Patents

Literature

111 results about "Stone removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

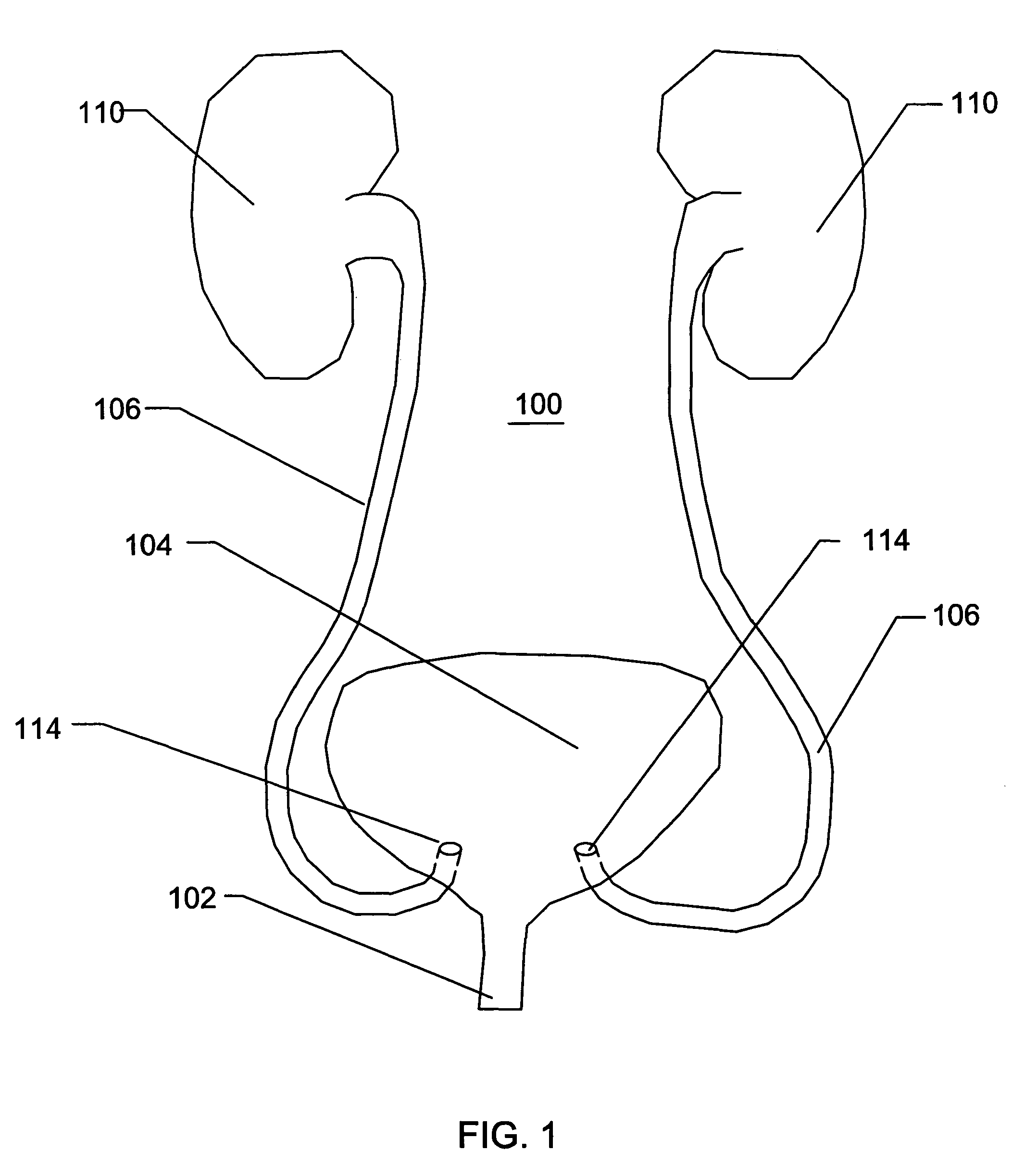

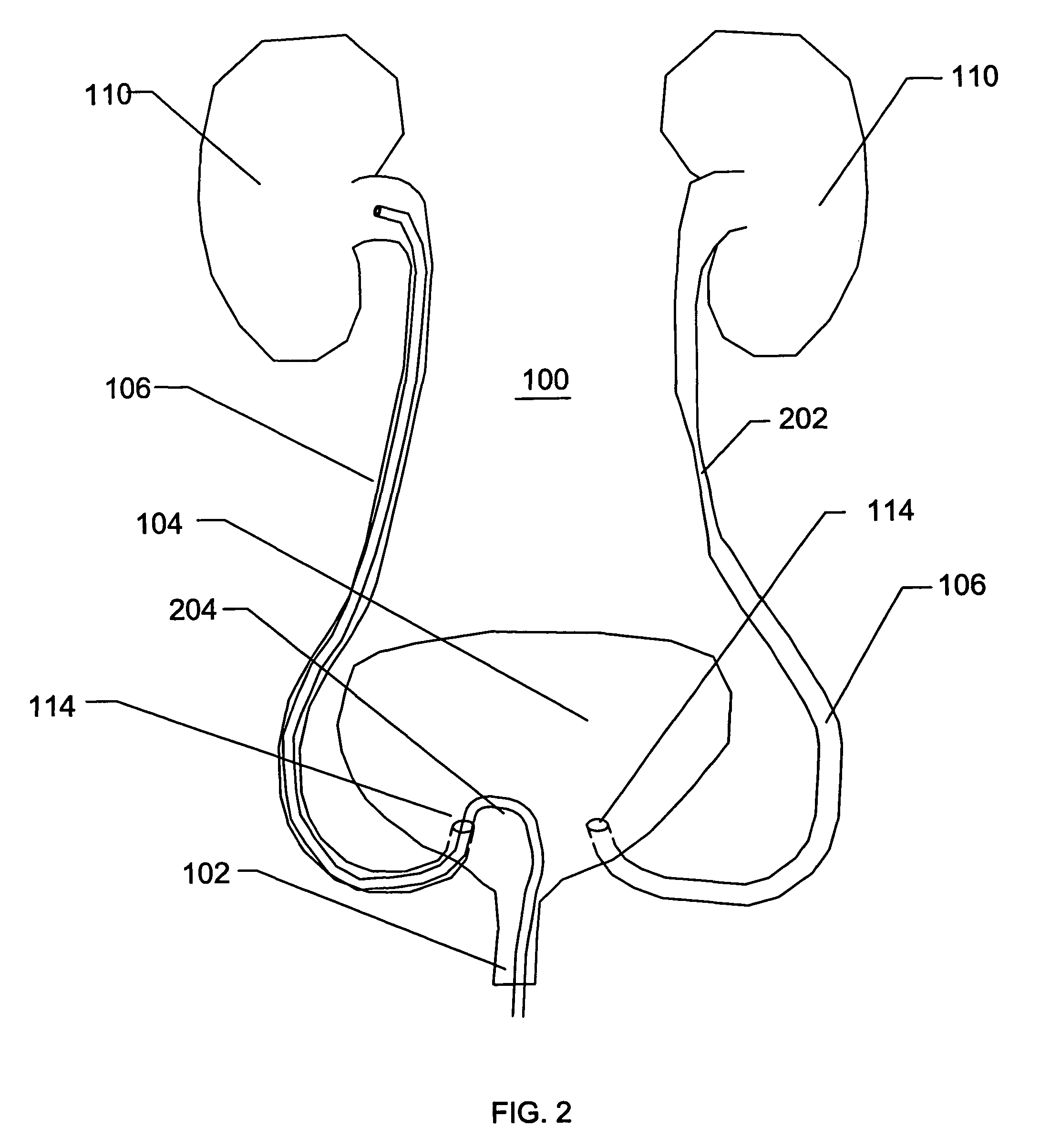

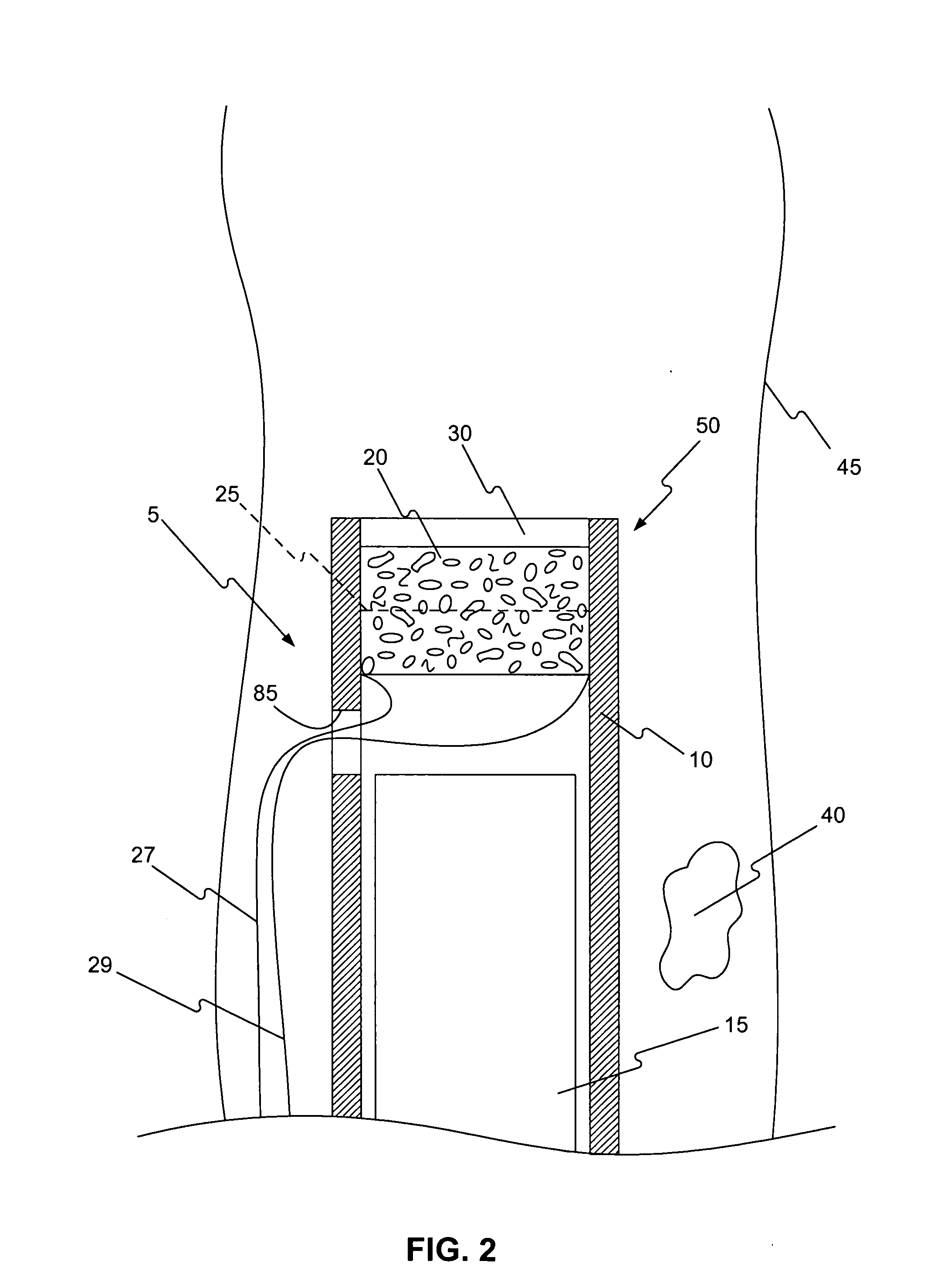

In this procedure of kidney stone removal, the surgeon makes an insignificant incision in the back and makes a tunnel immediately into the kidney. By means of an instrument called a nephroscope, the stone is positioned and removed.

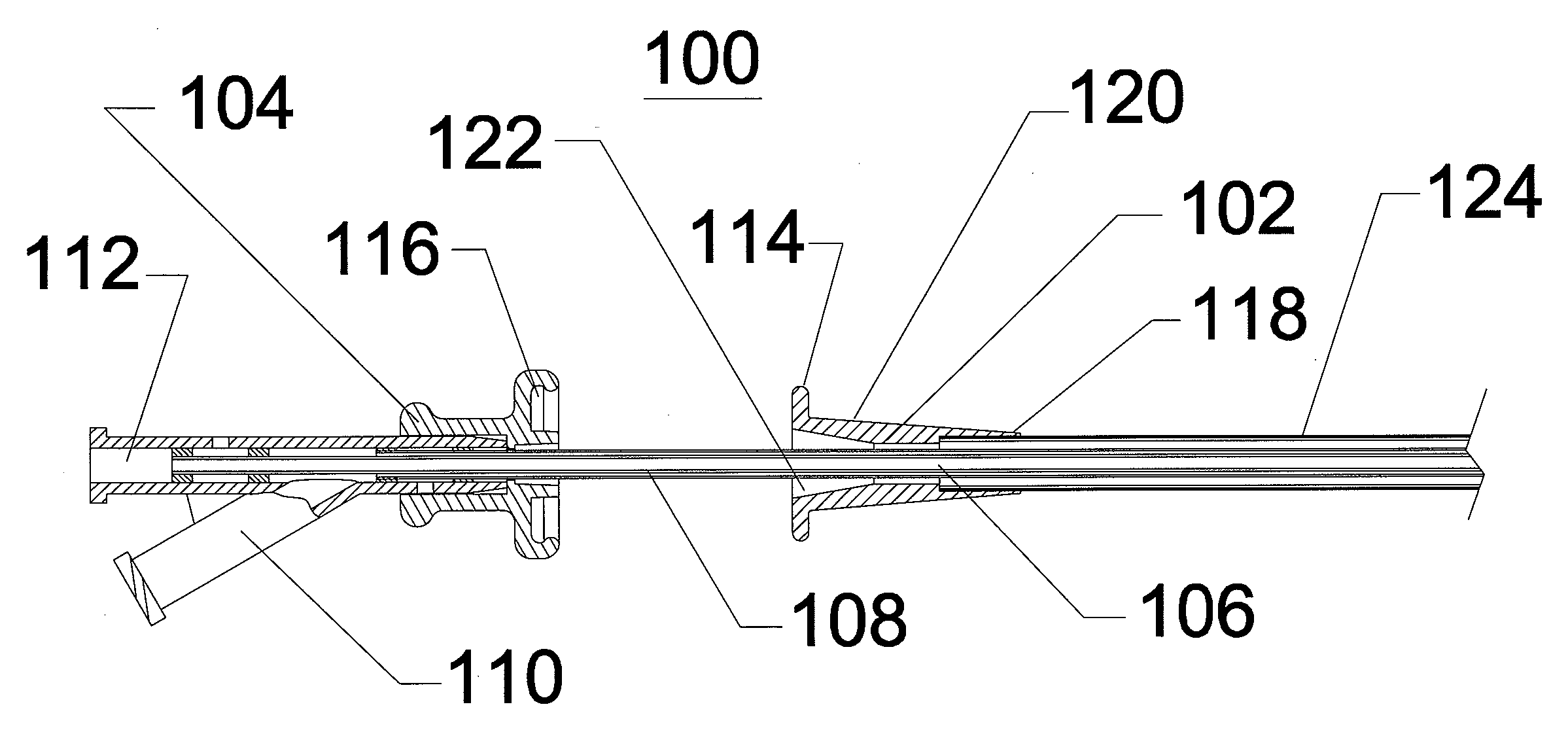

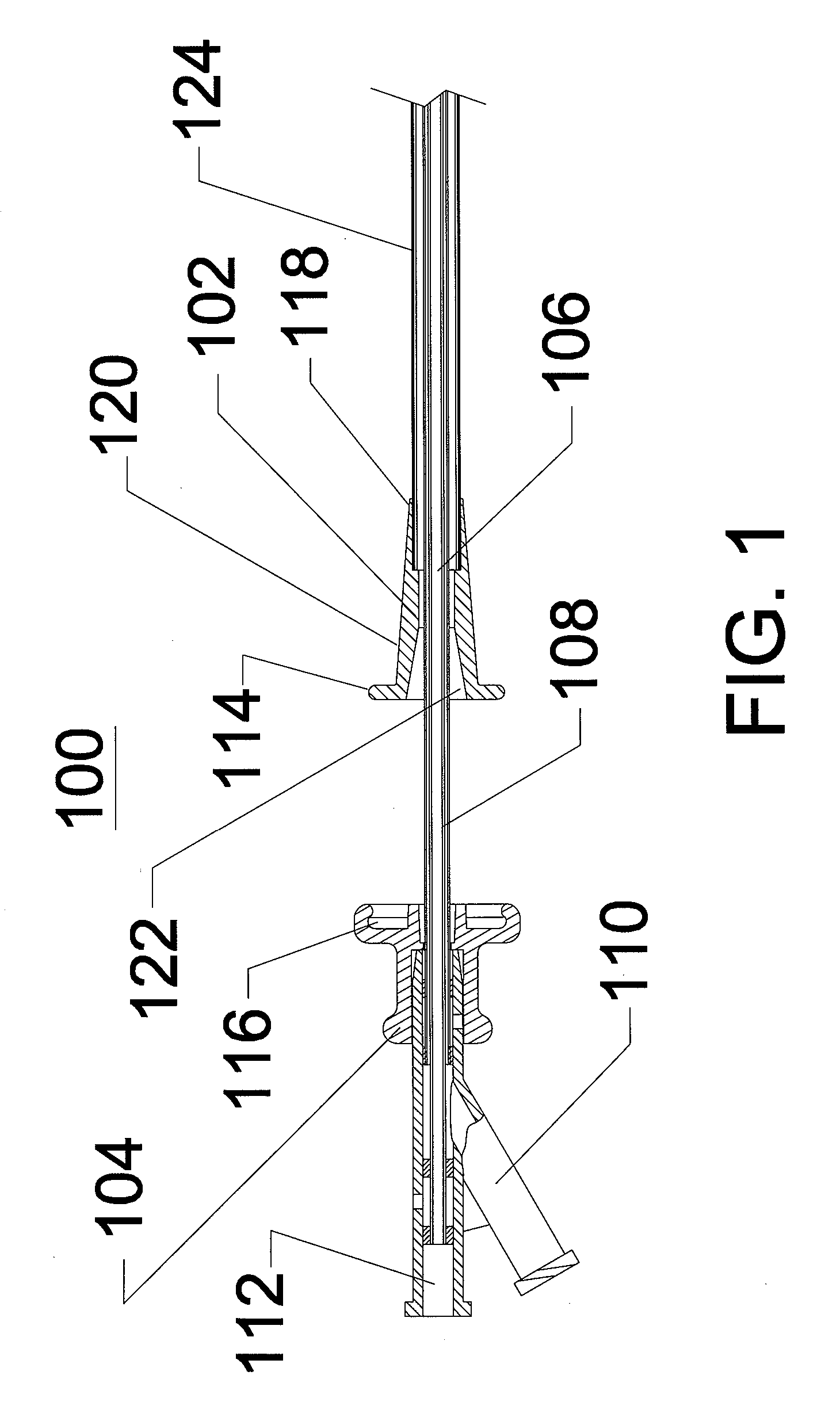

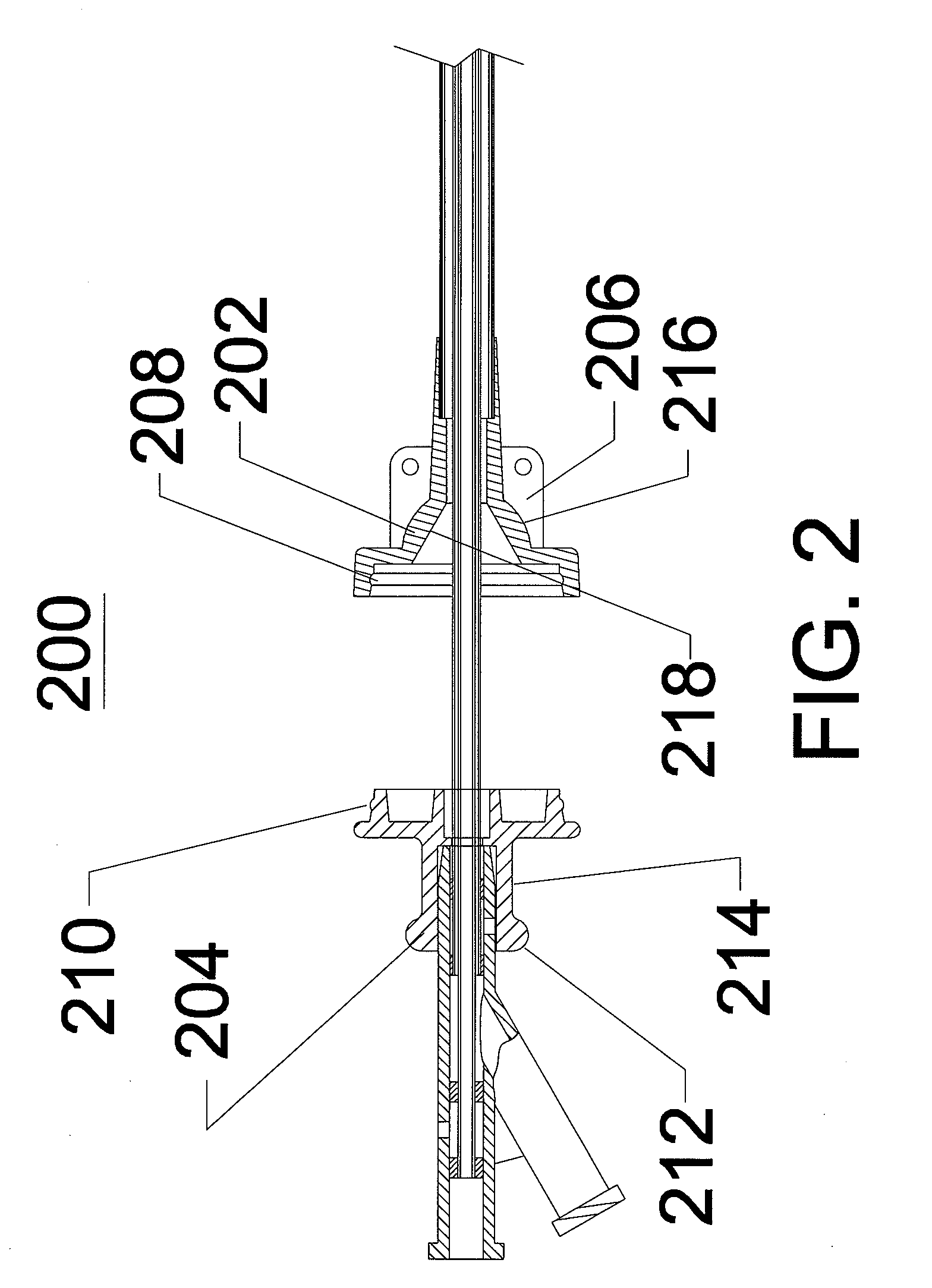

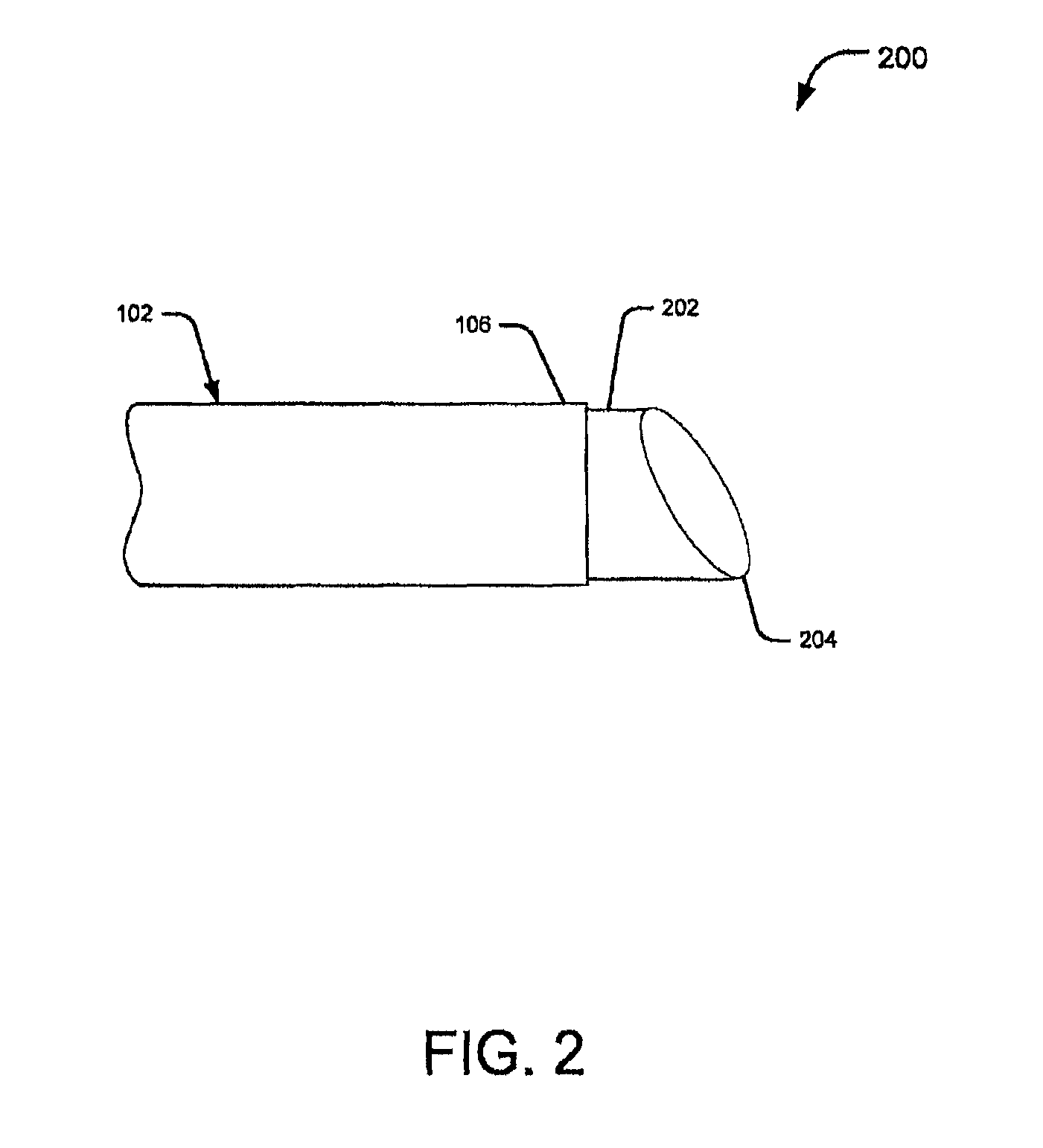

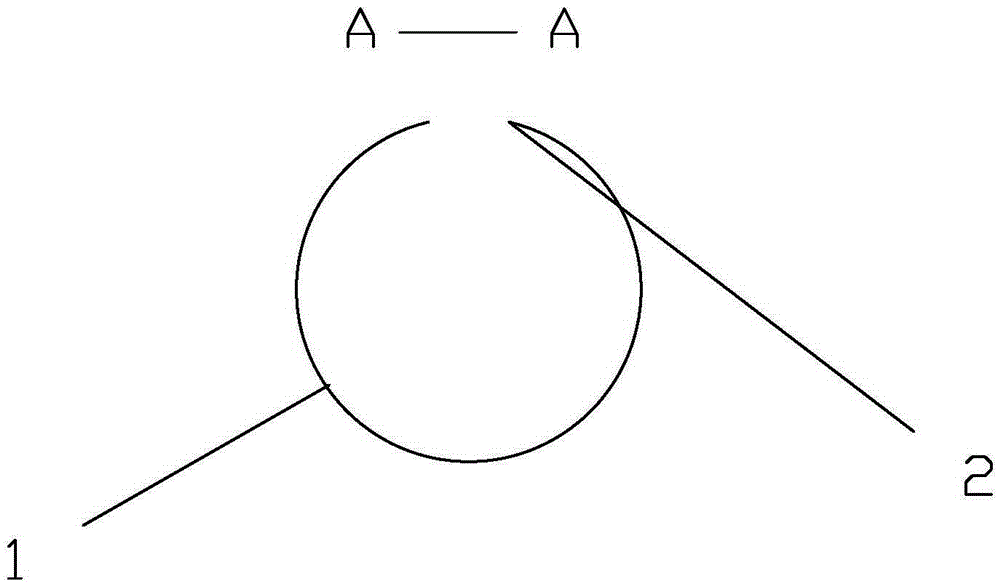

Expandable transluminal sheath

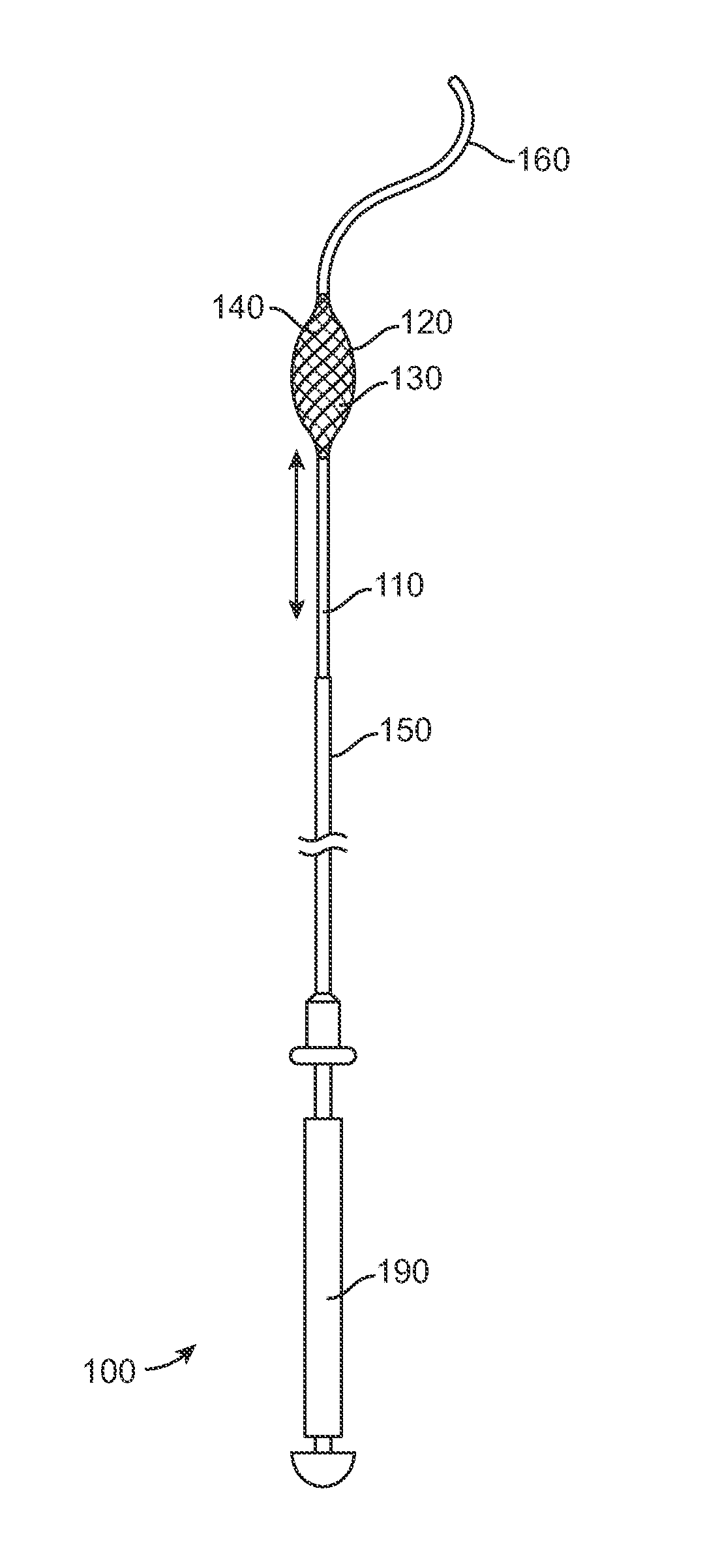

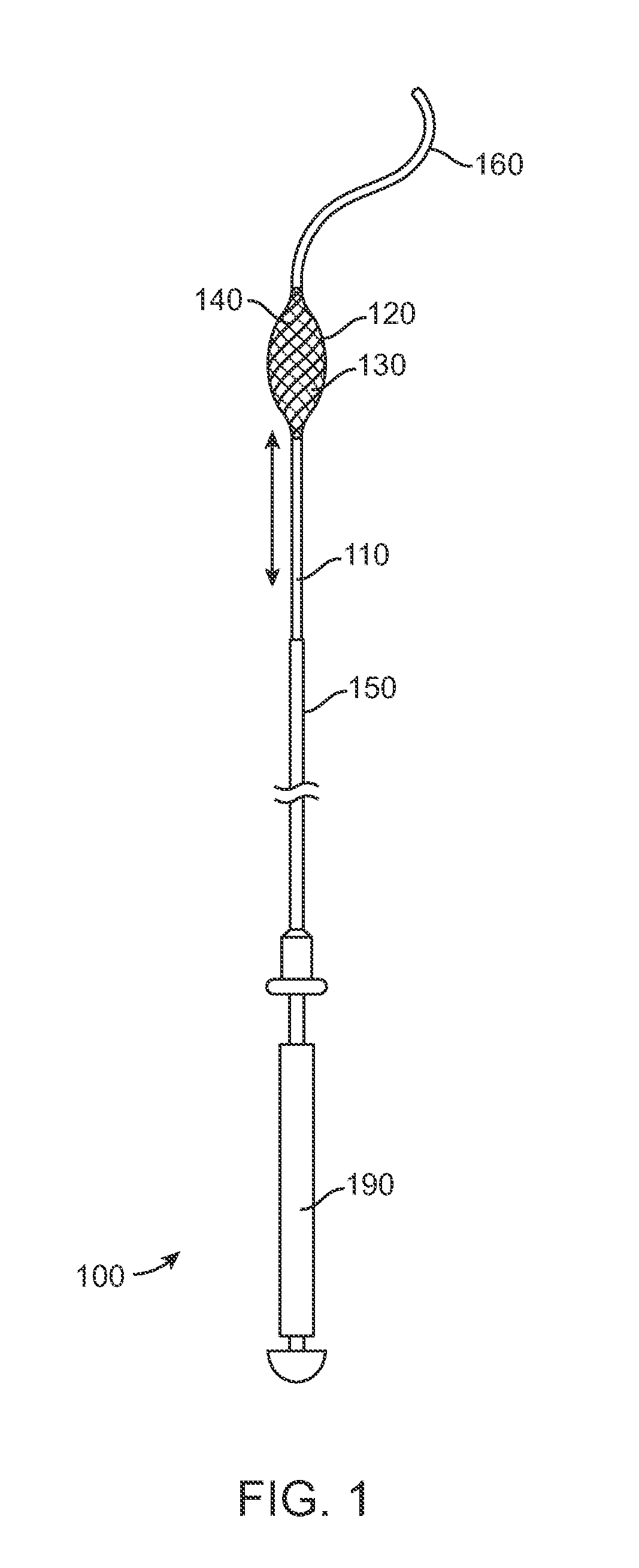

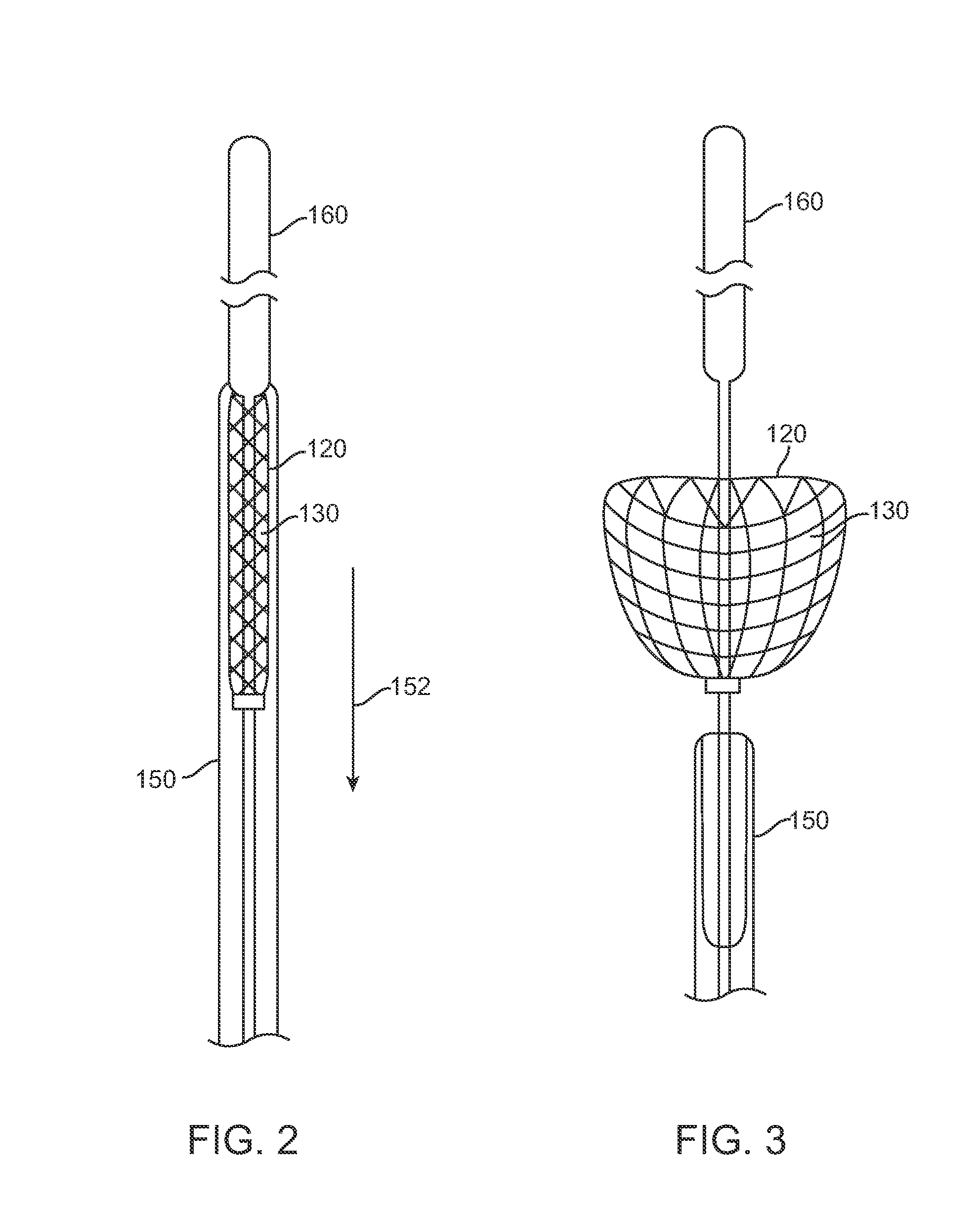

ActiveUS20060052750A1Reduce manufacturing costMinimize abrasion and damageGuide needlesStentsStone removalBiomedical engineering

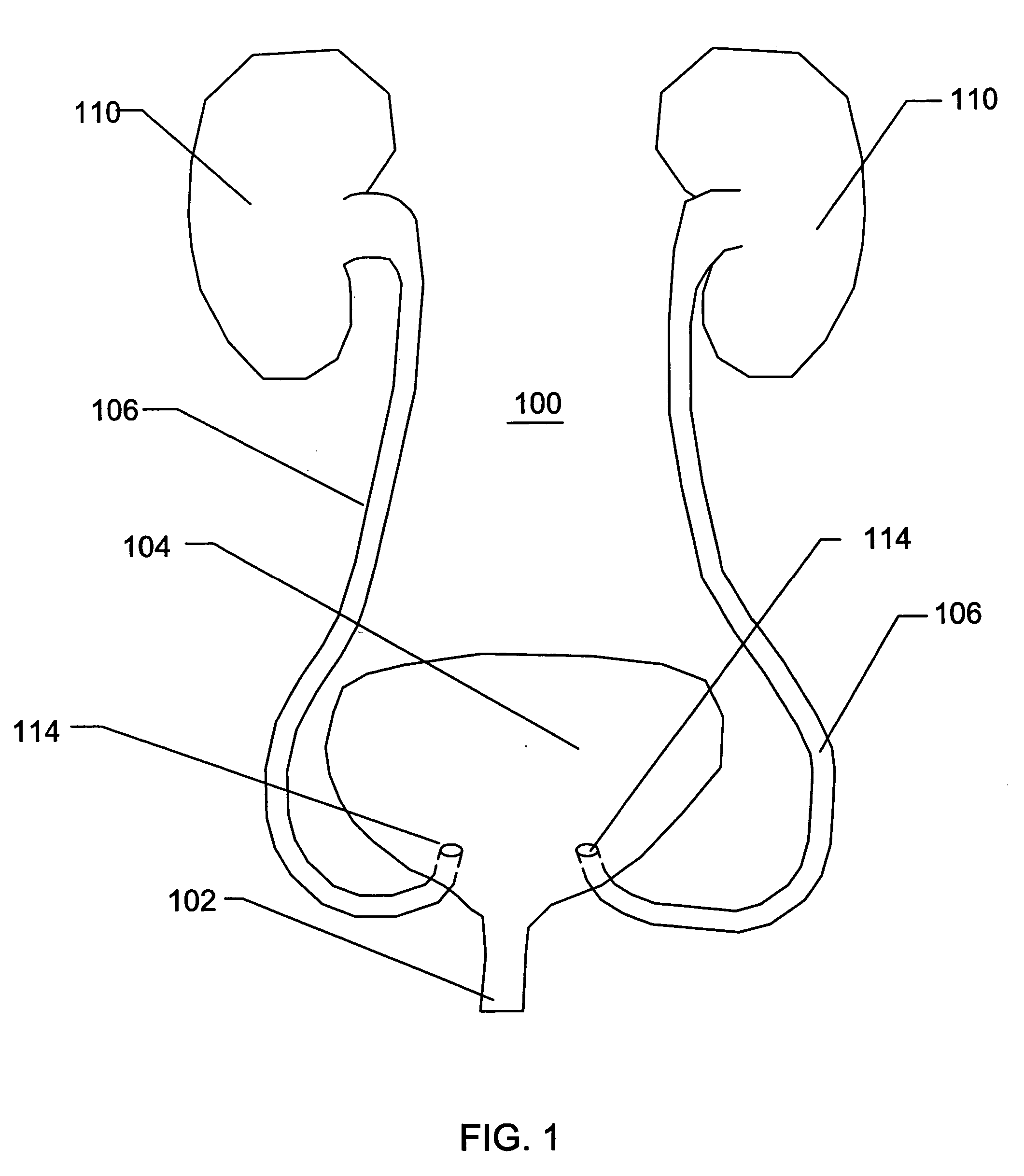

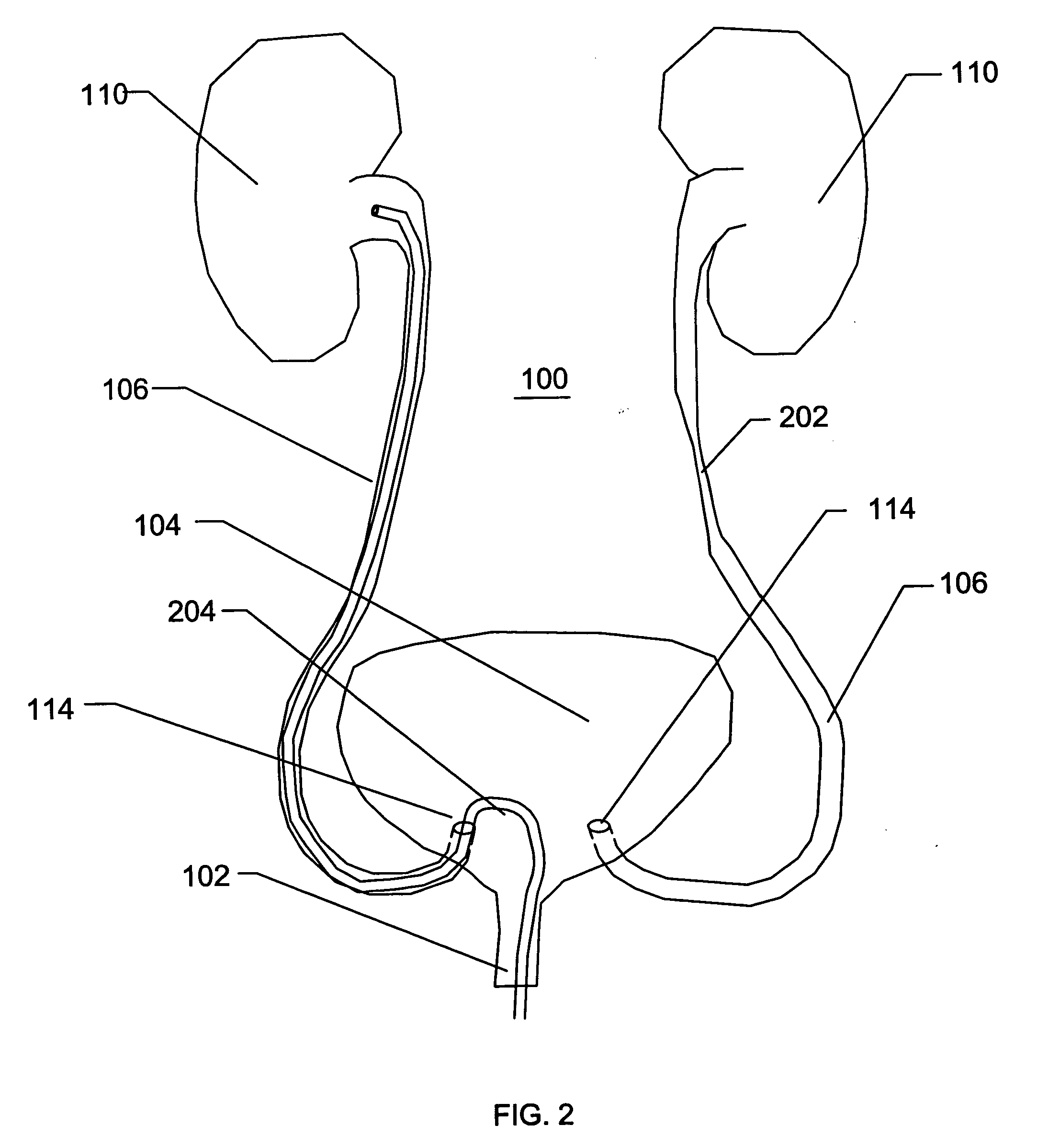

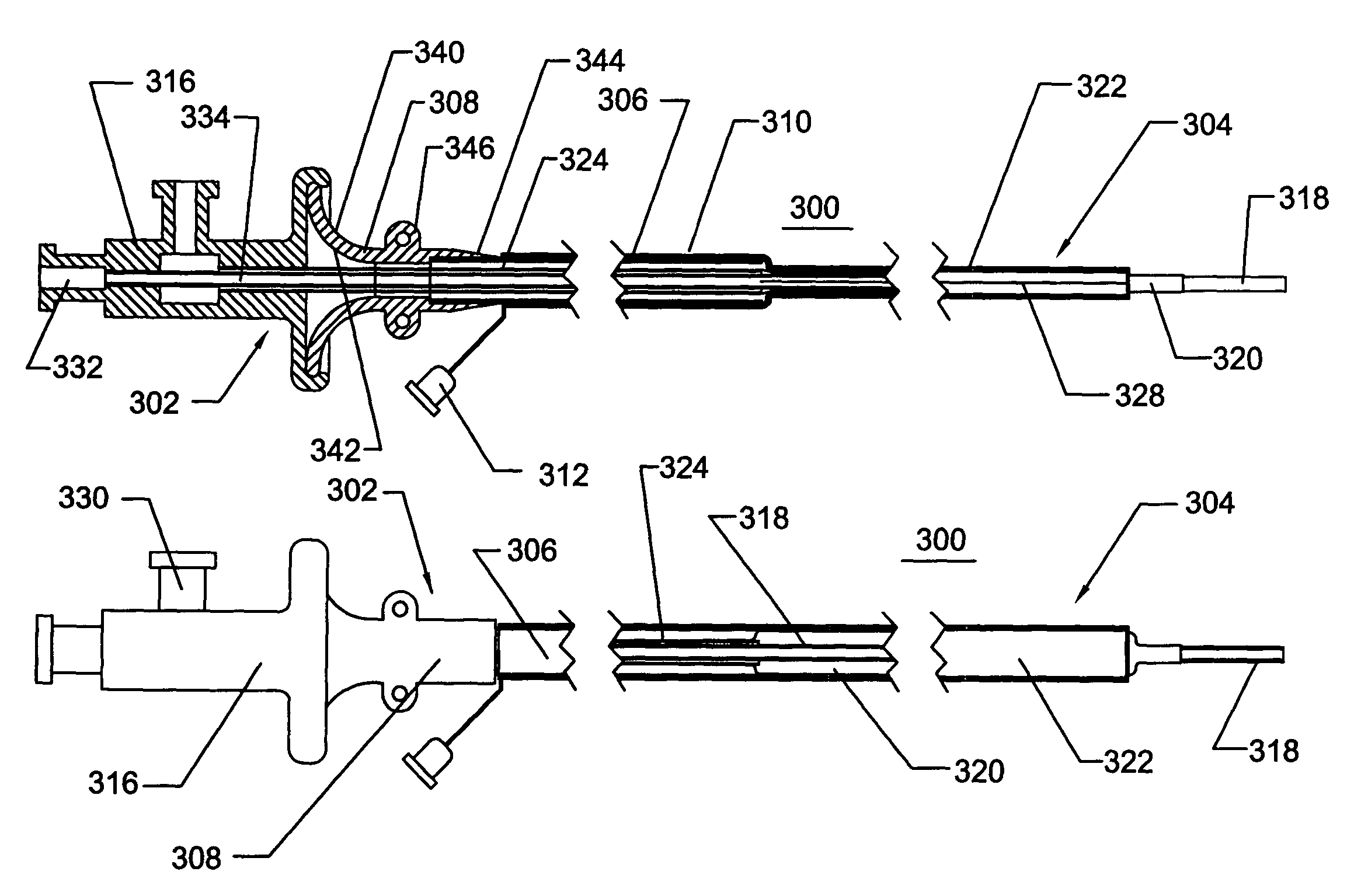

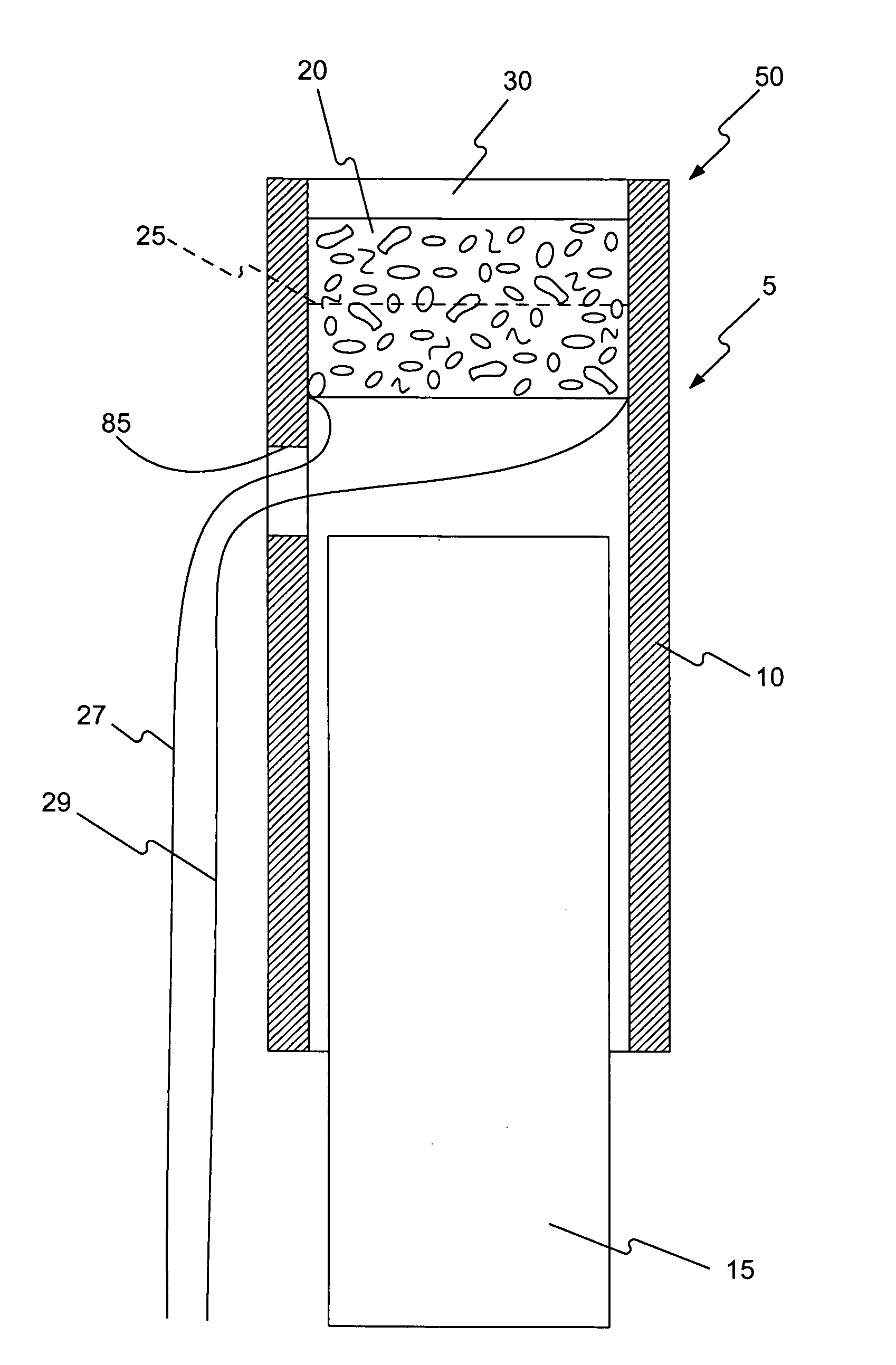

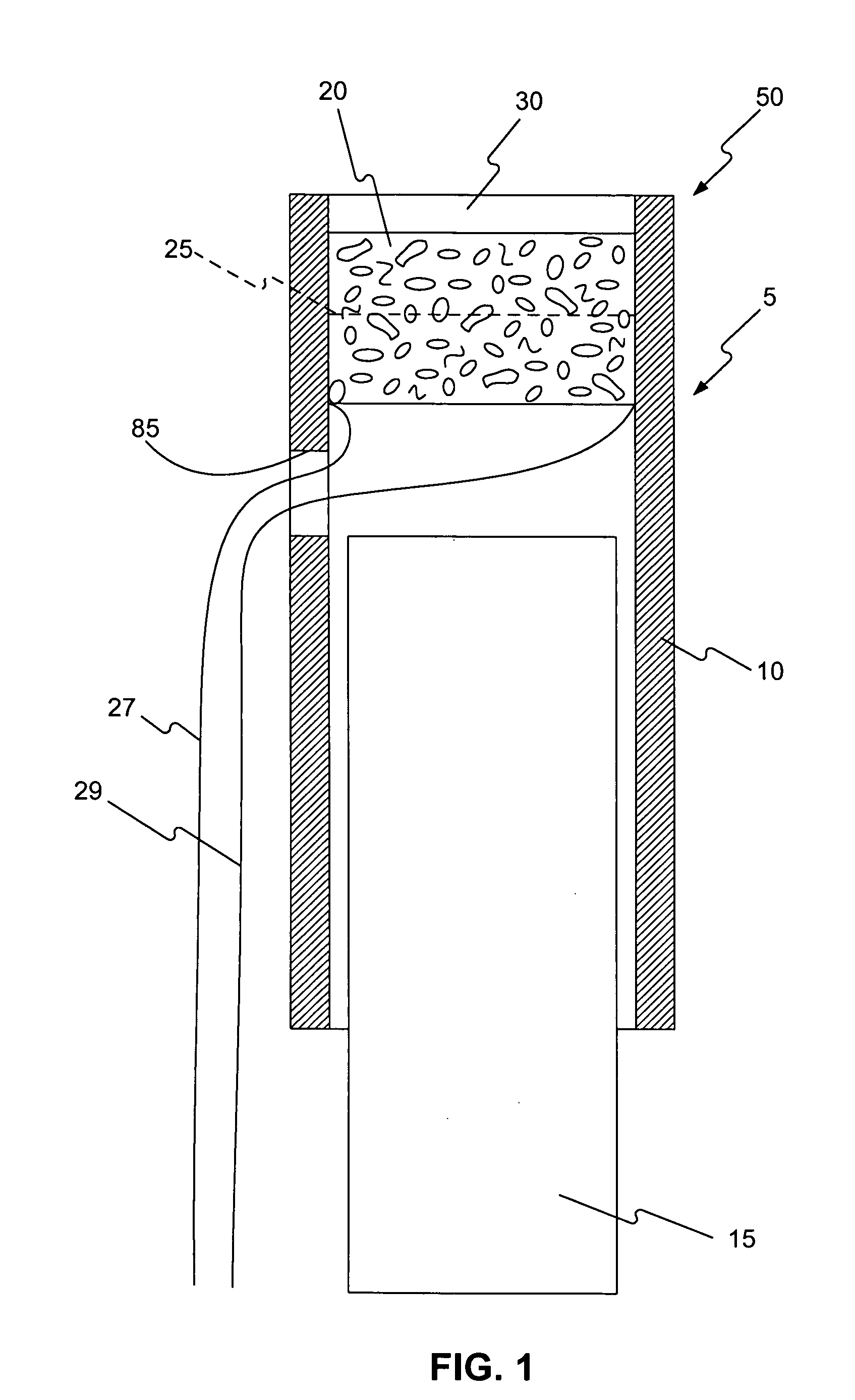

Disclosed is an expandable transluminal sheath, for introduction into the body while in a first, low cross-sectional area configuration, and subsequent expansion of at least a part of the distal end of the sheath to a second, enlarged cross-sectional configuration. The distal end of the sheath is maintained in the first, low cross-sectional configuration and expanded using a radial dilatation device. In an exemplary application, the sheath is utilized to provide access for a diagnostic or therapeutic procedure such as ureteroscopy or stone removal.

Owner:ONSET MEDICAL CORP

Expandable transluminal sheath

ActiveUS7892203B2Reduce manufacturing costMinimize abrasion and damageStentsGuide needlesMedicineStone removal

Disclosed is an expandable transluminal sheath, for introduction into the body while in a first, low cross-sectional area configuration, and subsequent expansion of at least a part of the distal end of the sheath to a second, enlarged cross-sectional configuration. The distal end of the sheath is maintained in the first, low cross-sectional configuration and expanded using a radial dilatation device. In an exemplary application, the sheath is utilized to provide access for a diagnostic or therapeutic procedure such as ureteroscopy or stone removal.

Owner:ONSET MEDICAL CORP

Device to aid in stone removal and laser lithotripsy

InactiveUS20060020269A1Easy to disassembleSurgical instrument detailsLaser lithotripsyMedical device

A medical device includes a delivery tube and a sponge configured for deployment from the delivery tube and into the urinary tract for assisting in the removal of a stone.

Owner:SCI MED LIFE SYST

Transluminal sheath hub

Disclosed is a hub for a transluminal sheath. The hub provides a handle for grasping the sheath, provides connections for fluid inlet and outlet lines, and provides for attaching mechanisms between the sheath and a dilator. The hub can be used on a non-radially expandable sheath, or it can be used on a sheath having a radially expandable configuration. In an exemplary application, the hub is fitted to a sheath, which provides access for a diagnostic or therapeutic procedure such as ureteroscopy or stone removal.

Owner:ONSET MEDICAL CORP

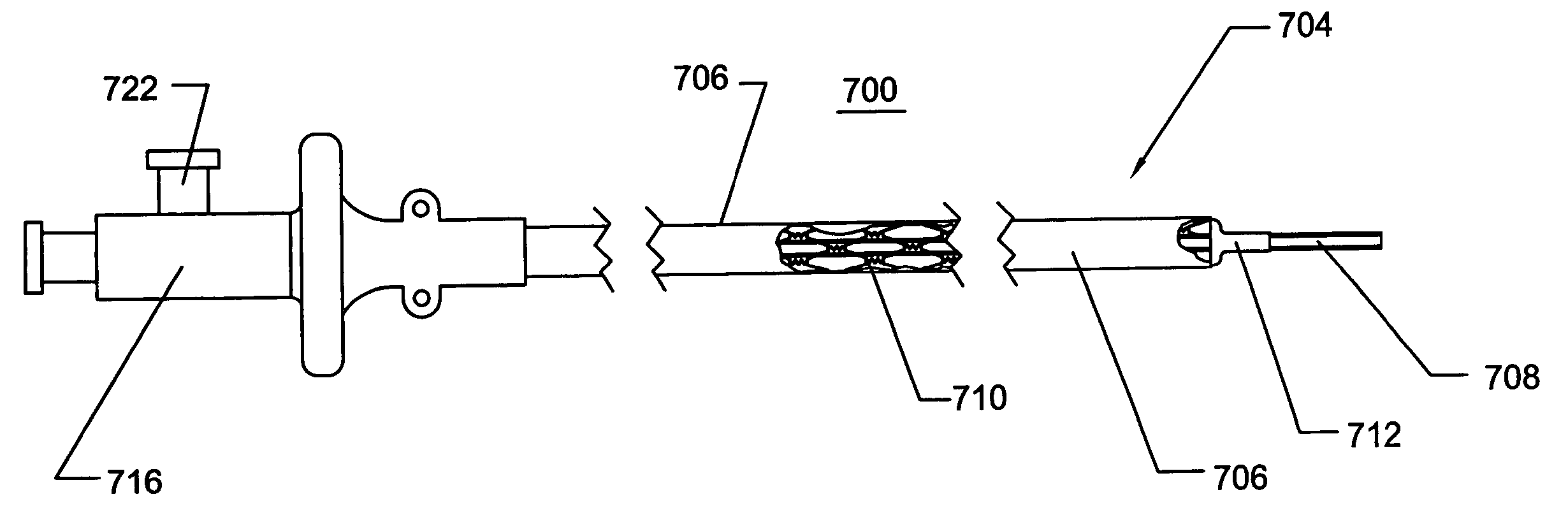

Expandable devices and methods of use

A sieving device and related methods including an expandable sieve mounted on a surgical guide wire. The expandable sieve may be a self-expandable braided filter which is mounted on the guide wire in an axially fixed position, or moveable in one or more directions. The sieving device is deployable in an obstructed ureter, or other body lumen, such as at the beginning of a stone removal procedure, prior to actual stone defragmentation (lithotripsy) phase. The expandable sieve may be set distal to the obstructive stone and expanded to span the entire local ureter cross section in order to retain stone fragments larger than a predetermined size from migrating distally towards the kidney under high irrigation rates / pressures during lithotripsy.

Owner:XENOLITH MEDICAL

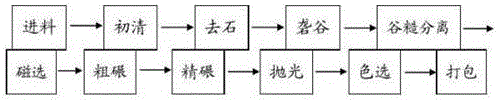

Processing method for increasing retention rate of rice germs

The invention discloses a processing method for increasing the retention rate of rice germs. The method comprises steps as follows: A, screening of unhusked rice; B, stone removal for the unhusked rice; C, husking; D, a husked rice separation and magnetic separation procedure; E, a rice milling procedure; F, polishing of the rice; G, color sorting and classification of the rice; particularly, a buffer device is added to the husking procedure, the rice flow impact force is reduced, the manner that multiple machines are adopted for gentle milling is adopted in the rice milling procedure, and the moisture content of unpolished rice is adjusted before polishing; the cold rice polishing manner is adopted for polishing of the rice; the retention rate of the rice germs is increased with the processes. The method is simple and convenient to use, damage to rice germ parts can be reduced, and the retention rate of the rice germs can be substantially increased to at least 80%.

Owner:青岛家盛农业科技发展有限公司

Rice fine processing technology

InactiveCN106391168AImprove drying efficiencyThe processing procedure is simpleGrain huskingGrain polishingBroken riceWhite rice

The invention discloses a rice fine processing technology which comprises the following steps of unhusked rice screening, stone removal, magnetic separation, soaking in a dietary alkali solution, washing, drying and moisture removal, rice husking, husked rice separation, thickness classification, rice milling, soaking in a soaking solution, drying and moisture removal, white rice classification, rice cooling, polishing, color sorting, secondary white rice classification, sterilization and packaging. According to the method, processing technological procedures are simple, the milled rice rate is high, the production cost of rice processing enterprises can be reduced, and the rice produced through the method is clean, good in degree of finish and low in broken rice rate.

Owner:金健粮食(益阳)有限公司

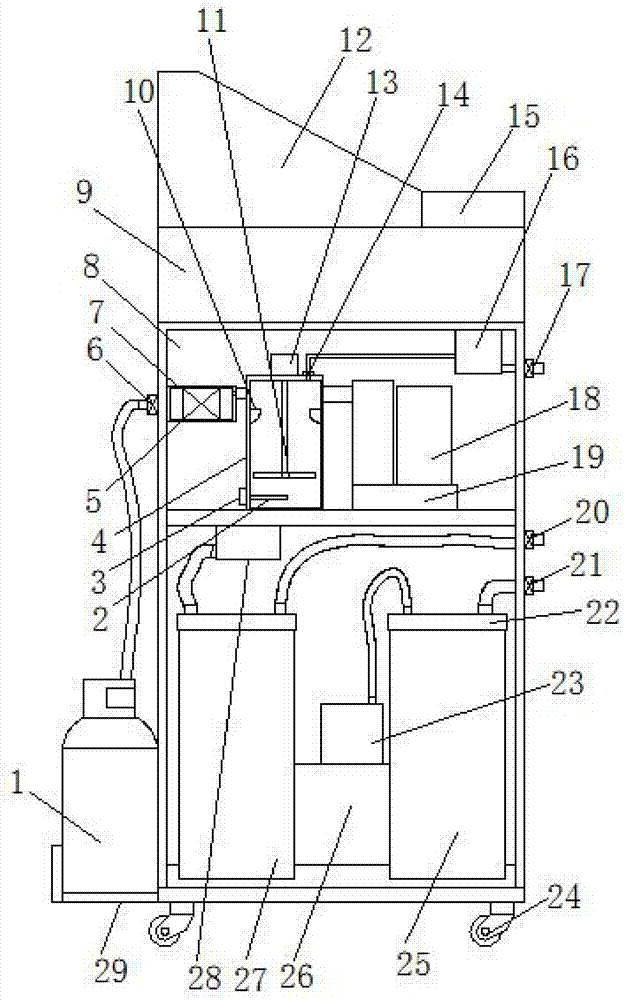

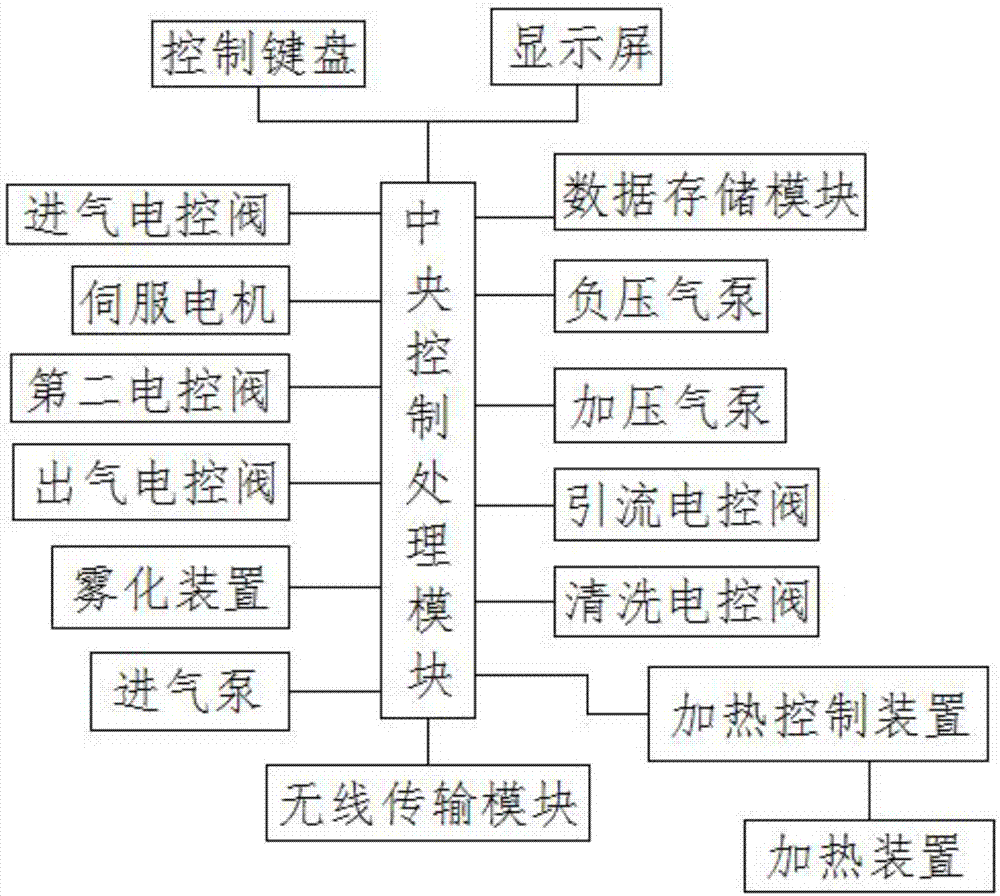

Stone removal device for hepatological surgery department and method thereof

The invention discloses a stone removal device for hepatological surgery department. The stone removal device comprises a moving box body, a drainage tank and a physiological saline tank are installedinside the moving box body, the drainage tank is connected to a negative pressure gas pump, the drainage tank is also connected to a drainage electric control valve, the physiological saline tank isconnected to a pressurized gas pump, the physiological saline tank is also connected to a cleaning electric control valve, a carbon dioxide gas treatment box is also installed inside the moving box body, the upper end of the carbon dioxide gas treatment box is connected to a gas intake pump through a second electronic control valve, the gas intake pump is connected to a gas outlet control valve, acontrol box is installed at the upper end of the moving box body, and a display screen and a control keyboard are installed at the upper end of the control box. The stone removal device is used for removing all gallstones in a gallbladder under the direct vision of a fiber choledochoscope, can achieve the functions of negative pressure drainage, physiological saline cleaning and tissue bulging bycarbon dioxide, greatly facilitates the stone removal work, improves the surgical efficiency of medical staff, facilitates the surgery, greatly reduces the preparation time and workload of the medical staff, provides a patient with good medical experience and is conducive to disease rehabilitation.

Owner:孔新亮

Production process of potato whole flour

The invention relates to a processing process of a potato crop, and in particular relates to a production process of a potato whole flour. The process comprises steps of raw material receiving, stone removal by cleaning, rasion, sand removal, emulsion dehydration, backfill type airflow drying and packaging. The production process of potato whole flour has related sections, and can realize automatic production. At the same time, the process can quickly process fresh potato into a whole flour with water content of 12%. The process has advantages of small amount of water used in the process, little waste, wide usage, environmental protection, low cell breaking rate, high nutritional value guarantee, short processing cycle, and little loss of nutrients.

Owner:安徽瑞德华机电设备有限公司

Efficient environmental-friendly automatic processing control system for dehydrated vegetables

ActiveCN104799419AHigh in nutrientsHigh spicinessVegetable peelingFood treatmentStone removalAutomatic processing

The invention discloses an efficient environmental-friendly automatic processing control system for dehydrated vegetables. The processing process of the efficient environmental-friendly automatic processing control system is characterized by concretely comprising the following steps: (1) feeding; (2) sectioned peeling; (3) primary rinsing; (4) stone removal; (5) secondary rinsing; (6) temporary material storage; (7) slicing; (8) drying. A slicer is connected with a conveying belt for a drying box. Slices are free of cleaning before drying, various nutrients in the product are kept, the strong taste of the product is promoted, the yield of primary product reaches to 32 percent and is increased by 5 percent compared with the same industry, and the use of raw materials is saved. A novel drying machine has the advantages of high heat utilization rate, high yield, uniform product color and constant water, adopts natural gas or electricity as a heat source, and achieves the target of clean production. The novel processing process for the dehydrated vegetables is high in yield of primary product, keeps the original nutritional value, and is wide in applicability.

Owner:QINGDAO UNISONECO FOOD & TECH CO LTD

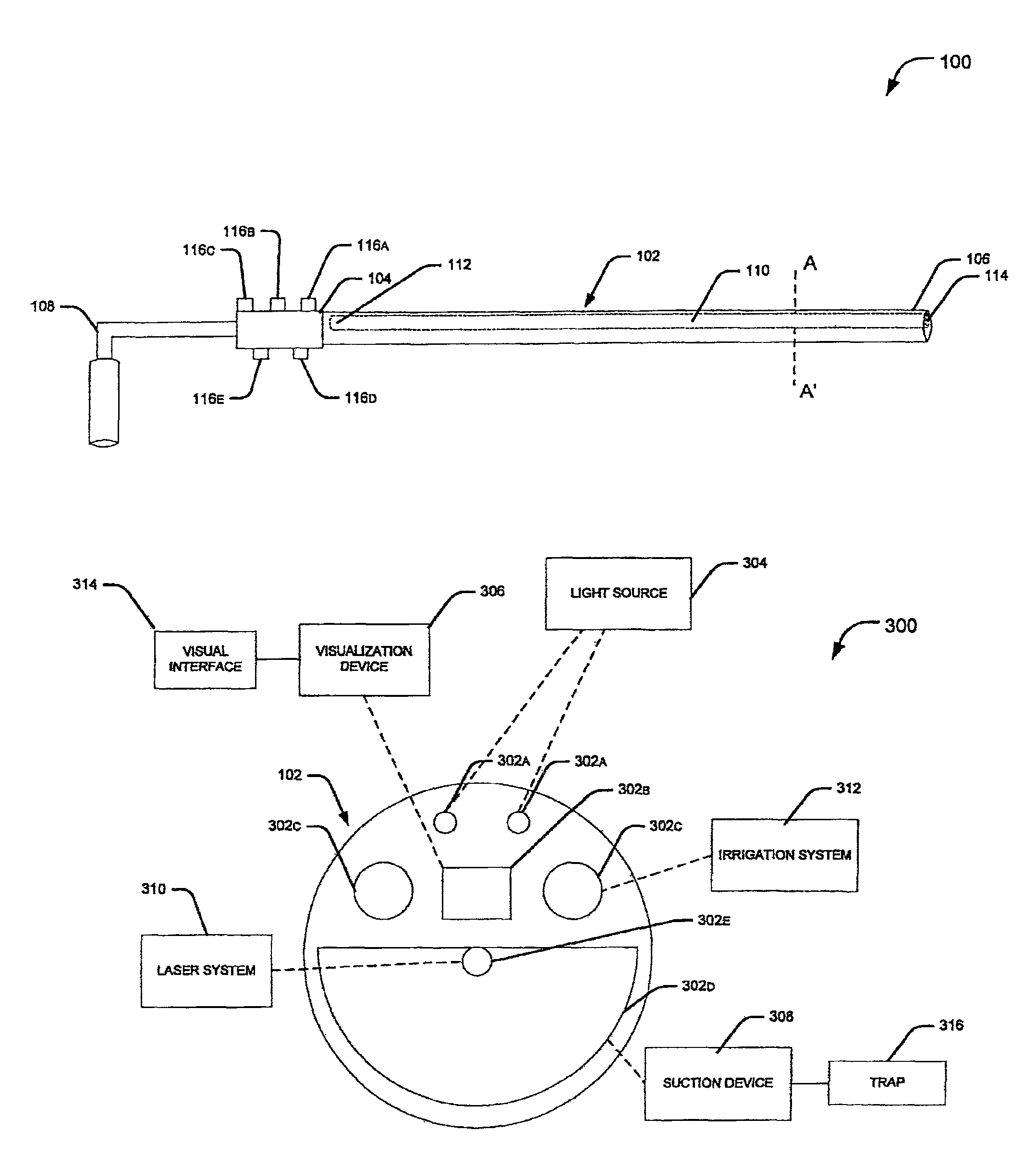

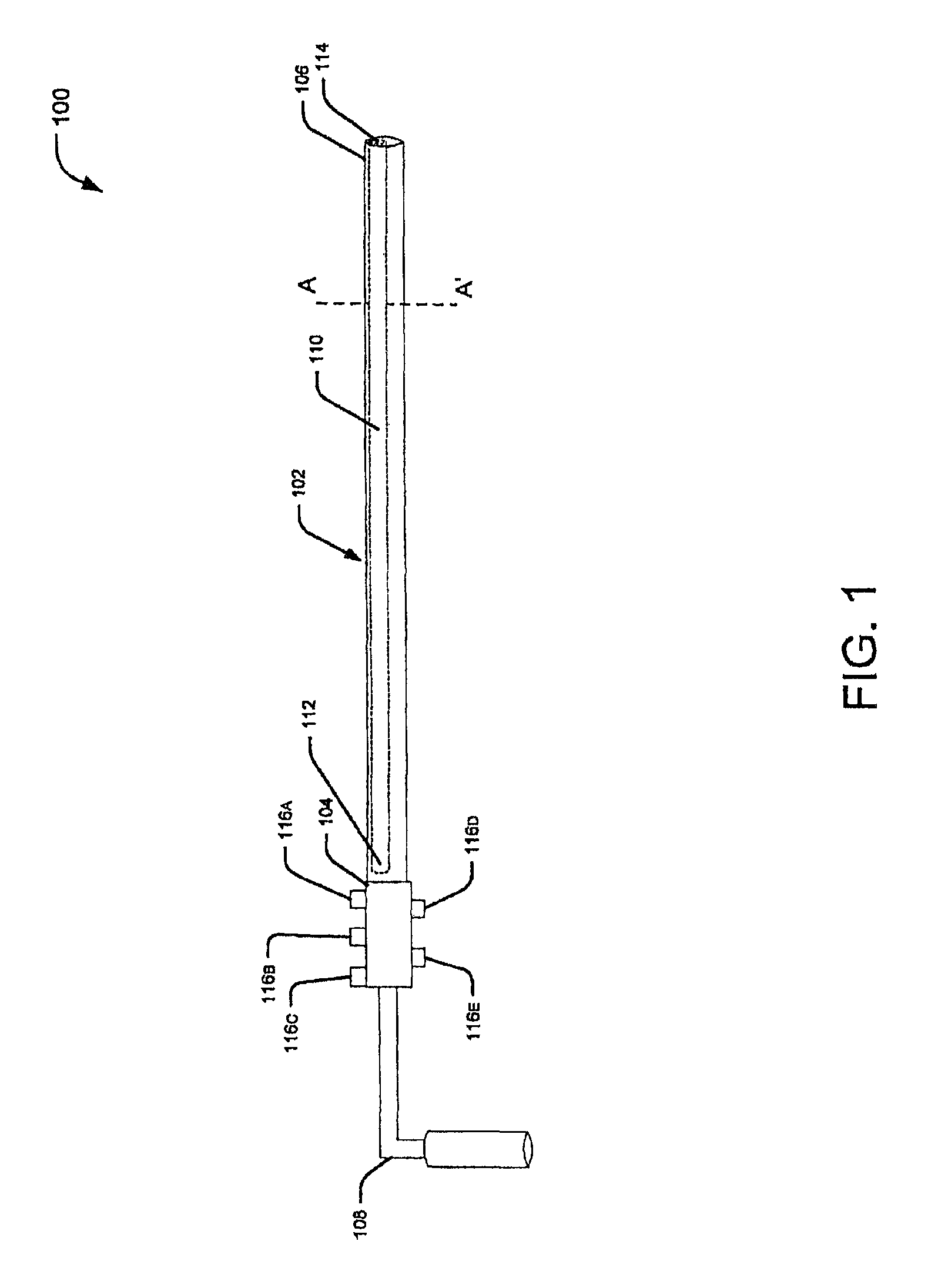

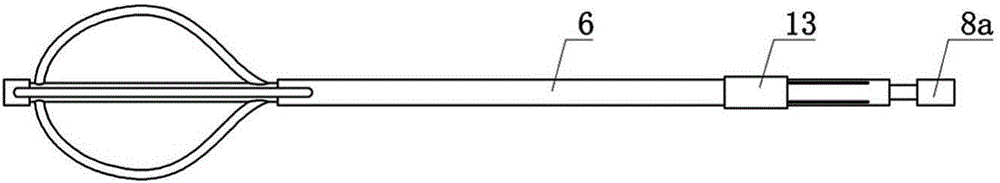

Tissue and stone removal device and related methods of use

Embodiments of a medical device and related methods of use are provided for extracting tissue. The device may include an elongate member having a proximal end and a distal end. Two or more channels may extend through the elongate member from the proximal end to the distal end, and a morcellating device may be included in one of the channels. In addition, one of the channels may be configured as a return channel for extracting the morcellated tissue.

Owner:BOSTON SCI SCIMED INC

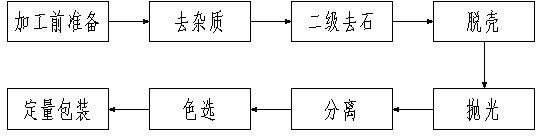

Coarse cereal processing method

A coarse cereal processing method includes the steps of preparation before processing, impurity removal, two-stage stone removal, husking, polishing, separating, color sorting and quantitative packaging. In the step of two-stage stone removal, coarse cereals are subjected to stone removal by two stoners after being subjected to impurity removal, then fall to a stone-removing screen which is arranged at the horizontal inclination of 10-14 degrees, and finally are blown out by wind at the rate of 3900m<3> / h-4100m<3> / h. In the step of separating, broken cereals with the diameter smaller than 0.5mm are separated from the other cereals by a separator, and then are directly discharged to be packaged. In the steps of color sorting, the residual cereals are subjected to color sorting processing by a color sorter, and by the aid of a high-definition camera during color sorting, the discolored cereals are ejected by an ejection gun and then rejected. The broken cereals separated by the separator can be individually used for cooking porridge suitable for the confinement period; the discolored cereals are rejected by the aid of the color sorter, so that quality of the finished coarse cereals is improved. Since the cereals are subjected to continuous stone removal by the two stoners before being husked, the defect that the cereals are crashed due to the process of stone removal in the later period is overcome, and the yield is increased.

Owner:LIAONING JULONG ORGANIC FOOD

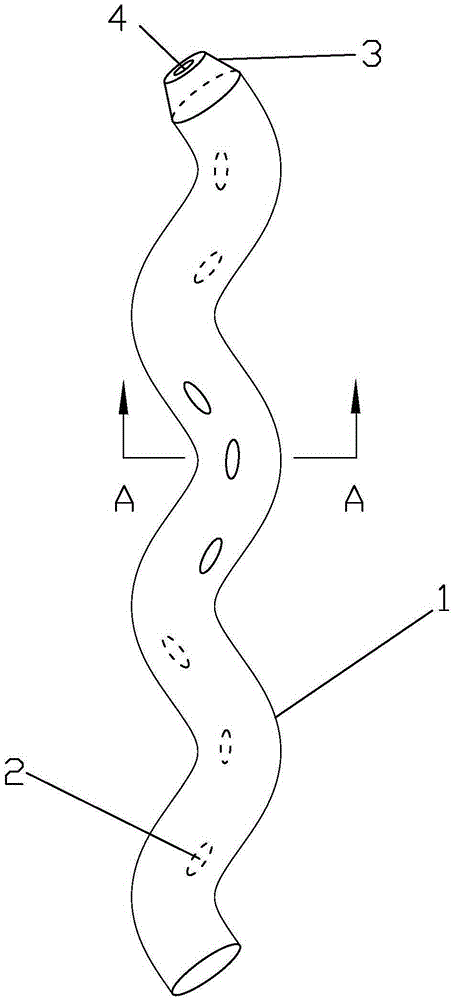

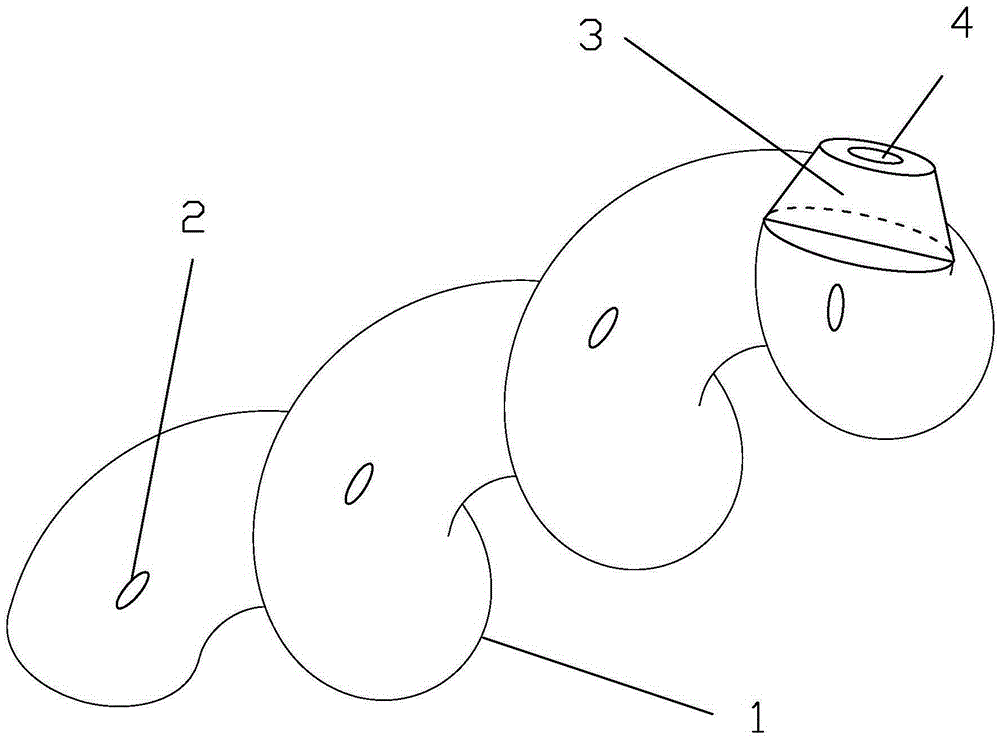

Spiral internal biliary drainage tube

The invention discloses a spiral internal biliary drainage tube, which comprises a spiral tube, wherein a plurality of through holes I are arranged on the outer wall of the spiral tube; the spiral tube is 7-11cm long, the spiral tube is 1-2mm in inner diameter, the spiral tube is 4-5mm in outer diameter, the spiral tube includes 2-5 cycles and the spiral tube is 5-8.5Fr in pipe diameter. The spiral tube disclosed by the invention has an anti-sliding function, and the spiral internal biliary drainage tube is low in probability of internal displacement or takeoff; the drainage tube is capable of preventing biliary wall mucosa from being adsorbed on and from blocking the through holes I and is conducive to the drainage of infectious thick bile; the bile is discharged into duodena through the through holes I and the inner cavity of the spiral tube, and the bile also flows out through an inner cavity formed by the spiral tube; the main body of the spiral tube has an effect on compressing stones in common bile duct; the drainage tube, when preventing the stones in the common bile duct from displacing, can bring about a friction effect on the stones through the sidewall thereof, so that the volume of the stones is diminished to create conditions for secondary stone removal through ERCP (endoscopic retrograde cholangiopancreatography).

Owner:DALIAN UNIVERSITY

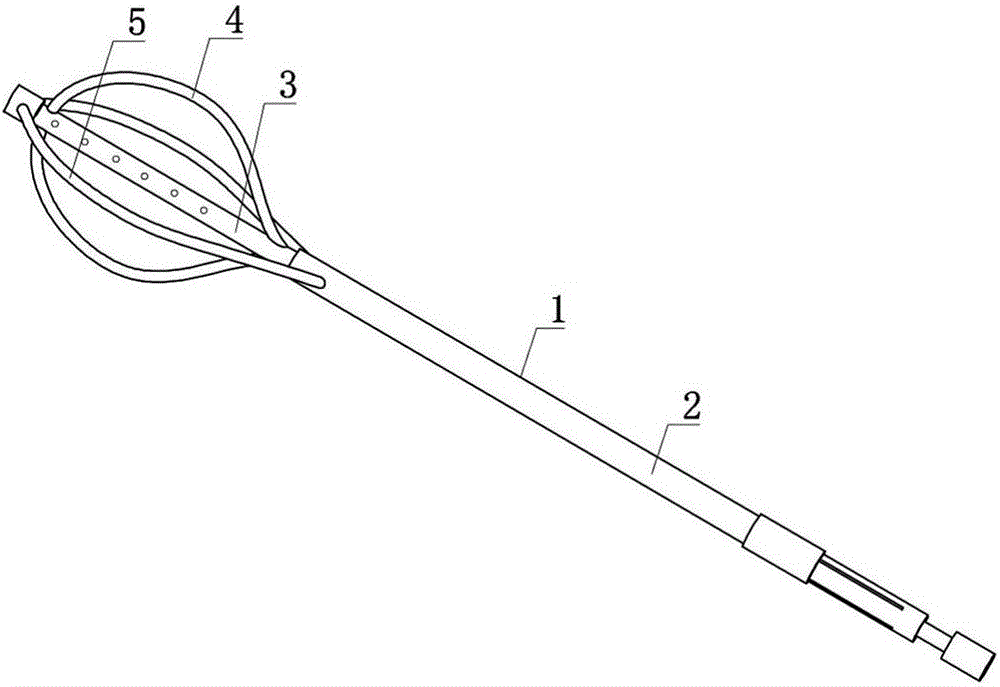

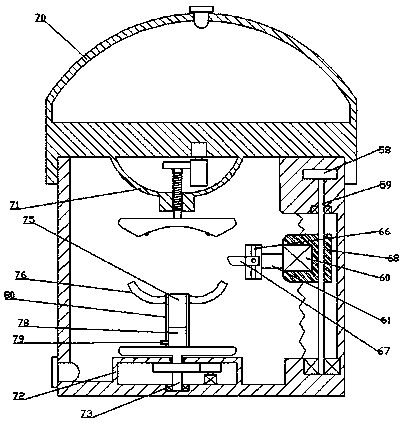

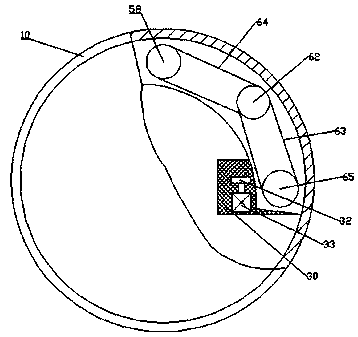

Three-endoscopic joint microinvasive gallbladder-protected lithotomy

The invention discloses a three-mirror combined minimally invasive gallbladder-preserving stone removal operation, which relates to medical equipment and is used to solve the problem that the existing stone removal mesh basket will touch the inner wall of the gallbladder, and the operation process is prone to pain, trauma, bleeding, and cannot collect gallbladder stones. , flushing, imaging and expansion in one. It includes a stone extraction basket, a choledochoscope, a laparoscope, and a duodenoscope. The stone extraction basket includes a catheter, a hollow guide head positioned at the left end of the catheter, and a wire basket positioned on the guide head. The wire basket includes at least 2 first net baskets, at least 2 second net baskets, the conduit includes outer tubes, sliding tubes, inner tubes and sliding couplings arranged from outside to inside, the sliding couplings include first terminals, second The terminal is used to connect the coupling shaft of the first terminal and the second terminal. The retractable mesh basket design prevents the stone extraction mesh basket from touching the inner wall of the gallbladder. There is no pain, trauma, or bleeding during the operation, and it can integrate gallbladder stone extraction, washing, imaging, and expansion.

Owner:南宁博锐医院有限公司

Use of a magnetic material in removal of stones

InactiveUS20180271609A1Safely and efficiently removingConvenient treatmentHeavy metal active ingredientsTransportation and packagingNanoparticleStone removal

The invention relates to a method of a magnetic material in stone removal, nanoparticles, a preparation method thereof and a stone removing device. Wherein, the magnetic material constitutes a nanoparticle core and a surface modifier monomer is attached to the nanoparticle core by an initiator and / or a crosslinking agent to form a nanoparticle shell. The prepared nanoparticles can surround stones in ureter, thereby, small stones remaining in body can be removed quickly without damage from the body under action of external magnetic field, that is, the stone can be drawn and moved without injuring ureteral wall, and the nanoparticles are placed conveniently without shift.

Owner:SHANGHAI CLINICAL ENGINE TECH DEV CO LTD

Low-temperature wheat flour processing method, system device adopting method and application

InactiveCN106423398AIncrease productivityReduce high temperatureGrain treatmentsPrimary screeningMoisture

The invention discloses a low-temperature wheat flour processing method, a system device adopting the method and application. Wheat is stored in a dry environment of 15-20 DEG C, the wheat is processed by using the wheat processing device, primary screening, stone removal and wheat wetting are performed for 10-12 hours, the wheat wetting temperature is 18-25 DEG C, 6-12 KGy gamma ray irradiation sterilization, secondary roughening, twice breaking, flat-screen screening and cooling are performed, the rotation speed is 38 r / min-40 r / min after the first time of stone-mill grinding, and then wheat flour is produced through three times of flat-screen screening and stone-mill grinding. The method is high in production efficiency and free of additives, a cooler is added to reduce high material temperature caused by a flour mill, meanwhile the rotation speed of a stone mill is improved from 20 r / min to 40 r / min, the powder yield can be up to 87%, it is detected that the moisture content of the produced wheat flour is below 4.5%, the ash content is below 0.8%, the magnetic metal content is below 0.00015%, and gluten quality is up to 28%.

Owner:XINJIANG DETIANLI AGRI DEV CO LTD

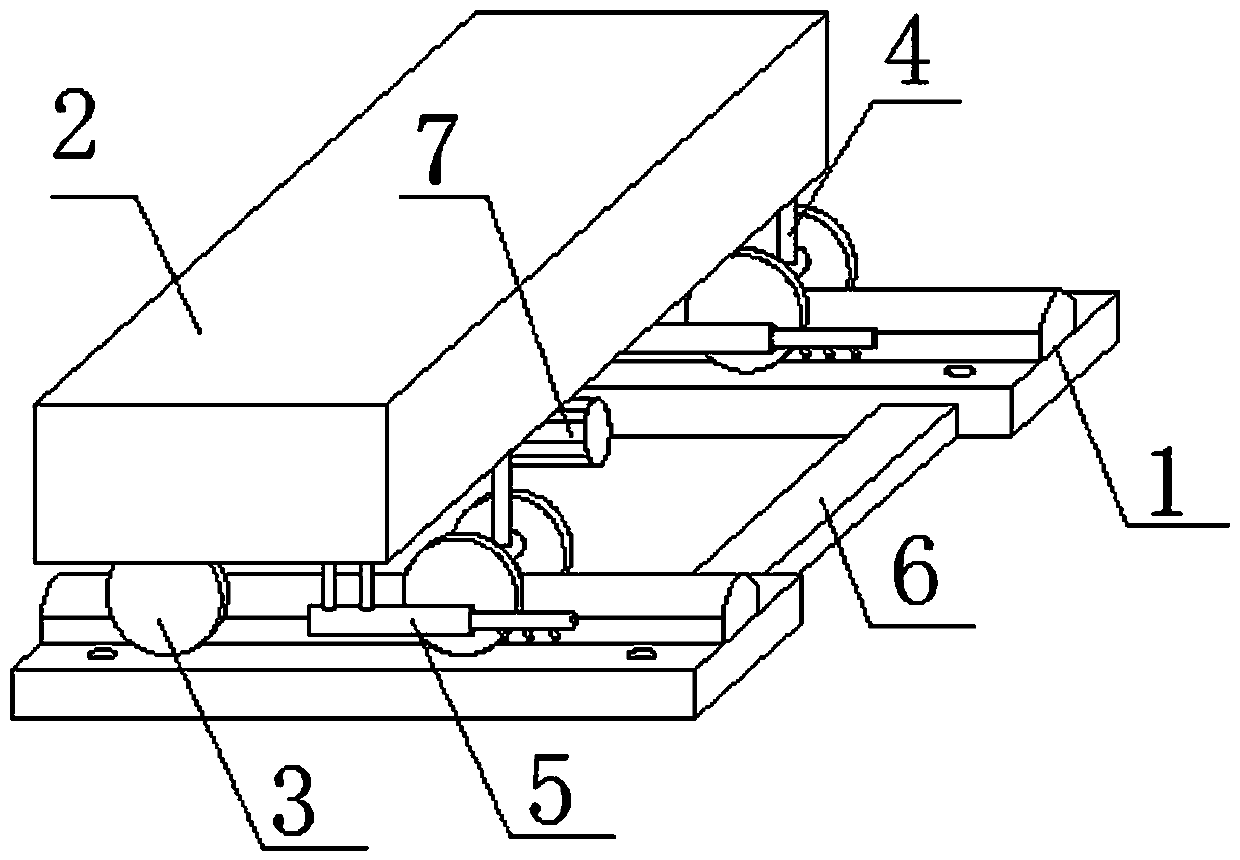

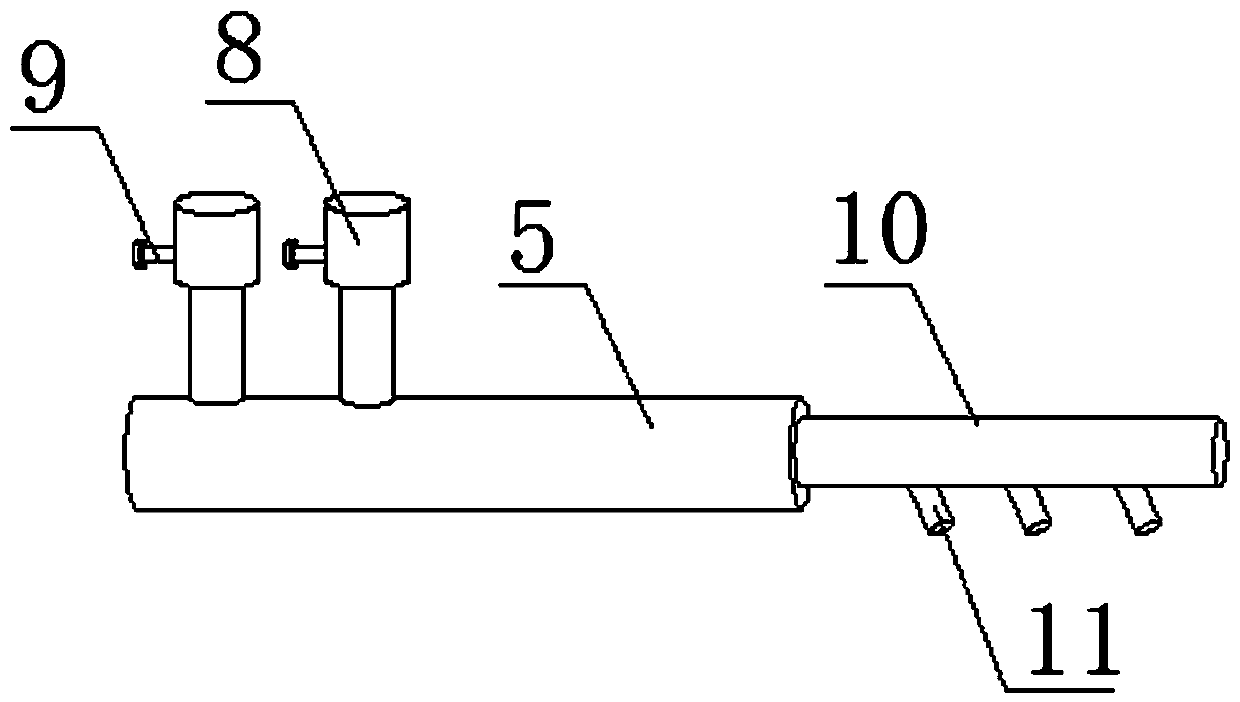

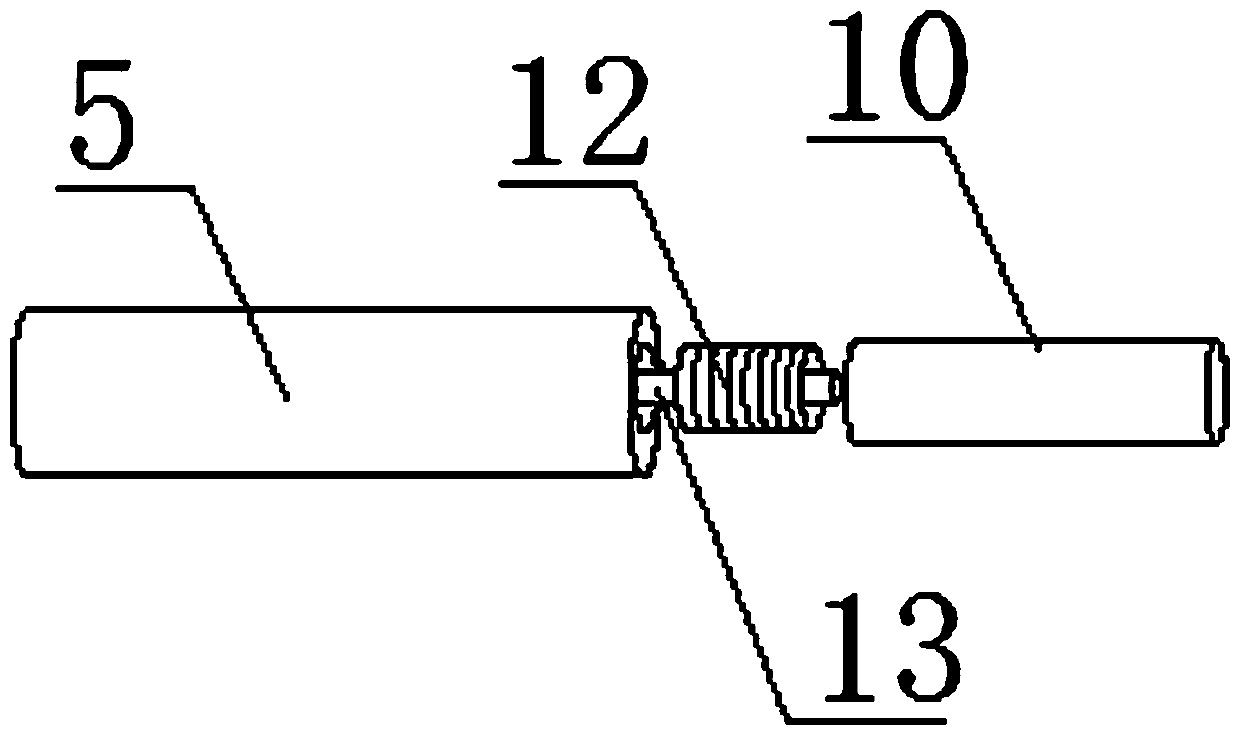

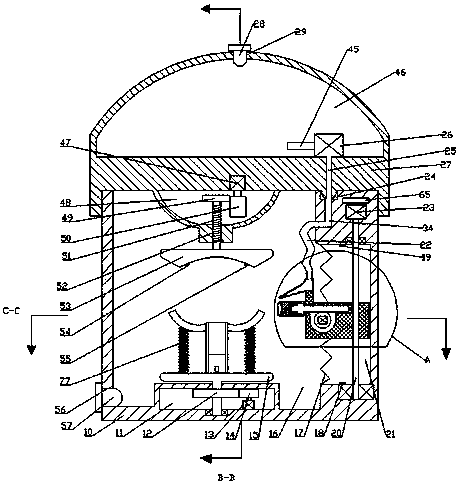

ERCP (Endoscopic Retrograde Cholangiopancreatography) auxiliary mechanical arm device

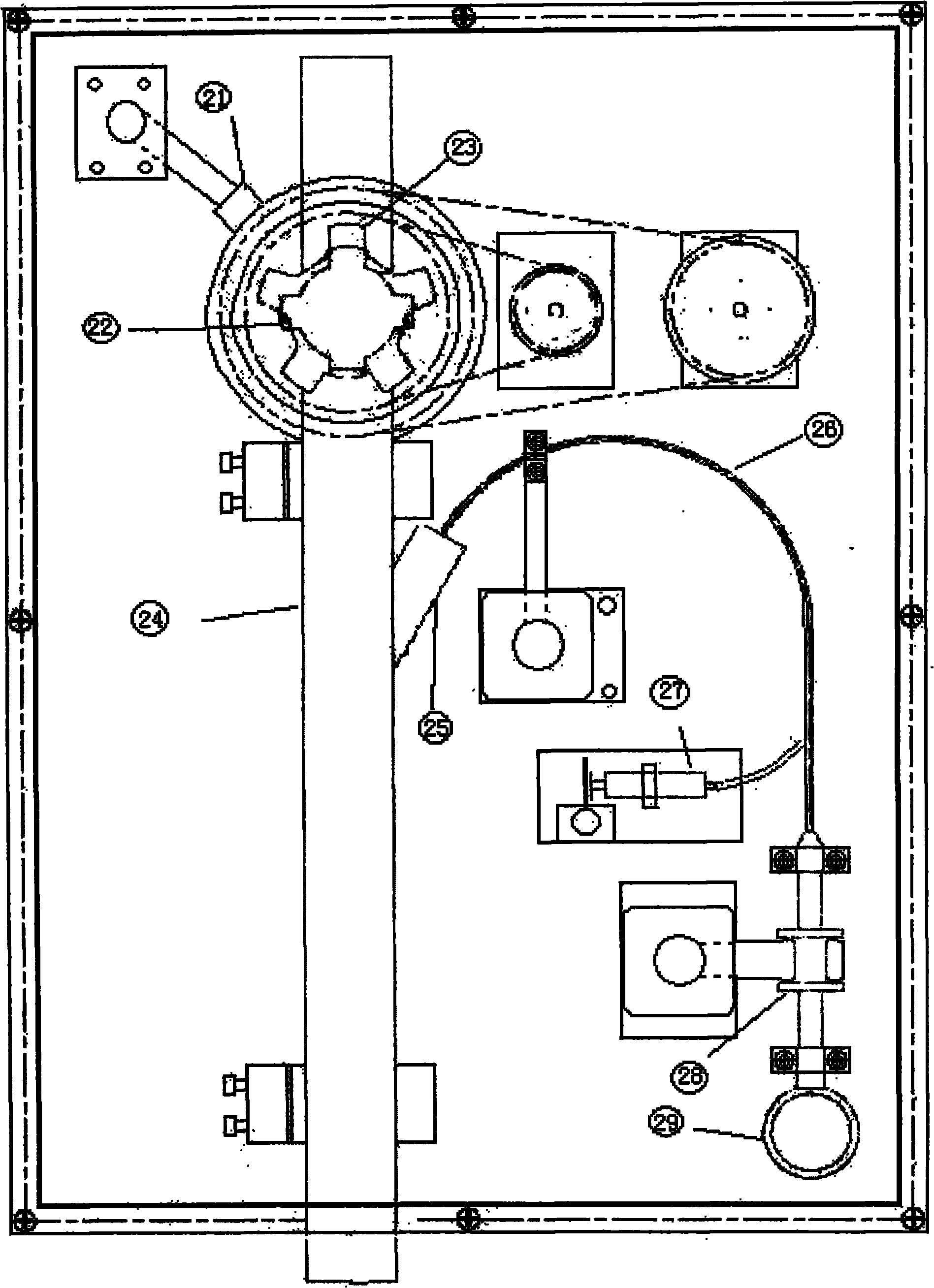

The invention relates to an ERCP (Endoscopic Retrograde Cholangiopancreatography) auxiliary mechanical arm device which is a machinery automation device for assisting in completing various treatment operations based on ERCP. The ERCP auxiliary mechanical arm device is designed according to duodenoscope and various instruments, the duodenoscope is placed in a descending part of a duodenum, the duodenoscope and / or an assistant device is fixed on corresponding positions, remote control of movement of a mechanical device is realized by a control system, and operations of intubatton, radiography, stone removal, and the like are finished. Therefore, the damage of X ray to the health of medical staff in the process of curing patients is avoided. In the mechanical arm device, each button of the duodenoscope and various related devices are firmly fixed so that various operations with endoscopes are accurately completed, and in addition, the automation control technology is applied so that medical staff can control with long distance so as to avoid the damage of the X ray.

Owner:曹罡 +2

Method for preparing dried mango and prepared dried mango

InactiveCN109349403AReduce moisture contentCrispy tasteFood freezingConfectioneryHuman bodySaccharum

The invention discloses a method for preparing a dried mango and the prepared dried mango. The method includes selecting the mango which is eight-mature, free from decay, bruise and pesticide residueas a raw material, and performing cleaning, disinfection, rinsing, peeling, stone removal, dicing, blending, pulping, colloid milling, pan laying, quick freezing and freeze drying to obtain the driedmango. The dried mango has the advantages of low water content, crisp taste, convenience for eating and easy preservation, so that the dried mango is a product suitable for all ages. A composition ofthe product does not comprise sucrose, trehalose and oligosaccharides are specially added, so that the product has the functions of preventing tooth decay, adjusting intestinal flora of a human body,activating the proliferation of probiotics and inhibiting harmful bacteria, is beneficial to the absorption of trace elements by the human body, and is low in heat and suitable in sweetness. The product refines the mango by pulping, and mango dietary fiber is refined, such as mangoes, pineapples and the like, so that the taste of the product can be greatly improved, and the product is richer in nutrition and easier to digest and absorb.

Owner:西充恒河农牧业开发有限公司

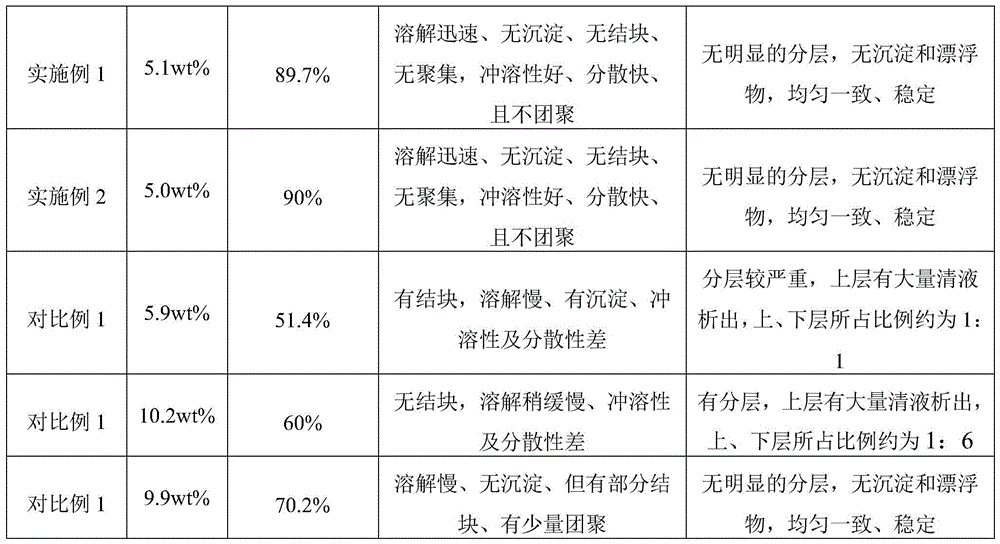

Preparation method of high-purity instant fruit powder

The invention relates to a preparation method of high-purity instant fruit powder. The preparation method comprises steps as follows: raw materials are screened, washed, peeled, subjected to stone removal, pulped, subjected to enzymolysis, filtered, concentrated and mixed, the wall of a spray drying tower is rotationally blown and swept by dedusted clean air in the drying process, dry fruit powder output by the spray drying tower is conveyed to a material collection cylinder through dehumidified clean air, the purity of the fruit powder can reach 80%-90% on a dry matter basis, and the solubility is higher than or equal to 95%. Compared with an existing fruit powder preparation method adopting a spray drying technique, the provided preparation method of the instant fruit powder has the advantages that the quantity of added auxiliaries is remarkably reduced, the purity of the product is remarkably improved, and the purity and the nutritional ingredients of the fruit powder are guaranteed. The state of the dissolved fruit powder is uniform, the flavor is strong and mellow, the moisture content of the product is low, and the storage time is prolonged.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

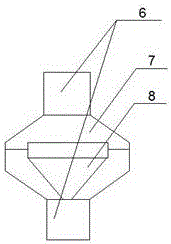

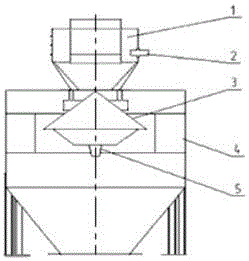

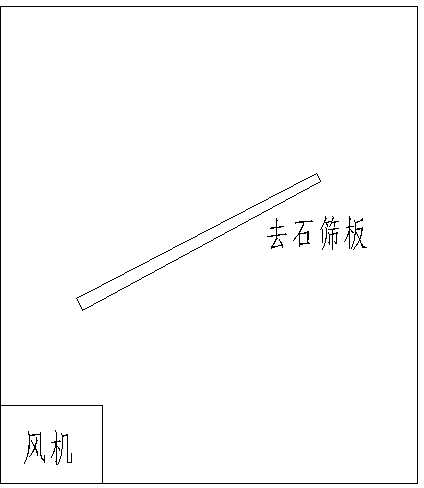

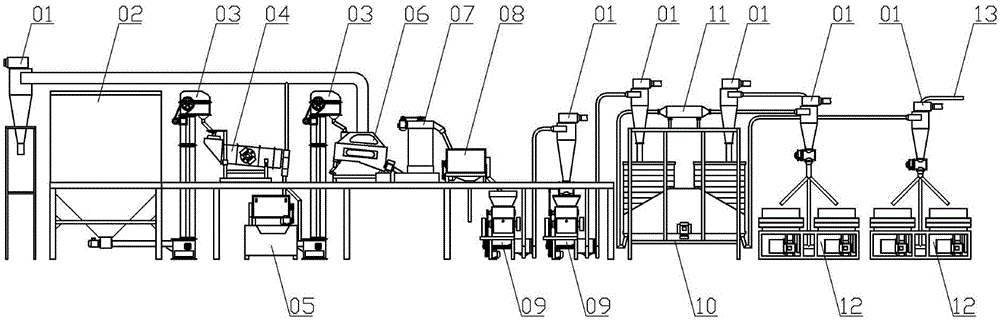

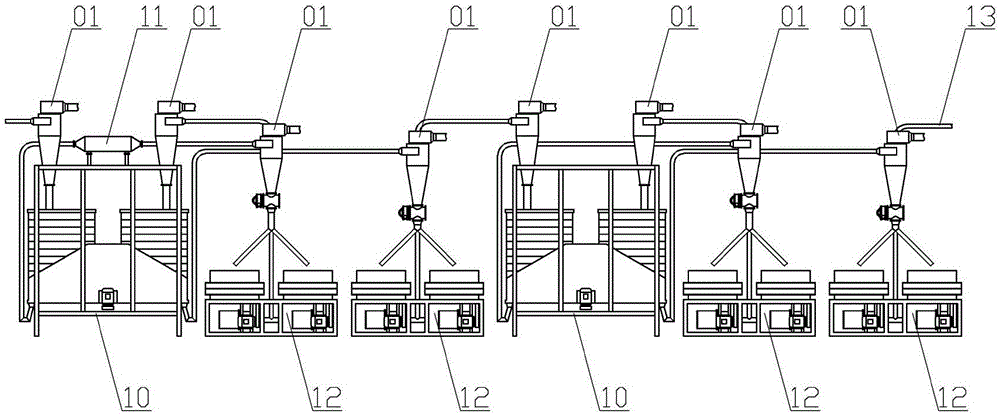

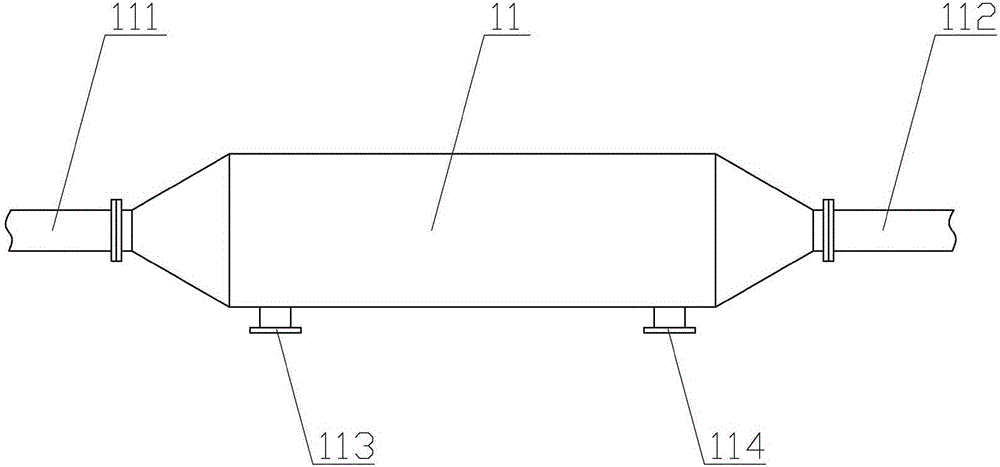

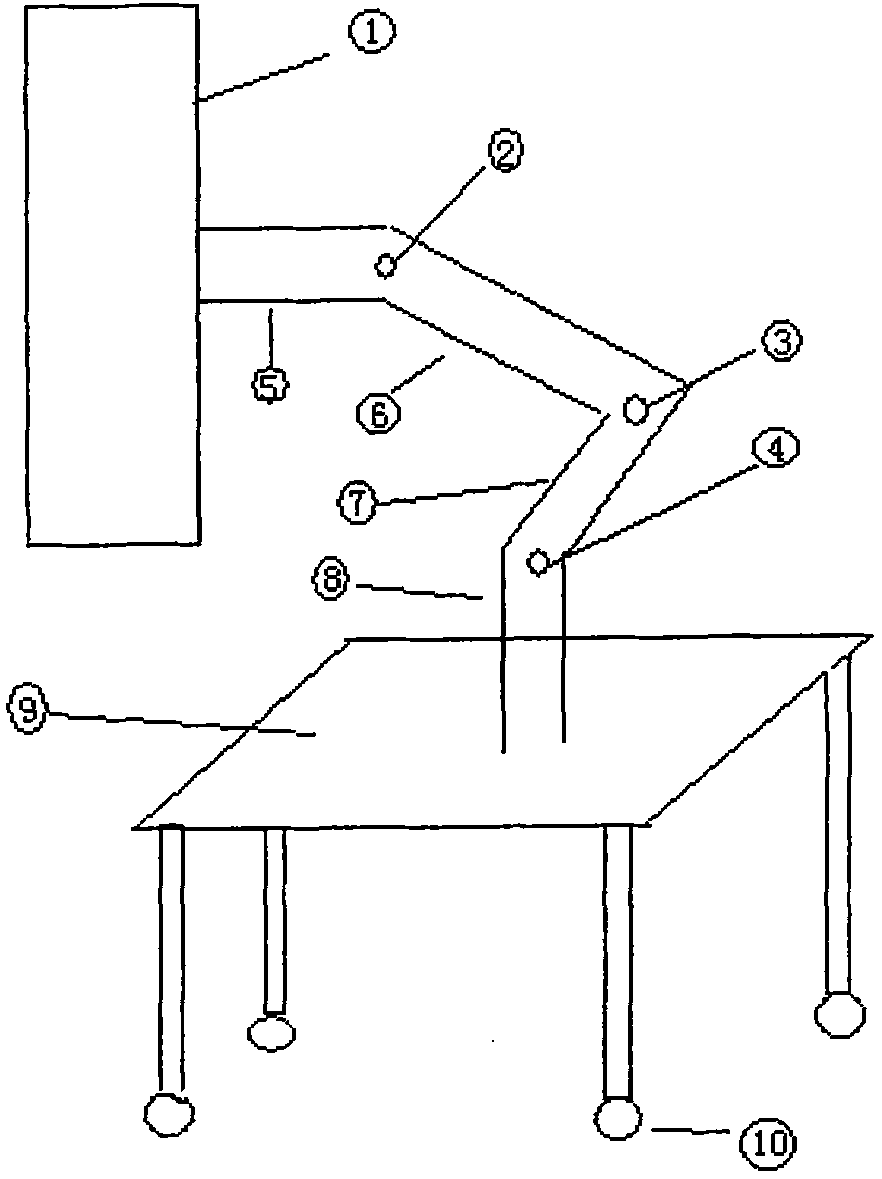

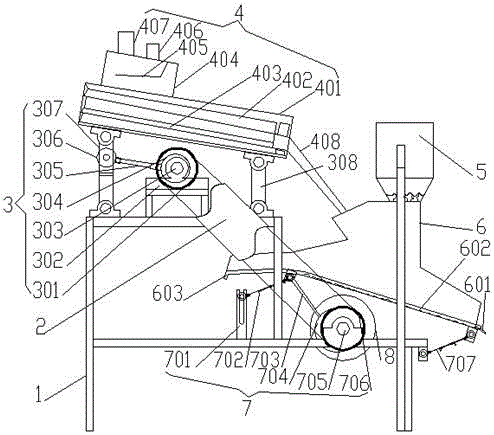

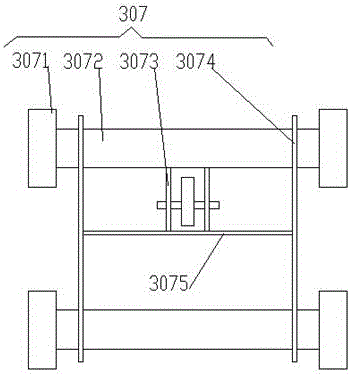

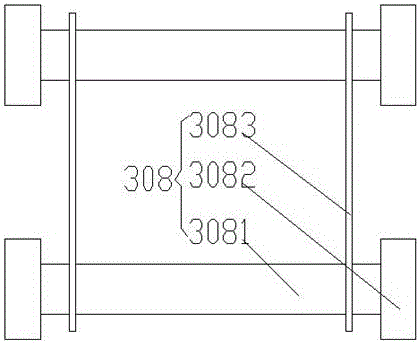

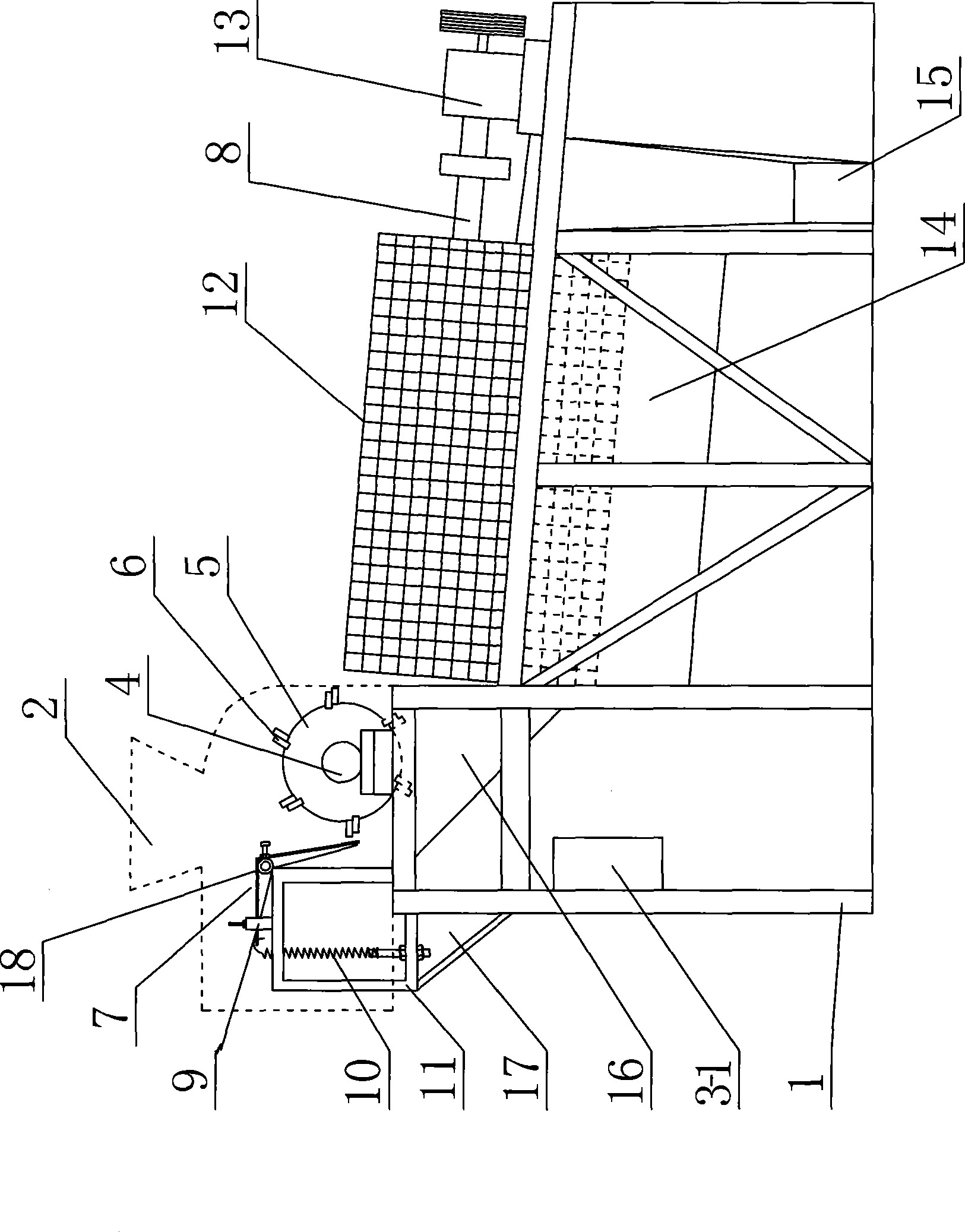

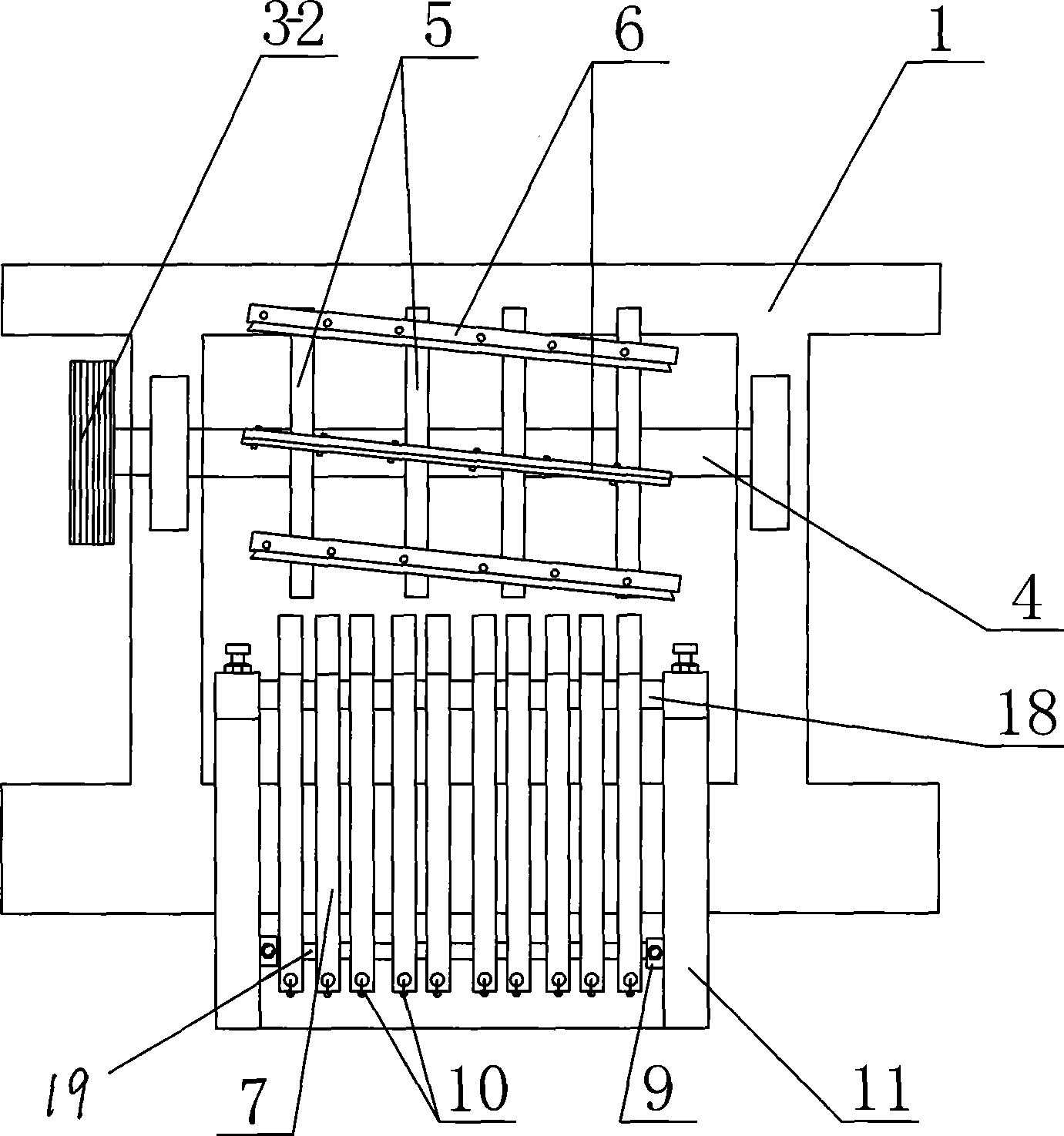

Suction type impurity and stone removing machine for grains

ActiveCN106166547AImprove stone removal efficiencyEasy to separateSievingGas current separationPower beltAgricultural engineering

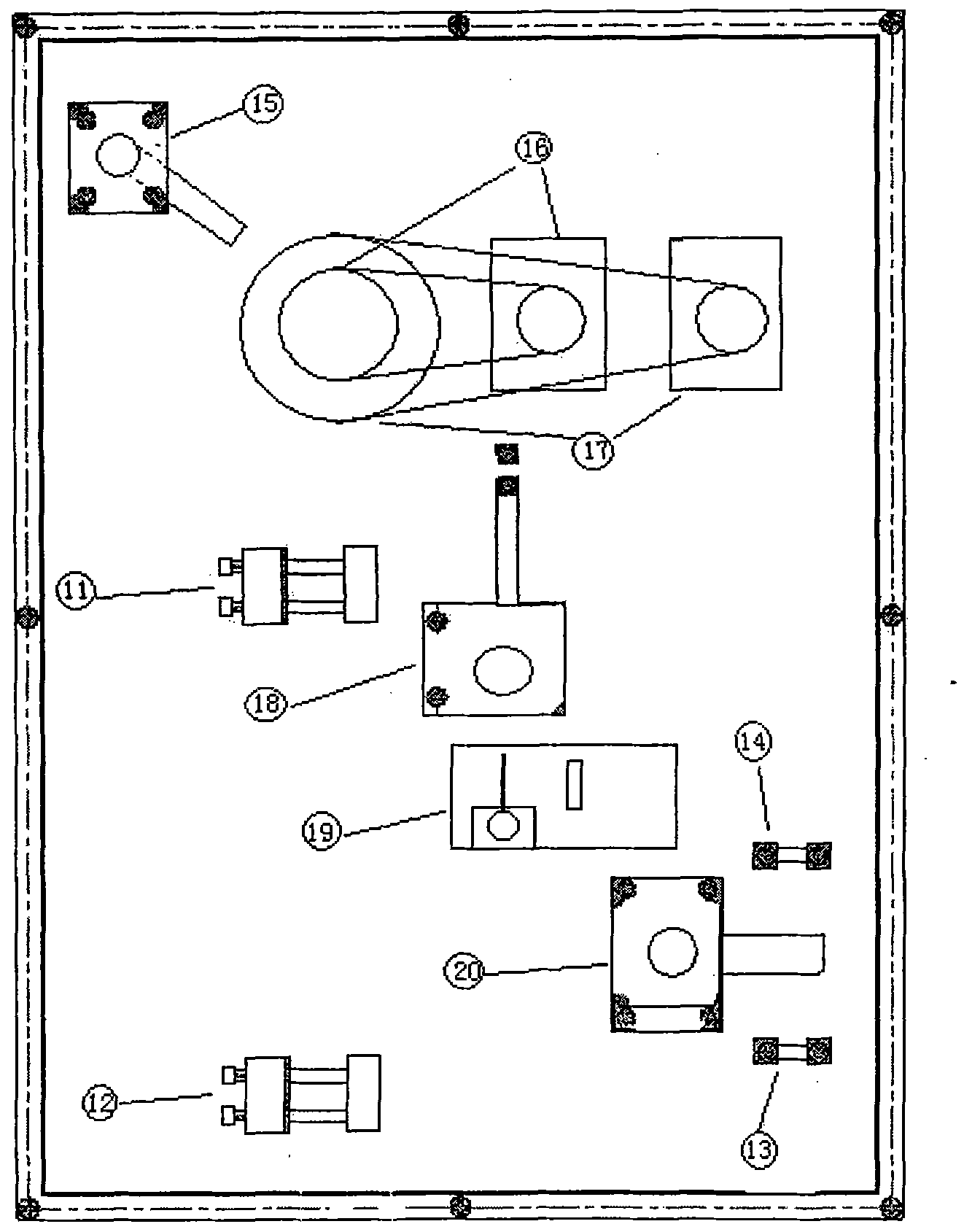

The present invention discloses a suction type impurity and stone removing machine for grains. The suction type impurity and stone removing machine comprises a rack, an upper eccentric mechanism, a flat screen, a fan, a stone remover, a lower eccentric mechanism and a big belt wheel; the upper left portion of the rack is connected with the upper eccentric mechanism; the upper eccentric mechanism is connected with the flat screen; a discharging plate of the flat screen is aligned with a feeding port stretching into the stone remover; the stone remover is erected at the right side of the rack through the lower eccentric mechanism; an upper portion of the stone remover is connected with the suction fan; the suction fan is fixedly connected between vertical rods at the right side of the rack; a rear end of a main shaft of the lower eccentric mechanism is connected with the big belt wheel; the big belt wheel is connected with a motor through a belt; the motor is installed at a lower portion of the rack; a front end of the main shaft of the lower eccentric mechanism is connected with a lower belt wheel connecting an upper belt wheel of the upper eccentric mechanism through a power belt; and a shield covers the upper belt wheel, the power belt and the lower belt wheel and is fixedly connected at the front side of the rack. The suction type impurity and stone removing machine has the beneficial effects that impurities are separated clearly, stone removal efficiency is relatively high, the whole machine is sealed, dust spread is prevented, rubber bearings are adopted for reciprocating swing, and the noise is reduced to be lowest.

Owner:CHAOHU CITY NEW ASIA FOOD MACHINERY

Processing flow for organic rice

The invention provides a processing flow for organic rice. The processing flow comprises the steps of preparation of unhulled rice, preliminary cleaning, cleaning, stone removal, rice husking, hulled rice separation, brown rice selection (thickness grading), multi-level light grinding, white rice grading, multi-level polishing, white rice grading, white rice selection (length grading), color sorting and purification, packaging and storage. According to the processing flow for rice, rice of multiple grades can be provided, the broken rice rate is less than 10%, and the rate of remained germ in polished rice is more than 80%; the obtained rice does not need to be washed for eating, and nutrient elements kept during eating can be increased; and the processed rice meets the standards required by China and health management laws and regulations.

Owner:NANTONG JIHE RICE CO LTD

Compound red jujube powder and processing methods thereof

InactiveCN103960609ASimple production processRetain nutrientsFood shapingFood preparationPearl barleyFlavor

The invention discloses a series of compound red jujube powder processing methods. One method comprises the steps as follows: the compound red jujube powder adopts red jujubes as a main material and adopts poria cocos, black sesames, oats, pearl barley, red beans and lotus seeds as auxiliary materials, the red jujubes are subjected to cleaning, stone removal, softening, pulping, peeling and enzymolysis, compounded with one or more types of plant powder and subjected to blending, homogenizing, vacuum drying and grinding screening and filtration to obtain the compound red jujube powder. According to the invention, the red jujubes are compounded with one or more types of plant powder with dual purposes of medicine and food, and the compound jujube powder is good in color, flavor and taste, rich in nutrients and beneficial to health after long-term eating; and further, the compound jujube powder is wide in application, can be taken as the stuffing and used for cooling porridge, and can be directly brewed for drinking.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Corn starch processing technology

The invention discloses a corn starch processing technology and relates to the technical field of starch processing. The corn starch processing technology is characterized by comprising the following steps: storage, purification, soaking, crushing and fine grinding of corn, separation, washing and drying of fiber, and separation, washing and drying of starch, wherein the crushing of corn is that soaked corns enter a wet corn storage hopper from a wet corn delivery pump via a stone removal device and then enter a first convex teeth mill to be crushed into four to six pieces, the content of entire corns is not greater than 1%, 75-85% of germs are separated, and 20-25% of starch is released. According to the processing technology, the process is reasonable, the speed and the efficiency are high, and the prepared starch is fine and high in quality.

Owner:安徽年康面业有限责任公司

Gravel clearing device for train rails

InactiveCN109898374AAvoid bumpingImprove ride comfort performanceBallastwayRailway cleaningEngineeringHigh pressure

The invention discloses a gravel clearing device for train rails, comprising rails, a locomotive, wheels, shock absorption arms, connecting rods, sleepers, an air pump, telescopic columns, fastening bolts, stone removal rods, high-pressure nozzles, shock absorption springs and air hoses. By installing the telescopic columns on two sides, which are close to the wheels, of the bottom of the locomotive, and installing the connecting rods and the stone removal rods on one sides of the telescopic columns, the stone removal rods can push stone, which are on the rails of two sides of the wheels, to be away from the rails, the jolt of a vehicle caused by direct contact of the wheels and the stone is avoided, and the riding comfort of the vehicle is improved. The high-pressure nozzles at the bottomof the stone removal rods can eject high-pressure gas towards two sides of the rails to blow the stone, which has a relatively small volume, to be away from the rails, so that the travelling stability of trains is improved.

Owner:湘潭市锦程半导体科技有限公司

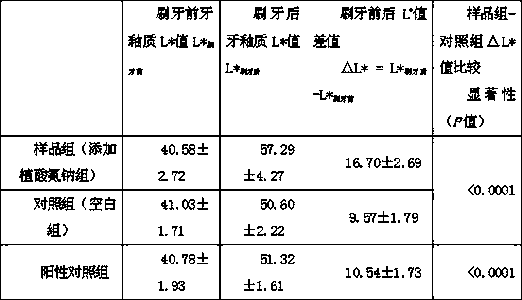

Biological active substance sodium ammonium phytate, and application of biological active substance sodium ammonium phytate in oral care products

InactiveCN110478265AScale inhibition achievedGood scale inhibitionCosmetic preparationsToilet preparationsCalcium silicateAdditive ingredient

The invention discloses a biological active substance sodium ammonium phytate, and application of the biological active substance sodium ammonium phytate in oral care products. Sodium ammonium phytateis mainly composed of basic components including C6H18O24.P6, Na2O, P2O5, C3H7NO2 and C6H9N3O2, and a large number of decontamination and scale inhibition active groups are included, such as a phosphate group, a hydroxyl group, a carboxyl group and an amino group; the active substance sodium ammonium phytate can be used in toothpaste, tooth powder, an oral care solution and oral care gel, the total effective rate of phosphate group molecules containing phytic acid to inhibit CaCO3 scale and phosphate scale in an oral cavity is greater than or equal to 95%, and the inhibition rate to scale ofcalcium silicate is almost 100%; and through active functional groups in amino acid and protein residues, the high dissolving and penetrating capacity of combination of the hydroxyl group, the carboxyl group and the amino group, and the high combination capacity with protein molecules, more active groups can be brought into dental plaque and dental calculus, the formed dental plaque and dental calculus are separated together and peeled off, and then effects of scale inhibition, stone removal and skin whitening are achieved.

Owner:靖江市盛金科技有限公司

Preparation method of warm-pressed plant oil

InactiveCN103436355AIncrease the fragranceQuality improvementFatty-oils/fats productionEdible oils/fatsOil and greaseFiltration

Aiming at the defects that skinned high-temperature cooked raw materials are energy-wasting, high-temperature cooking causes volatilization of oil in the raw materials, damages the nutritional ingredients in grease and reduces the flavor of the plant oil, and the volatilizing oil ingredients are mixed in atmosphere and cause environment pollution in the existing plant oil hot-pressing technology, the invention provides a preparation method of warm-pressed plant oil. The preparation method comprises the following steps: raw material selection, raw material cleaning, stone removal, skinning, embryo pressing, gradient temperature cooking, warm pressing, filtration, refined filtration, finished product formation. The plant oil produced by the method has a high oil yield, pure color, a nose greeting aroma and guaranteed quality; in addition, the method is energy-saving and does not pollute environment during production.

Owner:XUCHANG WEIERKANG PLANT OIL

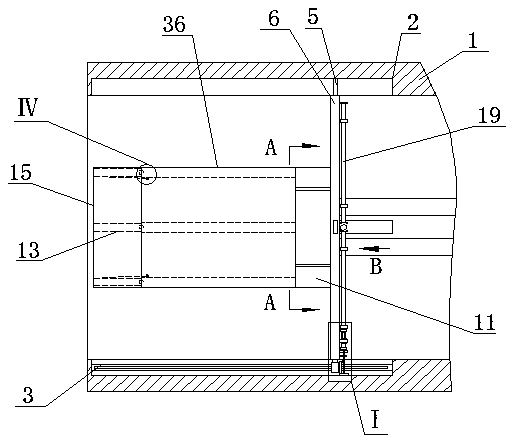

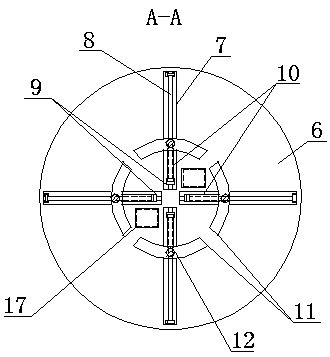

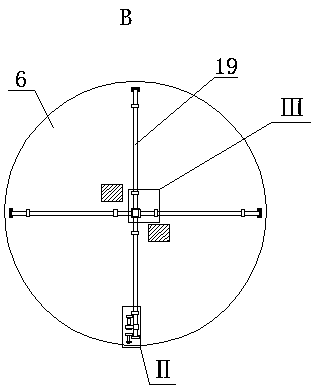

Stone removal device for hepatobiliary surgery clinics

A stone removal device for hepatobiliary surgery clinics comprises a tube, four holding grooves are formed in the inner wall of one end of the tube, the four holding grooves are uniformly distributedwith respect to the center of circle of the tube, one holding groove is located in the middle of the lower portion of the tube, a horizontal screw is movably mounted in the lower holding groove, a nutis fitted on the screw, sliding blocks are respectively arranged in the remaining three holding grooves, and the three sliding blocks are fixedly connected with one nut through a vertical round plate. The minimally invasive operation can be carried out through the stone removal device for hepatobiliary surgery clinics, less injury is caused to a patient, the wrapping range of first elastic clothis controlled according to the size of stones, the applicable range is wider, and the stones are prevented from remaining in the body and being unable to be removed in the stone breaking process; a closed space is formed by wrapping of the first elastic cloth and second elastic cloth, so that the small stones are prevented from falling out in the stone breaking process.

Owner:田舍

Roller screen type stone extractor for separating soil and stone

InactiveCN101462089AWide range of moisture contentImprove stone removal effectSievingScreeningEngineeringStone removal

The invention discloses a soil-stone separation roller screen stone extractor, which comprises a frame, wherein the inside of the machine frame is provided with a delivery hopper, a storage hopper and a stone outlet groove; a roller shaft is arranged above the delivery hopper; a plurality of rotary discs are uniformly arranged on the roller shaft which is provided with soil crushing knifes through the rotary discs; a fixed rack for fixing a movable swinging arm is arranged on the left of the roller shaft; the movable swinging arm consists of a horizontal section and a swinging section which is inclined downwards; a frame top shell is arranged on exteriors of the movable swinging arm, a spring and the roller shaft; a feed hopper is arranged on a top plate of the frame top shell and positioned above the roller shaft and the swinging section of the movable swinging arm; a roller screen is inclined above the storage hopper; a left opening of the roller screen is communicated with the delivery hopper, and a right opening of the roller screen is communicated with the stone outlet groove; and the roller shaft and a second drive unit are connected with a first drive unit and a second drive unit respectively. The soil-stone separation roller screen stone extractor has the advantages of compact structure, good stone removal effect, high work efficiency and low cost.

Owner:史怀孝

Preparation method of coal active carbon with low heavy metal content

ActiveCN107555429AGood removal effectReduce heavy metal contentCarbon compoundsOther chemical processesActivated carbonWater vapor

The invention provides a preparation method of coal active carbon with low heavy metal content. The preparation method comprises the following steps: respectively carrying out stone removal and flotation on a first coal type and a second coal type, thereby obtaining a first type of float coal and a second type of float coal, wherein for the first coal type, the ash content is 4 to 6 weight percent, the volatile component content is 31 to 36 weight percent, and the caking index is 0.8 to 2.6, and for the second coal type, the ash content is 2.5 to 5 weight percent, the volatile component content is 27 to 30 weight percent, and the caking index is less than or equal to 1; the densities of heavy liquid for floatation of the first coal type and the second coal type are independently 1.35 to 1.45 g.cm<-3>; mixing the first type of float coal and the second type of float coal, and carrying out grinding, briquettingm carbonization and activation on the mixture, thereby obtaining an activatedmaterial; crushing and washing the activated mixture in sequence, thereby obtaining the coal active carbon with the low heavy metal content, wherein washing comprises alkaline washing, water washing,acidic washing and water vapor heating washing. The preparation method can obviously reduce the heavy metal content of the coal active carbon.

Owner:大同市金盛豪达炭业有限责任公司

Improved fruit peeling device

InactiveCN108968626AAccurate pressureConstant pressureKitchen fruit stoningPeelersGear wheelDrive shaft

The invention discloses an improved fruit peeling device. For the improved fruit peeling device, a fruit placing main body cavity is arranged in a fruit placing box, a fruit peeling rotation box is arranged on the bottom wall of the fruit placing main body cavity, a peeling rotation cavity is arranged in the fruit peeling rotation box, a first motor is fixedly mounted on the bottom wall of the peeling rotation cavity, a first transmission gear is fixedly mounted on the end face of the top of an output shaft above the first motor, a first transmission shaft is mounted between the upper and lower inner walls of the peeling rotation cavity in a rotation match manner, a second transmission gear is fixedly mounted on the first transmission shaft, the first transmission gear is meshed with the second transmission gear, a rotation base is fixedly mounted on the end face of the top of the first transmission shaft, a fruit stone removal device is fixedly mounted on the end face of the top of the rotation base, a cutter moving cavity is arranged on the right side of the fruit placing main body cavity, an upper folding plate is fixedly mounted on the top wall of the cutter moving cavity, anda lower folding plate is fixedly mounted on the bottom wall of the cutter moving cavity.

Owner:叶惠婷

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com