Method of quickly manufacturing vacuum glass

A technology of vacuum glass and glass, which is applied in the field of rapid preparation of vacuum glass, can solve the problems of difficult control of the height of edge sealing materials, inability to make supports, and large support points, etc., and achieves a fast and efficient preparation method, suitable for Large-scale production, the effect of consistent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings; the following embodiments are illustrative, not restrictive, and the protection scope of the present invention cannot be limited by the following embodiments.

[0026] A kind of rapid preparation method of vacuum glass, the steps of its preparation method are:

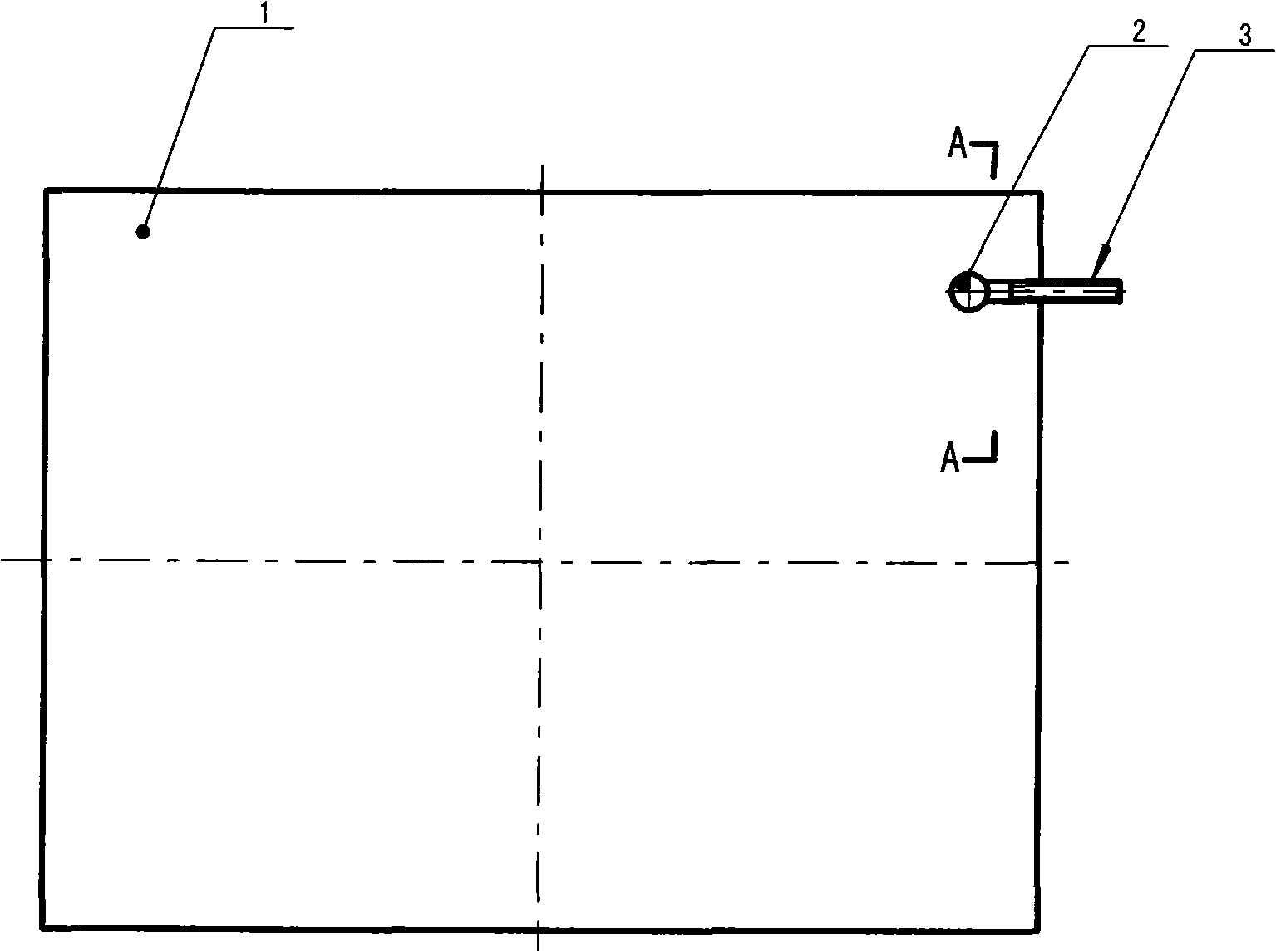

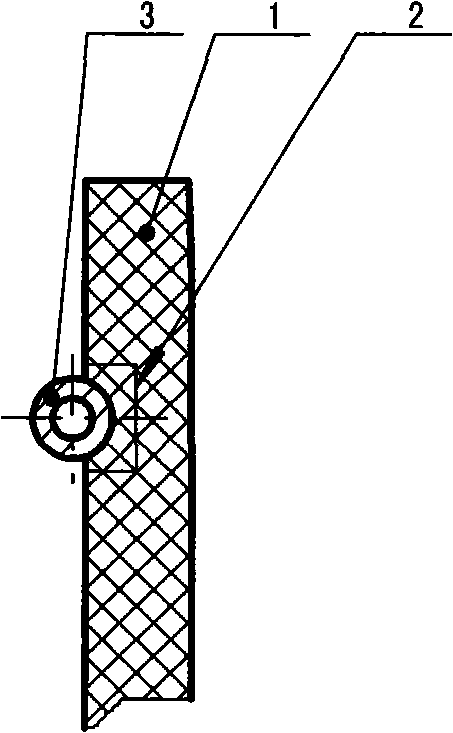

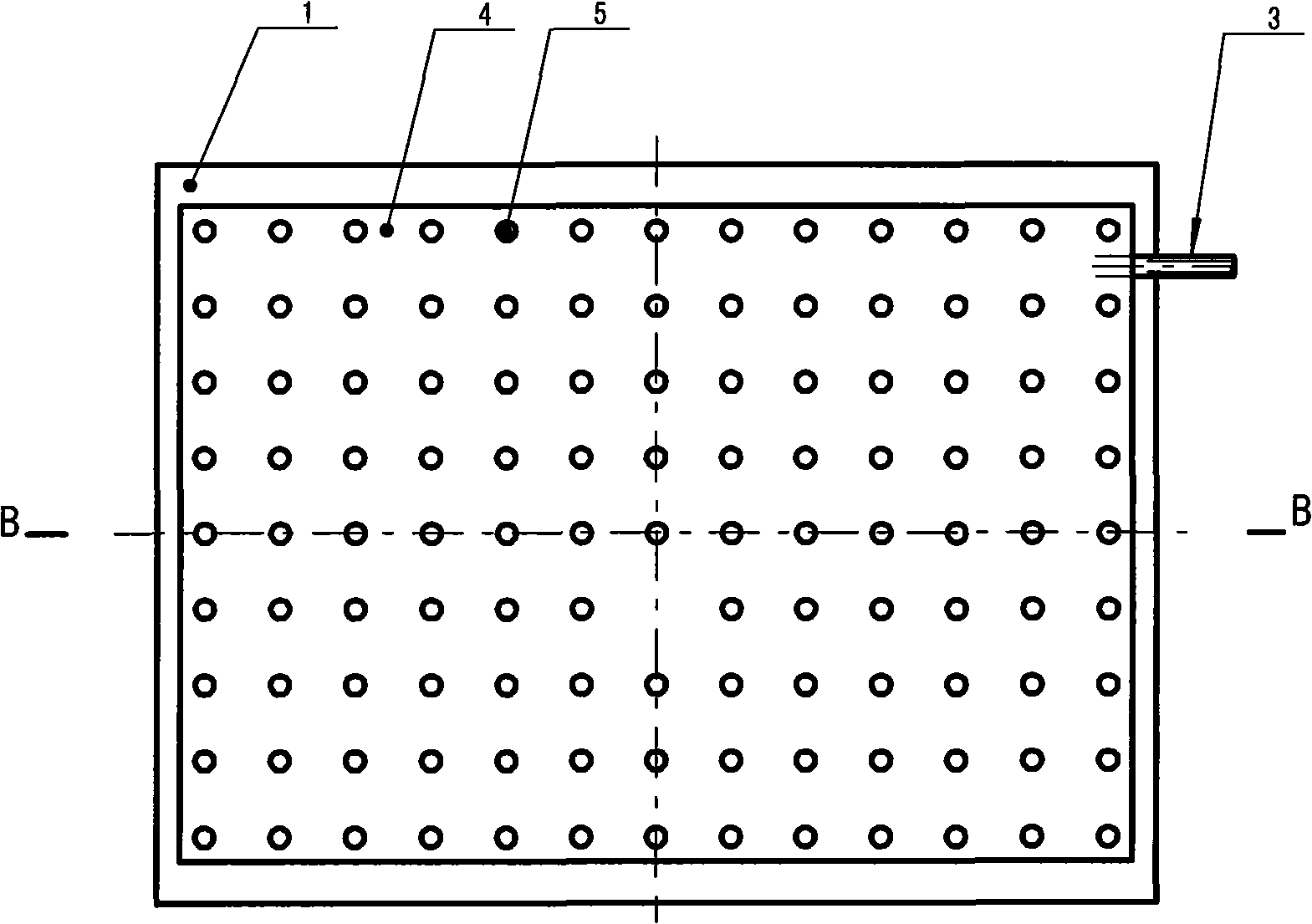

[0027] (1). One piece of glass is used as substrate glass 1, another piece of glass is used as top glass 7, two pieces of glass are cleaned and dried, a through hole is made on the top glass and suction glass tube 9 is installed (such as Figure 5 ), or grind out a semicircular groove on which the suction glass tube 3 can be placed on the near edge corner of any side on the substrate glass (such as figure 1 , figure 2 , image 3 ); In addition, a blind hole 2 that can place a getter can also be made at the end of the semicircular groove made of the substrate glass.

[0028] (2). Place the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com