Patents

Literature

265results about "Textile selvedges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Total polyester superfine denier fabric and its processing method

InactiveCN101423997AInsufficiency to avoid strong influenceSoft touchTextile selvedgesHeating/cooling textile fabricsPolyesterFiber

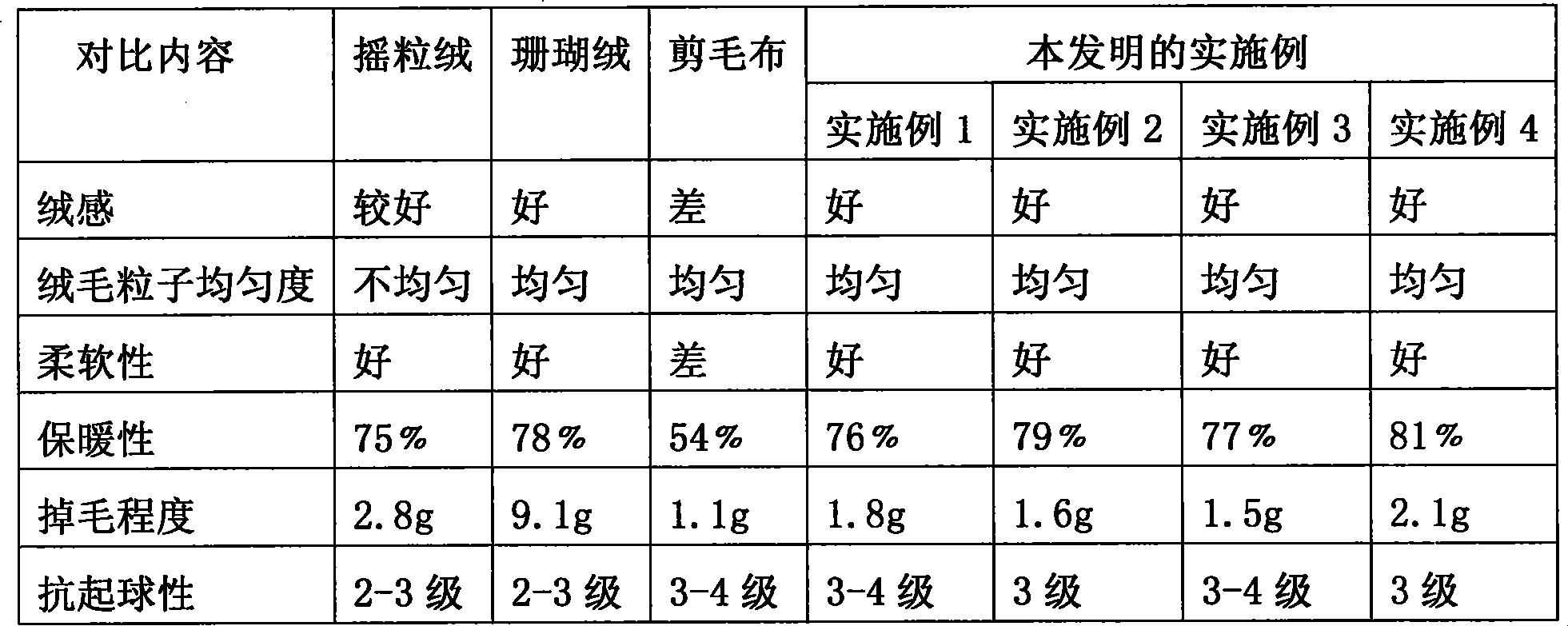

The invention relates to superfine full-polyester denier fabrics and a processing method thereof, which belong to the technical field of polyester fiber products. The superfine full-polyester denier fabrics comprise surface threads and bottom threads, wherein the surface threads use 150D / 288F or 100D / 144F DTY polyester threads as raw materials, and the bottom threads use 100D / 36F DTY polyester threads as raw materials; and the content of the surface threads occupies 60 to 70 percent of the total compositions, and the content of the bottom threads occupies 40 to 30 percent of the total compositions. The invention has the advantages that the raw materials of the surface threads and the bottom threads are reasonablely selected; full polyester obtained is superfine, light and fluffy, and has soft hand feeling, plump fluffy feeling, good warmth retention property and uniform particle size; small fiber clearance is guaranteed, and the superfine full-polyester denier fabrics have the function of isolating inner air and outer air and preventing heat energy loss as dresses; the processing method forms texture surfaces without texturing, prevents the phenomenon of wool falling when people wear and repeatedly wash the texture due to the fact that fibers are broken by ruleless mechanical external force to form a hairy surface, and prevents the phenomena of pilling and grinning; and the technological steps are simple.

Owner:常熟市东方染整有限公司

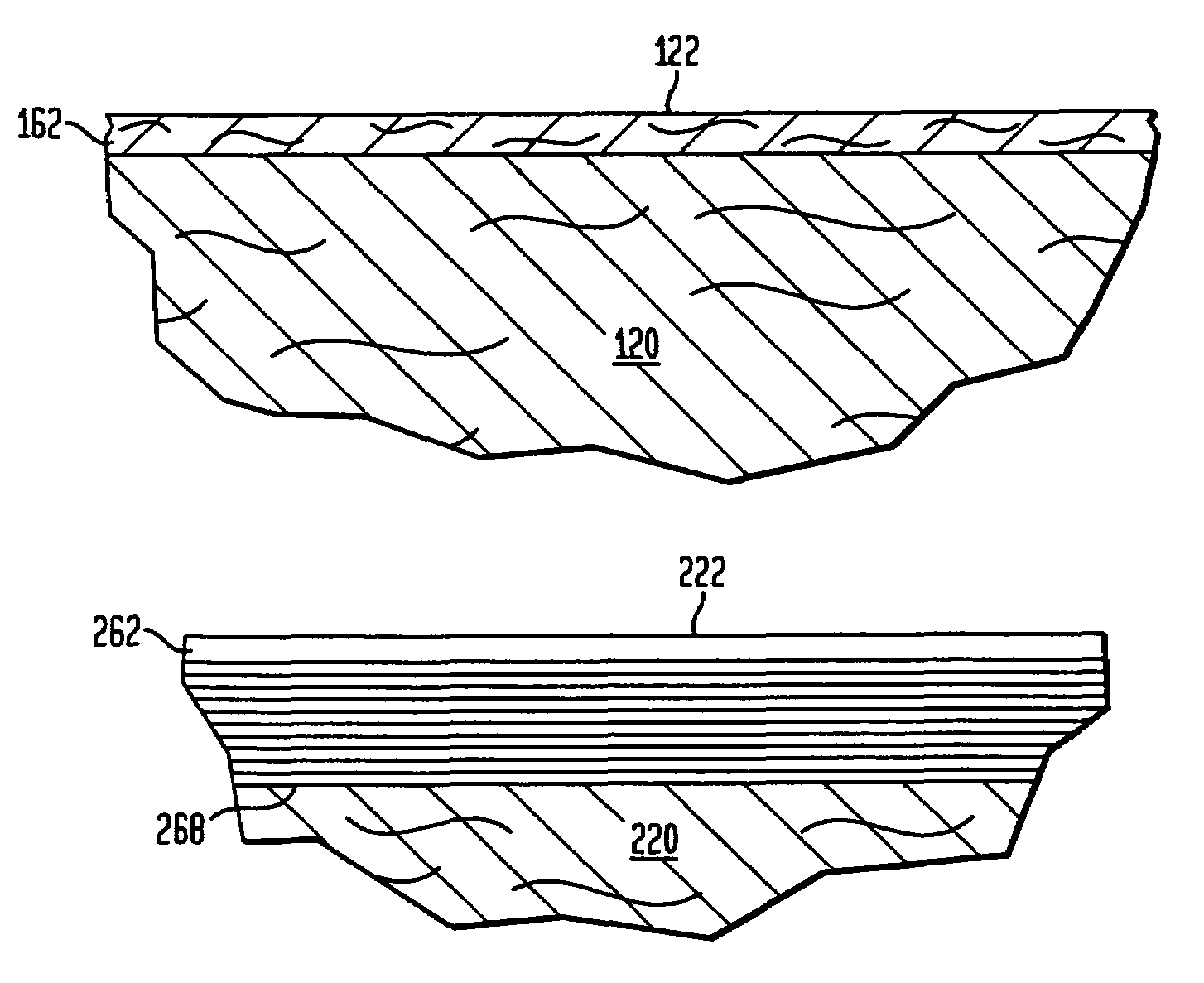

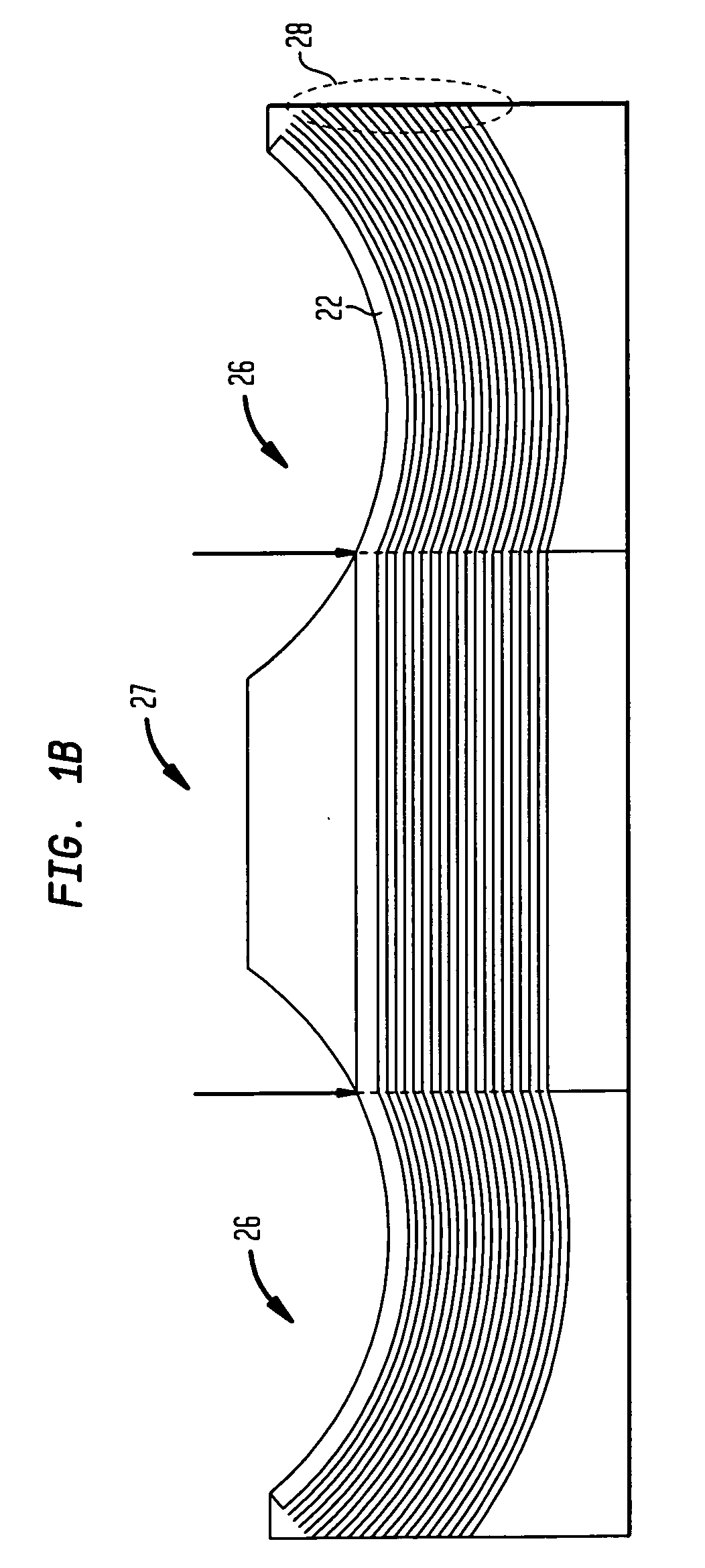

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

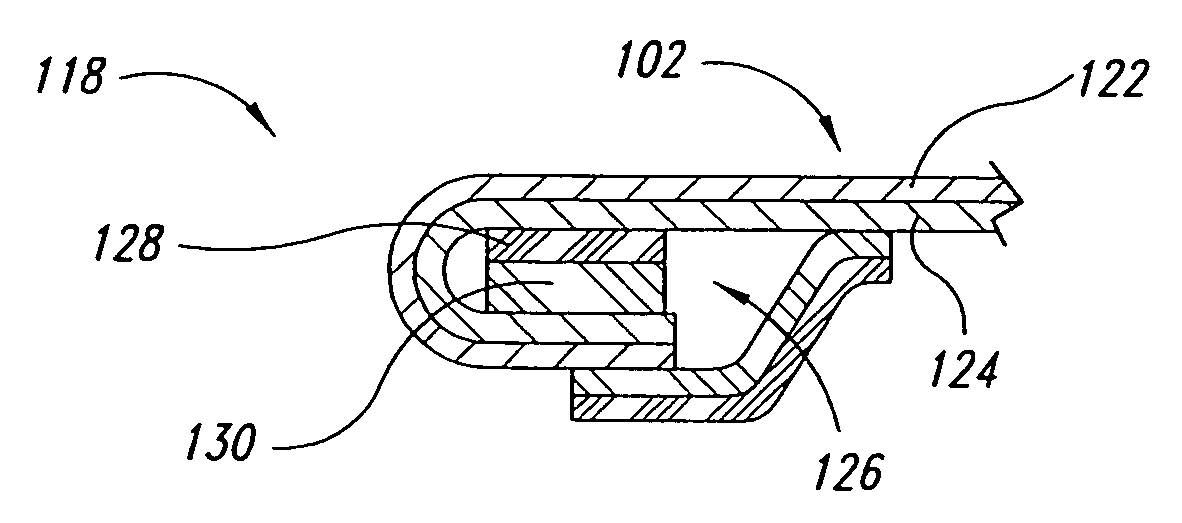

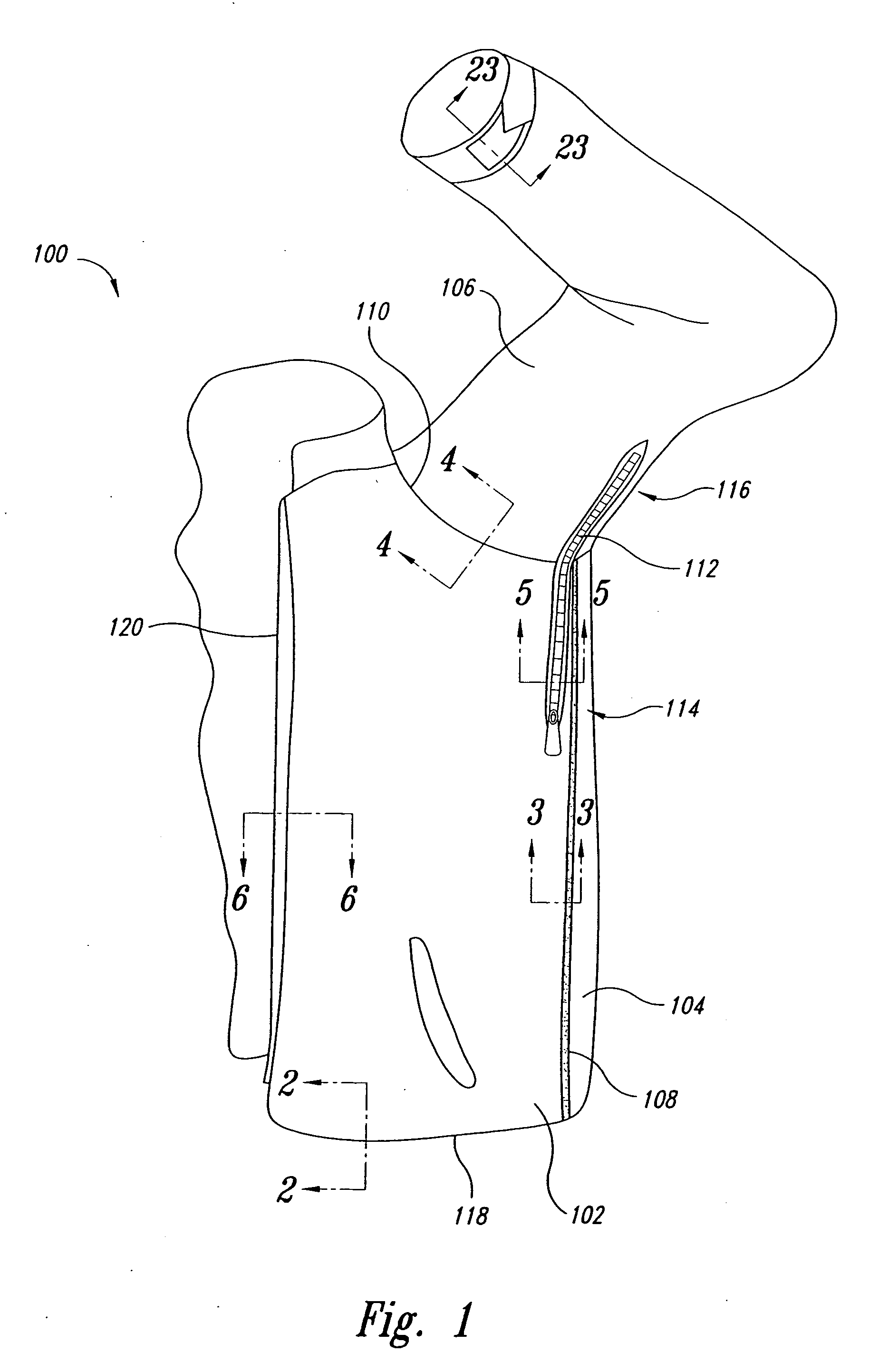

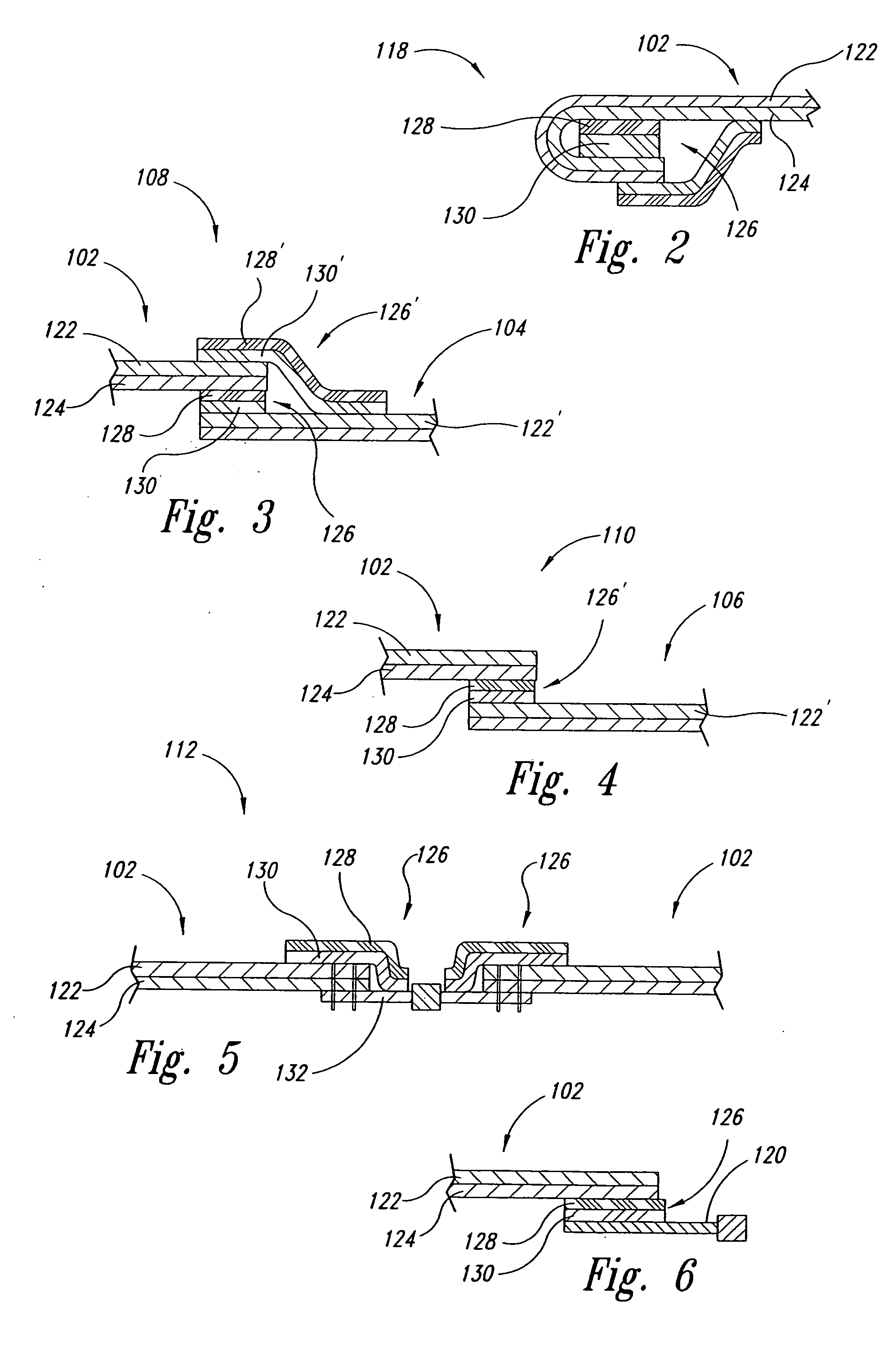

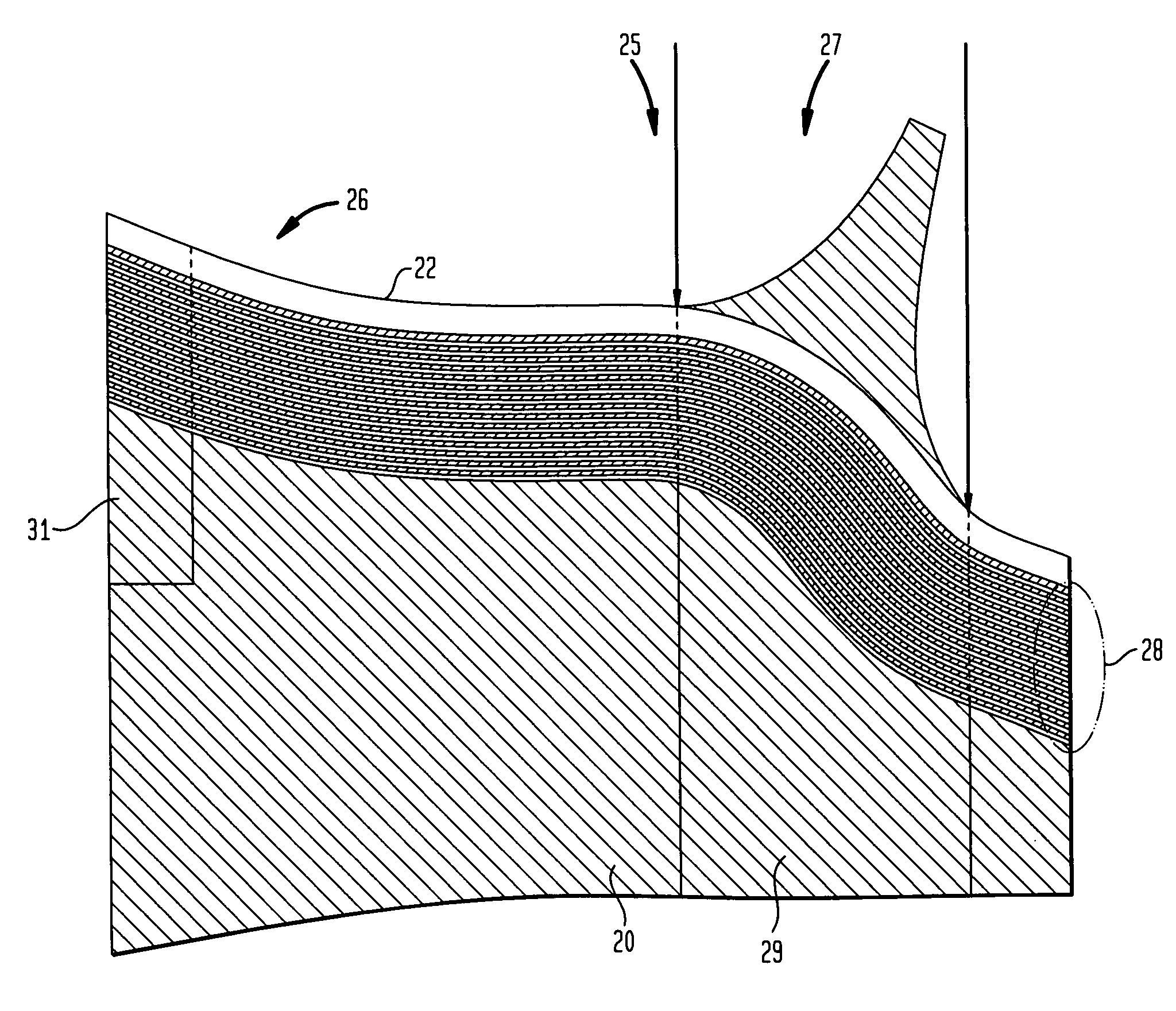

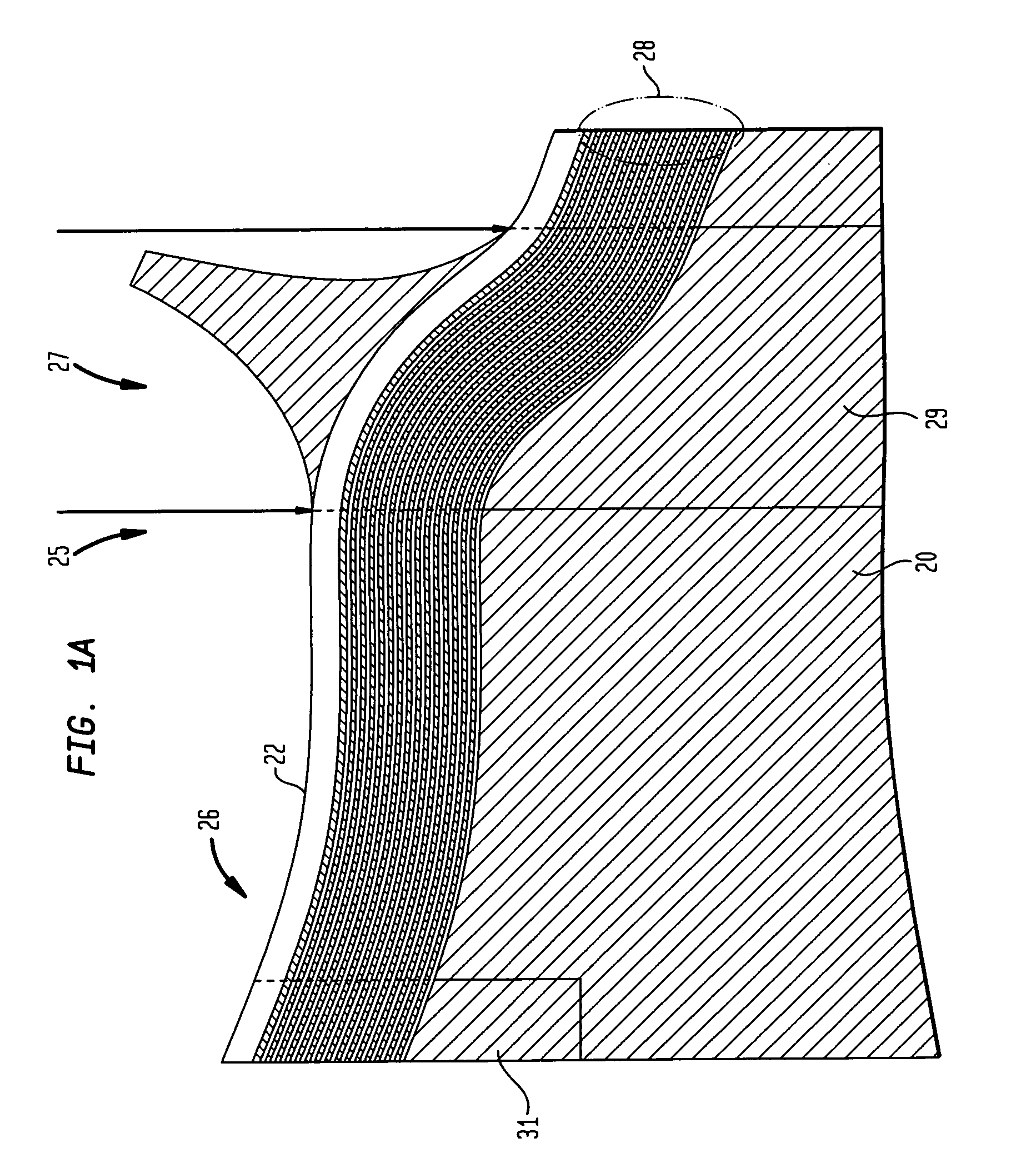

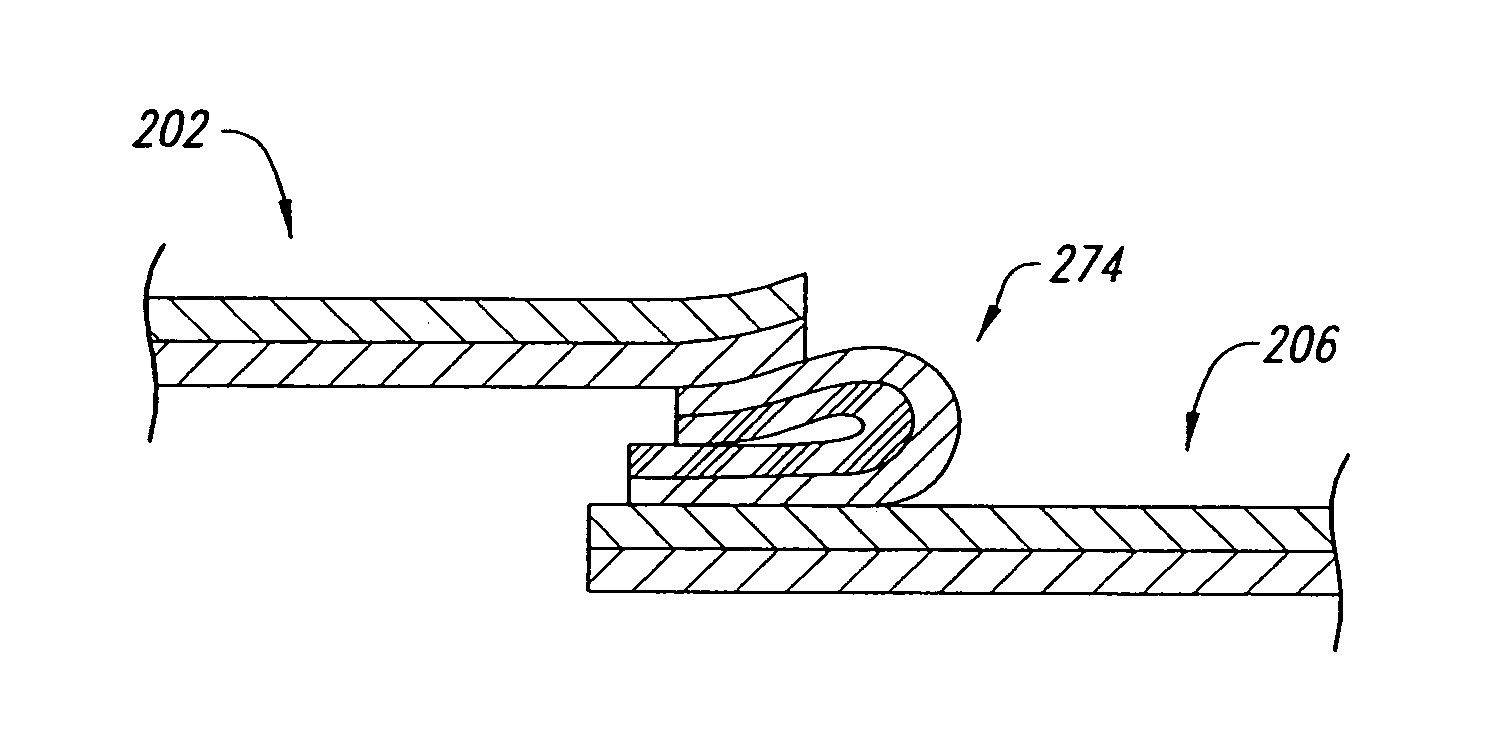

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER

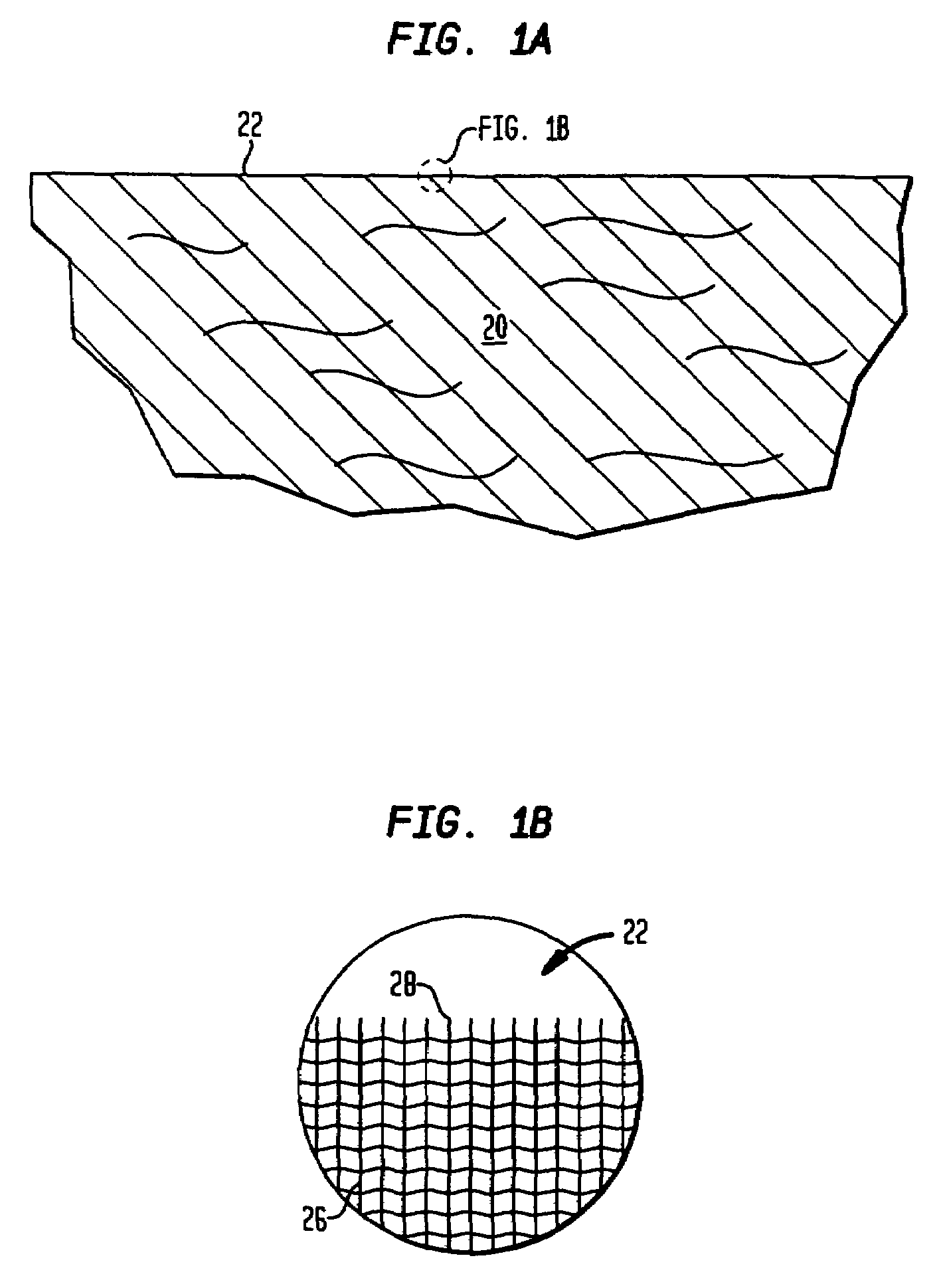

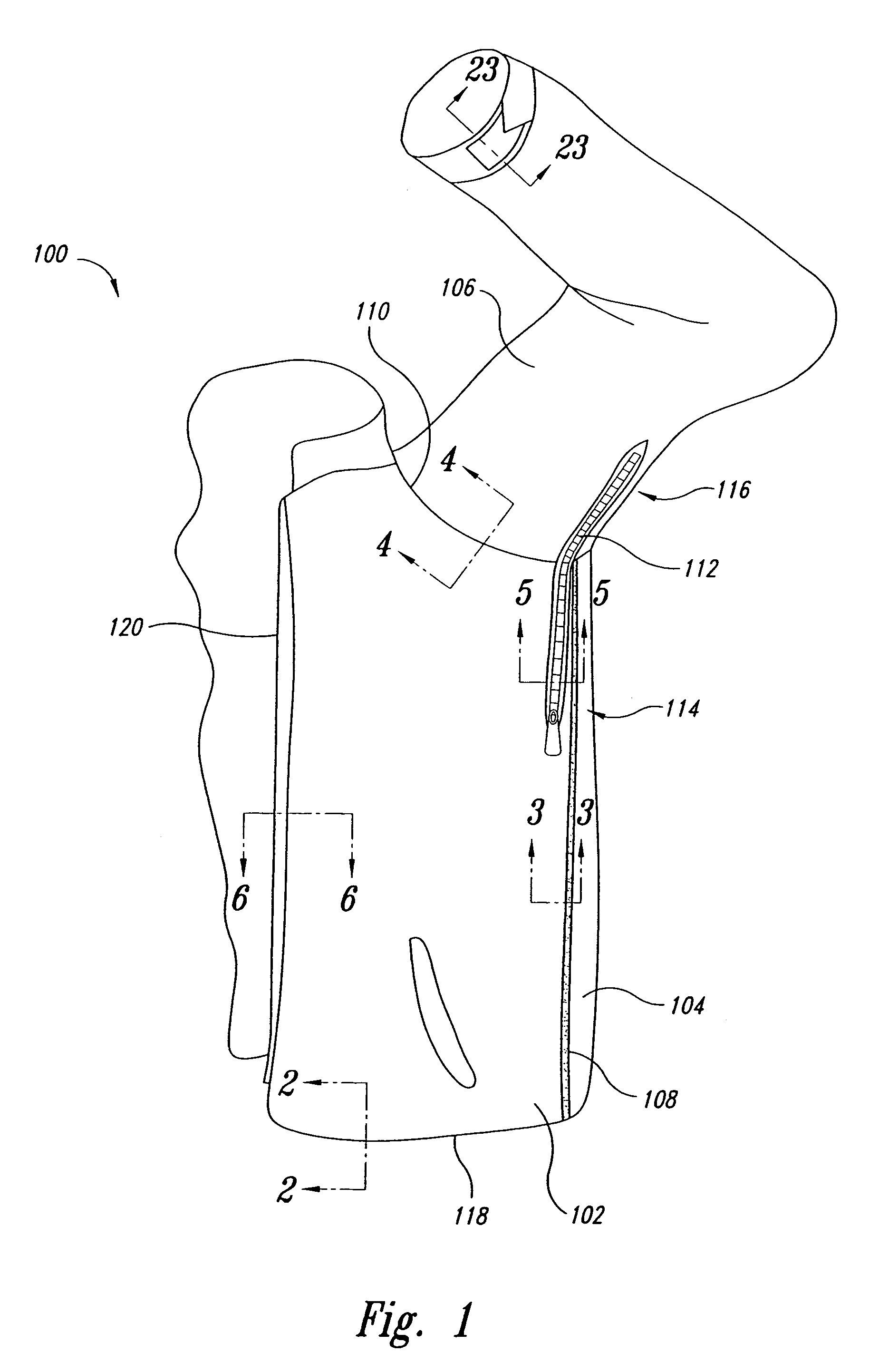

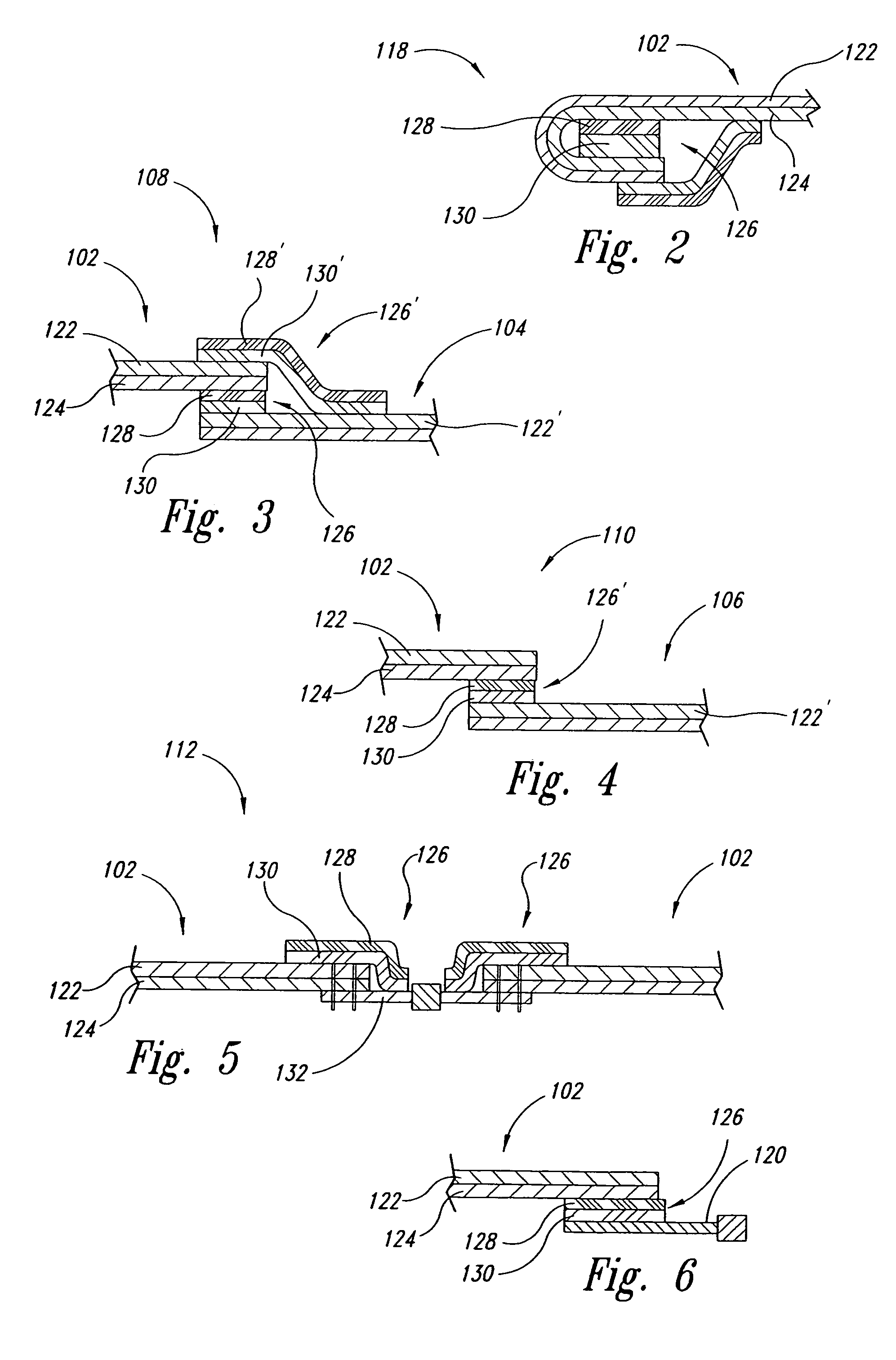

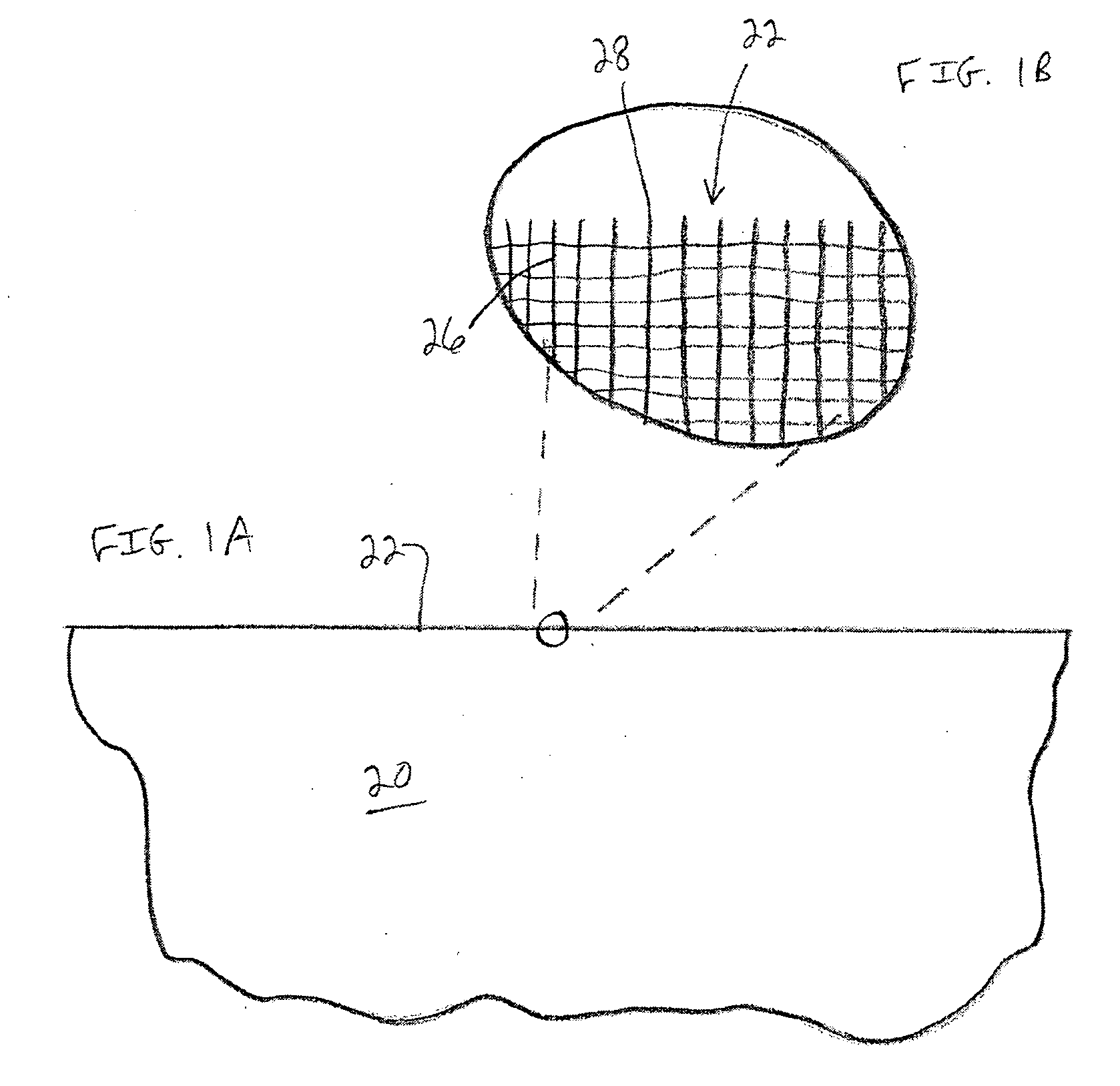

Undergarments having finished edges and methods therefor

ActiveUS7228809B2Improve material yieldDirect contact guaranteeLeather sewingWork-feeding meansFiberEngineering

A method of making a fabric having a finished edge includes providing a fabric having a plurality of fibers with free ends of the fibers at an edge of the fabric, disposing a curable polymer such as silicone over the edge of the fabric so that the curable polymer engages the free ends of the fibers at the edge of the fabric, and, after the disposing step, curing the polymer for finishing the edge of the fabric. The polymer binds the free ends of the fibers to prevent fraying of the fabric. The fabric is cut into a pattern piece for a garment before the step of disposing the curable polymer on the edge of the fabric.

Owner:CUPID FOUND

Method for sewing stretchable cloths

Owner:ITO MITSURU

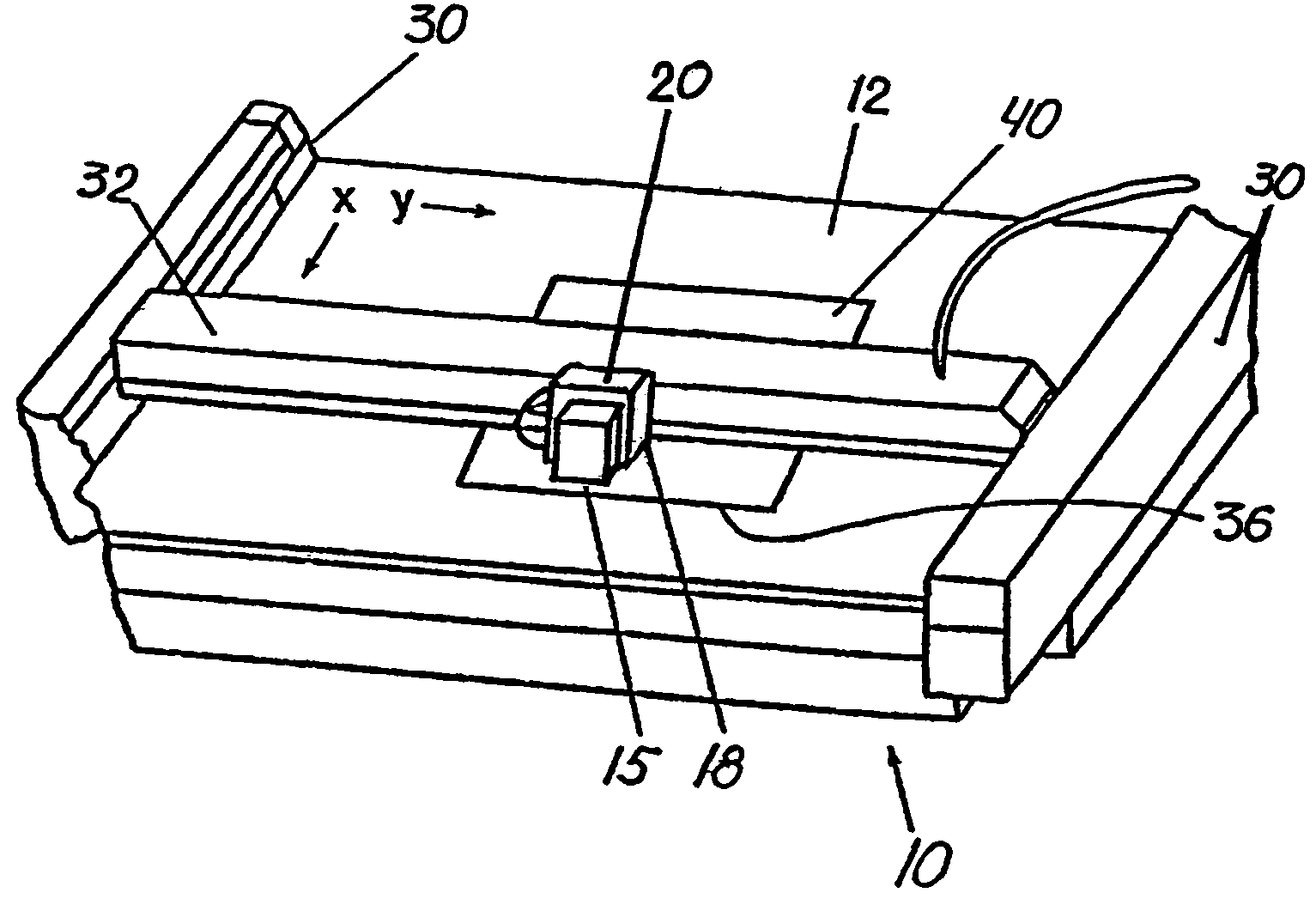

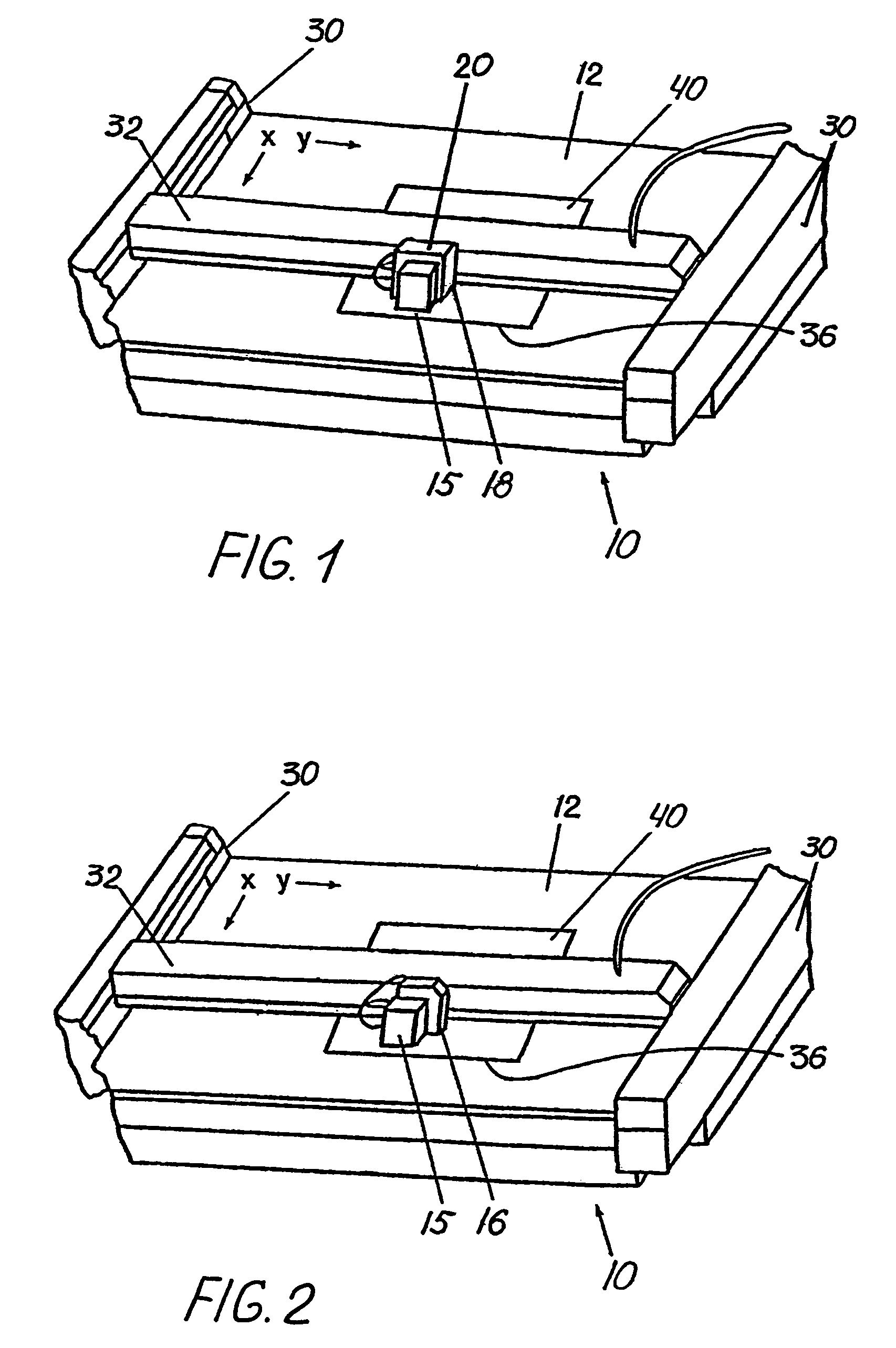

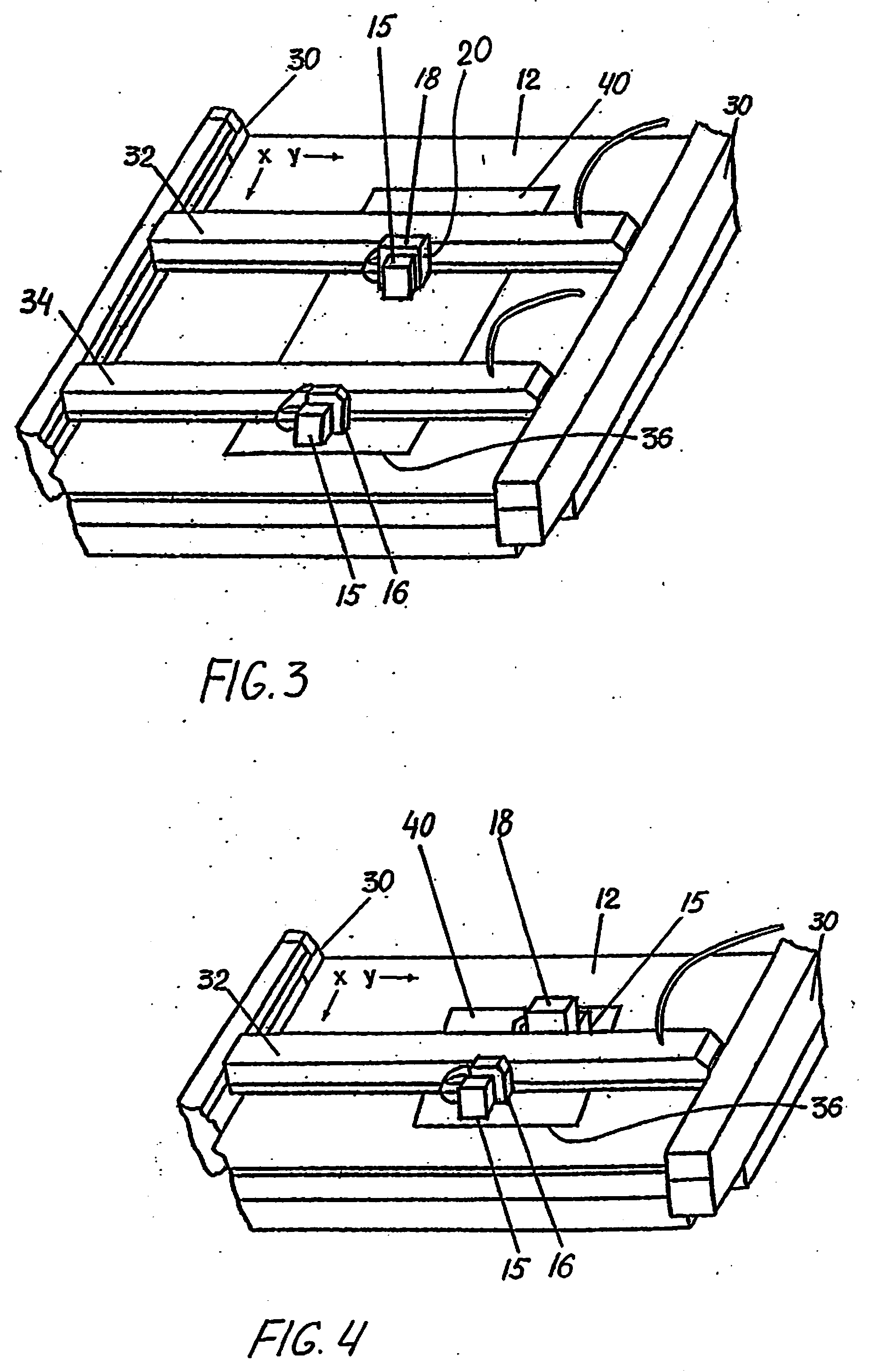

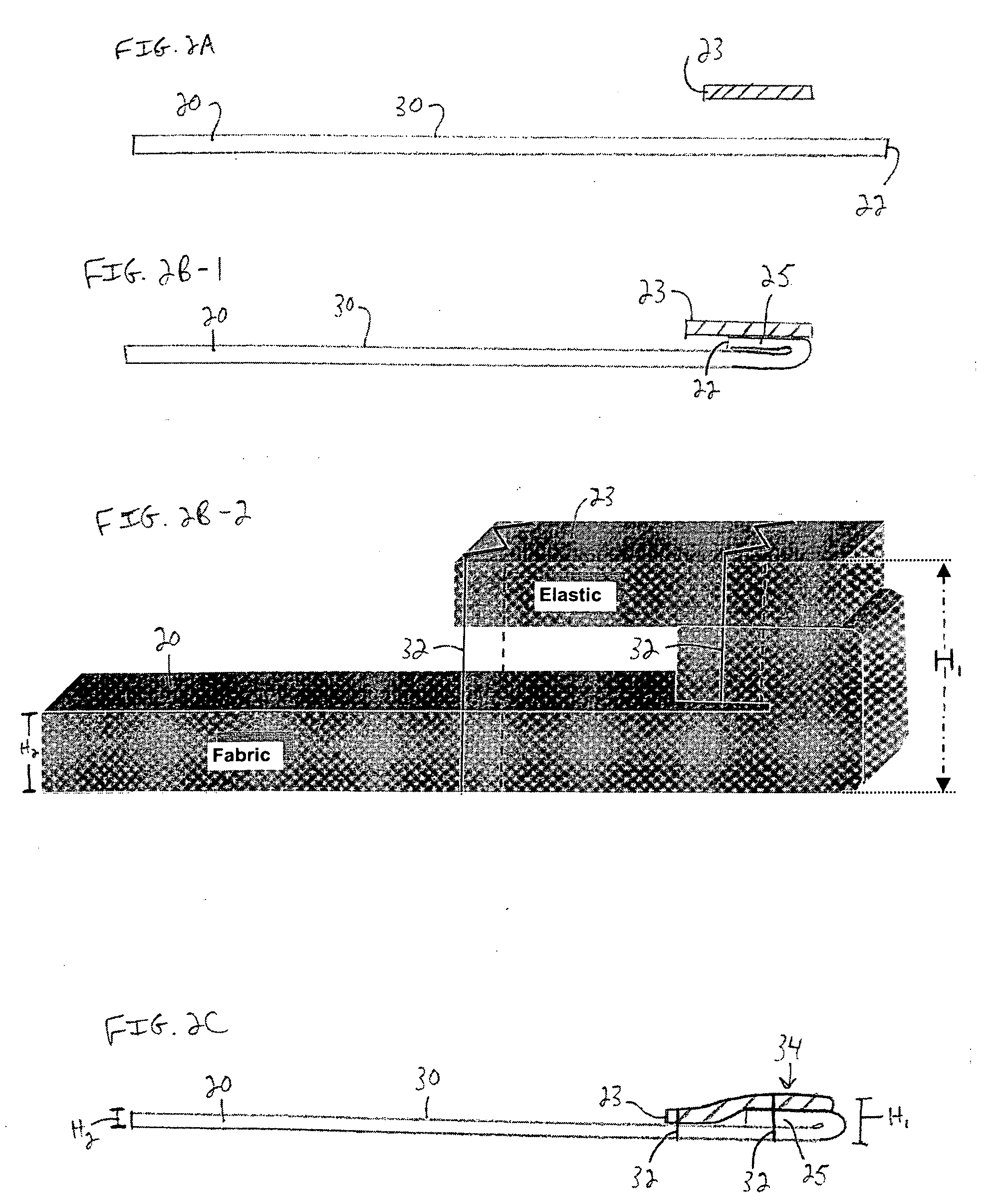

Garments having a curable polymer thereon and a system and method for its manufacture

InactiveUS20090047481A1Improve tensile propertiesMinimize the possibilityTextile selvedgesDecorative surface effectsFiberEngineering

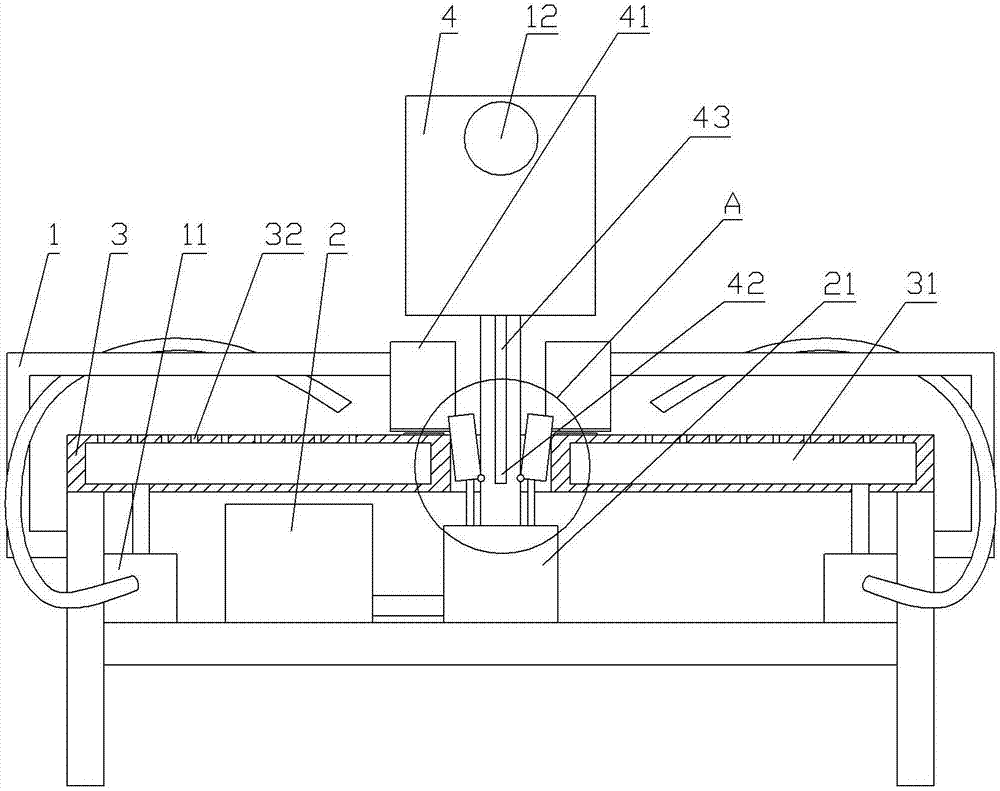

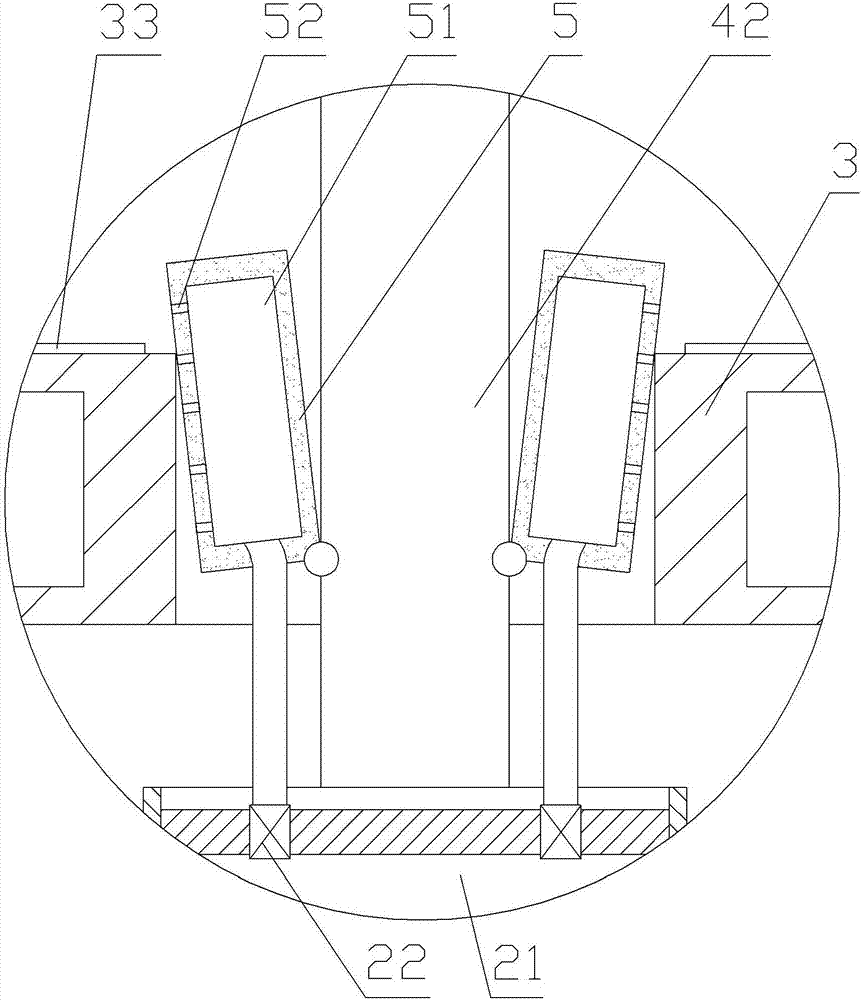

A method and system for garment manufacture fixes a curable polymer in either a continuous bead or in a non-continuous or segmented bead onto a cut fabric piece. The cut fabric piece, the continuous bead and the non-continuous, segmented bead have a wide array of configurations. If the cut fabric piece has a contoured edge region, a silicone bead proximate that edge has a conforming configuration. In the method, the cut fabric piece is placed in a coordinate space. The location of the cut fabric piece is sensed and that information is used to control the movement of a curable polymer dispenser. The dispenser applies a curable polymer from the curable polymer dispenser onto the cut fabric piece in the desired configuration after which the polymer is cured. If the fabric is cotton, the curable polymer is drawn into the cotton fibers prior to cure. The flow of curable polymer from the dispensing head can be started and stopped as the dispensing head moves relative to the fabric, allowing the curable polymer to be deposited on the fabric in any configuration.

Owner:CUPID FOUND

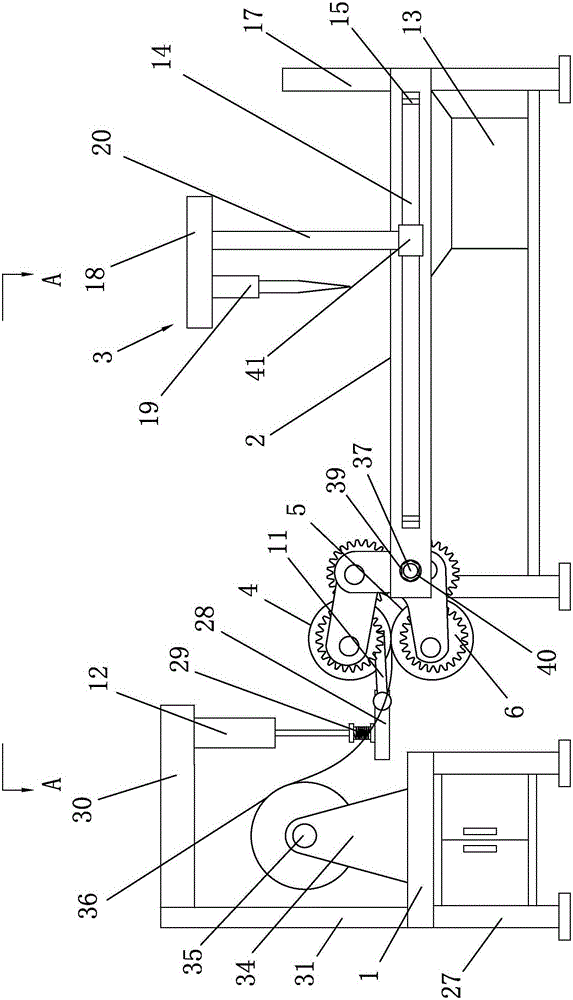

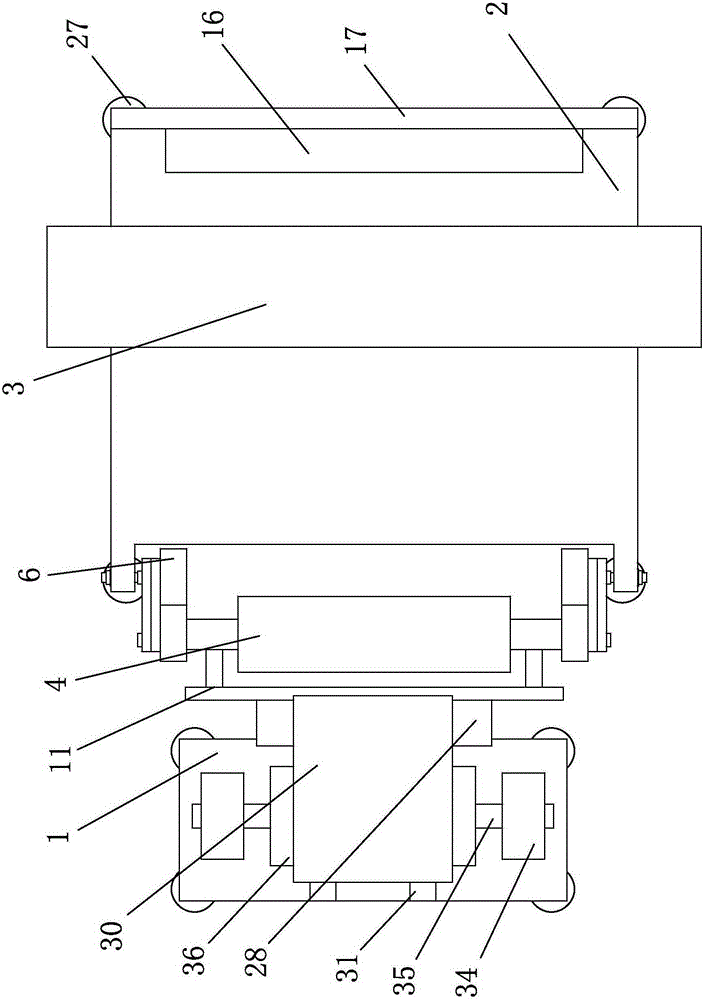

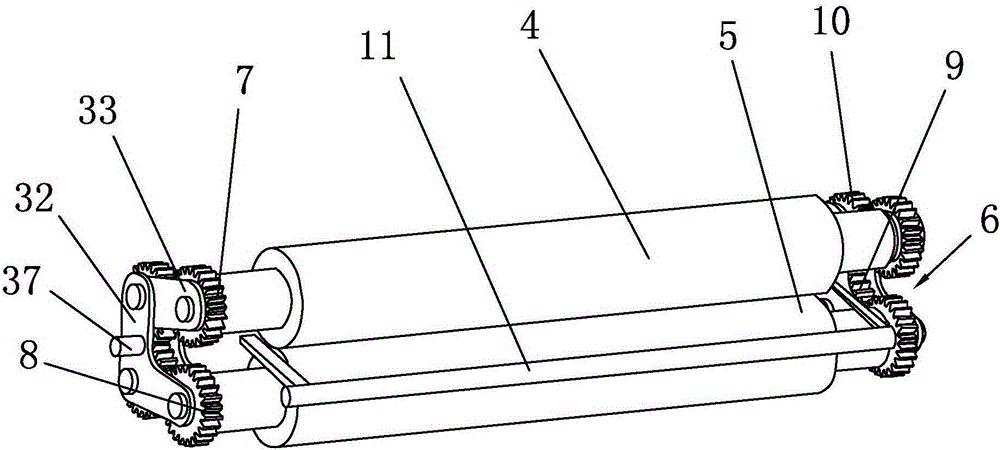

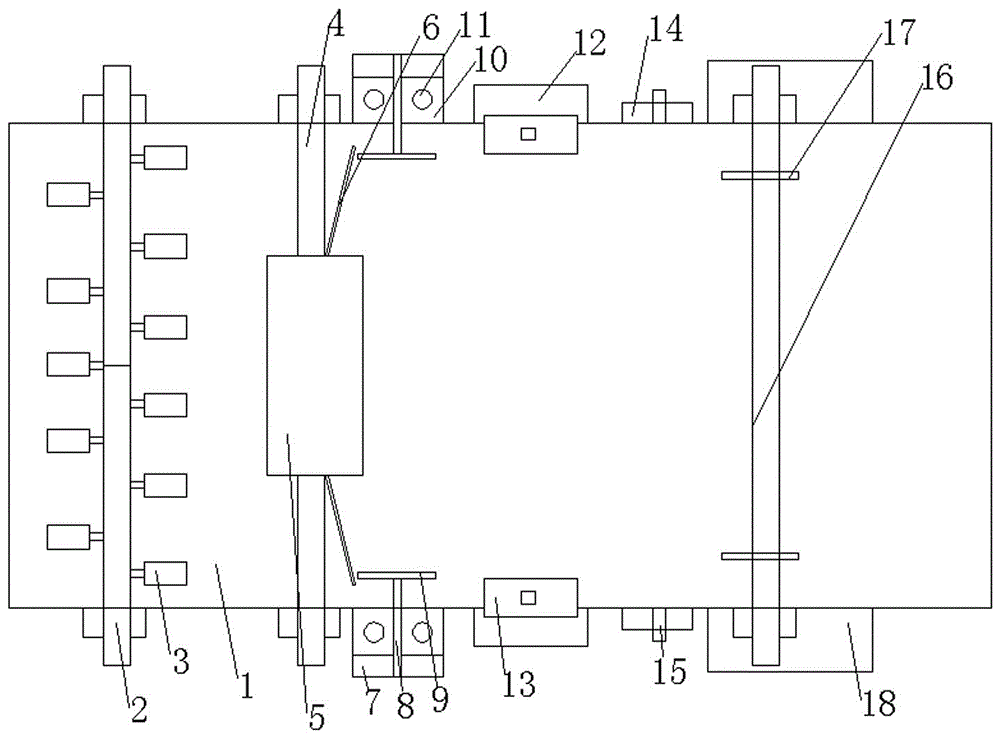

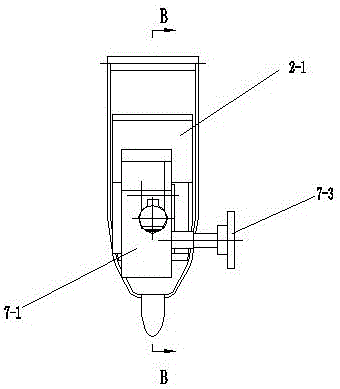

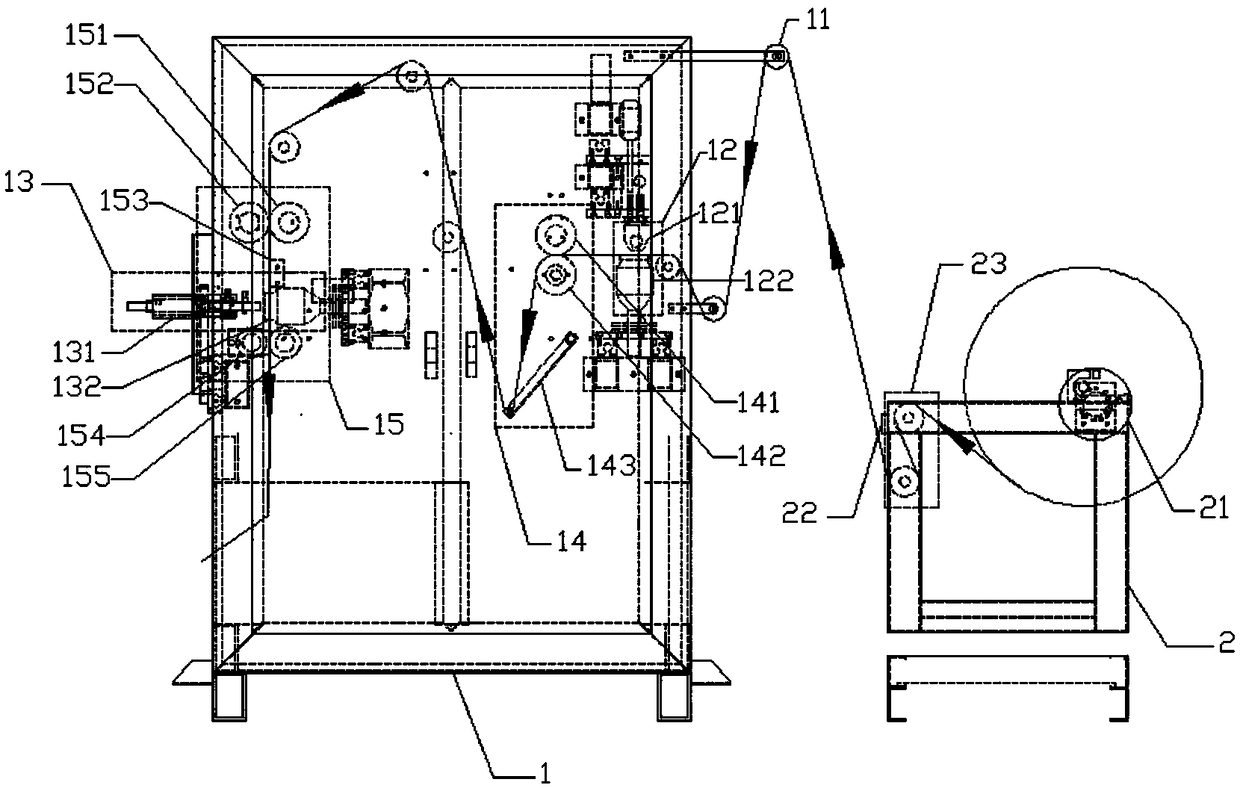

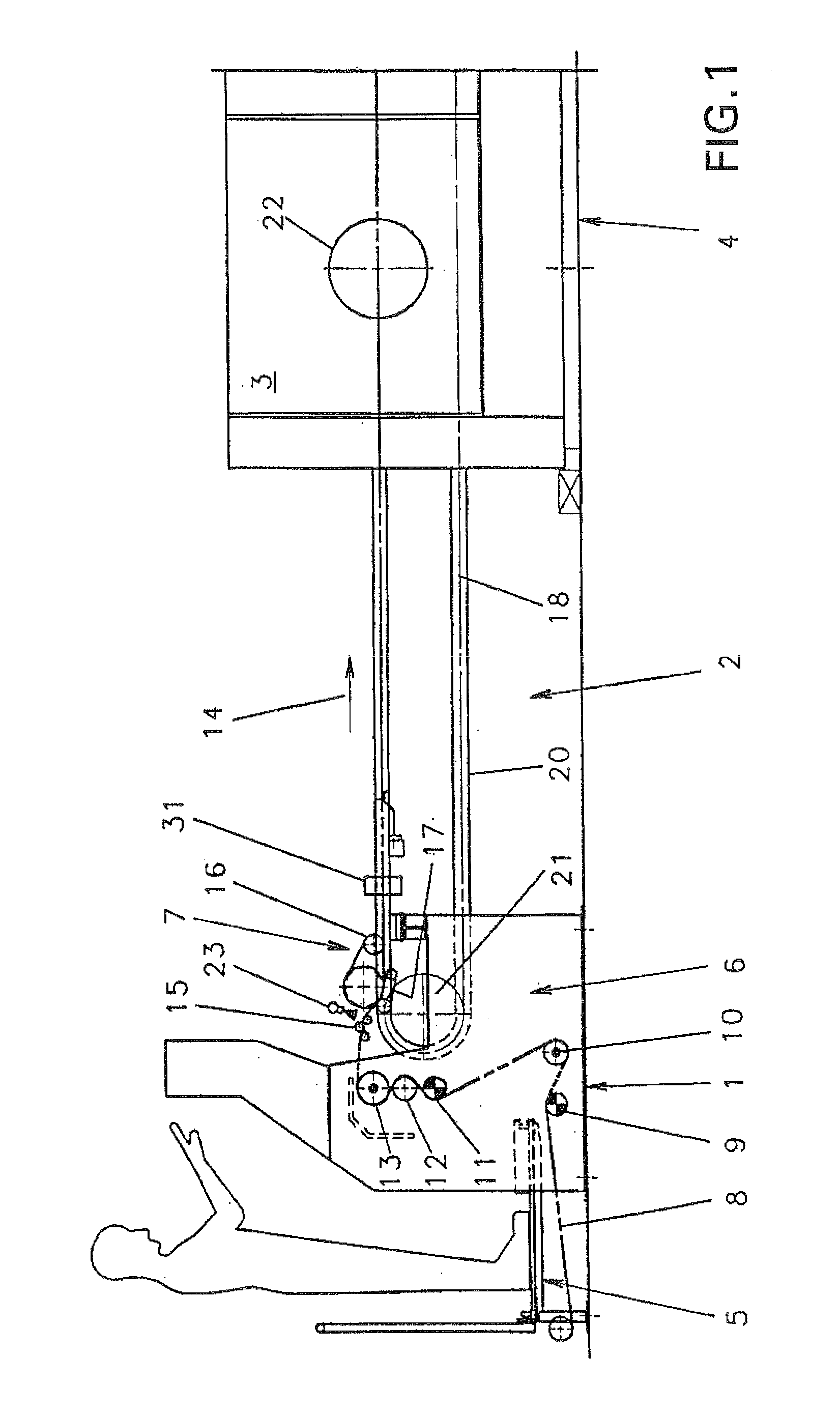

A cutting machine used for necktie fabric processing

InactiveCN105316928AImplement automatic transferIncrease transfer rateTextile selvedgesSevering textilesEngineeringMechanical engineering

The invention provides a cutting machine used for necktie fabric processing. The cutting machine comprises a material holding stand, a material feeding device, a cutting platform and a cutter device. The material feeding device comprises an upper clamping roller and a lower clamping roller. A driving lever device is arranged below the upper clamping roller and comprises a driving lever and a driving lever cylinder. The top surface of the cutting platform is provided with a material falling groove and a protecting plate. The cutter device comprises a horizontal guide rail and a cutting knife. A heating device is arranged in the cutter device and comprises a heater, a heat conduction plate and a heat conduction tube. The cutting machine is simple in structure and highly practical; with the material feeding device, fabric can be conveyed more conveniently; with a gear assembly, the length of fabric cutting can be controlled and the transmission is more stable; with the heating device, the temperature of the cutting knife can be made to rise and through high temperature cutting, cut fabric has the advantages of high quality, smooth cuts and zero burr and the processing of the next procedure is facilitated; energy consumption is reduced and the comprehensive utilization rate is increased.

Owner:SHAOXING HENRY TIE FASHION

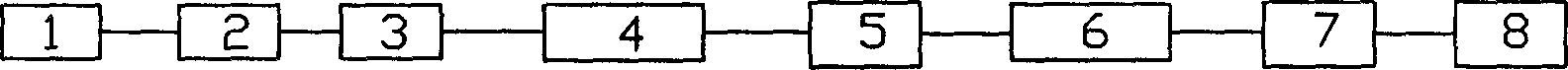

Cloth deburring equipment

InactiveCN106350957AGuaranteed parallelGuaranteed tidyTextile selvedgesSevering textilesMechanical engineeringAir drying

The invention discloses cloth deburring equipment which comprises a conveying belt, wherein a feeding device, a gluing device, an air drying device and a cutting device are sequentially arranged on the conveying belt; the feeding device comprises a material pressing bracket arranged above the conveying belt; multiple material pressing rollers are arranged on the material pressing bracket; the gluing device comprises a gluing bracket arranged on the conveying belt; a glue barrel is arranged on the gluing bracket; the two sides of the glue barrel are connected with a glue pipe respectively; the air drying device comprises air drying brackets arranged on the two sides of the conveying belt; multiple blow pipes connected with a blower are arranged on the air drying bracket; the cutting device comprises a cutting bracket arranged above the conveying belt; and a cloth hot cutter is arranged on a position corresponding to the burr edge of the cloth on the cutting bracket. The cloth deburring equipment disclosed by the invention has the advantages of simple structure, reasonable and novel design and convenience in operation, effectively and quickly finishes the removal of the burr edge of the cloth, improves the working efficiency and guarantees the safety of operation.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

Gum dipping, stentering forming method of earthwork grid cloth

InactiveCN1789540AGuaranteed not to shrinkGuaranteed FounderLiquid surface applicatorsTextile selvedgesMesh gridTowing

The invention relates gumming stretching shaped method, comprising the following steps: accumulating, gumming, stretching and drying, discharging cloth, cooling, towing, accumulating and winding; putting the grid into impregnating groove; before accumulating, carrying out hemming and straightening weft; after accumulating, setting the draught device which is composed at least a drawoff roller, and after stretching and drying, setting cloth discharge and cooling draught device to cool and draw the grid. The method is simple and the grid is not out of shape.

Owner:管昆明

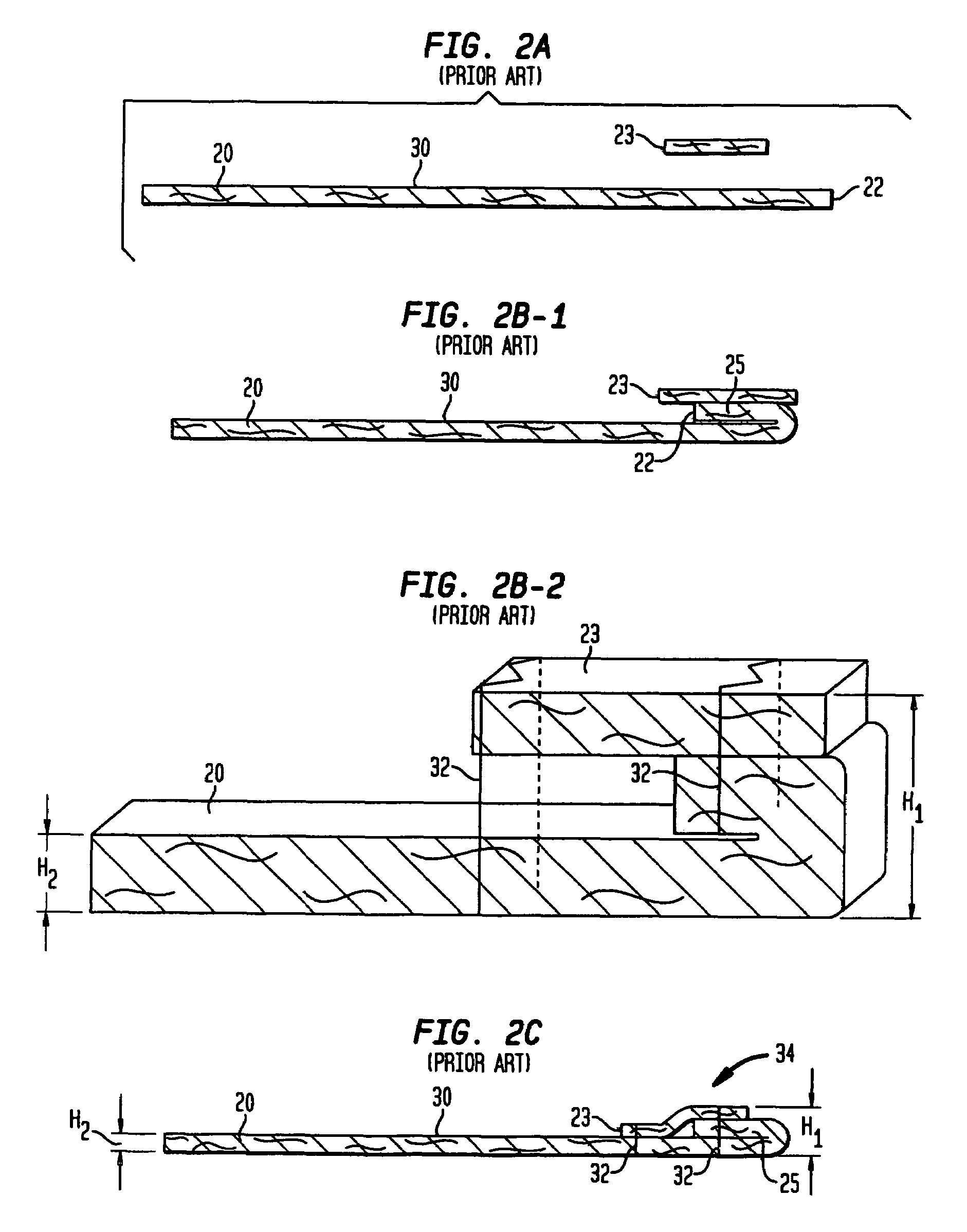

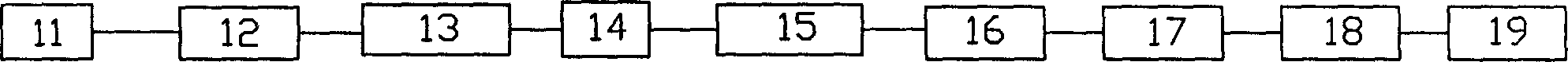

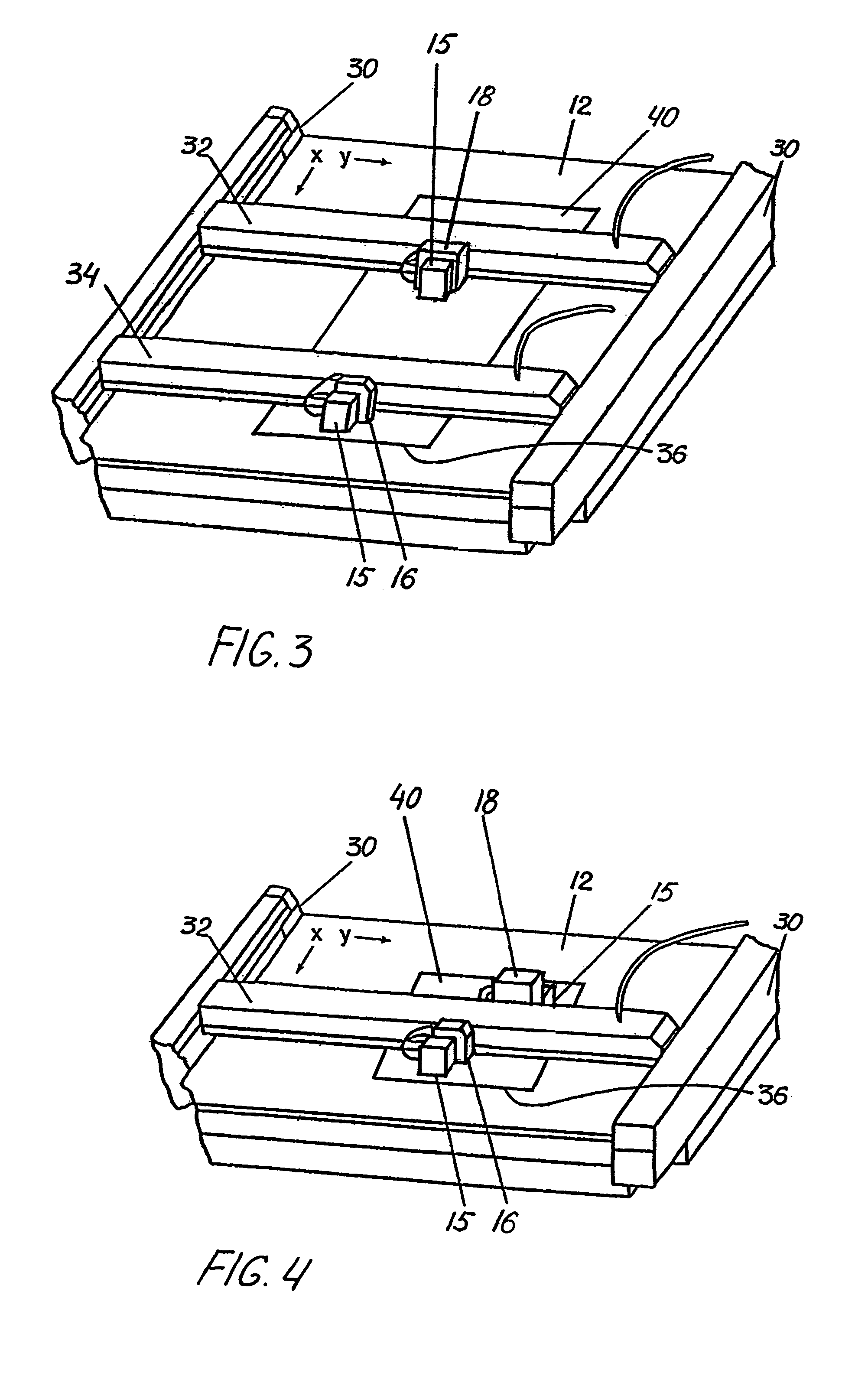

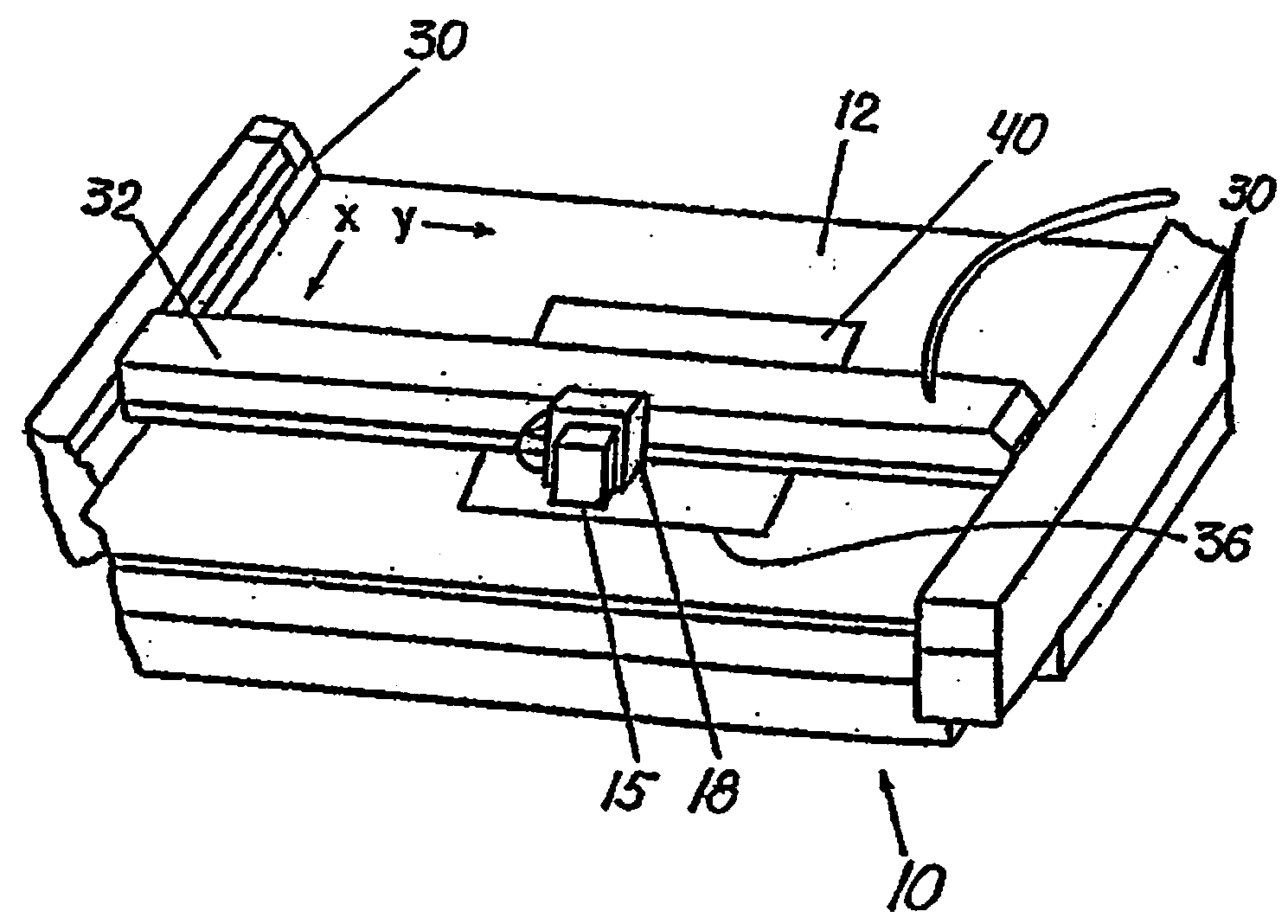

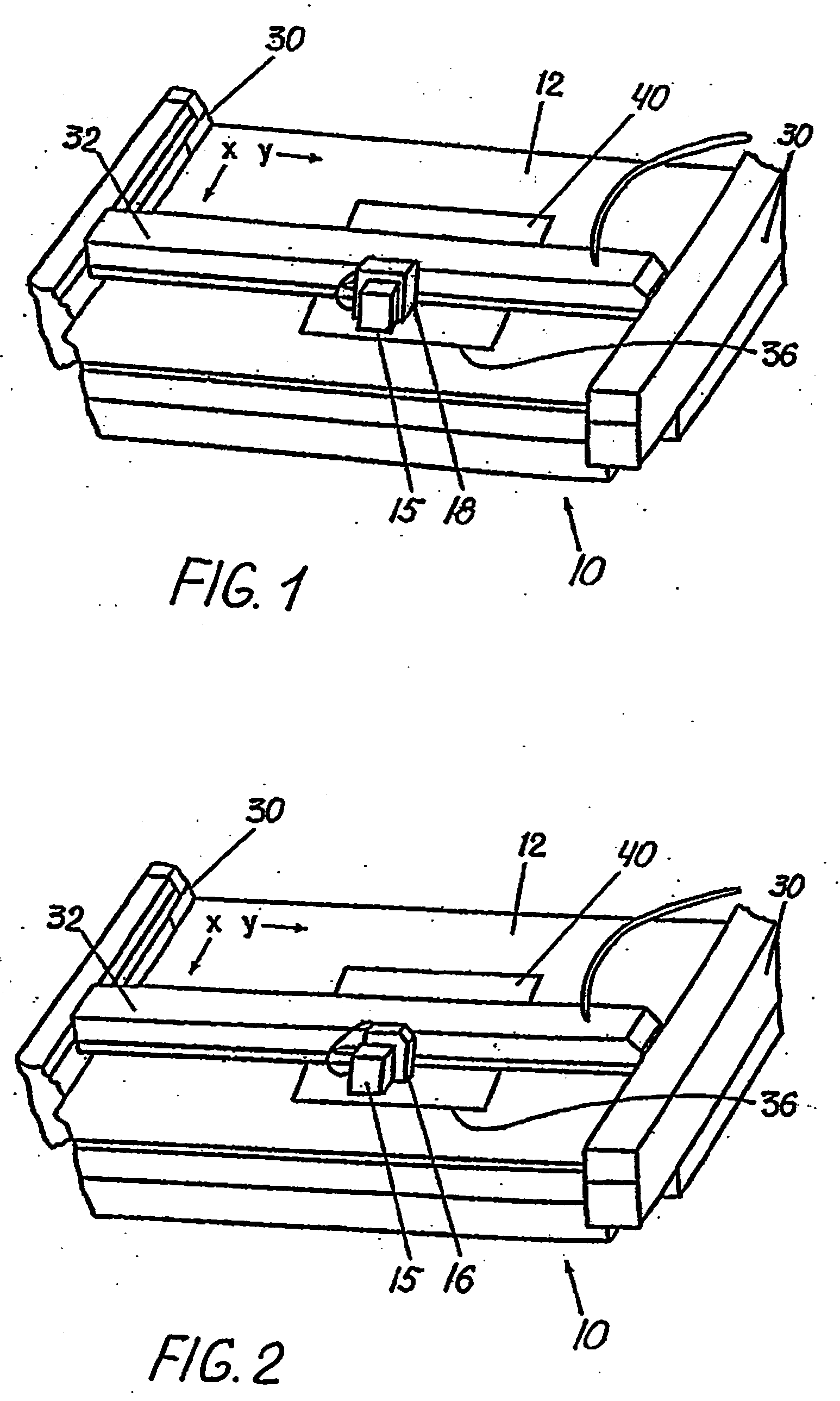

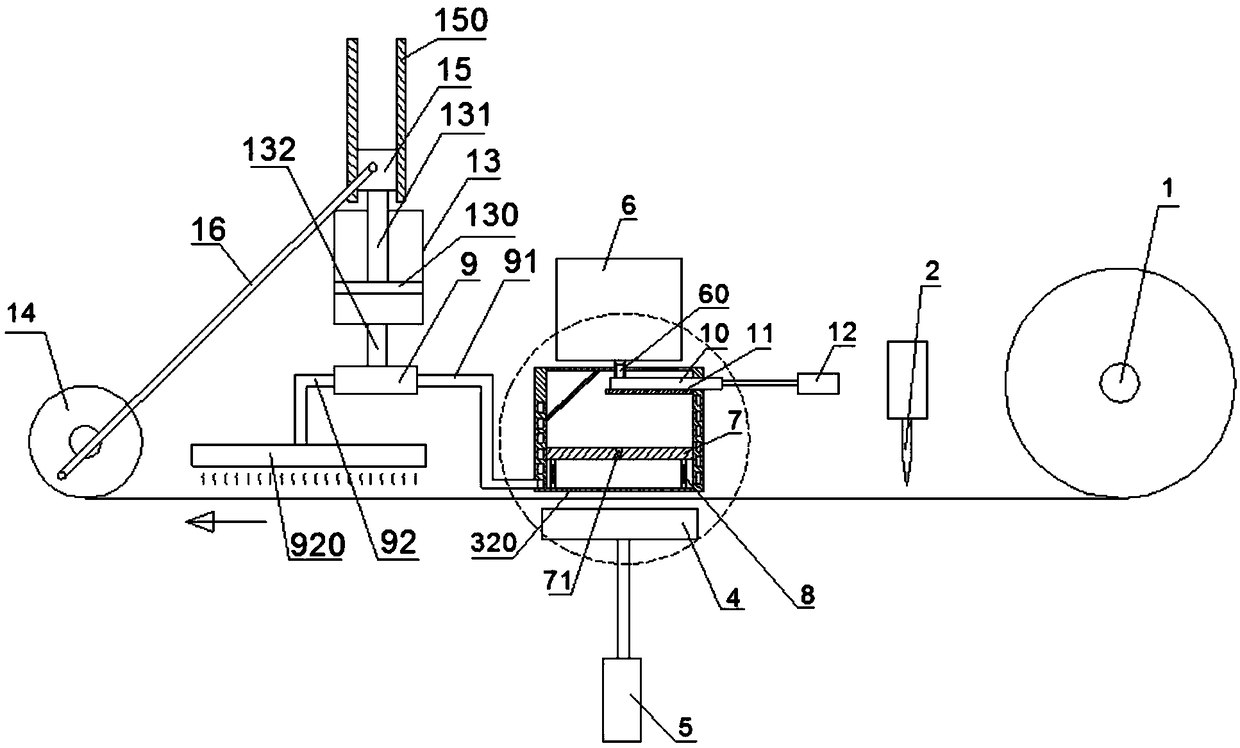

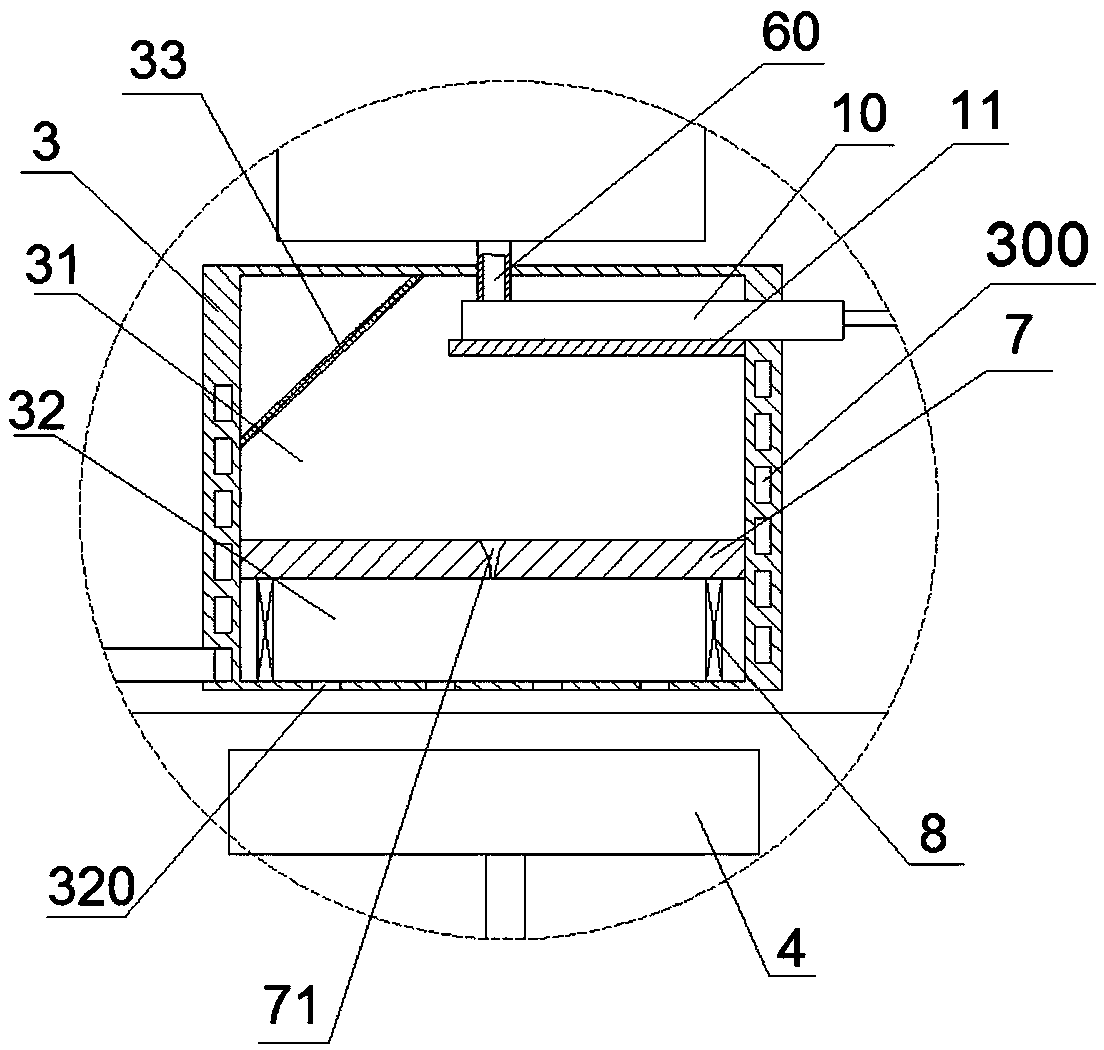

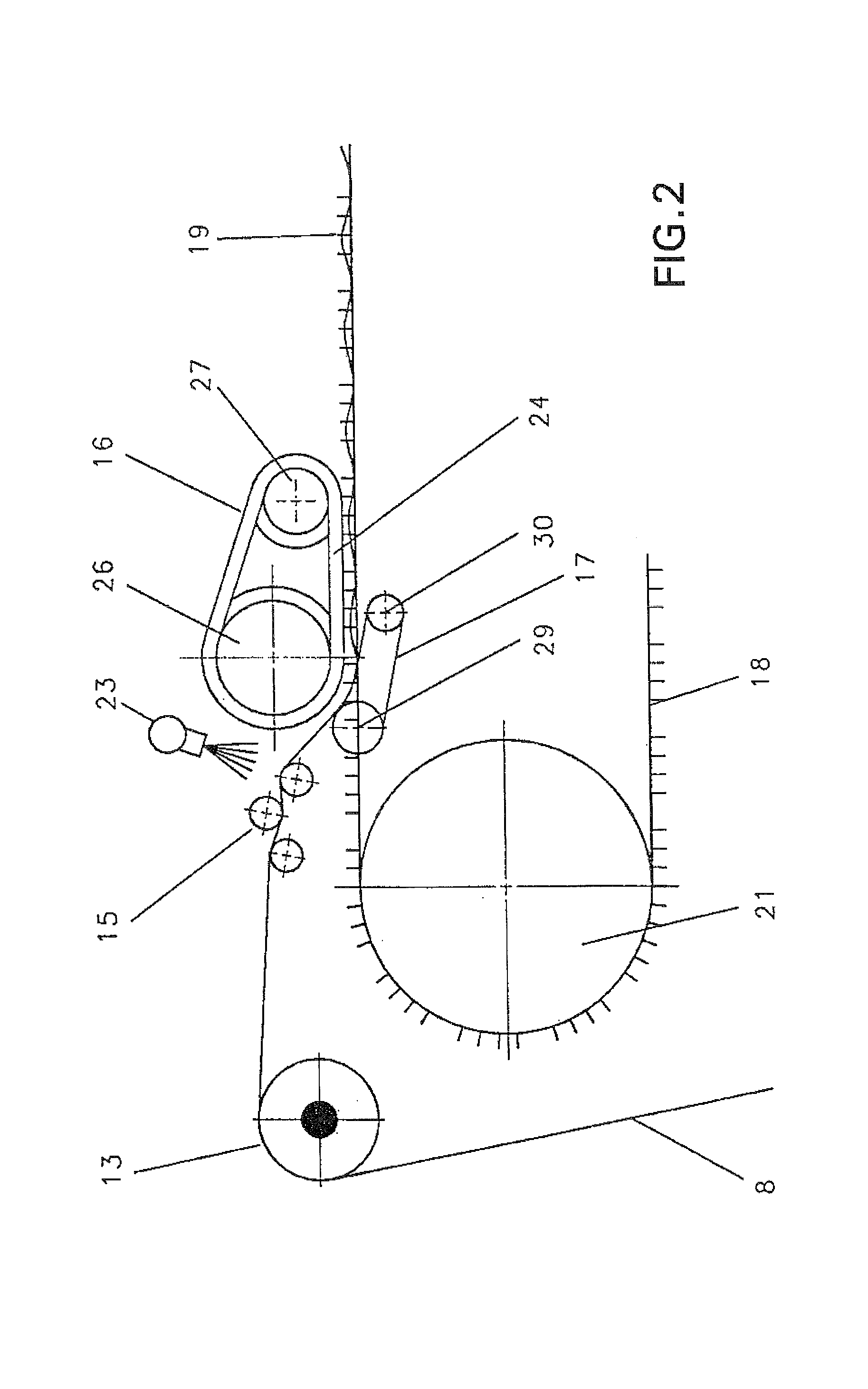

Method and apparatus for fray-free textile cutting

InactiveUS7615128B2Improve productivityLiquid surface applicatorsTextile selvedgesAs DirectedBiomedical engineering

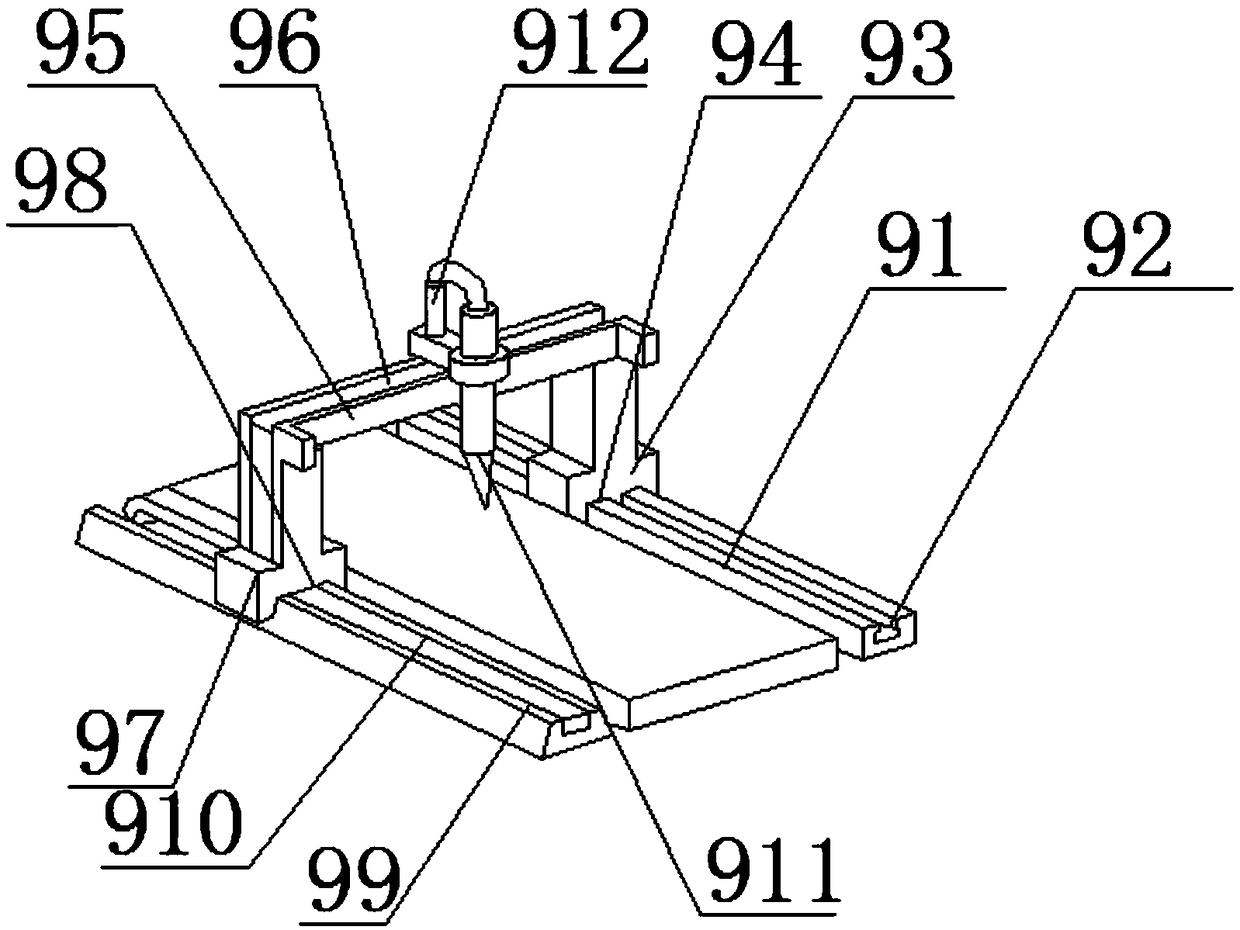

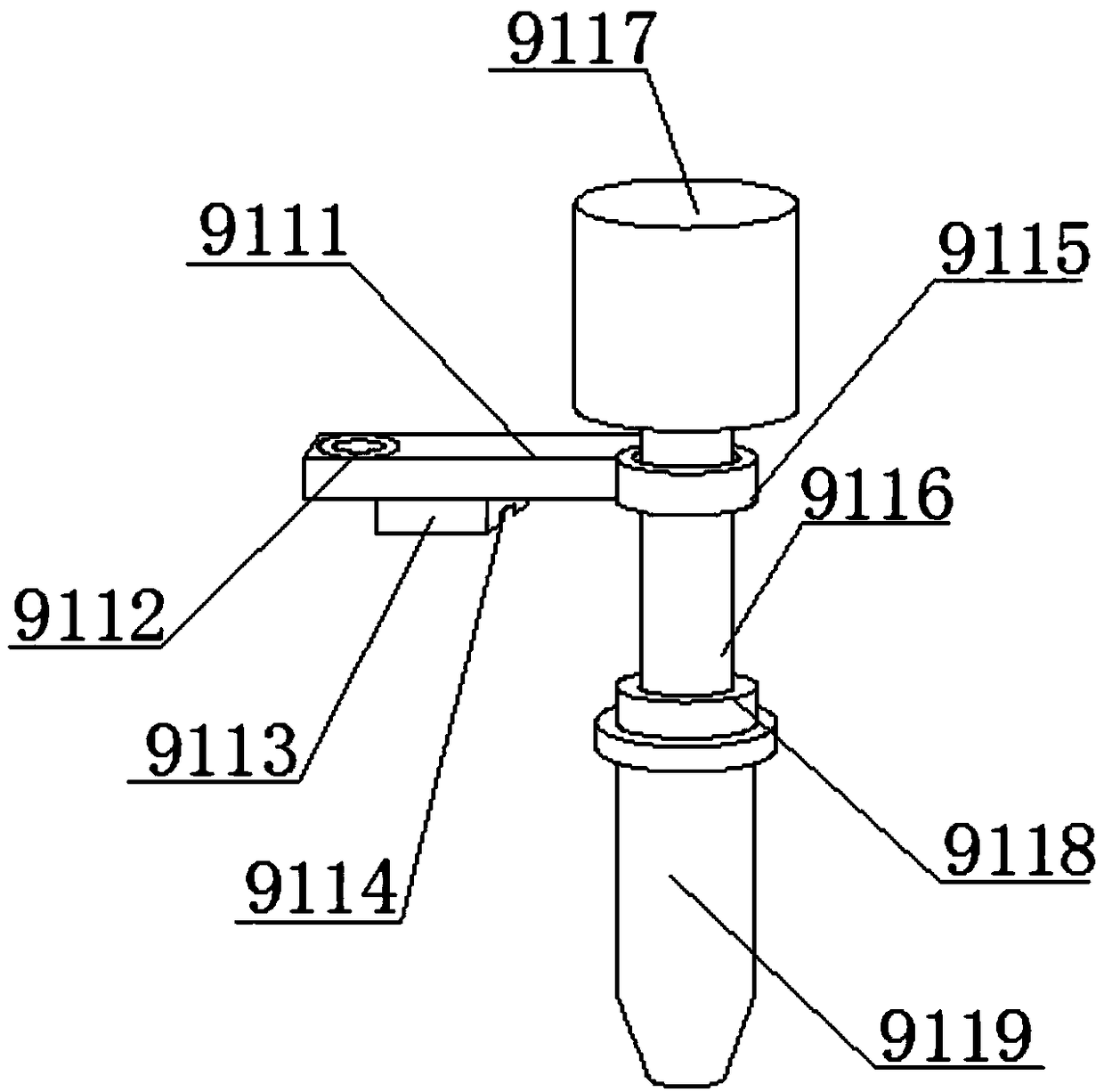

A method and apparatus for fray-free cutting at the perimeter of an area of a textile sheet on a textile-receiving surface, including applying an anti-fray substance onto the sheet along a path at the perimeter by an anti-fray substance applicator movable along the surface as directed by a controller based on programmed information regarding the perimeter, and cutting the sheet at the perimeter by a cutter movable along the surface as directed by the controller based on the programmed information.

Owner:ESKO GRAPHICS KONGSBERG

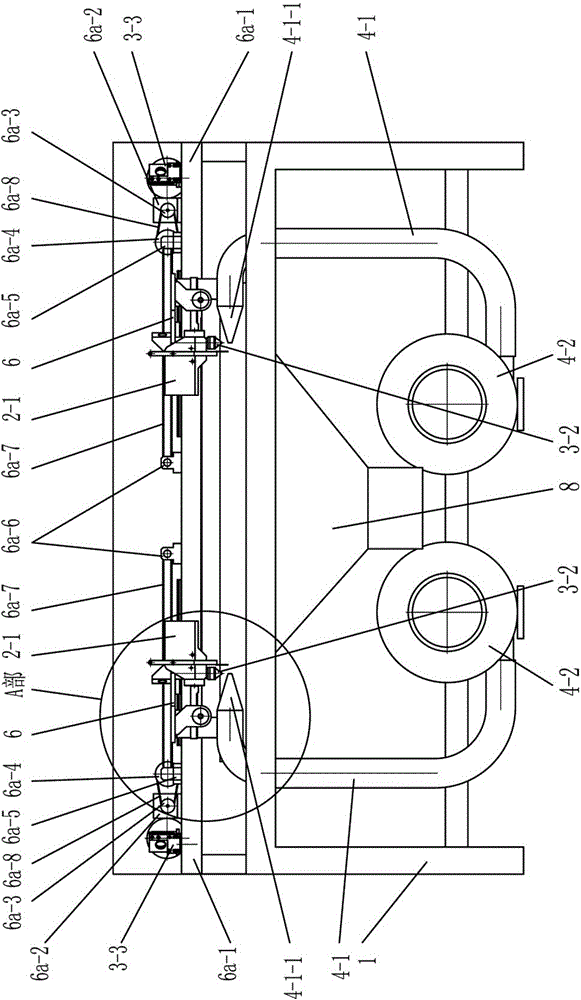

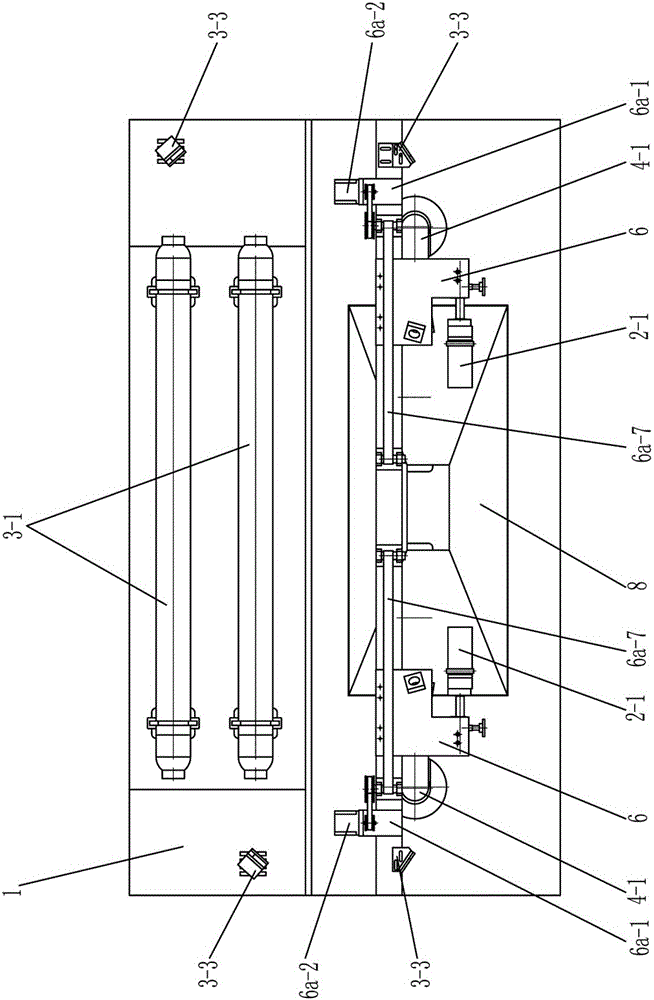

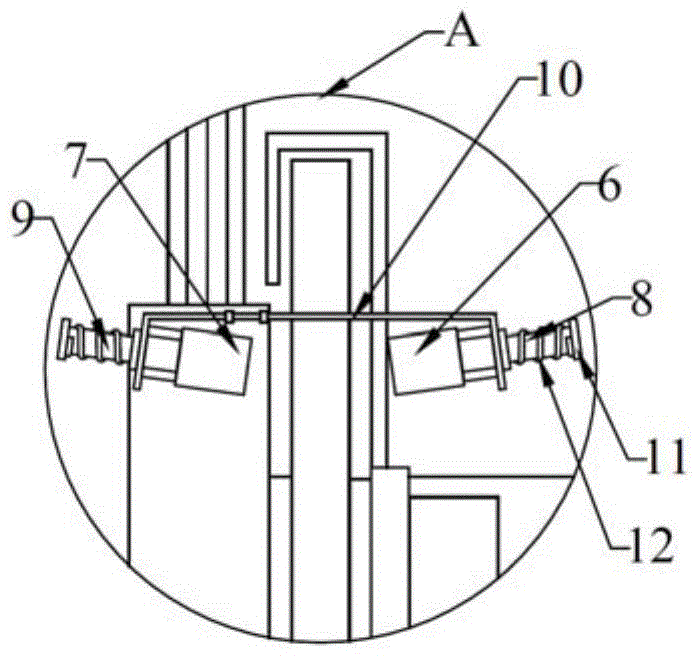

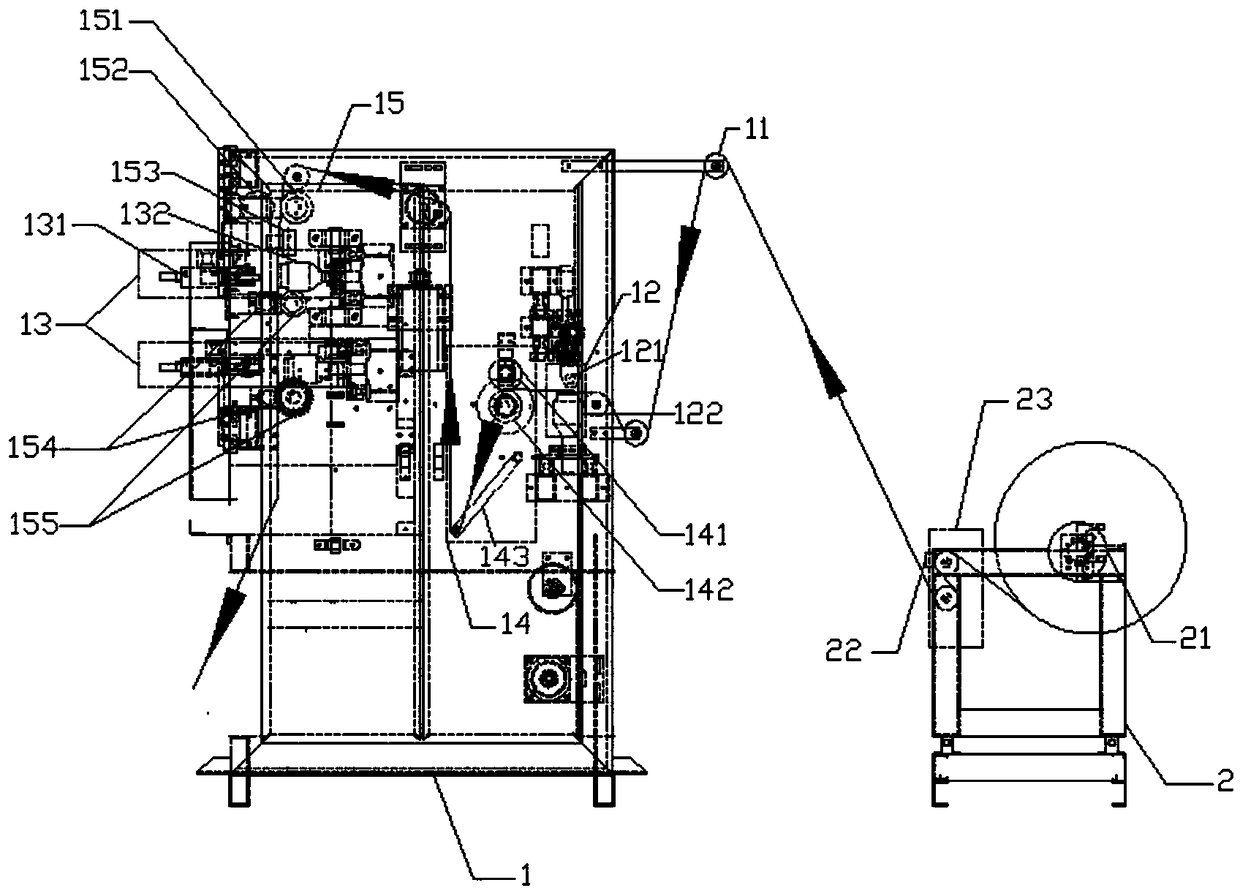

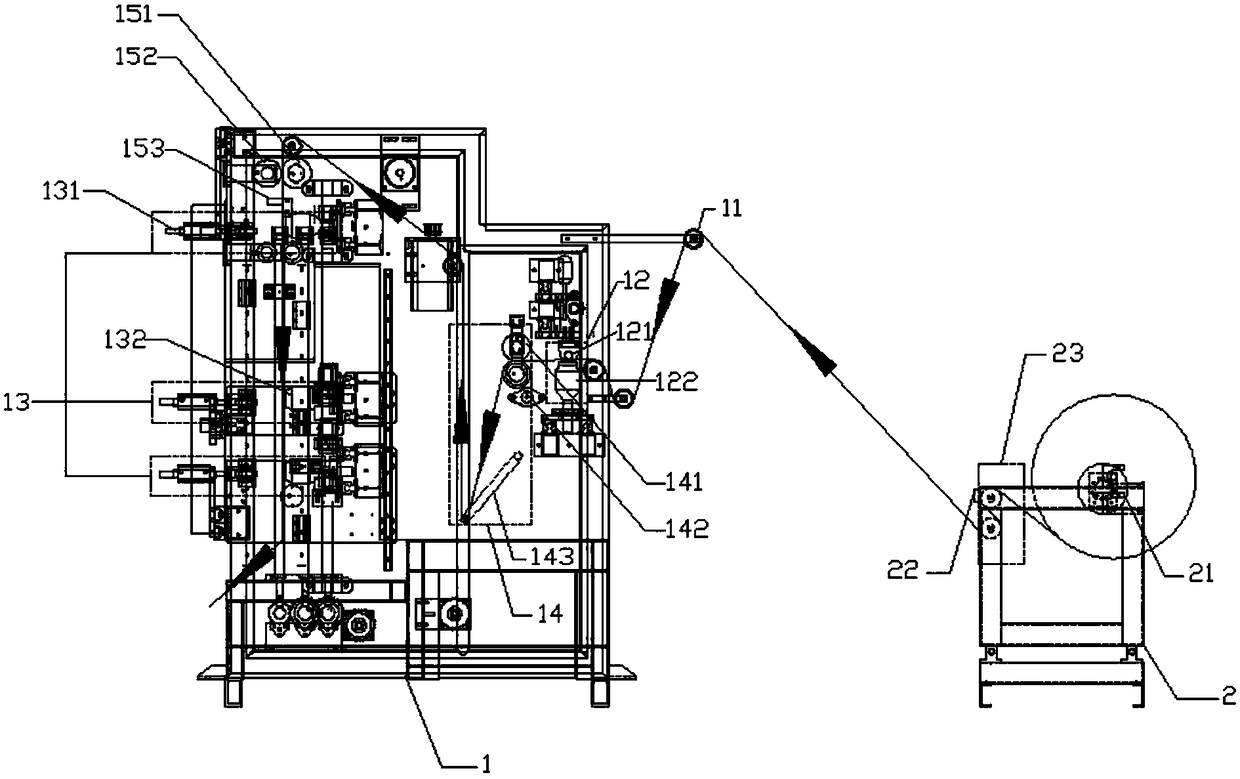

Fabric rough selvedge cut-off device

ActiveCN106112281ASpeed up vaporizationEasy resectionTextile selvedgesLaser beam welding apparatusLaser cuttingEngineering

The invention relates to a fabric rough selvedge cut-off device. The fabric rough selvedge cut-off device comprises a rack, fabric selvedge detecting mechanisms and selvedge detecting and cut-off transmission mechanisms, wherein the fabric selvedge detecting mechanisms and the selvedge detecting and cut-off transmission mechanisms are arranged at the two ends of the rack. Each selvedge detecting and cut-off transmission mechanism comprises a movable carriage. Each fabric selvedge detecting mechanism comprises a position detector which is installed on the movable carriage of the corresponding selvedge detecting and cut-off transmission mechanism. The fabric rough selvedge cut-off device further comprises a laser cut-off mechanism and rough selvedge finishing mechanisms. The laser cut-off mechanism comprises laser tubes, laser cutting heads and laser reflectors. Both the laser tubes and the laser reflectors are fixed to the rack, and the laser cutting heads are arranged on the movable carriages of the selvedge detecting and cut-off transmission mechanisms at the two ends of the rack correspondingly. Laser beams emitted by the laser tubes are projected onto the laser cutting heads through the laser reflectors. The rough selvedge finishing mechanisms are arranged at the two ends of the rack correspondingly. The fabric rough selvedge cut-off device is applicable to various fabric varieties, high in production efficiency, safe, reliable and convenient to operate.

Owner:常州宏大智慧科技有限公司

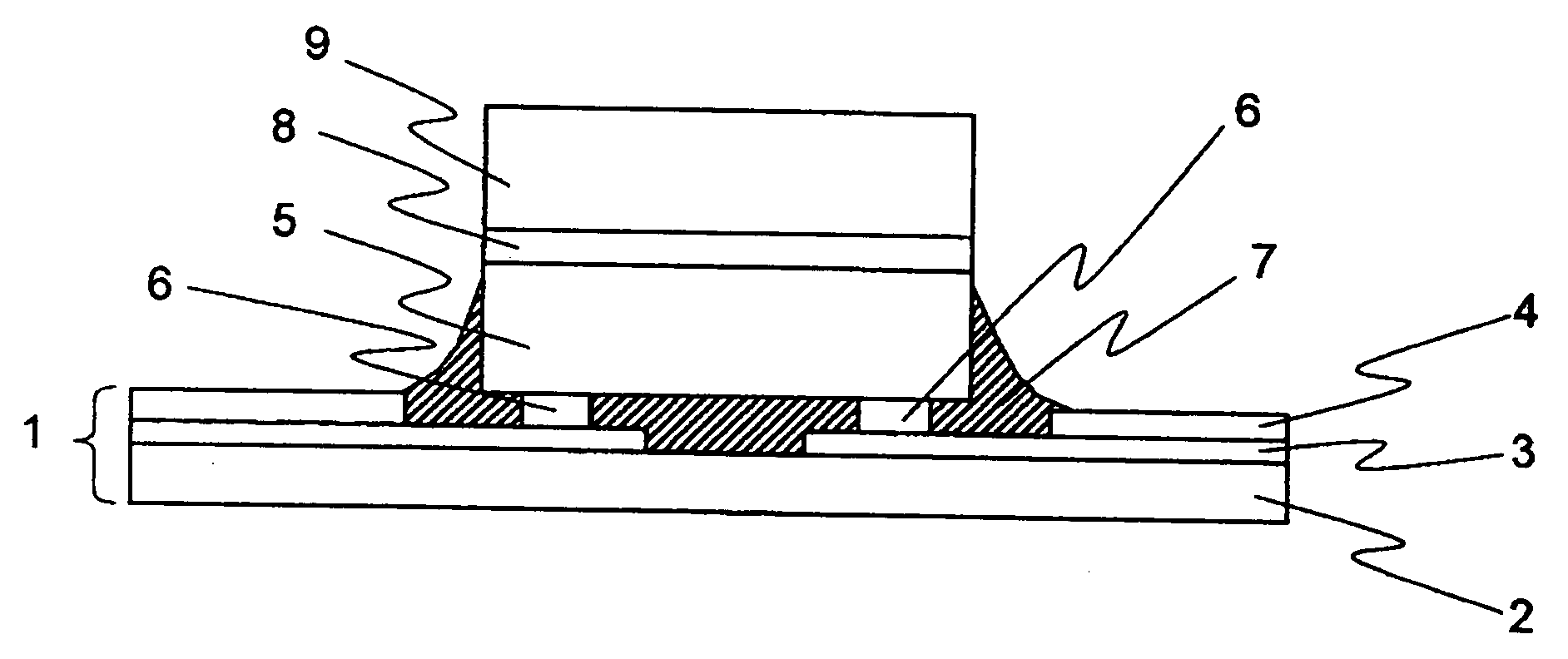

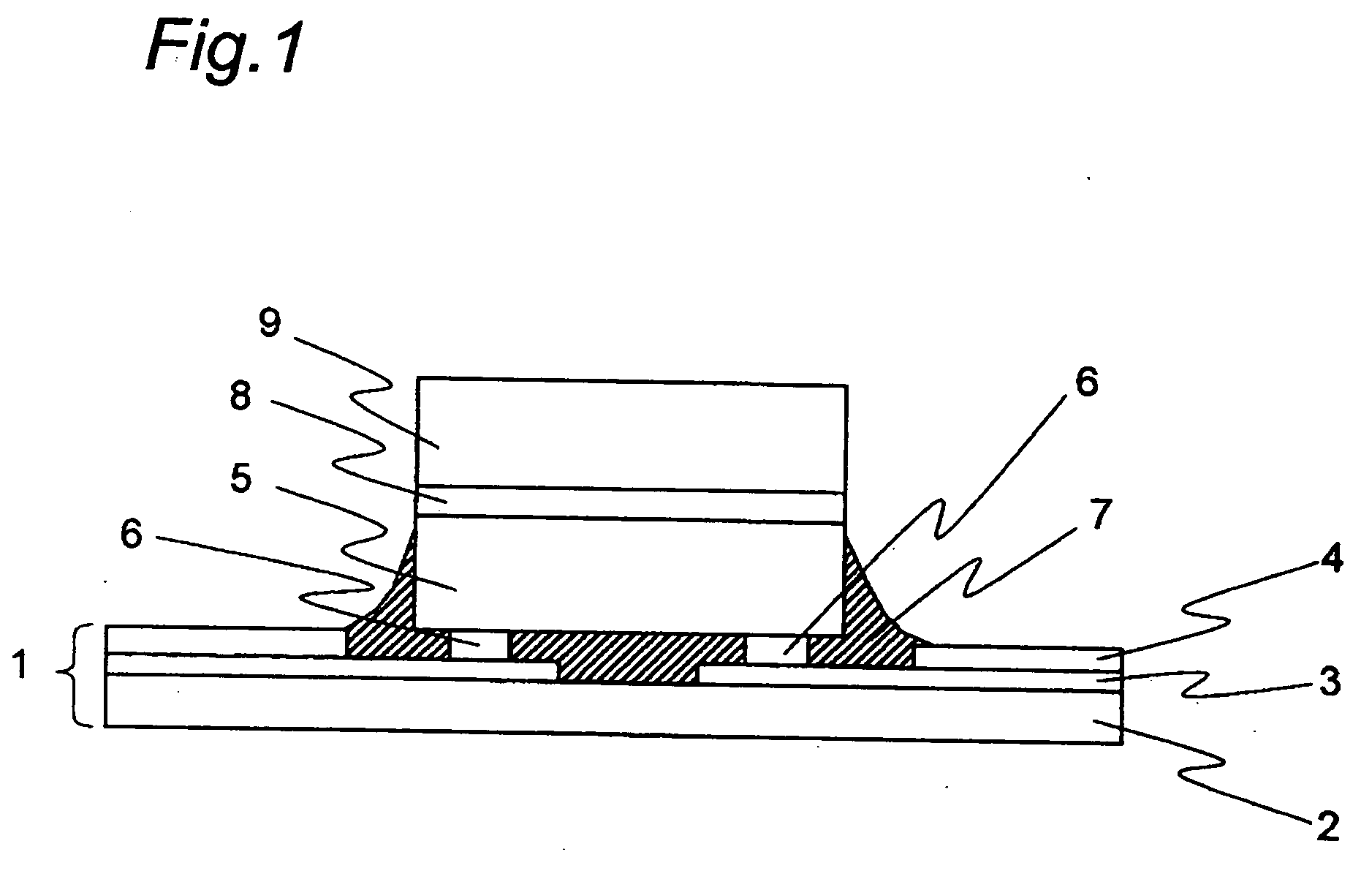

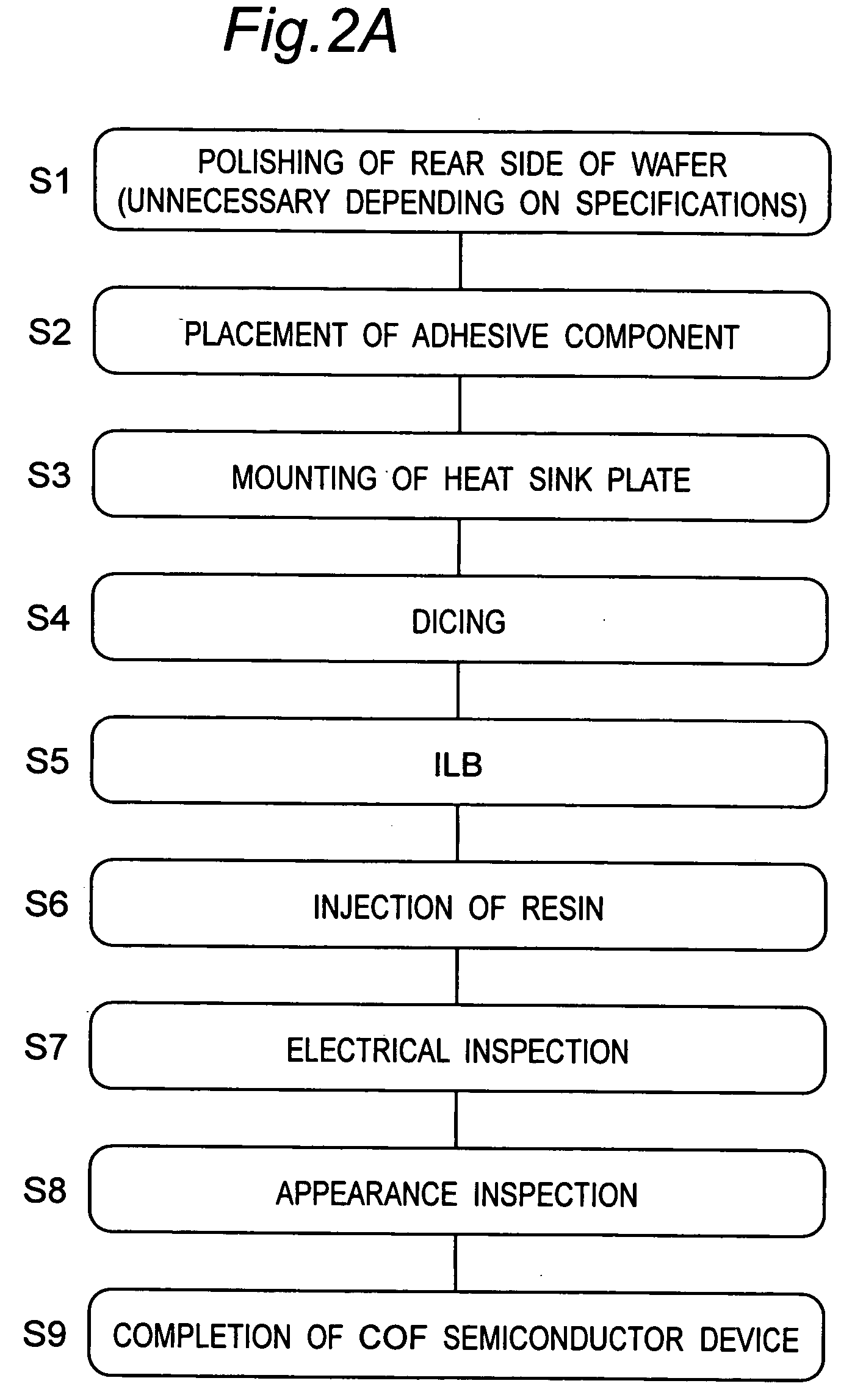

Semiconductor device and manufacturing method therefor

InactiveUS20060209514A1Simple manufacturing processReduce manufacturing costTextile selvedgesSemiconductor/solid-state device detailsDevice materialEngineering

The semiconductor device of the invention has a heat spreader 9 mounted on a semiconductor element 5. The area of one surface of the heat spreader 9 closer to the semiconductor element 5 is generally equal to the area of one surface of the semiconductor element 5 closer to the heat spreader 9. With this structure, manufacturing cost of the semiconductor device can be reduced and moreover its reliability can be enhanced.

Owner:SHARP KK

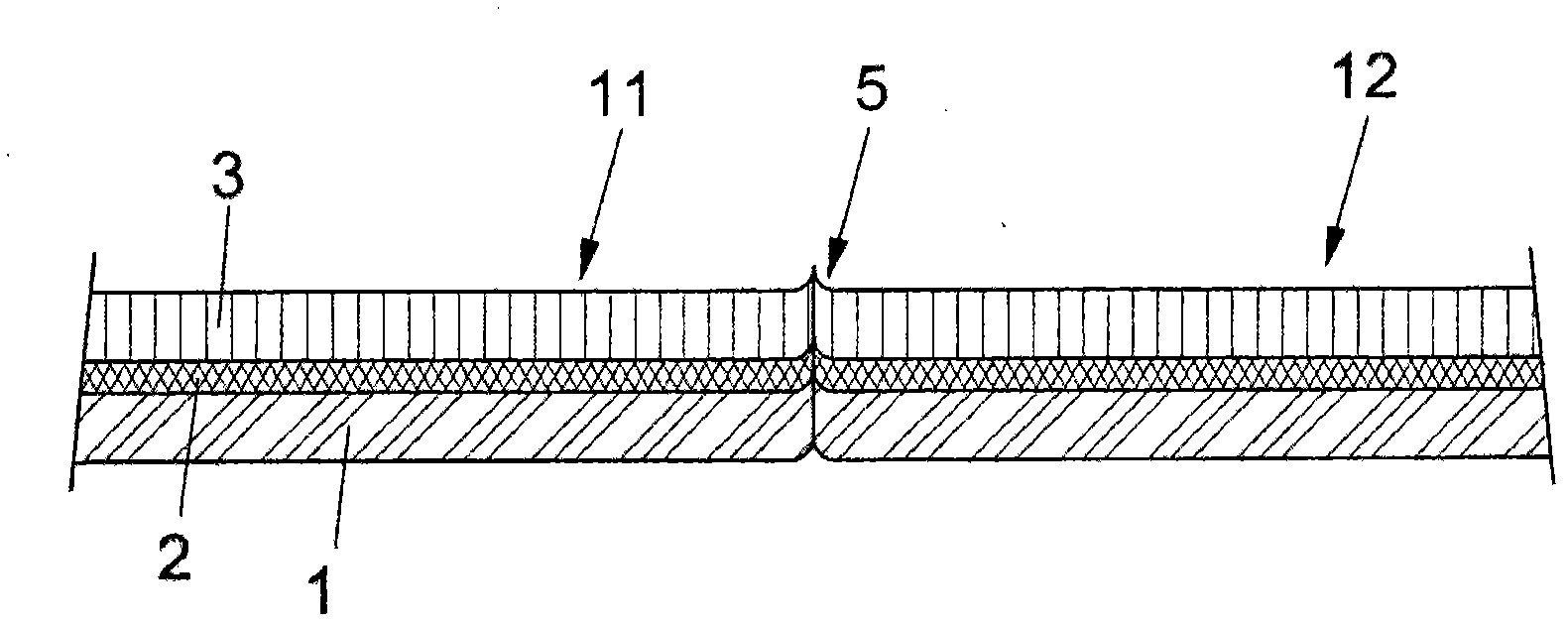

Hems, edges, patches and seams for durable, water repellant woven fabric, and methods for making the same

Edges, hems, patches and seams for woven fabric that has been treated for water repellency, and methods for making the same, are shown and described. In one particular embodiment of the invention, for example, a lapped seam between two pieces of water repellent fabric has an outer material at least partially overlapping an inner material, and a laminate strip positioned between the overlapping portions of the materials. The outer and inner materials, which are both oriented in the same direction, have an exterior layer of woven fabric that has been treated with water repellent and / or stain repellent chemicals, and an inner layer comprising a polymer membrane, such as polyurethane. The laminate strip has a bottom portion in contact with the outer layer of the inner material. The bottom portion has a low melt point, high flow rate adhesive system of one or more layers that penetrates and surrounds the fibers in the woven fiber of the outer layer of the inner piece of material. The laminate strip also has a top layer in contact with the inner layer of the outer piece of material. The top layer of the laminate is a thin, elastic, highly abrasion resistant material with a strong bonding affinity for polyurethane. The layers of the laminate strip bond to the adjacent layers of the overlapped material to create a strong lap seam.

Owner:FOWLER

Edgecomb resistance polyester

ActiveUS20060040577A1Inferior edge combing resistanceIncrease edge combing resistanceOrnamental textile articlesTextile selvedgesPolyesterCombing

The present invention concerns polyester fabric that is employed in airbags. In particular, the polyester fabric has improved resistance to edge combing—the relative tendency of a fabric to pull apart under seam stress or similar action such as inflation of inflatable restraints. Further, the polyester fabric of the invention must have an edge comb resistance of greater than about 350 Newtons at room temperature (20° C.) and greater than 250 Newtons at 90° C. The polyester fabric of the invention has an acrylic polymer or copolymer finish, or a mixture of acrylic and non-acrylic polymers. The finish is applied from about 1 to about 4 wt. % nominal solids add-on of said fabric.

Owner:INV PERFORMANCE MATERIALS LLC

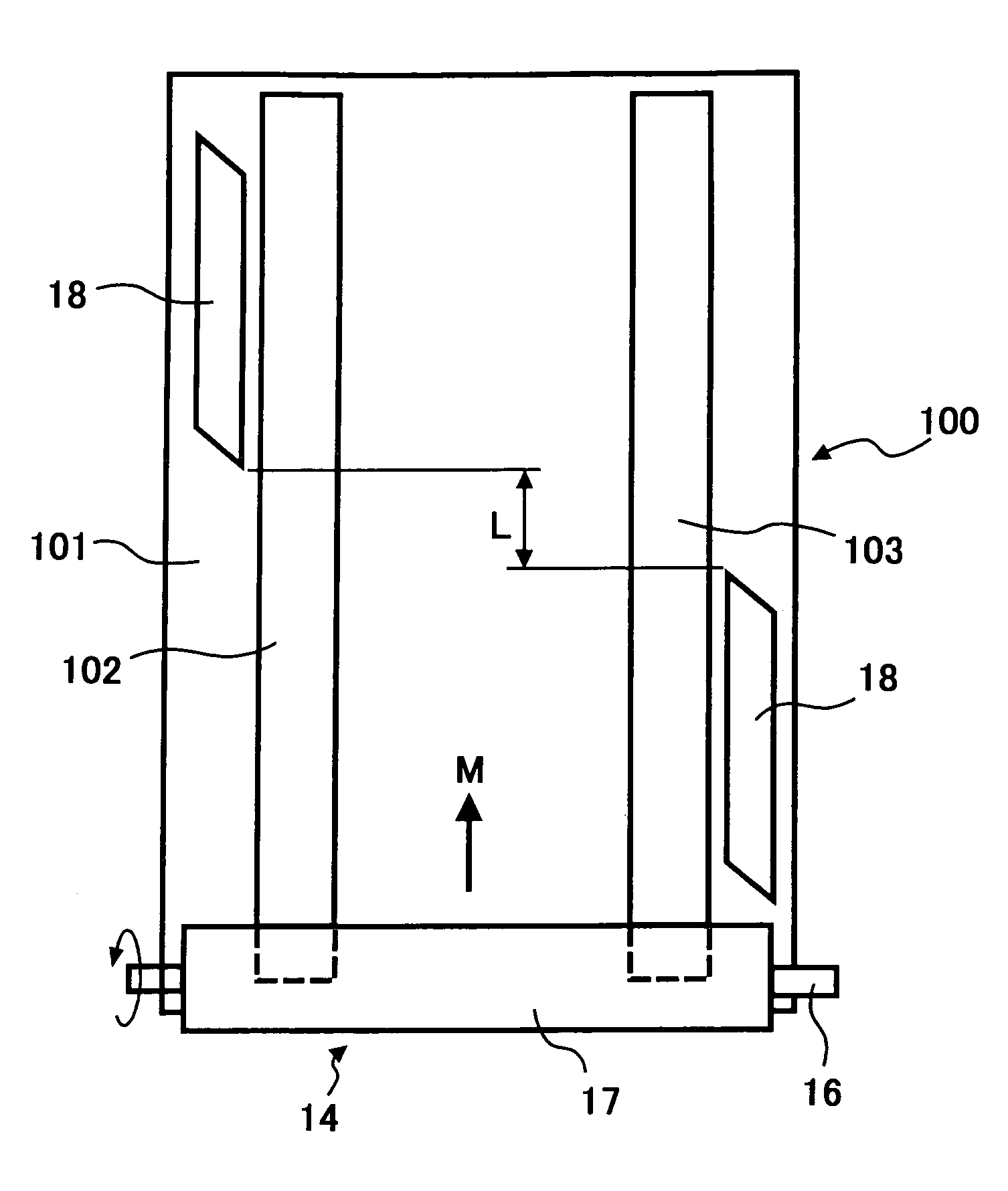

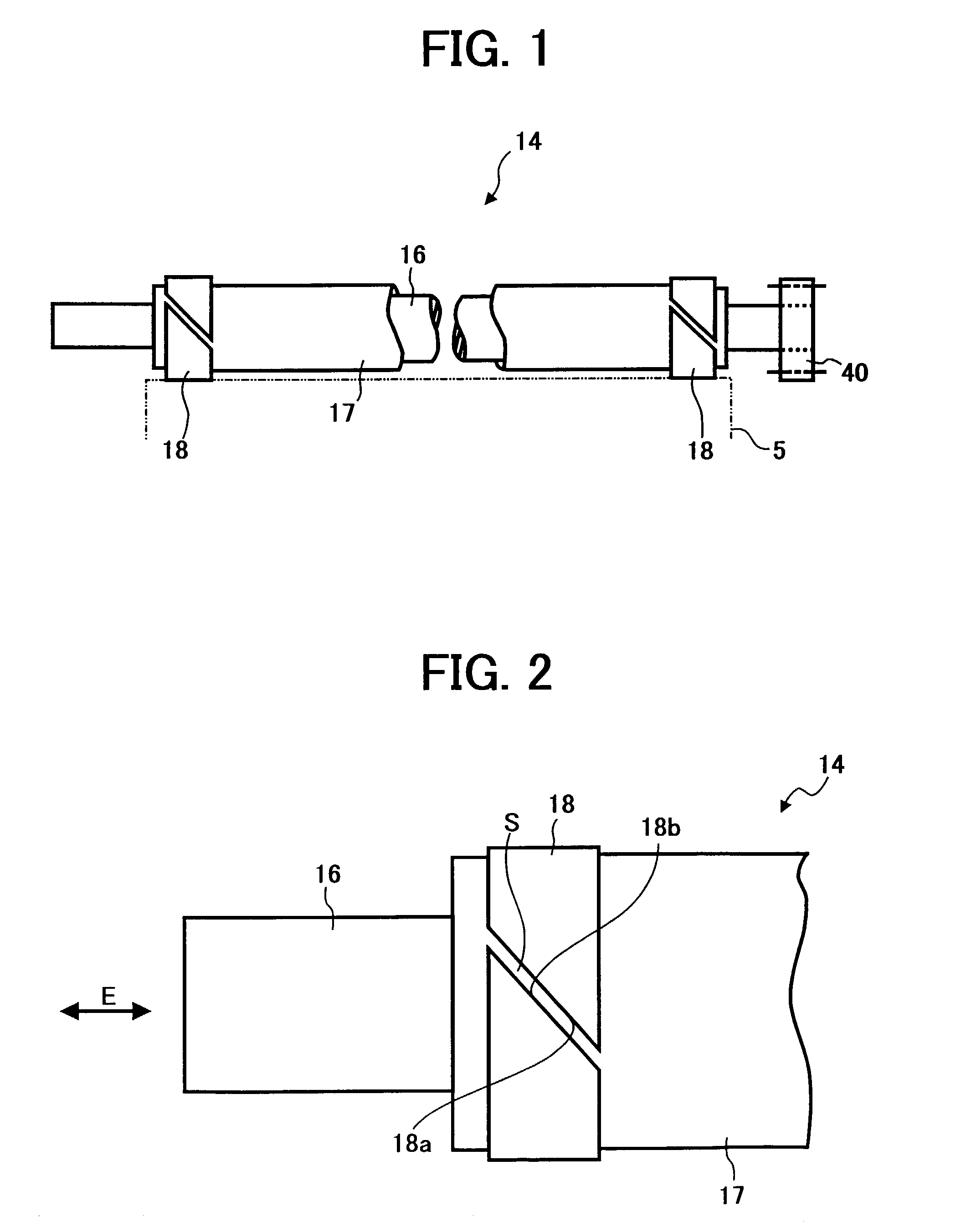

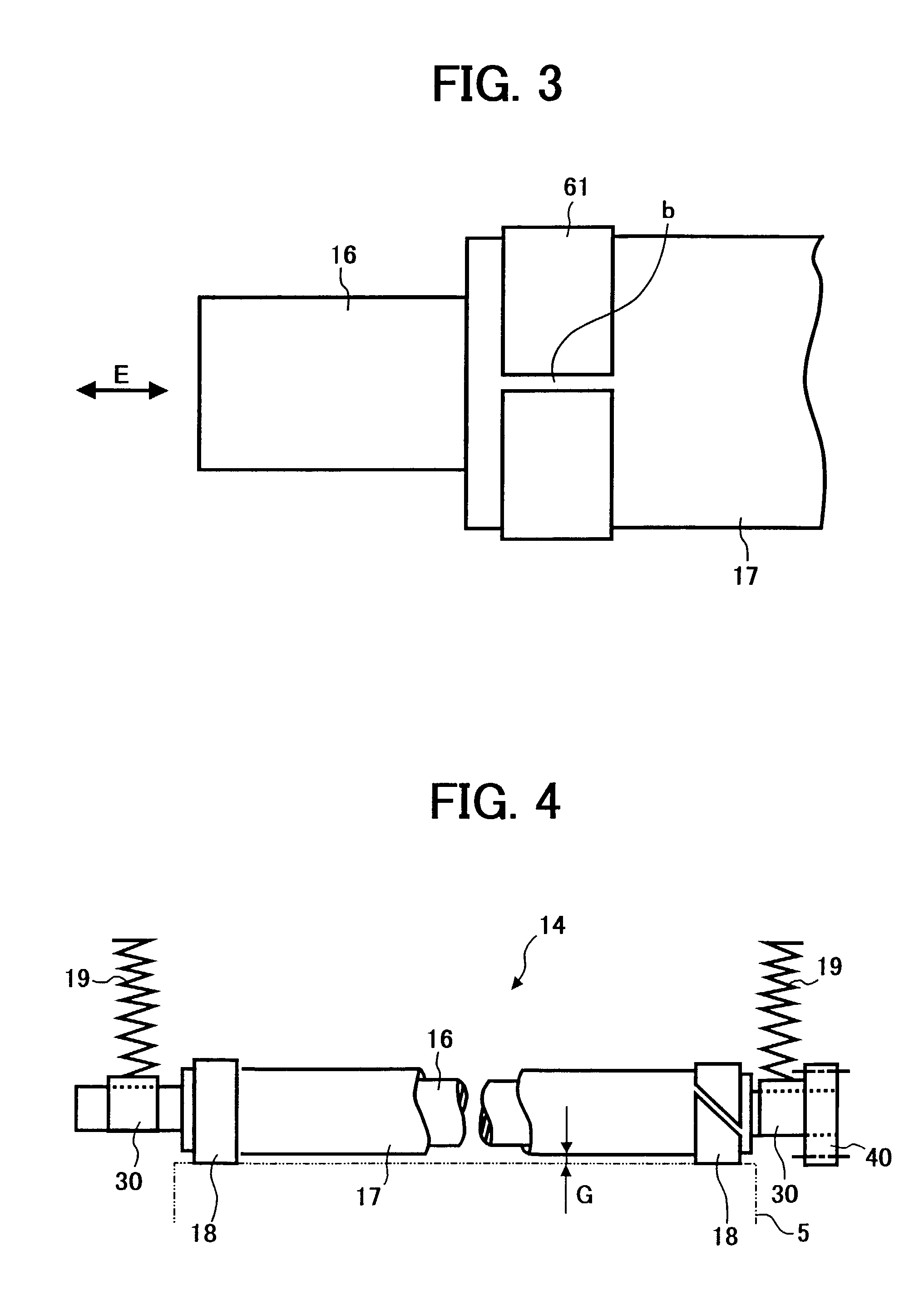

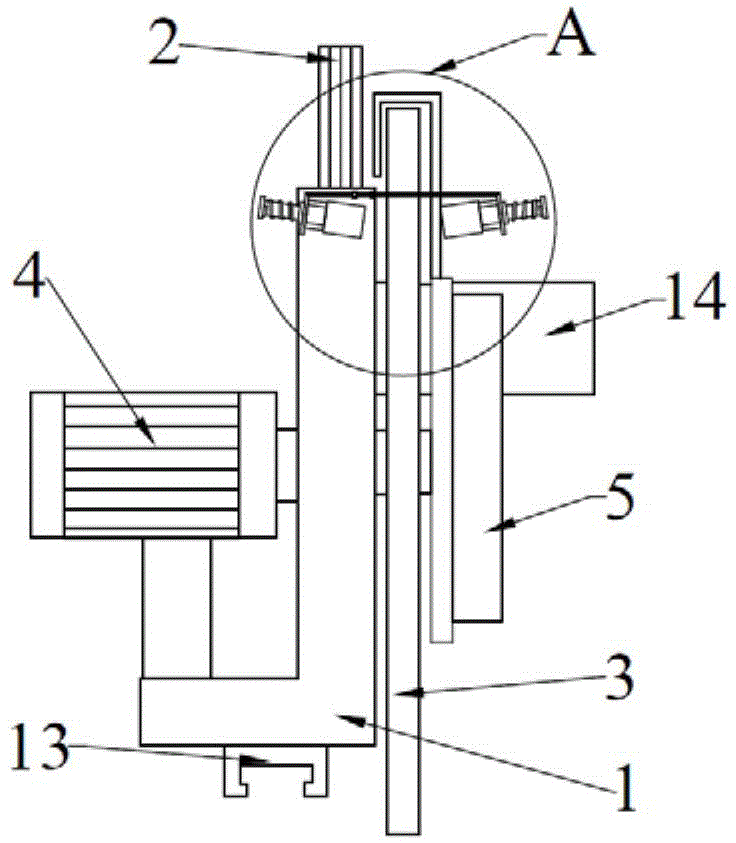

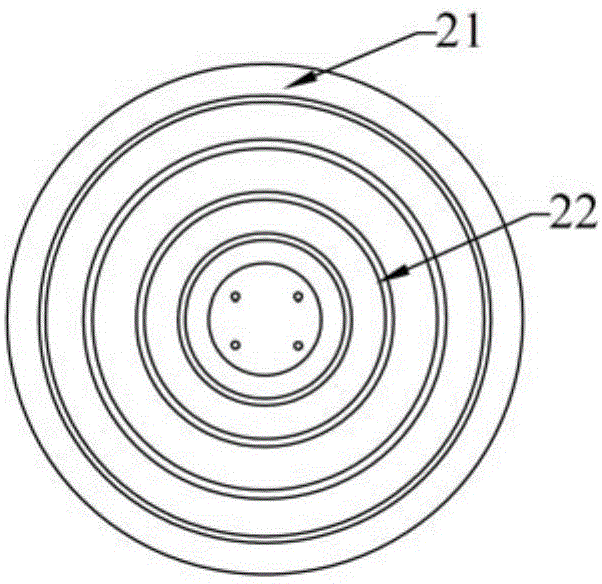

Method and apparatus for performing a charging process on an image carrying device

A charge roller that includes a metal core, an elastic member configured wrapped around the metal core, and film members is disclosed. Each of the film members is wrapped around each end of the elastic member in a circumferential direction of the metal core such that at least a part of each of the film members exists at every position around the ends of the elastic member in an axial direction of the metal core. Portions of the film members do not overlap each other in an radial direction of the metal core.

Owner:RICOH KK

Handheld type heating cloth-cutting device

ActiveCN104060455ASimple structureFirmly connectedTextile selvedgesSevering textilesChemical fiber clothHand held

The invention discloses a handheld type heating cloth-cutting device. The handheld type heating cloth-cutting device comprises a rack, wherein a handheld handle is arranged on the rack; a blade with a round outer profile is arranged on the rack by a connecting part and is connected with the output end of a driving motor by a transmission part; the driving motor is used for driving the blade to rotate. The cloth-cutting device also comprises a heating device for heating the blade. The handheld type heating cloth-cutting device disclosed by the invention has the advantages that the structure is simple; by matching arrangement of the heating device on a cutter, before cloth is cut, the cutter is firstly heated, then the cutter is used for cutting materials such as chemical-fiber cloth, silks, geotextile cloth and plastic braided fabrics, so that the phenomenon of fiber dispersion at cut edges can be completely avoided, the connection among cloths after the cut cloths are sewn is firm, and the use effect is good.

Owner:JIANGSU SUNSHINE

Self-adhesive flame-retardant roller shutter fabric without resin adhesive and manufacturing method thereof

InactiveCN109137220AHigh flame retardant efficiencyEffective adhesionFlame-proof filament manufactureTextile selvedgesBromineNitrogen

The invention provides a self-adhesive flame-retardant roller shutter fabric without a resin adhesive and a manufacturing method thereof. The fabric comprises a yarn and a flame retardant. The yarn comprises a warp yarn and a weft yarn. The self-adhesive roller shutter fabric also comprises a 75D-300D thermofuse. The flame retardant is a phosphorus based flame retardant, or the mixture of the phosphorus-based flame retardant and a nitrogen-based flame retardant. In the invention, a condition that an additionally-added resin is taken as the adhesive and a bromine antimony system flame retardantis replaced, appropriate adhesiveness and stiffness can be possessed, a flame retardant effect, energy saving and environmental protection are achieved, the fabric can be recycled, cost is reduced, and technology processes are saved.

Owner:CHEN HONG TEXTILES TECH

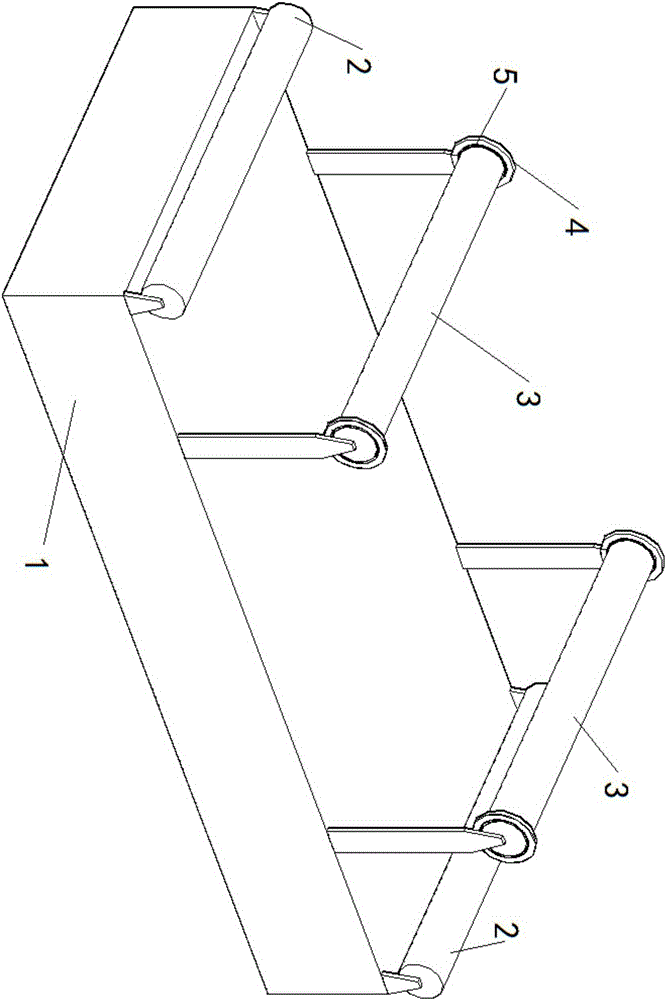

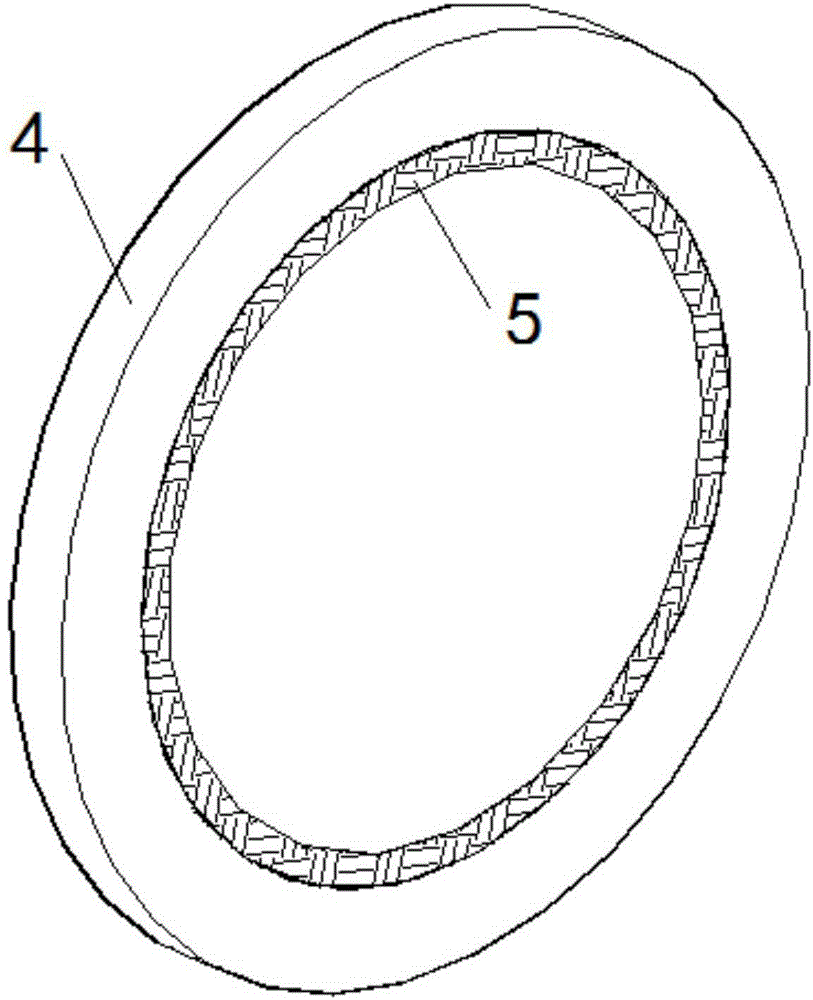

Cloth burr trimming device

InactiveCN105297321AGood thermochemical performance and stabilityHigh electrothermal conversion efficiencyTextile selvedgesSingeingThermal insulationEngineering

The invention discloses a cloth burr trimming device. The device comprises a conveying platform, first-grade conveying rollers and second-grade conveying rollers are arranged at the two ends of the upper surface of the conveying platform respectively, the height, relative to the upper surface of the conveying platform, of each second-grade conveying roller is larger than that of the corresponding first-grade conveying roller, and workers are protected from being burnt in the operation process; the two ends of each second-grade conveying roller are sleeved with ceramic electric heaters respectively, and each ceramic electric heater is in a circular-ring shape; a circular-ring-shaped foaming thermal insulation layer is arranged between the surface of each second-grade conveying roller and the corresponding ceramic electric heater in a partitioning mode, and each foaming thermal insulation layer is in a circular-ring shape. According to the cloth burr trimming device, the four ceramic electric heaters are arranged at the two ends of the device, the ceramic electric heaters are utilized for removing burrs of cloth, the burrs at the two sides are burnt off while the cloth is moved, the operation is extremely convenient, work efficiency is obviously improved, and the success rate is obviously raised; each foaming thermal insulation layer is arranged between the corresponding ceramic electric heater and the corresponding conveying roller, the conveying rollers are prevented from being heated and burning hot, and operation safety is improved.

Owner:上海顺簿贸易经营服务部

Water-soluble edge-coating viscose glue for elastic cloth and uses

InactiveCN101289603AExcellent adhesionEasy to useTextile selvedgesPolyureas/polyurethane adhesivesRoom temperatureWater soluble

The invention relates to aqueous bead coating gluewater used in an elastic woven material and a use of the same. The compositions in percentage by weight of the aqueous bead coating gluewater are: 80 to 99 percent of aqueous urethane resin, 0.2 to 7 percent of antifoaming agent, 0.1 to 7 percent of wetting agent and 0.1 to 9 percent of thickening agent; or 80 to 95 percent of aqueous urethane resin, 0.2 to 2 percent of antifoaming agent, 0.1 to 2 percent of wetting agent, 0.1 to 3 percent of thickening agent and 1 to 19 percent of aqueous color paste; the solid content in the aqueous urethane resin is equal to or more than 40 percent, while the extensibility is equal to or more than 600 percent; and at 20 DEG C room temperature, the viscosity of the bead coating gluewater is of between 14,000 to 18,000cps. The aqueous bead coating gluewater does not contain solvents such as NMP, DMSO and DMF, and accords with the requirements of environmental protection; moreover, the thickness of a gluewater coating is easy to control, and a film coating has excellent adhesive force on various aquatic sports clothing materials and resists seawater immersion.

Owner:深圳市美丽华科技股份有限公司

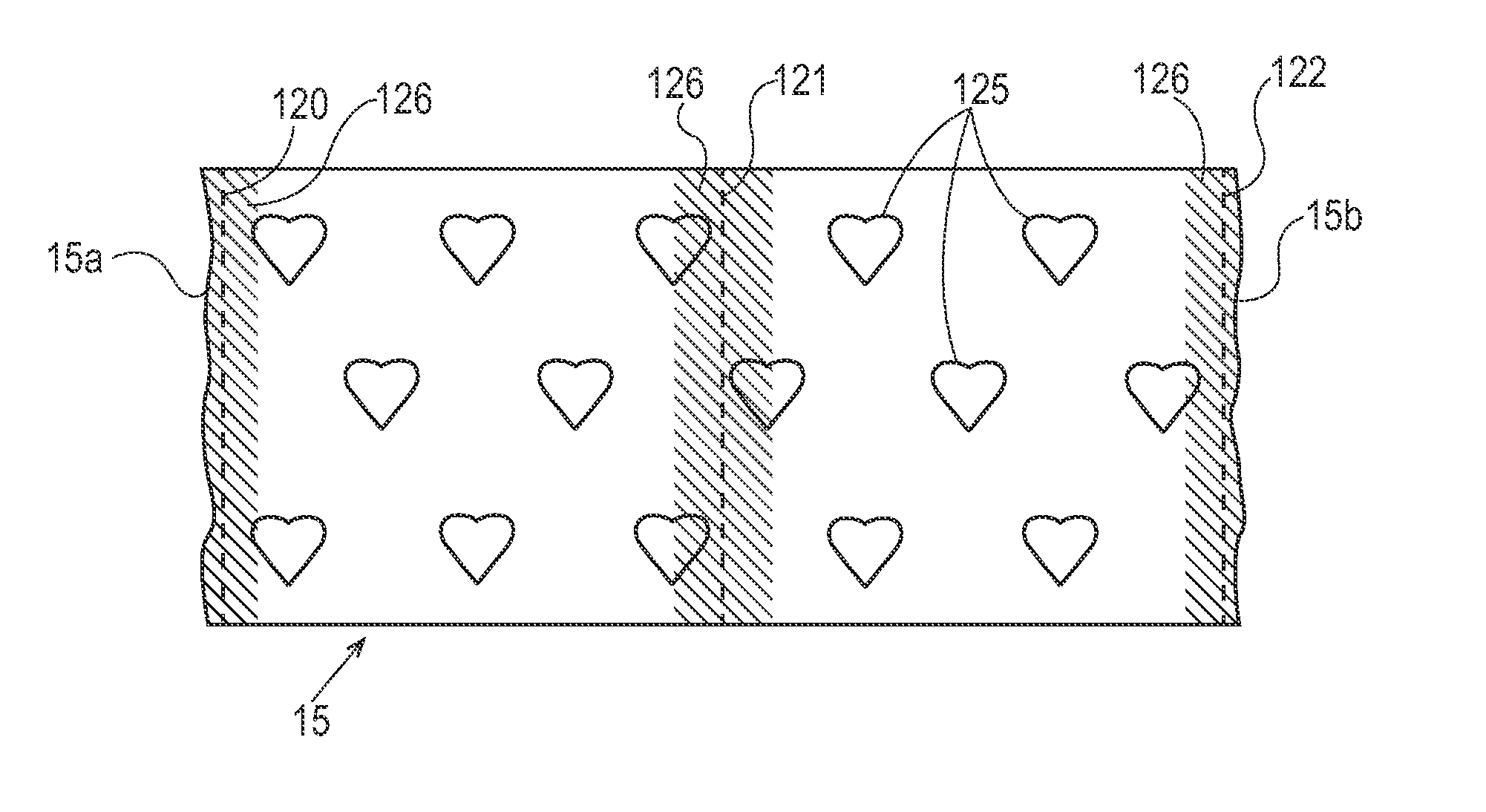

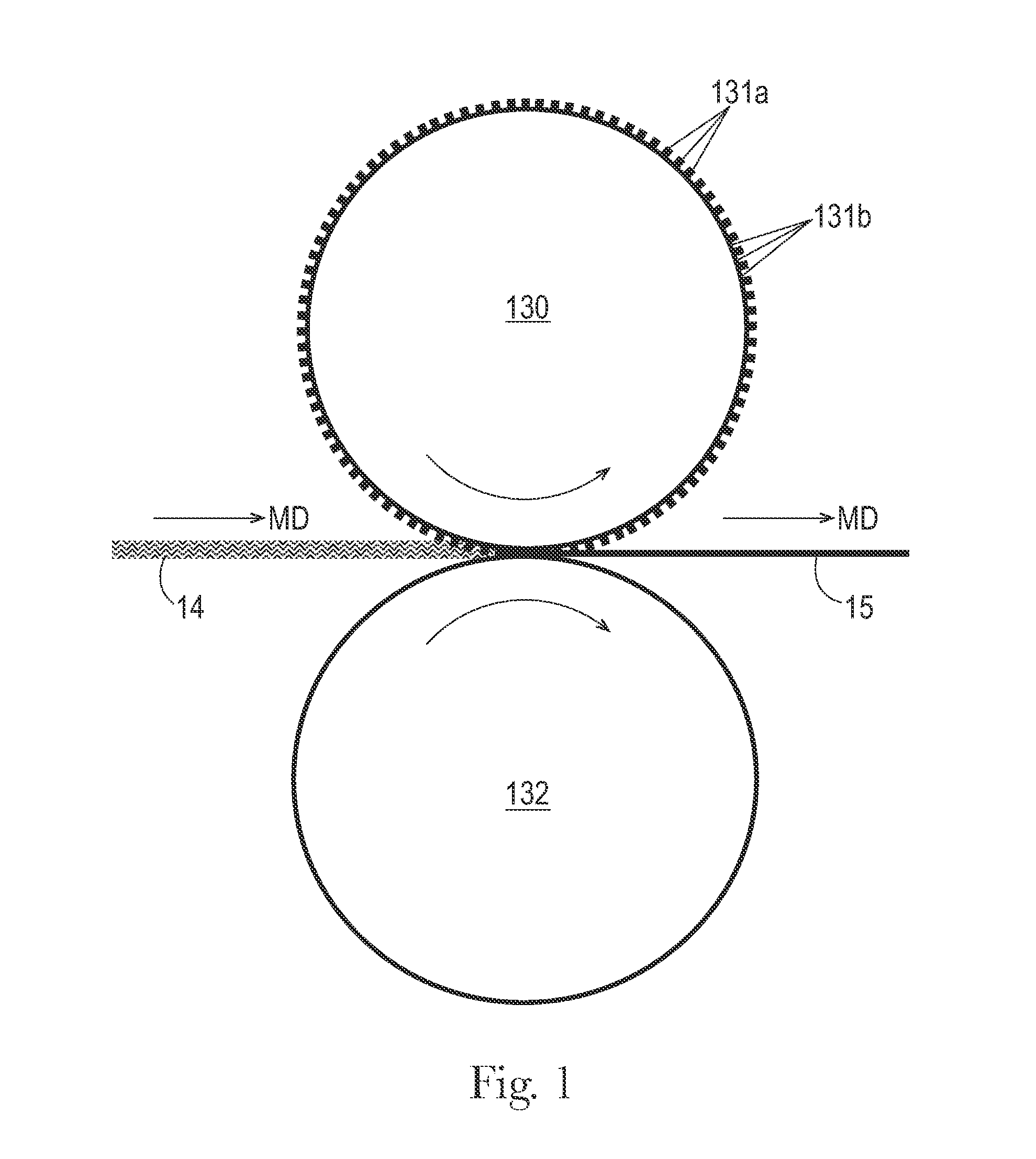

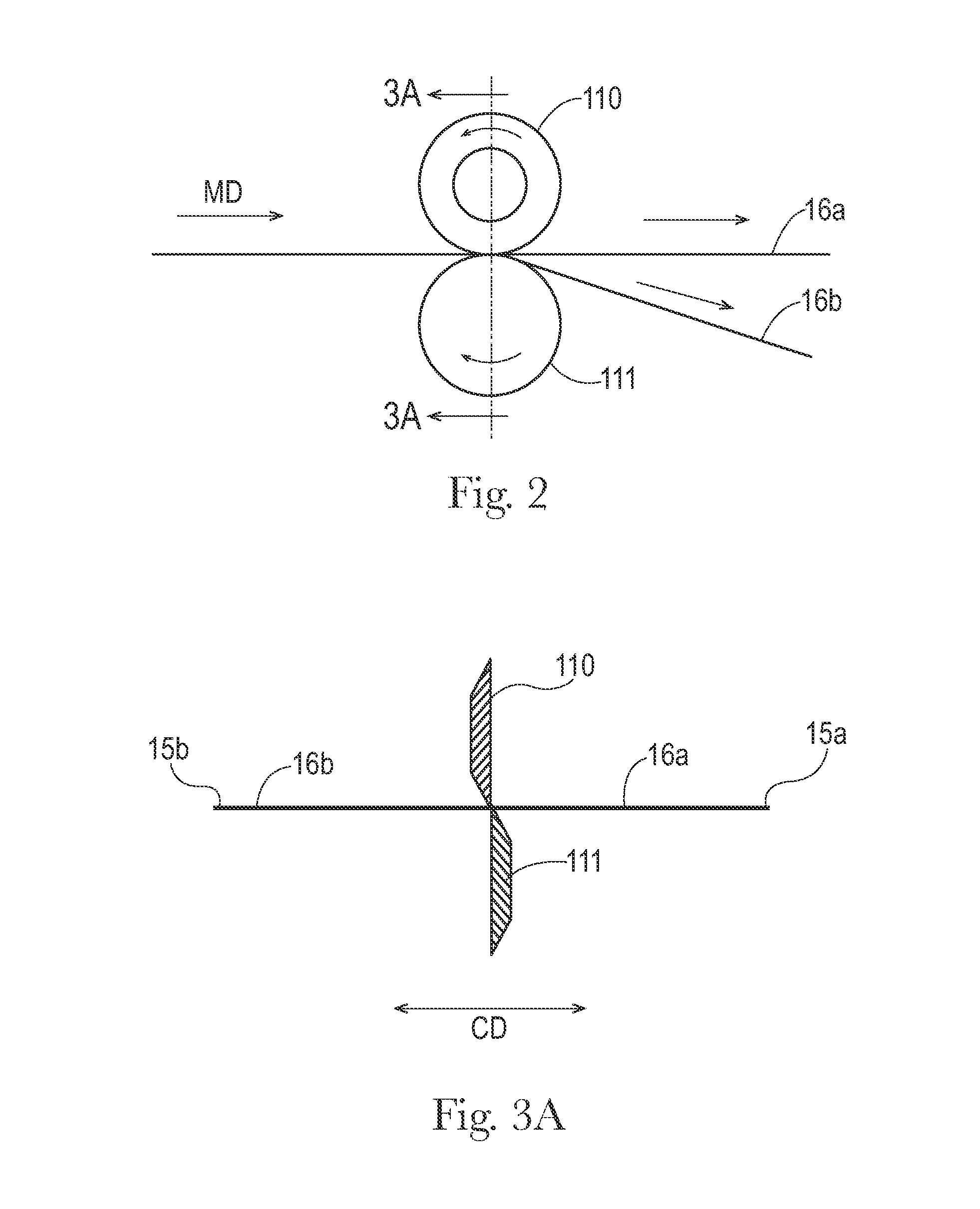

Nonwoven web with improved cut edge quality, and process for imparting

A process for producing a nonwoven web material with improved edge quality, and the product thereof, are disclosed. The process may include the steps of forming a batt of polymeric fibers; consolidating the batt in a z-direction and thereby forming a nonwoven web material, conveying the nonwoven web material to a nip between a bonding roller and anvil roller, and impressing a pattern of bond impressions into the nonwoven web material, the bond impressions lying a long a cut path. When the web is subsequently cut along the cut path, fibers proximate the cut path are immobilized by the bonds, providing for relatively neater, cleaner cut edges and reducing the number of loose fibers that may be released into the plant environment in downstream processing operations.

Owner:THE PROCTER & GAMBLE COMPANY

Method and Apparatus for Fray-Free Cutting with Laser Anti-Fray Inducement

InactiveUS20070234862A1Accurate conditionTextile selvedgesSevering textilesAs DirectedBiomedical engineering

A method and apparatus for fray-free cutting at the perimeter of an area of a textile sheet on a textile-receiving surface, including creating an anti-fray condition in the sheet along a path at the perimeter by an anti-fray instrument movable along the surface as directed by a controller based on programmed information regarding the perimeter, and cutting the sheet at the perimeter by a cutter movable along the surface as directed by the controller based on the programmed information. The anti-fray instrument is preferably an anti-fray substance applicator or, if the textile is a thermoplastic textile, a laser device configured and arranged to induce an anti-fray state therein.

Owner:MIKKELSEN GRAPHIC ENG

Trademark cutting device

InactiveCN108823940ASolve quality problemsSolve aestheticsLiquid surface applicatorsTextile selvedgesTrademarkHot melt

The invention belongs to the technical field of advertisements and printing and specifically discloses a trademark cutting device. The trademark cutting device comprises a rack, and a cutting mechanism and an ironing and glue coating mechanism are arranged on the rack in a trademark conveying direction in sequence; the ironing and glue coating mechanism comprises a first ironing plate fixedly disposed on the rack and a second ironing plate vertically and slidingly disposed on the rack, electric heating pieces are arranged in the first ironing plate and the second ironing plate respectively, and the interior of the first ironing plate is hollow; a piston is slidingly disposed in the first ironing plate and divides the first ironing plate into a first chamber and a second chamber, a glue inlet is formed in the piston and internally provided with a one-way valve, and a glue outlet is formed in the bottom of the second chamber and internally provided with a pressure valve; a storage box isarranged above the first ironing plate and filled with hot melt glue particles. By adopting the device, the problems that lines on the edges of existing trademarks are easily detached after the trademarks are cut, and correspondingly the quality and appearance of the trademarks are affected can be solved.

Owner:重庆川之舟印务设计有限公司

Cutting, clipping and winding three-in-one device for textile

PendingCN108637499AMeet needsImprove cutting efficiencyTextile selvedgesFilament handlingFunctional diversityEngineering

The invention discloses a cutting, clipping and winding three-in-one device for textile. The cutting, clipping and winding three-in-one device comprises a distribution box. The periphery of the lowerportion of the distribution box is fixedly connected with a base. One side of the distribution box is movably connected with an inspection door. The upper surface of the distribution box is fixedly connected with a conveying belt shell. An indication lamp is mounted on one side of the outer wall of the conveying belt shell. A switch button is arranged on one side of the indication lamp. The left end of the conveying belt shell is fixedly connected with a storage plate. A triangular fixing steel frame is arranged on the lower surface of the storage plate. The two sides of the conveying belt shell are fixedly connected with clipping positioning devices. By arranging the distribution box, the inspection door, the clipping positioning devices and a winding device, the cutting, clipping and winding three-in-one effect can be achieved, the cutting efficiency is high, the operation quality is ensured, the labor intensity is relieved, the different application requirements are met, the maintaining cost is reduced, thus, the function diversity is improved, the optimal application effect is achieved, and application and popularization are facilitated.

Owner:JIANGSU HONGYE MACHINERY

Cloth cutting device

ActiveCN108004758AReduce wasteAvoid constant proliferationTextile selvedgesSevering textilesHydraulic cylinderPulp and paper industry

The invention relates to the field of textile and particularly discloses a cloth cutting device. The cloth cutting device comprises a frame, a hydraulic cylinder, a cutter, a worktable and a glue applying mechanism, wherein the frame is fixedly provided with a guide bar and a spring; the piston rod of the hydraulic cylinder is fixedly provided with a sliding bar; the cutter is fixed onto the sliding bar; the worktable is provided with a sliding groove; a rotating block is hinged to the sliding bar, and the hinge point of the rotating block and the sliding bar is arranged at the bottom of the rotating block; the hydraulic cylinder is provided with an L-shaped separating blade; the glue applying mechanism comprises a glue storage tank and an air cylinder, the glue storage tank is provided with a glue inlet, the air cylinder is provided with a glue inlet check valve, and the glue storage tank is communicated with the glue inlet check valve; the piston of the air cylinder is fixedly provided with a glue outlet check valve, the inside of the air cylinder is provided with a pressure spring, the inside of the rotating block is provided with a cavity, and the side wall of the cavity is provided with a through hole. The cloth cutting device can avoid yarn slippage after cloth is cut.

Owner:NINGBO WENZE TEXTILE CO LTD

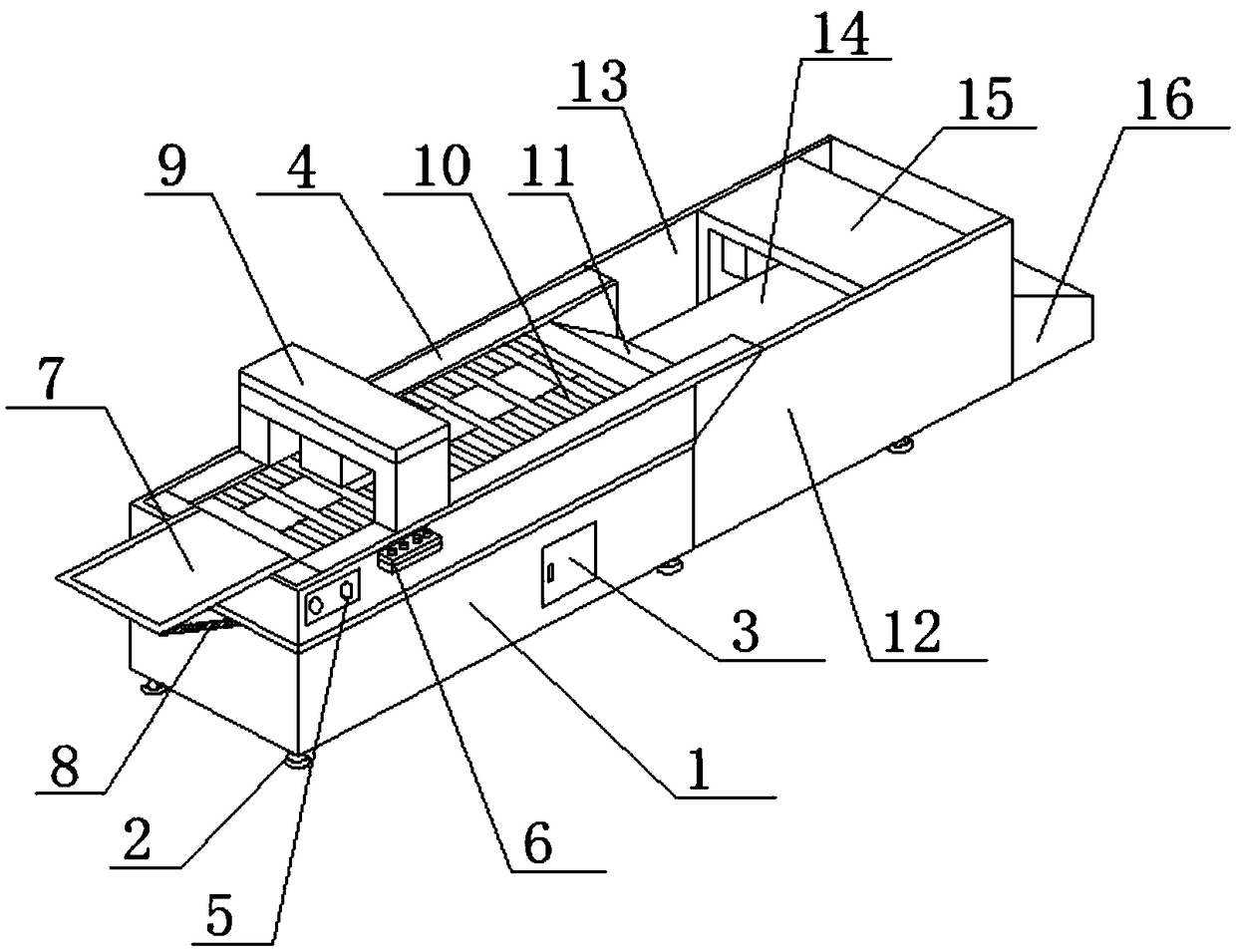

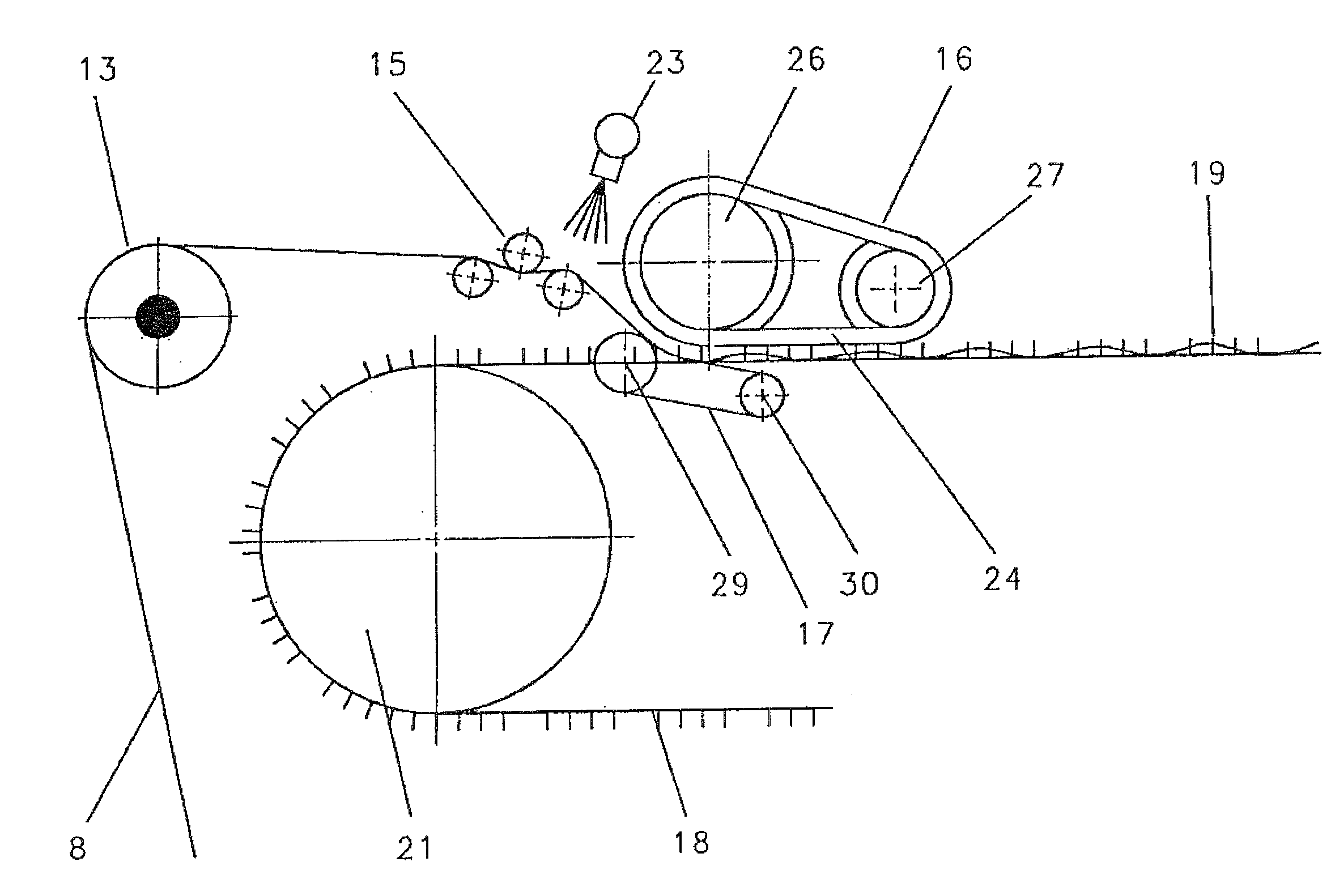

Slitting and crosscutting all-in-one machine for towel cloth

PendingCN109322136ASoft cut edgeEliminate thread suture processTextile selvedgesSevering textilesFiberIntegrated operations

The invention provides a slitting and crosscutting all-in-one machine for towel cloth. The slitting and crosscutting all-in-one machine comprises a main machine body, a material placing rack mechanismand an ultrasonic unit cabinet, wherein the material placing rack mechanism and the ultrasonic unit cabinet are arranged at the two sides of the main machine body respectively, the material placing rack mechanism is provided with a magnetic powder brake, a deviation rectifying device and a turning roller, the main machine body is provided with a draw roller, a longitudinal cutting mechanism, a crosscutting mechanism, a rear feeding traction device and a cloth pressing device, and the ultrasonic unit cabinet is provided with an ultrasonic vibration part set and a control panel. According to the slitting and crosscutting all-in-one machine for the towel cloth, slitting and crosscutting processing is carried out on the entire roll of superfine fiber fabric, oxford cloth, non-woven fabric andother chemical fiber fabric according to the required length size by adopting ultrasonic wave, and edge banding is carried out on a notch after slitting; the scrap edge is soft; no melting edge, no raw edge and no rough edge exists; the edge does not discolor, does not black and does not scorch; edge warping of the cross section cannot occur, and the cross section is attractive and smooth; a thread removal and seaming technology is omitted. The slitting and crosscutting all-in-one machine for the towel cloth has the advantages that full-automatic integrated operation from feeding to finishedproduct production can be achieved, the production efficiency is effectively improved, and the manpower is saved.

Owner:常州双超超声波科技有限公司

Method of edge glueing, and a tensioning aggregate with a device for edge glueing

InactiveUS7322312B1Less glueLess drying energyLiquid surface applicatorsTextile selvedgesEngineering

Owner:BABCOCK TEXTILMASCH

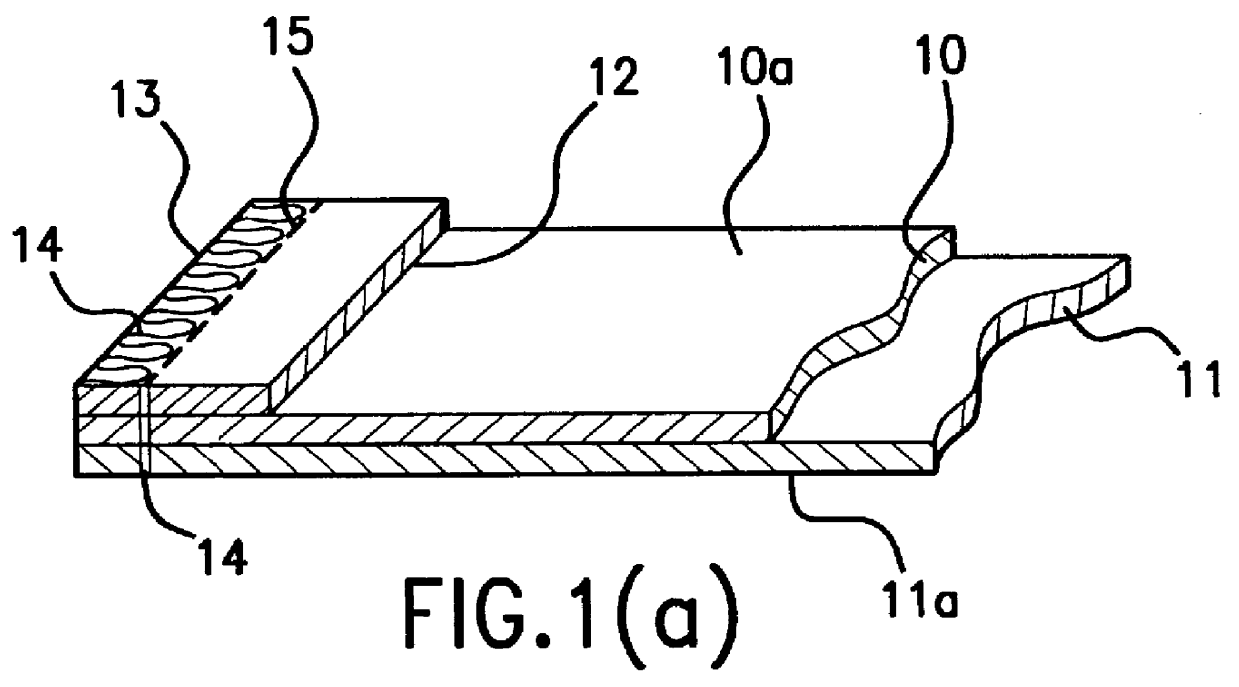

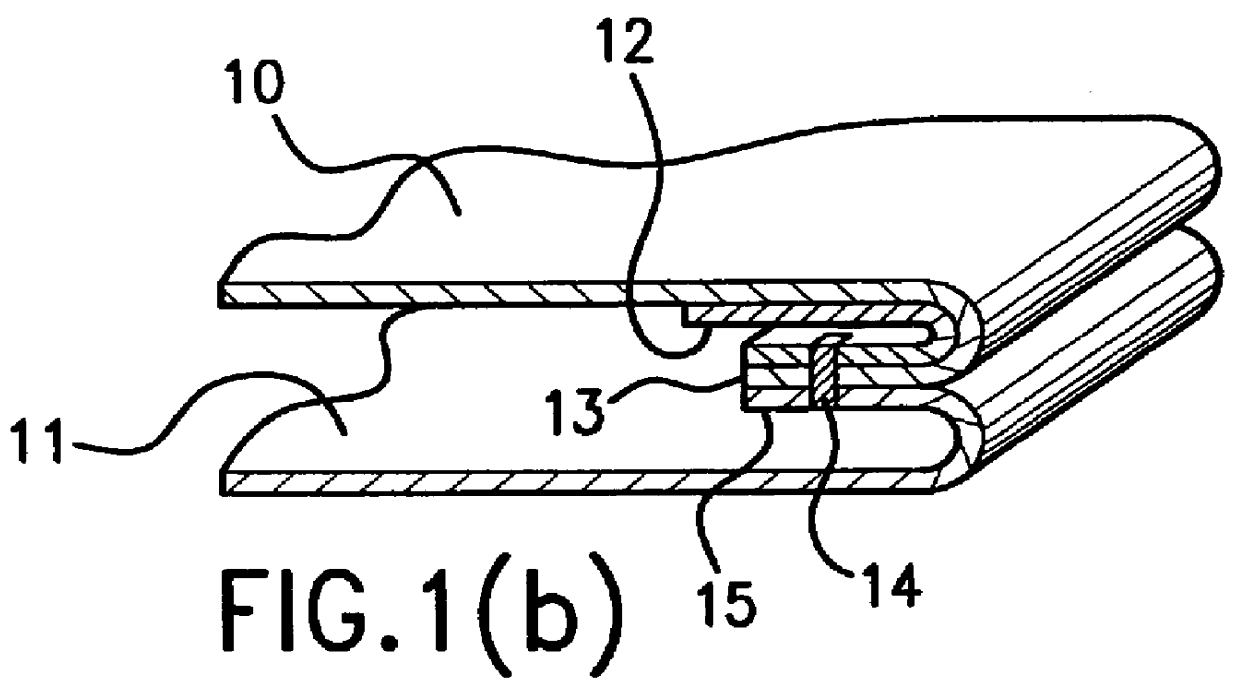

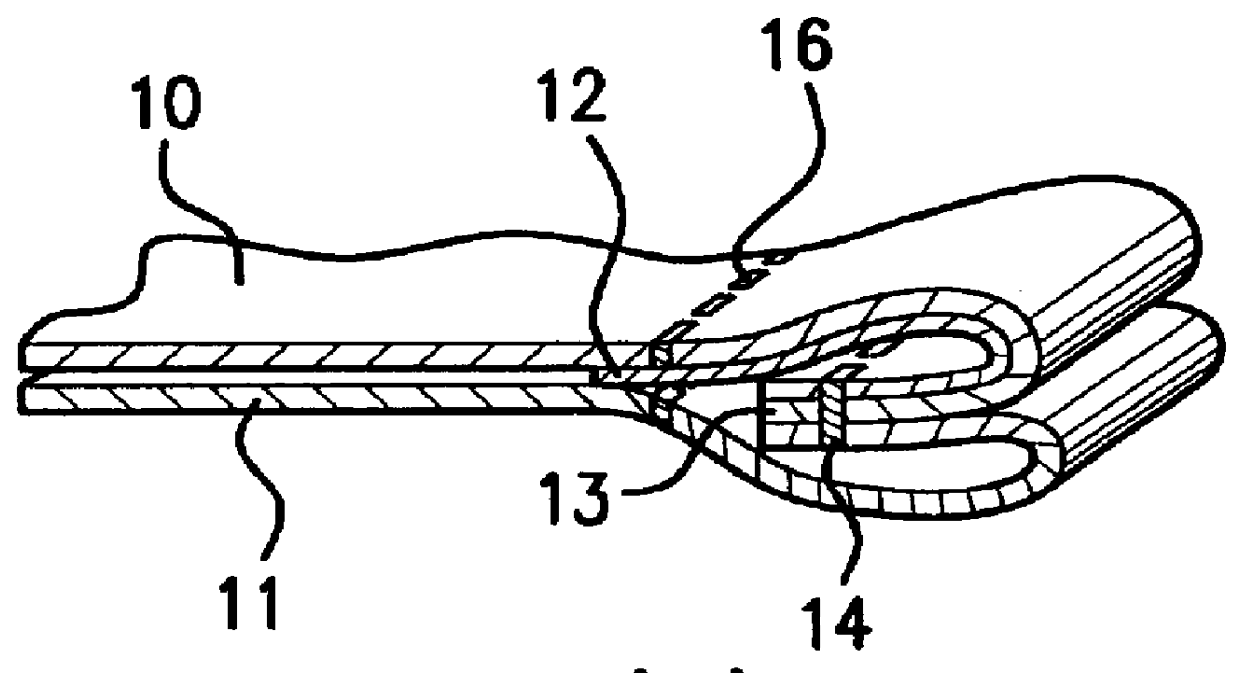

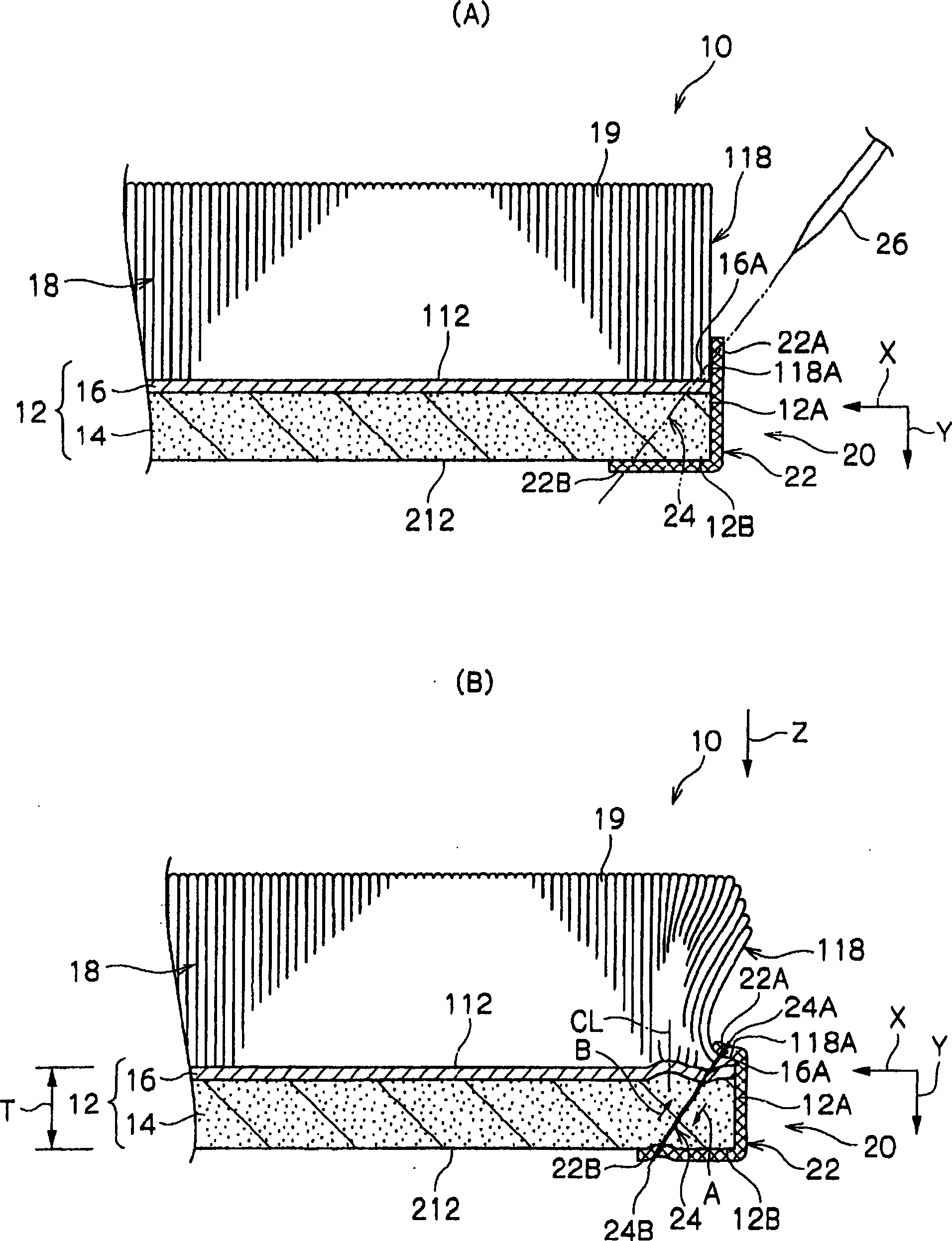

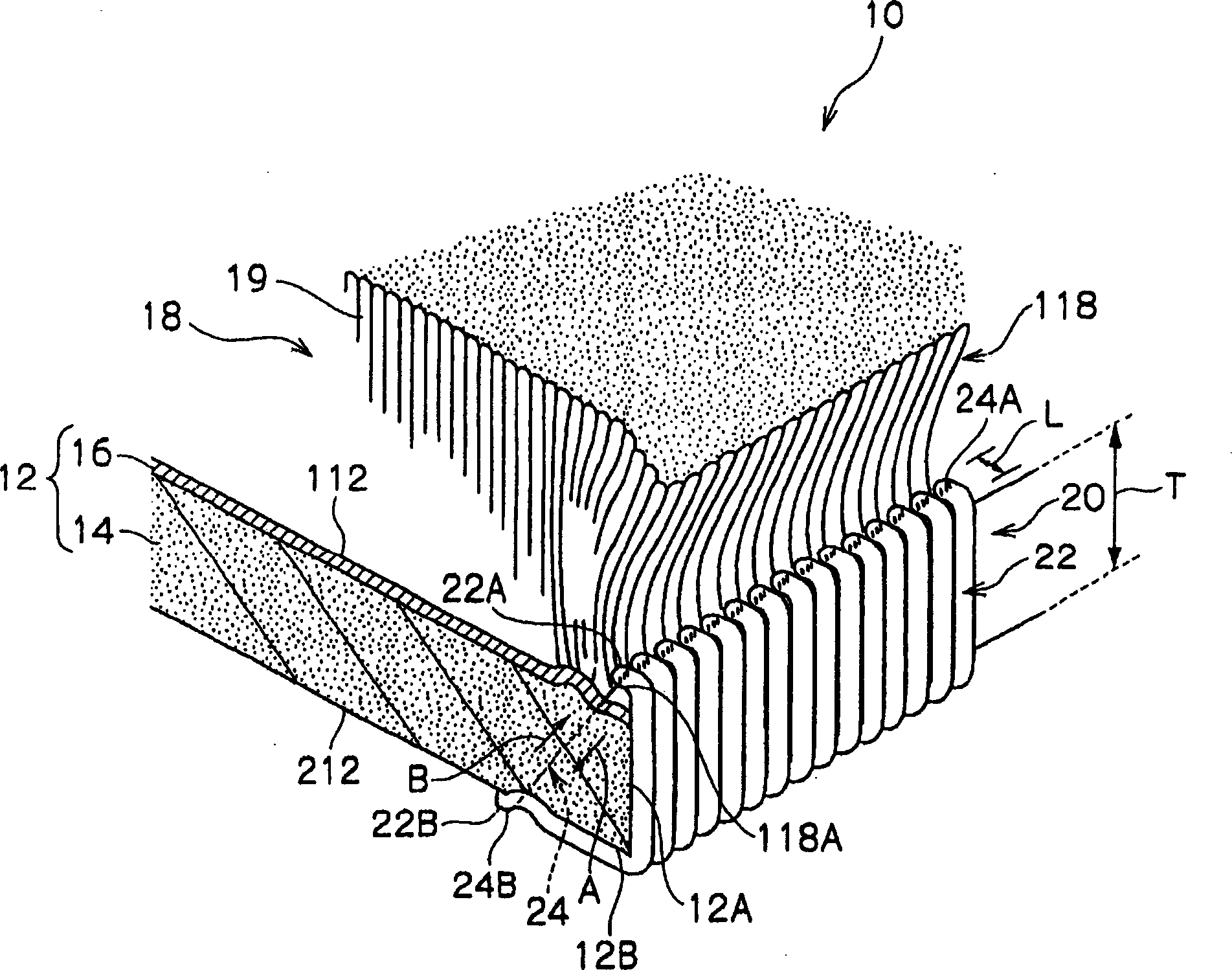

Pad material, method of sewing pad material and apparatus of sewing pad material

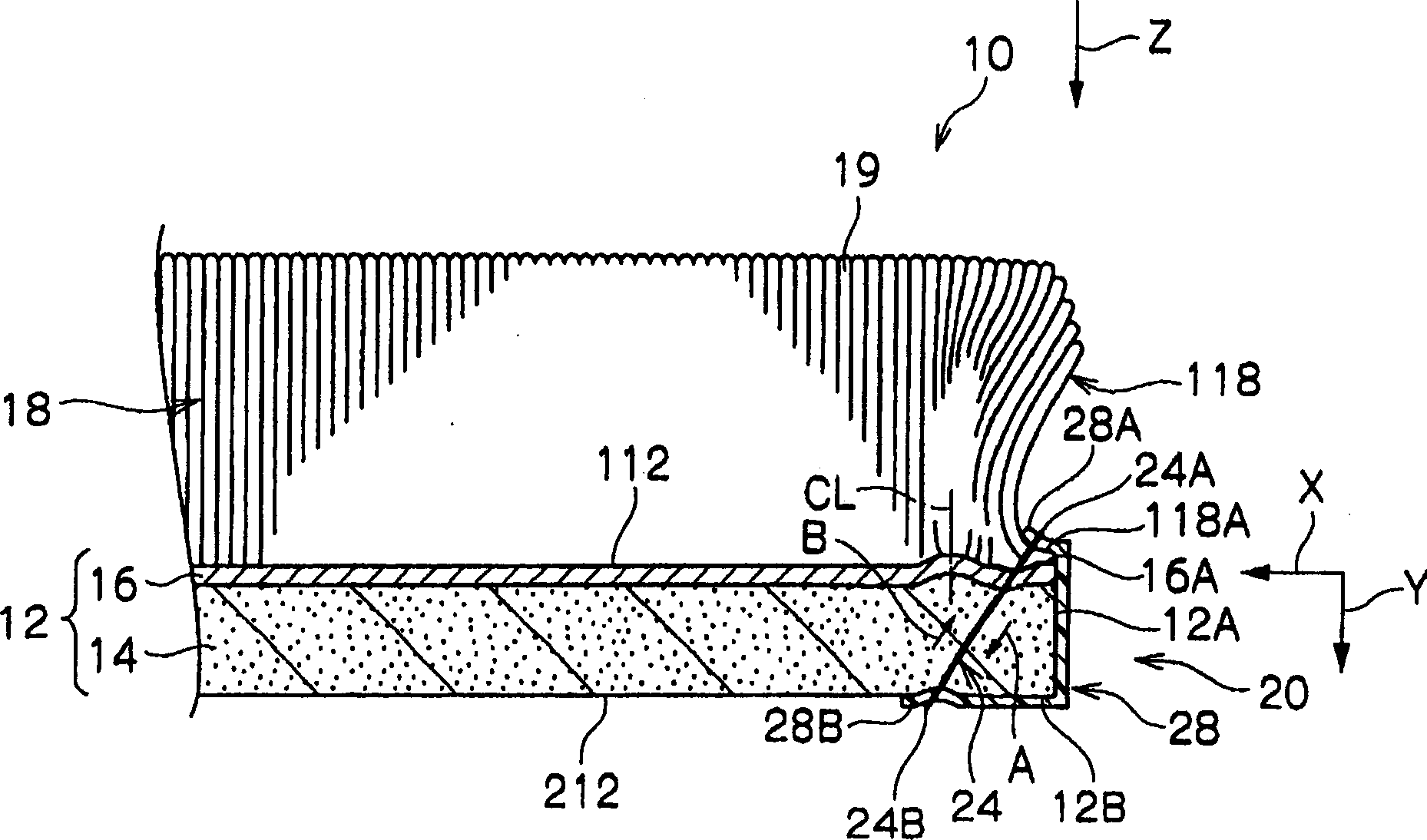

The invention provides a mat material providing integrity with a center section to a circumference section while protecting the circumference section. A fiber skin layer (18) covering the surface of a mat base material (12) to an end terminal part (16A) is supported by the mat base (12). Regarding a circumference protection part (20), a decorative thread (22) integrally covers the base side part (118A) of the side face part (118) of the skin layer (18), the side face (12A) of the mat base (12) and the rear face end part (12B) of the mat base (12). By sewing with an engaging thread (24), the base side part (118A) is held and restrained by pressurizing it obliquely inward derection toward a rear surface (212) from the front surface(112) of the mat base (12). Thus, the circumference section is protected and the circumference protection part (20) becomes difficult to see, so that the circumference section of a floor mat (10) is provided with integrity with the center section of the floor mat (10).

Owner:TOYOTA BOSHOKU KK

Blue-light cured adhesives for joining fabric

InactiveUS20090183826A1Seam can be createdMechanical working/deformationLamination ancillary operationsAdhesiveEngineering

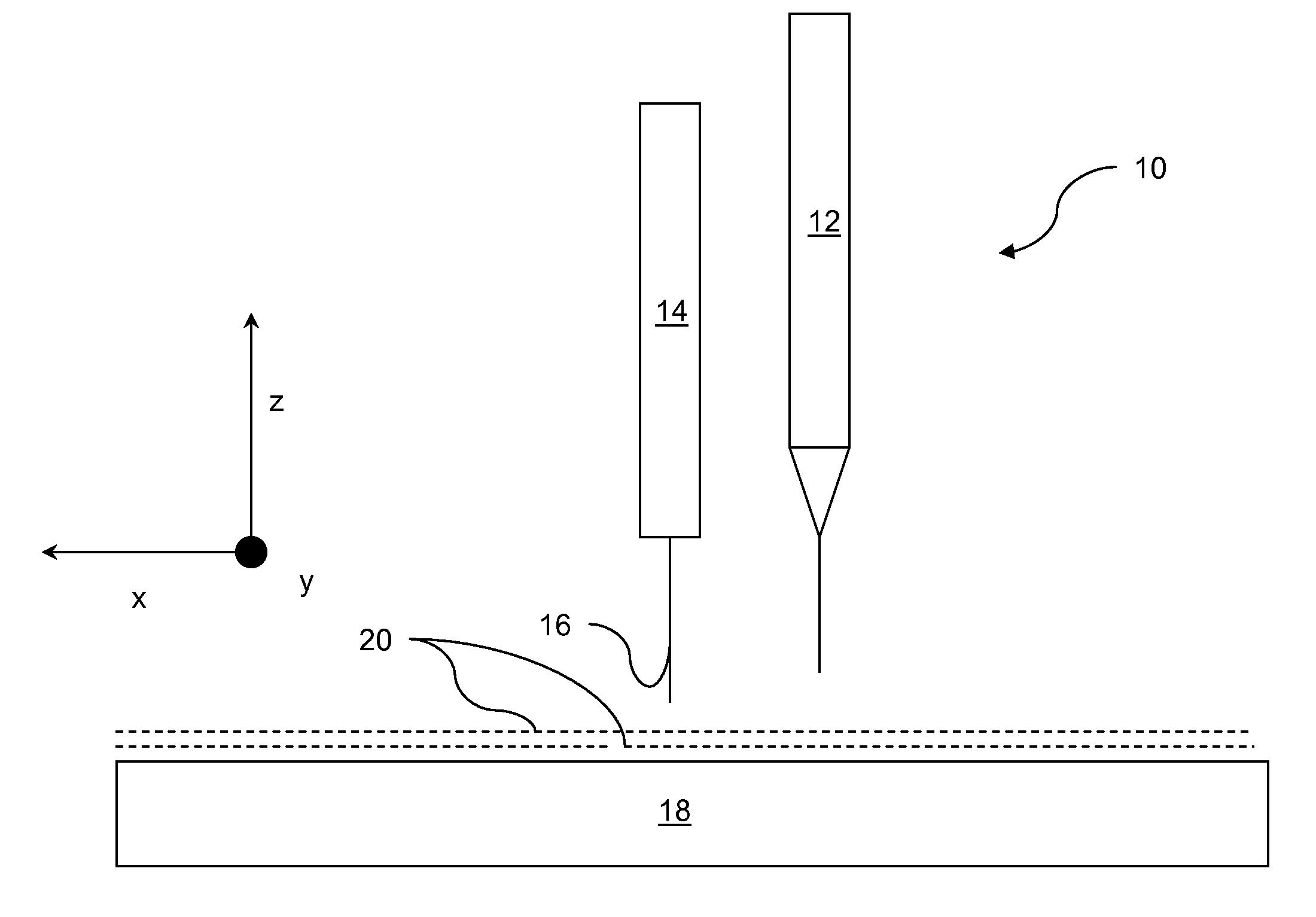

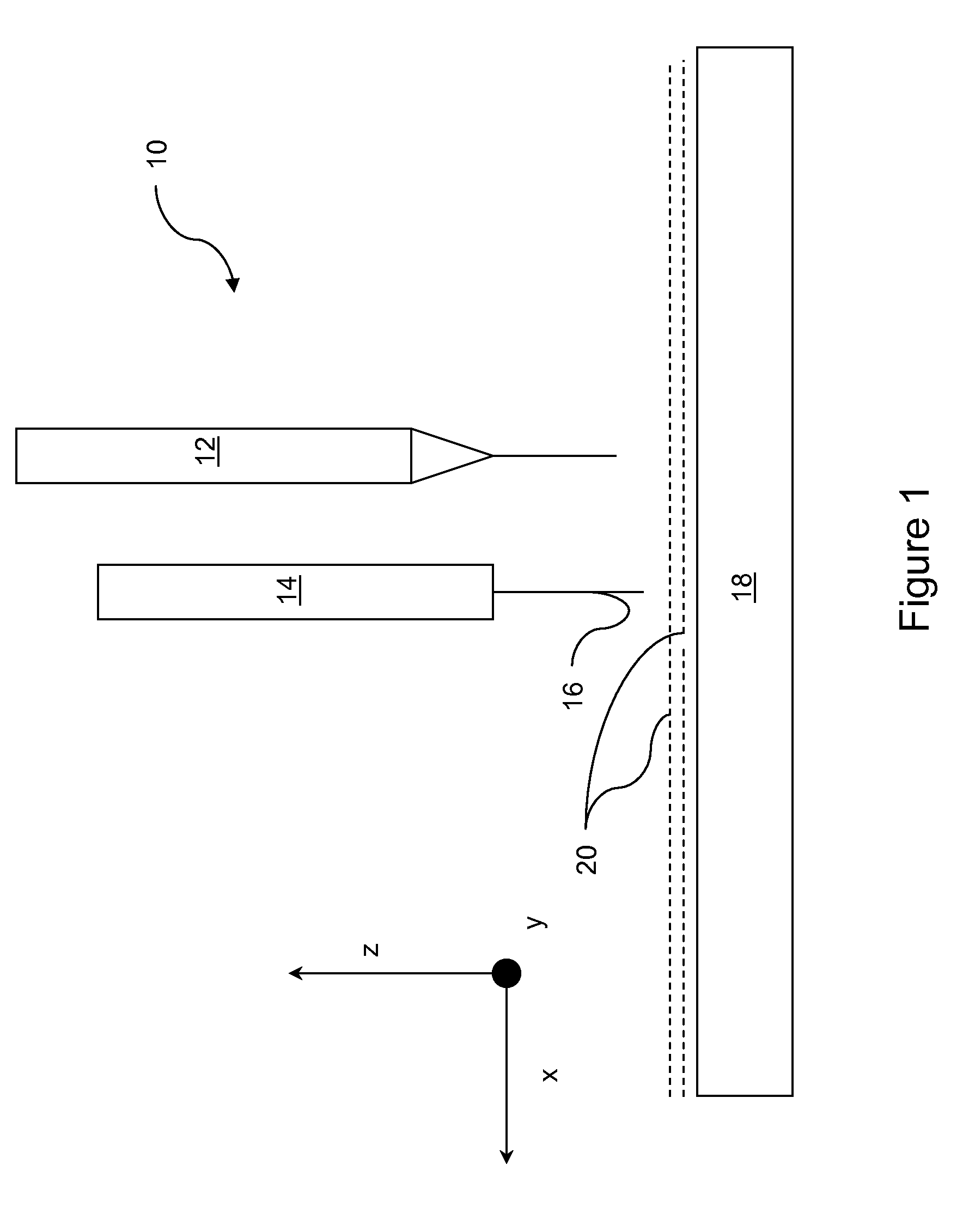

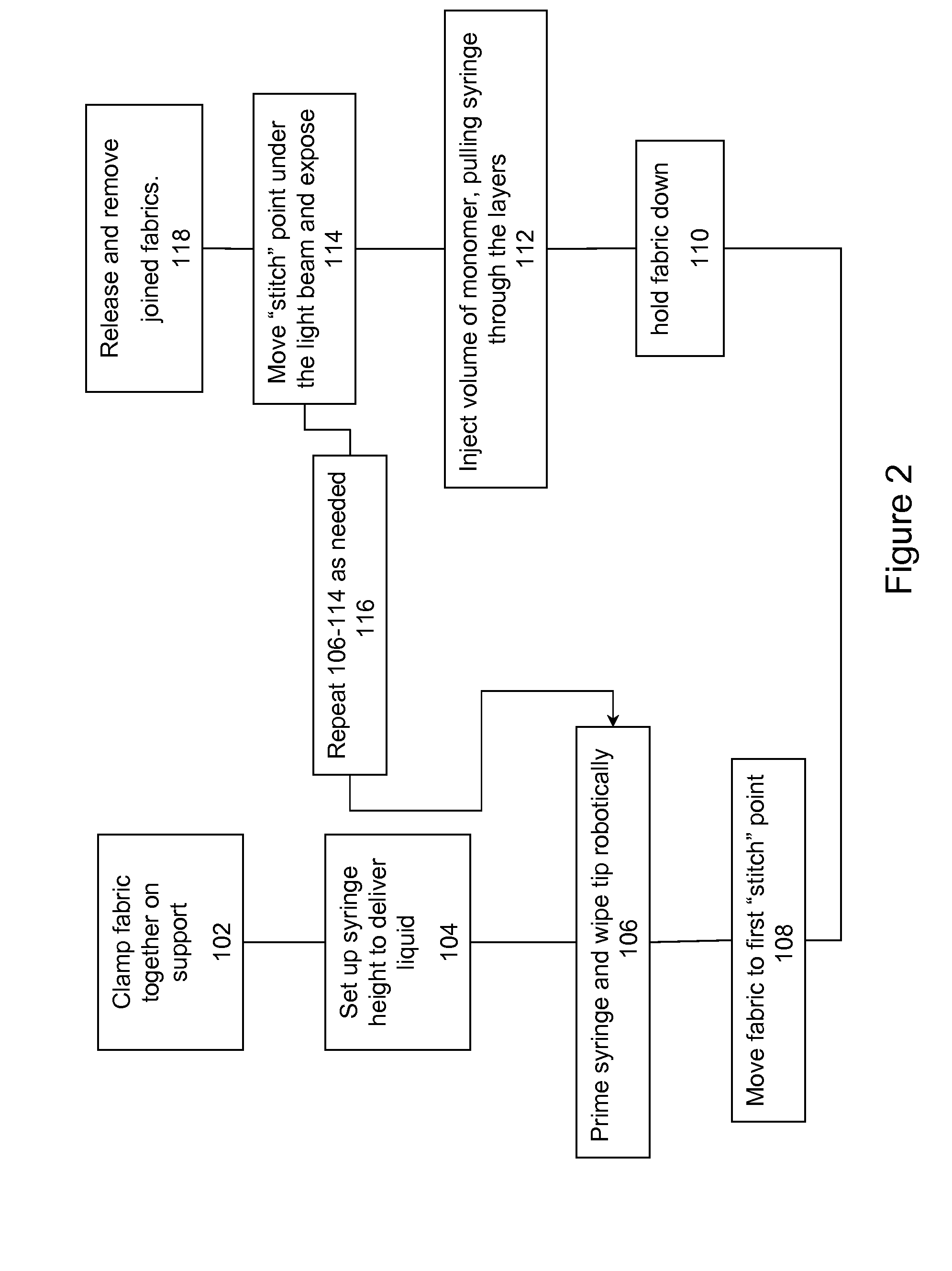

A system is provided for joining fabrics by lines or arrays of dots of adhesive, the system comprising: a blue light source; a dispenser, disposed proximally with the blue light source, the dispensing system being configured to deposit at least one drop of a monomer on first and second proximate fabric surfaces; a conveyance whereby the light source and the dispensing system change position relative to the first and second fabric surfaces.

Owner:UNIV OF MASSACHUSETTS

Undergarments having finished edges and methods therefor

ActiveUS20050233137A1Improve material yieldDirect contact guaranteeTextile selvedgesLoomsFiberEngineering

A method of making a fabric having a finished edge includes providing a fabric having a plurality of fibers with free ends of the fibers at an edge of the fabric, disposing a curable polymer such as silicone over the edge of the fabric so that the curable polymer engages the free ends of the fibers at the edge of the fabric, and, after the disposing step, curing the polymer for finishing the edge of the fabric. The polymer binds the free ends of the fibers to prevent fraying of the fabric. The fabric is cut into a pattern piece for a garment before the step of disposing the curable polymer on the edge of the fabric.

Owner:CUPID FOUND

Simplified method for making an impermeable joining on three-layer or bi-layer fabric materials

InactiveCN102605602ASimple manufacturing methodImprove penetration resistanceGarment special featuresTextile selvedgesComposite constructionBi layer

A simplified method for making an impermeable joining on three-layer or bi-layer fabric materials, either with or without a complex construction on a joining side thereof, and being preliminarily joined by a stitching or ultrasound joining arrangement, wherein said method comprises only two method steps, a first joining step of joining two fabric material panels and a second impermeabilizing step carried out by cauterizing and sealing a strip element, and being performed by a single machine in a single operation thereof. The invention provides simplified, economical method used for preventing the leakage, and compared to the prior art, the production technology is simplified and the products are beautiful and comfortable, and have good leakage prevention performance.

Owner:MACPI PRESSING DIV SPA

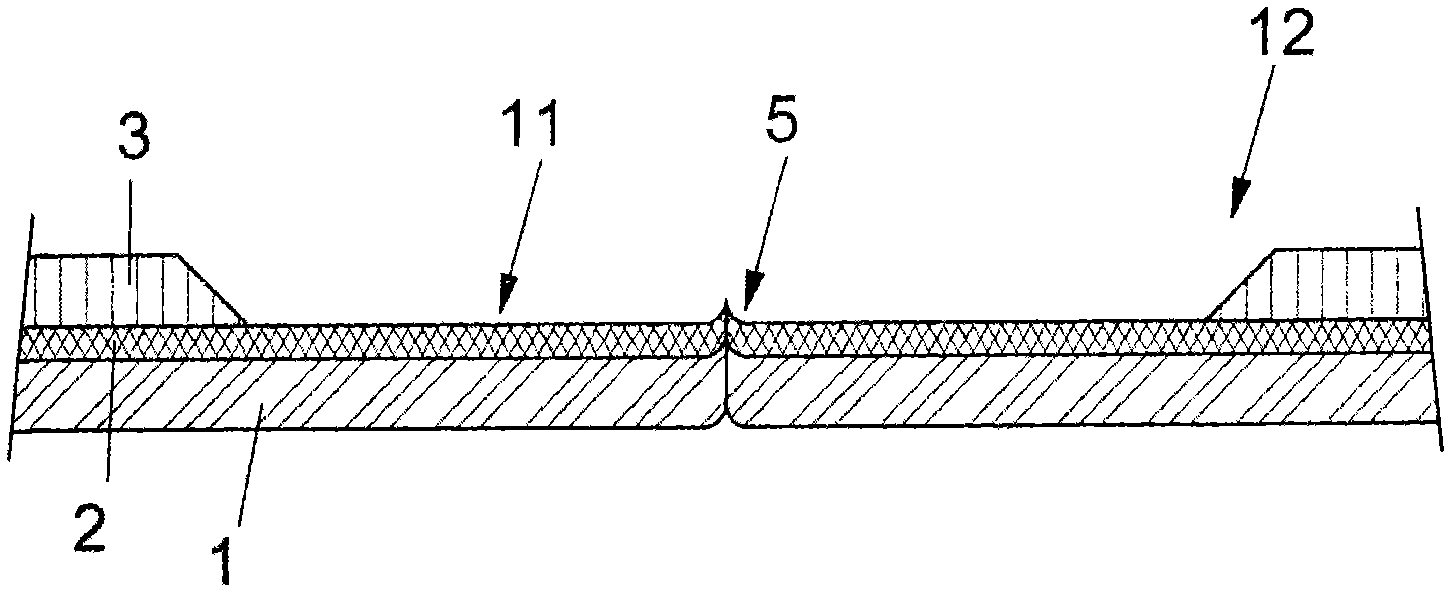

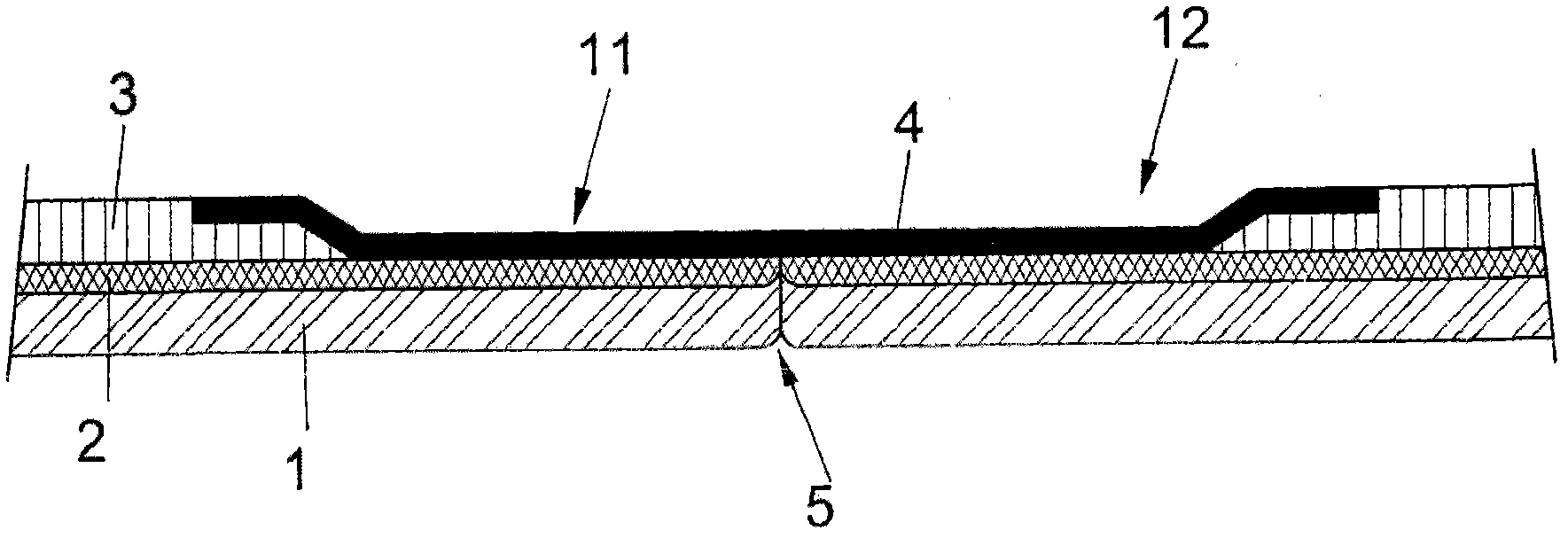

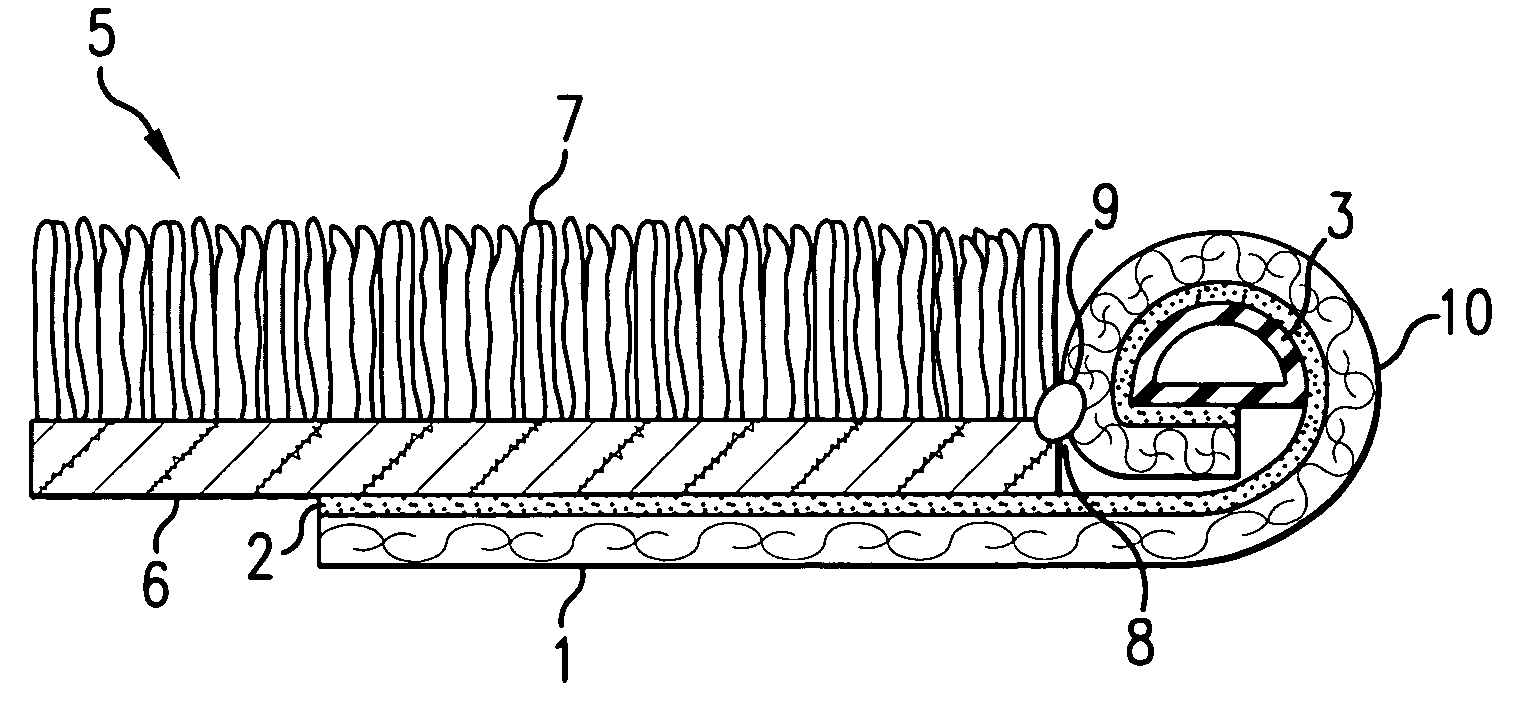

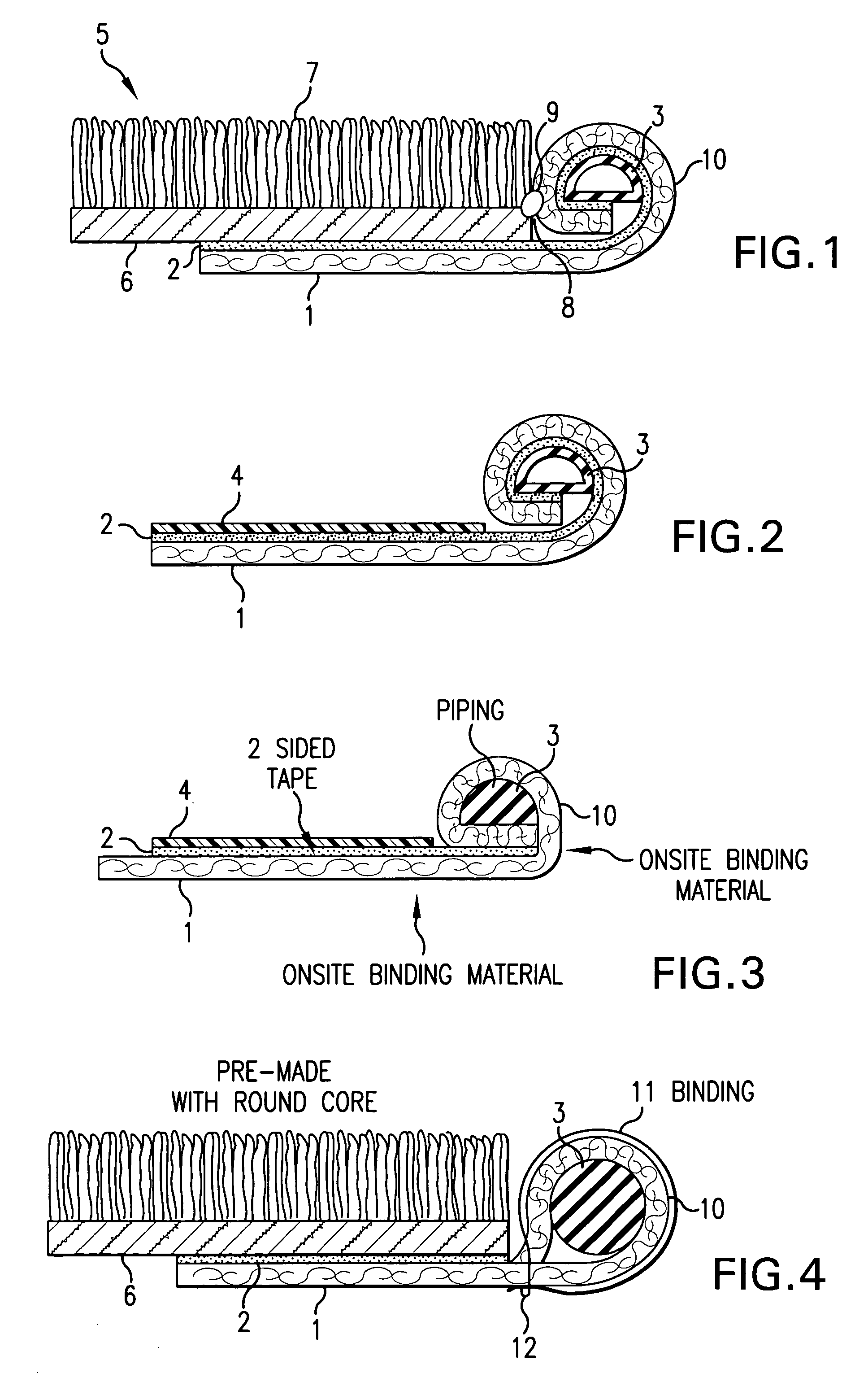

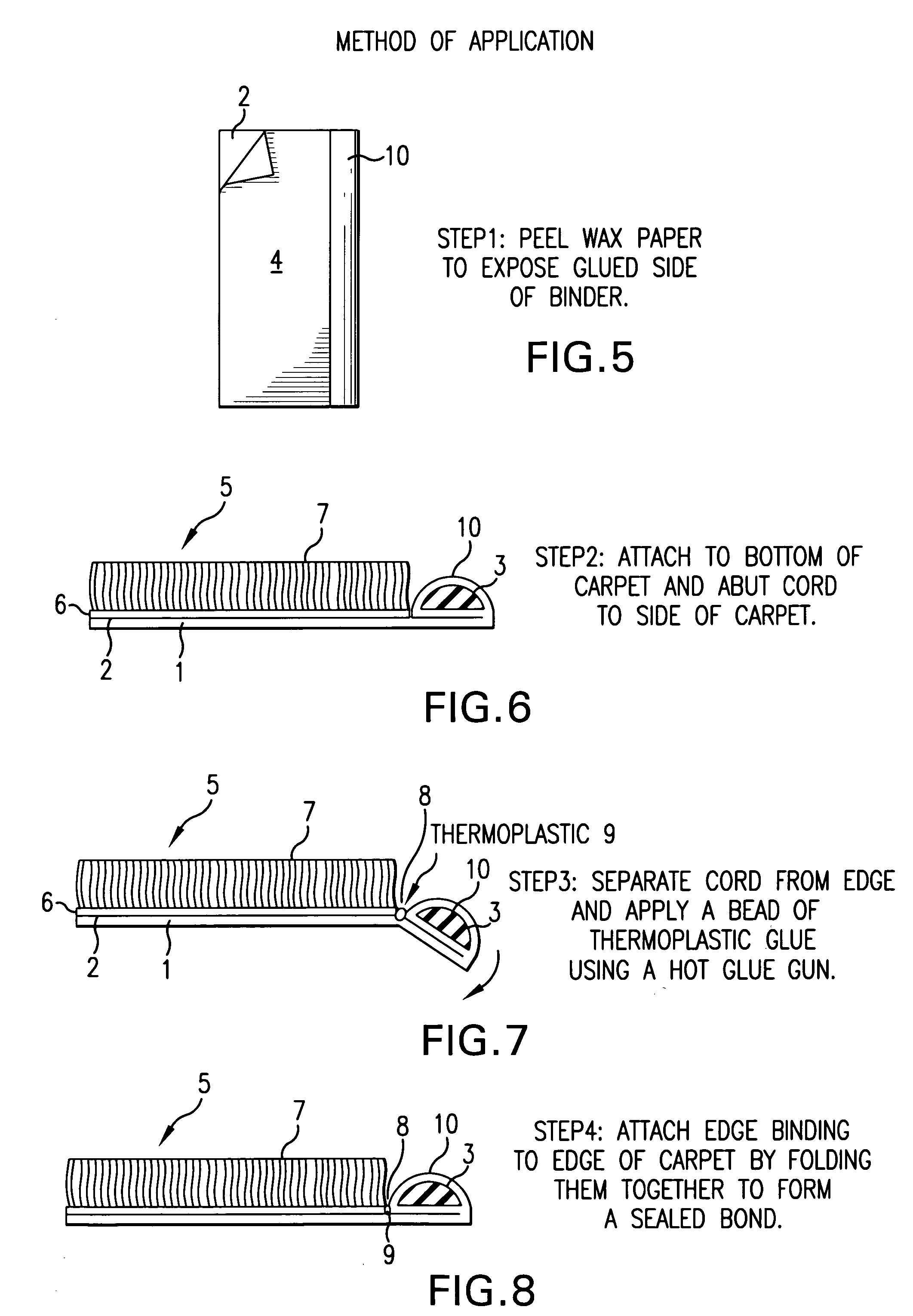

Stitchless on-site binding application method and device

On-site binding for carpets and the like wherein a covered welting material is provided with a strip with adhesive on both sides. One side is covered with peel-off wax paper which is removed to adhere the welting material flush against the edge of the carpet's pile. The adhesive underside of the paper has an extension of the welting material adhered thereto. A thermal plastic glue is applied between the carpet pile and welting material whereby the welting material binding is secured the carpet by the underlying strip (with adhesive on both sides) and the thermalplastic bead.

Owner:BOND PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com