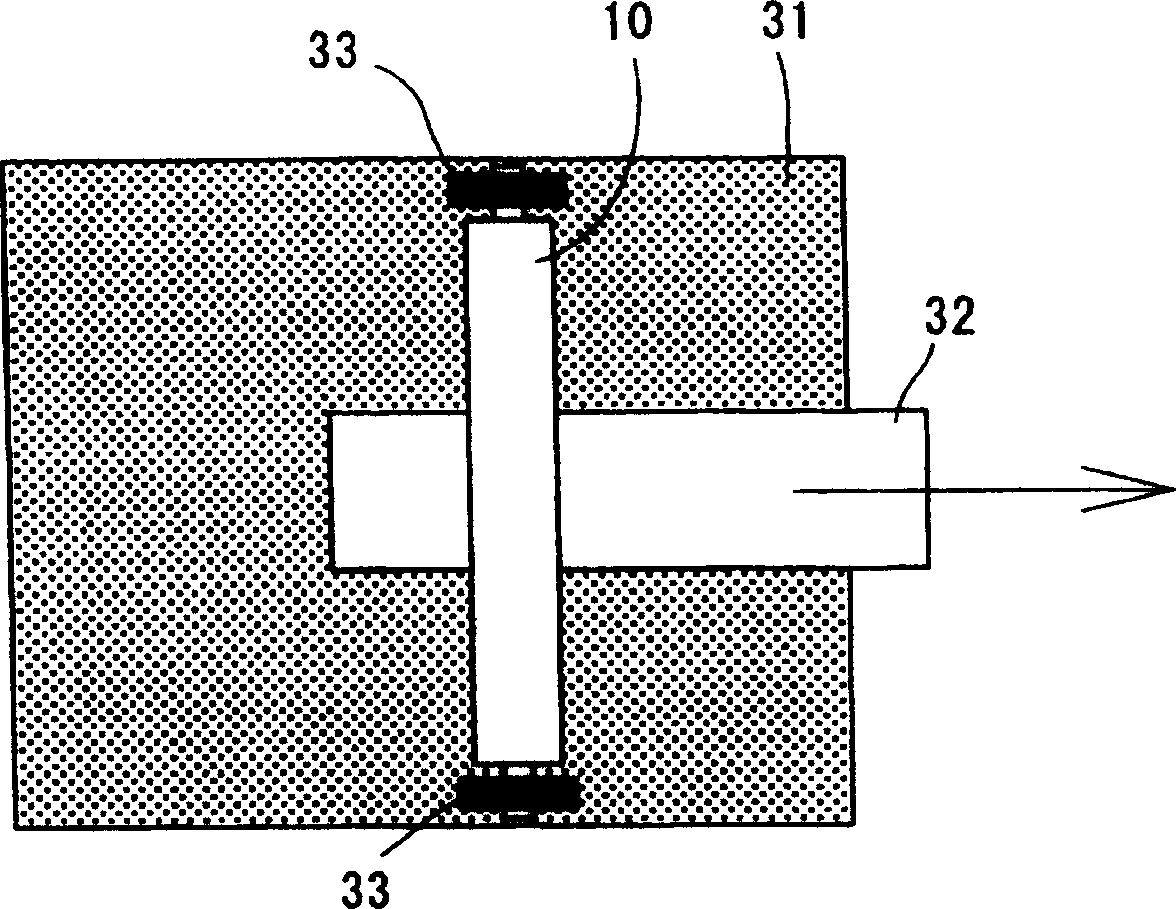

Semi-conductive rubber part

InactiveCN1655288AOvercoming high surface free energyOvercoming processabilityNon-insulated conductorsShaft and bearingsForeign matterEngineering

To provide a semiconductive rubber member causing no substantial sticking of foreign matter represented by a toner outer additive for a long period through reducing the surface free energy of the rubber member while maintaining its electrical properties' uniformity and design values' repeated reproducibility, excellent in processability and substantially exhibiting no surface defects including molding unevenness and cracks. This semiconductive rubber member is obtained by compounding 100 pts. mass of an ionically conductive rubber including a rubber having polyether linkages with 0.1-5 pt(s). mass of a wax. In this rubber member, it is preferable that the rubber having the polyether linkages to be used consists of a polymer made from a halogen-containing ether-based monomer and, when desired, a halogen-free ether-based monomer and / or a copolymerizable unsaturated epoxide-based monomer.

Owner:SUMITOMO RUBBER IND LTD

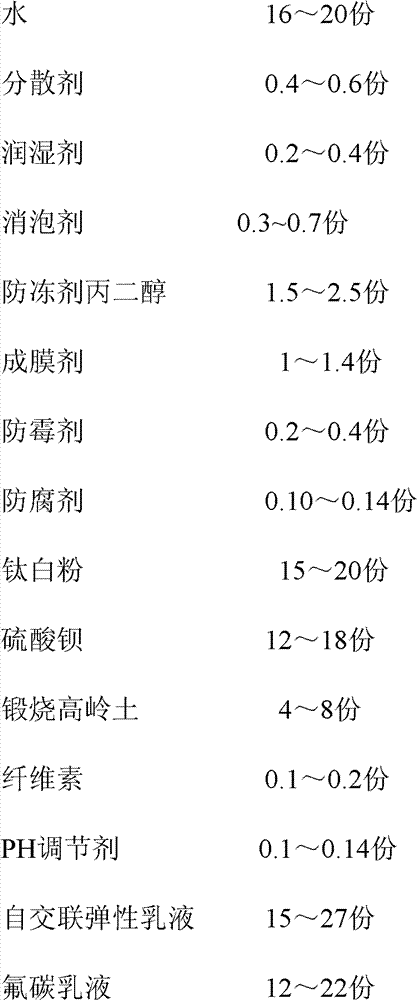

Nano water-based fluorocarbon insulated elastic exterior wall paint and preparation method thereof

InactiveCN103483951ALower surface free energyGood oil repellencyAntifouling/underwater paintsPaints with biocidesWater basedFree energies

The invention relates to a nano water-based fluorocarbon insulated elastic exterior wall paint which is characterized by comprising the following components: nano ATO powder, titanium dioxide, calcined kaolin, calcium carbonate, a nano zirconia dispersion liquid, cellulose, a self-crosslinking elastic emulsion, a fluorocarbon emulsion, a covering emulsion, hollow glass microbeads, auxiliary agents, and the balance being water. The paint has the advantages that a paint film has lower surface free energy and is endowed with a good oleophobicity; a paint film formed by adding the self-crosslinking emulsion is more dense so as to make the paint film less susceptible to contaminate by stains, and simultaneously is more easily washed cleanly after being contaminated by the stains; and finally, in cooperation with a proper amount of the hollow glass microbeads, the nano zirconia dispersion liquid, the nano ATO powder and other functional additives, the insulation, anti-cracking and antifouling requirements of people on exterior walls are satisfied, the paint film is not damaged after the stains are washed cleanly, and thus the novel high-performance weather-proof exterior wall emulsion paint is provided for exterior wall decoration.

Owner:上海展辰涂料有限公司 +4

Physisorption-based microcontact printing process capable of controlling film thickness

InactiveUS20080110363A1Effectively controls thicknessControl thicknessNanoinformaticsPhotomechanical apparatusMicrocontact printingSurface roughness

The disclosed is a physisorption-based microcontact printing process capable of controlling film thickness, primarily for creating patterns of thin film of organic molecules in micron and submicron scales, comprising an inking phase, a printing phase, and a demolding phase. The inking phase is combined with a thin-film growth approach, wherein the thin-film approach enables growth of an organic thin film with desired thickness onto a stamp, effectively controls the thickness of the pattern of the organic thin film transferred in the next printing phase. The demolding phase enables proper control of the temperature of and the printing pressure upon the transferred thin-film pattern to control the quality of surface roughness and residual internal stress in the printed pattern.

Owner:NATIONAL CHUNG CHENG UNIV

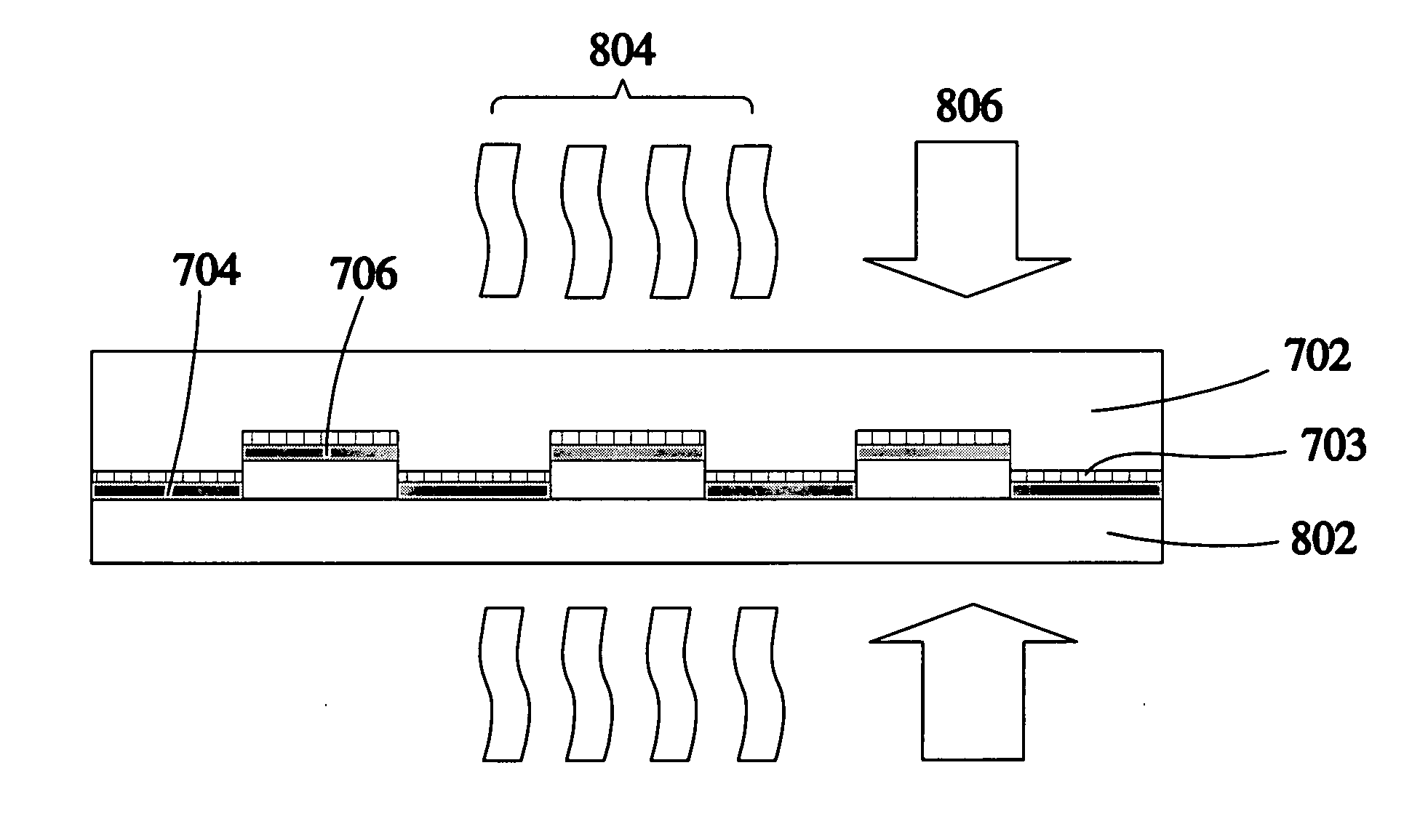

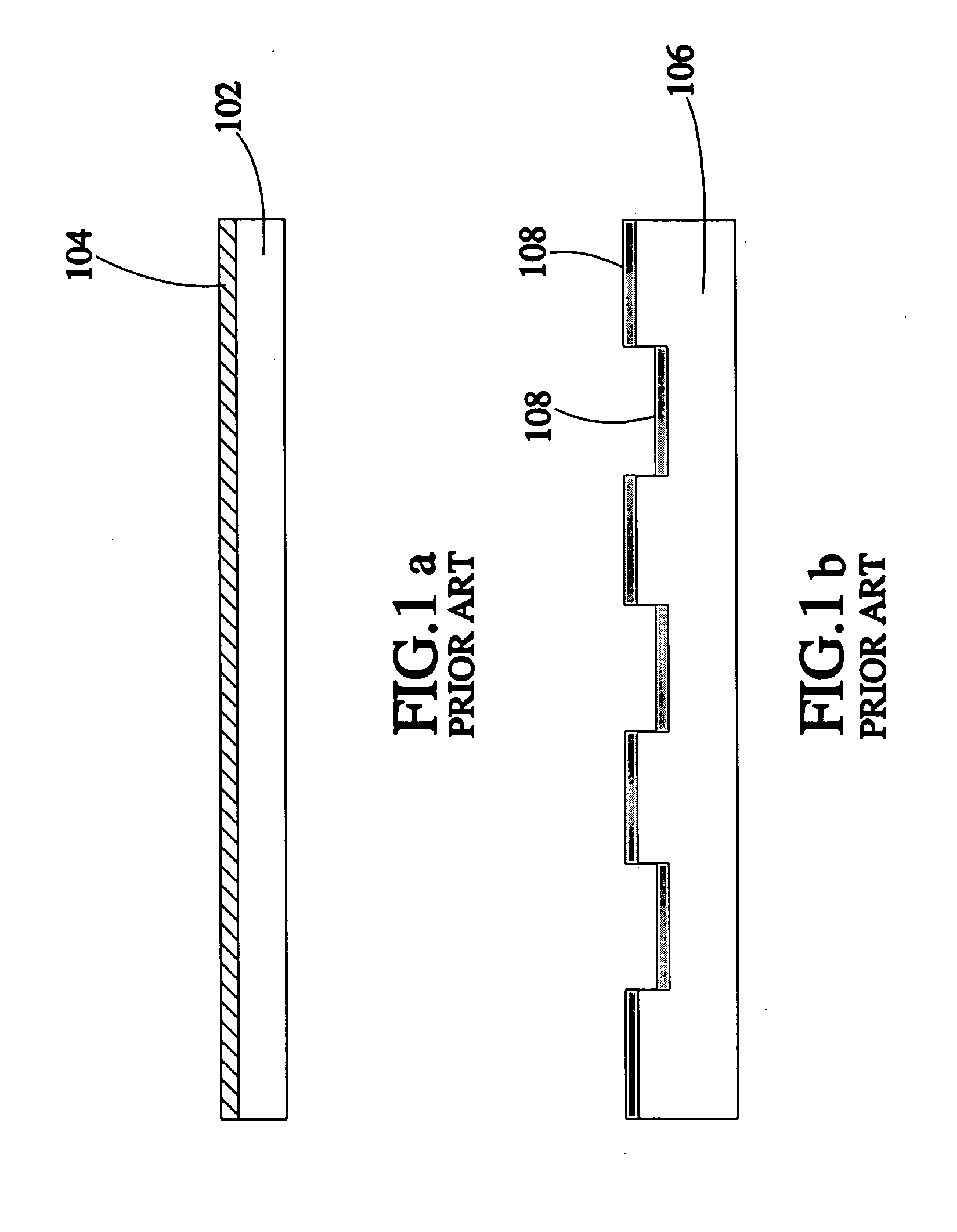

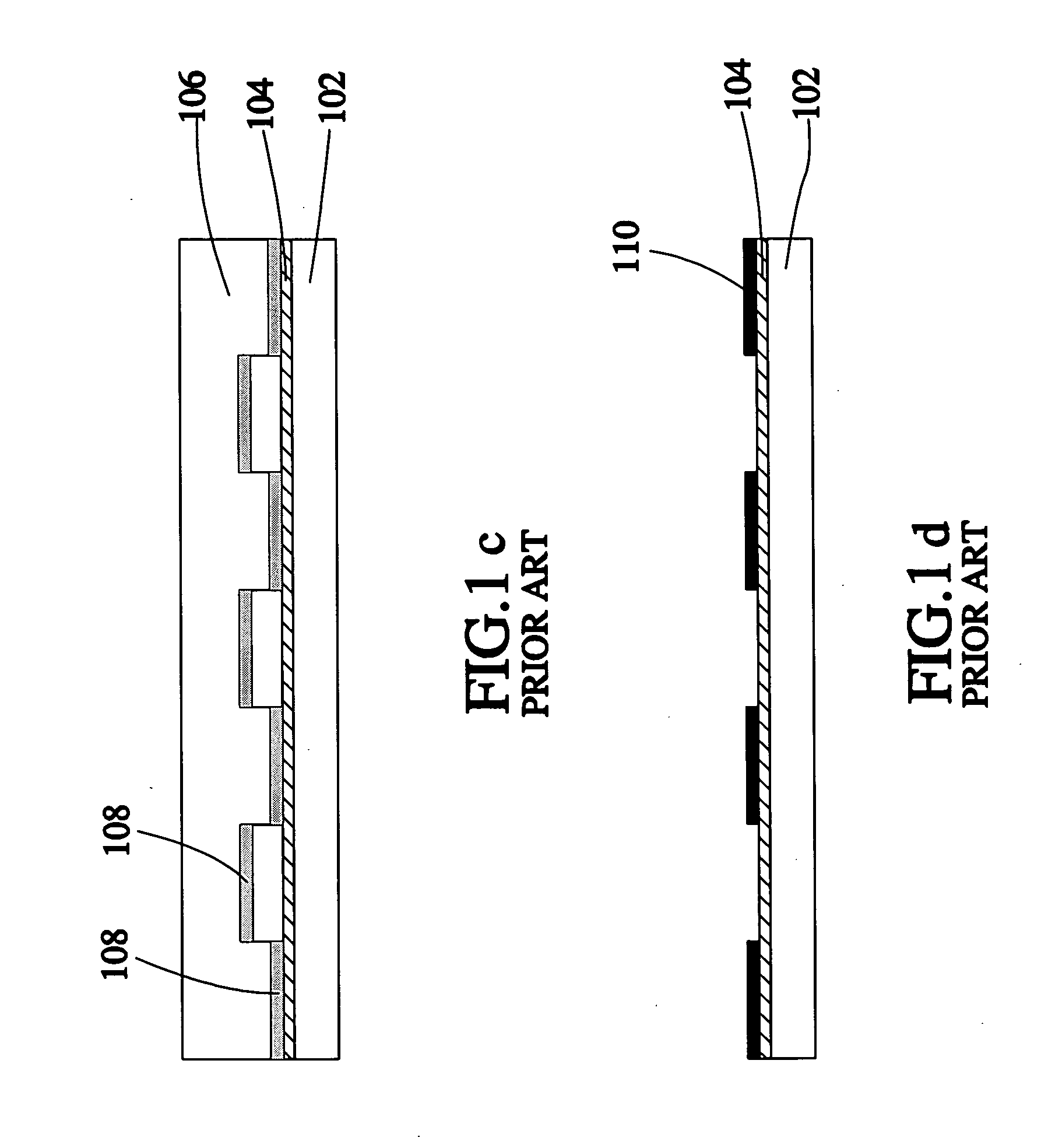

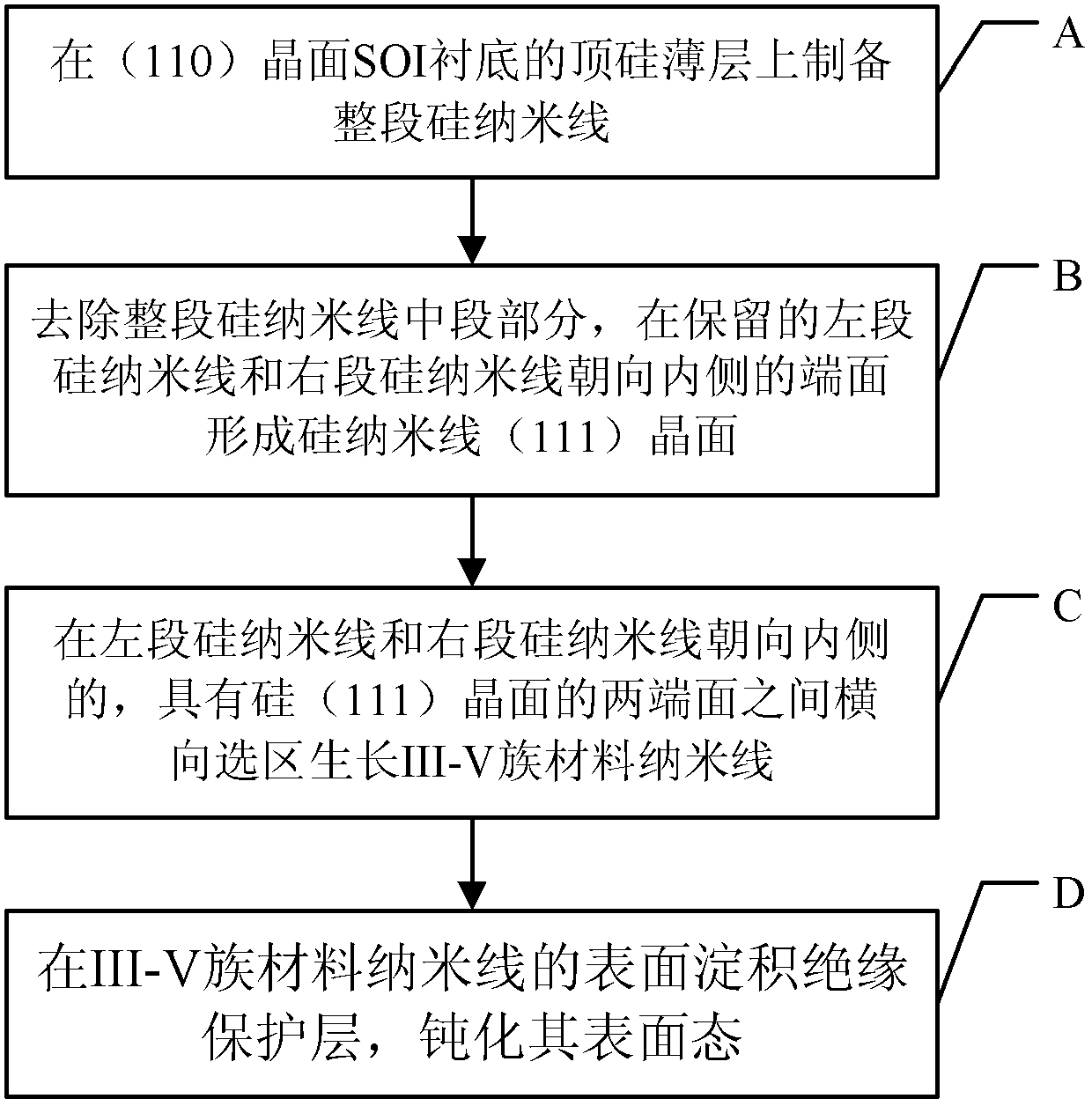

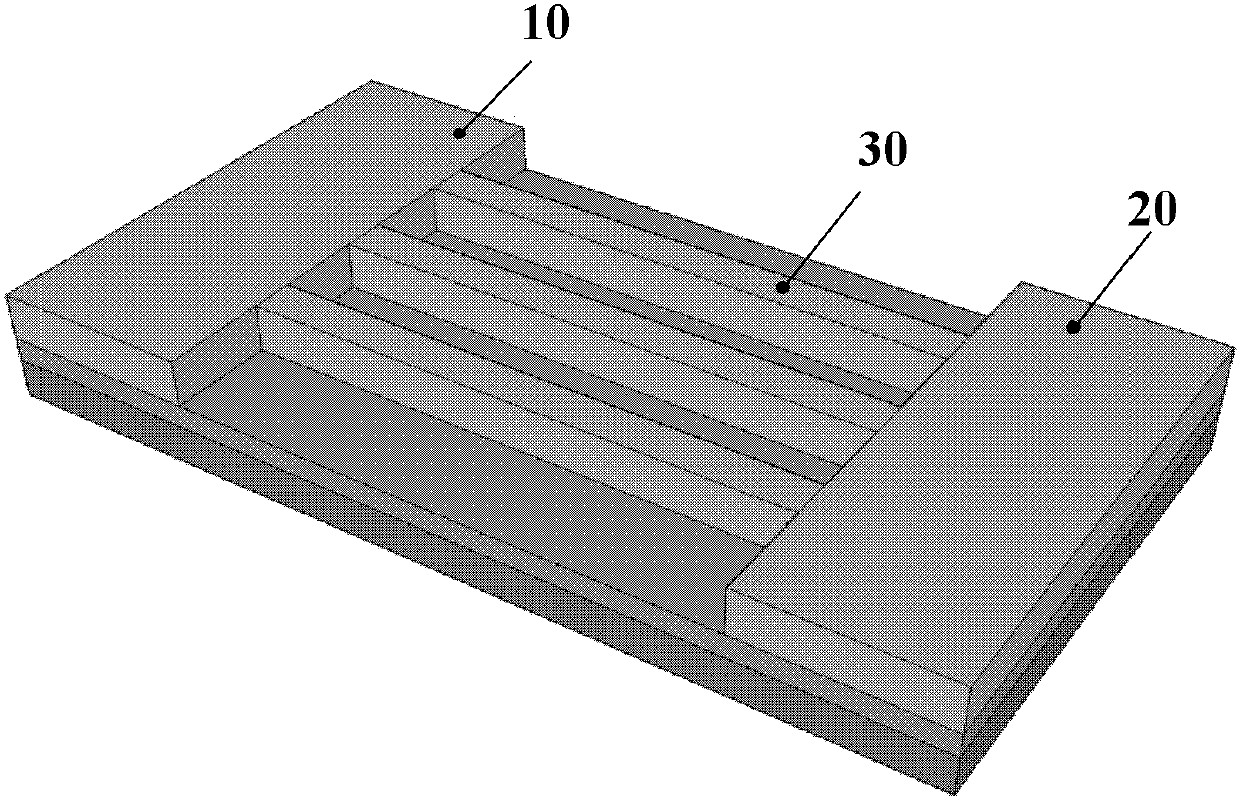

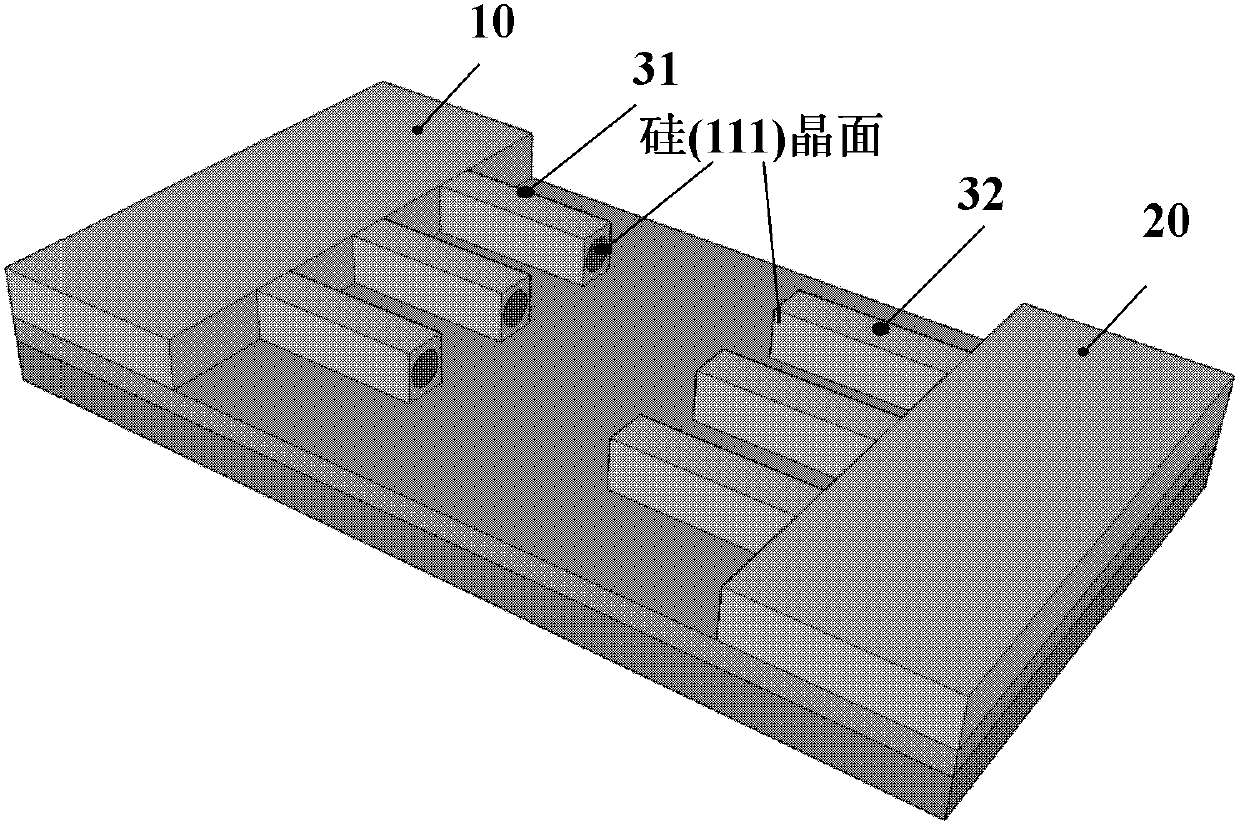

Method of silicon substrate III-V group nanowire area selection transverse epitaxial growth

InactiveCN103346070ALower surface free energyLow costSemiconductor/solid-state device manufacturingNanotechnologyThin layerSilicon nanowires

The invention provides a method of silicon substrate III-V group nanowire area selection transverse epitaxial growth. The method comprises the steps of A, preparing the whole segment of silicon nanowire on a top silicon thin layer of a crystal face SOI substrate (110); B, removing the middle segment of the whole segment of silicon nanowire, and forming silicon crystal faces (111) on the end faces, facing the inner sides, of the reserved left segment of silicon nanowire and the right segment of silicon nanowire; C, transversely growing III-V group material nanowires between the two end faces, provided with the silicon crystal faces (111) and facing the inner side, of the left segment of silicon nanowire and the right segment of silicon nanowire in an area selection mode, and forming a heterojunction bridging structure. The characteristics that the silicon crystal faces (111) have the higher dangling bond density and the lower surface free energy are utilized by the method, and the area selection transverse growth of the III-V group nanowires can be achieved on the side walls of the silicon crystal faces (111) between the left segment of silicon nanowire and the right segment of silicon nanowire with the low cost.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

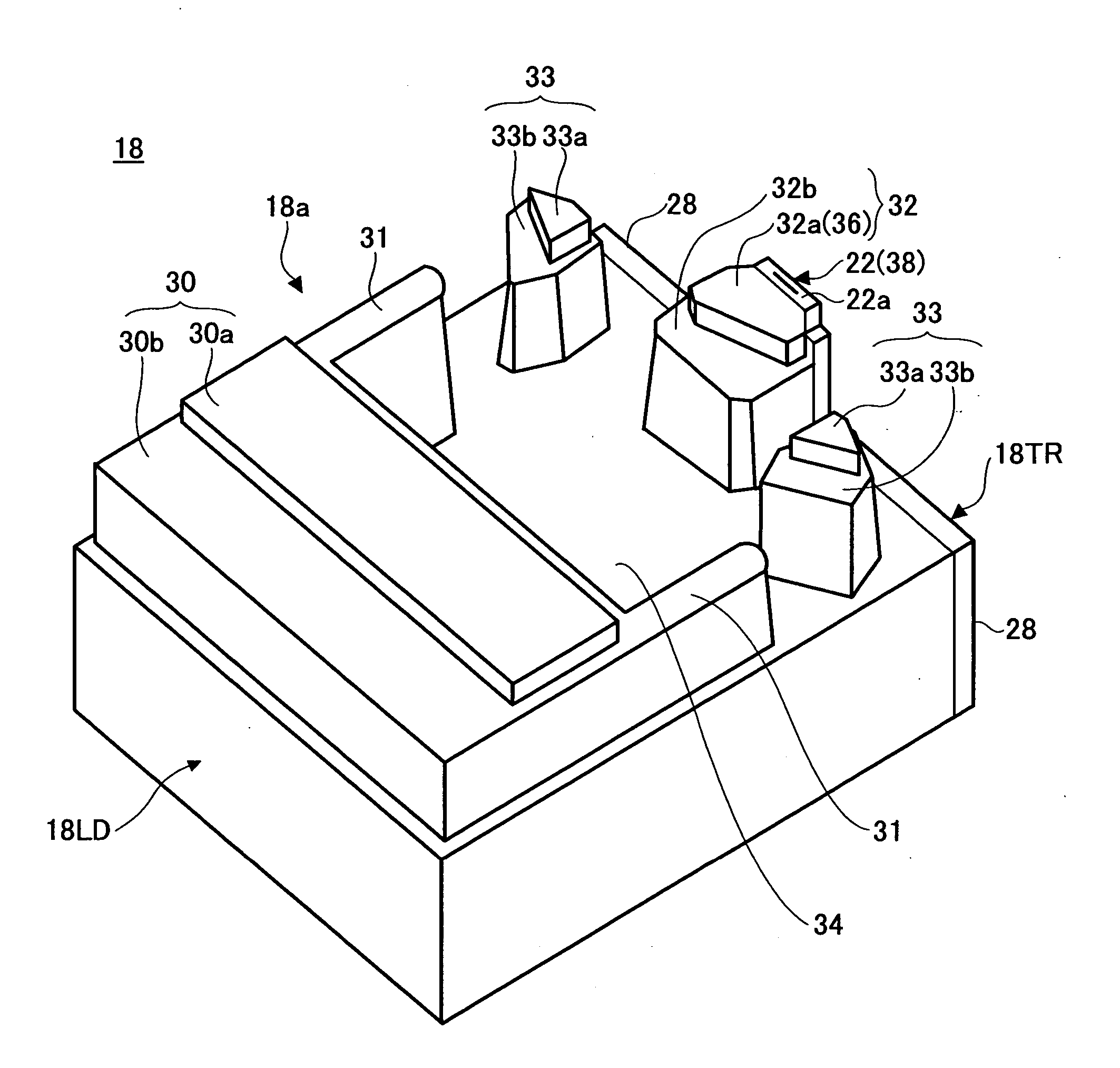

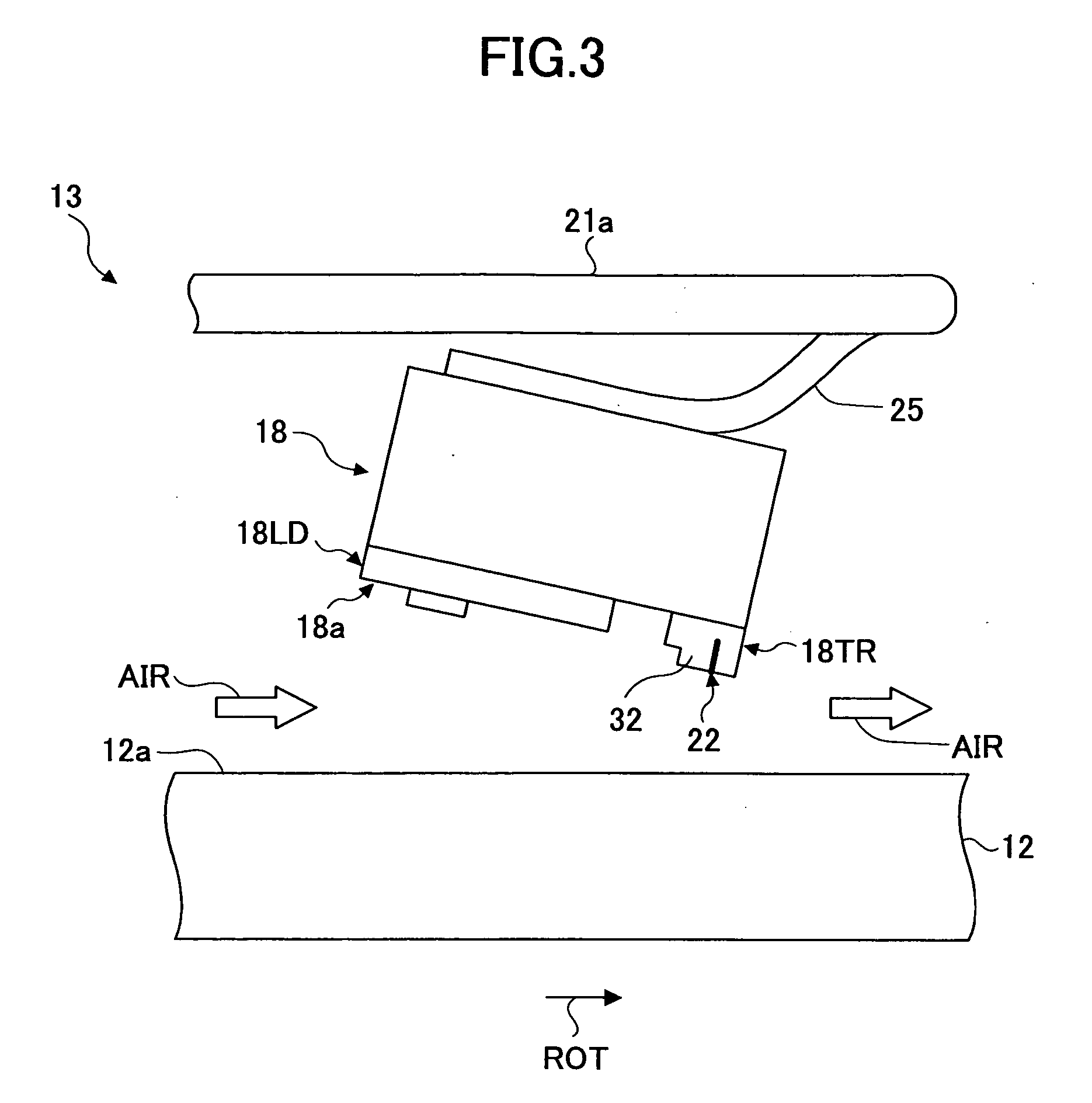

Magnetic head and manufacturing method of the same

InactiveUS20060221502A1Quality improvementImprove floating stabilityFluid-dynamic spacing of headsRecord information storageSurface roughnessWater repellent

A magnetic head includes a head slider configured to float above a recording medium and having an element part for recording to and reproducing from the recording medium, the element part being situated on a medium facing surface facing to the recording medium. The medium facing surface has a first air bearing surface situated in a vicinity of a side of an air flow-out end. The medium facing surface has a rear rail having the element part situated at the side of the air flow-out end of the first air bearing surface. The first air bearing surface is covered with a lubricating layer made of water repellent resin and has an average surface roughness larger than an average surface roughness of a surface of the element part.

Owner:FUJITSU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com