Patents

Literature

167 results about "Ferrite layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

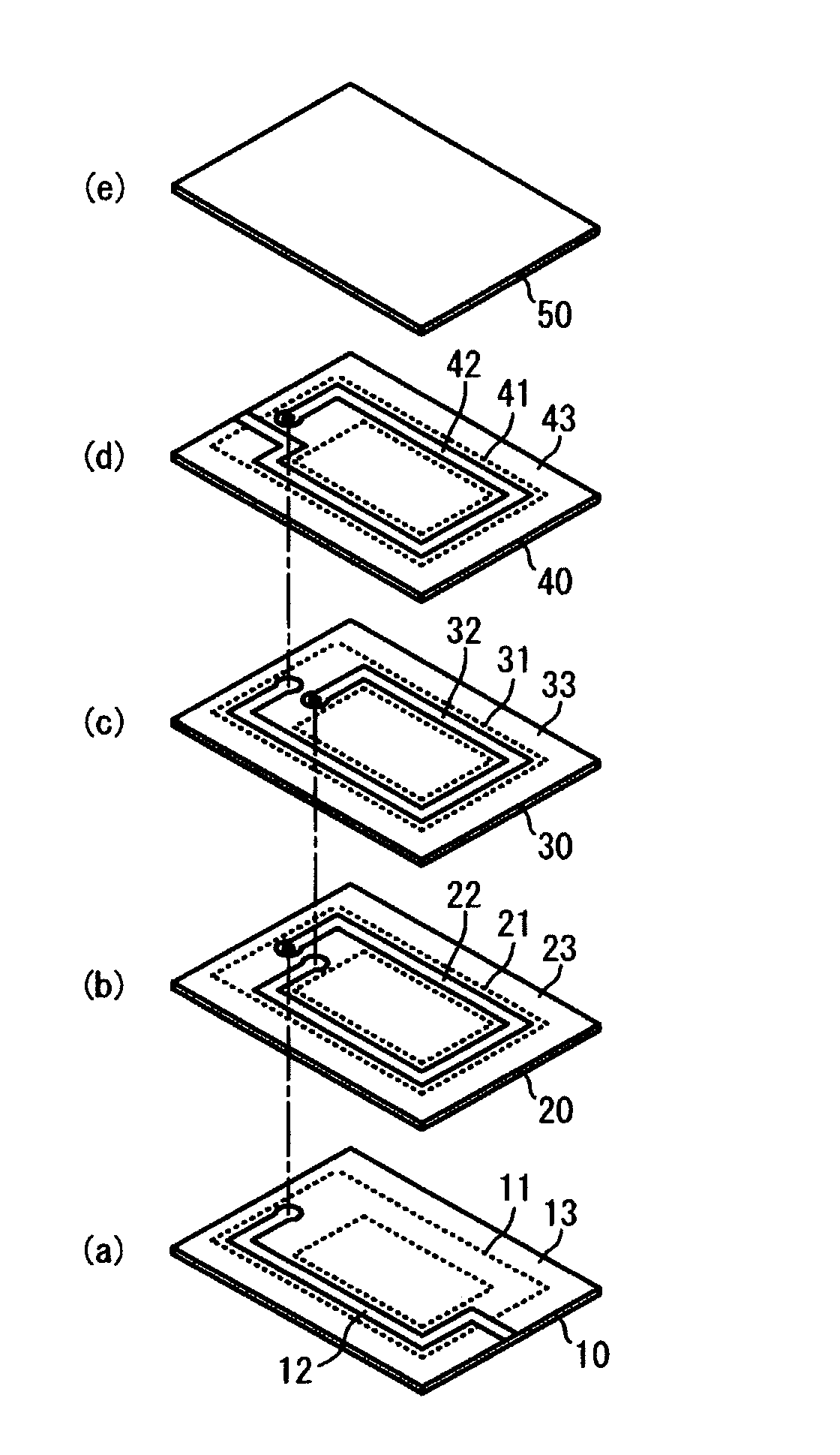

Laminated device

ActiveUS20100033286A1Stable characteristicsExcellent superposition characteristicTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFerrite layerElectrical conductor

A laminated device comprising pluralities of magnetic ferrite layers, conductor patterns each formed on each magnetic ferrite layer and connected in a lamination direction to form a coil, and a non-magnetic ceramic layer formed on at least one magnetic ferrite layer such that it overlaps the conductor patterns in a lamination direction, the non-magnetic ceramic layer comprising as main components non-magnetic ceramics having higher sintering temperatures than that of the magnetic ferrite, and further one or more of Cu, Zn and Bi in the form of an oxide.

Owner:HITACHI METALS LTD

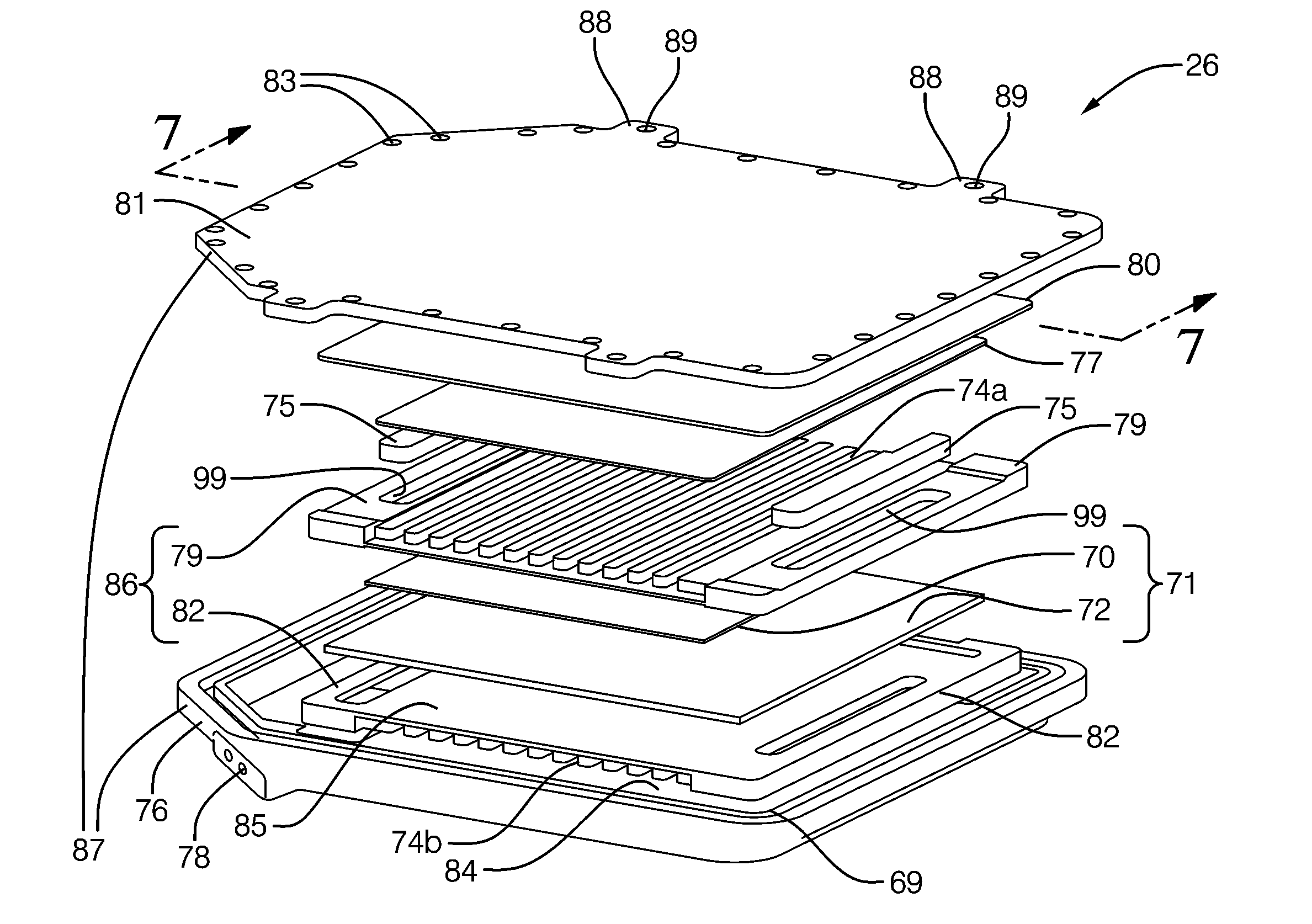

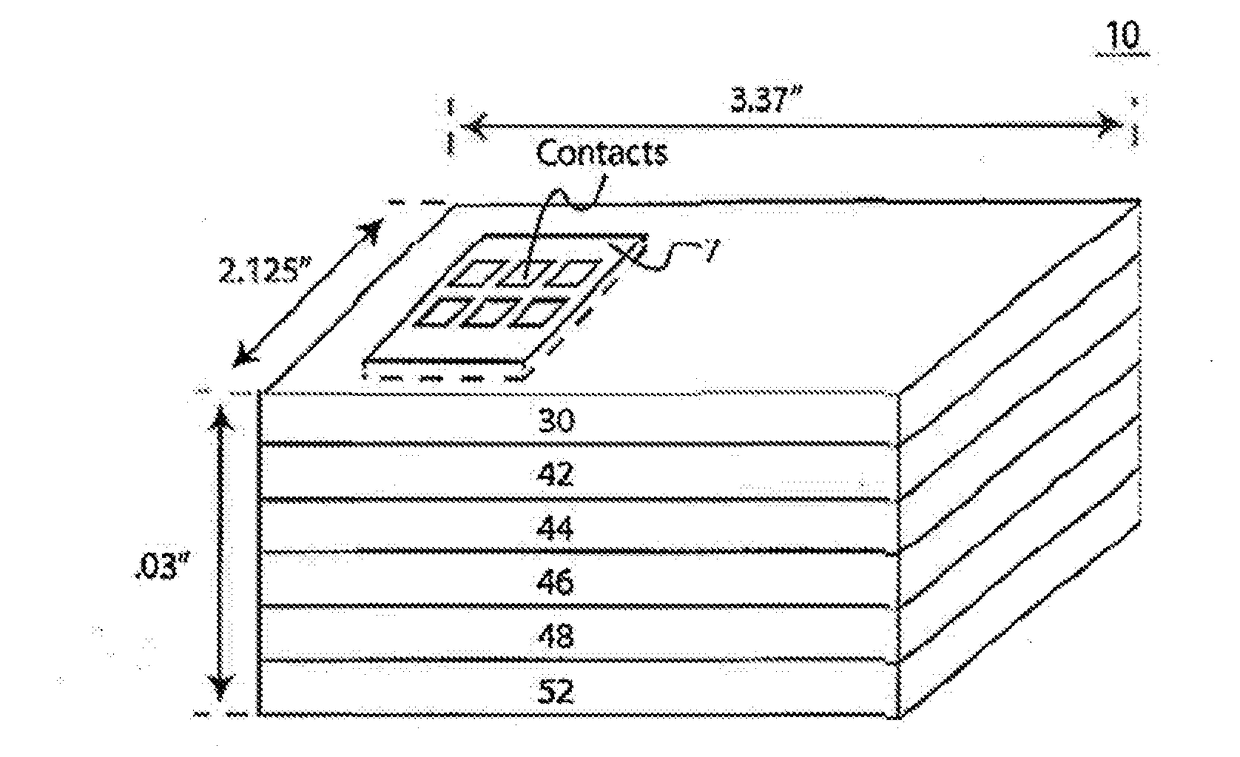

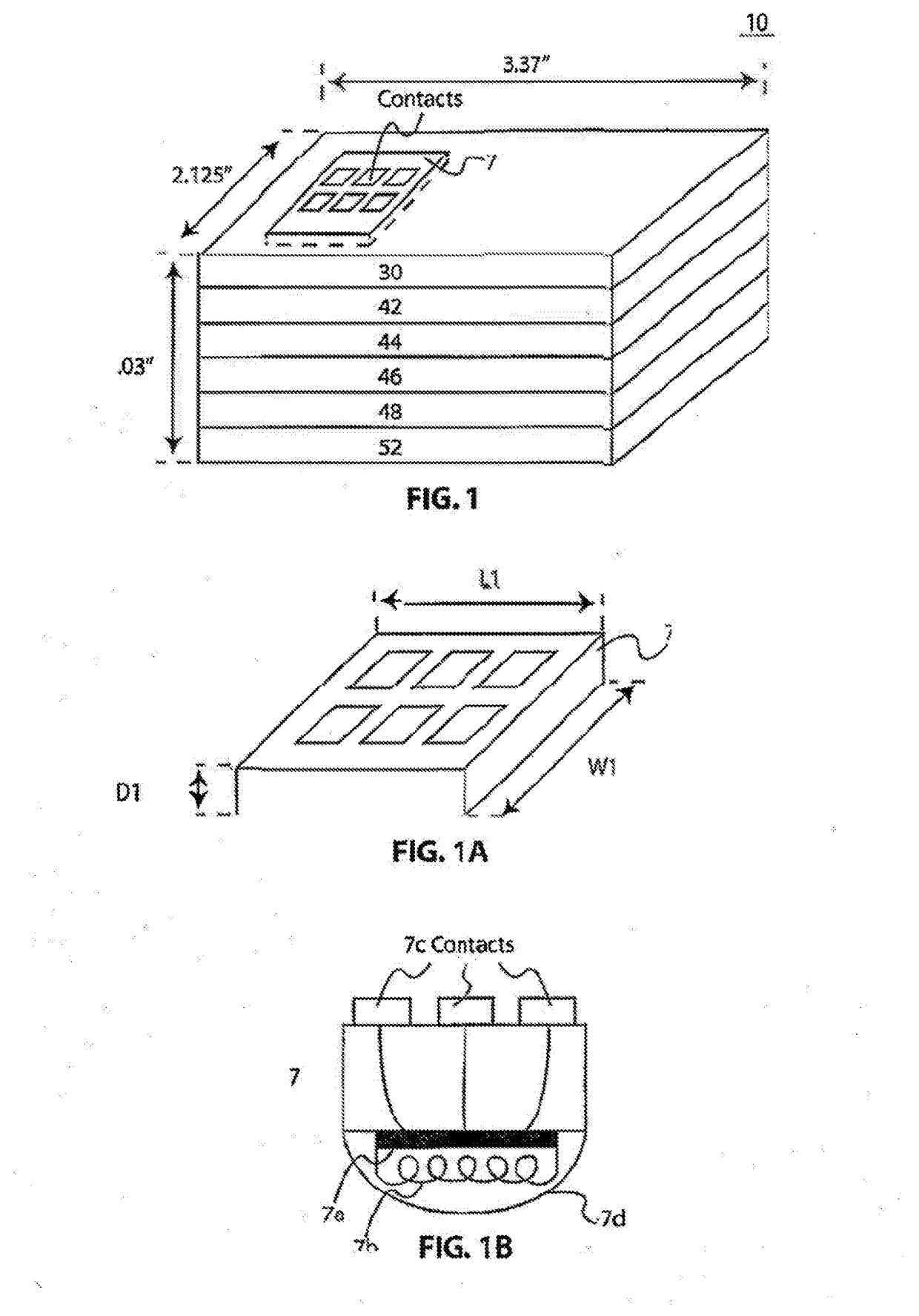

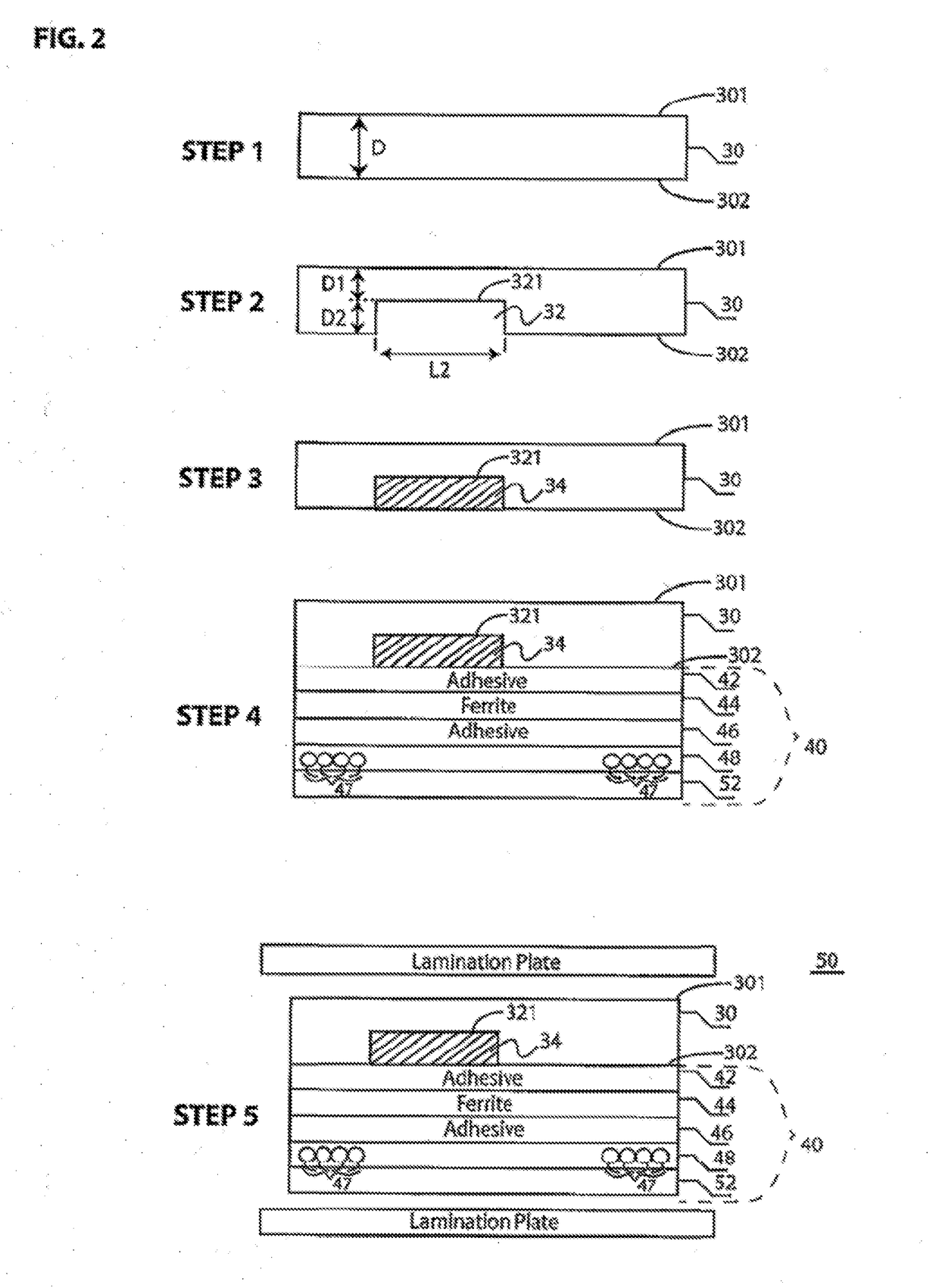

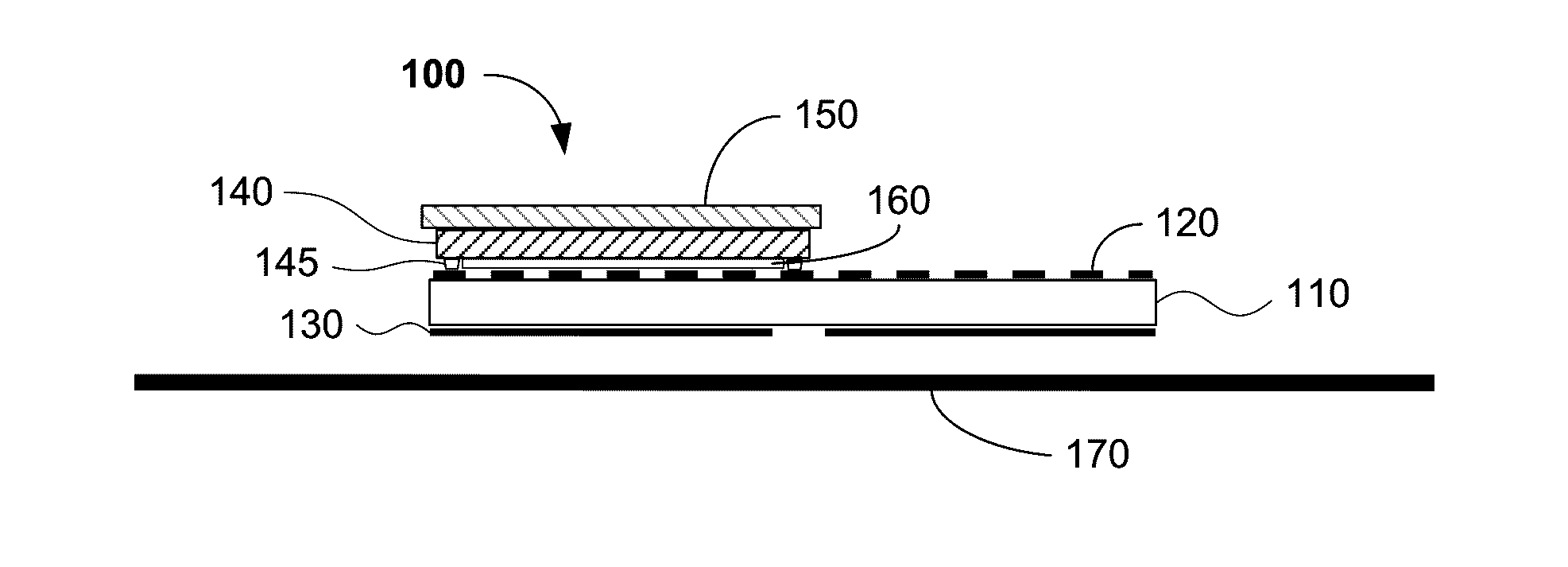

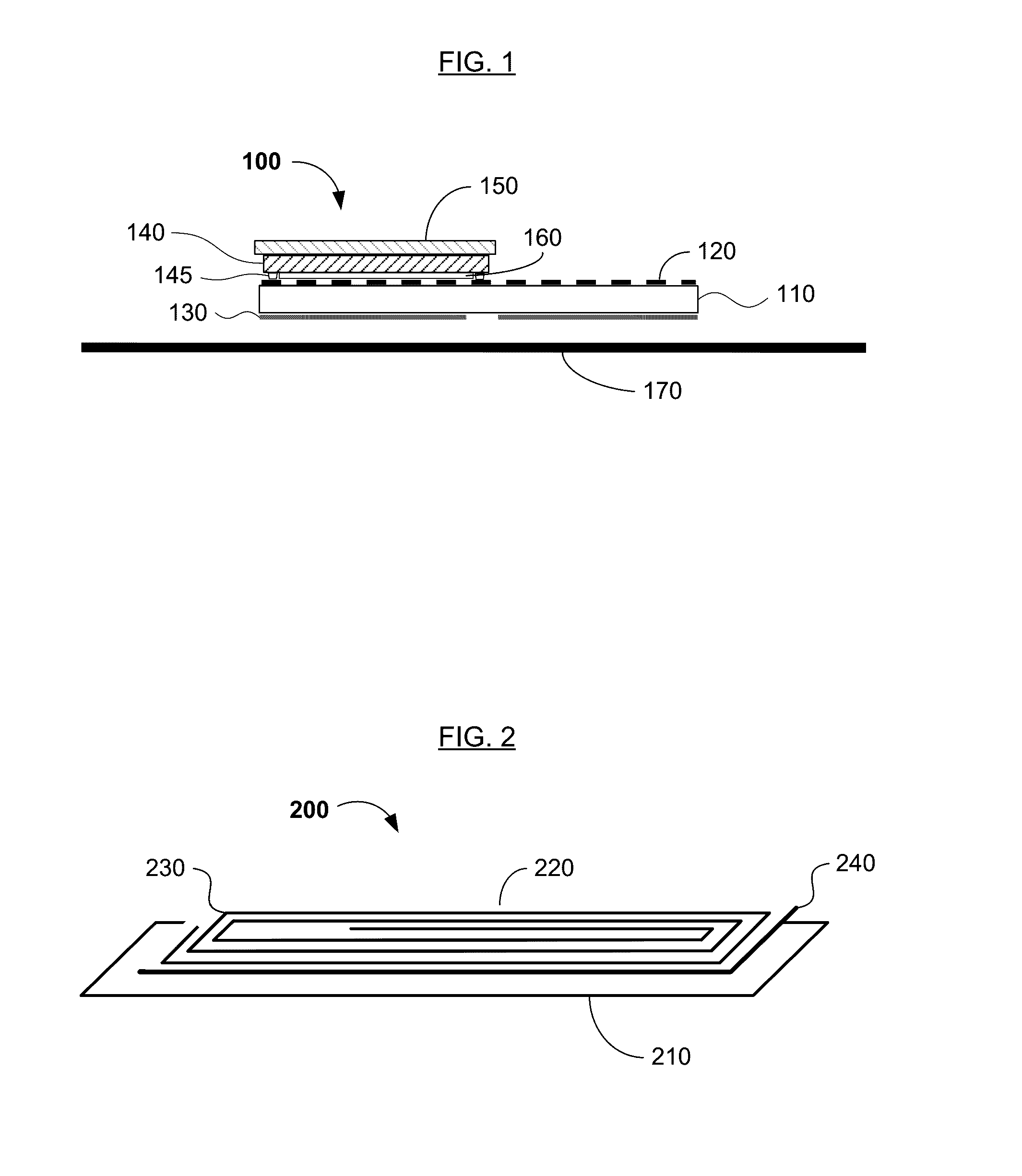

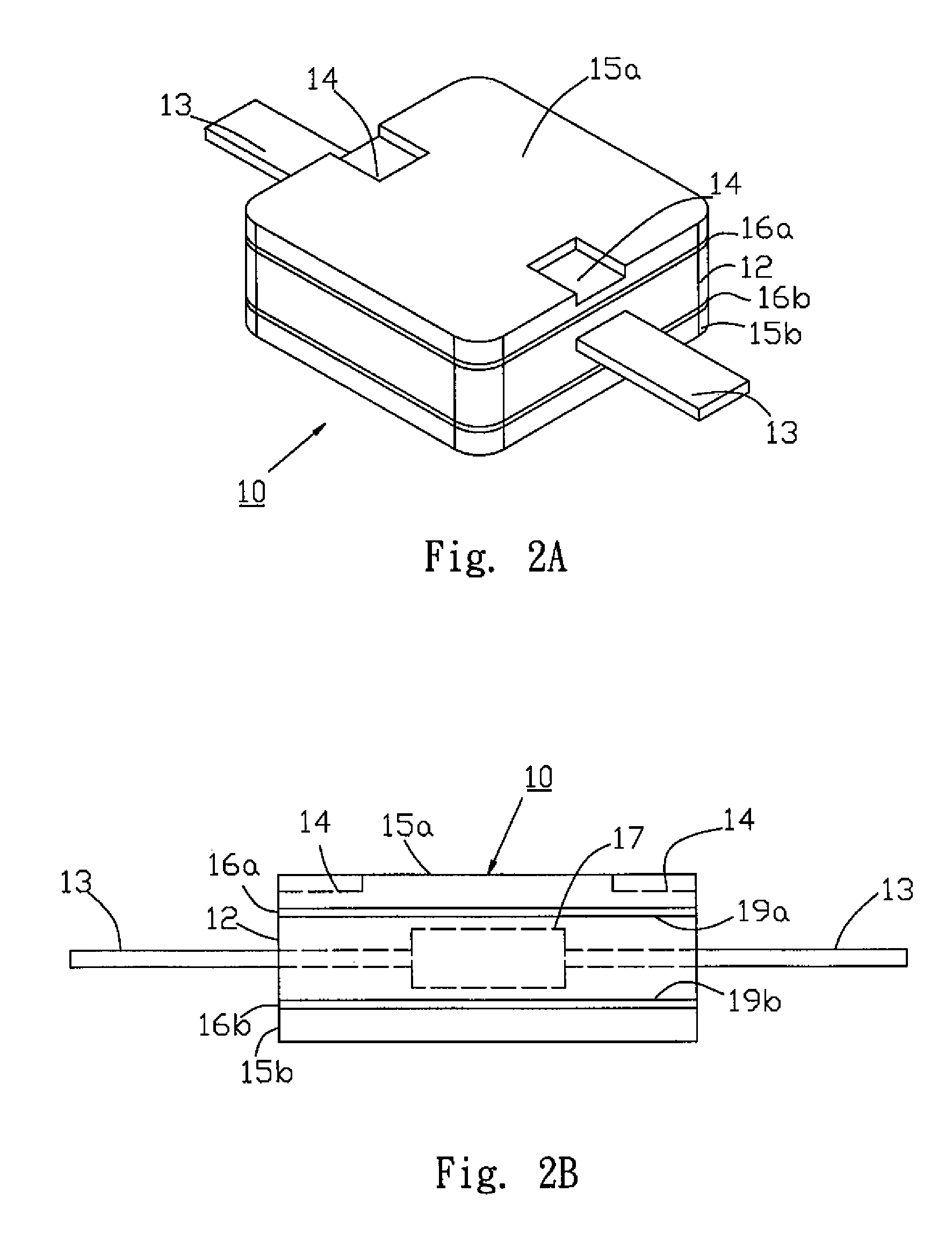

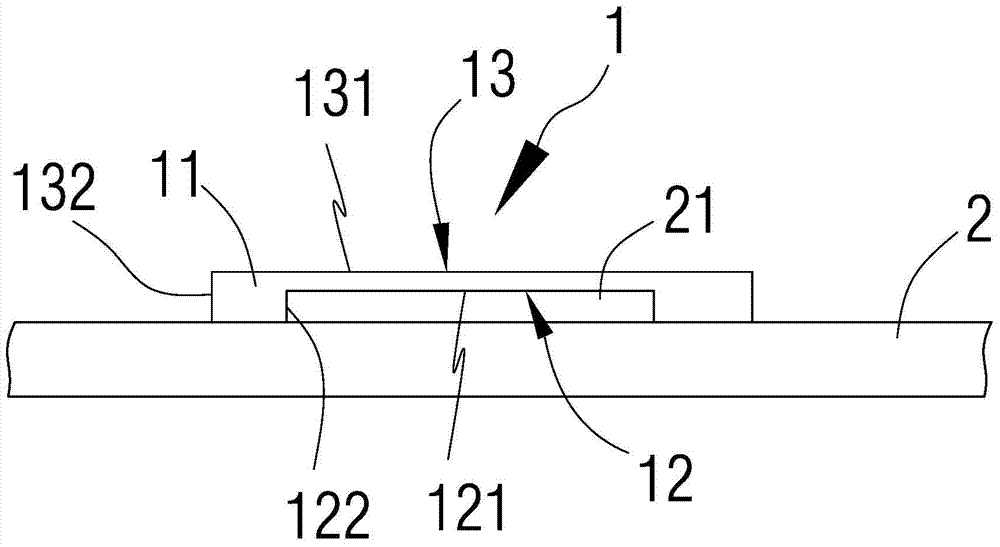

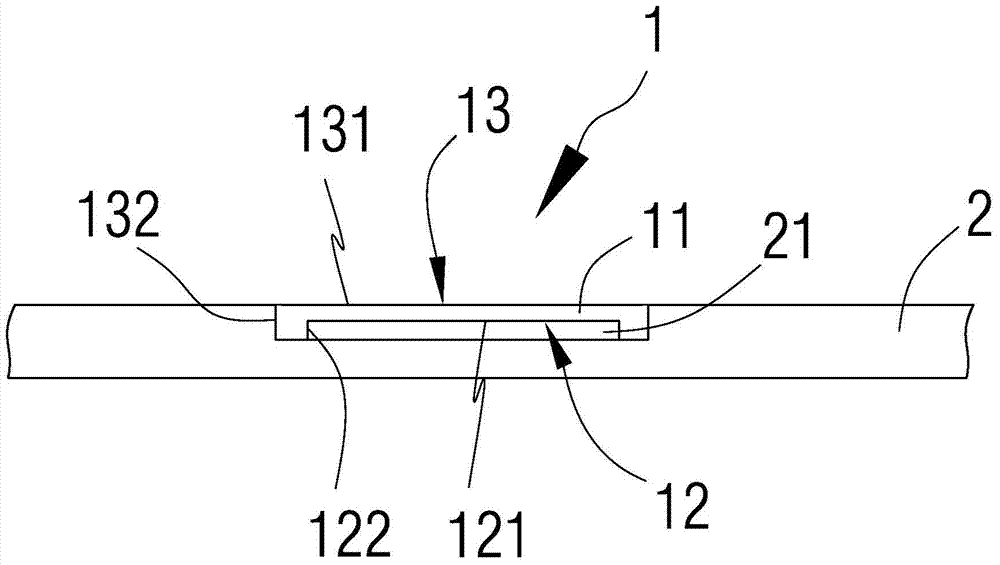

Coil apparatus having coil arrangement that includes a ferrite layer and a thermally-conductive silicone layer

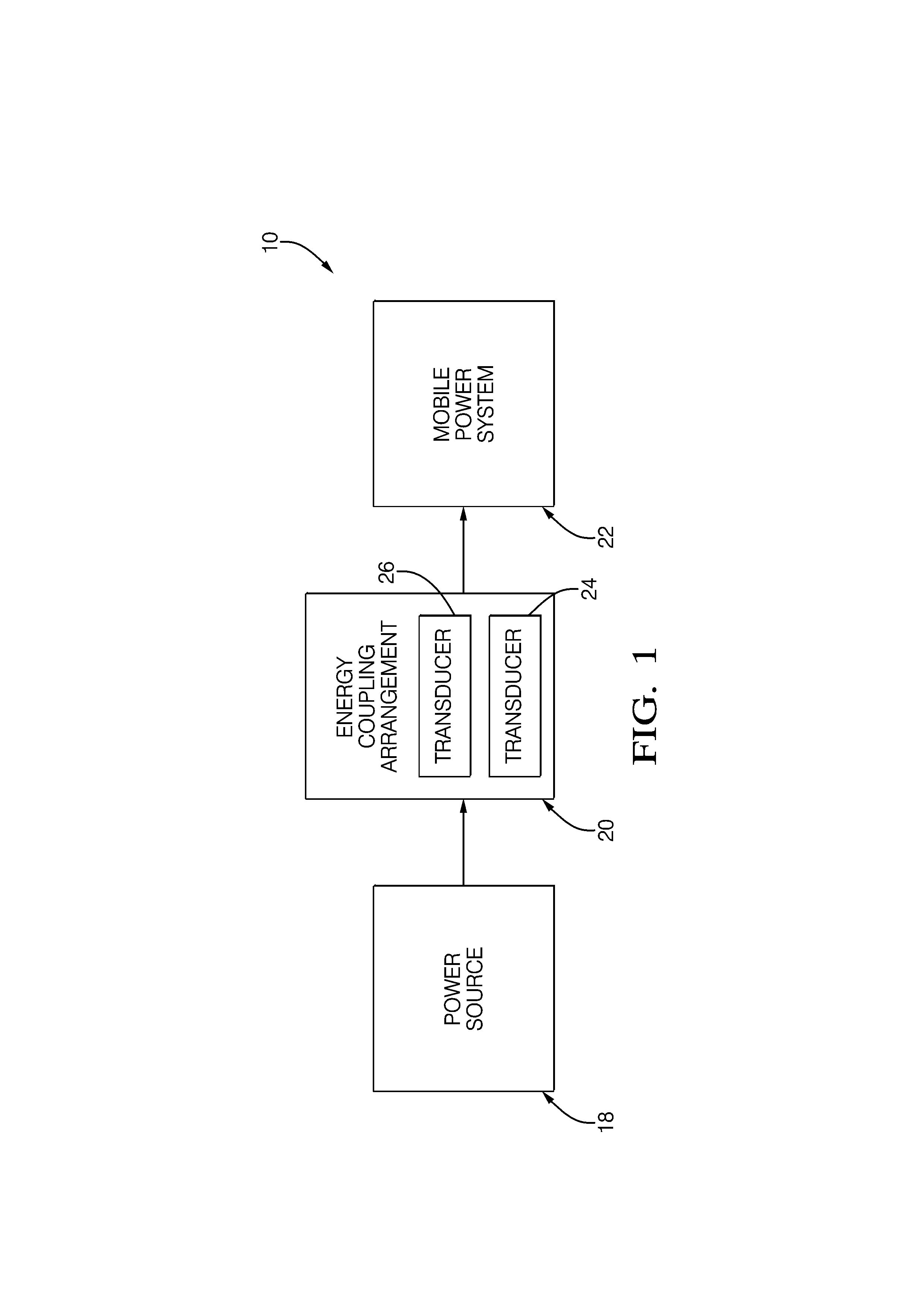

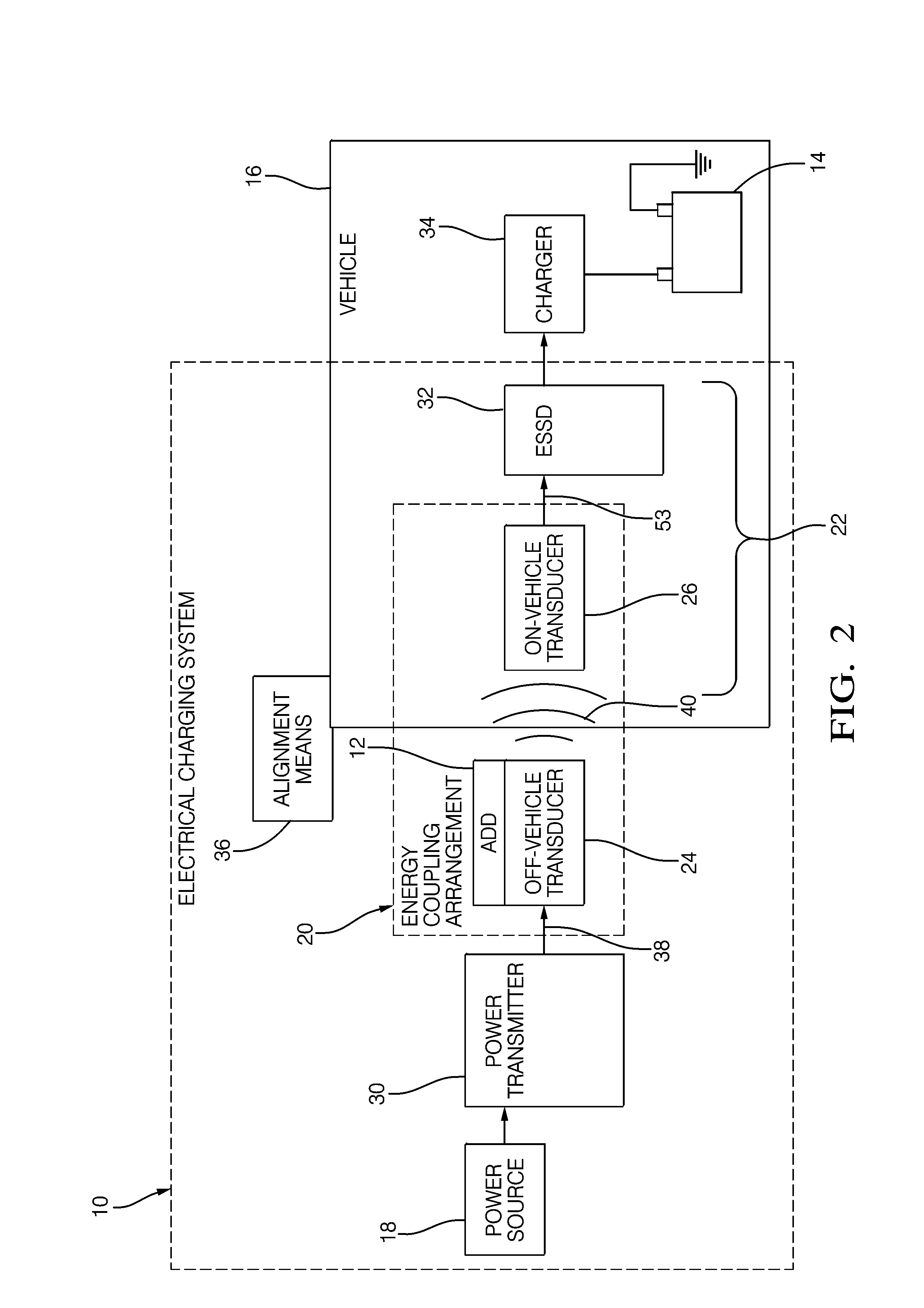

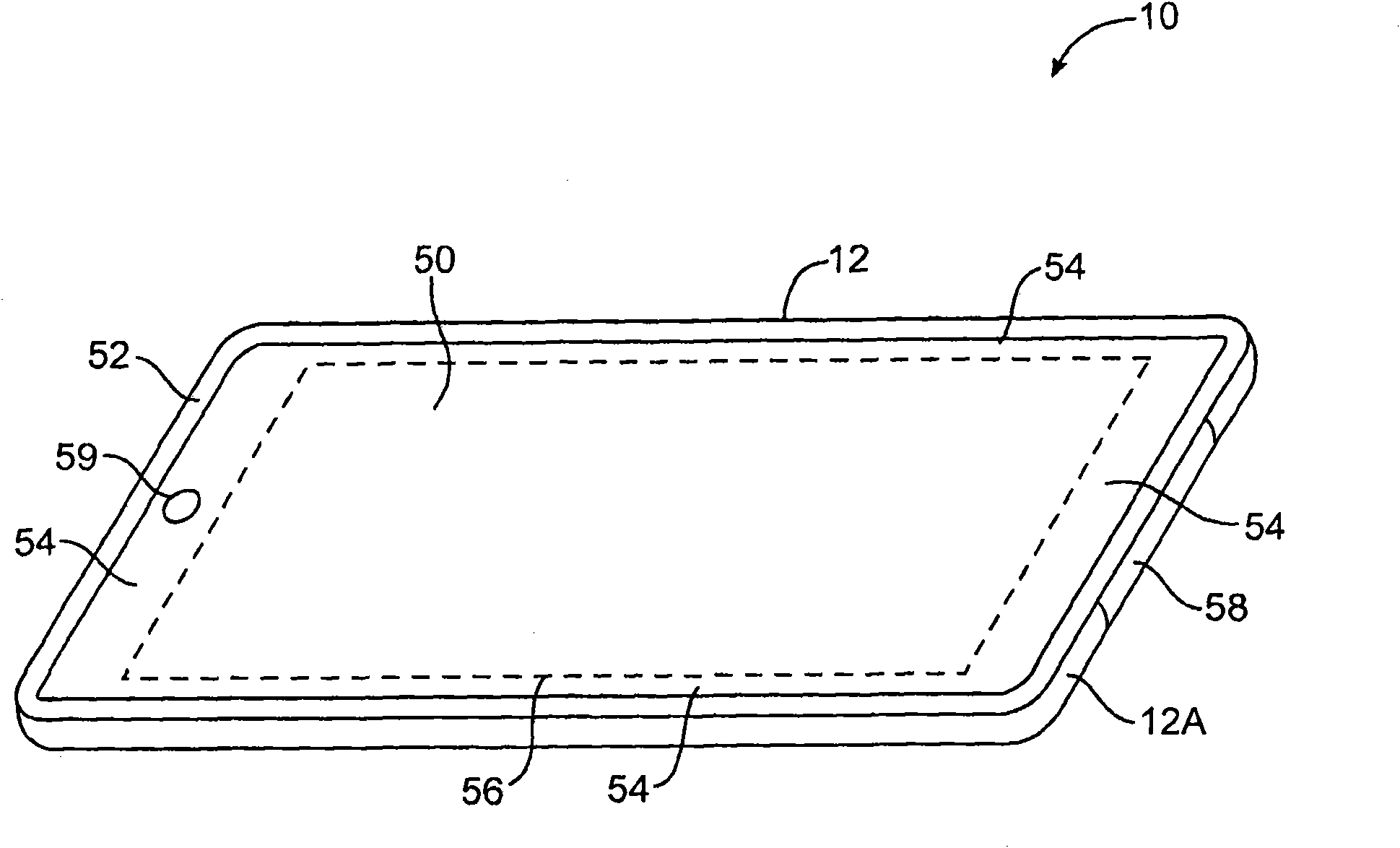

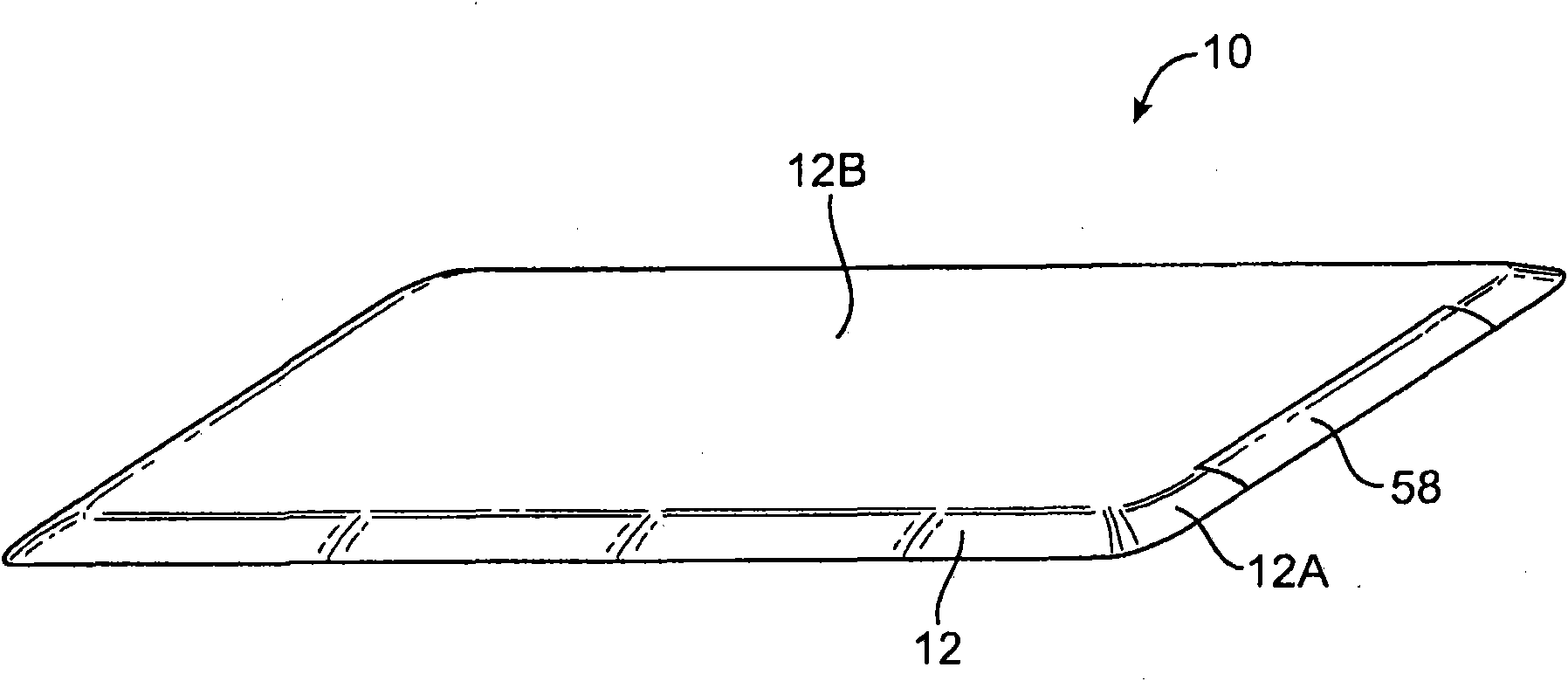

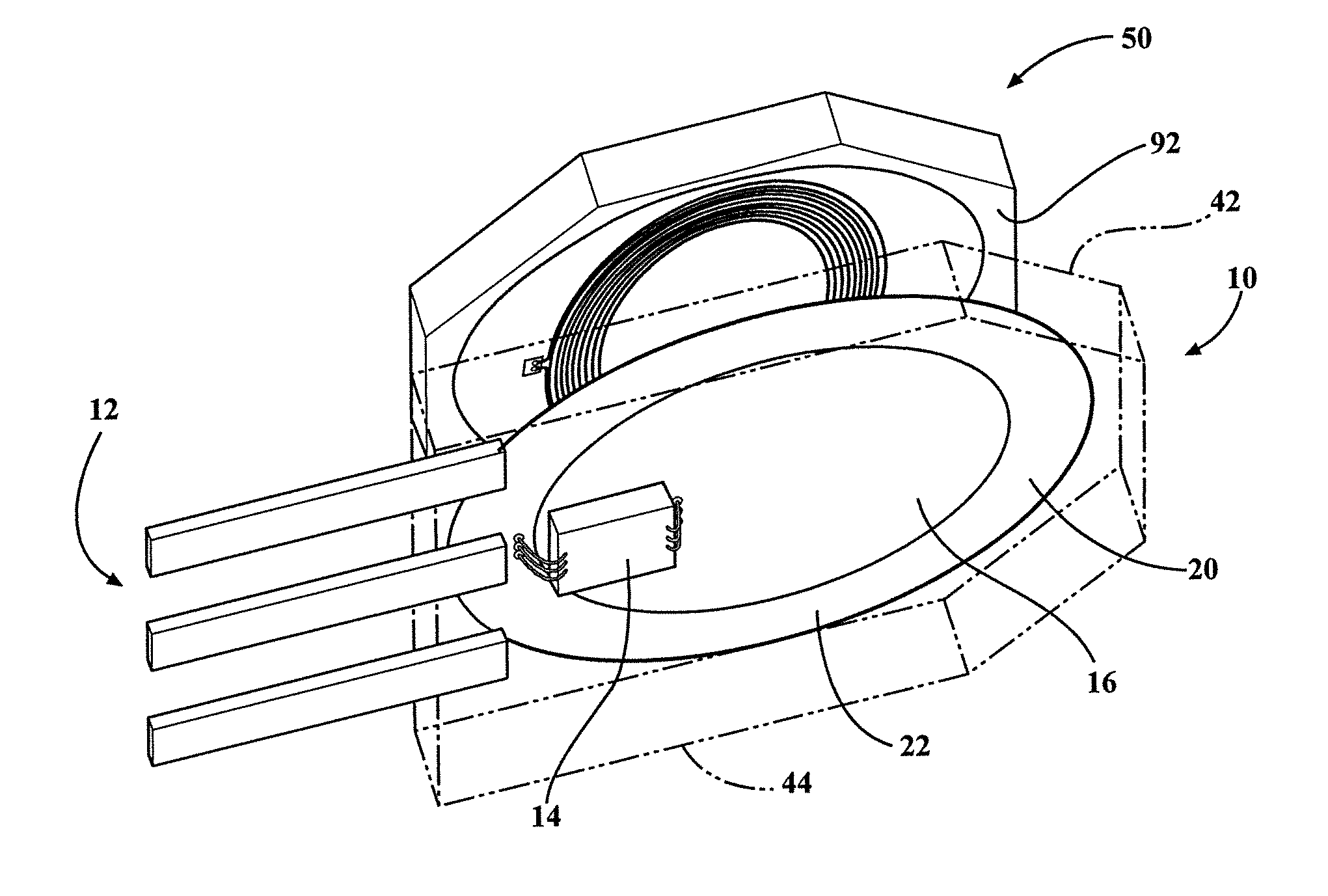

InactiveUS20130181797A1Transformers/inductances coolingCharging stationsFerrite layerMotorized vehicle

A coil apparatus includes a first housing and a second housing that surroundingly encloses the first housing. The first housing has a coil arrangement disposed therein. The coil arrangement includes a ferrite layer and a thermally-conductive silicone layer that overlies the ferrite layer. A wire conductor surrounds the first housing. A structure is received in a opening defined in the first housing to be in thermal communication with the thermally-conductive silicone layer. Another thermally-conductive silicone layer overlies the first housing and the structure so that the structure is also in thermal communication therewith. A metal layer further overlies the thermally-conductive silicone layer that overlies the first housing. The second housing includes a non-dielectric cover and a dielectric cavity portion that receives the coil arrangement. The coil apparatus is associated with an electrical charging system (ECS) that electrically charges an energy storage device (ESD) disposed on a motorized vehicle.

Owner:DELPHI TECH INC

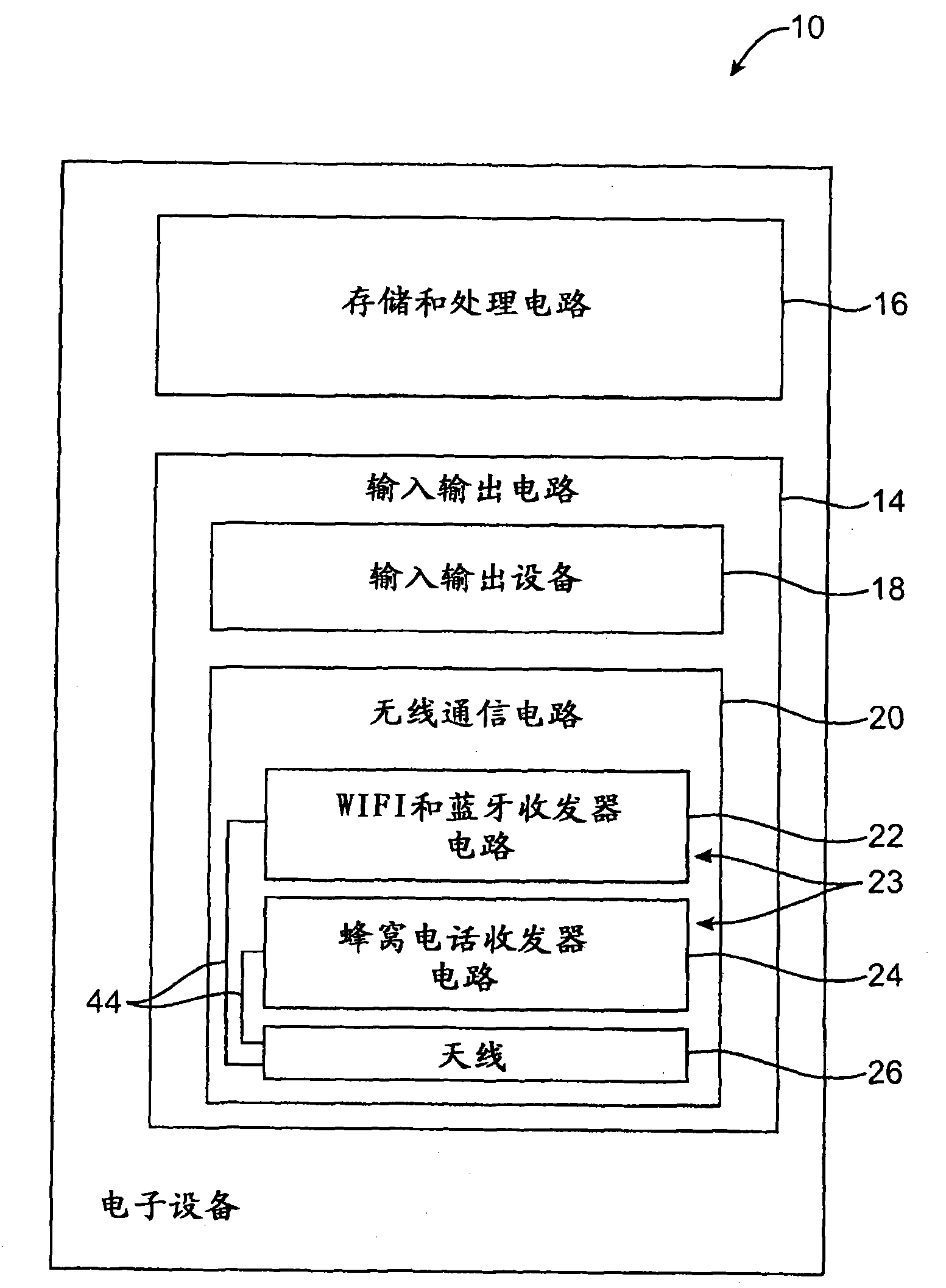

Electronic devices with parasitic antenna resonating elements that reduce near field radiation

ActiveCN101958454AAdd other featuresSimultaneous aerial operationsDigital data processing detailsDielectricFerrite layer

The invention relates to electronic devices with parasitic antenna resonating elements that reduce near field radiation. Antennas are provided for electronic devices such as portable computers. An electronic device may have a housing in which an antenna is mounted. The housing may be formed of conductive materials. A dielectric antenna window may be mounted in the housing to allow radio- frequency signals to be transmitted from the antenna and to allow the antenna to receive radio-frequency signals. Near-field radiation limits may be satisfied by reducing transmit power when an external object is detected in the vicinity of the dielectric antenna window and the antenna. A proximity sensor may be used in detecting external objects. A parasitic antenna resonating element may be interposed between the antenna resonating element and the dielectric antenna window to minimize near-field radiation hotspots. The parasitic antenna resonating element may be formed using a capacitor electrode for the proximity sensor. A ferrite layer may be interposed between the parasitic element and the antenna window.

Owner:APPLE INC

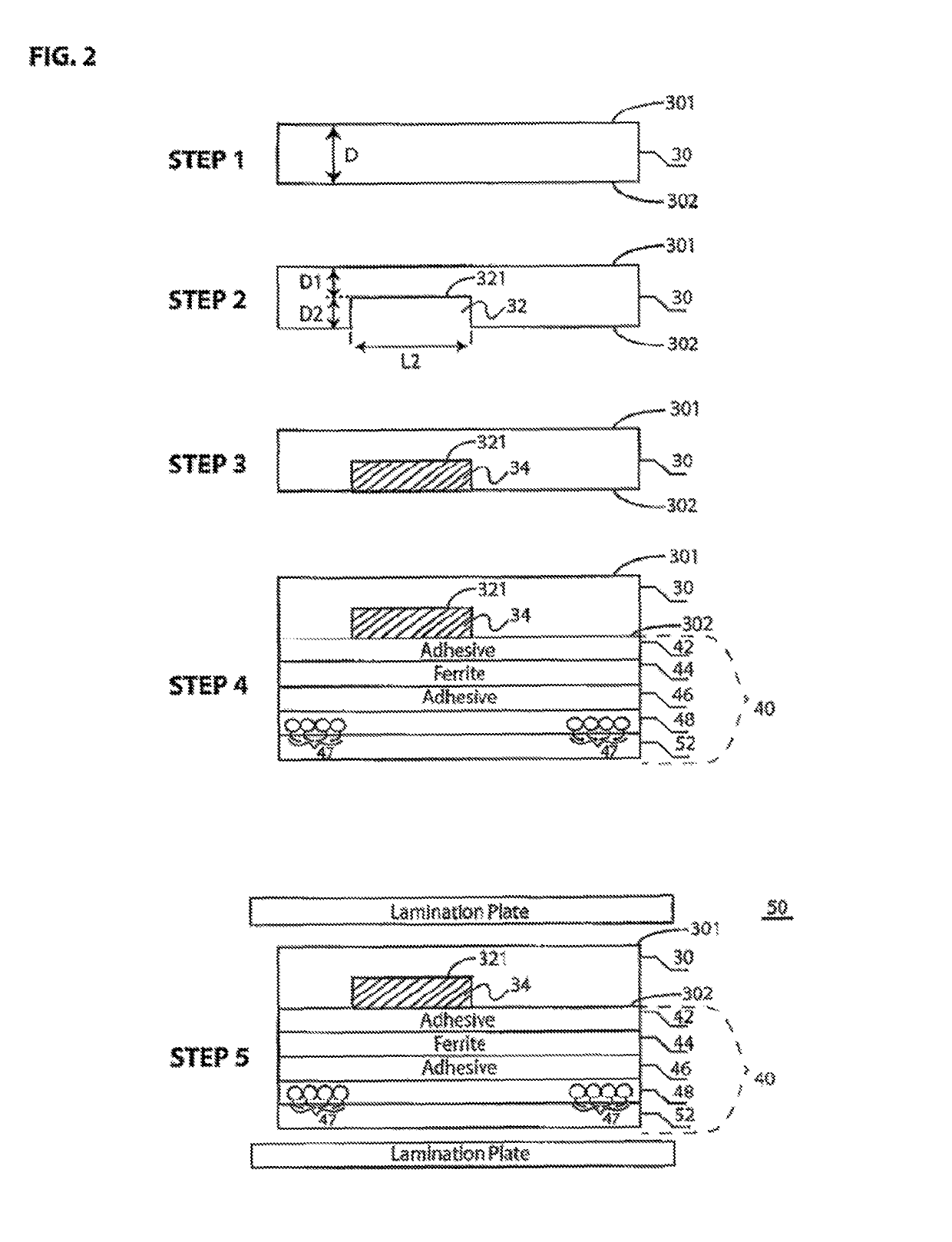

Precision batch production method for manufacturing ferrite rods

InactiveUS20160254579A1Optimize layoutReduce decreaseSemiconductor/solid-state device manufacturingConductive/insulating/magnetic material on magnetic film applicationCrystallographyFerrite layer

The present invention relates to a method of manufacturing a ferrite rod. The method comprises etching cavities into two semiconductor substrates and depositing ferrite layers into the cavities. The semiconductor substrates are attached to each other such that the ferriote layers form a ferrite rod. The present invention employs conventional photolithography and bulk isotropic micromachining of semiconductor wafers to precisely and repeatably form a template or mould, into which magnetic material can be deposited to form a Faraday rotation or phase-shifting element.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

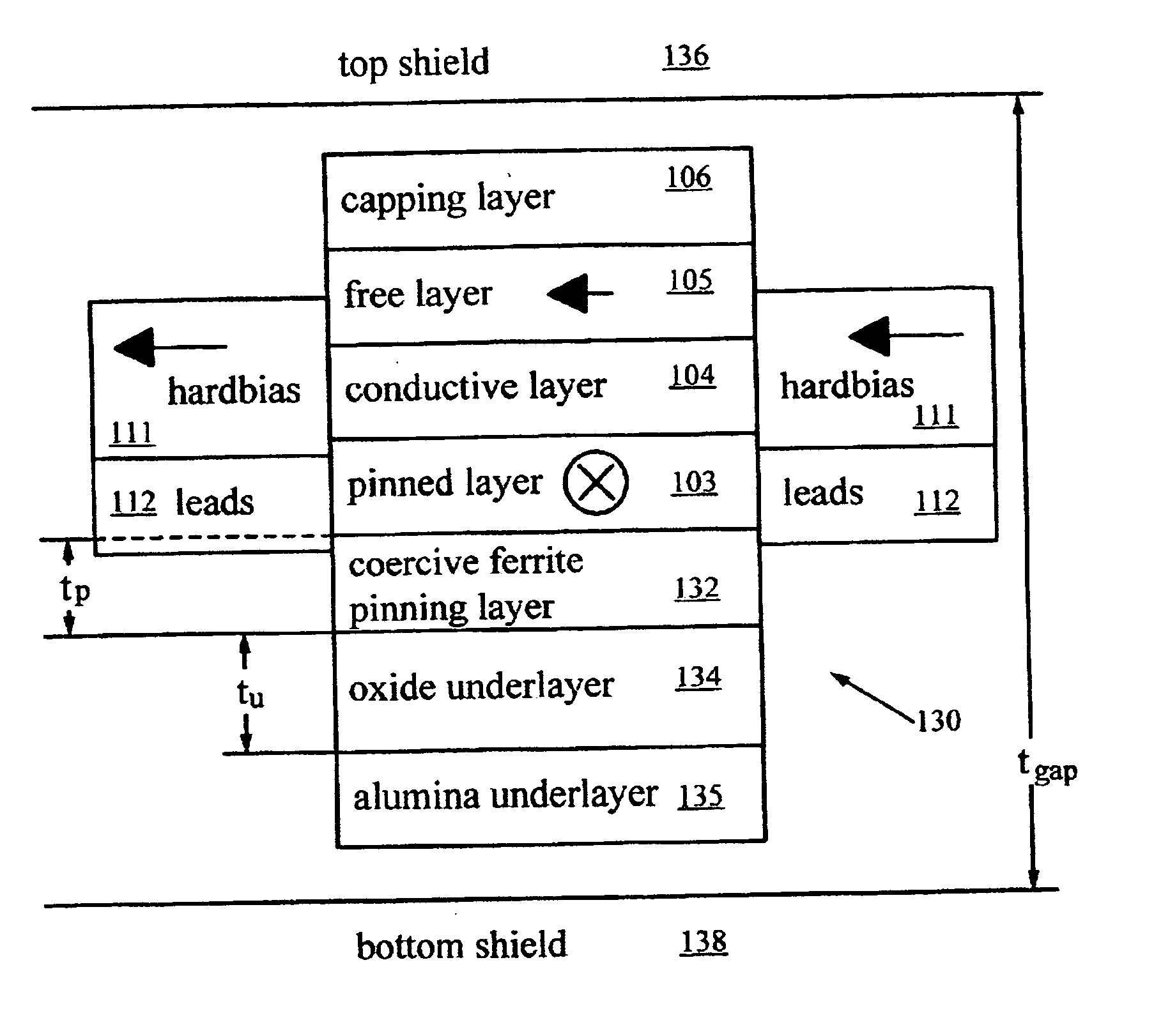

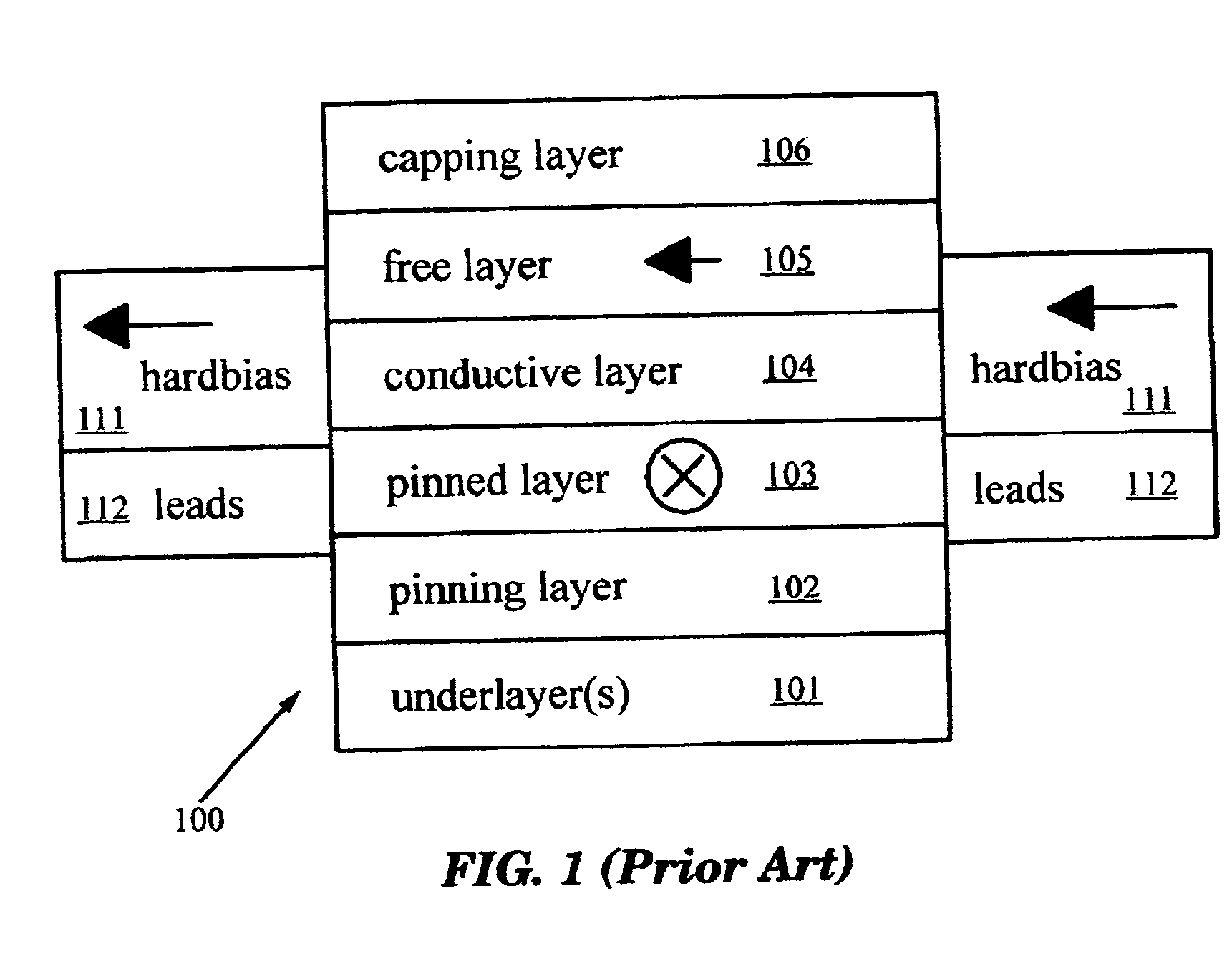

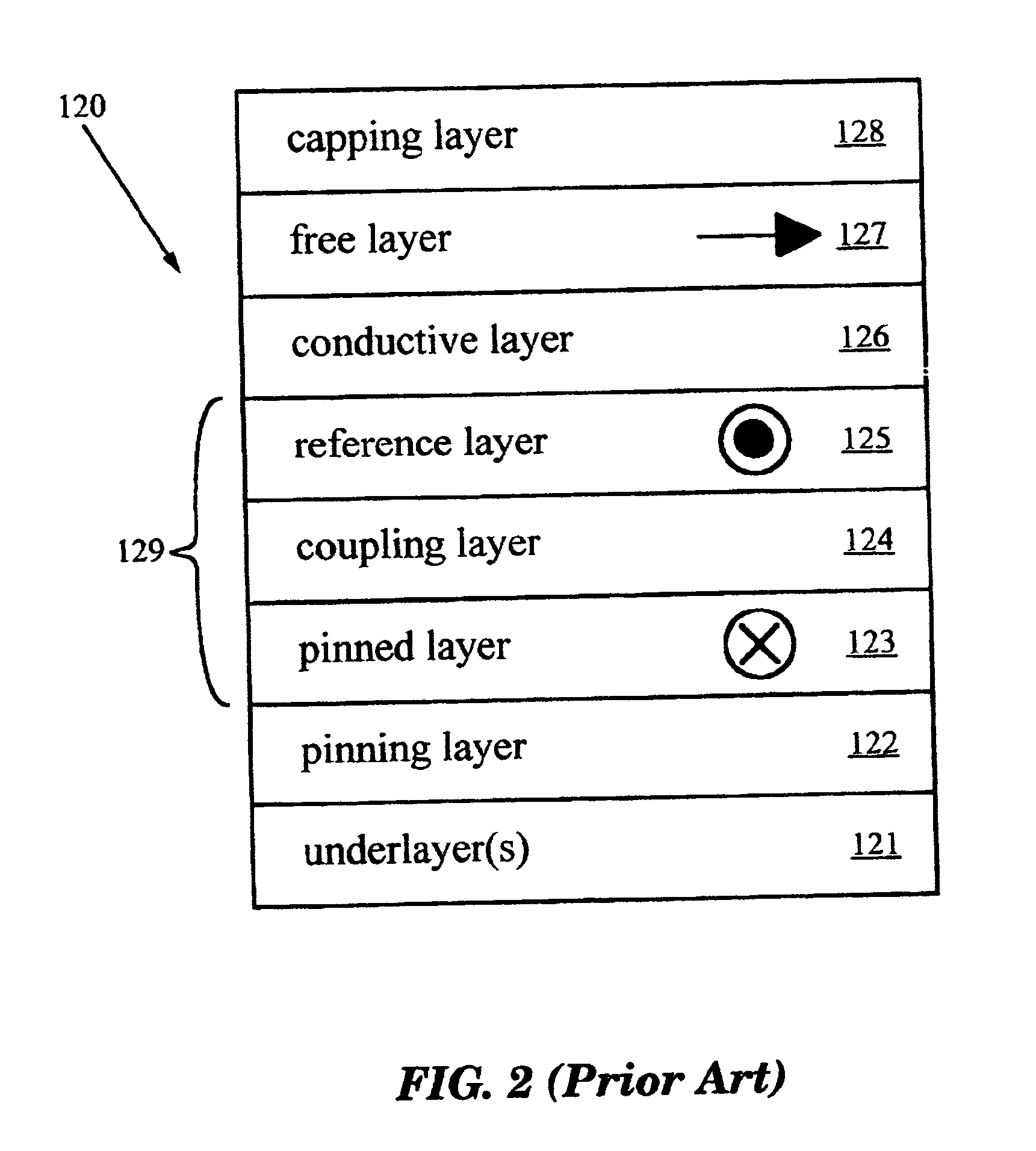

Stability-enhancing underlayer for exchange-coupled magnetic structures, magnetoresistive sensors, and magnetic disk drive systems

Owner:CAREY MATTHEW JOSEPH +5

Carrier for electrophotographic developer, and electrophotographic developer using the same

ActiveUS20070048649A1Excellent in charge imparting capabilityImprove stabilityDevelopersFerrite layerImage density

A carrier for an electrophotographic developer which is used as an electrophotographic developer in a mixture with a toner and which secures sufficiently the image density and can maintain high-quality images for a long period, and an electrophotographic developer using the carrier, are provided. A resin-filled ferrite carrier for electrophotographic developer obtained by filling, with a resin, avoid of a porous ferrite core whose void continues from the surface to reach the interior of the core, the carrier comprising a plurality of three-dimensional laminate structures in which resin layers and ferrite layers are alternately present, and an electrophotographic developer including the carrier and a toner, are employed.

Owner:POWDERTECH

Dual interface metal smart card with booster antenna

ActiveUS20180307962A1Improved RF transmissionAntenna supports/mountingsSemiconductor/solid-state device detailsFerrite layerComputer module

Owner:COMPOSECURE LLC

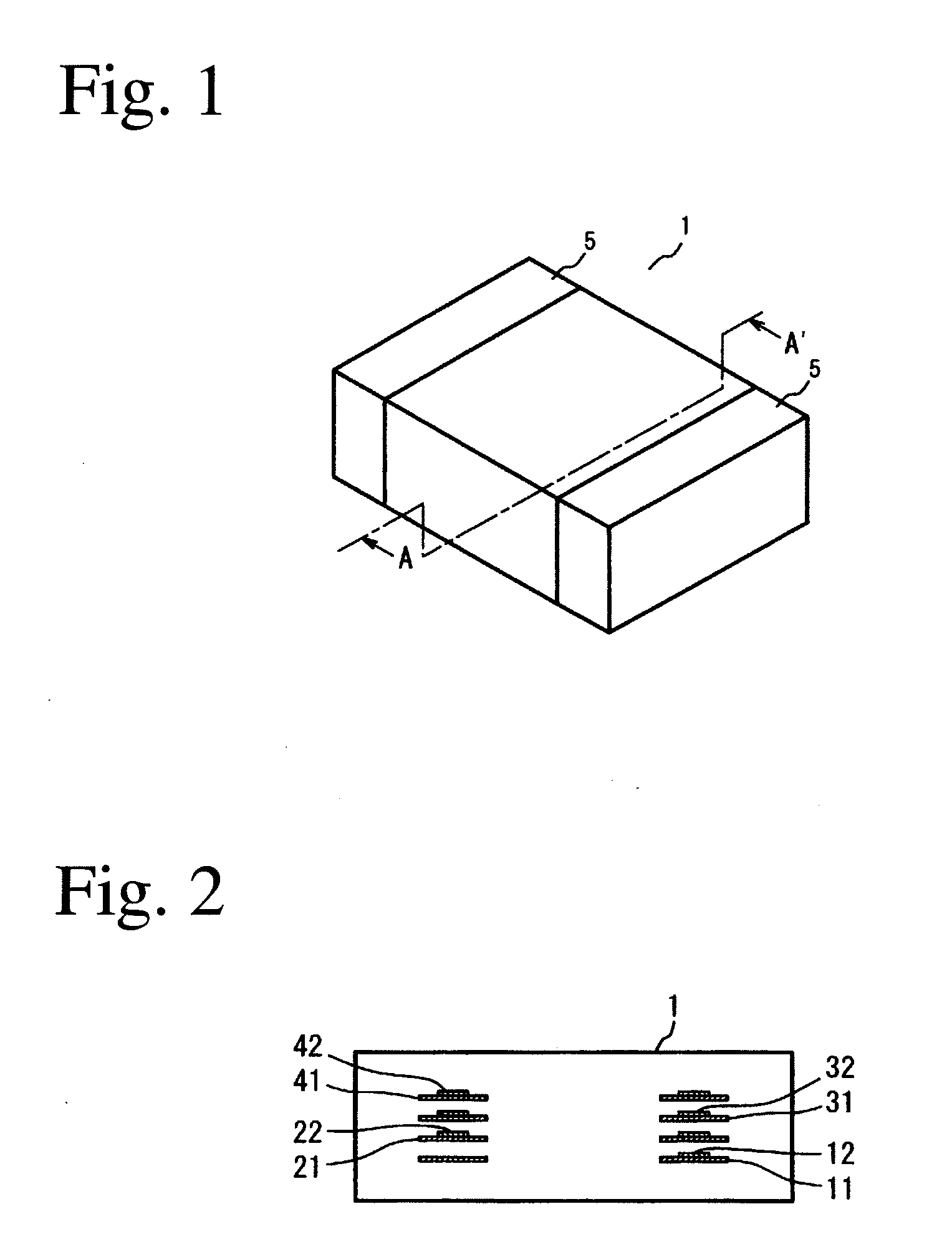

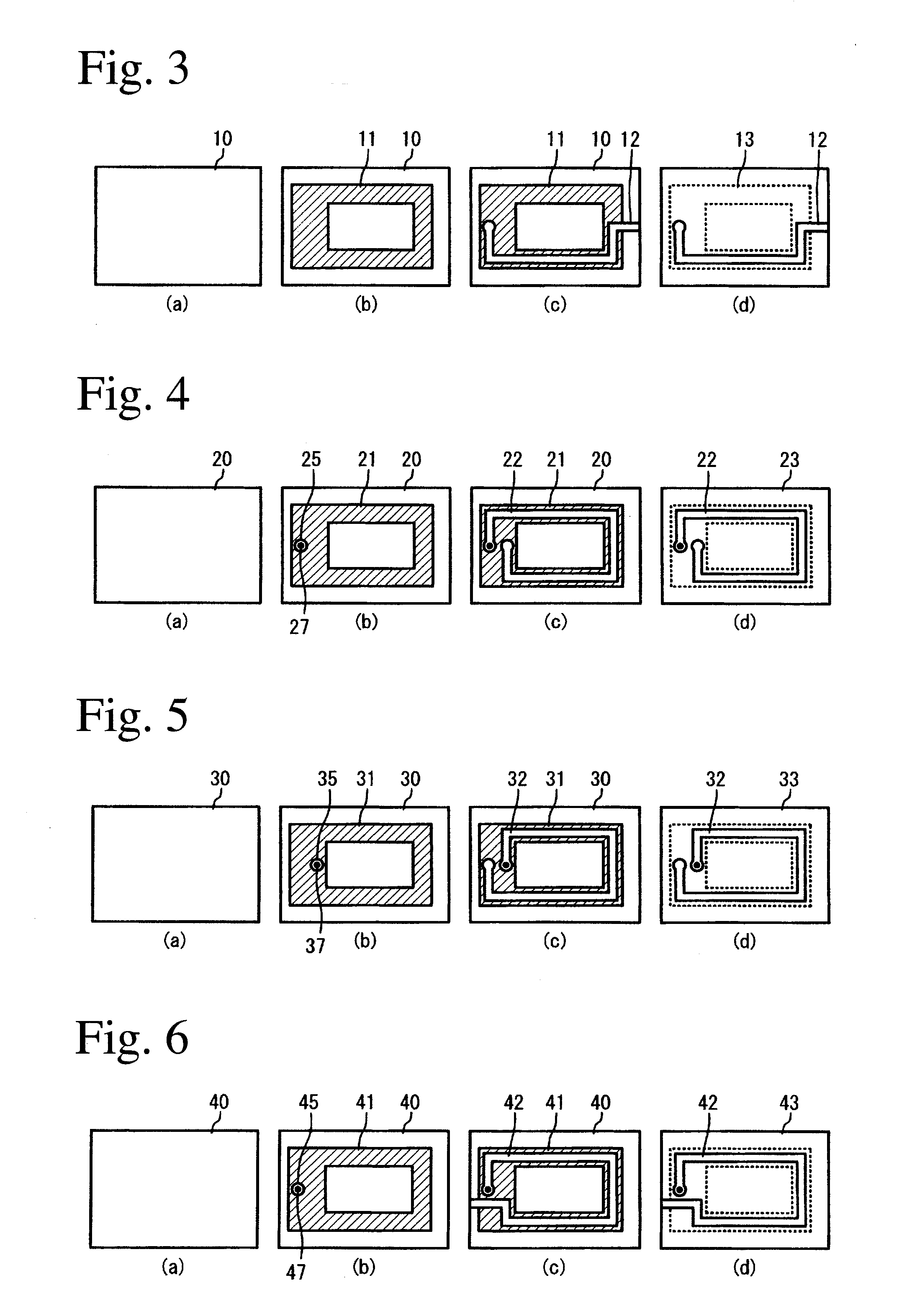

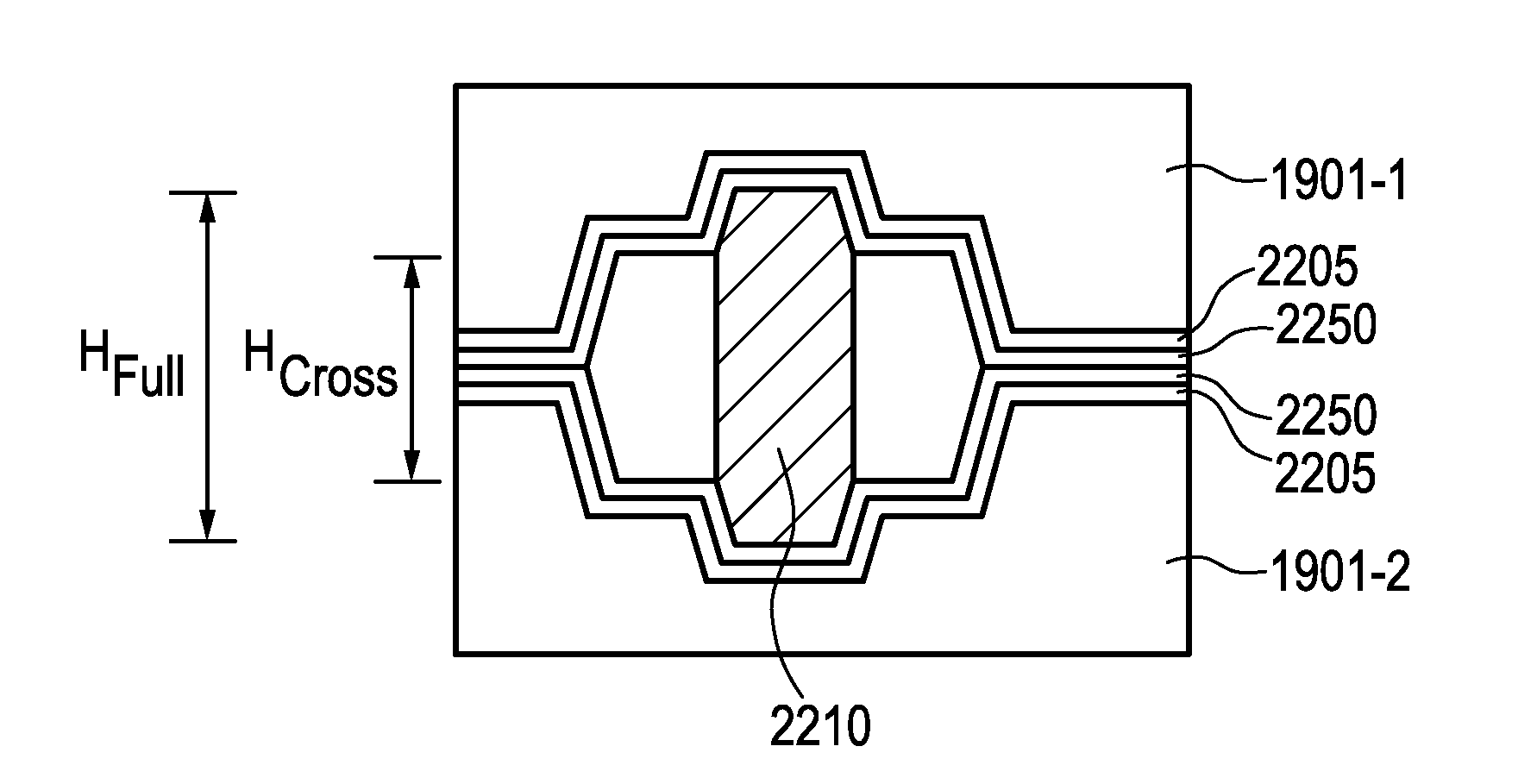

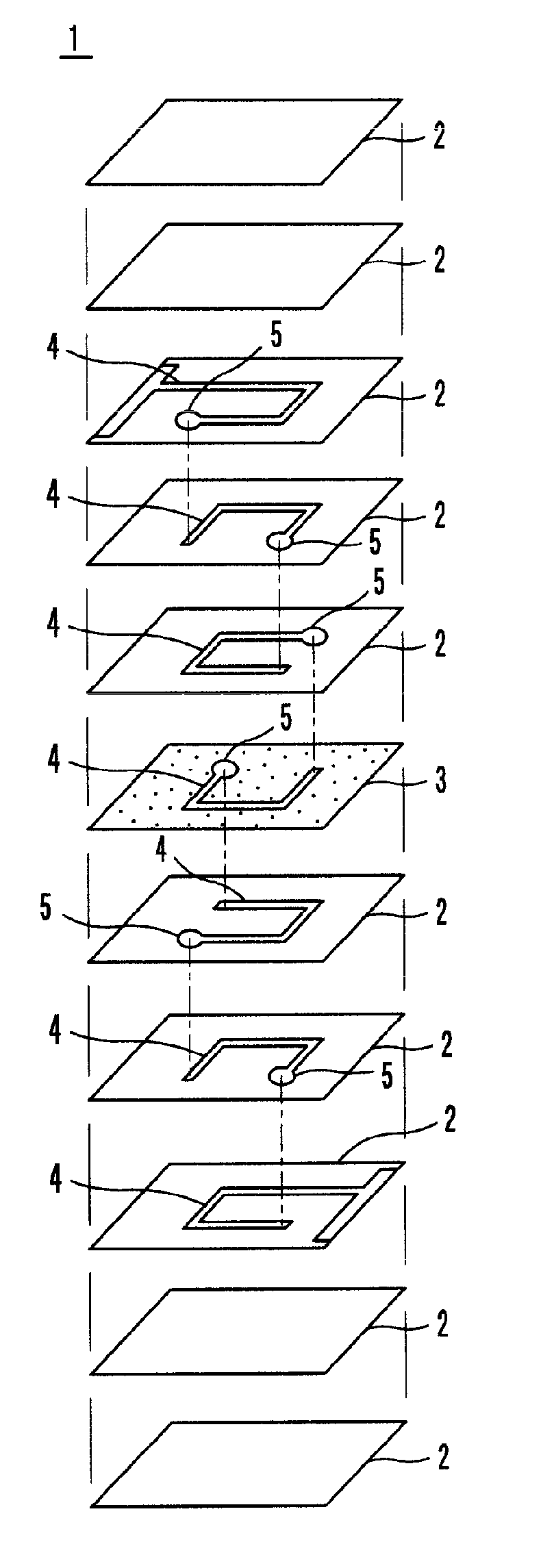

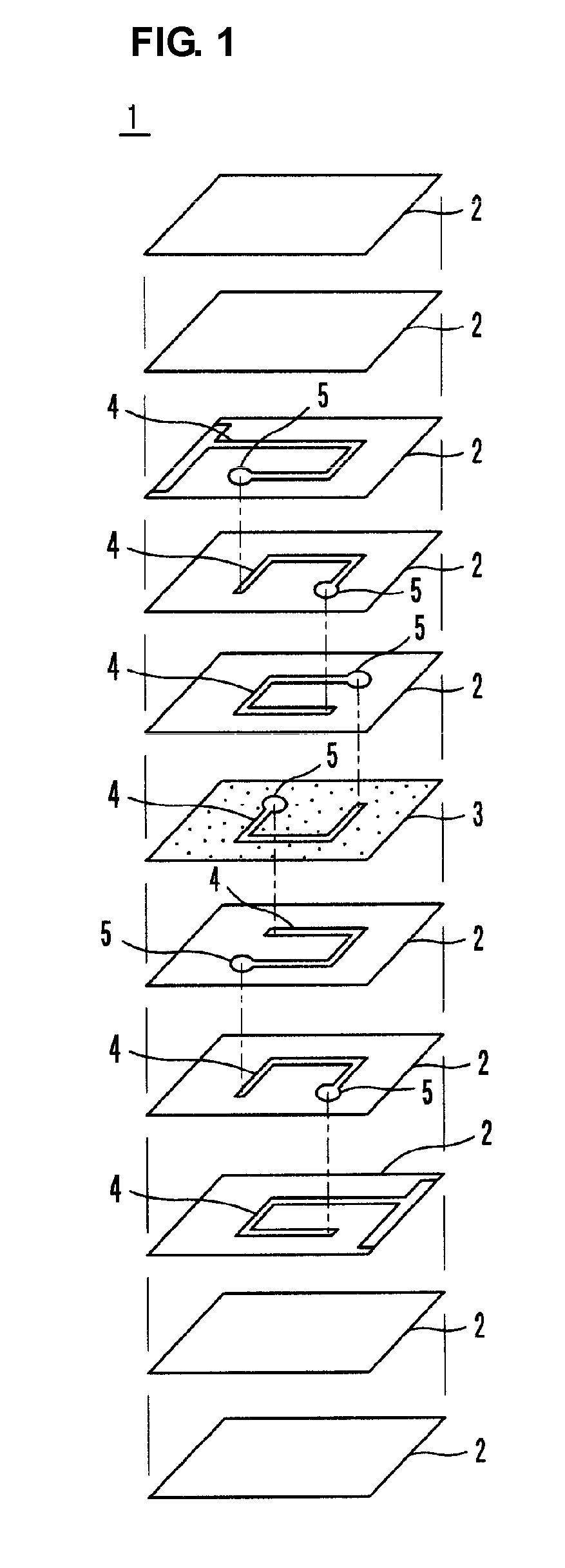

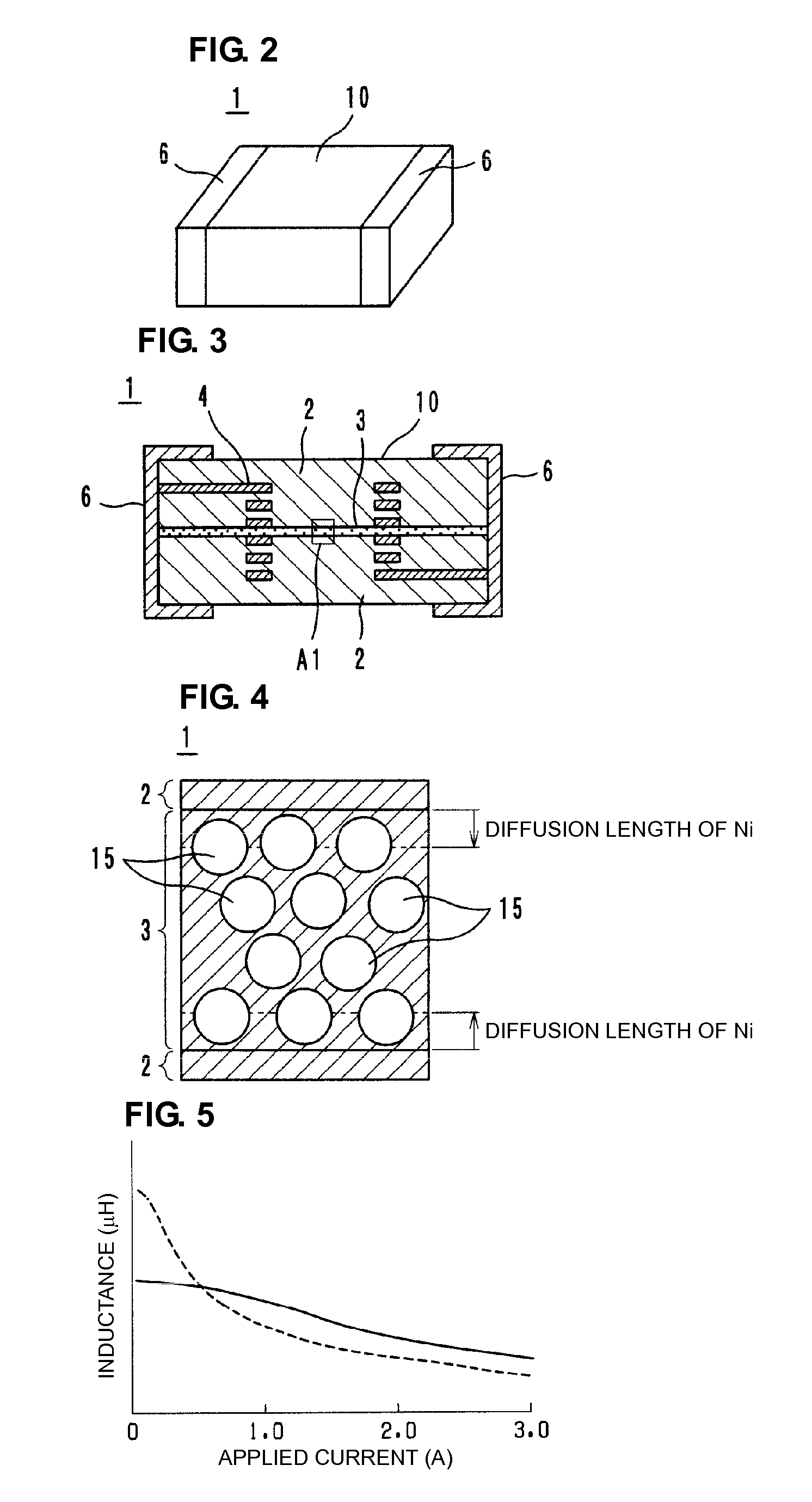

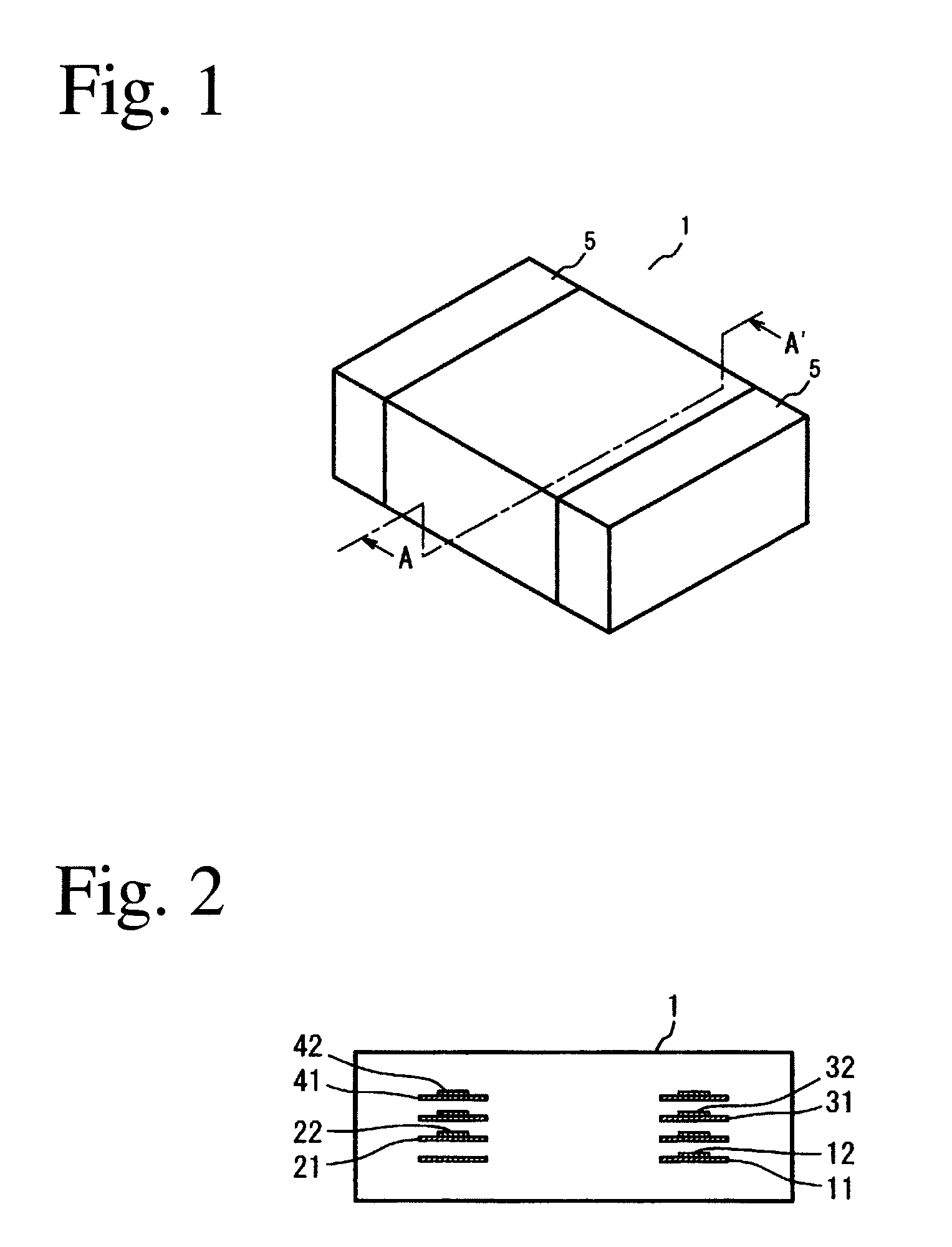

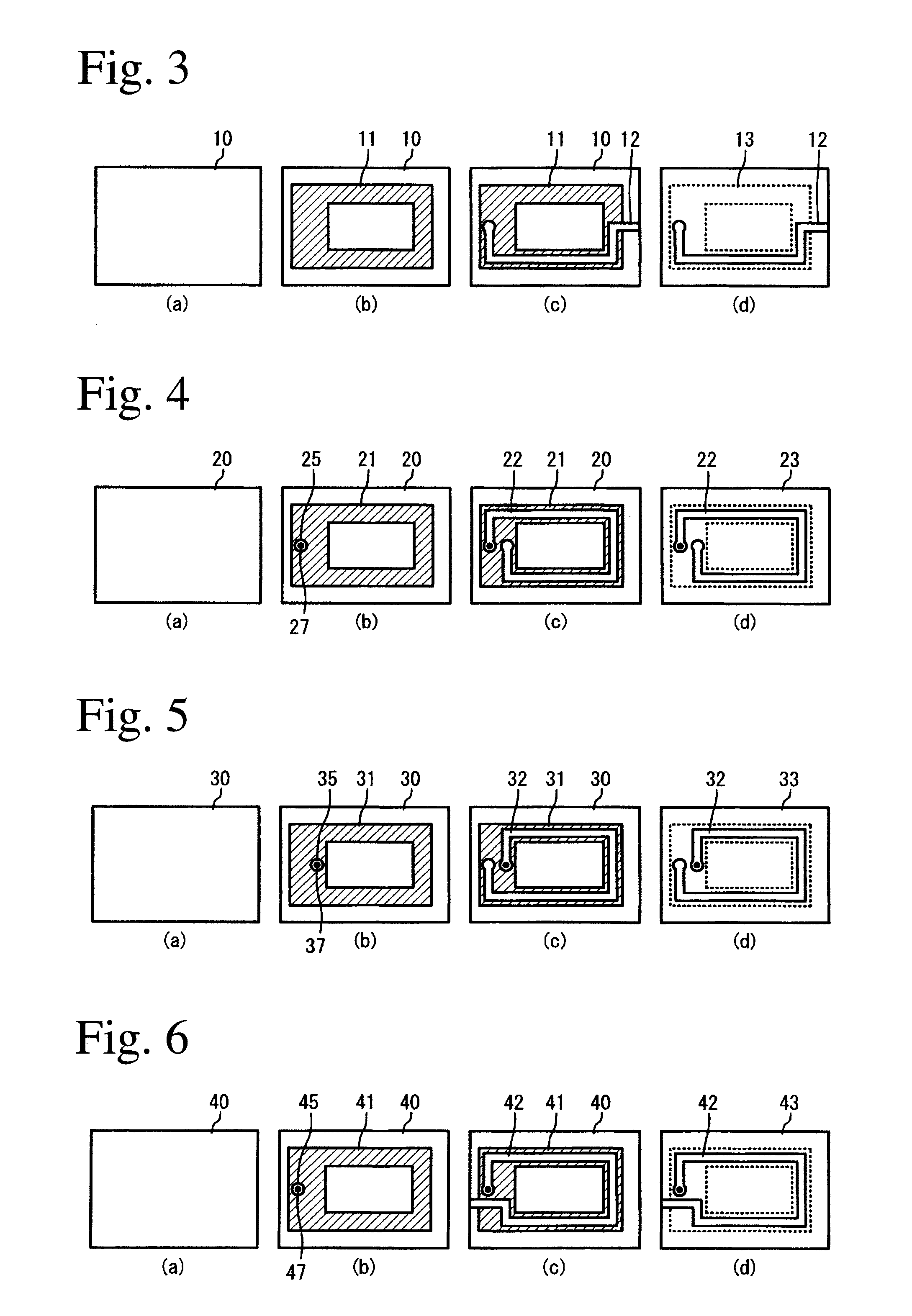

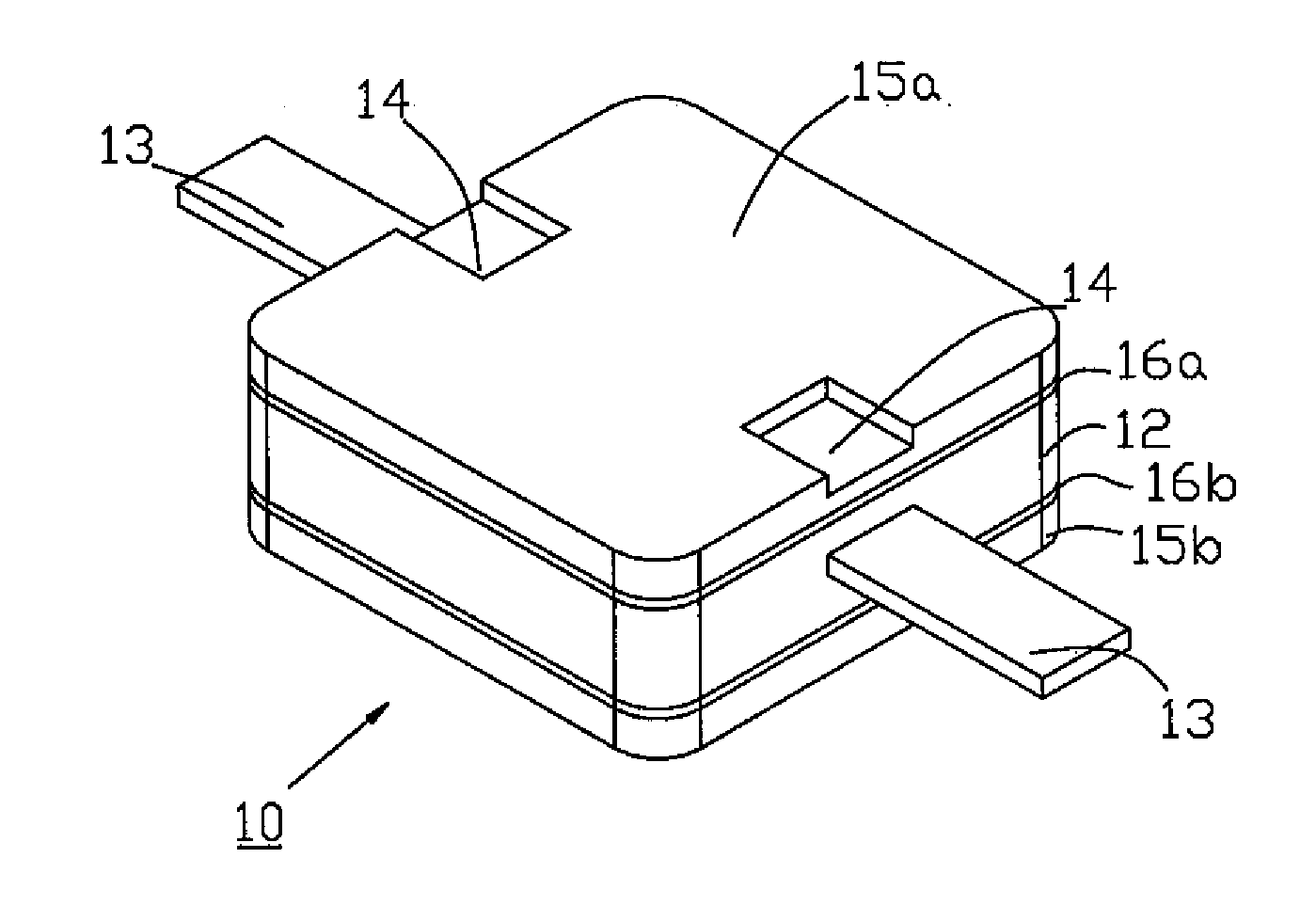

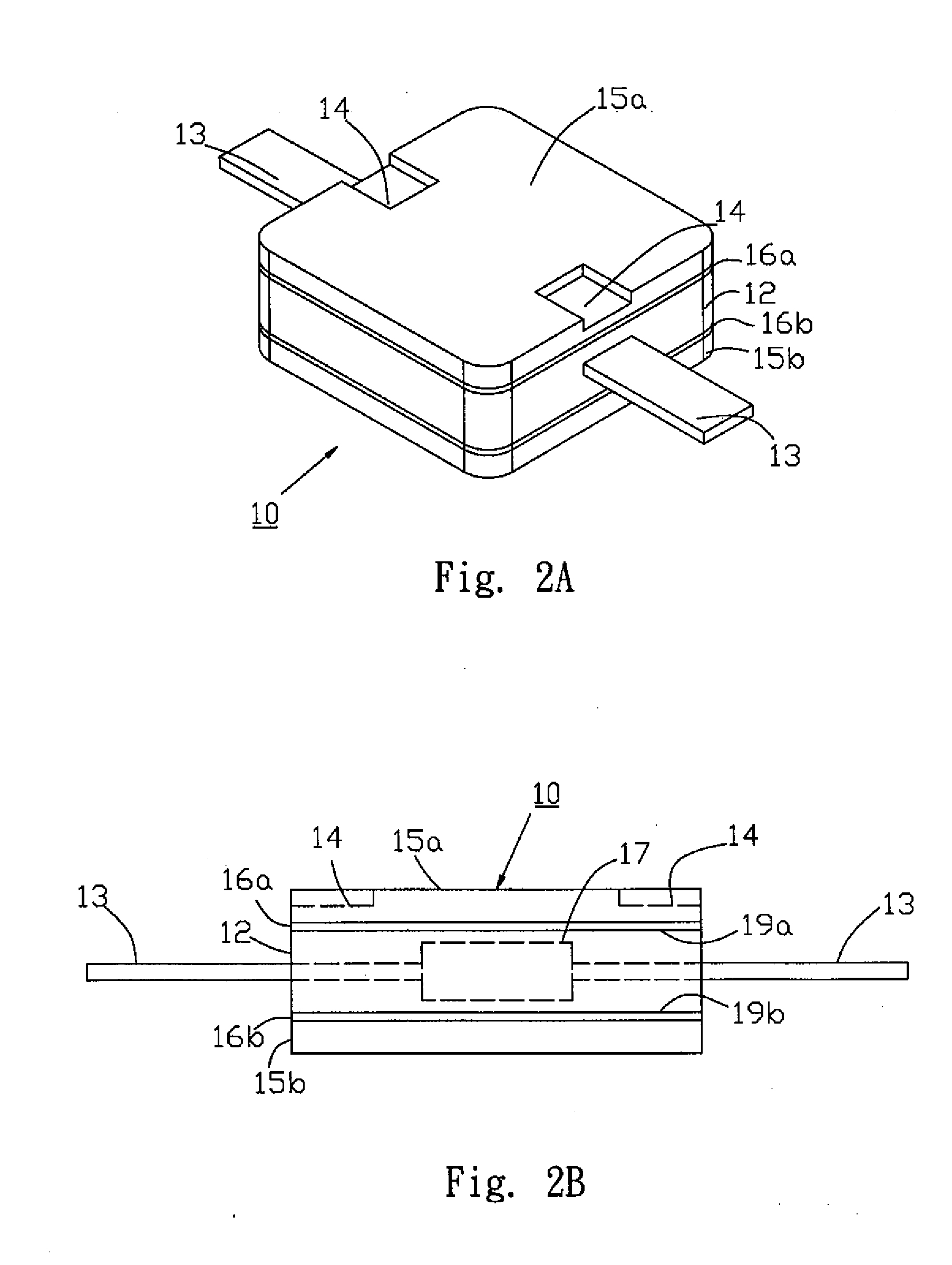

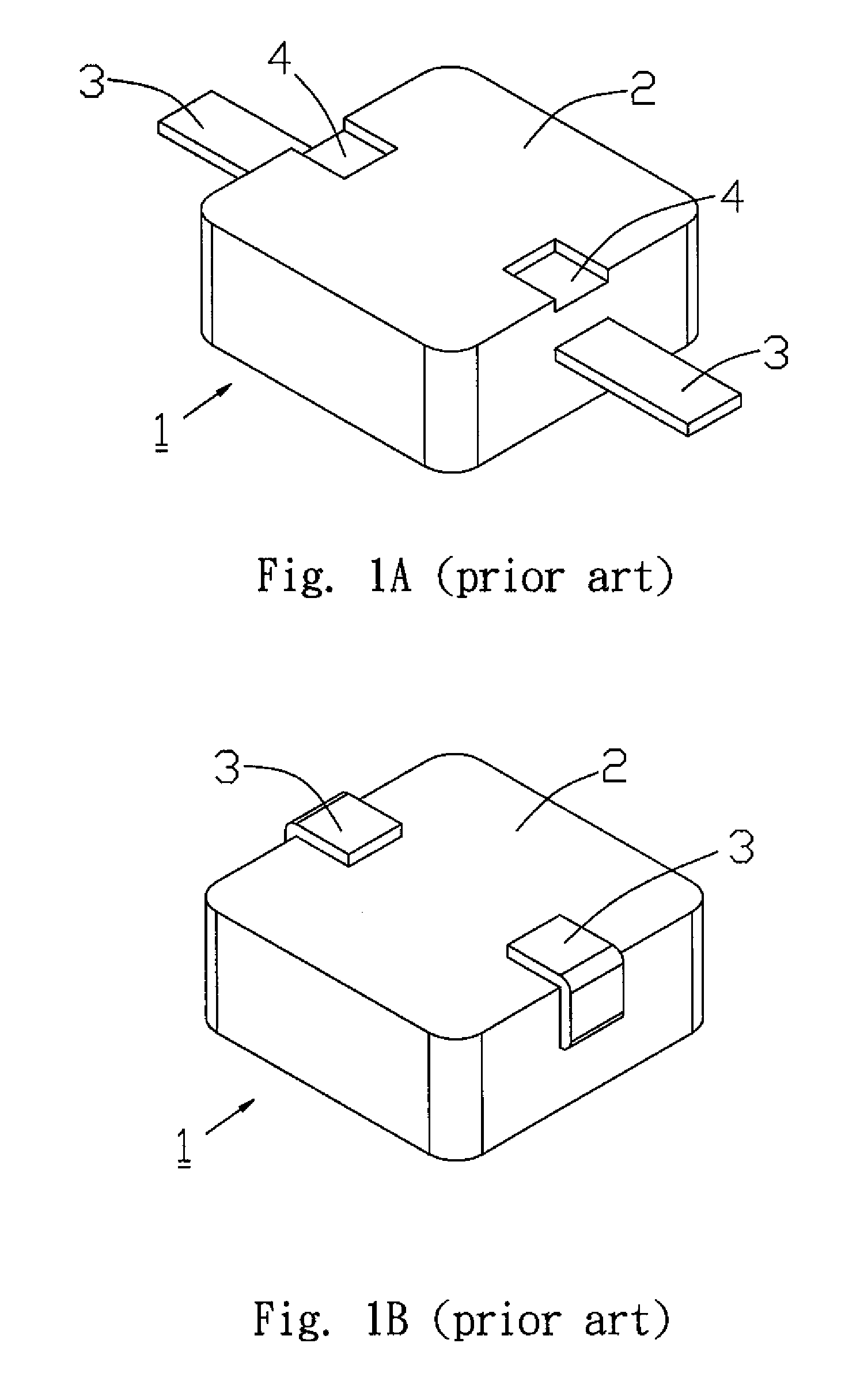

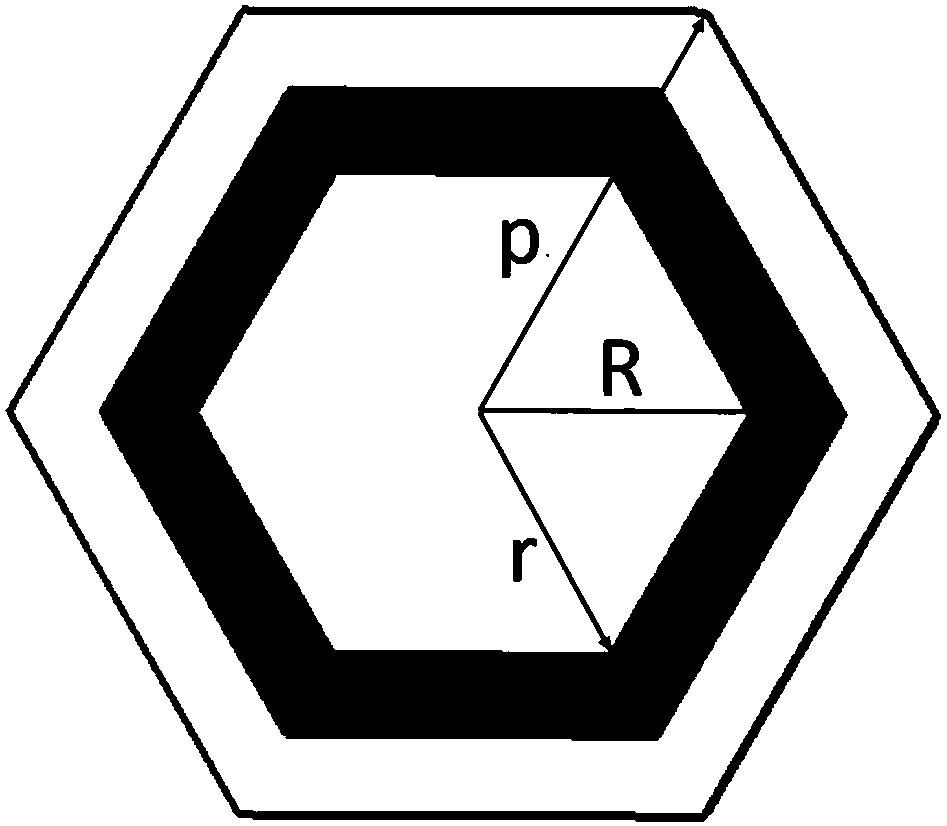

Laminated coil component

ActiveUS7719399B2Satisfactory direct-current superposition characteristicInhibition thicknessTransformers/inductances magnetic coresInductance with magnetic coreFerrite layerNickel

A laminated coil component includes high-magnetic-permeability ferrite layers that are disposed on both main surfaces of a low-magnetic-permeability ferrite layer. Pores or pores filled with a resin are formed in the low-magnetic-permeability ferrite layer. Nickel in the high-magnetic-permeability ferrite layers does not significantly diffuse into the pores or the pores filled with the resin during firing, and thus, Ni does not readily diffuse into the low-magnetic-permeability ferrite layer.

Owner:MURATA MFG CO LTD

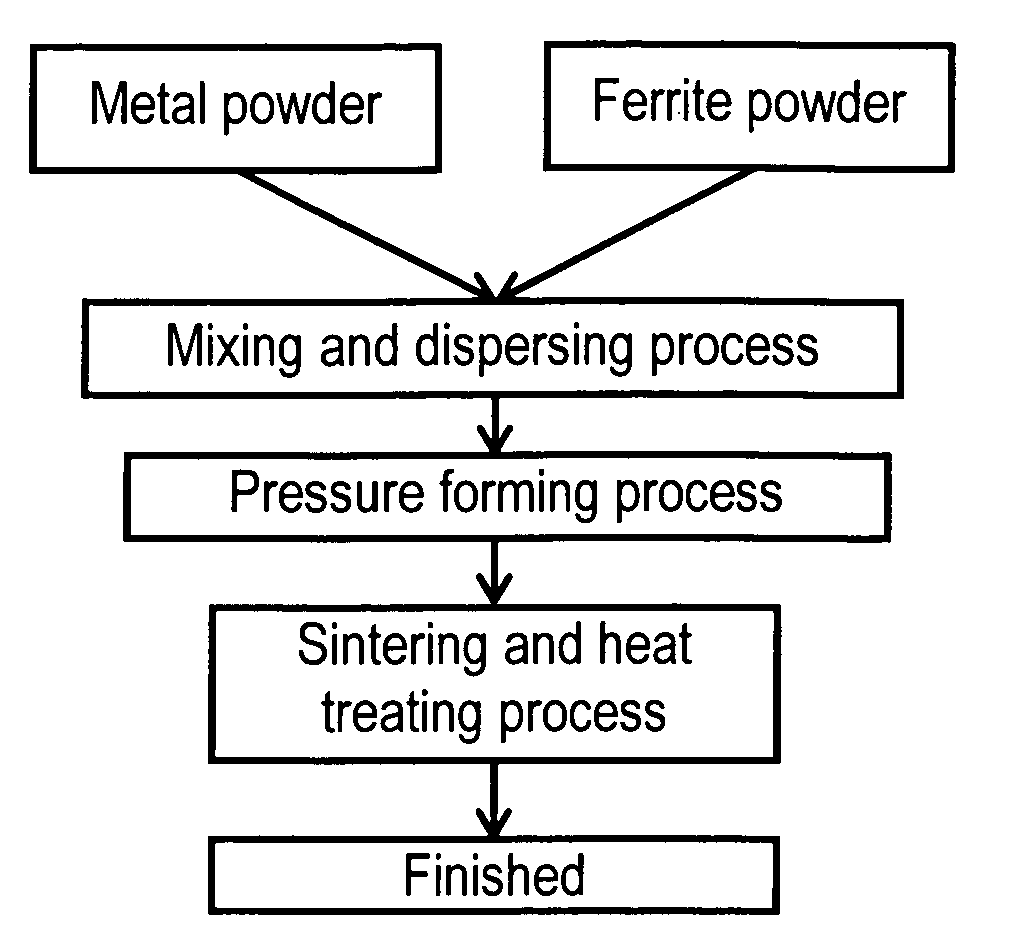

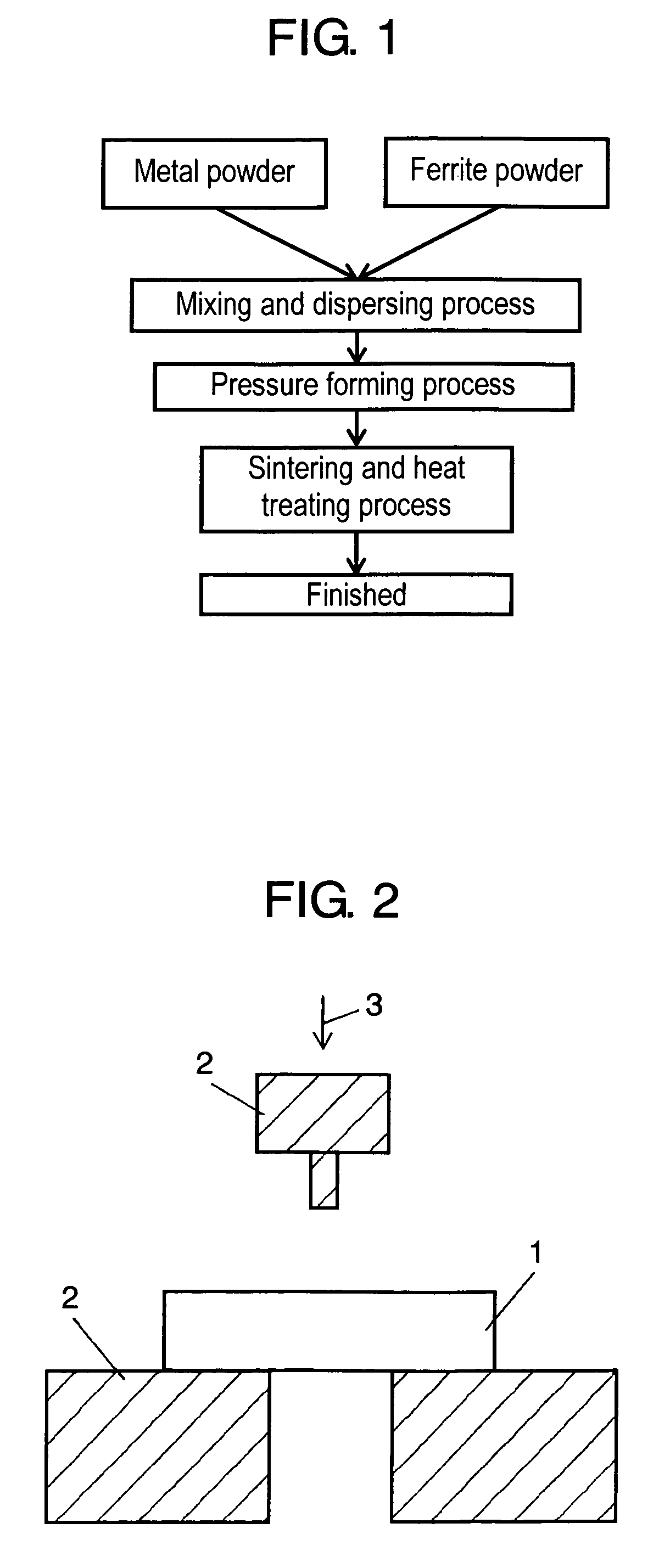

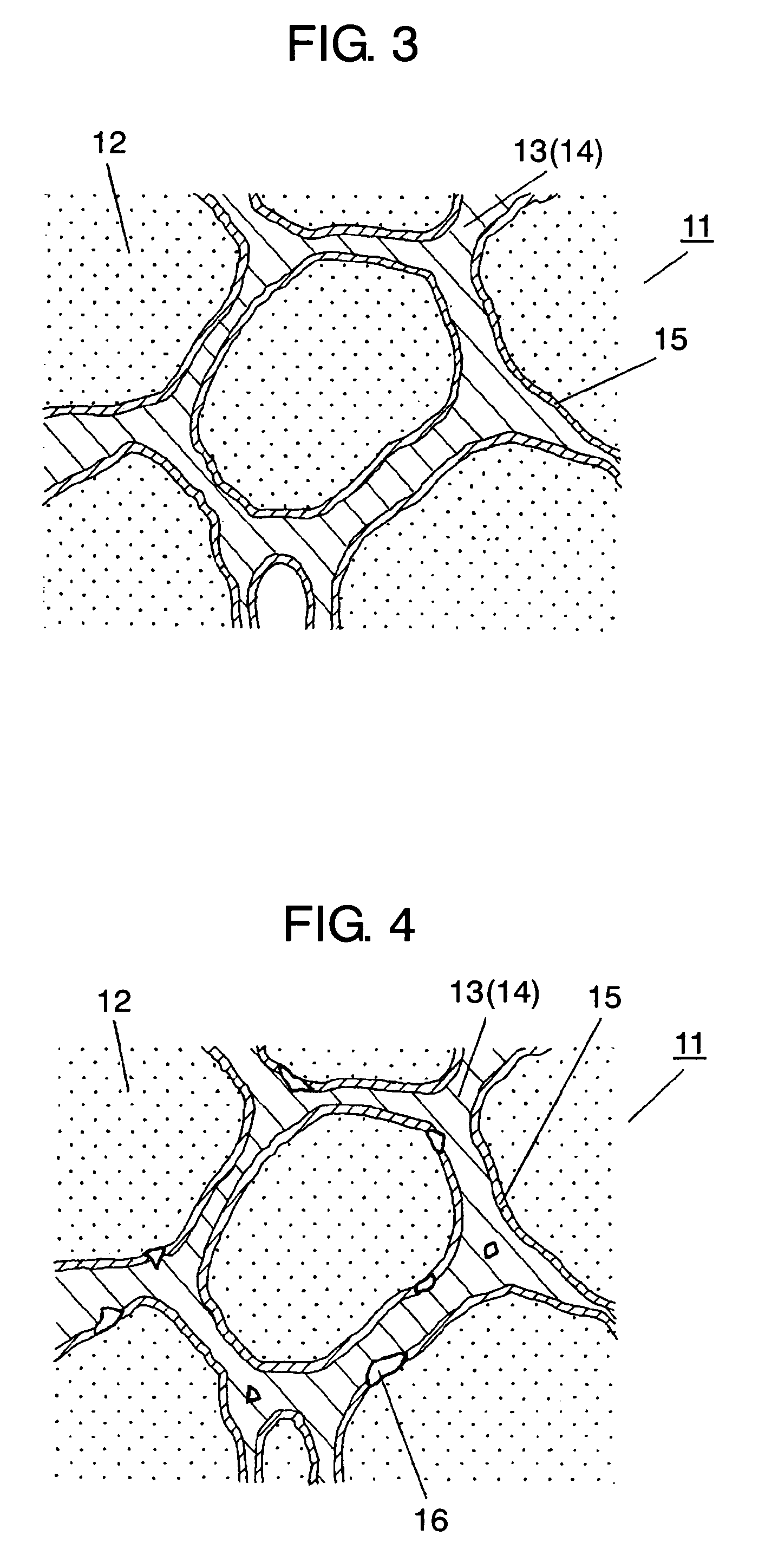

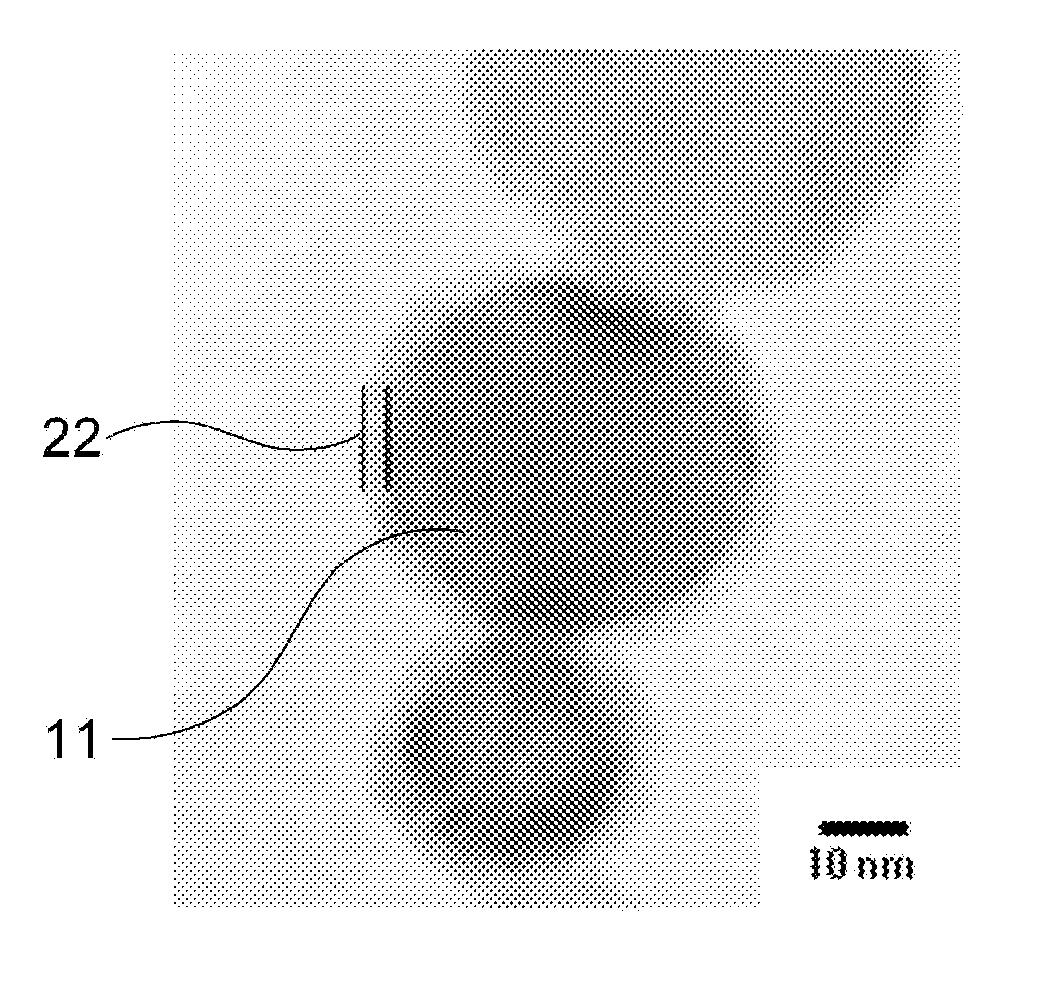

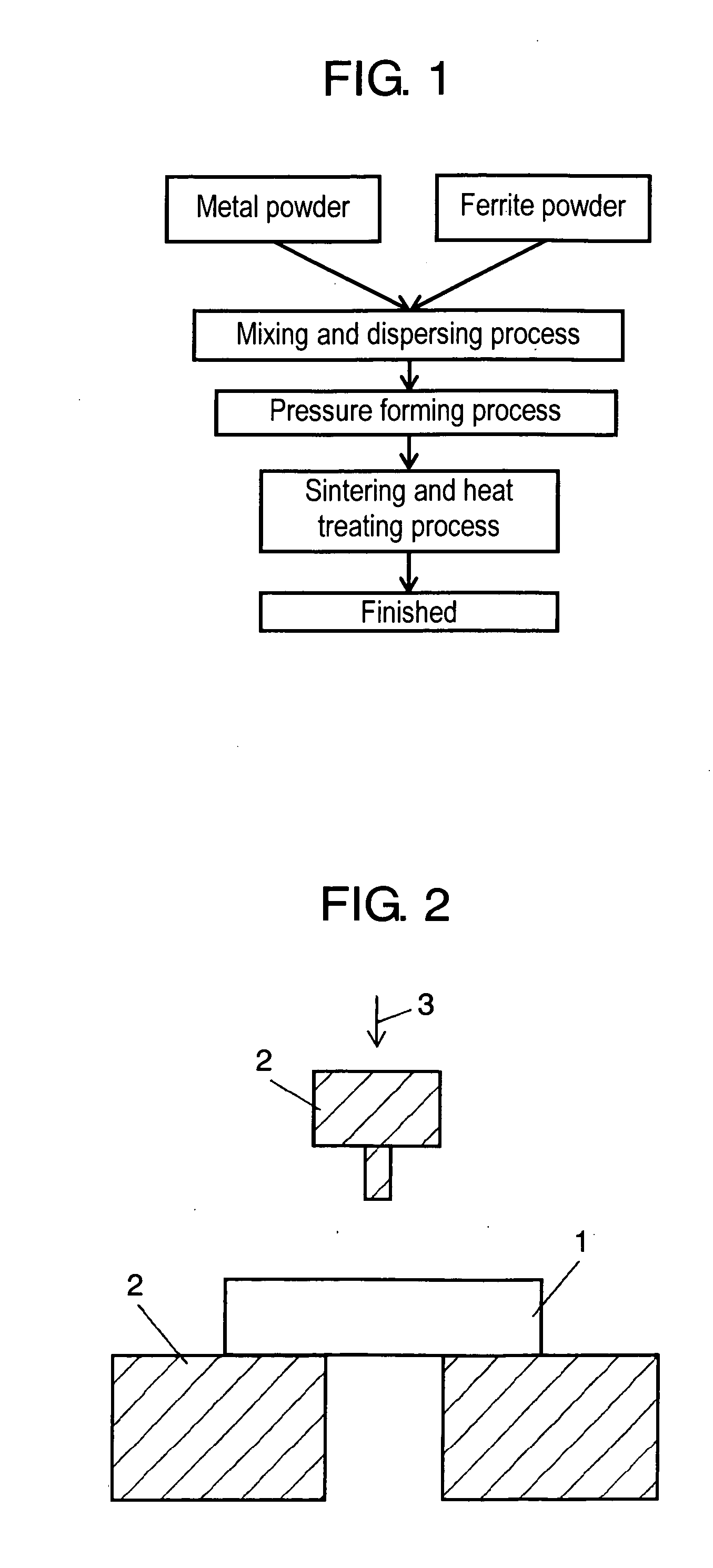

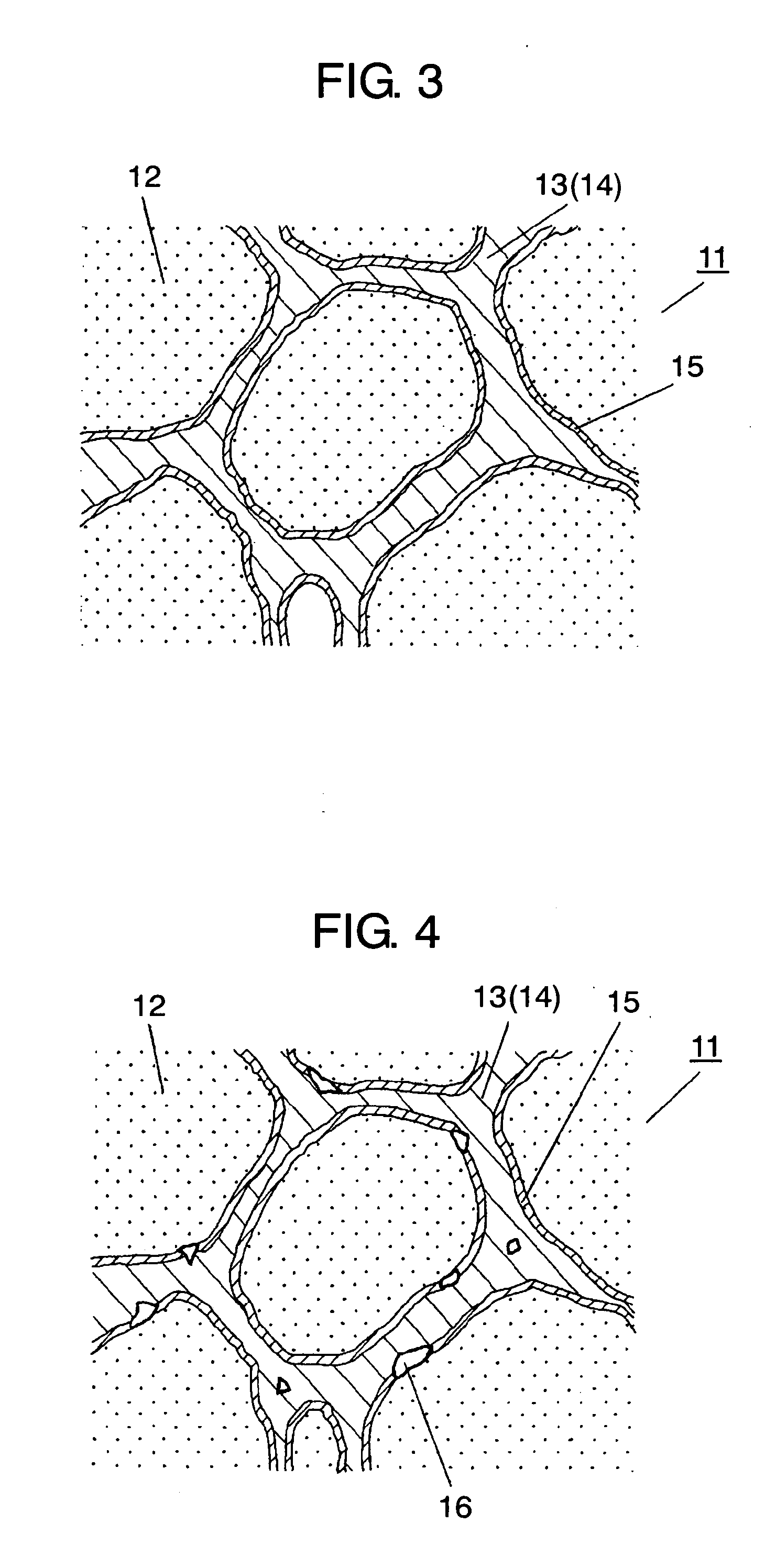

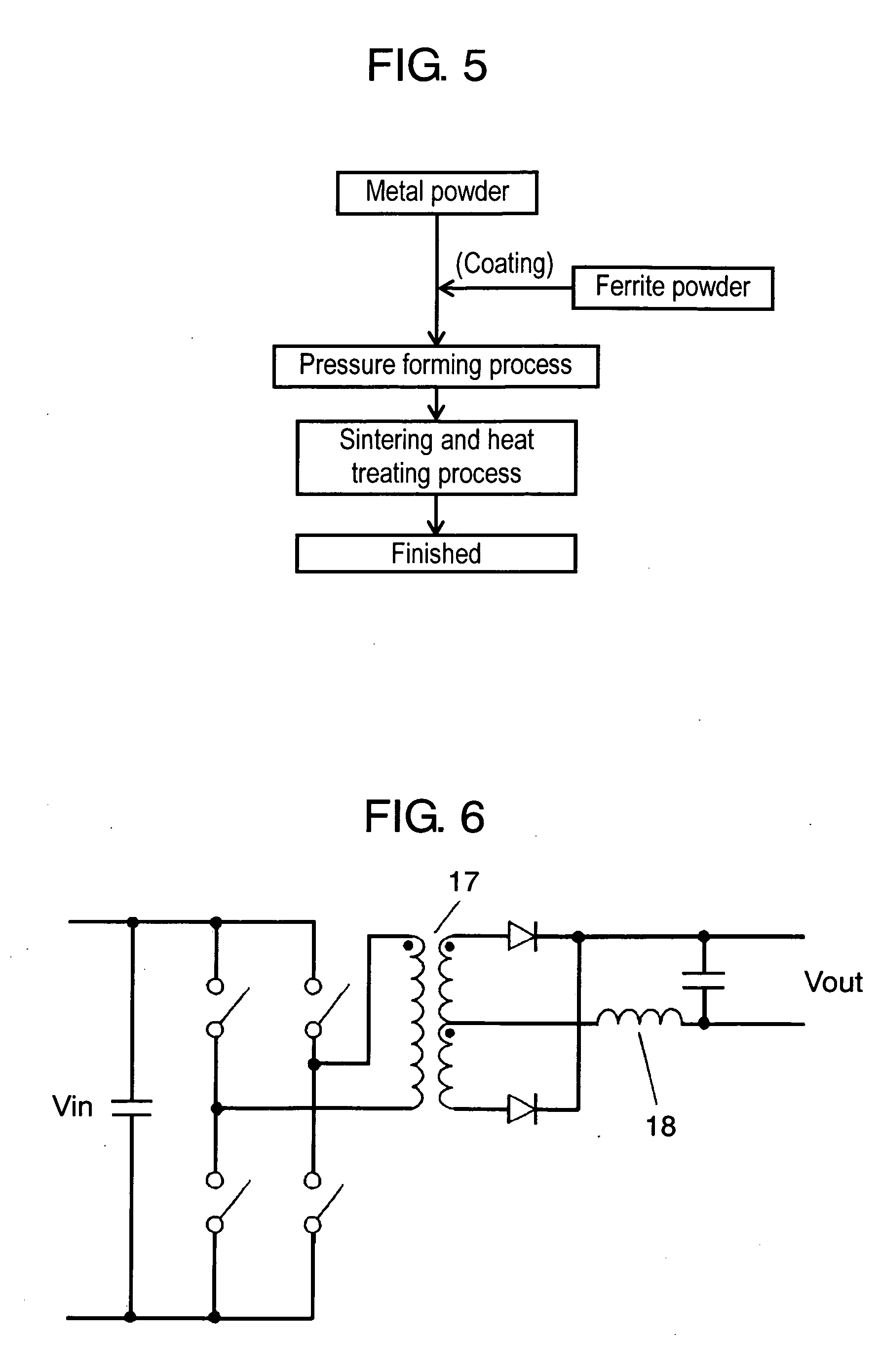

Composite sintered magnetic material, its manufacturing method, and magnetic element using composite sintered magnetic material

A composite sintered magnetic material comprises a kind of metal powder at least one selected from the group consisting of Fe, Fe—Si type, Fe—Ni type, Fe—Ni—Mo type, and Fe—Si—Al type, and a ferrite layer formed from a kind of ferrite powder at least one selected from the group consisting of Ni—Zn type, Mn—Zn type, and Mg—Zn type, wherein a diffusion layer is formed by sintering between both of these to integrates the both.

Owner:PANASONIC CORP

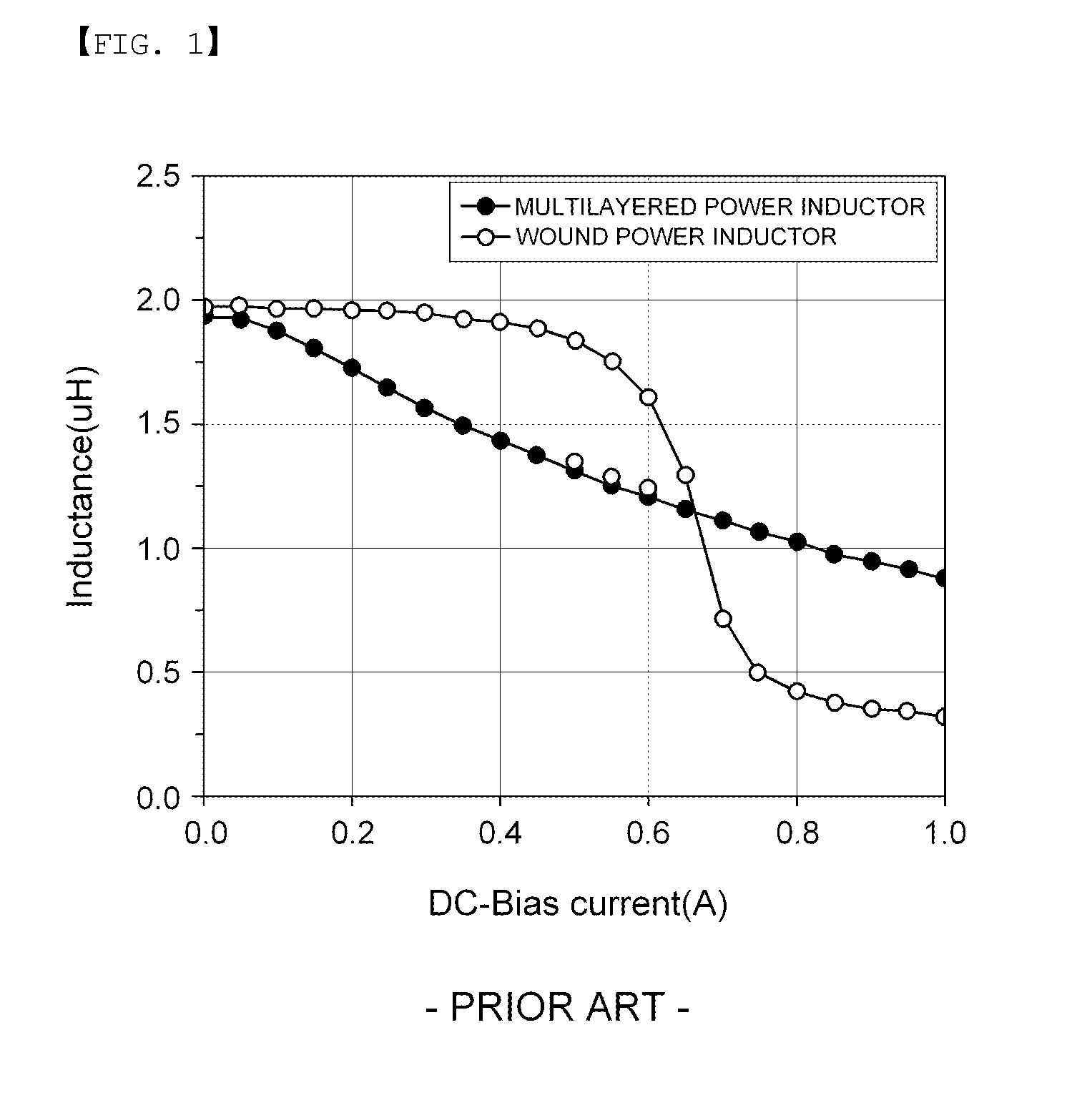

Ferrite powder of metal, ferrite material comprising the same, and multilayered chip components comprising ferrite layer using the ferrite material

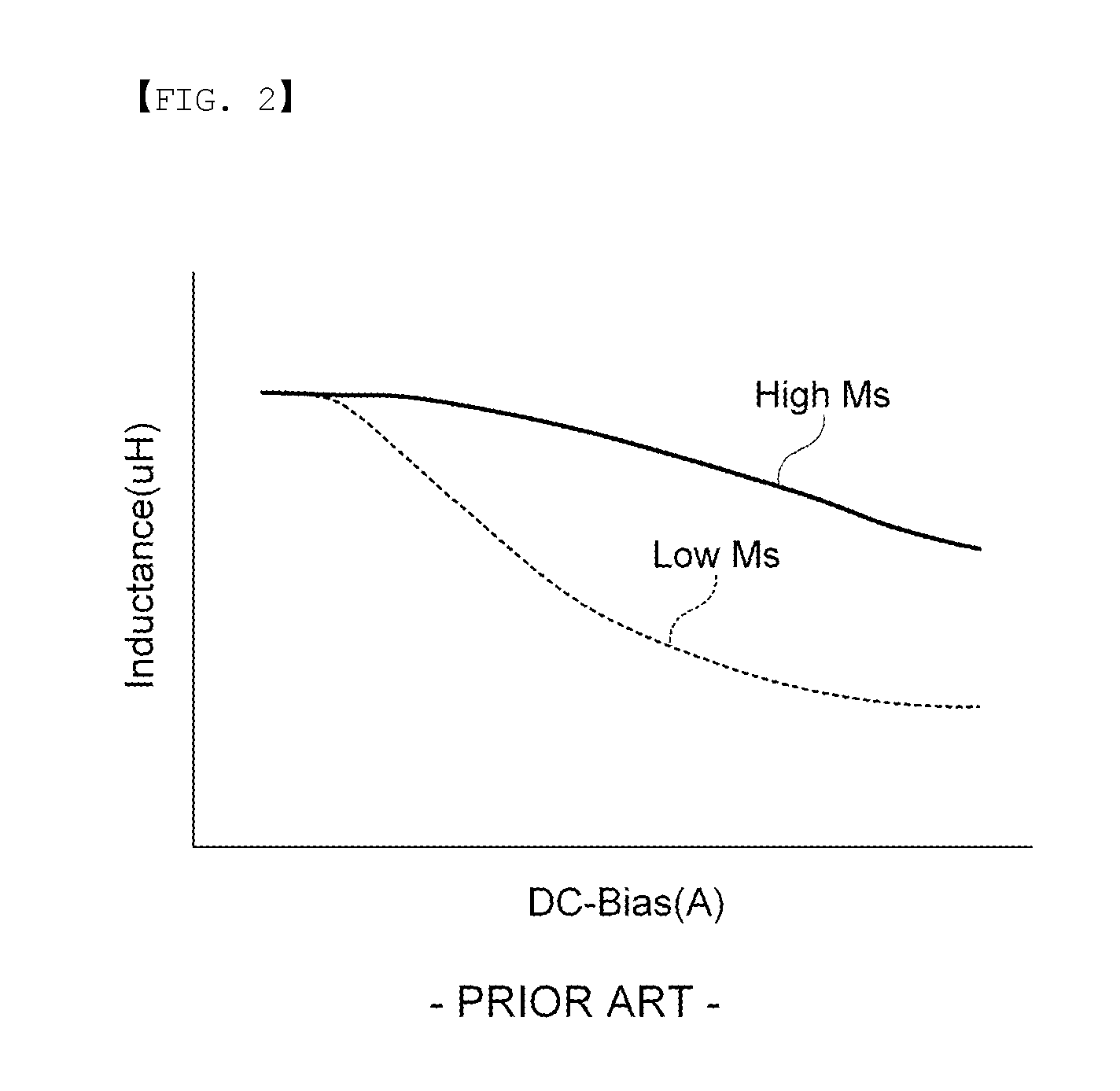

InactiveUS20130033354A1Reduce the chance of changeInorganic material magnetismFerroso-ferric oxidesFerrite layerMagnetization

Disclosed herein are a ferrite powder having a core-shell structure, the core being made of iron (Fe) or iron-based compounds comprising iron (Fe) and the shell being made of metal oxides, a ferrite material comprising the ferrite powder and the glass, and multilayered chip components including the ferrite layer using the ferrite material, inner electrodes, and outer electrodes. According to the exemplary embodiments of the present invention, it is possible to provide the ferrite material capable of improving the change in the inductance L value in response to applied current by suppressing magnetization at high current. The multilayered chip components including the ferrite material according to the exemplary embodiment of the present invention can also be used in a band of MHz.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Micro inductive sensor

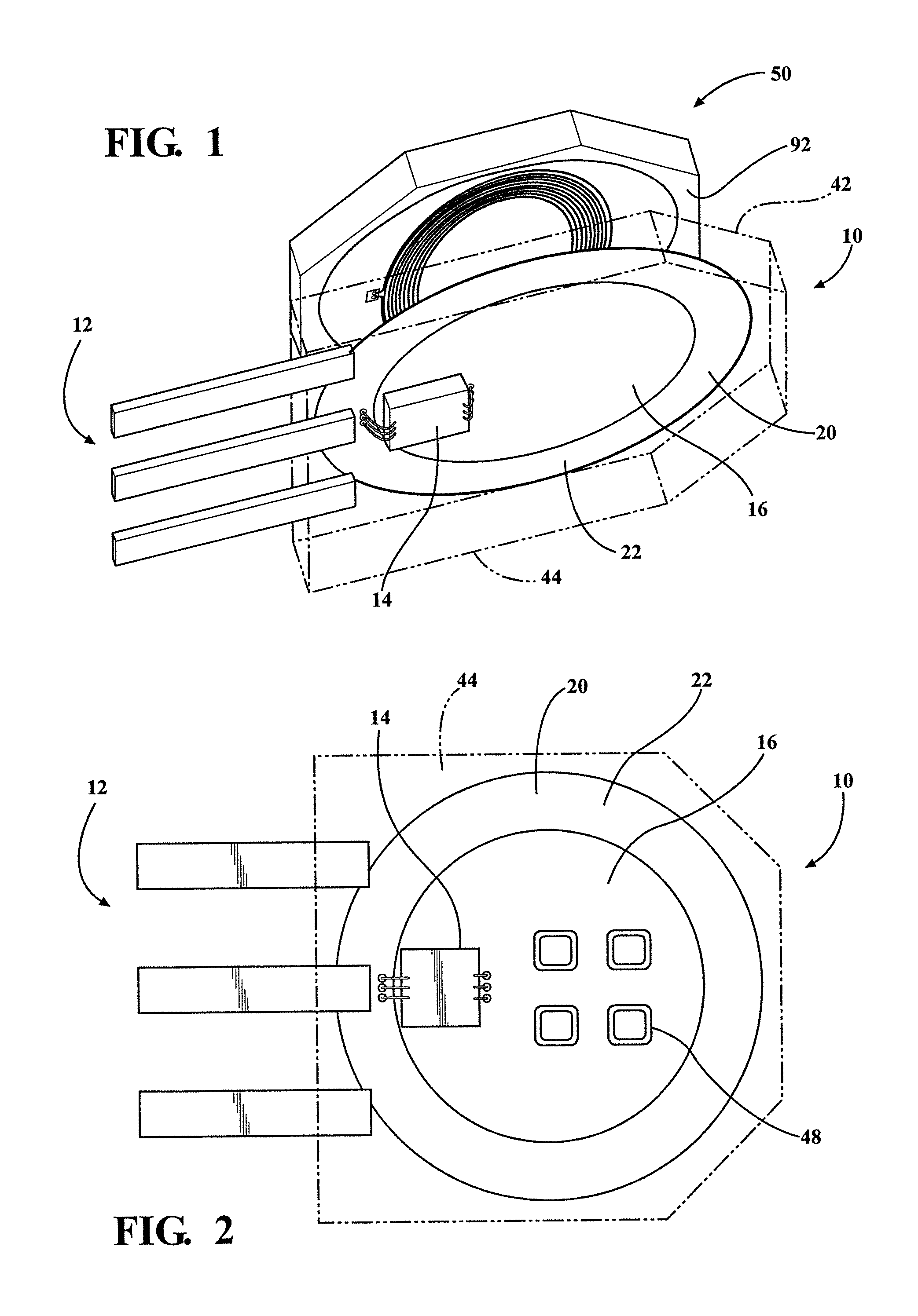

InactiveUS20140327432A1High quality factorSmall sizeUsing electrical meansConverting sensor output electrically/magneticallyFerrite layerTransmitter coil

An inductive sensor includes a sensor package and a coupler package. The sensor package includes a signal processor, an integrated capacitor, a ferrite layer, a transmitter coil, a two part receiving coil, and a plurality of discrete components. The coupler package includes an integrated capacitor, a ferrite layer, and a coupler coil. The transmitter coil in the sensor package is energized by an external power source which in turn energizes the coupler coil in the coupler package. The sensor then measures the rotational position of the coupler package relative to the sensor package by detecting and measuring, with the two part receiving coil, the signal returned by the coupler coil. The signal processor calculates the position of the coupler package relative to the sensor package by comparing the coupling factors between the coupler package and the sensor package.

Owner:KSR IP HLDG

Composite sintered magnetic material, its manufacturing method, and magnetic element using composite sintered magnetic material

InactiveUS20050072955A1Inorganic material magnetismCeramic shaping apparatusFerrite layerFerrite powder

A composite sintered magnetic material comprises a kind of metal powder at least one selected from the group consisting of Fe, Fe—Si type, Fe—Ni type, Fe—Ni—Mo type, and Fe—Si—Al type, and a ferrite layer formed from a kind of ferrite powder at least one selected from the group consisting of Ni—Zn type, Mn—Zn type, and Mg—Zn type, wherein a diffusion layer is formed by sintering between both of these to integrates the both.

Owner:PANASONIC CORP

Dual interface metal smart card with booster antenna

ActiveUS10318859B2Semiconductor/solid-state device detailsAntenna supports/mountingsFerrite layerComputer module

A card having a metal layer and an opening or cut-out region in the metal layer, with a dual-interface integrated circuit (IC) module disposed in the opening or cut-out region. A ferrite layer is disposed below the metal layer and a booster antenna is attached to the ferrite layer. A vertical hole extends beneath the IC module through the ferrite layer. The booster antenna may be physically connected to the IC module or may be configured to inductively couple to the IC module. In some embodiments, the IC may be disposed in or on a non-conductive plug disposed within the opening or cut-out region, or the vertical hole may have a non-conductive lining, or a connector may be disposed between the booster antenna and the IC module in the vertical hole.

Owner:COMPOSECURE LLC

Magnetic expanded graphite for absorbing greasy dirt in water area and its production

InactiveCN101028590ACause secondary pollutionImprove adsorption capacityFatty/oily/floating substances removal devicesOther chemical processesFerrite layerSewage

A magnetic expanded graphite for adsorbing the oily sewage in a water region is prepared from expanded graphite particles as carrier through depositing a ferrite layer on their surfaces chemically or physically. After said magnetic expanded graphite particles are spread on the water surface in oil polluted region, a mixture system of magnetic expanded graphite and oily sewage is formed, and then can be collected under the action of magnetic field.

Owner:TONGJI UNIV

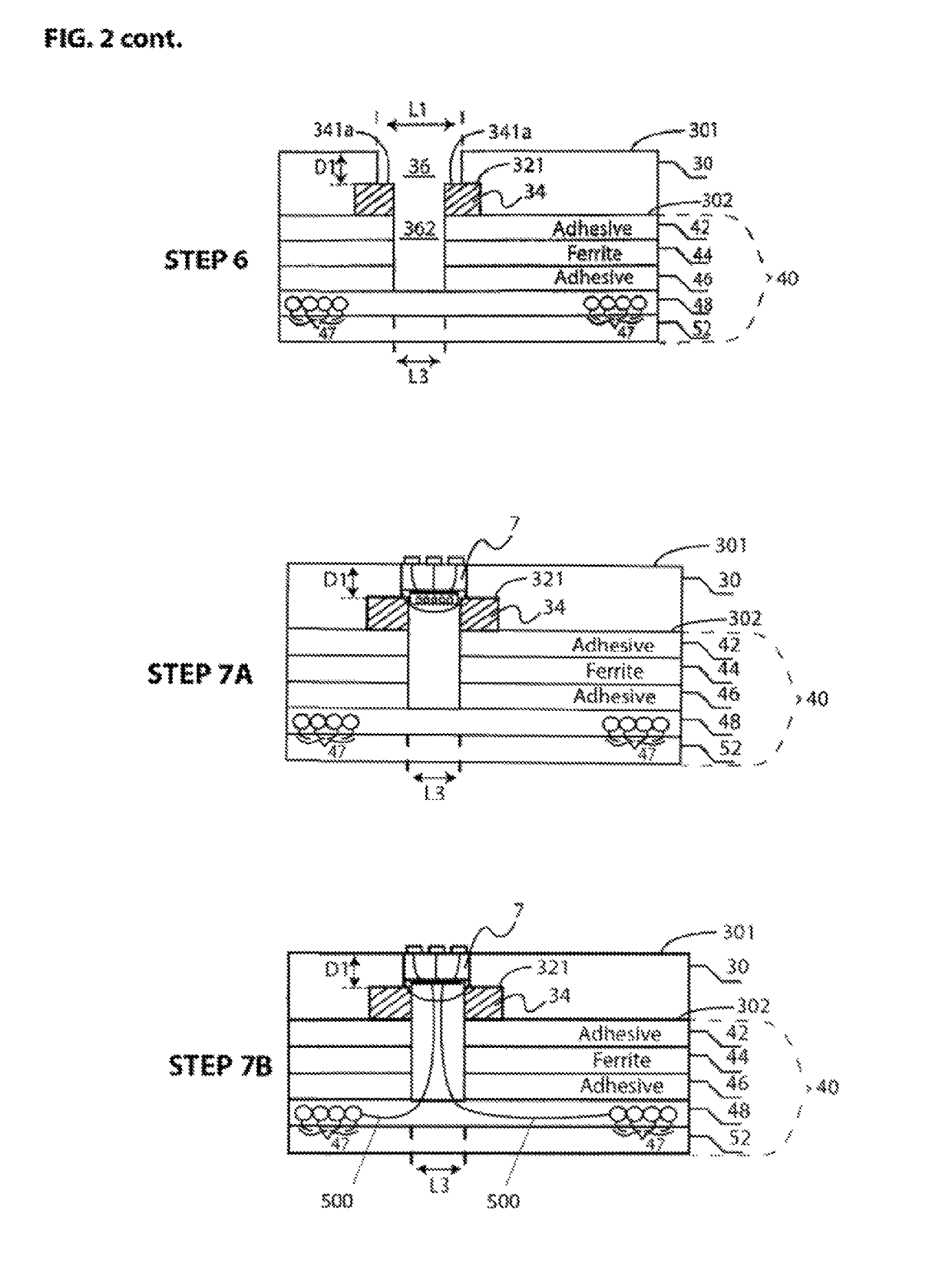

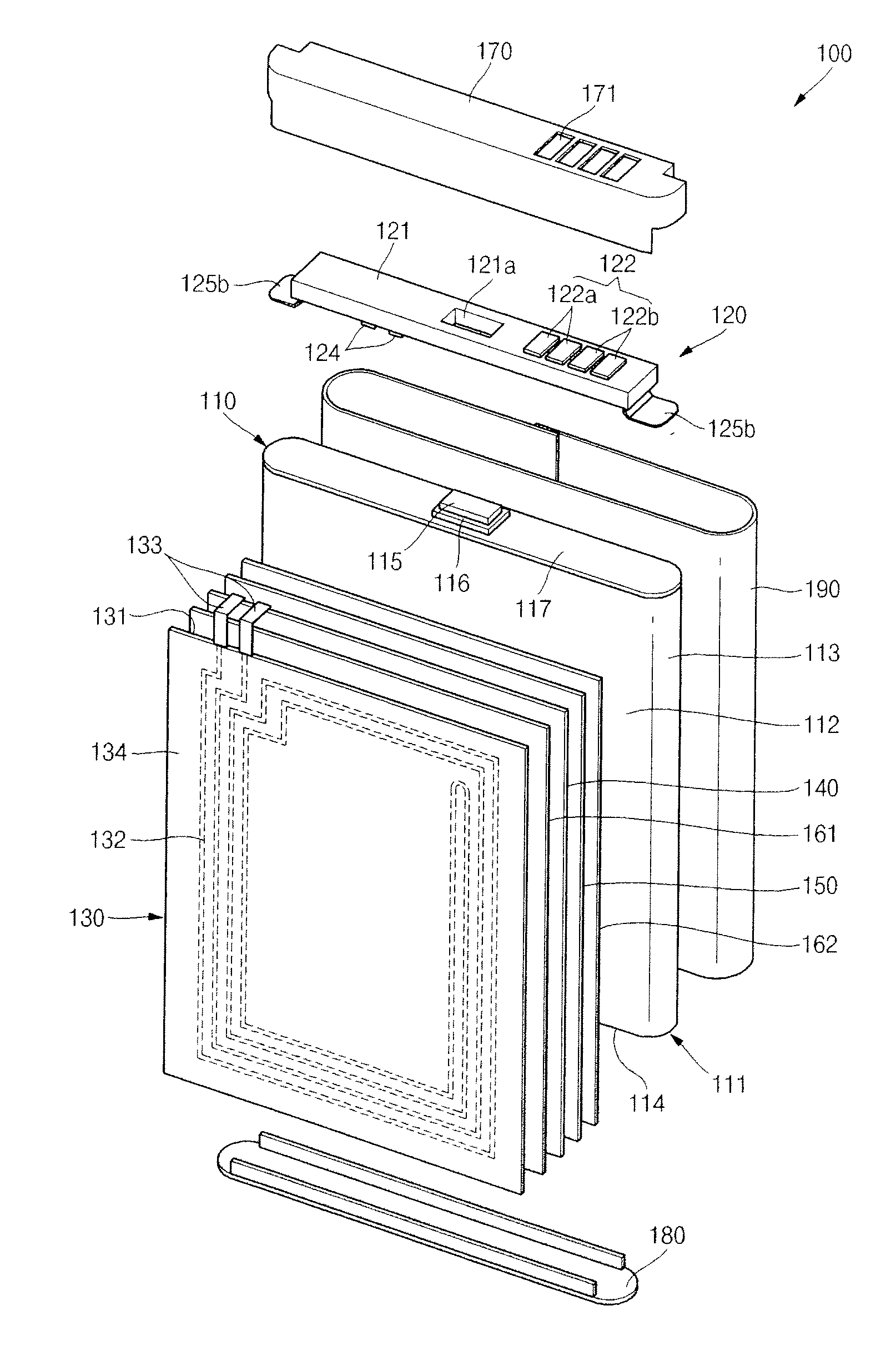

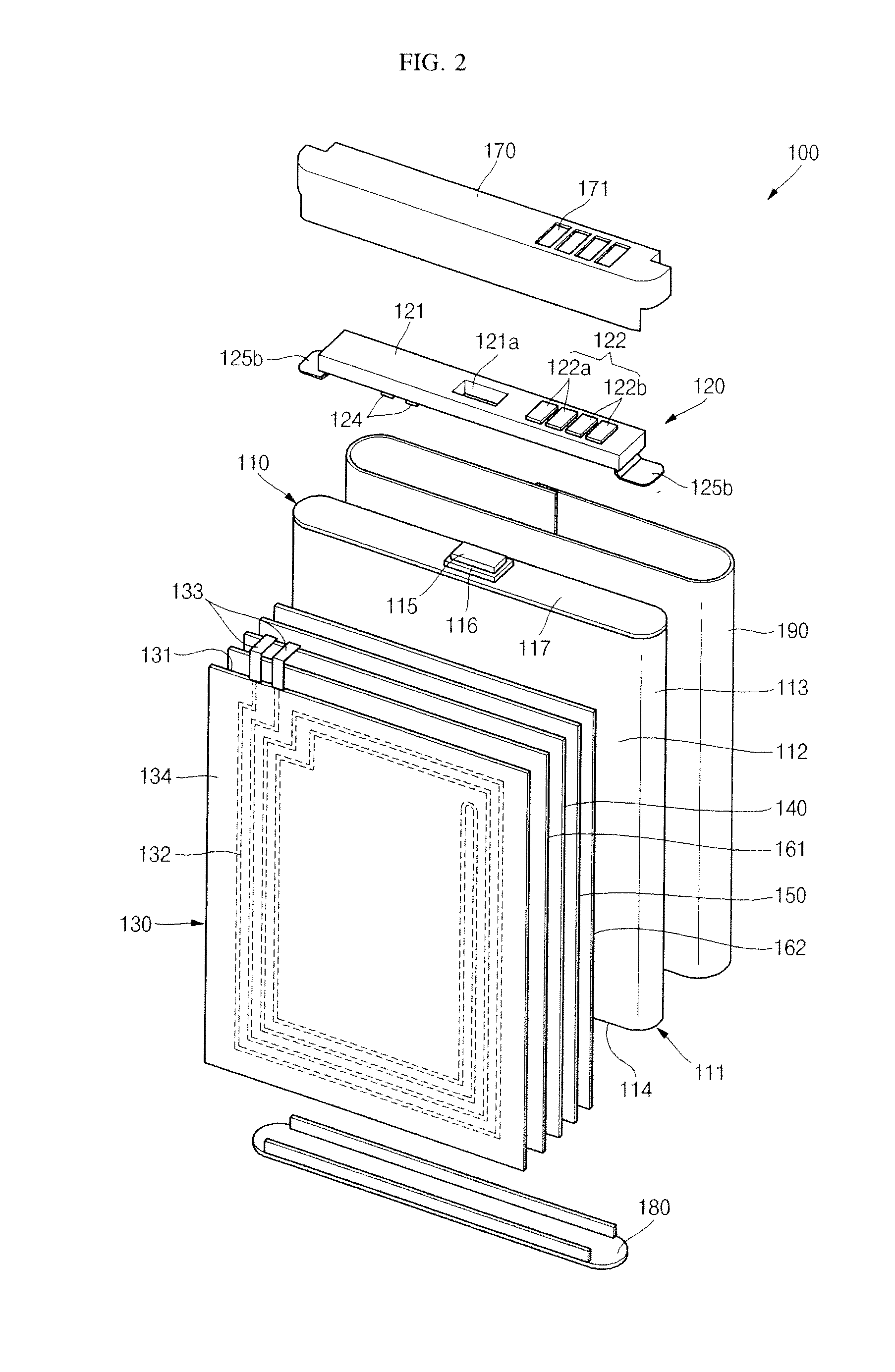

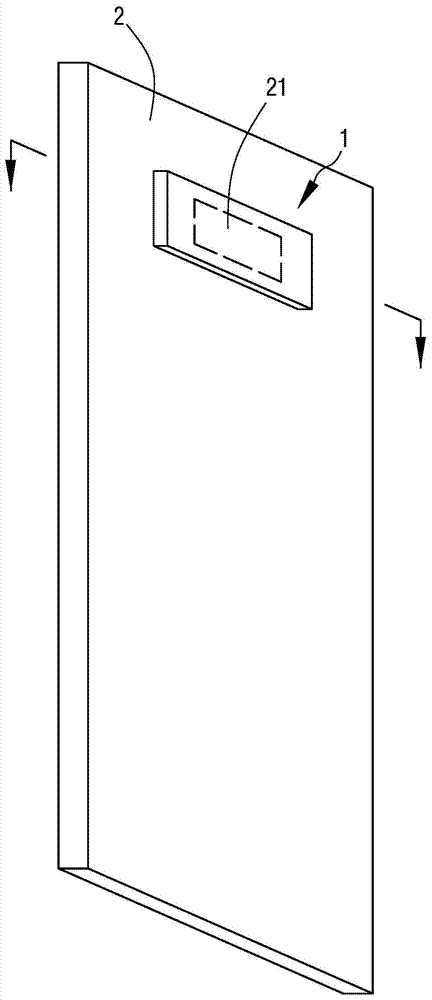

Battery pack with antenna

InactiveUS20140287274A1Excellent NFC functionReduce adhesionFinal product manufactureAntenna supports/mountingsFerrite layerEngineering

Provided is a battery pack including a battery cell; a ferrite layer at a side surface of the battery cell; a film antenna at a side surface of the ferrite layer; and a reinforcement layer between the battery cell and the ferrite layer.

Owner:SAMSUNG SDI CO LTD

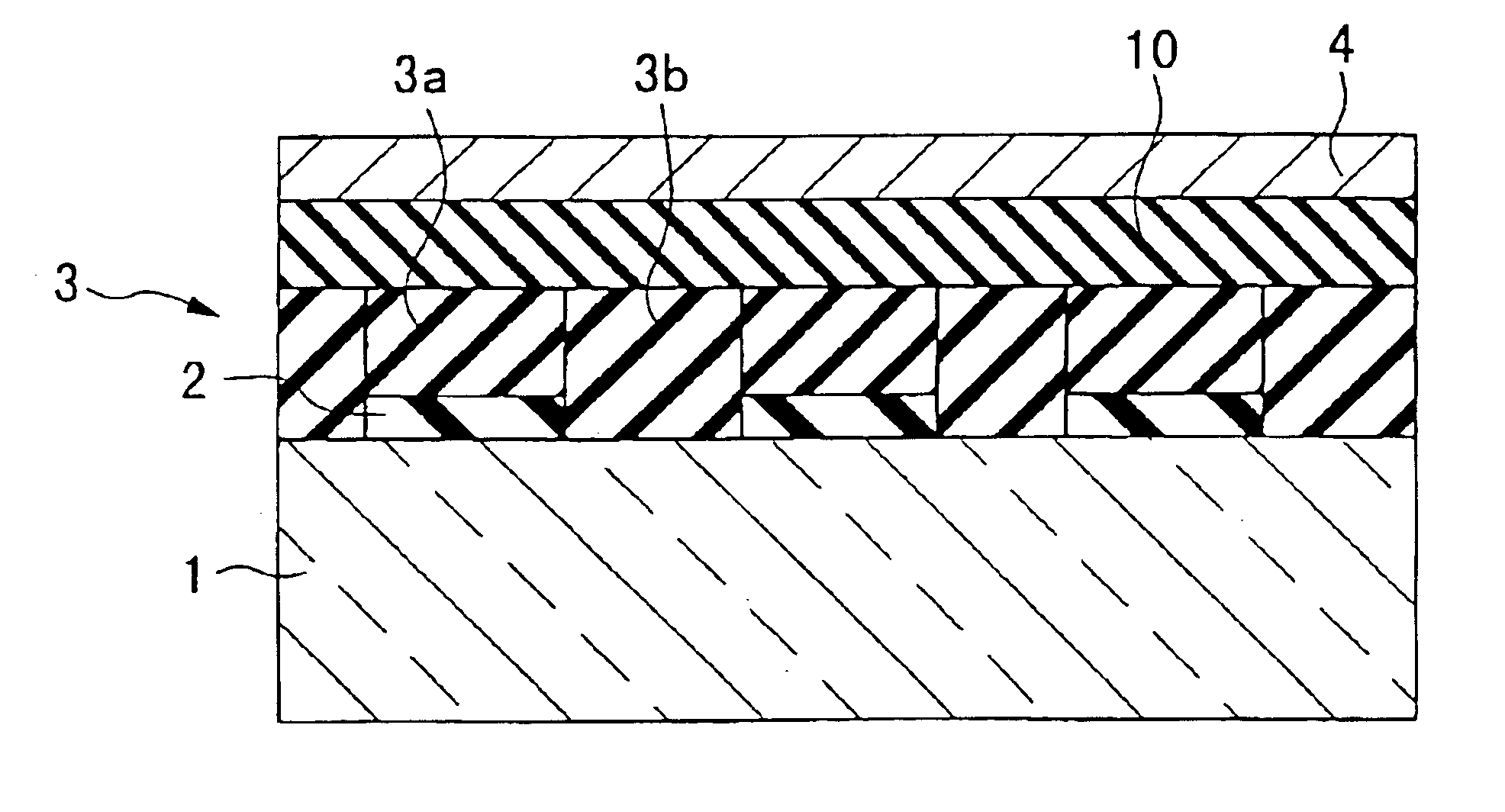

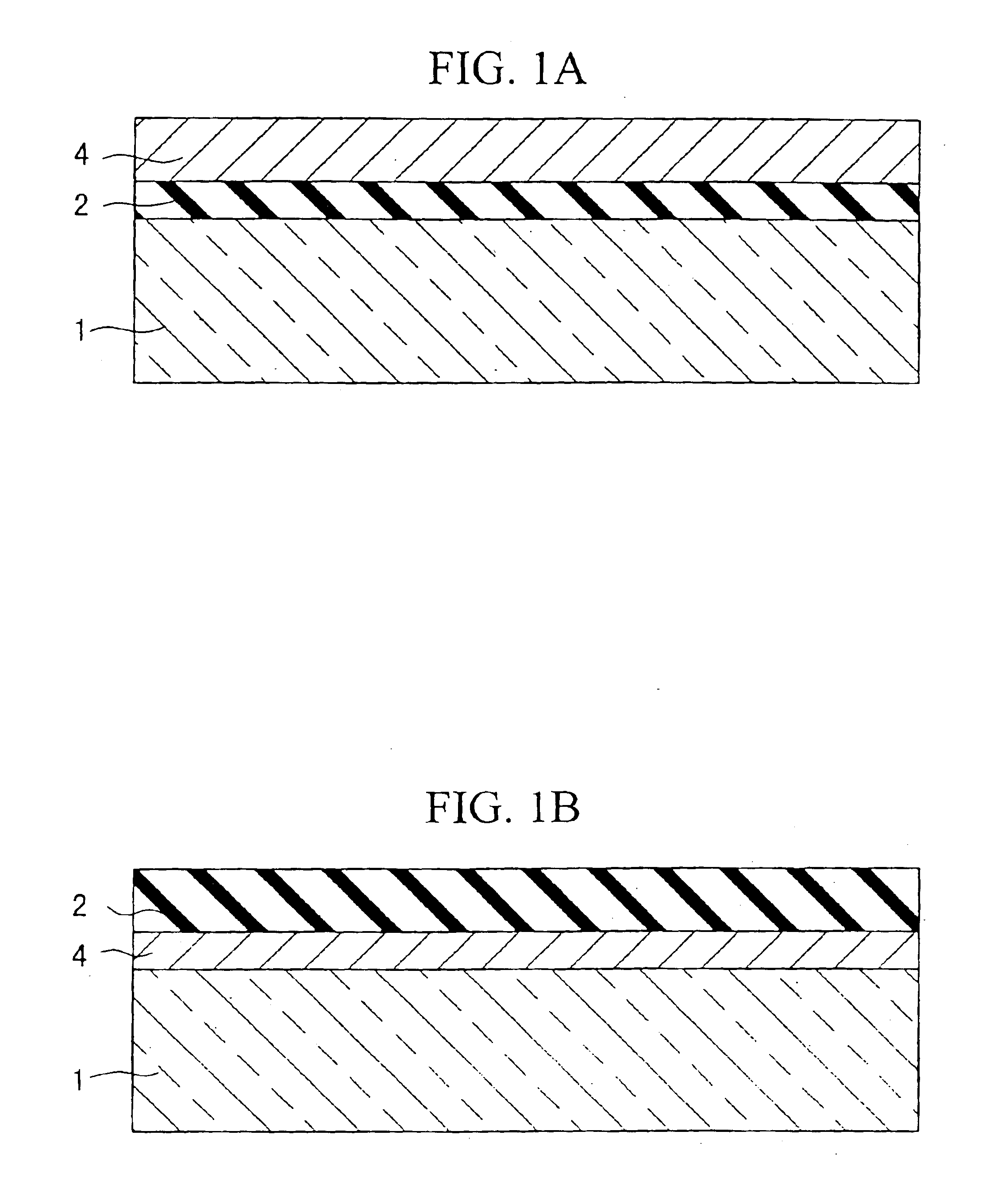

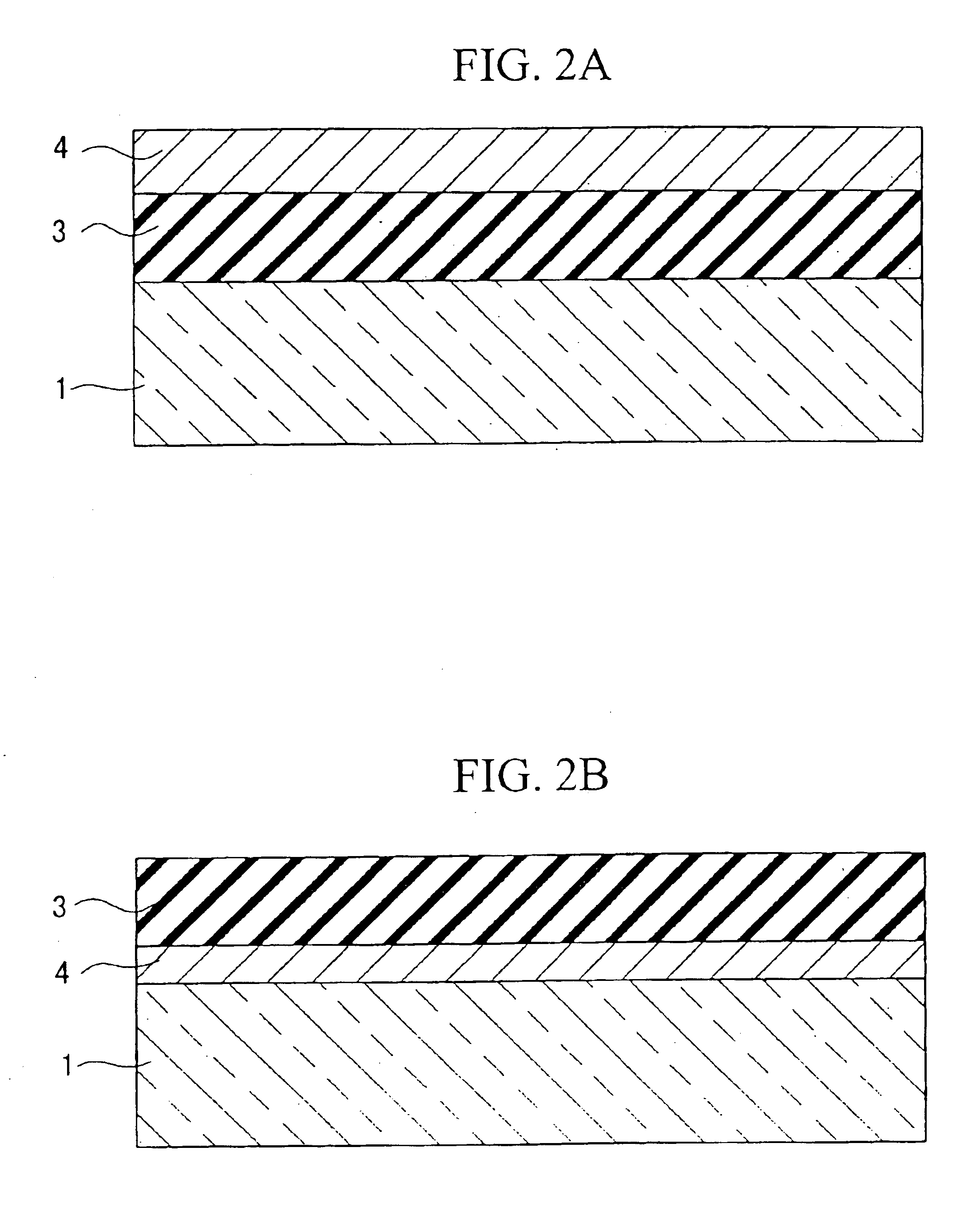

Opto-magnetic recording medium with a garnet ferrite recording layer, and opto-magnetic information recording/reproducing device

InactiveUS6759137B1Raise the ratioReduce the required powerRecord information storageMagnetic materialsFerrite layerRecording layer

This invention relates to magneto-optical recording media such as magneto-optical disks and cards, manufacturing methods of the medium and a magneto-optical recording and playback device to record and play back data using the magneto-optical recording media. The magneto-optical recording medium of the present invention has a recording layer and a reflective layer on a substrate, and the recording layer has a layered structure in which at least one spinel ferrite (or rutile-type oxide or hematite) layer and at least one garnet ferrite layer are piled together. It is preferable that the layered structure is formed on tracks where data are recorded. The manufacturing method of the present invention comprises the steps of heat treatment in the range of 500-700° C., preferably 600-630° C., after the formation of the recording layer. In the magneto-optical recording and playback device to record and play back data of the present invention, the wavelength of light for recording data is different from that for reading data, which is preferable for a magneto-optical recording medium comprising a garnet ferrite layer.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Laminated device

ActiveUS8004381B2Stable characteristicsExcellent superposition characteristicTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresFerrite layerElectrical conductor

A laminated device comprising pluralities of magnetic ferrite layers, conductor patterns each formed on each magnetic ferrite layer and connected in a lamination direction to form a coil, and a non-magnetic ceramic layer formed on at least one magnetic ferrite layer such that it overlaps the conductor patterns in a lamination direction, the non-magnetic ceramic layer comprising as main components non-magnetic ceramics having higher sintering temperatures than that of the magnetic ferrite, and further one or more of Cu, Zn and Bi in the form of an oxide.

Owner:HITACHI METALS LTD

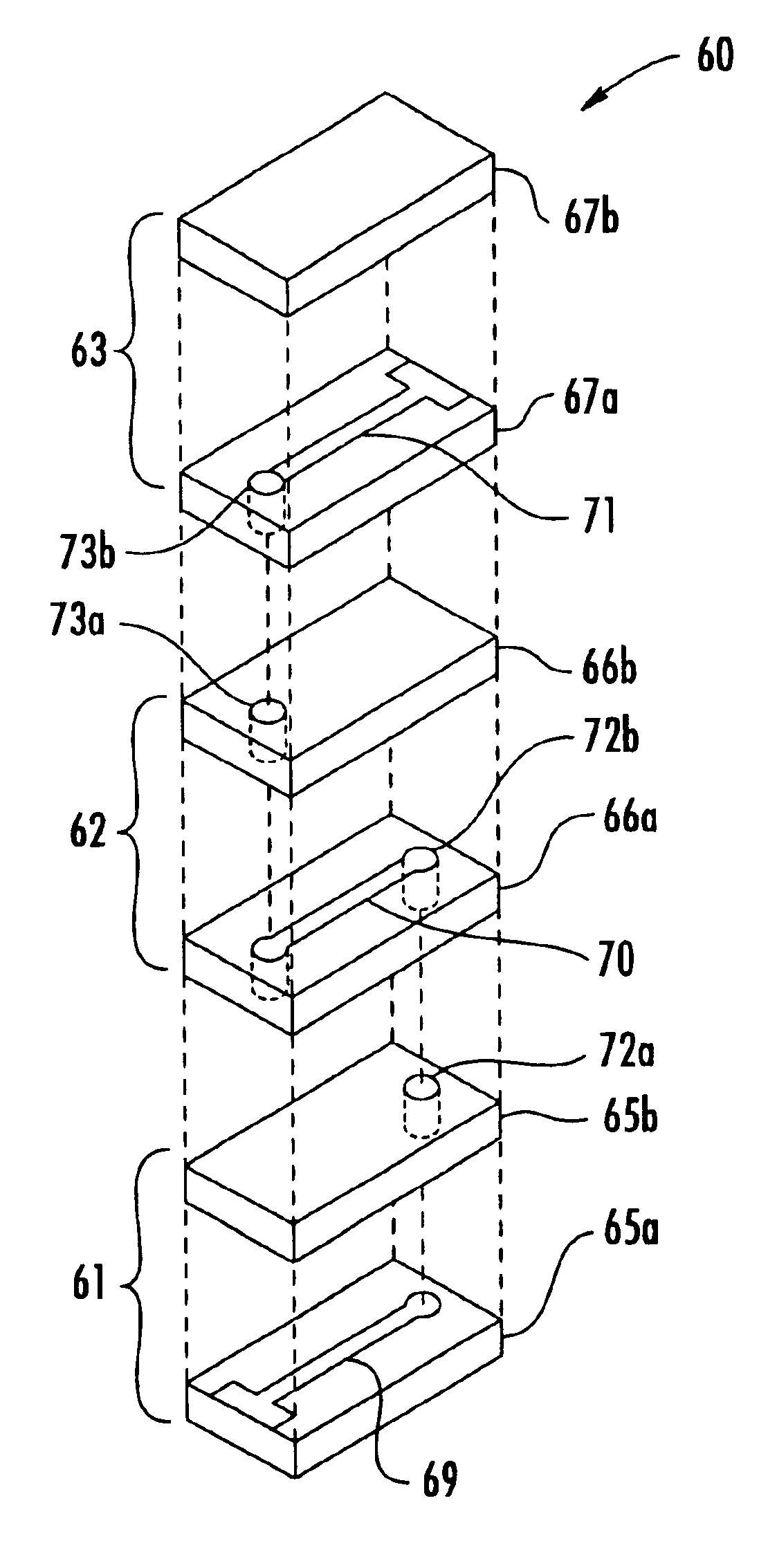

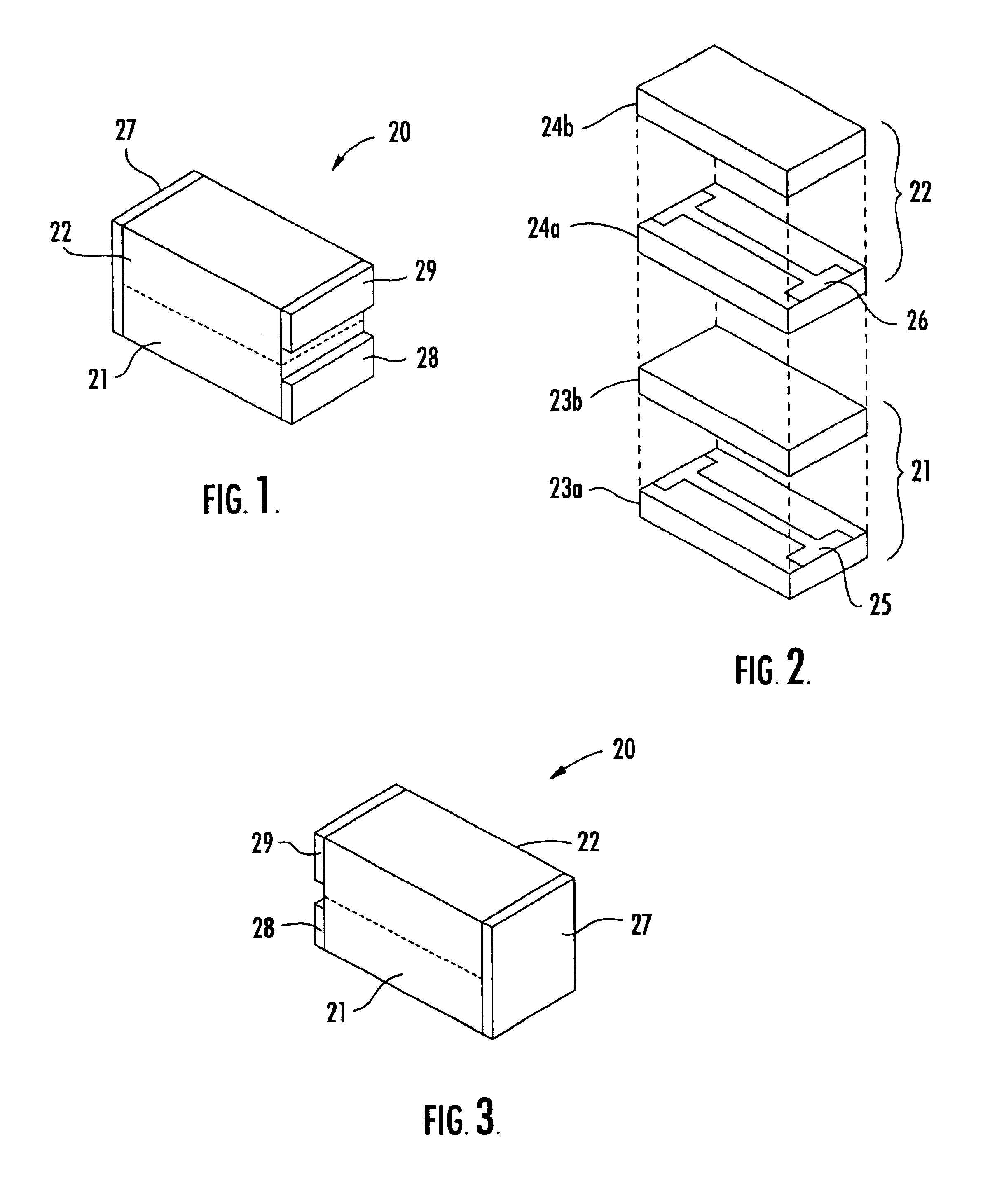

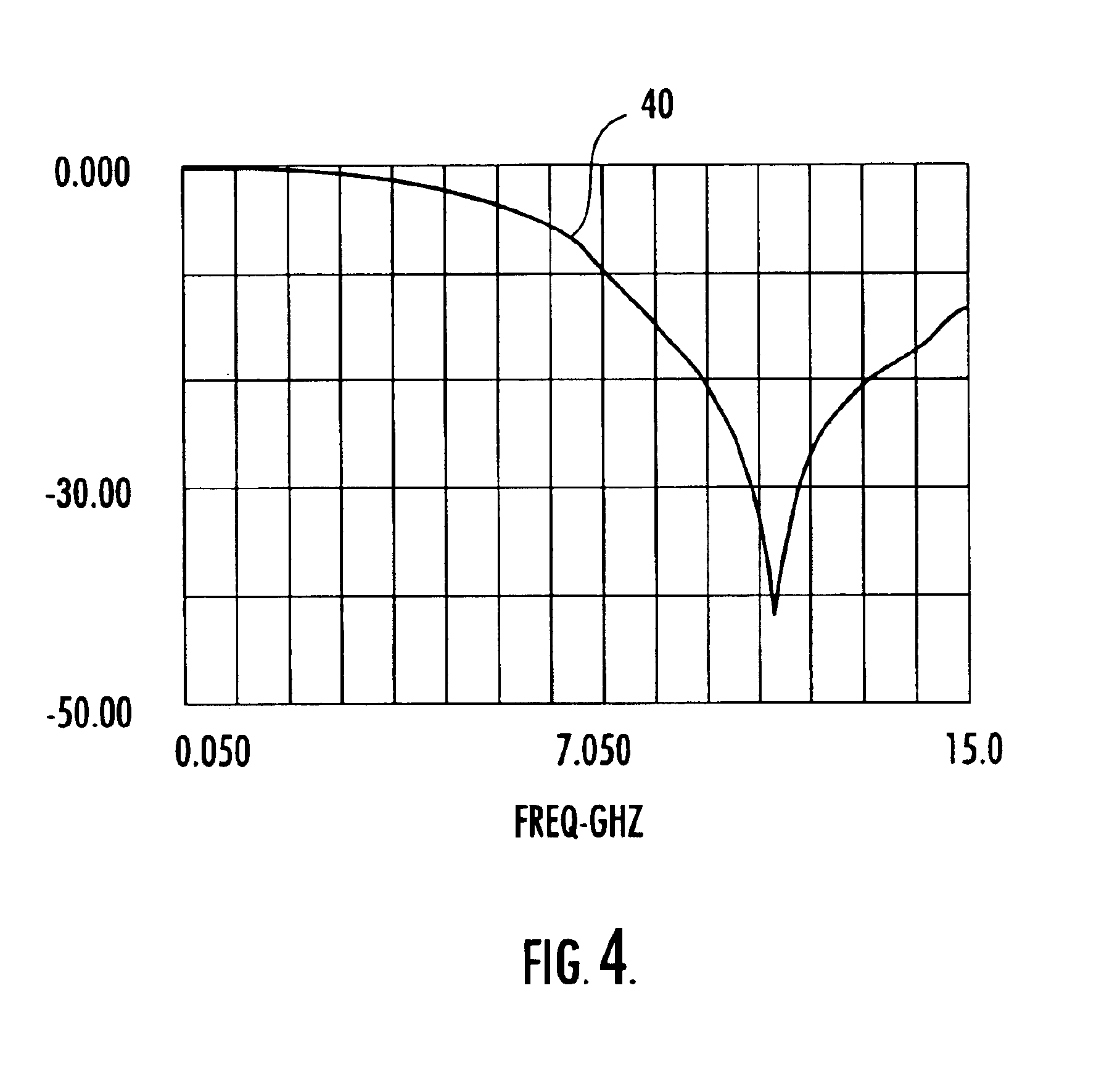

High frequency filter device and related methods

InactiveUS6911889B2Increase the frequency bandDifferent impedanceMultiple-port networksTransformers/inductances coils/windings/connectionsFerrite layerUltrasound attenuation

A filter device may include a plurality of ferrite filters laminated together in vertically stacked relation, where each ferrite filter may include a pair of ferrite layers laminated together in vertically stacked relation and a lateral conductor extending therebetween. The filter device may also include at least one vertical conductor connecting the lateral conductors together in series. Moreover, at least some of the ferrite filters may have different operating characteristics. In particular, the different operating characteristics may be different impedance versus frequency characteristics to thereby broaden an attenuation frequency band of the filter device.

Owner:LAIRD TECH INC

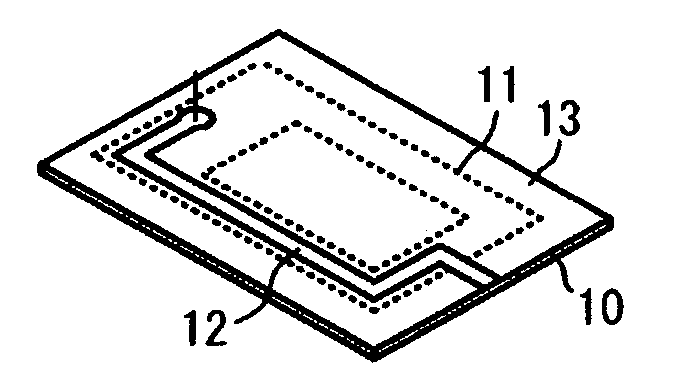

Wireless Communication Device with Integrated Ferrite Shield and Antenna, and Methods of Manufacturing the Same

InactiveUS20170040665A1Low costSufficient shieldingLoop antennas with ferromagnetic coreAntenna supports/mountingsFerrite layerElectricity

A wireless communication device and methods of manufacturing and using the same are disclosed. The wireless communication device includes a substrate with an antenna and / or inductor thereon, a patterned ferrite layer overlapping the antenna and / or inductor, and a capacitor electrically connected to the antenna and / or inductor. The wireless communication device may further include an integrated circuit including a receiver configured to convert a first wireless signal to an electric signal and a transmitter configured to generate a second wireless signal, the antenna being configured to receive the first wireless signal and transmit or broadcast the second wireless signal. The patterned ferrite layer advantageously mitigates the deleterious effect of metal objects in proximity to a reader and / or transponder magnetically coupled to the antenna.

Owner:ENSURGE MICROPOWER ASA

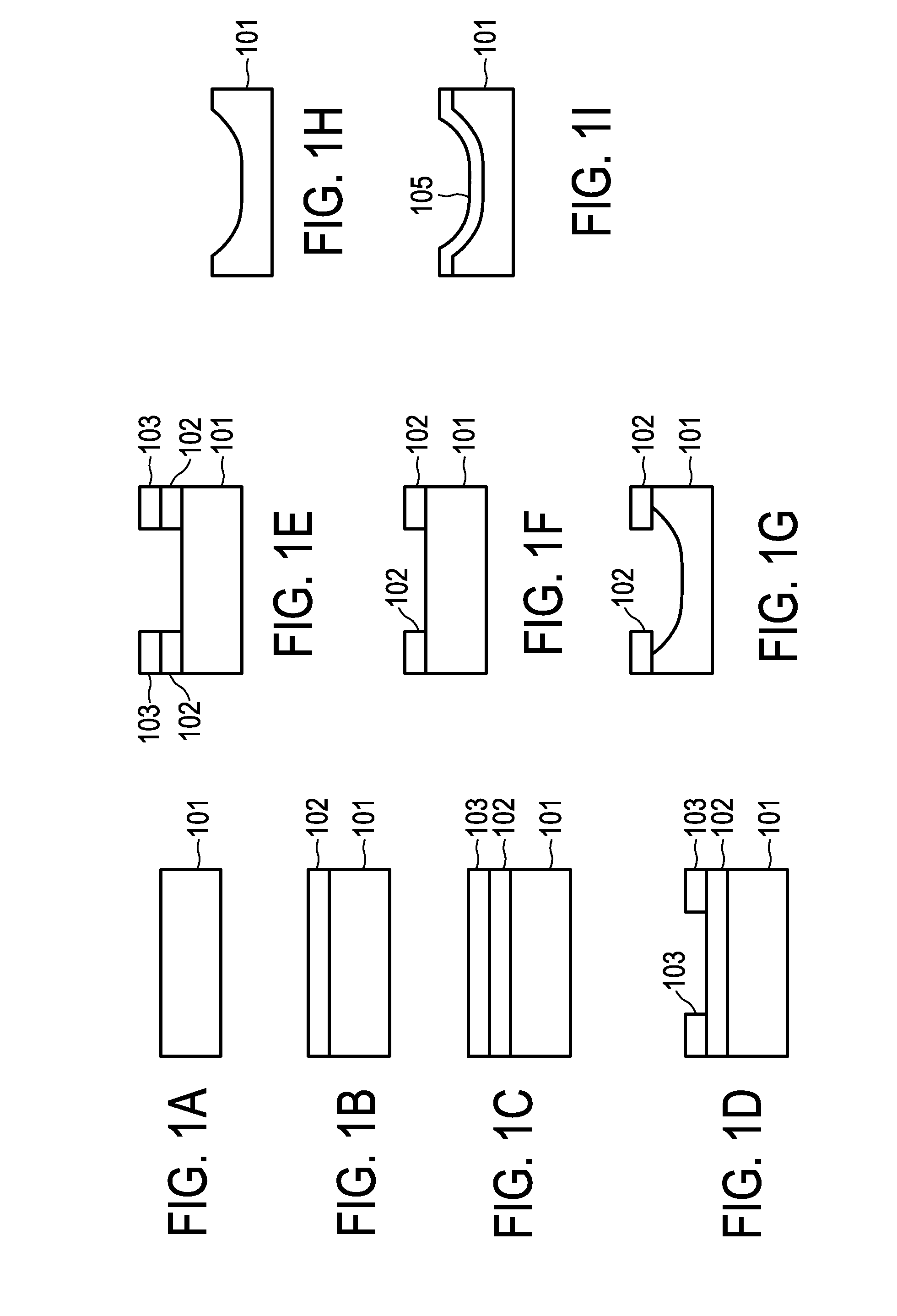

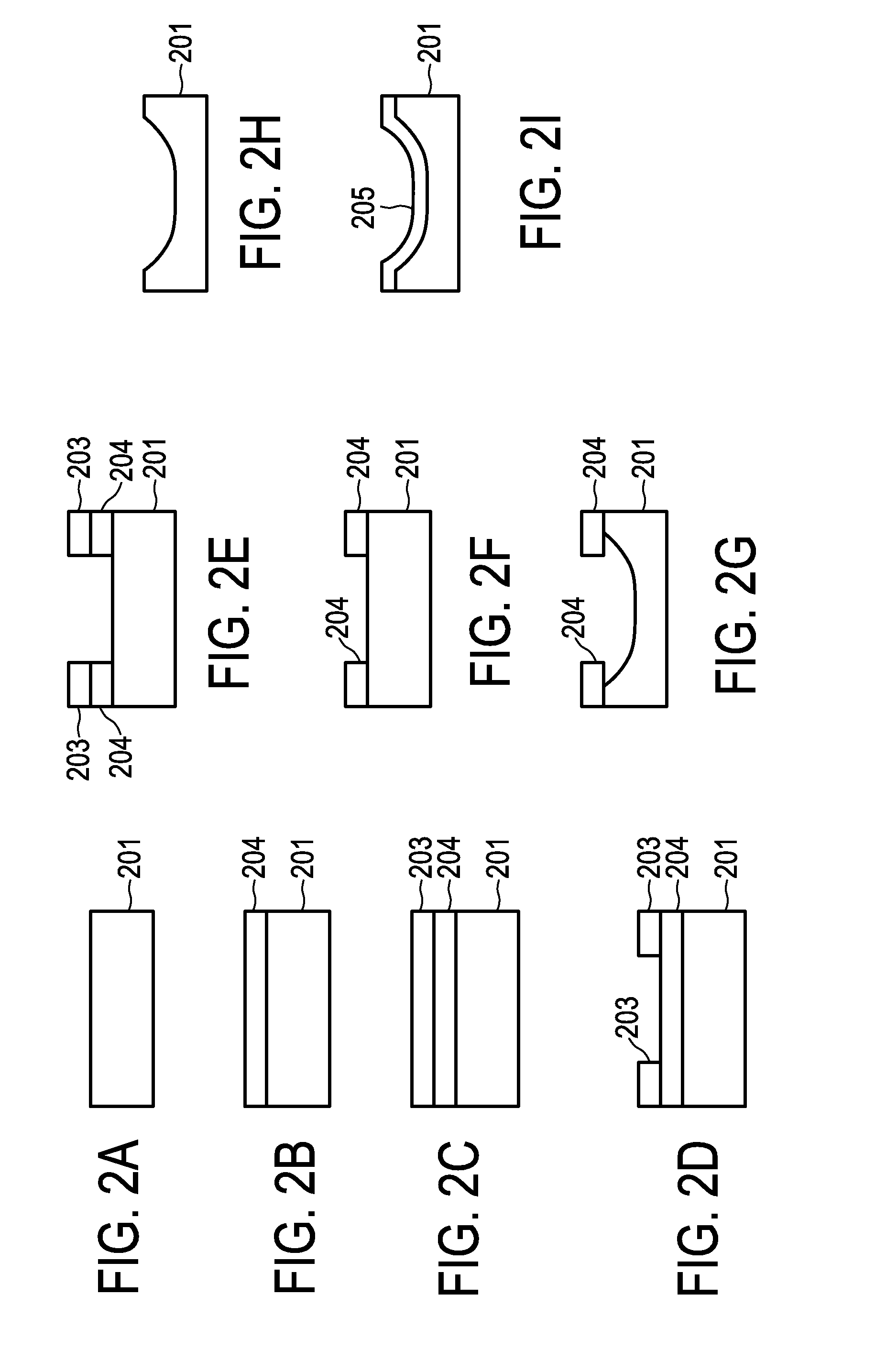

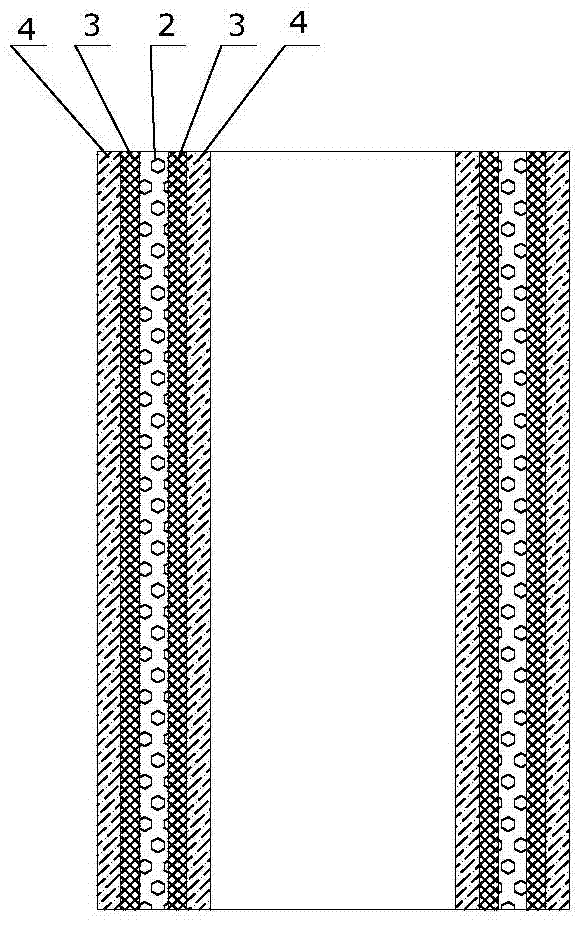

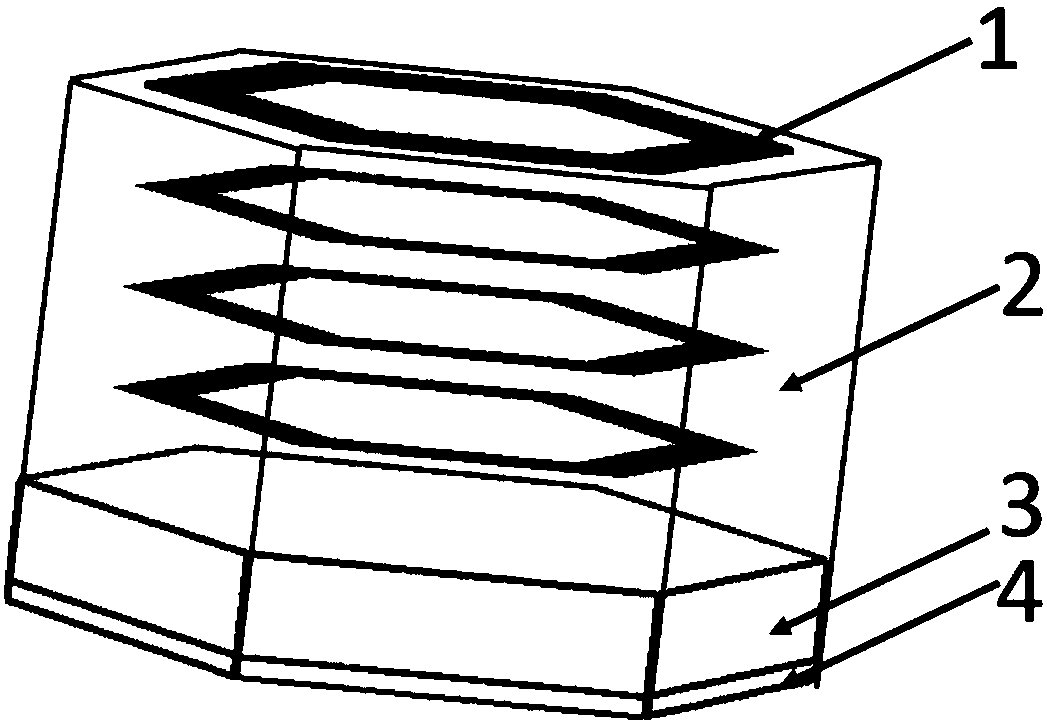

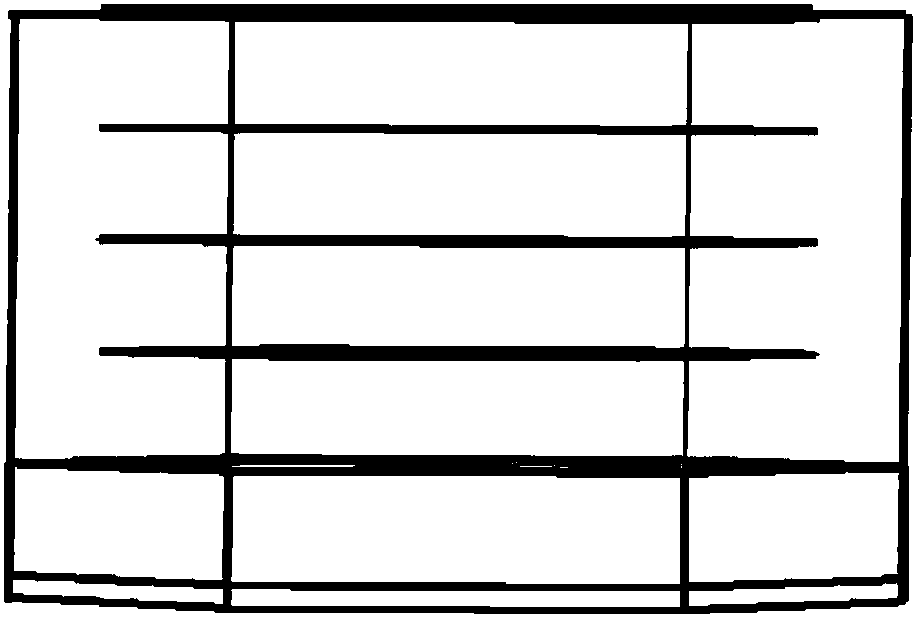

Inductor and manufacture method thereof

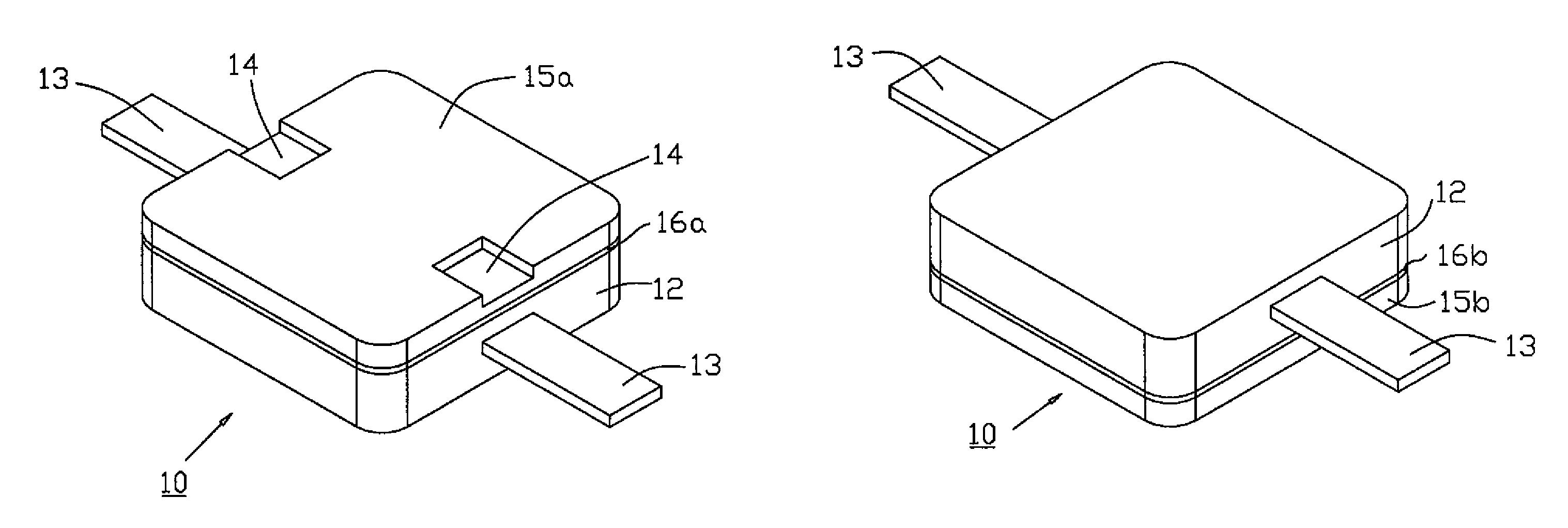

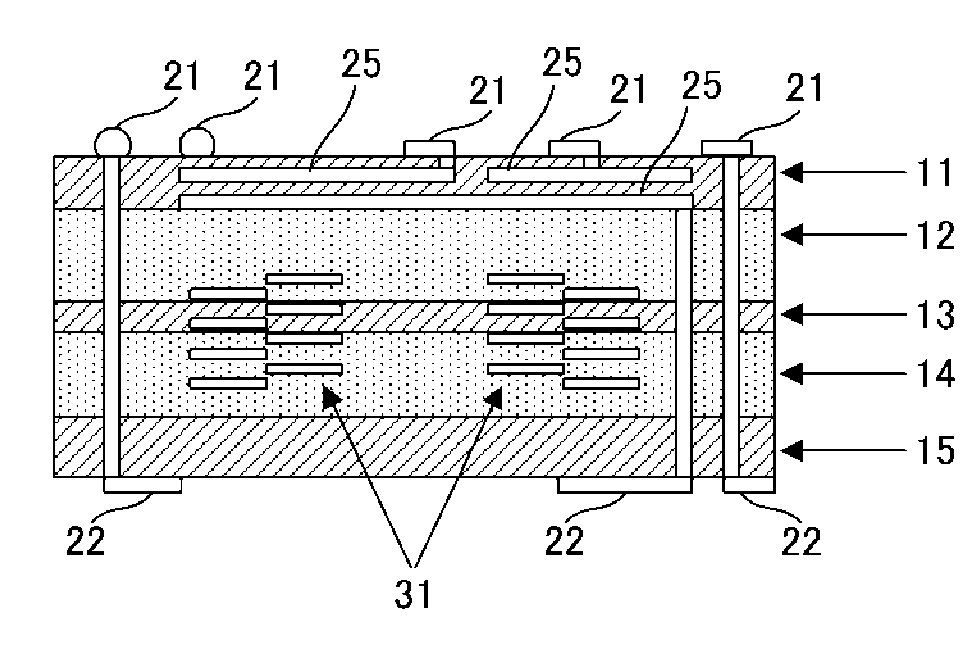

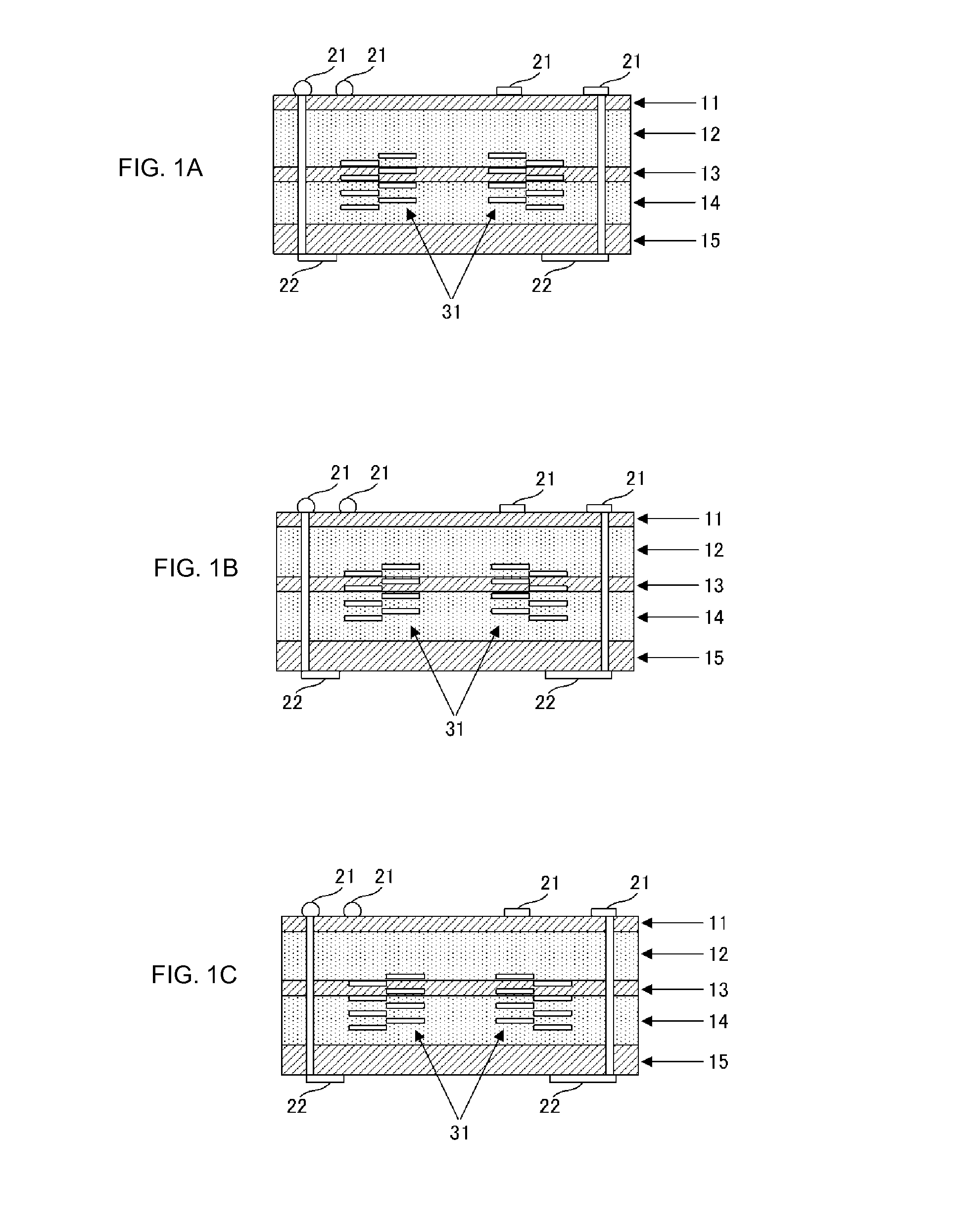

ActiveUS20090085703A1Transformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureFerrite layerInductor

An inductor comprises a coil, a non-ferrite layer, two electrodes, a first ferrite layer, and a second ferrite layer, where the coil is encapsulated by the non-ferrite layer having a first surface and a second surface opposite to the first surface, two electrodes coupled to the coil are respectively extended out from the non-ferrite layer for connecting a module, and the first ferrite layer and the second ferrite layer are respectively arranged adjacent to the first surface and the second surface of the non-ferrite layer.

Owner:CYNTEC

Carrier for electrophotographic developer, and electrophotographic developer using the same

ActiveUS7566519B2Excellent in charge imparting capability and its stabilityHigh strengthDevelopersFerrite layerImage density

A carrier for an electrophotographic developer which is used as an electrophotographic developer in a mixture with a toner and which secures sufficiently the image density and can maintain high-quality images for a long period, and an electrophotographic developer using the carrier, are provided. A resin-filled ferrite carrier for electrophotographic developer obtained by filling, with a resin, avoid of a porous ferrite core whose void continues from the surface to reach the interior of the core, the carrier comprising a plurality of three-dimensional laminate structures in which resin layers and ferrite layers are alternately present, and an electrophotographic developer including the carrier and a toner, are employed.

Owner:POWDERTECH

Inductor and manufacture method thereof

ActiveUS7675396B2Transformers/inductances coils/windings/connectionsElectromagnetsFerrite layerInductor

Owner:CYNTEC

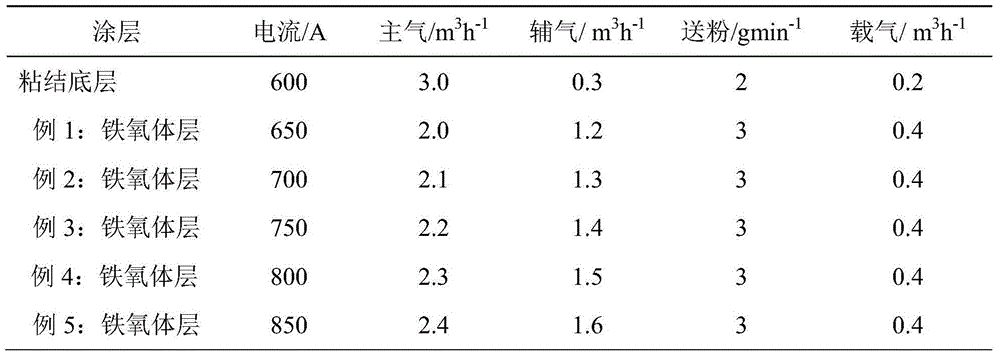

Ferrite conductive coating and preparation method thereof

ActiveCN103602941AHigh bonding strengthGuaranteed electrical conductivityMolten spray coatingThermal sprayingConductive coating

The invention provides a ferrite conductive coating for resisting corrosion on electrical engineering earthing devices and a preparation method thereof. The ferrite conductive coating is a composite coating and mainly comprises a bonding base layer and a ferrite layer. The bonding base layer is coated on a base material. The ferrite layer is coated on the bonding base layer. The bonding base layer comprises Al, Zn, Co and Cu metal materials or an alloy material. The ferrite layer comprises a ferrite material having a molecular formula of MFe2O4. The composite coating has good corrosion resistance, electrical conductivity and thermal spraying adaptability. The preparation method has simple processes, a low cost and strong repeatability. The ferrite conductive coating can be used for surfaces of metal bases having different shapes or sizes, has obvious superiority in large-scale preparation of the corrosion-resistant conductive ceramic coating in practical application and is suitable for industrial popularization.

Owner:STATE GRID CORP OF CHINA +1

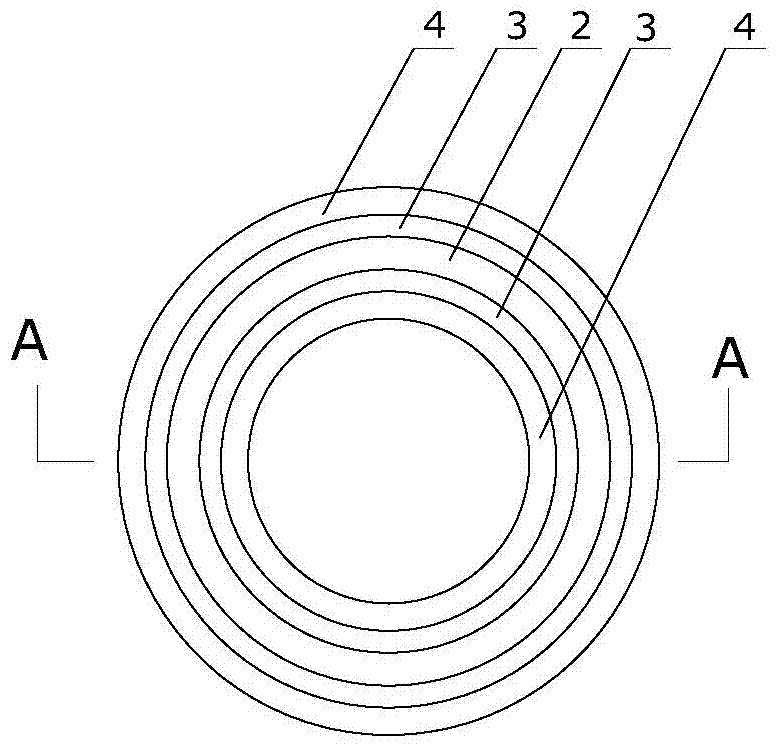

Magnetic hollow circular cylinder filler based on residual activated sludge and preparation method thereof

InactiveCN103880152AAchieve recyclingLow costBiological water/sewage treatmentFerrite layerActivated sludge

The invention relates to magnetic hollow circular cylinder filler based on residual activated sludge and a preparation method thereof. The magnetic hollow circular cylinder filler based on the residual activated sludge is composed of a matrix, magnetic ferrite layers and biofilm carrier layers, wherein the matrix is a hollow circular cylinder, each of the inner surface and the outer surface of the hollow circular cylinder is covered with a magnetic ferrite layer, and the surface of each magnetic ferrite layer is covered with a biofilm carrier layer. The preparation method comprises the following steps: adopting a cylindrical mould, coating coal ash, yellow sand and cement paste which form the matrix on the surface of the cylindrical mould; after the matrix is formed, separating the matrix from the cylindrical mould, and maintaining the matrix at room temperature; then applying glue on the inner surface and the outer surface of the matrix and covering each of the inner surface and the outer surface of the matrix with a magnetic ferrite powder layer, so as to form magnetic ferrite layers; after the glue is dried and the magnetic ferrite powder is stable, coating slurry forming the biofilm carrier layer on the surface of the magnetic ferrite layer.

Owner:JIANGSU UNIV

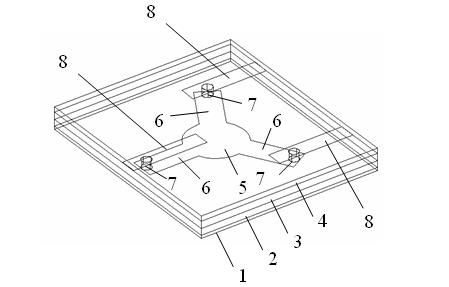

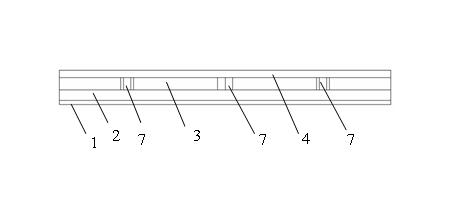

Sub-wavelength layered three-dimensional broadband absorbing structure based on a loss type frequency selective surface

ActiveCN108493623AOvercome the problems of small size, thicker thickness, and poor low-frequency absorption effectAchieve broadband absorbing effectAntennasFerrite layerConductive materials

The invention discloses a sub-wavelength layered three-dimensional broadband absorbing structure based on a loss type frequency selective surface. The sub-wavelength layered three-dimensional broadband absorbing structure is a periodic array structure formed by a plurality of structural units. Each structural unit consists of four annular frequency selective surfaces a dielectric layer serving asa supporting layer, a ferrite layer arranged at the lower surface of the dielectric layer, and a metal backing plate arranged at the lower surface of the ferrite layer; and the four annular frequencyselective surfaces are uniformly distributed in the dielectric layer in the vertical direction. The ferrite layer uses ferrite with a working frequency lower than 2 GHz; and the annular frequency selective surfaces are made of conductive materials with the electric conductivity of 100-200 S / m. According to the invention, with the sub-wavelength layered three-dimensional broadband absorbing structure, the wide-band absorption of spatial electromagnetic waves is realized. The sub-wavelength layered three-dimensional broadband absorbing structure has advantages of being insensitive to electromagnetic wave polarization, having the light weight, having a simple structure, being easy to process, having the low cost, having the wide working frequency band and having the relative thin thickness.

Owner:NANJING UNIV

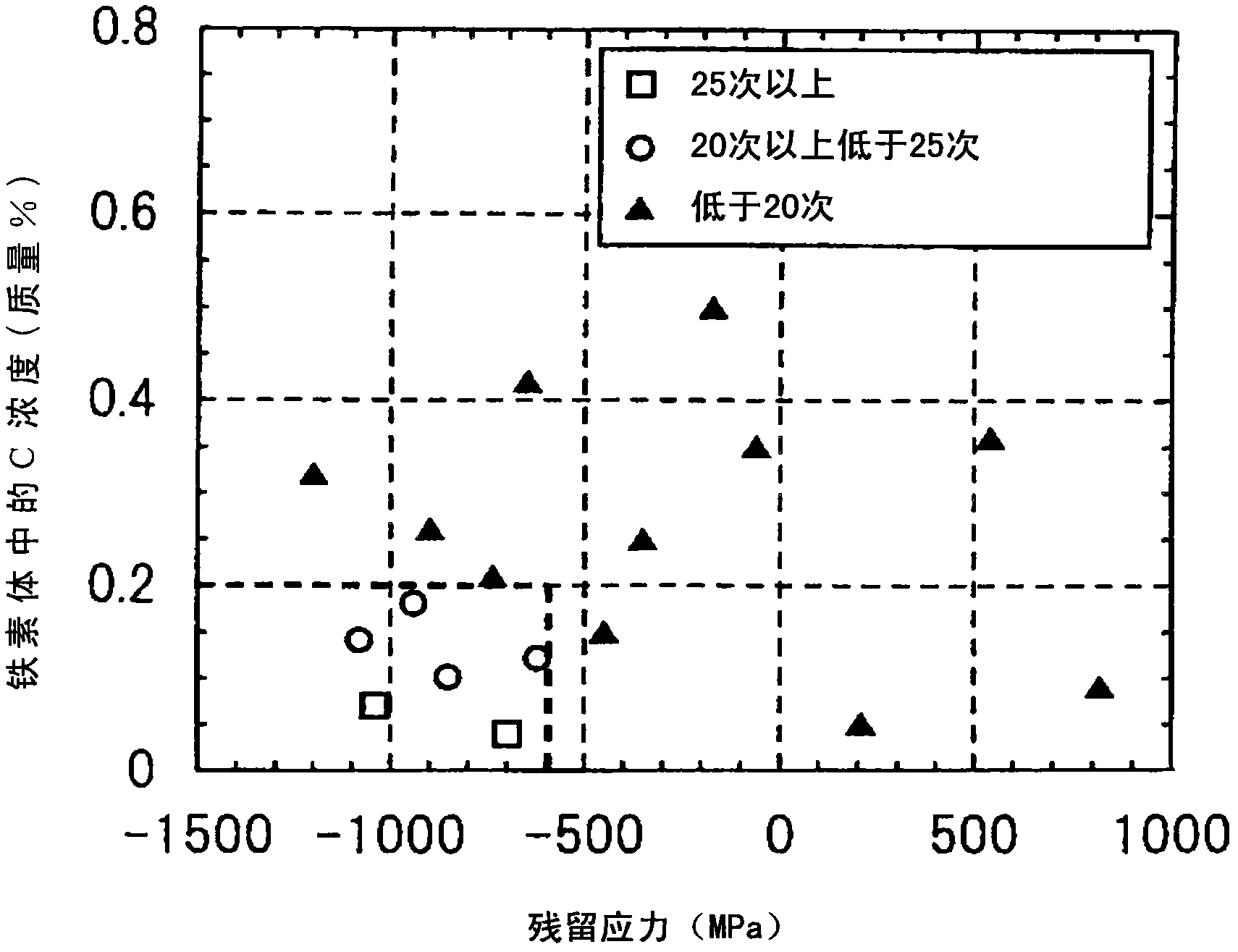

High-strength ultra-fine steel wire and manufacturing method therefor

ActiveCN102066599AHigh strengthImprove ductilityFurnace typesHeat treatment furnacesFerrite layerManganese

Provided is a steel wire containing, by mass, 0.7-1.2% carbon, 0.05-2.0% silicon, and 0.2-2.0% manganese, with the remainder comprising iron and unavoidable impurities. Said steel wire has a pearlite structure, a mean carbon concentration by mass of at most 0.2% in the central part of an outermost ferrite layer, and a residual compressive stress in the lengthwise direction of the wire of at least 600 MPa in said outermost layer.

Owner:NIPPON STEEL CORP

Ferrite module for electronic equipment and manufacturing method of ferrite module

ActiveCN103500878AReduce voidsImprove electromagnetic shielding performanceAntenna couplingsFerrite layerElectromagnetic shielding

The invention discloses a ferrite module for electronic equipment. The ferrite module comprises a ferrite layer, wherein the ferrite layer covers on the outer side of an antenna or a coil on the inner side wall of a casing of the electronic equipment; the ferrite layer is provided with an inner side surface and an outer side surface; the inner side surface is provide with a first profile surface of which the shape is consistent with that of the outer surface of the antenna or the coil; the outer side surface is provided with a second profile surface of which the shape is consistent with the inside shape of the electronic equipment opposite to the inner side wall of the casing. The invention also provides a manufacturing method of the ferrite module. The ferrite module for the electronic equipment, which is disclosed by the invention, can provide the ferrite layer which can individually cover the antenna or the coil on the inner side wall of the casing of the electronic equipment according to the shape of the inner side wall of the casing of the electronic equipment, so that the gap between the ferrite layer and the antenna or the coil can be reduced and a better electromagnetic shielding effect can be provided in a narrow space. In addition, according to the manufacturing method disclosed by the invention, the individual large-scale production can be conveniently operated.

Owner:LOVEPAC CONVERTING BEIJING +1

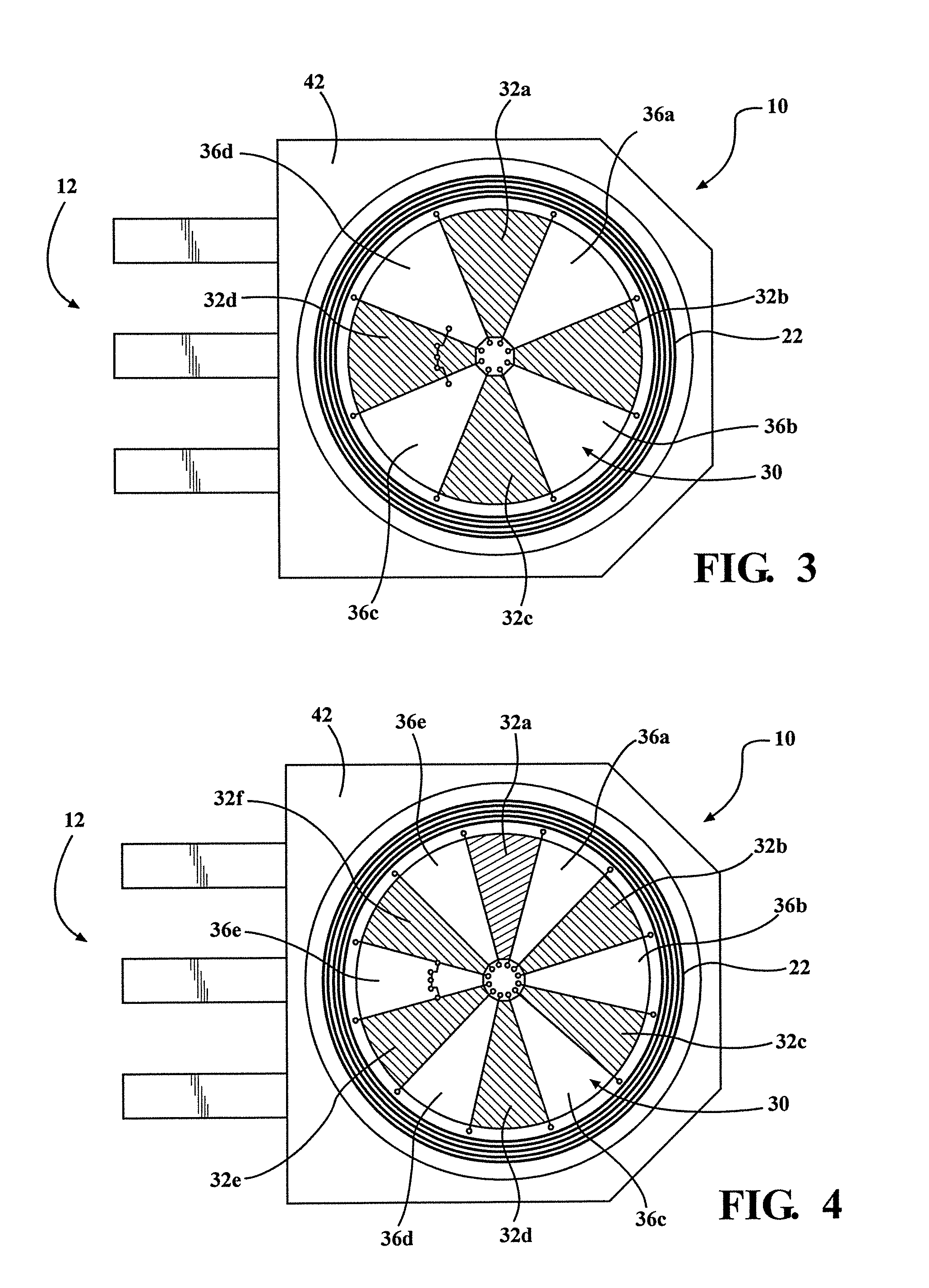

LTCC (Low Temperature Co-Fired Ceramic) laminated micro-strip ferrite circulator

InactiveCN102544663AEasy to adjustImprove developmentWaveguide type devicesFerrite layerMicrowave technology

The invention discloses an LTCC (Low Temperature Co-Fired Ceramic) laminated micro-strip ferrite circulator, belonging to the field of a micro-strip ferrite circulator in a microwave technology. The circulator comprises a metal ground layer, an LTCC ferrite layer, a first LTCC ceramic medium layer, a second LTCC ceramic medium layer, a center junction, a first micro-strip circuit, a metal filling hole and a second micro-strip circuit. The first micro-strip circuit and the center junction are located on the upper surface of the LTCC ferrite layer and are connected with each other; the second micro-strip circuit is located on the upper surface of the first LTCC ceramic medium layer and can be connected with three external ports to carry out feed; and the metal filling holes passes through the first LTCC ceramic medium layer to connect the first micro-strip circuit with the second micro-strip circuit, so as to form a three-dimensional laminated structure. With the adoption of a three-dimensional structure design, the micro-strip circuits are distributed on substrate materials with different types, thereby breaking through structure disadvantages and design disadvantages of the existing micro-strip ferrite circulator and realizing the compatibility with an LTCC technology and components.

Owner:彭龙

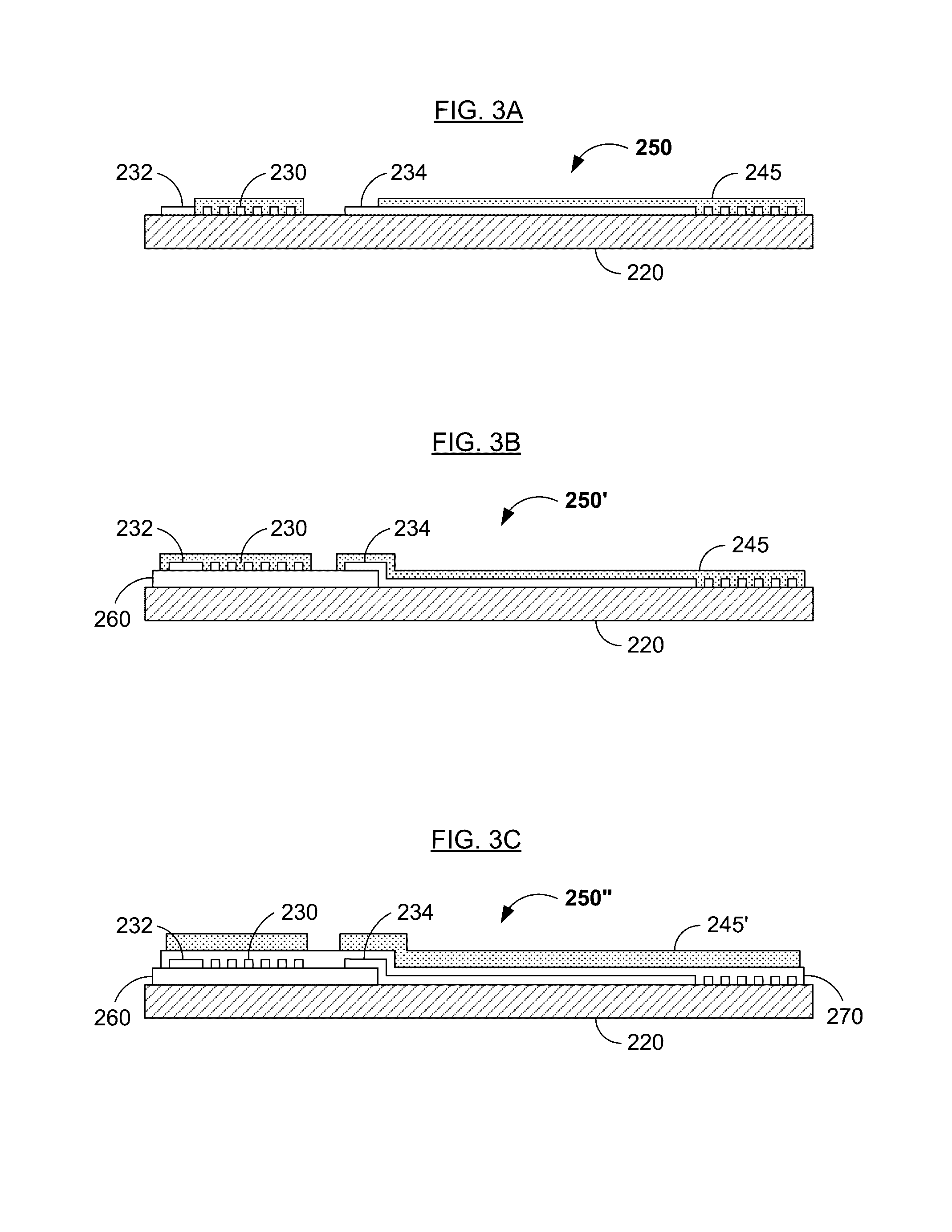

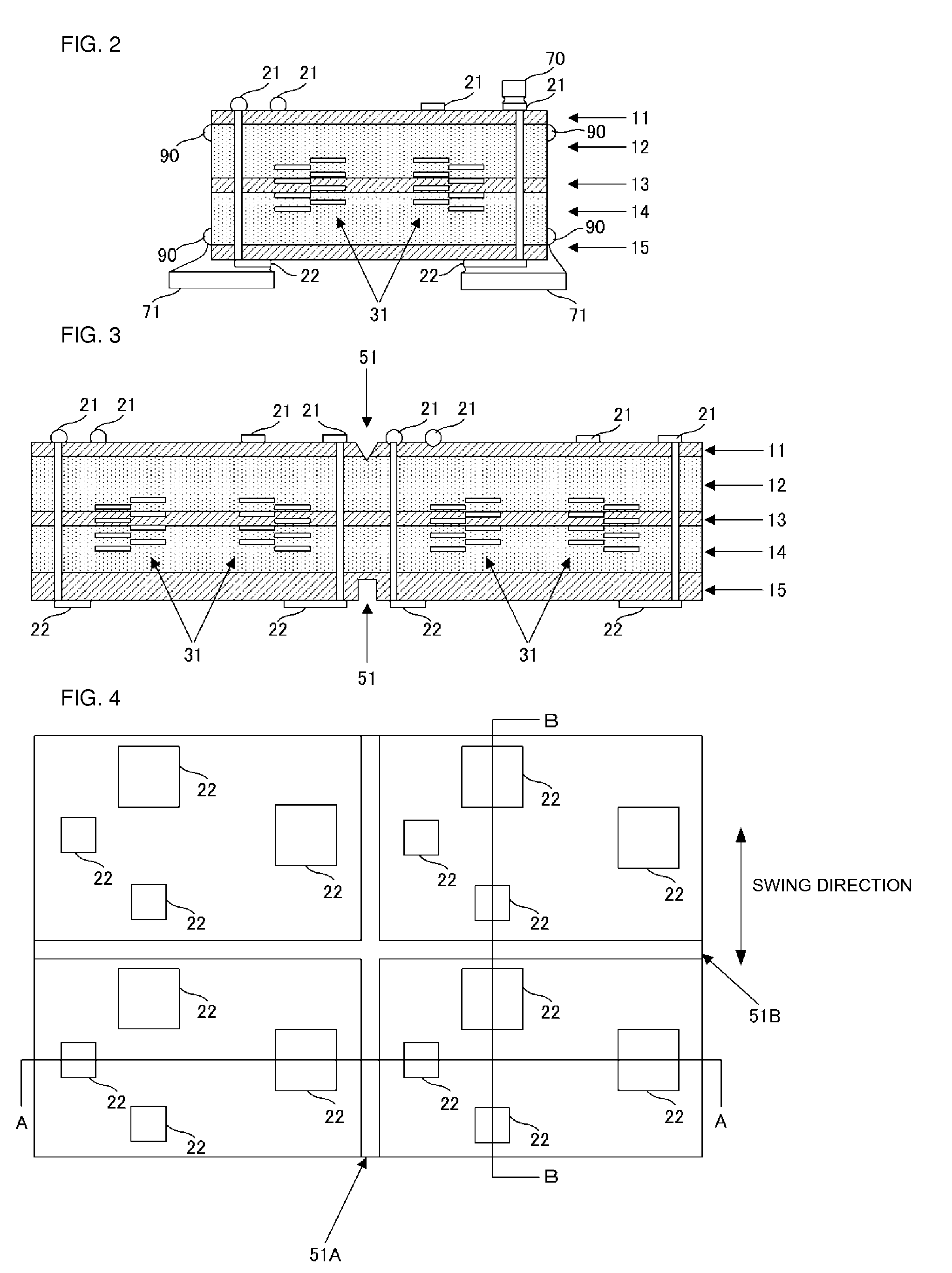

Laminated inductor element and manufacturing method thereof

ActiveUS20130314194A1Promote growthReduce thicknessInductances/transformers/magnets manufactureCoilsFerrite layerInductor

A laminated inductor element is configured to prevent warpage of the entire element with a structure in which a non-magnetic ferrite layer on an upper surface side is reduced in thickness to achieve a reduction in height of the entire element, a non-magnetic ferrite layer on a lower surface side is increased in thickness to be thicker than the non-magnetic ferrite layer so as to prevent a metal component diffused from a magnetic ferrite layer from coming into electrical contact with a land electrode of a mounting substrate, and an inductor is disposed toward the lower surface side across a non-magnetic ferrite layer.

Owner:MURATA MFG CO LTD

Magnetic Prussian blue pigment and preparation method thereof

The invention provides a magnetic Prussian blue pigment. The novel magnetic Prussian blue pigment with high chrominance and luminance is prepared by coating a ferrite layer on one or more of native mica, synthetic mica, glass sheets, silica sheets, aluminum oxide sheets, ferric oxide sheets, boron nitride sheets, bismuth oxychloride sheets and metal or metal-oxide-coated product of the sheet materials, and coating Prussian blue (Fe4[Fe (CN)6]3) on the substrate coated with the ferrite layer. The pigment is widely used in paint, cosmetics, printing ink, plastic, leather and other industries.

Owner:FUJIAN KUNCAI MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com