Patents

Literature

1711 results about "Edge banding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Edge Banding, or edgebanding, is the name of both a process and an associated narrow strip of material used to create durable and aesthetically pleasing trim edges during finish carpentry. Edge banding is used to cover the exposed sides of materials such as plywood, particle board or MDF, increasing durability and giving the appearance of a solid or more valuable material. Common substitutes for edgebanding include face frames or molding. Edge banding can be made of different materials including PVC, ABS, acrylic, melamine, wood or wood veneer.

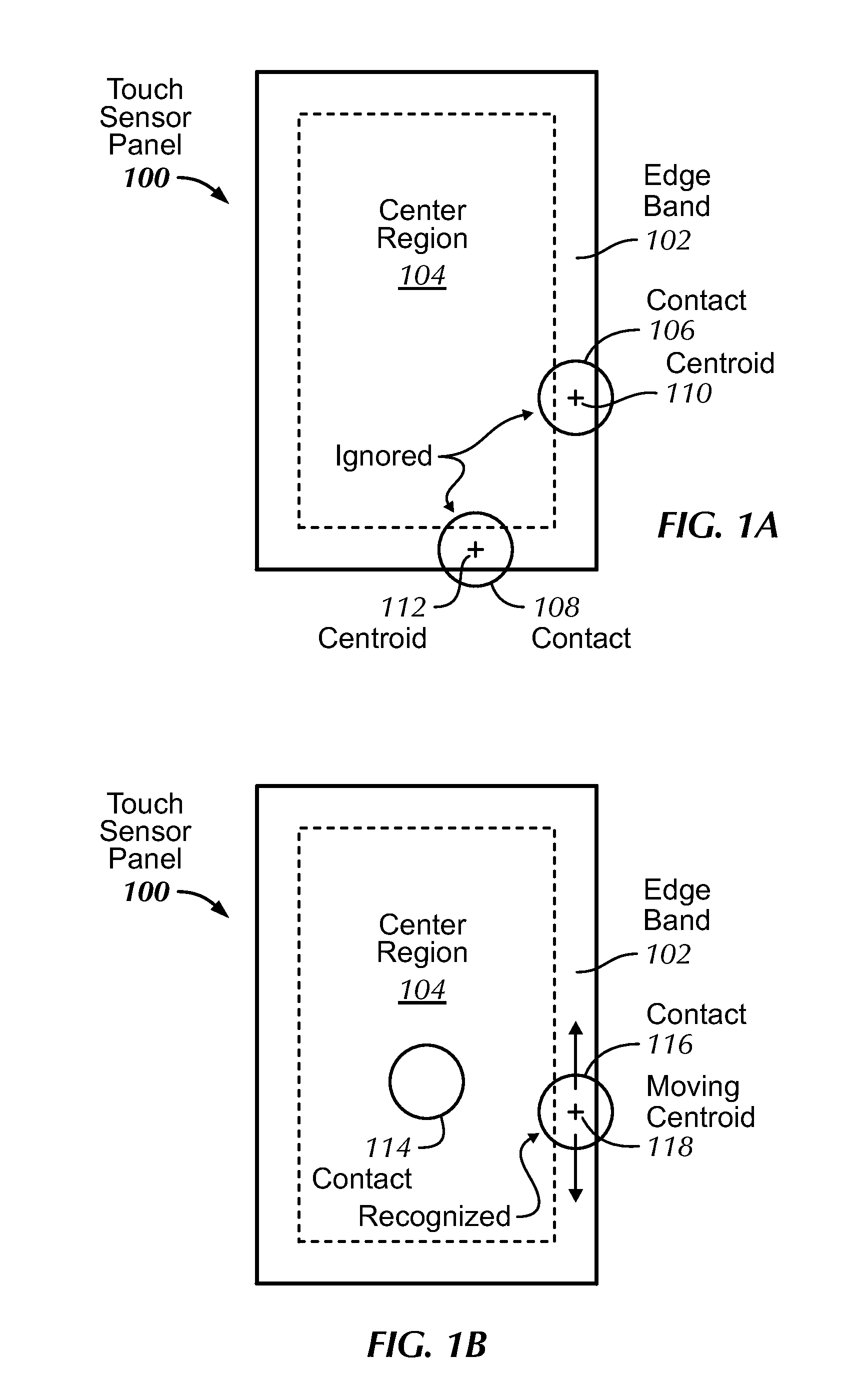

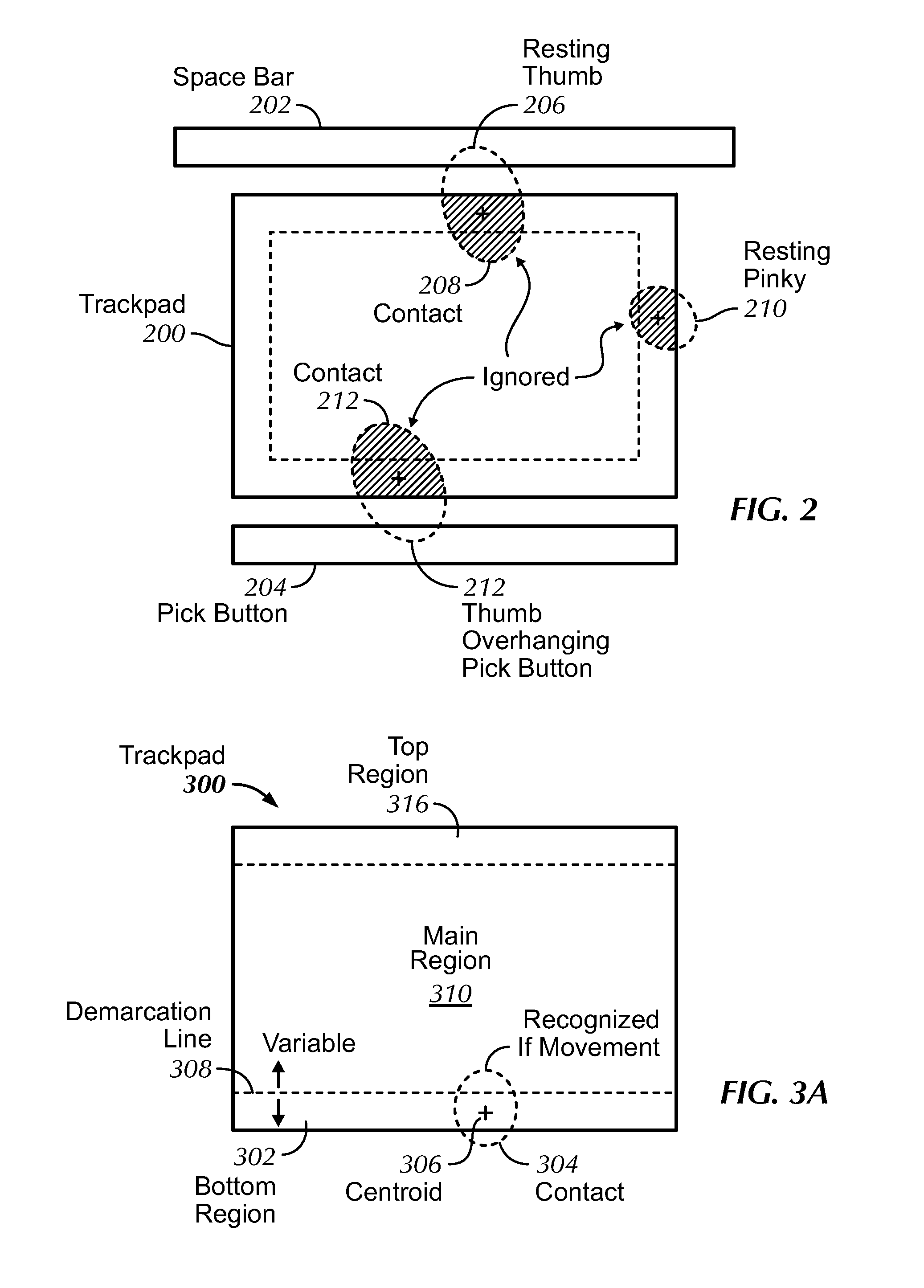

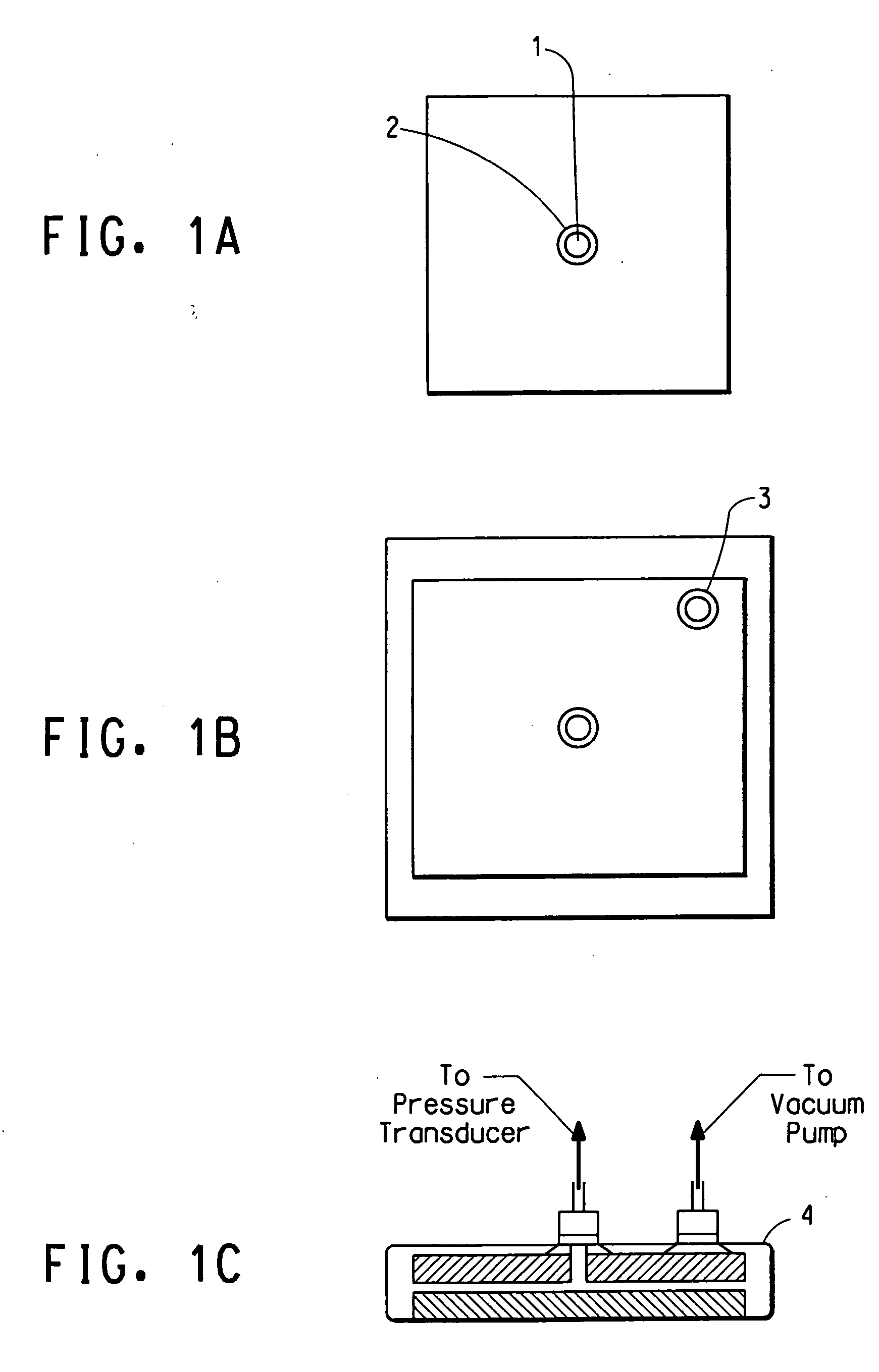

Selective Rejection of Touch Contacts in an Edge Region of a Touch Surface

InactiveUS20090174679A1Minimize unintended operationMaximize functionalityInput/output processes for data processingEngineeringFinger size

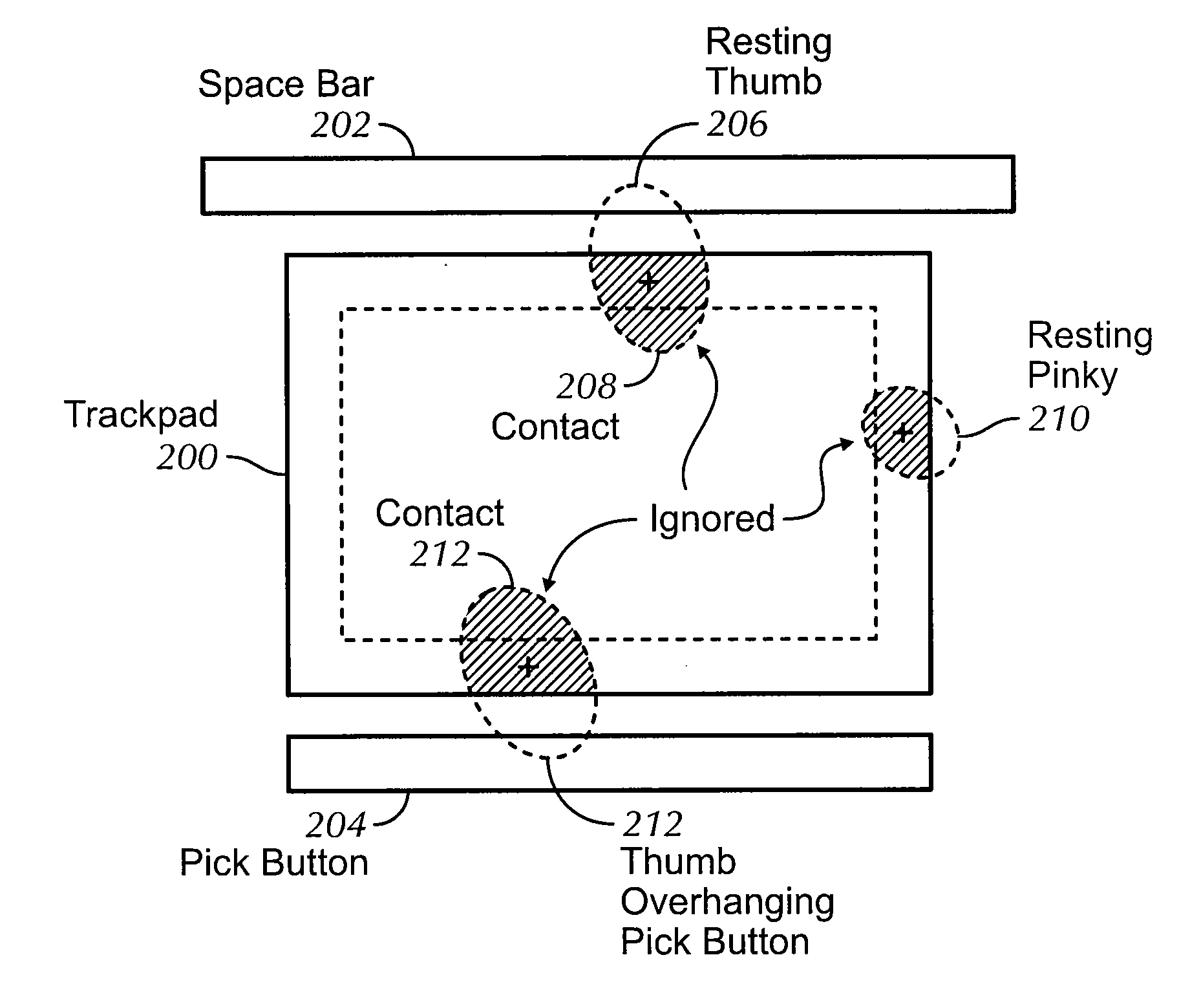

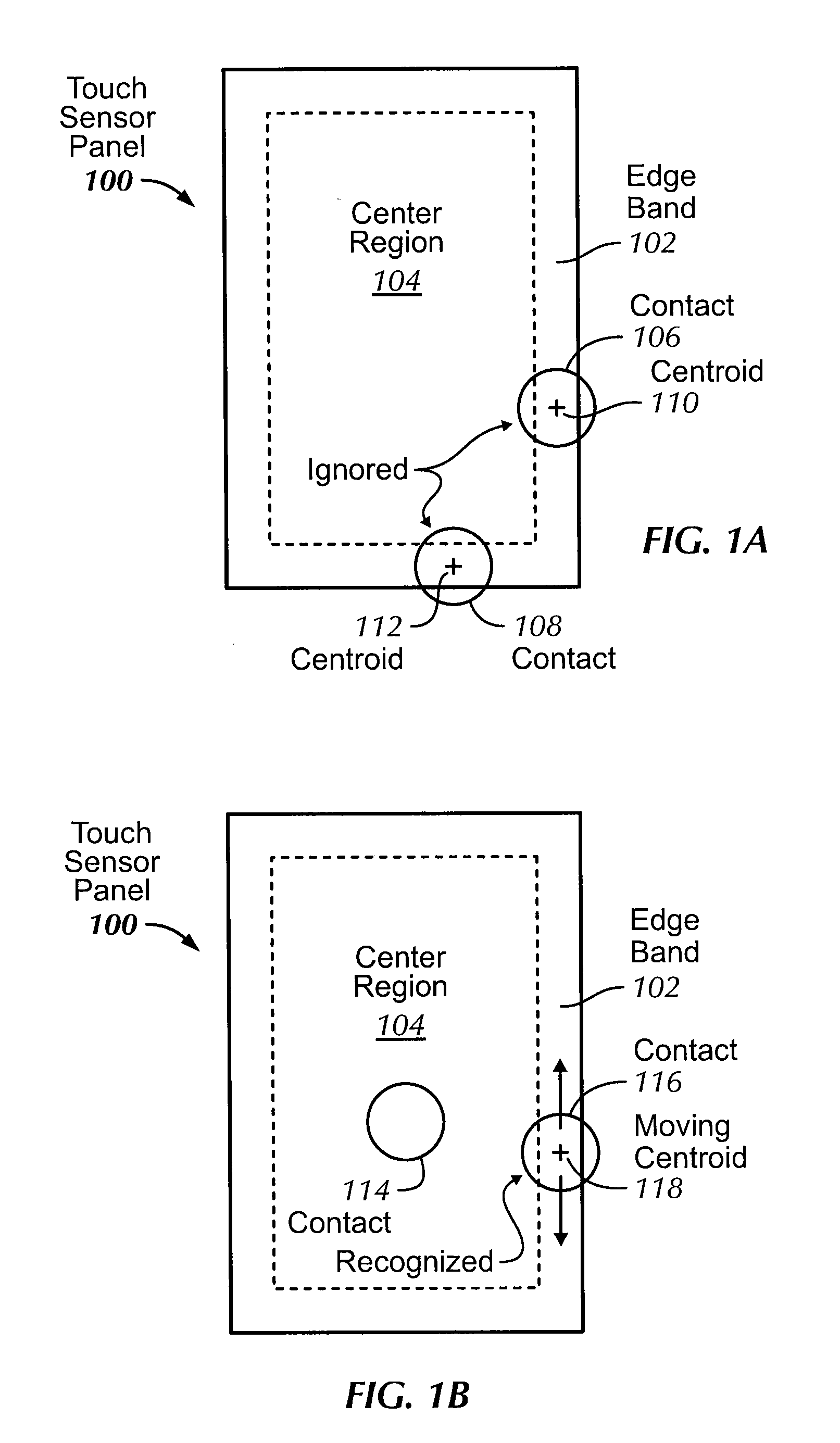

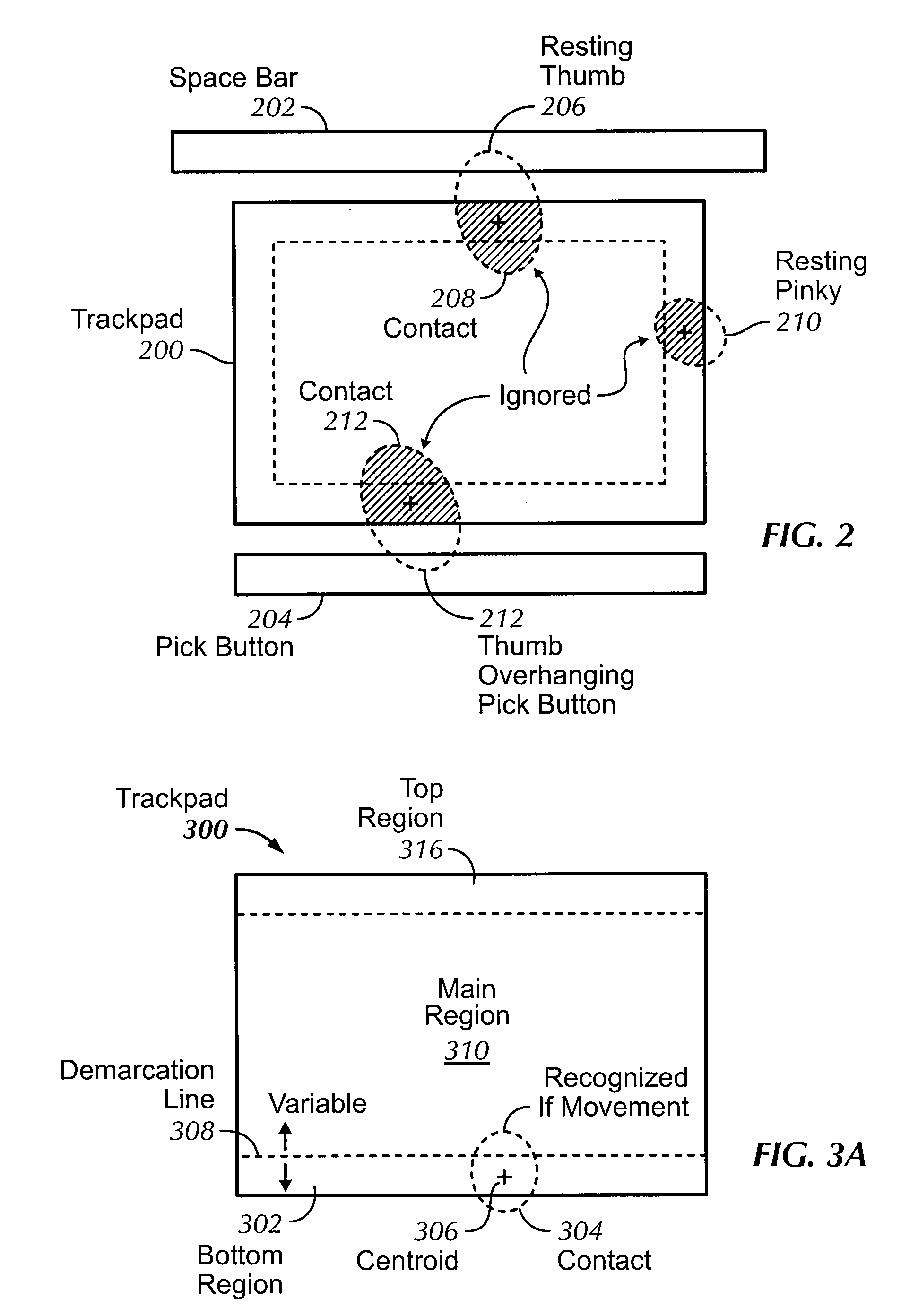

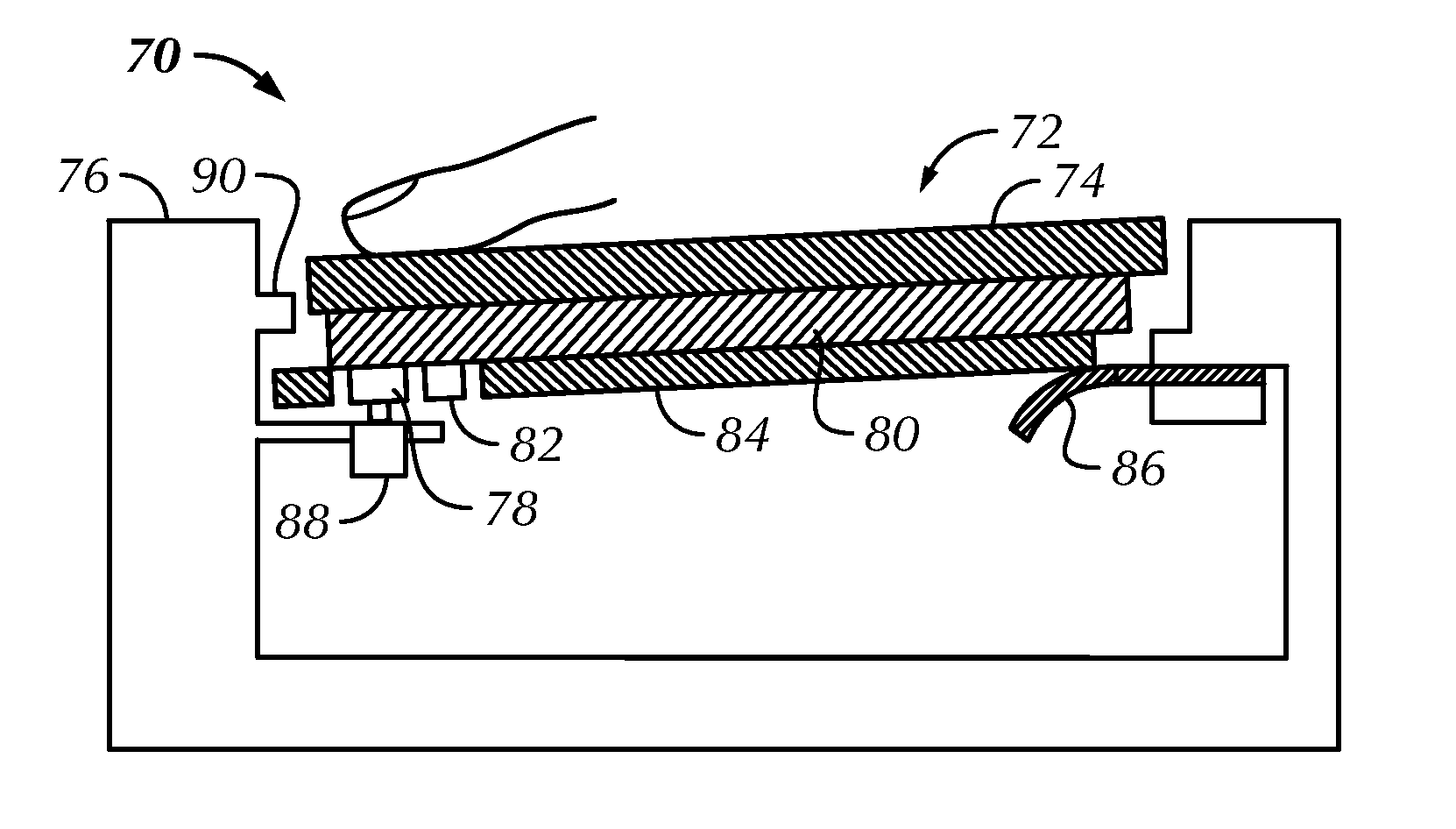

The selective rejection of touch contacts in an edge region of a touch sensor panel is disclosed. In addition, by providing certain exceptions to the rejection of edge contacts, the functionality of the touch sensor panel can be maximized. Contacts in edge bands around the perimeter of a touch sensor panel can be ignored. However, if a contact in the edge band moves beyond a threshold distance or speed, it can be recognized as part of a gesture. To accommodate different finger sizes, the size of the edge band can be modified based on the identification of the finger or thumb. Furthermore, if contacts in the center region of a touch sensor panel track the movement of contacts in the edge band, the contacts in the edge band can be recognized as part of a gesture.

Owner:APPLE INC

Selective rejection of touch contacts in an edge region of a touch surface

ActiveUS20120023459A1MiniaturizationMaximize functionalitySubstation equipmentTransmissionFinger sizeEngineering

The selective rejection of touch contacts in an edge region of a touch sensor panel is disclosed. In addition, by providing certain exceptions to the rejection of edge contacts, the functionality of the touch sensor panel can be maximized. Contacts in edge bands around the perimeter of a touch sensor panel can be ignored. However, if a contact in the edge band moves beyond a threshold distance or speed, it can be recognized as part of a gesture. To accommodate different finger sizes, the size of the edge band can be modified based on the identification of the finger or thumb. Furthermore, if contacts in the center region of a touch sensor panel track the movement of contacts in the edge band, the contacts in the edge band can be recognized as part of a gesture.

Owner:APPLE INC

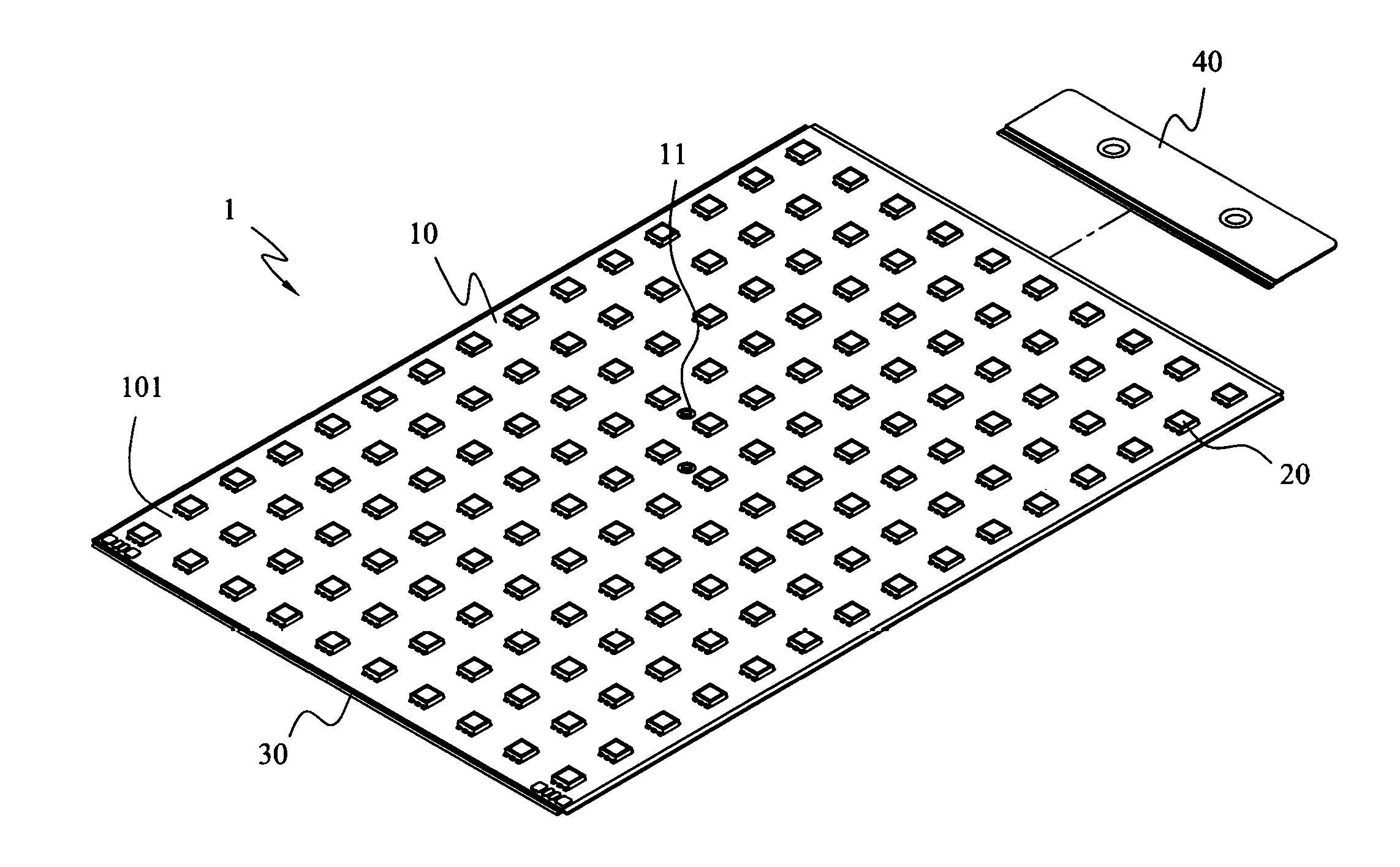

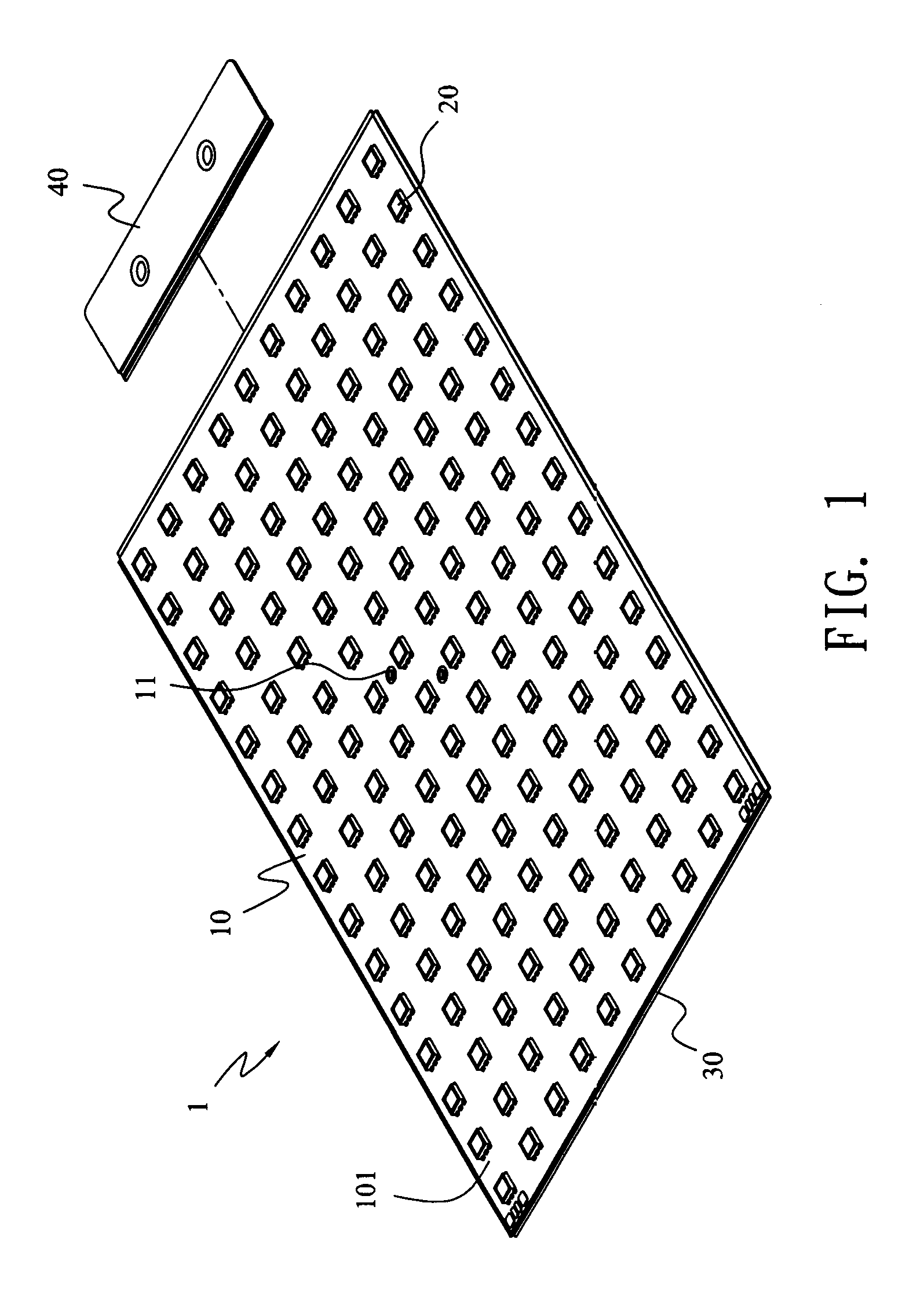

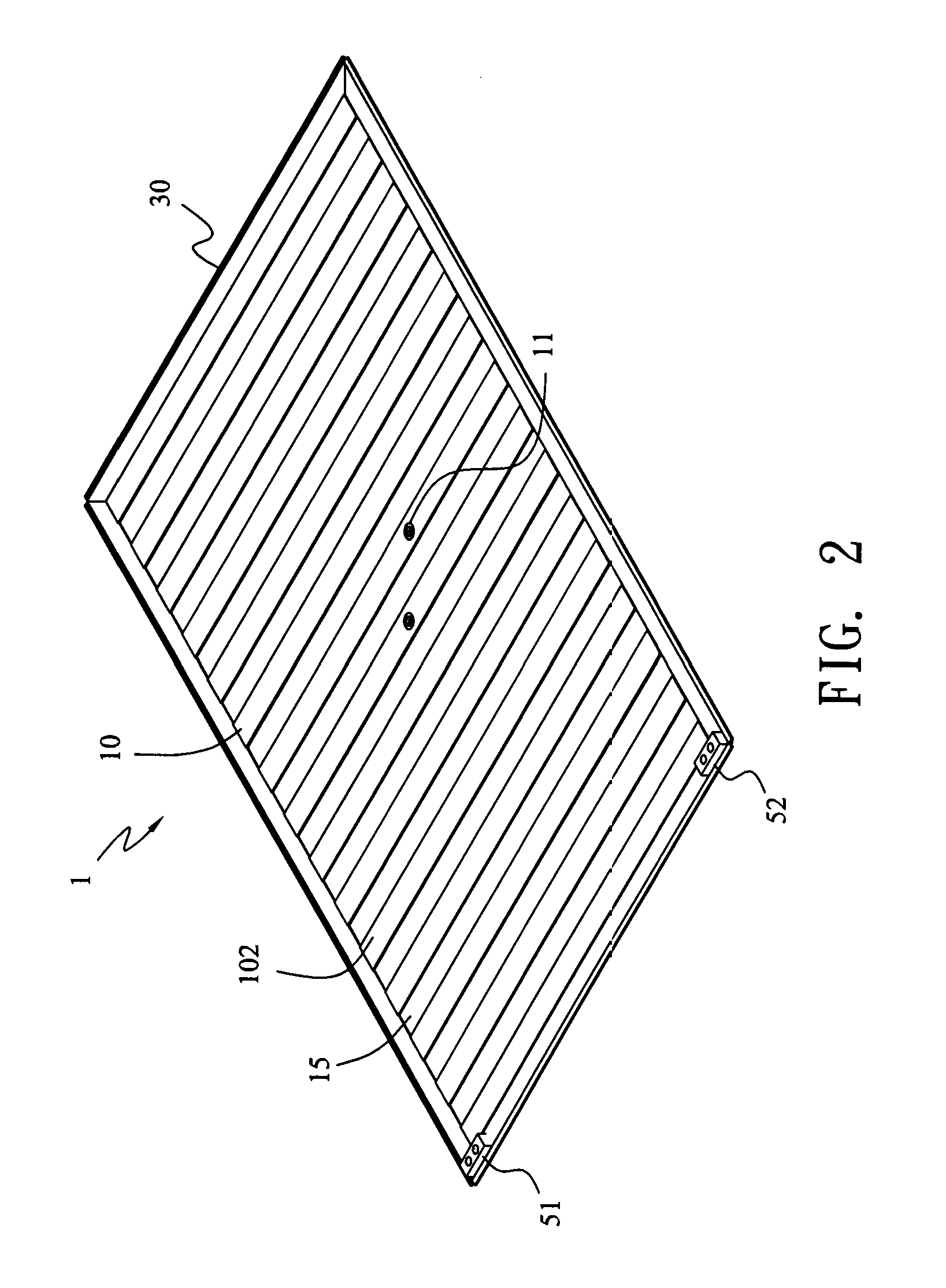

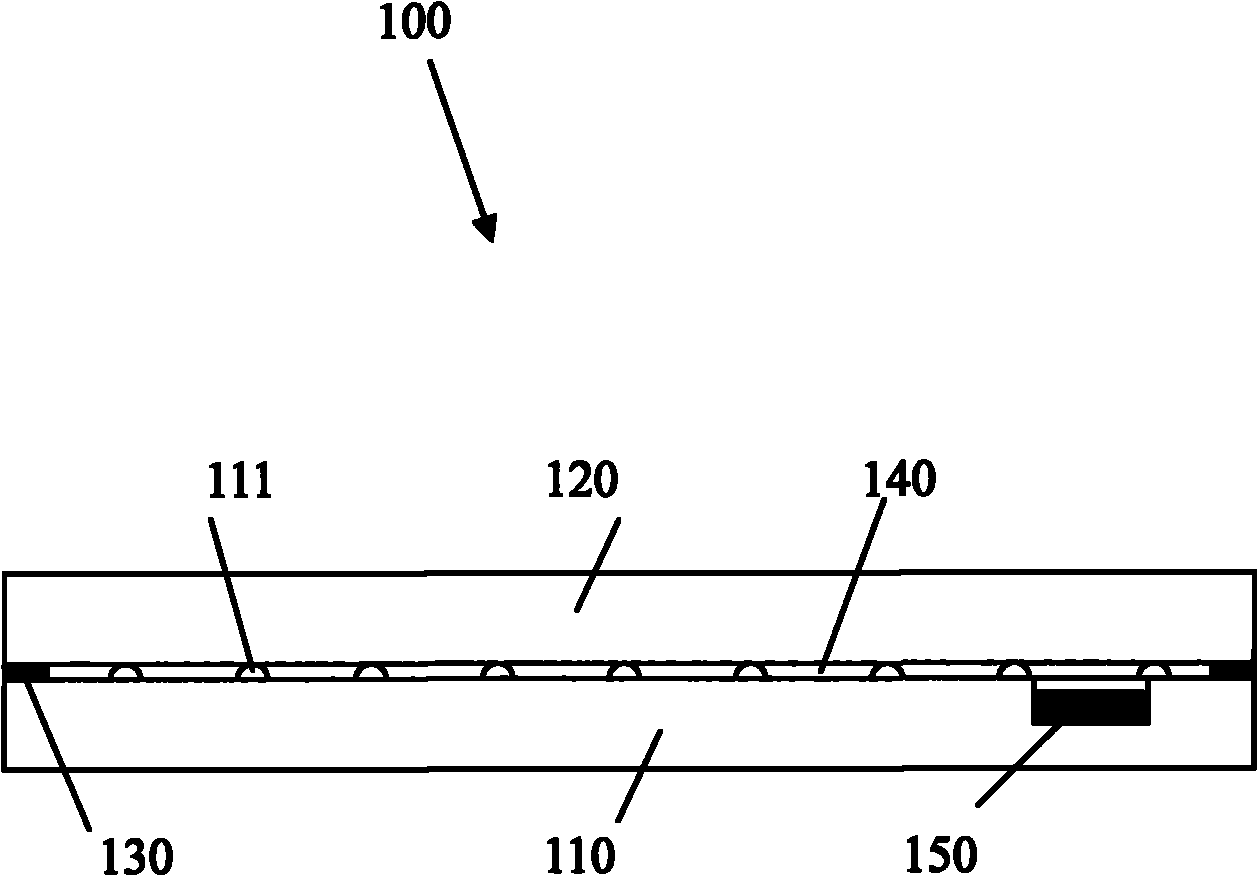

Modular LED display structure with connecting edge banding to connect each other

InactiveUS20120019490A1Easy to assembleEasy to takePrinted circuit aspectsCathode-ray tube indicatorsLED displayImage resolution

A modular LED (Light Emitting Diode) display structure includes full-color LED units to be arranged in a matrix on a flexible PCB, and plurality of protective plates to protect connection between the full-color LED units and the transmission line of the flexible PCB. Also, the edge of the display has a connecting edge banding with a hook to form a track thereunder. The hook can clip the track of another LED module plate for connection to develop a lager LED display. Moreover, by a hanger connecting to the connecting edge banding to simplify the suspending of the LED display. Furthermore, each full-color LED units has a driving chip to enhance the resolution of the LED display.

Owner:APA ELECTRONICS

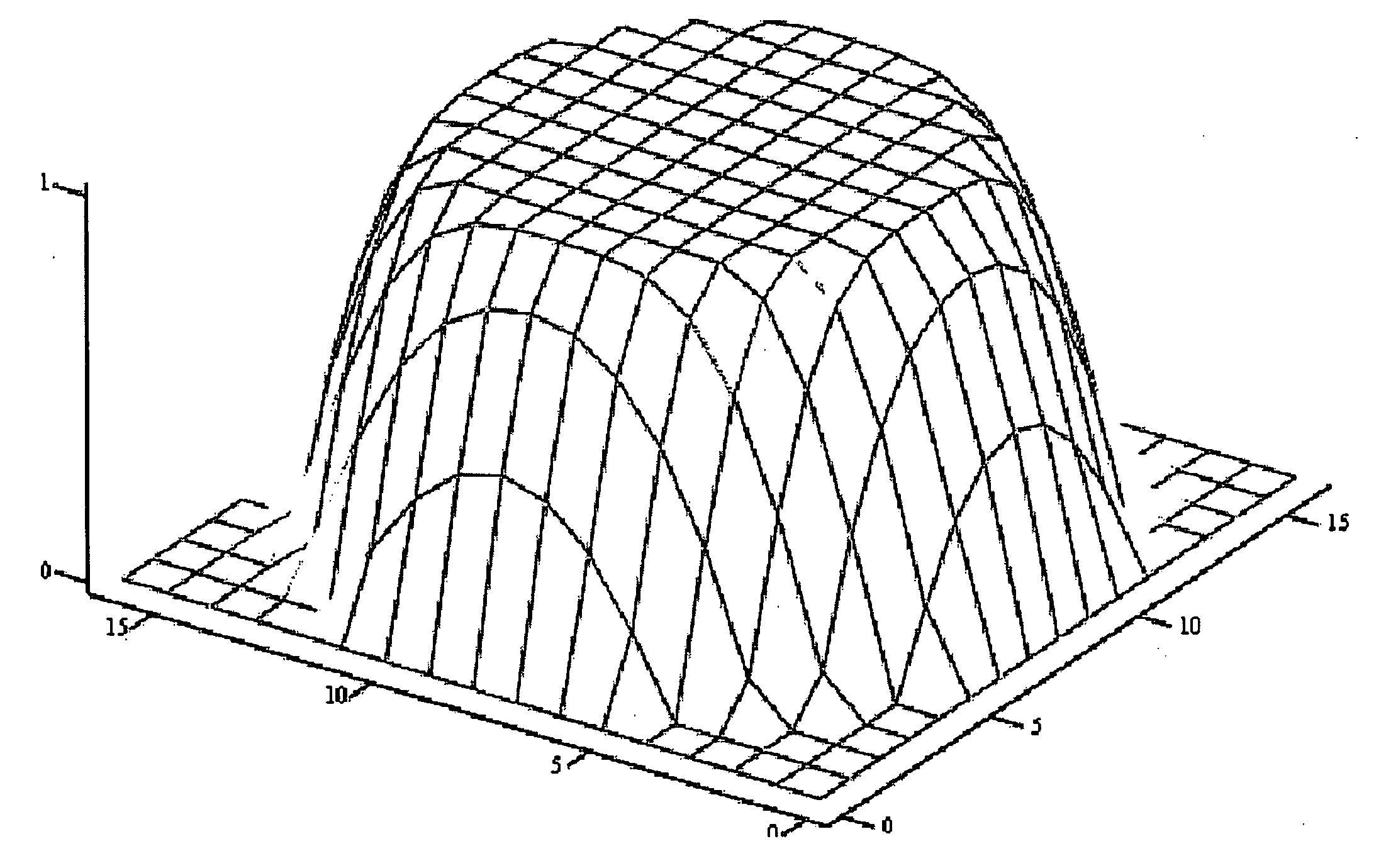

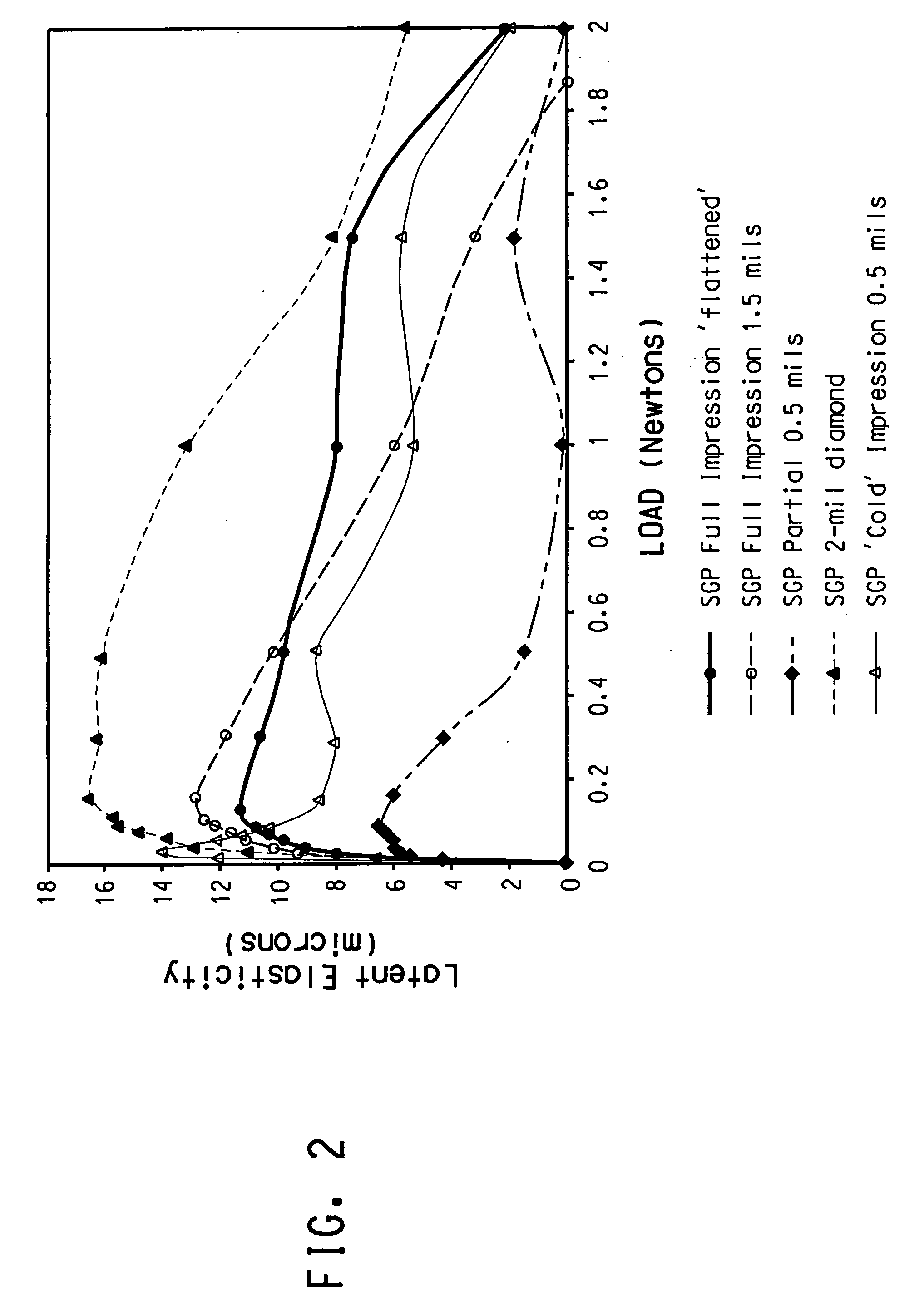

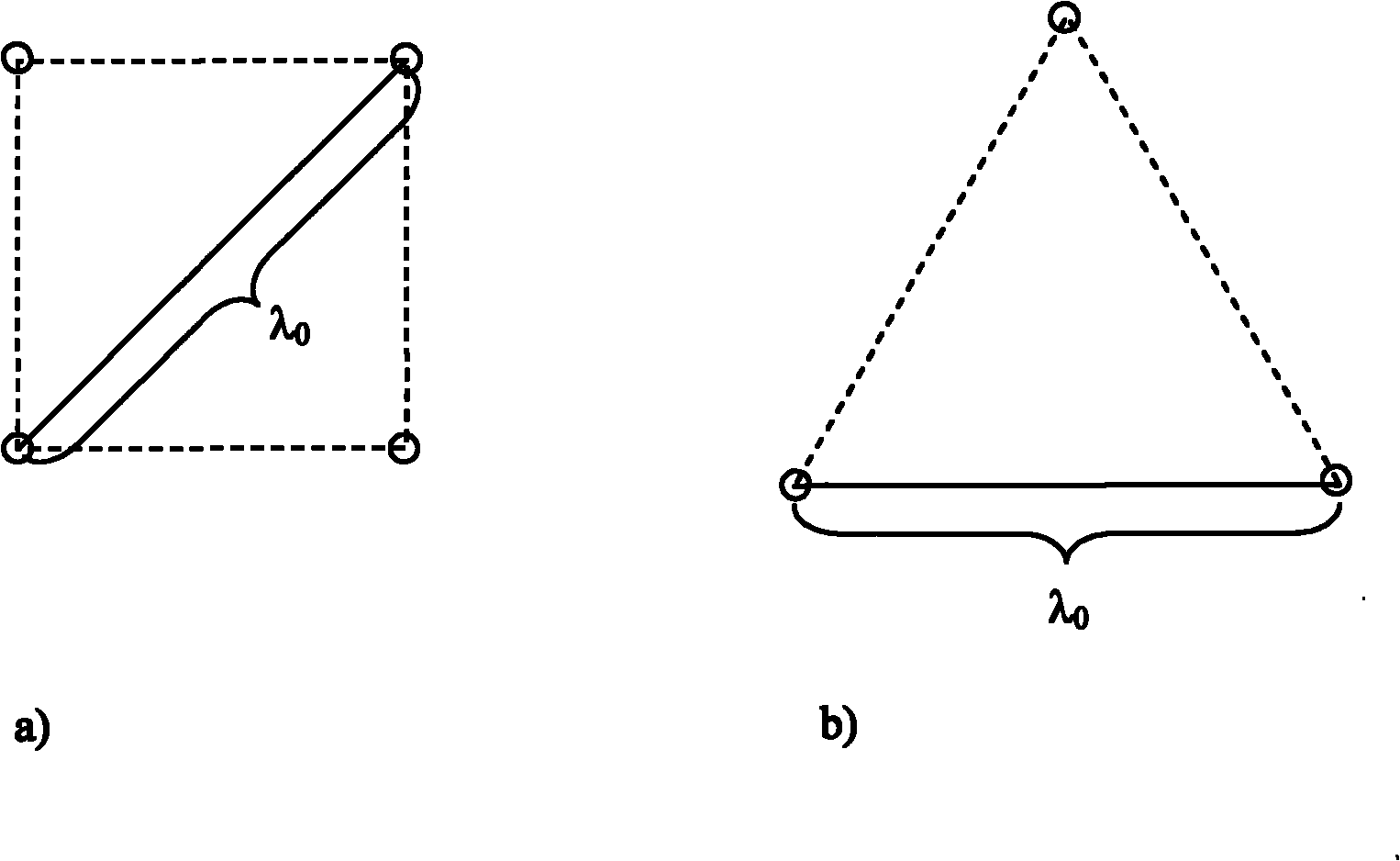

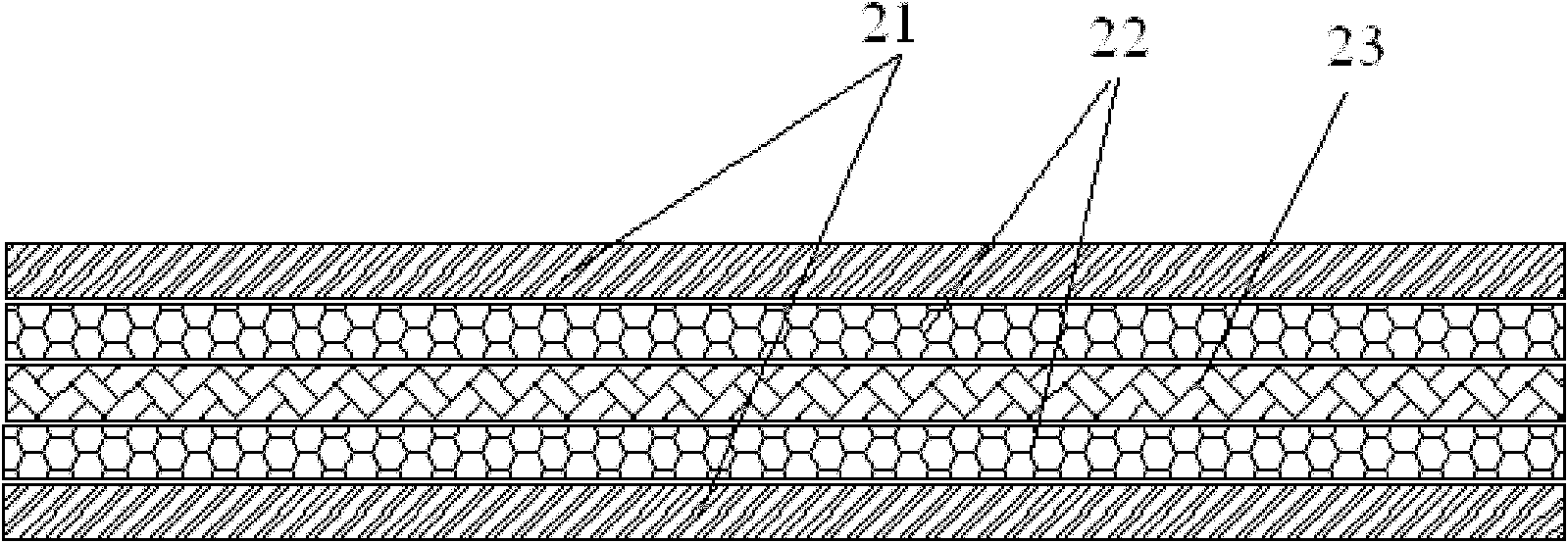

Interlayers for laminated safety glass with superior de-airing and laminating properties and process for making the same

This invention relates to thermoplastic interlayers for laminated safety glass with superior vacuum de-airing at elevated temperatures and superior tacking and edge sealing properties. The sheeting has surface pattern on at least one of the surfaces characterized by flat surfaces with substantially uninterrupted channels for airflow in at least two non-parallel directions. The channels allow for rapid de-airing while the area roughness parameter ratio ARp / ARt in the range of 0.52 to 0.62, ARt being less than 32 μm, and area kurtosis less than 2.5, allow for ease of tacking of the interlayer onto glass and edge sealing after de-airing has been completed. Said surface pattern may also be superimposed onto a pattern which is generated by melt fracture or other means on at least one side to enhance de-airing and aid edge sealing.

Owner:PERFORMANCE MATERIALS NA INC

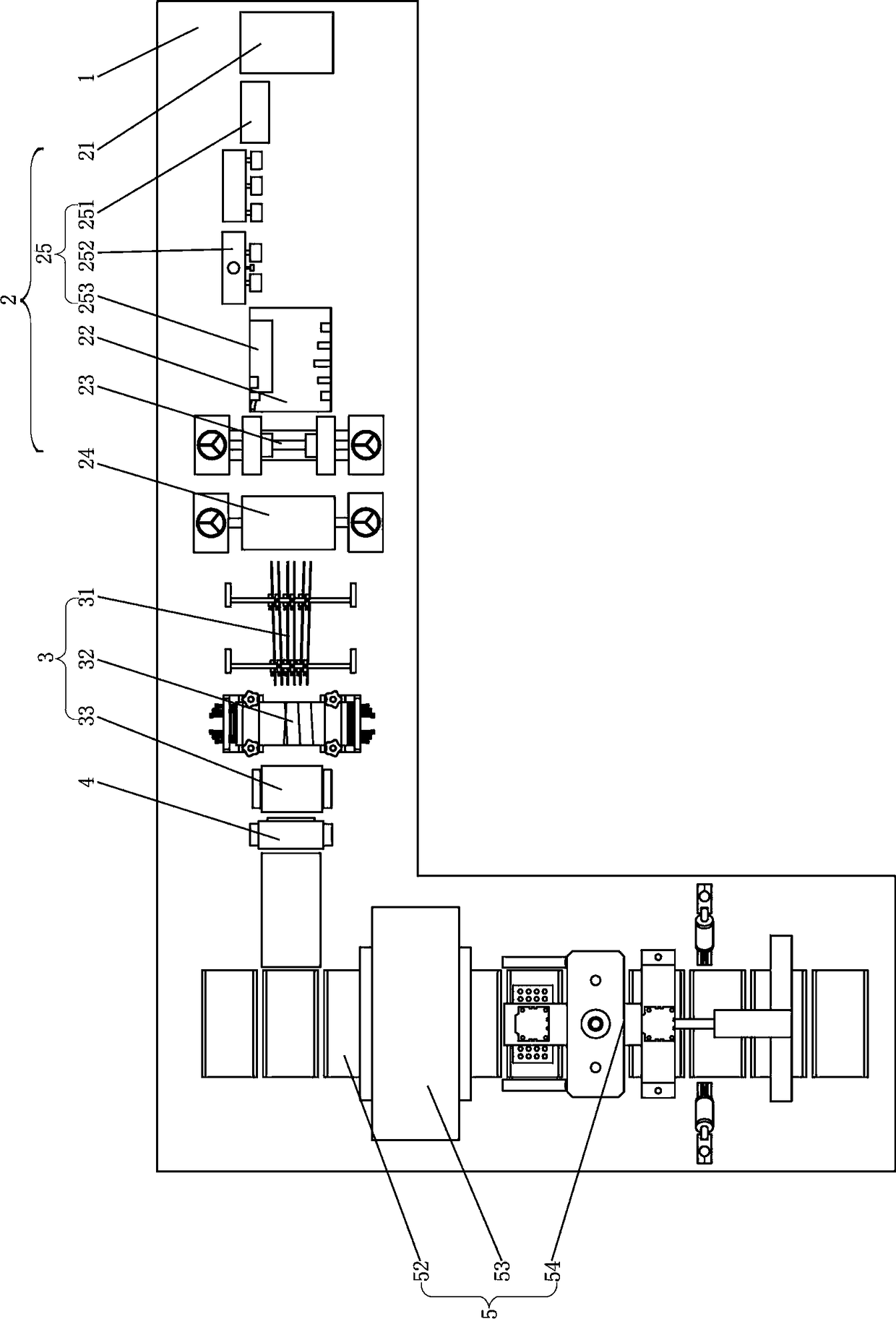

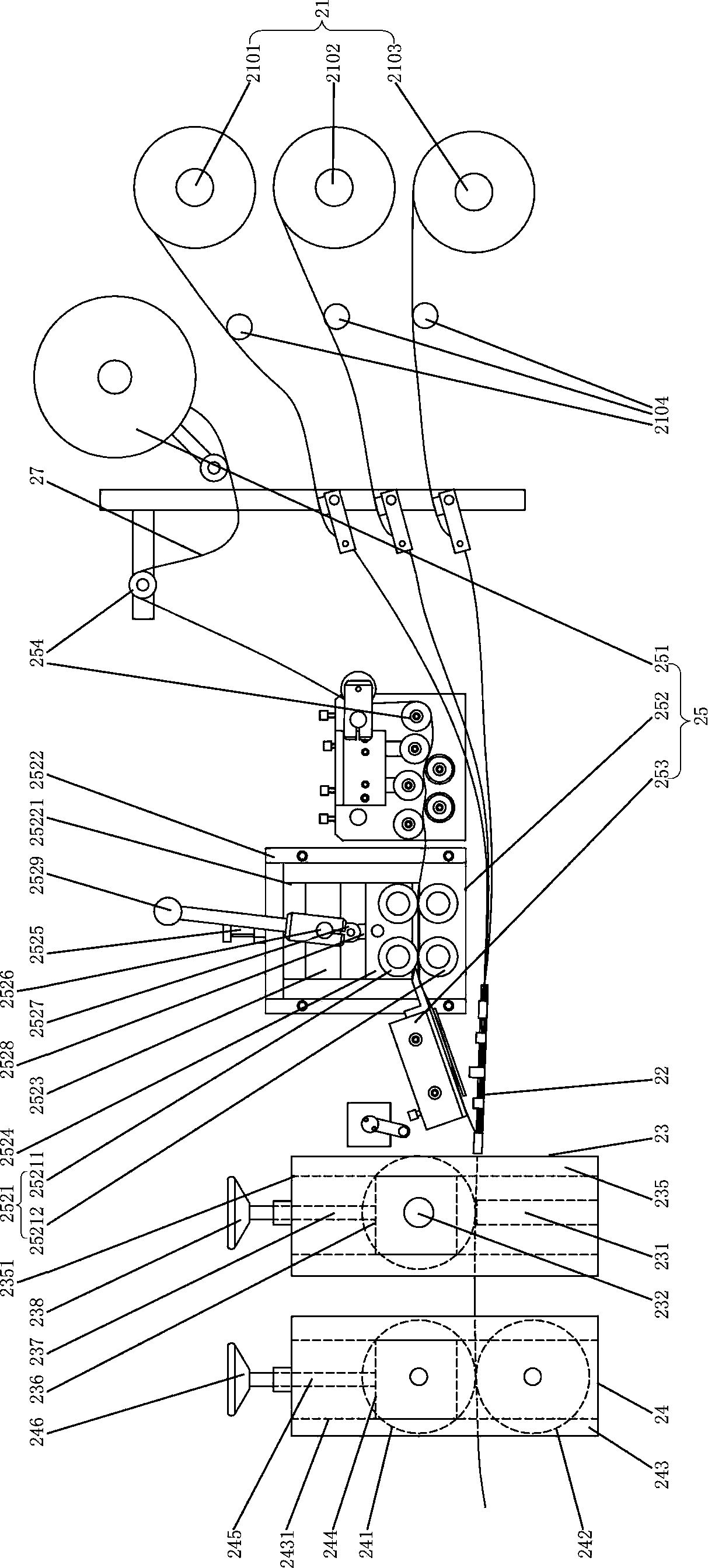

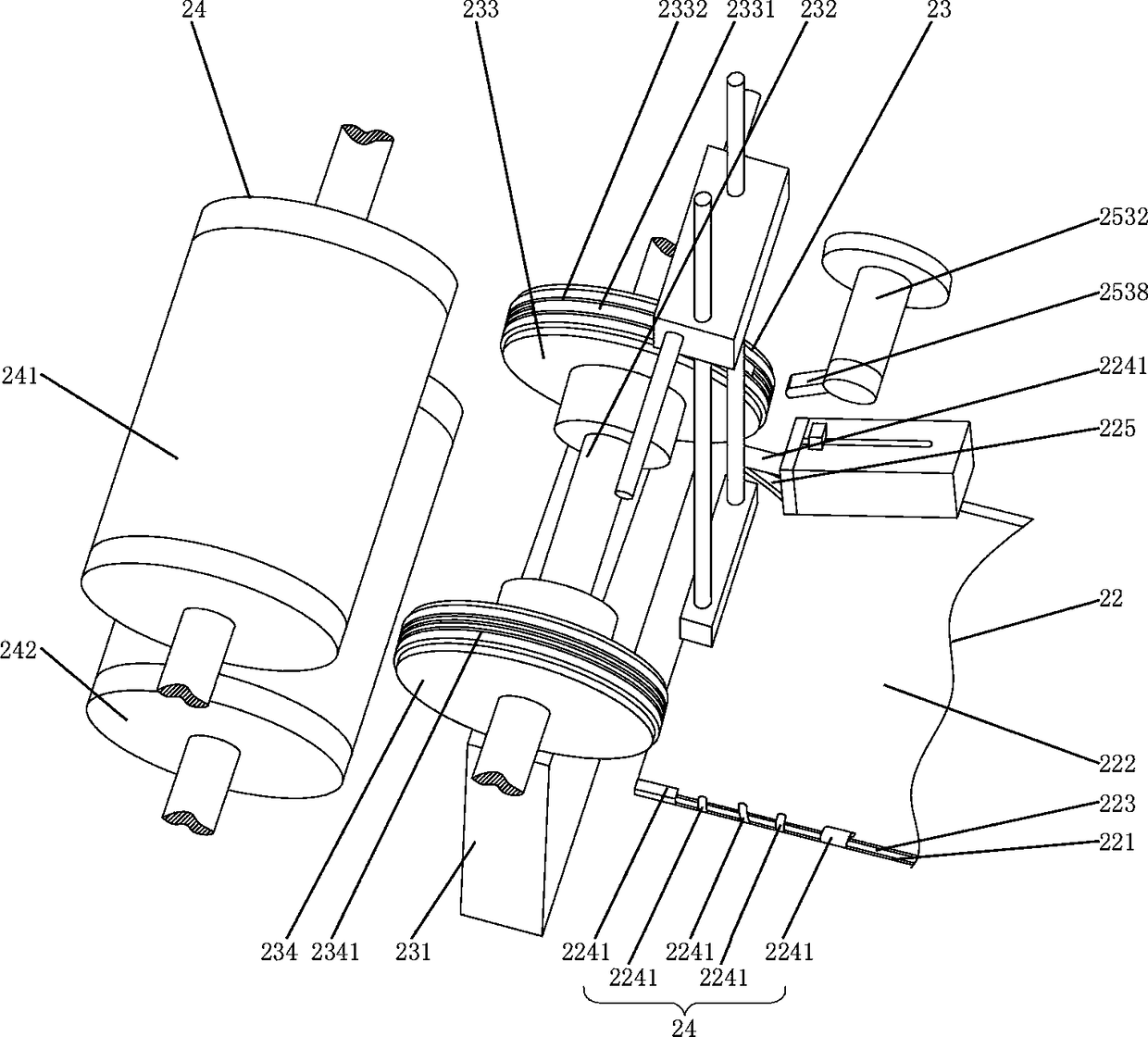

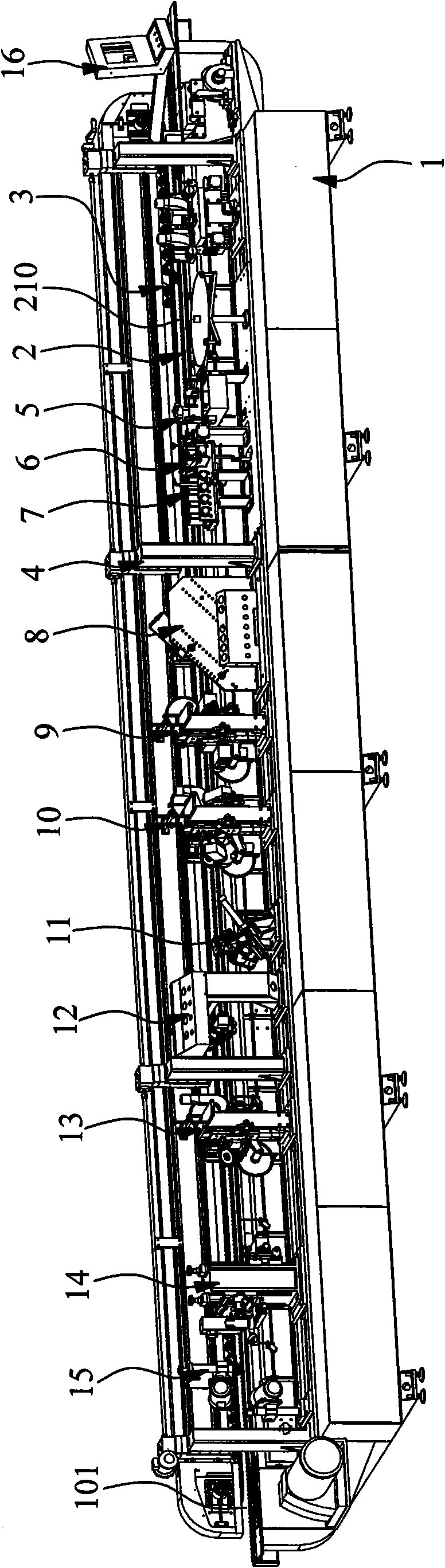

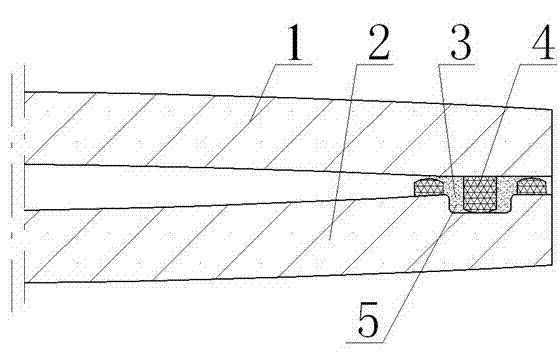

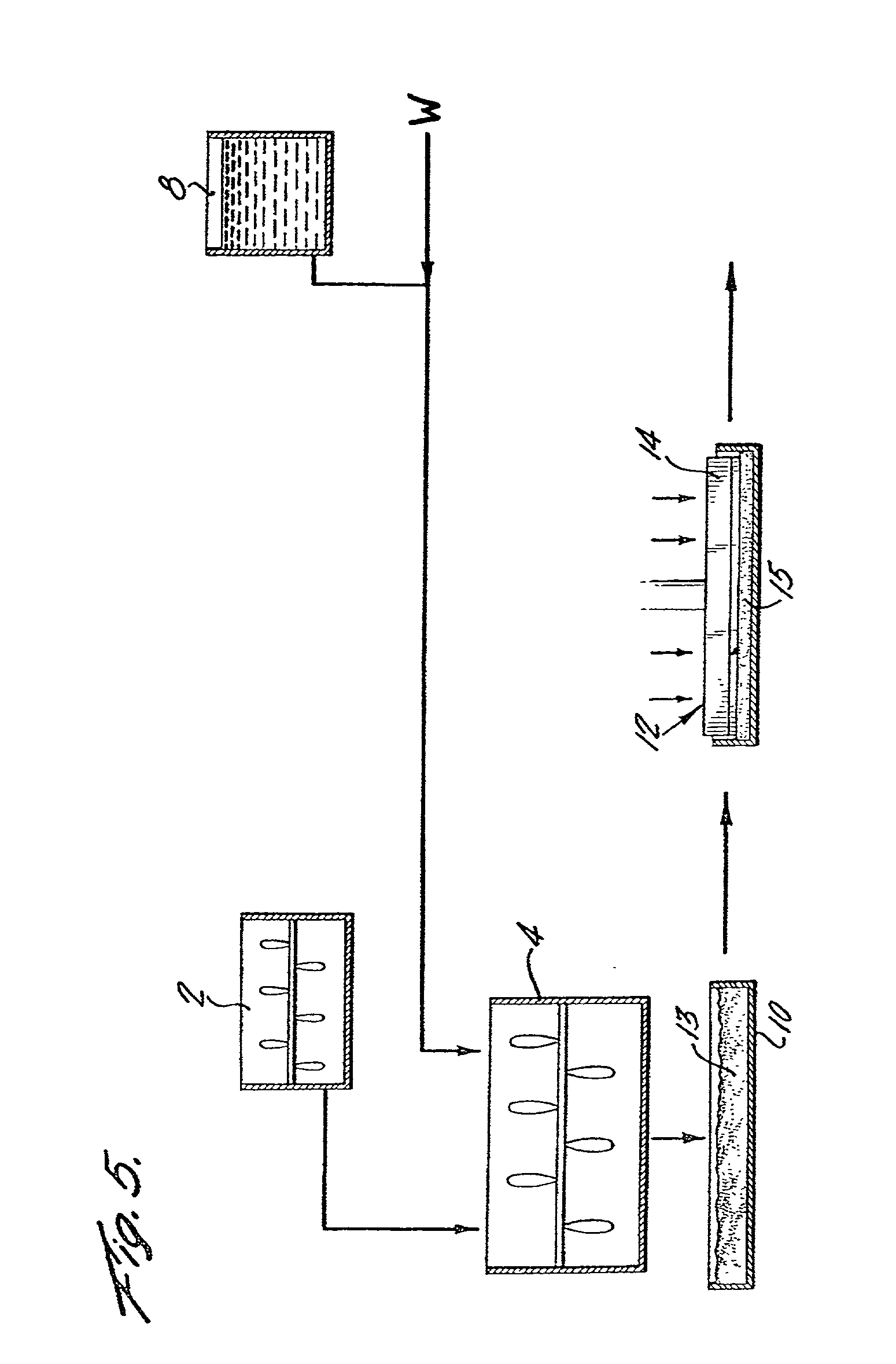

Full-automatic mask production line

The invention discloses a full-automatic mask production line. The production line comprises a machine frame, a mask fabric edge banding device, a mask surface folding device, a mask transverse sealing cutting device and an ear strip welding device; the mask fabric edge banding device comprises a fabric feeding device, a fabric edge folding device, a fabric splicing device, a fabric drawing mechanism and a nose bridge strip feeding device, the fabric edge folding device comprises a lower supporting plate and an upper pressing plate, the upper pressing plate is arranged above the lower supporting plate, two side edges of the lower supporting plate are provided with multiple edge folding side plates which are sequentially arranged from front to back, a nose bridge strip flowing pipe is arranged between the backmost edge folding side plate and the upper pressing plate, and the discharging port of the nose bridge strip feeding device faces the front end of the nose bridge strip flowing pipe; the fabric splicing device comprises a splicing motor, a first ultrasound mold, a rotary shaft, a first splicing wheel and a second splicing wheel, a strip-shaped groove is formed in the circumferential surface of the first splicing wheel, and the strip-shaped groove faces the rear end of the nose bridge strip flowing pipe. By means of the mask production line, edge banding process of fabrics can be automatically completed, and the nose bridge strip is accurately added into the edge banding parts of the fabrics.

Owner:汕头市泰恩康医用器材厂有限公司

Aromatic glycidyl amine-based epoxy edge seals for electrooptic devices

A method for sealing the peripheral edge surface of a laminated electrooptic device, wherein an aromatic glycidyl amine-based epoxy is used as a seal. Sealed devices are also disclosed.

Owner:PPG IND OHIO INC

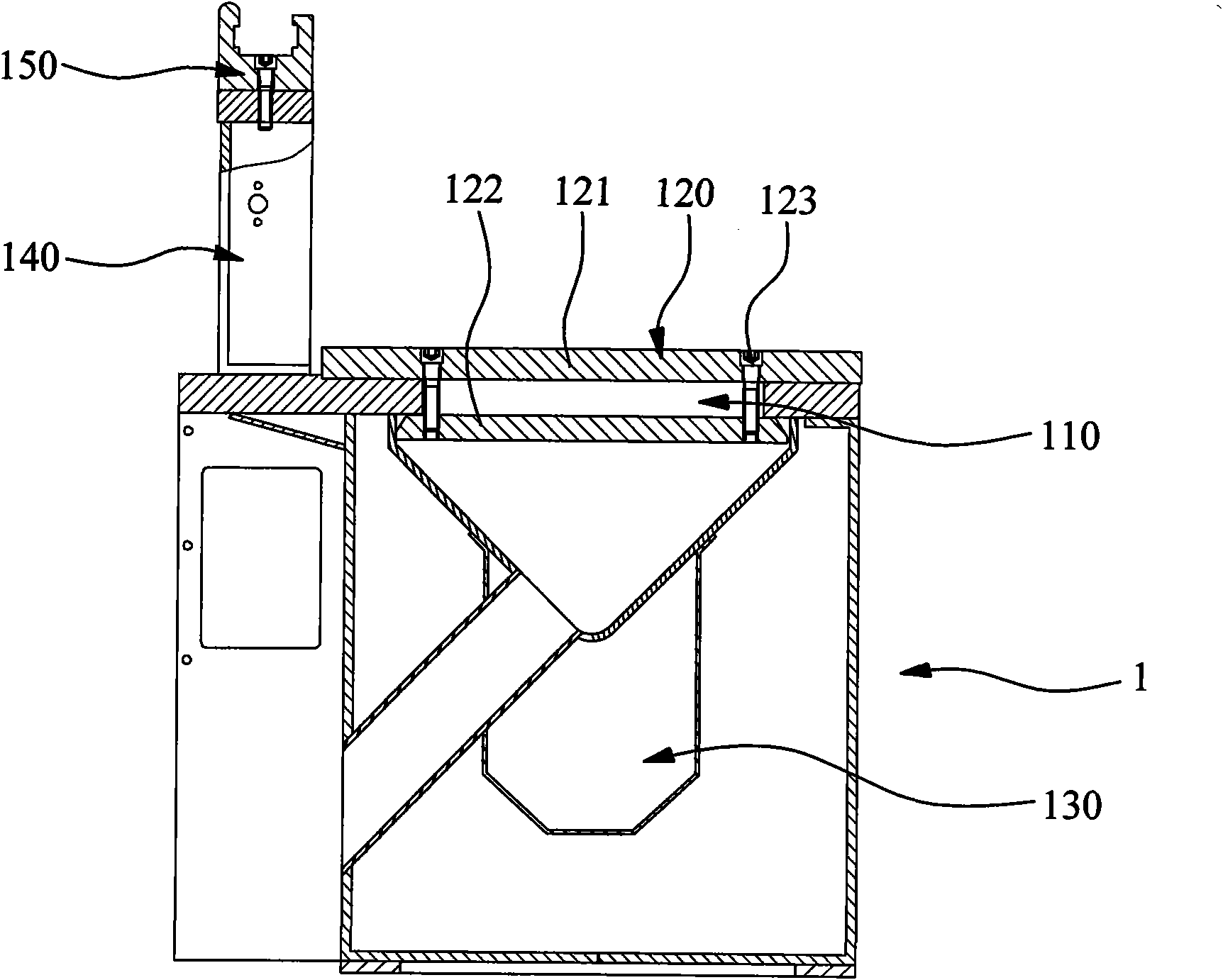

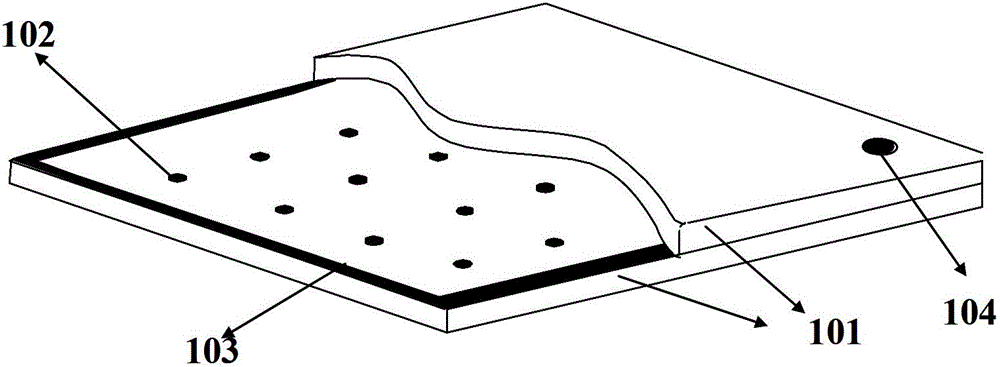

Low-cost toughened vacuum glass and manufacture method thereof

InactiveCN102050585ALow investment costReduce manufacturing costClimate change adaptationWindows/door improvementTransmittanceToughened glass

The invention provides vacuum glass and a manufacture method thereof, characterized in that micro-salient-point supporting objects melted together with an original glass sheet are used to substitute for a traditional stainless steel supporting object distributing process, a low-temperature metal braze-welding technology without causing the anneal of the original toughened glass sheet is used for sealing edges, and a traditional vacuum-layer vacuumizing process and an edge-sealing process are simplified and integrated into an integrated vacuumizing and edge-sealing process. Compared with traditional vacuum glass and the manufacture method thereof, the vacuum glass and the manufacture method thereof, which are provided by the invention, have simple process, high yield, low equipment investment and production cost, better heat and sound insulation, better appearance and light transmittance, high safety reaching the use standard of high-rise buildings, and the like.

Owner:刘伟杰

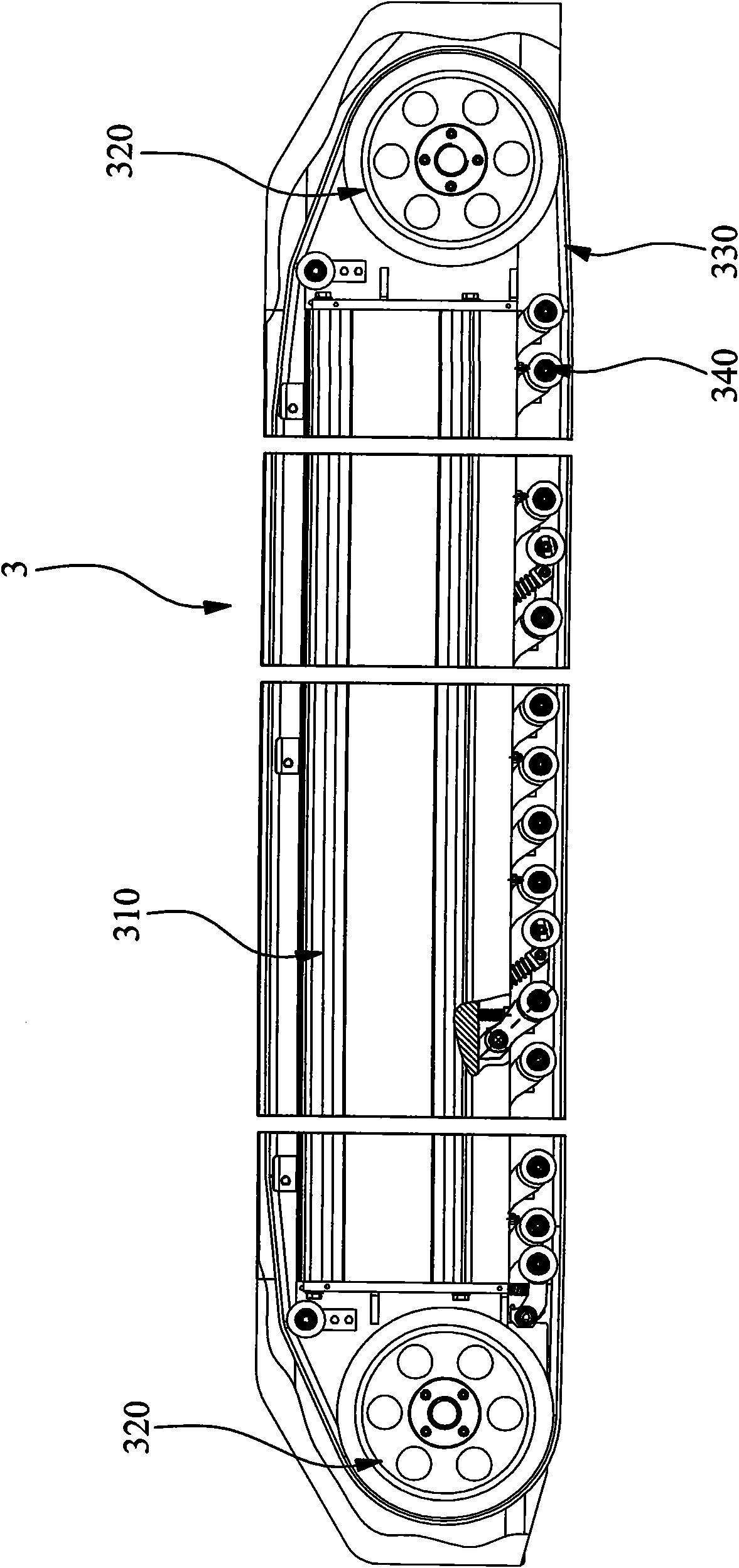

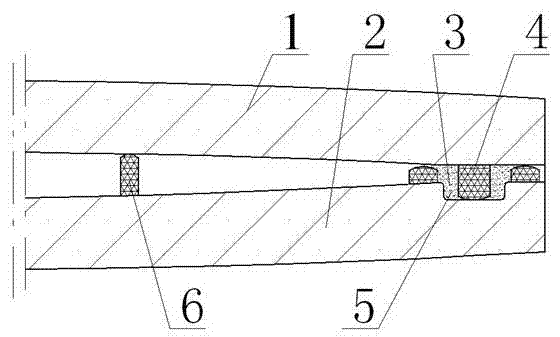

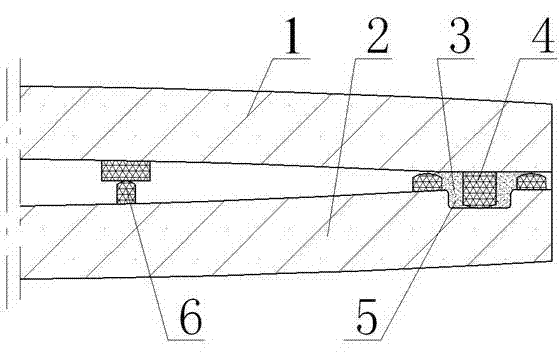

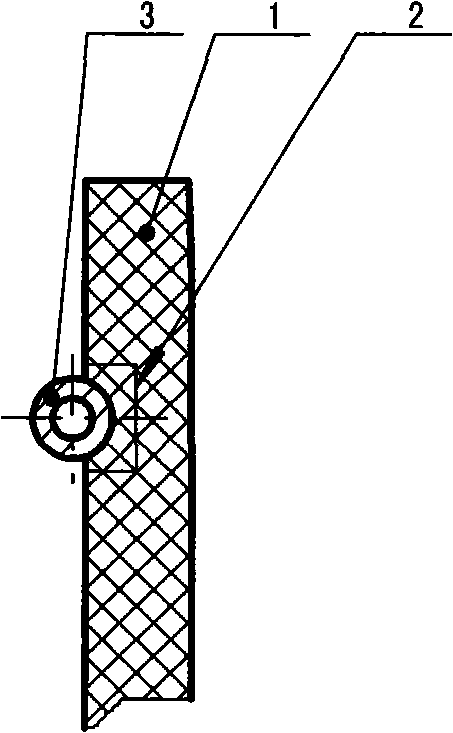

Heavy type automatic edge banding machine controlled by encoder

ActiveCN102114662ARealize the purpose of one machine with multiple functionsLow costWood working apparatusDomestic articlesMachine controlEngineering

The invention discloses a heavy type automatic edge banding machine controlled by an encoder, comprising a stand, a chain conveying device, a crawler-type pressing device, a glue supplying and belt pressing device, a belt cutting device, an up / down roughing device, an up / down finishing device, an up / down edge scraping device and an up / down polishing device; wherein the crawler type pressing device is arranged on the stand through a stand column assembly to ensure that the crawler type pressing device can ascend or descend relative to each stand column of the stand column assembly, and an upper roughing assembly of the up / down roughing device, an upper finishing assembly of the up / down finishing device, an upper edge scraping assembly of the up / down edge scraping device and an upper polishing assembly of the up / down polishing device are connected on a cross beam of the crawler type pressing device so as to ascend or descend synchronously along with the crawler type pressing device. The heavy type automatic edge banding machine can be used for carrying out edge banding operation on wood boards with higher specification in thickness, is free from the limit of the thickness of the wood boards, has a wide application range, is multipurpose and is beneficial to reduction of equipment cost for enterprises when edge banding operation and production are carried out on the wood boards.

Owner:NANXING MACHINERY CO LTD

Air insulating structure of vacuum insulation panel and packaging method thereof

InactiveCN101963267AReduce the number of heat-sealed edgesSave on packaging costsThermal insulationPipe protection by thermal insulationVacuum pumpingThermal bridge

The invention provides an air insulating structure of vacuum insulation panel, which is formed by composite material. The composite material does not contain aluminium foil layer; therefore, the heat bridge effect of seal edge during heat seal is avoided. The packaging method of the air insulating structure comprises the following steps of: folding a single piece of composite material to form a bag shaped air insulating structure having a size consistent with that of adiabatic core material according to the specification of the core material and form three seal edges; sealing part of sealing edges with heat, and keeping an opening for placing the adiabatic core material inside; filling the adiabatic core material in the air insulating structure, performing heat seal on the remained opening and keeping a vacuum pumping opening; and placing the air insulating structure, which is filled with the adiabatic core material and has a vacuum pumping opening, in a vacuum room and pumping to produce vacuum, and performing heat seal on the preserved vacuum pumping opening to form a vacuum thermal insulation panel. The air insulating structure has three seal edges, which are fewer than those of the conventional method; therefore, the integral heat bridge effect is reduced, the operation is simple, the appearance planeness of the vacuum insulation panel is improved, and the fold and air leakage of the air insulating structure in convention manufacturing process are avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

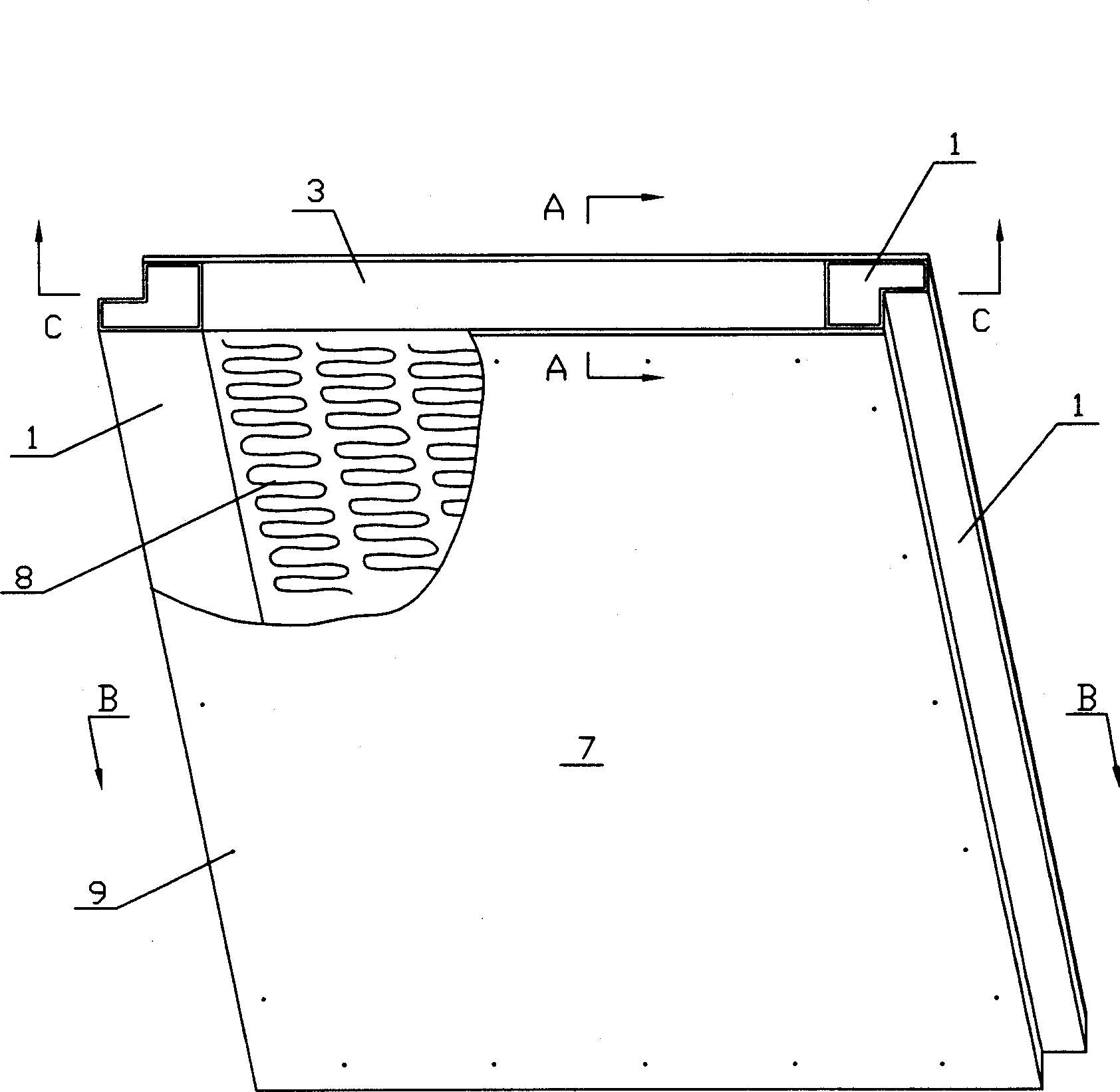

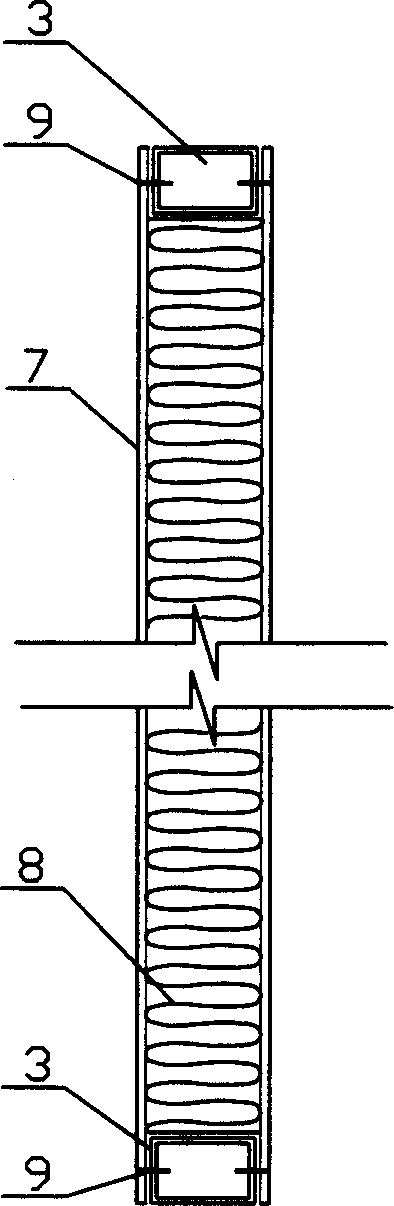

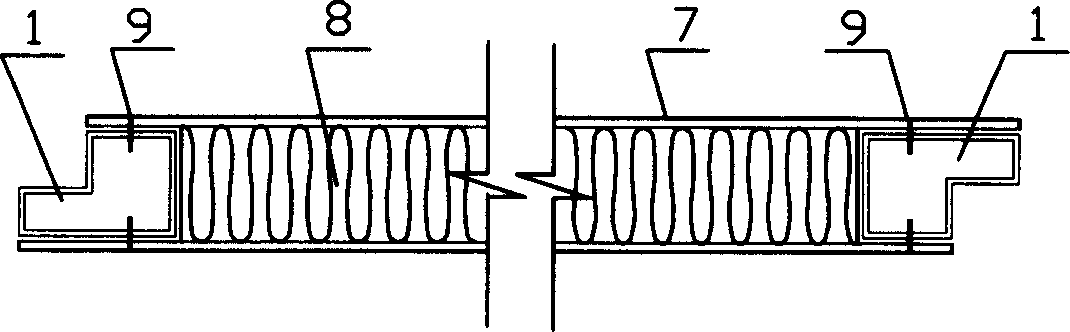

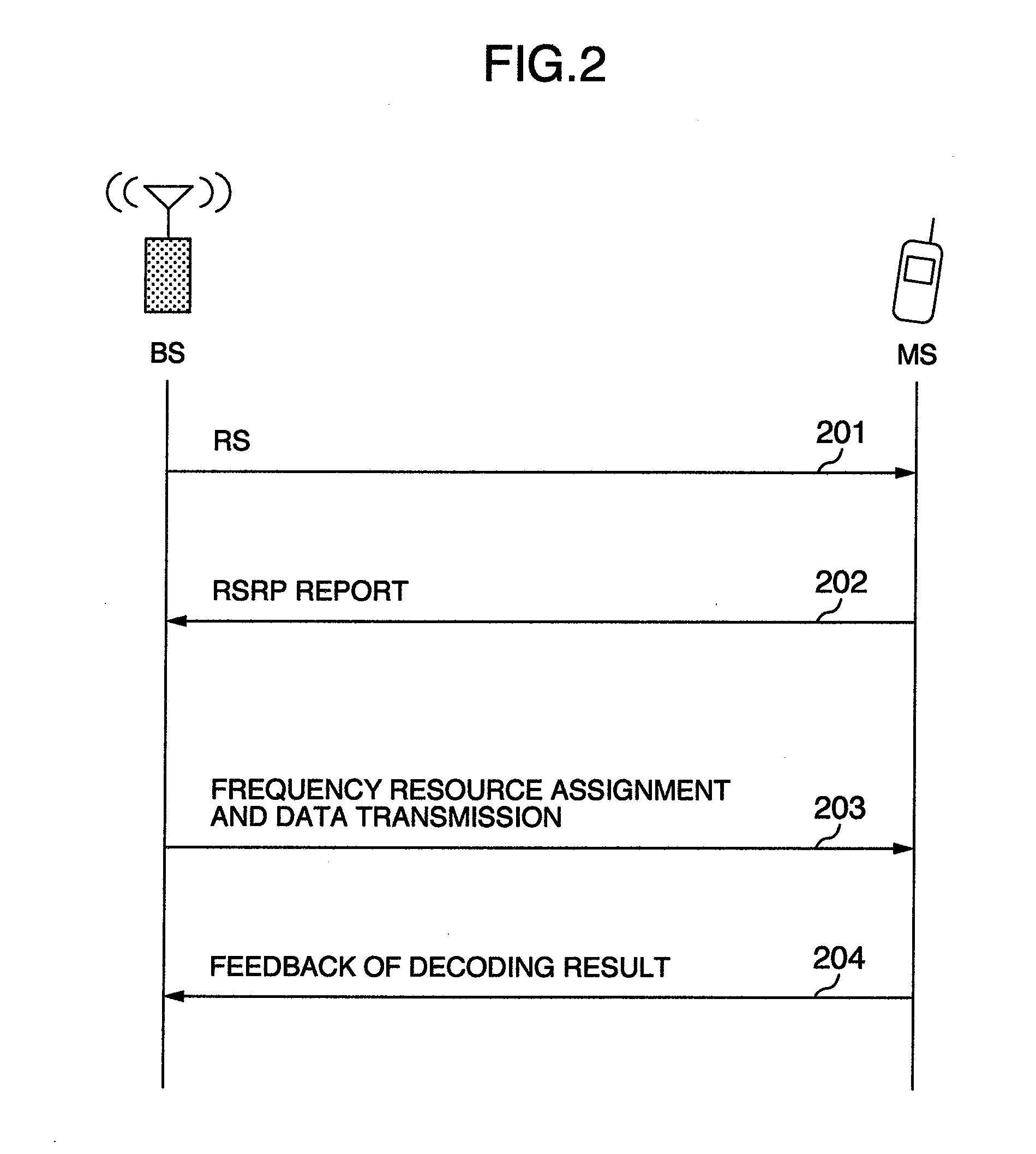

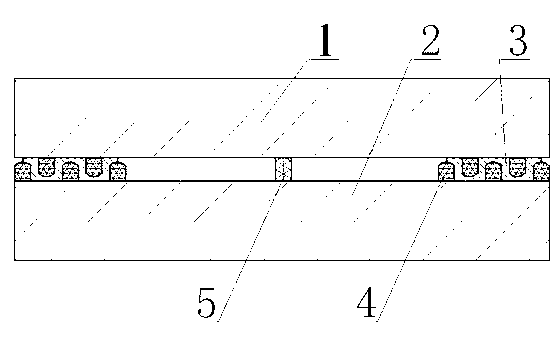

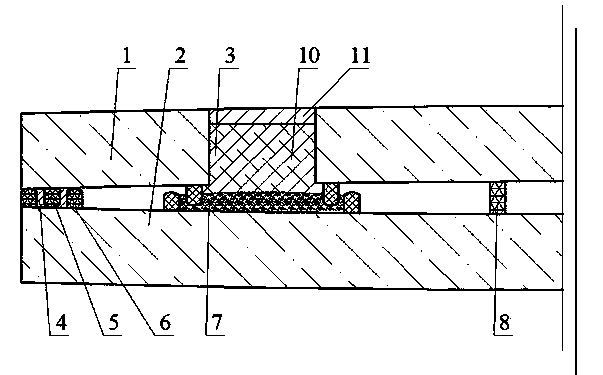

Assembled large-scale construction board with light frame and manufacturing process thereof

ActiveCN1884762AImprove structural performanceImprove seismic performanceBuilding componentsKeelEdge structure

The invention relates to an assembly light frame large-scale building sheet material and relative preparation, wherein said invention comprises: two plates and one core plate clamped between them; said core plate comprises a light frame at the edge to form sealed edge structure, and light thermal-insulated material filled into the chamber surrounded by said light frame; the plate and the light frame are connected via self-threading screw. And the preparation comprises filling type, rolling type and model compress type. The inventive sheet is preformed with light keel, which can confirm better structure of room, with anti-wind, anti-vibration and anti-theft functions (it arranges steel bar network inside the plate).

Owner:广州益群板业有限公司

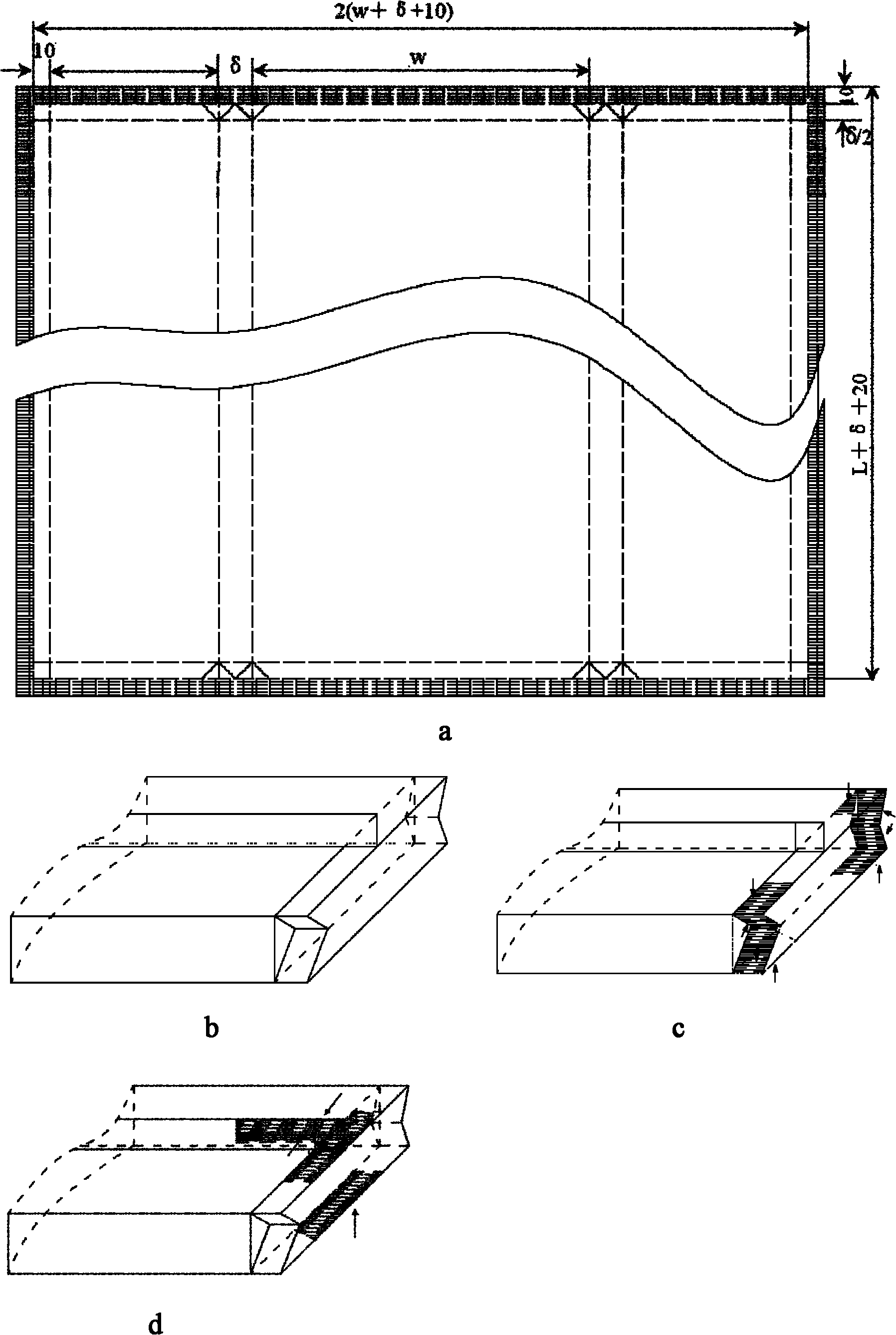

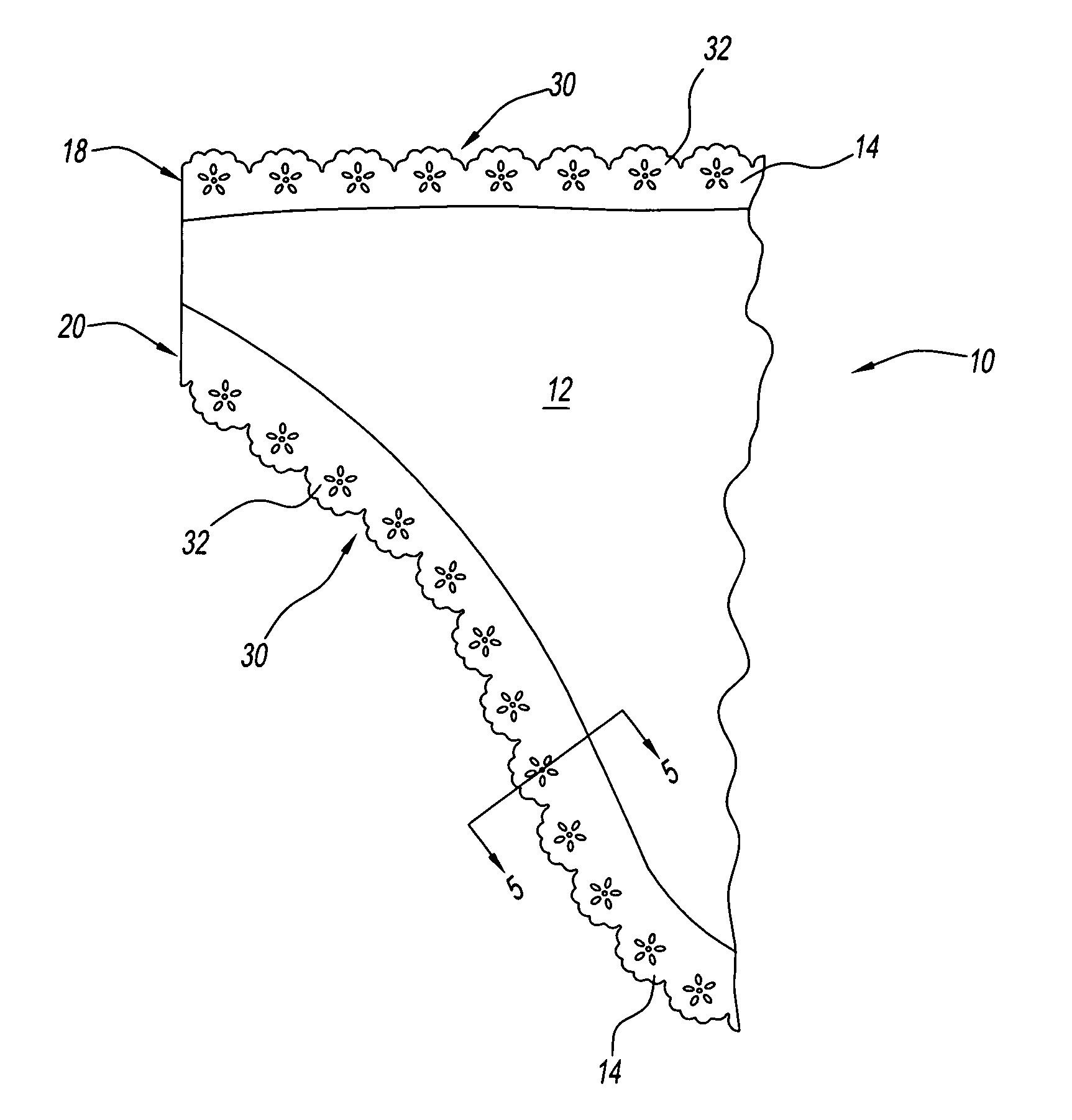

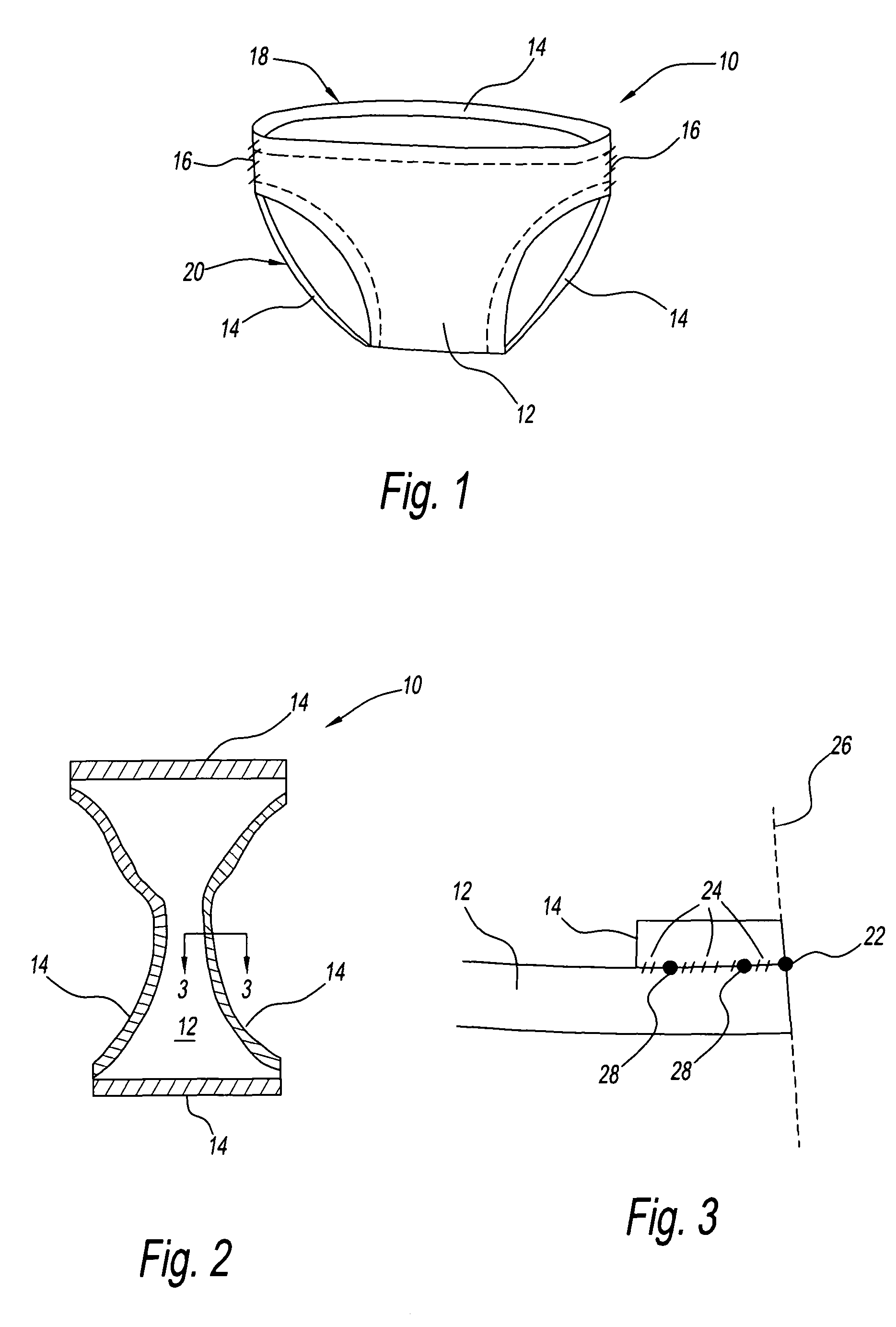

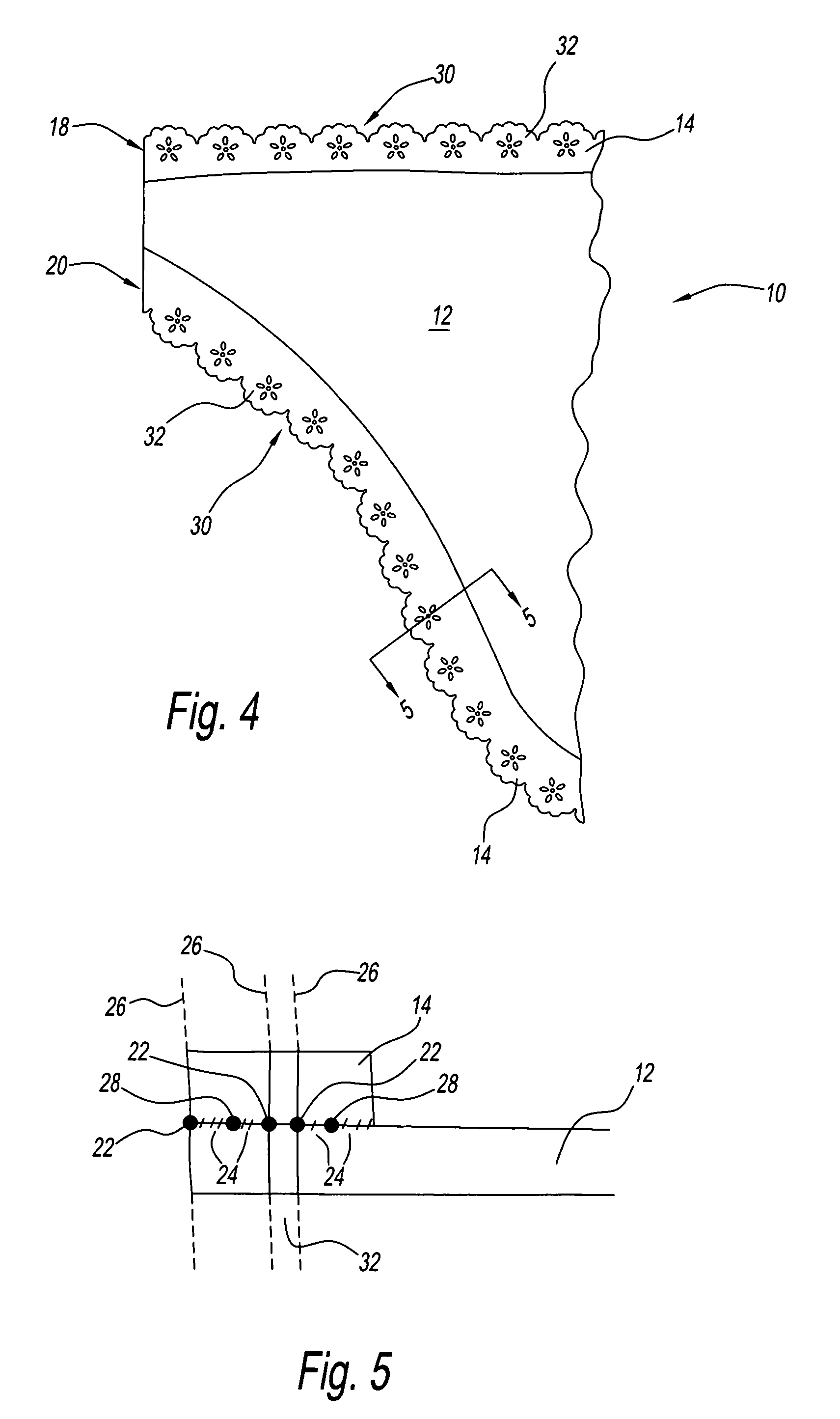

Garments having seamless edge bands and processes for making same

A garment having a fabric layer and an edge band is provided. The edge band and the fabric layer each include a sonically weldable material. The garment has a sonic edge weld securing the edge band to the fabric layer along a cut edge of the garment and an adhesive securing the edge band to the fabric layer. During manufacture, the edge band is placed on the fabric layer, sonic energy is applied so that the fabric layer and the edge band are simultaneously trimmed along a cut edge and welded to one another along the cut edge, and an adhesive between the fabric layer and the edge band is activated to adhere the edge band to the fabric layer.

Owner:HBI BRANDED APPAREL ENTERPRISES

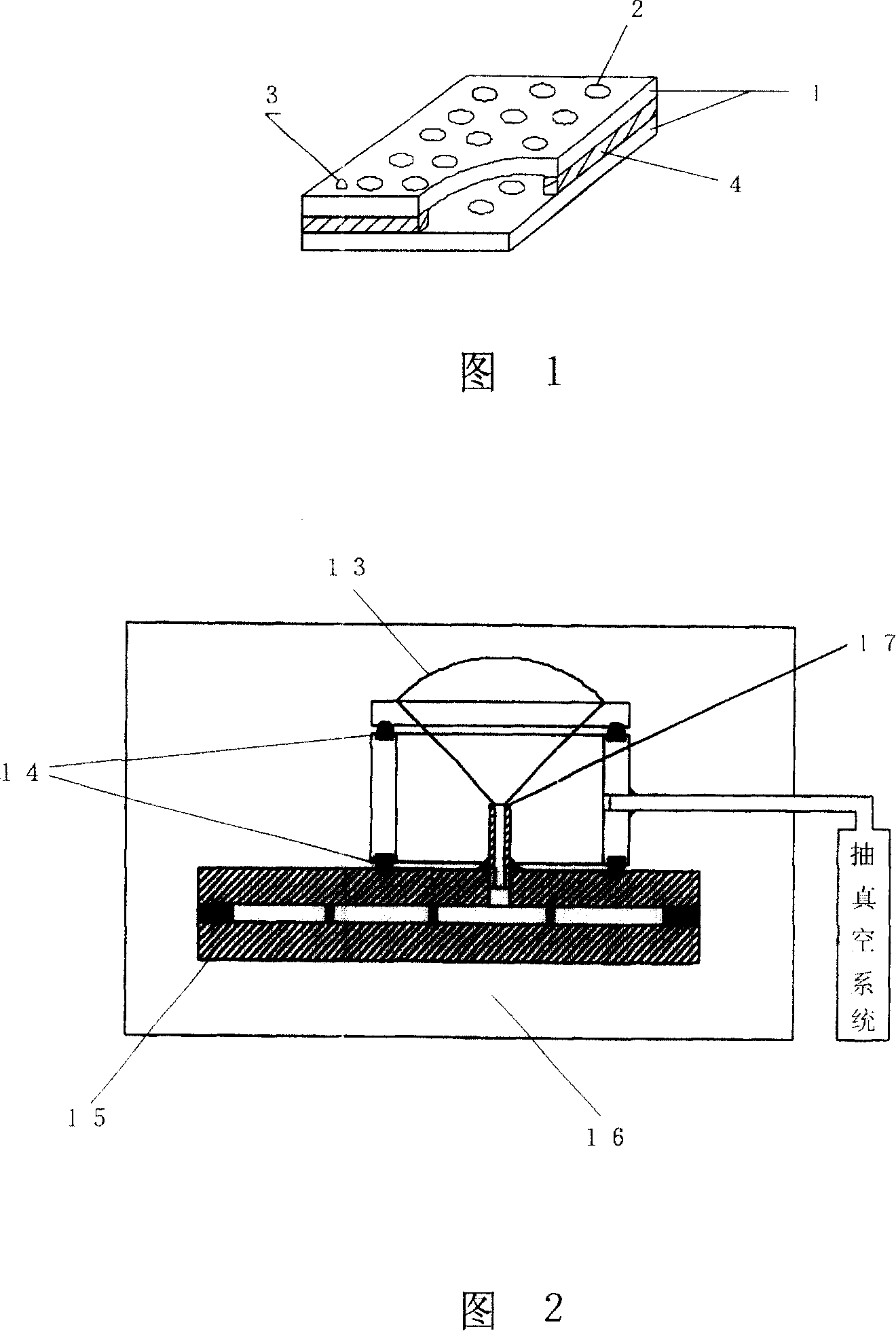

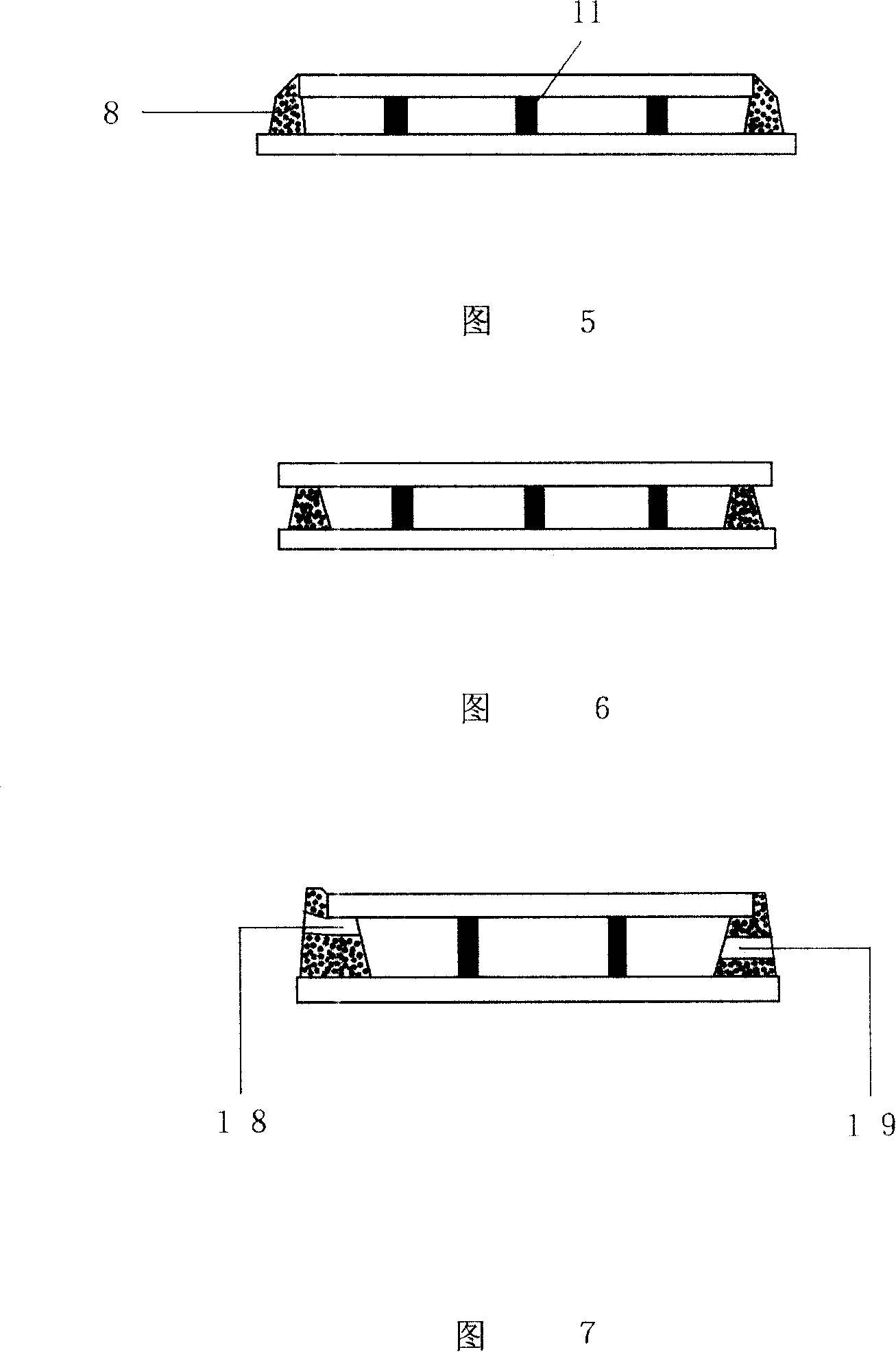

One-step forming vacuum glass and its manufacturing method and device

InactiveCN101148313ASmall apertureReduce resistanceGlass reforming apparatusGlass productionEngineeringGlass sheet

The vacuum glass formed through a one-step process consists of two glass plates, supporting pieces between two glass plates and sealing bodies around two glass plates, and features no air pumping holes. Its making process includes the following steps: setting glass plates and other parts, heating and vacuumizing, sealing, and cooling. The making process features that the vacummizing is completed through the gaps in welding glass powder and the gaps are sealed automatically after the glass powder is molten.

Owner:黄家军

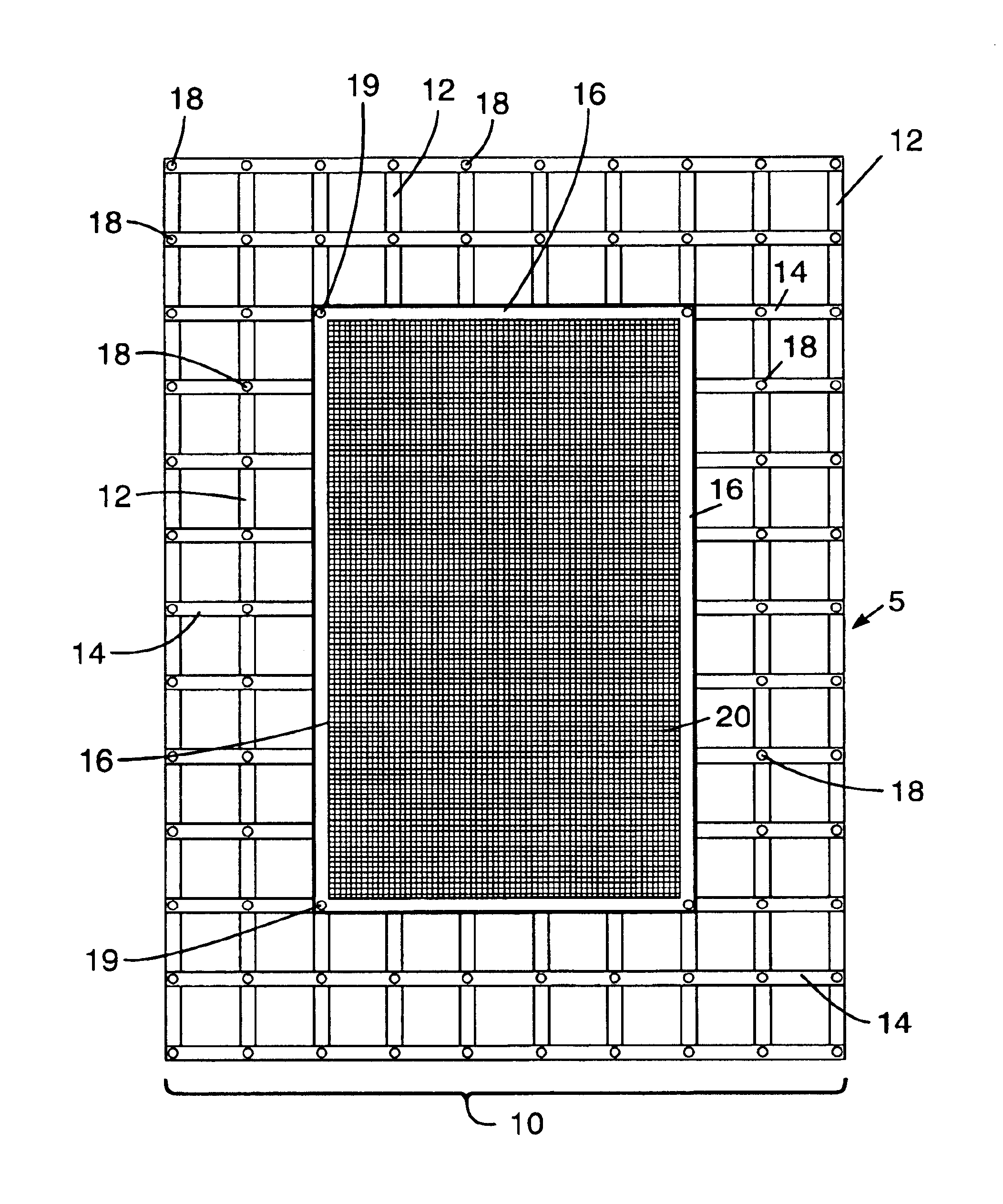

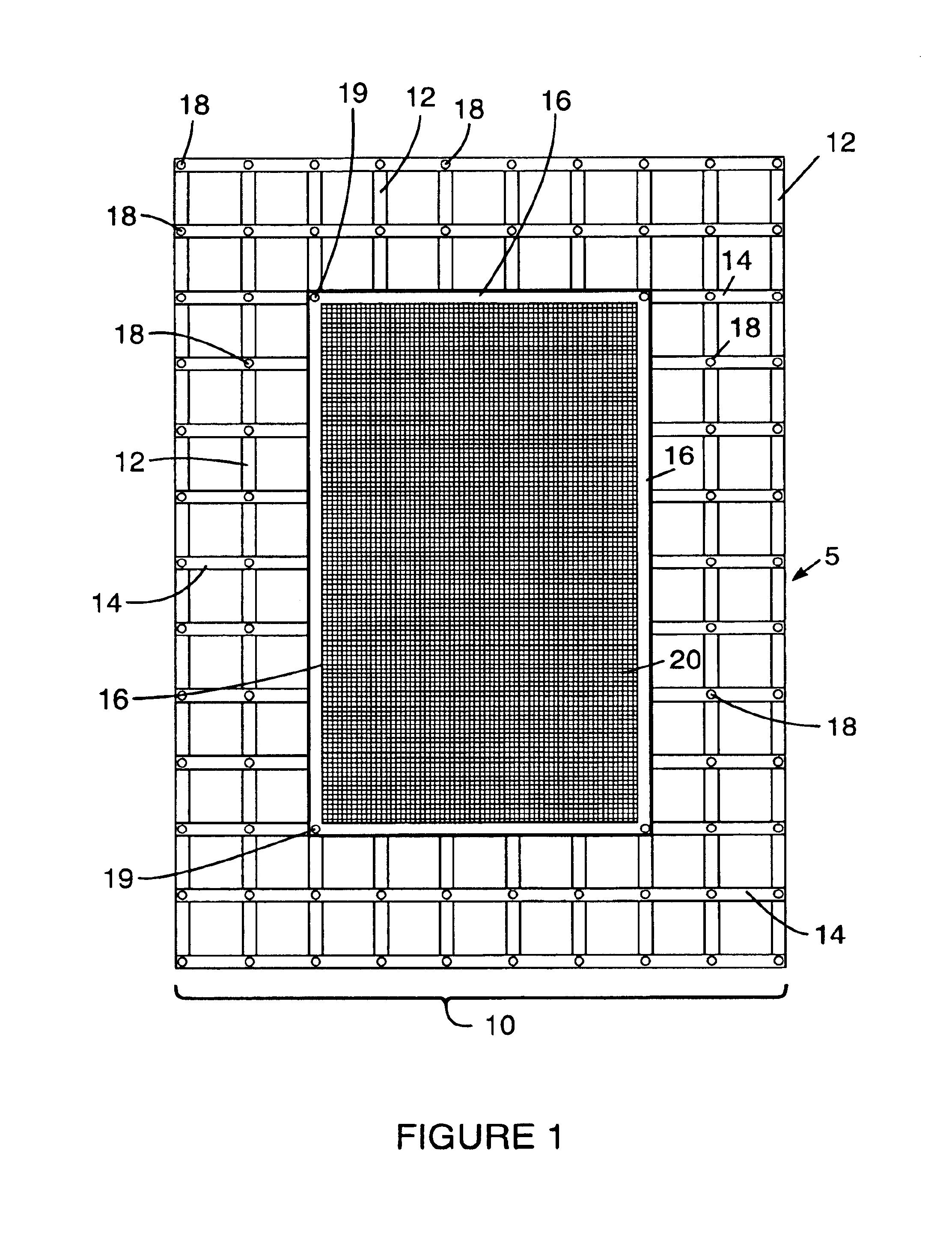

Cargo net/mesh tarp securing and sling device

Disclosed is a non-elastic cargo-securing and sling device having a central tarp with a perimeter edge band, a first set of grommets secured in the perimeter edge band, and an outer webbing net that surrounds the central tarp that is permanently secured to the perimeter edge band by stitching and the first set of grommets. The outer webbing net is fabricated from a set of longitudinal straps, a set of latitudinal straps, and a second set of grommets, with each of the second set of grommets permanently securing one longitudinal strap to one latitudinal strap, thereby producing the outer webbing net.

Owner:FOGGY BRUCE EDWARD

Convex low-altitude glass welded by metal solders and subjected to edge sealing by strip frame and groove, and manufacturing method of glass

InactiveCN102951814AReduce tensile stressHigh transparencyGlass reforming apparatusGlass productionConvex sideAlloy

The invention discloses low-altitude glass. The low-altitude glass is characterized in that upper glass and lower glass are convex; the welding peripheries of the upper glass and the lower glass are respectively provided with an edge sealing strip frame and an edge sealing groove; and the upper and lower glass are welded together by metal or alloy solders in a high-temperature edge sealing furnace, so that the low-altitude glass is simpler and more convenient to manufacture, and a sealing effect is ensured by the embedding combination of the edge sealing strip frame and the edge sealing groove. A manufacturing method of the low-altitude glass provided by the invention is simple in process, low in cost and high in production efficiency, can ensure reliable sealing connection and the good sealing effect, can be used for manufacturing low-altitude glass in mass by virtue of a one-step method, and not only can be used for manufacturing common low-altitude glass, but also is particularly suitable for manufacturing of tempered low-altitude glass; and the low-altitude glass manufactured by the method is high in wind pressure resistance and good in heat insulation and sound insulation.

Owner:戴长虹

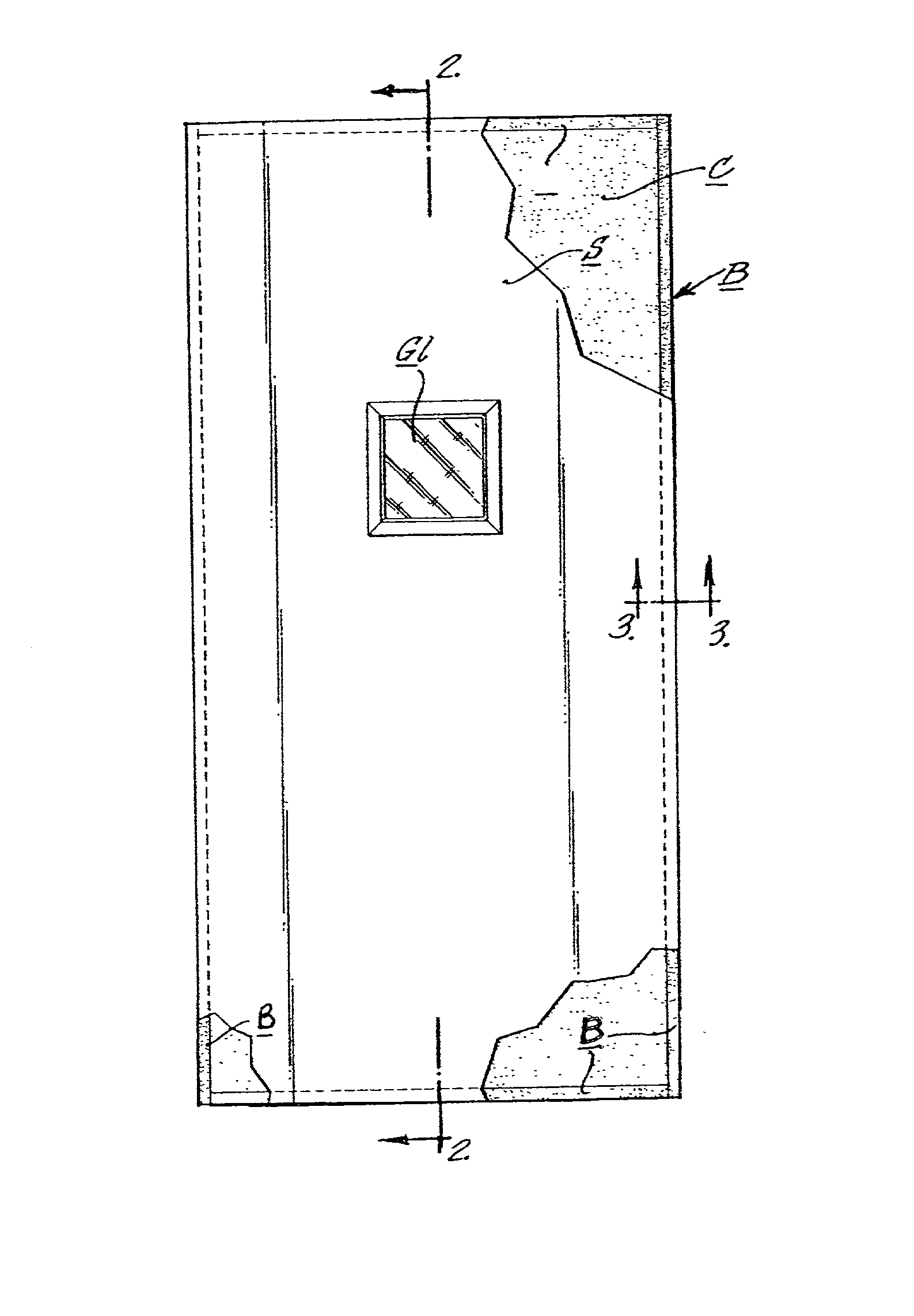

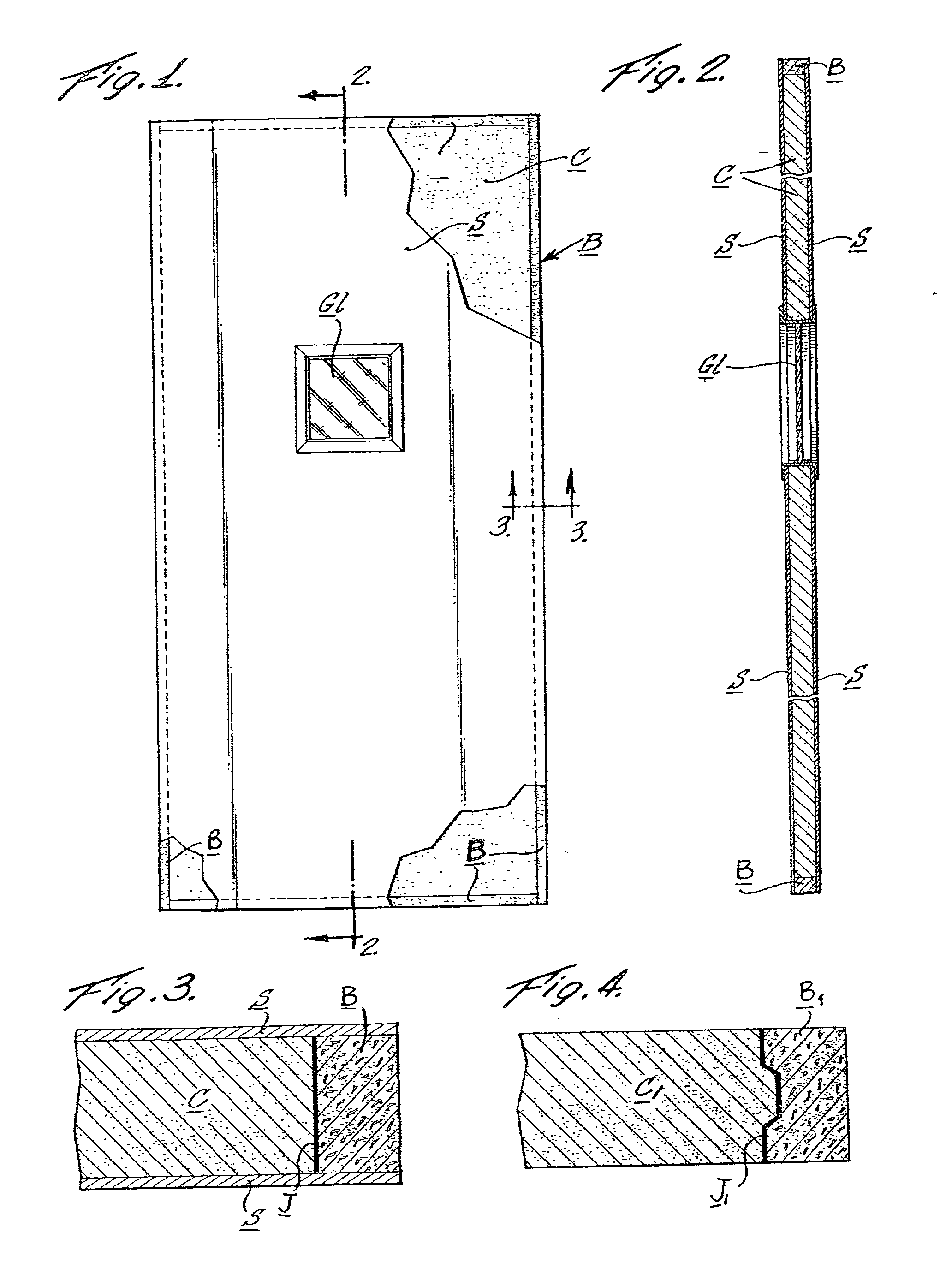

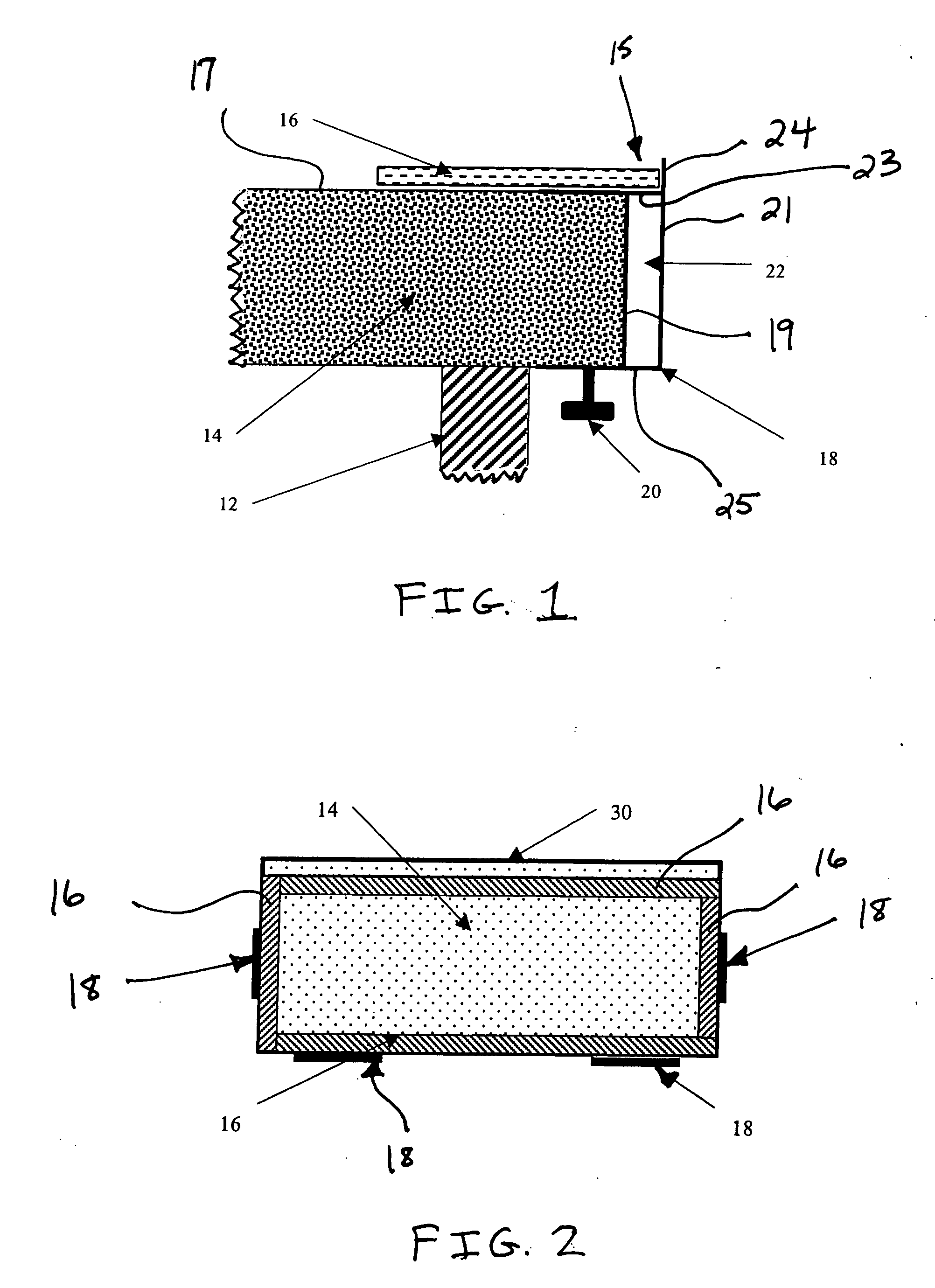

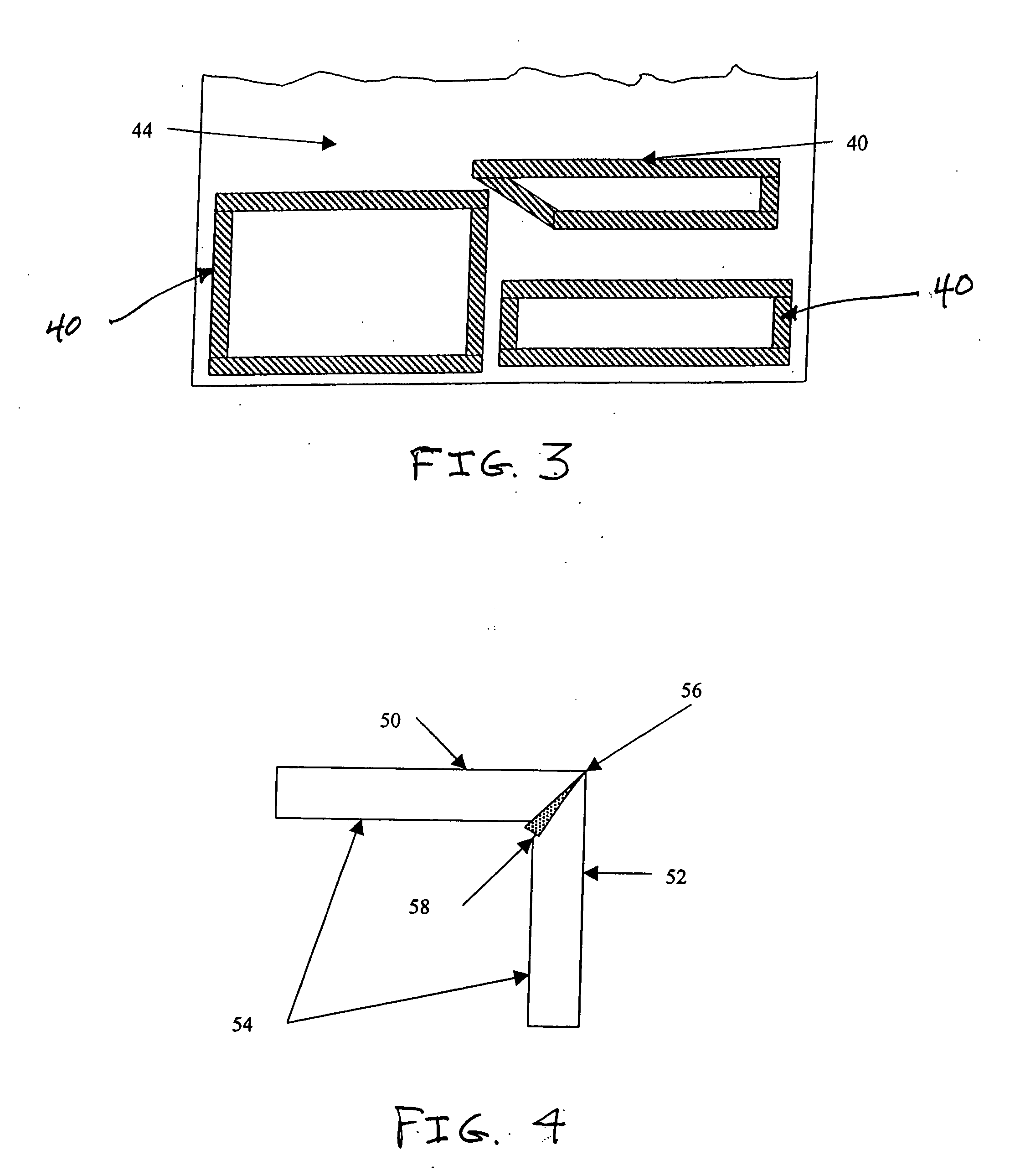

Fire door components and fire doors comprising the components

InactiveUS20030015124A1Simple and effective fitting and mountingConvenient and economical to manufactureSolid waste managementLaminationGypsumFire door

Structural components for a fire door comprising a core and edge banding and other structural components, the components comprising gypsum, expanded perlite, and cement, and having a density between about 60 and 80 lbs. / ft.3. Also, a method by which the structural components are made and a fire door comprising the components.

Owner:GEORGIA PACIFIC GYPSUM LLC

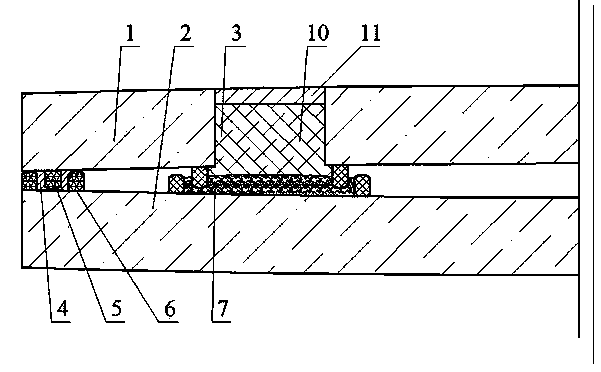

Polymer-Based Face Panel Veneer and Edgeband System for Producing Decorative Panels Having Increased Durability and Decorative Effect and Associated Methods for Producing Such a System

InactiveUS20080118713A1Maintain integrityOther plywood/veneer working apparatusLamination ancillary operationsPolymer resinAdhesive

The present invention discloses a polymeric resin-based veneer laminating system, associated article and method for producing, for maintaining a mating edge profile of top and edge applied laminates secured to a rigid substrate material, and without compromise to fit and finish in response to temperature and humidity variations existing between the materials. A first (typically PVA) adhesive is applied between the top laminate and associated top surface of the substratum according to a first application, a second adhesive (typically EVA) being applied to the adjoining side surface of the substratum and prior to application of the edgeband according to a further expedited heat and / or pressure application.

Owner:BORDENER ROBERT

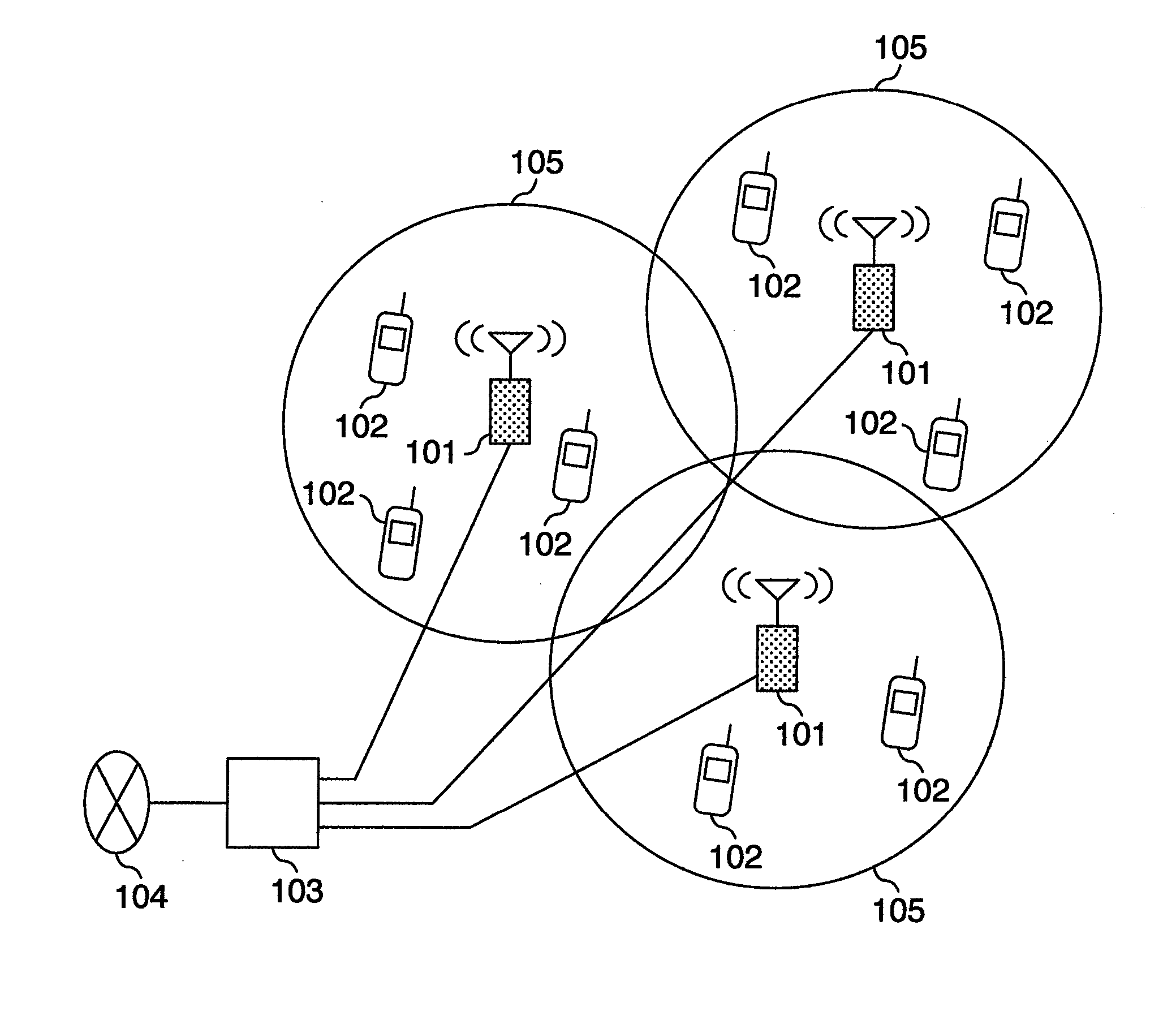

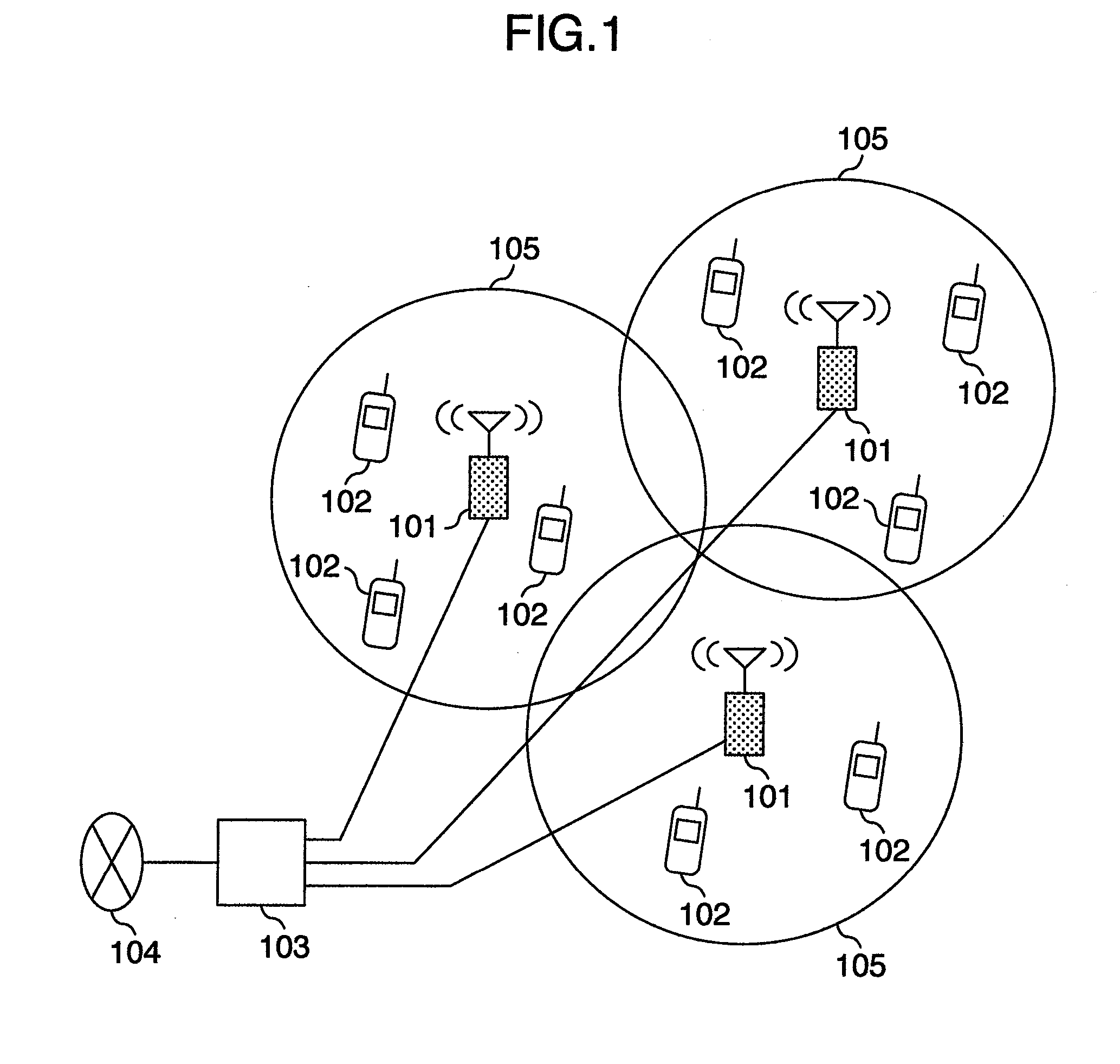

Wireless communication system, base station and mobile station

InactiveUS20100309866A1Prevents increase in interference powerImprove efficiencyWireless commuication servicesTransmission path sub-channels allocationCommunications systemEngineering

In a system of the present invention, the amount of cell-edge band is limited. In addition, the upper limit of the amount of cell-edge band in each cell is set for limiting the amount of cell-edge band based on the upper limit. The number of cell-edge MSs is also limited. In addition, the upper limit of the number of cell-edge MSs in each cell is set for limiting the number of cell-edge MSs based on the upper limit.

Owner:HITACHI LTD

Flat vacuum glass welded by using metal welding material and provided with strip frame edge sealing, and manufacturing method thereof

InactiveCN102976592AExtend your lifeGuaranteed tightnessGlass reforming apparatusGlass productionAlloyGlass manufacturing

The present invention relates to a vacuum glass, which is characterized in that peripheries of an upper glass and a lower glass of the vacuum glass comprise edge sealing strip frames, and a metal welding material or an alloy welding material is adopted to integratedly weld the upper glass and the lower glass in a vacuum edge sealing furnace, such that vacuum glass manufacturing is simple, and a sealing effect is ensured through engagement of the upper edge sealing strip frame and the lower edge sealing strip frame. The manufacturing method has characteristics of simple process, low cost, high production efficiency, reliable sealing and good sealing effect. With the technology, large mass manufacturing of the vacuum glass with no gas exhaust port through the one-step method can be achieved. In addition, with the method, the universal vacuum glass can be manufactured, and the tempered vacuum glass can be manufactured.

Owner:戴长虹

Environment-friendly PVC (polyvinyl chloride) household edge banding and preparation method thereof

The invention relates to an environment-friendly PVC (polyvinyl chloride) household edge banding and a preparation method thereof. The environment-friendly PVC household edge banding comprises the following components in parts by weight: 60-150 parts of PVC powder, 5-30 parts of nano calcium carbonate, 4-35 parts of plasticizer, 2-15 parts of PVC processing aid, 1.5-10 parts of stabilizer, 0.3-1.5 parts of internal lubricant, 0.3-2 parts of external lubricant, 0.05-0.1 part of ultraviolet light absorber and 0.1-1.5 parts of antioxygen agent. The safe and environment-friendly PVC household edge banding with excellent comprehensive property is prepared by a meticulous design of the material formula and simple and easy-to-control operation method; and the environment-friendly PVC household edge banding especially has excellent anti-scratch and wear-resisting properties.

Owner:SINOWOLF PLASTIC DEKOR

Odorless environmentally-friendly type PVC (polyvinyl chloride) edge-banding strip and preparation method thereof

The invention relates to the technical field of edge banding, in particular to an odorless environmentally-friendly type PVC (polyvinyl chloride) edge-banding strip and a preparation method thereof. The odorless environmentally-friendly type PVC edge-banding strip comprises the following raw materials in parts by weight: 75 to 125 parts of PVC resin, 8 to 25 parts of active nano-calcium carbonate, 6 to 32 parts of an odorless environmentally-friendly plasticizer, 3 to 33 parts of a modified aid, 3 to 13 parts of an odor eliminating agent, 2.5 to 6.5 parts of an environmentally-friendly calcium zinc composite stabilizer, 0.3 to 1.5 parts of an internal lubricating agent, 0.5 to 2.0 parts of an external lubricating agent, 0.1 to 0.8 part of an ultraviolet absorbent, 0.2 to 1.5 parts of an antioxidant and 0.5 to 1.5 parts of toner. The odorless environmentally-friendly type PVC edge-banding strip provided by the invention does not contain phthalate, heavy metals and other harmful substances, is environmentally-friendly and odorless, and has high weather resistance, high impact resistance and excellent comprehensive physical property.

Owner:XIONG YI PLASTIC PROD CO LTD

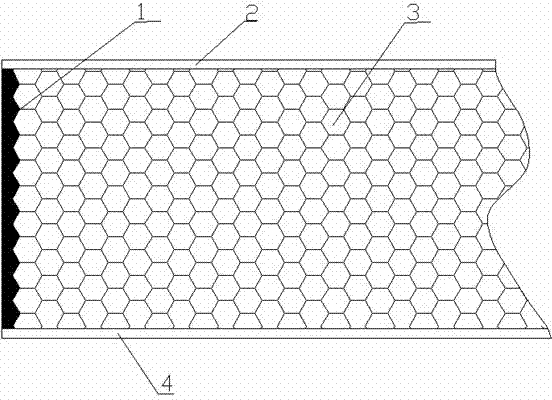

Edge sealing structure of honeycomb sandwich shelter wallboard, and edge sealing method thereof

InactiveCN103590532AImprove lateral pressure resistanceImprove rigiditySynthetic resin layered productsBuilding componentsHoneycombEngineering

The invention relates to an edge sealing structure of a honeycomb sandwich shelter wallboard, and an edge sealing method thereof. The edge sealing structure is low-density epoxy putty composed of an epoxy resin and a lightweight filler. The invention also relates to an edge sealing method of the honeycomb sandwich shelter wallboard by adopting the edge sealing structure. The edge sealing structure has a low cost, can substantially improve the side compression resistance and the whole rigidity of a honeycomb sandwich panel, and has frame reinforcing and waterproof sealing effects. The method is simple to operate, and is especially suitable for the rapid edge sealing treatment of a part with any shape in any positionof a honeycomb sandwich shelter wallboard after random perforation.

Owner:衡阳泰豪通信车辆有限公司

Method of surfacing a substrate

InactiveUS20050167027A1Increase productionImprove efficiencyCovering/liningsLamination ancillary operationsGlass fiberEngineering

A method is provided of resurfacing a substrate with a natural stone the substrate having a top surface and an edge, the method including placing a plurality of templating strips on the top surface to form a template defining an outside dimension, cutting out a top piece for resurfacing the top surface based on the outside dimension of the template, cutting out an edge band for resurfacing the edge of the substrate, bonding the edge band and the top piece together to form a replacement top and adhesively joining the replacement top to the substrate. A plurality of templating jigs may be used for forming a template. Pieces of natural stone may have respective bevel cuts made in their respective edges for adjoining with other pieces to form a replacement top of natural stone. Inside edges may be reinforced with a fiberglass cloth coated with a polyester resin. A plurality of natural stone pieces may be adjoined to form a segmented radius of curvature for covering a corresponding radius of curvature of an edge of the existing substrate.

Owner:LANE PAUL

Vacuum glass with edges and extraction opening both sealed with sealing strips as well as preparation method of vacuum glass

InactiveCN103420578AExtend your lifeImprove productivityGlass reforming apparatusGlass productionThermal insulationEngineering

The invention discloses vacuum glass with edges and extraction opening both sealed with sealing strips. The vacuum glass comprises upper glass and lower glass which are convex glass or plain glass, wherein an extraction opening is formed in the upper glass; at least one sealing strip I is arranged at the periphery of the upper glass as well as that of the extraction opening; at least two sealing strips II are arranged at the periphery of the lower glass; at least one sealing strip is arranged in a position, corresponding to the extraction opening, of the upper glass; the sealing strip I of the upper glass is inserted into one sealing strip II or between the sealing strips II; the peripheries of the upper glass and the lower glass are welded together through low-temperature glass solder in an edge sealing furnace under the normal pressure; the extraction opening is sealed automatically in a vacuum furnace through metal solder. According to the invention, the process of the preparation method of the vacuum glass is simple; vacuum glass and tempered glass prepared through the preparation method can overcome the defects in the prior art; the airtightness of the vacuum glass is guaranteed; the strength, the thermal insulation performance and sound insulation performance of the vacuum glass are improved.

Owner:戴长虹

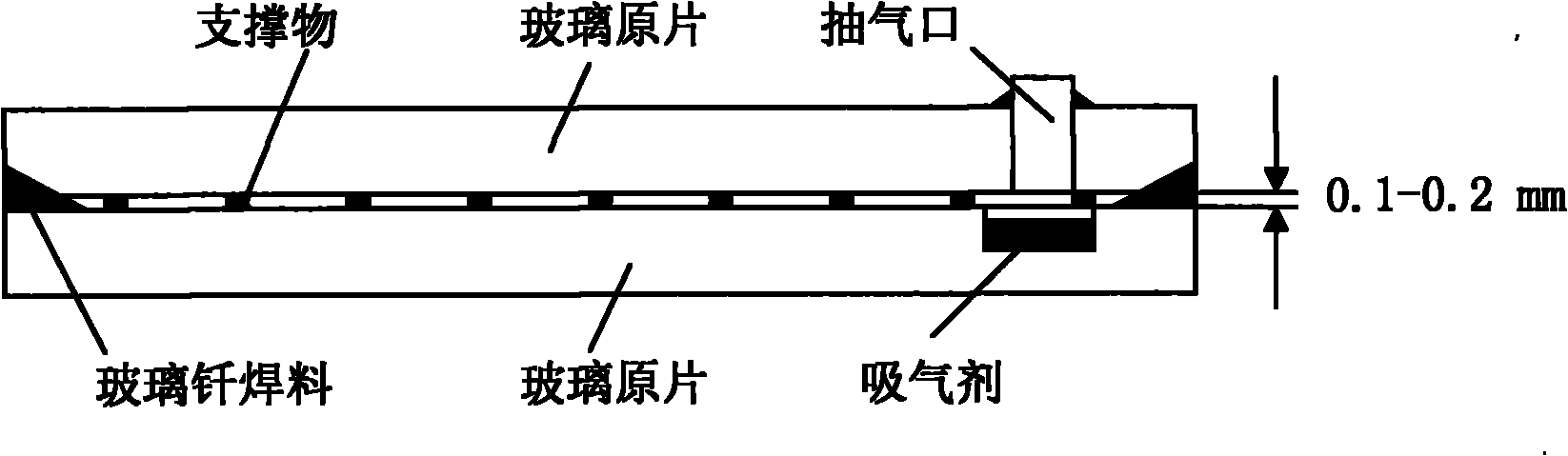

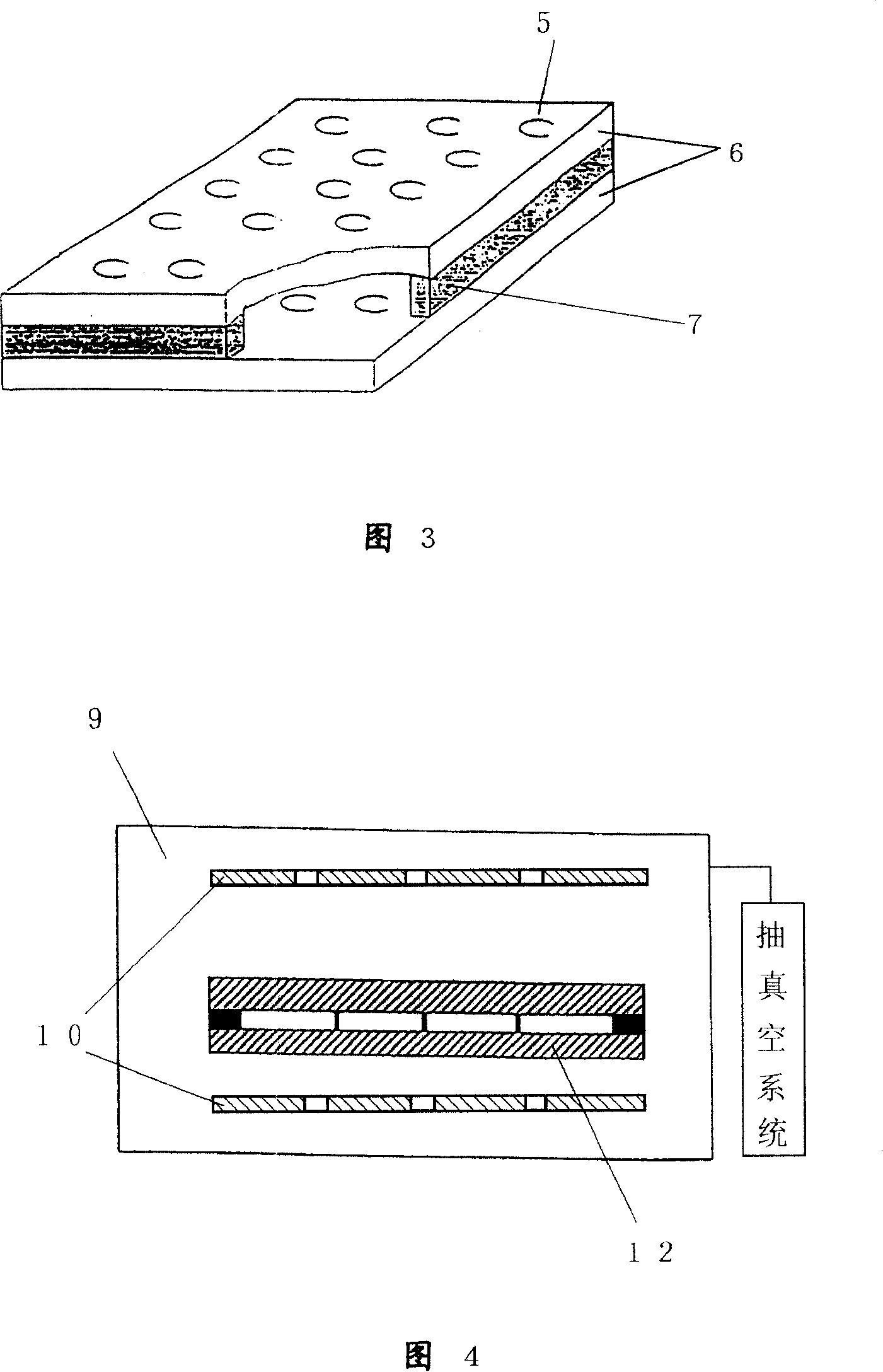

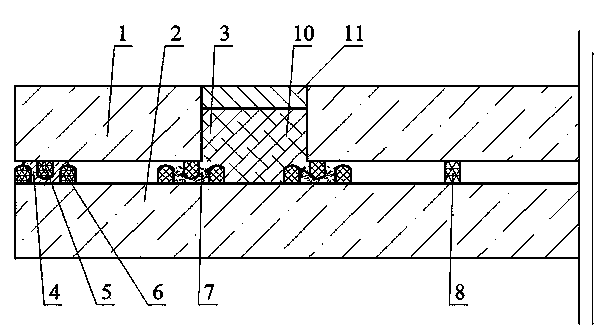

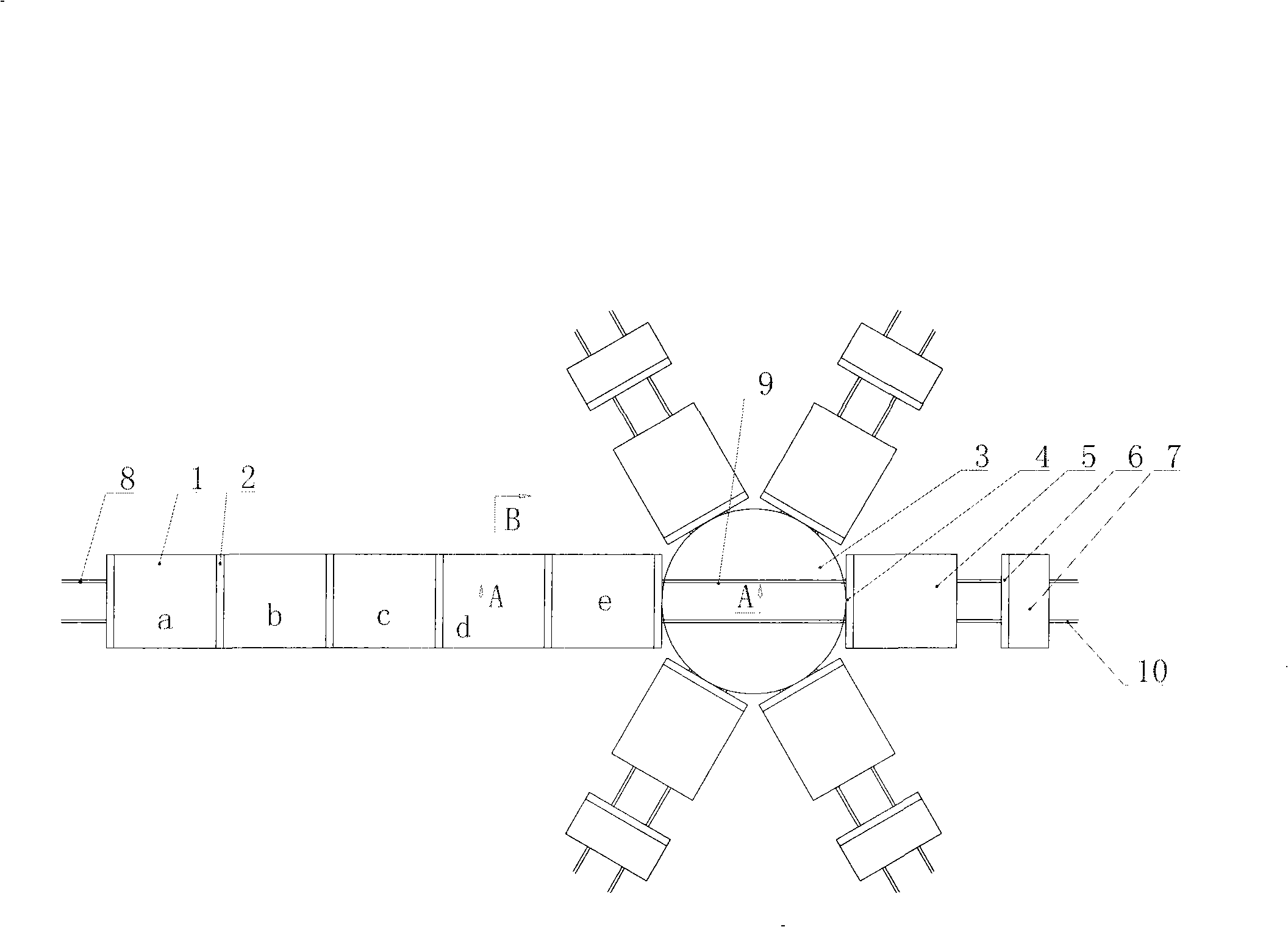

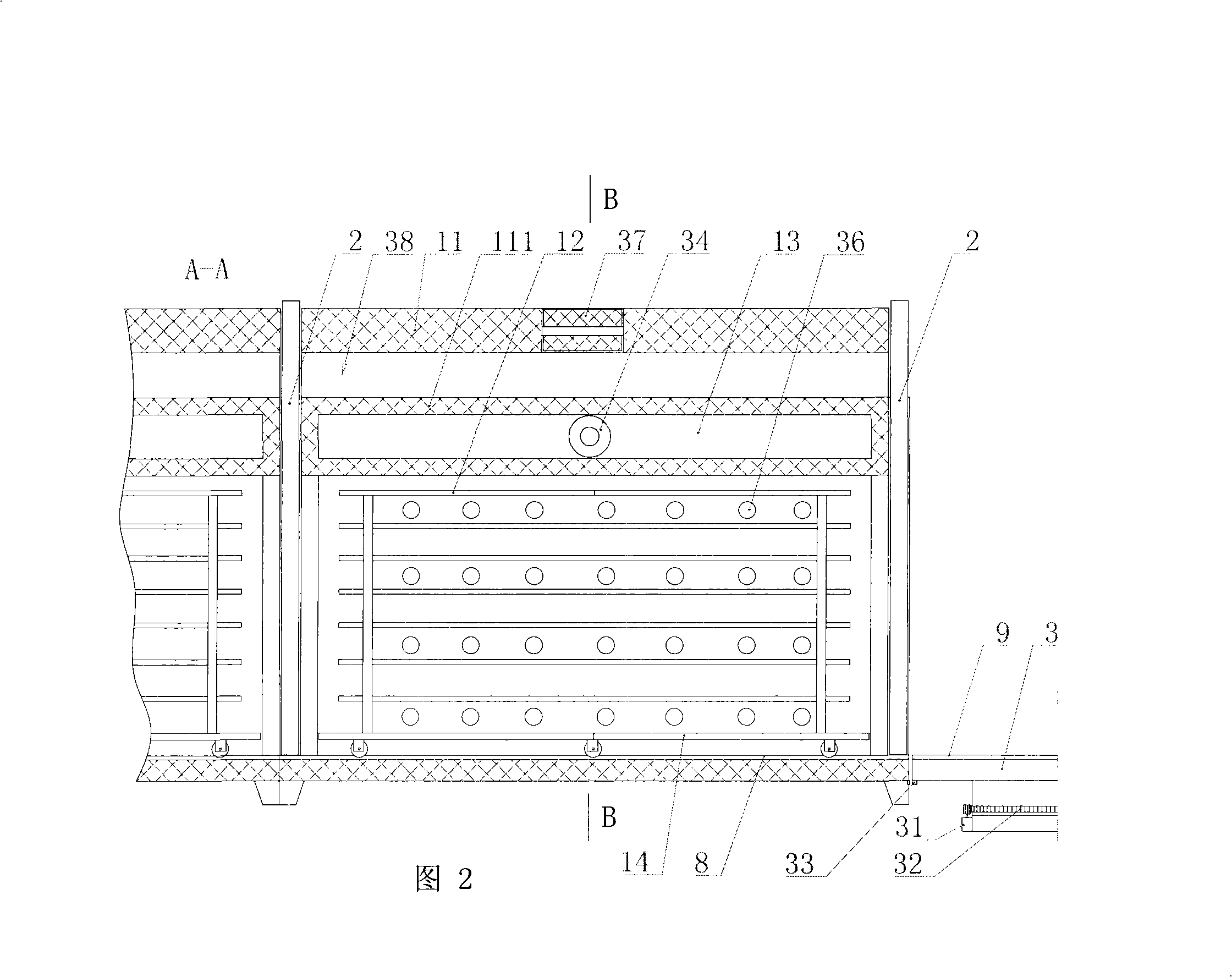

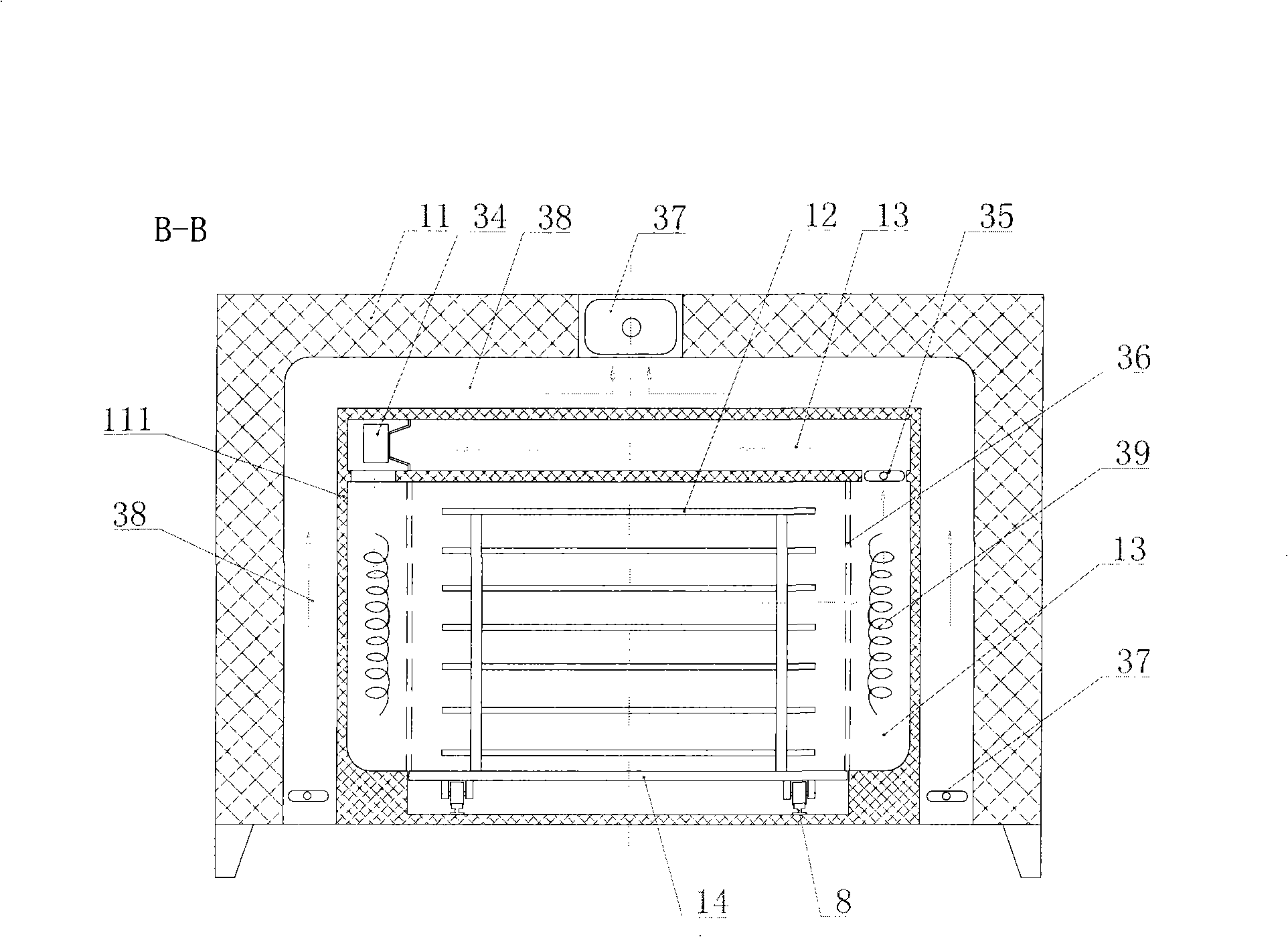

Continuous production method and apparatus for vacuum glass

ActiveCN101348326AUniform temperatureEasy to controlGlass reforming apparatusGlass productionFlat glassBogie

The invention relates to a method and equipment for realizing continuous production of vacuum glass. The method comprises the following steps that at least two layers of processed flat glass provided with an edge sealing material and a support material are placed on a feeding bogie, and are conveyed to edge sealing furnace bodies from a to e in turn so as to carry out preheating, heating, temperature maintaining, edge sealing (during which, edges of glass are sintered together by the inorganic edge sealing material) and cooling down; then, the feeding bogie carrying the edge sealed glass is conveyed to a sealing furnace body by a turntable so as to undergo roasting and gas exhaust; and finally, an exhaust port is sealed. The equipment is characterized in that a plurality of cavities at different temperatures are connected to form continuous production equipment, thereby realizing the function of integrated port sealing and edge sealing and increasing production efficiency; meanwhile, the equipment can also be divided into single furnace bodies for production.

Owner:青岛新亨达真空玻璃技术有限公司

Encapsulation method for vacuum glass getter

InactiveCN101792253AAvoid ability to declineIncrease vacuumGlass reforming apparatusFlat glassVacuum pumping

The invention relates to an encapsulation method for vacuum glass getter. The method comprises cutting flat-panel glass into pieces, manufacturing a groove, washing, laying supports, laminating the flat-panel glass pieces, putting a suction pipe, sealing edges, welding the suction pipe, putting the obtained glass product into a stove and heating the glass product to above 420 DEG C for fusing the edges and the suction pipe and vacuumizing outside the stove. After the edges of the two glass pieces are sealed and the two glass pieces are taken out from the stove and before the vacuum pumping is conducted, the getter is put in the suction pipe or is put into a suction groove pre-manufactured on the internal surface of the glass from the suction pipe, a vacuum pump is connected, the suction pipe is sealed after vacuum pumping and the getter is activated to finish the manufacturing of the flat-panel vacuum glass. The invention has the advantages that the design is scientific, the innovation is high, the defects caused when the conventional getter is directly heated and the vacuum glass is directly manufactured are changed, the manufacturing level of the vacuum glass is improved, the novel technology for the vacuum glass is exploited and the foundation is laid for the improvement of the cost and the technological level of the vacuum glass.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

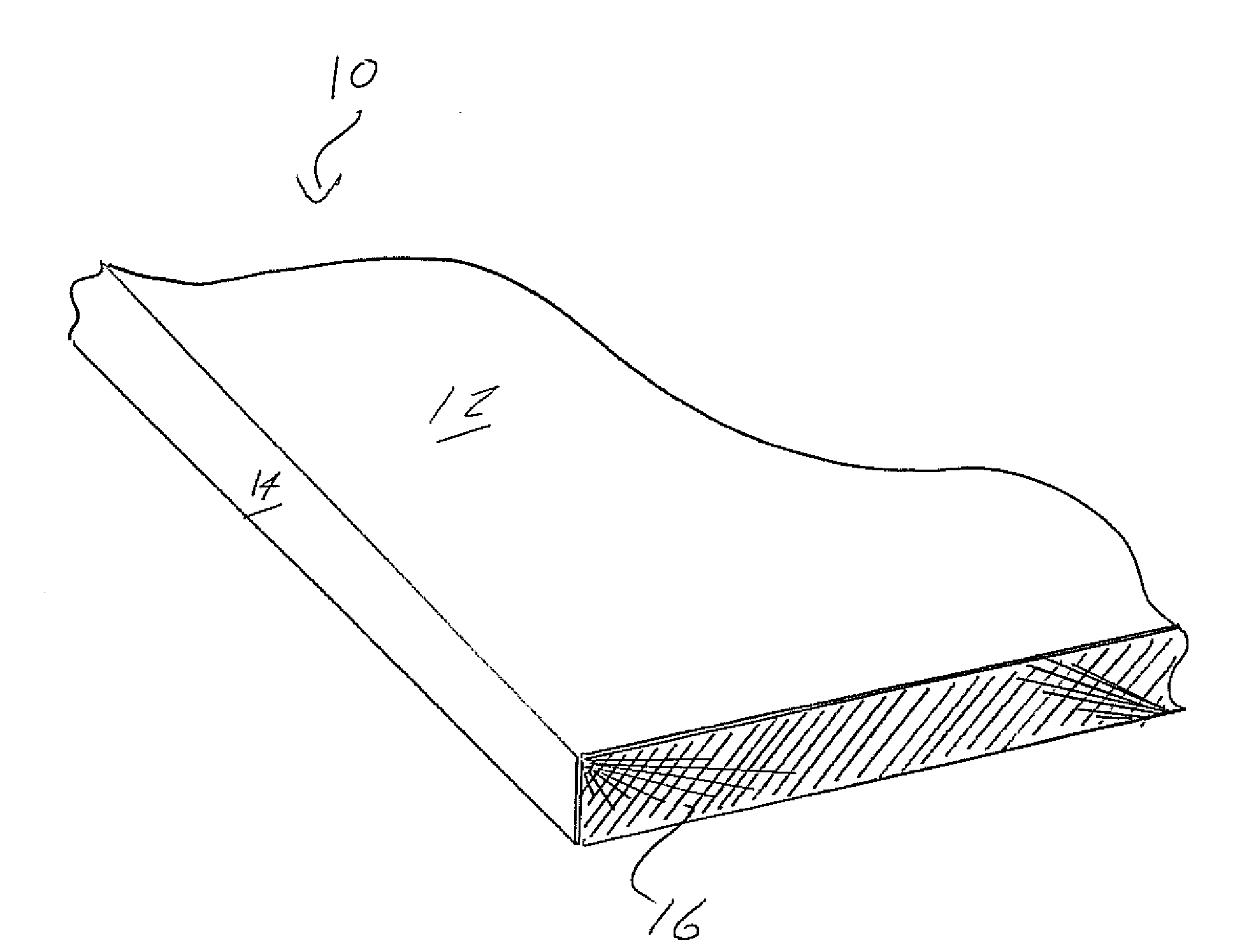

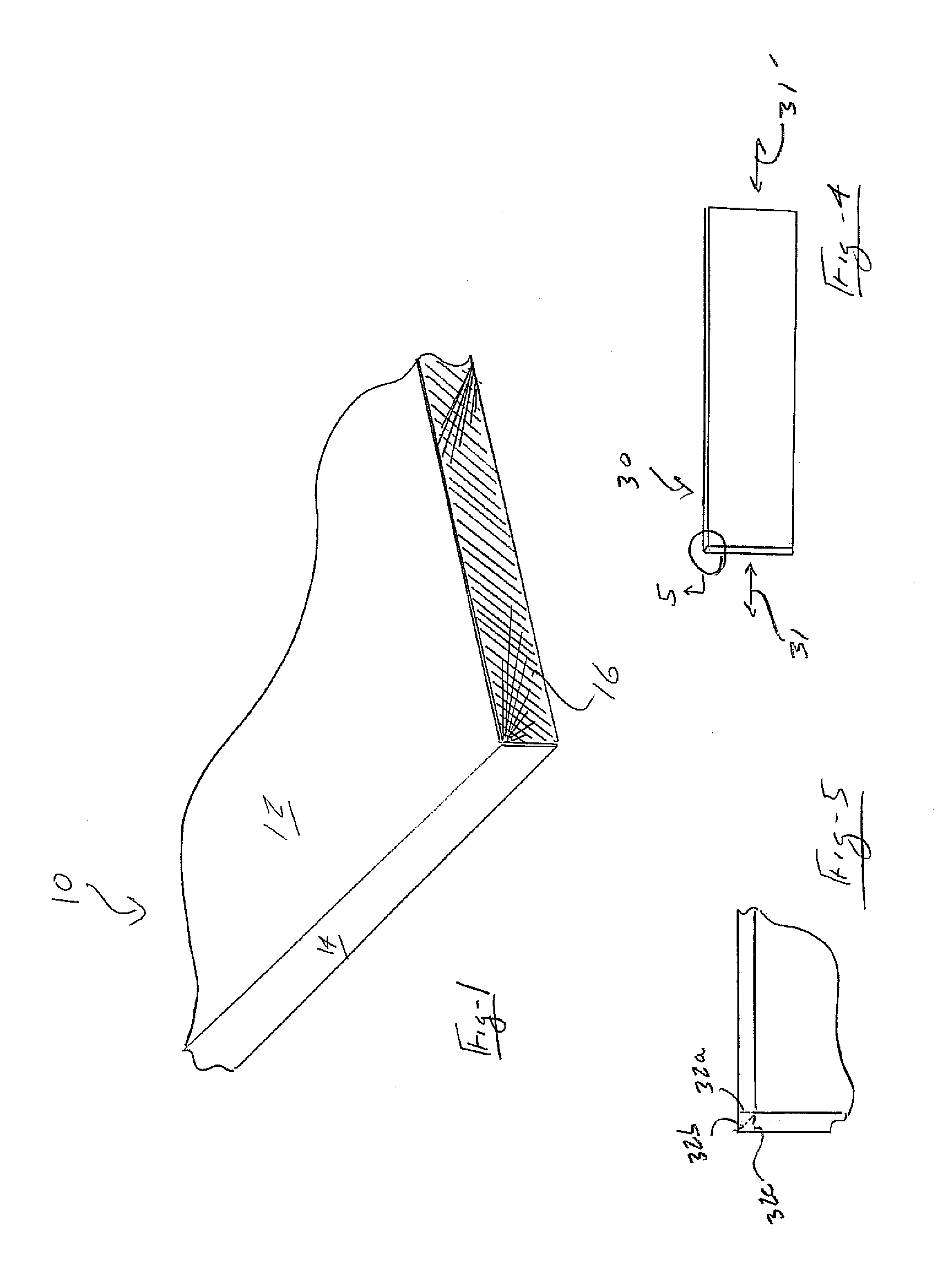

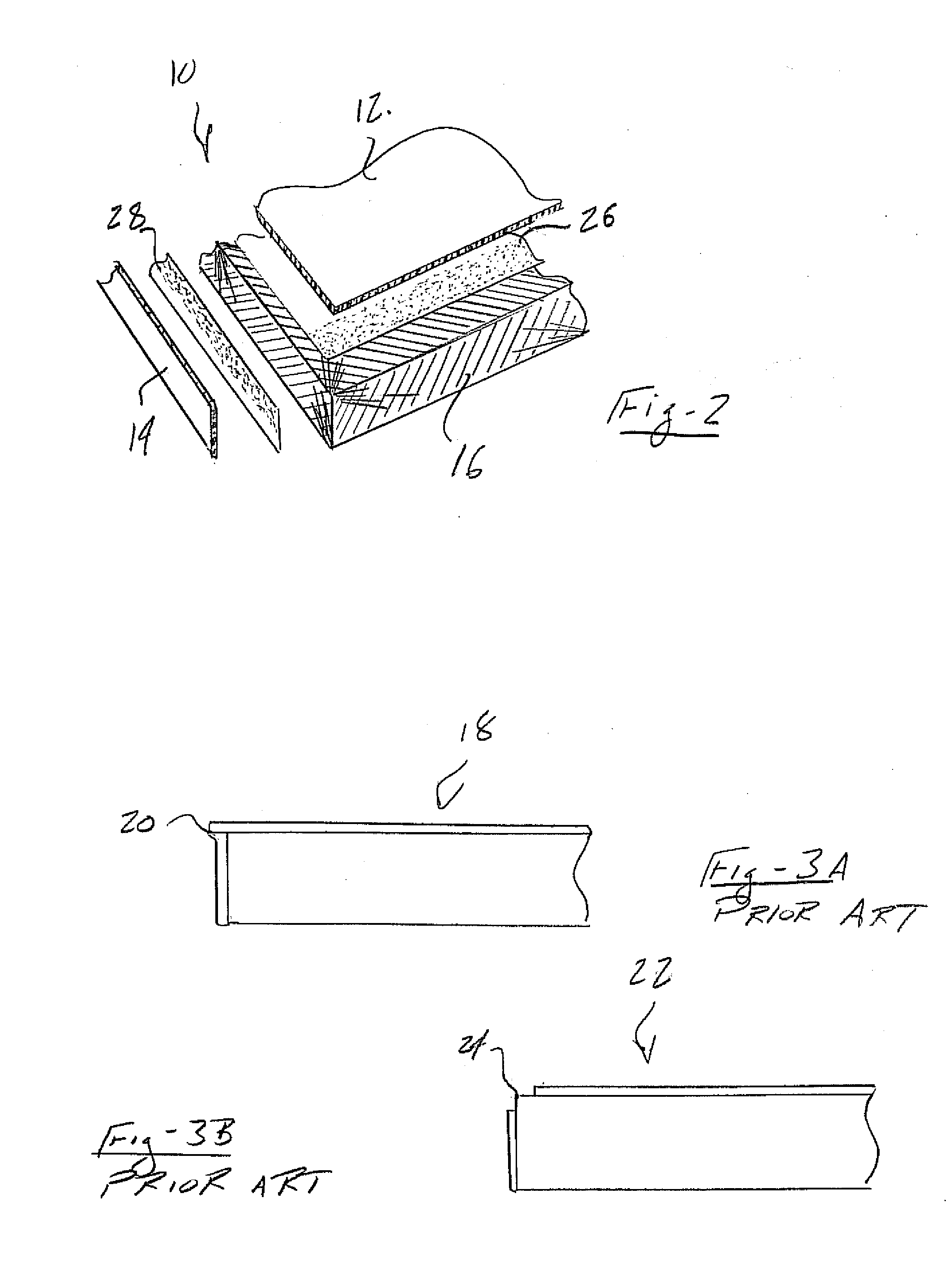

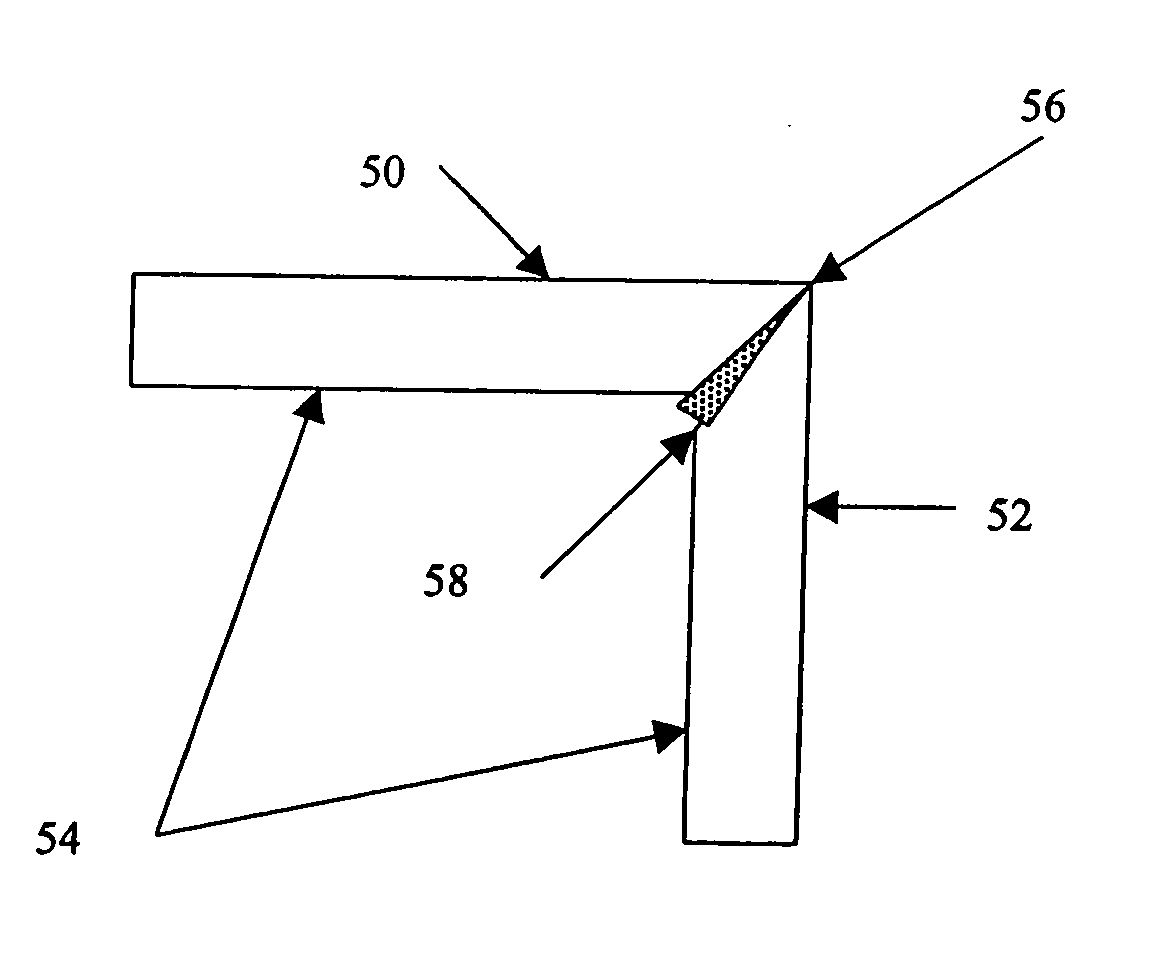

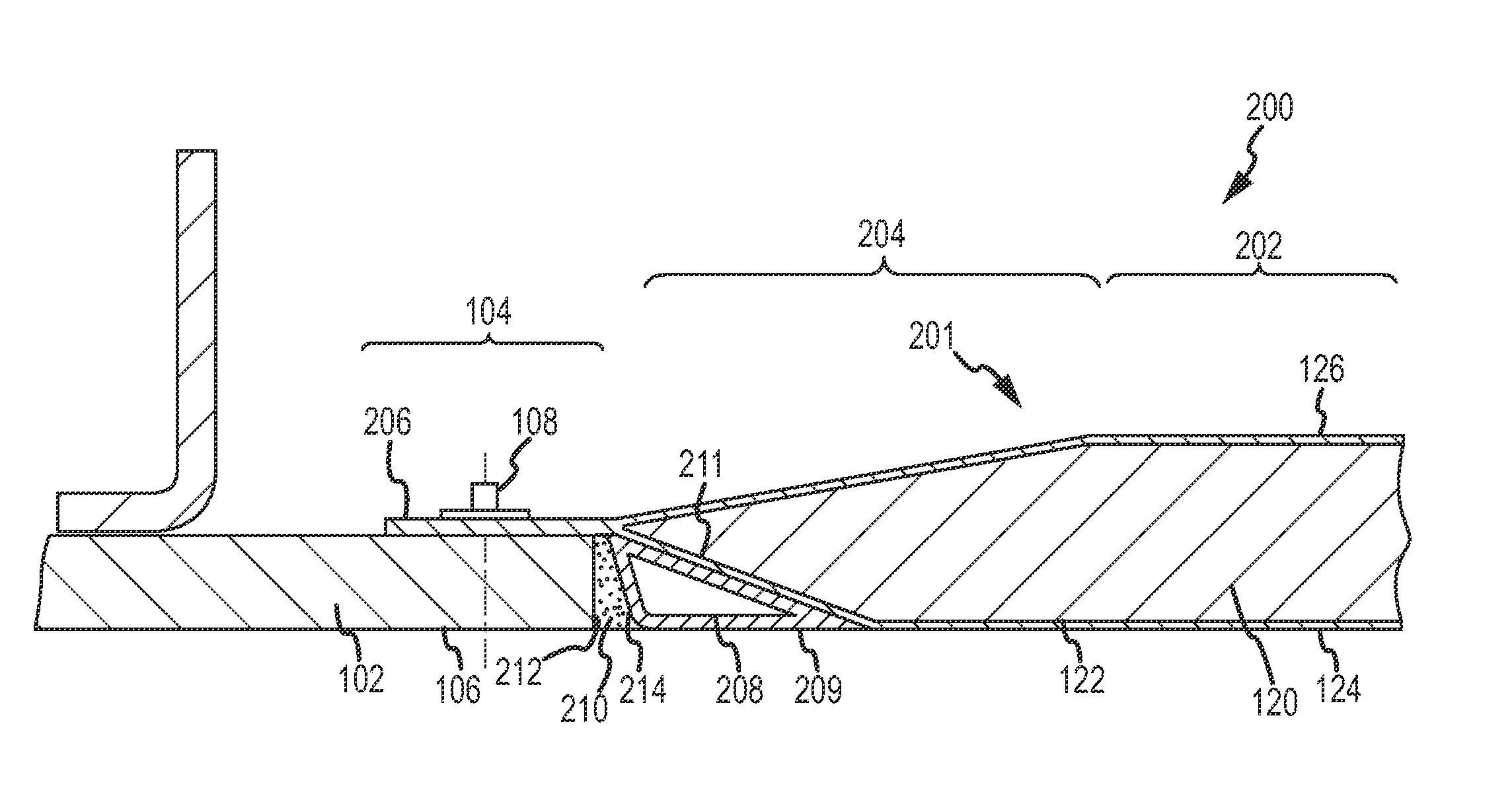

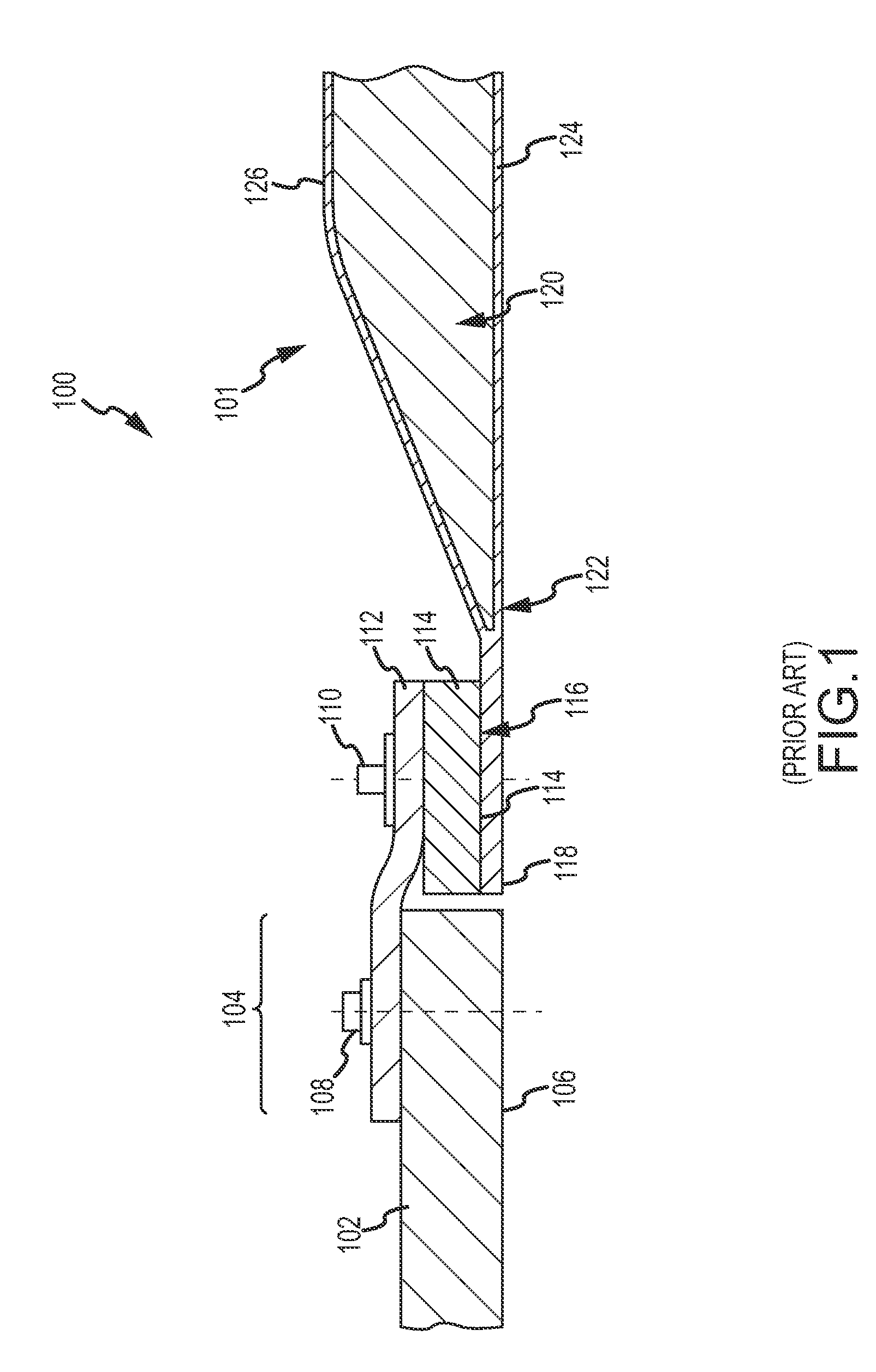

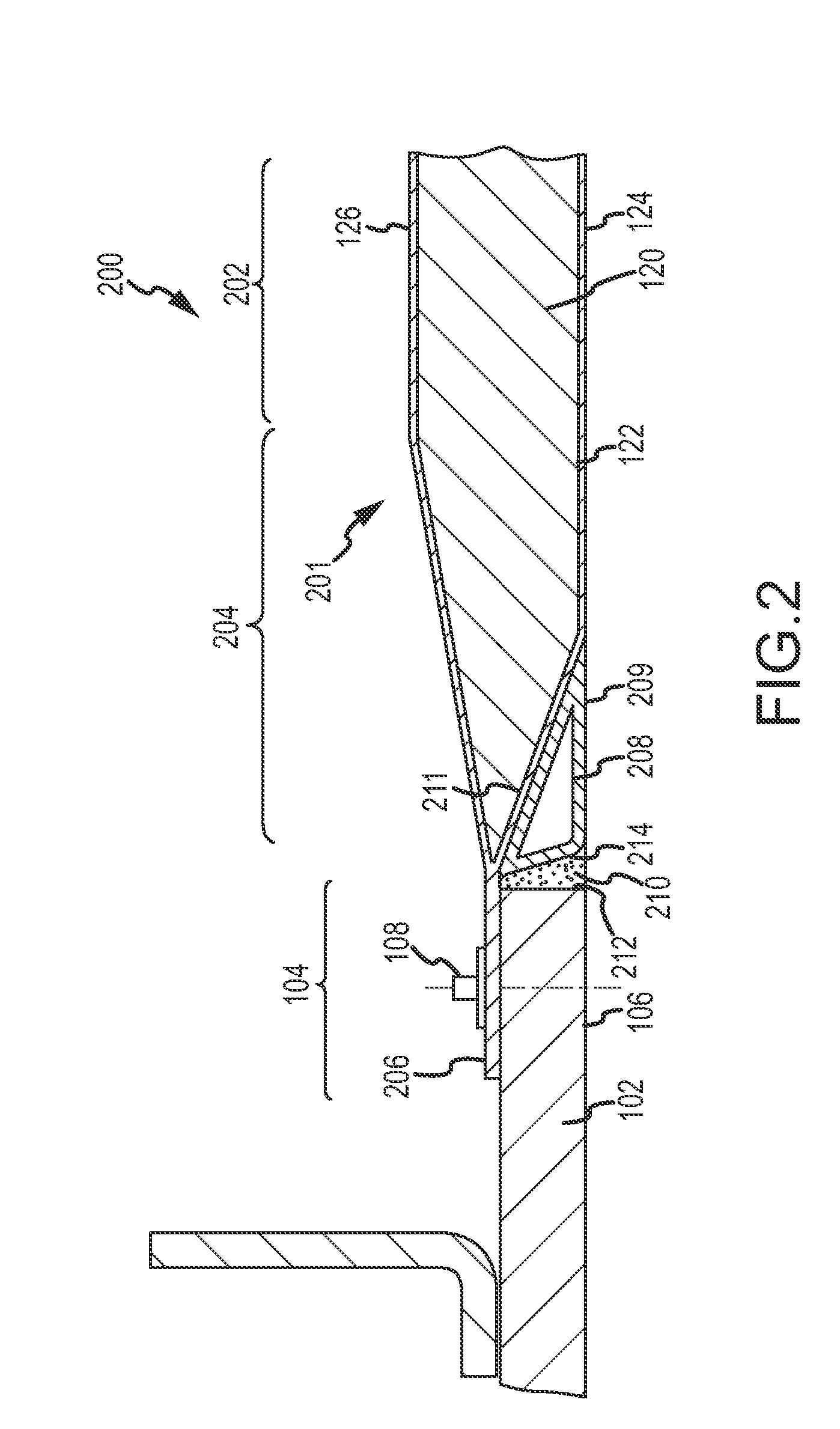

Methods and apparatus for an integrated aerodynamic panel

ActiveUS20090294589A1Reduce settingsSimple attachmentFuselage framesAircraft stabilisationLeading edgeGlass fiber

An integrated aerodynamic panel—e.g., for a trailing edge or leading edge of an aircraft aerodynamic surface—includes a first panel region defining inner and outer mold lines, and a second panel region contiguous with and extending from the first panel region in a tapering fashion. A splice plate region extends from the second panel region and includes an edge band region configured to accept a fastener. A filler region (e.g., a SYNCORE or fiberglass structure) adjacent the second panel region has an exposed surface substantially flush with the outer mold line.

Owner:THE BOEING CO

Method of quickly manufacturing vacuum glass

InactiveCN101492255AImprove ergonomicsConsistent external stressGlass reforming apparatusBreakage rateHot melt

The invention relates to a method for quickly preparing vacuum glass, which comprises the following steps: (1) machining a semicircular groove on substrate glass or drilling a through hole on an upper slice of glass; (2) leaking and brushing adhesive onto the substrate glass through a silk screen or a leaking plate to form point-shaped adhesives evenly distributed in interval with consistent size on the substrate glass; (3) scattering solid supports on the substrate glass so that part of the solid supports is adhered to the point-shaped adhesive; (4) stacking glass powder paste with low melting point on a position with side difference H which is formed by the upper slice of the glass and the substrate glass and is between 2 and 8 millimeters; (5) putting the glass into a heating furnace and heating the glass; and (6) sealing the glass by a hot-melting air suction glass tube, slowly reducing the temperature of the glass to below 60 DEG C, and then discharging the glass to obtain the vacuum glass. The method adopts the side difference sealing and is characterized in that the heated low glass powder paste fills in a gap of two pieces of glass and naturally levels under the siphon action of the glass gap formed the solid supports, the formed vacuum glass has the advantages of consistent internal stress and external stress, good transparency and consistent intensity, and reduces the breakage rate after evacuation; and the preparation method is quick and efficient, and is suitable for mass production.

Owner:左树森

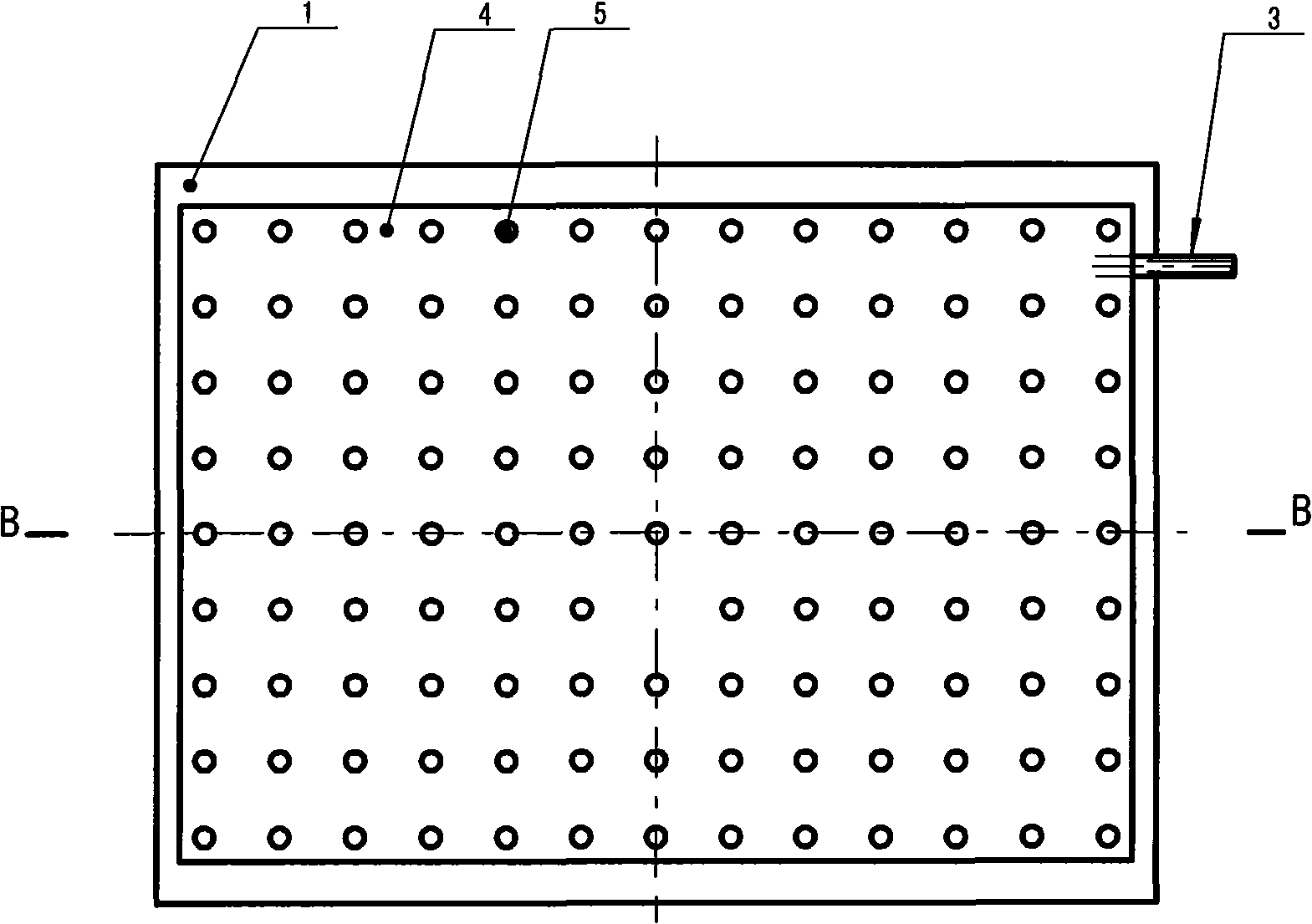

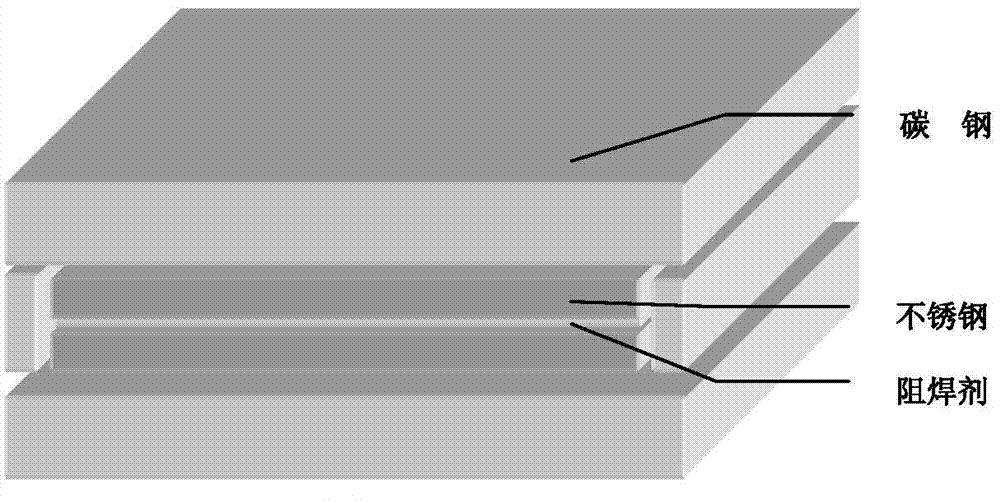

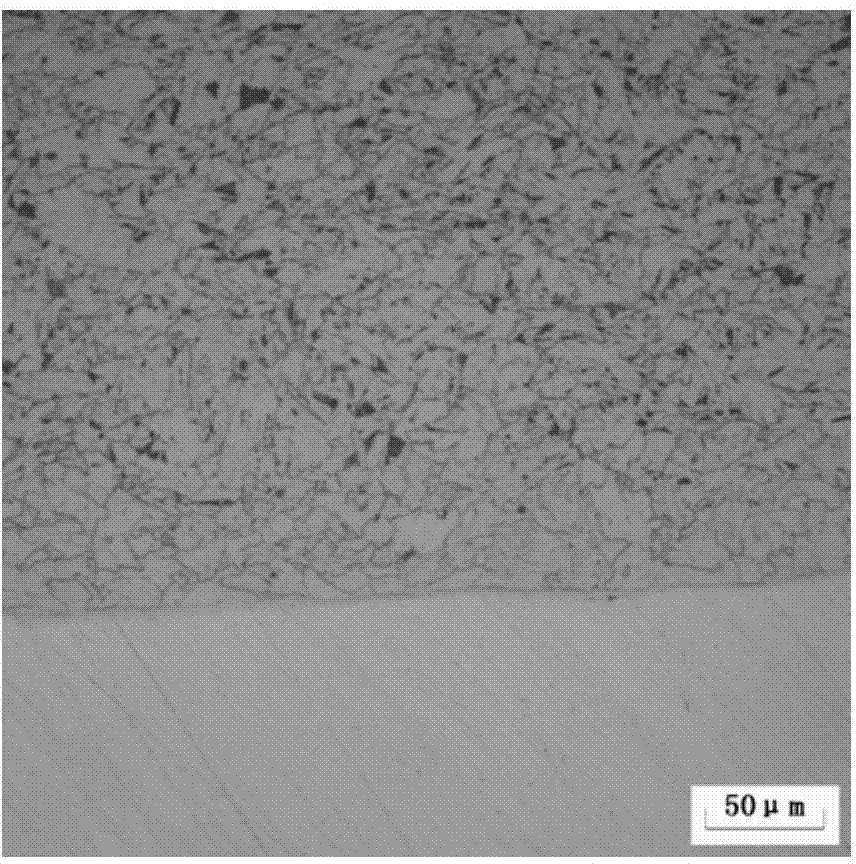

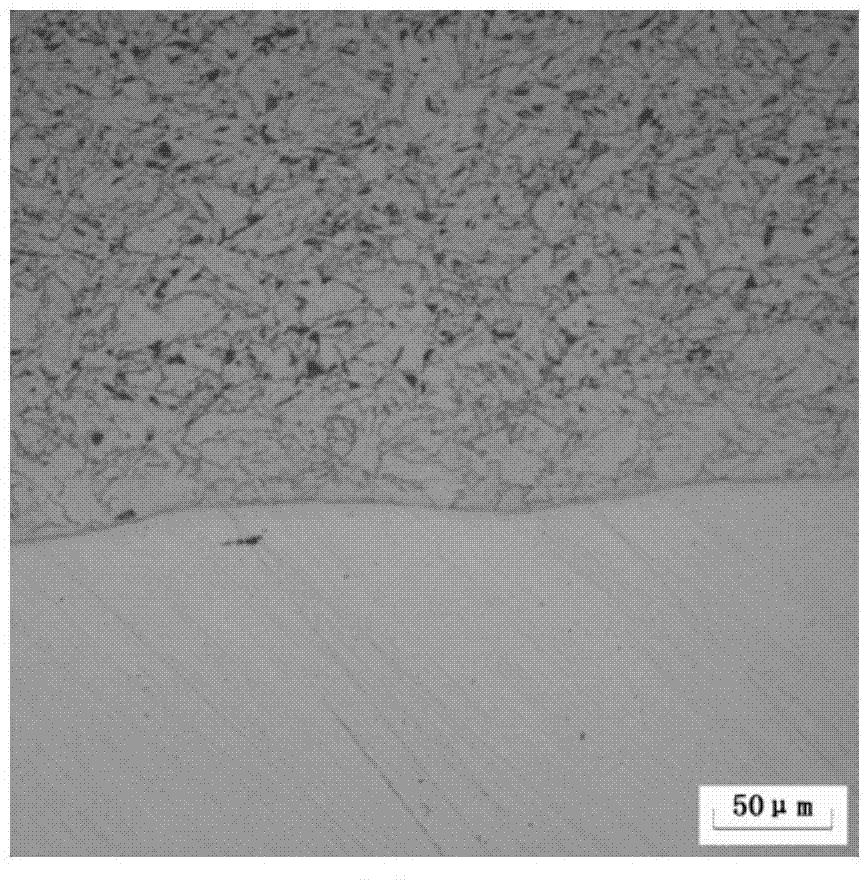

Carbon steel and austenitic stainless steel combined steel plate and production method thereof

InactiveCN104760351AImprove toughnessAccelerated corrosionMetal layered productsSheet steelComposite plate

The invention discloses a carbon steel and austenitic stainless steel combined steel plate and a production method thereof, and belongs to the technical field of metal composite plate production. A steel blank is adopted for symmetrical combination (dual-blank lamination) for the combined steel plate; the upper and lower layers are made from carbon steel made from X70 materials; the two middle layers are made from 316L stainless steel; scaling powder is not added between the carbon steel and the stainless steel; an insulation agent is added between stainless steel; then four edges of the steel blank are welded and sealed, and vacuumization treatment is carried out by using a vacuum dispersion pump. The blank assembling technology of the steel blank is that smelted X70 and 316L steel blanks are respectively subjected to blooming forging to the designed middle size; then the steel blank is subjected to surface polishing treatment; and then welding, edge sealing and vacuumization are carried out. The carbon steel and austenitic stainless steel combined steel plate and the production method thereof have the advantages that the use safety of a petroleum pipeline is improved, and great significance is achieved for the pipeline development of China.

Owner:SHOUGANG CORPORATION

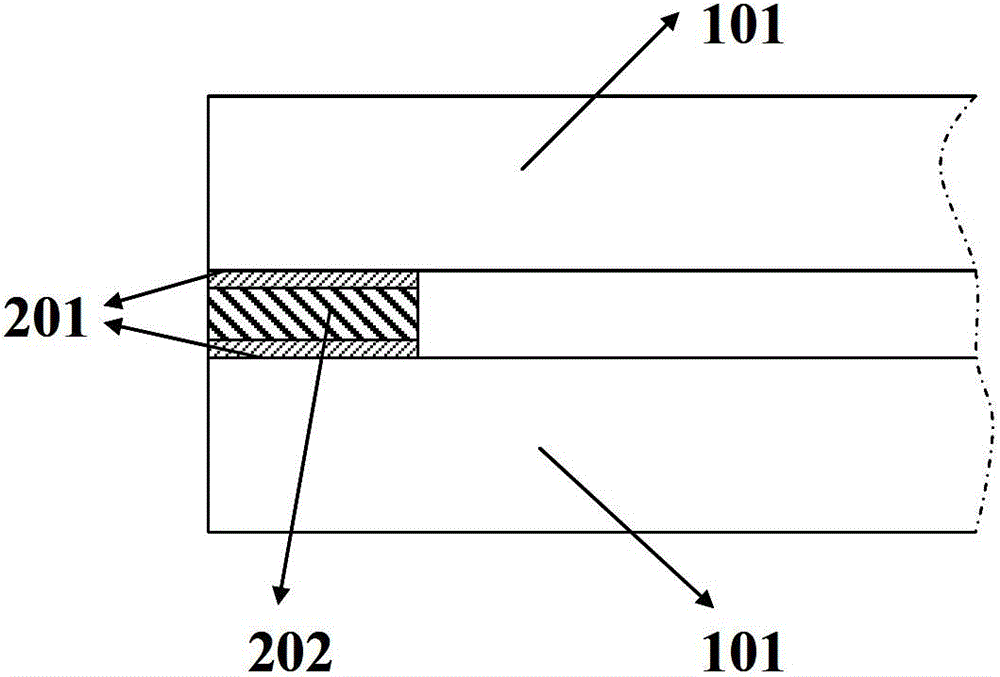

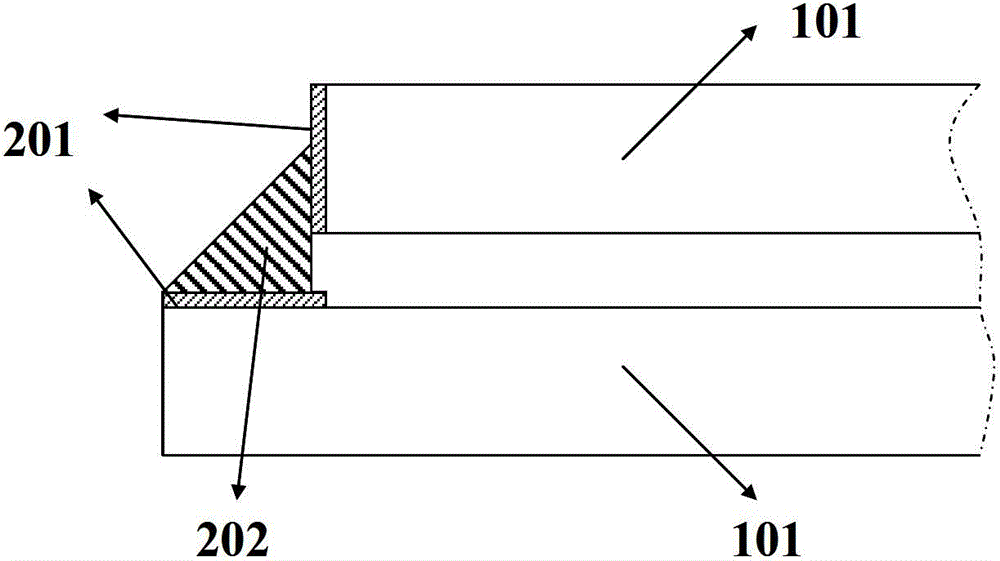

Vacuum glass with metal edge-sealing structure and making method thereof

Belonging to the field of vacuum glass and its edge-sealing technologies, the invention relates to a vacuum glass with a metal edge-sealing structure and a making method thereof. The vacuum glass comprises two flat glass sheets, a plurality of supports and a sealing layer. A metal transition layer is respectively cured on a sealing surface of the two flat glass sheets, and the two metal transition layers are fused and sealed by a metal layer formed by a low-melting-point metal welding material, and the fused and sealed metal transition layers and the metal layer form the low-melting-point metal sealing layer. The technical scheme involved in the invention not only can realize convenient and low-cost metal edge-sealing of vacuum glass, is easy to realize large-scale production, but at the same time also can realize low temperature (130DEG C-400DEG C) sealing of vacuum glass and lead-free manufacturing. Therefore, the vacuum glass and the method provided by the invention have great significance in reducing the production cost of vacuum glass and broadening the application scope of vacuum glass.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

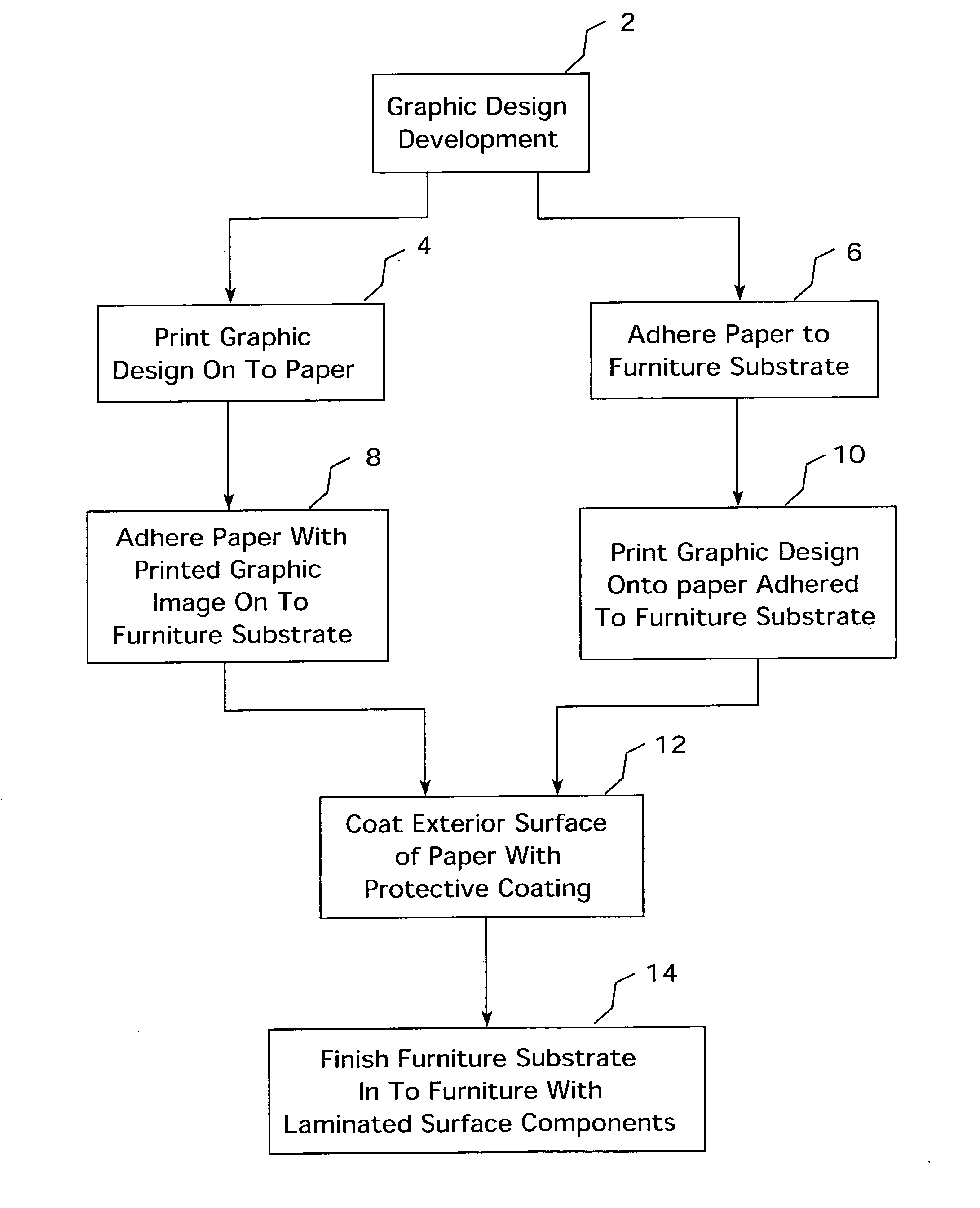

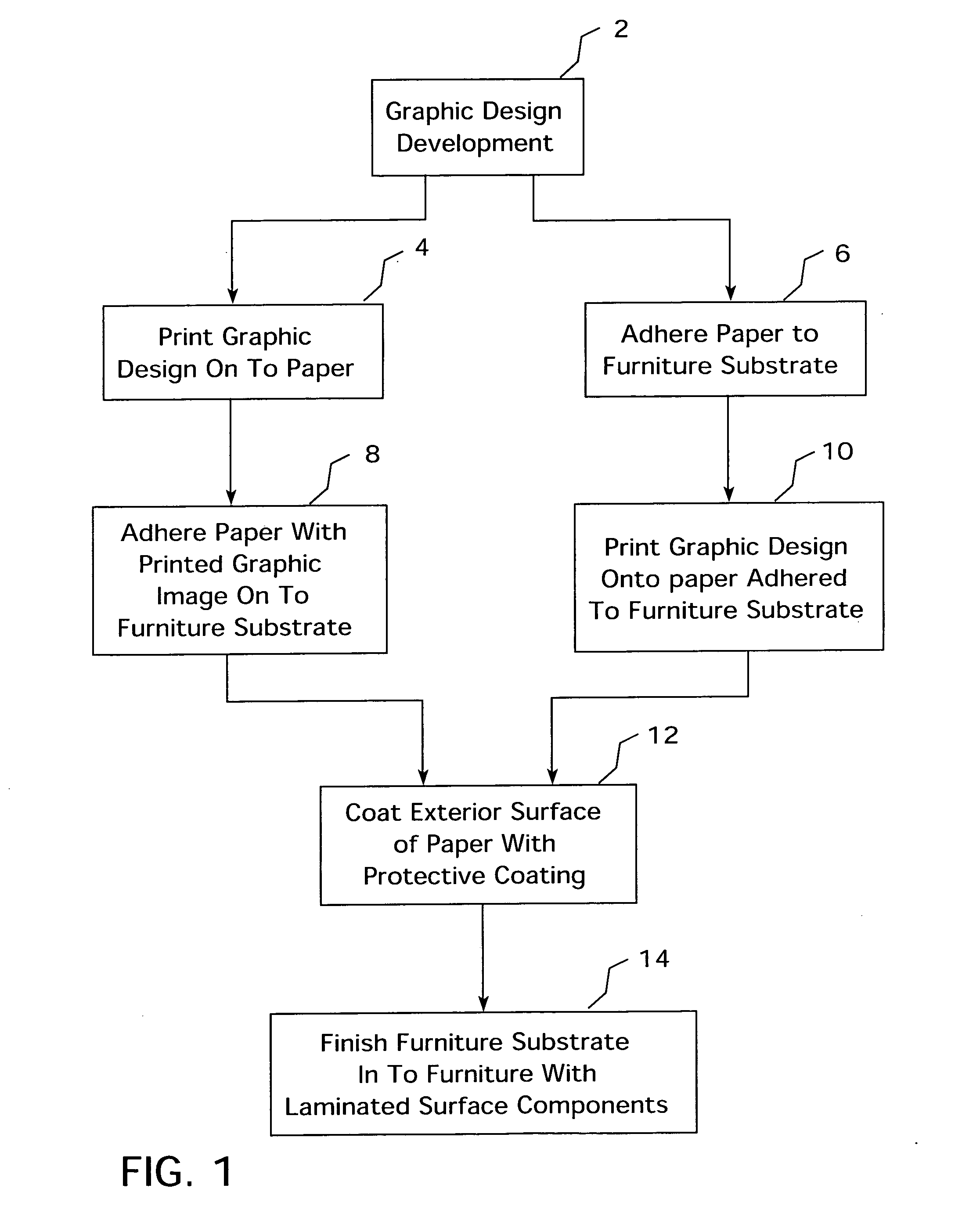

Digitally printed furniture and methods for manufacture thereof

InactiveUS20070001558A1Reduce manufacturing costQuality improvementNatural patternsSpecial ornamental structuresGraphicsEngineering

Manufacturing methods for furniture having a durable laminated surface with a digitally printed graphic image of a design include the steps of creating a graphic image of a design, printing the graphic image with a printer onto printer paper laminated to an uncut or precut furniture substrate, coating the paper with a protective coating, and finishing the laminated furniture components for later assembly. Optionally, the graphic image is printed on paper, which is later adhered to uncut or precut furniture substrate. The finishing steps include cutting the laminated furniture substrate into furniture components, edge banding the edges of the laminated furniture components and preparing the furniture components with fastener housings for later assembly. Ready-to-assemble furniture is provided with at least one exterior laminated furniture surface having a high quality digitally printed image of graphic design such as wood grain, wood inlay or other custom design.

Owner:BUSH IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com