Slitting and crosscutting all-in-one machine for towel cloth

An all-in-one machine and terry cloth technology, applied in textile and papermaking, fabric surface trimming, fabric edge trimming, etc., can solve the problems of low production efficiency, yellowing effect of trimming, slow speed, etc., saving labor and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

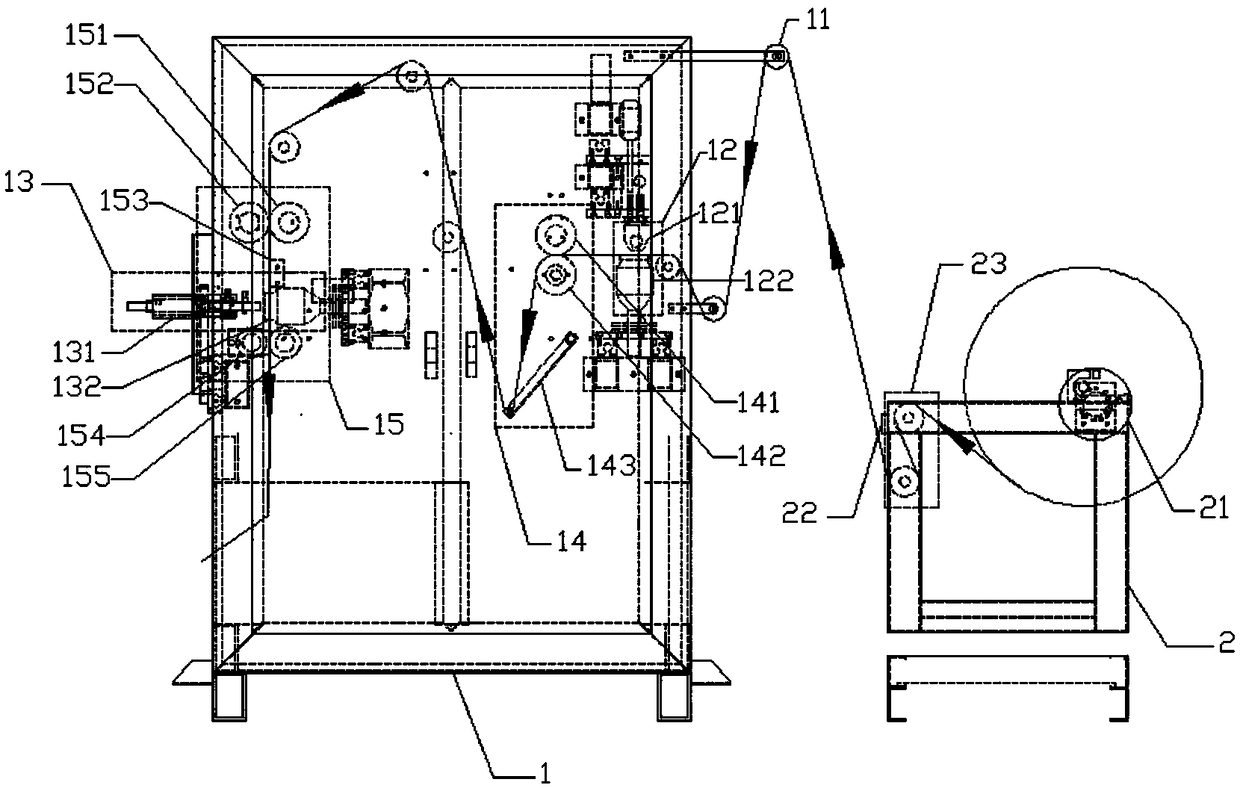

[0020] Such as figure 1 As shown, a terry cloth slitting and cross-cutting integrated machine of the present invention includes a main body 1, a discharge rack mechanism 2 and an ultrasonic unit cabinet, and the discharge rack mechanism 2 and the ultrasonic unit cabinet are respectively arranged on two sides of the main body 1. On the side, the discharge rack mechanism 2 is provided with a magnetic powder brake 21, a deviation correction device 22 and a steering roller 23, and the main body 1 is provided with a stretching roller 11, a slitting mechanism 12, a cross-cutting mechanism 13, a rear feeding Traction device 14 and cloth pressing device 15, the ultrasonic vibration part group and control panel are arranged on the ultrasonic unit cabinet. The slitting mechanism 12 includes multiple sets of longitudinal slitting devices 121 and a longitudinal transducer 122 , and the longitudinal transducer 122 is arranged below the multiple sets of longitudinal slitting devices 121 . ...

Embodiment 2

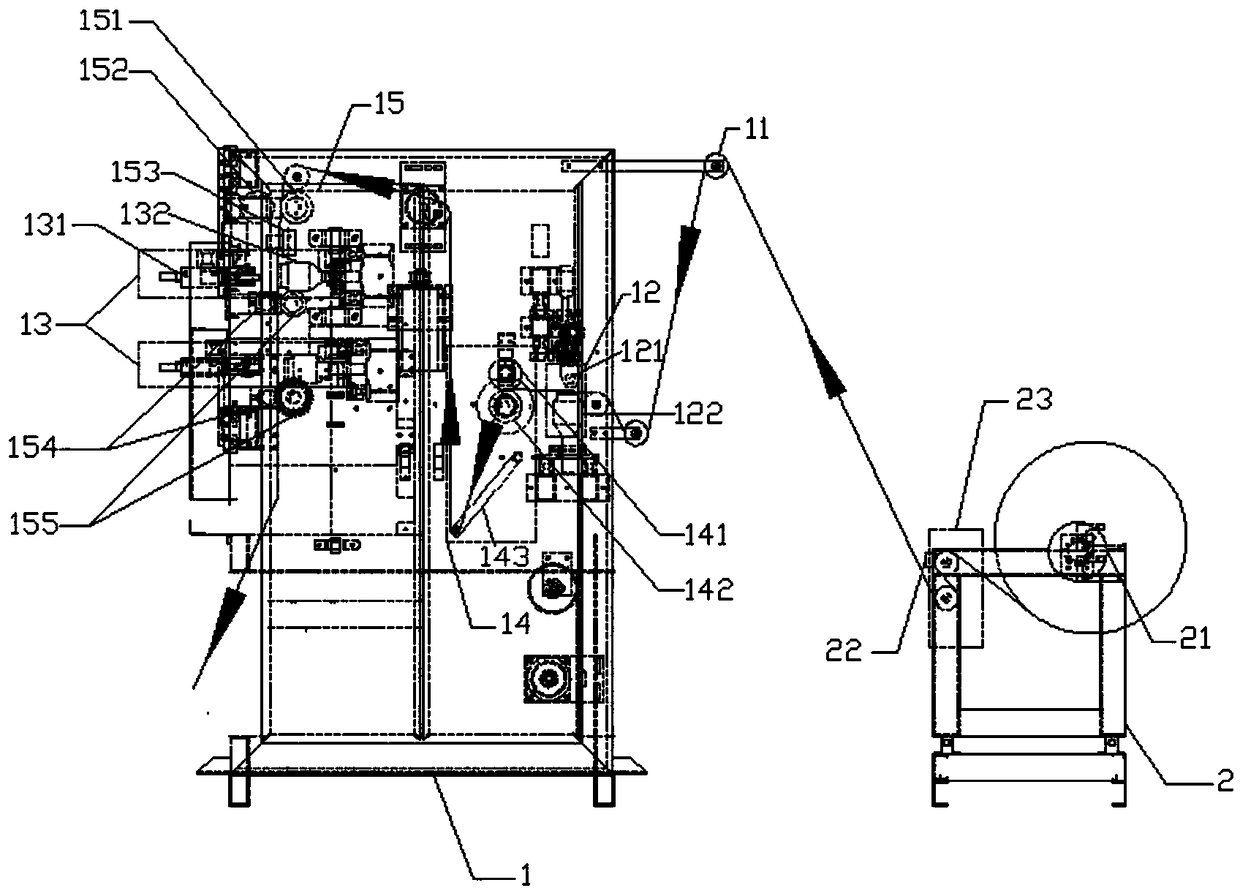

[0022] Such as figure 2 As shown, a terry cloth slitting and cross-cutting integrated machine of the present invention includes a main body 1, a discharge rack mechanism 2 and an ultrasonic unit cabinet, and the discharge rack mechanism 2 and the ultrasonic unit cabinet are respectively arranged on two sides of the main body 1. On the side, the discharge rack mechanism 2 is provided with a magnetic powder brake 21, a deviation correction device 22 and a steering roller 23, and the main body 1 is provided with a stretching roller 11, a slitting mechanism 12, a cross-cutting mechanism 13, a rear feeding Traction device 14 and cloth pressing device 15, the ultrasonic vibration part group and control panel are arranged on the ultrasonic unit cabinet. The slitting mechanism 12 includes multiple sets of longitudinal slitting devices 121 and a longitudinal transducer 122 , and the longitudinal transducer 122 is arranged below the multiple sets of longitudinal slitting devices 121 . ...

Embodiment 3

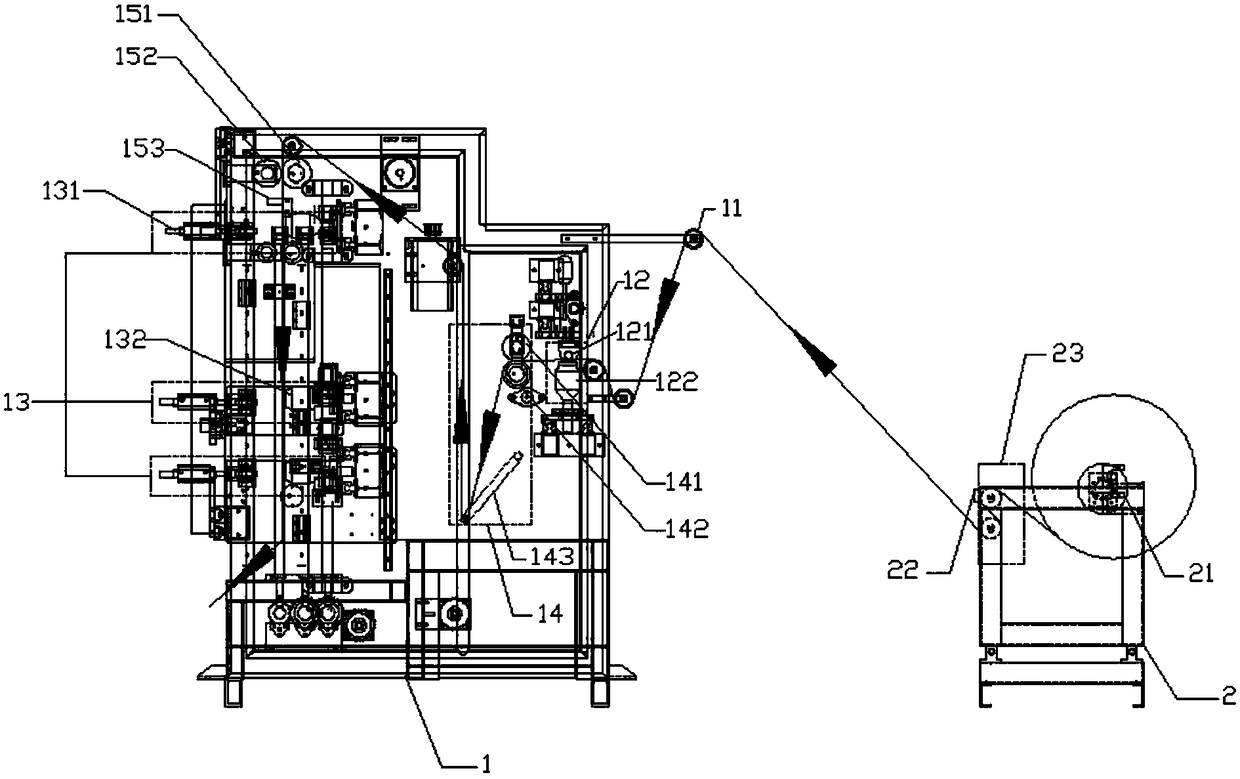

[0024] Such as image 3 As shown, a terry cloth slitting and cross-cutting integrated machine of the present invention includes a main body 1, a discharge rack mechanism 2 and an ultrasonic unit cabinet, and the discharge rack mechanism 2 and the ultrasonic unit cabinet are respectively arranged on two sides of the main body 1. On the side, the discharge rack mechanism 2 is provided with a magnetic powder brake 21, a deviation correction device 22 and a steering roller 23, and the main body 1 is provided with a stretching roller 11, a slitting mechanism 12, a cross-cutting mechanism 13, a rear feeding Pulling device 14 and cloth pressing device, described ultrasonic unit cabinet is provided with ultrasonic vibrating part group and control panel. The slitting mechanism 12 includes multiple sets of longitudinal slitting devices 121 and a longitudinal transducer 122 , and the longitudinal transducer 122 is arranged below the multiple sets of longitudinal slitting devices 121 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com