Patents

Literature

540 results about "Adhesive system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural modified epoxy adhesive compositions

InactiveUS6572971B2Raise the ratioReduce opening timeSynthetic resin layered productsEpoxy resin adhesivesFirming agentAliphatic amine

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

Structural modified epoxy adhesive compositions

InactiveUS20020164485A1Reduce opening timeGood substrate adhesionSynthetic resin layered productsThin material handlingSilanesFirming agent

The present invention is directed to an adhesive composition, which comprises an epoxy resin, a coupling agent, filler, and an effective amount of an amine-curing agent or curative for said epoxy resin. Advantageously, tri-functional and / or tetrafunctional epoxy resins and / or acrylate monomers will be incorporated into the adhesive composition in order to reduce open time and enhance substrate adhesion. Advantageously, a mixture of amines will be used in the curative including aliphatic amines, which have low viscosities and efficiently wet the substrate for enhancing adhesion; polyamines, which can be used to manipulate open time and allow for improved ratio tolerance of the adhesive system; and amine-terminated rubbers (ATBN), which can improve impact resistance and the toughness of the cured adhesive. Preferred coupling agents are silanes.

Owner:ASHLAND LICENSING & INTPROP LLC

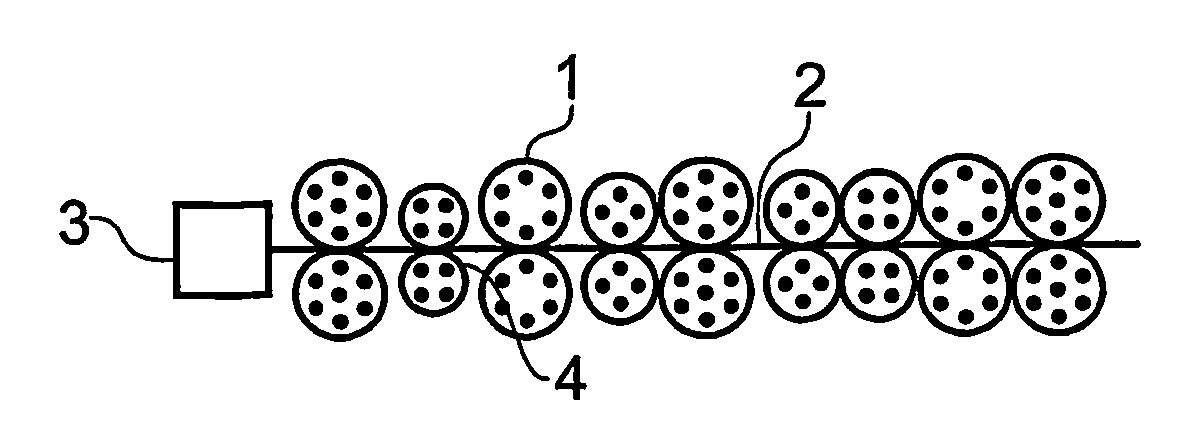

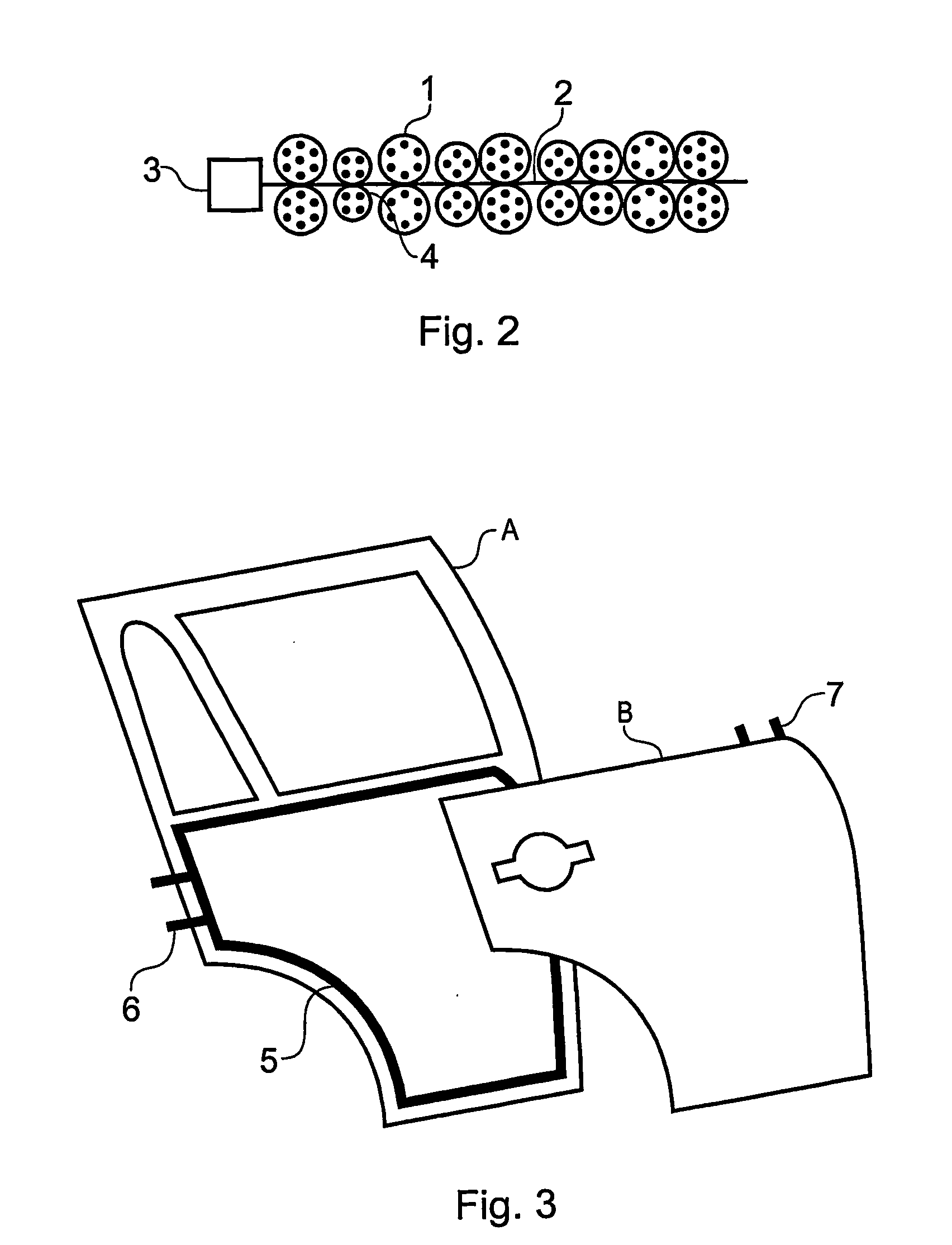

Magneto-active adhesive systems

A magneto-active adhesive and method of adhesive bonding by magnetic field. The method includes steps of providing at least two adherends to be bonded, providing a magneto-active adhesive system between the at least two adherends, the magneto-active adhesive system comprising a plurality of magnetic particles and an adhesive; and applying a non-cyclically varying magnetic field or a cyclically varying magnetic field induced by an alternating current having a frequency of less than 100 hz to the magneto-active adhesive system to change the adhesion of the magneto-active adhesive system to at least one of the adherends. Various carriers for microelectronic devices including magneto-active adhesive contact surfaces are also described within the scope of the invention.

Owner:ENTEGRIS INC

Encapsulated cure systems

ActiveUS20060073334A1Extensive curingLiquid surface applicatorsGlass/slag layered productsSemi solidBiomedical engineering

Encapsulated cure systems are provided wherein a curative is incorporated into a solid or semi-solid carrier material whereby mere fracturing or failure of the capsule wall encapsulating such cure systems will not provide for or allow sufficient release of the curative. Also provided are adhesive systems incorporating said encapsulated cure systems.

Owner:ENCAPSYS LLC

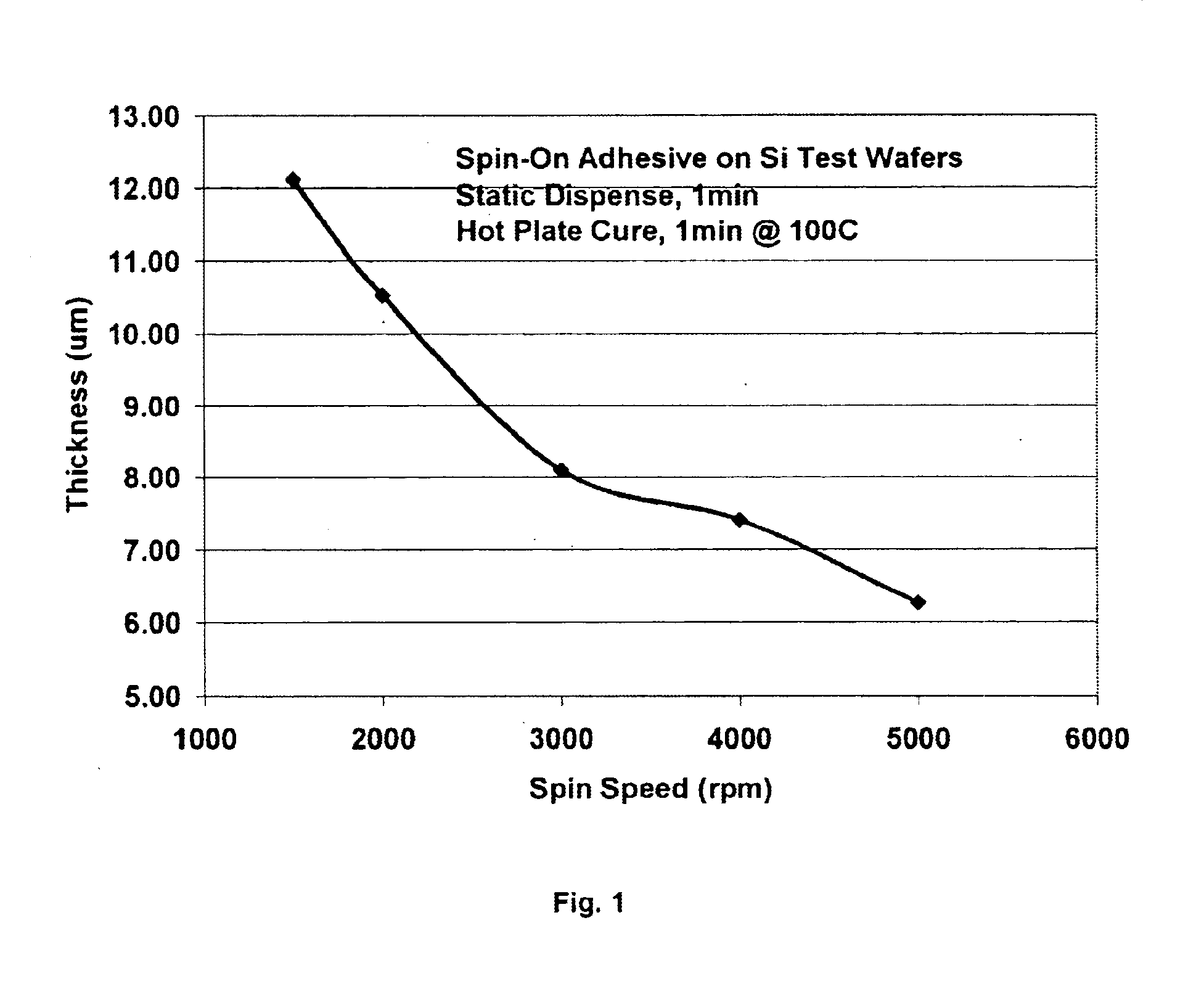

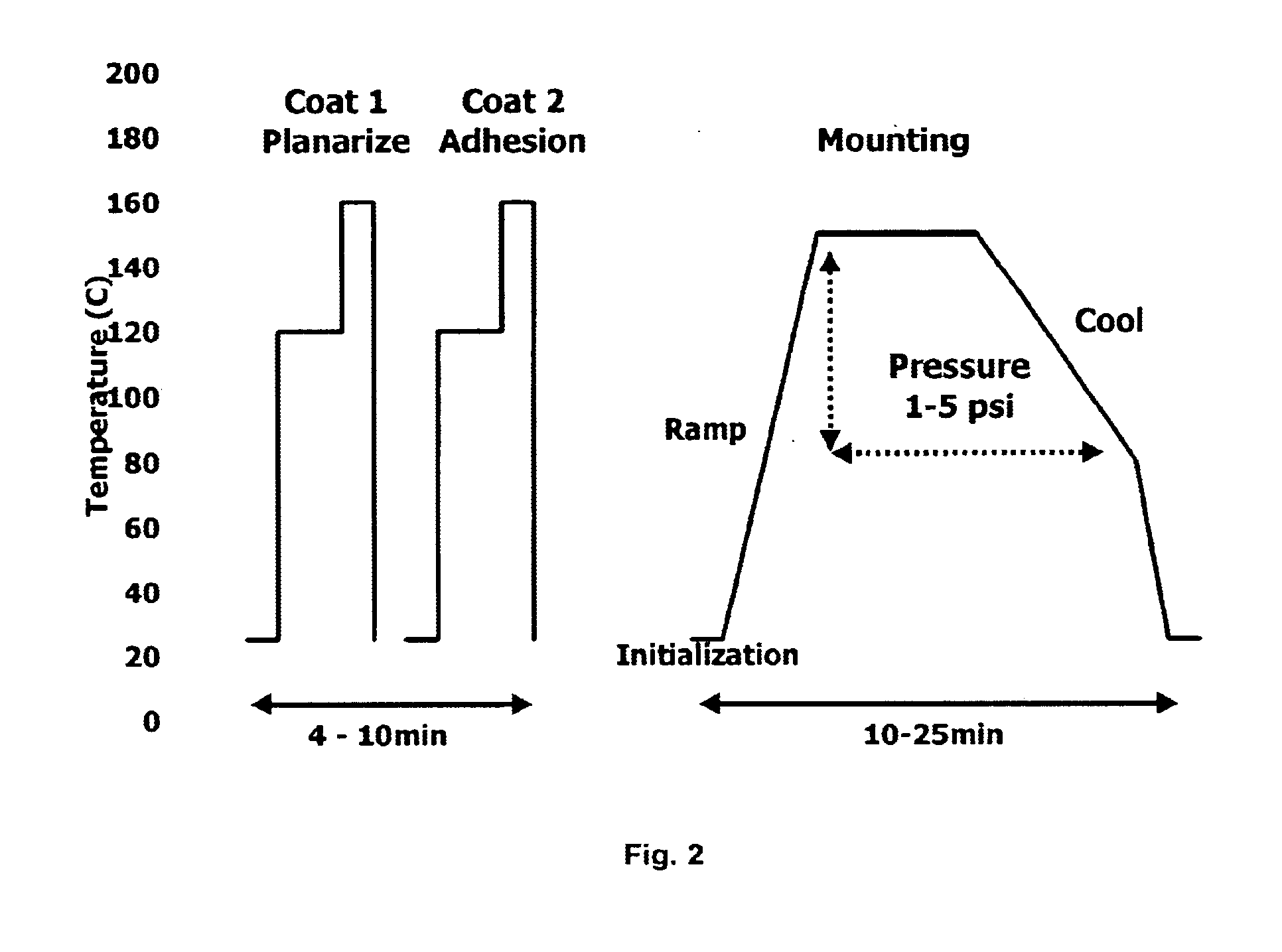

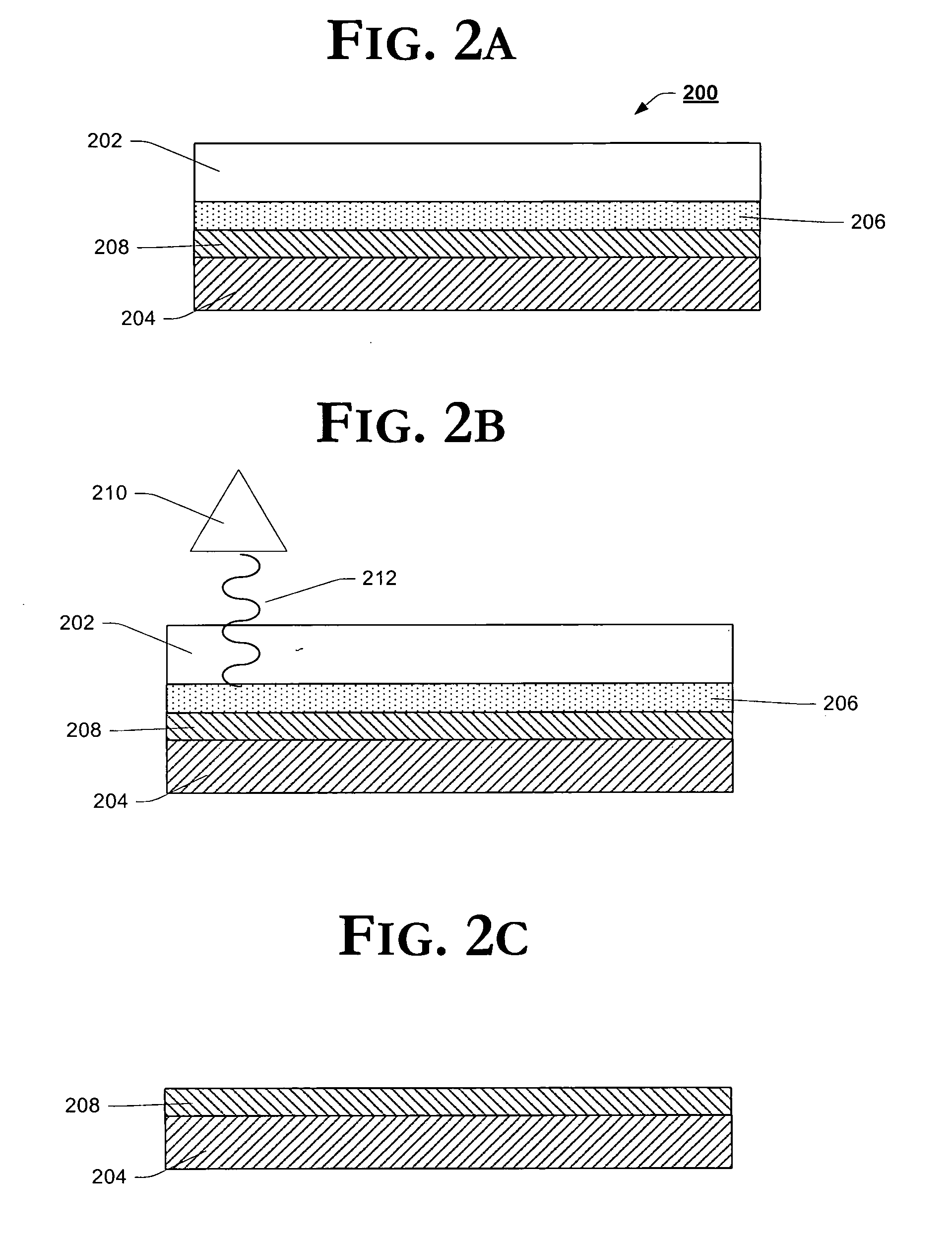

Spin-on adhesive for temporary wafer coating and mounting to support wafer thinning and backside processing

InactiveUS6869894B2Semiconductor/solid-state device testing/measurementSynthetic resin layered productsAdhesiveFluorescence

A liquid form adhesive system is provided for spin-coating on wafers and mounting to rigid carrier substrates to support thinning and backside processing. The liquid adhesive comprises about 30-35% of a rosin, between 5-10% of a thermoplastic urethane, a nonionic surfactant present between 1-3%, and a trace of an ultraviolet fluorescing dye. The entire system is dissolved in 50-65%, by weight, of a dual solvent mixture composed of dimethylacetamide and propylene glycol monomethyl ether. When the mixture is made to a specific viscosity, filtered, applied by a spin-coating method to the wafer frontside surface, and cured, the result is a uniform and smooth surface of defined thickness. When the coated wafer is mounted to a rigid substrate, it may be mechanically thinned to thicknesses down to and beyond 25 um, depending upon the wafer composition, diameter, and process. Once thinned, the adhesive is safe for backside processing and is dissolved away at completion to provide a thinned wafer that is clean and ready for final dicing or chipping operations.

Owner:GENERAL CHEM CORP +1

Non-Tacky Adhesive Fastening System

InactiveUS20080107861A1Improve versatilityImprove fitFlexible coversWrappersMechanical engineeringContamination

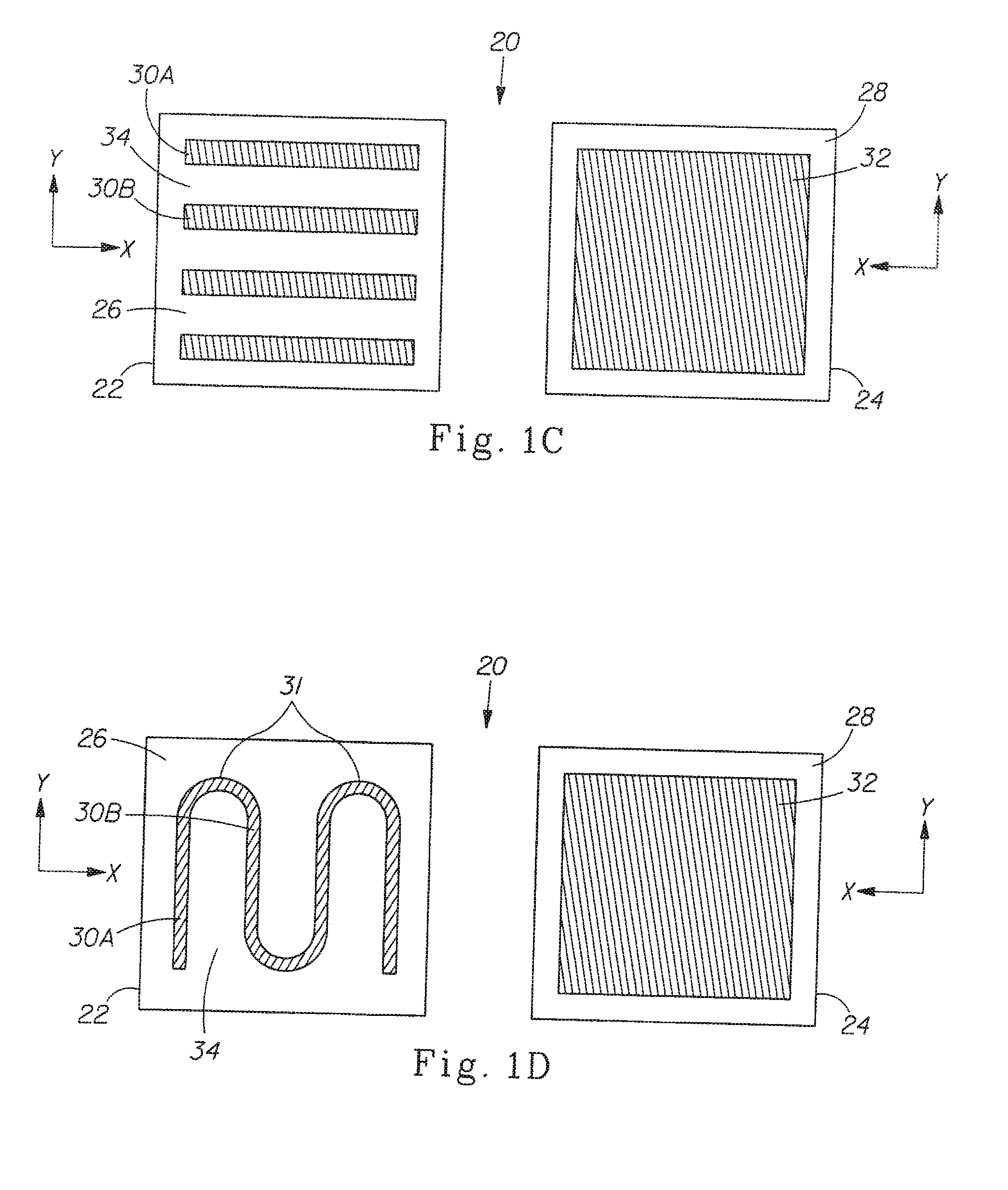

Non-tacky adhesive fastening systems are disclosed, which systems include non-tacky patterned adhesive systems and non-tacky three-dimensional adhesive systems. In a non-tacky adhesive fastening system, an engaging member including a non-tacky adherent is engageable with a receiving member including a non-tacky adherend. In a non-tacky patterned adhesive system, at least one of the engaging member and receiving member has the adherent / adherend disposed thereon in a patterned fashion. In a non-tacky three-dimensional adhesive system, at least one of the engaging member and receiving member includes a plurality of projections, thereby forming at least one three-dimensional adhesive surface. The non-tacky adhesive fastening systems exhibit advantageous peel characteristics and exhibit an increased resistance to contamination. The non-tacky adhesive fastening systems can be included in absorbent articles such as diapers and other consumer goods.

Owner:THE PROCTER & GAMBLE COMPANY

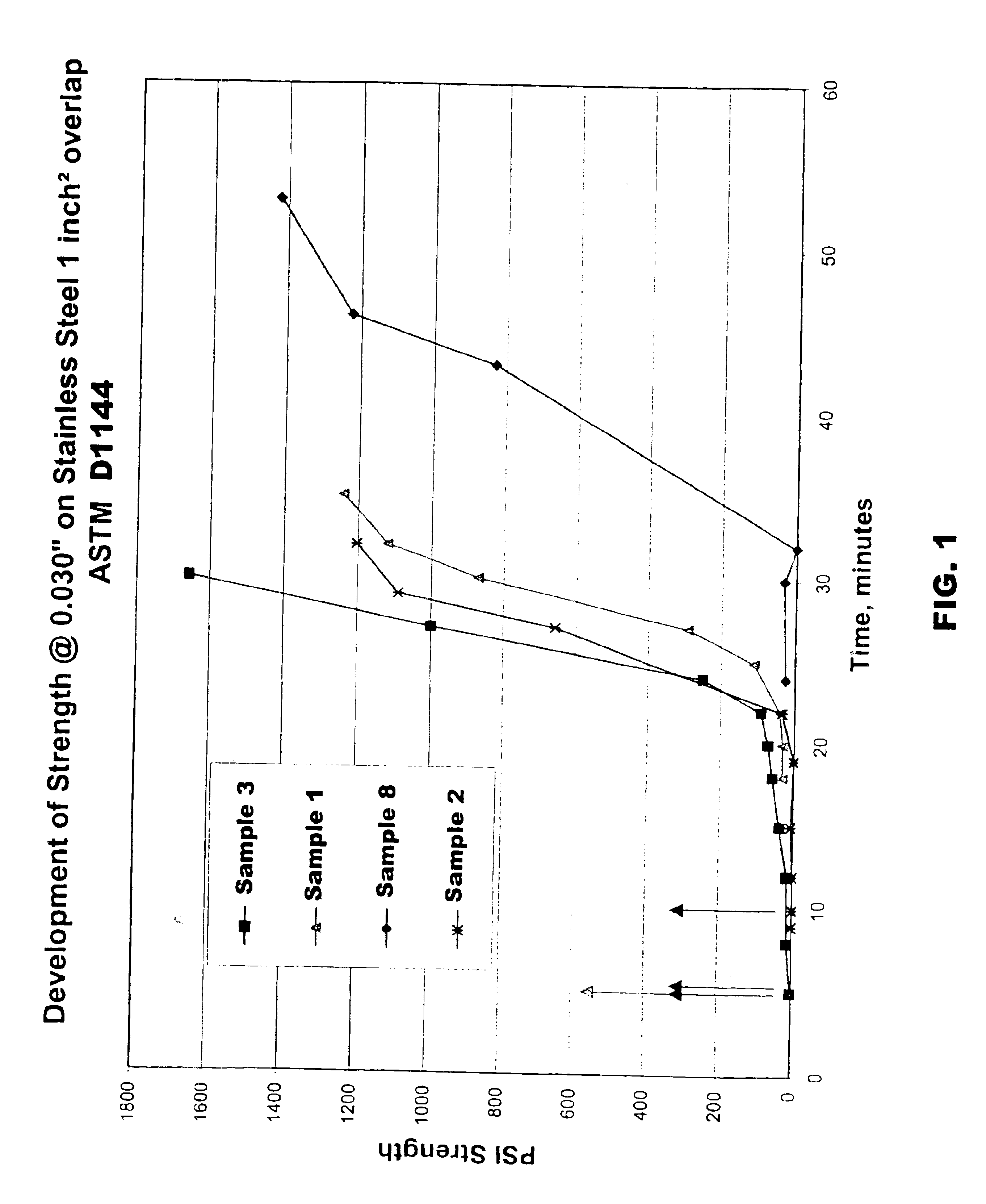

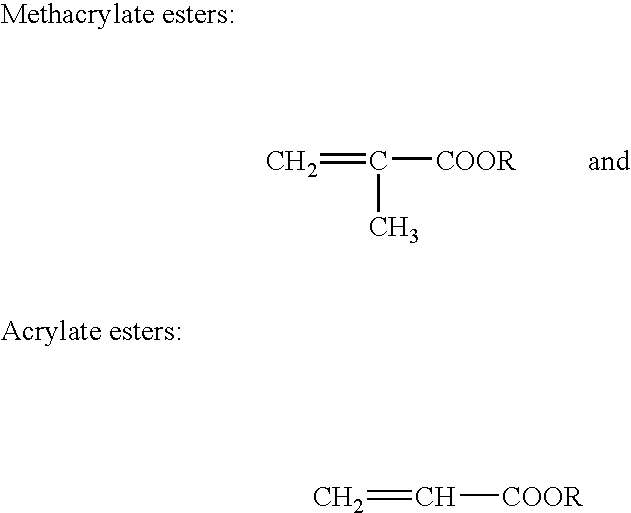

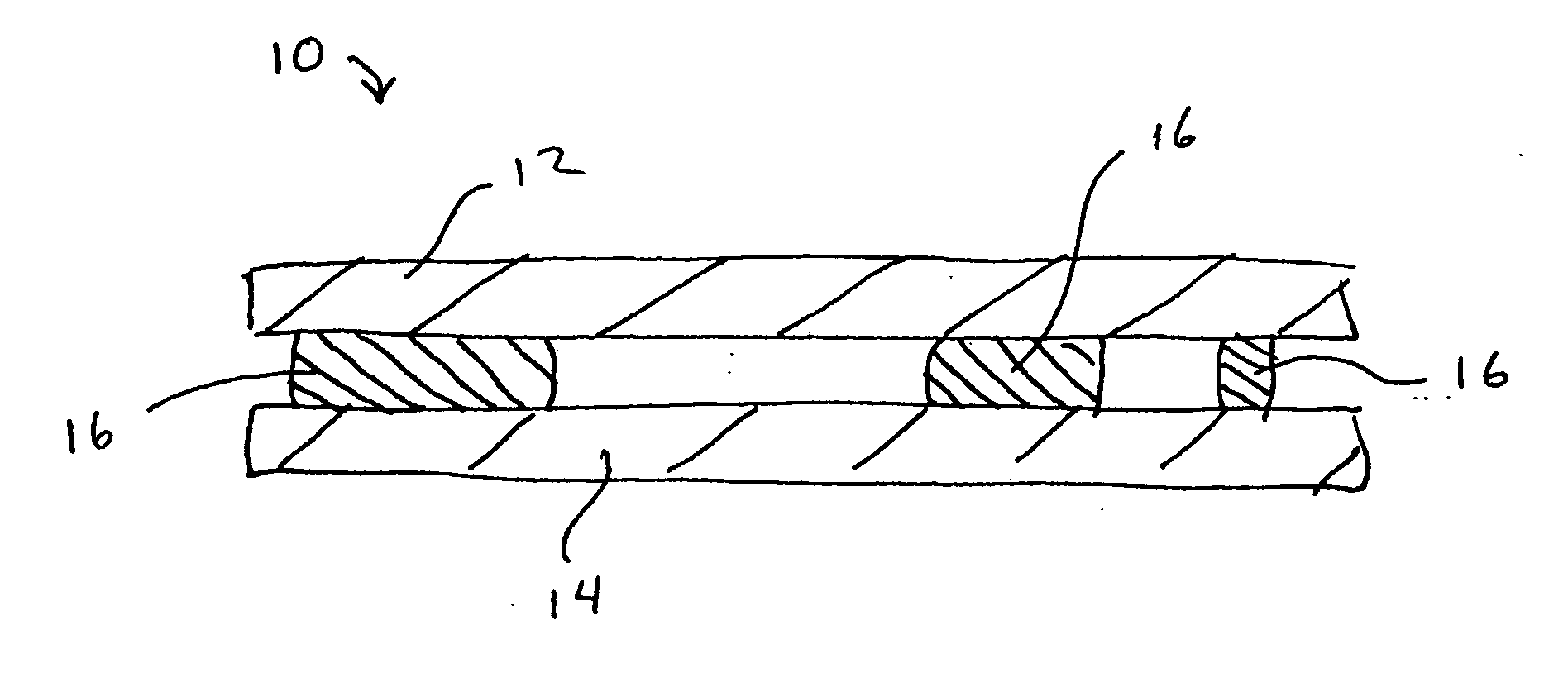

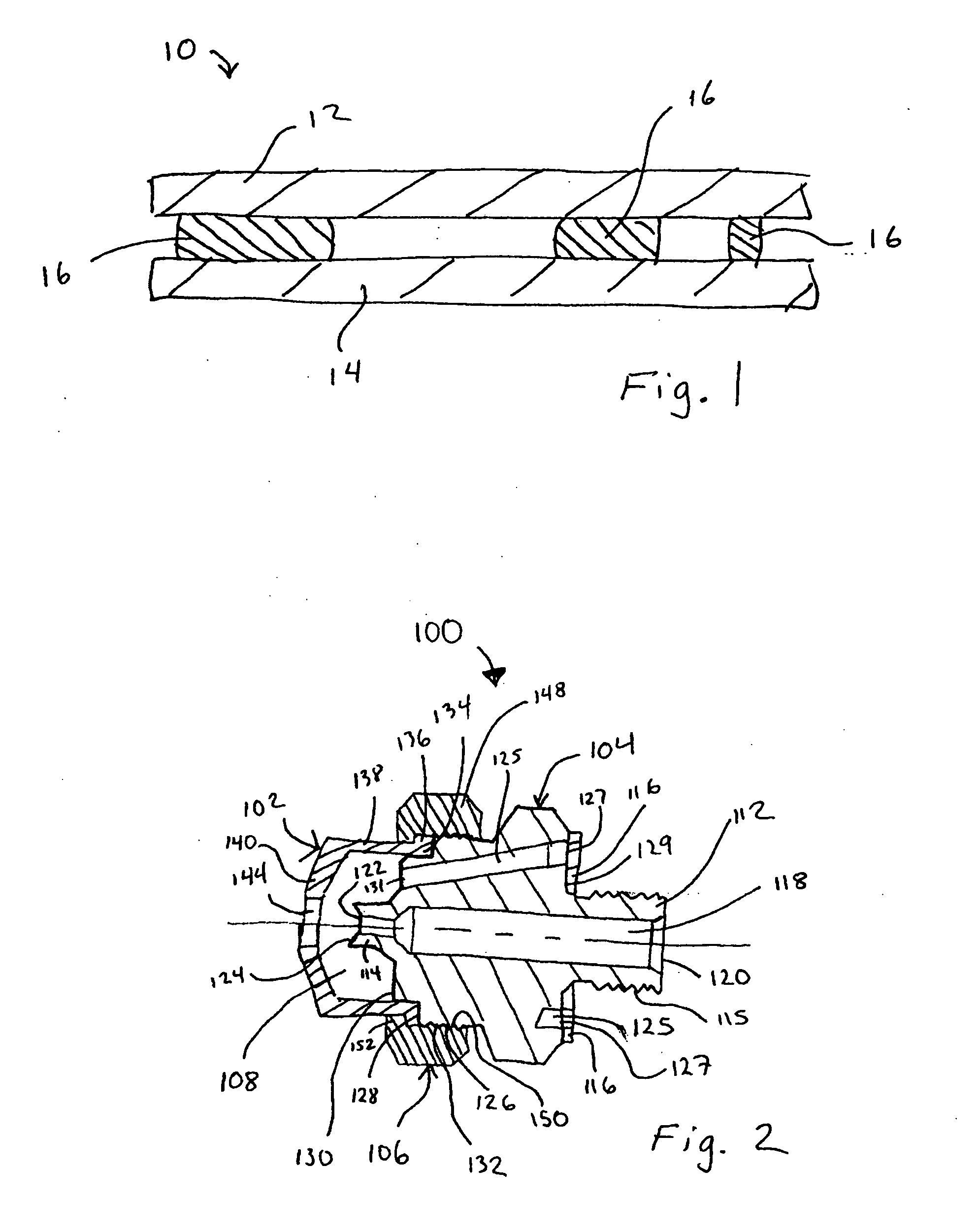

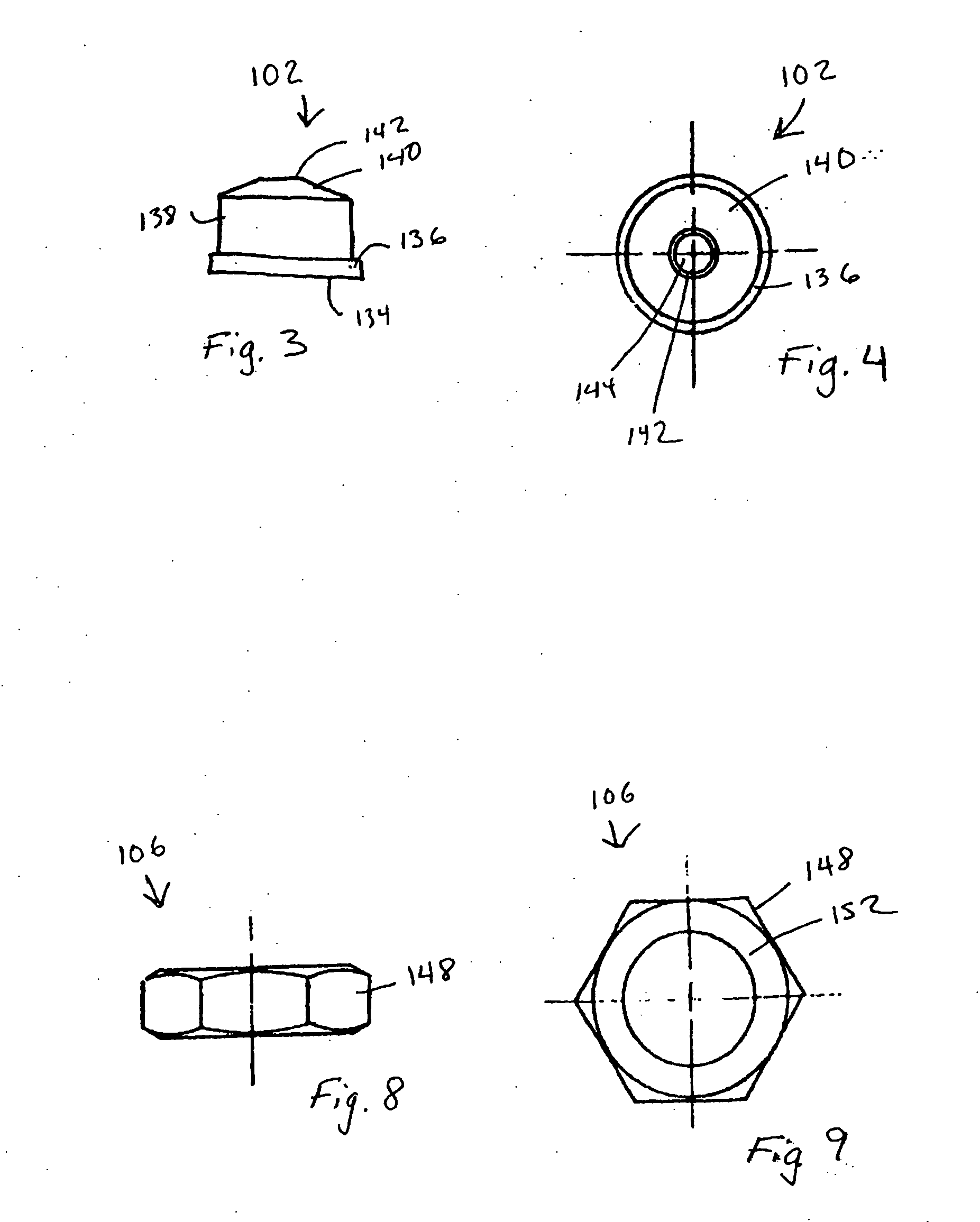

Two-part structural adhesive systems and laminates incorporating the same

InactiveUS6869497B2Improve handlingExtended opening timeSynthetic resin layered productsEster polymer adhesivesMolybdateAdhesive

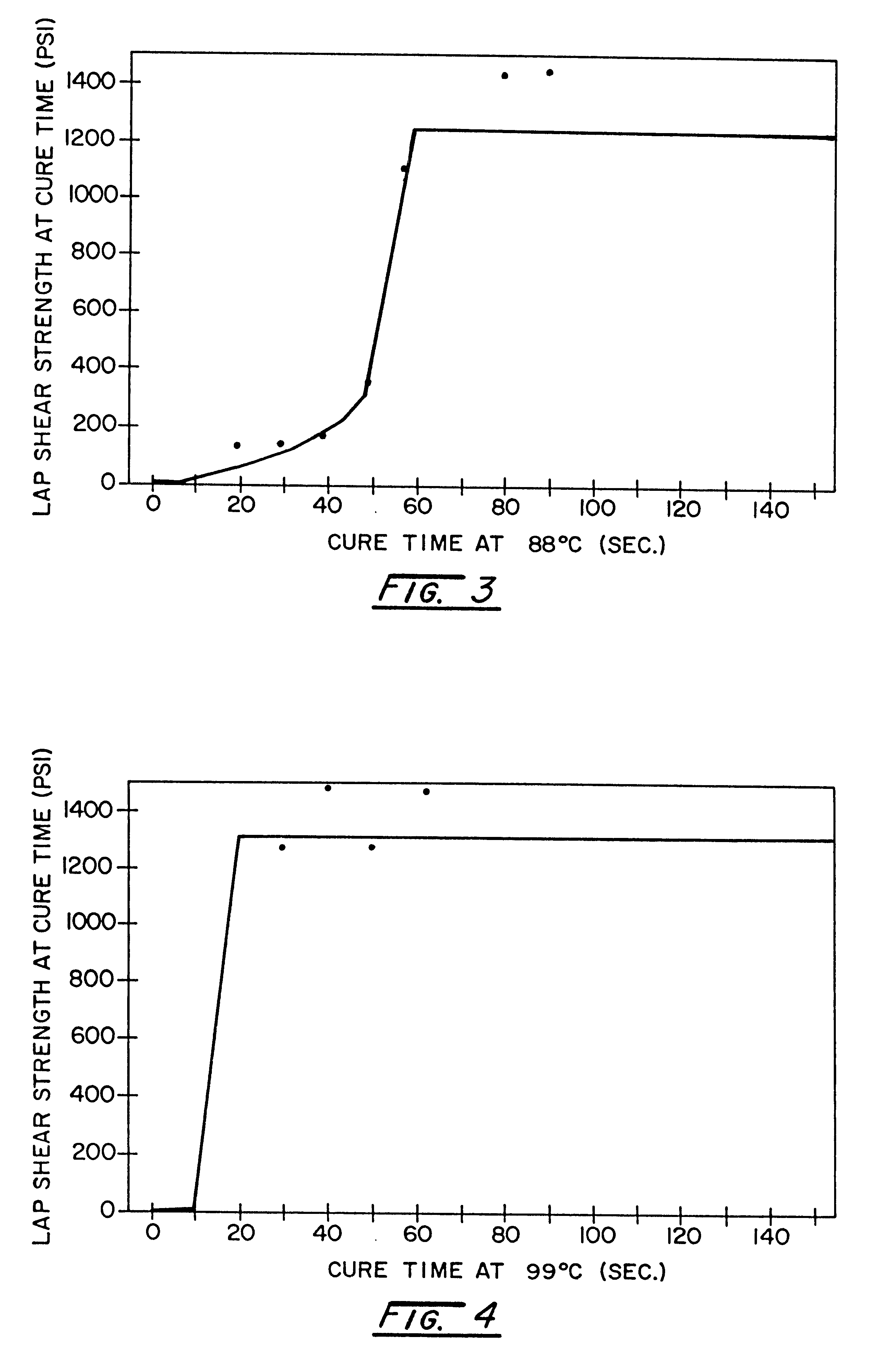

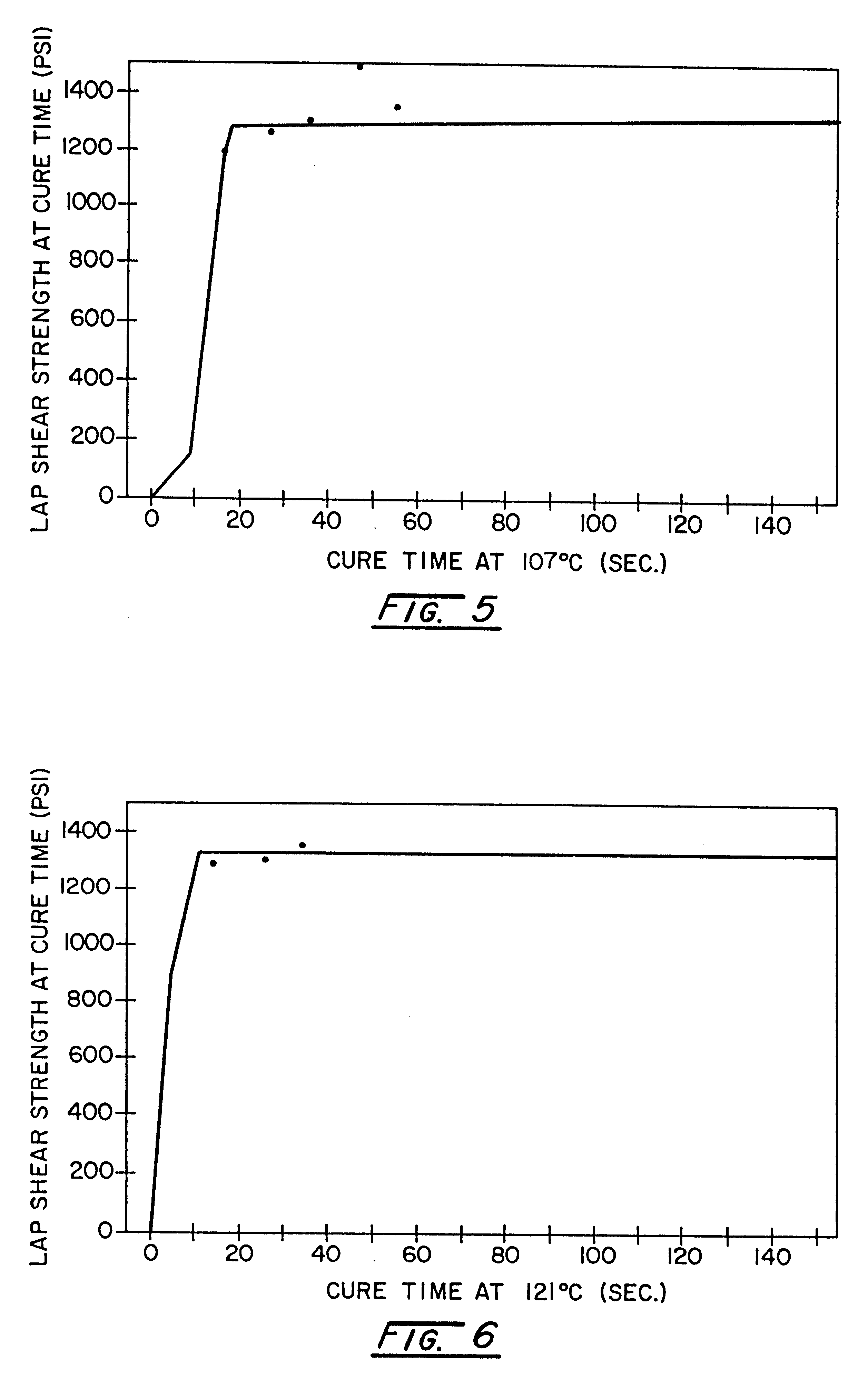

A two-part adhesive systems exhibiting improved fixture and open times are disclosed. In one embodiment, the system includes (a) an adhesive part being a mixture formed from (I) an ethylenically unsaturated monomer, (II) a metal molybdate, (III) a metal salt of an ethylenically unsaturated carboxylic acid in an amount less than 3 weight percent, and (IV) an ethylenically unsaturated carboxylic acid, and (b) an activator part which includes a free radical generator. In another embodiment, the system includes the above-described adhesive part substantially free of a metal salt of an ethylenically unsaturated carboxylic acid. Curable adhesives and laminates prepared with the two-part system are also disclosed.

Owner:ILLINOIS TOOL WORKS INC

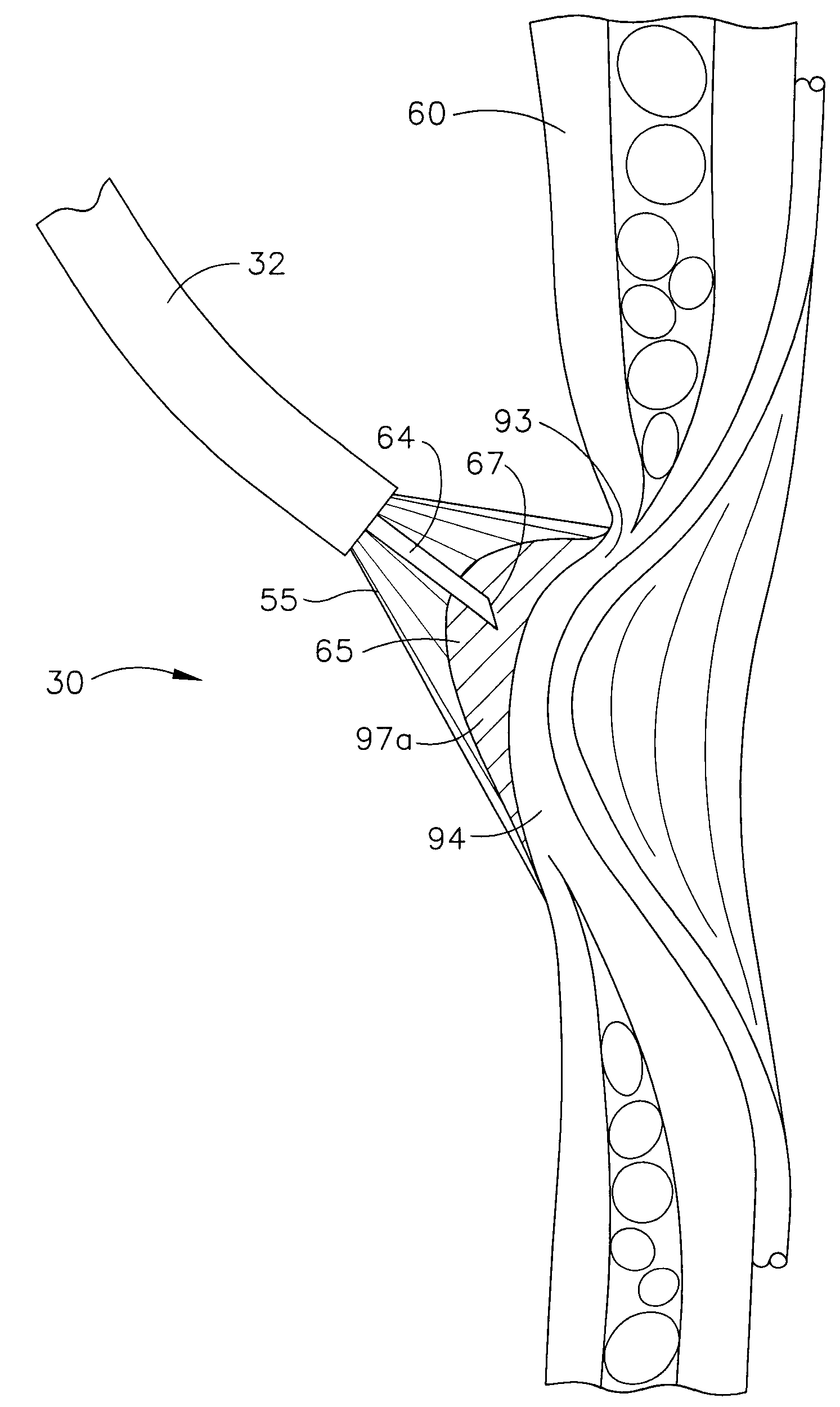

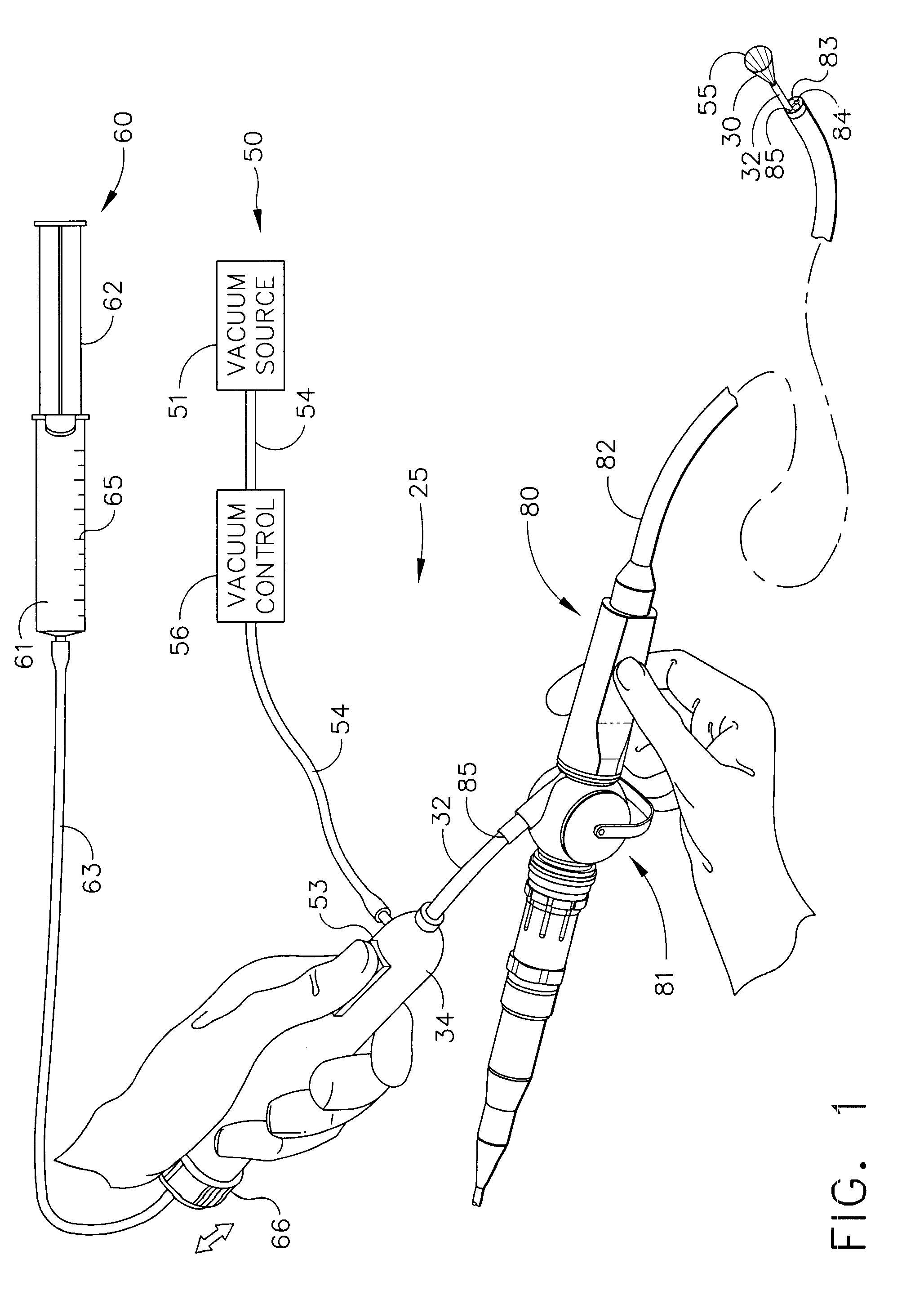

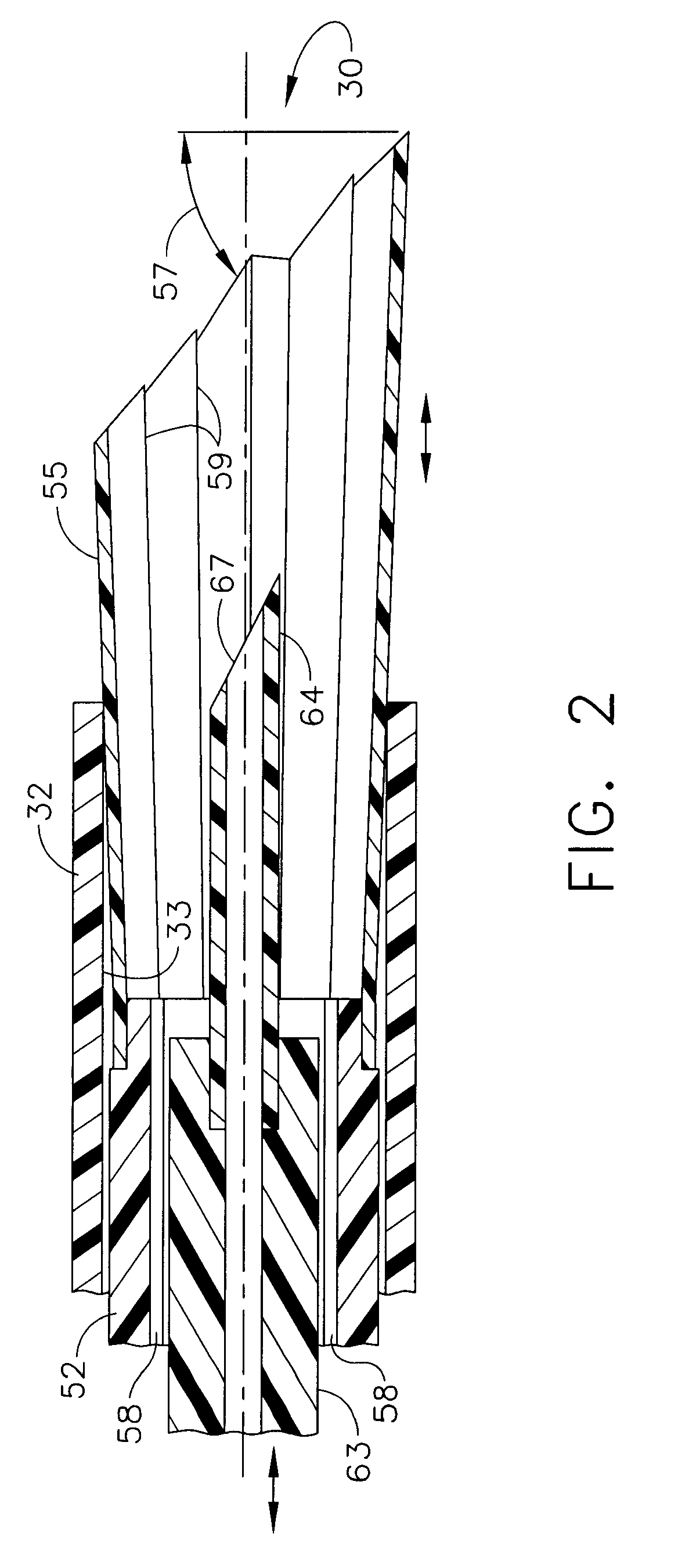

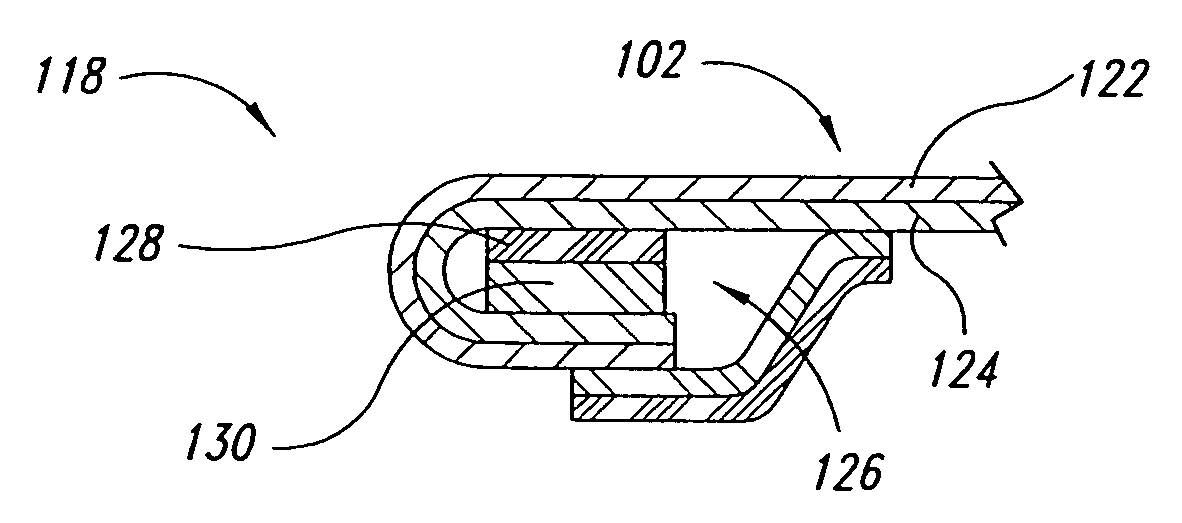

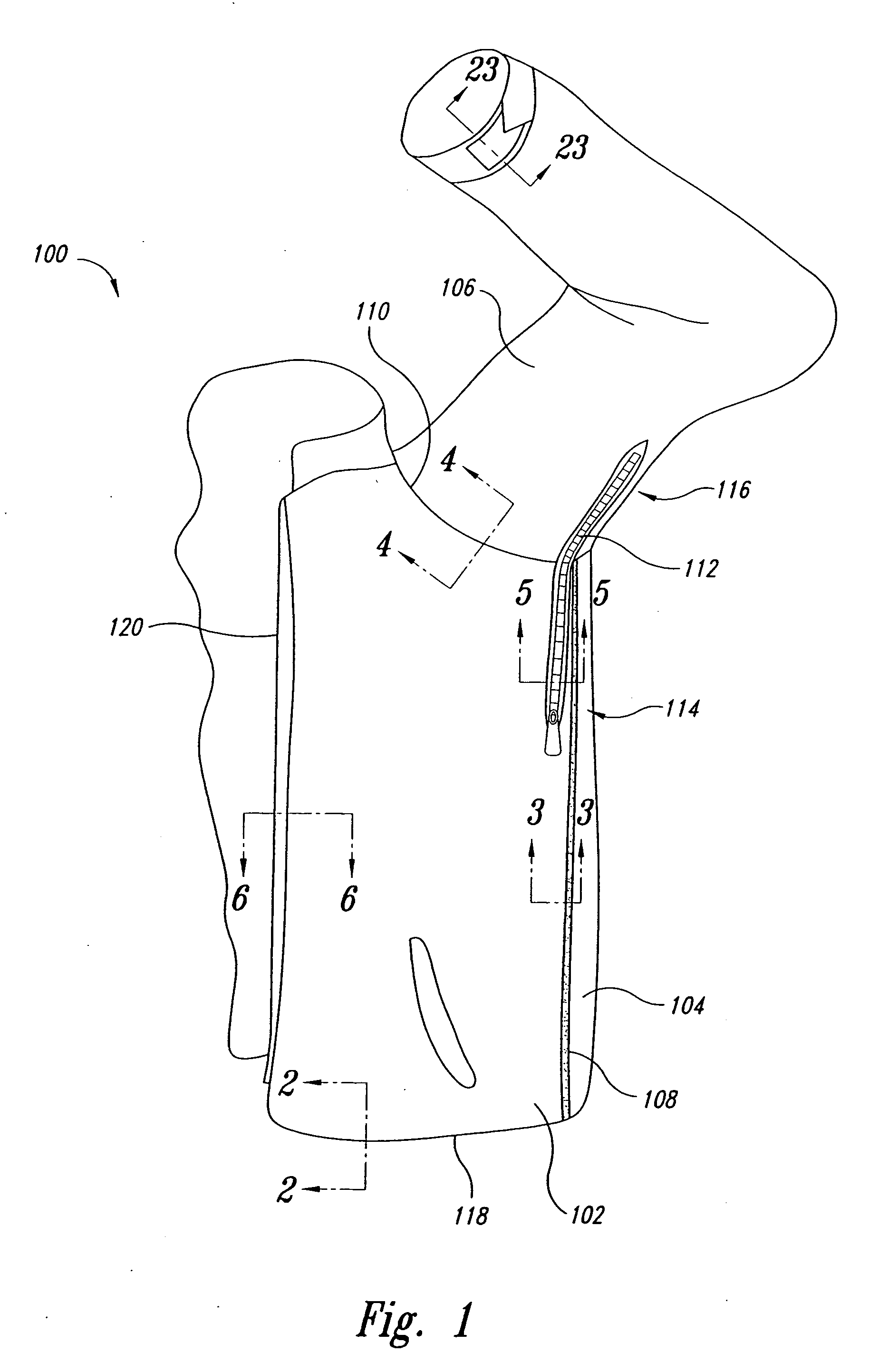

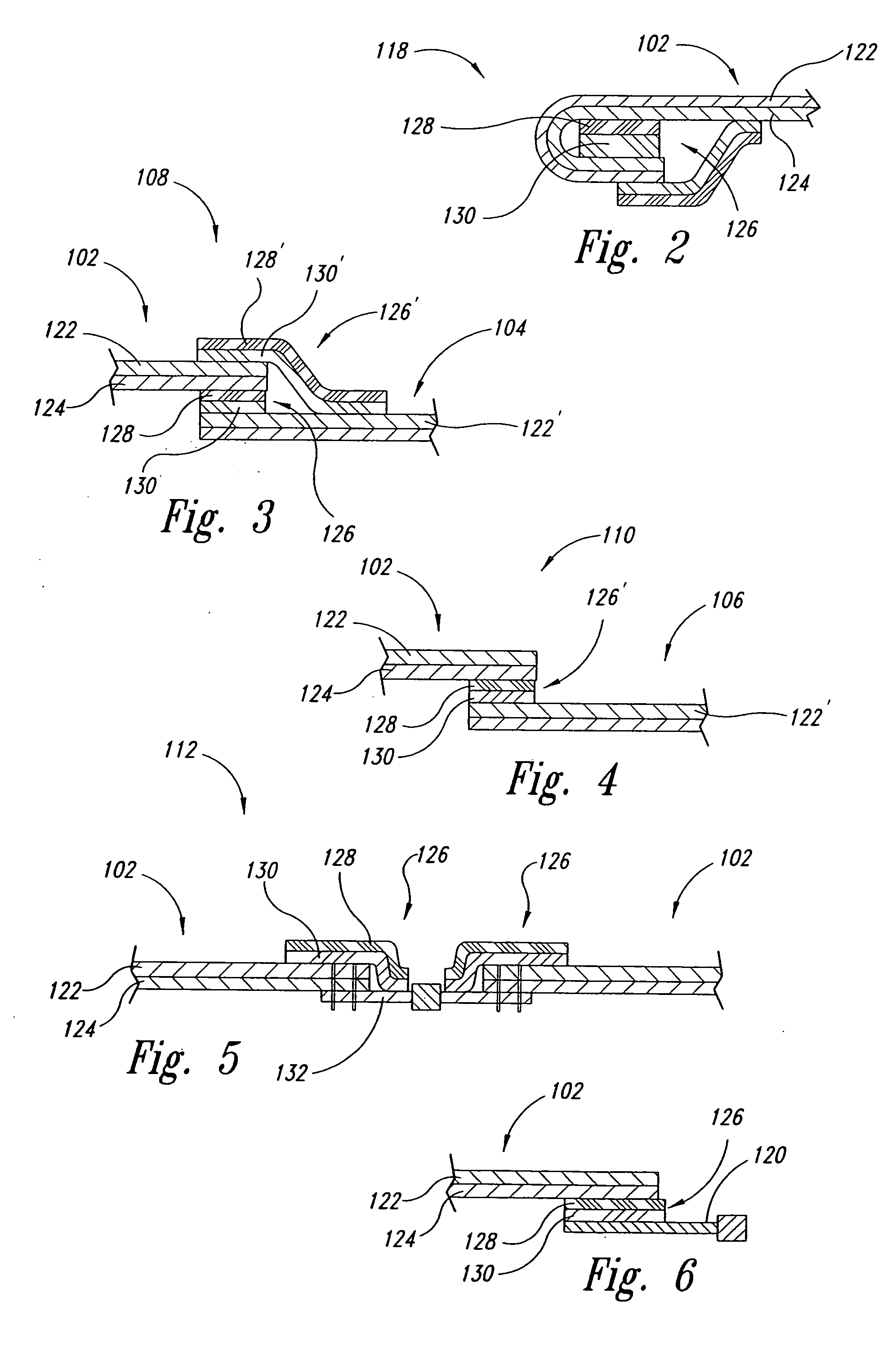

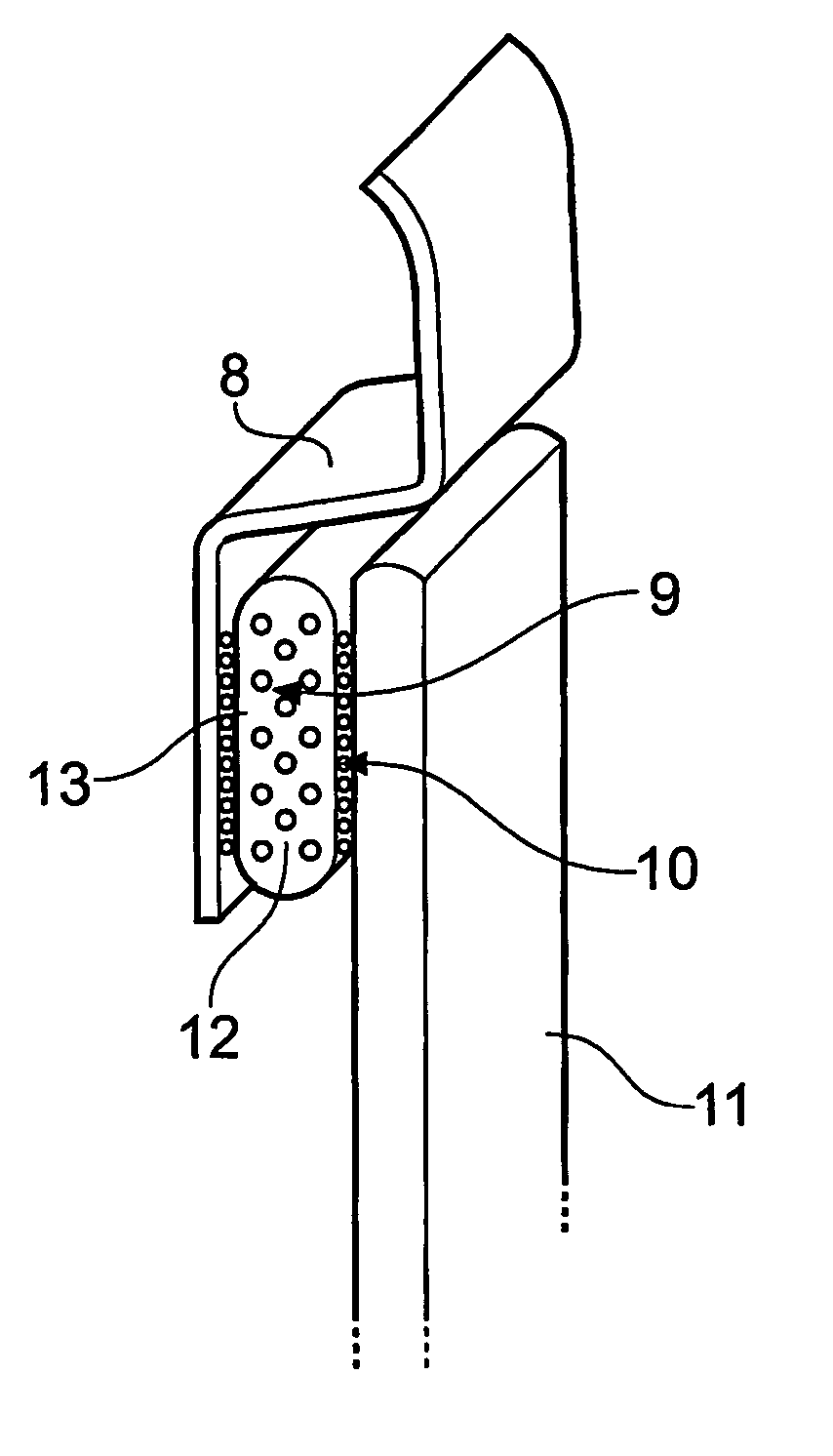

Use of an Adhesive to Treat Intraluminal Bleeding

A surgical device to stanch the flow of blood is disclosed. The surgical device can place an implantable adhesive over or around varices or other bleeders. The surgical device has a vacuum system for capturing tissue and an adhesive system to apply adhesive to the captured tissue. A vacuum chamber is used to contact tissue and contains a chamber therein for the reception of tissue. An adhesive applicator is provided within the vacuum chamber and moves longitudinally therein to apply adhesive to tissue. The surgical device can apply an adhesive patch to tissue or inject adhesive into tissue. Alternately, an adhesive actuator and a chemical agent can be dispensed to tissue within the vacuum chamber.

Owner:ETHICON ENDO SURGERY INC

Image graphic adhesive system and method for using same

InactiveUS6482288B1Bonded firmlyPredictive performanceLamination ancillary operationsPicture framesGraphicsAdhesive system

Owner:3M INNOVATIVE PROPERTIES CO

Polyurethane reaction system having a blocked catalyst combination

InactiveUS6348121B1Long open timeFast curing timePolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentPolyolMetal catalyst

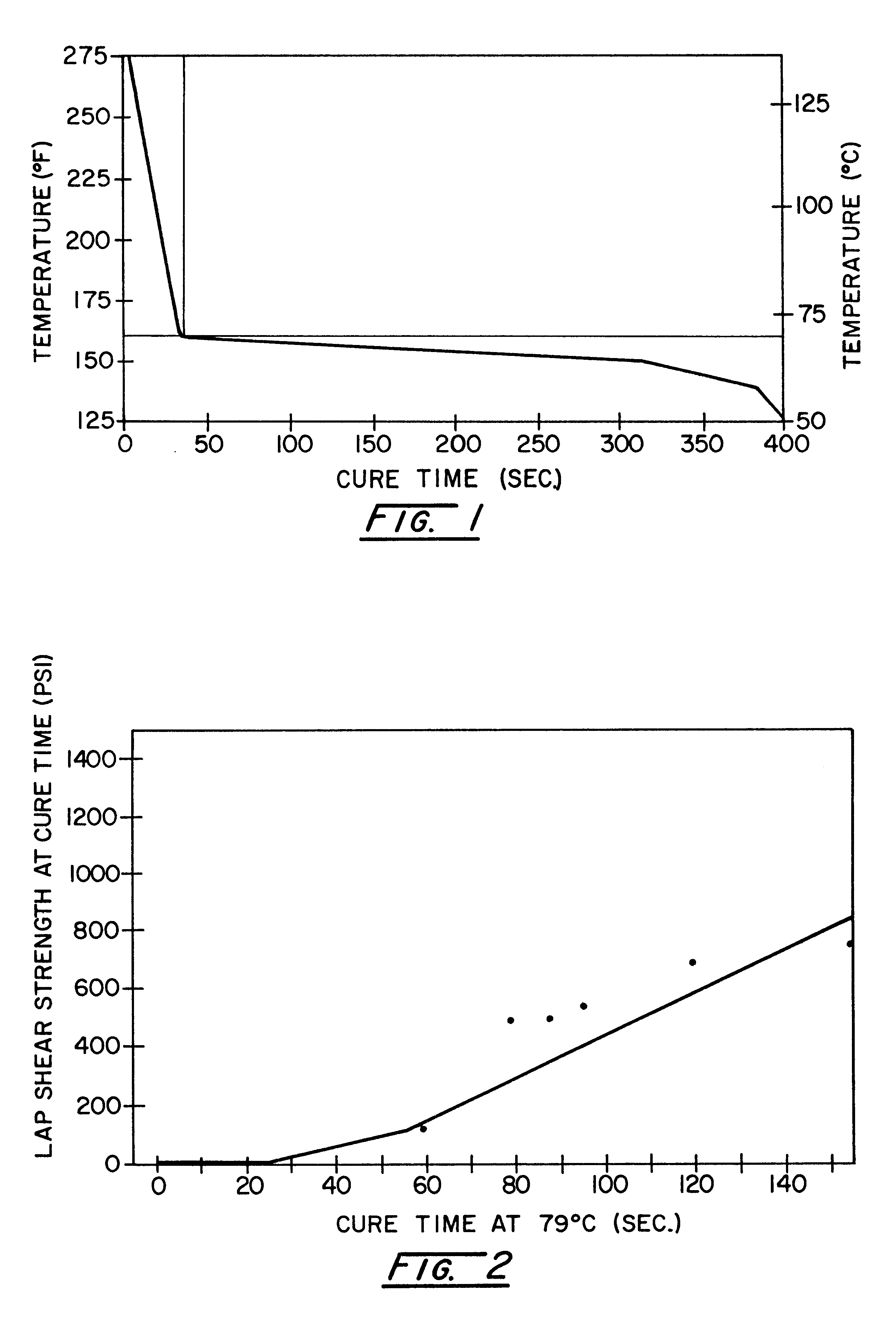

Disclosed is a polyol / polyisocyanate adhesive system having an isocyanate component and a catalyzed component which form a heat-cured composition when admixed and heated above a threshold temperature. The catalyzed component has a hydroxyl-functional component catalyzed with a catalyst combination of a heat-activatable amine or amine-like catalyst which is activated at temperatures above the threshold temperature, and an activatable complexed metal catalyst comprising the reaction product of tin or bismuth catalysts, or a mixture thereof, and a molar excess of a mercapto compound complexing agent. The catalyst combination is effective to maintain the processibility of the system at ambient temperatures while promoting the rapid cure of the system when heated above the threshold temperature.

Owner:ASHLAND LICENSING & INTPROP LLC

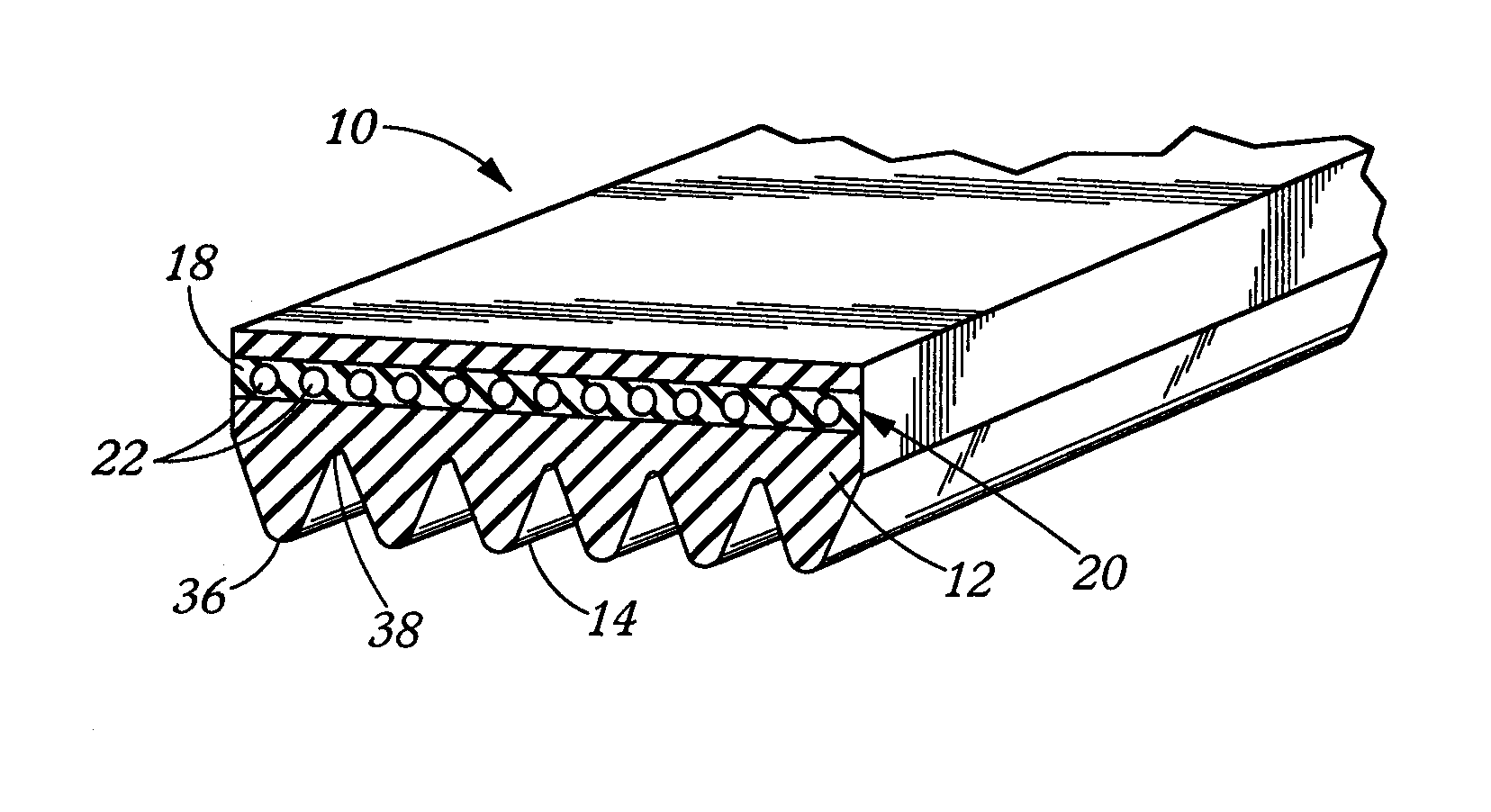

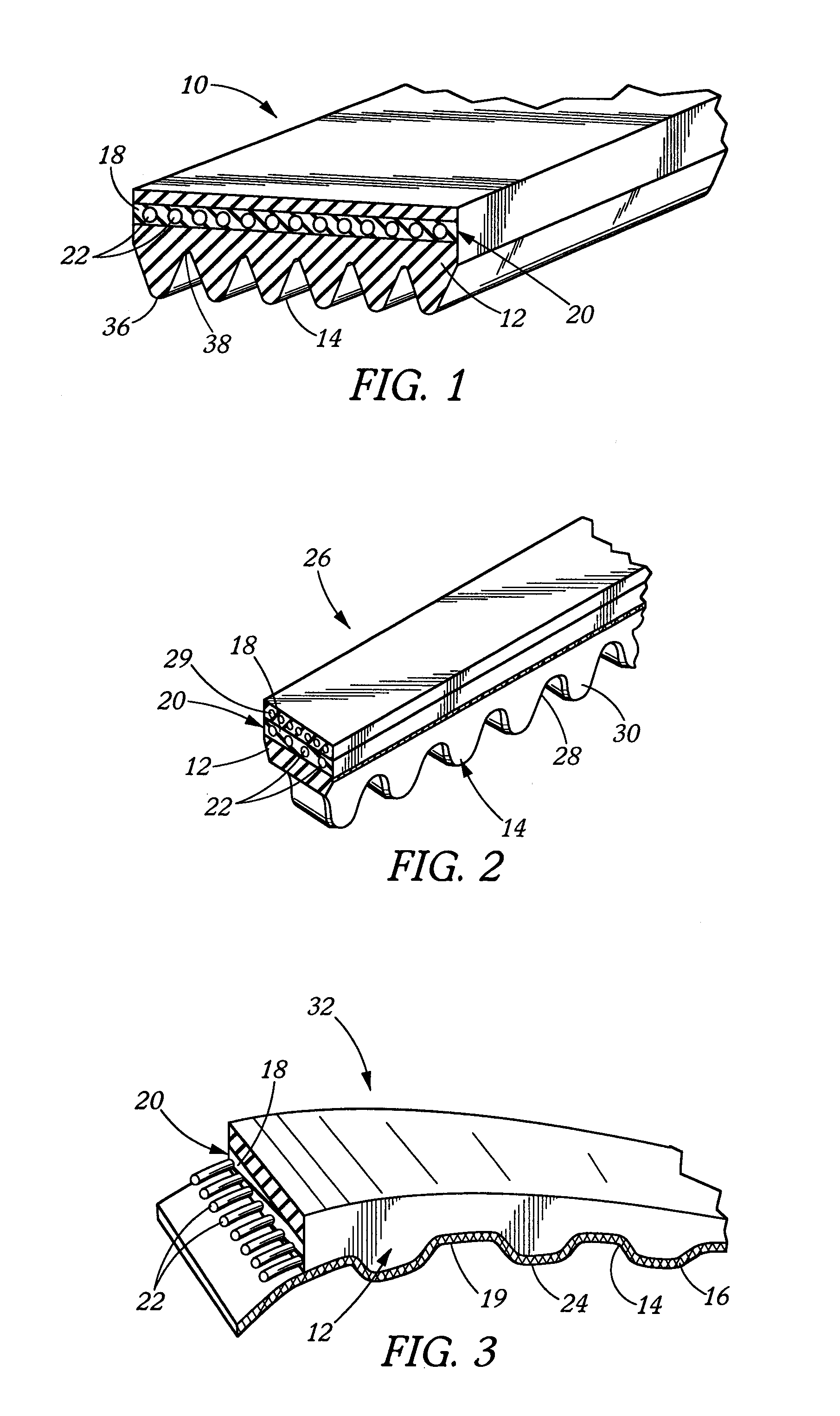

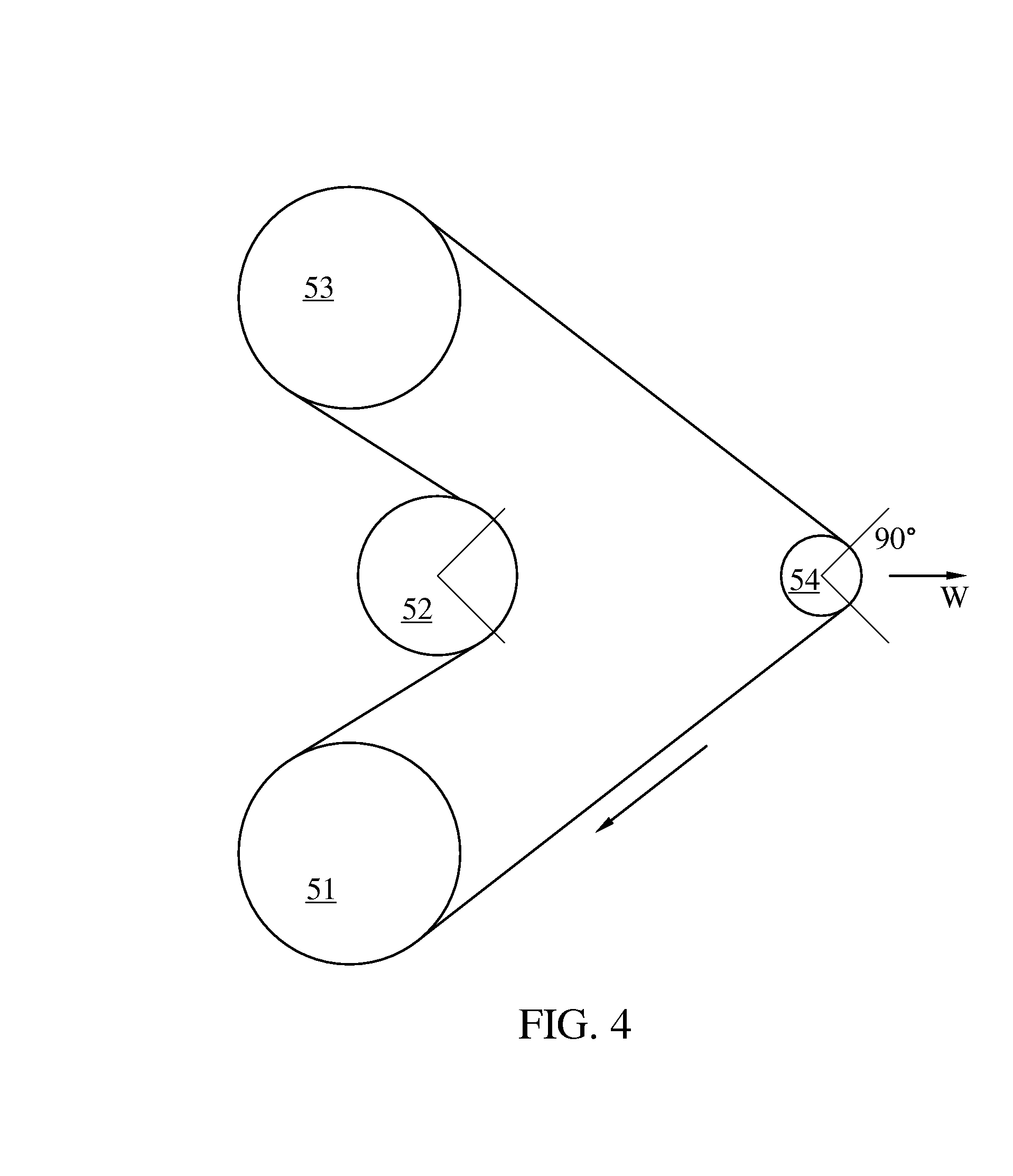

Power transmission belt and cord adhesive system and adhesion method

ActiveUS20090142572A1Improve balanceLow costV-beltsRopes and cables for vehicles/pulleyPolyesterElastomer

Owner:THE GATES CORP

Adhesive system and method of producing a wood based product

InactiveUS20070298274A1Suitable for useSufficient qualityAdhesive processesWood layered productsPolymerAdhesive system

The invention relates to a method of producing a wood based product, comprising applying an adhesive system onto one or more pieces of a wood-based material, and joining the one or more pieces with one or more further pieces of a material, the adhesive system comprises one component comprising starch and another component comprising one or more polymers (P) containing an amine group or an amide group. The present invention also relates to an adhesive system comprising one component comprising starch and another component comprising one or more polymers (P) containing an amine group or an amide group, the two components being present as unmixed separate components. The invention further relates to a wood based product.

Owner:AKZO NOBEL COATINGS INT BV

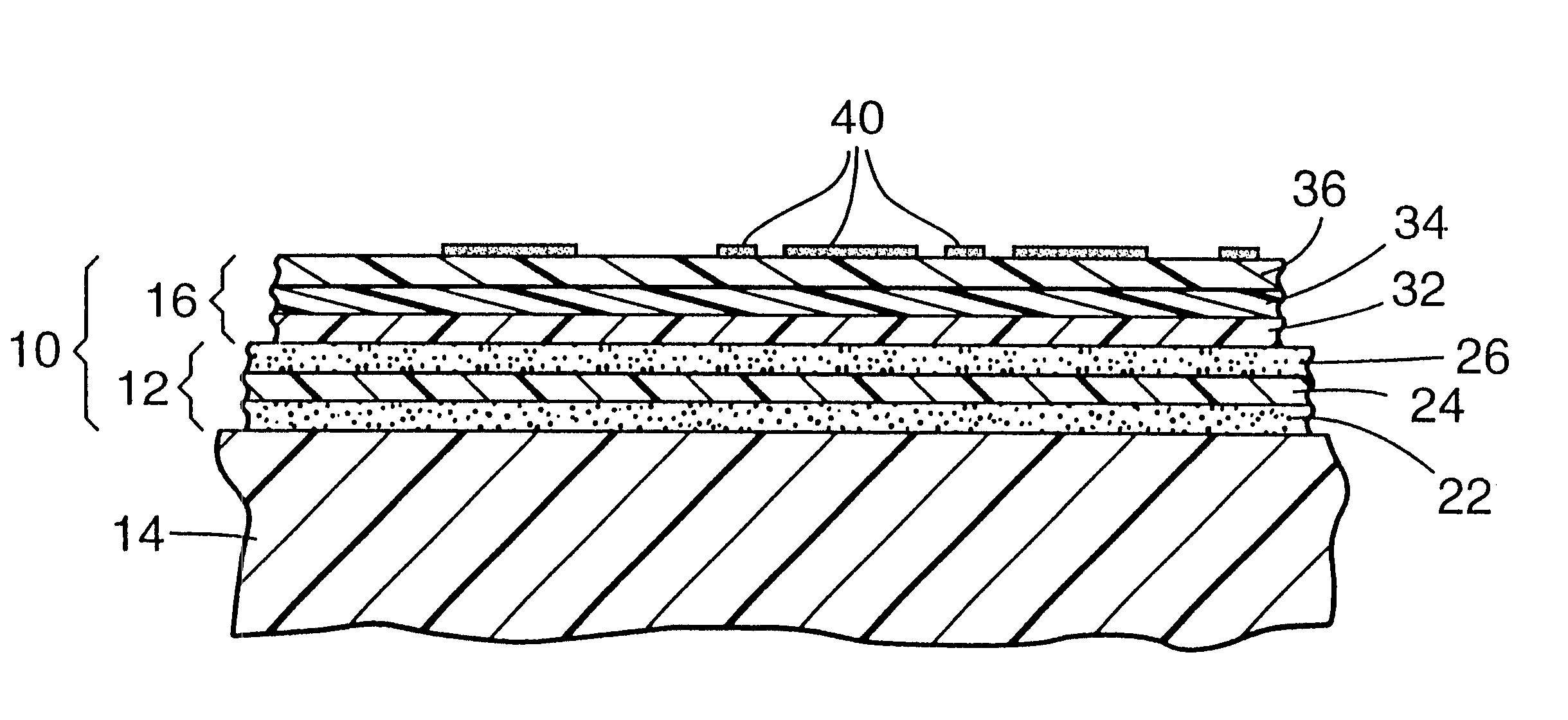

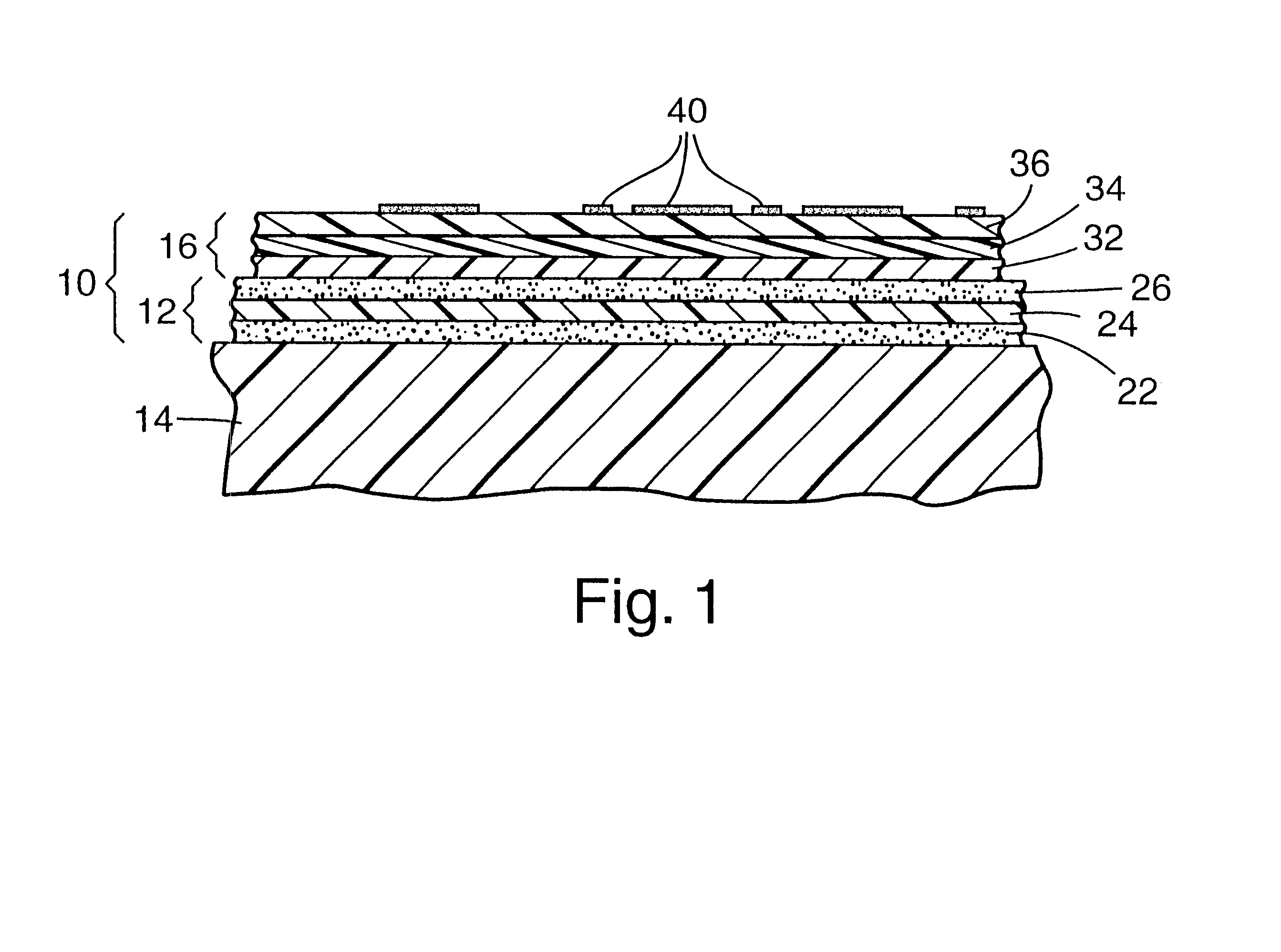

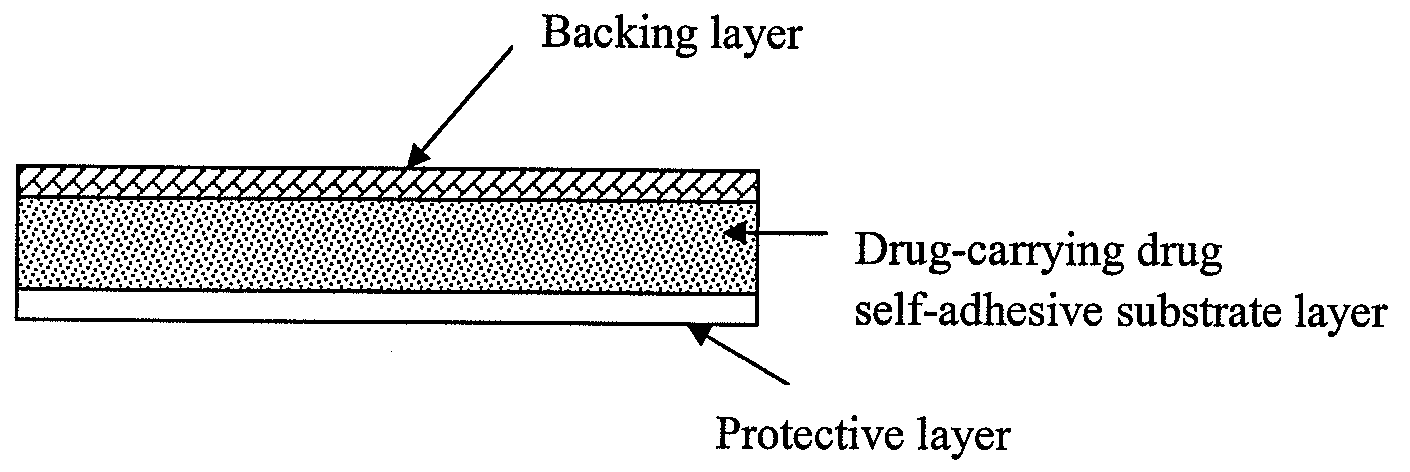

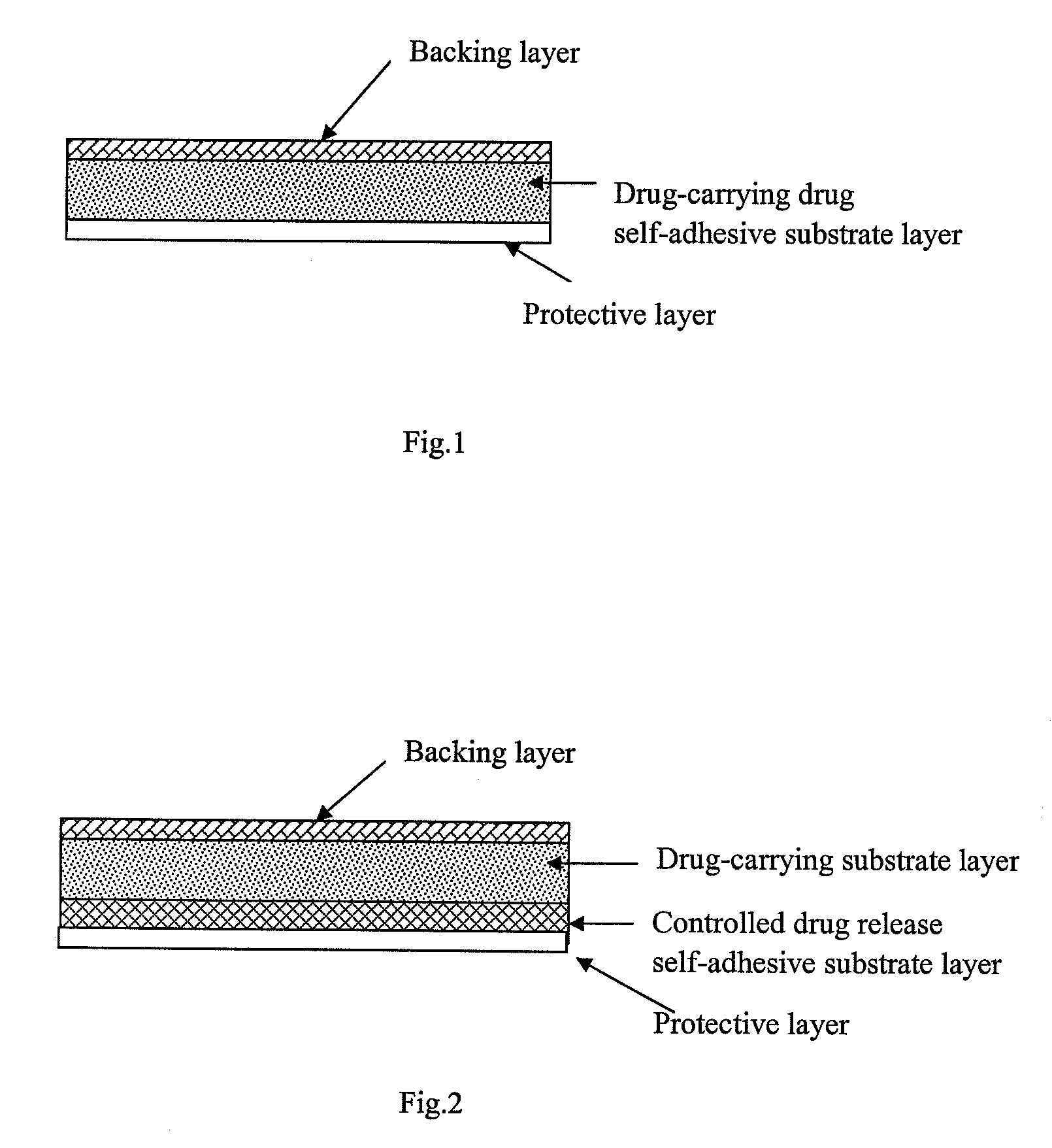

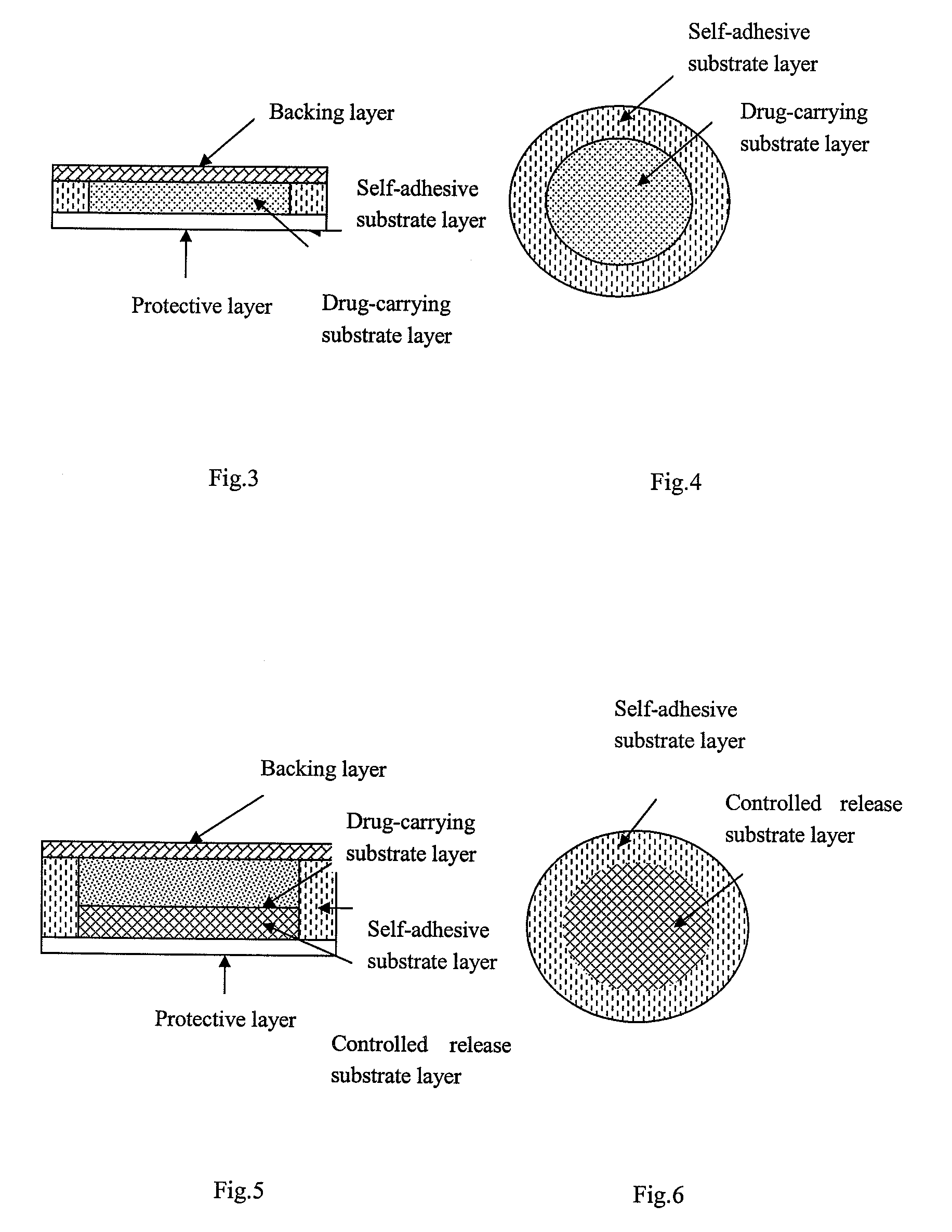

Transdermal patch containing rasagiline for treatment or prophylaxis of nervous system disease and its preparation process

InactiveUS20090136549A1Improve skin penetrationTreatment or prophylaxis of nervous system diseasesBiocideOrganic active ingredientsTransdermal patchPharmacy

The present invention relates to a rasagiline transdermal patch for treatment or prophylaxis of nervous system diseases, in which the patch comprises an inert backing layer chemically inert to substrate ingredients, a substrate layer comprising rasagiline or a pharmaceutically acceptable salt thereof, and a protective layer to be peeled off before use. The substrate layer is an adhesive system comprising an organic polymer material as basis and an inorganic or organic material as filler, and a plurality of micro-reservoirs containing rasagiline. The substrate further comprises one or more substances for enhancing the transdermal absorption of rasagiline, in which the above organic polymer material in the substrate is used for the reservoir of rasagiline and as adhesive.

Owner:CHONGQING PHARMA RES INST +1

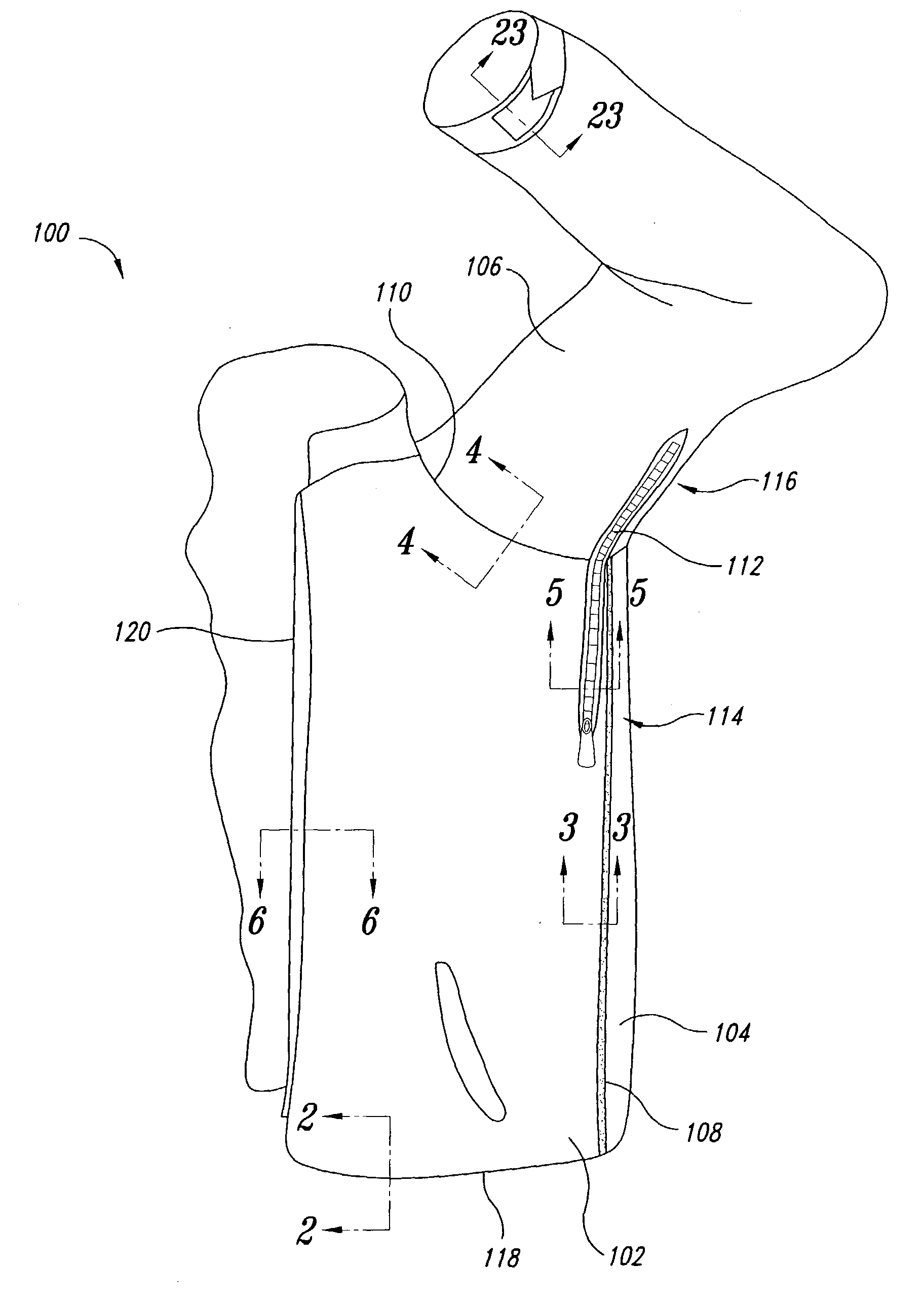

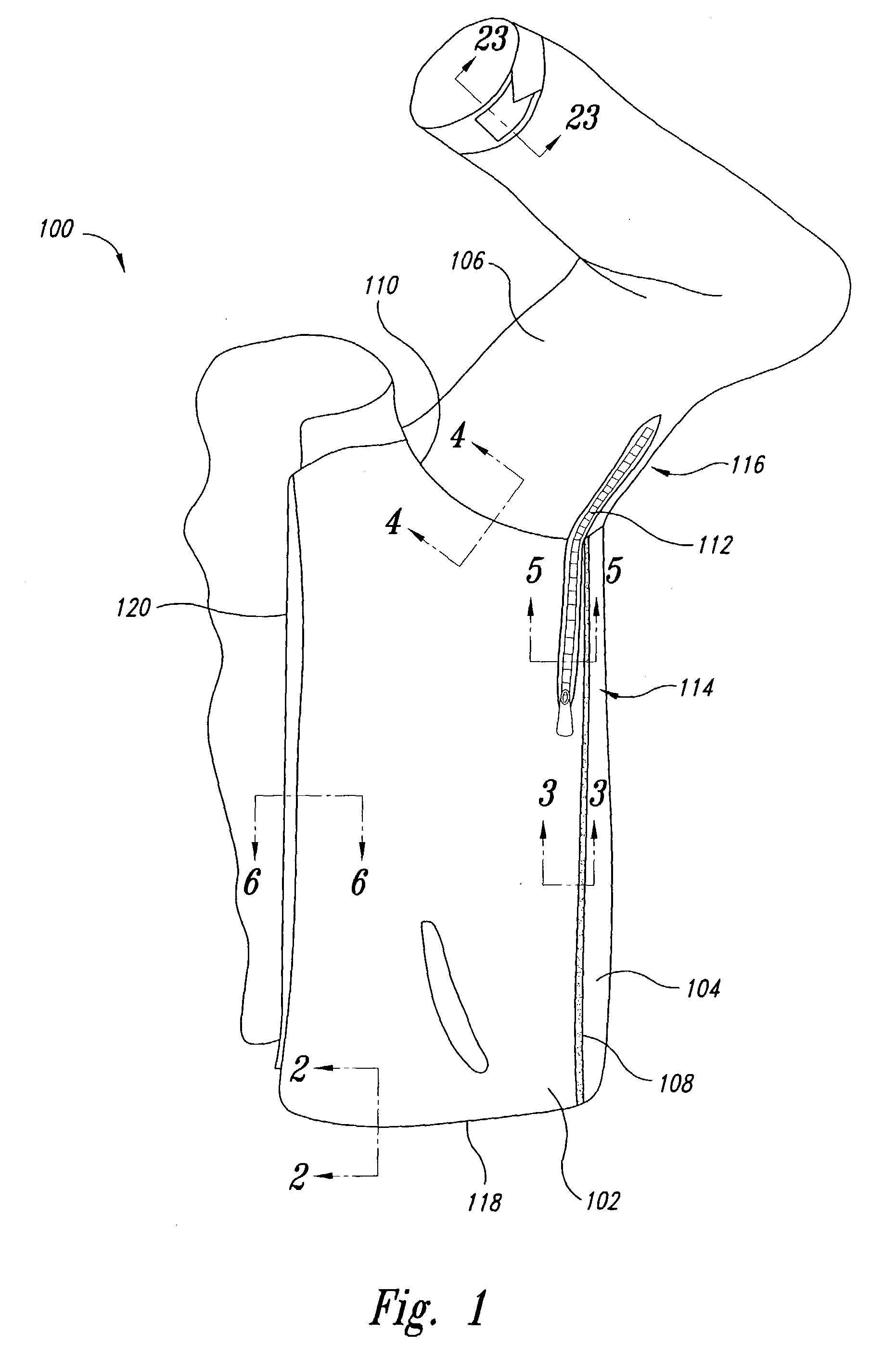

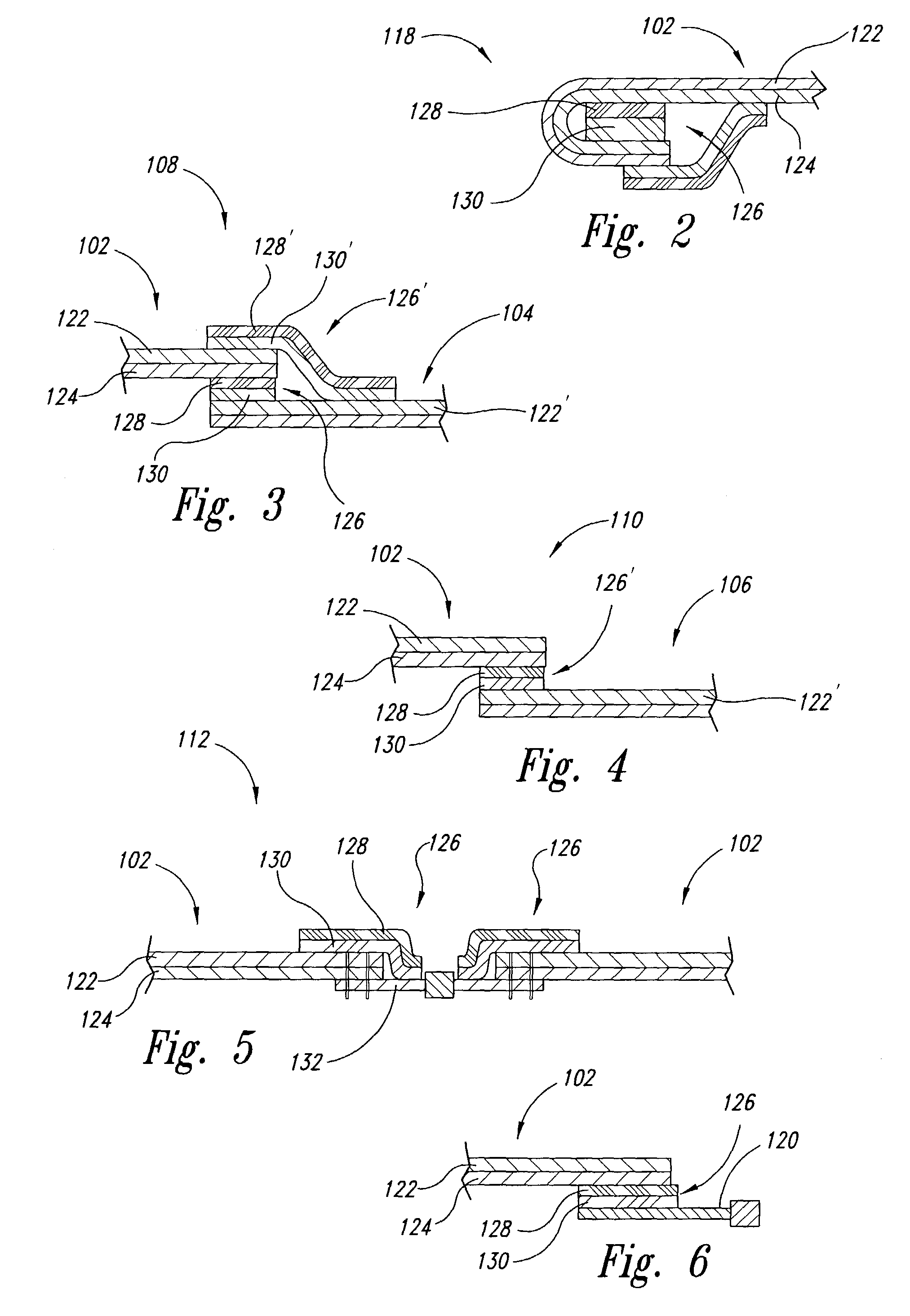

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER

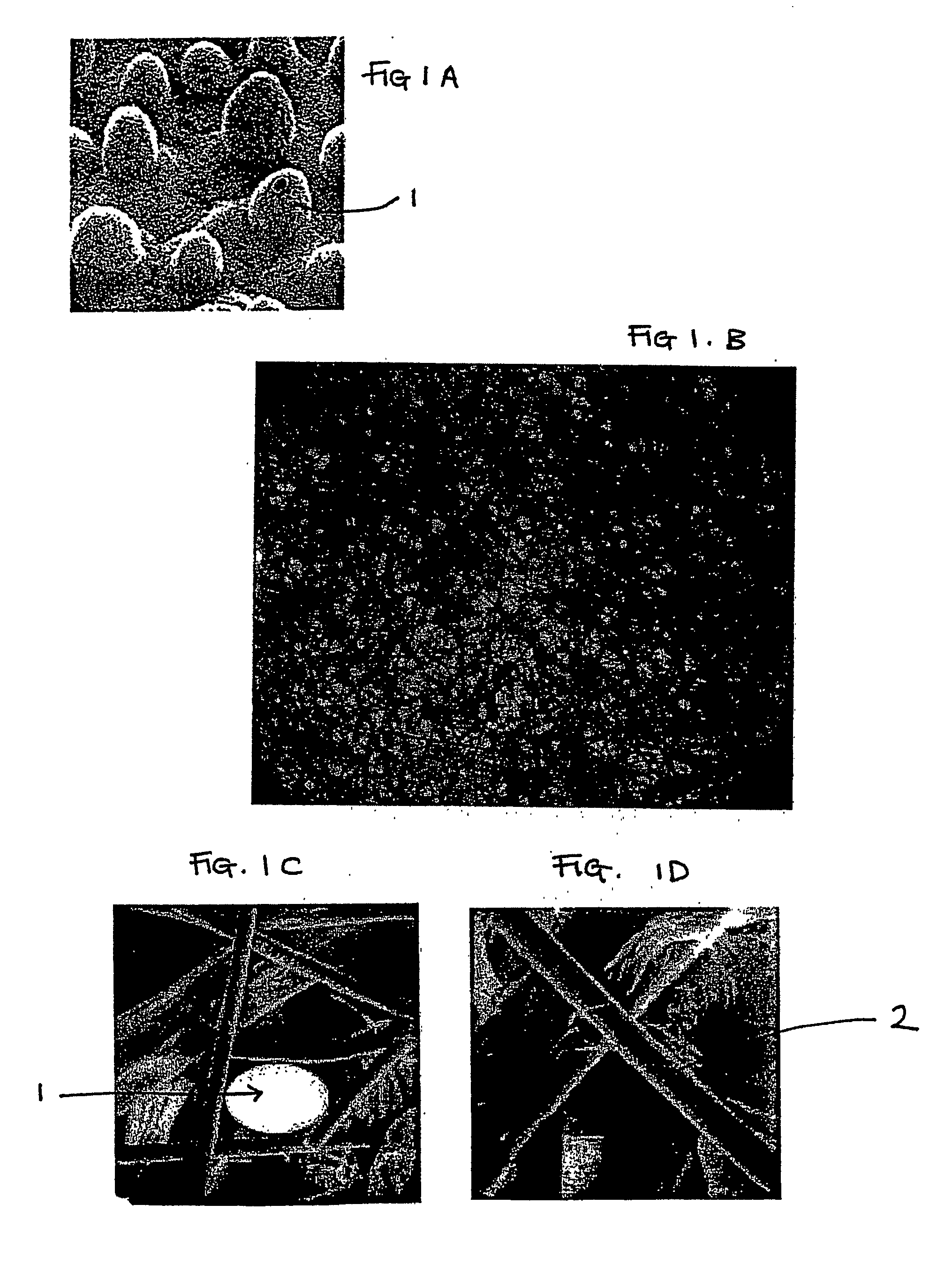

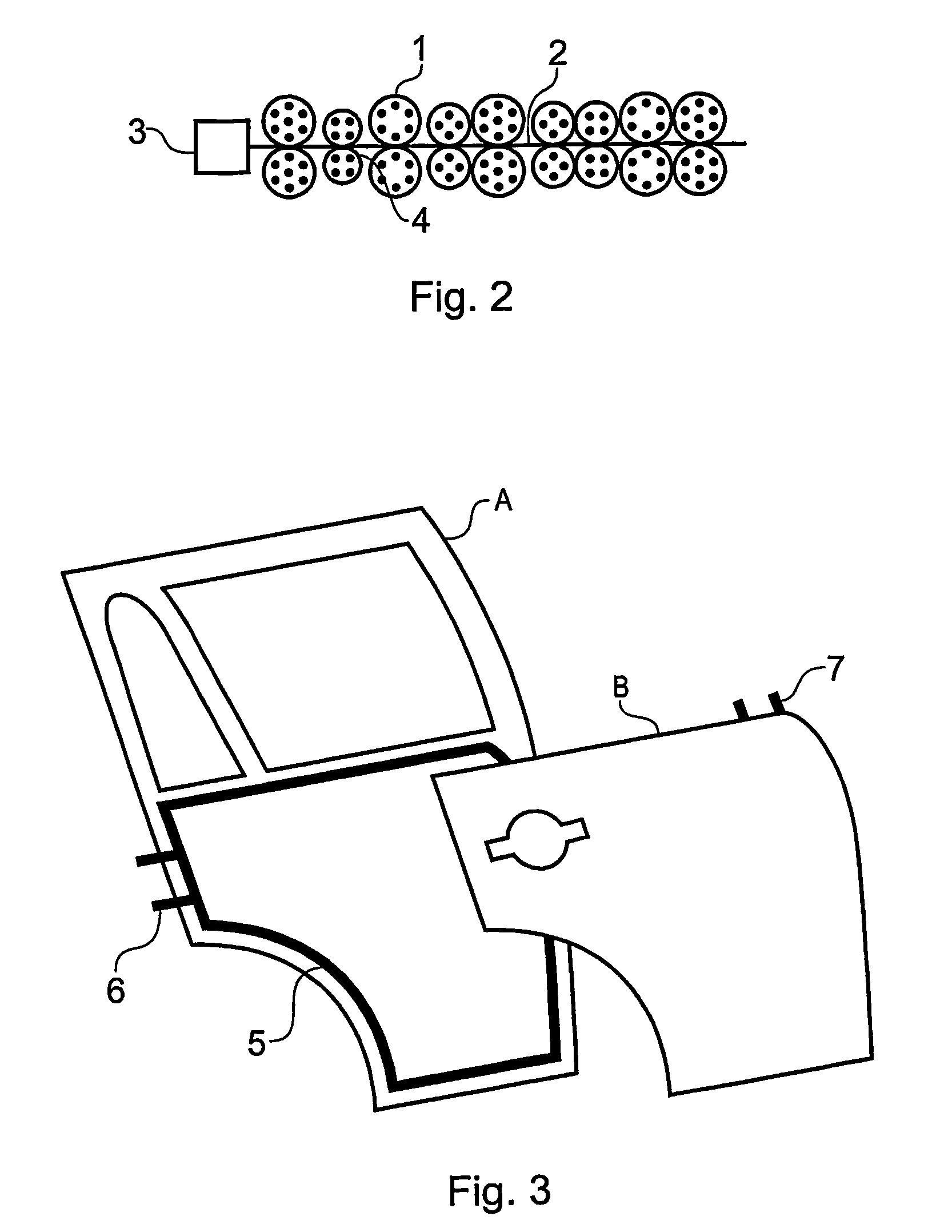

Method and apparatus for bonding and debonding adhesive interface surfaces

InactiveUS20060219350A1Shorten the timeEvenly distributedEngine sealsNanostructure manufactureThermal energyMicrosphere

The present invention relates to a system and a method of improving the debonding of two or more surfaces together. The invention utilises thermoexpanadable microspheres and thermal energy to debond interfaces in an adhesive system or as vehicle carriers. It also discloses a method of curing the adhesive system prior to the debonding step so that the same adhesive system may be used for both phases. It is especially useful in the automotive industry for end of vehicle life dismantling.

Owner:BAIN & COMPANY

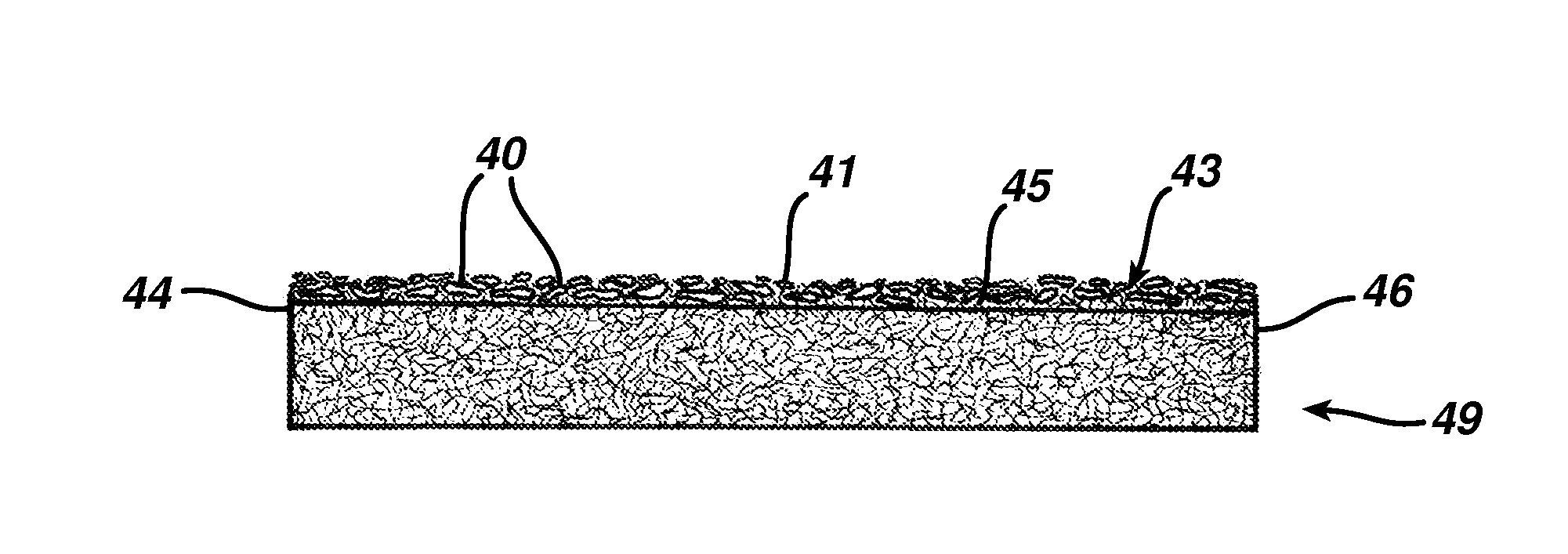

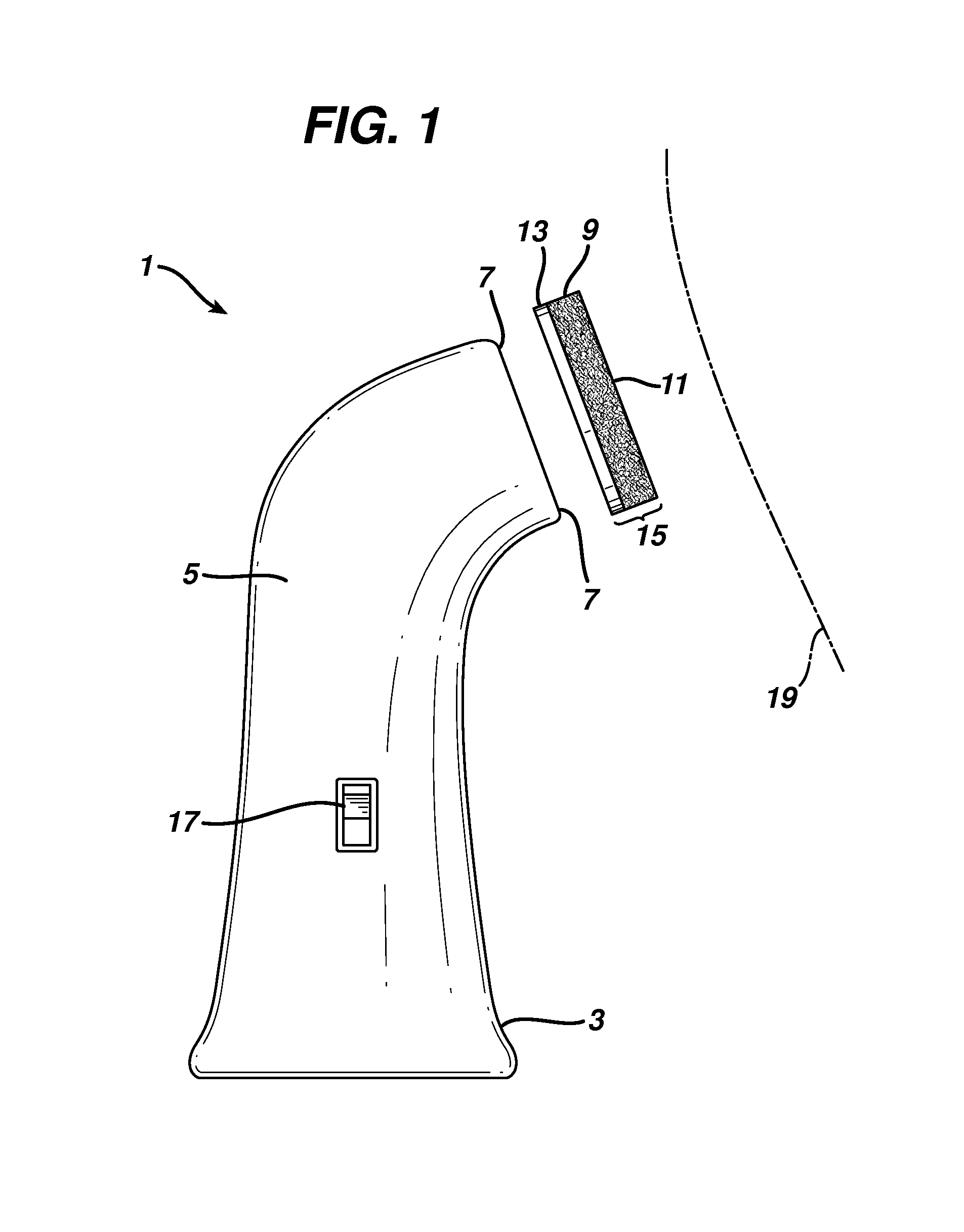

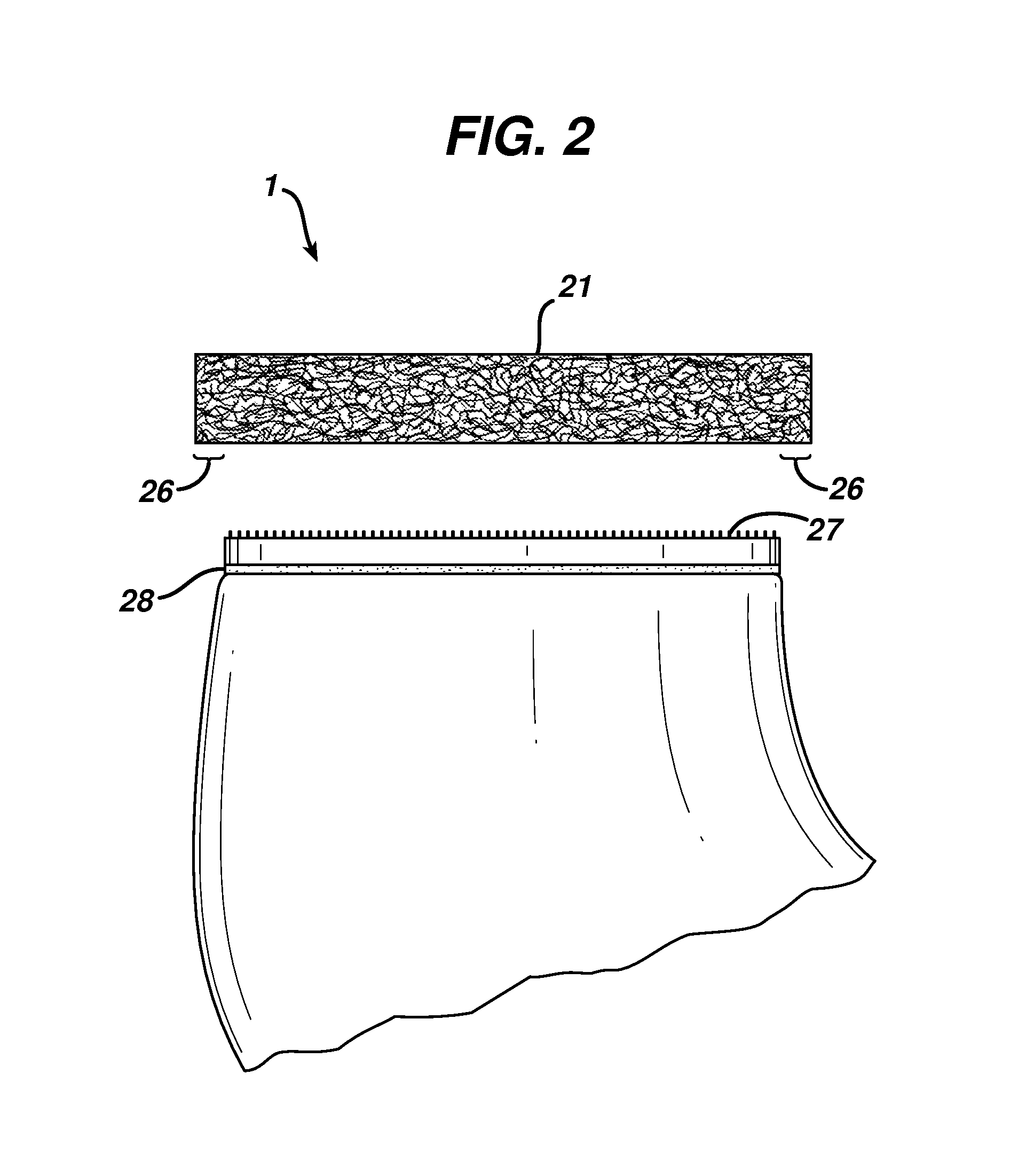

Mechanical skin resurfacing

InactiveUS20130345721A1High strengthExcision instrumentsAbrasive surgical cuttersFiberMotion generation

An article useful for mechanical skin resurfacing techniques is suitable for transferring mechanical energy from a handheld device to skin placed in contact with the article. The article may be characterized by its Durable Abrasiveness, Compressibility, Displacement, and / or surface roughness. The article may be formed of a fibrous structure having a first major surface having associated therewith an adhesive system and a second major surface, generally opposite the first major surface. The second major surface is arranged and configured to reversibly engage a fastener of a motion-generating unit. The invention also relates to a coupling device for coupling a motorized apparatus to a disposable skin-contactable element. The coupling device includes a water-resistant first attachment and a second attachment for releasably affixing said article to a surface of the motion generation unit.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Label adhesive and activation method for polymeric label

InactiveUS7943714B2Accelerates the removal of moistureSufficient resistanceStampsLiquid surface applicatorsWater basedActivation method

A water activated adhesive system is described that is particularly suited for applying non-paper polymeric labels to surfaces which have low moisture permeability. The adhesive system is characterized by a dry non-tacky surface that becomes tacky in less than one second when contacted with a water-based activator. While it is a water activated adhesive, it is also characterized after aging bonded to a substrate by resistance to adhesive failure during 72 hours of immersion in ice / water mixture. The adhesive is beneficial to allow use of existing paper labeling equipment with polymeric labels.

Owner:LUBRIZOL ADVANCED MATERIALS INC

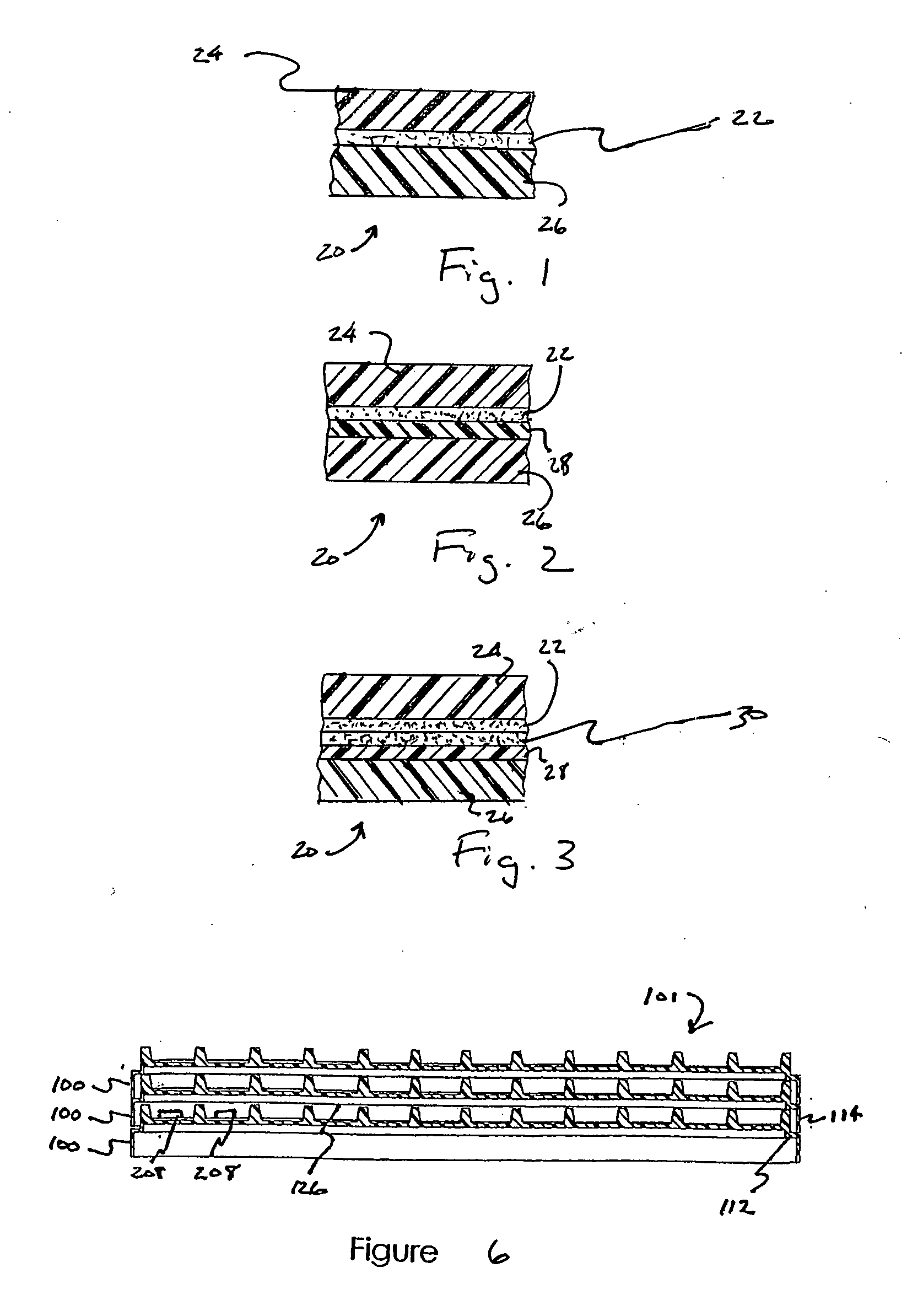

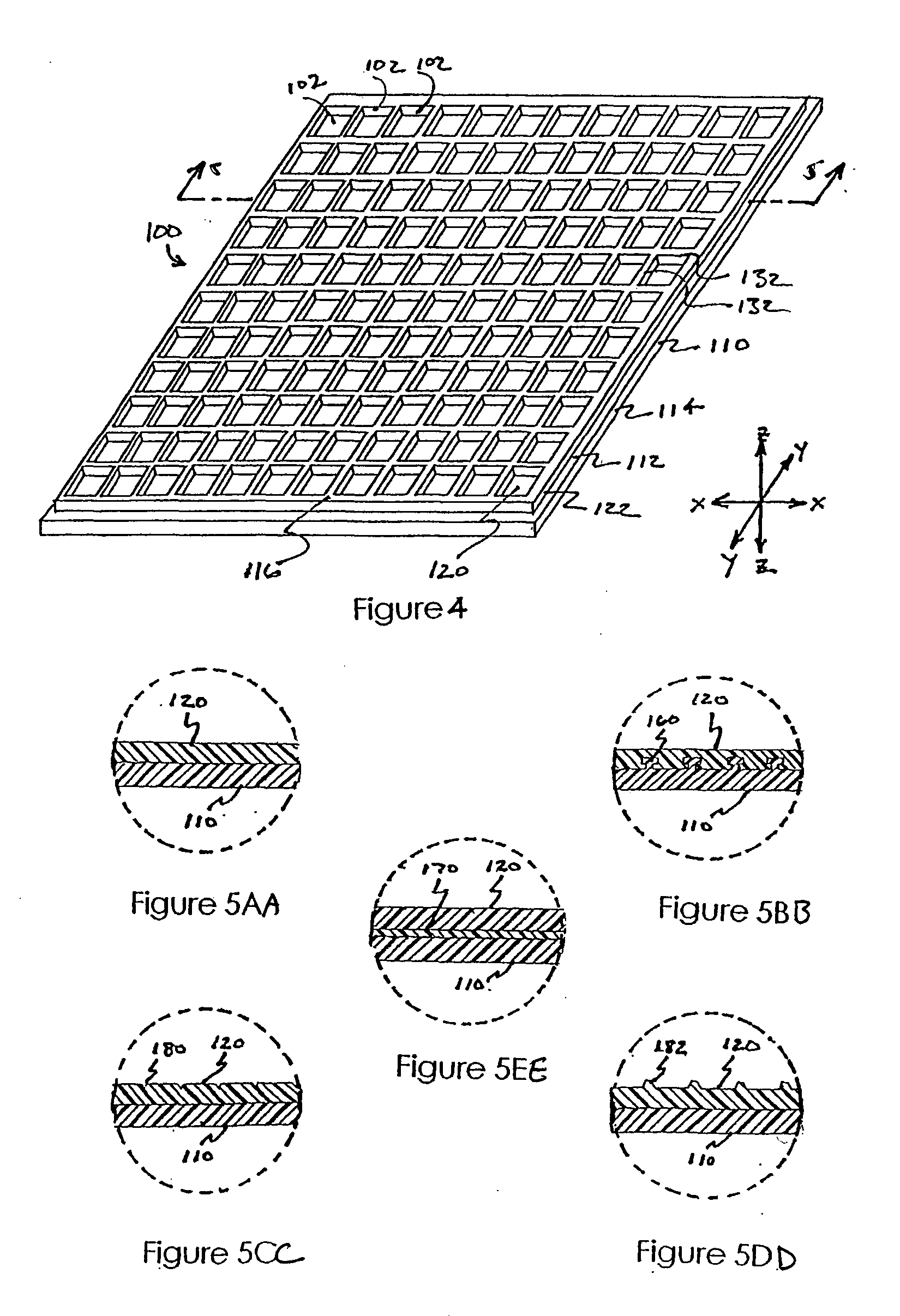

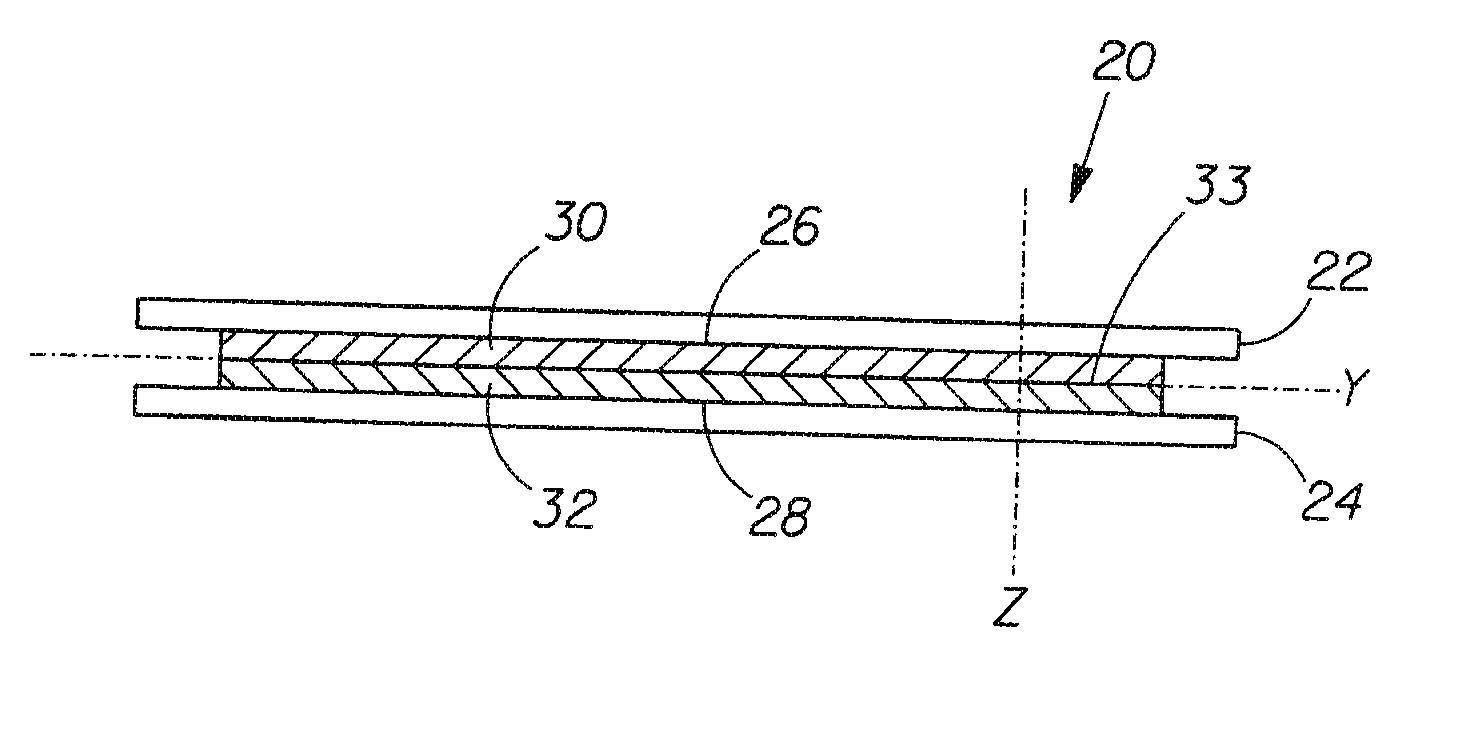

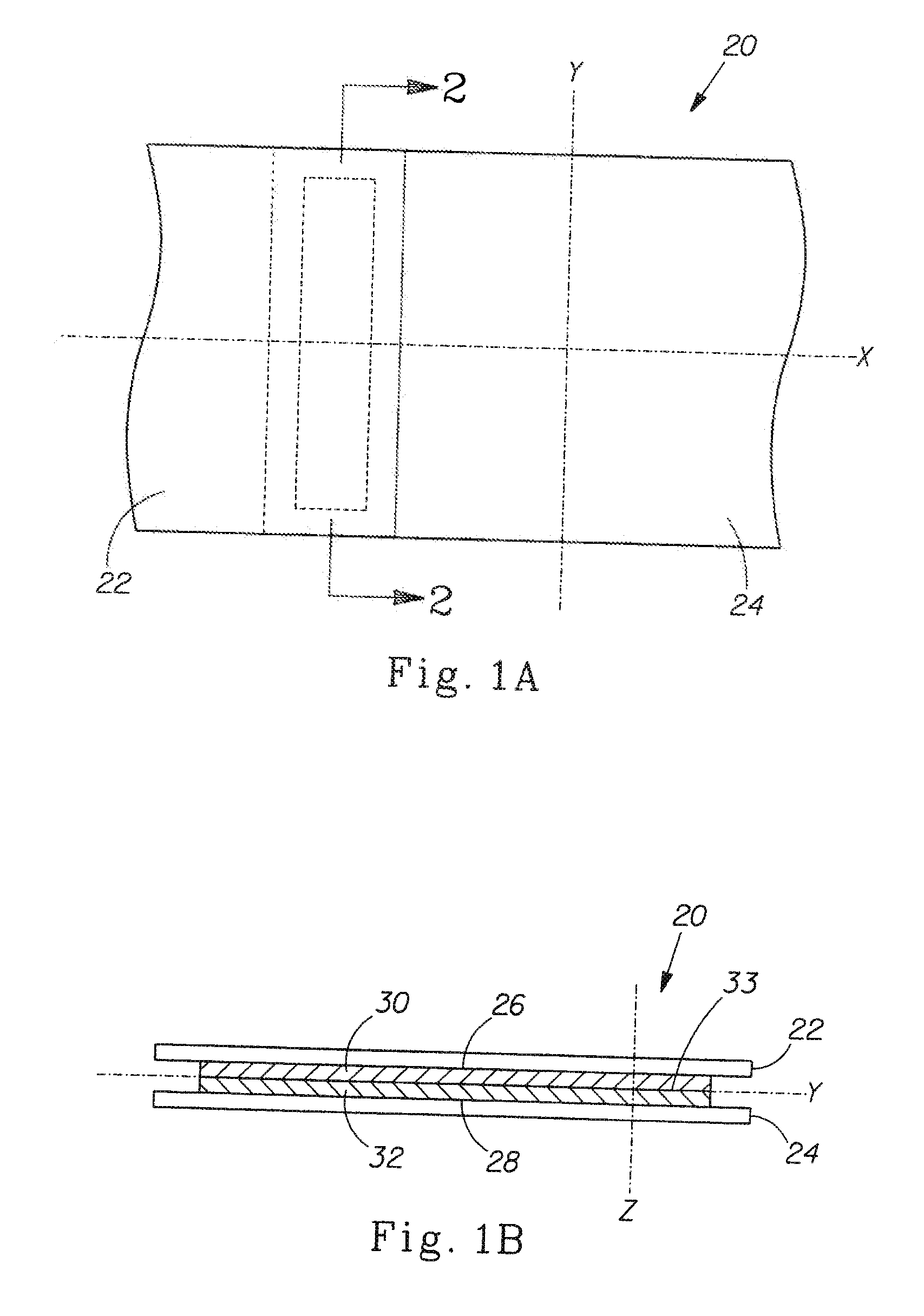

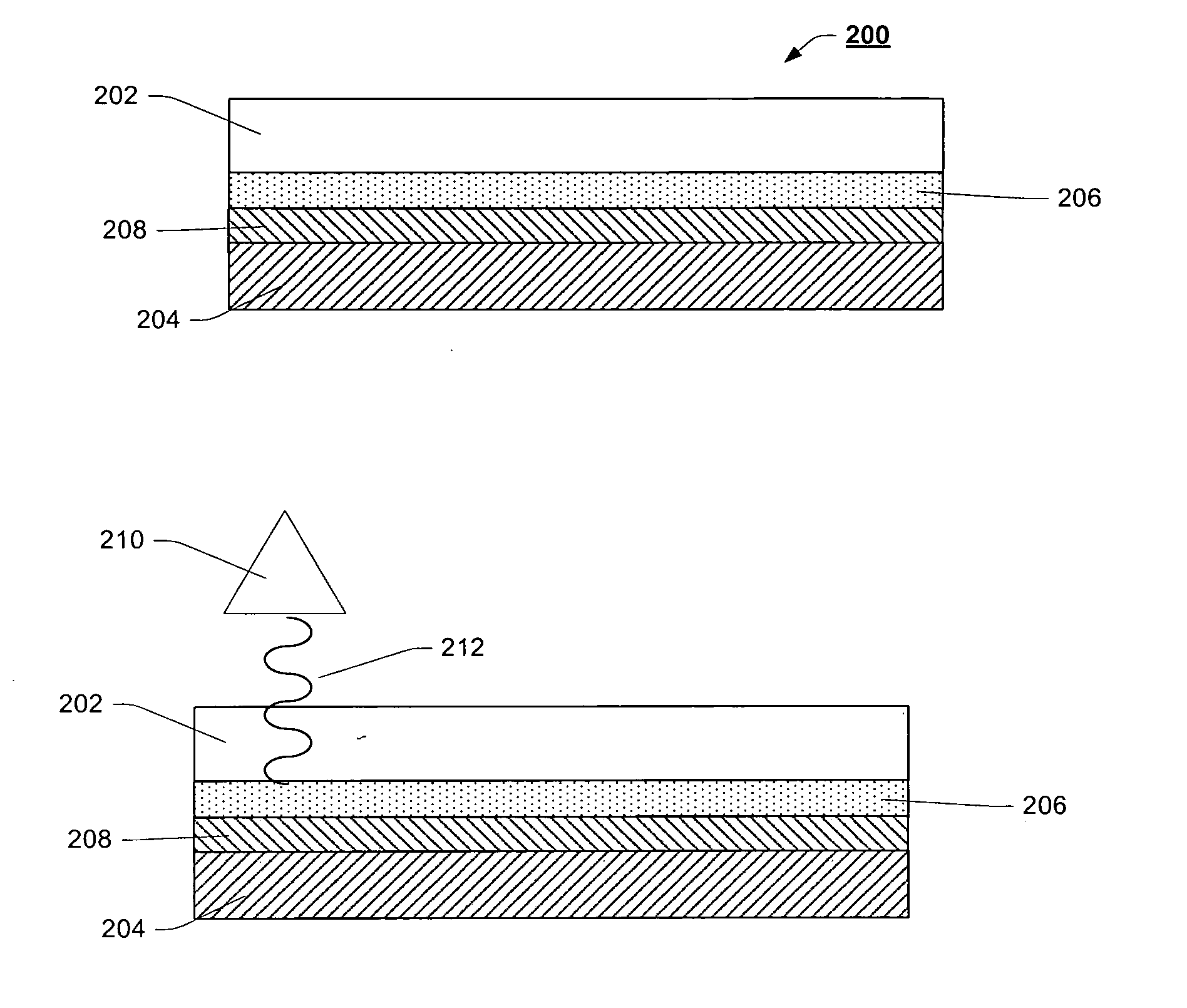

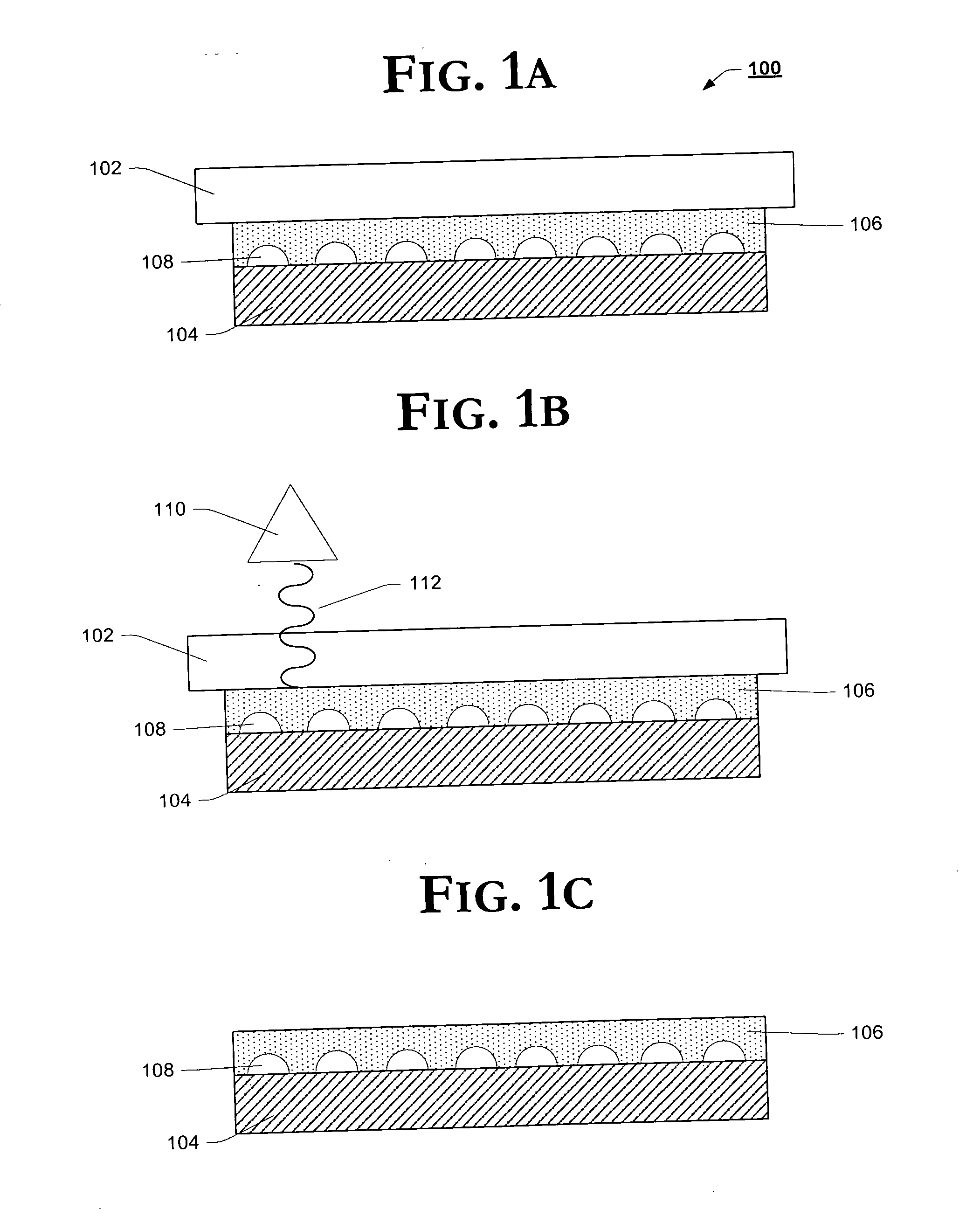

Adhesive system for supporting thin silicon wafer

InactiveUS20070077728A1Solid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

Owner:INTEL CORP

Collecting device for body fluids

A body waste collecting device comprising a collecting pouch and an adhesive wafer for attachment to the body, said adhesive wafer comprises a backing layer, a first adhesive and an additional second adhesive, wherein said additional second adhesive comprises a polyalkyleneoxide polymer and an organosiloxane based cross-linked adhesive system.

Owner:COLOPLAST AS

Nonreactive Thermoplastic Hot Melt Adhesives Based on Metallocene-Catalytically Manufactured Polyolefins

ActiveUS20080190541A1Different indexReduce the temperatureLaminationLamination apparatusWaxPolymer science

The invention relates to an adhesive system which is based on a non-reactive thermoplastic adhesive melt. The adhesive melt (A) contains a mixture of at least two metallocene-catalytically produced copolymers which are different from each other, and which are based on at least two a-olefins, whereby the copolymers of the mixture, which are different from each other, have different melt indices (MFIs); (B) optionally, at least one additional polymer; and (C) optionally, at least one resin and / or at least one wax. The inventive adhesive system is particularly suitable for use in the wood and furniture industry, e.g. for covering profiles or for gluing edges, in particular, by comparing copolymer adhesives to EVA melt adhesives which are used in a traditional manner, and the system enables considerably lower application temperatures to be used, and at the same time exhibiting improved adhesion capacity.

Owner:JOWAT

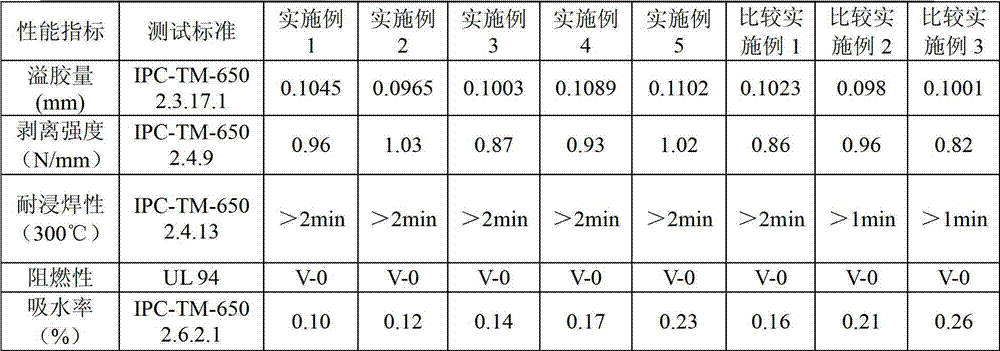

Halogen-free epoxy adhesive and cover film prepared by using halogen-free epoxy adhesive

InactiveCN103045143AWill not polluteCompliant with WEEENon-macromolecular adhesive additivesFilm/foil adhesivesAntioxidantFire resistance

The invention discloses a halogen-free epoxy adhesive which is prepared from the following components in parts by weight: 10-80 parts of phosphorus-containing epoxy resin, 10-40 parts of rubber modified epoxy resin, 10-50 parts of a toughening agent, 1-25 parts of a curing agent, 0.01-1.0 part of a curing accelerant, 0-80 parts of inorganic filler, 1-40 parts of a phosphorus-containing fire retardant, 1-40 parts of a nitrogenous fire retardant and 0.01-1.0% of an antioxidant. According to the invention, the components are dispersed into an organic solvent according to the proportion, so that the adhesive with the solid content of 30-50wt% can be obtained. The halogen-free epoxy adhesive does not contain halogen, and uses the phosphorus-containing fire retardant and the nitrogenous fire retardant to cooperate with a flame-retardant adhesive system, thus reducing the dosage of the phosphorus-containing fire retardant, and overcoming the negative effect caused by using a great deal of phosphorus-containing fire retardant; the halogen-free epoxy adhesive is good in fire resistance, excellent in heat resistance, high in reliability and better in mechanical property. The invention also discloses a cover film prepared from the halogen-free epoxy adhesive, and the cover film has the fire resistance of UL 94V-0 level, excellent stripping strength, heat resistance and processing performance.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

Paper laminates manufactured using foamed adhesive systems

InactiveUS20050045267A1Reliable and straightforwardNon-macromolecular adhesive additivesManual label dispensersAdhesivePaper towel

Foamed, aqueous adhesive compositions are used to manufacture tissue laminate products including or especially as bathroom tissue, facial tissue, paper towels, and the like. Foaming typically occurs by introducing pressurized gas and adhesive flows in a nozzle chamber on demand, wherein the kinetic energy of the flows is used to provide mixing energy. The adhesive preferably is dispensed as a plurality of discrete, foamed adhesive particles. The foamed adhesive can be used for intralamina bonds, interlaminate bonds, bonding loose sheet extremities, bonding roll to roll, and the like. The invention provides a reliable, straightforward way to accomplish in-nozzle foaming of an adhesive.

Owner:HB FULLER CO

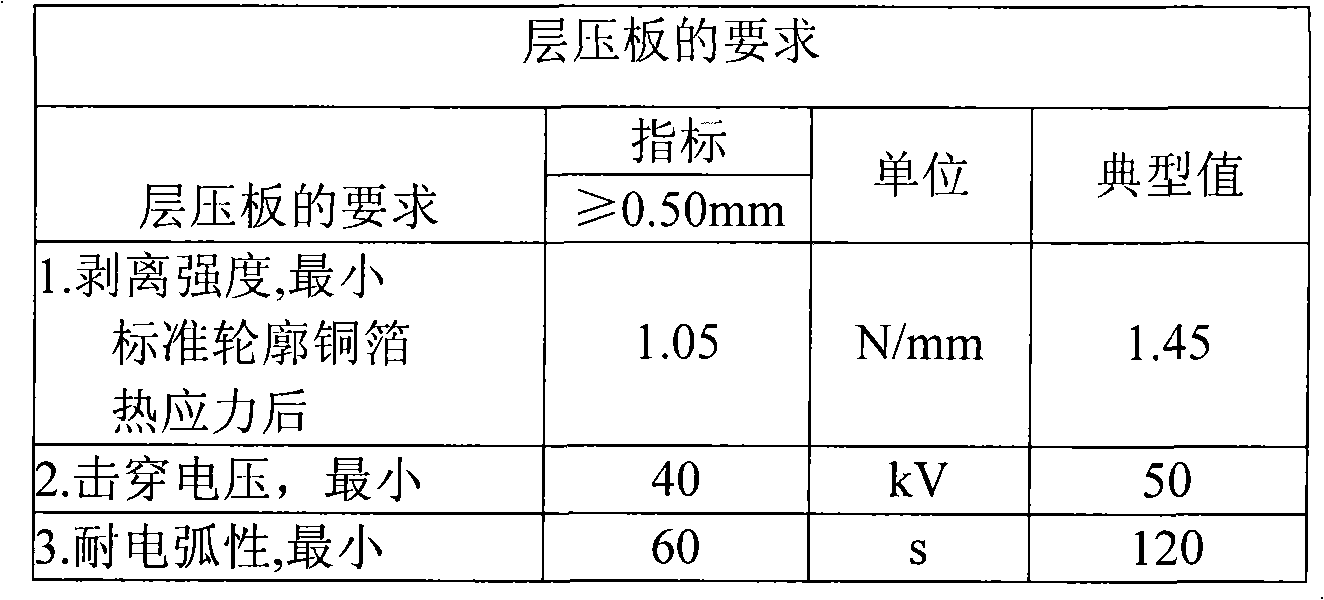

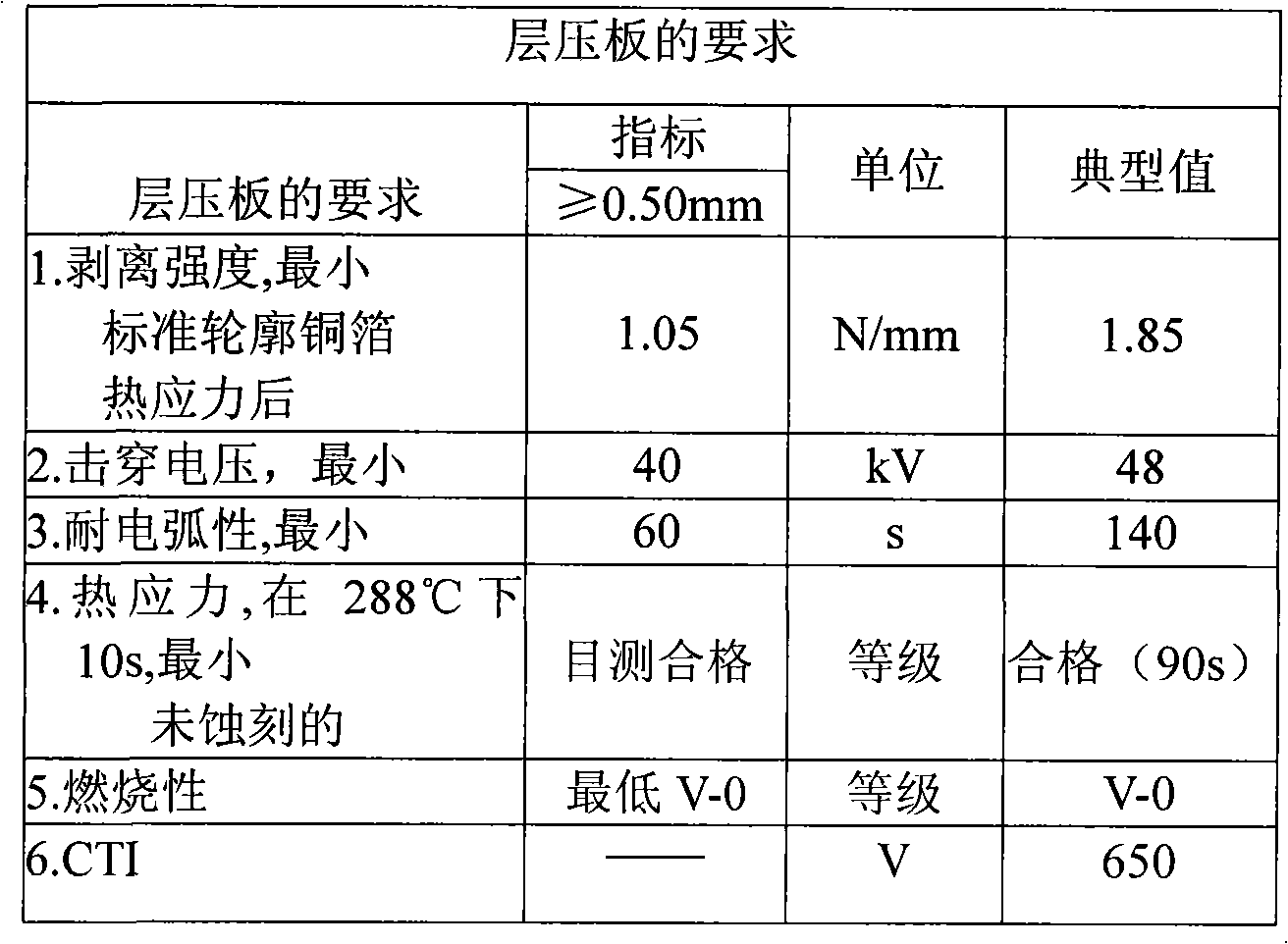

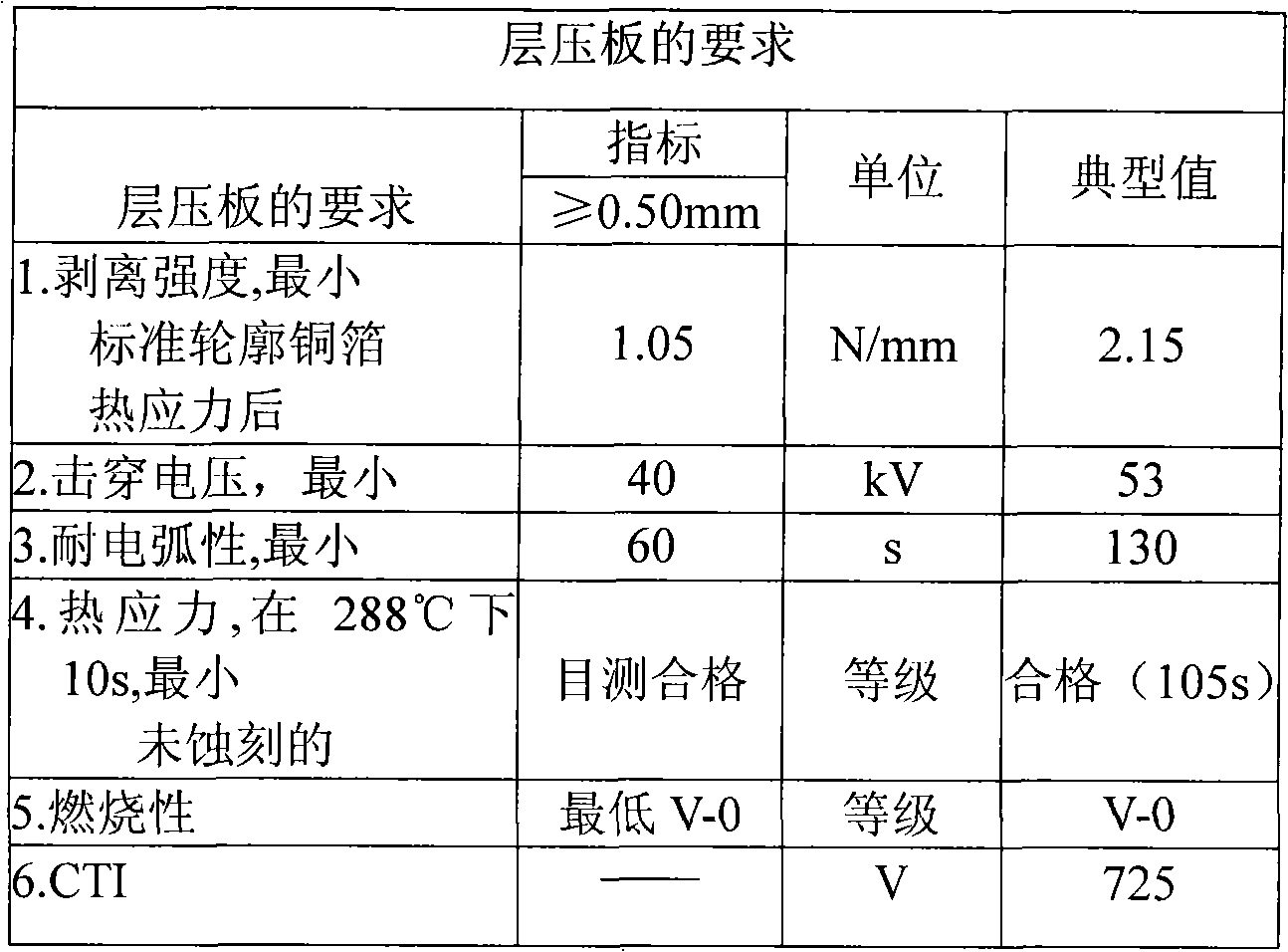

Method for manufacturing CTI copper-clad laminate

ActiveCN101654004AImprove tracking voltage resistanceExtended service lifeLamination ancillary operationsLaminationEpoxyTetrabromobisphenol A

The invention relates to a method for manufacturing a CTI copper-clad laminate. The method is realized by the following steps: glue mixing, sizing, plate arrangement, hot-press molding, disassembly, processing and inspecting, wherein an adhesive system in the step of the 'glue mixing' is composed of the following materials in mass ratio (kg): 125 to 133 kg of low brominated epoxy resin, 2.60 to 3.40 kg of dicyandiamide, 30 to 36 kg of dimethyl formamide, 0.060 to 0.080 kg of dimethyl imidazole, and 10 to 40 kg of aluminum hydroxide, wherein the low brominated epoxy resin belongs to tetrabromobisphenol A type brominated epoxy resin, and the content of bromine accounts for 10 to 14 mass percent of the low brominated epoxy resin. The method has the advantage of improving the tracking voltageresistance of a PCB substrate.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

Low volatile isocyanate monomer containing polyurethane prepolymer and adhesive system

InactiveUS20060079661A1Lower potential for exposurePolyureas/polyurethane adhesivesAdhesiveHigh pressure

In one aspect the invention is a composition comprising a prepolymer which is the reaction product of di(isocyanatophenyl)methane or a polymeric di(isocyanatophenyl)methane having an isocyanato functionality of about 2.1 to about 3.0 with a mixture of one or more diols and one or more triols wherein the ratio of isocyanate equivalents to hydroxyl equivalents in the reaction mixtures used to prepare the prepolymer is from about 1.2 to about 1.8 and the ratio of diol to triol where the diisocyanate is a di(isocyanatophenyl)methane in the reaction mixture is from about 5:1 to about 1:1. and where the isocyanate is a polymeric di(isocyanatophenyl)methane is from about 8:1 to about 4:1; wherein the prepolymer could further react with an isocyanate reactive monofunctional compound. The prepolymer herein has an isocyanate content of about 0.5 to about 1.5 percent by weight, a free isocyanate monomer content of about 1.0 percent by weight or less as measured by high pressure liquid chromatography. These prepolymers can be used in many applications including adhesive, sound dampening sealer and coating and especially in making adhesives or adhesive systems with a low content of monomeric isocyanate to bond together similar or dissimilar substrates such as metal, glass, ceramics, plastic and painted steel panel.

Owner:DOW GLOBAL TECH LLC

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER RICK

Label Adhesive And Activation Method For Polymeric Label

InactiveUS20080060756A1Sufficient tackImprove the immunityStampsAdhesive processes with surface pretreatmentActivation methodWater based

A water activated adhesive system is described that is particularly suited for applying non-paper polymeric labels to surfaces which have low moisture permeability. The adhesive system is characterized by a dry non-tacky surface that becomes tacky in less than one second when contacted with a water-based activator. While it is a water activated adhesive, it is also characterized after aging bonded to a substrate by resistance to adhesive failure during 72 hours of immersion in ice / water mixture. The adhesive is beneficial to allow use of existing paper labeling equipment with polymeric labels.

Owner:LUBRIZOL ADVANCED MATERIALS INC

Use of selected adhesive mixtures for overlap adhesion of round labels when applied to plastic bottles

InactiveUS6641911B1Low viscositySmooth spreadabilityLamination ancillary operationsPolyureas/polyurethane adhesivesAdhesiveMacromonomer

Owner:HENKEL KGAA

Curable silicon-containing compositions possessing high translucency

InactiveUS20090018260A1Rapid primerless bond strengthGood physical propertiesSpecial tyresPolymer scienceSilicon dioxide

The invention relates to curable, storage-stable silicon-containing compositions reinforced with functionalized silica useful as one and two-part sealant and adhesive systems. The cured compositions provide silicon-containing rubber having excellent translucency, physical properties and primerless adhesion.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Tackifiers For Composite Articles

InactiveUS20130131231A1Broaden applicationGood physical propertiesMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesCelluloseEngineering

A composite article comprises a plurality of lignocellulosic pieces and an adhesive system disposed on the plurality of lignocellulosic pieces for bonding the plurality of lignocellulosic pieces. The adhesive system comprises a binder component and a tackifier component. The tackifier component comprises a cationic polymer. The tackifier component is useful for maintaining orientation of the plurality of lignocellulosic pieces during manufacture of the composite article. The composite article may be various engineered lignocellulosic composites, such as particleboard.

Owner:BASF AG

Method and apparatus for bonding and debonding adhesive interface surfaces

InactiveUS7901532B2Strong and rapid powerEngine sealsNanostructure manufactureThermal energyMicrosphere

Owner:BAIN PETER STEWART

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com