Patents

Literature

6822results about How to "Improve the decorative effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible Materials for Flexible Containers

ActiveUS20130337244A1Less-expensiveImprove the decorative effectDomestic containersCoatingsEngineeringMechanical engineering

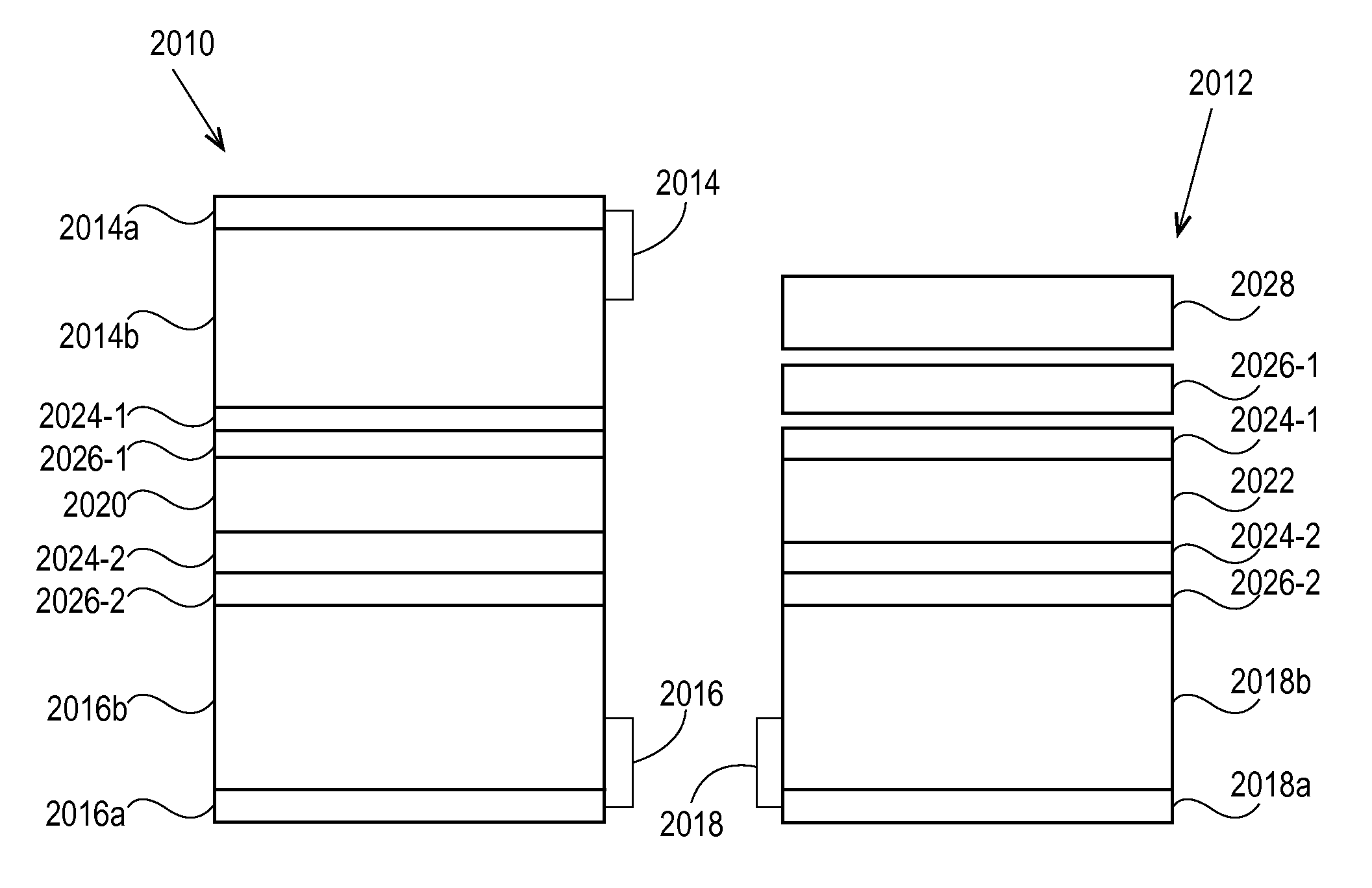

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

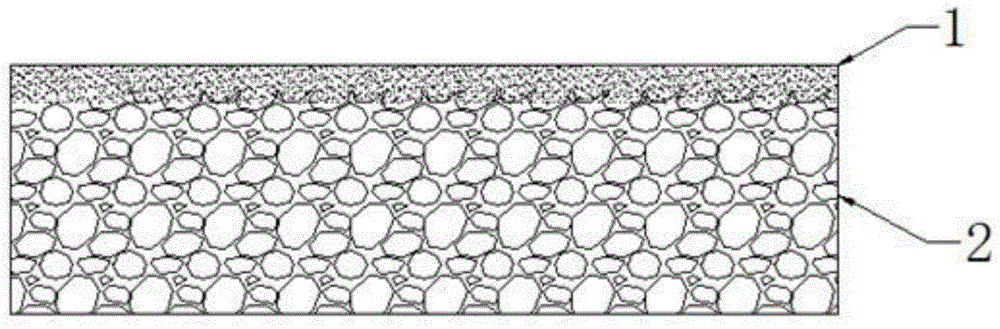

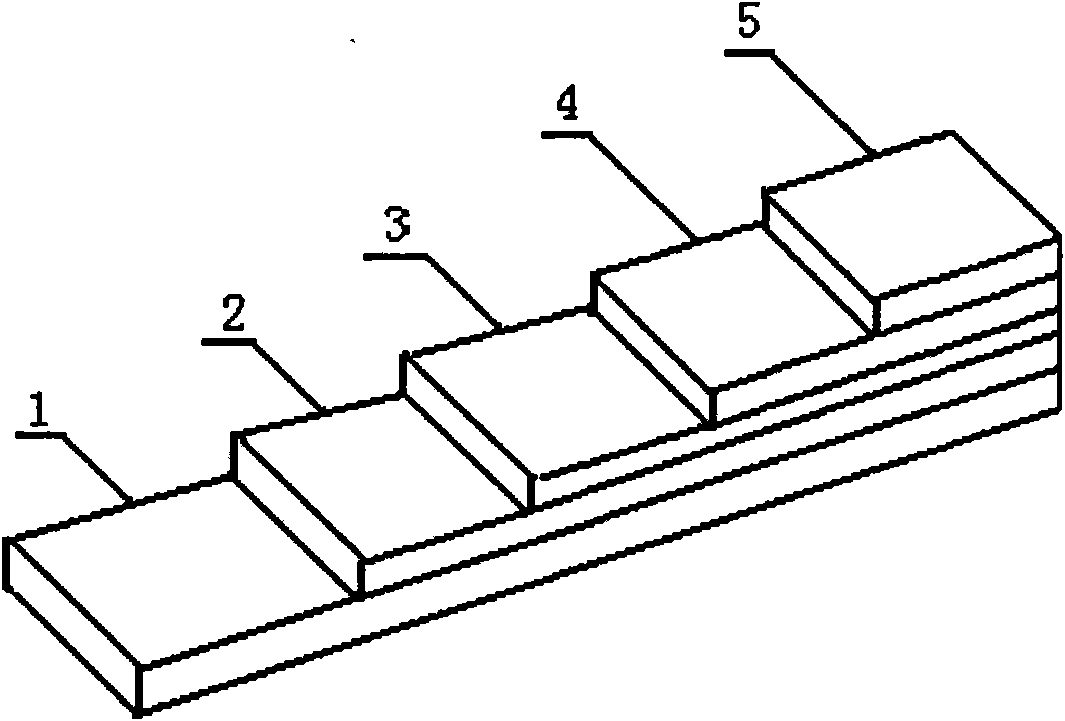

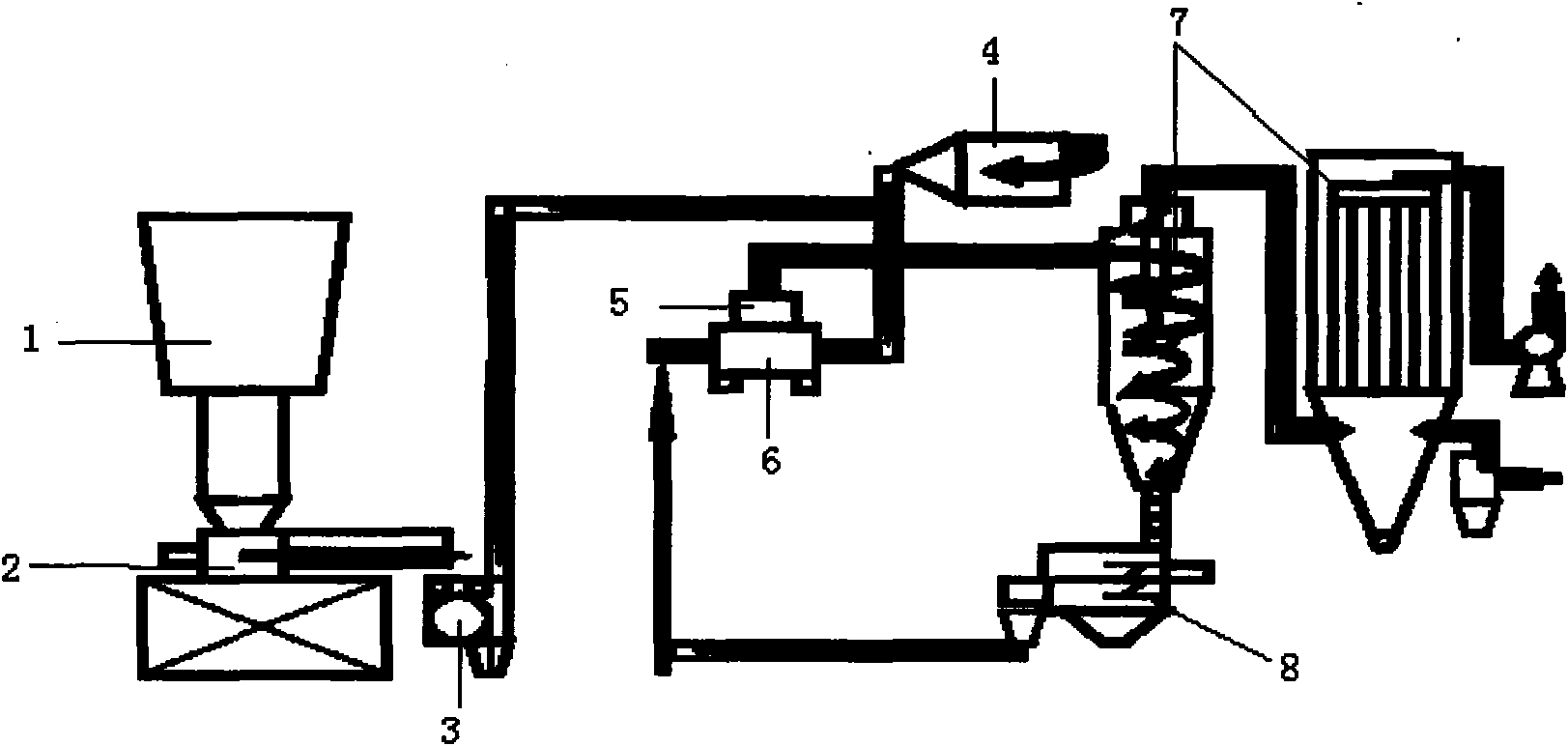

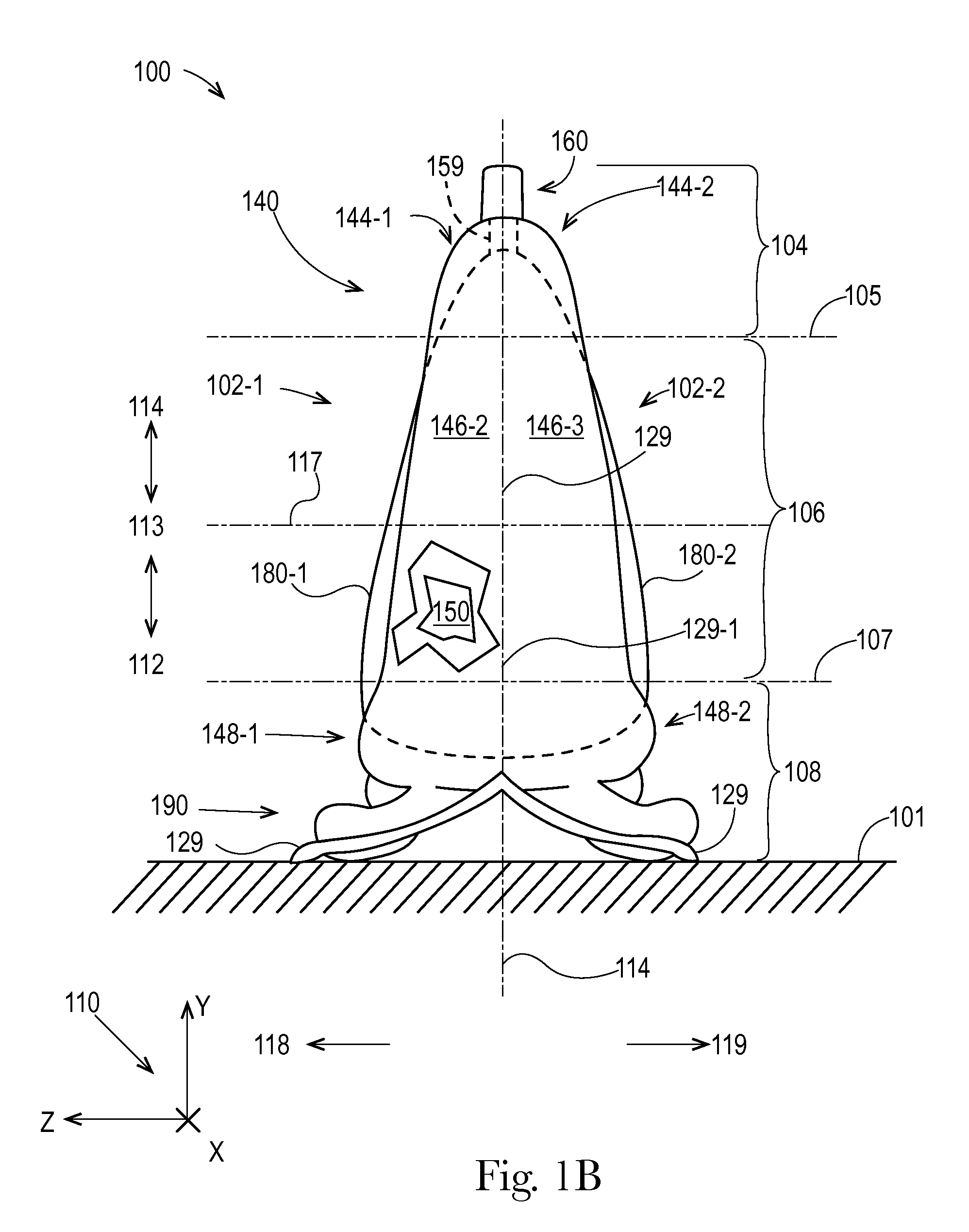

Water permeable brick and preparation method thereof

ActiveCN104452525AHigh porosityHigh strengthSolid waste managementSidewalk pavingsSolid componentBrick

The invention discloses a water permeable brick and a preparation method thereof. The water permeable brick comprises two parts, namely a surface layer and a base layer, wherein the material of the surface layer is prepared from the following components in percentage by mass: 60-70% of ceramic sand, 15-20% of sand and 15-20% of cement, and in addition to the solid components with the sum of 100% in percentage by mass, water accounting for 50-60% by mass of cement is further added; and the material of the base layer is prepared from the following components in percentage by mass: 45-65% of building silt unburned ceramsite, 10-15% of cement, 5-10% of fly ash, 10-15% of melon seed-shaped drug slices and 10-15% of sand, and in addition to the solid components with the sum of 100% in percentage by mass, the water accounting for 30-40% and a water reducer accounting for 1-1.5% relative to total mass of the cement and the fly ash are further added. The water permeable brick disclosed by the invention is prepared by using the building silt unburned ceramsite to replace natural aggregate or calcined ceramsite, on one hand, the using ways of the building silt unburned ceramsite can be expanded, the utilization rate of solid wastes is improved, and negative effects on an environment are reduced, and on the other hand, the obtained water permeable brick has excellent performance.

Owner:浙江合泽环境科技有限公司

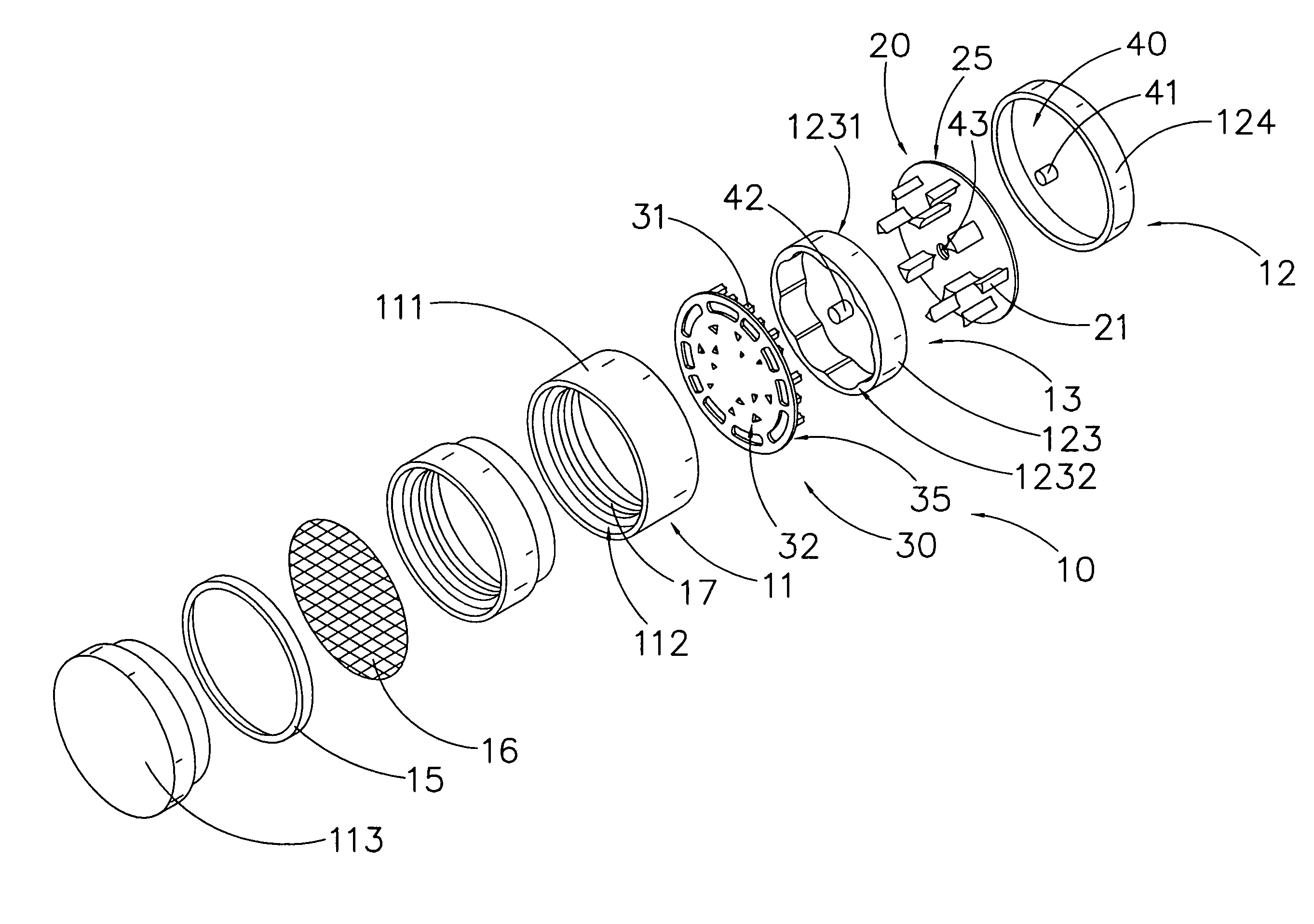

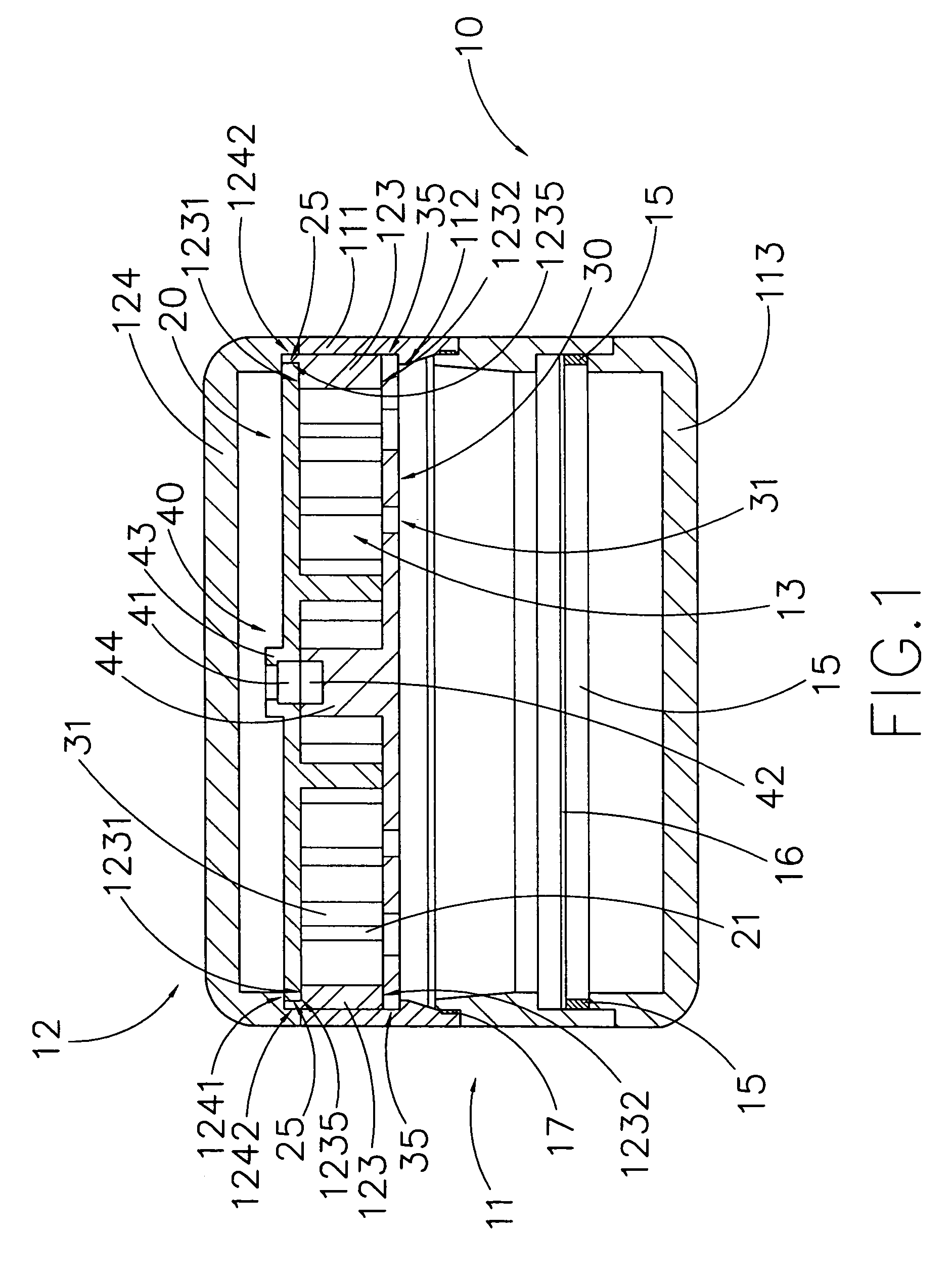

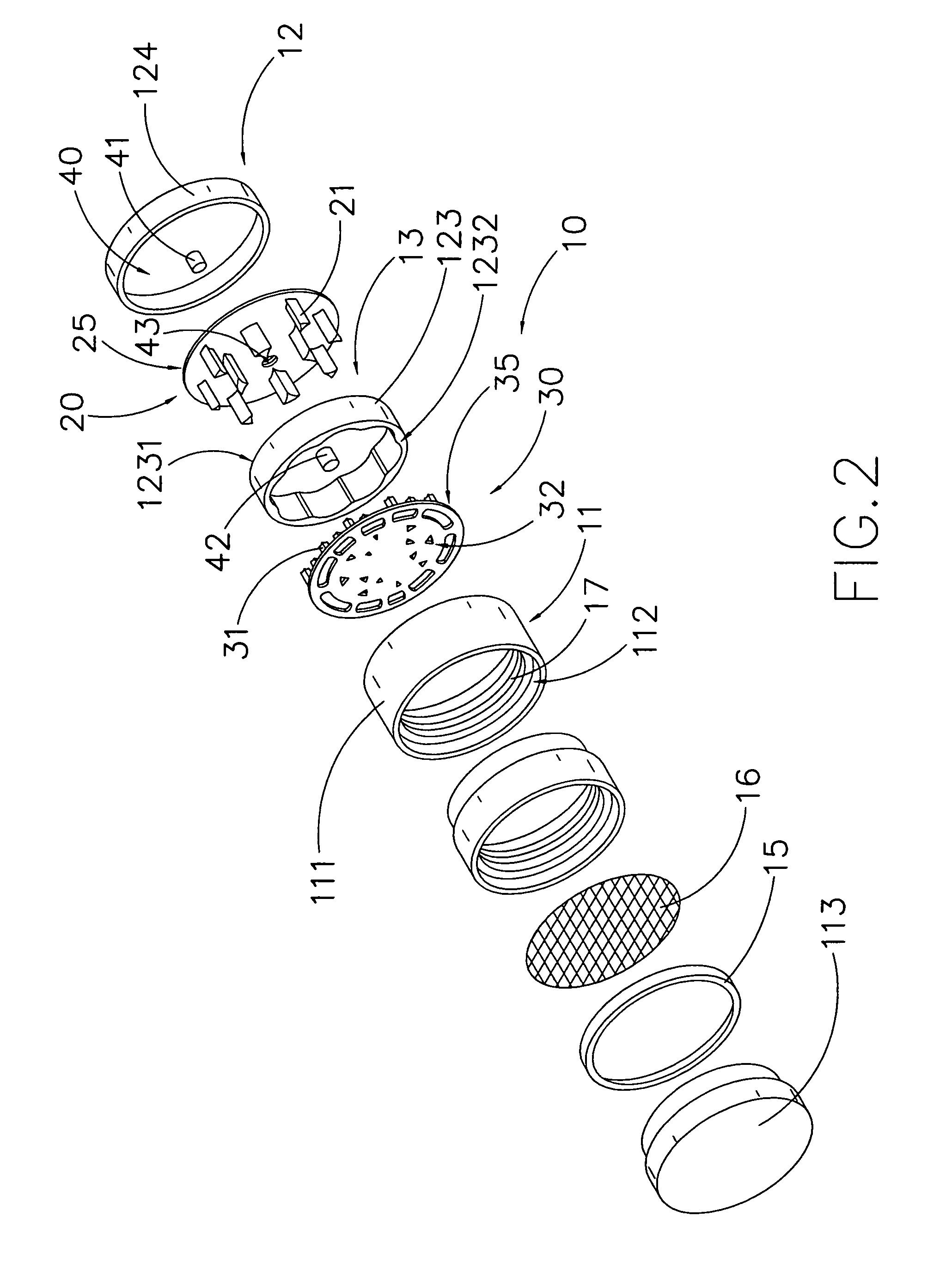

Leaves and seeds hand grinder

A grinder includes a grinder housing having a grinder actuator, a first grinding plate, a second grinding plate and a detachable coupling arrangement. The first grinding plate is detachably coupling with the grinder actuator, wherein the first grinding plate has a plurality of first grinding knifes downwardly and spacedly extended from a bottom side of the first grinding plate. The second grinding plate has a plurality of second grinding knifes upwardly and spacedly extended from the top side of the second grinding plate at a position that the first and second grinding knifes are spacedly disposed within a grinding compartment, such that when the grinder actuator is turned with respect to the grinder base to drive the first grinding plate to rotate, the first and second grinding knifes are correspondingly moved within the grinding compartment to provide a grinding action.

Owner:BAO FAN

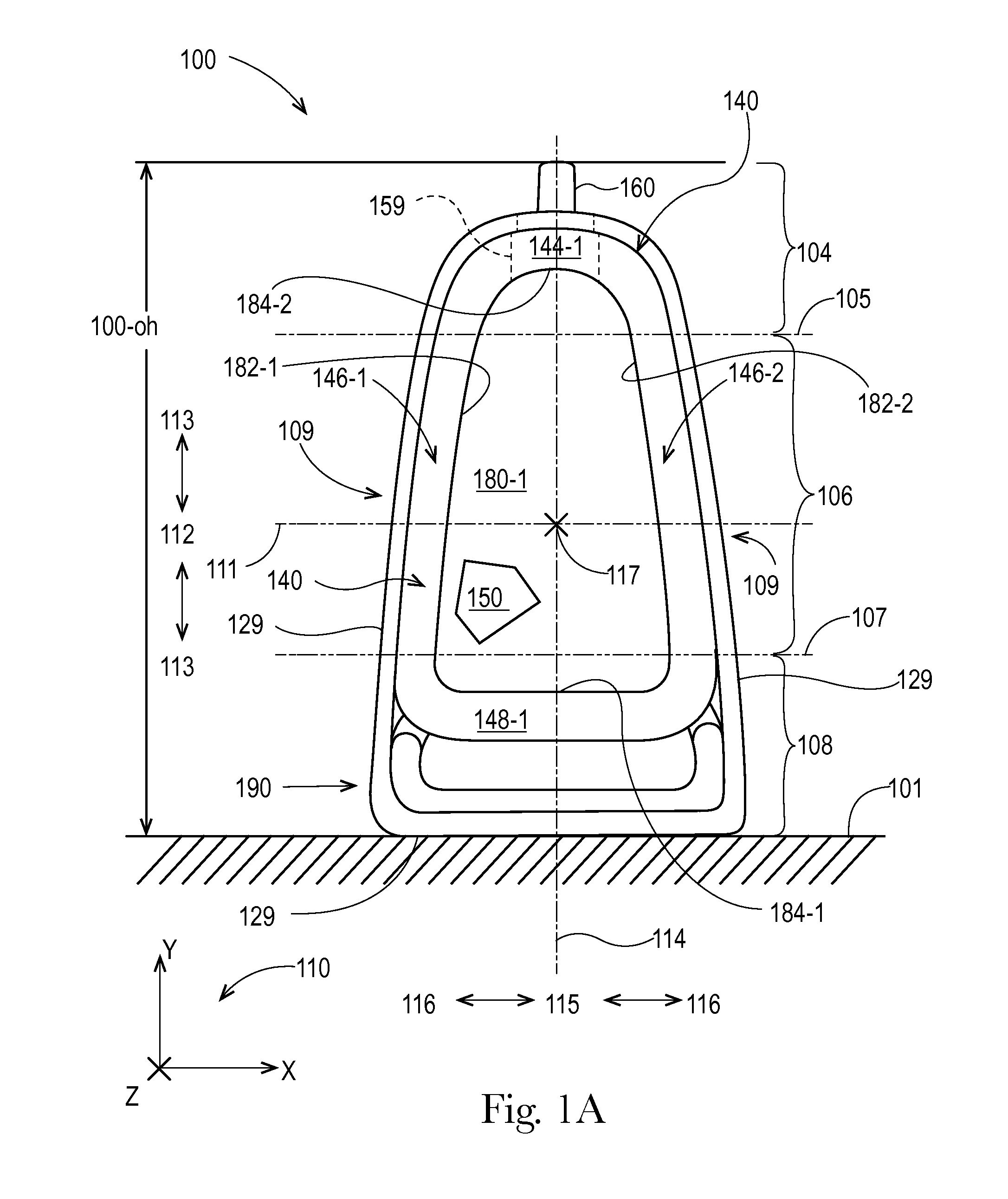

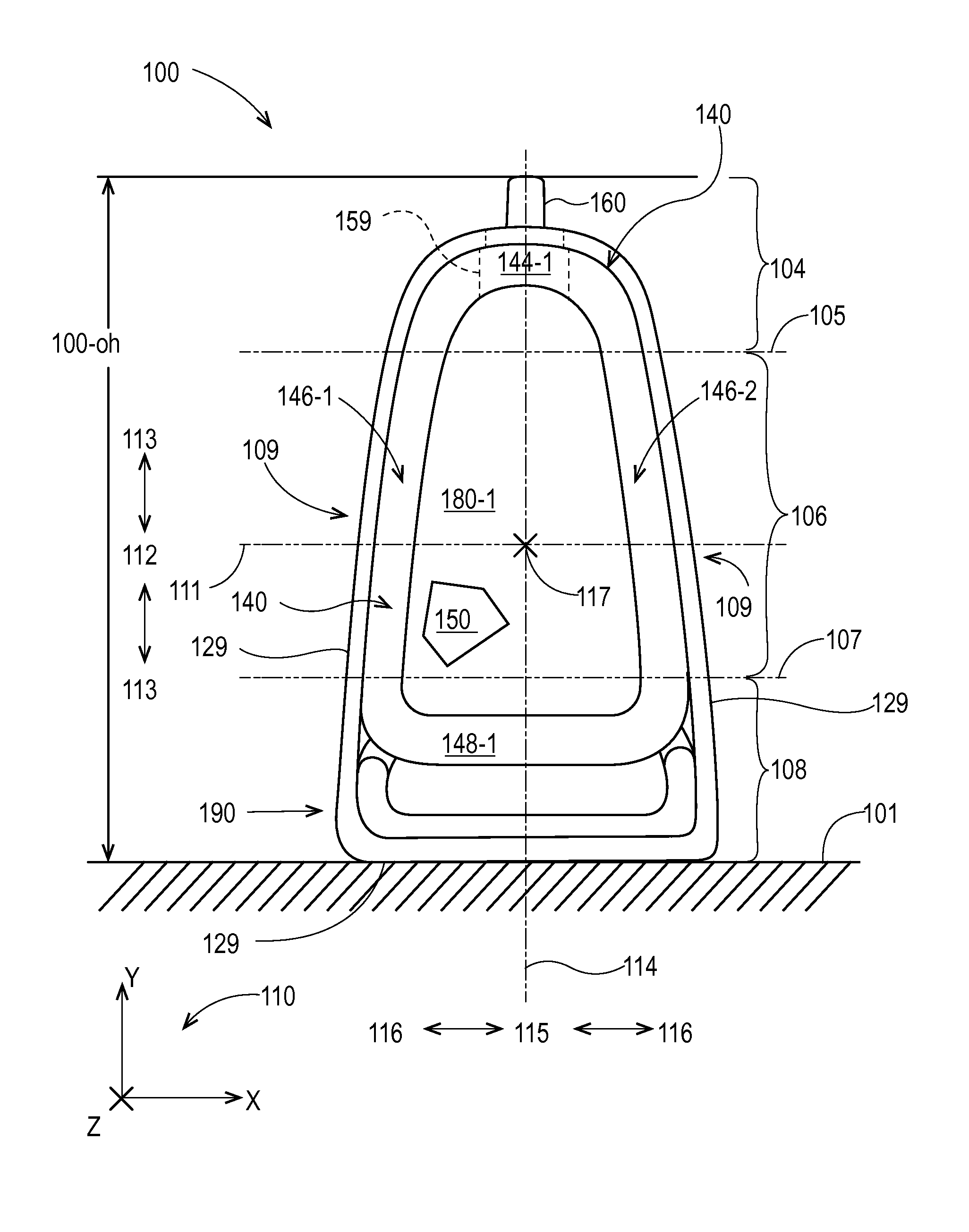

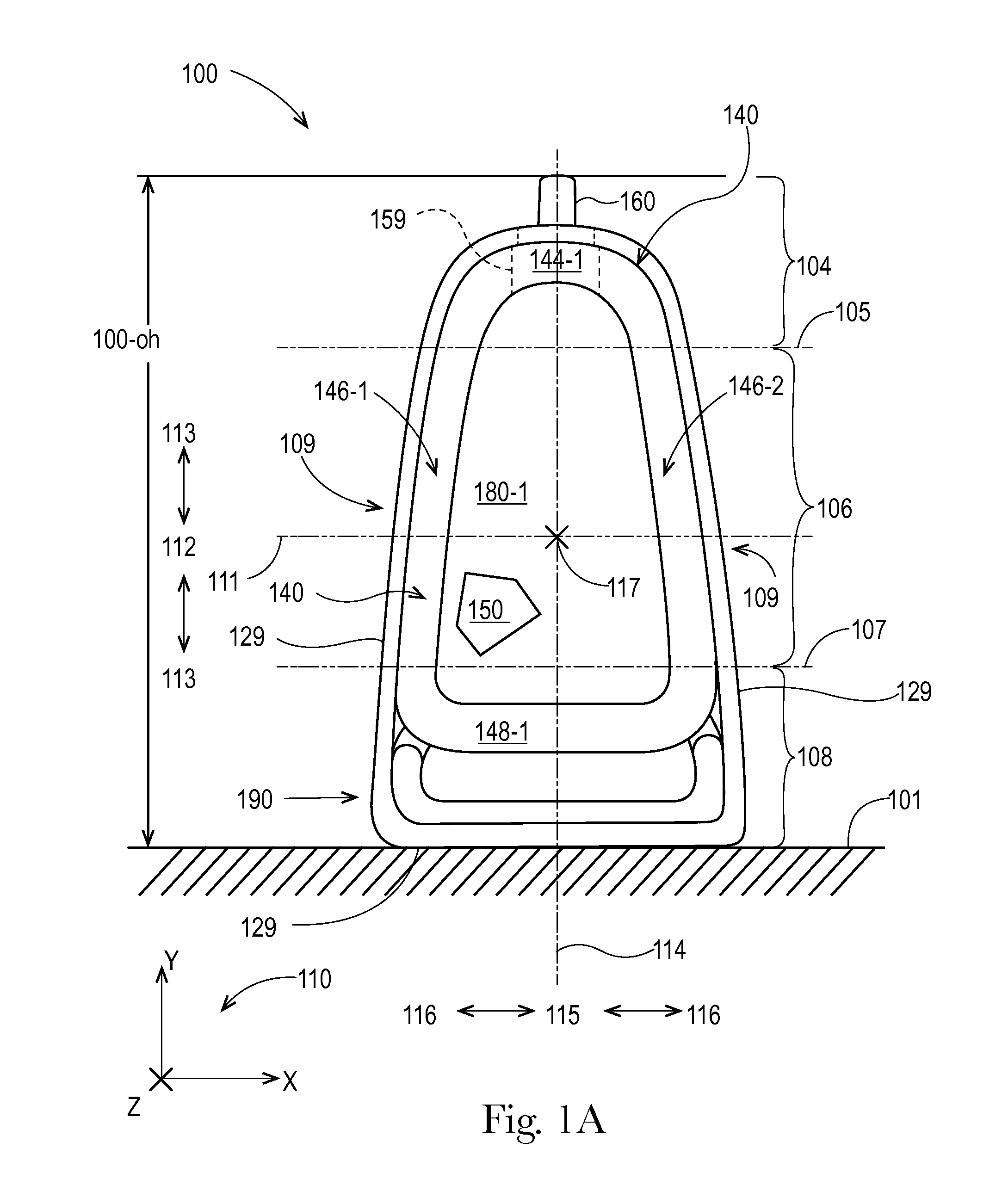

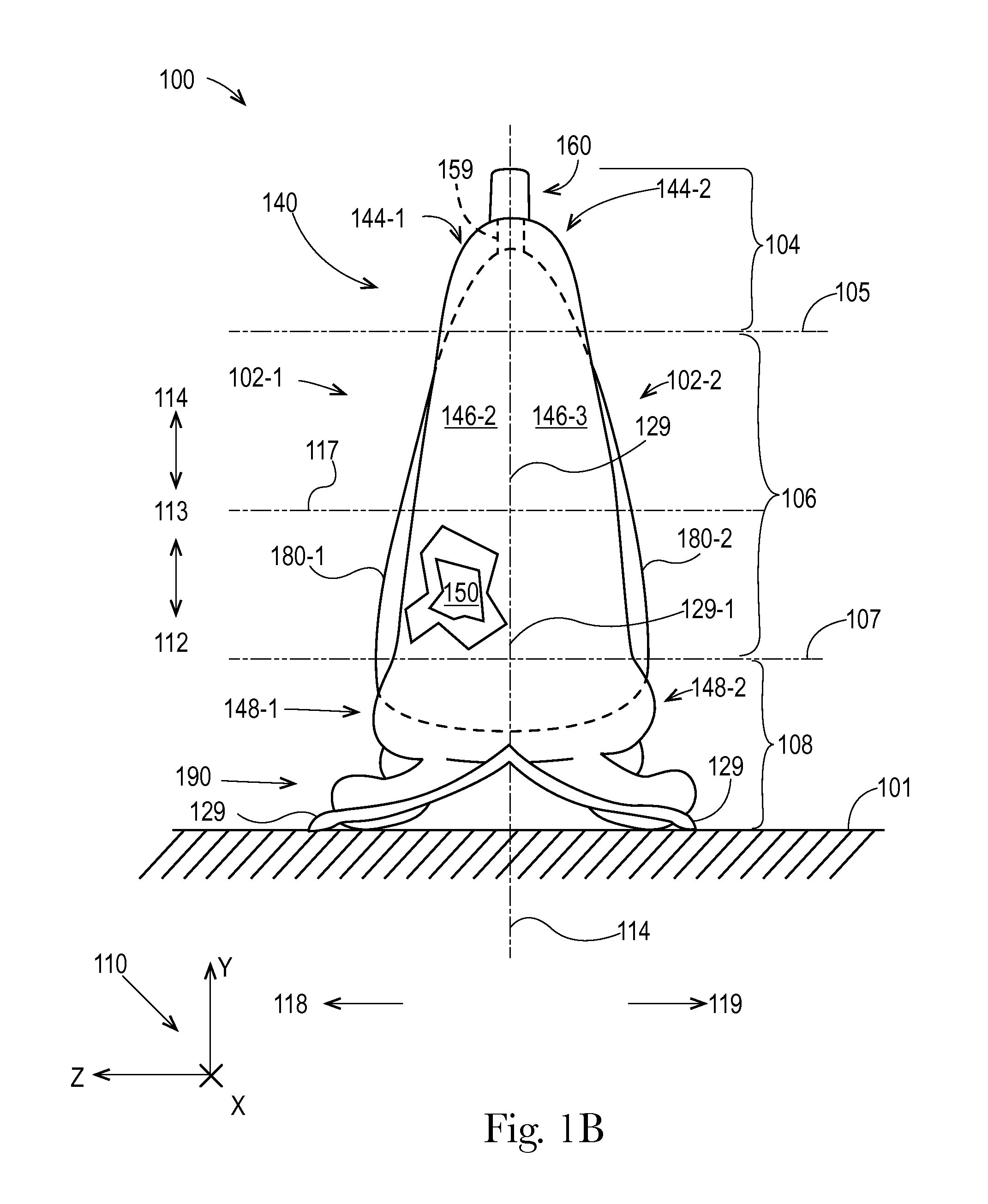

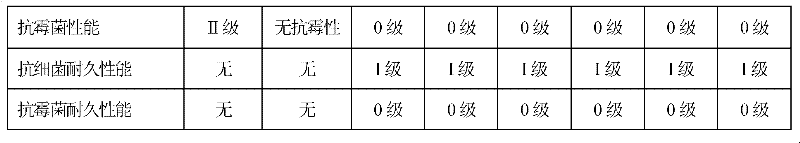

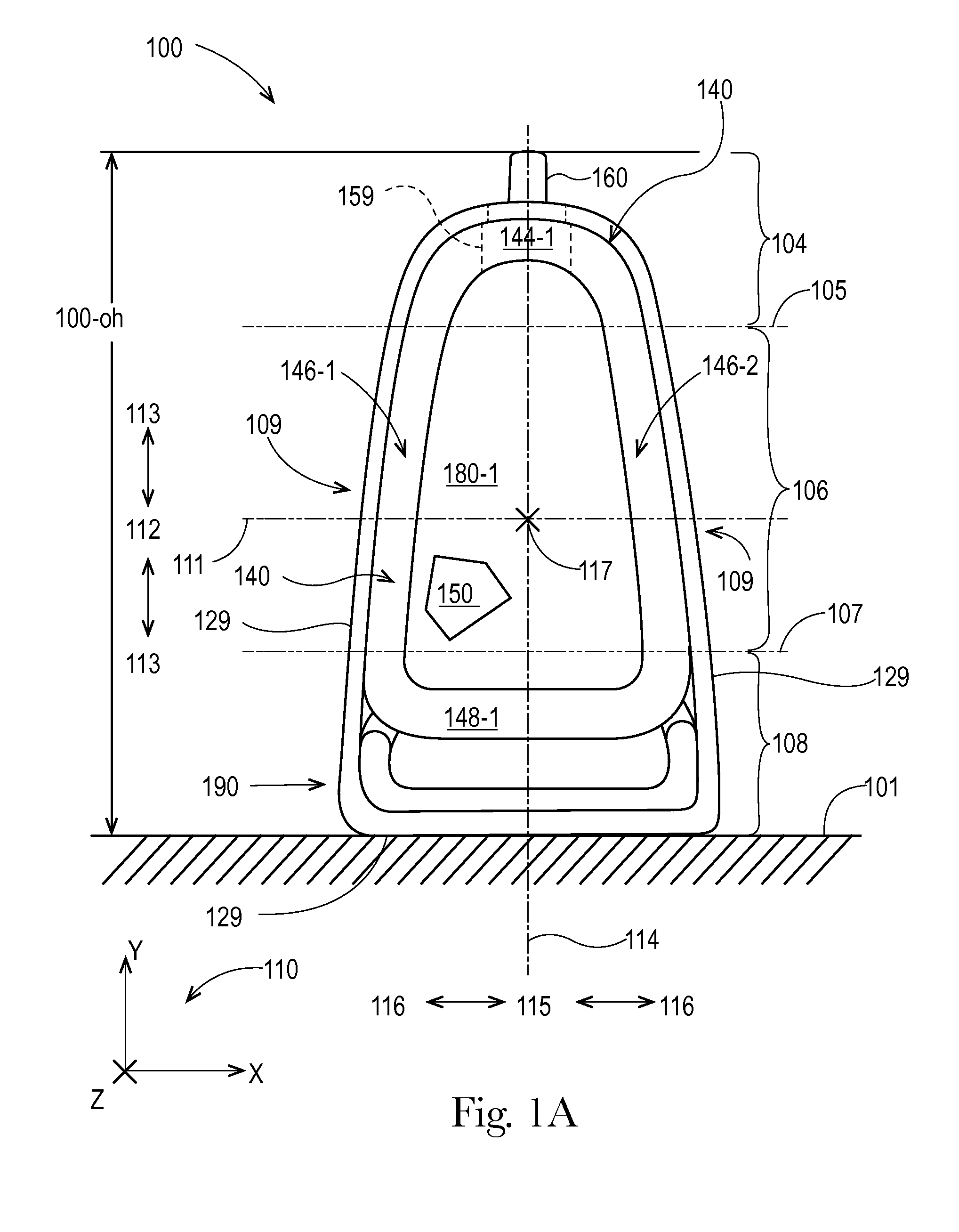

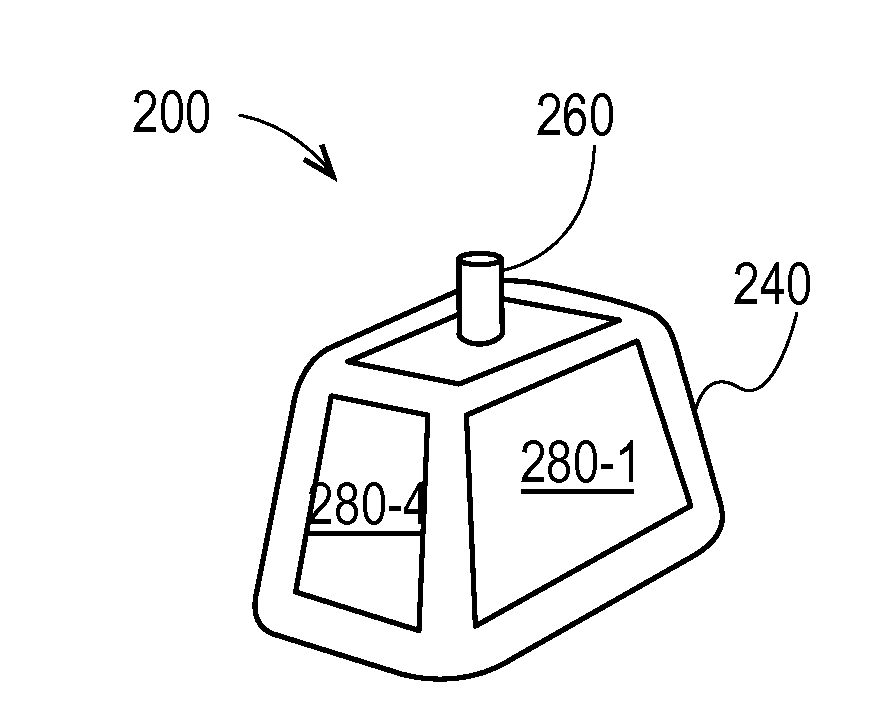

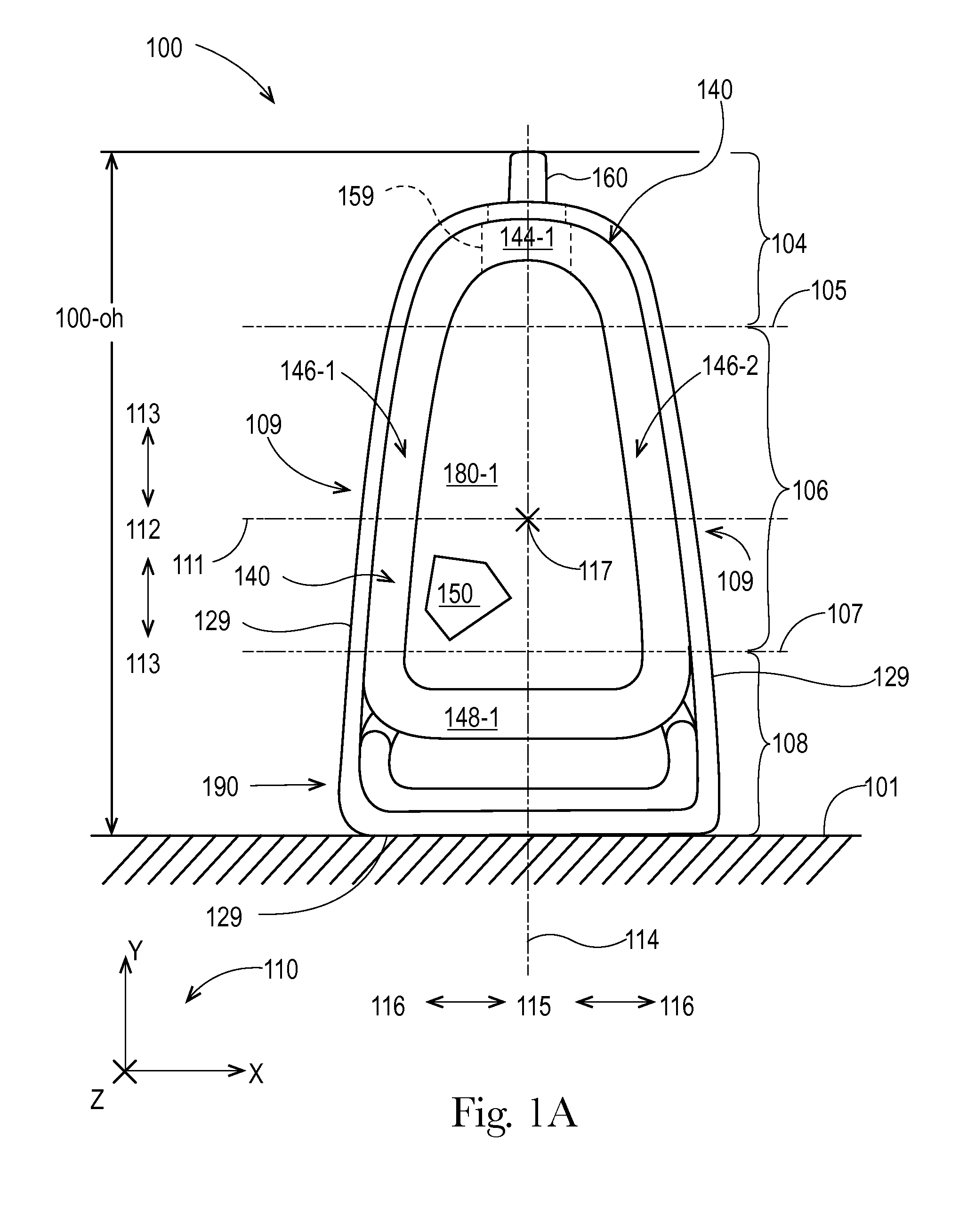

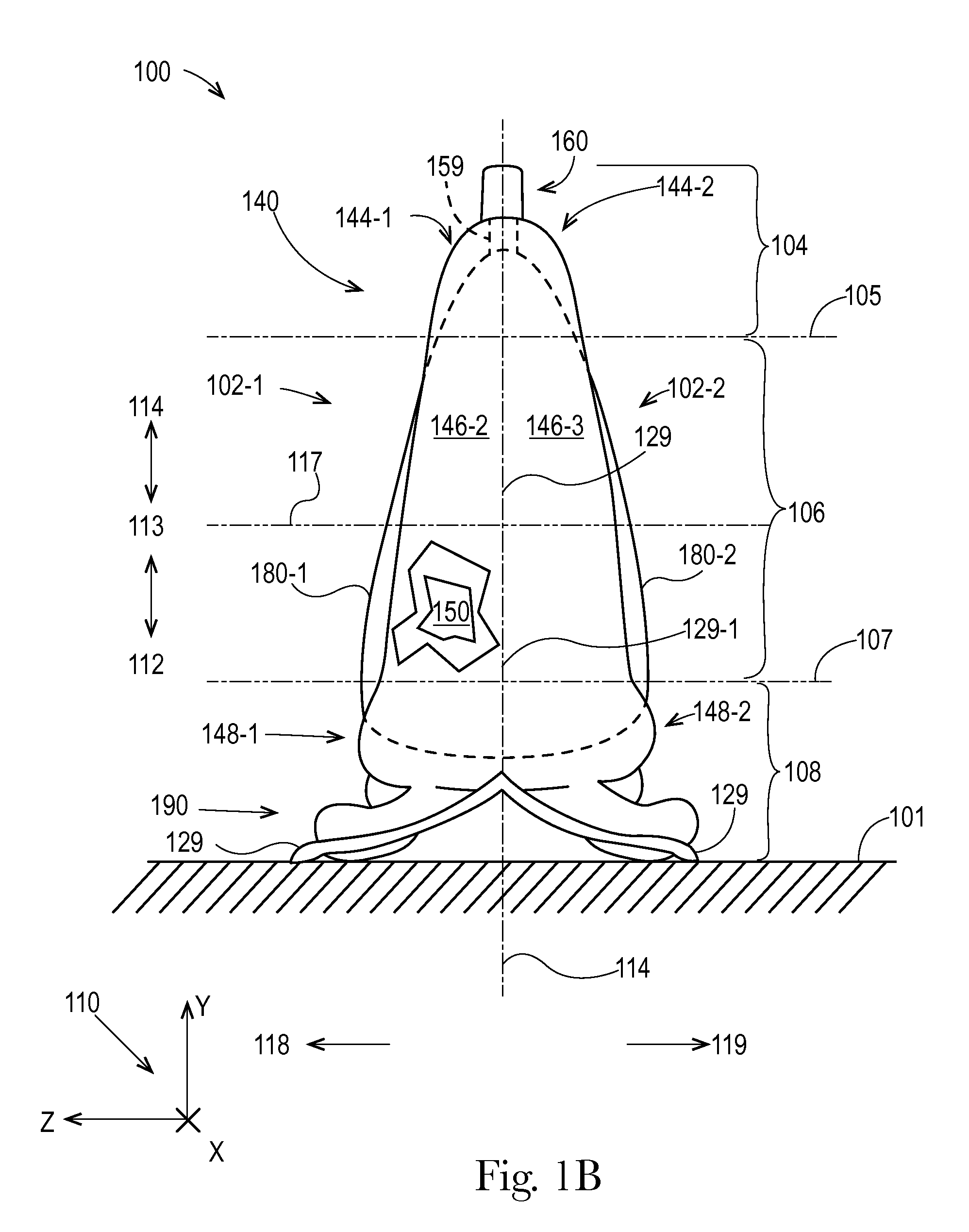

Disposable flexible containers having surface elements

ActiveUS20150034670A1Less-expensiveImprove the decorative effectDispensing apparatusPharmaceutical containersEngineeringSurface plate

Owner:THE PROCTER & GAMBLE COMPANY

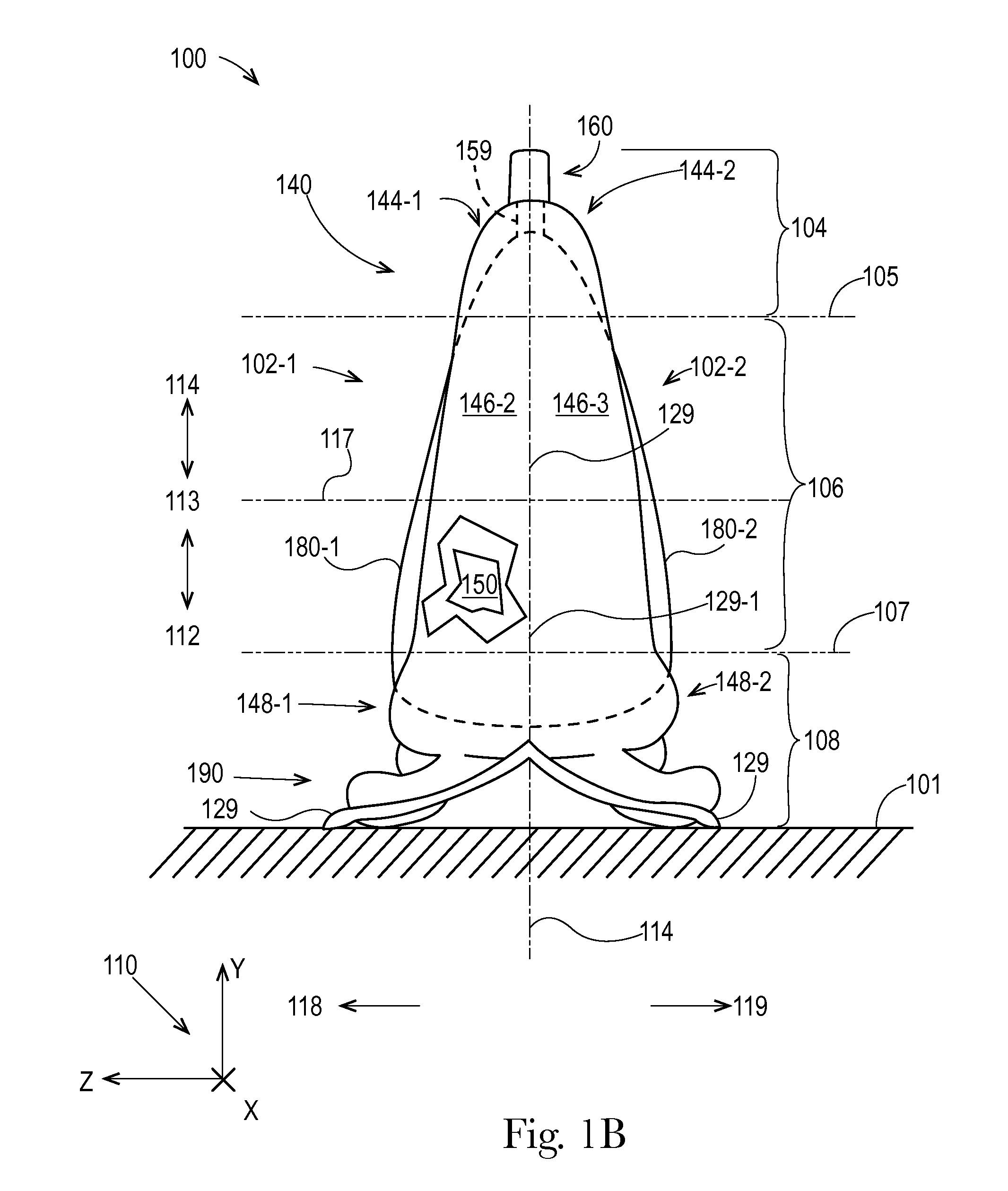

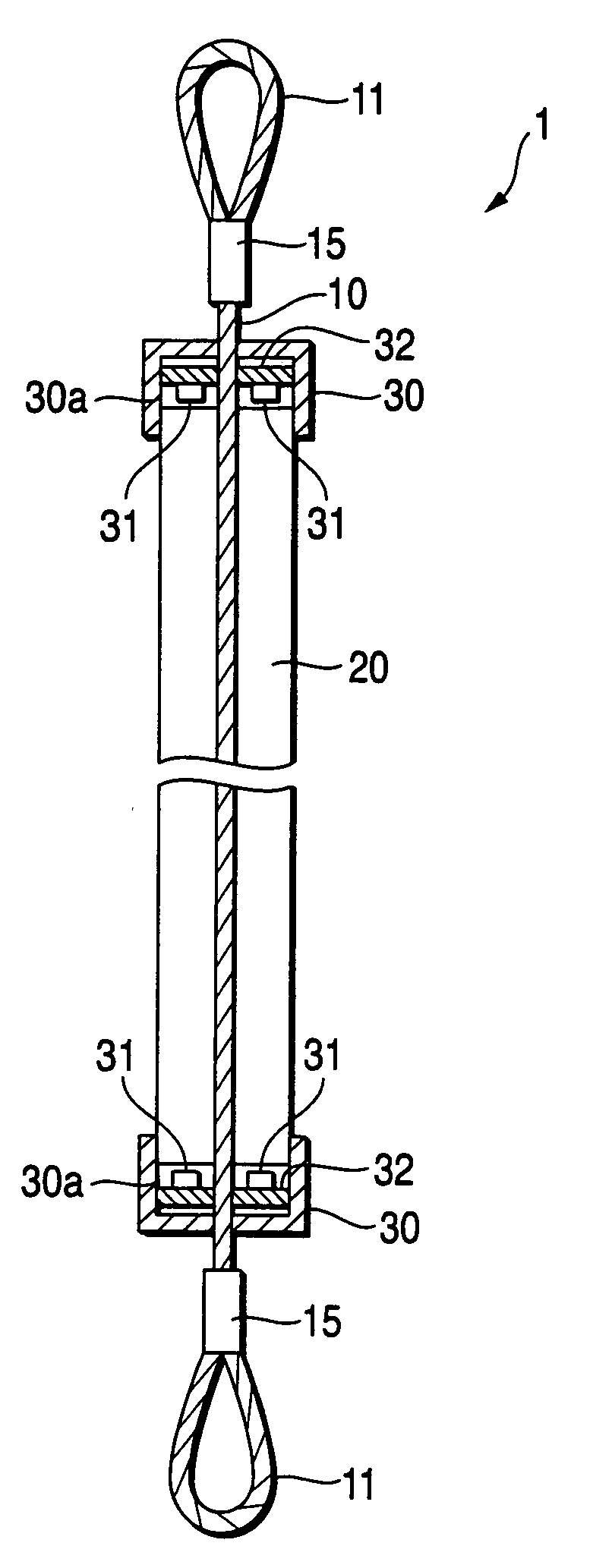

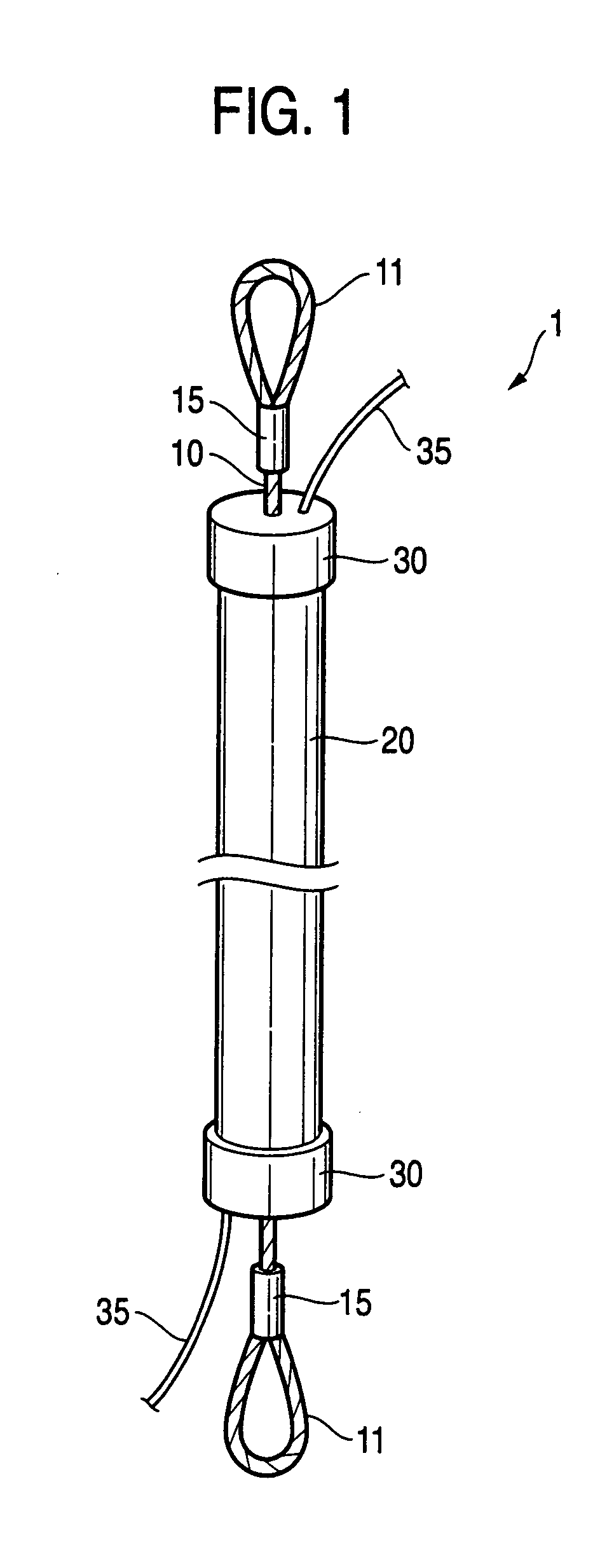

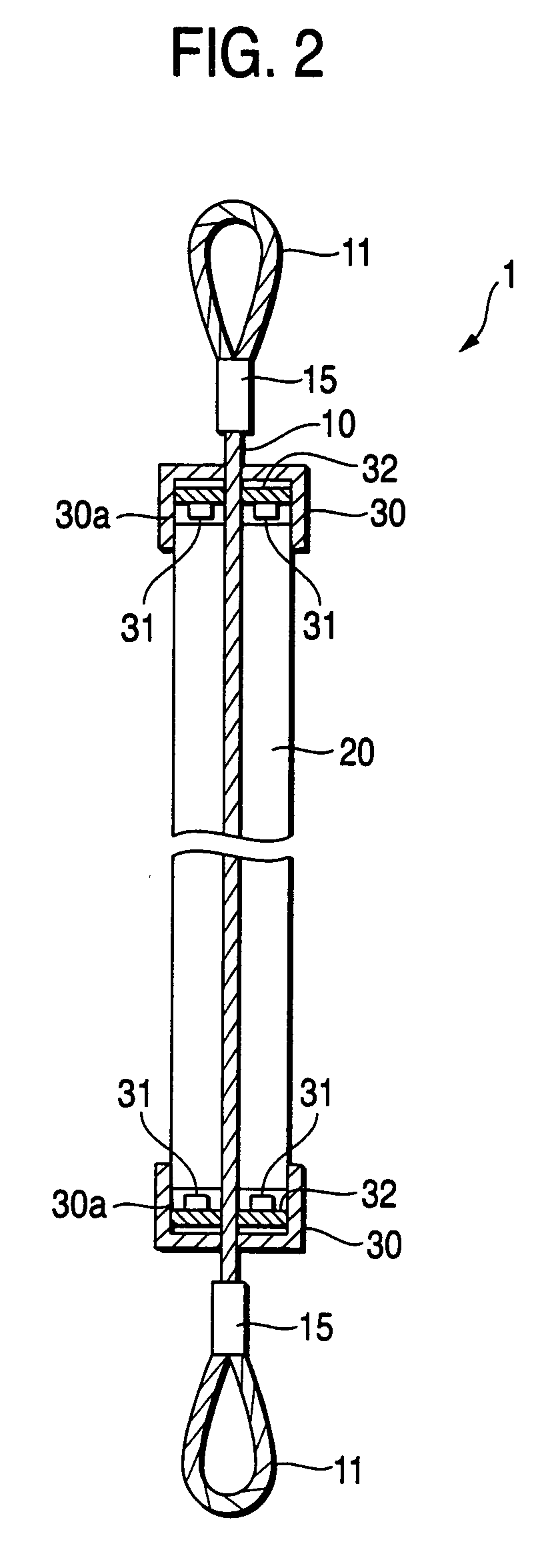

Linear luminous body and linear luminous structure

InactiveUS7021809B2Improve the decorative effectHigh strengthThermometer detailsMeasurement apparatus componentsLight guideOptoelectronics

The invention is directed to a linear luminous body comprising: a light source; a light source accommodating portion in which the light source is accommodated; and a light guide held by the light source accommodating portion so as to extend from the light source accommodating portion; wherein a light emitted from the light source is introduced into said light guide through an end surface of said light guide.

Owner:TOYODA GOSEI CO LTD

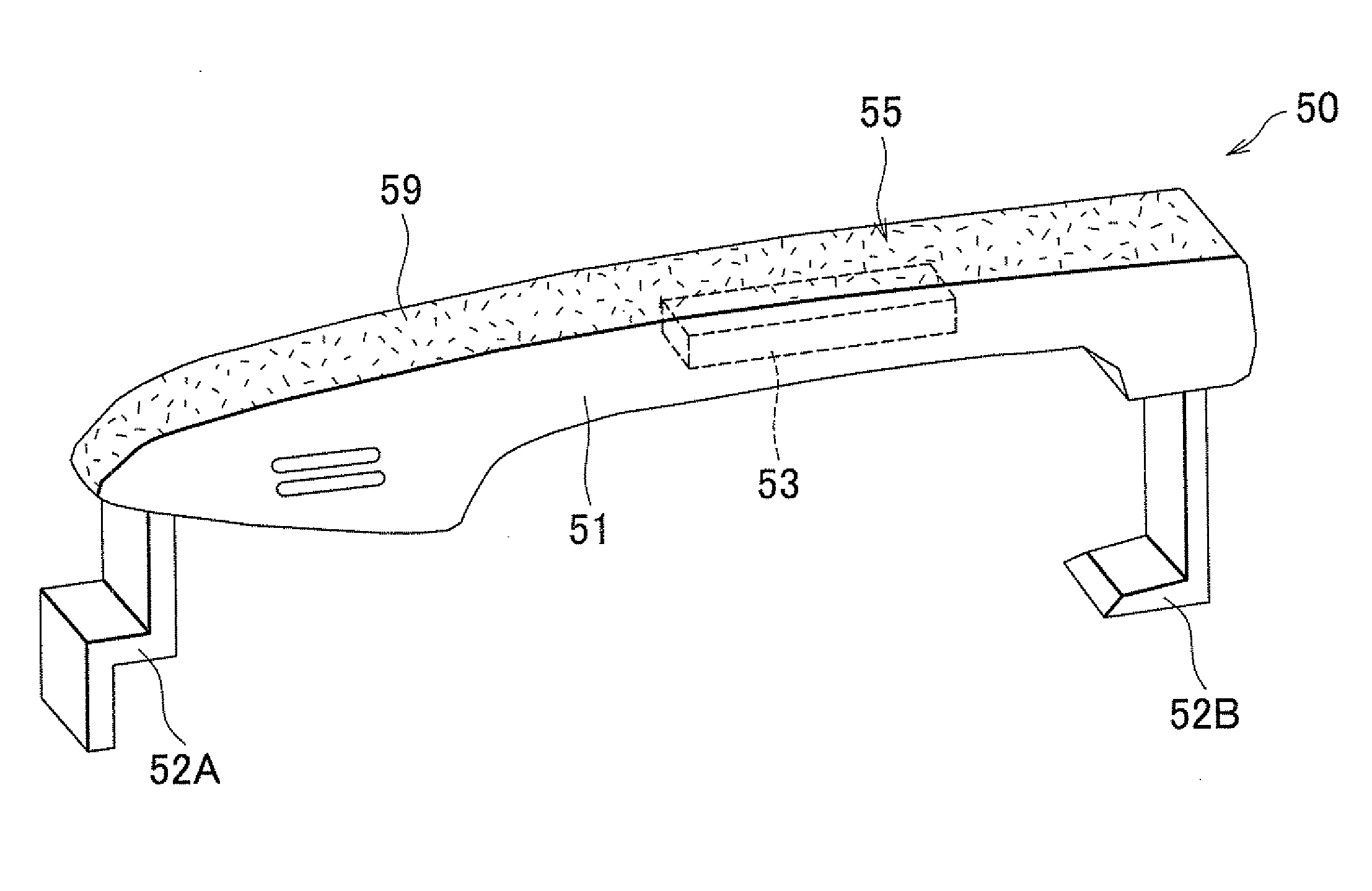

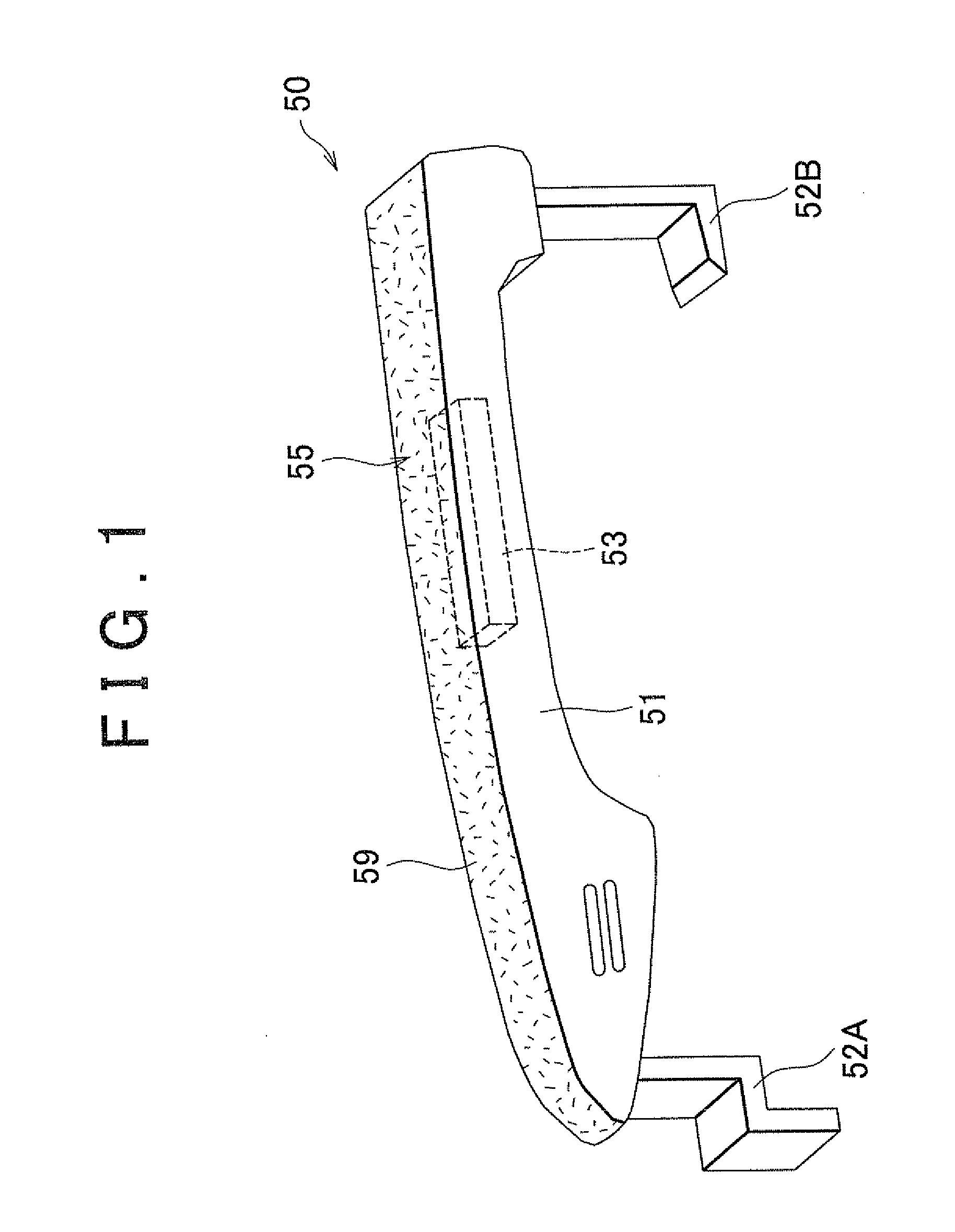

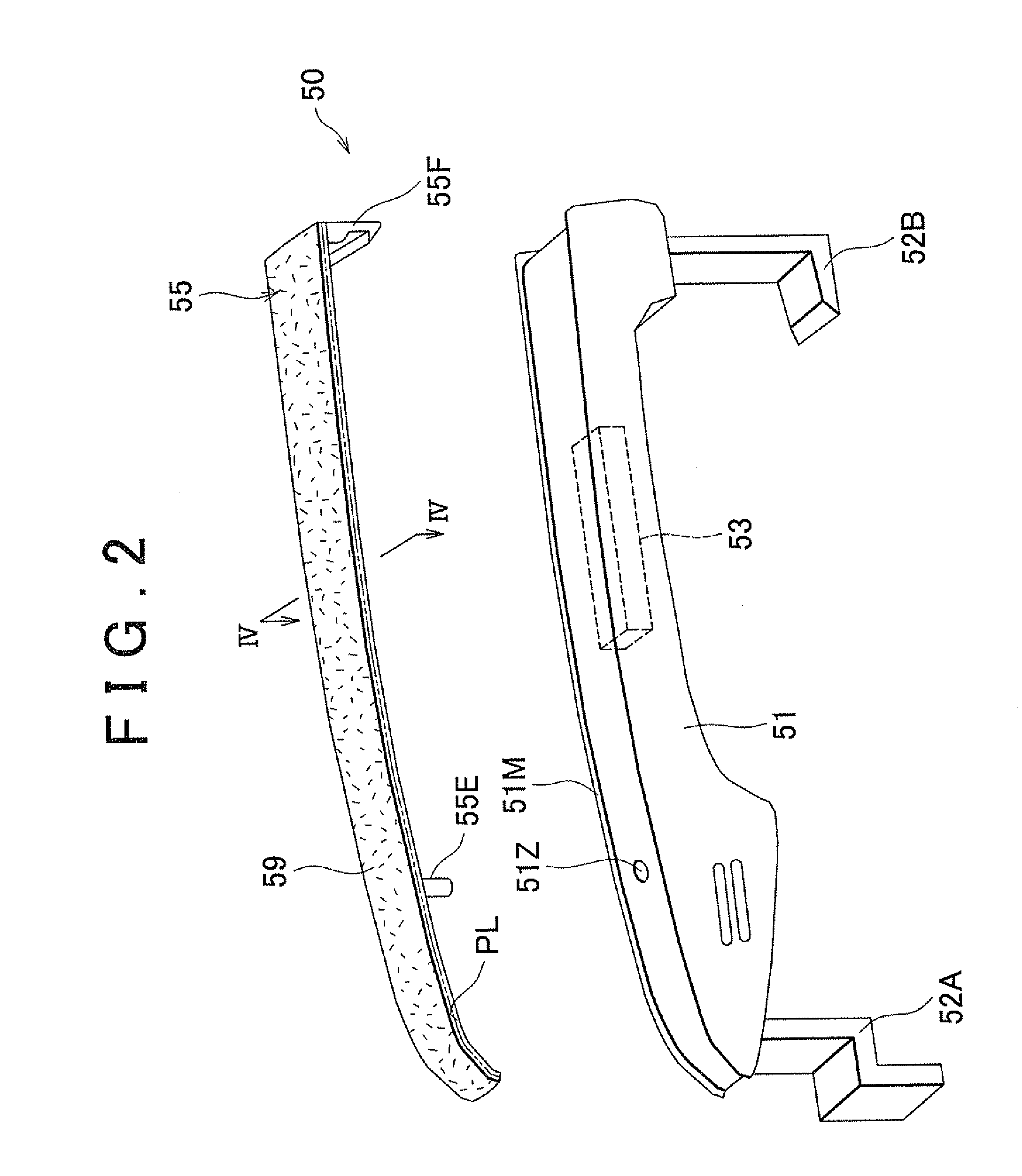

Metallic resin cover and method of producing the same, and door handle for vehicle

InactiveUS20110012378A1Improve the decorative effectReduce adverse effectsLock applicationsWing handlesCapacitance transducerBiomedical engineering

A metallic resin cover constitutes a portion of an outer wall of a human detection device in which a detection electrode of a capacitance sensor is provided, and which detects whether a human touches or approaches the human detection device. The metallic resin cover includes a covered body; and a metal layer that has a metal-object discretely arranged structure in which a plurality of metal objects are discretely arranged. The metal layer covers an outer surface of the covered body.

Owner:WAVELOCK ADVANCED TECH +1

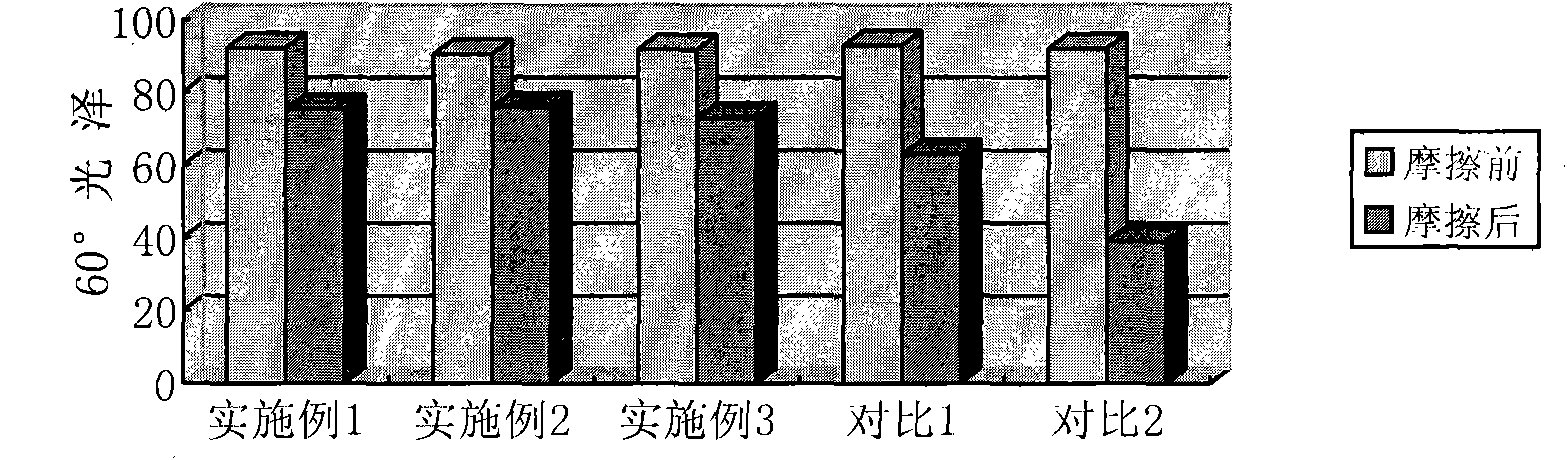

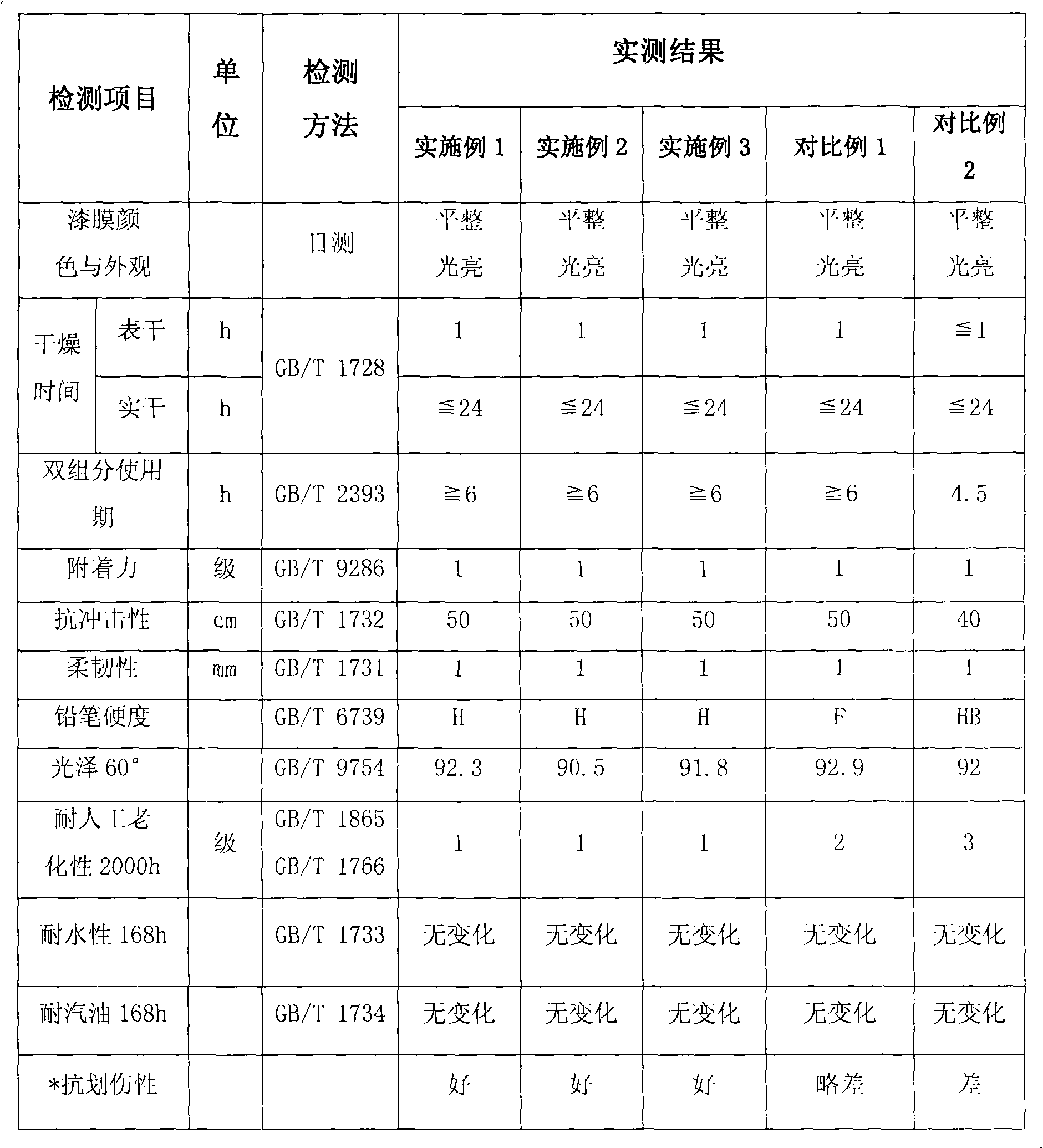

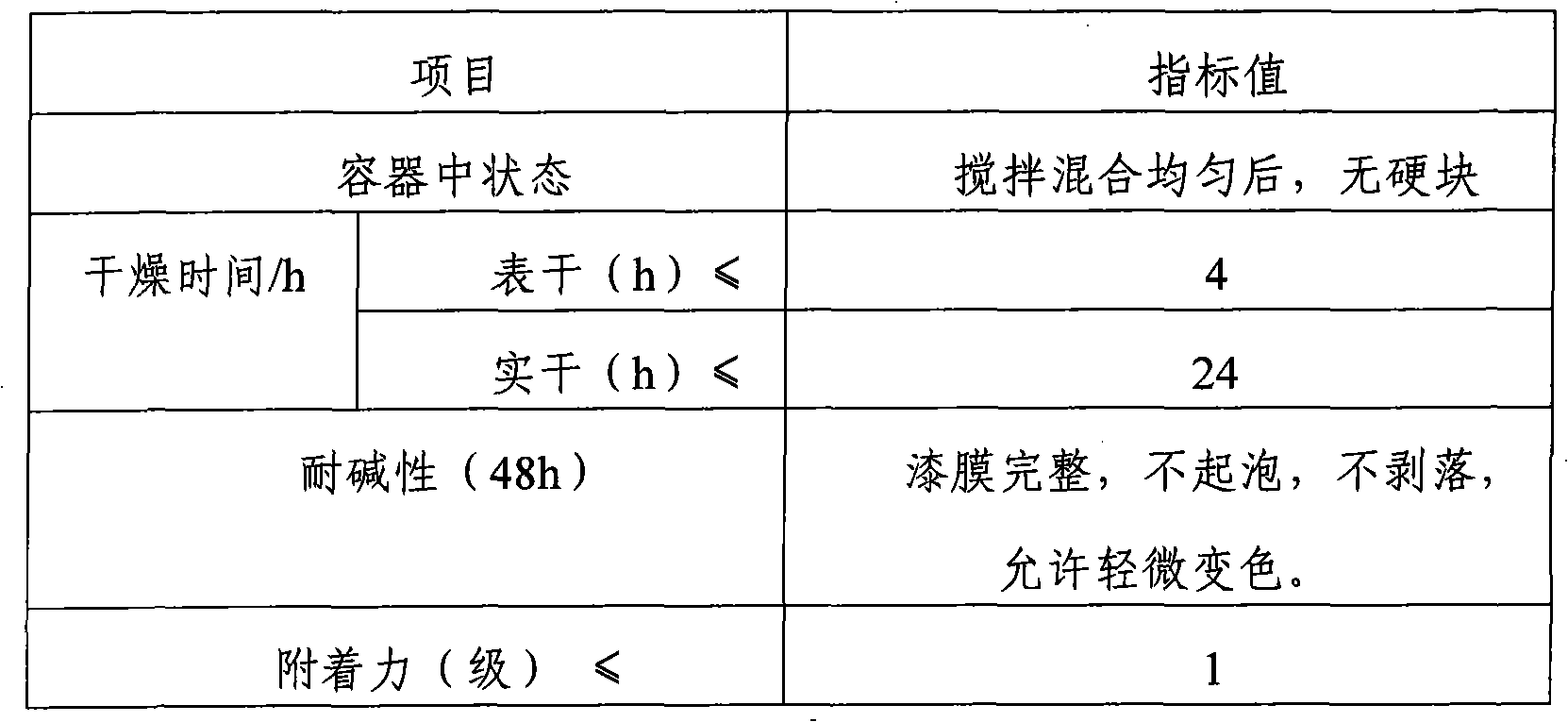

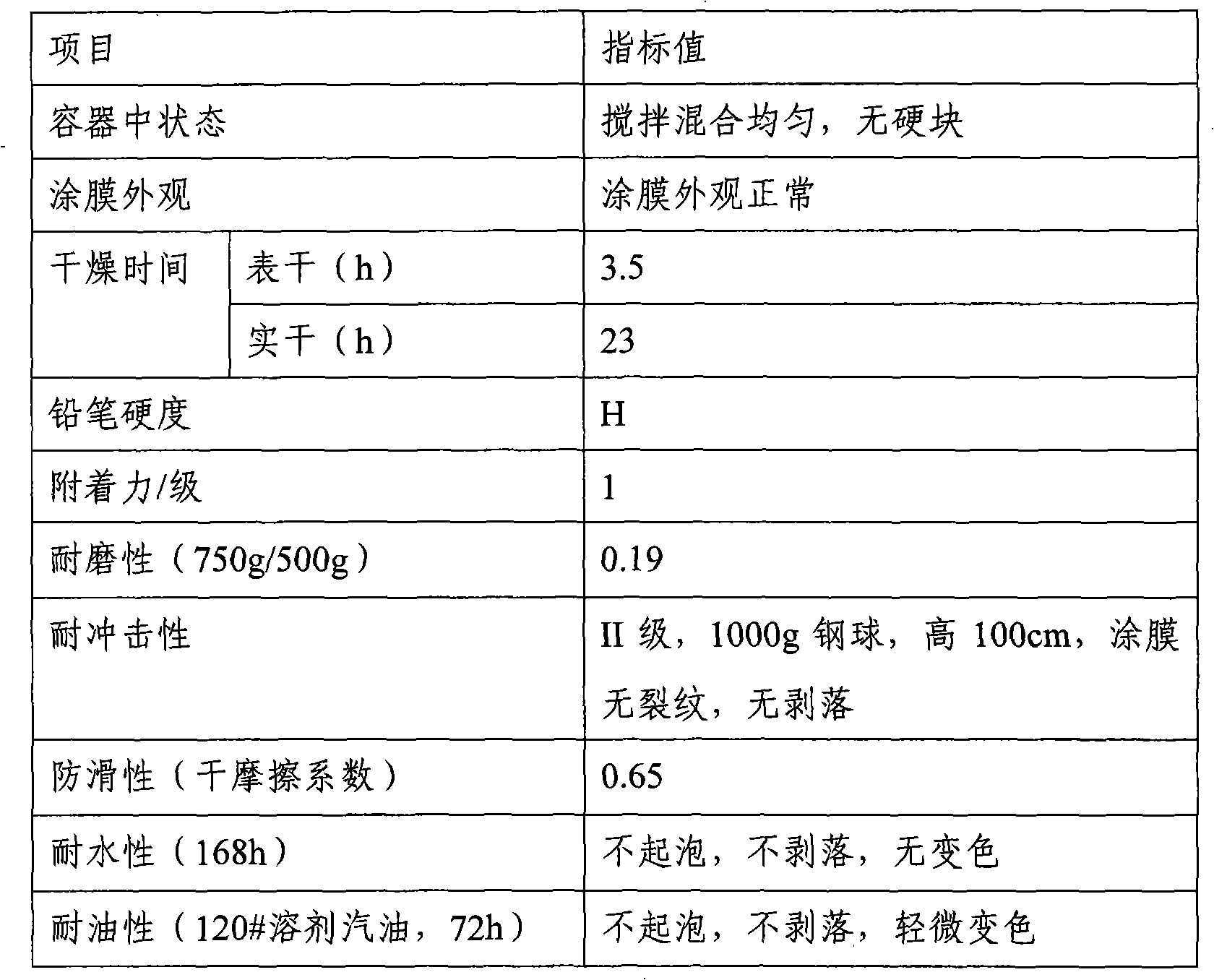

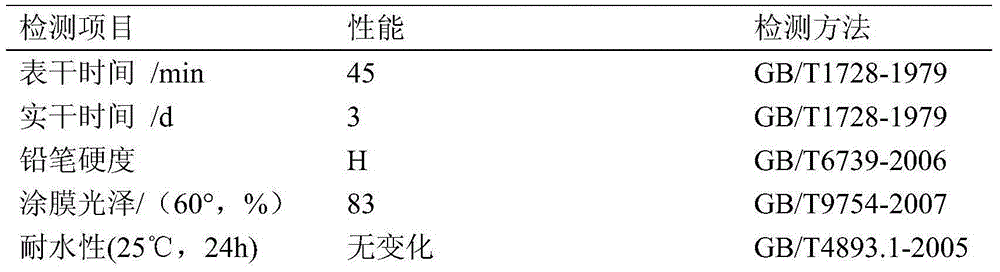

Wear-resisting scratch-resisting weather-proof polyurethane coating and preparation method thereof

ActiveCN101792639AImprove scratch resistanceGood weather resistancePolyurea/polyurethane coatingsPolyester coatingsScavengerAcrylic resin

The invention relates to a double-component polyurethane coating and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A comprises hydroxyl-containing acrylic resin, fluorocarbon resin, polyester resin, non-nanoscale titanium white, nanometer titanium dioxide, nanometer silicon dioxide and various auxiliary agents; and the component B comprises polyisocyanate curing agent, solvent and moisture scavenger. The component A and the component B are mixed at the weight ratio of 4:1-5:1 to obtain the polyurethane coating. The coating has excellent wear resistance, scratch resistance and weather proofness, has favorable decoration, and is suitable for coating the surfaces of rapid trains, automobiles and the like which have higher requirements on decoration and physiochemical performance.

Owner:DE LAITTERN ENVIRONMENTAL COATING BEIJING

Flexible materials for flexible containers

ActiveUS9469088B2Less-expensiveImprove the decorative effectDomestic containersCoatingsMechanical engineeringGas barrier

A flexible material for a flexible container can include a first laminate and a second laminate joined to at least a portion of the first laminate by at least one seal. The first laminate can include a first gas barrier layer disposed between first and second sealable layers, wherein the first and second sealable layers define opposed exterior layers of the first laminate. The second laminate can include a third sealable layer defining an exterior layer of the second laminate, and a second gas barrier layer. The at least one seal joins a portion of the third sealable layer to at least a portion of the second sealable layer.

Owner:PROCTER & GAMBLE CO

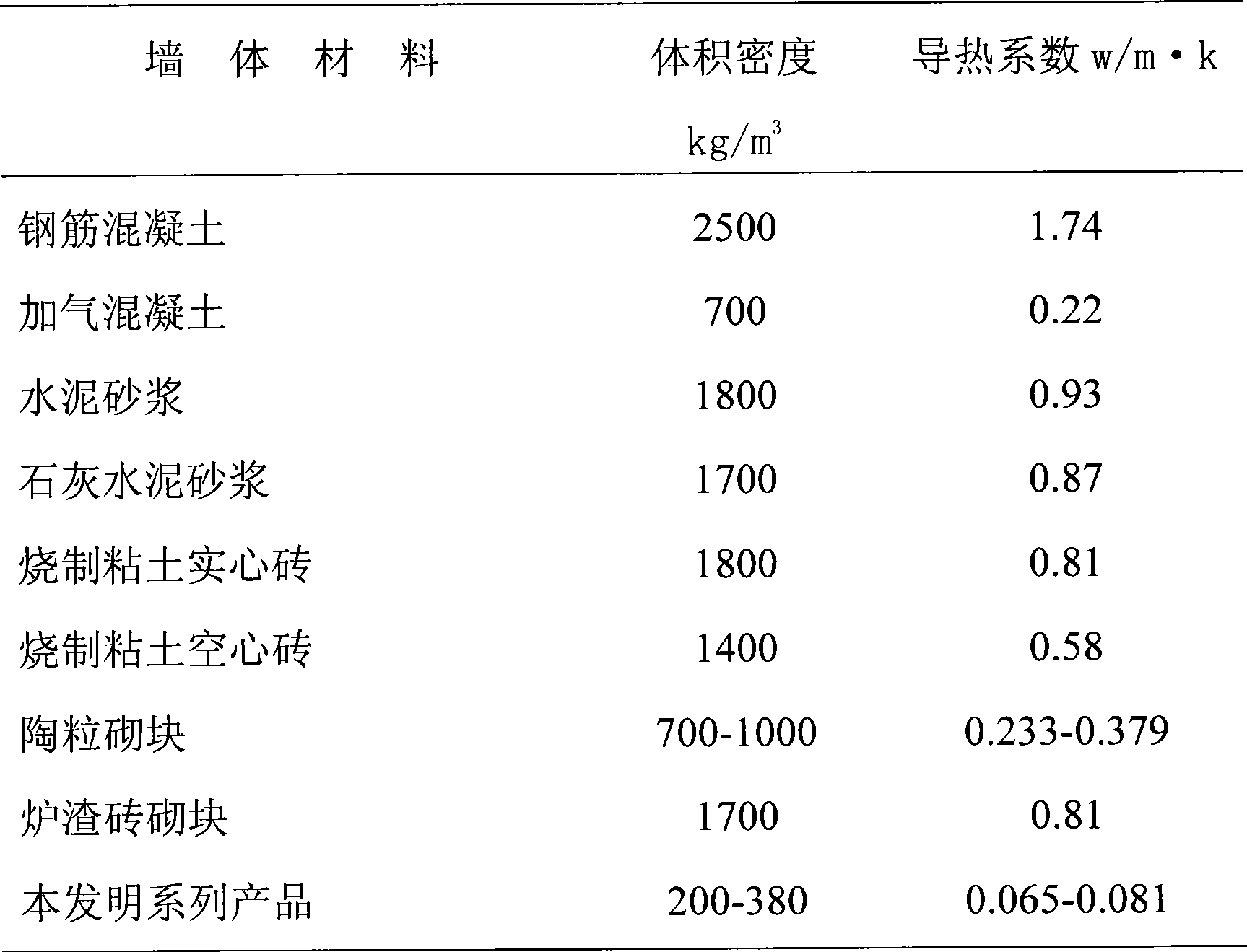

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

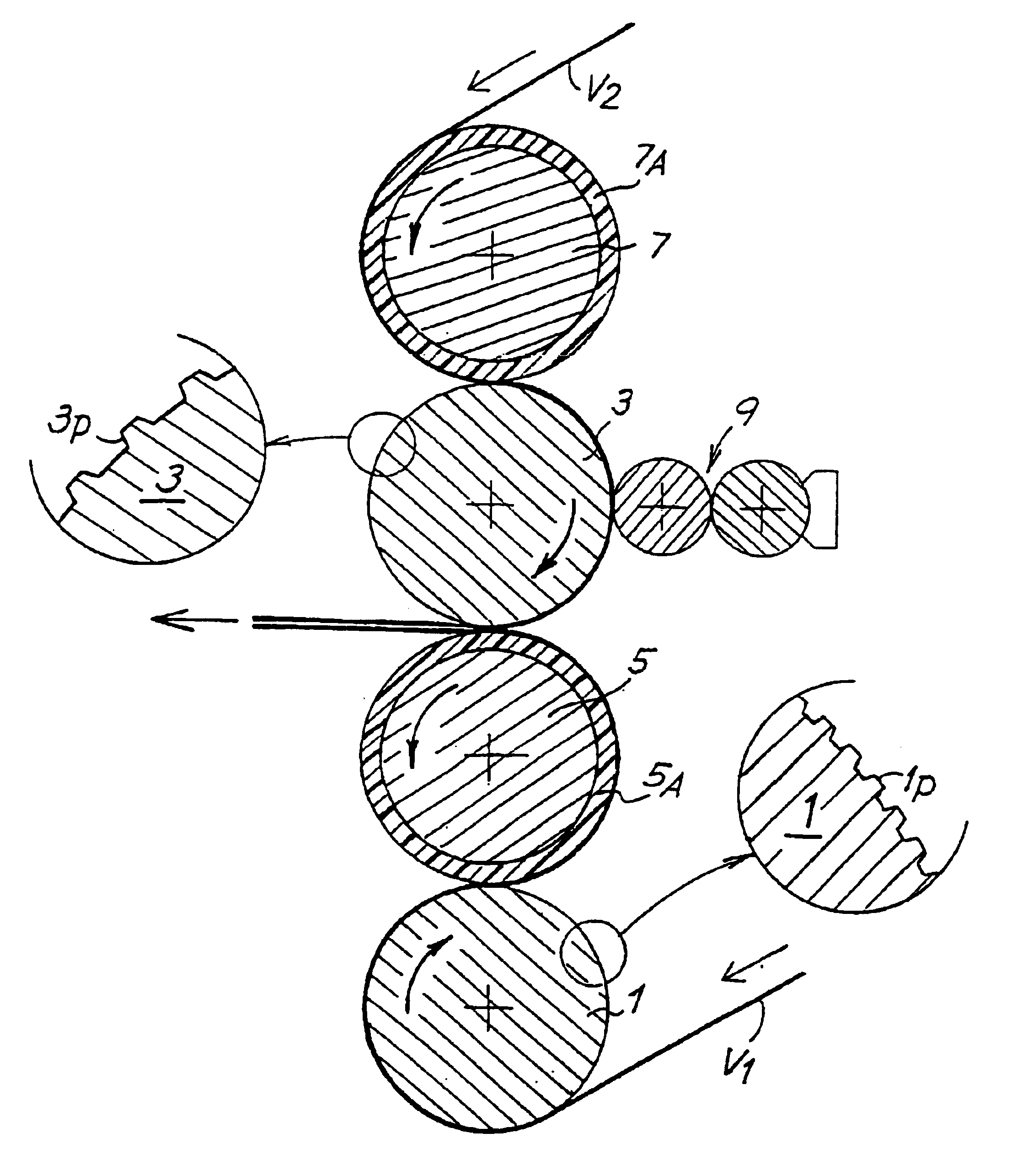

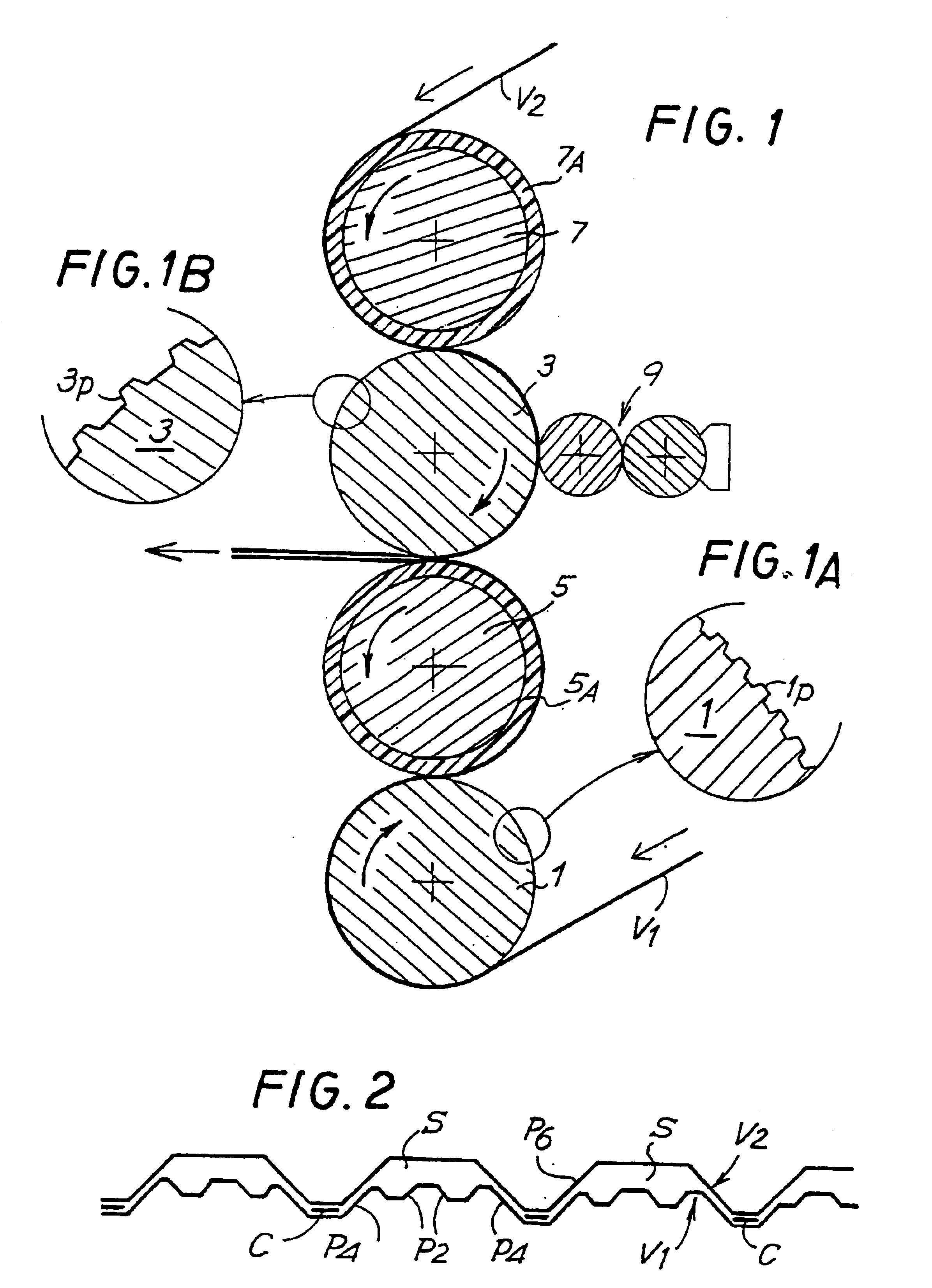

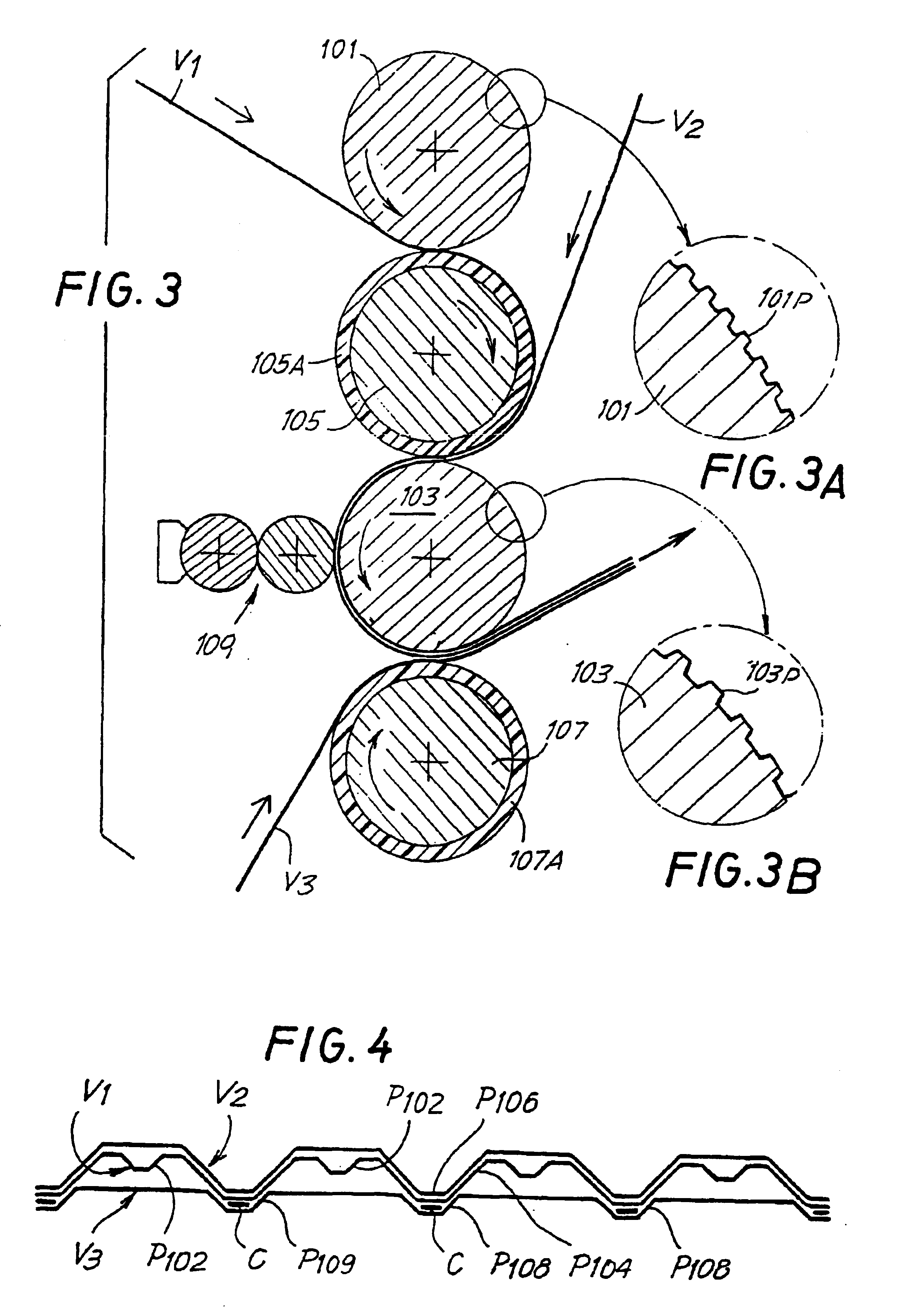

Method and device for producing an embossed web material and product made in this way

InactiveUS6755928B1Quality improvementLow modification costMechanical working/deformationLaminationEngineeringSheet material

For the production of a sheet product including at least two layers (V1, V2) it is suggested, among other things, an embossing device including a first pressure roller (5; 105) interacting with a first and a second embossing cylinder (1, 3; 101, 103) provided with respective points (1P, 3P, 101P, 103P) on their cylindrical surface.

Owner:FABIO PERINI SPA

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

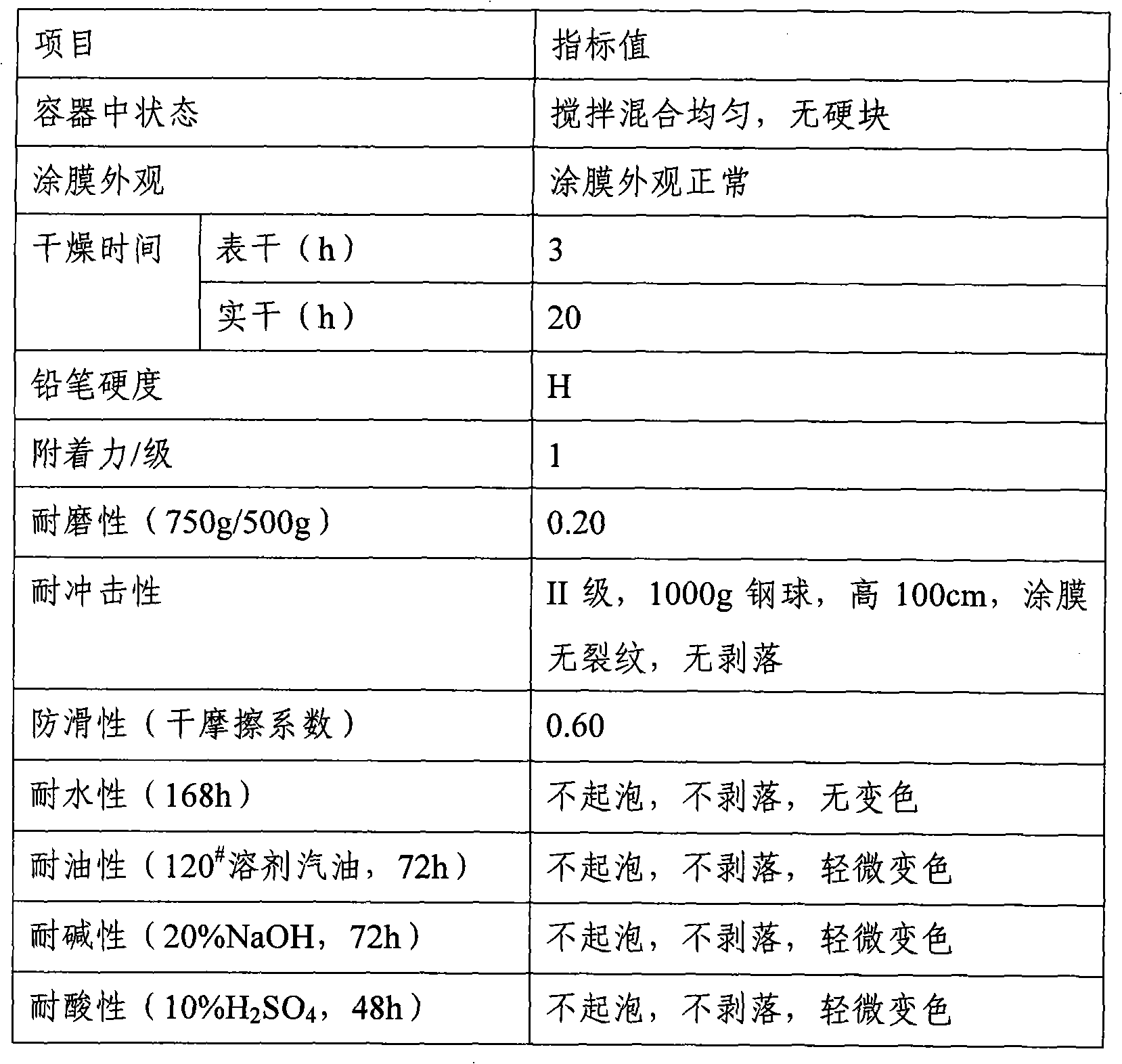

Compound epoxy flooring coating and preparation method thereof

InactiveCN101654583AHigh mechanical strengthImprove corrosion resistanceRosin coatingsEpoxy resin coatingsSolvent freeFirming agent

The invention relates to compound epoxy flooring coating adopting the mixture of epoxide resin and modified resin as a base material and further comprising organic solvent, dispersant, wetting agent, antifoaming agent, flatting agent, scratch resistance agent, pigment and stuffing as well as reactive diluent selected according to requirements. When in use, the coating is mixed and solidified withthe components of firming agent, accelerant, etc. By regulating the content of the components, the compound epoxy flooring coating of the invention can be used for manufacturing a solvent or solvent-free autolevelling epoxy floor. The compound epoxy flooring coating of the invention has favorable over-all properties, and not only has the characteristics of high mechanical strength, favorable anti-corrosion property, high adhesive force and good wear resistance property of the epoxide resin but also has the characteristics of good weather resistance, high decorative property and hardness and shock resistance of the modified resin; and the preparation method thereof is simple and practicable, is low-cost, and is suitable for mass preparation.

Owner:北京红狮科技发展有限公司

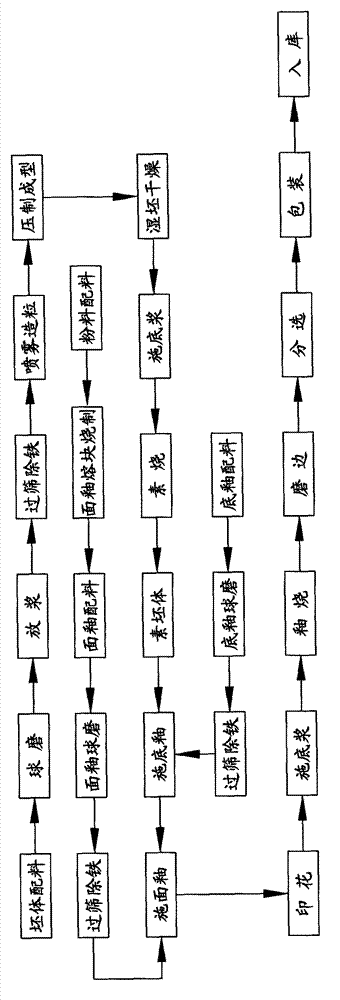

Formula and preparation method of national flag bright red glazed brick

The invention relates to a formula and preparation method of a national flag bright red glazed brick. On the basis of not changing the existing glazed brick production technique too much, the invention mainly adjusts and optimizes the composition of blank materials, the composition of base / cover coating fused blocks, the preference and proportion of the fused blocks having different properties in base / cover coating, the processing technique of the cover coating, the formula composition of the base coating, the water absorptivity of a biscuit, the firing temperature and the like, thereby ensuring that the fired national flag bright red glazed brick has a dazzlingly beautiful glaze color, is bright like a reflective mirror, and has a high decorative effect and an artistic aesthetic effect; and the color is as pure as the color of a national flag and is glossy and bright, so that the national flag bright red glazed brick can shine like the rising sun. Meanwhile, the technology has high universality, and is readily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +1

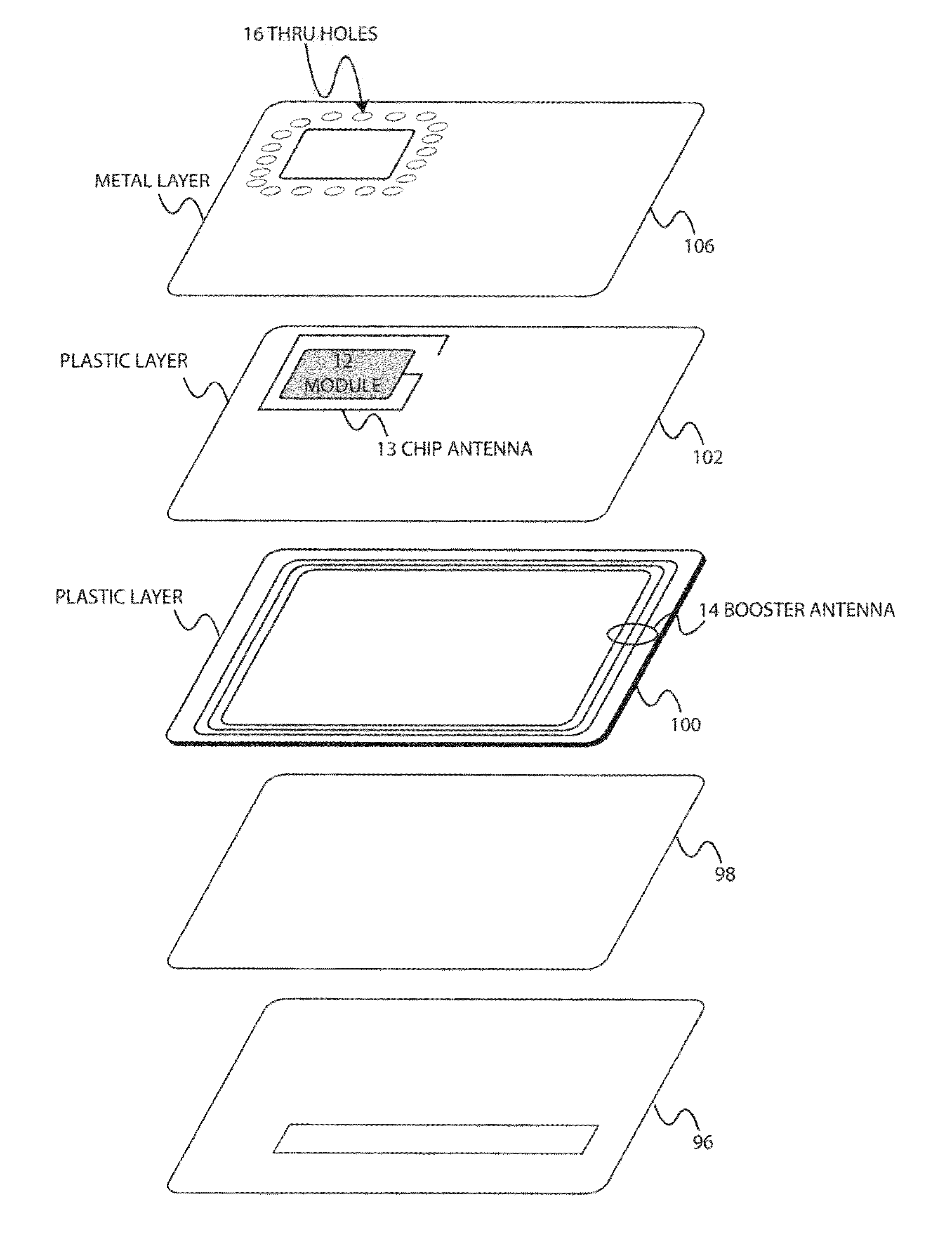

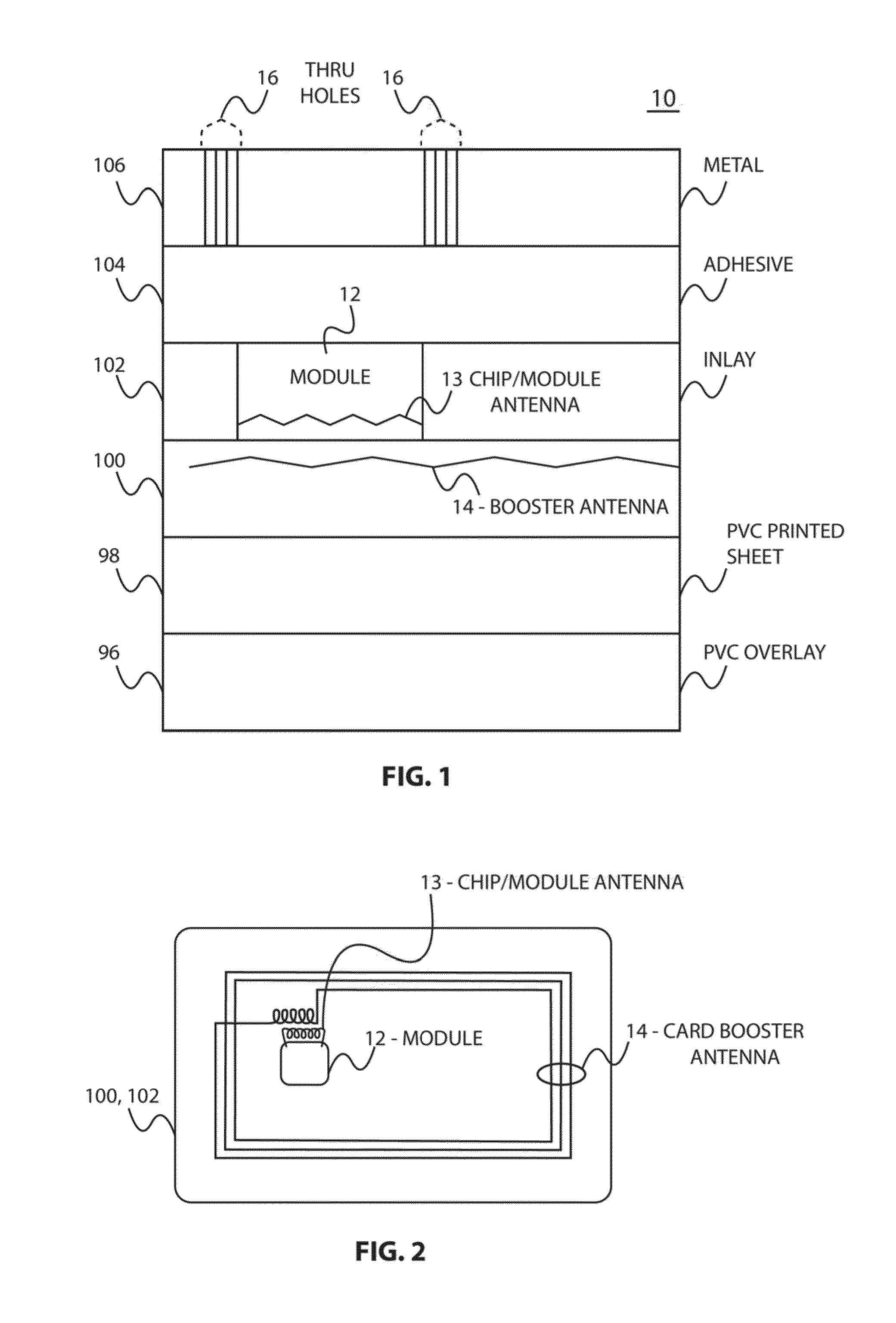

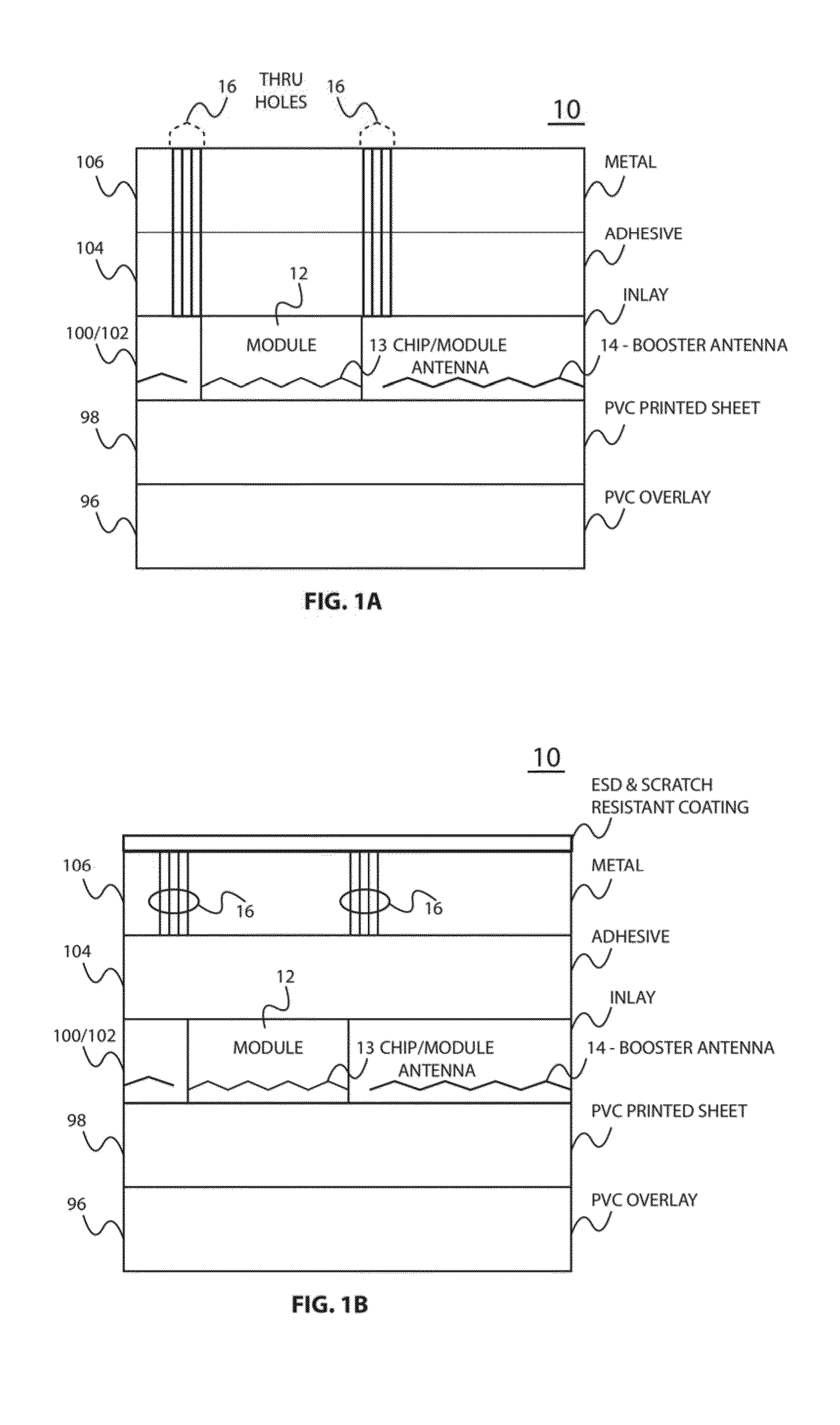

Metal card with radio frequency (RF) transmission capability

InactiveUS20150206047A1Improve decorative effectEnhance efficient reception/transmissionLoop antennas with ferromagnetic coreRecord carriers used with machinesRadio frequencyVIT signals

A smart card with a metal layer which can capture radio-frequency (RF) signals via an antenna system is made operable by modifying the metal layer to enable passage of RF signals through the metal layer and / or by introducing a ferrite layer to enhance the efficient reception / transmission of RF signals by the antenna system. In one embodiment apertures are formed in and through the metal layer to allow RF signals to pass through the metal layer without negatively impacting the decorative or esthetic and / or reflective nature of the metal layer. These modifications allow for dual interface and contactless smart card formats. In other embodiments of the invention, a ferrite layer is formed between the metal layer and the inductors / antennas mounted within the smart card to enhance the efficient reception / transmission of RF signals.

Owner:KEYBANK NAT ASSOC AS ADMINISTATIVE AGENT

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

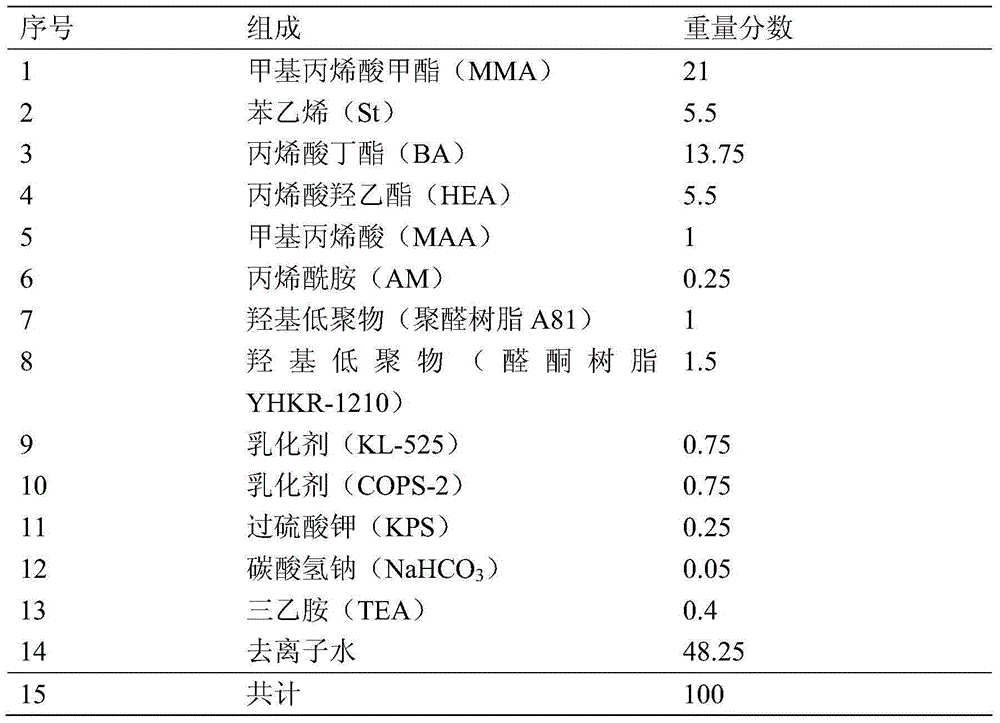

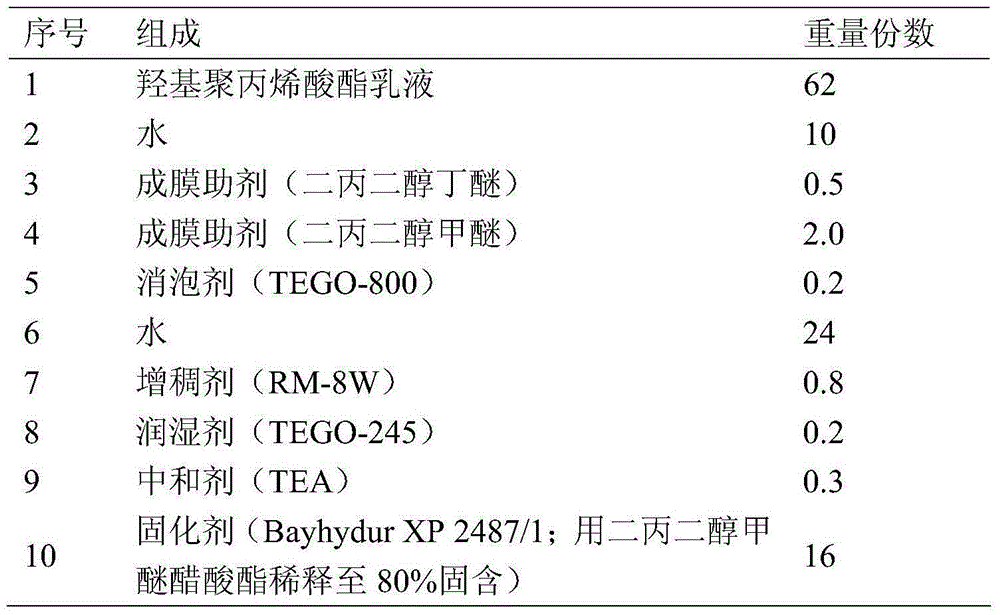

Hydroxypolyacrylate emulsion, and preparation method and application thereof

ActiveCN105061665AHydroxyl content is easy to adjustLarge adjustment rangePolyurea/polyurethane coatingsSodium bicarbonateMethacrylate

The invention discloses a hydroxypolyacrylate emulsion, and a preparation method and an application thereof. The preparation method comprises the following steps: weighing an acrylate monomer and / or a metacrylate monomer, a hydroxyacrylate monomer, an acrylic monomer, an acrylate function monomer and a hydroxy oligomer, uniformly mixing to prepare a monomer mixture, weighing 10-15% of the monomer mixture, and emulsifying by using an emulsifier to prepare a seed pre-emulsion for later use; and adding the emulsifier, sodium bicarbonate and deionized water into a reaction kettle, stirring, rising the temperature of a reaction system, adding an initiator, stabilizing, adding the seed pre-emulsion in a dropwise manner, stabilizing, adding the remaining monomer mixture and the remaining initiator in a dropwise manner, heating, slaking, cooling, neutralizing, carrying out heat insulation, cooling, and discharging to obtain the hydroxypolyacrylate emulsion. A film made by using an aqueous dual-component polyurethane coating prepared from the hydroxypolyacrylate emulsion and an aqueous polyisocyanate curing agent has the advantages of high hardness, high luster and excellent chemical resistance.

Owner:SOUTH CHINA UNIV OF TECH +1

Modified silicasol and application thereof in preparing water paint

The invention discloses a modified silica sol and application thereof in preparation of aqueous painting. The inventive modified silica sol is prepared from aqueous silica sol by regulate pH value of raw material to 3-6; charging organosilane with a mass ratio with SiO2 in silica sol of 1:1 - 5:1, water bathing at temperature of 50-80 DEG C., waiting for 0.5-5 hours, vaporizing by-products generated in hydrolysis to obtain transparent sol, which is final product. The modified silica sol has cheap raw material, simple preparation. When used as matrix in preparation of paint, the sol uses only water as solvent, without need of adding any organism such as alcohol. The preparation is simple, economic, environmental protecting. The prepared aqueous paint not only has high decorative, great adhesion and toughness of organic paint, but also has high rigidity, chemical resistance of inorganic paint, which can be used on surface of substrates of metal, glass, wood, plastic and in construction industry.

Owner:DALIAN JIAOTONG UNIVERSITY

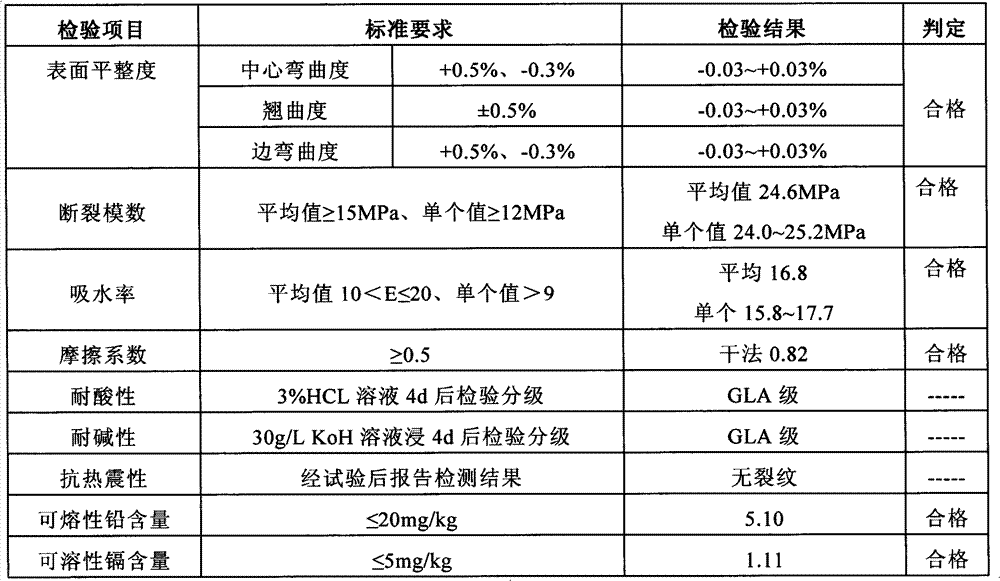

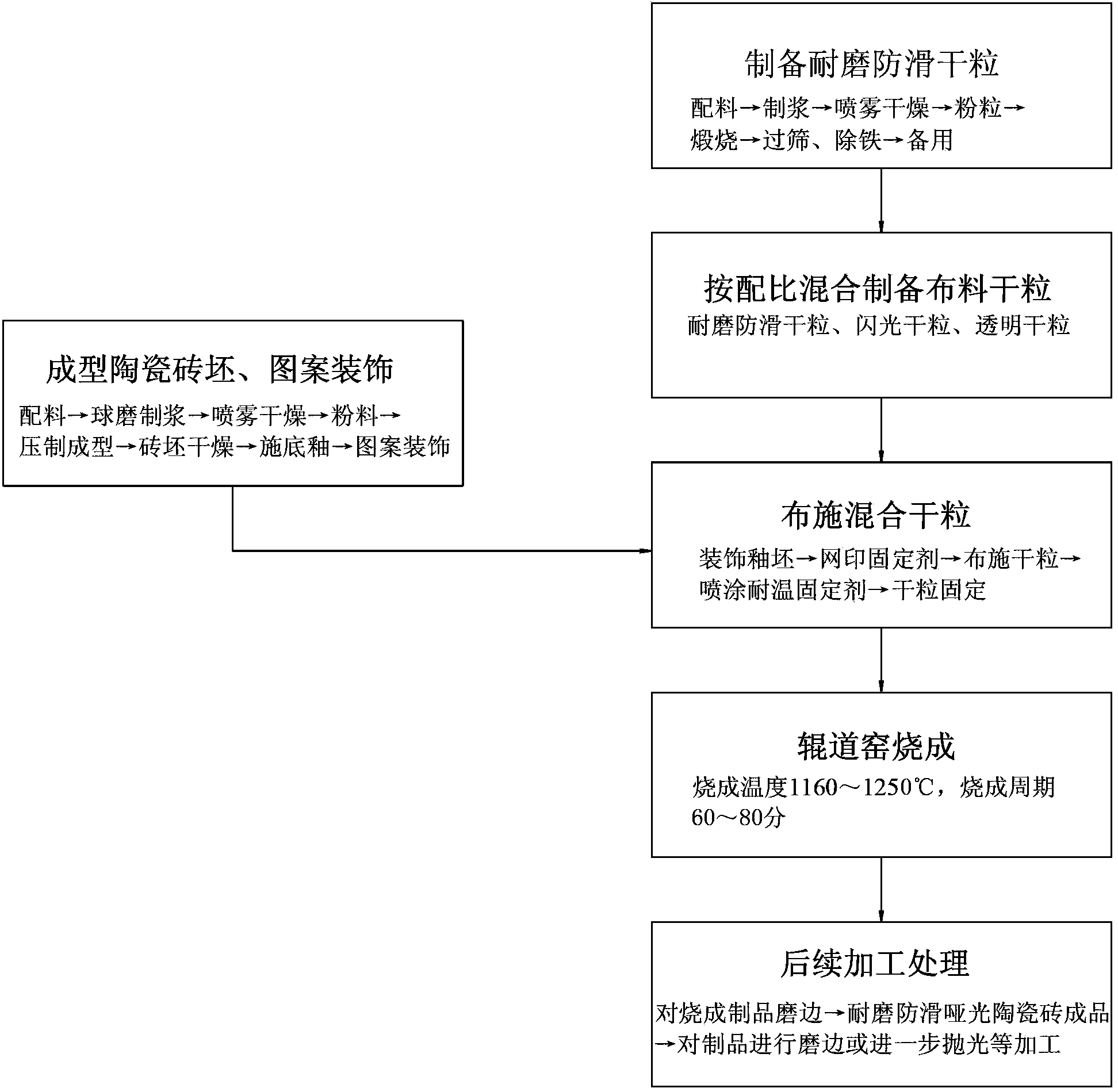

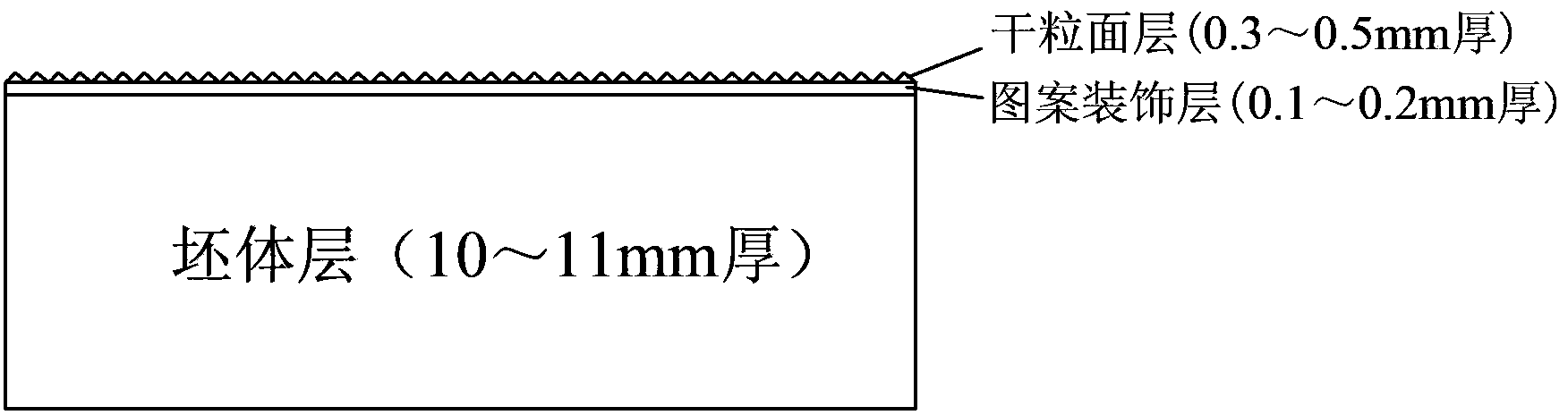

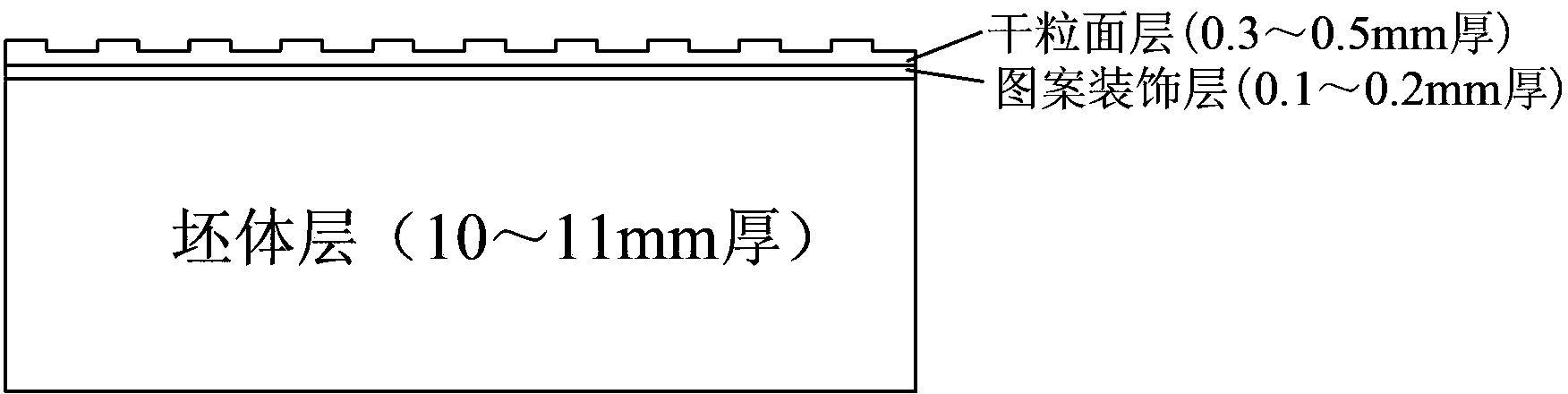

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

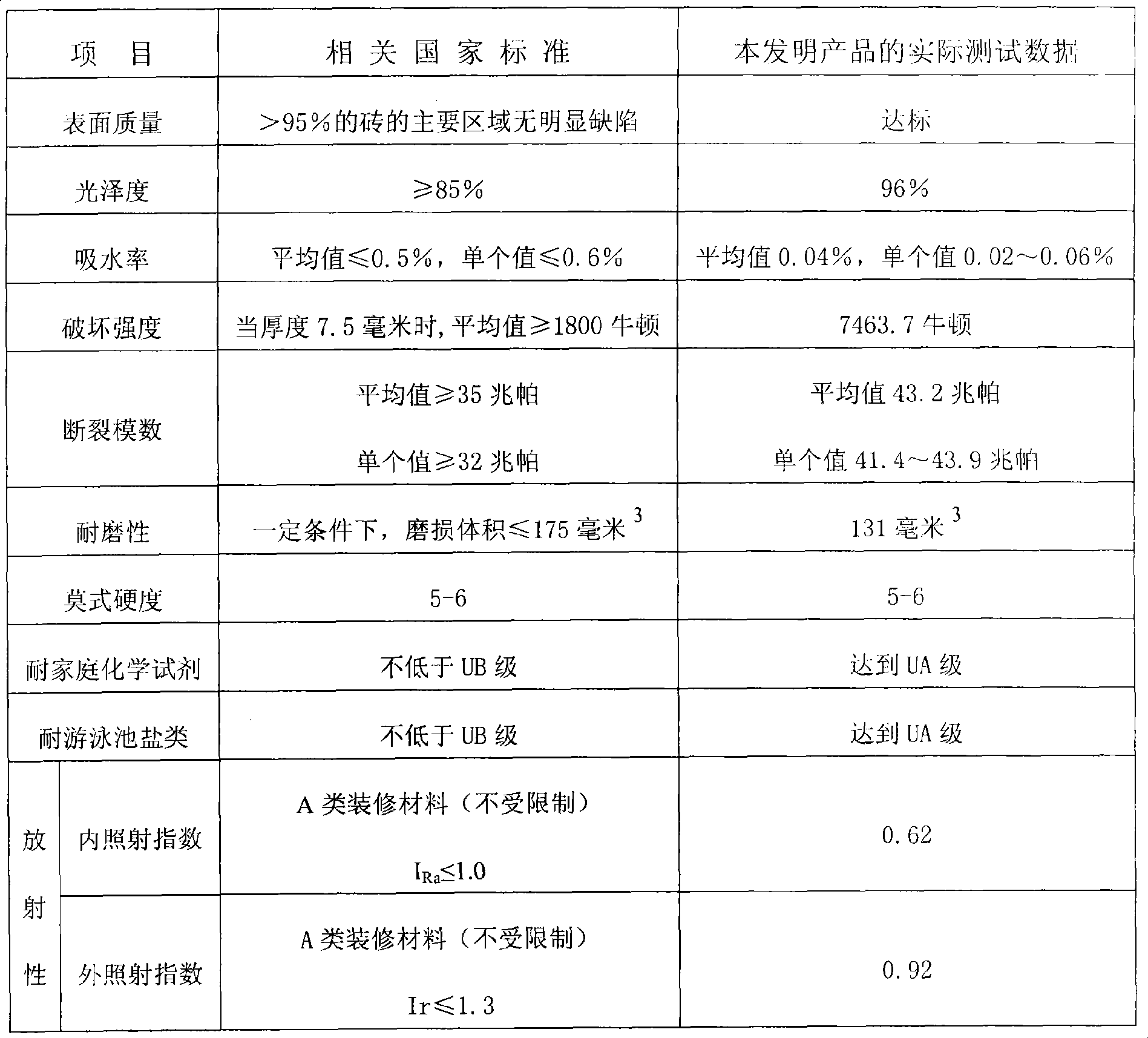

Method for producing microcrystalline glass-ceramics composite board with novel microcrystalline phase

The invention discloses a method for producing a microcrystalline glass-ceramics composite board with novel microcrystalline phase, which is characterized in that the composite board takes diopside-containing pyroxene as microcrystalline phase and the production method thereof comprises the steps as follows: firstly, microcrystalline glass granules are prepared; according to the weight percentage, the microcrystalline glass consist of 50-65% of SiO2, 5-25% of Al2O3, 5-20% OF CaO, 2-10% of MgO, 1-8% of K2O+NaO, 0-1% of Li2O, 0-8% of BaO, 0-8% of B2O3 and the balance of nucleating agent, clarifier and corant with the content ranging from 0 to 20%; secondly, a ceramic palette board is prepared; according to the weight percentage, the ceramic palette board comprises 66-75% of SiO2, 13-23% of Al2O3, 0.3-3% of CaO+MgO, 3-8% of K2O+Na2O and the balance of 0-2% of auxiliary raw material; finally, the raw materials are distributed, sintered and post-processed, thus gaining the finished product of the microcrystalline glass-ceramics composite board. The method has the advantages of low production cost, high product quality, good appearance effect, and the like.

Owner:GUANGDONG BODE FINE IND CONSTR MATERIAL

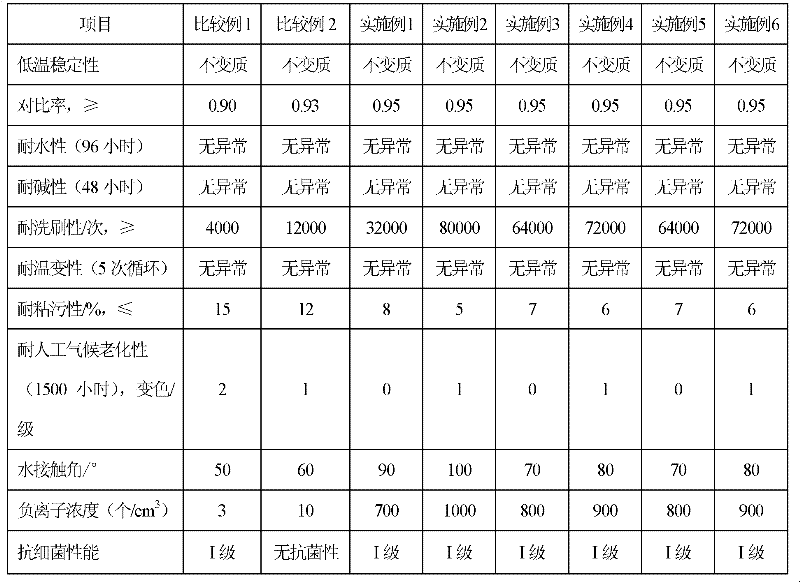

High-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and preparation method thereof

ActiveCN102417748AEasy to disperseStorage stableAntifouling/underwater paintsPaints with biocidesVolatile organic compoundEmulsion

The invention relates to a paint technology, an environment-friendly technology and an antibacterial mould-proof technology, in particular to high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and a preparation method thereof. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint comprises the following components in percentage by weight: 0.5 to 5 percent of wetting dispersant, 0.01 to 20 percent of inorganic composite nano antibacterial agent concentrated pulp, 0.5 to 10 percent of hydrophobing agent, 0.5 to 10 percent of anionic powder, 0.5 to 8 percent of film-forming aid, 0.1 to 2 percent of anti-settling agent, 0.8 to 10 percent of antifreezing agent, 0.1 to 3 percent of defoaming agent, 4 to 30 percent of pigment, 0 to 30 percent of filler, 15 to 45 percent of emulsion, 0.1 to 4 percent of thickening agent, 0.1 to 3 percent of flatting agent, 0 to 3 percent of pH regulator and 0.5 to 45 percent of water. The high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint is mainly prepared by adding the inorganic composite nano antibacterial agent into the basic materials, so that the paint has the coating characteristic of high performance, is low is cost, and has a function of purifying air, can eliminate harmful gas volatile organic compounds (VOC), formaldehyde and the like and also has a durable and high-efficiency antibacterial mould-proof function, so that the sterilizing rate within 6 hours reaches 100 percent and the mould-proof grade reaches the first grade. By the high-efficiency environment-friendly antibacterial mould-proof inorganic composite nano paint and the preparation method thereof, self-cleaning performance, hydrophobicity, scrubbing resistance, dirt resistance and weather resistance of the coating are improved; and the high-efficiency and durable antibacterial and mould-proof effect is achieved.

Owner:广东腐蚀科学与技术创新研究院

Enhancements to tactile interaction with film walled packaging having air filled structural support volumes

Owner:PROCTER & GAMBLE CO

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

Water industrial paint based on organosilicon acrylic acid epoxy ester water dispersion and preparation method thereof

InactiveCN1927968AImprove corrosion resistanceGood physical propertiesEmulsion paintsEpoxyDefoaming Agents

The present invention provides one kind of water thinned industrial paint based on water dispersed organosilicon epoxy acrylate. The water thinned industrial paint is prepared with water dispersed organosilicon epoxy acrylate, inert antirust pigment, active antirust pigment, nanometer material modified antirust pigment, stuffing, dispersant, wetting agent, thickener, drying agent, mildew inhibitor, preservative, defoaming agent, deionized water and other materials. The water thinned industrial paint with water dispersed organosilicon epoxy acrylate as base material can form coating with the features of high mechanical strength and high anticorrosive performance similar to that of epoxy resin as well as the features of high weather resistance and good decoration performance like acrylate resin. The water thinned industrial paint has convenient use and wide application range.

Owner:广州市允升环保科技有限公司

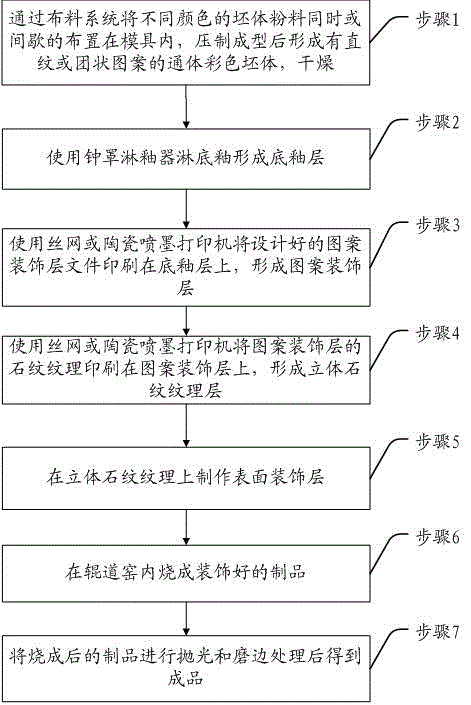

Whole-body polished porcelain tile having three-dimensional stone texture and production method of tile

The invention discloses a whole-body polished porcelain tile having three-dimensional stone texture and a production method of the tile. The tile comprises a whole-body colored blank layer, a ground coat layer, a pattern decoration layer, a three-dimensional stone texture layer and a surface decoration layer. The production method comprises steps as follows: 1) a whole-body colored blank is prepared; 2) the ground coat layer on the blank surface is formed; 3) the pattern decoration layer is formed; 4) ink or glaze having a dent effect is applied to the pattern decoration layer, a pattern corresponds to pattern texture of the decoration layer, and the three-dimensional stone texture layer is formed; 5) the surface decoration layer is formed; 6) a roller kiln is formed through sintering; 7) a finished product is obtained through polishing, edging and packaging. The surface color of the product produced with the scheme is integrated with the color of the blank, the stone texture changes naturally with the pattern texture of the product, the texture layer is protected by the surface decoration layer, and the tile has the decoration effect of natural stone. Properties of the product are superior to those of the natural stone, mining of the natural stone can be effectively reduced, and the natural environment is protected.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK +1

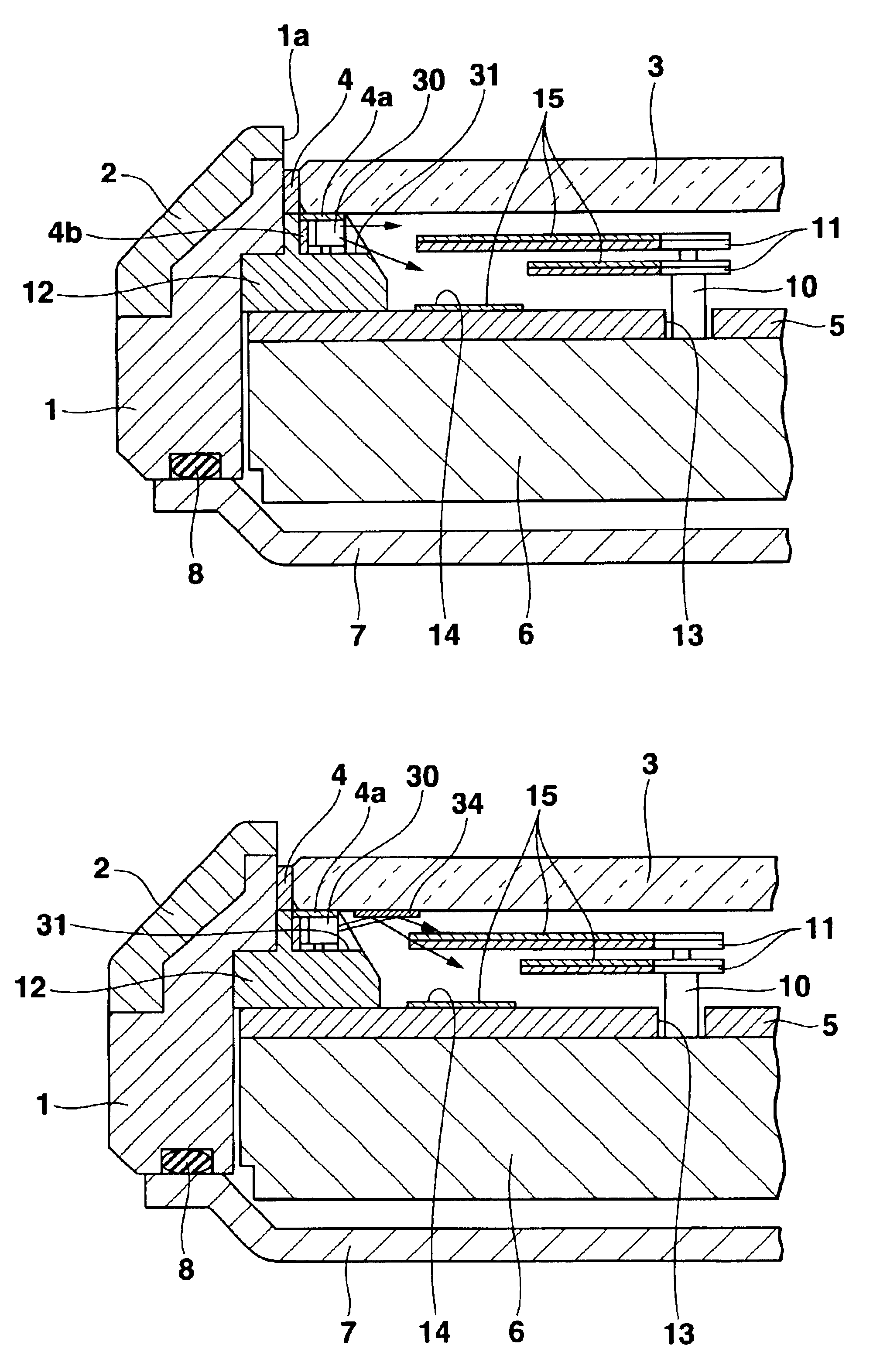

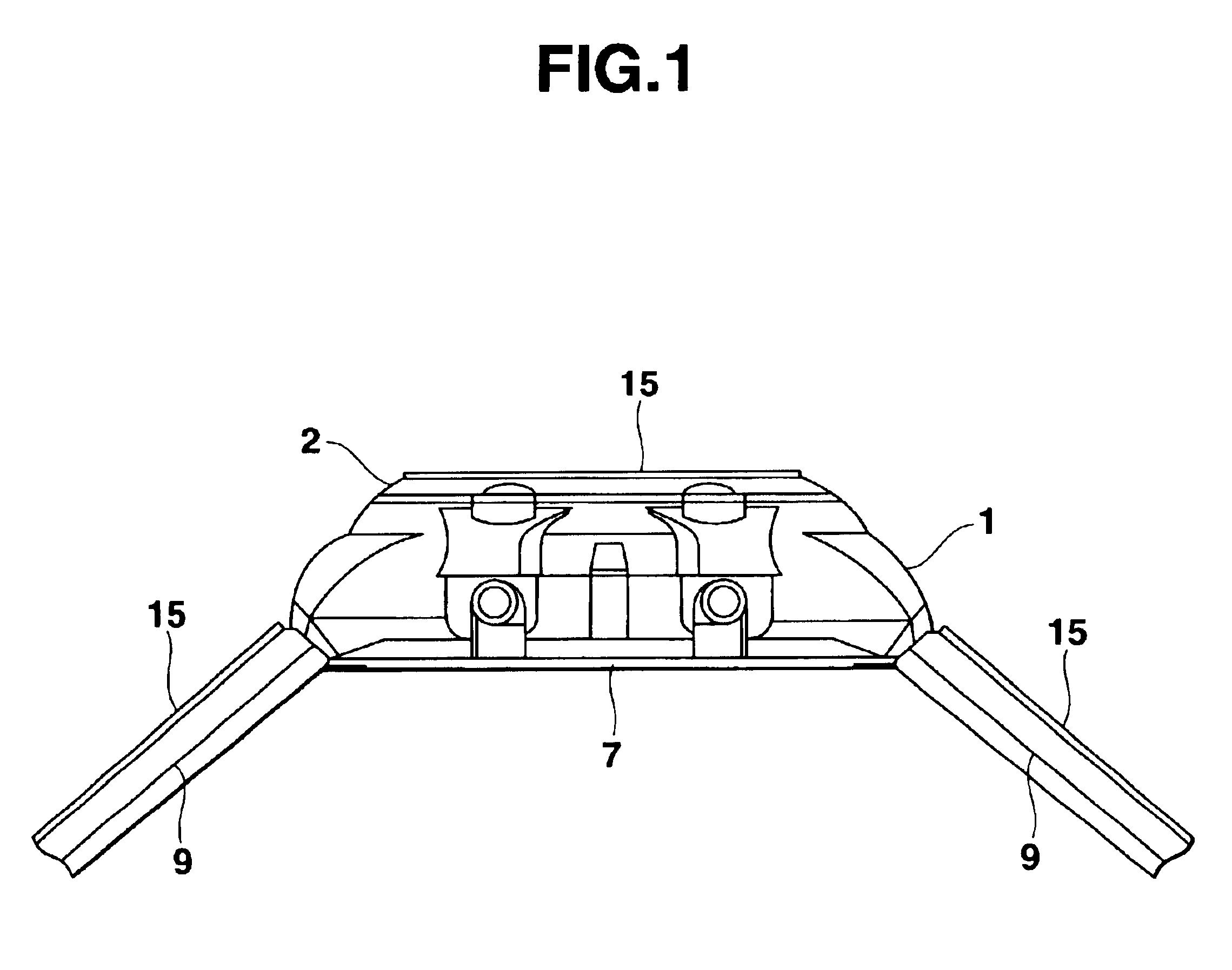

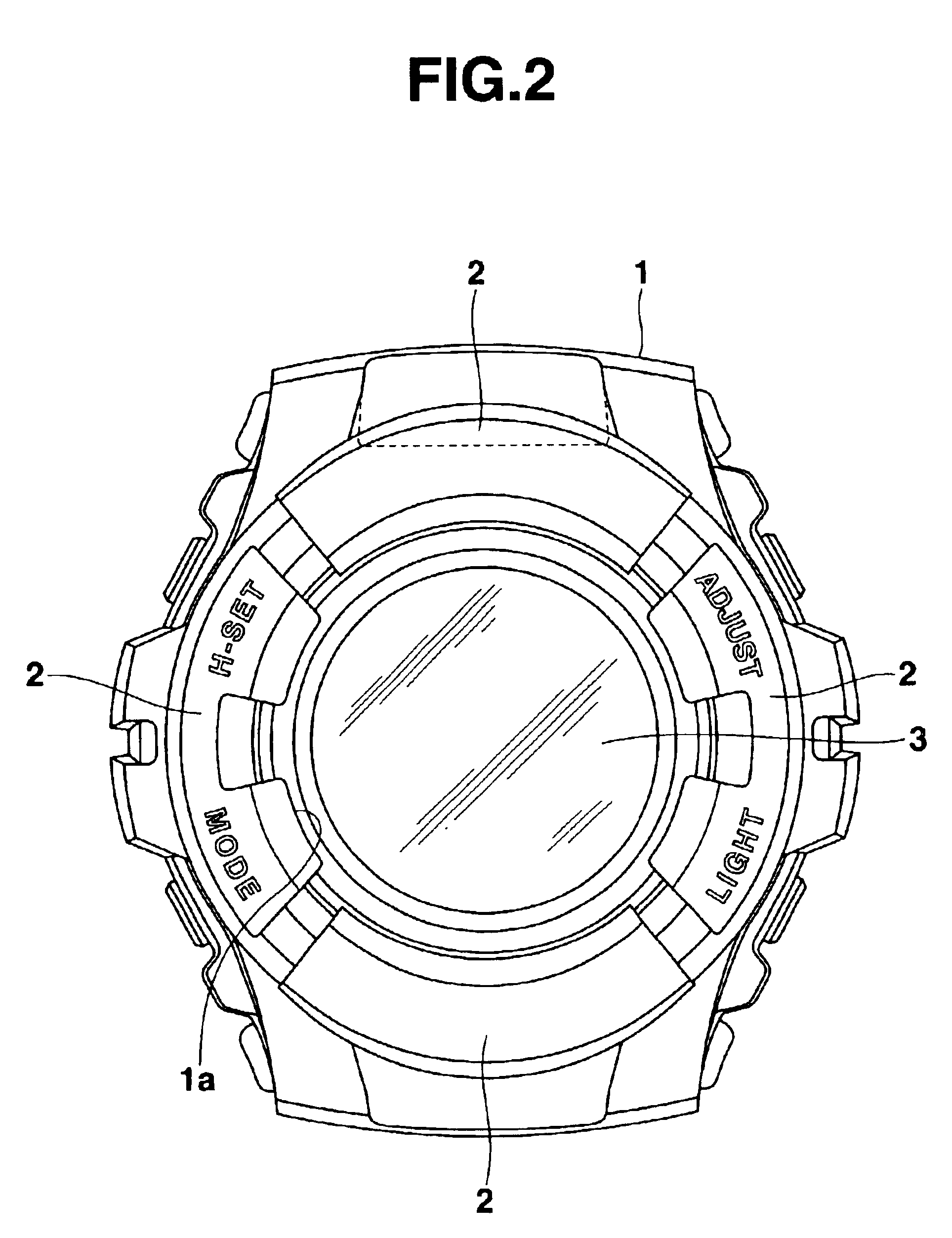

Electronic apparatus and liquid crystal display device for irradiating ultraviolet ray to luminescent layer

InactiveUS6806644B2Improve the decorative effectEffective exposureVisual indicationDischarge tube luminescnet screensLiquid-crystal displayProtective glasses

An ultraviolet ray-emitting element is provided in a frame-like member disposed between an apparatus module and an apparatus case by corresponding to a peripheral portion of a protective glass. A light in an ultraviolet range from the ultraviolet ray-emitting element is irradiated between the module and the protective glass. A luminescent layer to which an ultraviolet ray is irradiated emits a light.

Owner:CASIO COMPUTER CO LTD

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

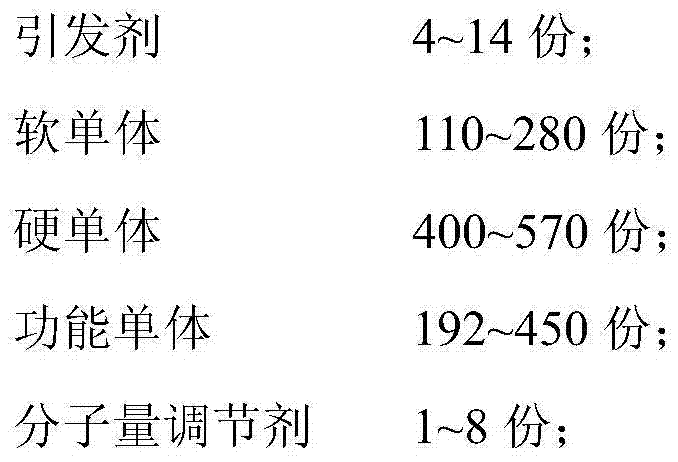

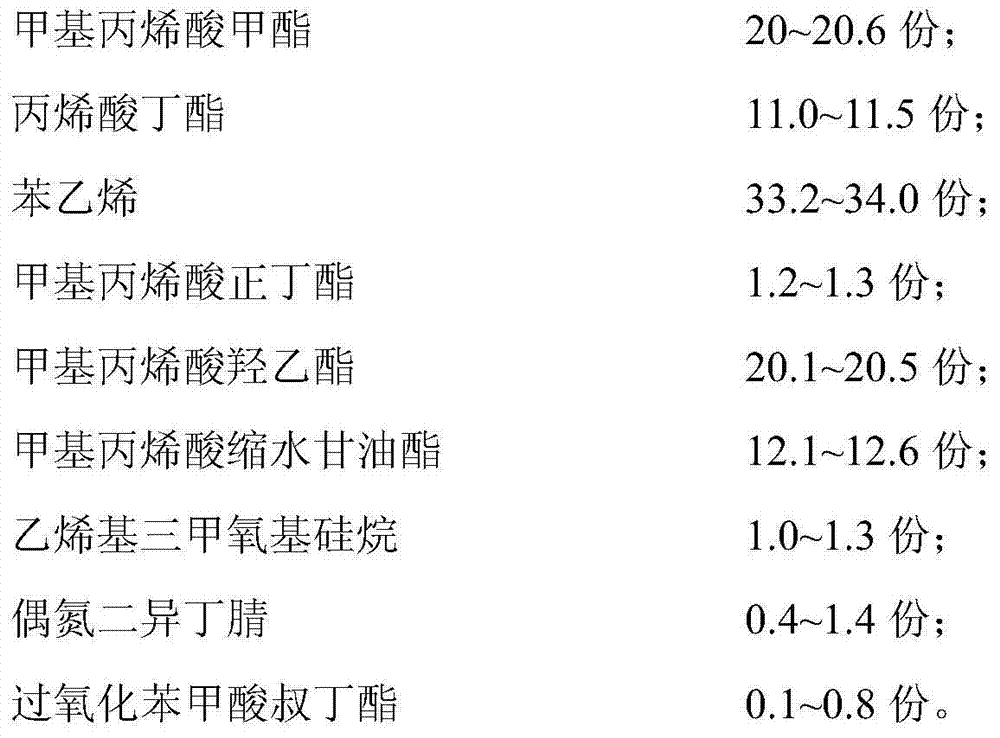

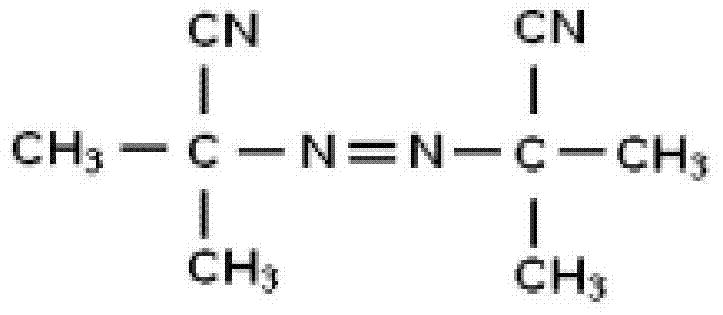

Thermosetting acrylic resin for powder coating as well as synthesis method and applications of thermosetting acrylic resin

The invention relates to thermosetting acrylic resin for a powder coating. The thermosetting acrylic resin is prepared from the following raw materials in parts by mass: 4-14 parts of an initiator, 110-280 parts of soft monomers, 400-570 parts of hard monomers, 192-450 parts of functional monomers, and 1-8 parts of a molecular weight regulator, wherein the soft monomers refer to acrylic acid alkyl ester compounds, and the hard monomers refer to methacrylate, styrene, or compounds of derivatives of methacrylate and styrene. The acrylic resin contains epoxy functional groups and hydroxyl functional groups simultaneously, wherein the epoxy equivalent is 570-630g / mol and the hydroxyl value is 40-50mgKOH / g; the acrylic resin can react with various substances such as carboxyl, amidogen and isocyanate and can be used for powder coating. A coating film, which is formed after the thermosetting powder coating prepared from the acrylic resin in combination with other materials is sprayed, has excellent weather resistance, good leveling performance, outstanding surface hardness, and high glossiness, durability and decorating performance; the powder coating can be used for indoor or outdoor metal sectional materials or building materials. The thermosetting acrylic resin can substitute for TGIC (triglycidyl isocyanurate) to a certain extent so as to avoid the use of the toxic substances.

Owner:阜阳市诗雅涤新材料科技有限公司

Lightweight acoustical paint and preparation method thereof

The present invention discloses one kind of light sound absorbing paint and its preparation process. The paint consists of acrylate emulsion of average grain size of 0.15-0.5 micron as the adhesive, open-pored expanded perlite as light aggregate, pigment, stuffing and assistants combined together. It is prepared through pre-mixing, dispersing grinding and blending via fast stirring. It has low density, non-toxicity, no smell, environment friendship, simple production, simple application, coating of 1-5 mm thickness, average sound absorbing coefficient higher than 0.4 and other advantages, and is suitable for use in household, meeting room, concert hall, theater, etc.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

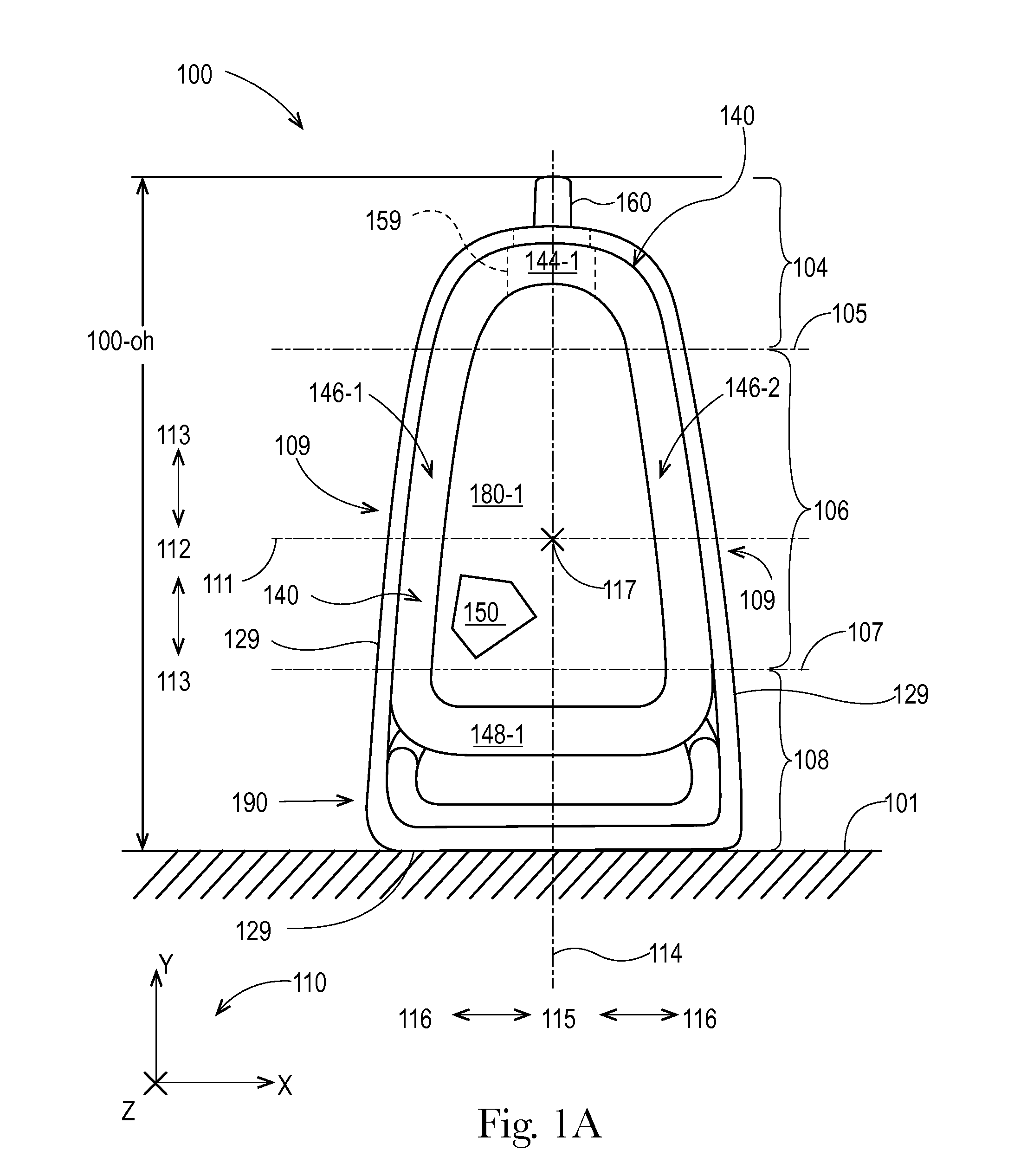

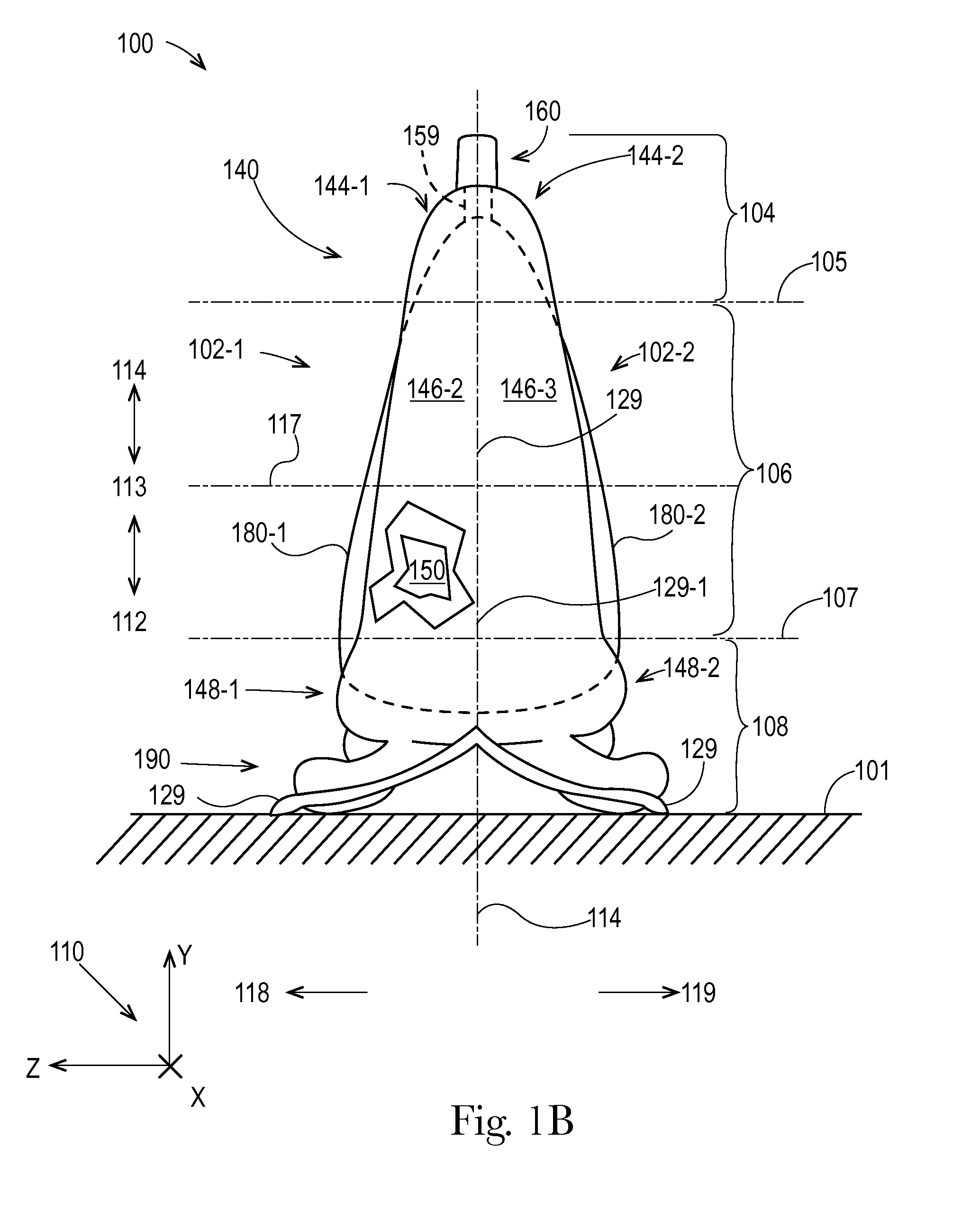

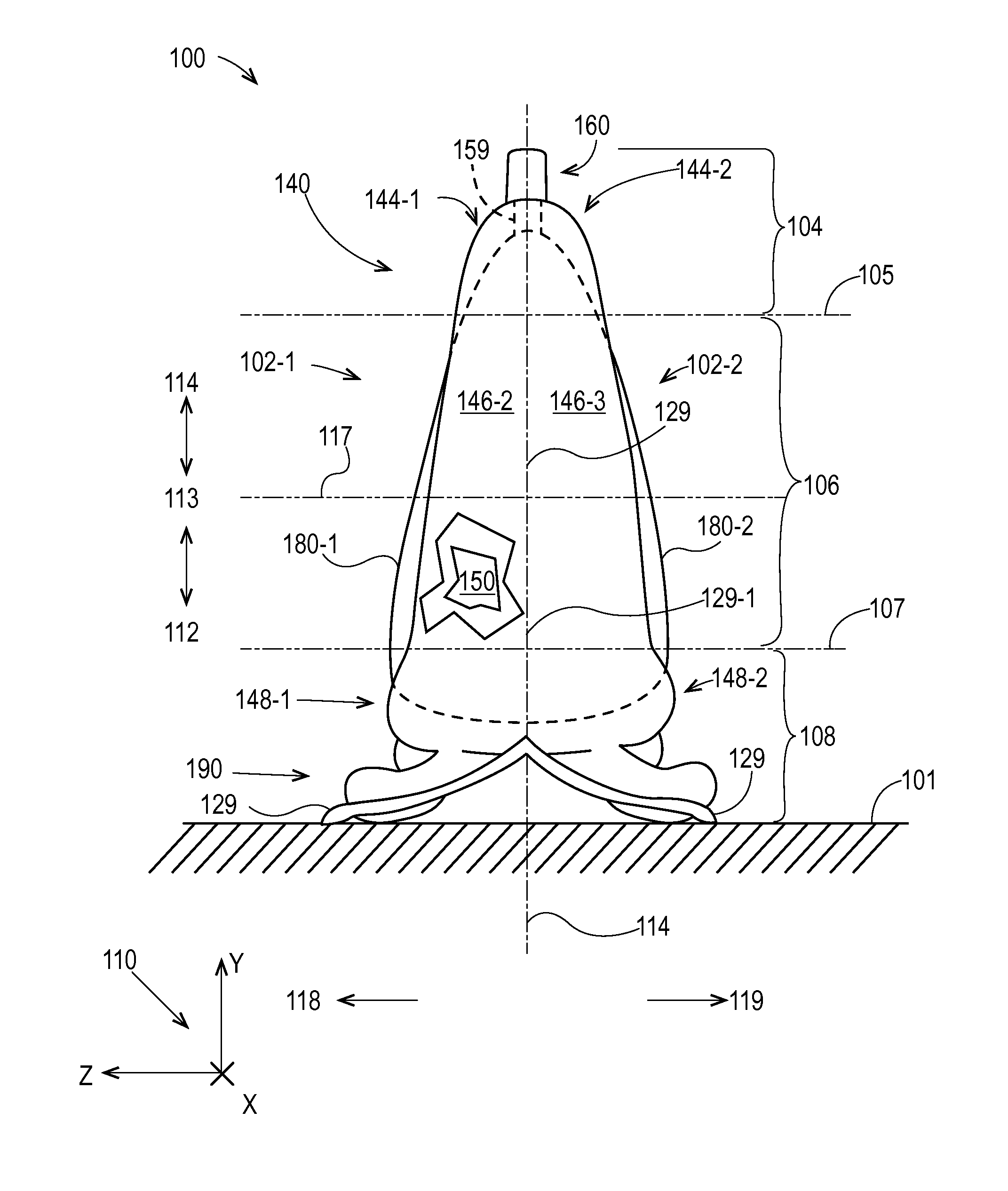

Enhancements to tactile interaction with film walled packaging having air filled structural support volumes

ActiveUS20150034662A1Easy to print and decorateCheap to makeLarge containersRigid containersEngineeringHardness

Non-durable self-supporting flexible containers having gradients where at least one of a plurality of physical characteristics that are perceptible via tactile interaction with an exterior surface of the container are varied across the exterior of the container. The flexible containers may permit users to perceive viscosity or relative thermal condition of contained product in discrete zones or regions of the container through one or more outer surface of the container without direct interaction with the product, or vary hardness or softness of the container.

Owner:THE PROCTER & GAMBNE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com