Patents

Literature

2578results about "Linings/internal coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

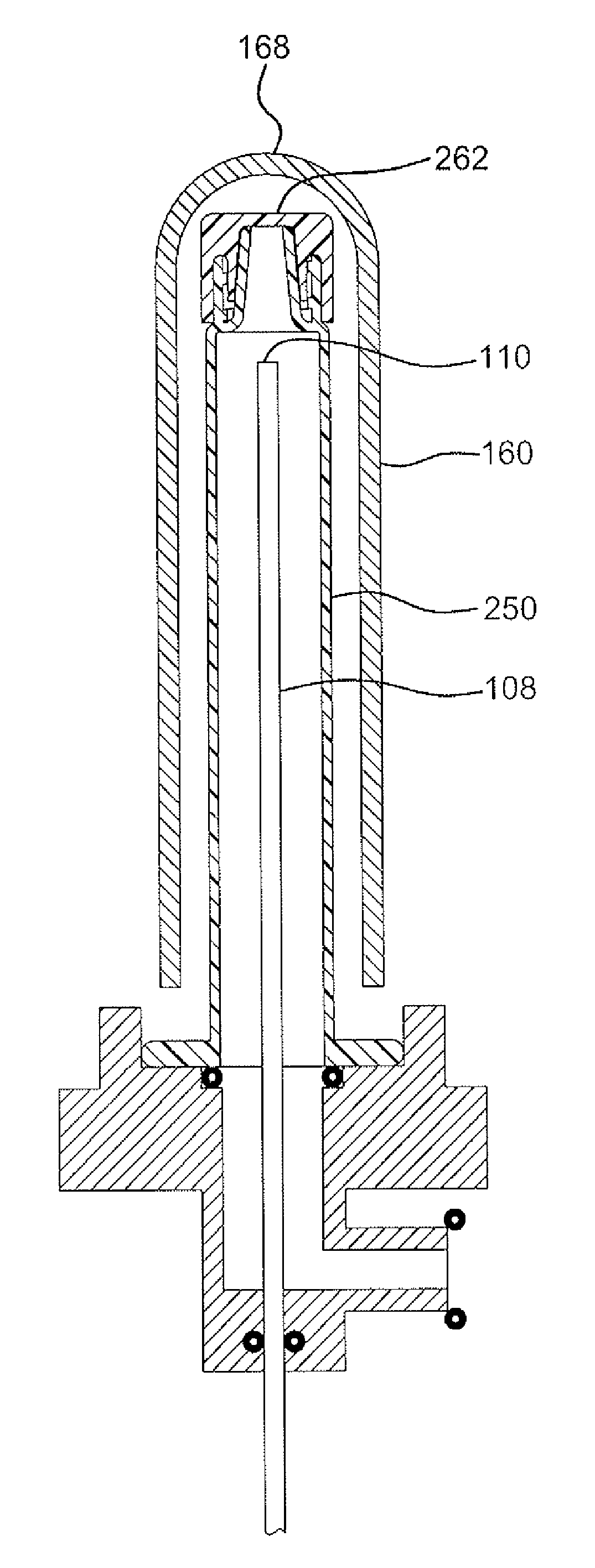

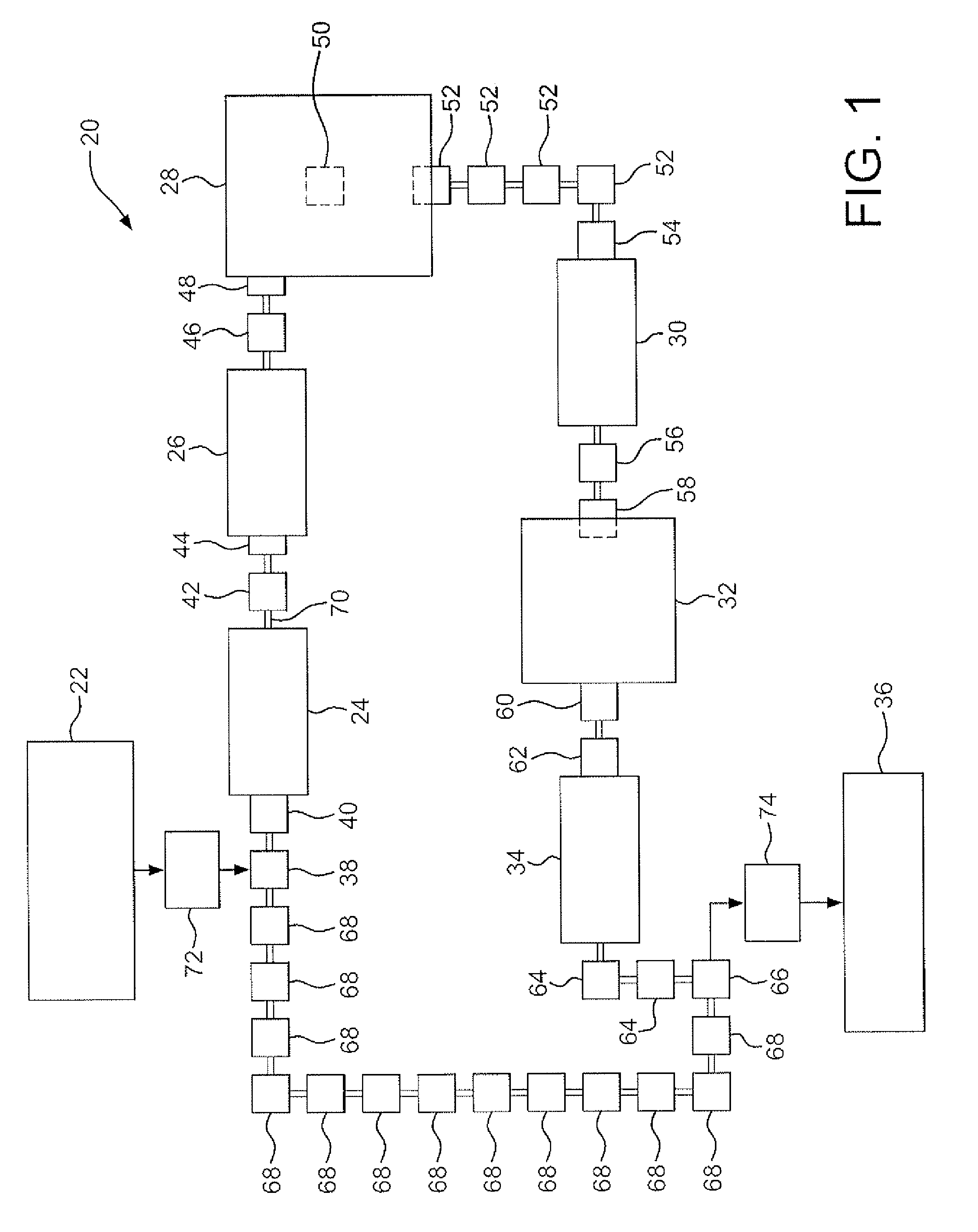

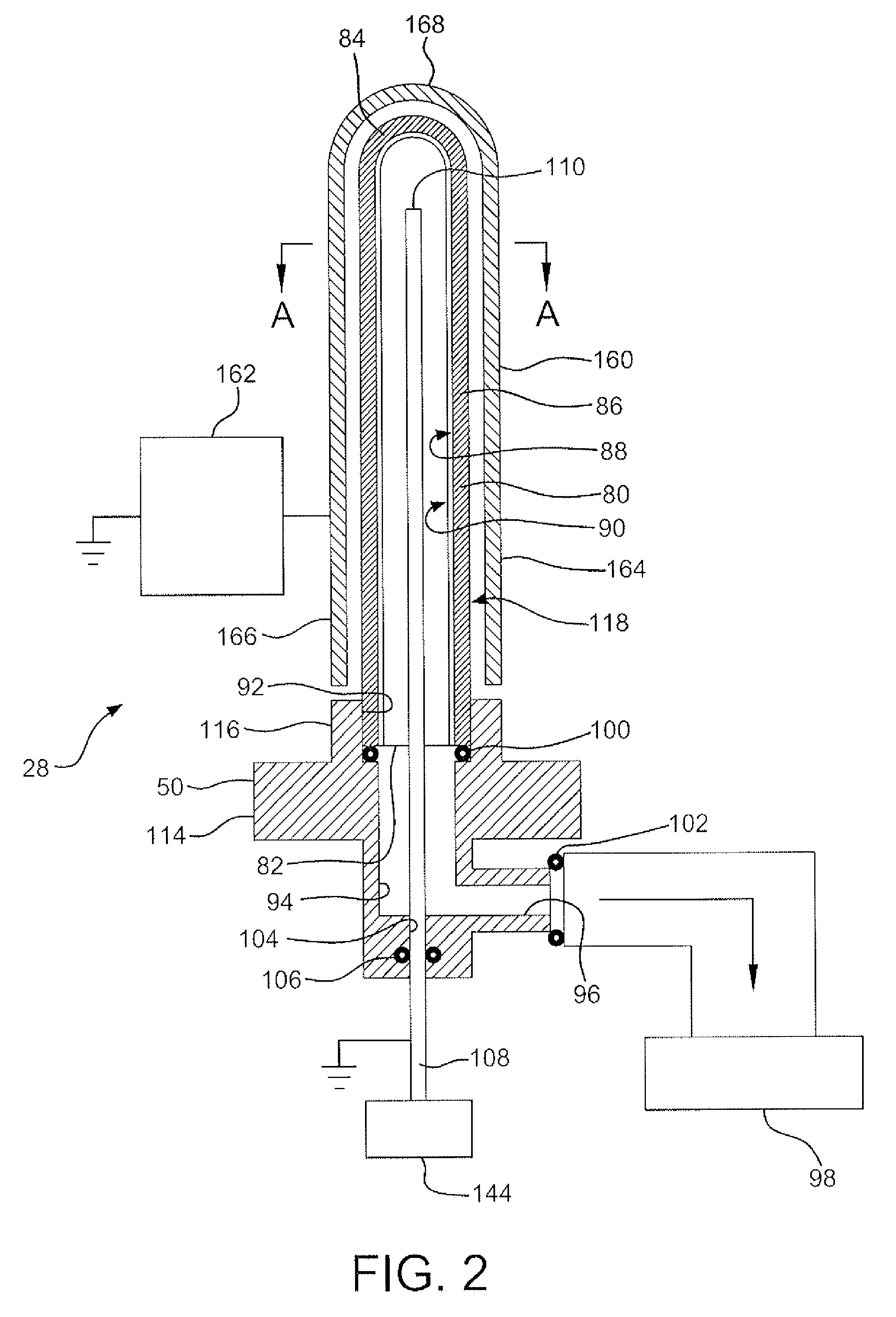

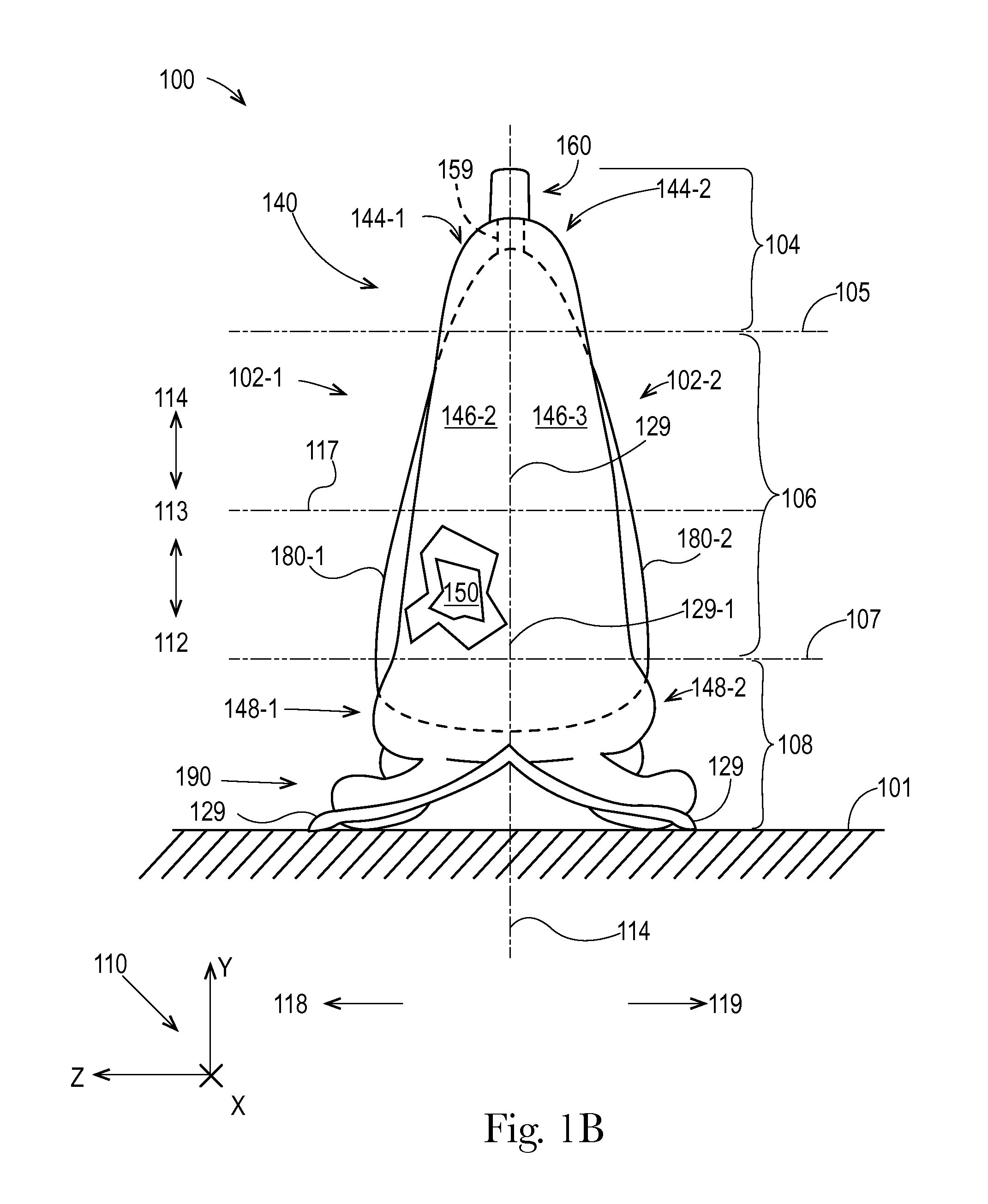

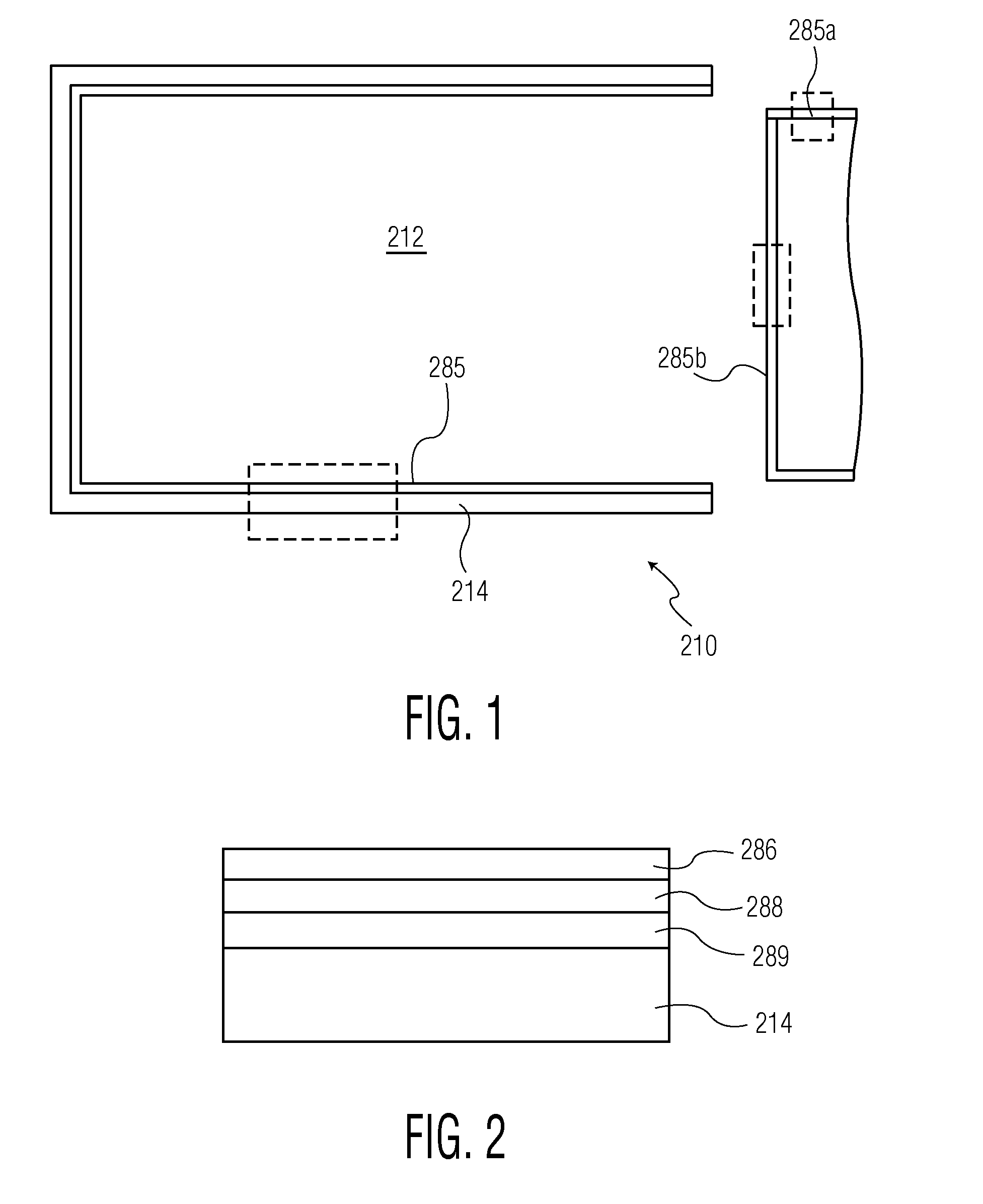

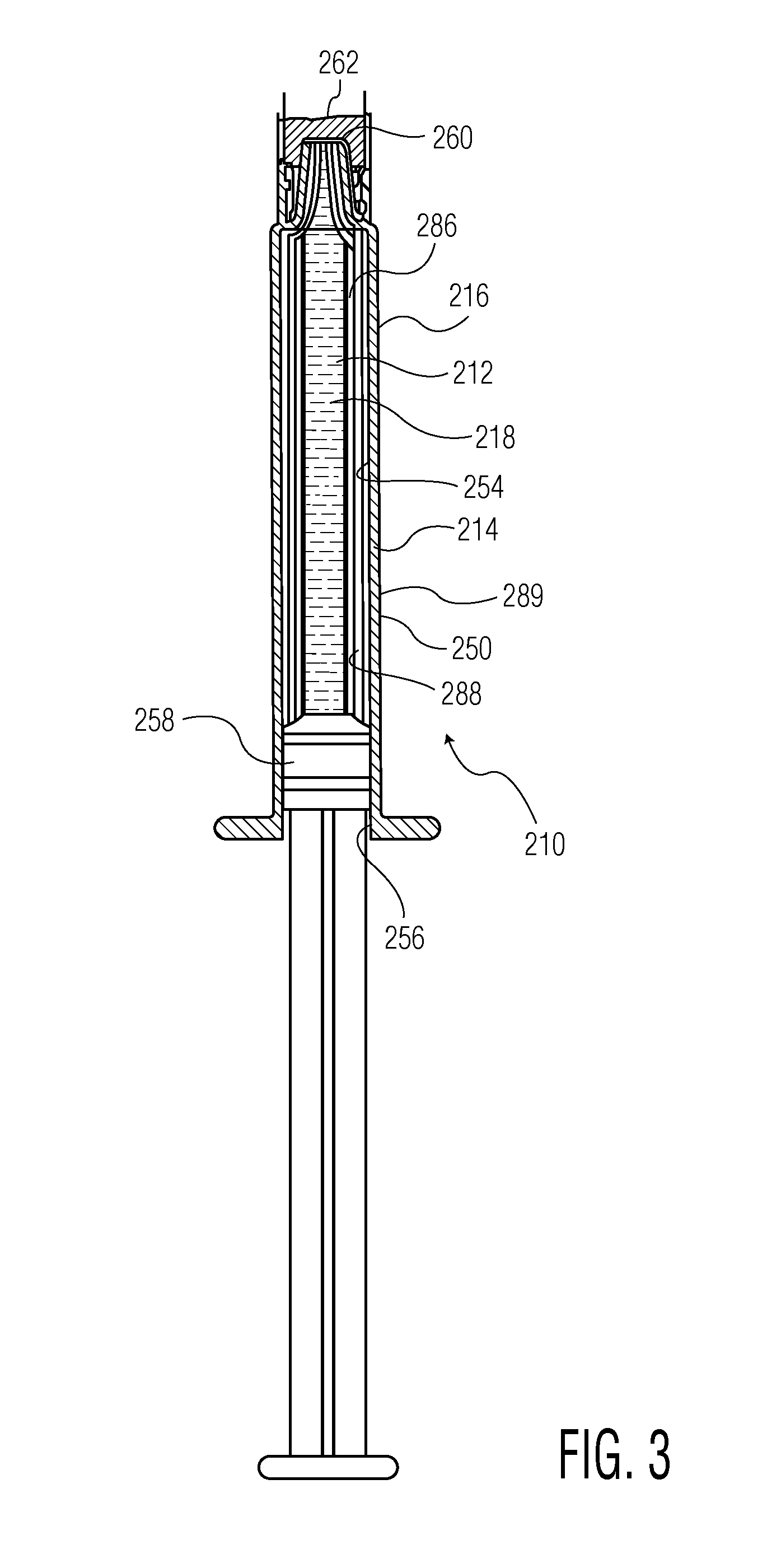

Vessel, coating, inspection and processing apparatus

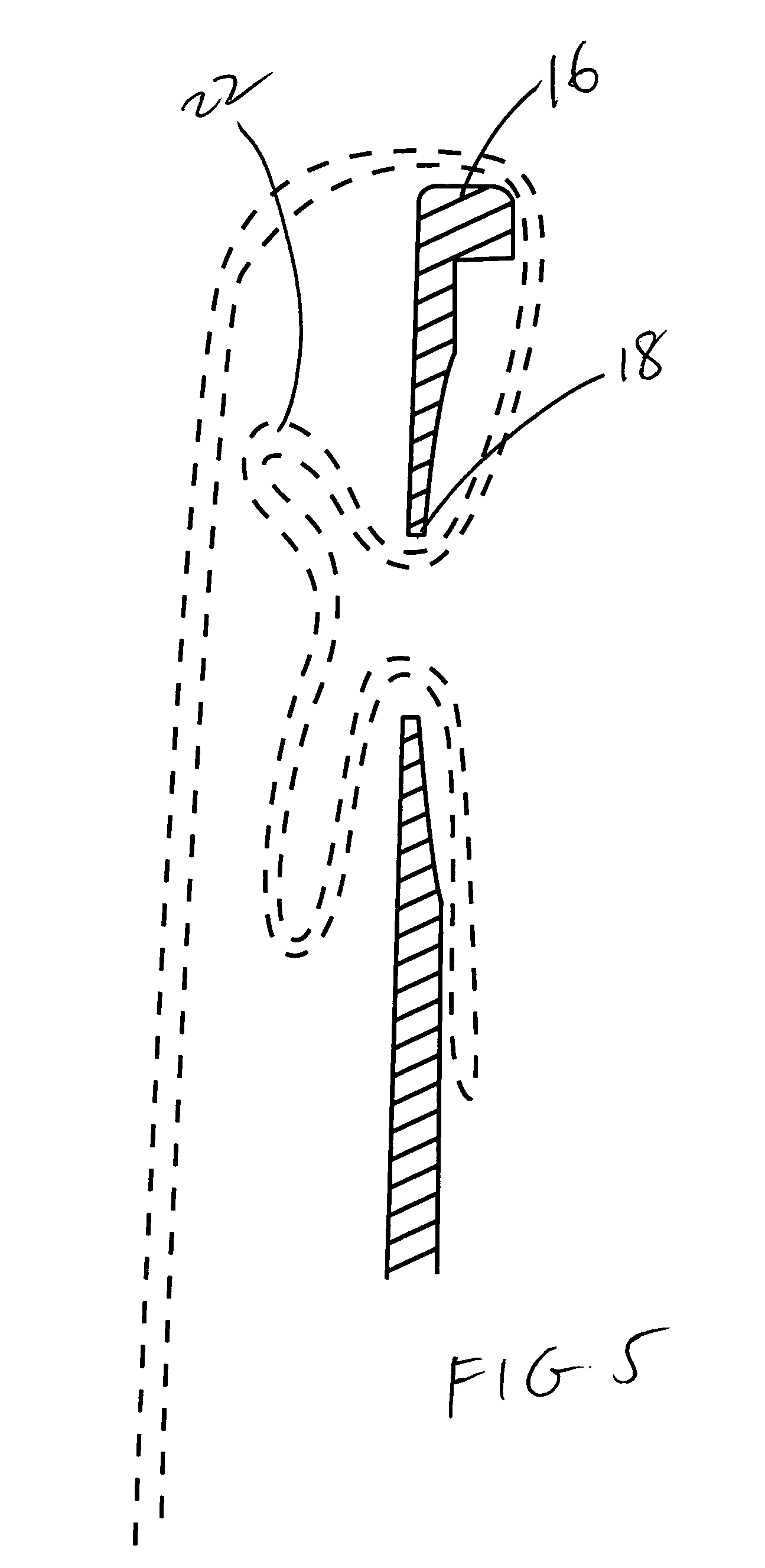

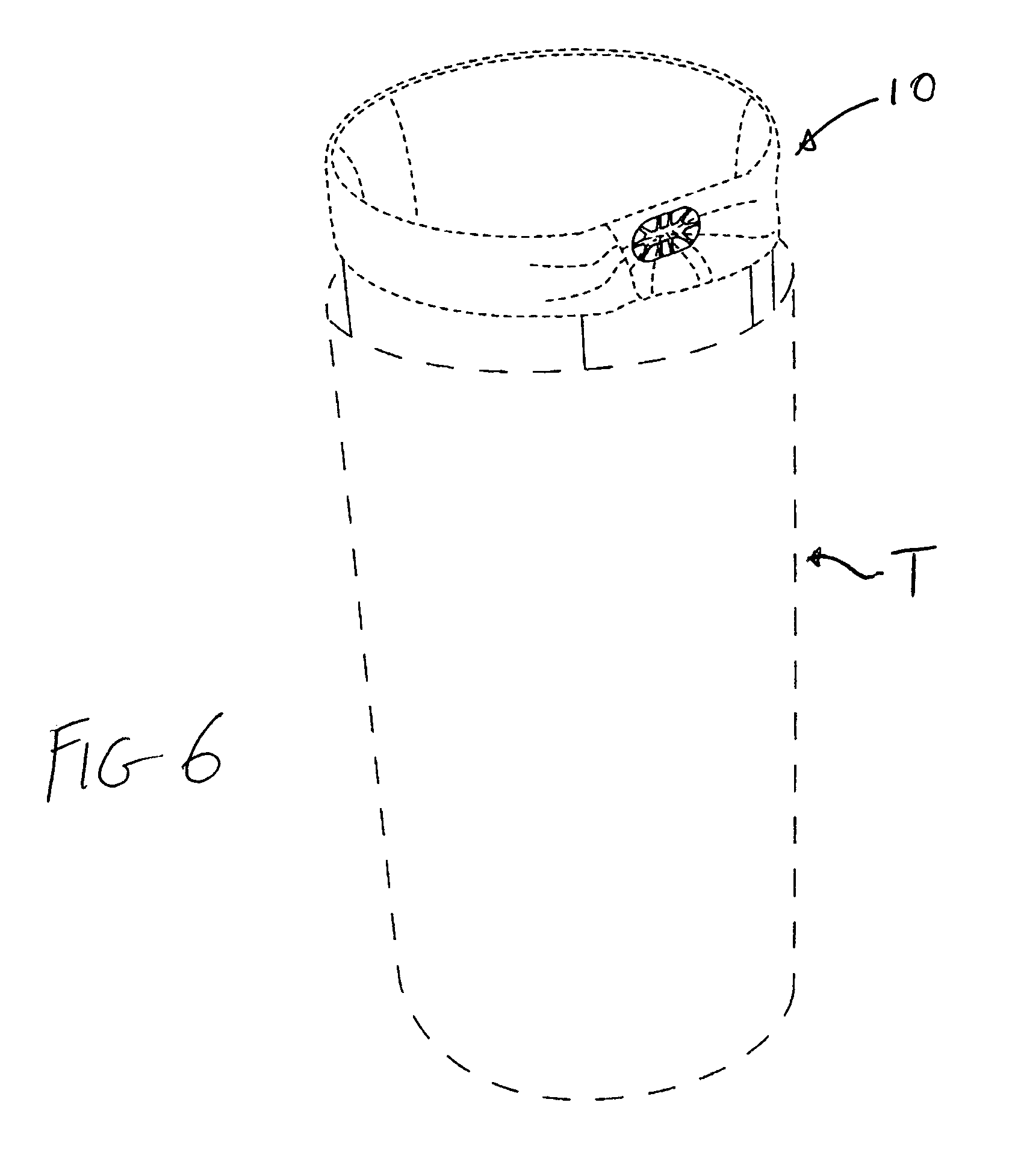

ActiveUS7985188B2Vacuum evaporation coatingSemiconductor/solid-state device manufacturingMarine engineeringProduct gas

Methods for processing a vessel, for example to provide a gas barrier or lubricity, are disclosed. First and second PECVD or other vessel processing stations or devices and a vessel holder comprising a vessel port are provided. An opening of the vessel can be seated on the vessel port. The interior surface of the seated vessel can be processed via the vessel port by the first and second processing stations or devices. Vessel barrier, lubricity and hydrophobic coatings and coated vessels, for example syringes and medical sample collection tubes are disclosed. A vessel processing system and vessel inspection apparatus and methods are also disclosed.

Owner:SI02 MEDICAL PRODS

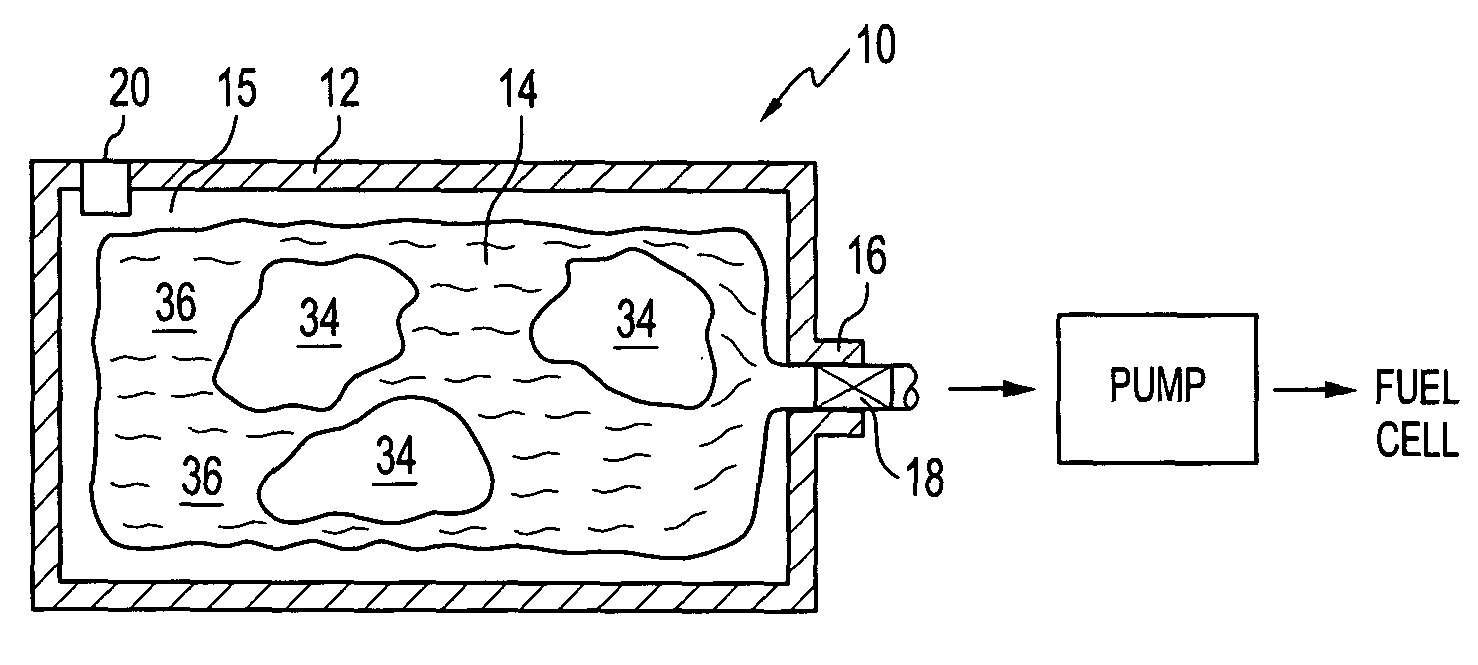

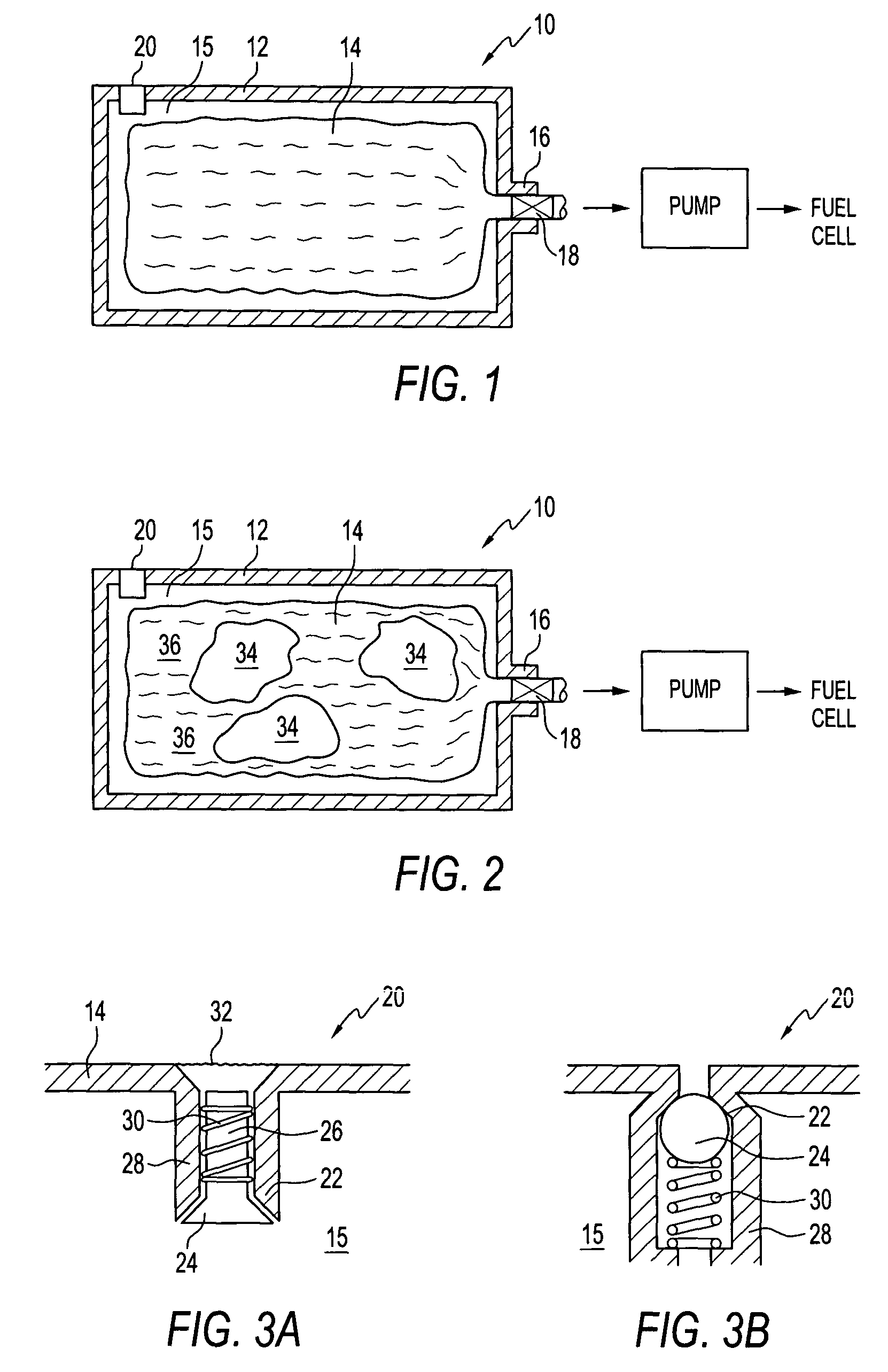

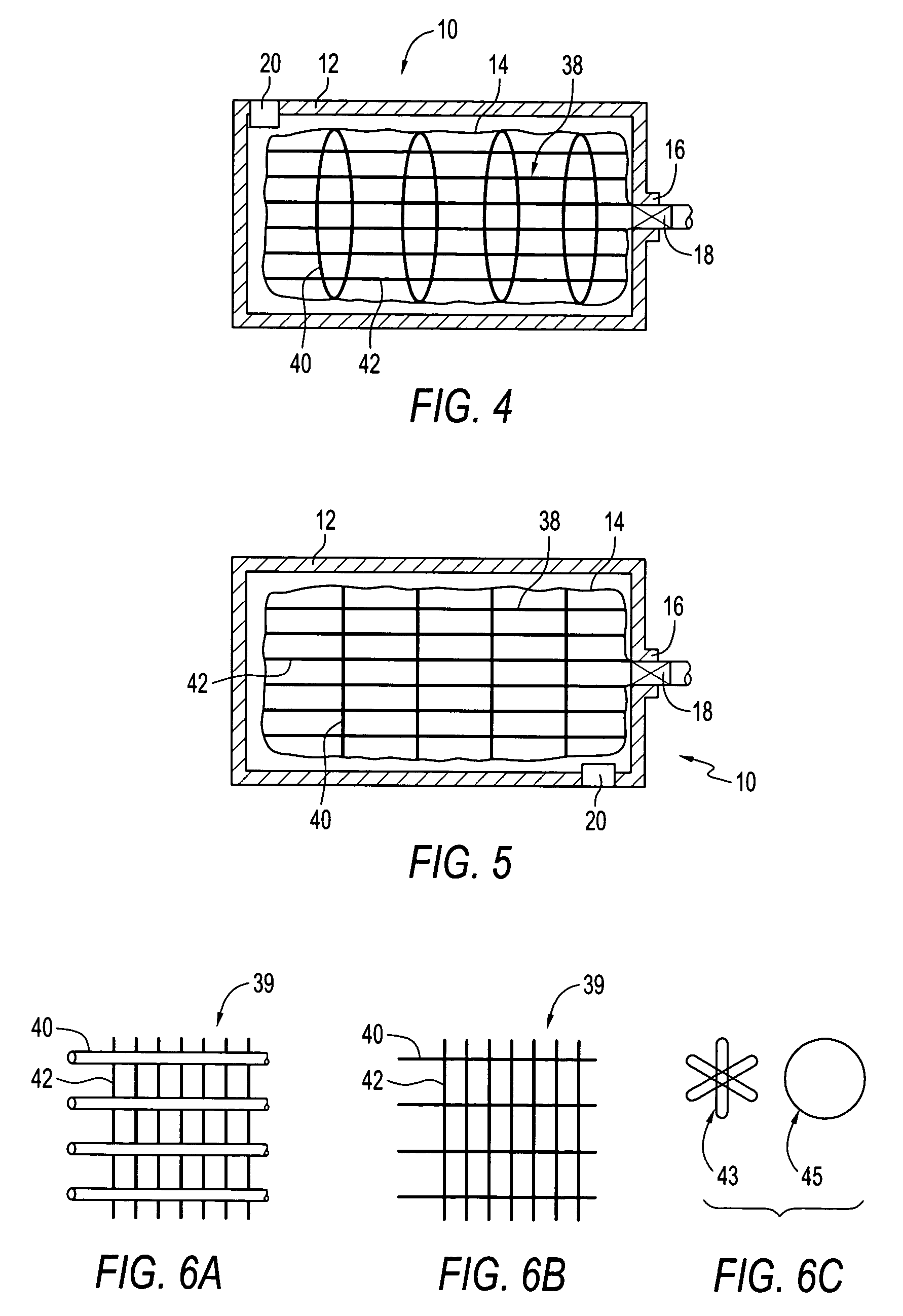

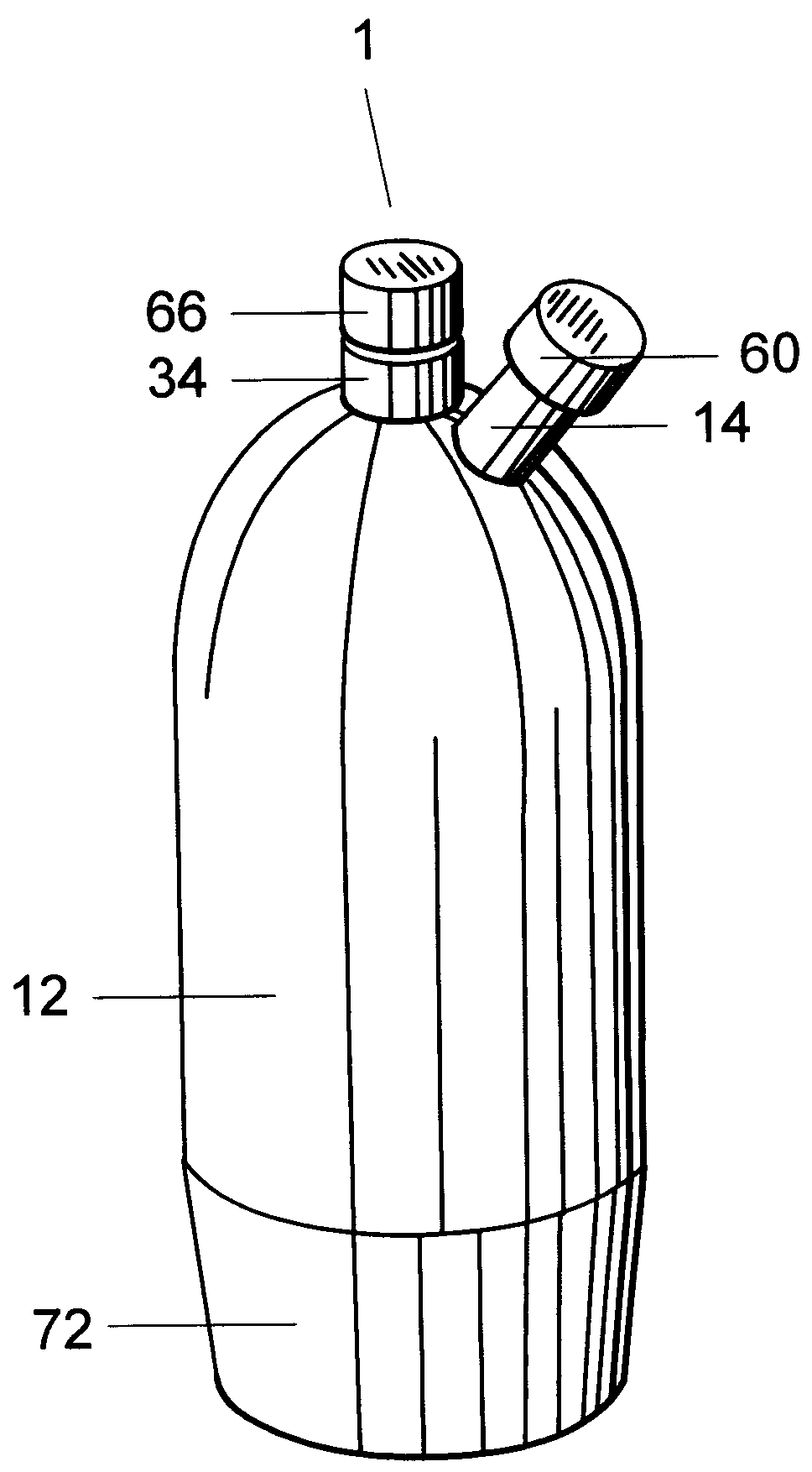

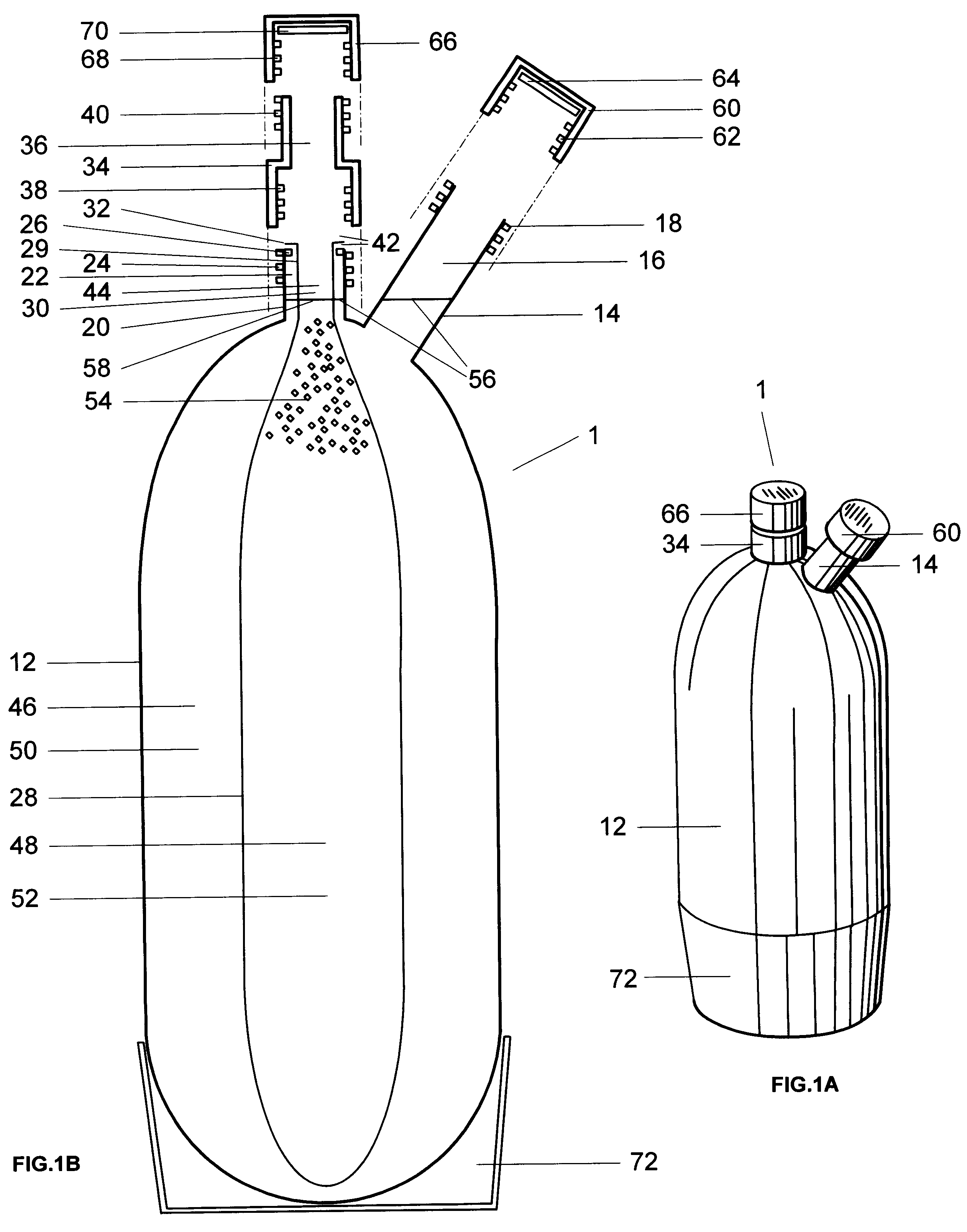

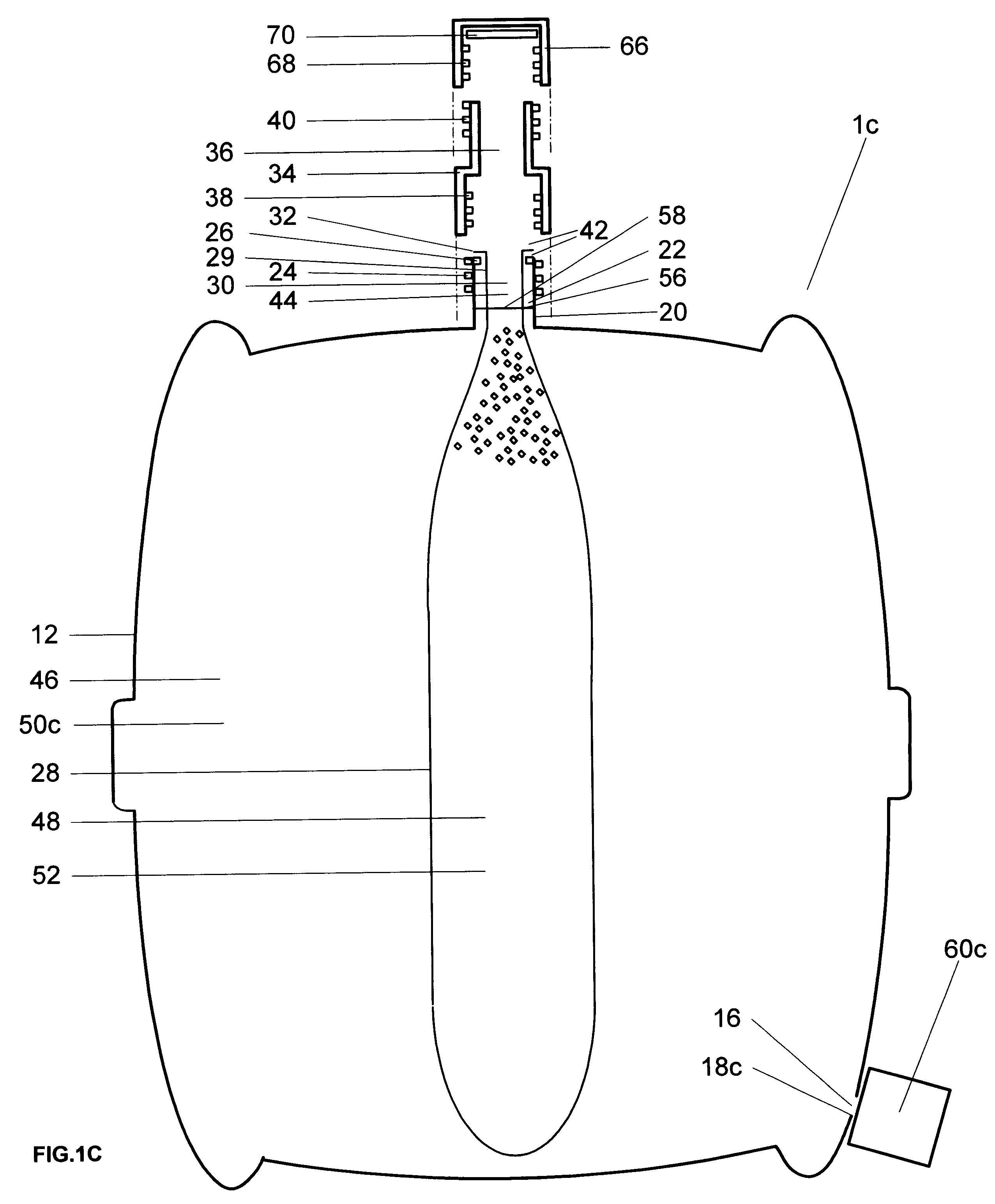

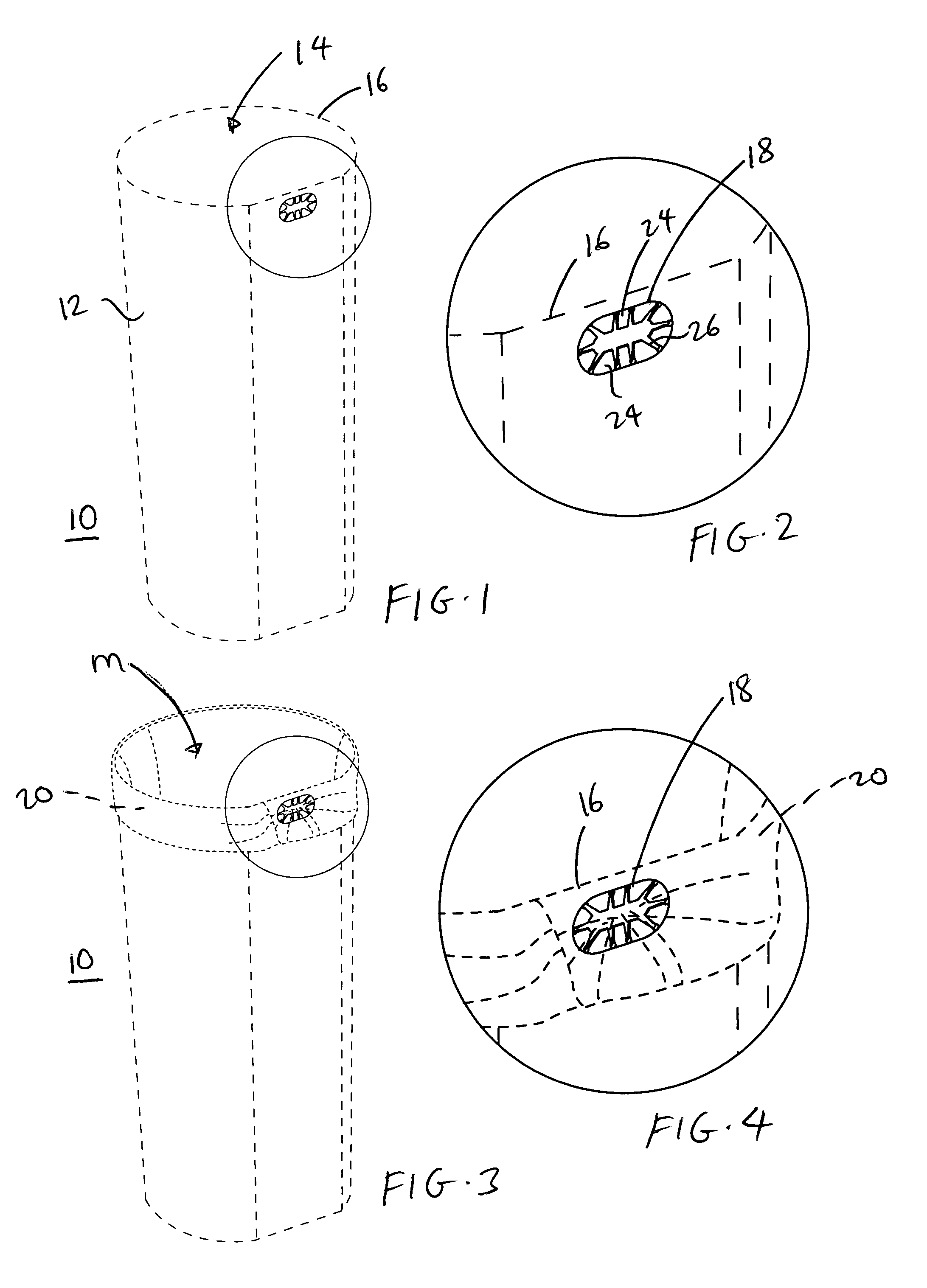

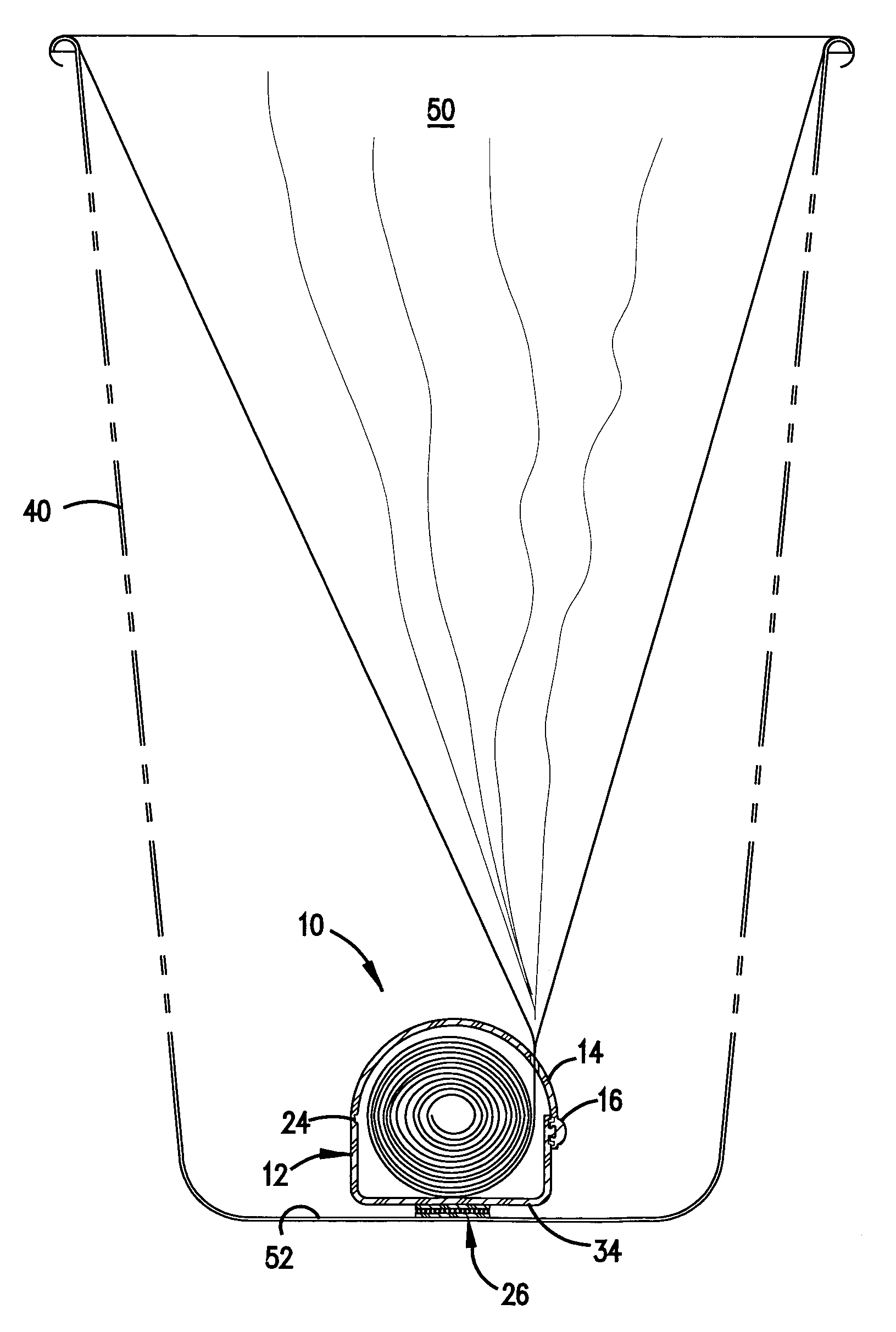

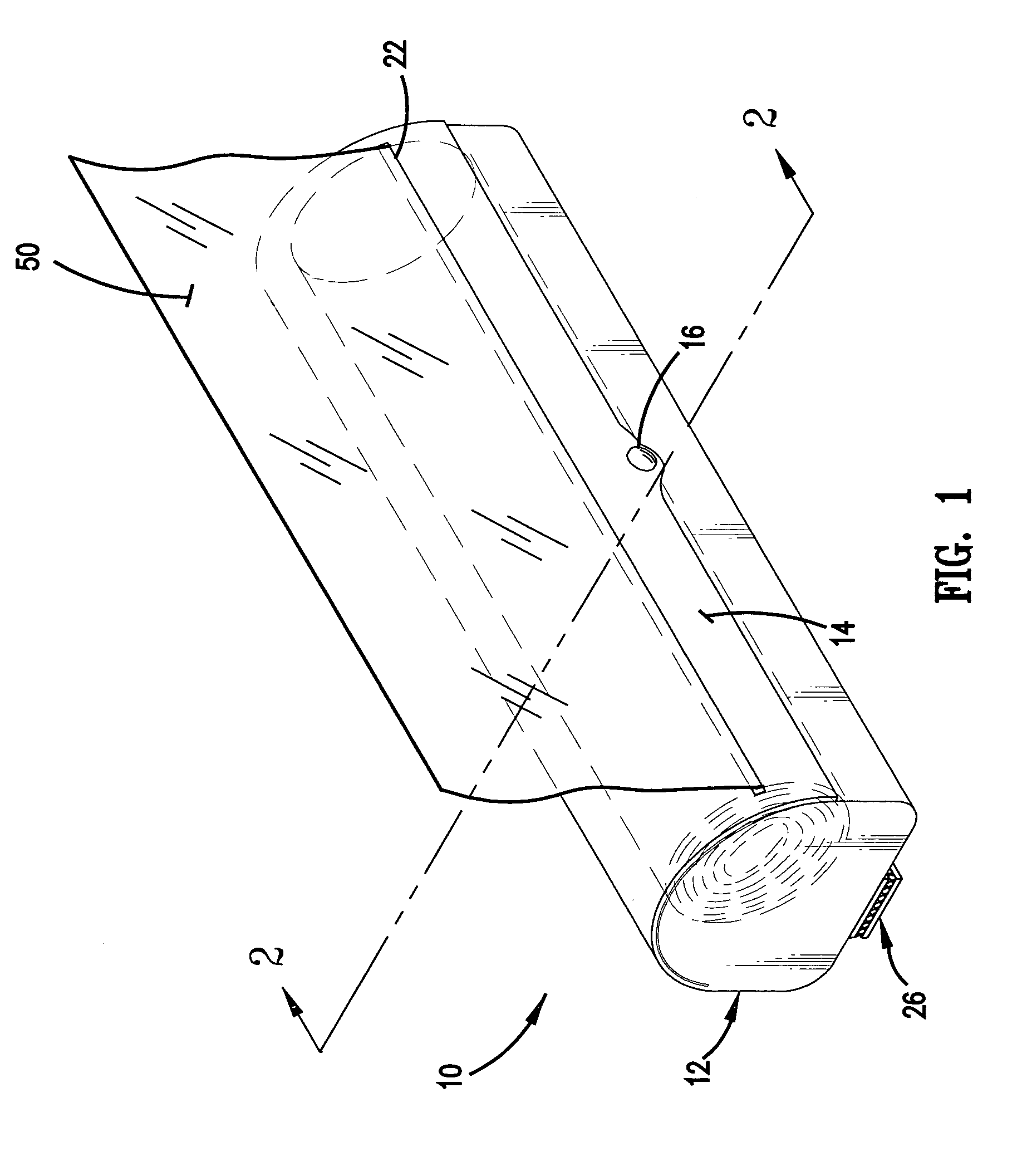

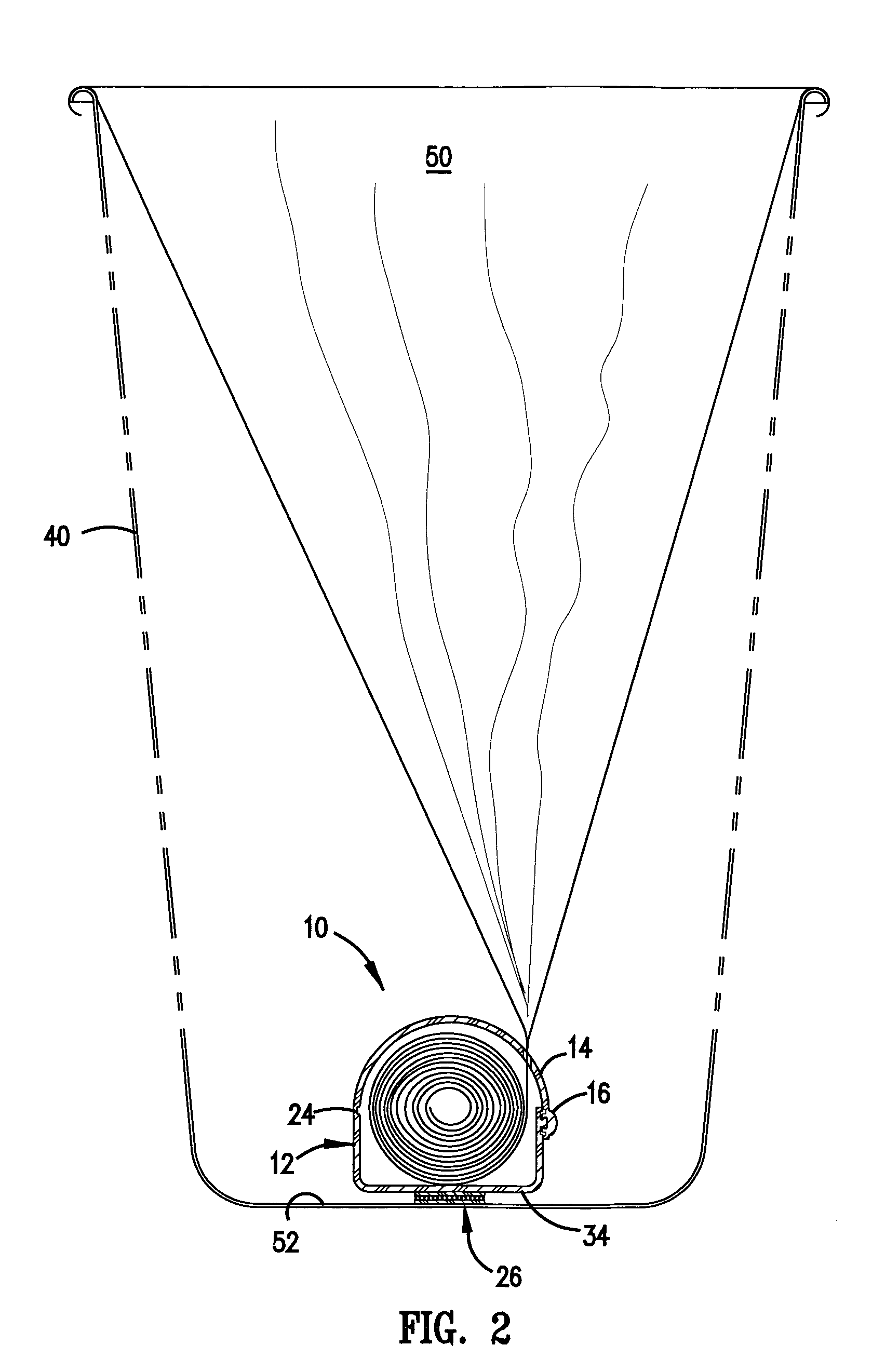

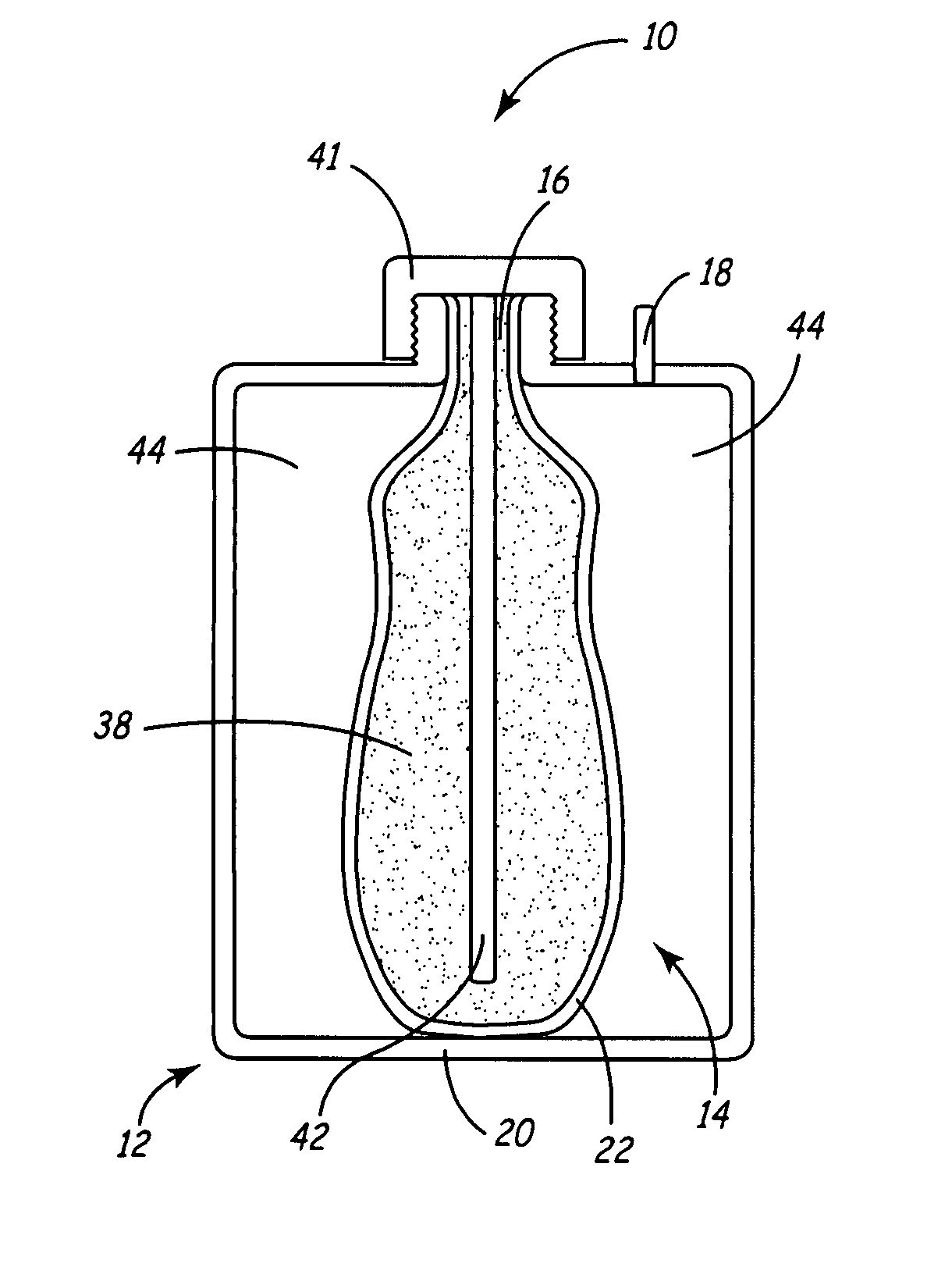

Fuel cartridge with flexible liner

A cartridge connectable to a fuel cell is disclosed. The cartridge comprises an outer casing and an inner flexible liner containing fuel for the fuel cell. The inner flexible liner may have an insert disposed inside the inner liner to facilitate the transport of fuel from the cartridge to the fuel cell. The insert minimizes the fuel that is trapped within the cartridge. The inner flexible liner can be used without the outer casing. The outer casing can be substantially rigid or flexible. The cartridge is also adaptable to receive byproducts from the fuel cell. The cartridge can also be pressurized to push fuel to the fuel cell. Unidirectional relief valves are also disclosed to prevent internal pressure in the cartridge from becoming too high or too low.

Owner:INTELLIGENT ENERGY LTD

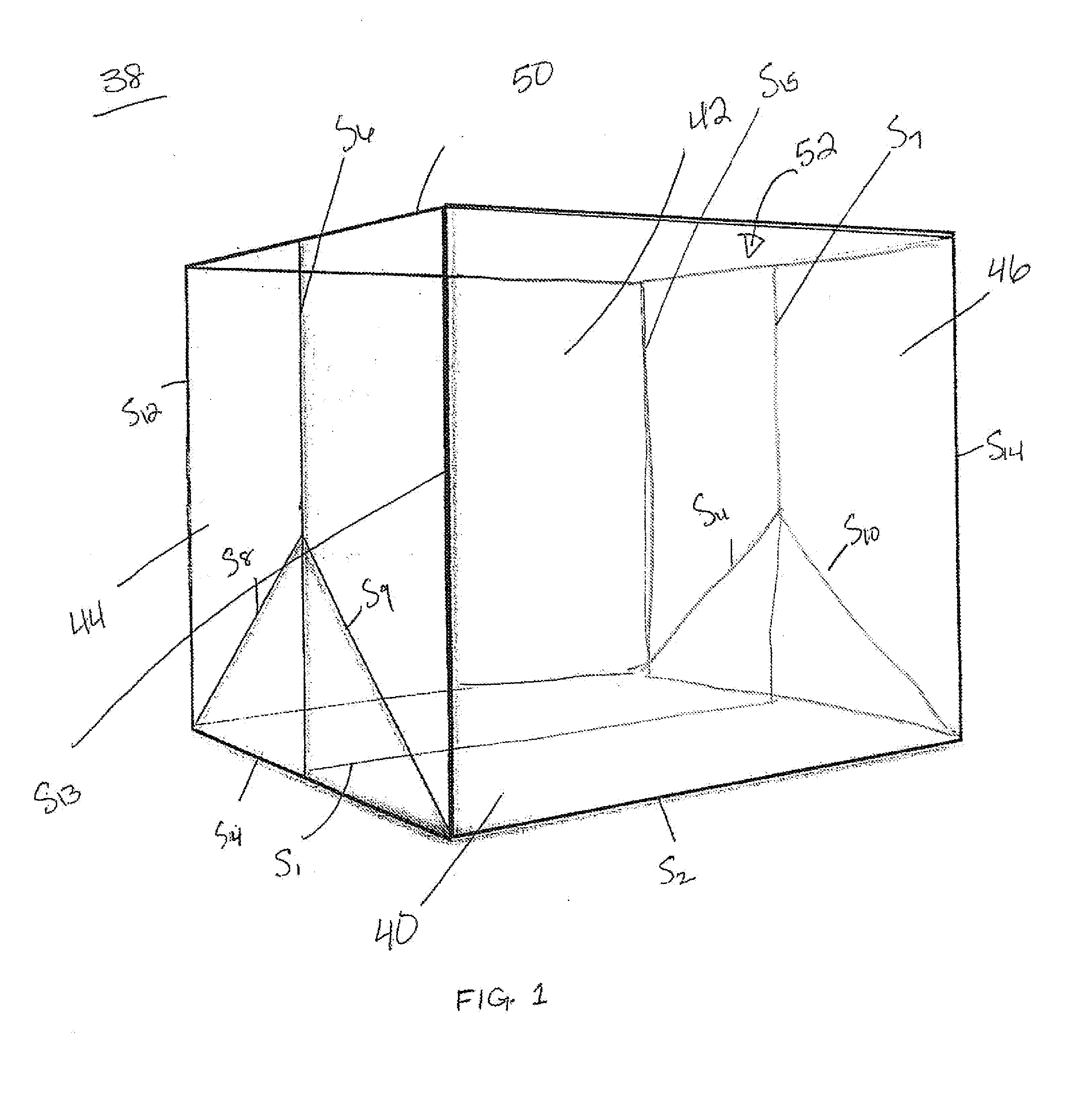

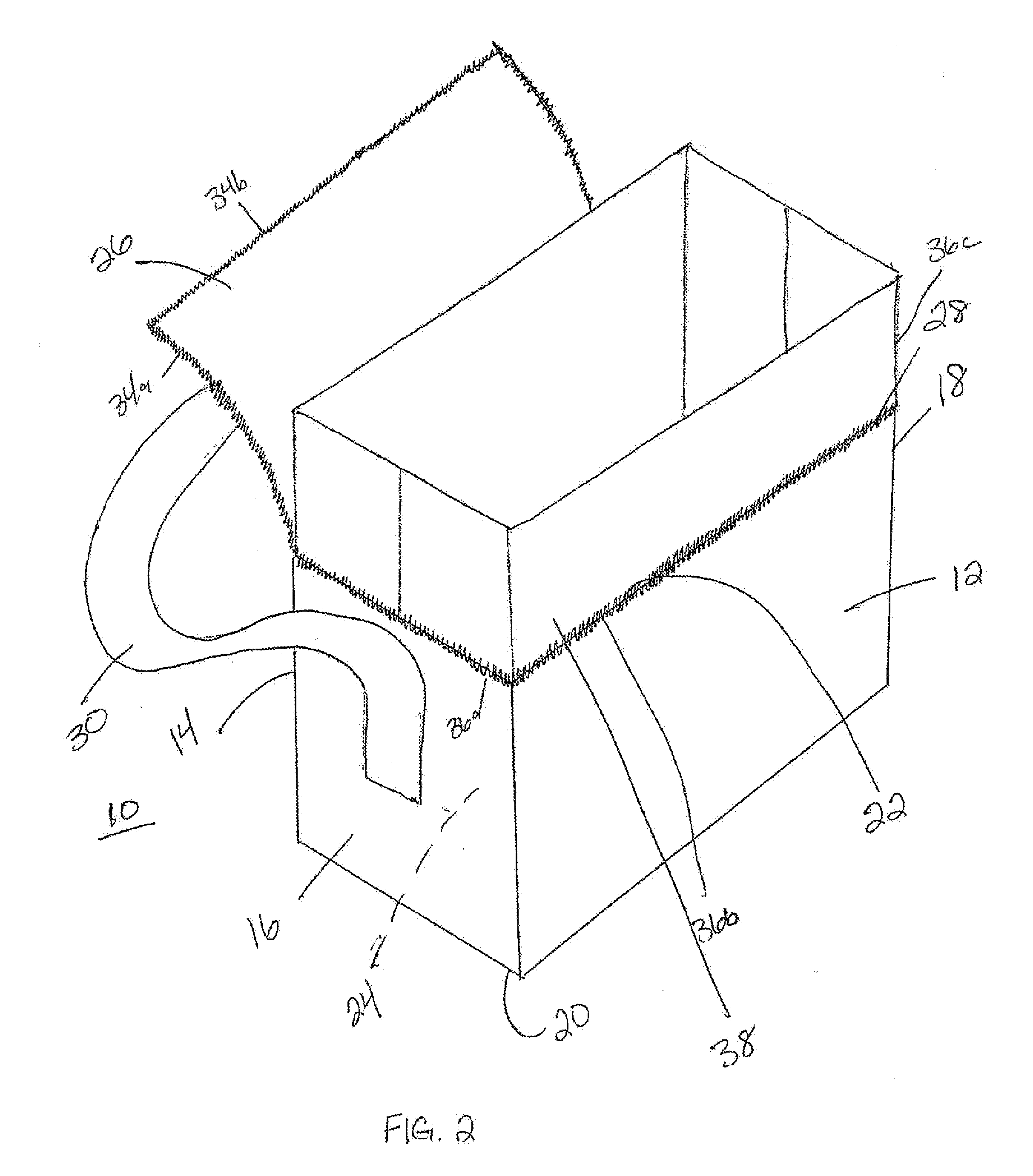

Rigid collapsible liner for insulated container

InactiveUS20150175338A1Domestic cooling apparatusLighting and heating apparatusEngineeringMechanical engineering

Owner:THE COLEMAN CO INC

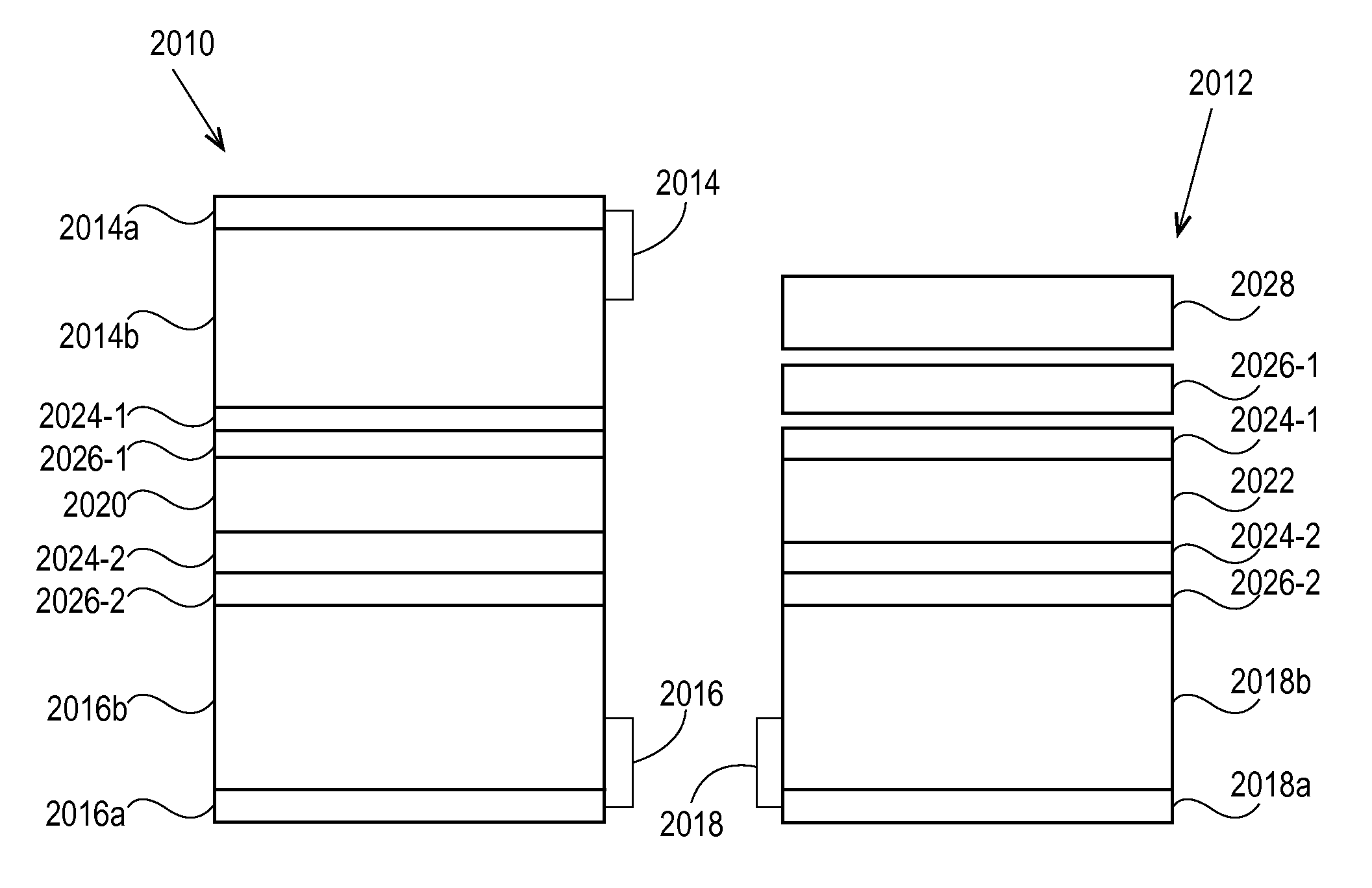

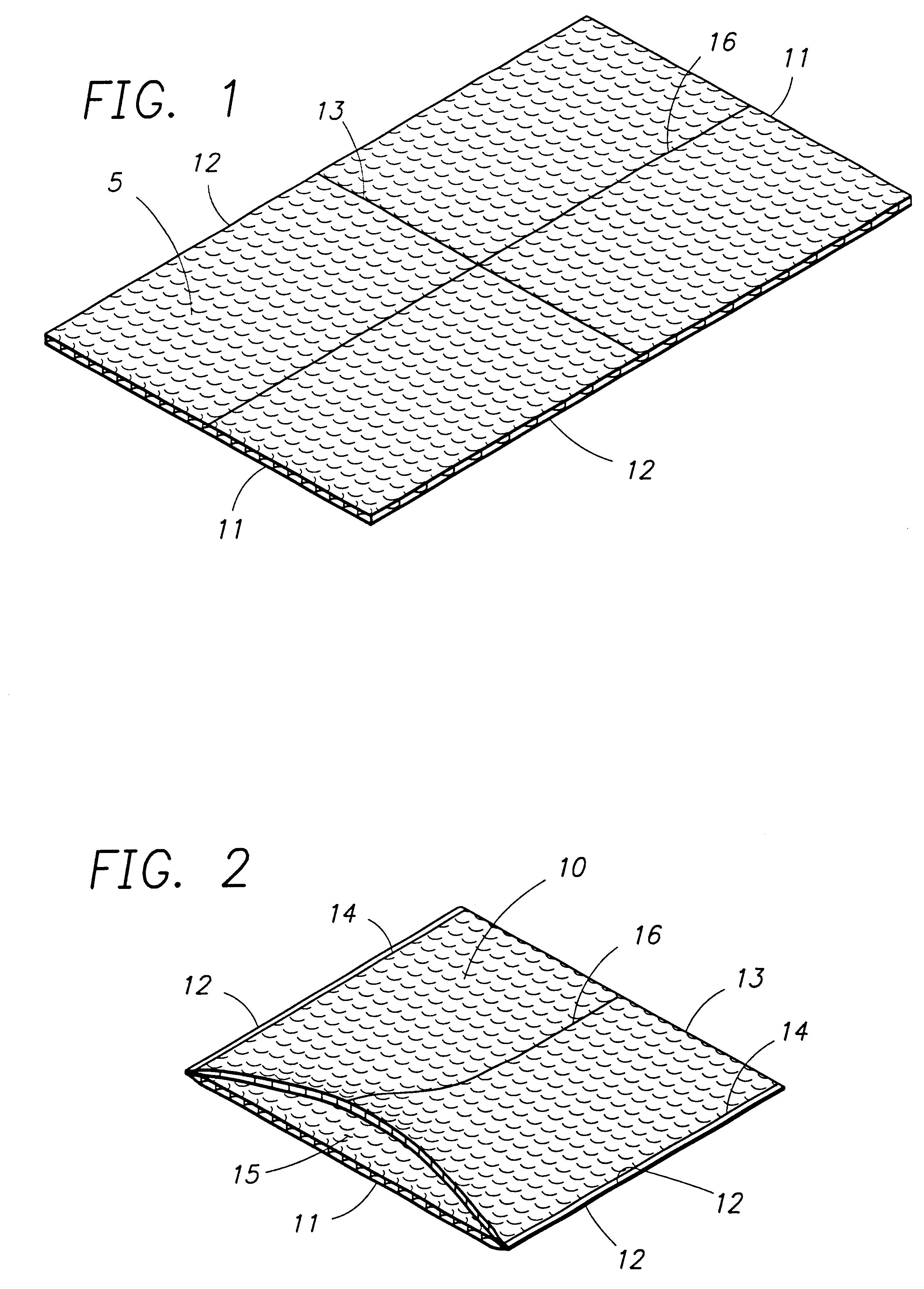

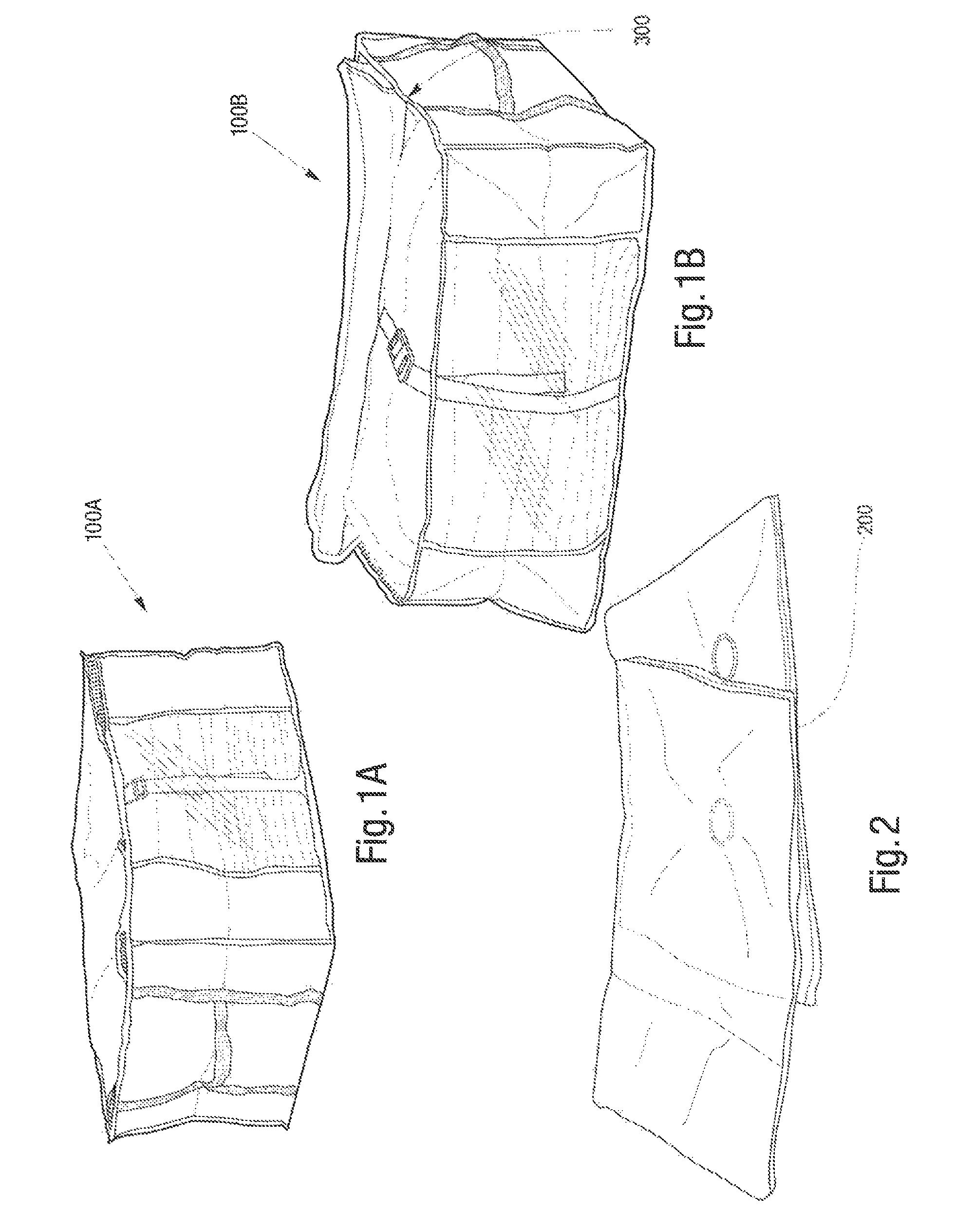

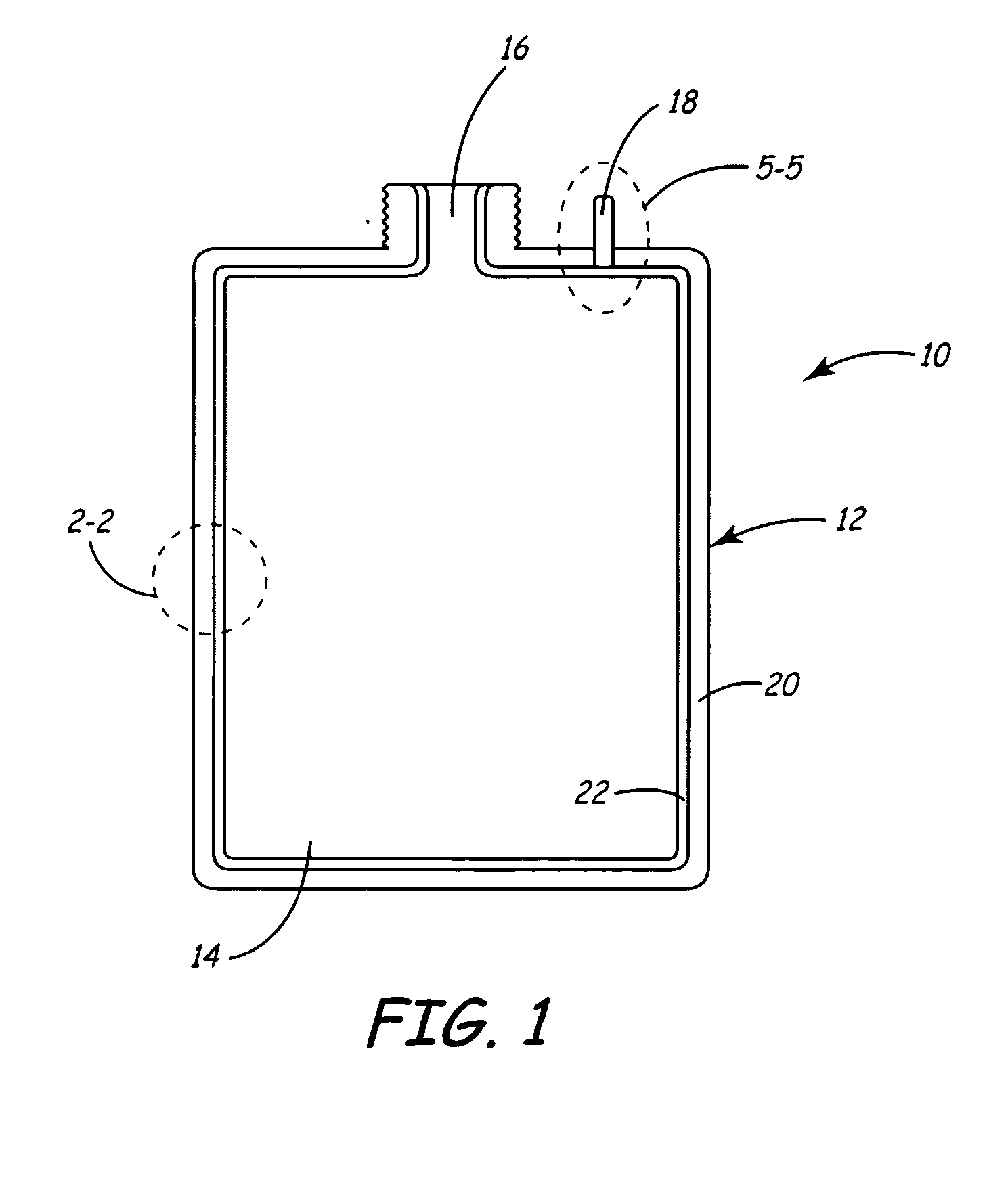

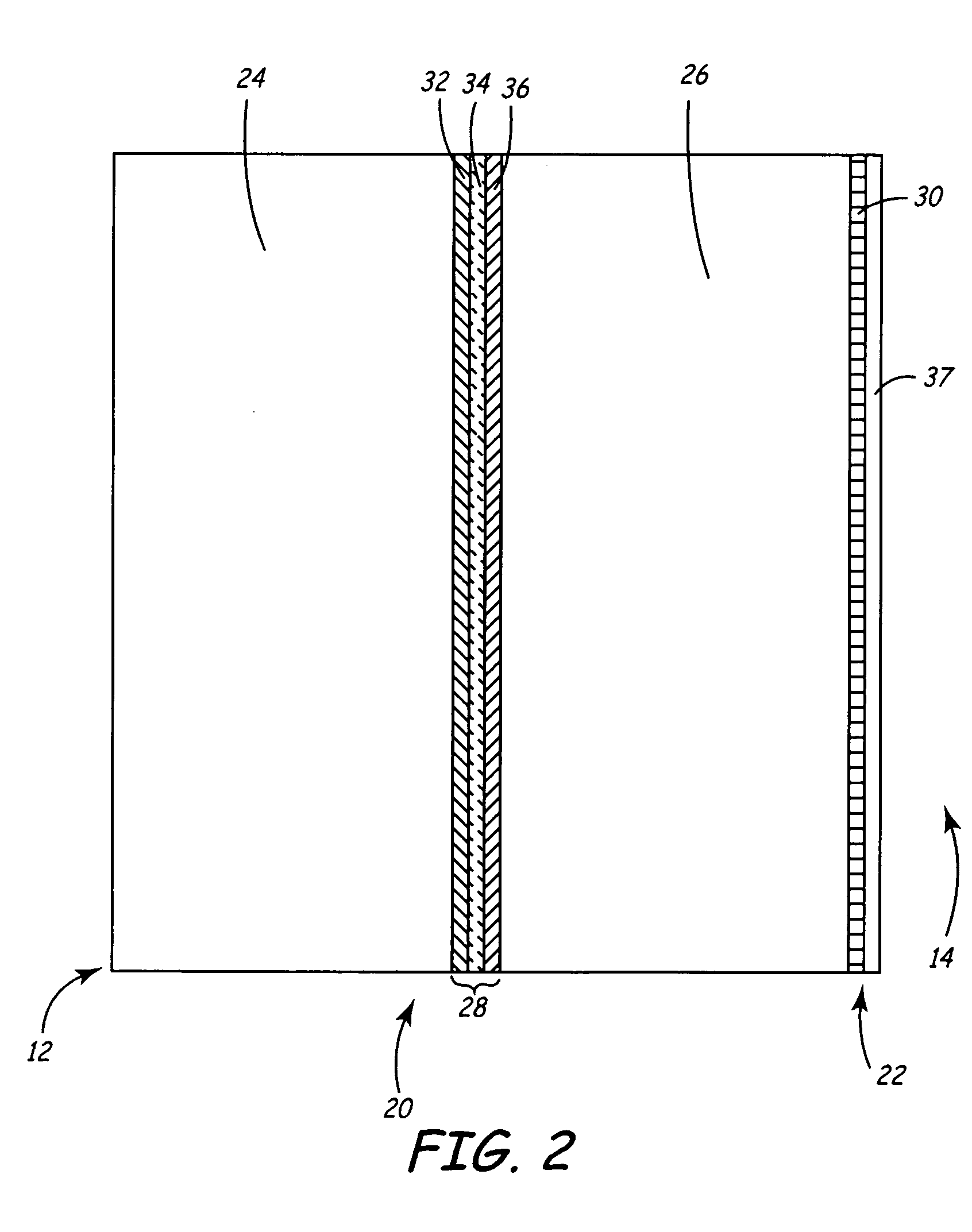

Flexible Materials for Flexible Containers

ActiveUS20130337244A1Less-expensiveImprove the decorative effectDomestic containersCoatingsEngineeringMechanical engineering

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

Flexible Materials for Flexible Containers

ActiveUS20130294711A1Less-expensiveImprove the decorative effectDomestic containersCoatingsEngineeringMechanical engineering

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:THE PROCTER & GAMBLE COMPANY

Insulated water-tight container

InactiveUS6296134B1Easy and inexpensive to manufacturePreserving spaceDomestic cooling apparatusLighting and heating apparatusEngineeringWater resistant

An insulated container for shipping, transporting, or storing warm or cold items is disclosed, useful for maintaining temperature of items stored or shipped within the container, the container assembly consisting of at least one layer of rigid or semi-rigid material, and at least one layer of flexible, thermally insulating, water-resistant material, in the form of a pouch, which pouch is secured to the rigid material at areas which allow easy reconfiguration of the container to form a finished container having desirable insulating and water-resistant characteristics.

Owner:THERMAL SHIPPING SOLUTIONS

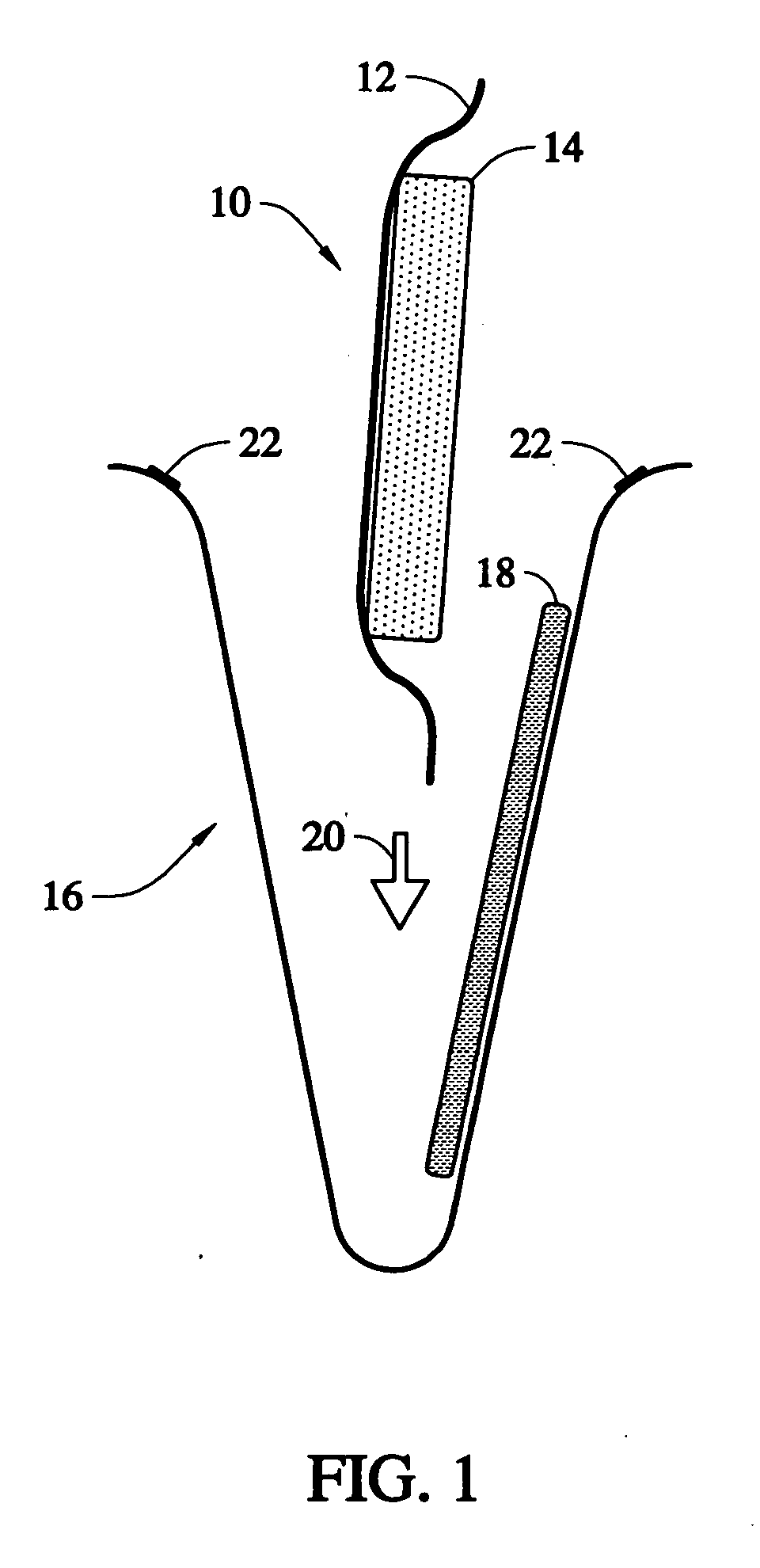

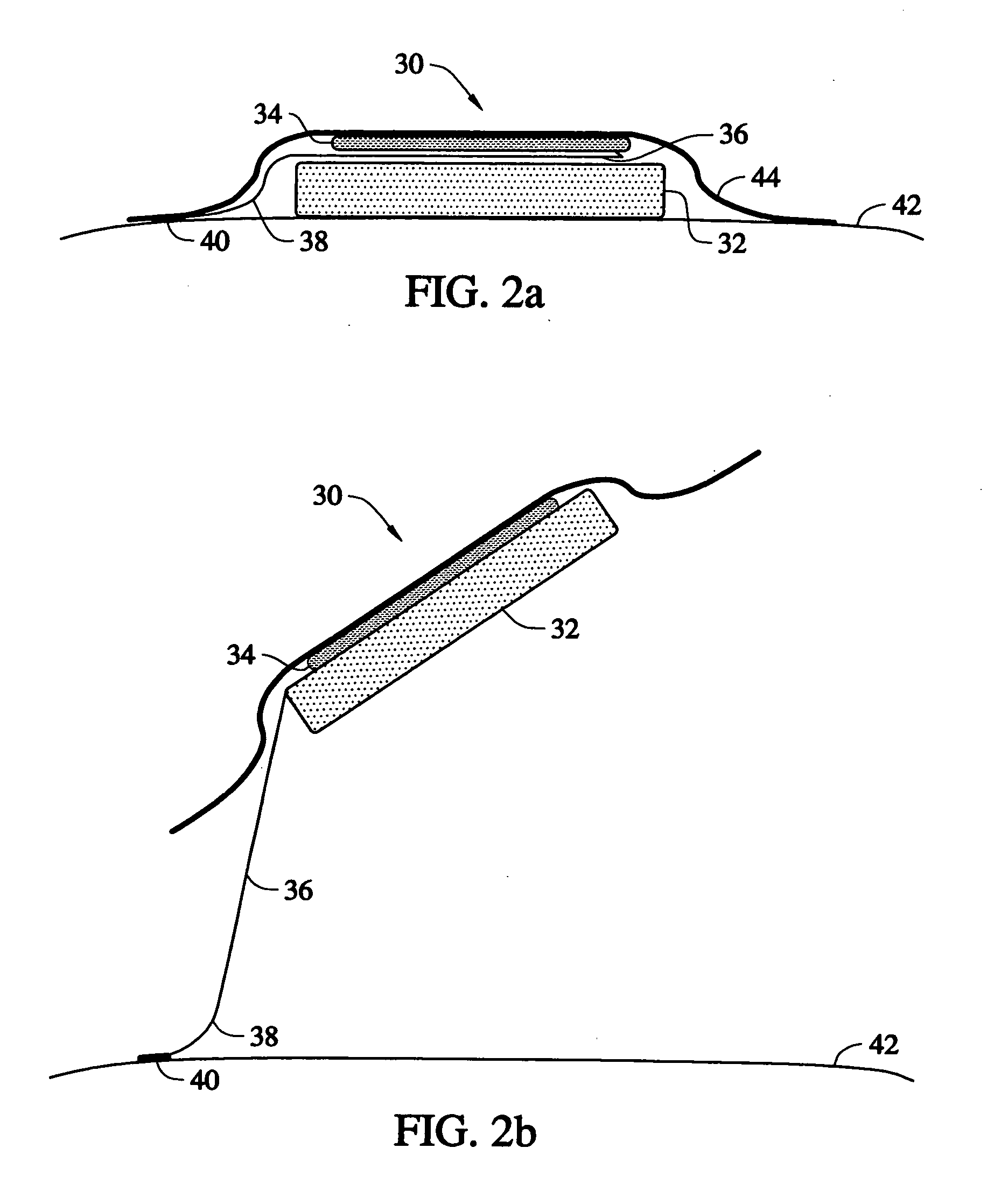

Abuse potential reduction in abusable substance dosage form

ActiveUS20050163717A1Lower potentialReducing the potential for abuseBiocideNervous disorderSubstance abuserMedicine

The potential for substance abuse involving residual amounts of abusable substances remaining in used skin-worn patches is reduced by the provision of a system and method for combining the abusable substance with a separate anti-abuse substance agent as part of a removal or disposal procedure.

Owner:VERDE ENVIRONMENTAL TECH INC

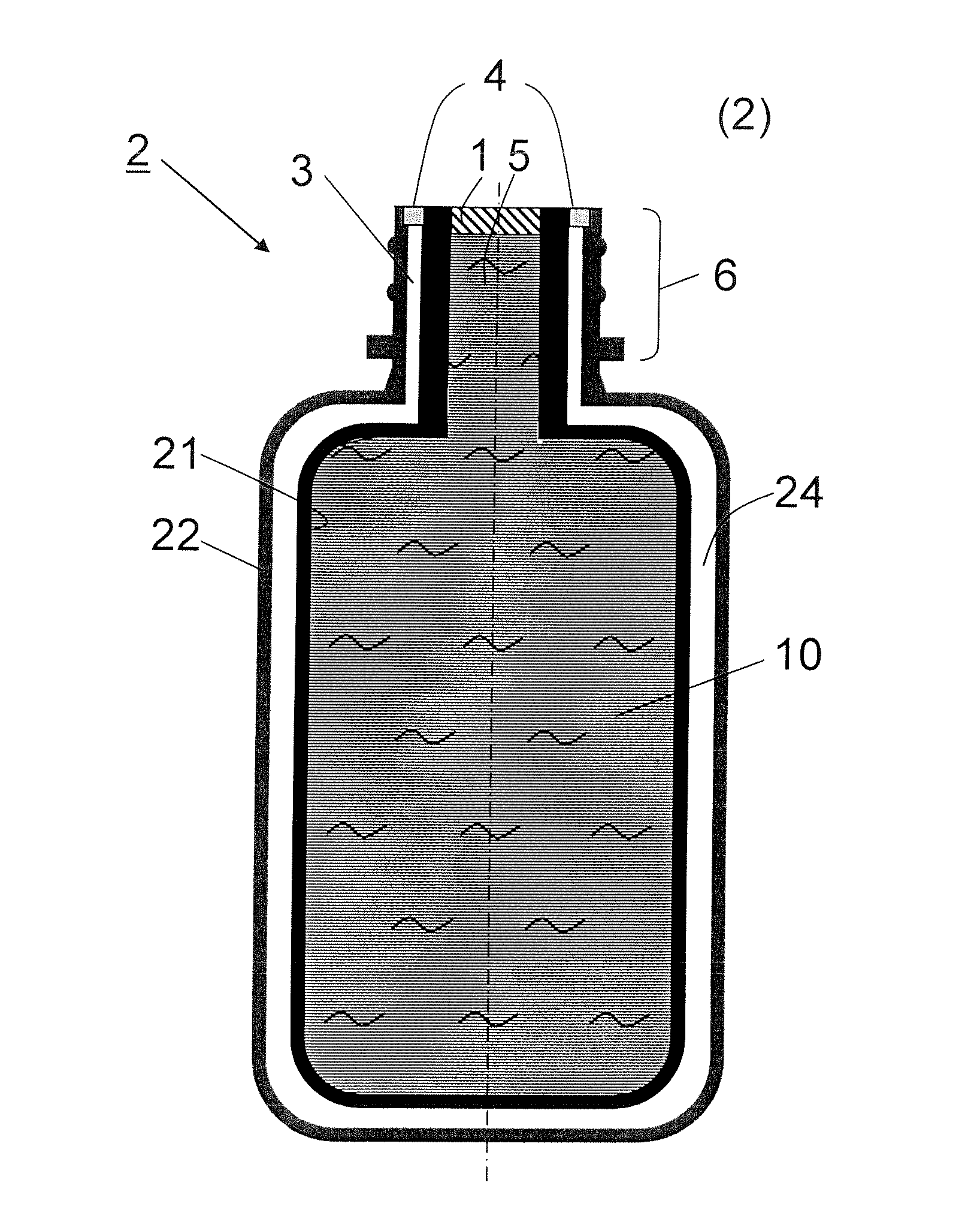

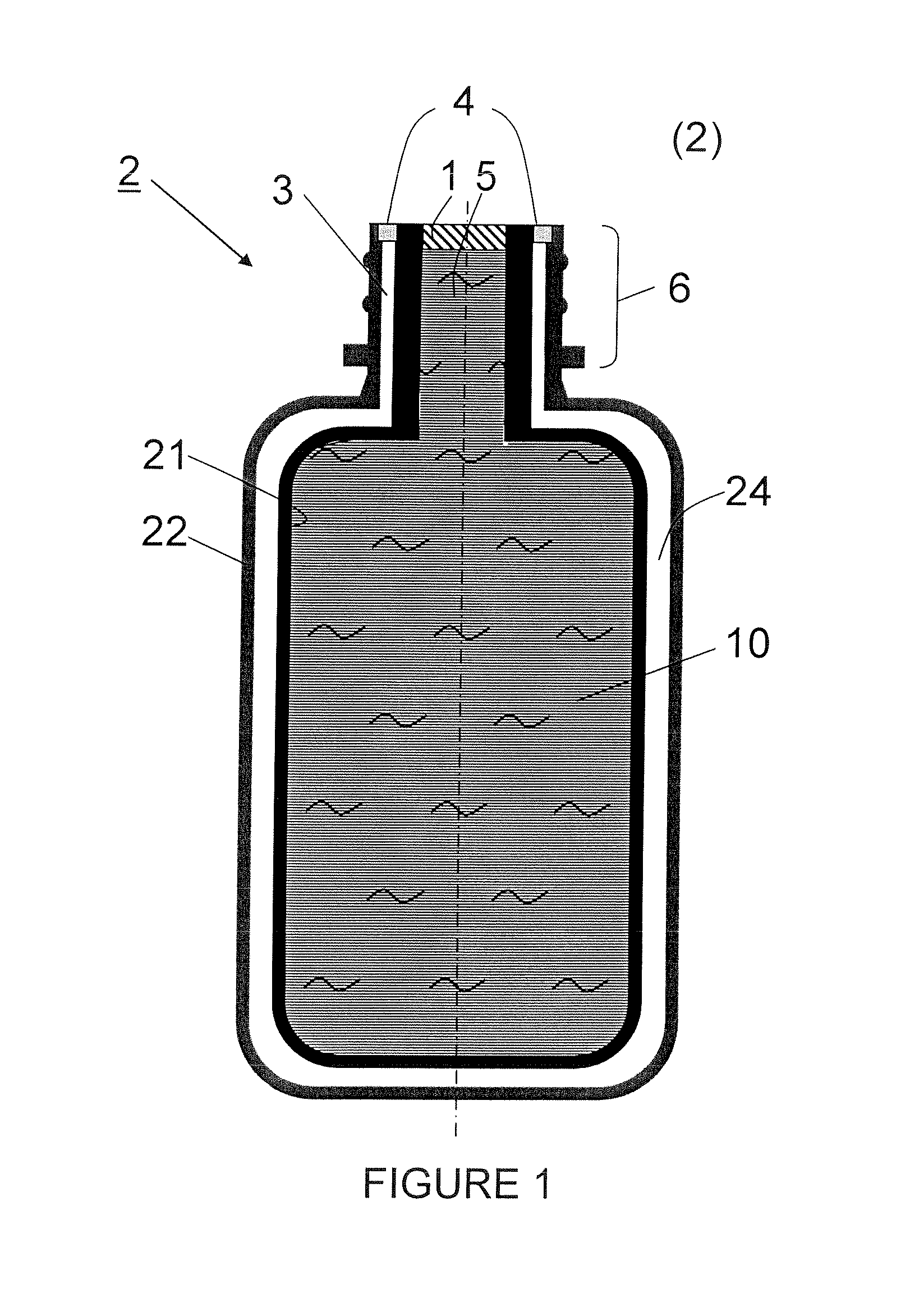

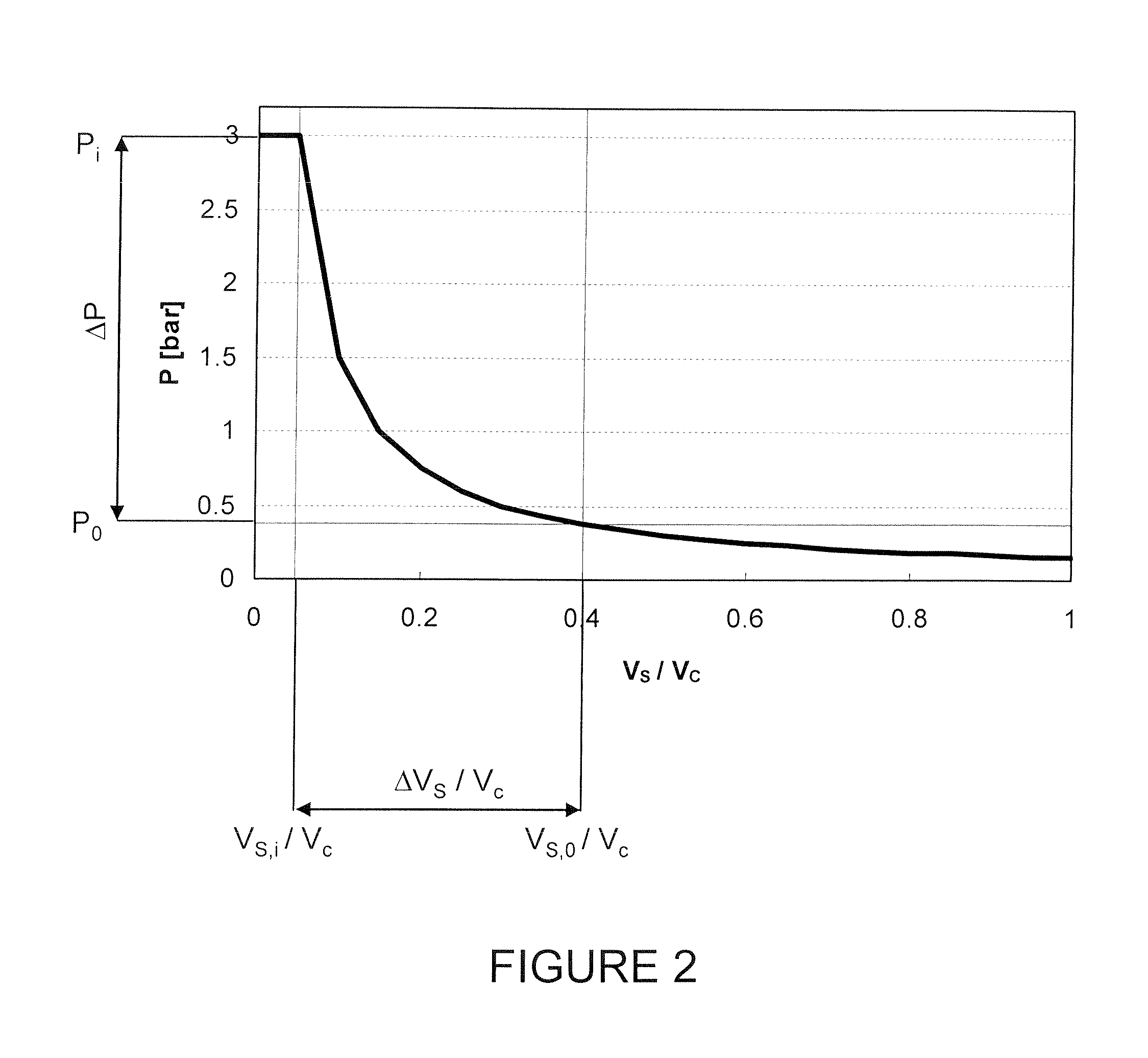

Bag-in-container with prepressurized space between inner bag and outer container

InactiveUS20110248035A1Extended shelf lifeLarge containersLinings/internal coatingsEngineeringControl space

Bag-in-container having an inner layer forming a bag filled with a fluid, the bag being separatable from an outer layer forming the container. The bag-in-container has a mouth fluidly connecting the volume defined by the bag to the atmosphere and separated therefrom by a seal. The container further having at least one space vent fluidly connecting the space between inner and outer layers and to the atmosphere. A vent provides a closure to control the gas flow between the space and the atmosphere. The space contains an amount of gas (Vs,i) at a pressure (Pi) insufficient to compress the bag to drive out more than 80% of the fluid contained therein. The present invention also concerns a kit of parts including a bag-in-container and a dispensing appliance.

Owner:ANHEUSER BUSCH INBEV SA

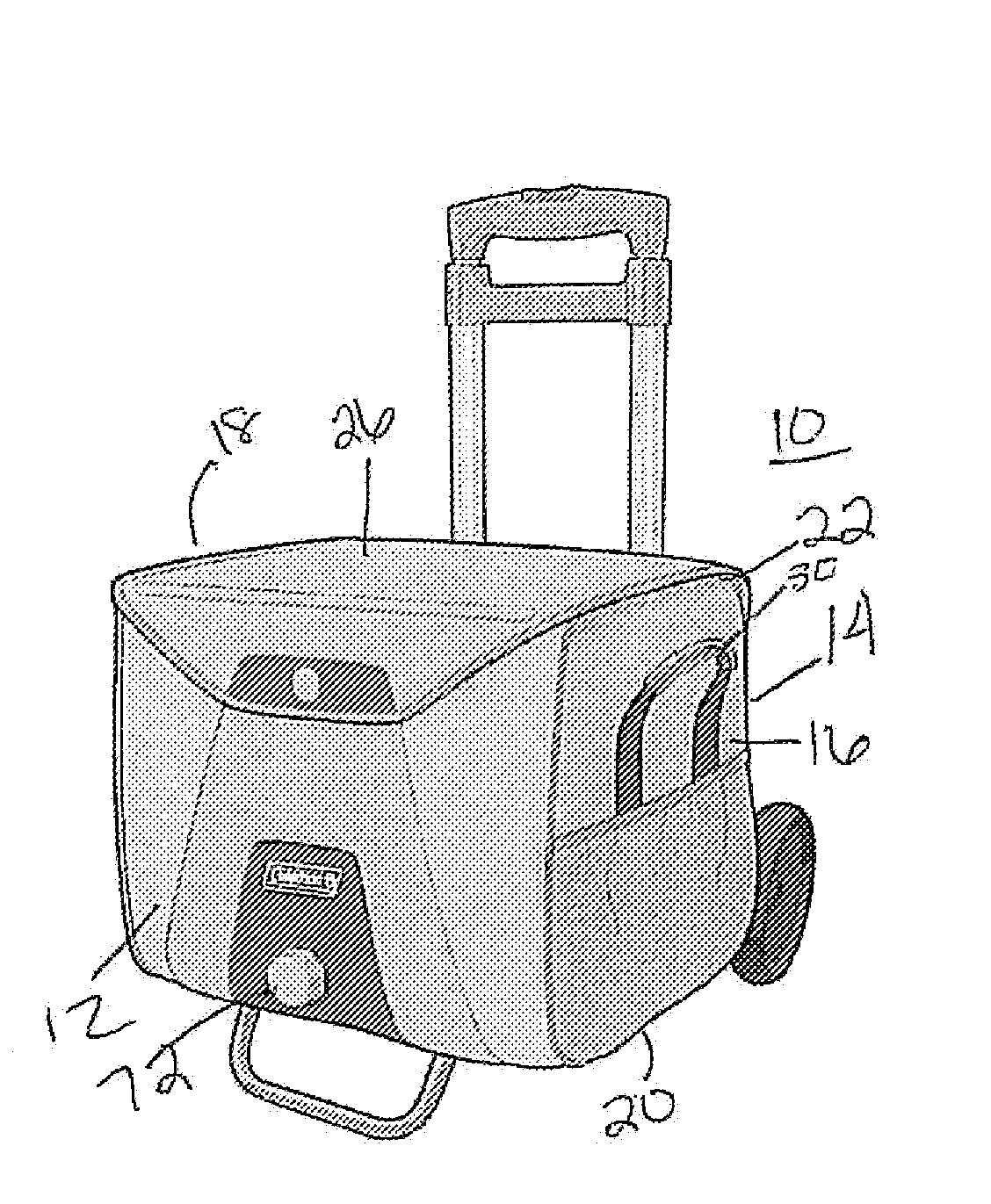

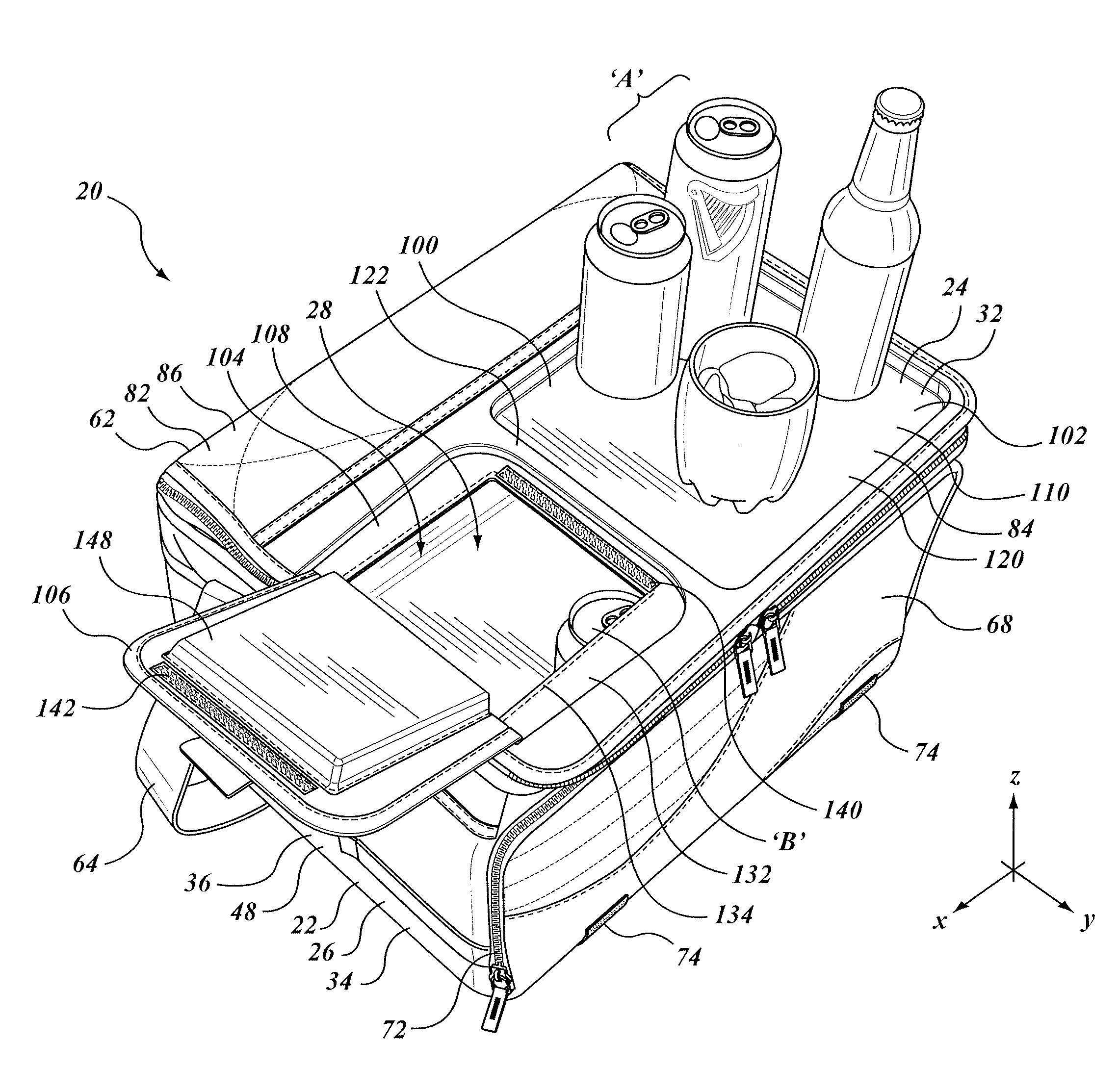

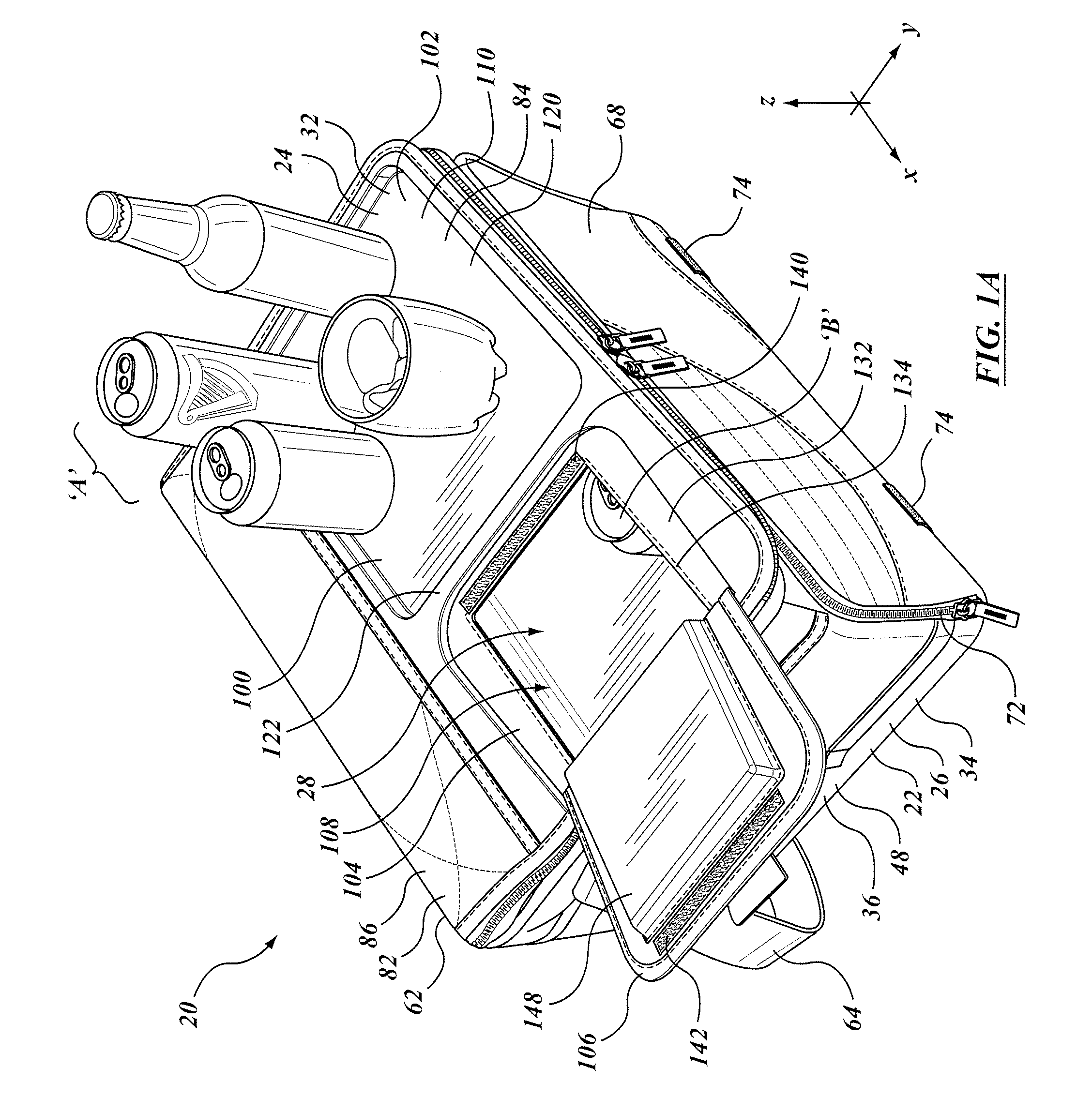

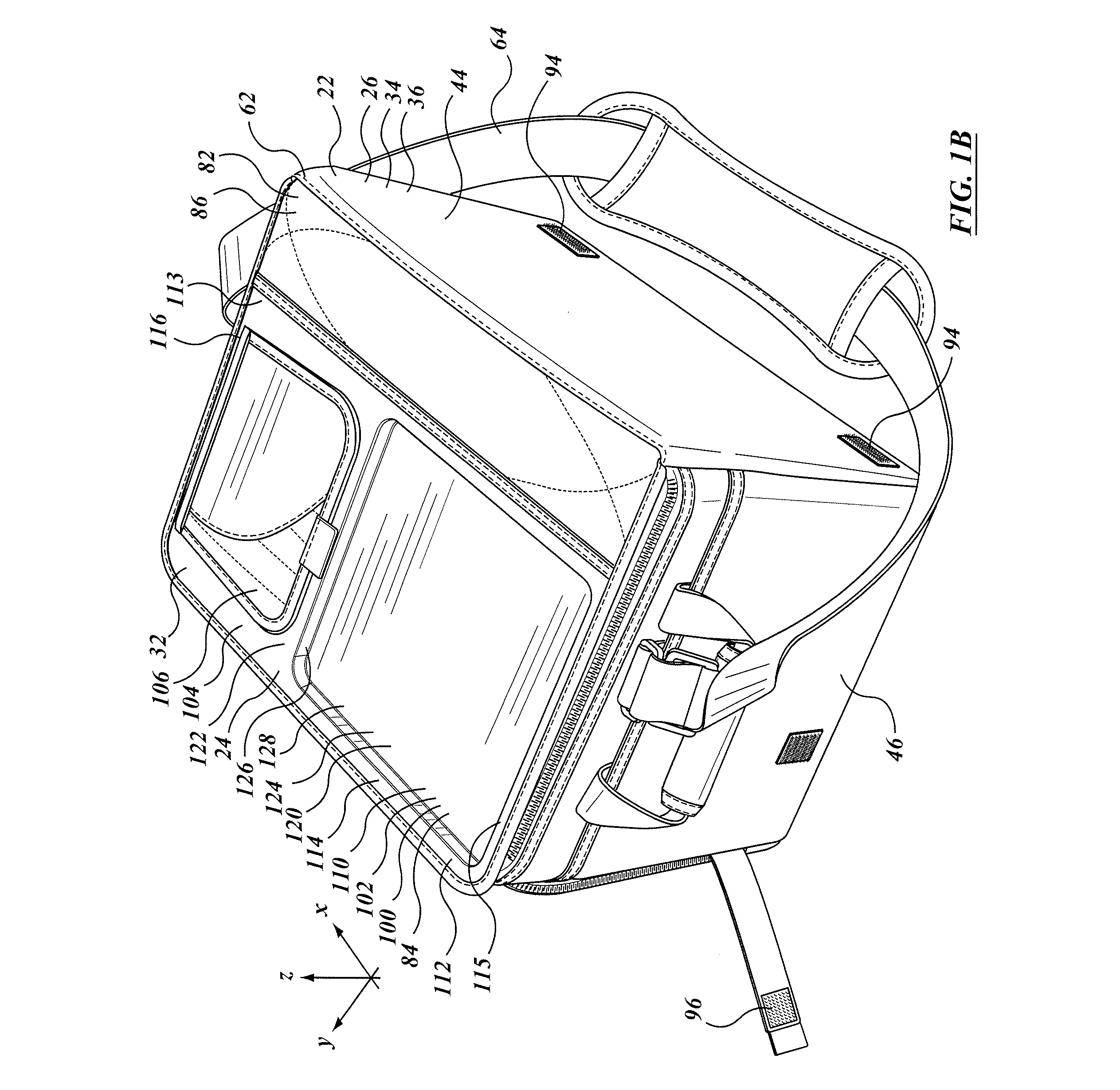

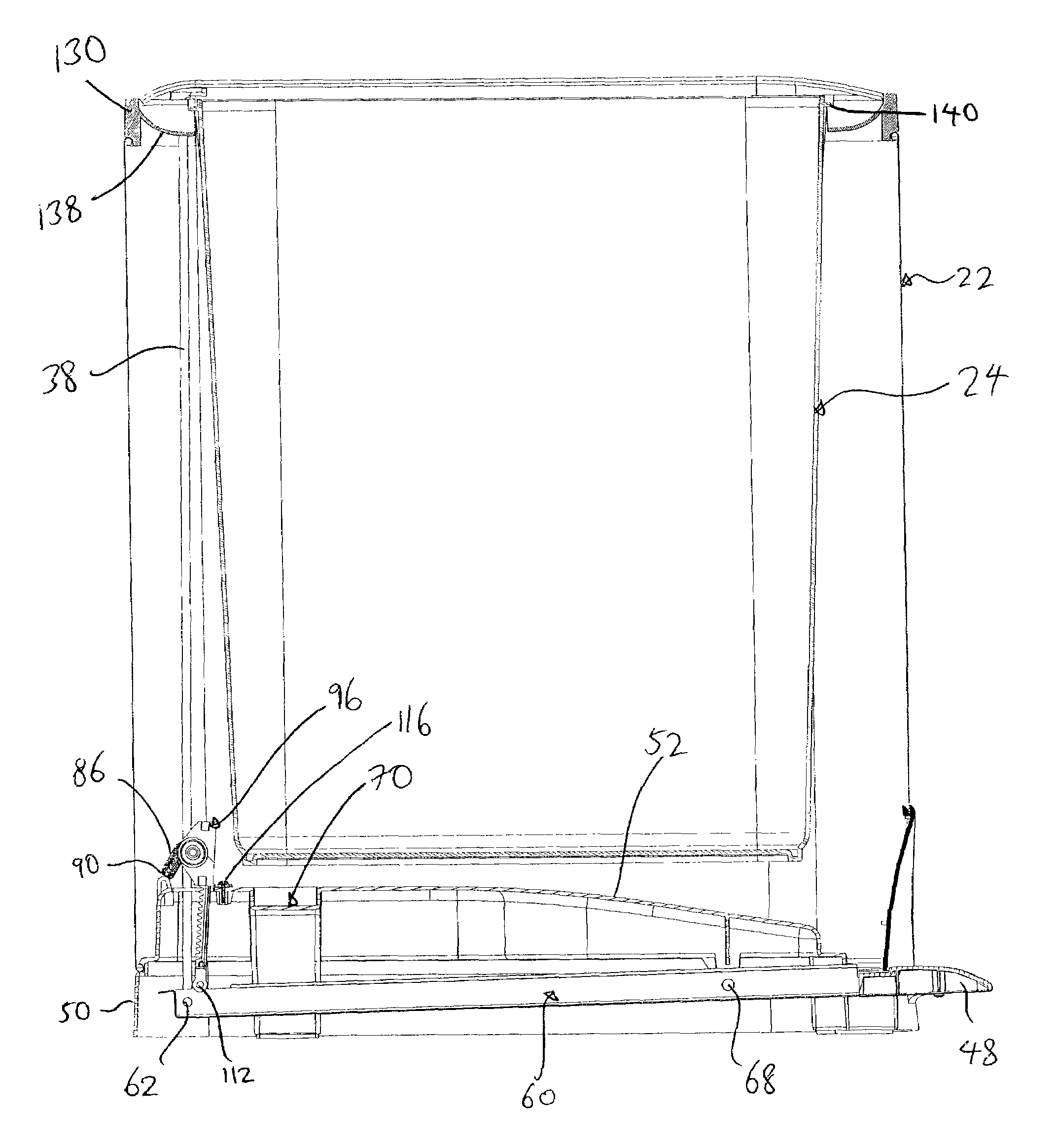

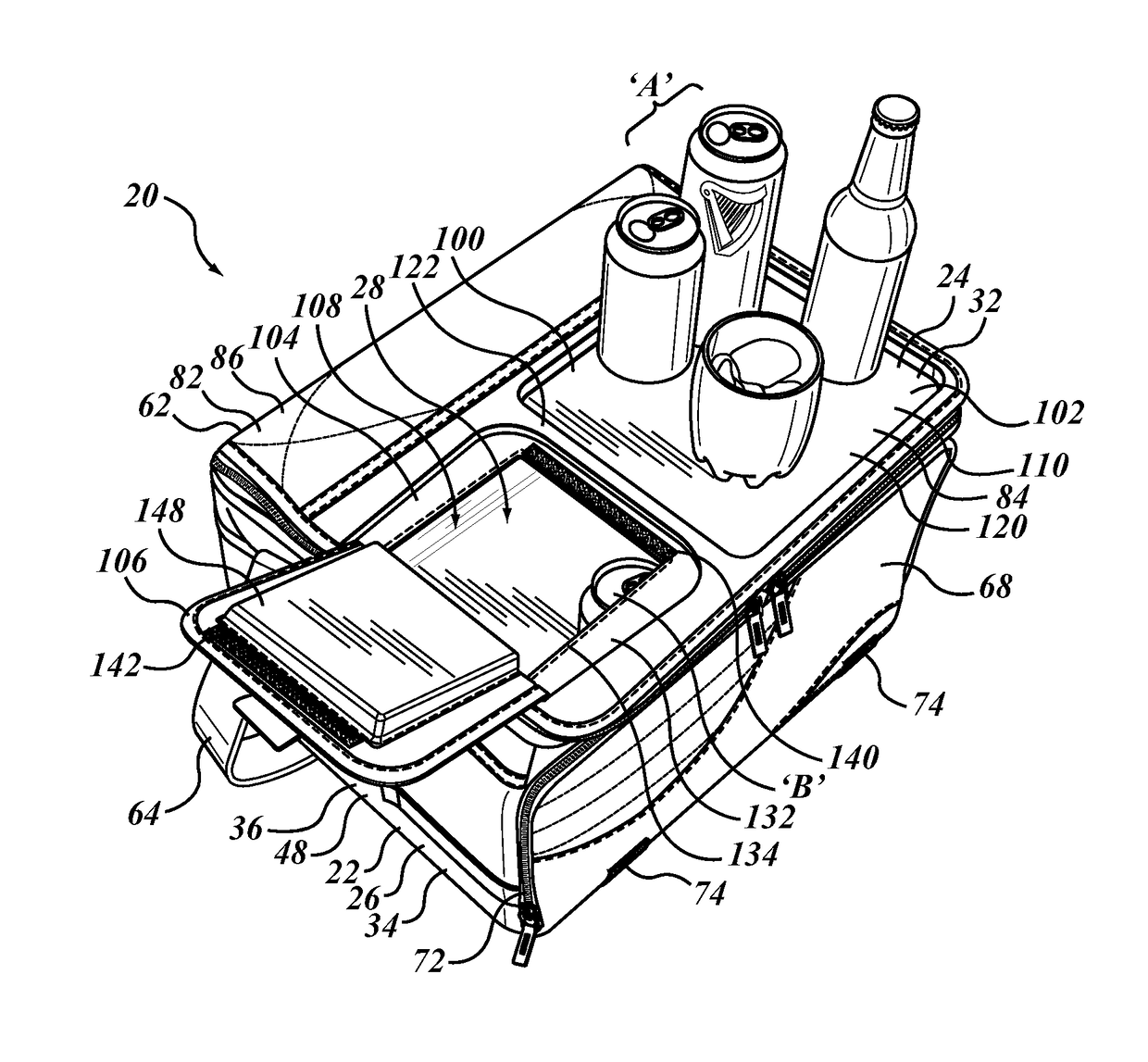

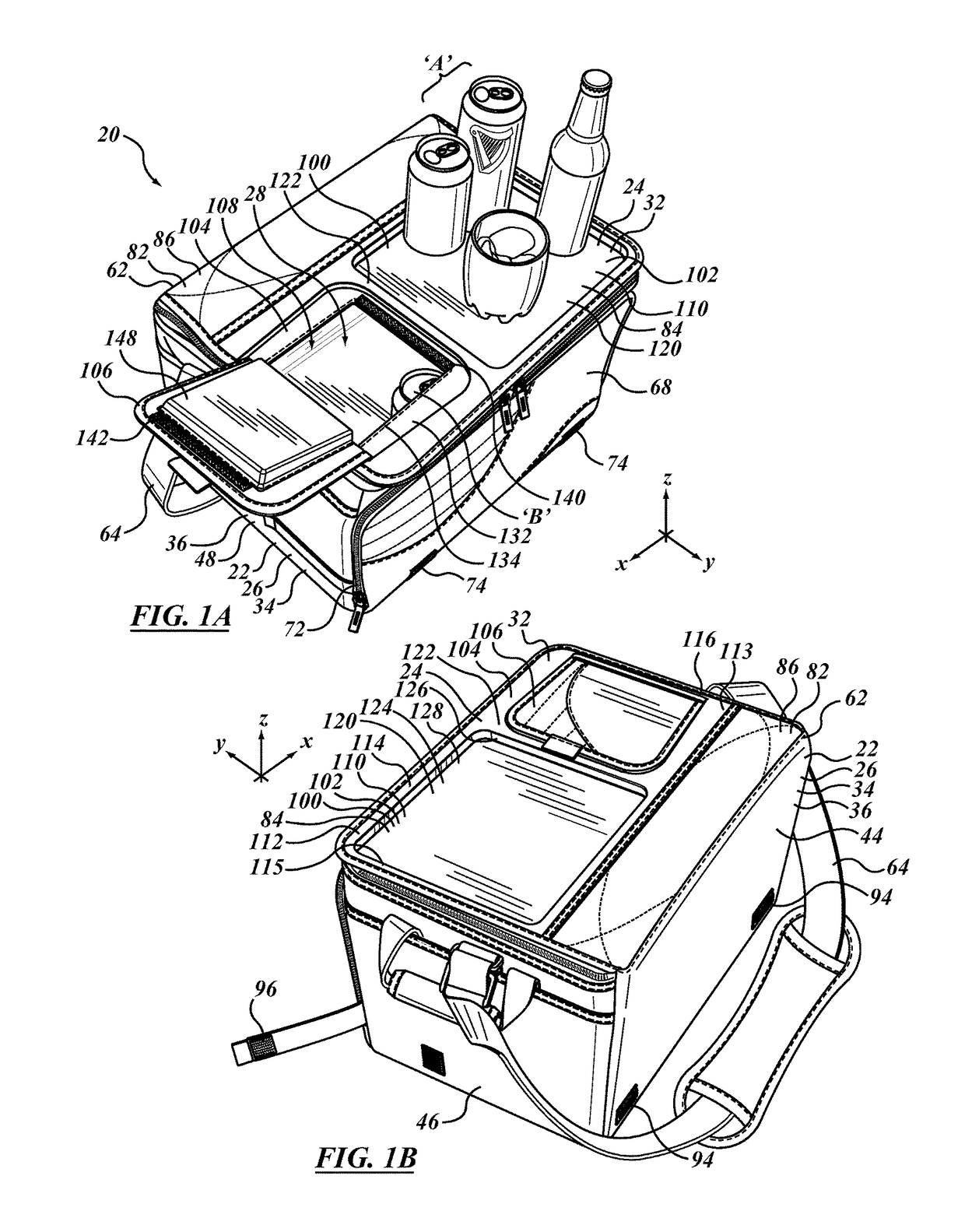

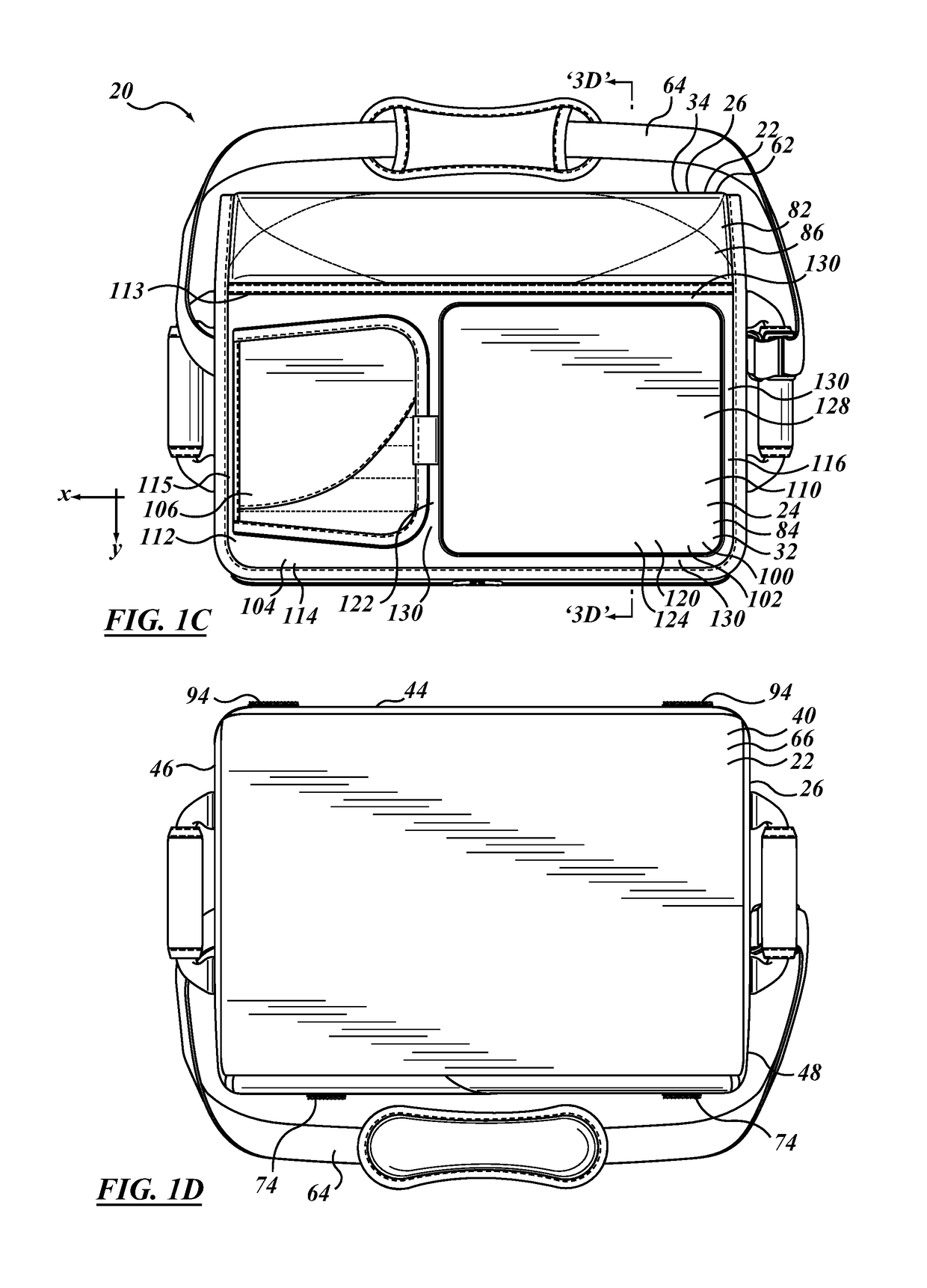

Insulated container with work surface

A soft sided insulated container assembly includes a first portion having an insulated, soft sided external wall structure, and a second portion that defined a lid co-operable with the first portion. The lid includes an auxiliary access opening and closure member that are smaller than the main opening, and that can be operated one-handed. A rigid work surface is provided, typically immediately adjacent to the secondary closure member, the work surface providing a place for holding or mixing a drink or for preparing a snack. In some embodiments the work surface may be movable relative to the container, whether slidable in a co-planar or parallel planar manner in translation, or folding as in a foldable shelf. The entire container assembly may be foldable or collapsible to a storage condition, and the rigid member, whether fixed or movable, does not impede that folding or collapsing.

Owner:CALIFORNIA INNOVATIONS

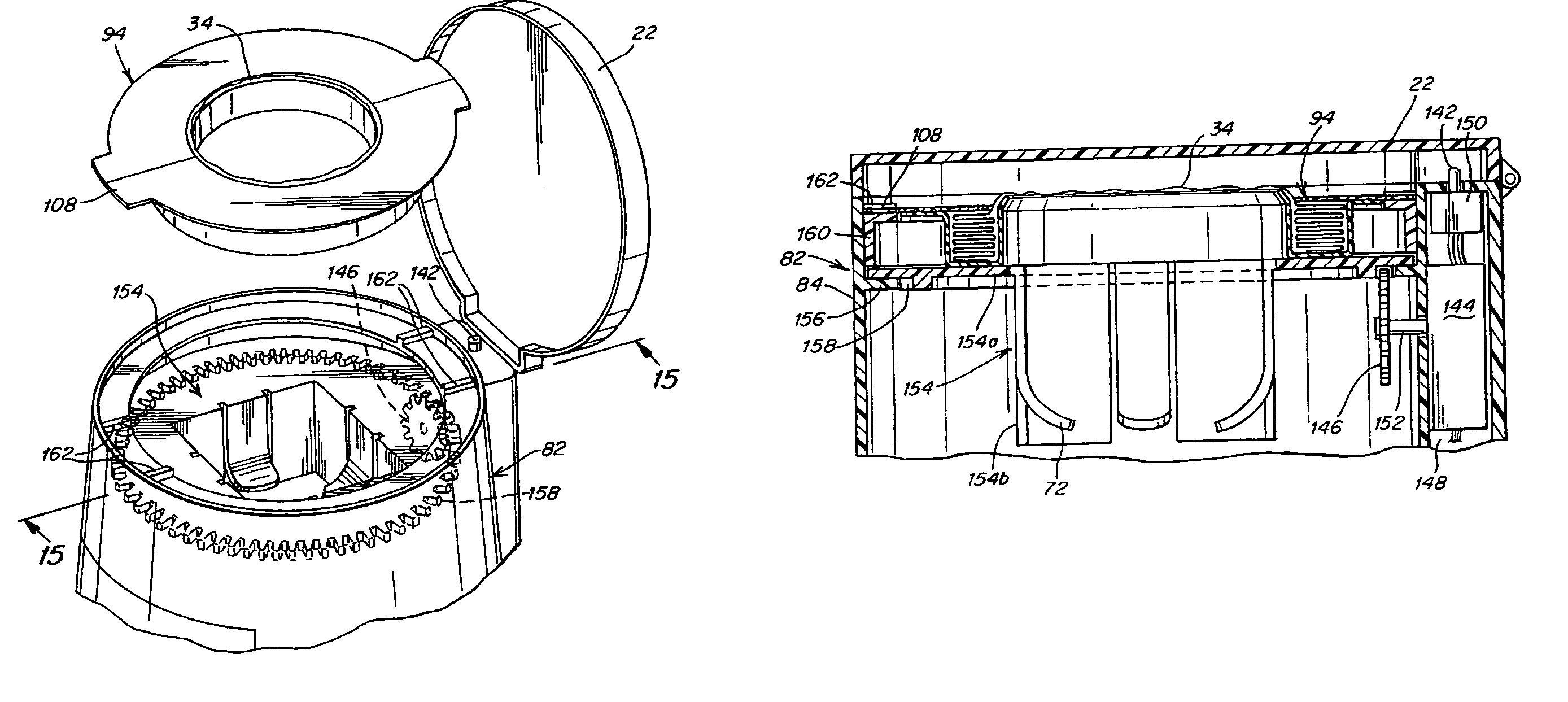

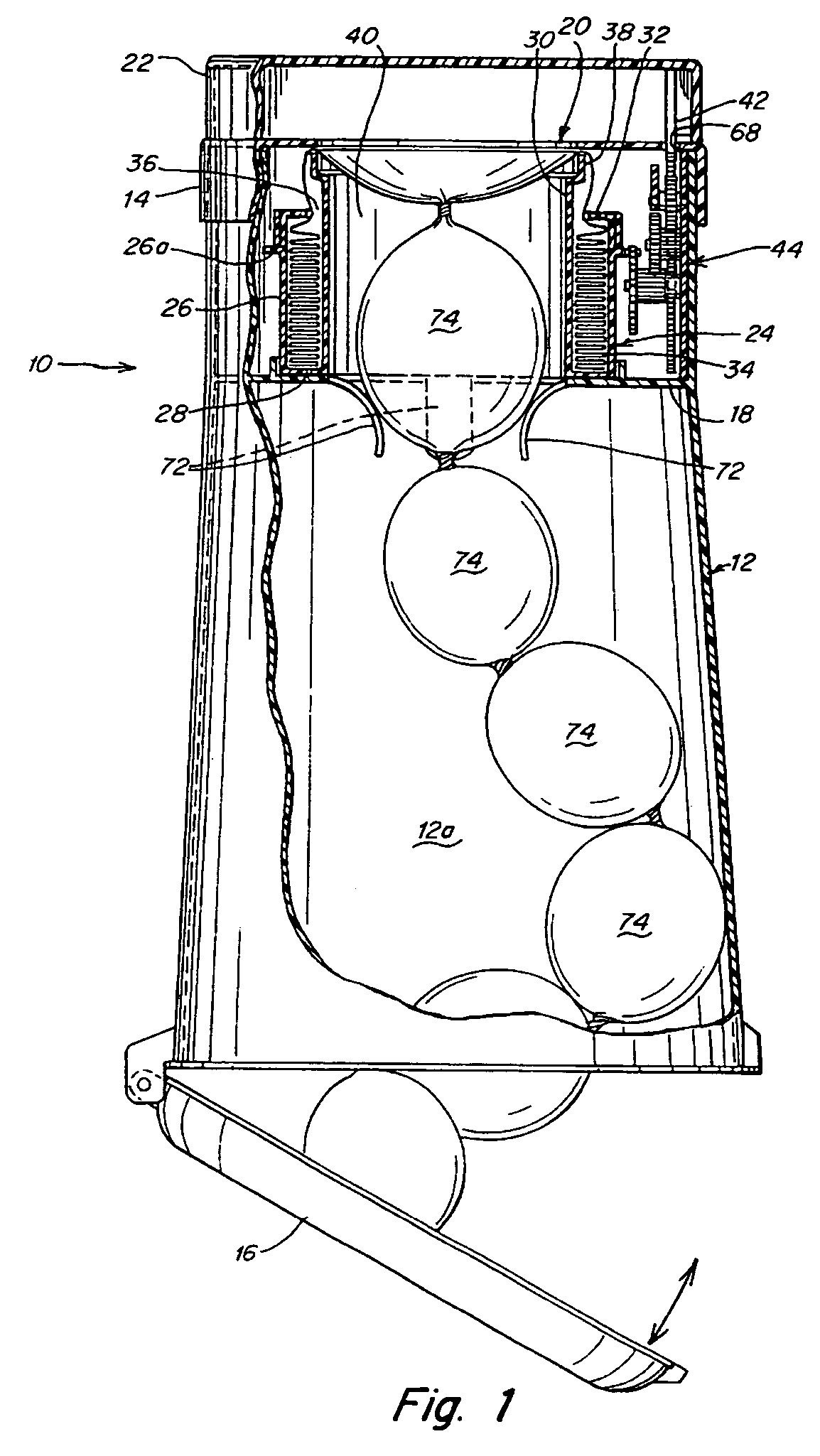

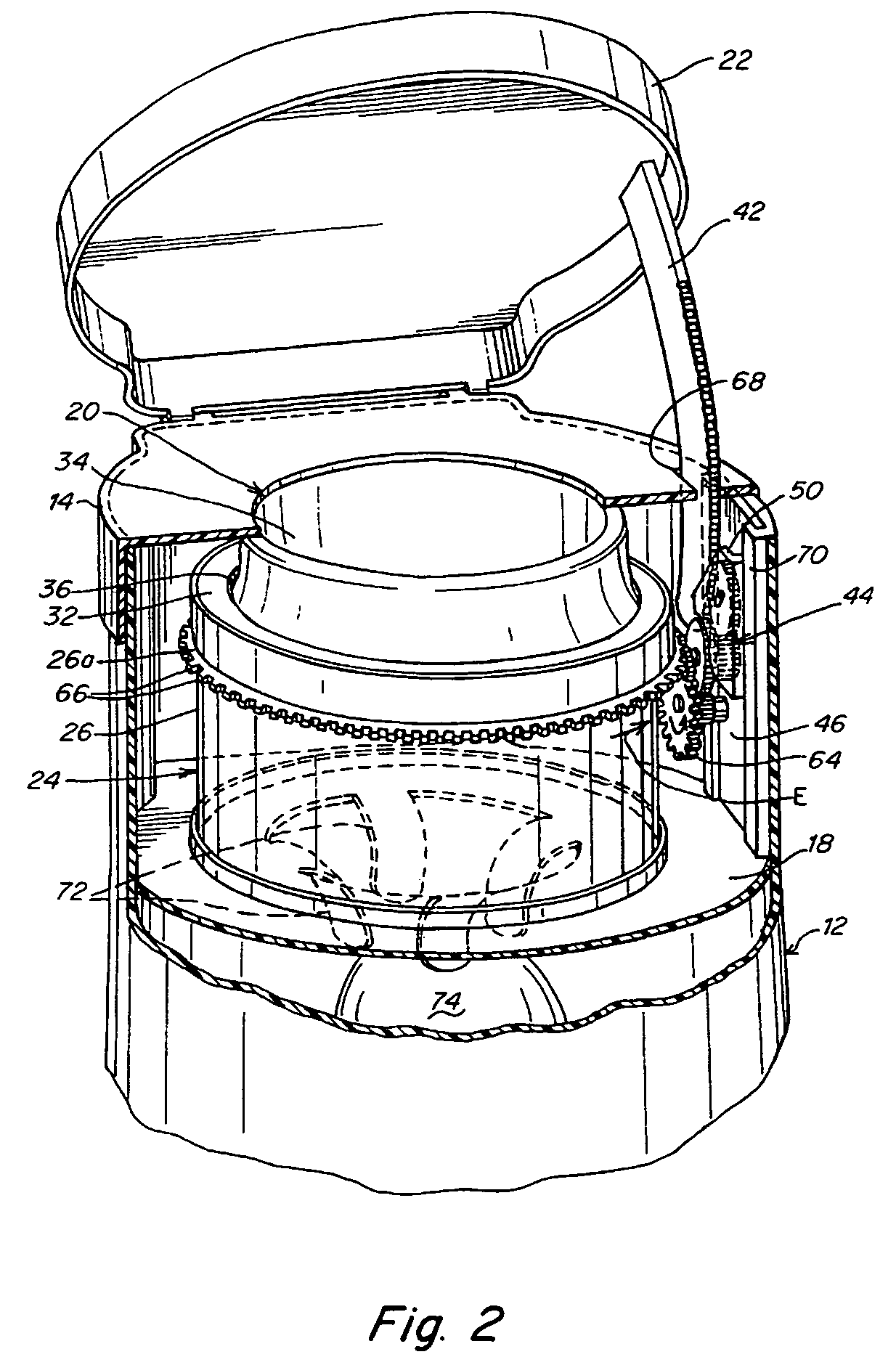

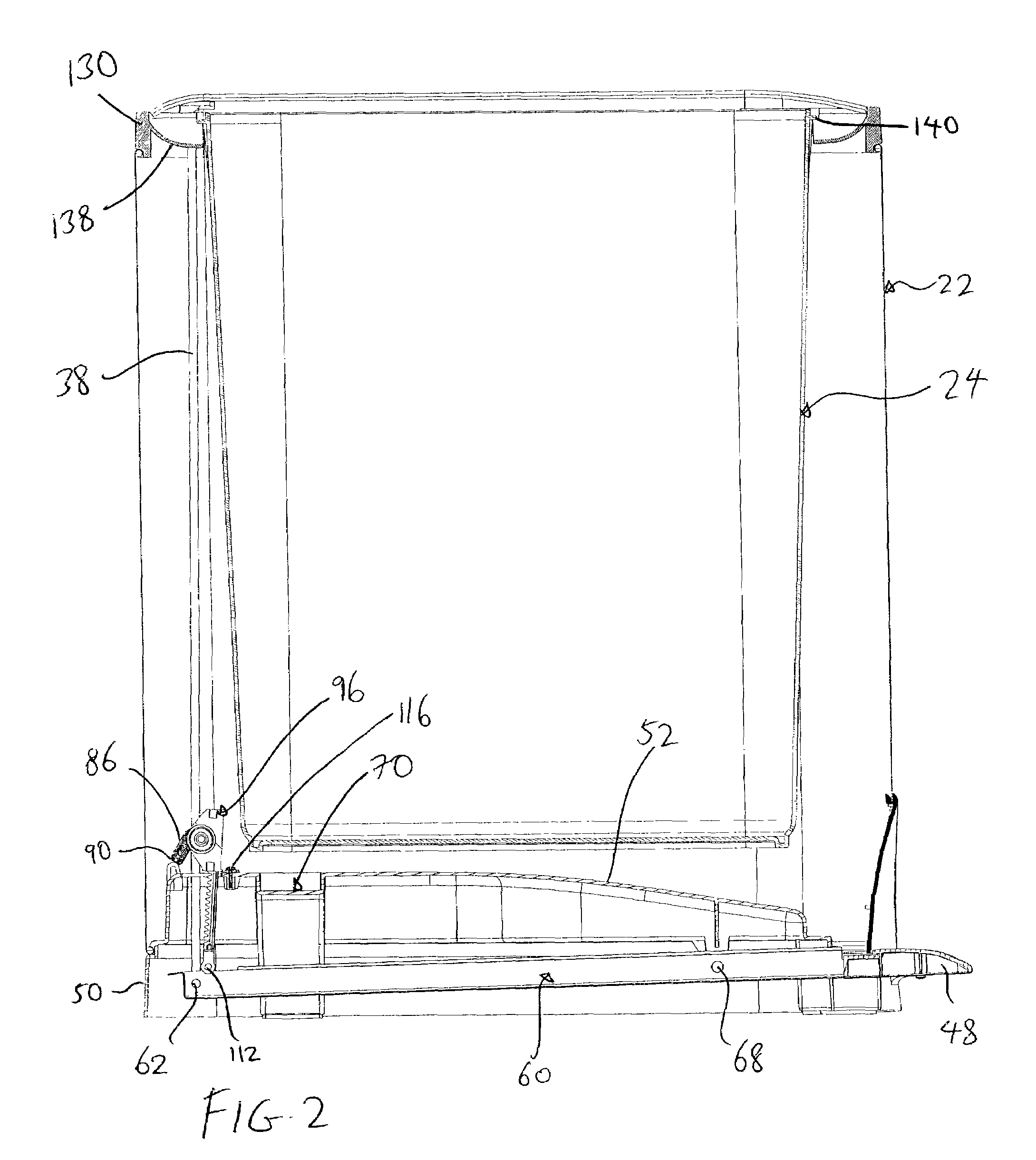

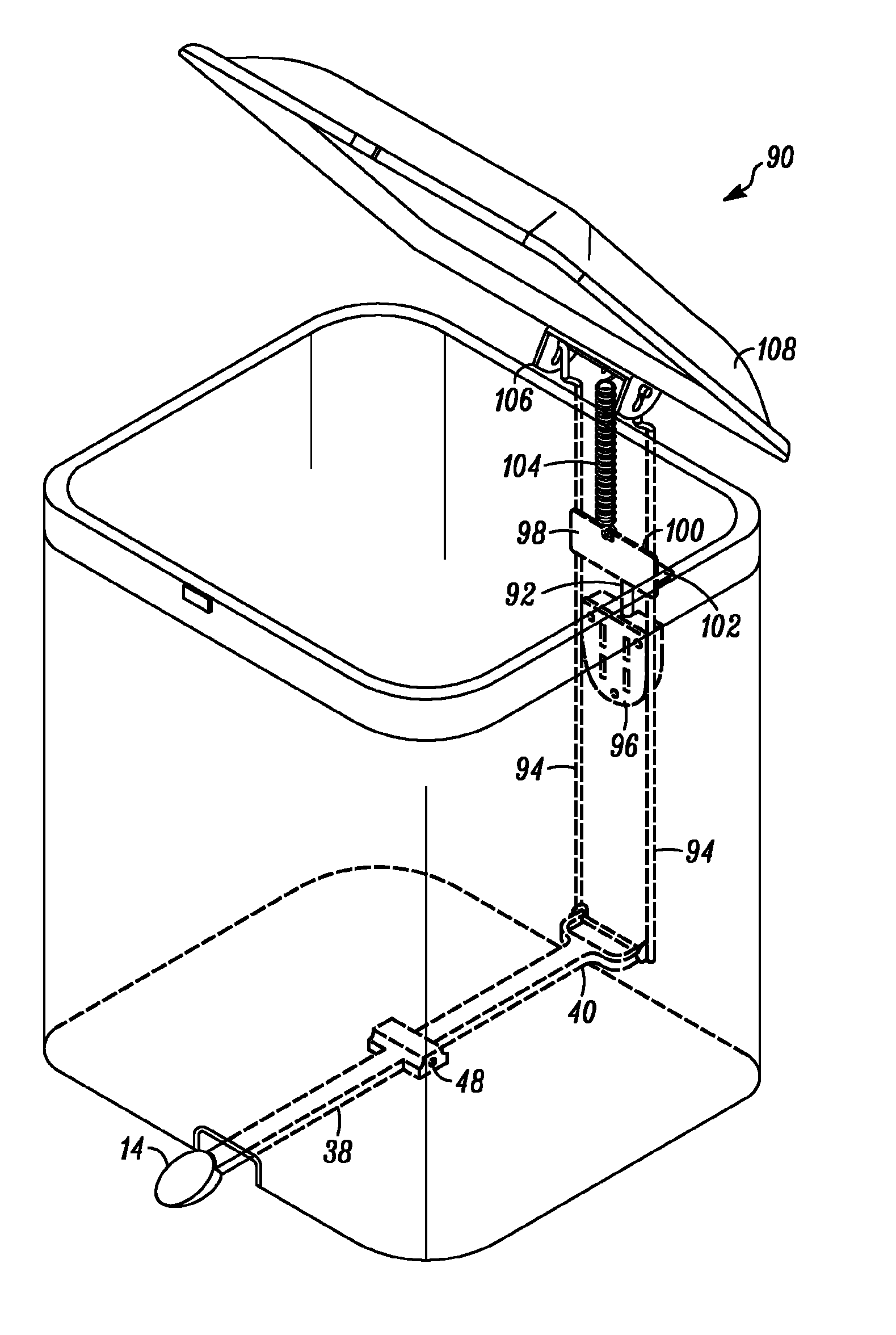

Waste disposal device including a sensing mechanism for delaying the rotation of a cartridge

InactiveUS7712285B2Effectively contains and prevents the release of odors from waste packagesEasy to disassembleContact operating partsLarge containersWaste materialWaste disposal

A waste disposal device including a sensing mechanism for delaying the rotation of a cartridge. The waste disposal device comprises a container defining a waste chamber for receiving encapsulated waste in a flexible tubing. The rotatable cartridge contains the flexible tubing. A lid is coupled to the device and is capable of moving between an open and closed position on the container. A rotation mechanism is operatively configured to engage the rotatable cartridge. A sensing mechanism is arranged to allow for delay in rotation of the cartridge until the lid assumes the closed position so that the waste is encapsulated in the flexible tubing after the closing of the lid, and after the subsequent twisting of the flexible tubing about the waste material caused by the rotation of the cartridge.

Owner:PLAYTEX PROD INC

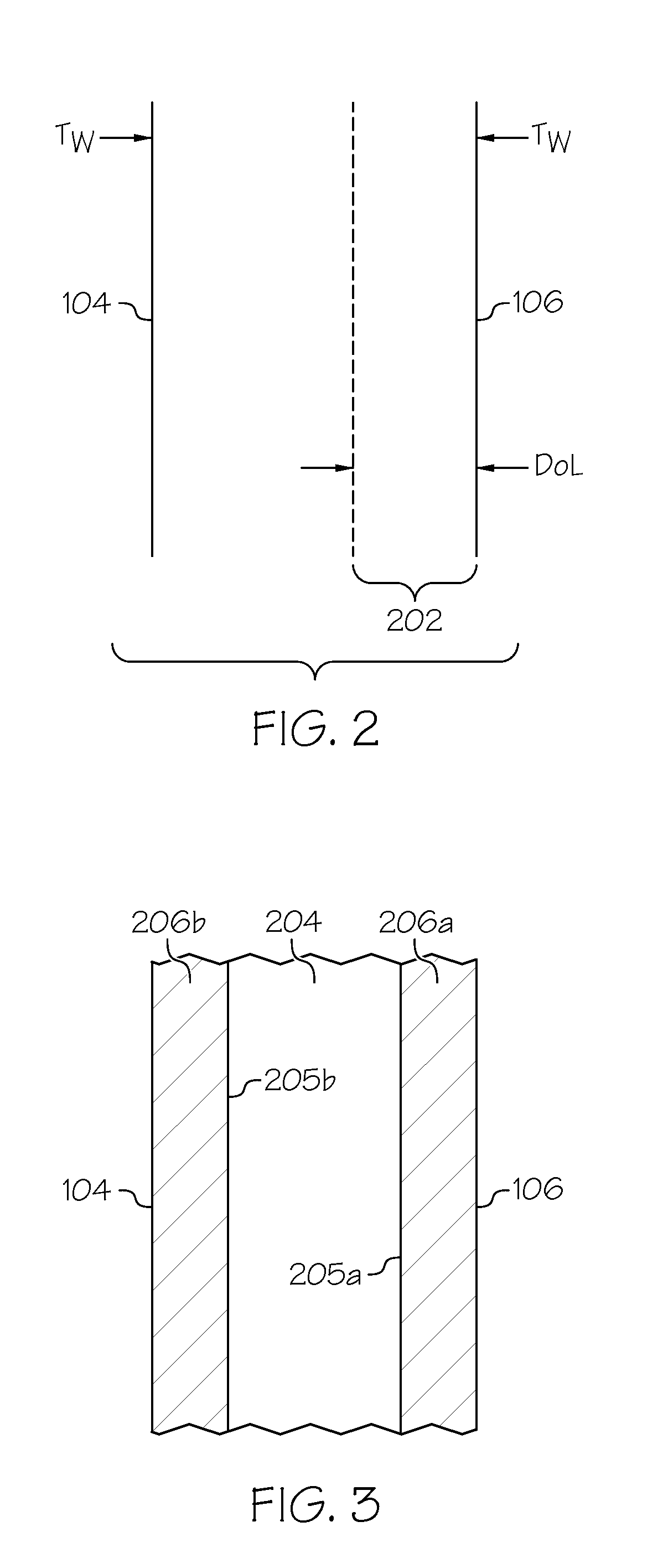

Strengthened glass containers resistant to delamination and damage

ActiveUS20140151370A1Pharmaceutical containersLarge containersUltimate tensile strengthMaterials science

The glass containers described herein are resistant to delamination, have improved strength, and increased damage resistance. In one embodiment, a glass container may include a body having an inner surface, an outer surface and a wall thickness extending between the outer surface and the inner surface. At least the inner surface of the body may have a delamination factor less than or equal to 10. The body may also have a compressively stressed layer extending from the outer surface of the body into the wall thickness. The compressively stressed layer may have a surface compressive stress greater than or equal to 150 MPa. A lubricous coating may be positioned around at least a portion of the outer surface of the body, such that the outer surface of the body with the lubricous coating has a coefficient of friction less than or equal to 0.7.

Owner:CORNING INC

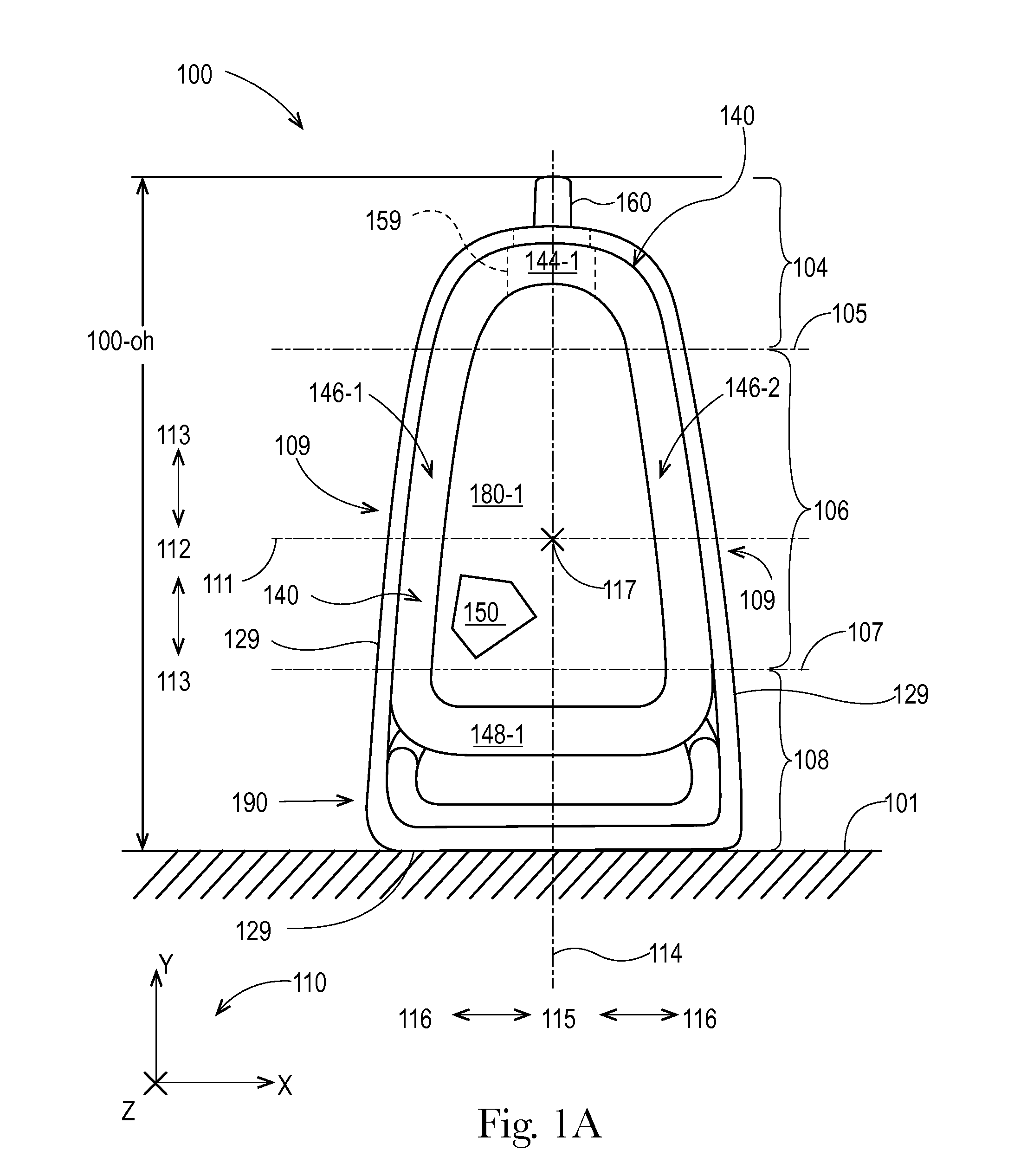

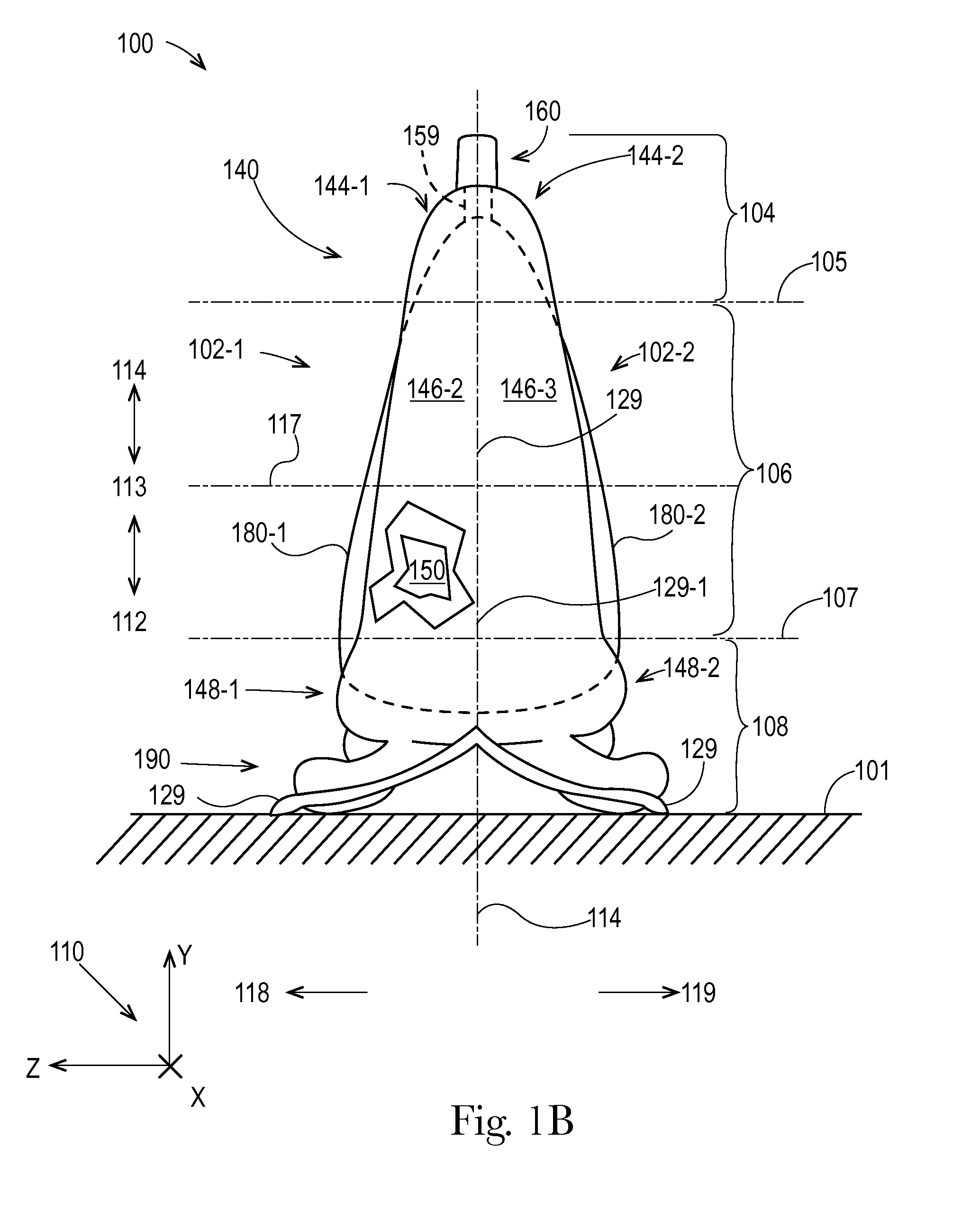

Glass Articles With Low-Friction Coatings

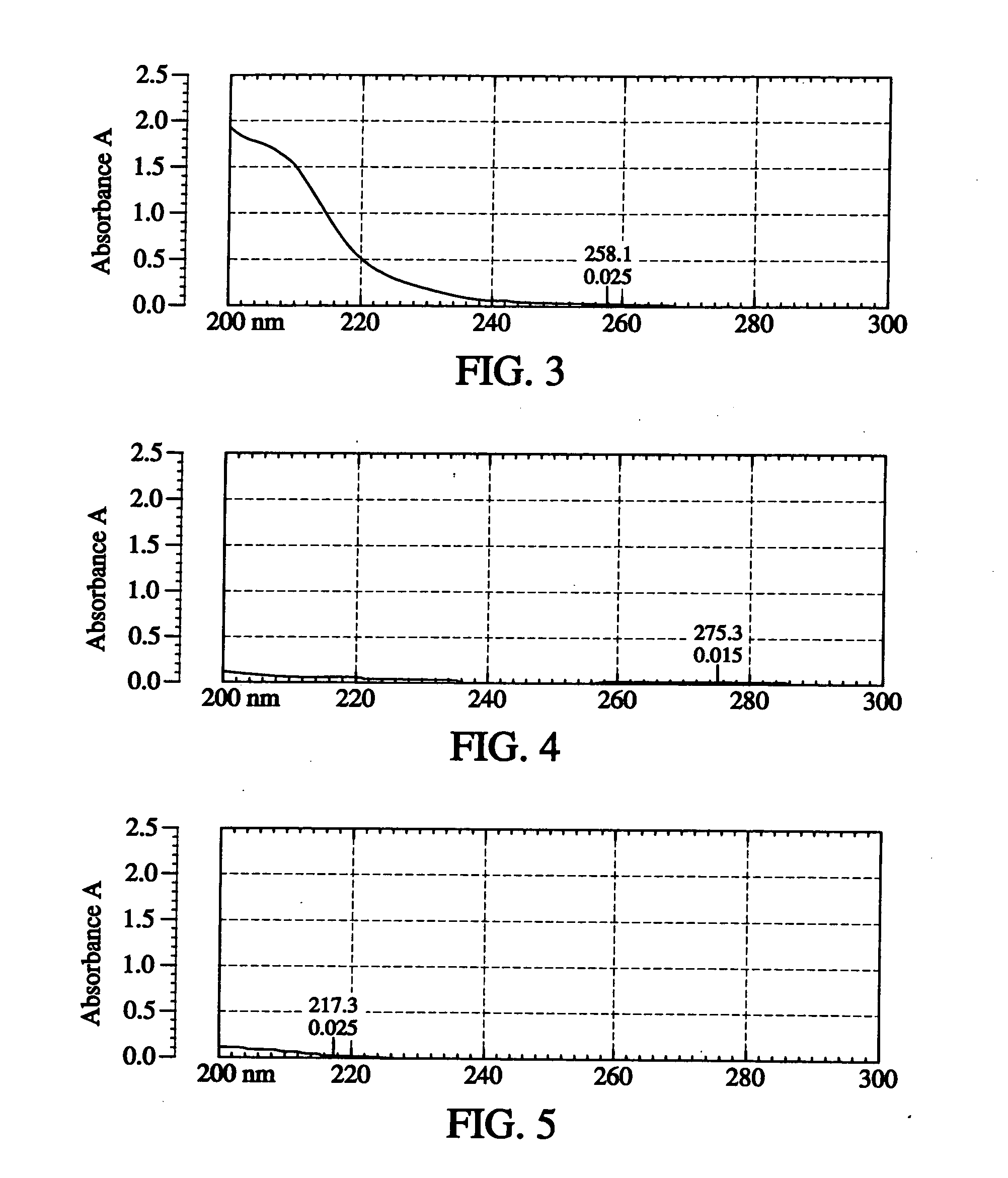

ActiveUS20130171456A1Thermally stablePharmaceutical containersMedical packagingChemical compositionLength wave

Low-friction coatings and glass articles with low-friction coatings are disclosed. According to one embodiment, a coated glass article may include a glass body comprising a first surface and a low-friction coating positioned on at least a portion of the first surface of the glass body. The low-friction coating may include a polymer chemical composition. The coated glass article may be thermally stable at a temperature of at least about 260° C. for 30 minutes. A light transmission through the coated glass article may be greater than or equal to about 55% of a light transmission through an uncoated glass article for wavelengths from about 400 nm to about 700 nm. The low-friction coating may have a mass loss of less than about 5% of its mass when heated from a temperature of 150° C. to 350° C. at a ramp rate of about 10° C. / minute.

Owner:CORNING INC

Combined apparatus for storage

ActiveUS8474640B2Low profileEasy to storeContainers for flexible articlesGarmentsEngineeringMechanical engineering

Owner:ARMSTRONG STEPHEN G

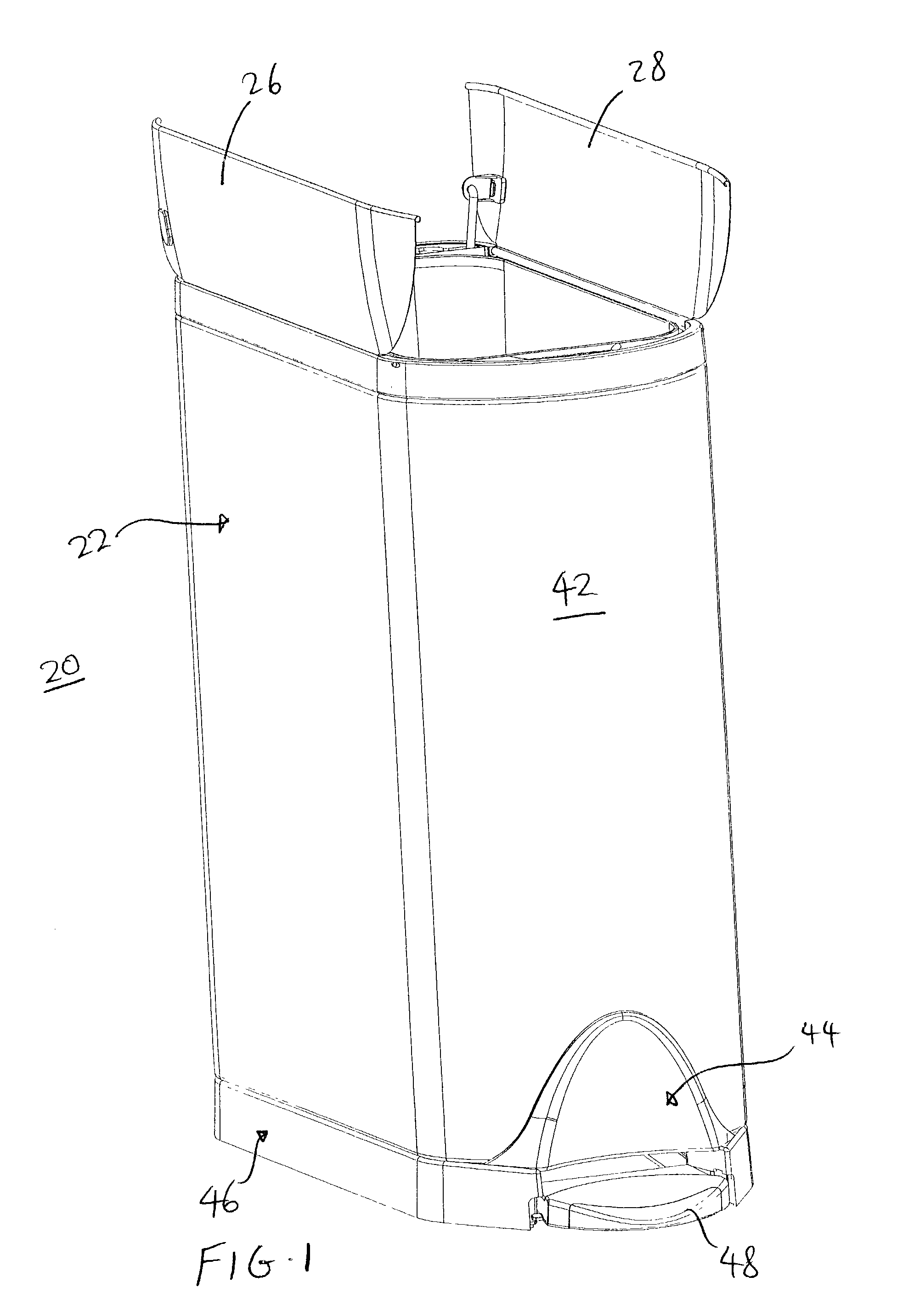

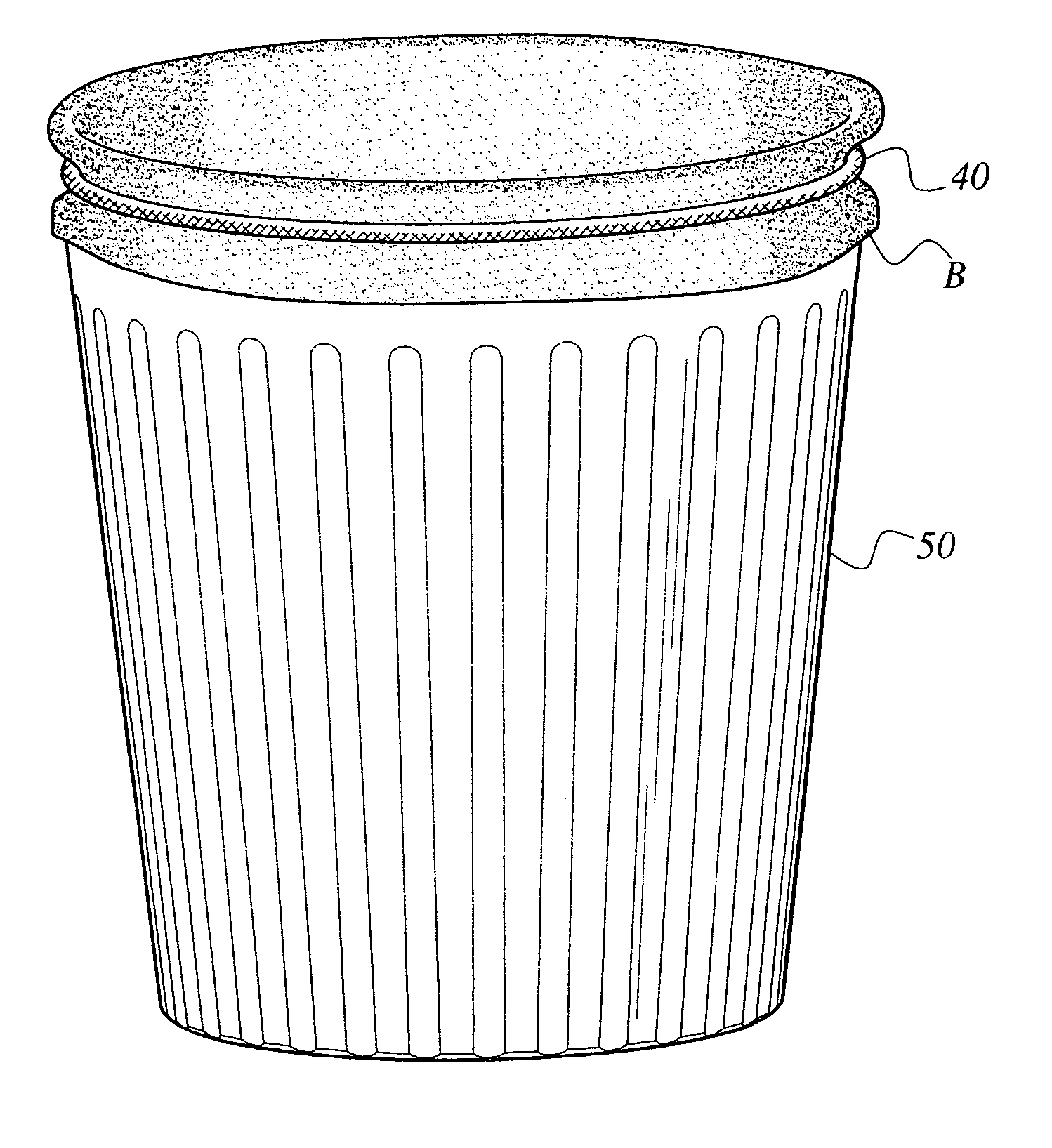

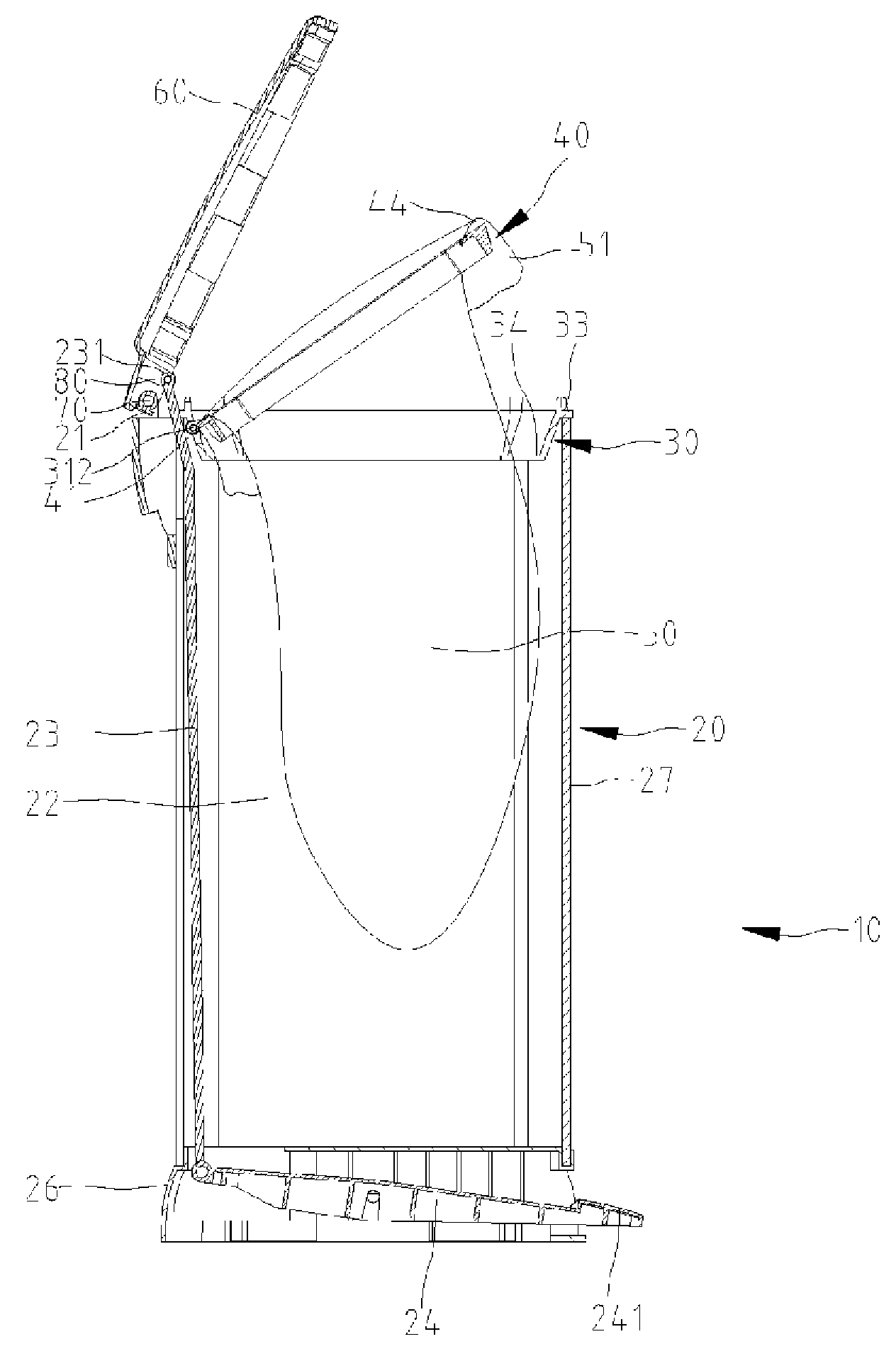

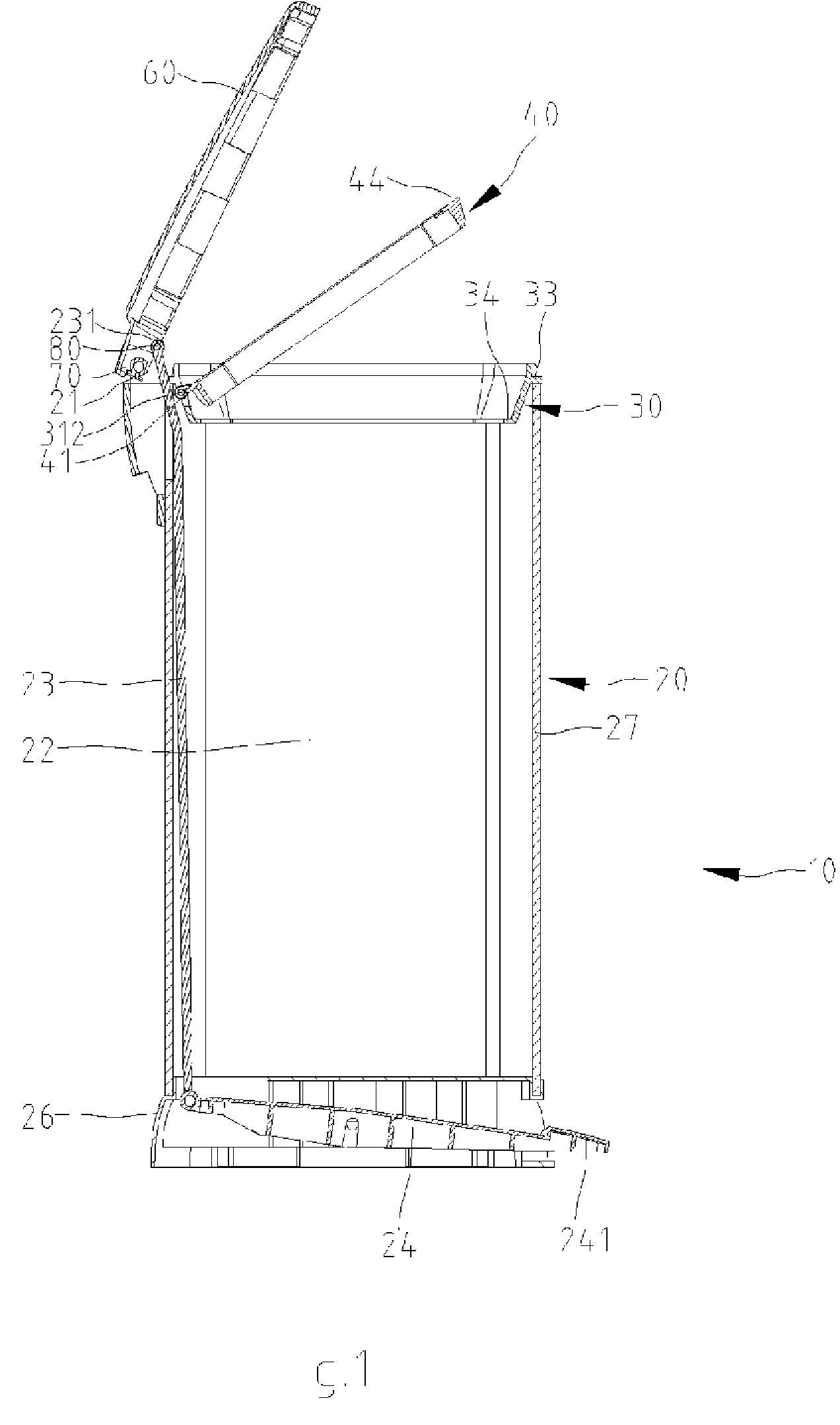

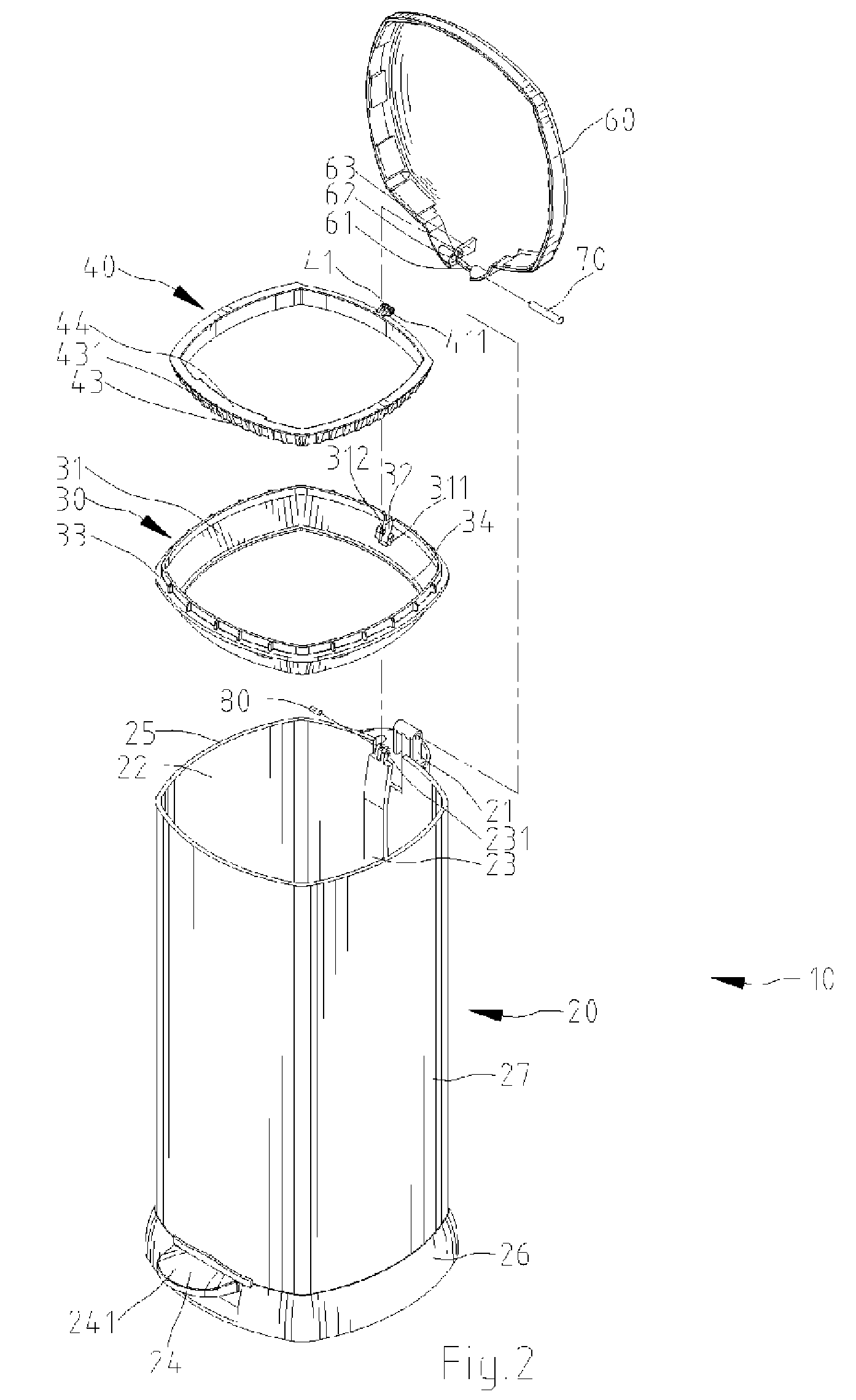

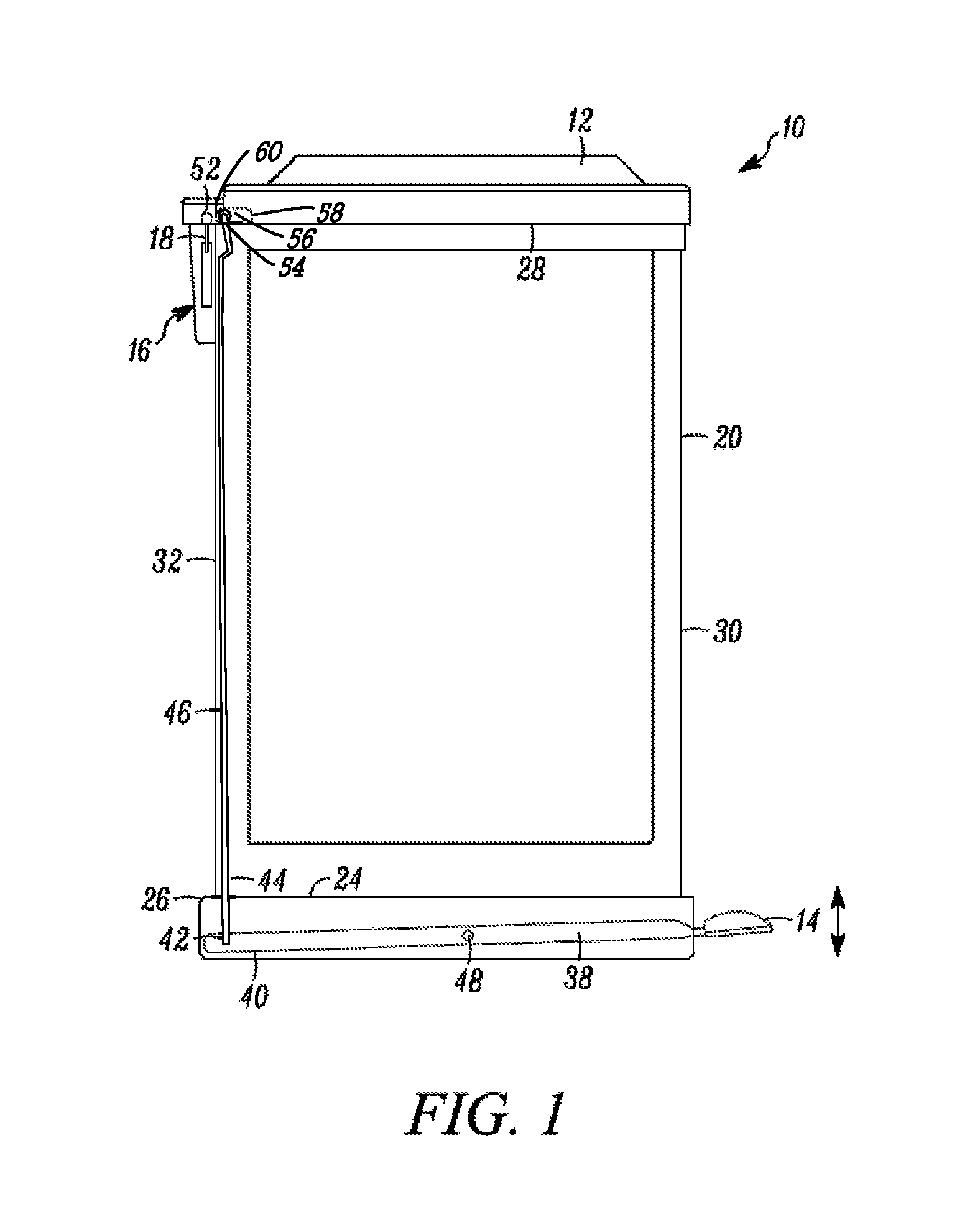

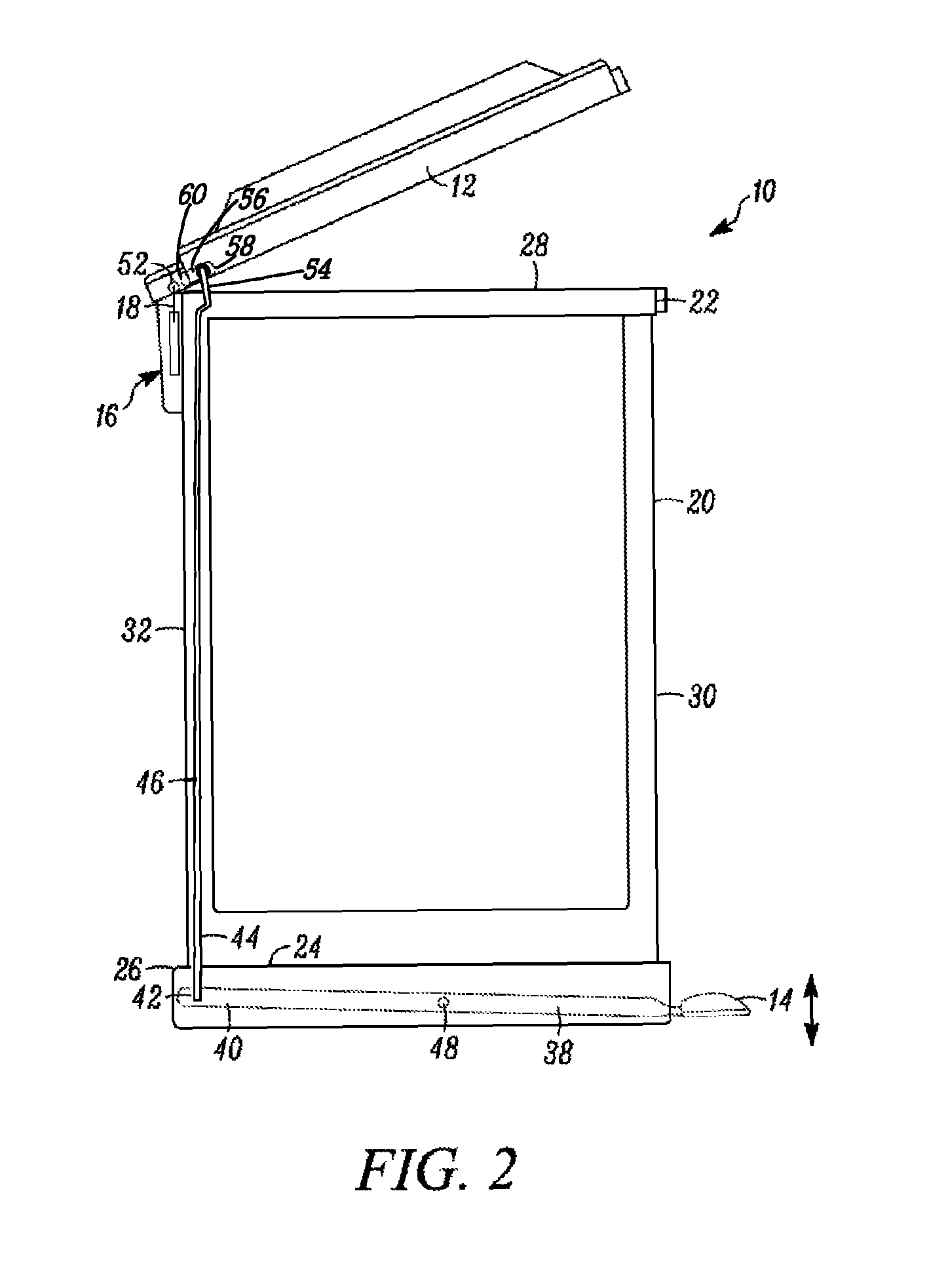

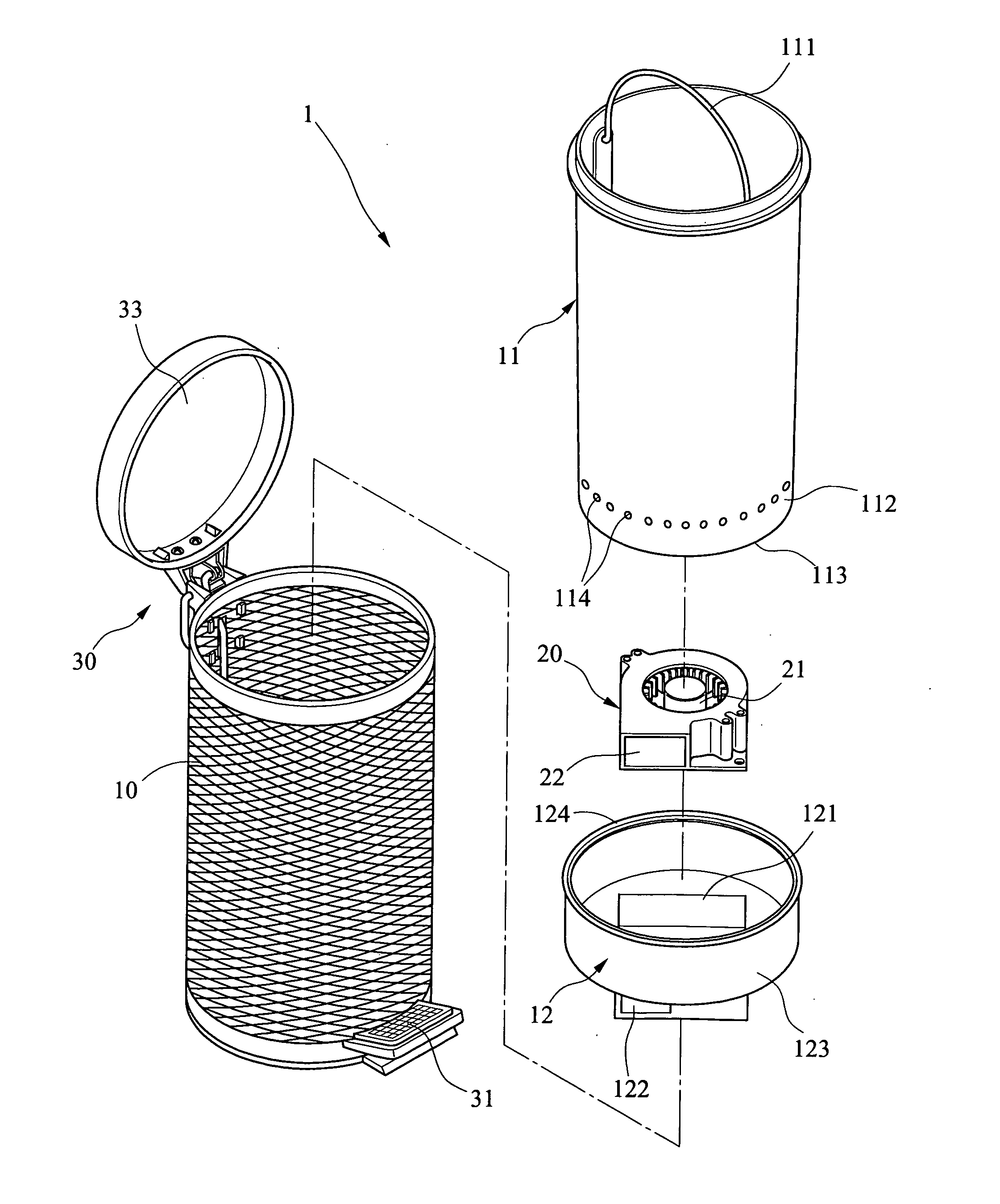

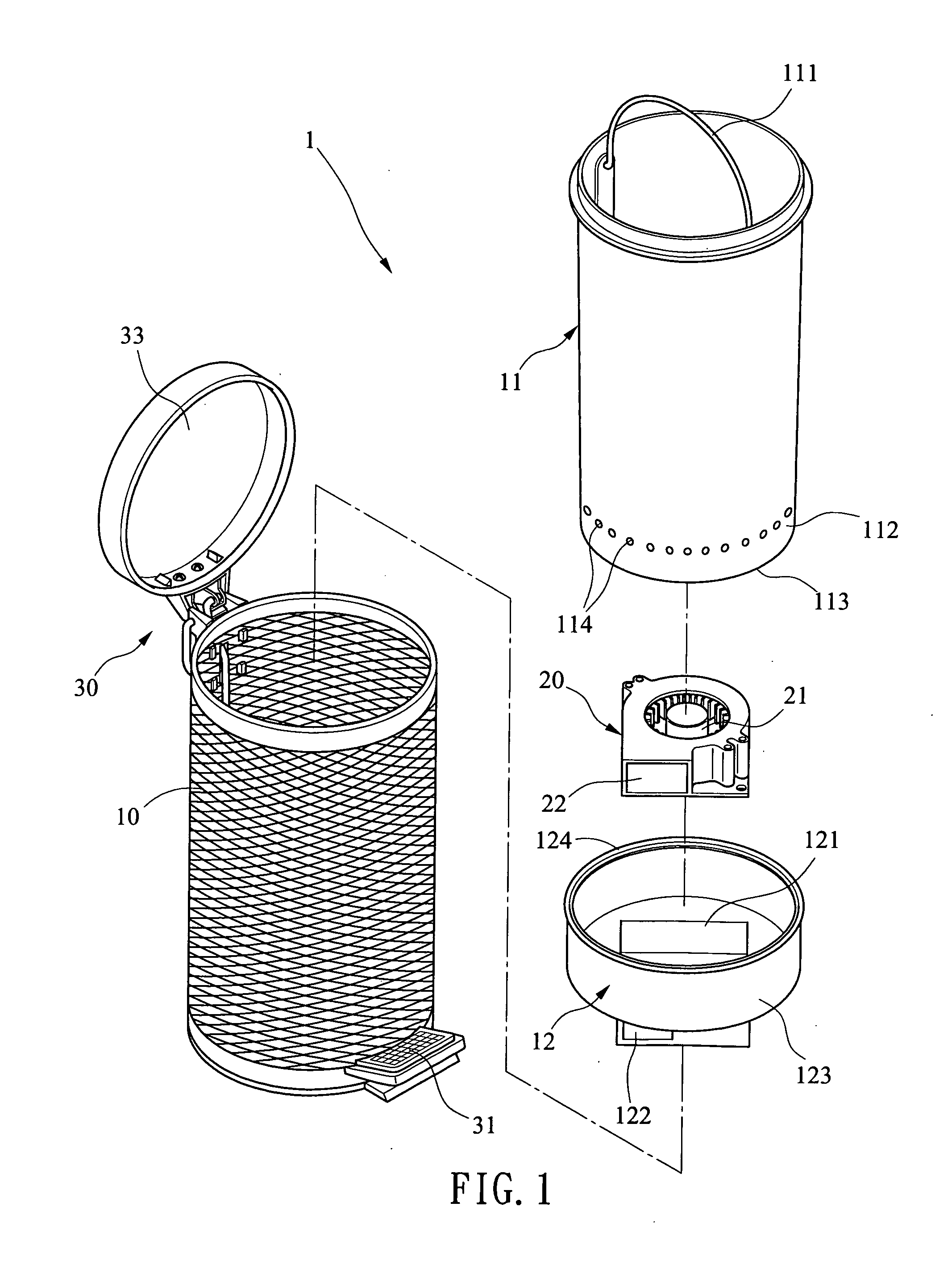

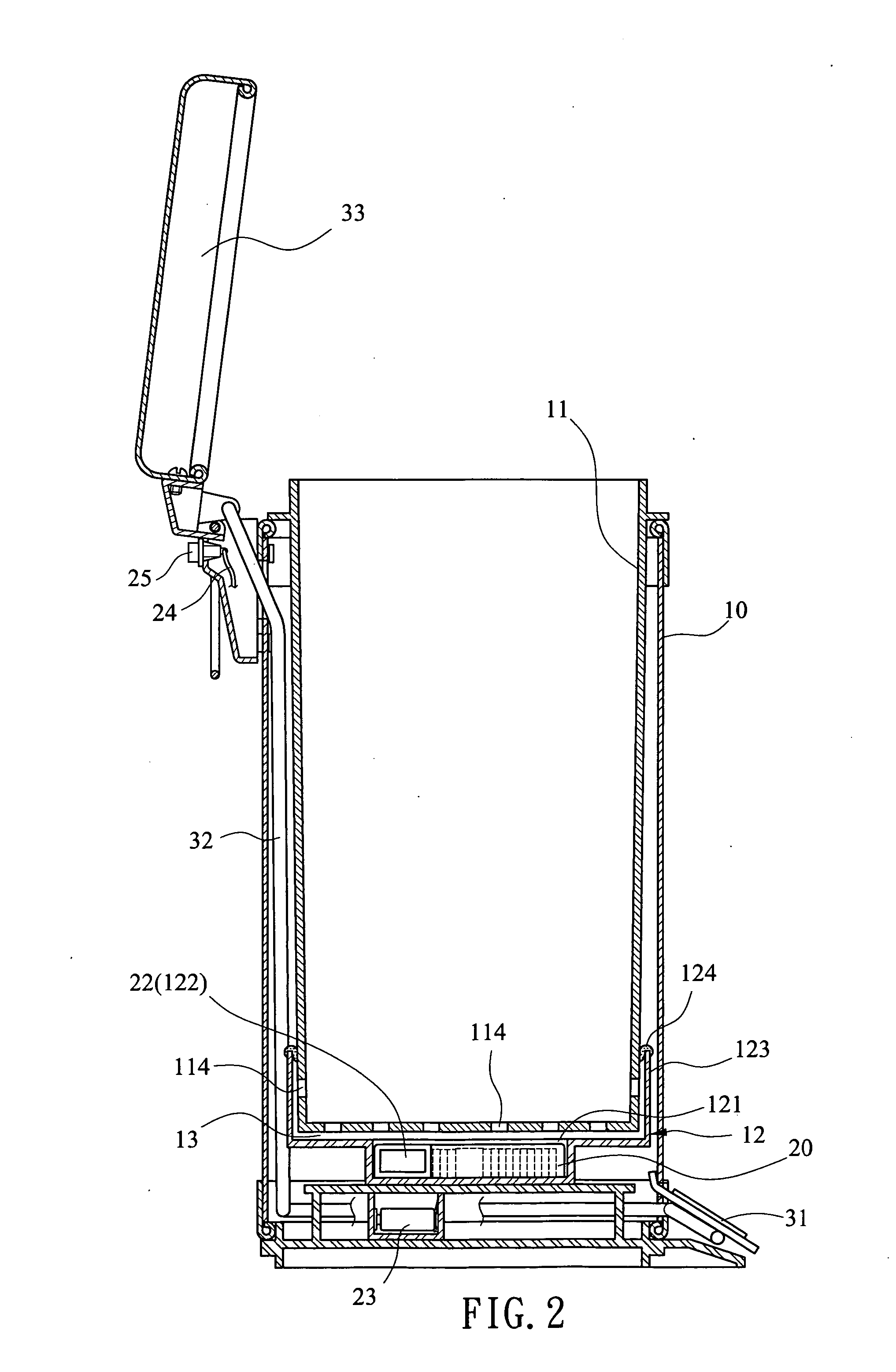

Trash can assembly

A trash can assembly has a shell, a lid fitted over the top end of the shell, a pedal positioned adjacent the bottom end of the shell, a link assembly coupling the pedal and the lid, and a motion damper coupled to the link assembly for slowing the closing motion of the lid. The assembly also includes an inner liner that is retained inside the shell, with a support frame secured to the top end of the shell and having a ridge on which a peripheral lip of the inner liner rests.

Owner:SIMPLEHUMAN

Bisphenol a and aromatic glycidyl ether-free coatings

ActiveUS20070036903A1Good metal substrateGood inter-coat adhesionLiquid surface applicatorsSynthetic resin layered productsPolyesterMeth-

Disclosed are Bisphenol A (BPA), Bisphenol F, Bisphenol A diglycidyl ether (BADGE), and Bisphenol F diglycidyl ether (BFDGE)-free coating compositions for metal substrates including an under-coat composition containing a polyester (co)polymer, and an under-coat cross-linker; and an over-coat composition containing a poly(vinyl chloride) (co)polymer dispersed in a substantially nonaqueous carrier liquid, an over-coat cross-linker, and a functional (meth)acrylic (co)polymer. Also provided is a method of coating a metal substrate using the BPA, BPF, BADGE and BFDGE-free coating system to produce a hardened protective coating useful in fabricating metal storage containers. The coated substrate is particularly useful in fabricating multi-part foodstuffs storage containers with “easy-open” end closures.

Owner:SWIMC LLC

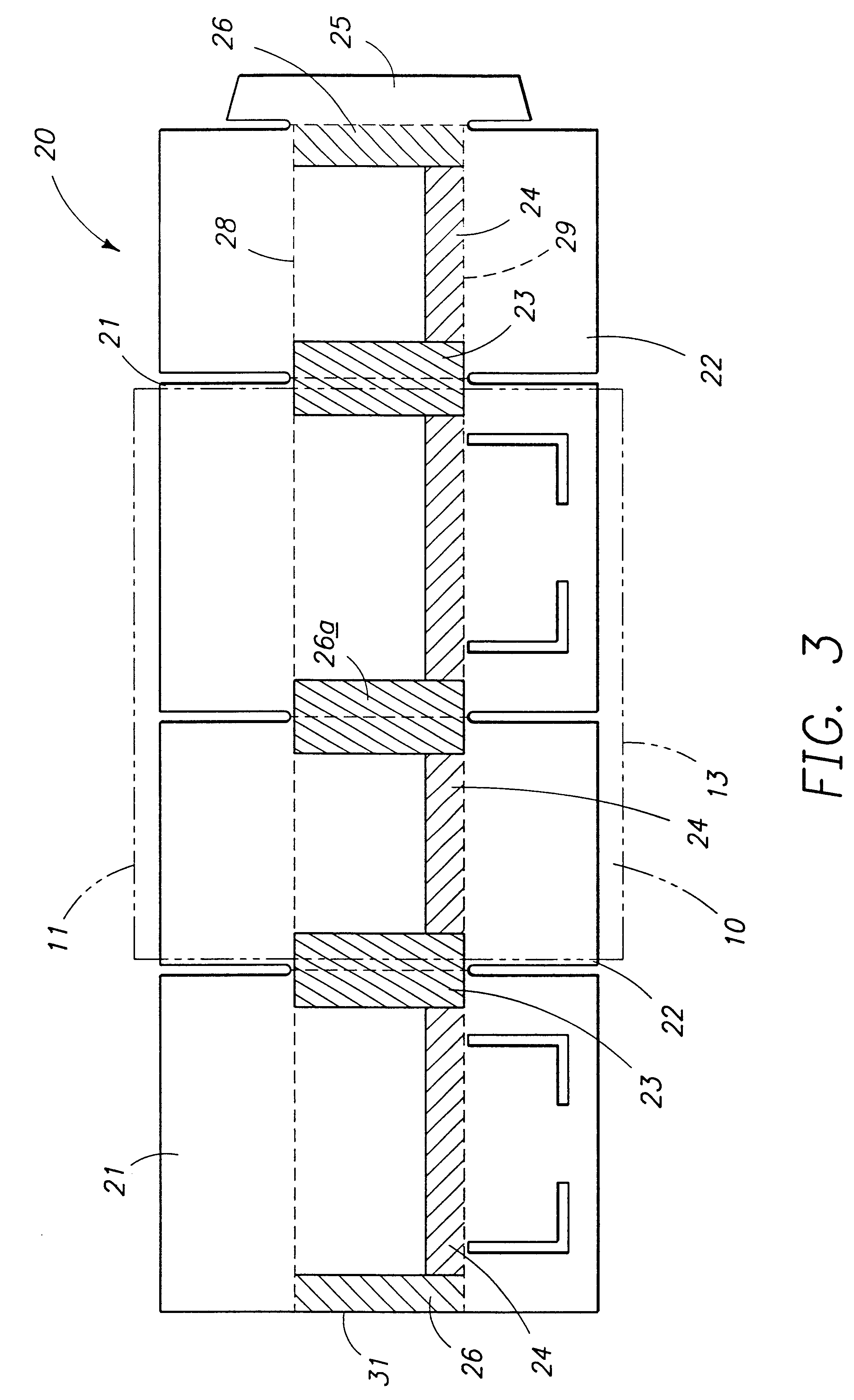

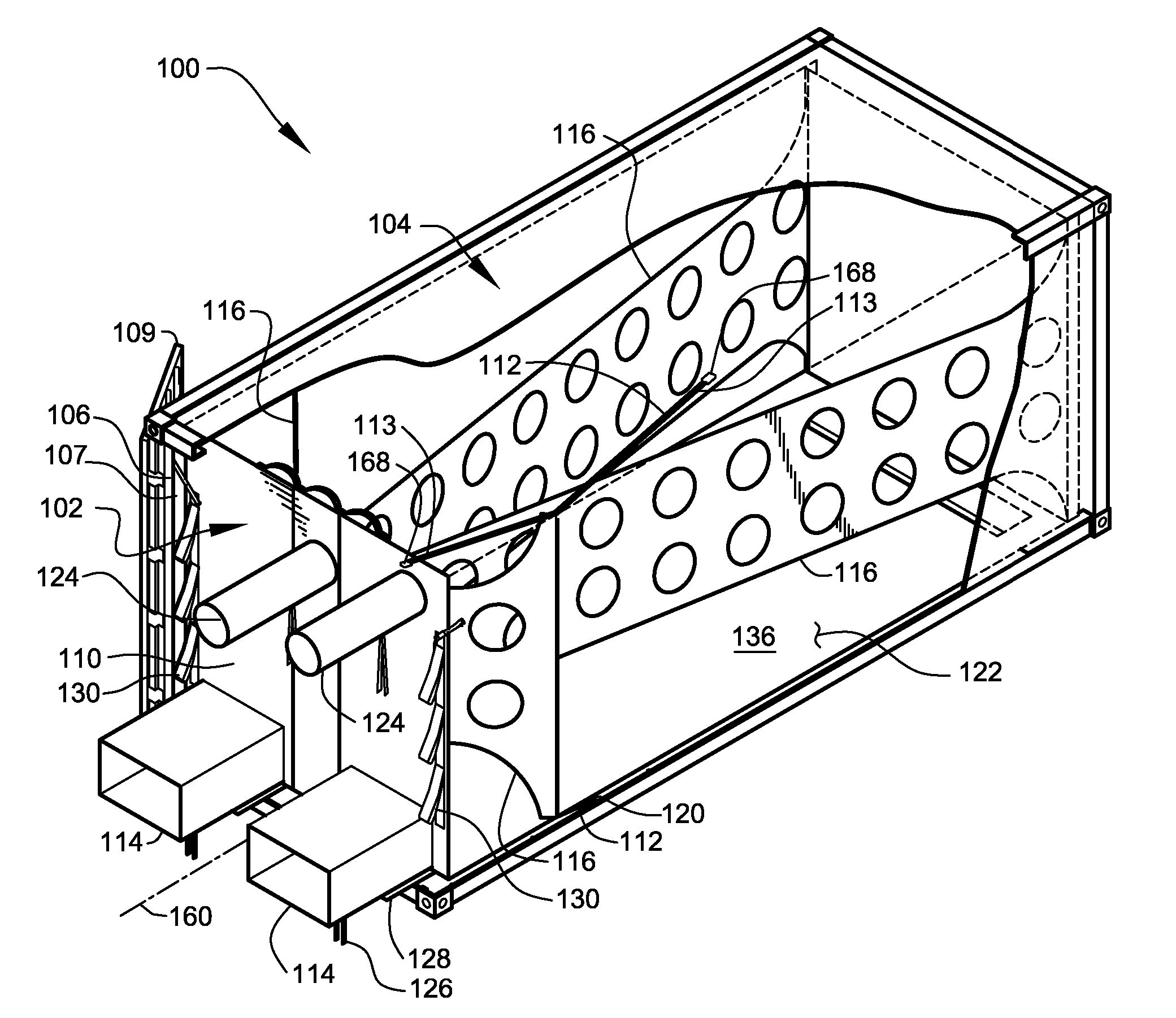

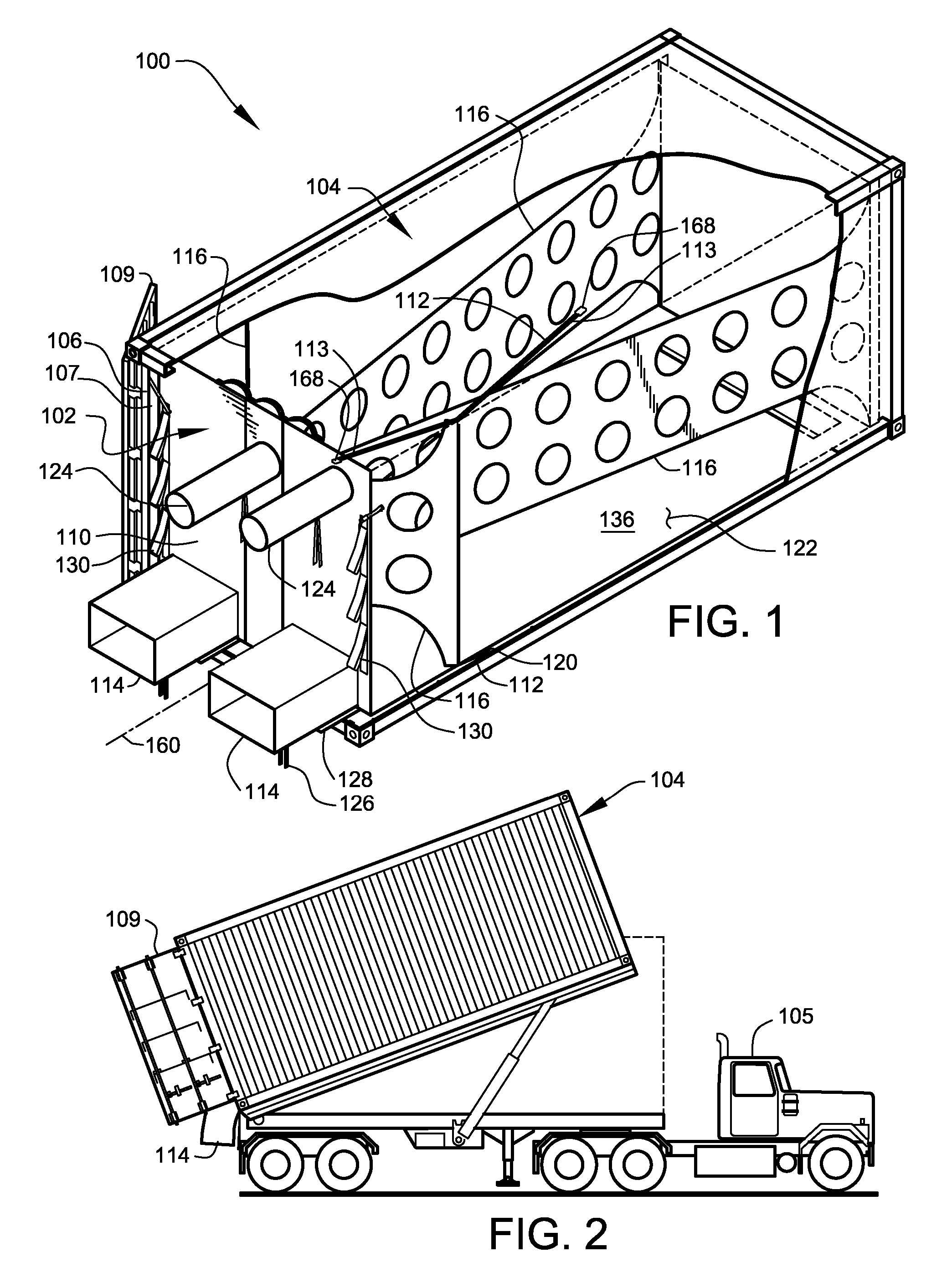

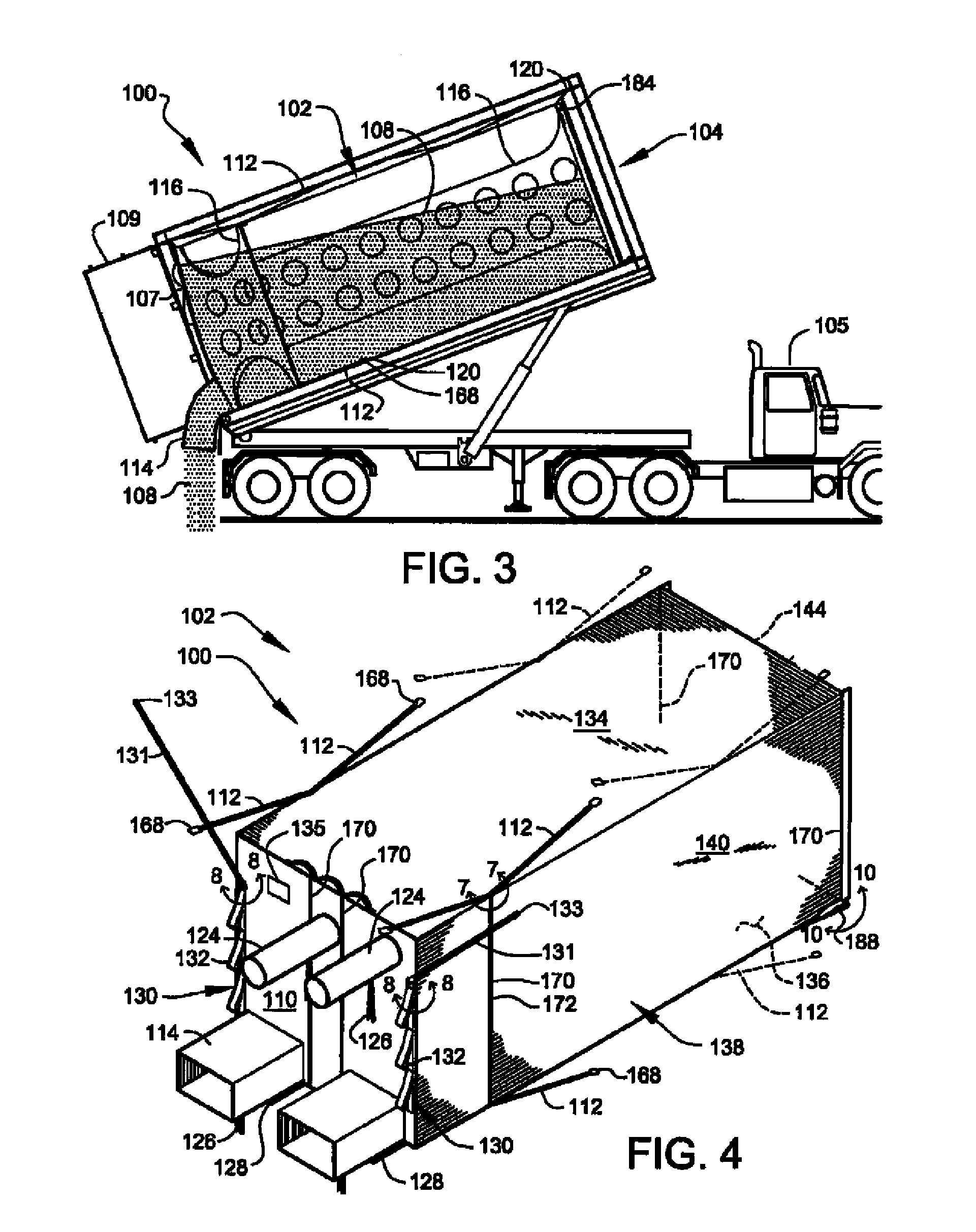

Container liner systems

A shipping container liner system for use in the shipping of bulk flowable products is described. The system comprises a specially adapted shipping container liner that is self-supporting without the need of rear-mounted rigid supportive bars to retain the liner within the shipping container during filling and discharge. The system comprises an arrangement of interior support baffles operating in conjunction with a plurality of exterior anchor straps adapted to distribute the cargo load throughout the length of the liner. A specialized hopper for unloading the bulk material is also disclosed.

Owner:TOWNSEND ARTHUR M

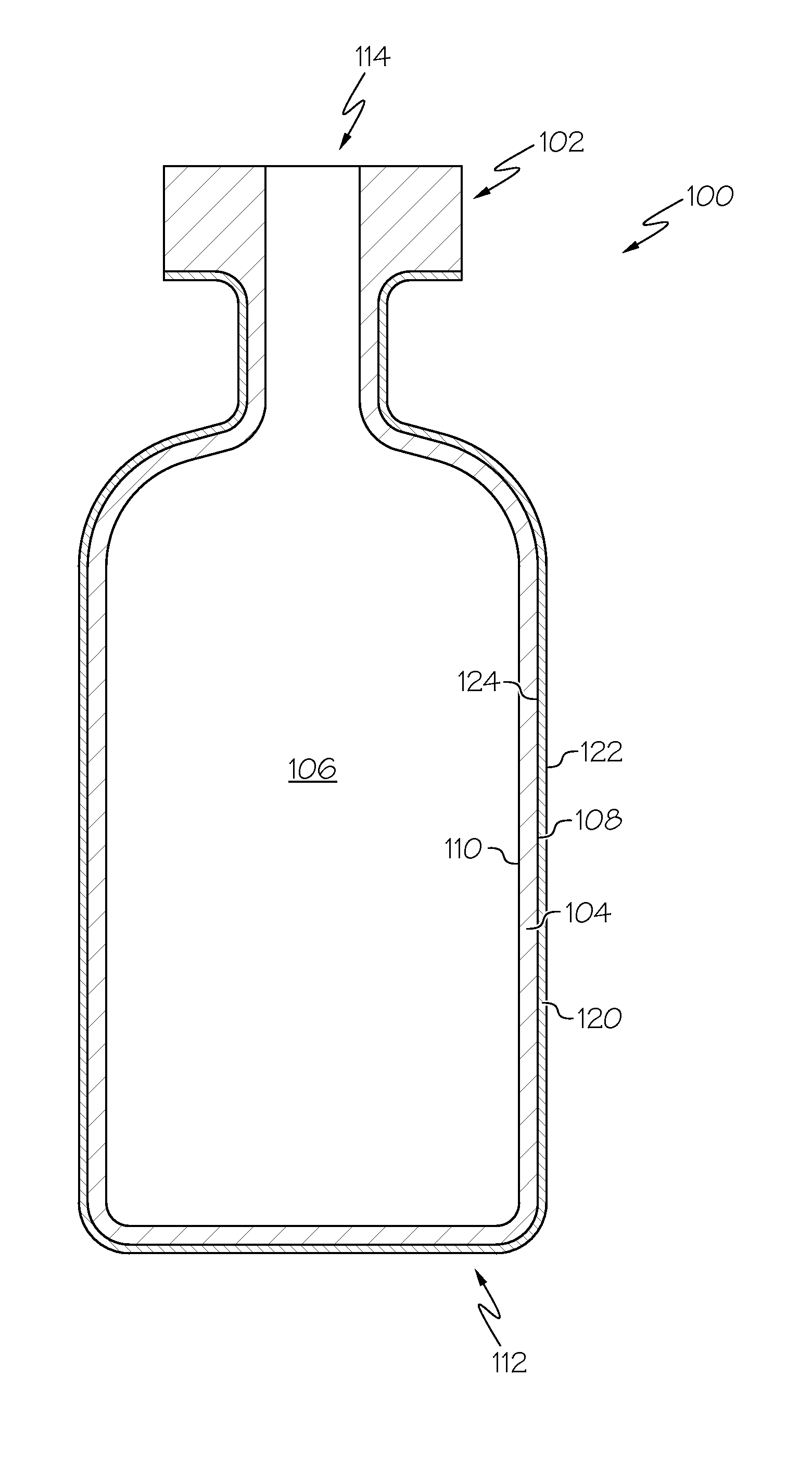

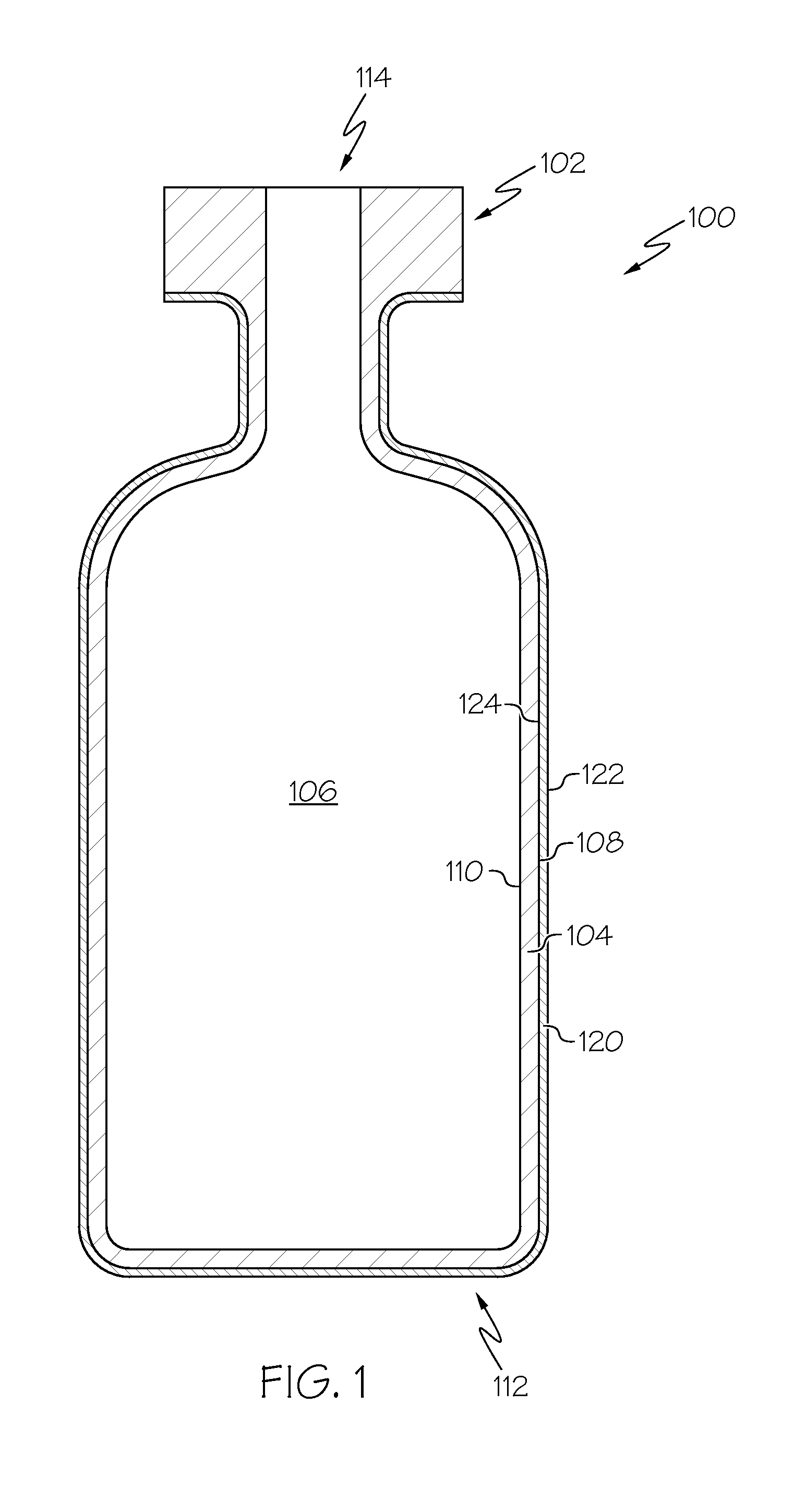

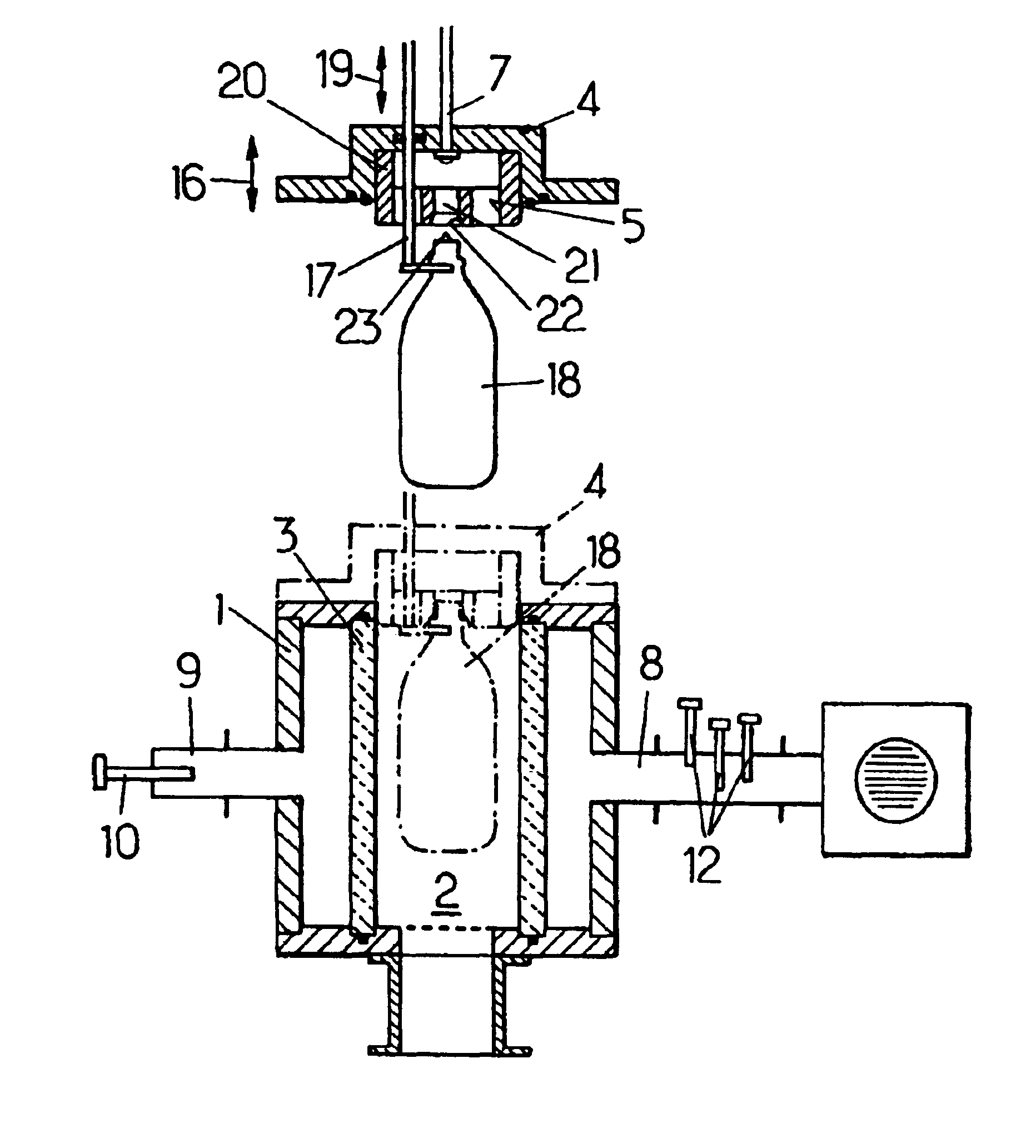

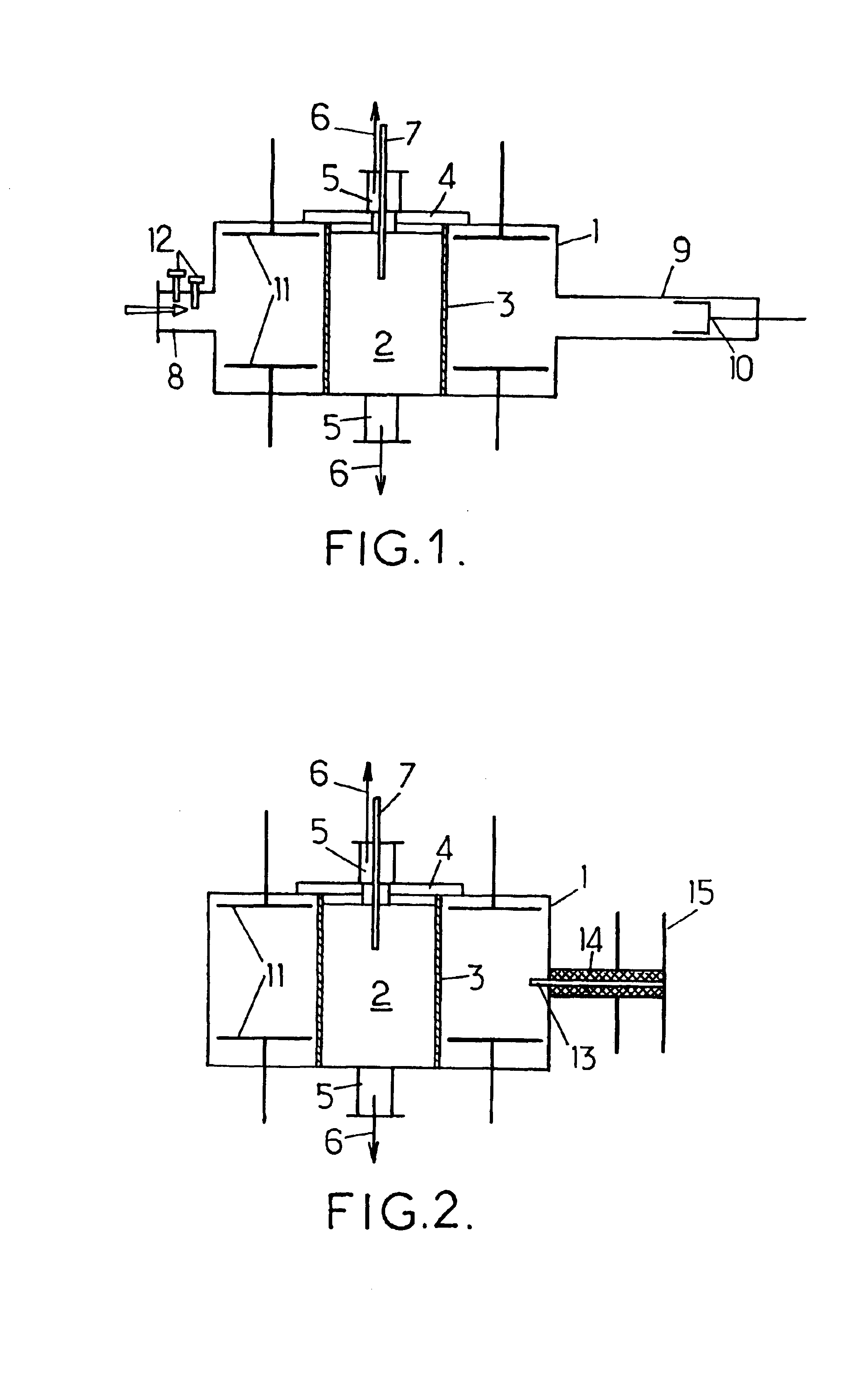

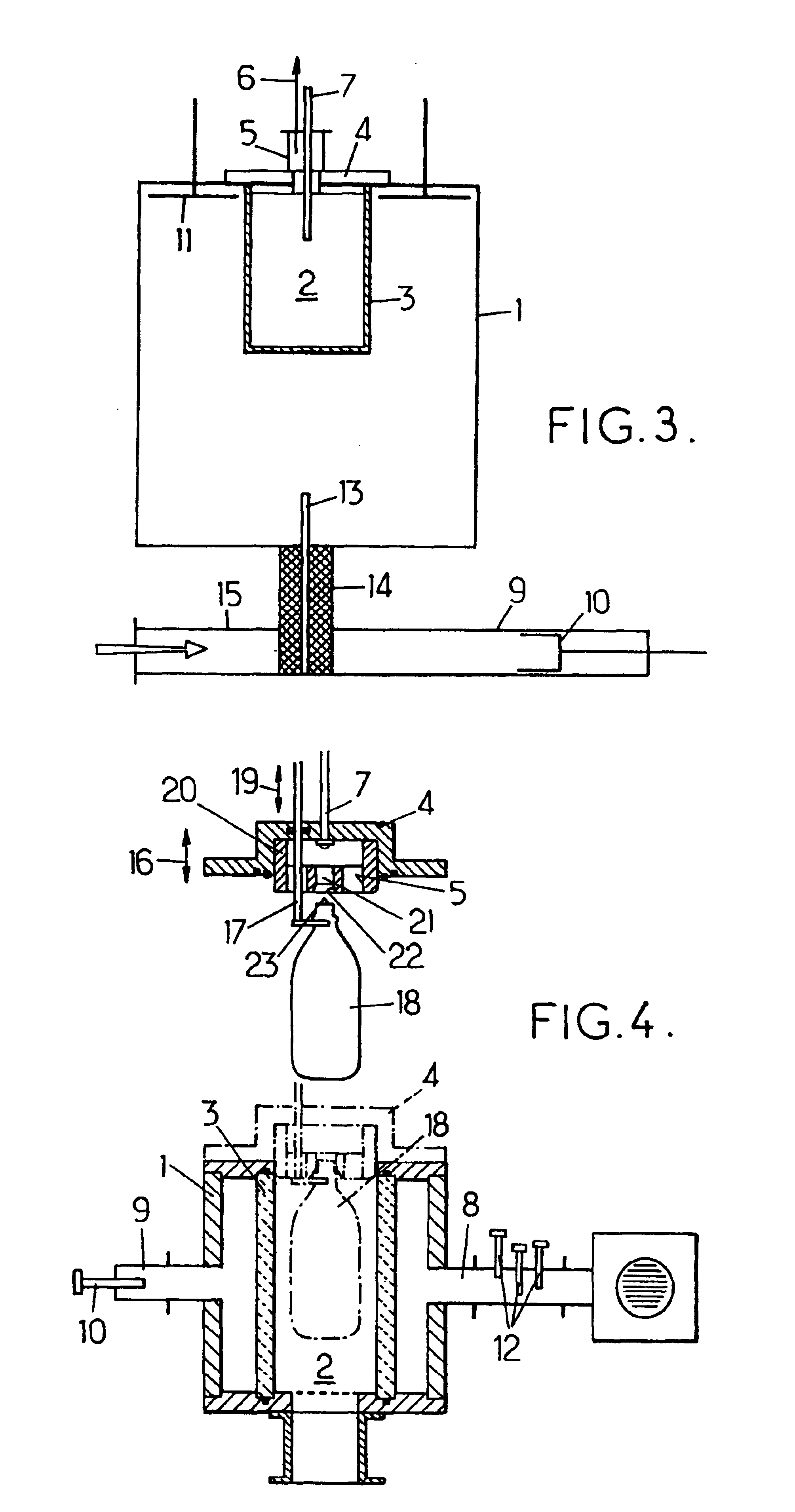

Container with material coating having barrier effect and method and apparatus for making same

InactiveUS6919114B1Easy to manufactureImprove barrier propertiesLiquid surface applicatorsBottlesBarrier effectBottle

The invention provides a container such as a bottle or flask, made heterogeneously from a material with a barrier effect and a polymer material, characterised in that the material with a barrier effect is an amorphous carbon material with a polymer tendency which is applied as a coating on a substrate of polymer material.

Owner:SIDEL PARTICIPATIONS SAS

Trash can liner with bag securing mechanism

InactiveUS7694838B2Prevent slippingLarge containersRefuse receptaclesEngineeringMechanical engineering

Owner:SIMPLEHUMAN

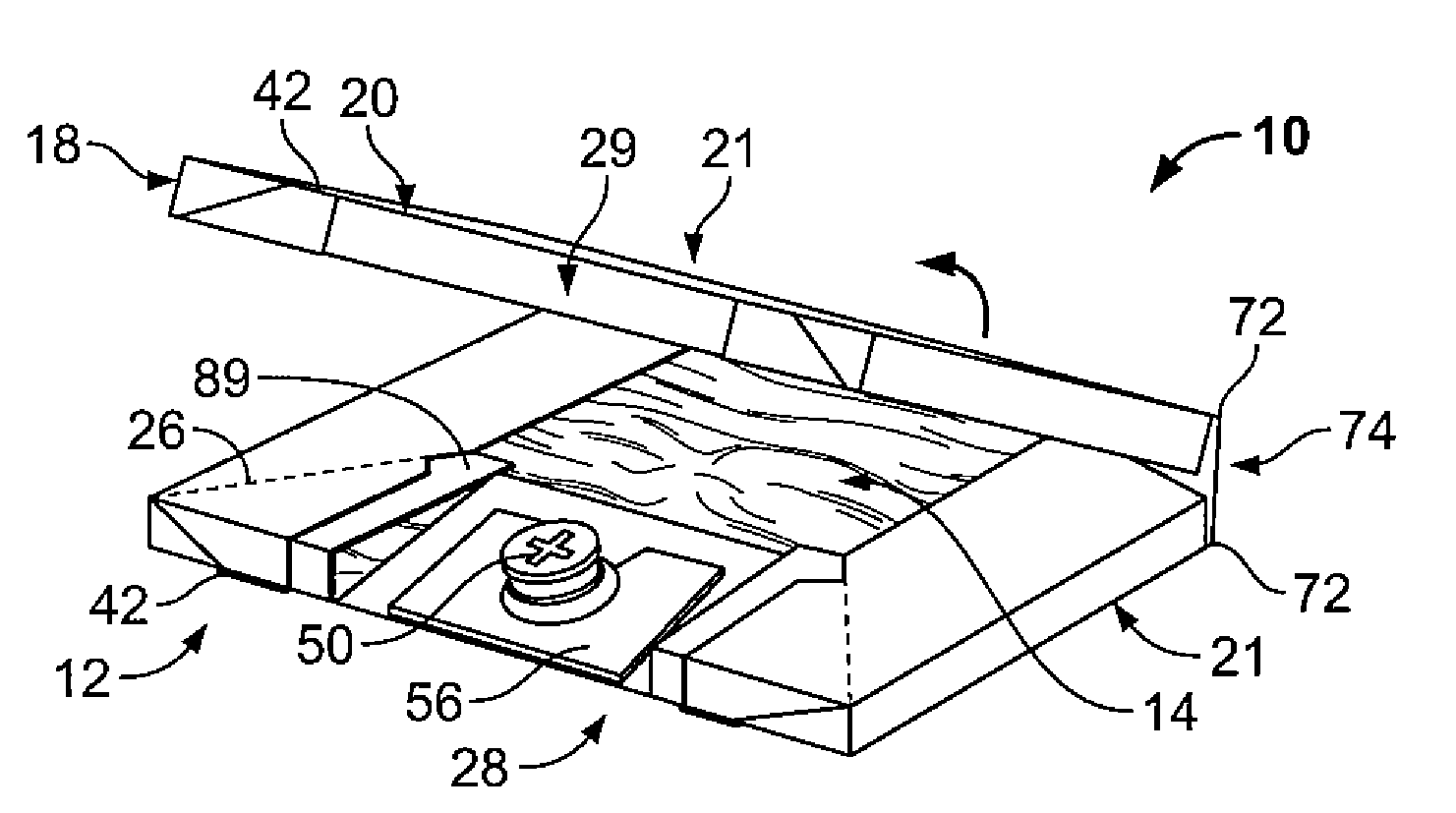

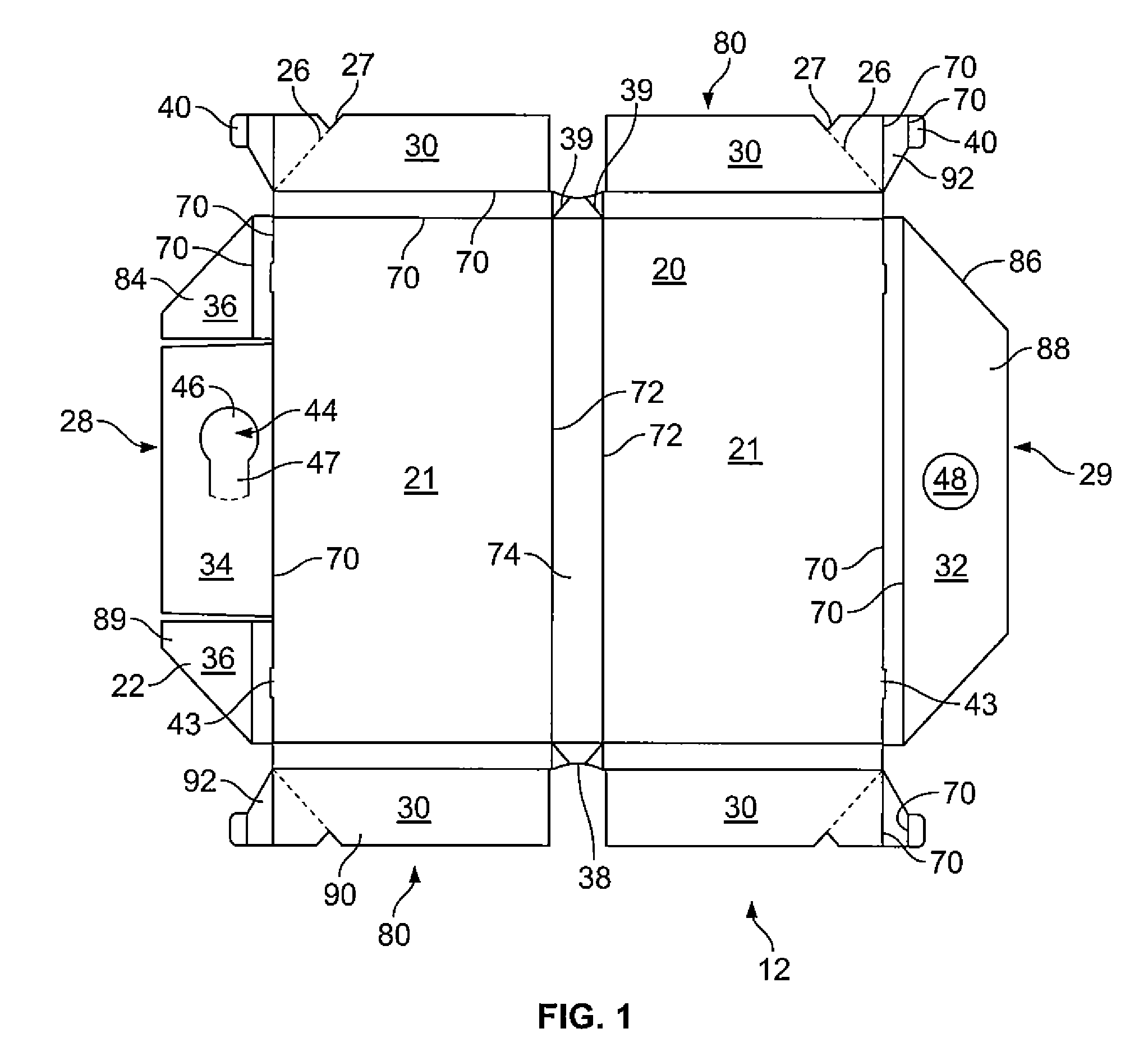

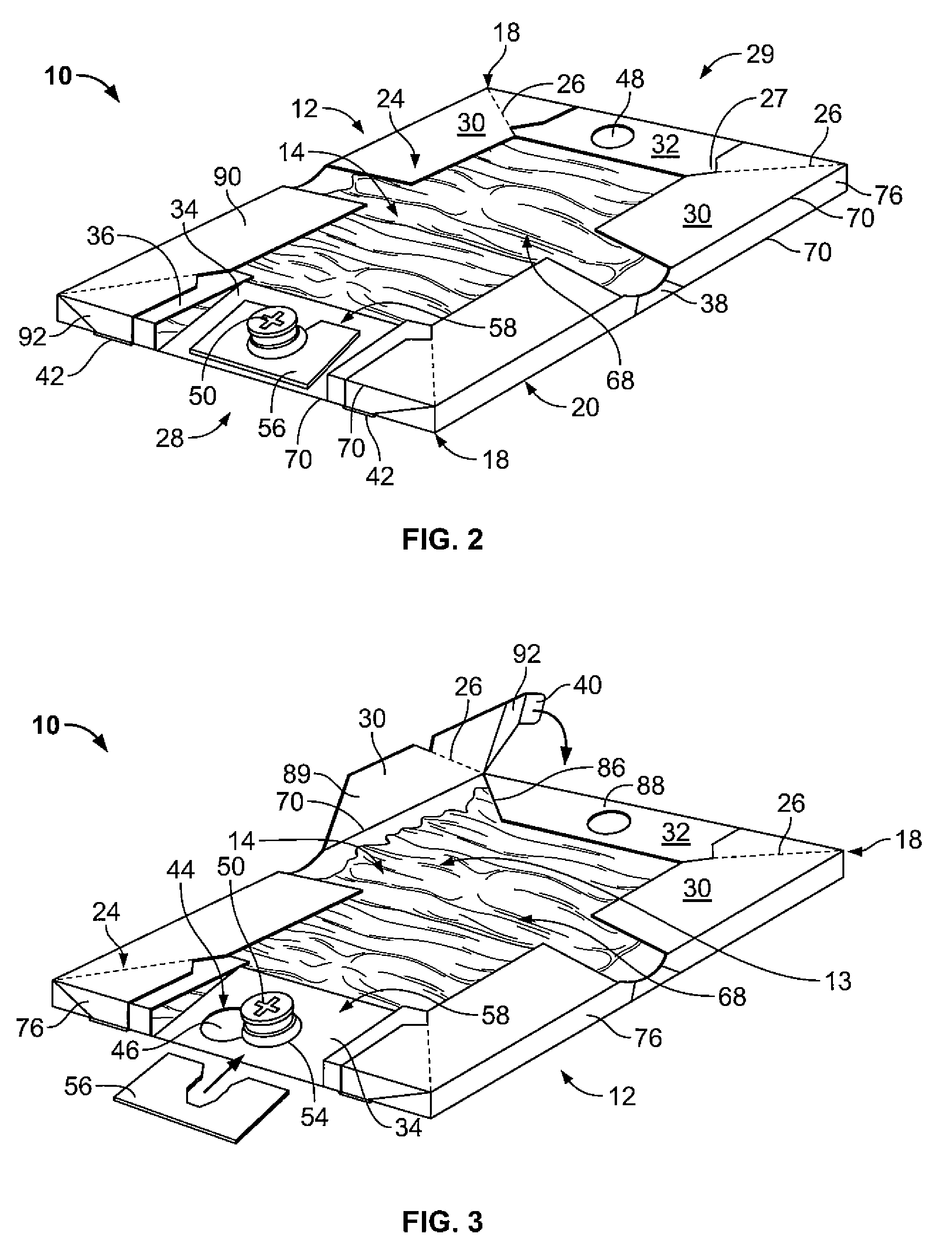

Soft-sided insulated container with lid fitting

A soft-sided insulated container assembly has a generally box-shaped form like a school lunch box, having a main body and a lid. The lid is formed of one of the largest panels of the box-structure, and is joined to the main body of the box by a hinge that lets the lid lie flat next to the main body when the box is open. The inside face of the lid then defines a work surface on which to place objects such as foodstuffs and beverages. The work surface may be formed in a substantially rigid molded stiffener member, and may be divided into sub-regions with raised retainers to discourage sliding of objects where not precisely level. The container assembly may include a rigid internal liner with which the lid may mate zipperlessly. The mating portion of the lid may be formed in the same rigid member as the work surface.

Owner:CALIFORNIA INNOVATIONS

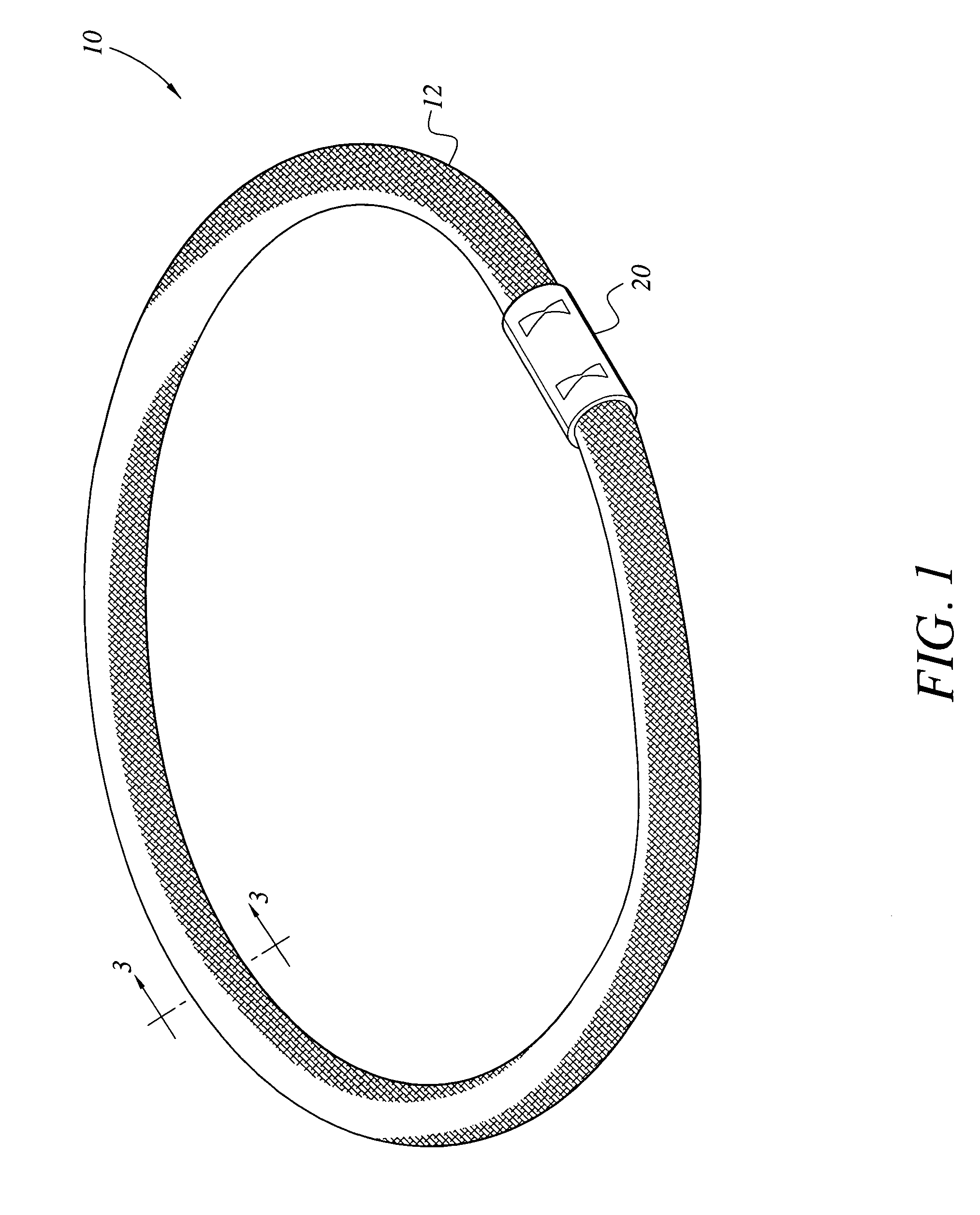

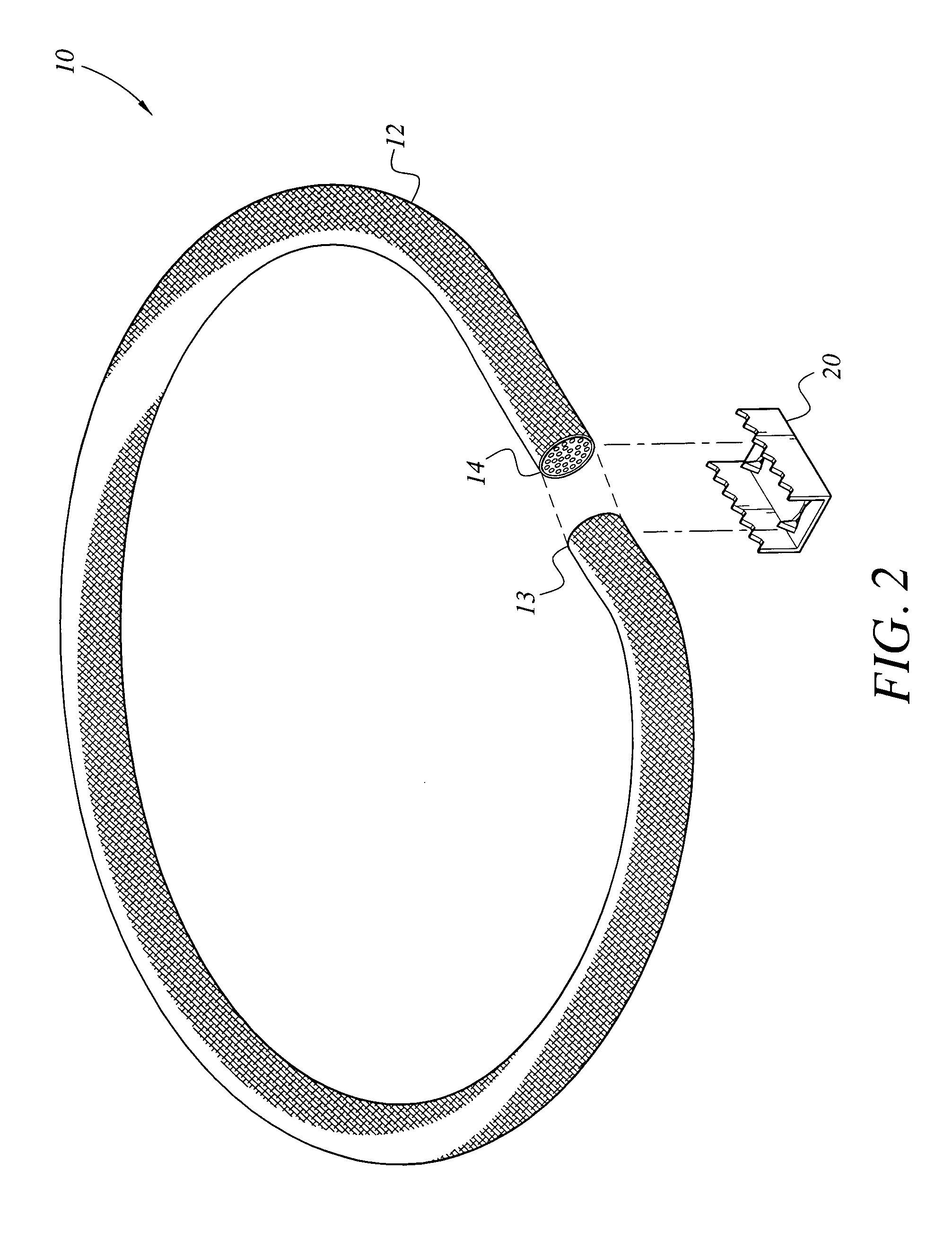

Elastic loop for securing a bag to a trashcan

Owner:SIEGEL JEFFREY M +1

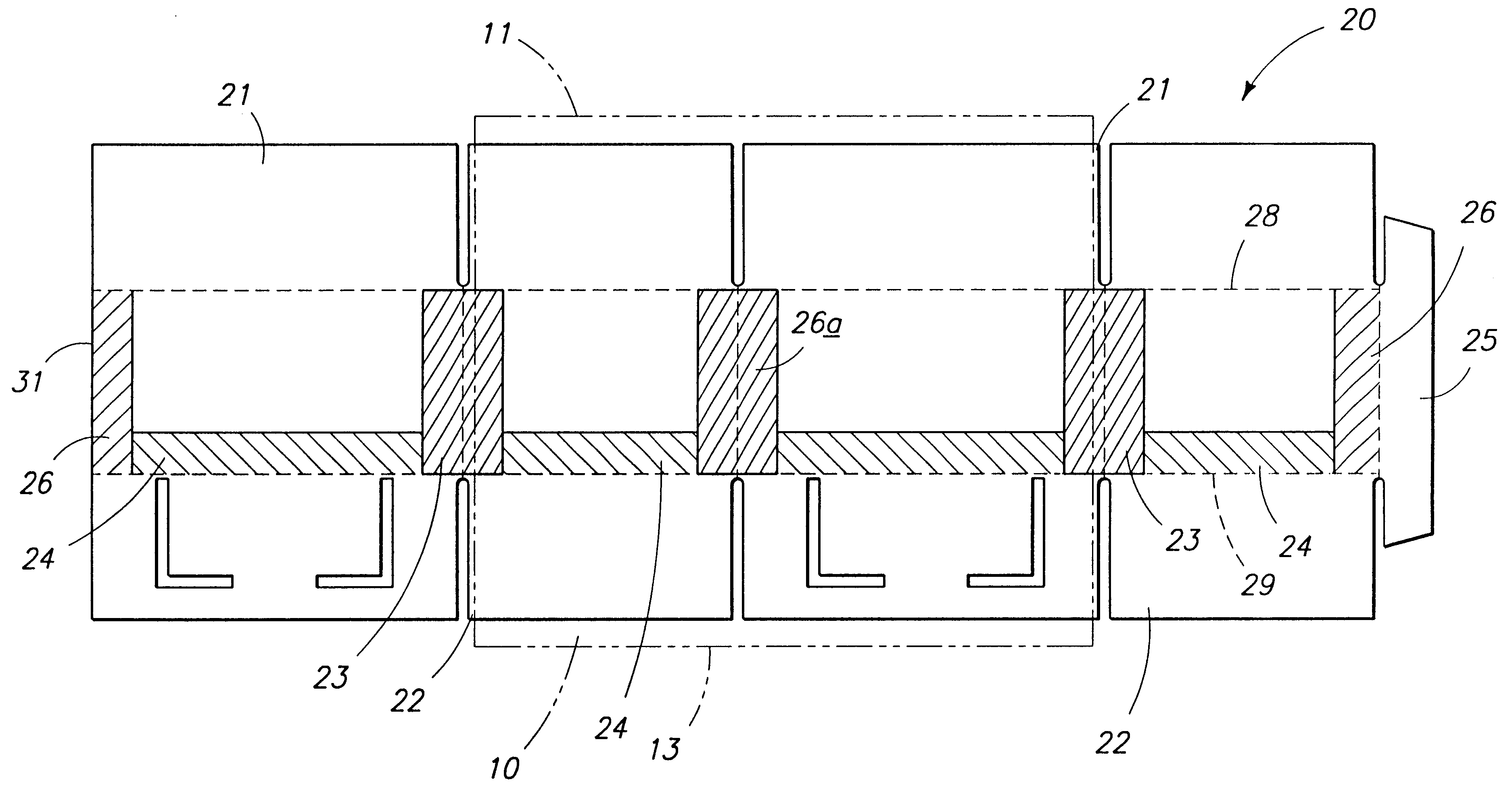

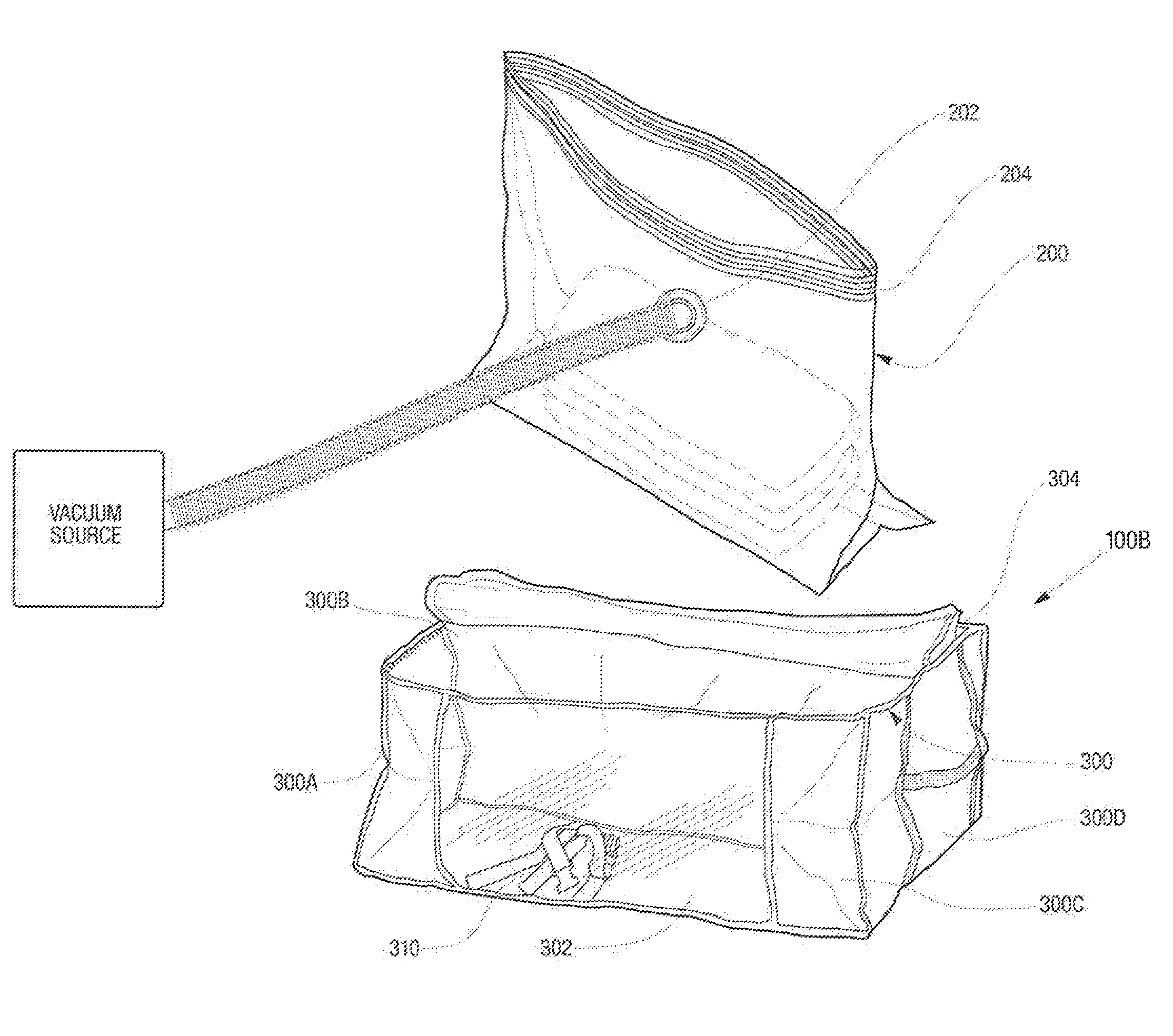

Cartridge and method for filling a bulk container with a flowable substance

A cartridge for storing a flowable substance in a bulk container is disclosed. The cartridge includes a shell having a breakable score line and configured to sit inside the bulk container and a bag positioned within the shell and configured to be filled with the flowable substance. The bag has a port for introducing the flowable substance into the bag and a drain spout in fluid communication with the bag, allowing the flowable substance to be drained from the bag after filling. The breakable score line is configured to separate due to force exerted on the shell as the bag is filled, allowing the bag to expand inside the bulk container. A method of filling a bulk container with a flowable substance using the cartridge is also disclosed.

Owner:MENASHA

Garbage bin

Owner:LIN TSONG YOW

Flexible materials for flexible containers

ActiveUS9469088B2Less-expensiveImprove the decorative effectDomestic containersCoatingsMechanical engineeringGas barrier

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

Trash bag dispenser

A trash bag dispenser, for receiving a trash bag continuously joined to and separable from another trash bag, for receiving a trash receptacle and for dispensing the trash bag from the trash receptacle is provided. The trash bag dispenser comprising a housing for containing the trash bag and a cover having a slot therein for guiding the trash bag therethrough. The cover is movably connected to the housing and integral therewith for allowing the cover to capture the trash bag and to allow the trash bag to freely move when urged through the slot. A closure, comprises a snap button fastener. The trash bag dispenser is attachable to an interior of the trash receptacle with an adhesive backed hook and loop type fastener.

Owner:MILLER CHRISTOPHER J

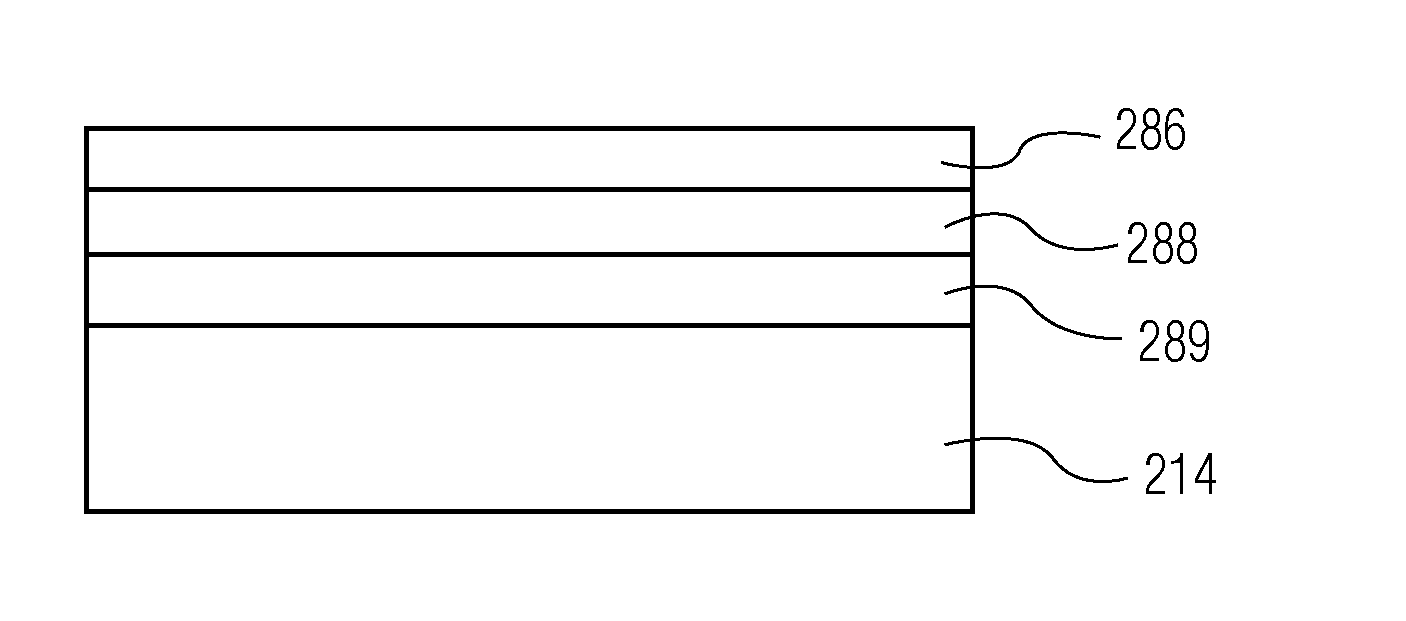

Trilayer coated pharmaceutical packaging

ActiveUS20140251859A1Reduce decreaseSurgeryMaterial analysis by electric/magnetic meansPolymer sciencePolysilazane

An article is described including an article surface and a coating set comprising a tie coating or layer of SiOxCy or Si(NH)xCy applied to the article surface, a barrier coating or layer of Six, and a pH protective layer of SiOxCy or Si(NH)xCy. The respective coatings or layers can be applied by chemical vapor deposition of a polysiloxane or polysilazane precursor in the presence of oxygen. Examples of such an article are a prefilled thermoplastic syringe or thermoplastic pharmaceutical vial with a coated interior portion containing a pharmaceutical preparation or other fluid with a pH of 4 to 8, alternatively 5 to 9. The barrier coating or layer prevents oxygen from penetrating into the thermoplastic syringe or vial, and the tie coating or layer and pH protective coating or layer together protect the barrier layer from the contents of the syringe or vial.

Owner:SI02 MEDICAL PRODS

Trash can assembly

Owner:TEST RITE PRODS

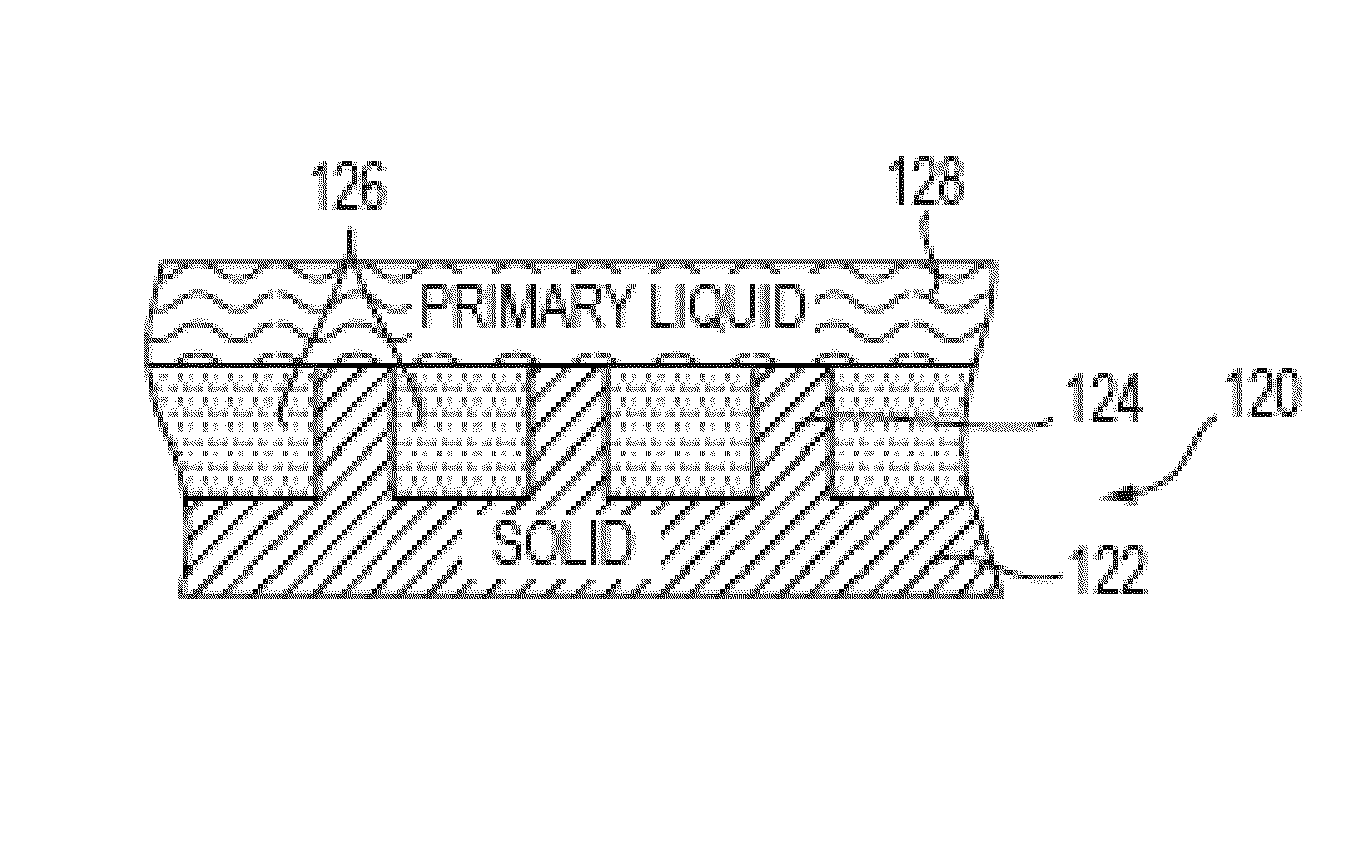

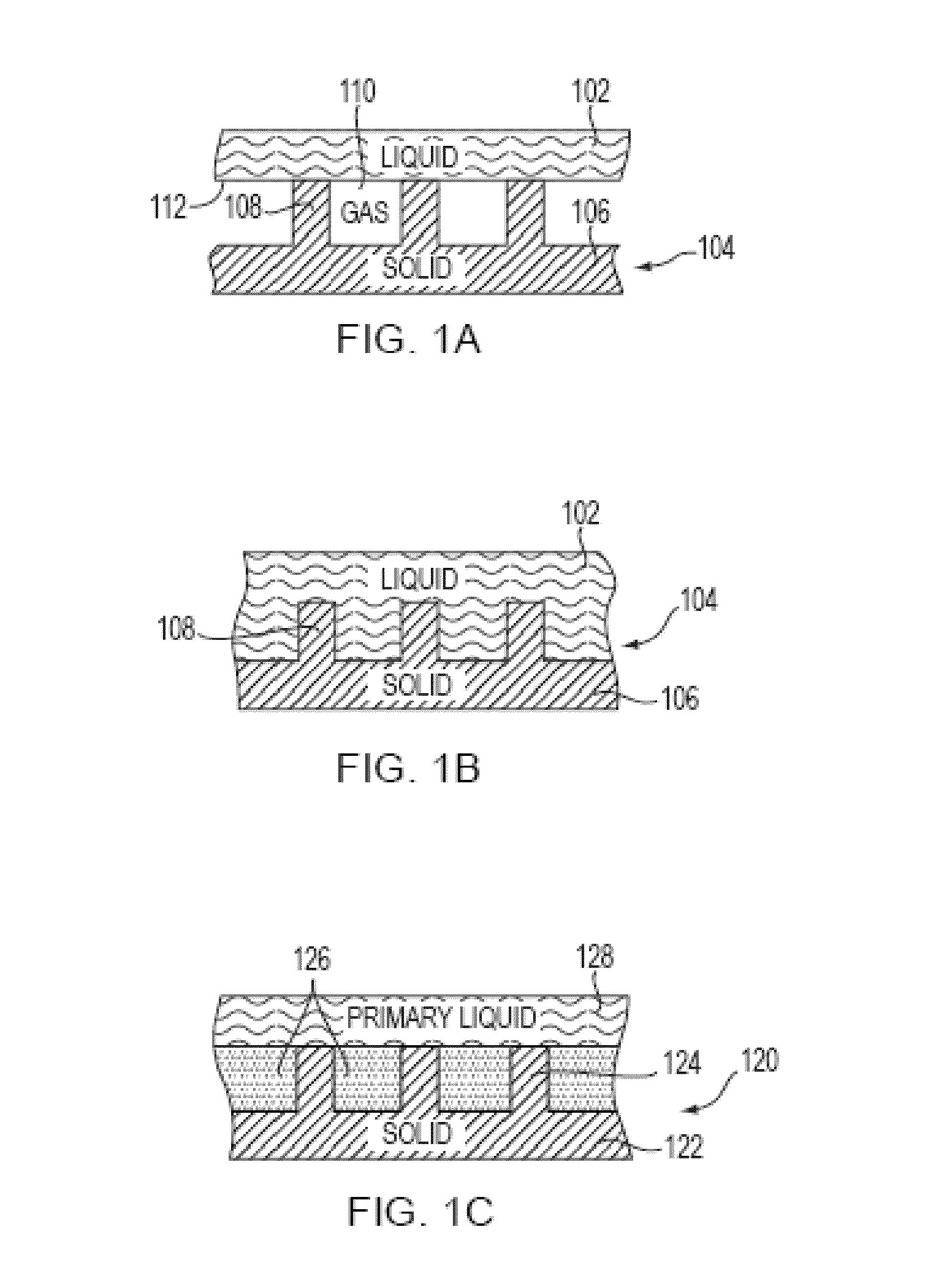

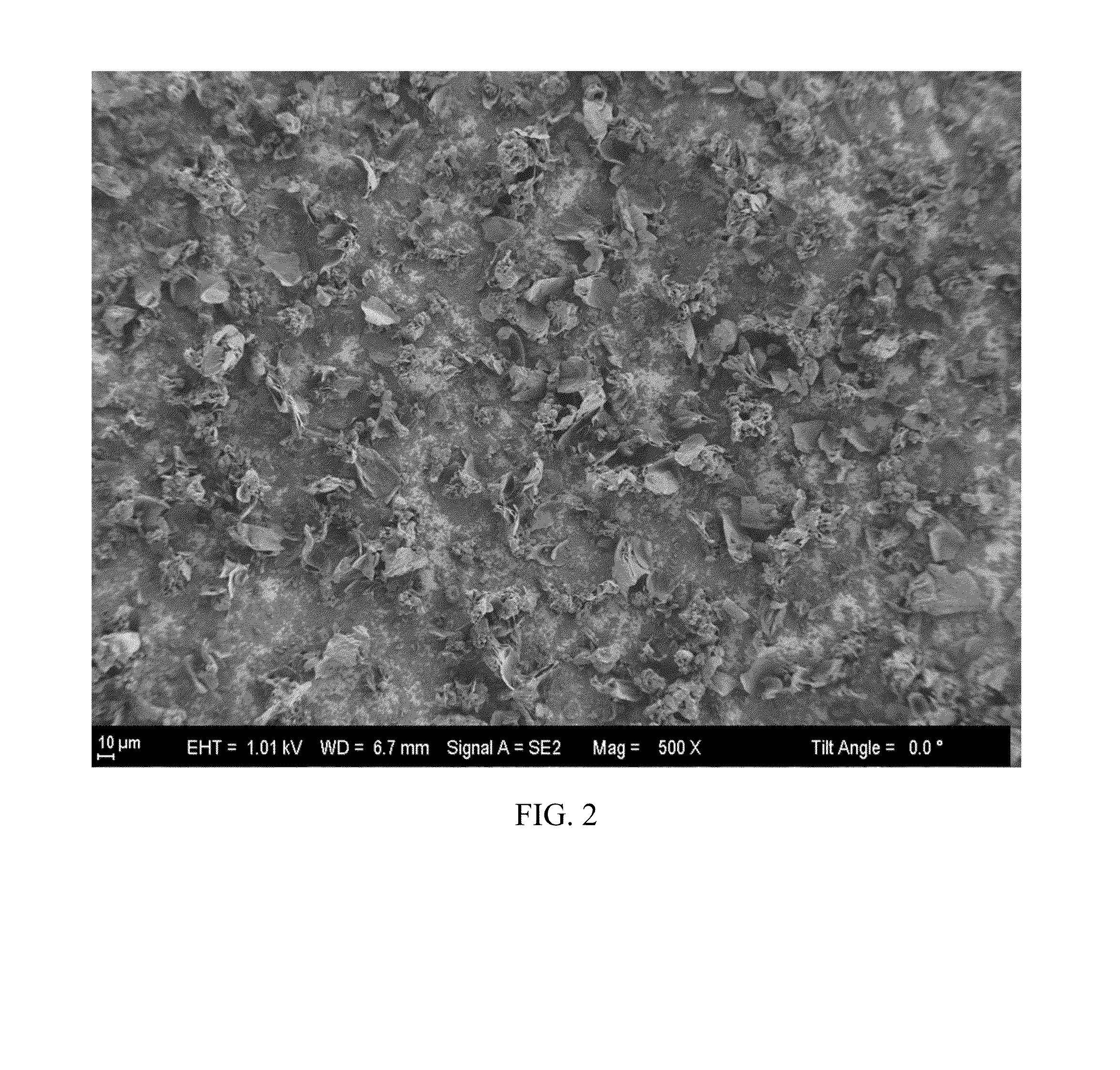

Self-lubricating surfaces for food packaging and food processing equipment

ActiveUS8535779B1Improve health and safetyAvoid leachingRecord information storageMagnetic recordingFood packagingTomato ketchup

In certain embodiments, the invention relates to an article having a liquid-impregnated surface. The surface includes a matrix of solid features (e.g., non-toxic and / or edible features) spaced sufficiently close to stably contain a liquid therebetween or therewithin, wherein the liquid is non-toxic and / or edible. The article may contain, for example, a food or other consumer product, such as ketchup, mustard, or mayonnaise.

Owner:MASSACHUSETTS INST OF TECH

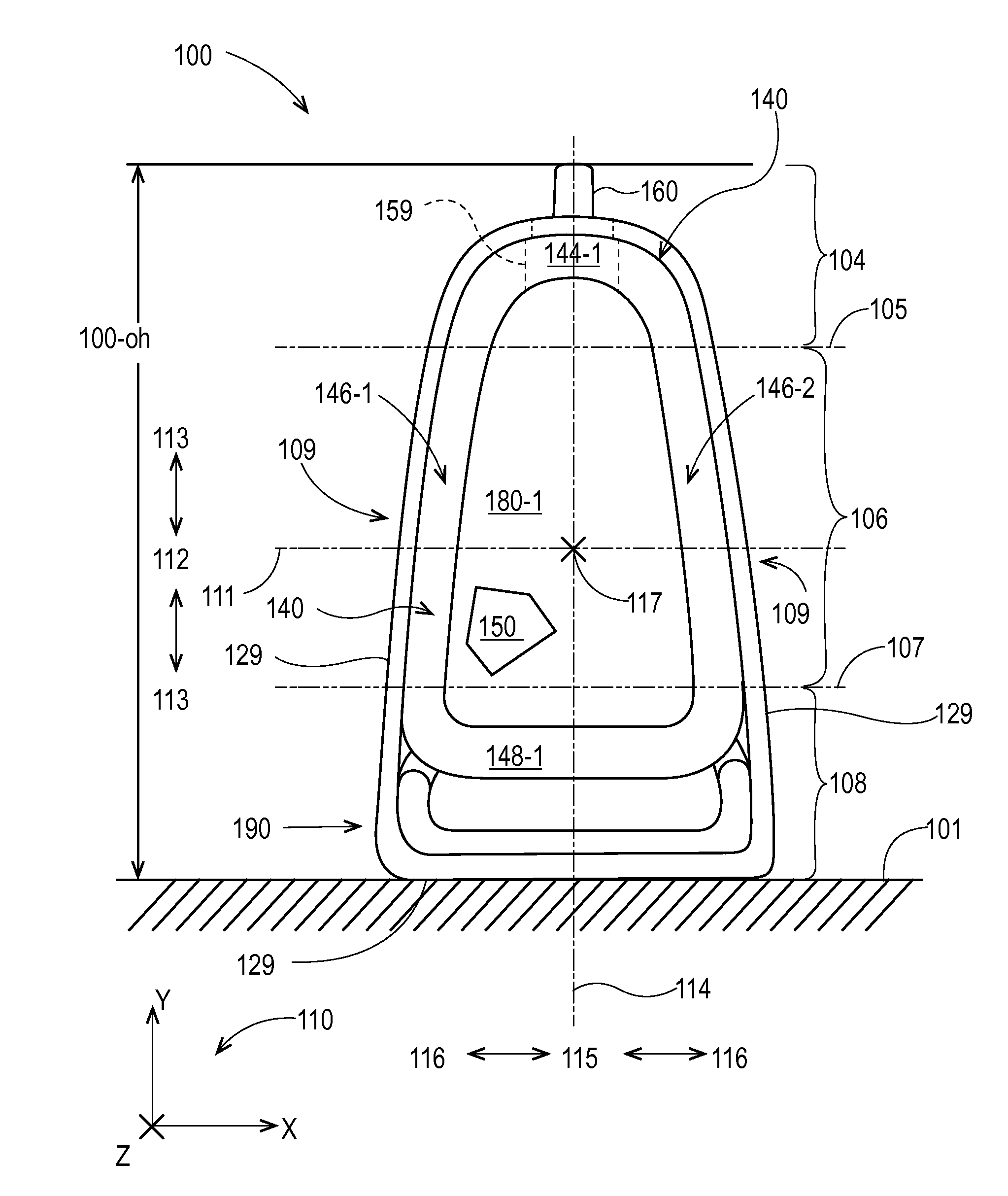

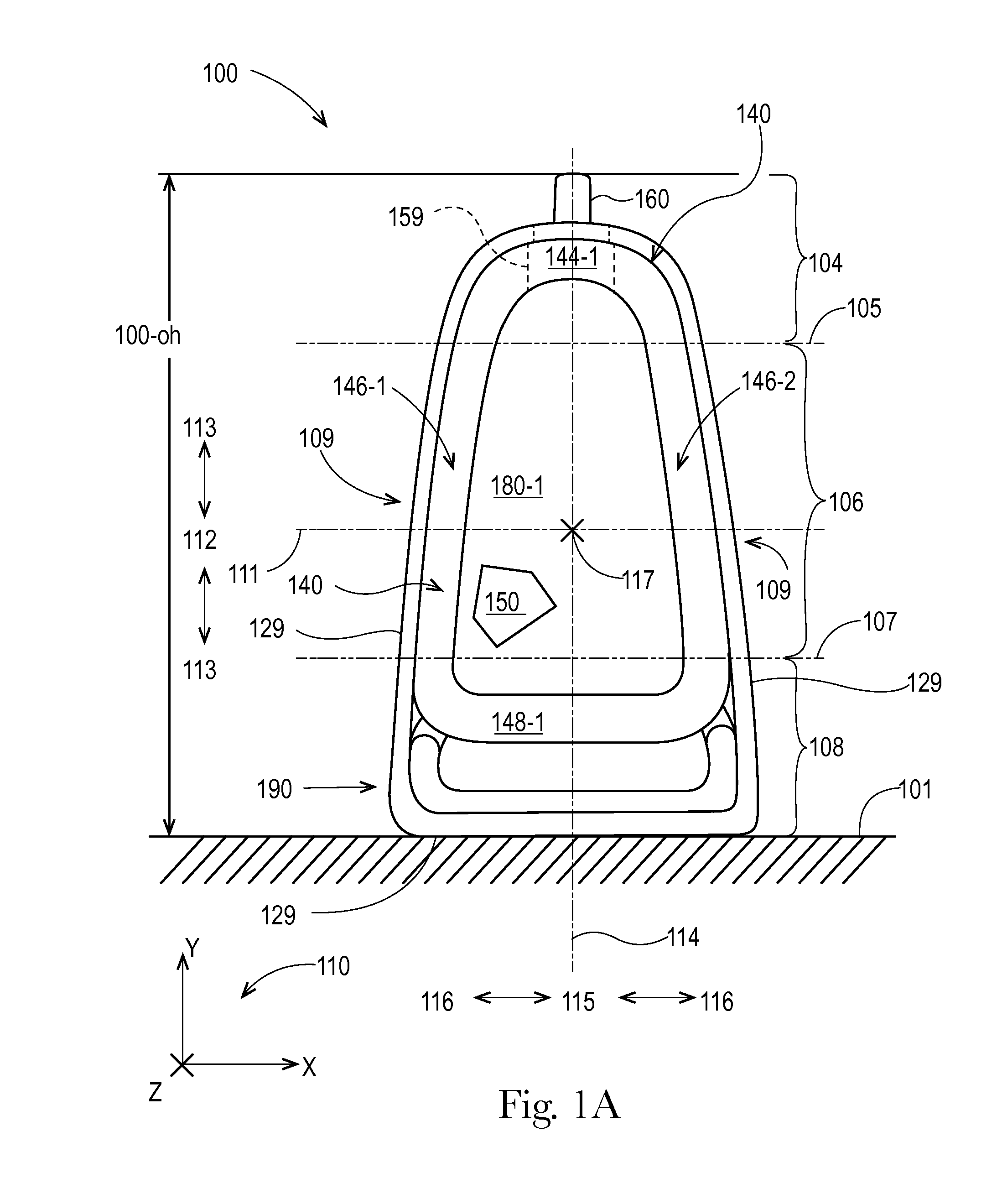

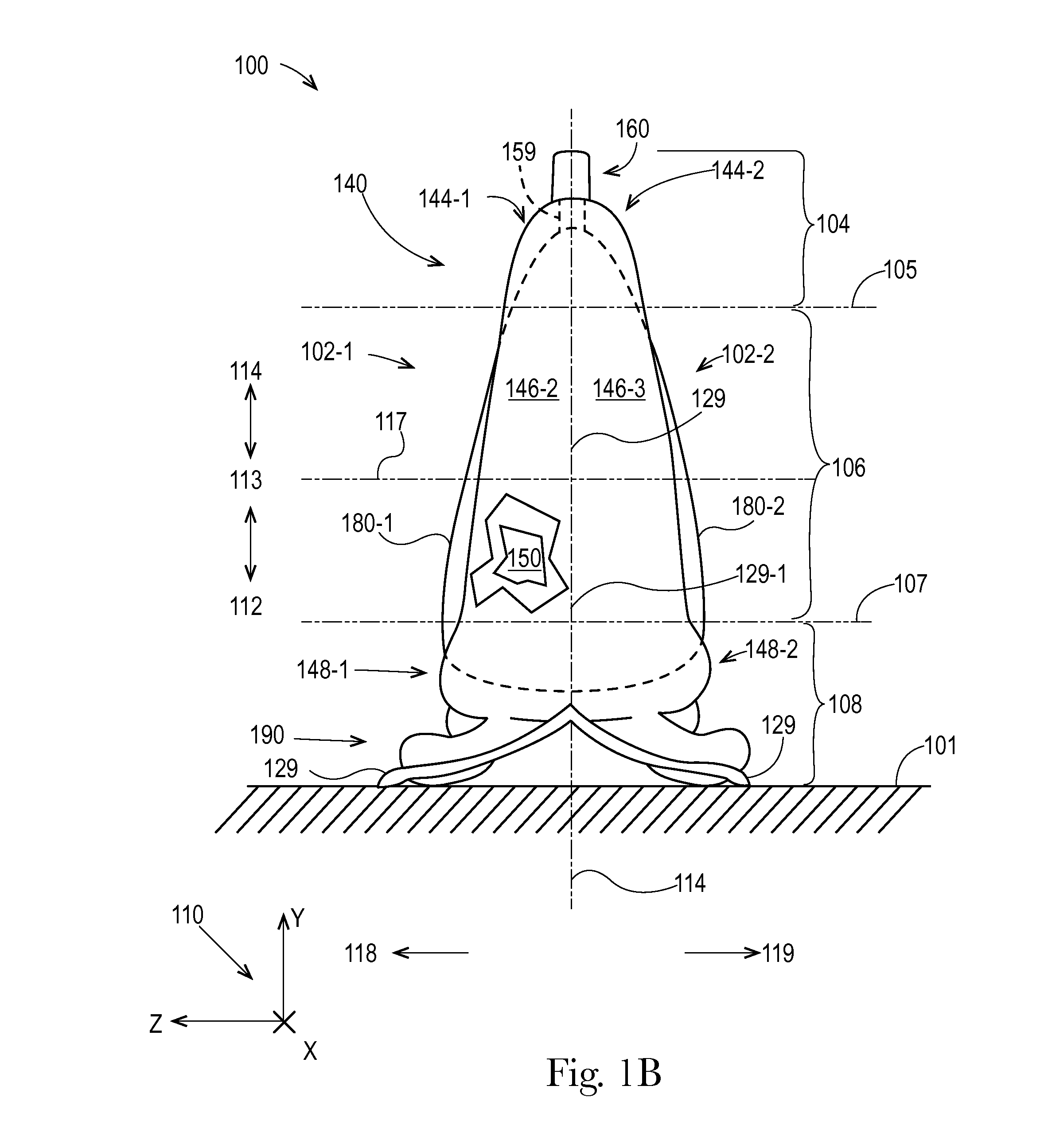

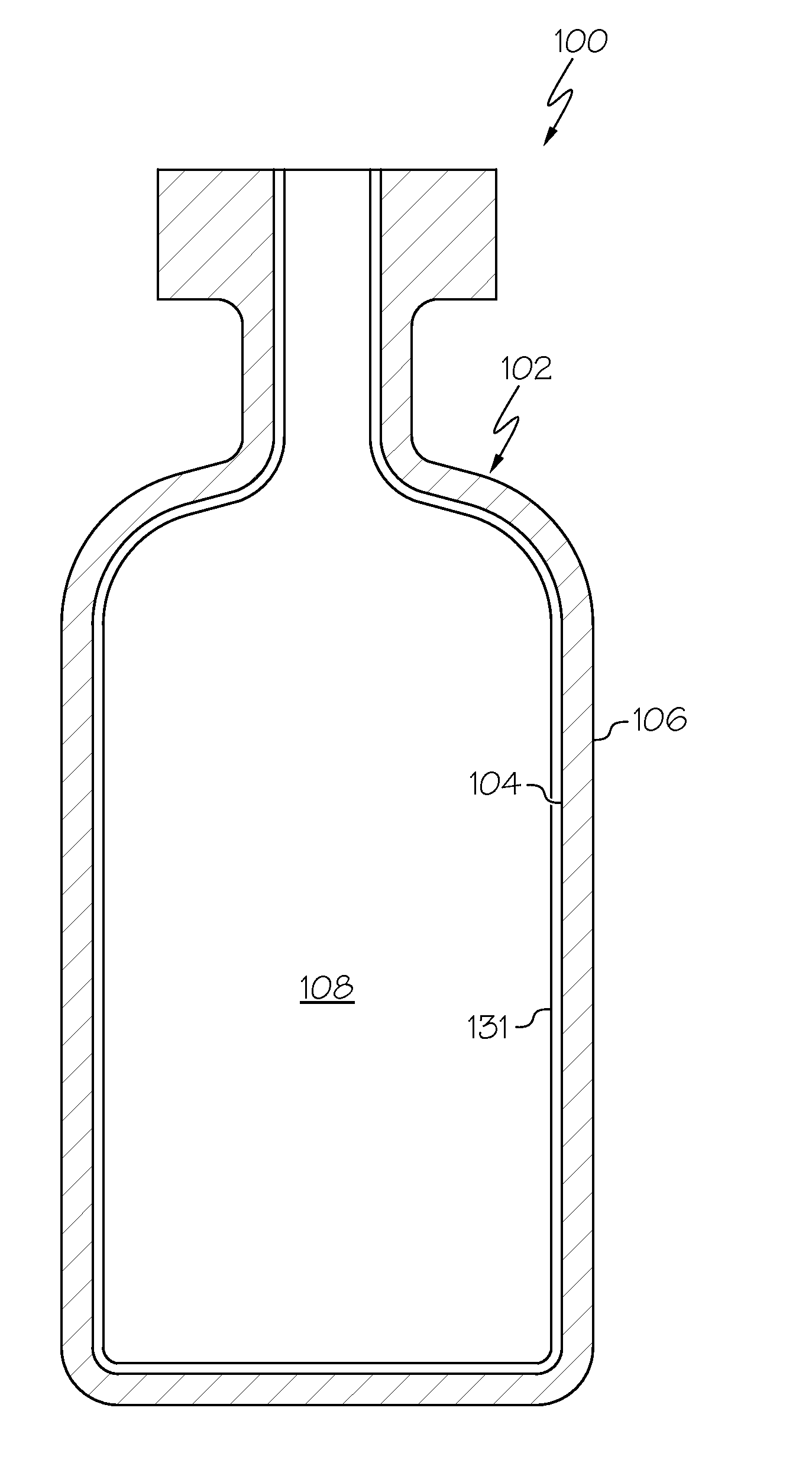

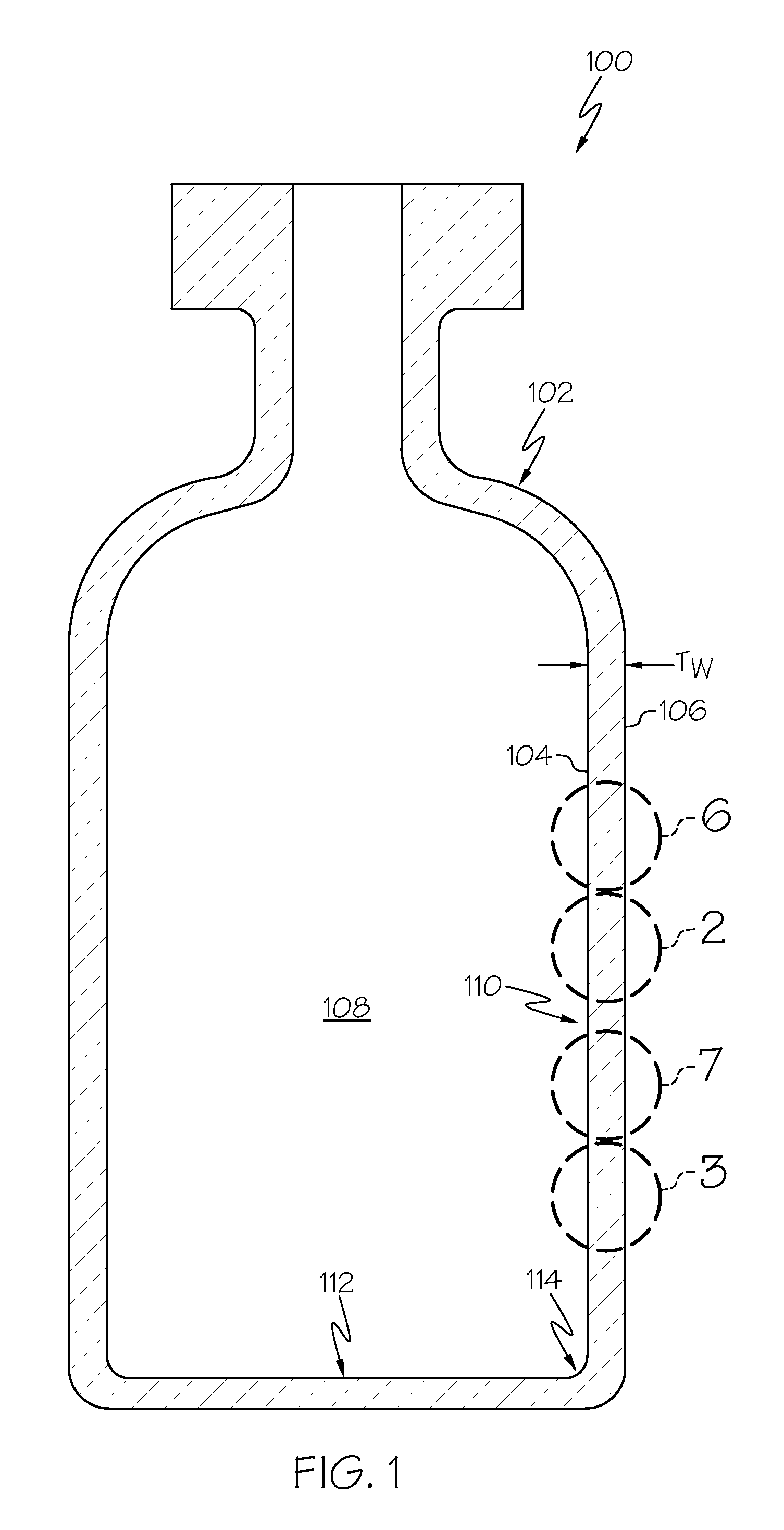

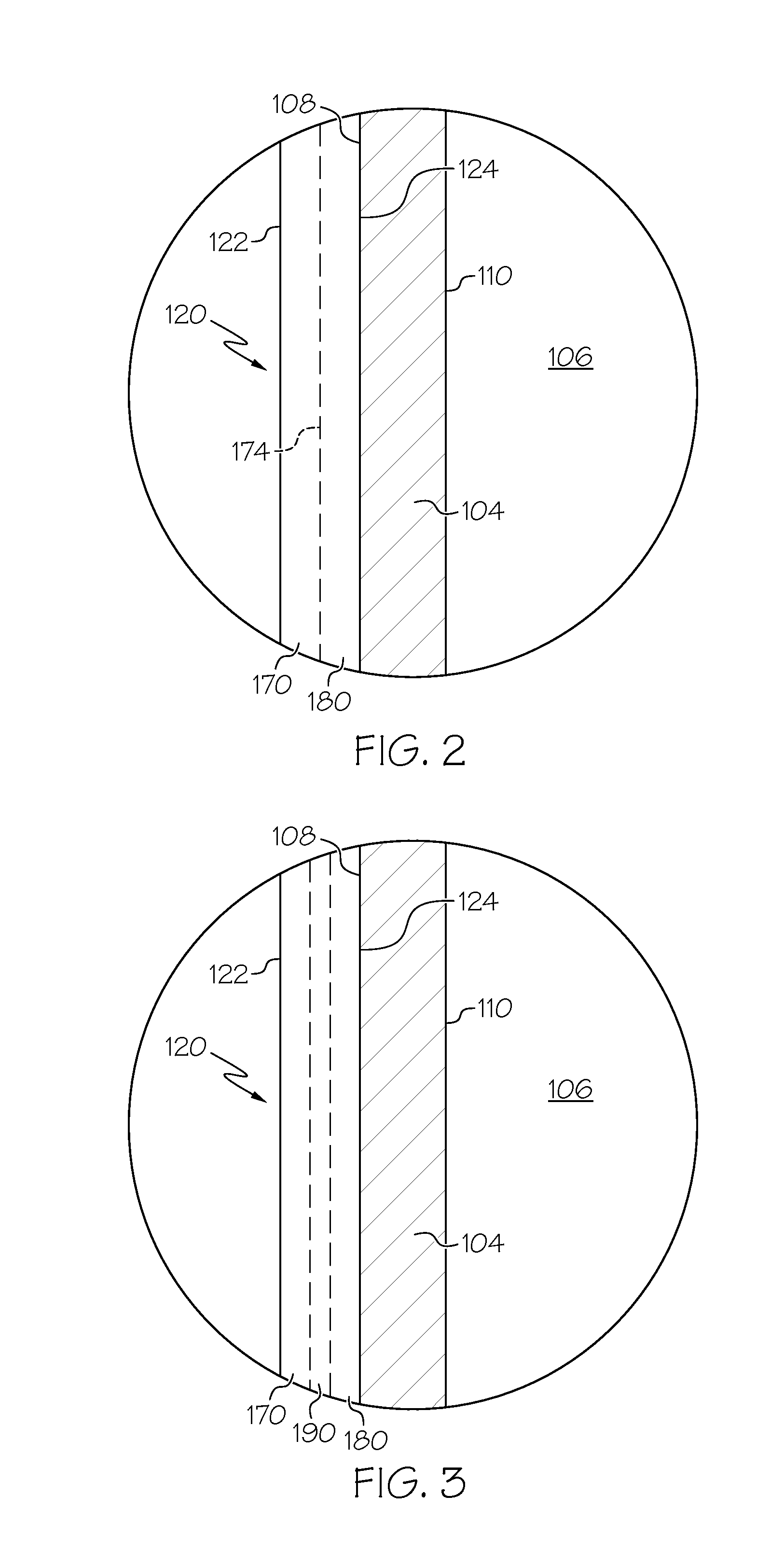

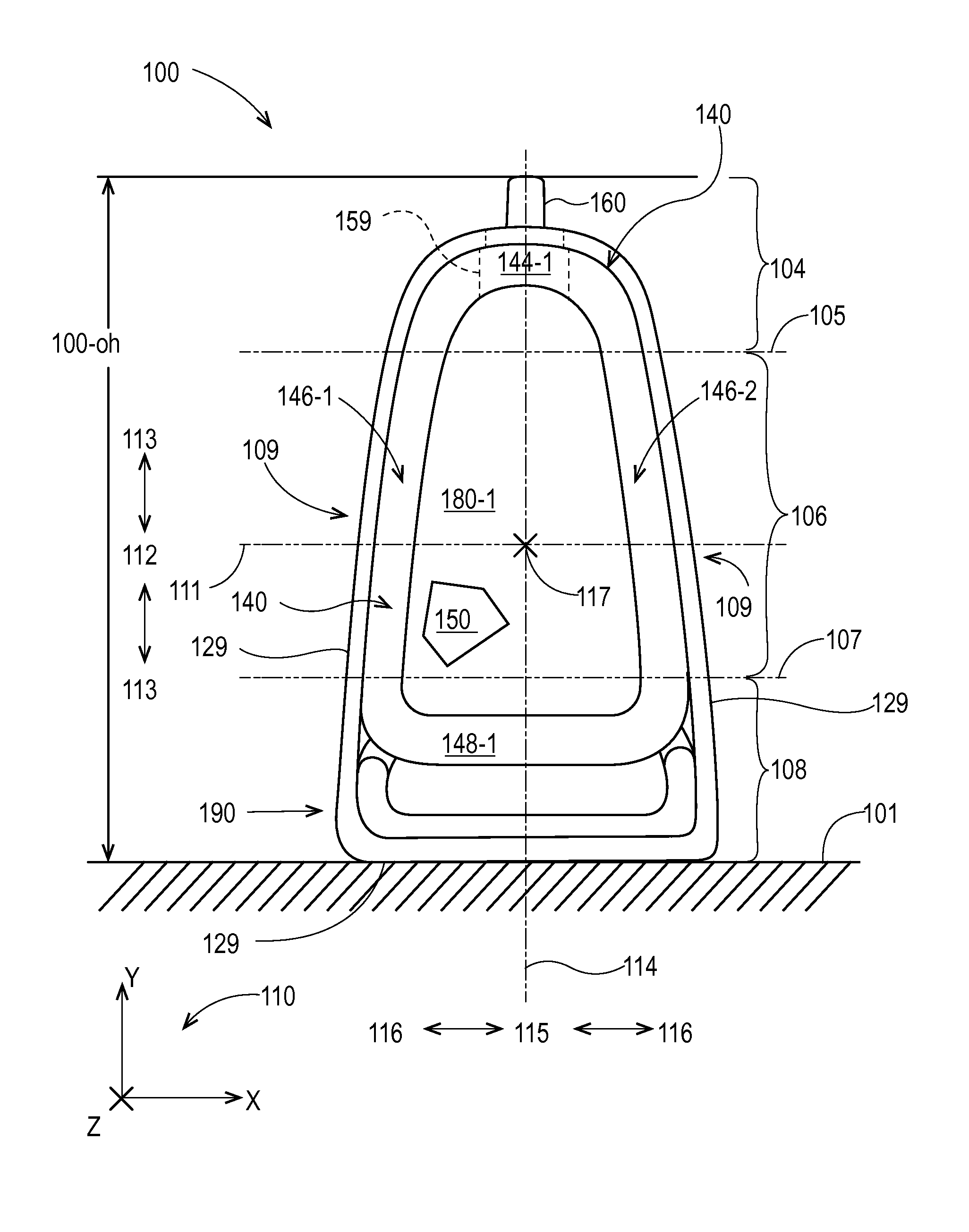

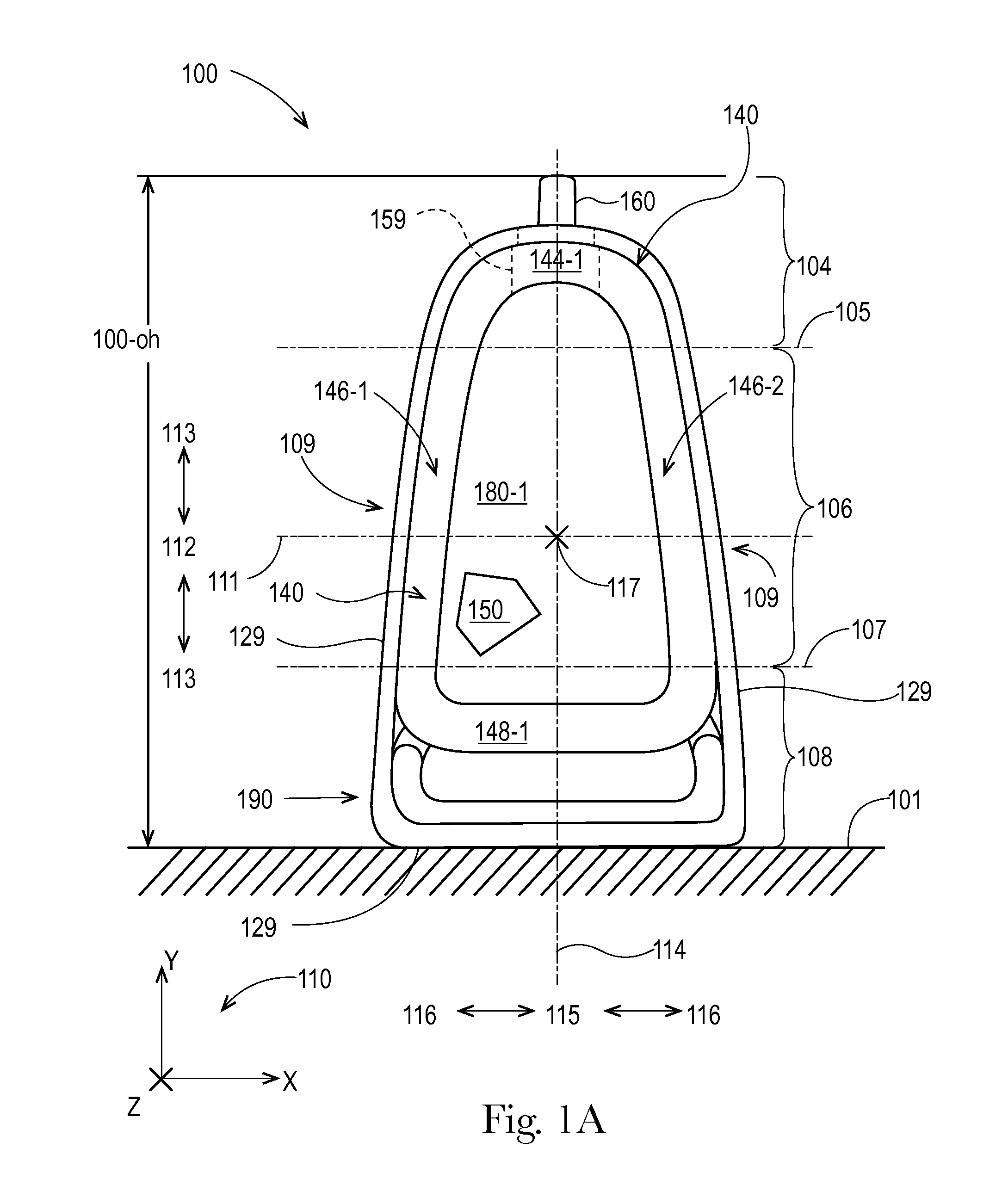

Blown bottle with intrinsic liner

InactiveUS20050103802A1Differing bond strengthOpening closed containersBottle/container closureEngineeringBlowing bottles

A container for holding and dispensing liquid having a container wall comprising a rigid portion that dimensionally defines the container, a liner portion disposed within the container adjacent to the rigid portion, and an adhesive layer disposed between the rigid portion and the liner portion. The adhesive layer removably secures the liner portion to the rigid portion such that the liner portion is capable of being separated from the rigid portion and collapsed within the container, for dispensing the liquid.

Owner:ADVANCED TECH MATERIALS INC

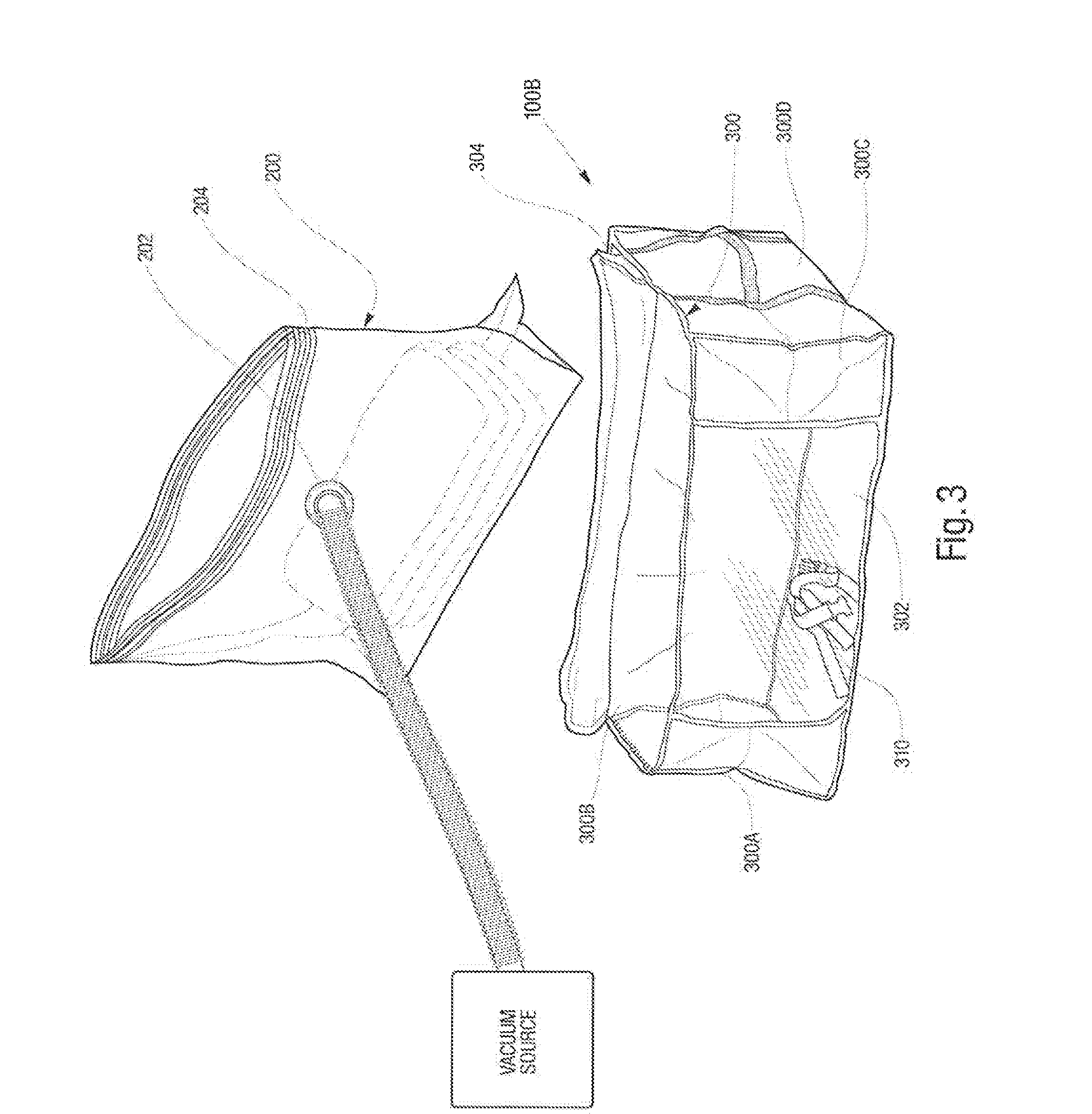

Trash can with function of sucking litterbag

InactiveUS20060175336A1Disposition is simplifiedLarge containersRefuse receptaclesAir pumpEngineering

A trash can with function of sucking litterbags having a plurality of intake hole arranged surrounding the lower part or bottom side thereof. The intake holes are connected to a closed space with an air pump therein for expelling air into a vacuum status so as to make the litterbag inside be sucked by the intake holes. When a litterbag is disposed into the trash can, the opening of the litterbag is arranged on the edge of the opening of the trash can. Then the bottom of the litterbag is pressed down to the bottom of the trash can and the air pump is turned on to make the intake holes adsorb the litterbag. Thus the litterbag is spread out completely on the bottom of the trash can so that the disposition of the litterbag is simplified and the litterbag is set down more properly.

Owner:WANG LI CHUN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com