Patents

Literature

9947 results about "Closed space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

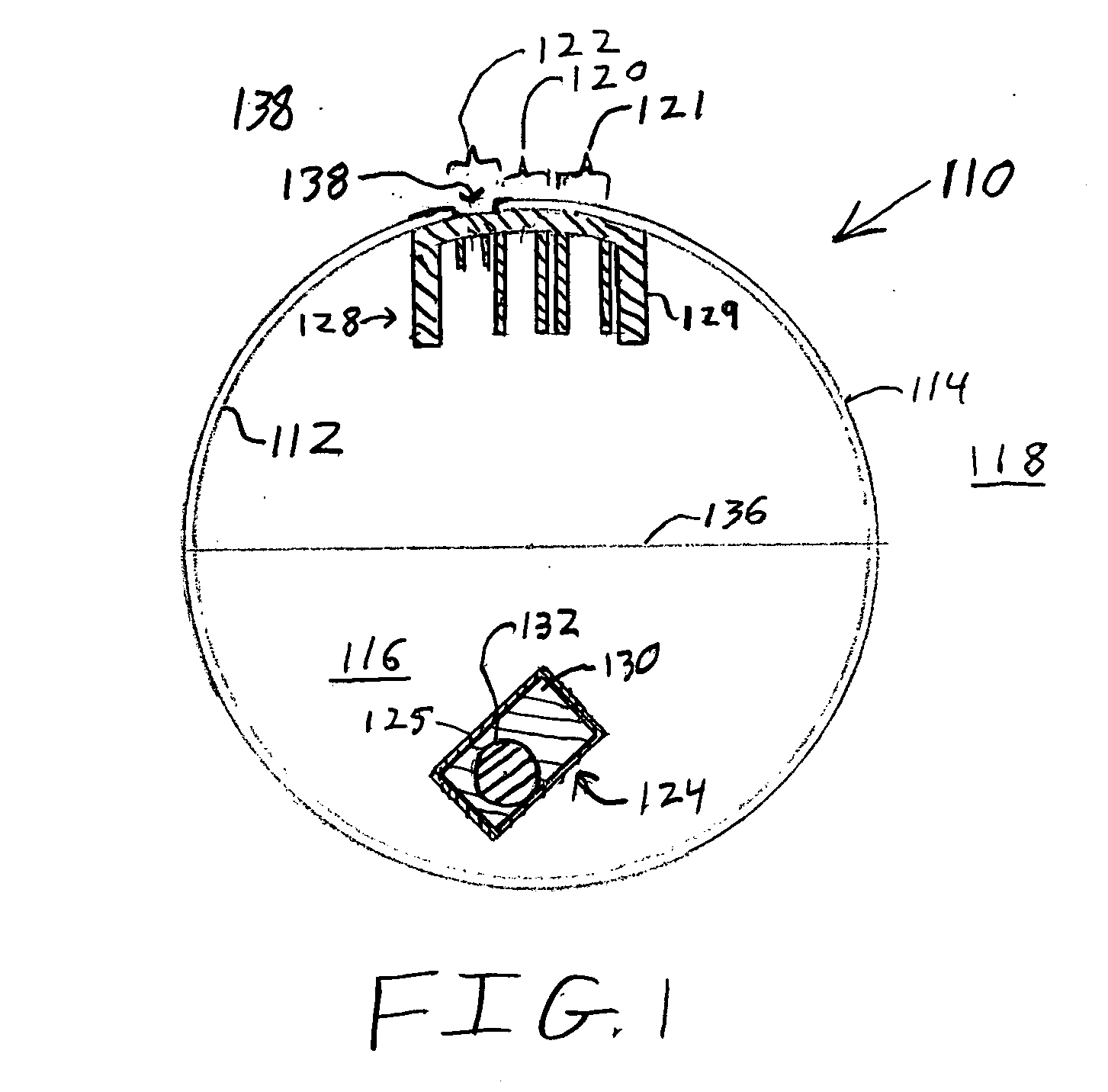

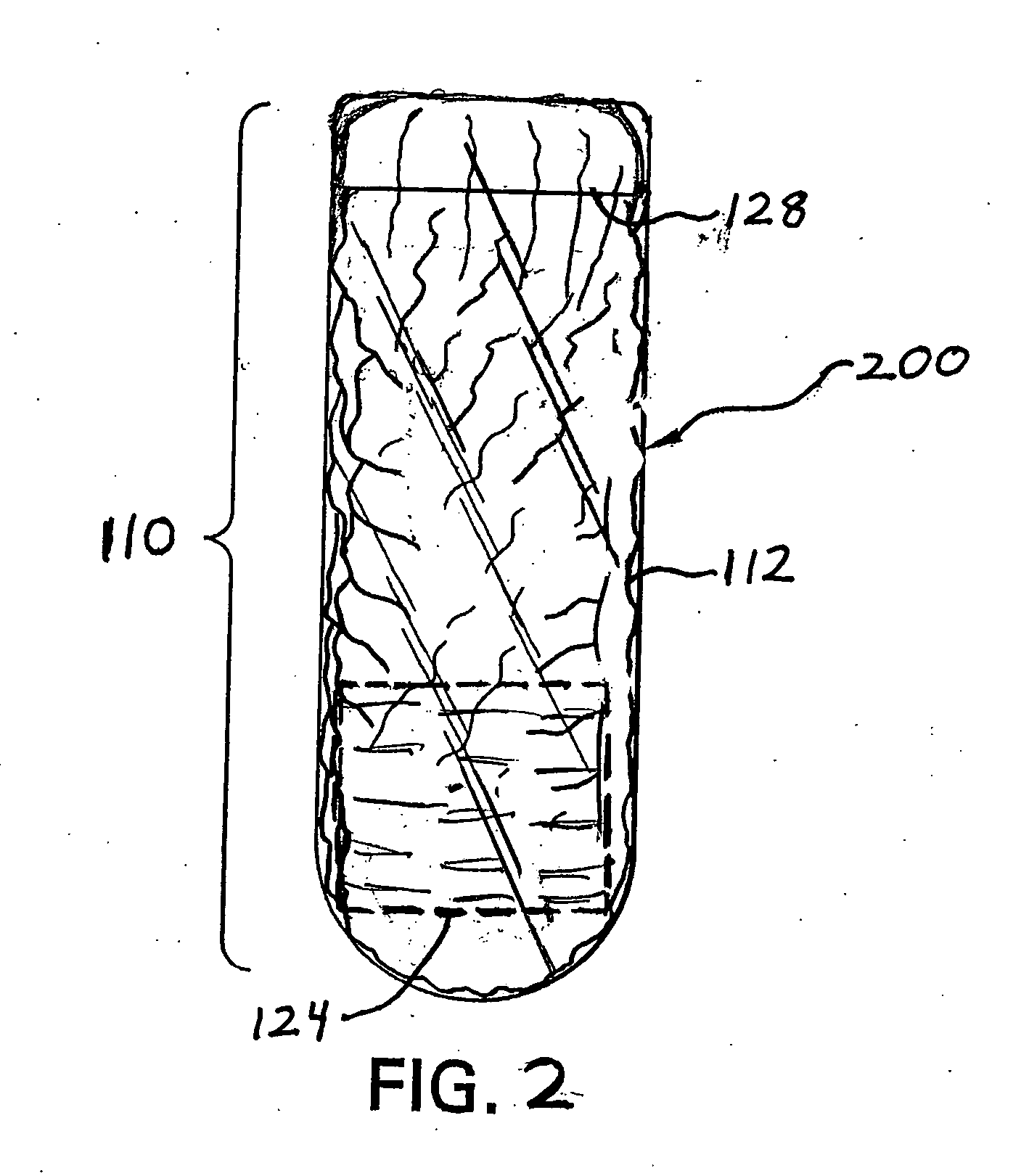

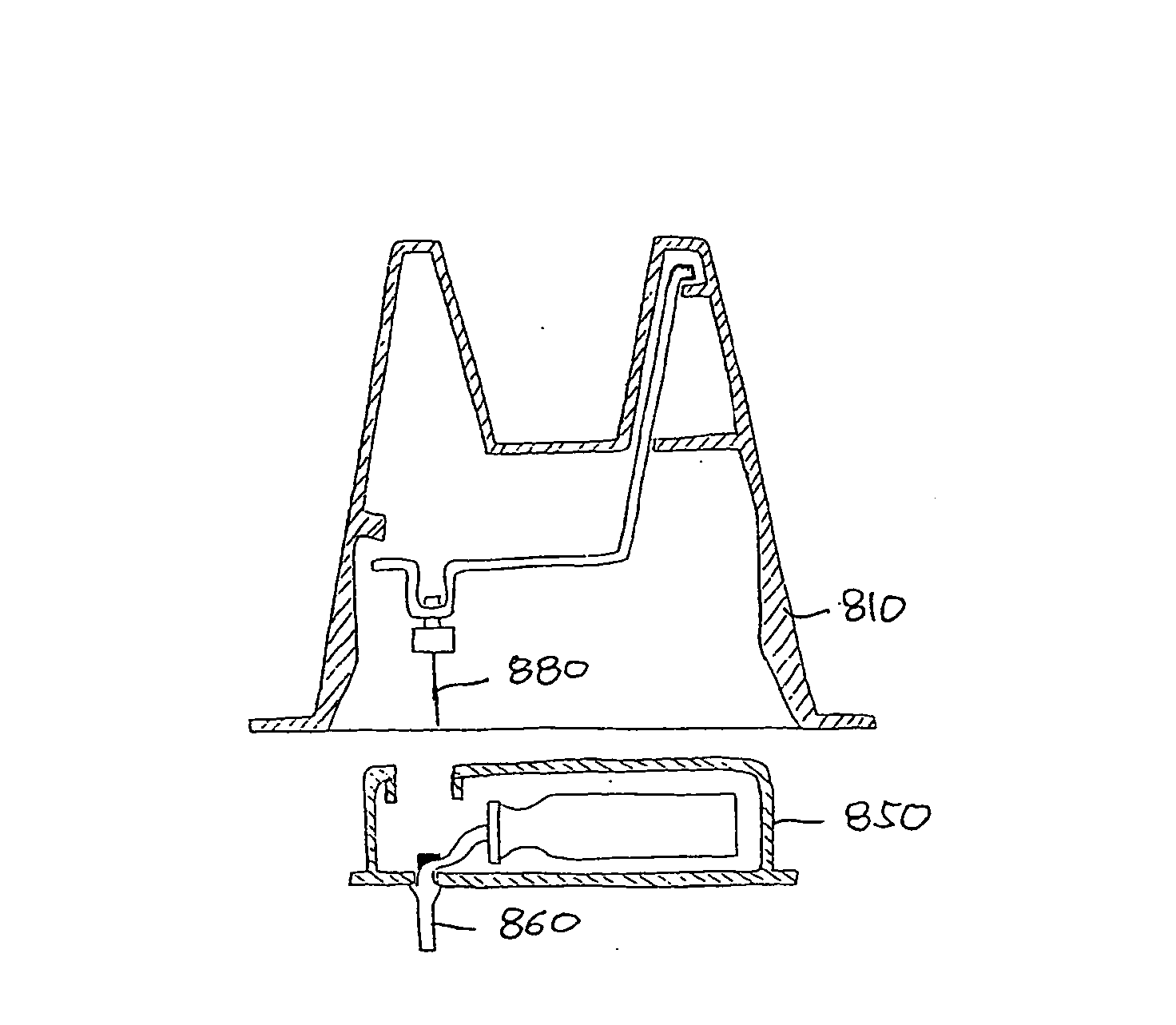

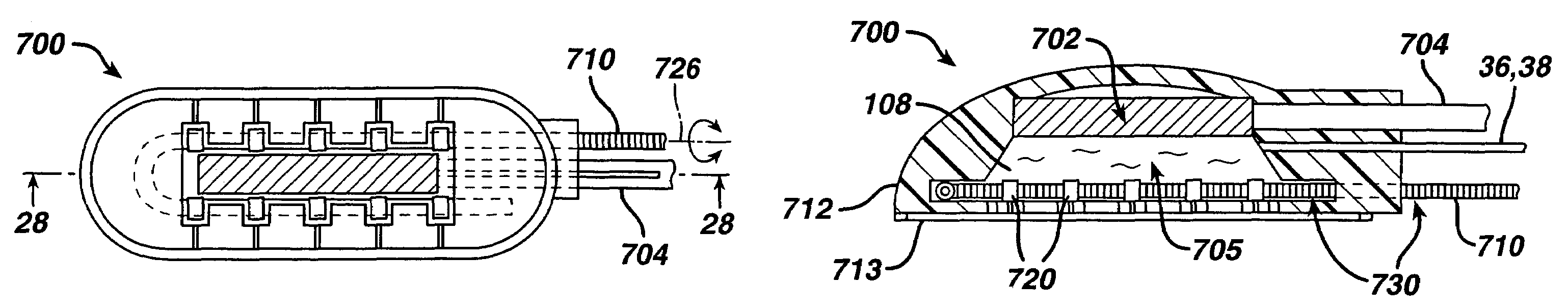

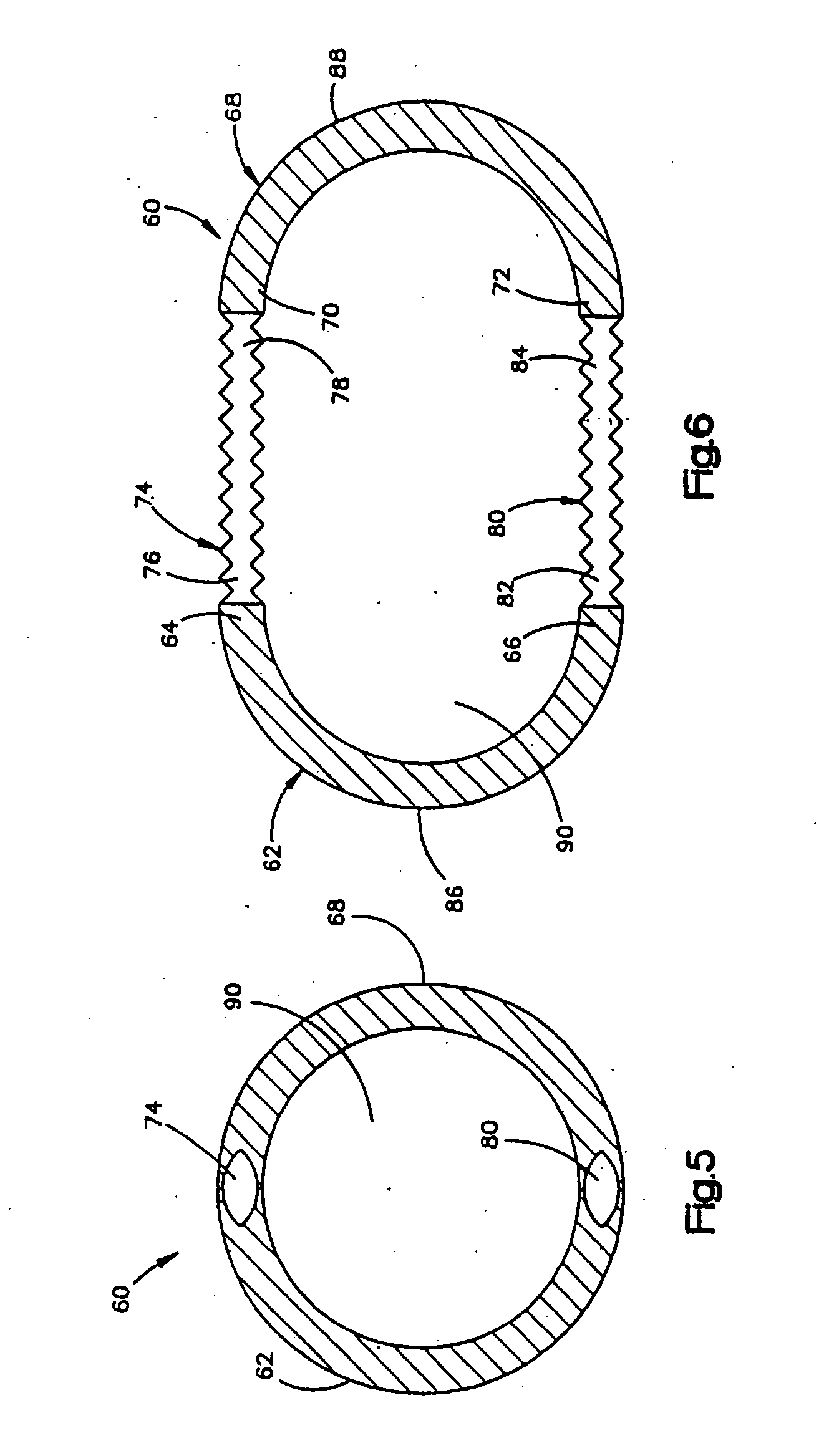

Intragastric volume-occupying device

A self-inflating and self-deflating orally ingestible device that is able to traverse the entirety of the alimentary canal is described. In one embodiment, the device includes a closed balloon having a surface separating an enclosed space internal to the balloon from a space external to the balloon, at least one self-sealing valve integrated with the surface of the balloon to provide access to the enclosed space internal to the balloon from the space external to the balloon, a vent comprised of a dissolvable seal integrated with the surface of the balloon, and a vessel located within the enclosed space internal to the balloon to separate internal contents of the vessel from the enclosed space internal to the balloon.

Owner:OBALON THERAPEUTICS

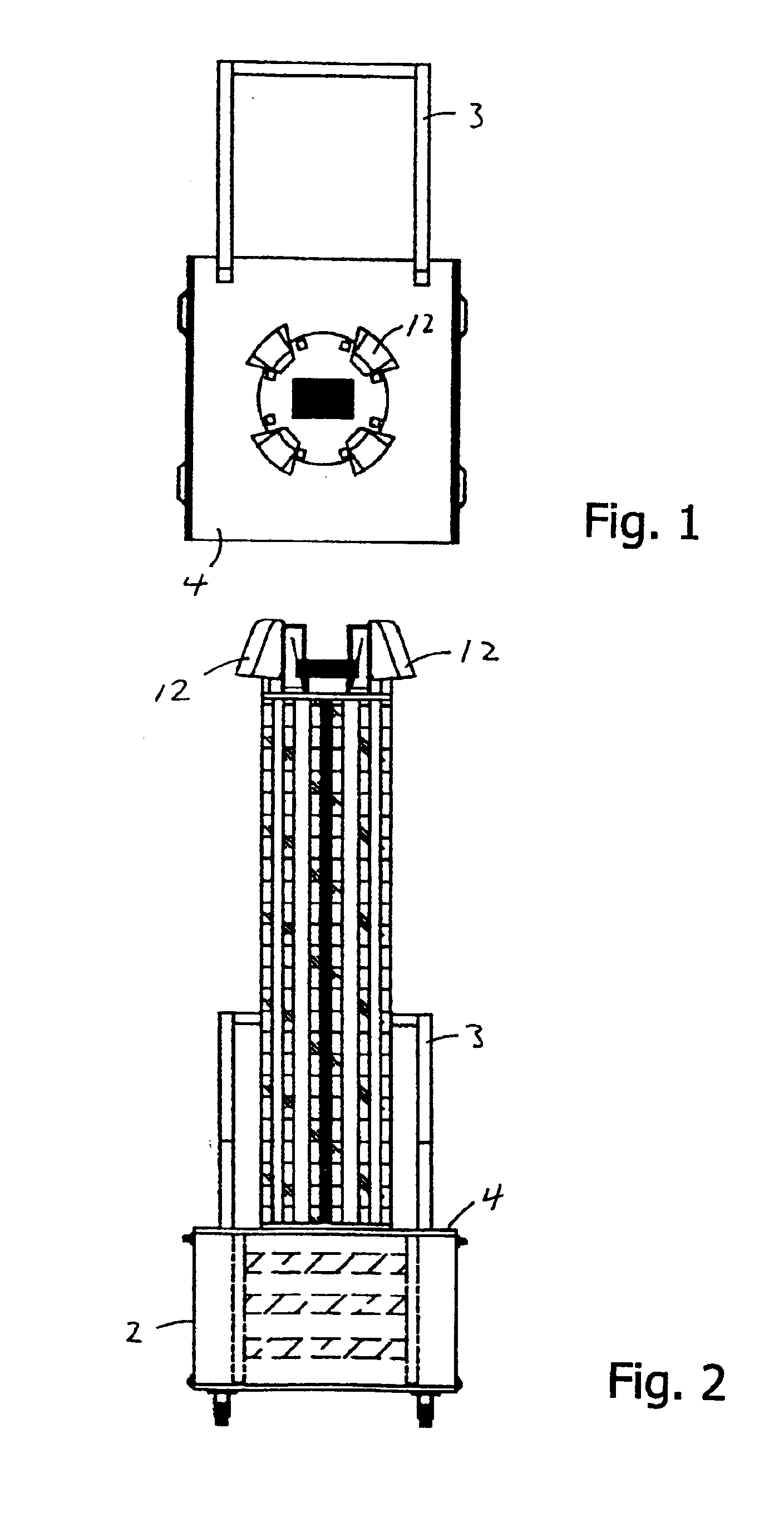

Integrated package

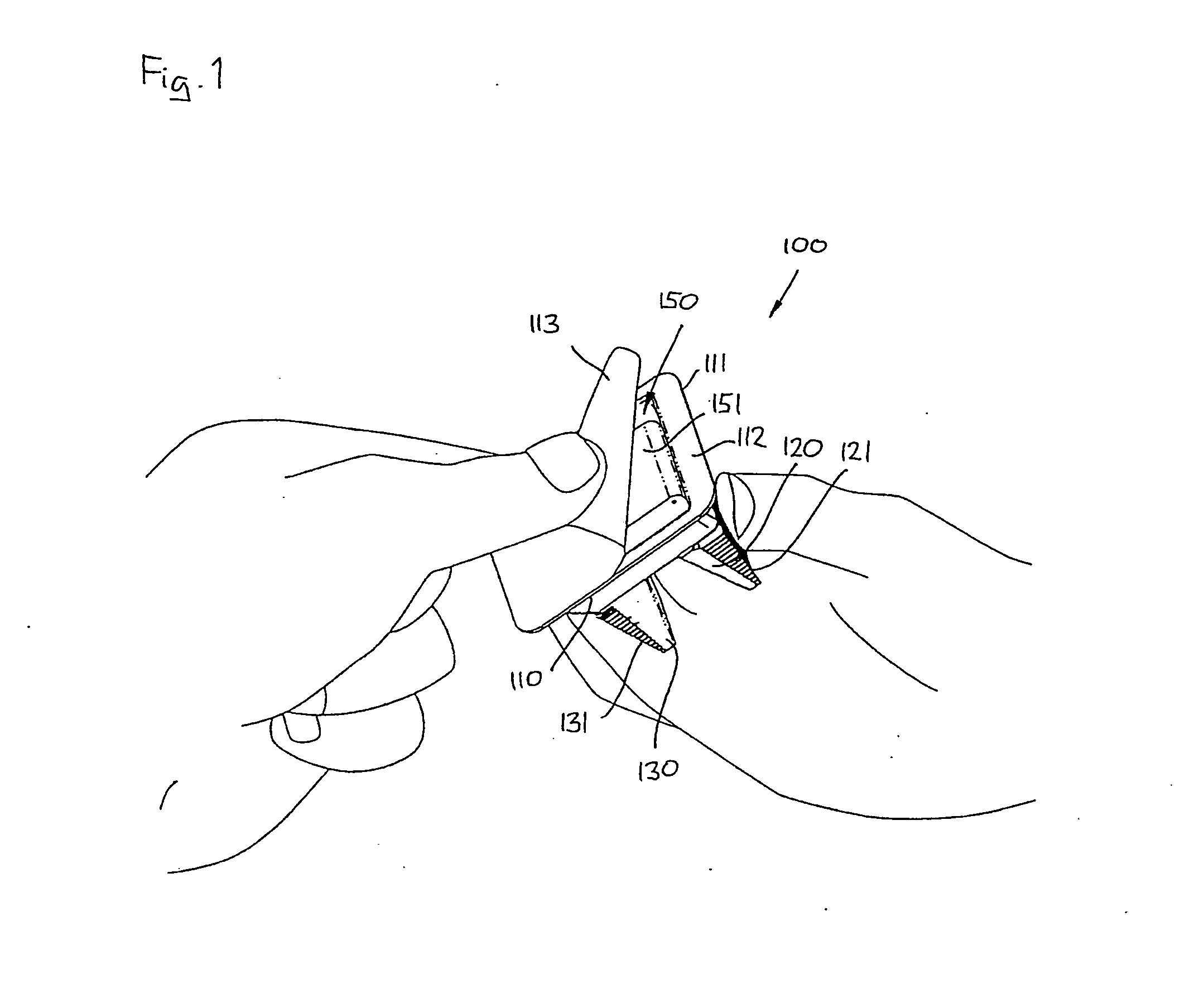

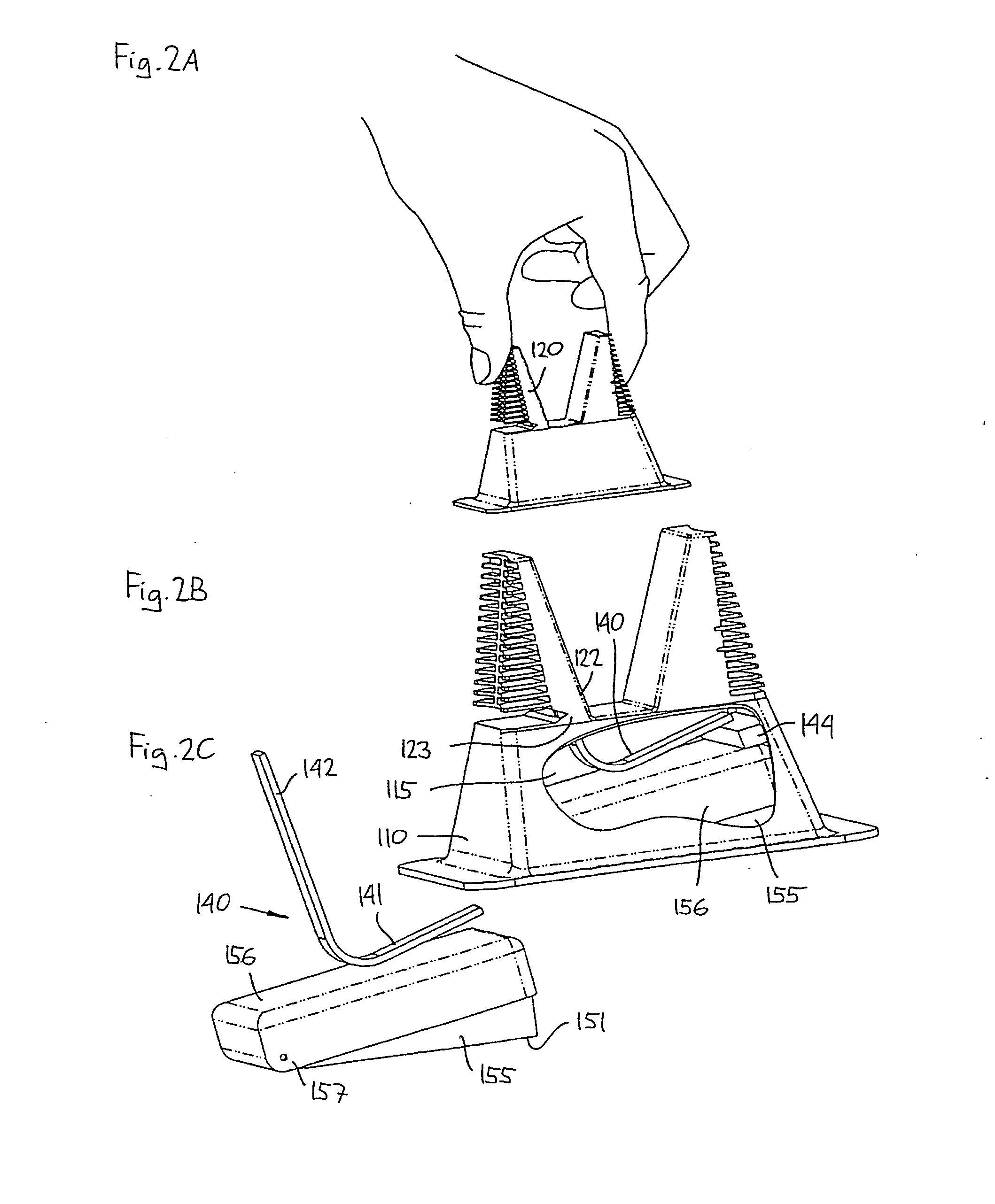

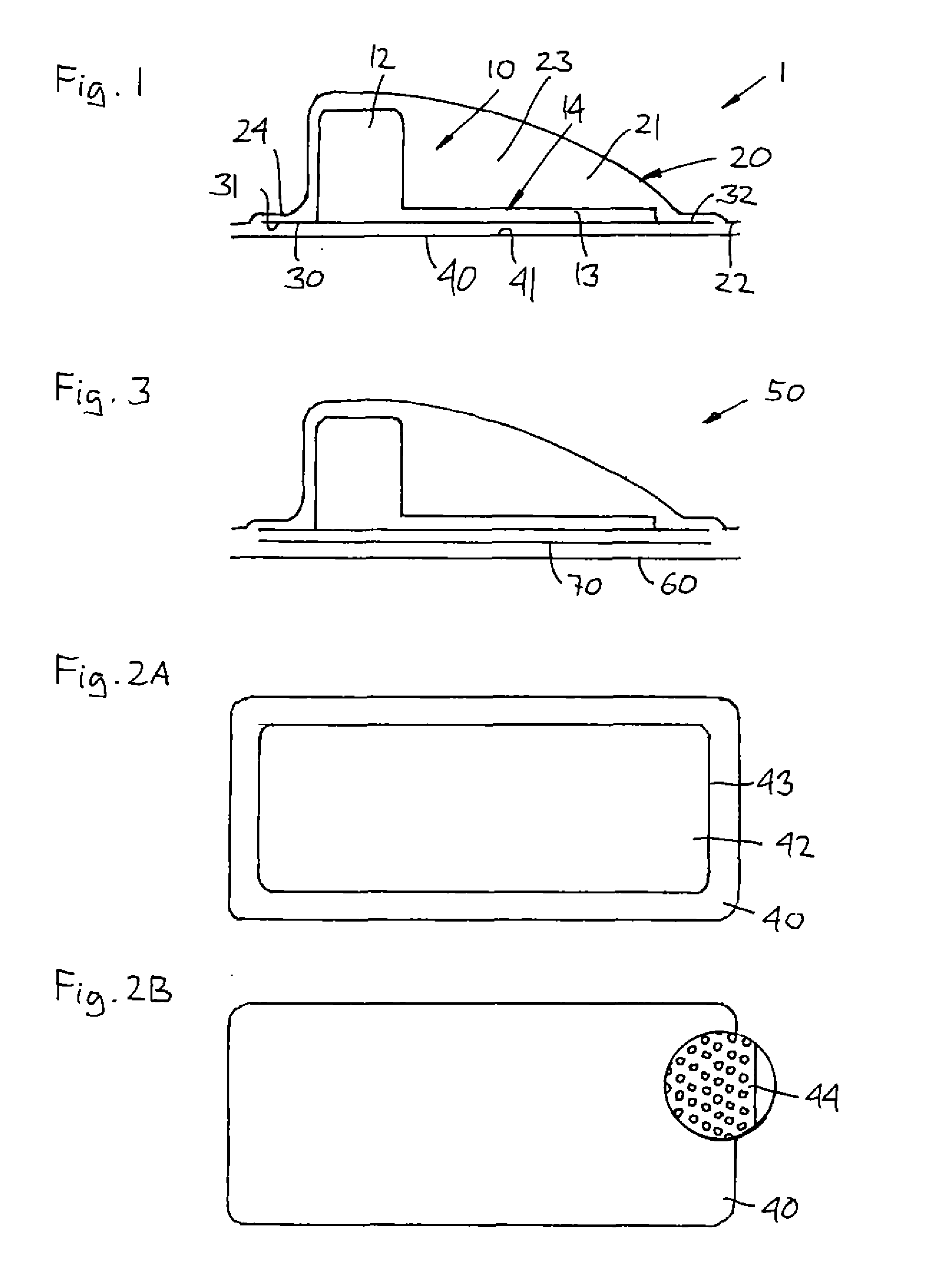

InactiveUS20080009805A1Easy to handleEasy to useMedical devicesPressure infusionInterior spaceAdhesive

The present invention generally relates to skin-mountable devices. A device in accordance with the invention comprises a first skin-mountable unit having a mounting surface comprising adhesive means for adhering the unit to the skin of a subject, and a second handling unit releasably attached to the skin-mountable unit. The handling unit comprises an interior space at least partially accommodating the skin-mountable unit and has an opening through which the skin-mountable member can be moved when detached from the handling unit, the handling unit having a portion surrounding the opening. The device further comprises a seal member releasably attached to the circumferential portion, thereby providing a closed space for the skin-mountable unit. In this way a device is provided allowing for easy handling as a user can use the handling unit to grip and handle the combined device during operation thereof, just as the second unit can be designed and optimized for ease of use during manipulation of the skin-mountable unit.

Owner:NOVO NORDISK AS

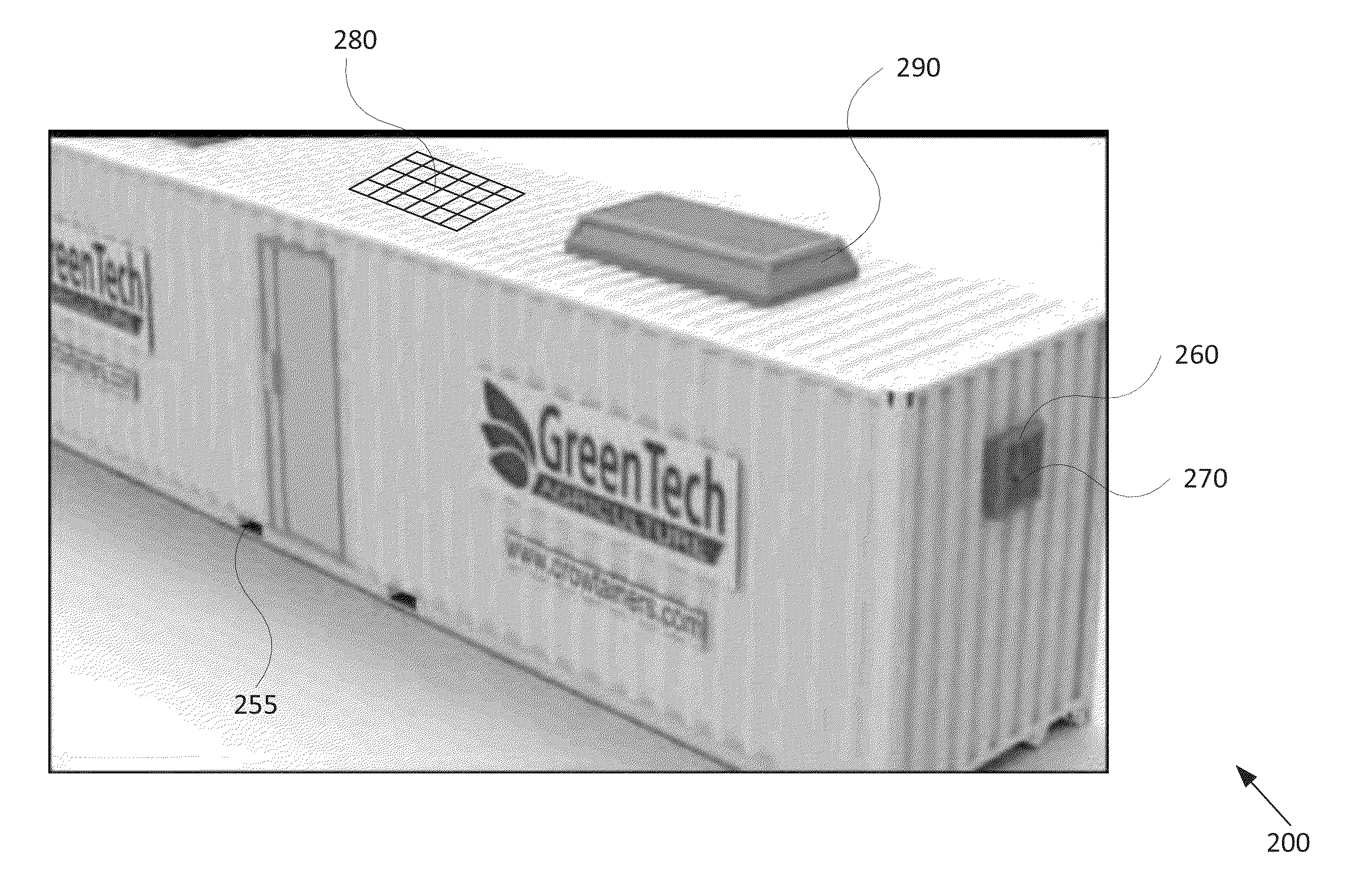

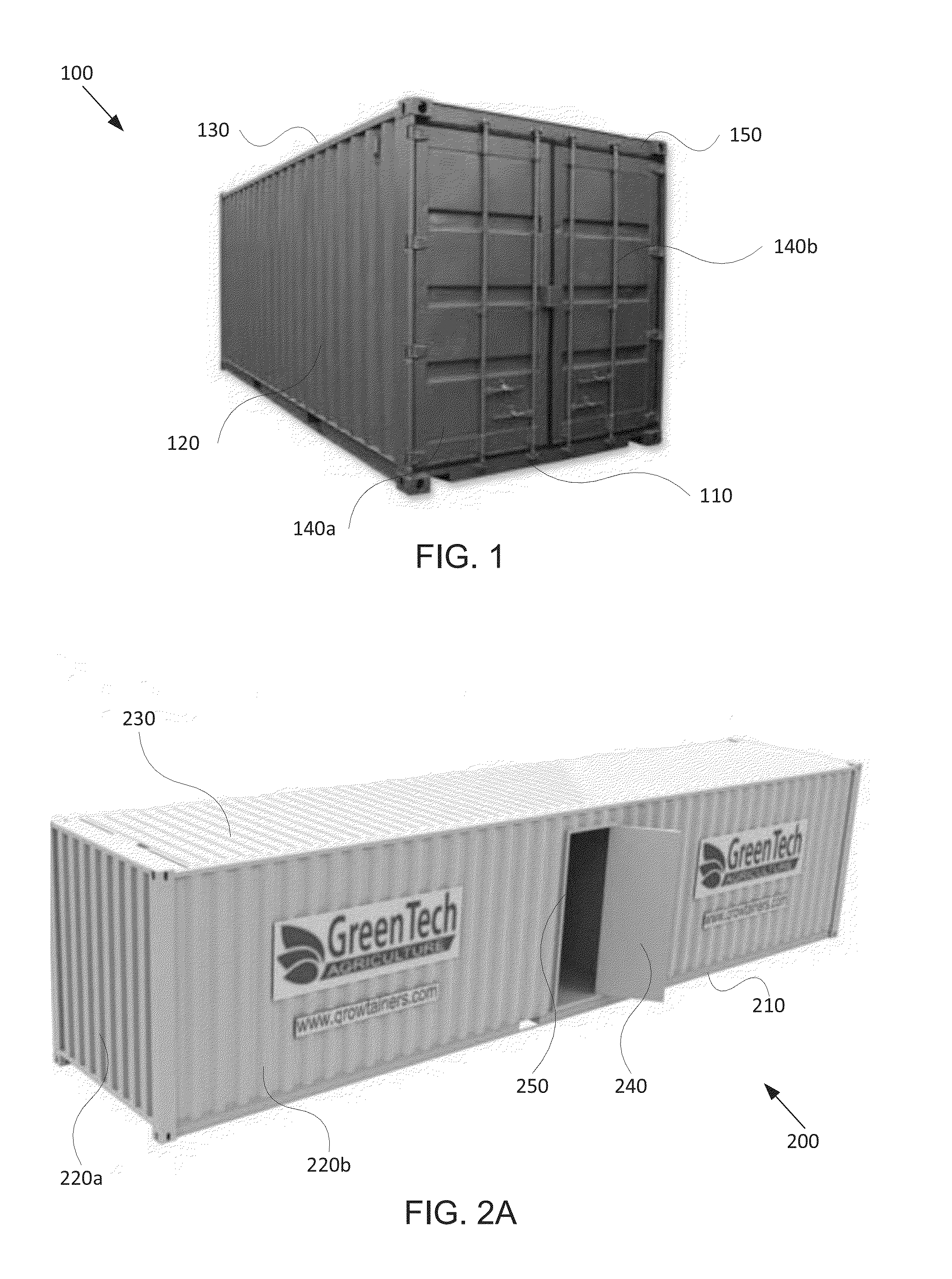

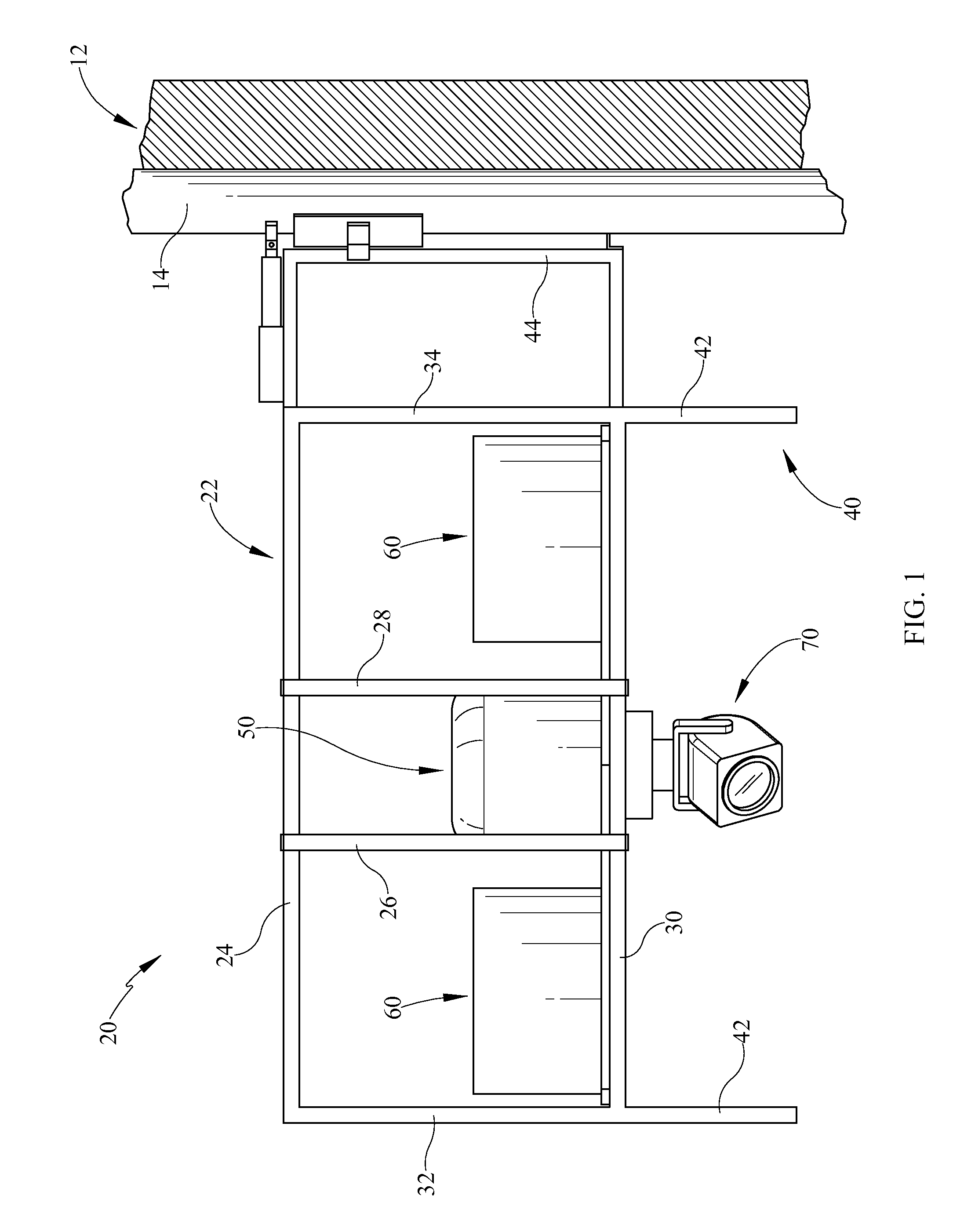

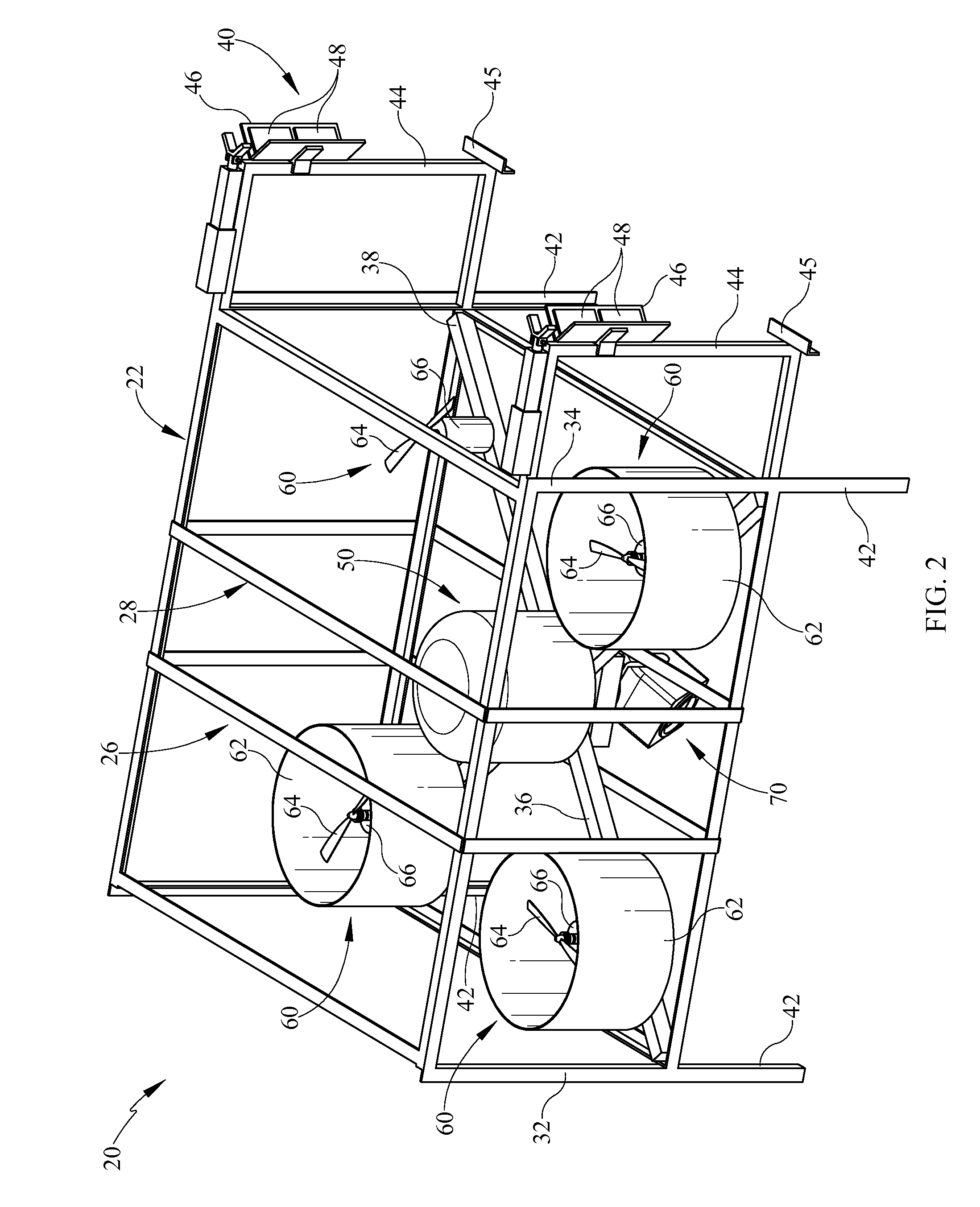

Self-sustaining artificially controllable environment within a storage container or other enclosed space

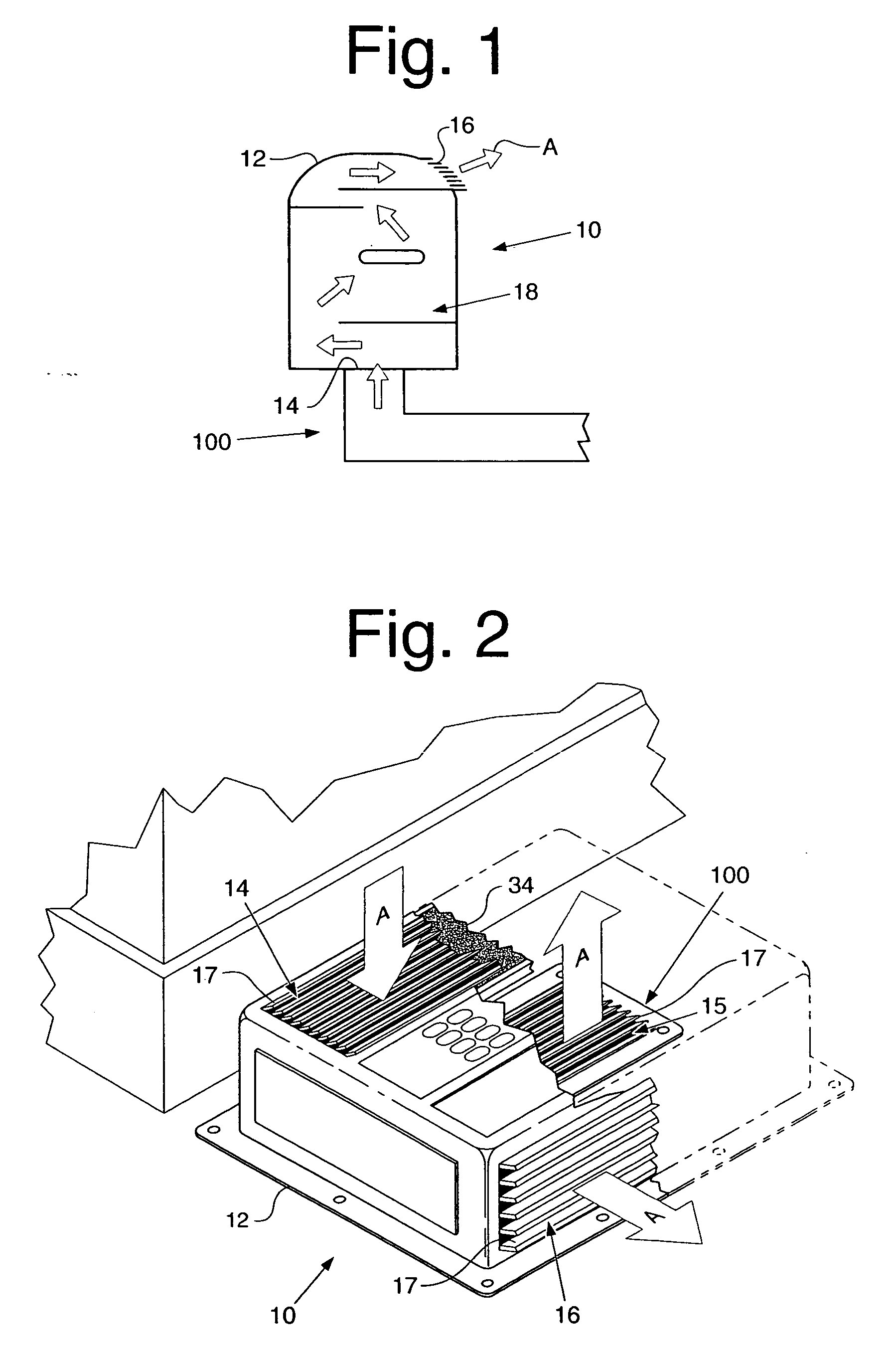

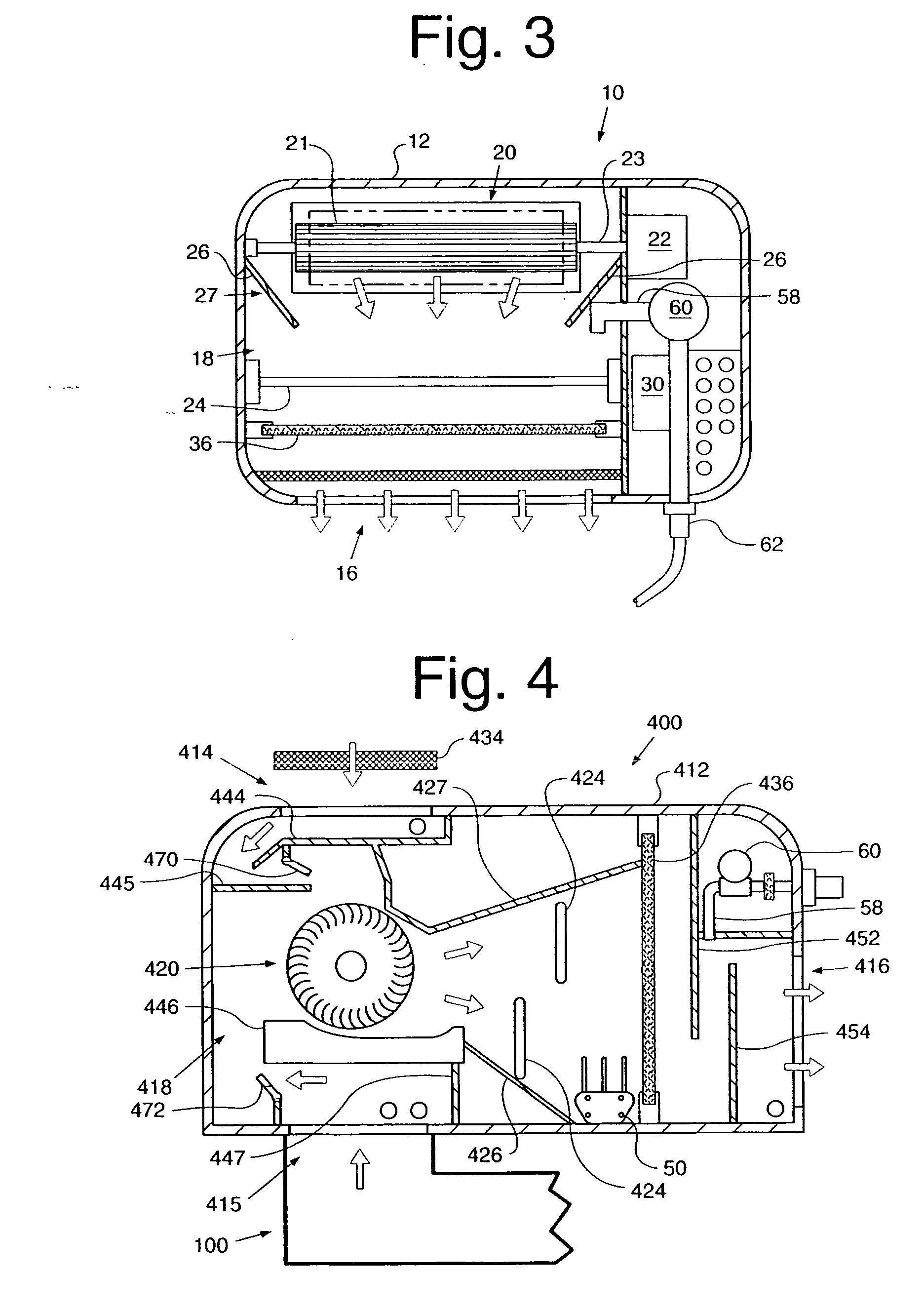

InactiveUS20140115958A1Readily apparentSeed and root treatmentClimate change adaptationEngineeringActuator

A system includes an enclosed space defining a controllable environment chamber. The system also includes at least one monitoring device configured to measure multiple characteristics of an environment within the chamber. The system further includes multiple actuators configured to alter the characteristics of the environment within the chamber. The enclosed space includes at least one rack system configured to be placed within the enclosed space. Each rack system includes multiple layers configured to receive multiple plants to be grown in the chamber. The actuators are configured to adjust the characteristics of the environment within the chamber to condition the environment based on the plants to be grown in the chamber.

Owner:GREENTECH AGRO

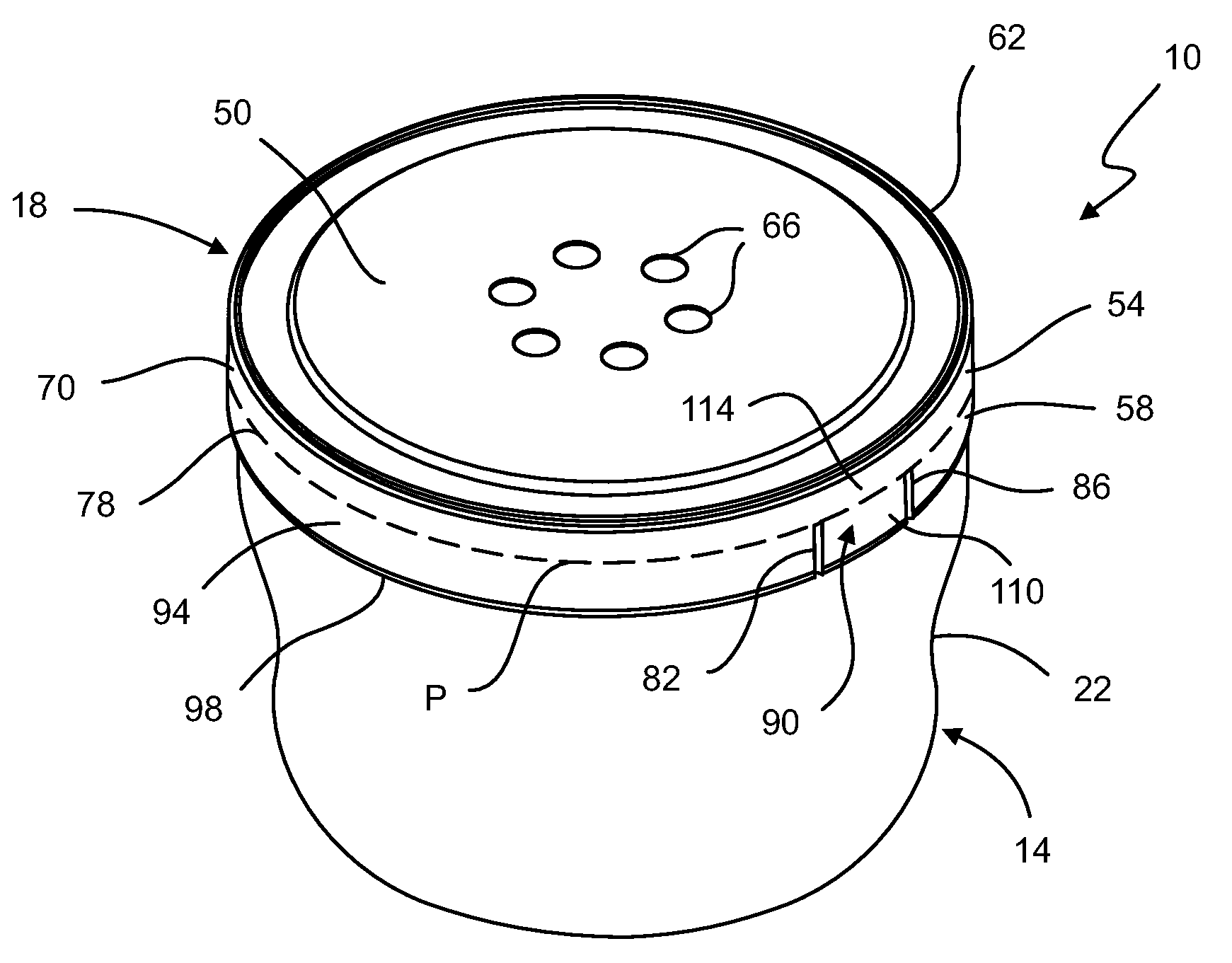

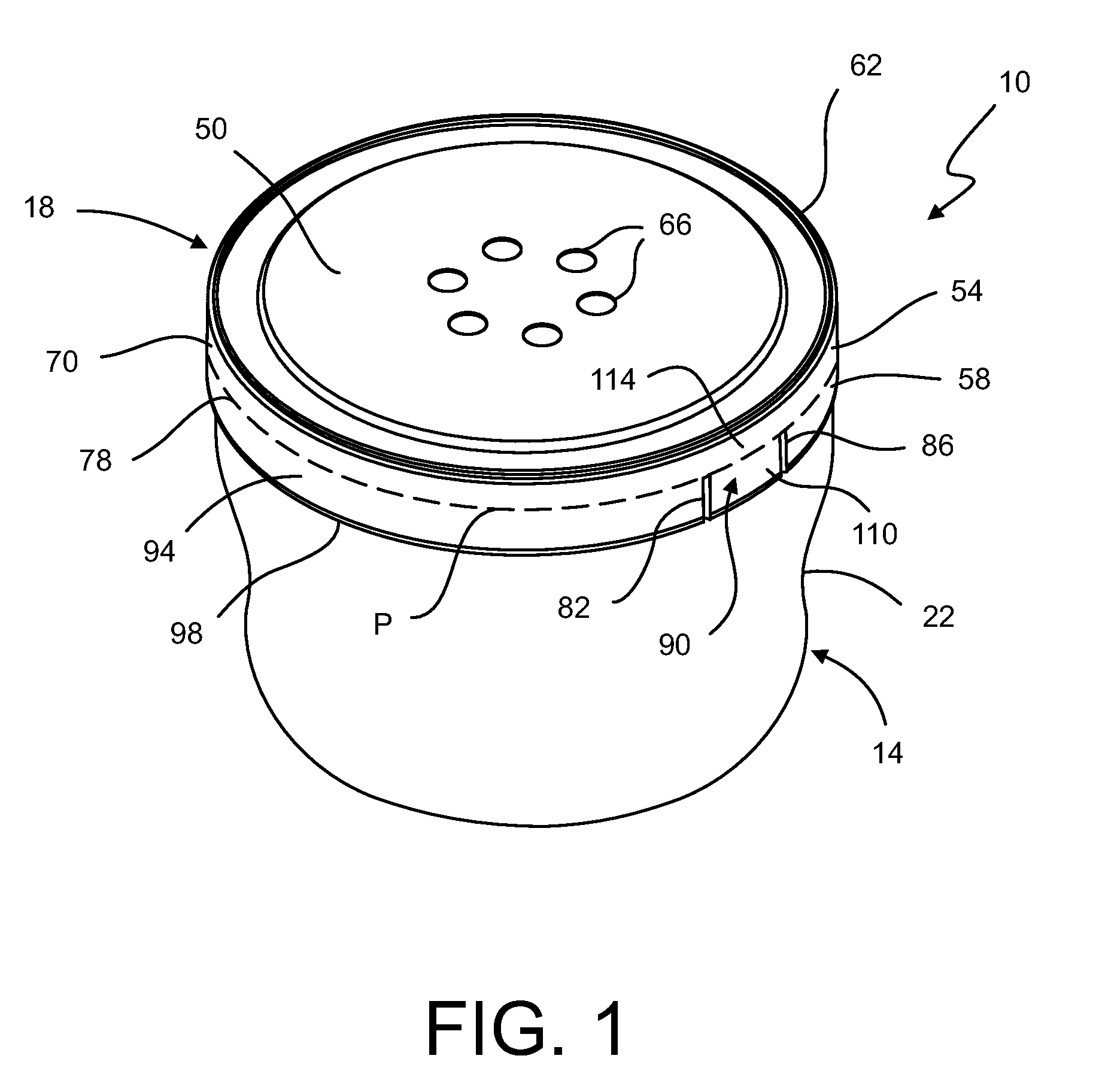

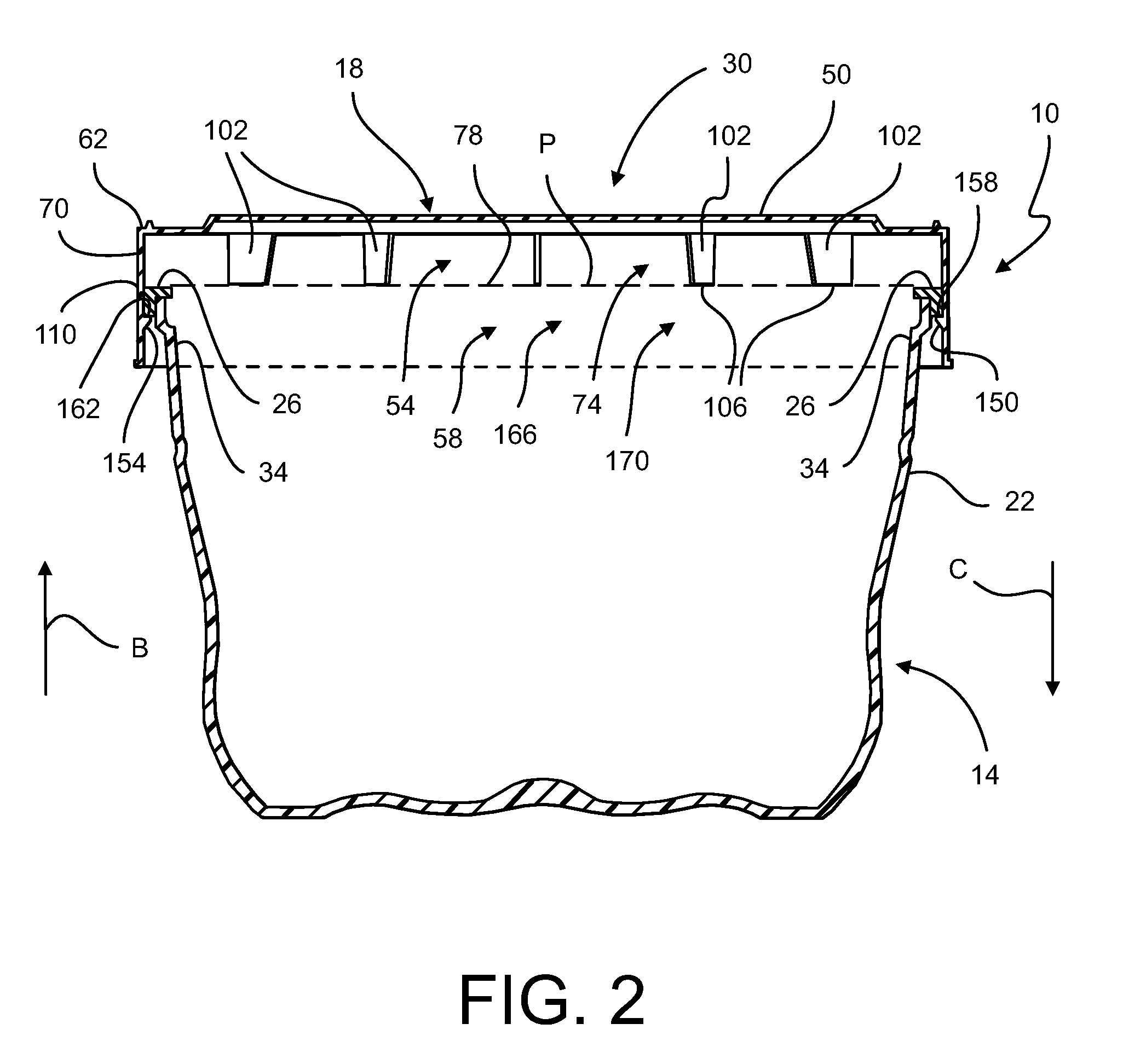

Container and closure assembly

A container and closure assembly includes a container defining an opening and having a lip positioned around the opening. The assembly also includes a closure configured to be attached to the container. The closure includes a top portion defining a circular periphery, and a first skirt portion extending downwardly from the circular periphery to form a cylindrical structure defining a first internal closure space. The closure also includes a second skirt portion extending downwardly from a first part of the cylindrical structure. The second skirt portion has a first side edge and a second side edge that form a gap. A tab extends downwardly from a second part of the cylindrical structure and is positioned in the gap. A first vertex segment is attached to the second skirt portion, and a second vertex segment is attached to the tab.

Owner:TECH II

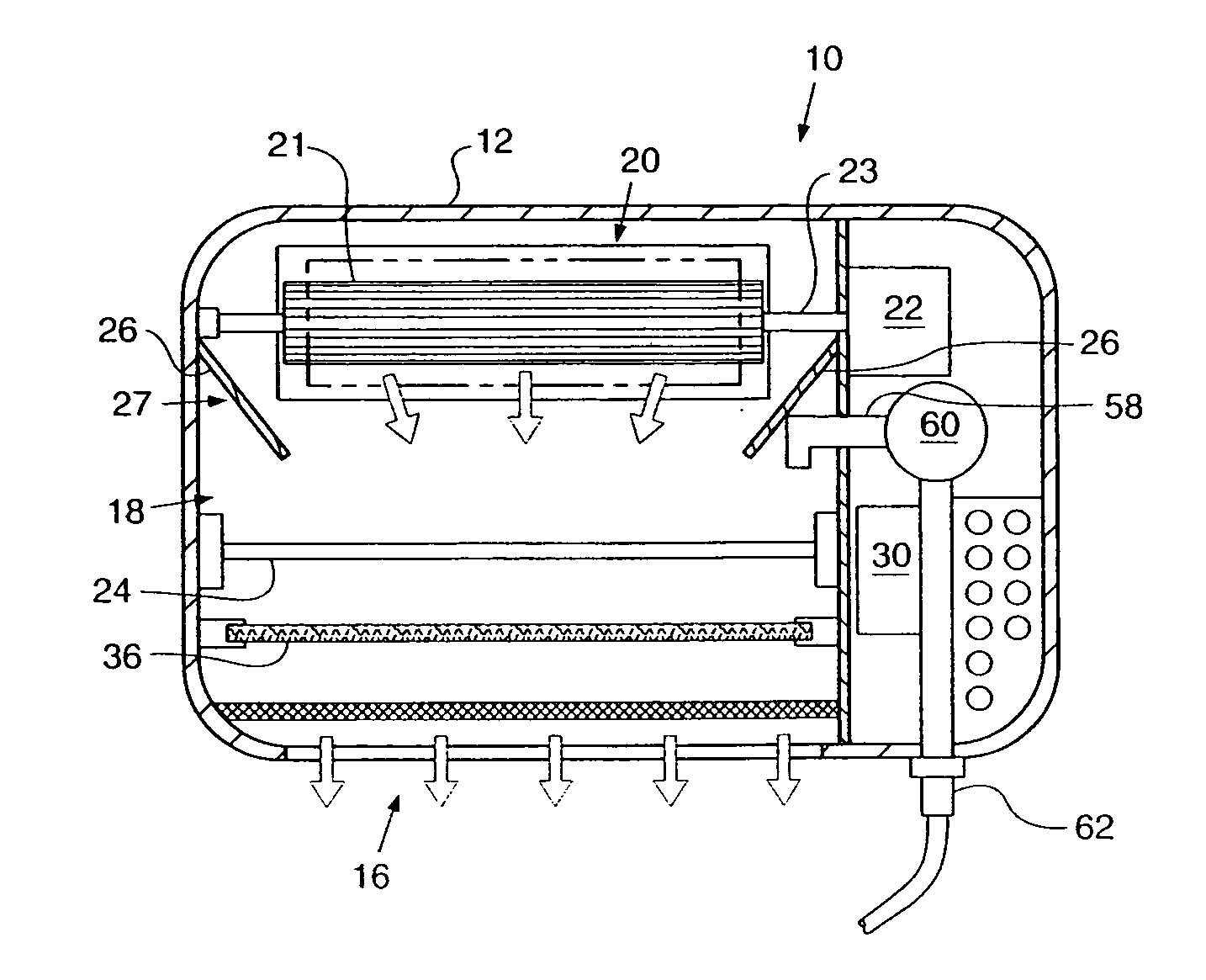

an air purifier

InactiveCN103861421BLarger than surface and uniformGood adsorption and decomposition effectOther chemical processesDispersed particle separationActivated carbonHazardous substance

Owner:QINGDAO CHUANSHAN NEW MATERIALS

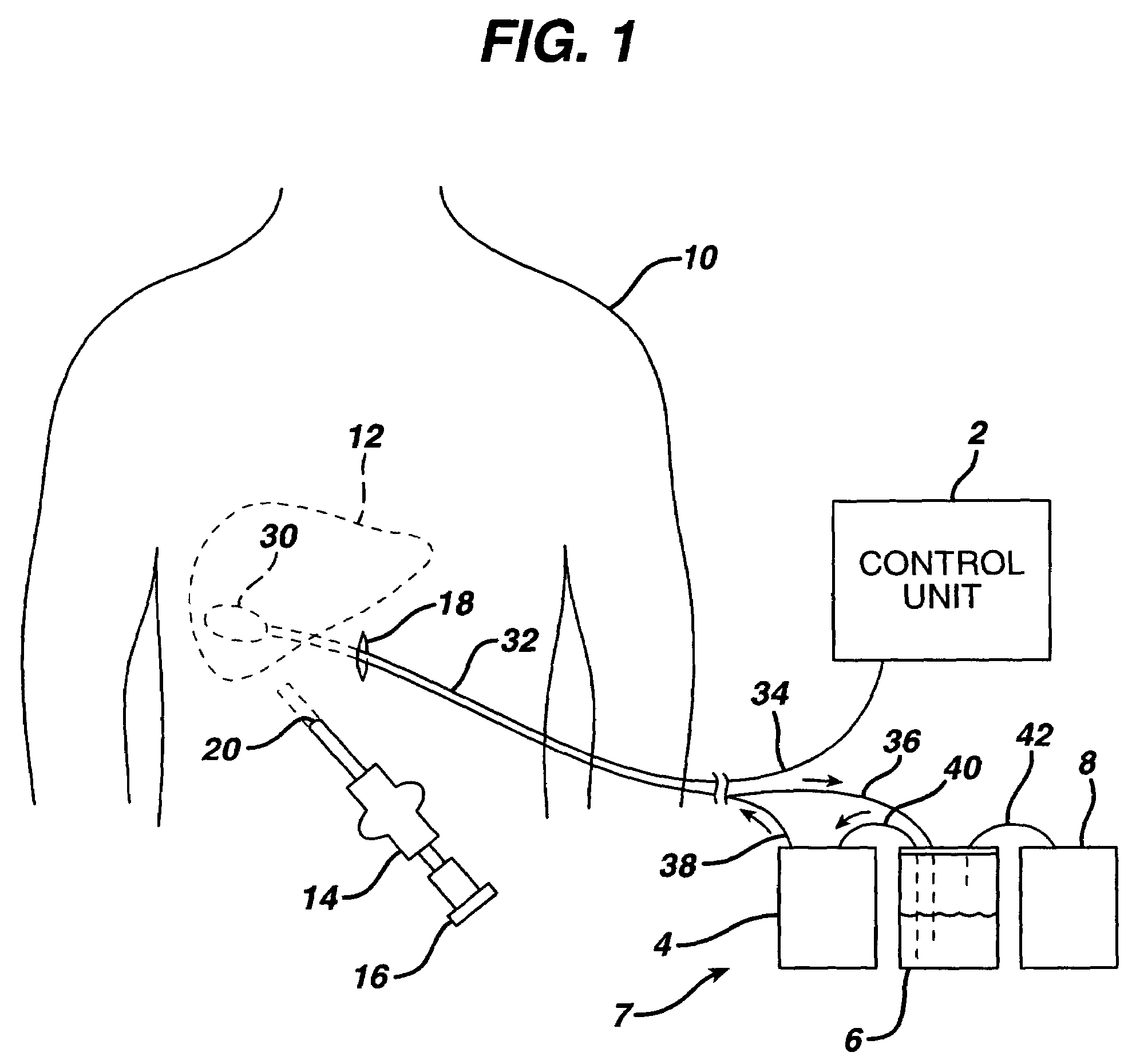

Medical device that removably attaches to a bodily organ

InactiveUS7223239B2Ultrasonic/sonic/infrasonic diagnosticsUltrasound therapyElectricityEnergy transfer

A medical device for use on a bodily organ includes a concave support element that is removably attachable to the surface of the bodily organ, thereby defining an enclosed space adjacent to the bodily organ. The enclosed space is fluidly connected to a fluid management system for circulating a fluid inside of the enclosed space. The medical device also has an energy transfer element mounted to the concave support element and electrically connected to a control unit. In some embodiments, the energy transfer element transmits intense ultrasound energy in a frequency range of 1–30 megahertz, and the fluid acoustically couples the energy transfer element to the bodily organ, and the fluid also cools the energy transfer element.

Owner:ETHICON ENDO SURGERY INC

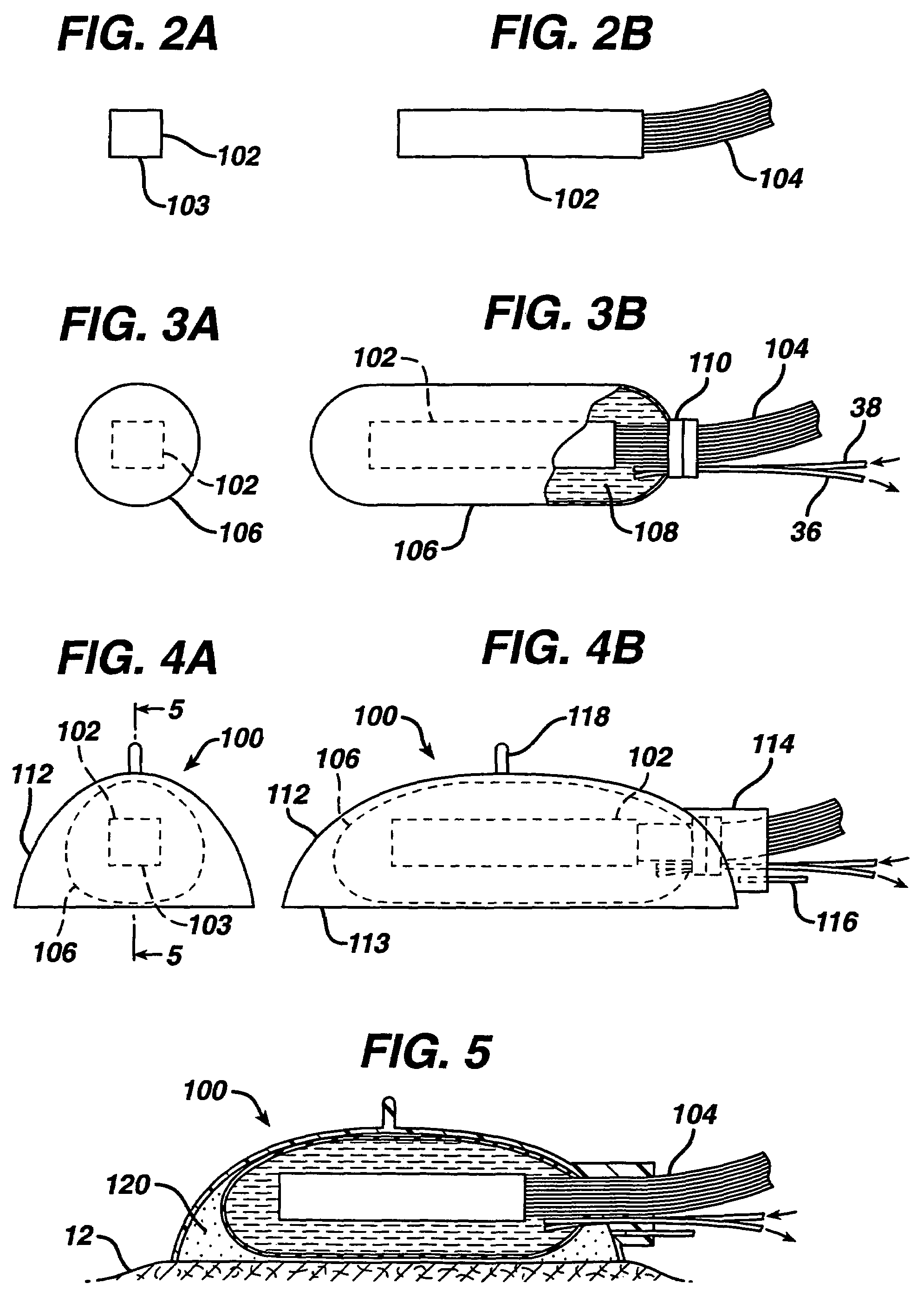

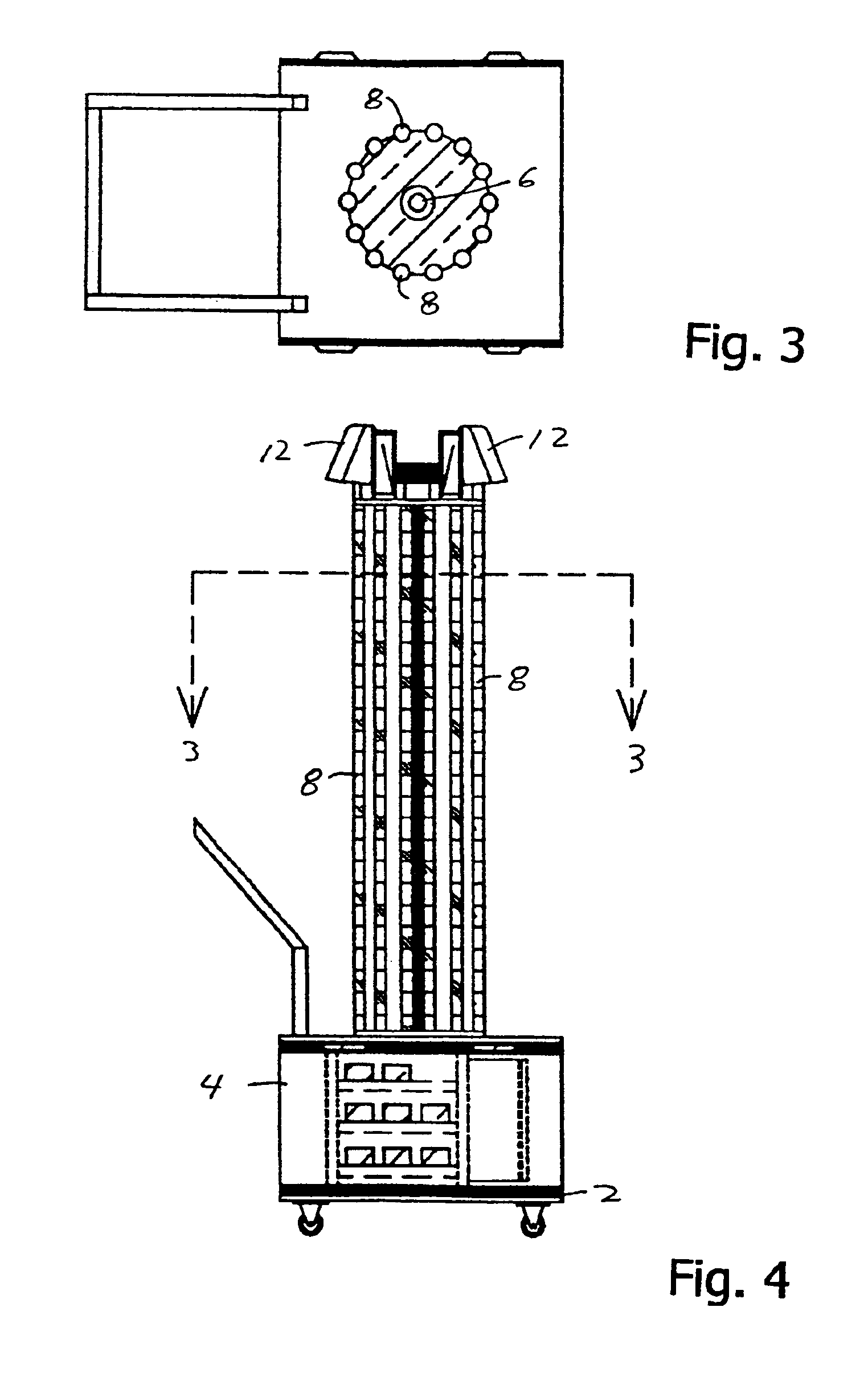

Ultraviolet area sterilizer and method of area sterilization using ultraviolet radiation

An ultraviolet area sterilizer (UVAS) is mobile or stationary. The UVAS is positioned in a room, such an operating room or intensive care unit. Motion detectors sense movement, to assure that personnel have evacuated the space to be sterilized. Subsequently, UV-C generators, such mercury bulbs, generate UV-C from multiple locations within the room or other enclosed space. Multiple UV-C sensors scan the room, and determine the area reflecting the lowest level of UV-C back to the sensors. The device calculates the time required to obtain a bactericidal dose of UV-C reflected back to the sensors. Once an effective bactericidal dose has been reflected to all the sensors, the unit notifies the operator and shuts down.

Owner:UVAS

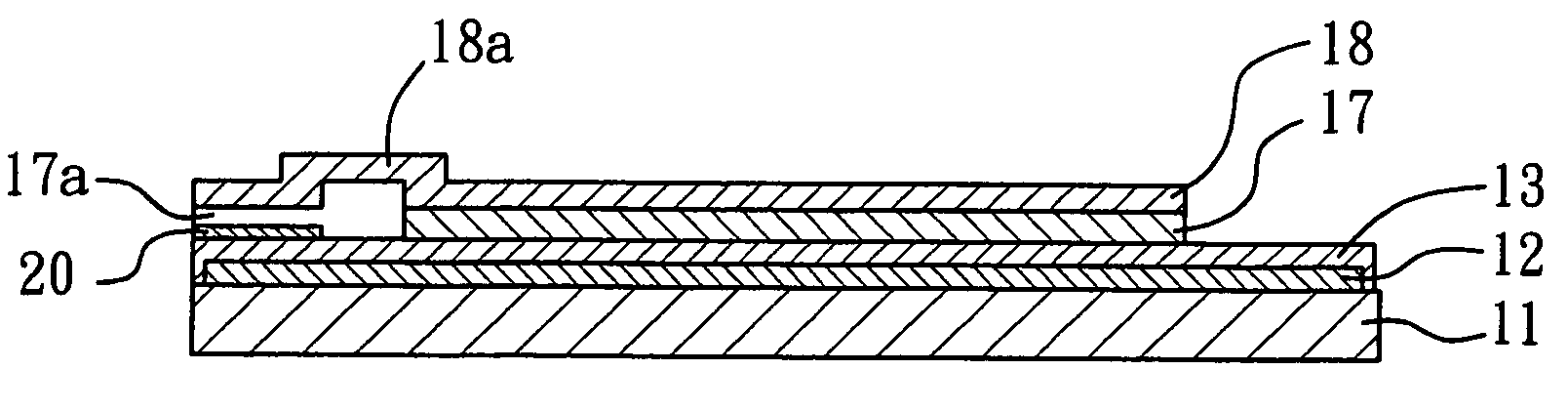

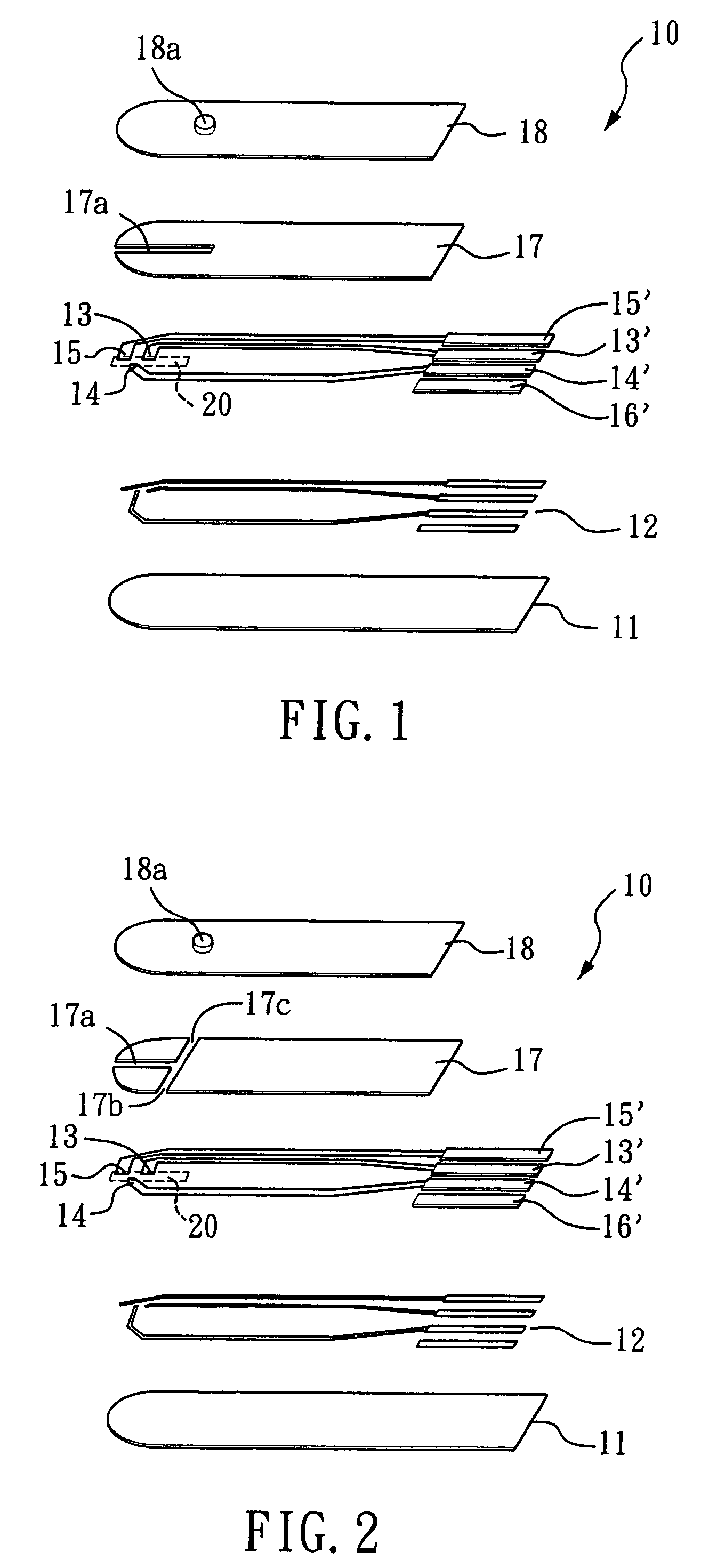

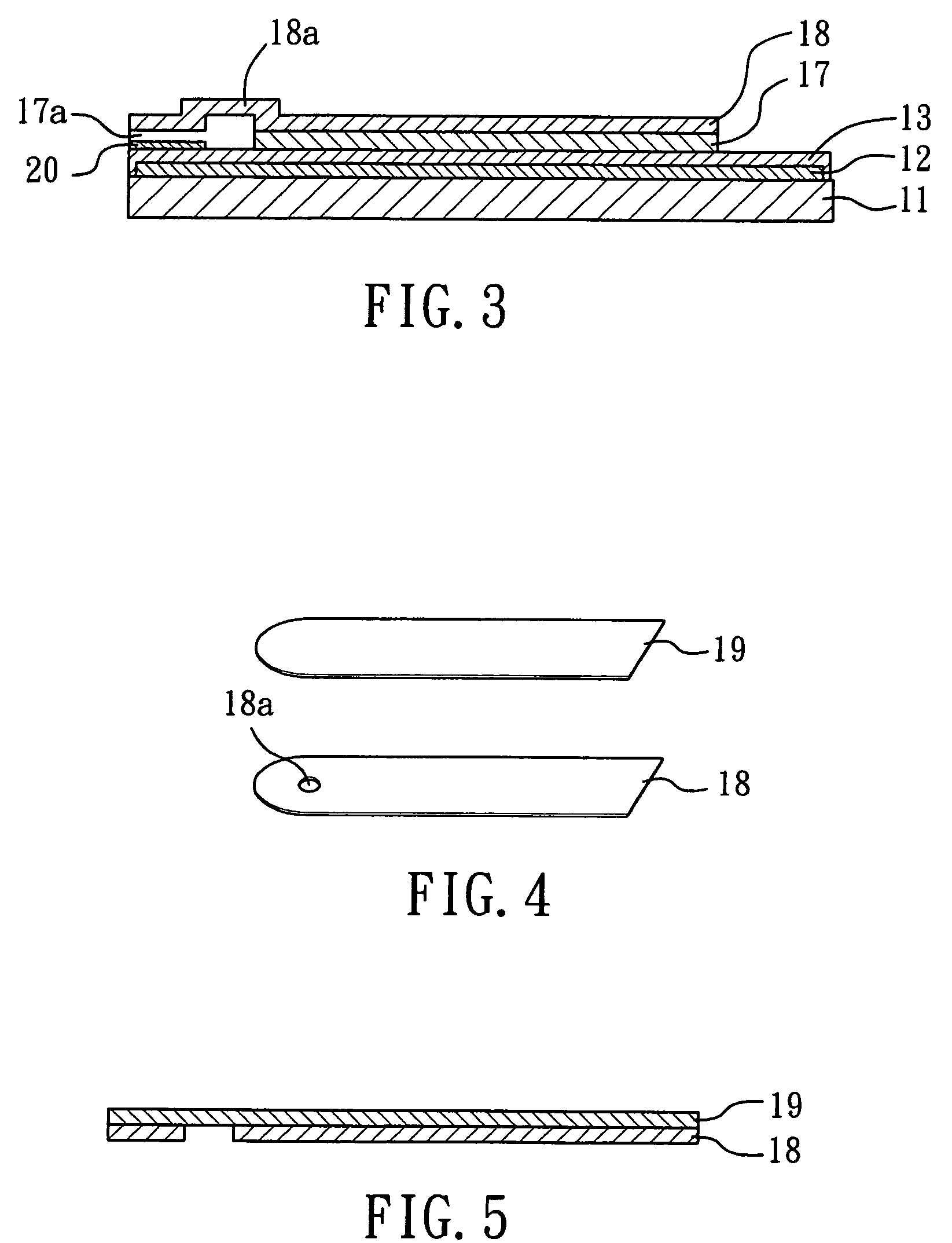

Electrochemical biosensor by screen printing and method of fabricating same

ActiveUS7138041B2Rapid sample inflowSmall volumeImmobilised enzymesBioreactor/fermenter combinationsReaction layerSiphon

An electrochemical biosensor formed by screen printing and method of fabricating such biosensor is disclosed in the present invention. The biosensor can quickly absorb a sample to be measured therein, effectively control volume of the sample fed and “fill-and-position” the sample therein. The biosensor includes an electrode layer (electrode area) comprising two or three electrodes, which are a working electrode, a reference electrode and an auxiliary electrode (tri-electrode) on an insulating substrate. An active reaction layer containing reactant, reaction catalyst, mediator, wetting agent and surfactant is spread on the surface of the electrode layer. A sample inflow area is formed above the electrode area by adding an upper cover on top of a middle insulating layer with a U-shaped opening formed therein. Sample solution with a minute amount about 0.8 to 1 μl can be rapidly introduced into the electrode area and the active reaction layer via the inflow area by siphon or capillary, where the ingredient of the sample can be analysed by measuring reaction between the sample, reaction catalyst and mediator in the reaction layer using electrochemical potentiometric or amperometric method. An upwardly extended closed space formed within the upper cover above the electrode area adjacent to the front of conductive wires can be effectively used to control sample volume and “fill-and-position” the sample.

Owner:GENERAL LIFE BIOTECHNOLGOY

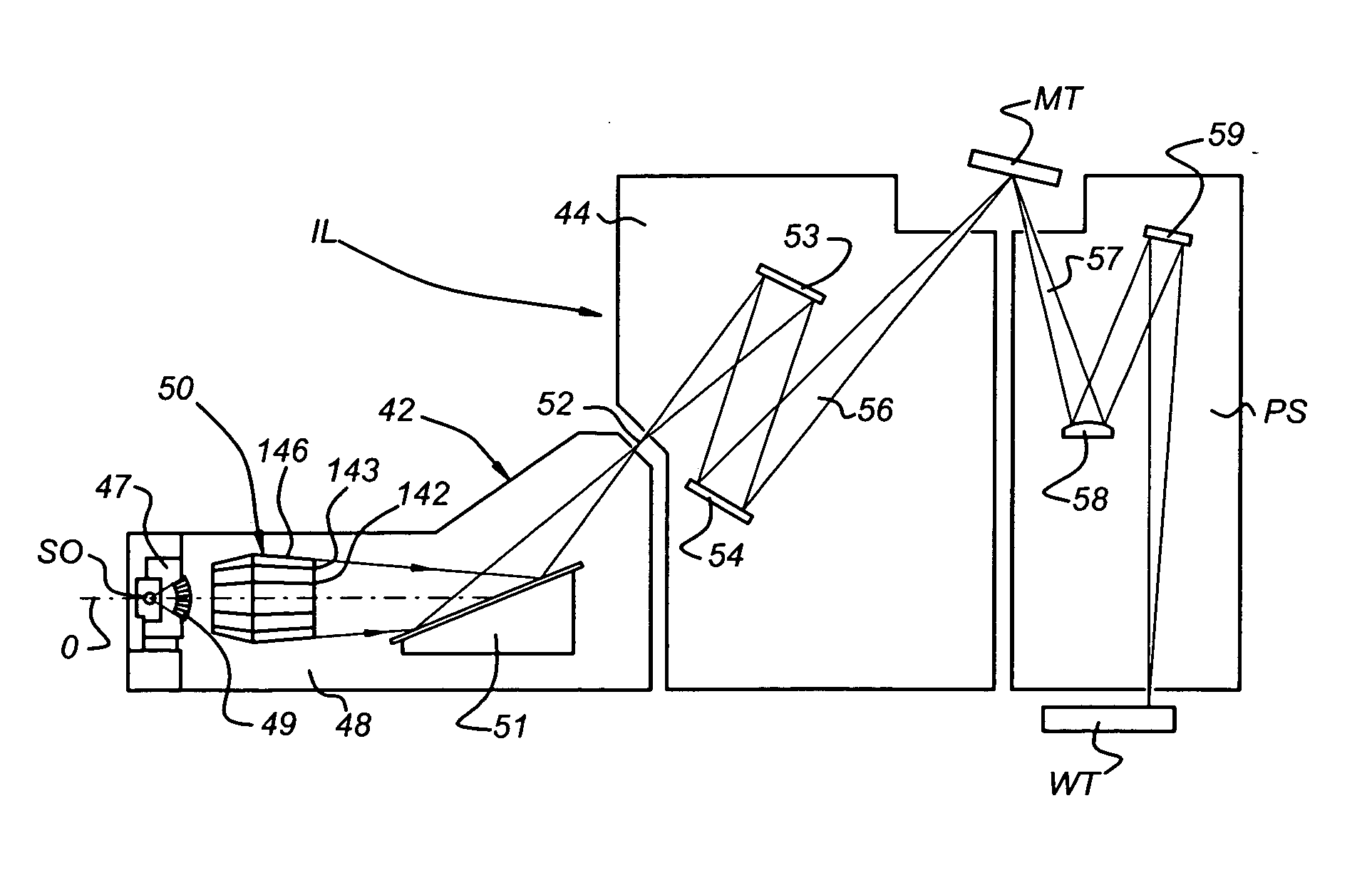

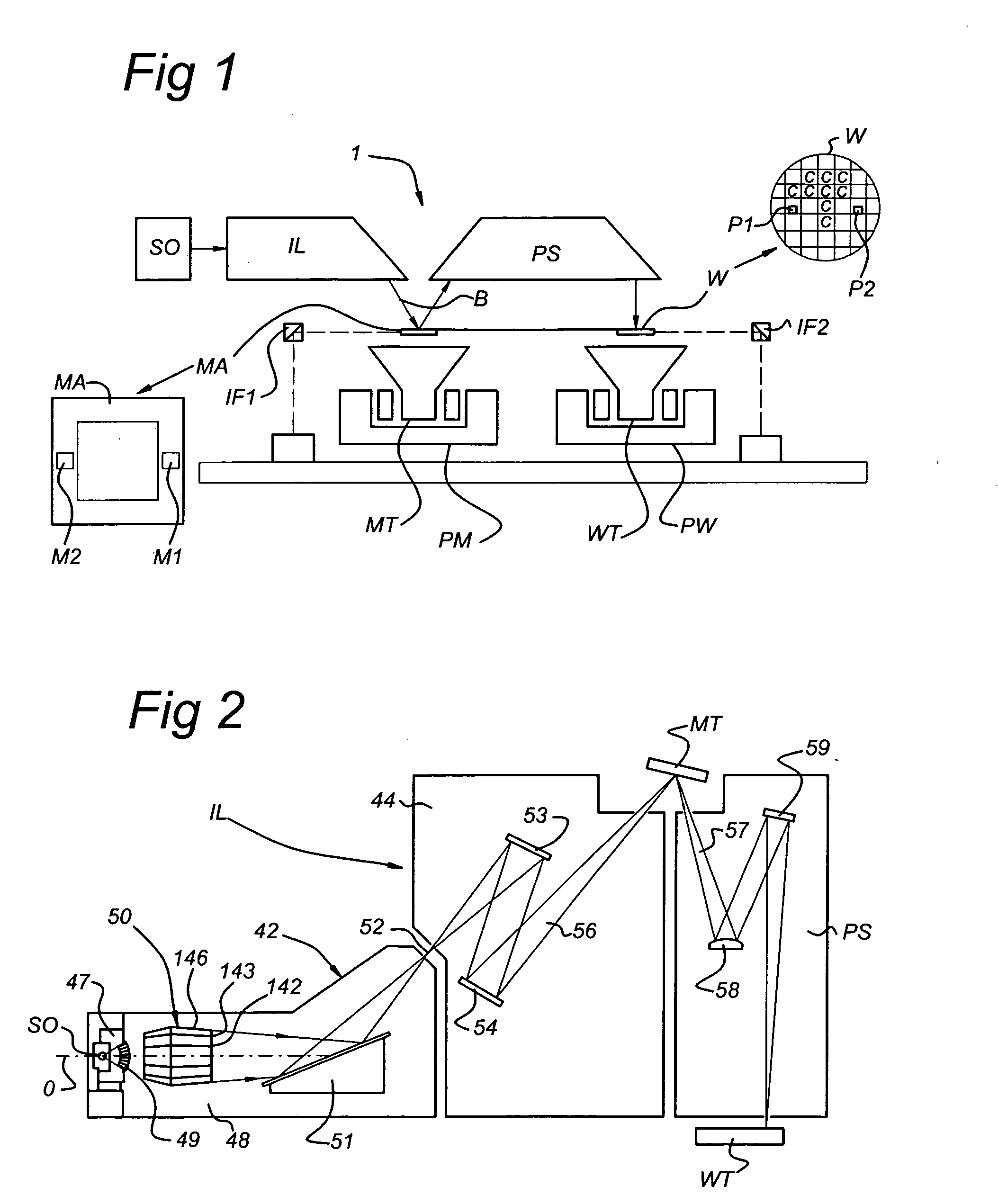

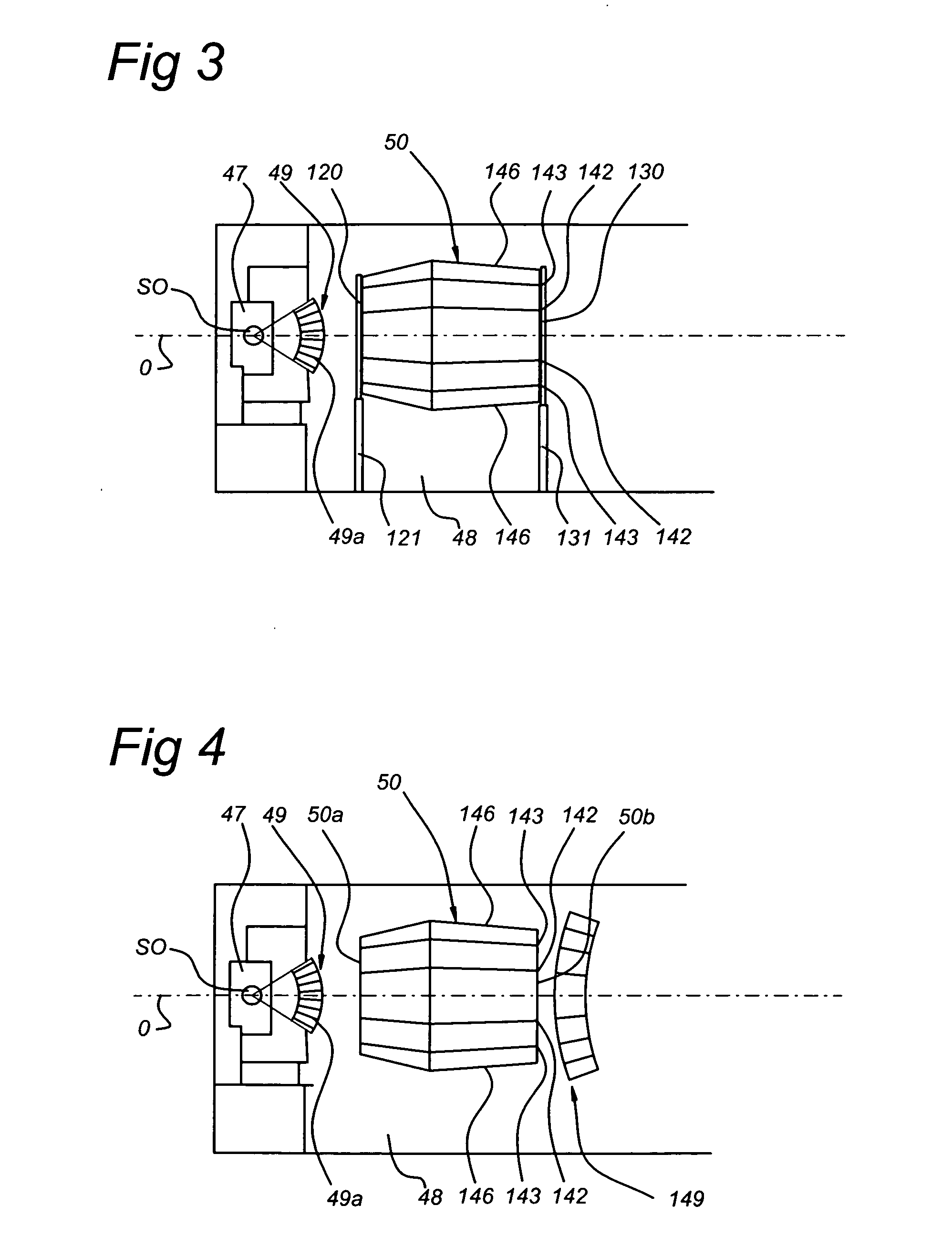

Method for removal of deposition on an optical element, lithographic apparatus, device manufacturing method, and device manufactured thereby

A method for removal of deposition on a radiation collector of a lithographic apparatus includes providing a gas barrier to an end of a radiation collector, thereby providing a radiation collector enclosure volume; providing a gas to the enclosure volume, the gas selected from a halogen containing gas and a hydrogen containing gas; and removing at least part of the deposition from the radiation collector. A lithographic apparatus includes a radiation collector; a circumferential hull enclosing the radiation collector; a gas barrier at an end of the radiation collector, thereby providing a radiation collector enclosure volume. The radiation collector is enclosed by the circumferential hull and the gas barrier. An inlet provides a gas to the radiation collector enclosure volume and an outlet removes a gas from the radiation collector enclosure volume.

Owner:ASML NETHERLANDS BV

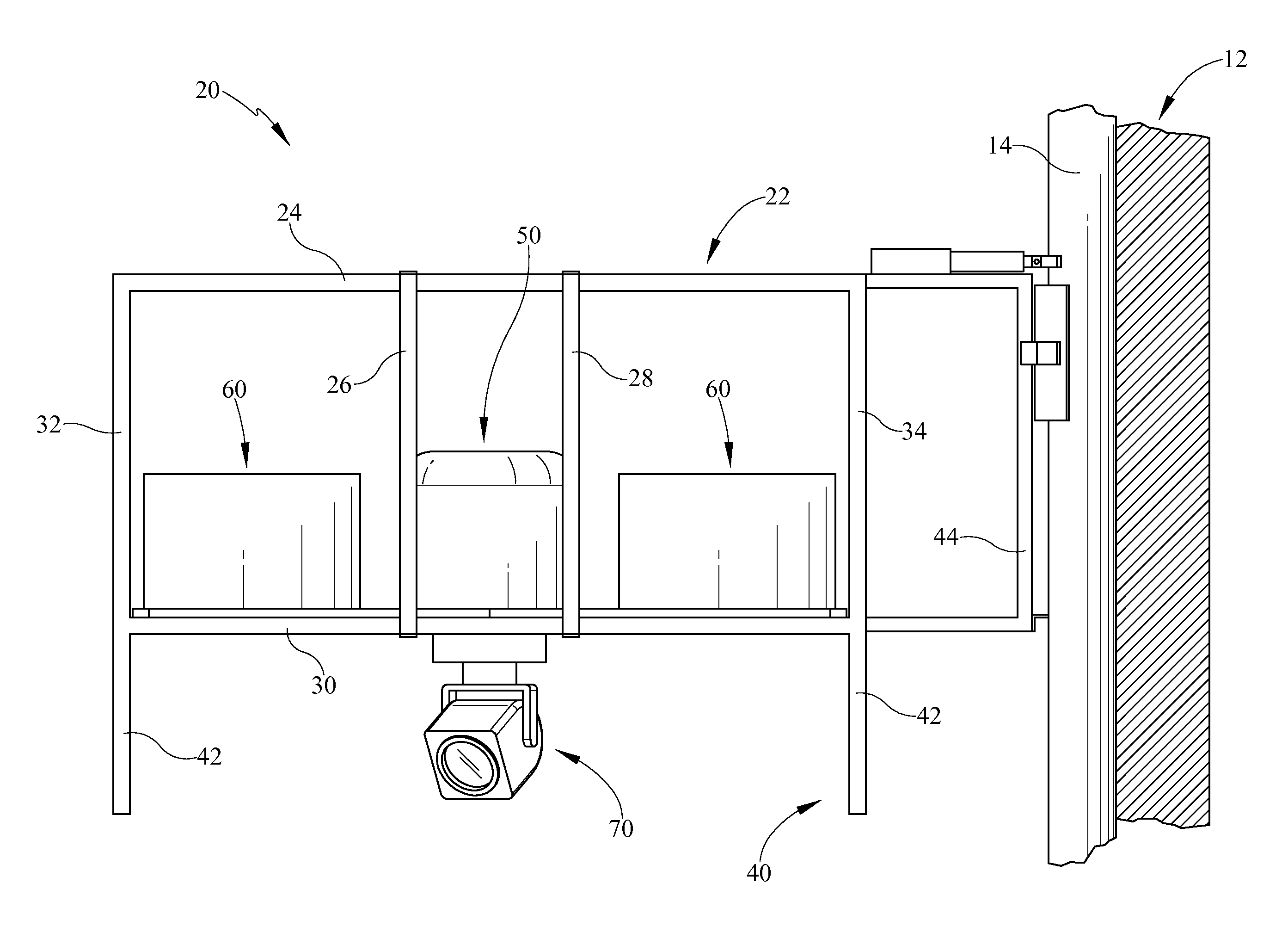

Drone for inspection of enclosed space and method thereof

Embodiments of a drone for inspection and a method of use are depicted wherein the drone is utilized in an enclosed space and is capable of being controlled with or without line of sight to the aircraft. The drone may land on generally horizontal or vertical surfaces. A method of use is taught as well.

Owner:UNITED DYNAMICS ADVANCED TECH

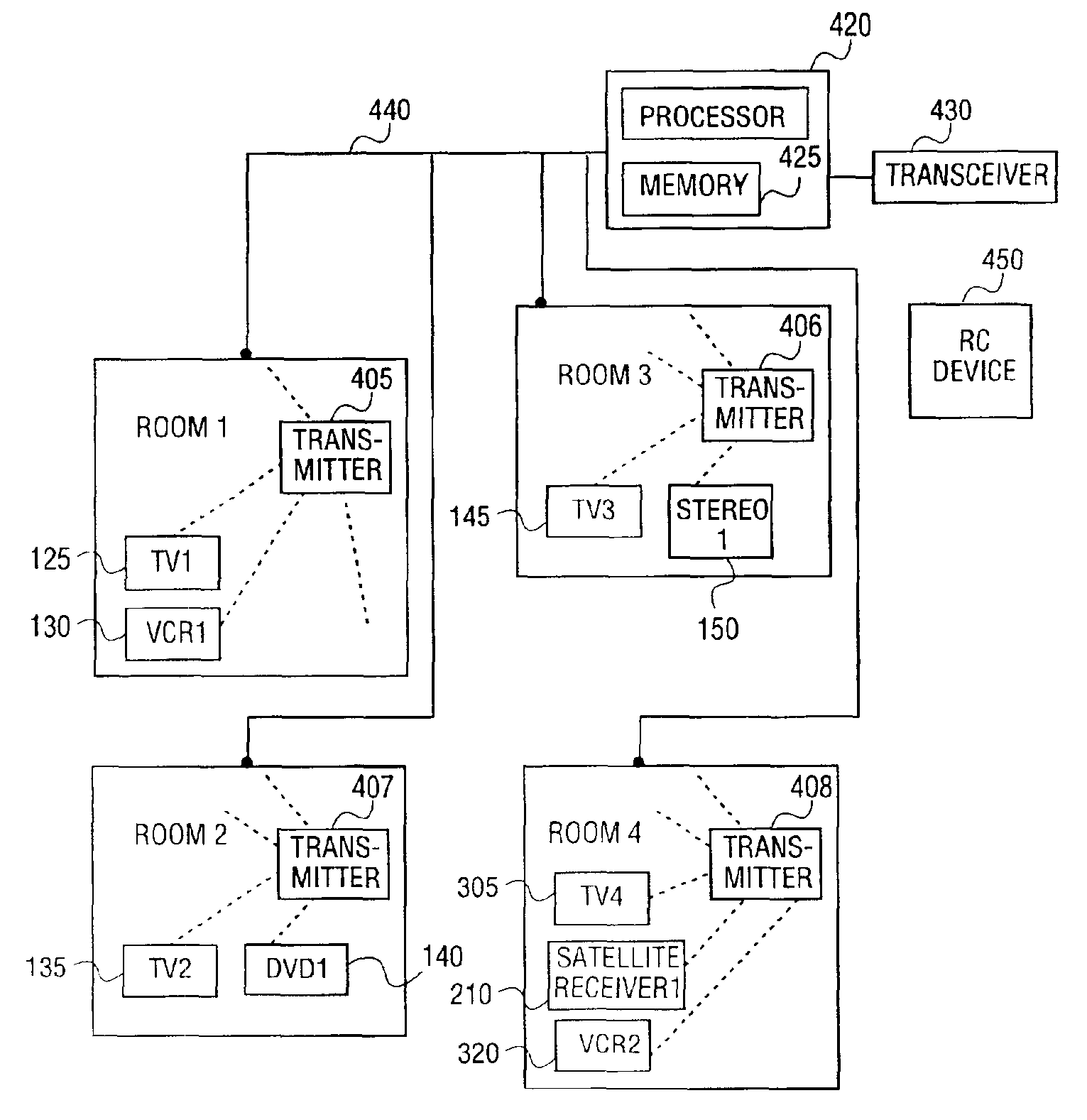

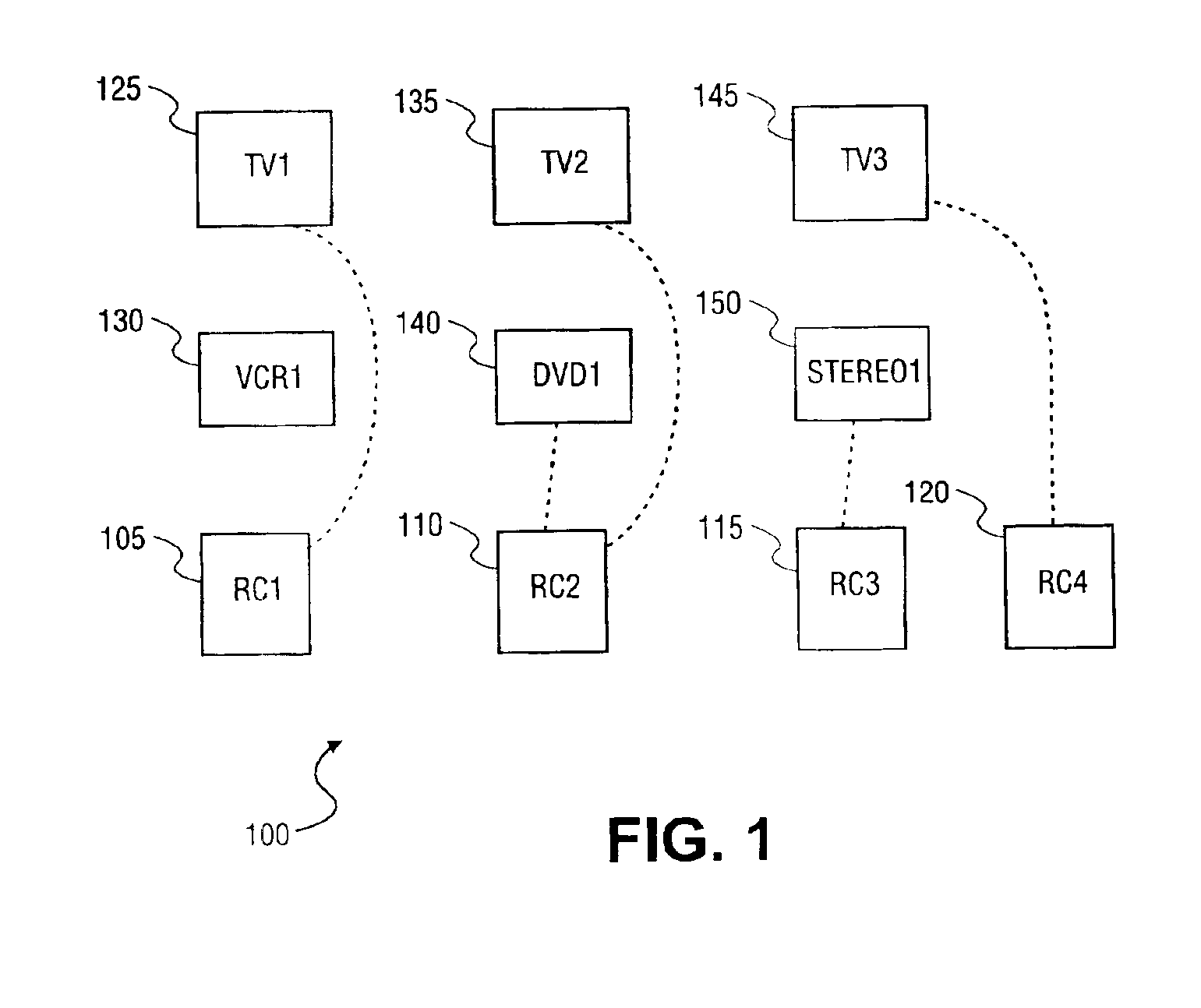

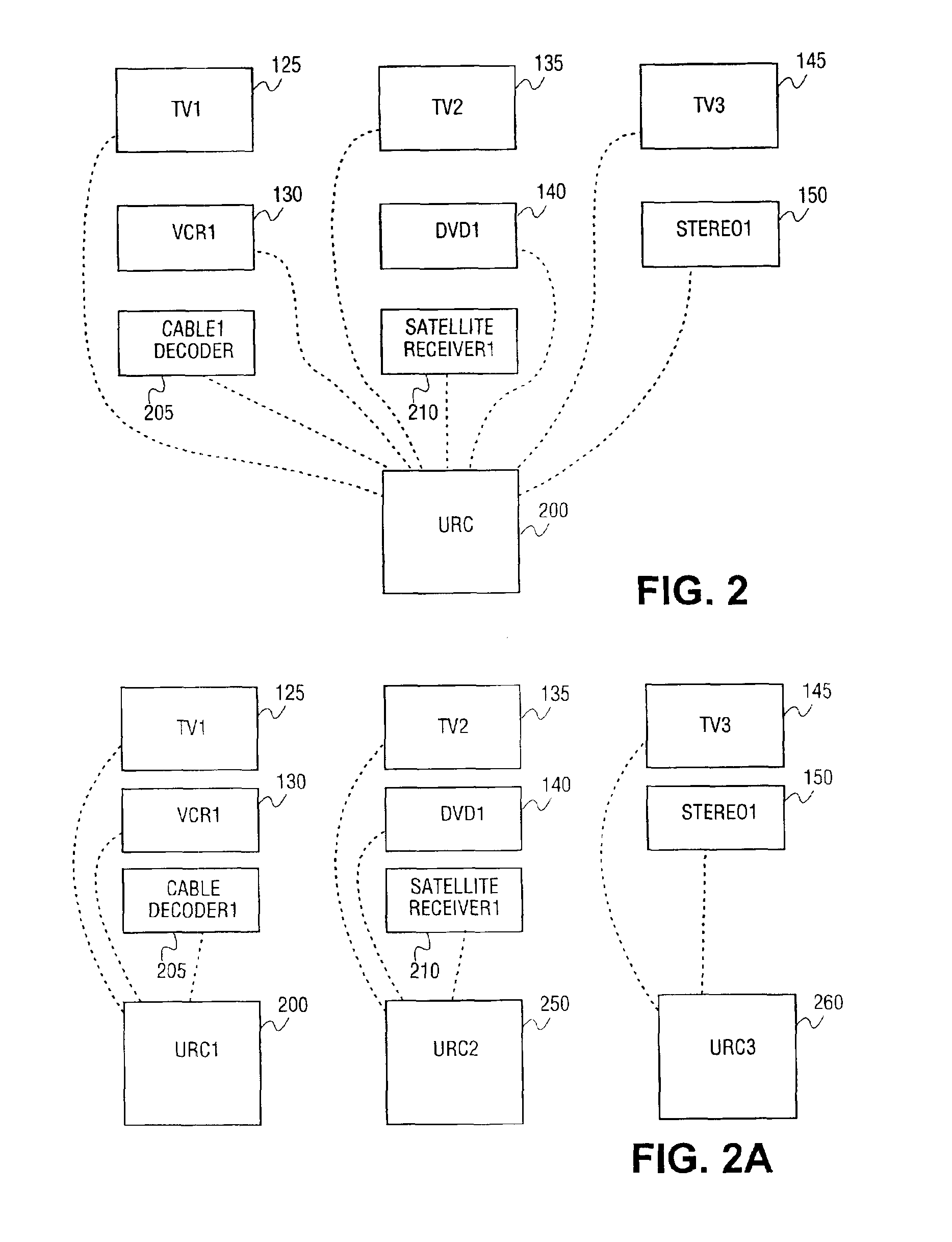

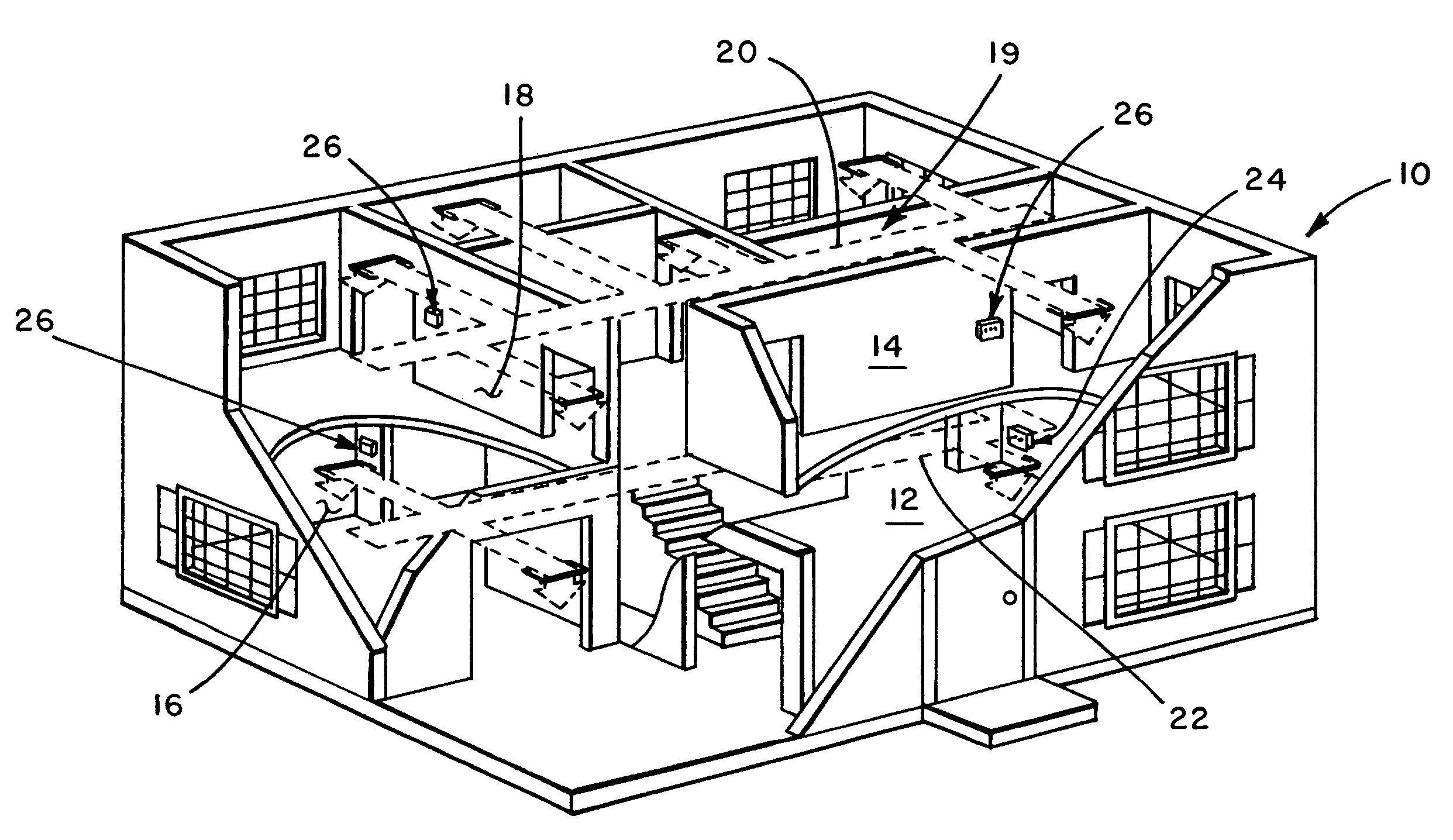

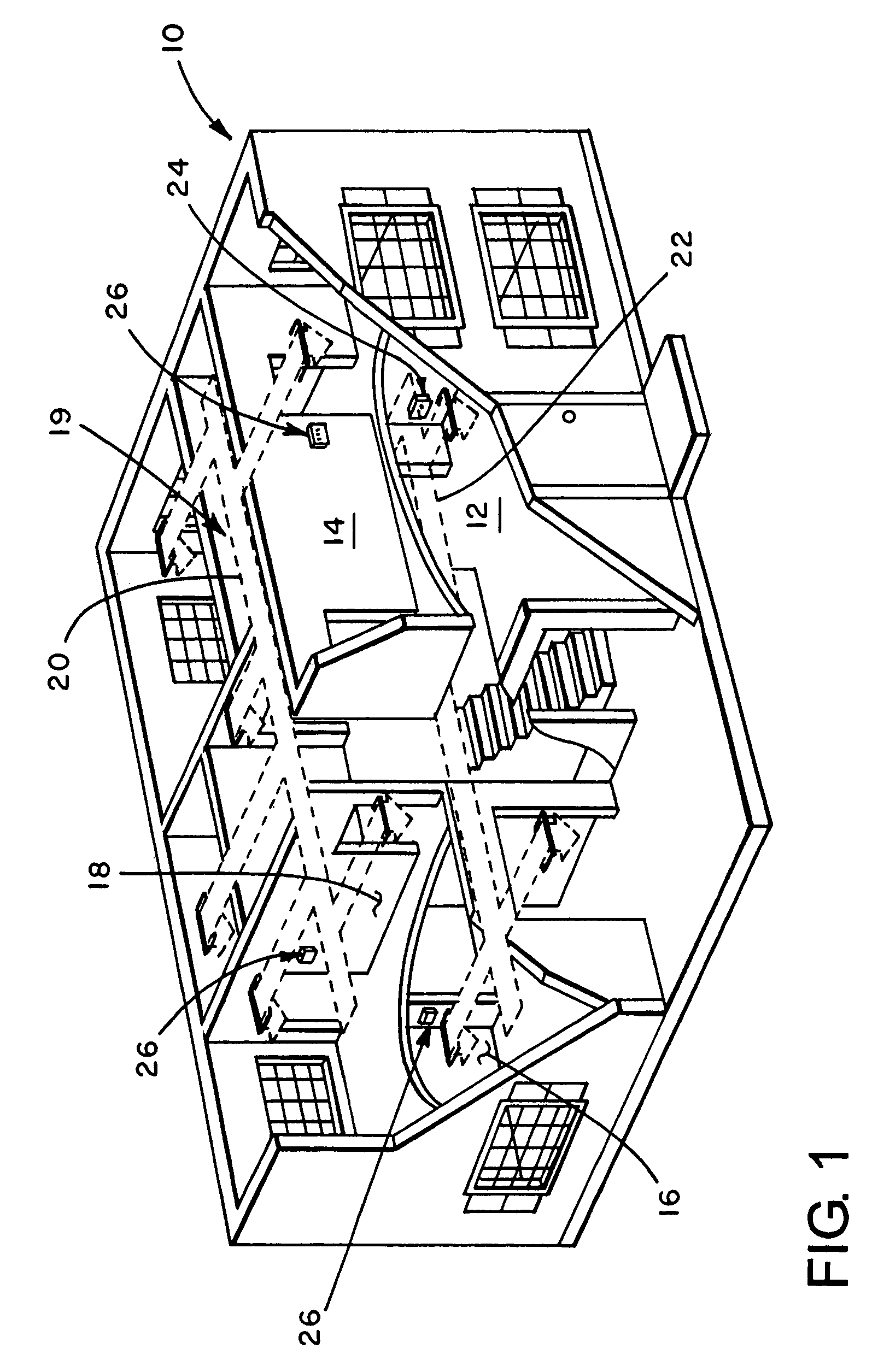

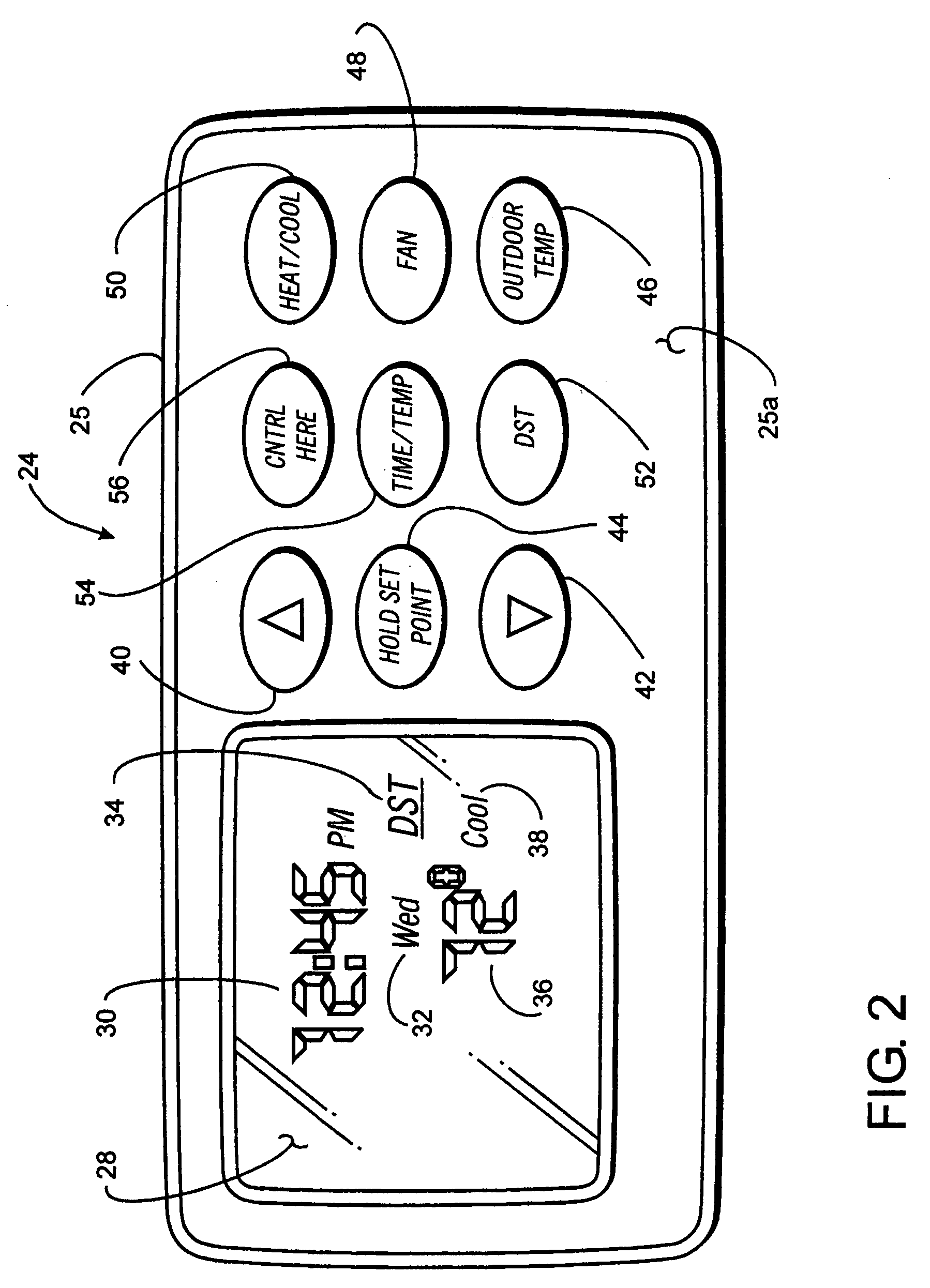

Multiple thermostats for air conditioning system with time setting feature

ActiveUS7600694B2Mechanical apparatusTemperature control with auxillary non-electric powerTransceiverThermostat

An air conditioning (HVAC) system for a residential dwelling or other building with enclosed spaces includes multiple thermostats hard wire interconnected or communicating via radio frequency transceivers. The thermostats each include control circuits for adjusting the setpoint temperature at any one thermostat and displaying the set temperature at all thermostats, setting the time at any one thermostat and displaying the time at all thermostats, controlling the thermostat temperature setting from a selected one of the thermostats and providing a setpoint for control of the air conditioning system based on an average temperature sensed by all of the thermostats. A method for correctly setting a thermostat time display to one of Daylight Saving Time or Standard Time and displaying an icon identifying one or the other is disclosed.

Owner:TRANE INT INC

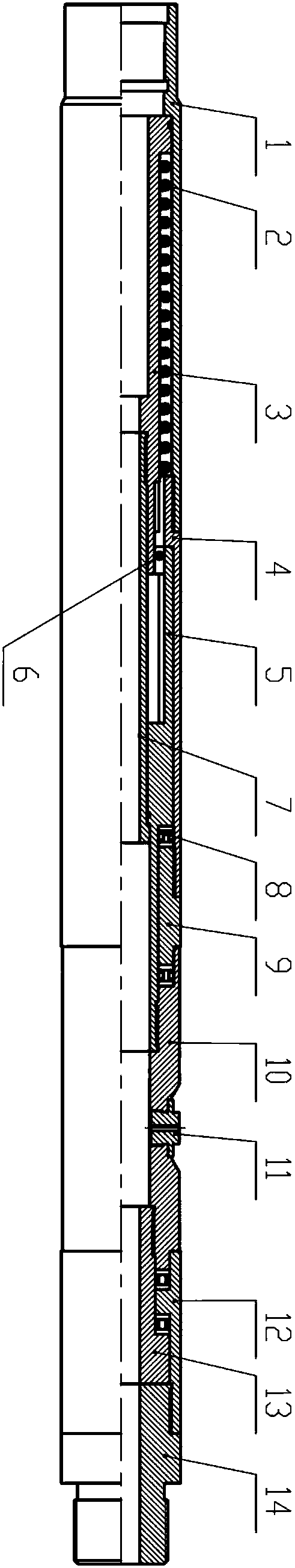

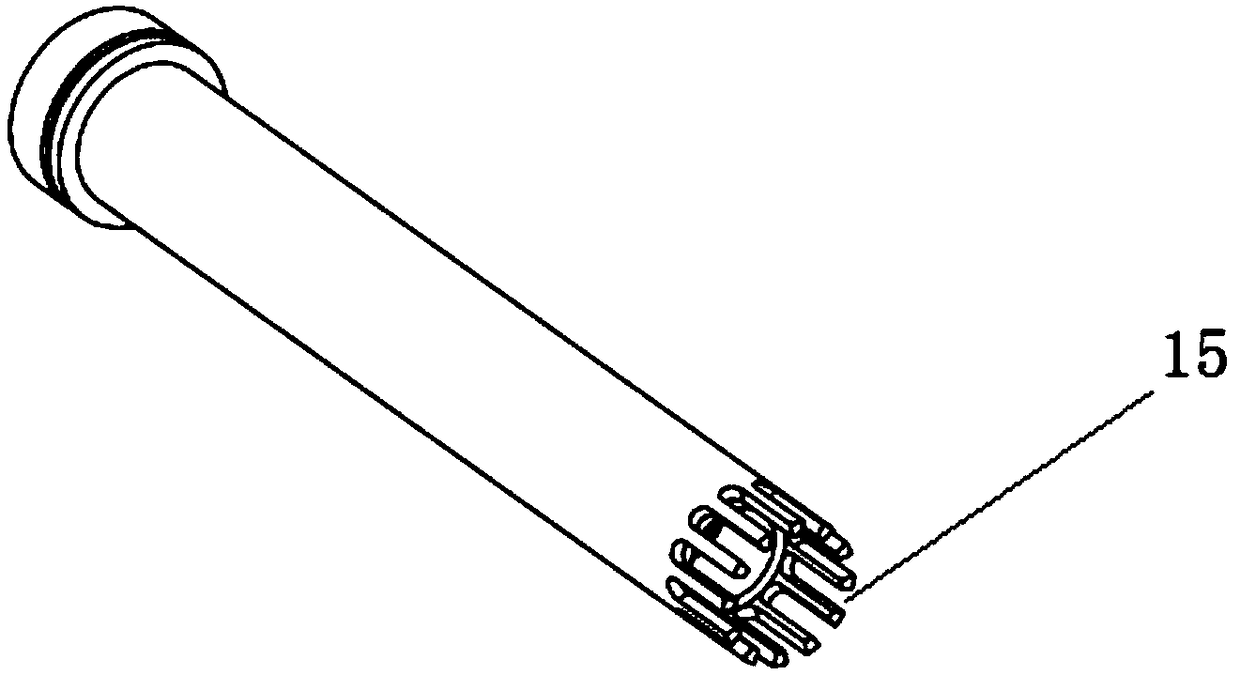

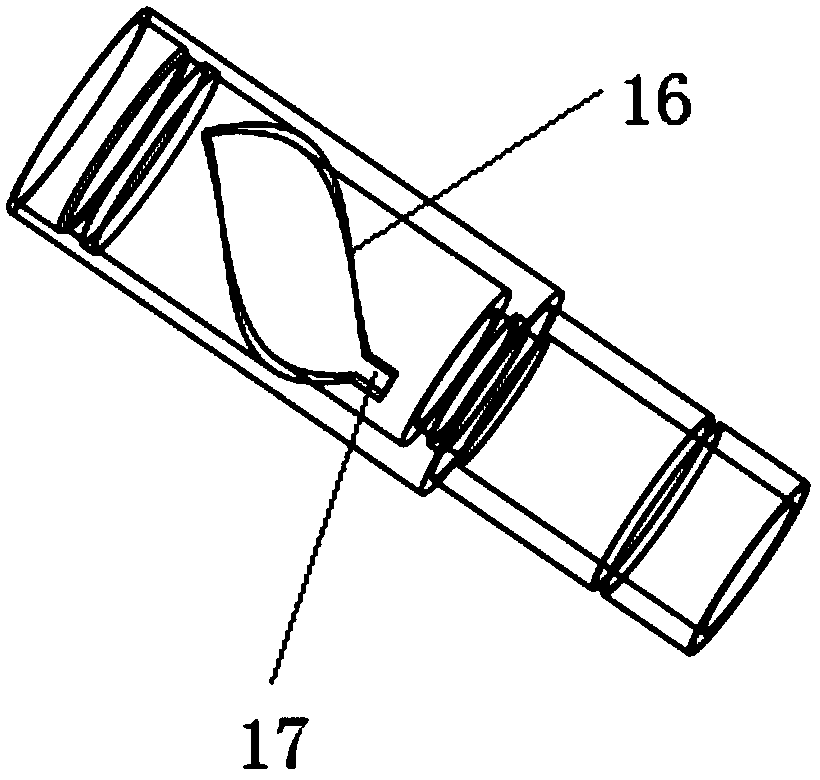

Horizontal well hydraulic directional spraying gun

The invention relates to the technical field of oil and gas well production increase and fracturing operation, in particular to a horizontal well hydraulic directional spraying gun. The horizontal well hydraulic directional spraying gun comprises a directional split tooth cylinder, an enveloping line sleeve, a directional steel ball, thrust bearings and nozzles. The directional split tooth cylinder and an upper connector form an annular space, a reset spring is arranged in the annular space, the right end of the upper connector is connected with an upper housing, the enveloping line sleeve issleeved with the interior of the upper housing, a central rod penetrates through the interior of the enveloping line sleeve to be connected to an internal thread at the right end of the directional split tooth cylinder, and a closed space is defined by the upper housing, the directional split cylinder and the enveloping line sleeve; the directional steel ball is placed in the closed space, the right end of the upper housing is in threaded connection with a connecting sleeve, the thrust bearings are symmetrically disposed at both ends of the connecting sleeve, and the right end of the enveloping line sleeve is connected with a spraying gun casing. Forced orientation of the spraying gun casing can be achieved by a hydraulic driving mode, the orientation success rate is high, tools can be reused after maintenance and protection, and the cost is low.

Owner:JEREH ENERGY SERVICES

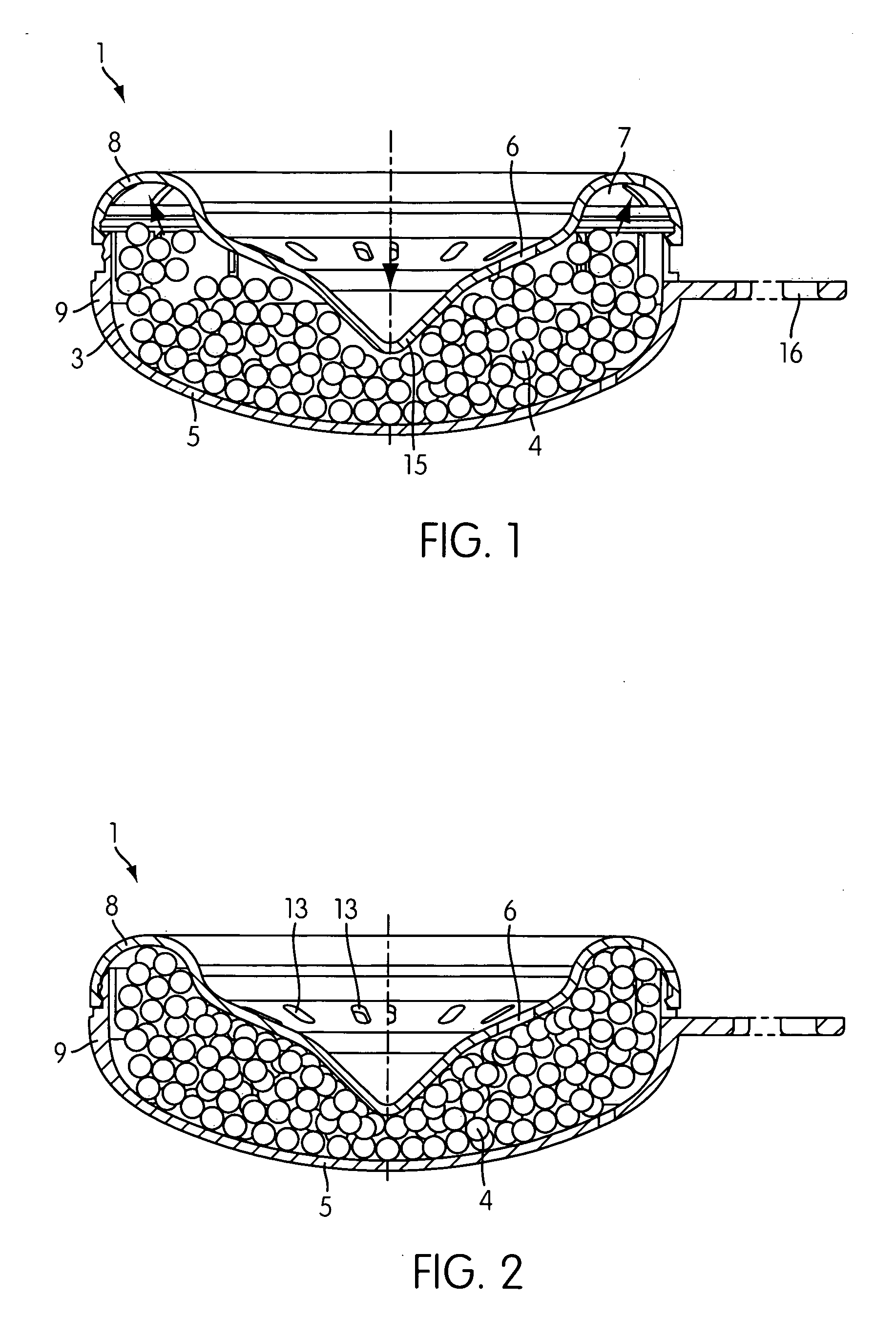

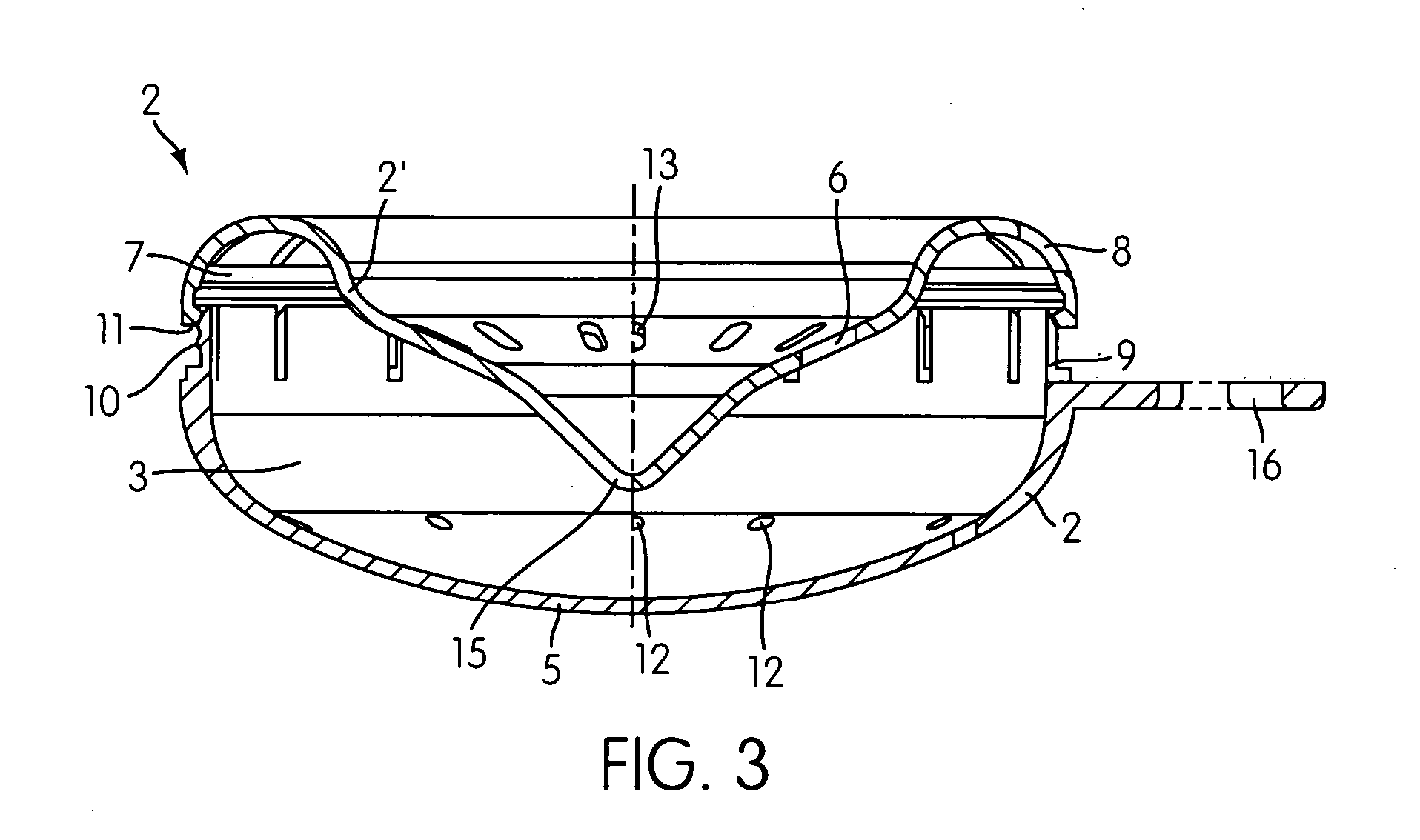

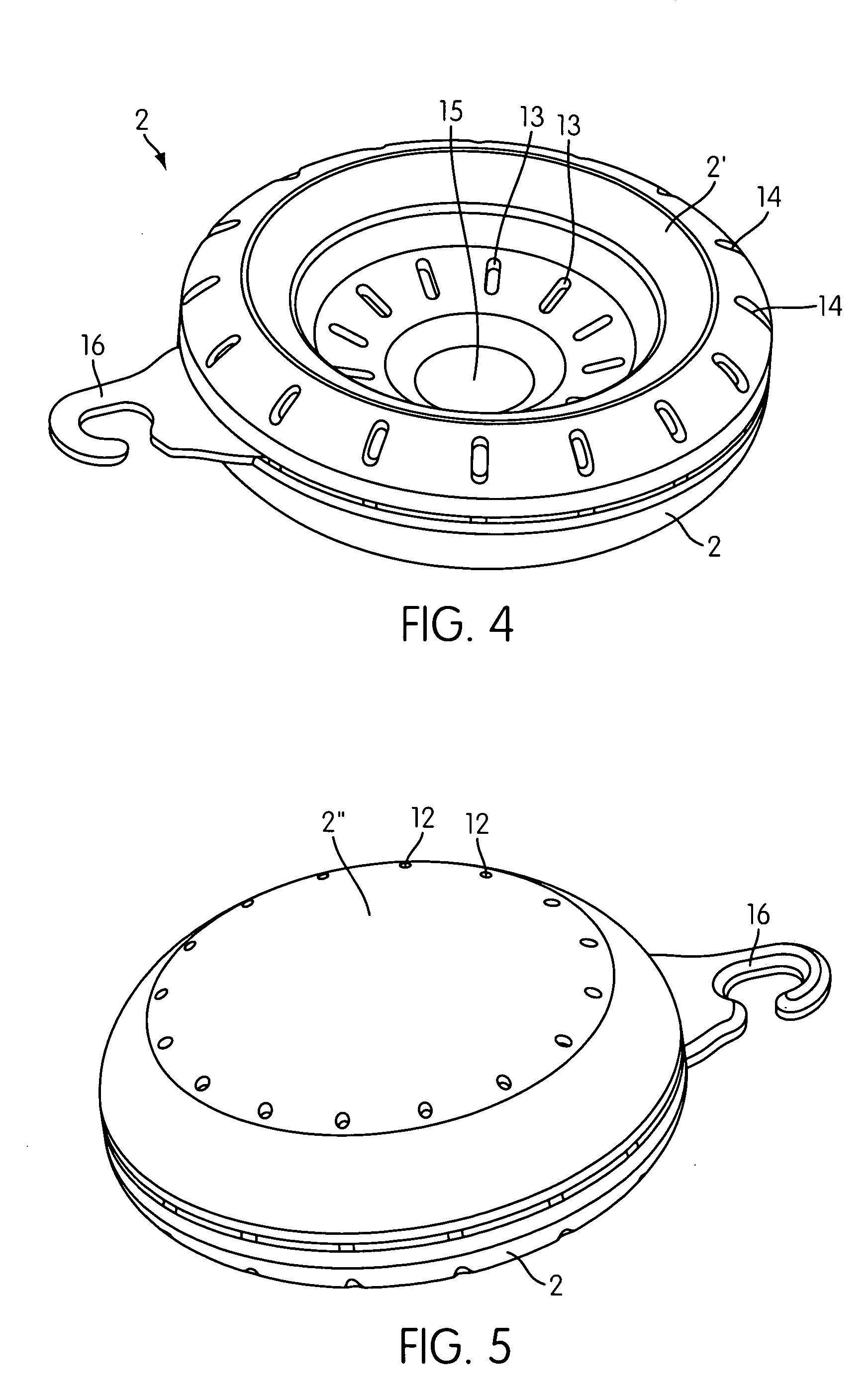

Fragrance release system

InactiveUS20050148479A1Increased fragrance releaseConstant fragrancingCosmetic preparationsTableware washing/rinsing machine detailsEngineeringCarrier material

A fragrance release system having a substantially rotationally symmetric container having a chamber accommodating a multitude of particles for deodorizing or fragrancing an open or closed space, the particles comprising a carrier material and at least one fragrance, and the container having a plurality of orifices through which emission of the fragrances of the particles from the accommodation chamber outward is possible, wherein the accommodation chamber (3) of the substantially rotationally symmetric container (2) has a crescent-like cross-sectional shape with a convex front wall (5) and a concave back wall (6).

Owner:HENKEL KGAA

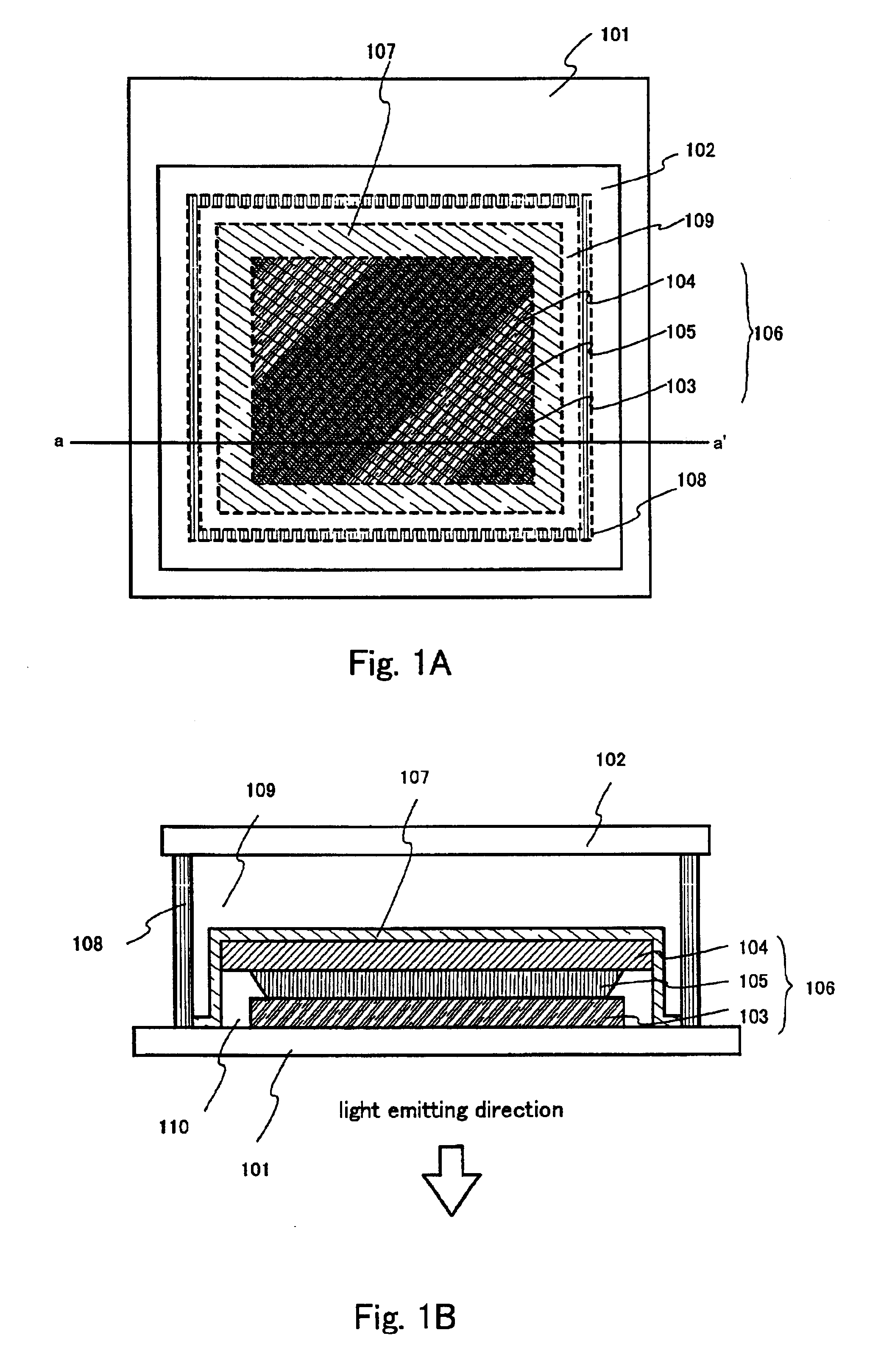

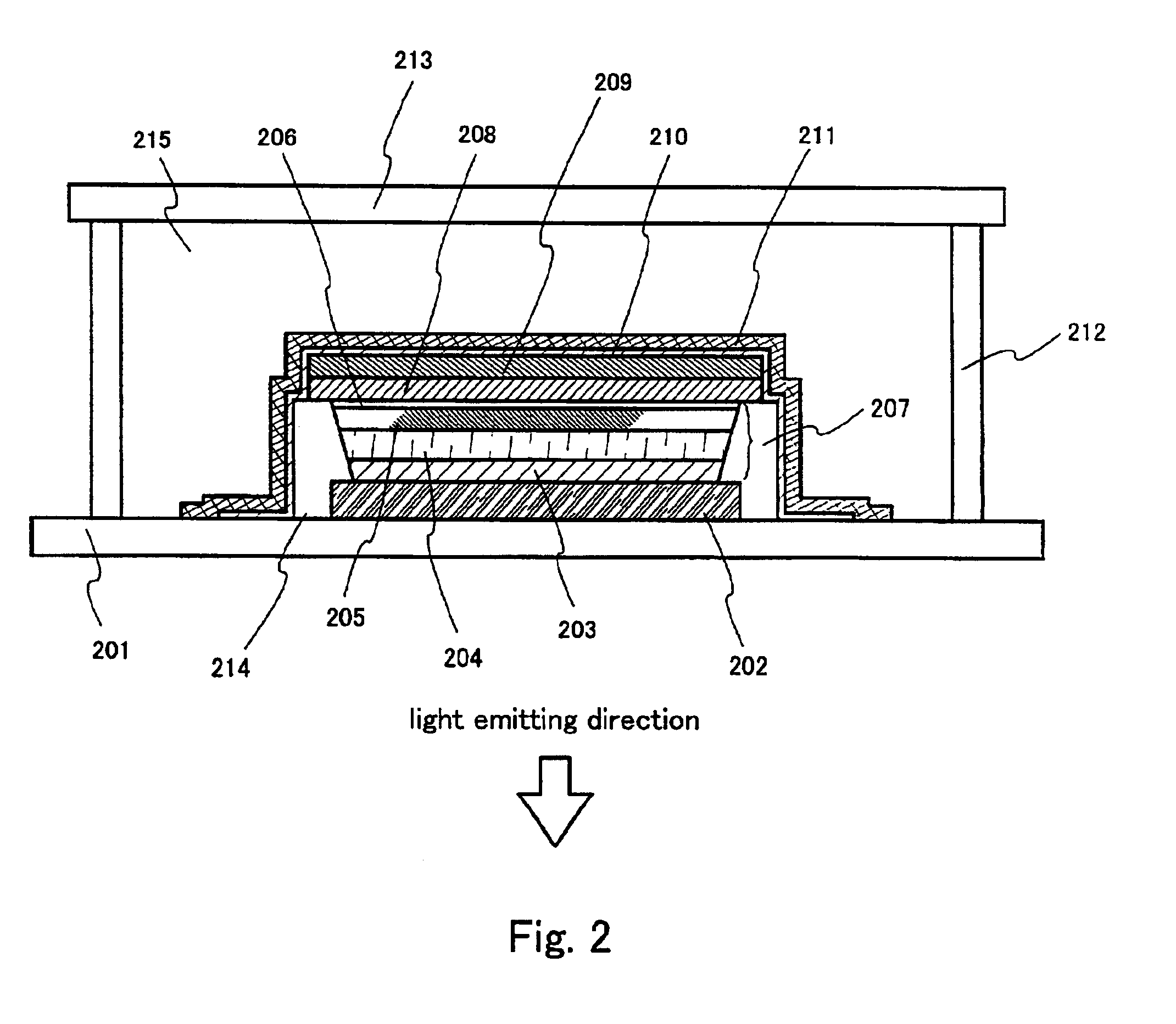

Light emitting device

InactiveUS6924594B2Prevent EL element deteriorationThe process is simple and effectiveDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringOxygen

A technique for sealing an EL panel of a light emitting device is provided. By preparing a absorption metal as a film on EL elements on the inside of an enclosed space, it becomes easy to made the interior of the space possess a absorption function, and further, an enclosure structure can be fabricated without the penetration of oxygen and moisture into the space because the absorption film is formed in succession after formation of the EL elements, according to the present invention.

Owner:SEMICON ENERGY LAB CO LTD

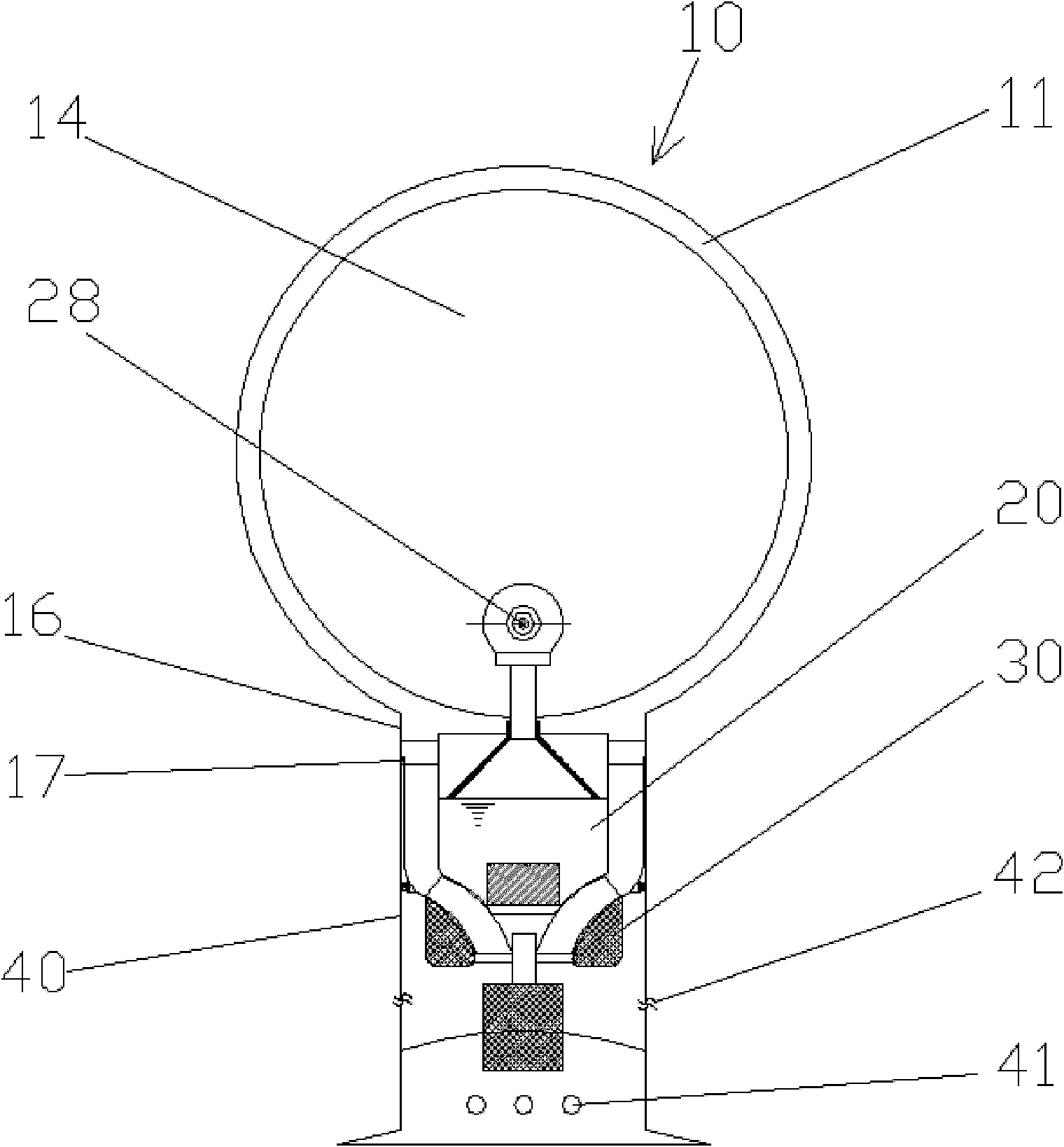

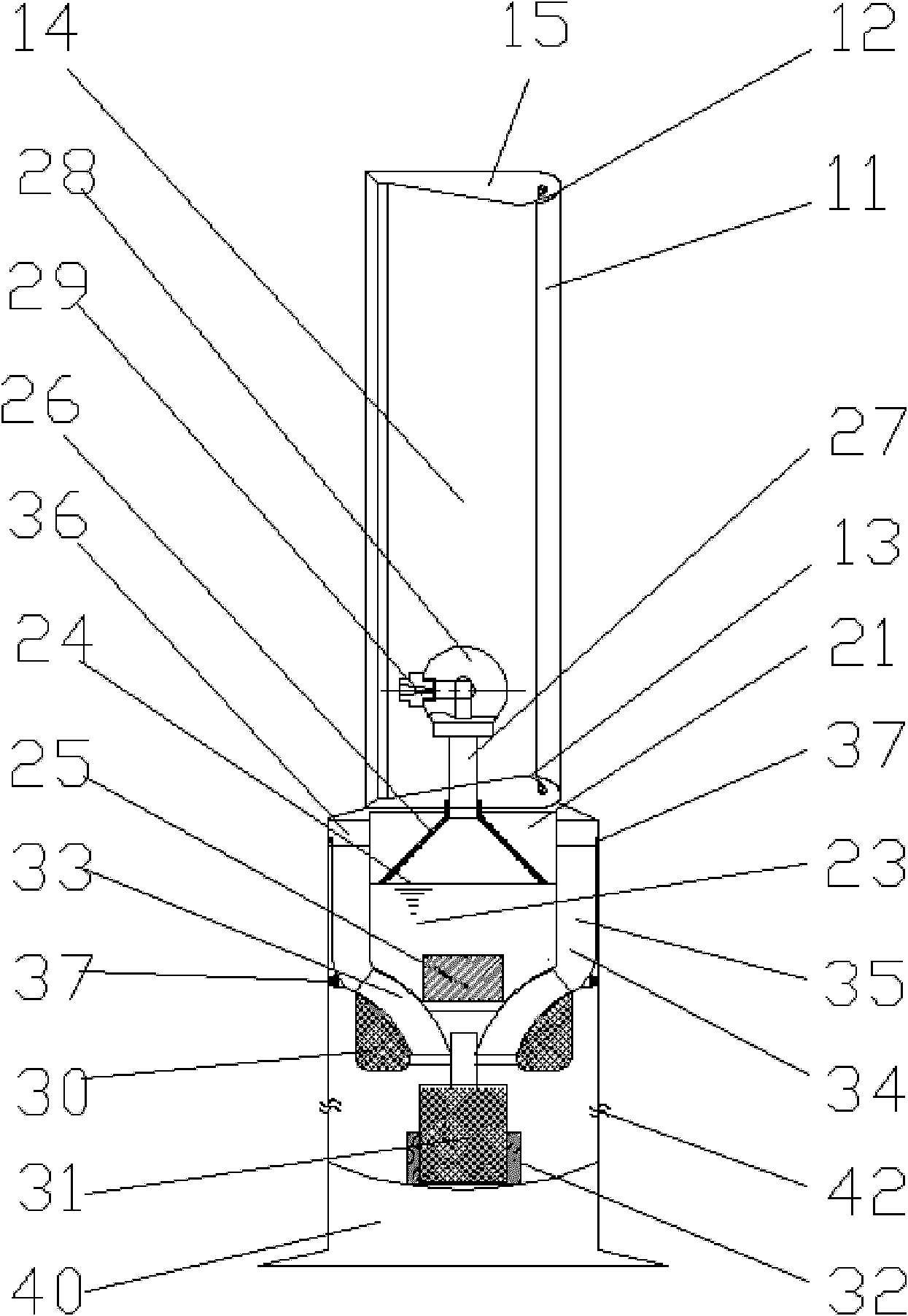

Ventilation device

InactiveCN102095236APromote absorptionImprove cooling effectLighting and heating apparatusJet pumpsWater vaporEngineering

The invention discloses a ventilation device, which aims to solve the problem that the conventional ventilation device does not have an air adjusting function. The device comprises a pedestal, a high-speed air blower and an annular ejector, wherein the high-speed air blower is arranged at the bottom of the pedestal; the annular ejector is arranged at an air outlet of the high-speed air blower and is fixed on the pedestal; and the air inlet or the air outlet of the high-speed air blower is provided with a vapor generator which is fixed on the pedestal for producing water vapor. In the ventilation device, the water vapor is produced through the vapor generator and is ejected through an atomization nozzle at a high speed to produce fog of smaller granularity, so that a hot air flow can more easily absorb the latent heat of vaporization, and the ventilation device has a humidification effect and a heat absorption and temperature reduction effect on a large amount of hot air sucked by the annular nozzle, and brings comfortable cool air similar to air on the shore of a lake or a sea to the surrounding environment. In the ventilation device, an external circulating device is not required to be mounted, so the cost is low; the space is not required to be closed, so that air convection is guaranteed; and the ventilation device is more energy-saving in the same temperature reduction range compared with a fan and an air conditioner, and can be used conveniently and safely.

Owner:曾小颖 +1

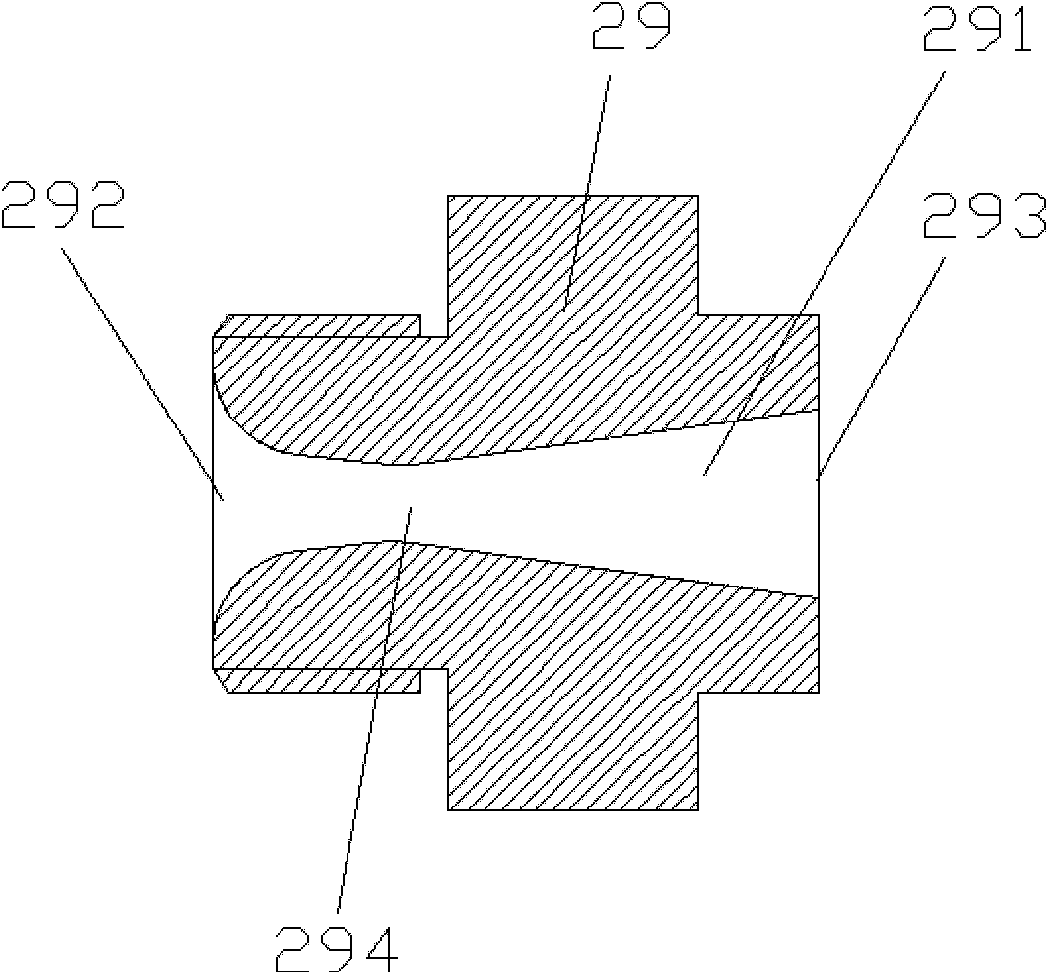

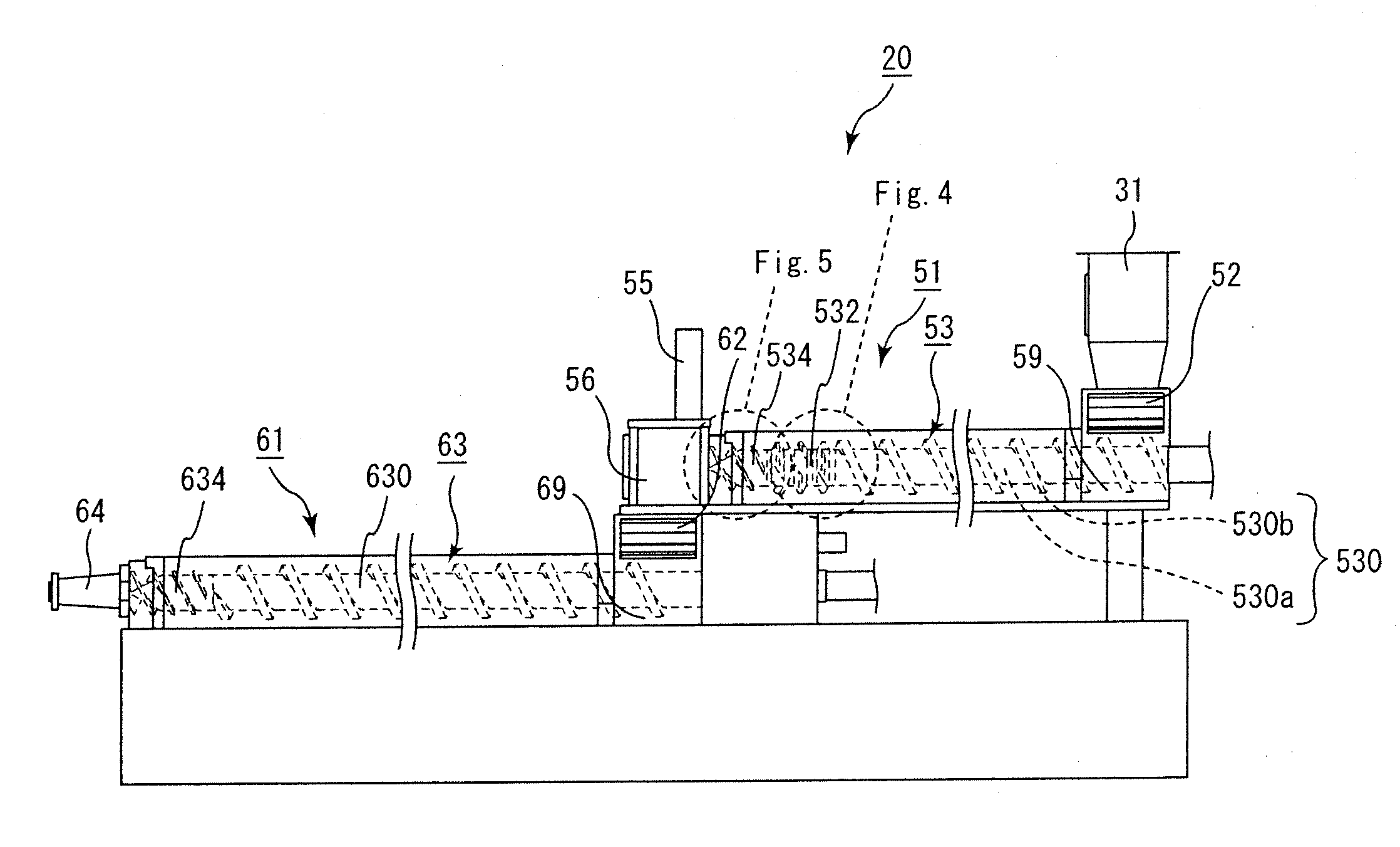

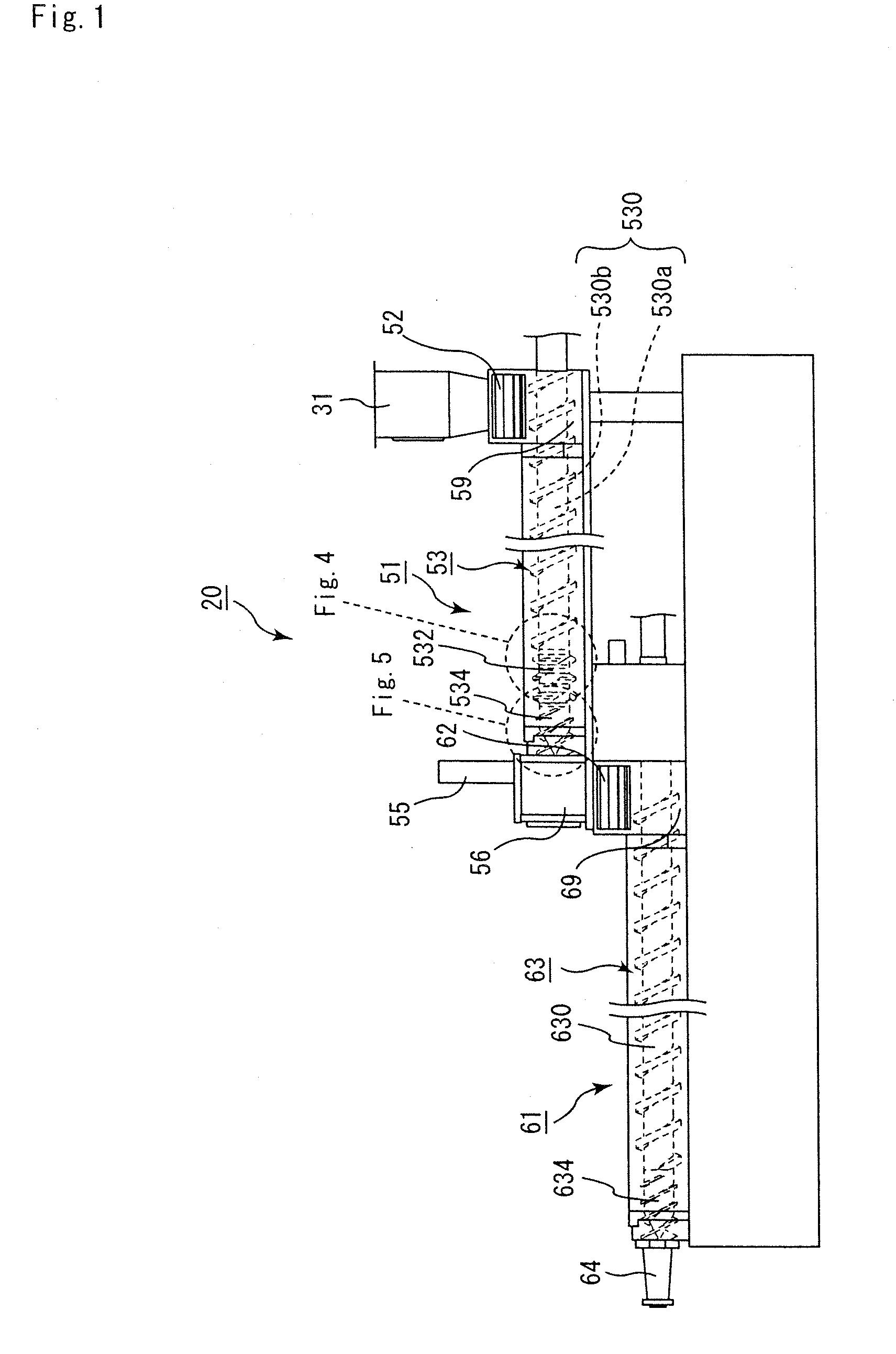

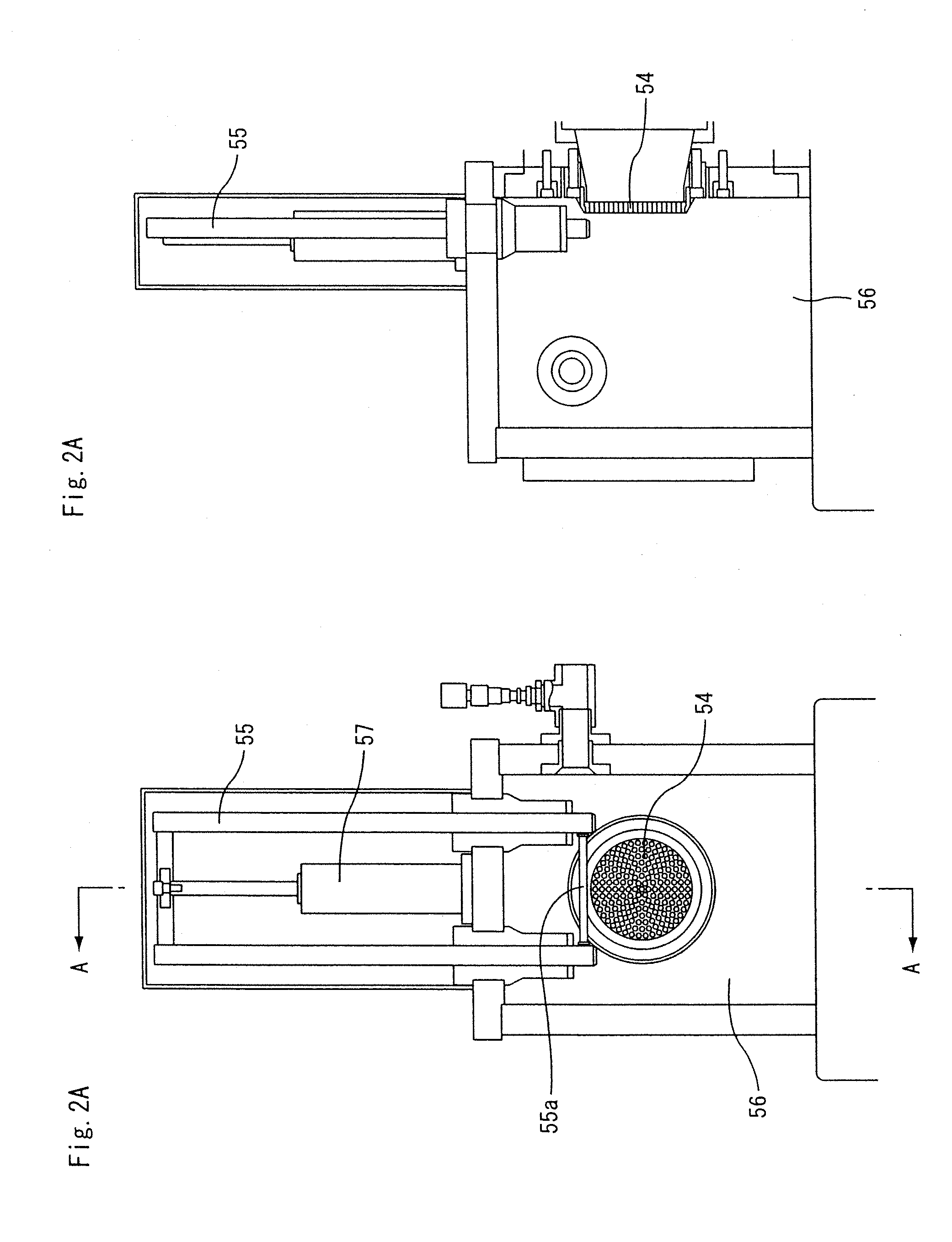

Extrusion-molding machine, extrusion-molding method, and method for manufacturing honeycomb structured body

An extrusion-molding machine according to the present invention comprises: a screw having a blade portion for extruding a molding material, the screw disposed in a tightly-closed space; and a die for molding an extruded molding material, wherein the space is maintained in a reduced-pressure atmosphere, and a high-hardness coat layer is formed at least on the blade portion.

Owner:IBIDEN CO LTD

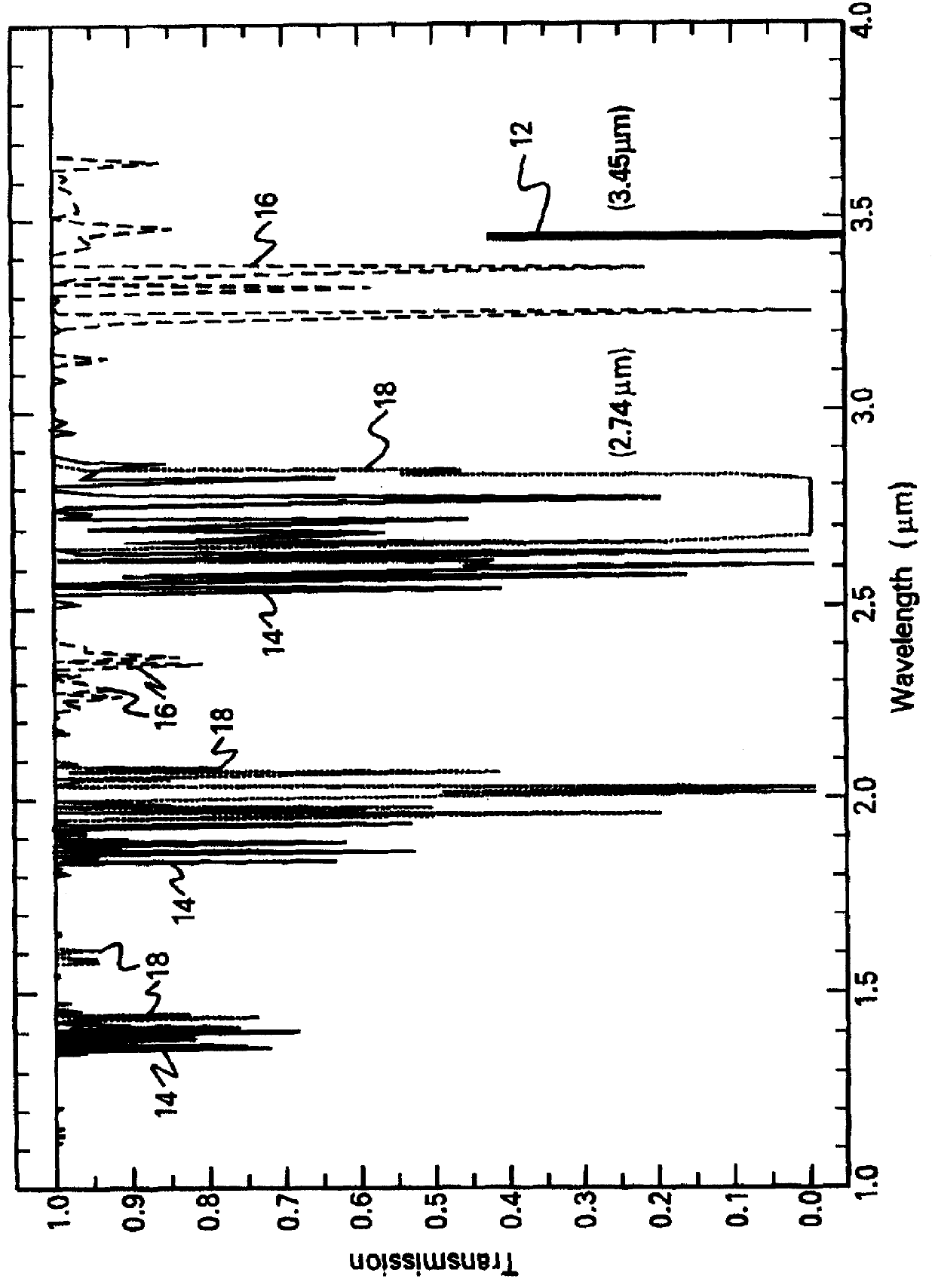

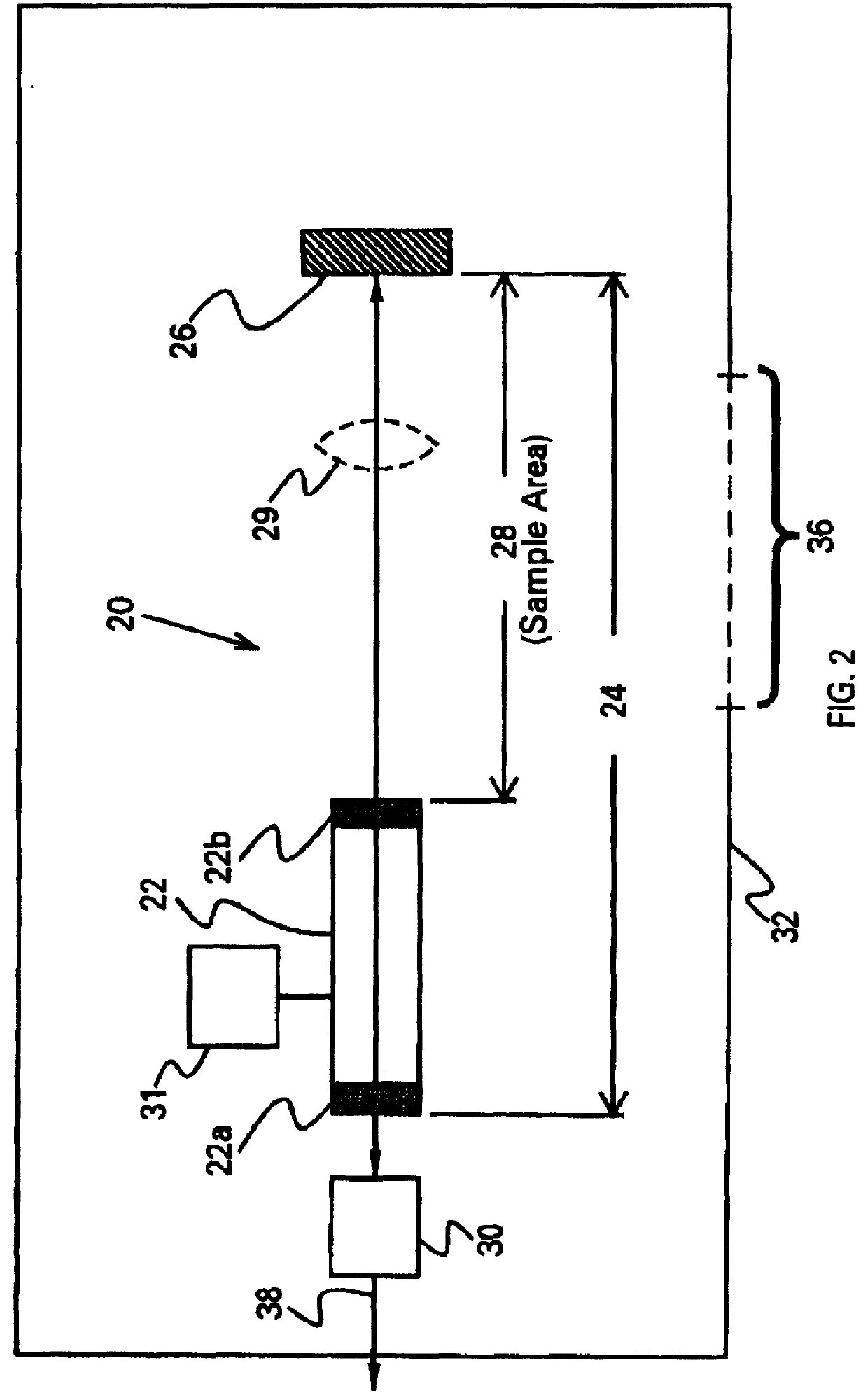

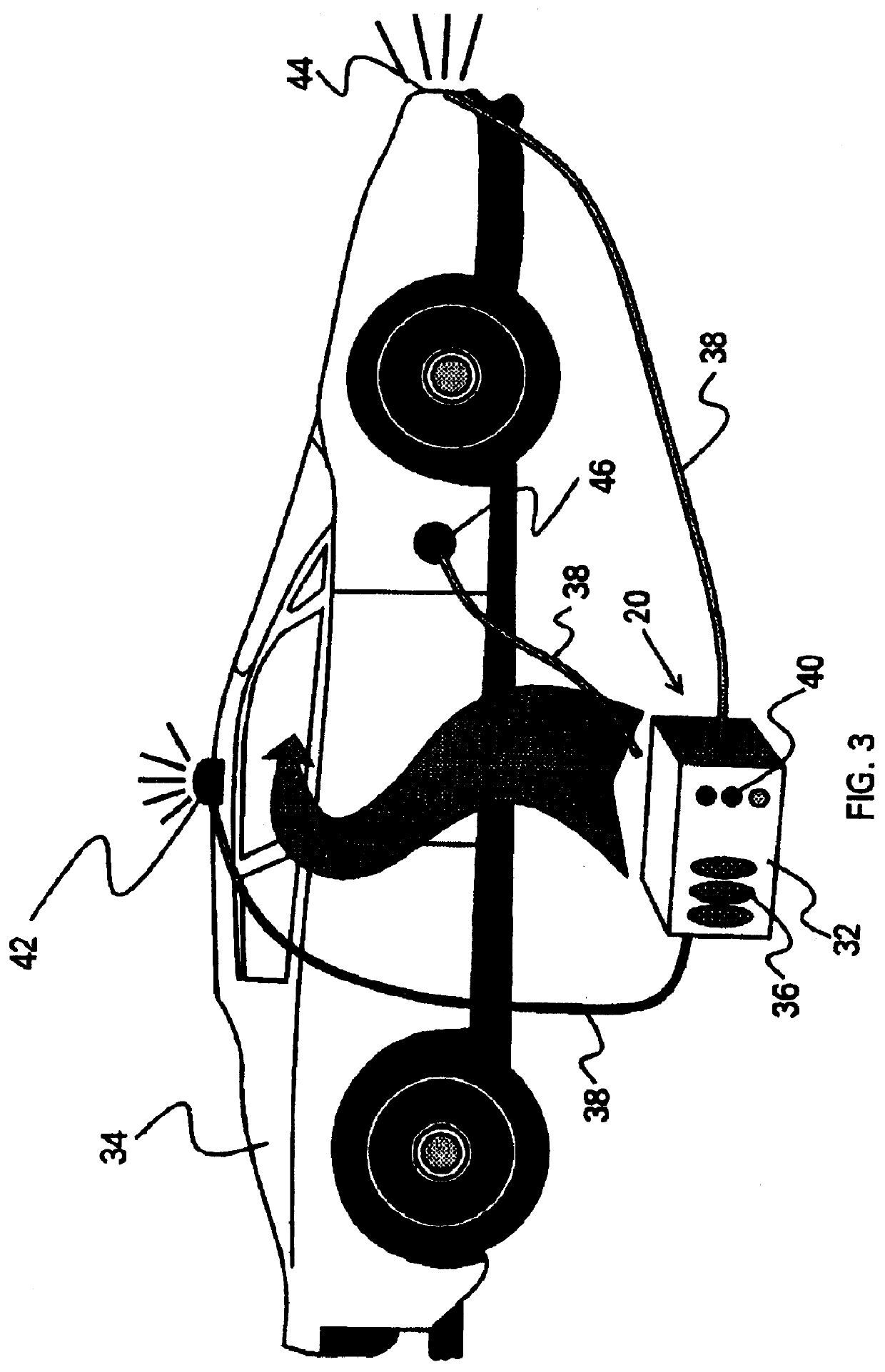

ILS sensors for drug detection within vehicles

On-board ILS sensors for detecting illegal drugs and based on intracavity laser spectroscopy (ILS) are provided for detecting the presence of drugs and their metabolized by-product vapors in an enclosed space, such as a vehicle. The sensor comprises: (a) a laser comprising a gain medium having two opposed facets within a laser resonator and functioning as an intracavity spectroscopic device having a first end and a second end, the first end operatively associated with a partially reflecting (i.e., partially transmitting) surface; (b) a reflective or dispersive optical element (e.g., a mirror or a diffraction grating) operatively associated with the second end to define a broadband wavelength laser resonator between the optical element and the first end and to thereby define an external cavity region between at least one facet of the gain medium and either the first end or the second end or both ends; (c) the external cavity region being exposed to air in the enclosed space to enable any drugs or their metabolized by-product molecules to enter thereinto; (d) a detector spaced from the first end; (e) appropriate electronics for measuring and analyzing the detector signal; (f) a housing for containing at least the laser, the partially reflecting surface, and the optical element, the housing being configured to prevent escape of stray radiation into the enclosed space and to permit air from the enclosed space to continuously circulate through the external cavity region for analysis; and (g) means for driving the laser (e.g., electrical or optical). A method is provided for measuring concentration of drug vapors and their metabolized by-product vapors in the vehicle or other enclosed space employing the on-board sensor. The method comprises: (1) sensing any drugs and their metabolized by-product vapors in the enclosed space by the on-board sensor; and (2) providing a signal indicative of presence of any drugs or metabolized vapors.

Owner:INNOVATIVE LASERS

Positive pressure air purification and conditioning system

InactiveUS20060177356A1Reduces overall air purification requirementAvoid enteringMechanical apparatusSpace heating and ventilation safety systemsPositive pressureEngineering

An air purification system utilizing an ultraviolet germicidal lamp is disclosed. The air purification system is in fluid communication with a ventilation duct. The air purification system may also be in fluid communication with the ambient air. The air purification system may incorporate an actuator for the selection of the ambient air, the ventilation duct, or both as an air source for treatment. The air purification system may also be used to obtain a positive pressure within an enclosed space.

Owner:MILLER GREGORY ROBERT

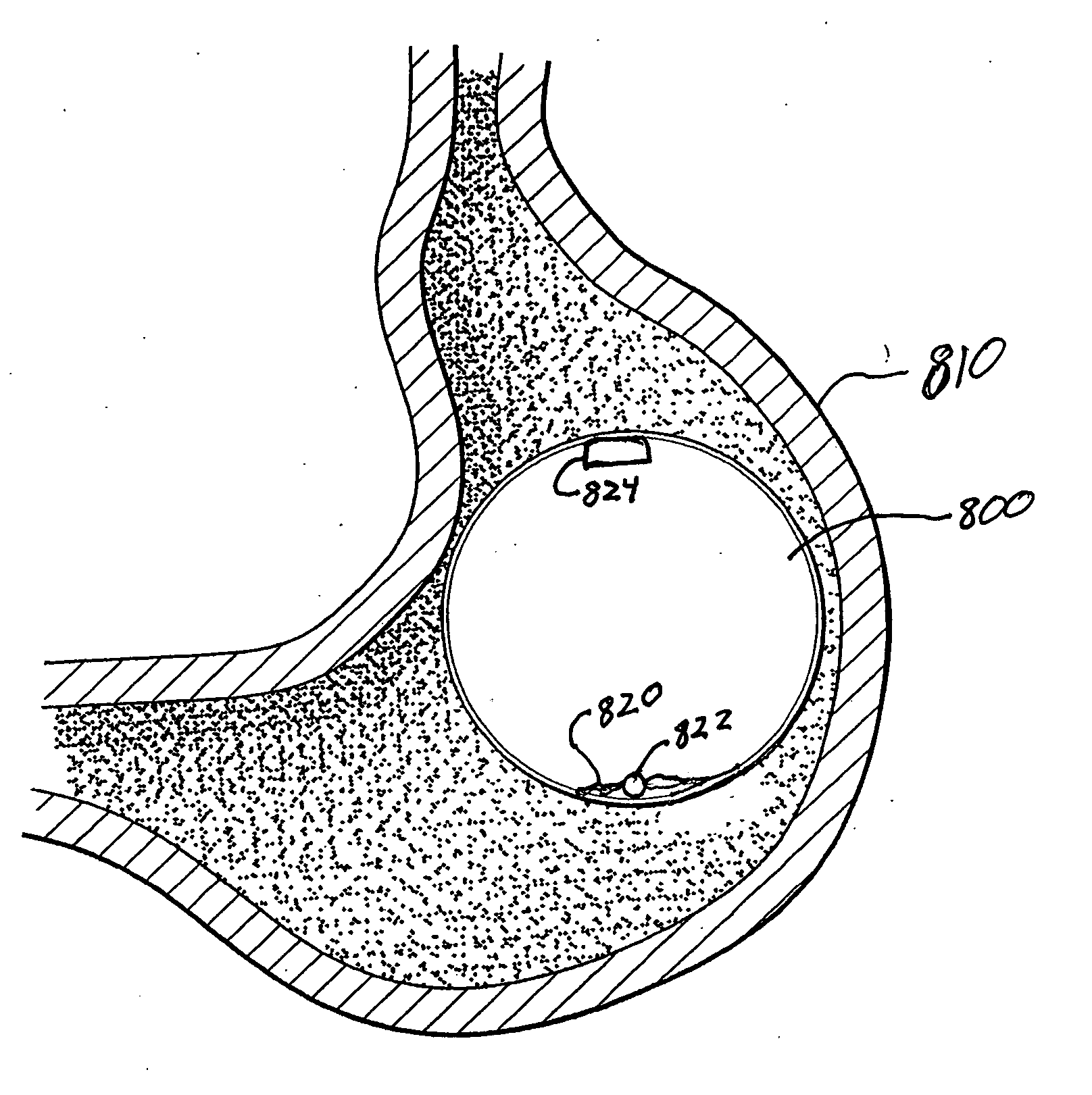

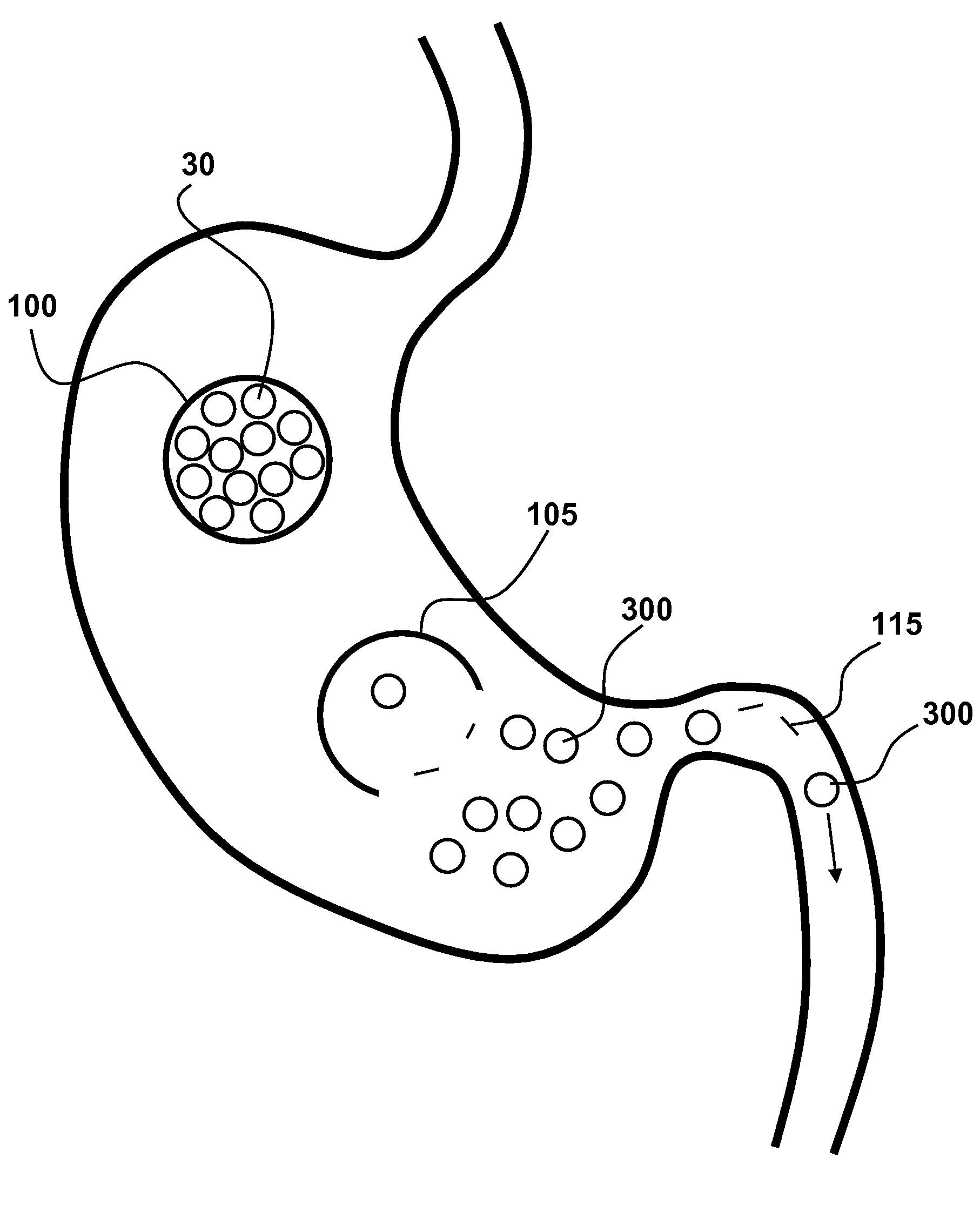

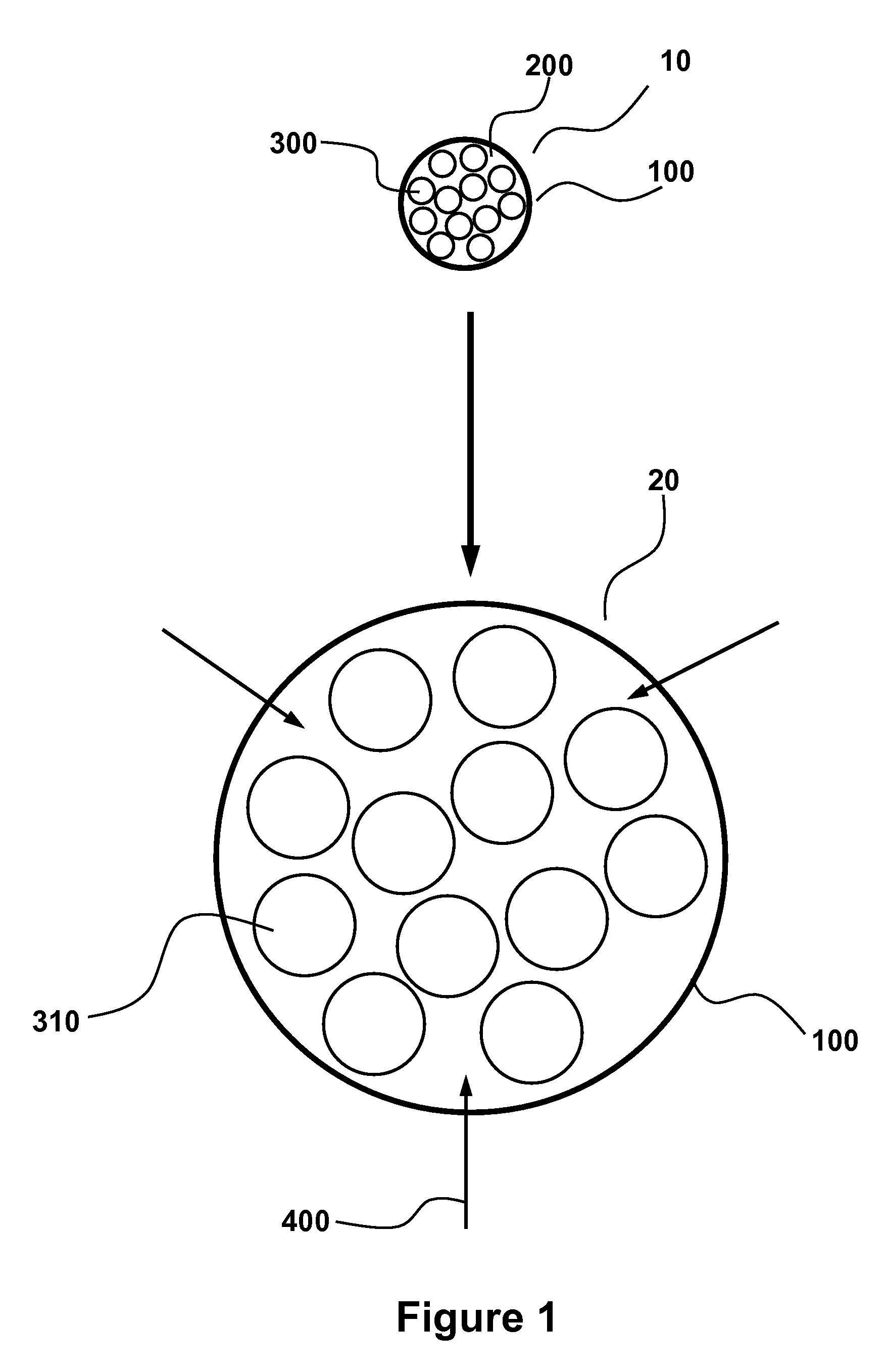

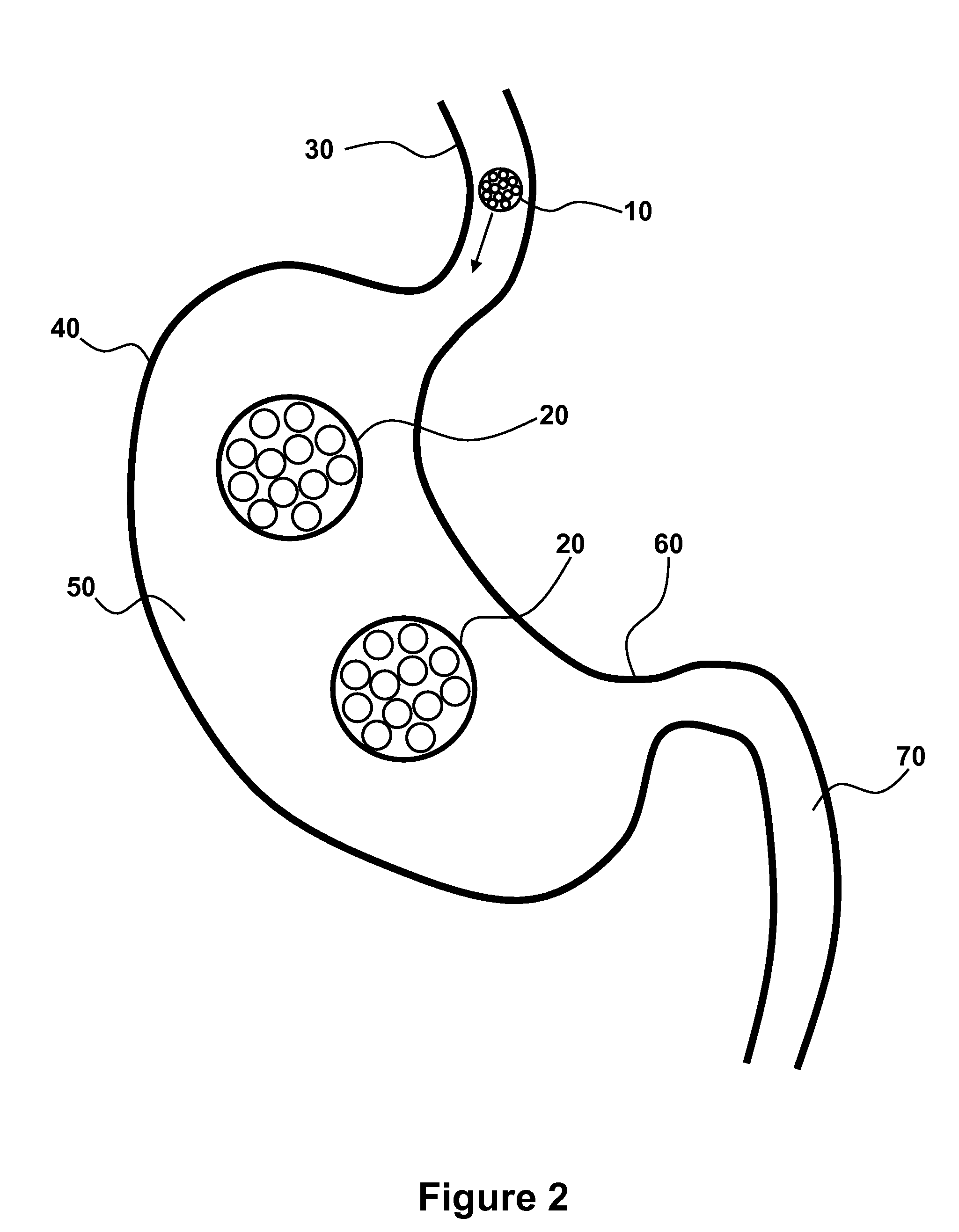

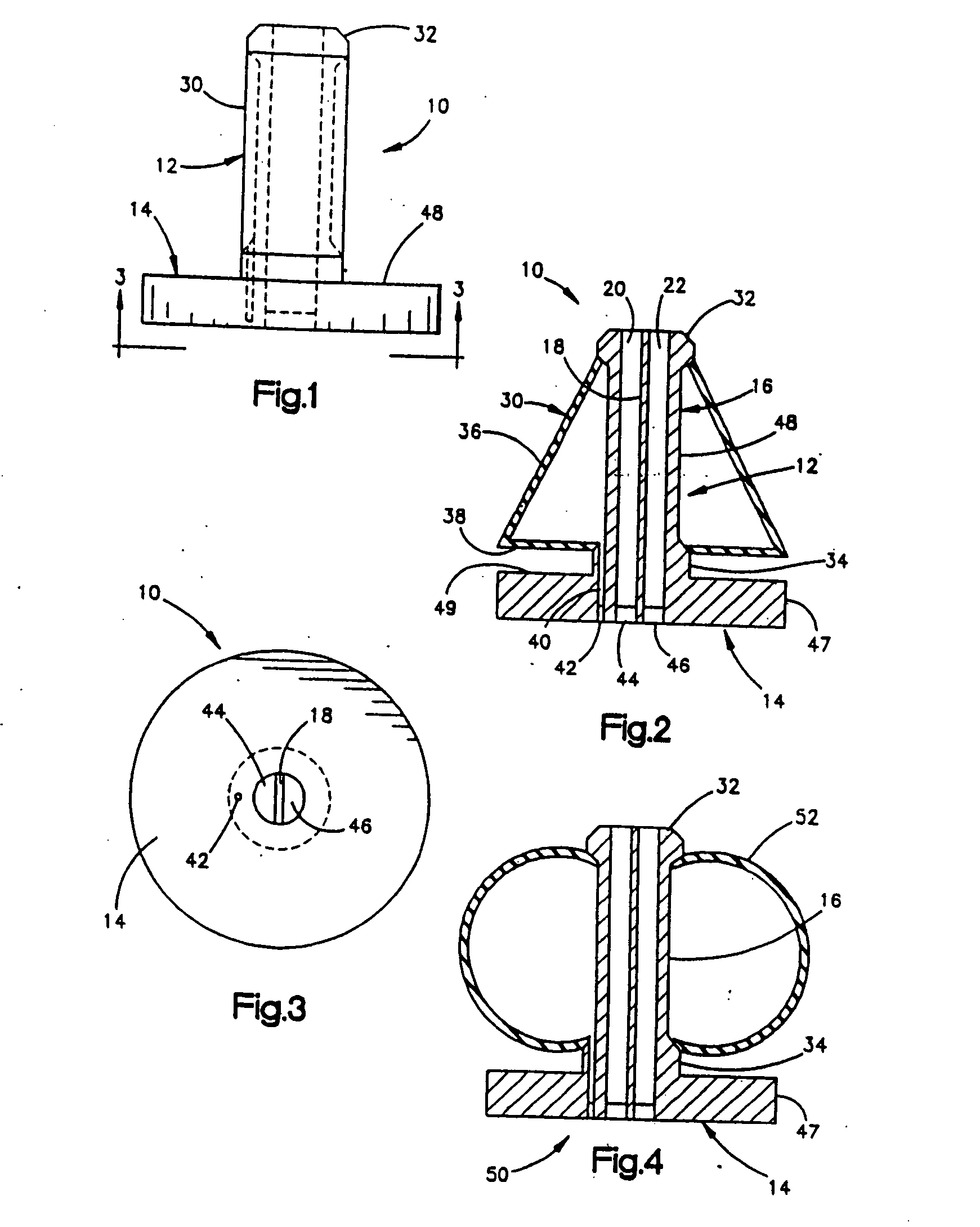

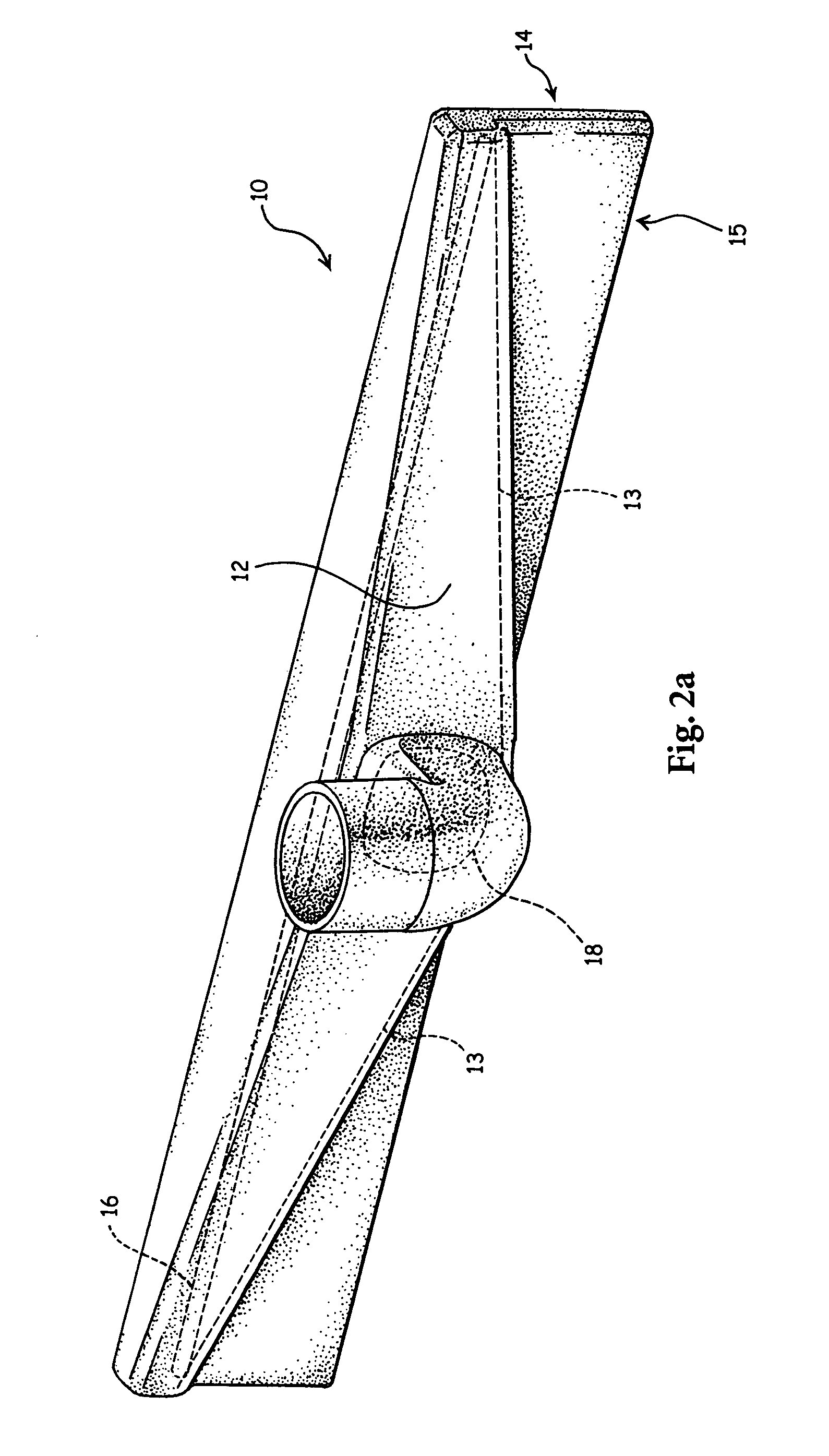

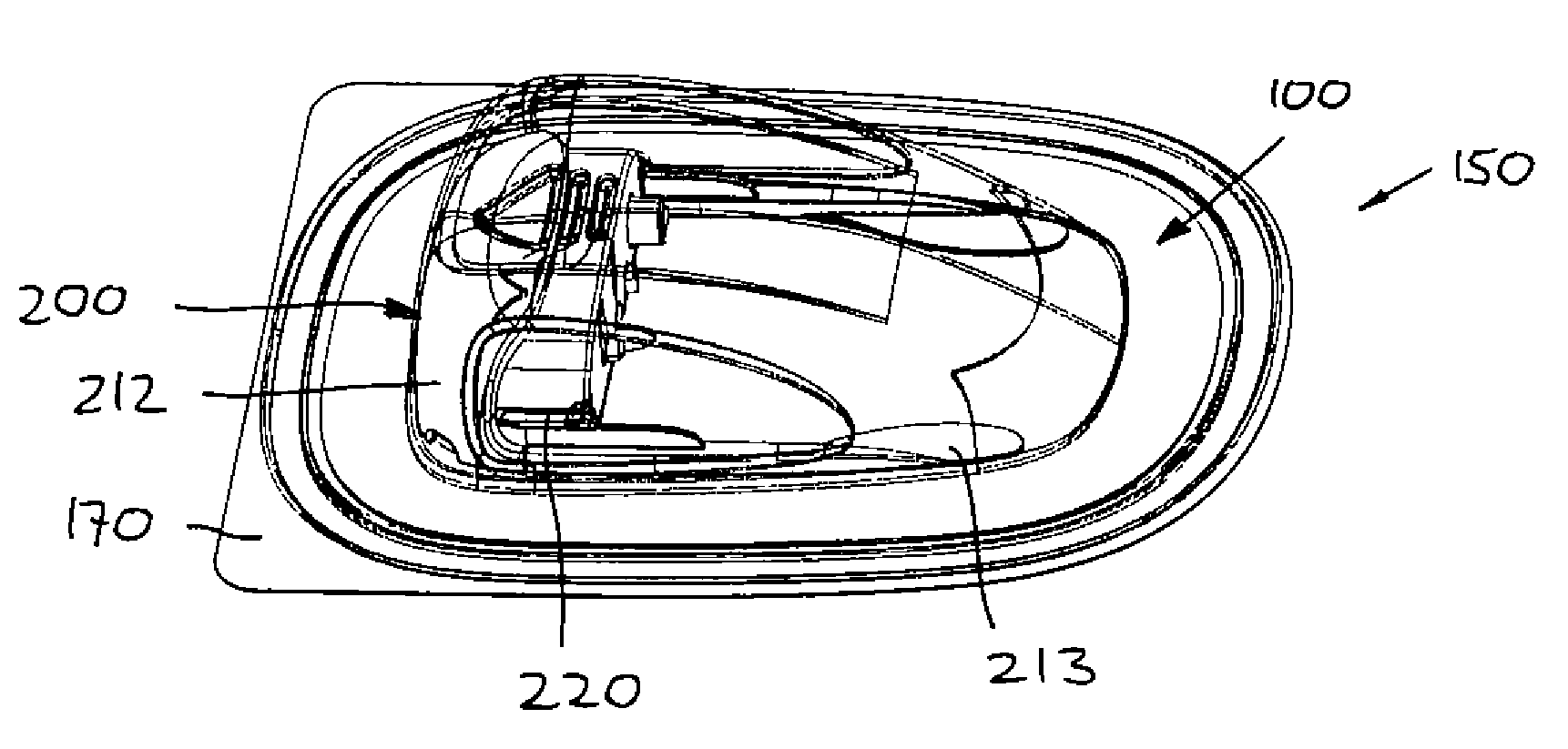

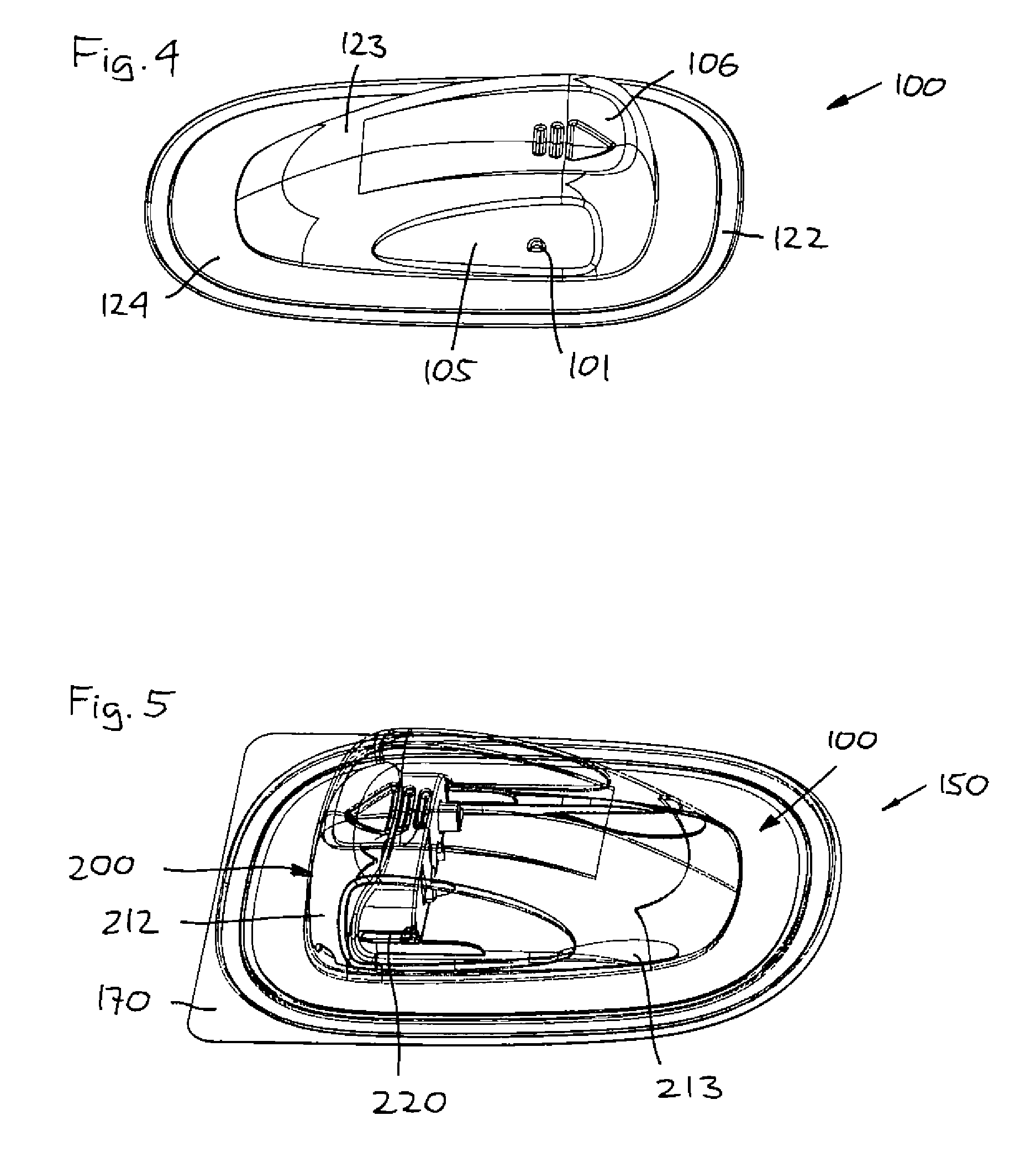

Swallowable Self-Expanding Gastric Space Occupying Device

InactiveUS20090192535A1Suppresses individual 's hungerFilling stomachDilatorsObesity treatmentGastric fluidMembrane configuration

Disclosed is a swallowable self-expanding gastric space occupying device and related methods of making and using the device to control obesity. The device has a membrane through which gastric liquid can pass, wherein the membrane provides an enclosure volume separated from the gastric environment by the membrane. A plurality of self-expanding components is contained in the enclosure volume, so that the components expand in volume upon contact with the gastric fluid, thereby expanding the device from an unexpanded volume to an expanded volume. Composite membranes provide the ability to precisely control how and when the membrane degrades in the stomach, to release the self-expanding components from the enclosure and to ensure that the released pieces are sufficiently small to not obstruct any portion of the gastrointestinal system.

Owner:7L LLC

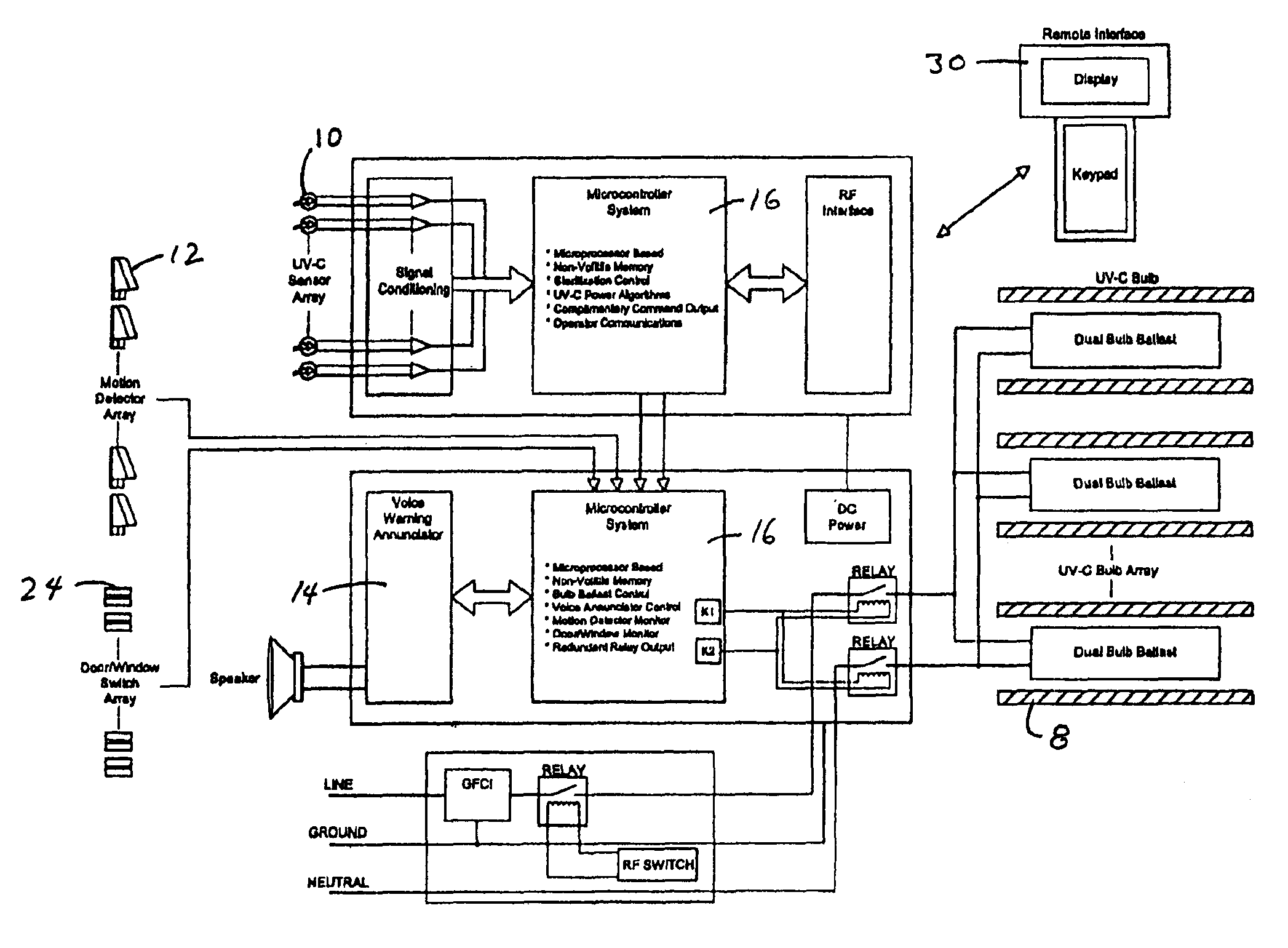

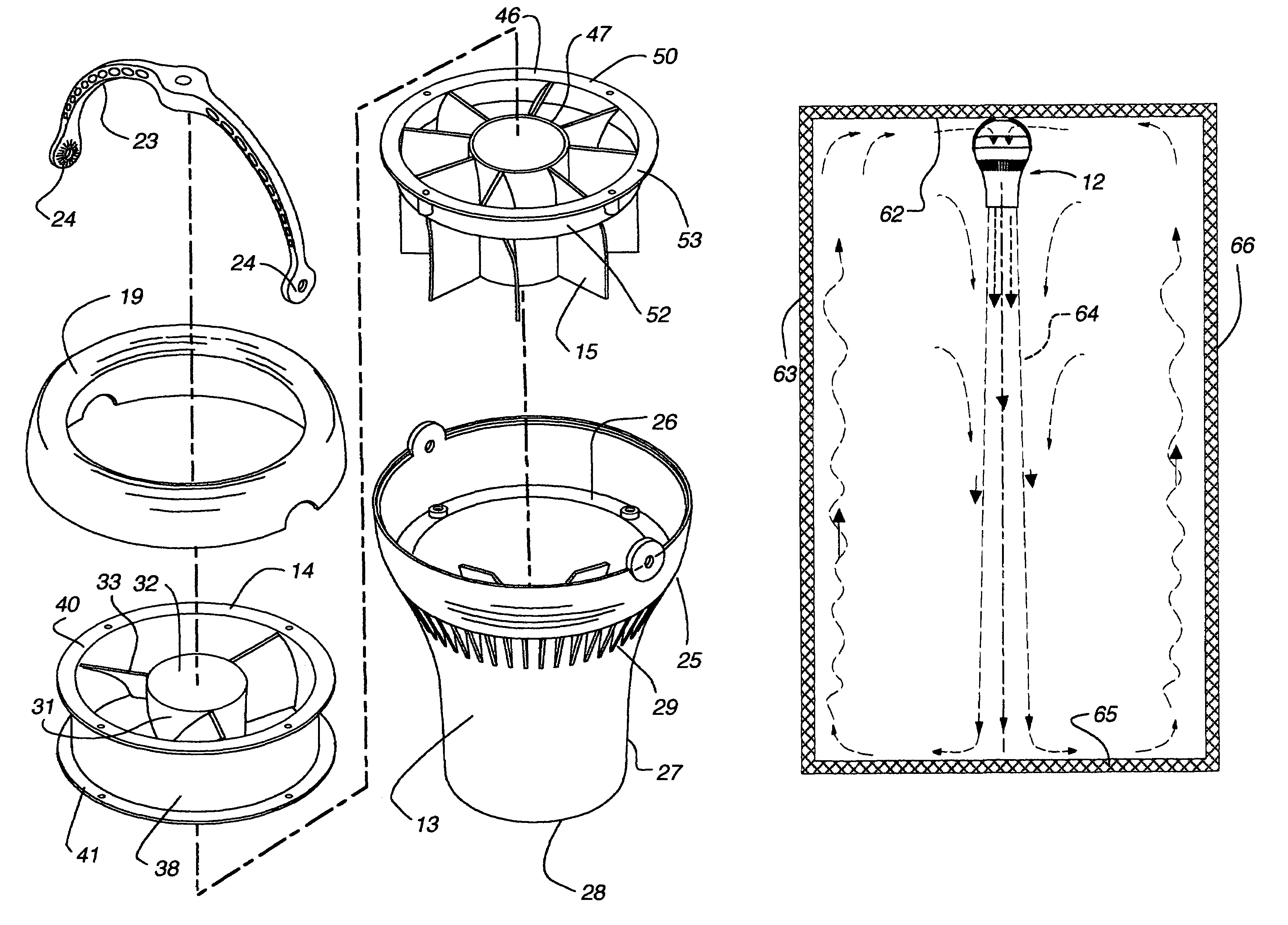

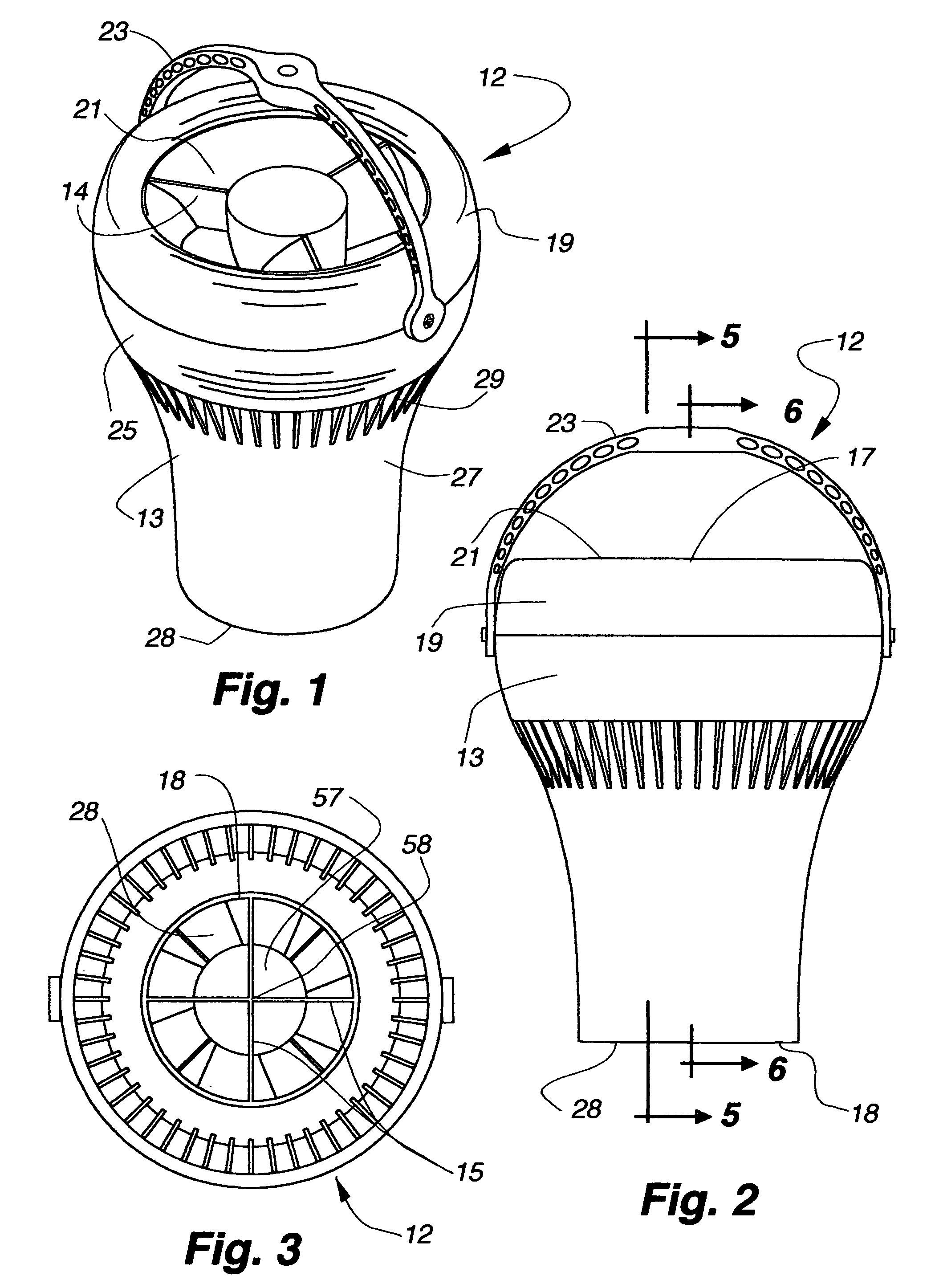

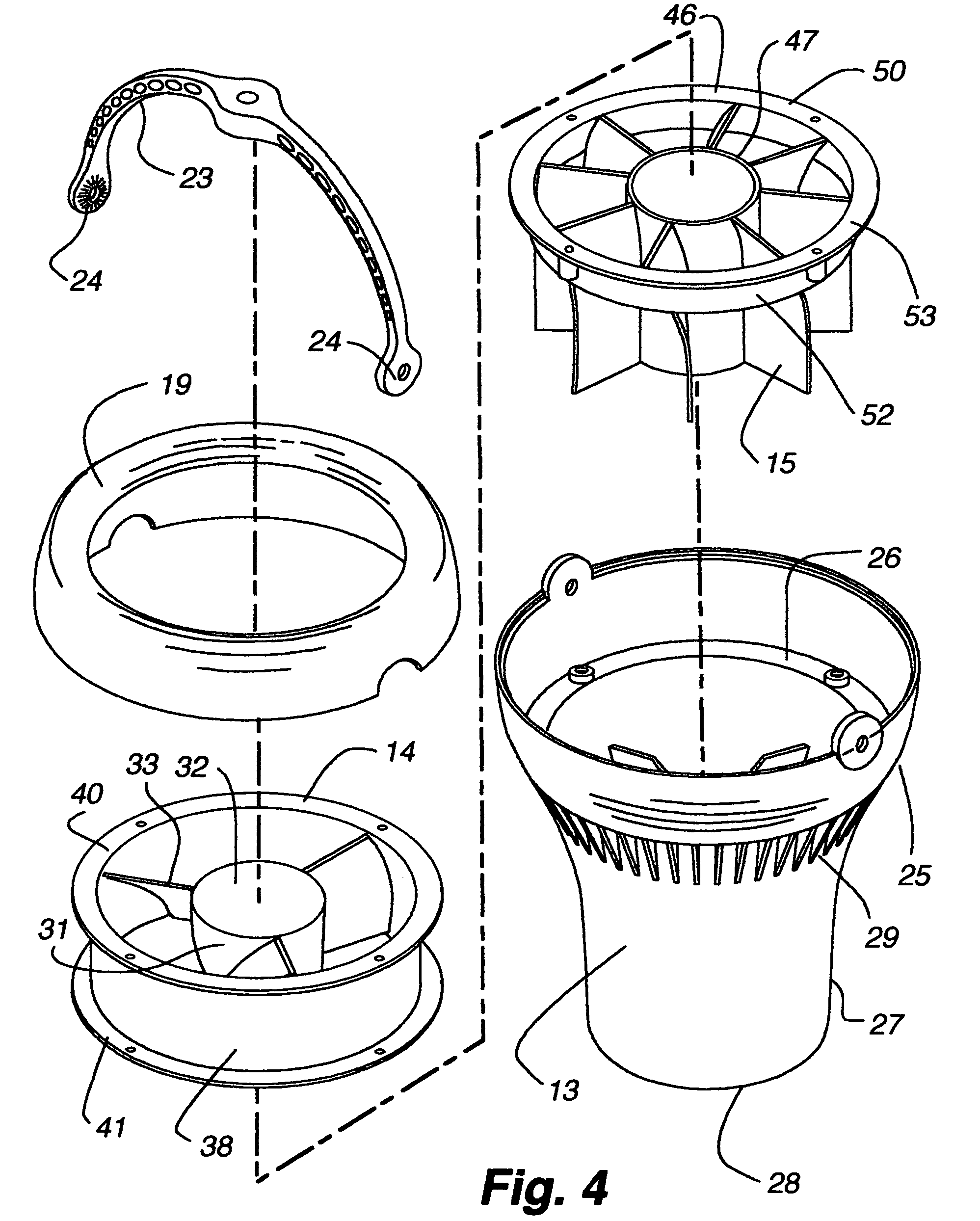

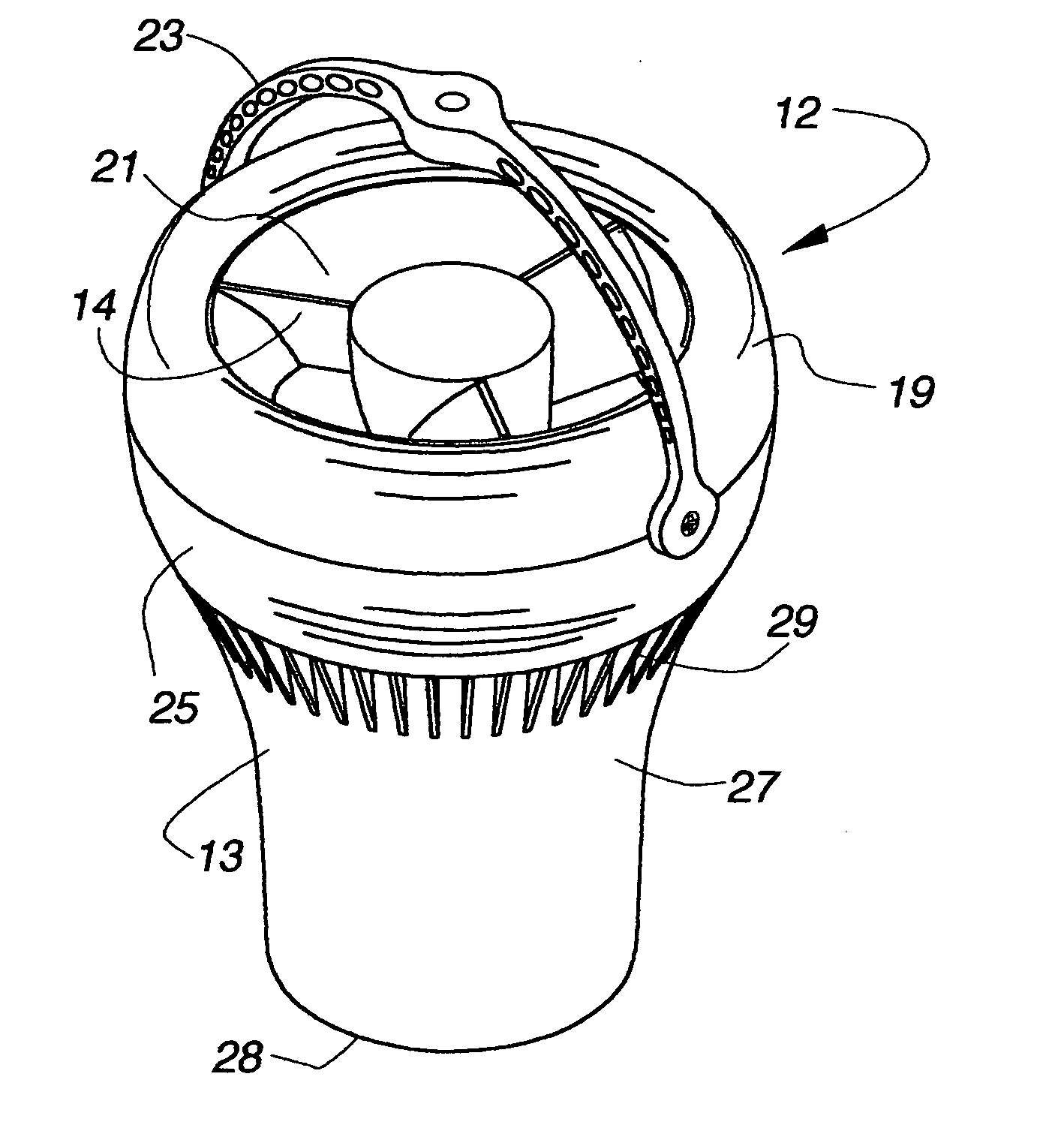

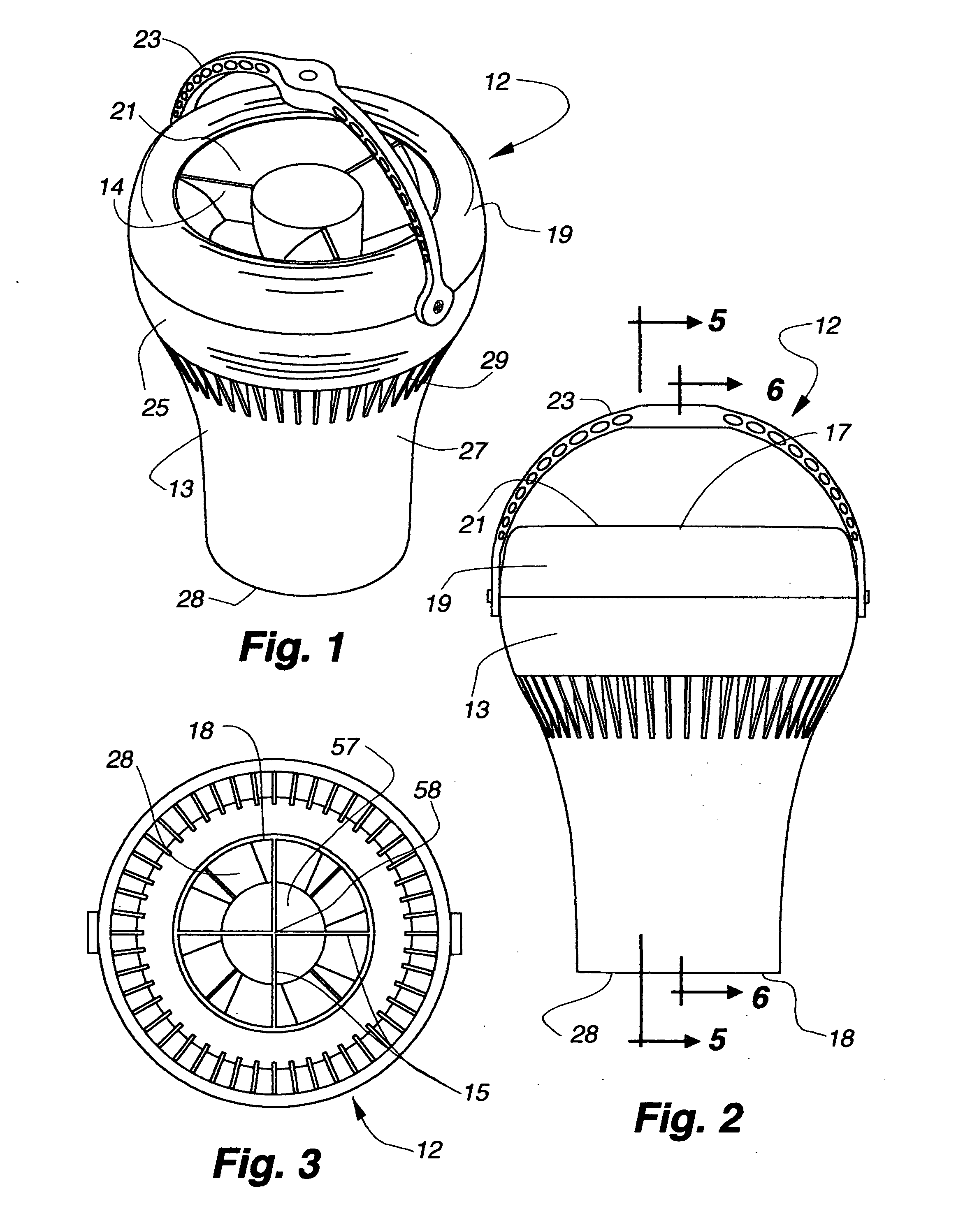

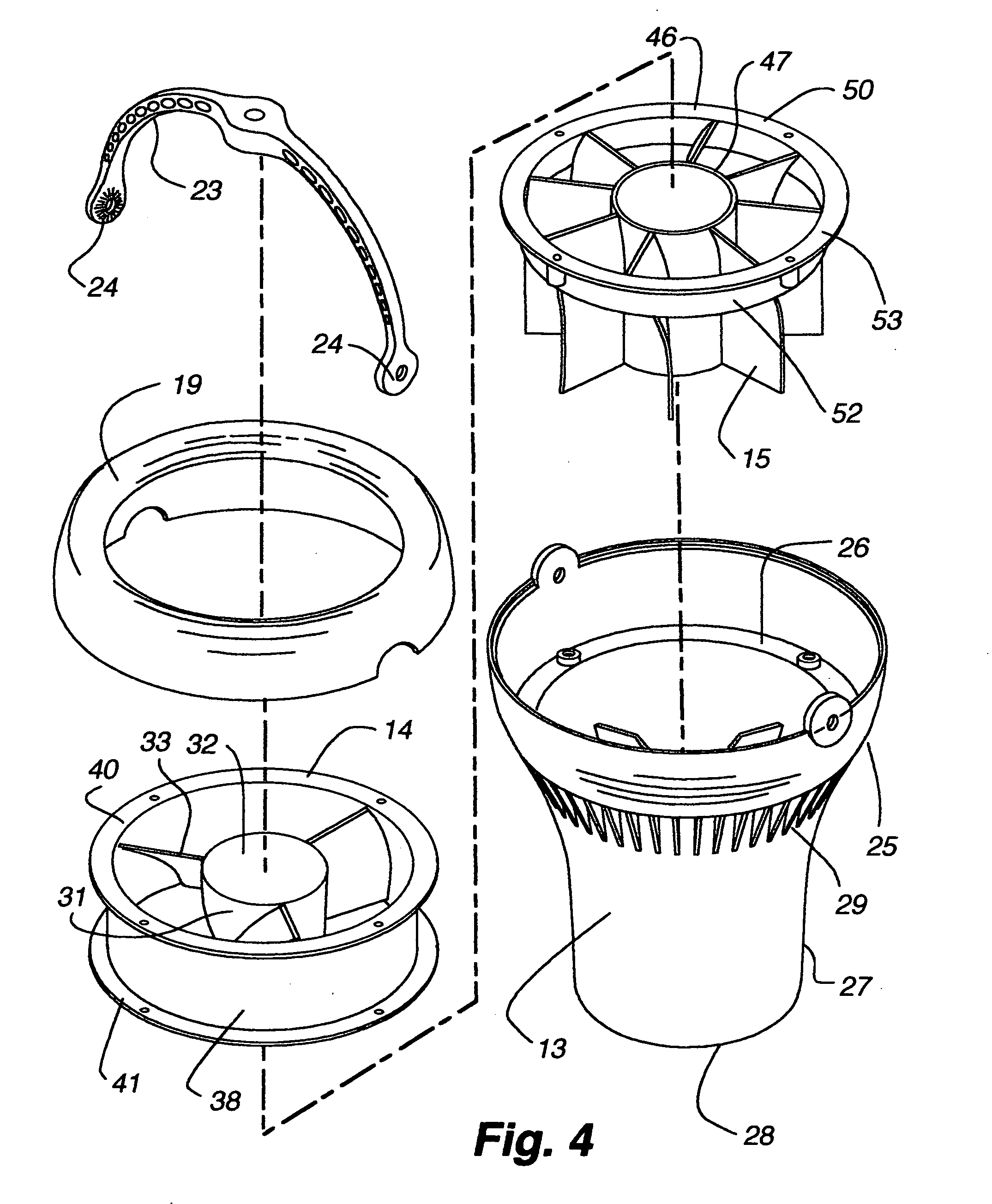

Columnar air moving devices, systems and methods

Air moving device includes a housing, an impeller in the housing for generating a downward air flow, and vanes in the housing in close proximity to and a selected distance below the impeller to straighten the air flow. The device produces an air flow that substantially remains in a column over a substantial distance. The method includes producing an air flow that substantially remains in a column over a substantial distance and directing the air flow from the ceiling towards the floor to provide temperature destratification of the air in an enclosed space. The method also includes directing warm air from the ceiling to the floor and storing heat in the floor, apparatus on the floor and ground under the floor. The stored heat is released when the ceiling is cooler than the floor.

Owner:AIRIUS IP HLDG

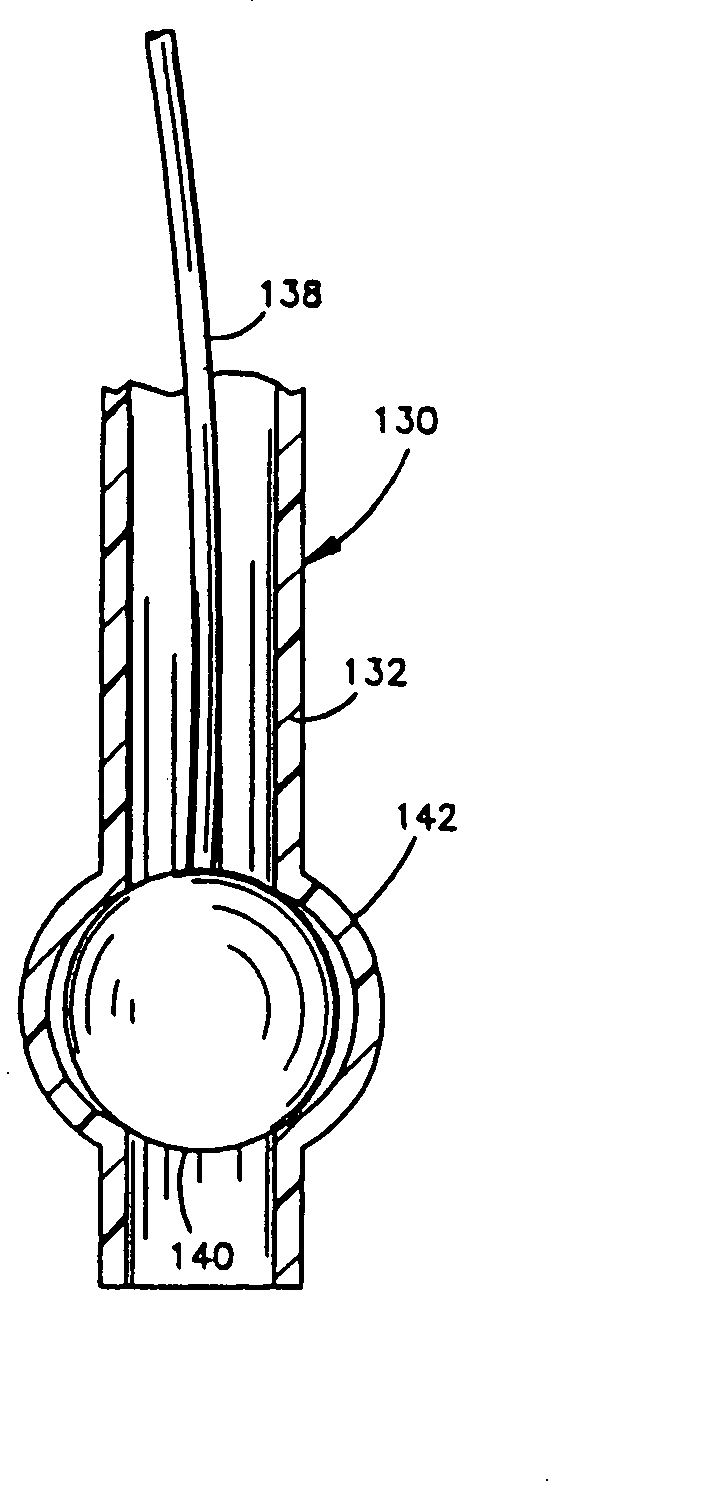

Active cannulas

InactiveUS20080065140A1Simple and safe processSafely visualize appropriate tissue and operateGuide needlesStentsMedicineSkin opening

An active cannula which does more than merely maintain a passage is usable to create and / or enlarge a passage, to position a scope or instrument, to move or locate tissue, etc. The cannula can vary in size or shape as needed, intraoperatively. Because a cannula of the present invention is expandable, the surgeon can make a relatively small incision, stretch the tissue with the expandable cannula, contract the cannula and remove it, allowing the skin to come back to its unstretched condition. Thus, a smaller incision can be made to fit the same size instrument. The cannulas can assume such a non-circular shape, to fit into a natural skin opening and cause less trauma. The devices can be used to seal off a space, expand an existing space or a potential space for working or visualization, move tissue (for example, to stretch an incision), or protect tissue.

Owner:BONUTTI PETER

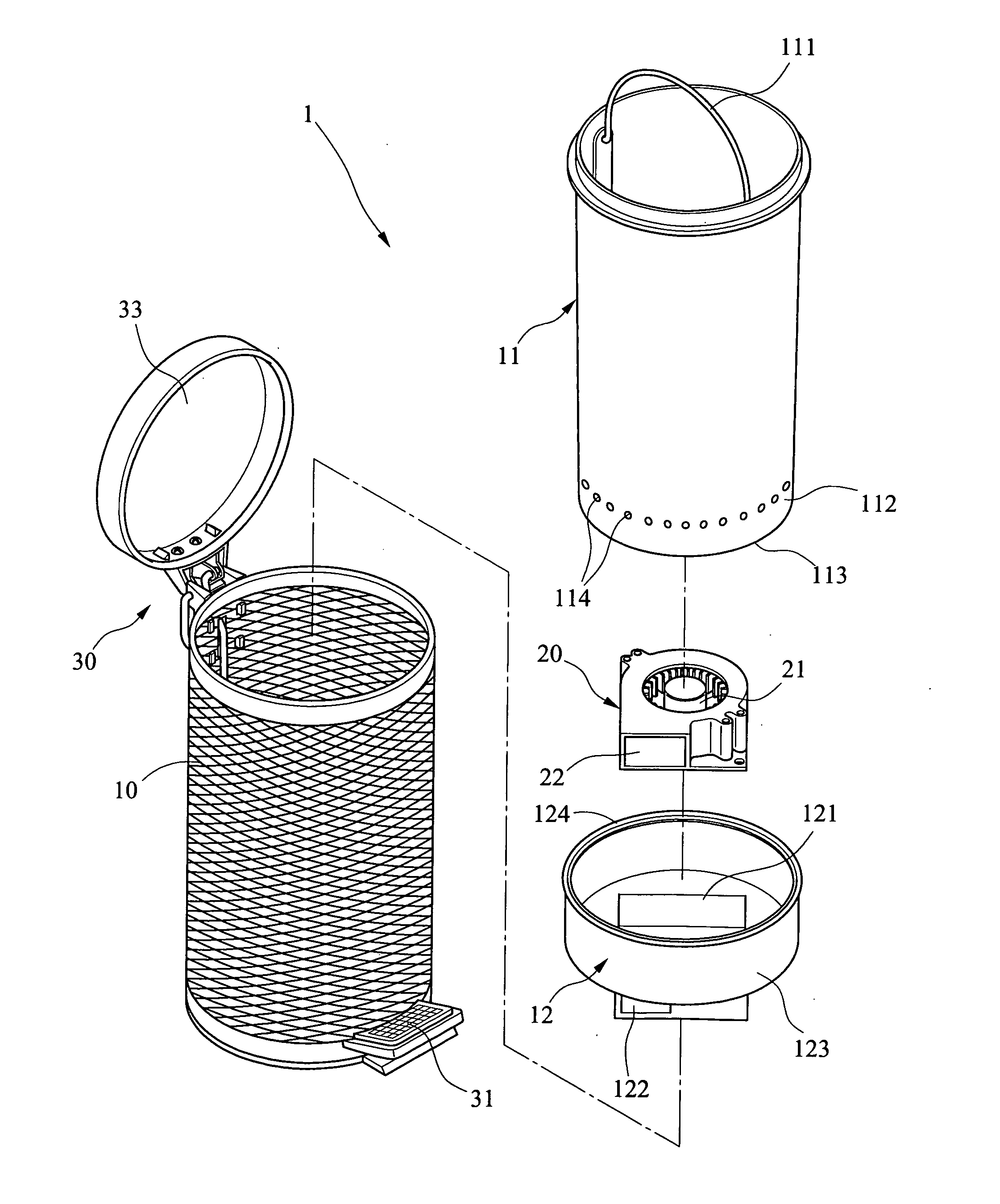

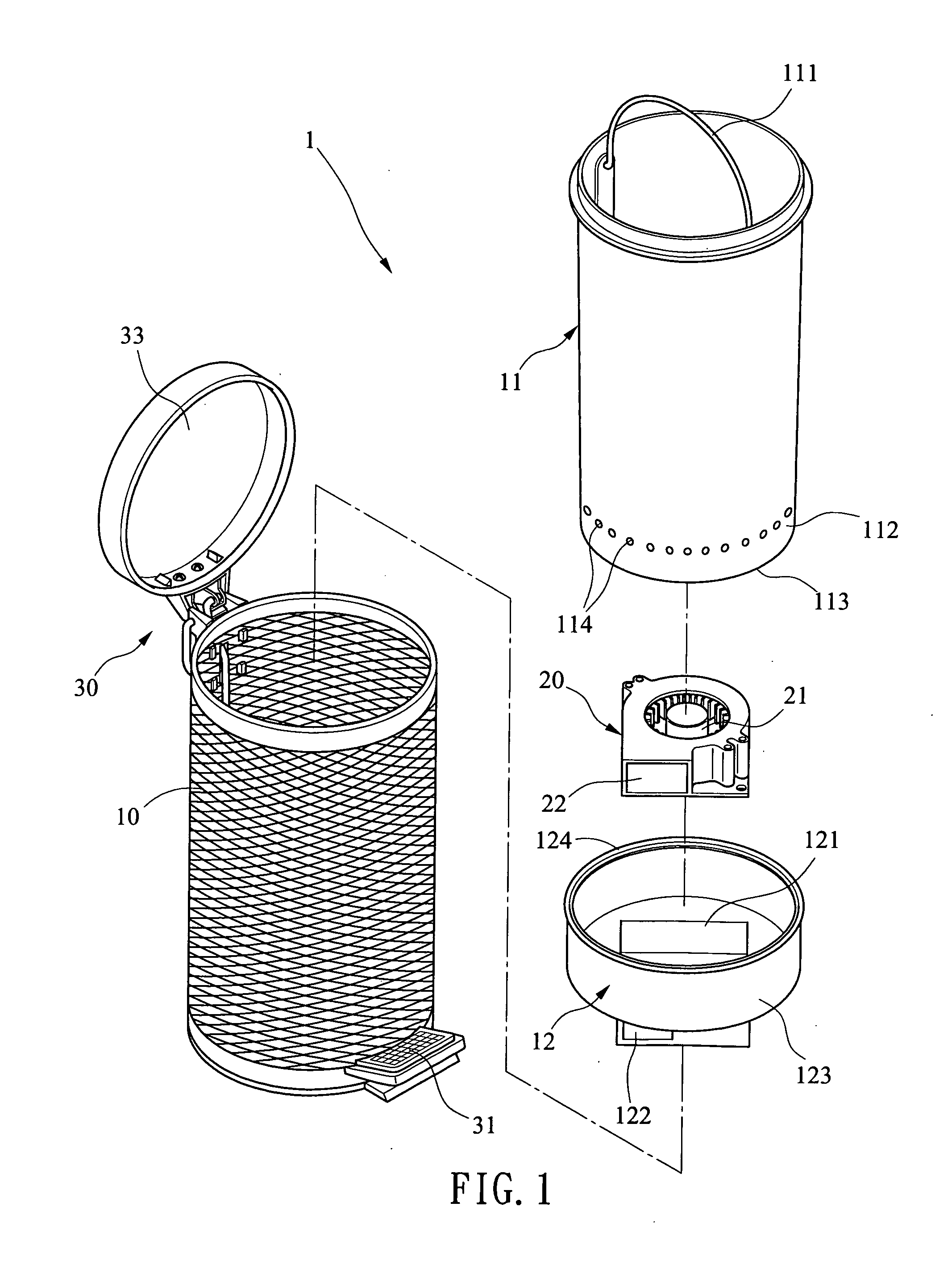

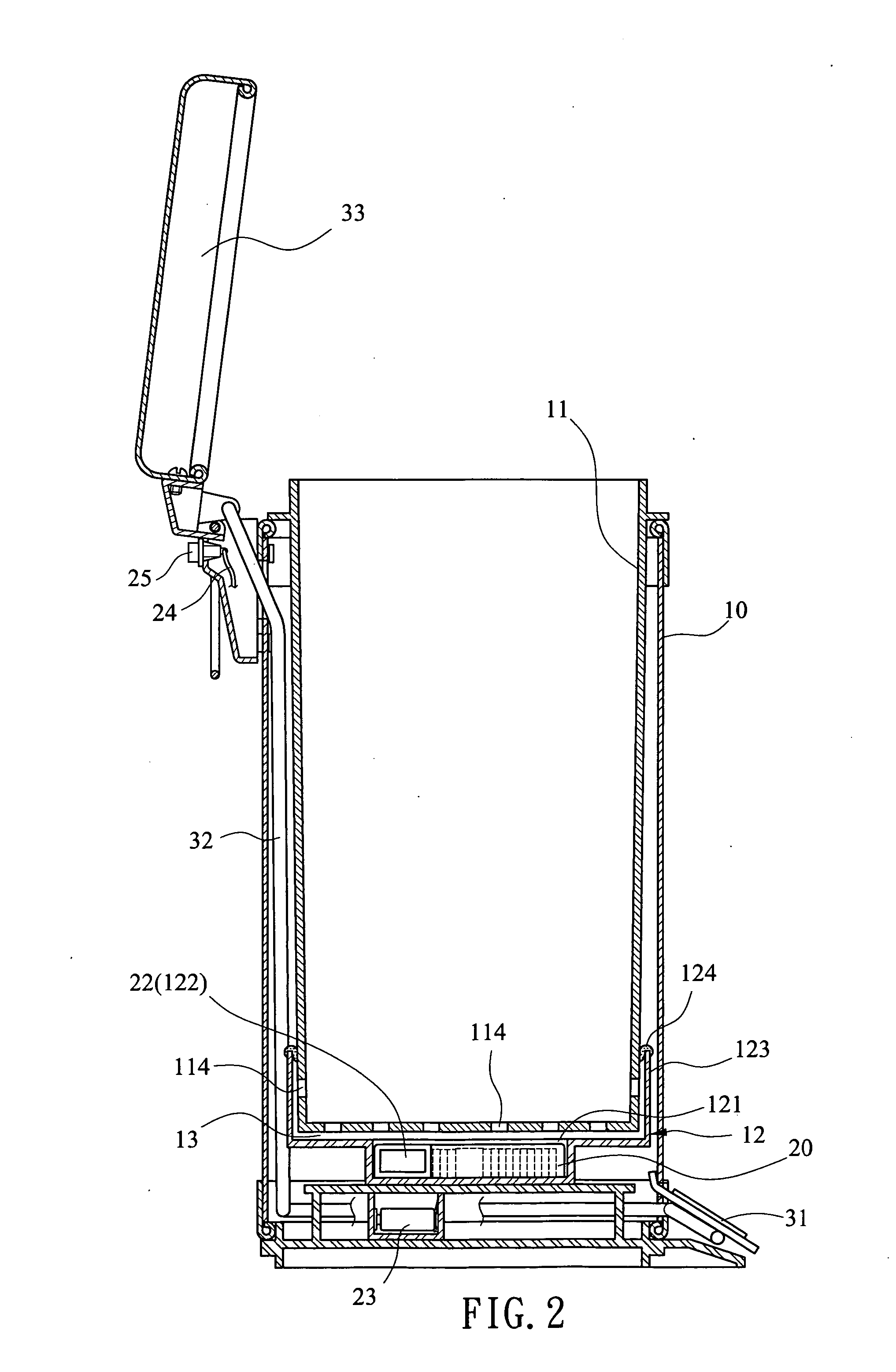

Trash can with function of sucking litterbag

InactiveUS20060175336A1Disposition is simplifiedLarge containersRefuse receptaclesAir pumpEngineering

A trash can with function of sucking litterbags having a plurality of intake hole arranged surrounding the lower part or bottom side thereof. The intake holes are connected to a closed space with an air pump therein for expelling air into a vacuum status so as to make the litterbag inside be sucked by the intake holes. When a litterbag is disposed into the trash can, the opening of the litterbag is arranged on the edge of the opening of the trash can. Then the bottom of the litterbag is pressed down to the bottom of the trash can and the air pump is turned on to make the intake holes adsorb the litterbag. Thus the litterbag is spread out completely on the bottom of the trash can so that the disposition of the litterbag is simplified and the litterbag is set down more properly.

Owner:WANG LI CHUN

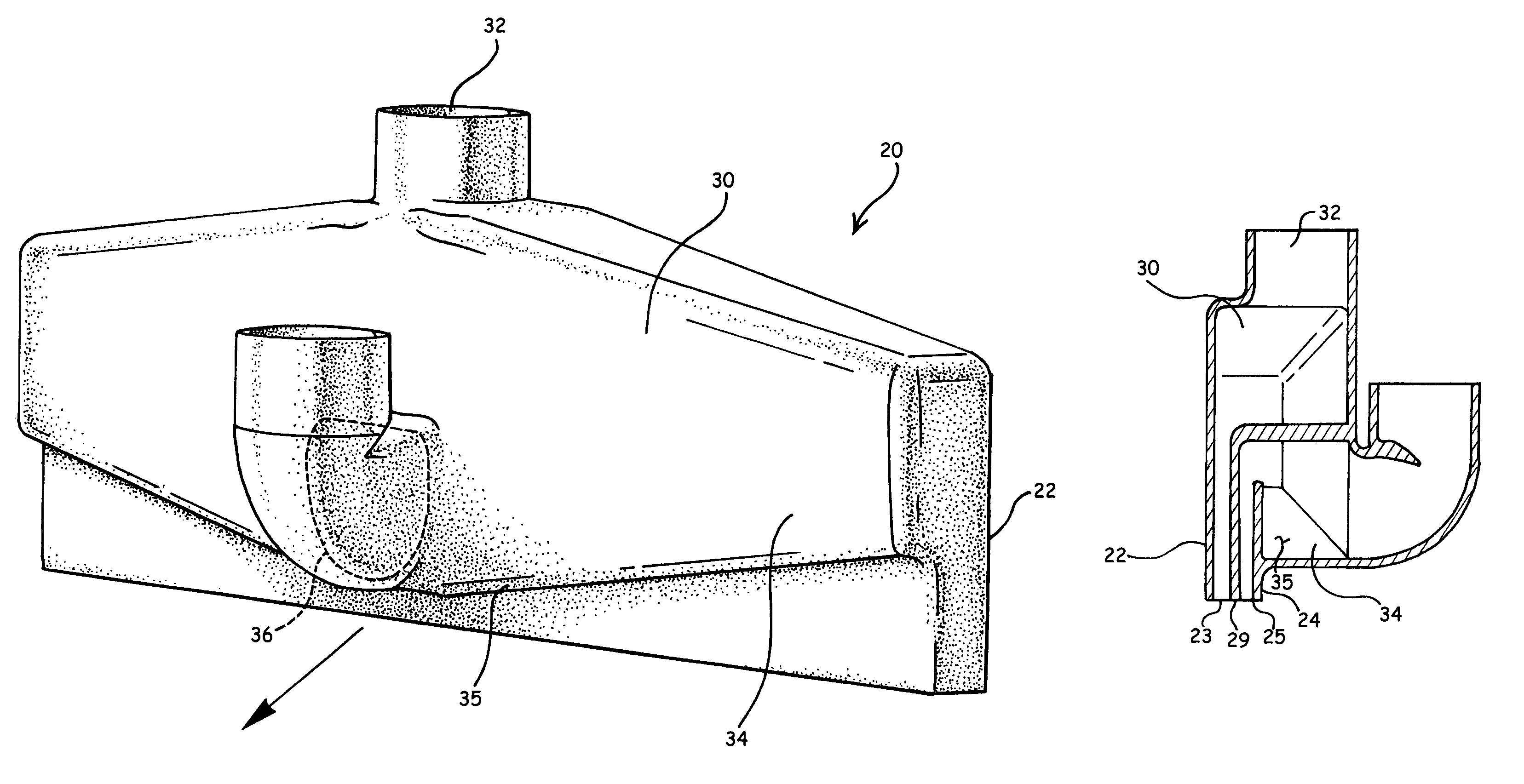

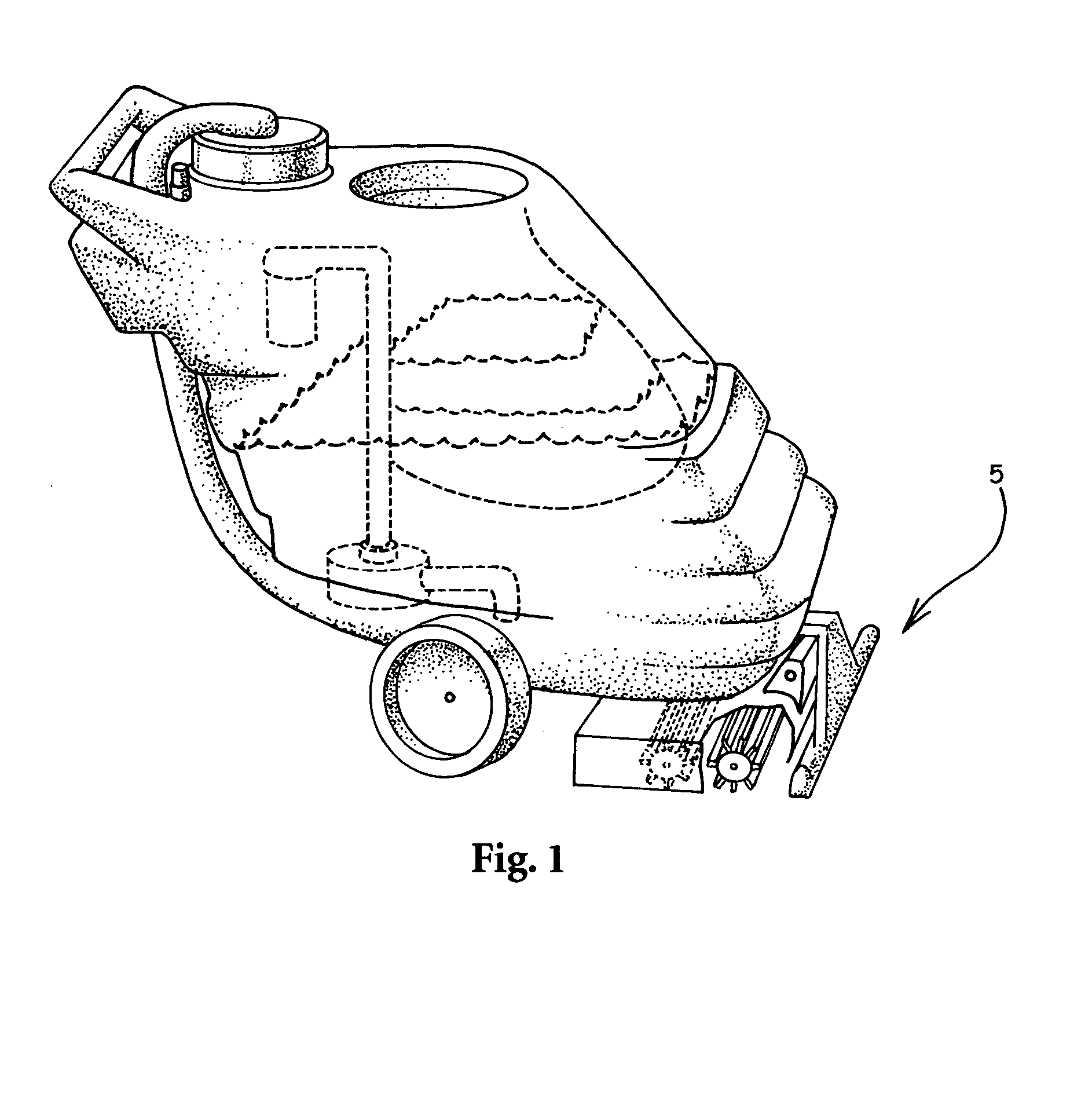

Fluid recovery device

An apparatus and method for extracting soiled cleaning solution from carpets and other surfaces utilizing a low-profile pick-up head is disclosed. The apparatus includes a vacuum chamber or enclosed space positioned in a fluid recovery device to provide a uniform vacuum along the entire width of the device. Also disclosed is a low-profile push-pull fluid recovery device which includes a positive pressure chamber and a vacuum chamber in the push-pull head to distribute positive and vacuum pressures, respectively, along the width of the push-pull head. Methods for using such pick-up heads are also disclosed.

Owner:TENNANT COMPANY

Columnar air moving devices, systems and methods

ActiveUS20050202776A1Minimize rotary componentMinimal lateral dispersionPump componentsLighting and heating apparatusImpellerEngineering

Air moving device includes a housing, an impeller in the housing for generating a downward air flow, and vanes in the housing in close proximity to and a selected distance below the impeller to straighten the air flow. The device produces an air flow that substantially remains in a column over a substantial distance. The method includes producing an air flow that substantially remains in a column over a substantial distance and directing the air flow from the ceiling towards the floor to provide temperature destratification of the air in an enclosed space. The method also includes directing warm air from the ceiling to the floor and storing heat in the floor, apparatus on the floor and ground under the floor. The stored heat is released when the ceiling is cooler than the floor.

Owner:AIRIUS IP HLDG

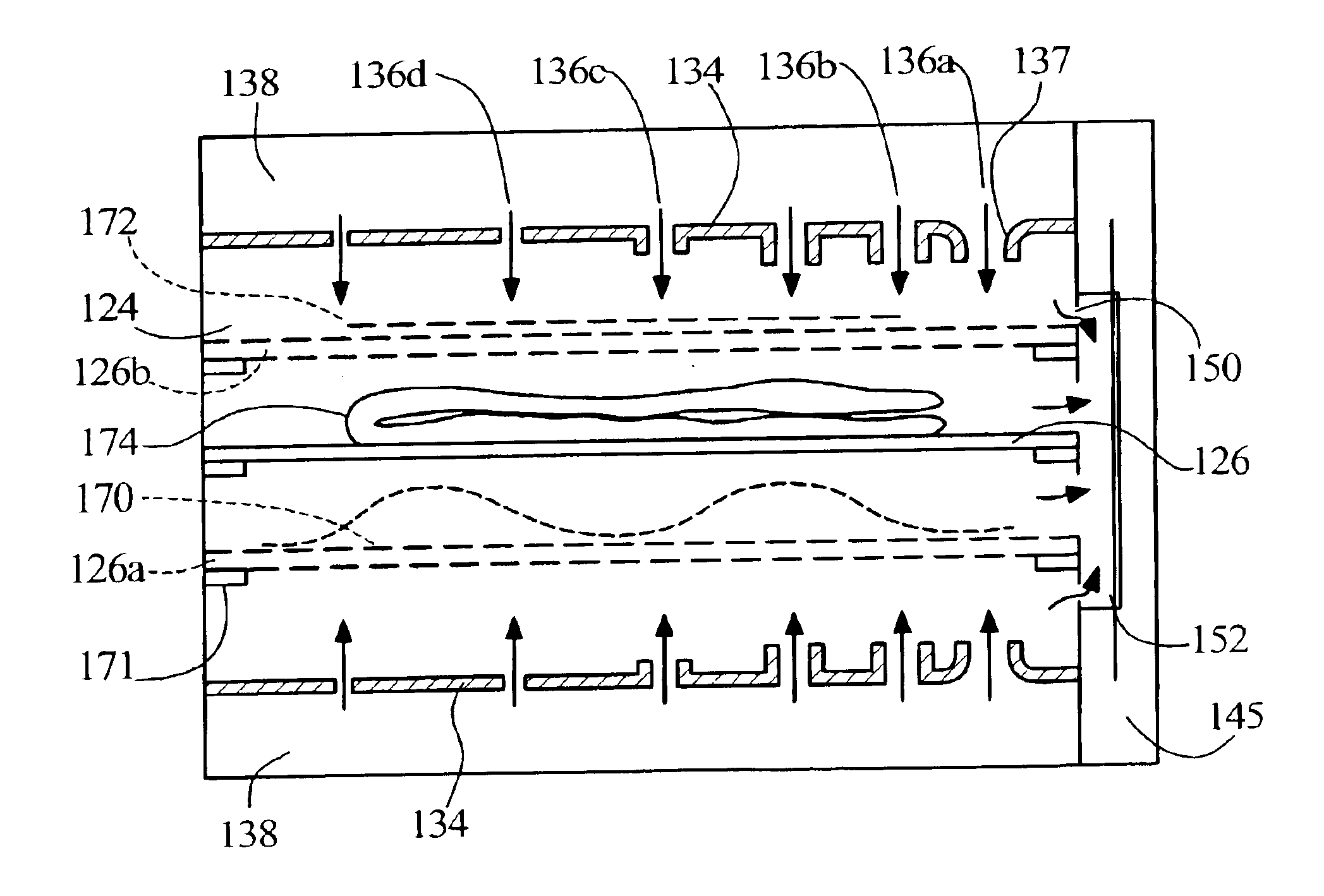

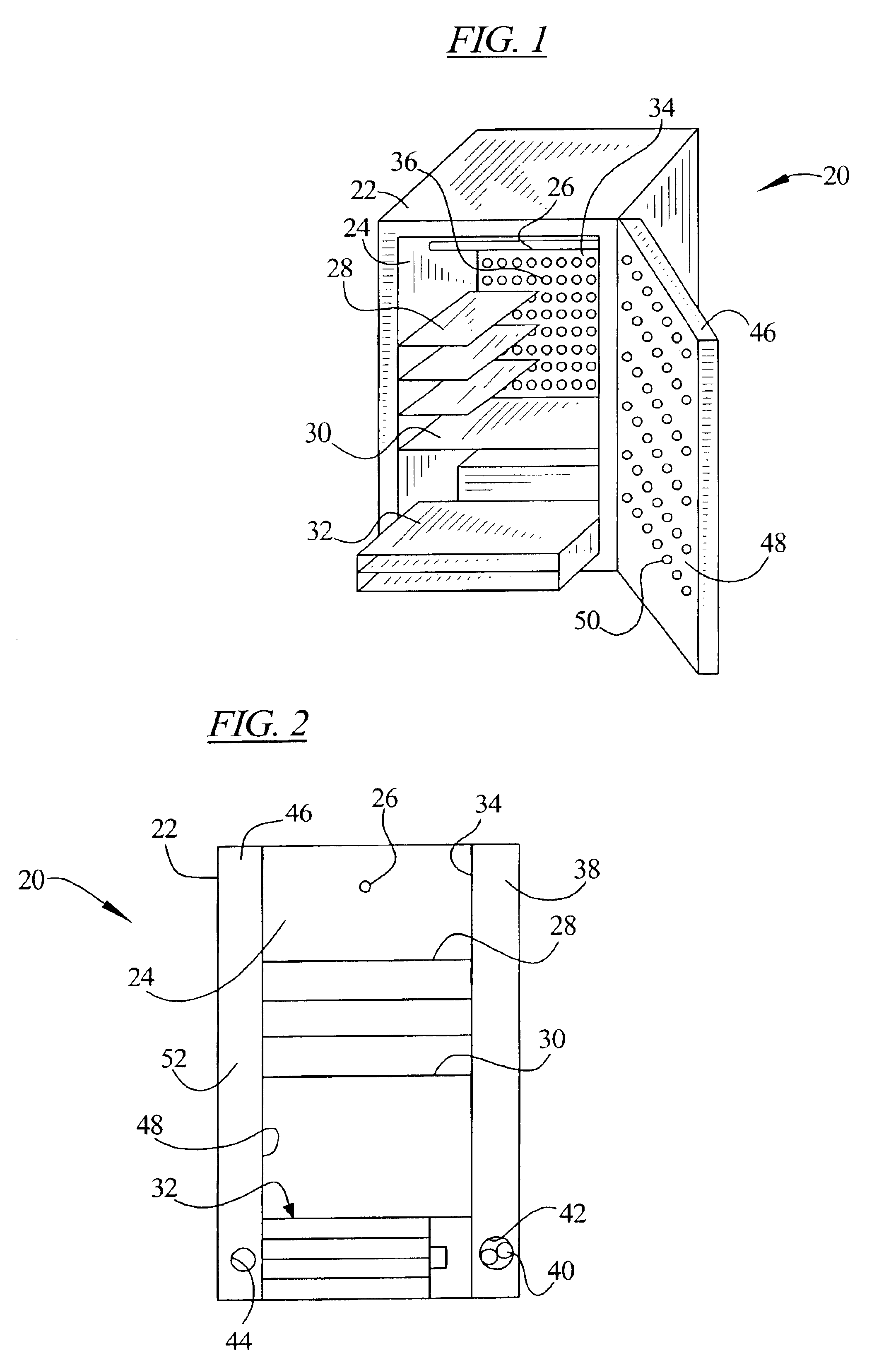

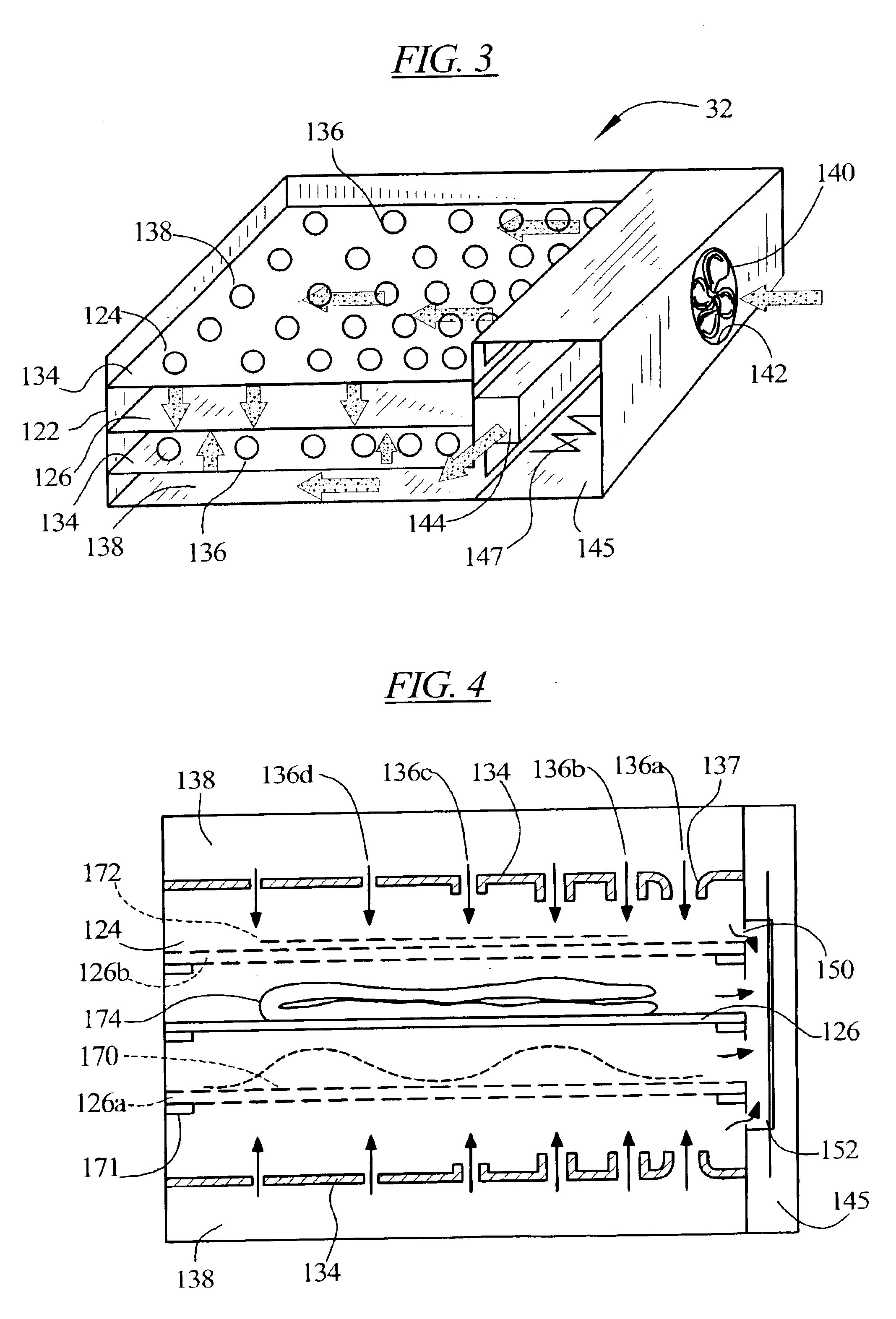

Stationary clothes drying apparatus with jet nozzles

InactiveUS6860032B2Improve performanceIncrease heat transfer rateDrying chambers/containersDrying solid materialsDistributorMaterial Perforation

A stationary dryer, useful as a clothes dryer, is provided comprising a housing enclosing a space and a stationary clothes support located within the space. An air moving device is provided for generating an air flow through the space from an air inlet to an air outlet. An air distributor mechanism comprising a distribution plenum is positioned between the air inlet and the clothes support, with a plenum wall having a plurality of perforations therein. The perforations are sized, shaped and arranged so as to provide jets of air against the clothes support and to equalize an air flow distribution over the clothes support.

Owner:WHIRLPOOL CORP

Skin-Mountable Device in Packaging Comprising Coated Seal Member

The present invention provides an assembly comprising a skin-mountable device (10) with an adhesive mounting surface (31), the device being arranged in a packaging (20) comprising an opening with a surrounding portion and being closed with a seal member (40) releasably attached to the surrounding portion (22), thereby providing a closed space for the device. The seal member has an inner surface releasably attached to the adhesive, the seal member being penetratable by a sterilizing gas, wherein the inner surface is partially coated with a material (42, 44) allowing the seal member to be peeled from the adhesive, yet allows the sterilizing gas to penetrate the seal member. In this way a seal member is provided which to a high degree has two desirable properties: being gas penetratable yet allows the seal member to be peeled from the adhesive surface.

Owner:NOVO NORDISK AS

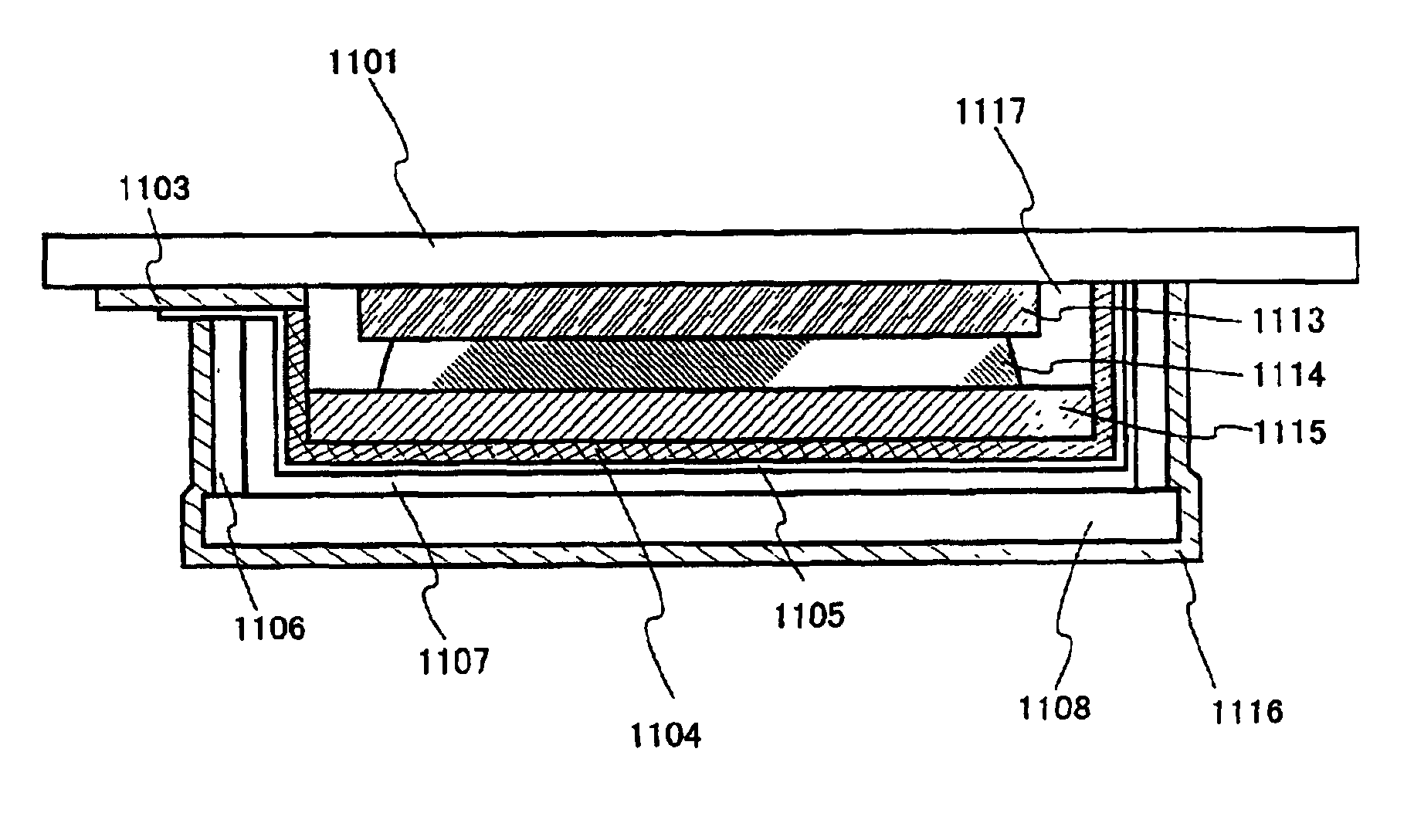

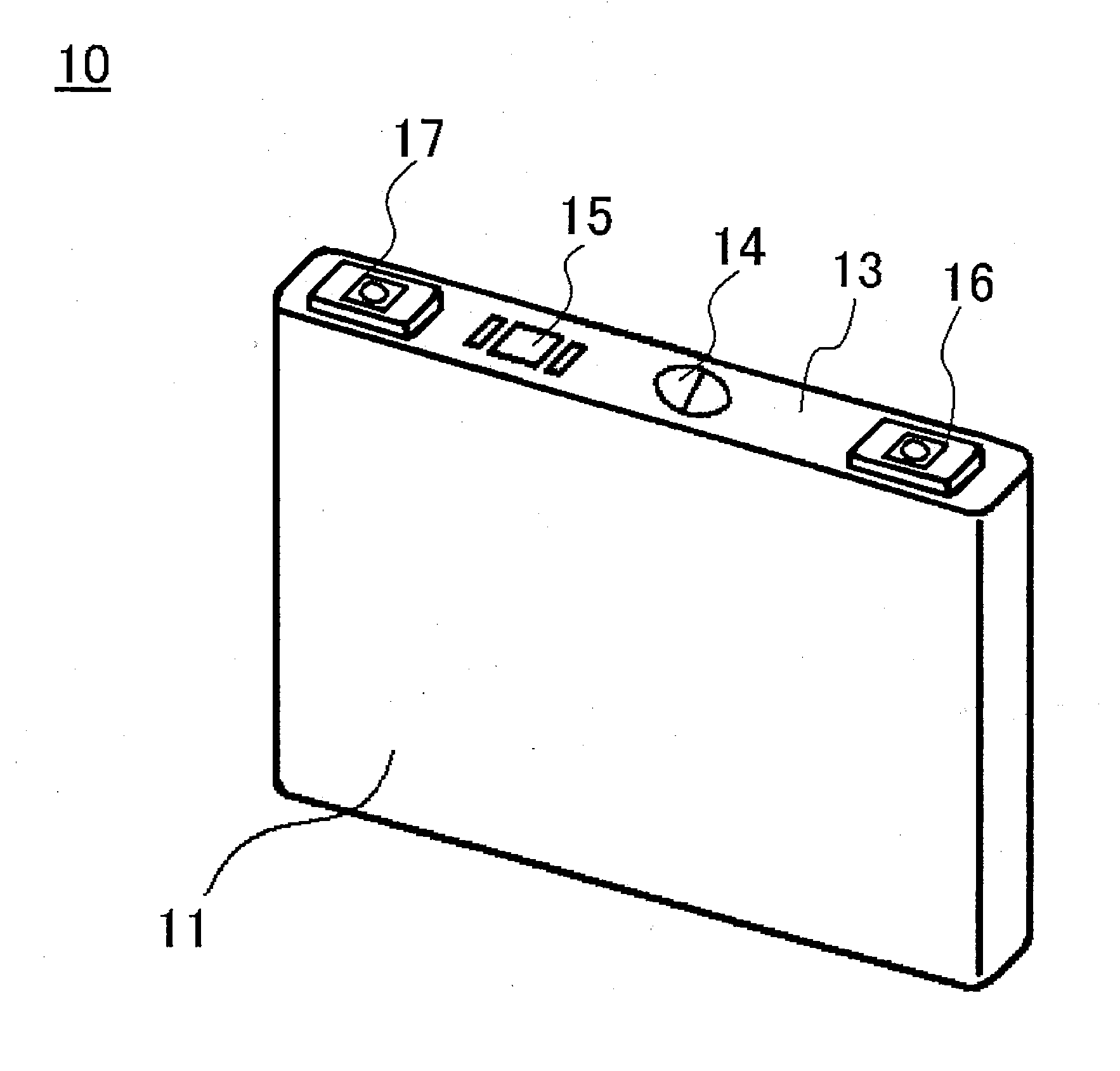

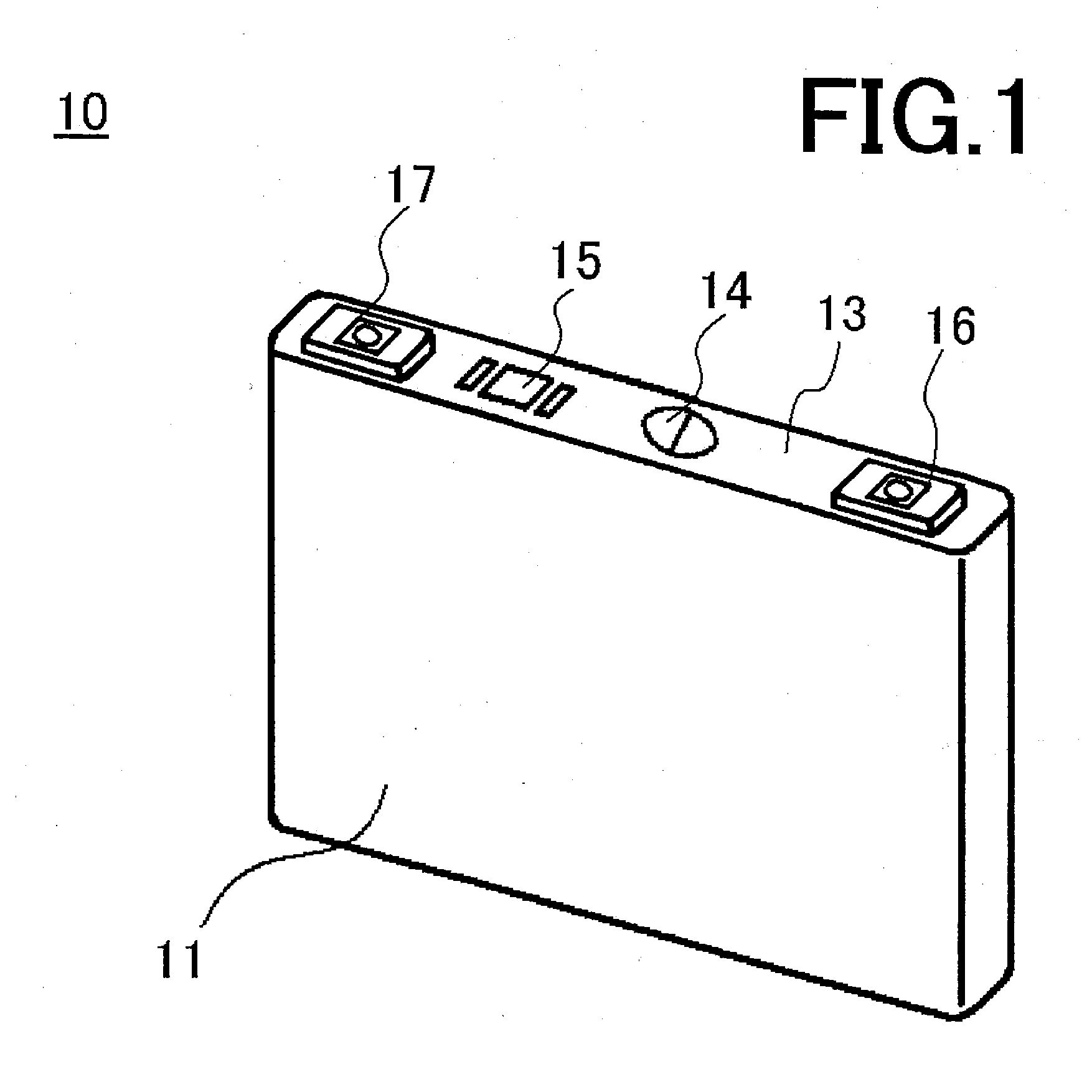

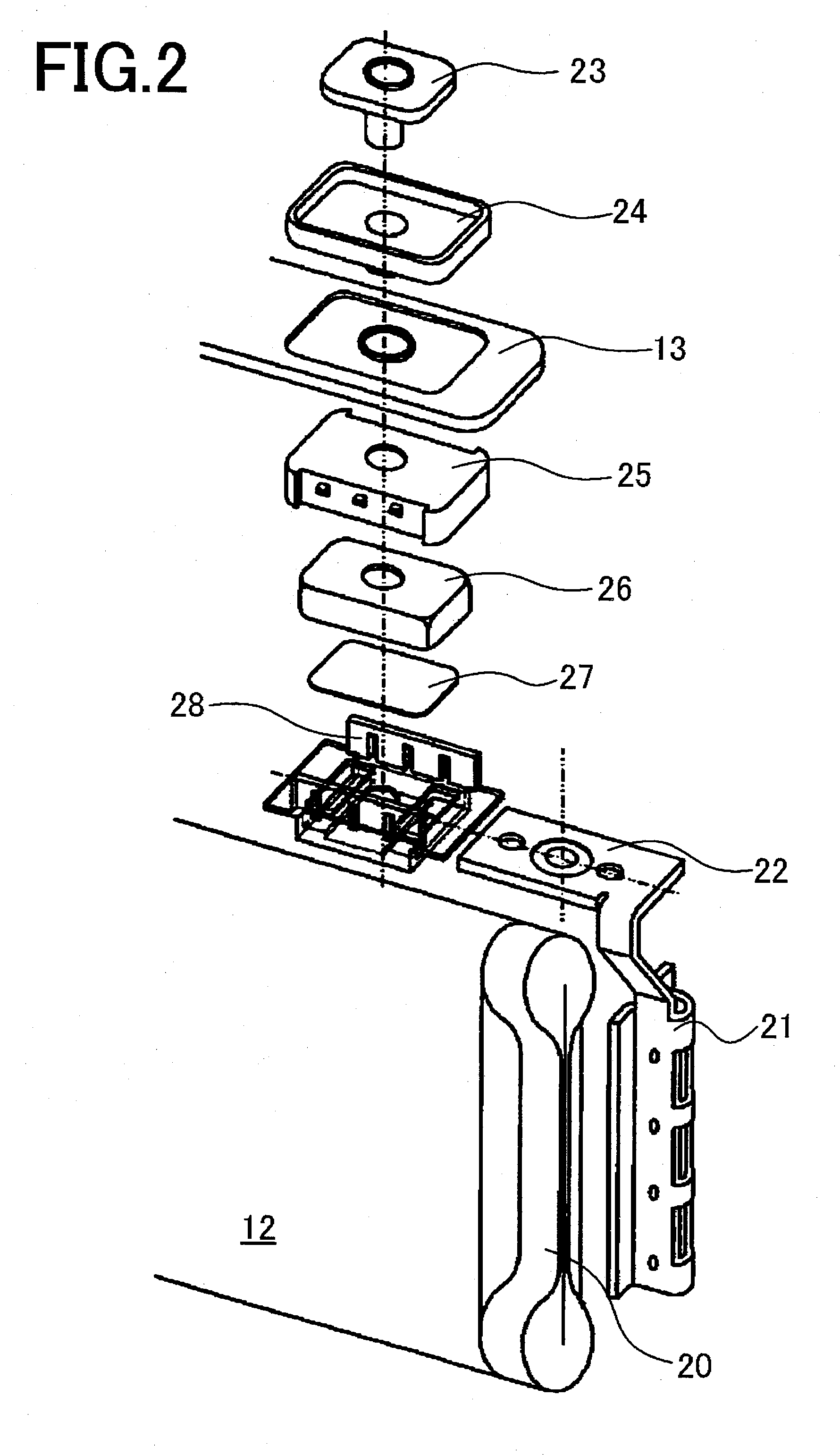

Sealed battery and method for manufacturing the same

ActiveUS20100233529A1Improve reliabilityImprove sealingFinal product manufactureSmall-sized cells cases/jacketsEngineeringElectrolyte

The sealed battery includes a sealing plate 13 sealing a mouth of an outer can, an external terminal 16 attached to the sealing plate 13 and having a connecting terminal 23, and a current interruption mechanism 18 interrupting current in response to pressure increase in the outer can that is installed in a conductive pathway electrically connecting the connecting terminal 23 and an electrode assembly. In the connecting terminal 23, a through-hole 23b continuing to the space on the current interruption mechanism 18 at the side corresponding to the outside of the battery is formed. The through-hole 23b is sealed with a terminal stopper 30 made of an elastic member so as to form a closed space between the terminal stopper 30 and current interruption mechanism 18. An electrolyte or washing solution hardly enters the current interruption mechanism during the manufacture can be provided.

Owner:SANYO ELECTRIC CO LTD

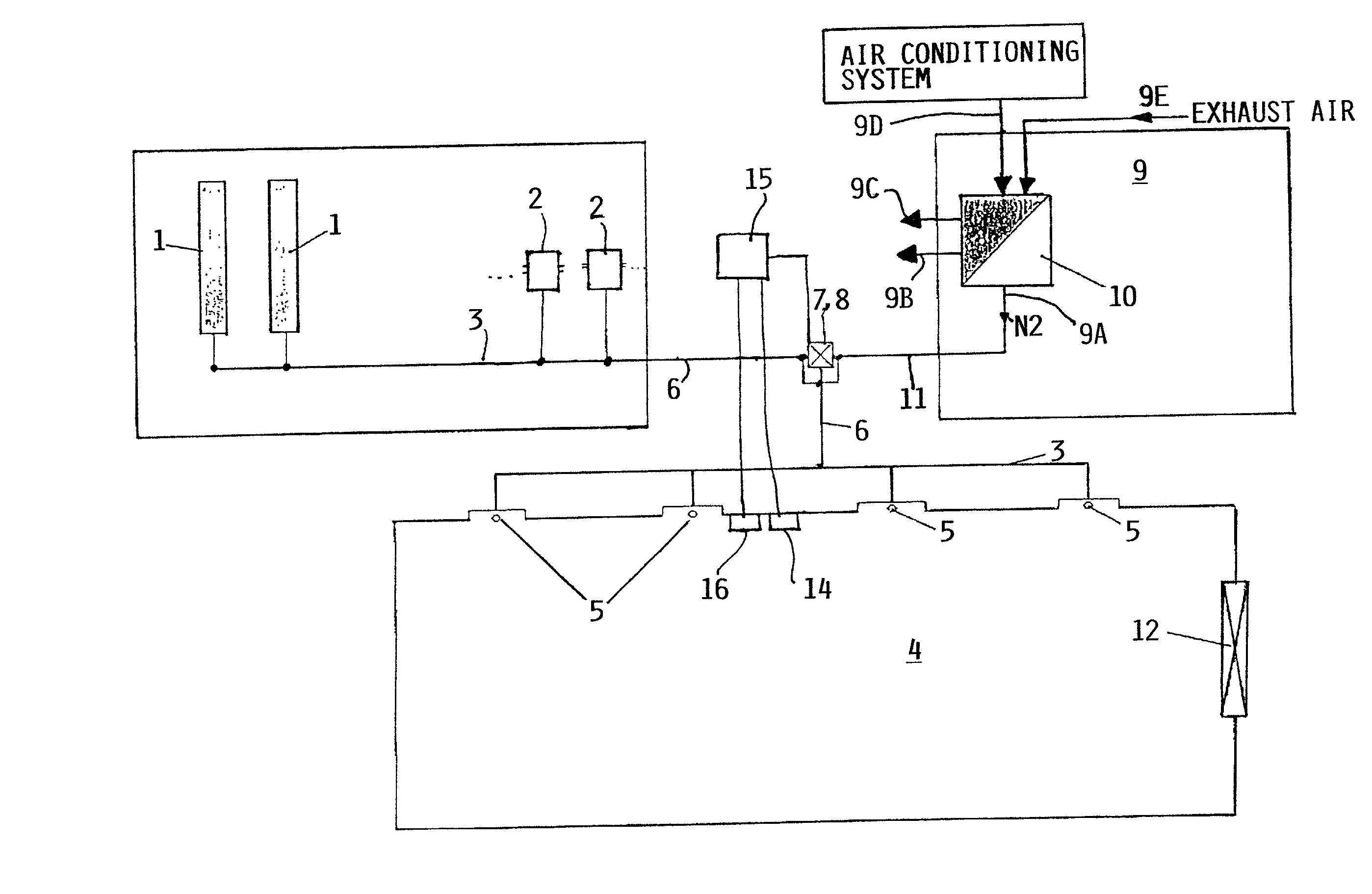

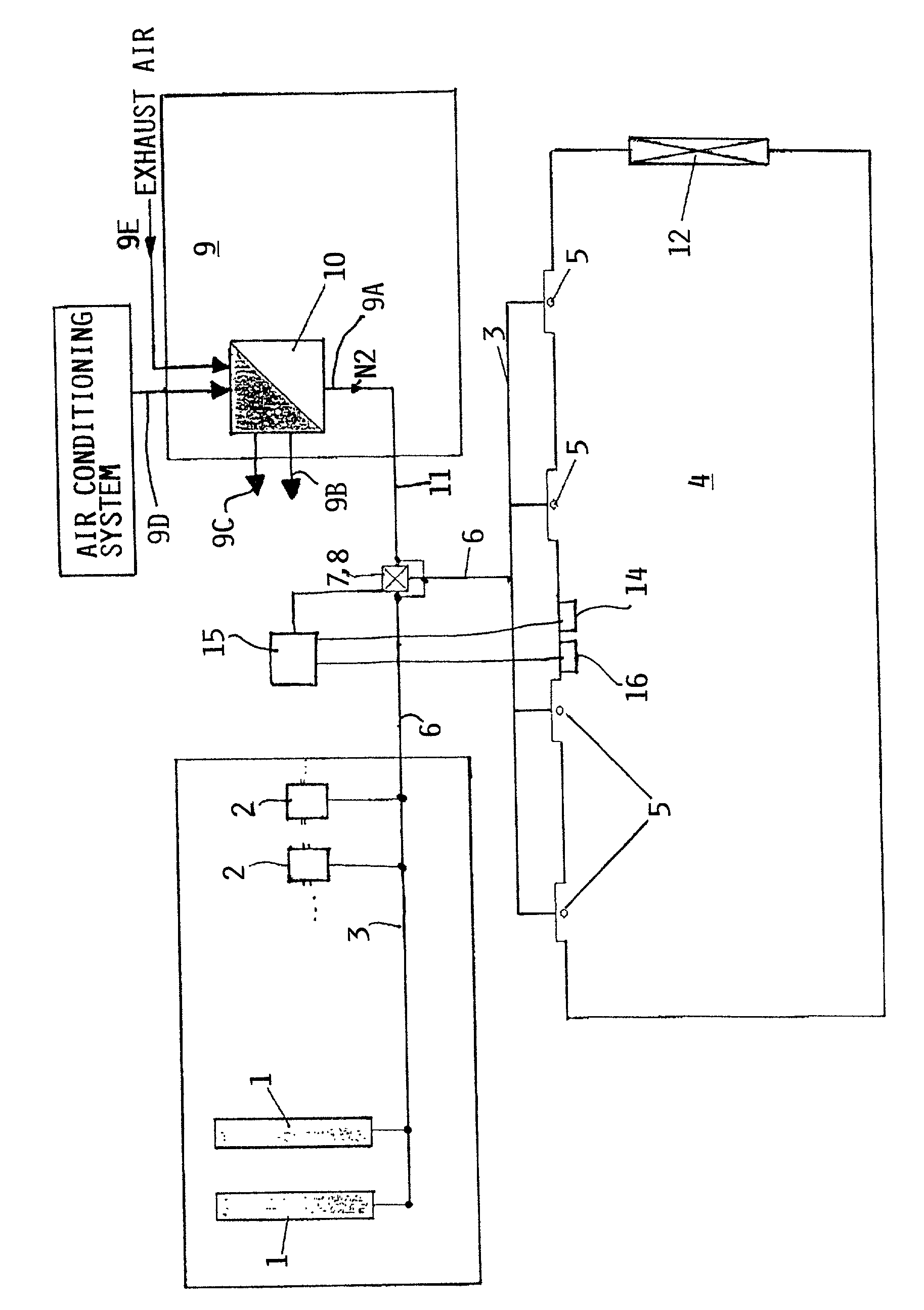

Method and system for extinguishing fire in an enclosed space

InactiveUS20020070035A1Reduce oxygen concentrationImprove concentrationAir-treatment apparatus arrangementsSpraying apparatusHigh rateNitrogen

A system for suppressing fire in an enclosed space, e.g. an aircraft cabin or freight compartment, includes nitrogen tanks and / or generators to rapidly supply a limited quantity of nitrogen with a high flow rate, and a membrane system to supply an essentially unlimited quantity of nitrogen at a lower supply rate for a long duration. The membrane system includes a selectively permeable membrane that separates nitrogen gas from ambient environmental air that is supplied into the membrane system. Once a fire is detected, nitrogen is supplied from the nitrogen gas tanks and / or generators at a high rate to rapidly increase the nitrogen concentration and establish a reduced oxygen concentration (e.g. 12 vol. %) in the enclosed space. Then, nitrogen is supplied from the membrane system at a reduced rate for a long duration to maintain the reduced oxygen concentration in the enclosed space until the fire is extinguished by oxygen starvation.

Owner:AIRBUS OPERATIONS GMBH

Method for preparing antibacterial air-filtering membrane

InactiveCN102302875AEasy to prepareLow equipment requirementsDispersed particle filtrationFiltration separationAir filterElectrospinning

The invention relates to a method for preparing an antibacterial air-filtering membrane. The method comprises the following steps of: co-mixing and dissolving an antibacterial agent, a polymer, an addition agent and a solvent and obtaining a stable co-mixed solution; or obtaining a uniform fusant through fusing and co-mixing the antibacterial agent and the polymer; and then weaving nanofibers of the co-mixed solution or the fusant on the surface of a non-woven fabric through electrostatic spinning and obtaining the antibacterial air-filtering membrane. The preparation method provided by the invention has the advantages of simplicity, low cost, low requirement for equipment and suitability for scale production; and the product prepared by the method has good long-term antibacterial capability and can be applied to closed spaces with concentrated personnel, such as hospitals, stations and the like and can also be applied to places with lower requirements, such as ordinary families and the like.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com