Trash can with function of sucking litterbag

a technology of trash cans and litterbags, applied in the directions of transportation and packaging, pliable tubular containers, refuse gathering, etc., can solve the problems of troublesome cleaning up garbage outside the litterbag, not easy to spread out the general litterbags, and not so easy to attach closely, etc., to simplify the disposition of the litterbag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

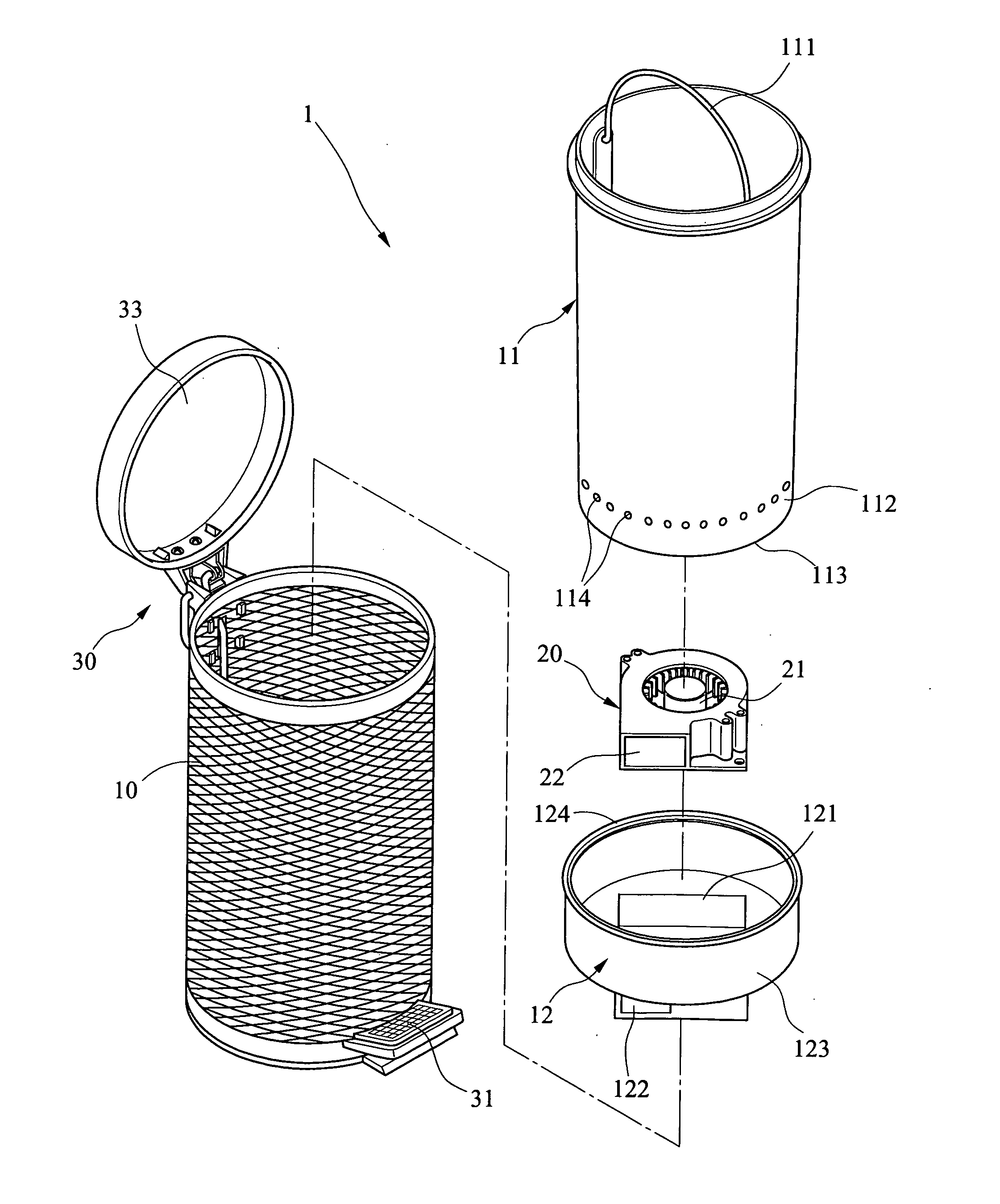

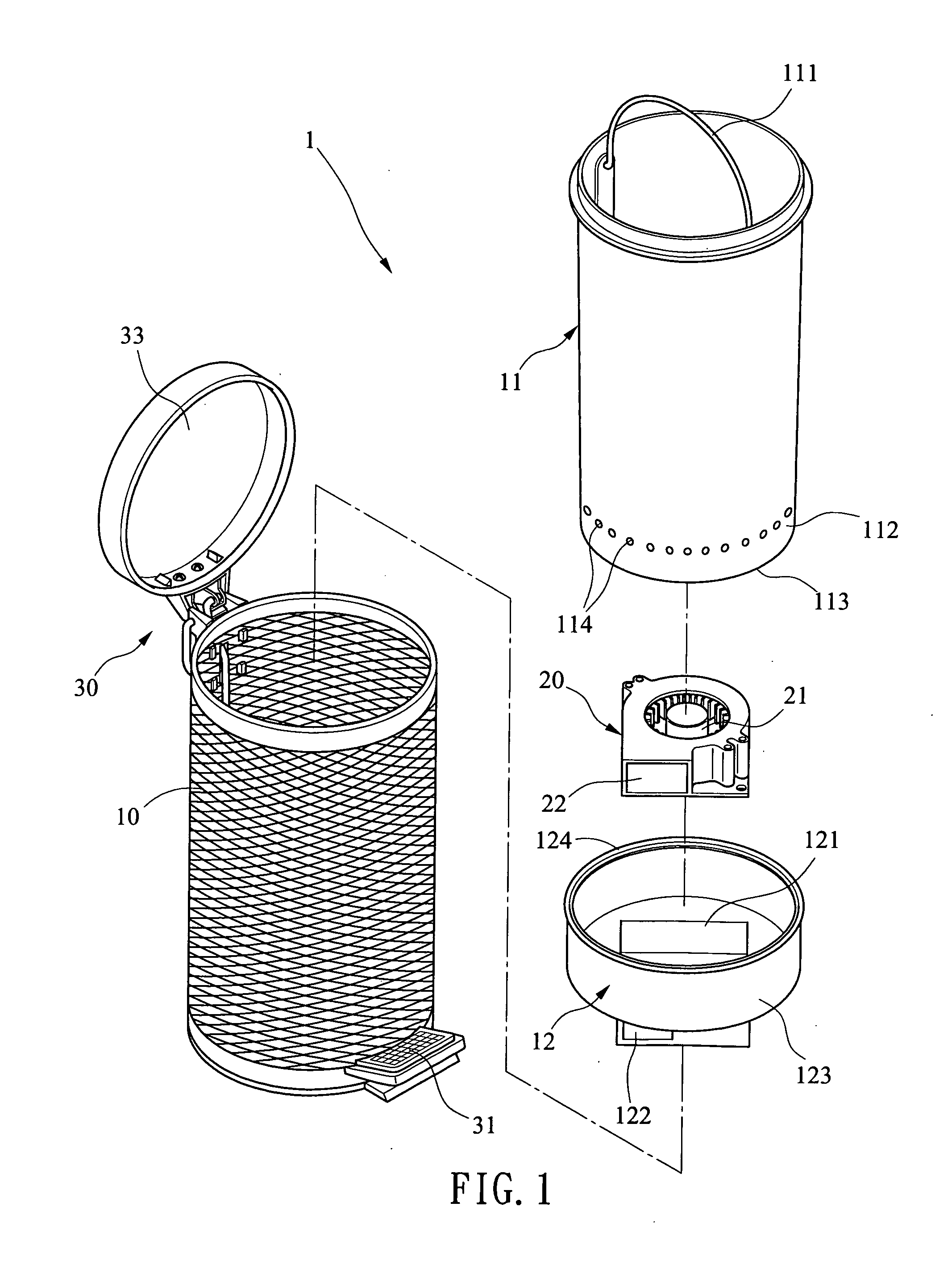

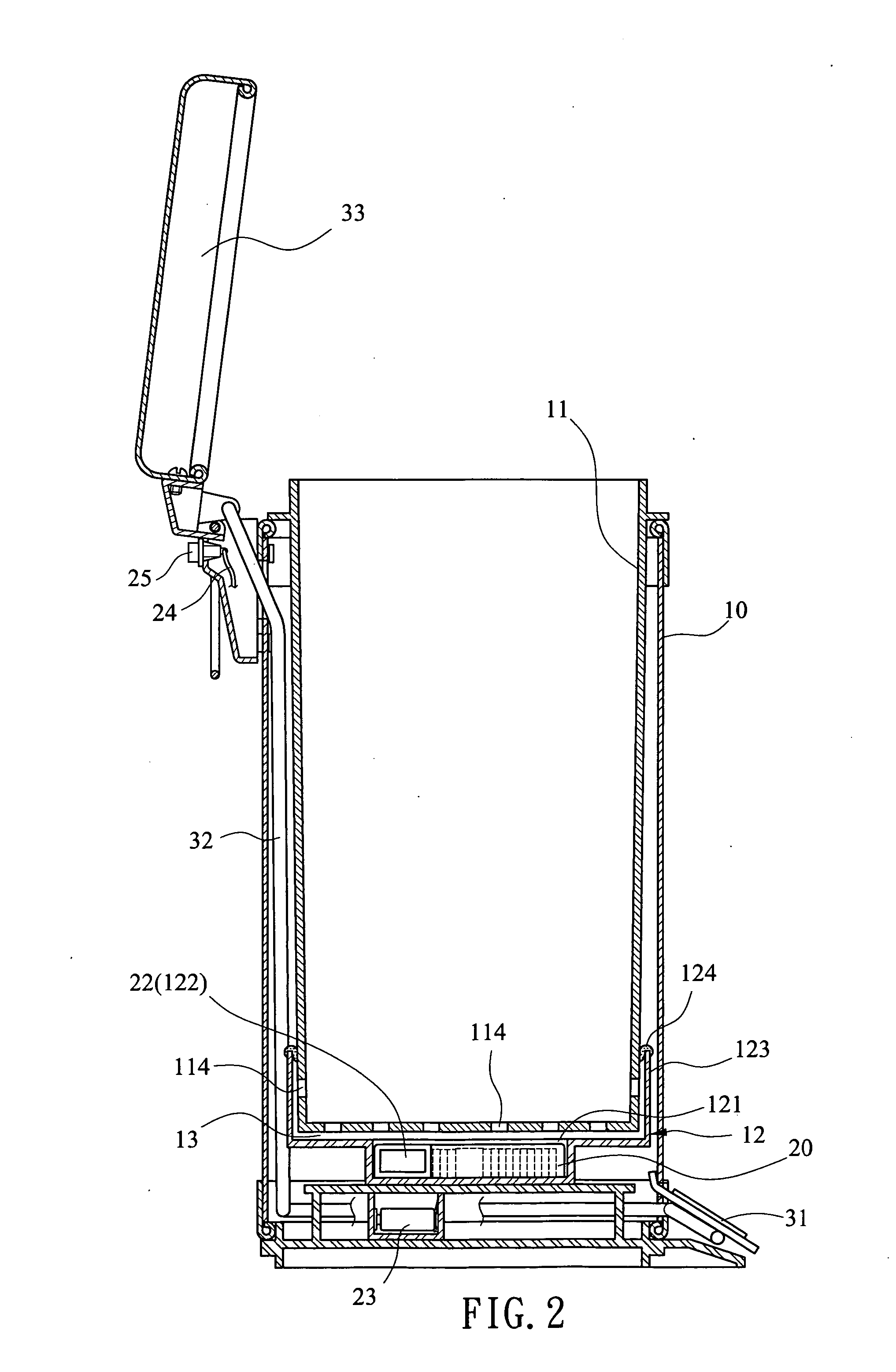

[0015] Refer to FIG. 1, FIG. 2&FIG. 2A, a trash can 1 in accordance with the present invention is improved from a conventional trash can having an outer cylinder 10 and an inner cylinder 11. The space inside the inner cylinder 11 is for accommodating garbage. A handle 111 is pivoted on top of the inner cylinder 11 for easily putting the inner cylinder 11 into the outer cylinder 10 or taking it out. A pedal device for flip-top 30 composed by a pedal 31, a diving rods set 32 and a pivoted top cover 33 is disposed on the outer cylinder 10. In usage, an opening 41 of a litterbag 40 is arranged on the edge of opening of the inner cylinder 11, then the bottom of the litterbag 40 is pressed down and spread out to the bottom of the inner cylinder 11, as shown in FIG. 3.

[0016] The present invention features on that a plurality of intake holes 114 is arranged on the bottom side 113 or surrounding a circular surface 112 of the inner cylinder 11 and is connected with a closed space 13. An air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com