Patents

Literature

104results about How to "Increased repellency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated ester melt additives for thermoplastic fibers

InactiveUS6063474AImparting alcohol repellencyIncreased repellencyWoven fabricsNon-woven fabricsFiberPolyester

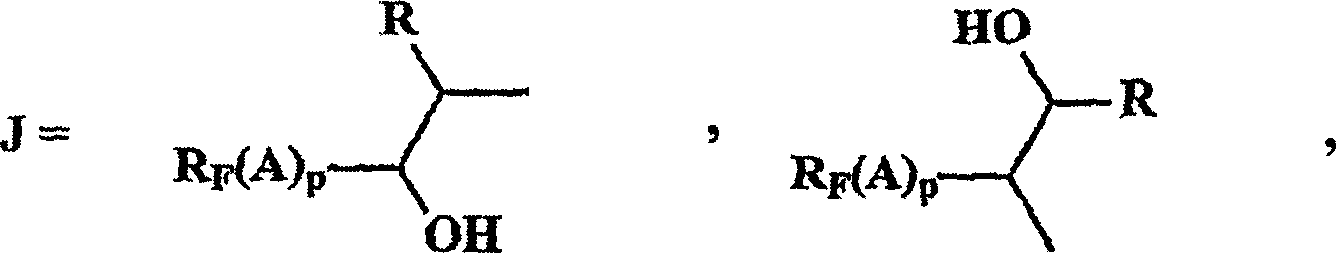

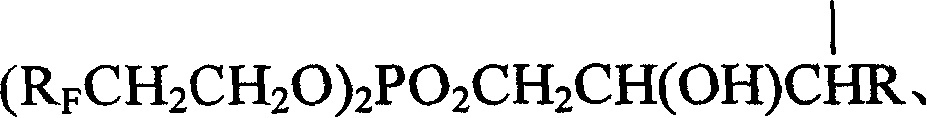

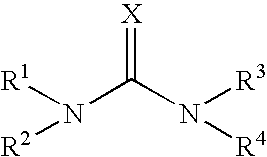

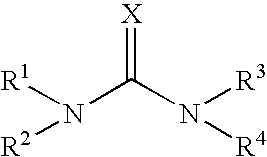

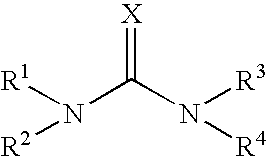

A composition having repellency to low surface tension fluids comprising a material prepared by forming a mixture of a polymer selected from the group consisting of polyolefin, polyamide, polyester, polyacrylate, and blends and copolymers thereof, and a fluorochemical compound comprising a fluorocarbon / hydrocarbon ester of the formulae: wherein Rf is selected from the group consisting of: 1) F(CF.sub.2).sub.x --(CH.sub.2).sub.m wherein x is from about 4 to about 20 and m is from about 0 to about 6; and 2) F(CF.sub.2).sub.x --SO.sub.2 N(R.sub.2)--R.sub.3 where x is a positive integer from about 4 to about 20, R.sub.2 is an alkyl radical of from about 1 to about 4 carbon atoms, R.sub.3 is an alkylene radical of from about 1 to about 12 carbon atoms; and R.sub.1 is an aliphatic hydrocarbon having from about 12 to about 76 carbon atoms; and provided that said fluorochemical compound is other than perfluoroalkylethyl stearate; and melt extruding the mixture.

Owner:EI DU PONT DE NEMOURS & CO

Surface modifier

InactiveCN101151269AEasy to wipe offAvoid stickingGroup 4/14 element organic compoundsCoatingsMedicinal chemistryHydrocarbon

A surface modifier comprising an organosilicone compound represented by General Formula (A) and / or General Formula(B): F-(CF2)q-(OC3F6)m-(OC2F4)n-(OCF2)o(CH2)pX(CH2)r Si(X')3-a(R1)a (A) and F-(CF2)q-(OC3F6)m-(OC2F4)n-(OCF2)o(CH2)pX(CH2)r (X')2-a(R1)aSiO(F-(CF2)q-(OC3F6)m-(OC2F4)n-(OCF2)o(CH2)pX(CH2)r (X')1-a(R1)aSiO)zF-(CF2)q-(OC3F6)m-(OC2F4)n-(OCF2)o(CH2)pX(CH2)r (X')2-a(R1)aSi (B) wherein q is an integer from 1 to 3; m, n, and o are independently integers from 0 to 200; p is 1 or 2; X is O or a bivalent organic group; r is an integer from 2 to 20; R1 is a C1-22 linear or branched hydrocarbon group; a is an integer from 0 to 2; X' is hydrolysable group; and z is an integer from 0 to 10 when a is 0 or 1.

Owner:DAIKIN IND LTD +1

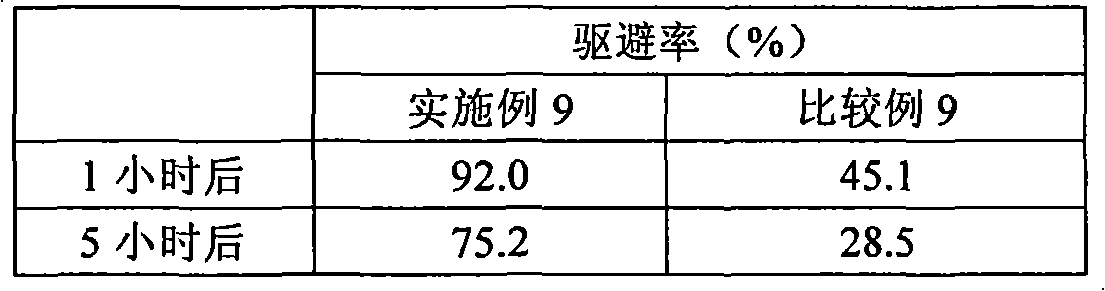

Anti-mosquito finishing process of textile fabric

InactiveCN102154841AReduce absorptionReduced release rateFibre treatmentMicroballoon preparationPolyesterEmulsion

The invention discloses an anti-mosquito finishing process of a textile fabric. The textile fabric is cotton, tencel, modal, blended cotton (viscose cotton, polyester cotton, polyamide cotton), silk, a wool cotton dyed fabric, a thin chemical fiber fabric, a pair of socks, a mosquito net and the like. The process comprises the steps of: selecting a mosquito repellent and a low-temperature fixative, carrying out nano microencapsulation on the mosquito repellent by utilizing a microencapsulation technology, carrying out anti-mosquito finishing on a textile fabric to form an anti-mosquito emulsion through the low-temperature fixative, dehydrating and curing to finally obtain the anti-mosquito finished fabric. The anti-mosquito fabric fabricated by the anti-mosquito finishing process has a fast mosquito killing function, a repelling rate of the anti-mosquito finishing process on aedes albopicus, culex pipiens pallens and the like is higher than 90 percent and an anti-biting rate of the anti-mosquito finishing process is 100 percent; the anti-mosquito fabric does not have bad influence on physical indices such as appearance, strength, moisture absorbing property and the like of the fabric; the anti-mosquito fabric has a good anti-mosquito effect after being washed 15 times; and the anti-mosquito finished fabric does not stimulate or cause allergy to skin, is safe and non-toxic to a human body, and is comfortable to wear.

Owner:FUJIAN ZHONGHE

Mite and mosquito-bite preventing underwear, sleepwear and home wear

InactiveCN102251412AHeat-clearing and damp-dryingAnti-miteHeating/cooling textile fabricsDyeing processFiberDisease

The invention relates to the technical field of fibers, in particular to a mite and mosquito-bite preventing underwear, sleepwear and home wear which is characterized by comprising the following processing steps of: preparing medical liquid; carrying out dyeing and printing and other pre-treatments on cottons or cotton blended fabrics; preparing bleaching and dyeing liquid; dyeing cloth; carrying out high temperature tentering; and processing so as to prepare the underwear, the sleepwear and the home wear. According to the invention, the fabrics provided by the invention have the obvious effects of mite preventing, mosquito preventing, anti-bacterium, deodorization, rot resistance, itching relieving, blood circulation invigoration and meridians activation and the like; the repellent rate of dust mite is as high as 99 percent; the repellent rate of mosquito is 95 percent; the repellent rate of termite is 95 percent; fabric-touching pathogens such as staphylococcus aureus, staphylococcus epidermidis, gonococcus and esherichia coli and the like can be completely killed; all efficacies of the fabrics still reach to over 97 percent after the fabrics are washed for 50 times; and the fabrics have the advantages of no irritation to skin, no anaphylactic reaction, no toxicity to the human body, comfort for wearing and can effectively prevent the infection of asthma and other diseases.

Owner:王建波

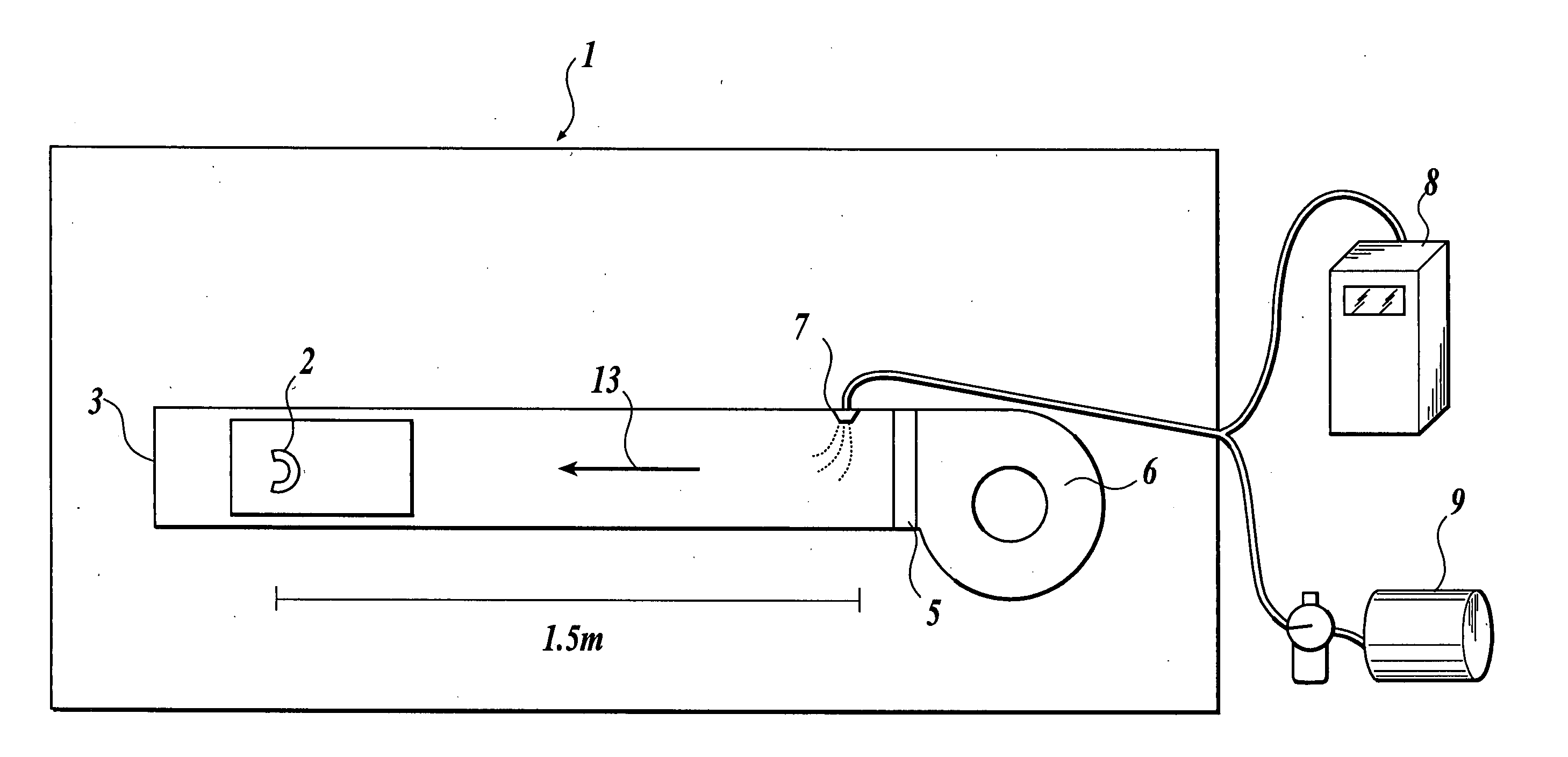

Air purification filter and process for producing the same

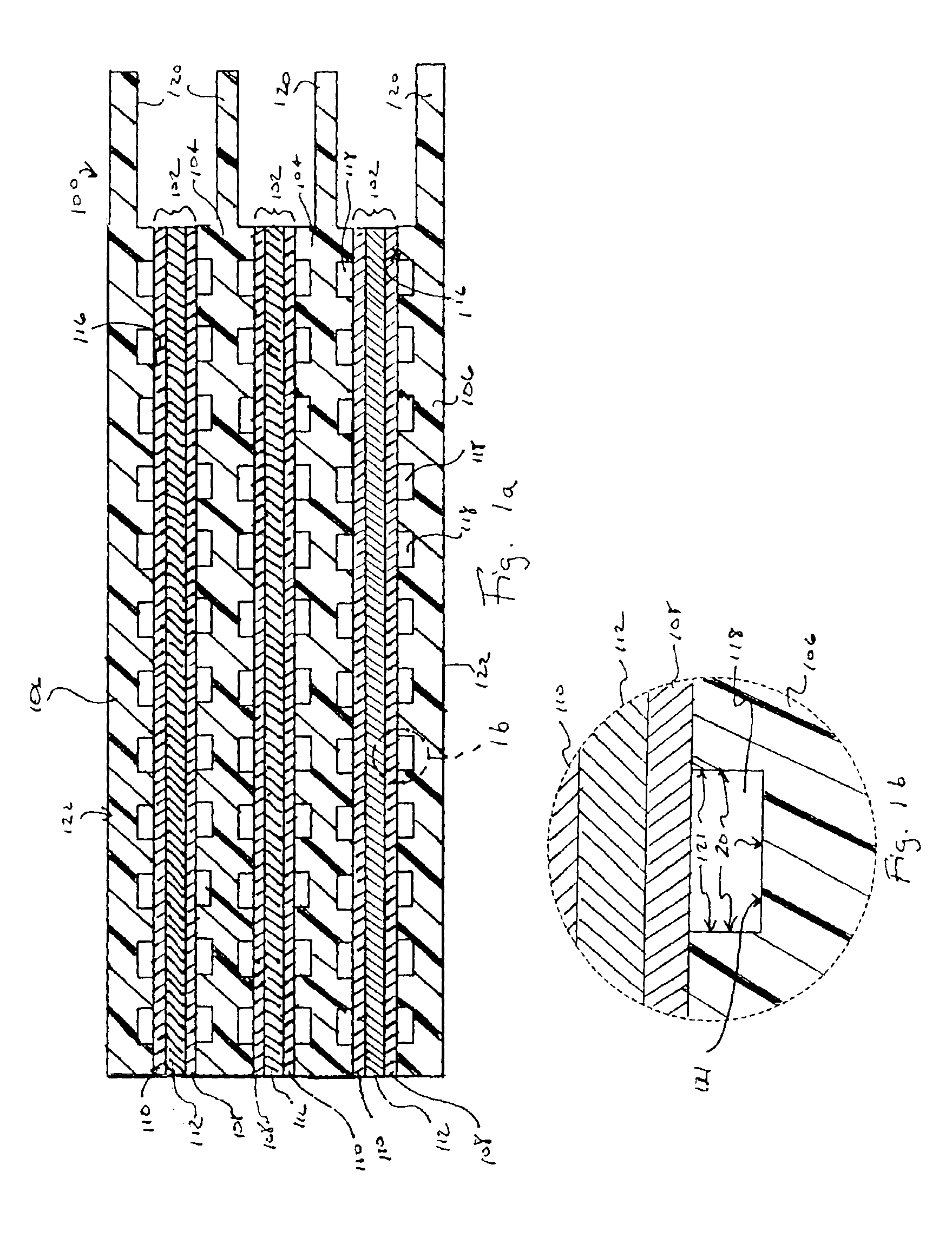

InactiveUS20060117958A1Improves the bactericidal/sterilizing or antimicrobial means propertiesHigh tensile strengthCombination devicesAuxillary pretreatmentFiberGas phase

It is intended to provide an air purification filter which has a high dry tensile strength, a high wet tensile strength in association with a high water resistance and a high water repellency and exhibits a bactericidal effect due to a gas phase reaction in a gas phase. Namely, an air purification filter having a high dry tensile strength, a high wet tensile strength (a high water resistance) and a high water repellency as well as a bactericidal effect which is obtained by blending a filter fiber having a functional group with a mixture of a modification enzyme which has an ionic polarity opposite to the ionic polarity of the whole filter fiber as described above and a bactericidal effect with an ionic synthetic resin binder having the opposite ionic polarity similar to the modification enzyme.

Owner:NIKKI UNIVERSAL CO LTD +1

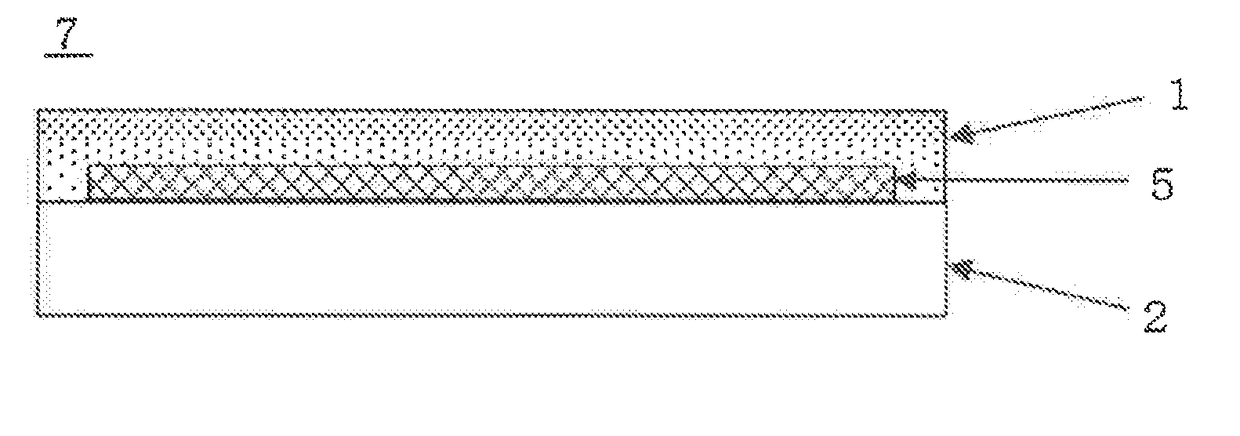

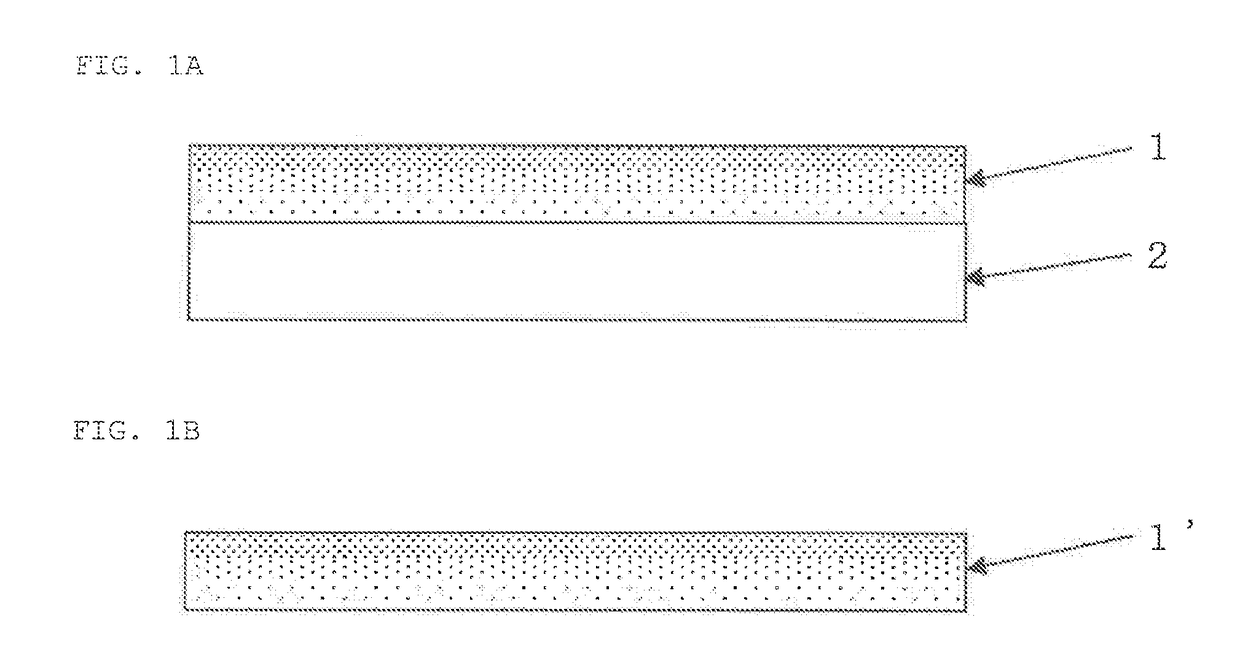

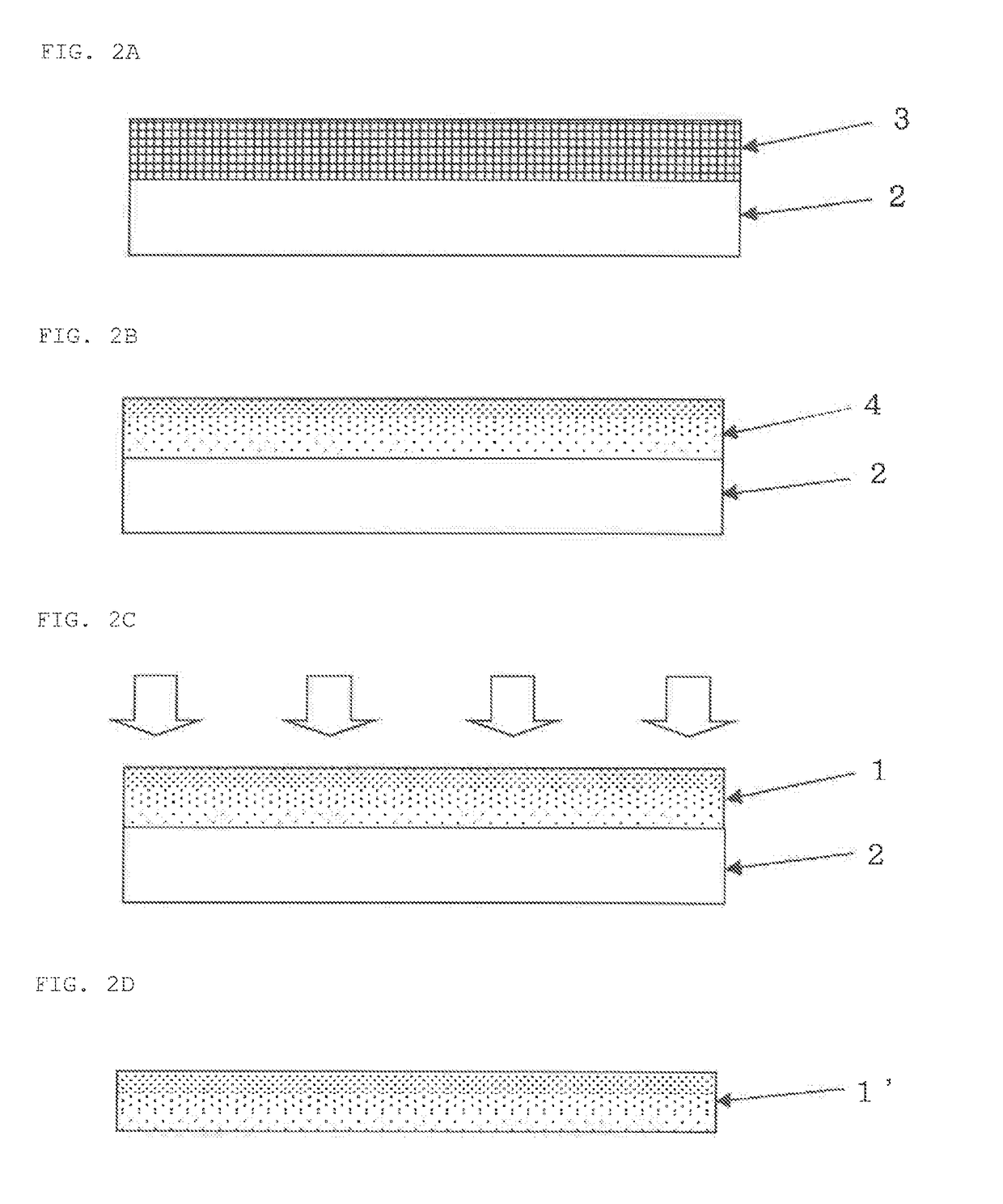

Stretchable film, method for forming the same, stretchable wiring film, and method for manufacturing the same

ActiveUS20180134860A1High strengthGood stretchabilityNon-metal conductorsPolyurea/polyurethane coatingsMeth-Organic solvent

The present invention provides a stretchable film including: a cured product of a composition which contains (A) a poly(meth)acrylate compound having a polymerizable double bond and a siloxane bond, (B) a (meth)acrylate compound having a urethane bond, and (C) an organic solvent having a boiling point in the range of 115 to 200° C. at atmospheric pressure; wherein the component (A) is localized in the direction of the surface of the film. The stretchable film of the present invention is excellent in stretchability and strength as well as repellency on the film surface.

Owner:SHIN ETSU CHEM IND CO LTD

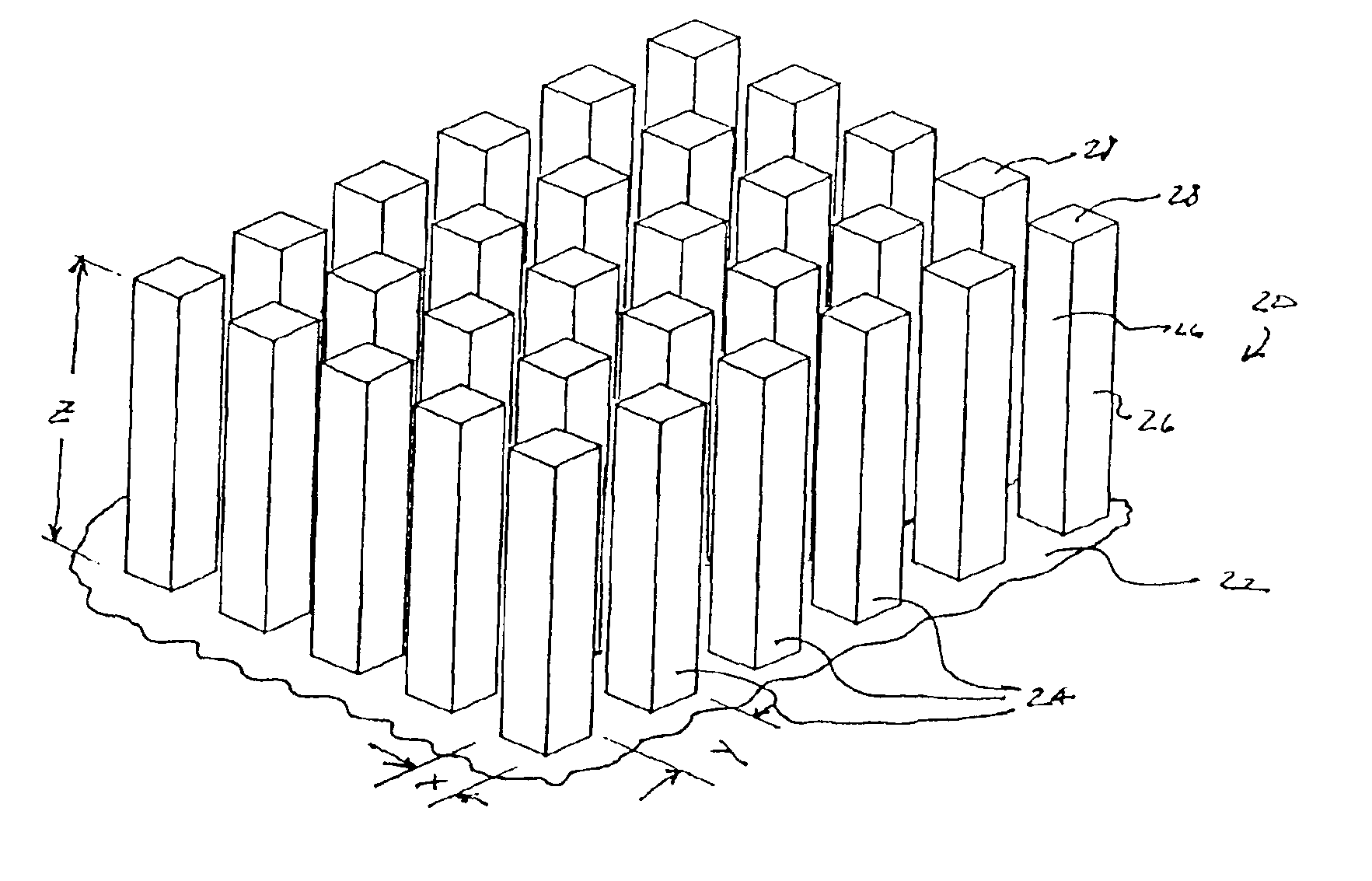

Fuel cell with ultraphobic surfaces

InactiveUS6911276B2Easy to drainAvoids tendencyMaterial nanotechnologyFuel cells groupingFuel cellsEngineering

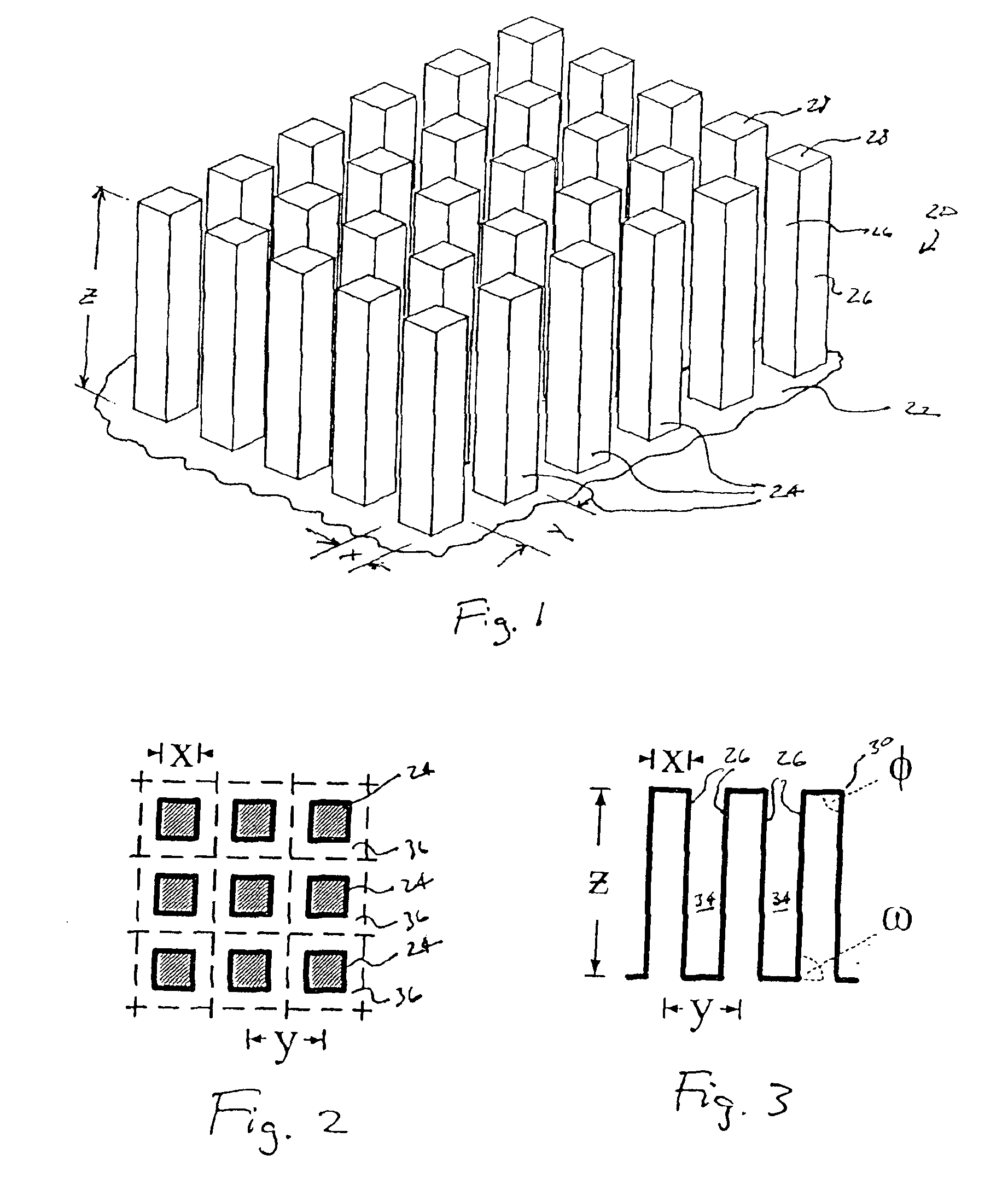

A fuel cell with components having durable ultraphobic surfaces at selected locations where condensation of water may occur. The ultraphobic surface generally includes a substrate portion with a multiplicity of projecting microscale or nanoscale asperities disposed so that the surface has a predetermined contact line density equal to or greater than a critical contact line density.

Owner:ENTEGRIS INC

High-toughness haydite concrete and preparation method thereof

ActiveCN105541201AEffectively exert the effect of synergistic tougheningPreparation conditions are easy to meetCrack resistanceSlag

The invention discloses a high-toughness haydite concrete and a preparation method thereof. The high-toughness haydite concrete is prepared from the following raw materials in parts by weight: 320-360 parts of cement, 40-80 parts of lithium slag powder, 20-40 parts of silica fume, 700-900 parts of regenerated coarse aggregate, 500-800 parts of haydite, 3-4 parts of water reducing agent, 100-120 parts of water, 10-20 parts of polyacrylate, 20-30 parts of toughening additive, 0.05-0.1 part of sodium gluconate and 10-15 parts of triethanolamine. A modified composite carbon nano material, activated wood meal and isotactic polypropylene are combined to prepare the unique toughening additive under the surface modification actions of a coupling agent and a compatilizer; and the toughening additive can be sufficiently dispersed in the concrete to effectively display the synergic toughening effect of the materials, so that the prepared concrete has the advantages of favorable toughness, favorable fatigue resistance, favorable isotropy, favorable impact resistance, favorable earthquake resistance and favorable crack resistance.

Owner:上犹万年青新型材料有限公司

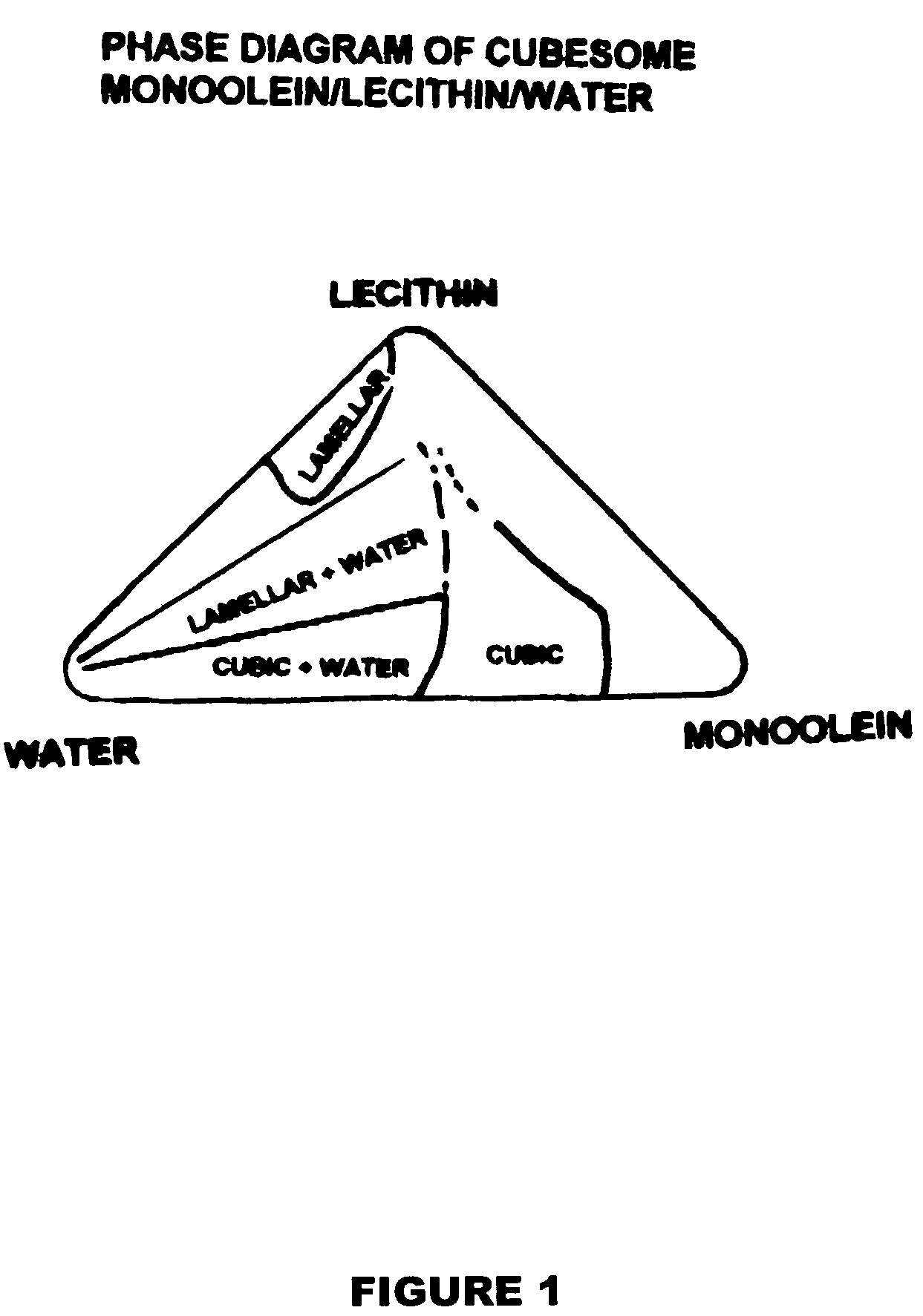

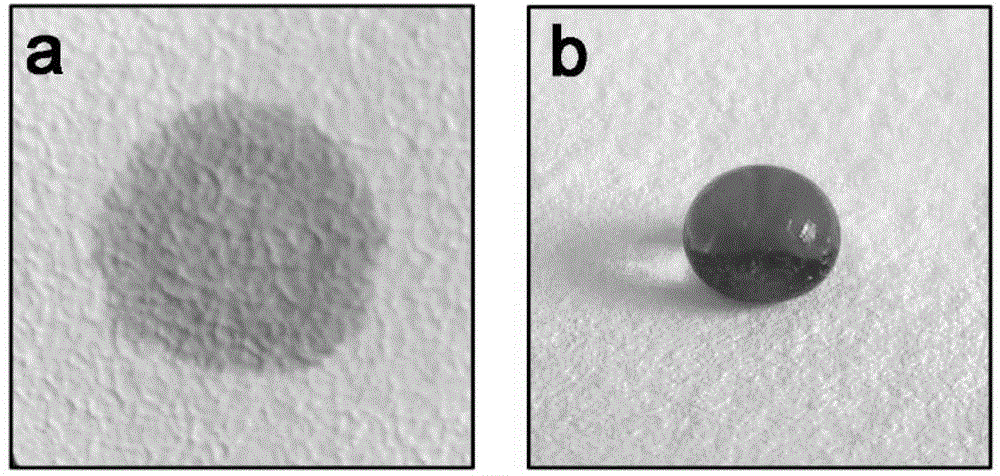

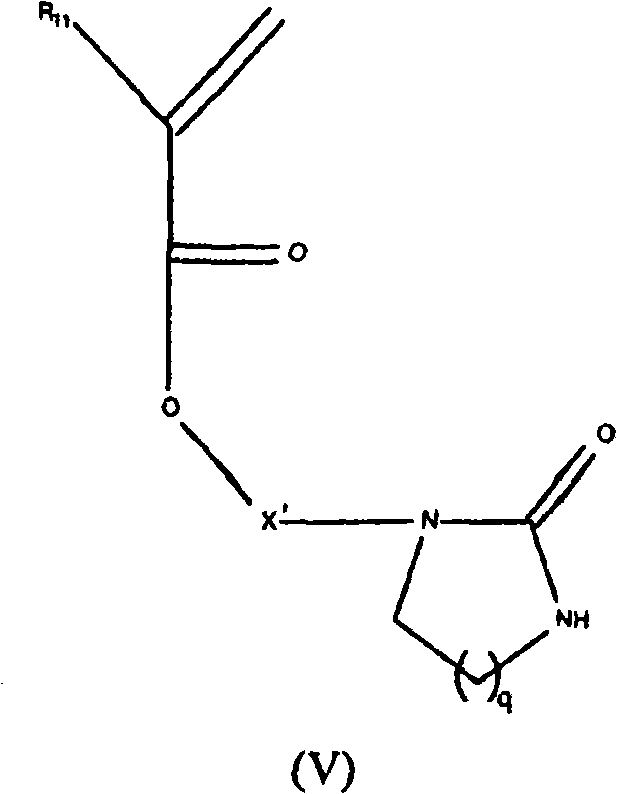

Compositions and methods of crop protection

InactiveUS7052708B2Avoid lostIncreased repellencyBiocidePharmaceutical delivery mechanismAbsorbable polymersGround hog

The invention is an animal repellant composition containing one or more toxins, including for example one or more alkaloids isolated from for example, one or more members of the family Narcissus, and optionally containing one or more polymers, including for example one or more bioerodible polymers and / or more non-absorbable polymers. The animal repellant composition is useful for repelling animals from vegetation and for rendering vegetation unpalatable to animals. The invention also includes methods for repelling animals, as well as methods for treating vegetation to render the vegetation unpalatable to animals, such animals including for example, deer, voles, moles, ground hogs, mice, rats, rodents, raccoons, nematodes, larvae, worms, fungi, molds, bacteria, vegetative organisms, and insects. A suberin-polymer-repellant chemical complex and a method for treating damaged vegetation are also disclosed. Various other systems and methods for complexing biopolymers, toxins, and polymers for treating plants, microbially inactivating the bioburden of vegetation, and for repelling animals are disclosed.

Owner:THE CORATO FOUND

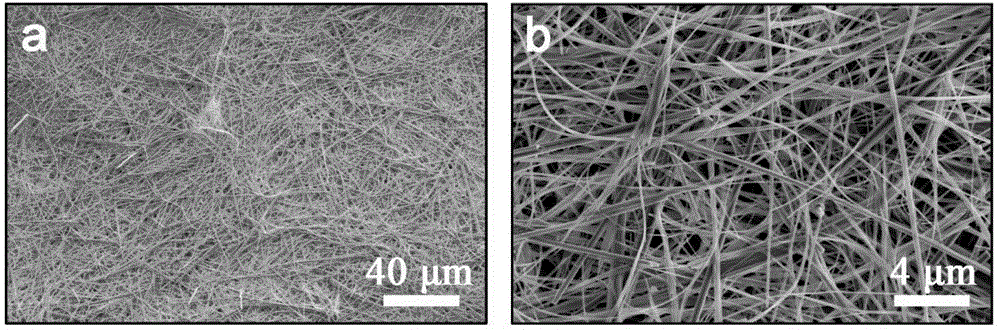

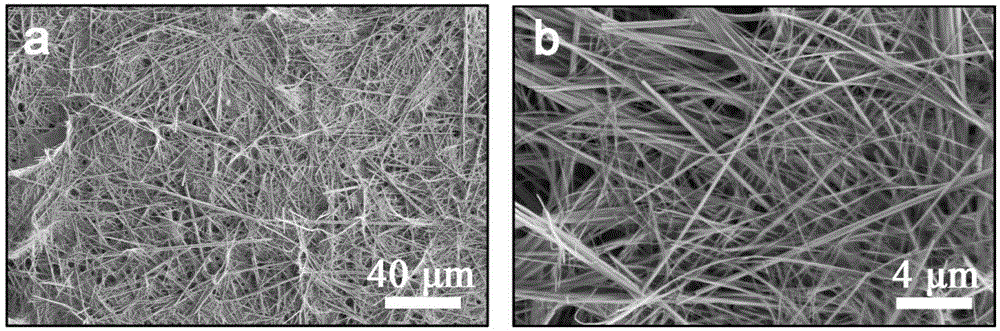

Hydroxyapatite overlength nanowire flameproof paper with waterproof function

ActiveCN106522015AWaterproofWith waterproof functionWater-repelling agents additionPaper/cardboardNanowireApatite

The invention relates to hydroxyapatite overlength nanowire flameproof paper with a waterproof function. The hydroxyapatite overlength nanowire flameproof paper with the waterproof function has super-hydrophobicity and fireproof and flame-retardant functions. The main component of the flameproof paper is hydroxyapatite overlength nanowire. The product also contains fatty acid salt or a perfluorinated compound modified on the hydroxyapatite overlength nanowire. The fatty acid salt or the perfluorinated compound carries out surface modification on the hydroxyapatite overlength nanowire. As hydroxyapatite overlength nanowire has rich surface reactive groups, the hydroxyapatite overlength nanowire is easy to undergo surface modification. Thus, the hydroxyapatite overlength nanowire is easy to combine with the fatty acid salt or the perfluorinated compound such that the hydroxyapatite overlength nanowire flameproof paper is endowed with an excellent waterproof function.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Emusion paint with mosquito preventing and antibiosis function and production process thereof

ActiveCN101045841AReduce contentReduce dosageAntifouling/underwater paintsPaints with biocidesAntibiosisPigment

This invention relates to a mosquito- repelled antibiosis latex paint and its production process. According to weight it includes 97 tp 98% latex paint and 2 to 3% hygienic finishing agent. The latex paint is composed by water, 7 to 10% styrene / acrylate copolymerization latices, 7 to 10%pigment, 38 -45% inert pigment, 12 to 23% accessory ingredient. Hygienic finishing agent is composed by 99.5 to 100% technical grade spin additive and 0 to 0.5% plant extractant. It first mix water, accessory ingredient, pigment, inert pigment and styrene / acrylate copolymerization latices, then add hygienic finishing agent and averaging, regulate pH 7.5 to 8.5, then gain product. This latex paint has dual efficacy of expelling and killing mosquito, and antibiosis function, reach Class A stand ard of GB17322.1 - 1998 stated.

Owner:黄戴宇

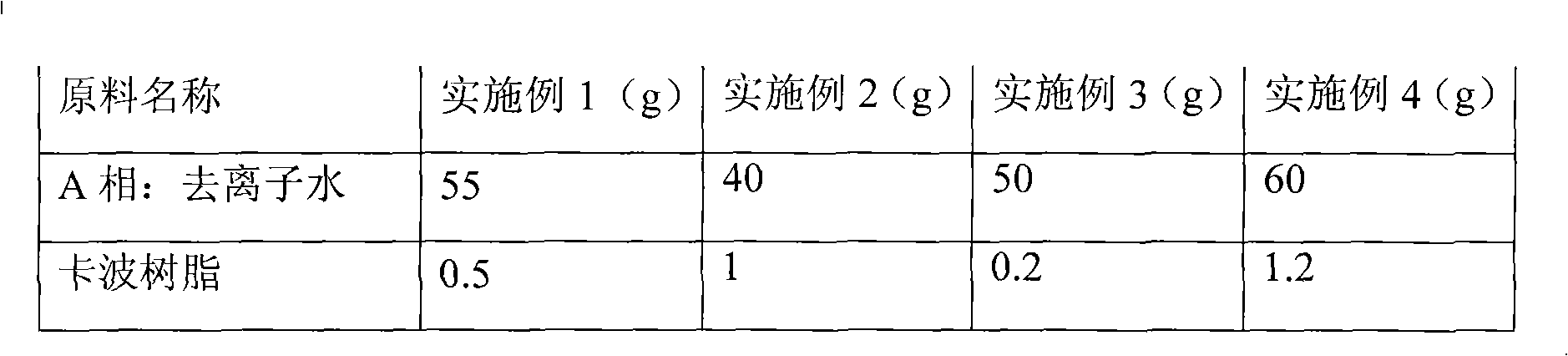

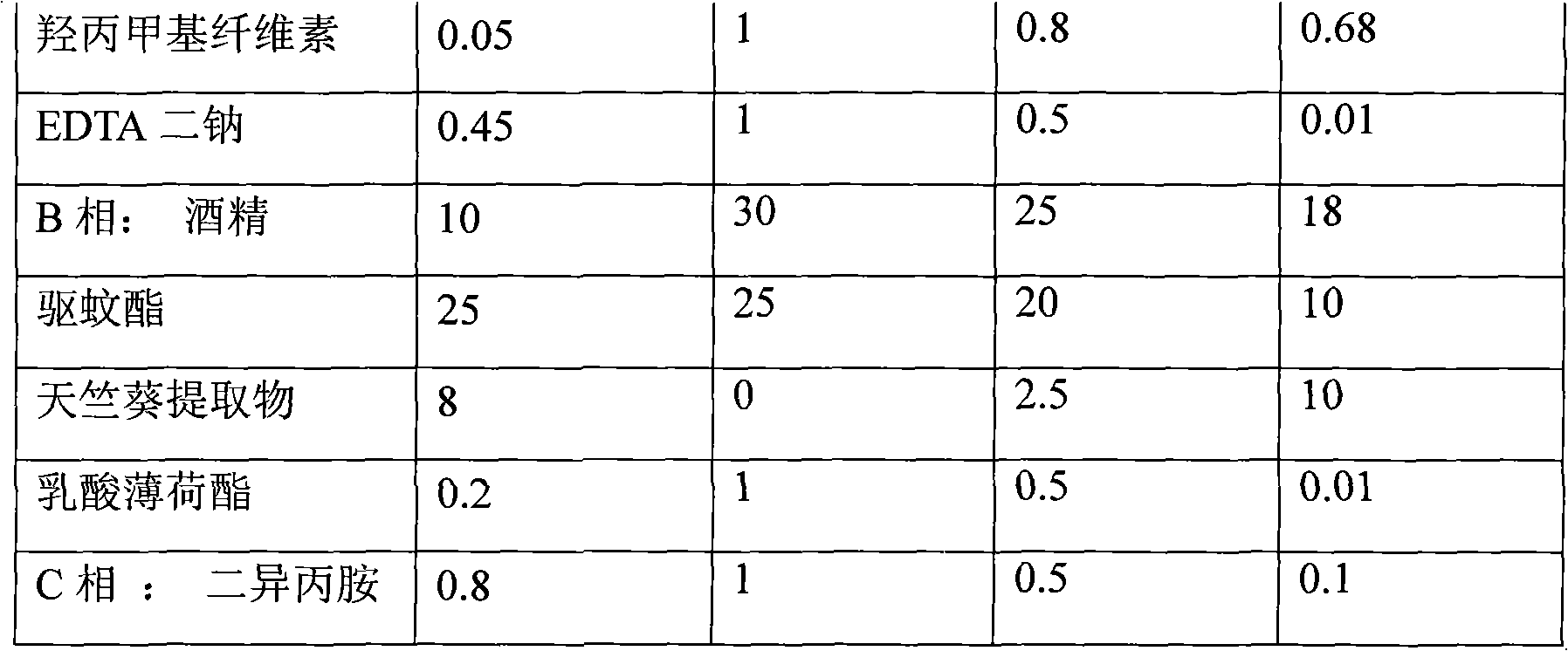

Long-acting mosquito-driving condensation dew

InactiveCN101491491AReduce divergenceImprove cool feelingCosmetic preparationsToilet preparationsAlcoholDiisopropylamine

The invention relates to a long-acting mosquito expelling gel and belongs to the field of daily chemical goods. The long-acting gel comprises an A phase, a B phase and a C phase in percentage by weight: the A phase: 40.00 to 60.00 percent of deionized water, 0.20 to 1.20 percent of carbomer resin, 0.05 to 1.00 percent of hydroxypropylmethyl cellulose and 0.01 to 1.00 percent of disodium EDTA; the B phase: 10.00 to 30.00 percent of alcohol, 10.00 to 25.00 percent of dimethyl phthalate, 0 to 10.00 percent of geranium extract and 0.01 to 1.00 percent of menthyl lactate; and the C phase: 0.10 to 1.00 percent of diisopropylamine. The long-acting mosquito expelling gel has a mild formulation, comfortable coating feel, is fresh and not sticky, has safe use and remarkable mosquito expelling effect which reaches over 10 hours and meets requirement of medicine specially needed for military.

Owner:北京如日中天科技发展有限公司

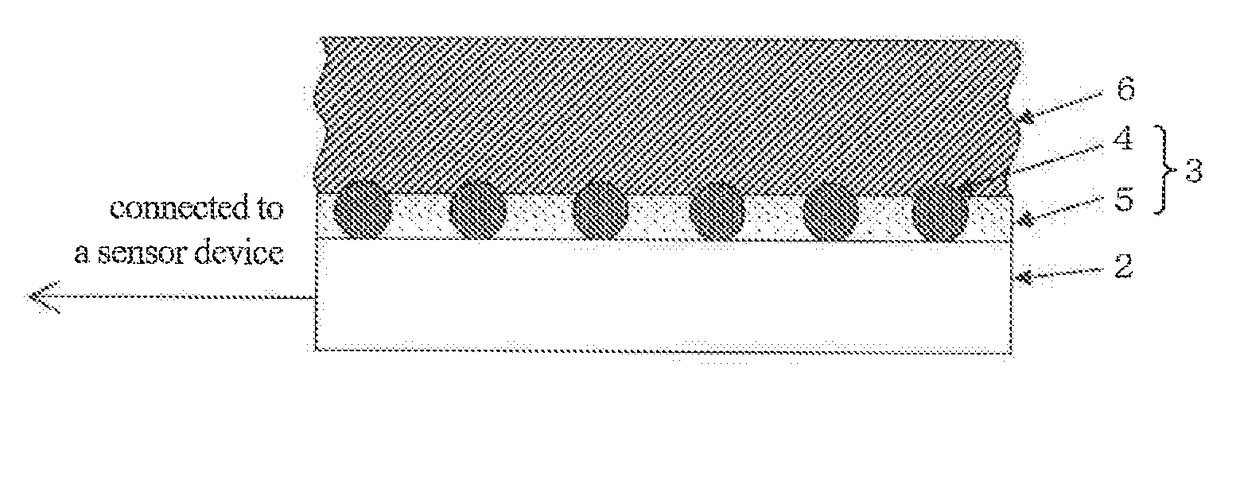

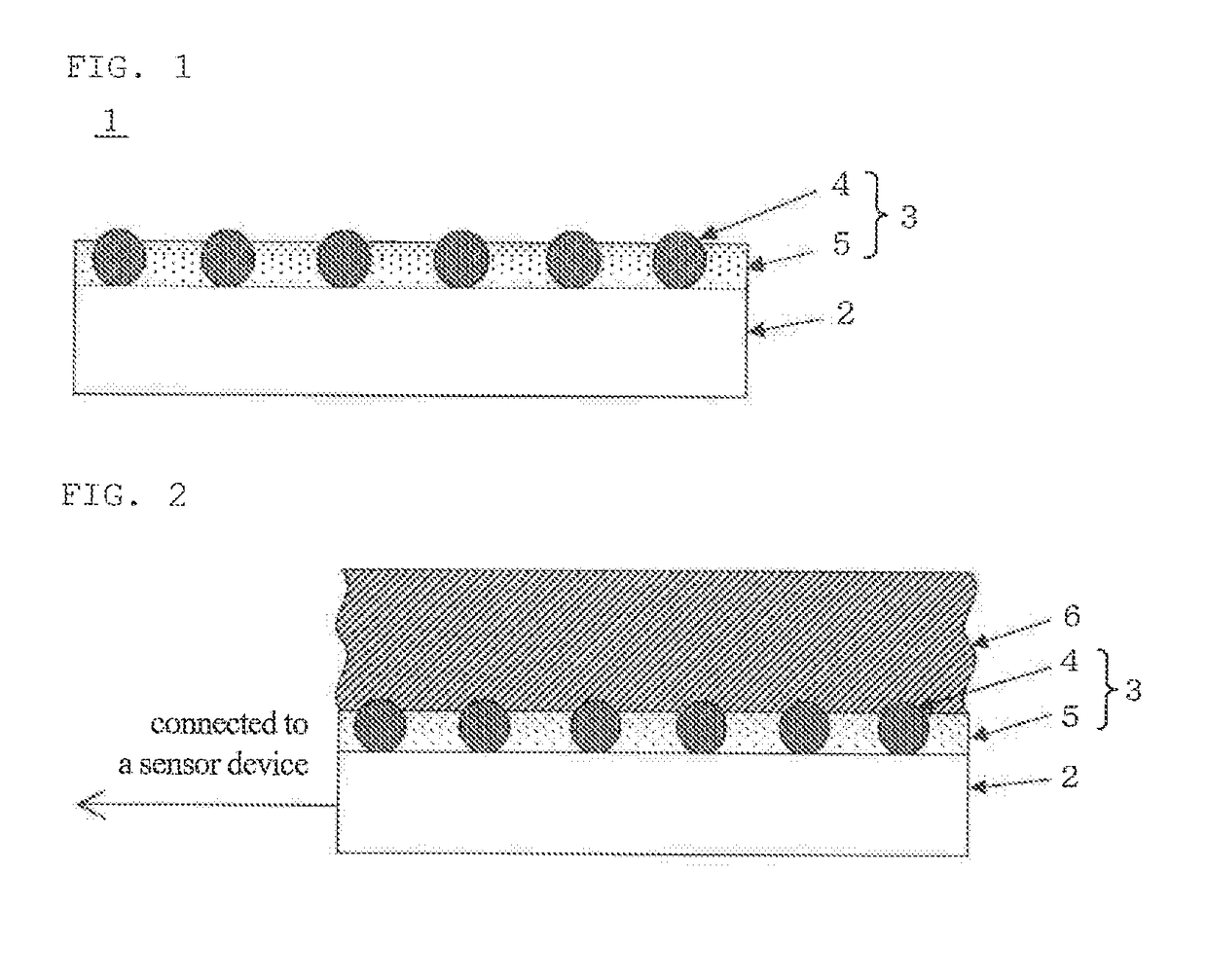

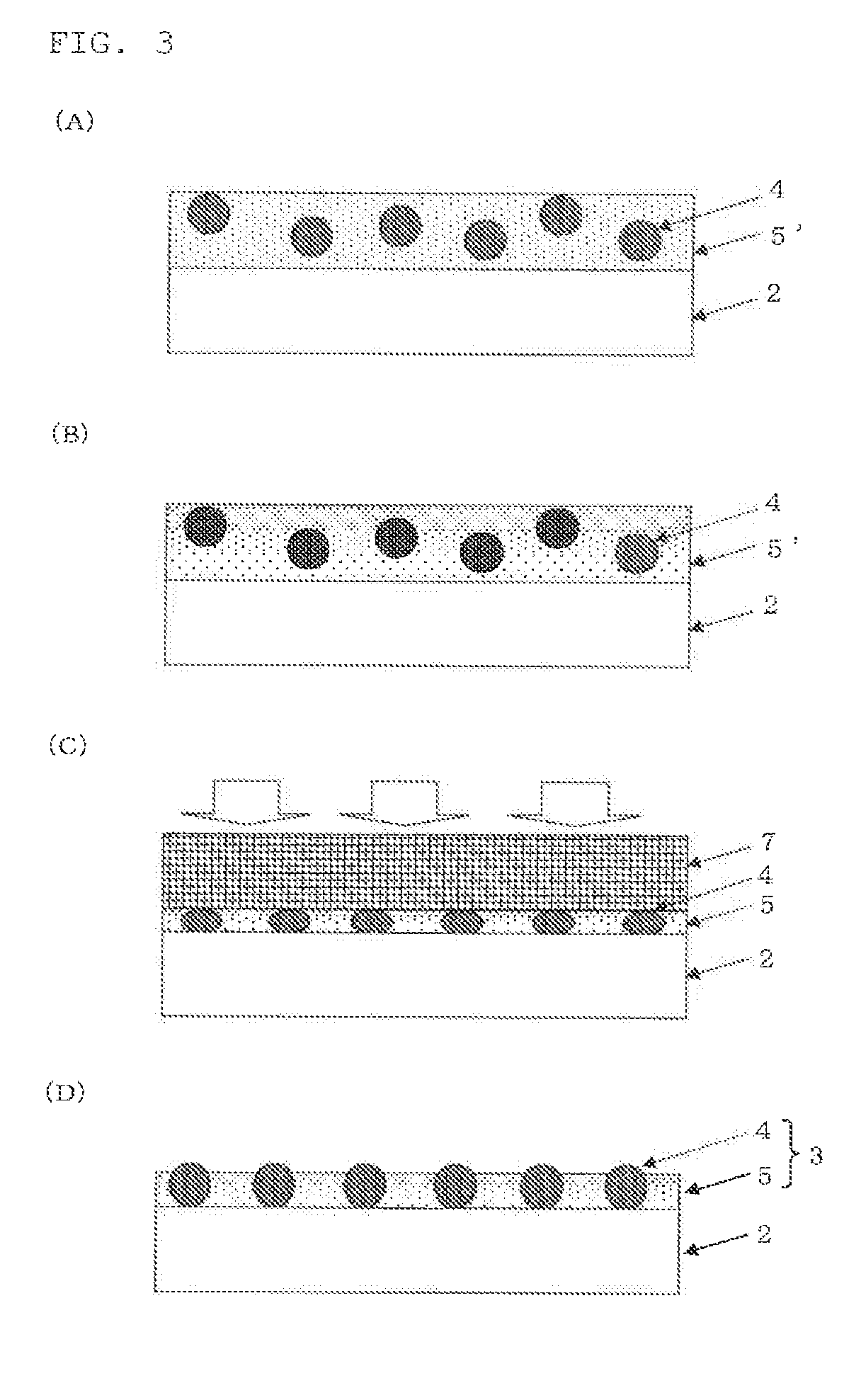

Bio-electrode and method for manufacturing the same

ActiveUS20170323698A1Efficiently conductedIncreased repellencyPlastic/resin/waxes insulatorsNon-conductive material with dispersed conductive materialPlatinumBiological body

The present invention provides a bio-electrode including an electro-conductive base material and a living body contact layer formed on the electro-conductive base material; wherein the living body contact layer contains a resin layer and particles dispersed in the resin layer, the particles being coated with gold, platinum, silver, or alloy of these metals; a thickness of the resin layer is equal to or thinner than an average particle size of the particles; the resin layer contains a silicon-containing resin and a non-silicon-containing resin; and the silicon-containing resin is localized in the direction of a surface of the resin layer. The bio-electrode of the present invention is superior in electric conductivity and biocompatibility, light in weight, can be manufactured at low cost, and can combine repellency of the resin layer surface and adhesion properties of the resin layer to particles.

Owner:SHIN ETSU CHEM IND CO LTD

Mixed coating material and manufacturing method of the same

InactiveUS20050234147A1High in anti-icing effectHigh in deicing effectOther chemical processesCoatingsTetrafluoroethyleneOrganic solvent

A mixed coating material includes: a mixed resin comprising an ultraviolet curable resin and a low molecular weight tetrafluoroethylene resin; and a hydrofluorocarbon-containing organic solvent, wherein the mixed resin and the hydrofluorocarbon-containing organic solvent are mixed to allow the coating material to have film hardness of 1H or more.

Owner:SUBARU CORP

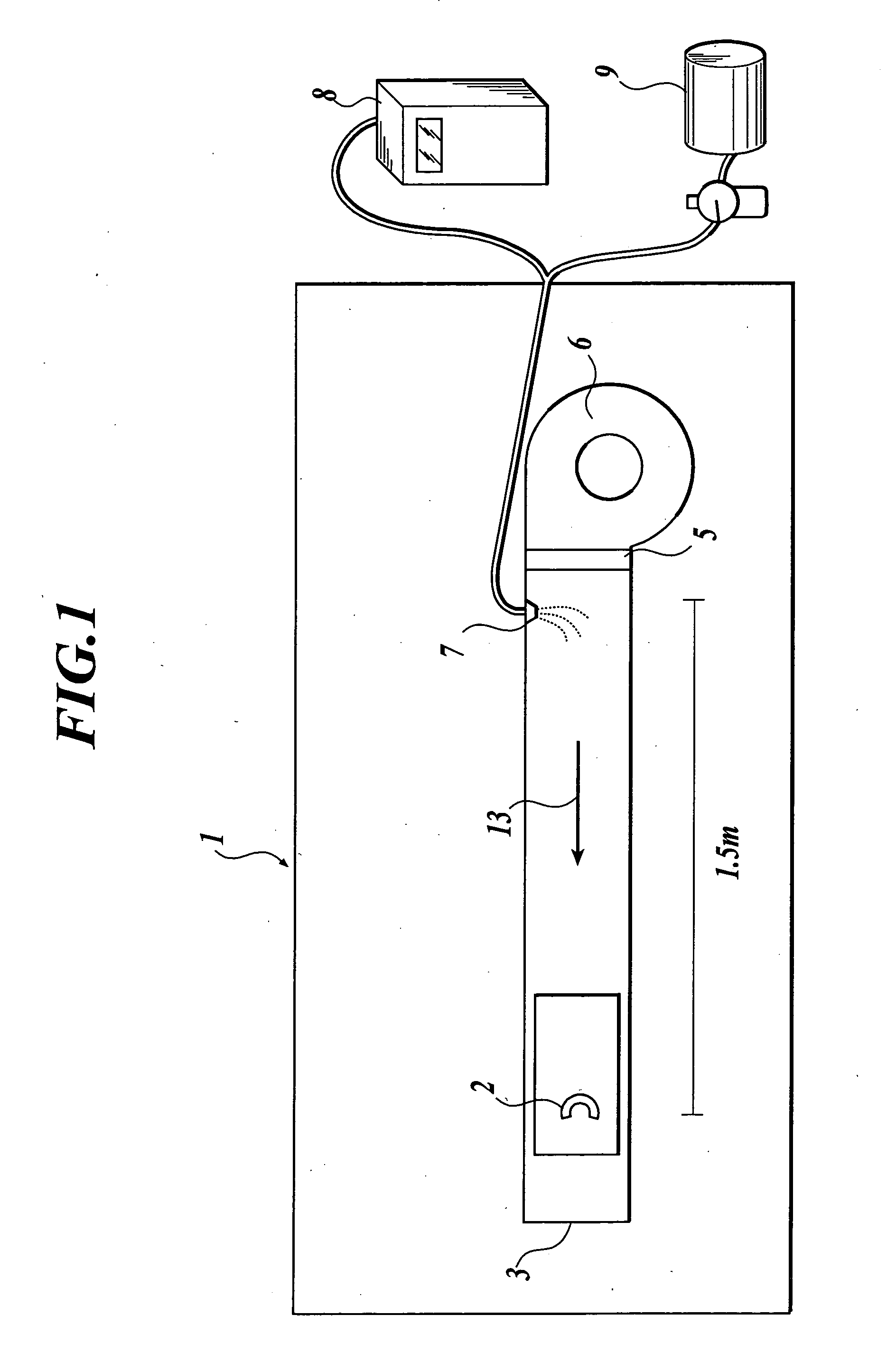

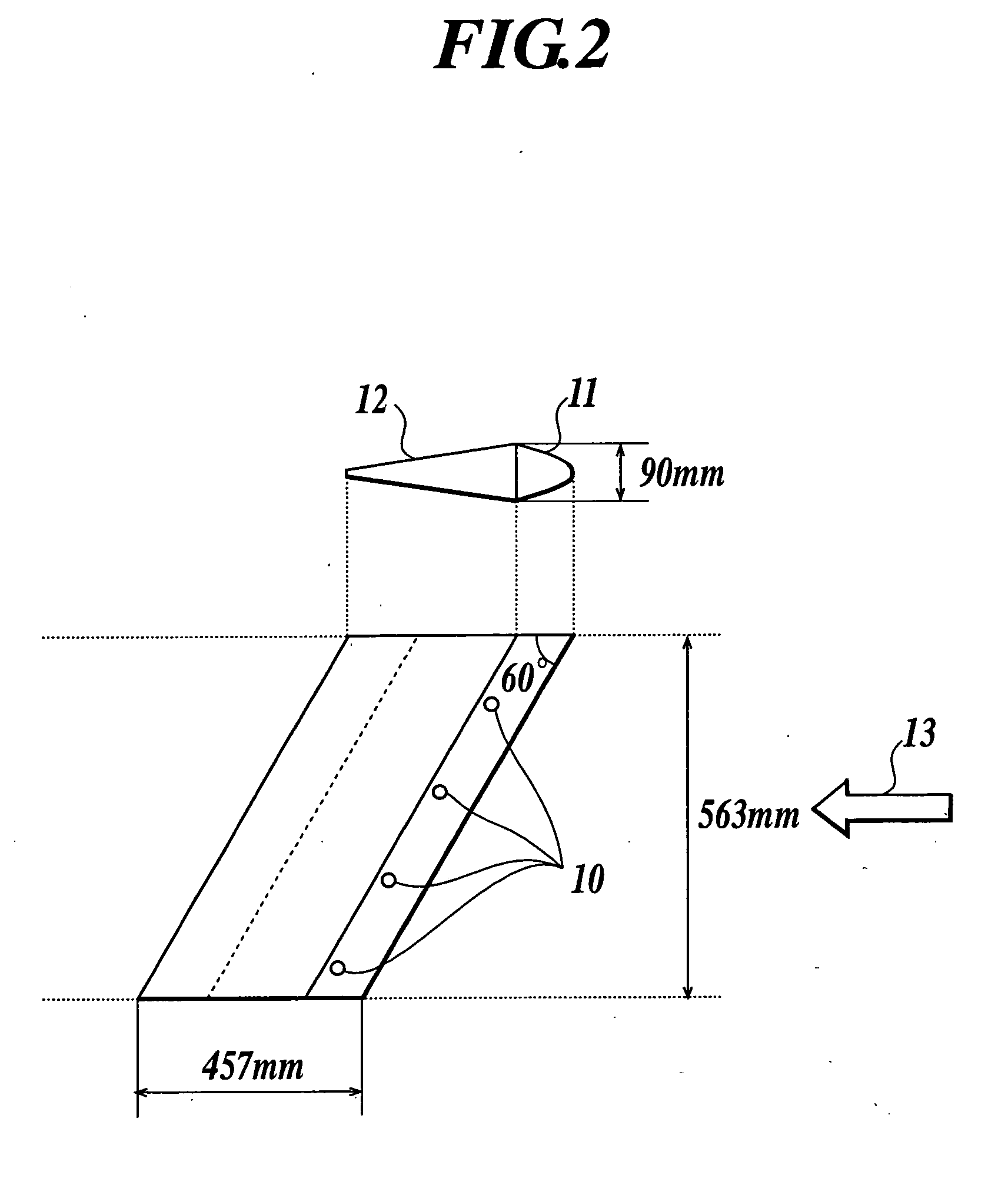

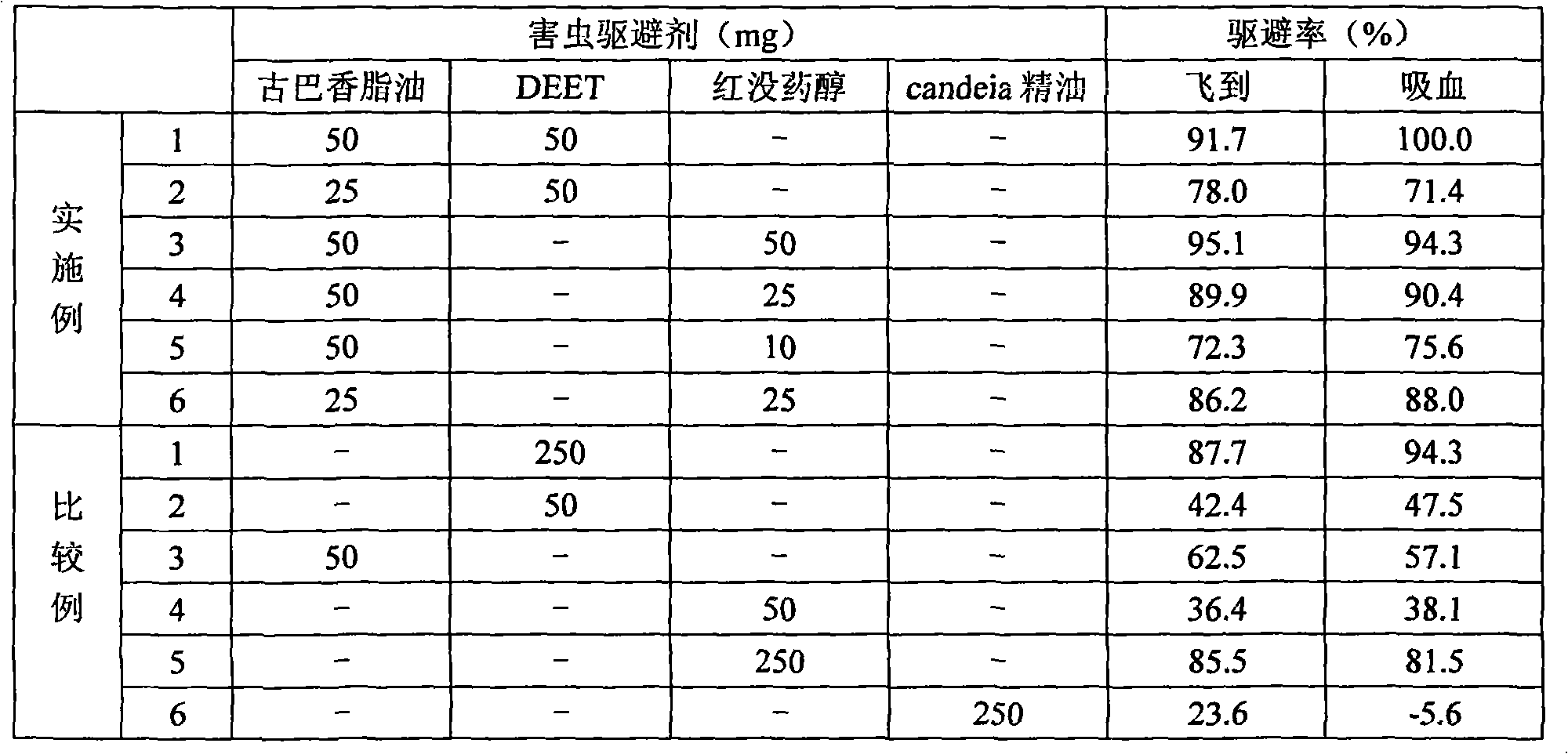

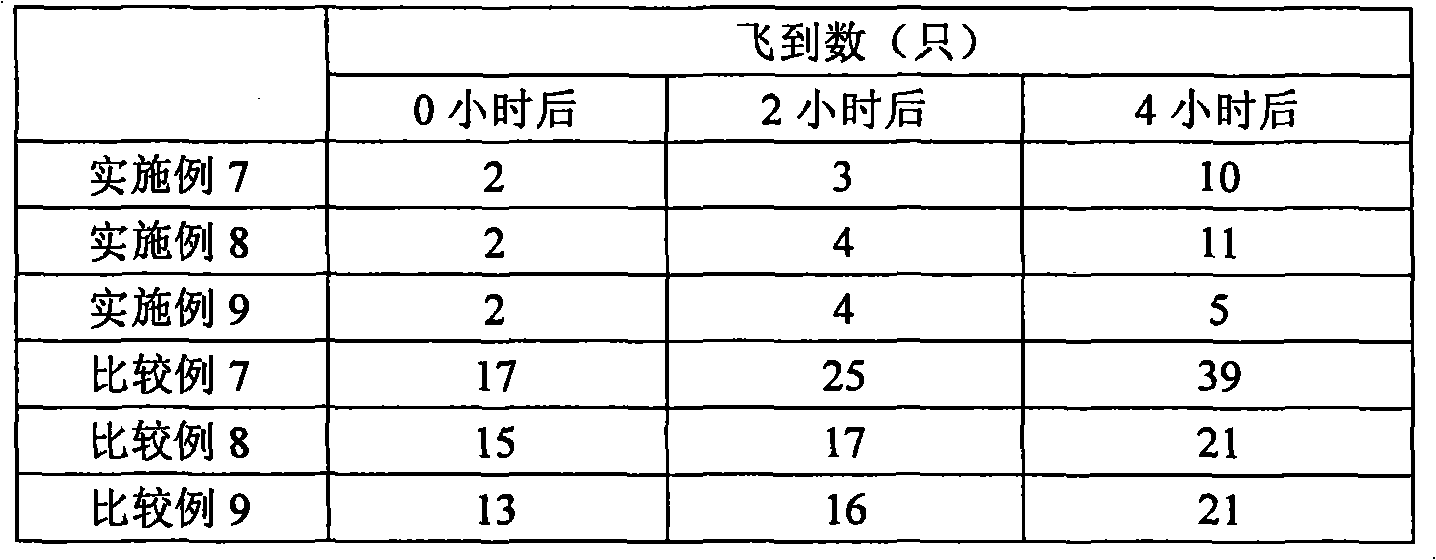

Pest repellent

Disclosed is a pest repellent which shows a high repellent effect on an insanitary insect such as mosquito over a prolonged period and has less risk to a human body. The pest repellent comprises a combination of Copaiba oil and / or an extract thereof and DEET and / or bisabolol.

Owner:KYOTO REFRE SHINYAKU +1

Composite toughened grouting cement mortar and preparation method thereof

ActiveCN105541202AEffectively exert the effect of synergistic tougheningThe preparation conditions are metEpoxyCrack resistance

The invention discloses a composite toughened grouting cement mortar and a preparation method thereof. The composite toughened grouting cement mortar is prepared from the following raw materials in parts by weight: 80-100 parts of cement, 120-180 parts of 50-200-mesh fine sand, 20-50 parts of water, 5-10 parts of polyurethane solution, 5-10 parts of epoxy resin emulsion, 10-15 parts of toughening additive, 1.5-6 parts of early-strength admixture, 2-9 parts of methacrylic acid, 2-6 parts of calcium formate, 2-8 parts of neopentyl glycol, 0.2-0.8 part of sodium dodecyl benzene sulfonate and 0.9-2.4 parts of water reducing agent. A modified composite carbon nano material, activated wood meal and isotactic polypropylene are combined to form the unique toughening additive under the surface modification actions of a coupling agent and a compatilizer; and when the toughening additive is used for preparing the cement mortar, the prepared cement mortar has the advantages of favorable toughness, favorable fatigue resistance and favorable isotropy, and is beneficial to enhancing the crack resistance of the grouting mortar and reducing the engineering maintenance cost in the later period.

Owner:福建省东霖建设工程有限公司

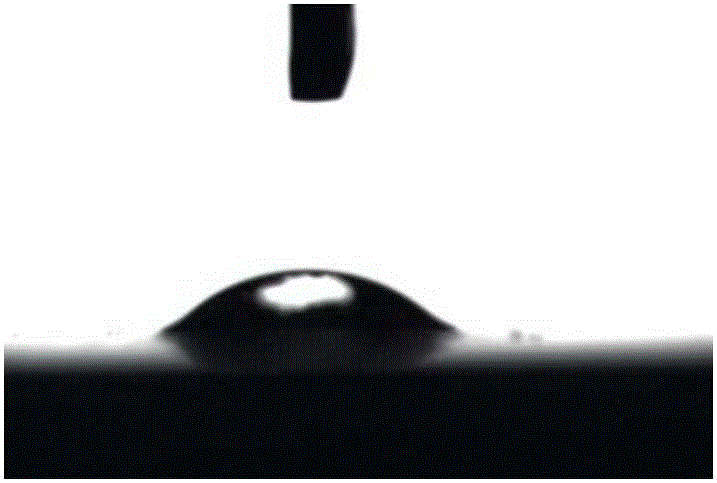

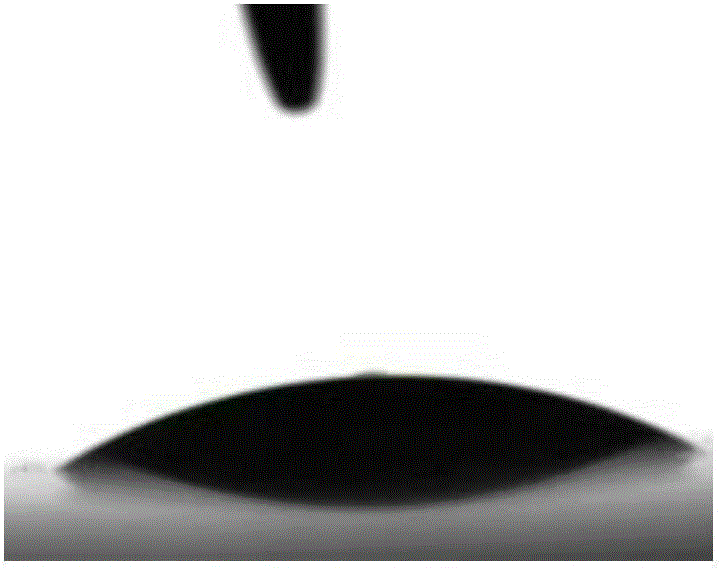

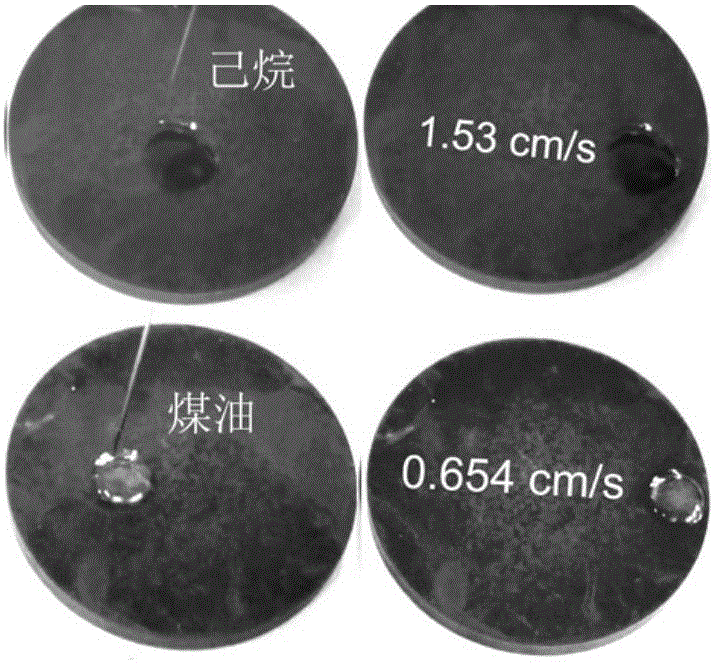

Lyophobic super-lubricant interface and preparation method thereof

ActiveCN106245011ASize is not requiredIncreased repellencyMetallic material coating processesMicro nanoSilanes

The invention discloses a lyophobic super-lubricant interface and a preparation method thereof. The lyophobic super-smooth interface is prepared by the steps of: by taking a 7075 aluminum alloy as a substrate, performing surface corrosion in an ultrasonic treatment state with nitric acid to form micro-nano structures; performing surface grafting with fluoroalkyl silane; and finally injecting a perfluoro lubricant into the micro-nano structures. The lyophobic super-lubricant interface disclosed by the invention is prepared by using a structural metal 7075 aluminum alloy which is widely applied. The prepared lyophobic super-lubricant interface has excellent repulsive interaction to water, oil and hexane with extremely low surface tension, and has a wide application prospect in the field of construction, machine manufacturing, aerospace, navigation and the like.

Owner:NANJING UNIV OF SCI & TECH

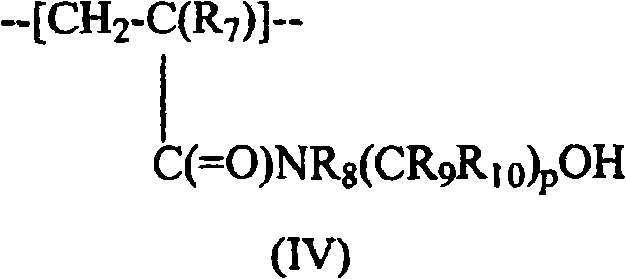

Oil/grease-and water sizing agent for treatment of cellulosic materials

InactiveCN1646767AIncreased repellencyImprove performanceWater-repelling agents additionPaper/cardboardCelluloseOil and grease

Owner:SOLENIS TECH CAYMAN

Preparation method of amphoteric cellulose ether for drilling fluid

InactiveCN108164606AIncrease resistance to movementGood dehydration functionDrilling compositionCelluloseEpoxy

The invention discloses a preparation method of amphoteric cellulose ether for drilling fluid, and belongs to the technical field of cellulose ether preparation. The preparation method comprises the steps: firstly, under an alkaline condition, cationic hydroxyethyl cellulose ether is obtained by etherification reaction of active hydroxyl on a molecular chain of hydroxyethyl cellulose and epoxy chloropropane, and then a viscous filtrate, namely 3-chloro-2-hydroxypropyl dimethylammonium acetate, is prepared, so that the motion resistance of water molecules is increased, and the cellulose ether has an excellent water loss reduction function in the drilling fluid; the number of anion groups in the amphoteric cellulose ether and the number of cation groups in the amphoteric cellulose ether areroughly equal, the electrostatic interaction force in the molecular chain is only electrostatic attraction force, resulting in contraction of polymer molecules, decrease of the hydrodynamic volume anddecrease of the viscosity of a solution, so an obvious antipolyelectrolyte solution behavior is showed, a large consistence can be still kept when the water content in the drilling fluid is high, andthe permeability of a salt solution is weakened, so the salt tolerance of the amphoteric cellulose ether in the drilling fluid is improved, and the prospect of application is broad.

Owner:江苏华友装饰工程有限公司

Anti-mosquito finishing method for textile

InactiveCN107841871AStrong repellent effectIncreased repellencyBiochemical fibre treatmentTraditional medicineImpurity

The invention relates to an anti-mosquito finishing method for a textile. The method comprises the following steps: (1) cleaning Chinese herbal medicines and removing impurities, adding water and decocting, and filtering to obtain liquid medicine and primary decoction dregs; (2) drying the primary decoction dregs, soaking with absolute ethanol with the weight 1-2 times that of the primary decoction dregs, and filtering to obtain extract and secondary decoction dregs; (3) mixing the liquid medicine and the extract, and adding bamboo vinegar and essential oil, thus obtaining finishing liquid; and (4) soaking the textile in the finishing liquid, then carrying out padding treatment, wherein pickup is 50%, then prebaking the textile subjected to the padding treatment, then baking, then washing,and drying. The textile finished by adopting the method provided by the invention has good effect of repelling mosquitoes, insects and flies, adopts natural raw materials, contains no chemical additive, is safe and harmless to human body and nonirritant to skin, produces no bad effect on physical indexes such as strength and hygroscopicity of a braided fabric and can be widely applied to beddings, mosquito nets, decoration fabrics such as curtains, clothing and military braided fabrics.

Owner:湖州南浔久辰纺织有限公司

Additive for toughening concrete and preparation method thereof

ActiveCN105645834AEffectively exert the effect of synergistic tougheningEasy accessPolypropyleneToughness

The invention discloses an additive for toughening concrete and a preparation method thereof. The additive comprises the following raw materials in parts by weight: 1-2 parts of a modified composite carbon nano-material, 35-40 parts of wood powder with activating treatment, 18-23 parts of isotactic polypropylene, 100-150 parts of water, 2.5-3.5 parts of a coupling agent, 3-5 parts of a filling material, and 2.2-3.2 parts of a compatilizer. The modified composite carbon nano-material, the wood powder with activating treatment and the isotactic polypropylene are combined, and a unique composite system is formed by a surface modification effect of the coupling agent and the compatilizer; the prepared additive can be fully dispersed in concrete, the synergistic toughening effect of the material is effectively performed, so that the prepared concrete has the advantages of good toughness, fatigue resistance and isotropy; and the additive is a high performance adding material for toughening concrete.

Owner:云南泺决建材有限公司

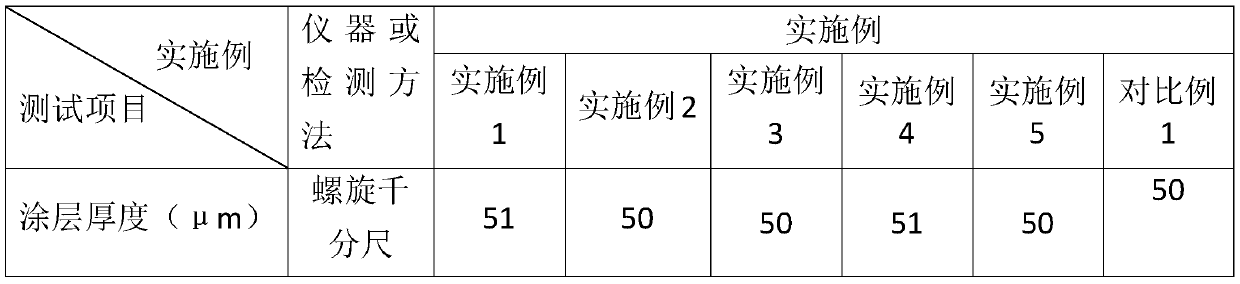

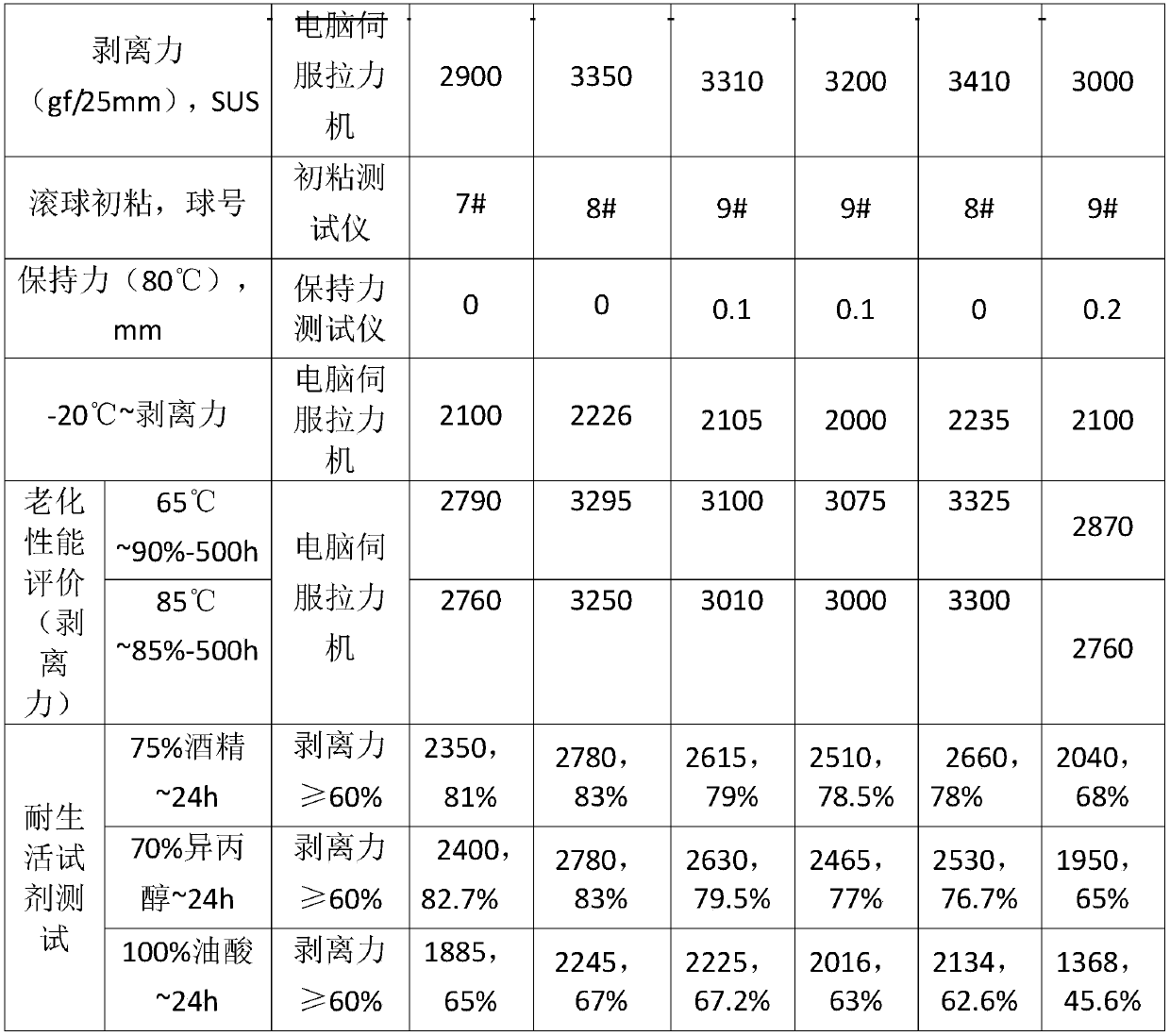

Life reagent-resistant pressure-sensitive adhesive composition and preparation method of life reagent-resistant adhesive tape

InactiveCN109913143AHigh bonding strengthStrong impact resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesElastomerPolymer science

The invention relates to a life reagent-resistant pressure-sensitive adhesive composition and a preparation method of a life reagent-resistant adhesive tape. Through adoption of a soft rubber elastomer polymer modified by a strong polar material and due to good repellency to non-polar greases and solvents, the resistance of pressure-sensitive adhesive coating to life reagents in life can be effectively improved, and the low temperature resistance is relatively good; through adoption of a strong polar tackifying resin system, by virtue of the strong polarity thereof and the insolubility thereofin some solvents, the life reagent resistance of the whole pressure-sensitive adhesive is enhanced again while the whole adhesive system is tackified; the whole rubber elastomer is further crosslinked into a network shape in a thermal crosslinking way, so that the crosslinking density is improved, the intermolecular space is reduced, erosion of life reagent molecules into the adhesive is effectively hindered, and the life reagent resistance of the adhesive is further improved.

Owner:新纶电子材料(常州)有限公司

Air purifying filter media and process for producing the same

InactiveUS7520912B2Improves the bactericidal/sterilizing or antimicrobial means propertiesHigh tensile strengthCombination devicesAuxillary pretreatmentFiberGas phase

It is intended to provide an air purification filter which has a high dry tensile strength, a high wet tensile strength in association with a high water resistance and a high water repellency and exhibits a bactericidal effect due to a gas phase reaction in a gas phase. Namely, an air purification filter having a high dry tensile strength, a high wet tensile strength (a high water resistance) and a high water repellency as well as a bactericidal effect which is obtained by blending a filter fiber having a functional group with a mixture of a modification enzyme which has an ionic polarity opposite to the ionic polarity of the whole filter fiber as described above and a bactericidal effect with an ionic synthetic resin binder having the opposite ionic polarity similar to the modification enzyme.

Owner:NIKKI UNIVERSAL CO LTD +1

Methods of treating and cleaning fibers, carpet yarns and carpets

InactiveUS7276085B2Negatively impactingIncreased repellencyPhysical treatmentDry-cleaning apparatus for textilesFiberYarn

Methods of enhancing stain resistance of fibers, carpet yarns and carpets are disclosed. In one aspect, the invention relates to a method of treating fiber, yarn or carpet comprising applying an aqueous treating composition to fiber, yarn or carpet, wherein the aqueous treating composition comprises tannic acid heating the fiber, yarn or carpet to a temperature of at least about 160° F.; applying a second topical treating composition to the fiber, carpet or yarn, wherein the second aqueous treating composition comprises a fluorochemical; and heating the fiber, yarn or carpet to a temperature of at least about 160° F.

Owner:COLUMBIA INSURANCE CO

Polymeric dispersions and applications thereof

ActiveUS20080234415A1Improved repellenciesIncrease resistanceOther chemical processesLayered productsEmulsionEmulsion polymerization

The present invention provides methods of conducting emulsion polymerizations and dispersion resulting therefrom. The present invention additionally provides substrates coated or treated with polymeric dispersions.

Owner:POLYVENTIVE LLC

Method of making lithographic printing plate substrate and imageable elements

InactiveCN101680096AImprove hydrophilicityIncreased repellencySurface reaction electrolytic coatingMetallic material coating processesPolymer sciencePrinting ink

Aluminum-containing substrates having an anodic oxide layer are coated with a interlayer by carefully controlling the concentration of phosphonic acid groups in an interlayer polymer and aluminum (+3)concentration in a post-treatment solution. These substrates have improved hydrophilicity, lithographic printing ink repellency, and overall improved printability when used as part of lithographic printing plates.

Owner:EASTMAN KODAK CO

Methods of treating and cleaning fibers, carpet yarns and carpets

InactiveUS20050015886A1Desired degree of resistanceNegatively impactingPhysical treatmentDry-cleaning apparatus for textilesYarnFiber

Owner:COLUMBIA INSURANCE CO

Physical control method for mosquito and fly pests of edible mushrooms

InactiveCN106172359AReduce the number of habitatsReduce the number of eggs spawnedAnimal repellantsCultivating equipmentsGreenhousePlastic mulch

The invention discloses a physical control method for mosquito and fly pests of edible mushrooms. The method comprises the procedures of carrying out site selecting, carrying out mulching film laying, carrying out bagging, carrying out inoculating, carrying out inoculated culture, carrying out mushroom emergence management and carrying out harvesting, wherein woven mulching films are laid to the ground of a mushroom hothouse or mushroom greenhouse, a medium substance is loaded to mushroom bags, sterilizing and inoculating are carried out, the mushroom bags are placed in an appropriate environment for culture and mushroom emergence, harvesting is carried out after mushroom caps are flat and smooth, and the color of the woven mulching films and the color of the mushroom bags are specific gray. According to the method, an environment, which plays a role in repelling the mosquito and fly pests of the edible mushrooms, is created in a culture place by using plastic products, for edible-mushroom culture, with the specific gray, so that the habitation and the quantity of propagation of the mosquito and fly pests in the culture place are reduced, and then, the aims of protecting the growth of the edible mushrooms and improving the yield and quality of the edible mushrooms are achieved.

Owner:GUANGXI UNIV

Methods of treating and cleaning fibers, carpet yarns and carpets

InactiveUS20050150057A1Negatively impactingIncreased repellencyPhysical treatmentDry-cleaning apparatus for textilesYarnFiber

Owner:COLUMBIA INSURANCE CO

Low-residue salt-tolerant fracturing fluid preparation method

PendingCN110358519AReduces and prevents hydrationImprove stabilityDrilling compositionViscous liquidPolymer science

The invention relates to a low-residue salt-tolerant fracturing fluid preparation method, and belongs to the technical field of fracturing fluid preparation. The preparation method comprises: mixing dimethylallylamine, chloroacetic acid and a sodium hydroxide solution to obtain a light yellow viscous liquid, introducing chlorine gas into the light yellow viscous liquid, carrying out heating distillation, adding anhydrous ethanol, cationic hydroxyethyl cellulose, river sand and an encapsulation gel breaker, and carrying out a stirring reaction to obtain the low-residue salt-resistant fracturingfluid. According to the present invention, the amphoteric cellulose ether in the fracturing fluid can effectively weaken and prevent the free water molecules in the aqueous fracturing fluid from hydration on the surface of the fracturing fluid particles and the pigment so as to improve the hydration dispersibility of the guar gum, completely break the gel and reduce the residue; the used guar gumcan improve the static viscosity of the aqueous fracturing fluid by rapidly hydrating with the water molecules through hydrogen bonding; and a large number of the cationic groups have good repellencyto the metal cation, such that the fracturing fluid has good salt-tolerant stability and has broad application prospects.

Owner:欧志飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com