Patents

Literature

1042 results about "Ionization chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The ionization chamber is the simplest of all gas-filled radiation detectors, and is widely used for the detection and measurement of certain types of ionizing radiation; X-rays, gamma rays, and beta particles. Conventionally, the term "ionization chamber" is used exclusively to describe those detectors which collect all the charges created by direct ionization within the gas through the application of an electric field. It only uses the discrete charges created by each interaction between the incident radiation and the gas, and does not involve the gas multiplication mechanisms used by other radiation instruments, such as the Geiger counter or the proportional counter.

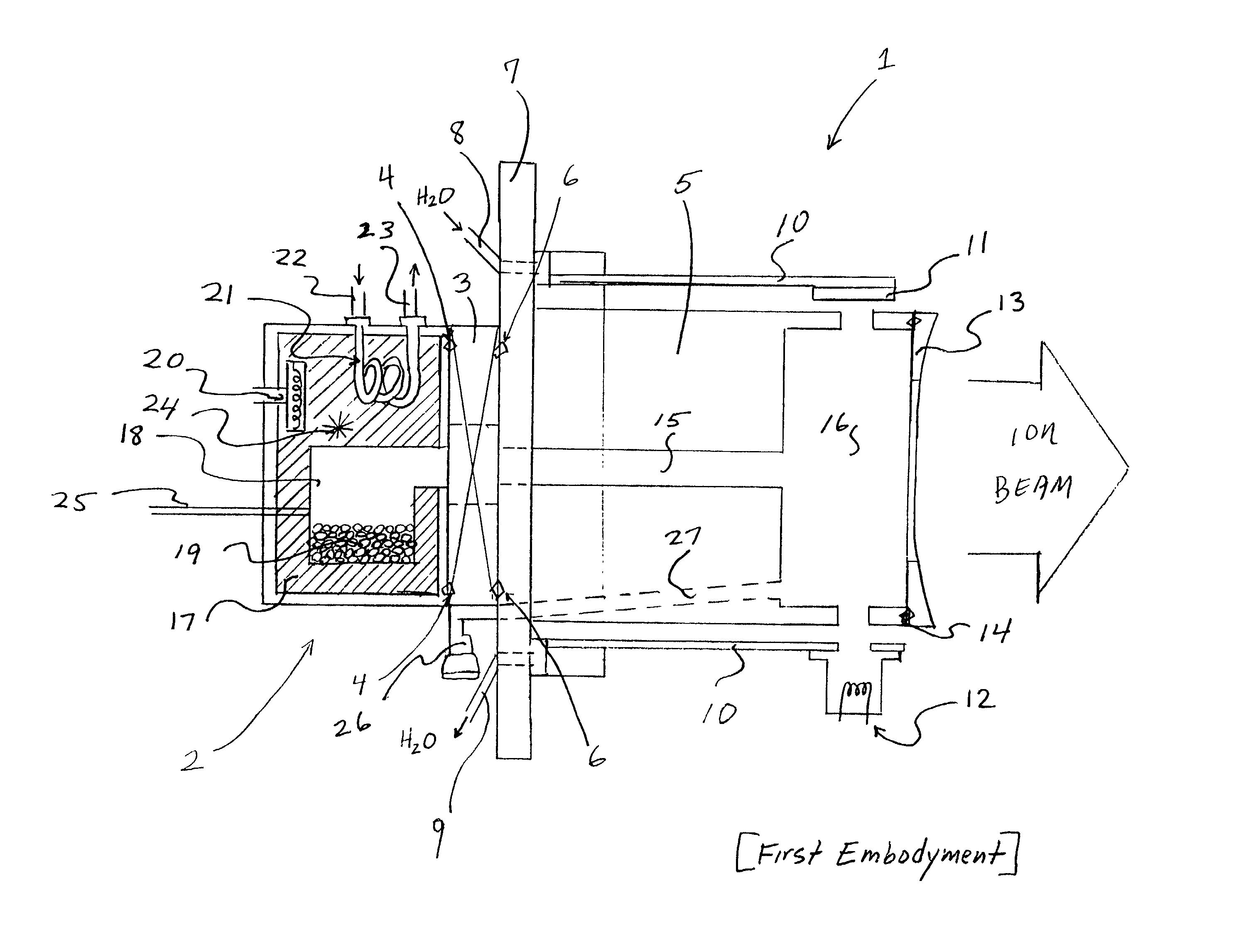

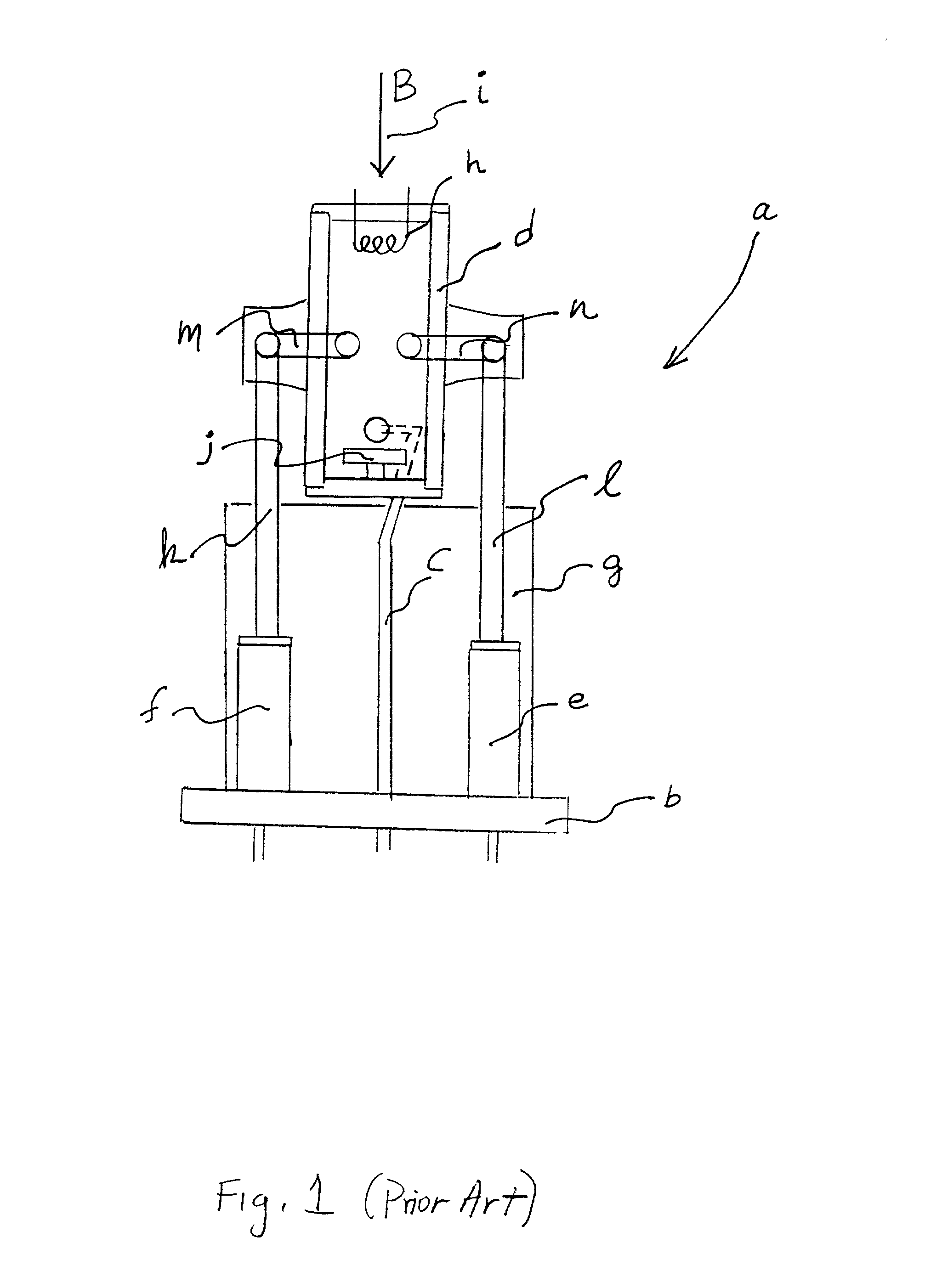

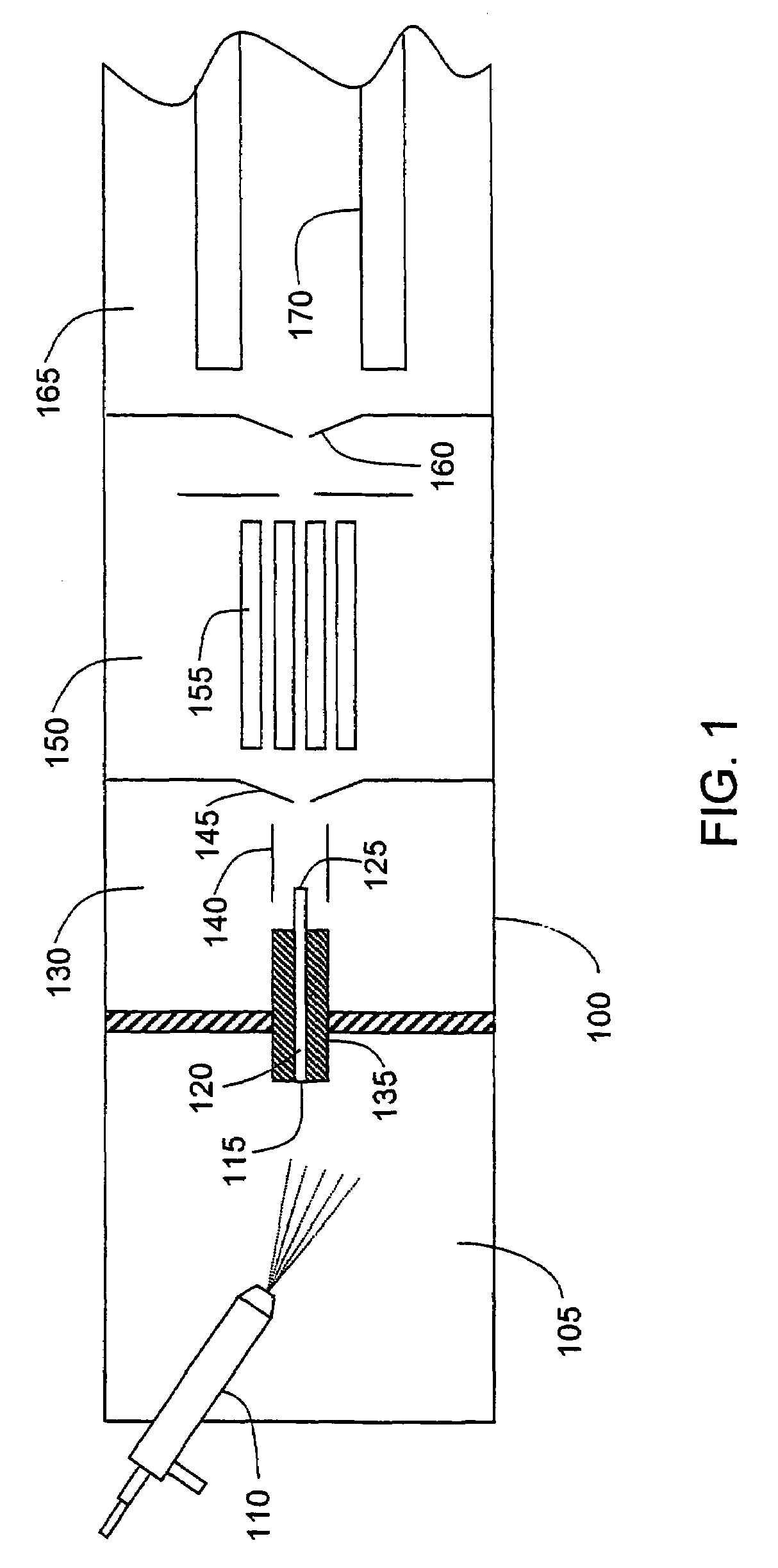

Apparatus for converting coal to hydrocarbons

InactiveUS6013158ALess producedLow costCombustible gas coke oven heatingDirect heating destructive distillationParticulatesSuspended particles

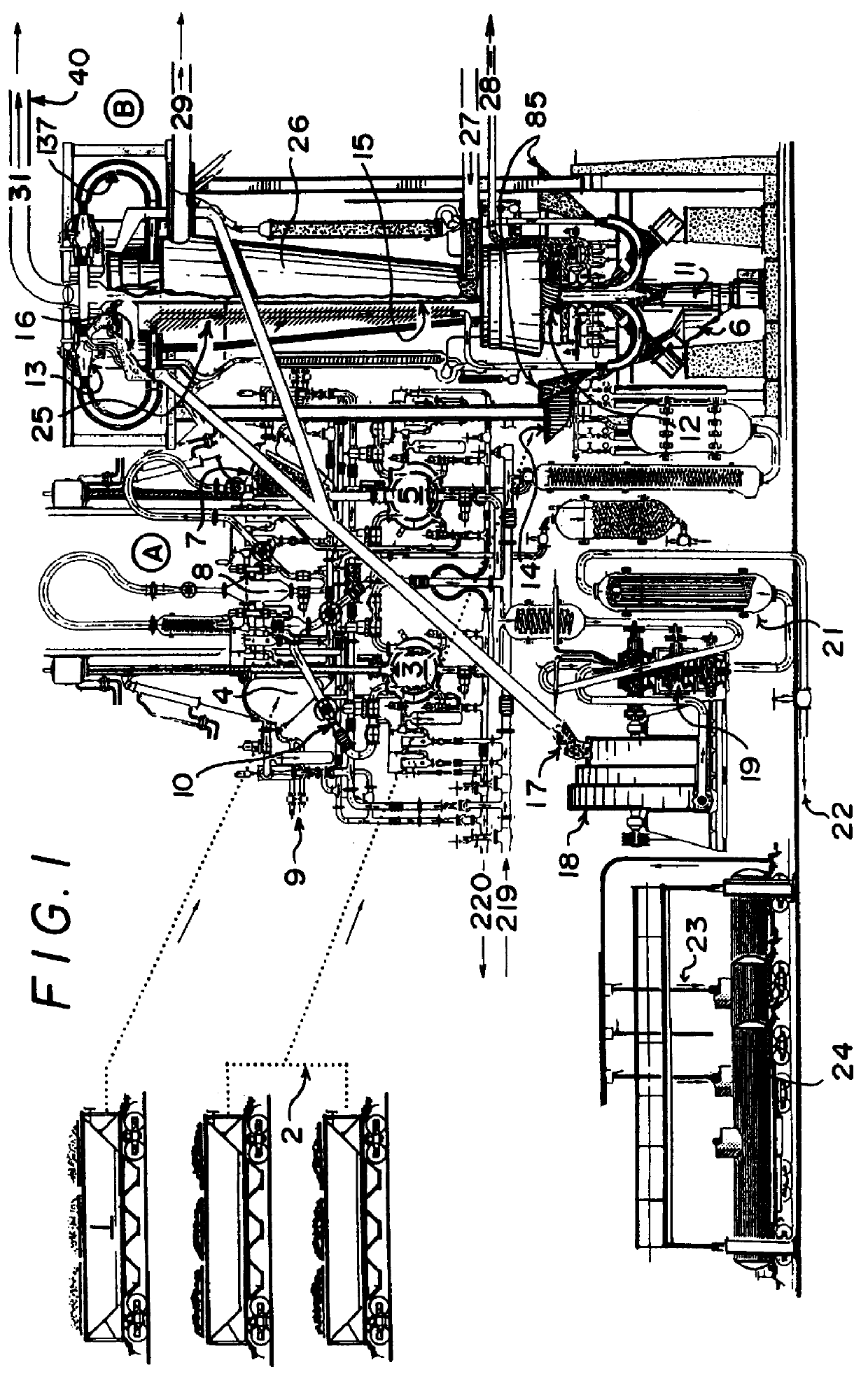

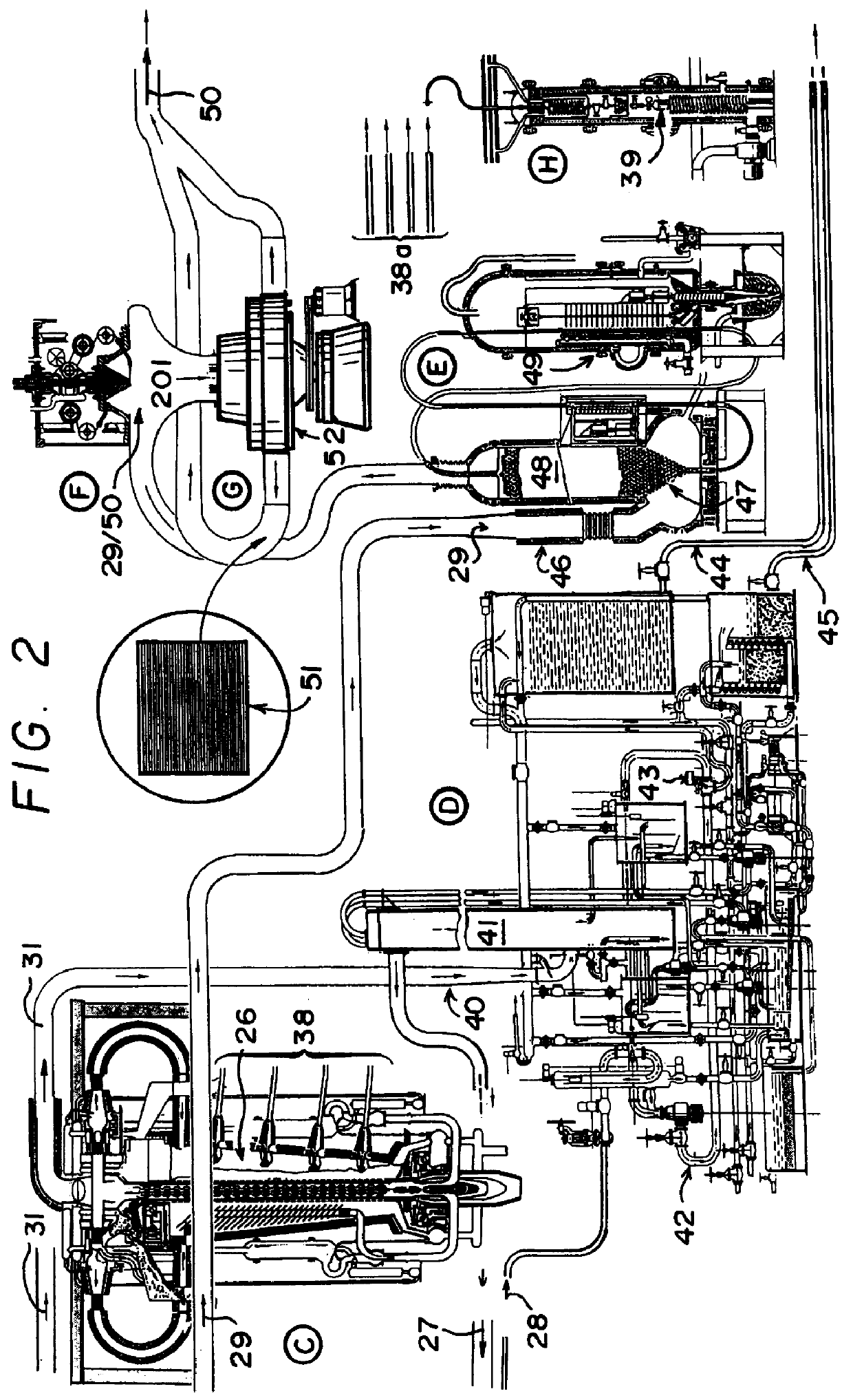

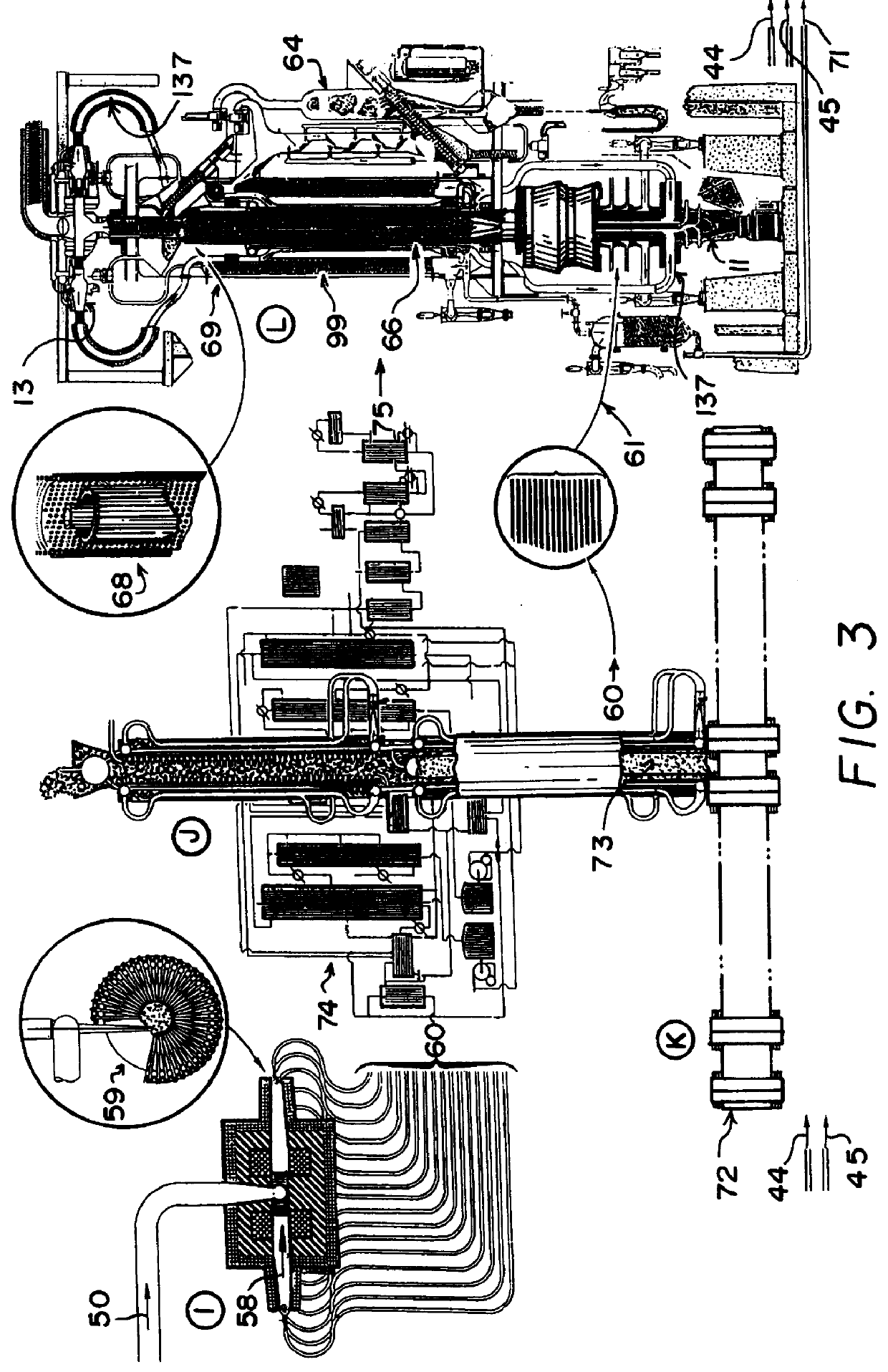

An apparatus for forming liquid hydrocarbons from solid coal. The coal is pulverized to provide a particulate coal feed, which is then extruded to provide a hollow tube of compressed coal supported inside of a support tube. A clay feed is extruded to provide a hollow tube of compressed clay supported inside of the coal tube and a combustible fuel is burned inside of the clay tube. The temperature of combustion is sufficient to fire the extruded clay and pyrolyze the extruded coal to produce hydrocarbon gases and coal char. The support tube has holes for releasing the hydrocarbon gases, which contain suspended particles formed during combustion. The suspended particles are removed from the hydrocarbon gases to provide clean gases, which are passed through an ionizing chamber to ionize at least a portion thereof. The ionized gases are then passed through a magnetic field to separate them from each other according to their molecular weight. Selected portions of at least some of the separated gases are mixed, and the mixed gases are cooled to provide at least one liquid hydrocarbon product of predetermined composition. Portions of the separated gases may also be mixed with the coal char and other input streams, such as waste plastics, and further treated to provide other hydrocarbon products.

Owner:WOOTTEN WILLIAM A

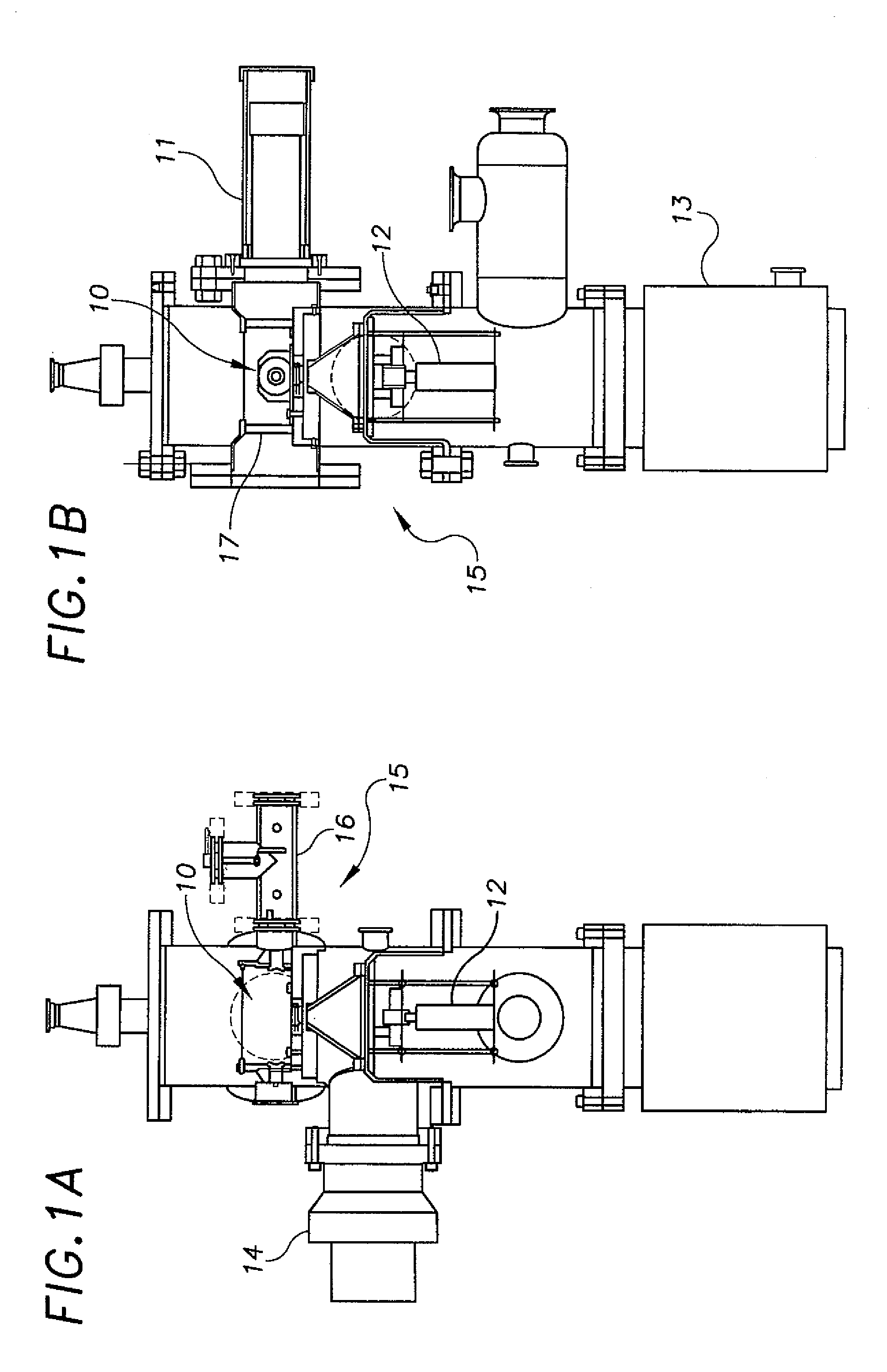

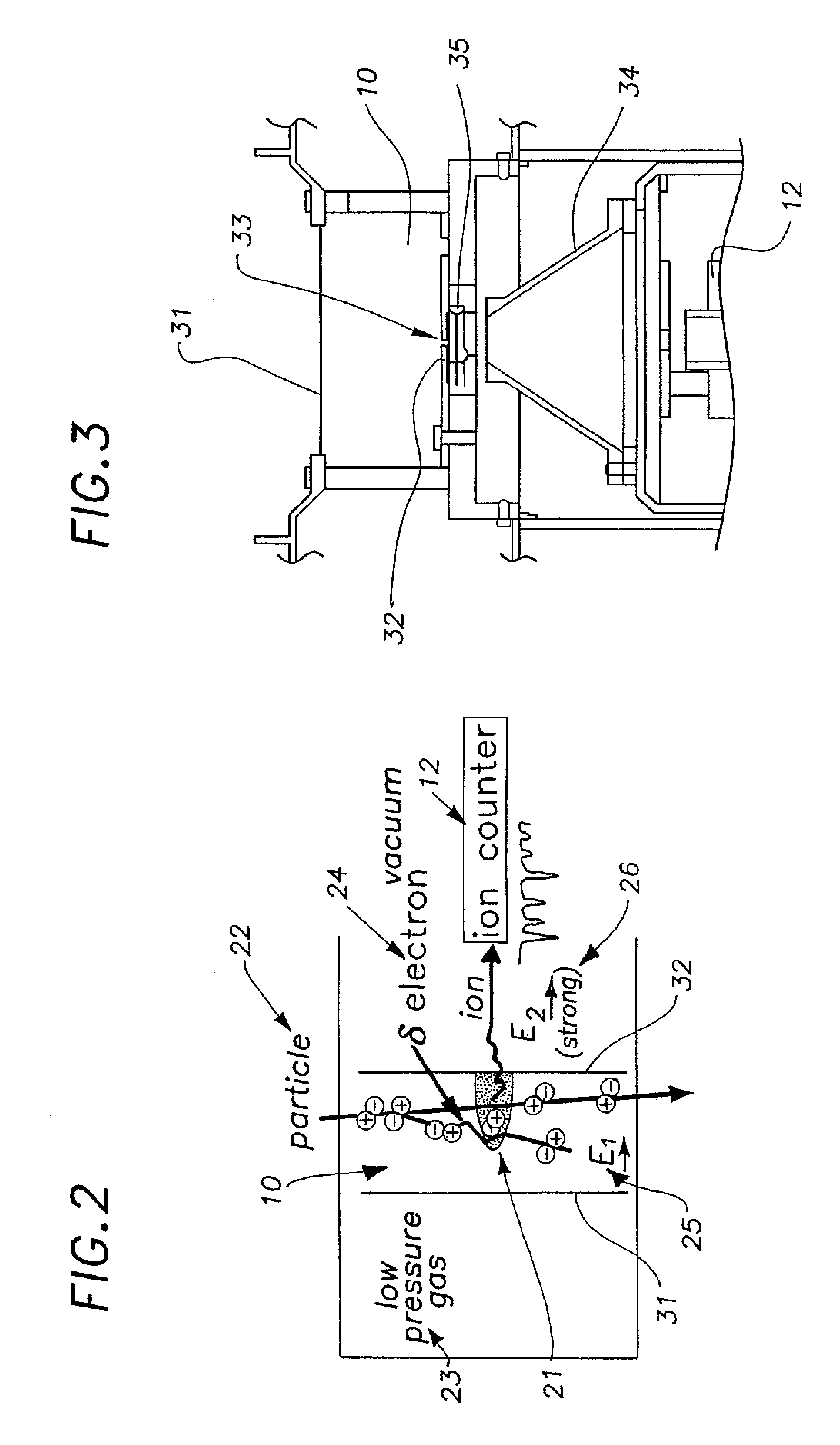

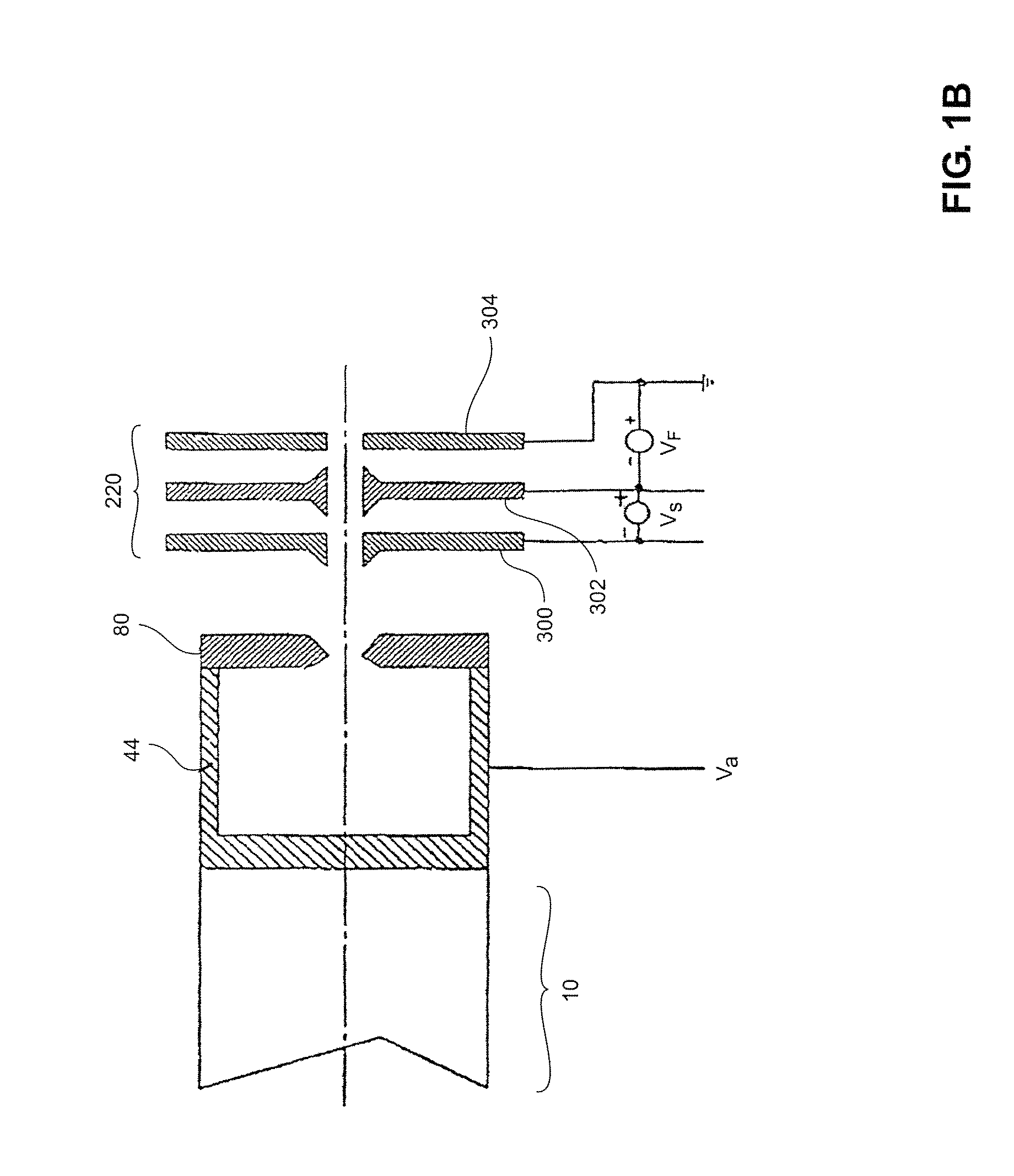

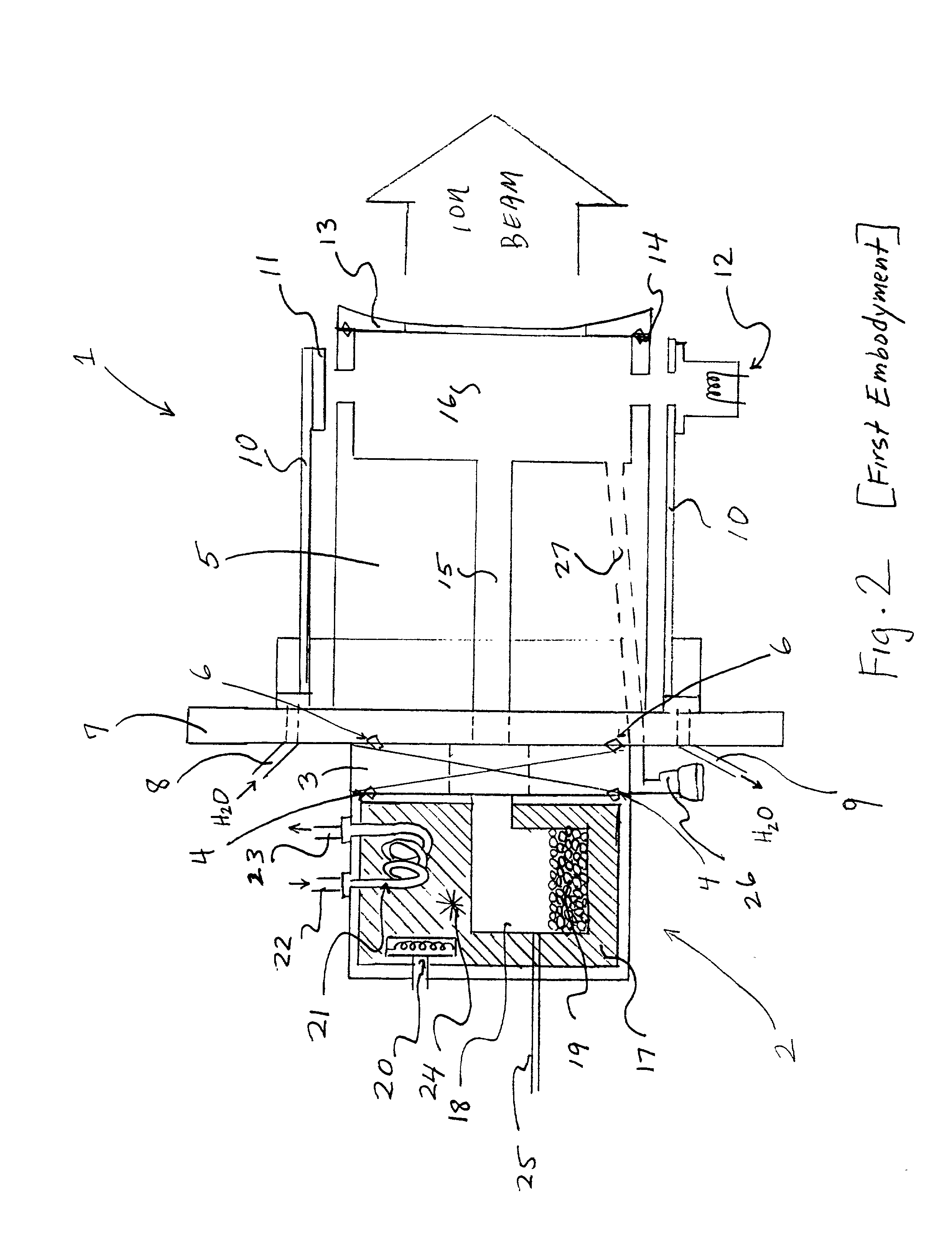

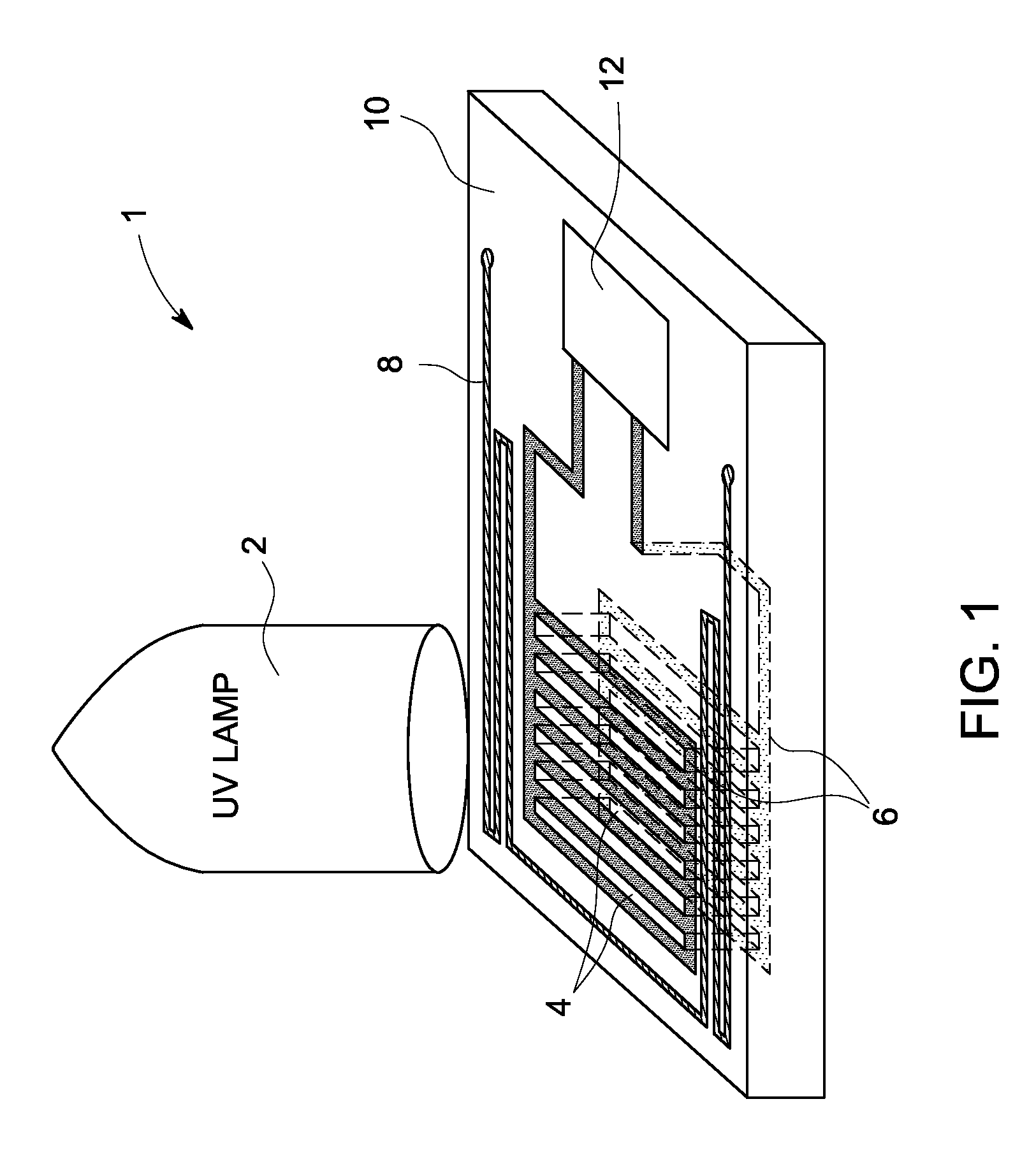

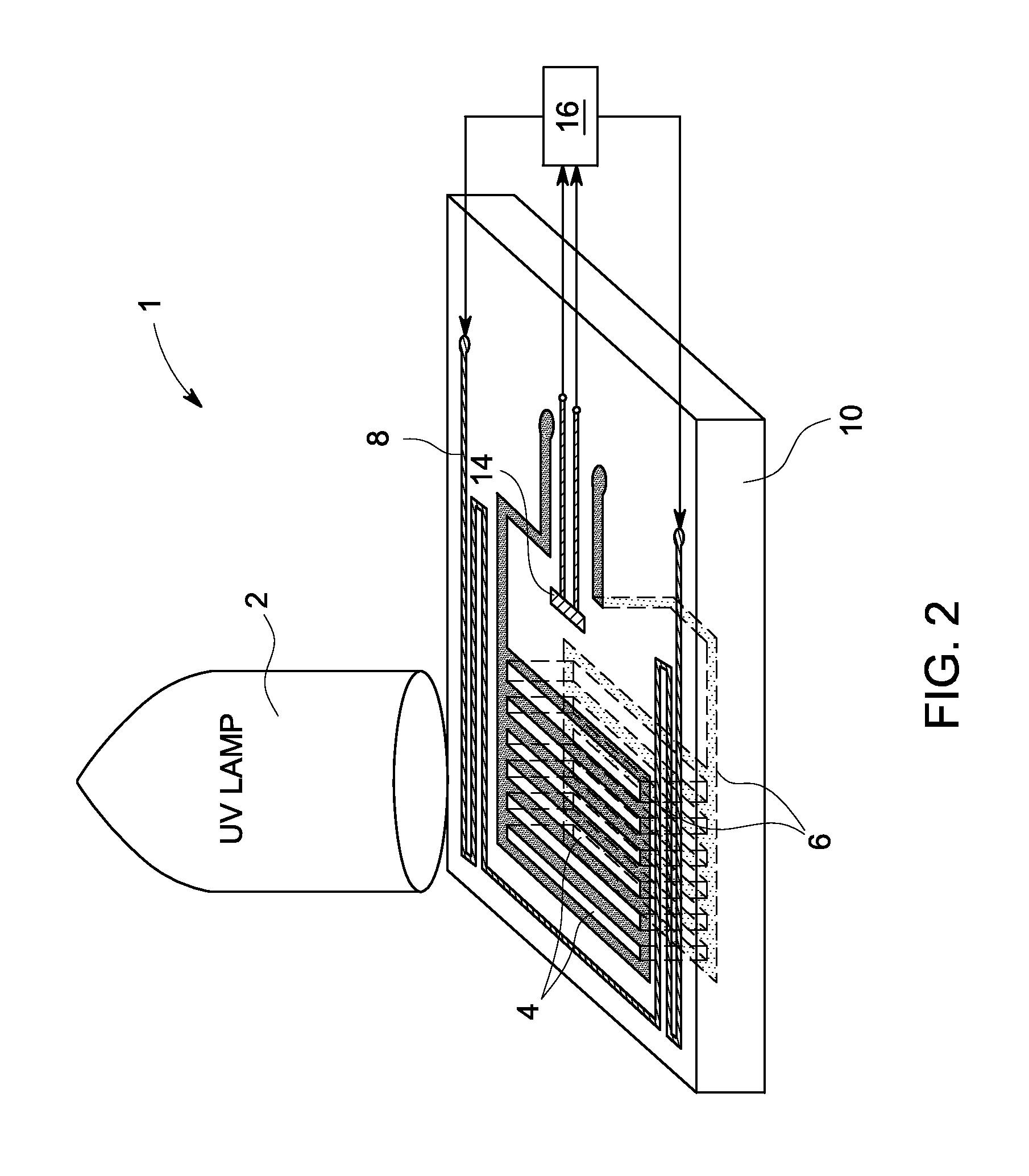

Nanodosimeter based on single ion detection

InactiveUS7081619B2Time-of-flight spectrometersMaterial analysis by electric/magnetic meansFluenceDosimeter

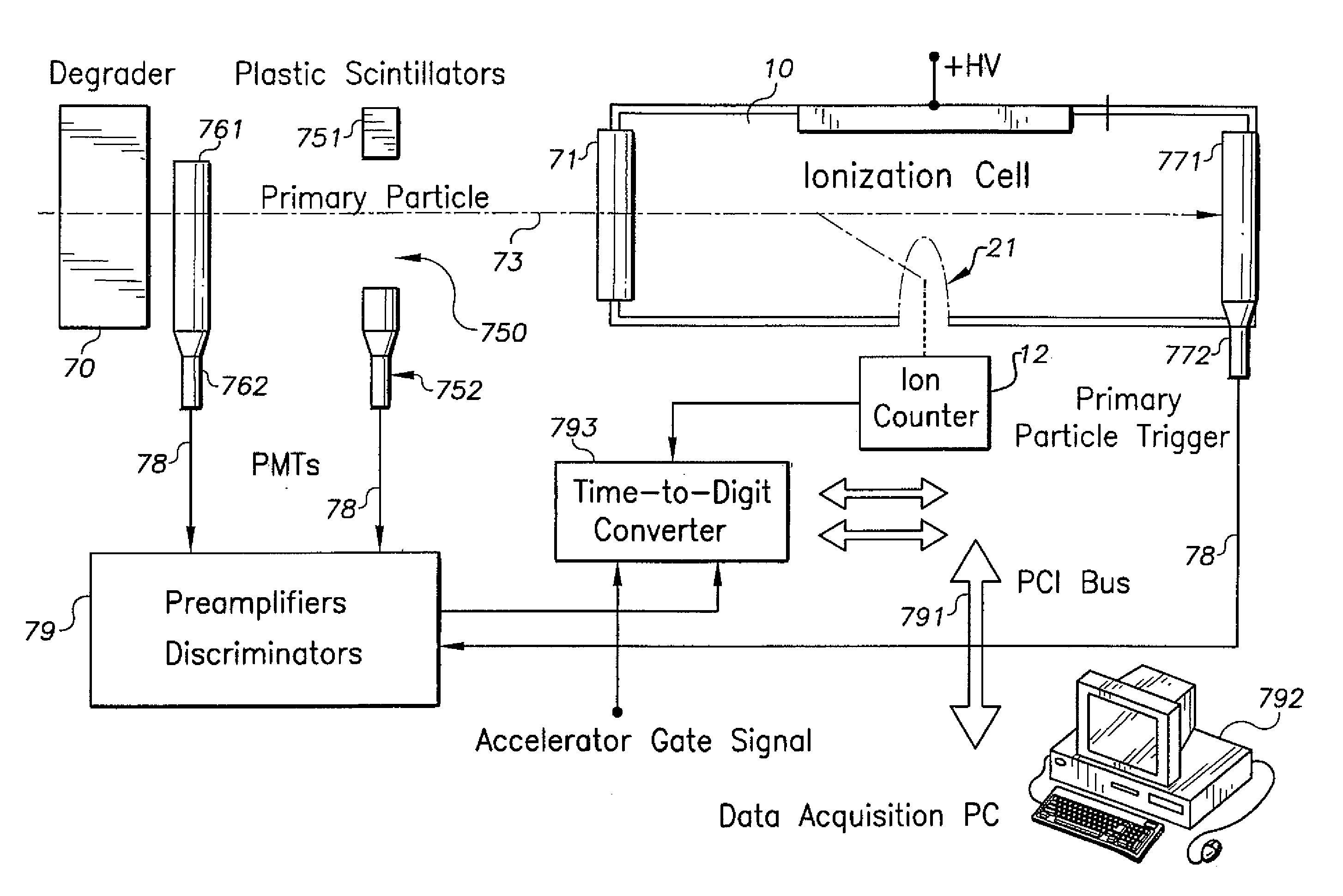

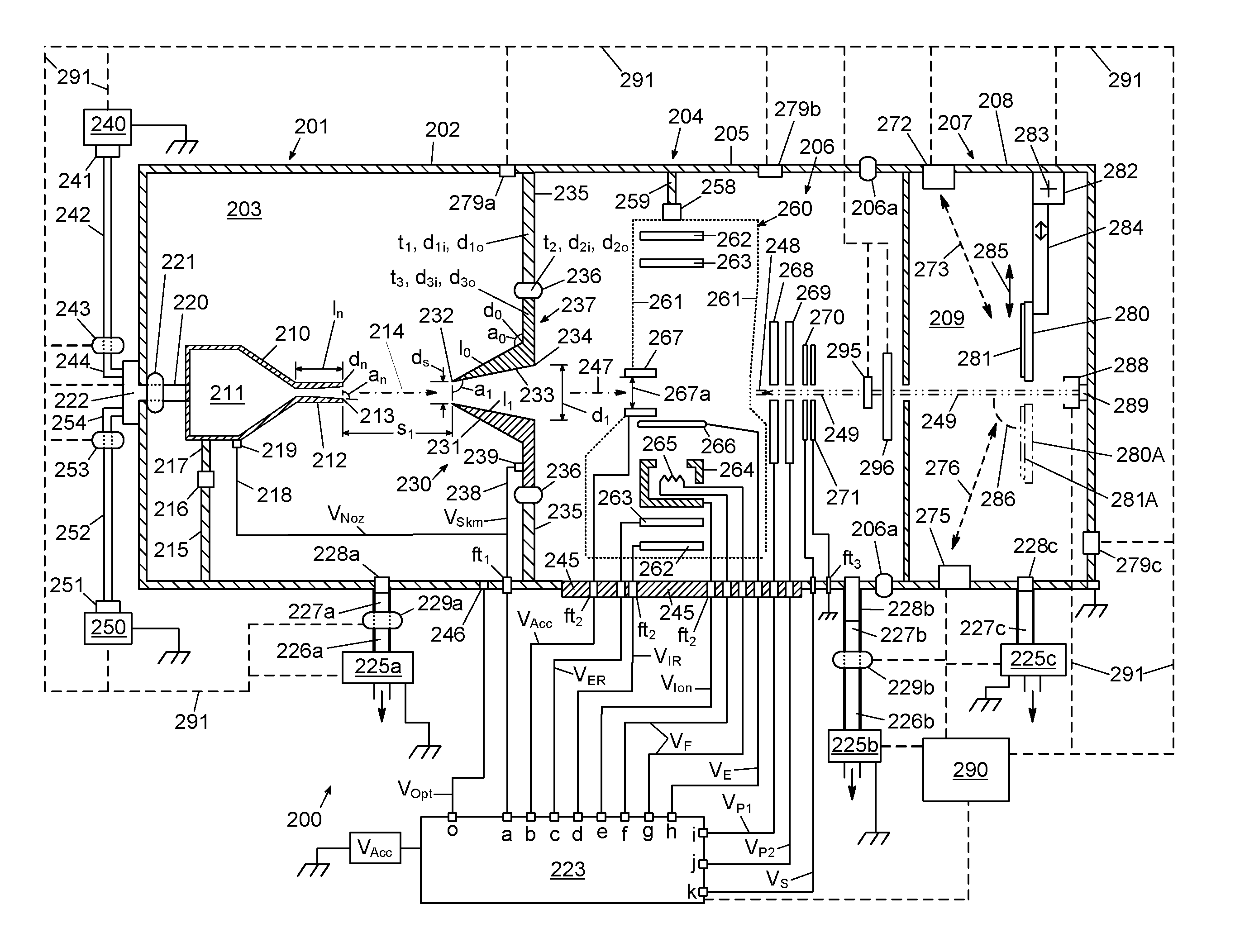

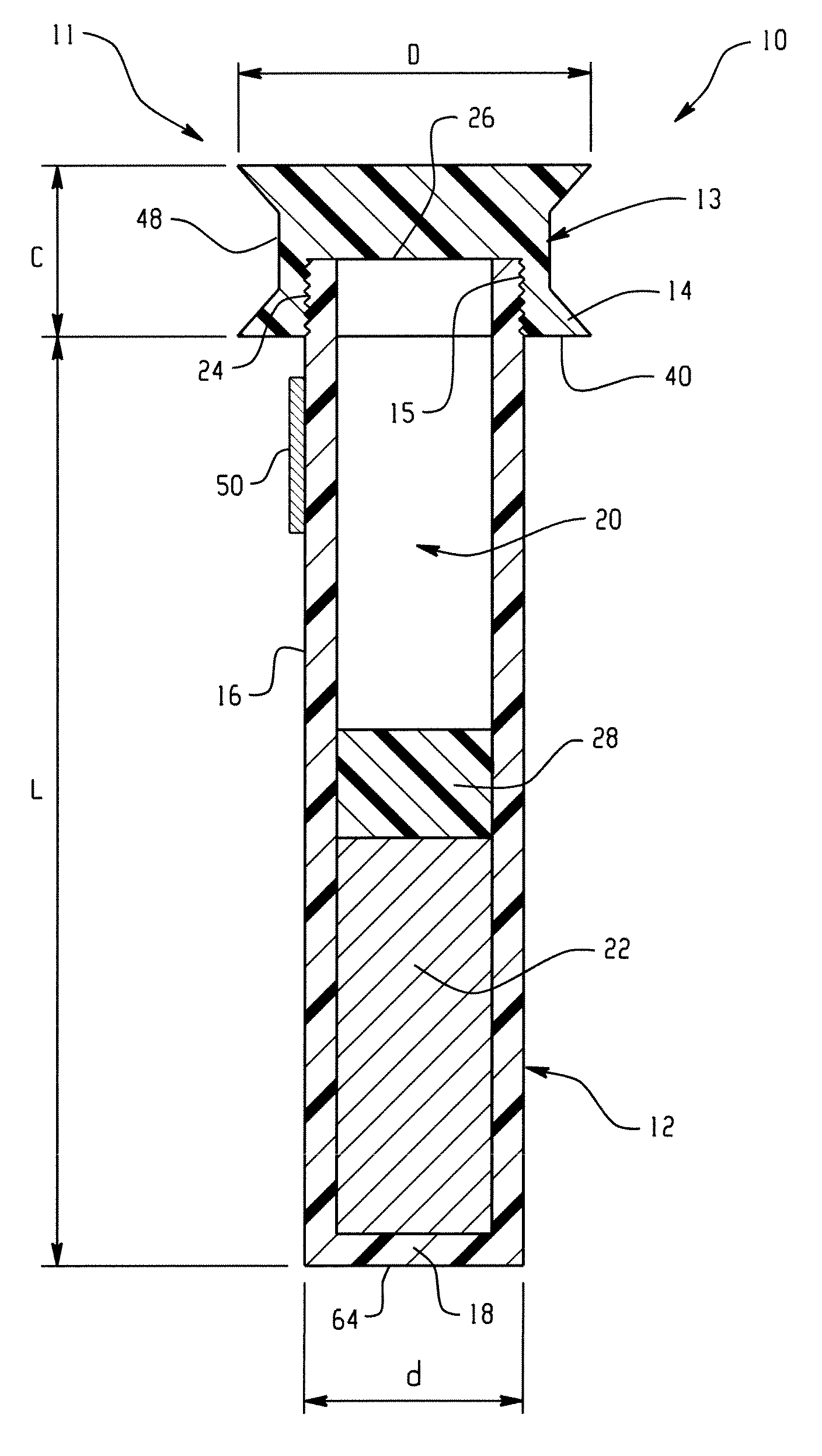

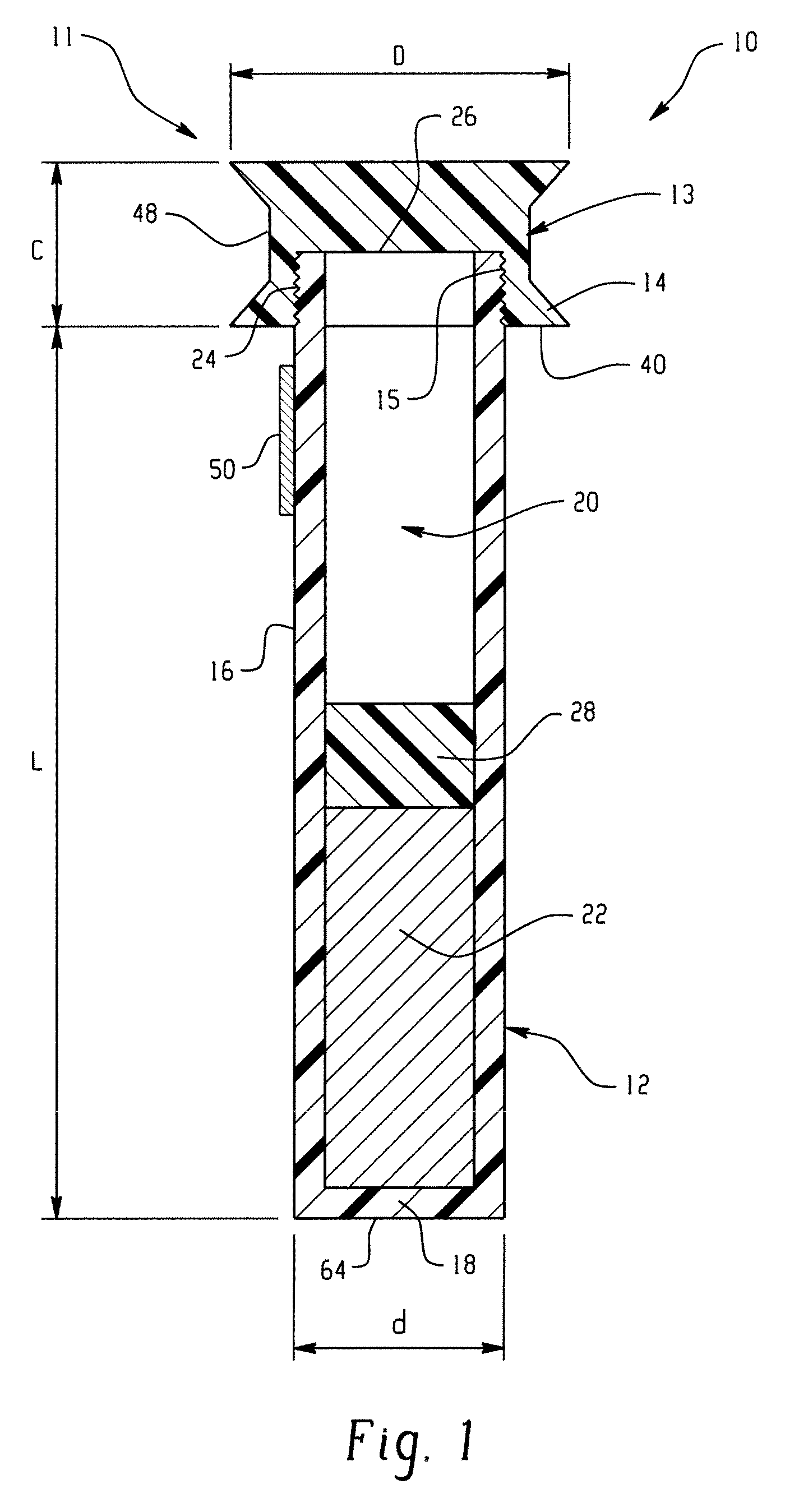

A nanodosimeter device (15) for detecting positive ions induced in a sensitive gas volume by a radiation field of primary particle, comprising an ionization chamber (10) for holding the sensitive gas volume to be irradiated by the radiation field of primary particles; an ion counter system connected to the ionization chamber (10) for detecting the positive ions which pass through the aperture opening and arrive at the ion counter (12) at an arrival time; a particle tracking system for position-sensitive detection of the primary particles passing through the sensitive gas volume; and a data acquisition system capable of coordinating the readout of all data signals and of performing data analysis correlating the arrival time of the positive ions detected by the ion counter system relative to the position sensitive data of primary particles detected by the particle tracking system. The invention further includes the use of the nanodosimeter for method of calibrating radiation exposure with damage to a nucleic acid within a sample. A volume of tissue-equivalent gas is radiated with a radiation field to induce positive ions. The resulting positive ions are measured and compared with a determination of presence or extent of damage resulting from irradiating a nucleic acid sample with an equivalent dose of radiation.

Owner:LOMA LINDA UNIVERSITY +1

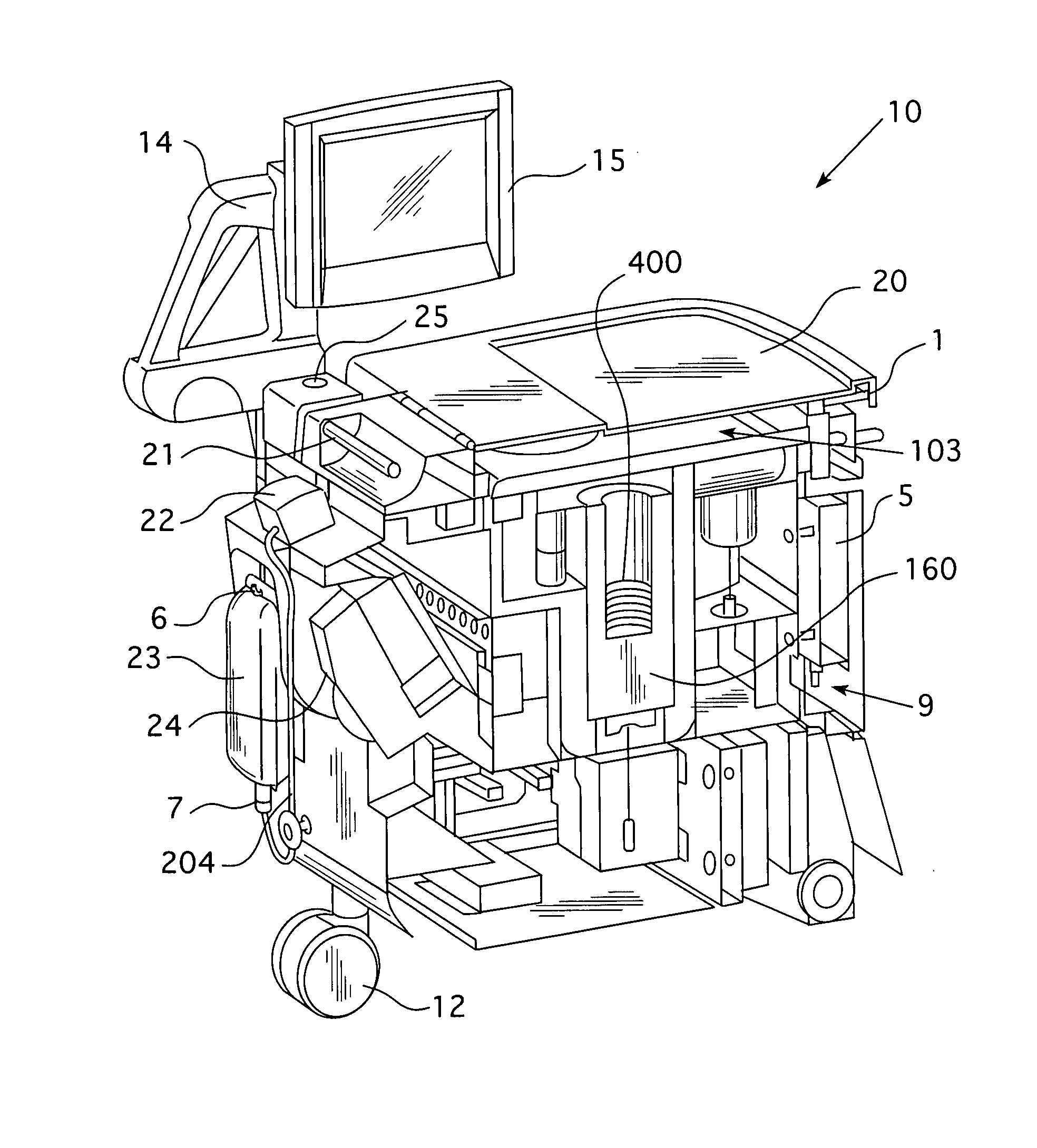

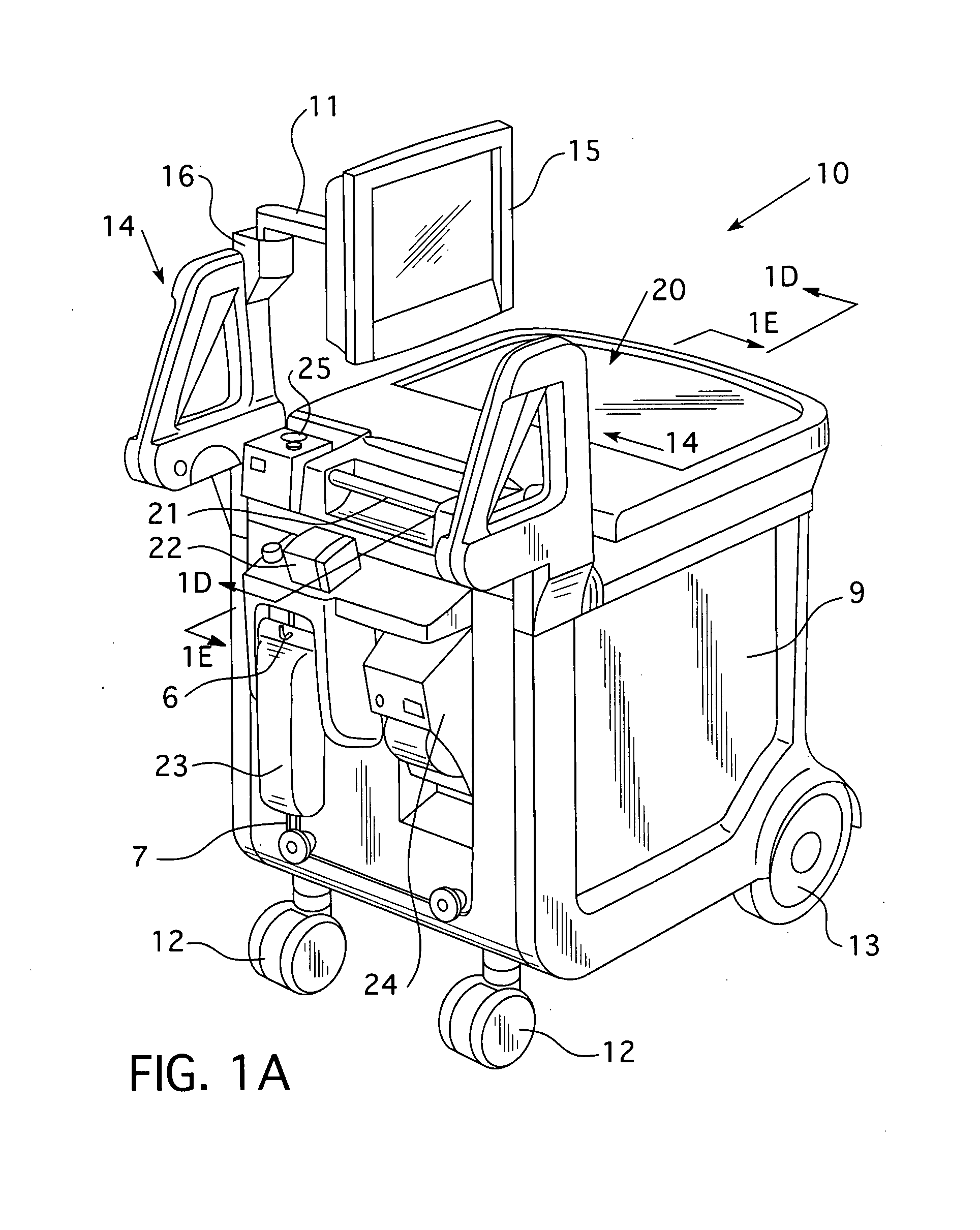

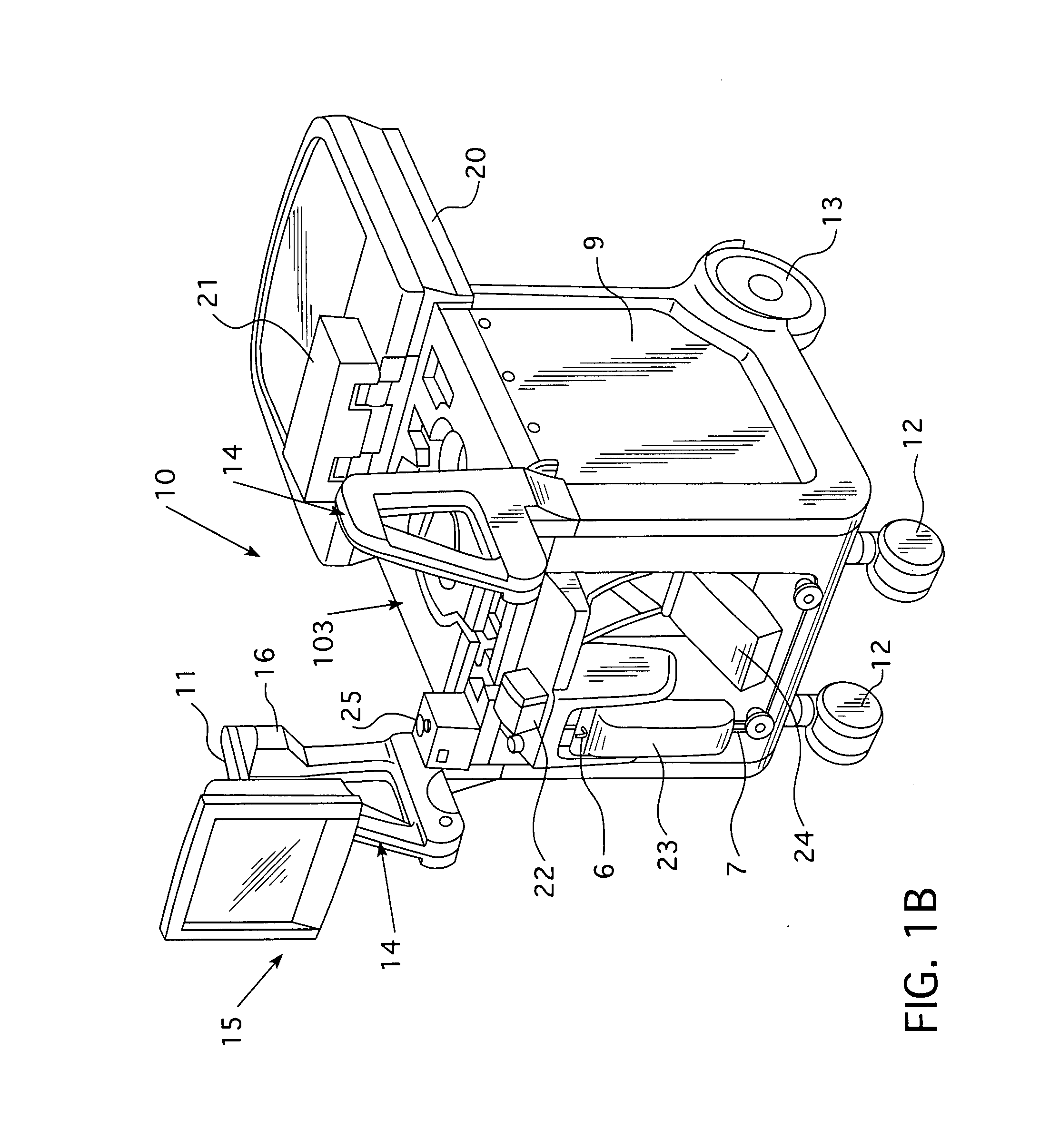

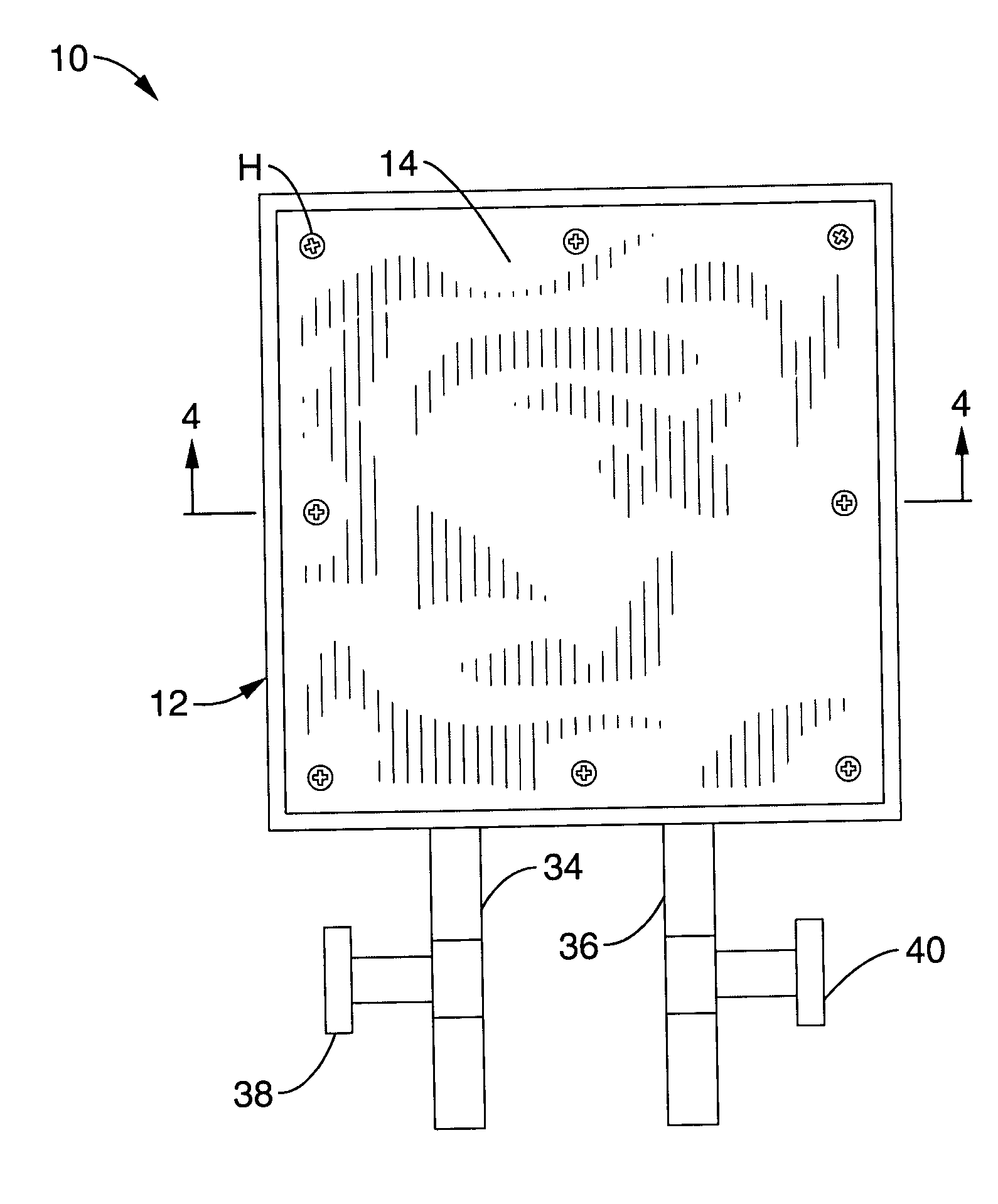

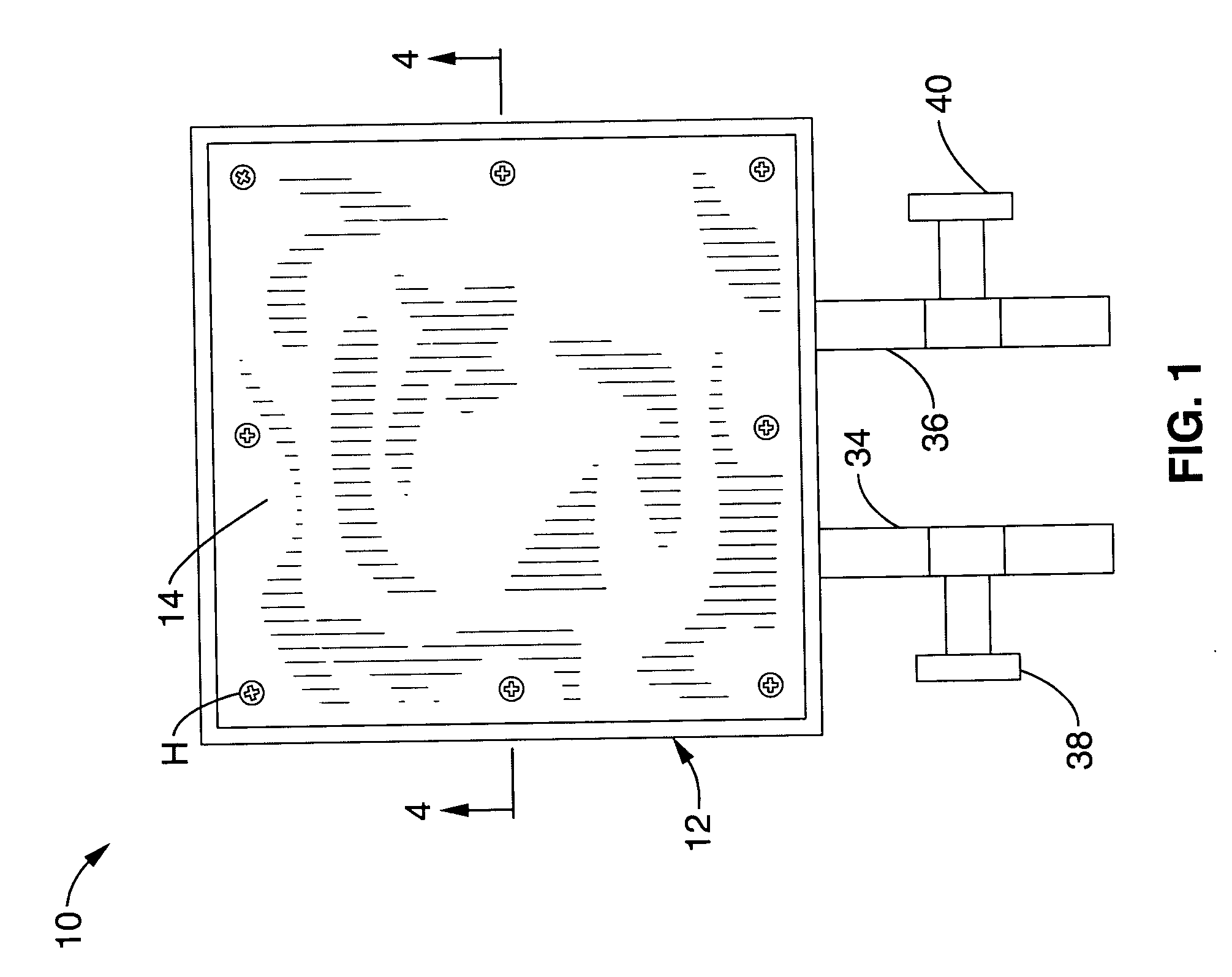

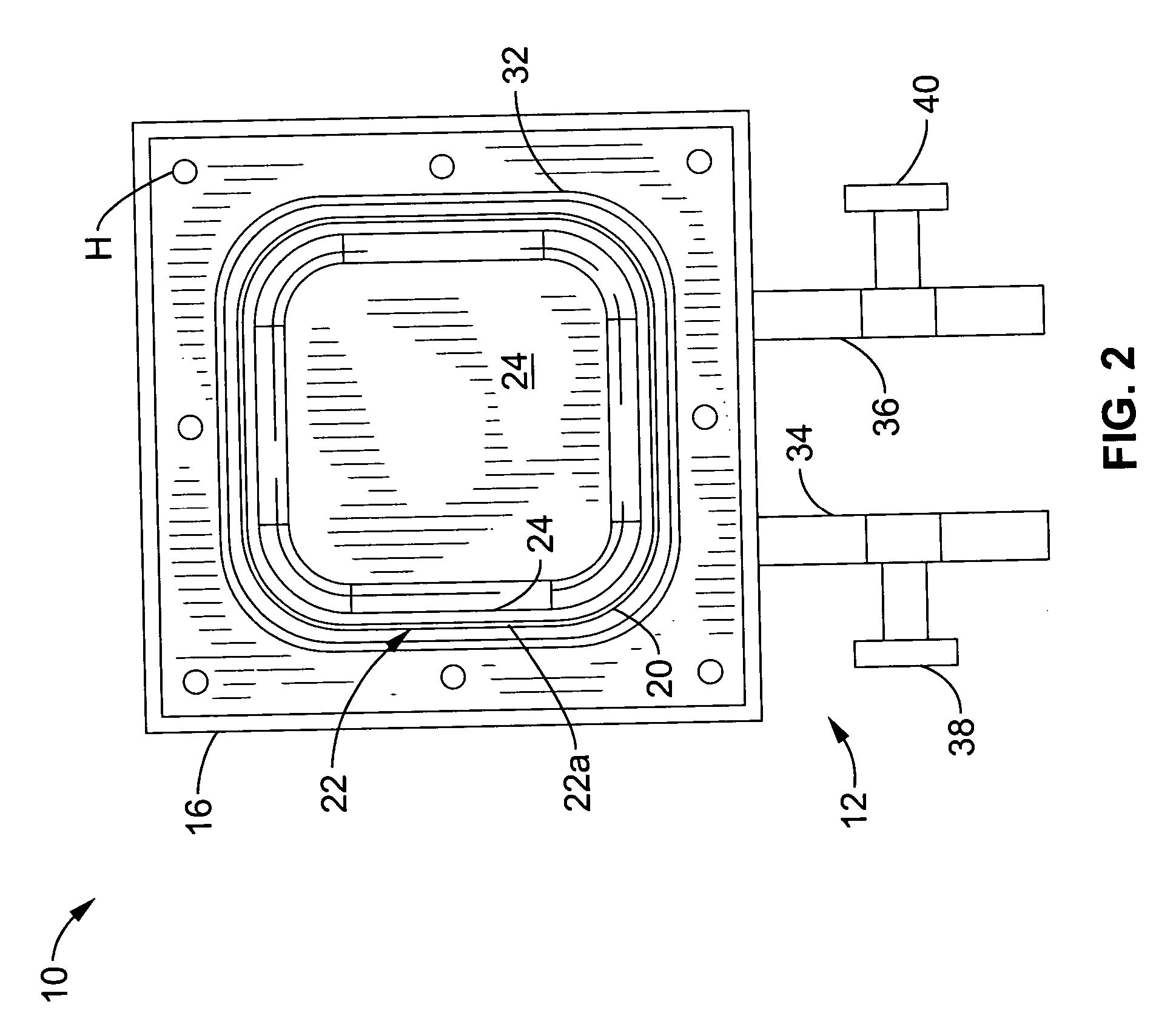

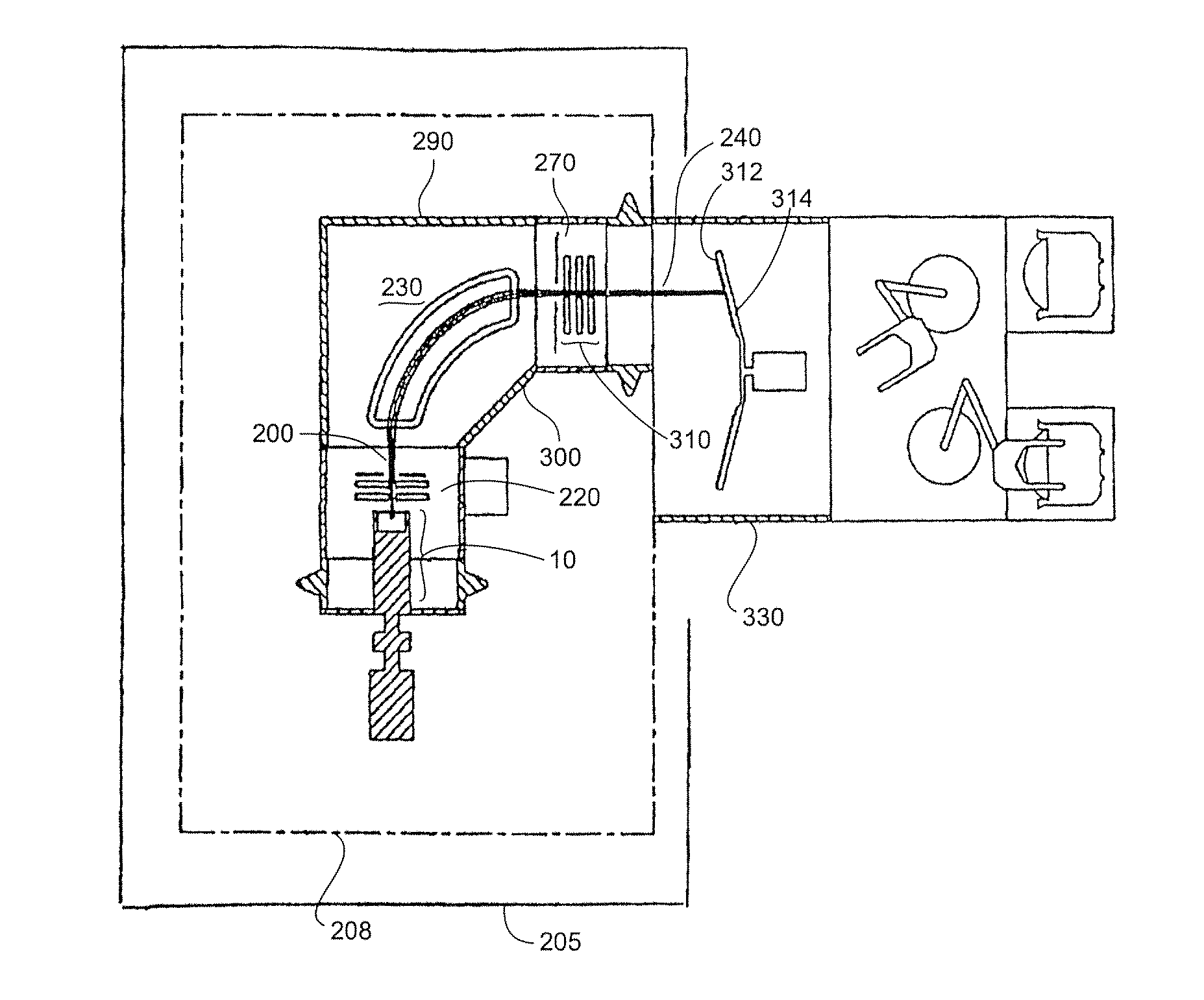

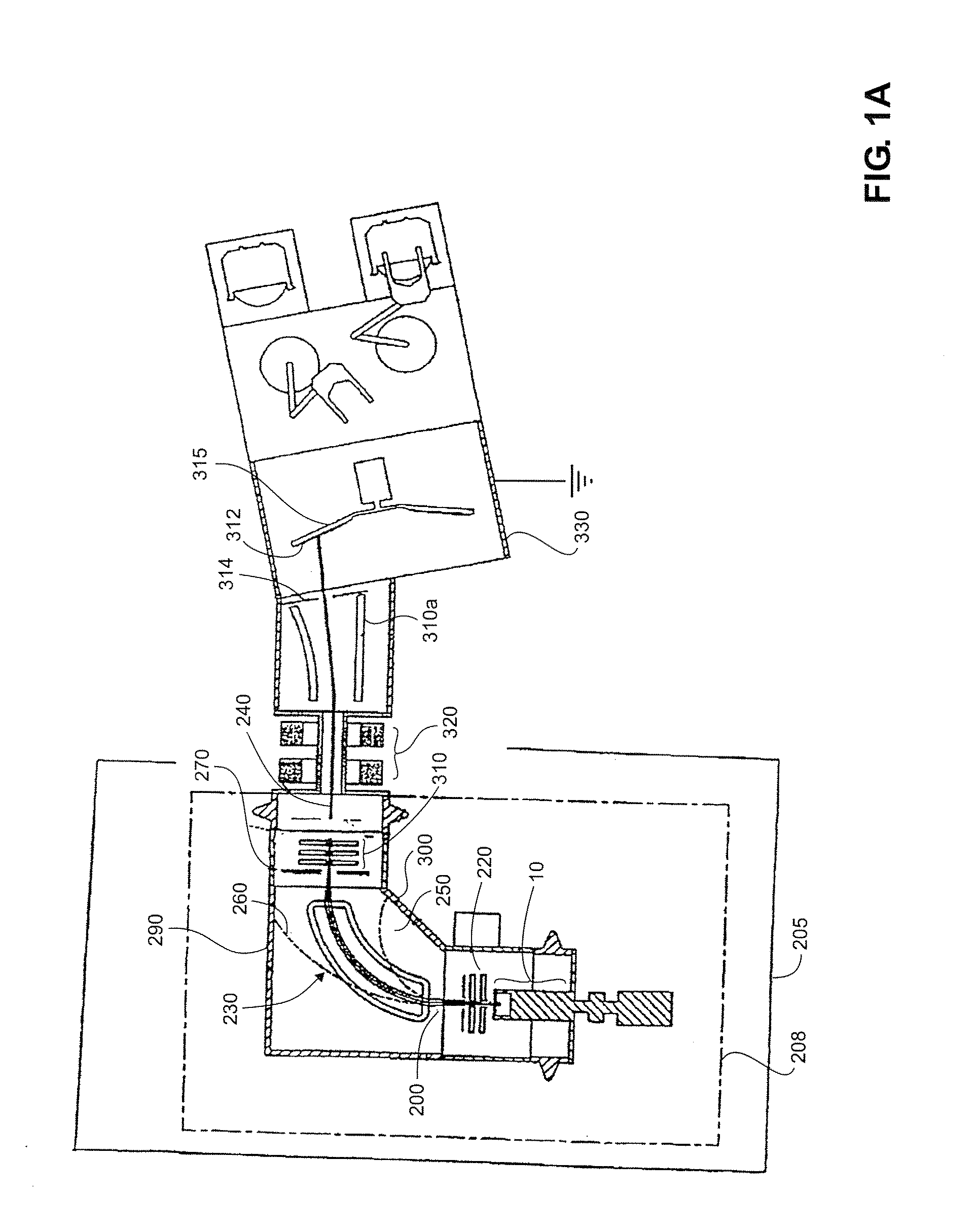

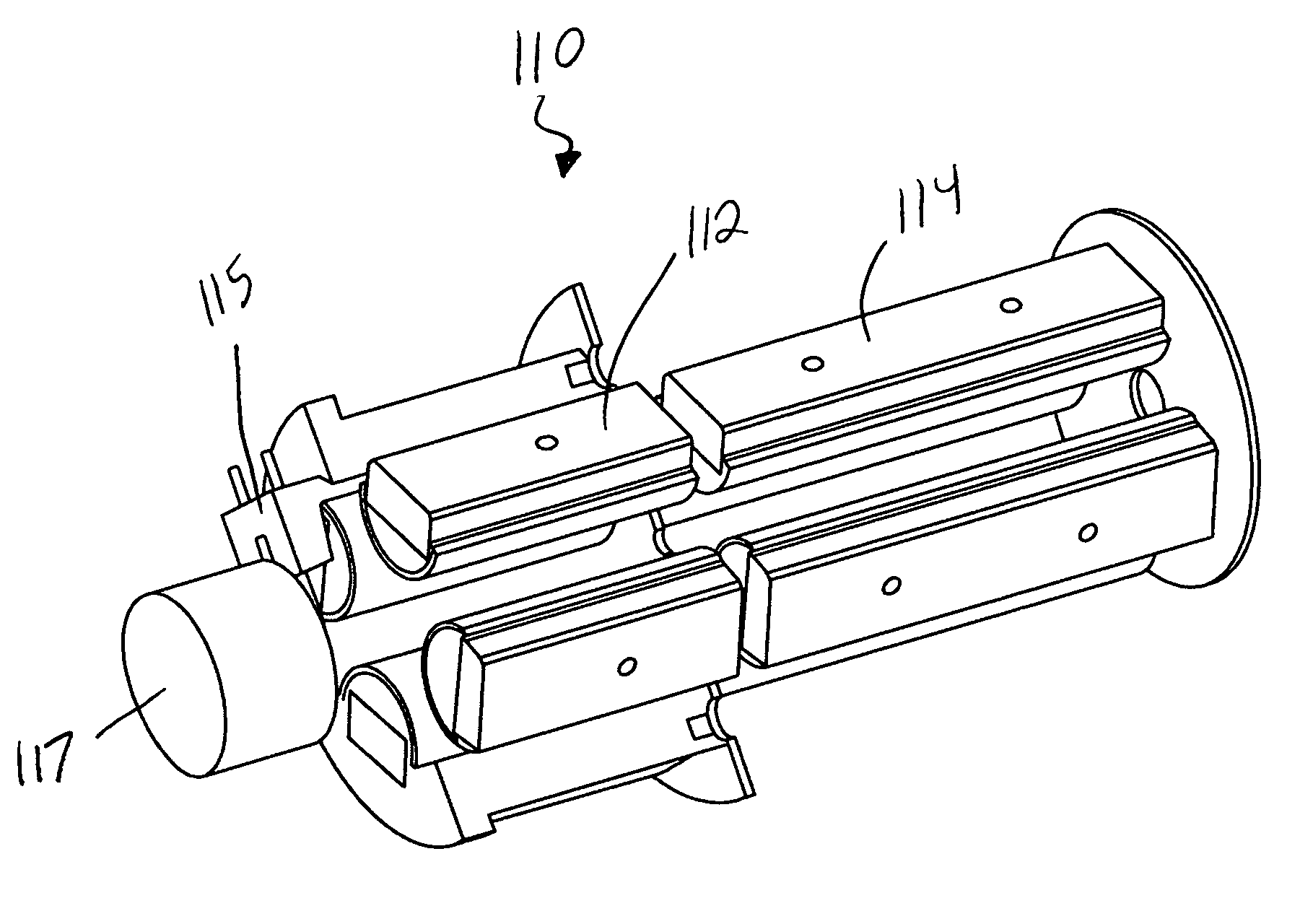

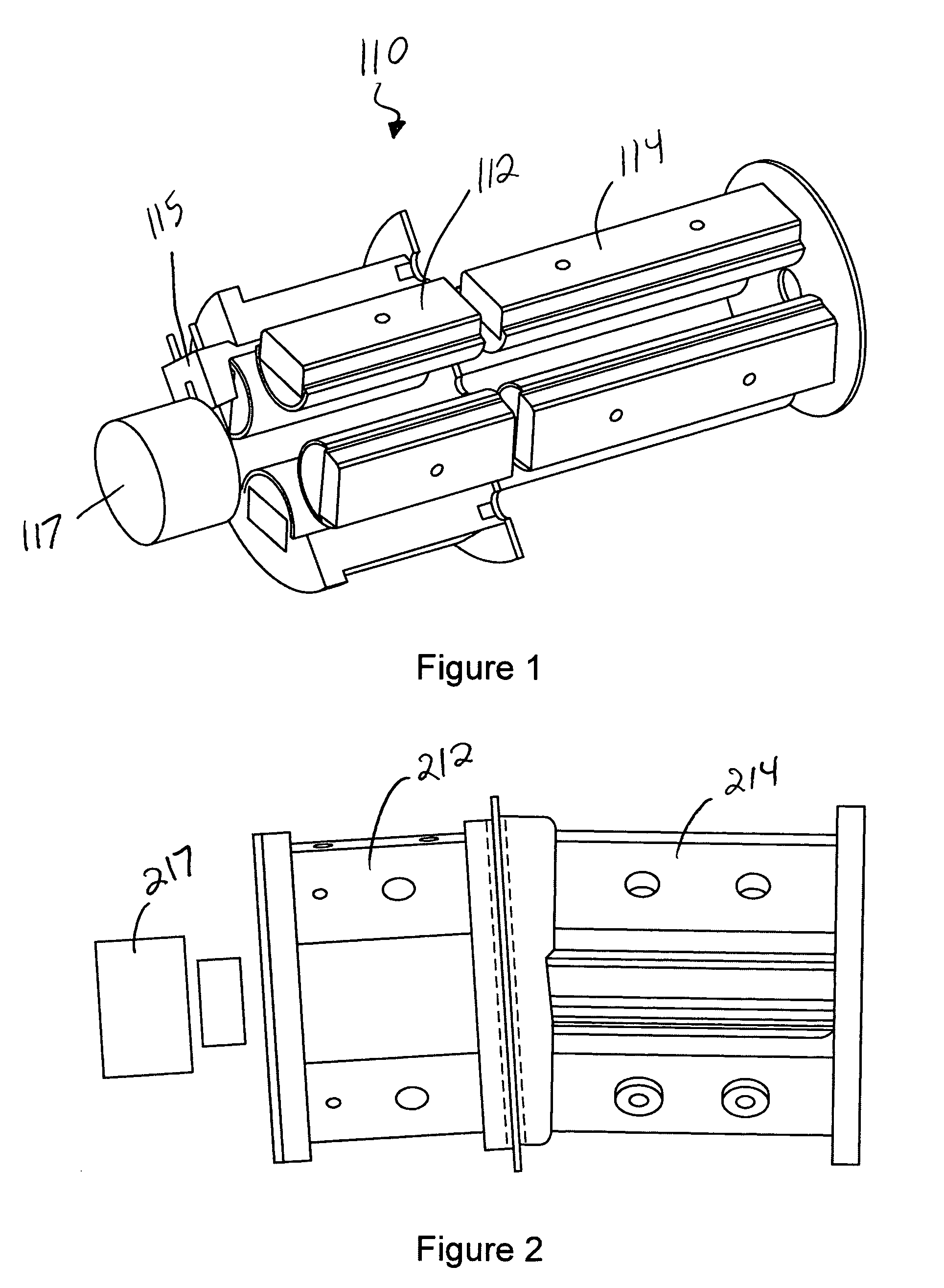

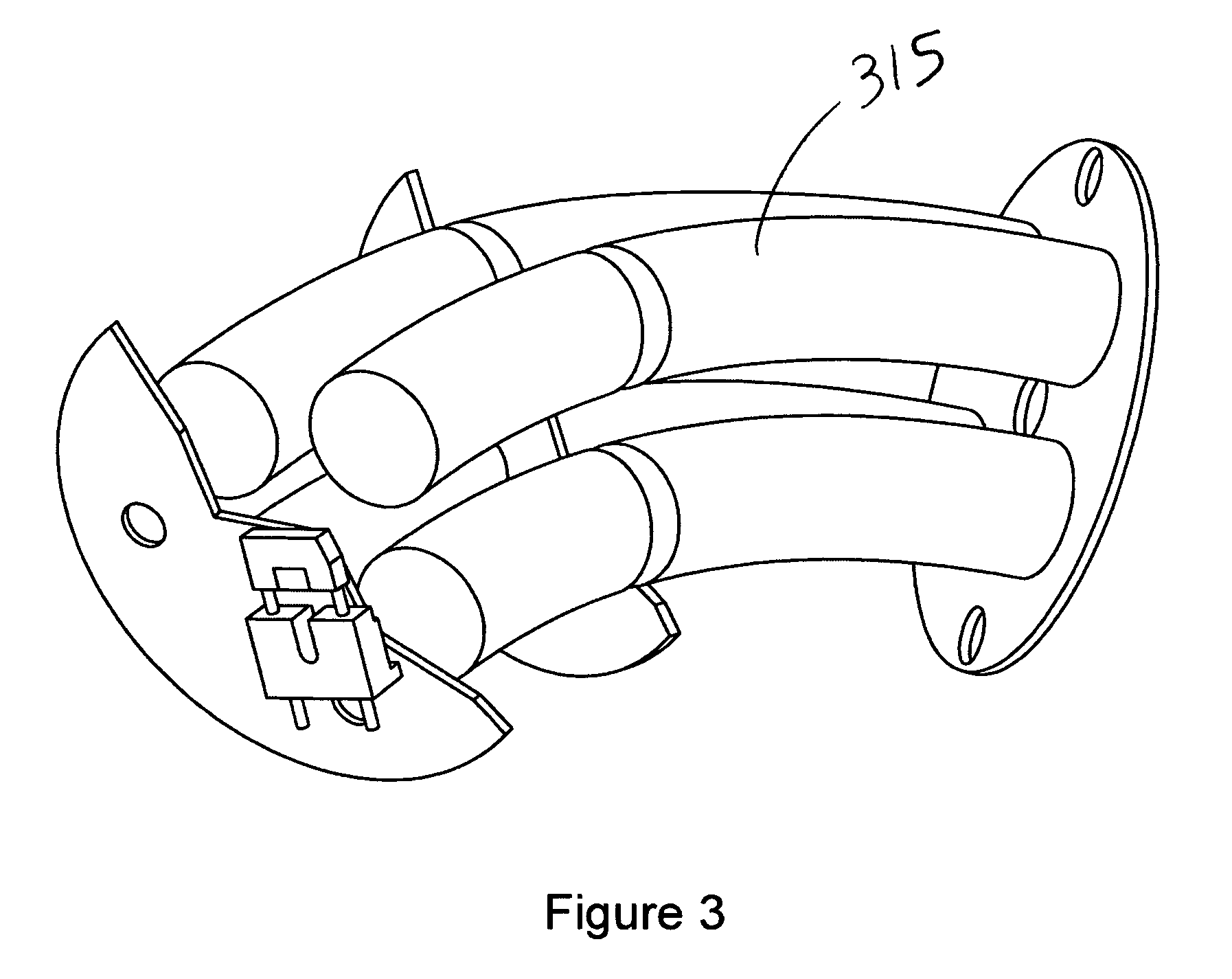

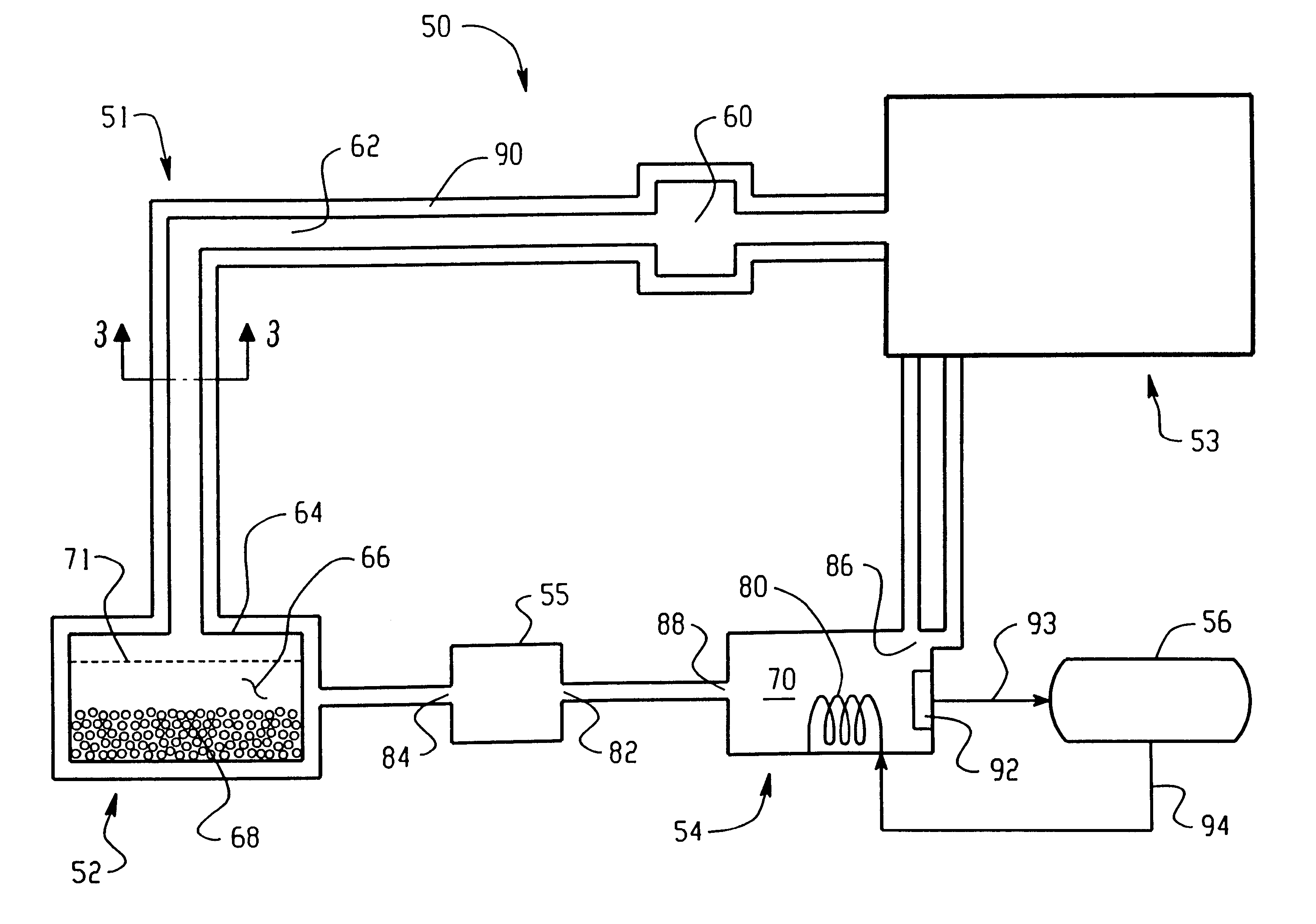

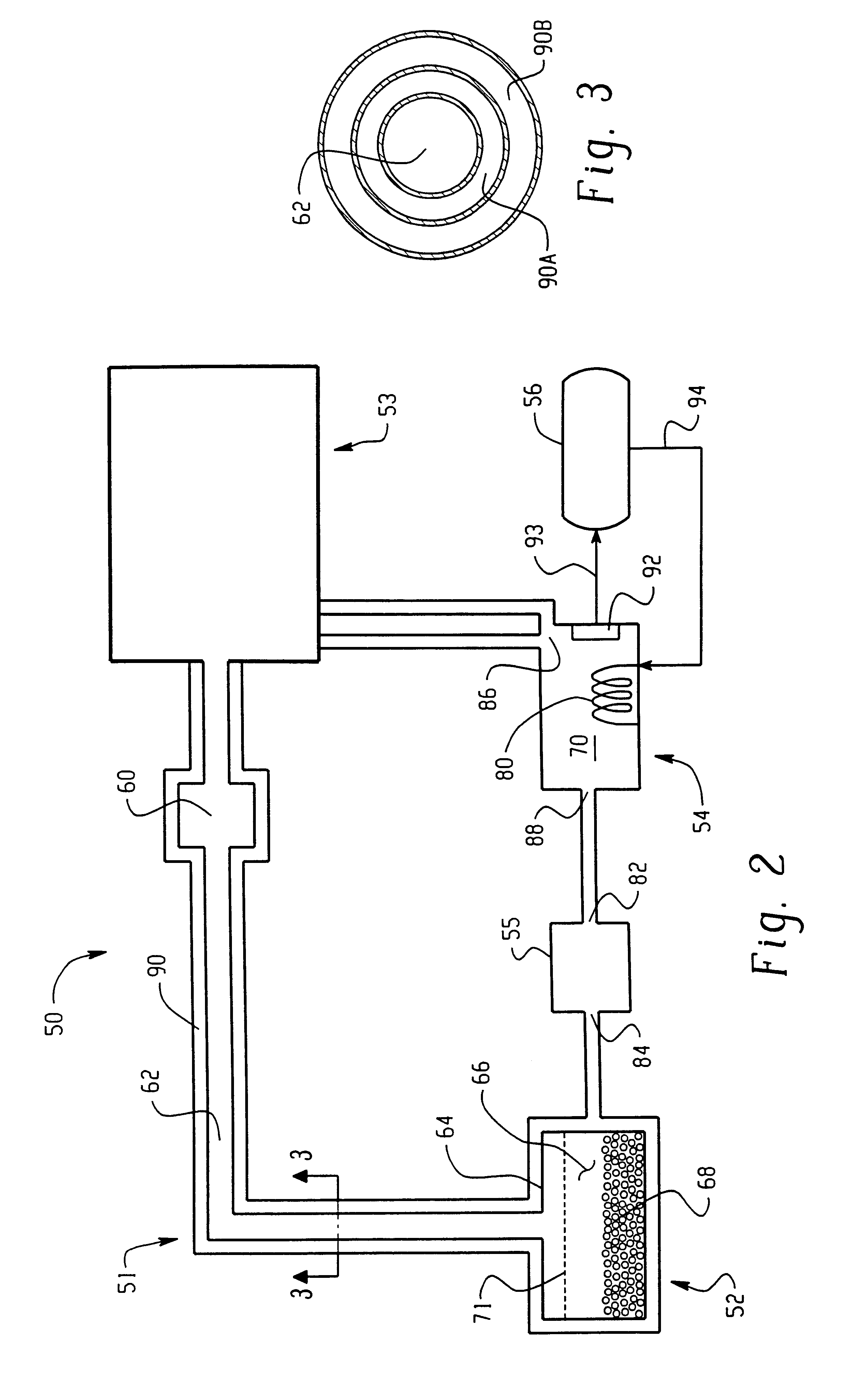

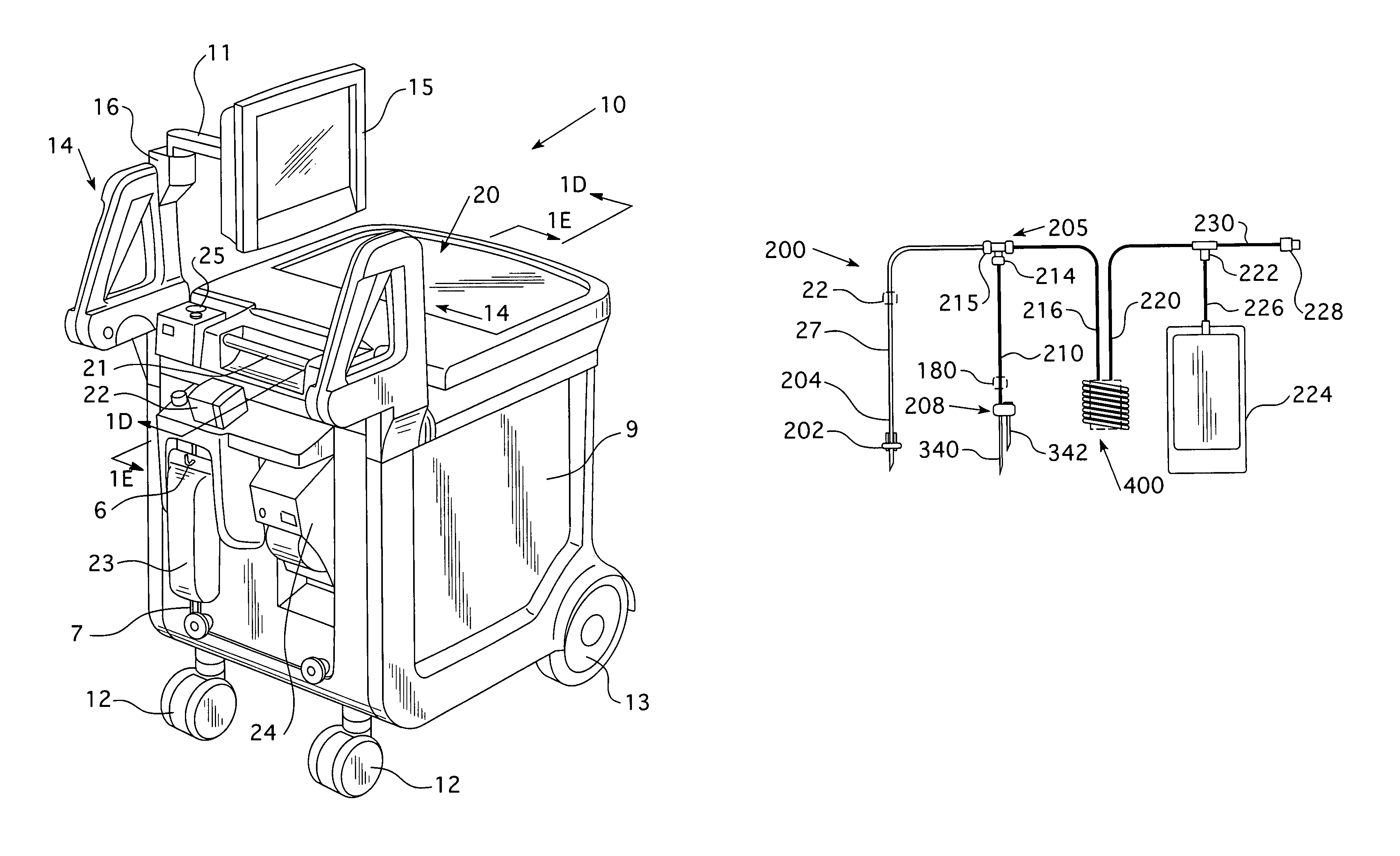

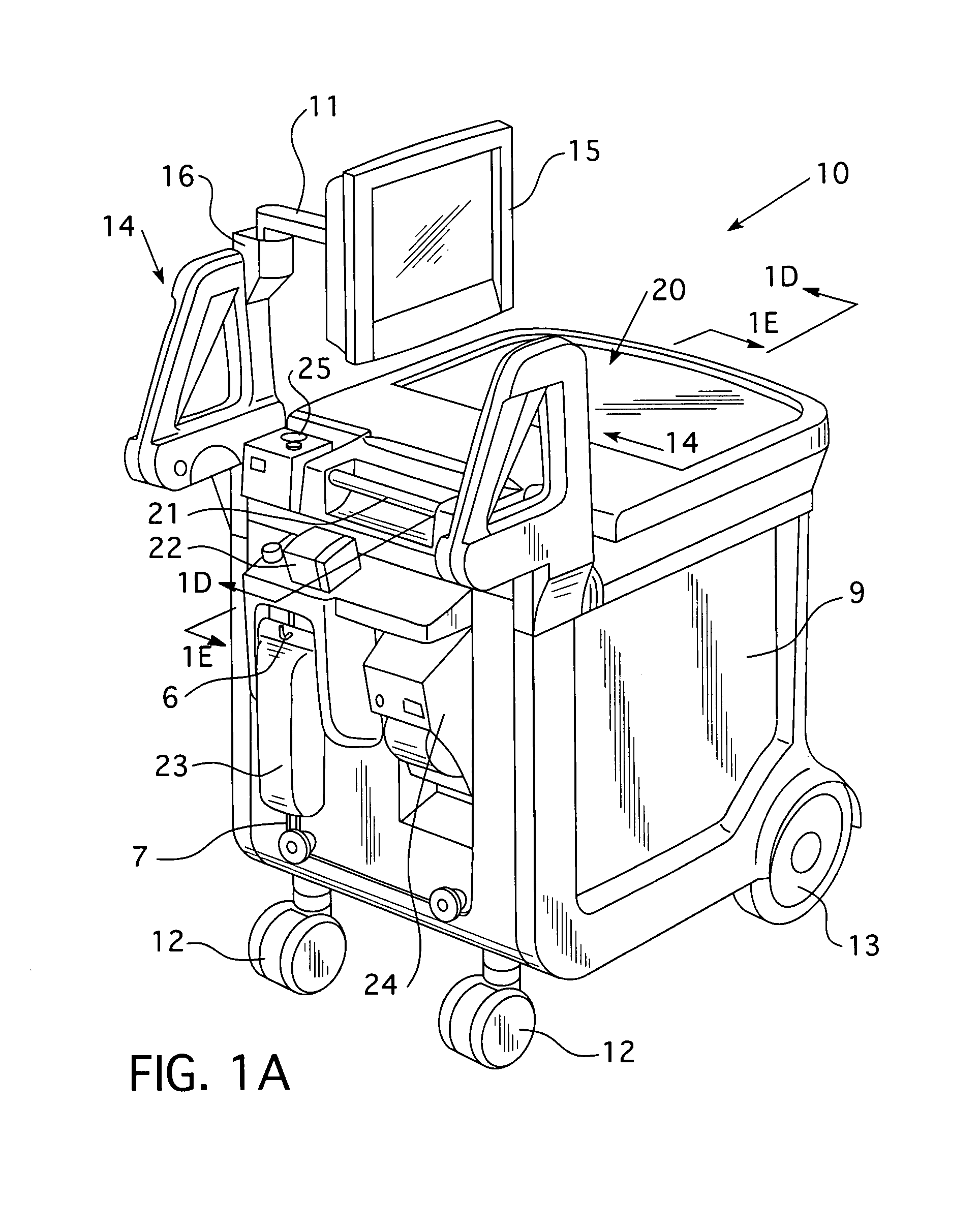

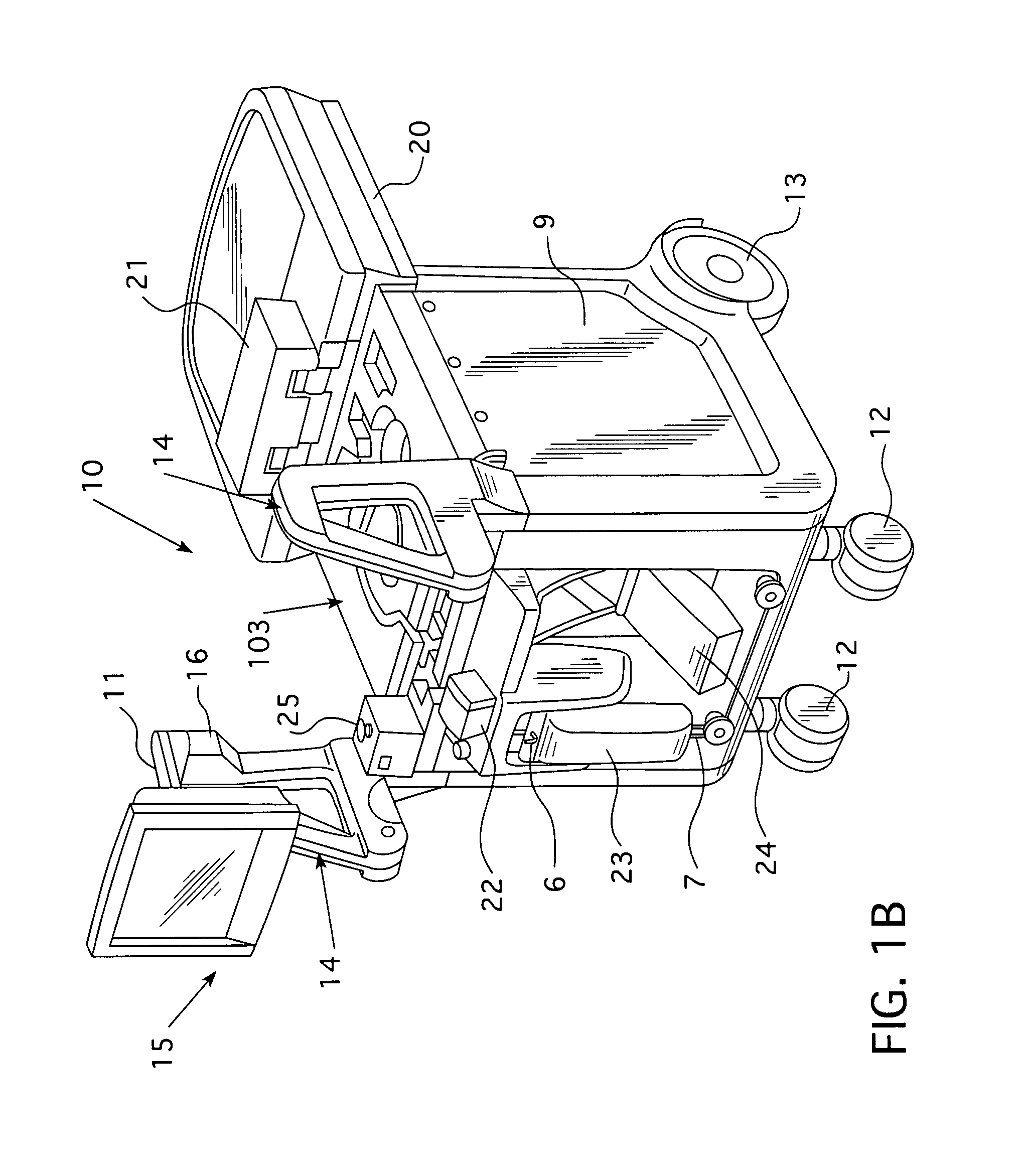

Radiopharmaceutical administration methods, fluid delivery systems and components thereof

ActiveUS20080177126A1Accurately calculating and delivering effective dosEasy extractionIn-vivo radioactive preparationsDrug and medicationsIonization chamberHandling system

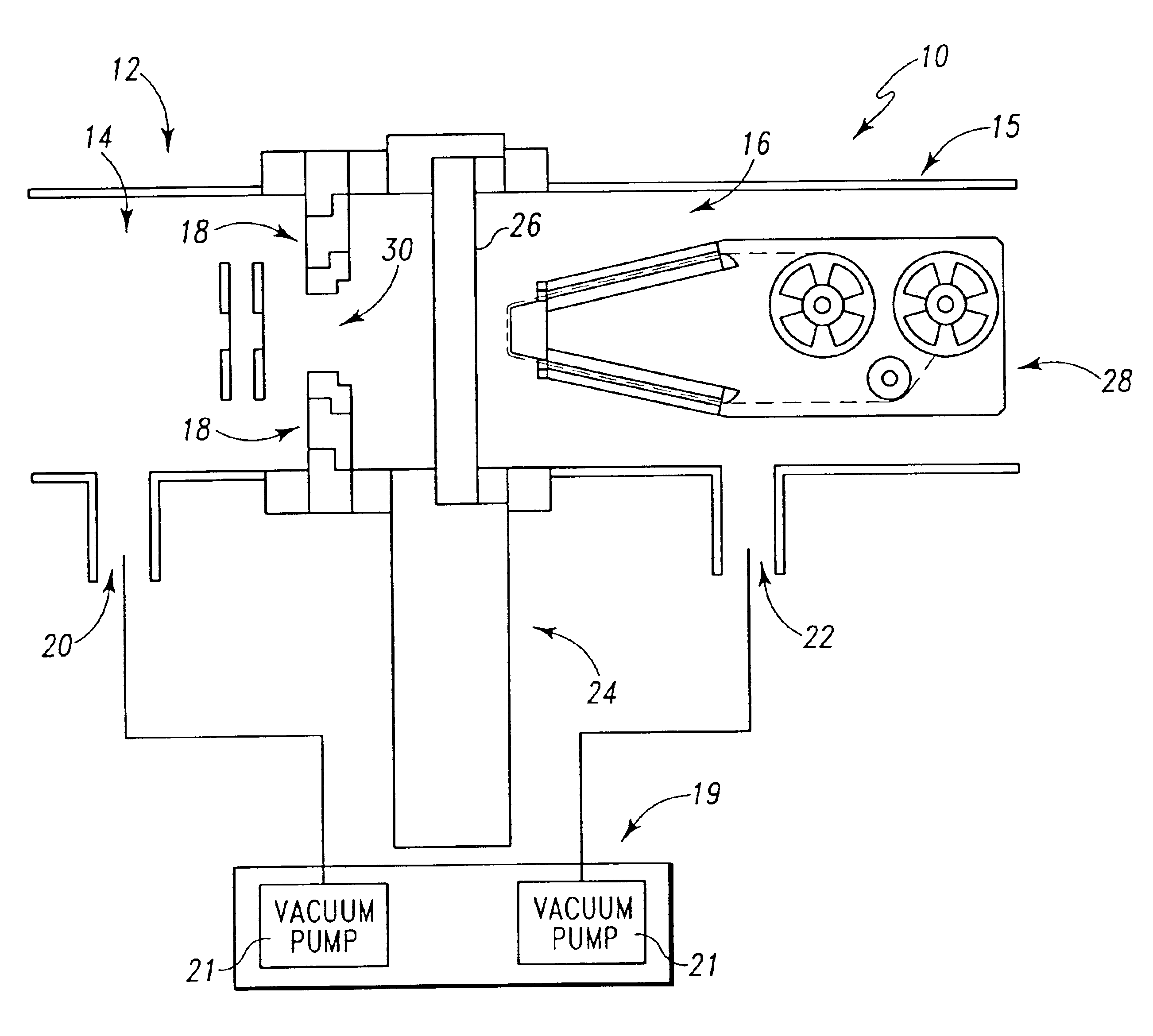

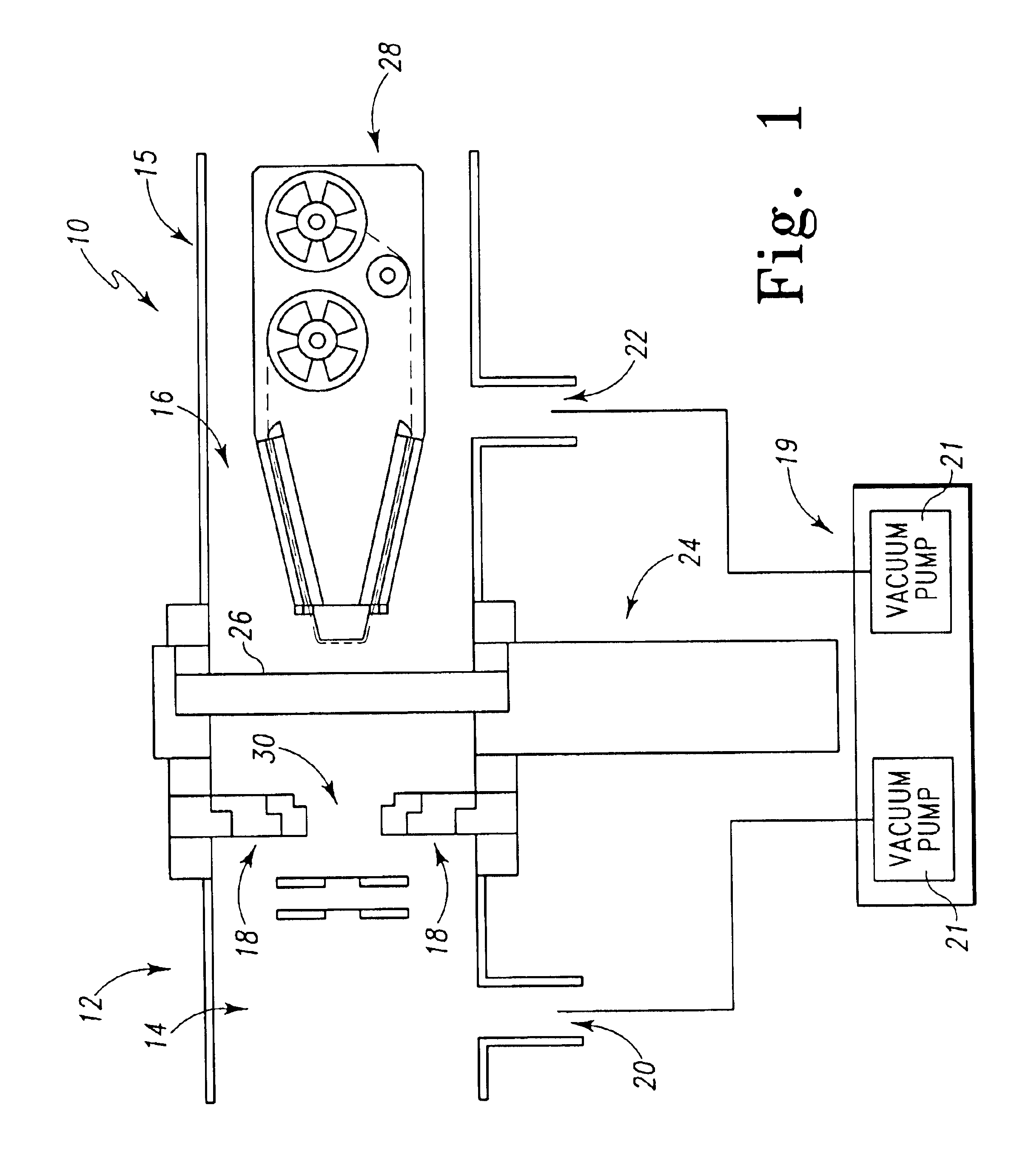

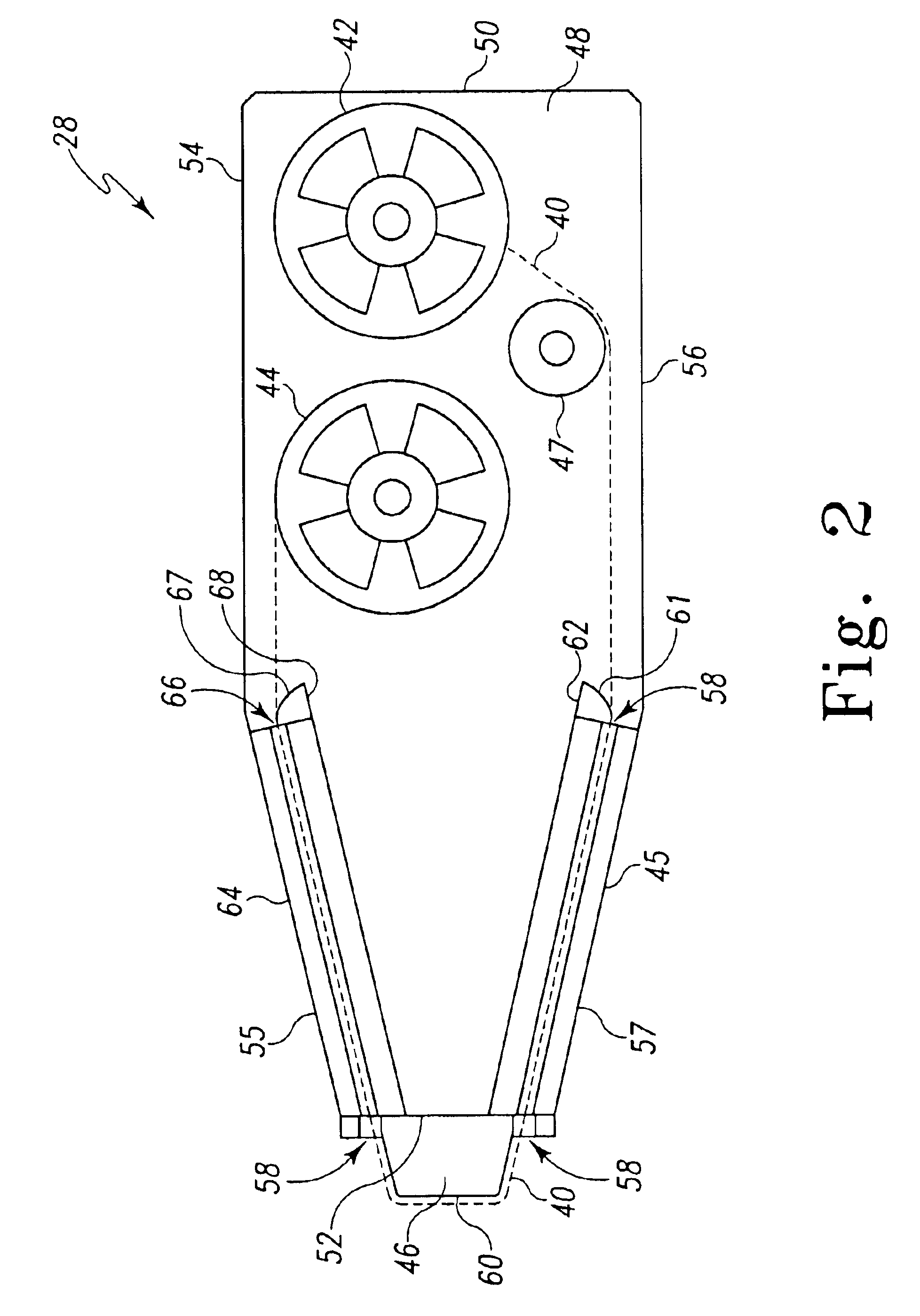

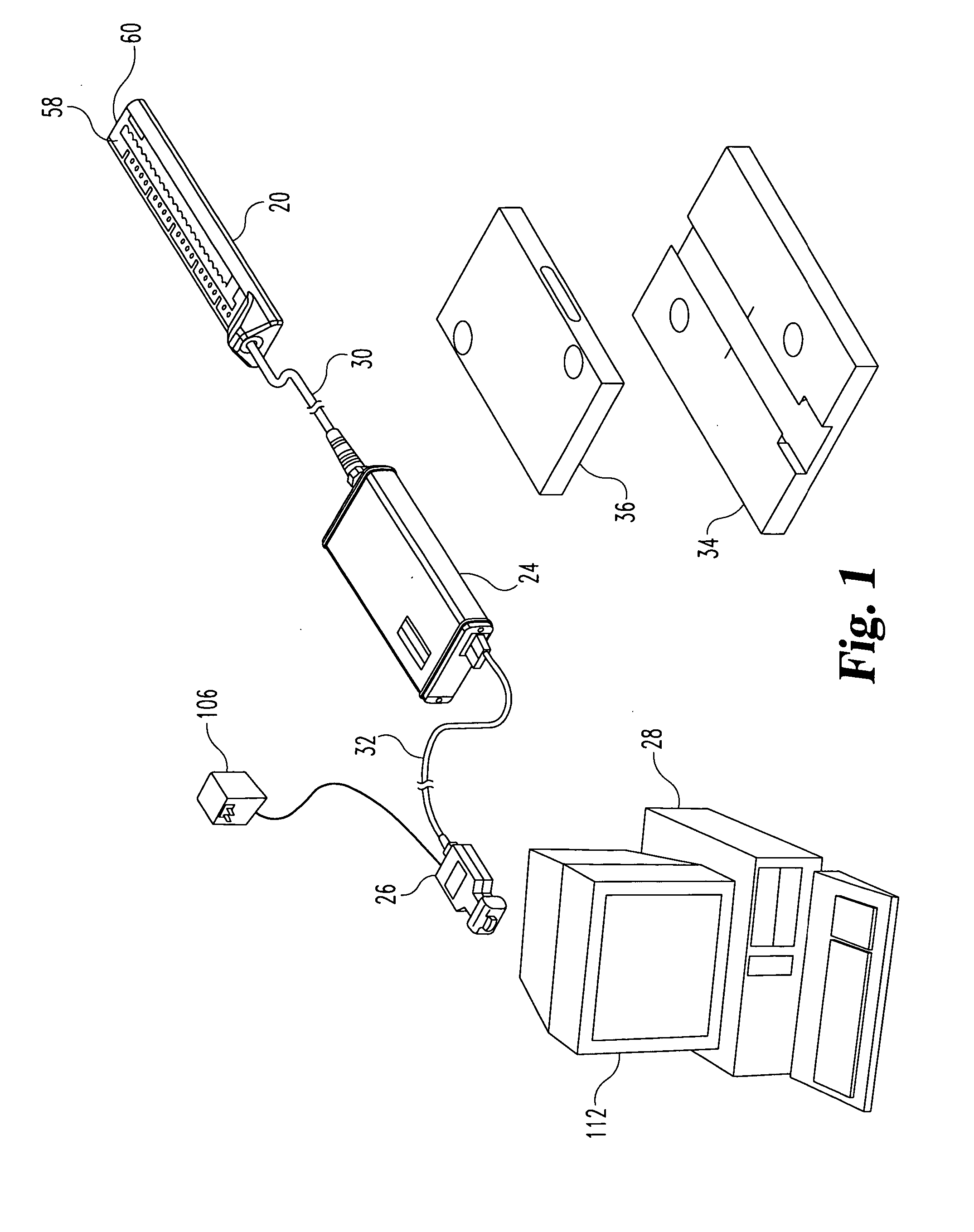

A fluid path set for a fluid delivery system includes a tube coil that is designed to optimally position one or more volumes of a pharmaceutical within an ionization chamber to optimally measure and prepare a pharmaceutical dose for administration to a patient. The tube coil may be maintained in a desired dimensional geometry by means of a core structure around which the tube coil is positioned. Novel developments in radiopharmaceutical administration methods and systems include, but are not limited to, the configuration and layout of a fluid path set for use in a fluid delivery system, arrangements for piercing and drawing fluid from a pharmaceutical container (such as a vial), arrangements for optimizing the positioning of a tube coil within an ionization chamber, a handling system for transporting vial shields that maintain an operator's hand and fingers at a safe distance from a pharmaceutical vial, a method for calibrating a radiopharmaceutical delivery system in which the difference between the expected and measured activities of two radioisotopes are used to calculate an estimated error in the measured activity of a third radioisotope and a vial access system that ensures an optimal draw of fluid from a radiopharmaceutical container.

Owner:BAYER HEALTHCARE LLC

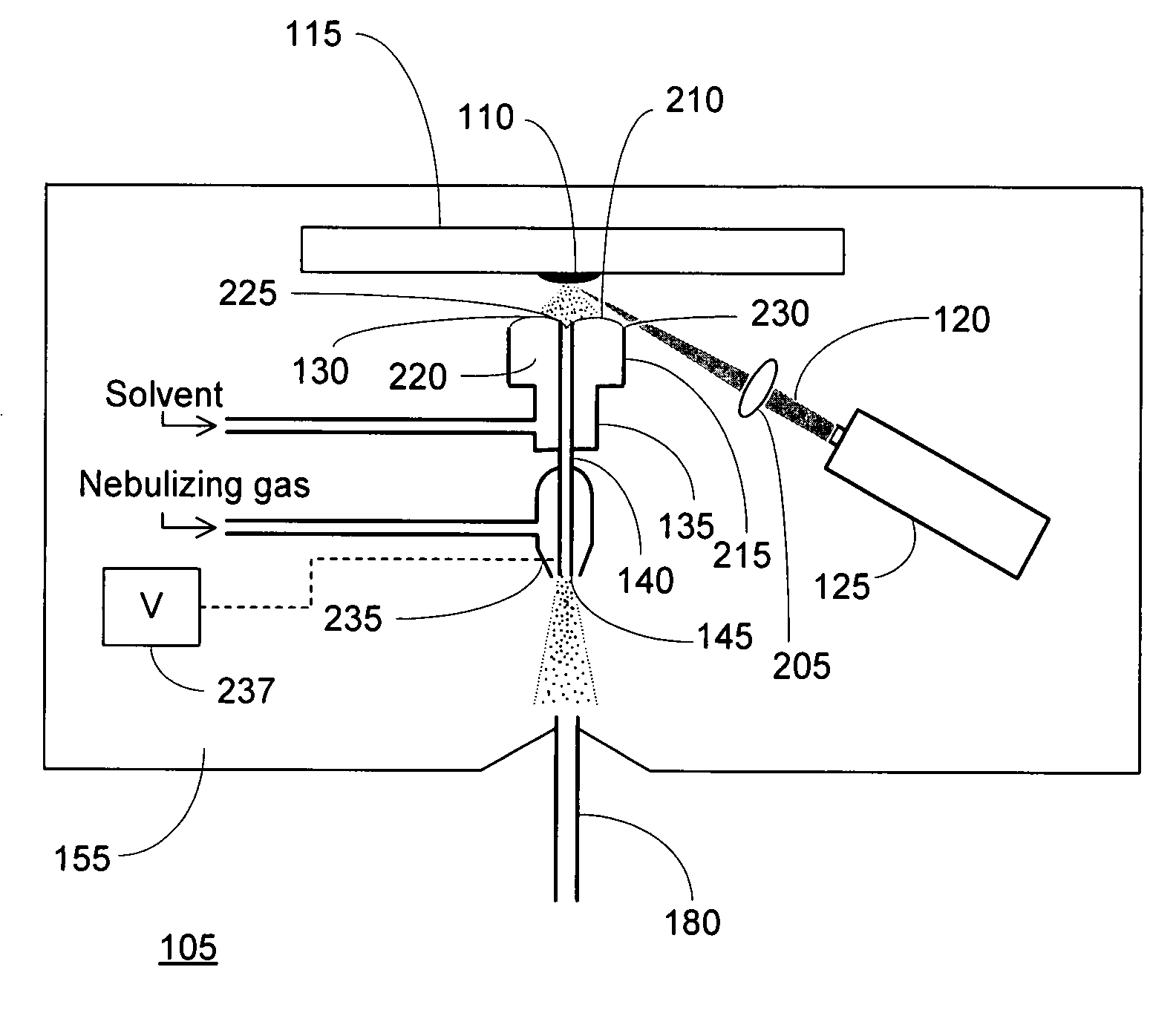

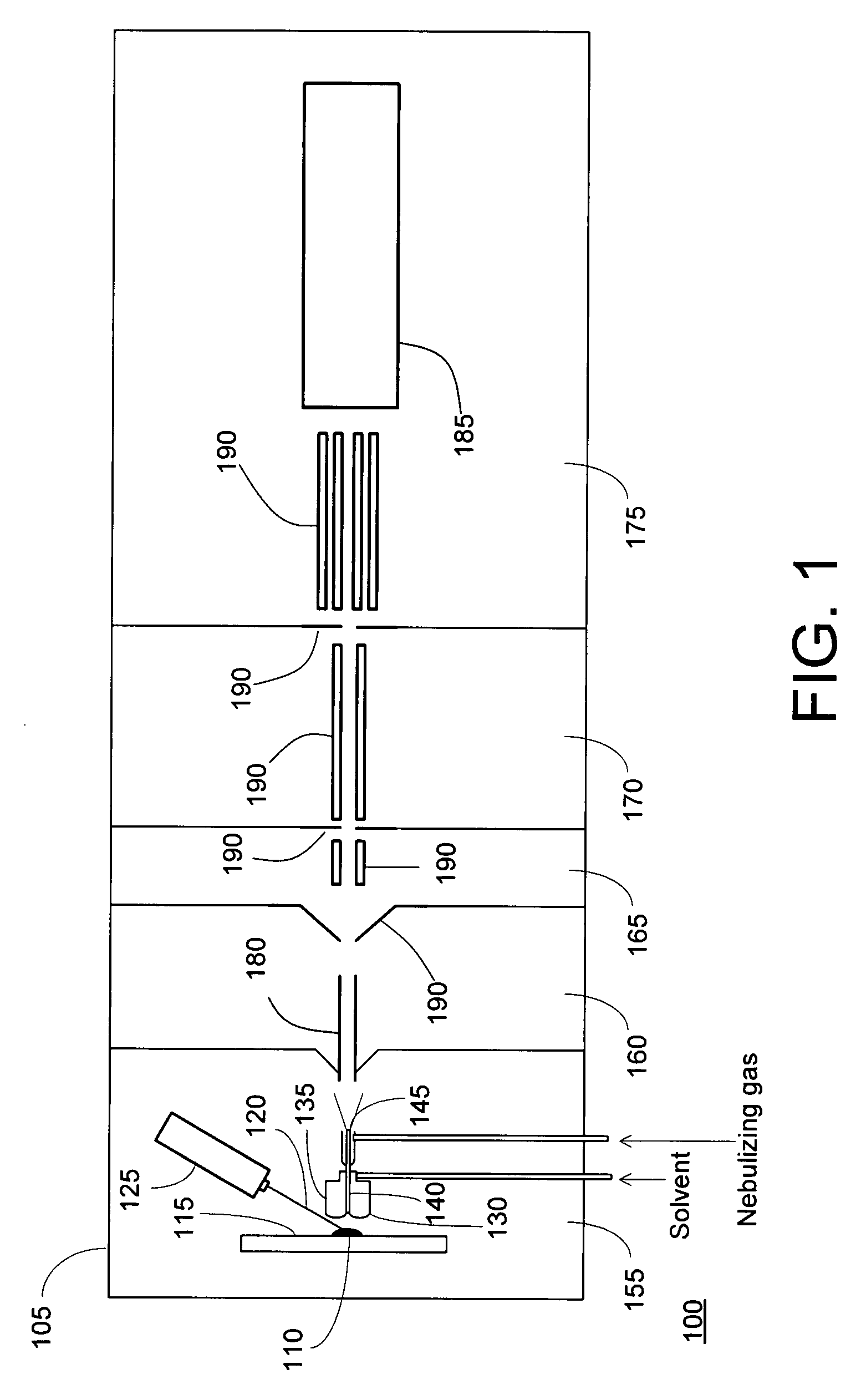

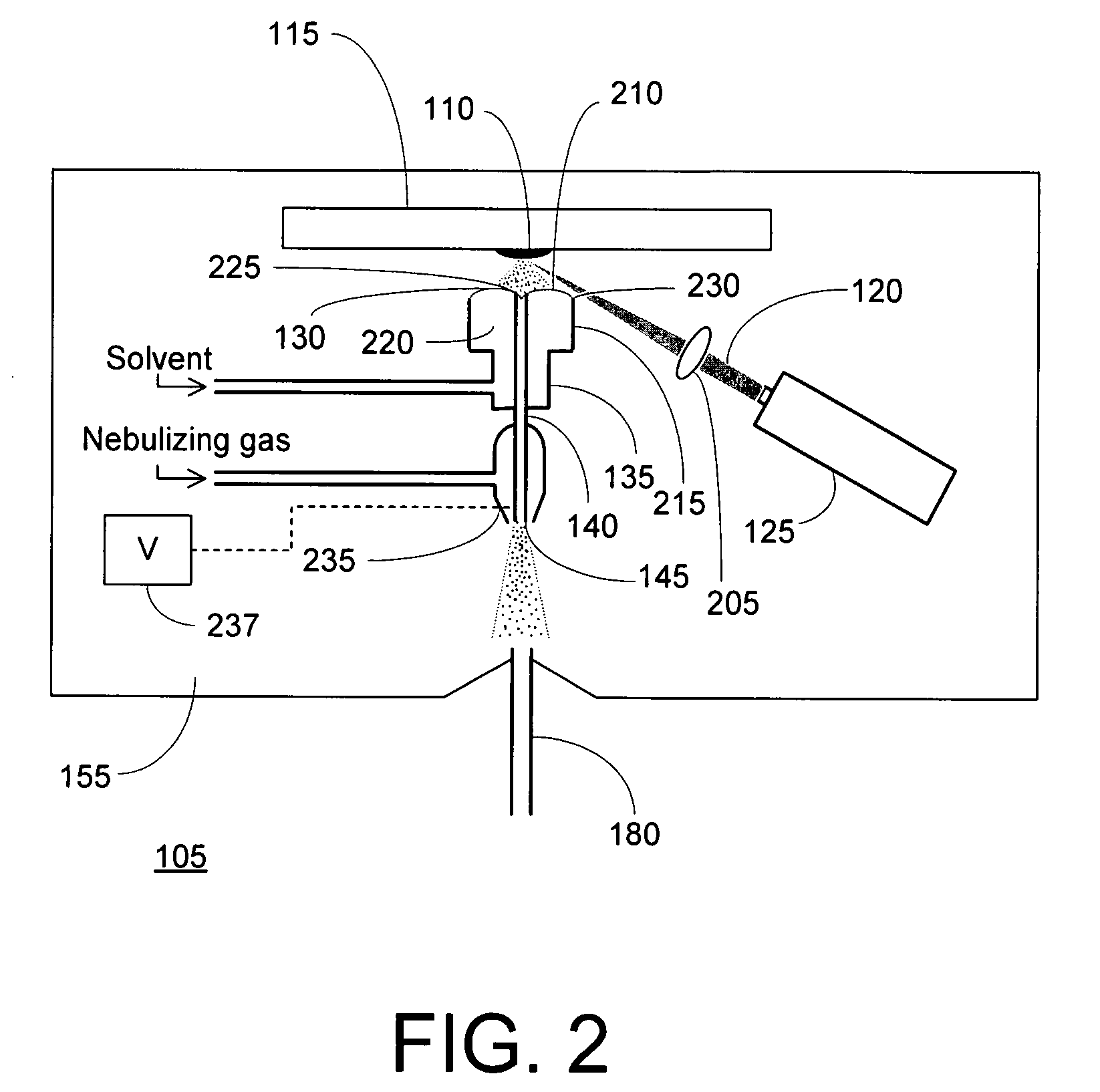

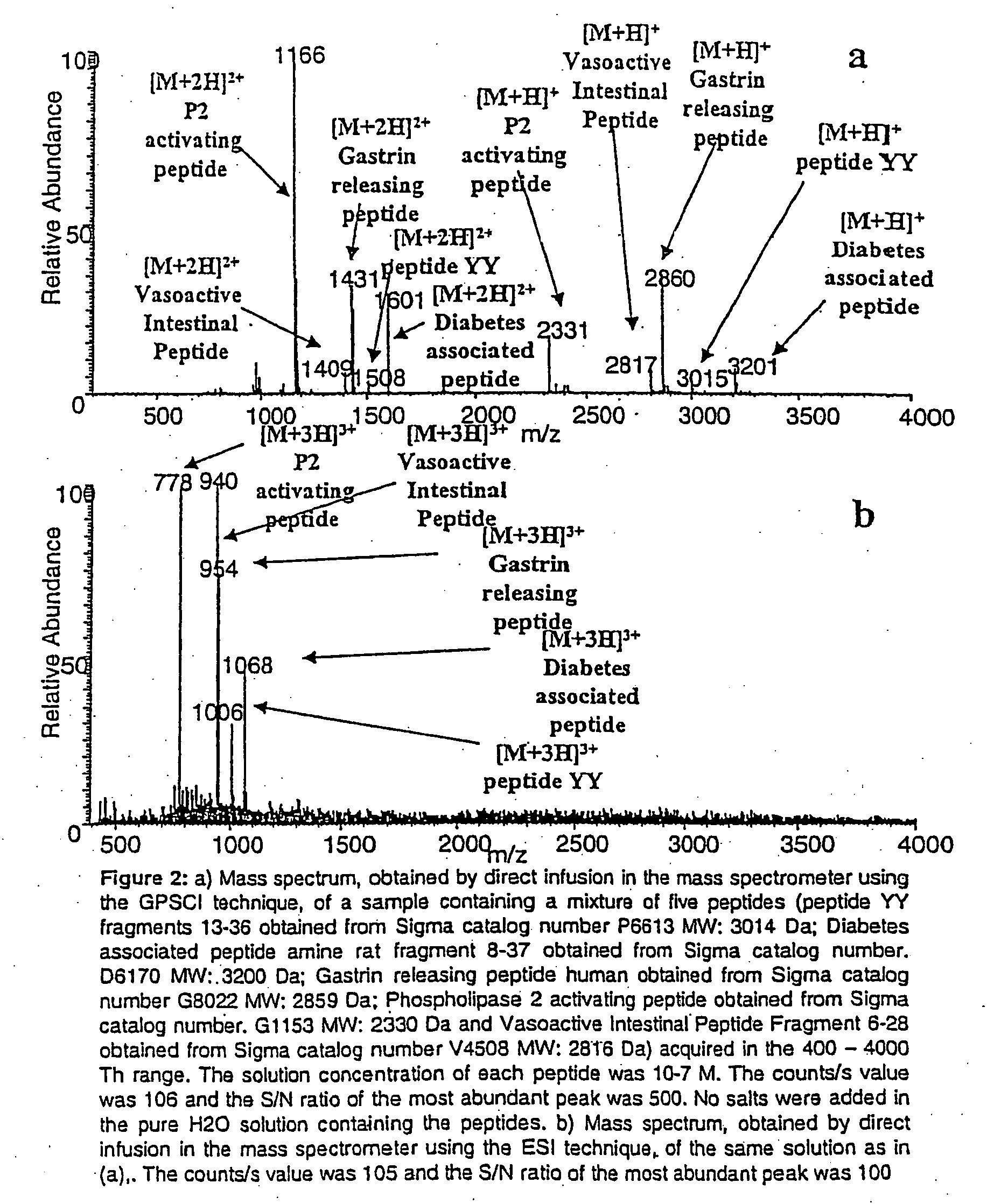

Laser desorption - electrospray ion (ESI) source for mass spectrometers

InactiveUS20080272294A1Minimize dilutionMaterial analysis by optical meansIon sources/gunsDesorptionElectrospray ionization

An ion source is disclosed for forming multiply-charged analyte ions from a solid sample. A beam of pulsed radiation is directed onto a portion of the sample to desorb analyte molecules. A retaining structure holding a solvent volume is positioned proximate the sample. Desorbed analyte molecules contact a free surface of the solvent and pass into solution. The solution is then conveyed through an outlet passageway to an electrospray apparatus, which introduces a spray of charged solvent droplets into an ionization chamber.

Owner:THERMO FINNIGAN

Neutron and gamma detector using an ionization chamber with an integrated body and moderator

InactiveUS20060138340A1Increase detector sensitivityEliminate the problemElectric discharge tubesMaterial analysis by optical meansIonization chamberDetector array

A detector for detecting neutrons and gamma radiation includes a cathode that defines an interior surface and an interior volume. A conductive neutron-capturing layer is disposed on the interior surface of the cathode and a plastic housing surrounds the cathode. A plastic lid is attached to the housing and encloses the interior volume of the cathode forming an ionization chamber, into the center of which an anode extends from the plastic lid. A working gas is disposed within the ionization chamber and a high biasing voltage is connected to the cathode. Processing electronics are coupled to the anode and process current pulses which are converted into Gaussian pulses, which are either counted as neutrons or integrated as gammas, in response to whether pulse amplitude crosses a neutron threshold. The detector according to the invention may be readily fabricated into single or multilayer detector arrays.

Owner:LOS ALAMOS NATIONAL SECURITY

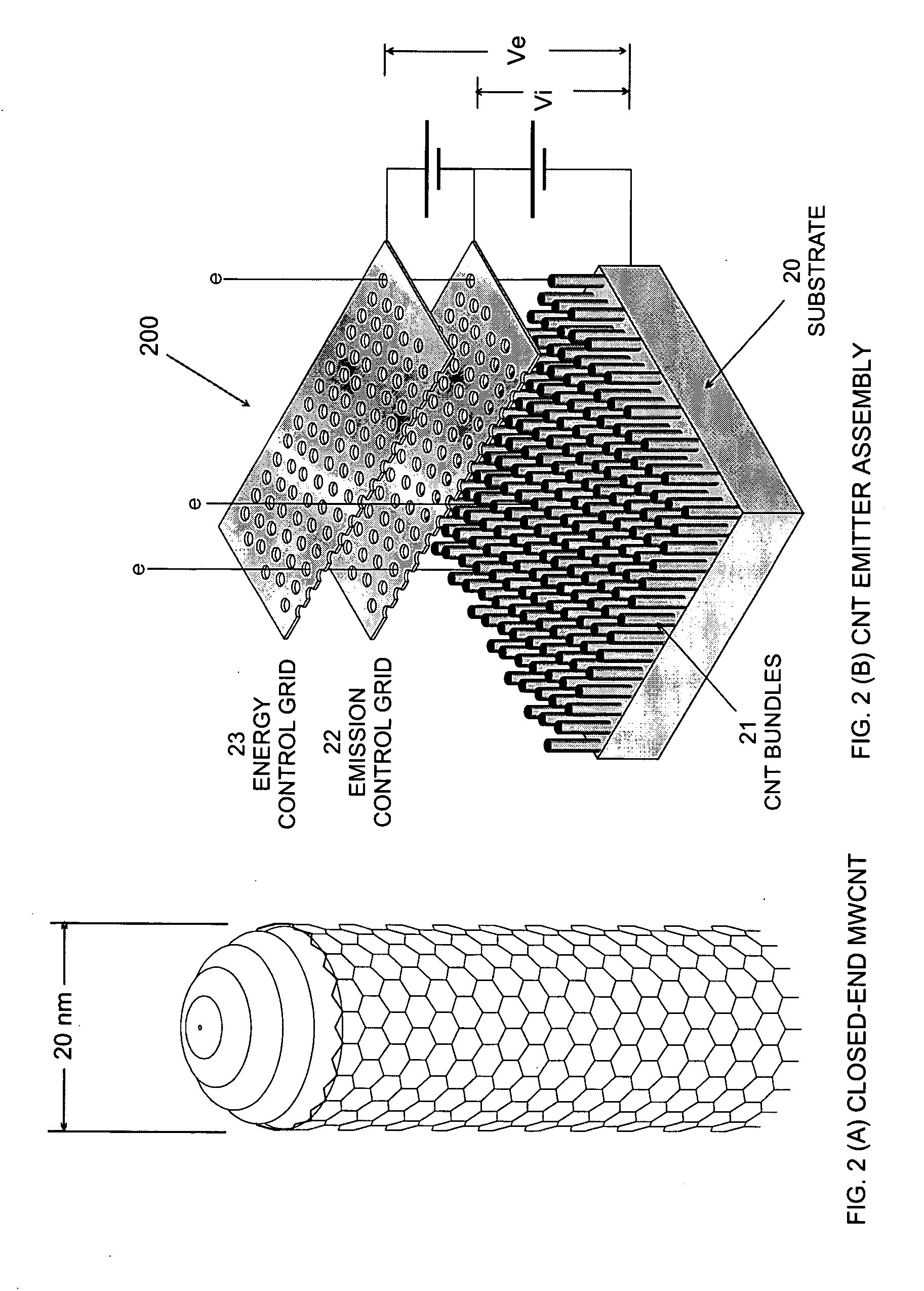

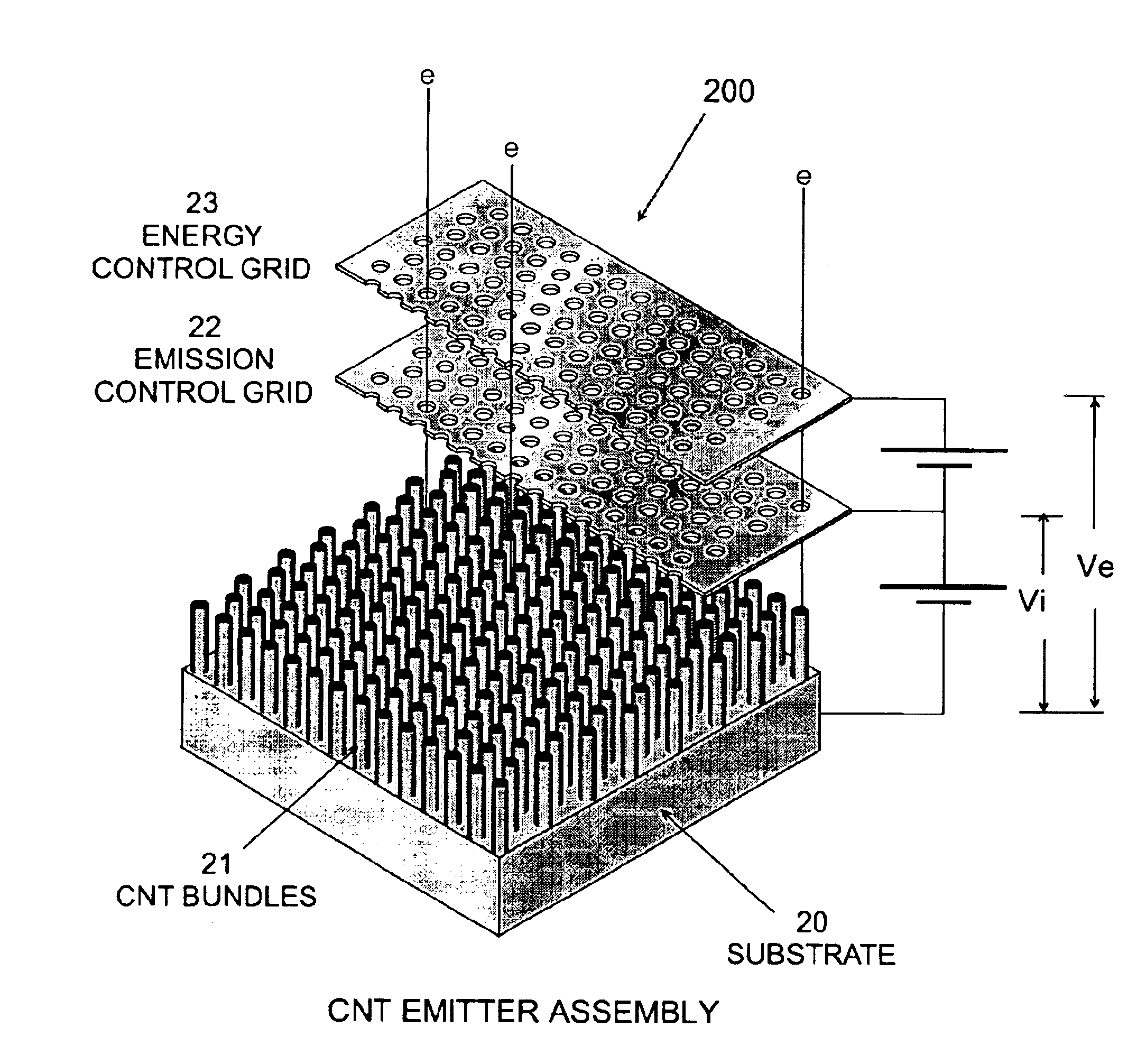

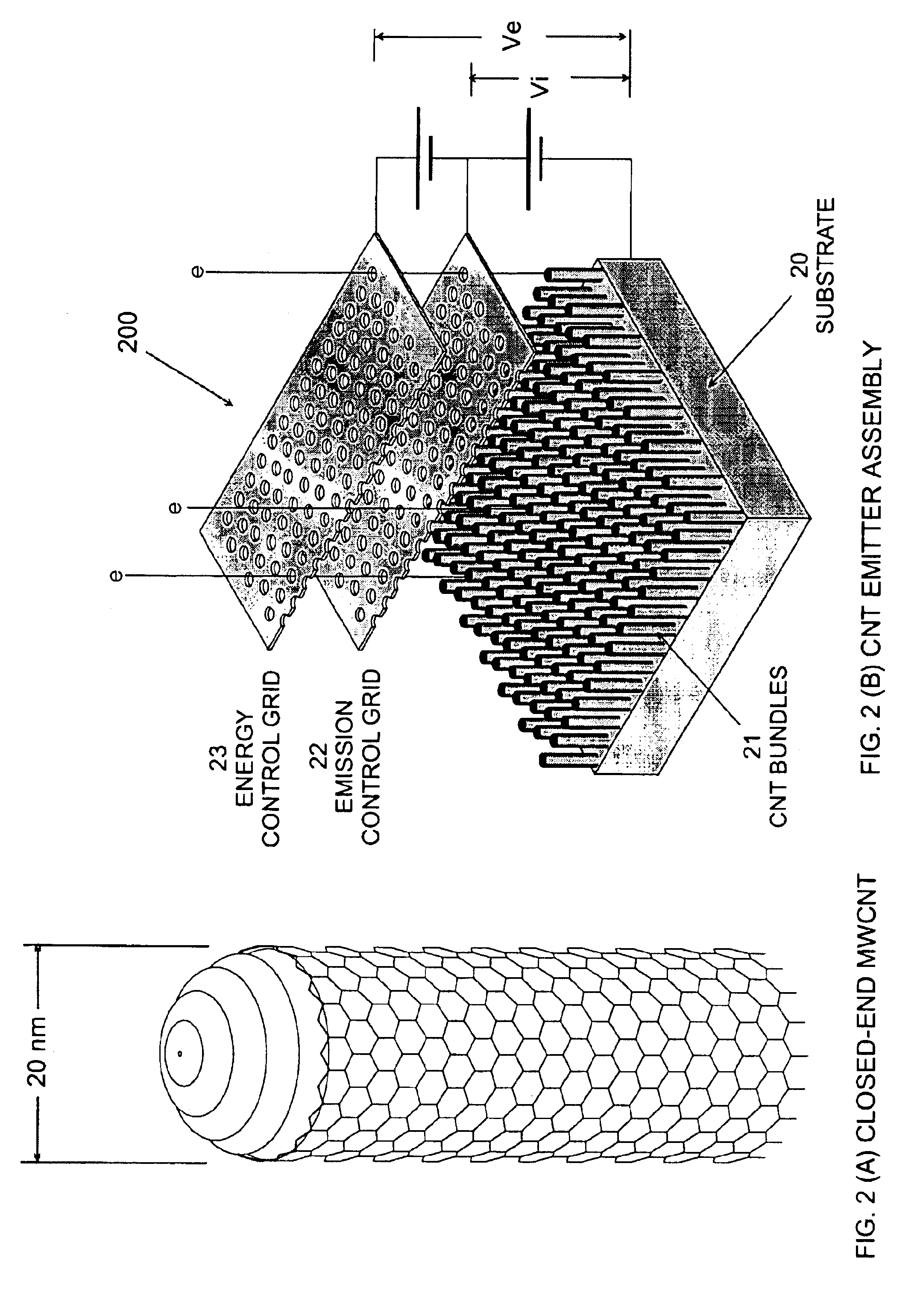

Carbon nanotube electron ionization sources

InactiveUS20050098720A1Reduce in quantityEasy CalibrationMaterial nanotechnologyNanoinformaticsCarbon nanotubeIonization chamber

Owner:THERMO ELECTRON A DE

Ionization source for mass spectrometry analysis

ActiveUS20060145089A1Samples introduction/extractionMaterial analysis by optical meansGas phaseMass analyzer

A new ionization source named Surface Activated Chemical Ionization (SACI) has been discovered and used to improve the sensitivity of the mass spectrometer. According to this invention the ionization chamber of a mass spectrometer is heated and contains a physical new surface to improve the ionization process. The analyte neutral molecules that are present in gas phase are ionized on this surface. The surface can be made of various materials and may also chemically modified so to bind different molecules. This new ionization source is able to generate ions with high molecular weight and low charge, an essential new key feature of the invention so to improve sensitivity and reduce noise. The new device can be especially used for the analysis of proteins, peptides and other macromolecules. The new invention overcomes some of the well known and critical limitations of the Electrospray (ESI) and Matrix Assisted Laser Desorption Ionization (MALDI) mass spectrometric techniques.

Owner:UNIV DELGI STUDI DI MILANO

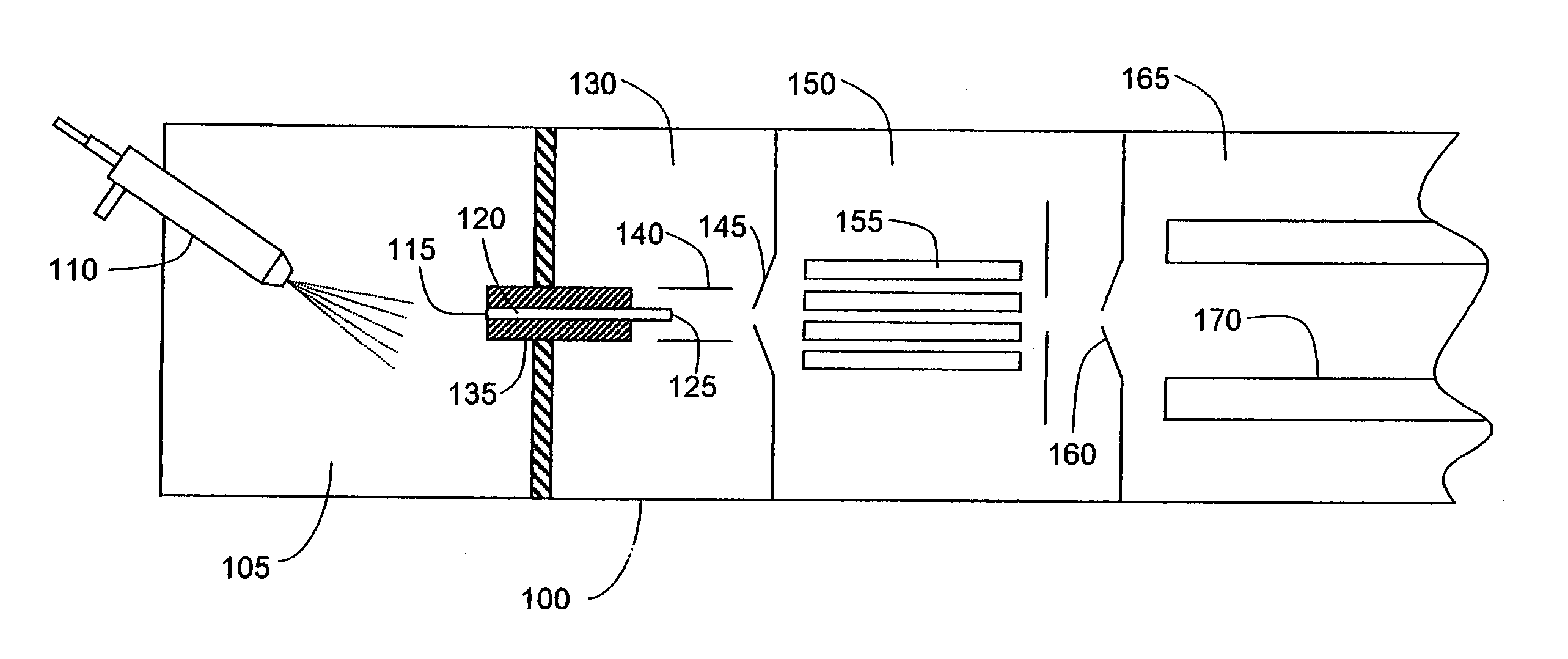

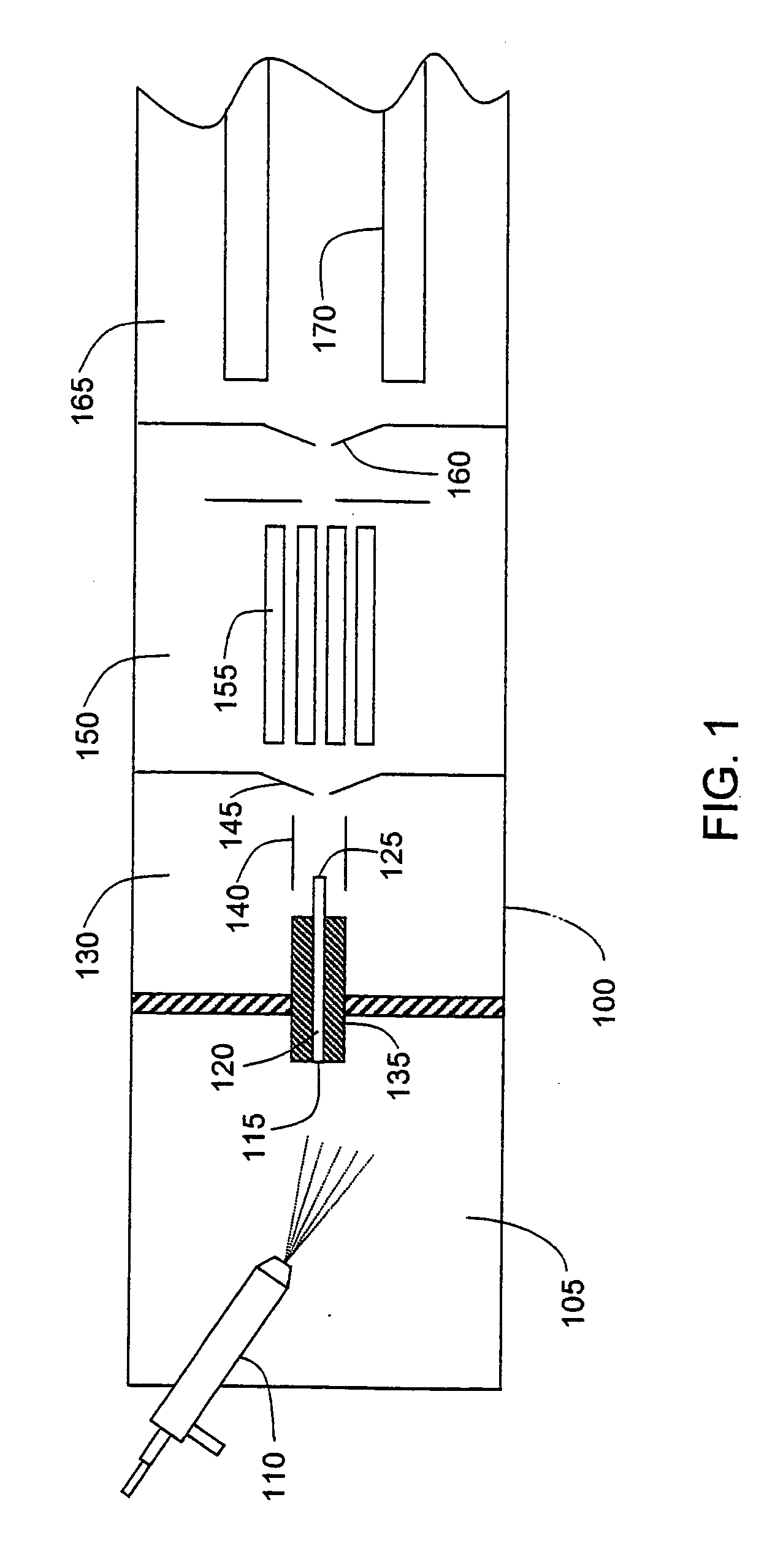

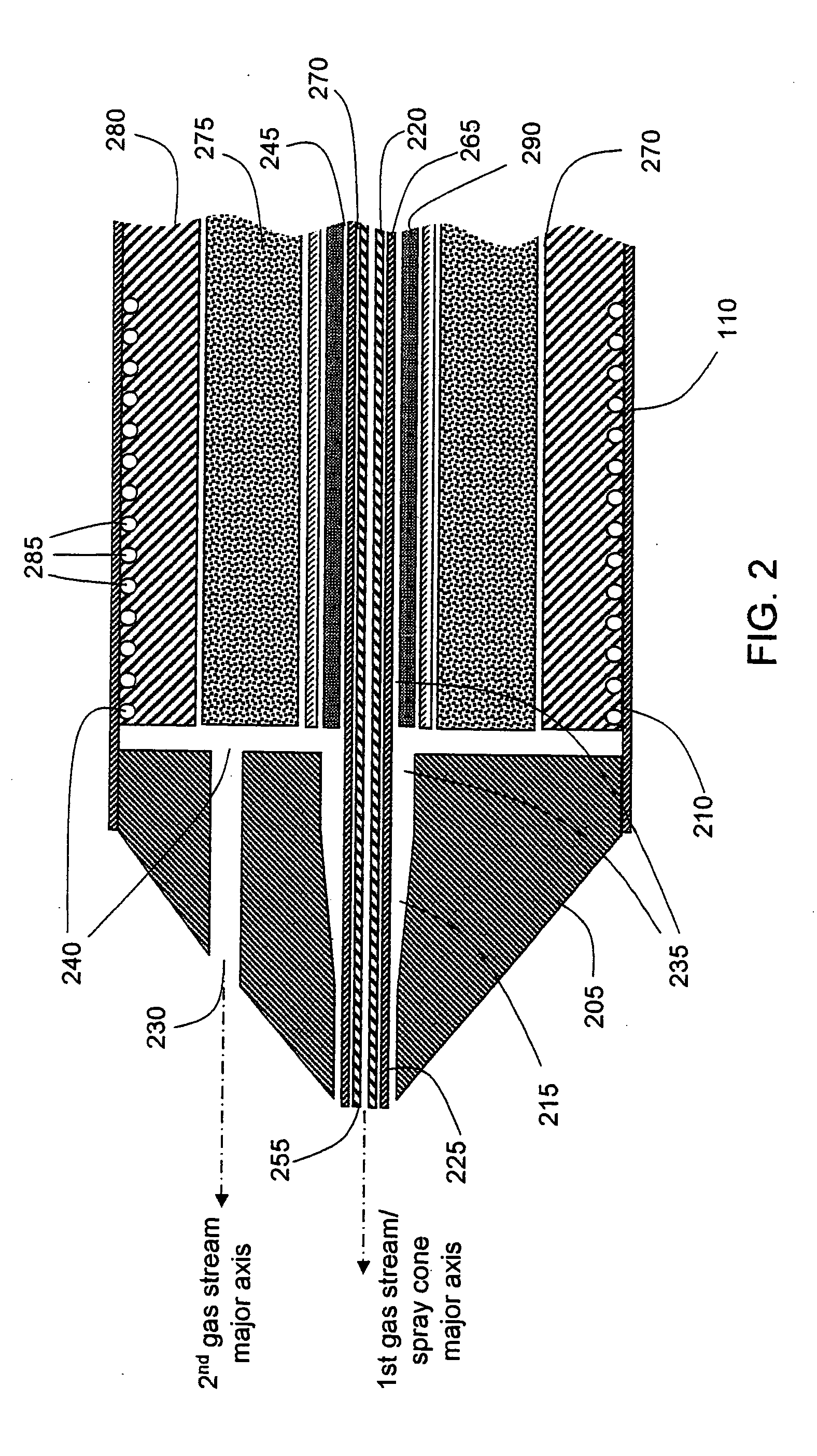

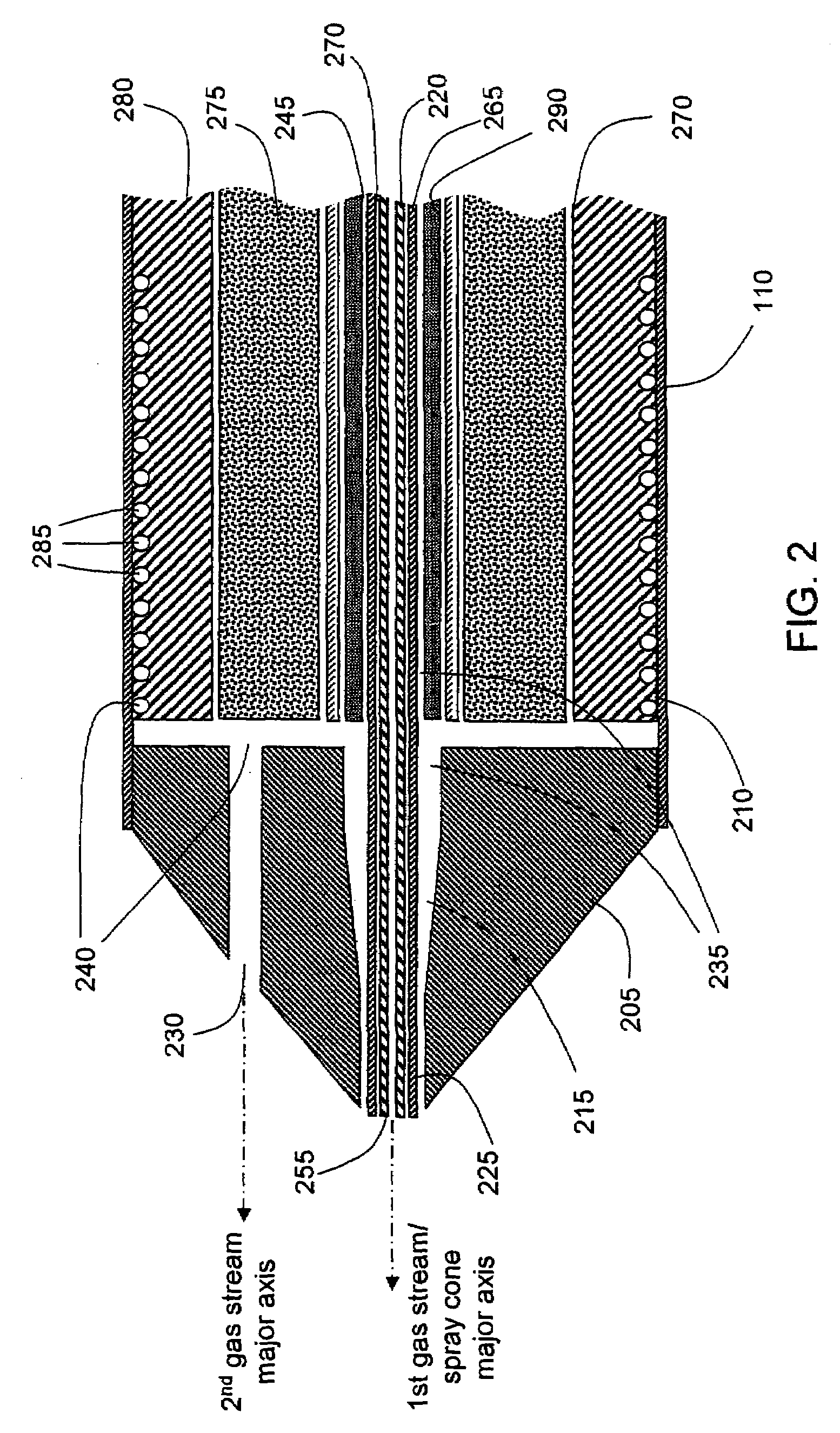

Electrospray ion source apparatus

ActiveUS20050258358A1Easy to produceIncreasing droplet desolvation rateClosuresSamples introduction/extractionAnalyteIonization chamber

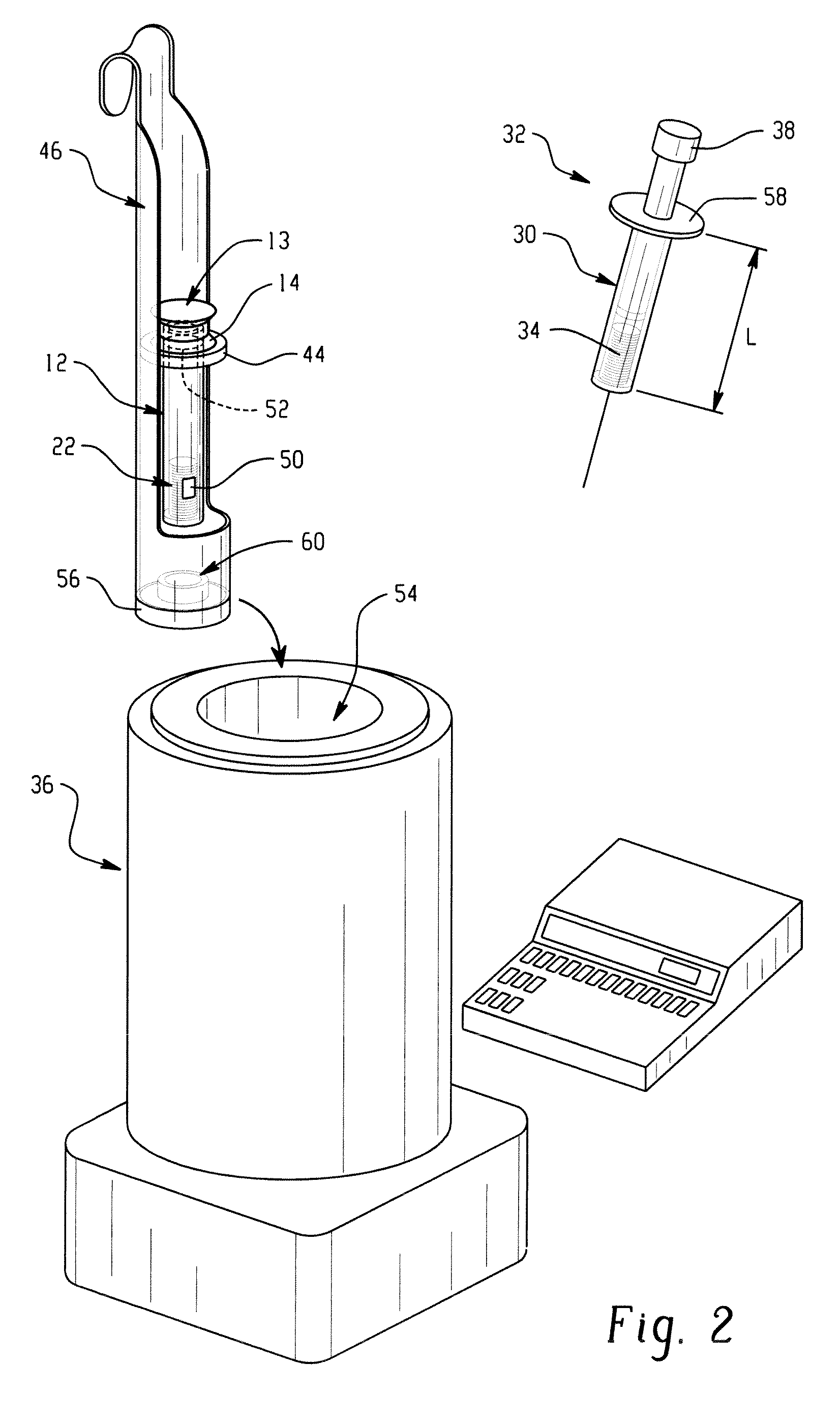

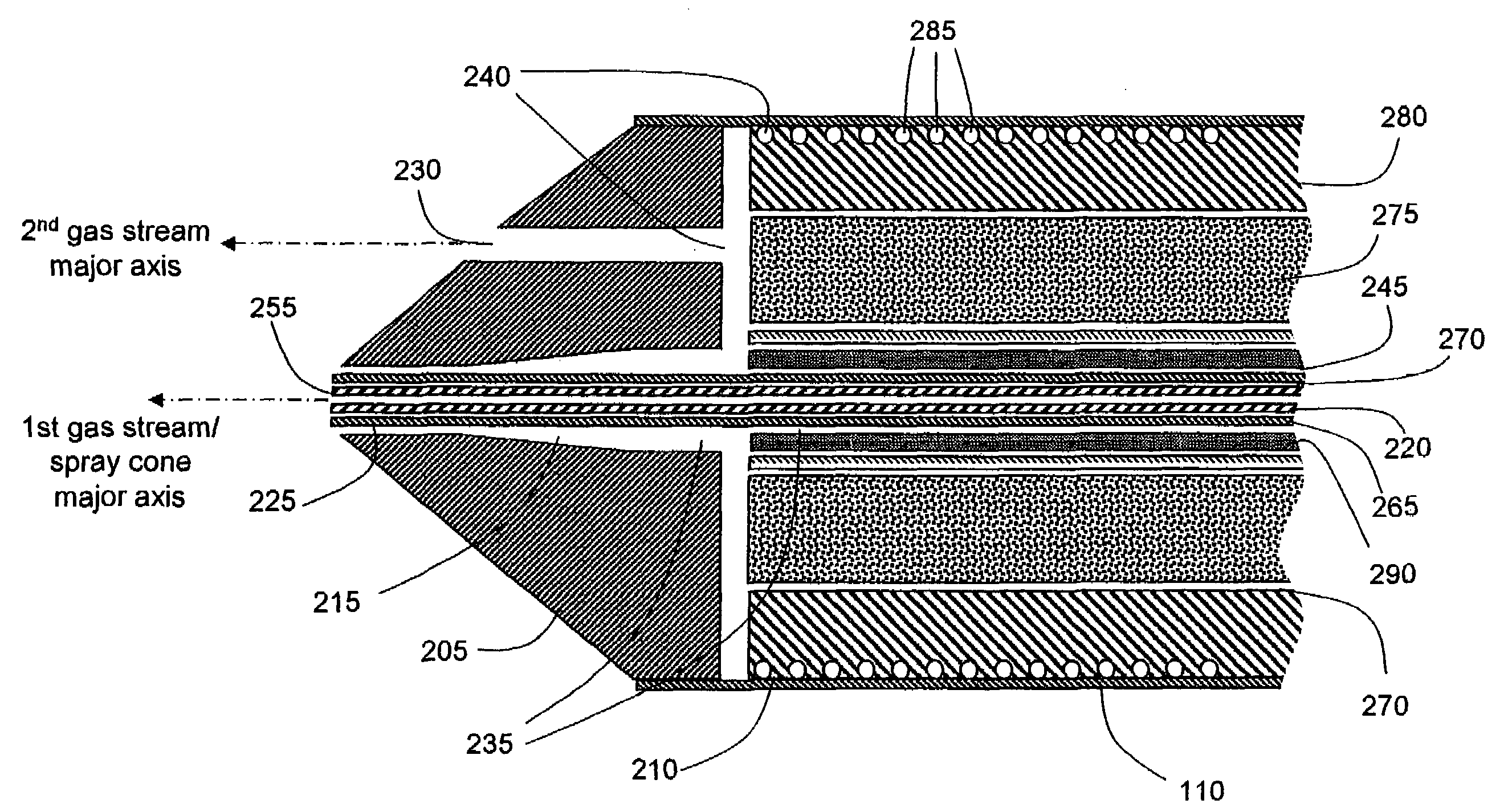

An electrospray interface for forming ions from a liquid sample in a mass analyzing system includes a capillary tube having a free end for introducing a spray of droplets into an ionization chamber, a first gas passageway positioned near the capillary tube for directing a first gas stream into the ionization chamber, and a second gas passageway positioned more remotely from the capillary tube for directing a second, low-velocity gas stream into the ionization chamber. The second gas stream is heated to increase the droplet desolvation rate. A heated sampling capillary having an end extending into the ionization chamber guides the analyte ions toward a mass analyzer and evaporates the solvent from any incompletely desolvated droplets entering the sampling capillary.

Owner:THERMO FINNIGAN

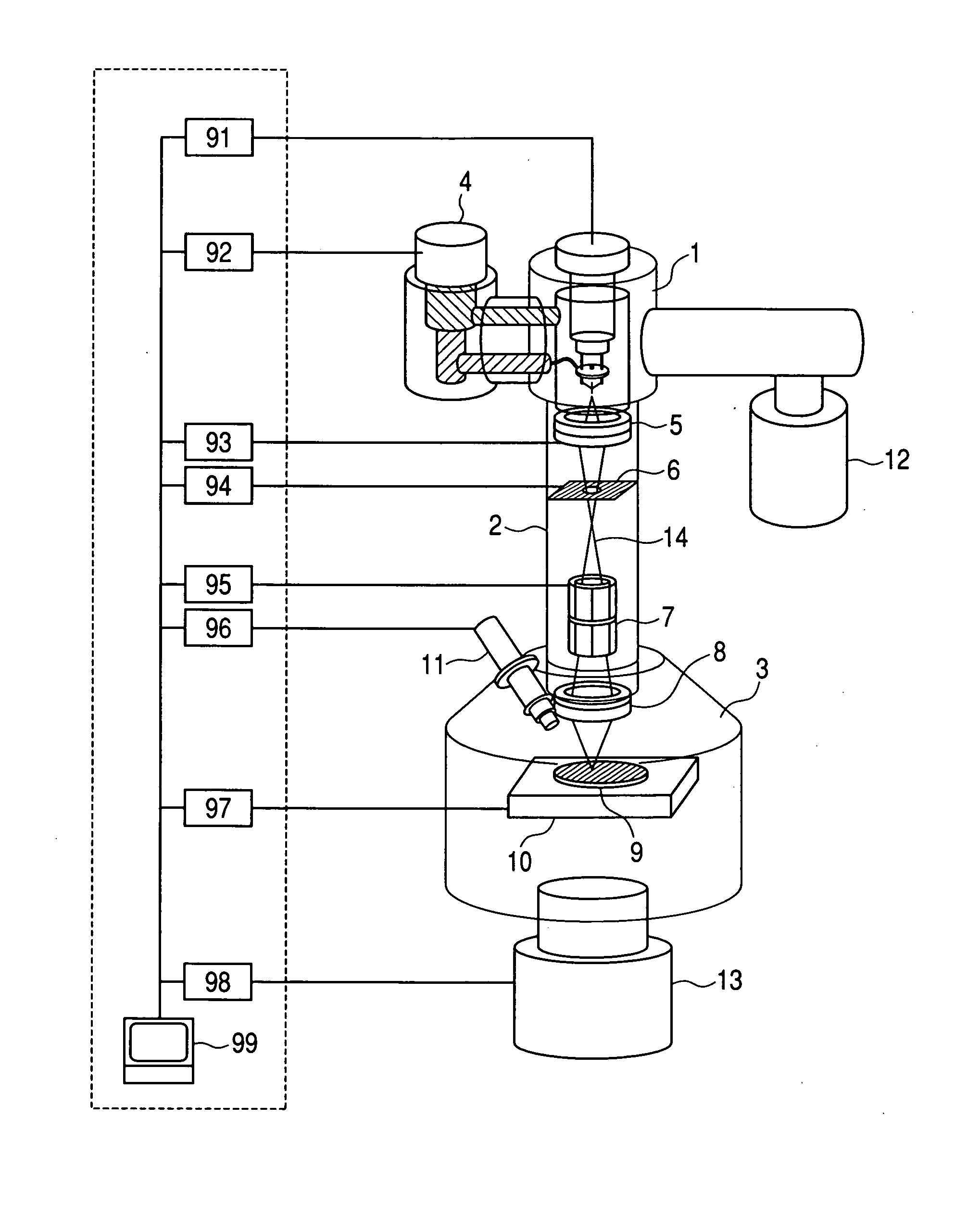

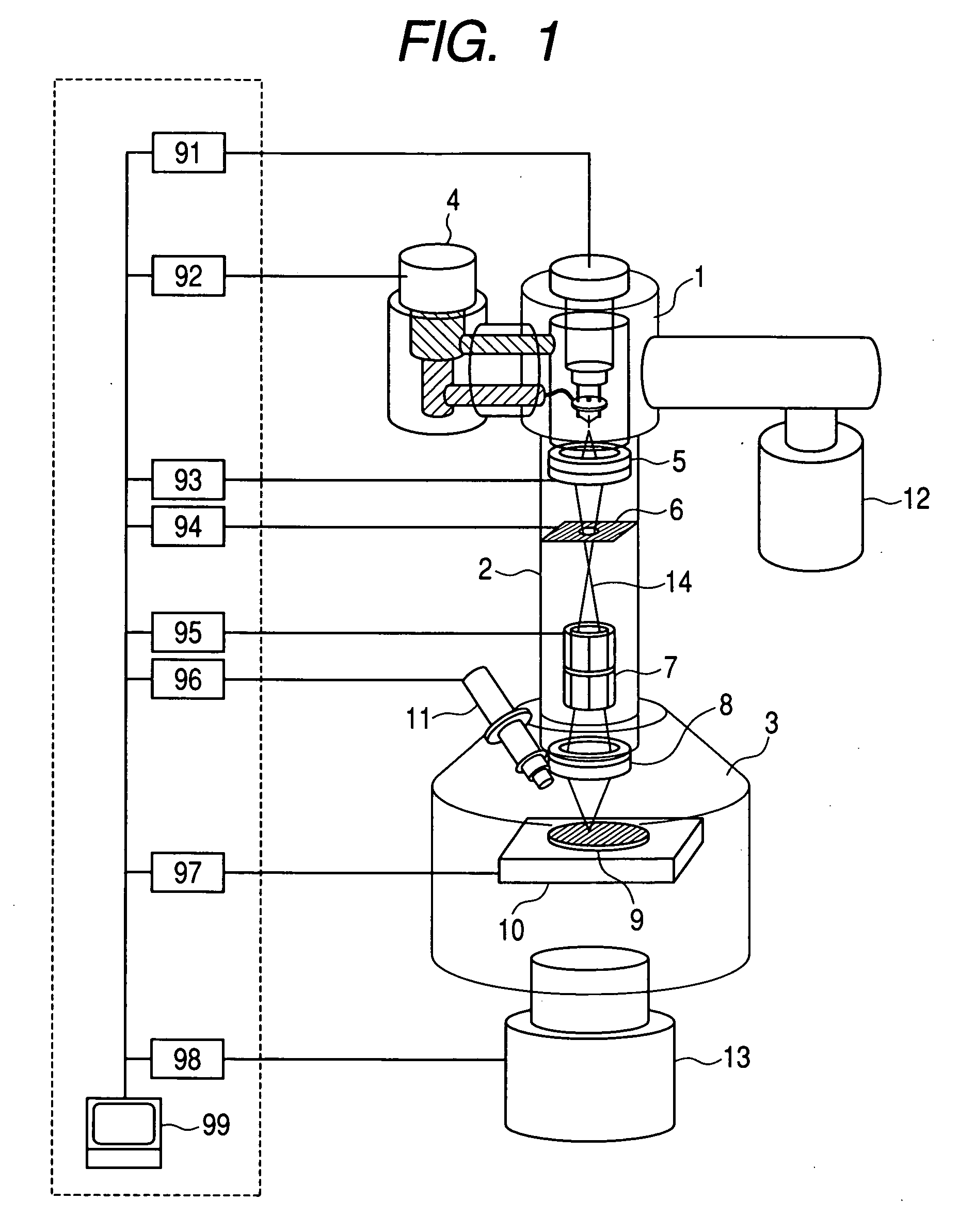

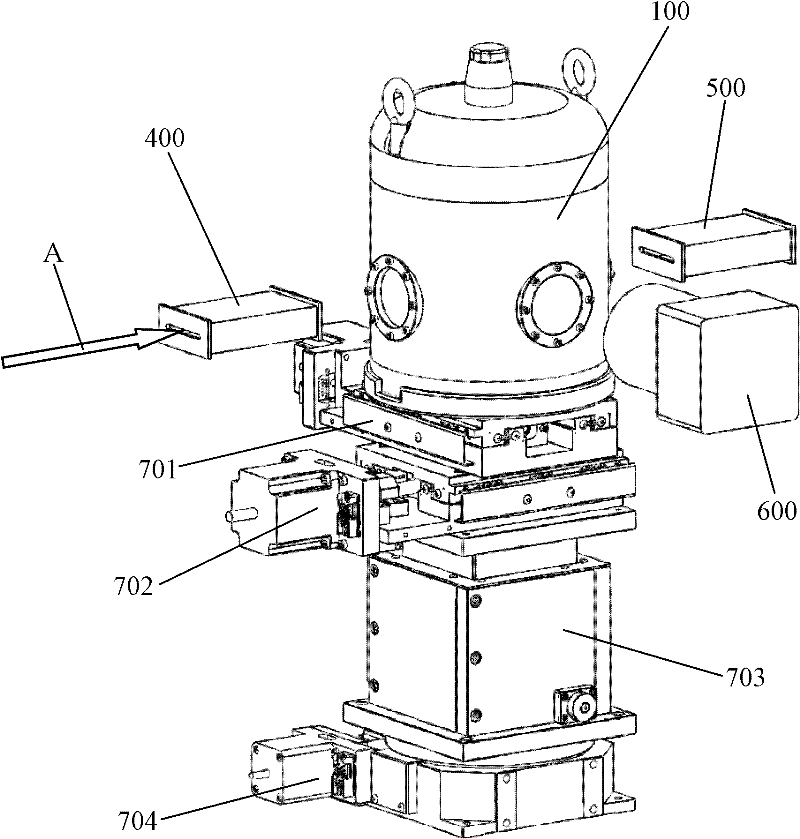

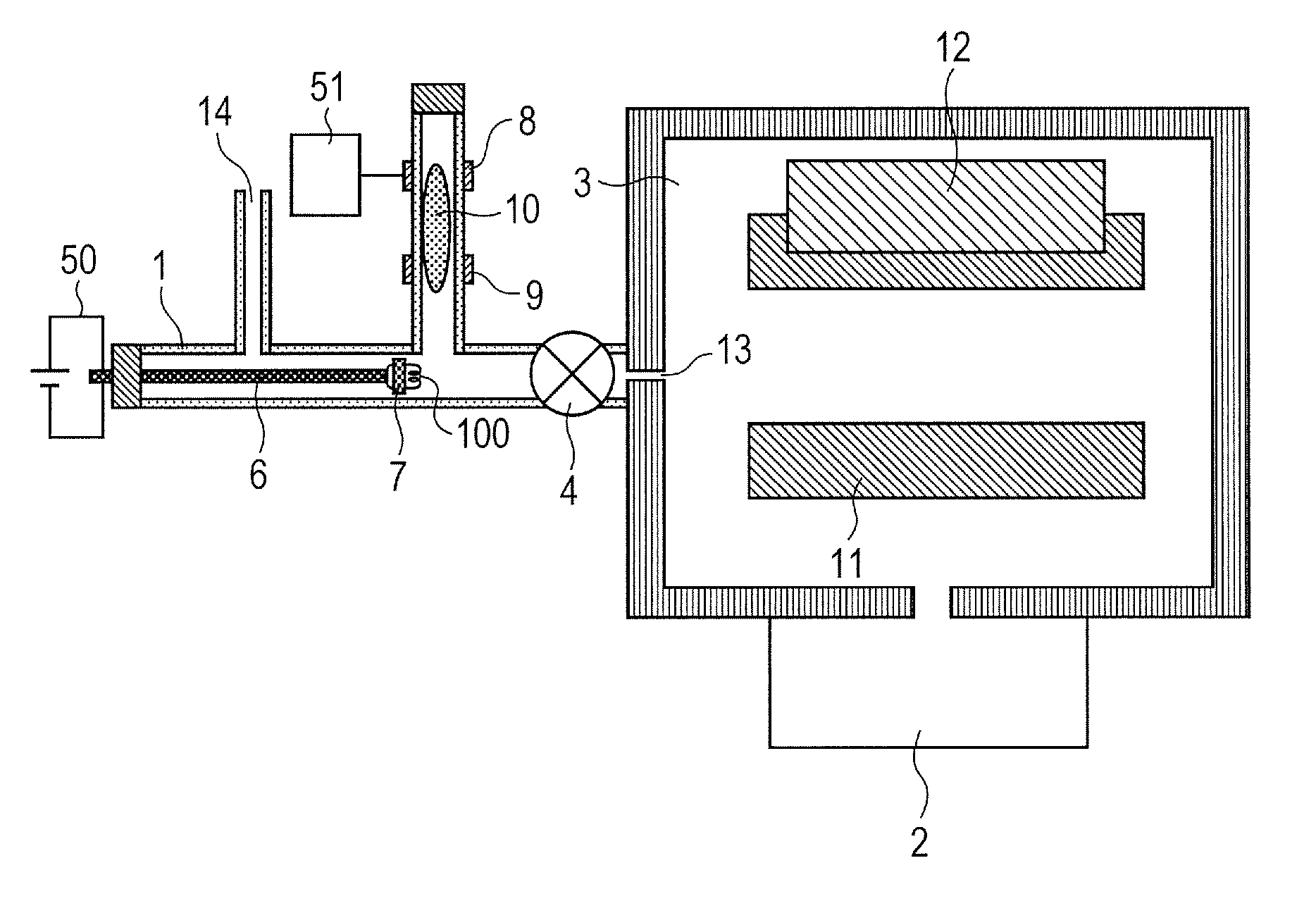

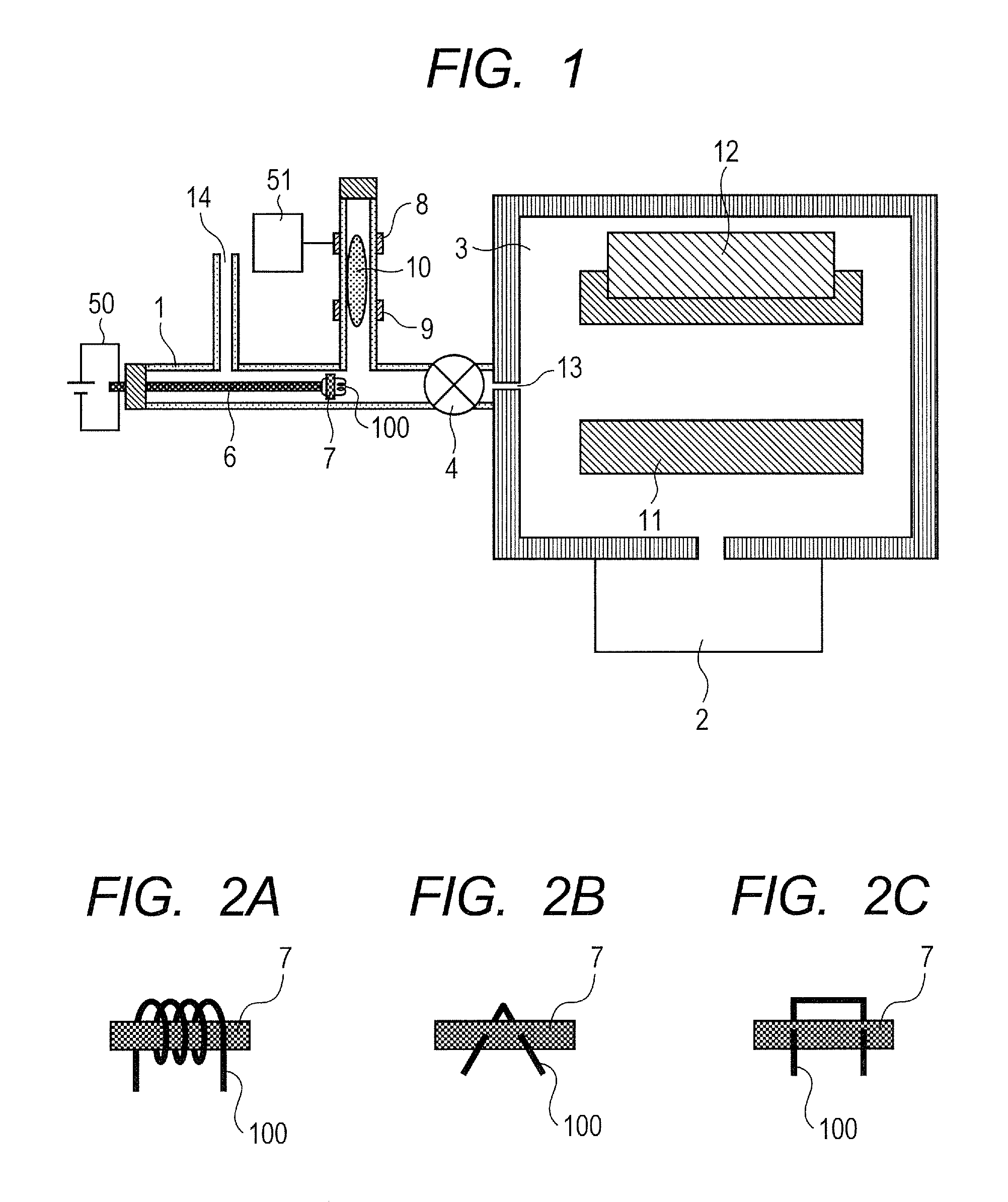

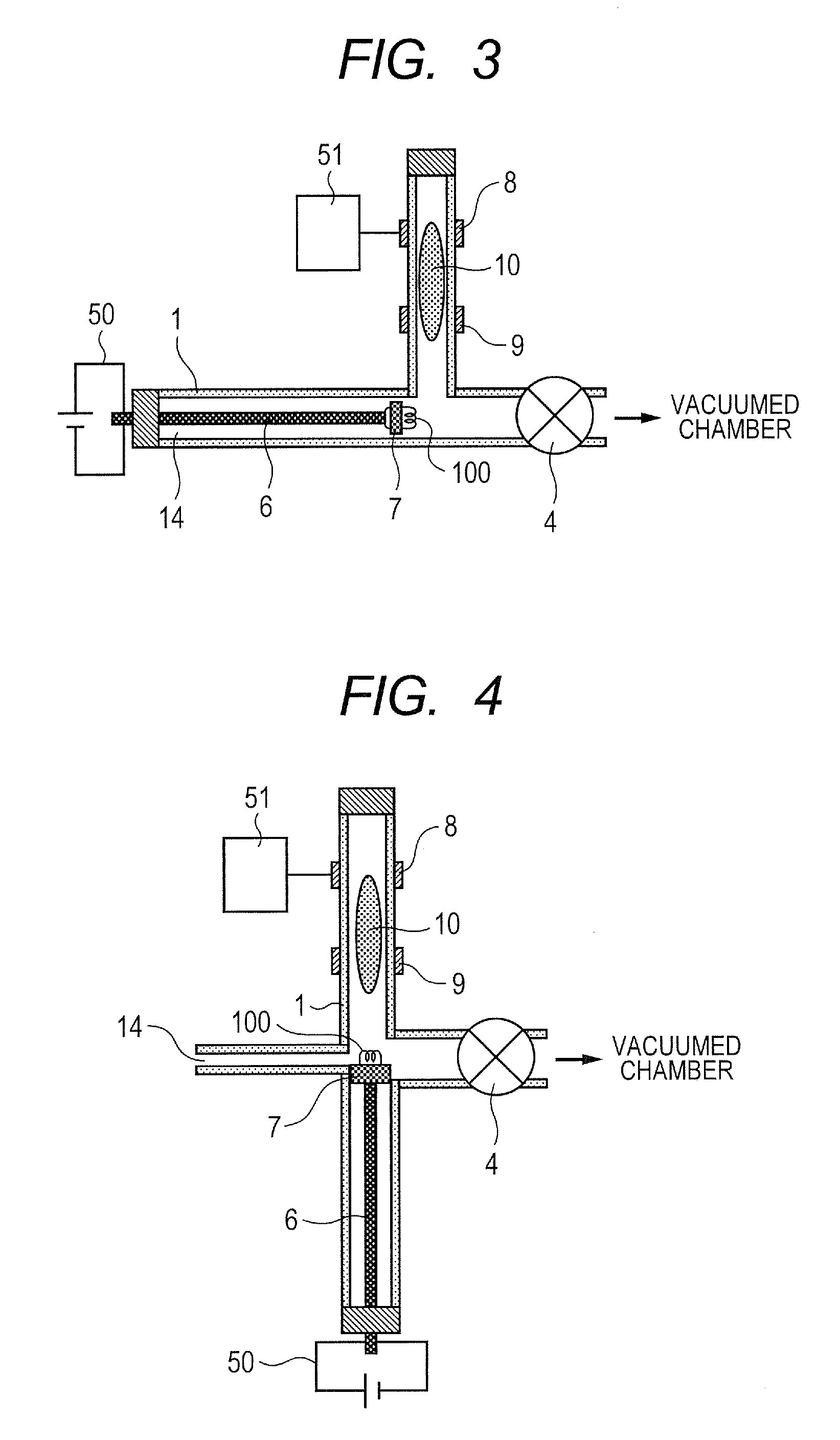

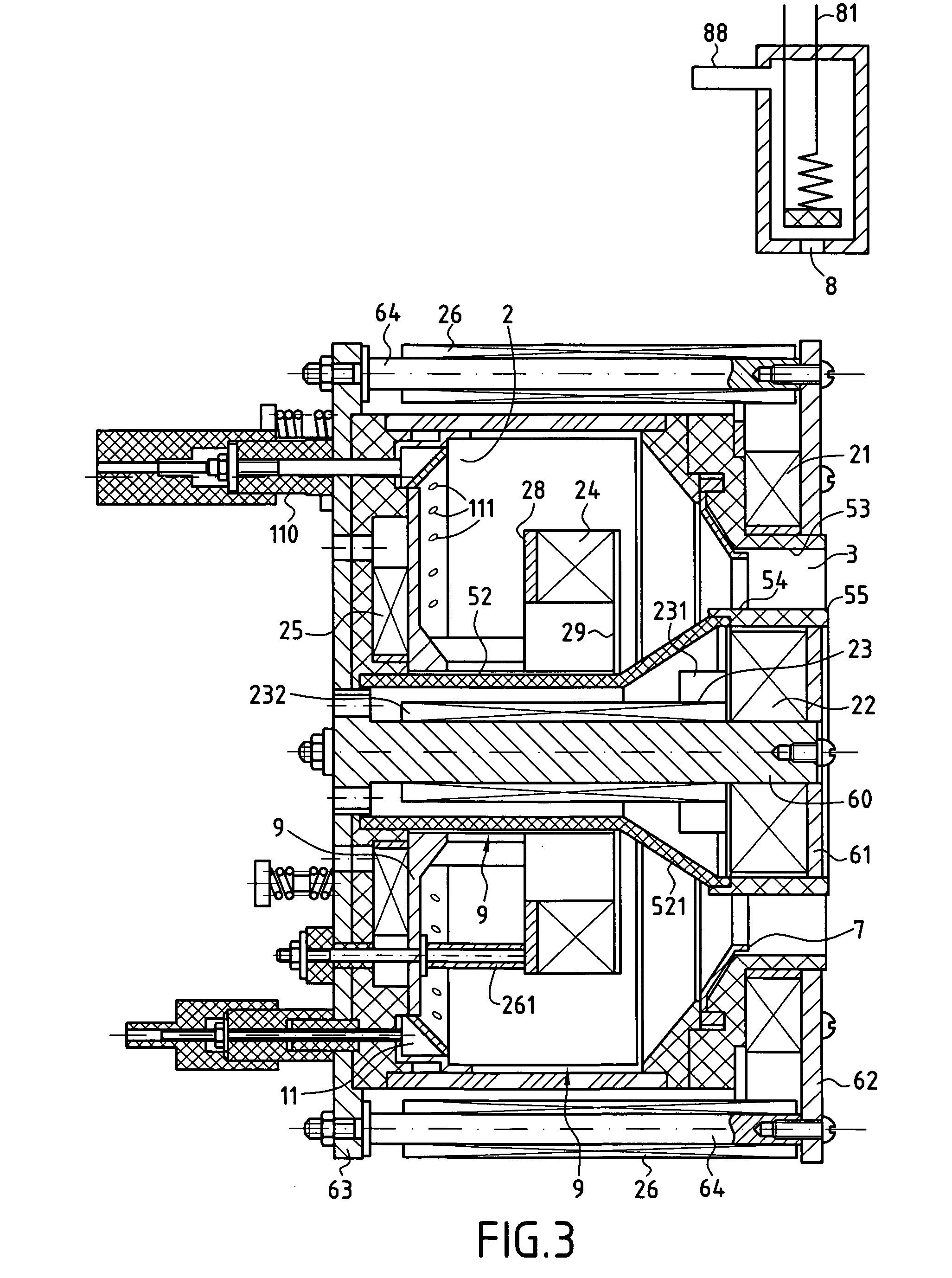

Ion beam device

ActiveUS20110147609A1Increase brightnessImprove focus performanceThermometer detailsStability-of-path spectrometersIon beamIonization chamber

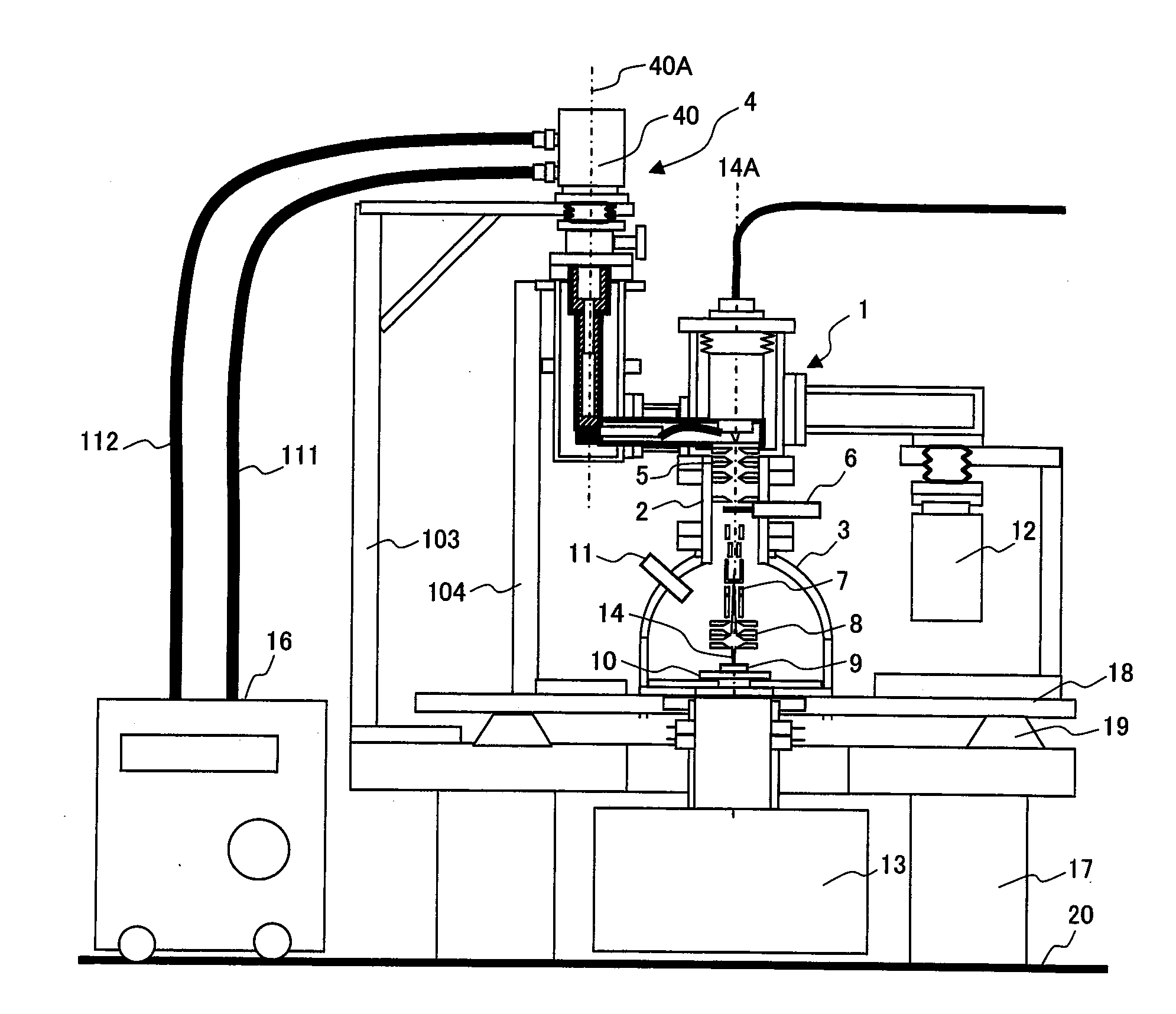

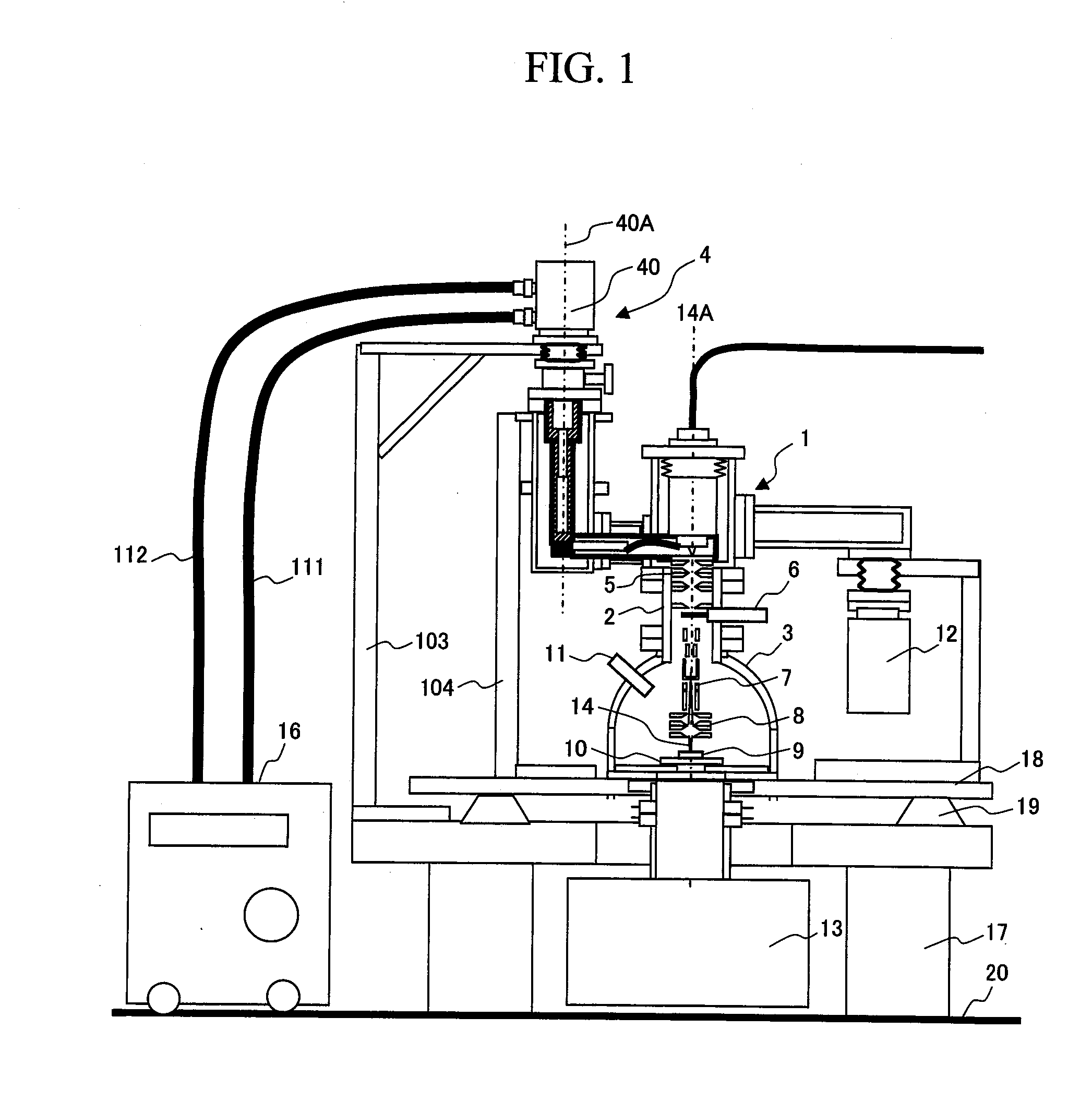

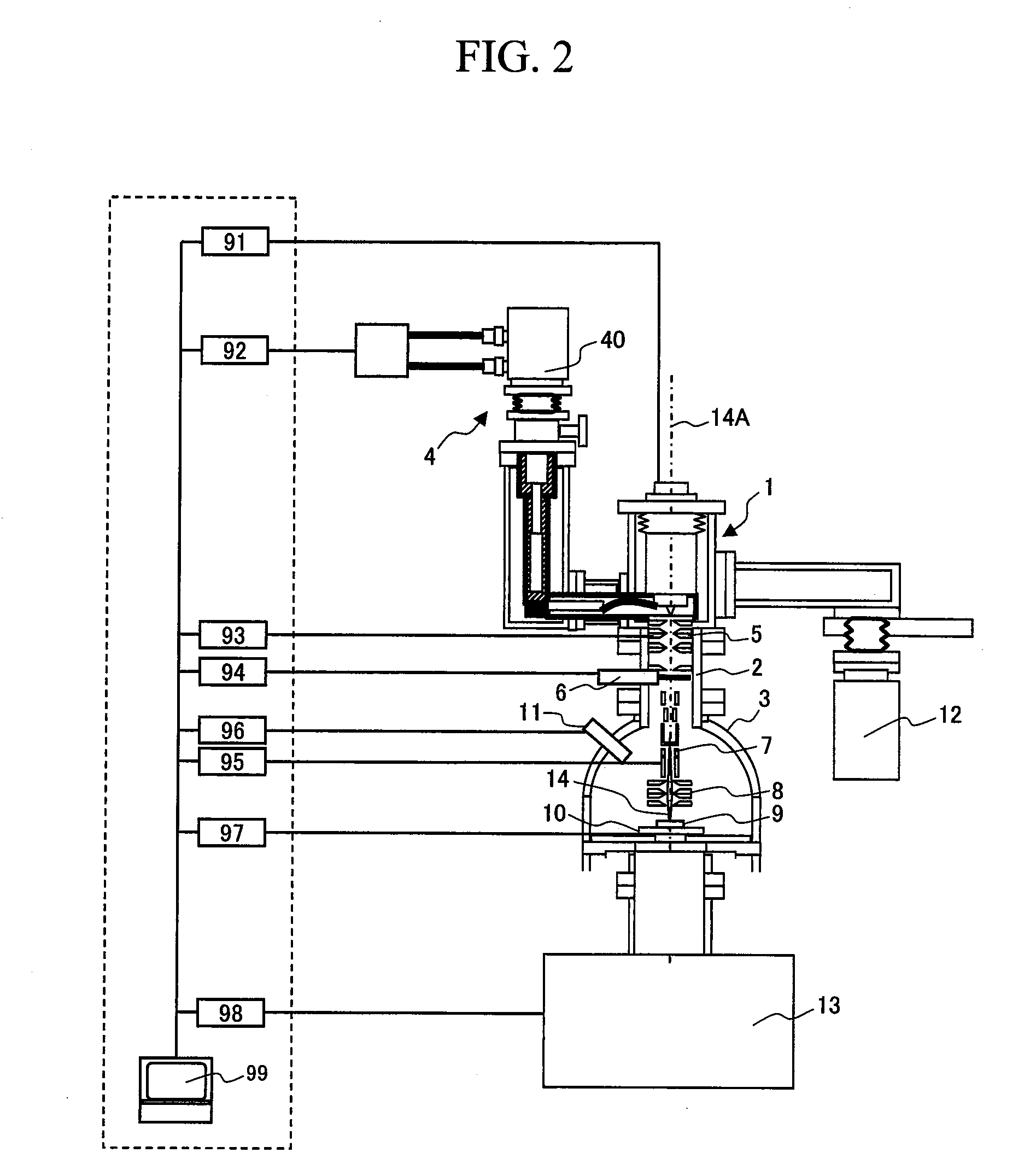

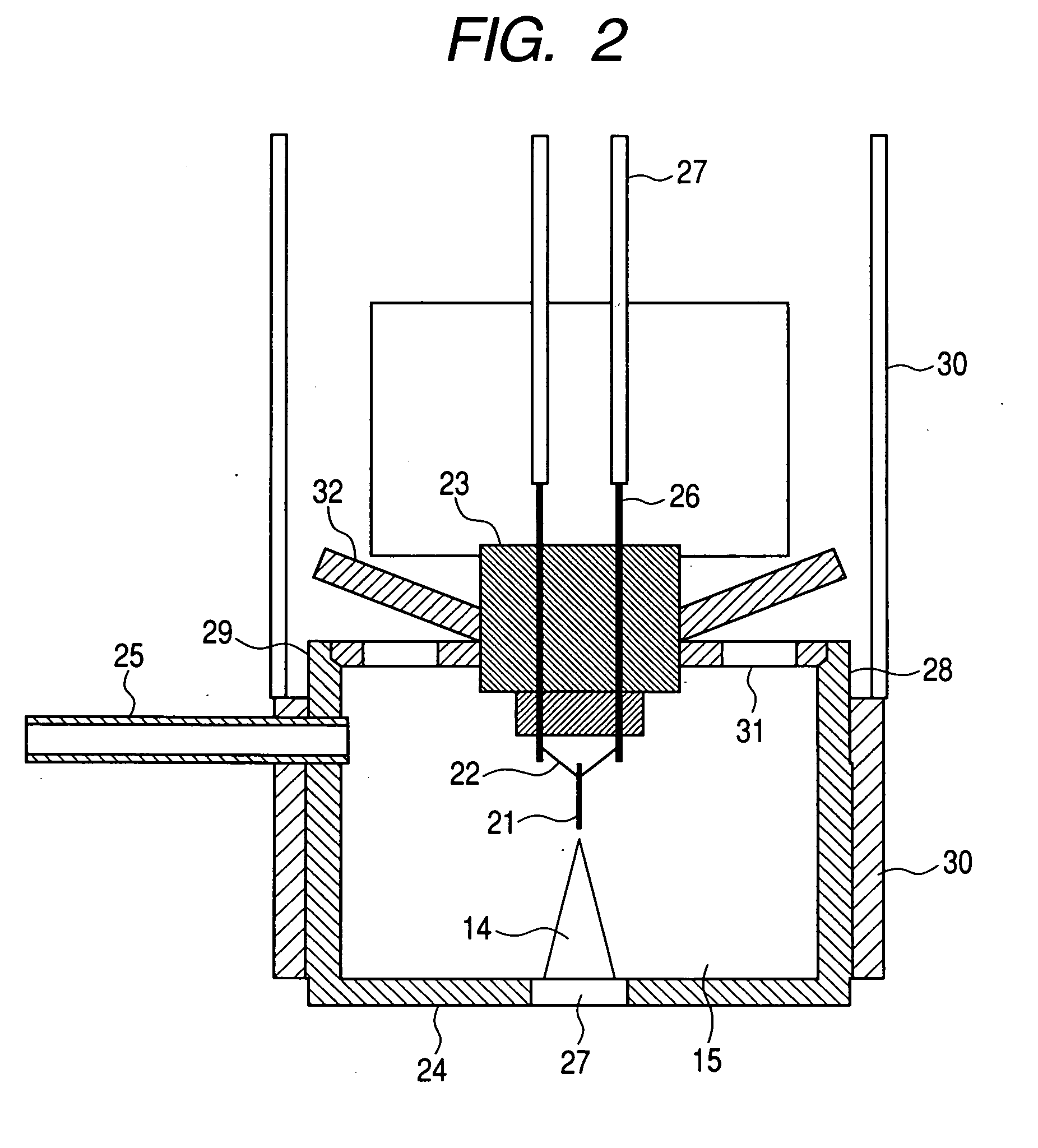

An ion beam device according to the present invention includes a gas field ion source (1) including an emitter tip (21) supported by an emitter base mount (64), a ionization chamber (15) including an extraction electrode (24) and being configured to surround the emitter tip (21), and a gas supply tube (25). A center axis line of the extraction electrode (24) overlaps or is parallel to a center axis line (14A) of the ion irradiation light system, and a center axis line (66) passing the emitter tip (21) and the emitter base mount (64) is inclinable with respect to a center axis line of the ionization chamber (15). Accordingly, an ion beam device including a gas field ion source capable of adjusting the direction of the emitter tip is provided.

Owner:HITACHI HIGH-TECH CORP

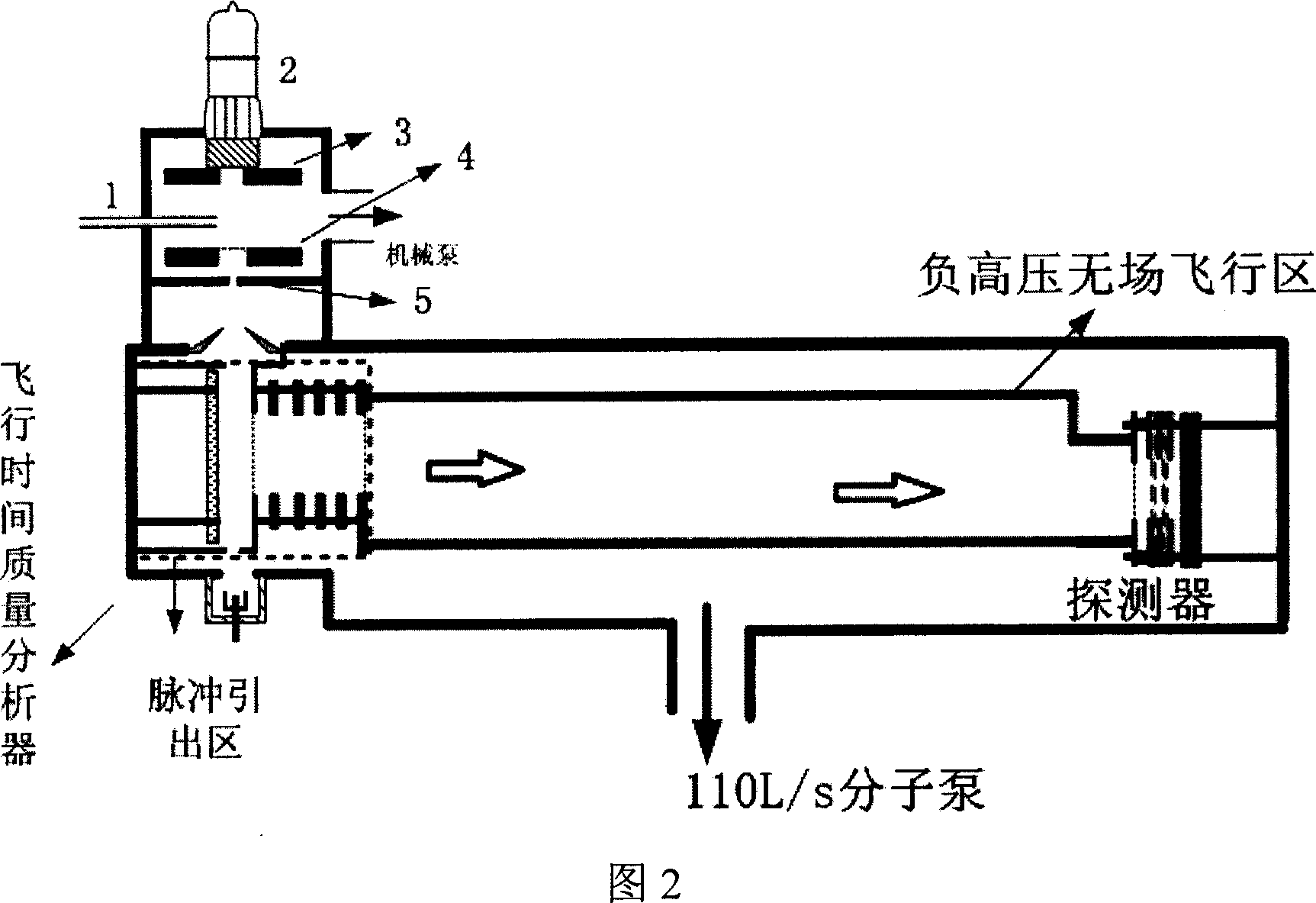

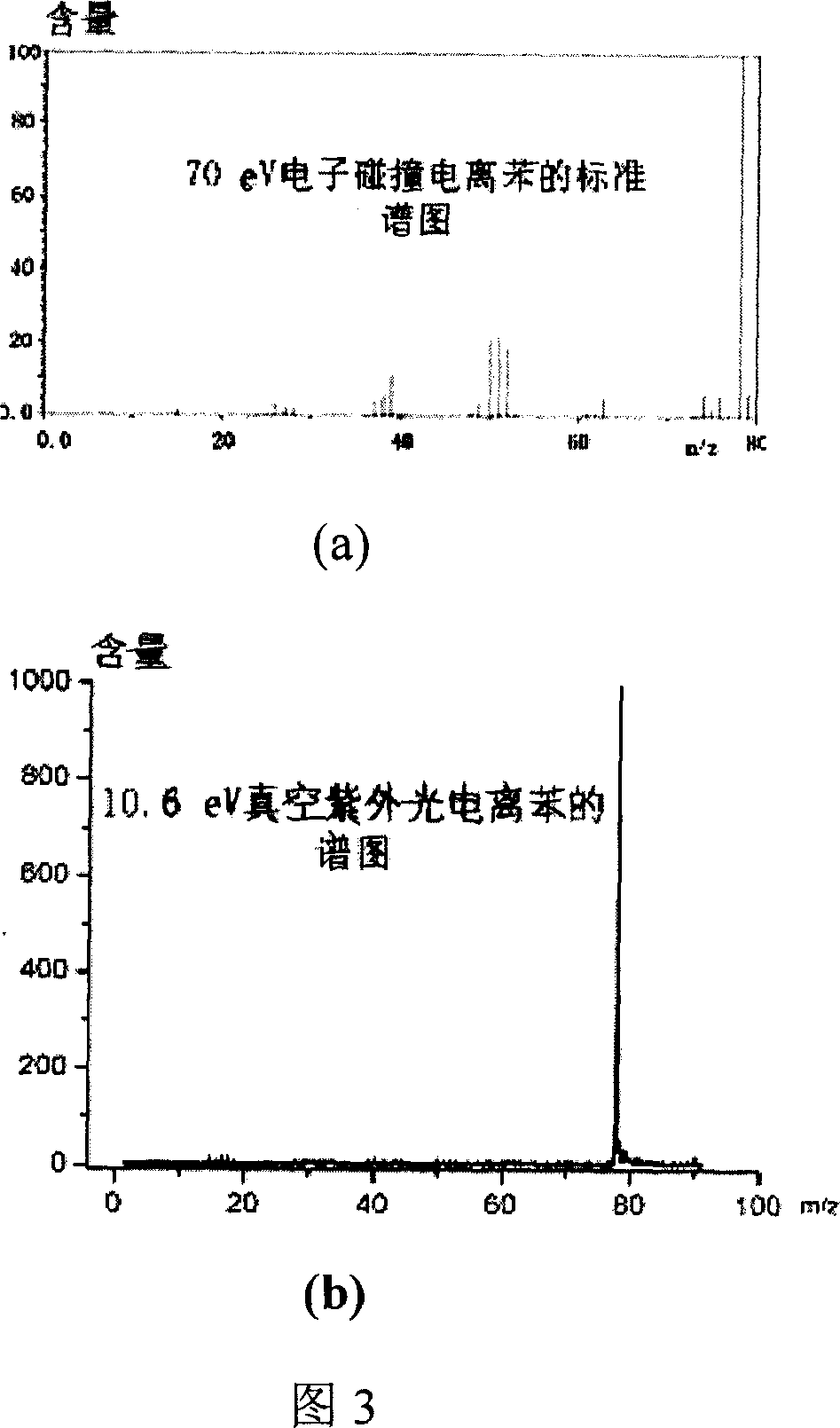

Vacuumeultraviolet lamp ionization device in time-of-flight mass spectrometer

ActiveCN101063673AImprove utilization efficiencyHigh sensitivityComponent separationTube electron sourcesMass analyzerTime of flight

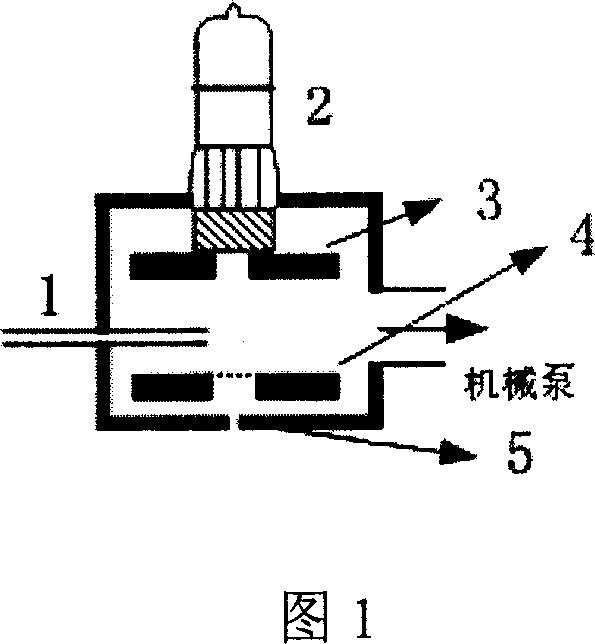

This invention relates to one fly time mass spectrum vacuum ultraviolet isolation device, which comprises the following parts: one ionization chamber fixed with vacuum ultraviolet lamp as ion source; one ion repel electrode in one to four mm to the lamp window and earth electrode at ten to fifteen mm to the dispel electrode; ion repel electrode and earth connection electrode weak field acceleration ion electron for isolation; light exit hole with diameter as two to 8mm down the electrodes; one capillary to lead vacuum ultraviolet lamp front end with light axis vertical to gas sample in direction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

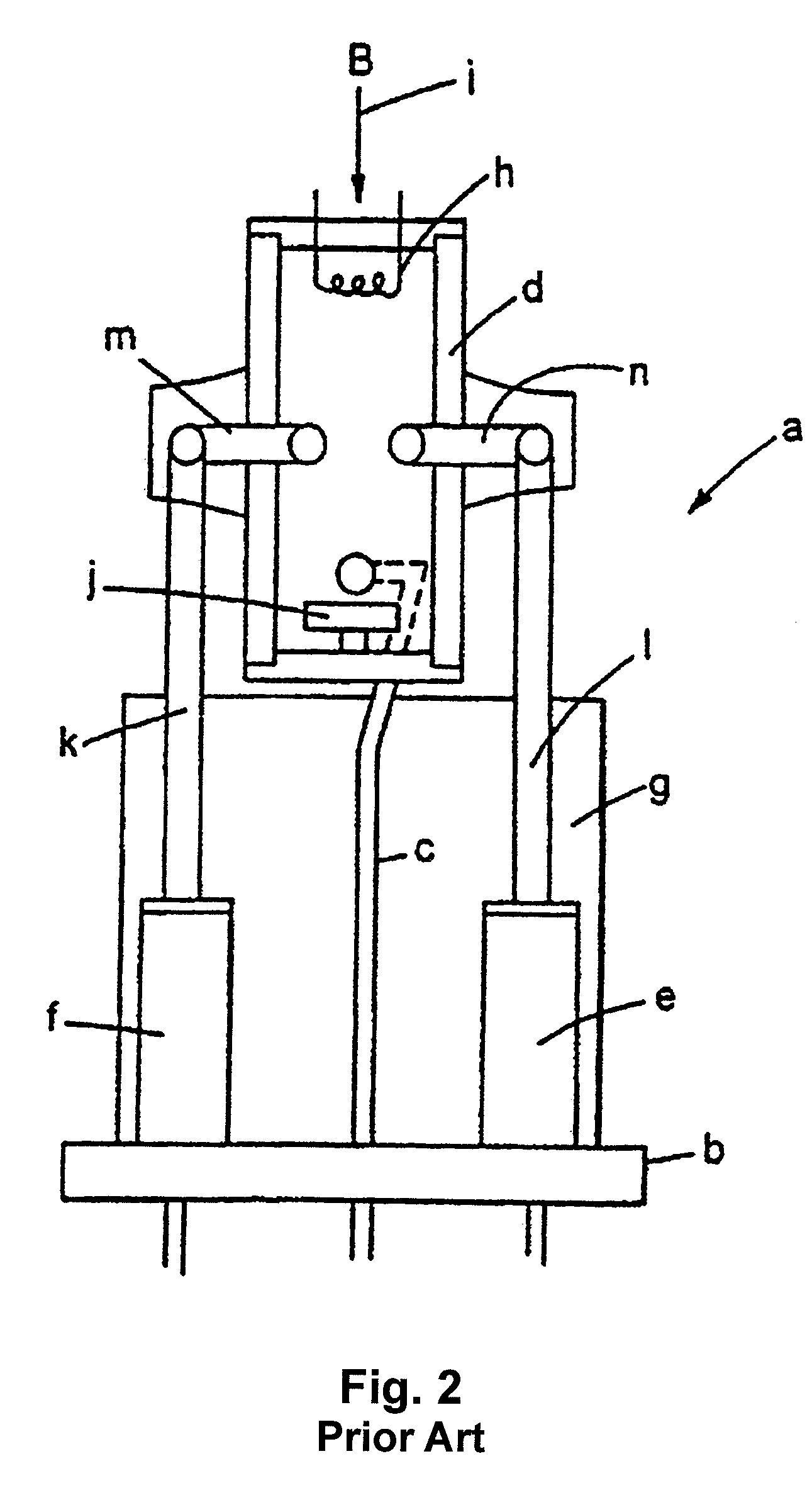

Gas field ion source, charged particle microscope, and apparatus

ActiveUS20090173888A1Reduce mechanical vibrationHigh conductanceThermometer detailsMaterial analysis using wave/particle radiationIon currentIon beam

A gas field ion source that can simultaneously increase a conductance during rough vacuuming and reduce an extraction electrode aperture diameter from the viewpoint of the increase of ion current. The gas field ion source has a mechanism to change a conductance in vacuuming a gas molecule ionization chamber. That is, the conductance in vacuuming a gas molecule ionization chamber is changed in accordance with whether or not an ion beam is extracted from the gas molecule ionization chamber. By forming lids as parts of the members constituting the mechanism to change the conductance with a bimetal alloy, the conductance can be changed in accordance with the temperature of the gas molecule ionization chamber, for example the conductance is changed to a relatively small conductance at a relatively low temperature and to a relatively large conductance at a relatively high temperature.

Owner:HITACHI HIGH-TECH CORP

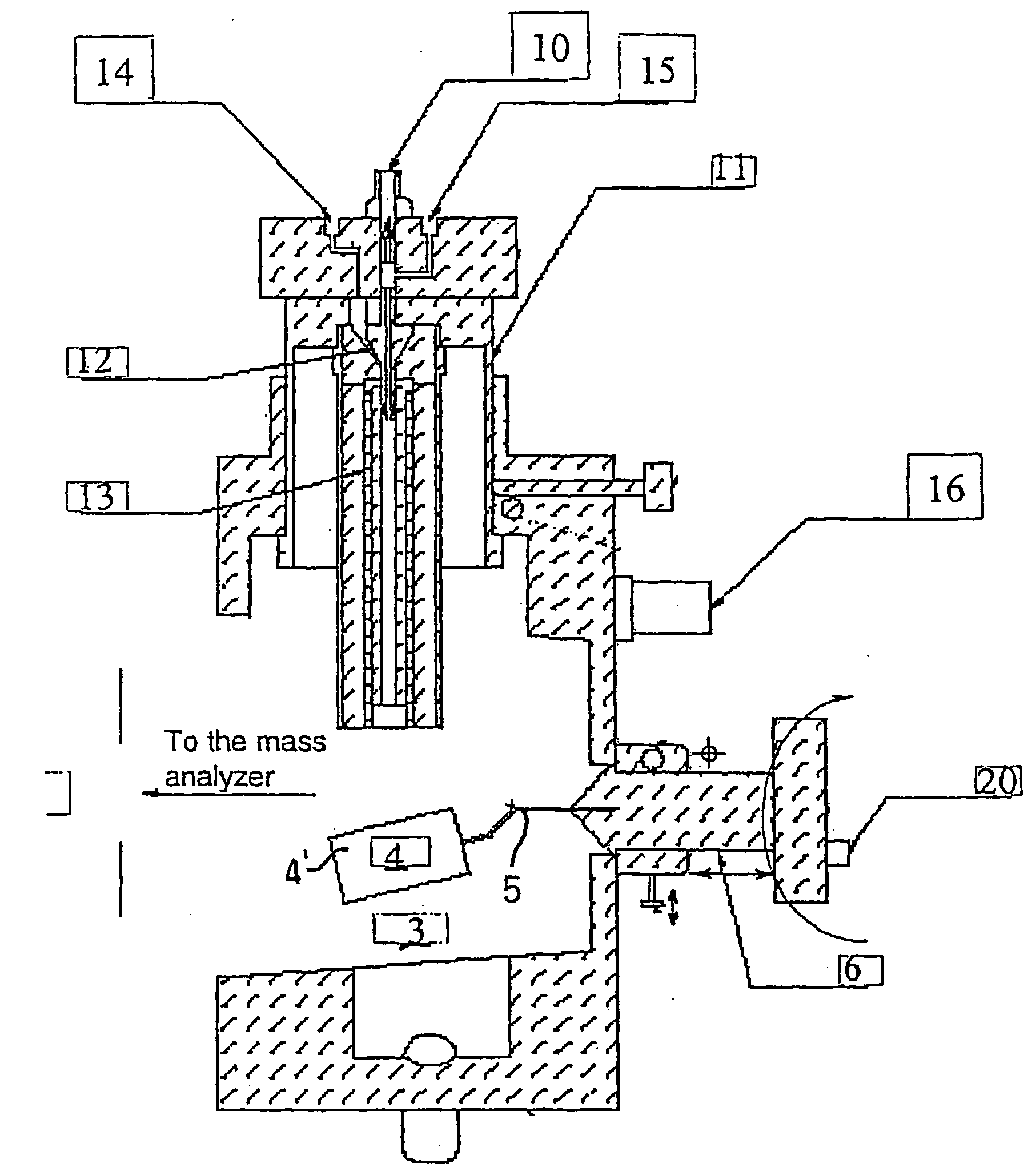

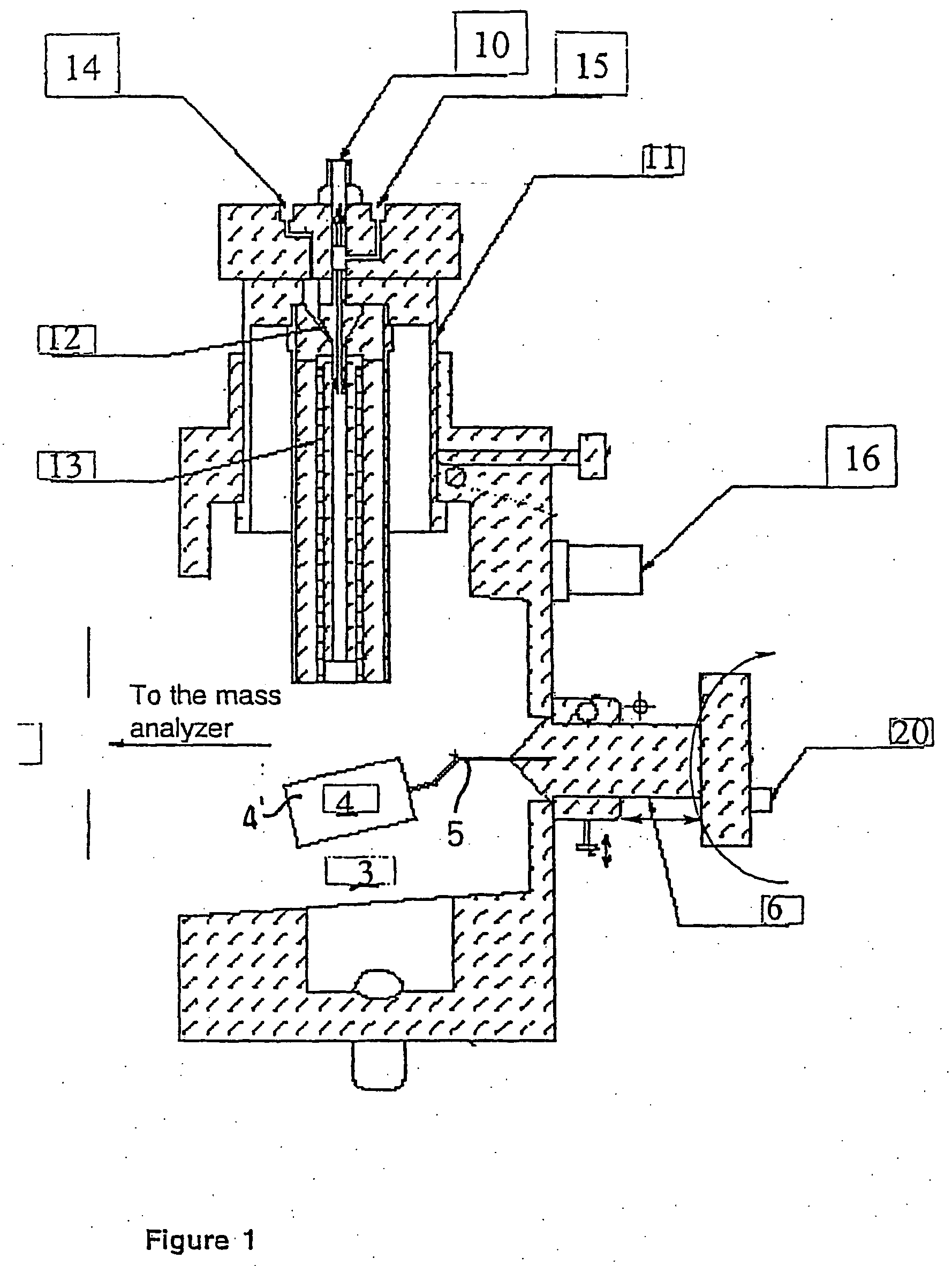

Method and apparatus for mass spectrometric analysis of samples

InactiveUS6861647B2Time-of-flight spectrometersSamples introduction/extractionPhysical chemistryIonization chamber

An MALDI mass spectrometer for the composition analysis of large batch sizes of samples includes a mass spectrometer having an ionization chamber and a sample chamber coupled to the ionization chamber. A transport cart is positioned in the sample chamber with a sample cassette removably coupled thereto. A method of operating a MALDI mass spectrometer is also disclosed.

Owner:INDIANA UNIV RES & TECH CORP

Ion implantation device and a method of semiconductor manufacturing by the implantation of boron hydride cluster ions

InactiveUS20070194252A1Improve productivityLow costTransistorSemiconductor/solid-state device manufacturingMolecular clusterDevice material

An ion implantation device and a method of manufacturing a semiconductor device is described, wherein ionized boron hydride molecular clusters are implanted to form P-type transistor structures. The molecular cluster ions have the chemical form BnHx+and BnHx−, where 10<n<100 and 0≦x≦n+4. The use of such boron hydride clusters results in a dramatic increase in wafer throughput, as well as improved device yields through the reduction of wafer charging. A method of manufacturing a semiconductor device is further described, comprising the steps of: providing a supply of molecules containing a plurality of dopant atoms into an ionization chamber, ionizing said molecules into dopant cluster ions, extracting and accelerating the dopant cluster ions with an electric field, selecting the desired cluster ions by mass analysis, modifying the final implant energy of the cluster ion through post-analysis ion optics, and implanting the dopant cluster ions into a semiconductor substrate.

Owner:SEMEQUIP

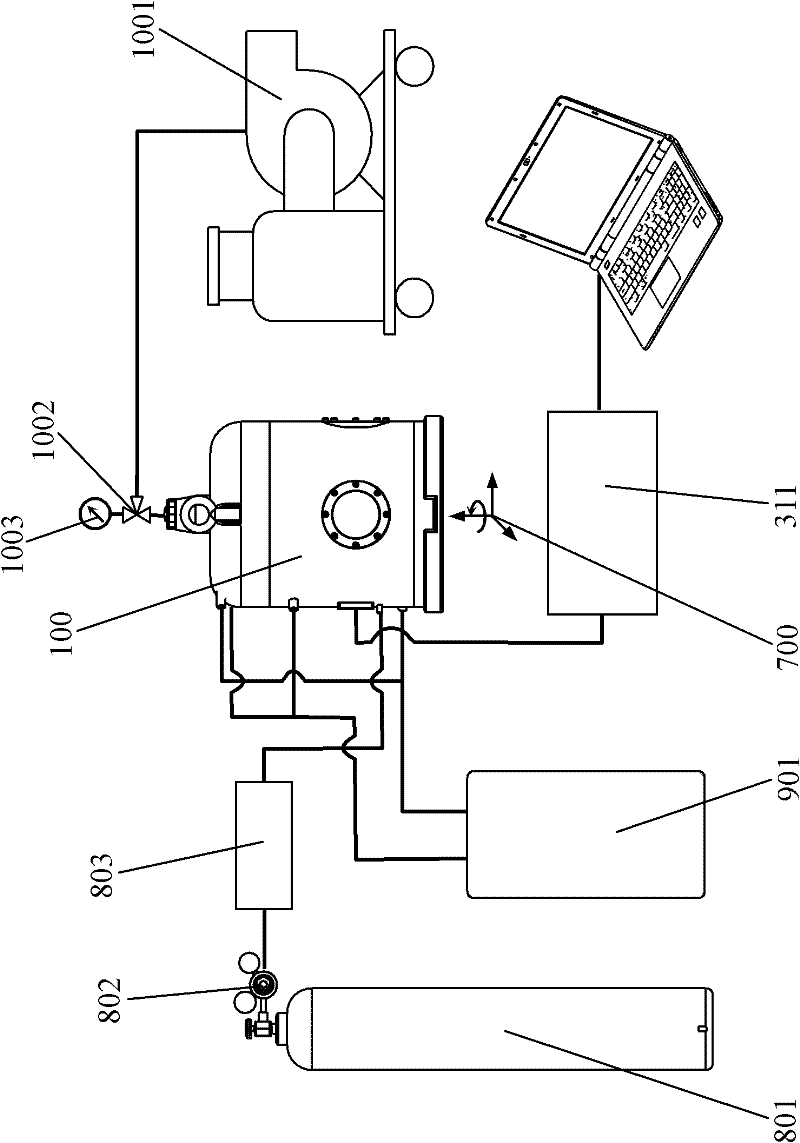

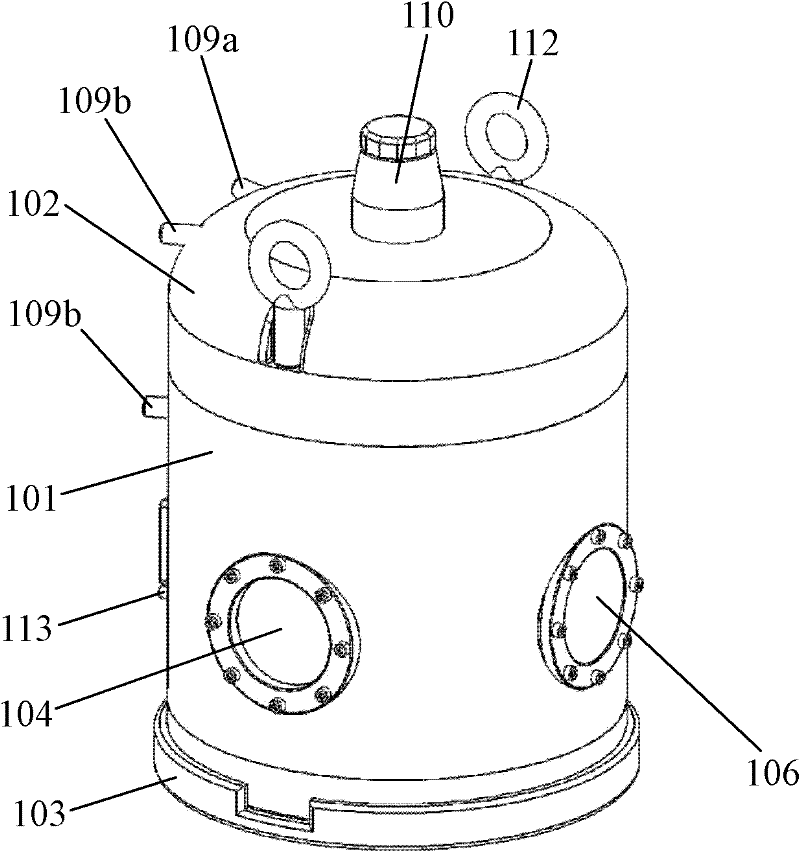

High-temperature fused salt synchrotron radiation in-situ research device

InactiveCN102590253AEliminate phenomena that introduce artifactsExpand the detection angleMaterial analysis using wave/particle radiationFluorescenceIonization chamber

The invention discloses a high-temperature synchrotron radiation in-situ research device. The high-temperature fused salt synchrotron radiation in-situ research device comprises a fused salt test tube, a vacuum furnace, a heating device, a first ionization chamber, a second ionization chamber or a charge coupled device (CCD) detector and an external fluorescence detector, wherein a cavity is formed in the vacuum furnace; an incident window, a transmission window and a fluorescence window are arranged on the furnace wall of the vacuum furnace; the incident window and the transmission window are arranged coaxially and collinearly; the axial line of the fluorescence window is vertical to that of the incident window and / or the transmission window; the heating device is arranged in the cavity of the vacuum furnace and is used for heating the fused salt test tube arranged in the heating device; an incident hole, a transmission hole and a fluorescence hole corresponding to the incident window, the transmission window and the fluorescence window respectively are formed on the heating device; the first ionization chamber corresponding to the incident window is arranged outside the vacuum furnace; the second ionization chamber or the CCD detector corresponding to the transmission window is arranged outside the vacuum furnace; and the external fluorescence detector corresponding to the fluorescence window is arranged outside the vacuum furnace.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

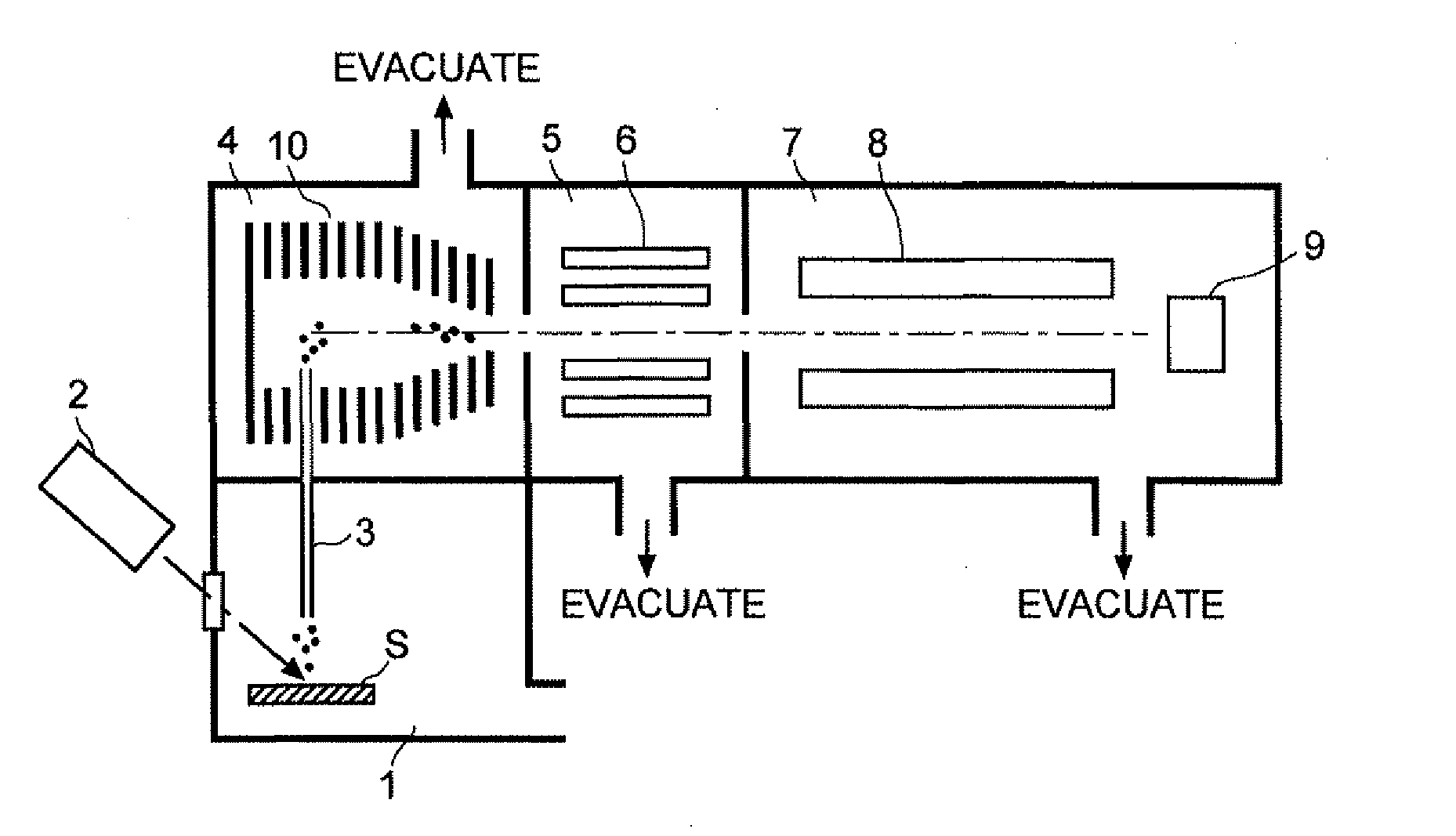

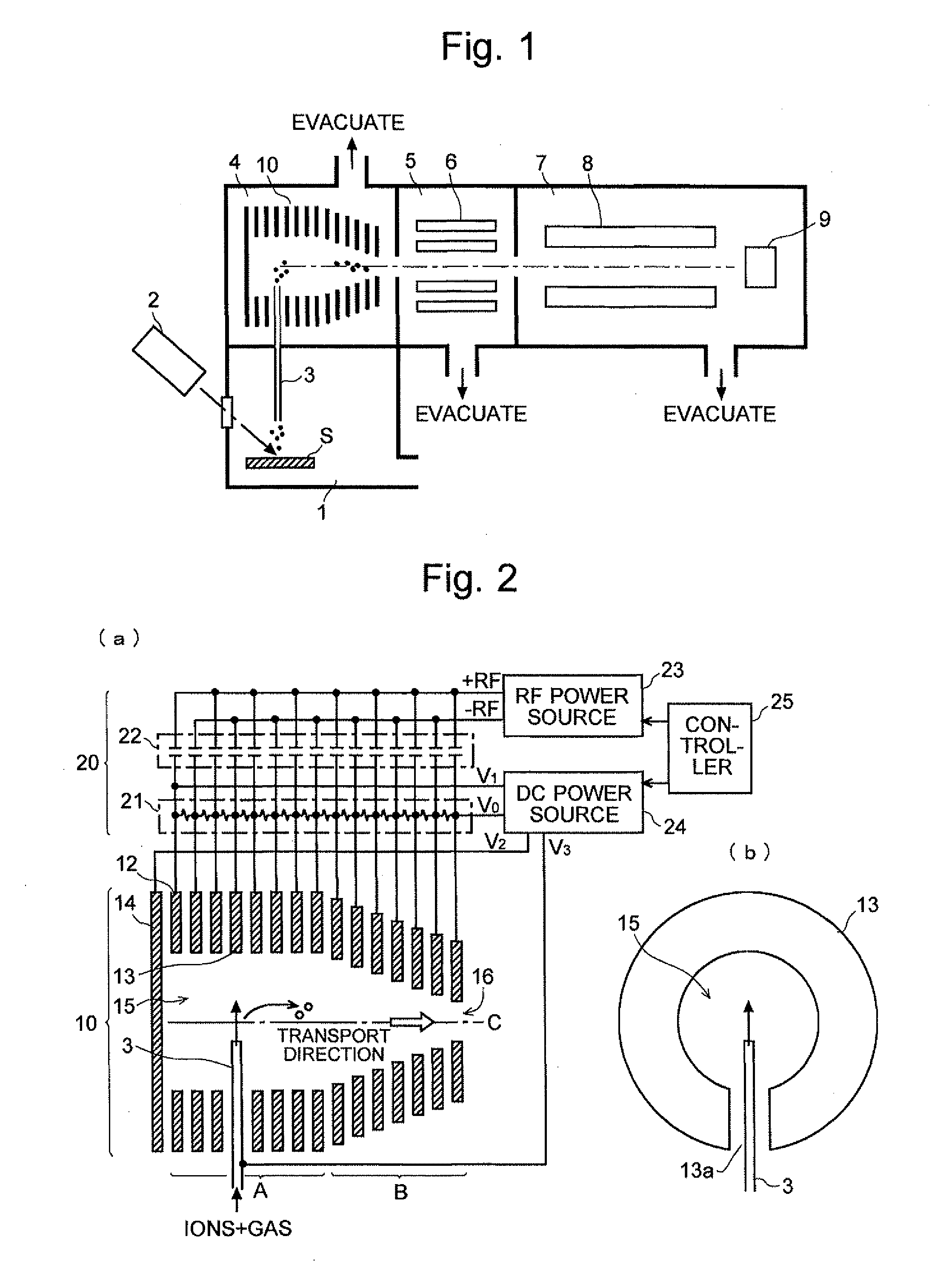

Mass Spectrometer

InactiveUS20110186732A1Improve efficiencyInhibit deteriorationIon sources/gunsIsotope separationMass analyzerRadio frequency

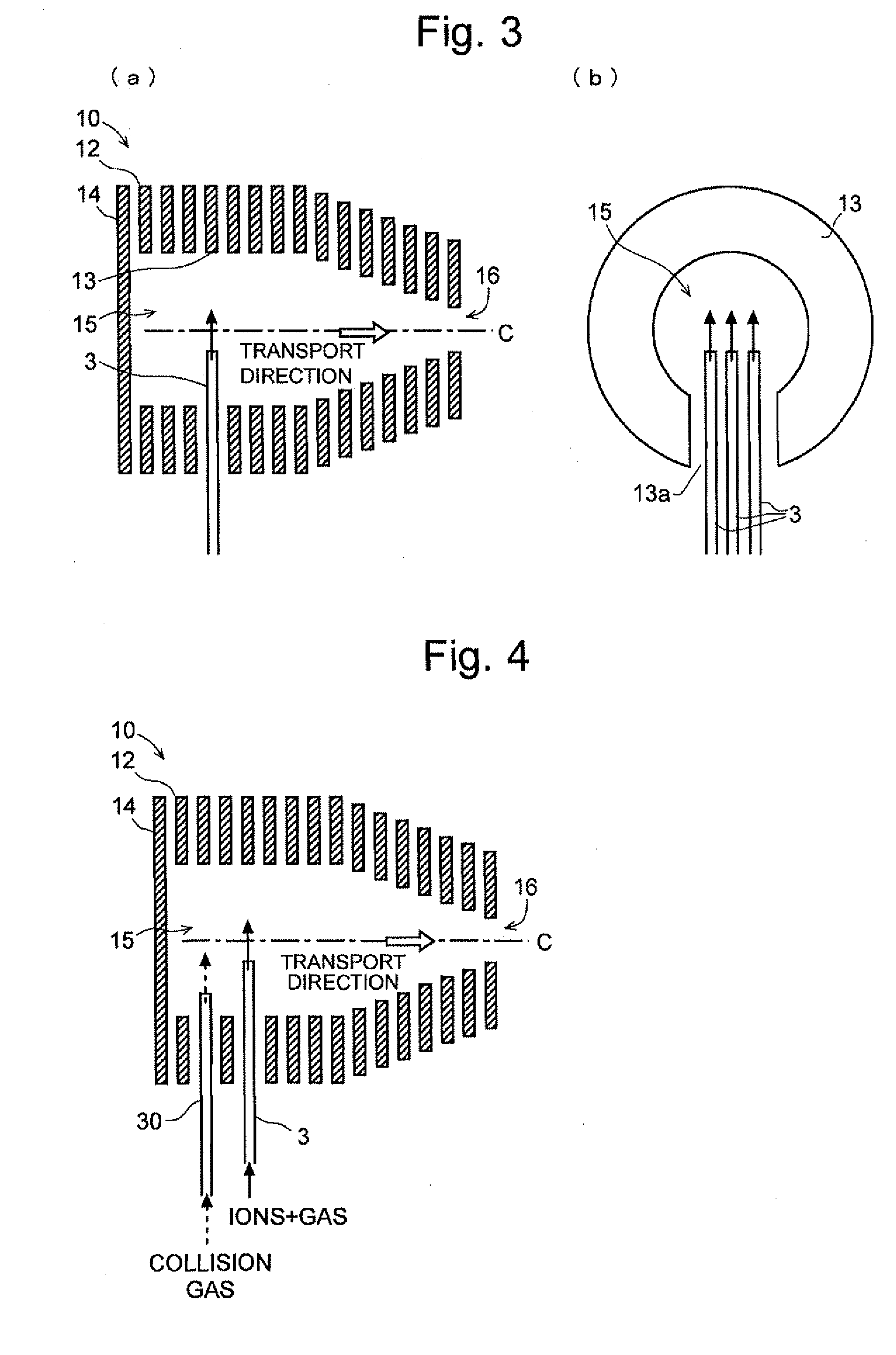

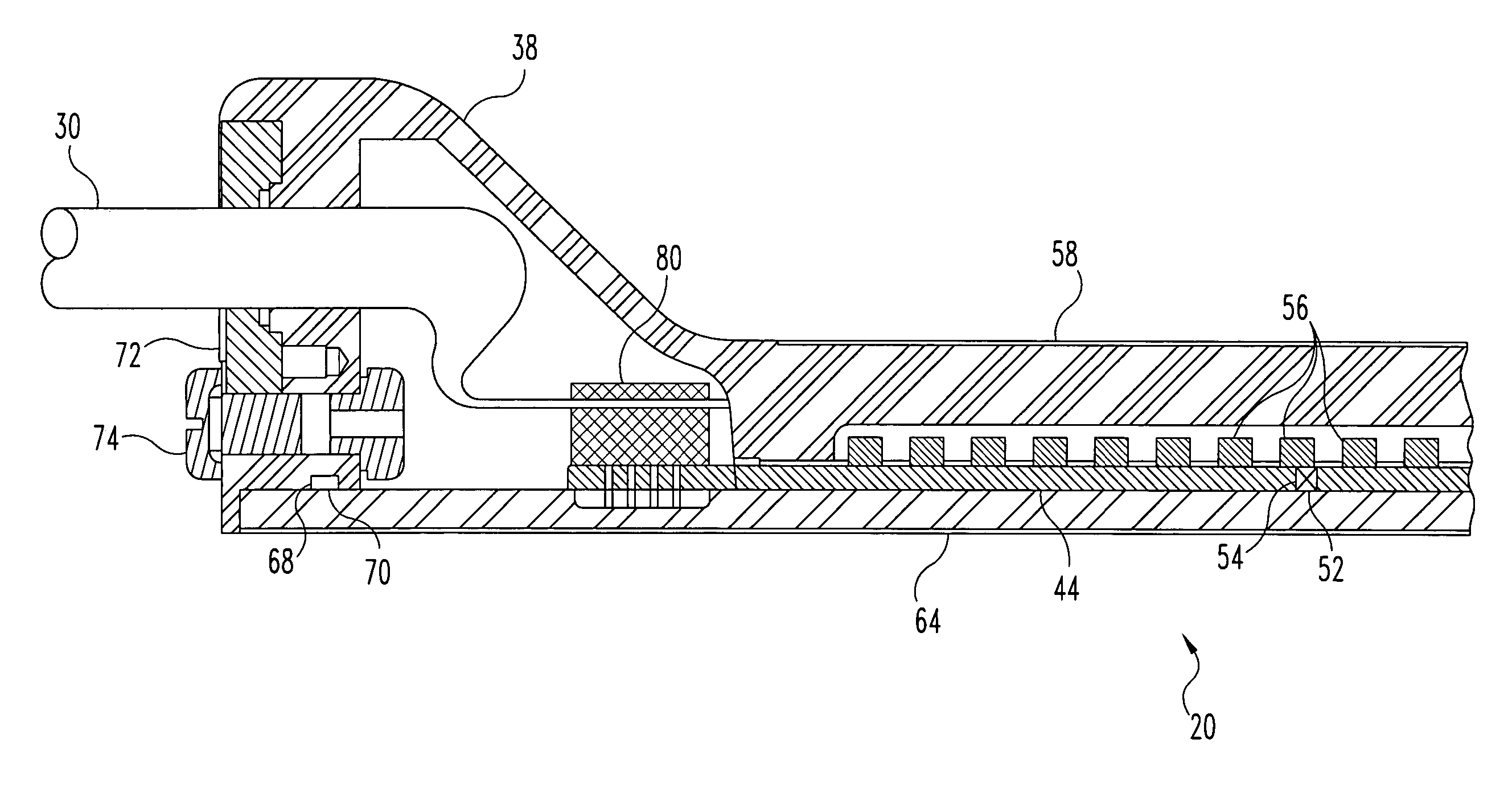

A technique for improving the efficiency of injecting ions into the electrode unit of a funnel structure having high ion-transport efficiency is provided to improve the overall ion-transport efficiency. From an ionization chamber 1 for ionizing a sample under atmospheric pressure, ions are injected through a straight capillary pipe 3 into the inner space of the electrode unit 10 of a funnel structure composed of ring electrodes in a first intermediate vacuum chamber 4. The space for setting the capillary pipe 3 is formed by replacing one or more ring electrodes with C-shaped electrodes whose circumference portion is partially removed. Each C-shaped electrode is arranged so that the ions will be injected perpendicularly to the ion-transport direction. The injected ions lose energy due to collision cooling, become converged onto the ion-beam axis C due to the ion-confining effect of a radio-frequency electric field, and efficiently move toward the exit aperture along a potential gradient created by a direct-current electric field. The gas stream carrying the ions passes through the gaps of the ring electrodes, without increasing the gas pressure at the exit of the ring-electrode inner space and thereby deteriorating the degree of vacuum in the next stage.

Owner:SHIMADZU CORP

Radiation detection apparatus

InactiveUS20050056791A1Lower potentialGreat cable flexibilityMicrobiological testing/measurementSolid-state devicesShielded cableElectrical conductor

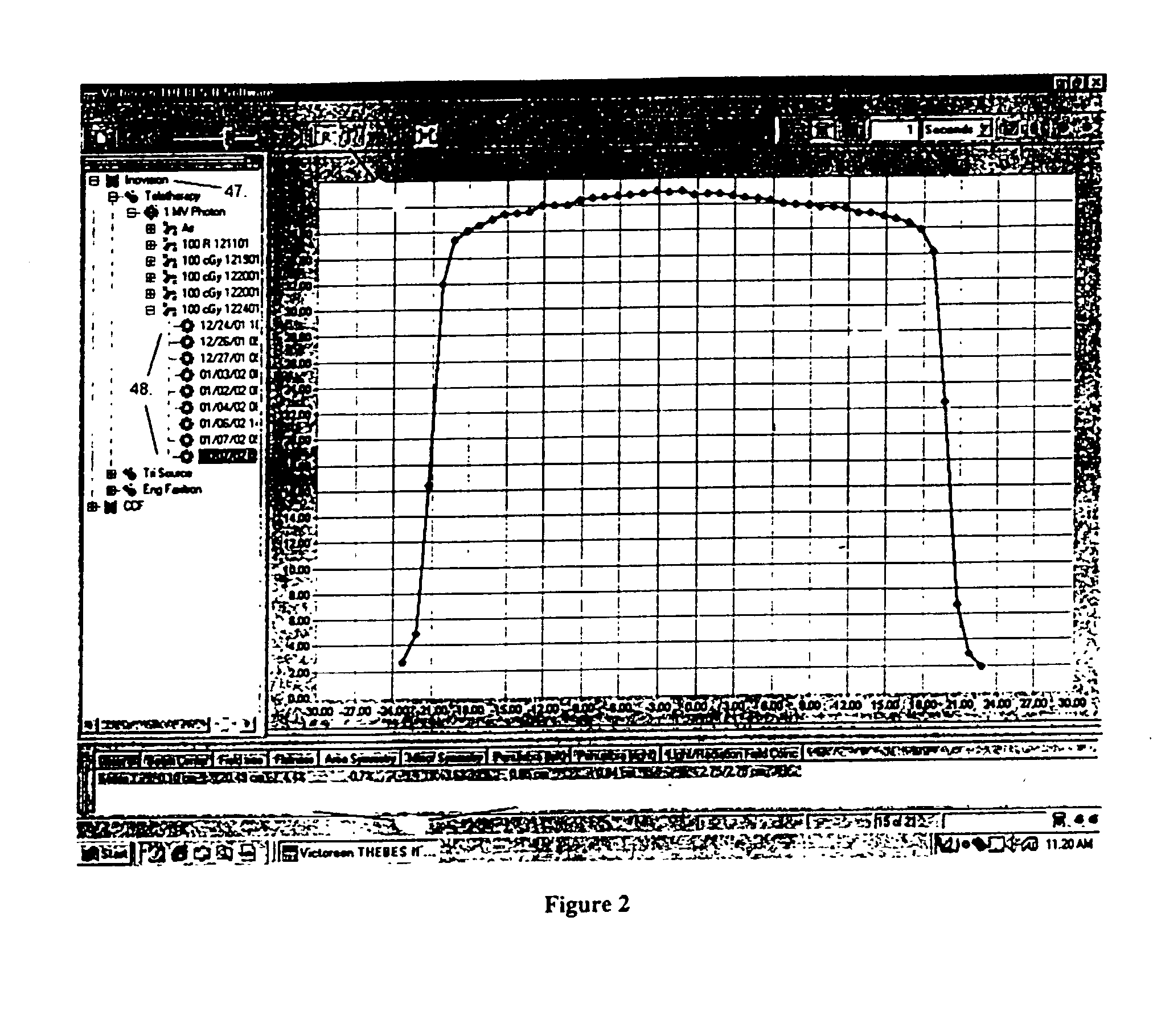

A radiation detection system has a linear array of radiation detectors, which are preferably ionization chambers. The detectors are connected, preferably permanently, to a multi-channel signal processor through a flexible multi-conductor shielded cable. The multi-channel signal processor is connected to a controller, such as a personal computer, through a multi-conductor cable and a communication interface device. Multiple detector arrays and multi-channel electrometers may be connected to a single personal computer and used simultaneously.

Owner:STANDARD IMAGING

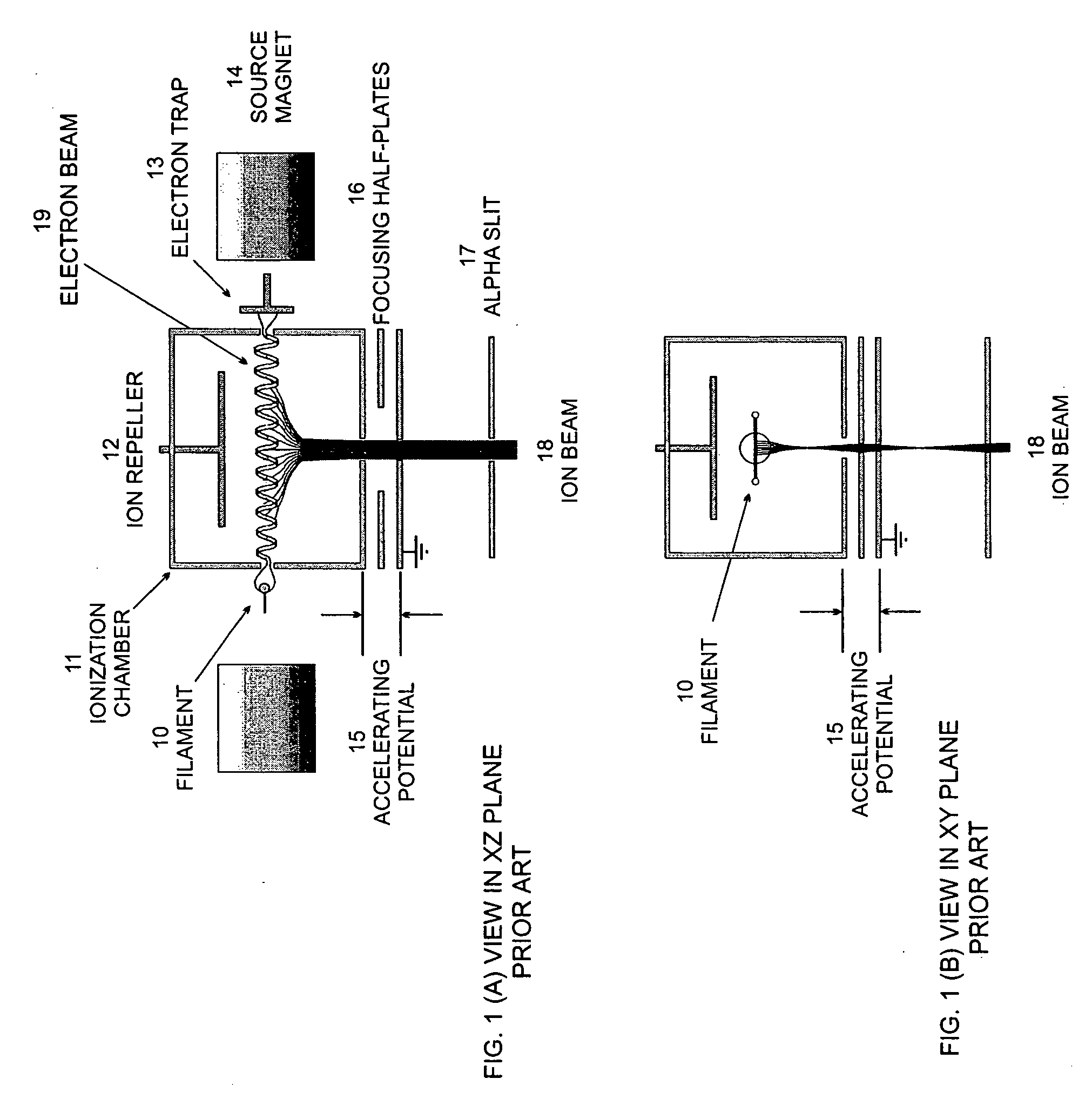

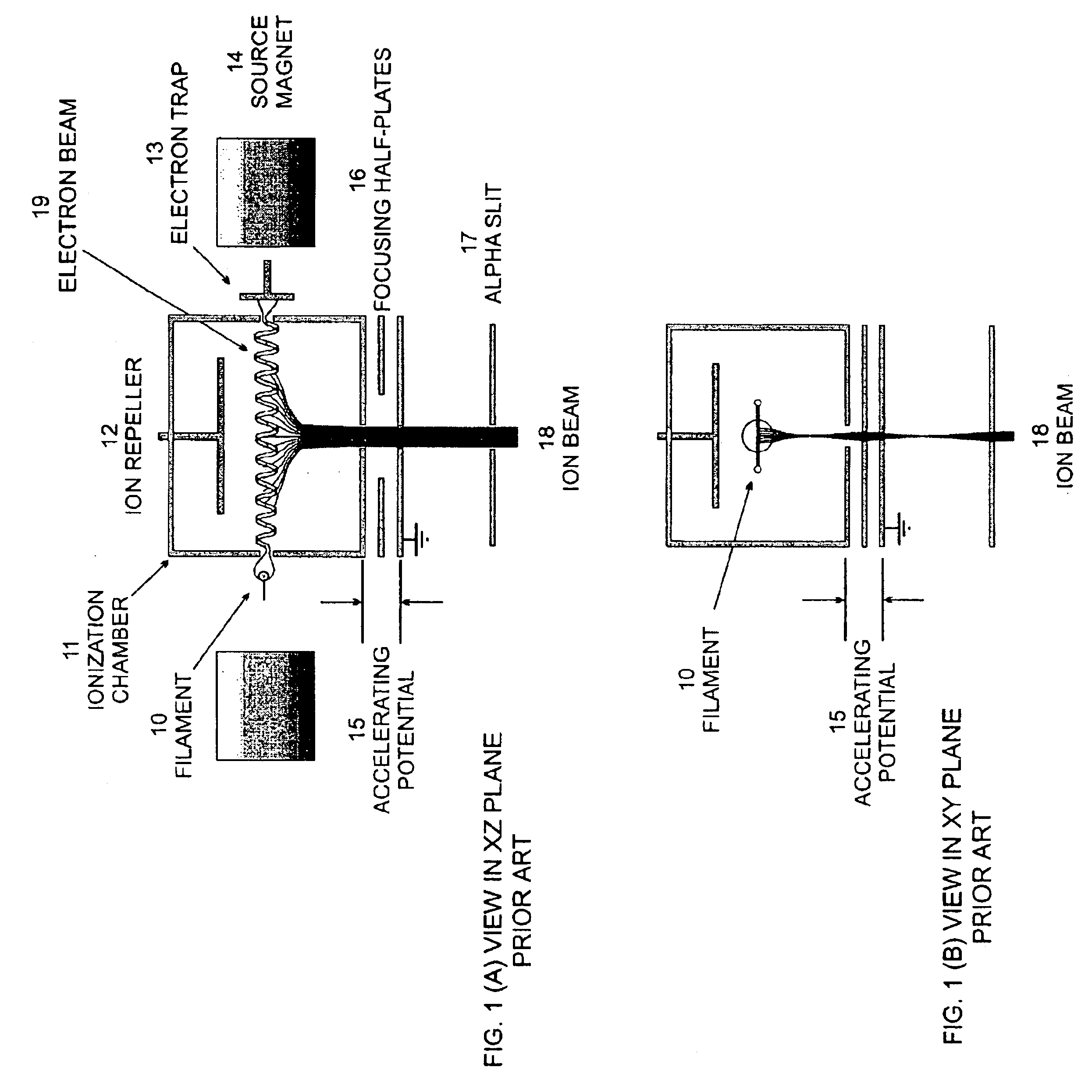

On-axis electron impact ion source

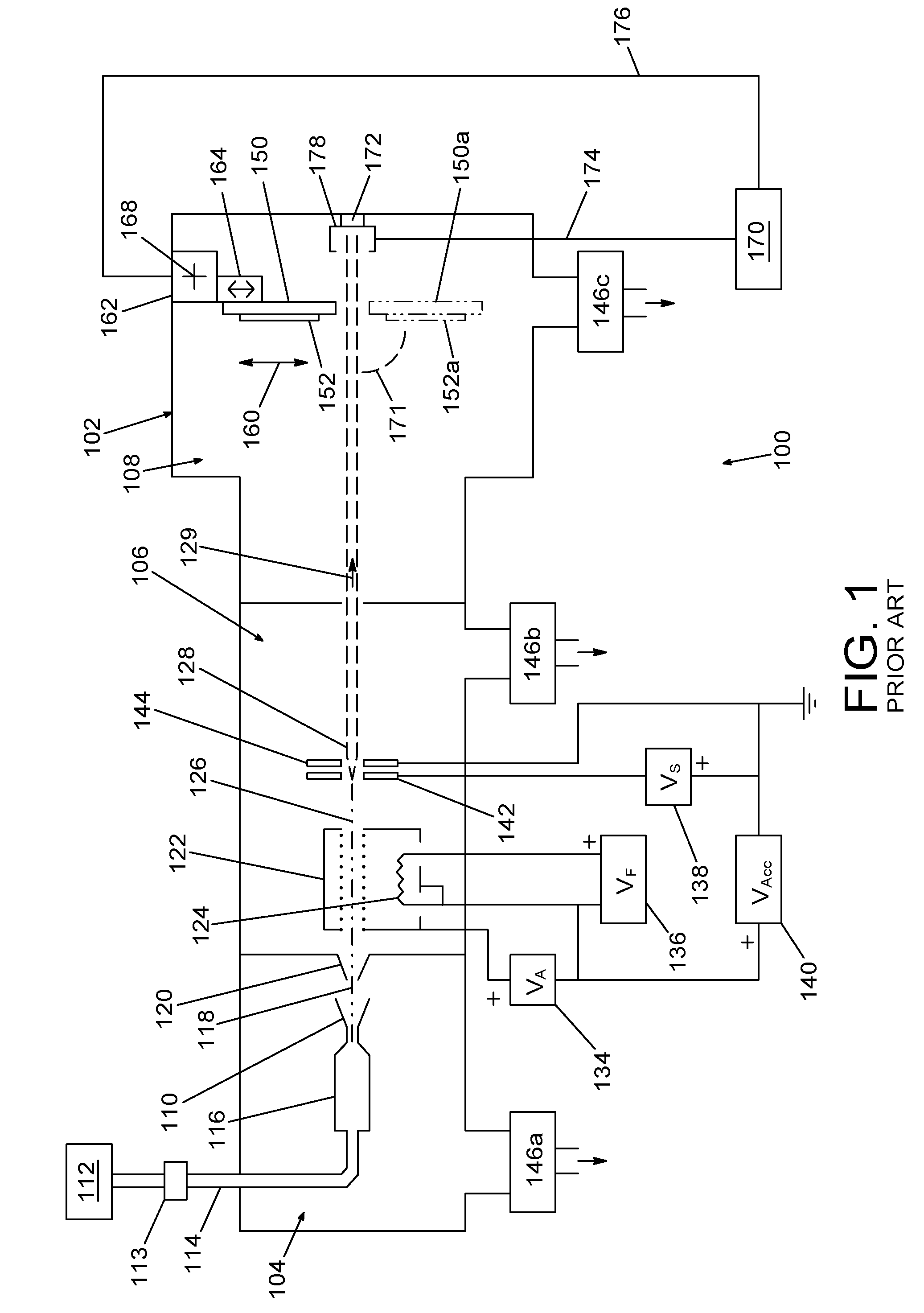

InactiveUS6998622B1Particle separator tubesMaterial analysis by optical meansAnalyteElectron collision

An electron impact ion source includes an ionization chamber in which a first rf multipole field can be generated and an ion guide positioned downstream from the ionization chamber in which a second rf multipole field can be generated wherein electrons are injected into the ionization chamber along the axis (on-axis) to ionize an analyte sample provided to the ionization chamber.

Owner:AGILENT TECH INC

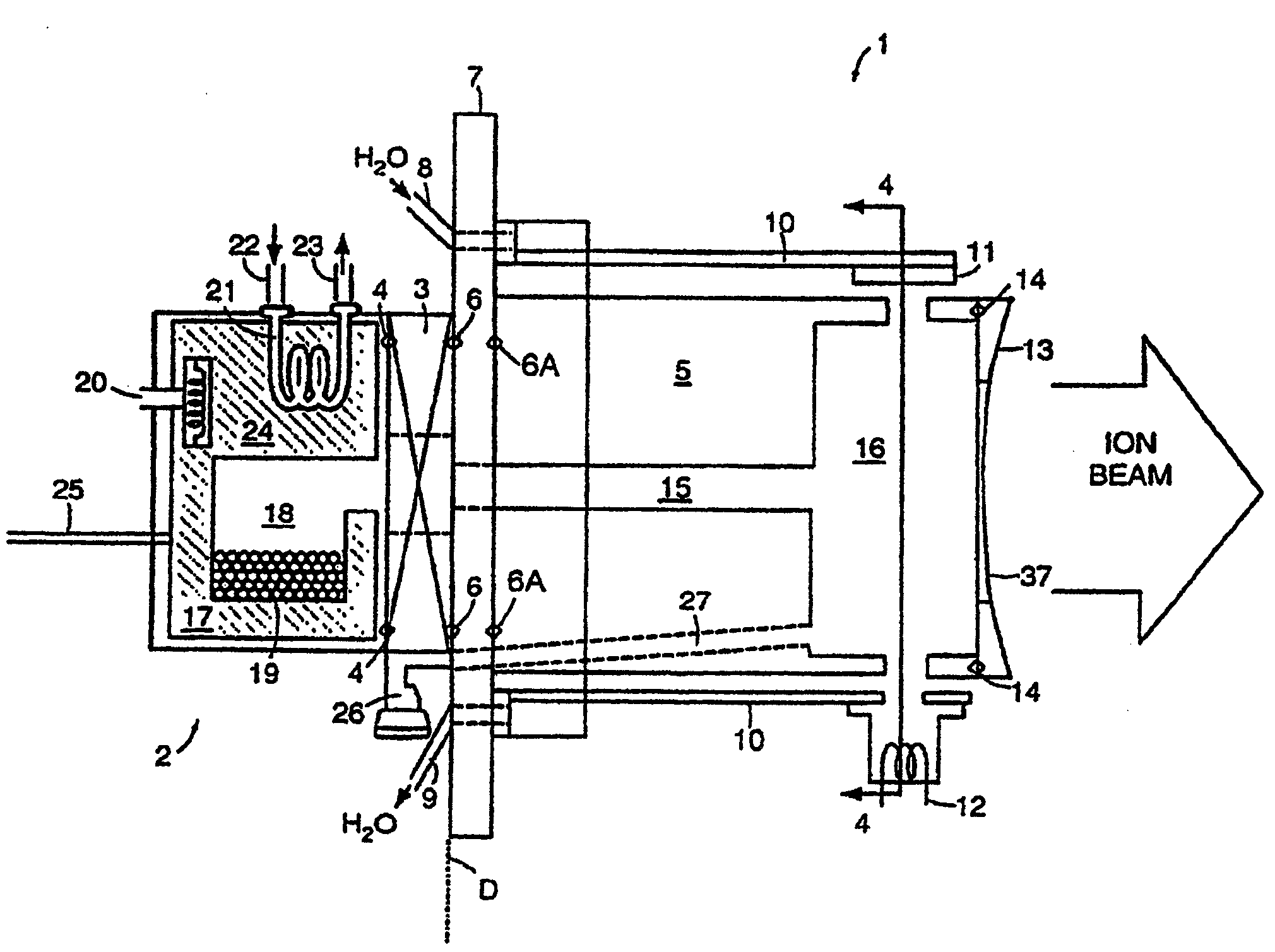

Electron beam ion source with integral low-temperature vaporizer

InactiveUS20020070672A1Maximizes conductanceMinimizes conductanceElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energy beamIon implantation

An ion source for ion implantation system and a method of ion implantation employs a controlled broad, directional electron beam to ionize process gas or vapor, such as decaborane, within an ionization volume by primary electron impact, in CMOS manufacturing and the like. Isolation of the electron gun for producing the energetic electron beam and of the beam dump to which the energetic beam is directed, as well as use of the thermally conductive members for cooling the ionization chamber and the vaporizer, enable use with large molecular species such as decaborane, and other materials which are unstable with temperature. Electron optics systems, facilitate focusing of electrons from an emitting surface to effectively ionize a desired volume of the gas or vapor that is located adjacent the extraction aperture. The components enable retrofit into ion implanters that have used other types of ion sources. Demountable vaporizers, and numerous other important features, realize economies in construction and operation. Achievement of production-worthy operation in respect of very shallow implants is realized.

Owner:SEMEQUIP

Mass spectrometer and mass analyzing method

ActiveUS20120326022A1High sensitivityImprove throughputSamples introduction/extractionIsotope separationIonization chamberMass analyzer

A mass spectrometer including a sample attaching member of attaching a sample, an ionizing chamber including an introductory port of the sample attaching member and an ionization source of generating a sample ion, a vacuumed chamber having a mass analyzer of analyzing the sample ion, and an opening / closing mechanism provided between the ionizing chamber and the vacuumed chamber, in which the opening / closing mechanism is controlled from a closed state to an open state after introducing the sample attaching member into the ionizing chamber to thereby enable to perform ionization with inconsiderable fragmentation at a high sensitivity with a high throughput

Owner:HITACHI HIGH-TECH CORP

External cathode ion source

An ion source is disclosed for use in fabrication of semiconductors. The ion source includes an electron emitter that includes a cathode mounted external to the ionization chamber for use in fabrication of semiconductors. In accordance with an important aspect of the invention, the electron emitter is employed without a corresponding anode or electron optics. As such, the distance between the cathode and the ionization chamber can be shortened to enable the ion source to be operated in an arc discharge mode or generate a plasma. Alternatively, the ion source can be operated in a dual mode with a single electron emitter by selectively varying the distance between the cathode and the ionization chamber.

Owner:SEMEQUIP

Method and Apparatus for Generation of Reagent Ions in a Mass Spectrometer

A front-end ion source for a mass spectrometer generates both analyte and reagent ions. The reagent source may include a heater for vaporizing a condensed-phase reagent substance and an electron source for ionizing reagent molecules. The interior of the reagent ionization chamber is purged with a purge gas to avoid or minimize reaction of the reagent ions with oxygen or other reactive species, thereby enabling operation of the reagent ionization chamber at or near atmospheric pressure. The reagent and analyte ions are directed into a reduced-pressure chamber through separate passageways. An ion transport optic selectively transmits one of the analyte ions or the reagent ions from the reduced-pressure chamber to downstream regions of the mass spectrometer.

Owner:THERMO FINNIGAN

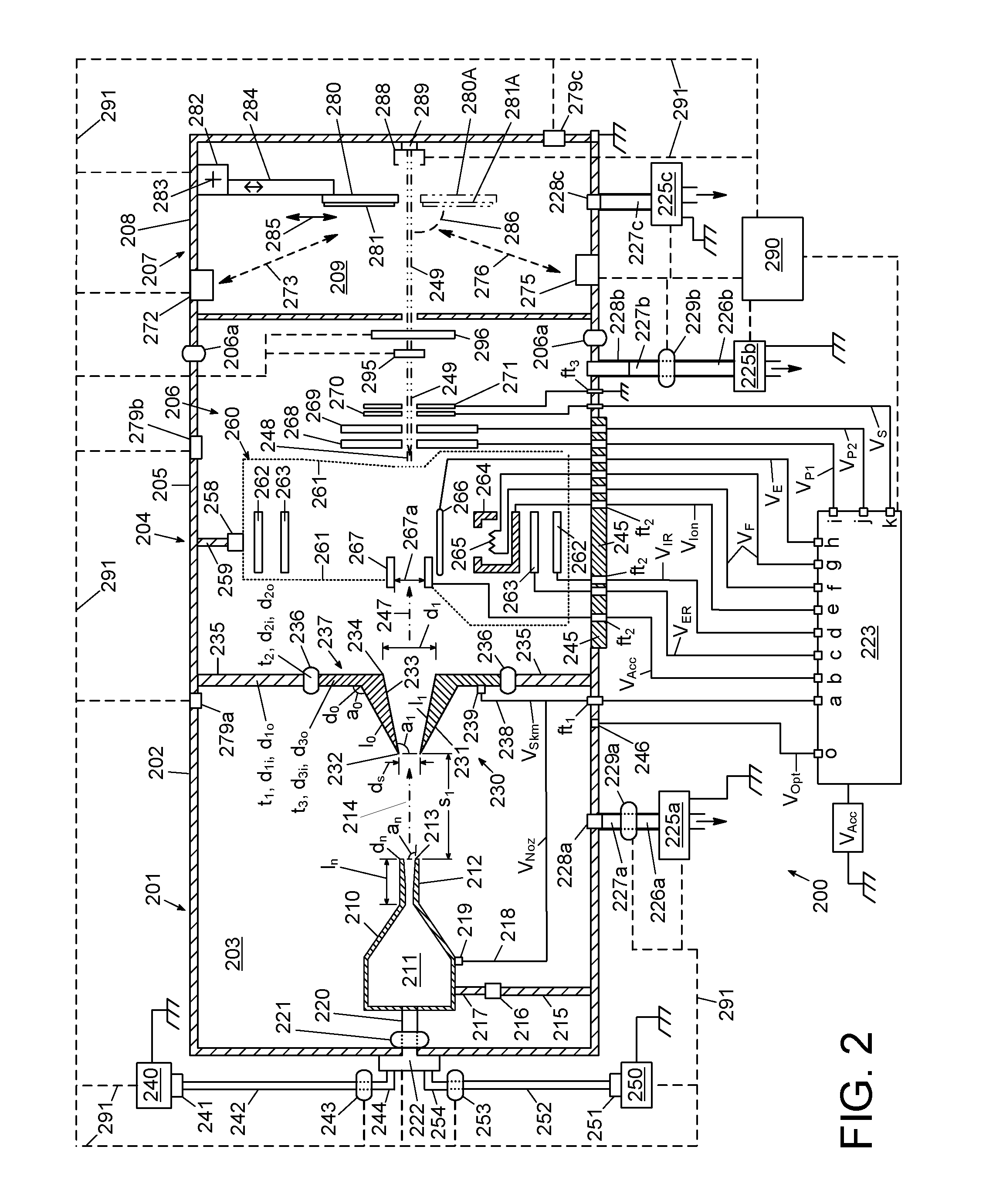

High-voltage gas cluster ion beam (GCIB) processing system

InactiveUS20110240602A1Electric discharge tubesDecorative surface effectsIonization chamberGas cluster ion beam

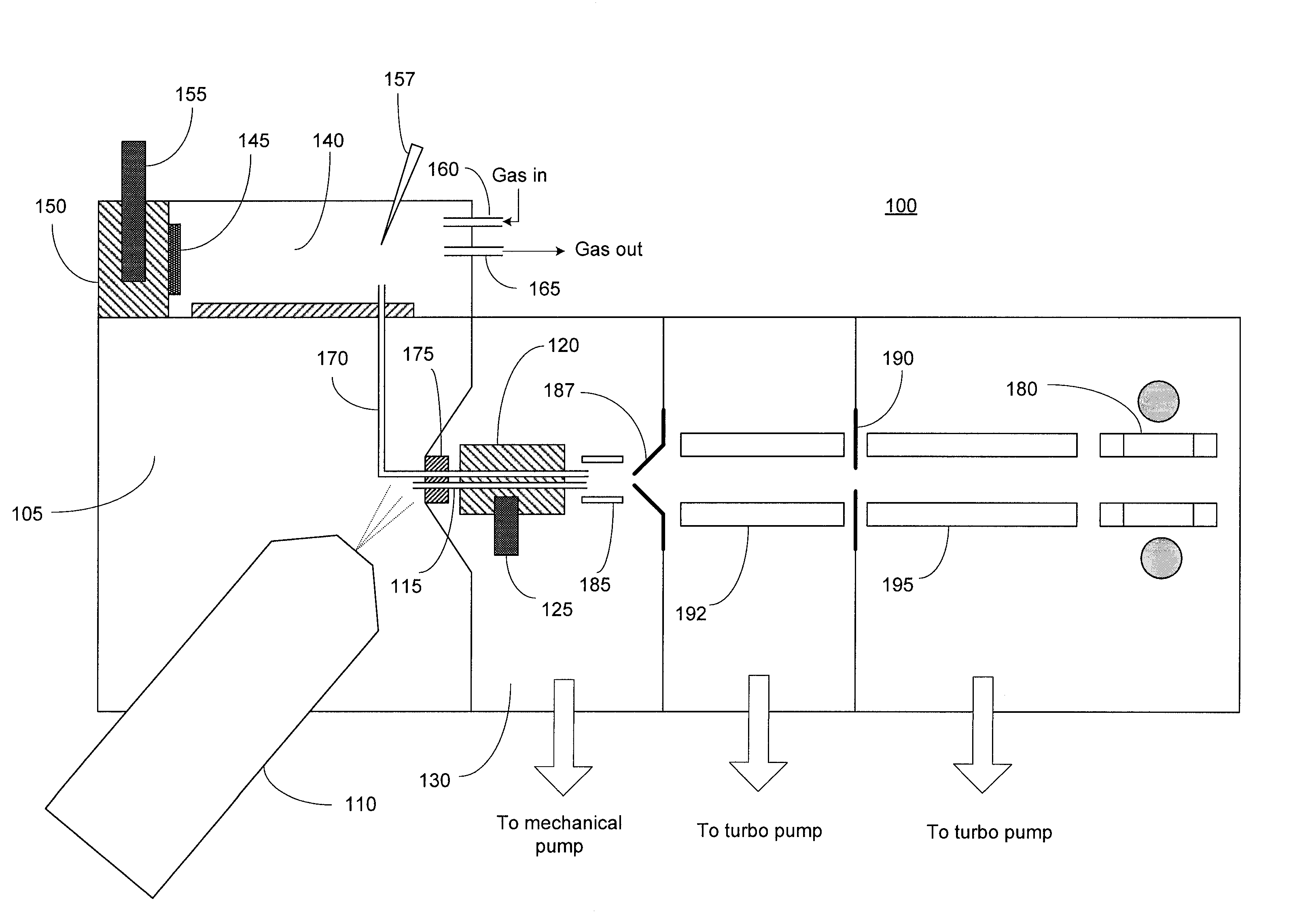

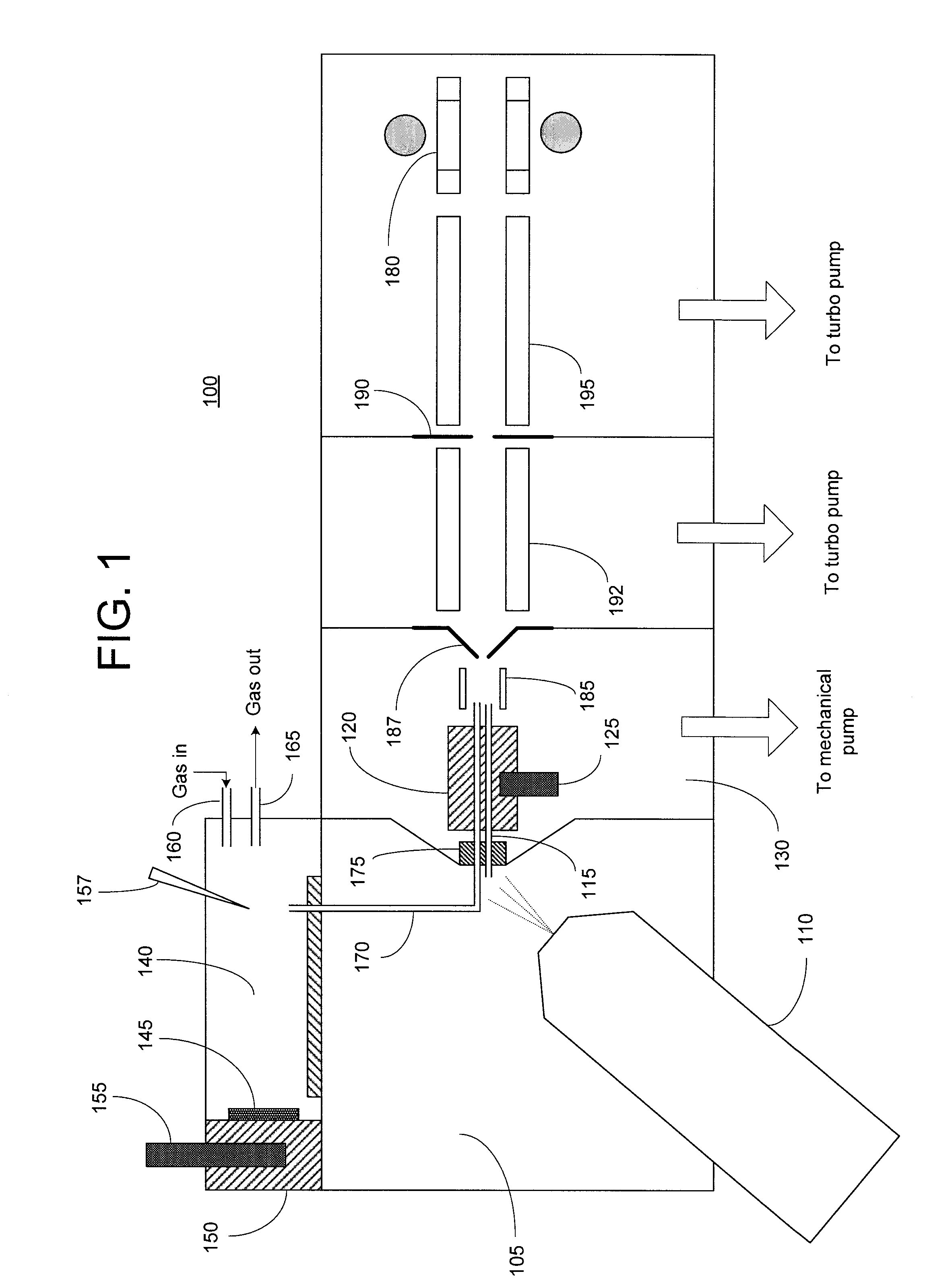

The invention includes a high-voltage gas cluster ion beam (GCIB) processing system for treating a workpiece using a gas cluster ion beam. The high-voltage GCIB processing system includes a high-voltage (HV) source system that includes a high-voltage (HV) source chamber having a high-voltage (HV) nozzle subassembly, a nozzle element, and a high-voltage (HV) skimmer subassembly therein. The high-voltage gas cluster ion beam (GCIB) processing system includes a high-voltage (HV) power supply coupled to the HV nozzle subassembly and the HV skimmer subassembly. A high-voltage (HV) ionization chamber can be coupled to the HV source chamber and can include an ionizer coupled to the chamber wall by an isolation structure. In addition, a grounded GCIB processing chamber can be coupled to the HV ionization chamber by an isolation structure and can include a scanable workpiece holder.

Owner:TEL EPION

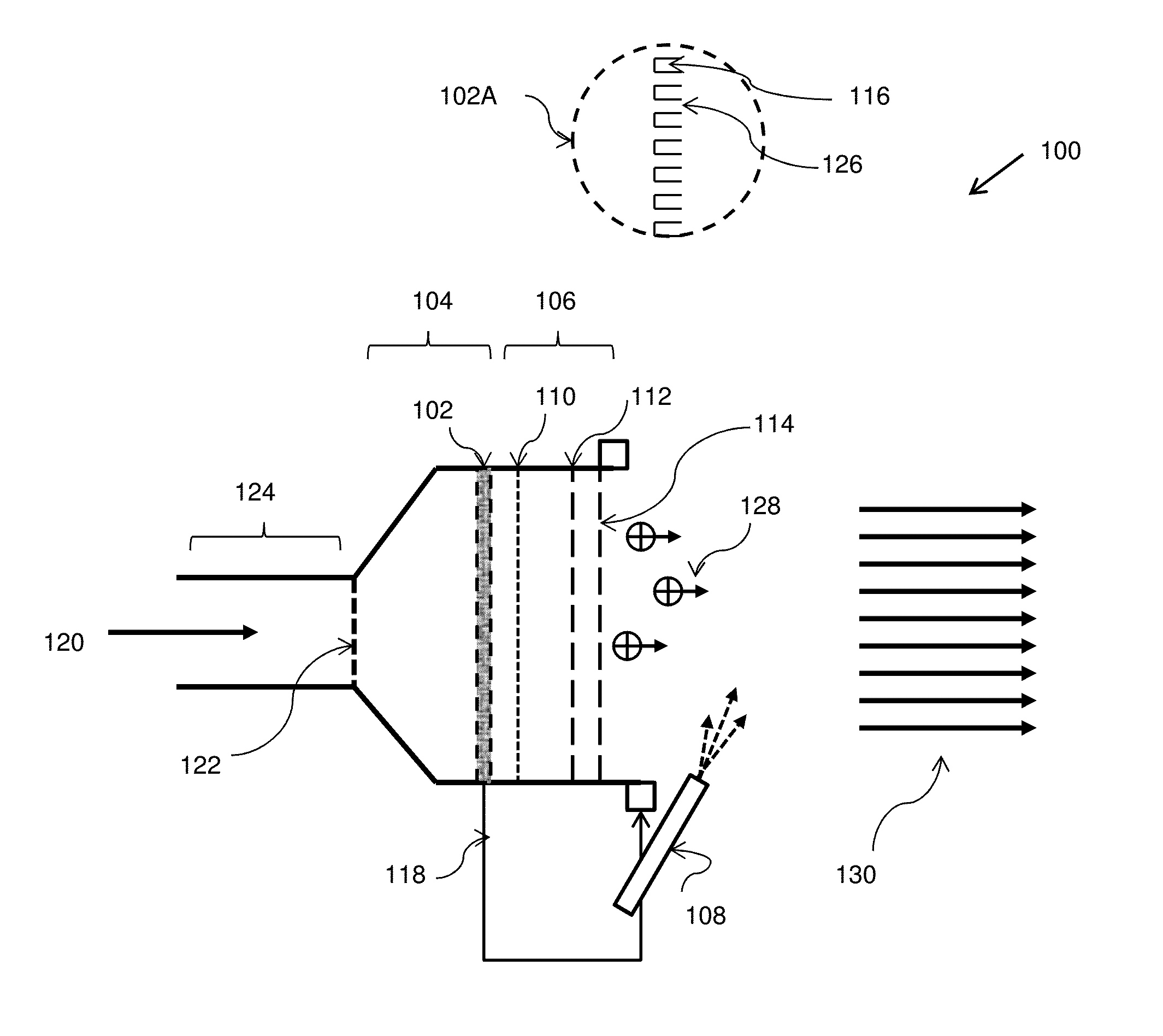

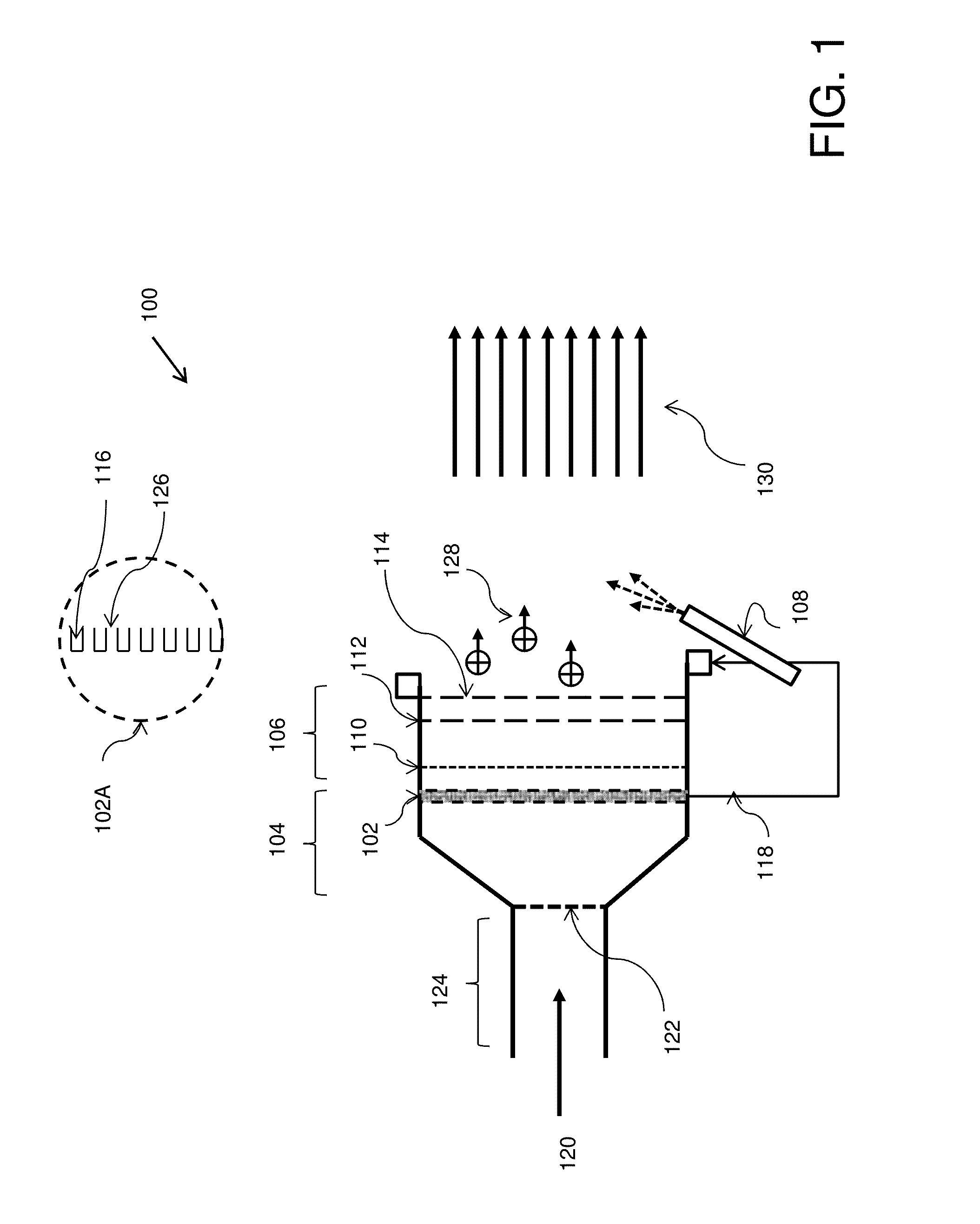

Field-ionization based electrical space ion thruster using a permeable substrate

ActiveUS9194379B1Cosmonautic vehiclesCosmonautic propulsion system apparatusField electron emissionCarbon nanotube

A field-ionization based electrical ion thruster utilizes a single propellant that can be used in either a high specific-impulse mode, i.e., ion-thruster mode, or a low-specific-impulse mode, i.e., a cold-gas thruster mode. In one embodiment, the high specific impulse mode (ion thruster mode) utilizes a miniaturized positive-ion field-ionization chamber including a permeable substrate infused with properly oriented carbon nanotubes (CNTs), which is fed propellant from a porous injection plug made from permeable carbon or equivalent material. In one embodiment, field-electron emission from a neutralizer, such as a carbon nanotube array neutralizer, positioned after one or more accelerator grids is used for ion neutralization. In one embodiment, the low specific-impulse (cold-gas mode) uses a conventional supersonic nozzle-expansion to generate thrust. In one embodiment, both the high specific-impulse mode and the low specific-impulse mode thruster embodiments share the same gas propellant, storage propellant tank, and delivery equipment.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Simulated dose calibrator source standard for positron emission tomography radionuclides

ActiveUS7825372B2Accurate activityCalibration apparatusPortable shielded containersEpoxyPositron emitters

A method for calibration and a calibrator source standard calibrated by the method are provided. The calibration method includes providing mock syringes, or other simulated dose container. A first of the mock syringes is filled with a short half life positron emitter. A second of the mock syringes is filled with a longer half life radionuclide set in a matrix material such as an epoxy. The activities of the two syringes can be determined, ideally in the same ion chamber, for example, against a radioactive source standard having a half life greater than the first and second radionuclides. This allows a conversion factor to be determined which can be used for a calibrator source standard formed as for the second mock syringe (i.e., with the same type of container containing the longer half life radionuclide set in a matrix material), when the calibrator source standard is used as a proxy for calibrating a calibrator for use in determining the activity of a dose container of the same configuration containing a dose of the short lived radionuclide.

Owner:RADQUAL

Electrospray ion source apparatus

ActiveUS7199364B2Easy to produceIncrease ratingsClosuresEnergy spectrometersAnalyteIonization chamber

An electrospray interface for forming ions from a liquid sample in a mass analyzing system includes a capillary tube having a free end for introducing a spray of droplets into an ionization chamber, a first gas passageway positioned near the capillary tube for directing a first gas stream into the ionization chamber, and a second gas passageway positioned more remotely from the capillary tube for directing a second, low-velocity gas stream into the ionization chamber. The second gas stream is heated to increase the droplet desolvation rate. A heated sampling capillary having an end extending into the ionization chamber guides the analyte ions toward a mass analyzer and evaporates the solvent from any incompletely desolvated droplets entering the sampling capillary.

Owner:THERMO FINNIGAN

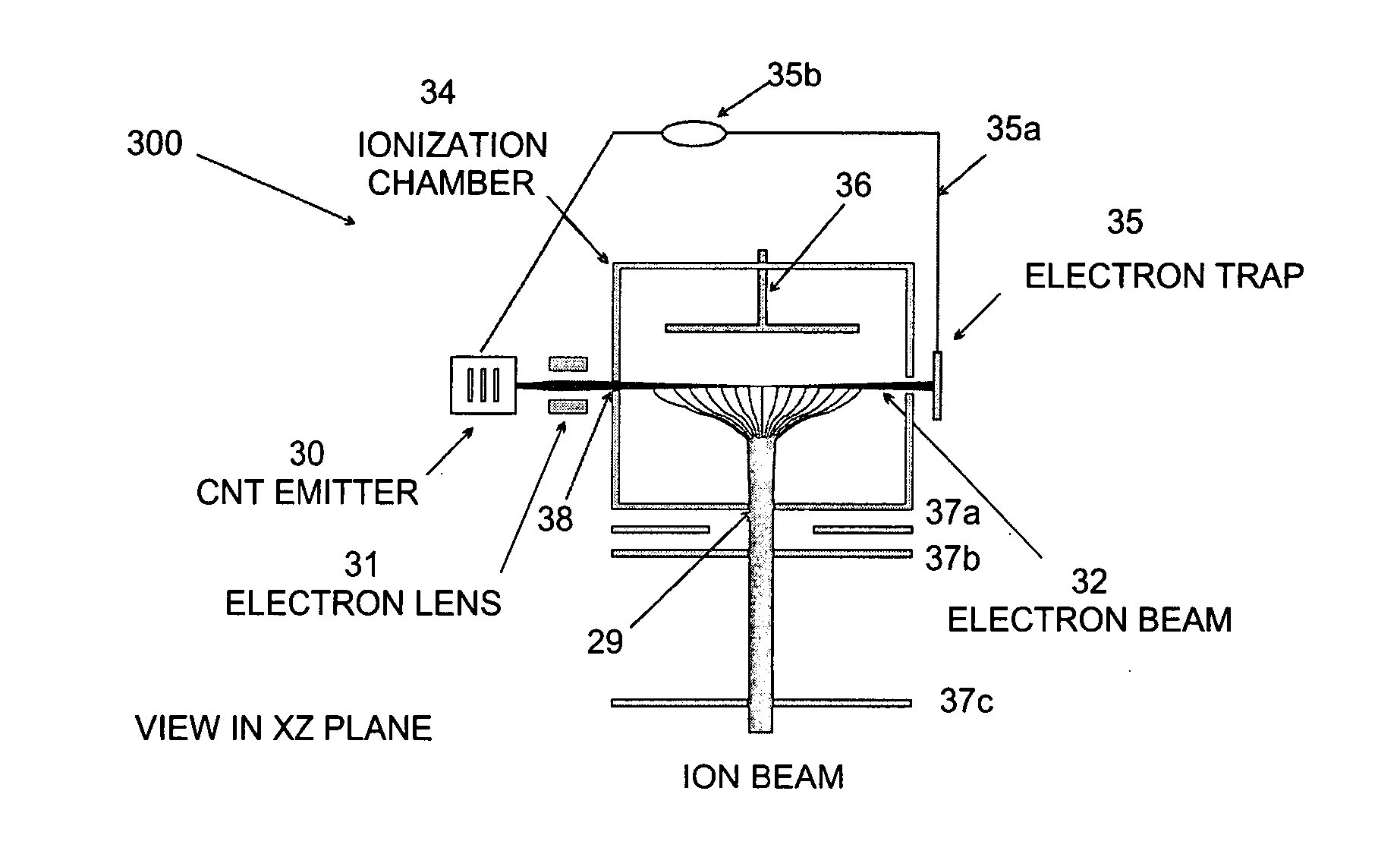

Carbon nanotube electron ionization sources

ActiveUS6885010B1Reduce in quantityEasy CalibrationMaterial nanotechnologyLamp incadescent bodiesLight beamIonization chamber

An ion source for use in a mass spectrometer includes an electron emitter assembly configured to emit electron beams, wherein the electron emitter assembly comprises carbon nanotube bundles fixed to a substrate for emitting the electron beams, a first control grid configured to control emission of the electron beams, and a second control grid configured to control energies of the electron beams; an ionization chamber having an electron-beam inlet to allow the electron beams to enter the ionization chamber, a sample inlet for sample introduction, and an ion-beam outlet to provide an exit for ionized sample molecules; an electron lens disposed between the electron emitter assembly and the ionization chamber to focus the electron beams; and at least one electrode disposed proximate the ion-beam outlet to focus the ionized sample molecules exiting the ionization chamber.

Owner:THERMO ELECTRON A DE

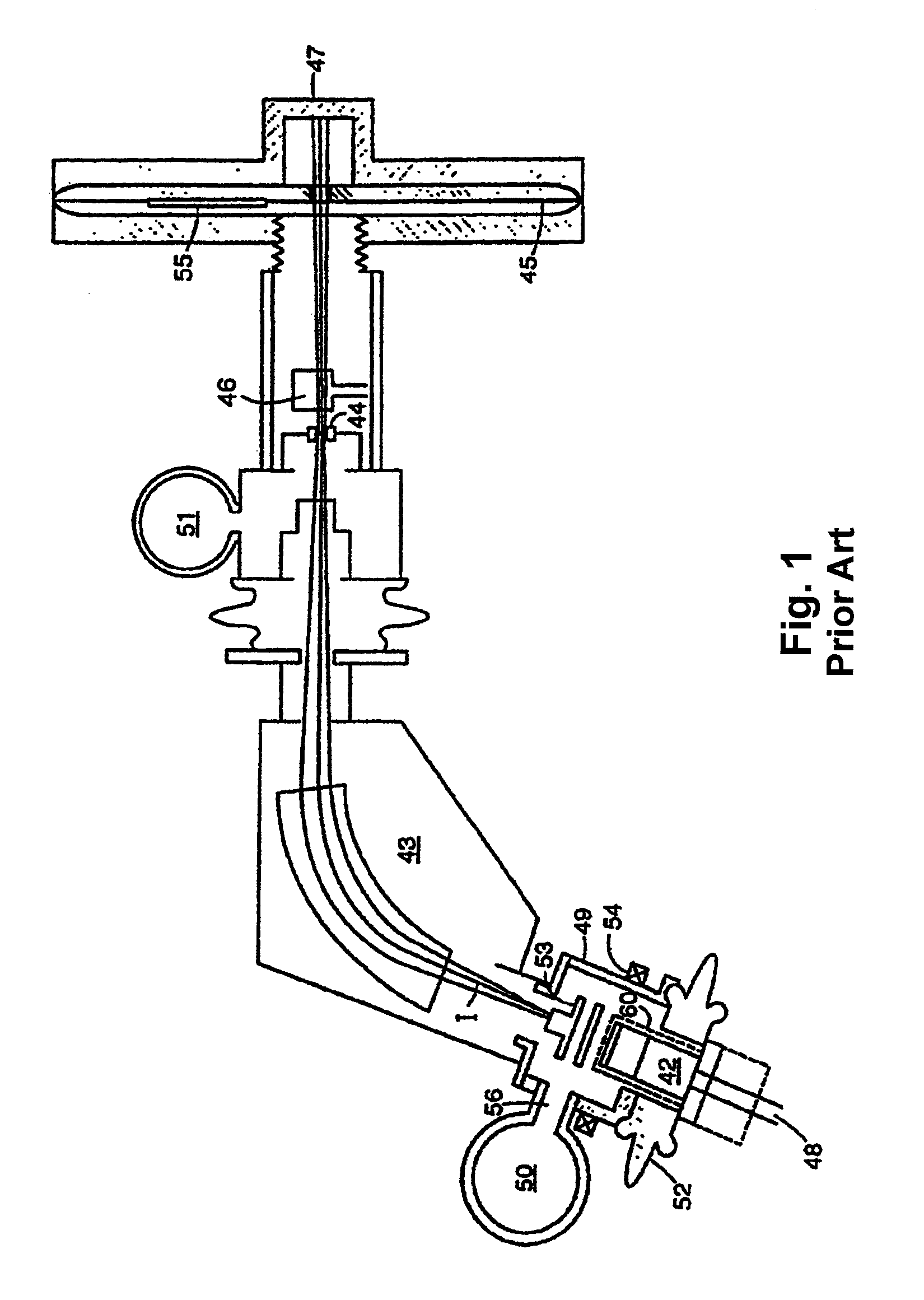

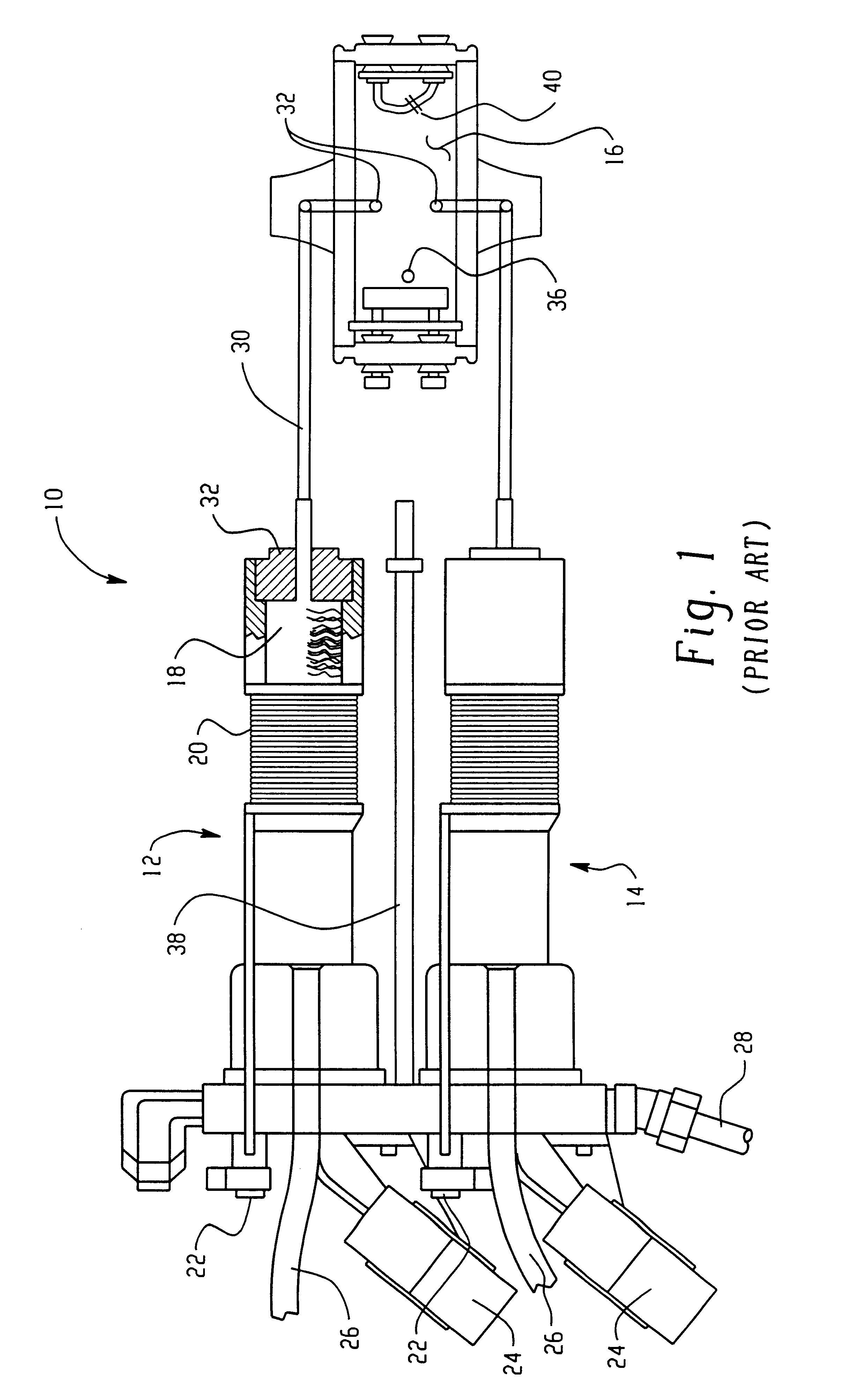

Decaborane ion source

InactiveUS6958481B2Minimize plasma densityAvoid dissociationMaterial analysis by optical meansIon beam tubesPlasma densitySource material

An ion source (50) for an ion implanter is provided, comprising a remotely located vaporizer (51) and an ionizer (53) connected to the vaporizer by a feed tube (62). The vaporizer comprises a sublimator (52) for receiving a solid source material such as decaborane and sublimating (vaporizing) the decaborane. A heating mechanism is provided for heating the sublimator, and the feed tube connecting the sublimator to the ionizer, to maintain a suitable temperature for the vaporized decaborane. The ionizer (53) comprises a body (96) having an inlet (119) for receiving the vaporized decaborane; an ionization chamber (108) in which the vaporized decaborane may be ionized by an energy-emitting element (110) to create a plasma; and an exit aperture (126) for extracting an ion beam comprised of the plasma. A cooling mechanism (100, 104) is provided for lowering the temperature of walls (128) of the ionization chamber (108) (e.g., to below 350° C.) during ionization of the vaporized decaborane to prevent dissociation of vaporized decaborane molecules into atomic boron ions. In addition, the energy-emitting element is operated at a sufficiently low power level to minimize plasma density within the ionization chamber (108) to prevent additional dissociation of the vaporized decaborane molecules by the plasma itself.

Owner:AXCELIS TECHNOLOGIES

Radiopharmaceutical administration methods, fluid delivery systems and components thereof

ActiveUS9056164B2Accurately calculating and delivering effective dosEasy extractionIn-vivo radioactive preparationsDrug and medicationsIonization chamberBiomedical engineering

A fluid path set for a fluid delivery system includes a tube coil that is designed to optimally position one or more volumes of a pharmaceutical within an ionization chamber to measure and prepare a pharmaceutical dose for administration to a patient. The fluid path set includes a medical fluid component having a first tubing section for connection to a source of a medical fluid, a pharmaceutical component having a second tubing section for connection to a source of a pharmaceutical, and a coil assembly which includes the tube coil. The tube coil may be maintained in a desired dimensional geometry by means of a core structure around which the tube coil is positioned.

Owner:BAYER HEALTHCARE LLC

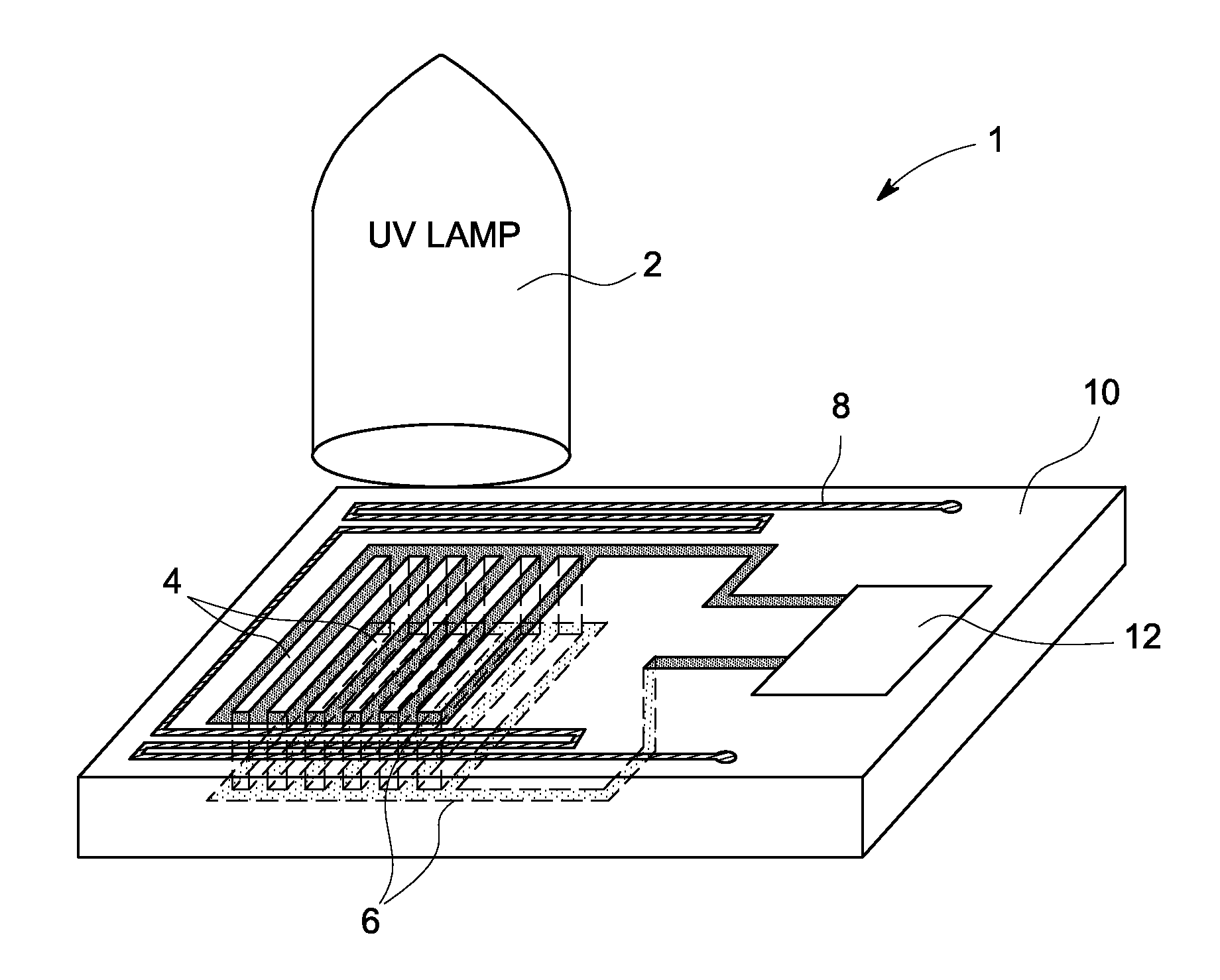

Photo-ionization detectors and associated methods thereof

InactiveUS20120136268A1High selectivityImprove efficiencyMaterial analysis by electric/magnetic meansRespiratory organ evaluationIonization chamberLight beam

A photo ionization detector (PID) is provided for selectively determining various compounds or gases present in a breath sample. The PID, comprises a substrate comprising a gas ionization chamber, at least one pair of ion sensing electrodes, and at least one amplifying circuit; and an ultraviolet (UV) ionization source to transmit a UV light beam into the gas ionization chamber. A system comprises the PID is also provided. A method of detecting a response pattern for various compounds or gases in breath using PID is also provided.

Owner:GENERAL ELECTRIC CO

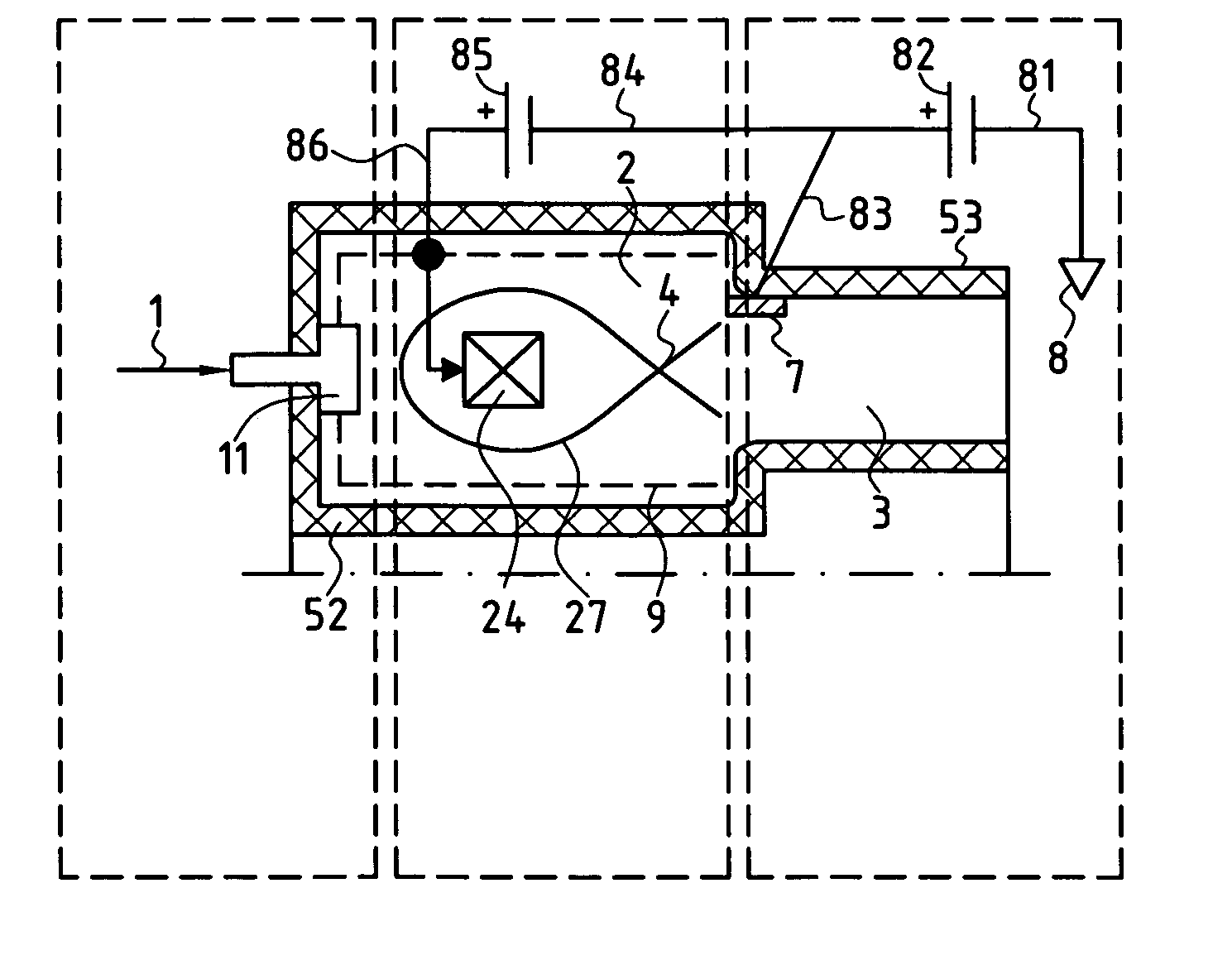

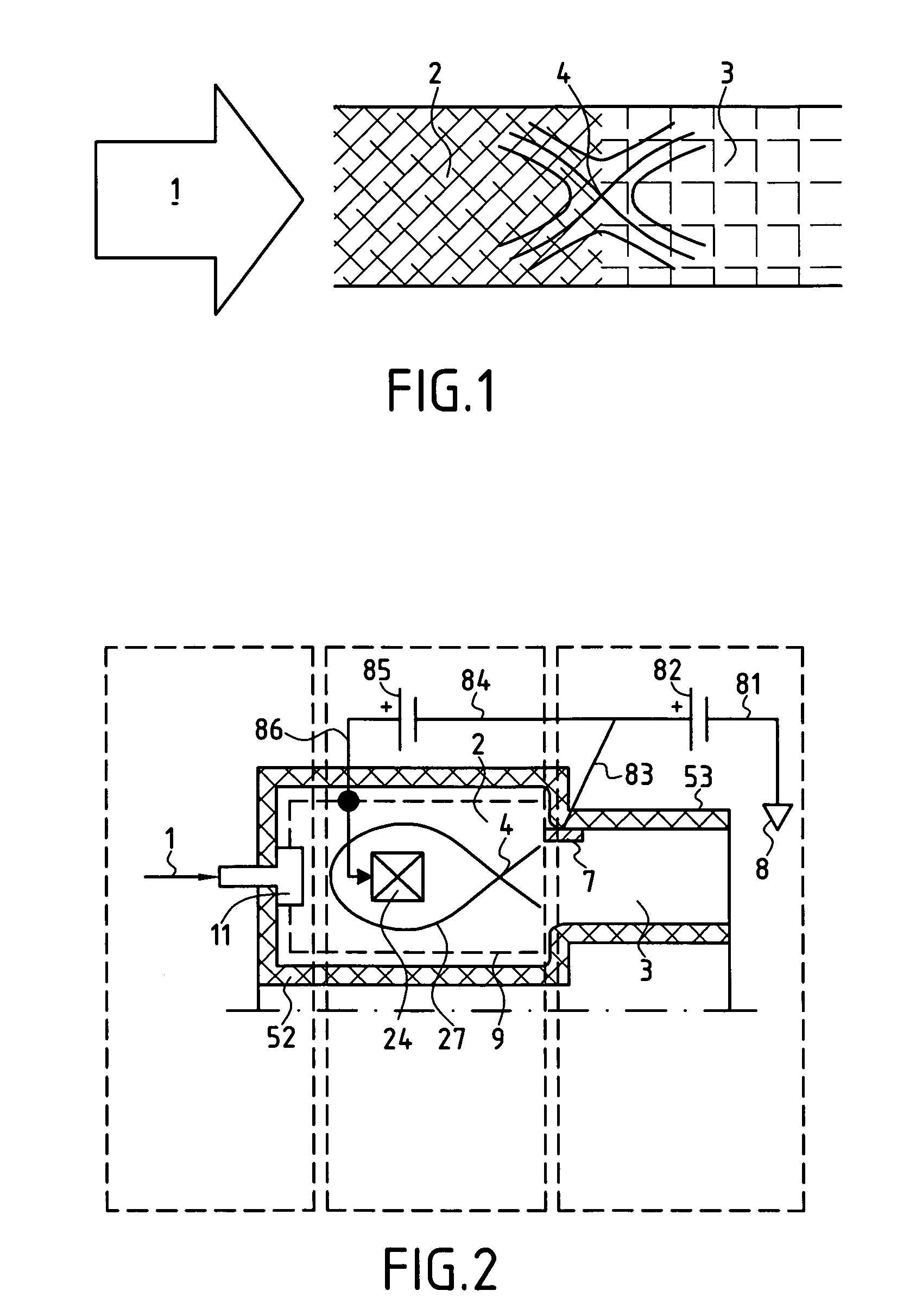

Plasma accelerator with closed electron drift

ActiveUS20050035731A1Improve efficiencyHigh yieldElectric arc lampsTransit-time tubesConductive materialsVoltage source

The closed electron drift plasma accelerator comprises an annular ionization chamber, an acceleration chamber on the same axis as the ionization chamber, an annular anode, a hollow cathode, a first DC voltage source, an annular gas manifold, a magnetic circuit, and magnetic field generators. A coaxial annular coil is placed in the cavity of the ionization chamber, is provided with bias conductive cladding connected, together with the electrically-conductive material of the inside faces of the walls of the ionization chamber, to the positive pole of a second voltage source whose negative pole is connected to the anode, and constitutes an additional magnetic field generator which, together with the other magnetic field generators, forms a magnetic field having a magnetic line of force with an “X” point corresponding to a magnetic field zero situated between the coaxial annular coil and the anode.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com