Patents

Literature

369 results about "Plasma density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Density of Blood. The density of blood plasma is approximately 1025 kg/m 3 and the density of blood cells circulating in the blood is approximately 1125 kg/m 3. Blood plasma and its contents is known as whole blood. The average density of whole blood for a human is about 1060 kg/M 3.

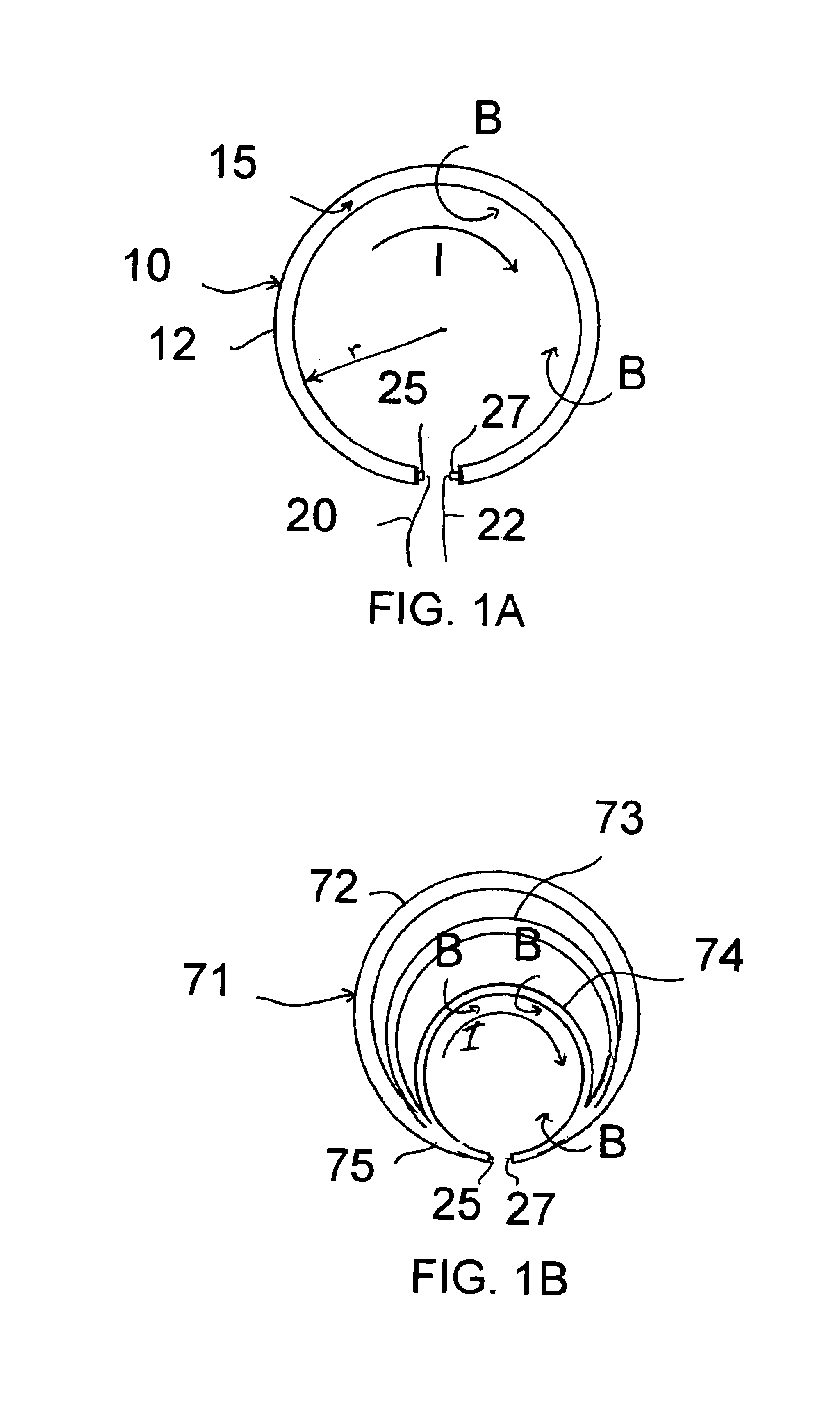

Method of controlling the film properties of PECVD-deposited thin films

ActiveUS20050255257A1Increase in hollow cathode effectIncrease surface areaElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma densityEngineering

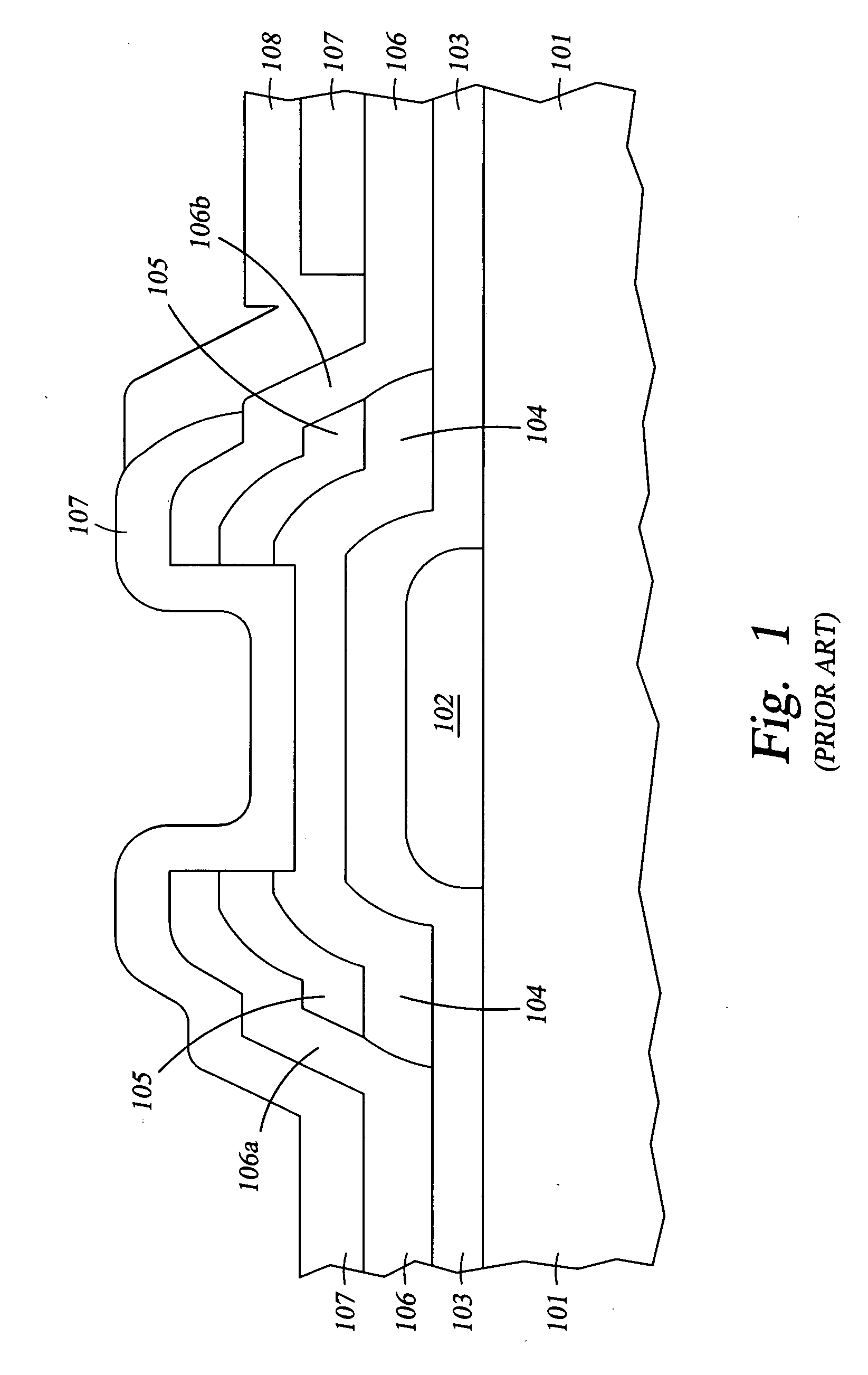

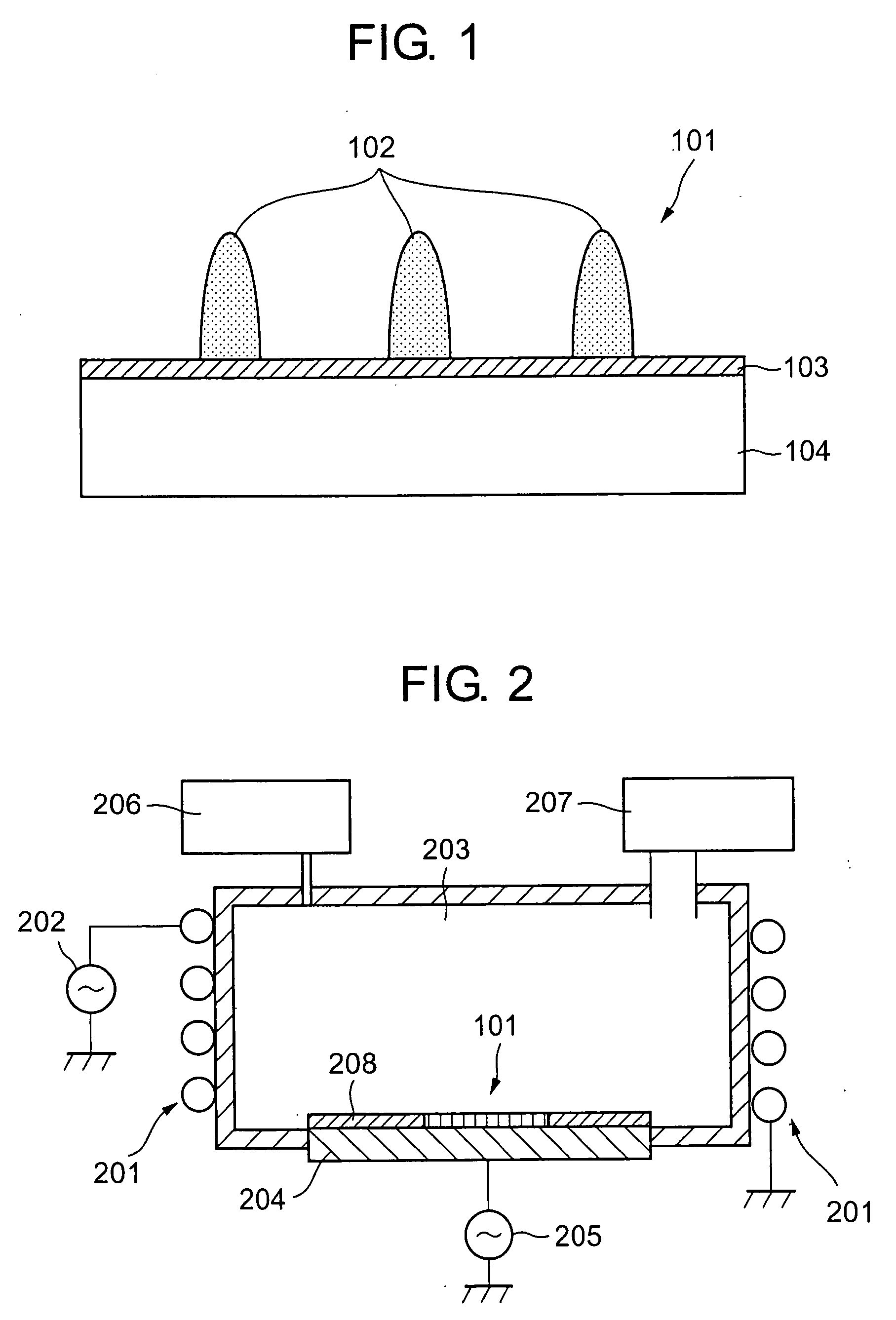

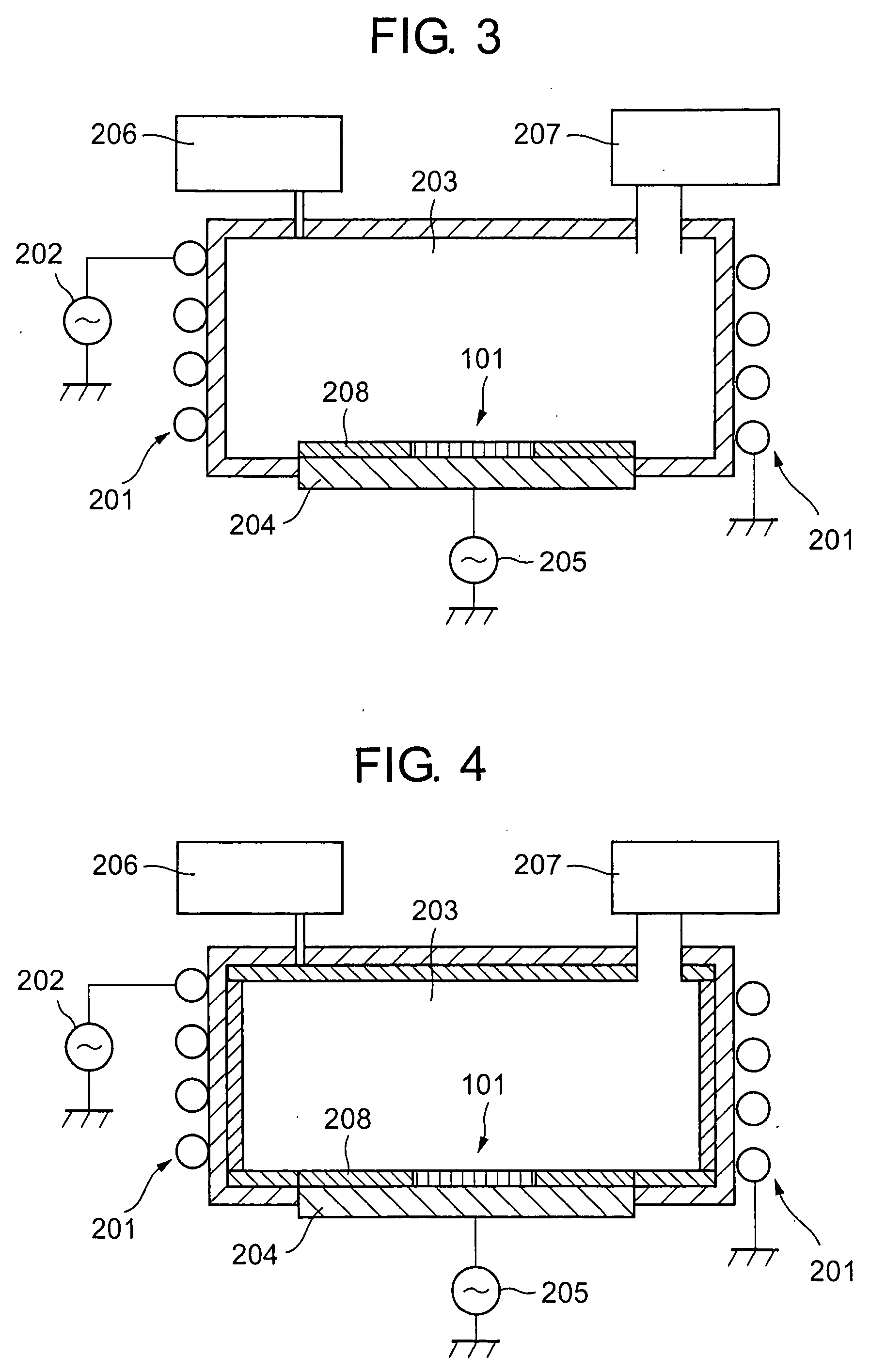

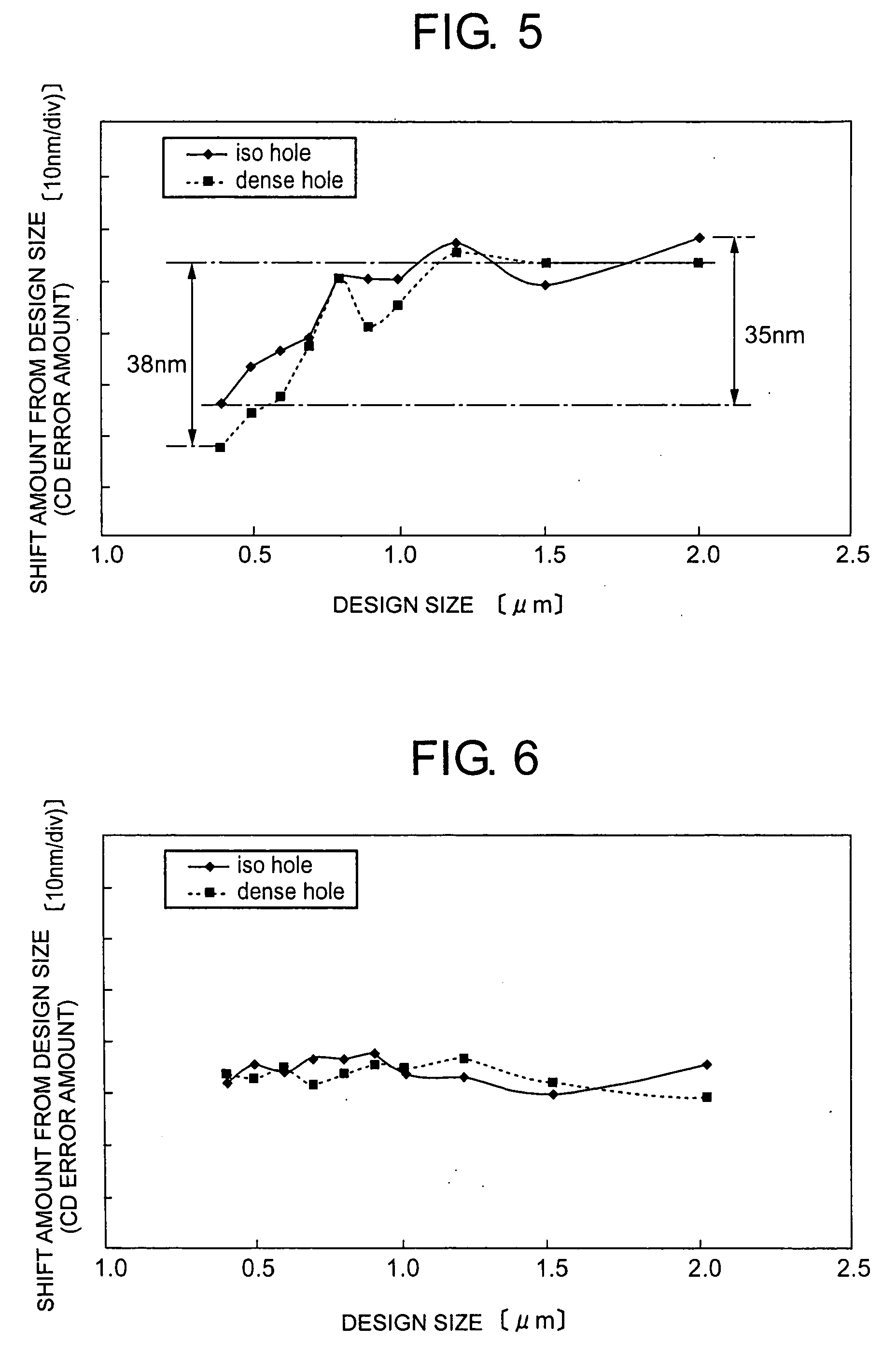

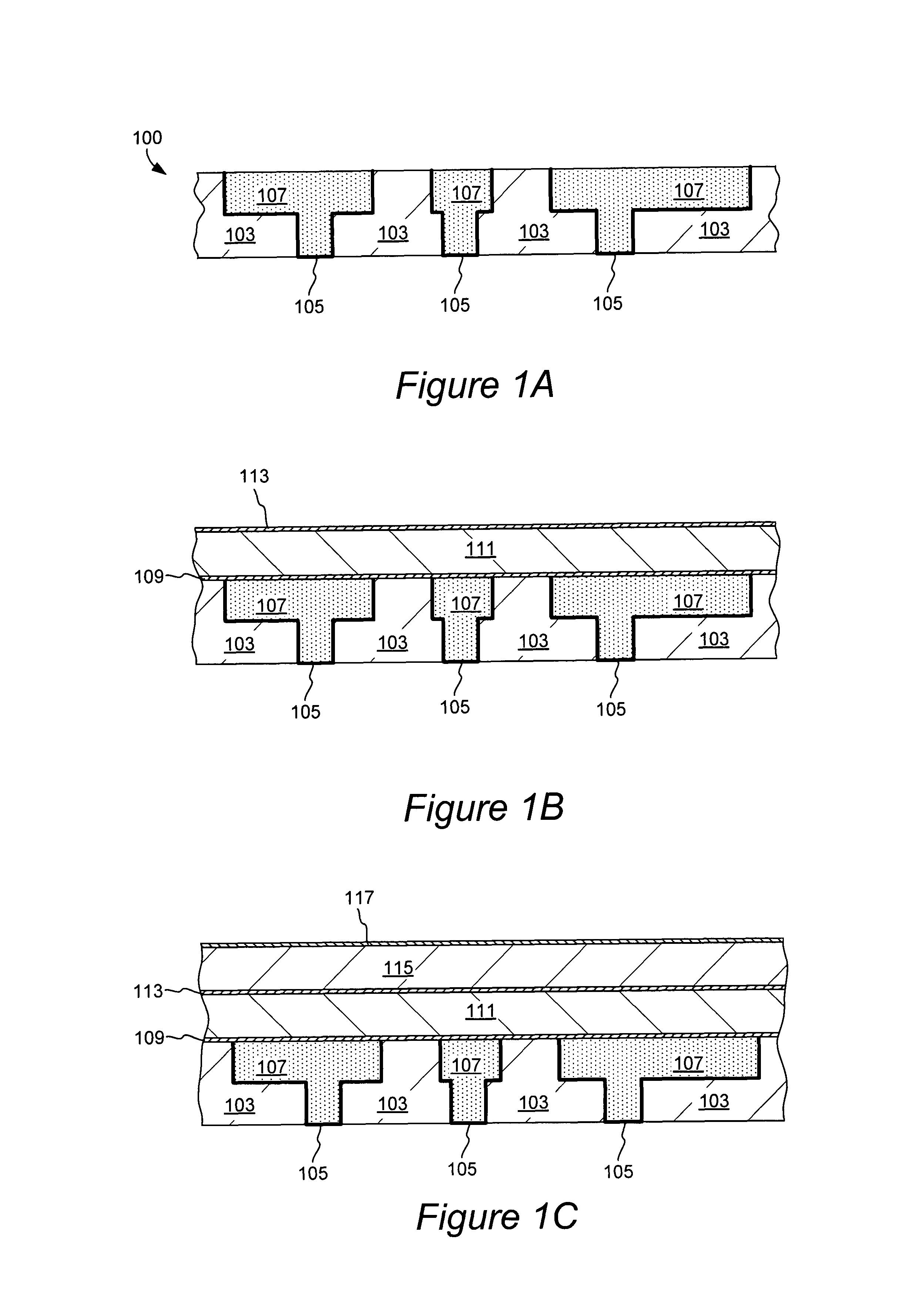

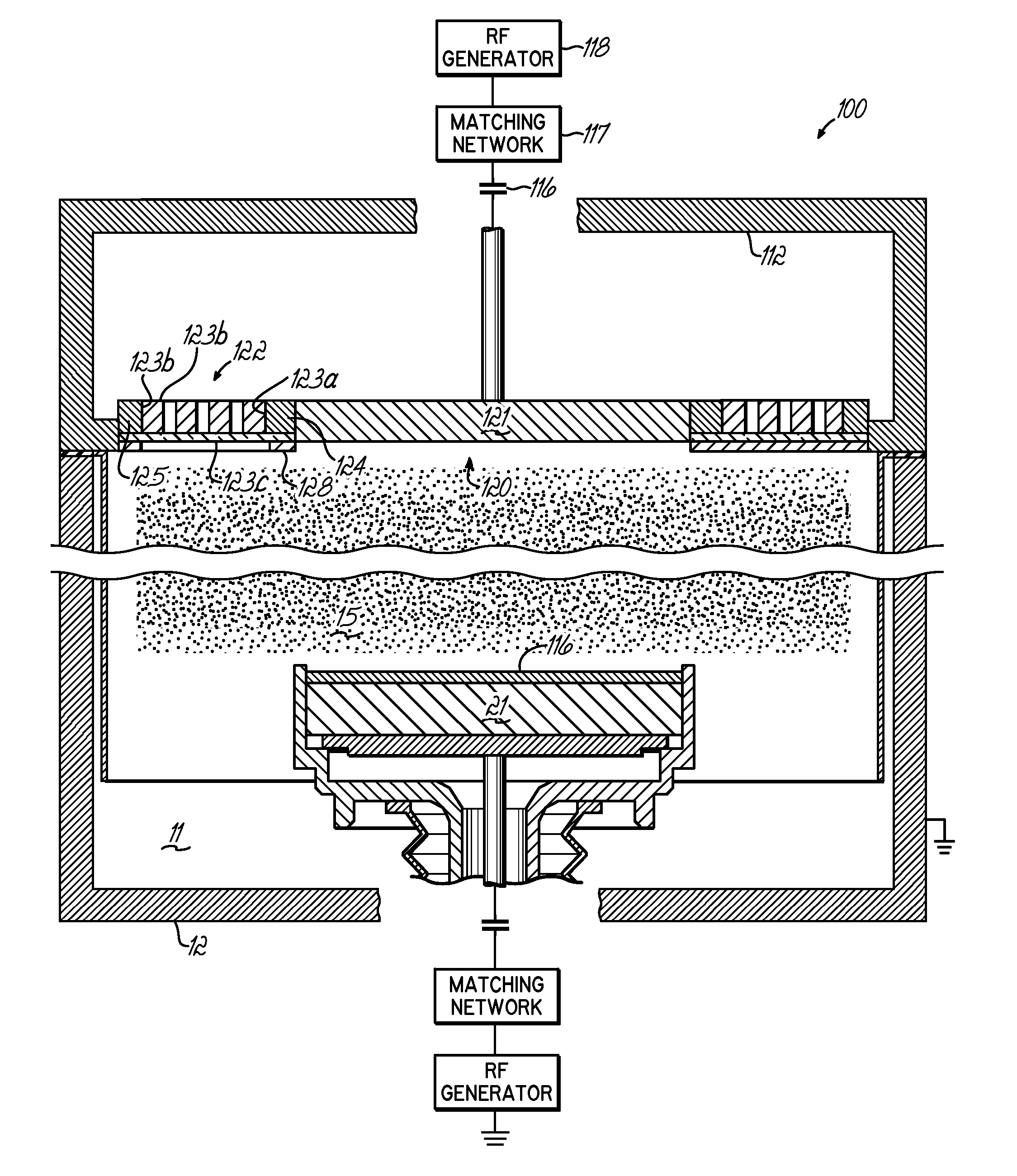

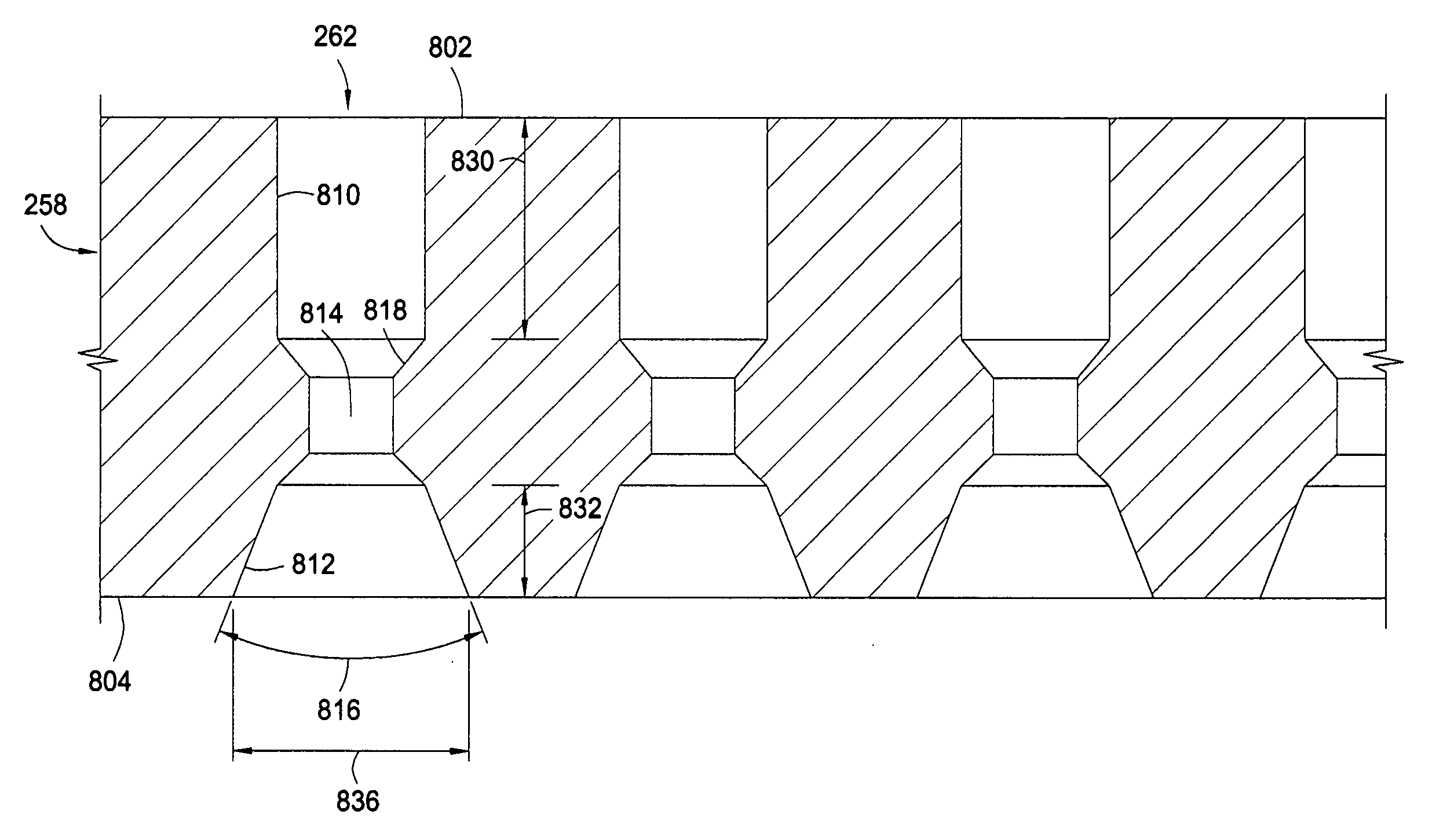

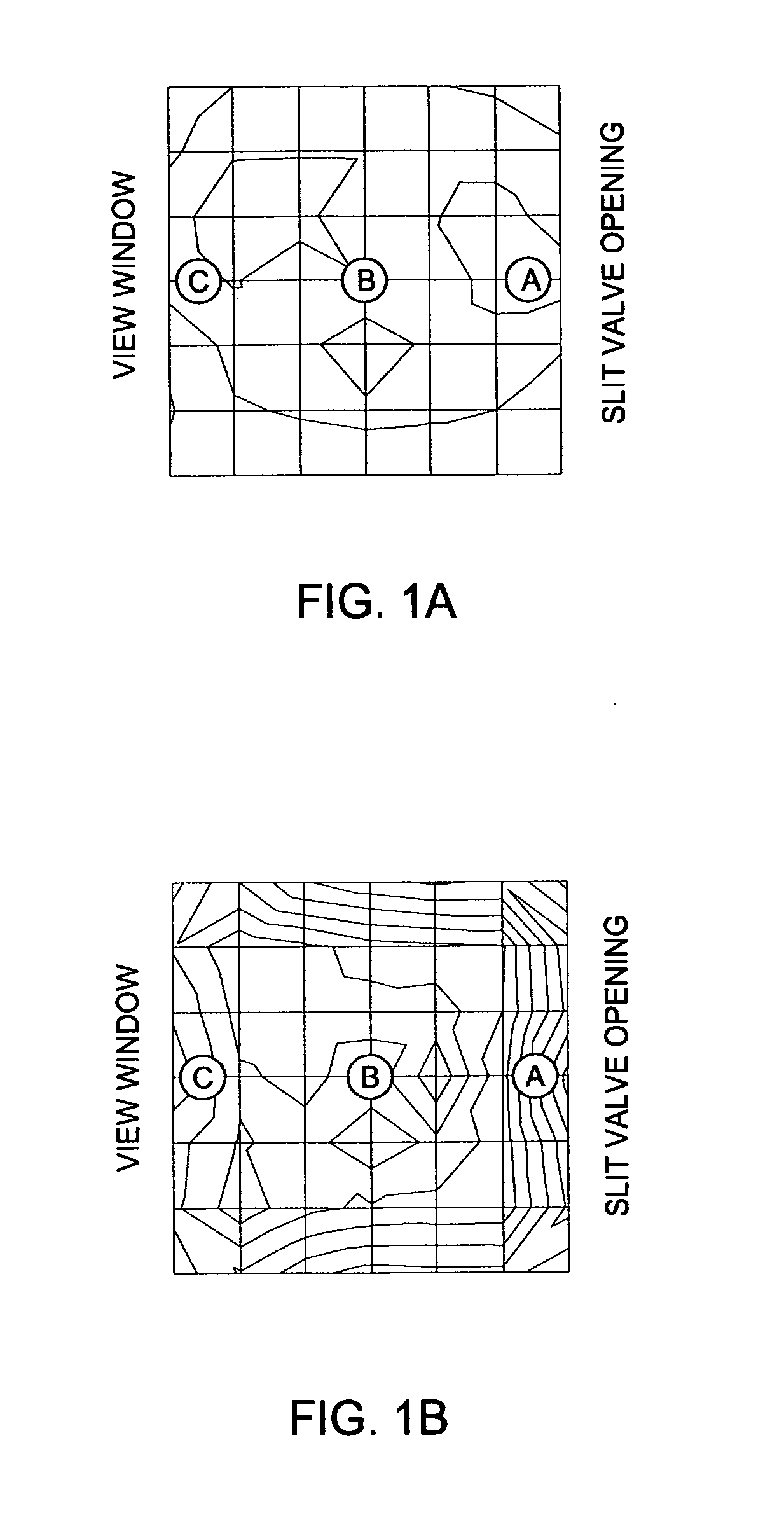

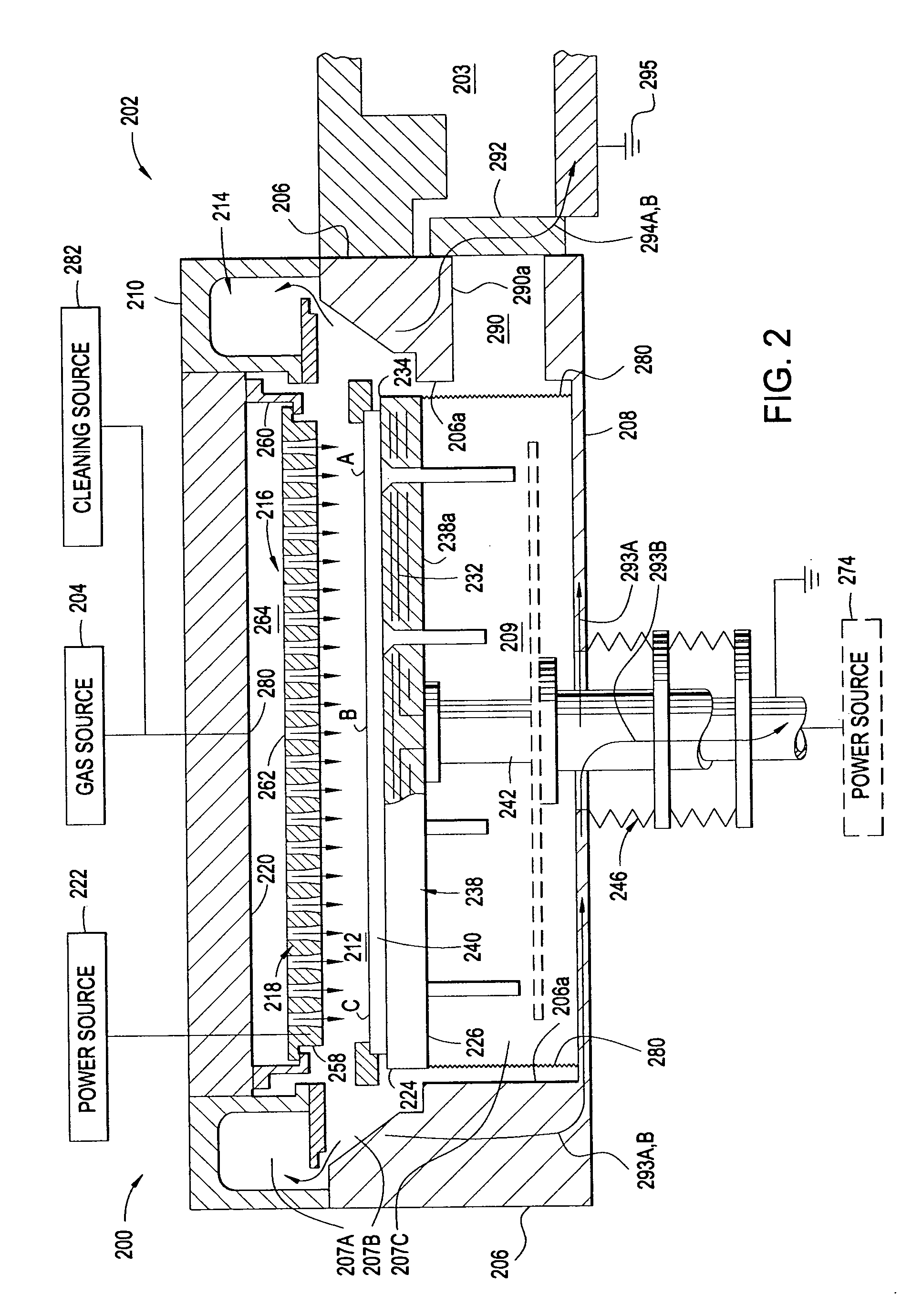

We have discovered methods of controlling a combination of PECVD deposition process parameters during deposition of thin films which provides improved control over surface standing wave effects which affect deposited film thickness uniformity and physical property uniformity. By minimizing surface standing wave effects, the uniformity of film properties across a substrate surface onto which the films have been deposited is improved. In addition, we have developed a gas diffusion plate design which assists in the control of plasma density to be symmetrical or asymmetrical over a substrate surface during film deposition, which also provides improved control over uniformity of deposited film thickness.

Owner:APPLIED MATERIALS INC

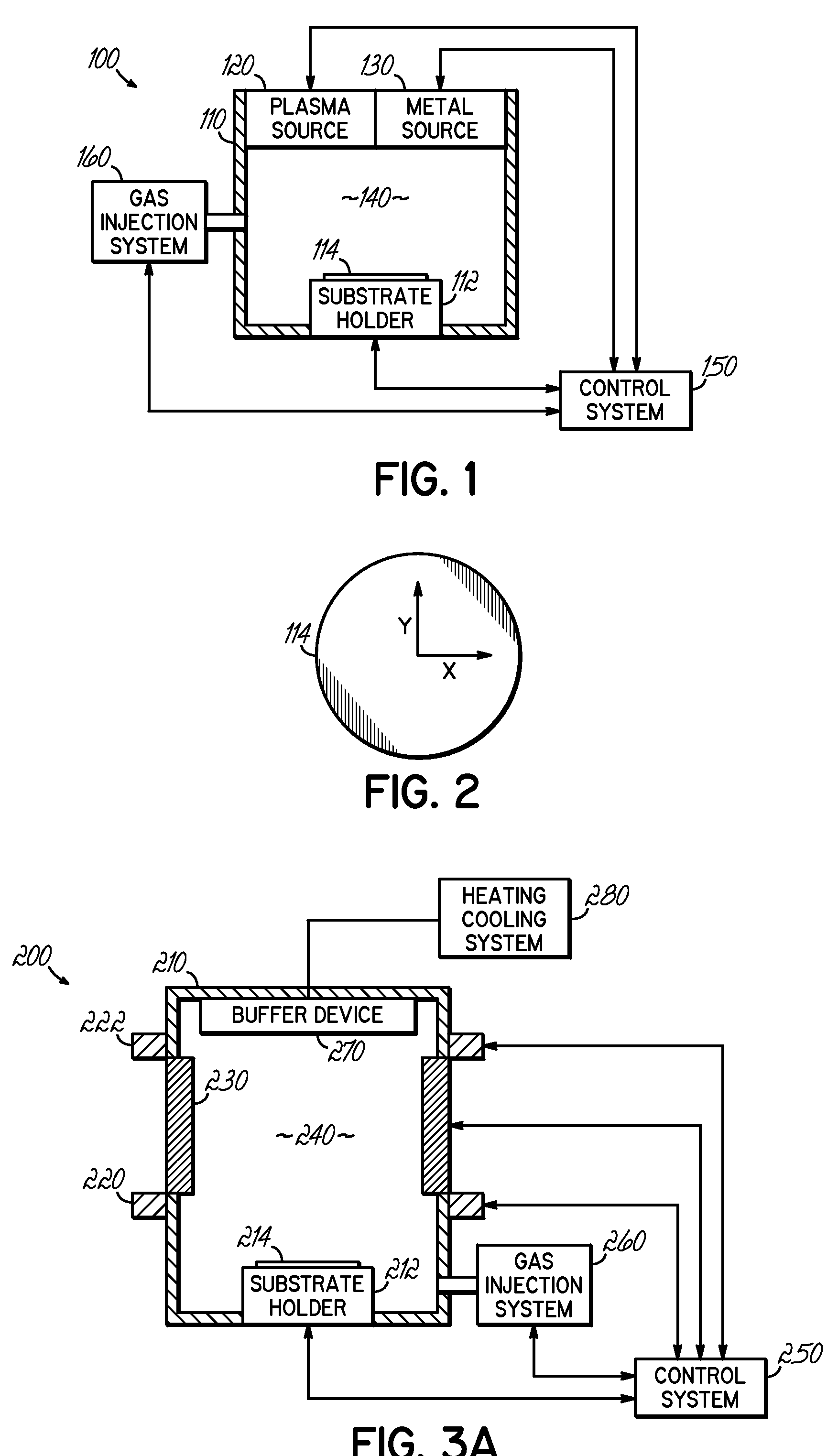

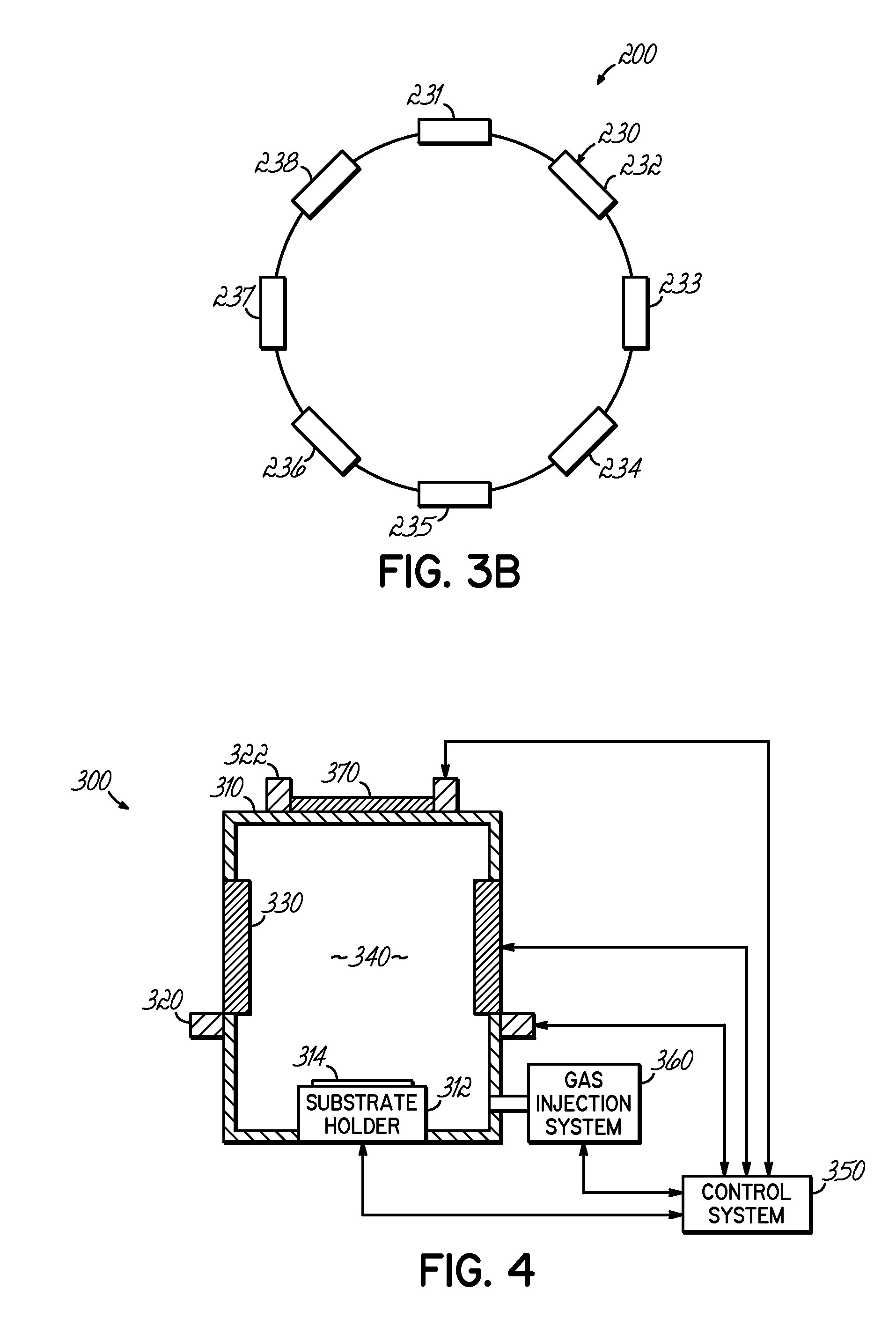

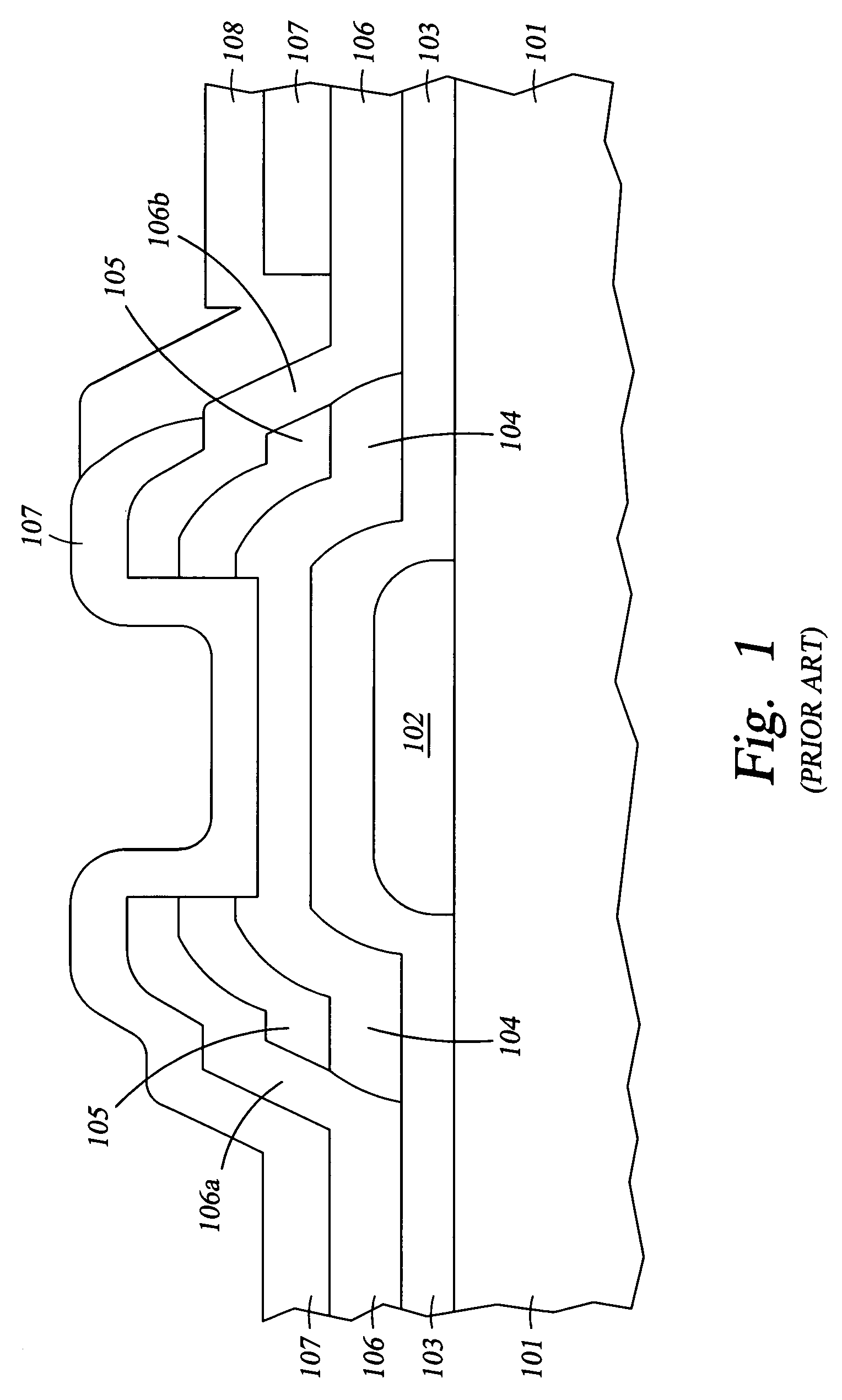

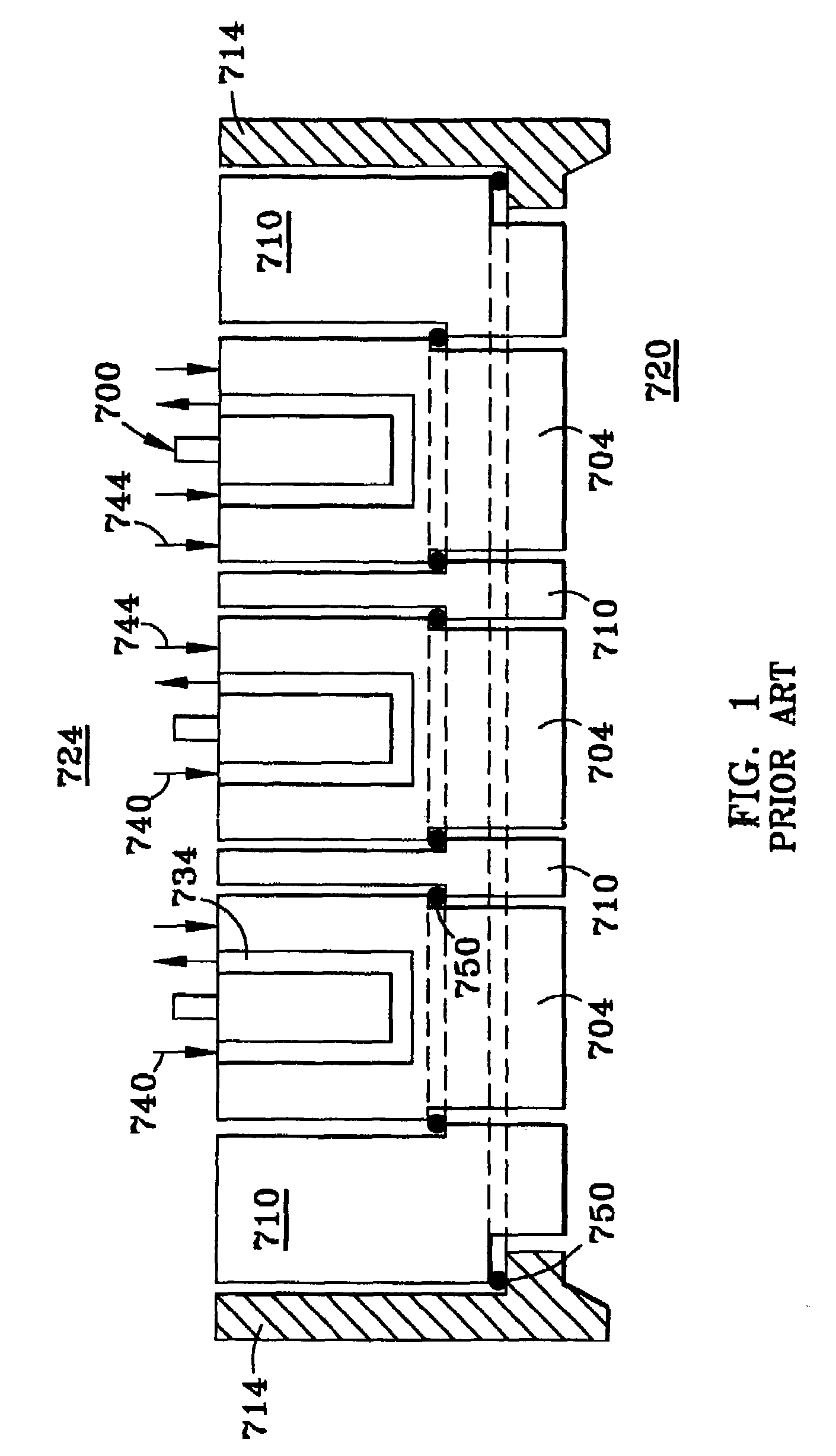

Method and apparatus of distributed plasma processing system for conformal ion stimulated nanoscale deposition process

InactiveUS20080026574A1Good coverageHigh aspect ratio (HAR) featuresVacuum evaporation coatingSputtering coatingPlasma densityHigh density

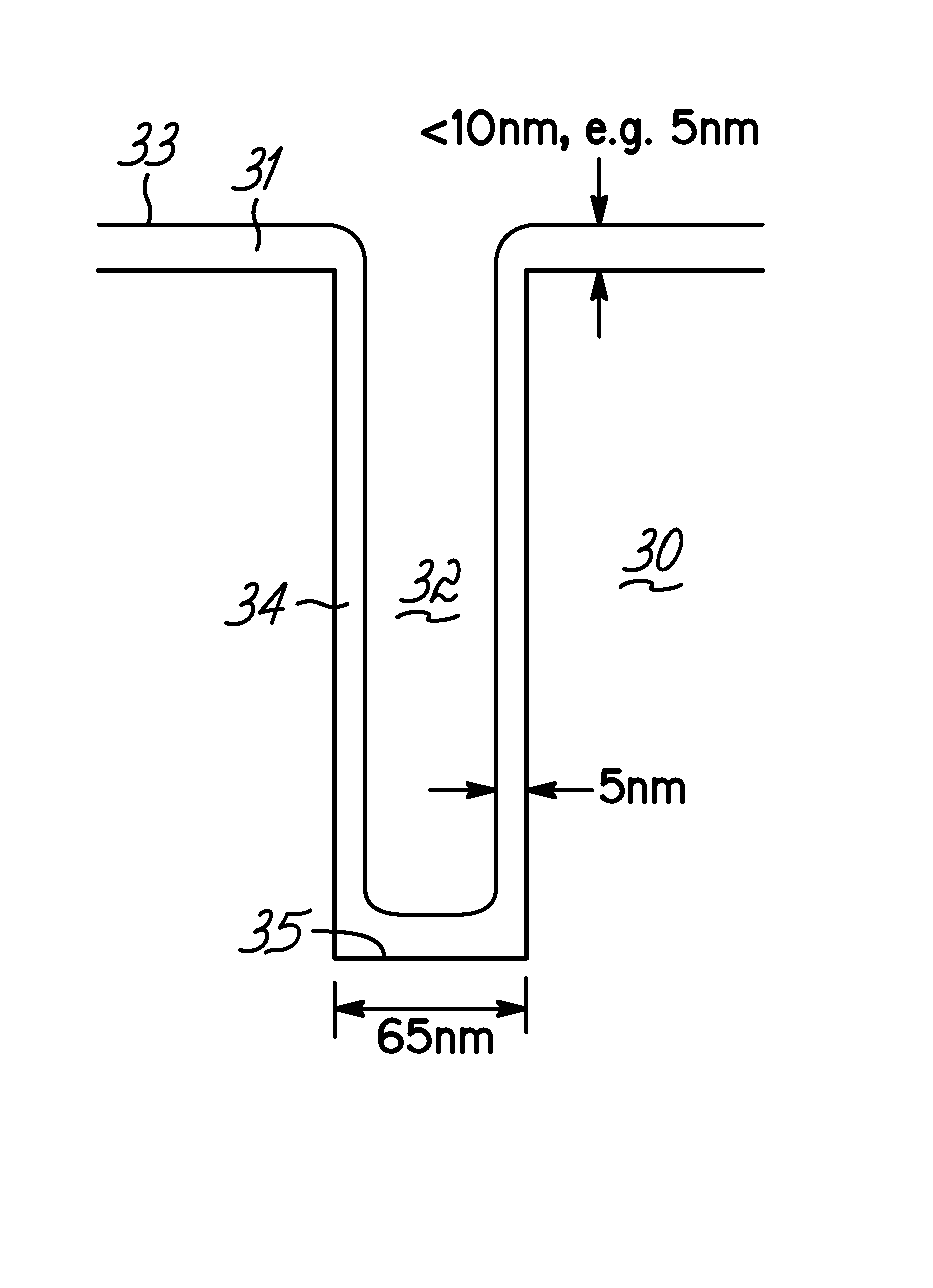

A deposition system and method of operating thereof is described for depositing a conformal metal or other similarly responsive coating material film in a high aspect ratio feature using a high density plasma is described. The deposition system includes a plasma source, and a distributed metal source for forming plasma and introducing metal vapor to the deposition system, respectively. The deposition system is configured to form a plasma having a plasma density and generate metal vapor having a metal density, wherein the ratio of the metal density to the plasma density proximate the substrate is less than or equal to unity. This ratio should exist at least within a distance from the surface of the substrate that is about twenty percent of the diameter of the substrate. A ratio that is uniform within plus or minus twenty-five percent substantially across the surface of said substrate is desirable. The ratio is particularly effective for plasma density exceeding 1012 cm−3, and for depositing film on substrates having nanoscale features with maximum film thickness less than half of the feature width, for example, at ten percent of the feature width.

Owner:TOKYO ELECTRON LTD

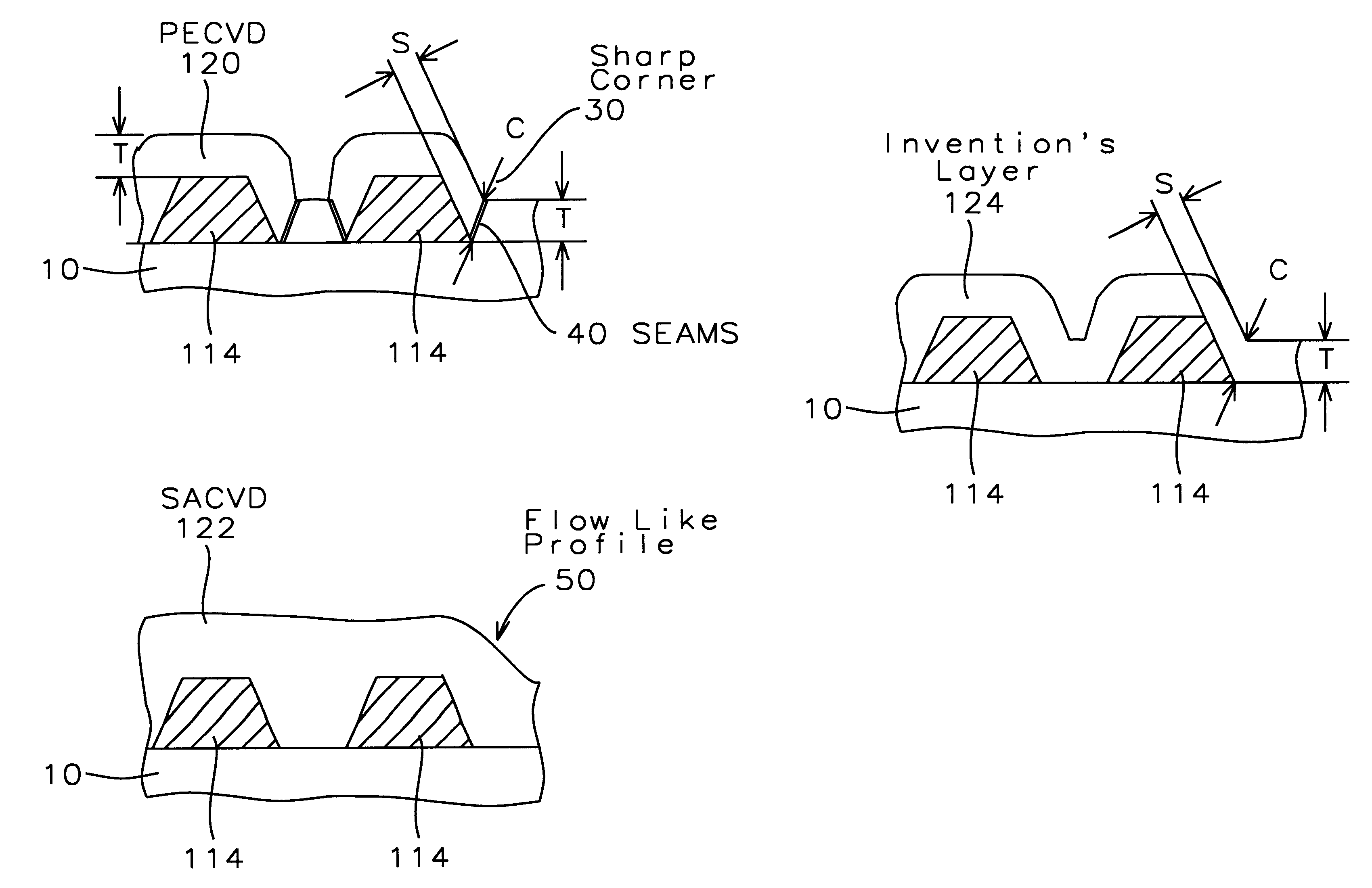

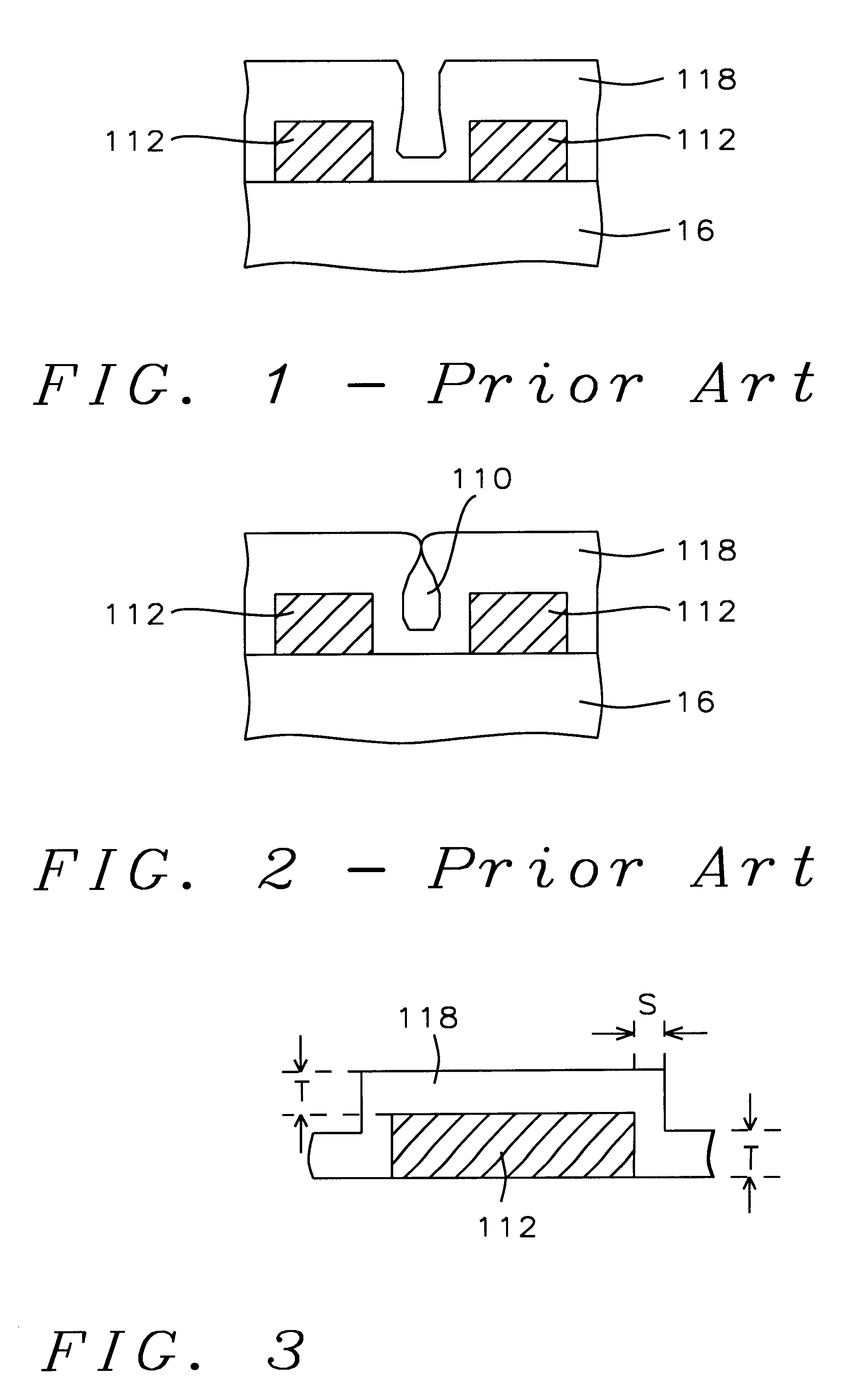

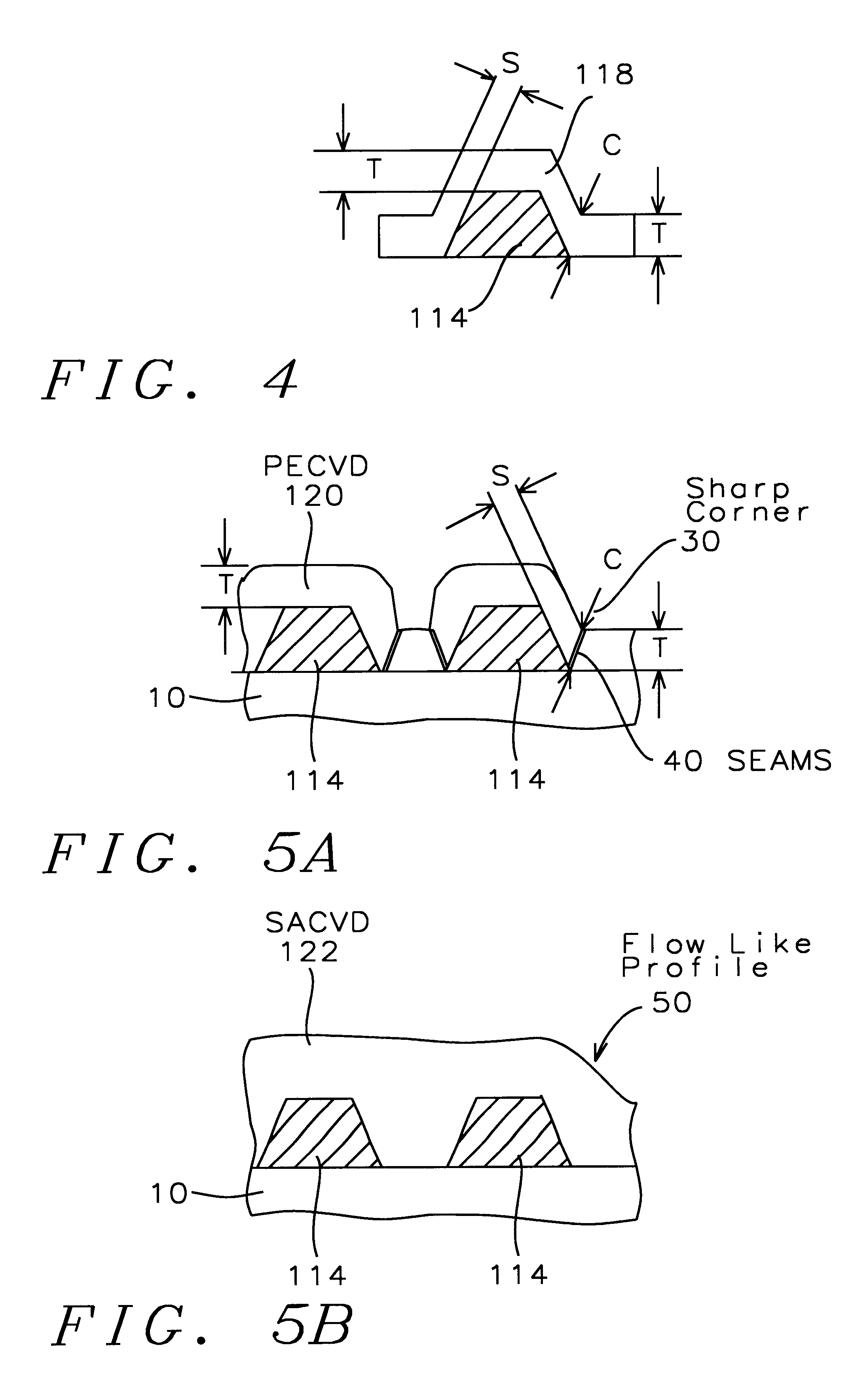

Method of silicon oxide and silicon glass films deposition

InactiveUS6197705B1Good step coverageImprove integrityPretreated surfacesSemiconductor/solid-state device manufacturingDielectricPlasma density

A method for fabricating a silicon oxide and silicon glass layers at low temperature using soft power-optimized Plasma-Activated CVD with a TEOS-ozone-oxygen reaction gas mixture (TEOS O3 / O2 PACVD) is described. It combines advantages of both low temperature Plasma-Enhanced Chemical Vapor Deposition (PECVD) and TEOS-ozone Sub-Atmospheric Chemical Vapor Deposition (SACVD) and yields a coating of silicon oxide with stable and high deposition rate, no surface sensitivity, good film properties, conformal step coverage and good gap-fill. Key features of the invention's O3 / O2 PACVD process are: a plasma is maintain throughout the entire deposition step in a parallel plate type reactor chamber, the precise RF plasma density, ozone concentration in oxygen and the deposition temperature. These features provide the reaction conditions for the proper O3 / O2 reaction mechanism that deposits a conformal silicon oxide layer. The process has significant implication for semiconductor device manufacturing involving the deposition of a dielectric over a conducting non-planar surface.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

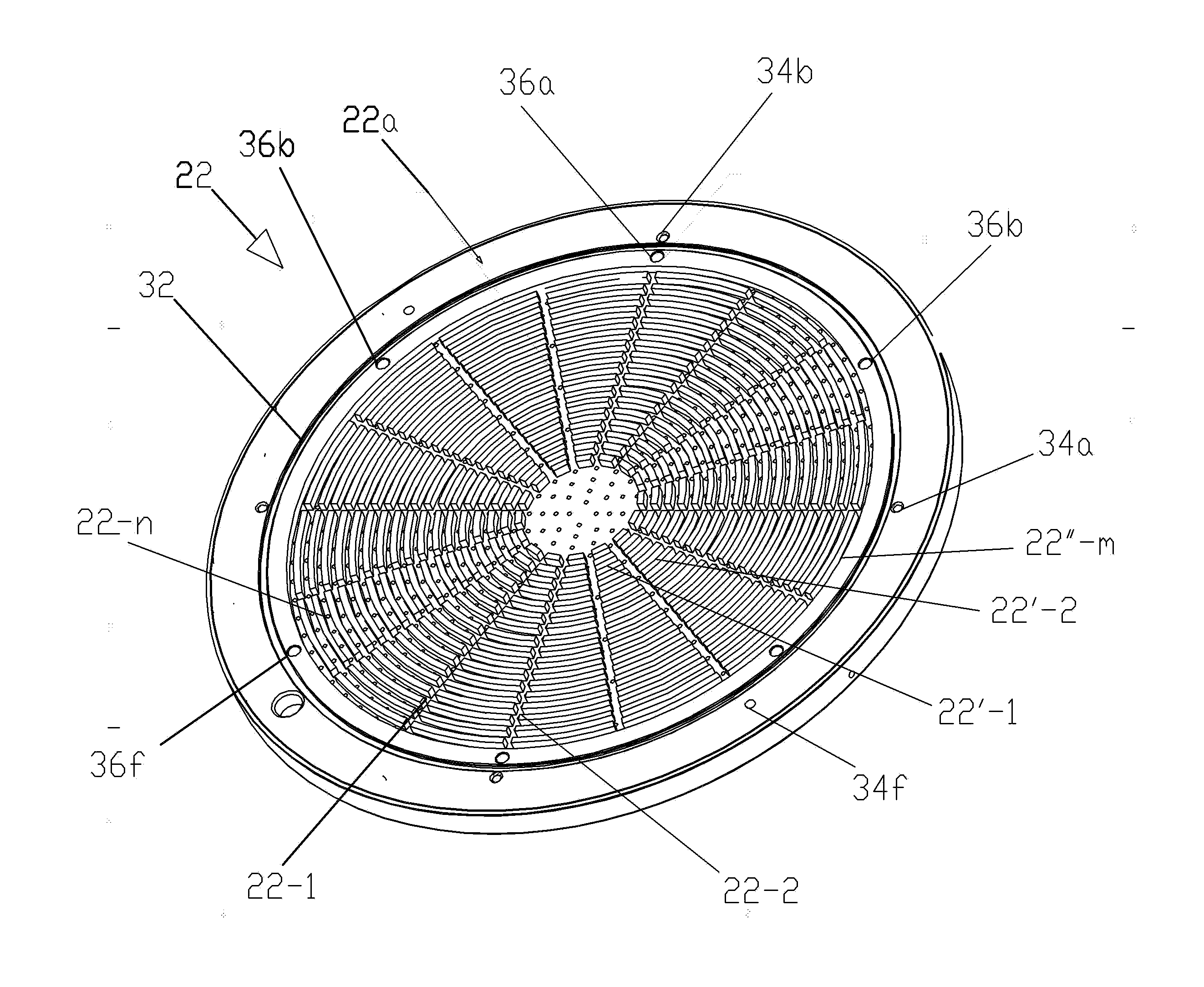

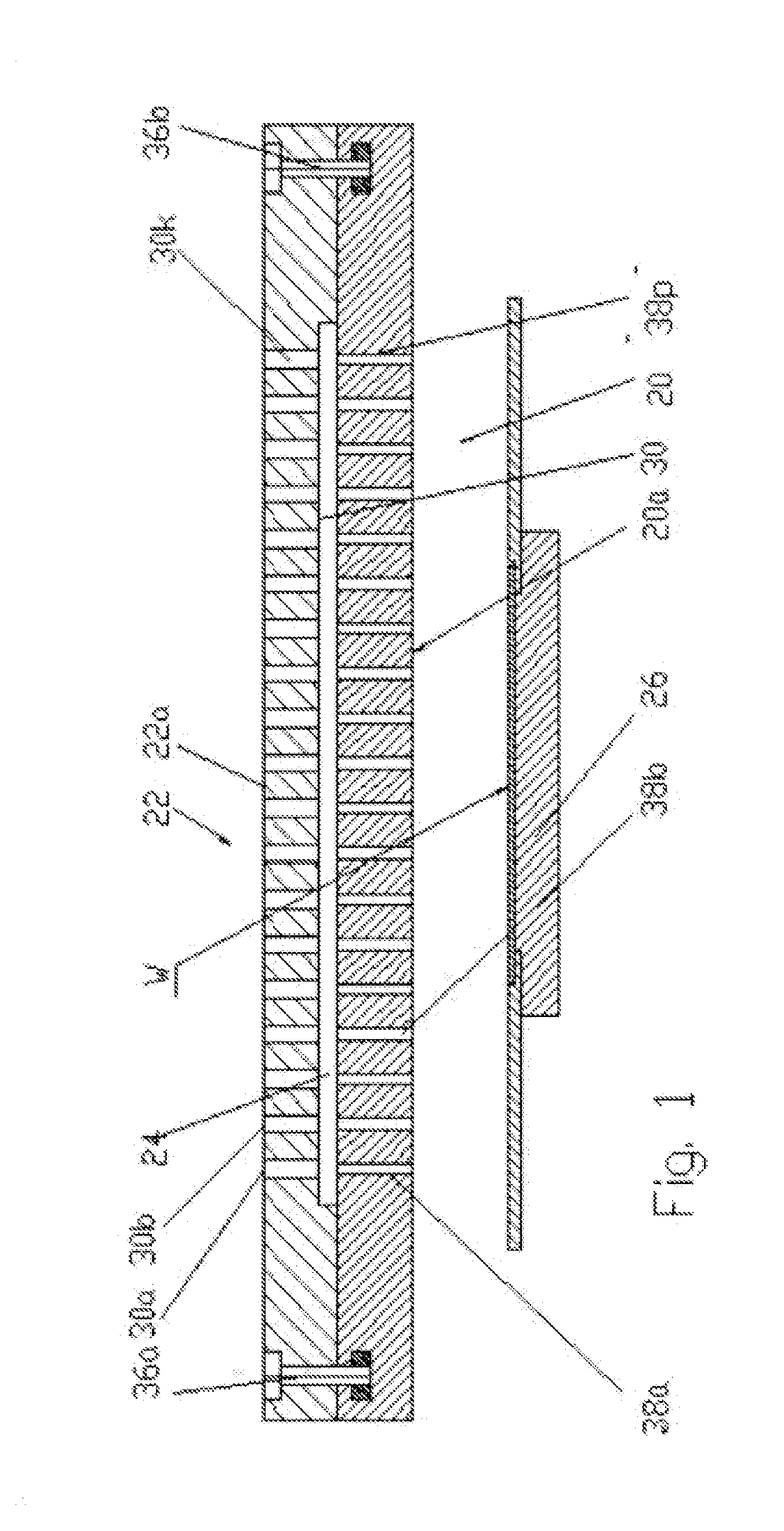

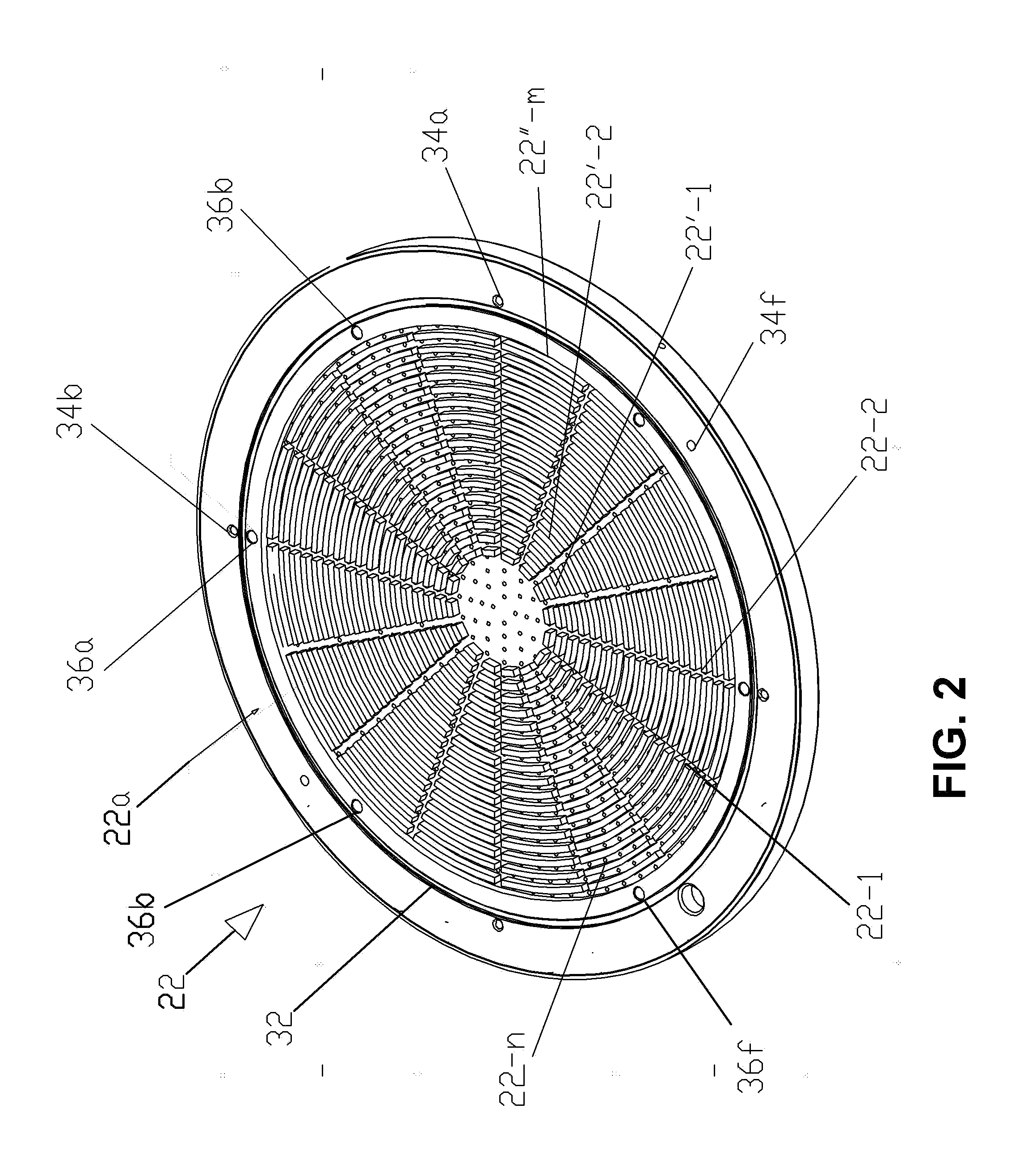

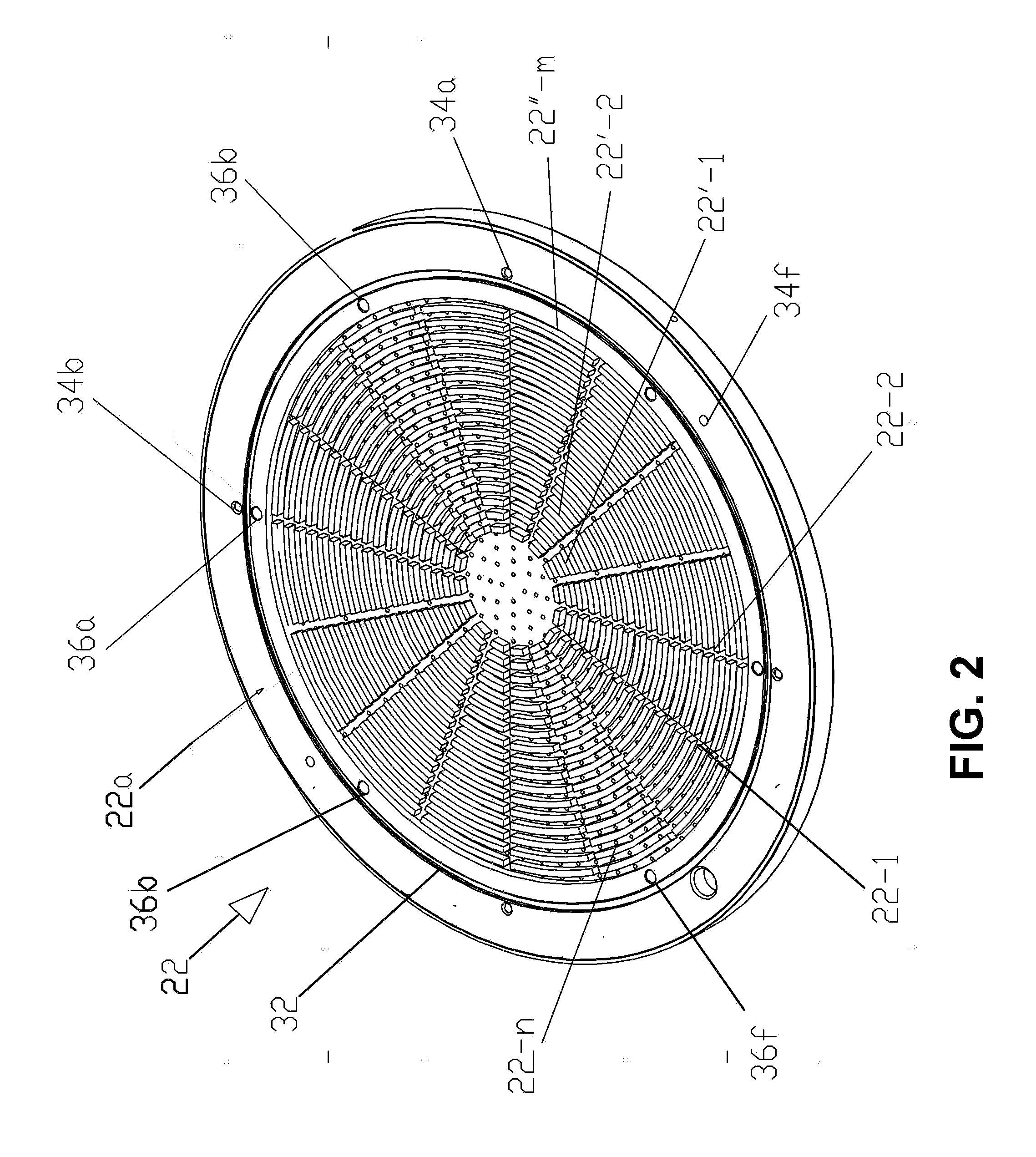

Method of controlling the film properties of PECVD-deposited thin films

ActiveUS7785672B2Improve performanceImprove uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingDiffusionPlasma density

We have discovered methods of controlling a combination of PECVD deposition process parameters during deposition of thin films which provides improved control over surface standing wave effects which affect deposited film thickness uniformity and physical property uniformity. By minimizing surface standing wave effects, the uniformity of film properties across a substrate surface onto which the films have been deposited is improved. In addition, we have developed a gas diffusion plate design which assists in the control of plasma density to be symmetrical or asymmetrical over a substrate surface during film deposition, which also provides improved control over uniformity of deposited film thickness.

Owner:APPLIED MATERIALS INC

Method for etching chromium thin film and method for producing photomask

ActiveUS20060102587A1Decorative surface effectsSemiconductor/solid-state device manufacturingResistChemical species

An object to be processed has a chromium-based thin film made of a material containing chromium. The thin film is etched using a resist pattern as a mask. The thin film is etched by the use of a chemical species produced by preparing a dry etching gas containing a halogen-containing gas and an oxygen-containing gas and supplying a plasma excitation power to the dry etching gas to thereby excite plasma. The thin film is etched using, as the plasma excitation power, a power lower than a plasma excitation power at which plasma density jump occurs.

Owner:HOYA CORP

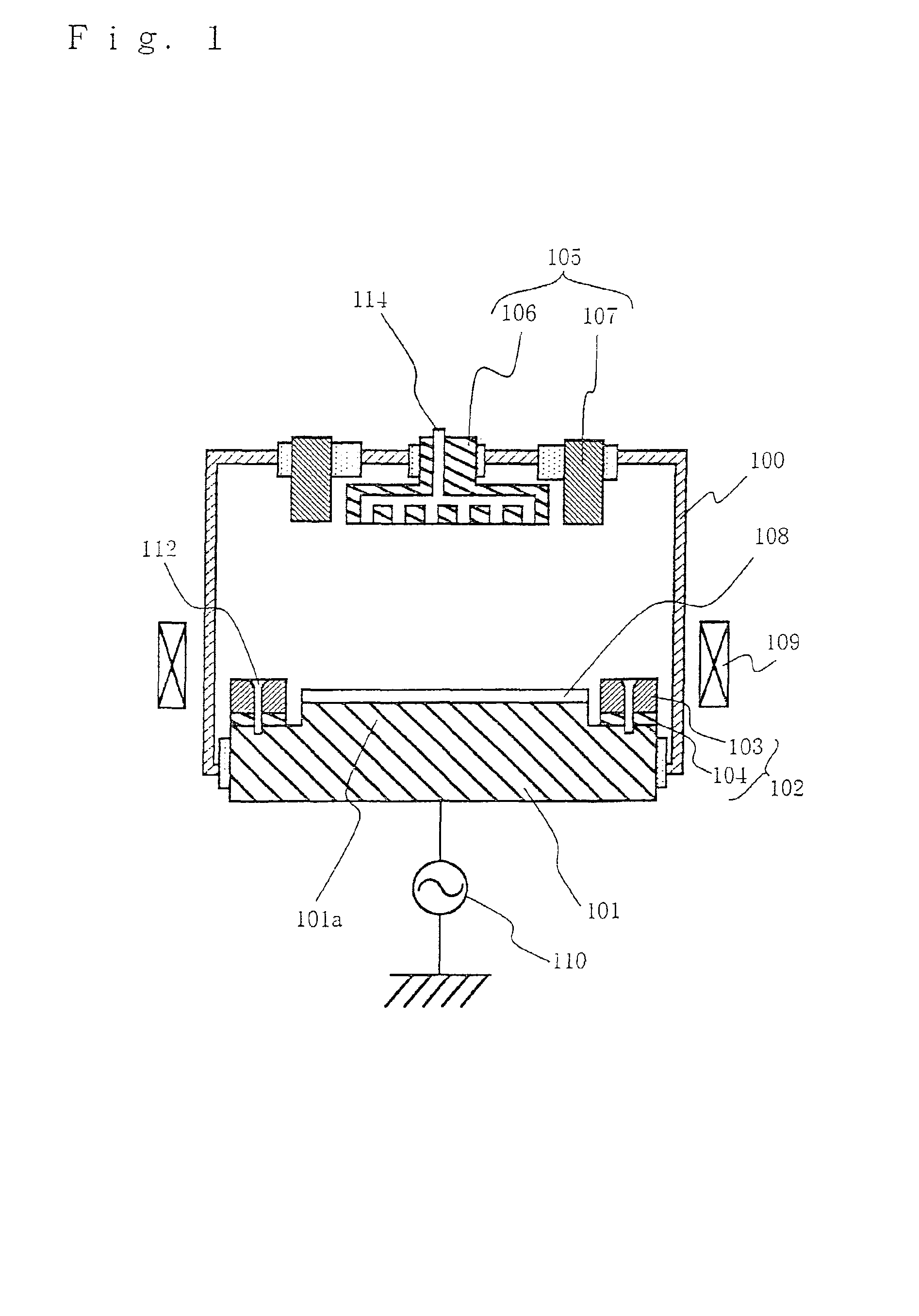

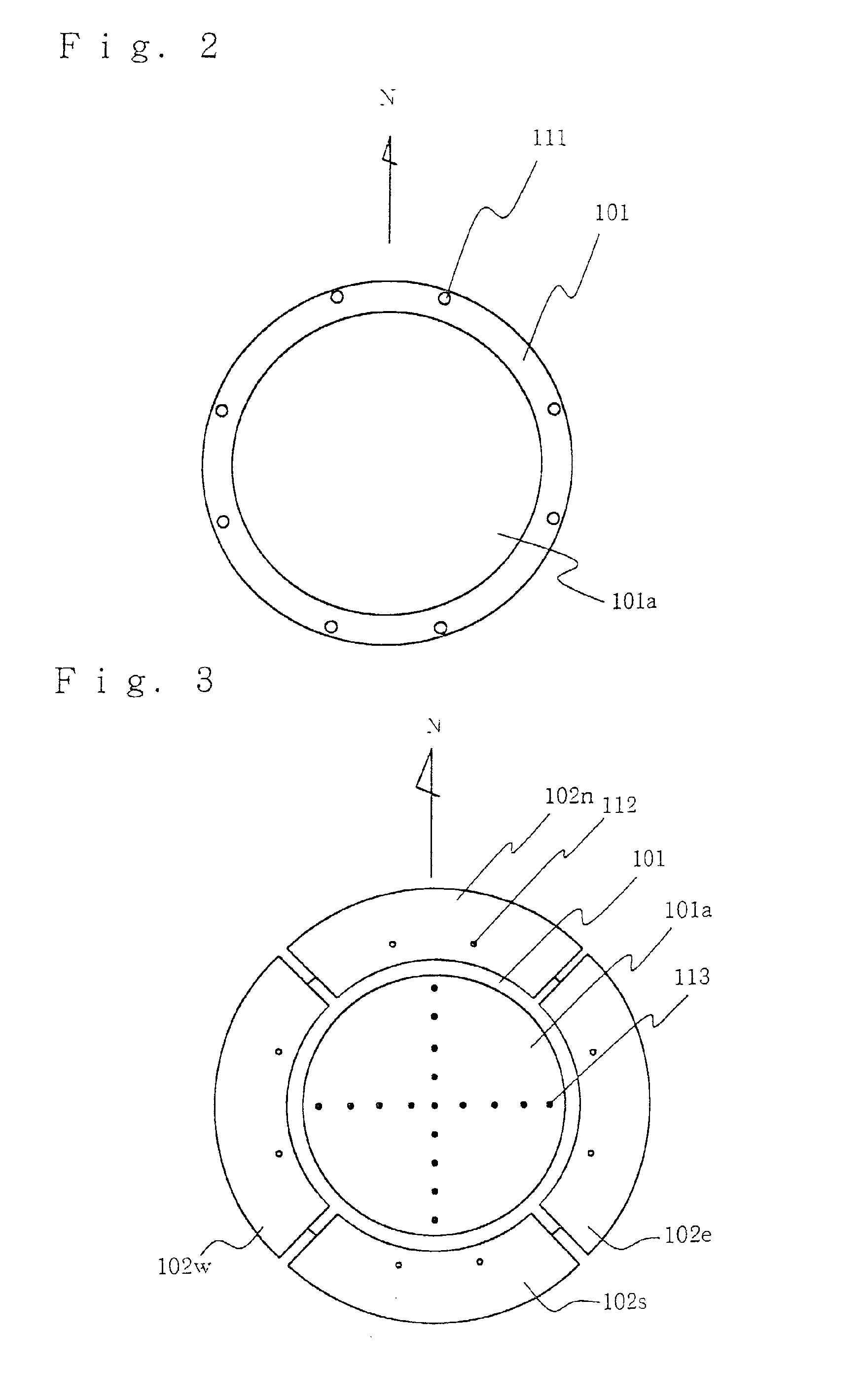

Plasma etching device

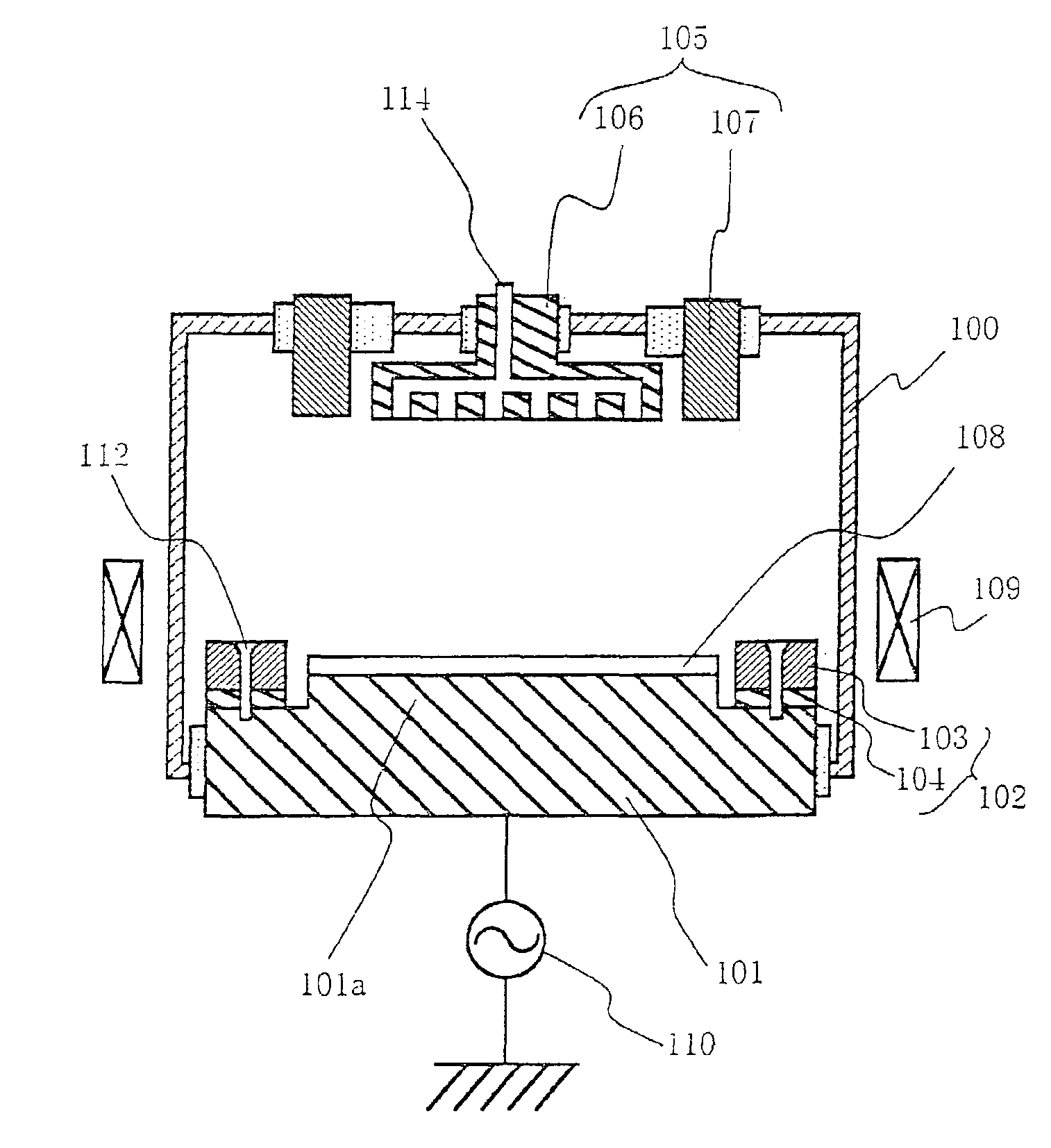

InactiveUS8114245B2Lower impedanceLiquid surface applicatorsElectric discharge tubesElectron currentElectricity

A plasma etching device which has an auxiliary electrode enabling realization of a uniform plasma density of generated plasma on the surface of a base and which enables uniform etching with respect to the base without depending upon pressure and without rotating a magnetic field applying means. The plasma etching device has magnetic field applying means which has two parallel plate electrodes I and II and RF power applying means, with the base set on the electrode I, and which is horizontal and unidirectional with respect to the surface of the base where plasma etching is carried out. In this plasma etching device, an auxiliary electrode is provided at least on the upstream side of the base in a flow of electron current generated by the magnetic field applying means. The auxiliary electrode includes a local electrode arranged on the side facing the electrode II and means for adjusting impedance provided at a part of the local electrode to be electrically connected with the electrode I.

Owner:OHMI TADAHIRO +1

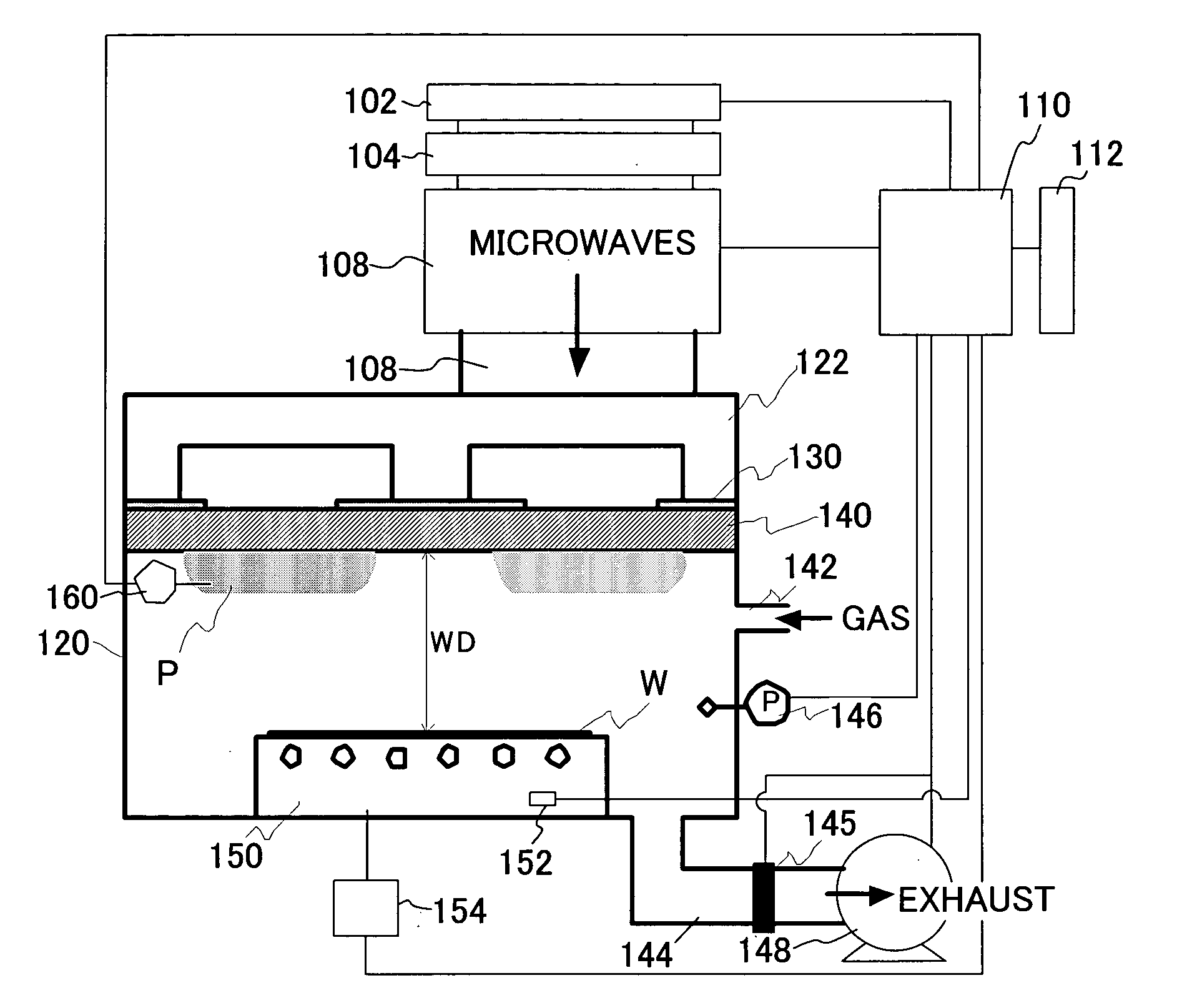

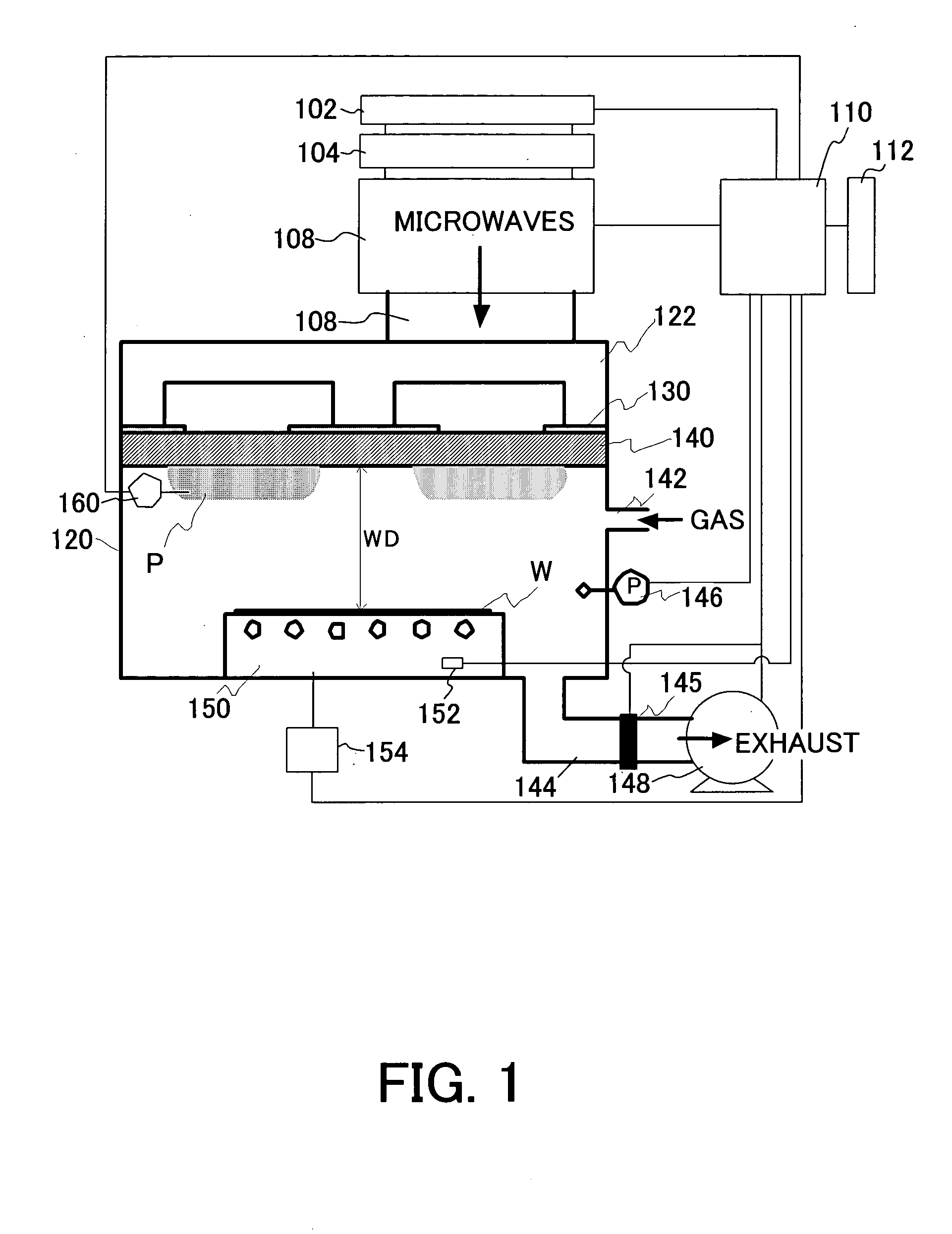

Processing apparatus and method

InactiveUS20050090078A1Minimized plasma damageEfficient terminationTransistorElectric discharge tubesDielectricTemperature control

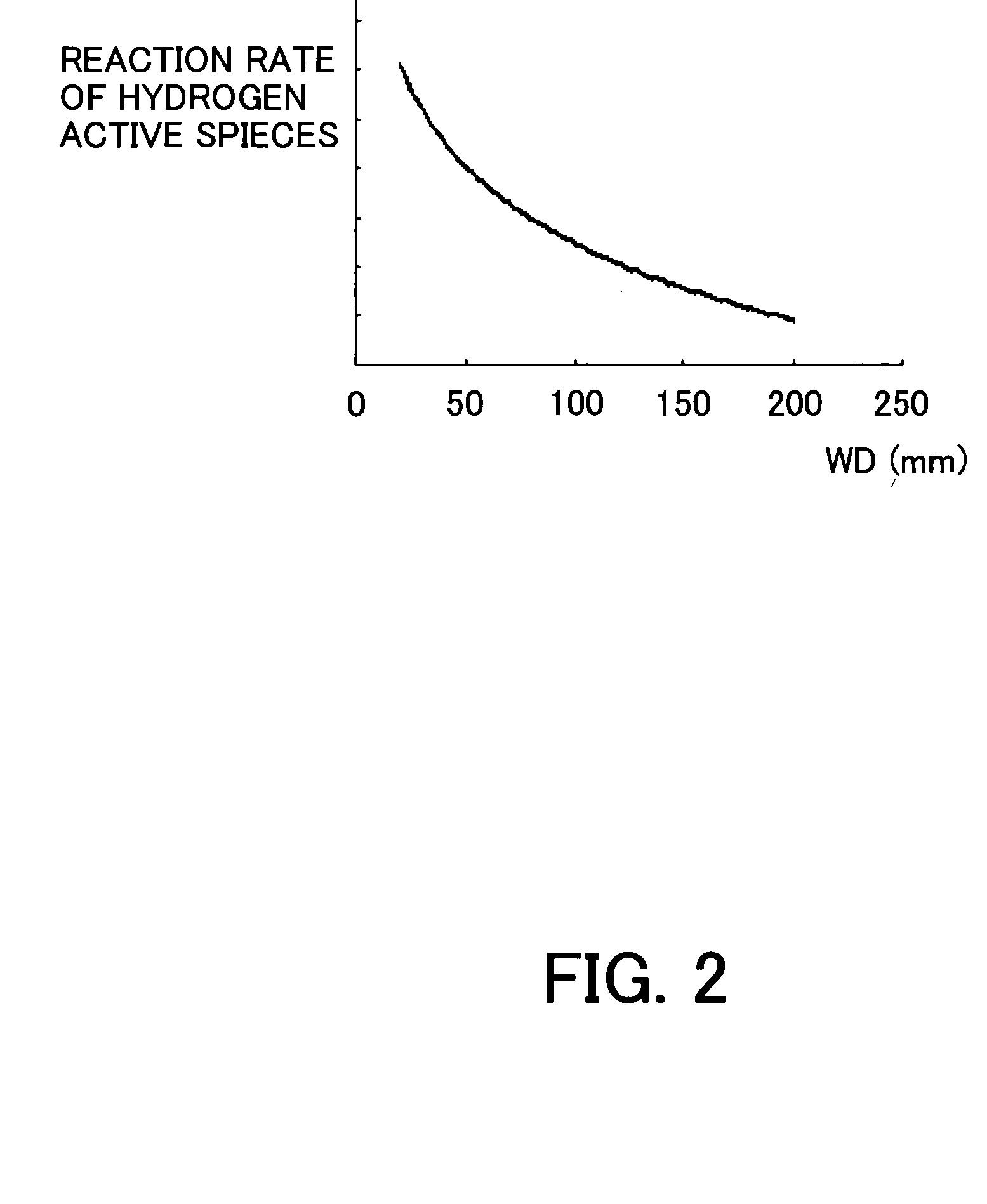

A processing method that uses process gas plasma that contains at least hydrogen to terminate dangling bonds in an object that at least partially contains a silicon system material includes the steps of placing the object on a susceptor in a process chamber that includes a dielectric window and the susceptor, and controlling a temperature of the susceptor to a predetermined temperature, controlling a pressure in the process chamber to a predetermined pressure, introducing the process gas into the process chamber, and introducing, via the dielectric window, microwaves for a plasma treatment to the object into the process chamber so that plasma of the process gas has plasma density of 1011 cm−3 or greater, wherein a distance between the dielectric window and the object is maintained between 20 mm and 200 mm.

Owner:CANON KK

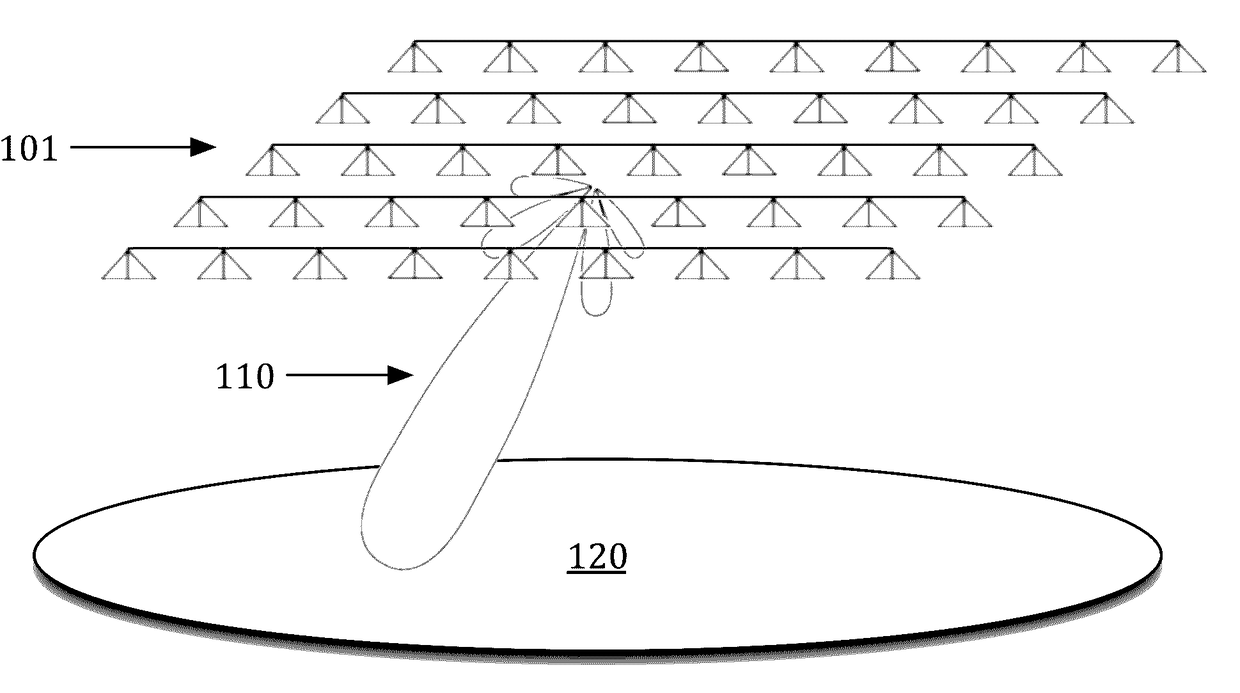

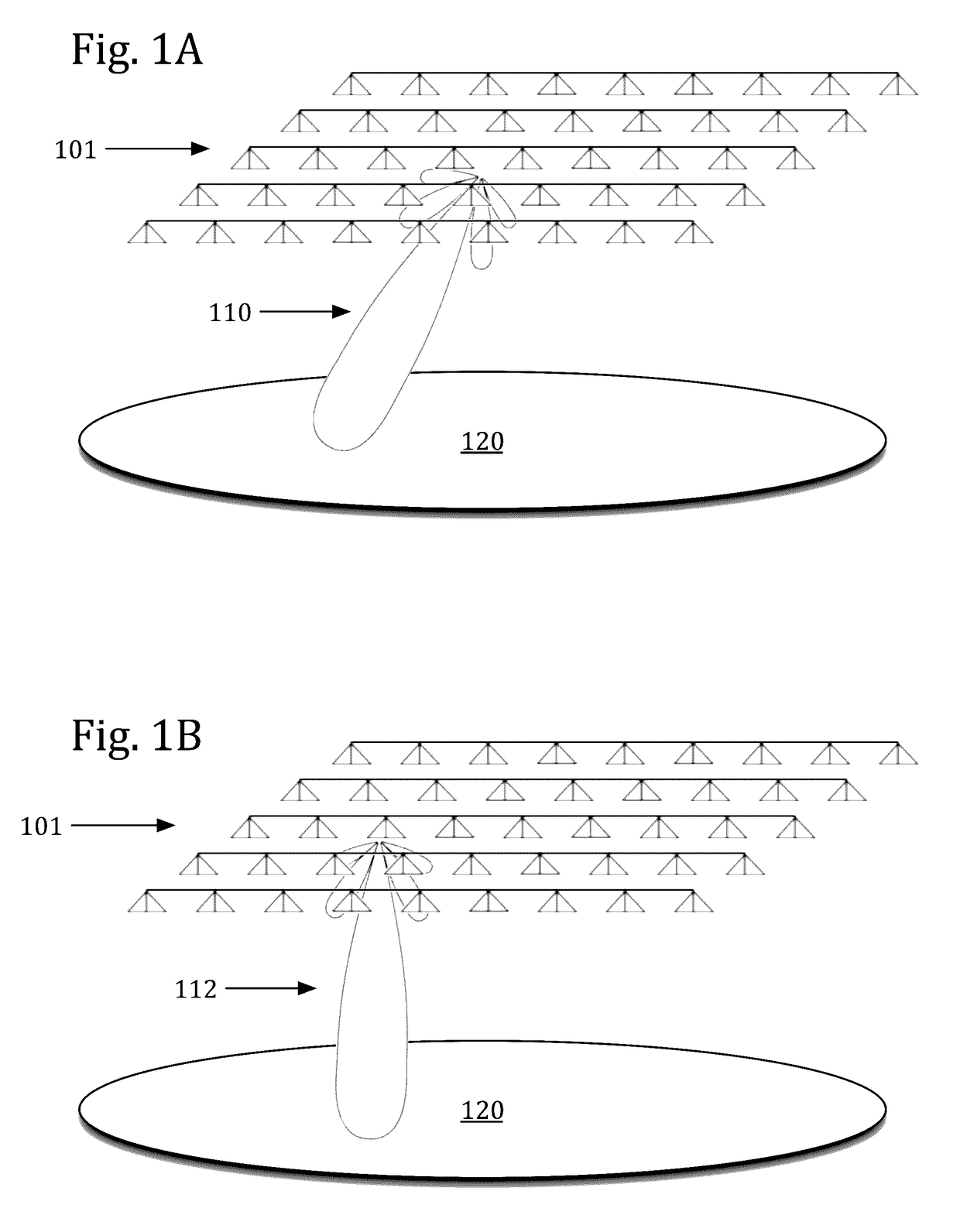

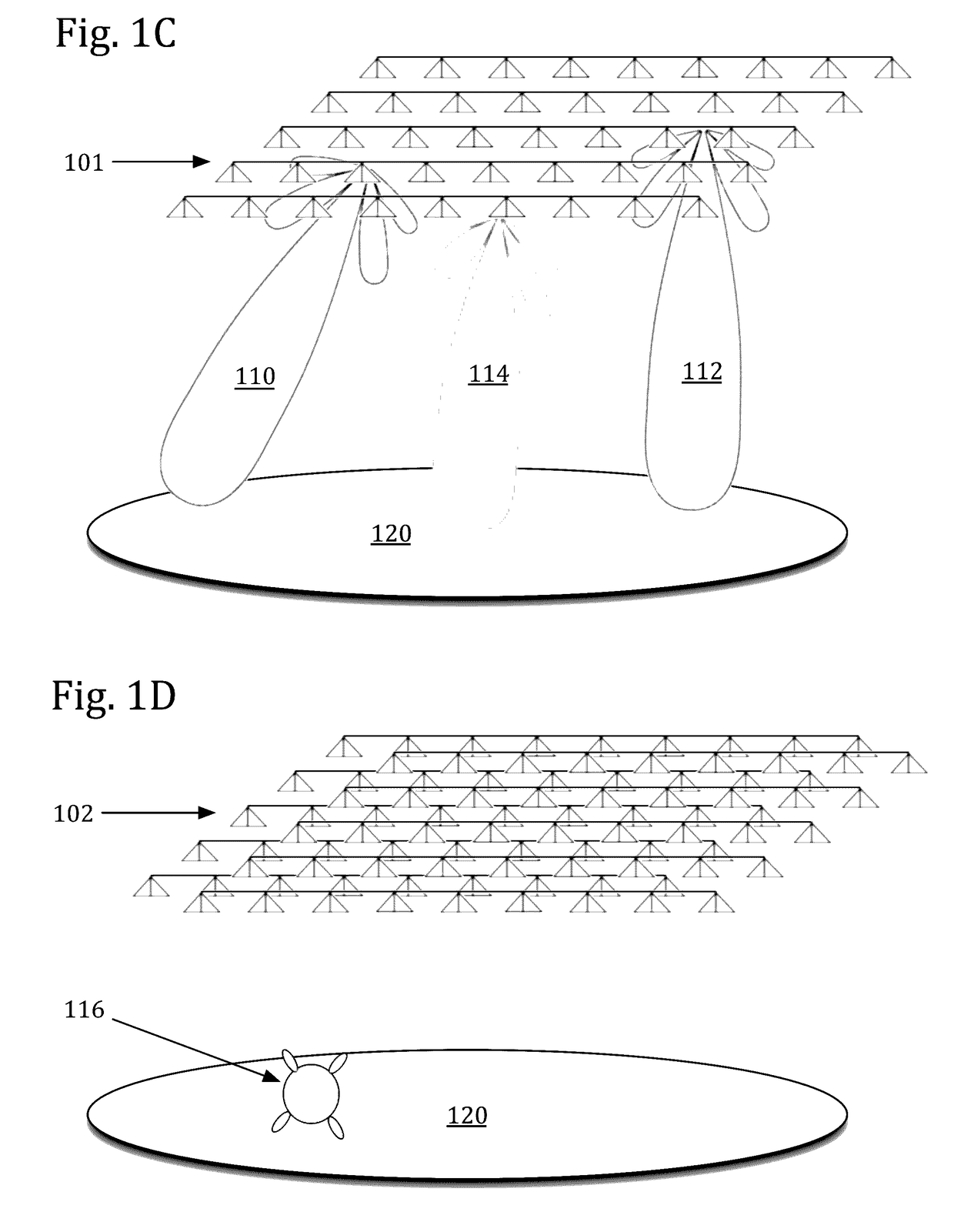

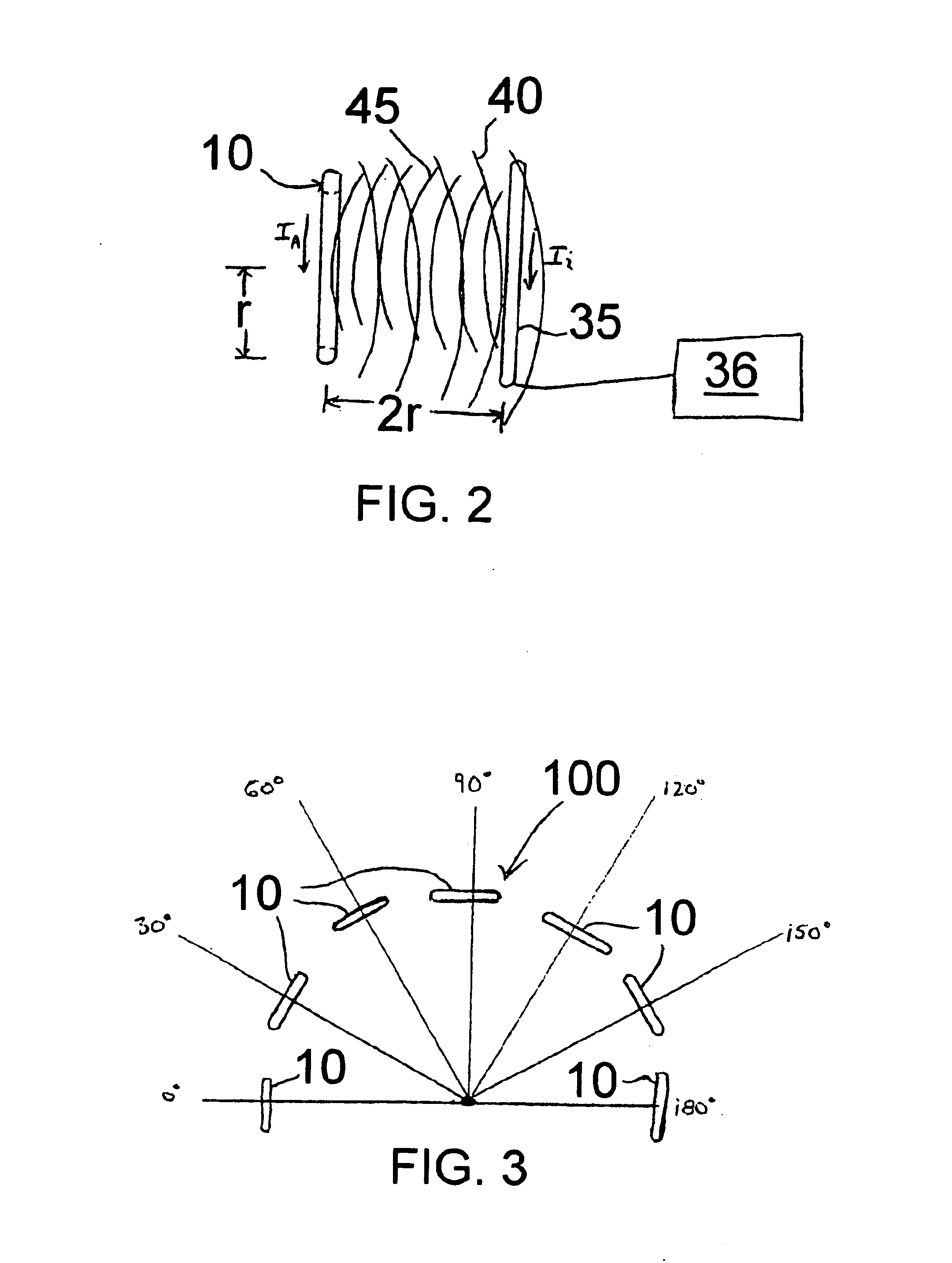

Computer addressable plasma density modification for etch and deposition processes

Disclosed herein are methods of modifying a reaction rate on a semiconductor substrate in a processing chamber which utilize a phased-array of microwave antennas. The methods may include energizing a plasma in a processing chamber, emitting a beam of microwave radiation from a phased-array of microwave antennas, and directing the beam into the plasma so as to cause a change in a reaction rate on the surface of a semiconductor substrate inside the processing chamber. Also disclosed herein are particular embodiments of phased-arrays of microwave antennas, as well as semiconductor processing apparatuses which include a phased-array of microwave antennas configured to emit a beam of microwave radiation into a processing chamber.

Owner:LAM RES CORP

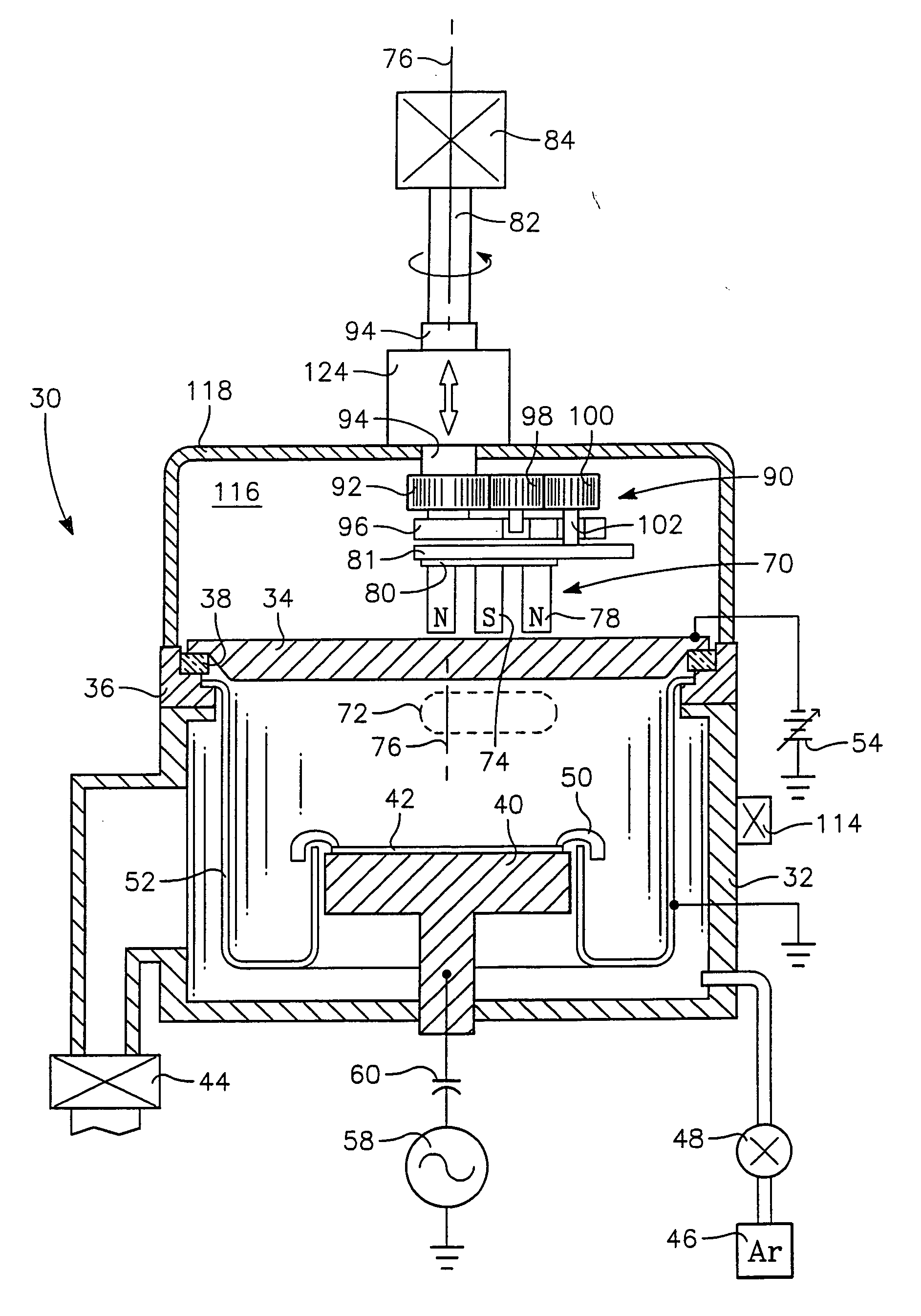

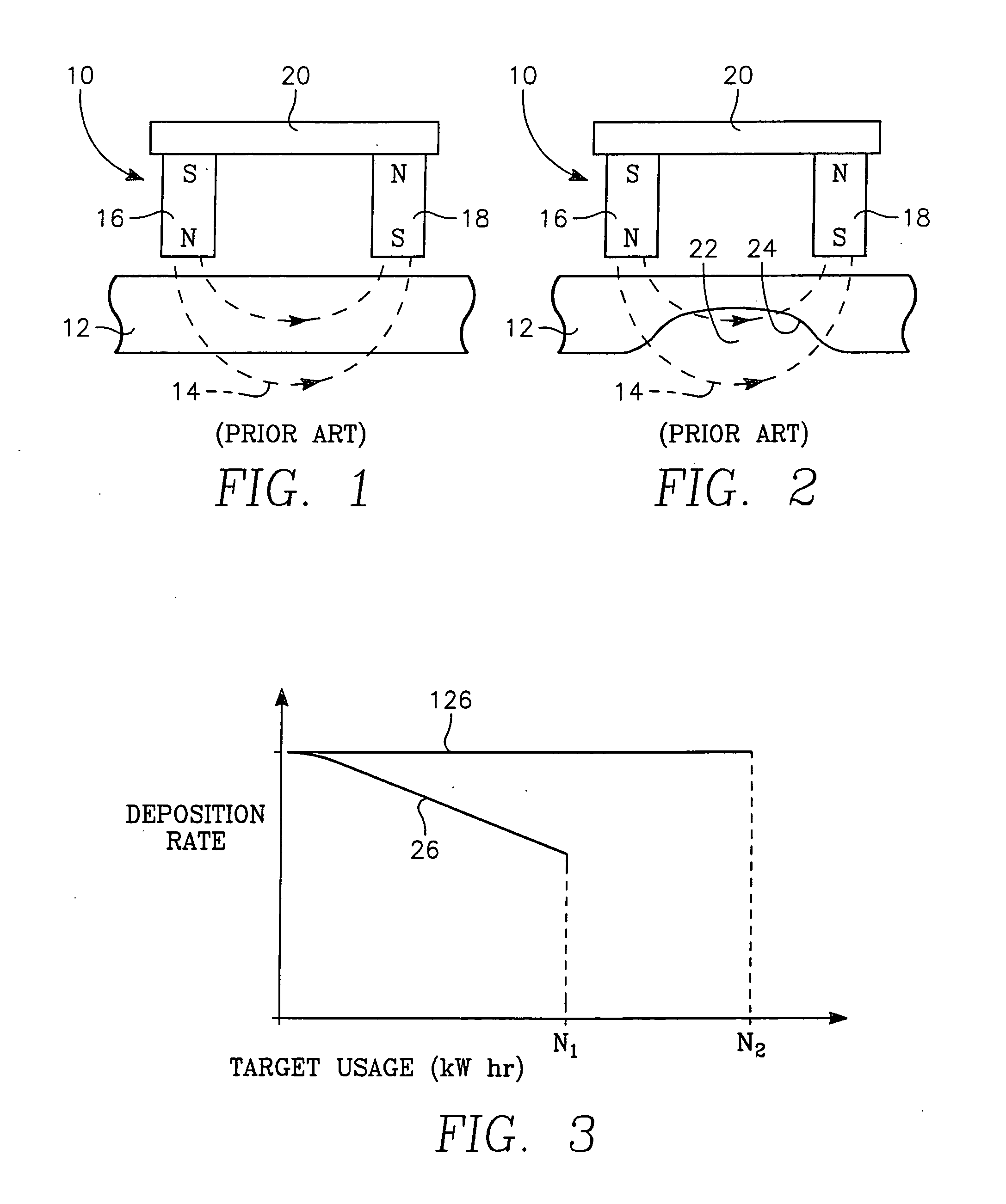

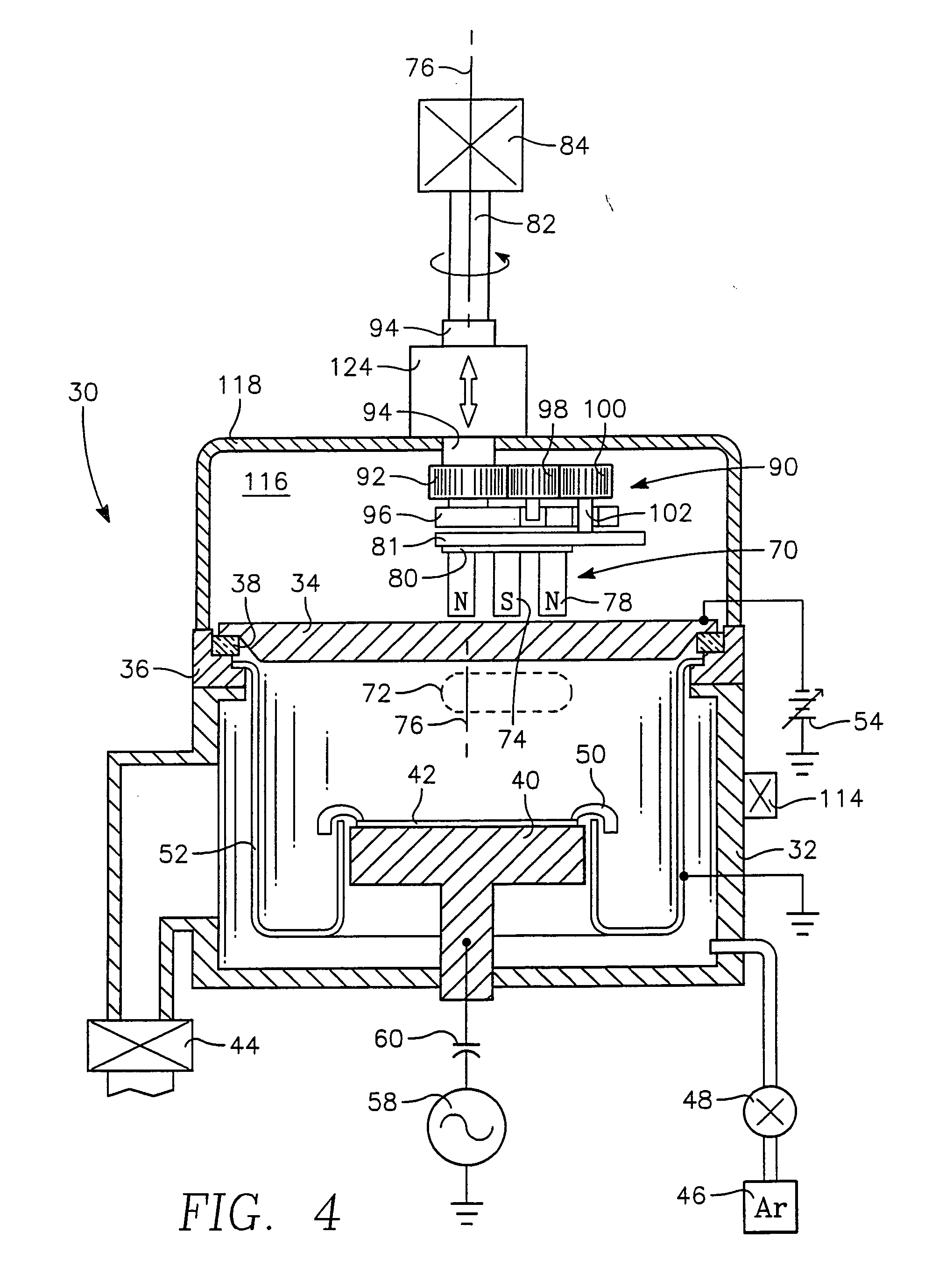

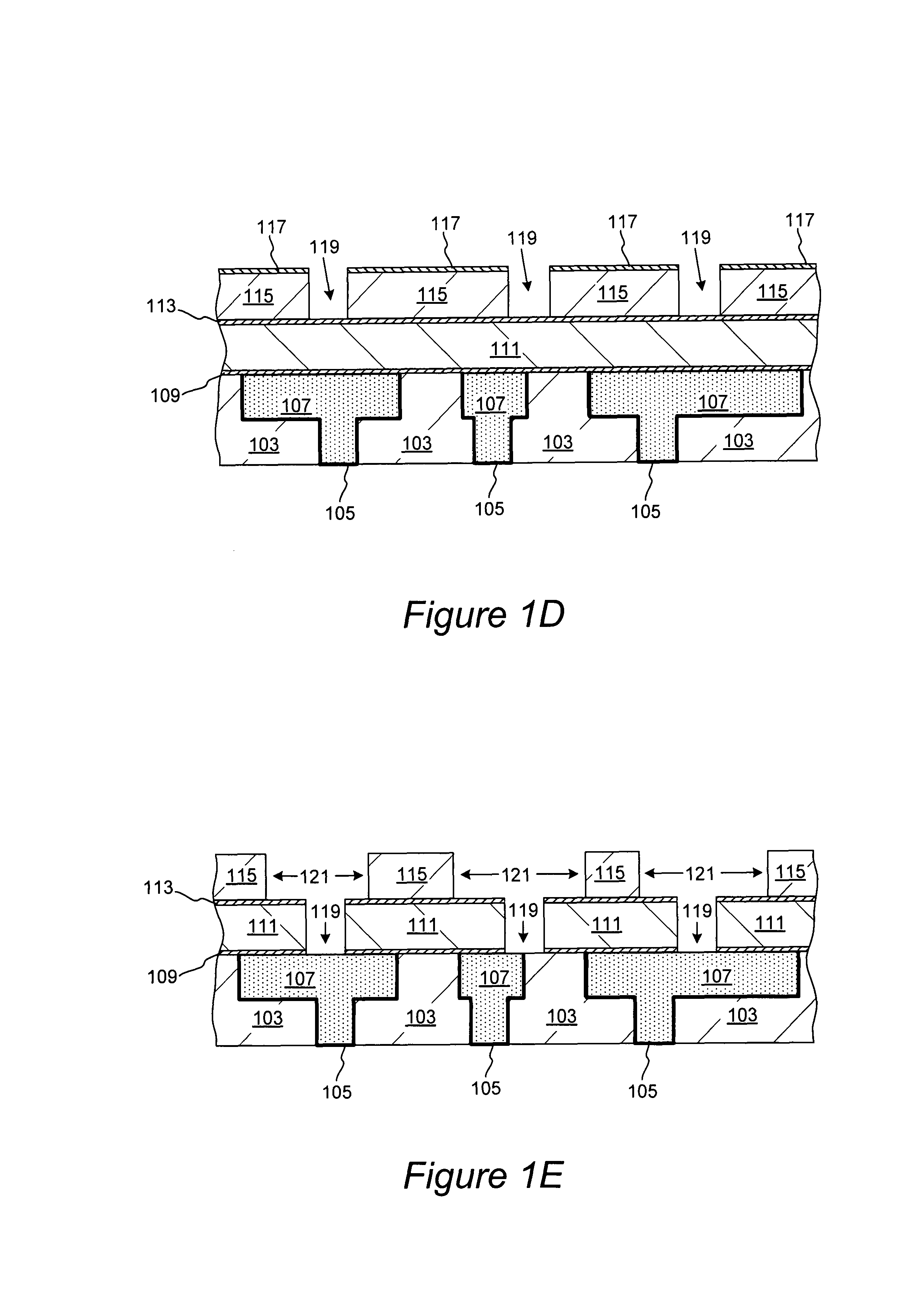

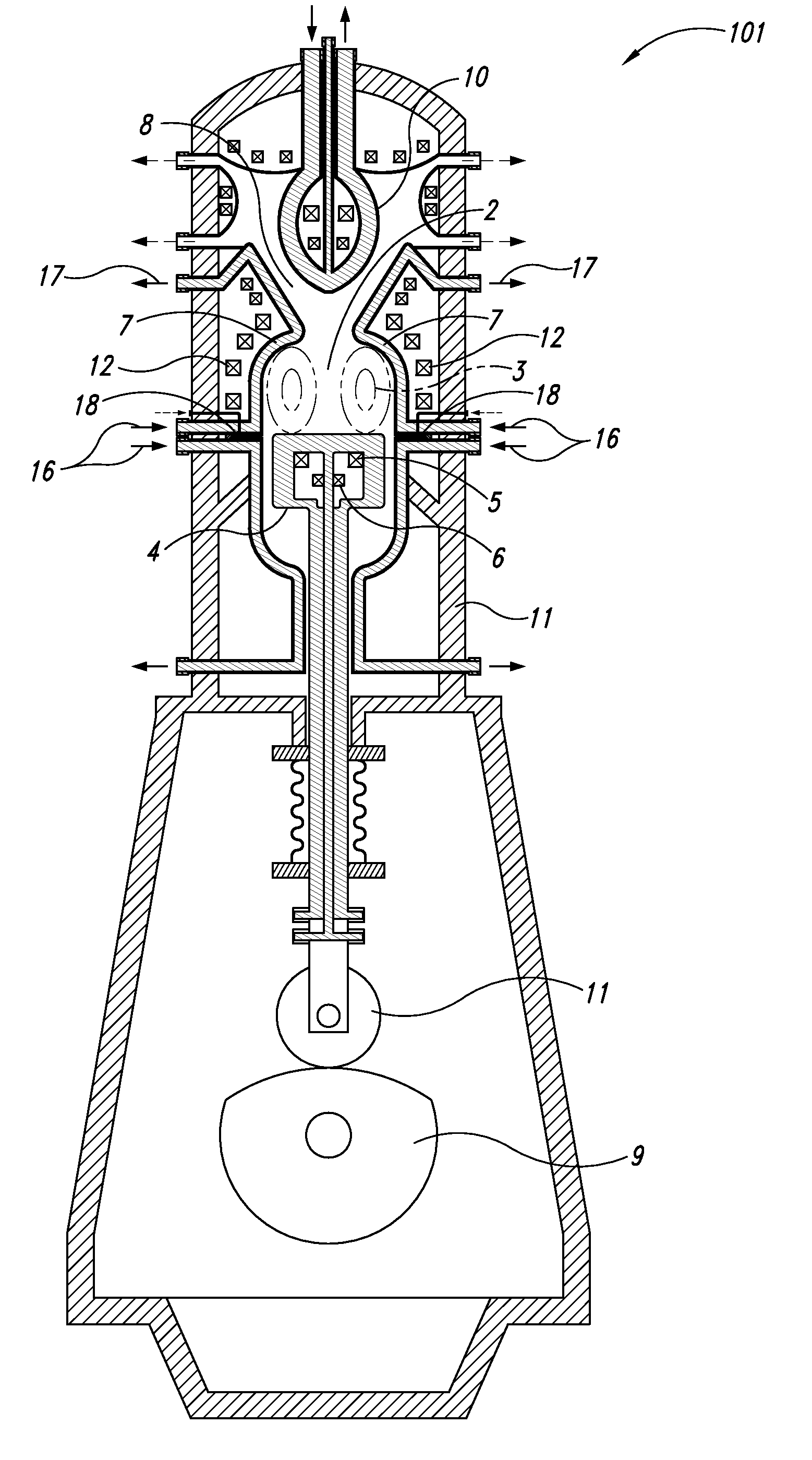

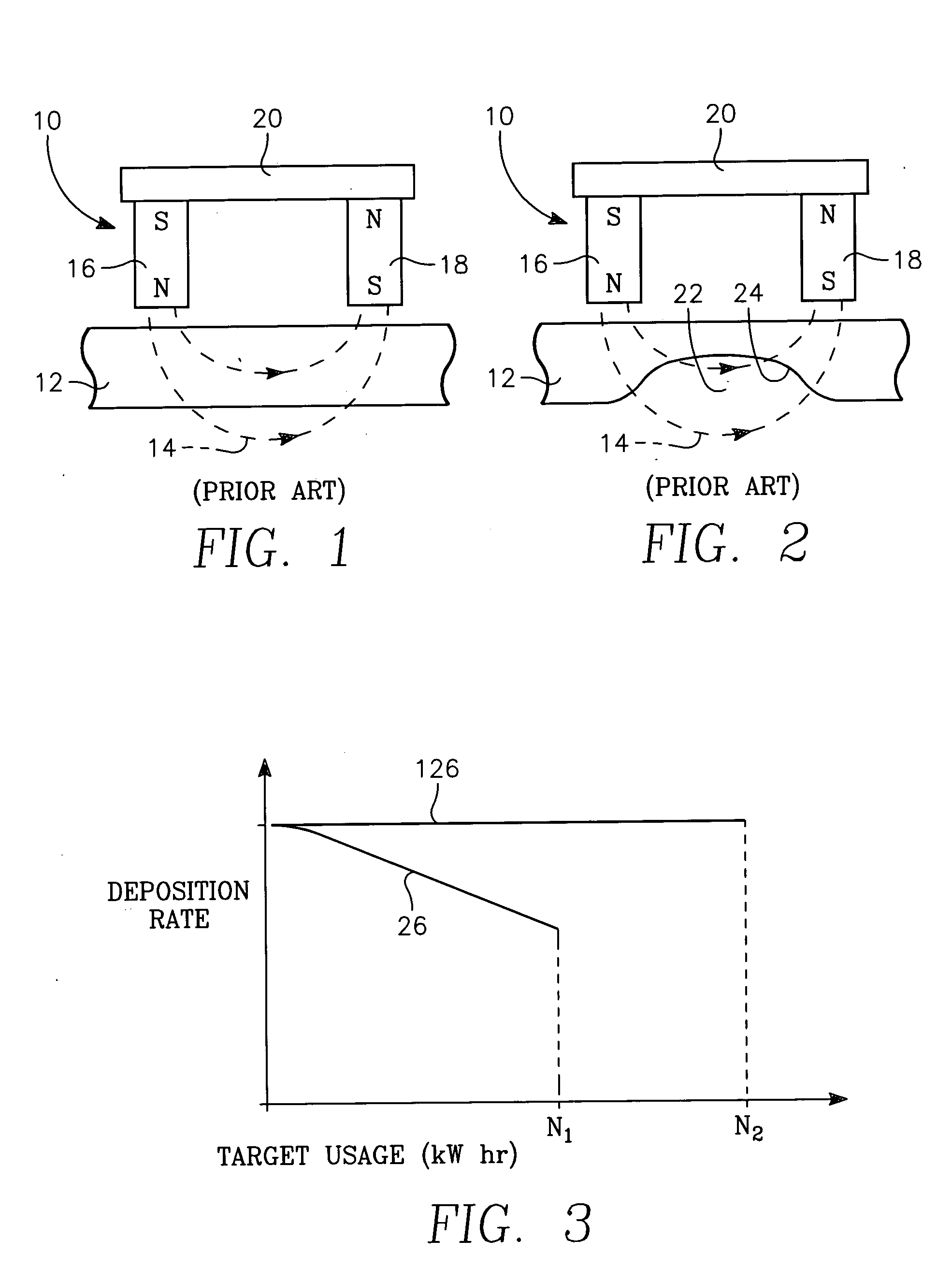

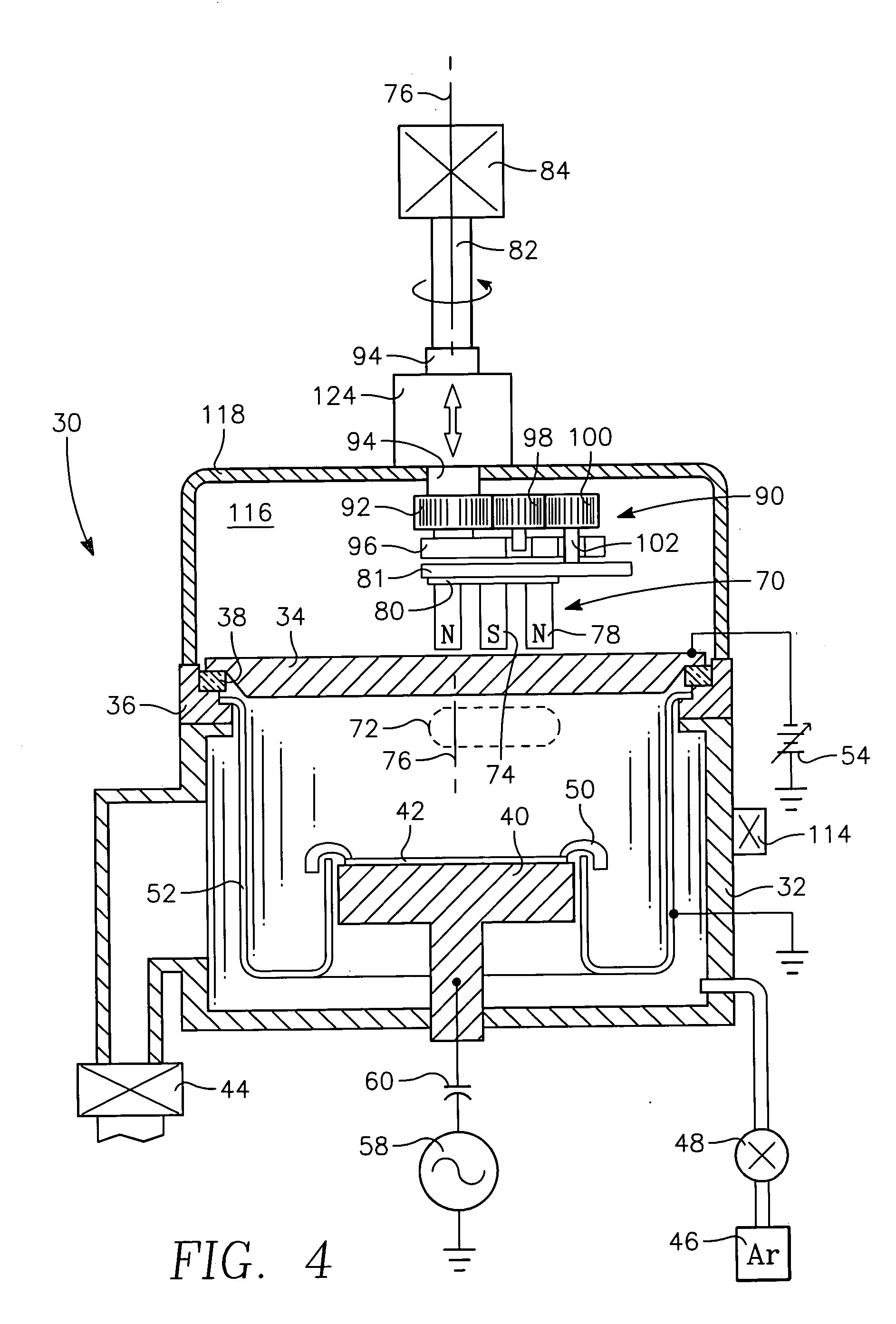

Compensation of spacing between magnetron and sputter target

InactiveUS20050133361A1Stable sputtering processConstant magnetic fieldCellsElectric discharge tubesSputteringPlasma density

A lift mechanism for and a corresponding use of a magnetron in a plasma sputter reactor. A magnetron rotating about the target axis is controllably lifted away from the back of the target to compensate for sputter erosion, thereby maintaining a constant magnetic field and resultant plasma density at the sputtered surface, which is particularly important for stable operation with a small magnetron, for example, one executing circular or planetary motion about the target axis. The lift mechanism can include a lead screw axially fixed to the magnetron support shaft and a lead nut engaged therewith to raise the magnetron as the lead nut is turned. Alternatively, the support shaft is axially fixed to a vertically moving slider. The amount of lift may be controlled according a recipe based on accumulated power applied to the target or by monitoring electrical characteristics of the target.

Owner:APPLIED MATERIALS INC

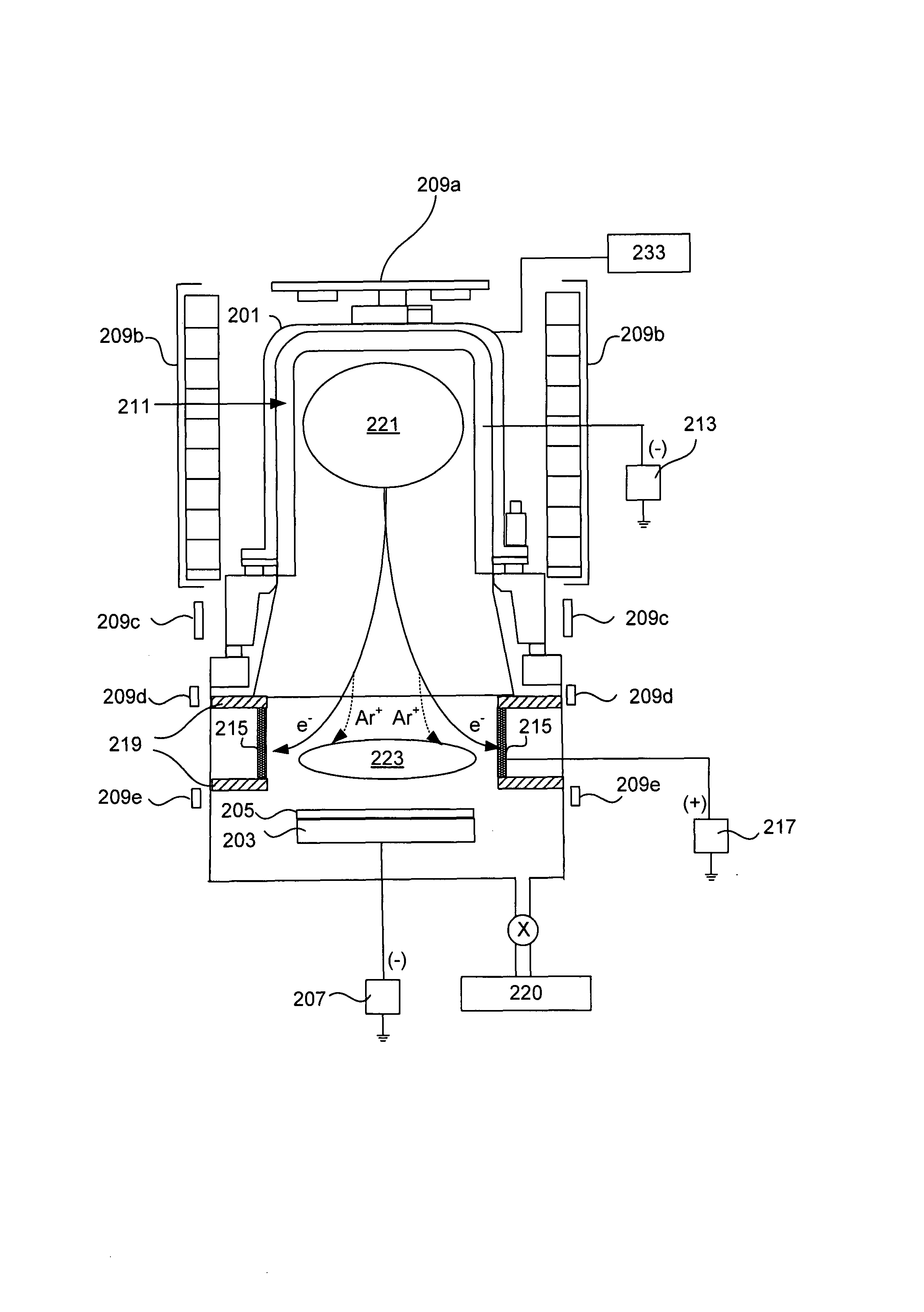

Method and apparatus for increasing local plasma density in magnetically confined plasma

ActiveUS7922880B1Easily damagedLow reliabilityCellsElectric discharge tubesPlasma densityHigh density

Local plasma density, e.g., the plasma density in the vicinity of the substrate, is increased by providing an ion extractor configured to transfer ions and electrons from a first region of magnetically confined plasma (typically a region of higher density plasma) to a second region of plasma (typically a region of lower density plasma). The second region of plasma is preferably also magnetically shaped or confined and resides between the first region of plasma and the substrate. A positively biased conductive member positioned proximate the second region of plasma serves as an ion extractor. A positive bias of about 50-300 V is applied to the ion extractor causing electrons and subsequently ions to be transferred from the first region of plasma to the vicinity of the substrate, thereby forming higher density plasma. Provided methods and apparatus are used for deposition and resputtering.

Owner:NOVELLUS SYSTEMS

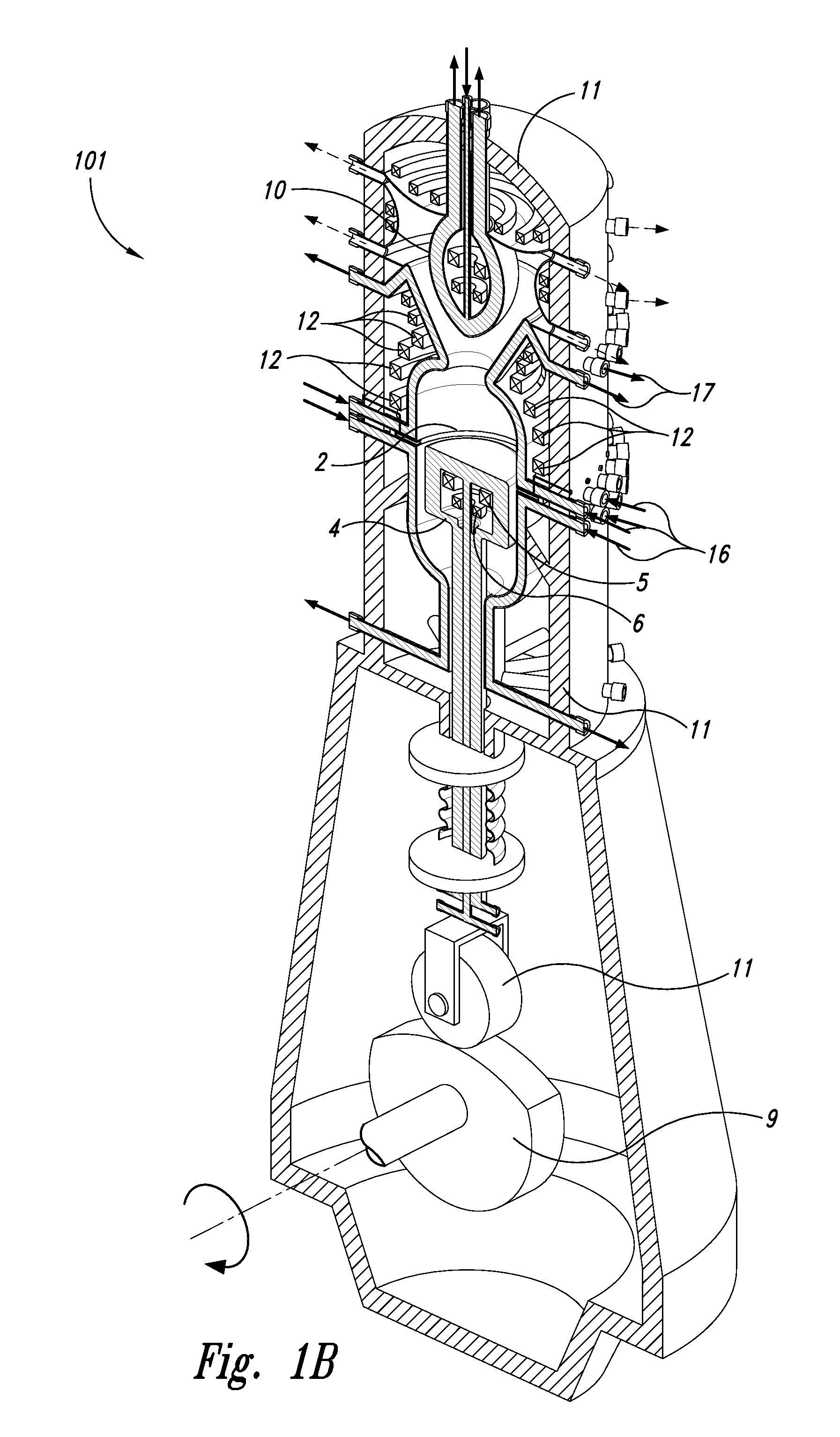

Device for compressing a compact toroidal plasma for use as a neutron source and fusion reactor

InactiveUS20110142185A1Improve isolationHigh densityNuclear energy generationAcceleratorsCombustion chamberPlasma density

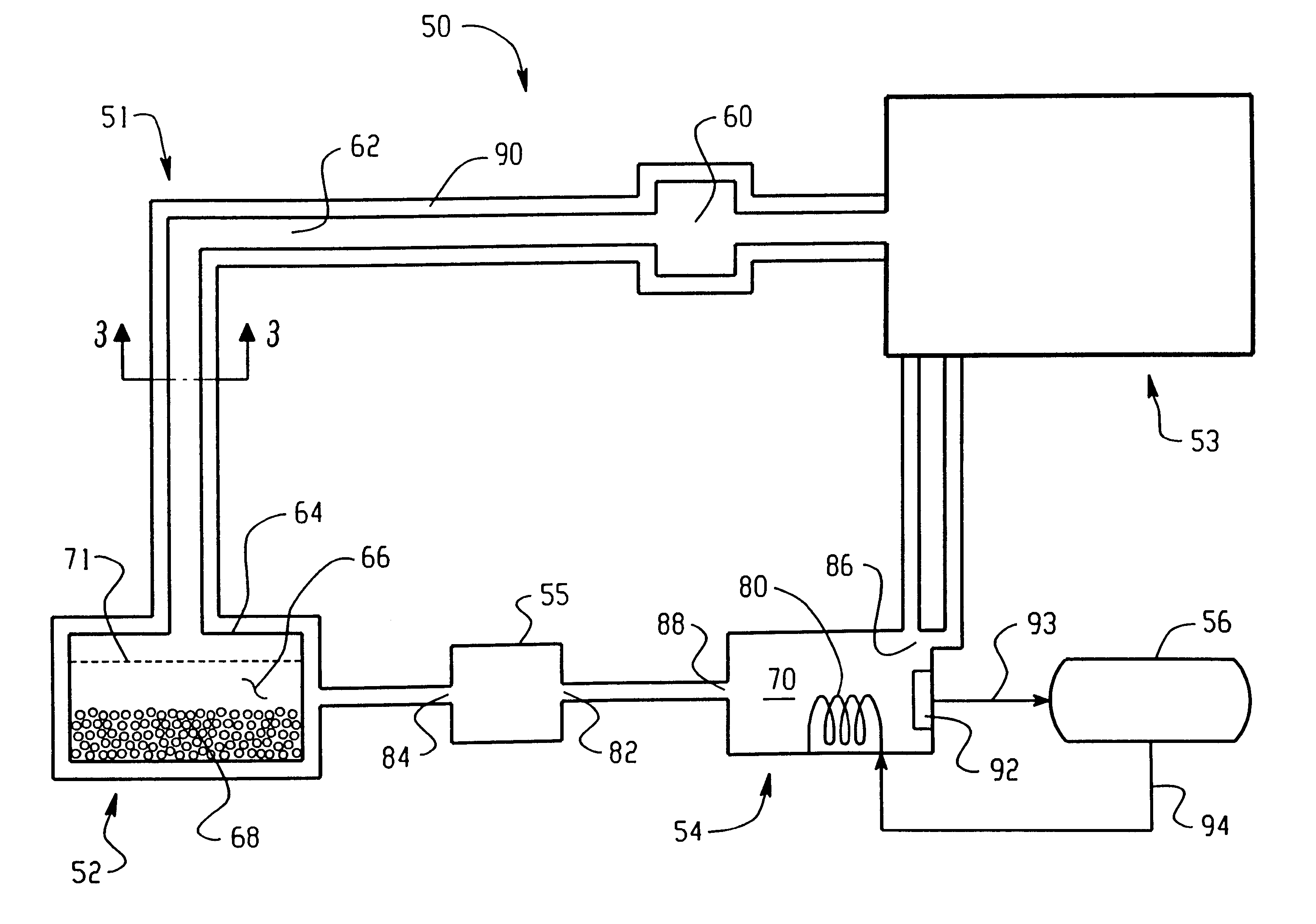

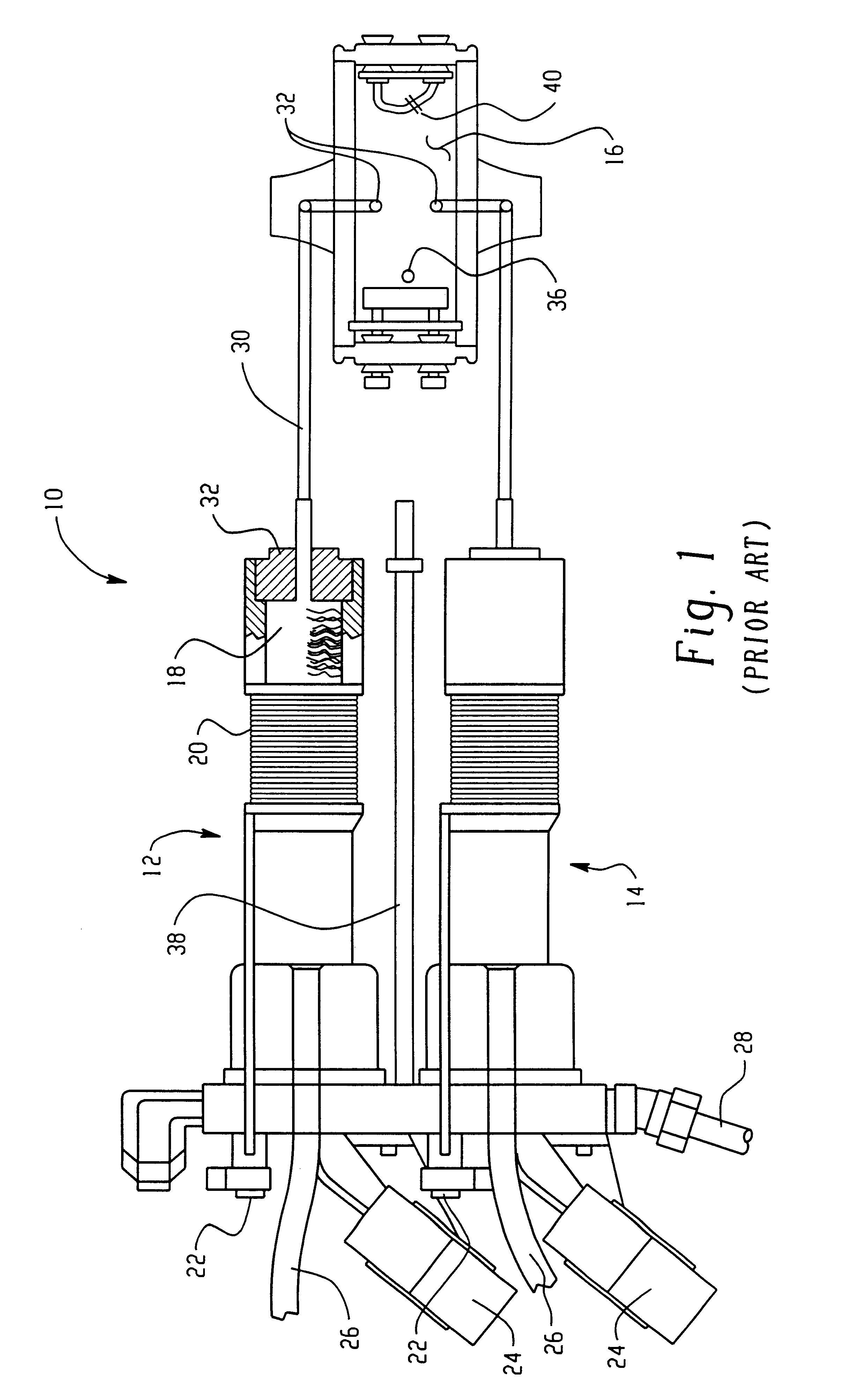

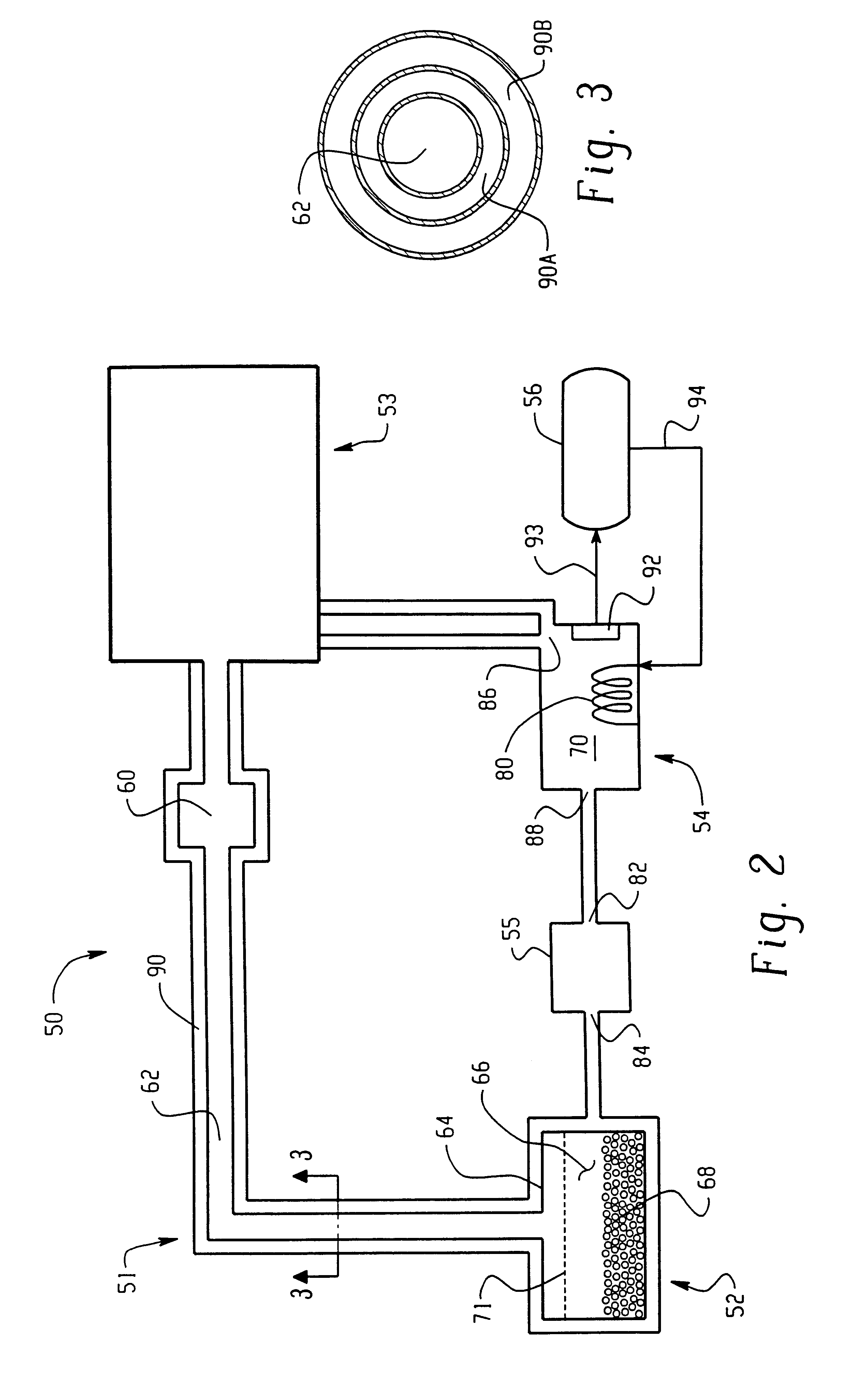

Provided are methods and devices for compression of a spheromak plasma (e.g., deuterium-trirtium (D-T)-derived) in a magnetic well configured within a plasma combustion chamber using an induction coil axially adjacent to the plasma, wherein a moveable member (e.g., piston, cam and follower) drives the induction coil toward the plasma, pushing the plasma via magnetic pressure into the magnetic well and compressing the plasma substantially adiabatically (e.g., coil motion is well below the plasma sound speed). The compression quickly increases both plasma density and temperature past the point of ignition, and after plasma burn, the coil is backed-off to allow the plasma to re-expand, providing for refueling and repetition of the compression cycle. Additionally provided are spaced annular plasma formation electrodes, suitably configured for generating and injecting magnetized plasma into a plasma combustion chamber. Preferably, spaced annular plasma formation electrodes are used in combination with moveable compression members as disclosed herein.

Owner:WOODRUFF SCI

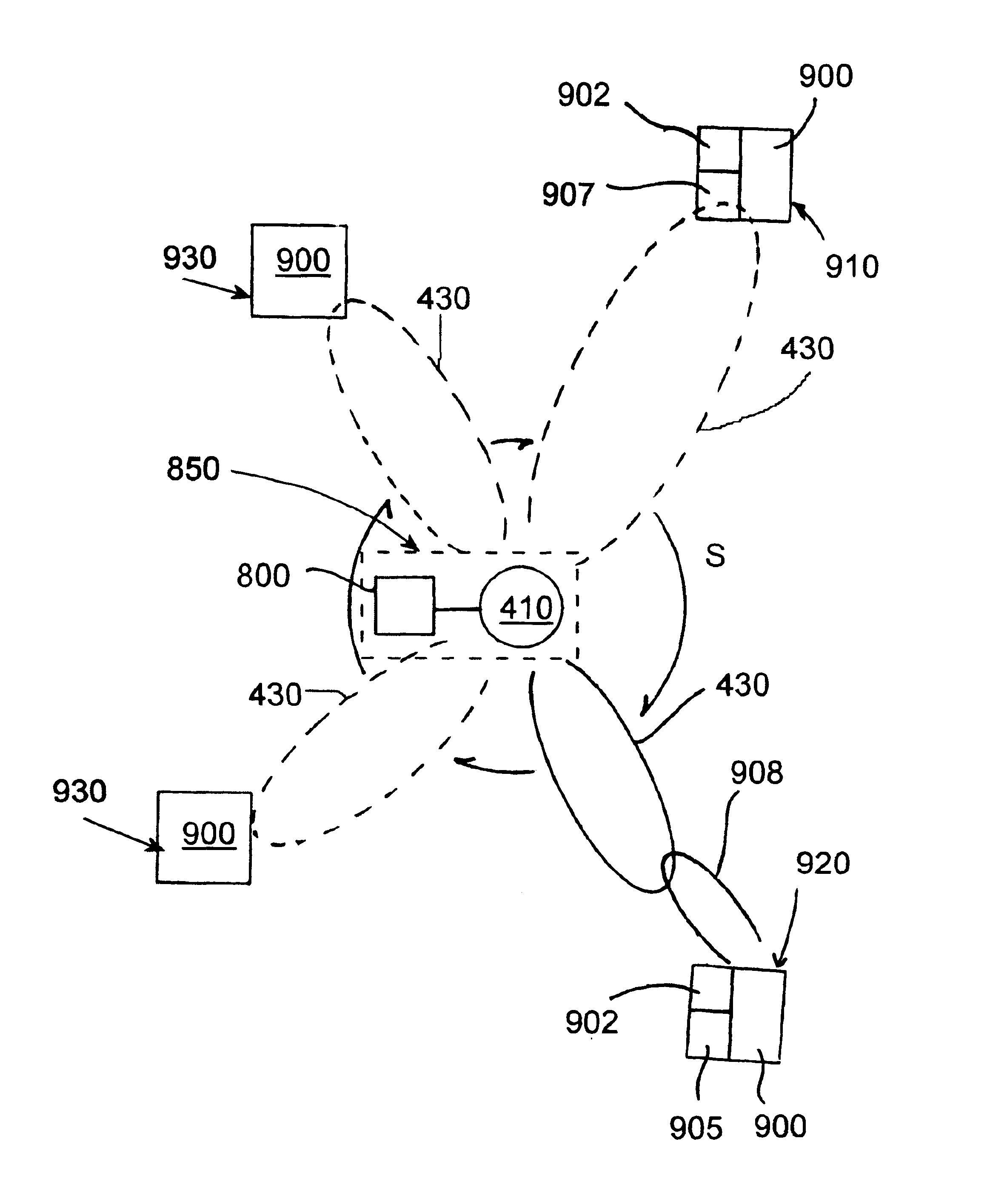

Reconfigurable scanner and RFID system using the scanner

InactiveUS6922173B2Eliminate distractionsElectric signal transmission systemsDigital data processing detailsPlasma densityPlasma window

A scanner has plasma loop or plasma window antennas for selectively scanning for ID tags along distinct radials of the scanner. Scanner elements are made electromagnetically invisible to adjacent elements by removing power or lowering plasma densities so that the scanner elements do not interfere with its own operation. Activatable ID tags and a shipping container suitable for scanning with electromagnetic energy are also disclosed.

Owner:ANDERSON THEODORE R

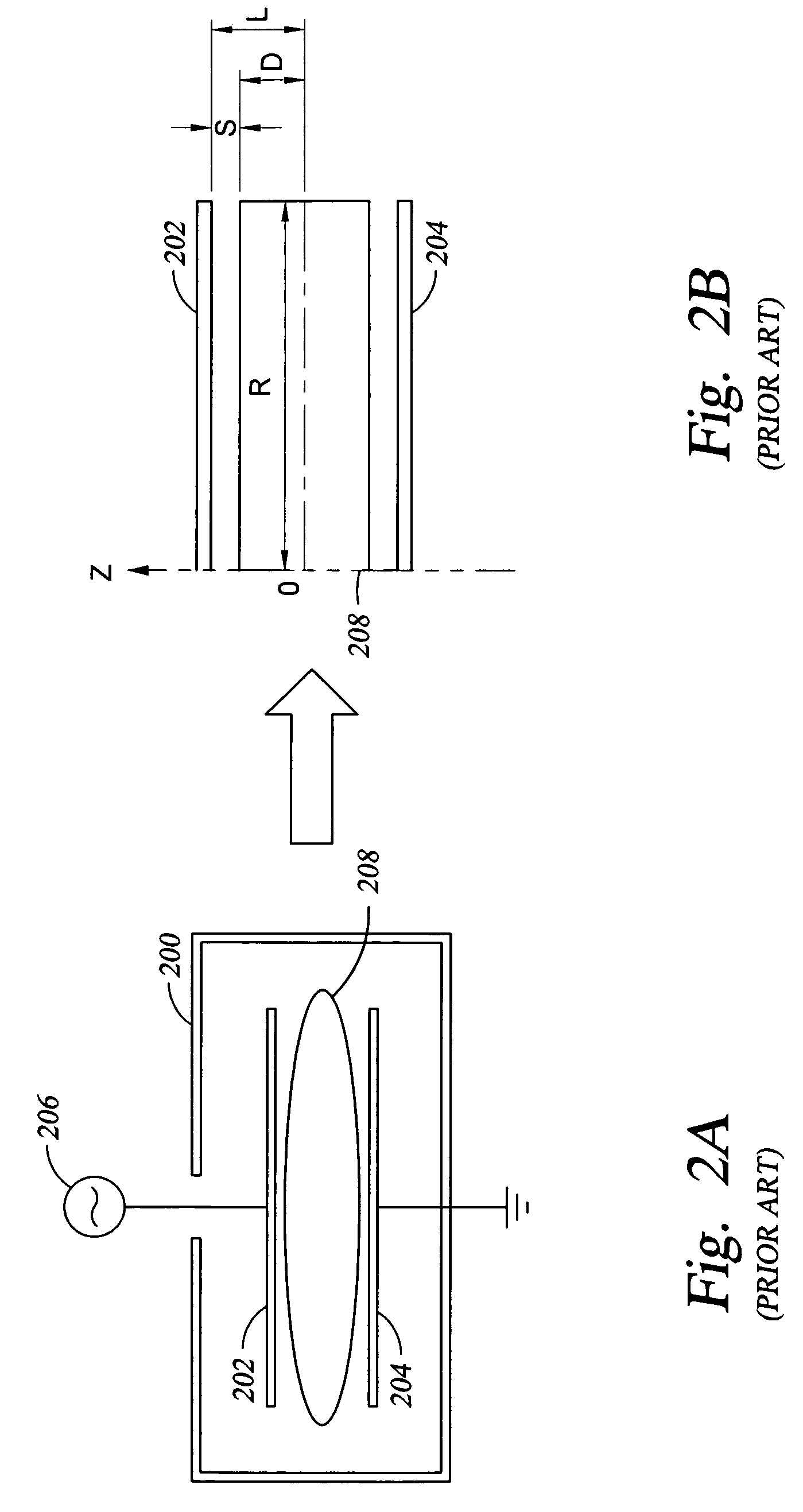

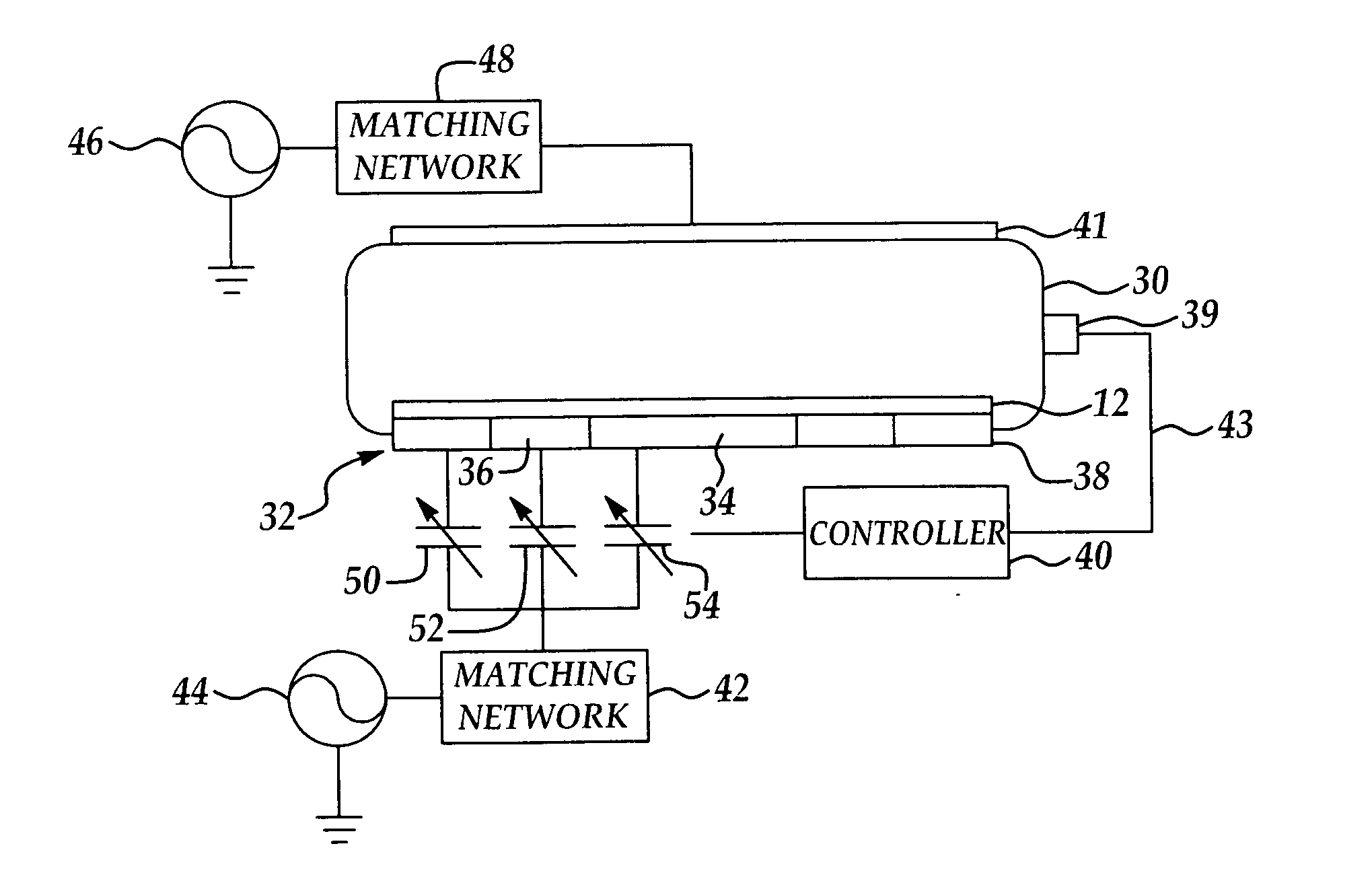

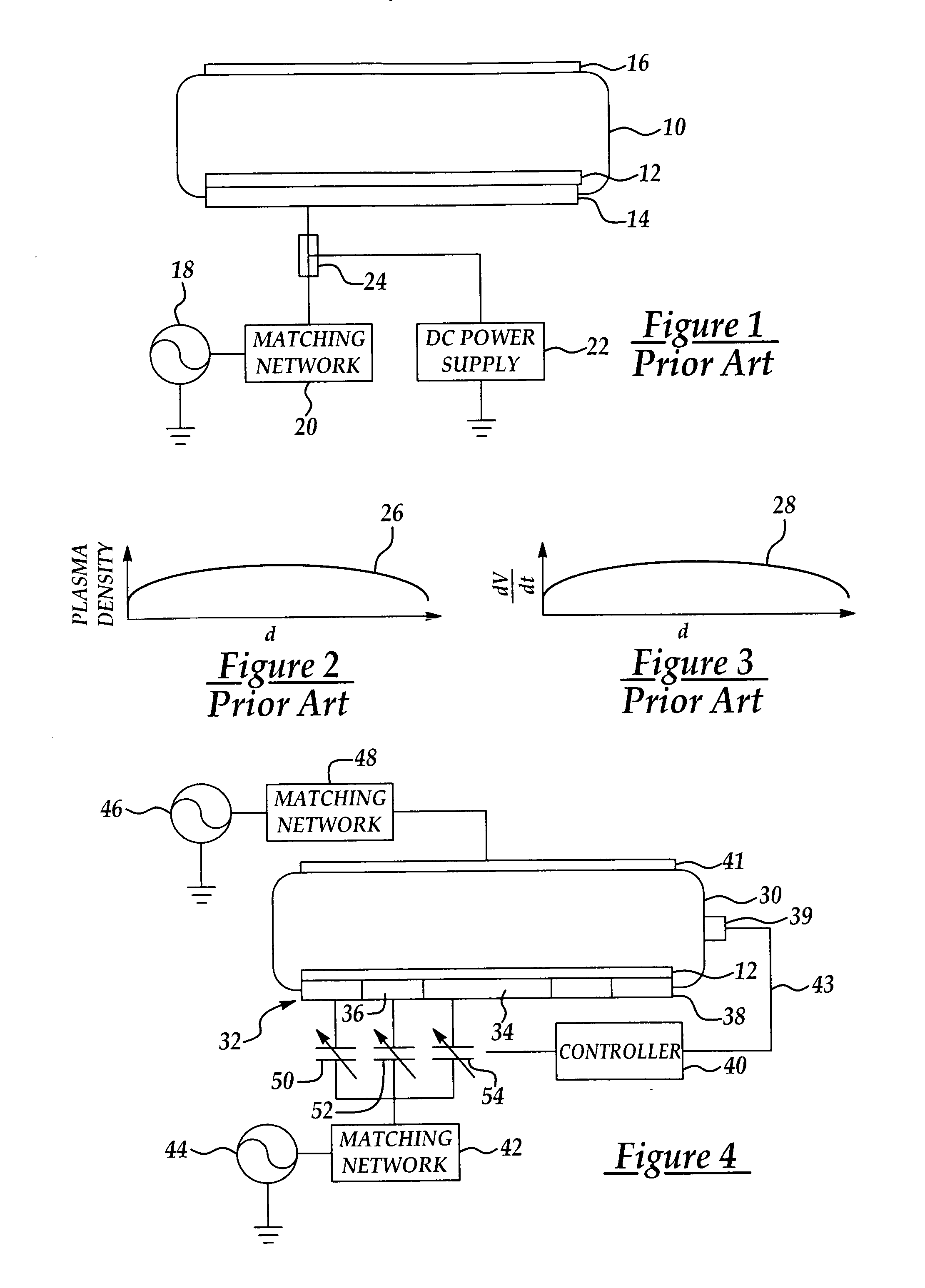

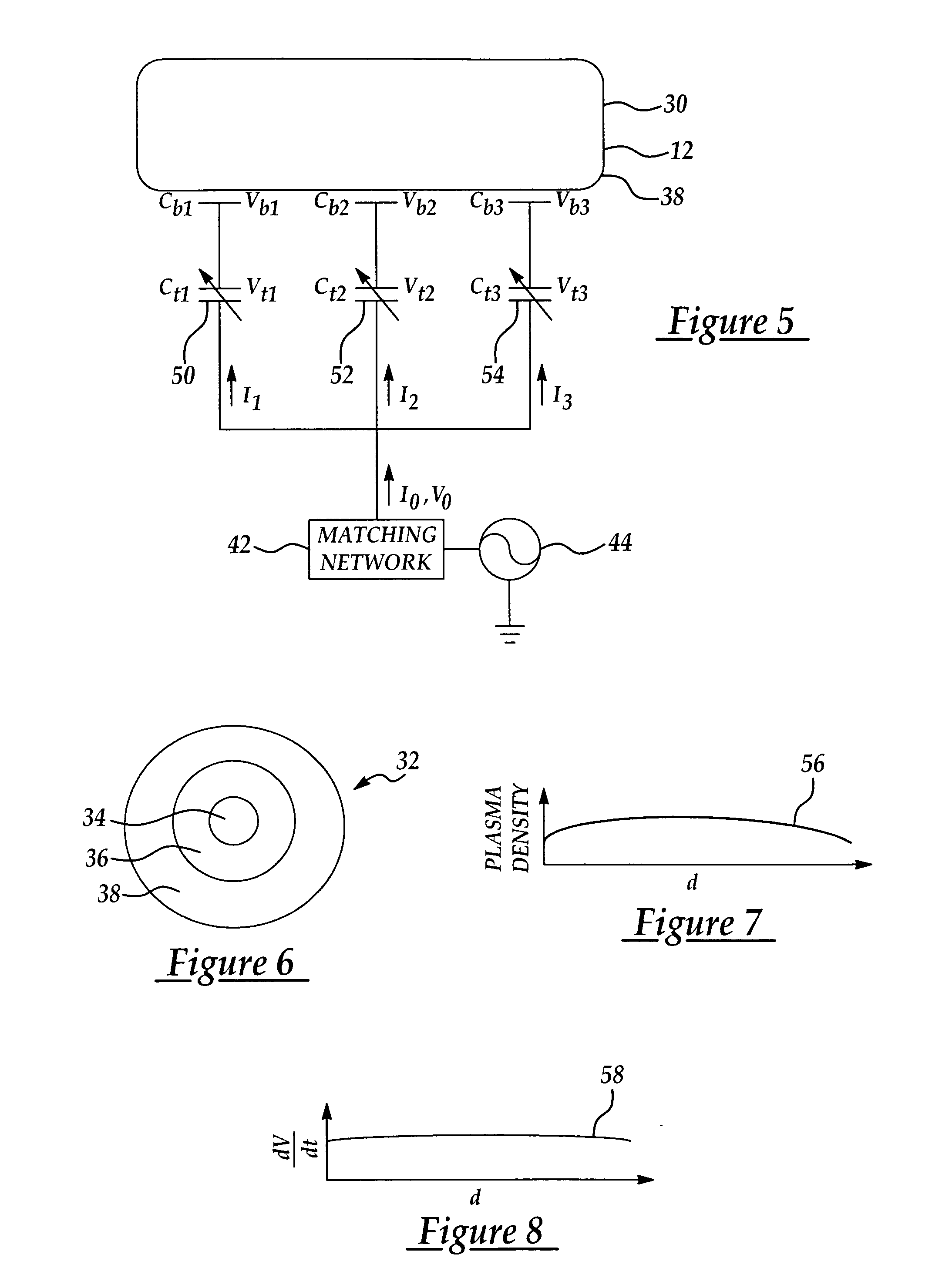

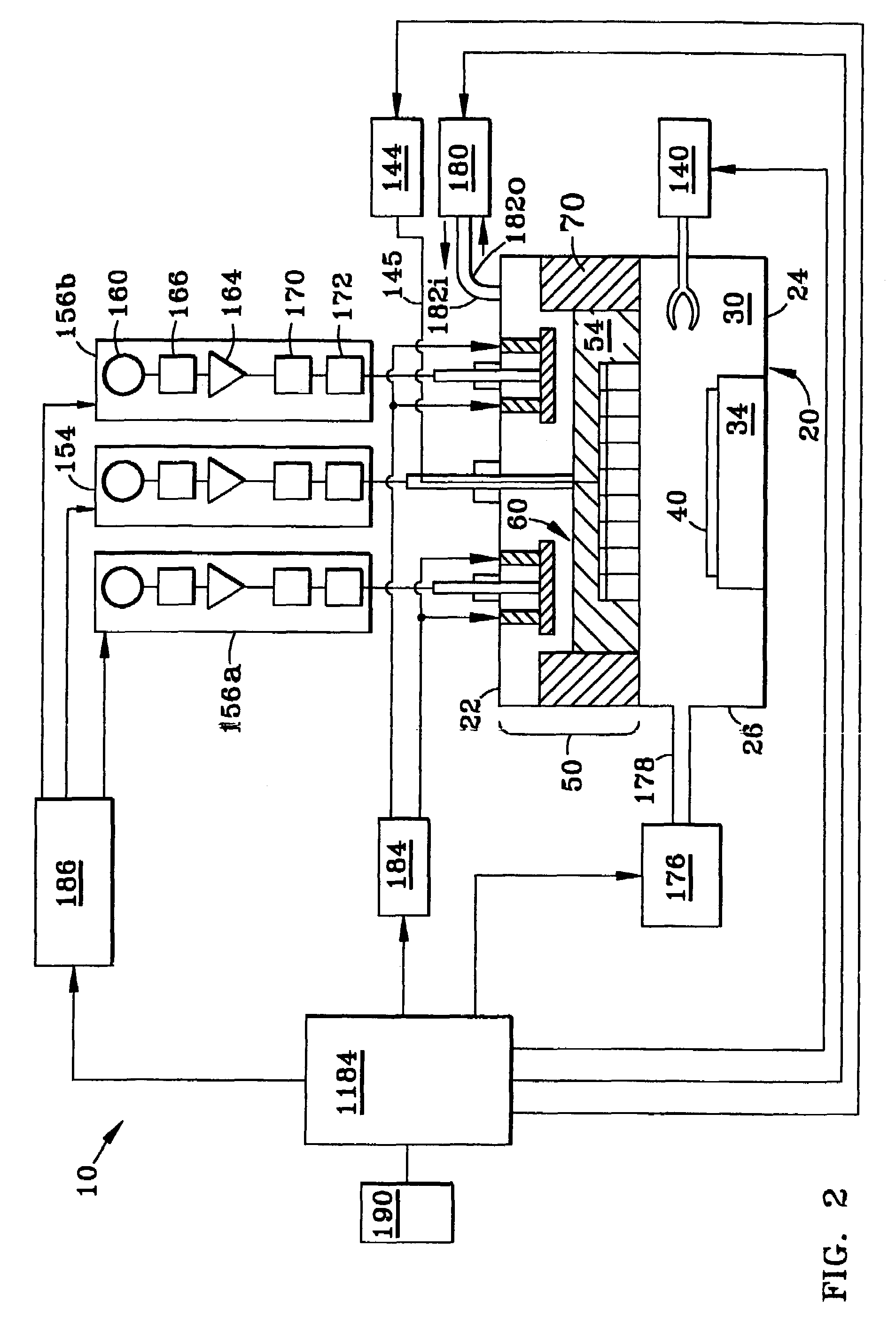

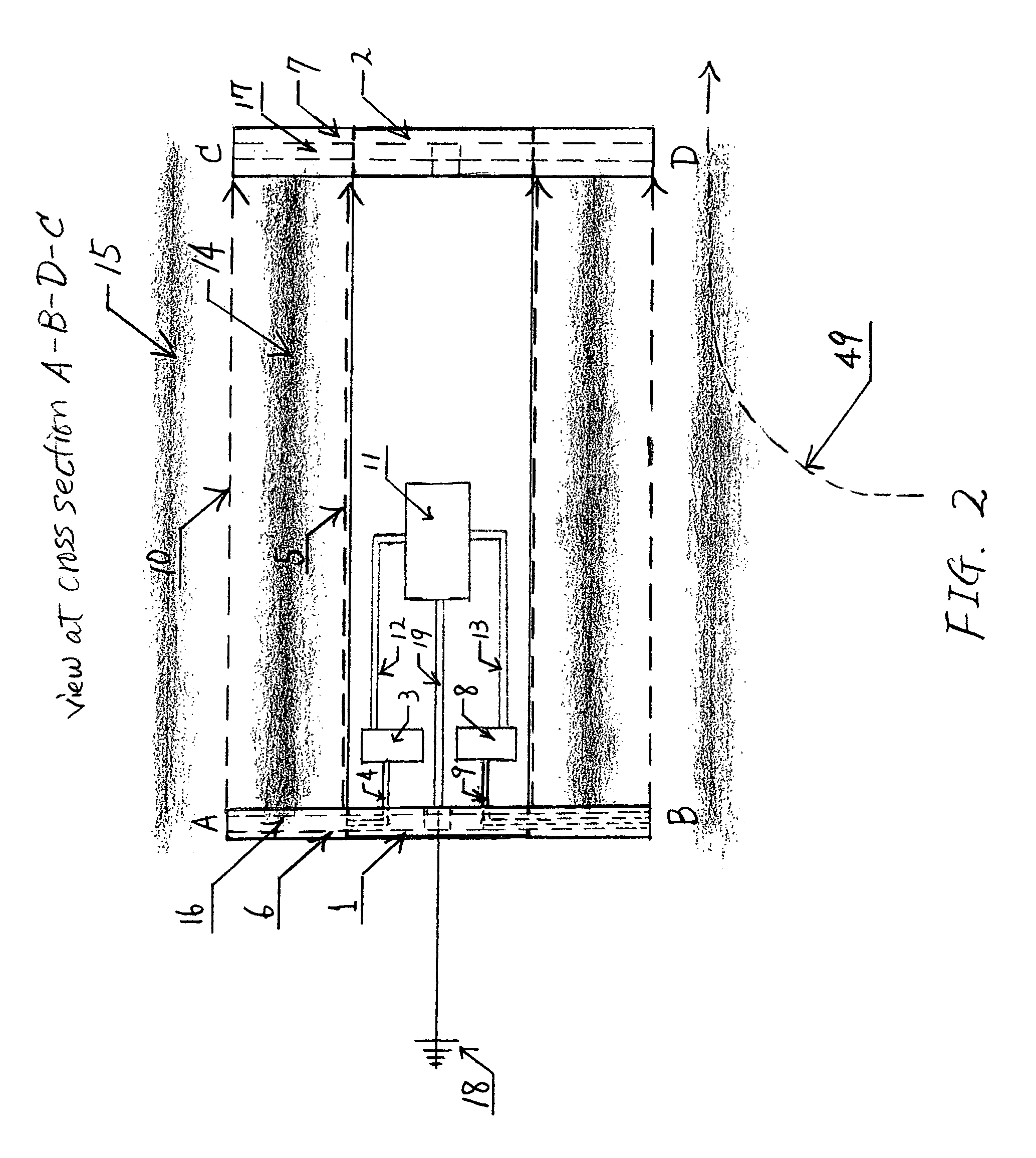

Method and apparatus for controlling spatial distribution of RF power and plasma density

InactiveUS20050031796A1Eliminate unevennessUniformityElectric discharge tubesProgram controlElectric field sensorPlasma density

Uniform spatial distribution of plasma over the face of a semiconductor wafer is achieved using a multi-zone electrode forming part of an electrostatic chuck used to hold the wafer in a processing chamber. The electrode includes a plurality of concentric electrode portions to which differing RF bias voltages may be applied to produce an electric field having a desired spatial distribution. Sensors are used to monitor either the spatial distribution of the plasma or the process effects of the plasma, and the sensed information is fed back to a controller that adjusts the bias voltage on the electrode portions in a manner to maintain the spatial uniformity of the plasma.

Owner:TAIWAN SEMICON MFG CO LTD

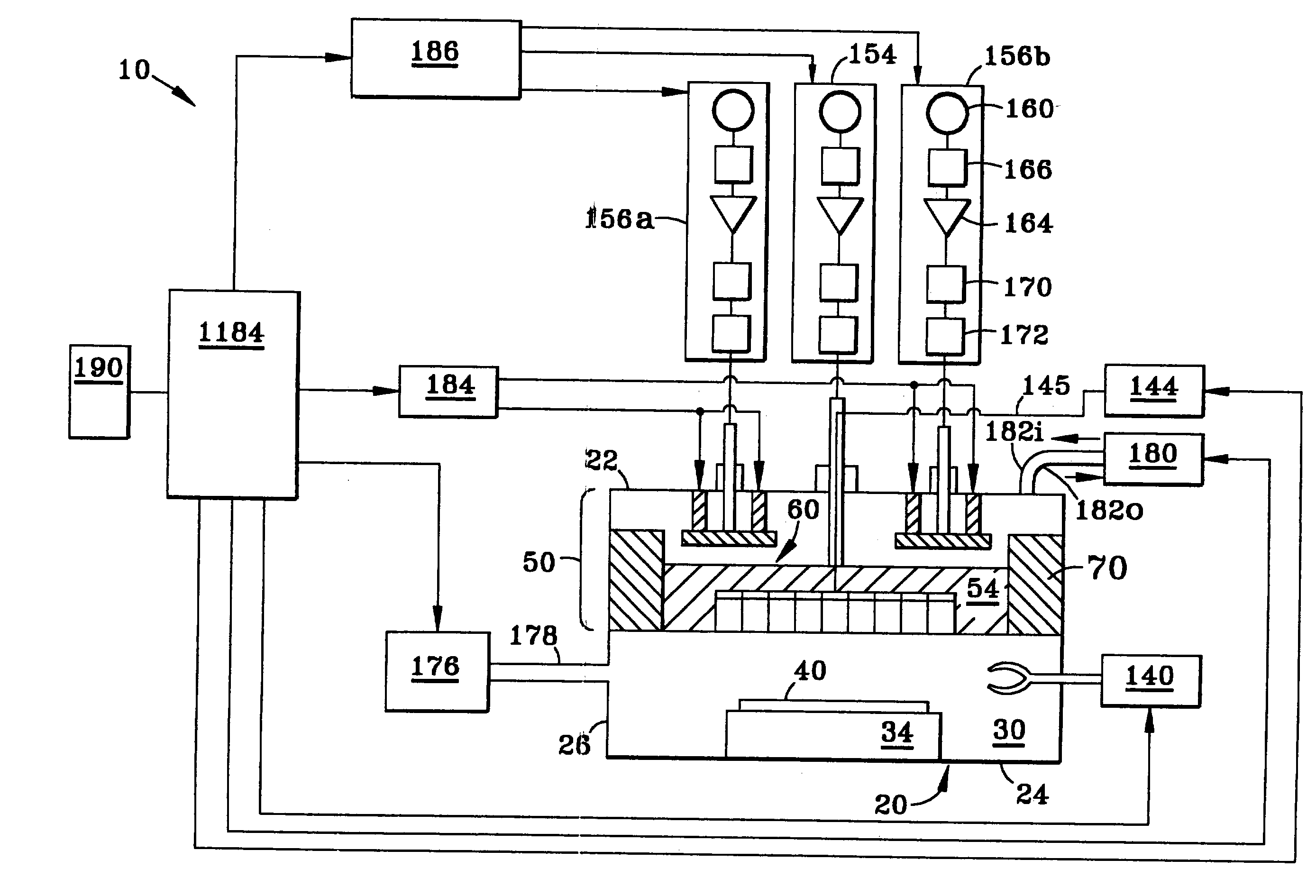

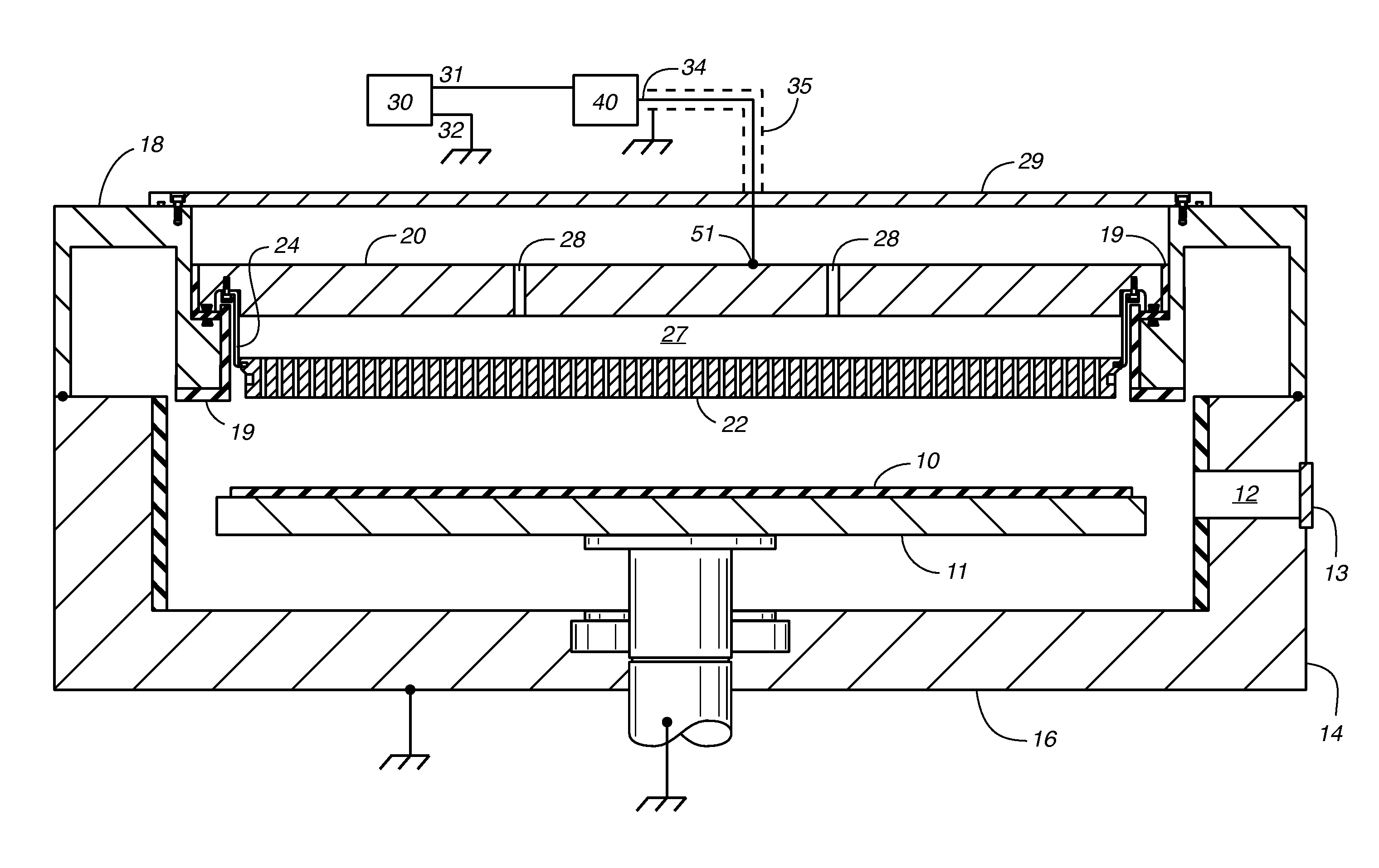

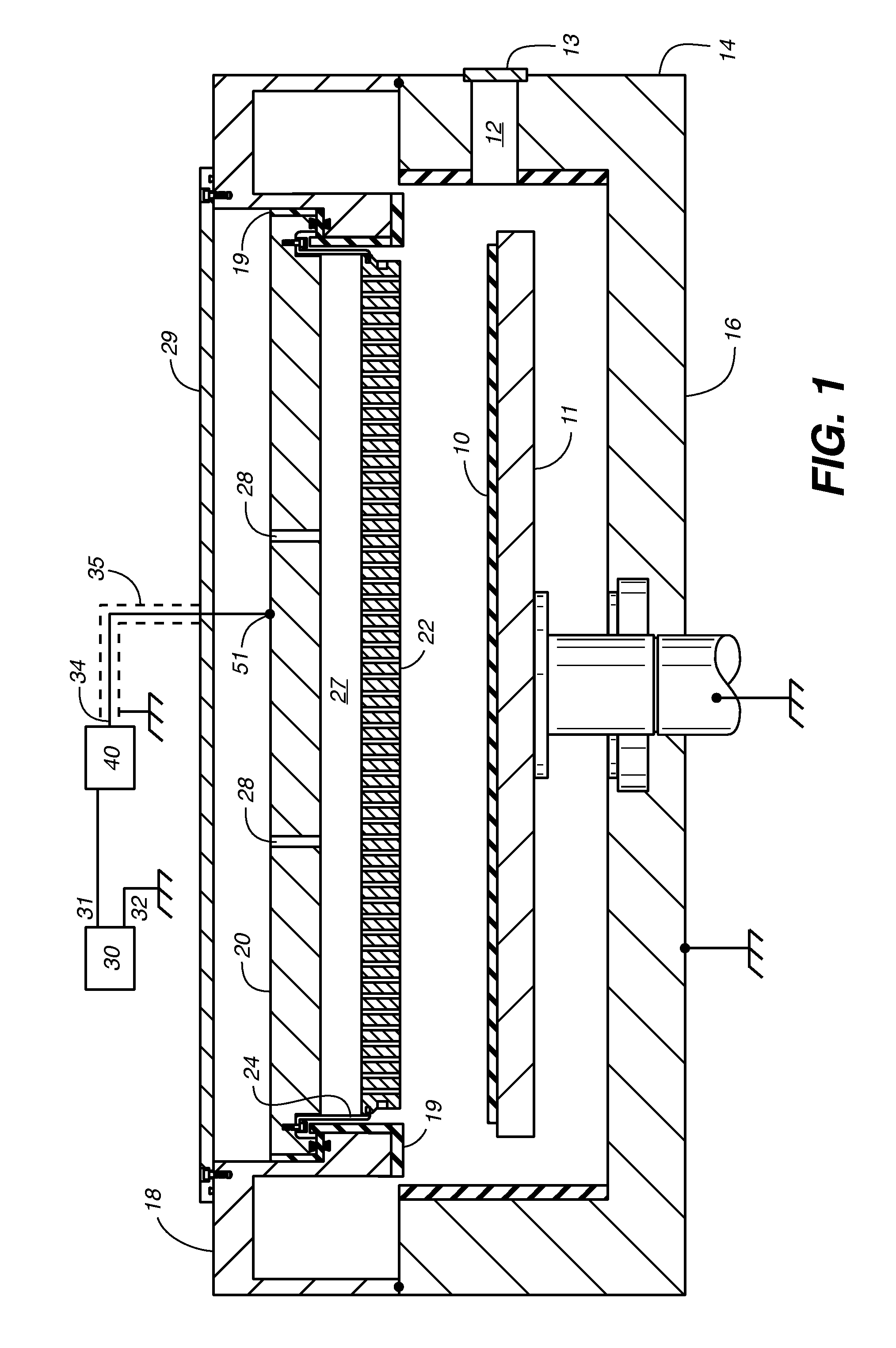

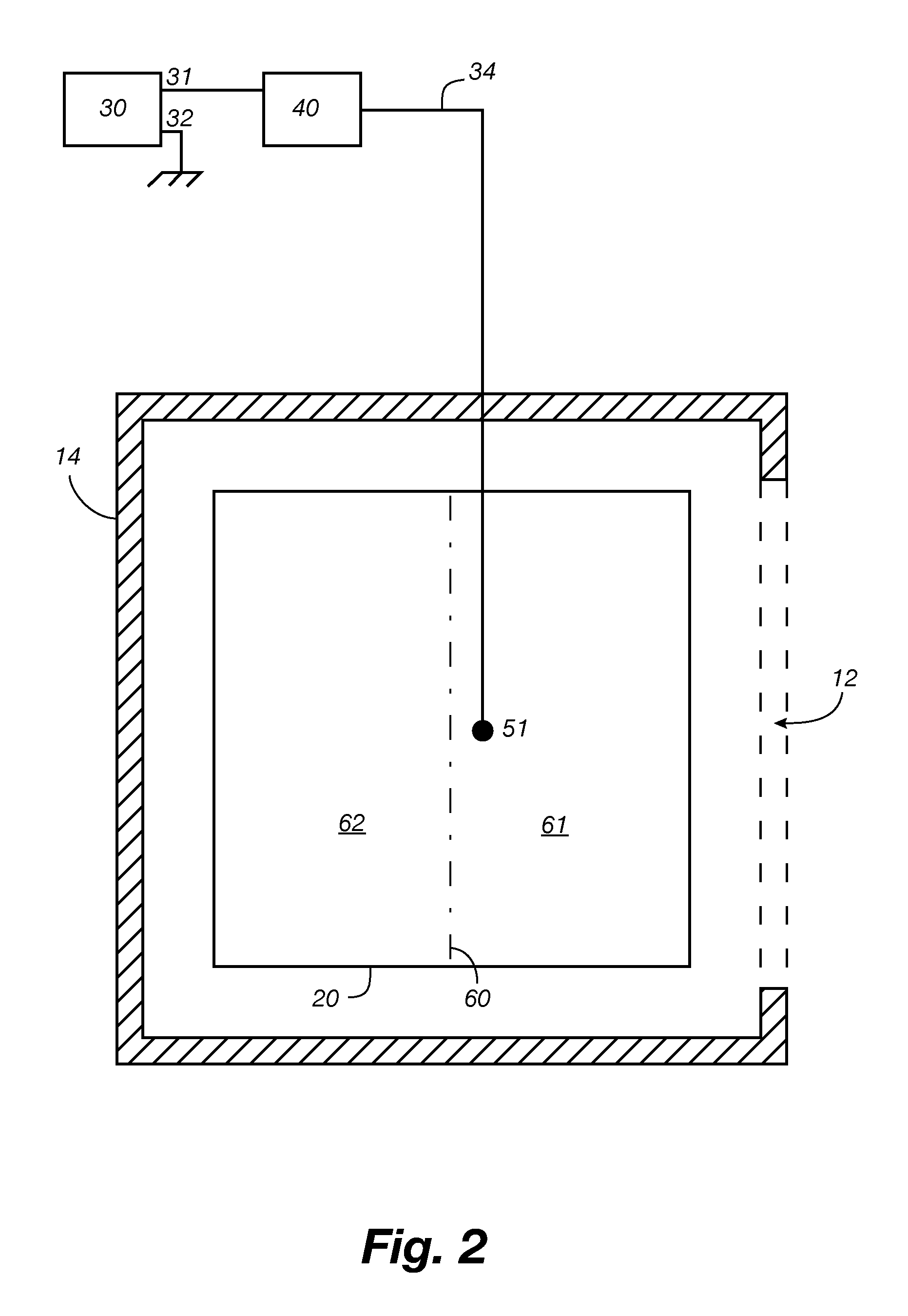

Controlled method for segmented electrode apparatus and method for plasma processing

InactiveUS6962664B2Electric discharge tubesVacuum gauge using ionisation effectsPlasma densityEngineering

An electrode assembly (50) and an associated plasma reactor system (10) and related methods for a variety of plasma processing applications. The electrode assembly provides control of a plasma density profile (202) within an interior region (30) of a plasma reactor chamber (20). The electrode assembly includes an upper electrode (54) having a lower surface (54L), an upper surface (54U) and an outer edge (54E). The lower surface of the upper electrode faces interior region of the plasma chamber housing the plasma (200), and thus interfaces with the plasma. The electrode assembly further includes a segmented electrode (60) arranged proximate to and preferably substantially parallel with the upper surface of the upper electrode. The segmented electrode comprises two or more separated electrode segments (62a, 62b, . . . 62n), each having an upper and lower surface. Each electrode segment is spaced apart from the upper electrode upper surface by a corresponding controlled gap (Ga, Gb, . . . Gn). The electrode assembly may further include one or more actuators (110) attached to one or more electrode segments at the upper surface of the one or more electrode segments. The actuators allow for movement of the one or more electrode segments to adjust one or more of the controlled gaps. The adjustable controlled gaps allow for controlling the shape of the plasma density profile within the interior region of the chamber, thereby allowing for a desired plasma process result.

Owner:TOKYO ELECTRON LTD

Asymmetrical RF Drive for Electrode of Plasma Chamber

ActiveUS20090159423A1Increase plasma densityDrop in plasma densityElectric discharge tubesDecorative surface effectsPlasma densityEngineering

RF power is coupled to one or more RF drive points (50-56) on an electrode (20-28) of a plasma chamber such that the level of RF power coupled to the RF drive points (51-52, 55-56) on the half (61) of the electrode that is closer to the workpiece passageway (12) exceeds the level of RF power coupled to the RF drive points (53-54), if any, on the other half (62) of the electrode. Alternatively, RF power is coupled to one or more RF drive points on an electrode of a plasma chamber such that the weighted mean of the drive point positions is between the center (60) of the electrode and the workpiece passageway. The weighted mean is based on weighting each drive point position by the time-averaged level of RF power coupled to that drive point position. The invention offsets an increase in plasma density that otherwise would exist adjacent the end of the electrode closest to the passageway.

Owner:APPLIED MATERIALS INC

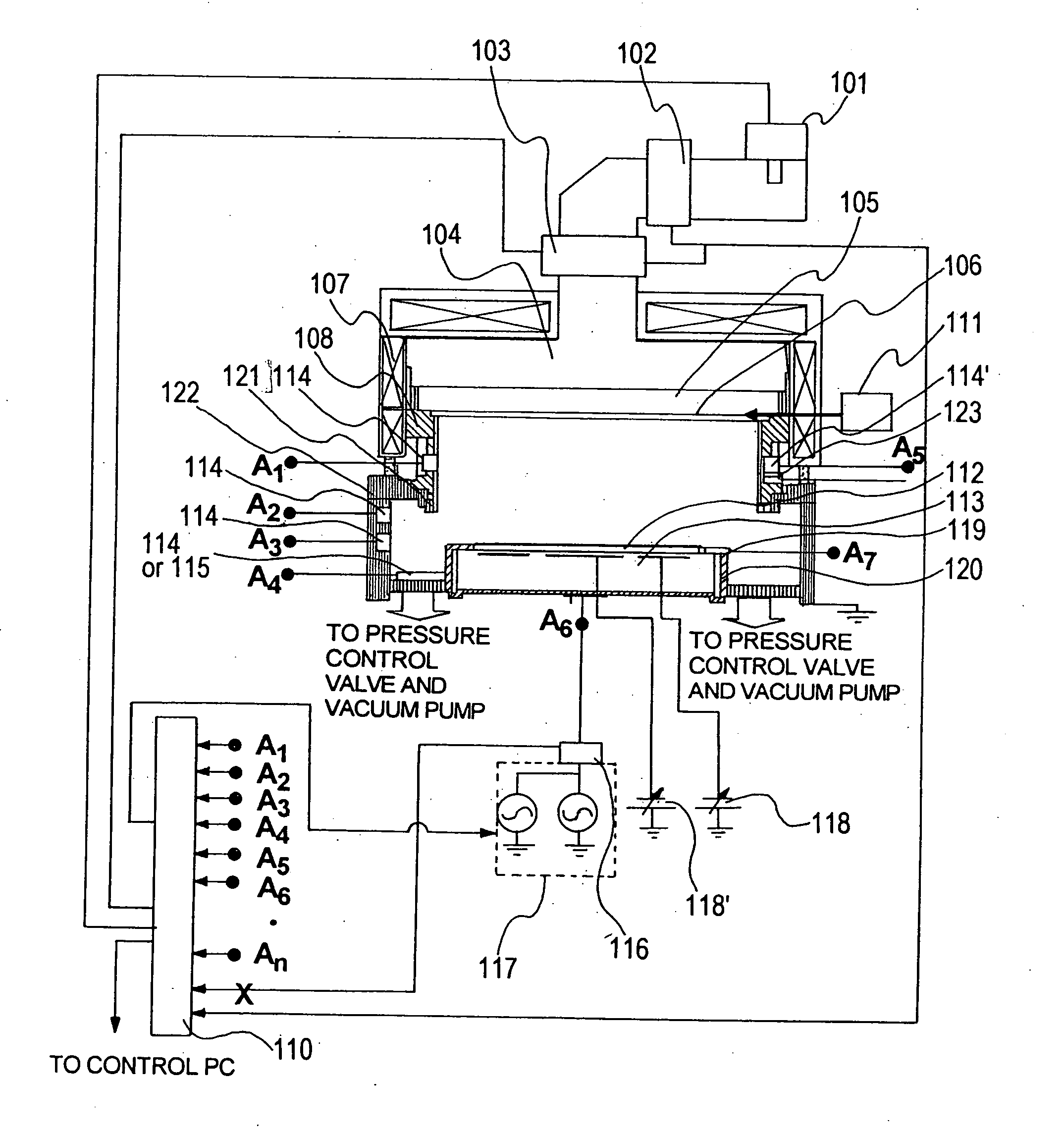

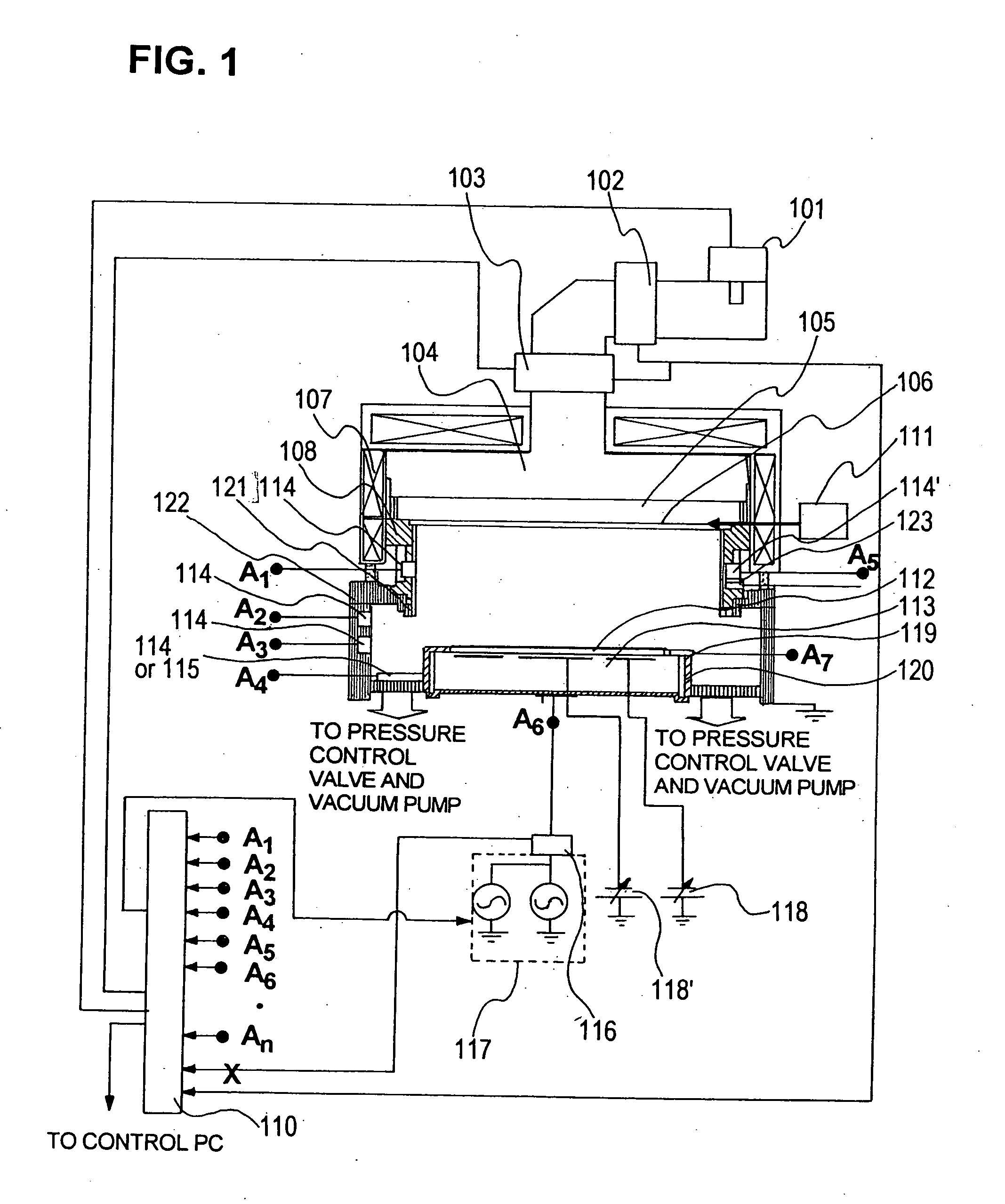

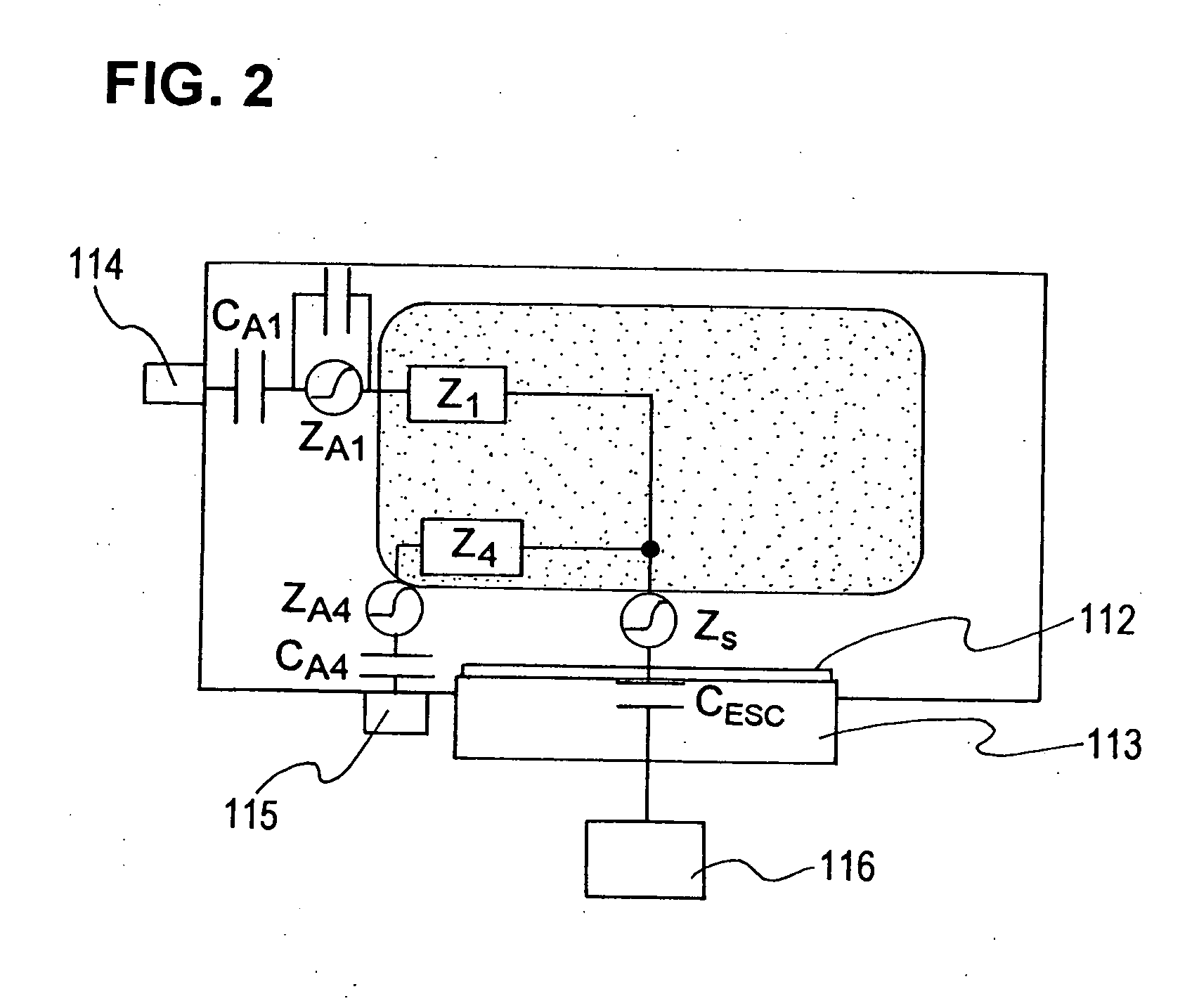

Plasma Processing Apparatus and Plasma Processing Method

InactiveUS20100258529A1Improve stabilityCondition can be detectedLiquid surface applicatorsElectric discharge tubesPlasma densityElectrical impedance

The invention provides a plasma processing apparatus comprising a means for detecting the apparatus condition related to the ion flux quantity of plasma (plasma density) and the distribution thereof for to stabilizing mass production and minimizing apparatus differences. The plasma processing apparatus comprises a vacuum reactor 108, a gas supply means 111, a pressure control means, a plasma source power supply 101, a lower electrode 113 on which an object to be processes 112 is placed within the vacuum reactor, and a high frequency bias power supply 117, further comprising a probe high frequency oscillation means 103 for supplying an oscillation frequency that differs from the plasma source power supply 101 and the high frequency bias power supply 117 into the plasma processing chamber, high frequency receivers 114 through 116 for receiving the high frequency supplied from the probe high frequency oscillation means 603 via a surface coming into contact with plasma, and a high frequency analysis means 110 for measuring the impedance per oscillation frequency within an electric circuit formed by the probe high frequency oscillation means 603 and the receivers 114 through 116, the reflectance and the transmittance, and the variation of harmonic components.

Owner:HITACHI HIGH-TECH CORP

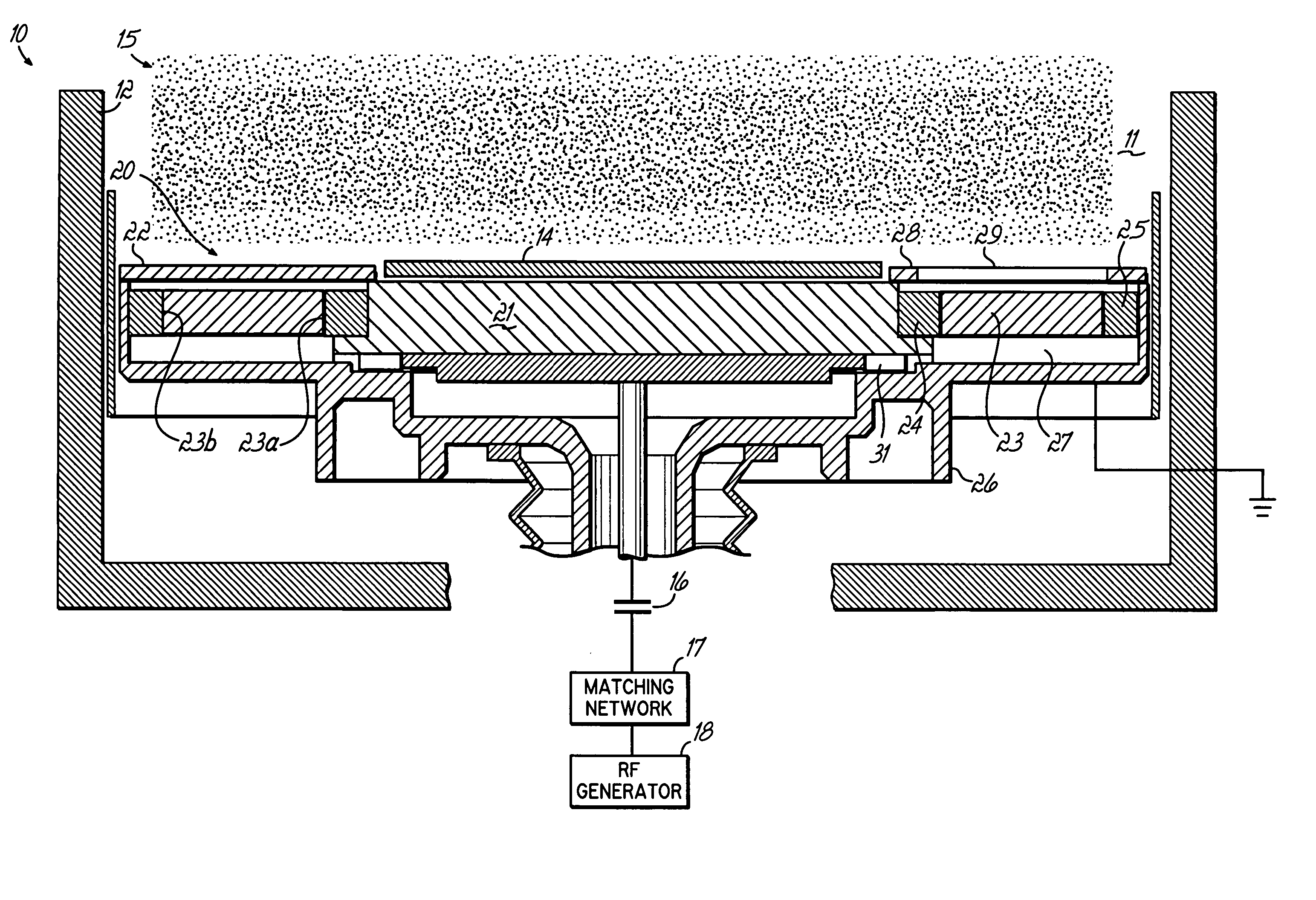

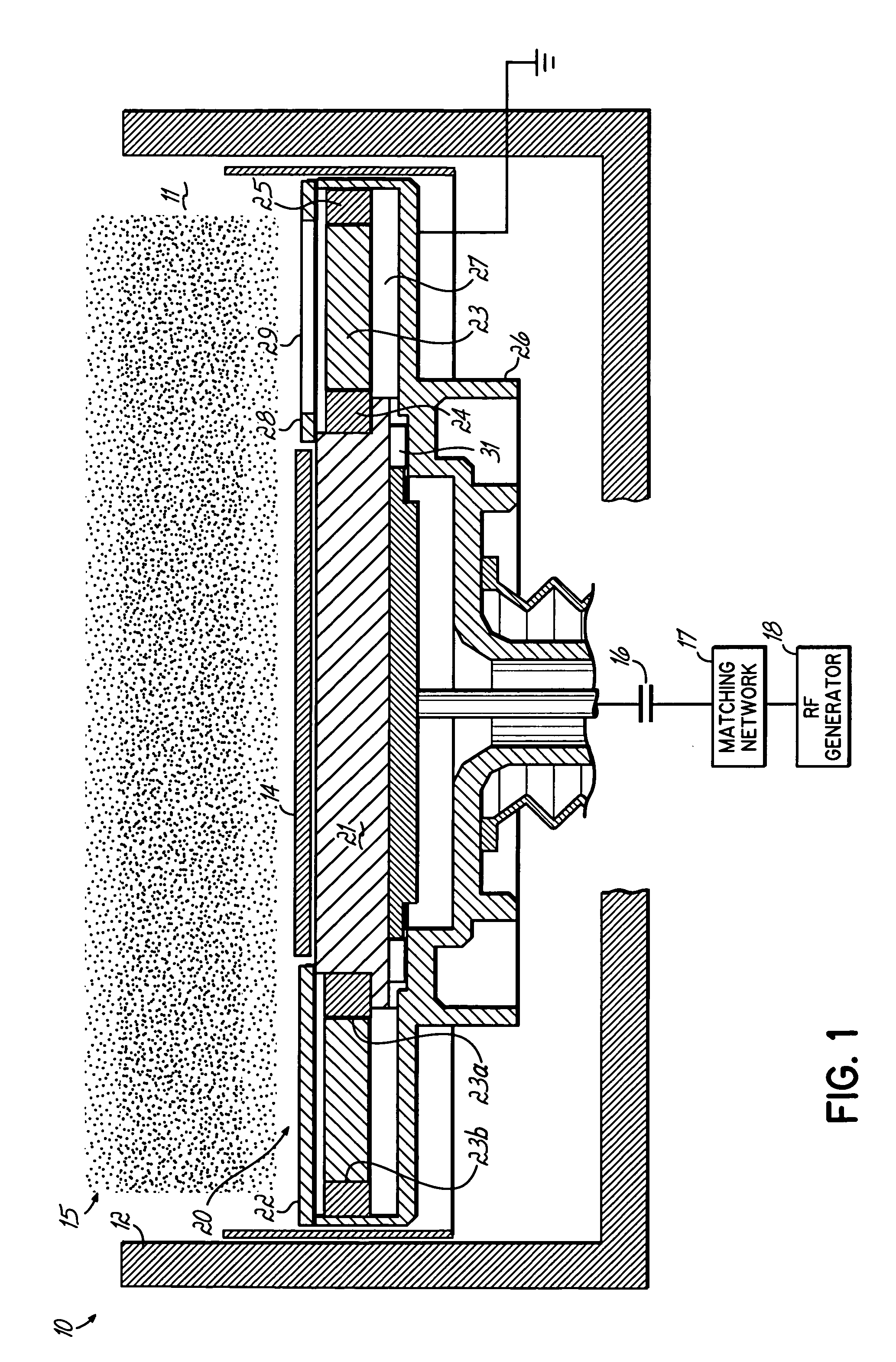

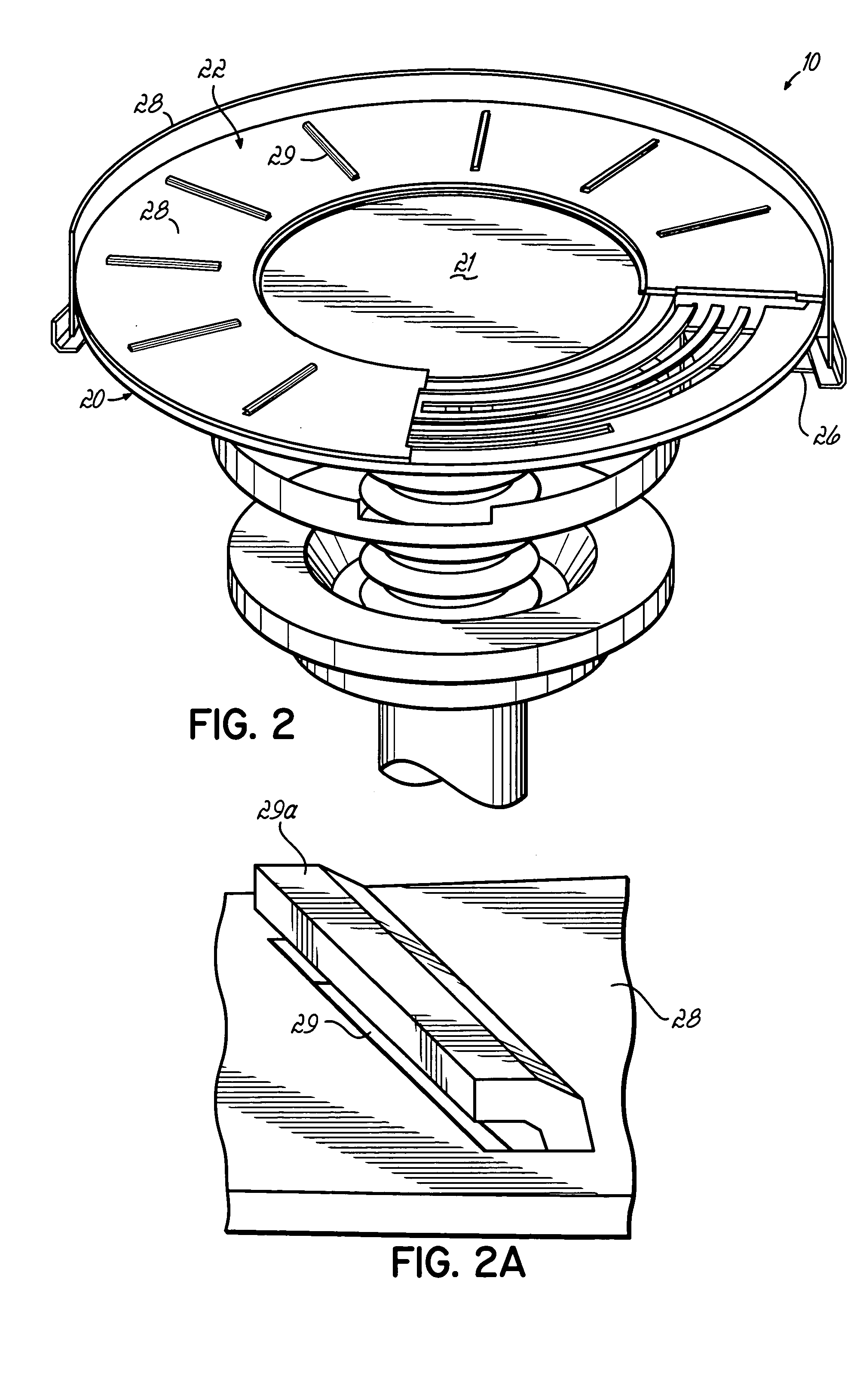

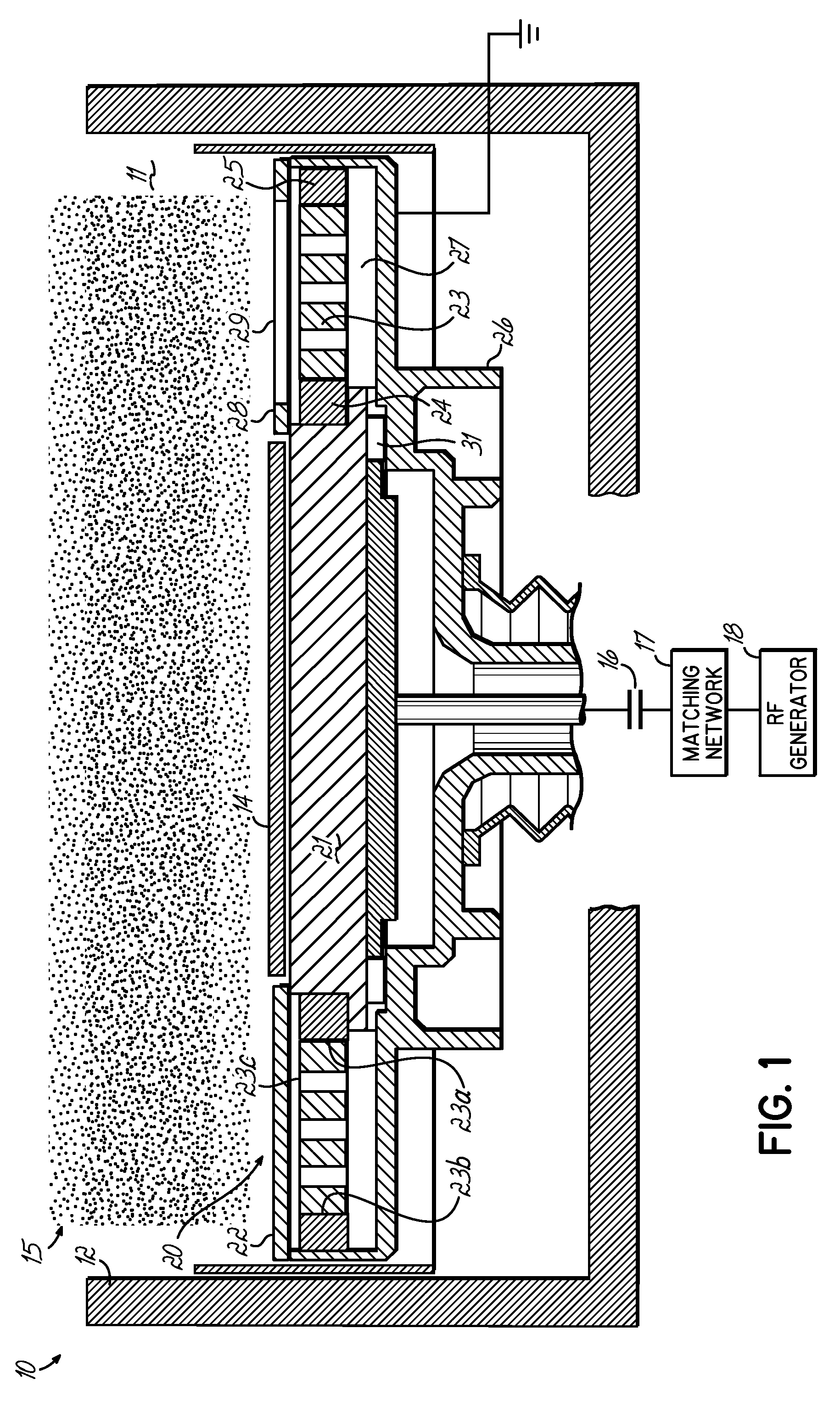

Integrated electrostatic inductive coupling for plasma processing

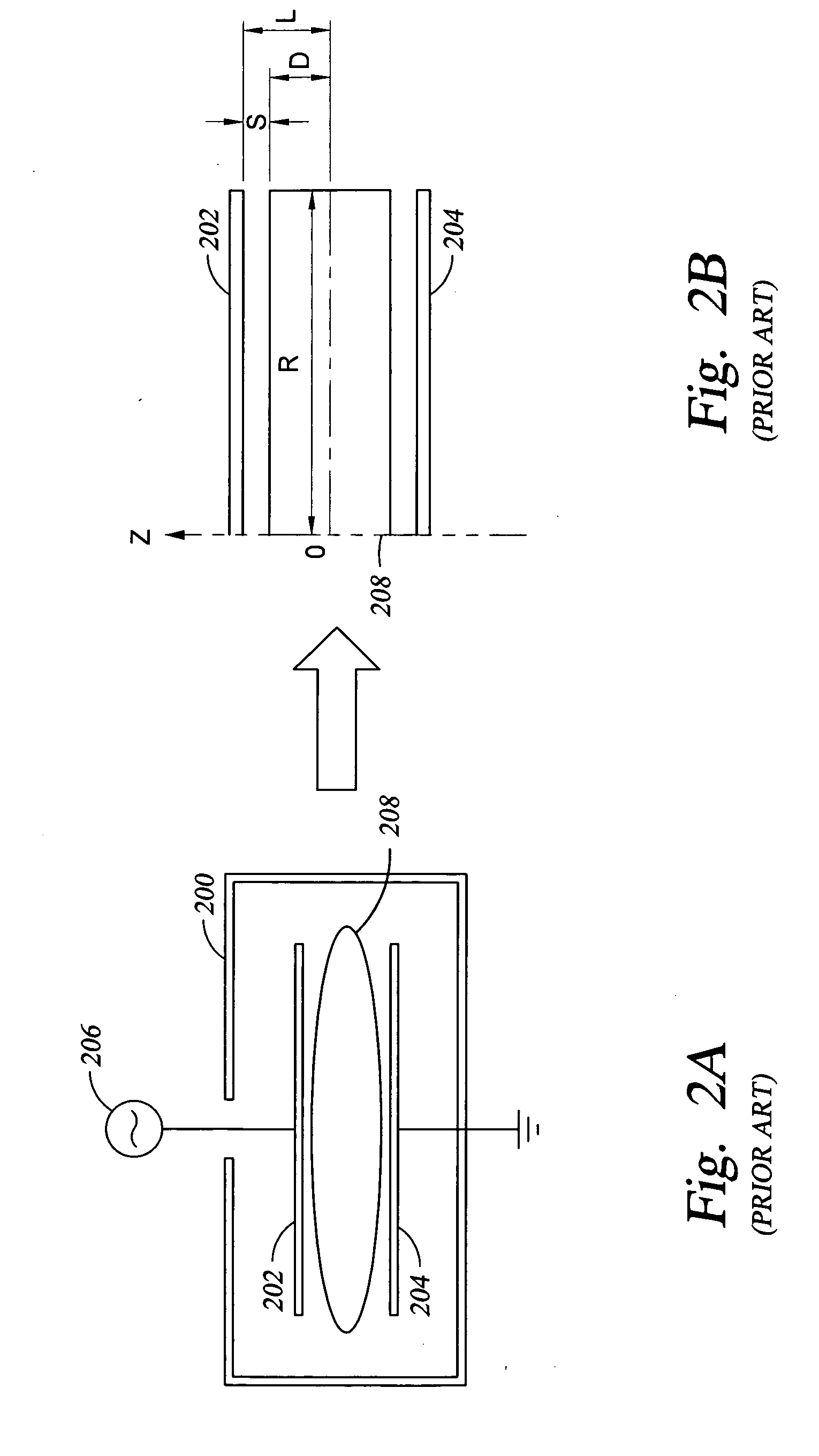

InactiveUS20050103444A1Highly effectiveLow costElectric discharge tubesElectric arc lampsCapacitancePlasma density

An integrated electrostatic inductively-coupled (i-ESIC) device is provided for plasma processing that may be used as a primary or secondary source for generating a plasma to prepare substrates for, and to process substrates by applying, dielectric and conductive coatings. The i-ESIC device is practical for processing advanced semiconductor devices and integrated circuits that require uniform and dense plasma. The invention may be embodied in an apparatus that contains a substrate support, typically including an electrostatic chuck, that controls ion energy by capacitively coupling RF power to the plasma and generating voltage bias on the wafer relative to the plasma potential. An integrated inductive coupling element is provided at the perimeter of the substrate support that increases plasma density at the perimeter of the wafer, compensating for the radial loss of charged particles toward chamber walls, to produce uniform plasma density above the processed wafer. An annular slotted shield protects the inductive coupling element from the plasma and provides conditions for effective inductive coupling of RF power into the plasma, such as eliminating capacitive coupling from the element to the plasma and unwanted sputtering of the element. The i-ESIC device has a capacitive coupling zone in its center where wafers are placed and an inductive coupling zone at the perimeter of the wafer coupled to a matching network and RF generator. Both zones together with plasma create a resonant circuit.

Owner:TOKYO ELECTRON LTD

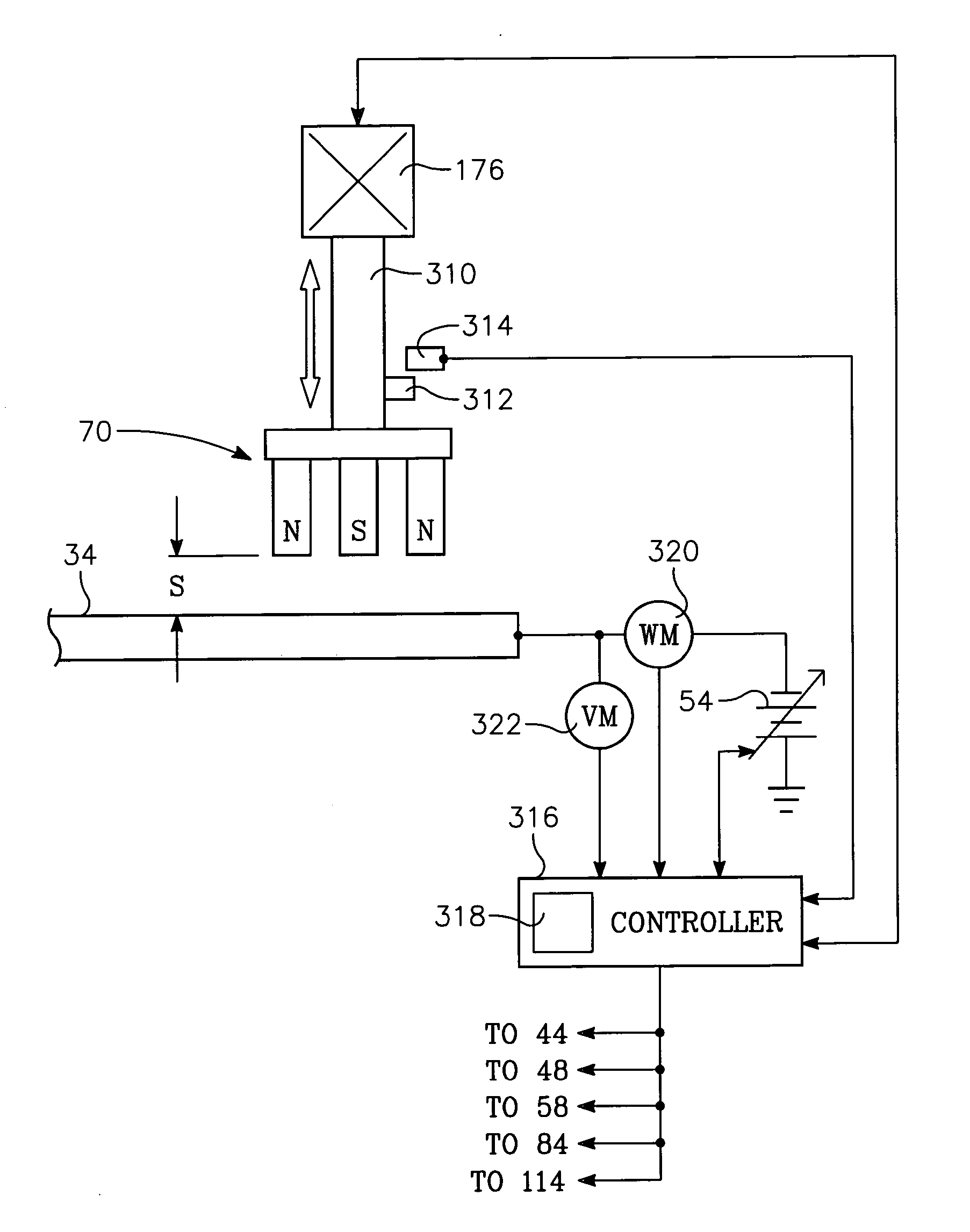

Mechanism for varying the spacing between sputter magnetron and target

ActiveUS20050133365A1Stable sputtering processConstant magnetic fieldCellsElectric discharge tubesSputteringPlasma density

A lift mechanism for and a corresponding use of a magnetron in a plasma sputter reactor. A magnetron rotating about the target axis is controllably lifted away from the back of the target to compensate for sputter erosion, thereby maintaining a constant magnetic field and resultant plasma density at the sputtered surface, which is particularly important for stable operation with a small magnetron, for example, one executing circular or planetary motion about the target axis. The lift mechanism can include a lead screw axially fixed to the magnetron support shaft and a lead nut engaged therewith to raise the magnetron as the lead nut is turned. Alternatively, the support shaft is axially fixed to a vertically moving slider. The amount of lift may be controlled according a recipe based on accumulated power applied to the target or by monitoring electrical characteristics of the target.

Owner:APPLIED MATERIALS INC

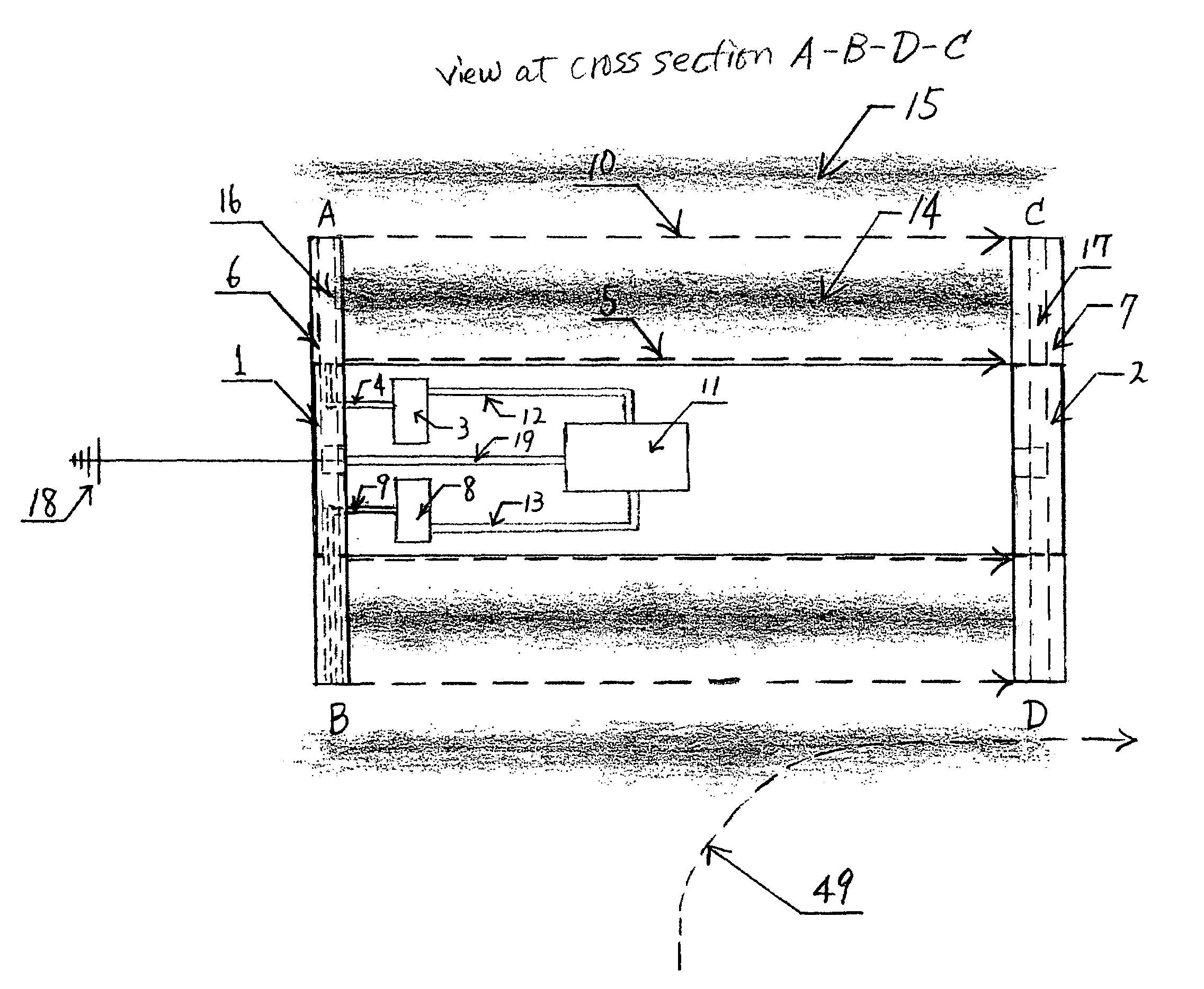

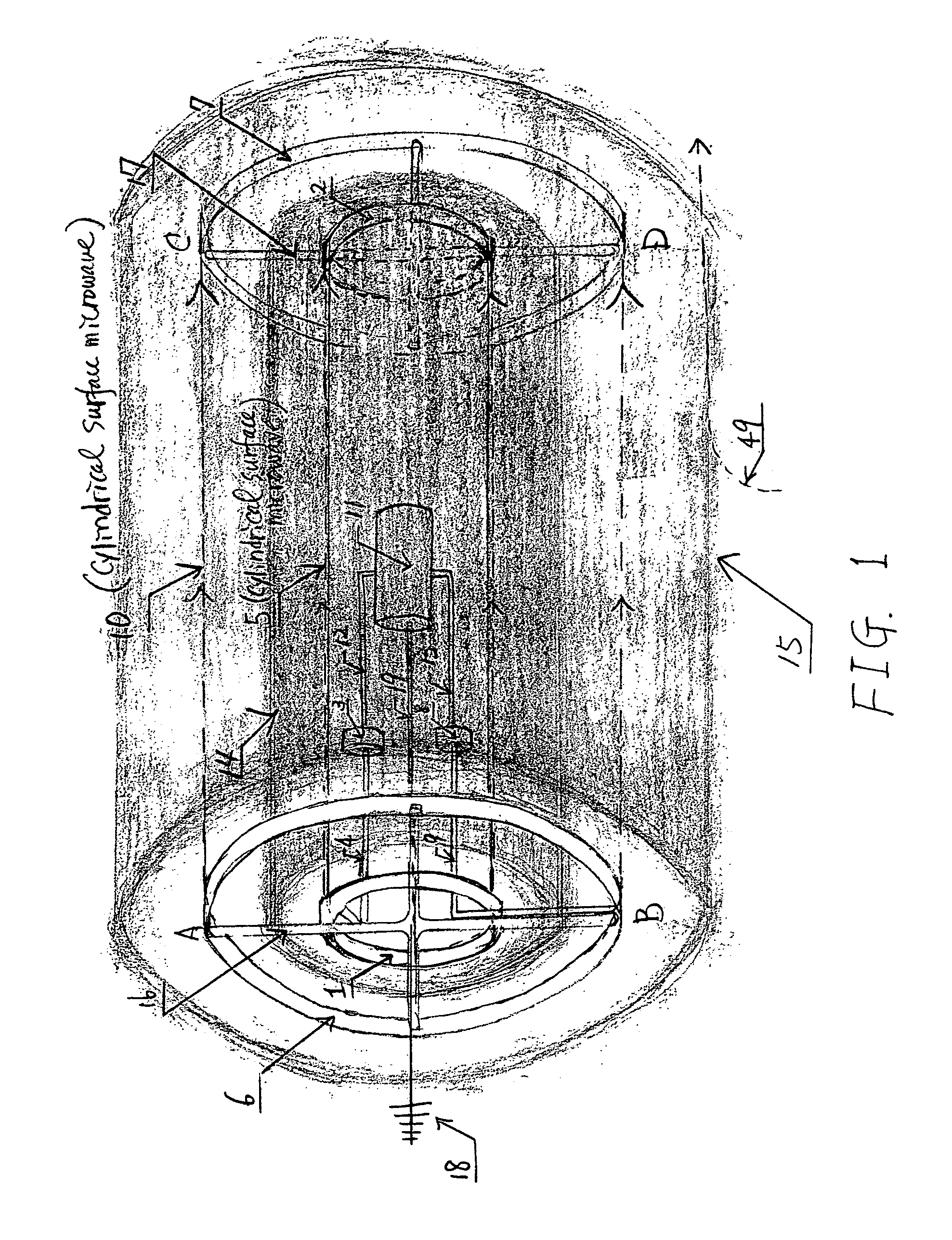

Pseudo surface microwave produced plasma shielding system

ActiveUS7255062B1Increase the magnetic field strengthSuppress DiffuseElectric discharge tubesElectric arc lampsPlasma densityCombustion chamber

A pseudo surface microwave produced plasma shielding system is a simple device that creates a prescribed plasma environment with a prescribed plasma density gradient, and protects an object surrounded by this environment as a shield. Pseudo surface microwaves interacting with an artificial intelligence equipped on board are used to create and to adjust this plasma environment for a particular application. This plasma environment provides potential capabilities of military applications of the plasma in the system. Examples of military applications include a stealth system from RADAR and SONAR, a protection system from WMD, and a weapon system to generate and launch plasmoids as a plasma gun. The scope of this invention extends to commercial applications of this plasma shielding system as a conditioned and controlled flow field, for example, a boundary layer and turbulence control system, and a lift control system to improve flight performance and flight economy of aircrafts. It further extends to develop a concept of a new type of engine using this plasma shielding system as a heating method alternative to the conventional combustion method that uses petroleum based fuel in the combustion chamber of an engine.

Owner:HIGMAN KUMIKO I

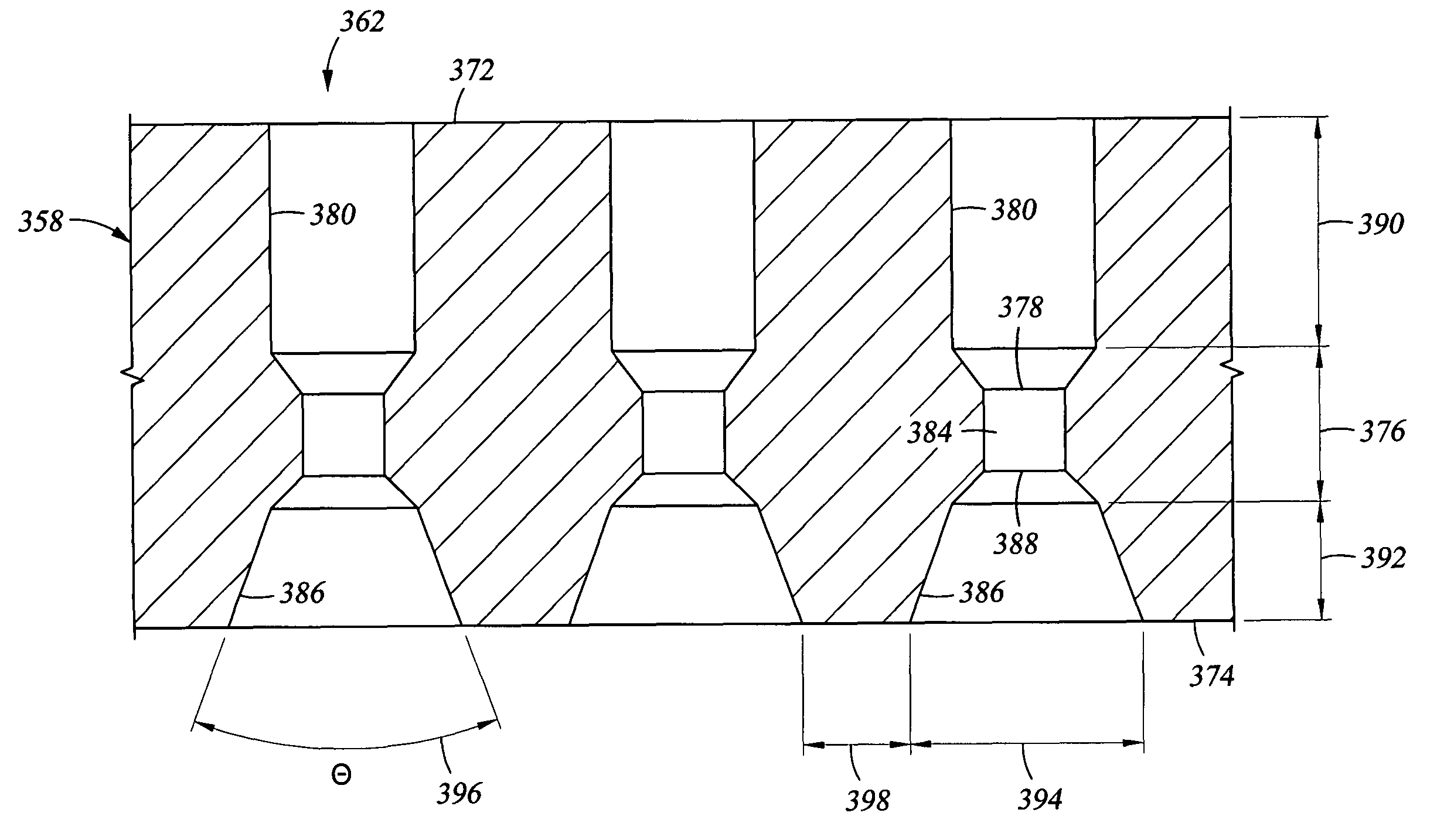

Method for providing uniform distribution of plasma density in a plasma treatment apparatus

ActiveUS20150214013A1High plasma uniformityEvenly distributedLiquid surface applicatorsElectric discharge tubesElectricityPlasma density

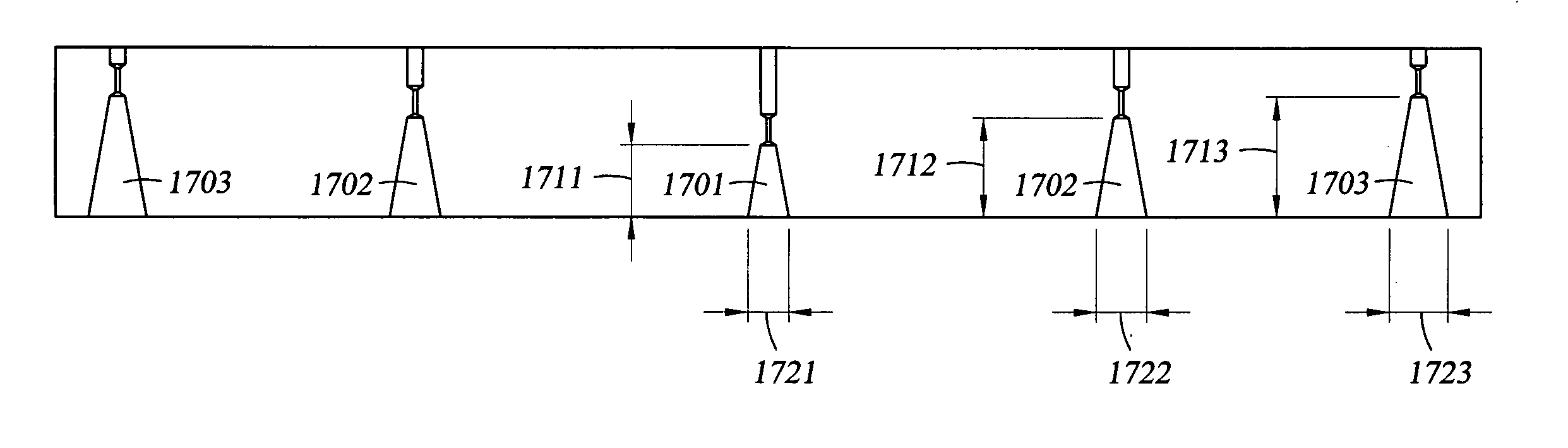

Proposed is a method for providing uniform distribution of plasma density in a CCP plasma processing apparatus. According to the method the through gas holes of the showerhead of used in the plasma processing chamber of the apparatus are provided with conical nozzles formed on the side of the gas holes that face the gas reservoir of the cooler plate. The cone angle θ of the nozzles decreases in the direction from the peripheral portion to the central area of the showerhead in the range from 120° to 0°. Since the conical nozzles increase the gas gap between the showerhead and the cooler plate, more favorable conditions are created for electric breakdown. In order to protect the surfaces of the conical nozzles and gas holes from deterioration by hollow cathode discharge, these surface are coated by a protective coating resistant to electrical breakdown and chemical corrosion.

Owner:GLUKHOY YURI

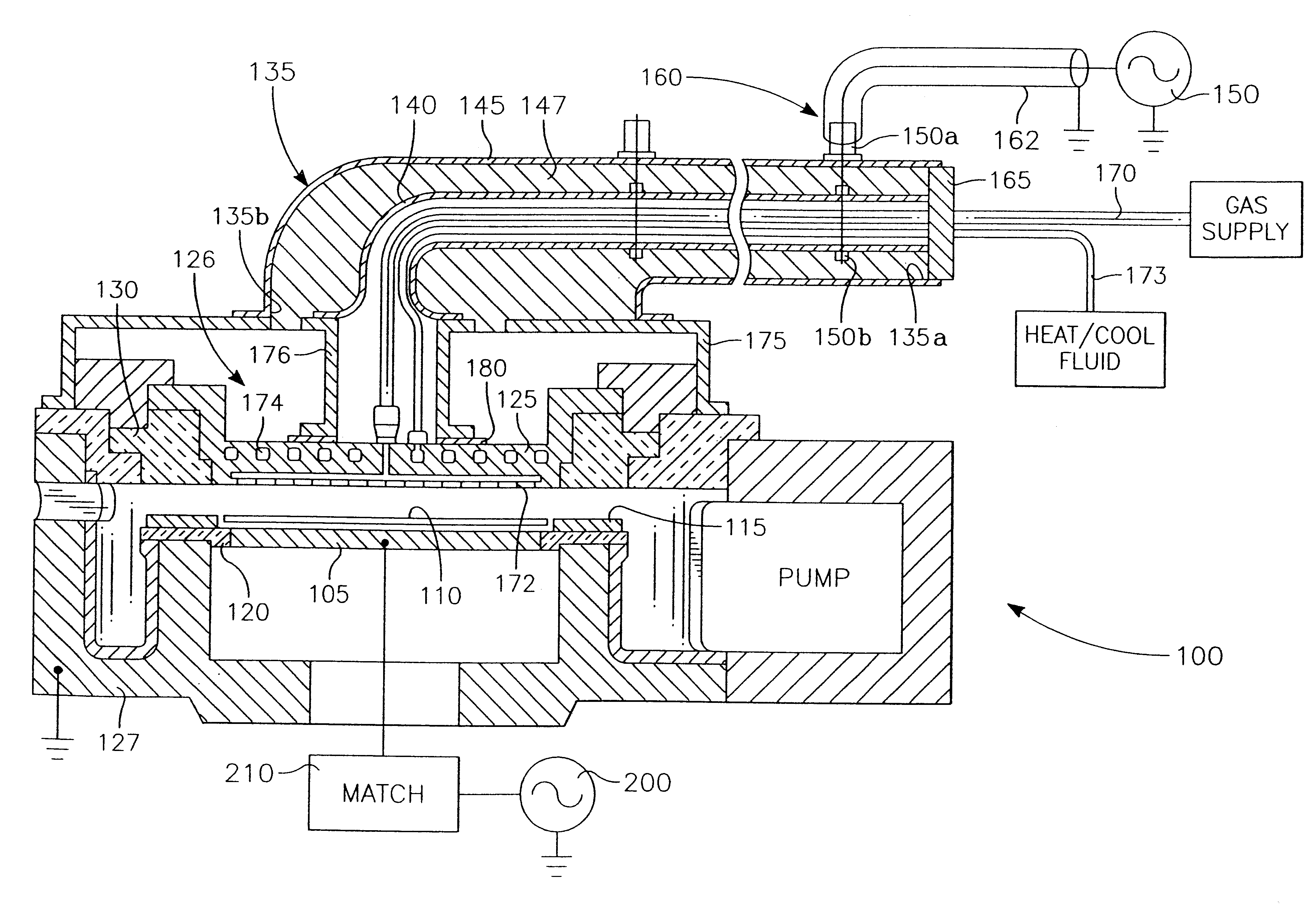

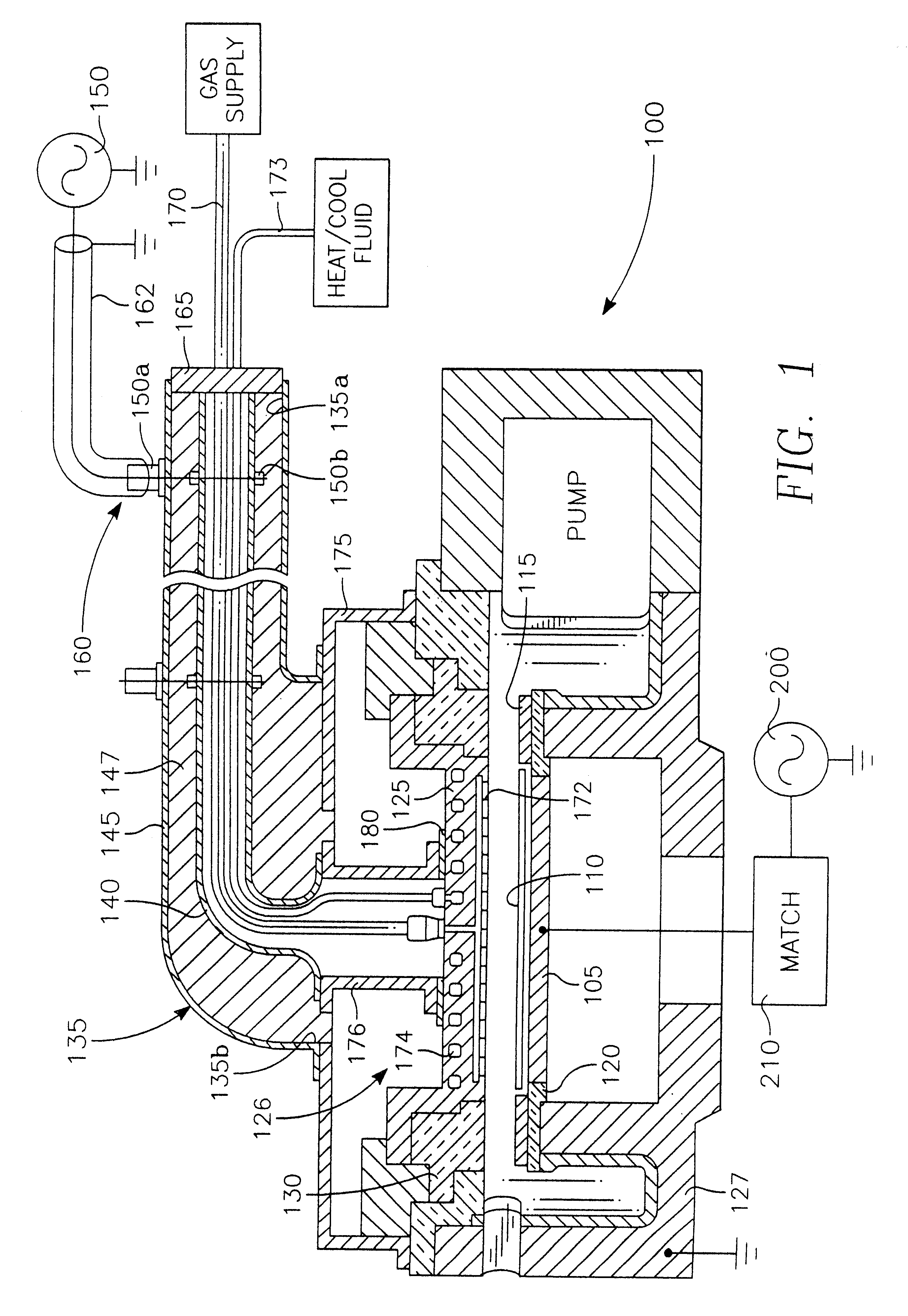

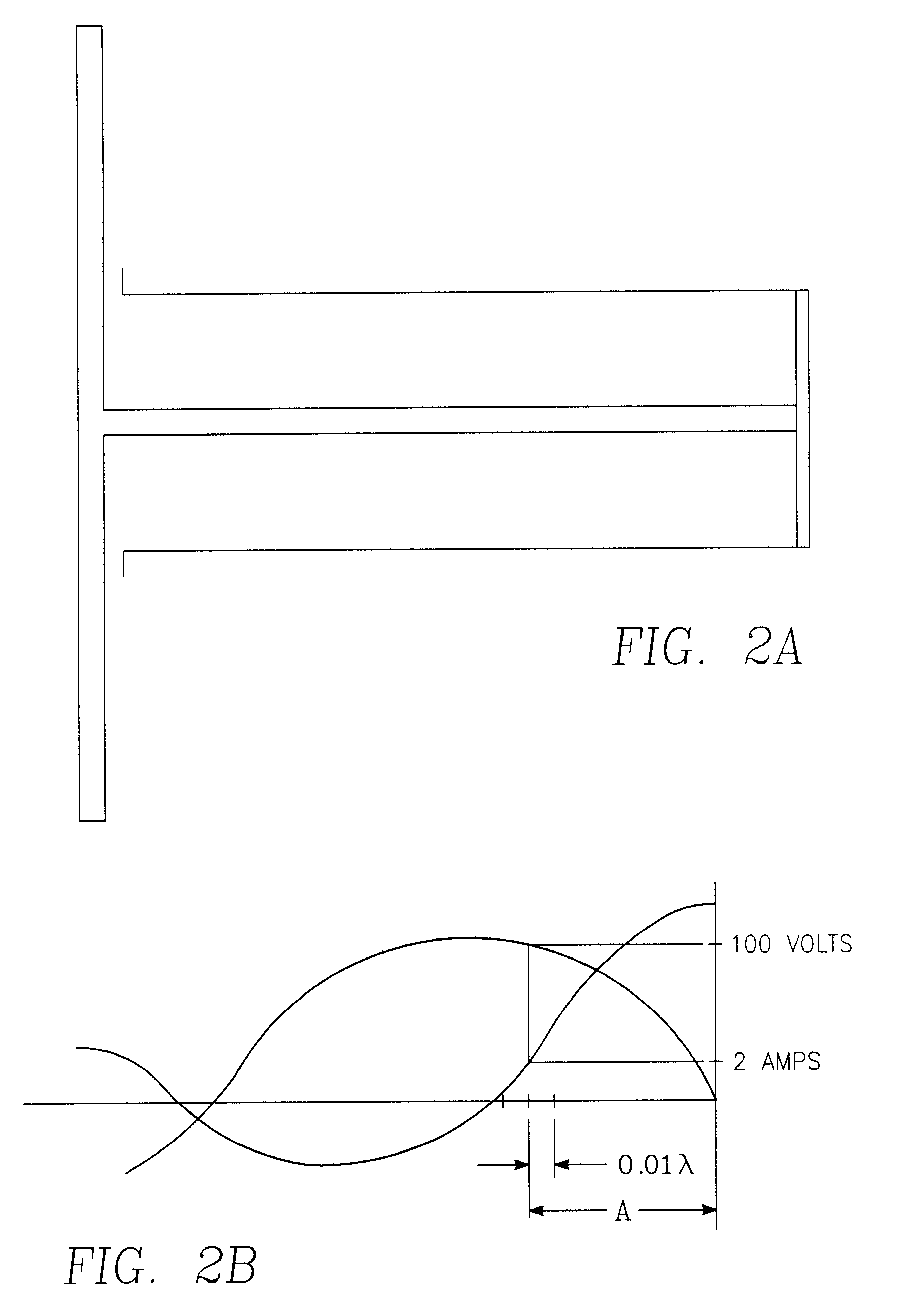

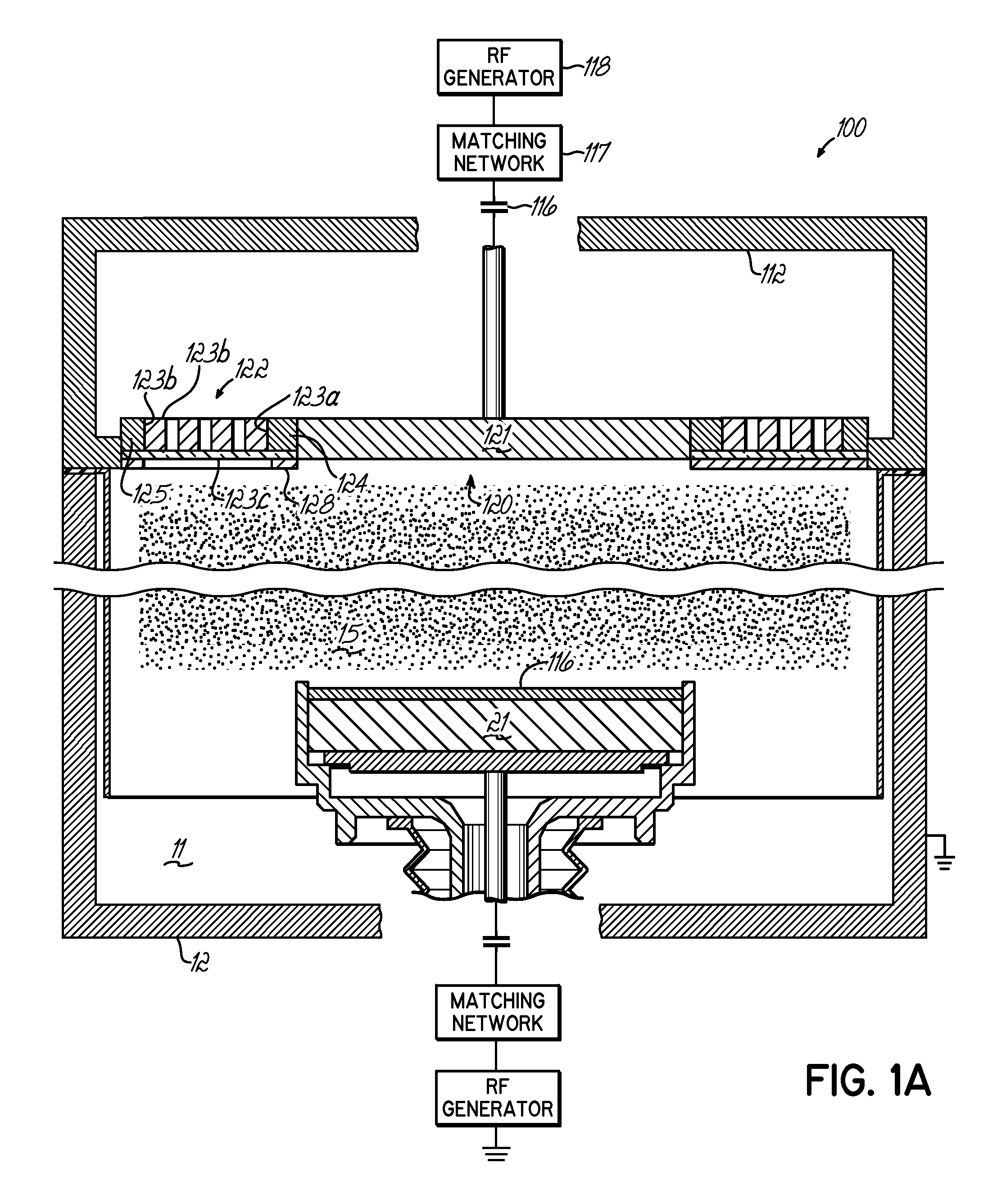

Plasma reactor with overhead RF electrode tuned to the plasma

InactiveUS6838635B2Electric discharge tubesSemiconductor/solid-state device manufacturingCapacitancePlasma density

In accordance with one aspect of the invention, a plasma reactor has a capacitive electrode driven by an RF power source, and the electrode capacitance is matched at the desired plasma density and RF source frequency to the negative capacitance of the plasma, to provide an electrode plasma resonance supportive of a broad process window within which the plasma may be sustained.

Owner:APPLIED MATERIALS INC

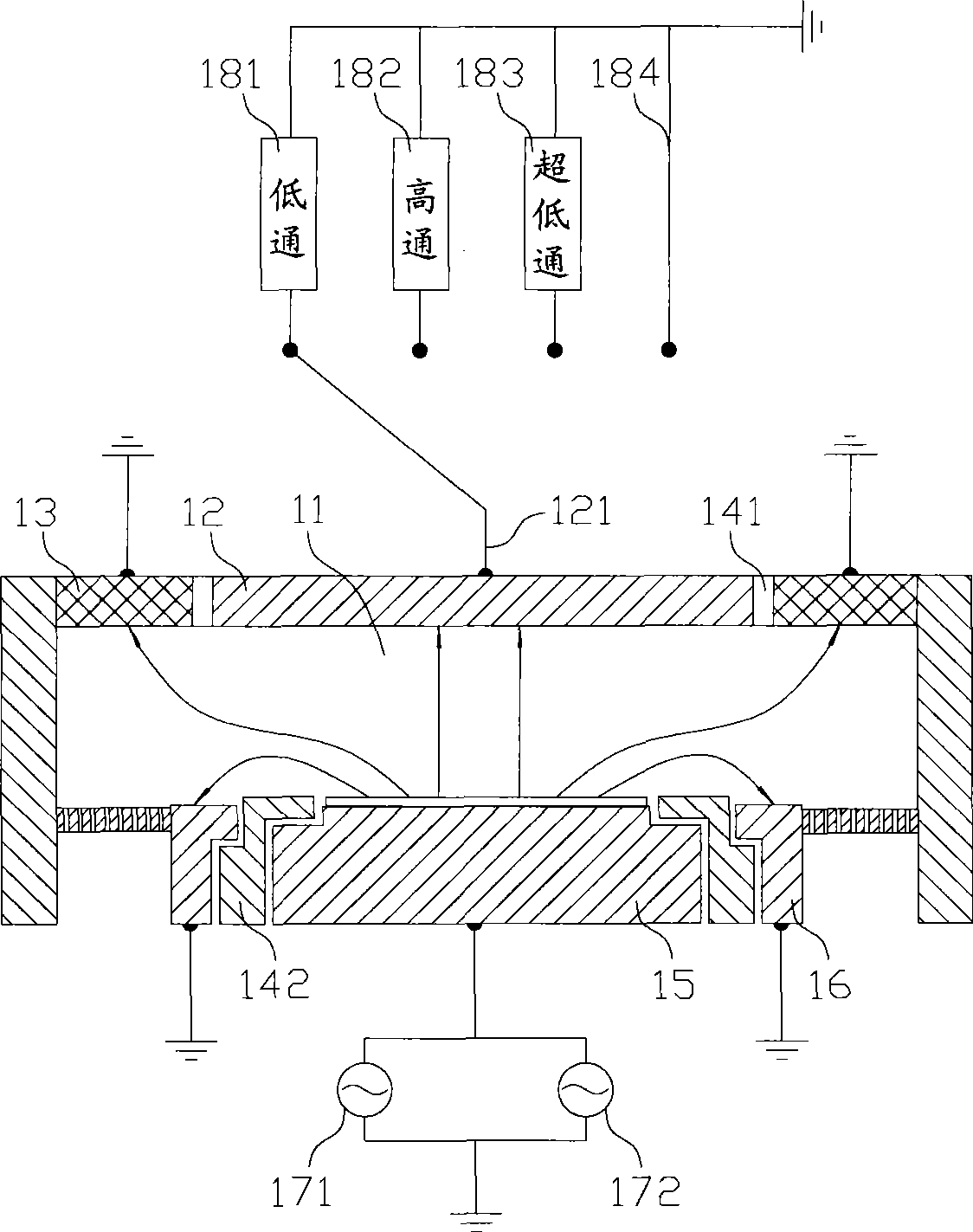

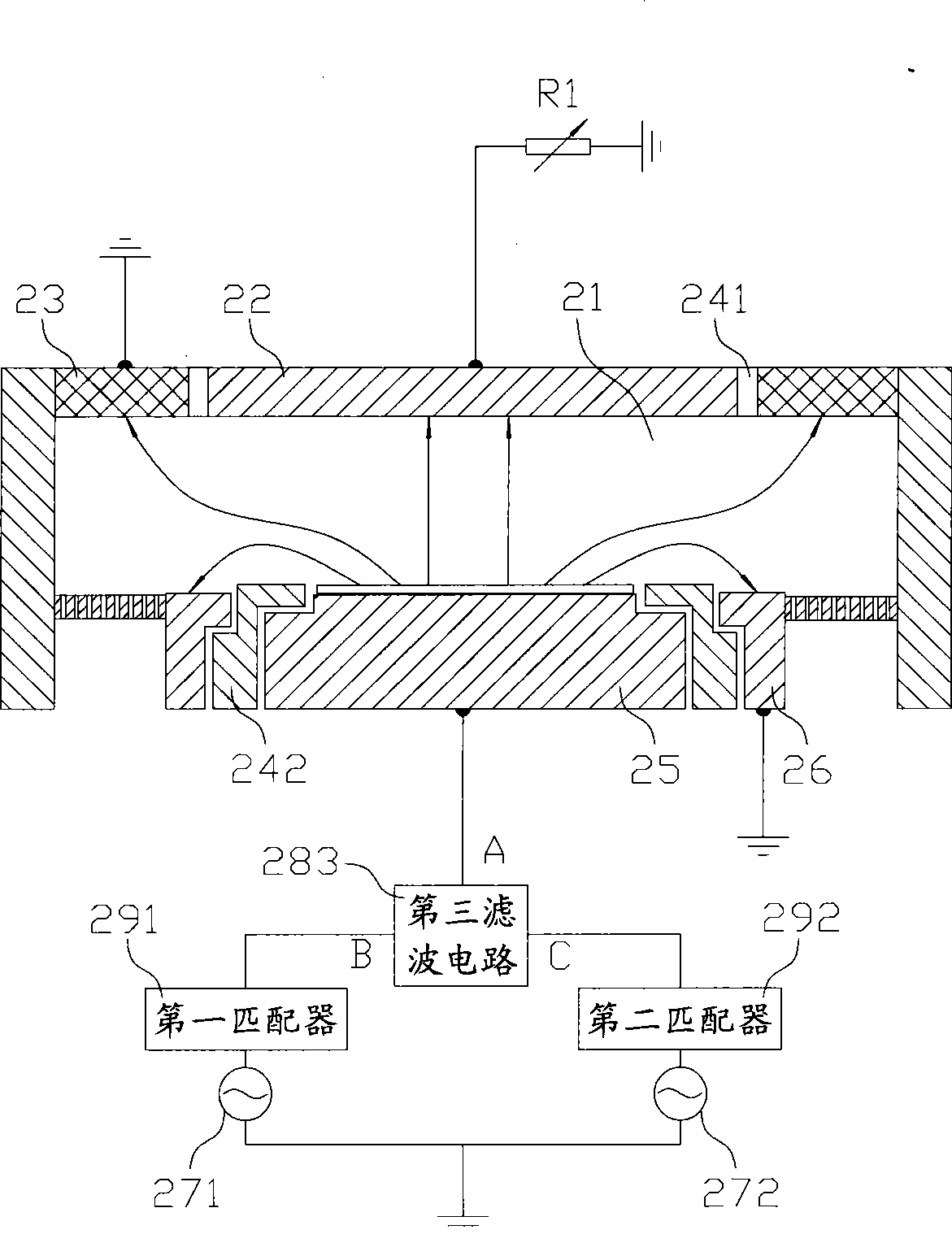

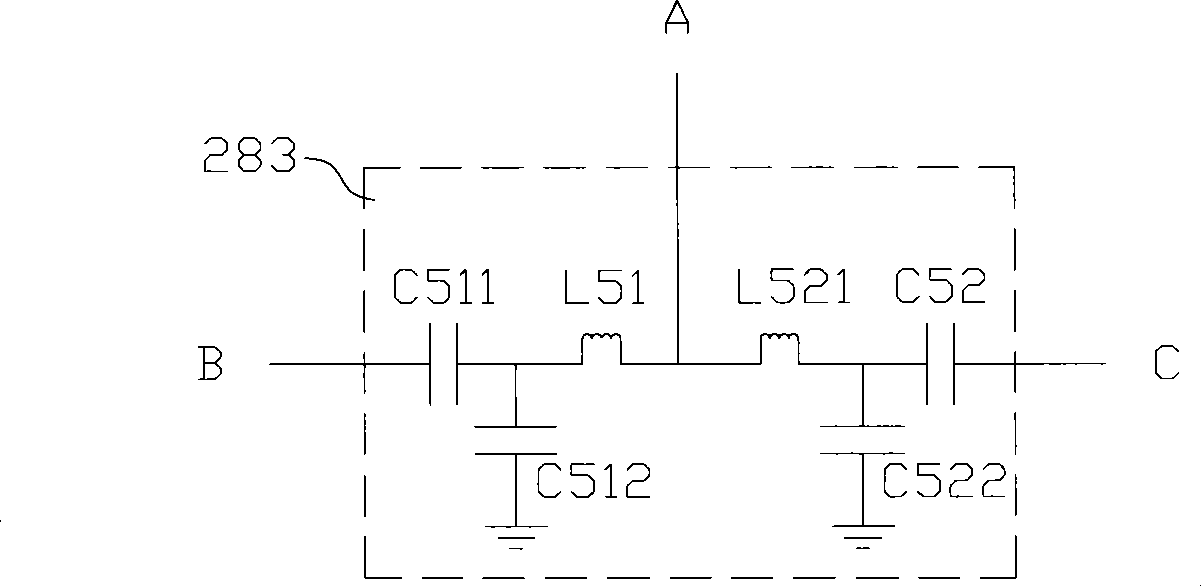

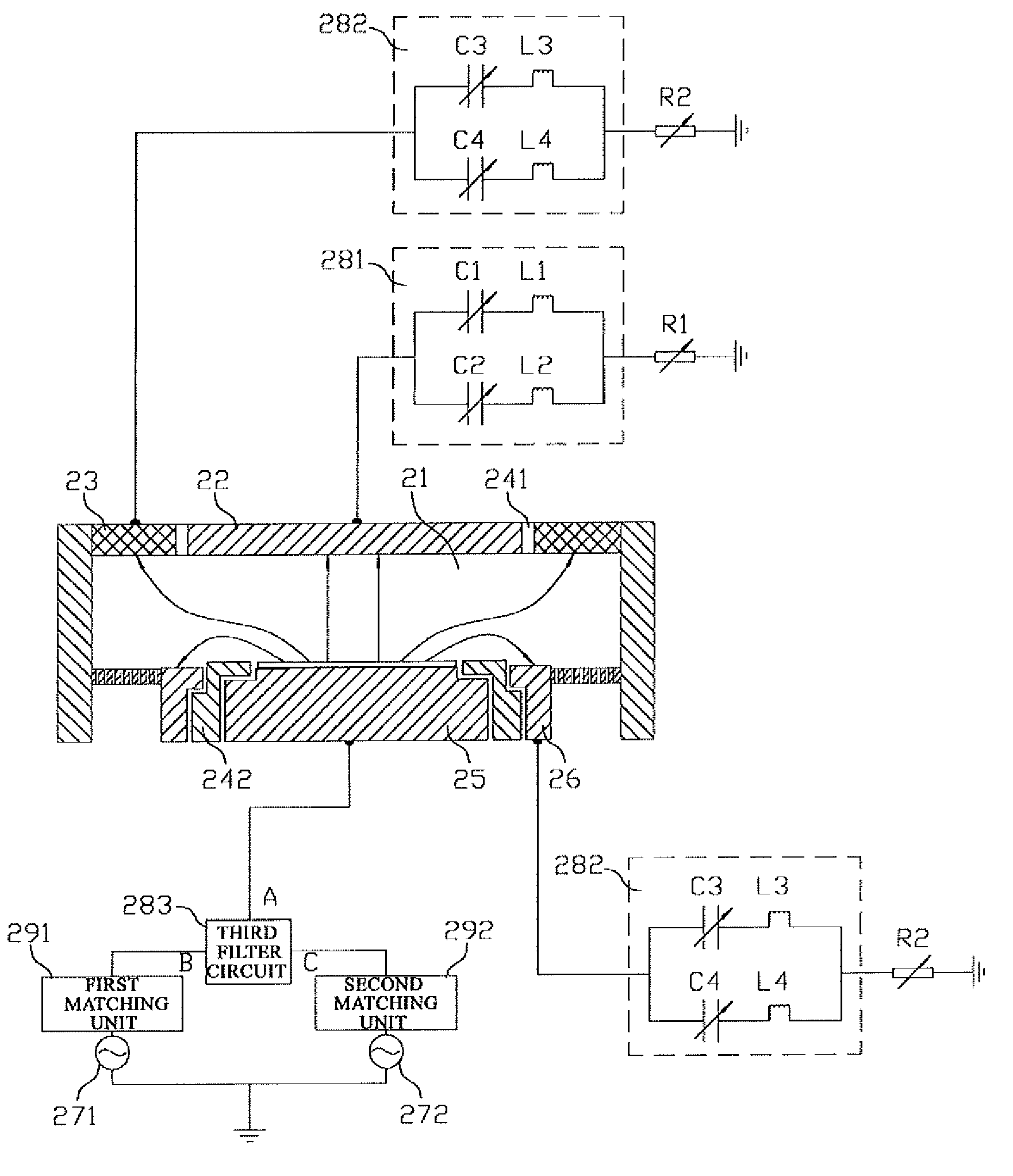

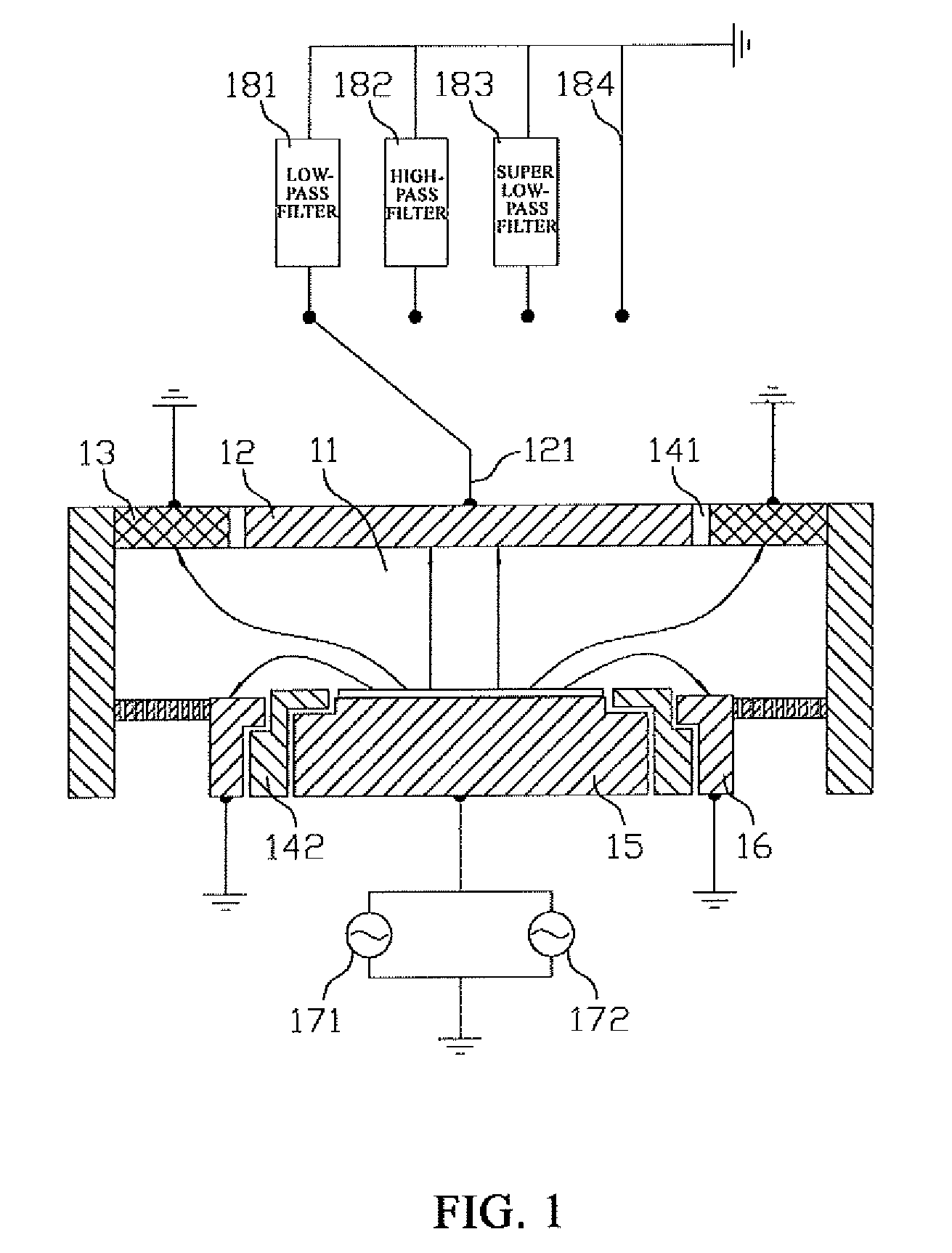

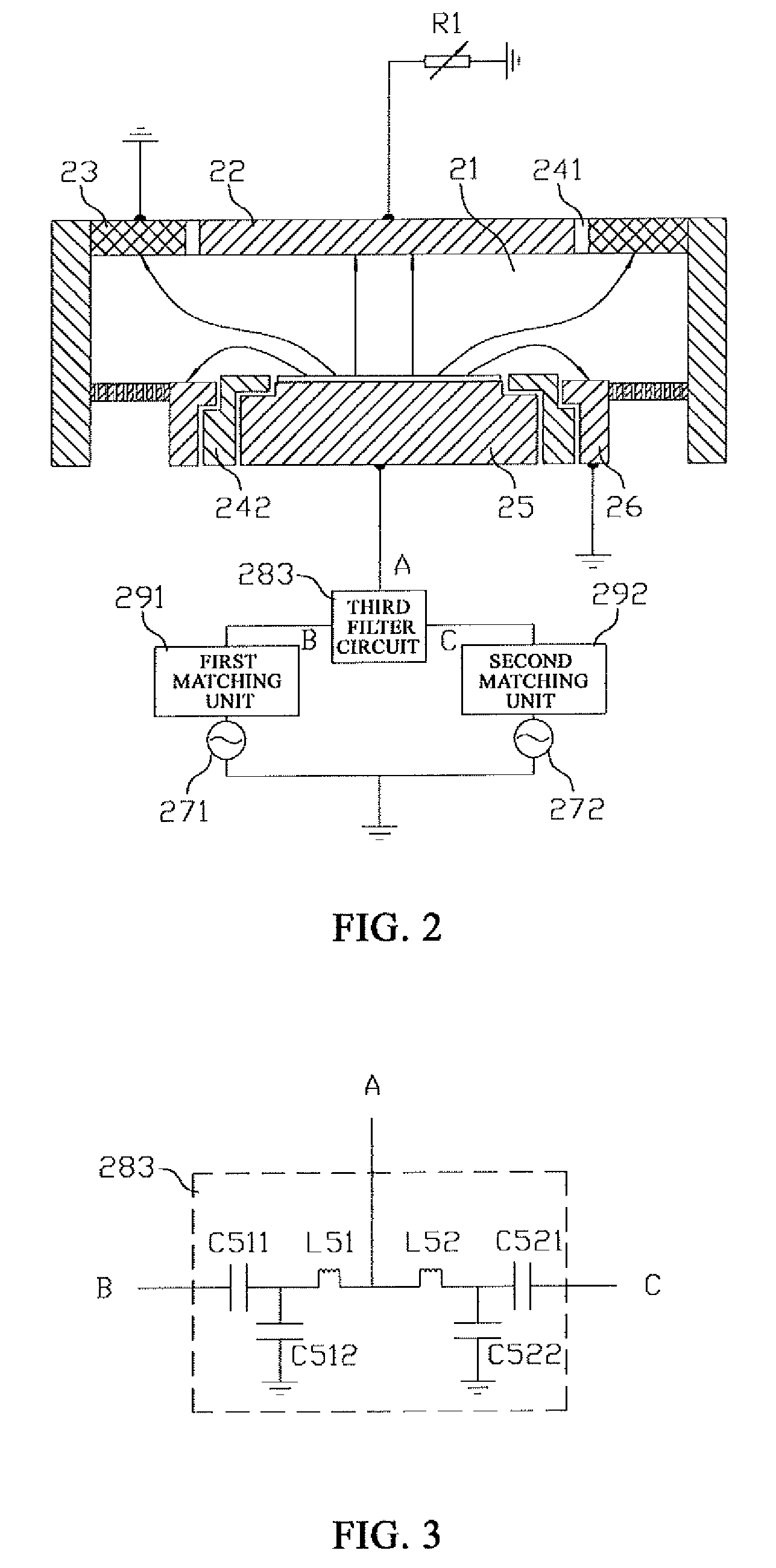

Plasma treatment apparatus

InactiveCN101478857AEnergy changeTo overcome the defect of conversionElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma densityEngineering

The invention discloses a plasma treatment device, which comprises oppositely arranged radio frequency driving electrode (25) and a passive electrode (22); the passive electrode (22) is encircled by a first grounding ring (23), which are insulated from each other; the radio frequency driving electrode (25) is encircled by a second grounding ring (23), which are insulated from each other; the radio frequency driving electrode (25) is connected respectively with a first radio frequency power source (271) and a second radio frequency power source (272); a first impedance regulating element is connected in series between the passive electrode (22) and a ground wire. The plasma treatment device provided by the invention overcomes a shortcoming of the current technology that energy of plasma can be converted only among several specific isolated values, and more craft processes required by different plasma density can be realized in the same reaction chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Etch system with integrated inductive coupling

InactiveUS20070113981A1Highly effectiveLow costElectric discharge tubesElectric arc lampsCapacitancePlasma density

An integrated capacitively-coupled and inductively-coupled device is provided for plasma etching that may be used as a primary or secondary source for generating a plasma to etch substrates. The device is practical for processing advanced semiconductor devices and integrated circuits that require uniform and dense plasma. The invention may be embodied in an apparatus that contains a substrate support, typically including an electrostatic chuck, that controls ion energy by capacitively coupling RF power to the plasma and generating voltage bias on the wafer relative to the plasma potential. An etching electrode is provided opposite the substrate support. An integrated inductive coupling element is provided at the perimeter of the etching electrode that increases plasma density at the perimeter of the wafer, compensating for the radial loss of charged particles toward chamber walls, to produce uniform plasma density above the processed wafer. The device has a capacitive coupling zone in its center for energizing etching ions and an inductive coupling zone at its perimeter of the wafer. Both zones together with plasma create a resonant circuit with the plasma.

Owner:TOKYO ELECTRON LTD

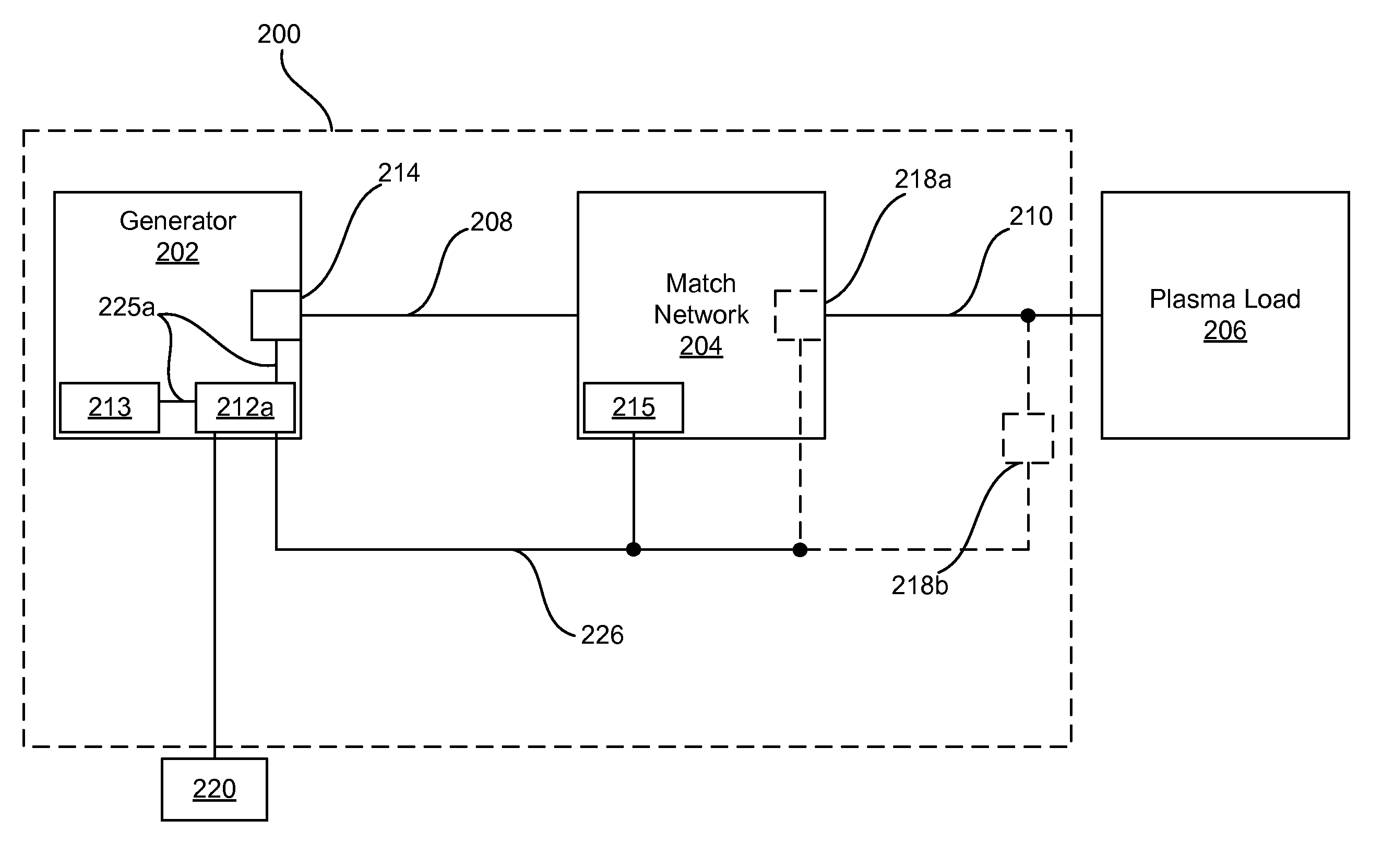

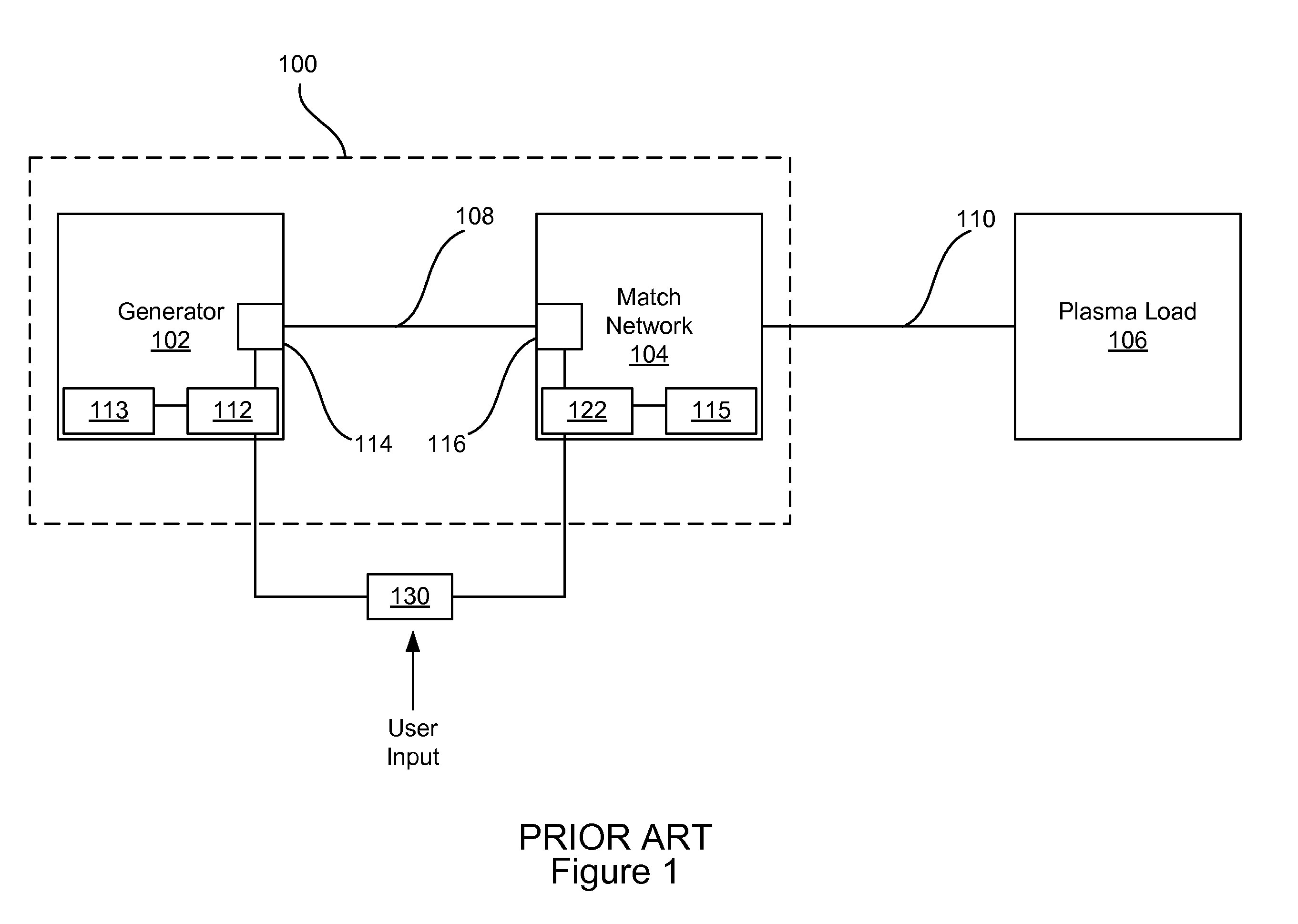

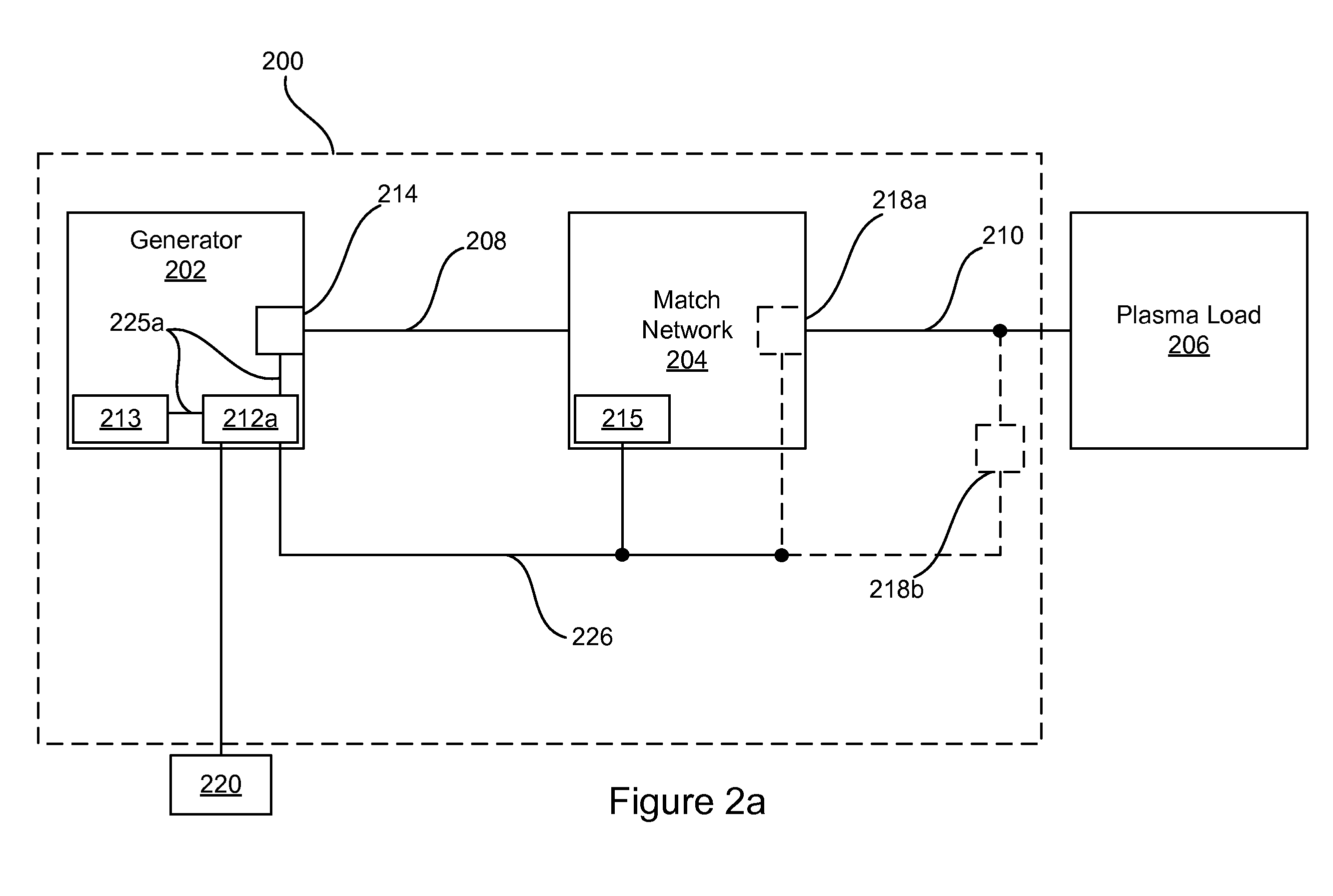

System level power delivery to a plasma processing load

InactiveUS20130002136A1Improve power delivery accuracyImprove consistencyMultiple-port networksElectric discharge tubesPlasma densityEngineering

The present disclosure discusses a power delivery system, and methods of operation, configured to monitor characteristics of a generator, a match network, and a plasma load, via one or more sensors, and control these components via a local controller in order to improve power delivery accuracy and consistency to the plasma load. Control can be based on a unified monitoring of power characteristics in the power delivery system as well as variations between components and even non-electrical characteristics such as plasma density, end point, and spectral components of plasma light emission, to name a few.

Owner:AES GLOBAL HLDG PTE LTD

Decaborane ion source

InactiveUS6958481B2Minimize plasma densityAvoid dissociationMaterial analysis by optical meansIon beam tubesPlasma densitySource material

An ion source (50) for an ion implanter is provided, comprising a remotely located vaporizer (51) and an ionizer (53) connected to the vaporizer by a feed tube (62). The vaporizer comprises a sublimator (52) for receiving a solid source material such as decaborane and sublimating (vaporizing) the decaborane. A heating mechanism is provided for heating the sublimator, and the feed tube connecting the sublimator to the ionizer, to maintain a suitable temperature for the vaporized decaborane. The ionizer (53) comprises a body (96) having an inlet (119) for receiving the vaporized decaborane; an ionization chamber (108) in which the vaporized decaborane may be ionized by an energy-emitting element (110) to create a plasma; and an exit aperture (126) for extracting an ion beam comprised of the plasma. A cooling mechanism (100, 104) is provided for lowering the temperature of walls (128) of the ionization chamber (108) (e.g., to below 350° C.) during ionization of the vaporized decaborane to prevent dissociation of vaporized decaborane molecules into atomic boron ions. In addition, the energy-emitting element is operated at a sufficiently low power level to minimize plasma density within the ionization chamber (108) to prevent additional dissociation of the vaporized decaborane molecules by the plasma itself.

Owner:AXCELIS TECHNOLOGIES

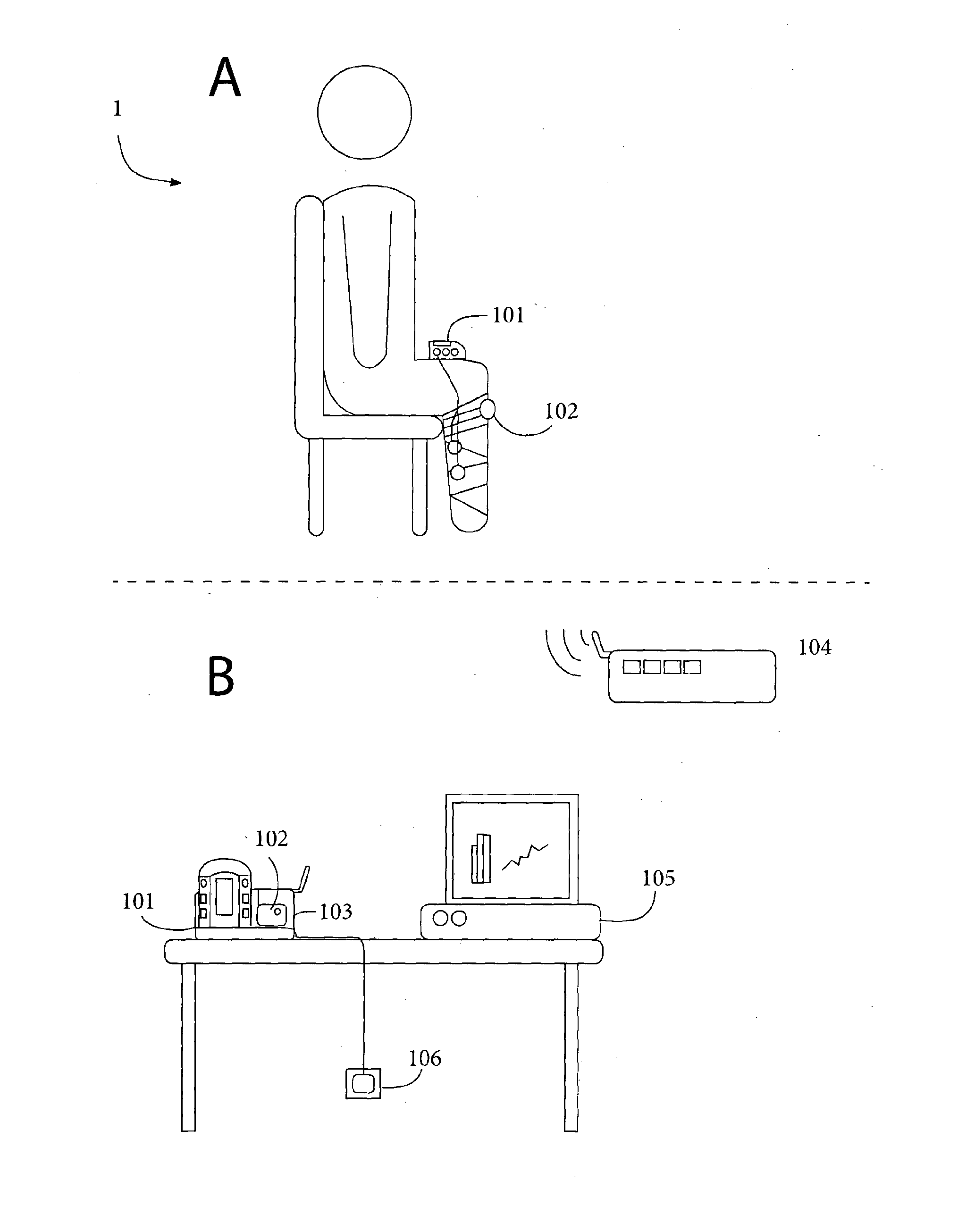

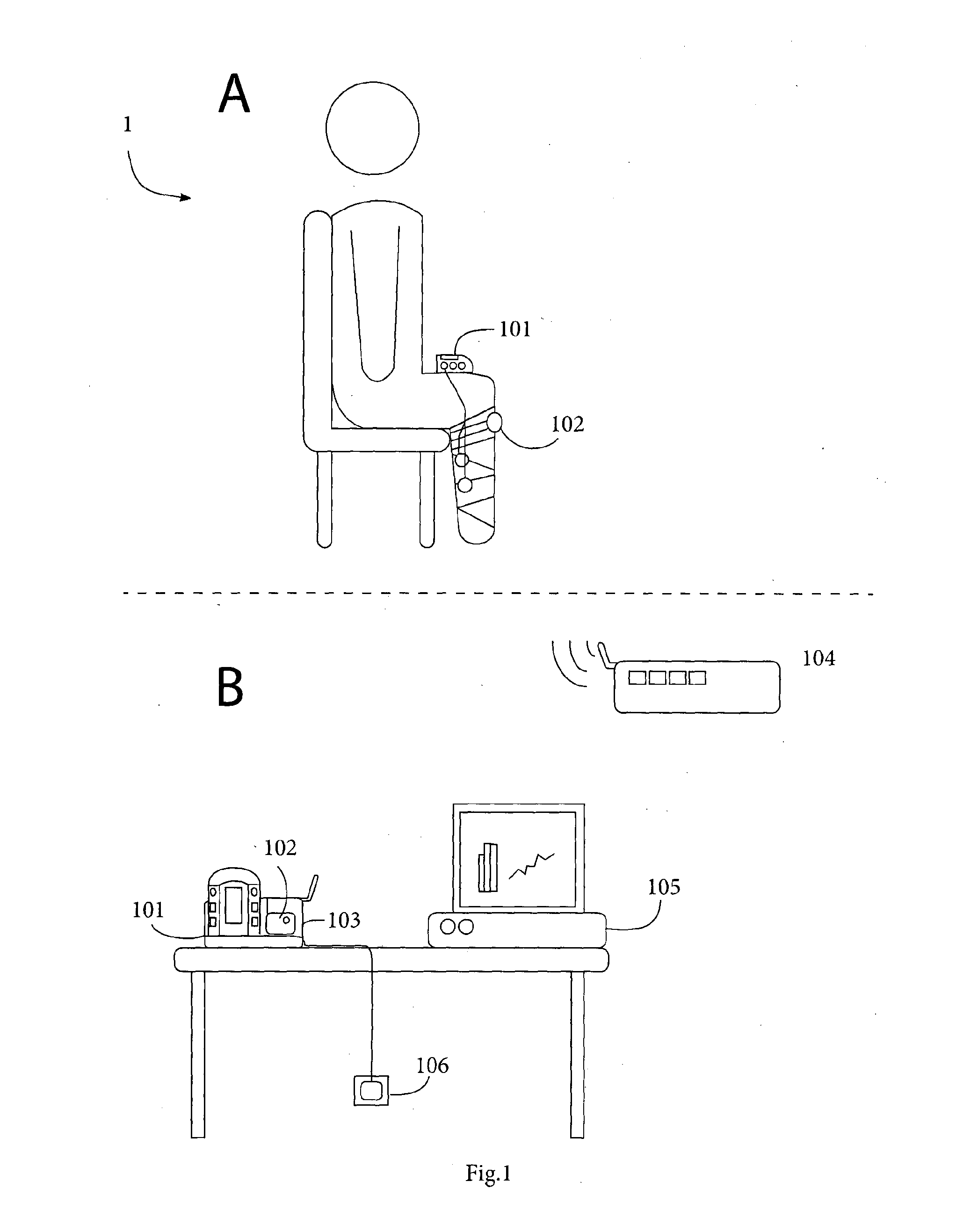

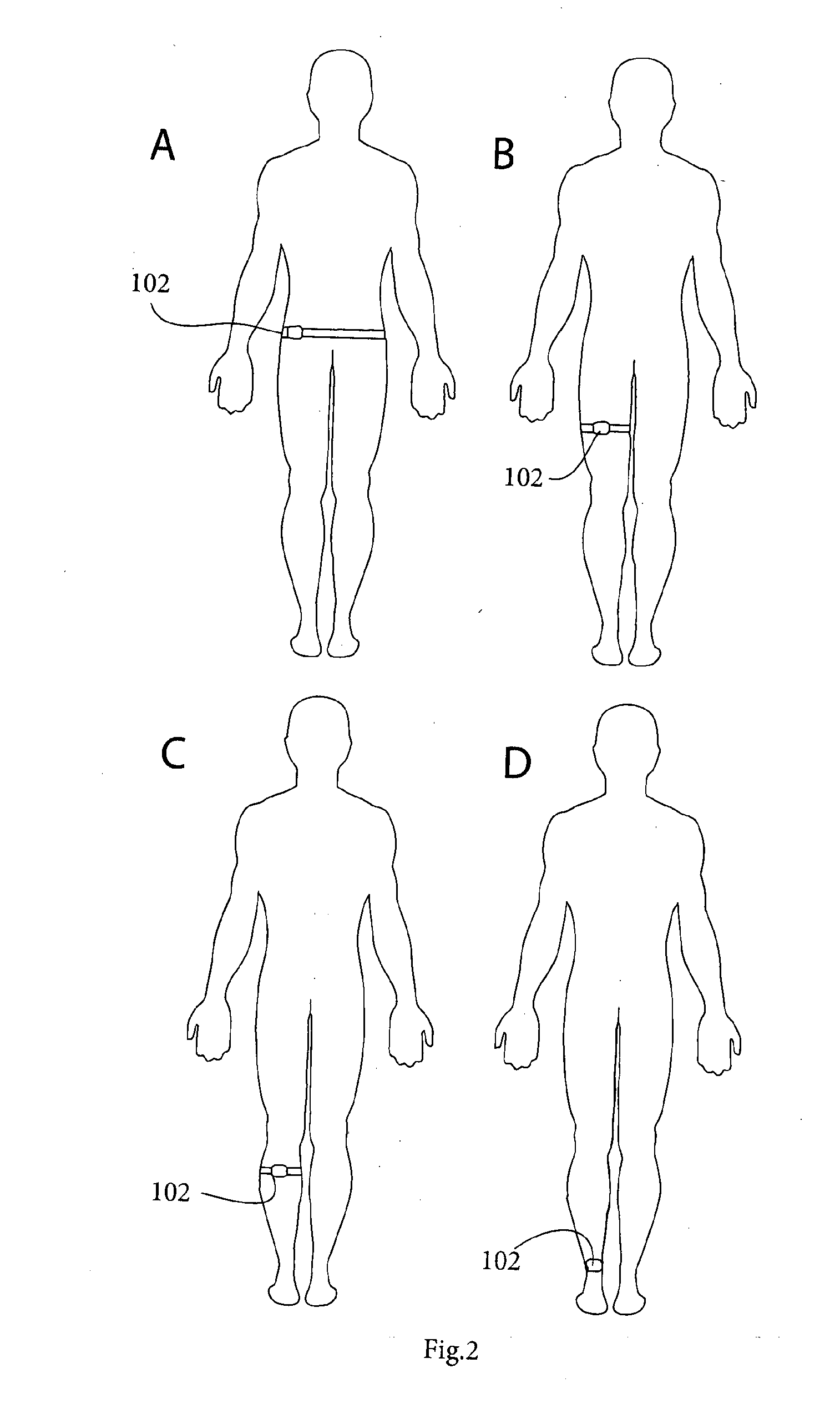

System for management and prevention of venous pooling

A monitoring system comprises sensors adapted to be worn by a user, and, a processor linked with the sensor. The processor receives sensor data and processes this data to determine user posture data including data indicative of vertical distance between level of the user's heart and ankle. Based on the posture data together with a value for degree of user chronic venous insufficiency and / or blood density, generate an estimate of user static venous pressure while the user is static, without calf muscle pump activity. The processor also processes the sensor data to determine if there is calf muscle pump activity, and generates an estimate of user active venous pressure according to the static venous pressure estimate, rate of calf muscle activity, and a value for degree of user chronic venous insufficiency. The processor may generate the venous pressure estimate in real time, and may control an NMES device accordingly.

Owner:THE NAT UNIV OF IRELAND GALWAY +1

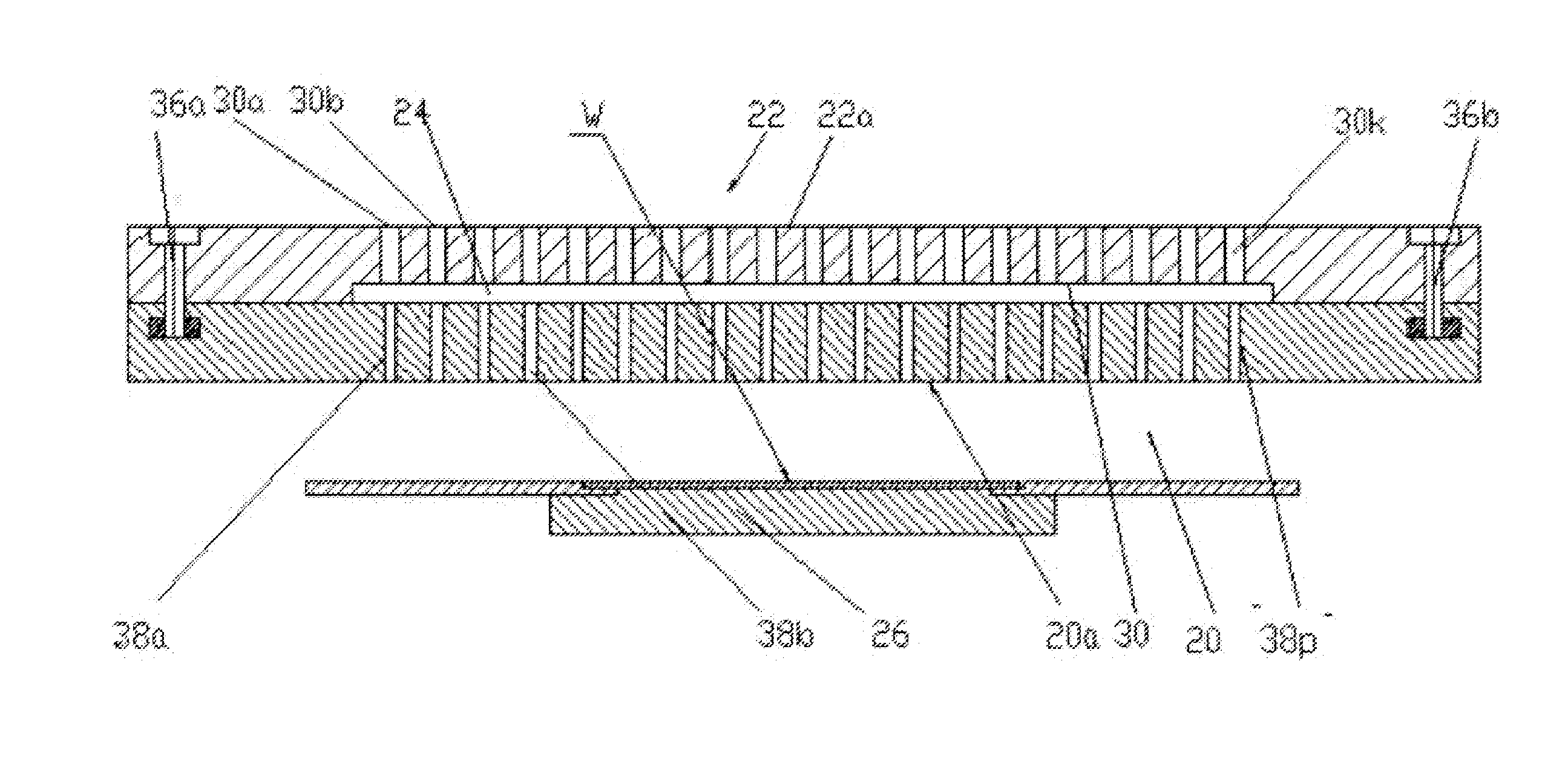

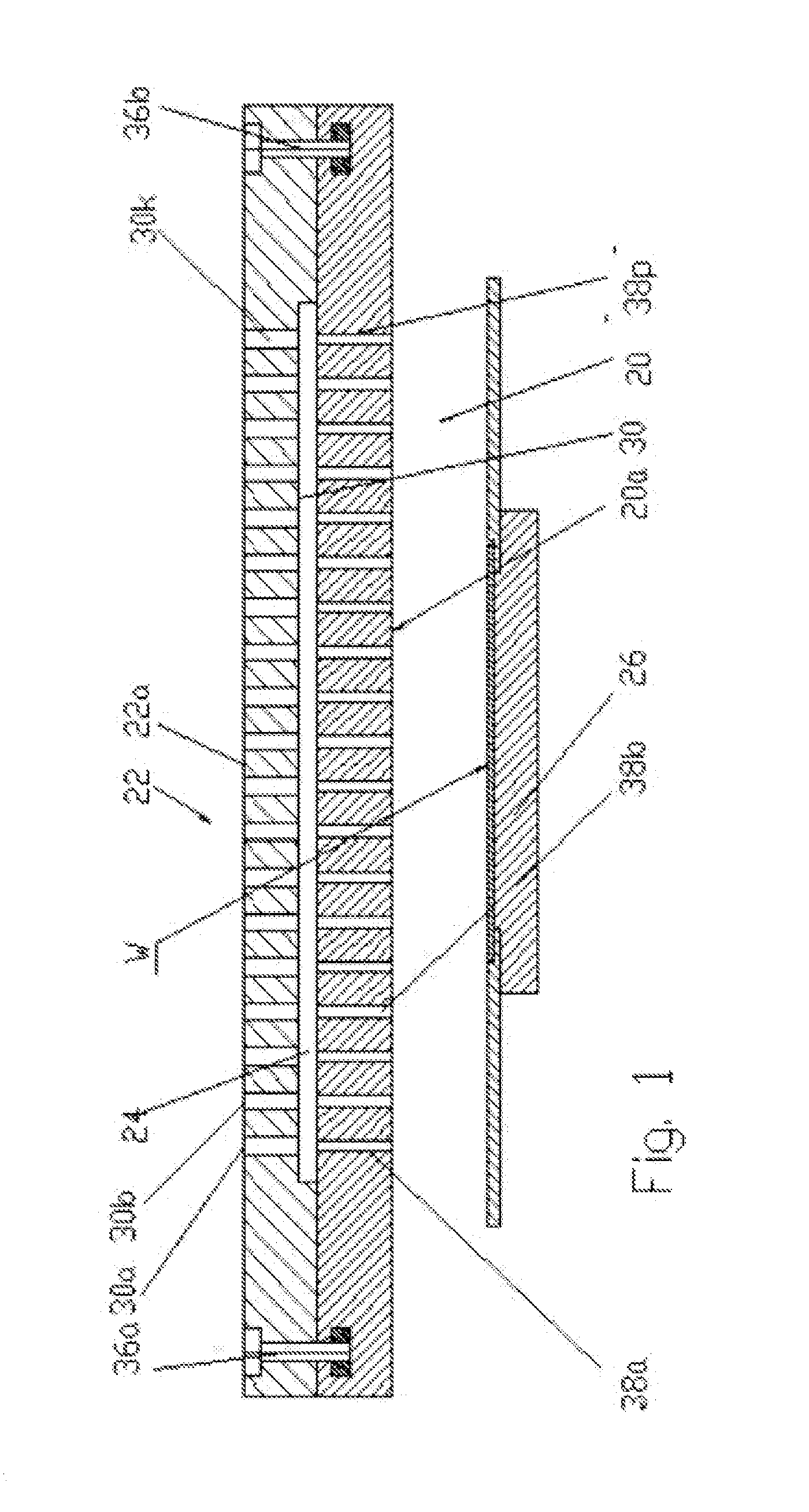

Showerhead-cooler system of a semiconductor-processing chamber for semiconductor wafers of large area

InactiveUS20150214009A1Uniform plasma densityAvoid turbulenceElectric discharge tubesSpraying apparatusPlasma densityEngineering

Proposed is a showerhead-cooler system of a semiconductor-processing chamber with uniform distribution of plasma density. The showerhead has a plurality of through gas holes that are coaxial with respective channels of the gas-feeding cooler plate. On the gas inlet side, the though passages of the showerhead are provided with unequal conical nozzles characterized by a central angle that decreases from the peripheral part of the showerhead to the showerhead center. Such design provides uniformity of plasma density. Furthermore, in order to protect the walls of the nozzle and the walls of the gas holes from erosion that may be caused by the hollow-cathode phenomenon, these areas are coated with a thin protective coating that is resistant to electrical breakdown and chemical corrosion.

Owner:GLUKHOY YURI +2

Plasma processing apparatus

InactiveUS20100294433A1More realizedImprove adaptabilityElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma densityVolumetric Mass Density

A plasma processing apparatus, comprising: a RF driving electrode (25) and a passive electrode (22) mounted face to face; a first grounded ring (23) surrounding the passive electrode (22) and insulated from it, a second grounded ring (26) surrounding the RF driving electrode (25) and insulated from it; the RF driving electrode (25) is connected with a first RF source (271) and a second RF source (272) respectively; a first impedance adjusting element is connected in series between the passive electrode (22) and the ground. The plasma processing apparatus overcomes a shortcoming that plasma energy can only be changed over among several certain isolated values, and thus technical processes with different plasma density requirements can be realized in one and the same reaction chamber.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Plasma processing apparatus

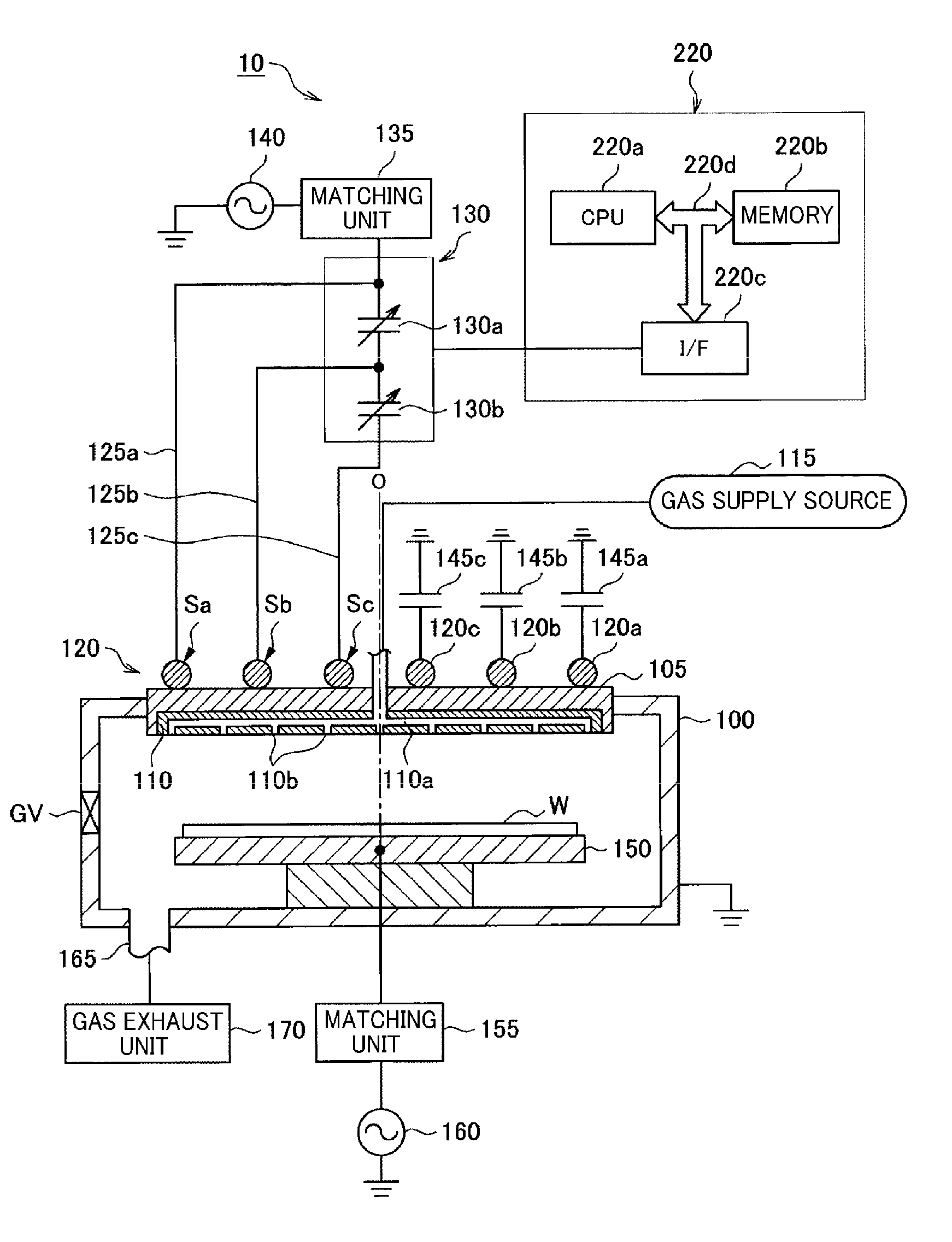

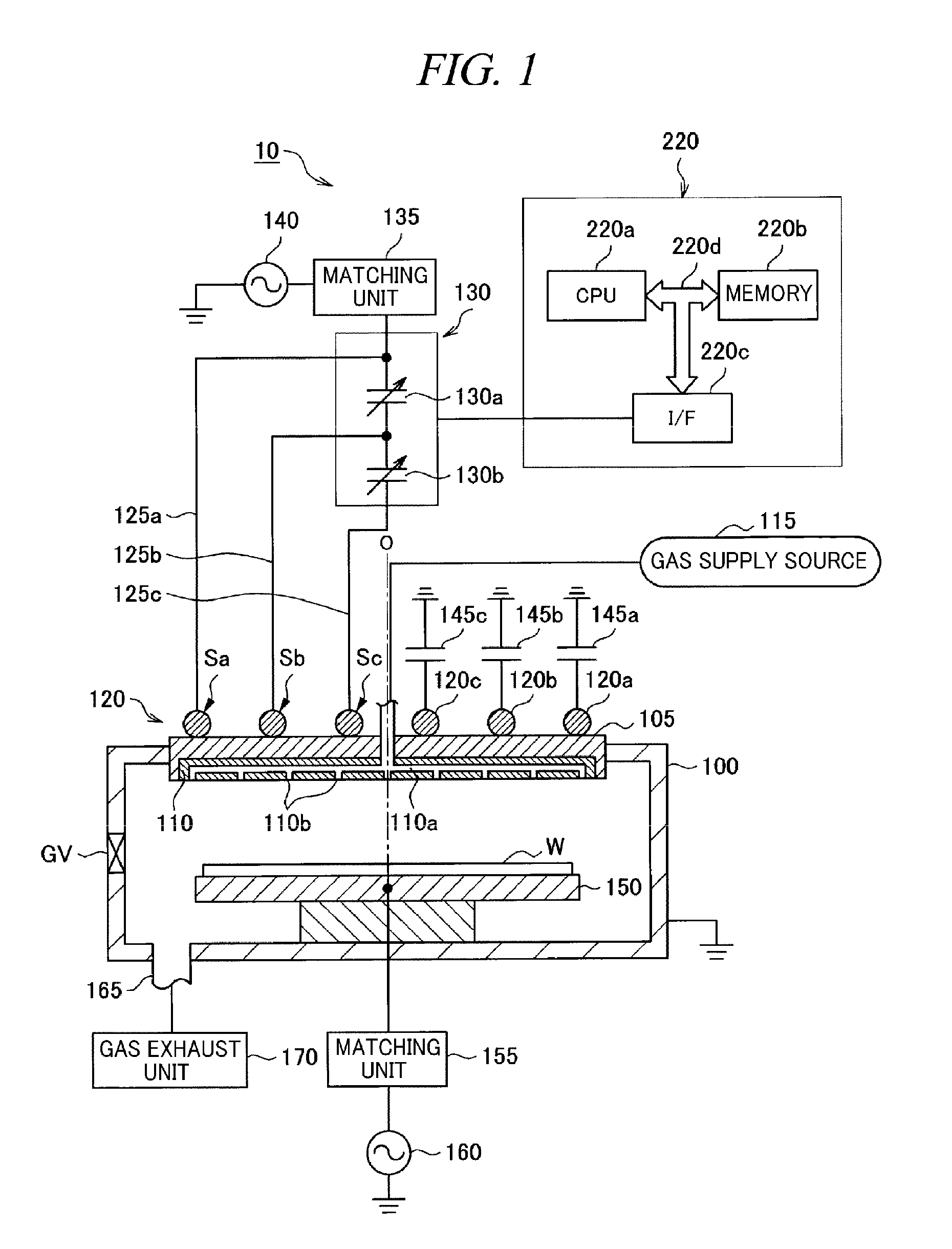

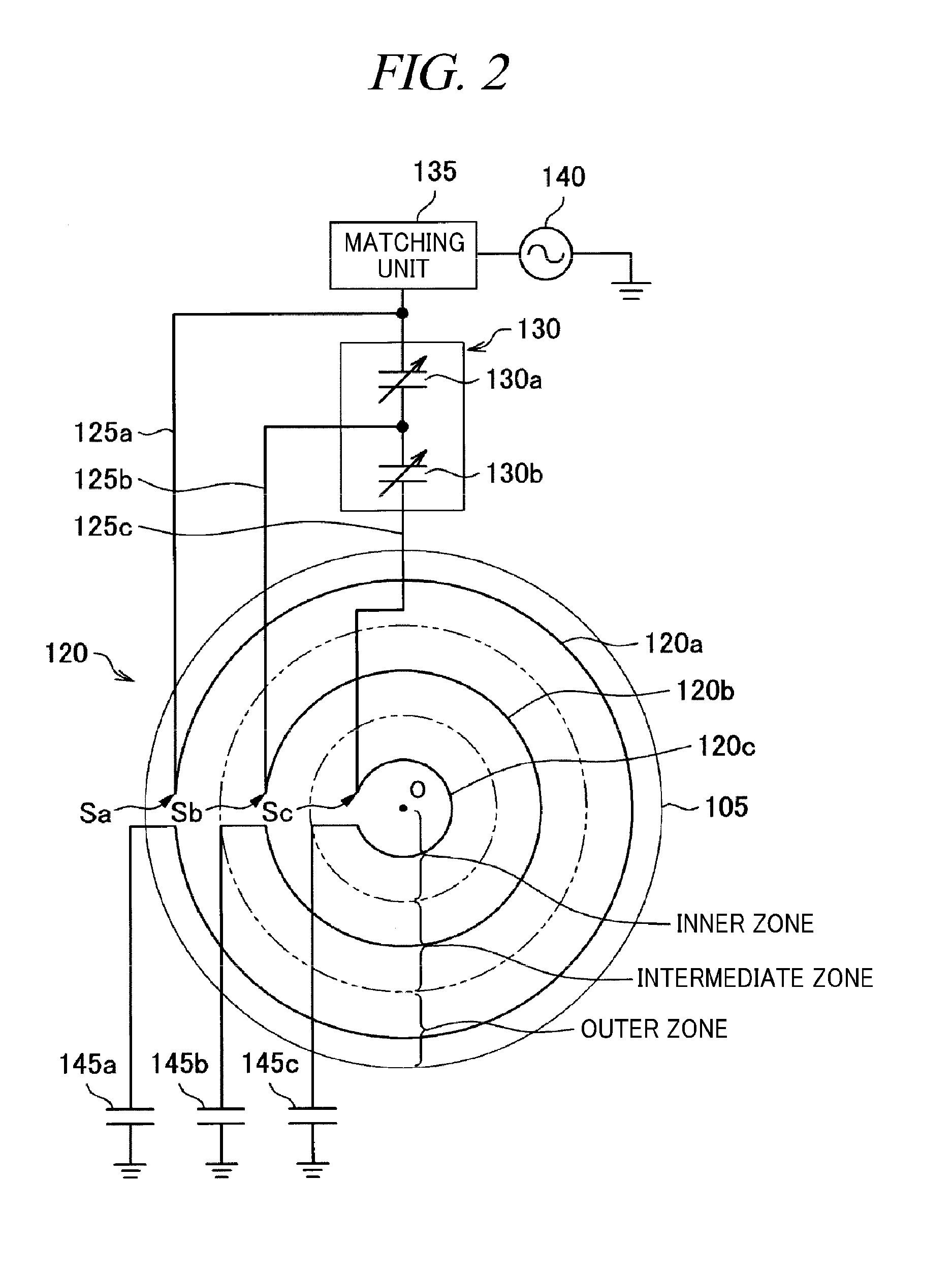

InactiveUS20100243162A1Improve uniformityLow densityElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma densityHigh frequency power

A uniformity of plasma density in a target object surface and plasma processing characteristics can be improved. A plasma processing apparatus 10 includes: a processing chamber 100 in which a plasma process is performed on a wafer W; a first high frequency power supply 140 configured to output a high frequency power; a high frequency antenna 120 including an outer coil, an inner coil and n (n is an integer equal to or greater than 1) number of intermediate coil(s) that are concentrically wound about a central axis outside the processing chamber 100; and a dielectric window 105 provided at a part of a wall of the processing chamber 100 and configured to introduce electromagnetic field energy generated from the high frequency antenna 120 into the processing chamber 100.

Owner:TOKYO ELECTRON LTD

Method and apparatus for improving uniformity of large-area substrates

InactiveUS20070221128A1Good film uniformityEnhanced vapor depositionChemical vapor deposition coatingElectricityPlasma density

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com