Patents

Literature

3909results about How to "Reduce breakage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

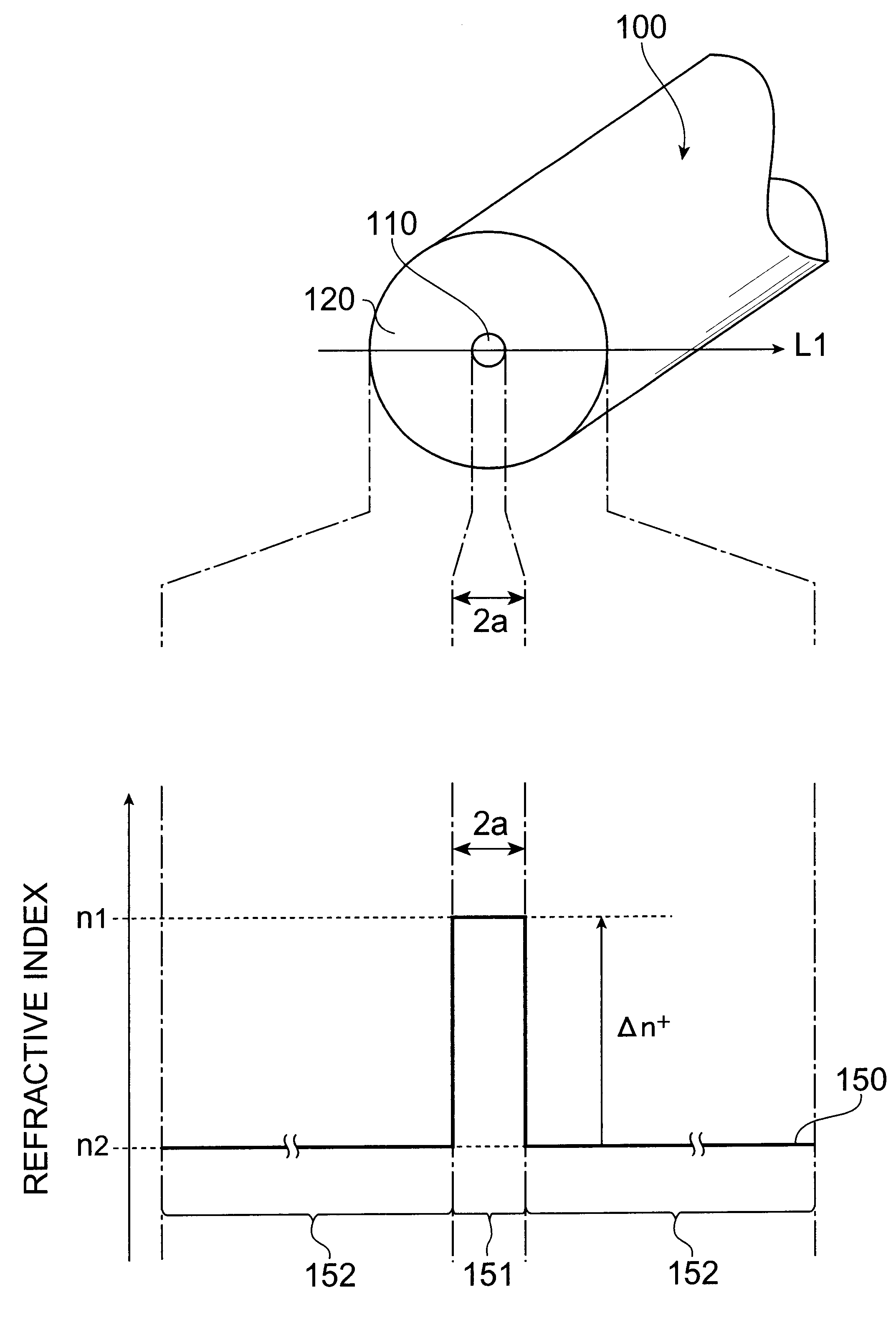

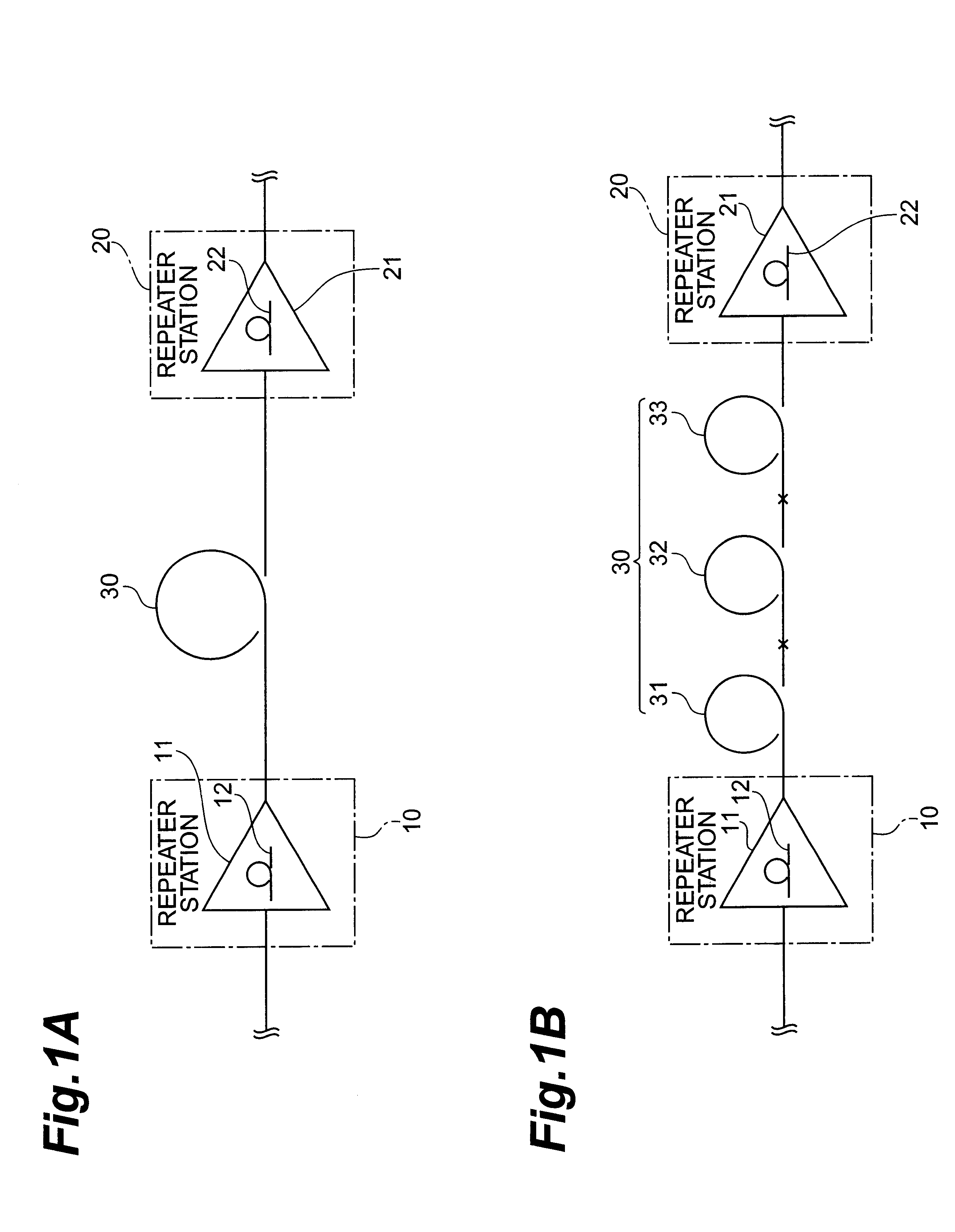

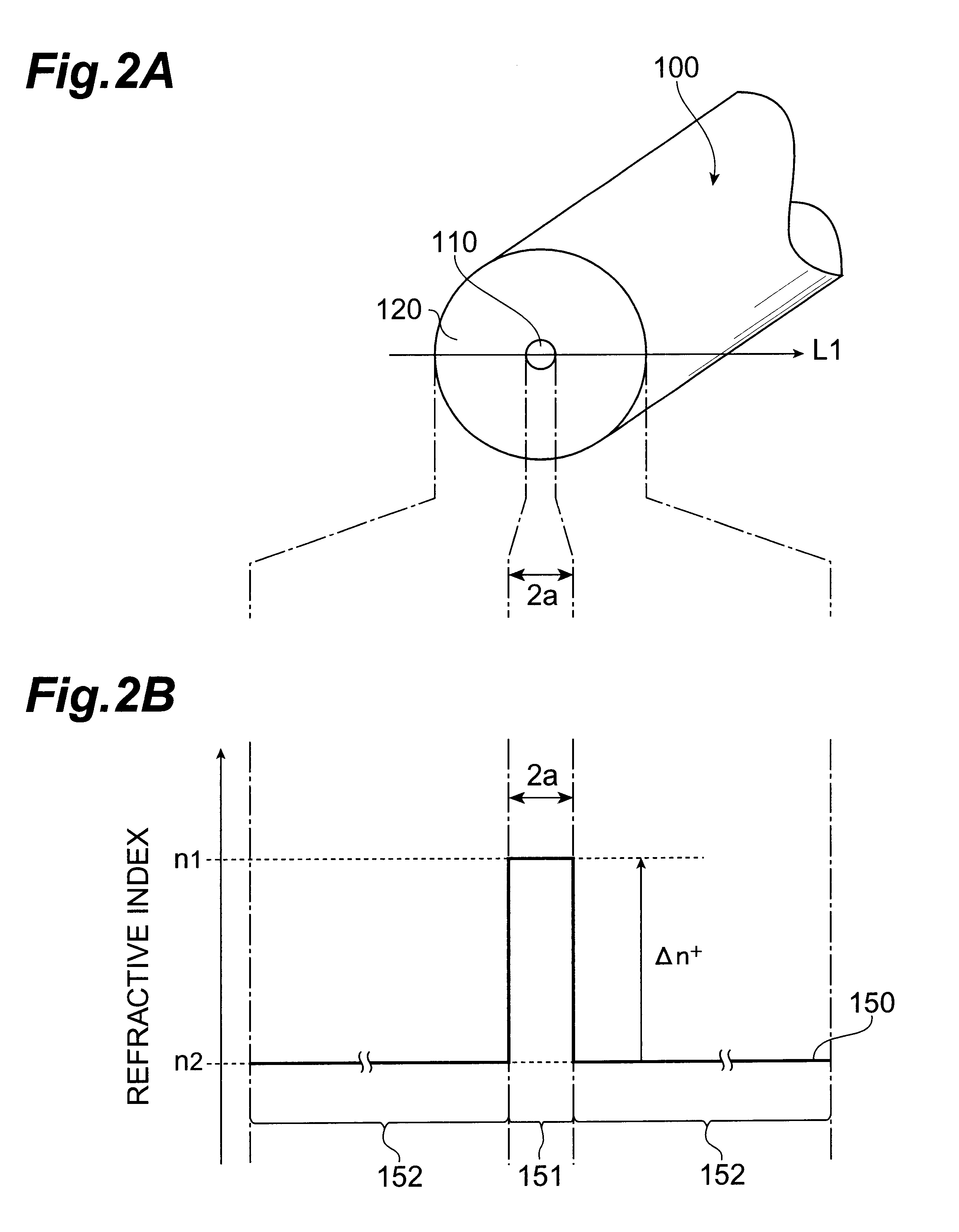

Optical fiber and optical communication system including the same

InactiveUS6658190B2Increase the effective areaRestrains nonlinear optical phenomenaOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingCommunications systemEngineering

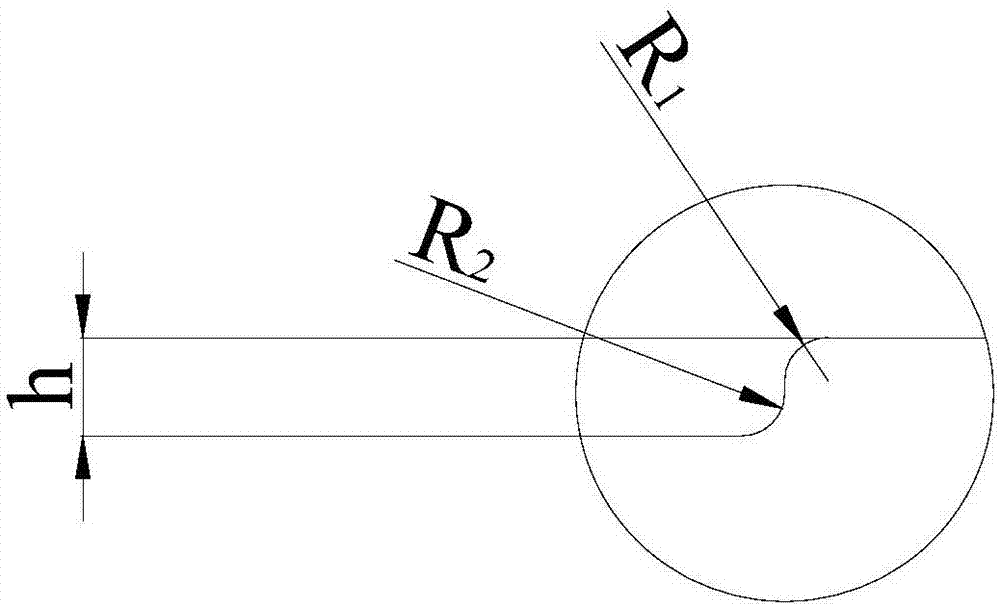

The present invention relates to an optical fiber having a structure suitable for long-distance optical communications, and an optical transmission line including the same. The optical fiber in accordance with the present invention comprises a core region extending along a predetermined axis, and a cladding region disposed so as to surround the outer periphery of the core region; and, as characteristics at a wavelength of 1.55 mum, an effective area of at least 110 mum<2>, a dispersion of 18 to 23 ps / nm / km, and a dispersion slope of 0.058 to 0.066 ps / nm<2> / km.

Owner:SUMITOMO ELECTRIC IND LTD

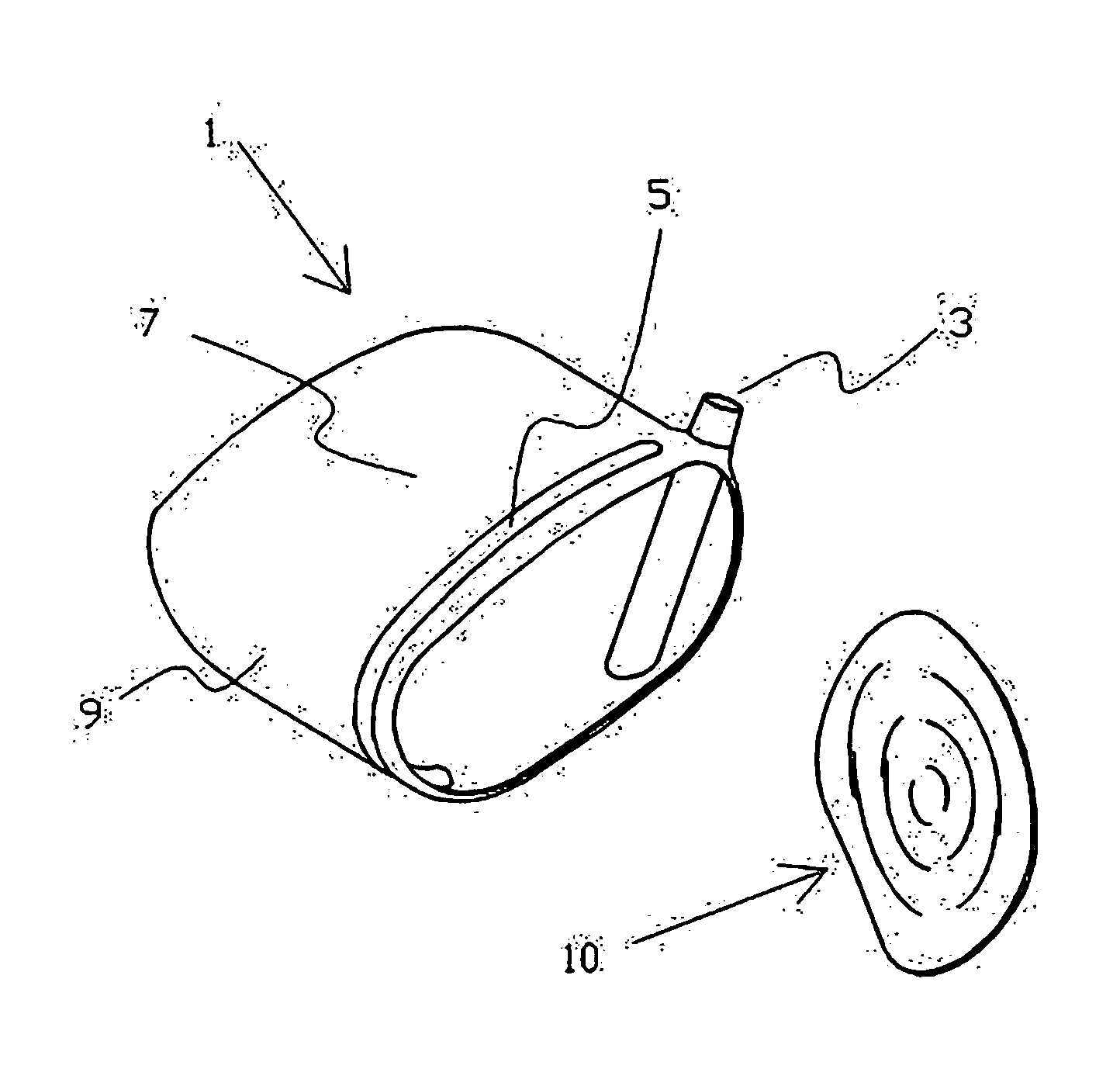

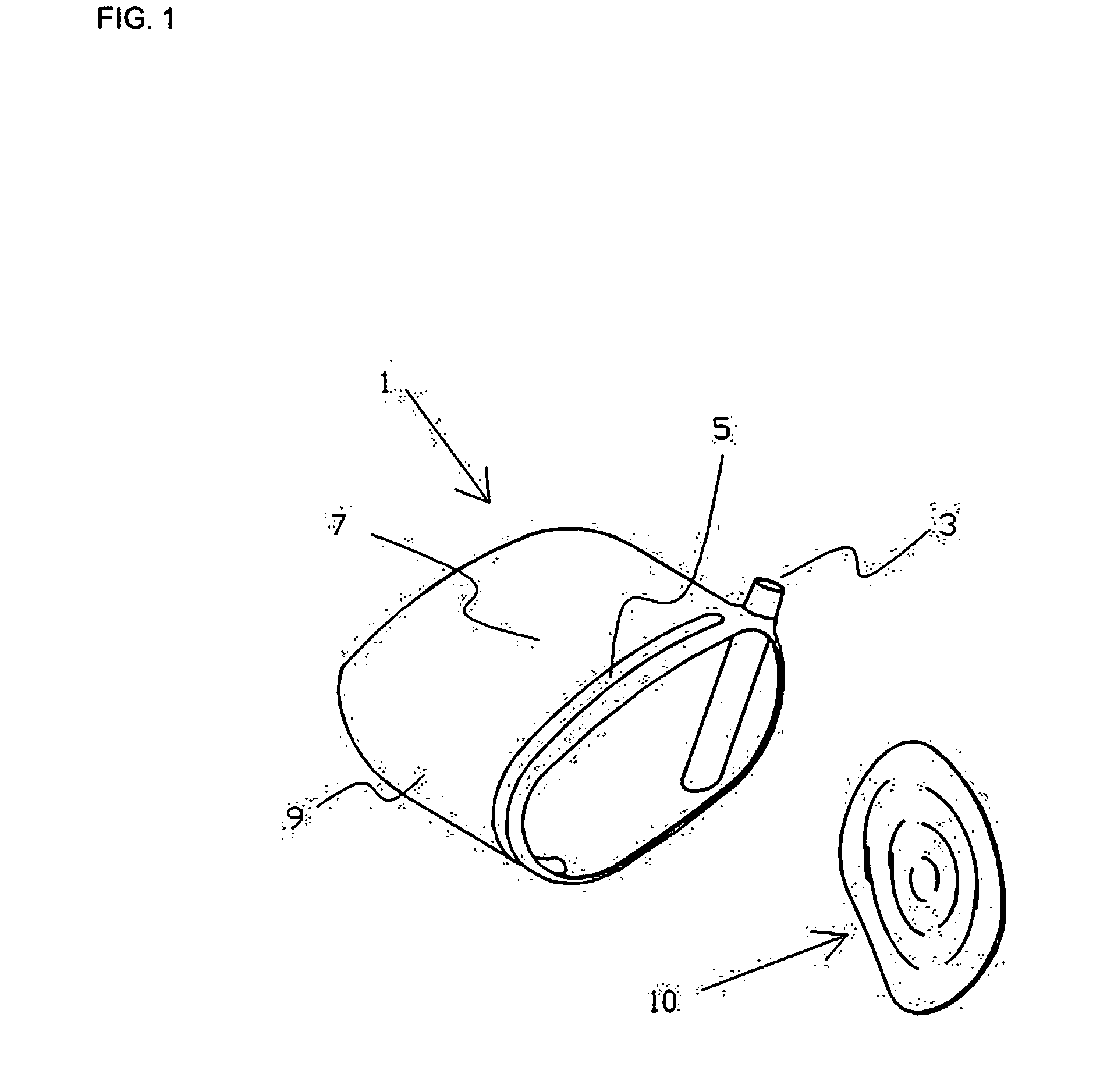

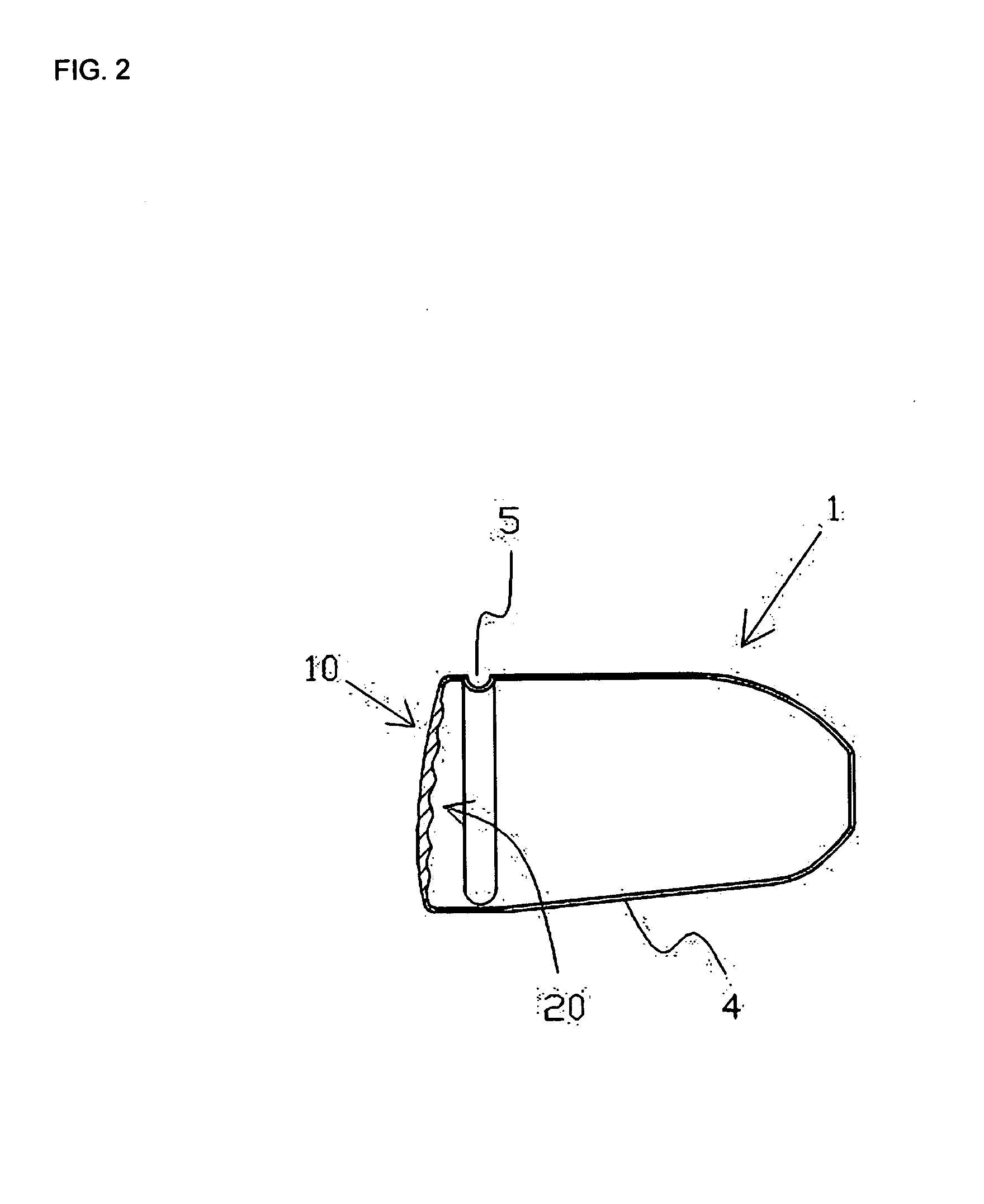

Golf Club Head with Ripple Structure

InactiveUS20090318245A1Improve energy transfer efficiencyReduce stress peaksGolf clubsStringed racketsEngineeringGolf Ball

A golf club head with a shell structure constituting with a body part and a hitting surface (face) incorporates, a groove is formed in the body part near the interface with the hitting surface. Several additional ripples are formed in the inner surface of the face plate. The groove in the body part and ripples of the inner surface of the face plate contributed as a powerful shock absorber but also preventing breakage of the head as well as strong repulsive mechanism improving flying distances.

Owner:YIM HYUNG JIN +1

Packaging method for high-capacity polymer lithium ion cells

InactiveCN107394279AControl thicknessGuaranteed electrical performanceFinal product manufactureElectrolyte accumulators manufactureLithiumBreakage rate

The invention discloses a packaging method for high-capacity polymer lithium ion cells. The packaging method comprises the following steps: (1) a bag is formed from at least one of two aluminum plastic films by stamping; when the thickness of a cell is smaller than 6 mm, one bag is formed from one aluminum plastic film by stamping, and when the thickness of a cell is larger than or equal to 6 mm, bags are formed from the two aluminum plastic films by stamping; (2) the cell is loaded into an opening of the bag formed from one aluminum plastic film by stamping, and the opening of the bag is correspondingly covered with the other aluminum plastic film; (3) three edges of the cell are sealed in a hot manner with seal heads. With adoption of the packaging method for the high-capacity polymer lithium ion cells, the breakage rate of the aluminum plastic films is reduced, the aluminum plastic film use efficiency is increased, and electrical performance of the high-capacity polymer lithium ion cells can be guaranteed effectively; the packaging method is simple to operate.

Owner:海口博澳国兴新能源科技有限公司

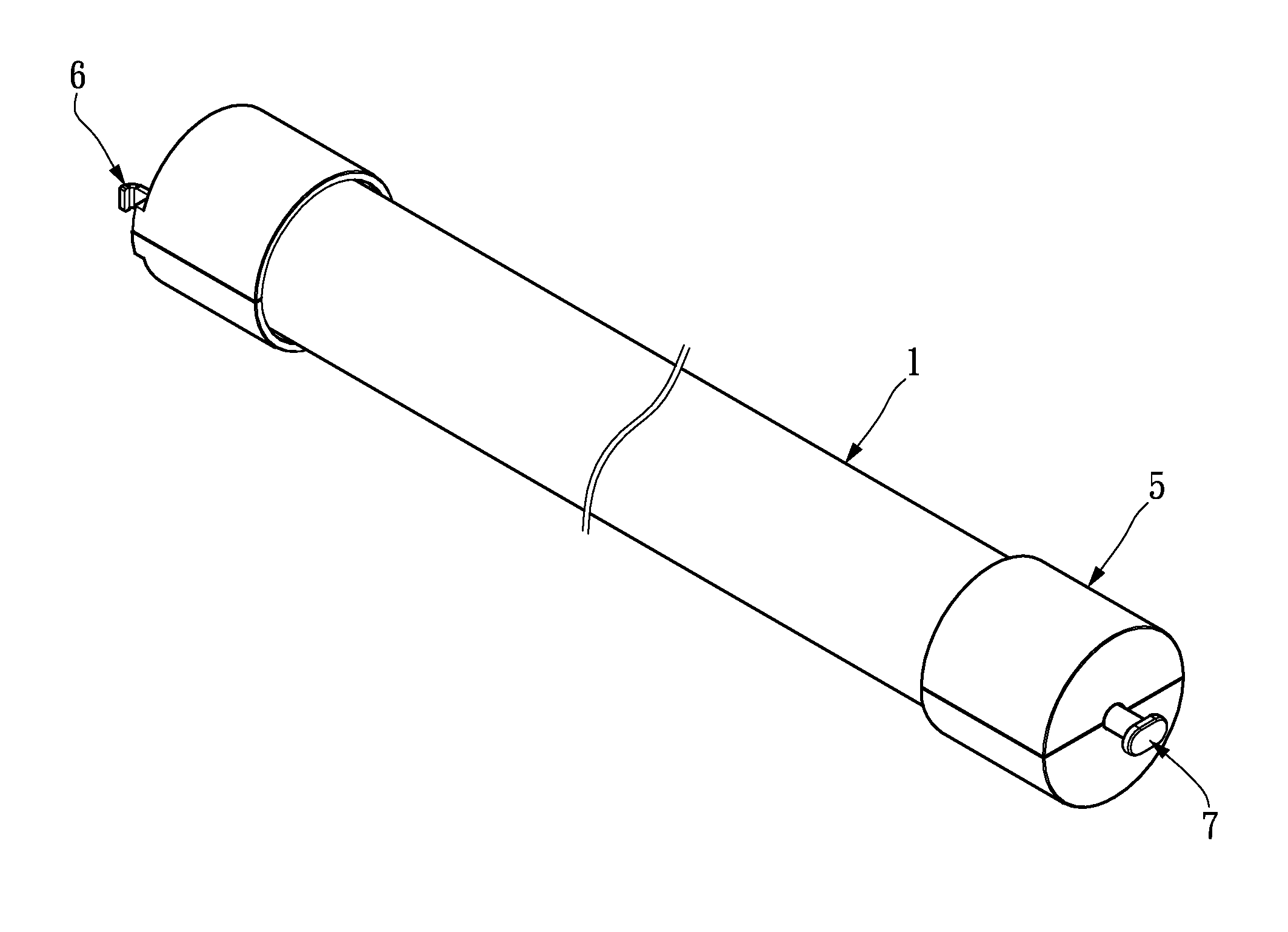

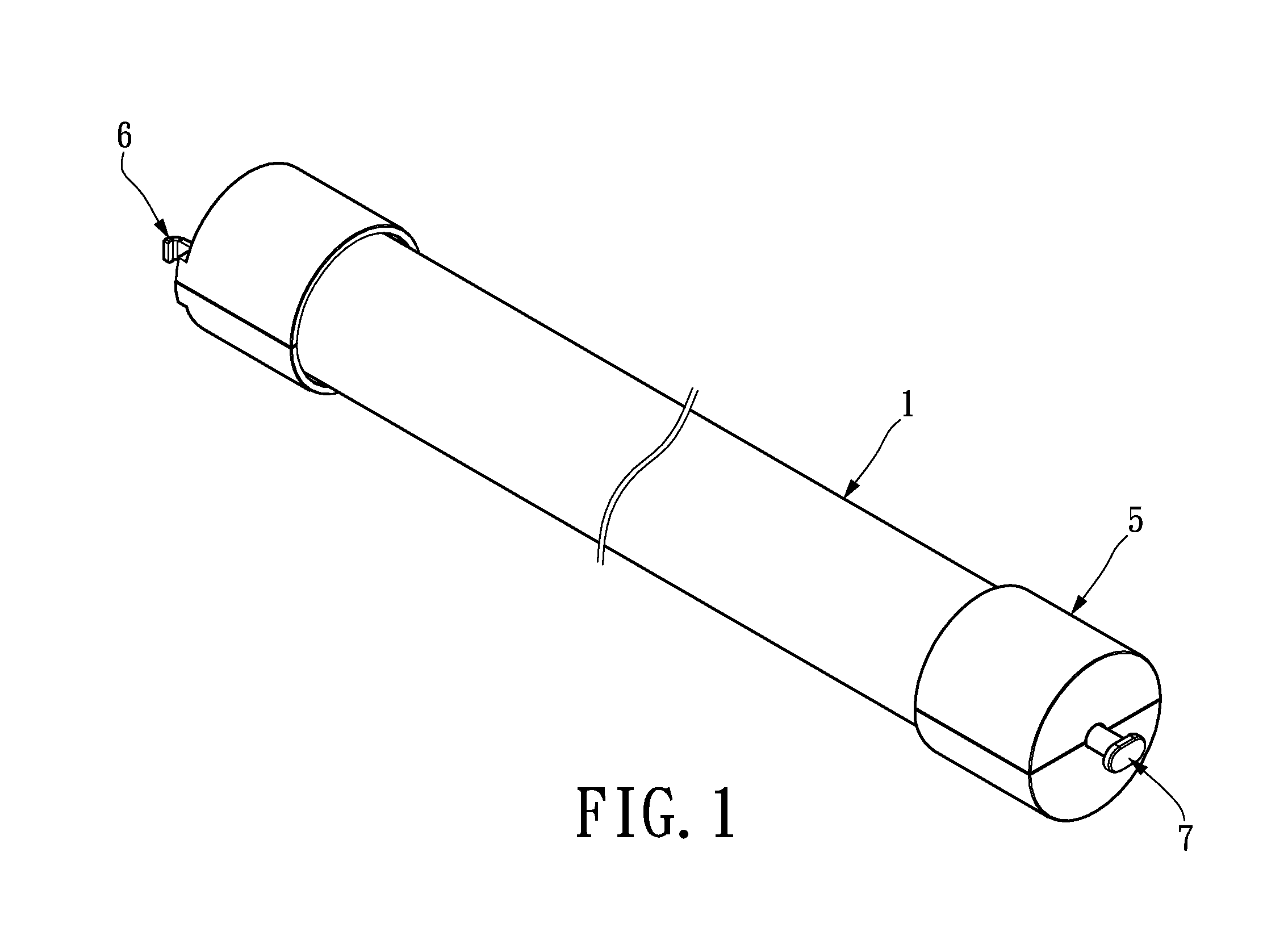

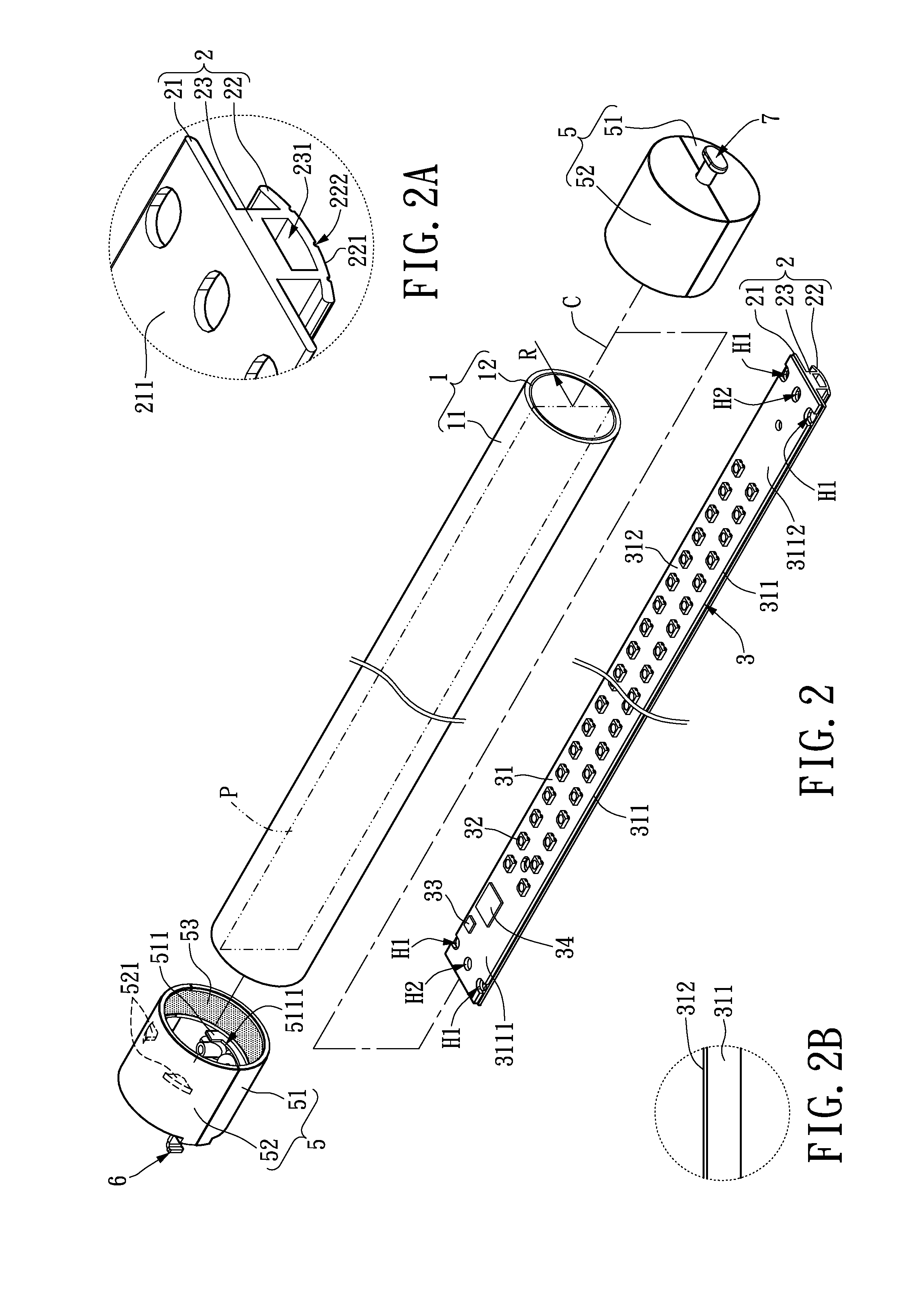

LED tube light

InactiveUS20130170196A1Improve structural durabilityReduce breakage ratePoint-like light sourceLighting support devicesEngineeringLED lamp

An LED tube light includes a glass tube, a base, a light emitting unit, and two lateral cover assemblies. The base has a length larger than the length of the glass tube, wherein two opposite end portions of the base are arranged out of a region defined by orthographically projecting from the glass tube to the base. The light emitting unit is fixed on the base and is used for emitting light, passing through the glass tube to illuminate. The two lateral cover assemblies are respectively covered around the two end portions of the glass tube, wherein the two lateral cover assemblies are respectively installed on the two end portions of the base for maintaining the relative position between the cover assemblies and the base.

Owner:LITE ON TECH CORP

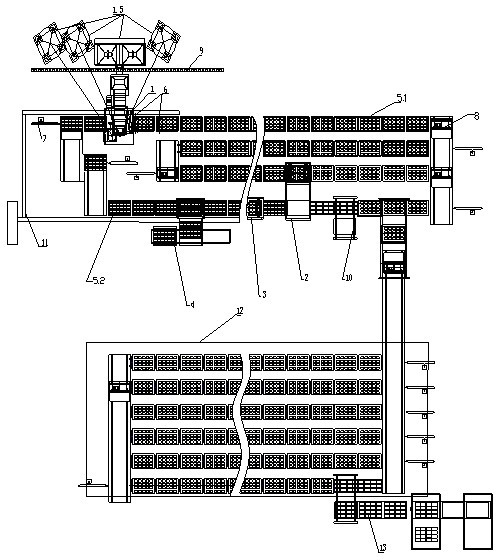

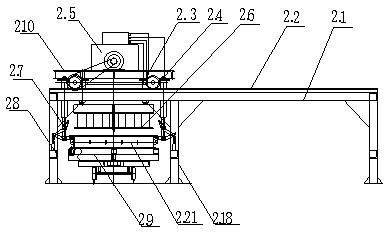

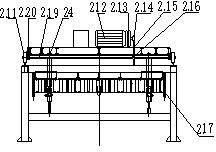

Production line for self-insulation building blocks

InactiveCN102555052AReduce occupancyReduce consumptionDischarging arrangementCeramic shaping plantsProduction lineBrick

The invention relates to a tool used in an insulation brick manufacturing process, in particular to a production line for self-insulation building blocks, which comprises a stirring machine. The production line is characterized in that automatic metering devices are arranged on a feeding port and at the bottom of the stirring machine, a production track capable of automatically conveying molds isdisposed below a distributing port of the stirring machine, a stripper is further arranged on the production track and is spaced from the stirring machine by a proper distance, a return track and a track leading into a maintenance area are respectively disposed on two sides of the other end of the stripper, the return track sequentially penetrates through a cleaning area, an oil injection area and a core setting area, a link plate machine is arranged at the other end of the maintenance area, and a manipulator is disposed at the other end of the link plate machine. The production line is high in production efficiency and annual yield, occupied land area and workshop investment are reduced, operating expense is saved, and the production line can operate continuously.

Owner:张建兴

Tobacco sheet producing process using improved paper making method

ActiveCN101011182AProminent smoke and smoke smellWoody smell is not obviousTobacco preparationPaper forming aids additionSlagUltra fine

The invention relates to a method for producing the tobacco sheet via improved paper making method, which comprises that preparing the tobacco slag, tobacco powder and ash via grinding machine to the tobacco powder at 60-80 deals and the ultra-fine tobacco powder at 120-800 deals; immerging the tobacco stem in water for 1-2 hours, separating the solid and liquid, concentrating the extractive solution into 15-25 degree / Be', adding the ultra-fine tobacco powder at 5-30% of the weight of concentrated solution, to obtain the coat liquid of sheet; the solid extracted from the tobacco stem is decomposed to prepare pulp, to be mixed with external pulped fiber, adjusting the density to 0.05-0.8%, to be mixed with the tobacco powder at 60-80 deals; preparing via paper machine, compressing, dewatering, drying to obtain the base sheet; immerging and coating the base sheet in the coat liquid, drying, breaking to obtain the final product. The invention can improve the smell of sheet tobacco.

Owner:CHINA TOBACCO HUNAN INDAL CORP

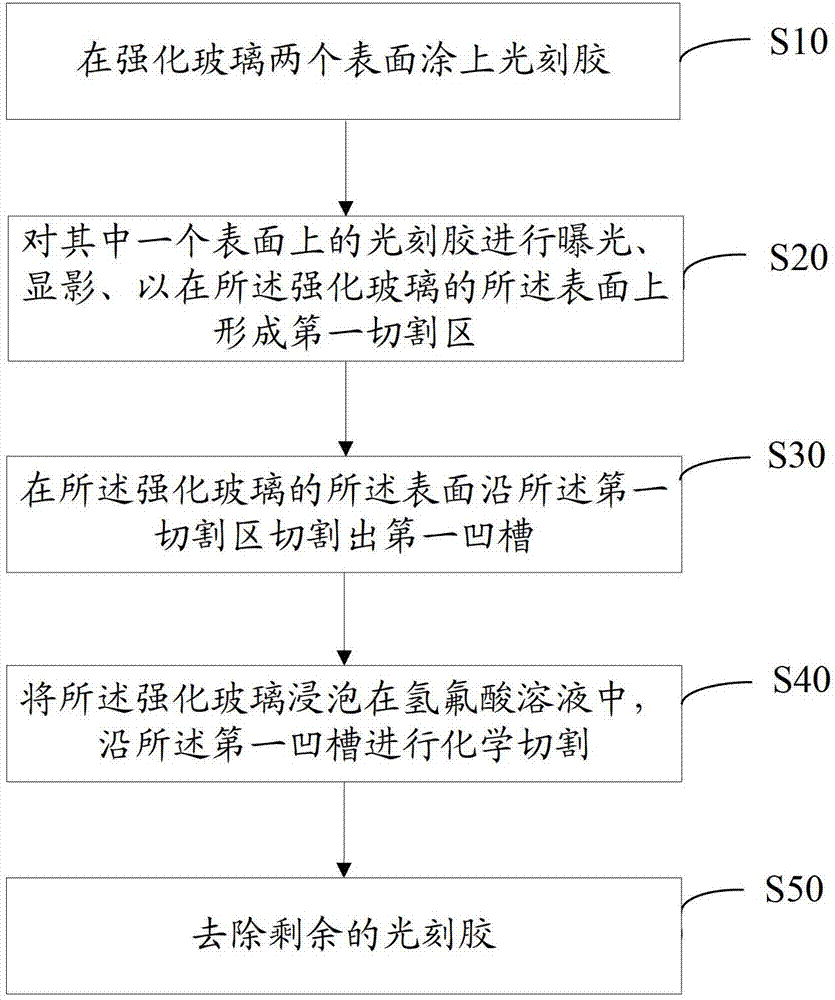

Method for cutting tempered glass

ActiveCN102923939AReduce breakage rateHigh compressive strengthGlass severing apparatusGlass productionPhotoresistBreakage rate

The invention provides a method for cutting tempered glass. The method comprises the following steps of: coating photoresist on two surfaces of the tempered glass, and performing exposure and developing on the photoresist on one surface, so that a first cutting area is formed on the surface of the tempered glass; cutting a first groove on the surface of the tempered glass along the first cutting area; soaking the tempered glass in a hydrofluoric acid solution, and performing chemical cutting along the first groove; and removing the residual photoresist. According to the method, the tempered glass is cut by using the hydrofluoric acid solution, and the edge of the tempered glass is smoothed, so that the compressive strength on the edge of the tempered glass is improved, the breakage rate of the cut tempered glass is reduced, and the production efficiency is improved.

Owner:WGTECH JIANGXI

Ultralight-weight proppant and preparation method thereof

The invention relates to an utralight-weight proppant and a preparation method thereof, belonging to the field of fracturing extraction of oil and gas wells. The preparation method of the utralight-weight proppant comprises the following steps: sintering 1-50 parts by weight of fly ash, 0.5-20 parts by weight of coal gangue, 20-50 parts by weight of clay and 10-30 parts by weight of bauxite whichare used as aggregate, and balling, thereby obtaining the utralight-weight haydite. The utralight-weight proppant provided by the invention utilizes industrial waste, and the production can be easilycontrolled; the sintering temperature is greatly lowered, ranging 1100-12500 DEG C; and the energy consumption is effectively lowered, and the energy can be saved by 20%. The percentage of damage of the utralight-weight proppant under 69 MPa is lower than 5%, the volume density is lower than 1.25g / cm<3>, and the apparent density is lower than 2.0g / cm<3>, so the utralight-weight proppant can completely substitute medium-density haydite.

Owner:BEIJING QISINTAL SCI & TECH

Paper making method tobacco sheet producing process using double-grid method

ActiveCN101011183AObvious style traitsShorten the timeTobacco preparationPaper forming aids additionFiberSlag

The invention relates to a method for producing the tobacco sheet via dual-mesh paper making method, which comprises that preparing the tobacco slag, tobacco powder and ash via grinding machine to the tobacco powder at 80-100 deals and the ultra-fine tobacco powder at 120-800 deals; immerging the tobacco stem in water for 1-2 hours, separating the solid and liquid, concentrating the extractive solution into 15-25 degree / Be', adding the ultra-fine tobacco powder at 5-30% of the weight of concentrated solution, to obtain the coat liquid of sheet; the solid extracted from the tobacco stem is decomposed to prepare pulp, to be mixed with external pulped fiber, to be divided into two parts to be shaped via the meshes; spraying the tobacco powder at 80-100 deals on the base sheet of one paper machine, and covering this base sheet via another wet base sheet produced by another paper machine, to obtain the composite wet base sheet; compressing, dewatering, drying to obtain the base sheet; immerging and coating the base sheet in the coat liquid, drying, breaking to obtain the final product. The invention can improve the smell of sheet tobacco.

Owner:CHINA TOBACCO HUNAN INDAL CORP

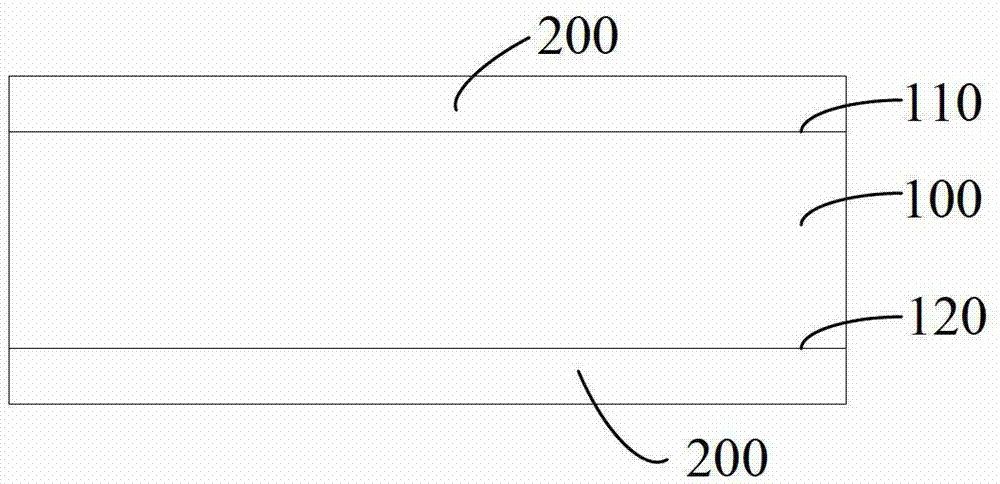

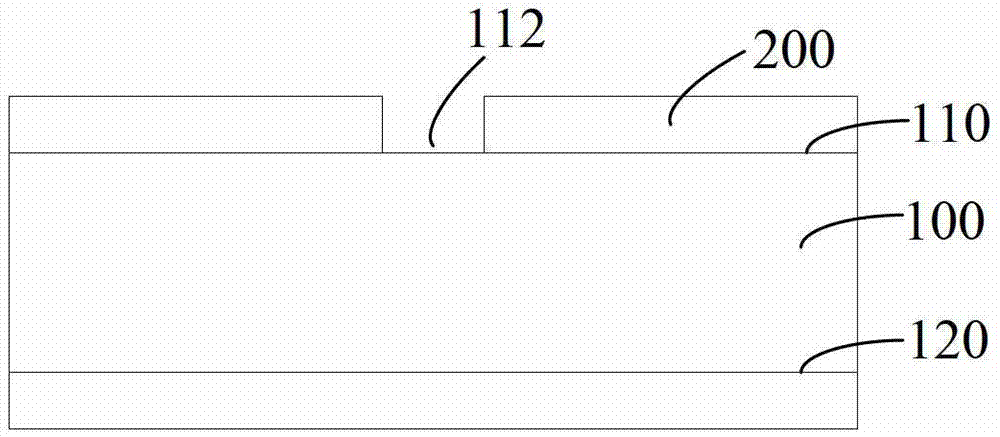

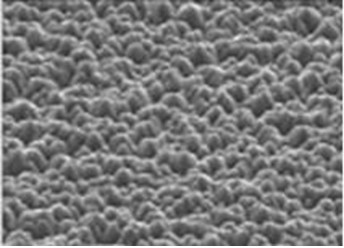

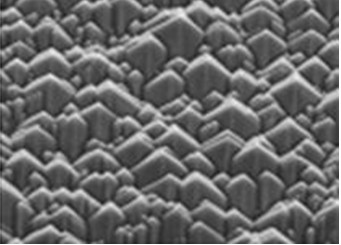

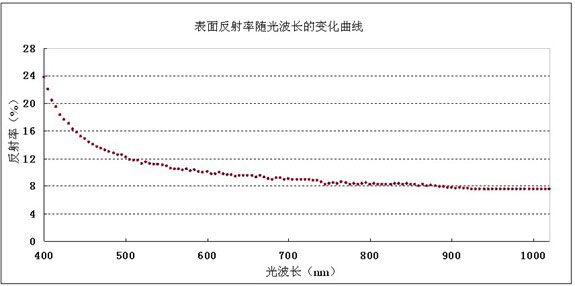

Single crystal silicon texture-making additive and single crystal silicon texture-making technology

InactiveCN102115915AIncrease productivityIncrease production capacityAfter-treatment detailsFinal product manufactureActive agentPotassium hydroxide

The invention relates to a single crystal silicon texture-making additive and a single crystal silicon texture-making technology. The single crystal silicon texture-making additive consists of a wetting agent and a defoaming agent. The additive is characterized in that the wetting agent is a nonionic surfactant. The single crystal silicon texture-making technology comprises the following steps: heating deionized water to 70-80 DEG C, adding sodium hydroxide or potassium hydroxide to obtain a single crystal silicon texture-making corrosive liquid, wherein the mass percentage of sodium hydroxide or potassium hydroxide is 1%-2%; adding the single crystal silicon texture-making additive in the single crystal silicon texture-making corrosive liquid to obtain a mixed solution, wherein the volume percentage of the additive is 0.3%-2%; and placing a precleaned raw silicon chip in the mixed solution for 600-1200s for texture-making. By adopting the additive and technology in the invention, the texture-making quality can be greatly increased, the cost is greatly reduced, the technological operation can be easier and the automatic solution preparation can be realized.

Owner:百力达太阳能股份有限公司

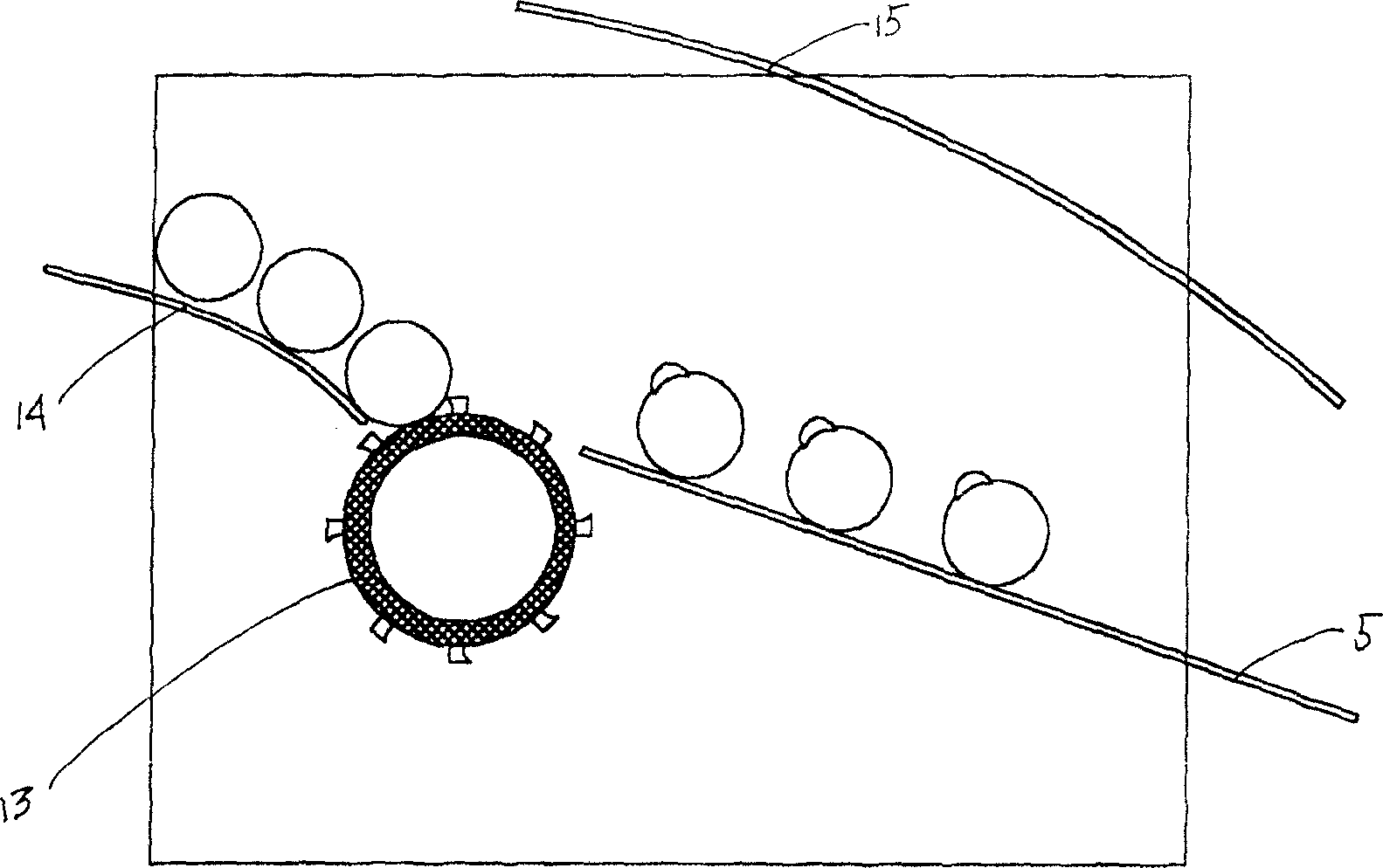

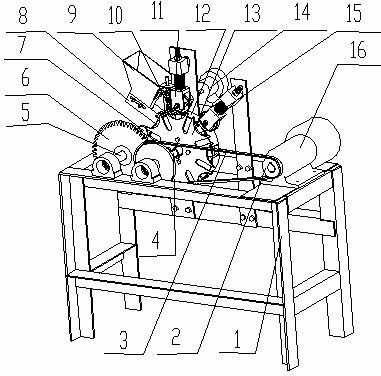

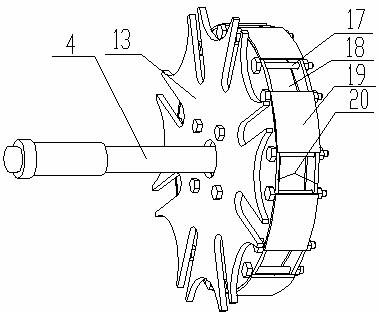

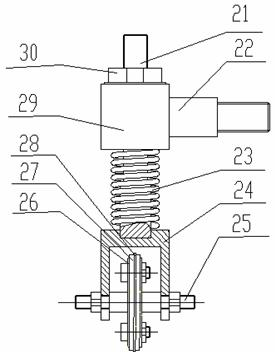

Oil tea fruit unshelling separator

InactiveCN102948912AReduce broken rateGood liquidityFatty-oils/fats productionHuskingMechanical engineeringCamellia oleifera

An oil tea fruit unshelling separator relates to an oil tea fruit unshelling and shell and tea seed seperation combination device. The oil tea fruit unshelling separator comprises a feed hopper, a unshelling rotary drum part, a shell and tea seed separating part, a power transmission part and a machine frame and is characterized in that the unshelling rotary drum part is positioned above the shell and tea seed separating part, the unshelling rotary drum part and the shell and tea seed separating part are arranged on the machine frame, the feed hopper is arranged above the unshelling rotary drum part, and the power transmission part is sequentially connected with the unshelling rotary drum part and the shell and tea seed separating part through a belt. The oil tea fruit unshelling separator has the beneficial effects of being capable of unshelling oil tea fruit, simultaneously also being capable of separating shells and tee seeds and unshelling fresh-picked wet tea fruits, retting piled micro-cracked fruit and cracked dried tea fruit and the characteristics of high unshelling efficiency, high seperation efficiency, little tee seed loss, low power dissipation, light and ingenious structure, is convenient to use and maintain and the like.

Owner:JIANGXI AGRI MACHINERY RES INST

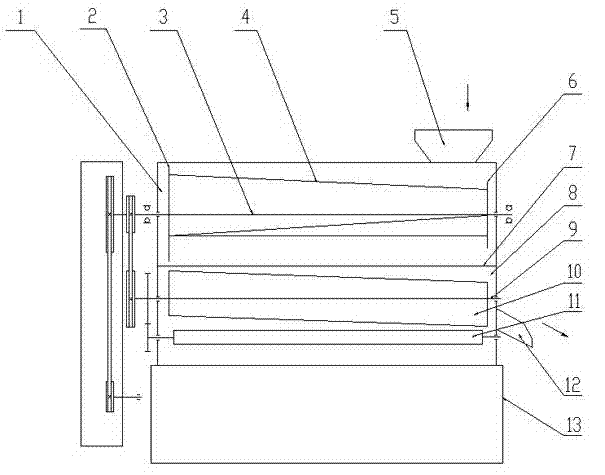

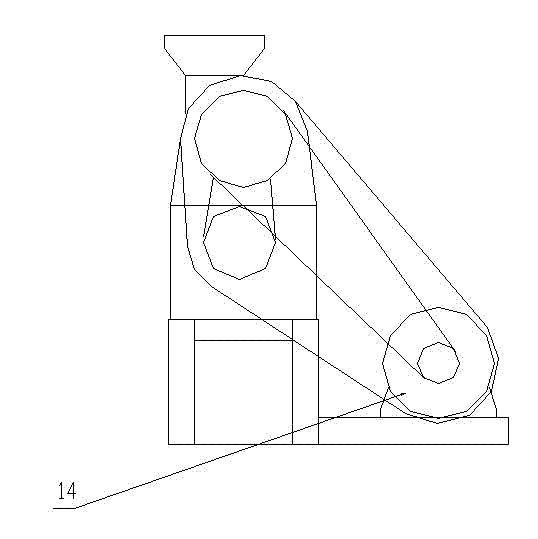

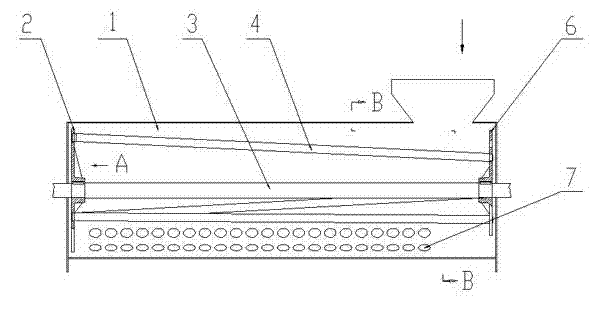

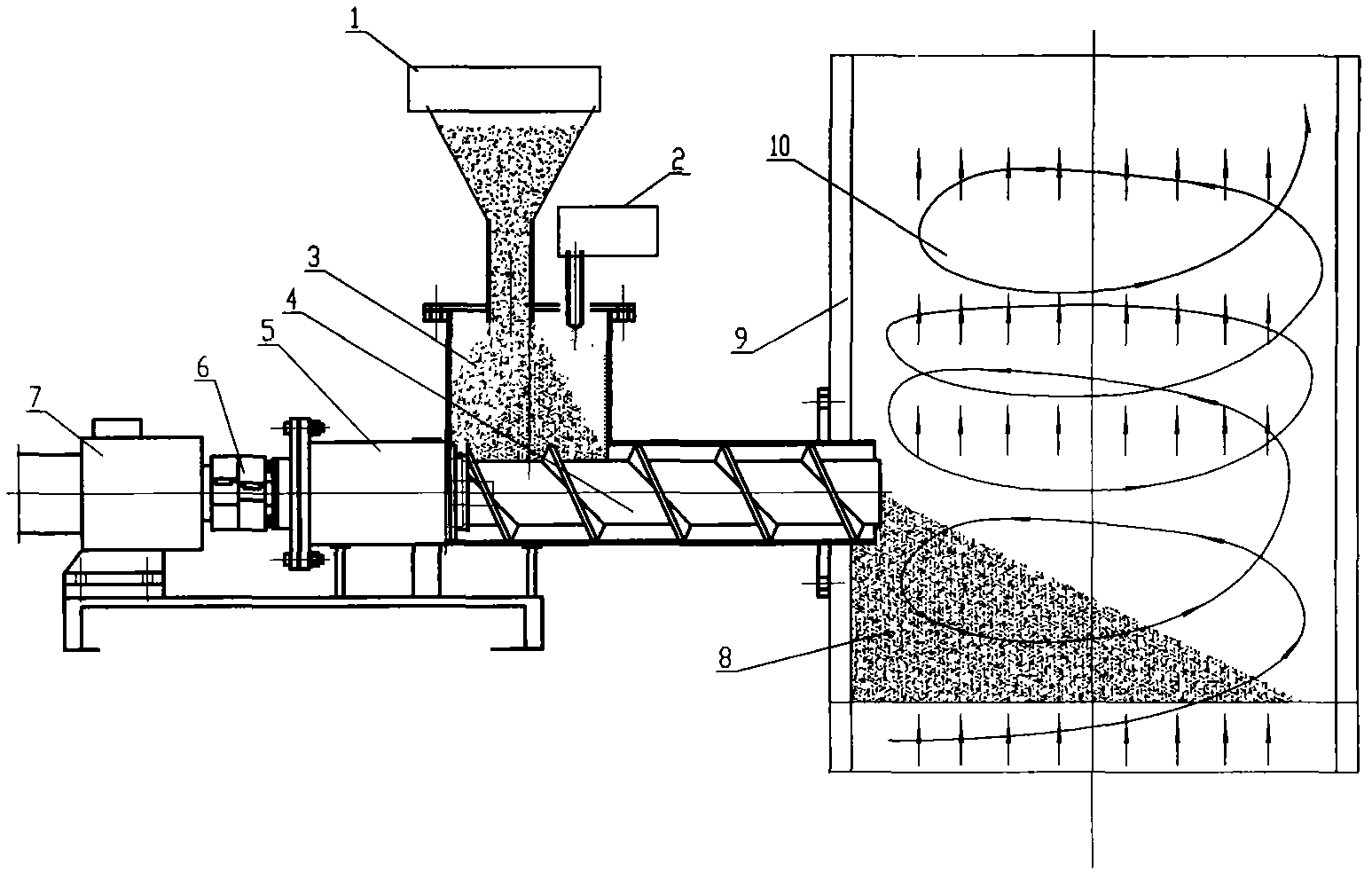

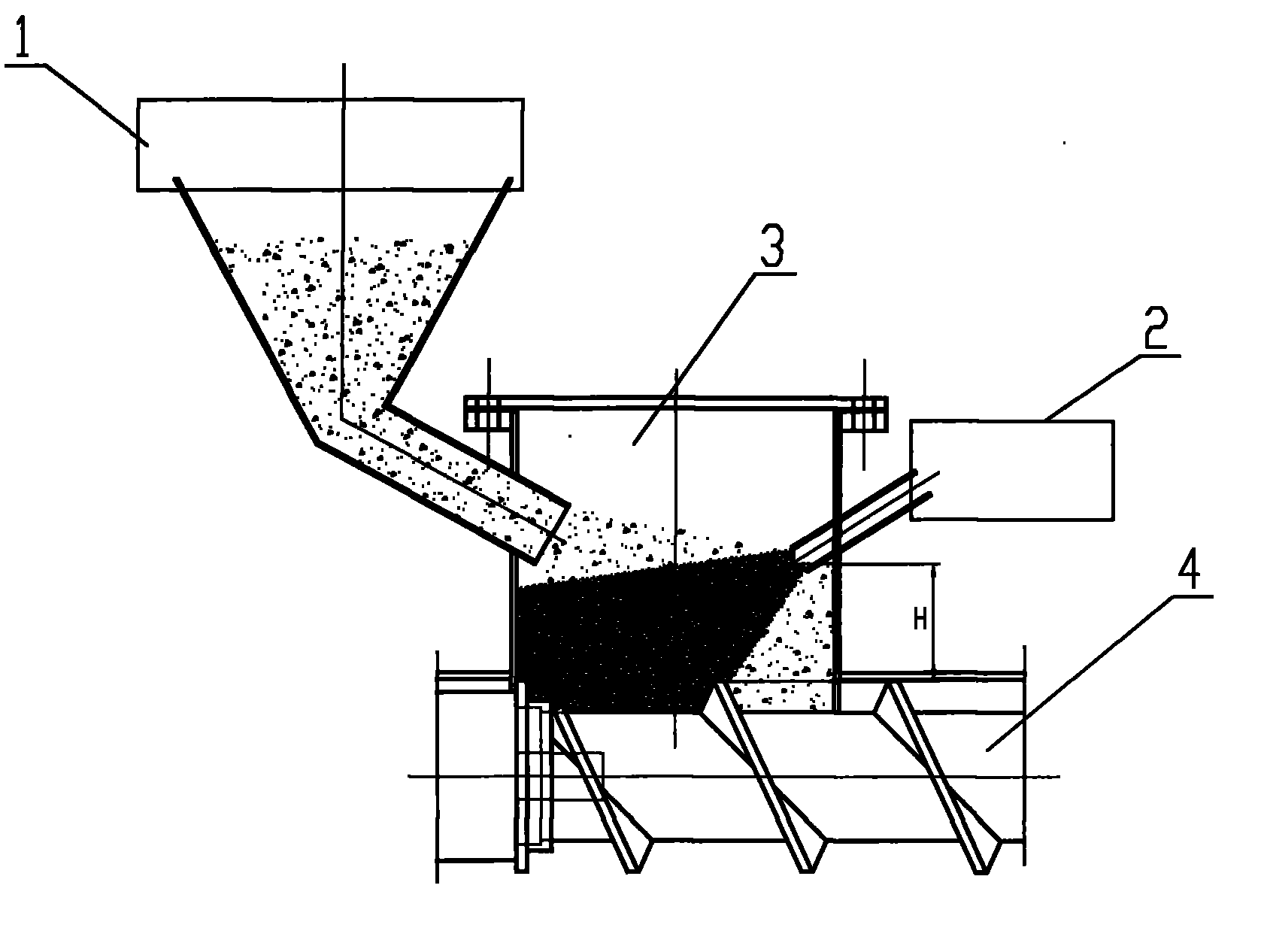

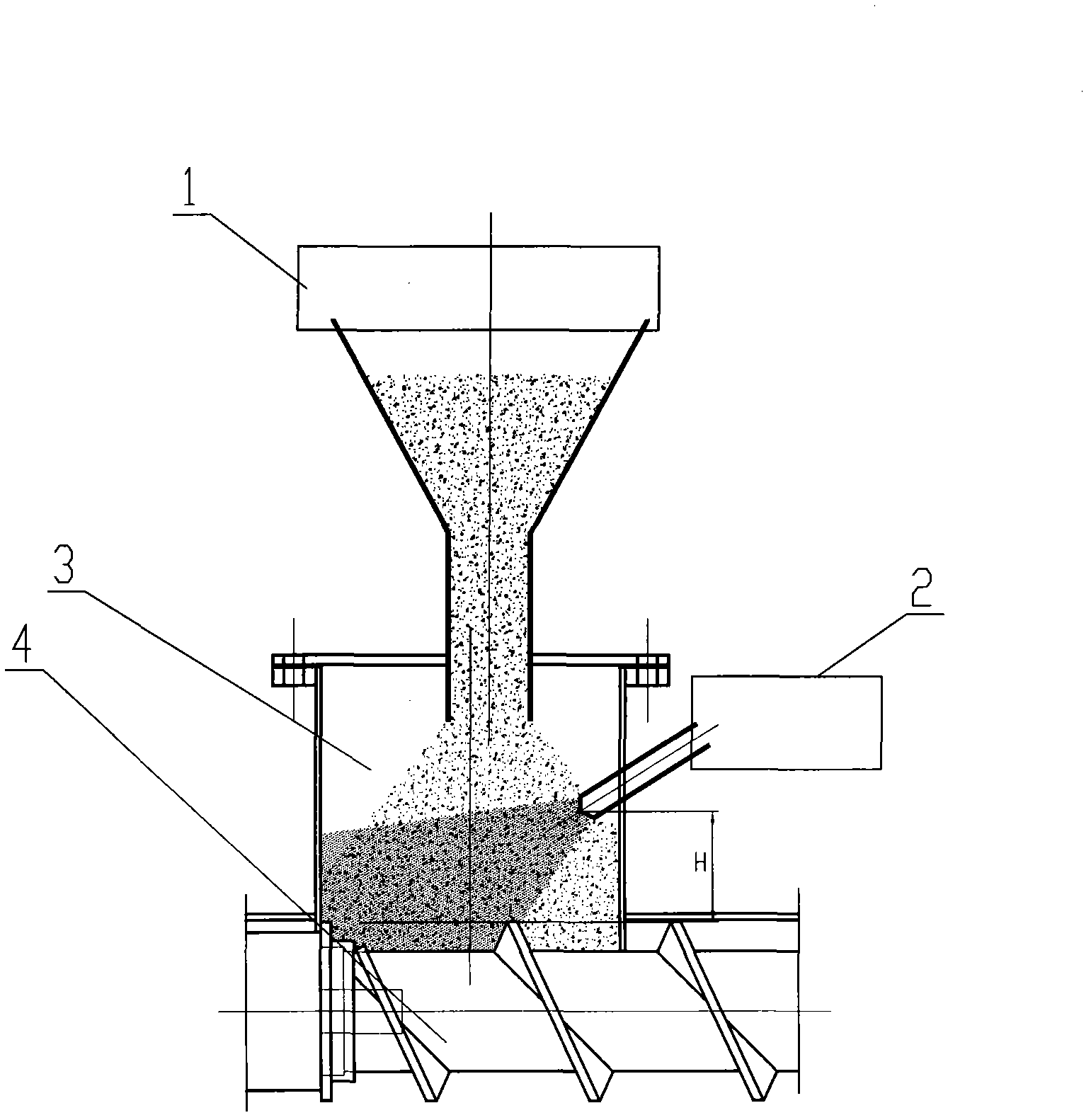

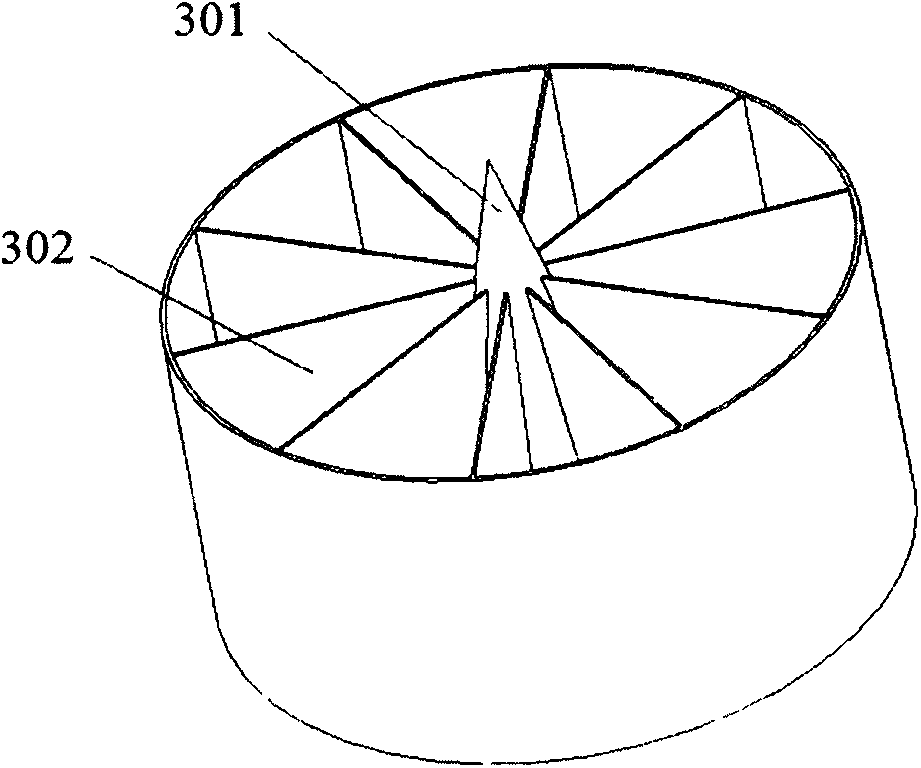

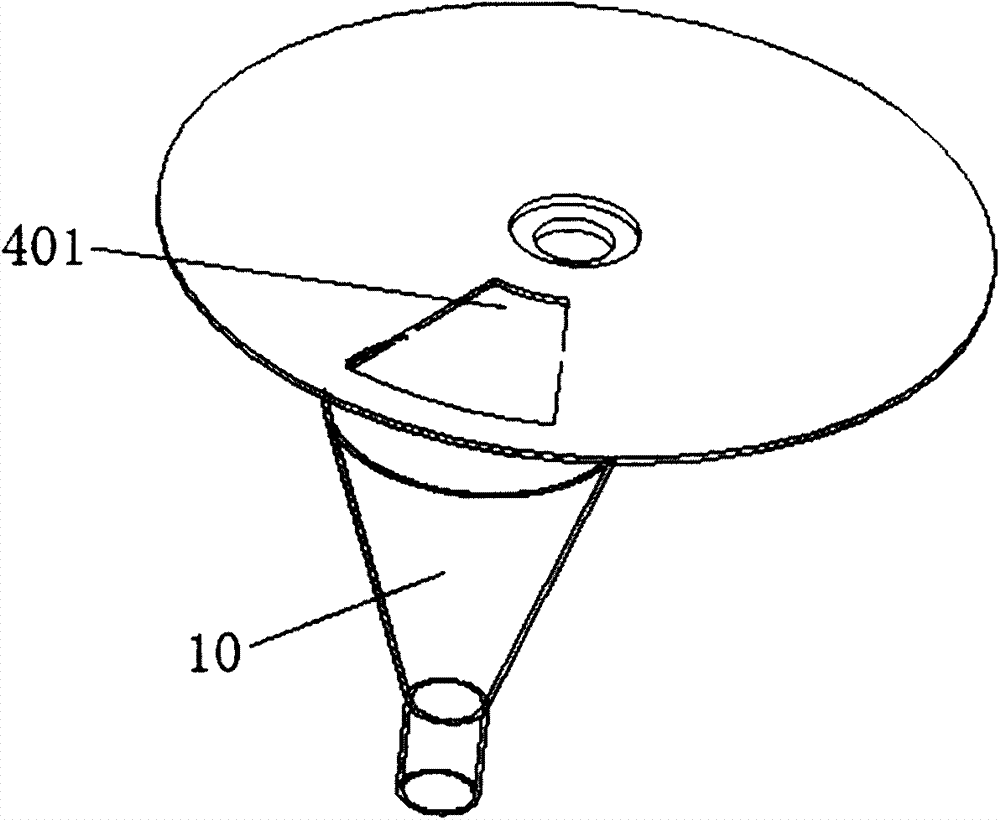

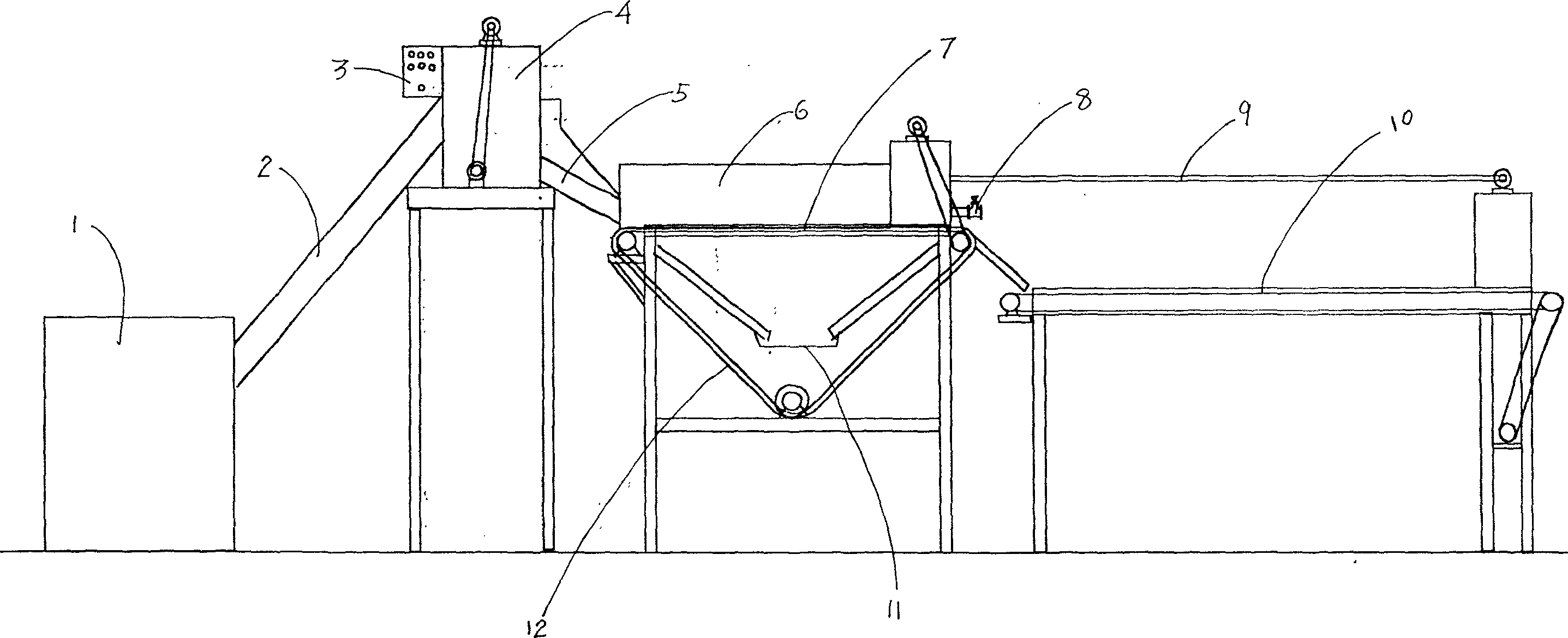

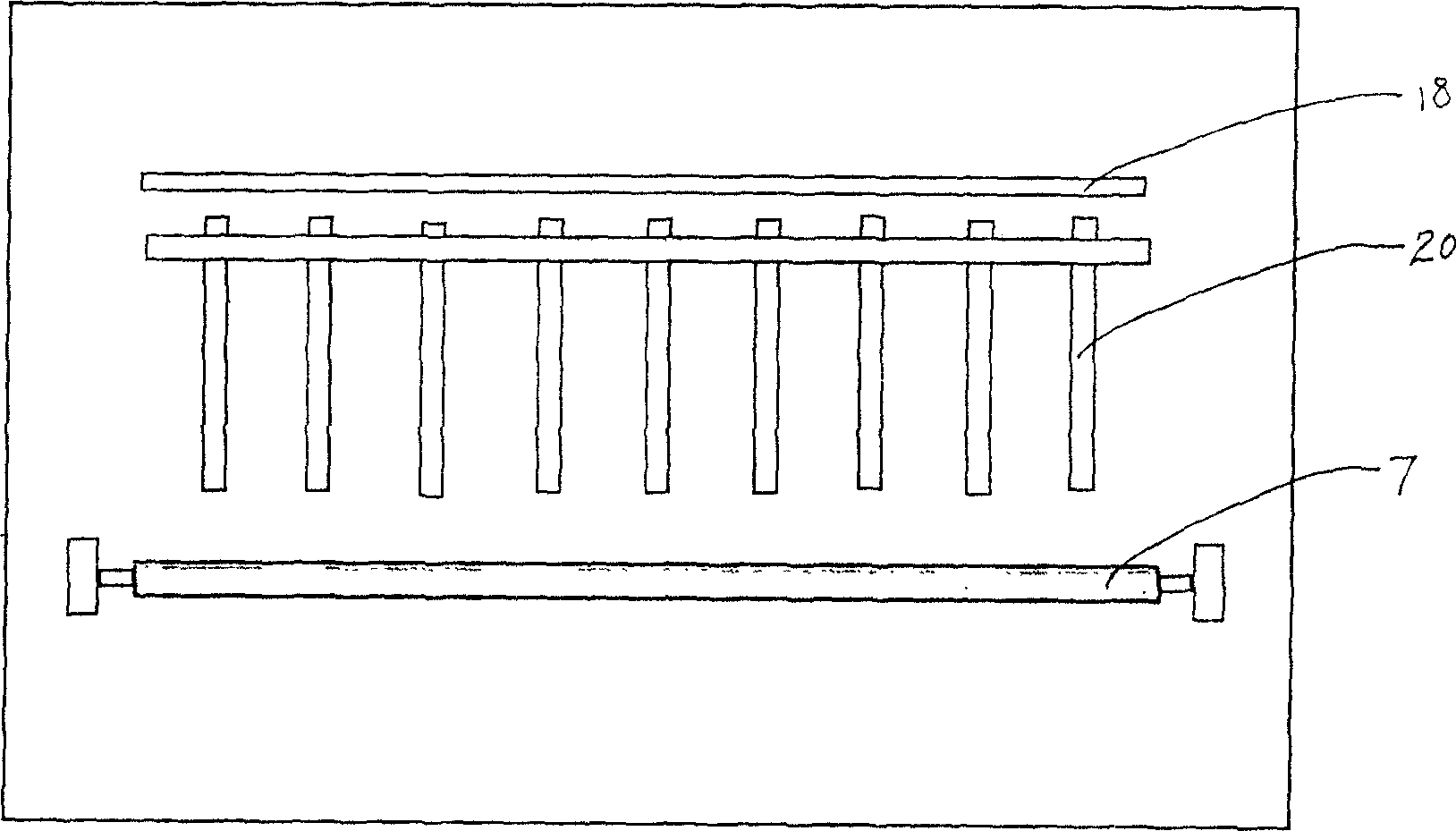

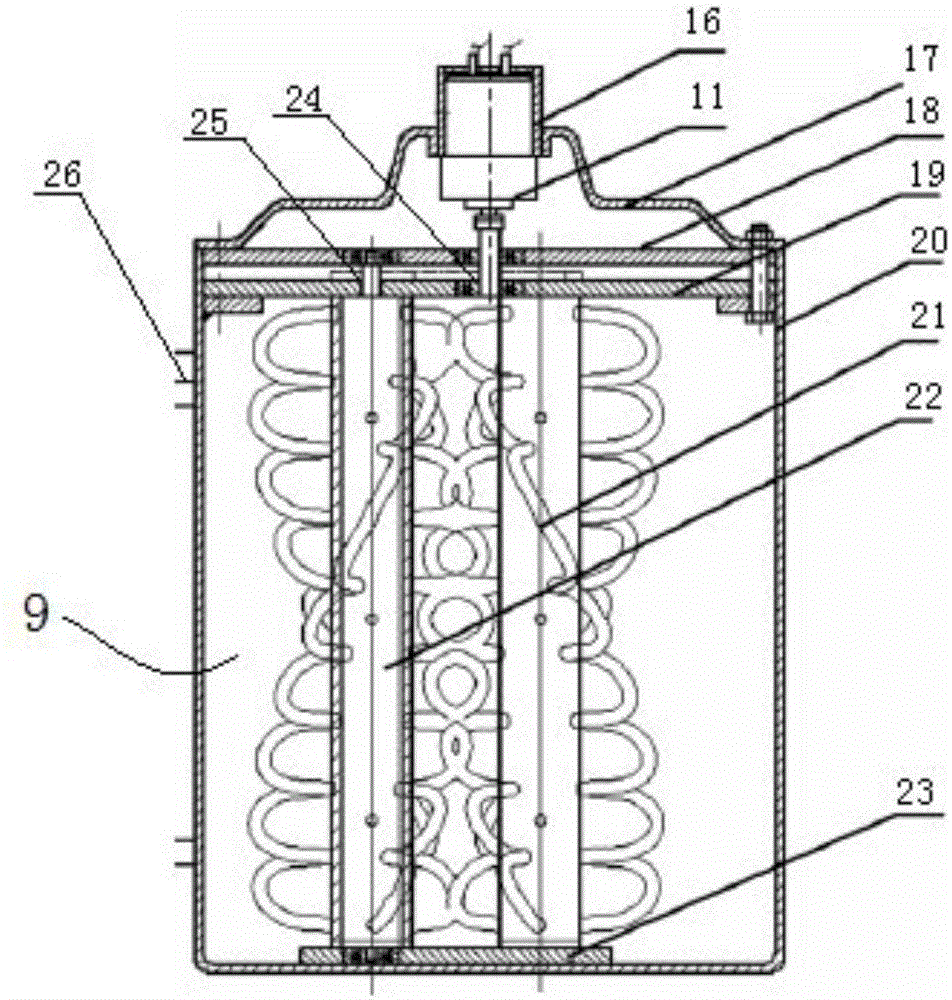

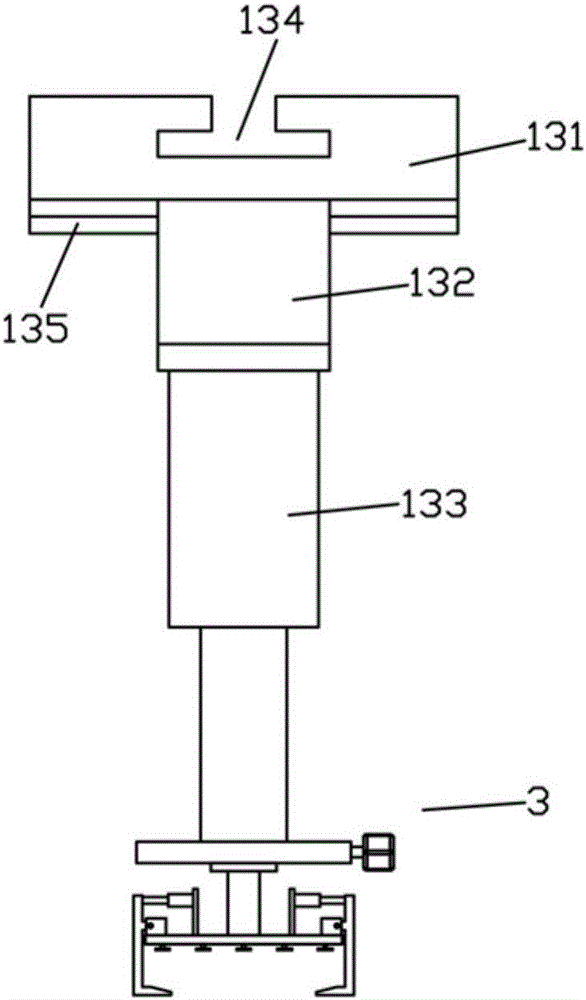

Catalyst successive impregnation equipment and method

ActiveCN102806109AImprove impregnation efficiencyImprove impregnation uniformityCatalyst activation/preparationEngineeringCatalyst support

The invention relates to catalyst successive impregnation equipment and a method. The catalyst successive impregnation equipment comprises a carrier continuous feeding system (1), an impregnation liquid conveying system (2), an impregnation chamber (3), a conveying part (4), a dryer (9) and a power system; the carrier continuous feeding system (1) and the impregnation liquid conveying system (2) are open in the impregnation chamber (3); the bottom of the impregnation chamber (3) is open at the initial end of the conveying part (4); the conveying part (4) is positioned between the impregnation chamber (3) and the dryer (9); an outlet at the tail end of the conveying part (4) is communicated with the dryer (9); and power is provided for the operation of the conveying part (4) by the power system. The invention also discloses the method applying the equipment. The catalyst successive impregnation equipment and the method which are provided by the invention can be used for carrying out catalyst carrier impregnation to prepare a catalyst; a catalyst carrier is continuously impregnated; the impregnation efficiency is high; the impregnation uniformity is good; and the catalyst carrier is crushed a little.

Owner:CHINA PETROLEUM & CHEM CORP +1

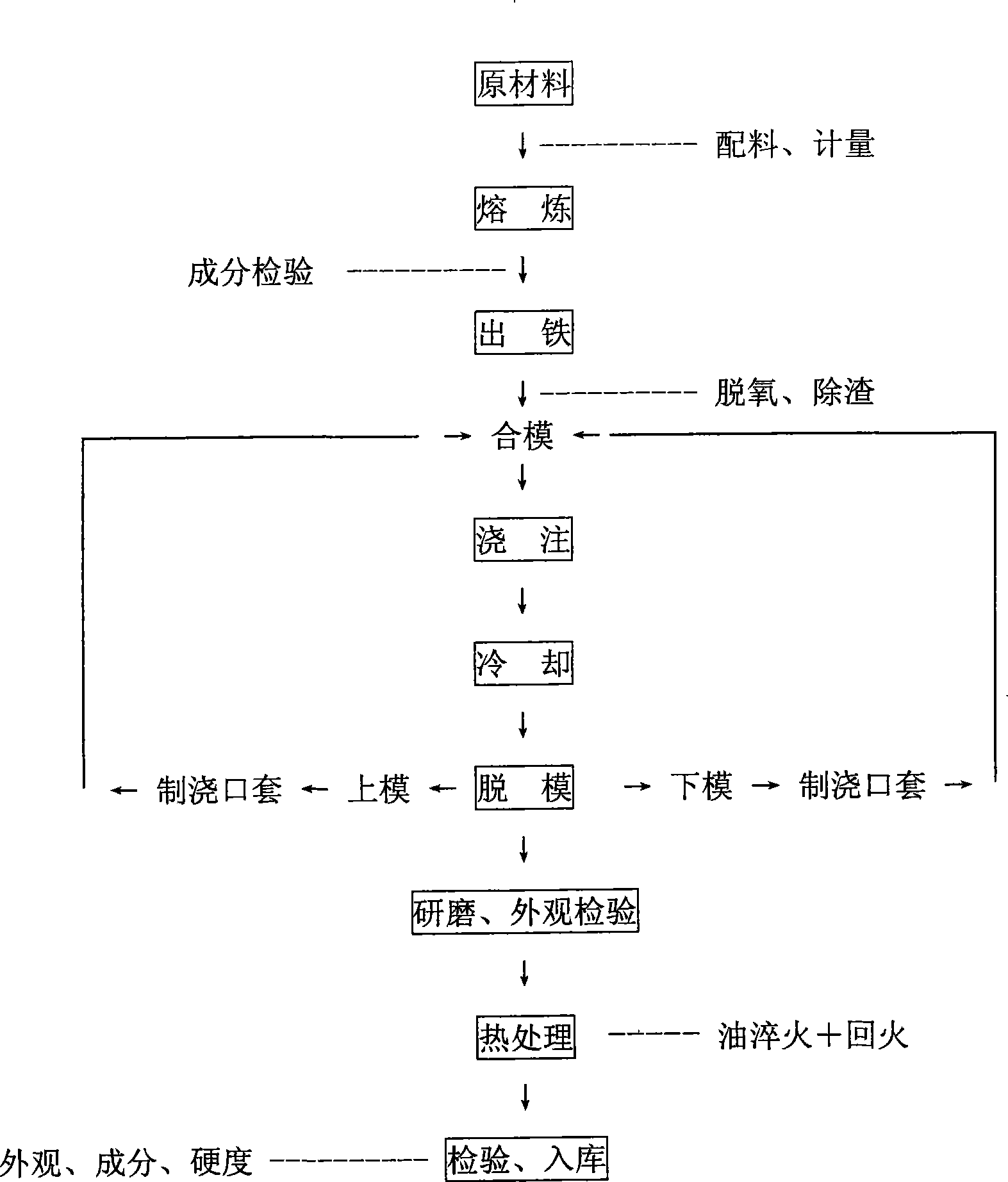

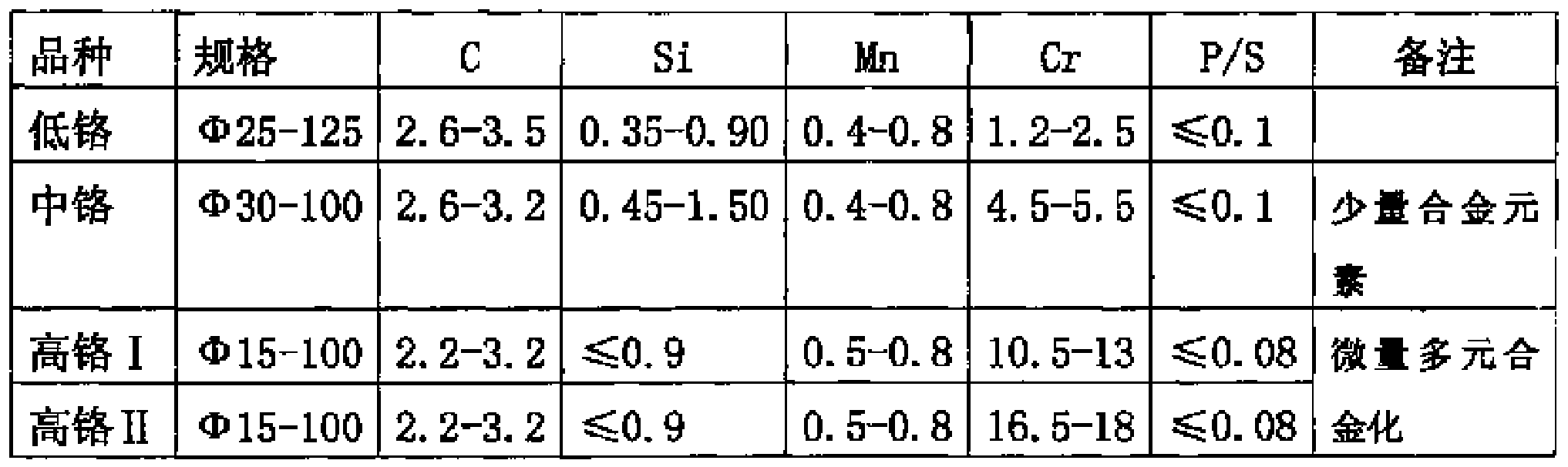

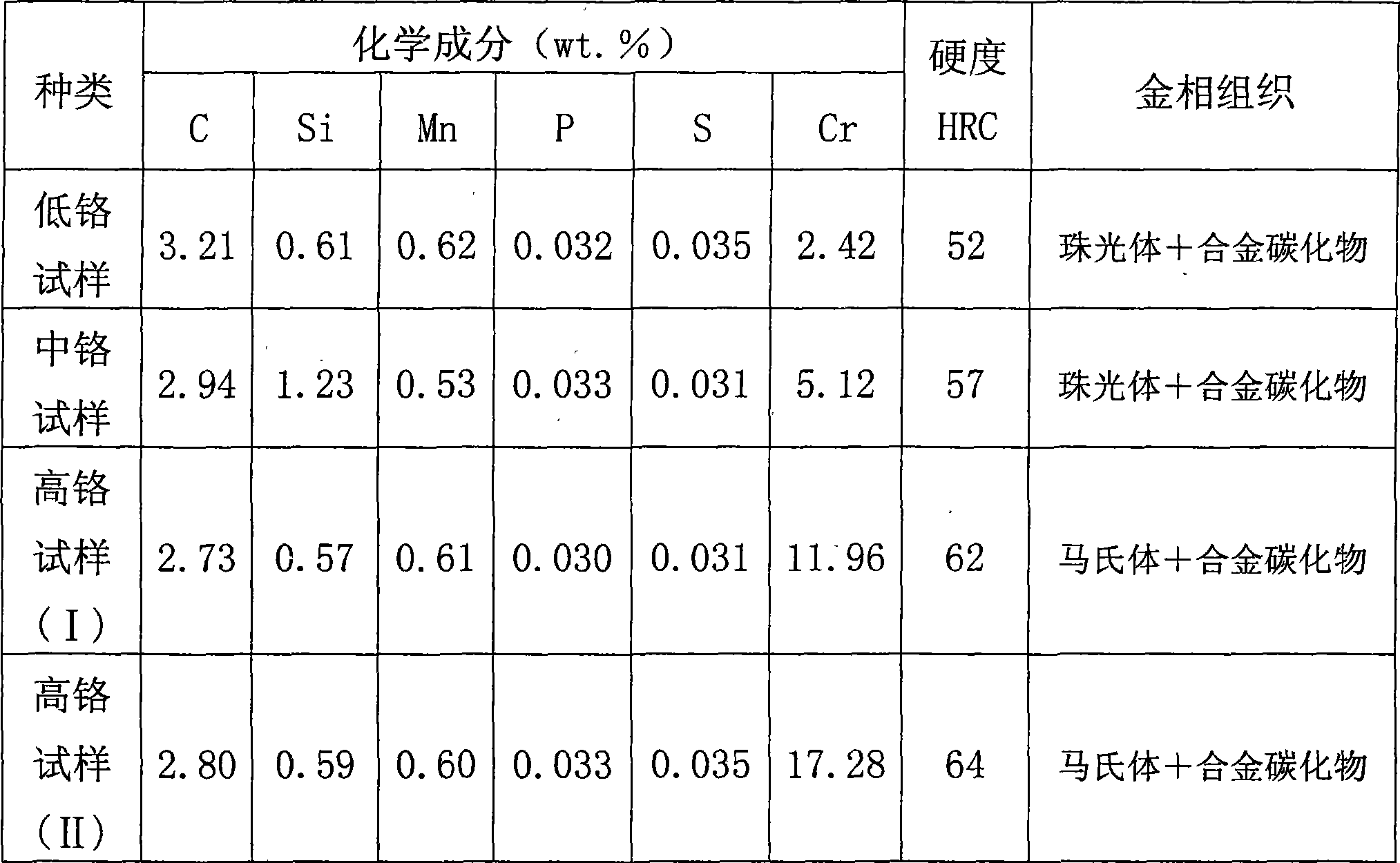

High abrasion proof re-synthesizing cast iron grinding ball and production method thereof

InactiveCN101445889AHigh hardnessImprove toughnessEdge grinding machinesPolishing machinesIntermediate frequencyCarbide

The invention relates to a high abrasion proof resynthesizing cast iron grinding ball for a ball grinding mill and a preparation method thereof. The method reduces the content of carbon in material on the premise that carbide is formed in materials, thereby reducing the contents of chrome and molybdenum in the material and simultaneously controlling the content of other elements, so that the obtained material of the grinding ball has good overall mechanical property and service performance. Compared with a No. 45 steel forging ball, the abrasion proof property of the grinding ball is improved by 3 to 10 times, so that both the consumption of steel products and the recourses are saved. In the method, cast iron is melted and synthesized by using an intermediate frequency electric furnace and a large amount of scrap steel, steel scraps and other renewable resources are utilized, so that not only the quality of synthetic cast iron products is improved and the performance is stabler, but also the pollution to environment is reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

High-carbon steel multi-alloy wear-resisting ball and production method thereof

ActiveCN101736200AGuaranteed wear resistanceHigh hardnessFurnace typesHeat treatment furnacesChemical compositionHigh carbon

The invention discloses a high-carbon steel multi-alloy wear-resisting ball and a production method thereof. The wear-resisting ball comprises the main chemical compositions in percentage by weight: 1.0-1.2% of C, 1.2-1.6% of Si, 1.6-2.2 % of Mn, less than or equal to 0.05% of P, less than or equal to 0.25% of S, 1.5-2.5% of Cr, 0.2-0.3% of Mo, 0.005-0.01% of B, 0.025-0.05% of Ti, 0.08-0.15% of V and the balance of Fe. The production method comprises the steps of melting stock, modifying twice, pouring, quenching, tempering and obtaining finished products. The grinding ball produced with the production method of the invention has high hardness, high wear resistance, high toughness and high impact resistance; the production method of the grinding ball is easy and simple to operate.

Owner:安徽中建材开源新材料科技有限公司

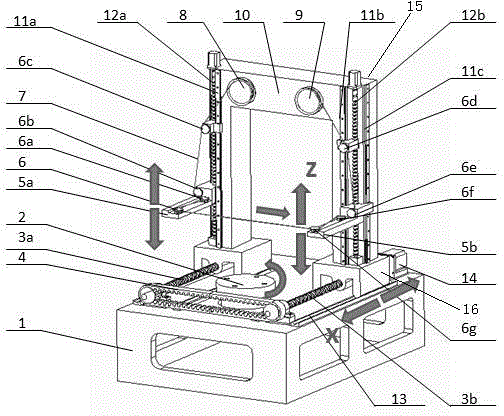

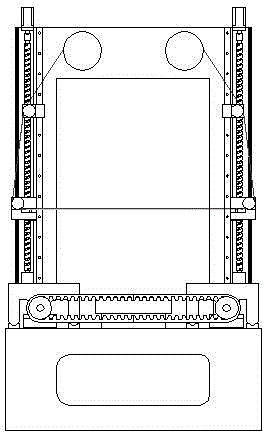

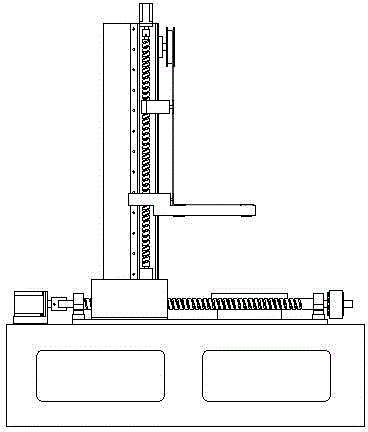

Horizontal diamond wire cutting machine tool

ActiveCN104890036AEasy clampingAvoid breakingMetal working apparatusStone-like material working toolsWire cuttingEngineering

Disclosed is a horizontal diamond wire cutting machine tool. The horizontal diamond wire cutting machine tool comprises a tool body (1), the tool body (1) is provided with a rotary worktable (2) for fixing workpieces, a portal frame (15), and a guide wheel group on the portal frame (15), wherein the portal frame (15) can be driven by an X-direction transmission mechanism on the tool body to move in an X direction. The horizontal diamond wire cutting machine tool is characterized in that the beam (10) of the portal frame (15) is provided with a pay-off drum (8) and a take-up drum (9), the stand columns on both sides of the portal frame (15) are respectively provided with an extending plate, and the cantilever end of each extending plate is provided with a cantilever end guide wheel; the extending plates on both sides are driven by the same or a separated Z-direction transmission mechanism to move up and down along the stand columns to control the height and accordingly to maintain a horizontal state so that a diamond wire on the cantilever end guide wheels on the cantilever ends can maintain a horizontal state and participate in cutting of the workpieces. The horizontal diamond wire cutting machine tool is convenient to fixe and high in machining efficiency and yield rate.

Owner:TAIZHOU CHEN HONG NC EQUIP MFG CO LTD +2

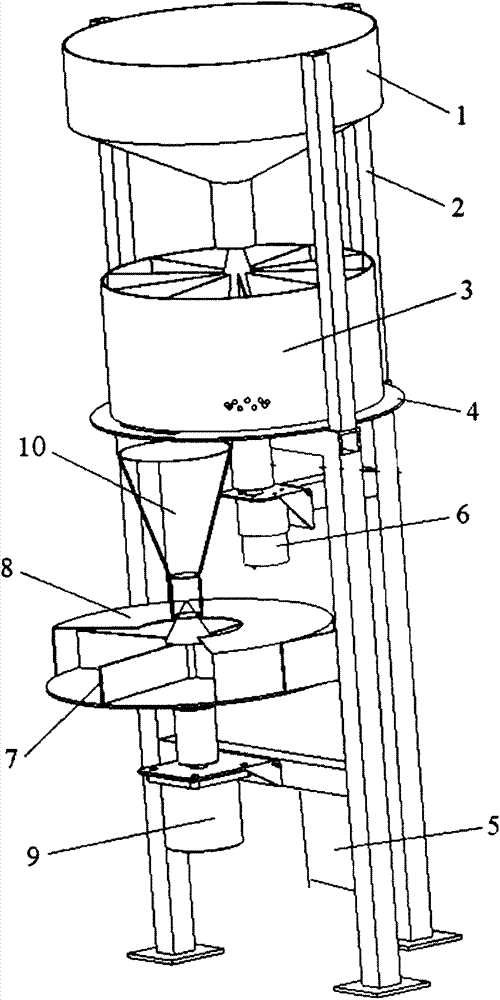

Quantitative material throwing device for aquaculture

InactiveCN103875579ASimple structureLow manufacturing costPisciculture and aquariaEngineeringAquaculture

The invention discloses a quantitative material throwing device for aquaculture and belongs to the field of aquaculture equipment. The device comprises a storage bin, a support, a quantitative bin, a quantitative tray, a conveying pipe, a feeding motor, a throwing tray, a throwing protection cover and a throwing motor, wherein the storage bin is fixedly installed on the top of the support, the quantitative bin is installed below the storage bin and is connected with the feeding motor, the quantitative tray is arranged on the bottom of the quantitative bin and is fixedly installed on the support, a quantitative hole is formed in the quantitative tray, the conveying pipe is arranged below the quantitative hole, the throwing tray is arranged below the conveying pipe and is connected with the throwing motor, and the throwing protection cover is arranged on the throwing tray in a covering mode. According to the device, the problem of uneven feed throwing is solved, even throwing all over the pond is realized in the true sense, the use efficiency of feed is improved, and the influence of aquaculture on the environment is reduced. Furthermore, the device is simple in structure and low in manufacturing cost and is worth popularization.

Owner:常州智能农业装备研究院有限公司

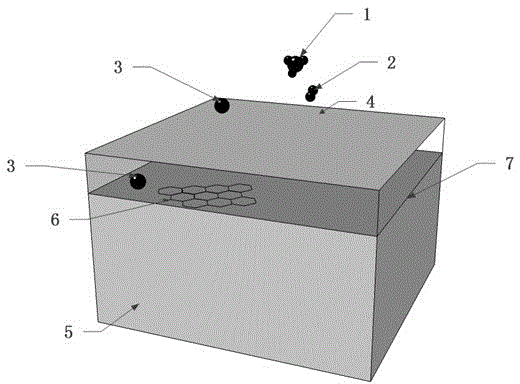

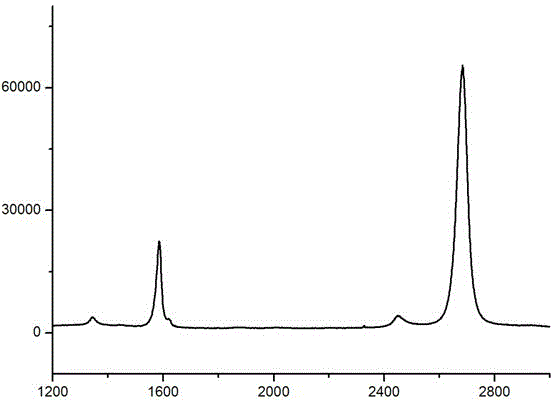

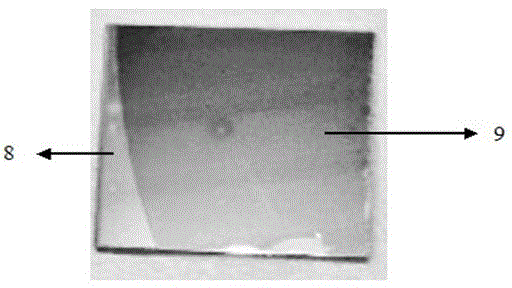

Graphene preparation method

ActiveCN103981507AImprove mobilityStrong adhesionChemical vapor deposition coatingHydrogenMetal catalyst

The invention discloses a graphene preparation method, belongs to the technical field of information materials, and aims at providing a novel method for preparing graphene by using plasma chemical vapor deposition. According to the technical scheme, the graphene preparation method comprises the following steps: cleaning a polished substrate; plating a metallic catalyst membrane on the substrate; putting the substrate plated with the metallic catalyst membrane in a reaction cavity of chemical vapor deposition equipment; feeding hydrogen into the reaction cavity; starting a plasma ball and a heating power supply; preheating to 500-900 DEG C, and feeding a carbon source gas, so graphene begins to grow; after completing the growth of the graphene, closing the heating power supply and a plasma power supply, and cooling the substrate; and after cooling to a room temperature, taking out the substrate, and removing the metal catalyst membrane by adopting an etching method, thus obtaining the graphene. The graphene preparation method is mainly used for manufacturing of graphene and graphene-based devices.

Owner:四川英能基科技有限公司

Peeling machine for orange

InactiveCN1631272AHigh success rate of one-time peelingImprove productivityVegetable peelingFood treatmentProduction rateSEMI-CIRCLE

Disclosed is an orange barking machine, which comprises a peel cutting device, a barking device, a transfer arrangement connected therewith, a mated sprinkling arrangement, and an electric controller, the peel cutting device comprises a high speed rotating peel cutting knife roller, an upper guide plate and a lower guide plate, the peel cutting knives on the knife roller are arranged along the single-head spiral lines at equal appearing interval on the roller surface, the barking device comprises bicycle chain conveyor belt and shift rod rows, each husking roll is equipped with even teeth in the shape of semi-circles with coated silicone rubber material.

Owner:象山双鱼轻工机械有限公司

Refined rice processing method

InactiveCN104815714AGuaranteed purityHigh purityGrain huskingGrain polishingBroken riceMoisture measurement

The invention discloses a refined rice processing method. The refined rice processing method comprises the following steps of rice screening, stone removal, magnetic separation and rice shelling, rice-bran separating, secondary shelling, thickness grading, moisture measurement and drying or atomizing, rice milling and white rice grading, rice cooling, polishing, color sorting, secondary white rice grading and moisture content detection, and packaging. The refined rice processing method comprises a plurality of impurity removal steps, and consequently, the purity of rice is guaranteed, the produced rice is high in purity, and the safety and the processing efficiency in the processing process are guaranteed. In the rice shelling and rice milling steps of the refined rice processing method, the material temperature is strictly controlled so that the material can be always kept in a relative low temperature appropriate environment, and the crack ratio and the broken rice rate can be reduced and the complete particle rate can be increased; the original faint scent of rice is maintained. The refined rice processing method is used for solving the problems of surface damage and uneven polishing in the rice polishing process by controlling the polishing water temperature and the dampening amount; as a result, the surfaces of all the rice grains polished can be kept smooth and clean, and the quality guarantee period of the rice can be prolonged.

Owner:ANHUI YOUYUAN FOOD

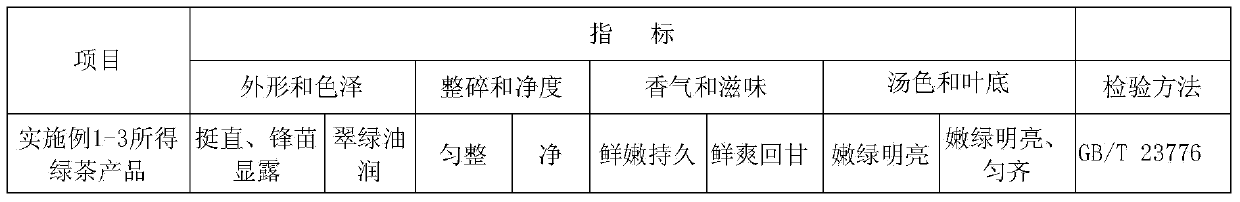

Green tea and processing method thereof

ActiveCN104186736AImprove freshnessImprove quality foundationPre-extraction tea treatmentGreen teasProcess engineering

The invention relates to a processing method of green tea. The processing method comprises the processing steps of raw material selection, picking, spreading, fixation, spreading, rolling, shaping, baking and the like, wherein the types of selected raw materials are strictly controlled to be Nanjiang #1, Zaobaijian #5 or Fuding Dabai tea; the raw materials are required to be picked in a harmless ecological tea garden at the elevation of 550-650m in sunny days in the middle of March under the temperature of 20-25 DEG C. The processing method is executed by the processing technologies such as high-quality raw material selection and optimized spreading, so that the quality of the green tea is improved.

Owner:CHONGQING YUNLING TEA IND TECH

Film-forming agent composition and starchiness vegetable adhesive containing the composition

InactiveCN101245157APromote digestion and absorptionReduce breakage rateMicroballoon preparationMicrocapsule preparationMicrobial pollutionAdhesive

The invention provides a film forming compound with modified starch as the main component, a film forming material containing the compound, and more particularly a hard-shell natural capsule made from the compound. The compound contains no or very little animal protein such as gelatin, etc. The compound can partially or completely replace the gelatin from animals for producing natural hard-shell capsules. The prepared natural capsule shell product has the advantages of excellent film forming property, high strength, good flexibility, high transparency, decomposability and microbial pollution resistance. The main component of the compound, modified starch, has stable quality and highly controllable performance.

Owner:长春大成特用玉米变性淀粉开发有限公司

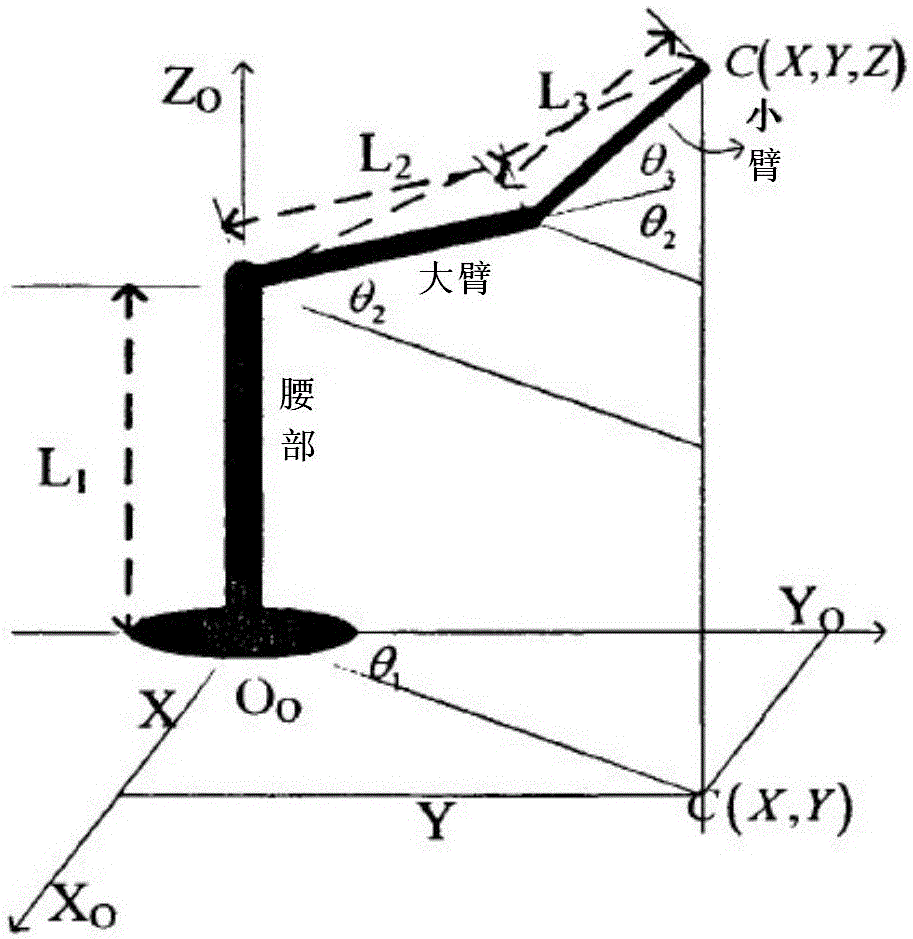

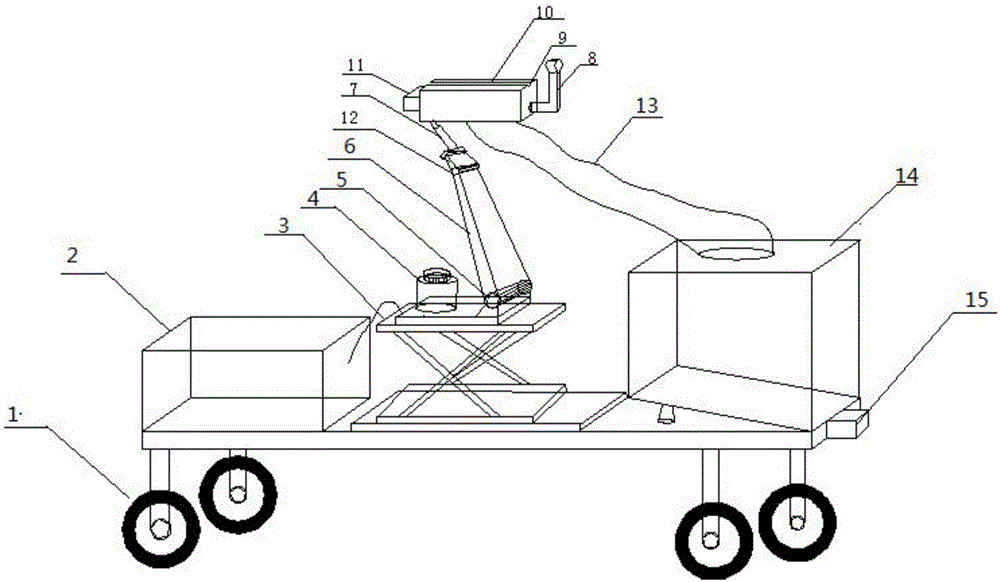

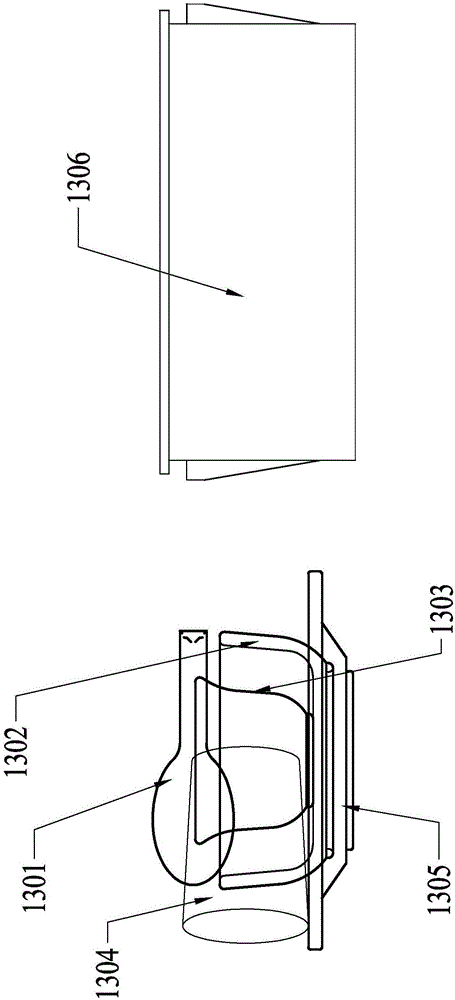

Wolfberry picking robot and control method thereof

InactiveCN105123127ARealize self-pickingRealize normal pickingPicking devicesControl mannerData acquisition

The invention discloses a wolfberry picking robot. A wolfberry picking robot system adopts a pinhole imaging technology and mainly comprises a data acquisition card and an analog-digital conversion module. A control method mainly adopts a fuzzy PID self-adaptive control way and is mainly used for controlling the vision. Hardware of the wolfberry picking robot mainly consists of a mechanical arm, a rotor structure, a picking head and various motors. By adopting the wolfberry picking robot, the automatic picking of wolfberry can be implemented, the manpower can be completely substituted, and the problem that the manual picking is subjected to the influence of the environment can be solved. The wolfberry picking robot is high in automation degree and high in picking efficiency.

Owner:BEIFANG UNIV OF NATITIES

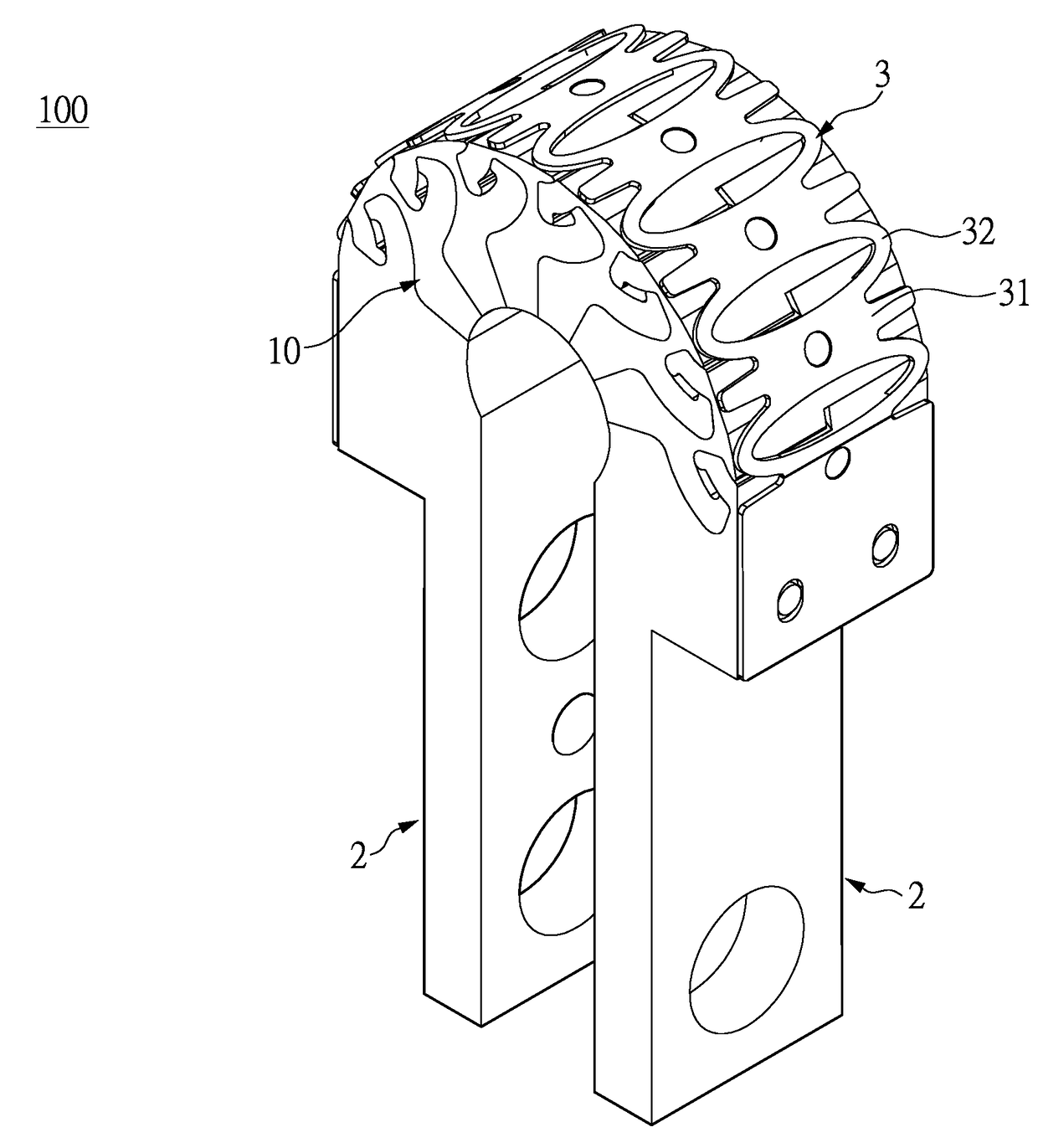

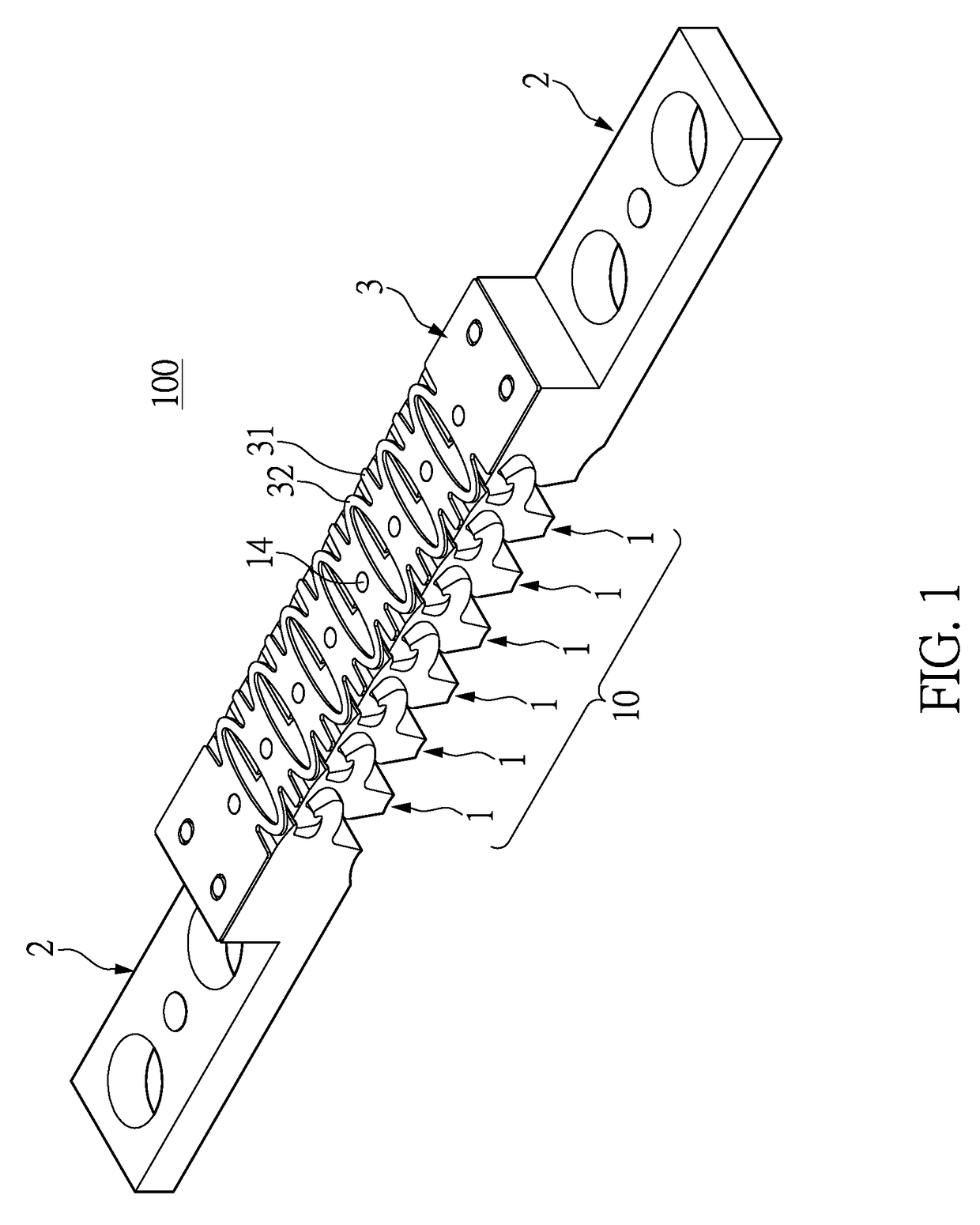

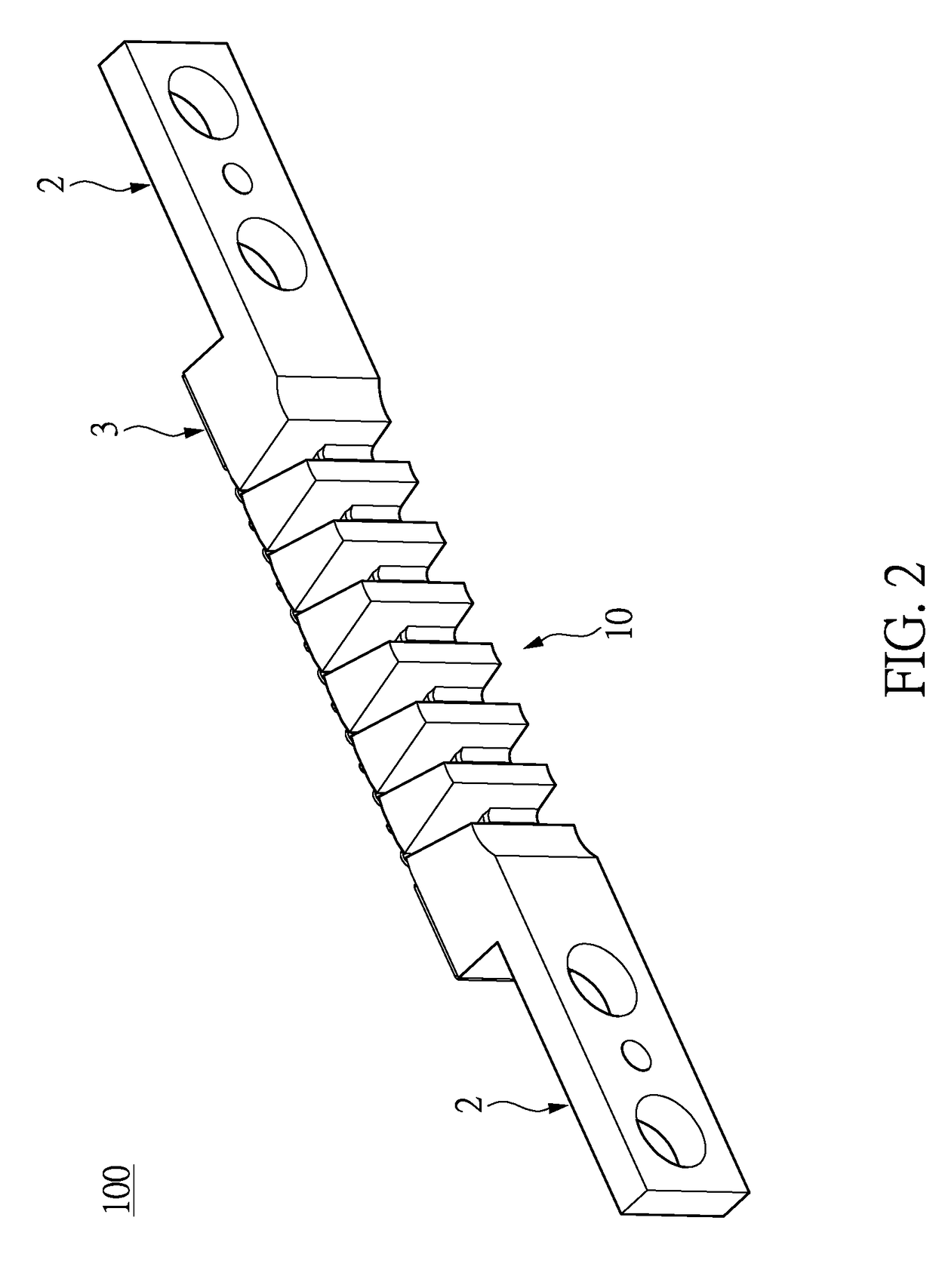

Supporting device and display apparatus

ActiveUS20180092223A1Efficient solutionReduce breakage rateDigital data processing detailsCasings with display/control unitsMechanical engineeringEngineering

A supporting device includes a modular joint assembly, two fixing members respectively installed on two opposite ends of the modular joint assembly, and a resilient sheet fixed on the outer surface of the modular joint assembly and the fixing members. The modular joint assembly includes a plurality of joints buckled in sequence. Each joint has an arced track groove recessed on a side surface thereof and a buckling portion extended from an opposite side surface thereof. An imaginary datum line is defined by connecting a center of circle of each track groove and is located at one side of the resilient sheet away from the modular joint assembly. When any two buckled joints are rotated with respect to each other, the resilient sheet is compressed and a length of the imaginary datum line is unchanged.

Owner:FIRST DOME

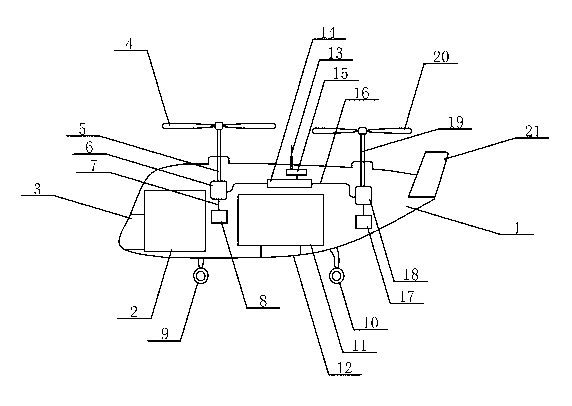

Unmanned aerial vehicle for express parcels

The invention relates to an unmanned aerial vehicle for express parcels, belonging to the technical field of unmanned aerial vehicle application. Parcels to be expressed are firstly loaded in a cargo hold A and a cargo hold B, respectively, and a cargo hold exit door A and a cargo hold exit door B are closed at the same time. A signal received by a wireless antenna is input into a navigation radar and a computer control center, a lithium ion battery A supplies power to drive a motor A, a transmission shaft A and a rotating wing A to rotate to generate flying power, a lithium ion battery B supplies power to drive a motor B, a transmission shaft B and a rotating wing B to rotate to generate flying power, the navigation radar and the computer control center control the rotation of the motor A and the rotating wing A and the rotation of the motor B and the rotating wing B, and the unmanned aerial vehicle flies to a destination according to a flight line set by the navigation radar and the computer control center control after the flight direction is regulated and controlled by a tail vane. A cargo hold door A is opened to take out the express parcels in the cargo hold A and a cargo hold door B is opened to take out the express parcels in the cargo hold B after forward walking wheels and backward walking wheels at the bottom part of the unmanned aerial vehicle land at the destination.

Owner:WUXI TONGCHUN NEW ENERGY TECH

Method for preparing micro expanded inorganic heat insulation mortar

ActiveCN102010166AWide variety of sourcesLow priceSolid waste managementCeramicwareMethyl celluloseEther

The invention discloses a method for preparing micro expanded inorganic heat insulation mortar. Materials such as common silicate cement, desulfuration ash, calcium carbonate powder, re-dispersible latex powder, hydroxypropyl methyl cellulose ether, wood fiber, polypropylene fiber, surfactant, foam stabilizer, water, vitrified micro bubbles and the like are adopted; and the mortar is obtained by adopting the steps of stirring, mixing, shaping, curing and the like. The method has the advantages of low cost, early micro expansion, low later linear shrinkage rate, fire resistance, durability and the like, is easy to construct, and achieves good effect of preparing the I-type building heat insulation mortar by using the III-class vitrified micro bubbles.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV +1

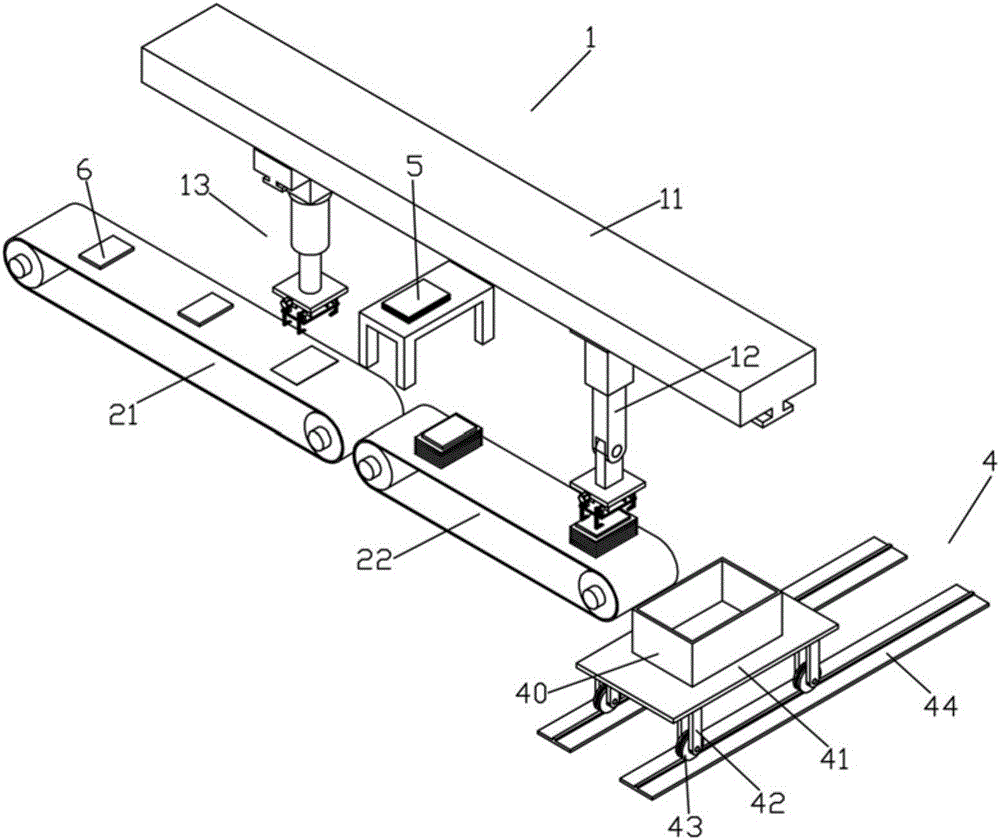

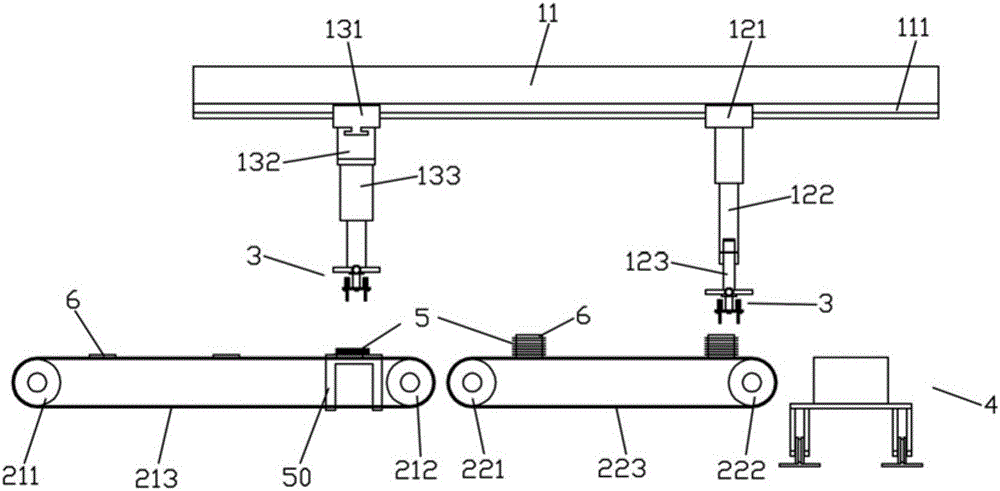

Architectural glass encasement device

ActiveCN105668235AReduce breakage rateEfficient handlingConveyorsCharge manipulationArchitectural glassProduction line

The invention discloses an architectural glass encasement device. The architectural glass encasement device comprises a stacking and packaging unit, a conveying unit, a finished product conveying unit, a protective layer supplying unit and a control unit, wherein the control unit is electrically connected to the stacking and packaging unit, the conveying unit and the finished product conveying unit and guarantees that each unit can complete corresponding operation on architectural glass. The architectural glass is conveyed to the conveying unit through a production line, and the stacking and packaging unit carries out stacking before encasing and encasing after stacking. According to the encasement device, carrying, packaging-protecting and stacking-encasing of the glass can be carried out efficiently and quickly, workers are prevented from working for a long time, the labor force is liberated greatly, the production efficiency is improved, the production cost is lowered, the breakage rate of the architectural glass is lowered, and the work accidents of the workers are greatly reduced.

Owner:YANGZHOU STRVALUE INFORMATION TECH CO LTD

Pre-sulfurizing process of hydrogenating catalyst

InactiveCN1417299AReduce breakage rateImprove broken rateHydrocarbon oils refiningSulfurRoom temperature

The pre-sulfurizing process of hydrogenating catalyst includes impregnating the hydrogenating catalyst in solution containing sulfurized olefin at room temp-220 deg.c for 0.5-5 hr, and heating catalyst in inert atmosphere. The solution containing sulfurizing olefin is in the temperature of room temperature to 220 deg.c and has dissolved S element, total S content of 4-40 wt% and the weight ratio between S in element state and S in sulfurized olefin of 0.5-7. The sulfurized hydrogenating catalyst contains S in 1-7.5 w. The pre-sulfurizing process of hydrogenating catalyst can lower its breaking rate greatly and raise the S retention degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

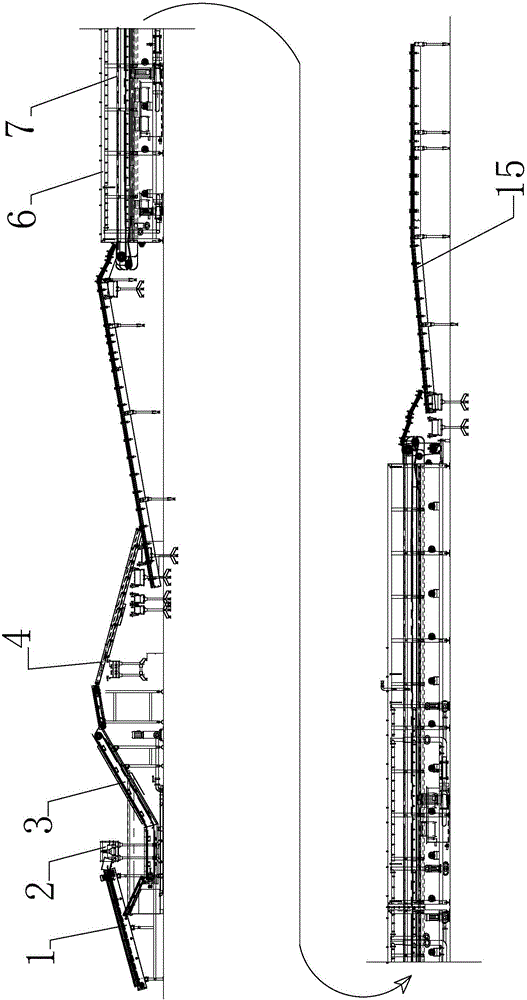

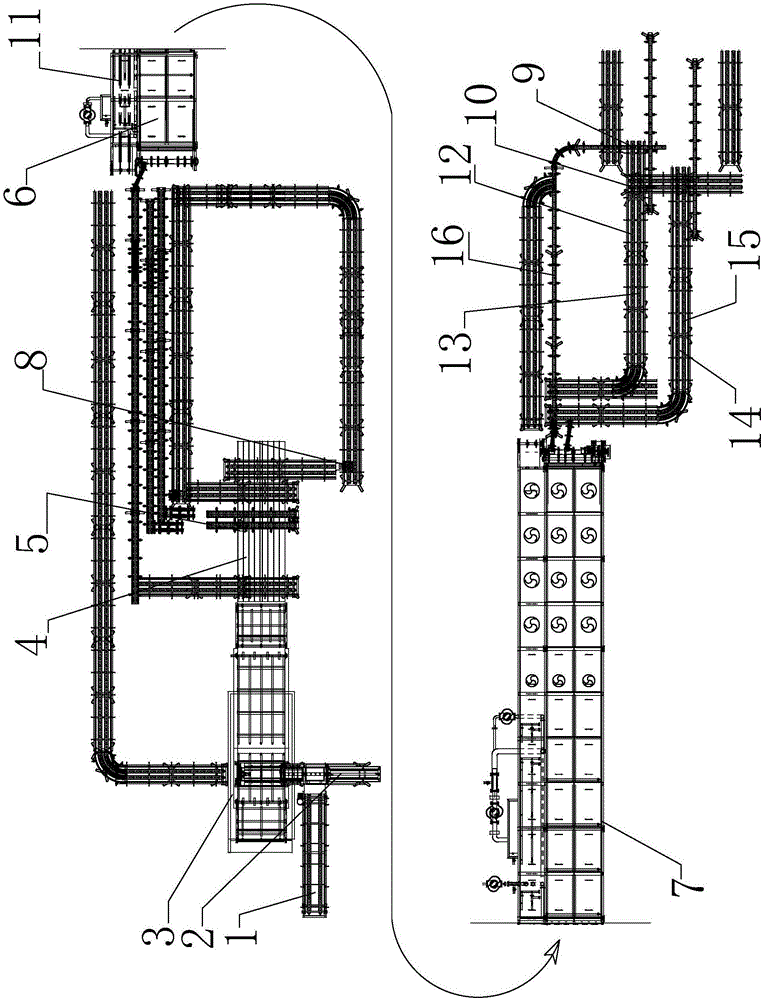

Tableware cleaning line

PendingCN106725183APrevent overturningAvoid wastingTableware washing/rinsing machine detailsCleaning equipmentSlagEngineering

The invention discloses a tableware cleaning line which comprises a top box elevator, an automatic turnover machine, a coarse washing machine, a box body conveyor, a tableware sorting device, tableware conveyor belts, a can turnover device, a cleaning tunnel, a packaging and conveying belt and a tableware assembly device, wherein the discharge end of the top box elevator is close to the feeding end of the automatic turnover machine; an inclined slag remover and a coarse washing machine elevator are arranged in a pond of the coarse washing machine separately; the discharge end of the coarse washing machine elevator is connected with the feeding end of an anti-patterning machine; the out-box end of the automatic turnover machine is provided with the box body conveyor which passes through a box body cleaning room of the cleaning tunnel; the discharge end of the anti-patterning machine is connected with the feeding end of the tableware sorting device; each tableware outlet of the tableware sorting device is correspondingly provided with one tableware conveyor belt separately; and spoons and chopsticks are directly conveyed through the tableware conveyor belts and enter the feeding end of a spoon and chopstick conveyor mesh belt. According to the tableware cleaning line, classifying and cleaning of the tableware are achieved, cleaning is more thorough, and the cleaning efficiency of a table set is greatly improved.

Owner:SHANDONG DINGTAISHENG FOOD IND EQUIP

Alcoholization agent for tobacco leaf and application in technique of threshing and redrying, procedure

An alcoholizing agent of tobacco leaf for improving the biologic property and quality of tobacco leaf and shortening its alcoholizing period contains the enzyme chosen from proteniase, peptidase, cellulase and amylase, one or more of isopentanal, benzoic acid, 2,6,6-trimethyl cyclohexyl-1,3-dienyl formaldehyde, etc, acetic acid and / or 1-methyl-4-isopropylcyclohexyl-3-alcohol, and propanediol.

Owner:SHENZHEN BOTON FLAVORS & FRAGRANCES

Hobbing type lotus seed shucker

The invention relates to a hobbing type lotus seed shucker, which is composed of a frame, a feeding mechanism, a conveying mechanism, a cutting mechanism, an uncoating mechanism, a motor and the like, wherein the conveying mechanism is driven by a grooved pulley, and step performing of lotus seed shucking and uncoating is realized by the intermittent movement of a grooved pulley mechanism, so that the shucking is more thorough and more effective; and spring adjustment systems are respectively installed on the shucking mechanism and the uncoating mechanism, and the springs can automatically adjust the distance between a cutting blade and an uncoating roller as well as a rubbing roller according to the lotus seed size, so that the shucking of lotus seeds with different sizes is adapted. The shucker has the characteristics of high shucking rate and low breakage rate in the shucking process, and has the characteristics of simple structure, small volume, low manufacturing cost, stability in operation and the like in the equipment performance.

Owner:NANCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com