Patents

Literature

155 results about "Γ ray radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

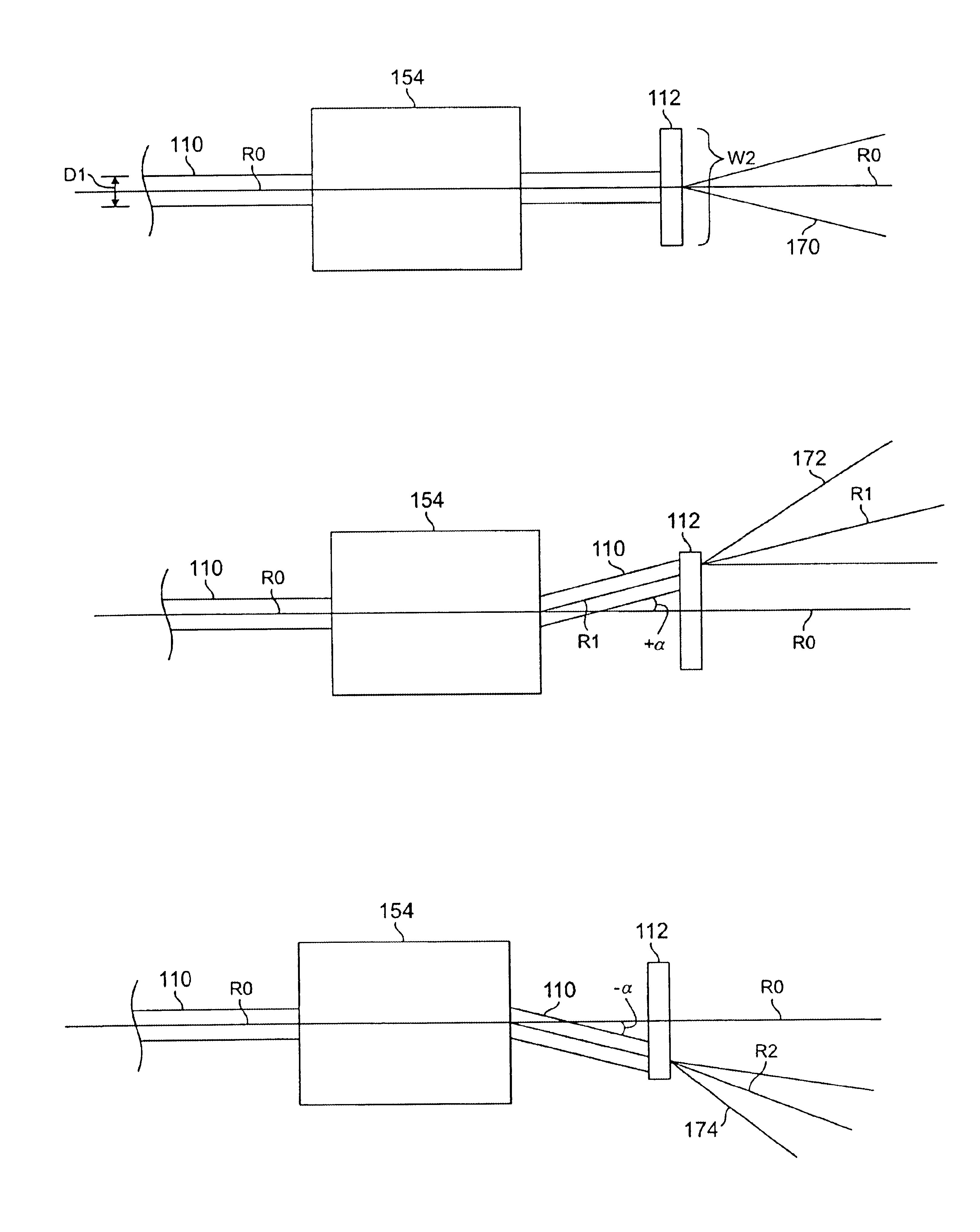

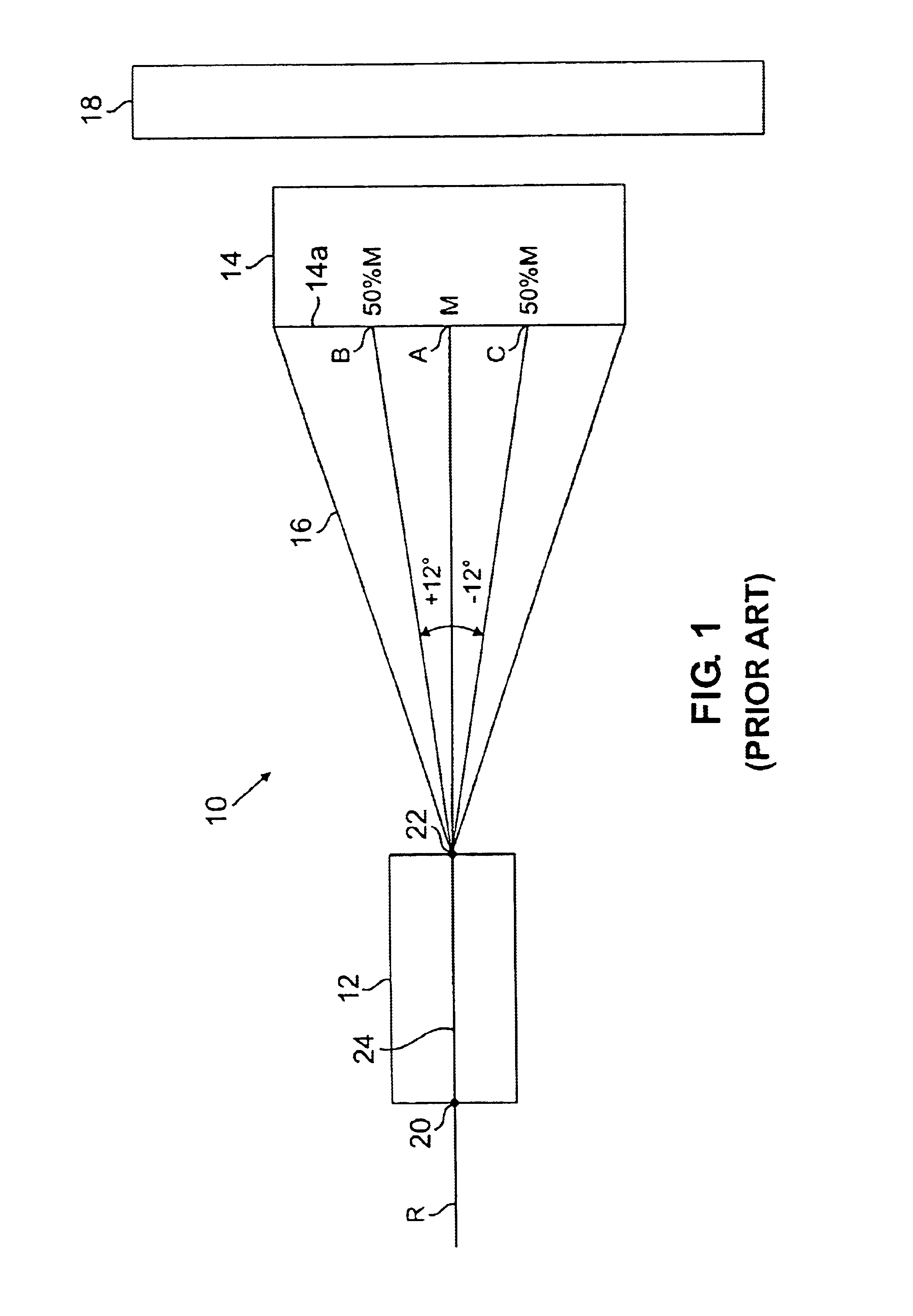

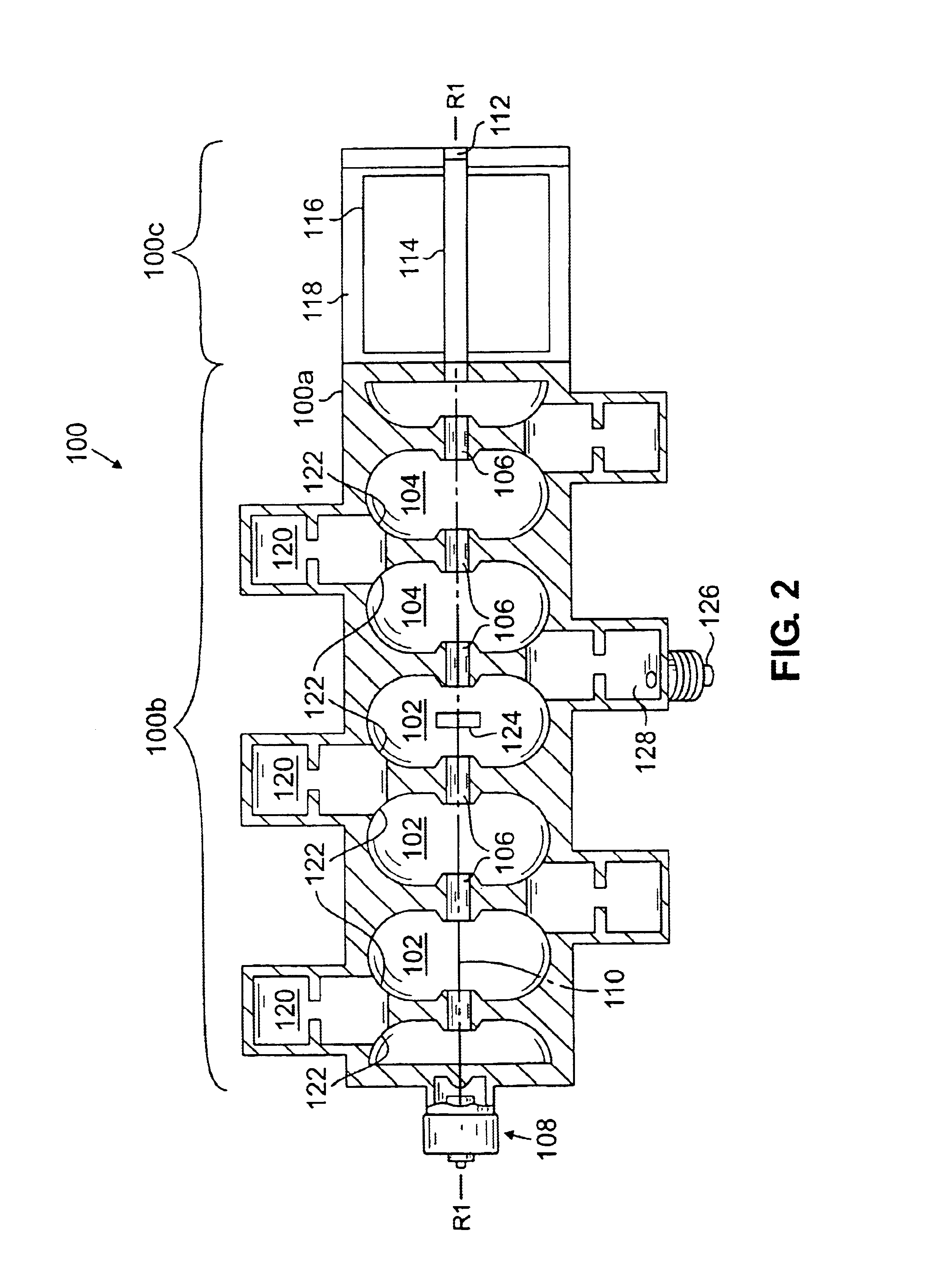

Radiation sources and radiation scanning systems with improved uniformity of radiation intensity

InactiveUS6954515B2Uniform radiation intensityImproved intensity distributionRadiation/particle handlingCathode ray concentrating/focusing/directingFluenceX-ray

A radiation source is disclosed comprising a source of charged particles that travel along a path. Target material lies along the path to generate radiation upon impact by the beam. A magnet is provided to deflect the beam prior to impacting the target. The magnet may generate a time-varying magnetic field or a constant magnetic field. A constant magnetic field may be varied spatially across the beam. The magnet may be an electromagnet or a permanent magnet. In one example, deflection of the beam results in impact of the beam on the target along a plurality of axes. In another example, portions of the beam are differentially deflected. The source may thereby irradiate an object to be scanned with more uniform radiation. The charged particles may be electrons or protons and the radiation may be X-ray or gamma ray radiation, or neutrons. Scanning systems incorporating such sources, methods of generating radiation and methods of examining objects are disclosed, as well.

Owner:VAREX IMAGING CORP

Obturator-type silicone rubber foam material, and its preparing method and use

InactiveCN1850908ACells are fine and uniformFlat surfaceOther chemical processesPolymer scienceFoaming agent

The invention discloses an isolated cell type silicon rubber foam material and the manufacture method and the application. The feature is that it is made up of 100 portions silicone rubber, 15-80 portions reinforcing agent, 2-15 portions constitution controller, 3-15 portions foaming agent, 0-3 portions blowing promoter, and 0-4 portions coupling assistant agent, after taking radiation by electron beam or gama radiation, the silicon rubber takes coupling reaction, and the radiation dose is 5-20KGy. Decomposing foaming by heating, the silicon rubber could immediately taking electron beam or gama radiation to take the second radiation coupling, the radiation dose is 20-50KGy to improve the complex performance of the silicon rubber foam material. The invention could be used as sealing, damping, insulating, sound insulating and thermal insulating material.

Owner:SICHUAN UNIV

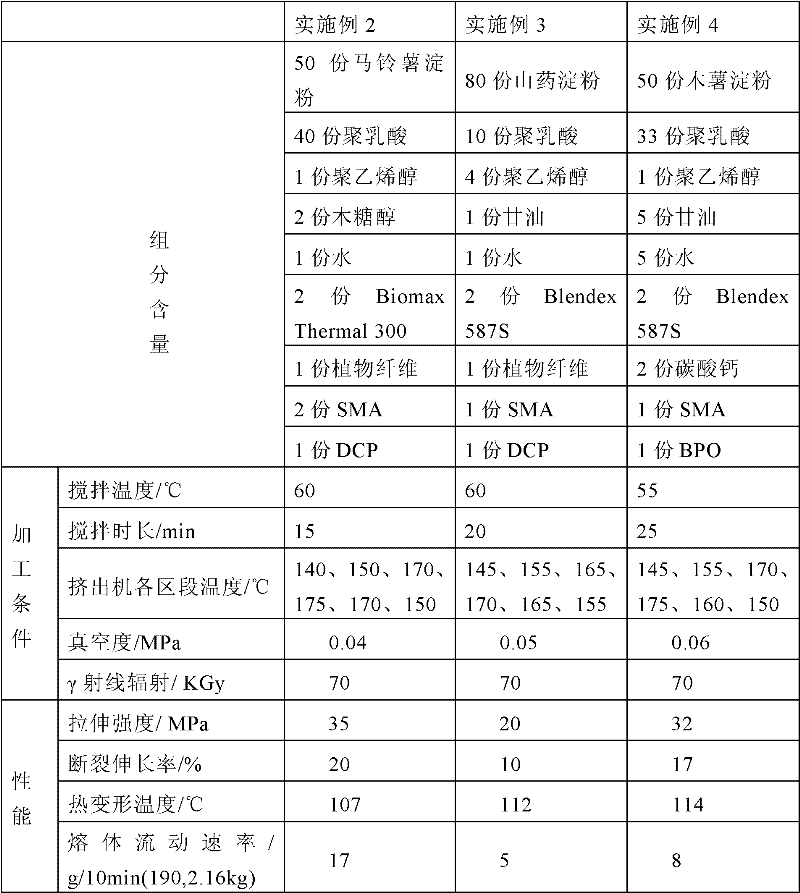

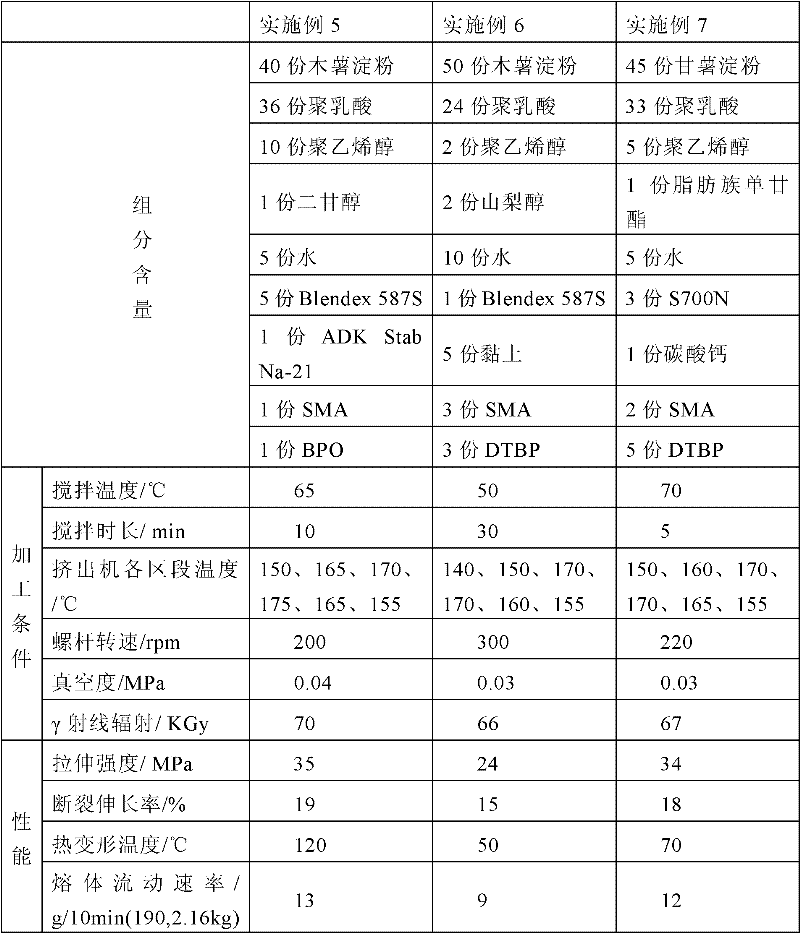

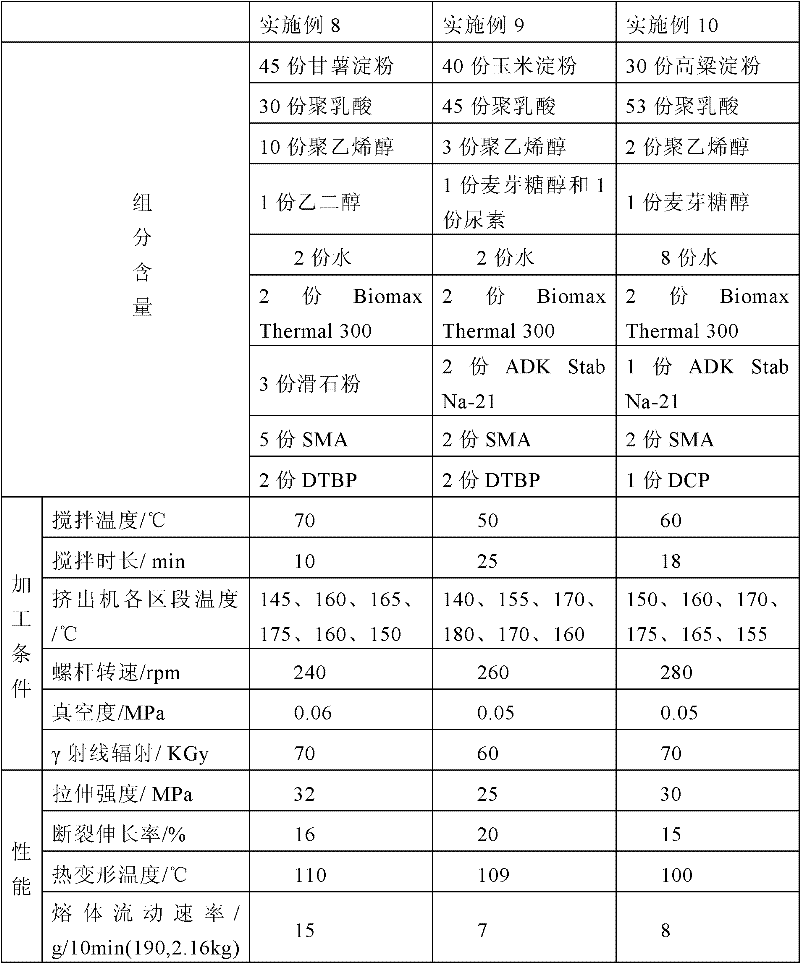

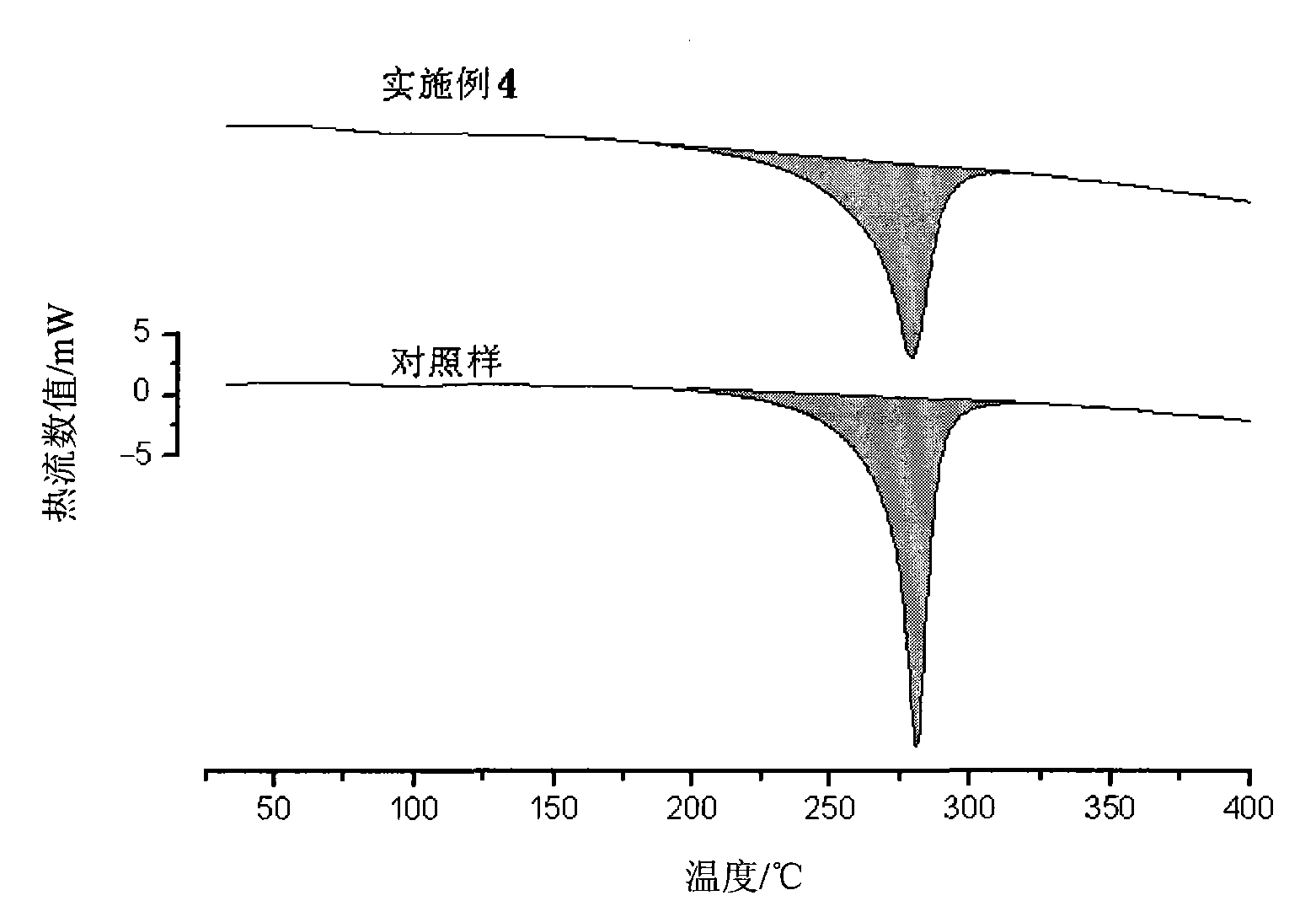

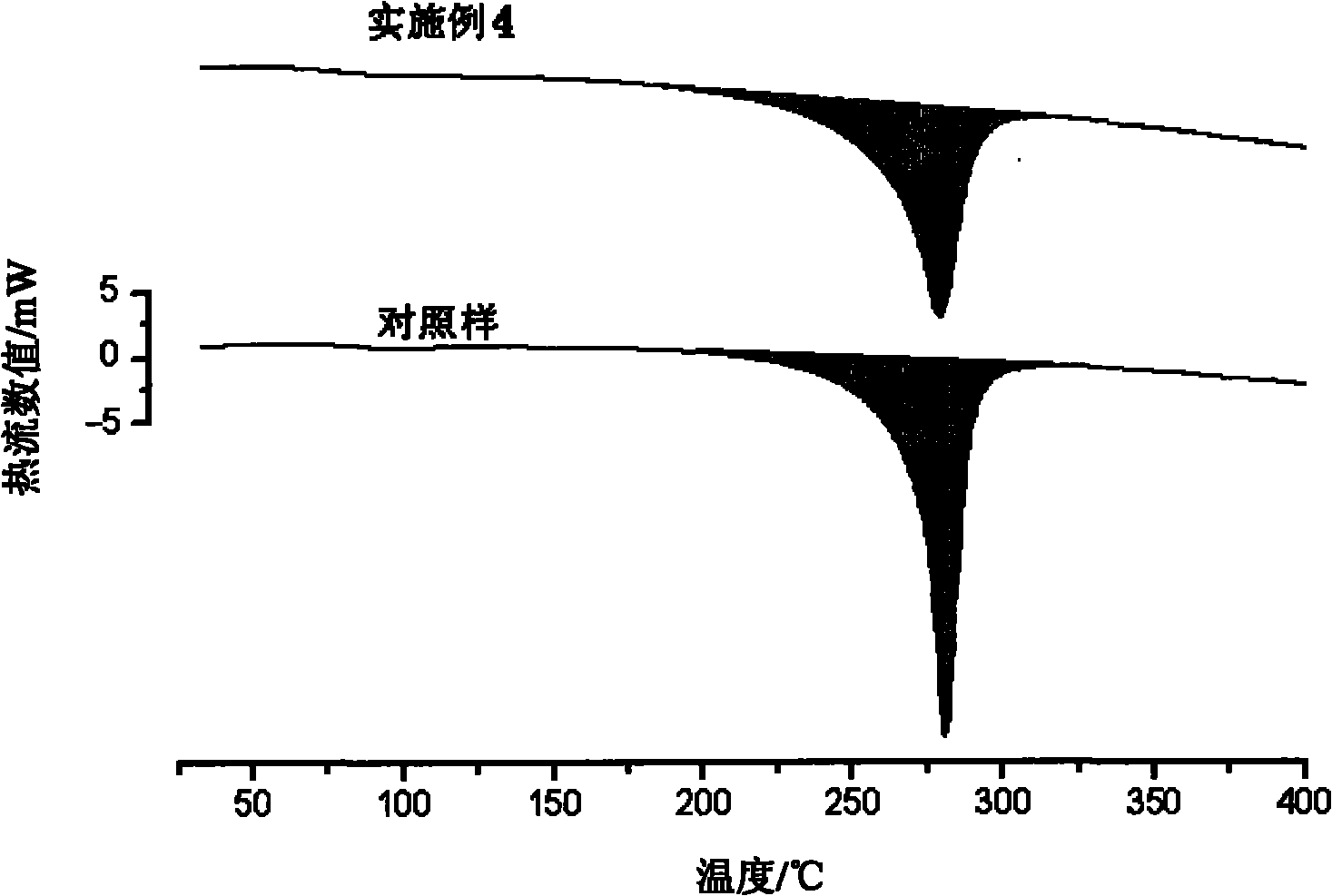

Biodegradable polylactic acid-starch heat-resistant composite material and preparation method thereof

ActiveCN102268144AImprove mechanical propertiesImprove heat resistancePolyvinyl alcoholResistant starch

The invention relates to a biodegradable polylactic acid-starch thermal-resistance composite material and a preparation method thereof. The biodegradable polylactic acid-starch thermal-resistance composite material consists of the following raw material components in part by weight: 20 to 80 parts of natural starch, 10 to 70 parts of polylactic acid, 1 to 10 parts of polyvinyl alcohol, 1 to 5 parts of plasticizer, 1 to 10 parts of water, 1 to 5 parts of thermal-resistance modifier, 1 to 5 parts of nucleating agent, 1 to 5 parts of compatilizer and 1 to 5 parts of crosslinking agent. The preparation process comprises: mixing raw material; extruding to form grains; irradiating by gamma rays; and the like. The composite material disclosed by the invention has high mechanical properties. The tensile strength of the composite material is 20 to 35MPa, the elongation at break is 10 to 20 percent and the heat distortion temperature is 90 to 120 DEG C. In addition, the composite material has high environmental degradability, high forming and processing performance, and can be formed into various products by extrusion, plastic injection, thermal pressing and other means on common plastic processing equipment.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

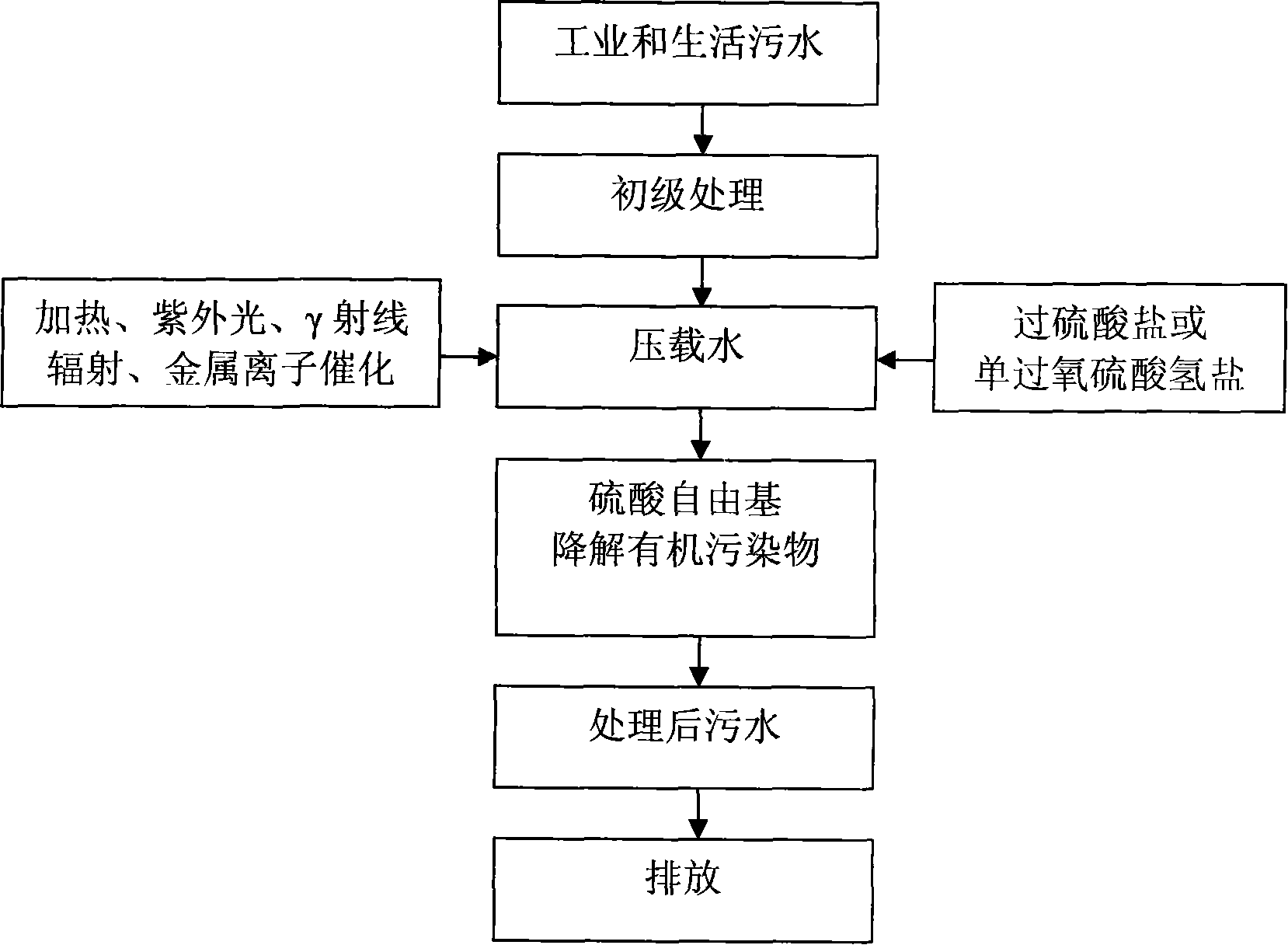

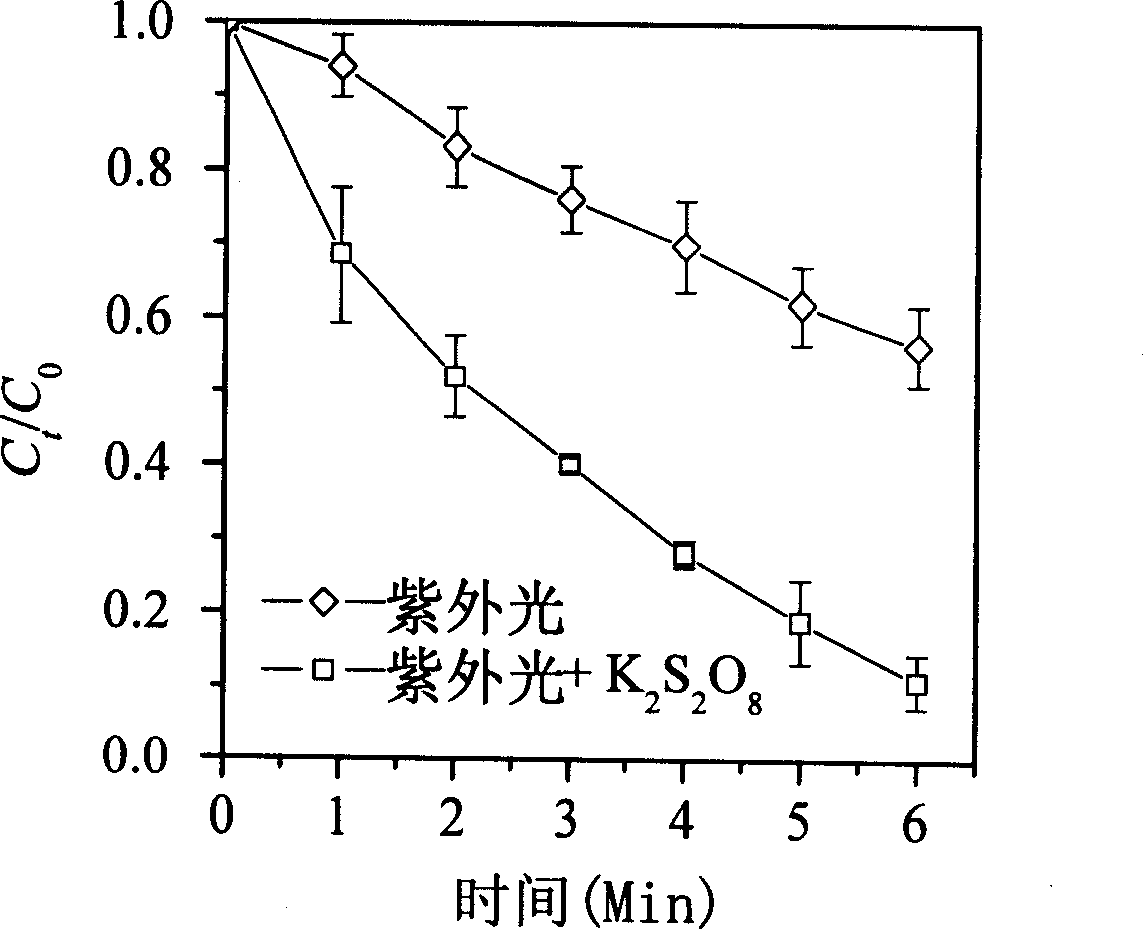

Method for processing sulphuric acid free radical oxidized water

InactiveCN101172691ANo secondary pollutionImprove processing efficiencyWater/sewage treatment by irradiationWater/sewage treatment by oxidationDecompositionFenton reagent

Owner:DALIAN MARITIME UNIVERSITY

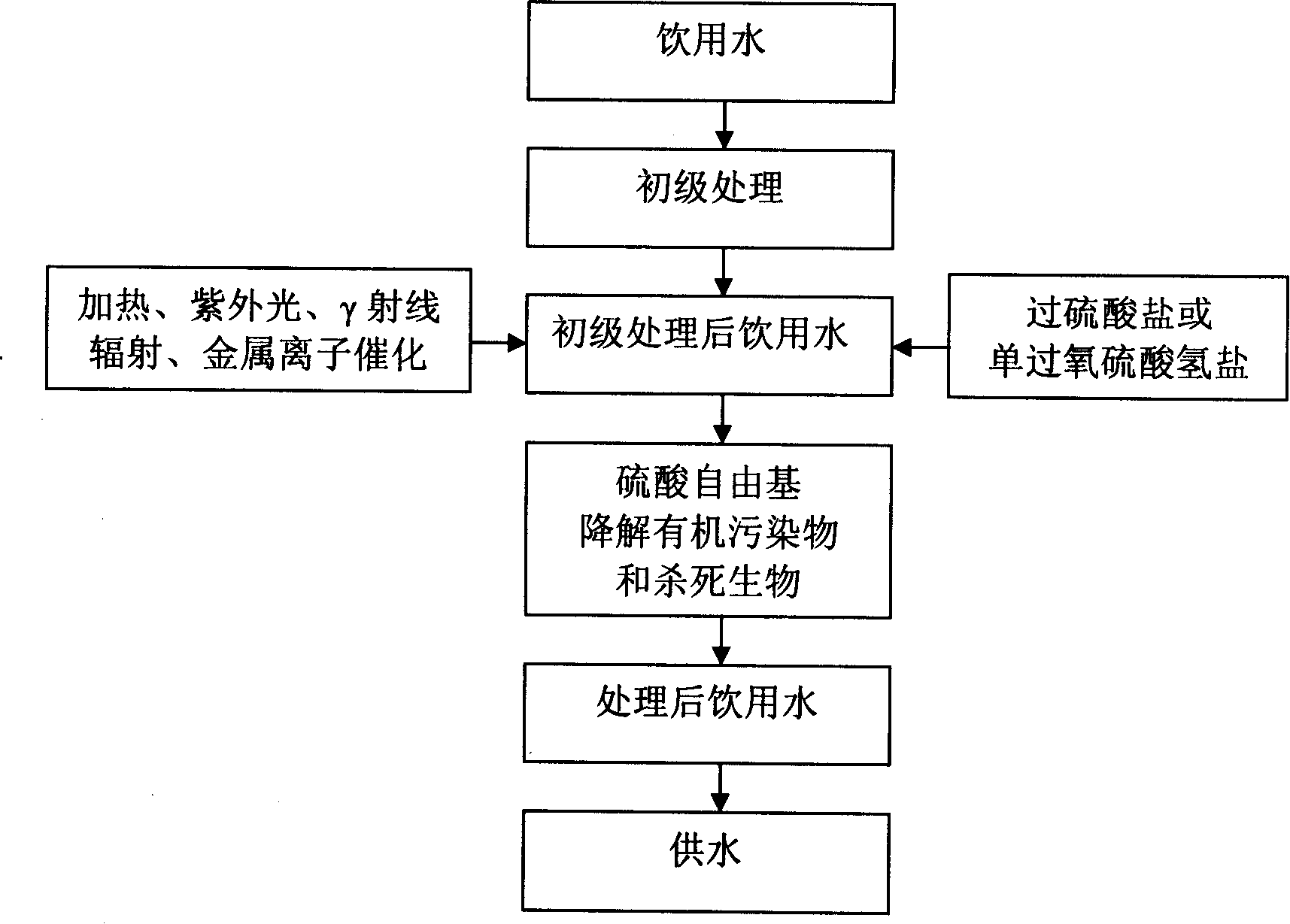

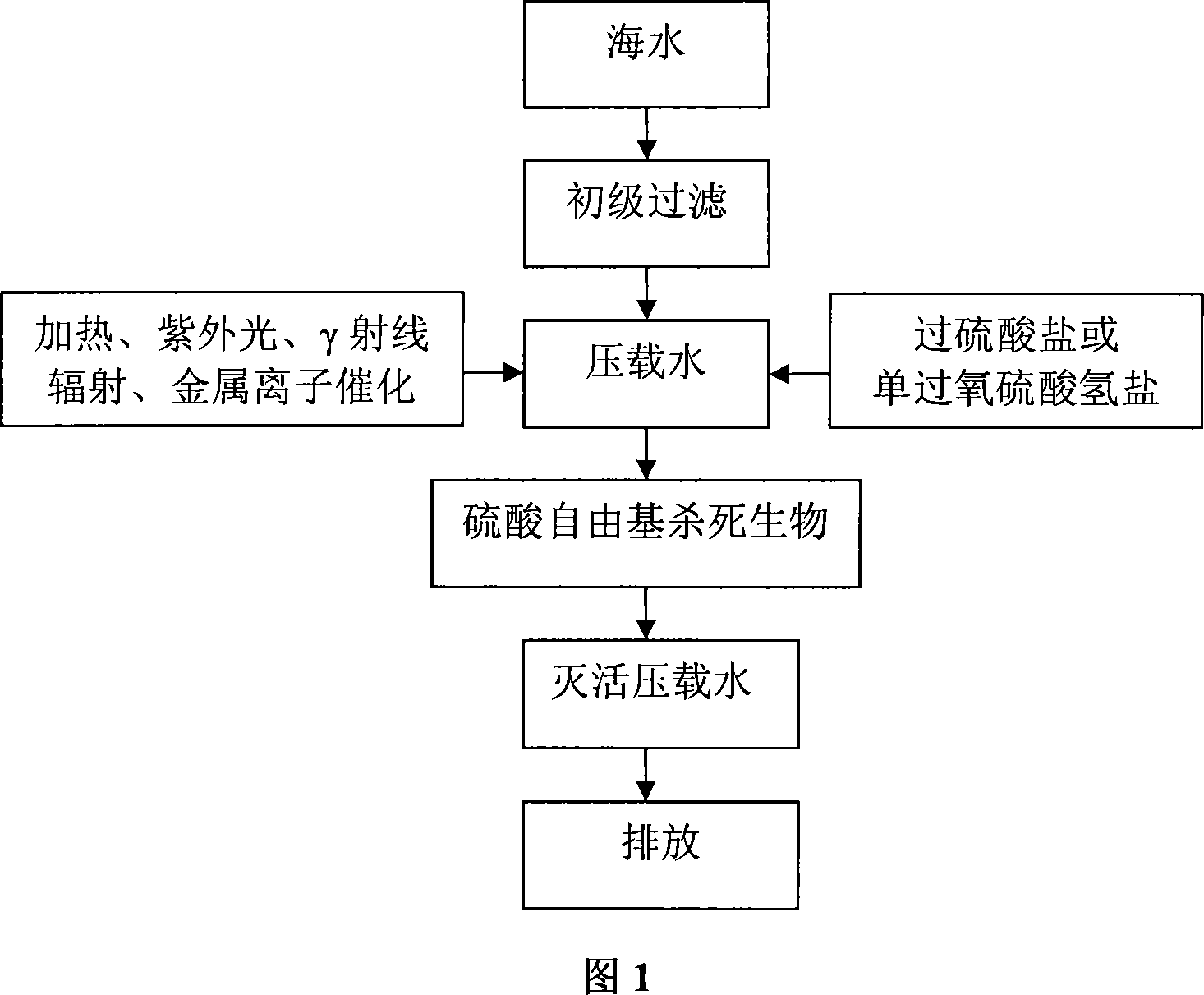

Method for treating ship ballast by high-level oxidation technology based on sulphuric acid free radical

InactiveCN101045573ANo secondary pollutionReduce energy consumptionWater/sewage treatment by irradiationSeawater treatmentHydrogenPersulfate

A process for treating the water-ballast of ship by high-grade oxidizing technique based on free radicals of sulfuric acid in order to kill the microbes in it includes such steps as filtering, adding persulfate or hydrogen monoperoxysulfate salt, generating the free radicals of sulfuric acid by thermo-decompsoing, ultraviolet decomposing, gamma-ray radiation, or metallic ion' s catalytic decomposing, and reaction between said free radicals and water-ballast.

Owner:DALIAN MARITIME UNIVERSITY

Preparation method of silicon rubber foam material

The invention discloses a preparation method of a silicon rubber foam material, which is characterized by mixing 100 parts of silicon rubber, 12-85 parts of white carbon black, 2-15 parts of constitution controller, 3-15 parts of foaming agent, 0-5 parts of blowing promoter and 0-8 parts of cross-linking agent promoter and forming, radiating the silicon rubber by electron beams or gamma rays to generate cross-linking reaction, heating the foaming agent for decomposing and foaming, immediately utilizing the electron beams or the gamma rays to carry out secondary radiation crosslinking after foaming the silicon rubber to further improve the comprehensive properties of the silicon rubber foam material. The silicon rubber foam material can be used for sealing, damping, insulation, sound insulation and thermal insulation materials.

Owner:WUJIANG LANGKE CHEM FIBER

Open- cells silicon rubber foam material and its preparation process and use

The invention discloses the open cell silicon rubber foamed material and preparing method, comprising the following steps: mixing the 100 parts silicon rubber, 15-80 parts strengthening agent, 2-15 parts structure control agent, 150-300 parts pore former and 0-4 parts cross-linking agent, radiating with electron beam or gamma ray with 20-100kGy radiation dose, washing cross-linking silicon rubber, getting pore former, and getting the product. The product can be used in damping, insulation and acoustic material.

Owner:SICHUAN UNIV

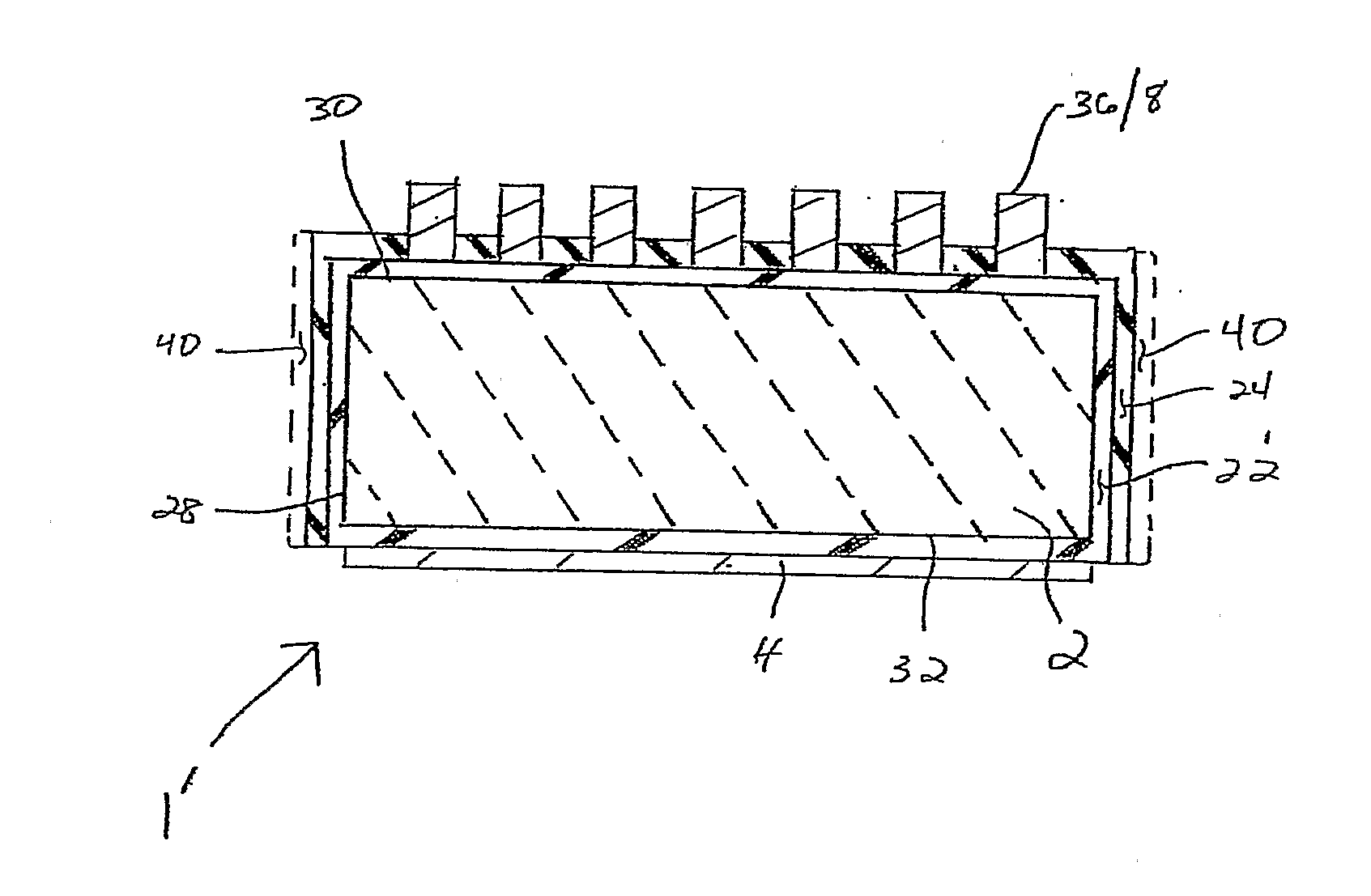

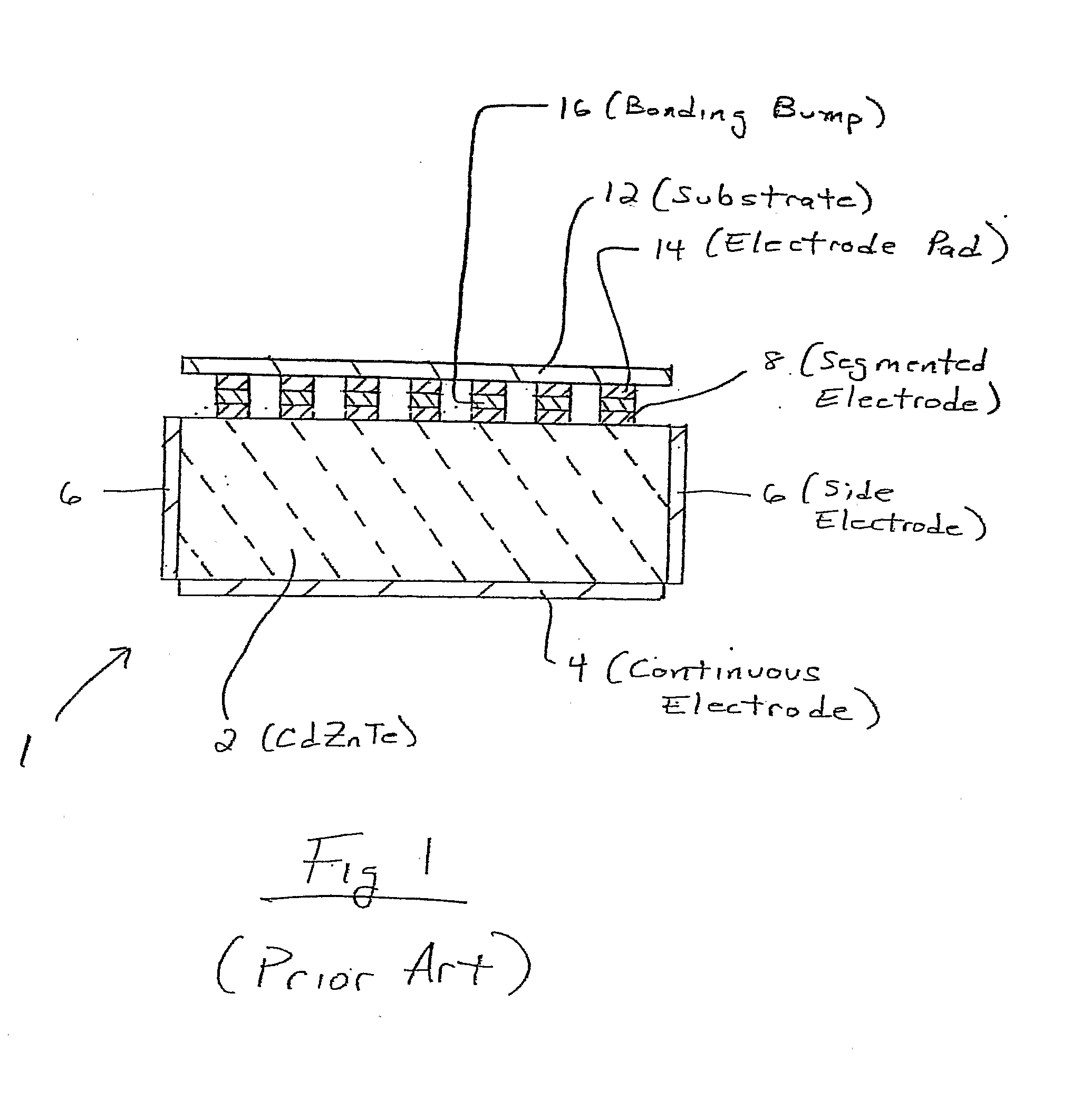

High Performance CdxZn1-xTe X-Ray and Gamma Ray Radiation Detector and Method of Manufacture Thereof

InactiveUS20080203514A1Improve performanceLong-term stabilityFinal product manufactureSolid-state devicesX-rayGamma ray

The present invention is a radiation detector that includes a crystalline substrate formed of a II-VI compound and a first electrode covering a substantial portion of one surface of the substrate. A plurality of second, segmented electrodes is provided in spaced relation on a surface of the substrate opposite the first electrode. A passivation layer is disposed between the second electrodes on the surface of the substrate opposite the first electrode. The passivation layer can also be positioned between the substrate and one or both of the first electrode and each second electrode. The present invention is also a method of forming the radiation detector.

Owner:ENDICOTT INTERCONNECT TECH

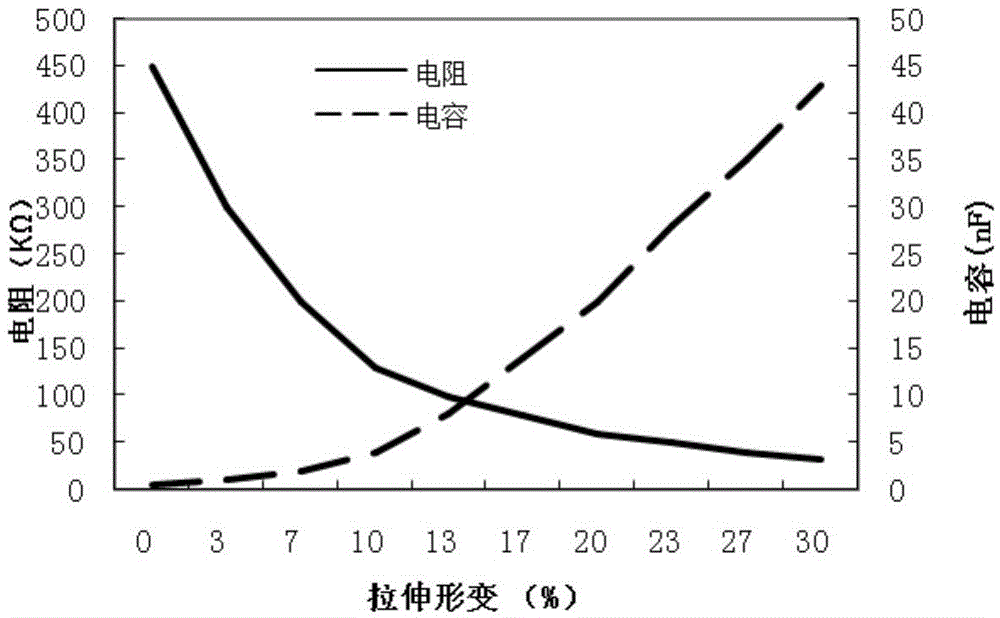

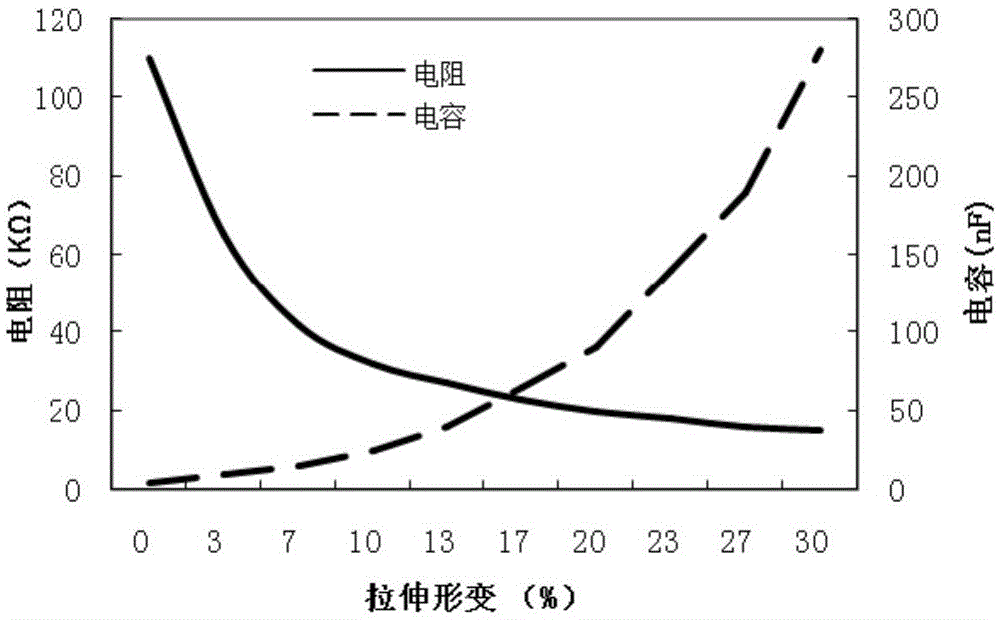

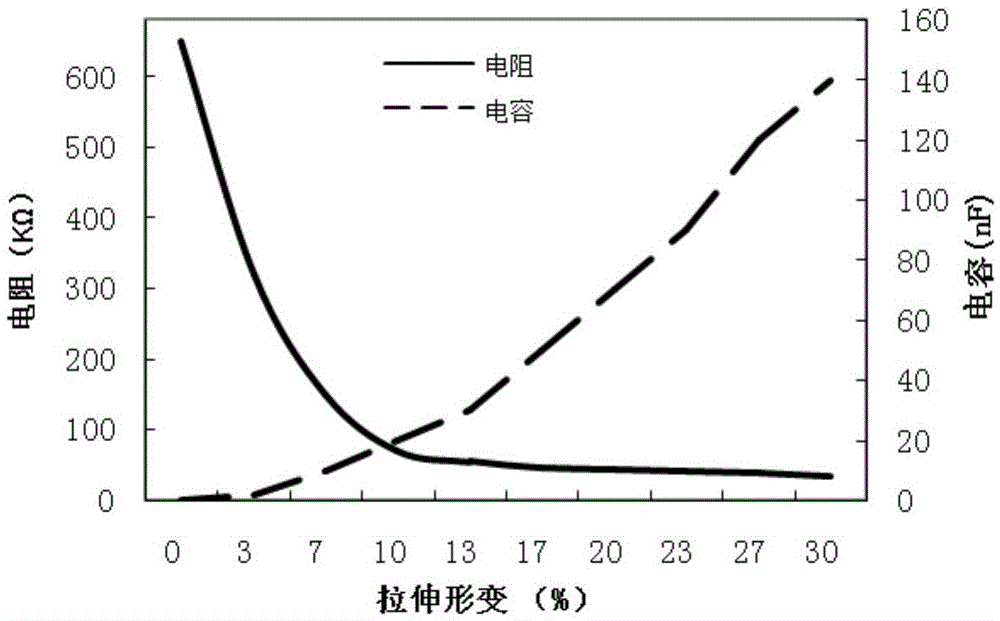

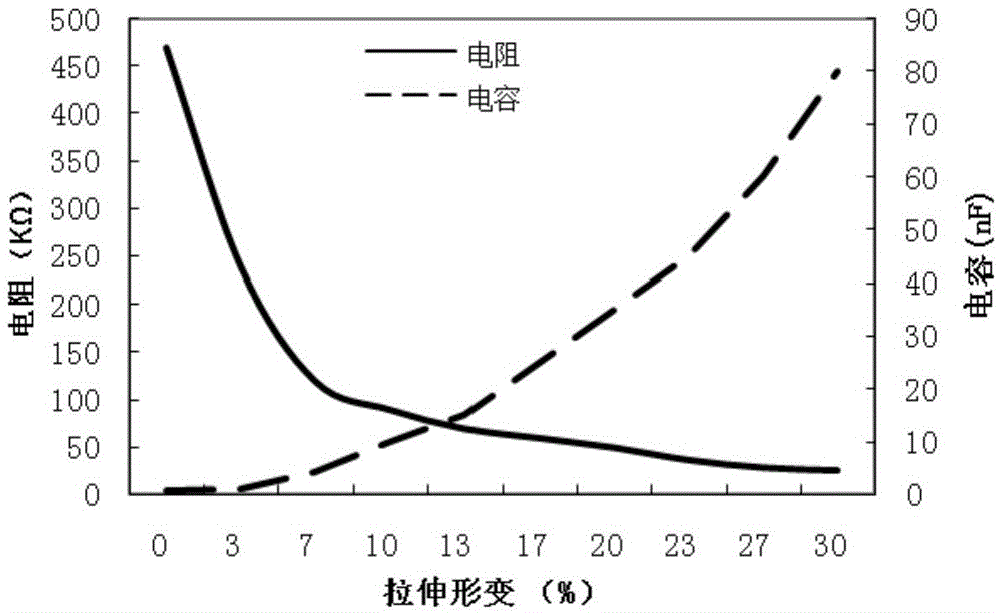

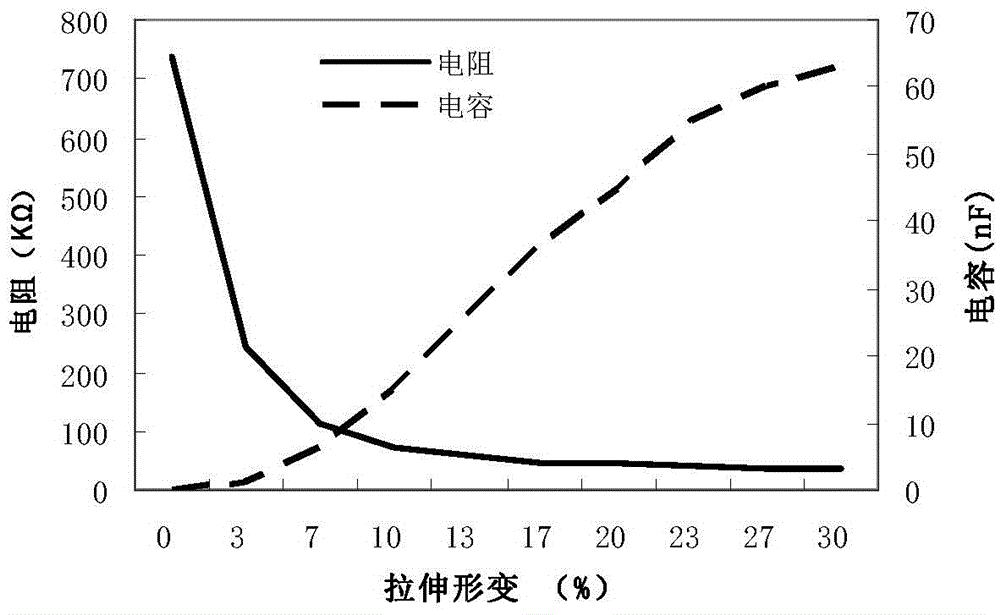

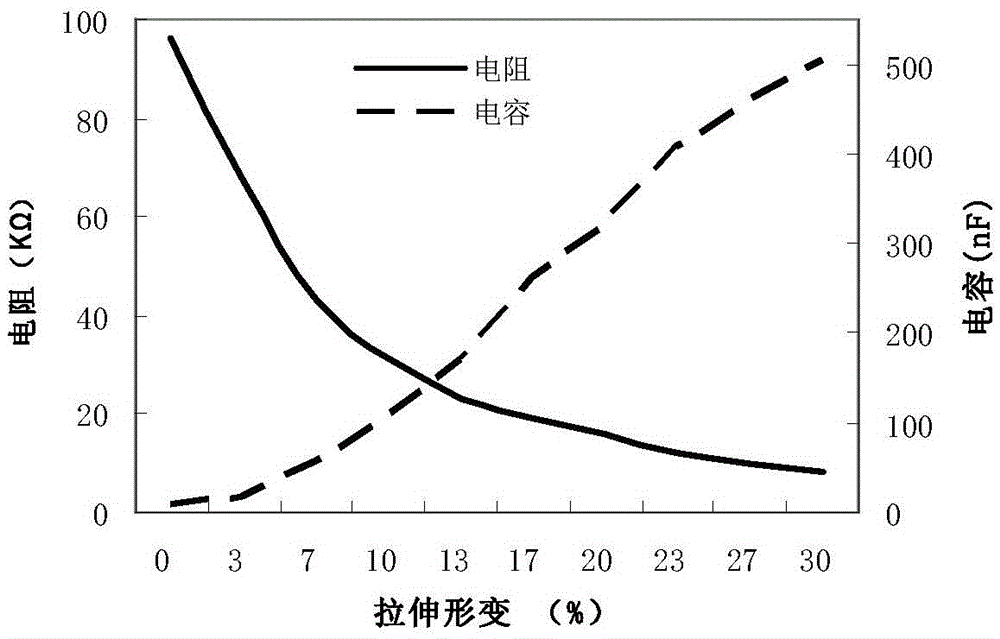

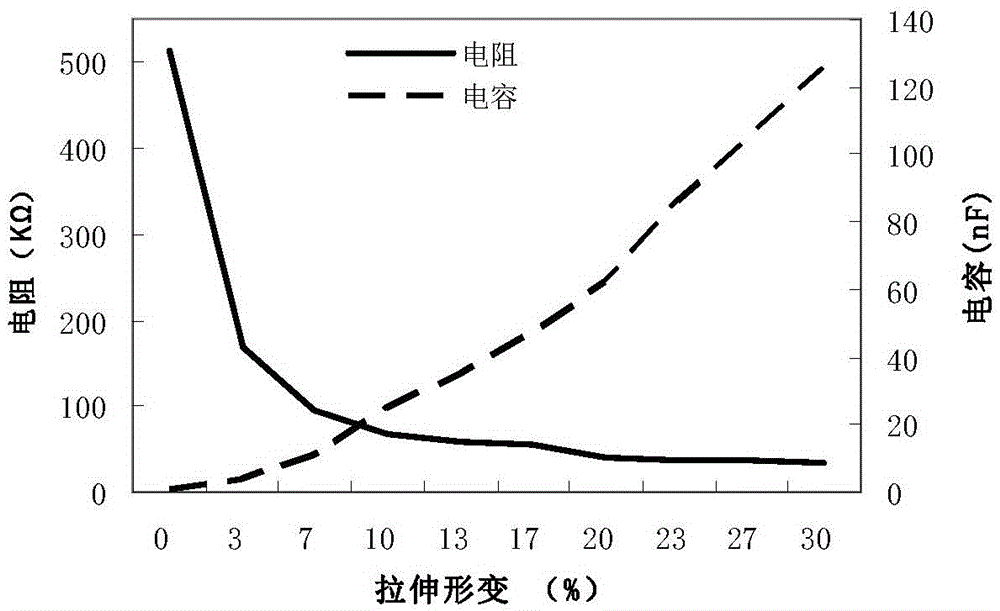

Conductive rubber material for flexible sensor and preparation method and application of conductive rubber material

InactiveCN105482176ANarrow resistance distributionReduce pollutionForce measurementRubber materialEngineering

The invention is applicable to the field of flexible sensors and provides a conductive rubber material for a flexible sensor and a preparation method and application of the conductive rubber material. The conductive rubber material comprises, by weight, 100 parts of rubber base bodies and conductive filler, wherein the conductive filler comprises, by weight, 5-50 parts of conductive black and / or 20-100 parts of silver-containing conductive filler bodies; the conductive rubber material is made in the mode that the conductive filler is dispersed in the rubber material, and radiation crosslinking is conducted through electron beams or gamma rays.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

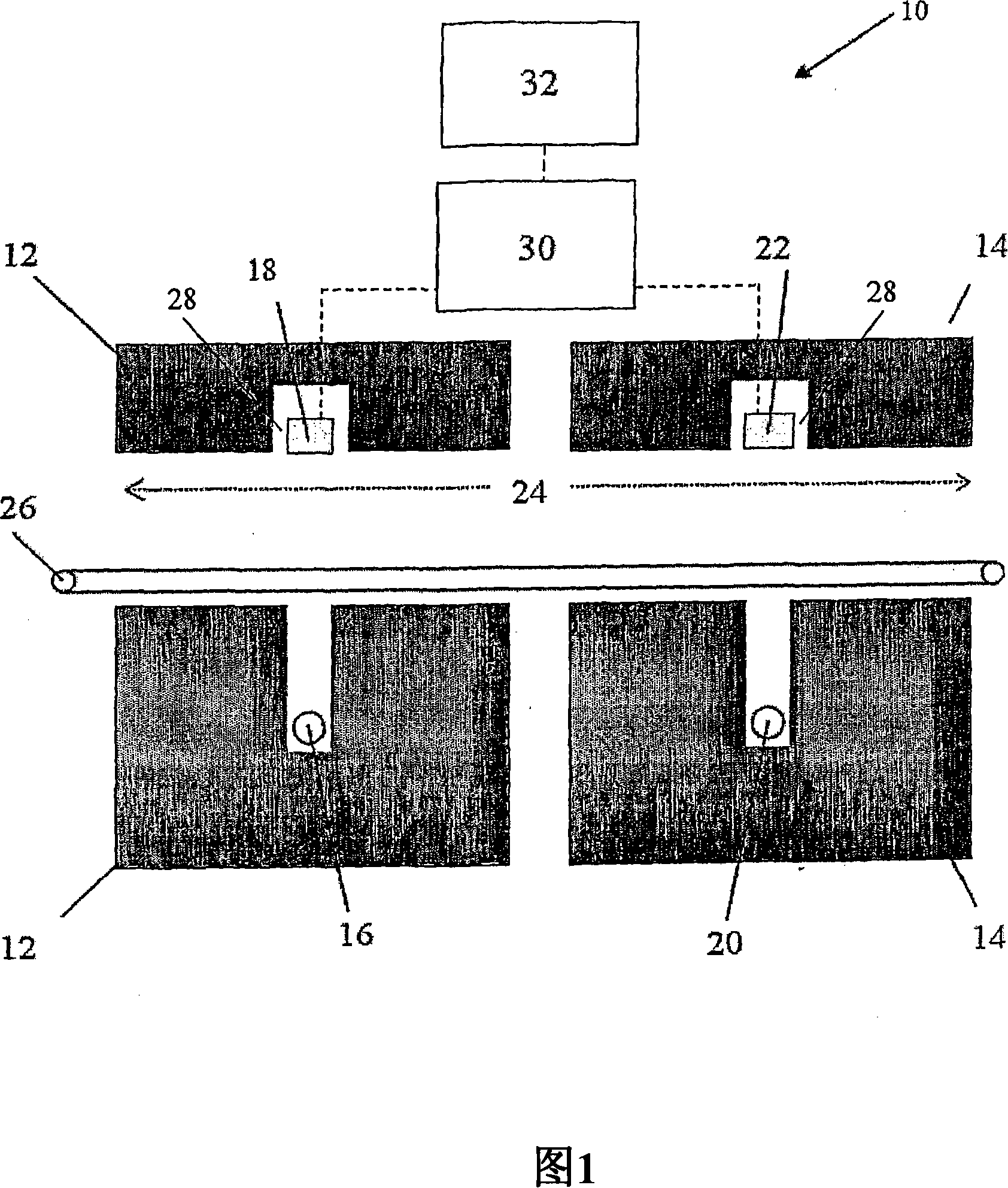

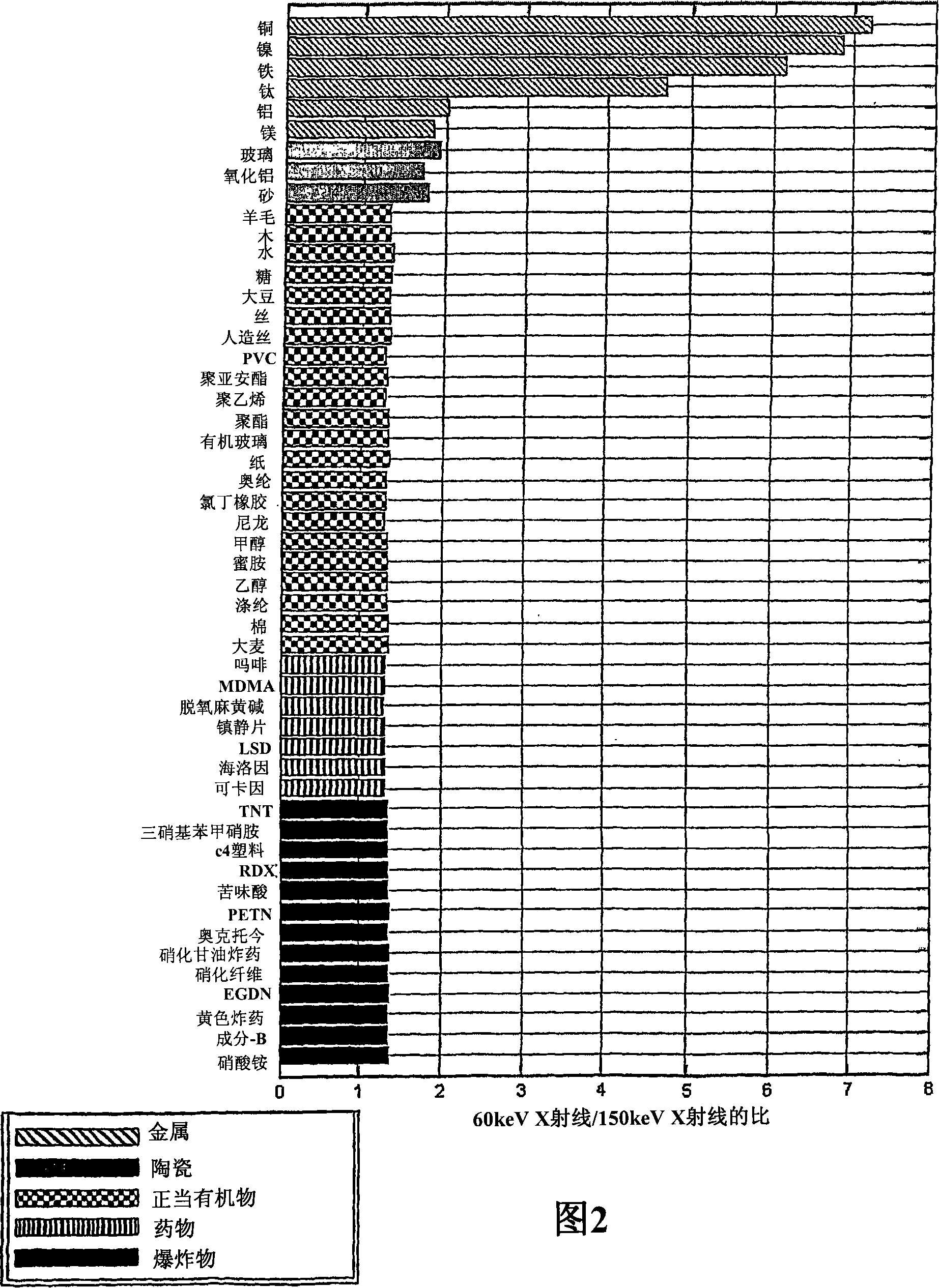

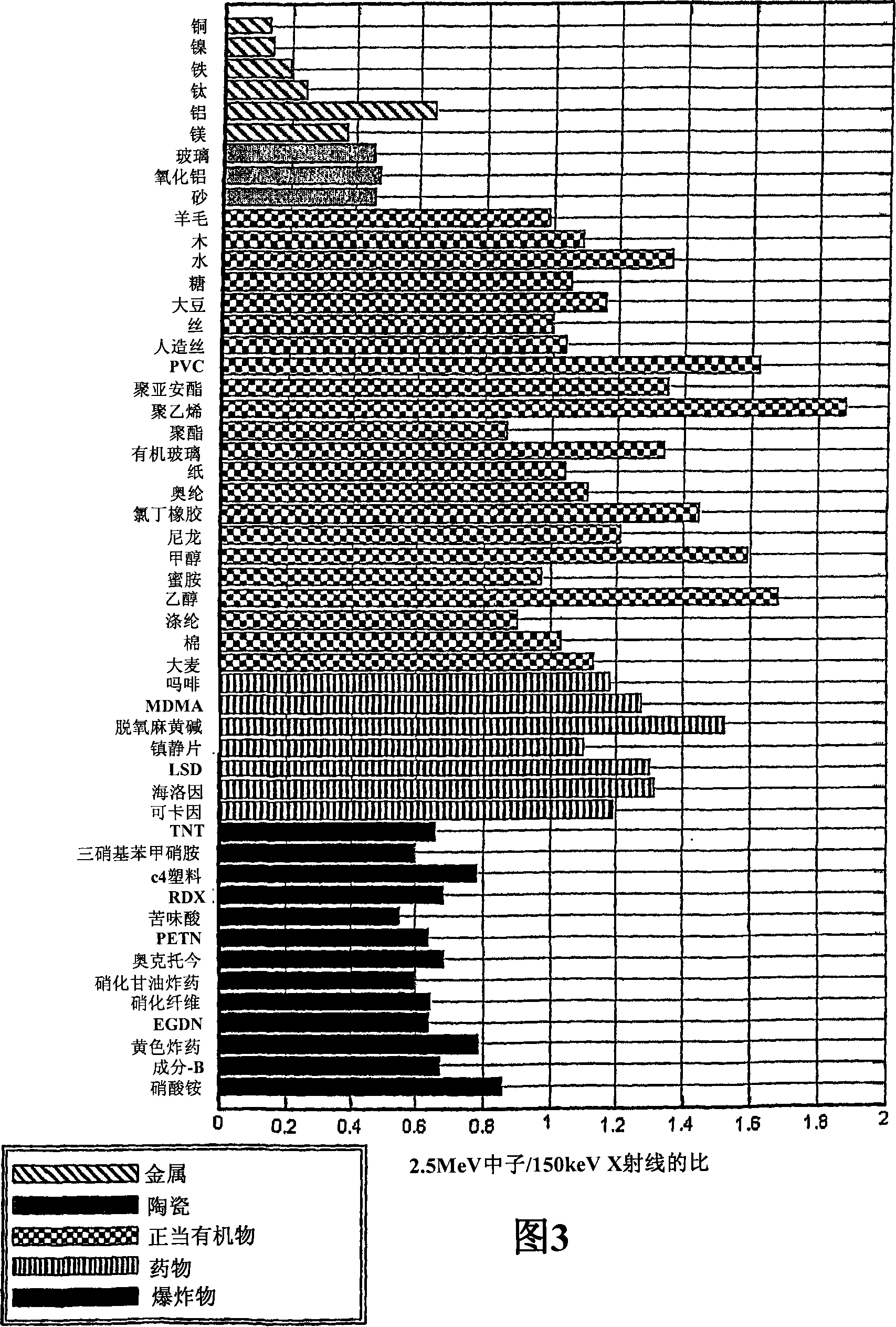

Radiographic equipment

InactiveCN101128731AClear distinctionEasy to separateMaterial analysis by transmitting radiationNuclear radiation detectionUltrasound attenuationSoft x ray

The invention concerns radiographic equipment for forming an image of an interior of an object. The equipment comprises a source of X-ray or gamma-ray radiation having two or more energies and operable to irradiate an object to be scanned and a radiation source producing neutrons operable to irradiate the object. The equipment also comprises a radiation detector array having a plurality of pixels, each sensitive to and arranged with respect to the X-ray or gamma-ray radiation source and the neutron producing radiation source and operable to measure the intensity of each type of radiation transmitted through the object; means to process the intensity of each type of radiation, to determine the attenuation of each type of radiation having passed through the object, and to form an image indicative of the shape and composition of the object's interior.

Owner:COMMONWEALTH SCI & IND RES ORG

Inner cap material for transfusion packages, and preparation method and applications thereof

The invention discloses an inner cap material for transfusion packages, and a preparation method and applications thereof. The preparation method comprises the following steps: uniformly mixing 30-70 parts of polypropylene, 0-30 parts of polyethylene, 10-40 parts of elastomer, 2-8 parts of flow modifier and 0.5-2 parts of antioxidant; adding the mixture into an extruder at 130-180 DEG C at the speed of 30-70 rpm; extruding at the speed of 200-500 rpm; water-cooling, drying, pelleting to obtain the inner cap material for transfusion packages, wherein the melt index of the inner cap material at 190 DEG C under the pressure of 2016g is 5-15g / 10 min. The inner cap material has the advantages of high toughness and good radiotolerance. The inner cap material for transfusion packages can be processed by direct injection molding to prepare inner caps for transfusion packages. The yellowness index of the inner cap radiated by 25kGy of gamma-rays is smaller than or equal to 10, and the rupture rate of the transfusion combination cap punctured by a transfusion contact pin can be smaller than or equal to 2%.

Owner:合诚技术股份有限公司

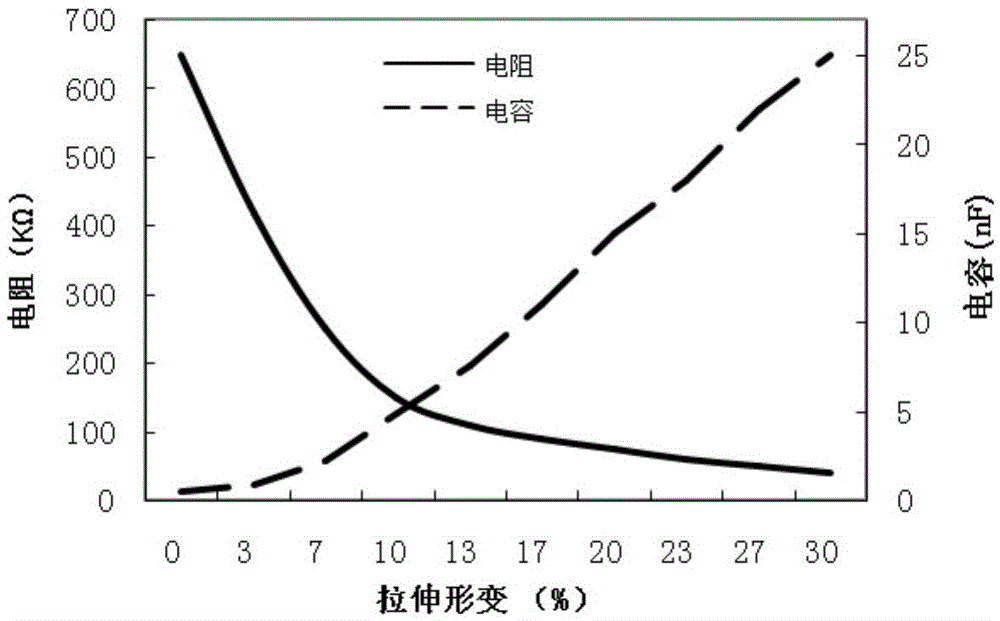

Conductive rubber material for flexible sensors and preparation method and application thereof

InactiveCN105647030ANarrow resistance distributionReduce pollutionNon-conductive material with dispersed conductive materialRubber materialEngineering

The invention is suitable for the field of flexible sensors and provides a conductive rubber material for flexible sensors and a preparation method and application thereof. The conductive rubber material is prepared from, by weight, 100 parts of rubber matrixes and 5-200 parts of conductive filler. The conductive rubber material is prepared in the mode that the conductive filler is dispersed in a rubber material and subjected to radiation crosslinking of electron beams or gamma rays.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

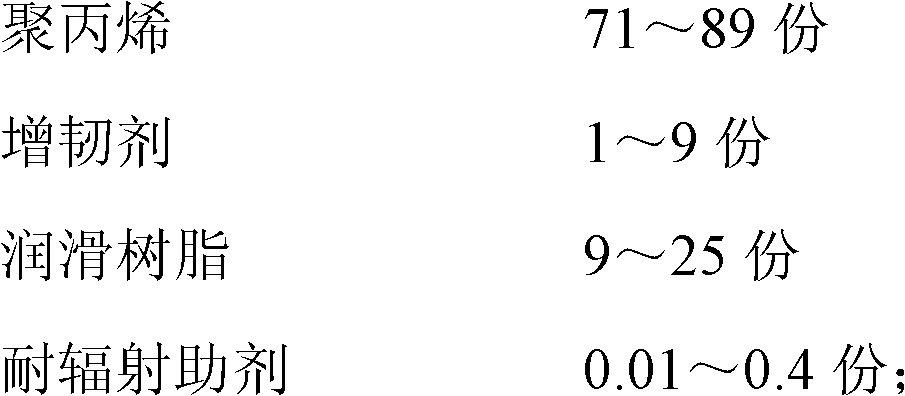

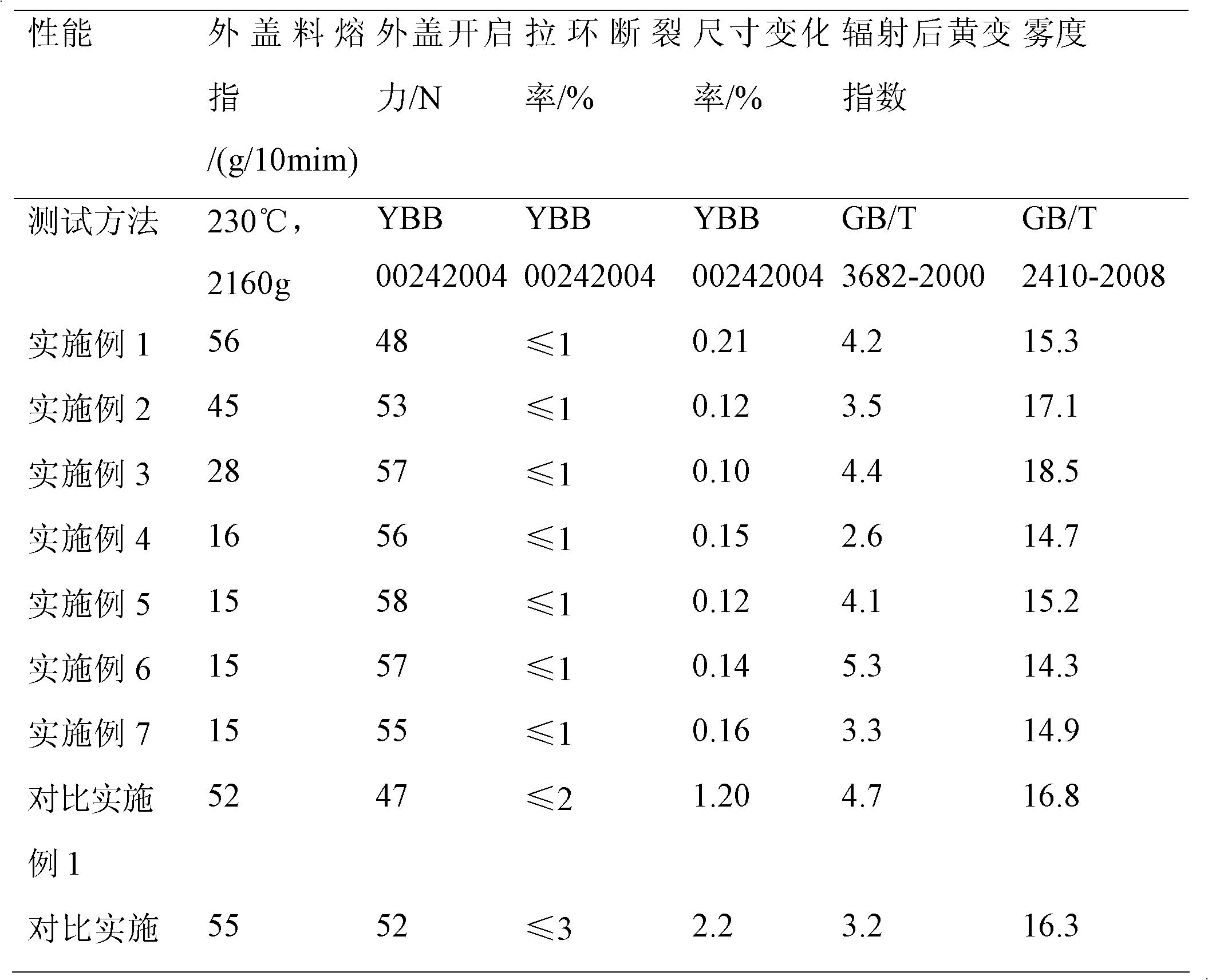

A kind of pull-tab outer cover material for infusion bottle or bag and preparation method thereof

ActiveCN102276932AGuaranteed melting temperatureGuaranteed welding strengthPharmaceutical containersMedical packagingRadiation resistantSize change

The invention discloses a pull-tab outer cover material used for infusion bottles or bags, and the material provided by the invention comprises the following components in parts by weight: 71-89 parts of polypropylene, 1-9 parts of flexibilizer, 9-25 parts of lubrication resin and 0.01-0.4 part of radiation-resistant accessory ingredient. The melting index of the pull-tab outer cover material used for infusion bottles or bags is 9-60g / min under the condition of 230DEG C and 2160g, and the outer cover material can be directly injected to prepare the pull-tab outer cover material used for infusion bottles or bags. A cover body and the infusion bottles or bags have high welding strength, a pull tab is easy to open, an opening edge is tidy, and the opening force is less than or equal to 60N; the pull tab has small possibility of being ruptured, and the fracture rate of the pull tab is less than or equal to 1%; no low-molecule ingredients are separated out, the size stability is good, and the size change rate of the outer cover is less than or equal to 0.5% before and after disinfection; and the radiation-resistant performance is good, the yellow index is less than or equal to 7 after the material is radiated by 60Co-gamma ray of 25kGy dose, and the material haze is less than or equal to 20.

Owner:合诚技术股份有限公司

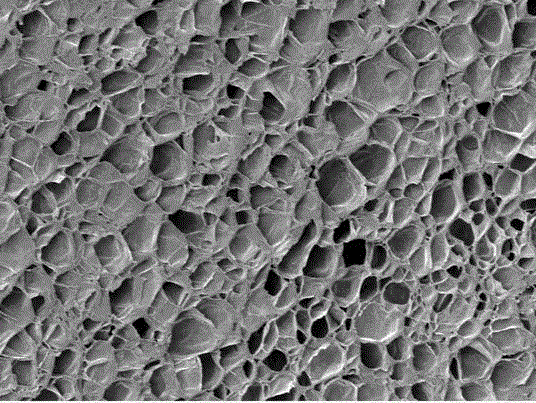

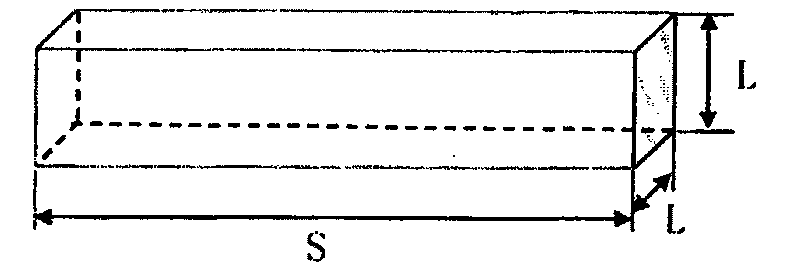

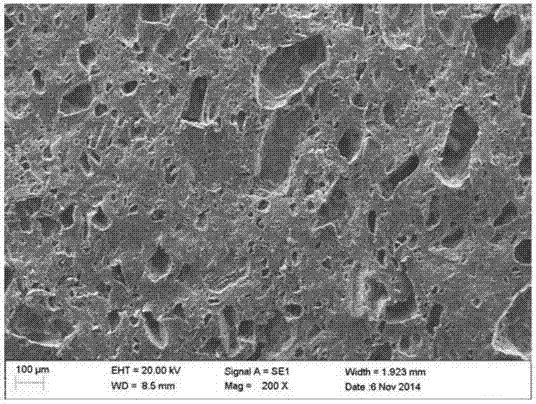

Silicone rubber microporous foam material adopting mixed cellular structure and preparation method of silicone rubber microporous foam material

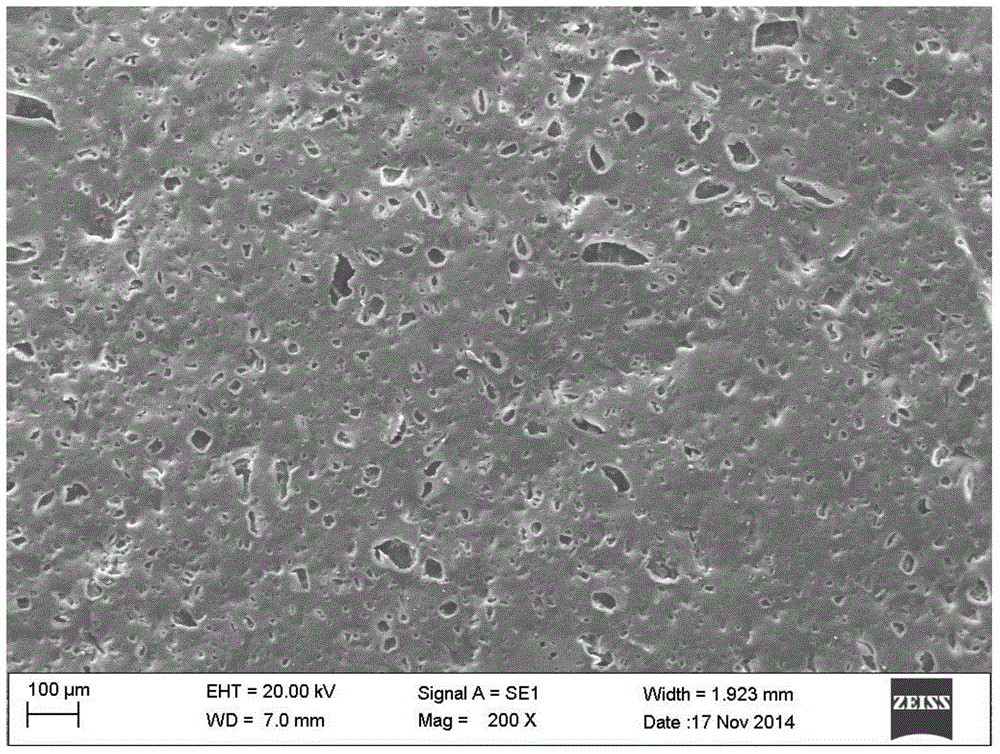

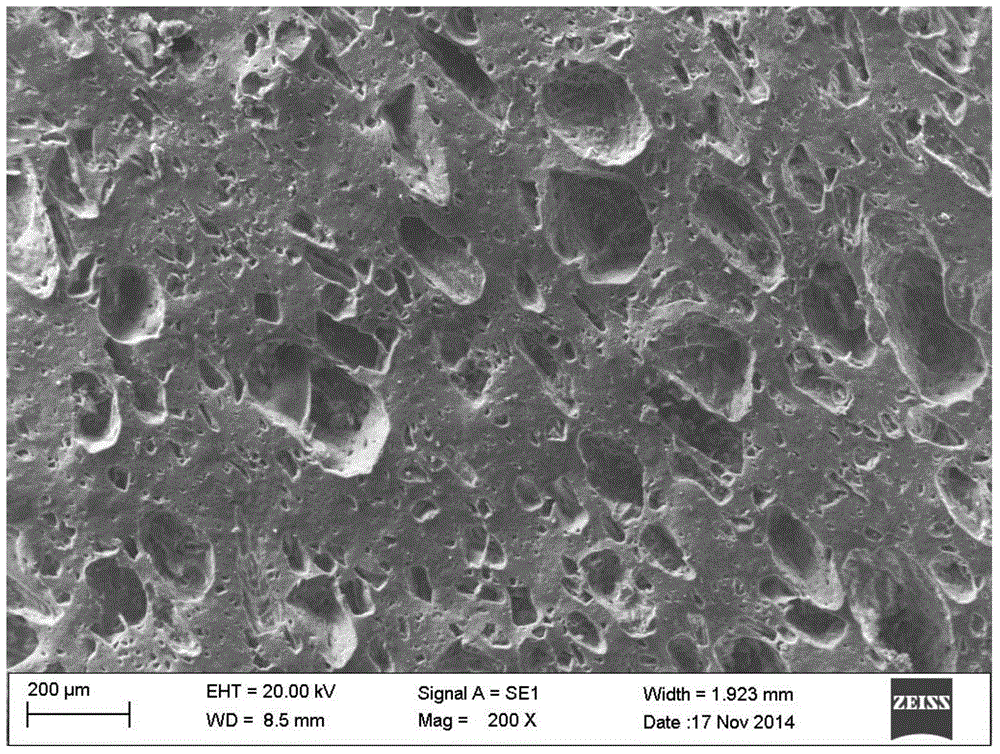

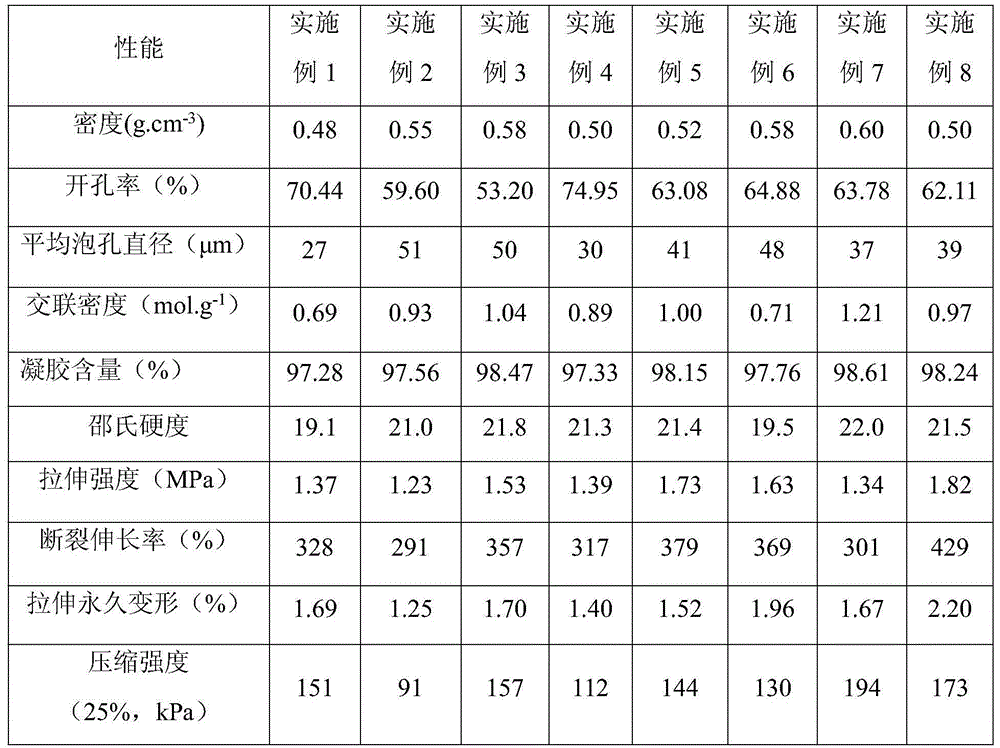

The invention discloses a silicone rubber microporous foam material adopting a mixed cellular structure and a preparation method of the silicone rubber microporous foam material. The preparation method is characterized by comprising the following steps: mixing 100 parts of a silicone rubber base material, 15-45 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 60-125 parts of a pore-forming agent and 3-5 parts of a radiosensitizer, forming, radiating through gamma rays so as to enable the formed product to be crosslinked, wherein the radiation absorbed dose is 30-70 kGy, performing solventing-out section by section to form holes, and drying, so as to obtain the silicone rubber microporous foam material with excellent performance. According to the invention, the method that radiation crosslinking cooperates with solventing-out hole forming is adopted, so that crosslinking is uniform, control is convenient, energy conservation and environment friendliness are realized, the process is simple, reproducibility is good, and production efficiency is high; the prepared silicone rubber microporous foam material adopts the mixed cellular structure, and is excellent in comprehensive performance, small in hole, pure white in color, soft in texture, proper in crosslinking density and gel content, high in tensile strength and elongation at break and low in permanent tensile deformation and compression deformation.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

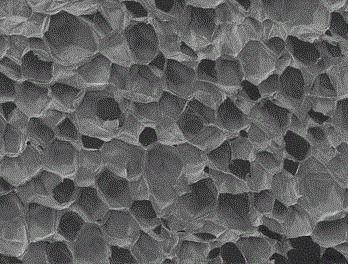

Method for preparing polylactic acid foaming material subjected to radiation modification by utilizing supercritical fluid CO2

The invention discloses a method for preparing polylactic acid foaming material subjected to radiation modification by utilizing supercritical fluid CO2 and belongs to the field of processing of high polymer materials. The method comprises the following steps of: 1) mixing polylactic acid with a sensitizer, and preparing a sheet through melt extrusion or injection molding; 2) performing 60Co-gamma ray radiation on the sheet; 3) putting the radiated sheet in a die cavity, filling the supercritical fluid CO2, and performing swelling penetration by controlling the swelling penetration time, the temperature and pressure; and 4) initiating nucleation foaming by controlling the pressure relief speed and cooling speed, and forming a polylactic acid microcellular foaming material which has uniform cells, the cell size of 5-500mu m and a controllable structure. By adoption of the 60Co-gamma ray radiation crosslinking, the difficulty that the polylactic acid melt is low in strength and difficult to foam is effectively solved, the method has the characteristics that the process is simple, green and environment-friendly, low in cost and high in production efficiency, and the prepared foaming material has excellent mechanical property and can be applied to the fields of biomedical use, food packaging and disposable tableware degradation.

Owner:ZHENGZHOU UNIV

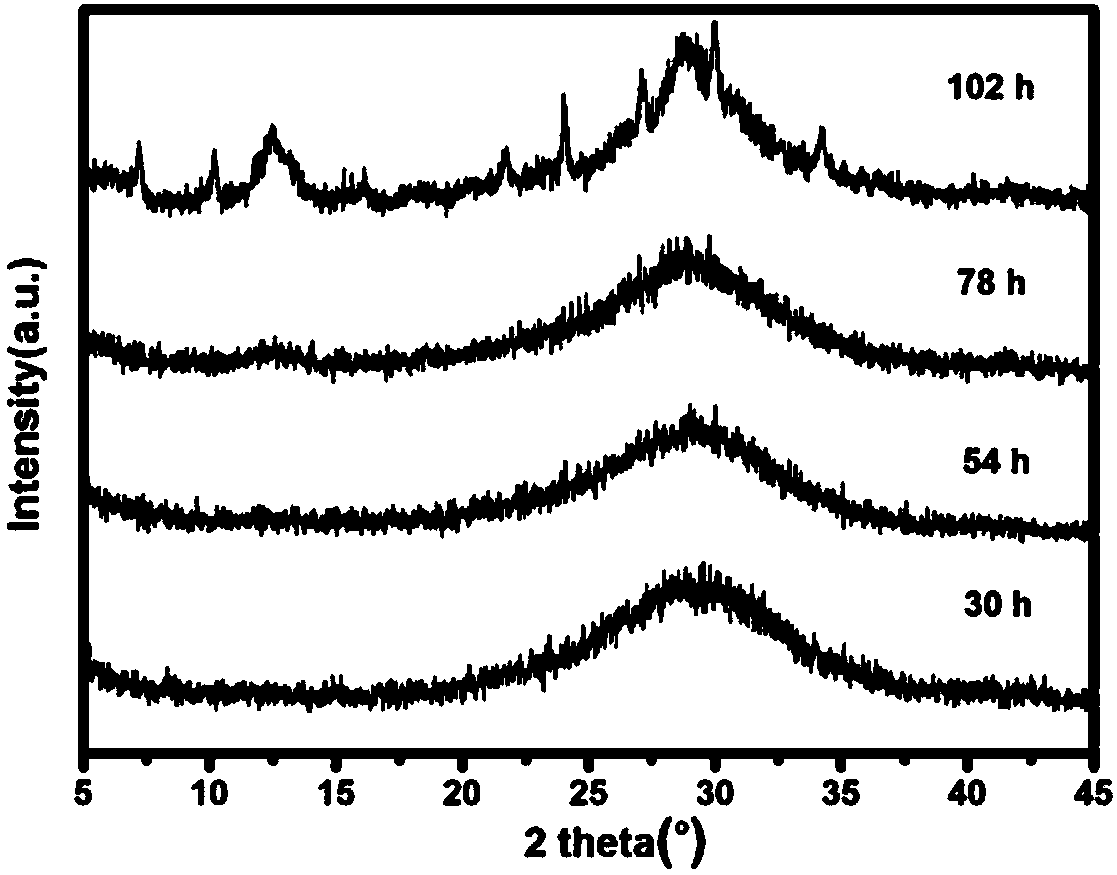

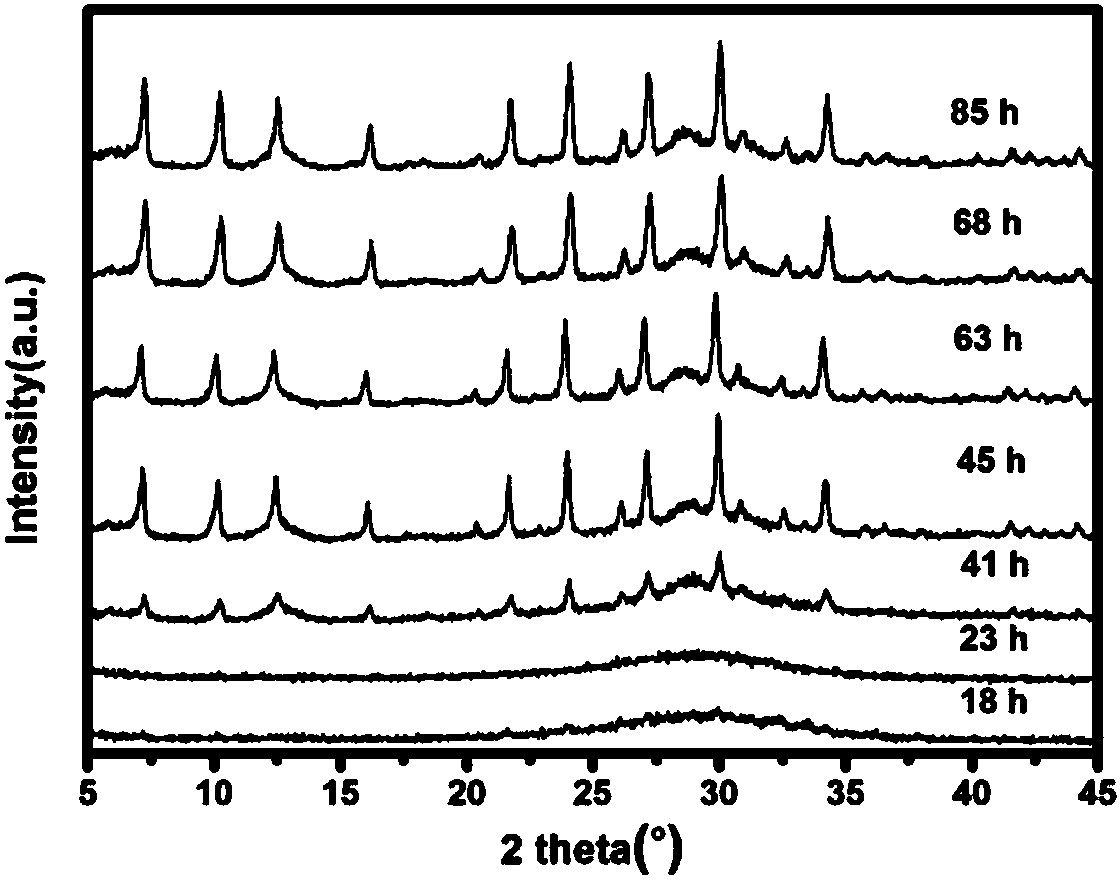

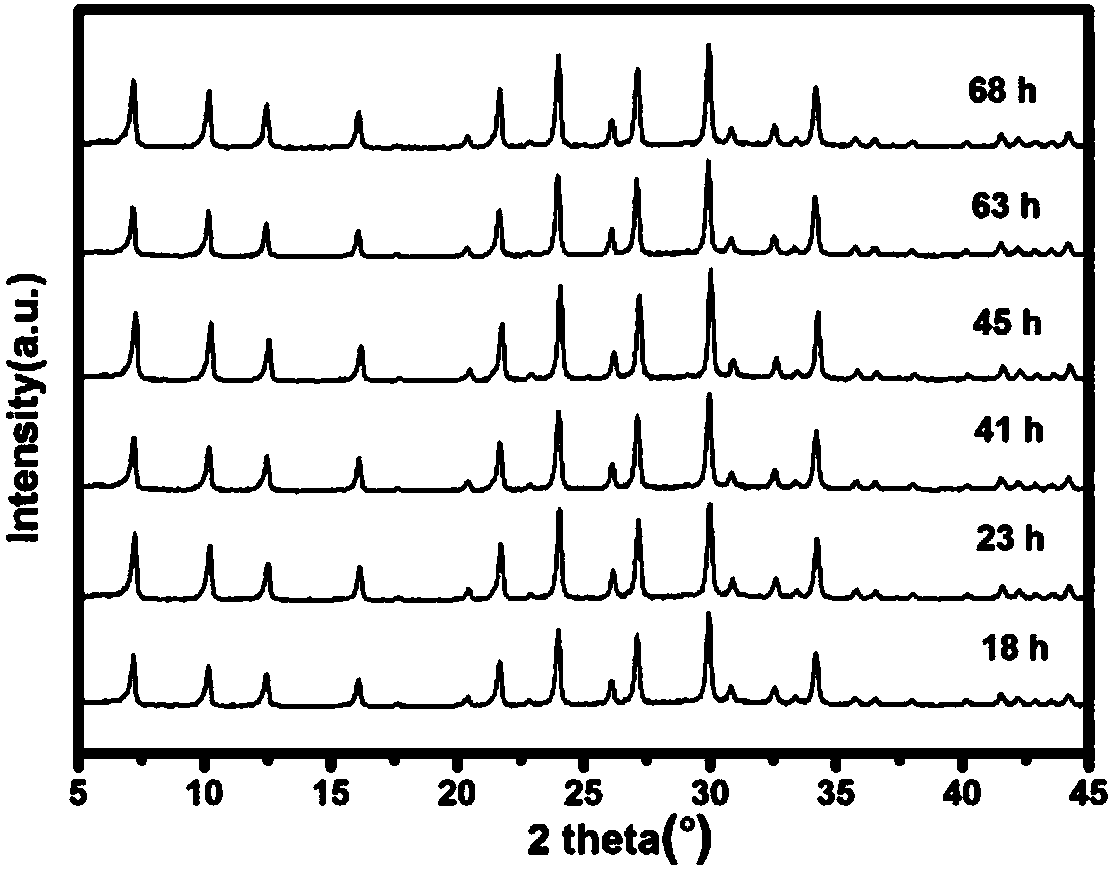

Method for preparing molecular sieve

ActiveCN108298553AShorten crystallization timeHigh crystallinityAluminosilicate zeolite type-AMolecular-sieve and base-exchange phosphatesMolecular sieveCrystallinity

The invention discloses a method for preparing a molecular sieve. The method comprises the following steps: preparing a molecular sieve gel, and crystallizing the molecular sieve gel under a gamma rayradiation condition to obtain the molecular sieve. The method greatly shortens the crystallization time of the synthesized molecular sieve and greatly improves the relative crystallinity of the molecular sieve.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

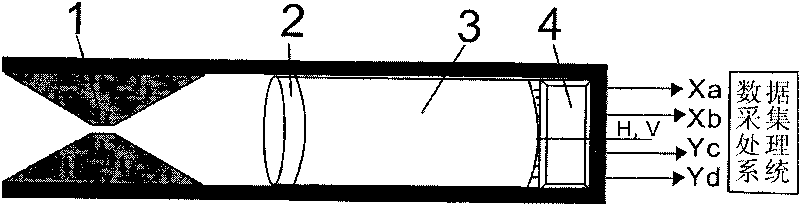

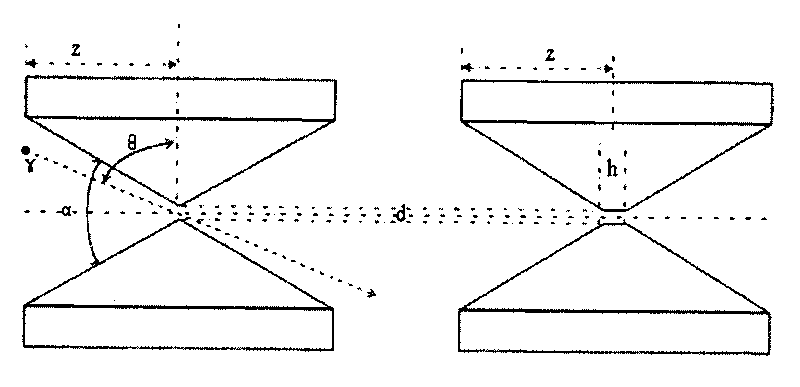

Gamma ray imaging device

InactiveCN101718875ASimple structureImprove linear correspondenceX/gamma/cosmic radiation measurmentData acquisitionScintillation crystals

The invention belongs to the field of Gamma ray radiation measurement, particularly relates to a Gamma ray imaging device which comprises a Gamma camera and a data acquisition processing system, wherein the Gamma camera comprises a pinhole collimator, a scintillation crystal, a position sensitive photo-multiplier tube and resistor grids; and electrical signals output by the resistor grids are input to the data acquisition processing system arranged outside the Gamma camera. The Gamma ray imaging device produced according to the technical scheme of the invention can measure the large-scaled decommissioning site of nuclear facilities in real time to obtain a region distribution map of hot points, which includes nuclide positioning, nuclide identification and nuclide dosage.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

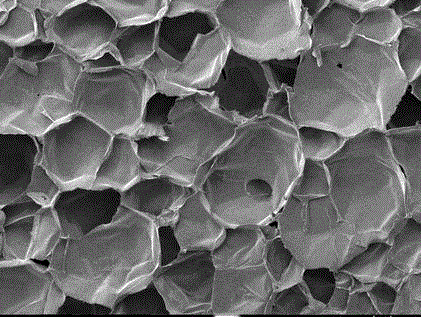

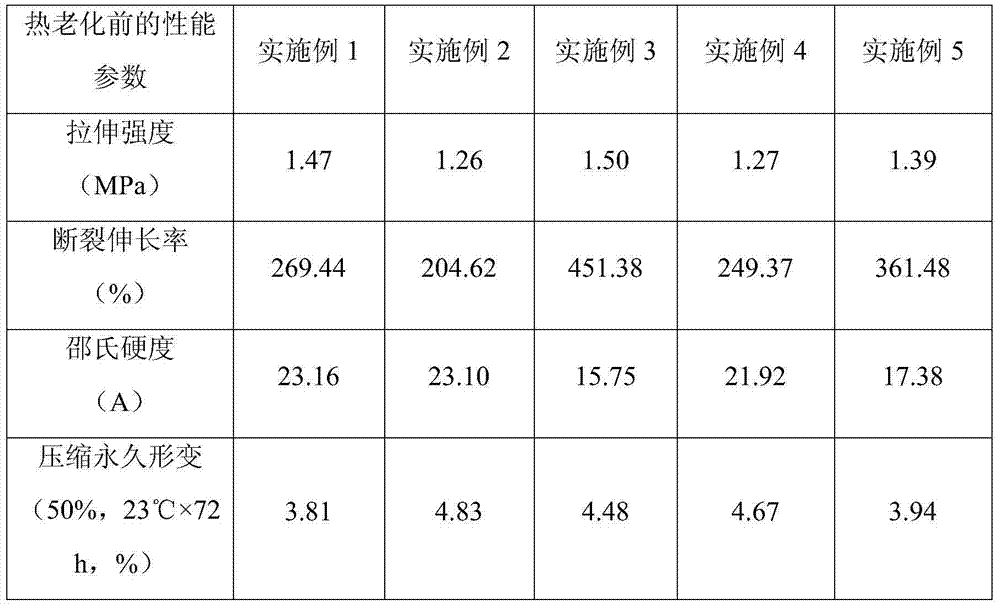

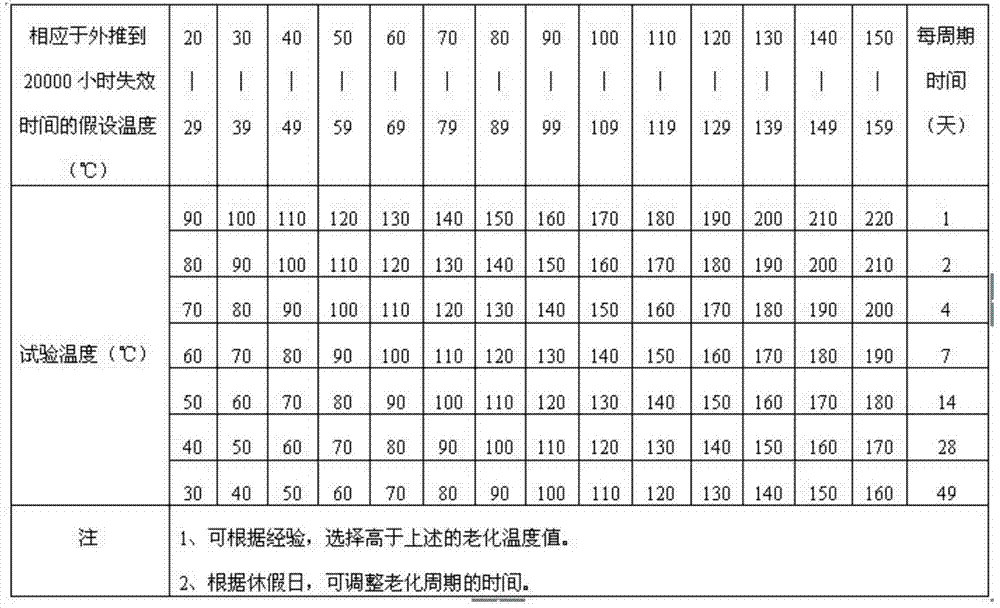

High-temperature-resistant silicone rubber foam material and preparation method thereof

The invention discloses a high-temperature-resistant silicone rubber foam material and a preparation method thereof. The preparation method of the high-temperature-resistant silicone rubber foam material is characterized by comprising the following steps: mixing 100 parts of silicone rubber base stock, 20-35 parts of a reinforcing agent, 2-3 parts of a structure controlling agent, 0-0.2 part of colour master batch, 60-150 parts of a pore-forming agent and 4-5 parts of a radiation sensitizer, moulding, crosslinking through gamma ray radiation, forming pores through subsection dissolving-out, and drying, so that the silicone rubber foam material which is resistant to high temperature of 250 DEG C and still maintains excellent performance after equivalent time of 20000 hours can be obtained. The preparation method of the high-temperature-resistant silicone rubber foam material has the advantages that radiation crosslinking and dissolving-out pore forming are combined, so that crosslinking is uniform, control is easy, energy conservation and environmental protection are realized, a technology is concise, reproducibility is good, and production efficiency is high; the high-temperature-resistant silicone rubber foam material still maintains high tensile strength, high weight loss, low longitudinal deformation and low surface hardness after the equivalent time of 20000 hours at the temperature of 250 DEG C, permanent compressive deformation is slightly increased, the high-temperature-resistant silicone rubber foam material does not become brittle or hard, and the high-temperature-resistant silicone rubber foam material can serve as filling and positioning, sealing cushion, cable insulation as well as buffer and vibration-absorptive materials or parts which are used in high-temperature environment.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

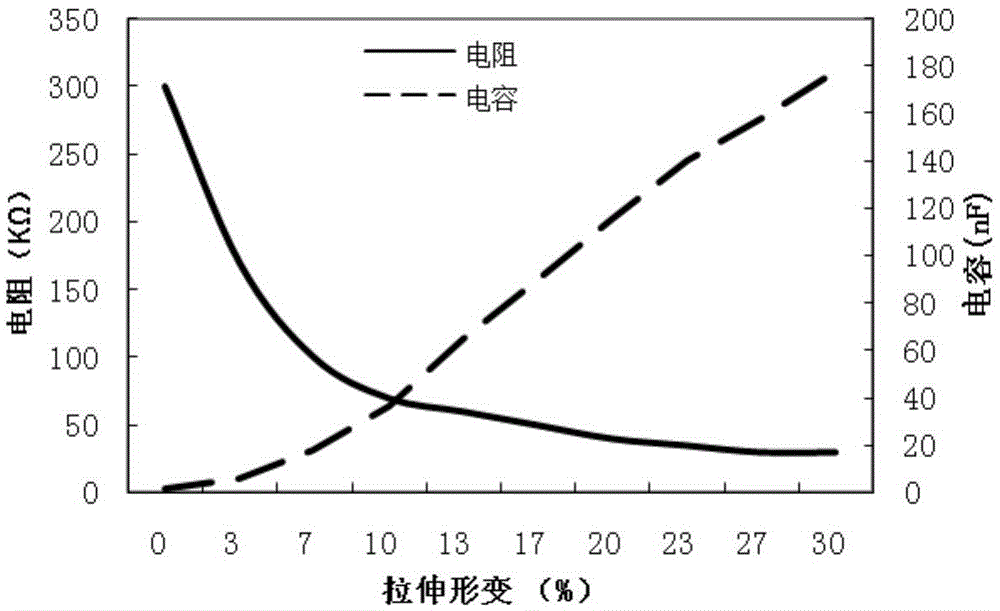

Conducting rubber material for flexible sensor and preparation method and application of conducting rubber material

The invention is applicable to the field of flexible sensors and provides a conducting rubber material for a flexible sensor and a preparation method and application of the conducting rubber material. The conducting rubber material is prepared from, by weight, 100 parts of rubber matrix, 5-90 parts of conducting filler and 0.1-15 parts of a bulking agent. The preparation method of the conducting rubber material comprises the steps of dispersing the conducting filler into a rubber material, and conducting electron beam or gamma-ray radiation crosslinking, so that the conducting rubber material is obtained.

Owner:SHENZHEN HUIRUI ELECTRONICS MATERIALS

Human embryonic stem cells and culturing methods thereof

Provided herein are human embryonic stem cells and their method of culturing. In one embodiment, the human embryonic stem cells are maintained in an environment containing an extracellular matrix isolated from feeder cells and a conditioned medium pre-conditioned by the feeder cells; the feeder cells are pre-inactivated by either gamma ray radiation or by mitomycin C treatment. The cultured human embryonic stem cells remain substantially undifferentiated and maintain their pluripotency to differentiate into three germ layer cells.

Owner:IND TECH RES INST

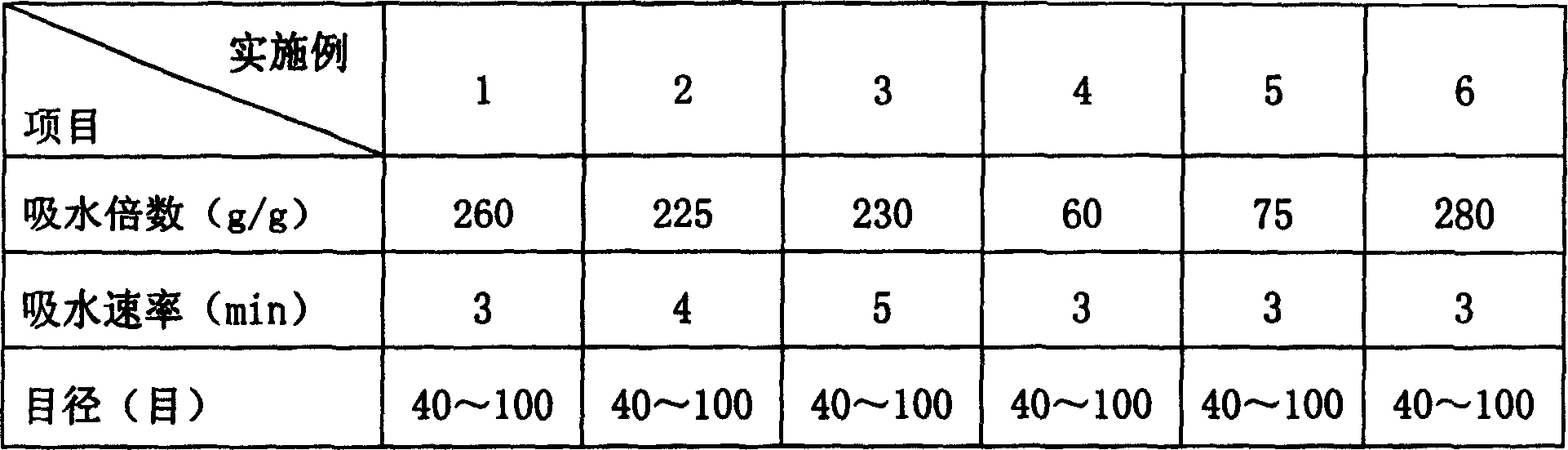

Preparation method of spherical water absorption resin

The present invention discloses a preparation method of spherical water absorption resin. Said preparation method is characterized by including the following steps: using water phase acroleic acid, alkali liquor, copolymer monomer and cross-linking agent and oil phase Span 80, monoglyceride and dispersing agent to prepare reverse suspension liquor, then placing the reverse suspension liquor in a container, and placing said container in an irradiation field to receive irradiation, irradiation dose is 0.5-0.2X10 to the power 2, after the reaction is completed, separating out oil phase, drying so as to obtain the invented spherical water absorption resin.

Owner:湖南省原子能农业应用研究所

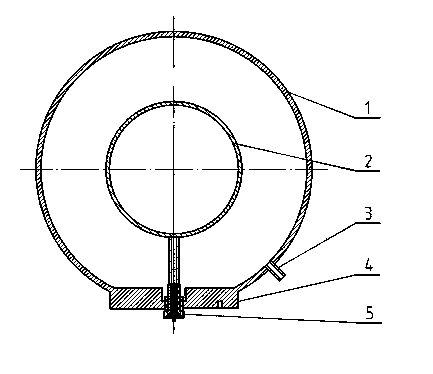

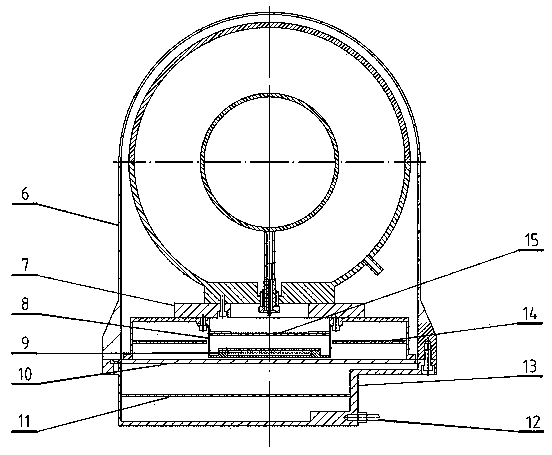

Detector for monitoring environmental radiation dose rate

The invention belongs to the field of radiation protection, and provides a detector for measuring the environmental level X ray and gamma ray radiation dose rate. The detector comprises a shell and a high atmospheric pressure ionization chamber. The outer wall of the high atmospheric pressure ionization chamber is of a spherical structure. An end cover through which the ionization chamber is conveniently connected with other parts inside the detector is arranged at the bottom of the outer wall. A spherical inner container which is concentric with the outer wall is arranged inside the ionization chamber. The inner container is connected with the end cover through an insulator. Except welding components of the insulator, the whole ionization chamber is made of aluminum or aluminum alloy. The detector is simple in structure and convenient to use, the problem that the high atmospheric pressure ionization chamber is high in energy lower limit in the environment monitoring process can be effectively solved, the sensitivity of the detector to lower-energy gamma rays is improved, energy response linearity and isotropy of the detector are improved, and credibility of the measuring result is improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Method for modifying polyacrylonitrile by using gamma ray irradiation

InactiveCN101798392AImprove pre-oxidation efficiencyCyclization exotherm reducedMonocomponent synthetic polymer artificial filamentPre treatmentGamma ray irradiation

The invention provides a method for modifying polyacrylonitrile (PAN) by using gamma ray irradiation. Being subjected to the gamma ray irradiation in air, inert atmosphere or a vacuum, the heat release of the cyclized PAN can be reduced in the process of heat treatment; and being subjected to the pretreatment of the gamma ray irradiation, the pre-oxidation rate of PAN fiber can be obviously increased. Undergoing the changes in performance, the invention can help control the sharp rise in the temperature of a sample and accelerate the oxidation in the process for PAN fiber or films to carry out high-temperature cyclization or oxidation crosslinking, particularly, the process of precursor pre-oxidation crosslinking for preparing PAN-based carbon fiber. Accordingly, the method of the invention is of potential application value to the reduction in production cost for PAN oxidation products, particularly, the reduction in production cost for PAN-based carbon fiber.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Cigarette Processing method for lowering benzo[a] pyrene content in smoke

InactiveCN1486643ABenzo[a]pyrene content decreasedPrevent mildewTobacco treatmentRubidium/caesium/francium compoundsBenzeneMildew

The present invention is processing method of effectively lowering the benzo[a]pyrene content in cigarette smoke. The cigarette product is irradiated with gamma ray inside a gamma ray chamber with gamma ray source of Co-60, Cs-137, Ir-192 or Se-75 and irradiation dosage 4-40 KGy to lower the benzo[a]pyrene content in cigarette smoke by 12-70%. The said processing method has no radical influence on quality of cigarette and can avoid mildew and rot of cigarette during storage.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

Process for preparing super strength water absorbent from polyglutamic acid prepared by microbe fermentation and synthesis

The invention relates to the utilization of particle radiation to process the high molecular substance, especially for using the polyglutamic acid fermentation synthesized from microbe to prepare the absorbent agent. The operation steps comprises: preparing the water solution of polyglutamic acid fermentation synthesized from microbe in the percentage by weight of 1-10 %; utilizing the cobalt 60Co as the gamma radiation source to radiate on the solution prepared in the first step in the condition of nitrogen protection while the radiation dose rate is 0.5 kGy / hour-5.0kGy / hour and the tatl radiation dose is 2-150 kGy; The radiated gel will fully swell in 2-8 Deg. C for 4-8 days while the water as the swell-medium should be replaced one time one day to remove the un-crosslinking monomers and the impurities in the gel; and freezing and drying the gel in common vacuum drier until constant weight to attain the absorbent agent. Said invention has simple manufacturing process without environment pollution, stable property and higher water absorption ratio.

Owner:NANKAI UNIV

Non-metallic component with metalized surface and manufacturing method thereof

ActiveCN101684551AReduce pollutionSimple processLiquid/solution decomposition chemical coatingChemical platingElectrical polarity

The invention provides a method for preparing a non-metallic component with a metalized surface by utilizing gamma ray, comprising the following steps: a). preparing solution containing metallic ionswhich adopts solvent as polar solvent; b). evenly distributing the solution of step a) in a preset area of the non-metallic component according to a preset shape; c). utilizing gamma ray to radiate the area distributed with the metallic ionic solution on the non-metallic component of step b); and d). utilizing chemical plating to plate a metallic layer on the area radiated by gamma ray in step c).The method overcomes the disadvantages of complicated operation and environmental pollution of the traditional chemical agent method for roughening the surface of nonmetal, and metallic plating withgood adhesion can be formed on inorganic nonmetallic materials such as glass and ceramic and the like with large surface hardness.

Owner:HAIYAN NEW SHENGDA FASTENER

Method for preparing water-absorbing resin by ultraviolet and gamma-ray radiation ionization technique

ActiveCN103224630AHigh absorption rateStrong resistance to salt absorptionDispersityFunctional monomer

The invention relates to a preparation method of a water-absorbing resin, particularly a method for preparing a water-absorbing resin by an ultraviolet and gamma-ray radiation ionization technique. The method comprises the following steps: 1) neutralizing acrylic acid monomer with an alkali solution to a neutralization degree of 60-90%, adding functional monomer which accounts for 0.2-40 wt% of the acrylic acid monomer to prepare a neutralized solution of which the mass percentage of the total monomers is 30-60%, and adding into a transparent reaction vessel; 2) irradiating the neutralized solution in the transparent neutralized solution under an ultraviolet light source so that the neutralized solution is subjected to polymerization reaction to generate an elastogel; 3) putting the elastogel obtained in the step 2) in a gamma-ray nuclear radiation device of which the radiation dose rate is 0.3-10 kGy / h, and carrying out dynamic irradiation with a delivery system until the irradiation dose reaches 3-20 kGy; and 4) after carrying out crushing, drying, pulverization and screening on the elastogel obtained in the step 3), carrying out dispersity and permeability surface treatment with a surface treating agent to obtain the water-absorbing resin.

Owner:史学明

Rubber foam material and manufacturing method thereof

The invention discloses a rubber foam material and a manufacturing method thereof. A rubber base material, a heat conducting filler, a radiation crosslinking sensitizing agent, an anti-aging system, a plasticizer, a vulcanization system and a foaming system are used as raw materials, mixing, piece cutting and gamma ray radiation preprocessing are performed, and then vulcanization, foaming and mold stripping are performed to obtain the rubber foam material. According to the preparation method, a film preprocessed by gamma ray radiation preprocessing has the certain pre-crosslinking degree before heat vulcanization foaming is started, the vulcanization speed and the foaming speed can be matched, and the problems that foam holes are not uniform, the foaming rate is low and the heat conductivity coefficient is low are solved. The obtained rubber foam material has excellent properties of uniform foam holes, the high foaming rate, the high heat conductivity coefficient, the high compression rate, the high rebound resilience, the low weight, good insulation, damping, sound absorption and the like, the technology is simple, operation is convenient, the prevulcanization time is shortened, and the rubber foam material can be widely applied to a heat conducting gap interface material of an electronic product.

Owner:LOVEPAC CONVERTING BEIJING +1

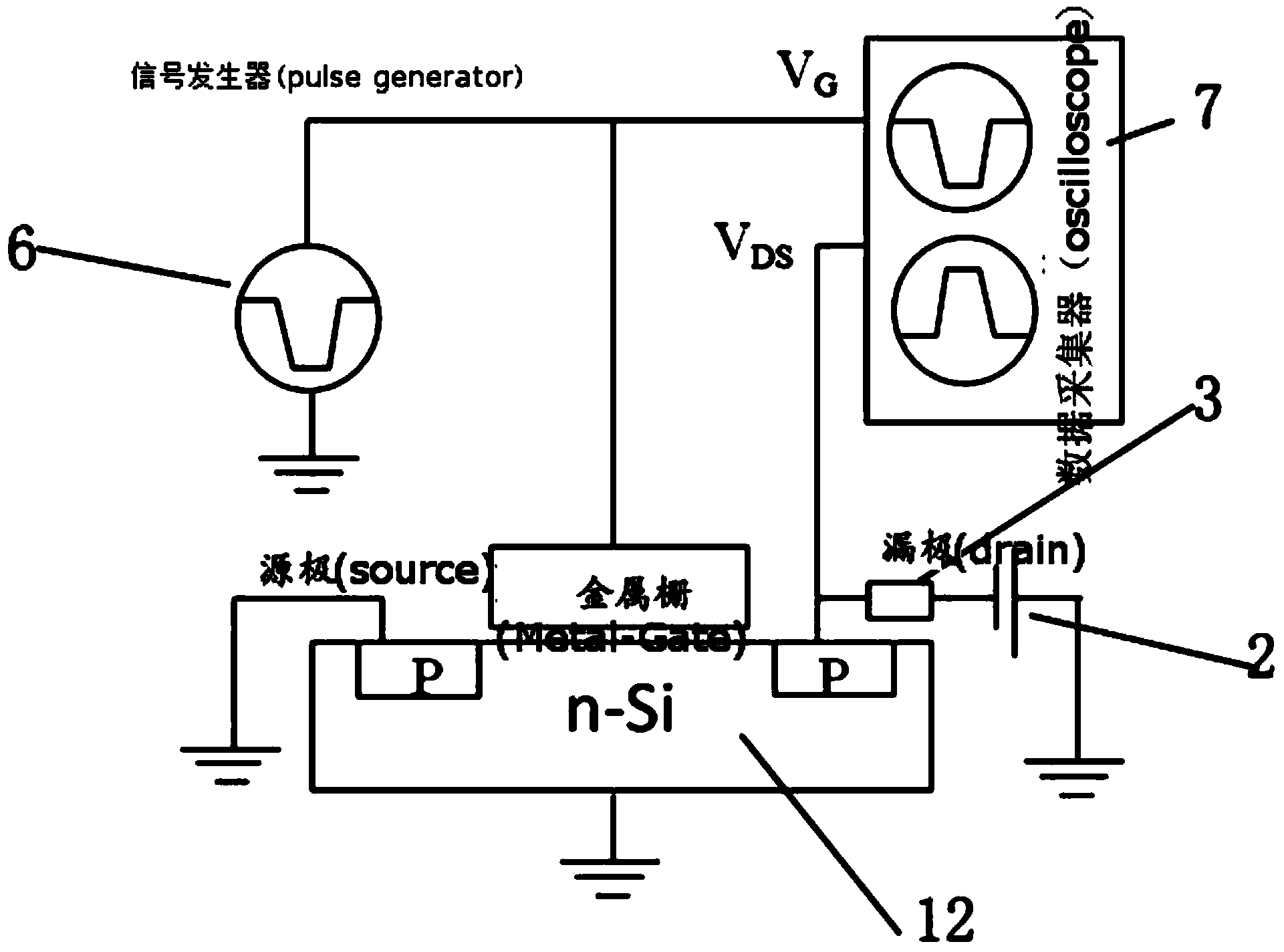

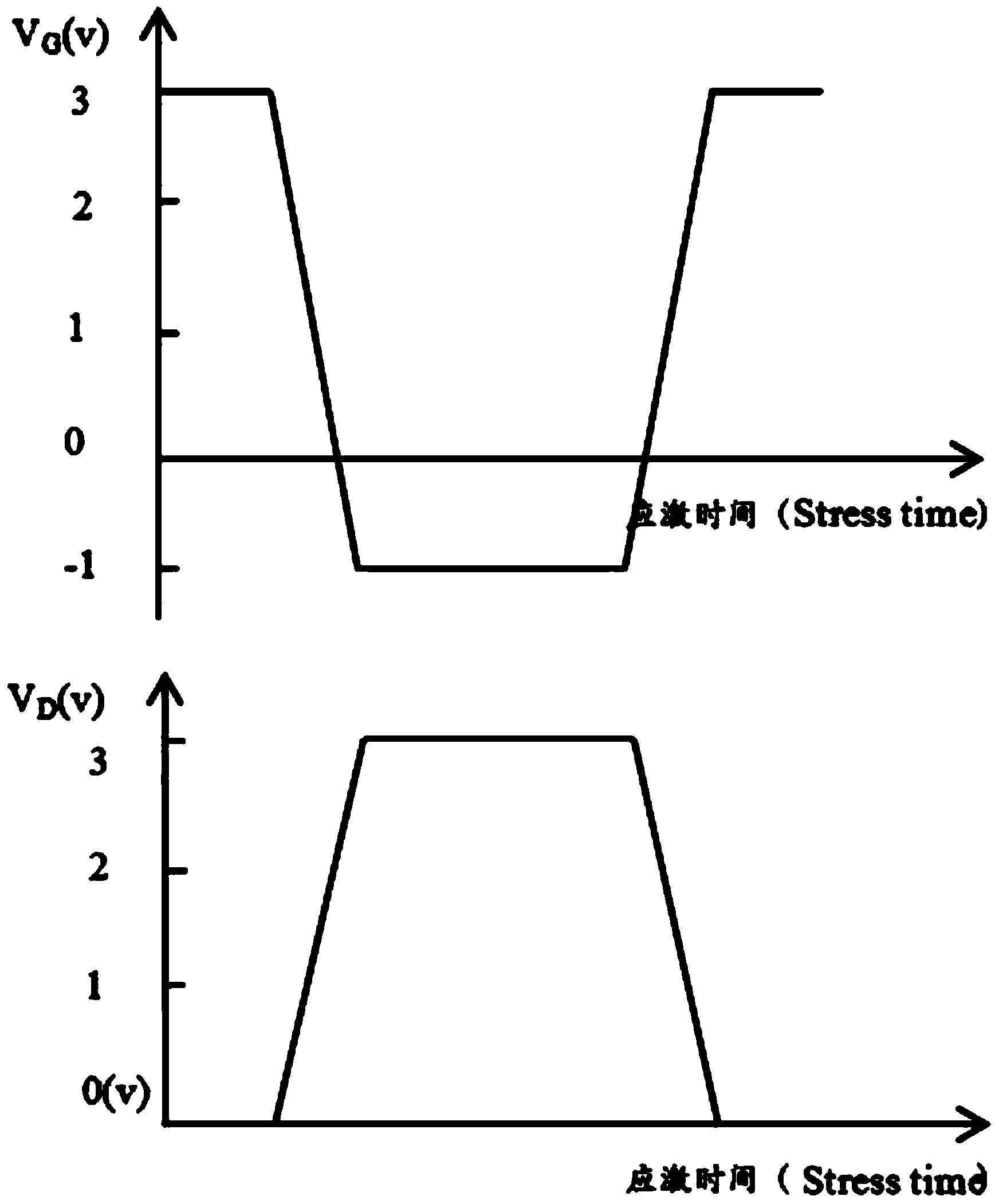

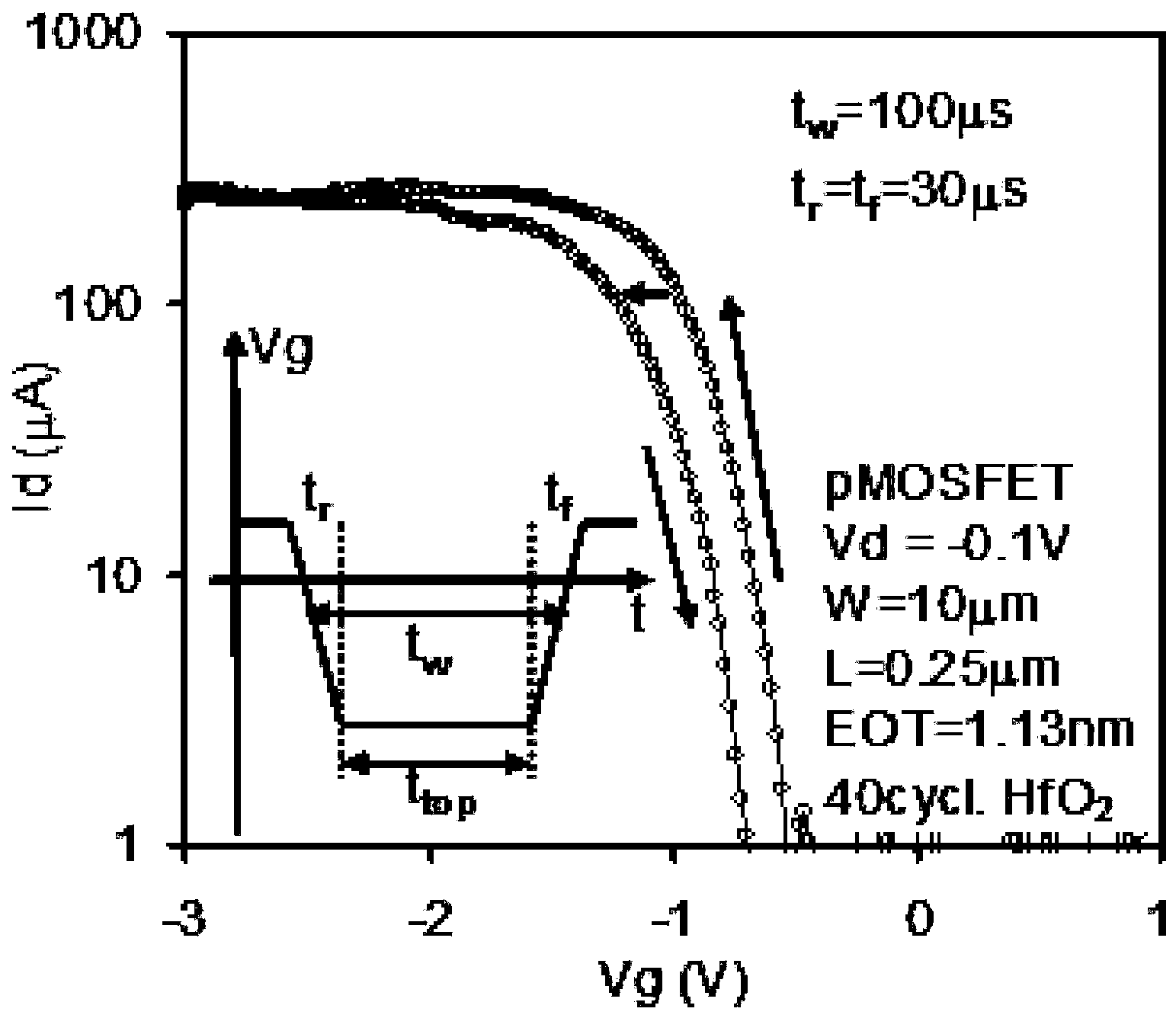

A real time on-line test system for MOS chip gamma ray radiation responses

InactiveCN103675646AObserving Ionizing Radiation DamageQuick saveElectronic circuit testingGamma rayRadioactive source

The invention discloses a real time on-line test system for MOS chip gamma ray radiation responses. The real time on-line test system is characterized in that: the system comprises a radiation response probe bench (1), a pulse I-V test system, a pulse C-V test system and an On-The-Fly test system. The radiation response probe bench (1) comprises a lead container with a built-in radioactive source (10), a to-be-tested chip (12) and a microscope (13) observing changes of the to-be-tested chip. The lead container has an opening at the upper end. The to-be-tested chip (12) is placed in the opening portion of the lead container. The upper end of the to-be-tested chip (12) is connected with a probe (14). The probe is separately connected with the pulse I-V test system, the pulse C-V test system and the On-The-Fly test system. The system fills a technical gap of real time on-line monitoring for the MOS chip gamma ray radiation responses, and a basis is provided for the development application of radiation-proof integrated circuits and high-K medium radiation responses.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

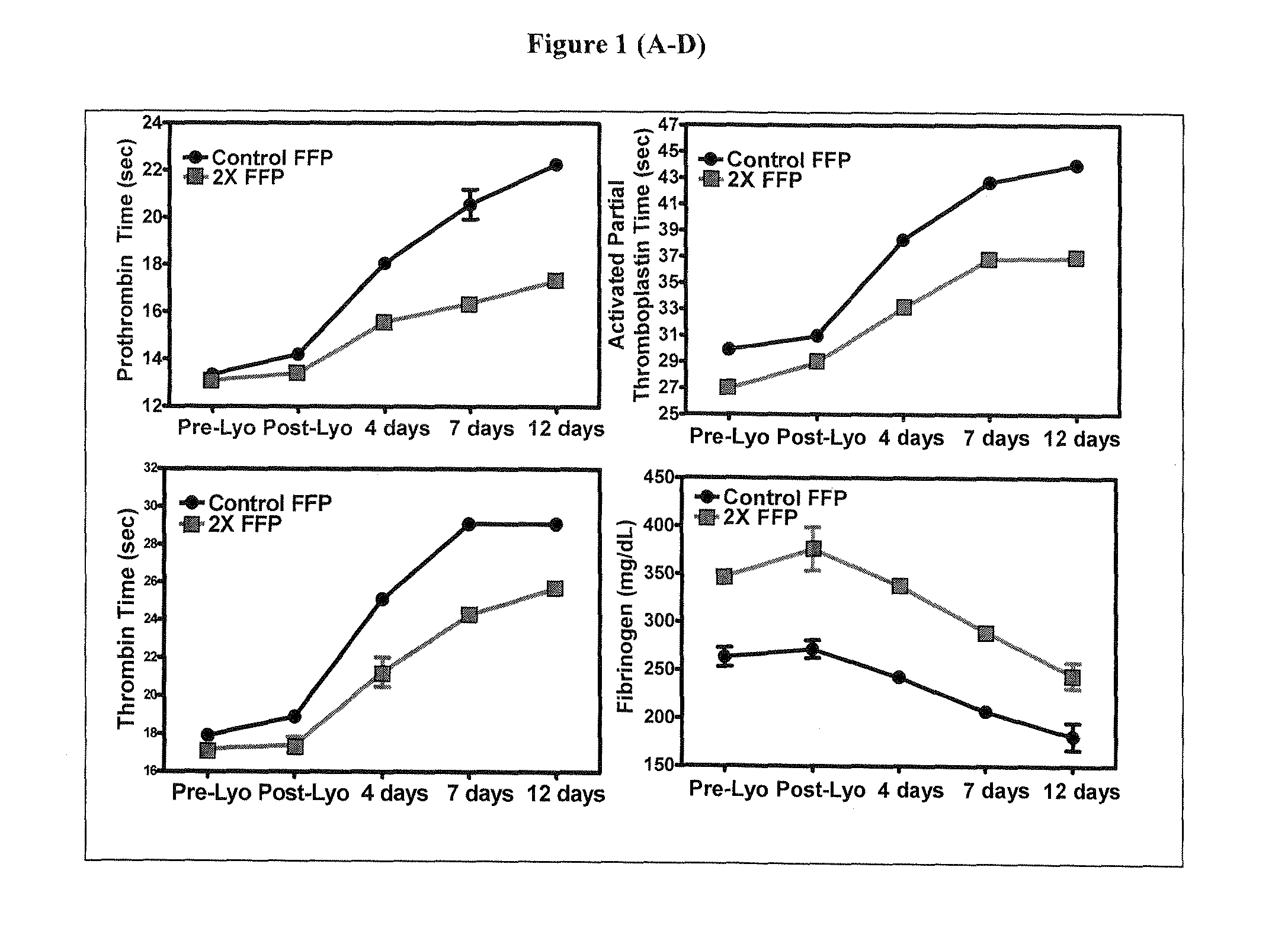

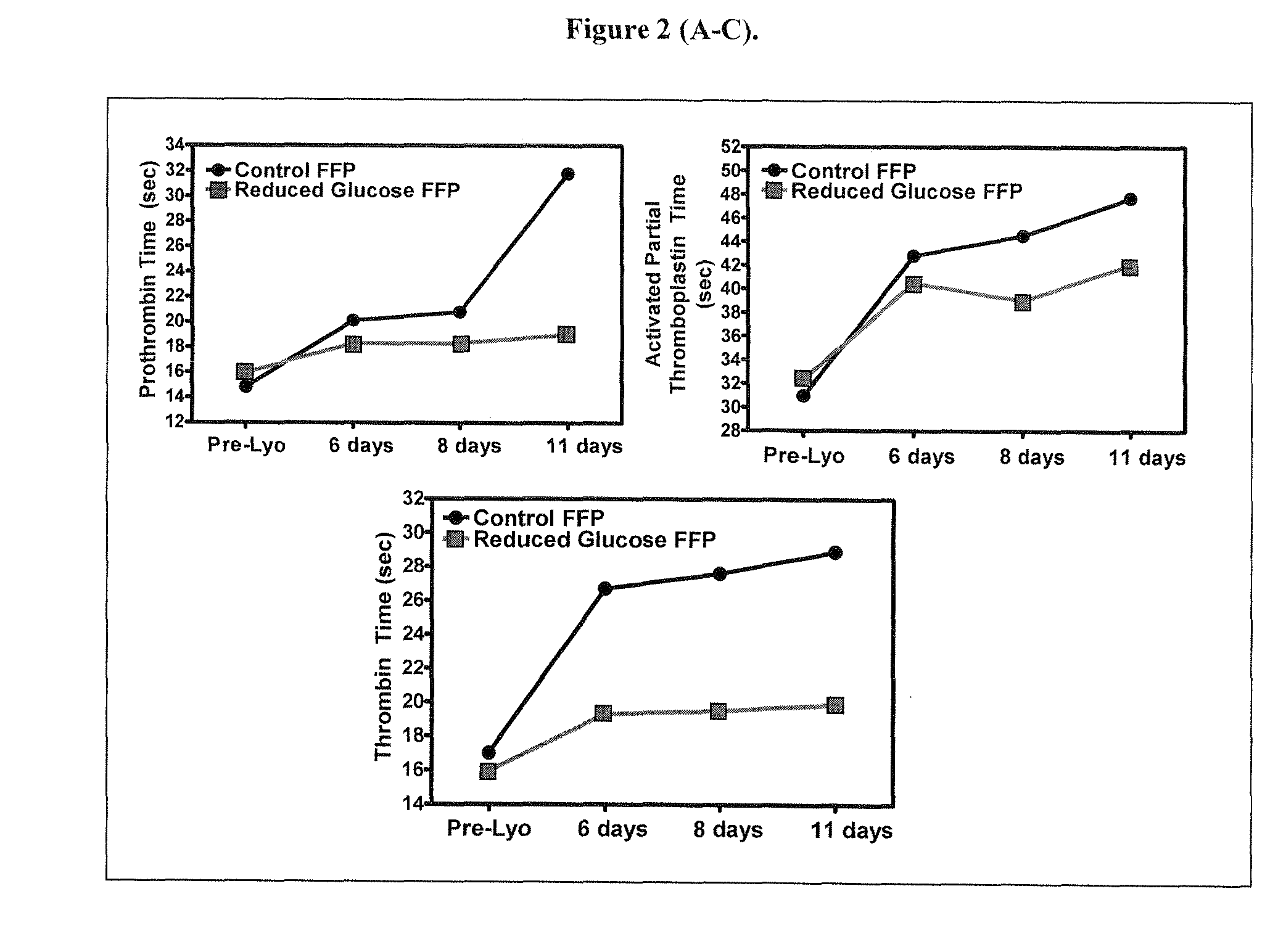

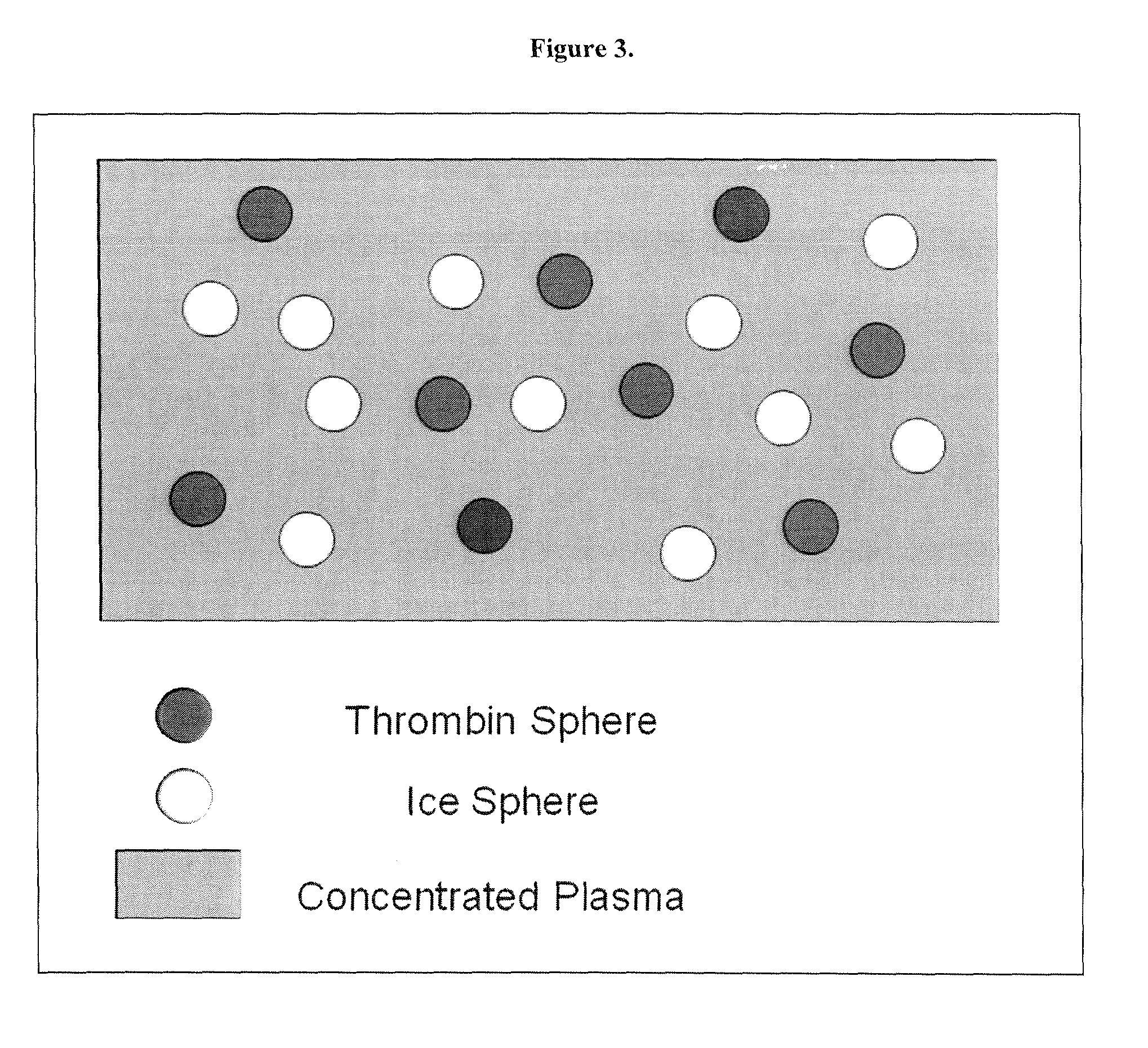

Freeze-dried plasma formats for the trauma care field

InactiveUS20100233671A1Increasing coagulation factor stabilityHigh protein concentrationDipeptide ingredientsMammal material medical ingredientsDipeptideFreeze-drying

Disclosed are freeze-dried plasma formats specifically designed for the trauma care field. Blood plasma is subjected to a glucose removal step, a protein fraction up-concentration step and addition of stabilizers prior to freeze-drying. Preferable stabilizers are glutamine dipeptides, glutamine and glycine. The glutamine based formulation is added direct to plasma and serves three main purposes: 1) Increases stability of plasma proteins and stabilizes pH in freeze-dried state; 2) Increases stability of plasma proteins against Gamma Irradiation and thus allows for the application of a terminal sterilization step; 3) Introduces supplements beneficial to the trauma patient.

Owner:BAKALTCHEVA IRINA B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com