Patents

Literature

53results about How to "Sufficient shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

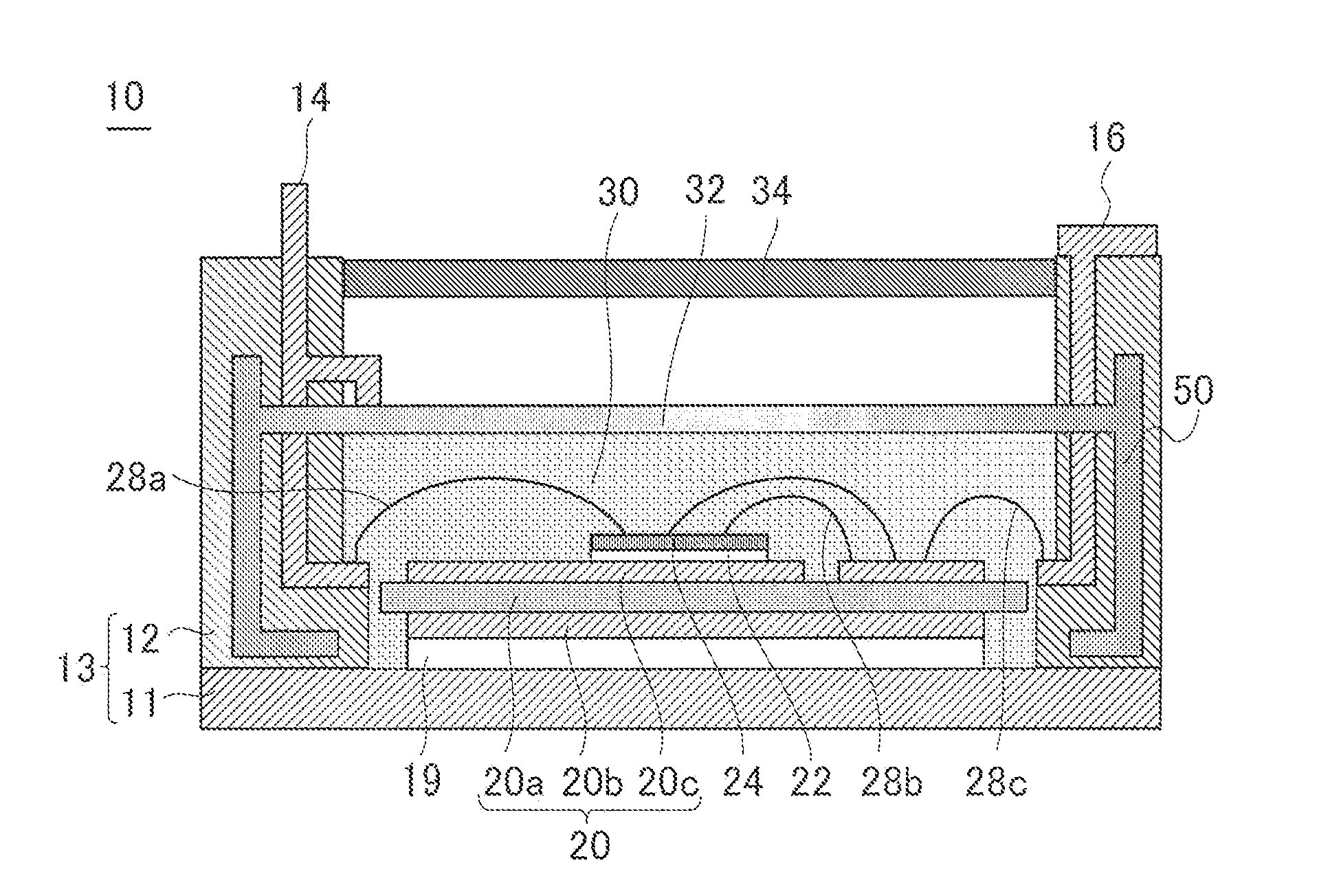

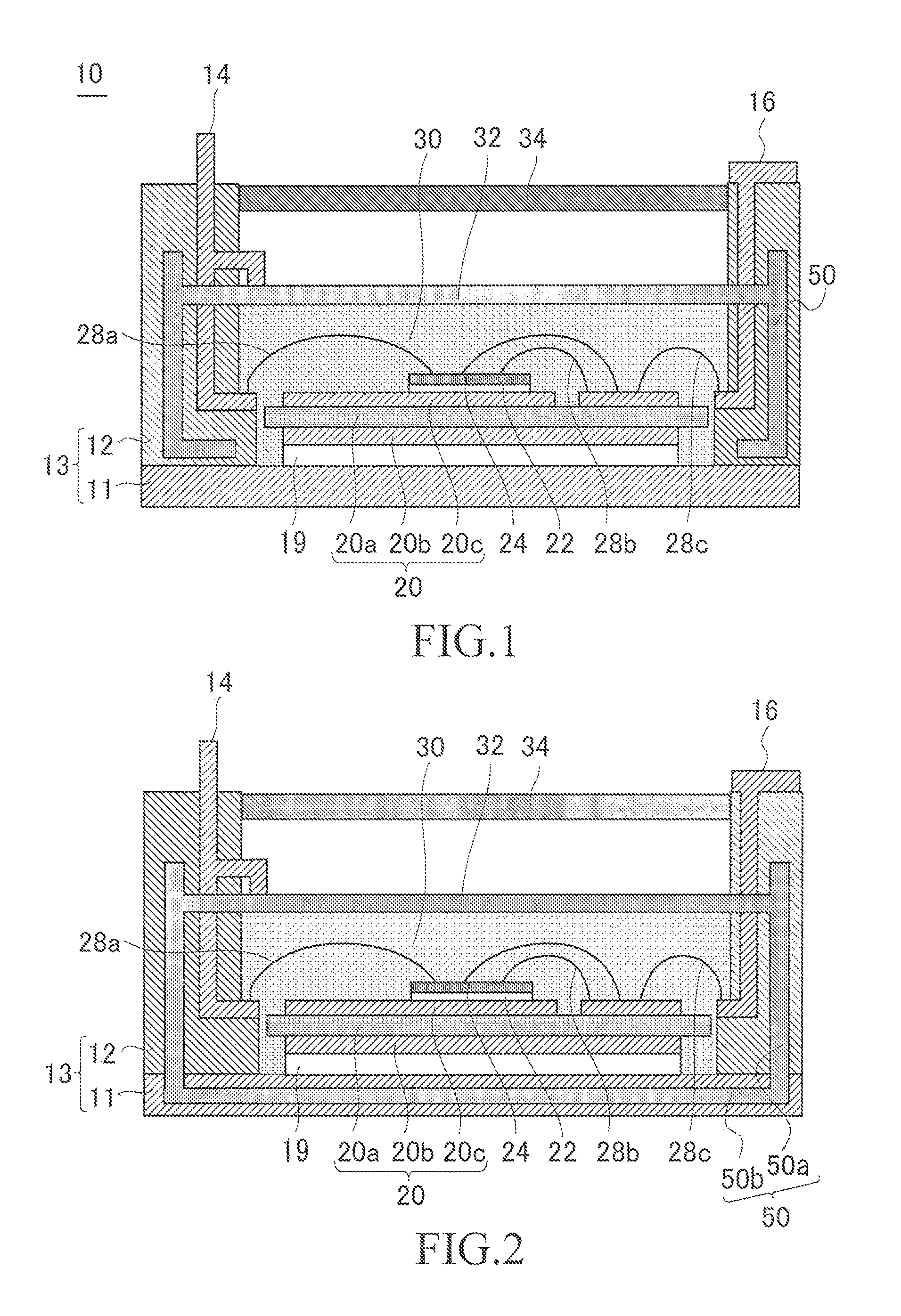

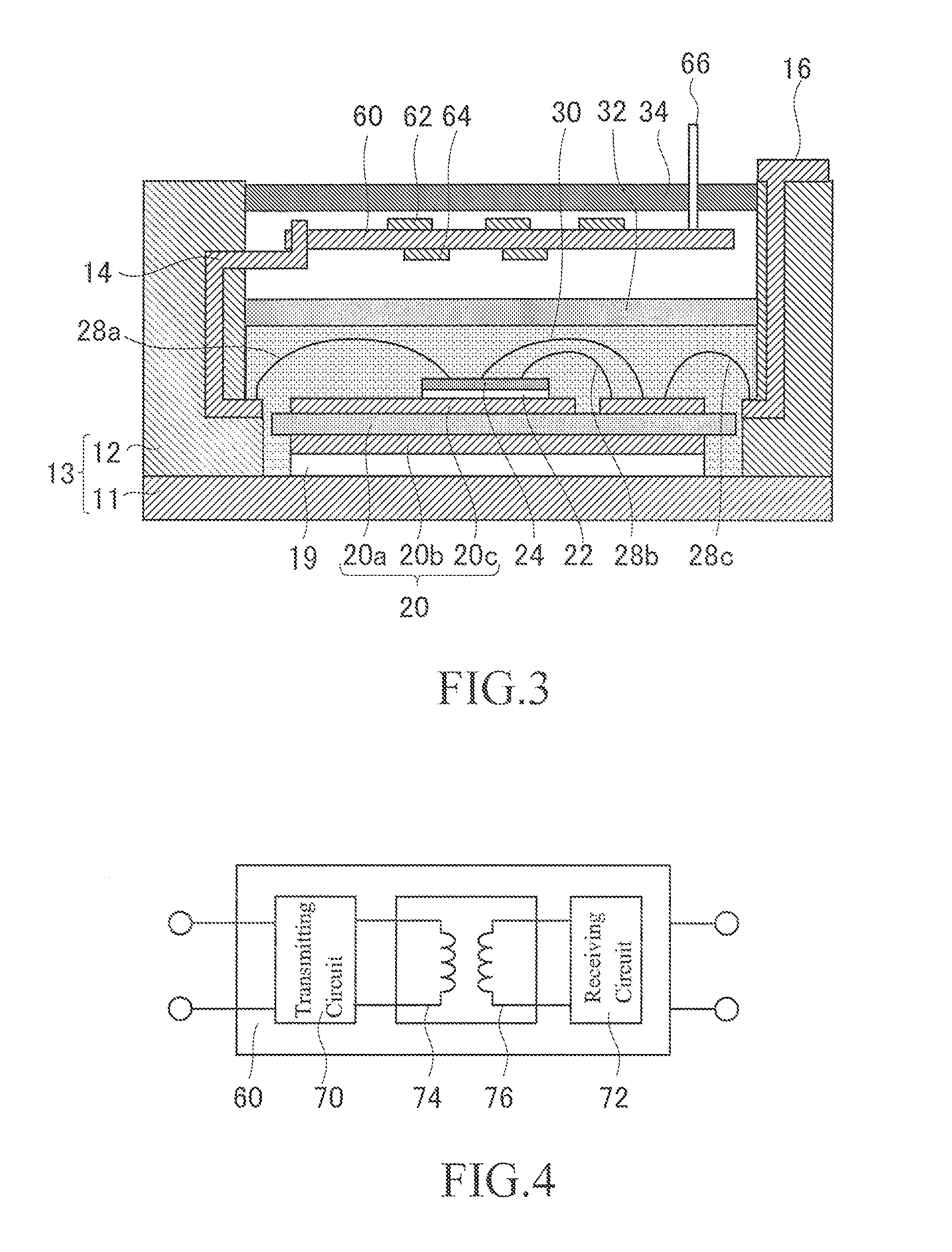

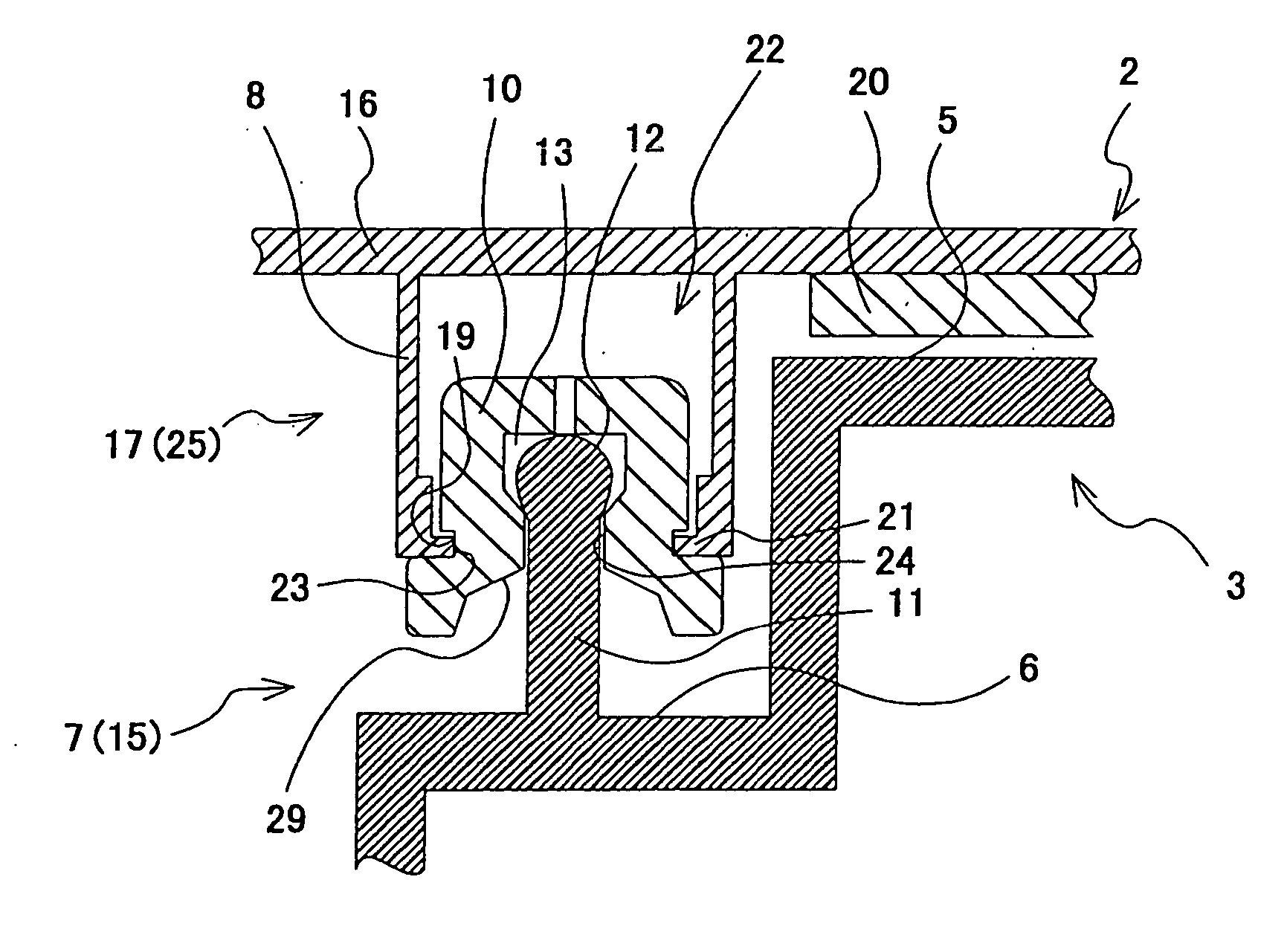

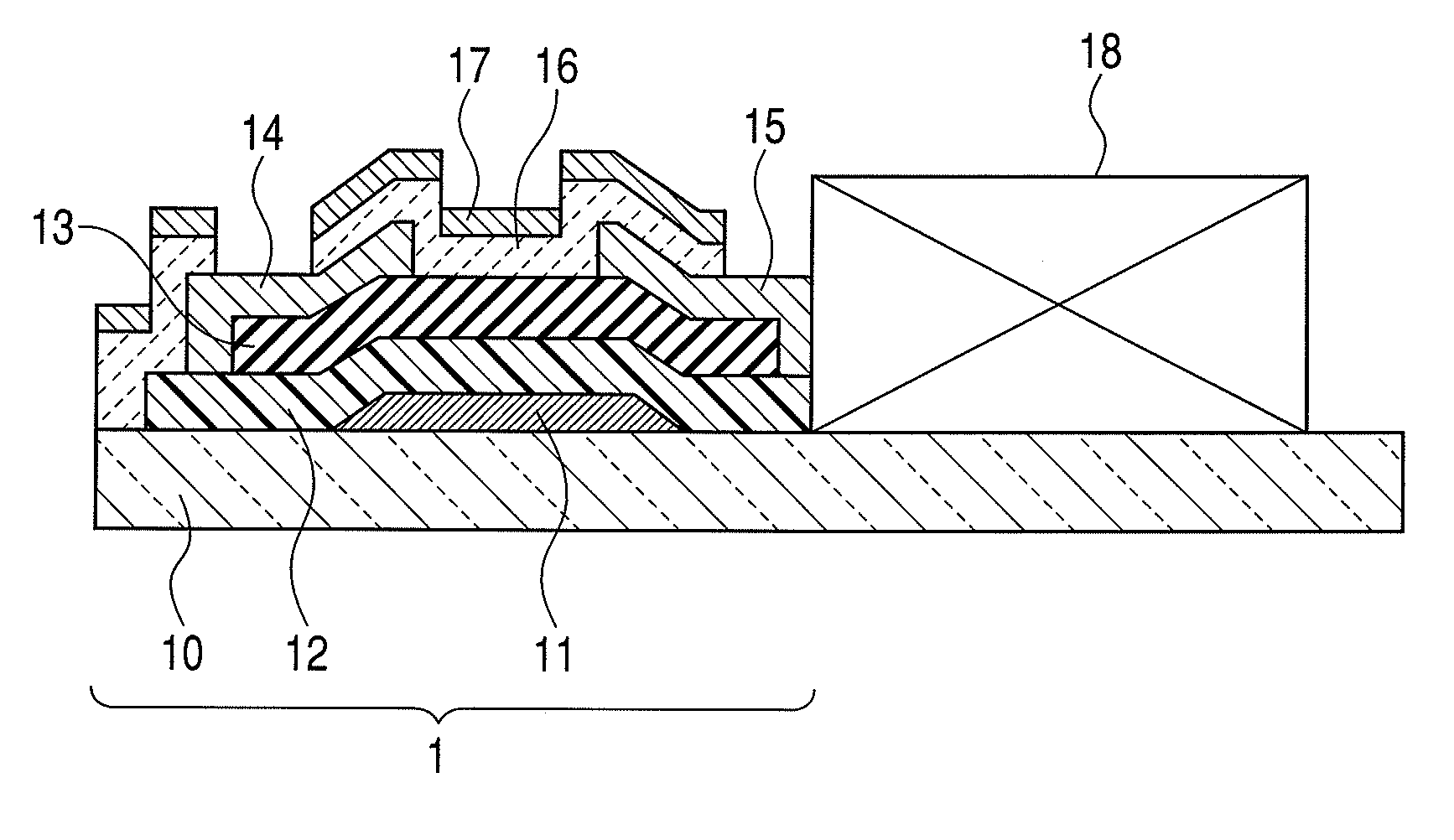

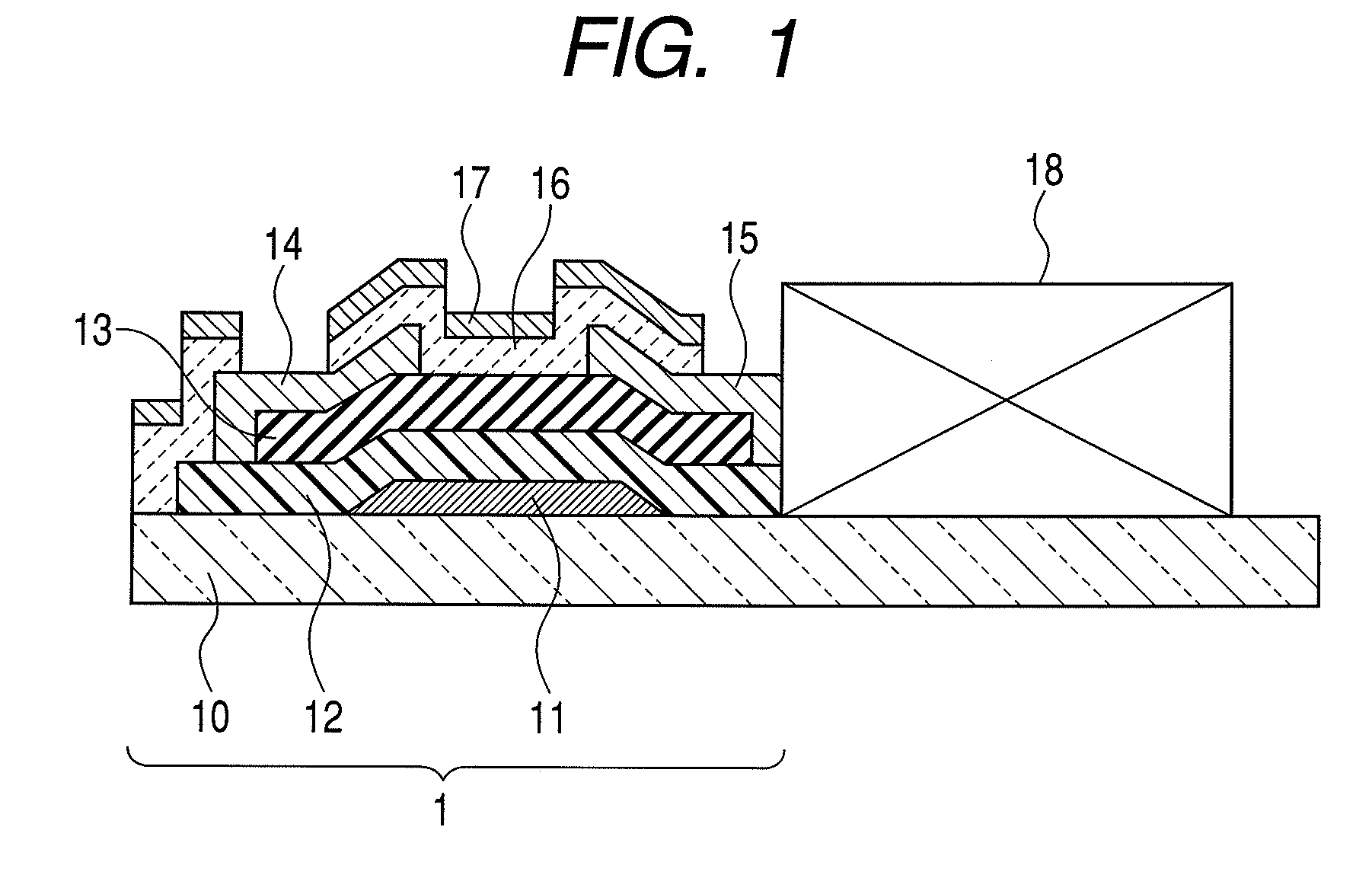

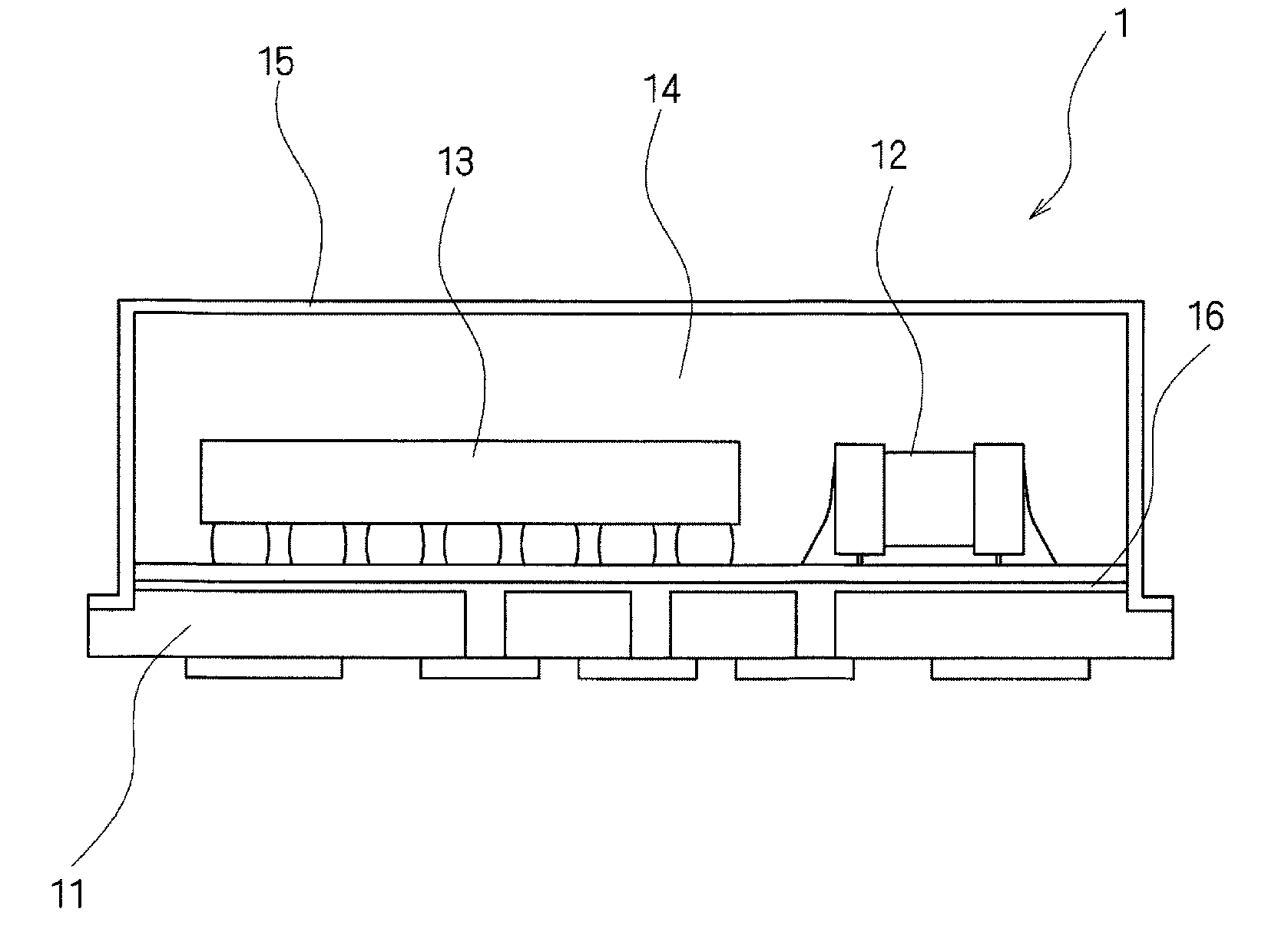

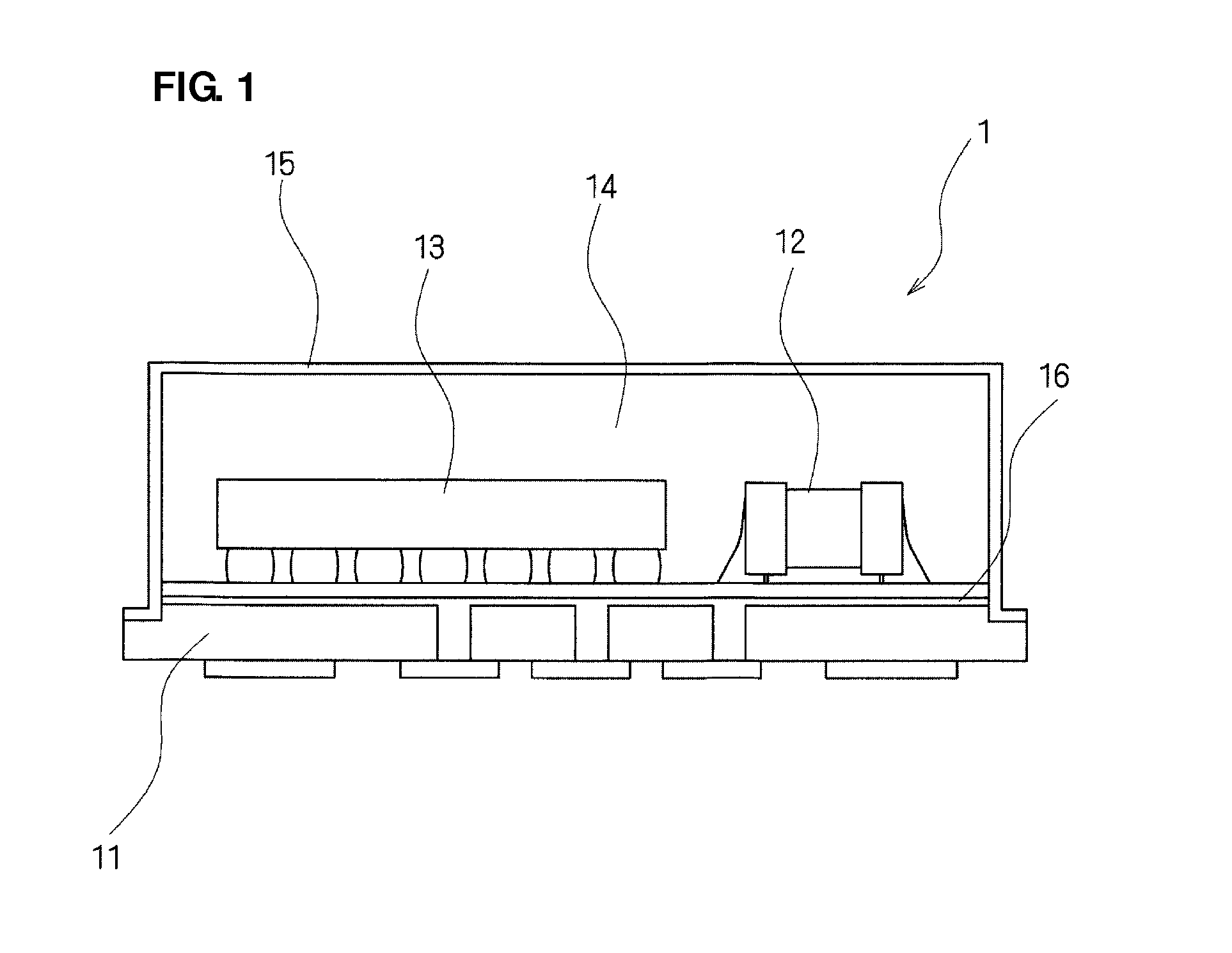

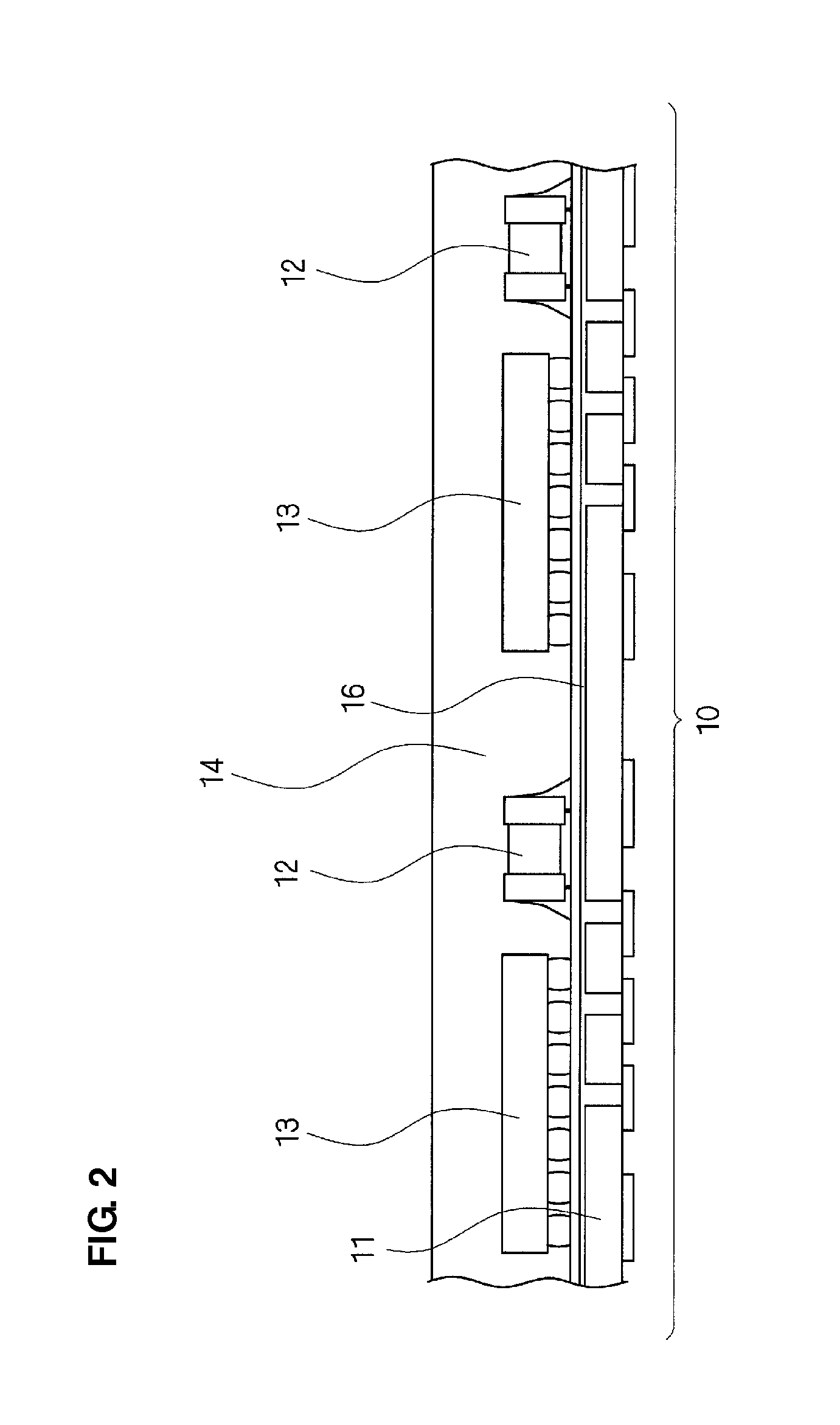

Semiconductor module and power converter

ActiveUS20160155706A1Sufficient shieldingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor componentsMagnetic shield

A semiconductor module includes a case, a semiconductor component provided in the case for switching a current, encapsulating resin provided in the case for covering the semiconductor component, a magnetic shield contacting the encapsulating resin and containing a magnetic material, and an embedded magnetic shield embedded in the case, the embedded magnetic shield containing a magnetic material.

Owner:MITSUBISHI ELECTRIC CORP

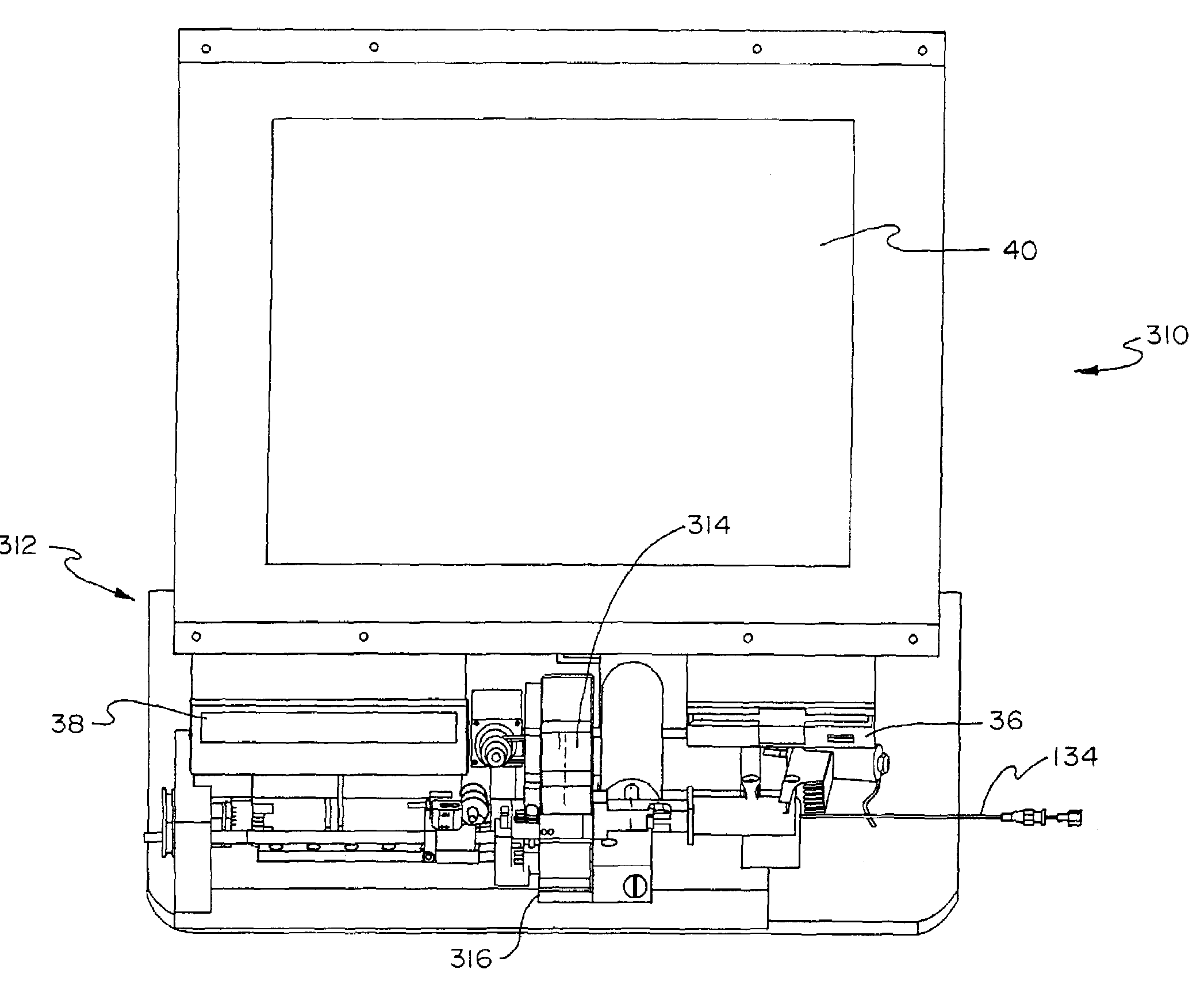

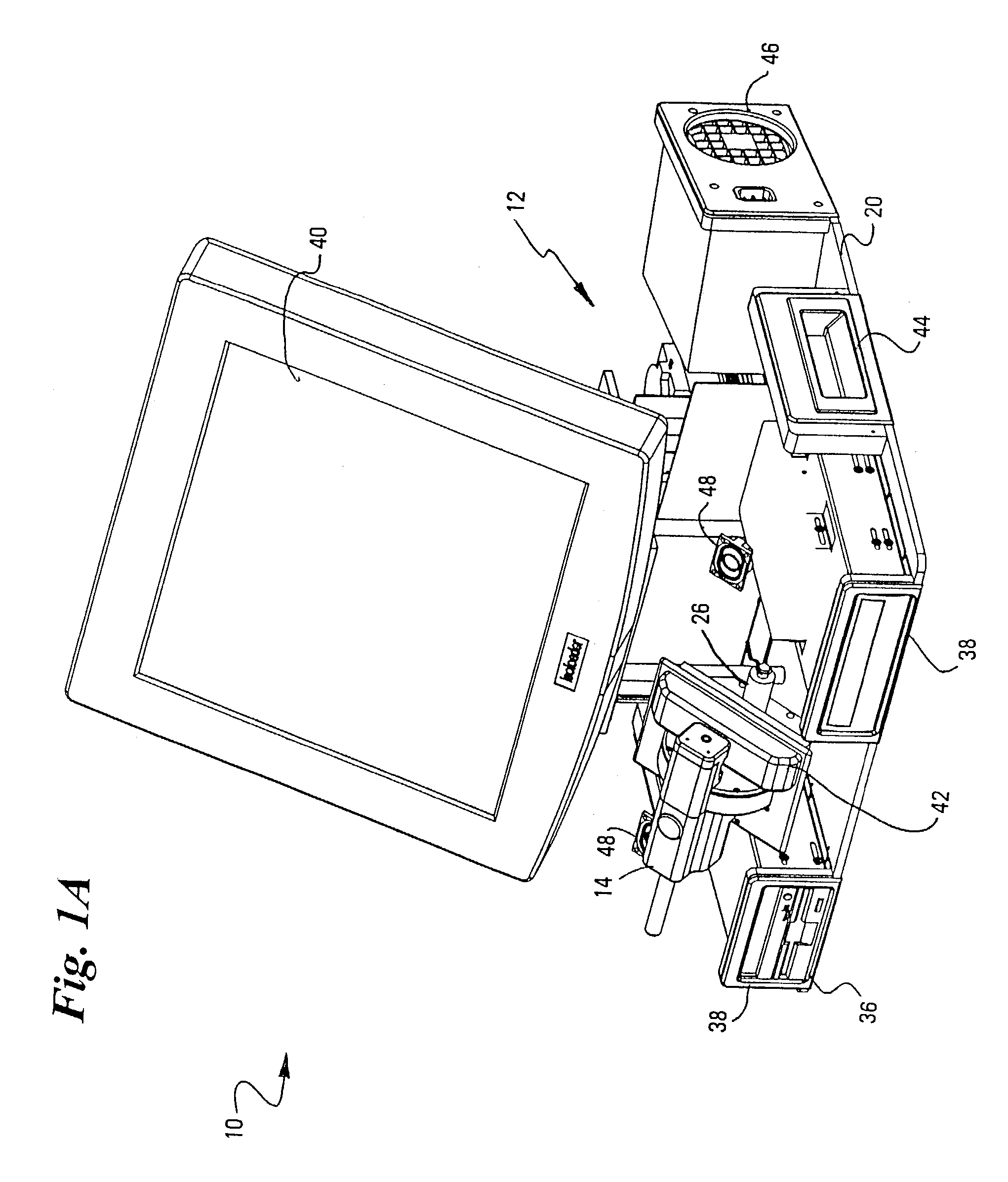

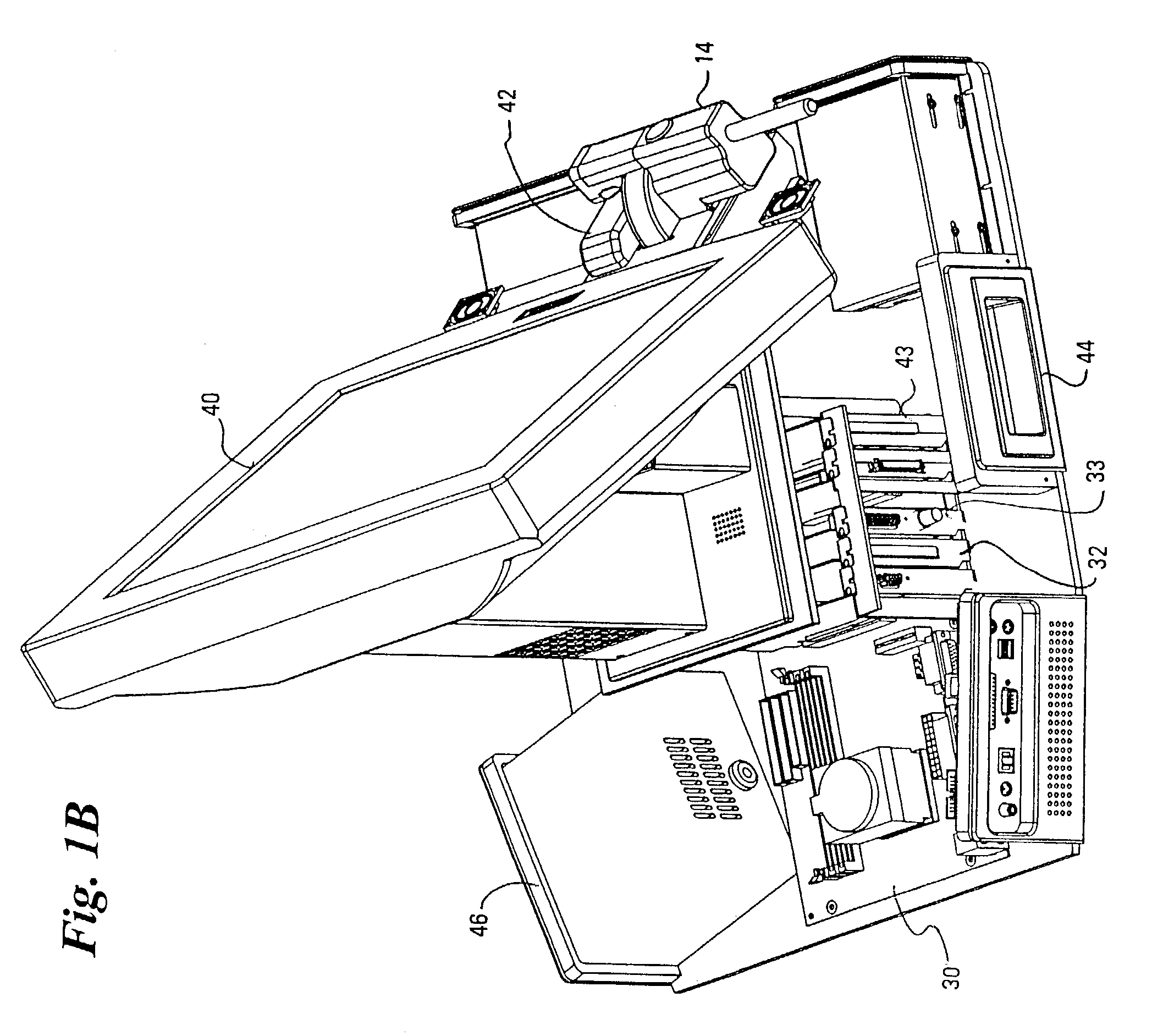

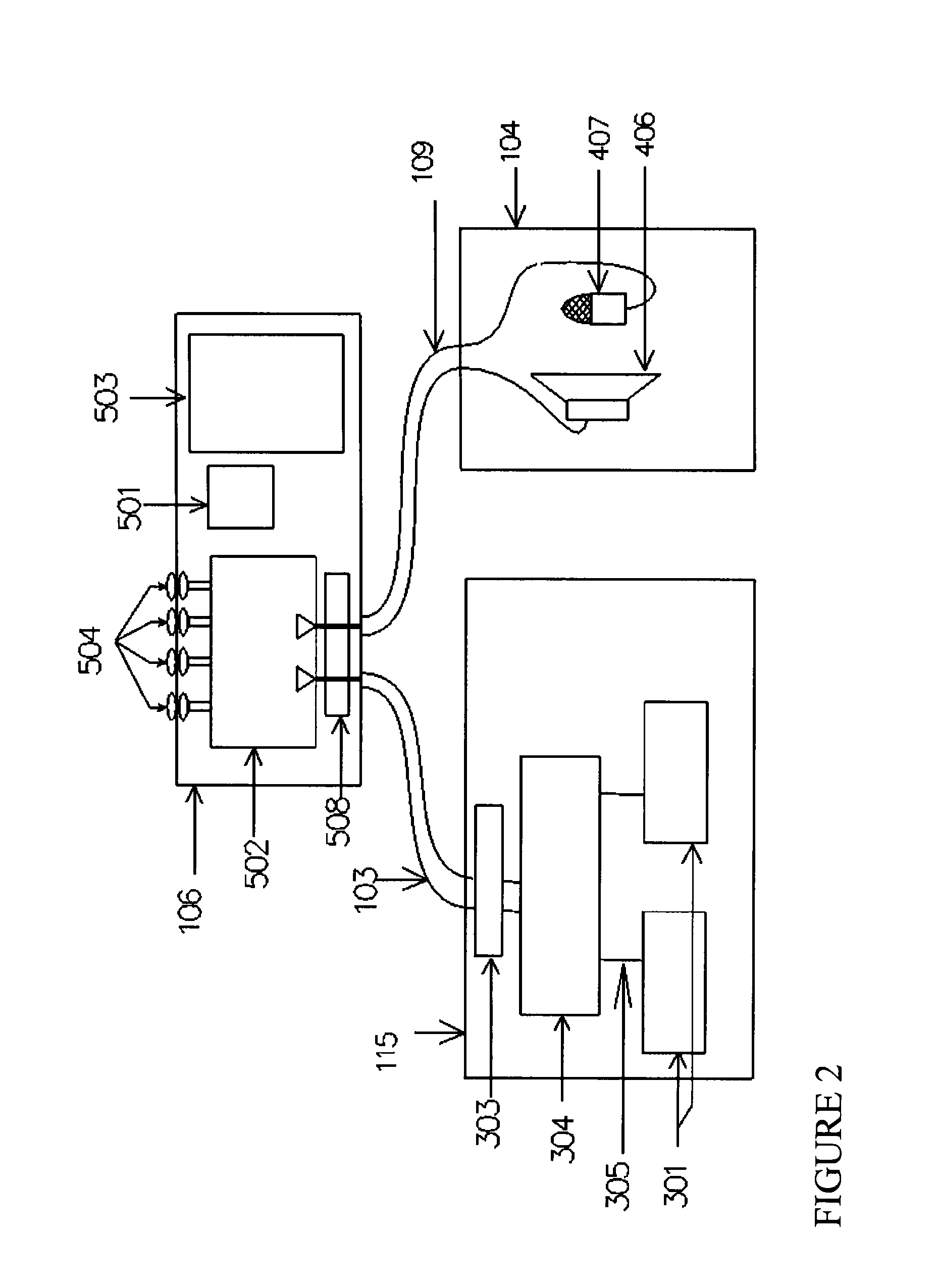

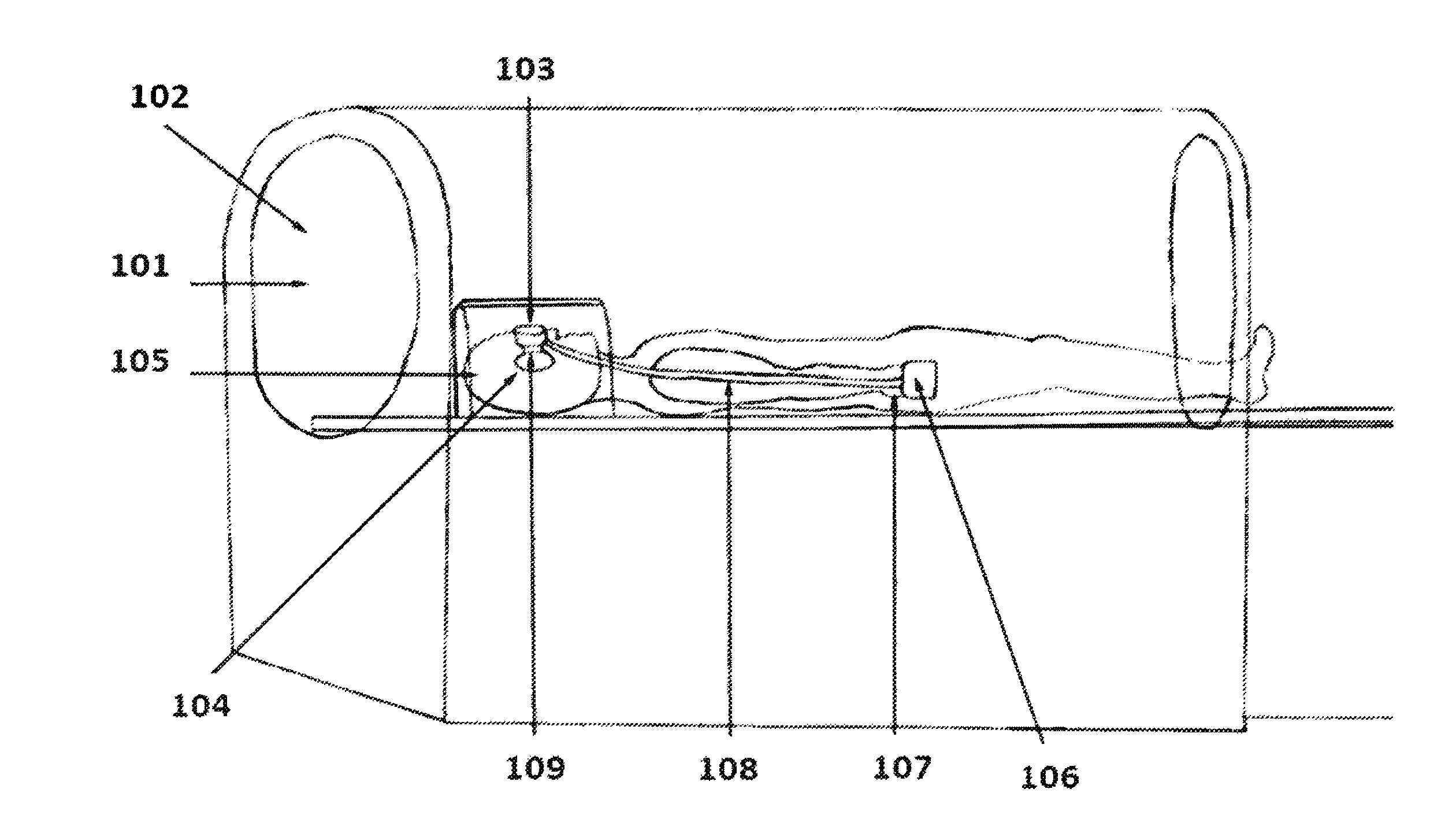

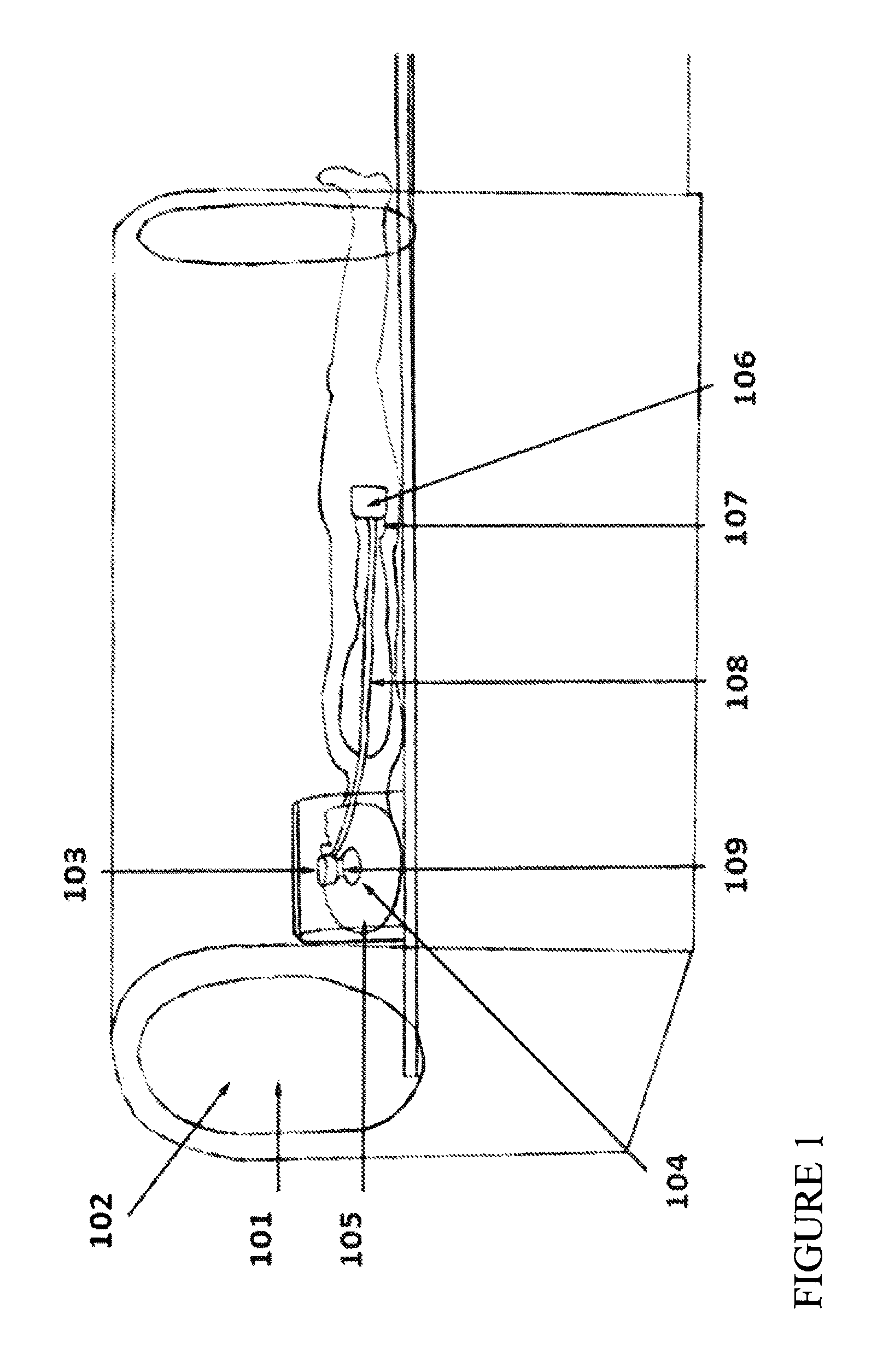

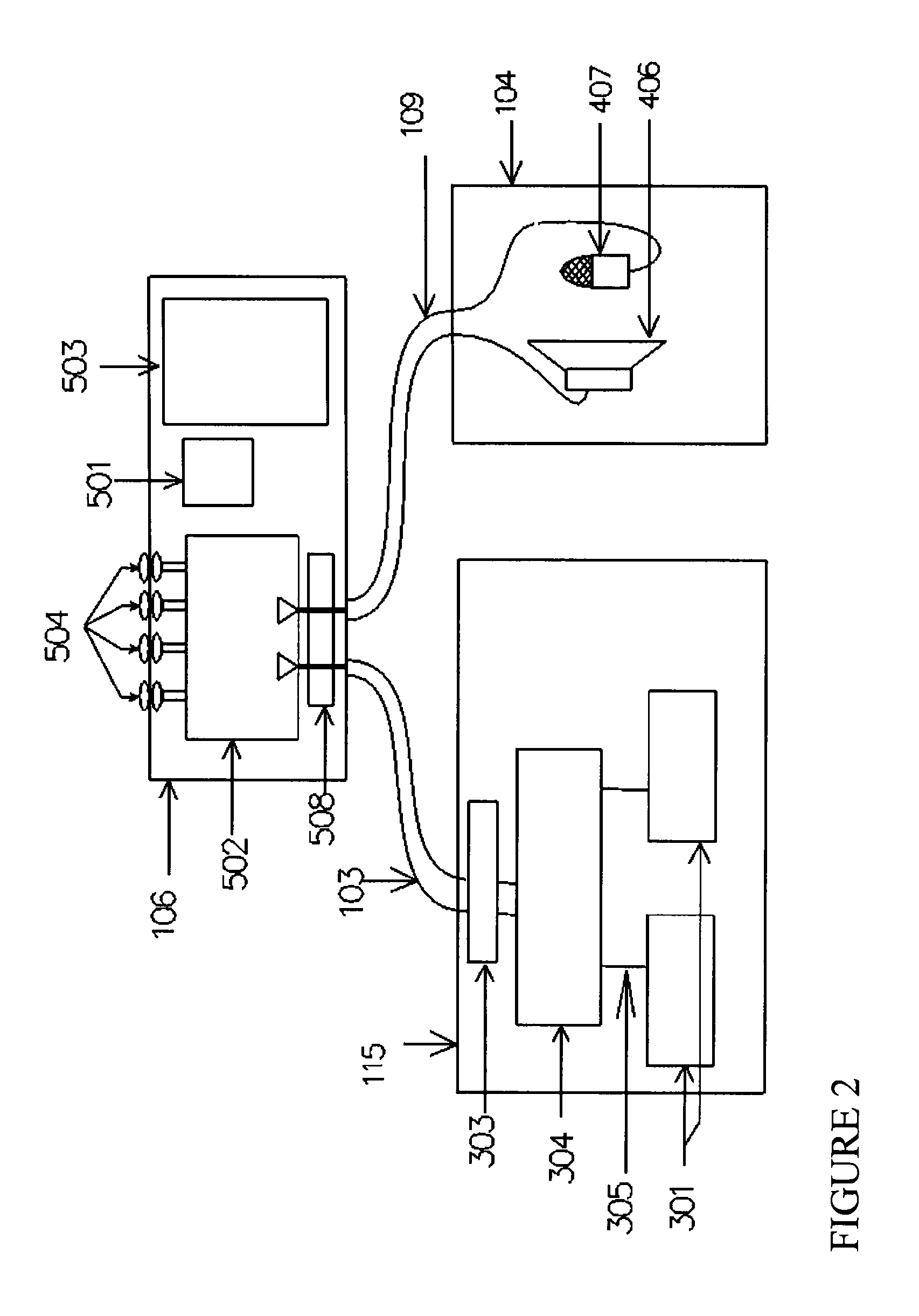

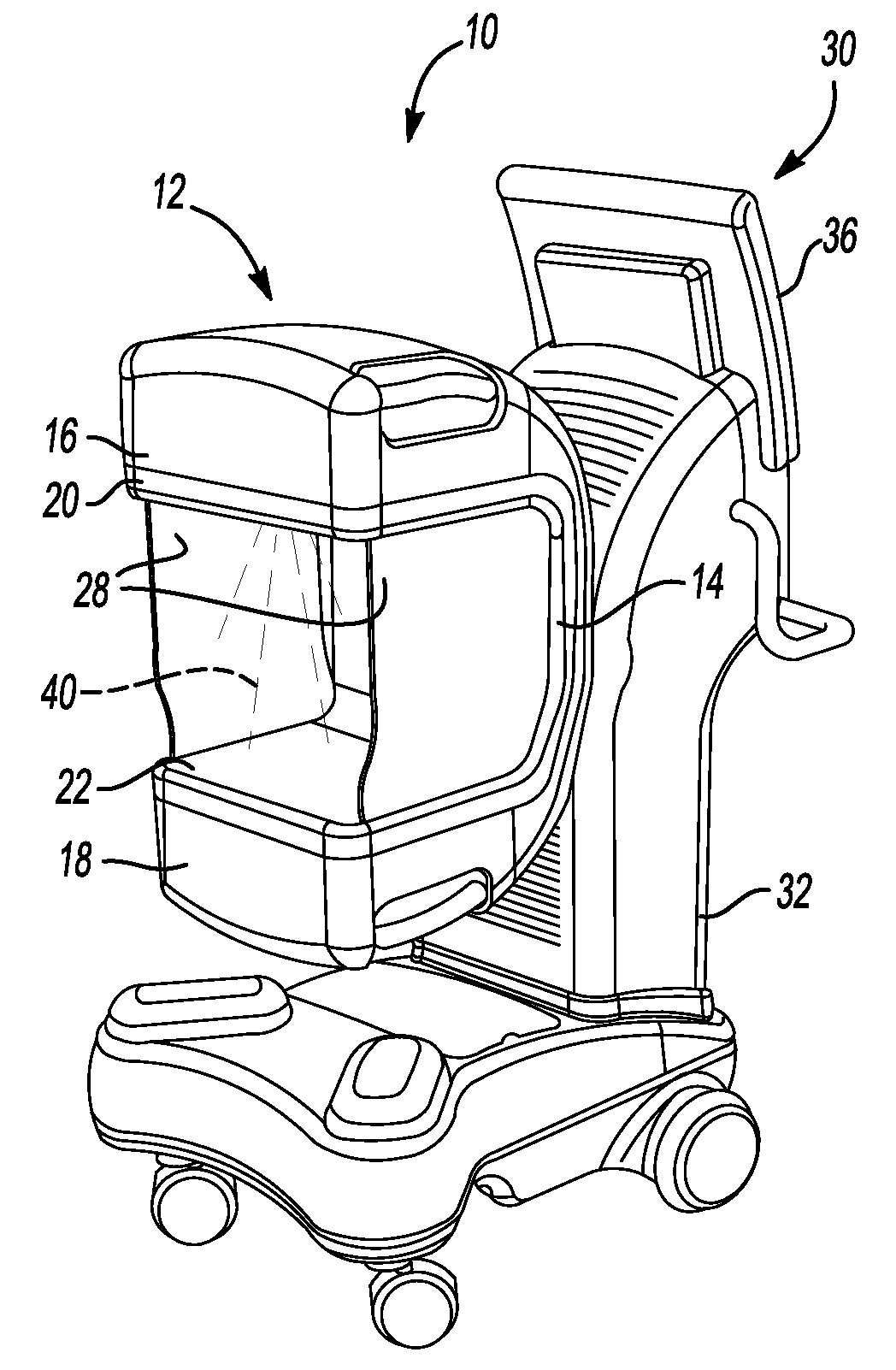

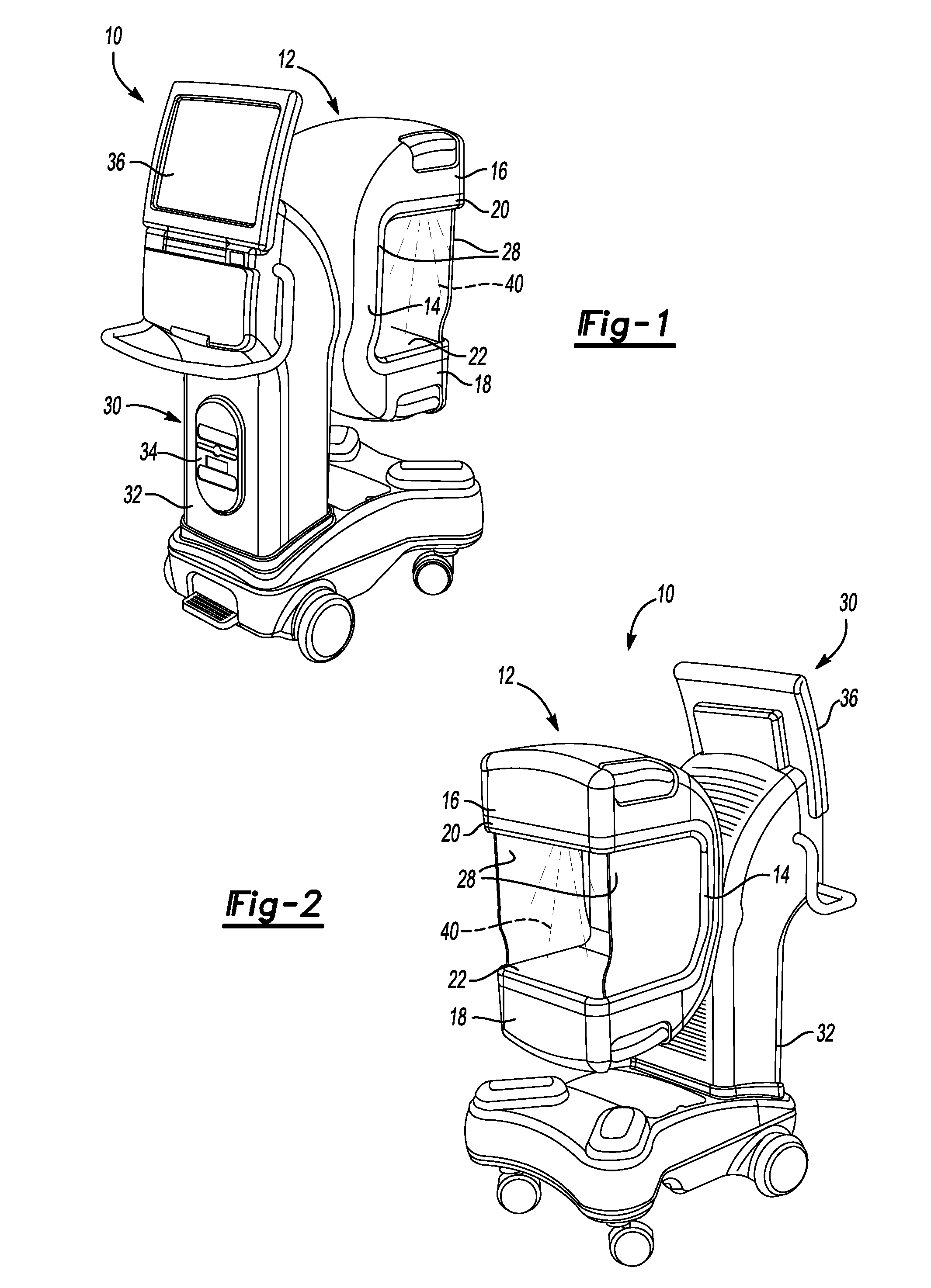

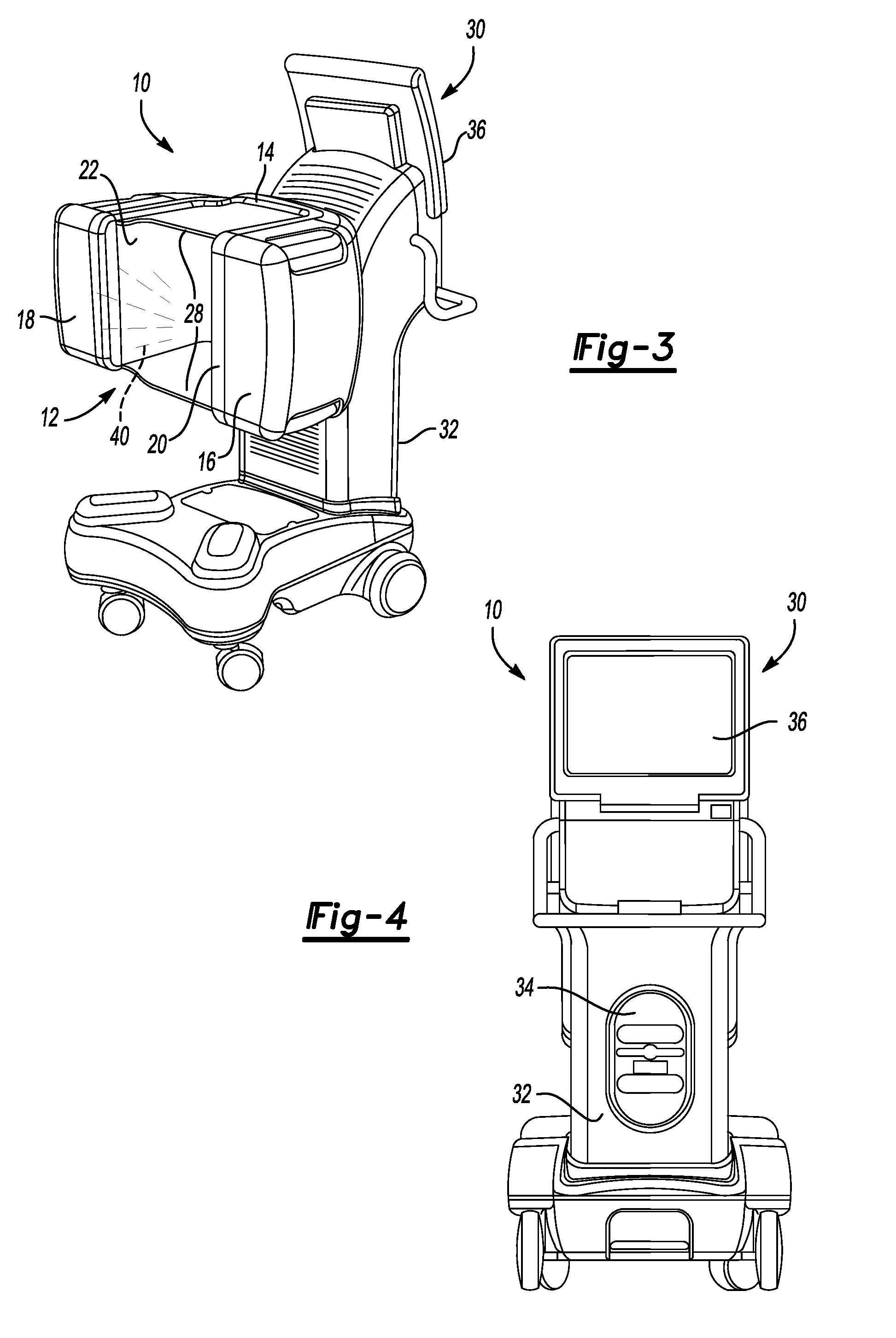

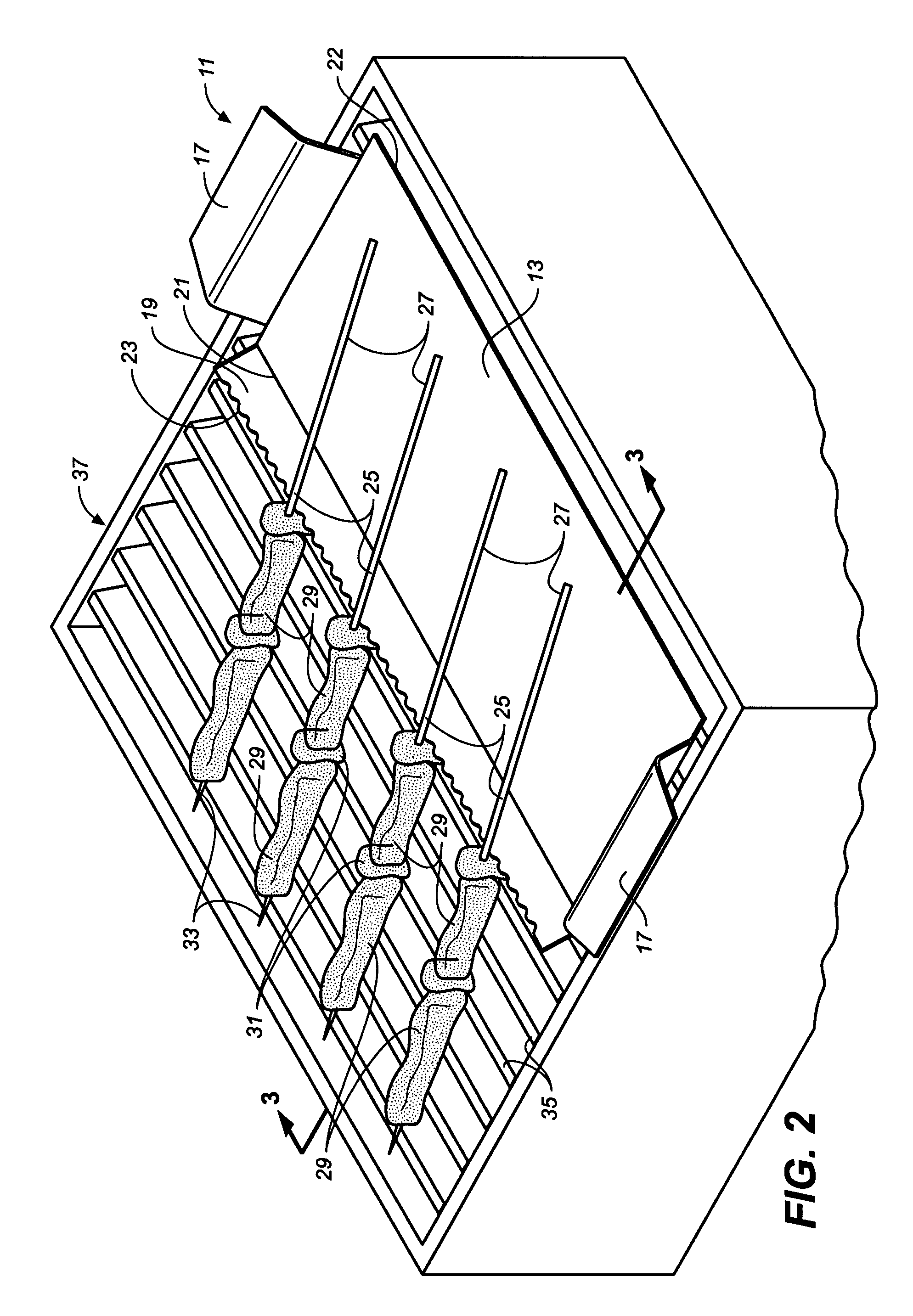

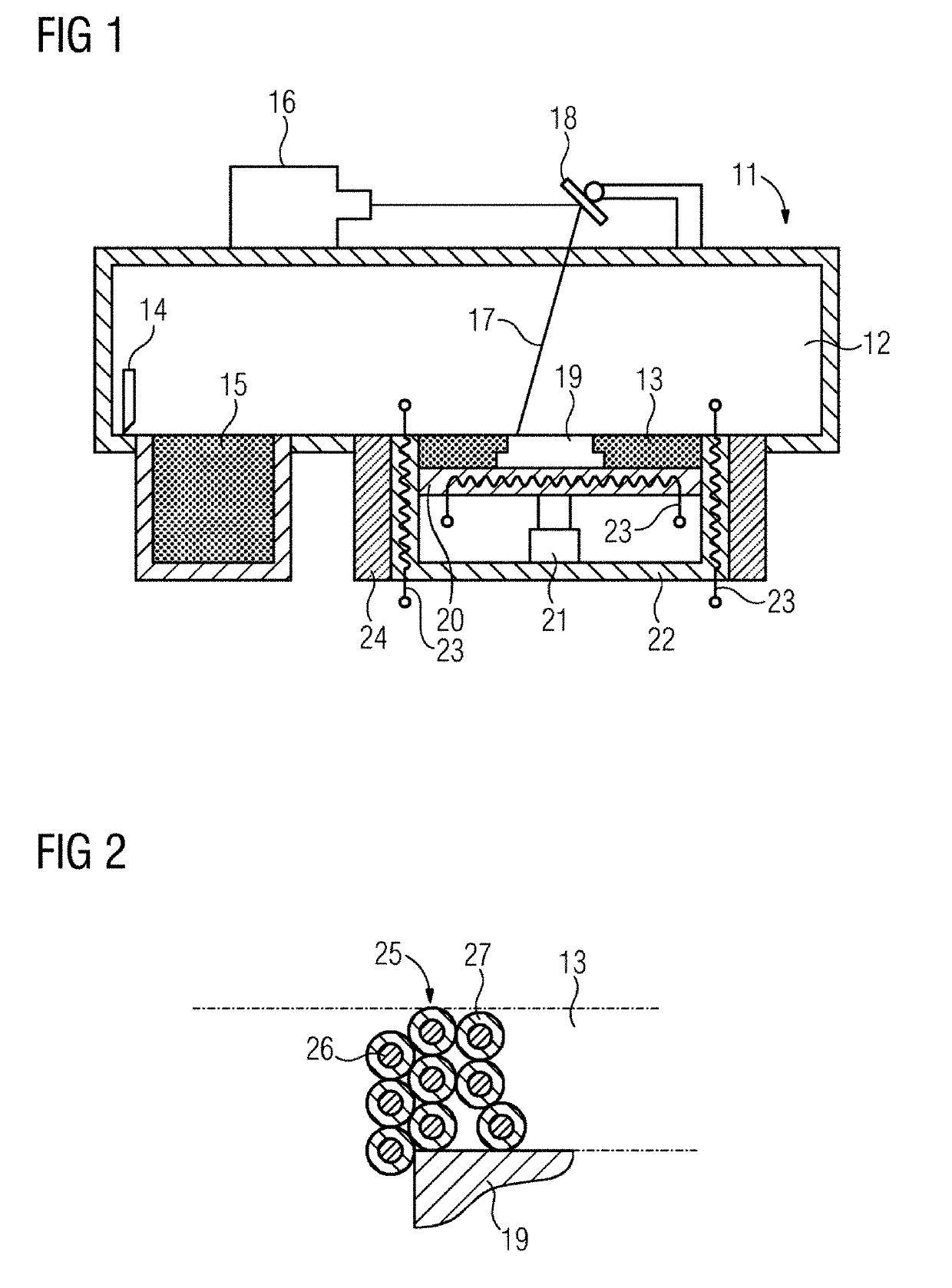

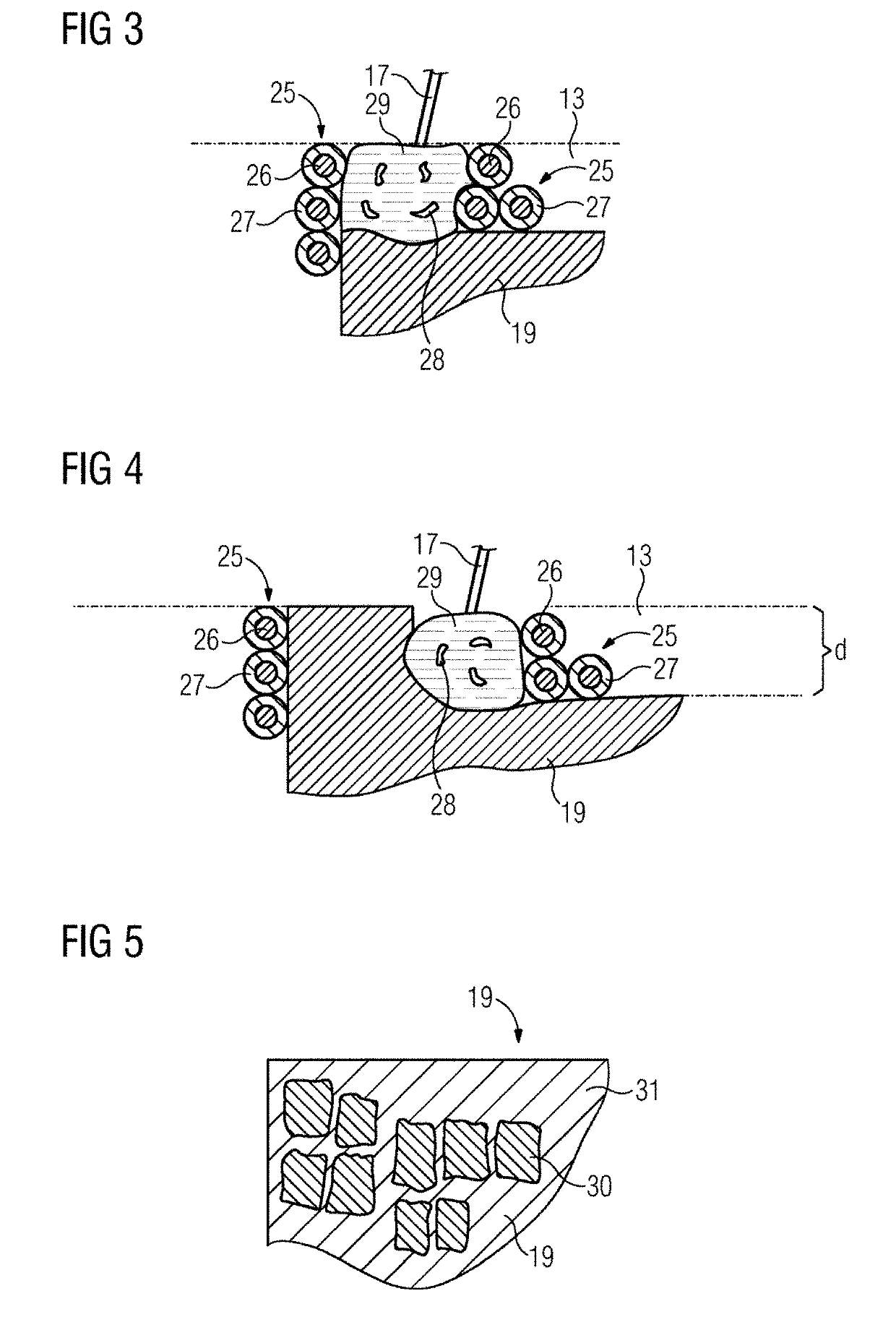

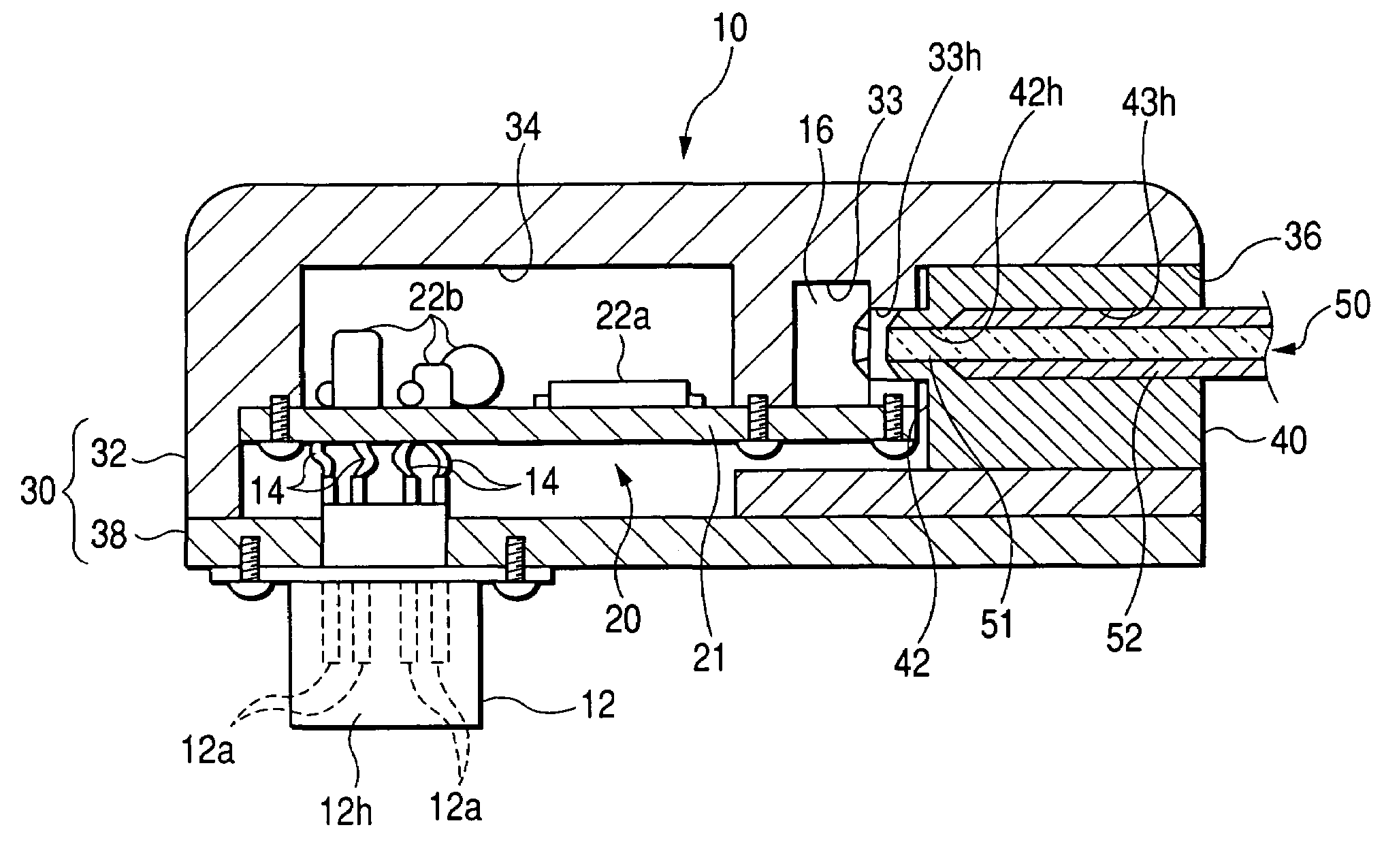

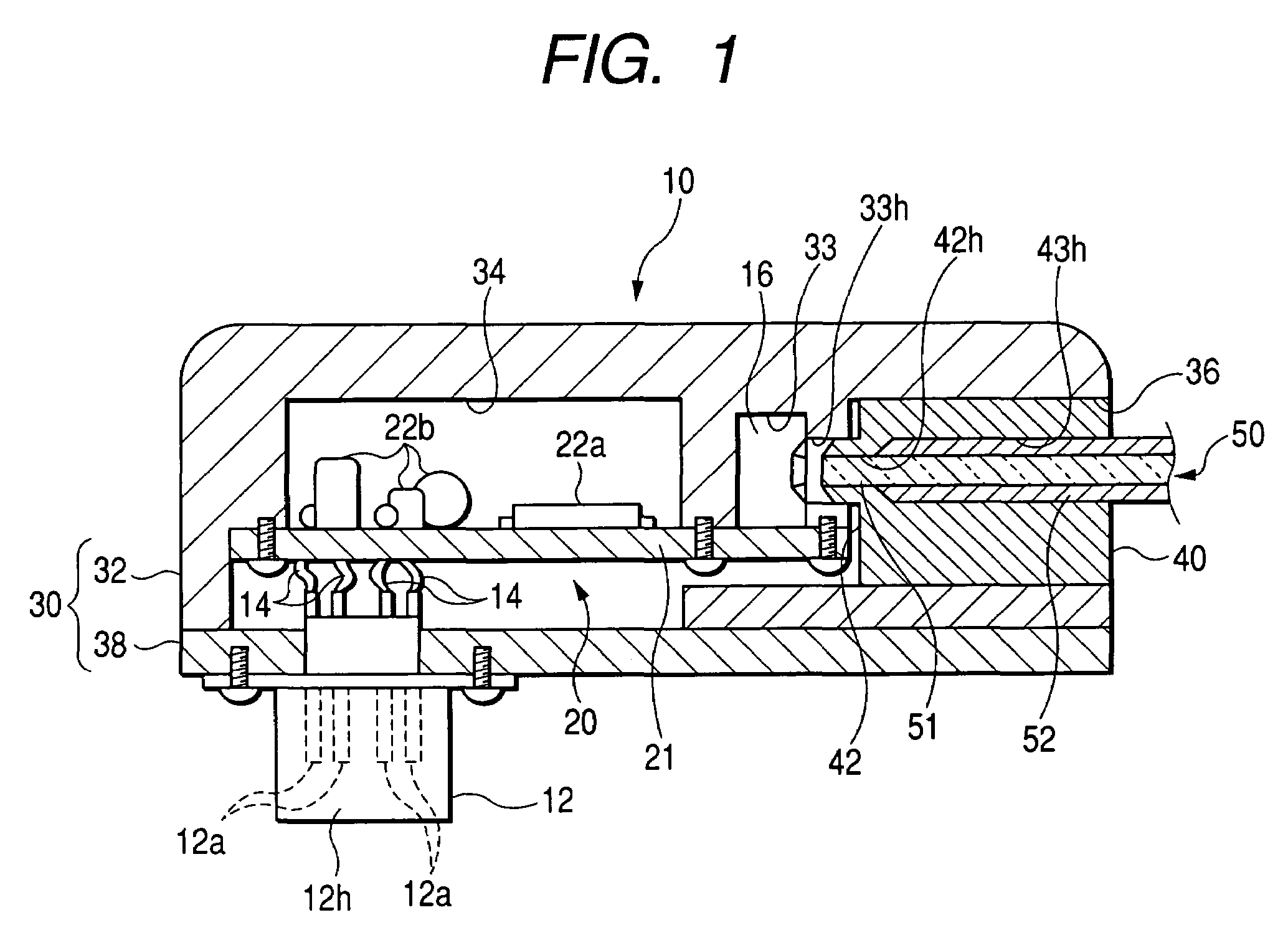

Automated radioisotope seed loader system for implant needles

InactiveUS7229400B2Minimize security issueSafe and efficientMedical devicesX-ray/gamma-ray/particle-irradiation therapyMovement controlAdemetionine

An automated system for loading low dose radioisotope seeds into a plurality of implant needles is comprised of a loading station into which a replaceable cartridge may be positioned. The cartridge is preloaded with a plurality of radioisotope seeds and a plurality of spacers. The cartridge has at least one aperture and preferably the radioisotope seeds and spacers are loaded around the periphery of a rotatable drum within the cartridge. The loading station has a cartridge receiving structure and an automated motion control system. When the cartridge is positioned in the cartridge receiving structure, the automated motion control system preferably drives a pair of stepper motors within the cartridge, one for rotating the rotatable drum and one for sliding a pushrod to selectively eject radioisotope seeds and spacers from the cartridge into each of a plurality of implant needles positioned so as to receive the radioisotopes seeds and spacers within the implant needle. In one embodiment, the implant needles are positioned tip first into the loading station, and once a predetermined arrangement of radioisotope seeds and spacers are loaded into the implant needle, a plug is positioned in the tip of the implant needle. Preferably, the automated system includes a computer processor having a touch screen user interface that is connected to and directs the operation of the automated motion control system to load the plurality of implant needles in accordance with a predetermined dose plan.

Owner:THERAGENICS CORP

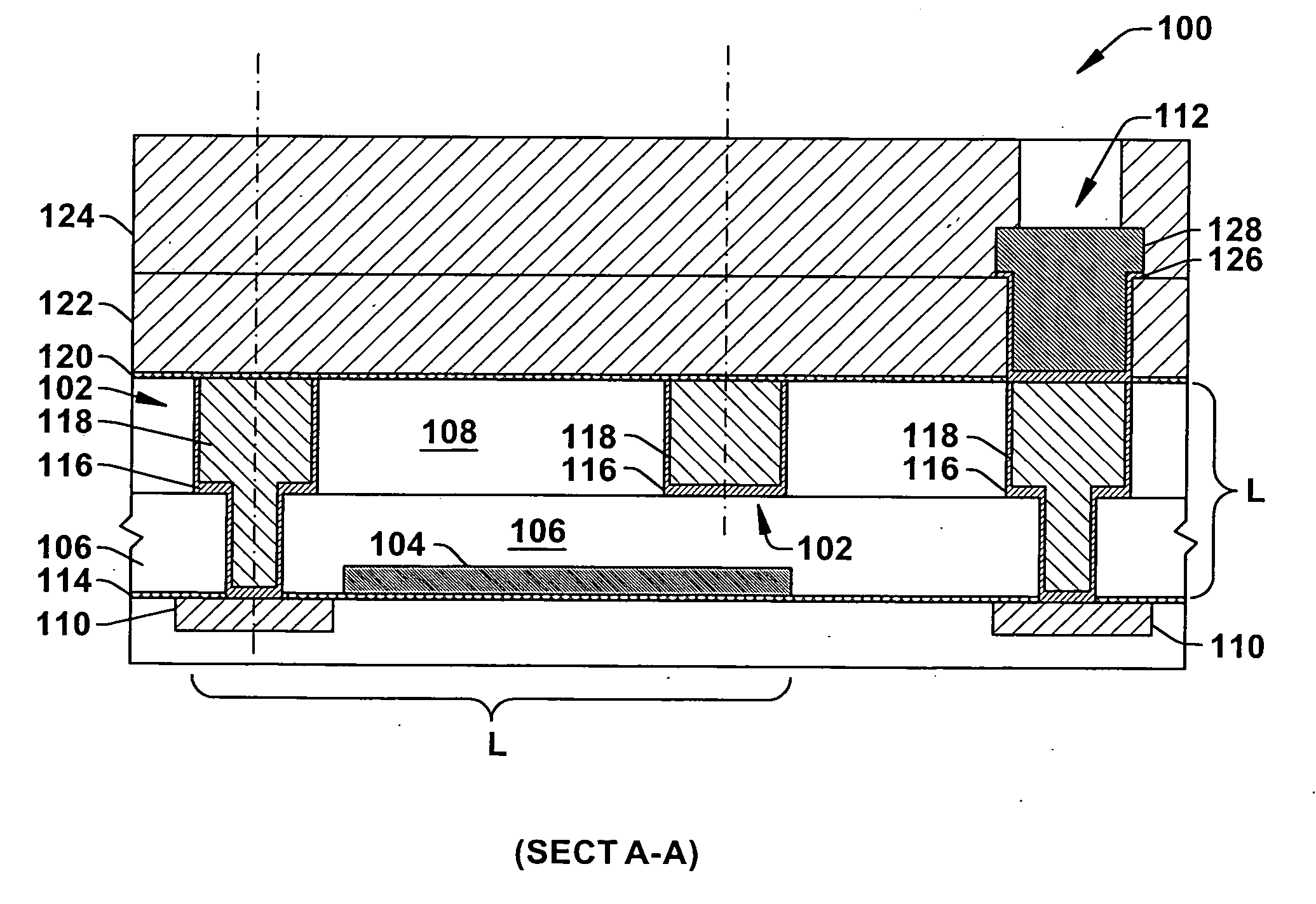

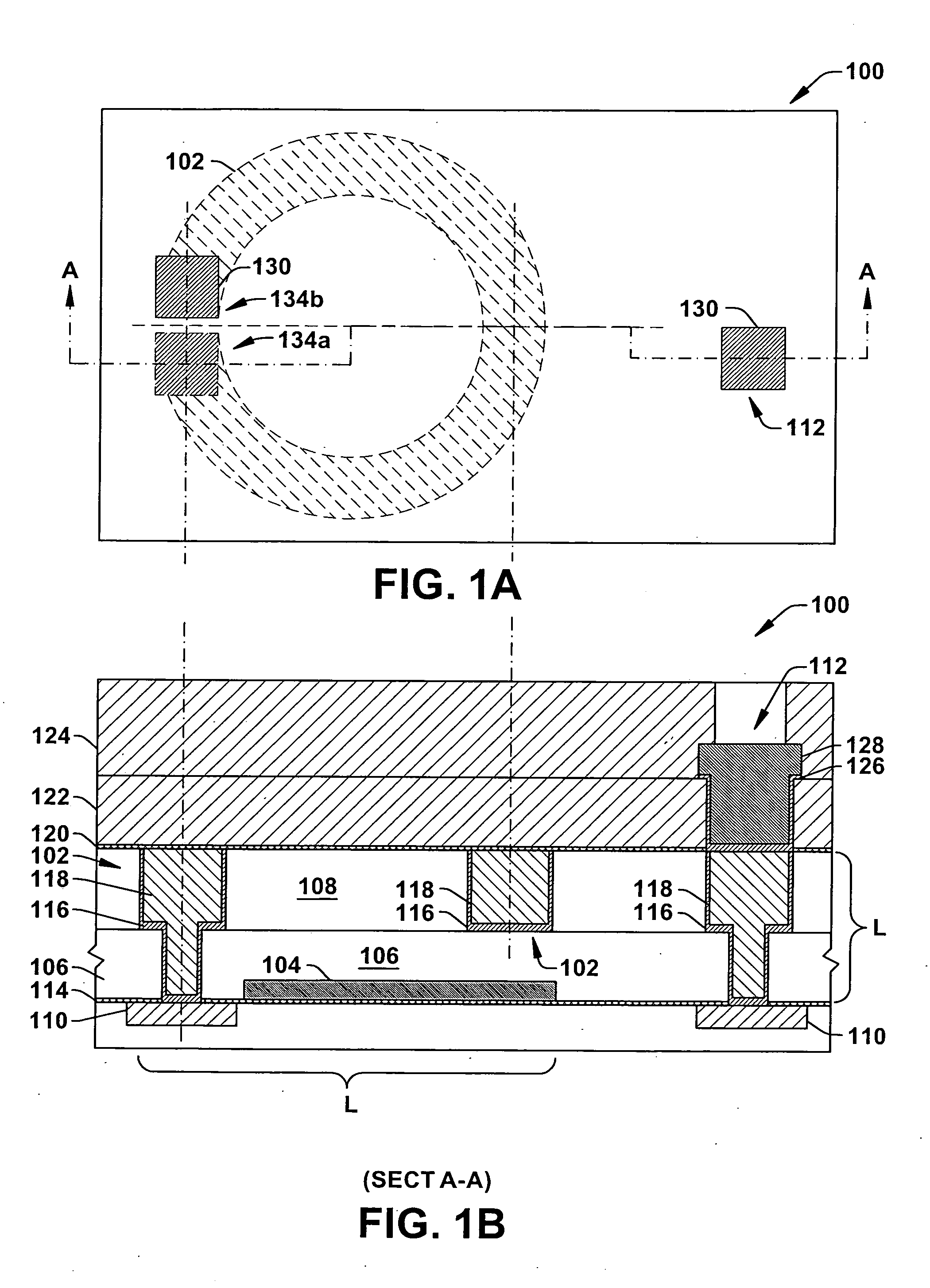

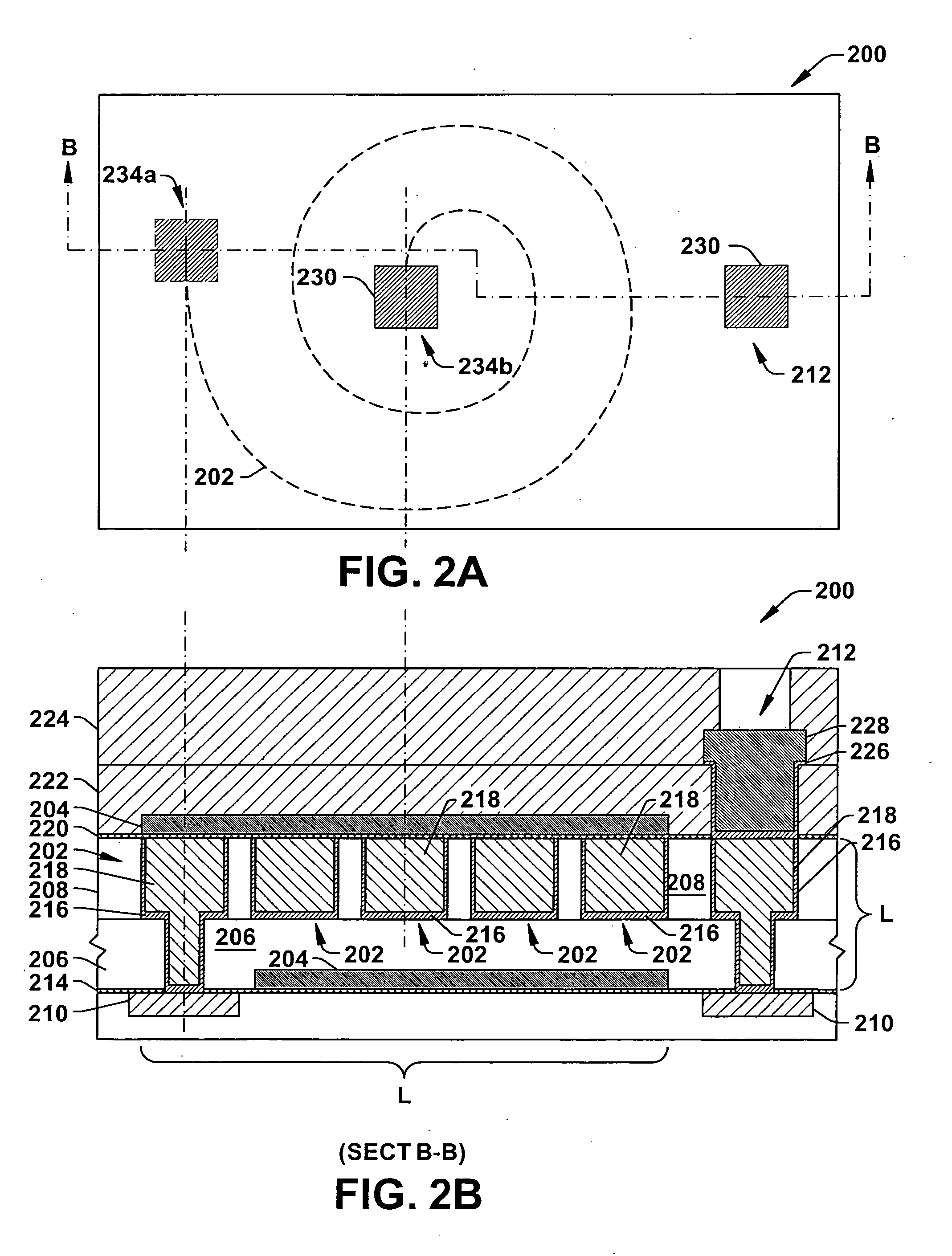

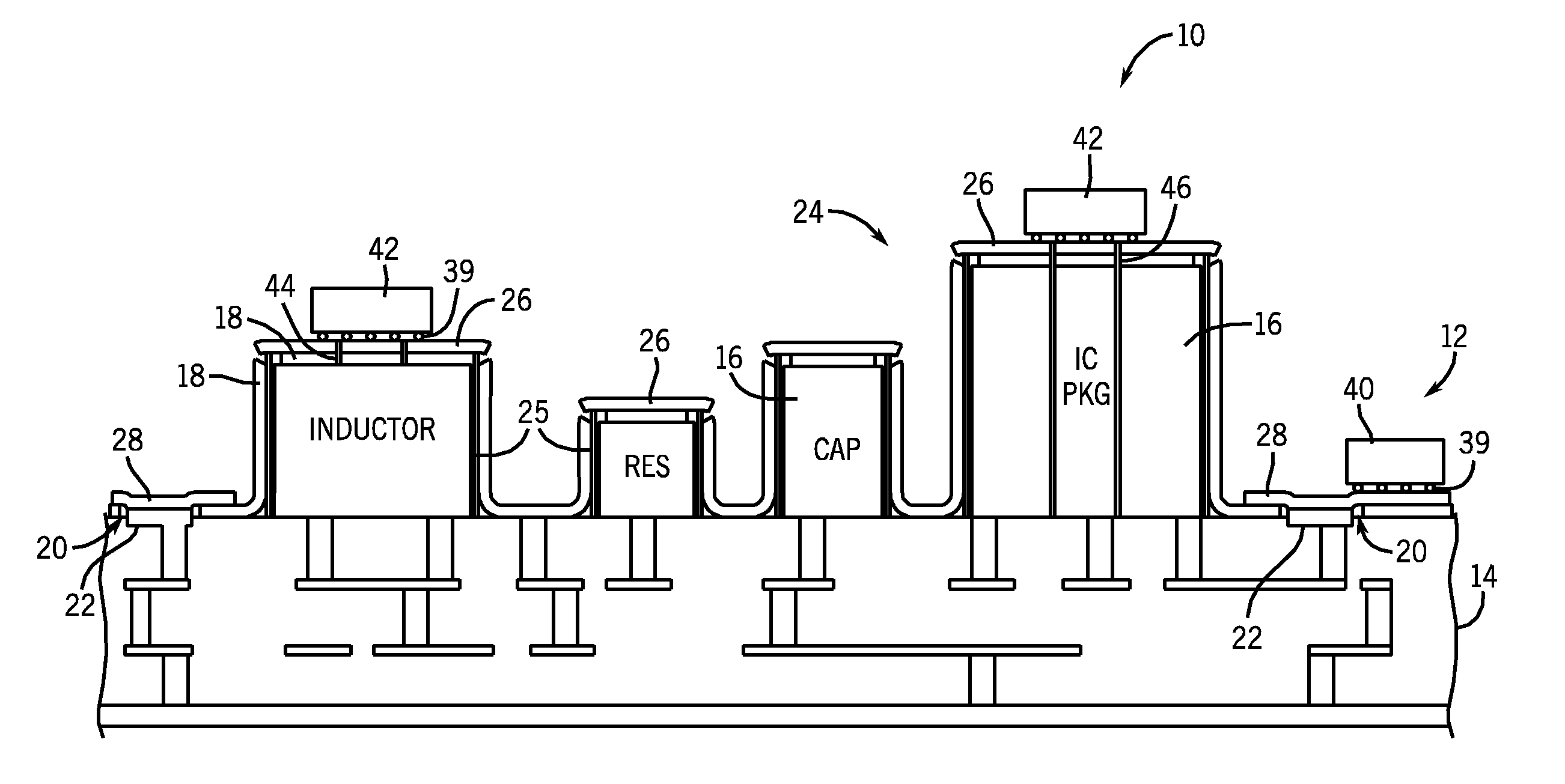

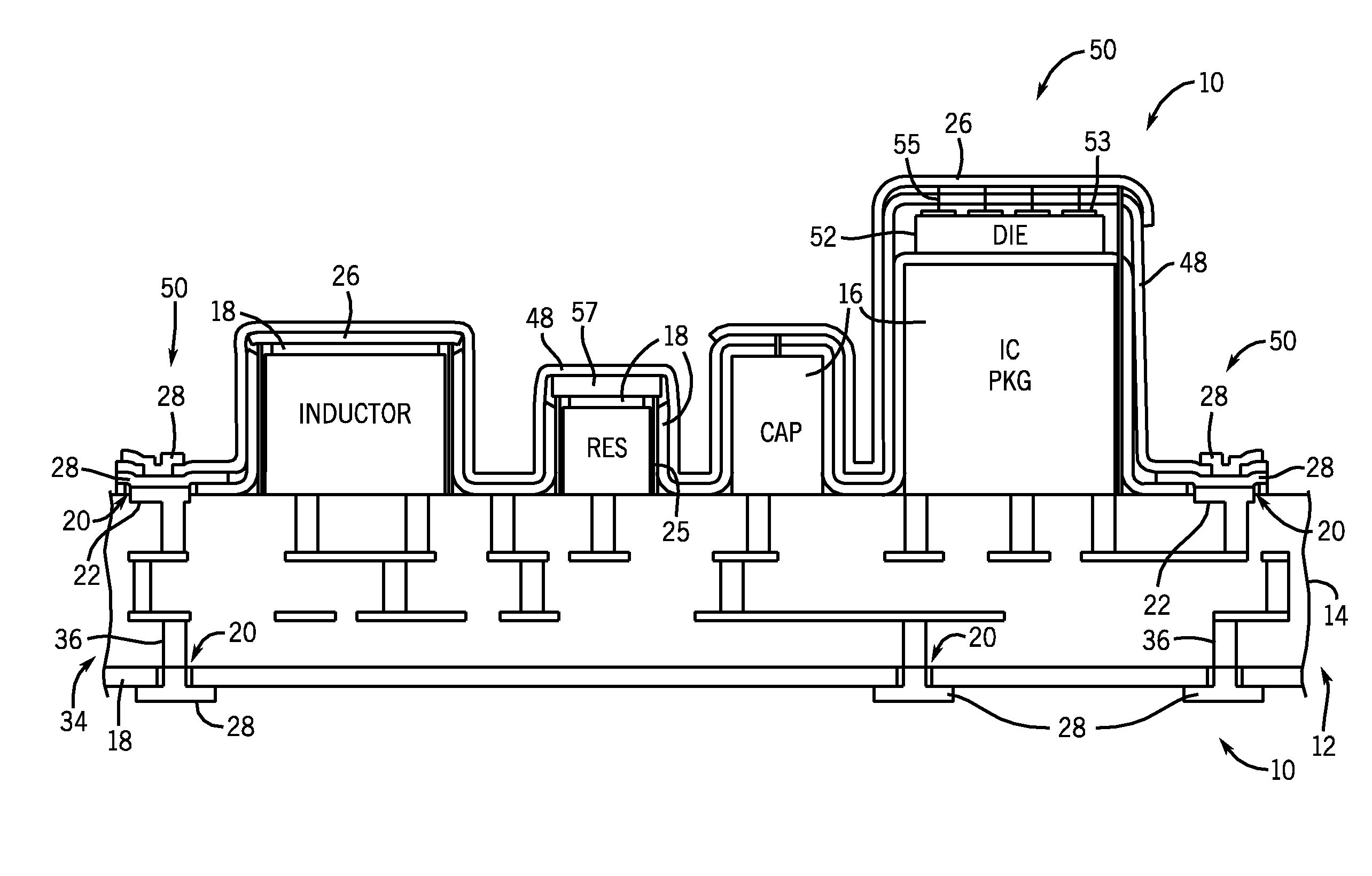

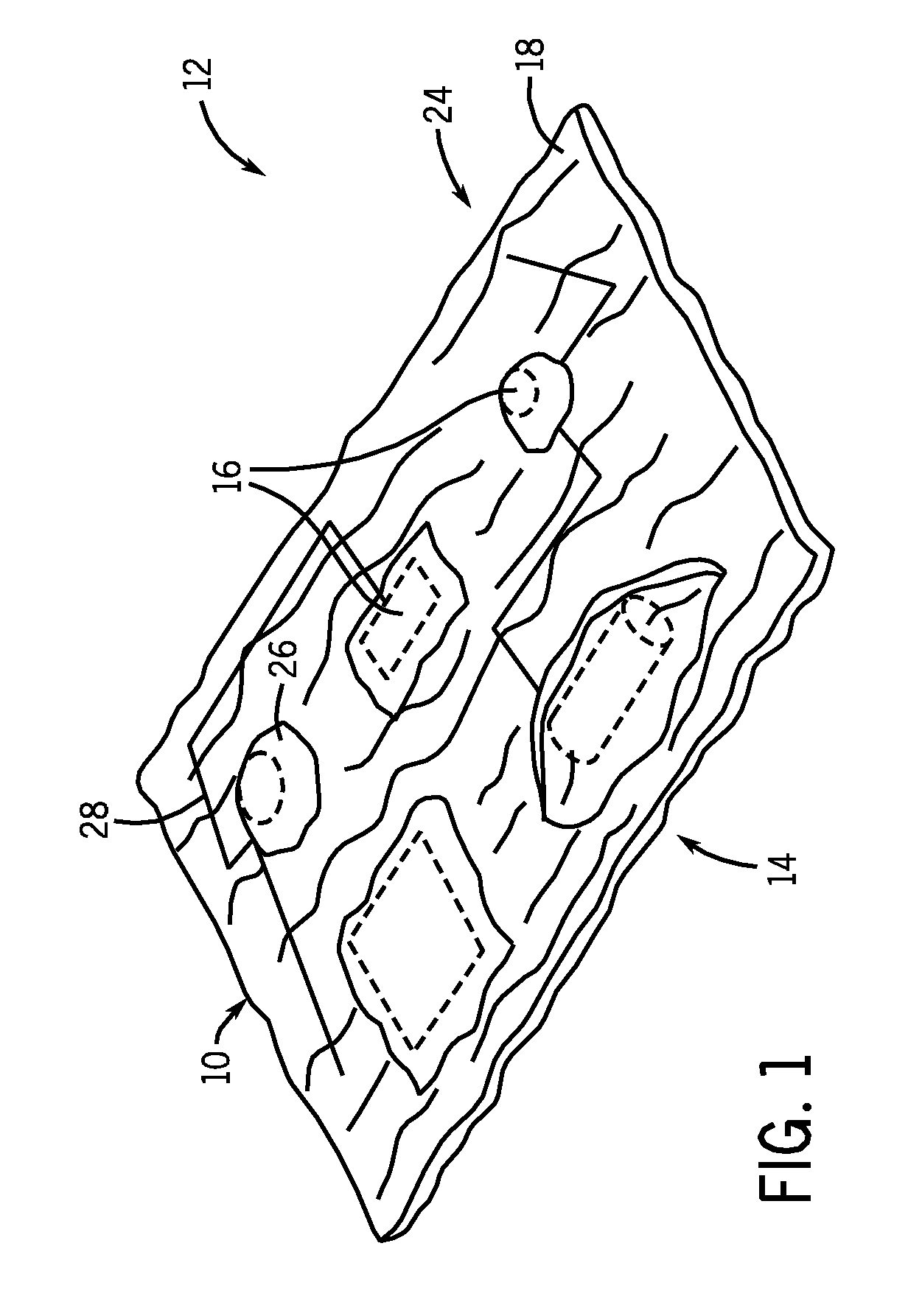

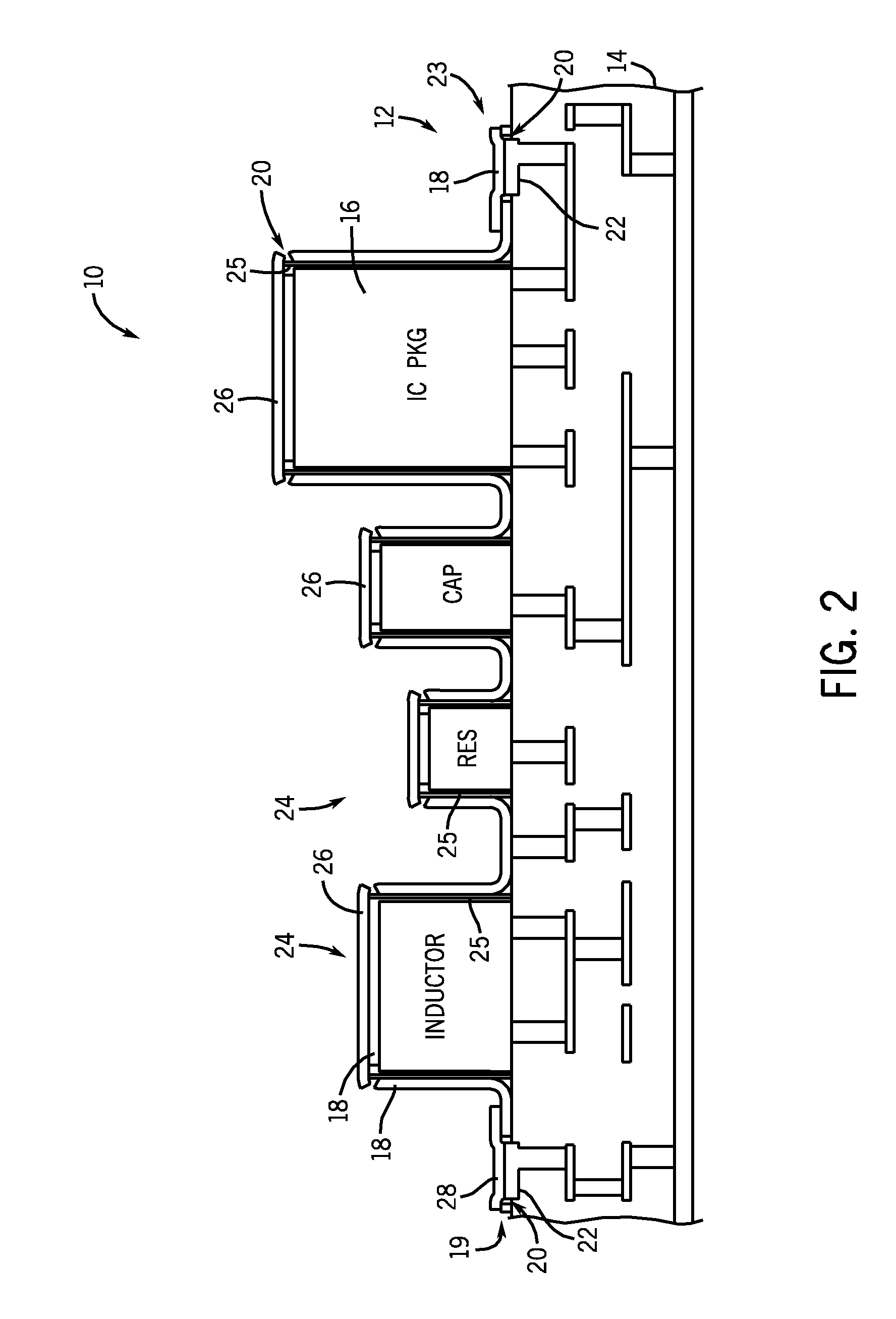

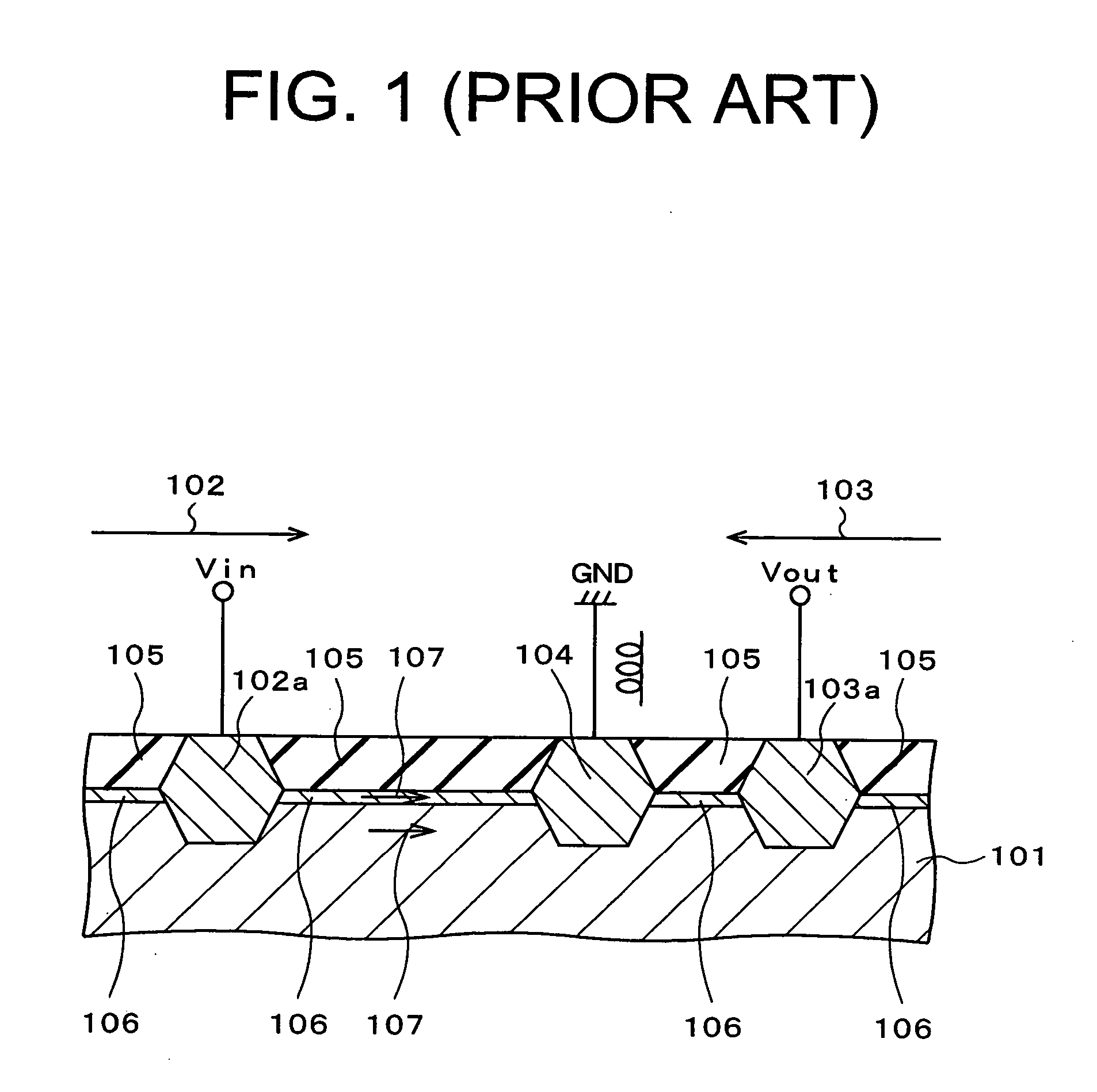

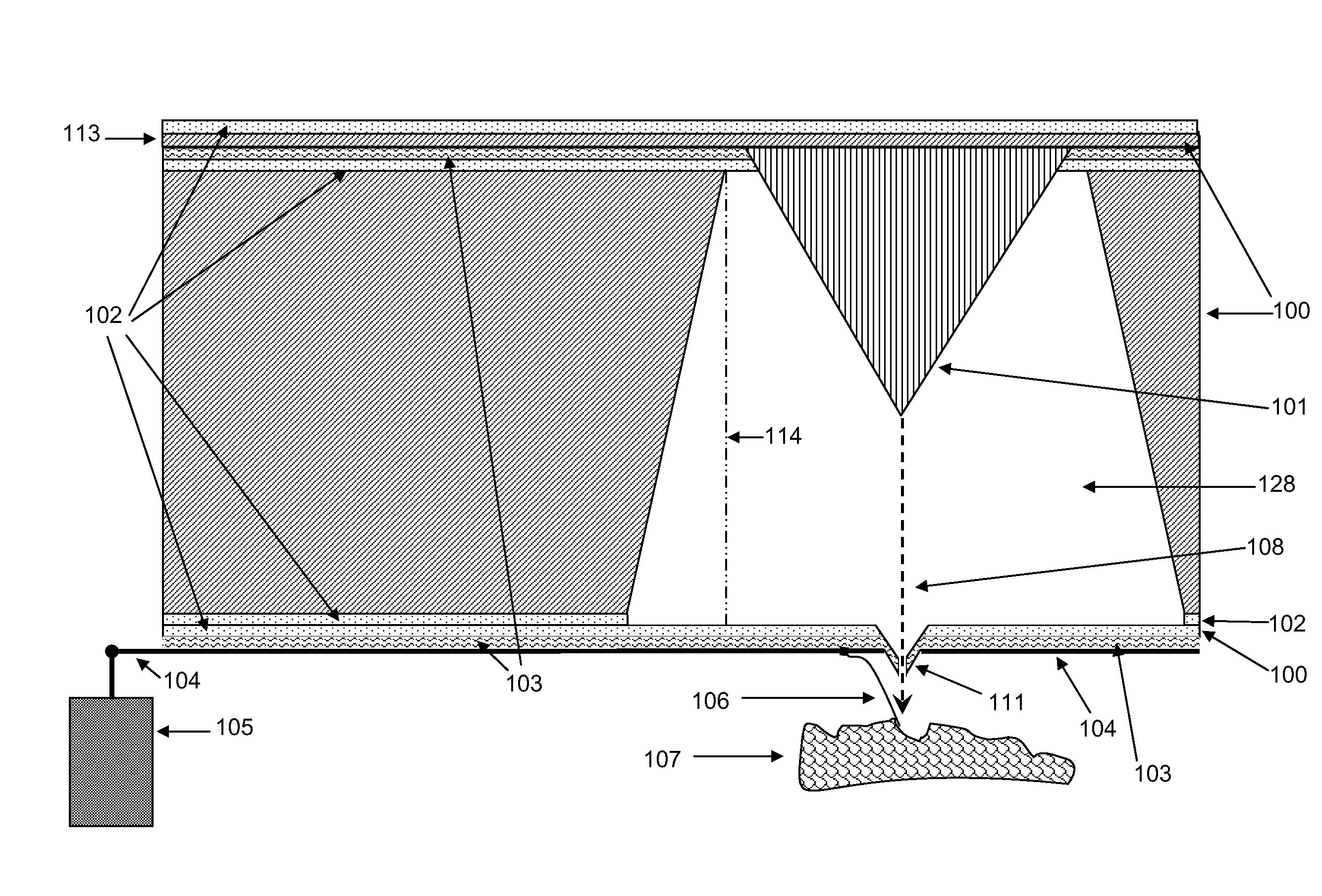

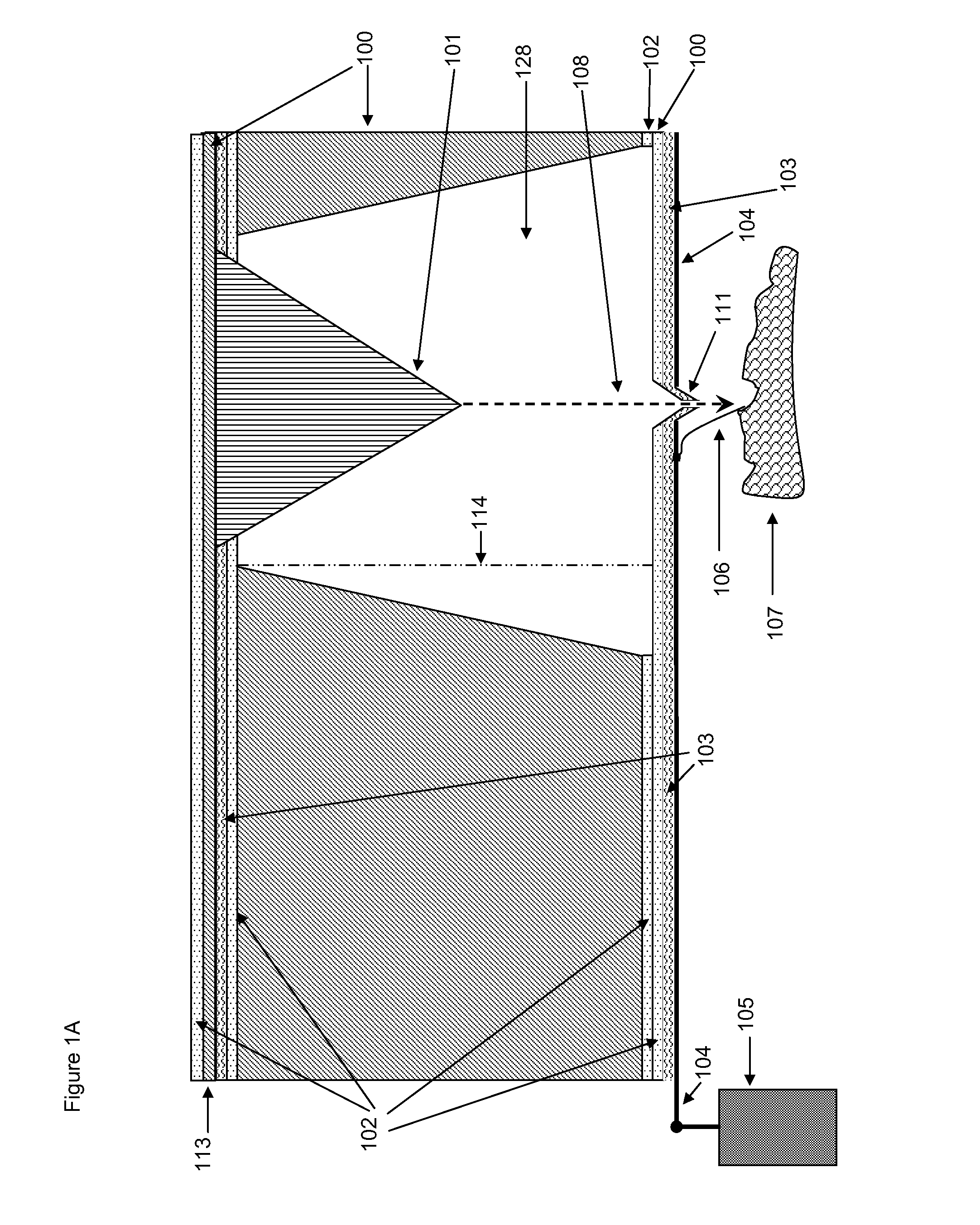

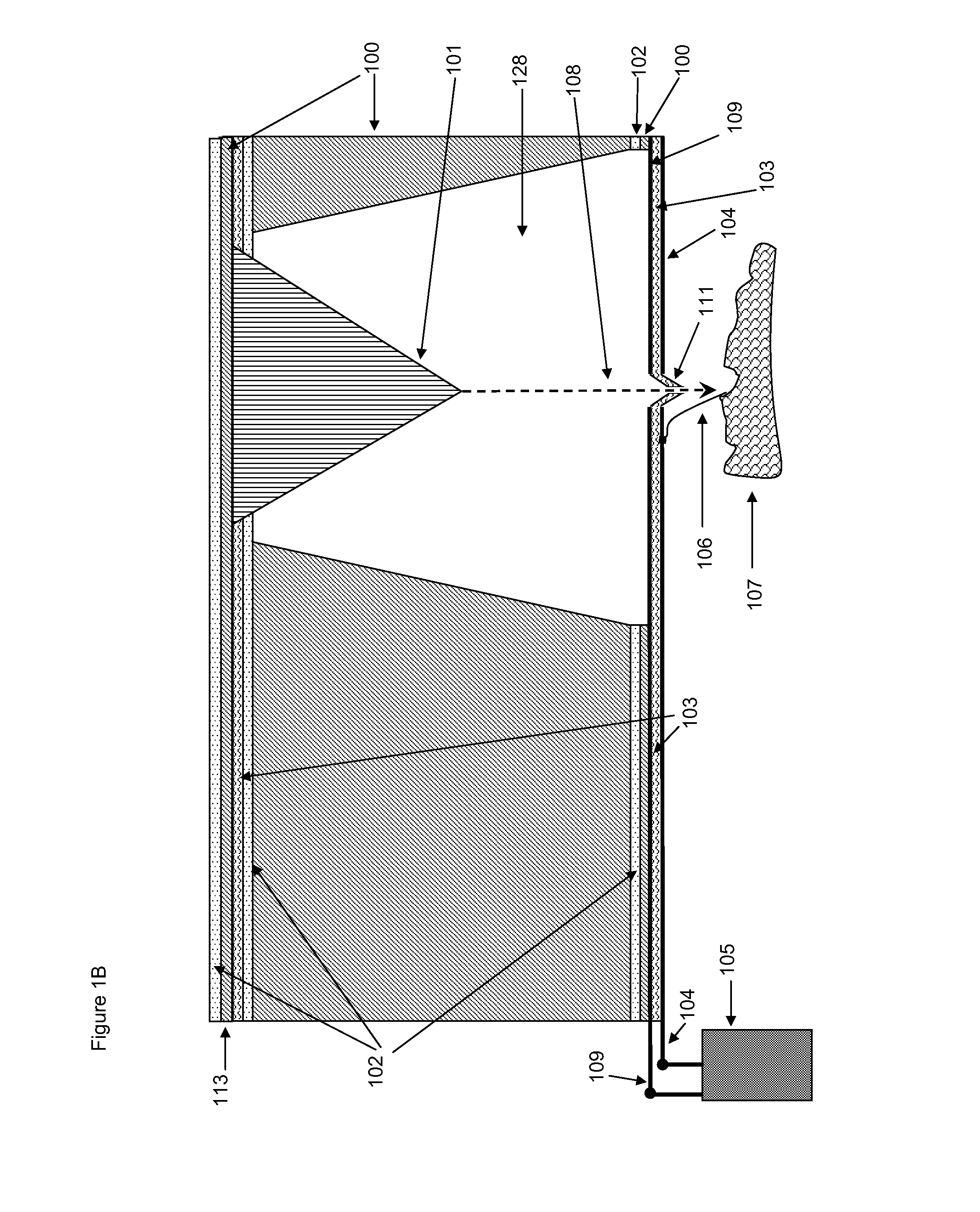

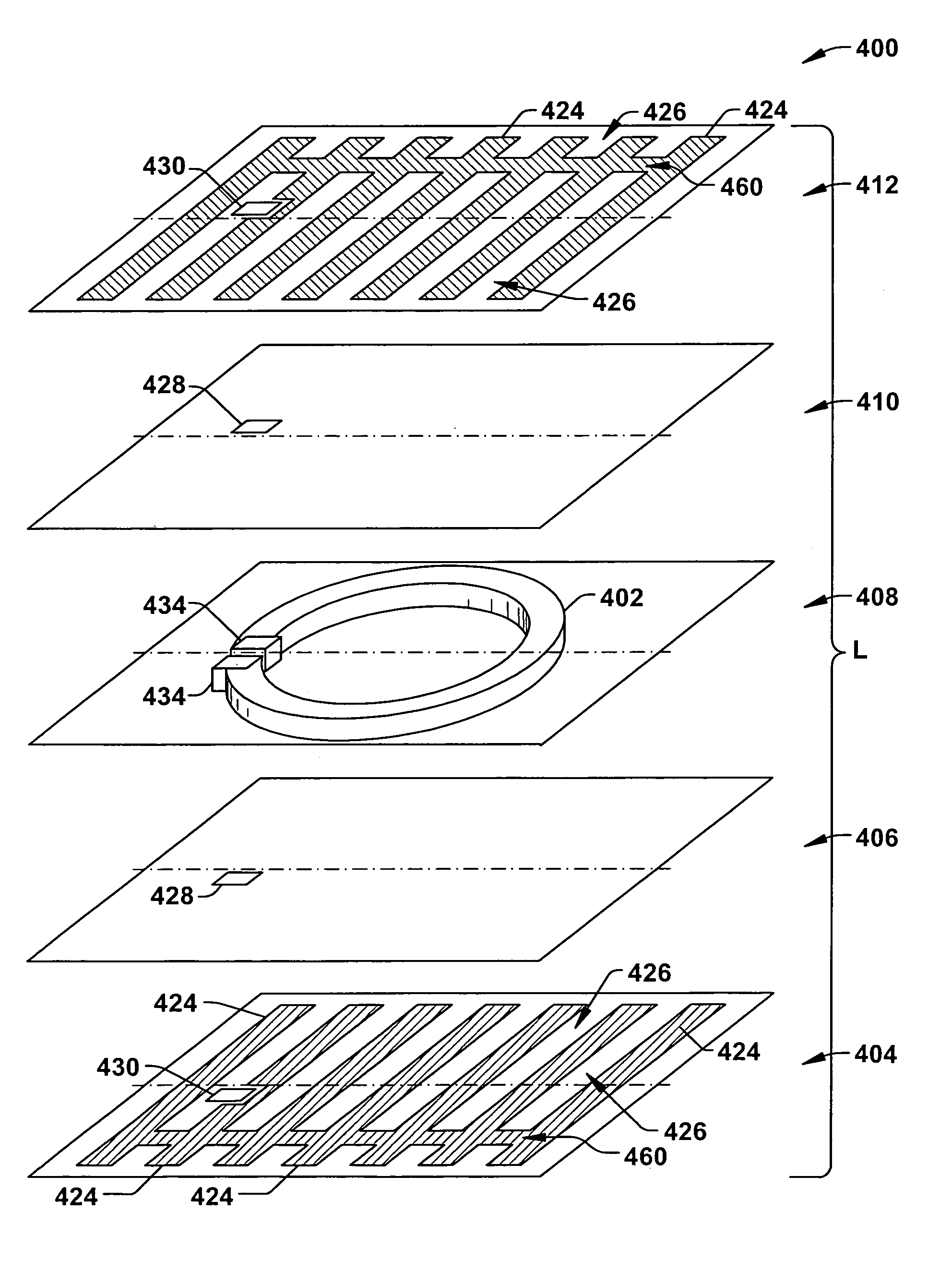

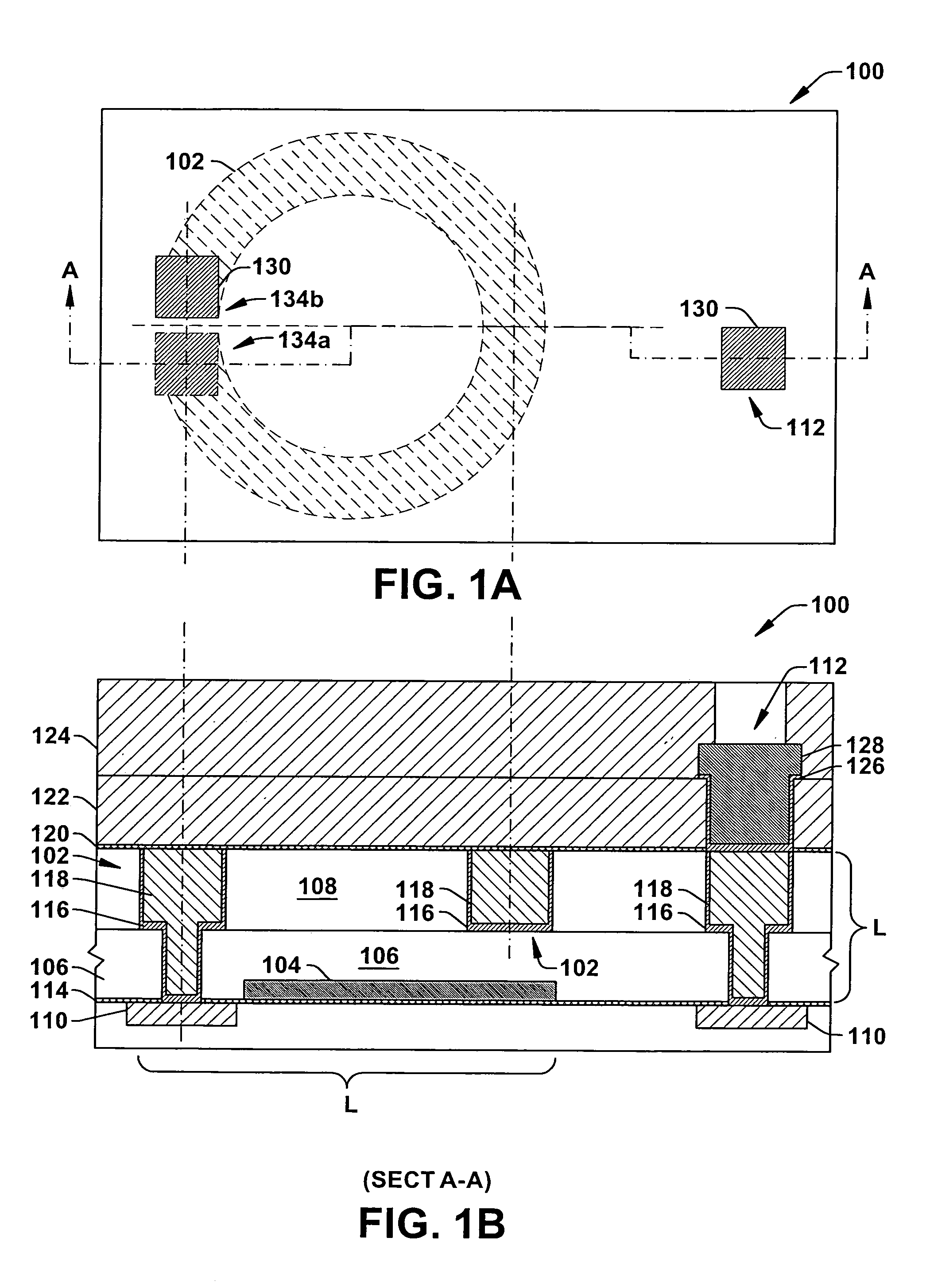

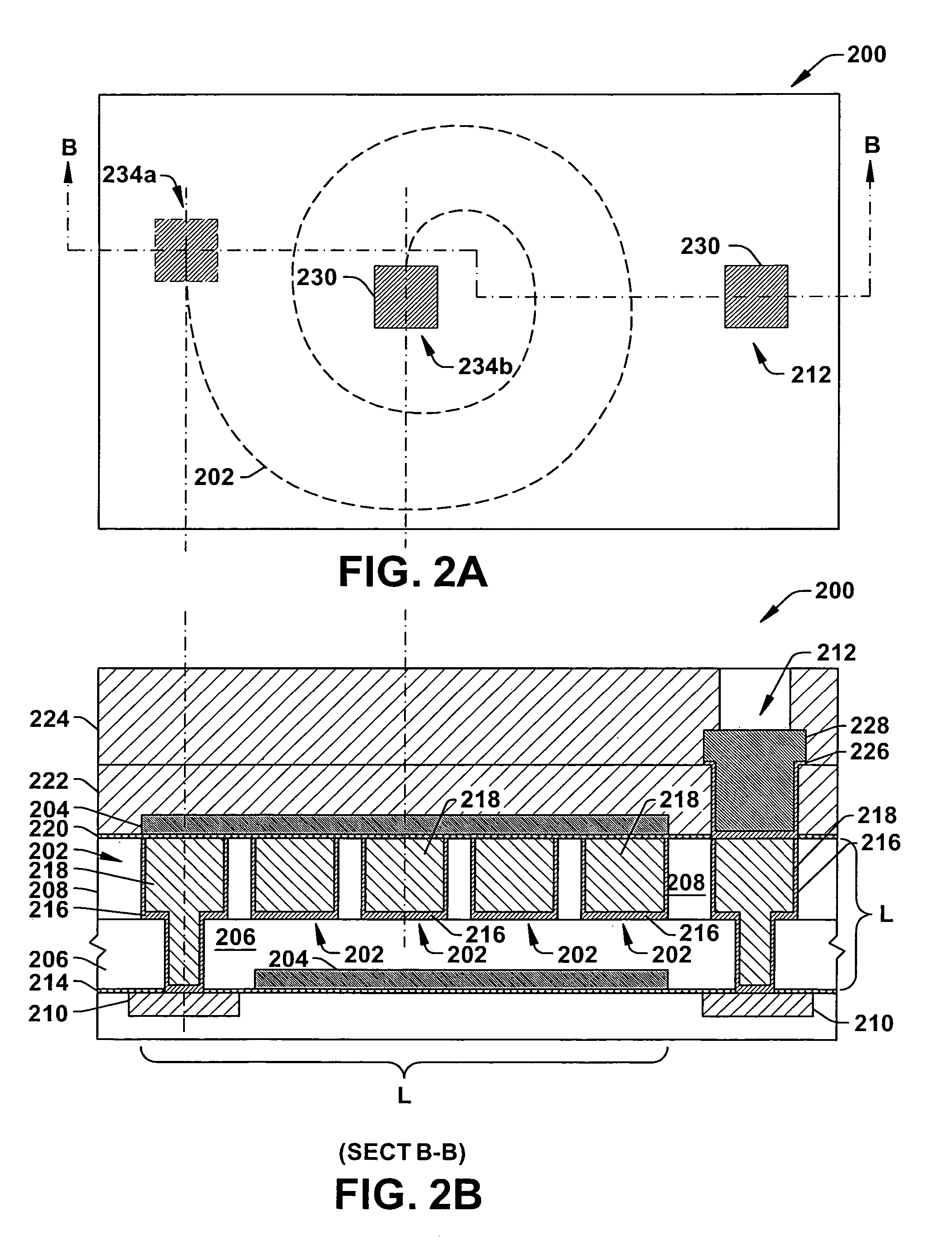

Method to improve inductance with a high-permeability slotted plate core in an integrated circuit

ActiveUS20060022787A1Mitigate eddy current lossIncrease inductanceSemiconductor/solid-state device detailsSolid-state devicesInductorIntegrated circuit

An inductor structure (102) formed in an integrated circuit (100) is disclosed, and includes a first isolation layer (106) and a first core plate (104) disposed over or within the first isolation layer (106, 114). The first core plate (104) includes a plurality of electrically coupled conductive traces composed of a conductive ferromagnetic material layer. A second isolation layer (108) overlies the first isolation layer and an inductor coil (102) composed of a conductive material layer (118) is formed within the second isolation layer (108). Another core plate may be formed over the coil. The one or more core plates increase an inductance (L) of the inductor coil (102).

Owner:TEXAS INSTR INC

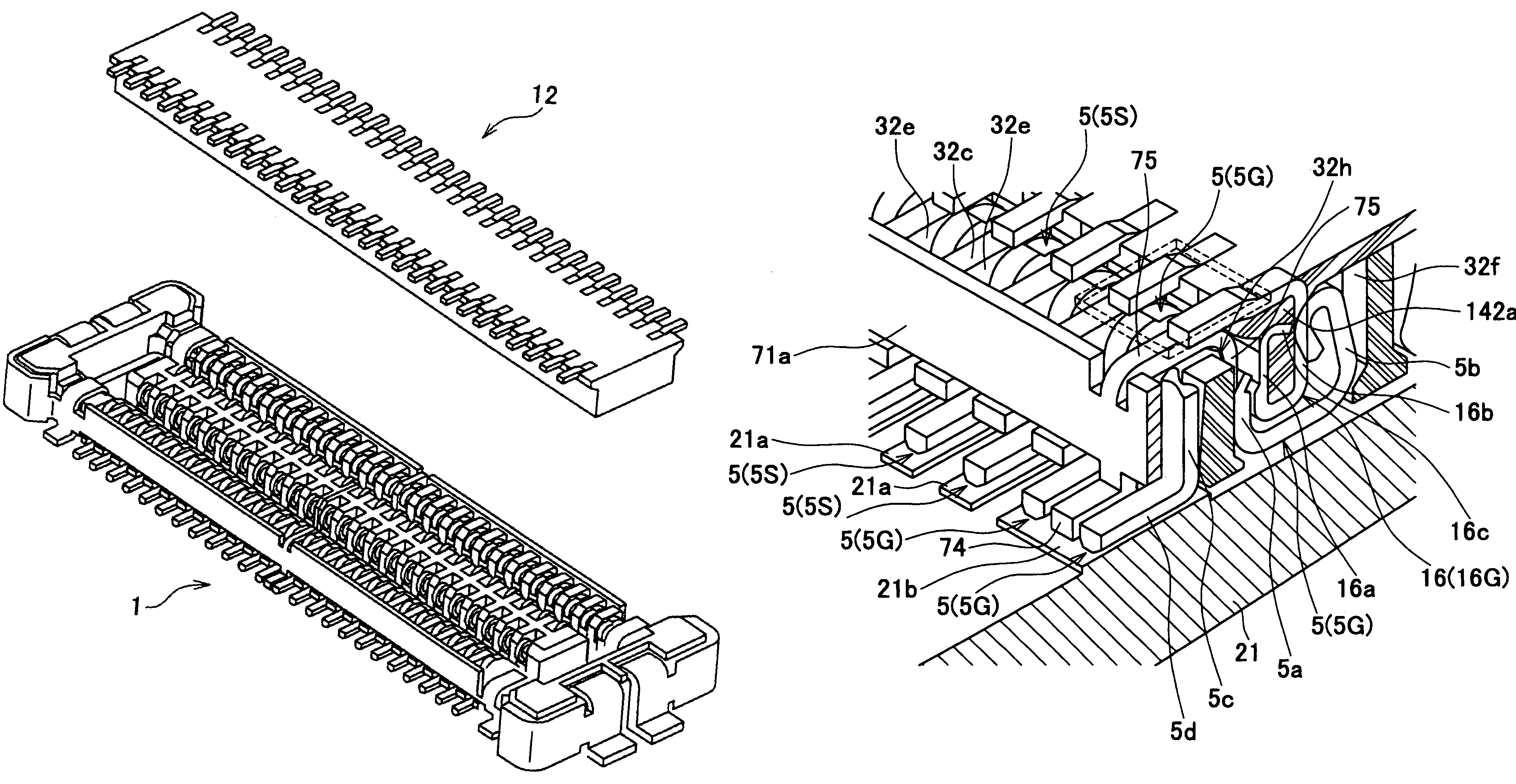

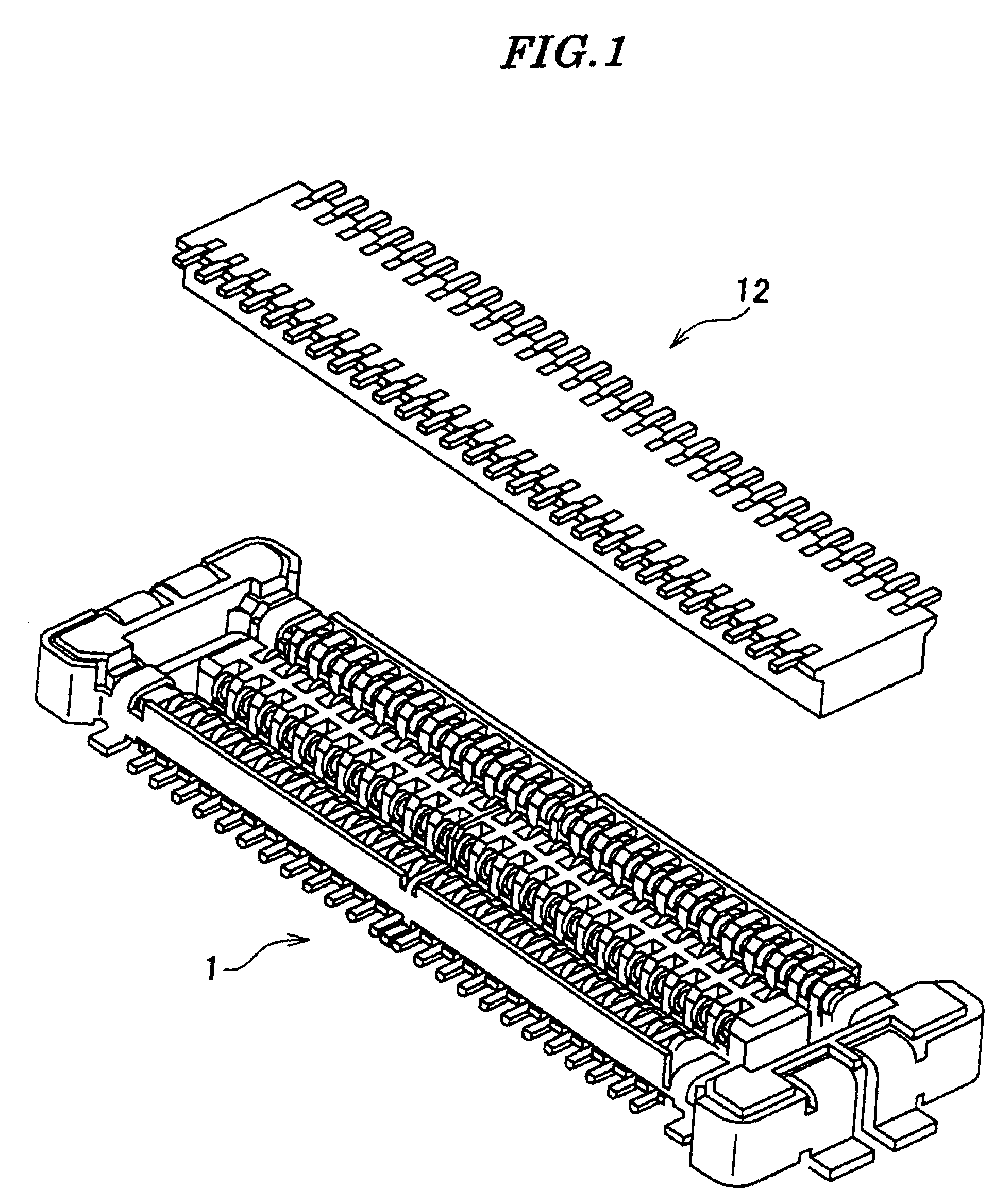

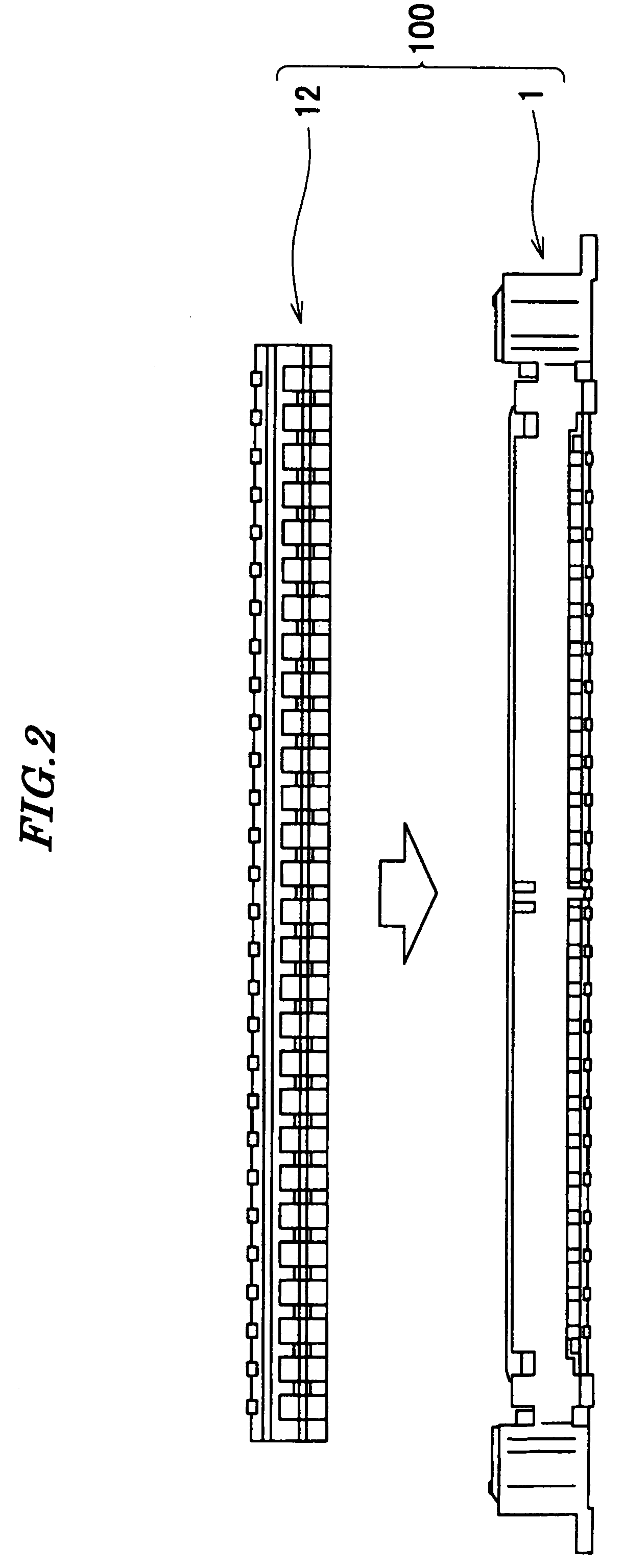

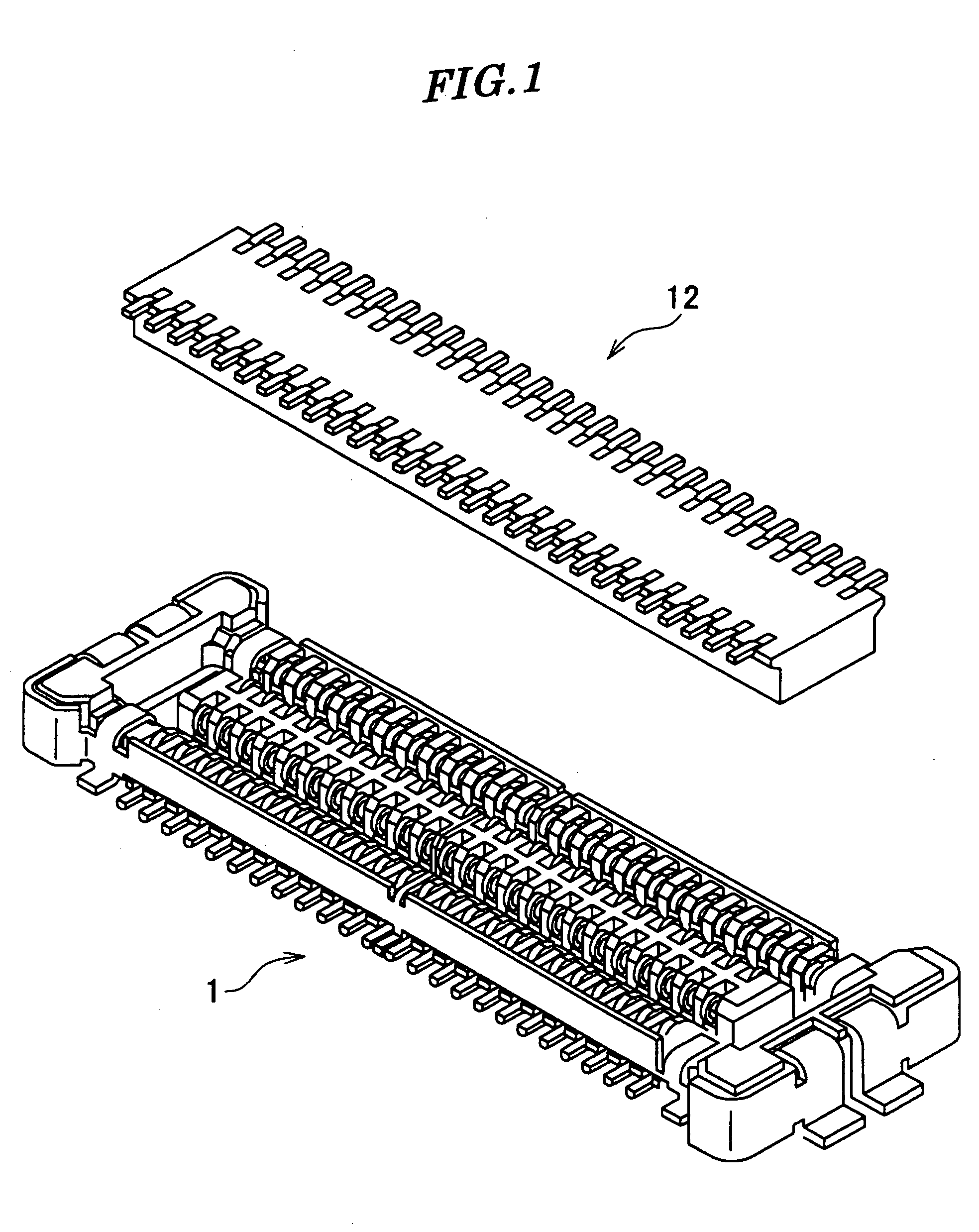

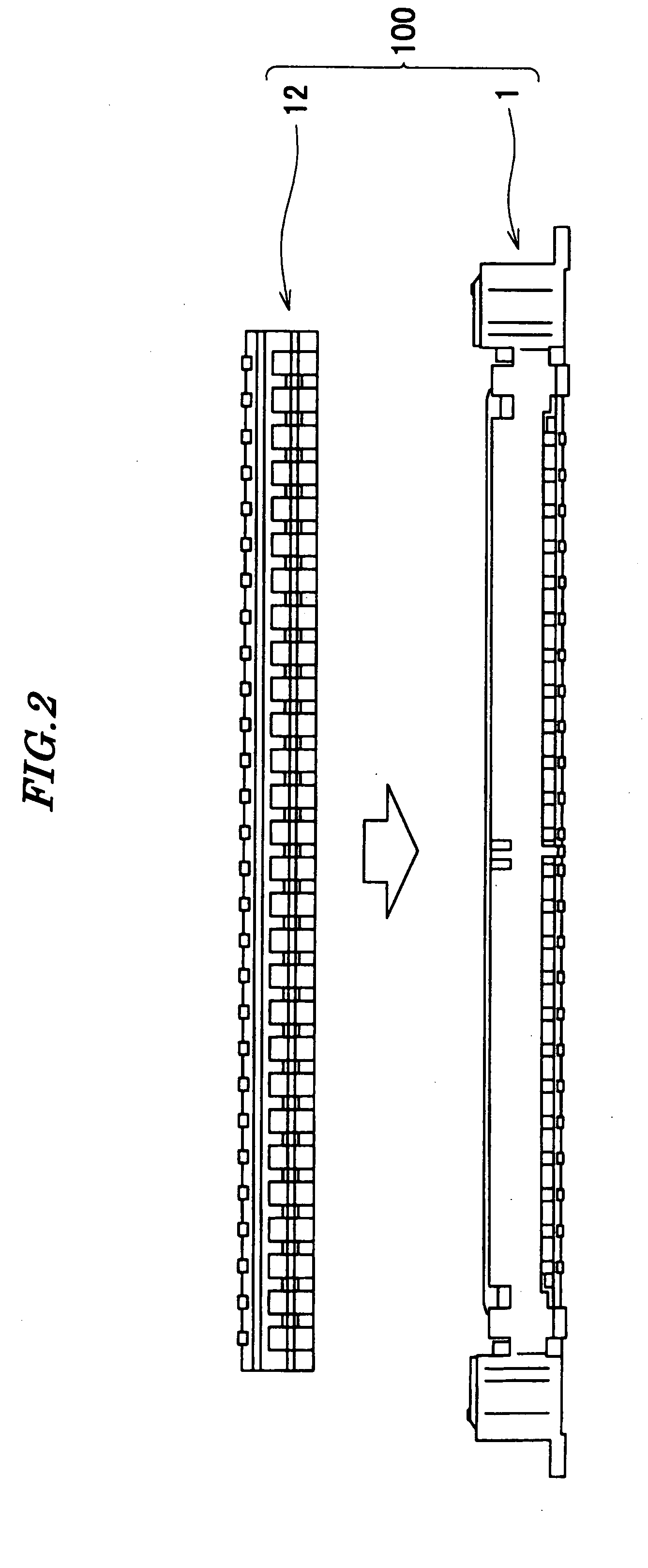

Connector

InactiveUS7585185B2Small sizeSufficient shieldingFixed connectionsPrinted circuitsGround contactPrinted circuit board

Owner:JAPAN AVIATION ELECTRONICS IND LTD

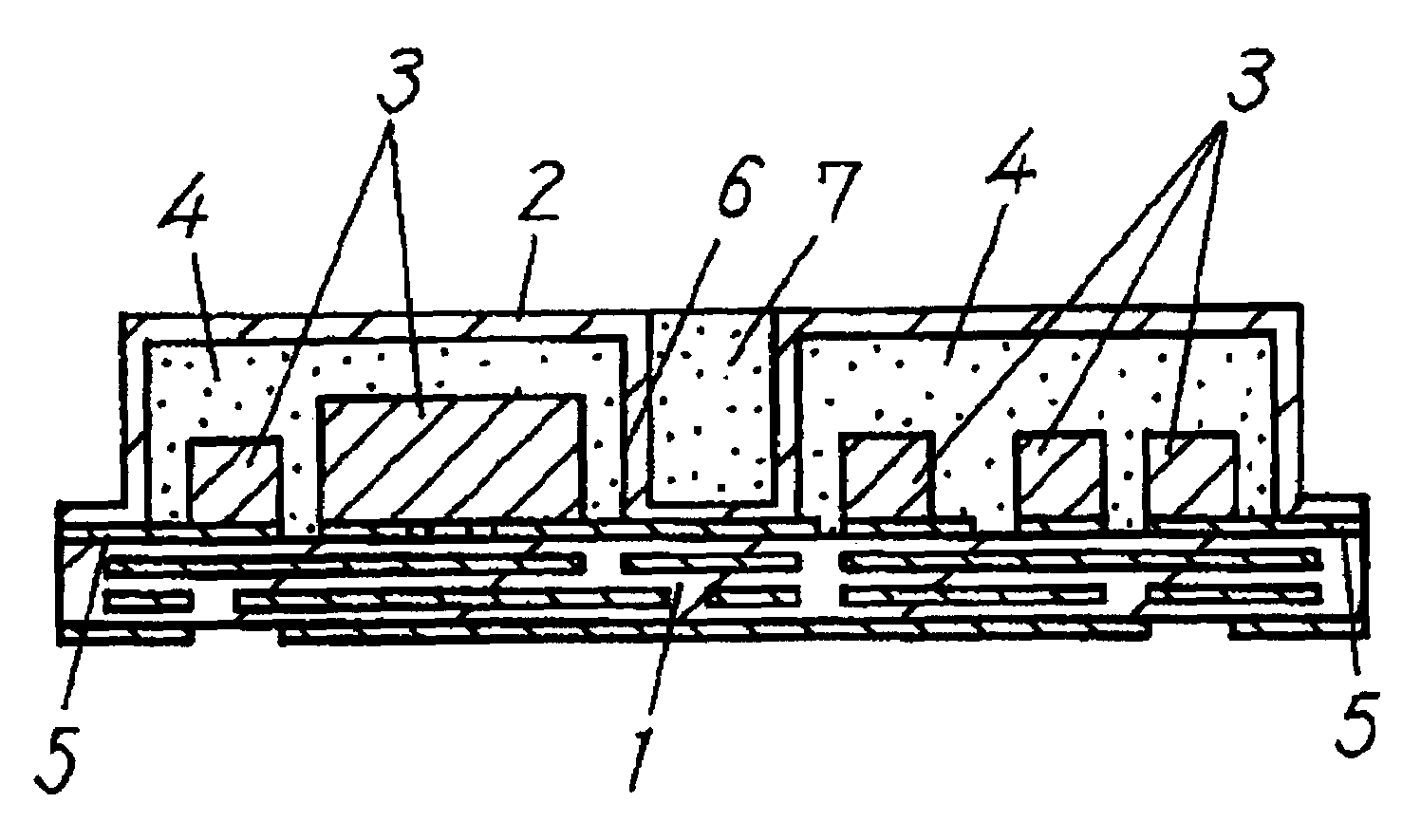

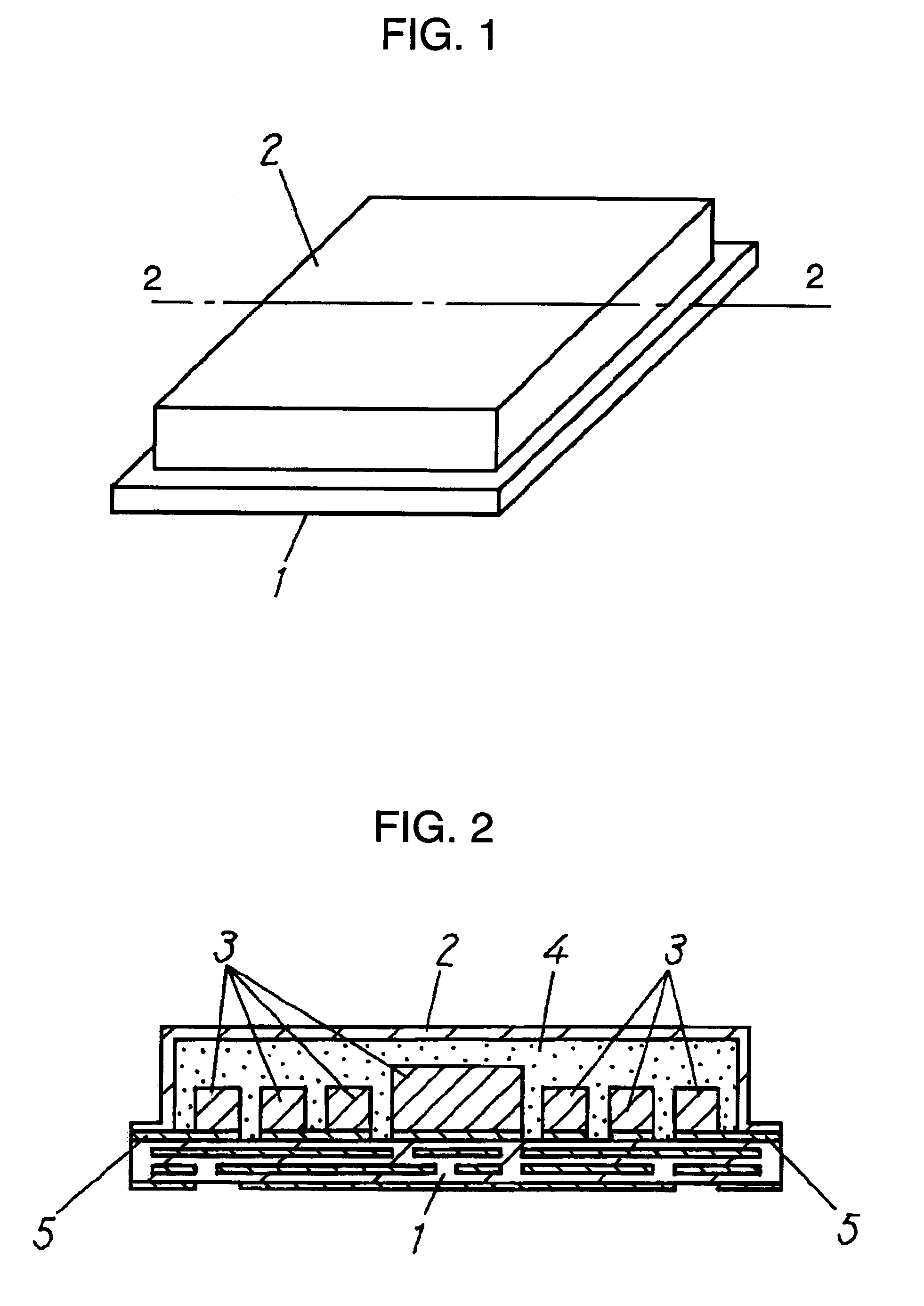

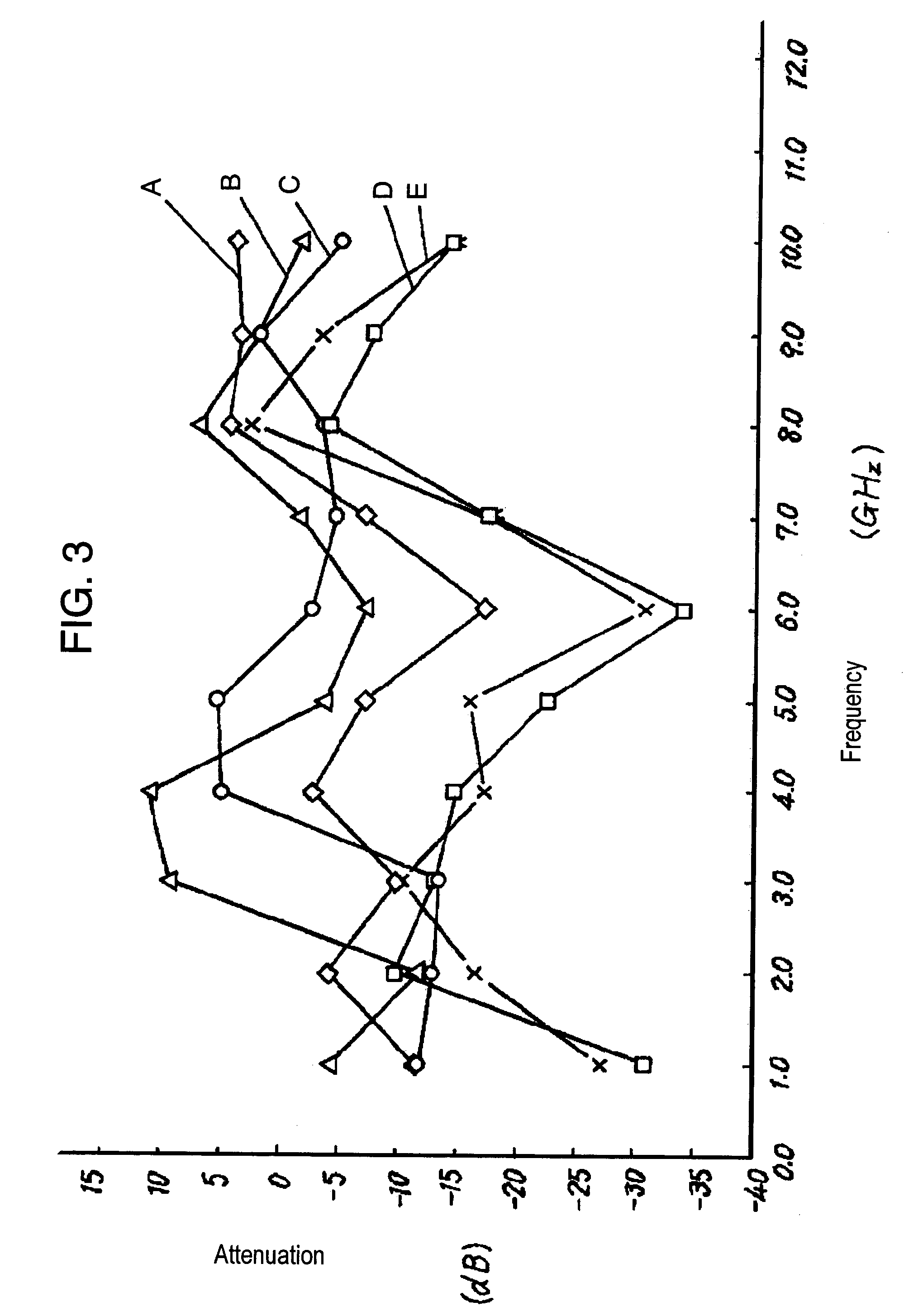

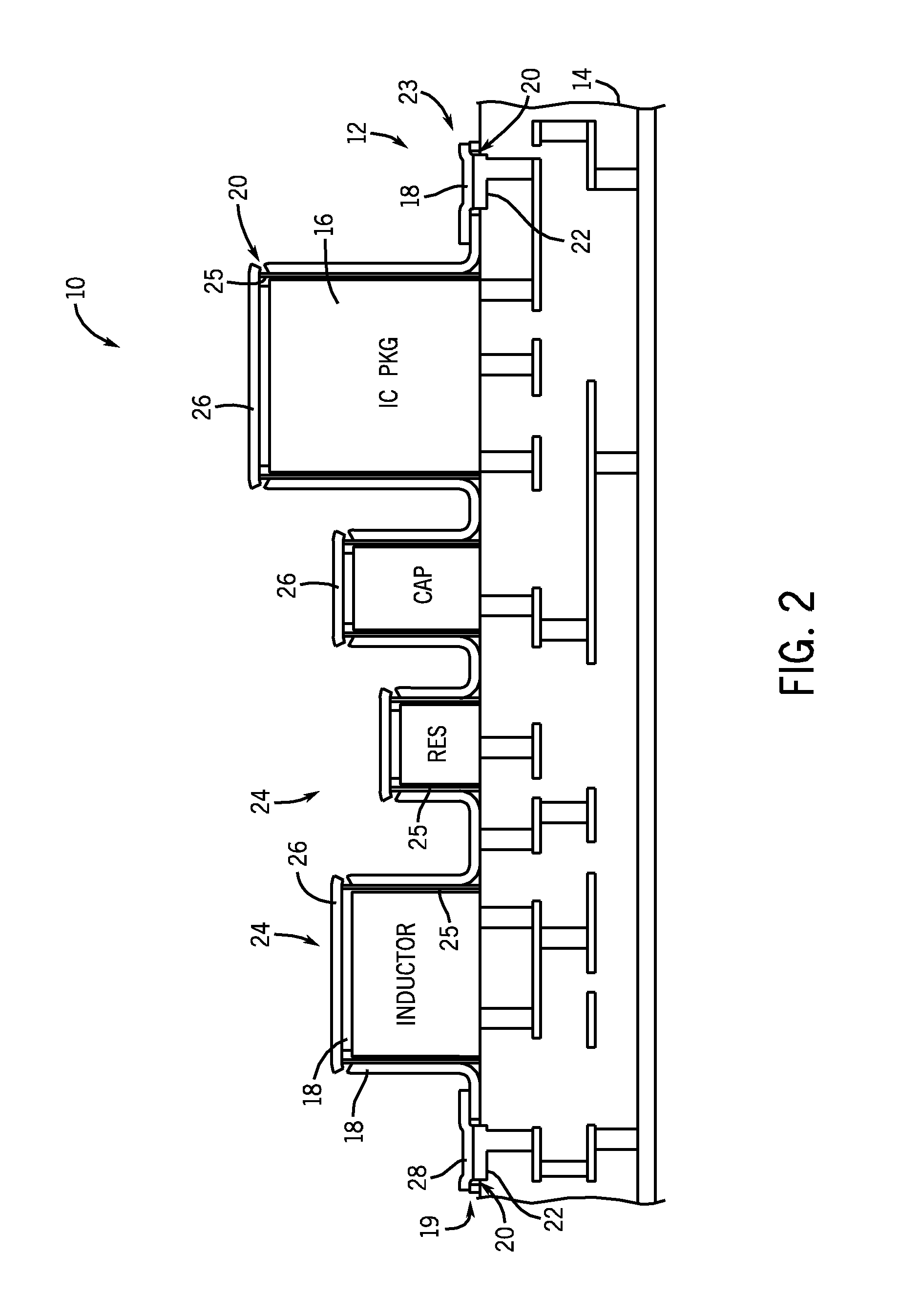

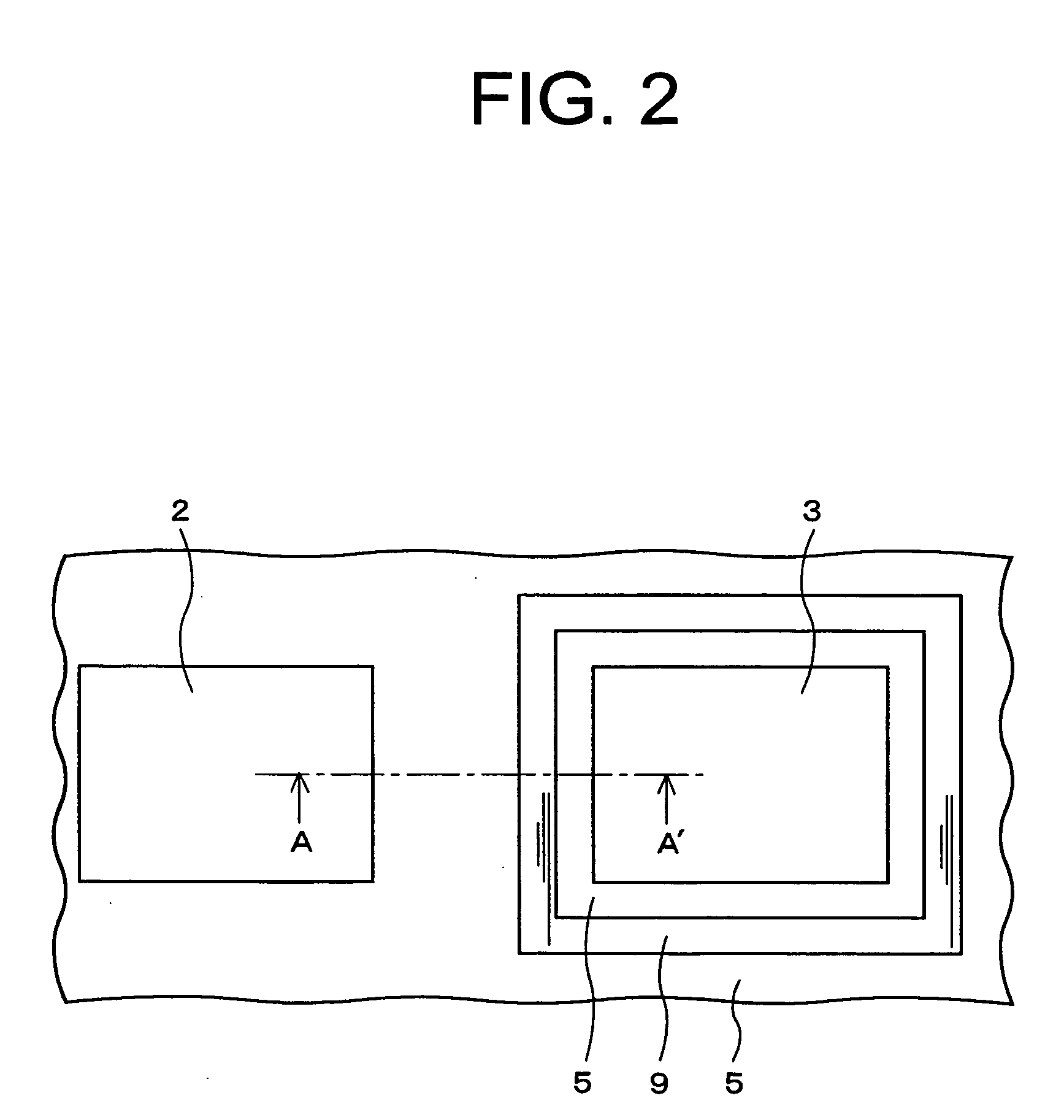

Module component

ActiveUS7161252B2Low profileSufficient shieldingSemiconductor/solid-state device detailsCross-talk/noise/interference reductionEngineeringGround pattern

A module includes a component, a circuit board having the component mounted thereon, a first grounding pattern formed on an outermost periphery of a surface portion of the circuit board; a first sealer provided on the circuit board and having a dimension projected on the circuit board, and a metal film covering the sealer and connected to the grounding pattern. The dimension of the first dealer is smaller than an outside dimension of the circuit board. The first sealer is made of first resin and sealing the component. The module has a low profile and is adequately shielded.

Owner:SAMSUNG ELECTRONICS CO LTD

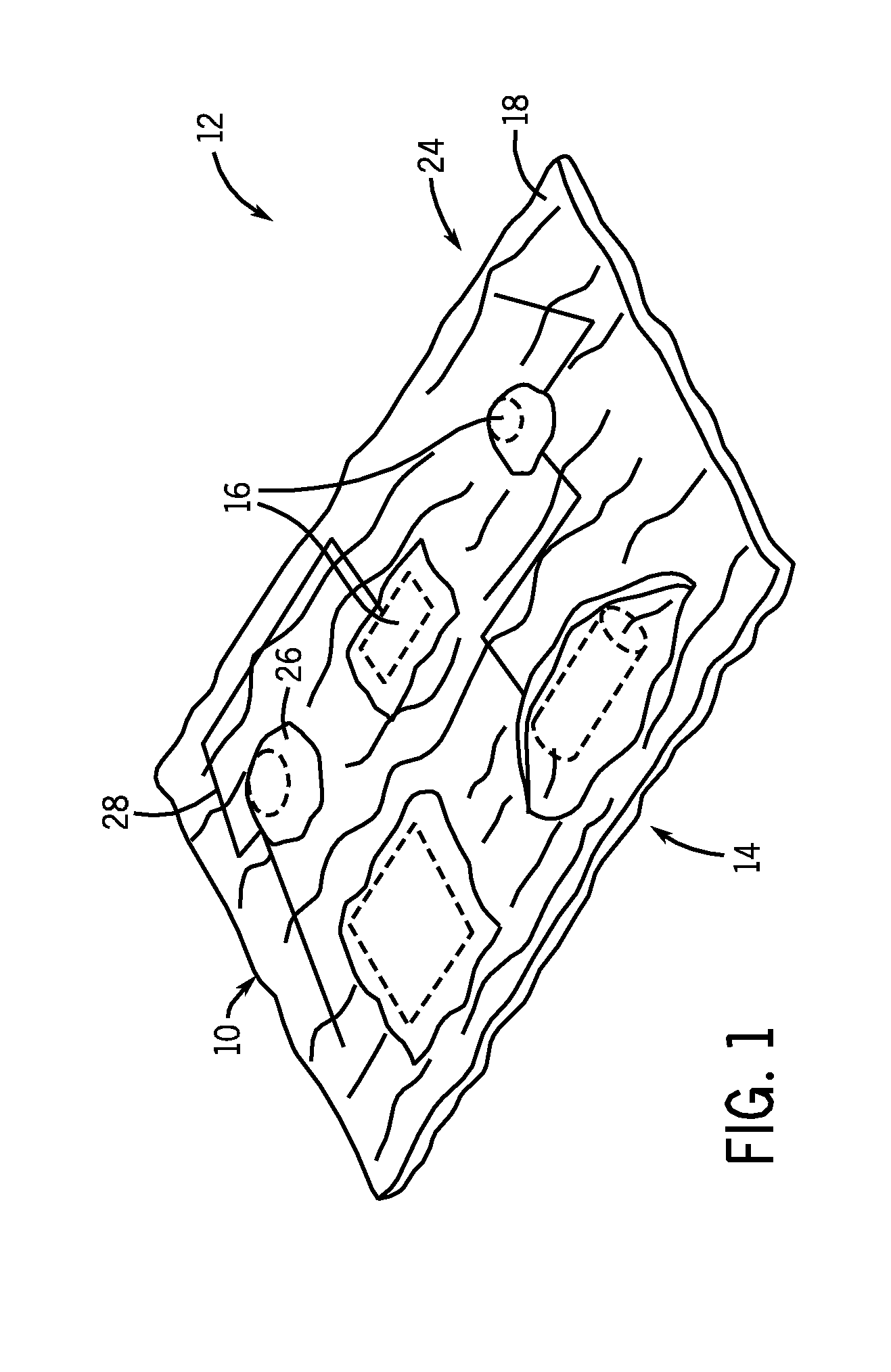

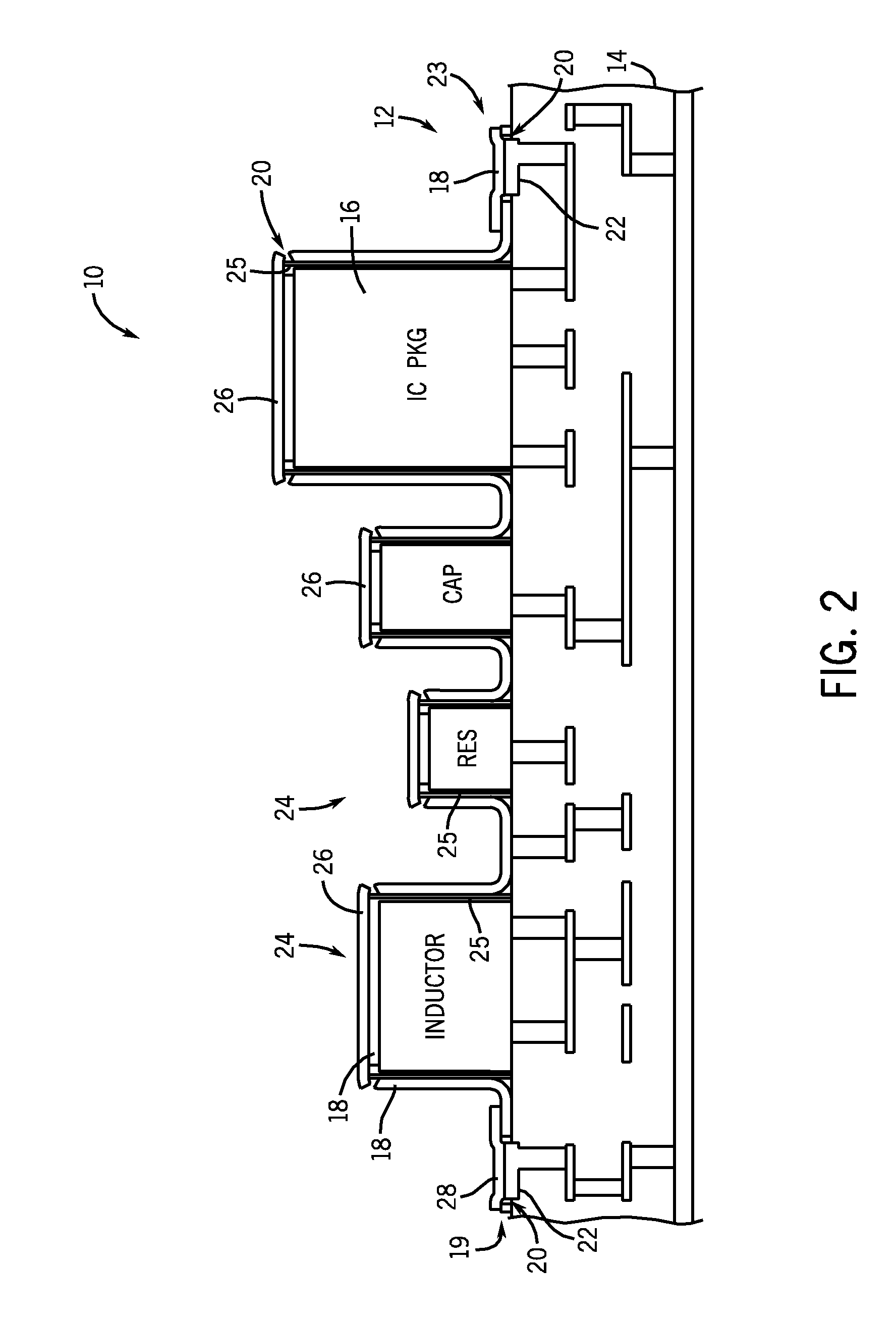

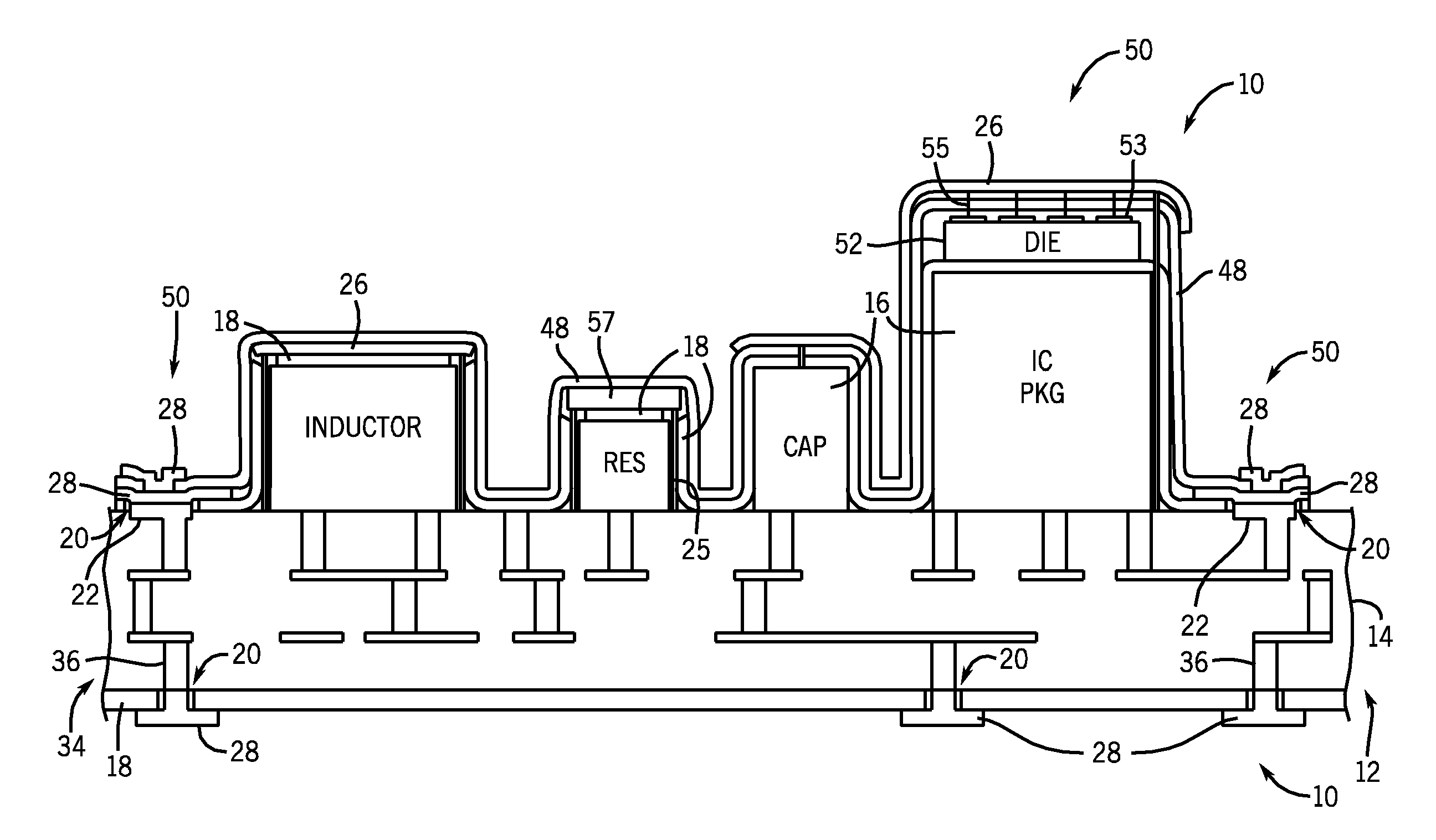

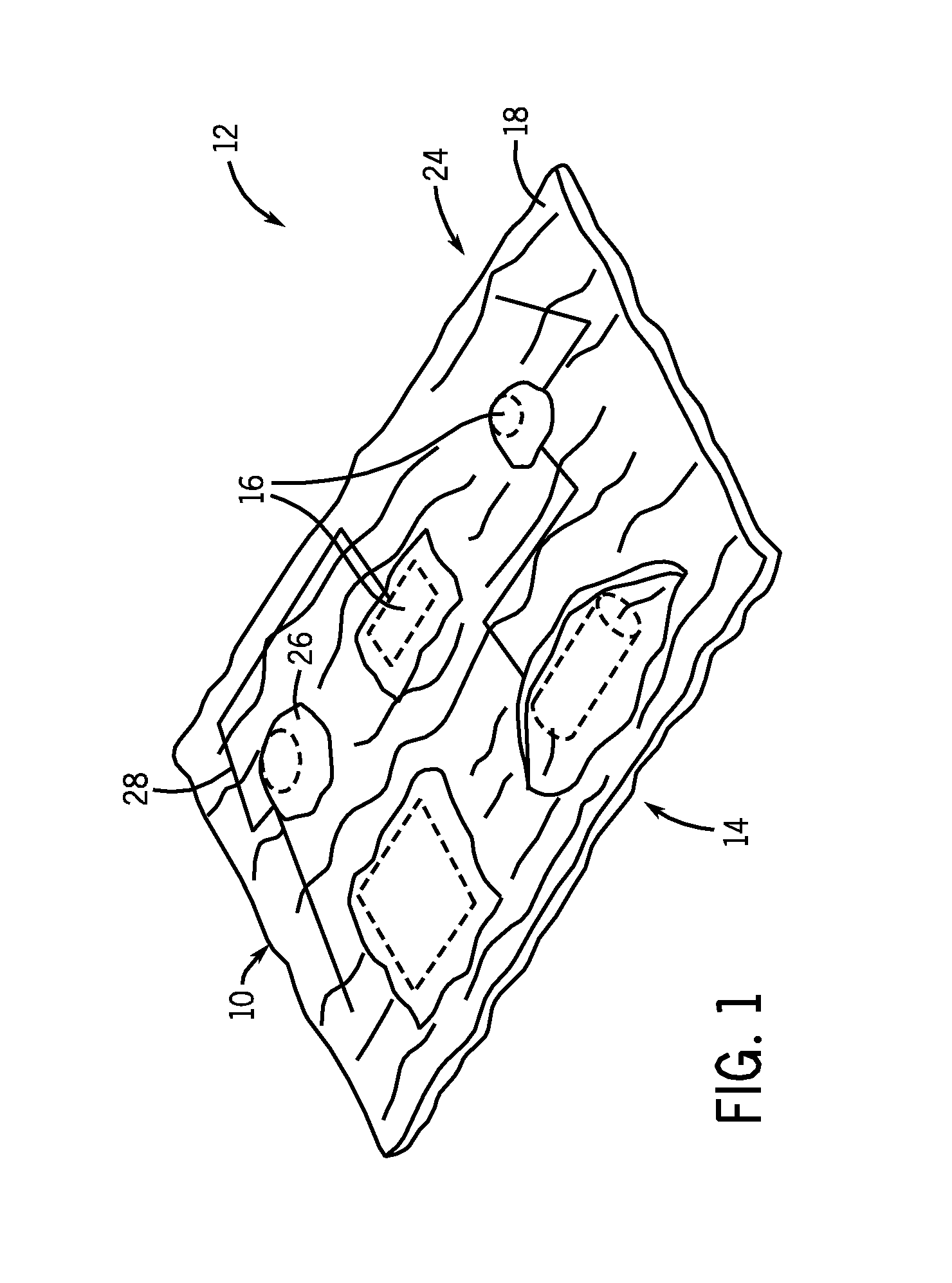

System and method of forming a patterned conformal structure

ActiveUS20100108370A1Improve functionalitySufficient shieldingPrinted circuit assemblingPrinted electric component incorporationContact padConductive coating

A system and method of forming a patterned conformal structure for an electrical system is disclosed. The conformal structure includes a dielectric coating shaped to conform to a surface of an electrical system, with the dielectric coating having a plurality of openings therein positioned over contact pads on the surface of the electrical system. The conformal structure also includes a patterned conductive coating layered on the dielectric coating and on the contact pads such that an electrical connection is formed between the patterned conductive coating and the contact pads. The patterned conductive coating comprises at least one of an interconnect system, a shielding structure, and a thermal path.

Owner:GENERAL ELECTRIC CO

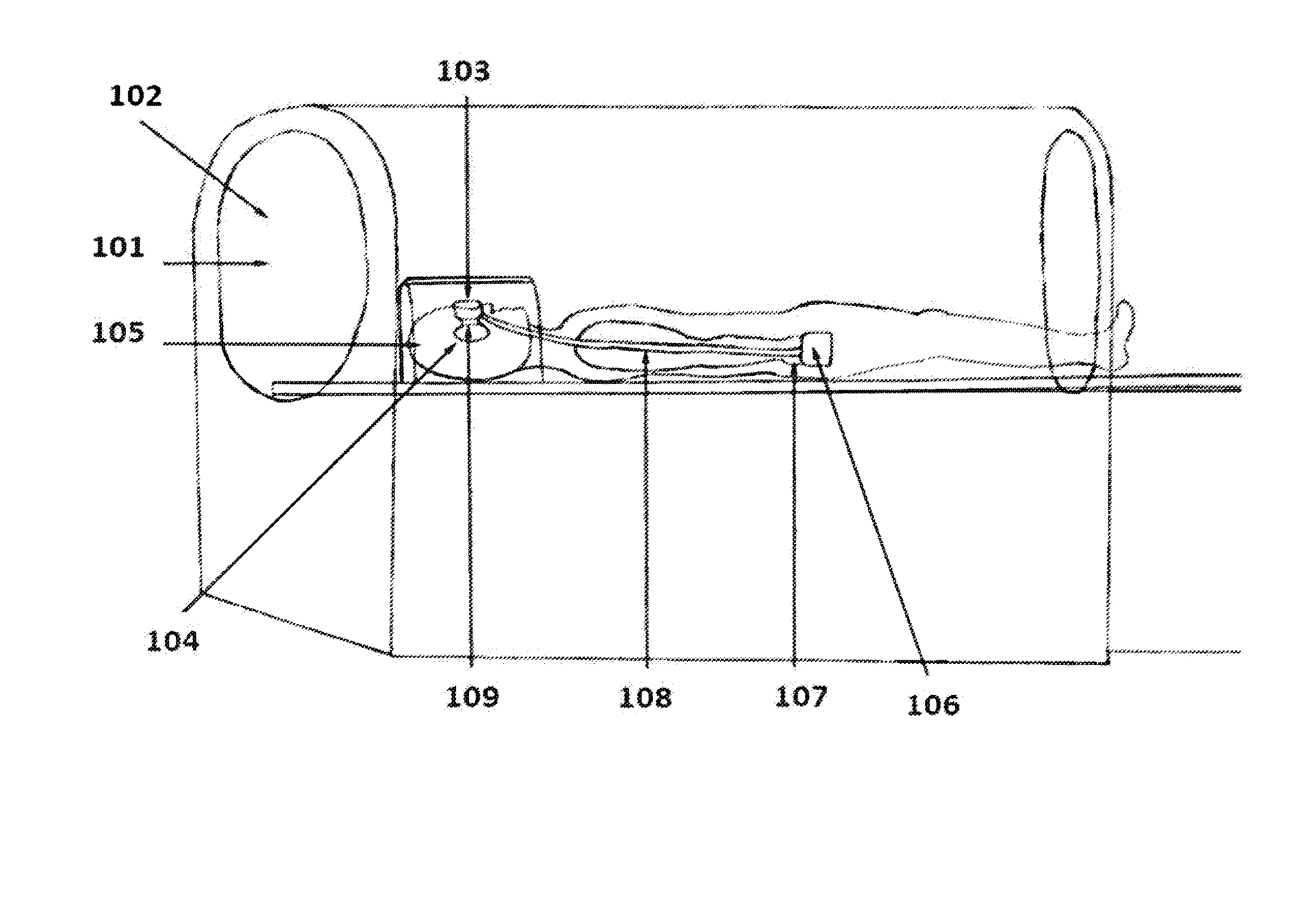

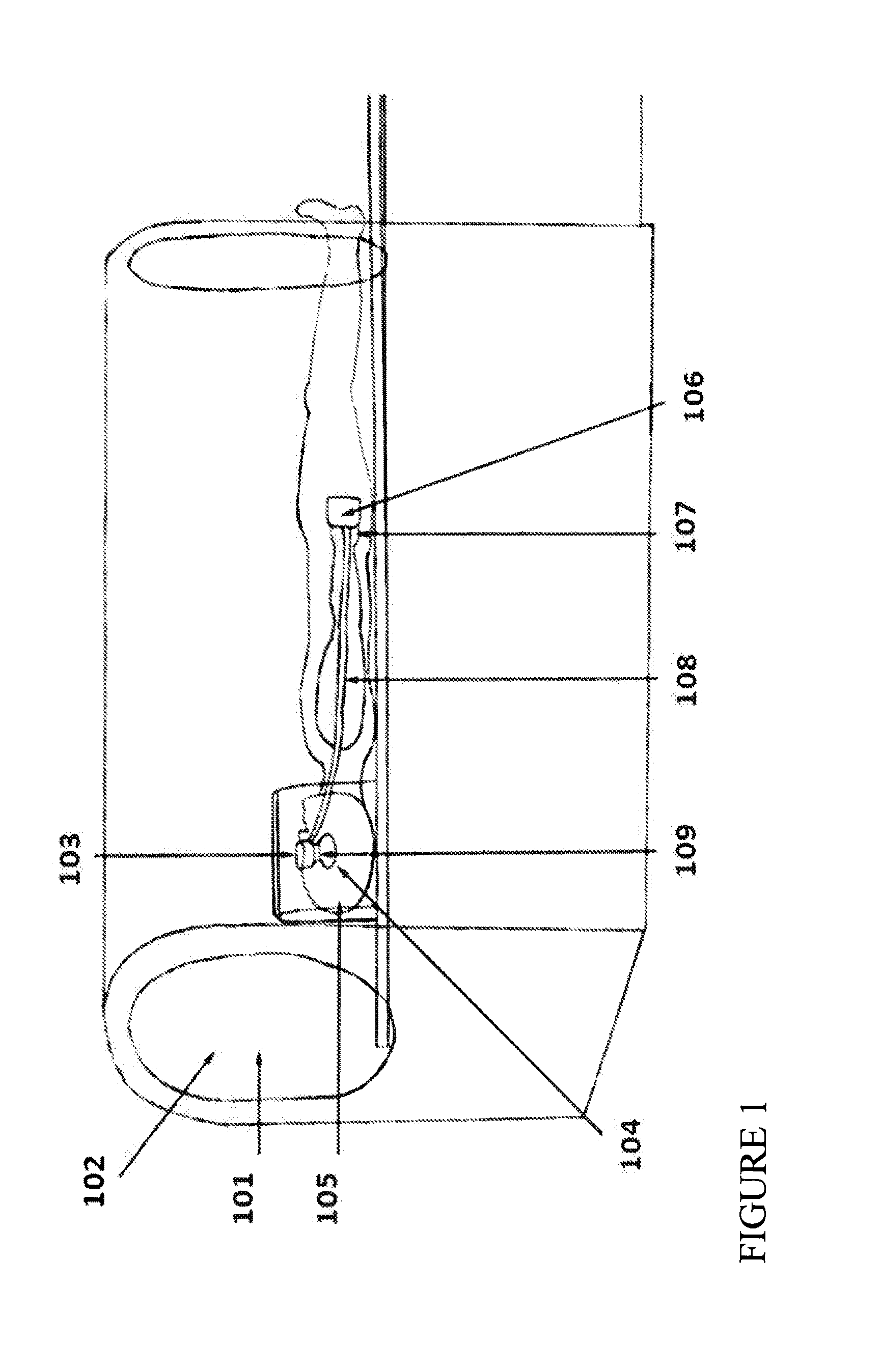

Entertainment system for use during the operation of a magnetic resonance imaging device

InactiveUS20100238362A1Reduce anxietyReduce noiseTelevision system detailsEar treatmentLow-pass filterEyewear

An entertainment system for use with a magnetic resonance imaging (MRI) device that includes video glasses and headphones. A Faraday shield encloses the entertainment system to reduce adequately RF signals from entering or leaving the entertainment system. The entertainment system may have non-ferromagnetic RF low-pass filters between parts of the system, such as the control unit and the video glasses, to reduce higher RF signals from entering or leaving those parts. To replace the battery and or entertainment media, a person opens the entertainment system's Faraday shield when not MRI imaging or outside the MRI magnet room. The door has an Faraday shield overlapping the system Faraday shield and making low resistance RF contact. The entertainment system has a minimal amount of ferromagnetic material so that it may operate within the high magnetic field of the MRI magnet bore with minimal performance degradation. The entertainment system uses non-ferromagnetic speakers in the headphone. Passive ear protection and noise cancellation reduce the loud noise of the MRI system heard by the patient to a level where the patient can hear the entertainment. The entertainment system includes a charger for the rechargeable batteries.

Owner:HUGHES BRIAN

System and method of forming a patterned conformal structure

ActiveUS8276268B2Sufficient shieldingPrinted circuit assemblingFinal product manufactureContact padConductive coating

A system and method of forming a patterned conformal structure for an electrical system is disclosed. The conformal structure includes a dielectric coating shaped to conform to a surface of an electrical system, with the dielectric coating having a plurality of openings therein positioned over contact pads on the surface of the electrical system. The conformal structure also includes a patterned conductive coating layered on the dielectric coating and on the contact pads such that an electrical connection is formed between the patterned conductive coating and the contact pads. The patterned conductive coating comprises at least one of an interconnect system, a shielding structure, and a thermal path.

Owner:GENERAL ELECTRIC CO

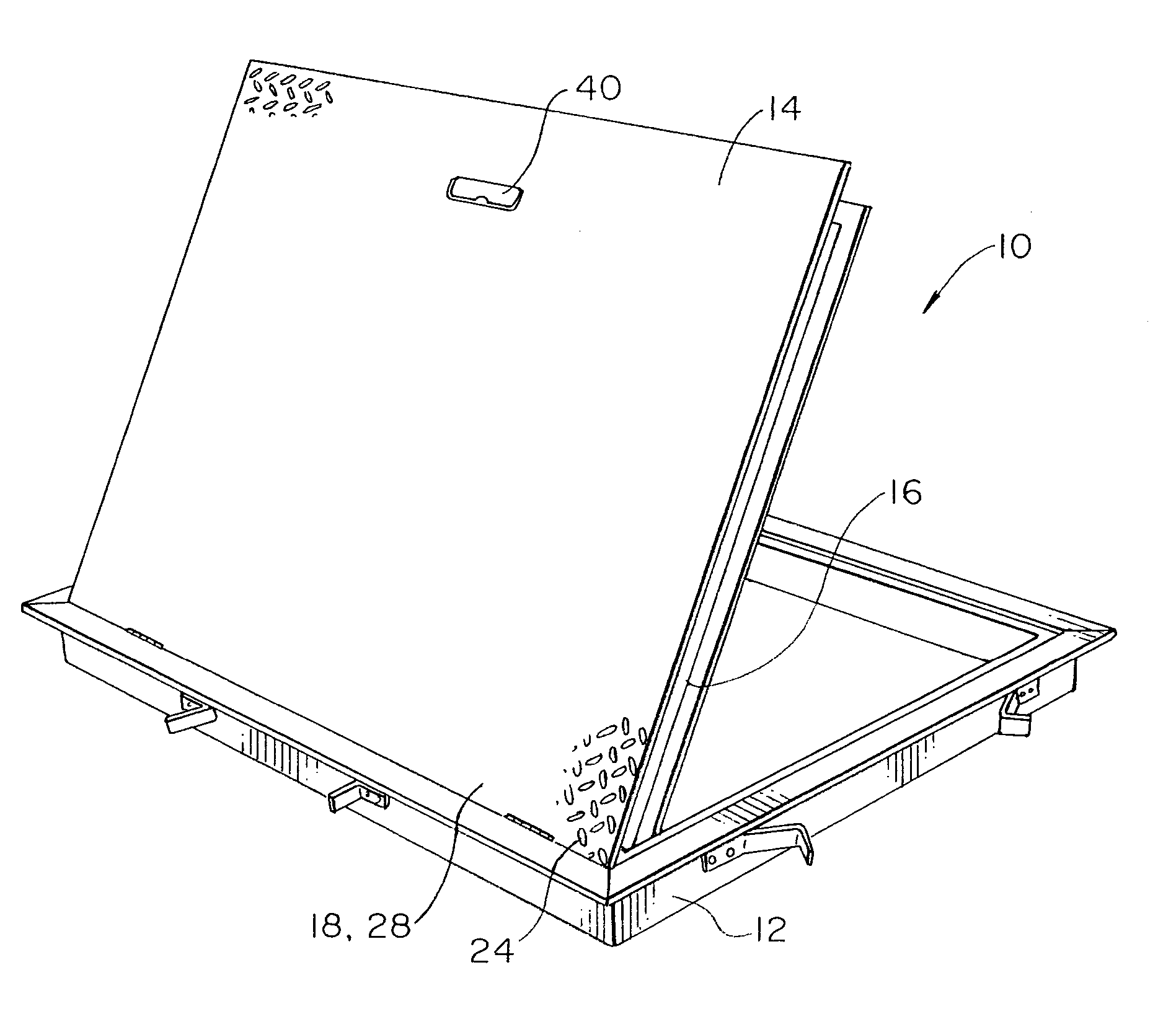

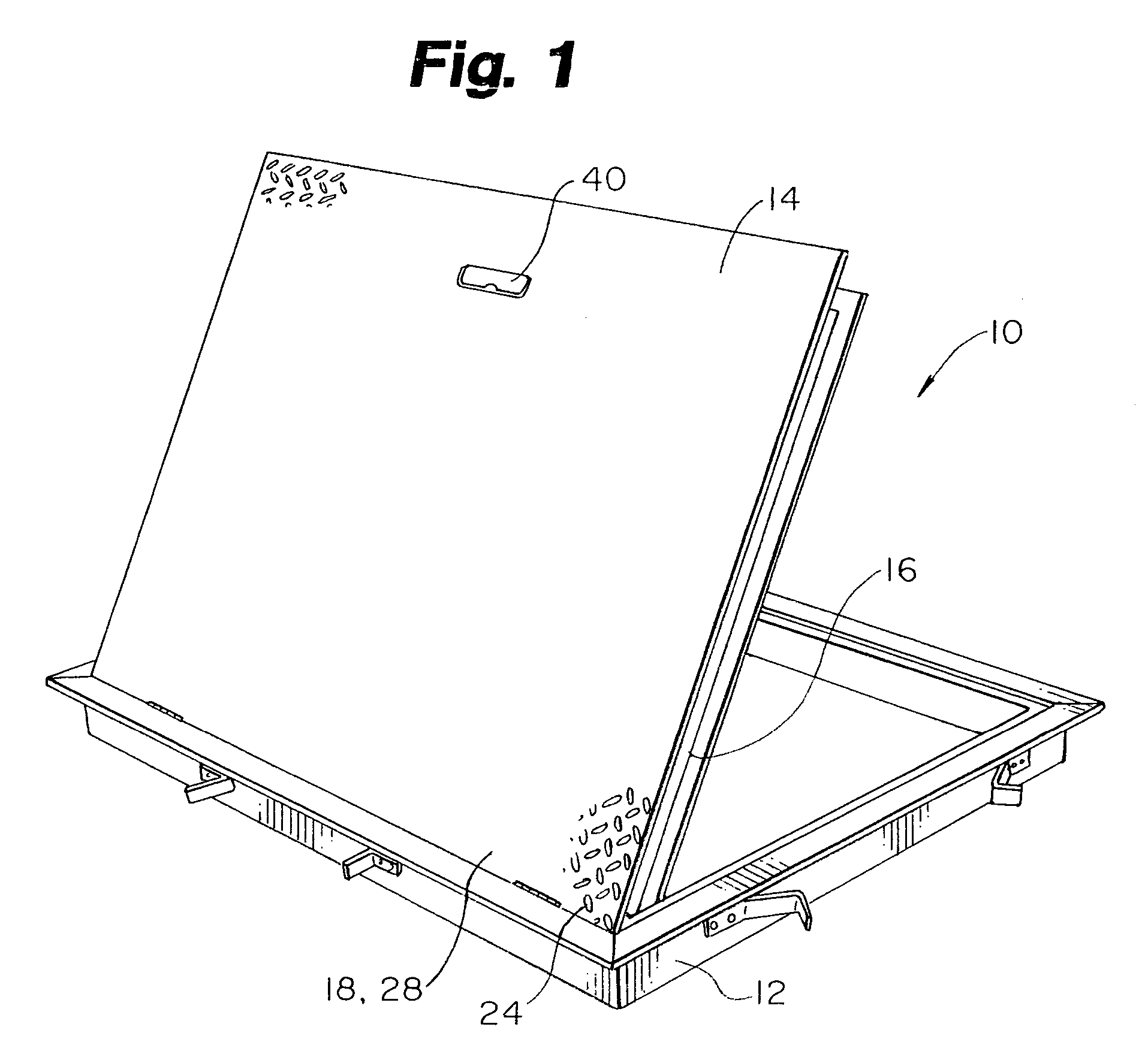

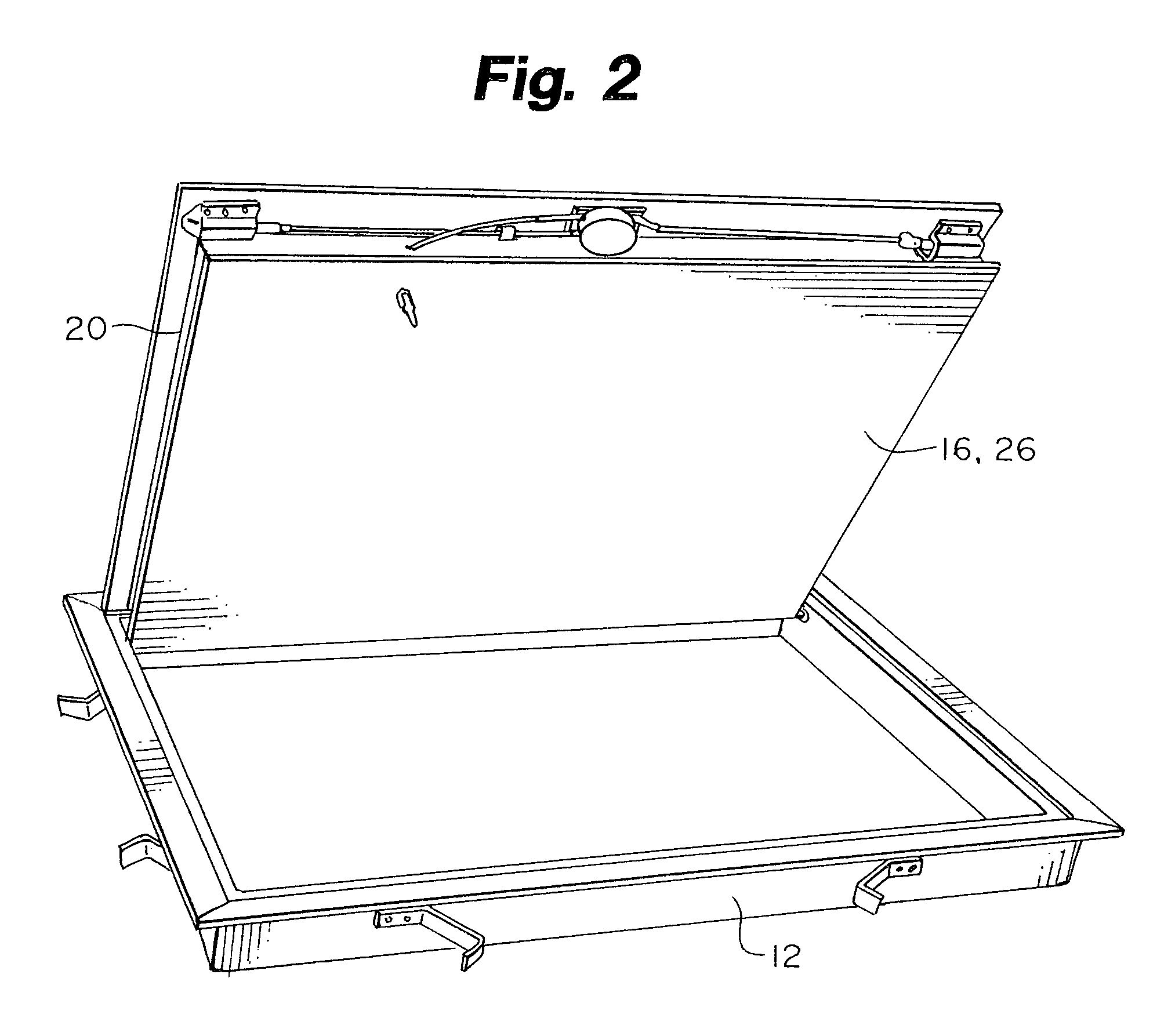

Fire-resistant door

InactiveUS7028431B2Adequate insulation performanceSufficient shieldingBuilding roofsArtificial islandsGas springEngineering

A fire-resistant, aluminum, cementitious-material-free, insulation-free door adapted to prevent the spread of fire and heat passing therethrough, consists of: a door frame, a door hingedly mounted on the door frame, the door having a bottom wall, a top wall, and side walls, the bottom wall, top wall and side walls enclosing a hollow central core not containing substantial amounts of insulating material, the bottom wall having an outside surface, and the top wall having an outside surface; and a layer of intumescent material on the outside surface of the bottom wall. A heat-activated self-closing mechanism allows the weight of the door to close the door in the vent of fire, by releasing gas from a supporting gas spring.

Owner:NYSTROM

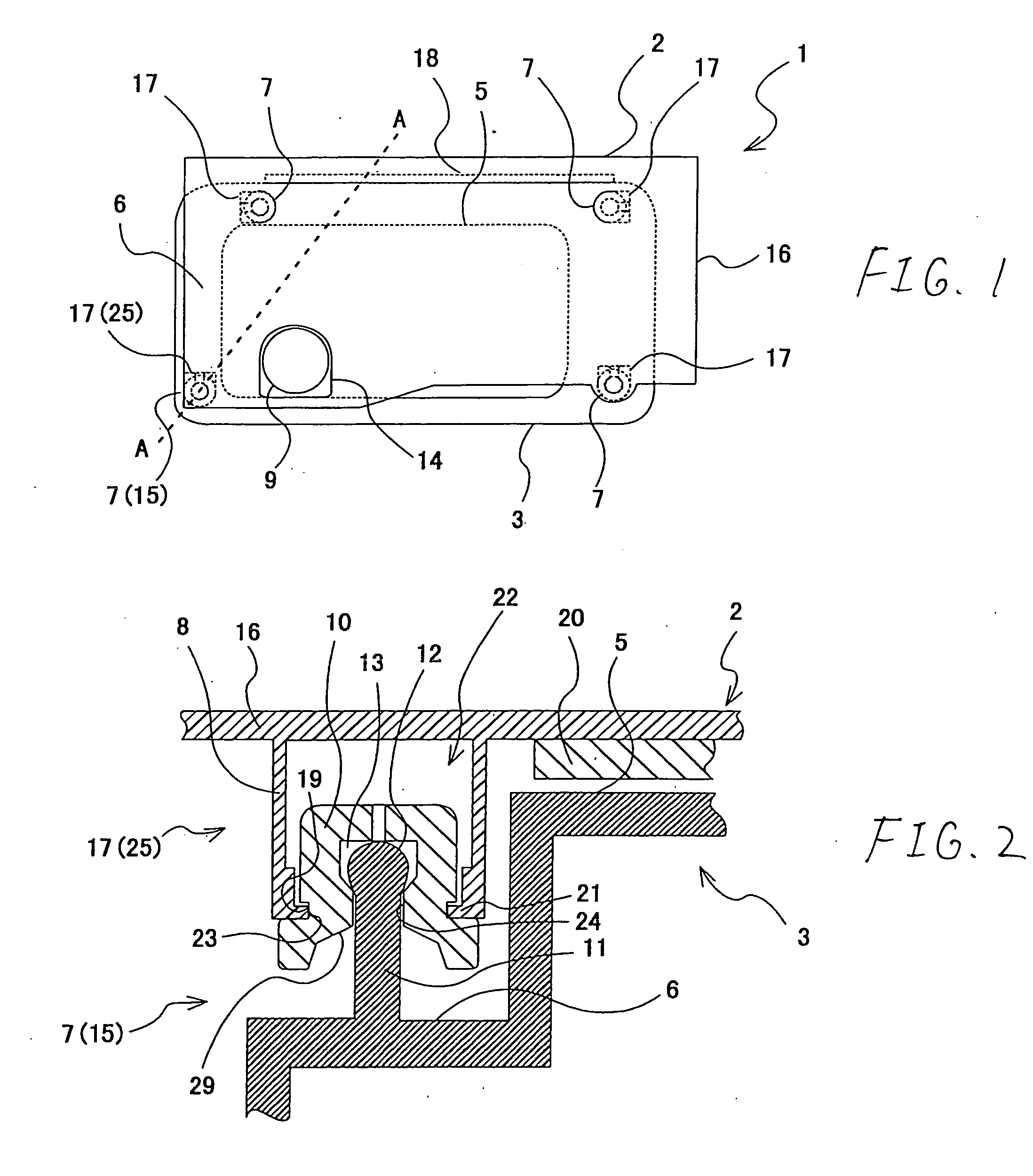

Mounting structure for engine cover

InactiveUS20050217634A1Improve Design PerformanceEasy to installCasingsNon-fuel substance addition to fuelCylinder headAbutment

An engine cover mounting structure comprising an engine member and an engine cover, wherein a plurality of portions to be fixed to which fixing portions provided on the engine cover are mounted are provided so as to be situated below an upper surface of a cylinder head cover of the engine member. In addition, a positioning portion is provided on the engine cover. Then, in a state where a base fixing portion is mounted or temporarily mounted to a base portion to be fixed, while the other fixing portions are not mounted to the other portions to be fixed, when the engine cover revolves about the base fixing portion, so that the positioning portion is brought into abutment with a surface of the engine member, the fixing portions other than the base fixing portion are disposed at positions facing the portions to be fixed, respectively.

Owner:TOYODA GOSEI CO LTD

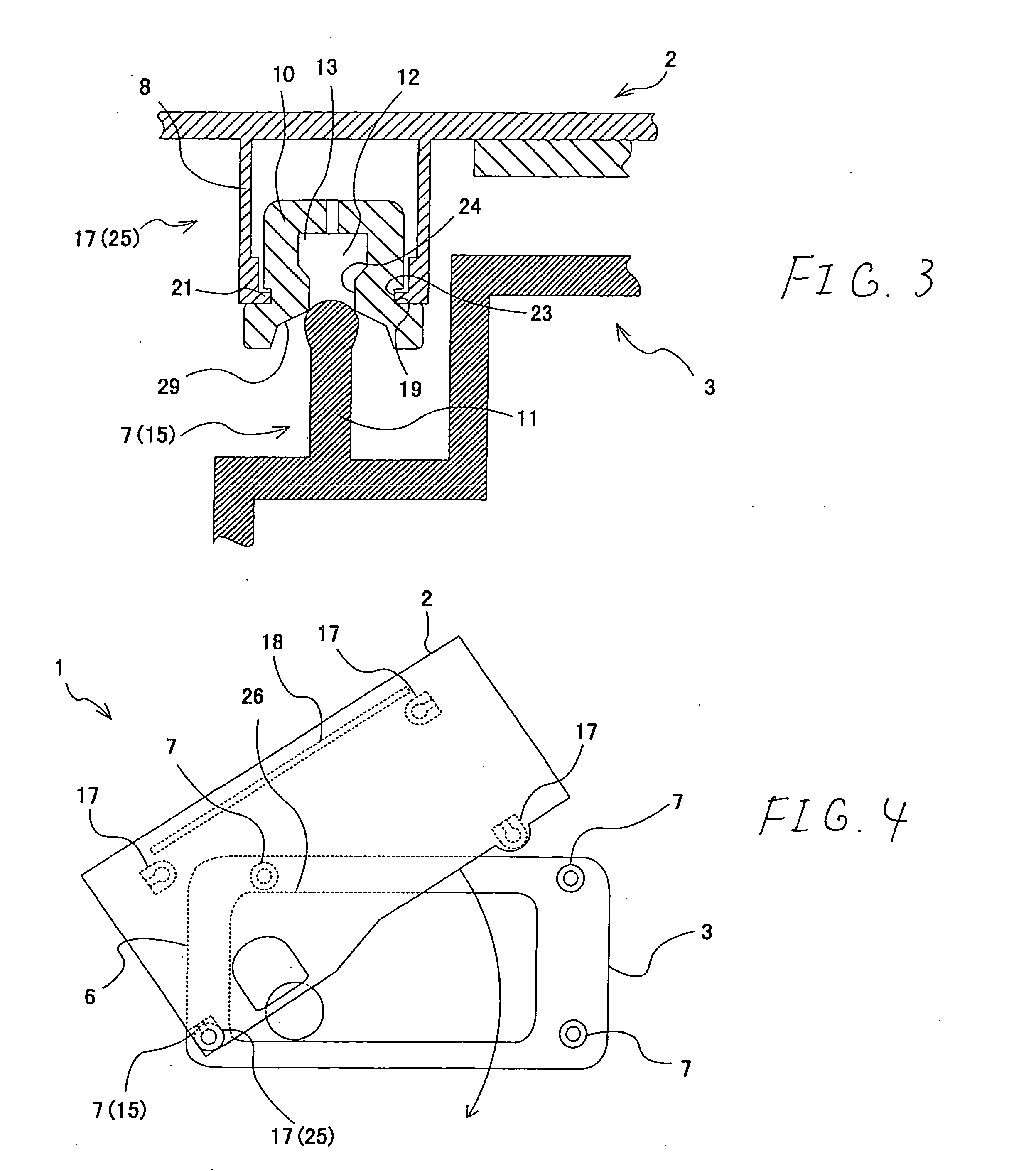

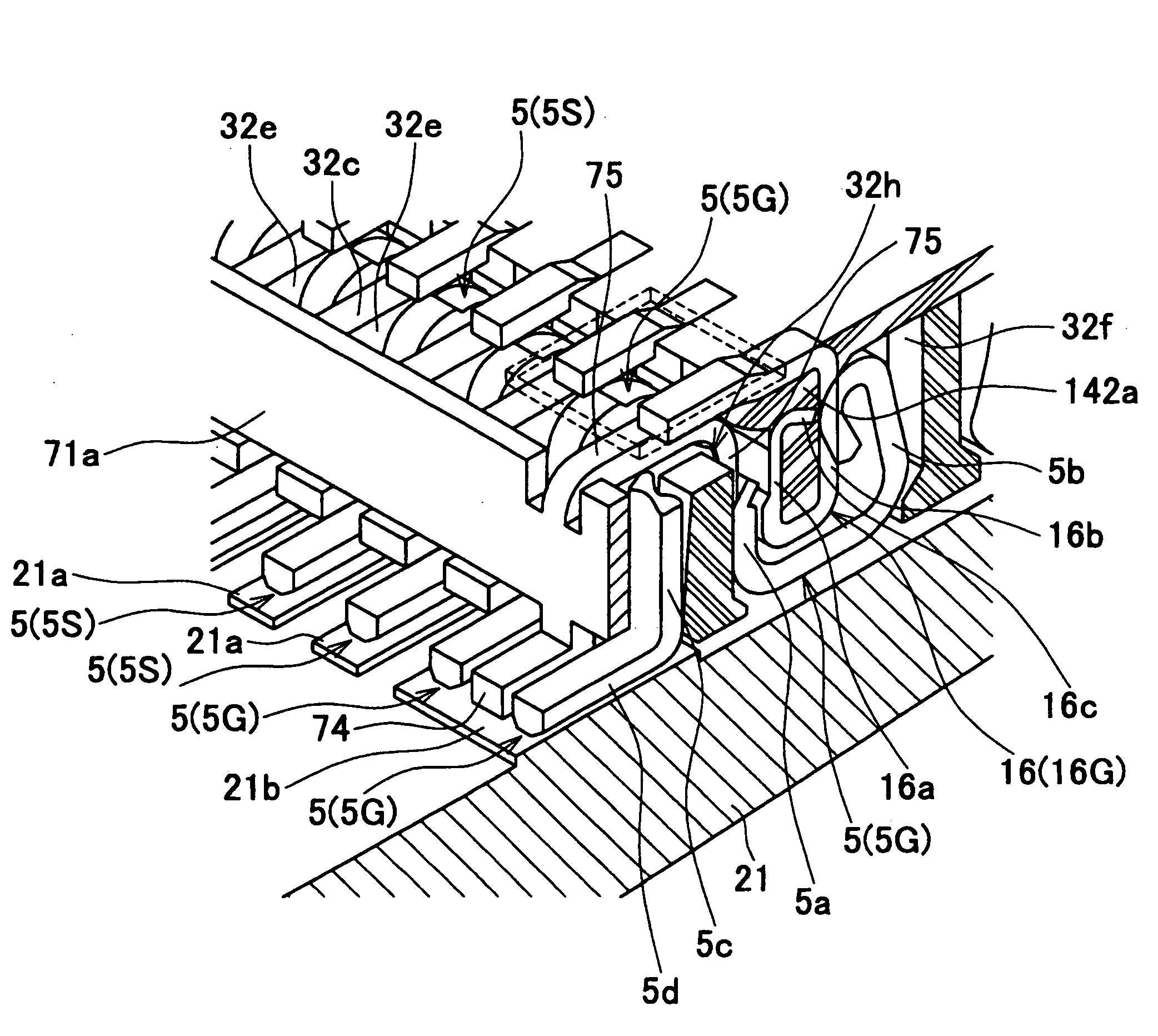

Connector

InactiveUS20080214051A1Small sizeSufficient shieldingFixed connectionsPrinted circuitsGround contactEngineering

A connector capable of sufficiently shielding two connectors for connecting two circuit boards, and further making the connectors compact in size. A receptacle-side fitting portion (32) for being fitted to a plug-side fitting portion (142) of a plug connector (12) is formed in a receptacle-side housing (3) disposed on a printed circuit board (21). A plurality of receptacle-side contacts (5) are arranged in the receptacle-side fitting portion (32). A shell body (71) disposed around the receptacle-side fitting portion (32) is provided in a shell (7) mounted in receptacle-side housing (3). The shell (7) is formed with shell contact portions (72) brought into contact with plug-side ground contacts (16G) of the plug connector (12), and a shell terminal portion (73) fixed to a ground pad (21) of the printed circuit board (21).

Owner:JAPAN AVIATION ELECTRONICS IND LTD

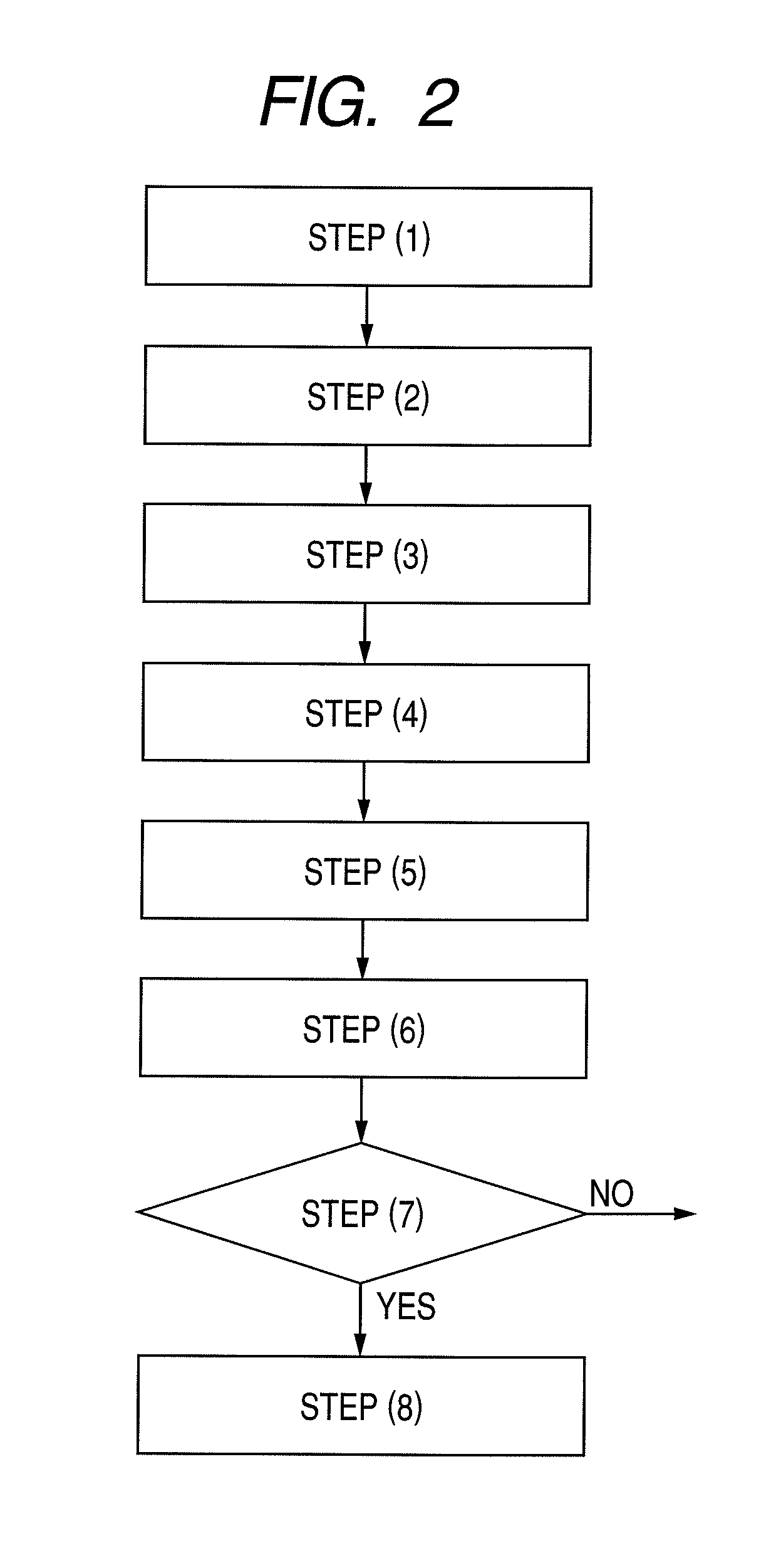

Method for manufacturing semiconductor device or apparatus, and apparatus for manufacturing the same

InactiveUS8216879B2Manufacturing is longOptimize timingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringLength wave

A method for manufacturing a semiconductor device or apparatus having at least a semiconductor as a component, characterized by including irradiating the semiconductor with light having a longer wavelength than the absorption edge wavelength of the semiconductor to change the threshold voltage of the semiconductor device or apparatus, and checking the threshold voltage of the semiconductor device or apparatus, after or during irradiation with the light, to determine whether the threshold voltage is in a predetermined range, during manufacturing the semiconductor device or apparatus.

Owner:CANON KK

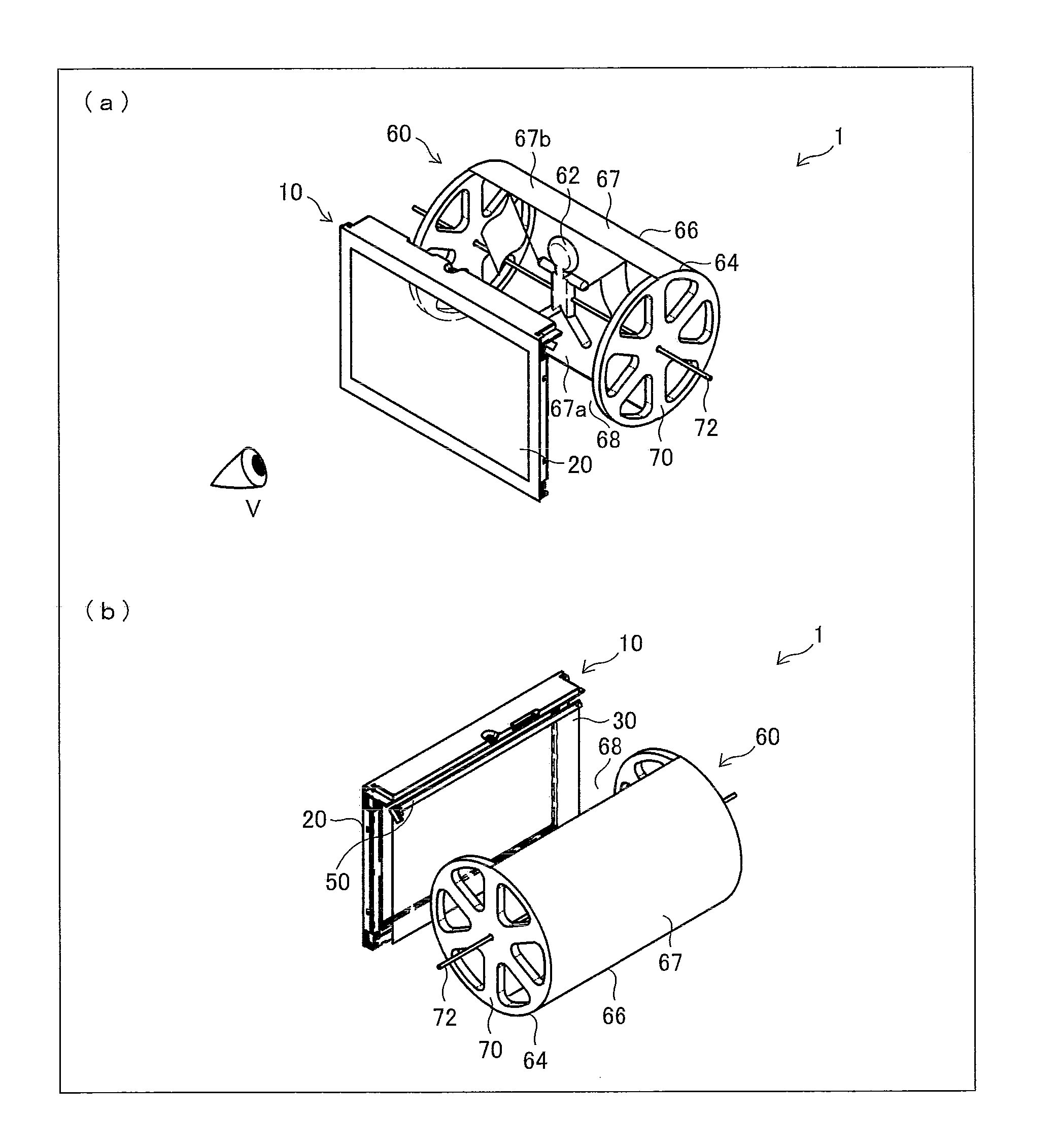

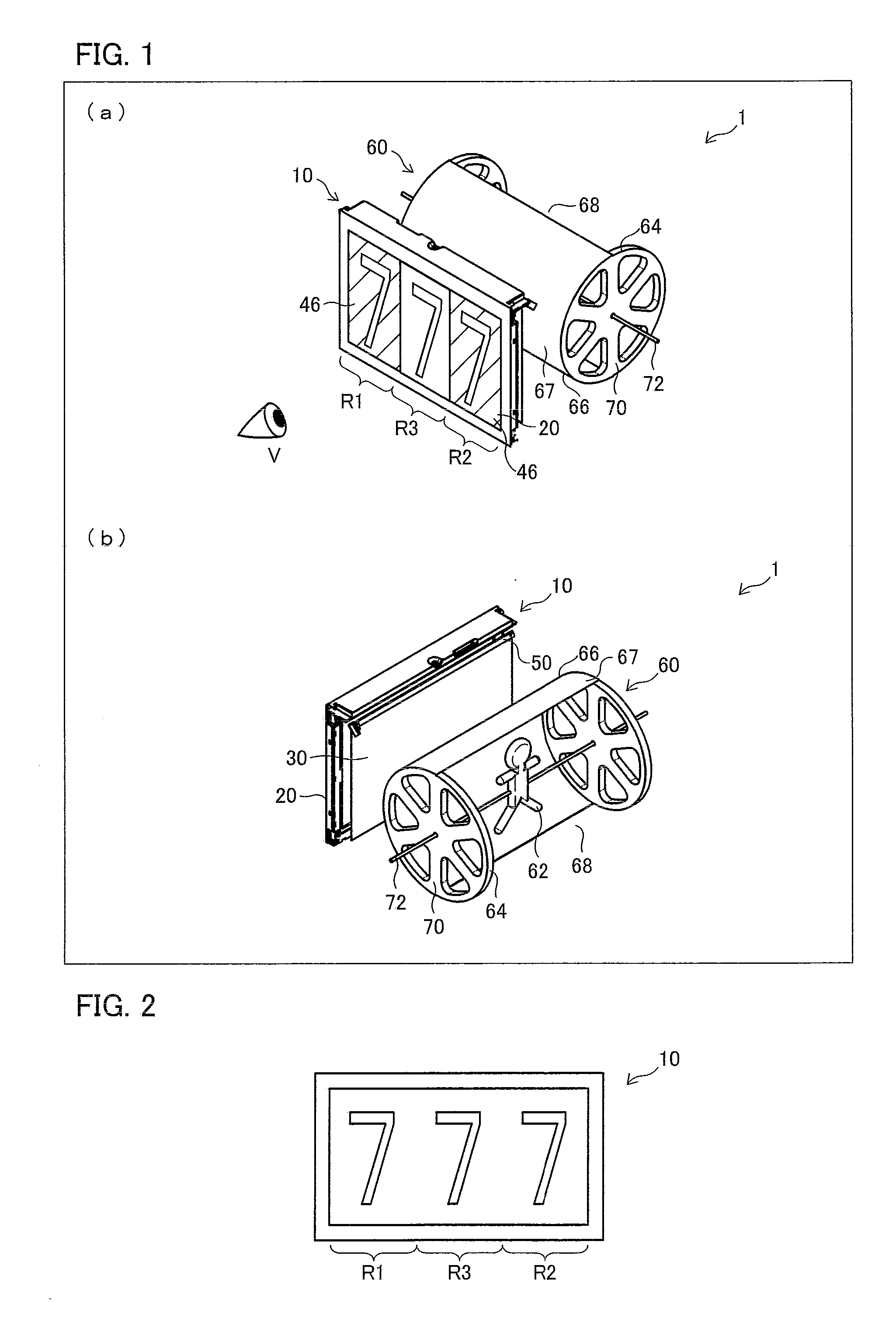

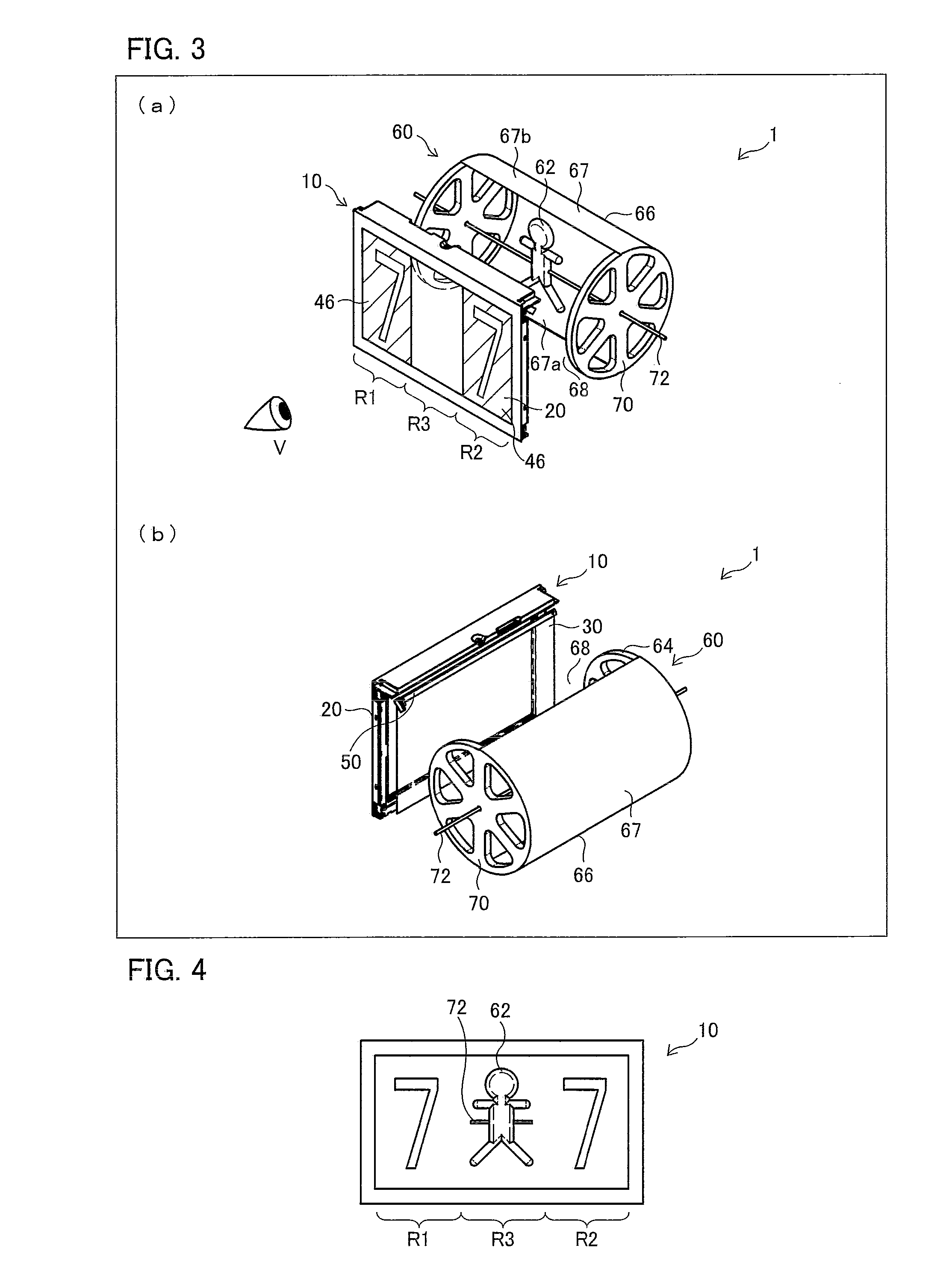

Liquid crystal display unit, game device and display method for use in liquid crystal display unit

InactiveUS20100184510A1Sufficient shieldingApparatus for meter-controlled dispensingVideo gamesLiquid-crystal displayEngineering

A display unit (1) of the present invention includes: a first liquid crystal display element (20) for displaying an image; a character object (62) disposed behind the first liquid crystal display element (20); a second liquid crystal display element (30) disposed between the first liquid crystal display element (20) and the character object (62), for shielding the character object (62); and a character object shielding section (64) which is a mechanical shielding device, disposed behind the second liquid crystal display element (30), for shielding the character object (62).

Owner:SHARP KK

Method for manufacturing electronic component module

ActiveUS20110006106A1Low profileSufficient shieldingSemiconductor/solid-state device detailsSolid-state devicesConductive pasteComputer module

A method for manufacturing an electronic component module is performed such that a shield layer can be formed as a thin film and an electronic component can be effectively shielded. A collective substrate including a plurality of electronic component modules including a plurality of electronic components is batch-sealed with a resin. A cut section is formed from a top surface of the sealed resin to a position that reaches a grounding electrode arranged in the substrate at a boundary section of the electronic component module so as to expose the grounding electrode. A conductive paste is applied on side surfaces and the top surface. Then, a conductive thin film is formed by spin coating, and the electronic component module is cut.

Owner:MURATA MFG CO LTD

System and method of forming a patterned conformal structure

ActiveUS20120069523A1Sufficient shieldingFinal product manufactureCross-talk/noise/interference reductionContact padConductive coating

A system and method of forming a patterned conformal structure for an electrical system is disclosed. The conformal structure includes a dielectric coating shaped to conform to a surface of an electrical system, with the dielectric coating having a plurality of openings therein positioned over contact pads on the surface of the electrical system. The conformal structure also includes a patterned conductive coating layered on the dielectric coating and on the contact pads such that an electrical connection is formed between the patterned conductive coating and the contact pads. The patterned conductive coating comprises at least one of an interconnect system, a shielding structure, and a thermal path.

Owner:GENERAL ELECTRIC CO

Entertainment system for use during the operation of a magnetic resonance imaging device

InactiveUS8363861B2Reduce anxietyReduce noiseTelevision system detailsMedical devicesLow-pass filterRechargeable cell

An entertainment system for use with a magnetic resonance imaging (MRI) device that includes video glasses and headphones. A Faraday shield encloses the entertainment system to reduce adequately RF signals from entering or leaving the entertainment system. The entertainment system may have non-ferromagnetic RF low-pass filters between parts of the system, such as the control unit and the video glasses, to reduce higher RF signals from entering or leaving those parts. To replace the battery and or entertainment media, a person opens the entertainment system's Faraday shield when not MRI imaging or outside the MRI magnet room. The door has an Faraday shield overlapping the system Faraday shield and making low resistance RF contact. The entertainment system has a minimal amount of ferromagnetic material so that it may operate within the high magnetic field of the MRI magnet bore with minimal performance degradation. The entertainment system uses non-ferromagnetic speakers in the headphone. Passive ear protection and noise cancellation reduce the loud noise of the MRI system heard by the patient to a level where the patient can hear the entertainment. The entertainment system includes a charger for the rechargeable batteries.

Owner:HUGHES BRIAN

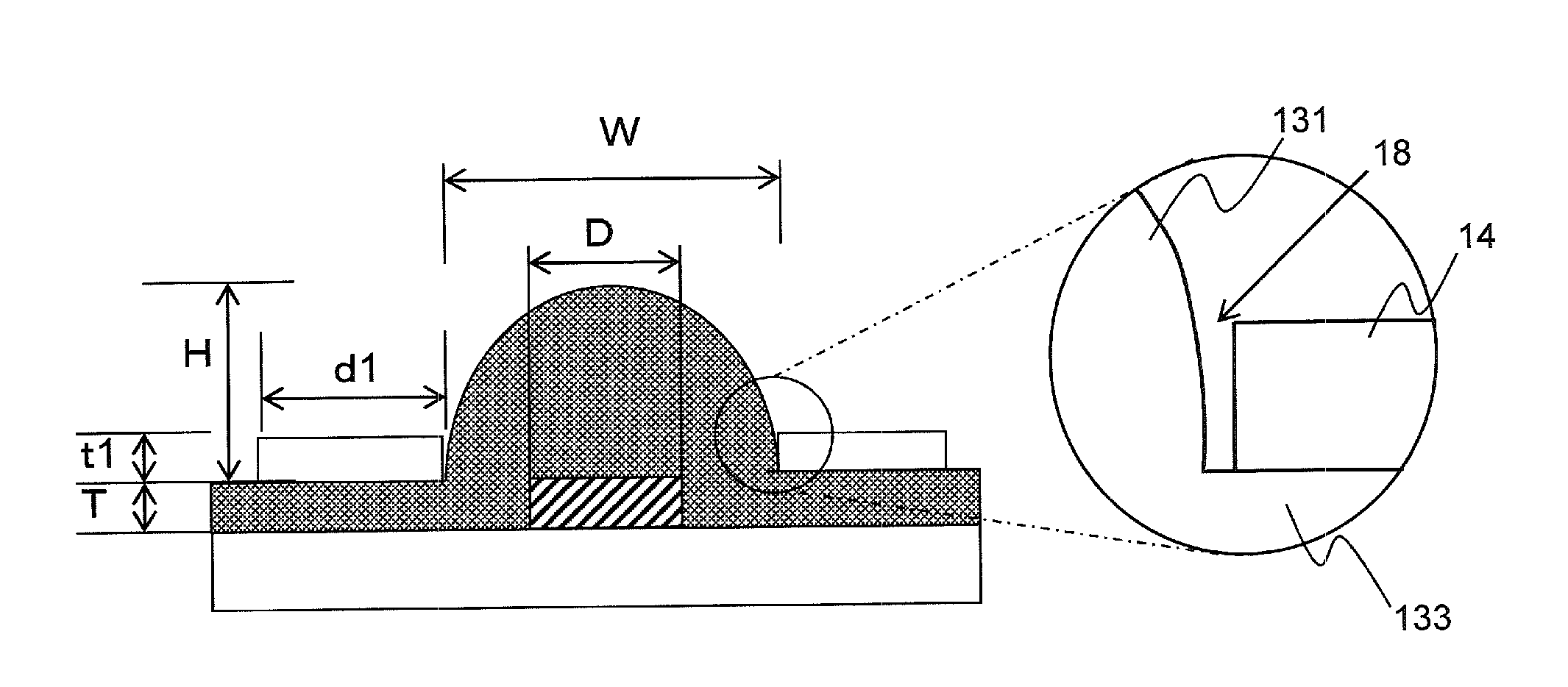

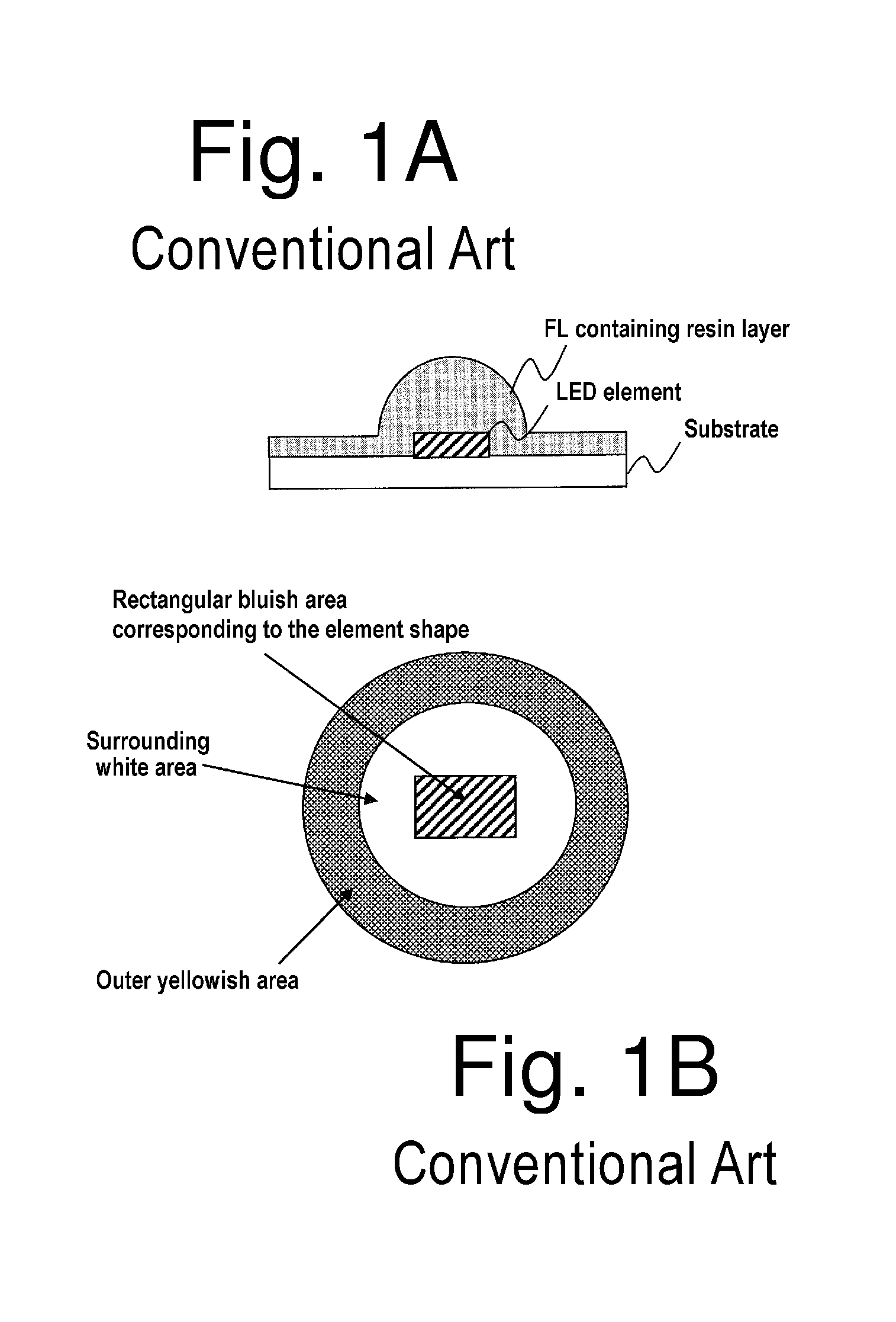

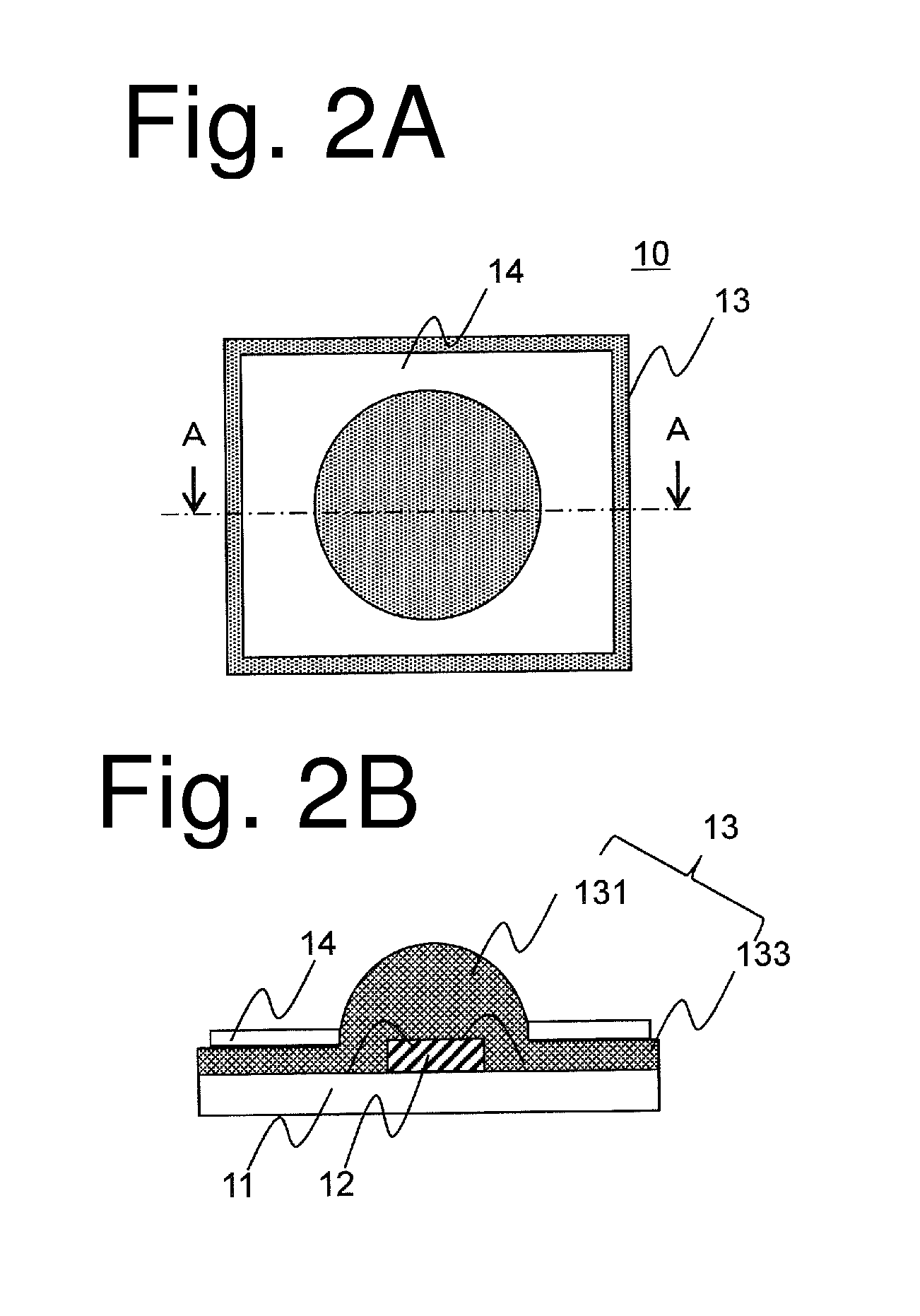

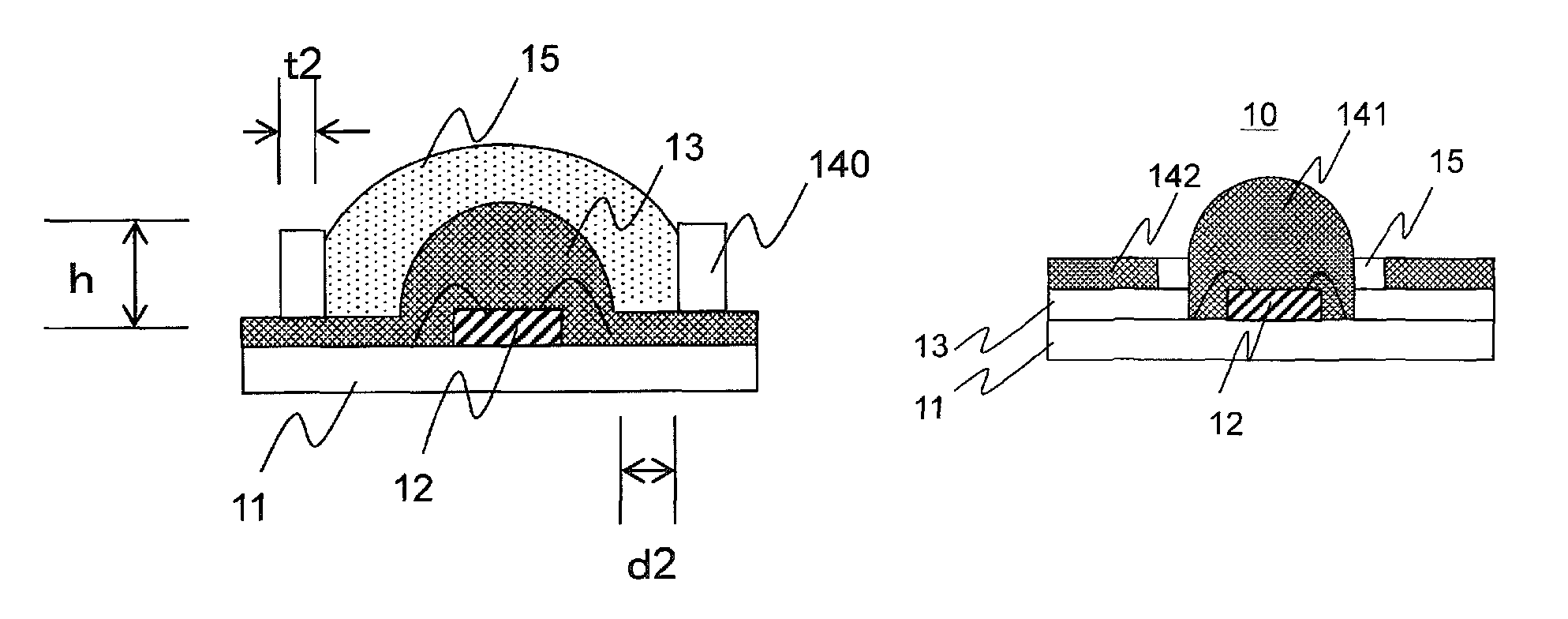

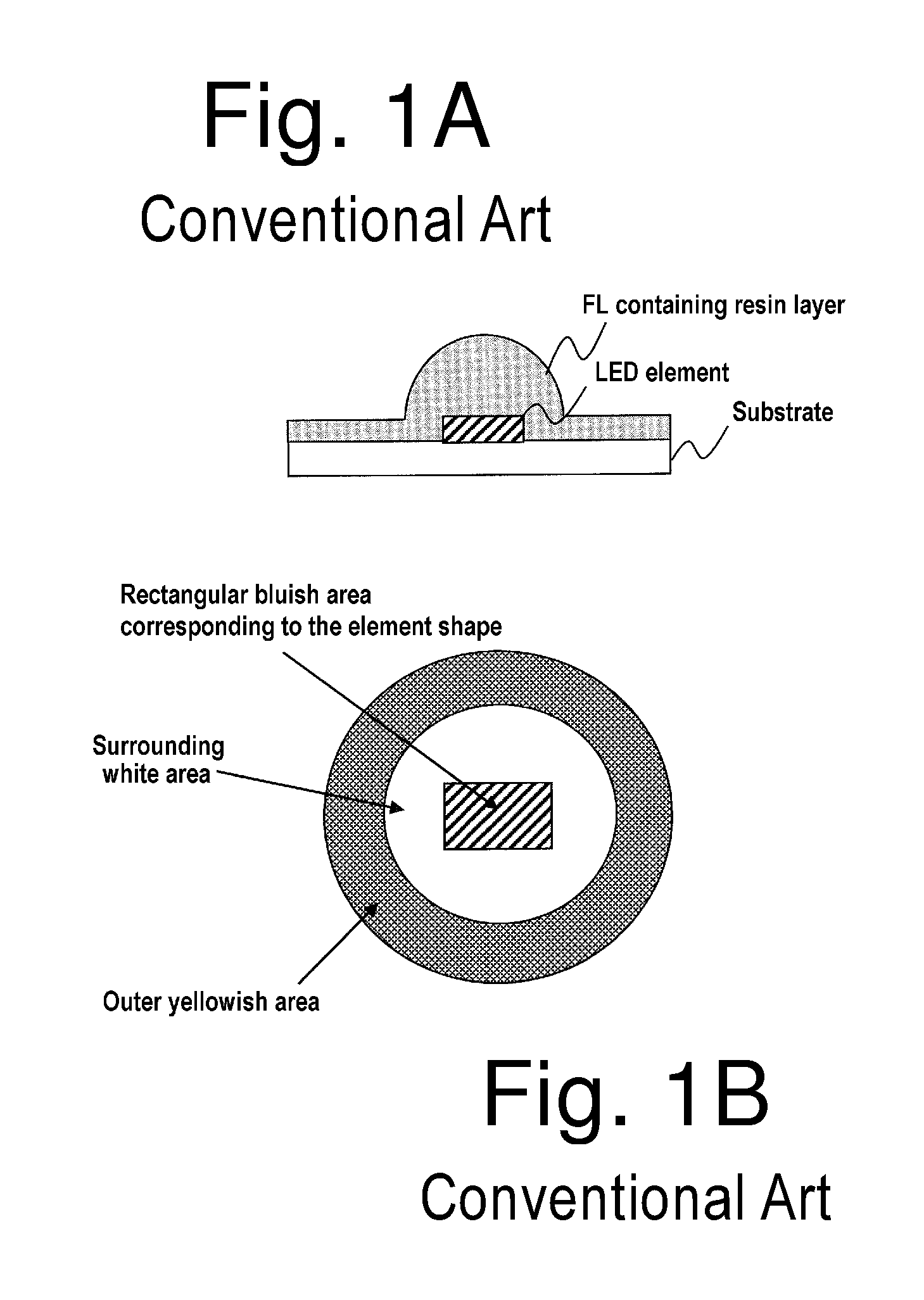

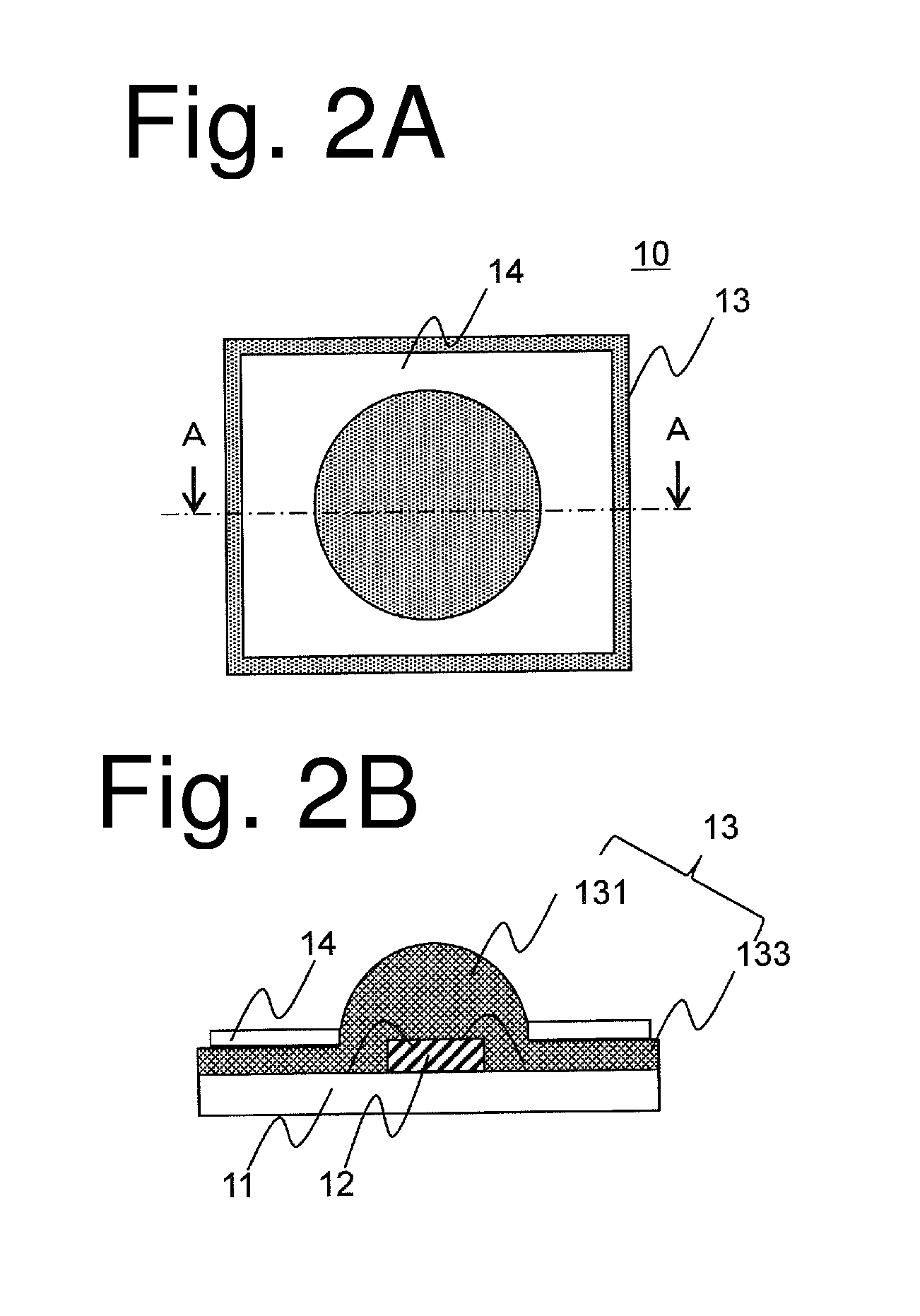

Light-emitting device, method for producing the same, and illuminating device

ActiveUS20120188772A1Easy to produceEfficient mixingDischarge tube luminescnet screensLamp detailsEngineeringLight emission

A light-emitting device having an LED element and a resin layer including a convex portion covering the LED element can suppress color unevenness to achieve light emission with uniform color distribution. The light-emitting device can include a substrate, an LED element mounted on the substrate, a resin layer which contains a wavelength conversion material and is formed on the substrate to cover the LED element, the resin layer including a convex portion directly covering the LED element and a flat thin film portion extending around the convex portion, and a reflective portion which is formed over the thin film portion around the convex portion. A diffusion portion can be formed to cover the convex portion of the resin layer.

Owner:STANLEY ELECTRIC CO LTD

Semiconductor device

InactiveUS20050189602A1Avoid passingSubstrate noise can be preventedThyristorSemiconductor/solid-state device detailsNon dopedP type silicon

An insulating film is provided in a region surrounding a circuit region on a p type silicon substrate, and a frame-shaped electrode is provided to surround the circuit region on the insulating film. The region directly under the electrode at the surface of the p type silicon substrate is formed as a non-doped region with no impurity implanted. Then, a positive power supply potential is applied to the electrode. In this way, a depletion layer is formed directly under the electrode at the surface of the p type silicon substrate. Consequently, the substrate noise is shielded.

Owner:RENESAS ELECTRONICS CORP

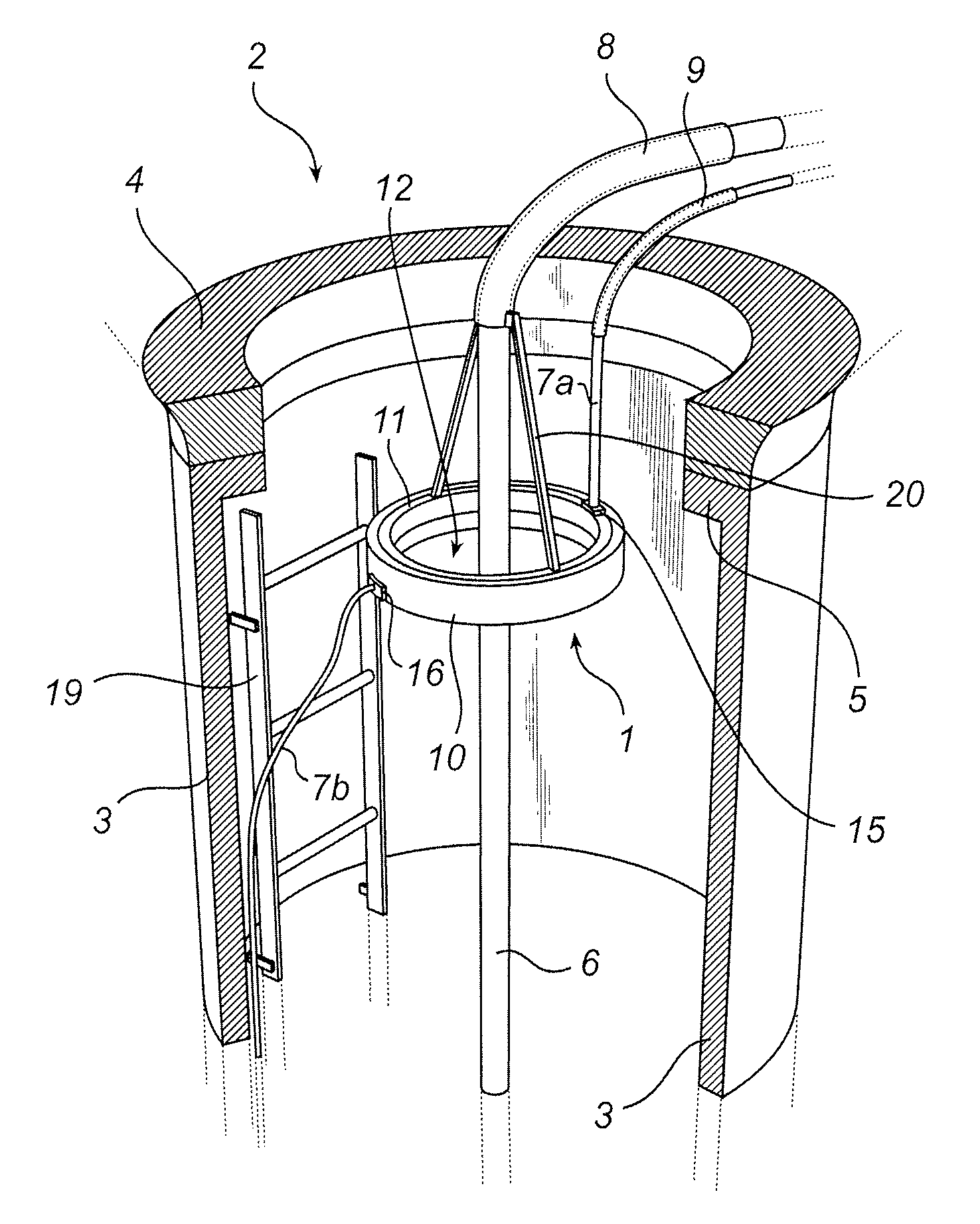

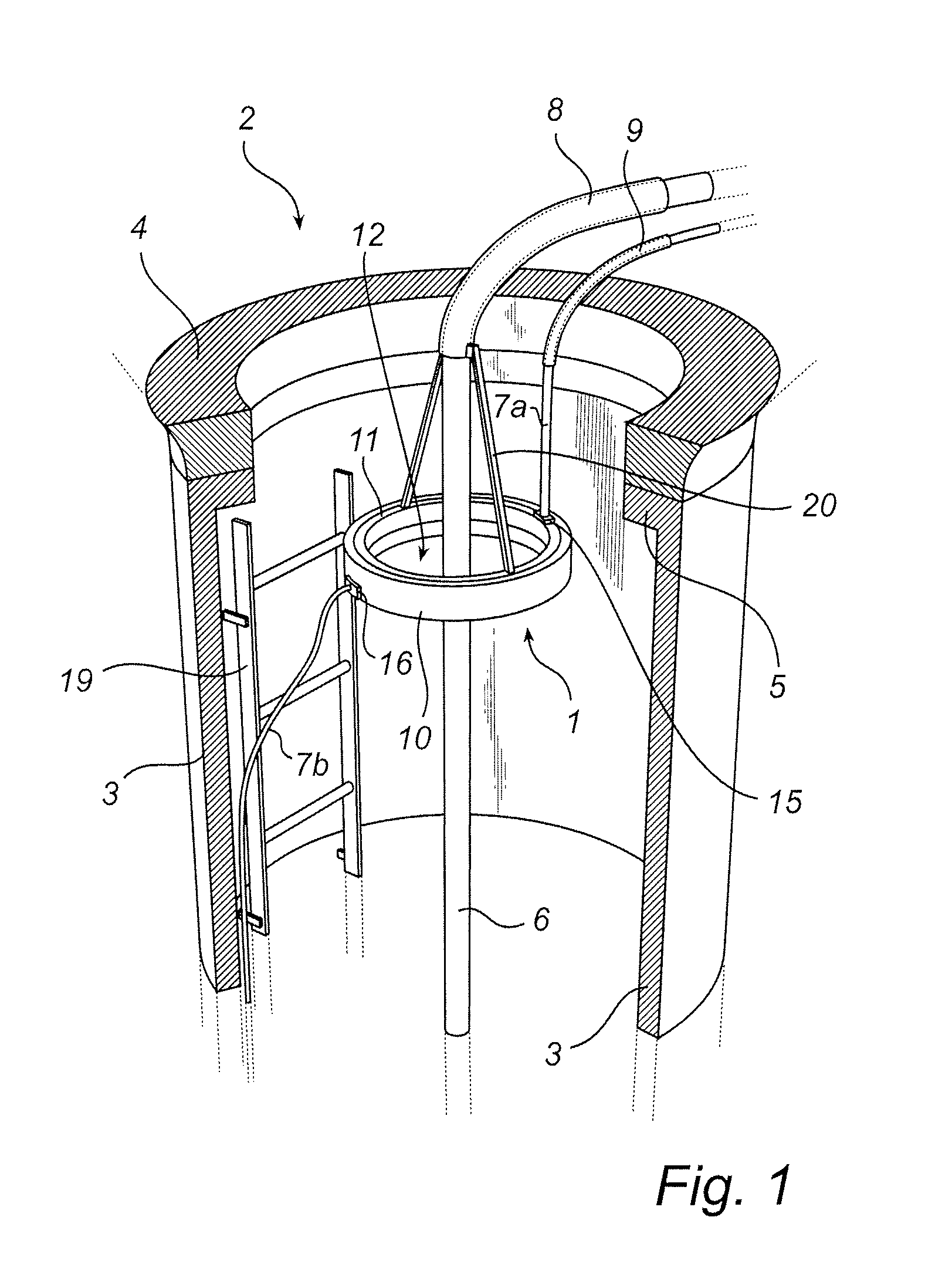

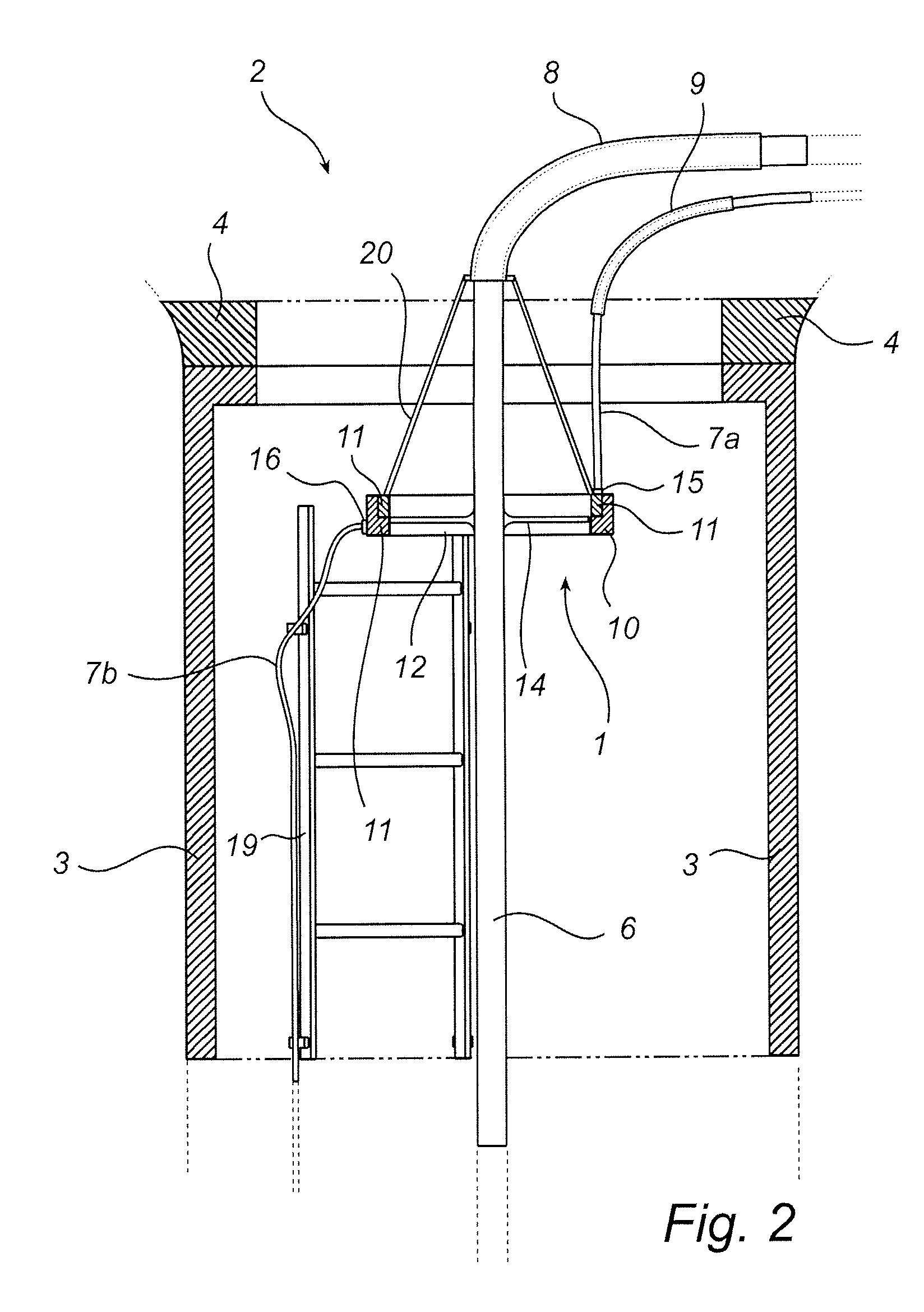

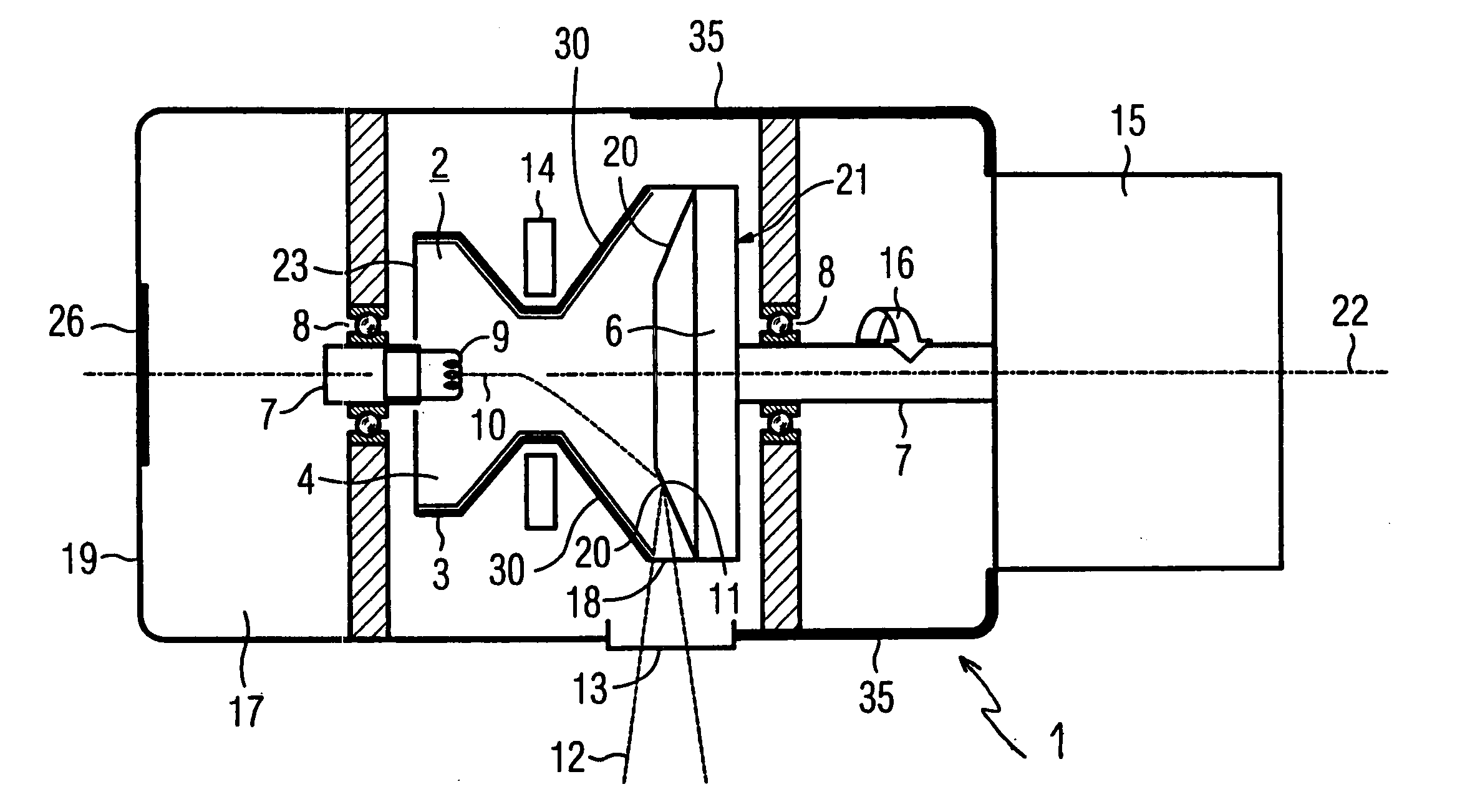

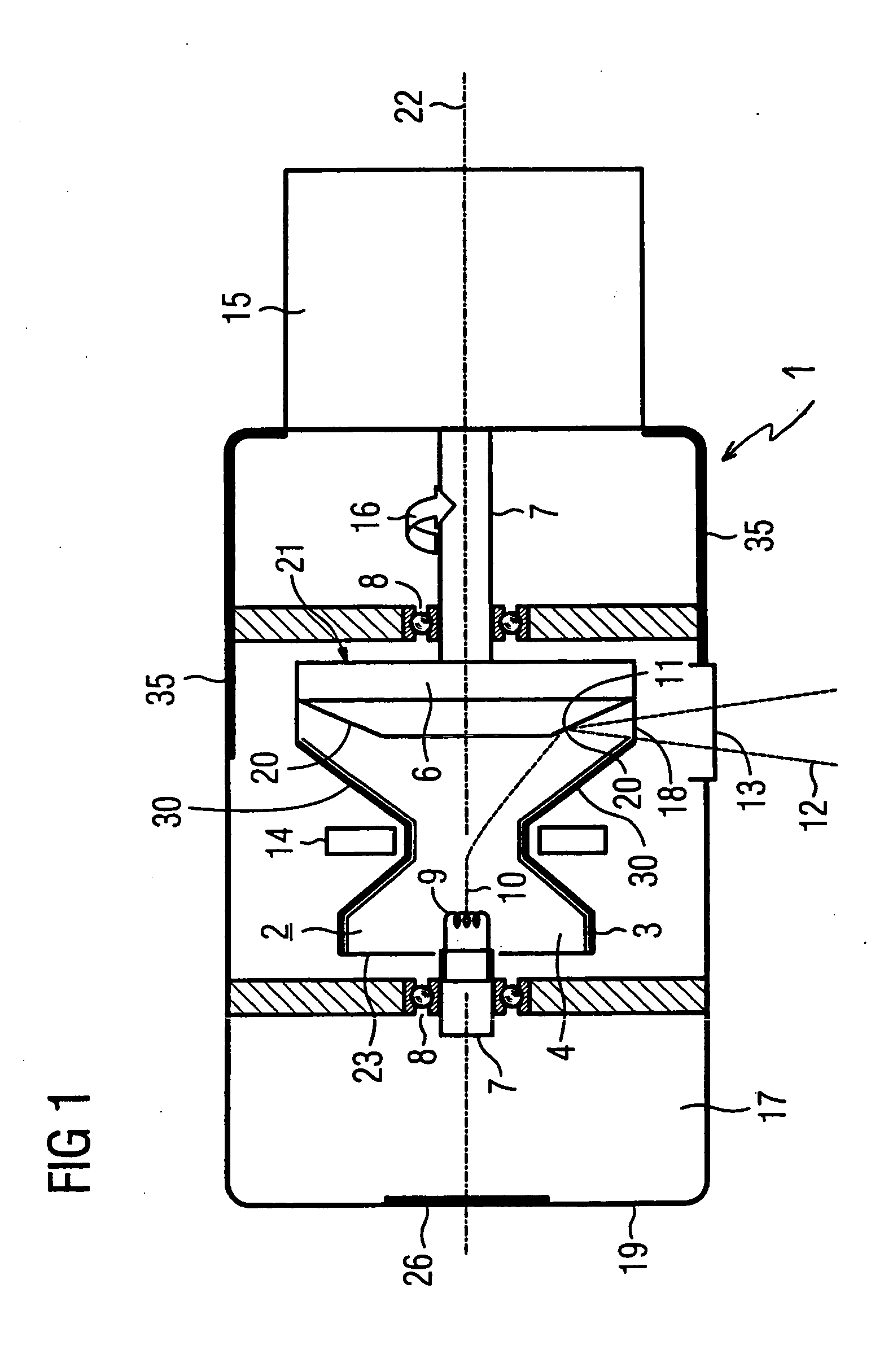

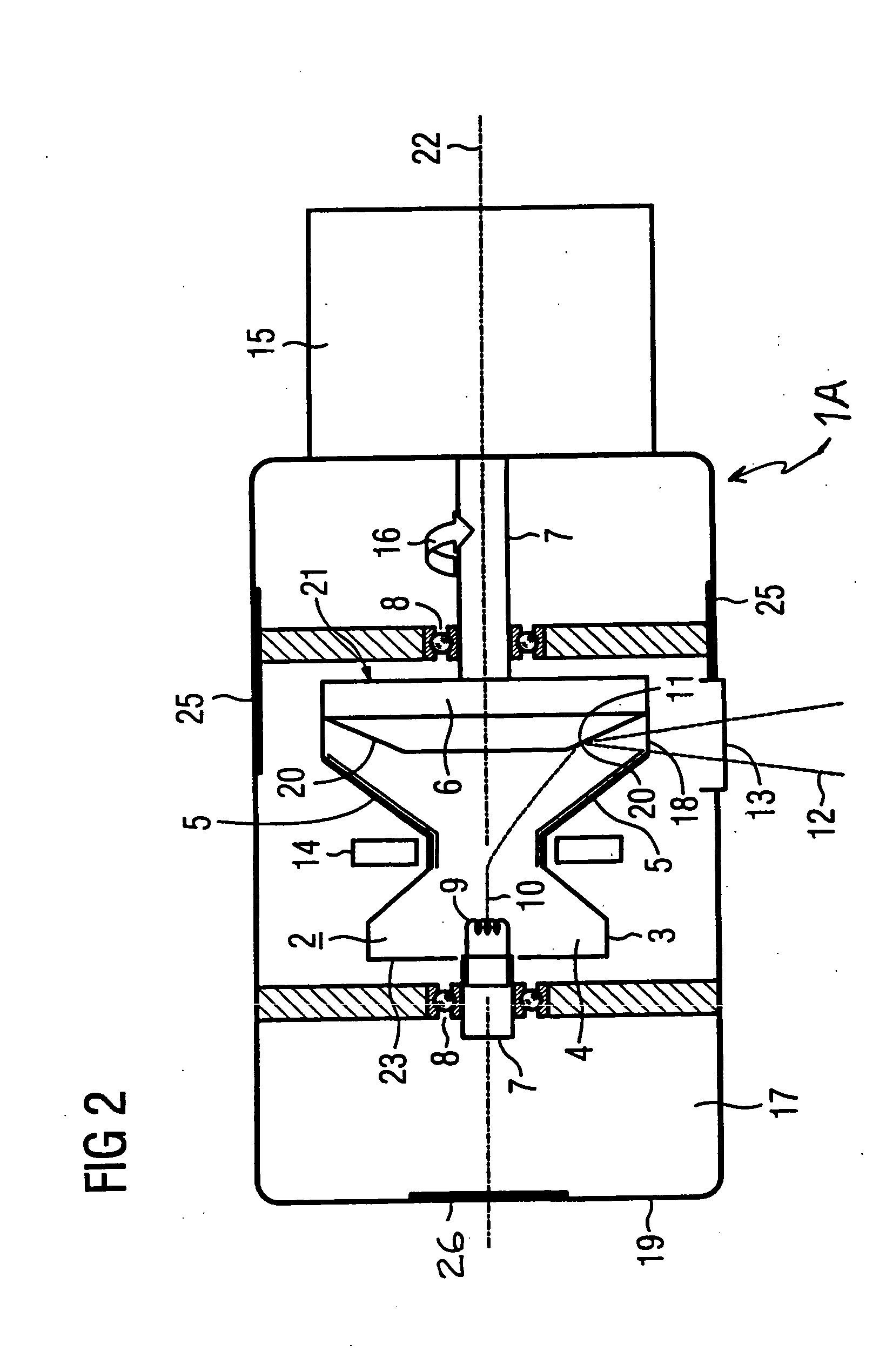

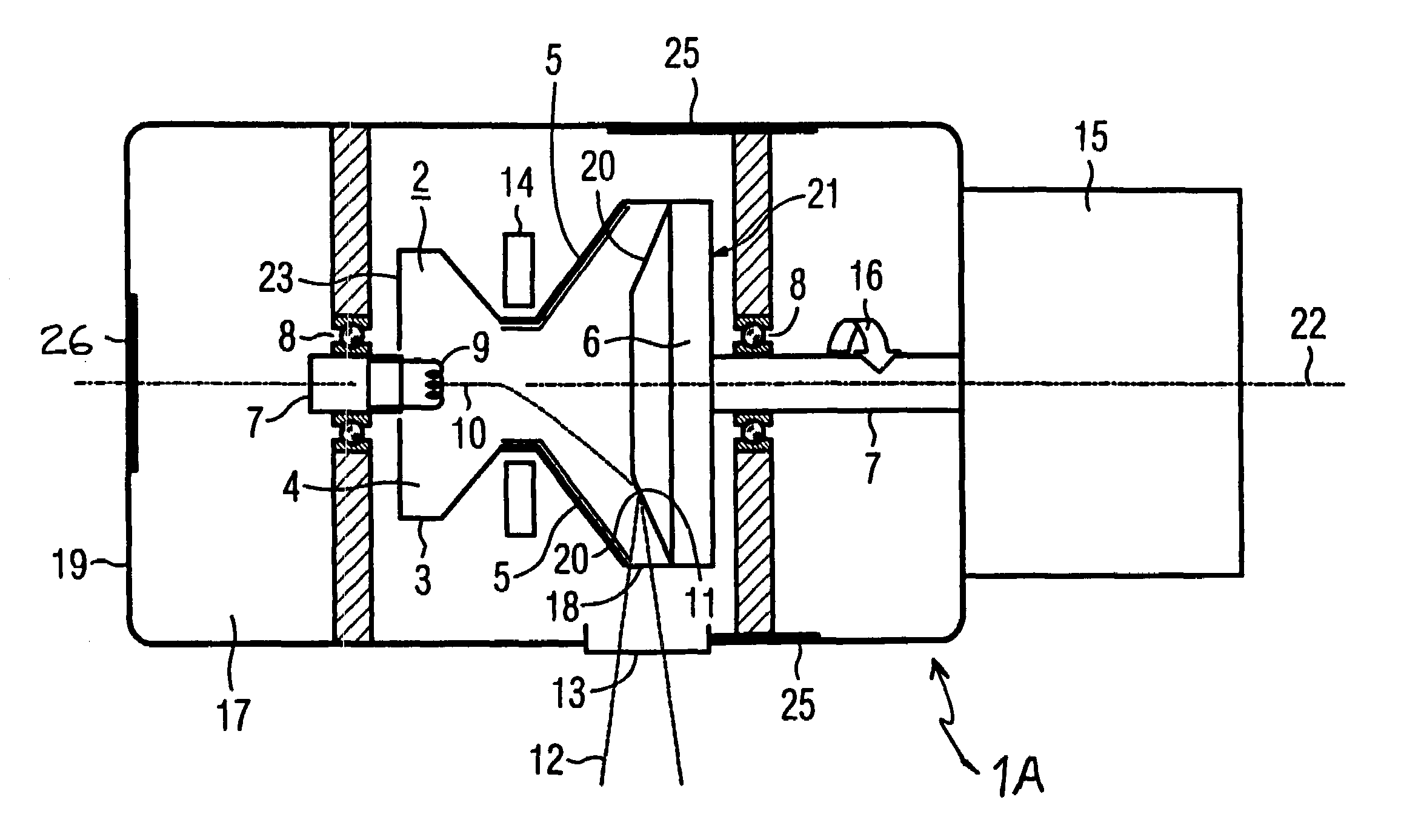

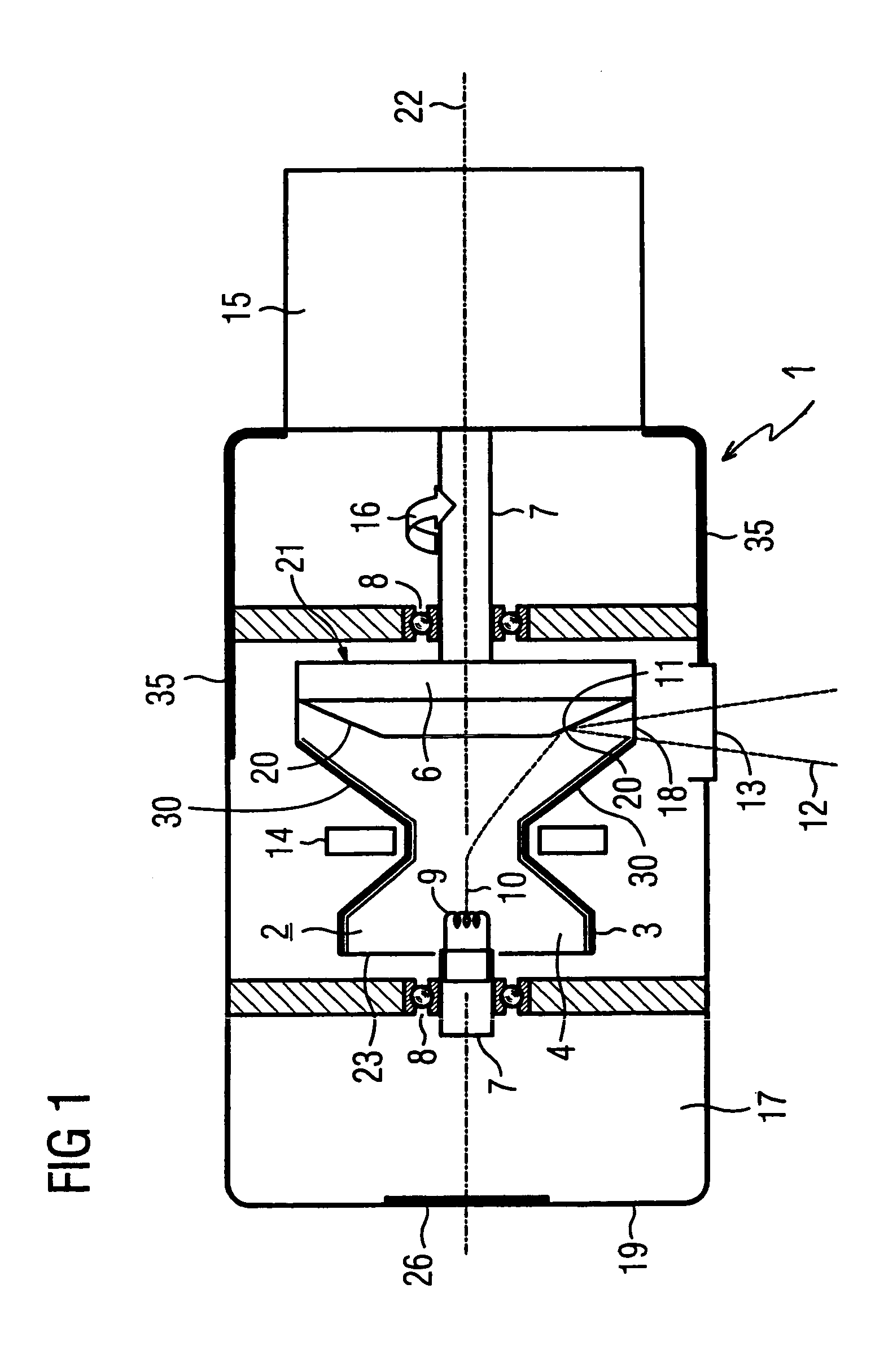

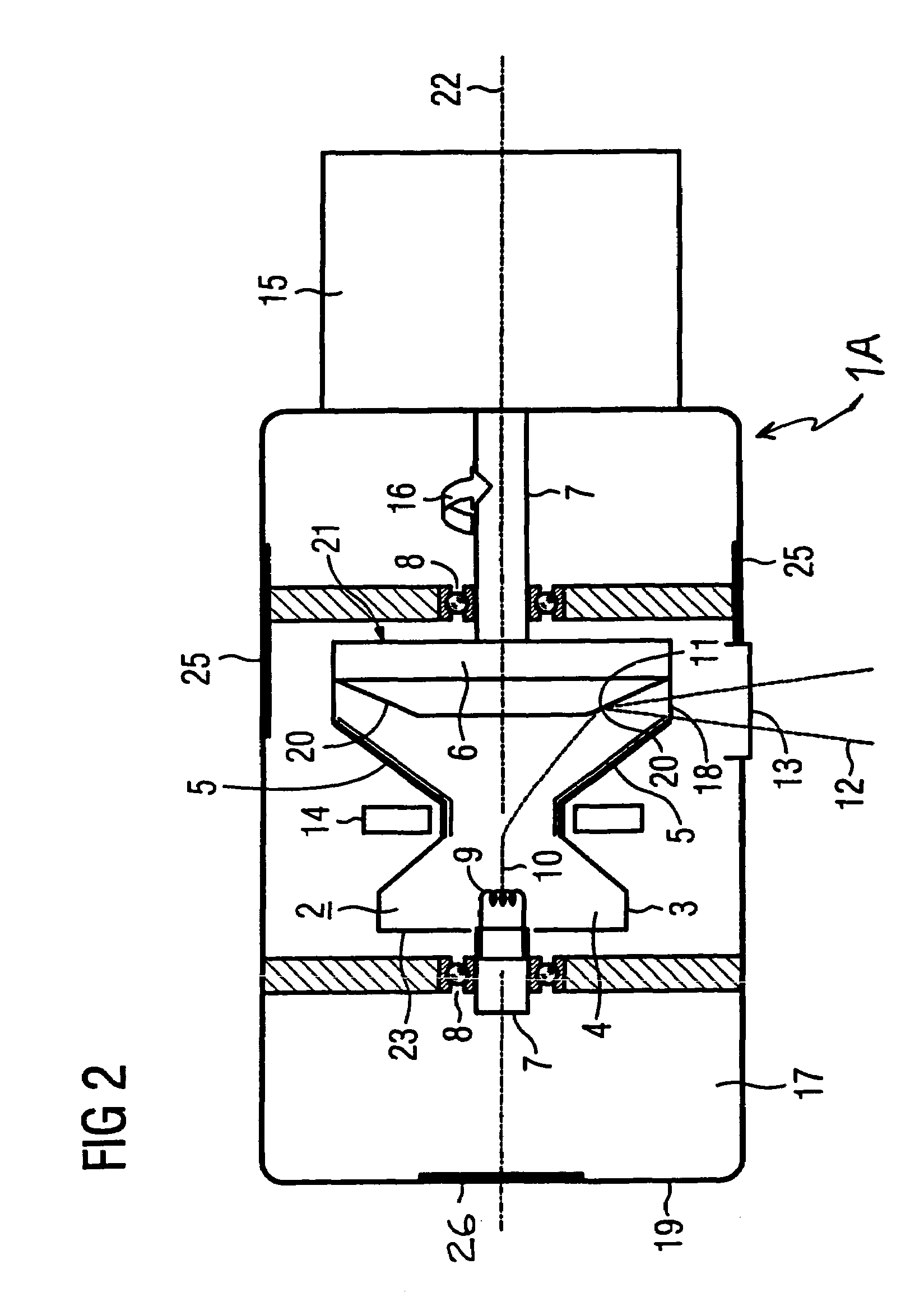

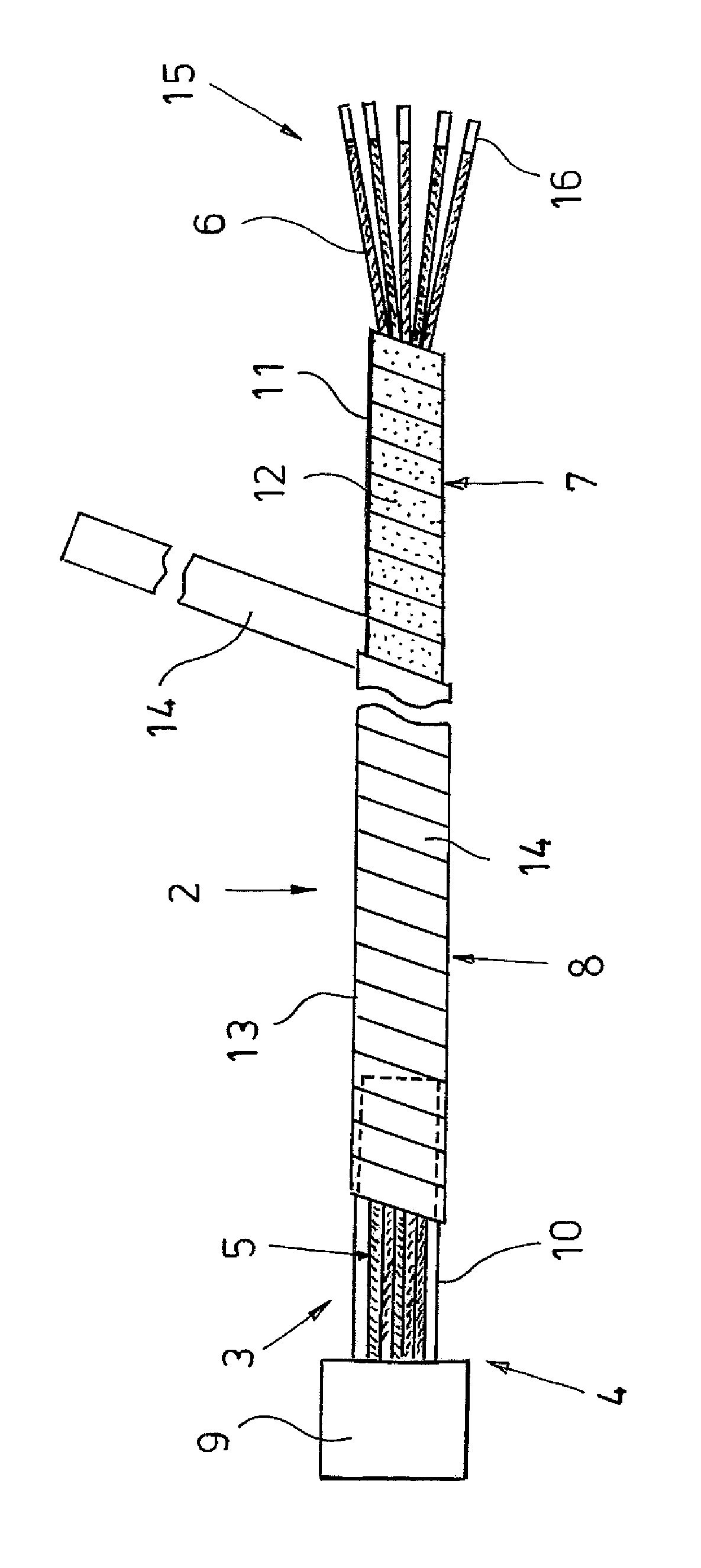

Wind turbine

ActiveUS20110254283A1Sufficient shieldingLow costWind motor combinationsMachines/enginesNacelleShielded cable

The present invention relates to a wind turbine (2) comprising a tower (3), a nacelle (4) arranged on top of said tower (3) and a slip ring assembly (1) having at least one slip ring (11), wherein a first cable (6) is extending from the nacelle (4) to the tower (3) via an interior bore (12) of the slip ring assembly (1), and at least one second cable (7a, 7b) is extending from the nacelle (4) to the tower (3) via said at least one slip ring (11), whereby a shielding distance is formed between an outer periphery of said first cable (6) and an inner circumference of said at least one slip ring (11). The present invention further relates to use of a slip ring assembly (1) comprising at least one slip ring (11) for shielding cables (6, 7a, 7b) in a wind turbine (2).

Owner:VESTAS WIND SYST AS

Micromachined electron or ion-beam source and secondary pickup for scanning probe microscopy or object modification

InactiveUS7960695B1Reliable and low methodEasy to operateMaterial analysis using wave/particle radiationBeam/ray focussing/reflecting arrangementsPositive pressureSecondary electrons

An e-beam or ion beam imaging and exposure system is built into the end of an AFM cantilever which images using the scanning capabilities built into the AFM. In one embodiment, a boron doped diamond cold cathode is formed into the cantilever with an associated accelerating electrode and secondary electron collection electrode. The assembly is brought within a few nanometers of the object to be imaged or exposed using the AFM. One or more gas channels built into the cantilever assembly provide a positive pressure of inert gas to prevent oxidative erosion of the cold cathode and can bleed any surface charge build up on the sample surface. After secondaries are collected the cantilever is moved to the next area to be exposed.

Owner:KLEY VICTOR B

Self-shielded ct scanner

ActiveUS20070189442A1Sufficient shieldingMaterial analysis using wave/particle radiationRadiation/particle handlingCt scannersX-ray

A CT scanner includes a pair of shields to protect an operator from x-rays from the CT scanner. The CT scanner has a gantry that provides structural support and housing for the components including an x-ray source and a detector arranged on the gantry to face one another. Lead shields are located on opposing sides of the x-ray source and extend between the x-ray source and the detector. The CT scanner further includes a computer located on an opposing side of the gantry from the x-ray source and the detector. The lead shields rotate with the gantry and prevent the x-ray from reaching the operator while the CT scanner is in operation.

Owner:XORAN TECH

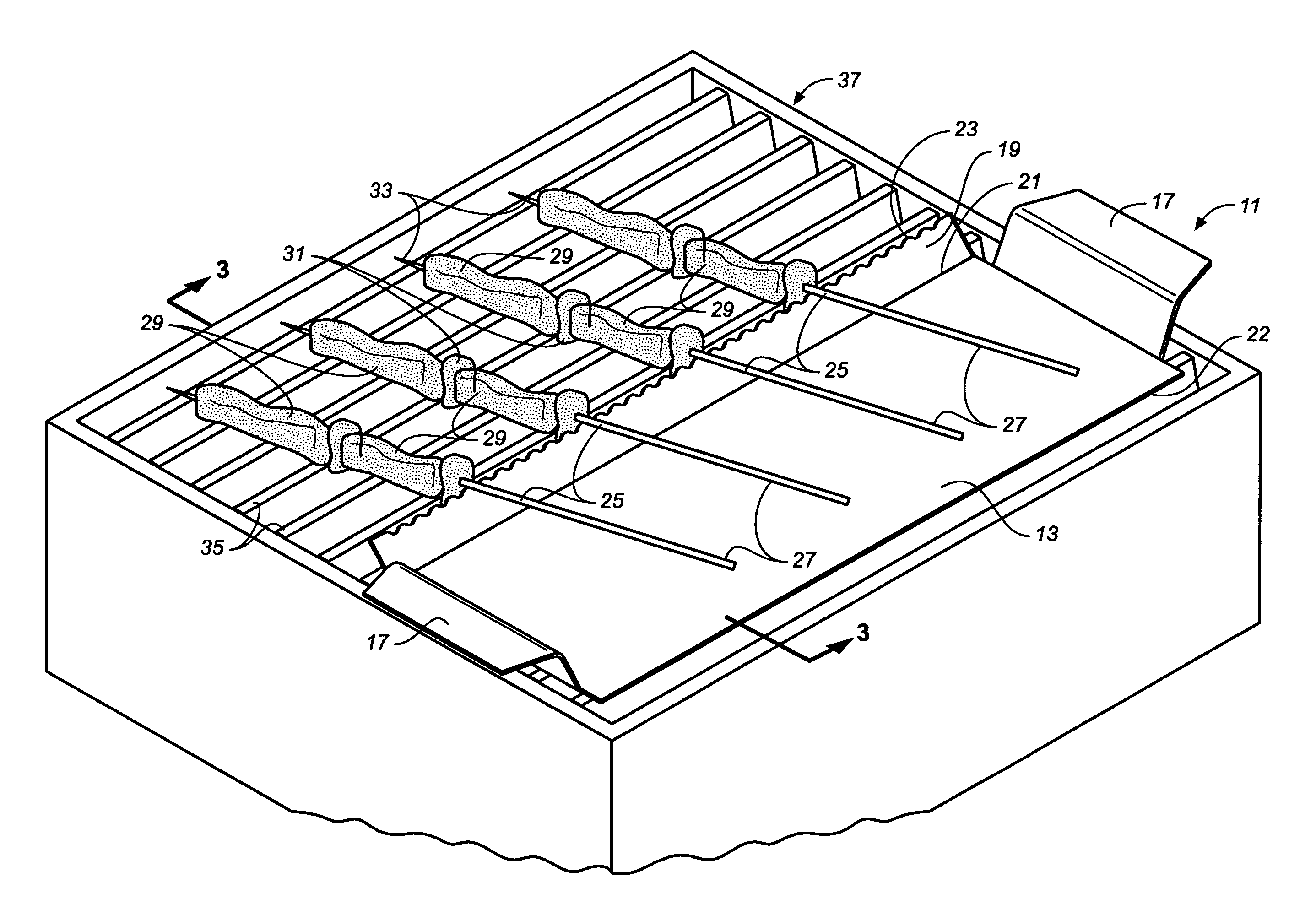

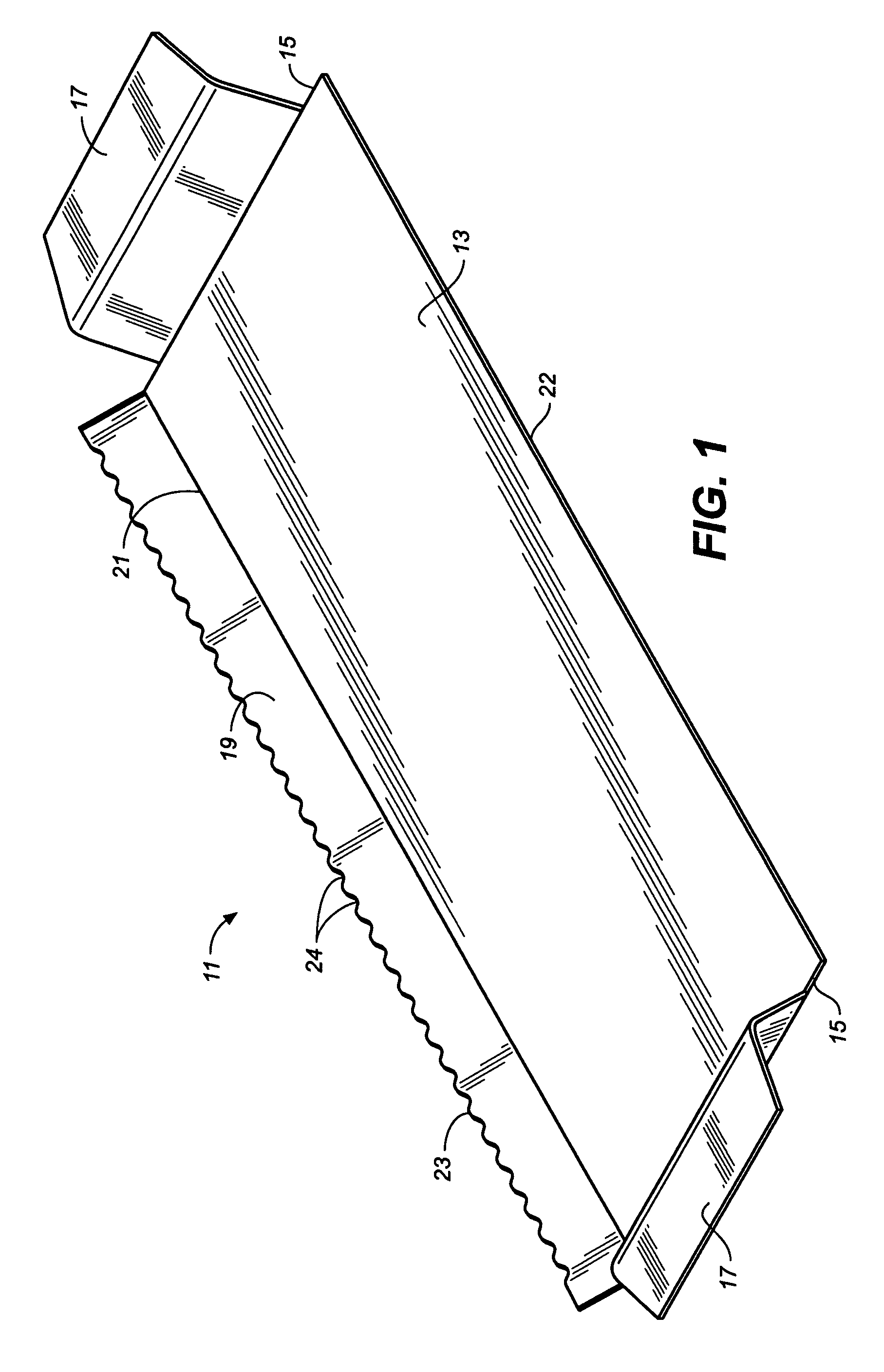

Skewer shield

InactiveUS7946223B2Easily picked up from the cooking grillSufficient shieldingRoasting apparatusRoasters/grillsMechanical engineeringEngineering

A skewer shield includes a shielding body adapted for placement on a cooking grill, and a skewer engaging portion extending upwardly from the shielding body. The skewer engaging portion has a top resting edge on which food-ladened skewers can be rested in such a manner that the shielding body of the skewer shield prevents the handle ends of the skewers from heating up.

Owner:CHARCOAL COMPANION

Method to improve inductance with a high-permeability slotted plate core in an integrated circuit

ActiveUS7436281B2Reduce eddy currentIncrease inductanceSemiconductor/solid-state device detailsSolid-state devicesIsolation layerEngineering

An inductor structure (102) formed in an integrated circuit (100) is disclosed, and includes a first isolation layer (106) and a first core plate (104) disposed over or within the first isolation layer (106, 114). The first core plate (104) includes a plurality of electrically coupled conductive traces composed of a conductive ferromagnetic material layer. A second isolation layer (108) overlies the first isolation layer and an inductor coil (102) composed of a conductive material layer (118) is formed within the second isolation layer (108). Another core plate may be formed over the coil. The one or more core plates increase an inductance (L) of the inductor coil (102).

Owner:TEXAS INSTR INC

Leakage radiation shielding arrangement for a rotary piston x-ray radiator

InactiveUS20060146985A1Sufficient shieldingLower the volumeX-ray tube electrodesX-ray tube vessels/containerPistonLeakage radiation

For reducing of the weight of leakage x-ray radiation shielding for a rotary piston x-ray tube that rotates in a cooling medium in a radiator housing of an x-ray radiator, the rotary piston x-ray tube having a rotary anode and a cathode fixedly connected with the vacuum housing thereof, the vacuum housing has at least one first region of a total shielding and the radiator housing has at least a second region of the total shielding. Only the respective regions of the vacuum housing and the radiator housing has that are irradiated by the leakage x-ray radiation are provided with shielding.

Owner:SIEMENS AG

Leakage radiation shielding arrangement for a rotary piston x-ray radiator

InactiveUS7382865B2Sufficient shieldingLower the volumeX-ray tube electrodesX-ray tube vessels/containerX-rayRadiation shield

Owner:SIEMENS AG

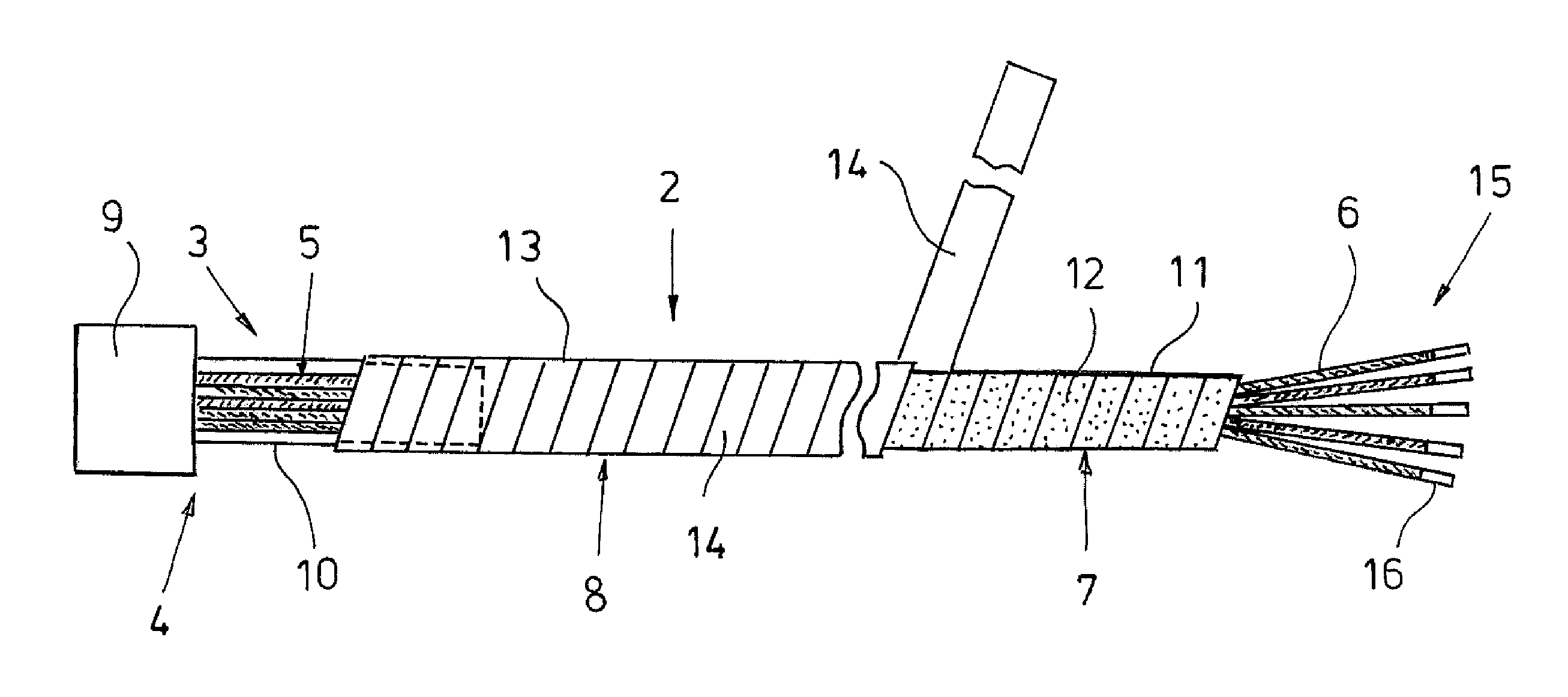

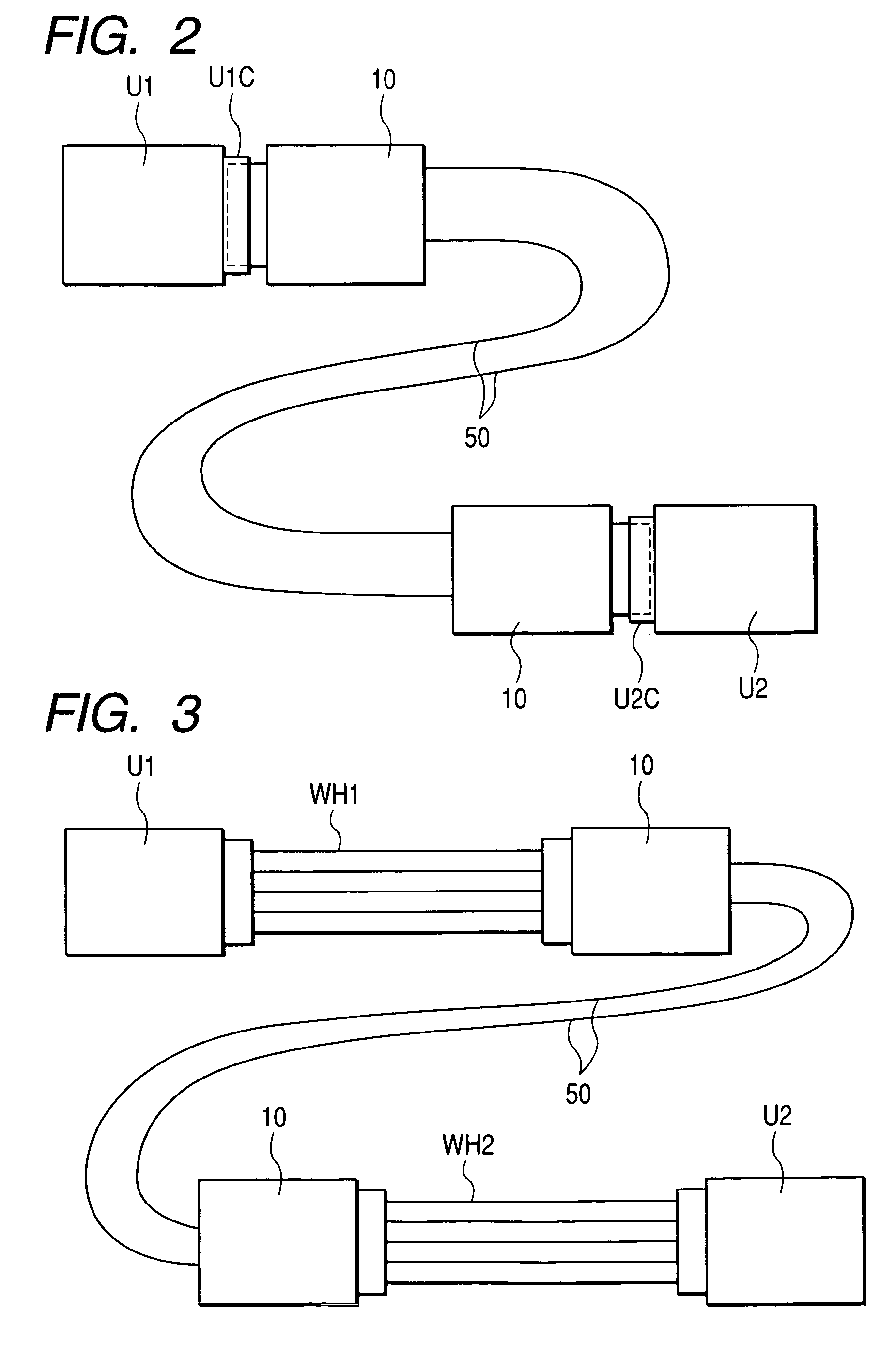

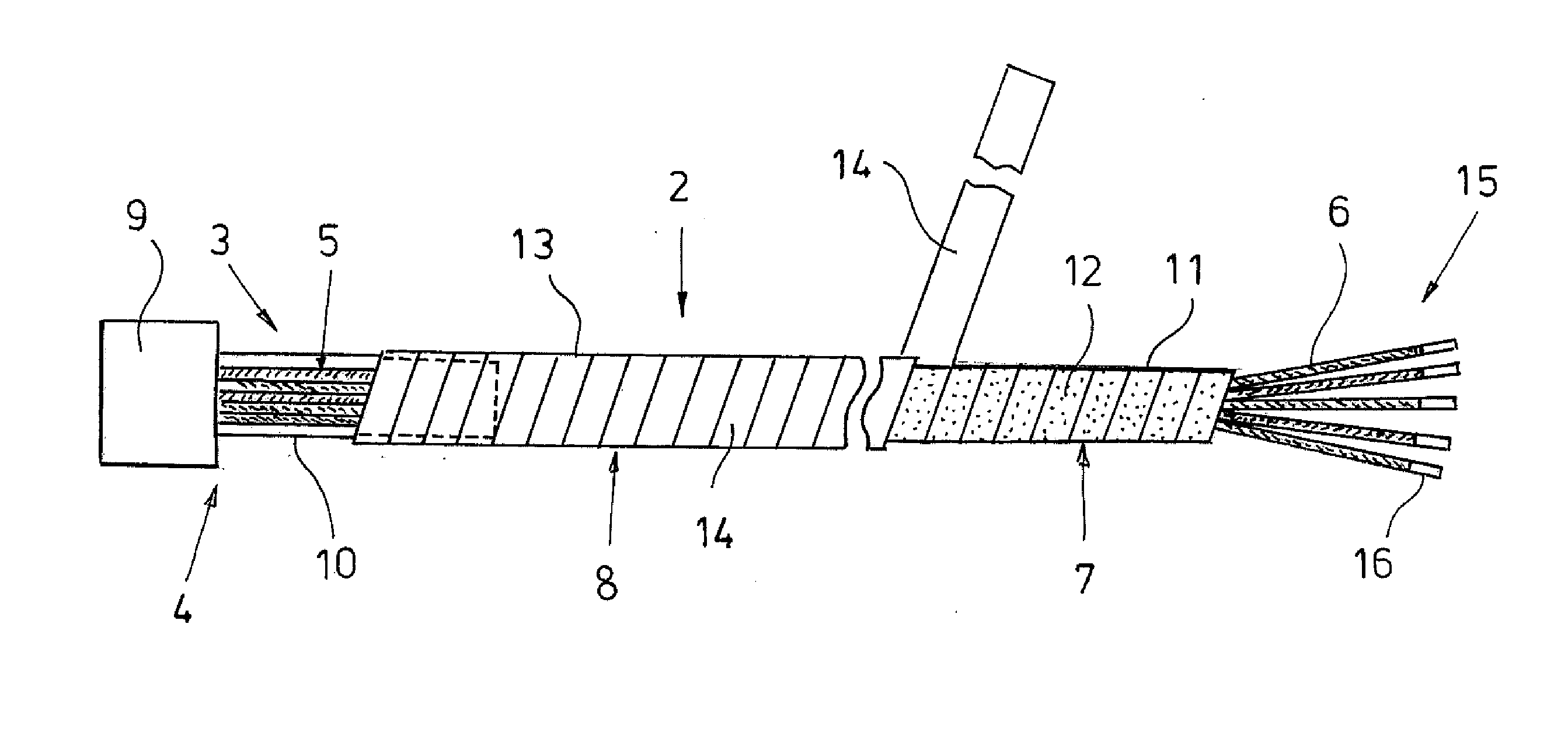

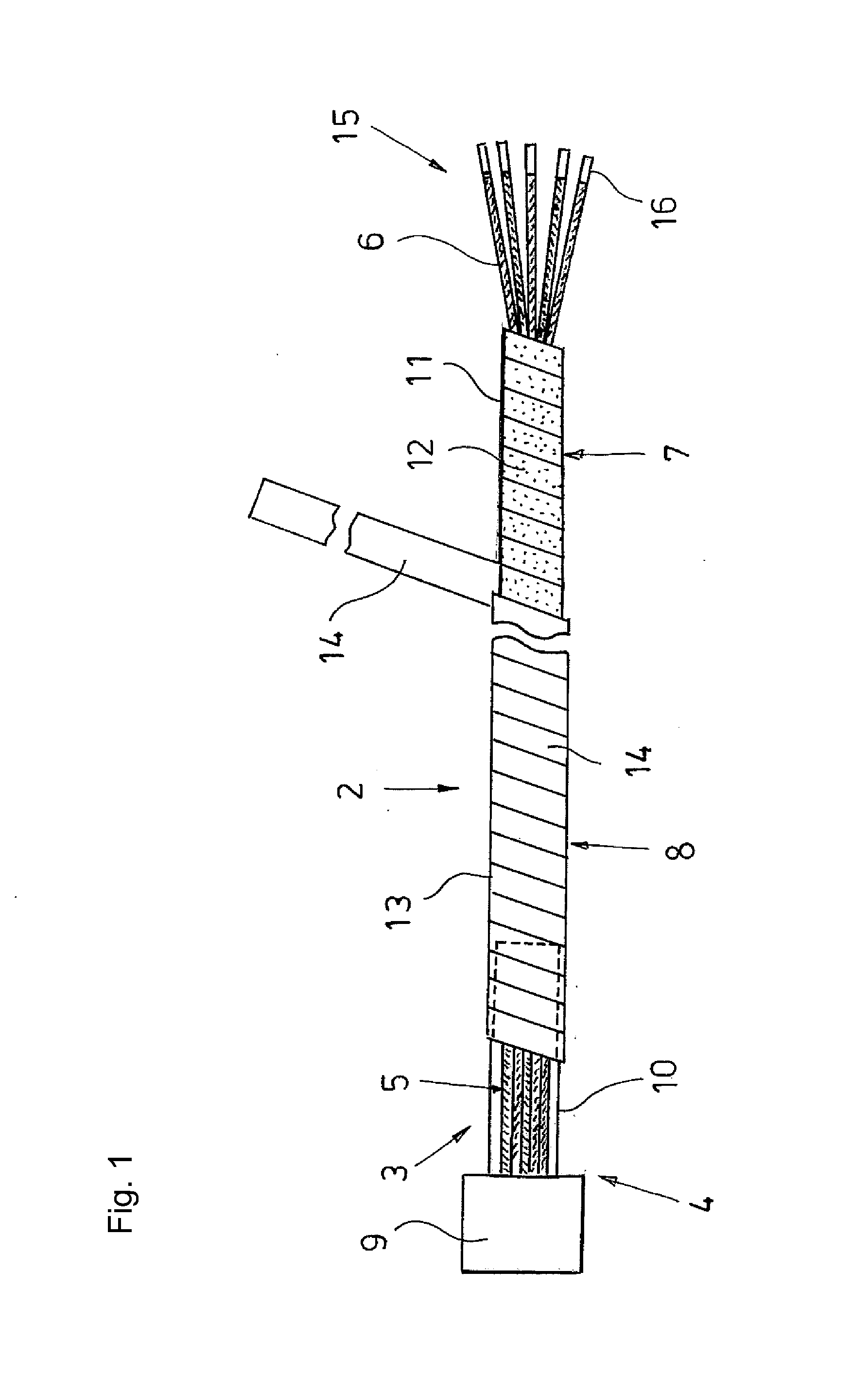

Electrical connecting cable

InactiveUS8704088B2Sufficient flexibilitySufficient shieldingLine/current collector detailsInsulated cablesElectrical conductorEngineering

An electrical connecting cable with a flexible electrical cable and with at least one electrical plug connector at one end of the cable, with the electrical cable including a bundle of conductors consisting of insulated stranded wires, a foil shield enclosing the bundle of conductors, and a protective sheath encasing the foil shield and serving as the outer surface of the cable. The plug connector includes a metallic plug connector housing, preferably a round housing, holding insulated contacts and a molded-on shield sleeve with which the stranded wires and the foil shield are connected in an electrically conductive manner. The foil shield includes at least one electrically conductive shield tape and the protective sheath includes at least one electrically non-conductive sheath tape that are both wrapped at an angle spiral-like with a lateral overlap along the stranded wires around the bundle of conductors and the shield sleeve.

Owner:CONINVERS

Method for generating a component by a power-bed-based additive manufacturing method and powder for use in such a method

ActiveUS20190193160A1High melting pointLow melting pointTurbinesAdditive manufacturing apparatusLaserAlloy composition

The disclosure relates to a powder and a method for generating a component by a powder-bed-based additive manufacturing method, such as laser melting. The powder includes particles having a core and a shell. The particles have an alloy composition of the component. The concentration of higher-melting alloy elements is greater in the shell and the concentration of lower-melting alloy elements is greater in the core, wherein the surface of the particles is higher in comparison with particles with a constant alloy composition. This advantageously prevents the particles from caking together in the powder bed during the production of the component, and so the powder bed may also be subjected to high preheating temperatures of up to 1000° C.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Light-emitting device, method for producing the same, and illuminating device

ActiveUS8757826B2Avoid lengthEasy to produceDischarge tube luminescnet screensLighting support devicesEngineeringLight emission

A light-emitting device having an LED element and a resin layer including a convex portion covering the LED element can suppress color unevenness to achieve light emission with uniform color distribution. The light-emitting device can include a substrate, an LED element mounted on the substrate, a resin layer which contains a wavelength conversion material and is formed on the substrate to cover the LED element, the resin layer including a convex portion directly covering the LED element and a flat thin film portion extending around the convex portion, and a reflective portion which is formed over the thin film portion around the convex portion. A diffusion portion can be formed to cover the convex portion of the resin layer.

Owner:STANLEY ELECTRIC CO LTD

Optical active connector

InactiveUS7186037B2Sufficient shieldingMagnetic/electric field screeningCoupling light guidesSignal transitionRelay

An electric connector portion, an optical element and a mounting board formed with a circuit executing a predetermined signal conversion and relay processing are held by a case. The case includes an optical element-containing recessed portion having electrical conductivity, and the optical element is arranged in the optical element-containing recessed portion. Further, the case may include a mounting part-containing recessed portion independently from the optical element-containing recessed portion, and mounting parts on the mounting board may be arranged in the mounting part-containing recessed portion.

Owner:AUTONETWORKS TECH LTD +2

Electrical connecting cable

InactiveUS20120103647A1Certain flexural stiffnessWear and resistantLine/current collector detailsMagnetic/electric field screeningElectrical conductorEngineering

An electrical connecting cable with a flexible electrical cable and with at least one electrical plug connector at one end of the cable, with the electrical cable including a bundle of conductors consisting of insulated stranded wires, a foil shield enclosing the bundle of conductors, and a protective sheath encasing the foil shield and serving as the outer surface of the cable. The plug connector includes a metallic plug connector housing, preferably a round housing, holding insulated contacts and a molded-on shield sleeve with which the stranded wires and the foil shield are connected in an electrically conductive manner. The foil shield includes at least one electrically conductive shield tape and the protective sheath includes at least one electrically non-conductive sheath tape that are both wrapped at an angle spiral-like with a lateral overlap along the stranded wires around the bundle of conductors and the shield sleeve.

Owner:CONINVERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com