Life reagent-resistant pressure-sensitive adhesive composition and preparation method of life reagent-resistant adhesive tape

A pressure-sensitive adhesive and composition technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of poor low temperature resistance, ozone resistance, low elasticity, etc., and achieve excellent solvent resistance and hinder erosion. , the effect of increasing the crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

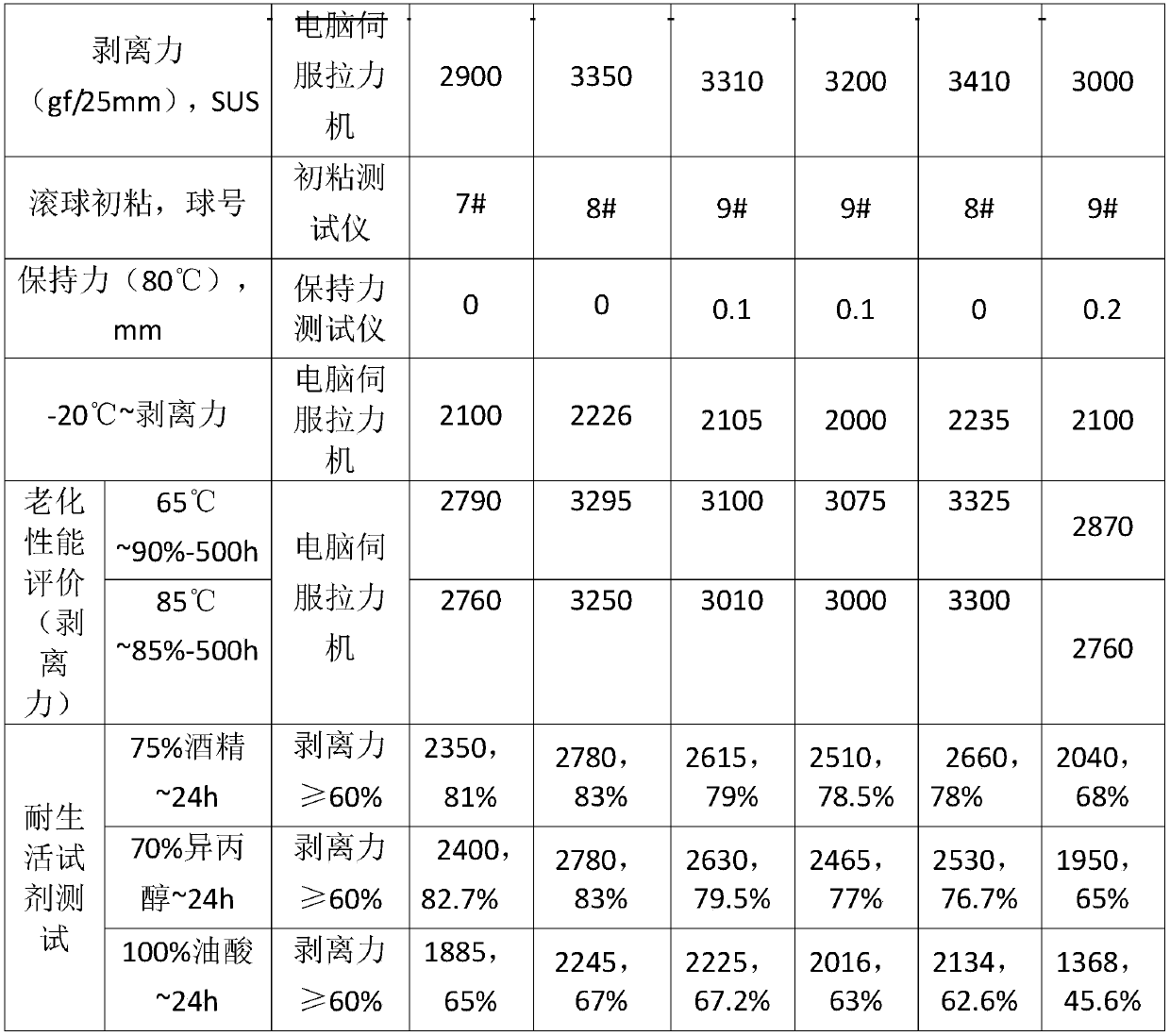

Embodiment 1

[0029]1) Prepare life-resistant reagent-type pressure-sensitive adhesive composition: put 16g of toluene into a 300ml beaker, then start the stirring device at a speed of 150rpm, and put in 100g of rubber modified polymer and 15g of highly polar tackifying resin H-50P in turn while stirring , Polar tackifying resin 803L 3g, light stabilizer UV-292 0.1g, after it dissolves, add crosslinking agent L-750.7g, and continue to stir for 30min, stop the stirring device, let it stand for more than 30min for natural defoaming , the life-resistant agent type pressure-sensitive adhesive coating composition can be obtained;

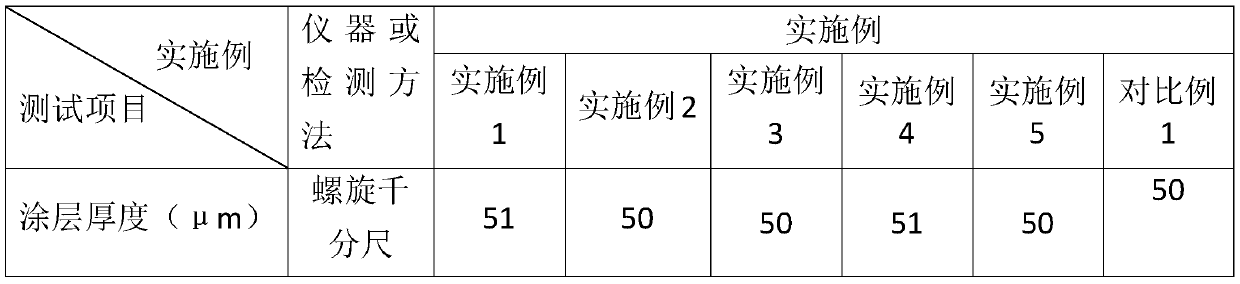

[0030] 2) Coating process of life-resistant reagent-resistant pressure-sensitive adhesive: Coating the life-resistant reagent-resistant pressure-sensitive adhesive on the corona-treated surface of the PET substrate, baking temperature is 120 ° C, baking time is 4 minutes, and a uniform thickness of about 50 μm is formed A pressure-sensitive adhesive coating, and then ...

Embodiment 2

[0032] 1) Prepare life-resistant reagent-type pressure-sensitive adhesive composition: put 16g of toluene into a 300ml beaker, then start the stirring device at a speed of 150rpm, and put in 100g of rubber modified polymer and 18g of highly polar tackifying resin H-50P in turn while stirring , Polar tackifying resin 803L 5g, light stabilizer UV-328 0.1g, after it dissolves, add crosslinking agent L-75 0.7g, and continue to stir for 30min, stop the stirring device, let it stand for more than 30min for natural defoaming , the life-resistant agent type pressure-sensitive adhesive coating composition can be obtained;

[0033] 2) Coating process of life-resistant reagent-resistant pressure-sensitive adhesive: Coating the life-resistant reagent-resistant pressure-sensitive adhesive on the corona-treated surface of the PET substrate, baking temperature is 120 ° C, baking time is 4 minutes, and a uniform thickness of about 50 μm is formed A pressure-sensitive adhesive coating, and the...

Embodiment 3

[0035] 1) Prepare life-resistant reagent-type pressure-sensitive adhesive composition: put 16g of toluene into a 300ml beaker, then start the stirring device at a speed of 150rpm, and put in 100g of rubber modified polymer and 20g of highly polar tackifying resin H-50P in sequence while stirring , Polar tackifying resin 803L 0.5g, light stabilizer UV-144 0.1g, after it dissolves, add cross-linking agent L-750.7g, and continue to stir for 30min, stop the stirring device, let it stand for more than 30min for natural defoaming , the life-resistant agent type pressure-sensitive adhesive coating composition can be obtained;

[0036] 2) Coating process of life-resistant reagent-resistant pressure-sensitive adhesive: Coating the life-resistant reagent-resistant pressure-sensitive adhesive on the corona-treated surface of the PET substrate, baking temperature is 120 ° C, baking time is 4 minutes, and a uniform thickness of about 50 μm is formed A pressure-sensitive adhesive coating, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com