Patents

Literature

33results about How to "Good oil-repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

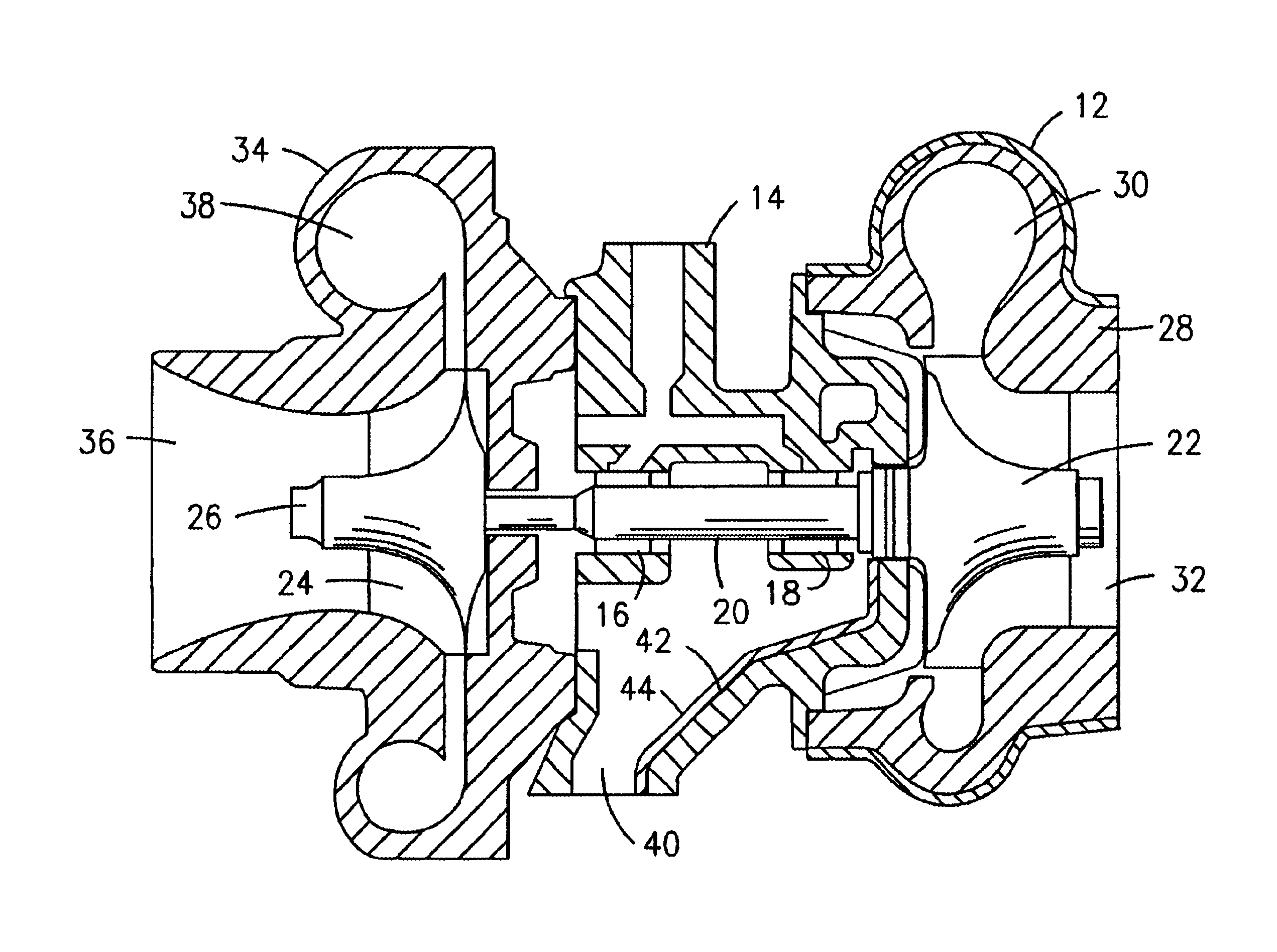

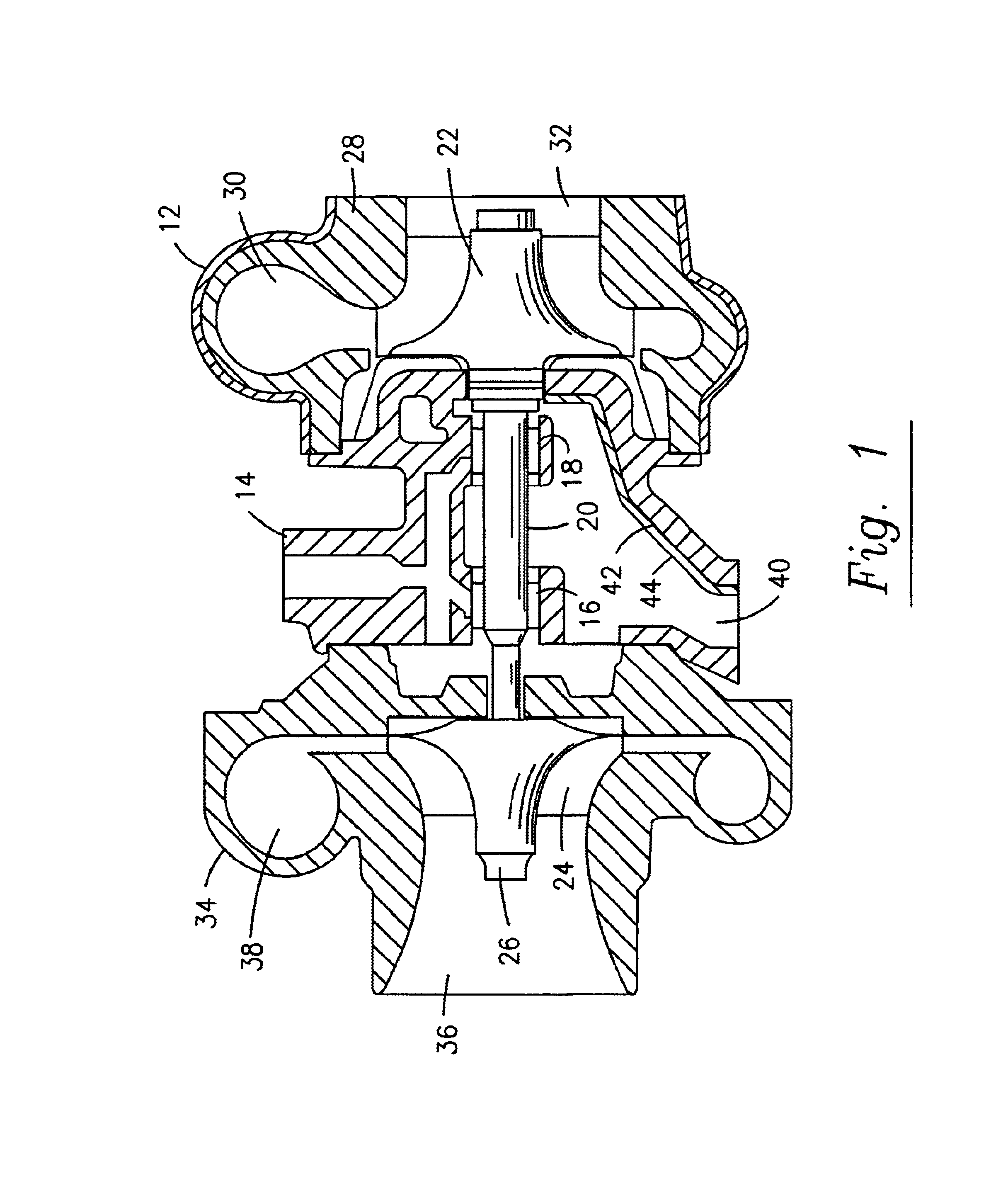

Turbocharger with reduced coking

InactiveUS6874998B2Increasing weightIncreasing volumePump componentsLayered productsTurbochargerEngineering

A turbocharger including means for preventing or reducing coking, particularly following engine shutdown, without noticeably increasing weight or volume of the turbocharger. The turbocharger bearing housing (14) has defined therein a lubrication flow path for bearing lubricant and a lubricant drain gallery (40) below a shaft (20), and in accordance with the invention at least a portion of a wall (42) of the lubricant drain gallery (40) is coated with an oil repellant and / or heat insulating coating (44).

Owner:BORGWARNER INC

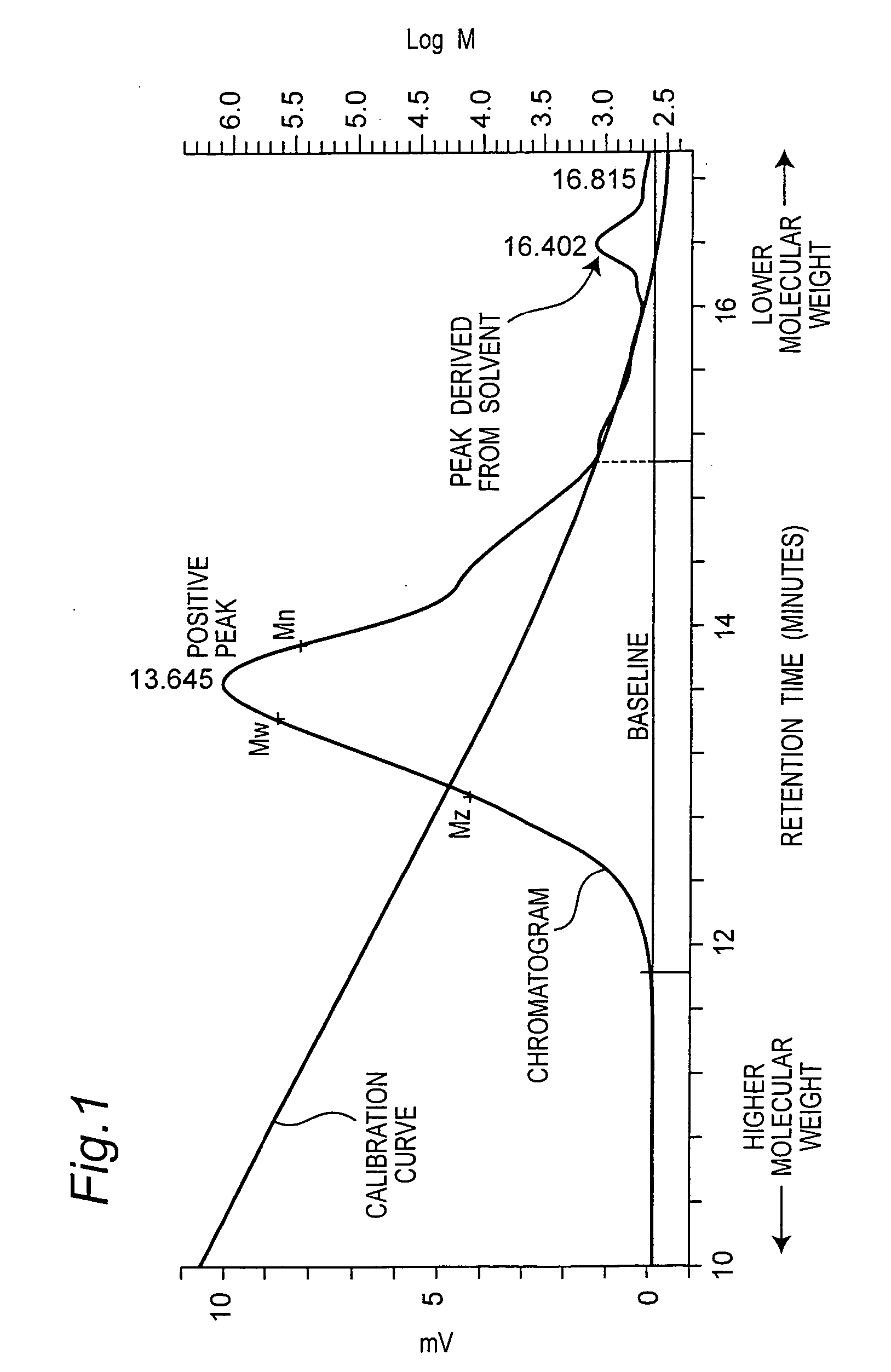

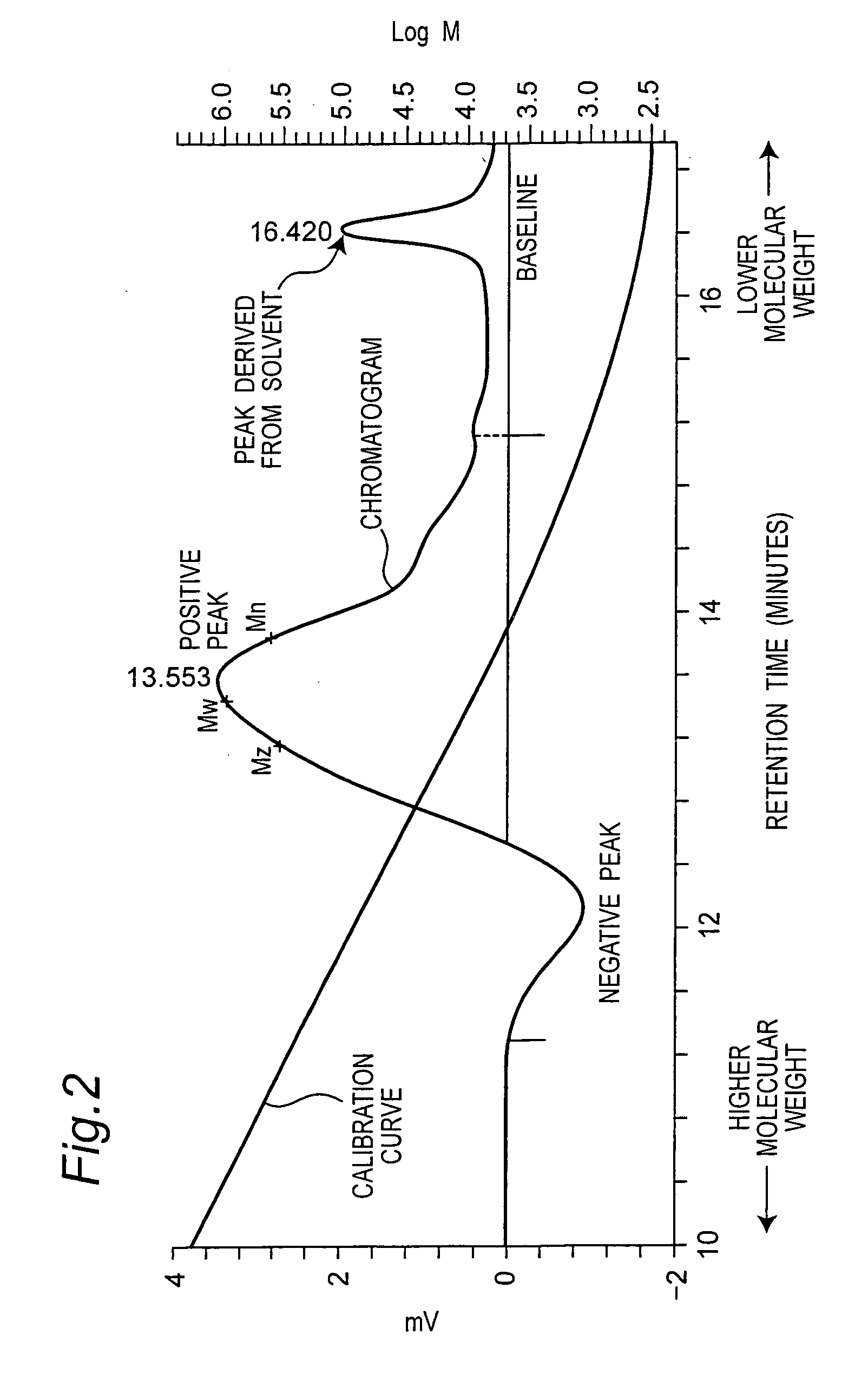

Water and oil repellent composition and treatment method

InactiveUS20070088141A1Improve performanceImprove copolymerization performanceFibre treatmentEmulsion paintsCarbon atomStereochemistry

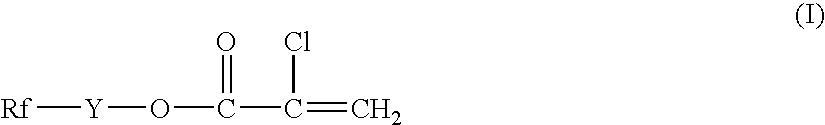

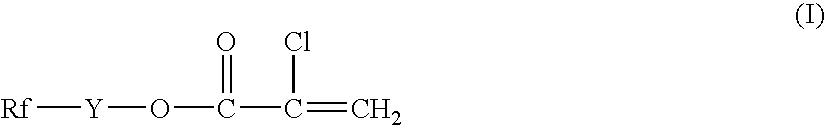

Disclosed is a water- and oil-repellent agent comprising the following fluorine-containing copolymer (A). The fluorine-containing copolymer (A) comprises: (a1) a fluoroalkyl group-containing polymerizable monomer of the formula: wherein Y is a divalent organic group [for example, an aliphatic group having 1 to 10 carbon atoms, an aromatic or cycloaliphatic group having 6 to 10 carbon atoms, a —SO2N(R1)R2— group (in which R1 is a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, and R2 is an alkylene group having 1 to 10 carbon atoms), a —CON(R1)R2— group (in which R1 is a hydrogen atom or an alkyl group having 1 to 4 carbon atoms, and R2 is an alkylene group having 1 to 10 carbon atoms), or a —CH2CH(OY1)CH2— group (in which Y1 is a hydrogen atom or an acyl group having 1 to 4 carbon atoms)]; and Rf is a linear or branched fluoroalkyl or fluoroalkenyl group having 1 to 6 carbon atoms; and (a2) vinylidene chloride.

Owner:DAIKIN IND LTD

Water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and preparation method of matt-leather-membrane aqueous coating adhesive

ActiveCN104831540AAssociative functionCombined with styleFibre treatmentIsooctyl acrylatePolymer science

The invention relates to a water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and a preparation method of the matt-leather-membrane aqueous coating adhesive. The preparation method comprises the steps of emulsifying isooctyl acrylate, isobornyl methacrylate, glycidyl methacrylate, trifluoroethyl methacrylate, vinyl trimethoxysilane, hydroxypropyl acrylate, fatty alcohol ethoxylate XL90 and dodecyl benzene sulfonate to trigger polymerization, and compounding a thickening agent, namely an associated polyurethane flatting rheological agent, a cross-linking agent, namely terminated isocyanate, a flatting agent, namely polymethyl urea resin and silicon dioxide with the particle size of 2-7 microns, so as to obtain the matt-leather-membrane aqueous coating adhesive.

Owner:DANDONG UNIK TEXTILE

Fluorooxyalkylene group-containing polymer composition, surface treatment agent containing the composition, and article and optical article treated with the surface treatment agent

InactiveUS20130108876A1Good oil-repellencyEasy to waterAntifouling/underwater paintsOther chemical processesSiloxanePolymer composition

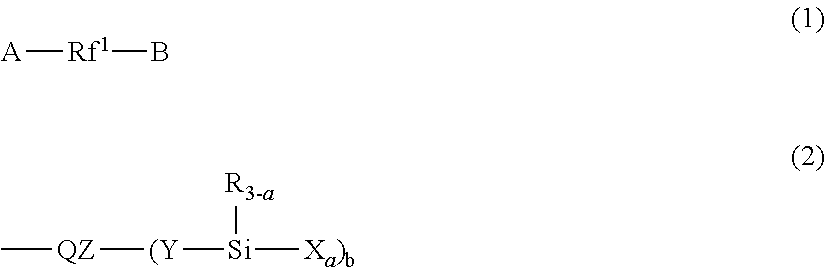

There is disclosed a fluorooxyalkylene group-containing polymer composition represented by the following average composition formula (1). In the formula, the ratio of the Rf2 group is 30 to 75 mole %, relative to a total of all of the terminal groups in the composition, and the fluorooxyalkylene group-containing polymer composition includes a one-terminal hydrolyzable silyl group-containing polymer and a both-terminal hydrolyzable silyl group-containing polymer,wherein Rf1 represents a divalent linear fluorooxyalkylene group, A and B represent groups represented by an Rf2 group or a group represented by the formula (2), Z represents a divalent to heptavalent linking group having a silalkylene structure or a silarylene structure but no siloxane bond, X represents a hydrolyzable group, and Y is a linking group represented by CcH2c or C2H4—CrF2r—C2H4.

Owner:SHIN ETSU CHEM IND CO LTD

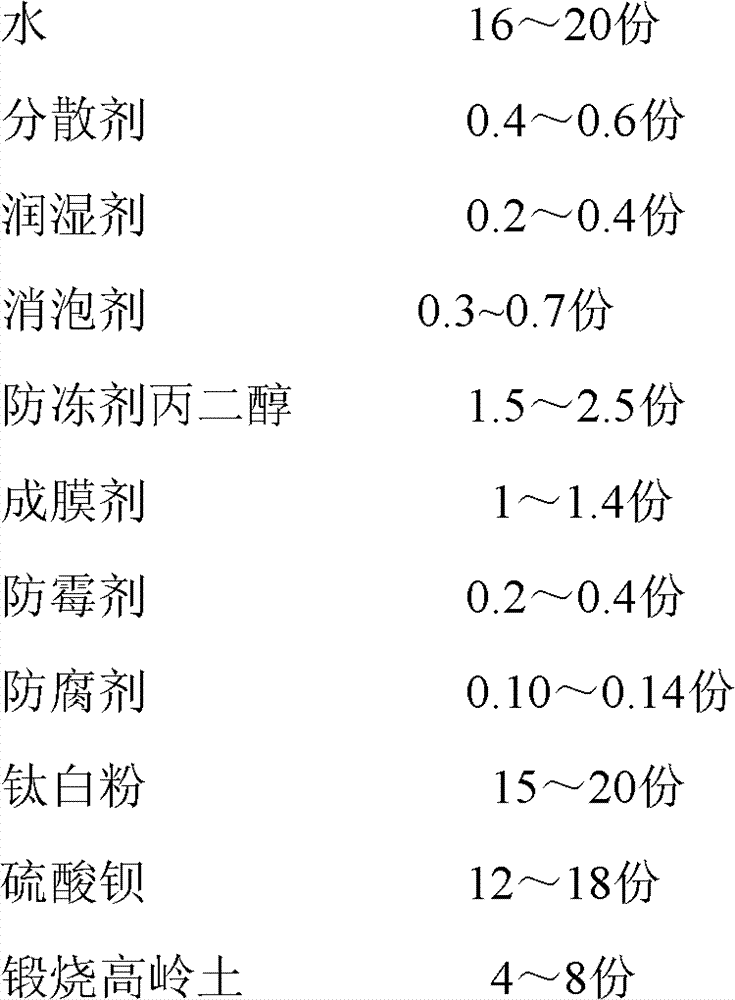

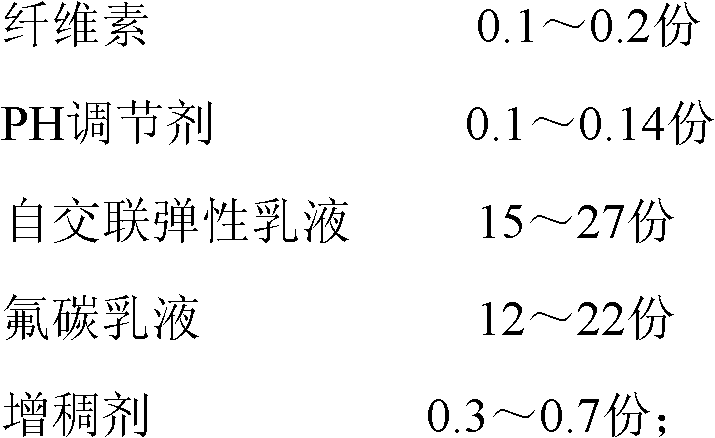

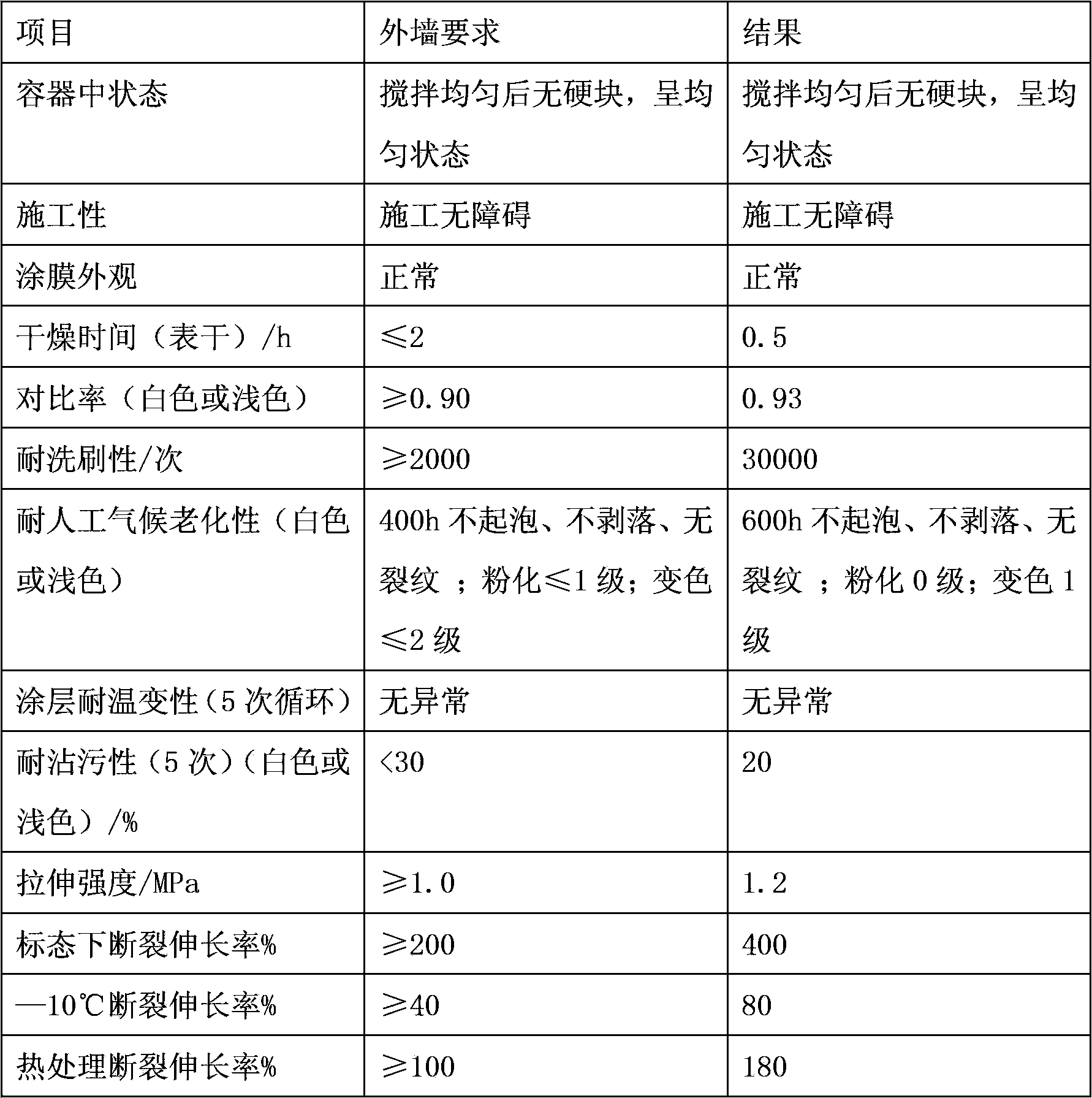

Elastic antifouling aqueous fluorocarbon exterior wall paint

ActiveCN103113796ALower surface free energyGood oil repellencyAnti-corrosive paintsEmulsion paintsEmulsionFree energies

The invention provides an elastic antifouling aqueous fluorocarbon exterior wall paint. The paint comprises the following components, by weight, 16-20 parts of water, 15-27 parts of a self-crosslinking elastic acrylic emulsion, 12-22 parts of an aqueous fluorocarbon emulsion, 15-20 parts of titanium dioxide, 12-18 parts of barium sulfate, 4-8 parts of calcined kaolin and 1-1.4 parts of a film forming agent. In the invention, the self-crosslinking elastic acrylic emulsion is treated as a main base material to reach an anti-crack requirement, and the aqueous fluorocarbon emulsion having a good compatibility is matched for modifying to make a paint film having low surface free energy and a good lipophobic property in order to make the formed film compact, so the paint film cannot be polluted by blots, and can be easily cleaned after the blot pollution; and rutile and titanium dioxide are simultaneously combined to improve the weather ability, the chemicals (acid rain, salts and the like) corrosion resistance of the film, so the film has good color and light maintenance properties, thereby the elastic antifouling aqueous fluorocarbon exterior wall paint is a new high-performance elastic antifouling aqueous fluorocarbon exterior wall paint.

Owner:珠海展辰新材料股份有限公司

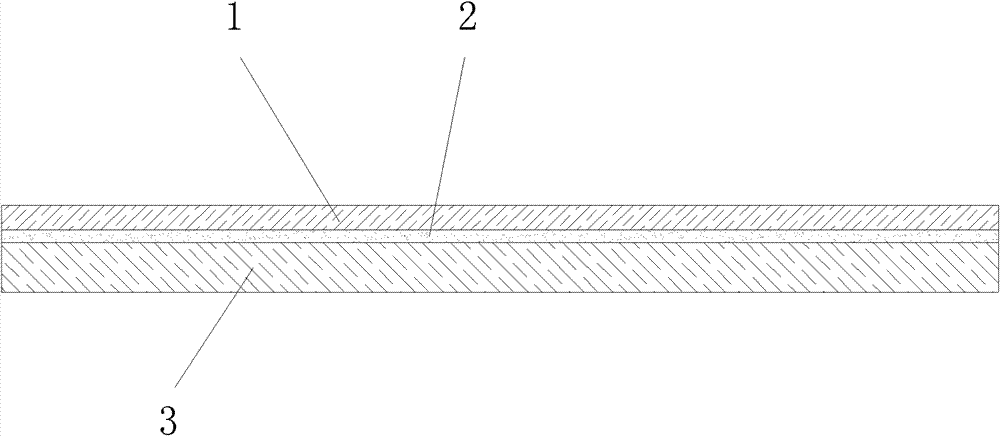

Waterproof ventilated membrane for car light and manufacturing method thereof

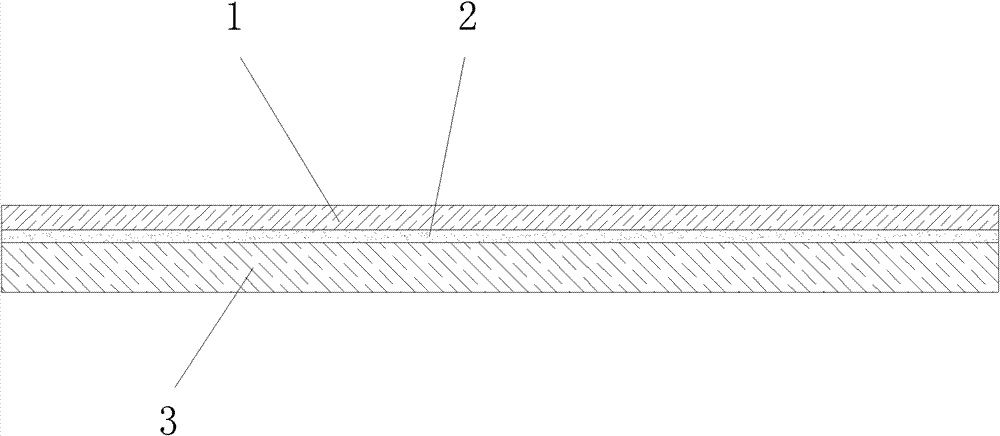

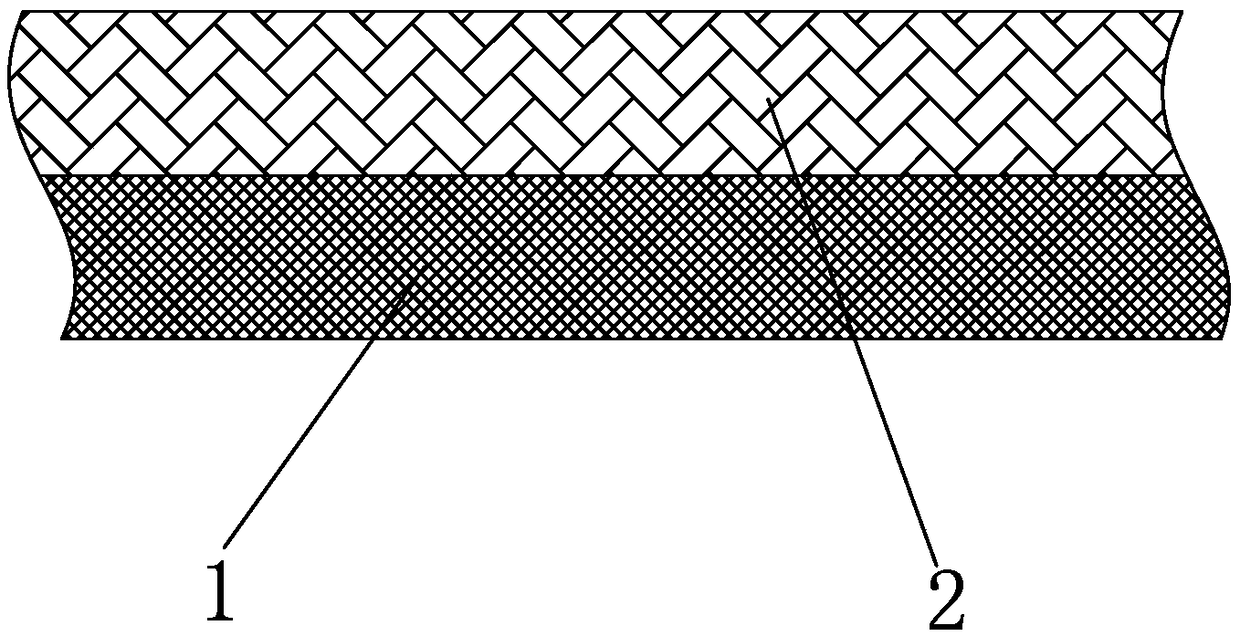

ActiveCN102765237AGood strengthHigh strengthSynthetic resin layered productsLaminationLayered structureTruck

The invention relates to a waterproof ventilated membrane for car light. The waterproof ventilated membrane is formed by compounding of three layered structures and comprises a fabric layer, a waterproof ventilated layer and a bonding layer which is arranged between the above fabric layer and the waterproof ventilated layer and is used for connecting the fabric layer and the waterproof ventilated layer. The invention solves defects existing in the prior art. According to the waterproof ventilated membrane for car light, a fabric material and an expanded polytetrafluoroethylene film undergo compounding, laminated water resistance and oil resistance processing so as to obtain a multifunctional high-molecular material, thus endowing the expanded polytetrafluoroethylene film with better strength, waterproofness, permeability, oleophobic performance, long life, weldability and the like and maintaining internal and external pressure balance. The waterproof ventilated membrane can be used to raise reliability of many automobile parts, including parts of a car light, an engine controller / anti-lock braking system module, a sensor, a connector, an electric car window motor, a fuel system and the like, and is applied in automobile and heavy trucks. Air exchange can be carried out rapidly according to the pressure variation generated by temperature change, and vehicles can be protected from being polluted by water, automobile discharged fluids and dust.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

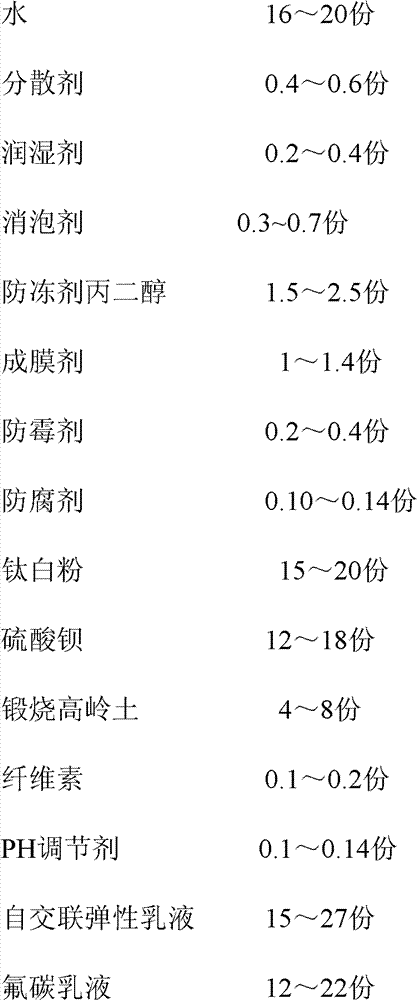

Nano water-based fluorocarbon insulated elastic exterior wall paint and preparation method thereof

InactiveCN103483951ALower surface free energyGood oil repellencyAntifouling/underwater paintsPaints with biocidesWater basedFree energies

The invention relates to a nano water-based fluorocarbon insulated elastic exterior wall paint which is characterized by comprising the following components: nano ATO powder, titanium dioxide, calcined kaolin, calcium carbonate, a nano zirconia dispersion liquid, cellulose, a self-crosslinking elastic emulsion, a fluorocarbon emulsion, a covering emulsion, hollow glass microbeads, auxiliary agents, and the balance being water. The paint has the advantages that a paint film has lower surface free energy and is endowed with a good oleophobicity; a paint film formed by adding the self-crosslinking emulsion is more dense so as to make the paint film less susceptible to contaminate by stains, and simultaneously is more easily washed cleanly after being contaminated by the stains; and finally, in cooperation with a proper amount of the hollow glass microbeads, the nano zirconia dispersion liquid, the nano ATO powder and other functional additives, the insulation, anti-cracking and antifouling requirements of people on exterior walls are satisfied, the paint film is not damaged after the stains are washed cleanly, and thus the novel high-performance weather-proof exterior wall emulsion paint is provided for exterior wall decoration.

Owner:上海展辰涂料有限公司 +4

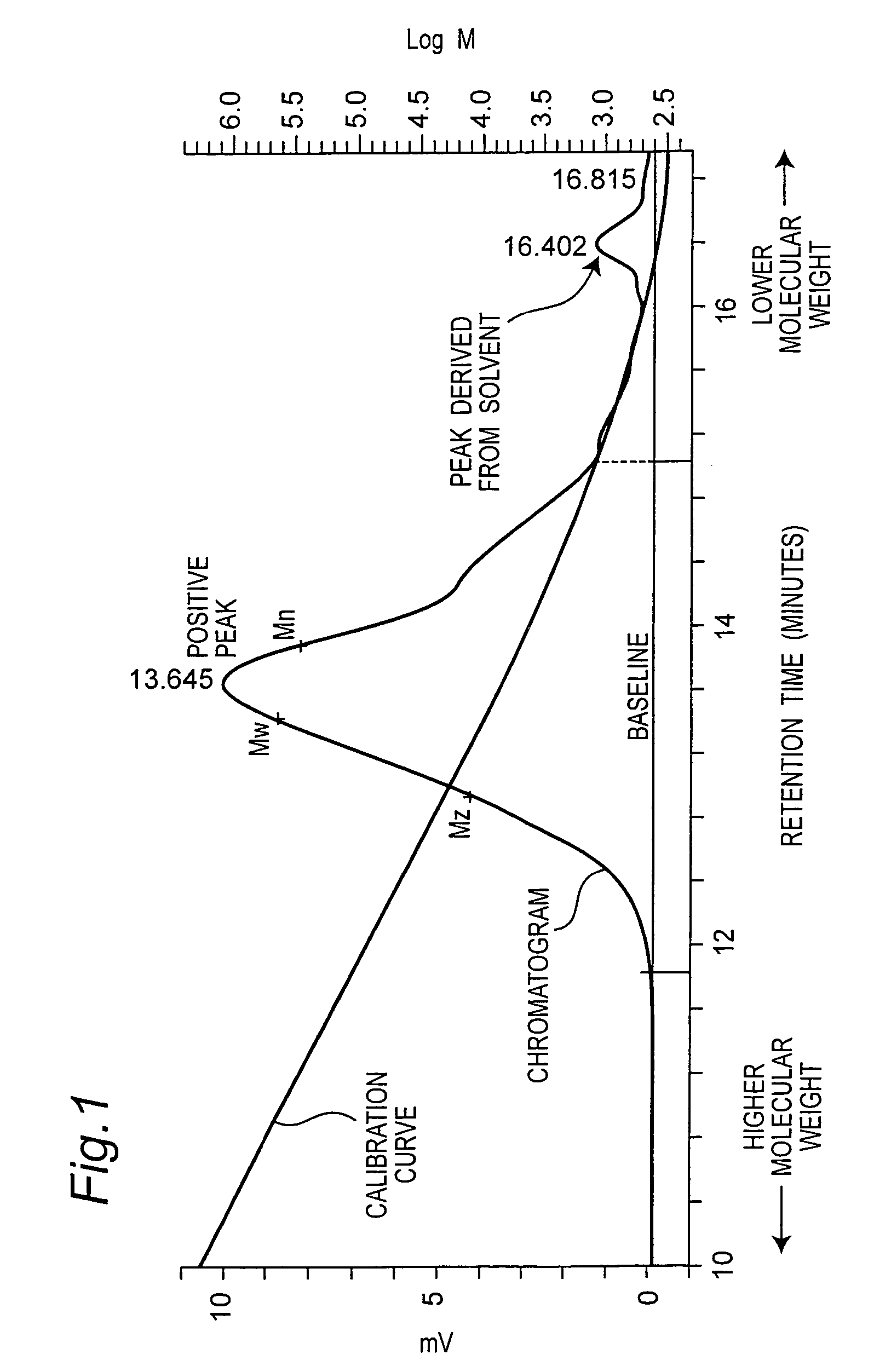

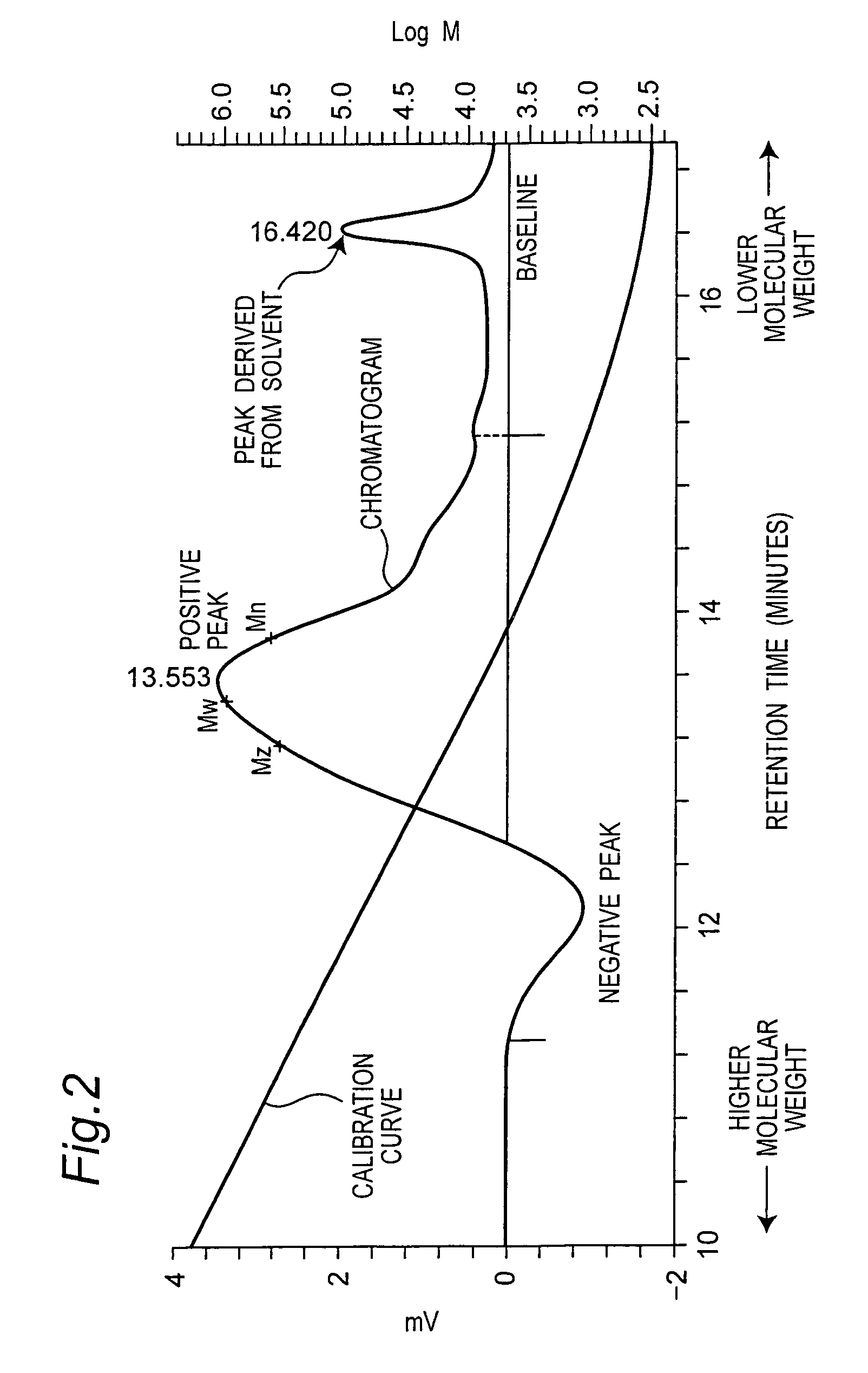

Water-and oil-repellent

InactiveUS8680223B2Low in bioaccumulation potentialFeel goodOther chemical processesLiquid repellent fibresHydrogen atomBULK ACTIVE INGREDIENT

A water- and oil-repellent includes, as an active ingredient, a fluorine-containing copolymer including as a copolymer unit (A) at least one of perfluoroalkylalkyl acrylates and corresponding methacrylates, (B) benzyl acrylate or benzyl methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2 (wherein R represents a hydrogen atom or a methyl group; n represents 4, 5, or 6; and m represents 1, 2, 3, or 4), (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate, and (D) a cross-linkable group-containing polymerizable monomer.

Owner:UNIMATEC CO LTD

Cationic fluorine-containing paper oil-proofing agent

InactiveCN103396510AGood water repellencyGood oil repellencyNon-fibrous pulp additionFiberFunctional monomer

The invention relates to a cationic fluorine-containing paper oil-proofing agent which is an acrylate high molecular polymer solution containing perfluorohexylethyl on a side chain, wherein the high molecular polymer solution is prepared from 55.0-85.0% of fluorine-containing monomer, 5.0-35.0% of methyl / acrylate monomer, 3.0-10.0% of cationic monomer, 3.0-10.0% of functional monomer and 2.0-10.0% of adhesion reinforcement monomer through copolymerization reaction. The oil-proofing agent provided by the invention has the characteristics of high adhesion, low consumption, favorable oil / water resistance and the like; and by adding the adhesion reinforcement monomer, the fluorine-containing activating agent can be adsorbed on fiber of paper, so that the surface property of the paper fiber is reduced, thereby improving the oil-proofing property of the paper and simultaneously increasing the strength and stiffness of the paper.

Owner:XIAMEN AISIKANG NEW MATERIAL

Cationic waterborne organic fluorine acrylate polymer as well as preparation method and application of cationic waterborne organic fluorine acrylate polymer

ActiveCN103980418AImprove performanceSimple production equipmentFibre treatmentEmulsionWater soluble

The invention discloses a cationic waterborne organic fluorine acrylate polymer as well as a preparation method and application of the cationic waterborne organic fluorine acrylate polymer. The cationic waterborne organic fluorine acrylate polymer is prepared by using a semicontinuous dripping method and taking perfluoroalkyl acrylates and acrylate as main monomers, a reactive unsaturated monomer as a modified monomer, a cationic Gemini surfactant and a nonionic emulsifying agent as an emulsion system and water-soluble azobis(isobutylamidine hydrochloride) as an initiator. The polymer system disclosed by the invention is high in stability, and the emulsion storage stability is not shorter than 12 months. A textile treated by using the emulsion prepared by the invention has better water and oil repellent effects.

Owner:深圳天鼎新材料有限公司

Water-and oil-repellent

InactiveUS20110257327A1Low in bioaccumulation potentialFeel goodOther chemical processesLiquid repellent fibresHydrogen atomBULK ACTIVE INGREDIENT

A water- and oil-repellent includes, as an active ingredient, a fluorine-containing copolymer including as a copolymer unit (A) at least one of perfluoroalkylalkyl acrylates and corresponding methacrylates, (B) benzyl acrylate or benzyl methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2 (wherein R represents a hydrogen atom or a methyl group; n represents 4, 5, or 6; and m represents 1, 2, 3, or 4), (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate, and (D) a cross-linkable group-containing polymerizable monomer.

Owner:UNIMATEC CO LTD

Fluoropolymer and surface treatment agent composition

ActiveCN108017745AExcellent water repellencyExcellent oil repellencyOther chemical processesLiquid repellent fibresFiberFluoropolymer

The present invention provides a fluoropolymer capable of giving excellent washing durability and water and oil repellency to fibers. The fluoropolymer has a repeating unit derived from a fluorine-containing monomer (a) containing a first fluorine-containing monomer (a1) and a second fluorine-containing monomer (a2), and the first fluorine-containing monomer (a1) is represented by CH2=C(-X1)-C(=O)-Y1-Z1-Rf1, wherein X1 is a halogen atom, Y1 is-O-or-NH-, Z1 is a valence bond or a divalent organic group, Rf1 is a fluoroalkyl group having 1 to 20 carbon atoms, the second fluorine-containing monomer (a2) is represented by CH2=C(-X2)-C(=O)-Y2-Z2-Rf2, in the formula, X2 is a monovalent organic group or a hydrogen atom, Y2 is-O-or-NH-, Z2 is a valence bond or a divalent organic group, and Rf2 isa fluoroalkyl group having 1 to 20 carbon atoms.

Owner:DAIKIN IND LTD

Fluorine-containing surface treatment agent and an article treated with the same

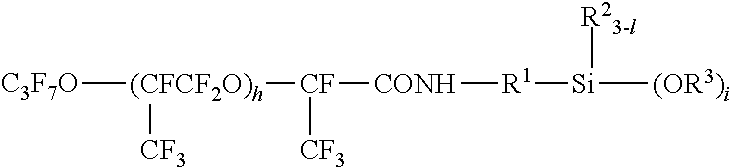

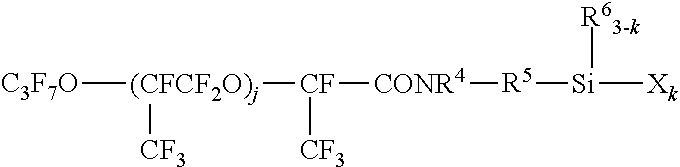

ActiveUS20150004419A1Easy to waterGood oil-repellencyFibre treatmentPolyether coatingsPolymer scienceGas phase

The invention provides a surface treatment agent wherein a fluorooxyalkylene group-containing polymer or a fluorooxyalkylene group-containing polymer composition comprising the polymers, which is controlled of a temperature range of vaporization of fluorooxyalkylene group-containing polymer(s). The fluorooxyalkylene group-containing polymer has a fluorooxyalkylene structure represented by —(OCF2)p(OCF2CF2)q— and hydrolysable groups bond to a silicon atom represented by the formula at least one terminal. The polymer composition shows a decrease of 75% or more in weight, relative to the total weight of the polymer, in a temperature range of from 150 to 350 degrees C. when this is heated at a rate of 2 degrees C. per minute and a pressure of 0.1 Pa or less. The present surface treatment agent forms a coating having water- and oil-repellency and scratch resistance regardless of a vapor deposition conditions, in particularly by a vapor deposition at a mild temperature such as 350 degrees C.

Owner:SHIN ETSU CHEM IND CO LTD

Method for producing an aqueous emulsion

InactiveUS20110086962A1Low bioaccumulation potentialGood effectOther chemical processesFibre treatmentPolymer scienceMeth-

Disclosed is a method for producing an aqueous emulsion containing a fluorine-containing copolymer comprising, as copolymerizable monomers, (A) at least one of a perfluoroalkylalkyl acrylate and a corresponding methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2, wherein R is hydrogen or methyl group, n is 4, 5, or 6, and m is 1, 2, 3, or 4; (B) benzyl acrylate or benzyl methacrylate; (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate; and (D) a crosslinkable group-containing polymerizable monomer; the copolymer being produced by previously subjecting 10 to 80 wt. % of the total weight of component (A) and 0 to 60 wt. % of the total weight of component (B) to a first polymerization reaction using an emulsion polymerization method; and then subjecting the remaining components to a second polymerization reaction using an emulsion polymerization method; wherein an emulsifier is used in the emulsion polymerization reaction in an amount of 21 to 150 parts by weight based on 100 parts by weight of the total weight of polymerizable monomers (A) and (B) used in the first polymerization reaction.

Owner:UNIMATEC CO LTD

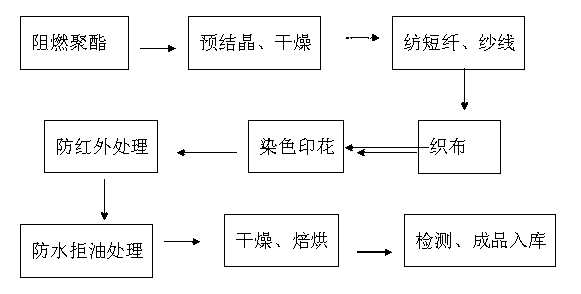

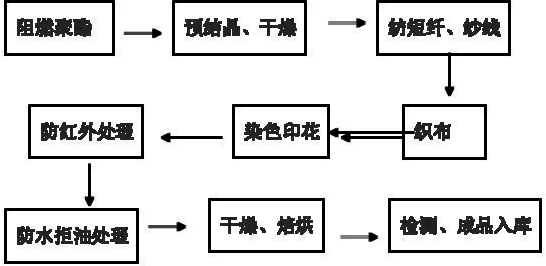

Manufacturing method of multifunctional outdoor protective fabric

InactiveCN102704277AGood flame retardant performanceGood waterproofFibre typesWoven fabricsMultiple functionWavelength

The invention relates to a manufacturing method of a multifunctional outdoor protective fabric. Flame-retardant polyester with a high phosphorus content is selected and used as a raw material, and is subjected to vacuum drying and pre-crystallization for 8-12 hours until the intrinsic viscosity is greater than or equal to 0.8 dl / g, high-strength fine-denier short fibers are obtained and are spun to be yarn, and the yarn is stranded, is woven and is subjected to post-processing technologies comprising water proofness, oil repellence, infrared proofness, and the like, so as to enable the multifunctional outdoor protective fabric to have following advantages that firstly, the flame-retardant performance is good: the oxygen index is greater than or equal to 37 percent and the multifunctional outdoor protective fabric is environmentally friendly and is permanent flame-retardant; secondly, the water-proof performance is good: the hydrostatic pressure is greater than or equal to that of 60 cm water column; thirdly, the oil-repellent performance is good: the oil-repellent performance reaches a level of six; fourthly, the infrared-proof performance is good: the wavelength is in the range of 750 nm to 1500 nm, and the transmissivity is in the range of 5.1 percent to 6.6 percent; fifthly, the breaking strength is large: the warp breaking strength of a base cloth is greater than or equal to 2700 N, and the weft breaking strength of the base cloth is greater than or equal to 1800 N; sixthly, the gram weight is greater than or equal to 200g / m<2>, and the multifunctional outdoor protective fabric is convenient to use; and seventhly, the air permeability is good, the water vapor permeability is greater than or equal to 8000g / m<2>.24h, and the multifunctional outdoor protective fabric is comfortable to use.

Owner:浙江真北纺织新材料研究院有限公司

Formula and application of washing-free agents for digital-printing polyester carpet

ActiveCN104074076ASave time and work spaceImprove work efficiencyDyeing processDigital printingChemistry

The invention relates to the technical field of spinning, in particular to a formula and application of washing-free agents for a digital-printing polyester carpet. The formula of the washing-free agents for the digital-printing polyester carpet is characterized by being composed of fluorine-containing acrylate polymer, polybasic carboxylic acid, epoxy curing agents EH and water. The percentage rate of the fluorinated acrylate polymer to the polybasic carboxylic acid to the epoxy curing agents EH to the water is 20 percent to 40 percent: 15 percent to 20 percent: 5 percent to 10 percent: 30 percent to 60 percent. Compared with the prior art, washing-free type printing dye-fixing agents are provided, the fluorinated acrylate polymer is widely applied to finishing agents of fabric, and the fabric has the good oil-repellent, water-repellent and dirt-resistant effects. The polybasic carboxylic acid is also widely applied to wash and wear finishers of the fabric, and it is well ensured that after dried, the fabric cannot be wrinkled and shrink; the epoxy curing agents EH have the good fixation effect, the color of the fabric can be durably preserved, a large amount of soaking time is saved, and subsequent washing processes are omitted.

Owner:SHANGHAI CCF CARPET & FURNISHING CO LTD

Oil-Repellent Coating Material Composition

InactiveUS20120251728A1Good oil-repellencyExcellent oil repellencyOther chemical processesPretreated surfacesHydrogen atomHalogen

An oil-repellent coating material composition containing:(A) an alkoxysilane, represented by the following general formula (1), having a hydrocarbon group to which at least one or more fluorine atoms are bonded;Rf[—X—Y—SiR1a(OR2)3−a]m (1)whereinRf represents an alkyl group, an alkenyl group, or an aromatic hydrocarbon group, the group having at least one fluorine atom and 1 to 20 carbon atoms;X represents an oxygen atom or a divalent organic group containing an oxygen atom;Y represents a spacer group (CH(Z)—)n wherein Z is a substituent selected from a hydrogen atom, a halogen atom, or a hydrocarbon group having 1 to 3 carbon atoms, and n is of 2 to 8;R1 and R2 may be the same or different hydrocarbon group(s) having 1 to 10 carbon atoms;m is 1 or 2; anda is 0, 1, or 2); and(B) a condensation catalyst.

Owner:WACKER CHEM GMBH

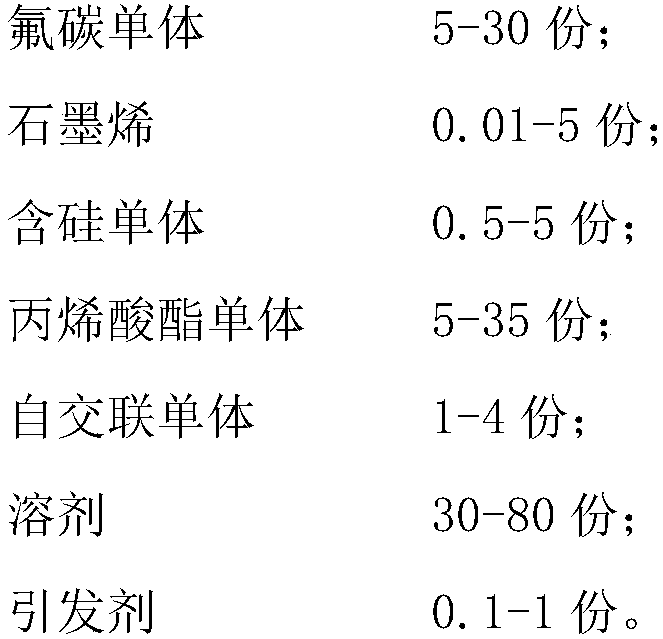

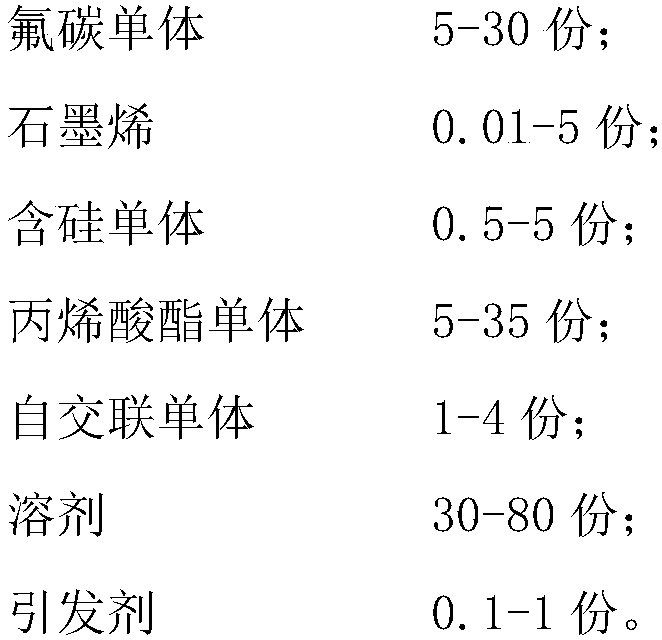

Novel fluorocarbon-graphene-acrylic polymer and preparation method thereof

InactiveCN108822251AImprove waterproof performanceGood anti-electricityStain/soil resistant fibresAntifouling/underwater paintsPolymer scienceSolvent

The invention discloses a novel fluorocarbon-graphene-acrylic polymer and a preparation method thereof. The polymer is prepared from components in parts by weight as follows: 5-30 parts of a fluorocarbon monomer, 0.01-5 parts of graphene, 0.5-5 parts of a silicon-containing monomer, 5-35 parts of an acrylate monomer, 1-4 parts of a self-crosslinking monomer, 30-80 parts of a solvent and 0.1-1 partof an initiator. The polymer further contains an emulsifier when in a form of solution or emulsion. A solution or emulsion prepared from the novel fluorocarbon-graphene-acrylic polymer has good waterproof, anti-corrosion, anti-power, oil-repellent, anti-fouling, aging-resistant and self-cleaning functions and the like, and is applicable to waterproofing, corrosion resistance, power resistance, oil repellency, fouling resistance, aging resistance and self-cleaning of polyester fibers, polyamide fibers, cotton fibers, cotton fibers / polyester fibers, cotton fibers / hemp fibers, artificial cottonfibers and (building, electronic and metal) coatings.

Owner:权家(厦门)新材料有限公司

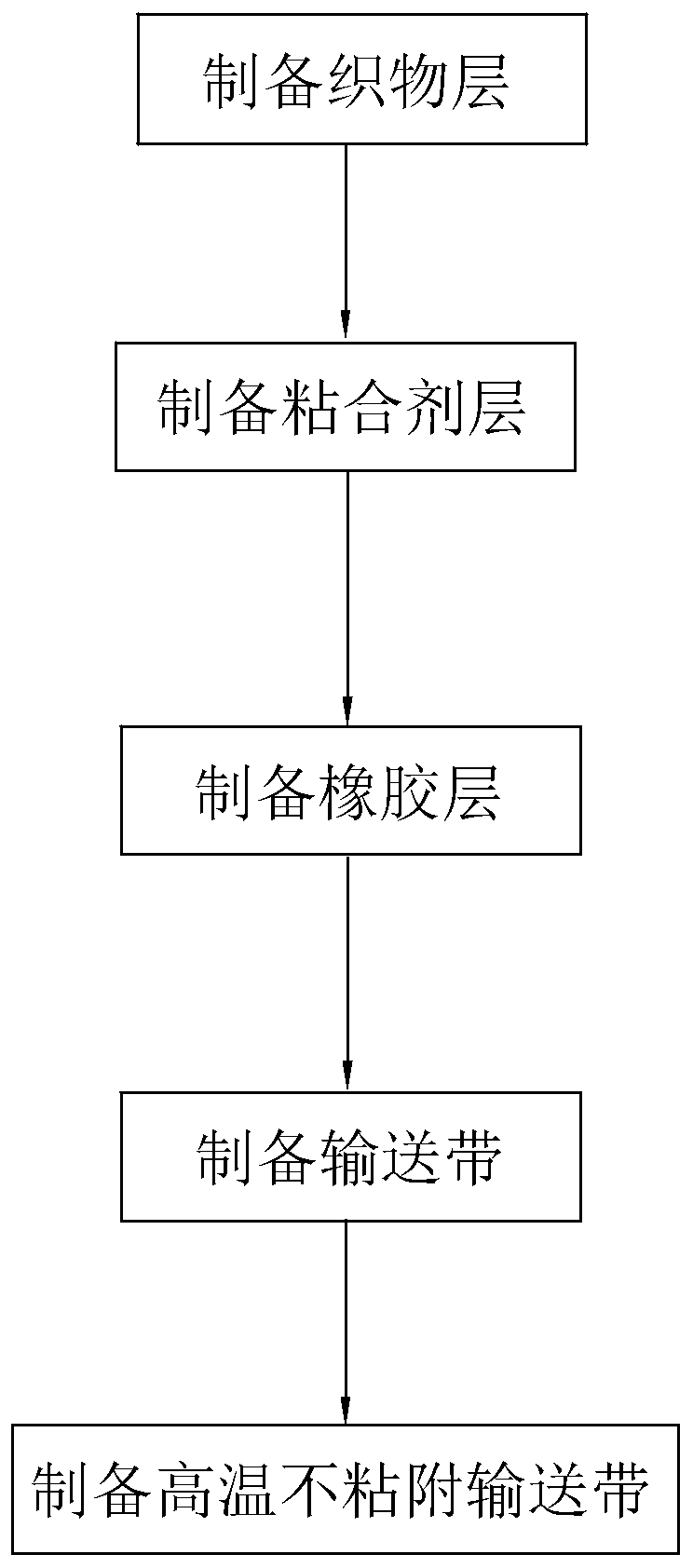

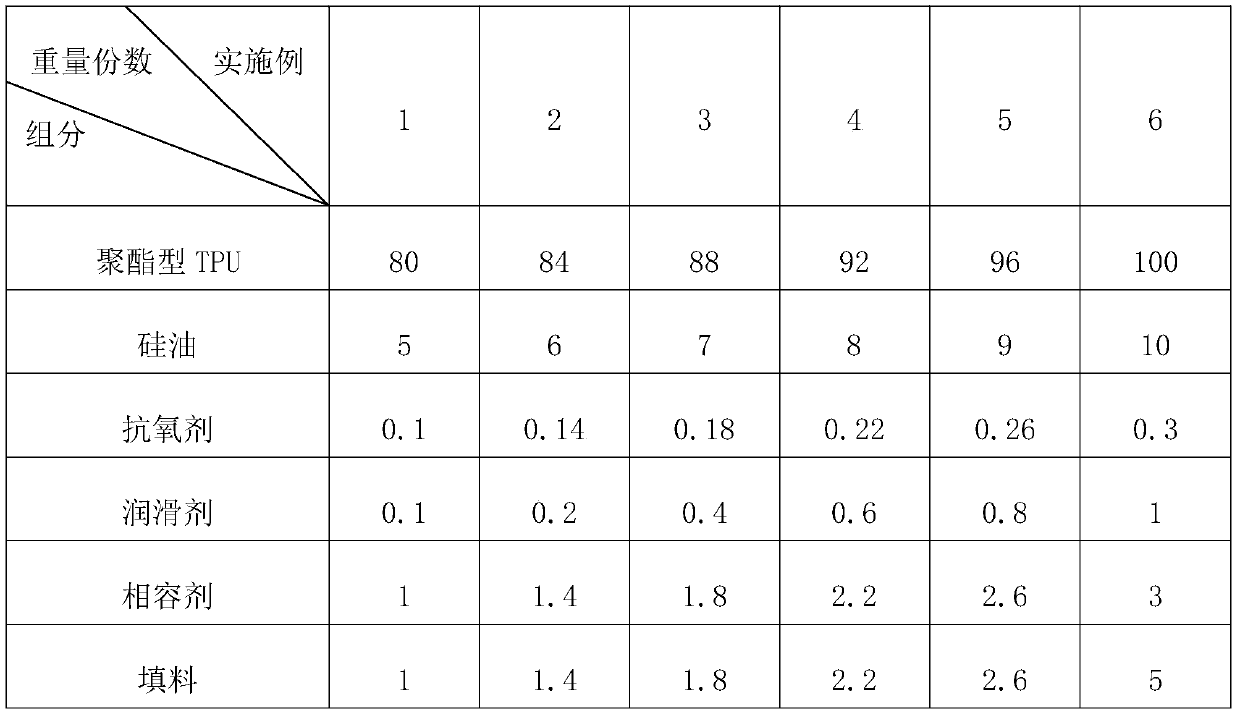

High-temperature-resistant non-adhesive conveying belt and preparation method thereof

InactiveCN111038037AGood oil repellencyImprove adhesionConveyorsSynthetic resin layered productsPolyesterFiber

The invention discloses a high-temperature-resistant non-adhesive conveying belt and a preparation method thereof, and relates to the technical field of conveying belt processing. The high-temperature-resistant non-adhesive conveying belt comprises a fabric layer, adhesive layers arranged on the two sides of the fabric layer, rubber layers fixed to the adhesive layers and coatings applied to the surfaces of the rubber layers in a coating manner, the fabric layer is made of polyester fibers, the adhesive layers are made of a PU agent, and each rubber layer is prepared from, by weight, 80-100 parts of polyester type TPU, 5-10 parts of silicone oil, 0.1-0.3 part of an antioxidant, 0.1-1 part of a lubricant, 1-3 parts of a compatilizer and 1-5 parts of a filler; and each coating adopts 0.5-1 part of polyurethane acrylate. The conveying belt is prepared by using the above formula, and the surface of the conveying belt is coated with the oleophobic coating, so that the obtained conveying belt has advantages of good high temperature resistance and no material adhesion.

Owner:上海米莜凯自动化装备有限公司

Method for producing an aqueous emulsion

InactiveUS9096695B2Low bioaccumulation potentialGood effectOther chemical processesFibre treatmentEmulsionHydrogen

Disclosed is a method for producing an aqueous emulsion containing a fluorine-containing copolymer comprising, as copolymerizable monomers, (A) at least one of a perfluoroalkylalkyl acrylate and a corresponding methacrylate represented by the general formula: CnF2n+1CmH2mOCOCR═CH2, wherein R is hydrogen or methyl group, n is 4, 5, or 6, and m is 1, 2, 3, or 4; (B) benzyl acrylate or benzyl methacrylate; (C) a fluorine-free polymerizable monomer other than benzyl acrylate and benzyl methacrylate; and (D) a crosslinkable group-containing polymerizable monomer; the copolymer being produced by previously subjecting 10 to 80 wt. % of the total weight of component (A) and 0 to 60 wt. % of the total weight of component (B) to a first polymerization reaction using an emulsion polymerization method; and then subjecting the remaining components to a second polymerization reaction using an emulsion polymerization method; wherein an emulsifier is used in the emulsion polymerization reaction in an amount of 21 to 150 parts by weight based on 100 parts by weight of the total weight of polymerizable monomers (A) and (B) used in the first polymerization reaction.

Owner:UNIMATEC CO LTD

Water and oil repellent composition and treatment method

InactiveUS7754836B2Improve performanceImprove copolymerization performancePhysical treatmentEmulsion paintsAcyl groupOrganic group

Owner:DAIKIN IND LTD

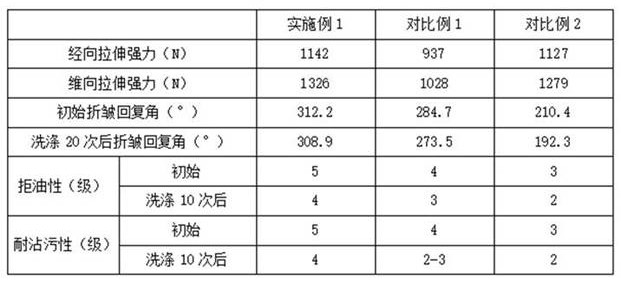

Garment with anti-fouling and anti-wrinkle fabric

ActiveCN114875554AGood oil resistanceExcellent anti-wrinkle propertiesSpinning solution filteringTextile/flexible product manufacturePolymer sciencePolyvinyl alcohol

The invention discloses a preparation method of a garment made of an anti-fouling and anti-wrinkle fabric. The preparation method comprises the following steps: (1) preparing modified polyamide fibers; (2) blending modified polyamide fibers and polyvinyl acetal fibers to obtain warp yarns, and blending the modified polyamide fibers and viscose fibers to obtain weft yarns; (3) weaving the warp yarns and the weft yarns according to a one-up one-down weaving mode to prepare a rough blank of the garment fabric; (4) carrying out post-treatment on the rough blank of the garment fabric to obtain the garment fabric; and (5) processing the garment fabric to complete the preparation of the garment. Compared with a conventional polyamide fiber fabric, the finally obtained garment fabric has more excellent oil stain resistance and crease resistance.

Owner:BIEM L FDLKK GARMENT CO LTD

Water-repellent, oil-repellent, light-resistant, twist-resistant, cold-resistant, matte film water-based coating glue for textiles and preparation method

ActiveCN104831540BEasy to produceExcellent water repellencyFibre treatmentIsooctyl acrylatePolymer science

Owner:DANDONG UNIK TEXTILE

A kind of polyester fabric oil-repellent finishing agent and preparation method thereof

The invention relates to a terylene fabric oil-repellent finishing agent and a preparation method, the terylene fabric oil-repellent finishing agent comprises the following components by weight ratio: 4-5 parts of dioctadecyl dimethyl ammonium chloride, 2-4 parts of diethyl phosphate, 7-9 parts of butylene glycol, 3-4 parts of lignin, 2-5 parts of ethyl caproate and 225-235 parts of water. The finishing agent is obtained by stirring and homogenizing the components, and the prepared finishing agent has good oil repellent performance.

Owner:南通市通州区家纺产业发展服务中心

Waterproof ventilated membrane for car light and manufacturing method thereof

ActiveCN102765237BHigh strengthImprove waterproof performanceSynthetic resin layered productsLaminationEngineeringElectric cars

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

Mothproof fabric

PendingCN109330069AGood skin affinityGood moisture absorption and air permeabilitySynthetic resin layered productsWoven fabricsEngineeringFabric structure

The invention discloses a mothproof fabric. The mothproof fabric comprises a fabric body of a double-layer fabric structure, the fabric body comprises an inner-layer fabric body and an outer-layer fabric body, the inner-layer fabric body and the outer-layer fabric body are separated woven, and polyurethane fiber yarn of a tucking structure is woven in series. A 2 / 1 twill weave structure is adopted, and milk protein yarn as warp yarn and bamboo charcoal fiber yarn as weft yarn are woven to form the inner-layer fabric body; a plain weave structure is adopted, and polypropylene fiber yarn as warpyarn and kawo kawo fiber yarn as weft yarn are woven to form the outer-layer fabric body. The warp density of the inner-layer fabric body is 180-210 pieces / 10 centimeters; the weft density of inner-layer fabric body is 160-180 pieces / 10 centimeters; the warp density of the outer-layer fabric body is 140-160 pieces / 10 centimeters; the weft density of outer-layer fabric body is 130-160 pieces / 10centimeters. The mothproof fabric wears comfortable, is high in heat retention property and wrinkle resistance and easy to store and has the mothproof function.

Owner:苏州高研纺织科技有限公司

Polytef microporous film for bio-drying and preparation method thereof

PendingCN109731485AFunctionalLarge apertureSemi-permeable membranesSludge treatmentHydrophilic coatingNano copper

The invention discloses a polytef microporous film for bio-drying and a preparation method thereof. The polytef microporous film comprises a base film, an oil-repellent coating and a hydrophilic coating are arranged on the front and the back of the base film respectively, the oil-repellent coating is a fluorinated acrylate polymer coating, and the hydrophilic coating is a weak cationic organosilicon hydrophilic agent coating. The preparation method includes following steps: A, taking polytef resin added with nano copper ion powder as a raw material, and performing two-way stretching to obtainthe base film; B, taking any face of the base film in the step A as a front, spraying fluorinated acrylate polymer treatment liquid, and drying to form the oil-repellent coating; C, spraying weak cationic organosilicon hydrophilic agent treatment liquid on the back of the base film in the step B, drying to form the hydrophilic coating, and obtaining the polytef microporous film. The polytef microporous film has oil-repellent and hydrophilic two-way heterogenous functions and has good antibacterial, deodorizing and air-permeable performance.

Owner:HUZHOU SENNUO FLUORINE MATERIAL TECH

Terylene fabric oil-repellent finishing agent and preparation method

The invention relates to a terylene fabric oil-repellent finishing agent and a preparation method, the terylene fabric oil-repellent finishing agent comprises the following components by weight ratio: 4-5 parts of dioctadecyl dimethyl ammonium chloride, 2-4 parts of diethyl phosphate, 7-9 parts of butylene glycol, 3-4 parts of lignin, 2-5 parts of ethyl caproate and 225-235 parts of water. The finishing agent is obtained by stirring and homogenizing the components, and the prepared finishing agent has good oil repellent performance.

Owner:南通市通州区家纺产业发展服务中心

A kind of dynamic oleophobic siloxane self-enrichment epoxy coating and its preparation method and application

ActiveCN112552798BIncreased repellencyGood antifoulingFireproof paintsAntifouling/underwater paintsEpoxyPolymer science

The invention provides a dynamic oleophobic siloxane self-enrichment epoxy coating and its preparation method and application, belonging to the technical field of polymer materials. The siloxane self-enrichment epoxy coating of the present invention is prepared from raw materials comprising polysiloxane, epoxy resin, 3-aminopropyltriethoxysilane and organic solvent; the epoxy resin, 3-ammonia The mass ratio of propyltriethoxysilane to the organic solvent is (1-10):(0.02-0.1):2; the mass of the polysiloxane is less than 70% of the mass of the epoxy resin. The dynamic oleophobic siloxane self-enrichment epoxy coating provided by the invention has oil repellency, stain resistance, high stability and strong adhesion to various substrates.

Owner:JILIN UNIV

Preparation method of nano rare-earth hydrosol

ActiveCN102091754BLow costImprove high temperature resistanceFoundry mouldsFoundry coresWater bathsAdhesive

The invention relates to a preparation method of a nano hydrosol, in particular to a preparation method of a nano rare-earth hydrosol, which comprises the following process flow: preparing a chloride solution into a solution A with the concentration of 0.2-1.5mol / L and the pH value of 1-5; placing in a water bath at 25-65 DEG C; adding hydrogen peroxide, wherein the volume ratio of the hydrogen peroxide to the solution A is 1:(30-75); stirring to obtain a mixed solution B; mixing strong ammonia water with water in the volume ratio to obtain a precipitant C; slightly heating at 30-45 DEG C, and then pouring into the mixed solution B; regulating the temperature to 55-85 DEG C for water bath for 2-5h; raising the temperature to 95 DEG C; stirring for 10-45 min, then filtering and washing; adding a saltpeter solution in a filter cake; and stirring at 70-95 DEG C for 25-60 min to obtain the nano rare-earth hydrosol. The invention solves the technical problem that a nano rare-earth oxide dispersion as a traditional adhesive in the conversional fired mold casting is easy to cause agglomeration.

Owner:CHANGZHOU GEOQUIN NANO NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com