Patents

Literature

182 results about "Plasma formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma is defined as a state of matter predominantly comprised of ions and electrons. An ion is formed when an atom or molecule gains or loses electrons, yielding an overall charge (either positive or negative). The presence of charged ions means that a plasma is highly electrically conductive and responds strongly to magnetic and electric fields.

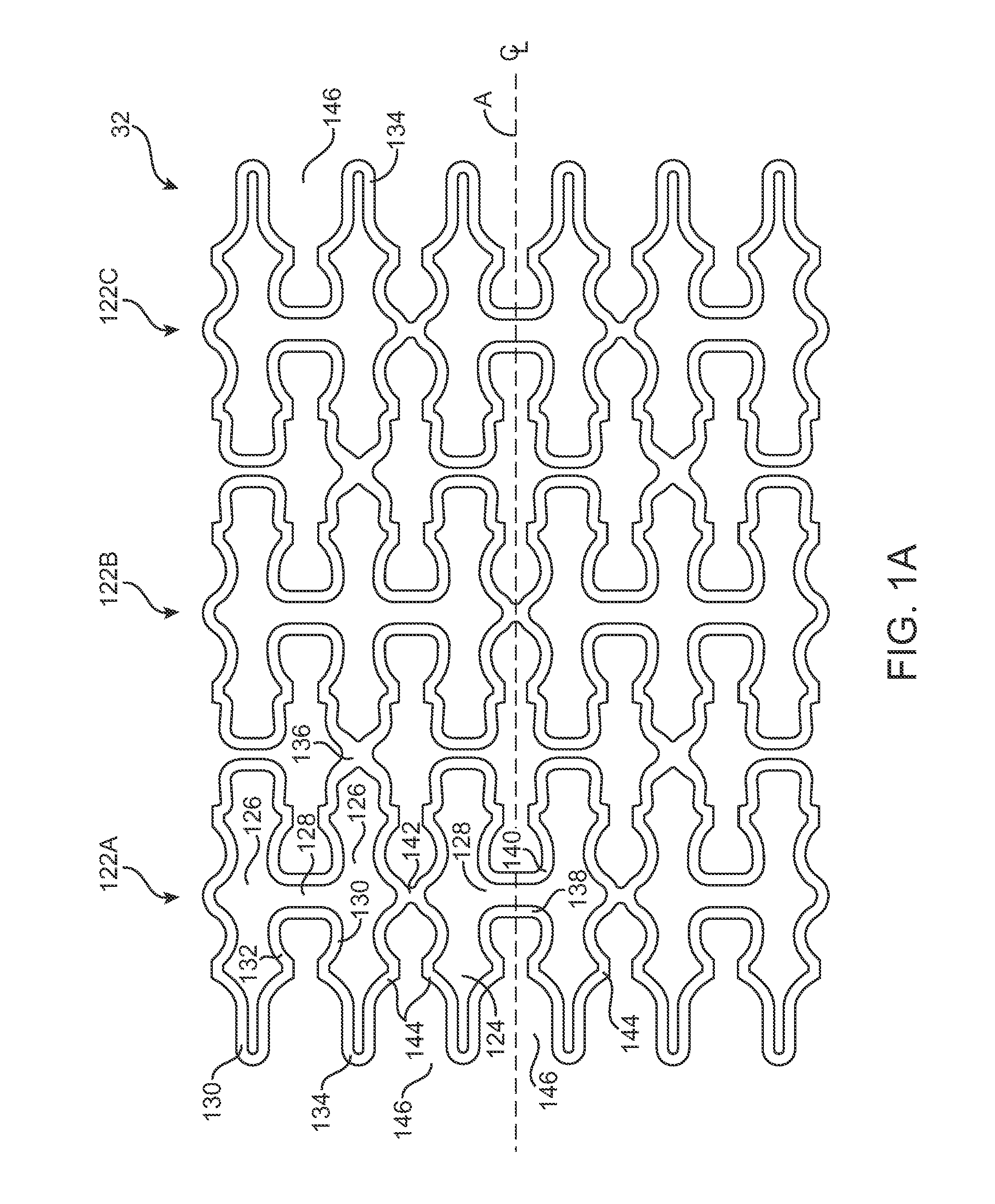

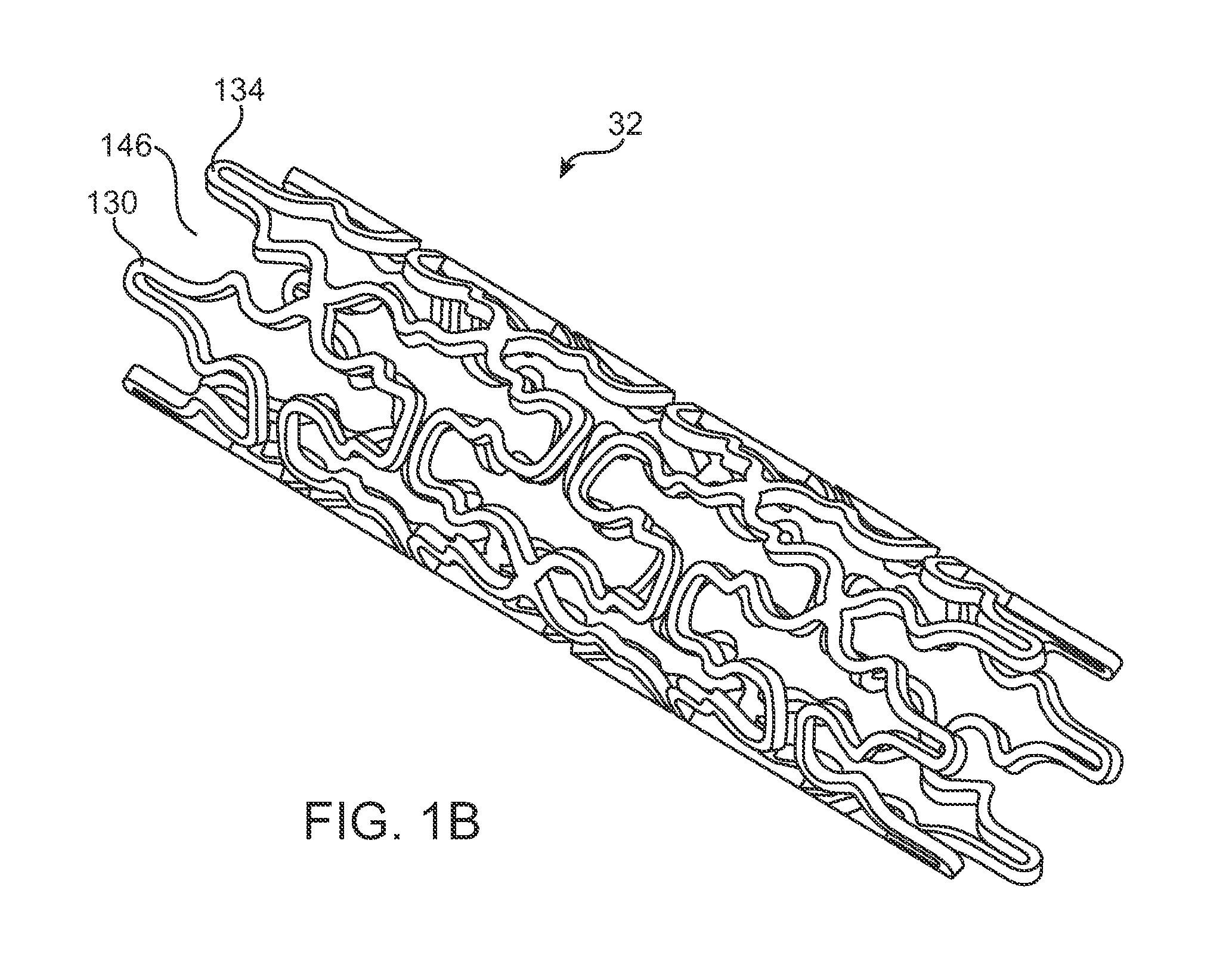

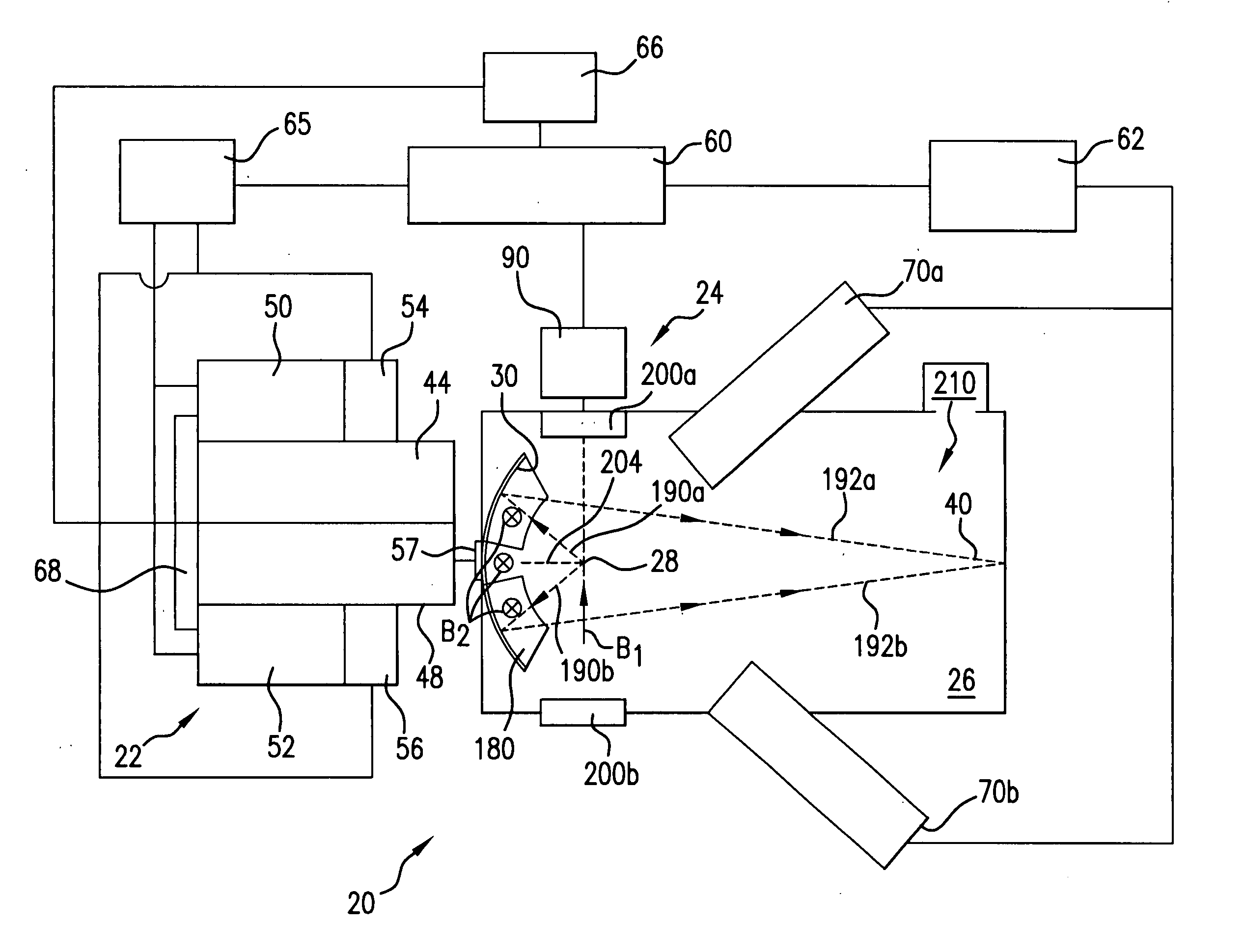

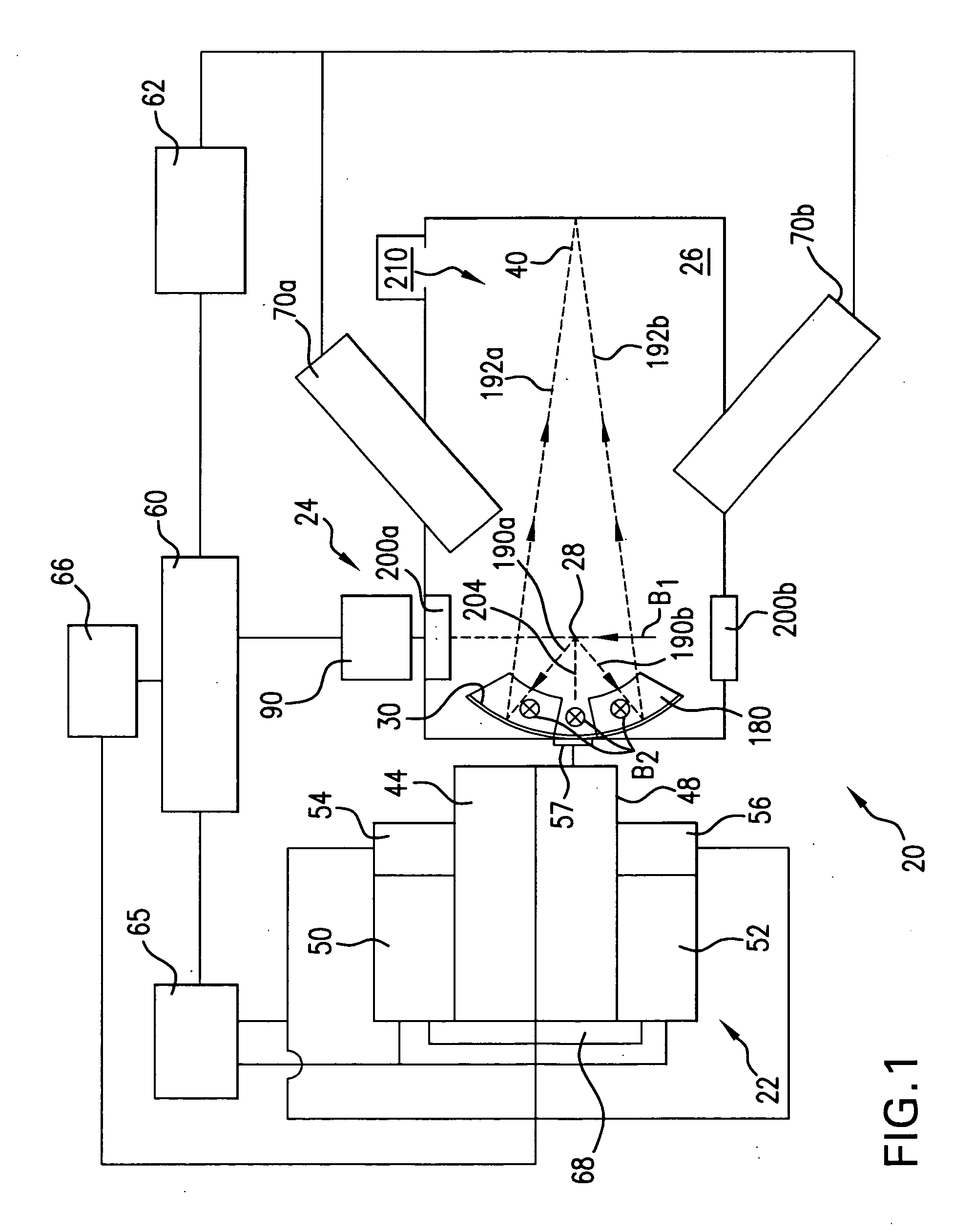

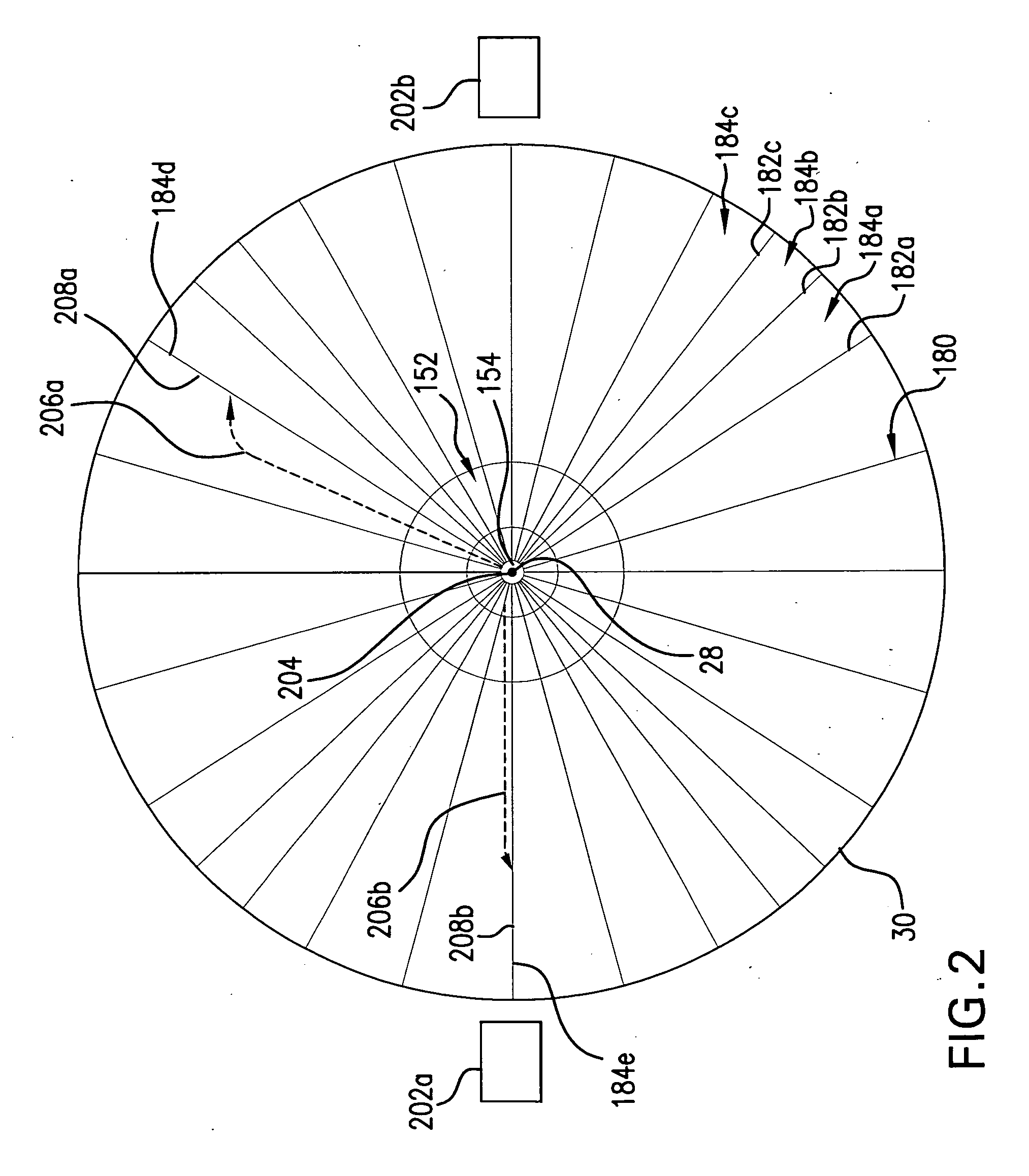

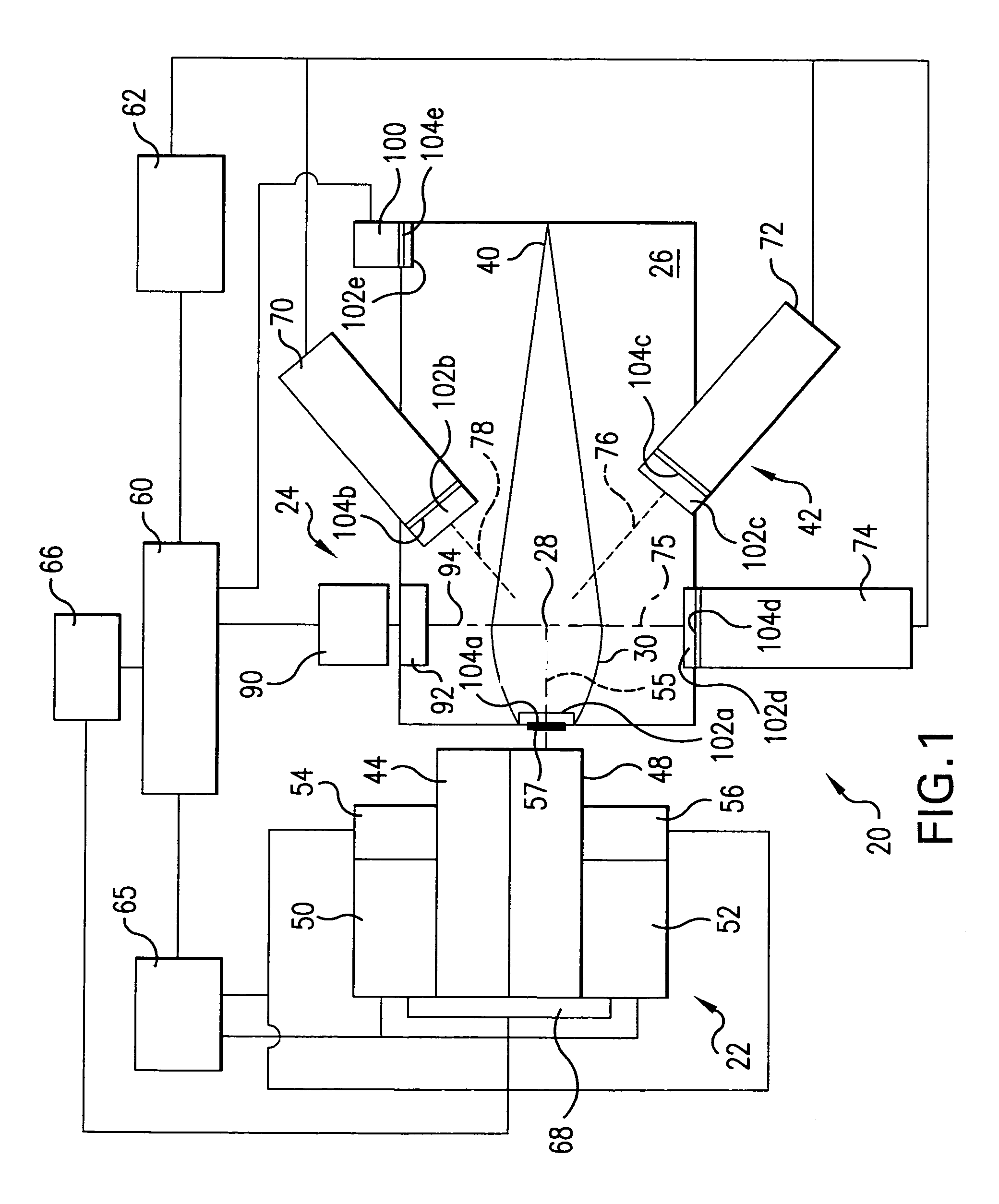

Electrosurgical ablation and aspiration apparatus having flow directing feature and methods related thereto

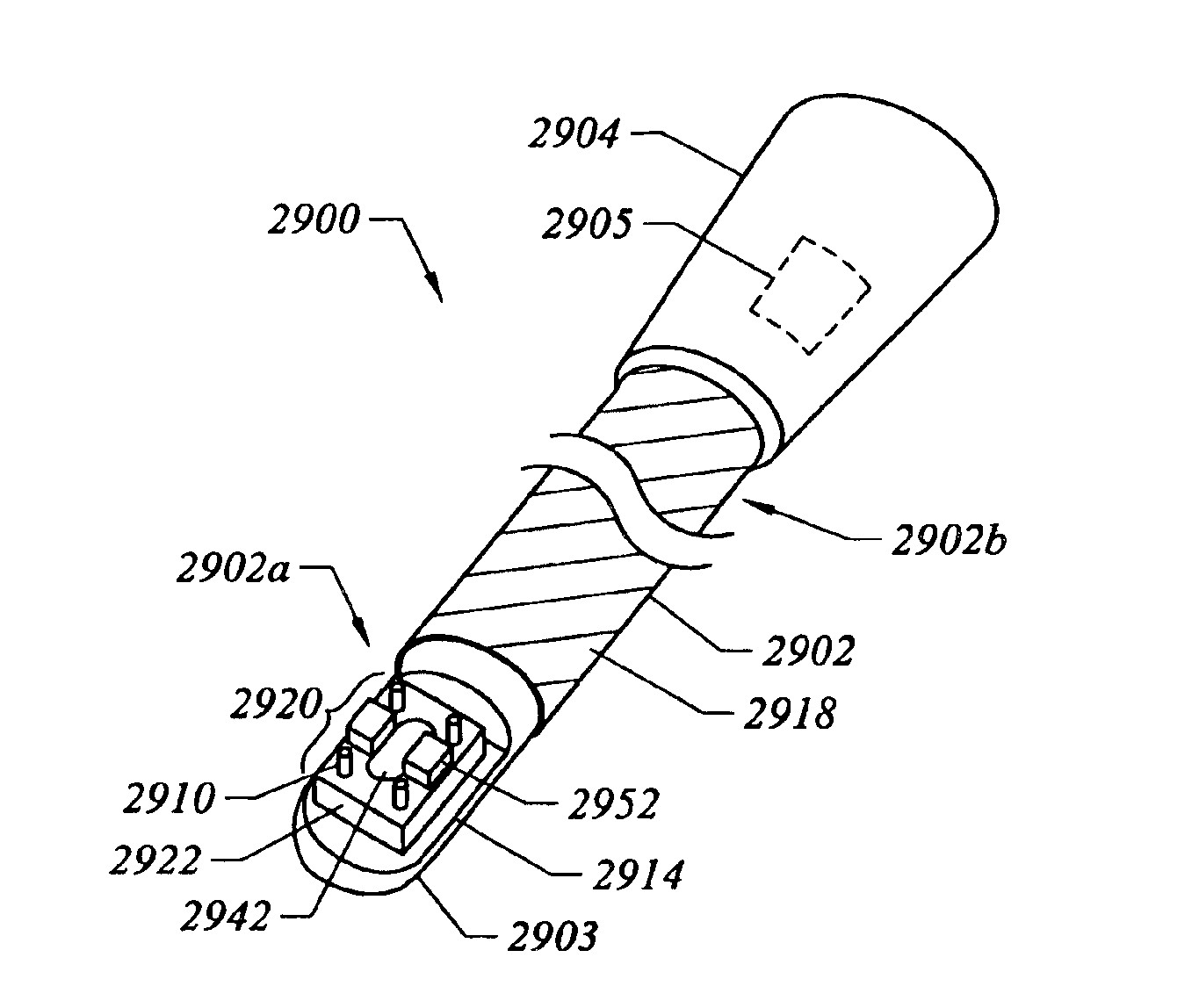

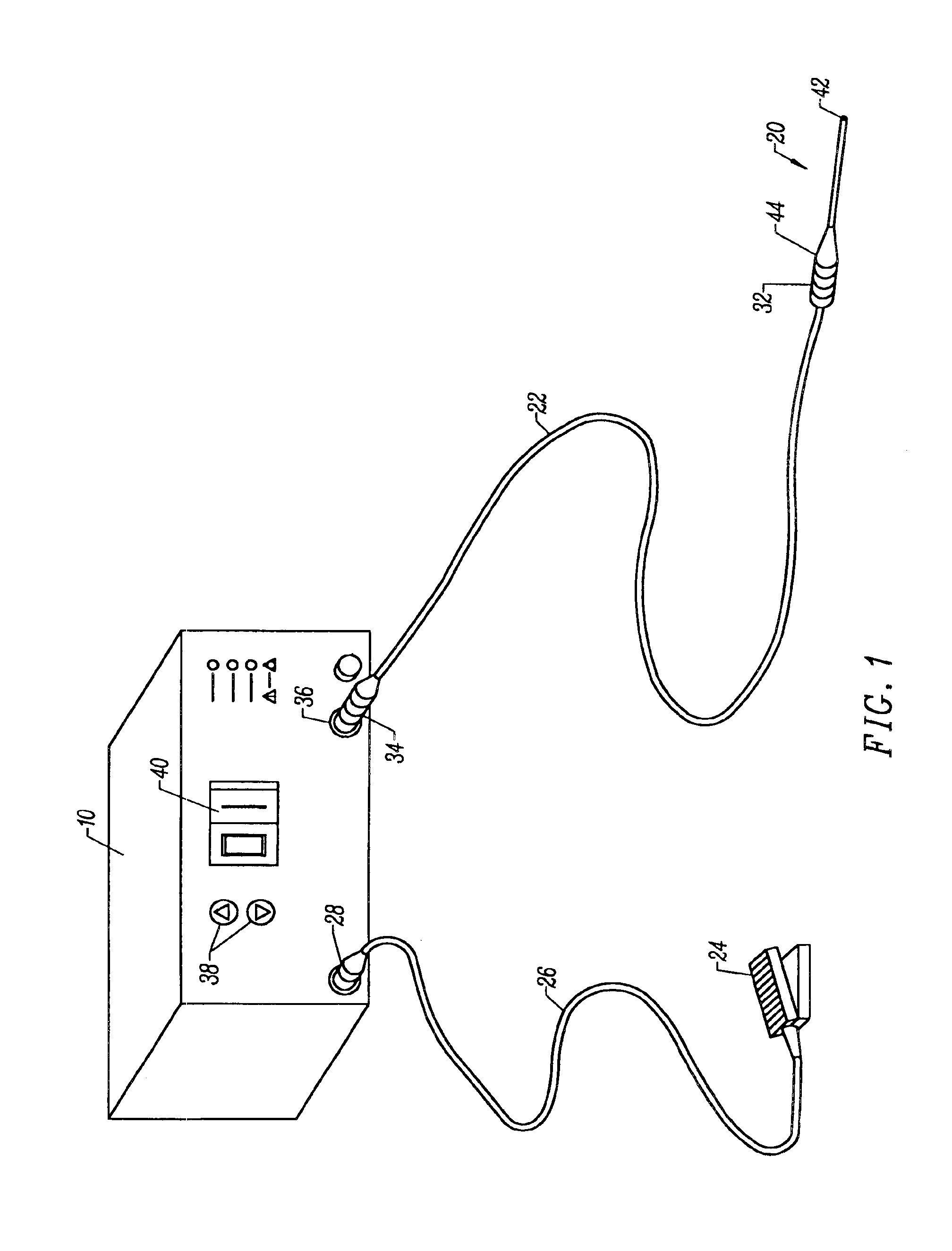

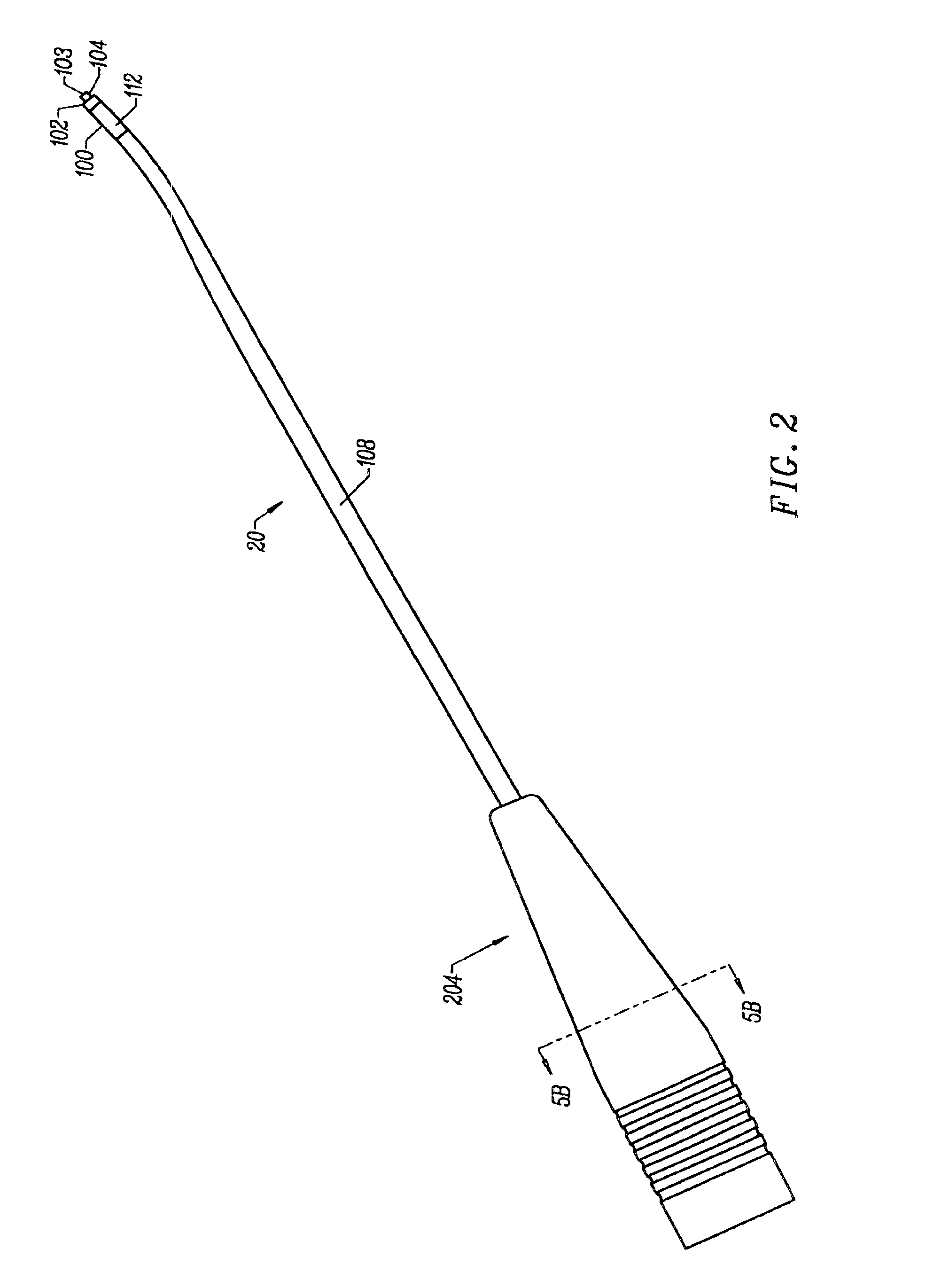

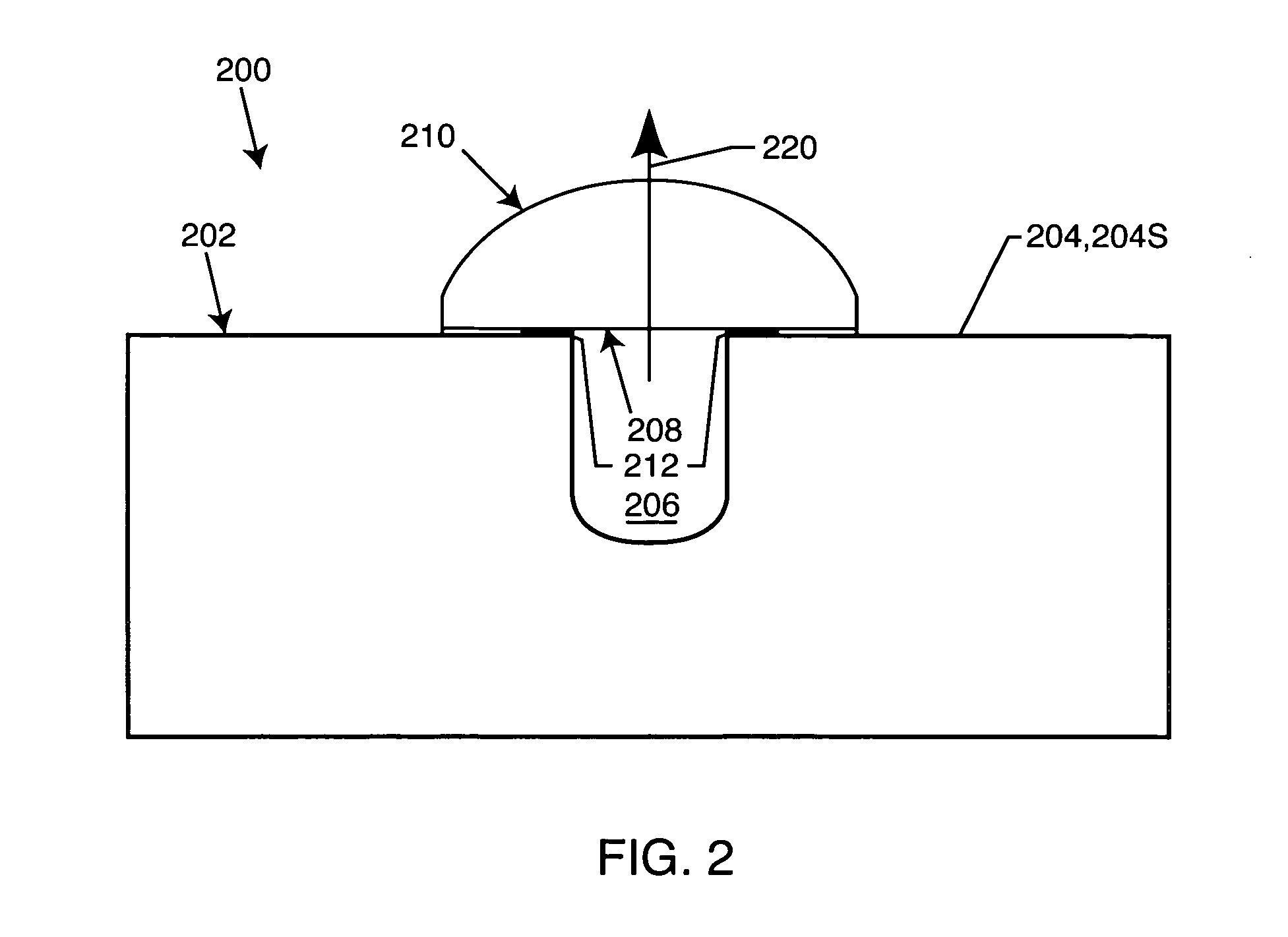

InactiveUS6949096B2Facilitates removing and ablatingImprove visualizationSurgical instruments for heatingSurgical instruments for aspiration of substancesSurgical siteActive electrode

Electrosurgical methods, systems, and apparatus for the controlled ablation of tissue from a target site of a patient. An electrosurgical apparatus of the invention includes an active electrode assembly having an active electrode screen surrounded by a plurality of flow protectors. Each flow protector defines a shielded region of the active electrode screen, each shielded region of the screen characterized by enhanced plasma formation. The active electrode assembly is adapted for removing tissue from a surgical site, and the active electrode screen is adapted for digesting fragments of resected tissue. In one embodiment, the apparatus is particularly suited to simultaneously removing both hard and soft tissue in, or around, a joint.

Owner:ARTHROCARE

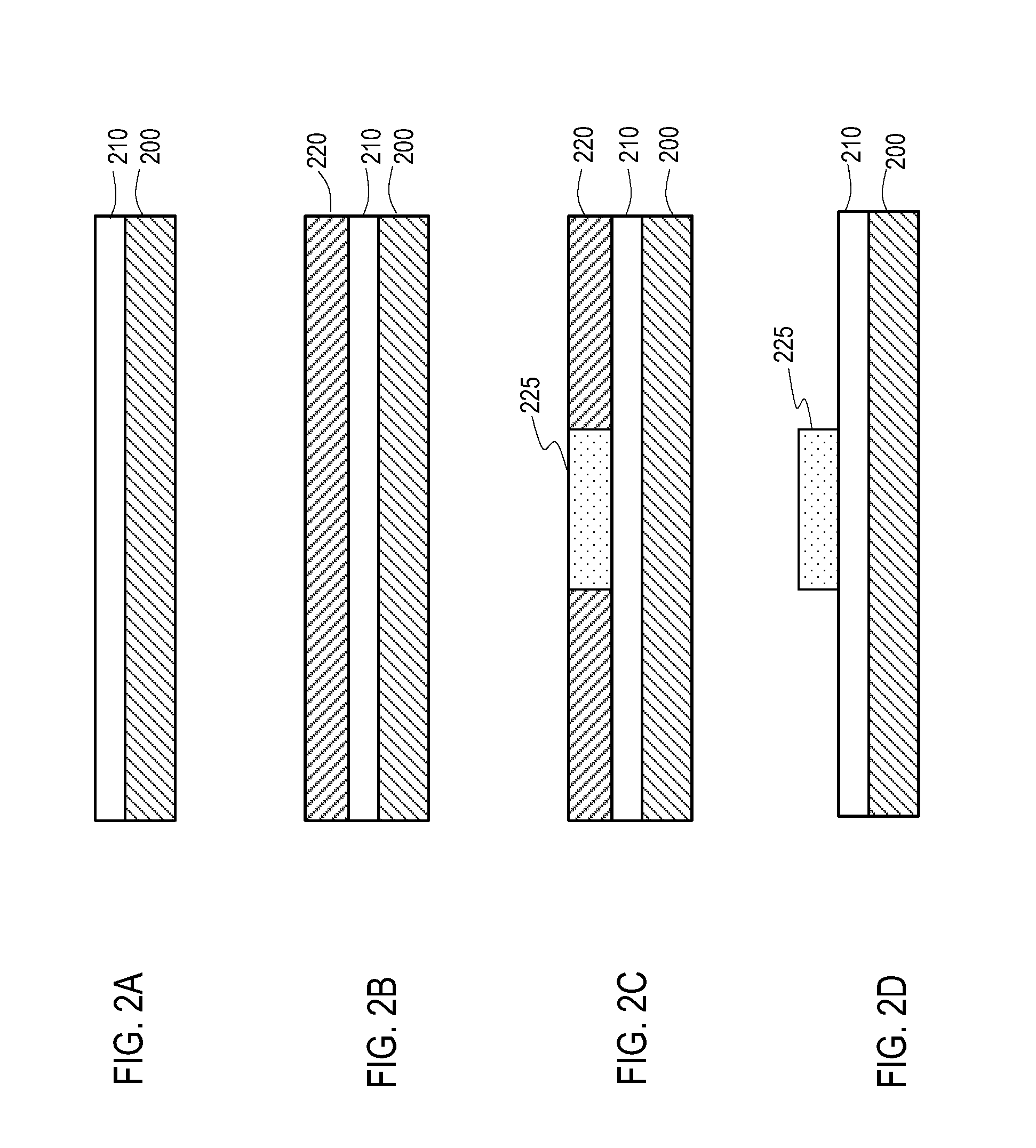

Radiation patternable CVD film

InactiveUS8465903B2Electric discharge tubesSemiconductor/solid-state device manufacturingCross-linkGas phase

Methods for forming photoresists sensitive to radiation on a substrate are provided. Described are chemical vapor deposition methods of forming films (e.g., silicon-containing films) as photoresists using a plasma which may be exposed to radiation to form a pattern. The deposition methods utilize precursors with cross-linkable moieties that will cross-link upon exposure to radiation. Radiation may be carried out in the with or without the presence of oxygen. Exposed or unexposed areas may then be developed in an aqueous base developer.

Owner:APPLIED MATERIALS INC

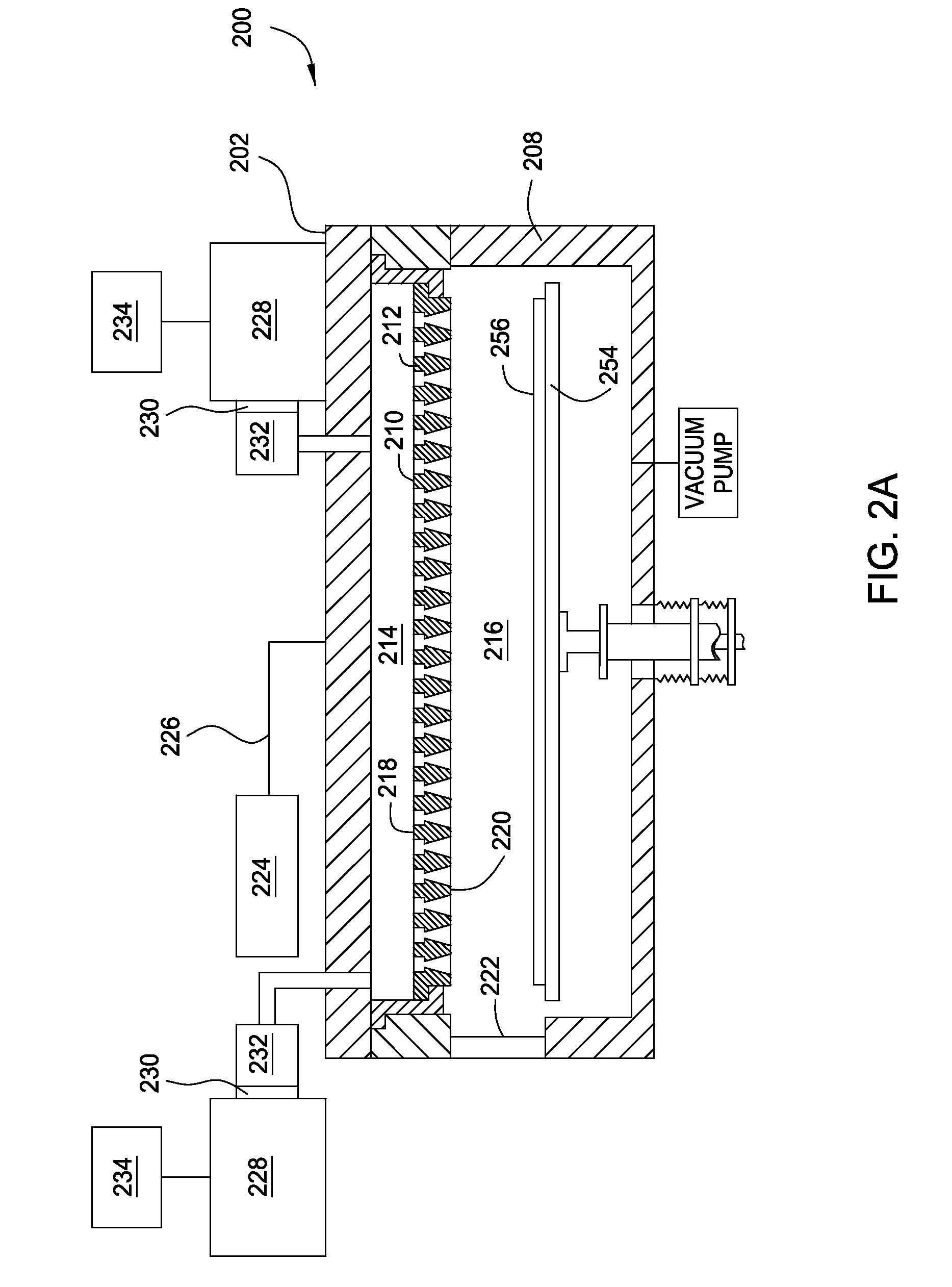

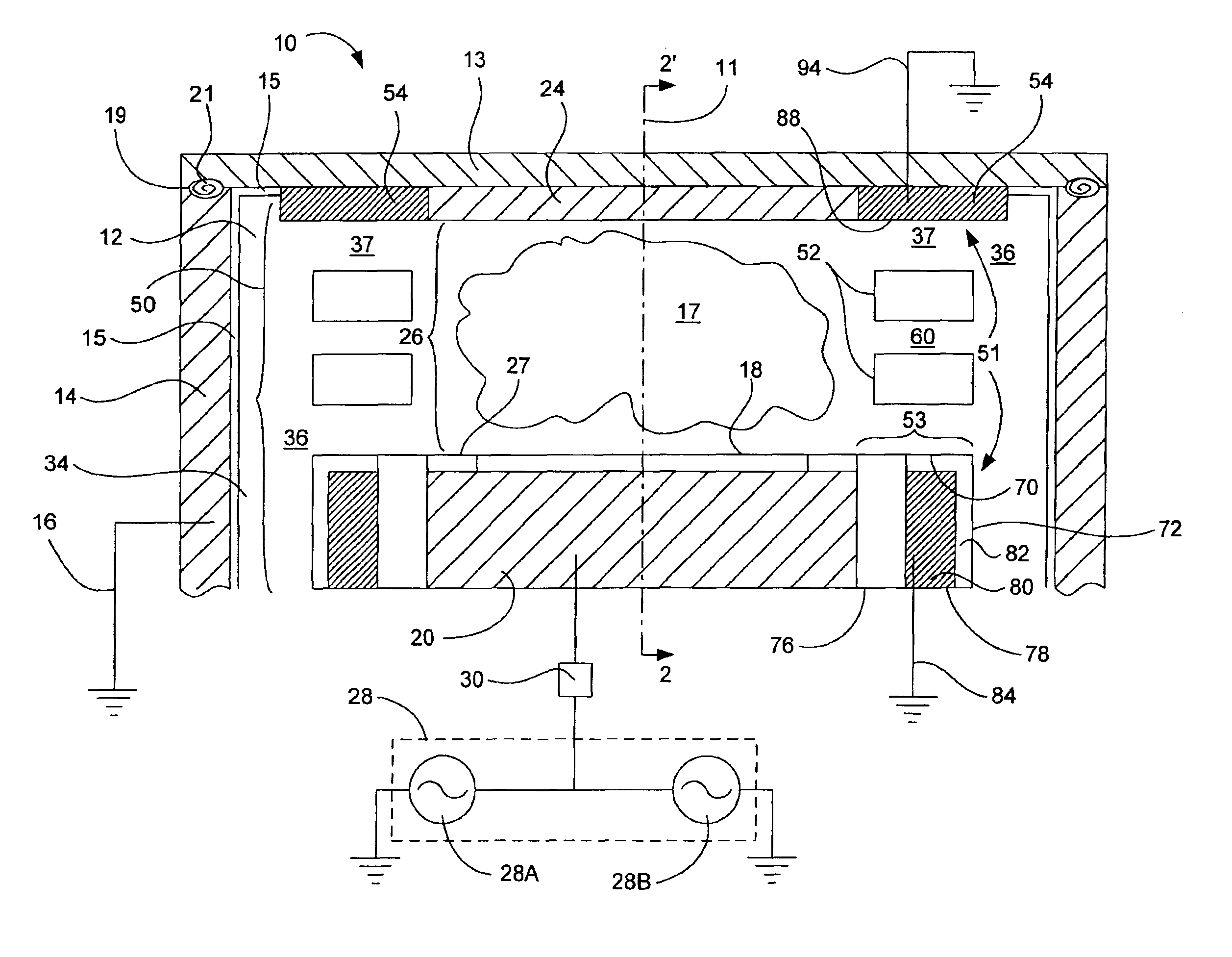

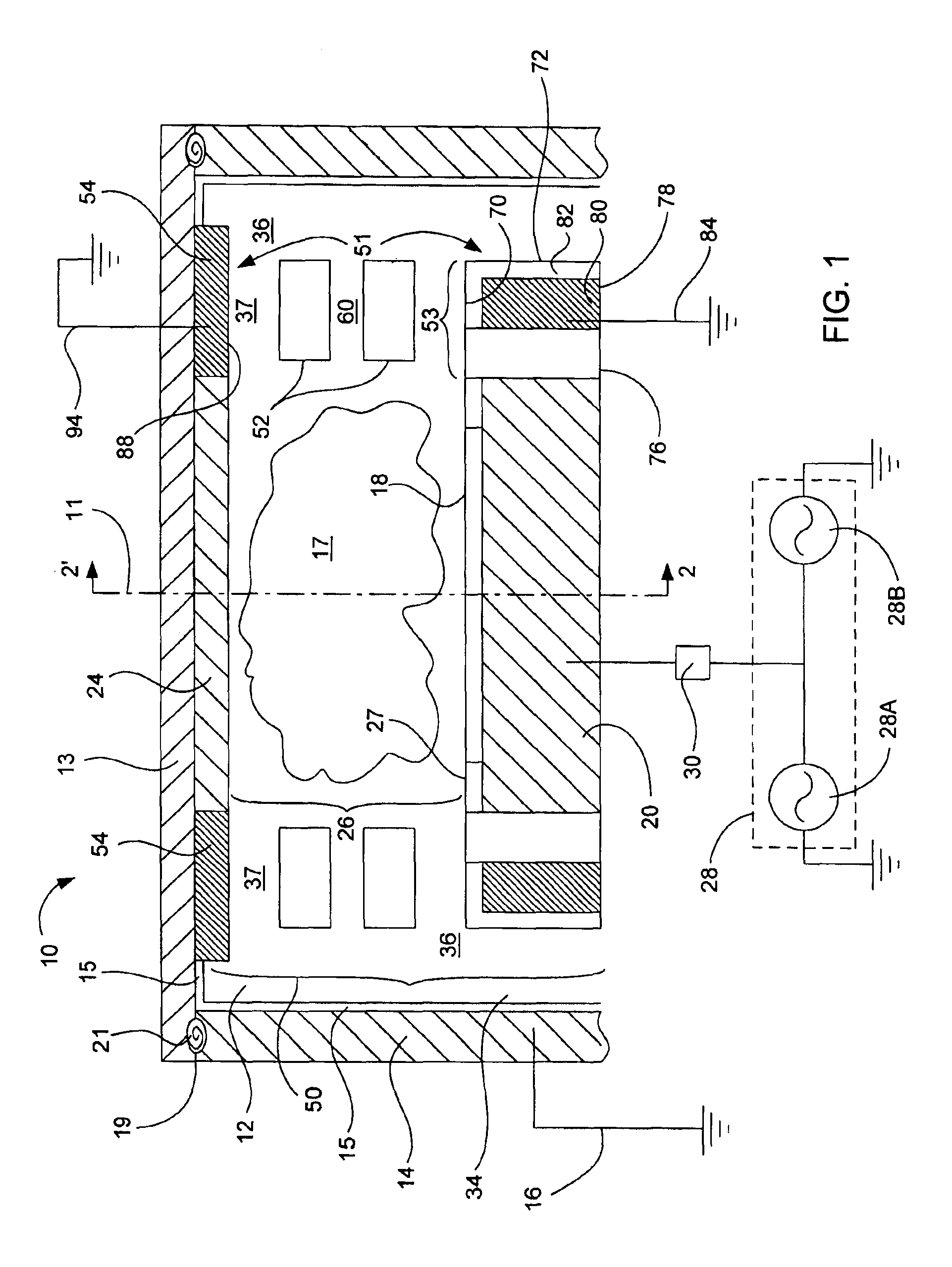

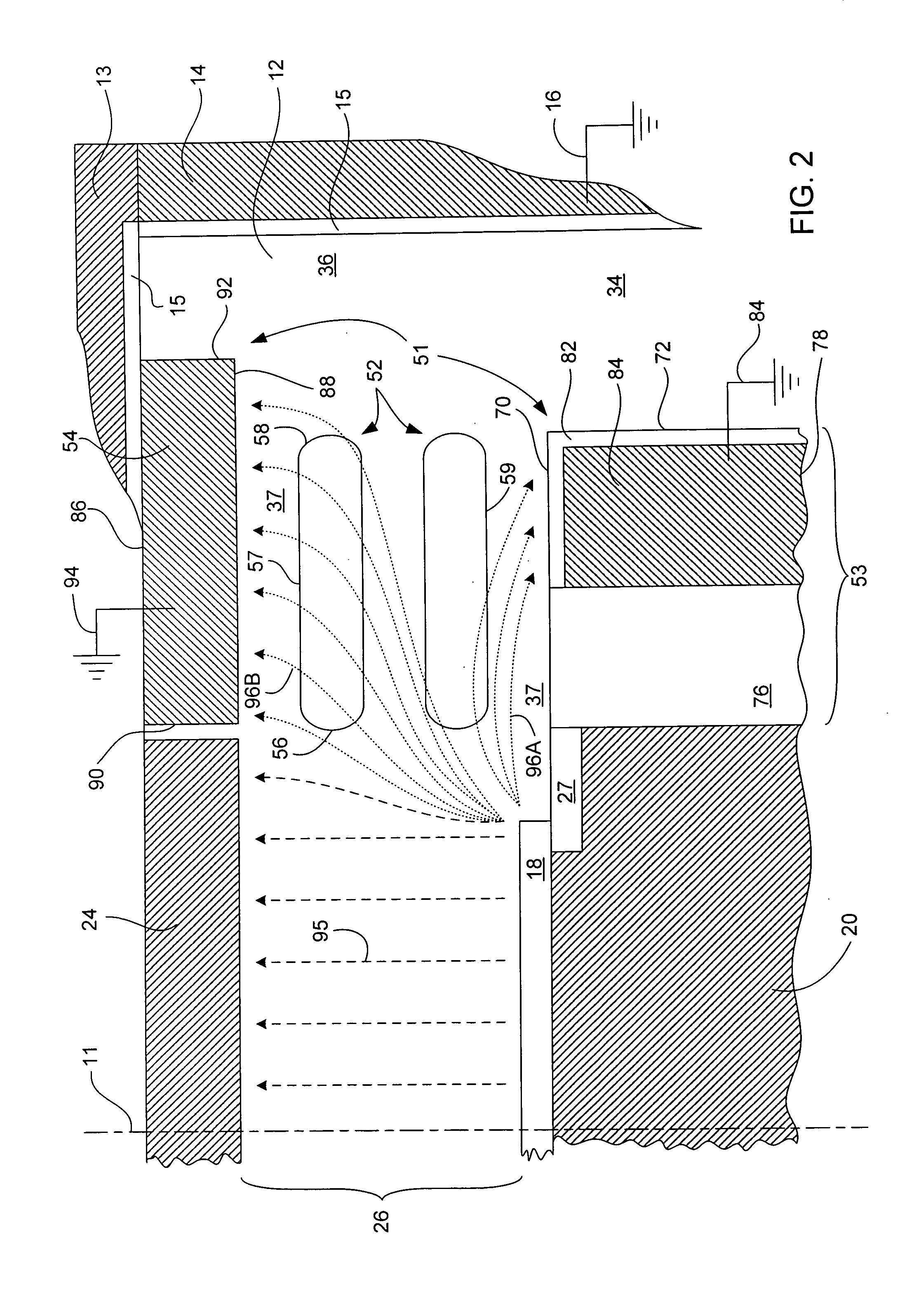

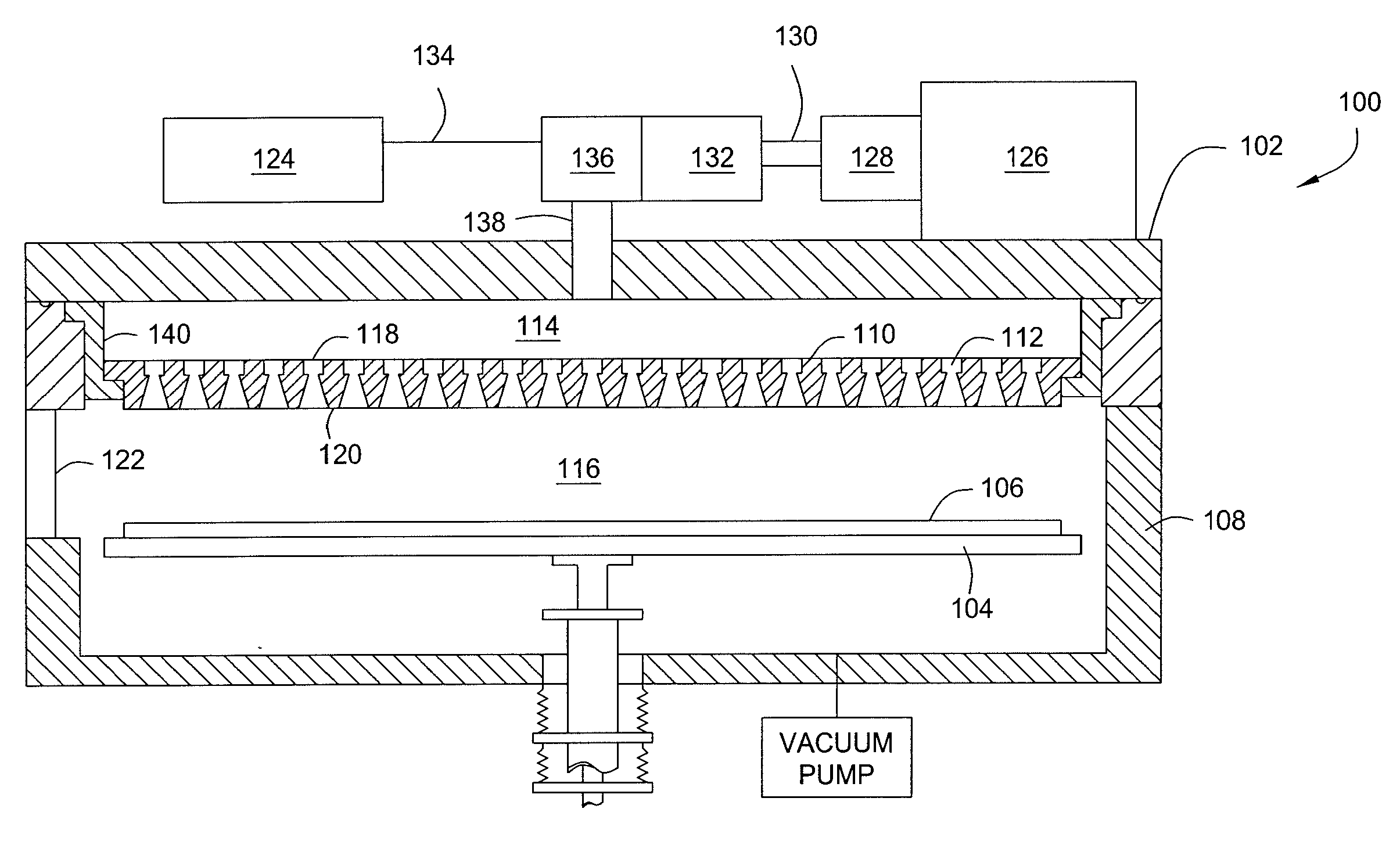

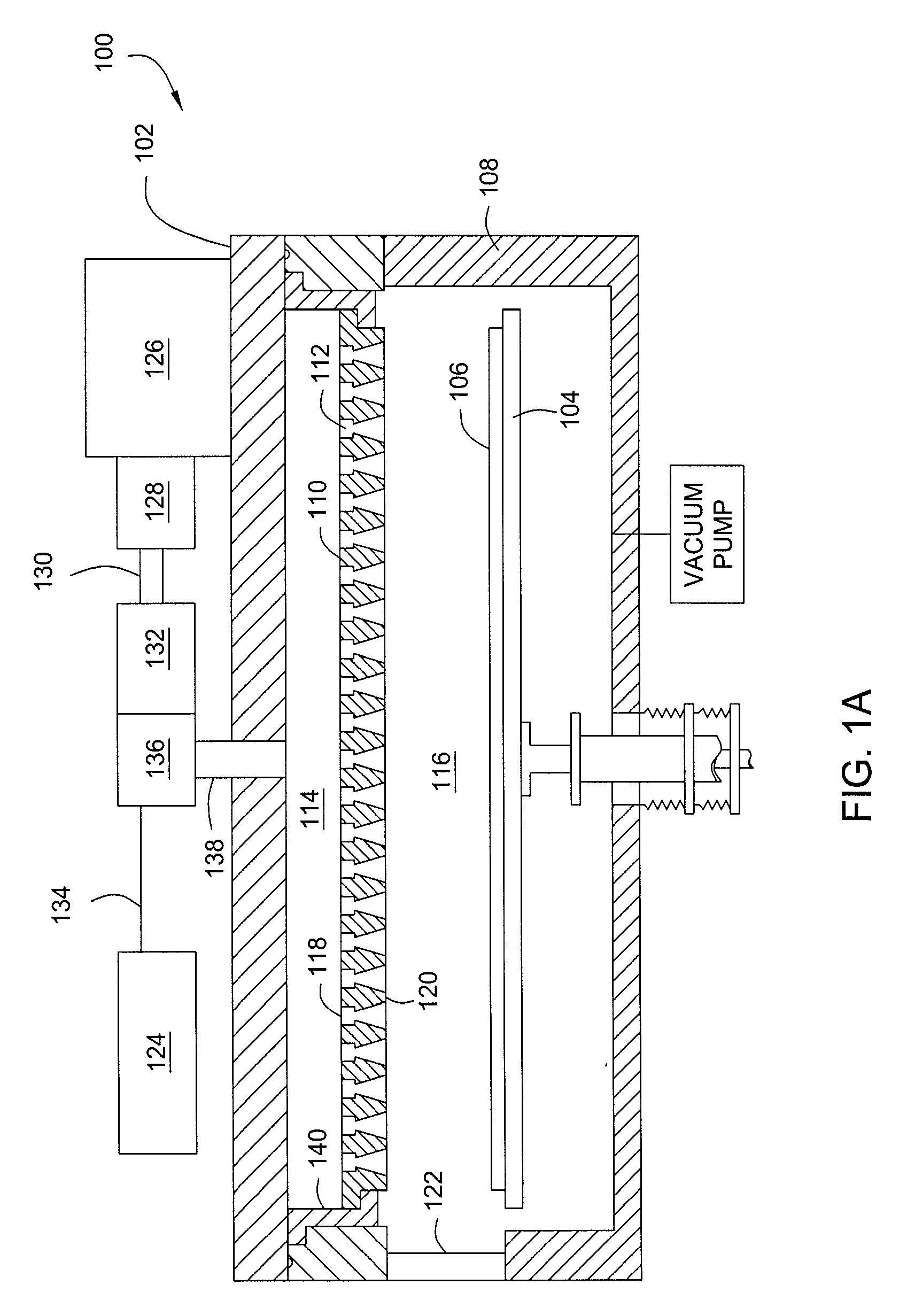

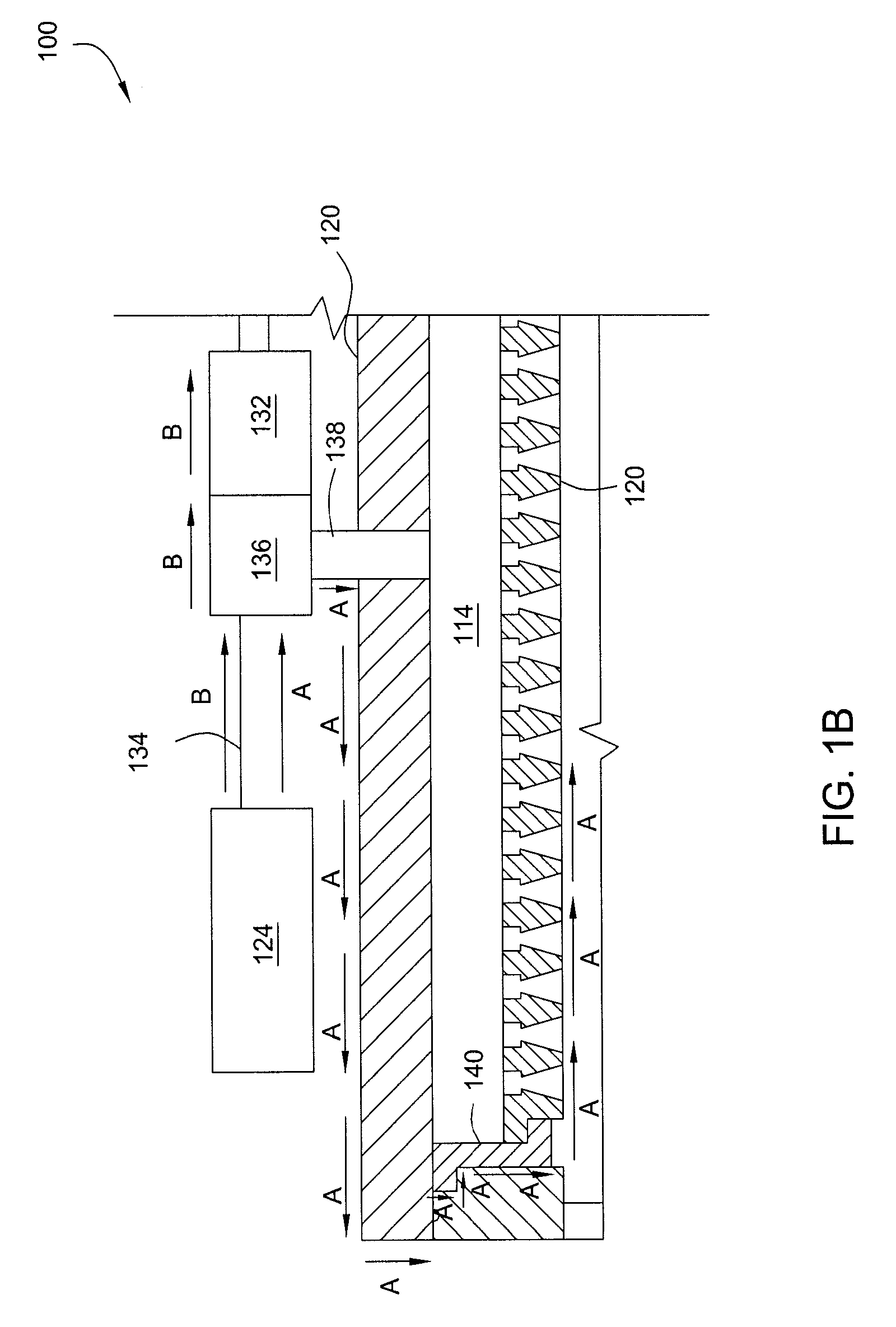

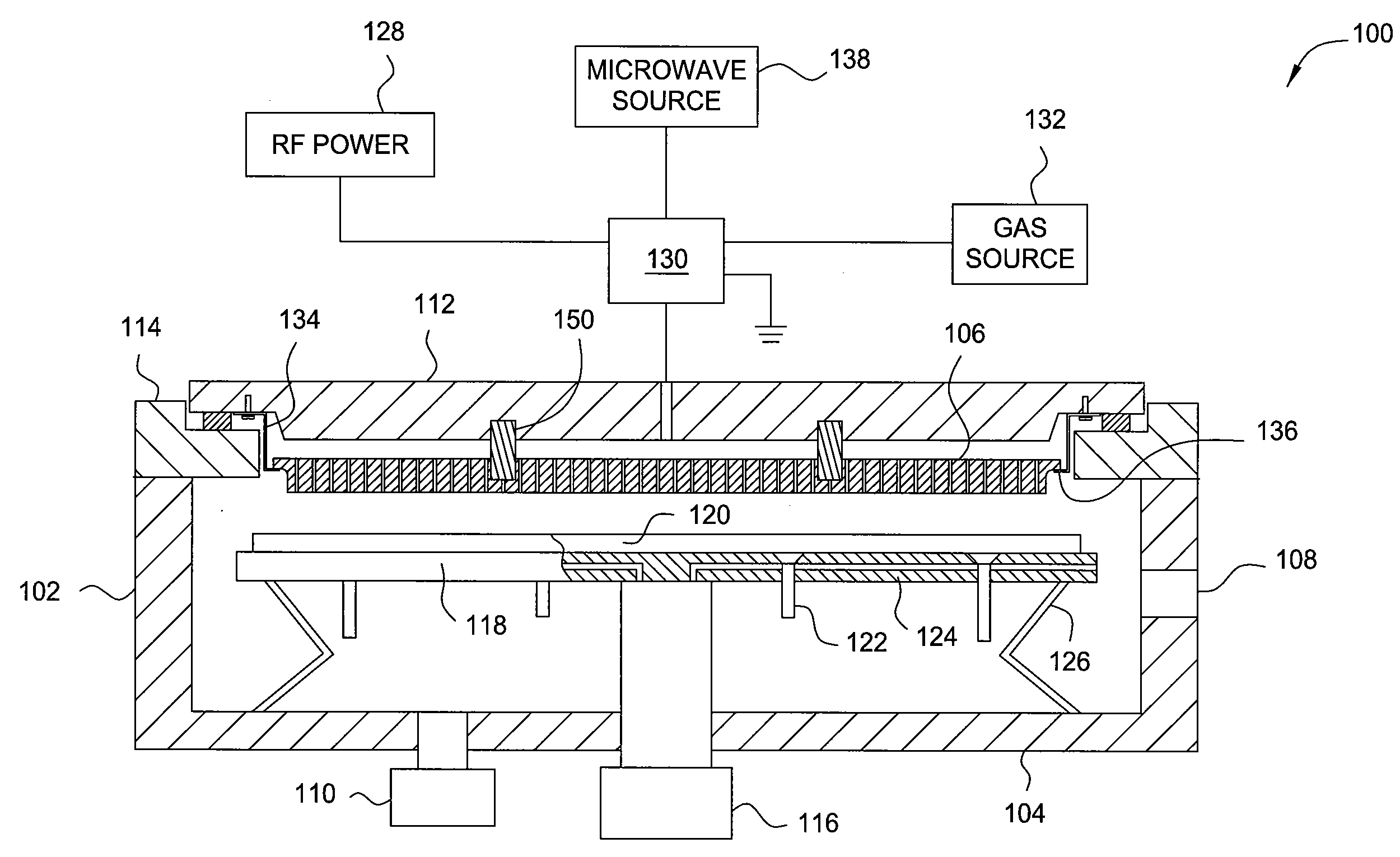

Plasma processing apparatus and method

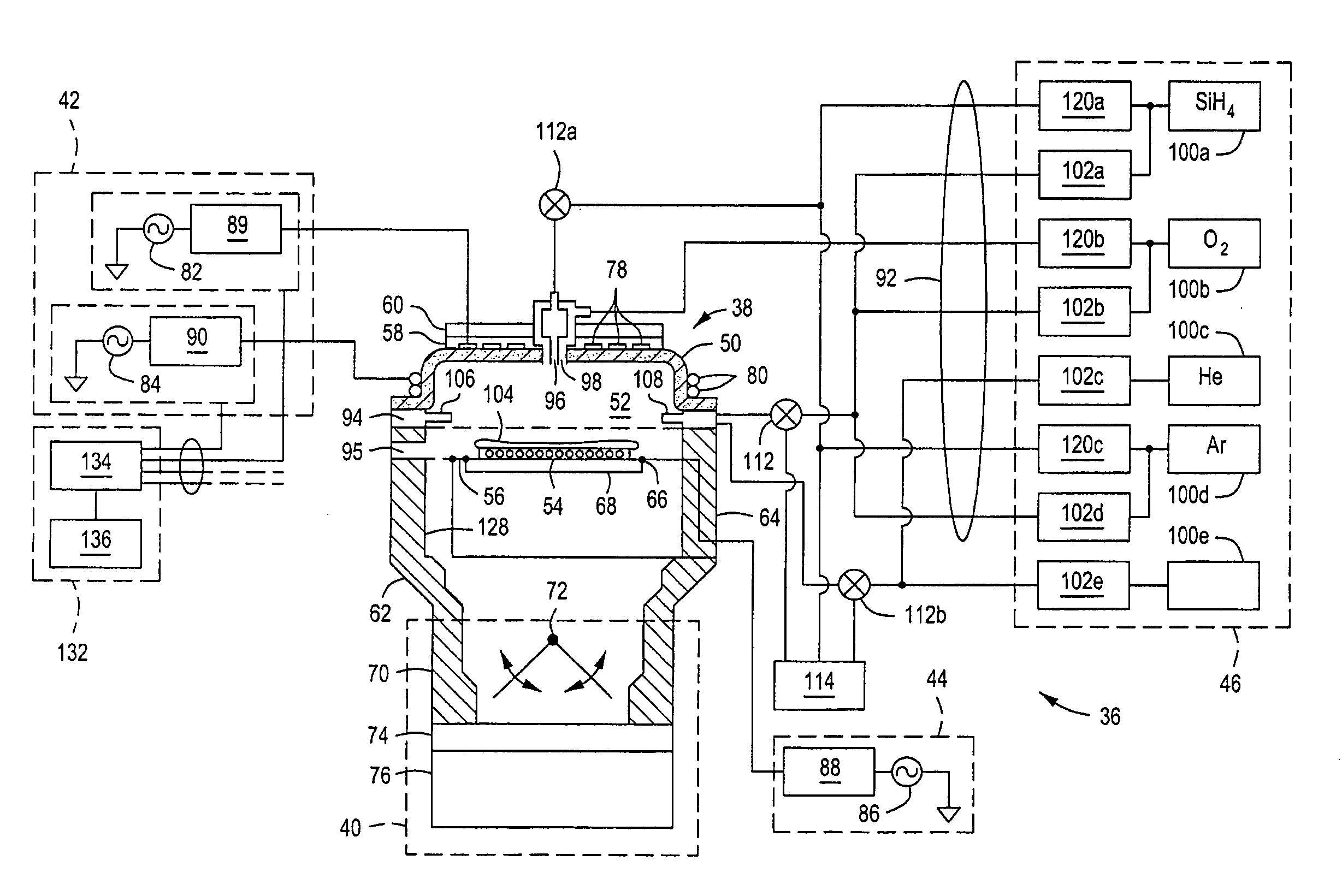

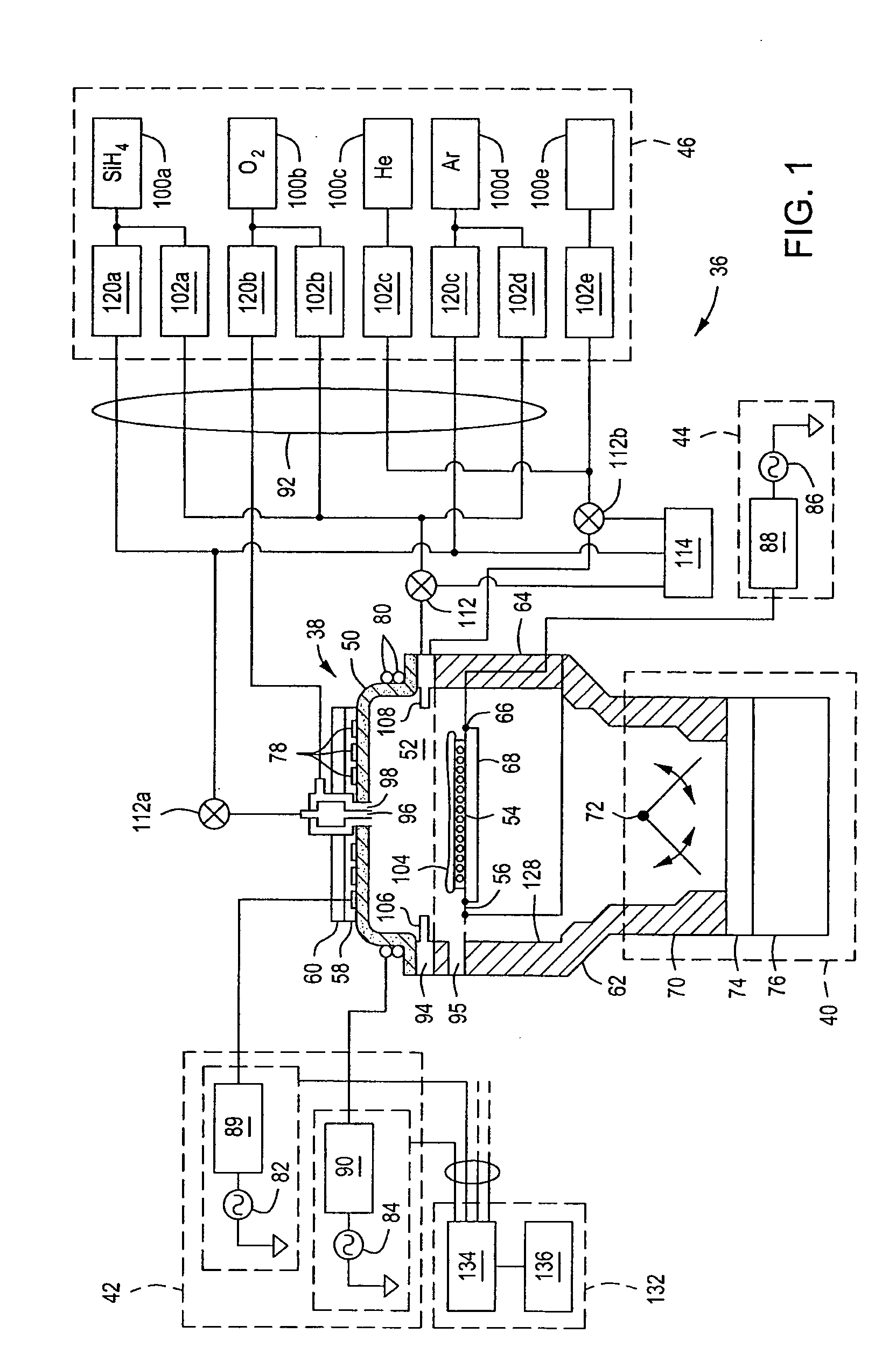

InactiveUS20090258162A1Reducing plasma formationElectric discharge tubesChemical vapor deposition coatingRemote plasmaEngineering

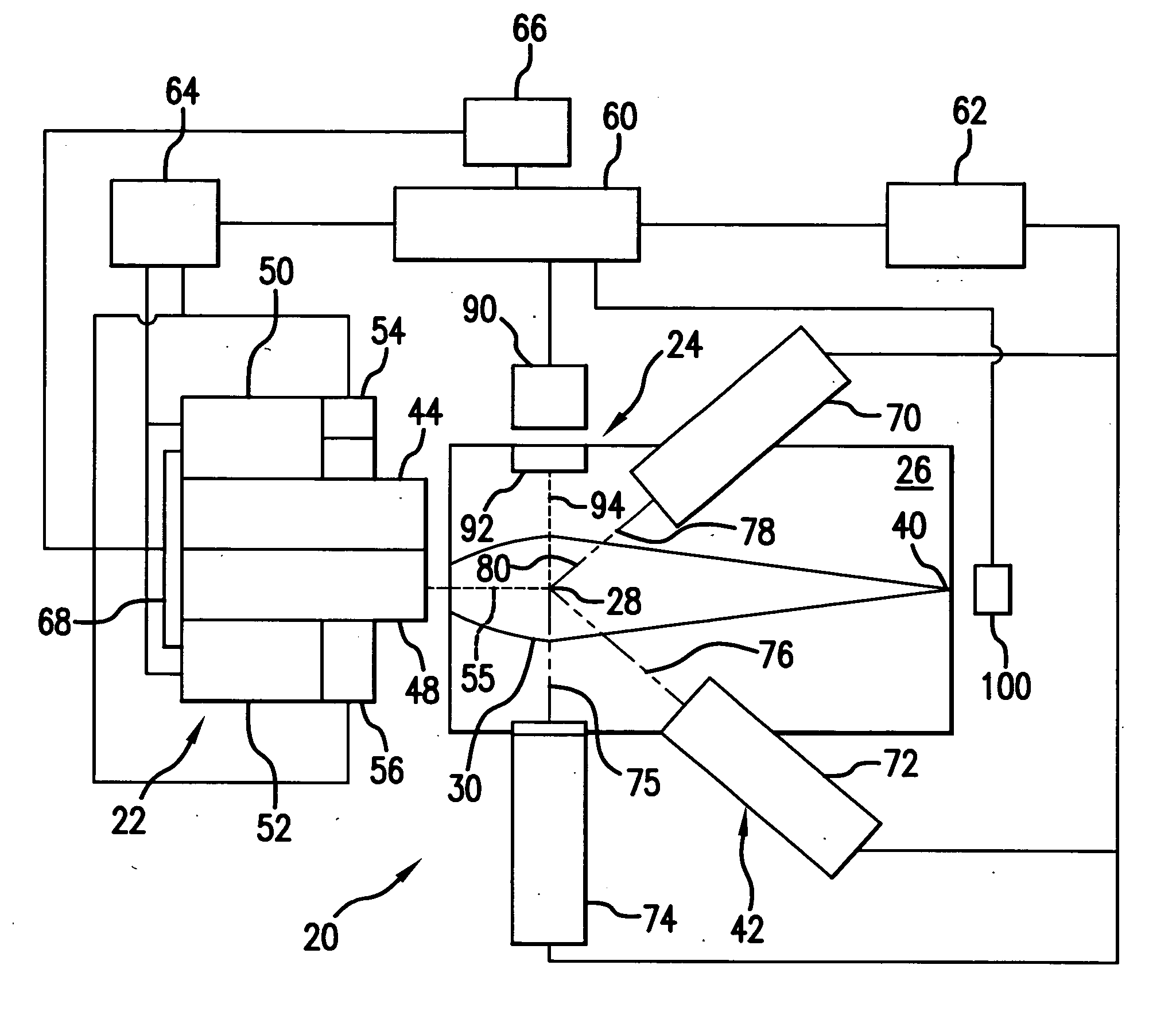

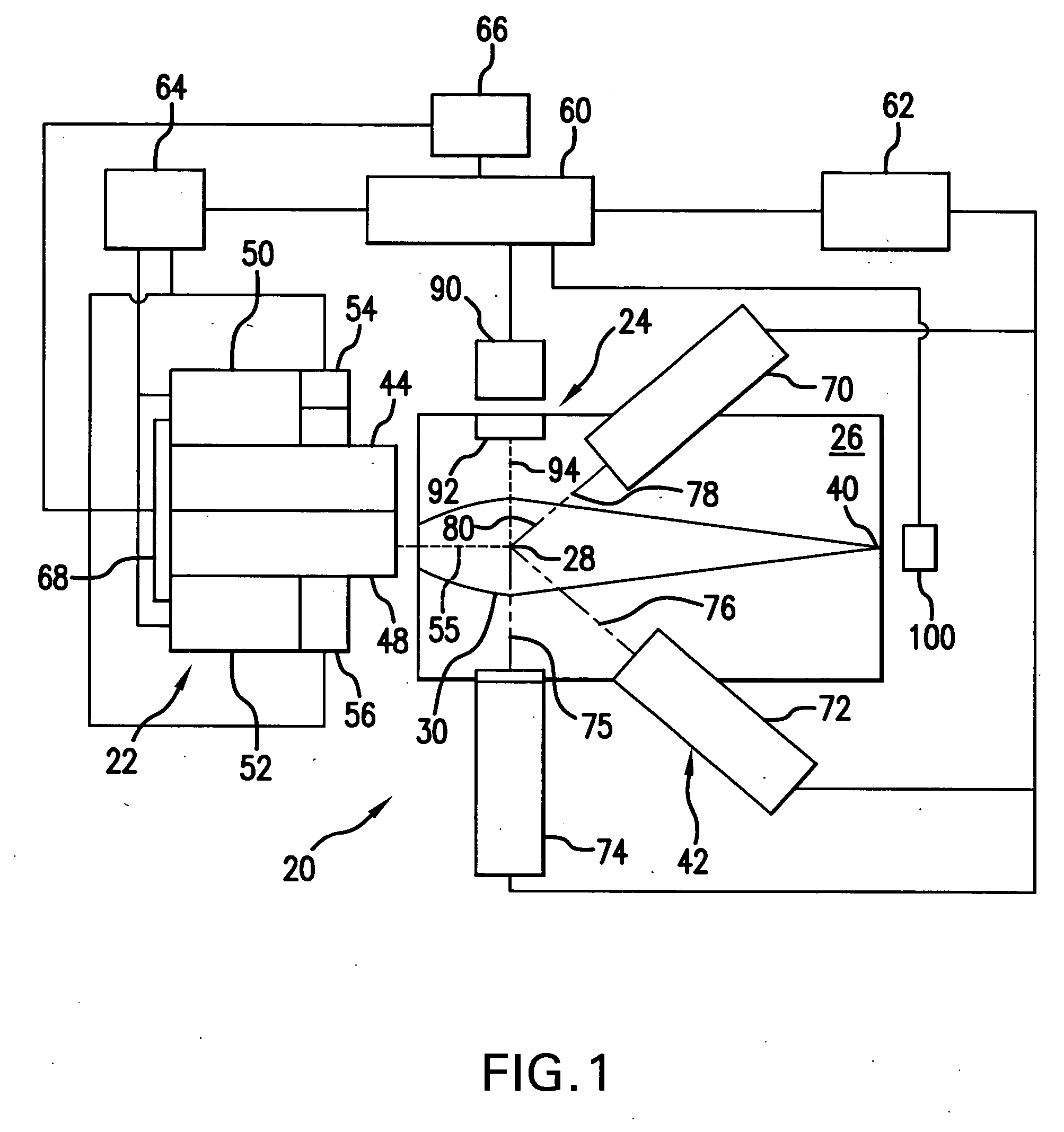

The present invention generally includes a plasma enhanced chemical vapor deposition (PECVD) processing chamber having an RF power source coupled to the backing plate at a location separate from the gas source. By feeding the gas into the processing chamber at a location separate from the RF power, parasitic plasma formation in the gas tubes leading to the processing chamber may be reduced. The gas may be fed to the chamber at a plurality of locations. At each location, the gas may be fed to the processing chamber from the gas source by passing through a remote plasma source as well as an RF choke or RF resistor.

Owner:APPLIED MATERIALS INC

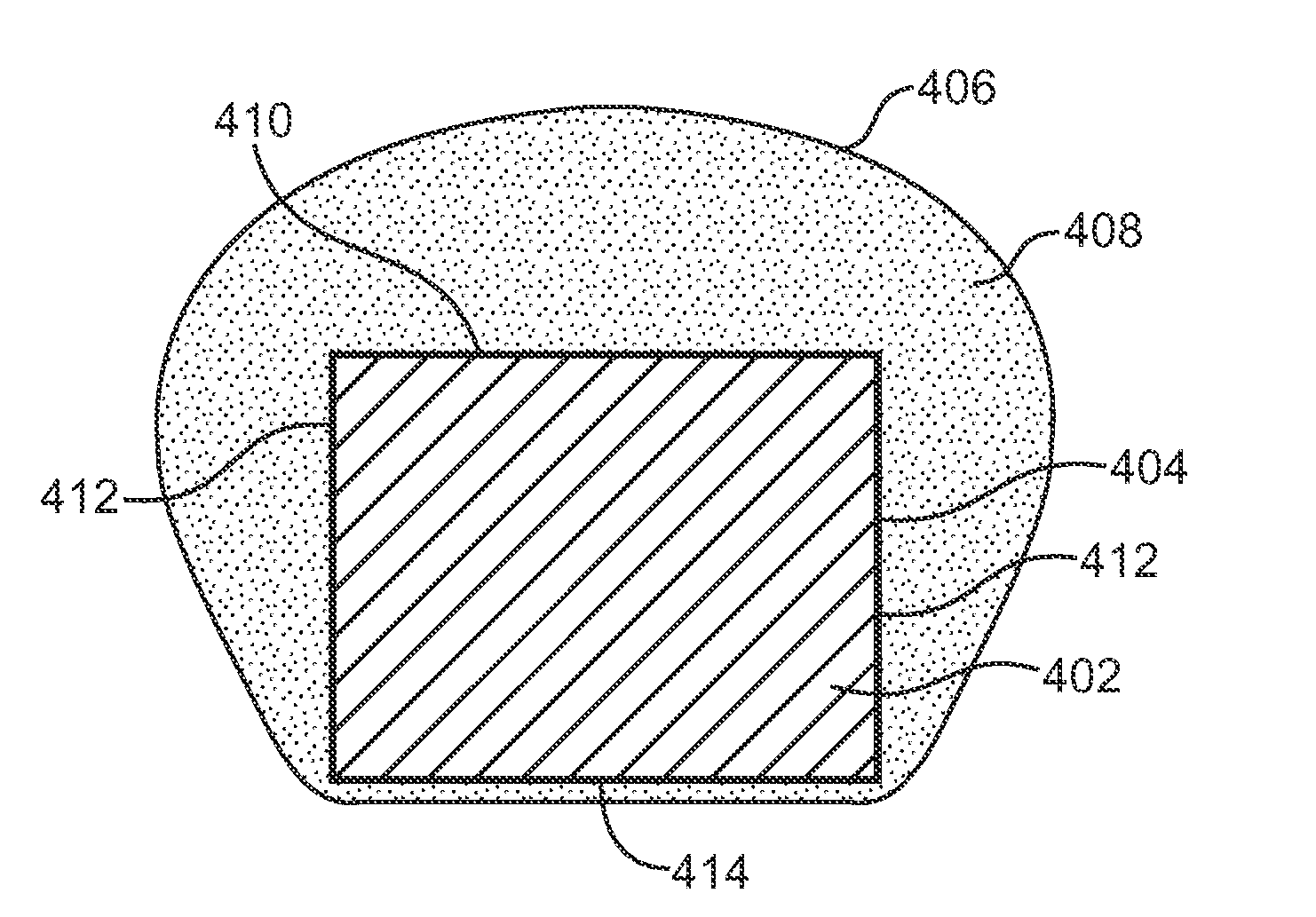

Use of plasma in formation of biodegradable stent coating

Metallic stents are treated with a gaseous species in a plasma state under conditions causing the species to polymerize and to be deposited in polymerized form on the metallic stent surface prior to the application of a drug-polymer mixture, which is done by conventional non-plasma deposition methods. The drug-polymer mixture once applied forms a coating on the stent surface that releases the drug in a time-release manner and gradually erodes, leaving only the underlying plasma-deposited polymer. In certain cases, the plasma-deposited polymer itself erodes or dissolves into the physiological medium over an extended period of time, leaving only the metallic stent. While the various polymers and drug remain on the stent, the plasma-deposited polymer enhances the adhesion of the drug-polymer anchor coating and maintains the coating intact upon exposure to the mechanical stresses encountered during stent deployment.

Owner:XTENT INC

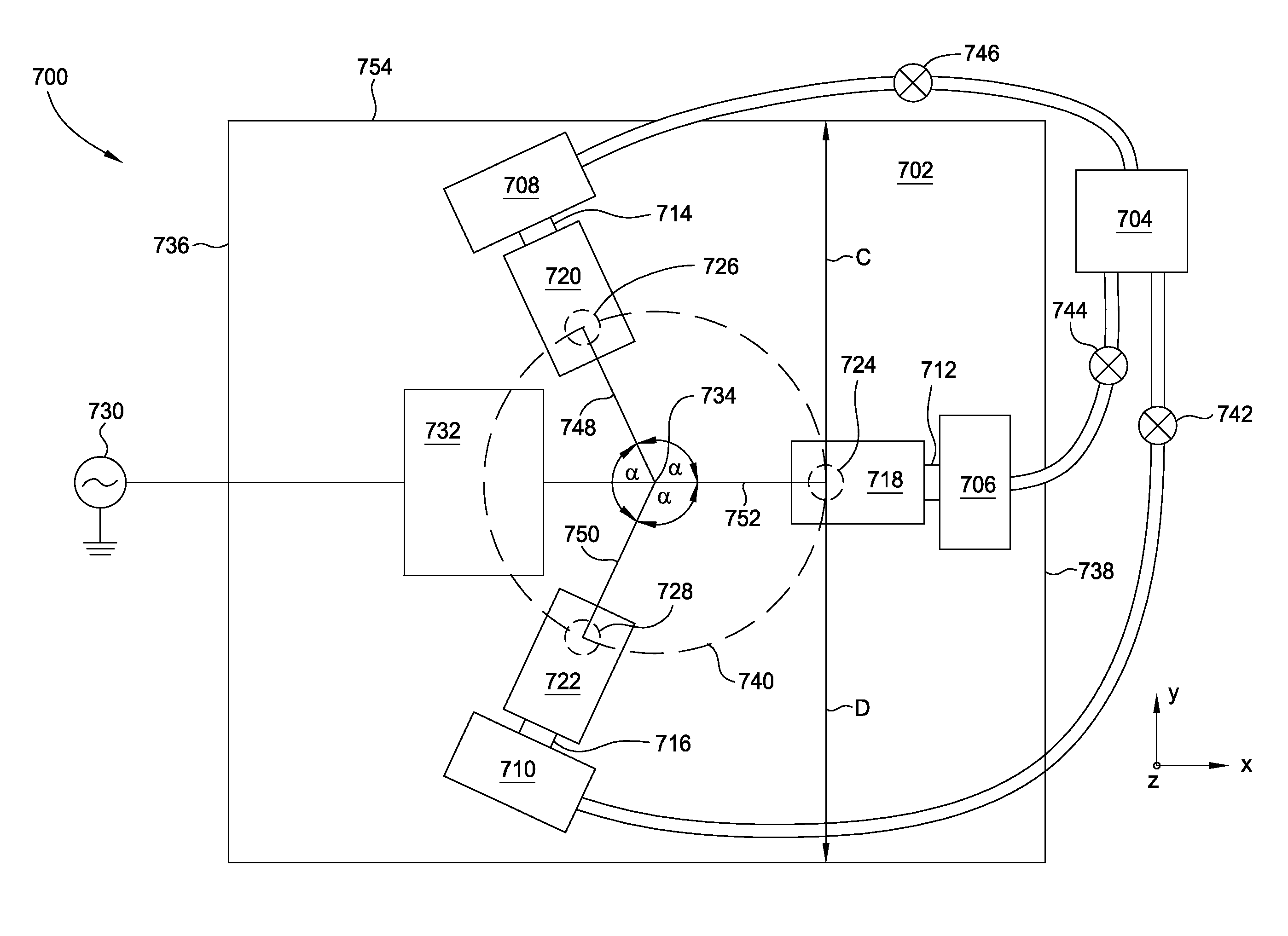

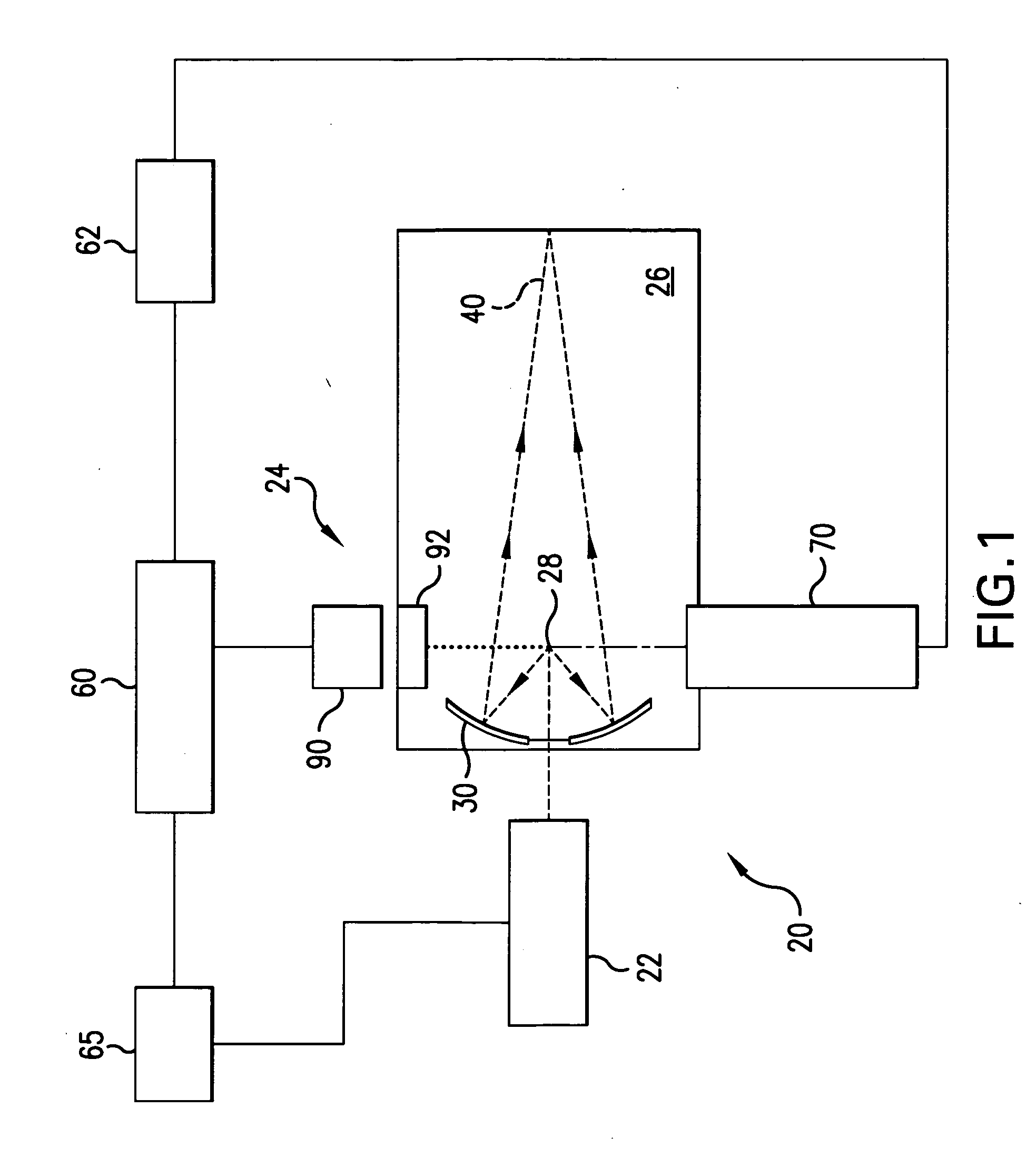

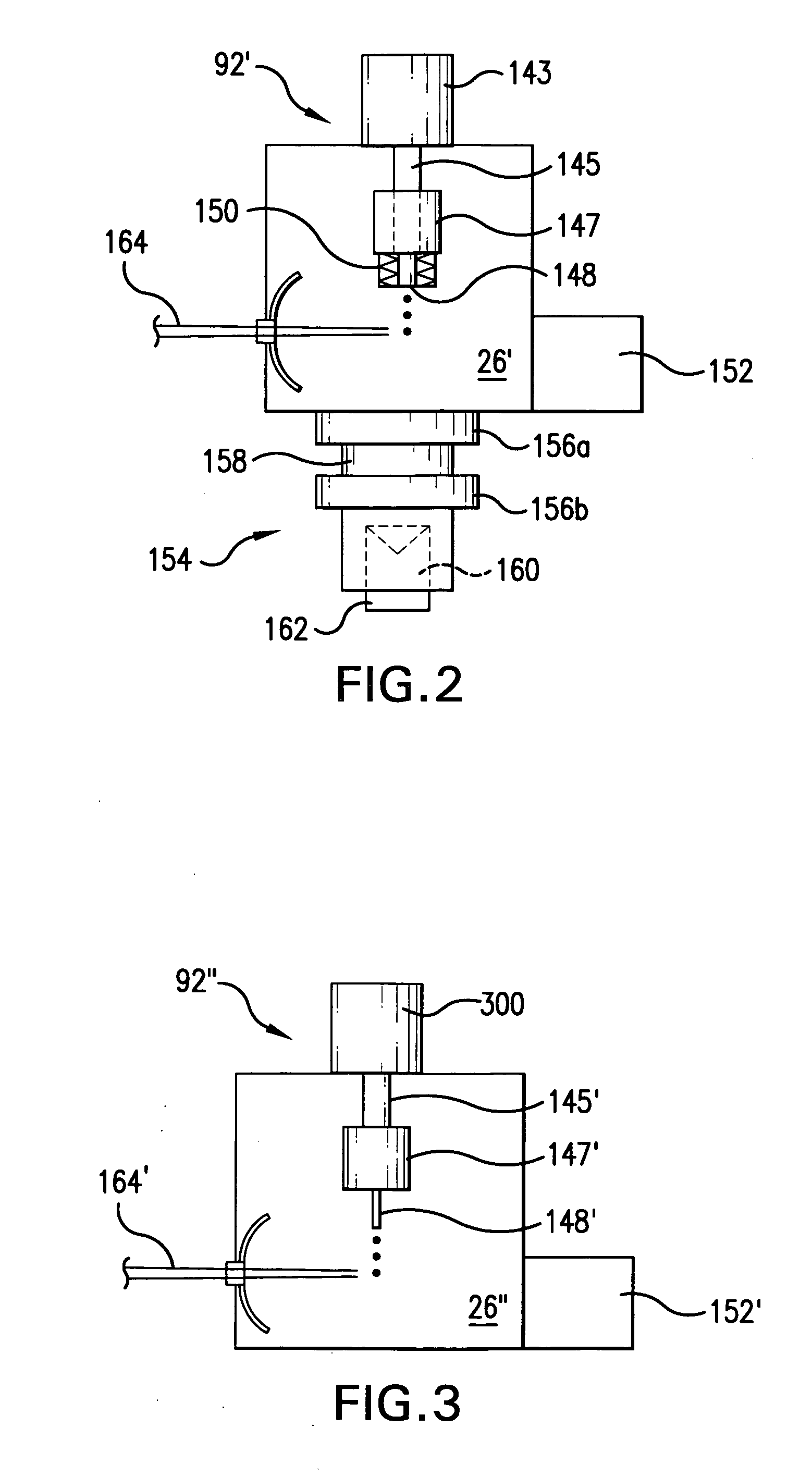

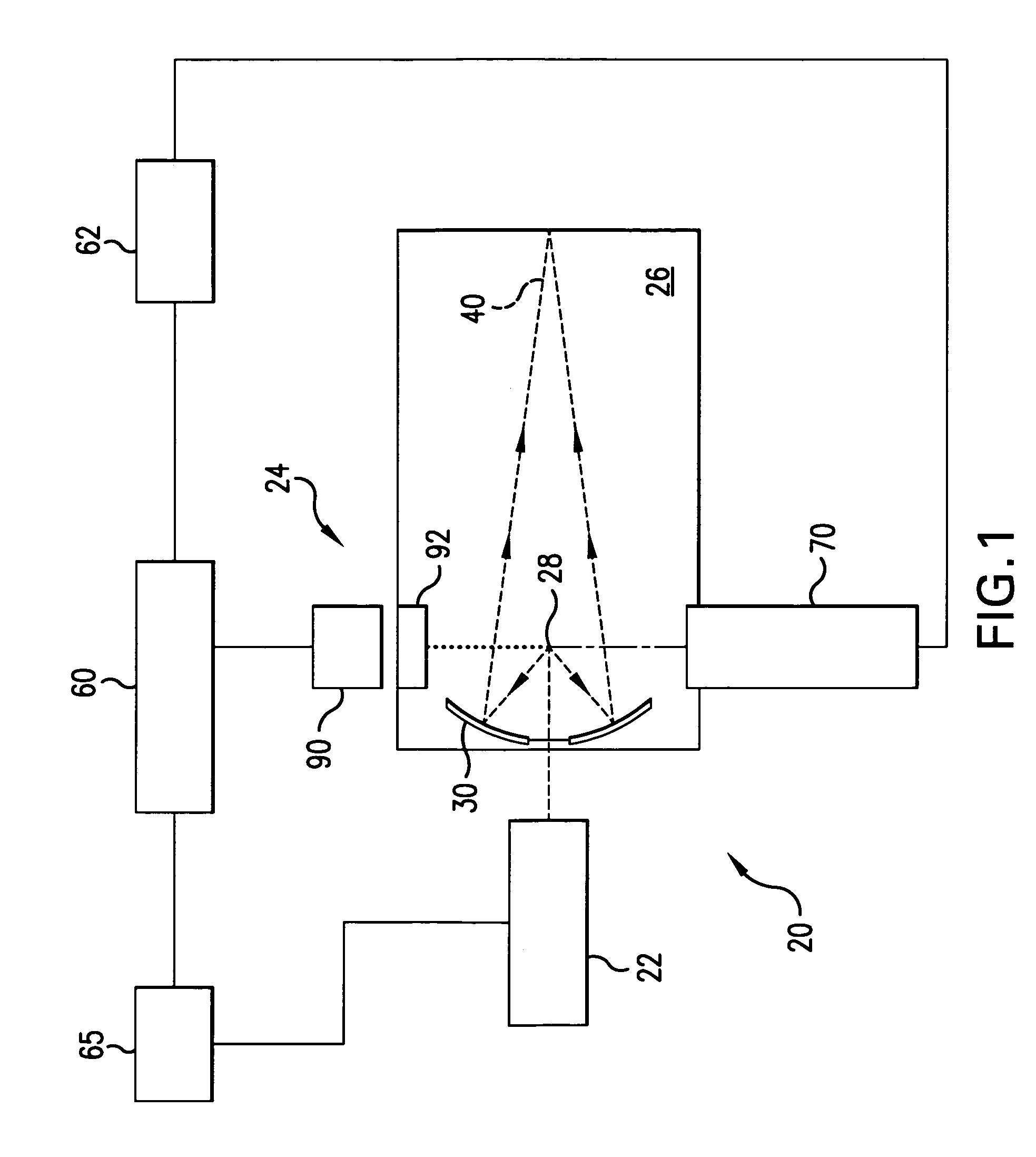

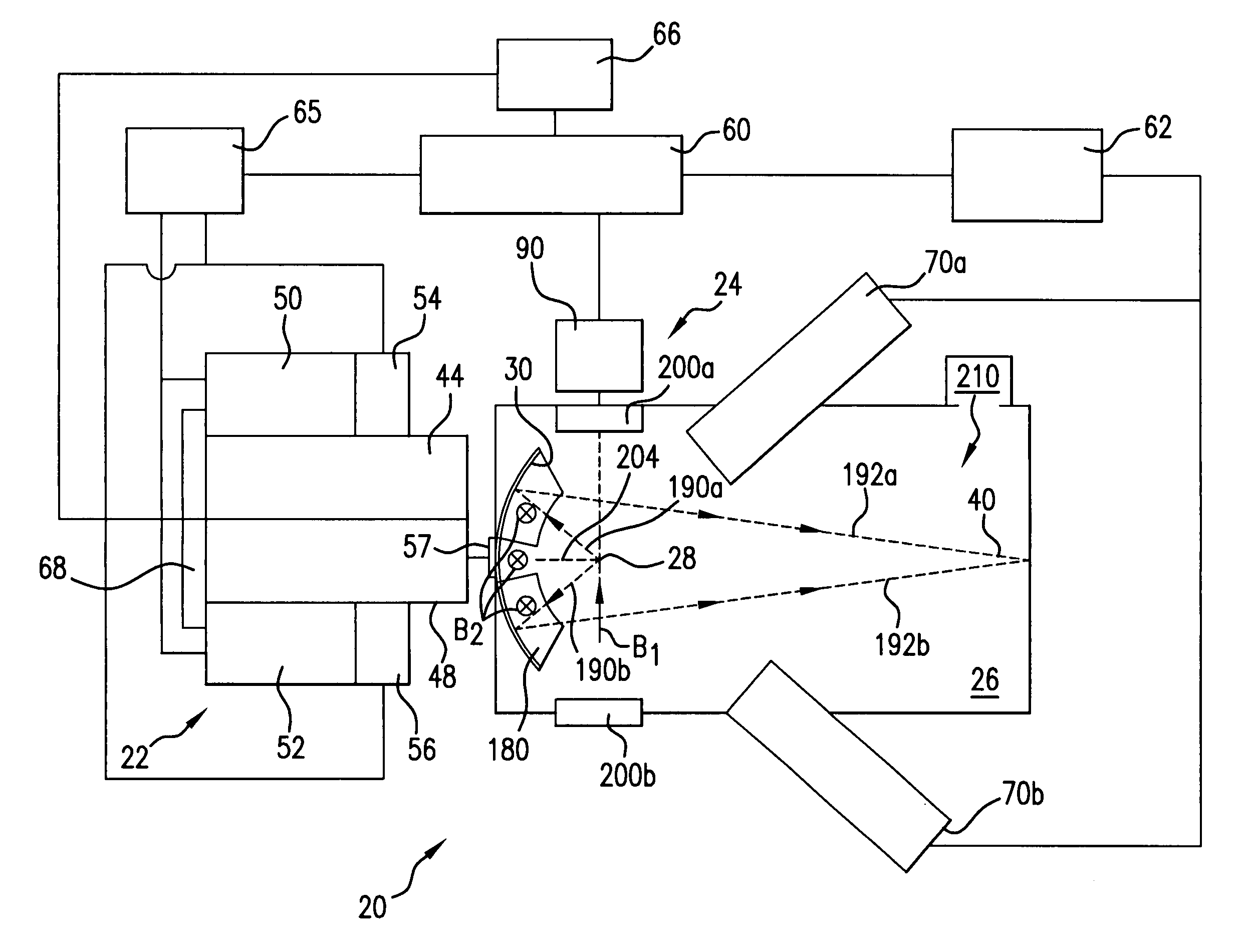

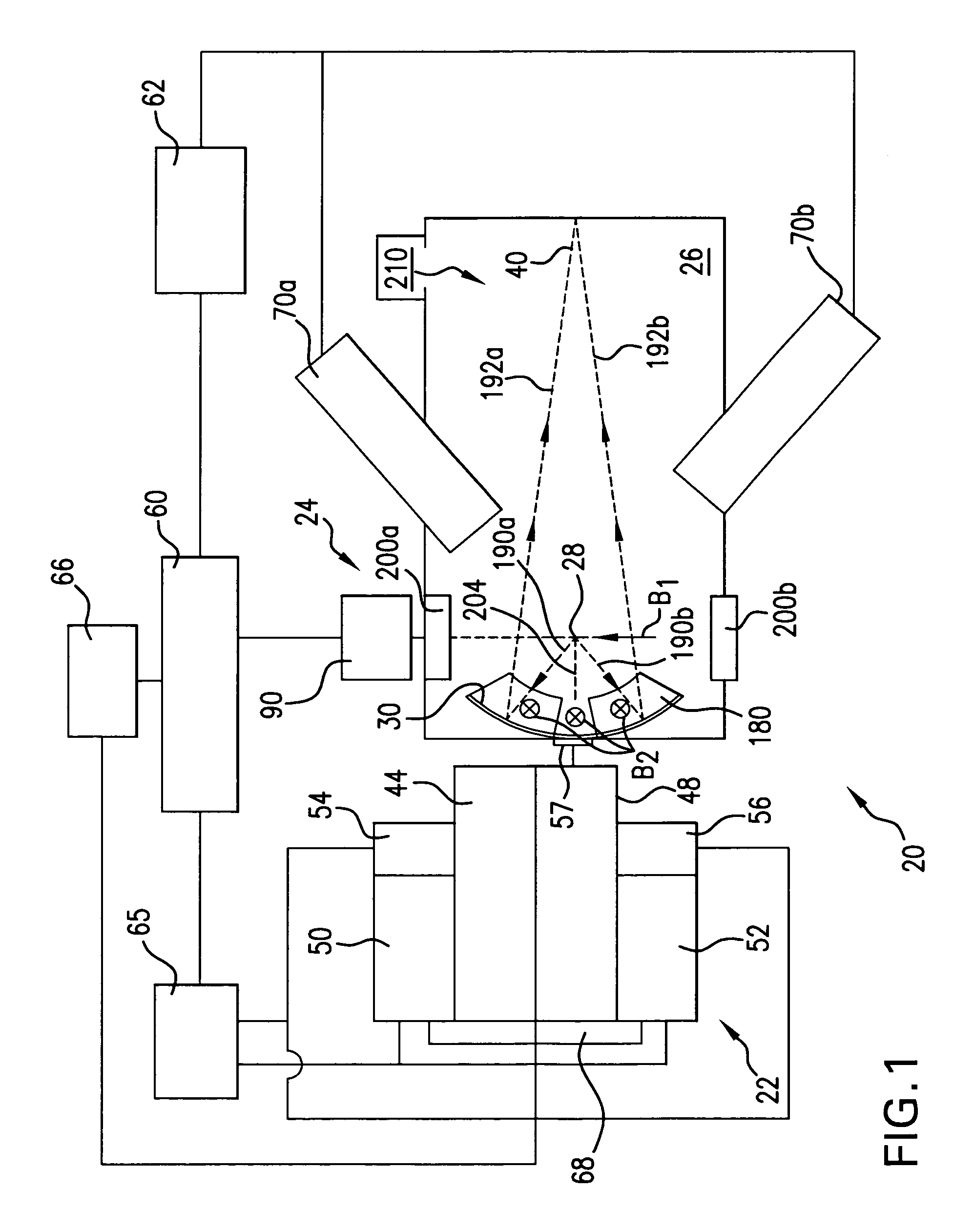

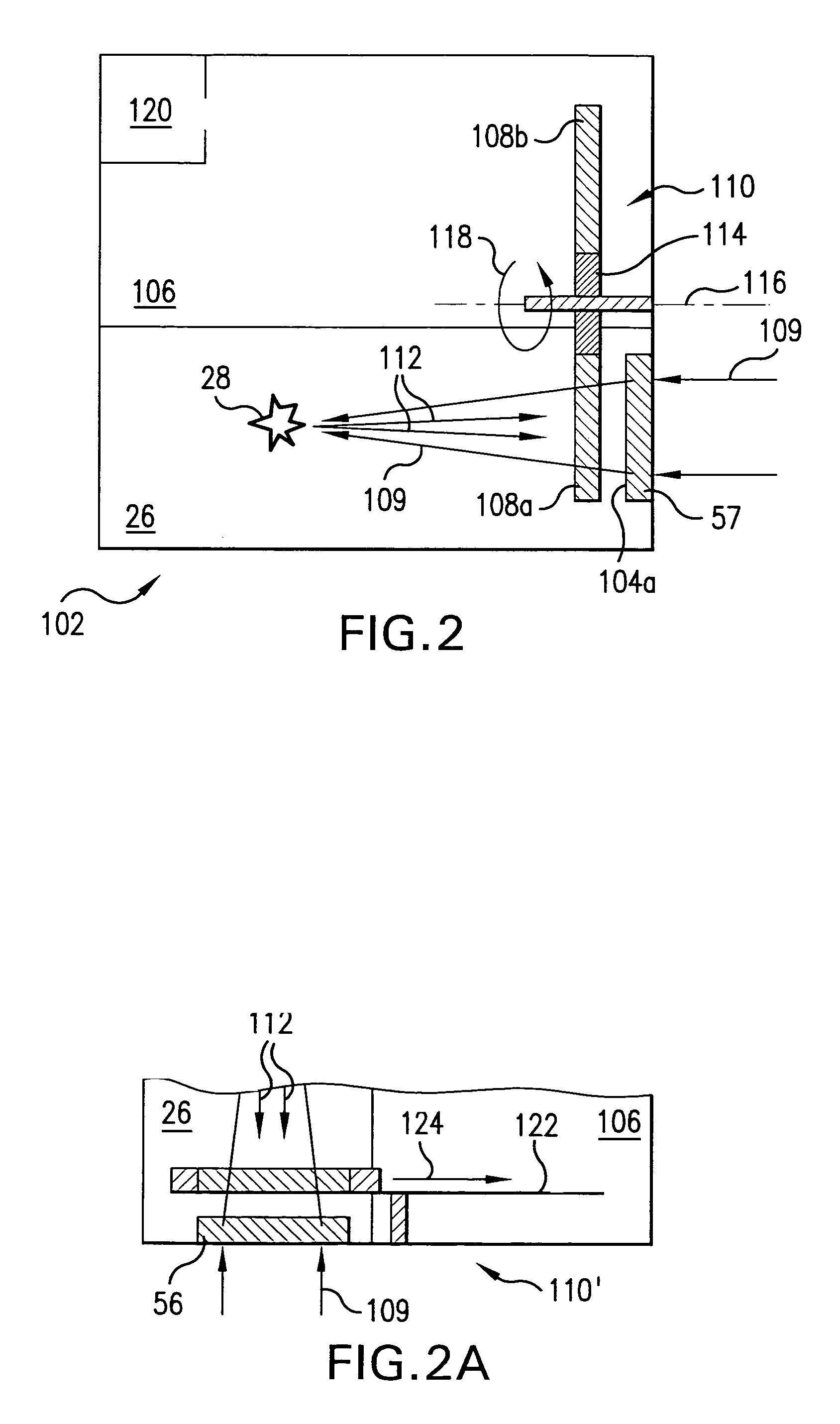

EUV light source

ActiveUS20050199829A1Sufficient sizeSufficient thermal massNanoinformaticsRadioactive sourcesControl systemDisplacement control

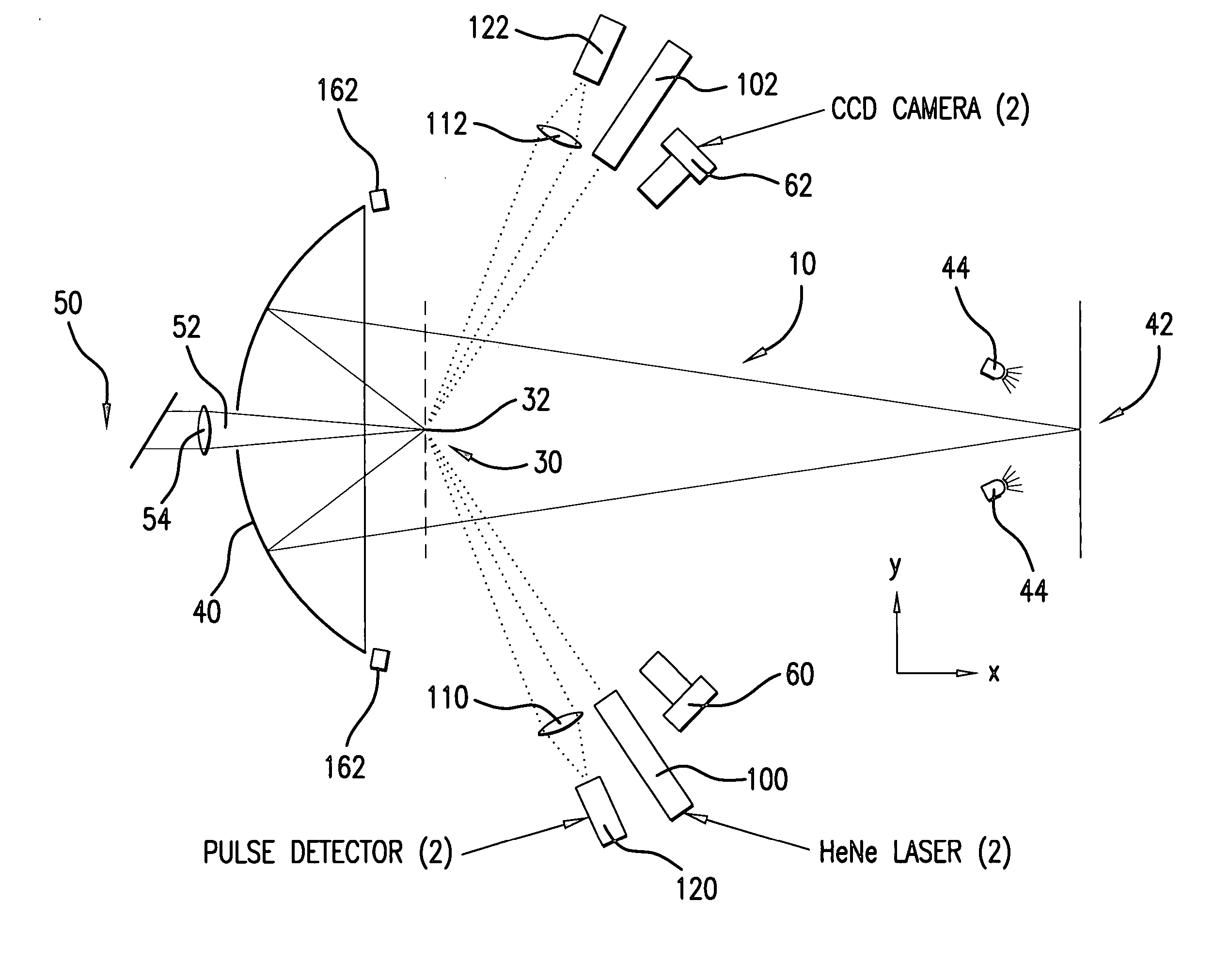

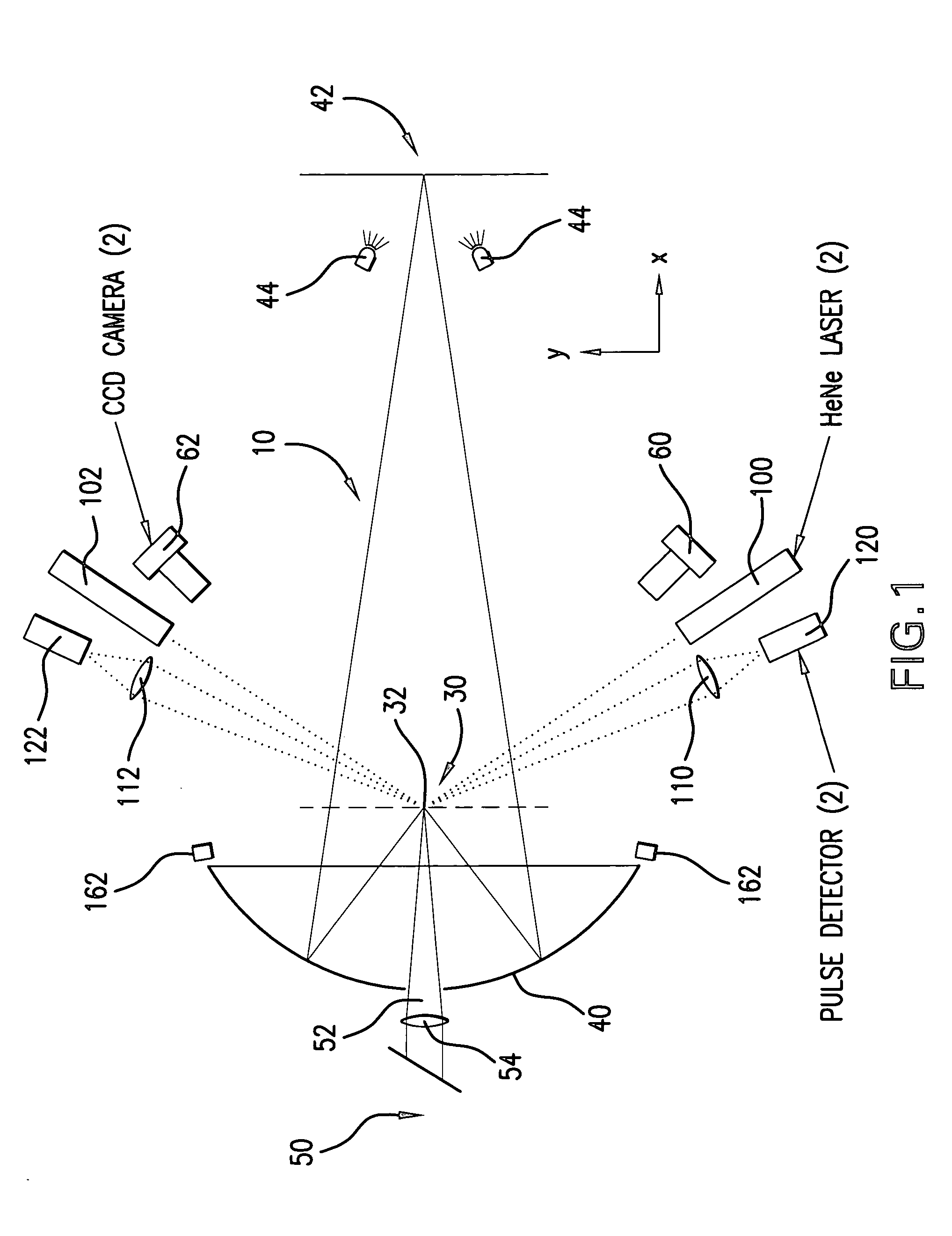

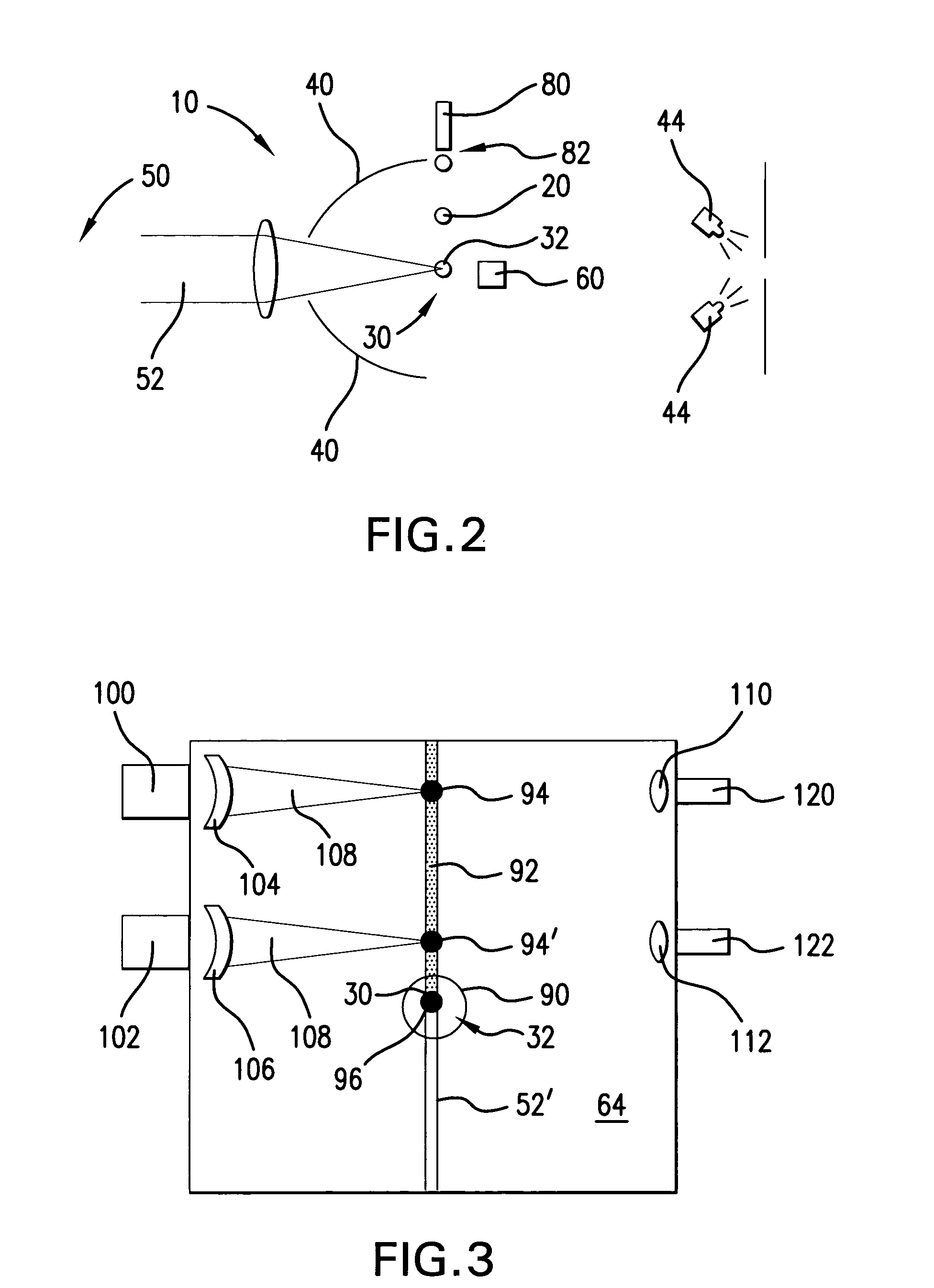

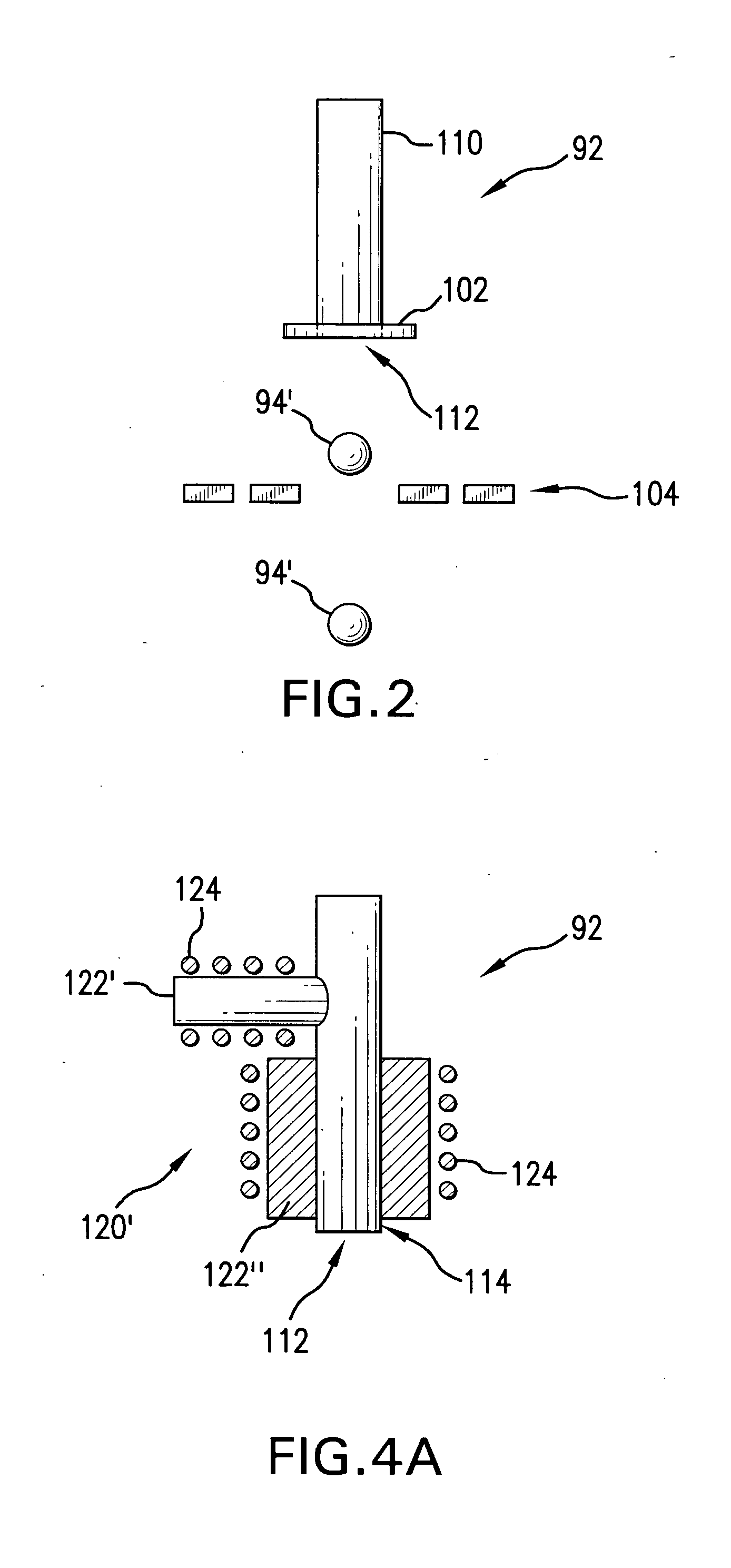

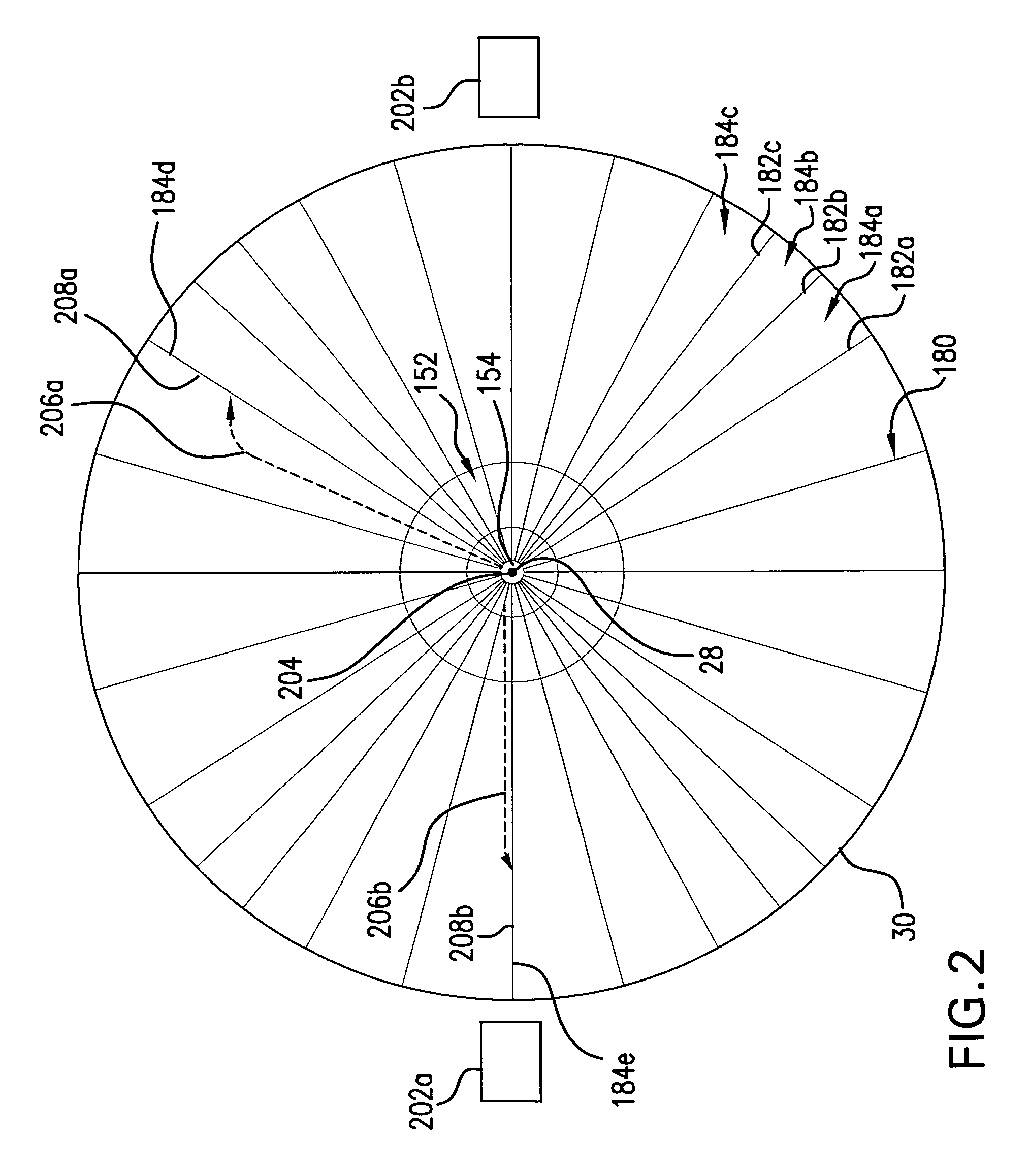

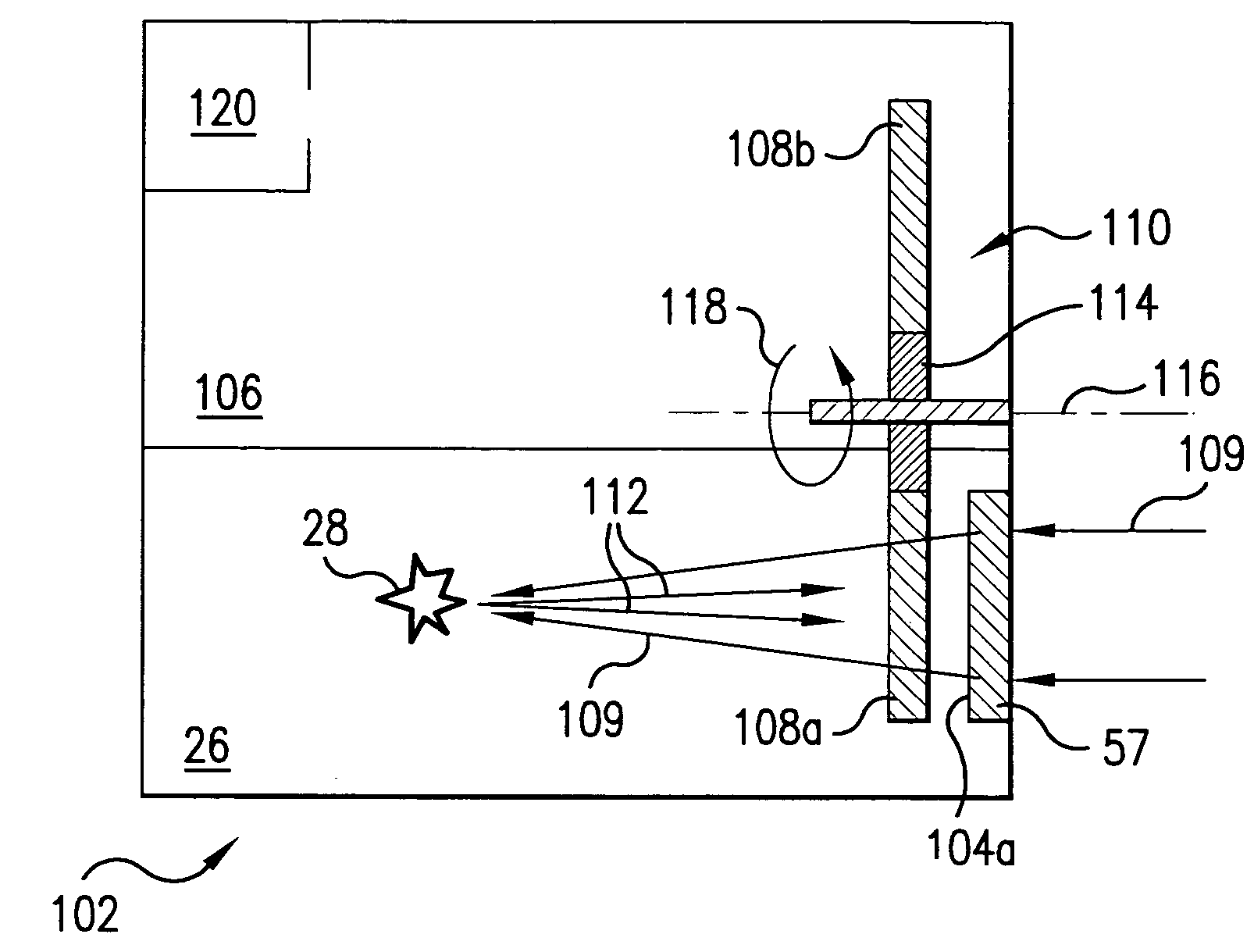

An apparatus and method for EUV light production is disclosed which may comprise a laser produced plasma (“LPP”) extreme ultraviolet (“EUV”) light source control system comprising a target delivery system adapted to deliver moving plasma initiation targets and an EUV light collection optic having a focus defining a desired plasma initiation site, comprising: a target tracking and feedback system comprising: at least one imaging device providing as an output an image of a target stream track, wherein the target stream track results from the imaging speed of the camera being too slow to image individual plasma formation targets forming the target stream imaged as the target stream track; a stream track error detector detecting an error in the position of the target stream track in at least one axis generally perpendicular to the target stream track from a desired stream track intersecting the desired plasma initiation site. At least one target crossing detector may be aimed at the target track and detecting the passage of a plasma formation target through a selected point in the target track. A drive laser triggering mechanism utilizing an output of the target crossing detector to determine the timing of a drive laser trigger in order for a drive laser output pulse to intersect the plasma initiation target at a selected plasma initiation site along the target track at generally its closest approach to the desired plasma initiation site. A plasma initiation detector may be aimed at the target track and detecting the location along the target track of a plasma initiation site for a respective target. An intermediate focus illuminator may illuminate an aperture formed at the intermediate focus to image the aperture in the at least one imaging device. The at least one imaging device may be at least two imaging devices each providing an error signal related to the separation of the target track from the vertical centerline axis of the image of the intermediate focus based upon an analysis of the image in the respective one of the at least two imaging devices. A target delivery feedback and control system may comprise a target delivery unit; a target delivery displacement control mechanism displacing the target delivery mechanism at least in an axis corresponding to a first displacement error signal derived from the analysis of the image in the first imaging device and at least in an axis corresponding to a second displacement error signal derived from the analysis of the image in the second imaging device.

Owner:ASML NETHERLANDS BV

Plasma source and applications thereof

A low-power atmospheric pressure plasma source, comprising a plasma-forming region for injection of a plasma-forming gas; an excitation region for injection of a source reactive species downstream of the plasma-forming region; and a narrow converging plasma exit for producing a narrow plasma jet, the source being electrically decoupled from a substrate under treatment by the plasma jet. The present source may found applications for example for skin treatment, etching of skin cancer cells, detachment of cells, removal of skin pigmentation and deposition of temporary organic films.

Owner:MCGILL UNIV

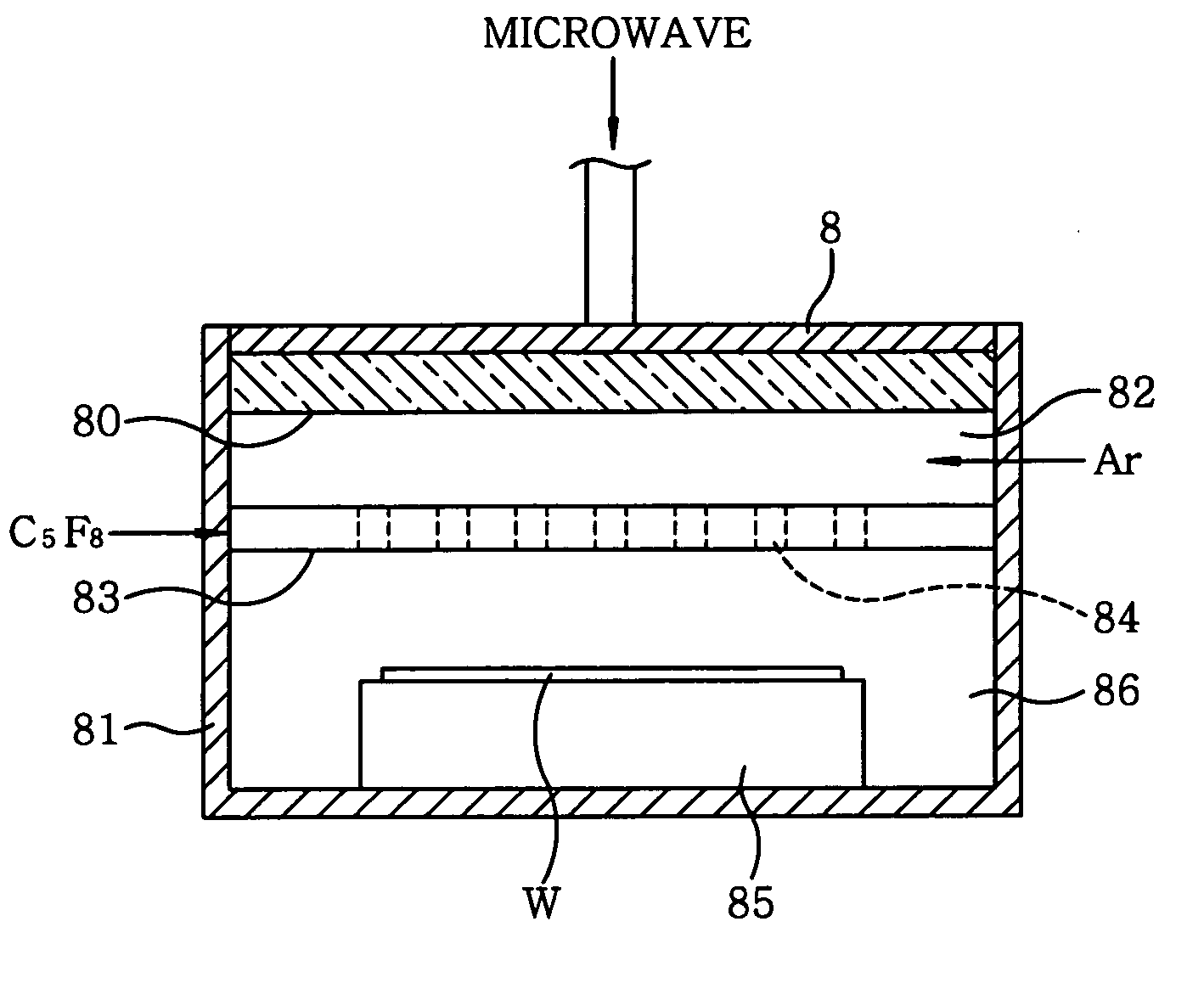

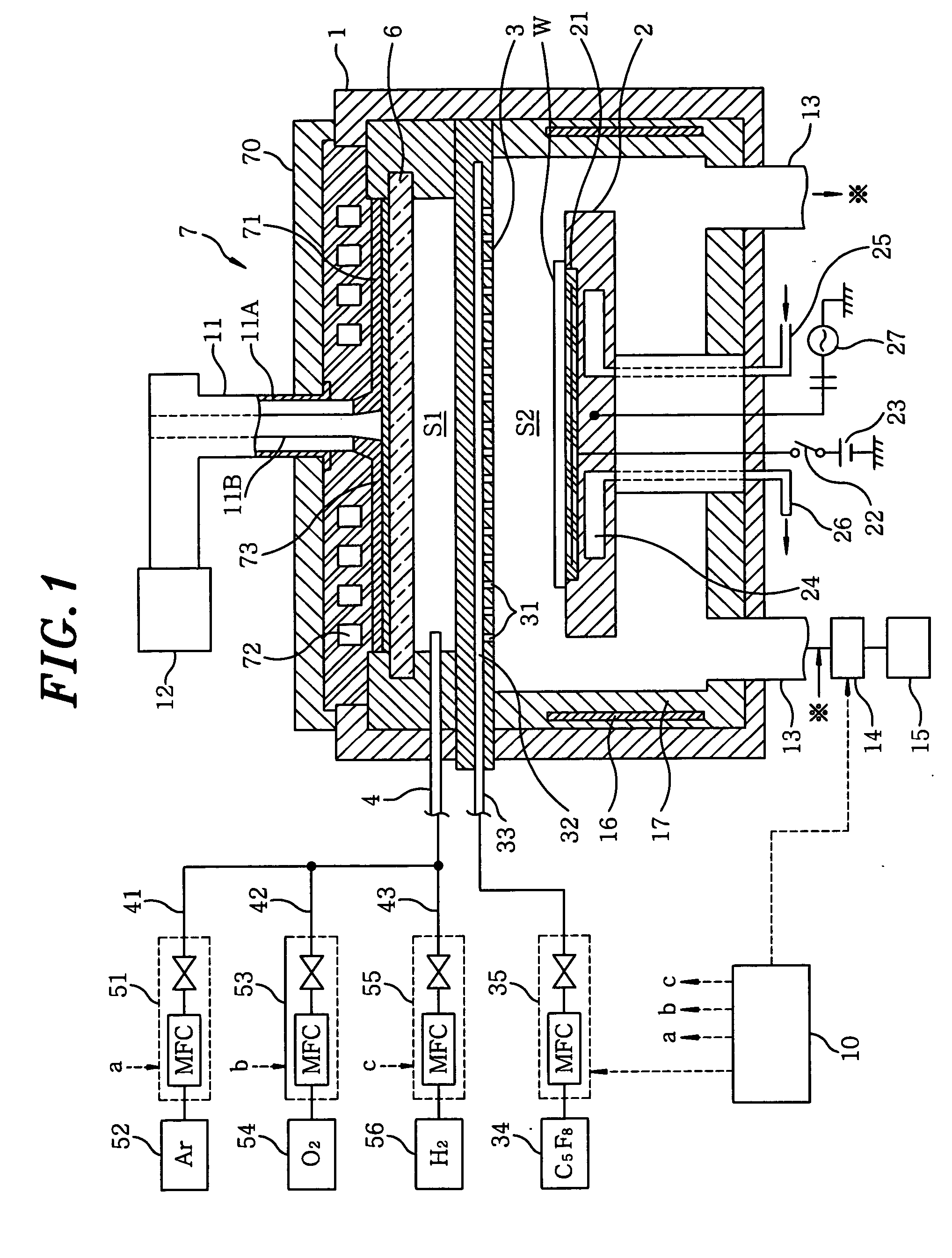

Plasma processing method and plasma processing apparatus

InactiveUS20070077737A1High densityLow electron temperatureElectric discharge tubesSemiconductor/solid-state device manufacturingCarbon filmEngineering

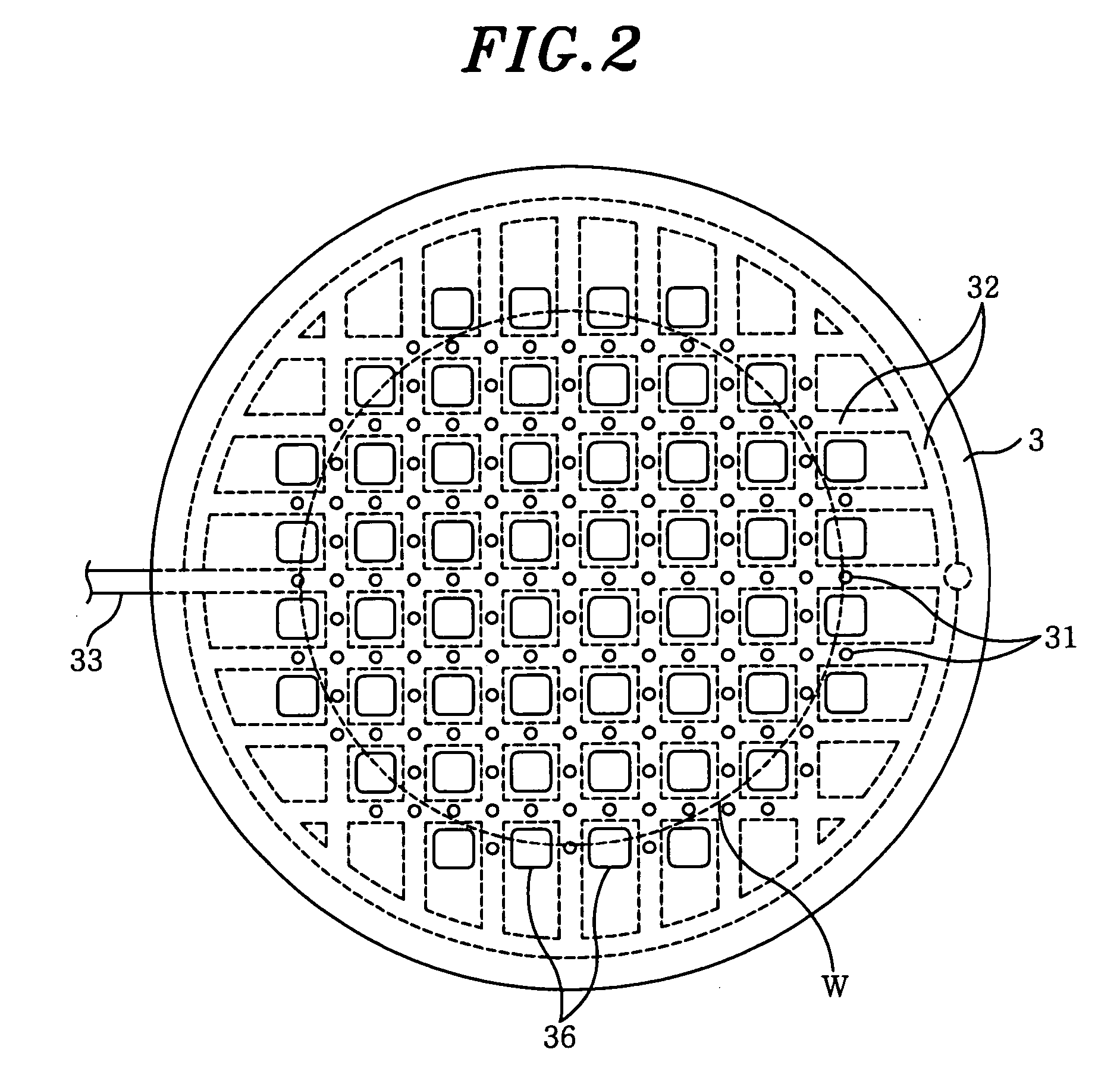

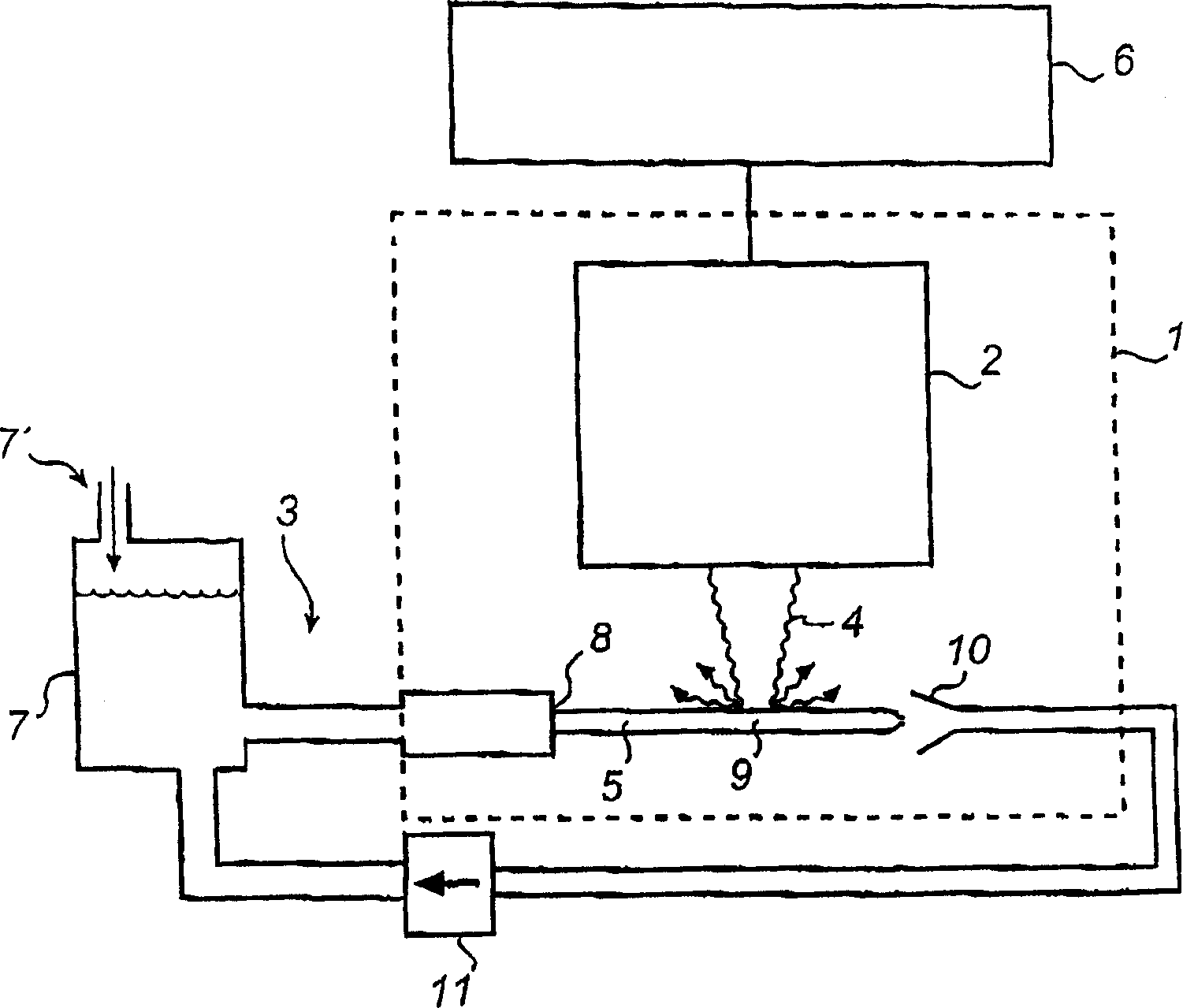

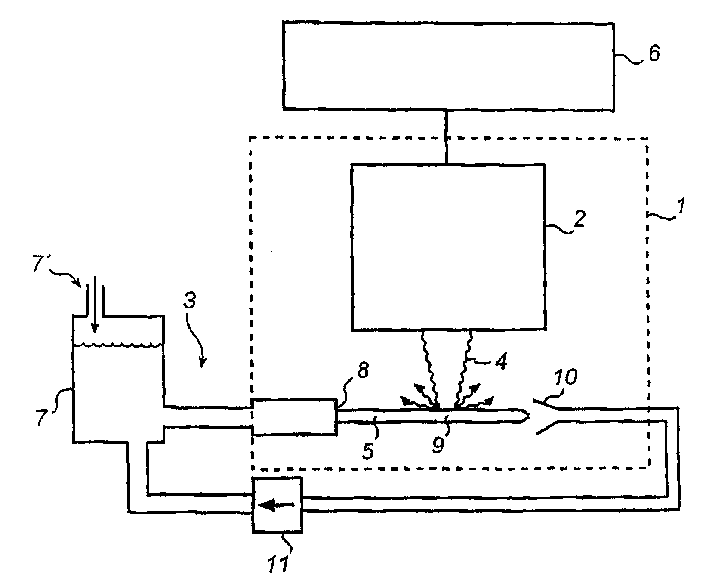

A microwave is radiated into a processing chamber (1) from a planar antenna member of an antenna (7) through a dielectric plate (6). With this, a C5F8 gas supplied into the processing chamber (1) from a gas supply member (3) is changed (activated) into a plasma so as to form a fluorine-containing carbon film of a certain thickness on a semiconductor wafer (W). Each time a film forming process of forming a film on one wafer is carried out, a cleaning process and a pre-coating process are carried out. In the cleaning process, the inside of the processing chamber is cleaned with a plasma of an oxygen gas and a hydrogen gas. In the pre-coating process, the C5F8 gas is changed into a plasma, and a pre-coat film of fluorine-containing carbon thinner than the fluorine-containing carbon film formed in the film forming process is formed.

Owner:TOKYO ELECTRON LTD

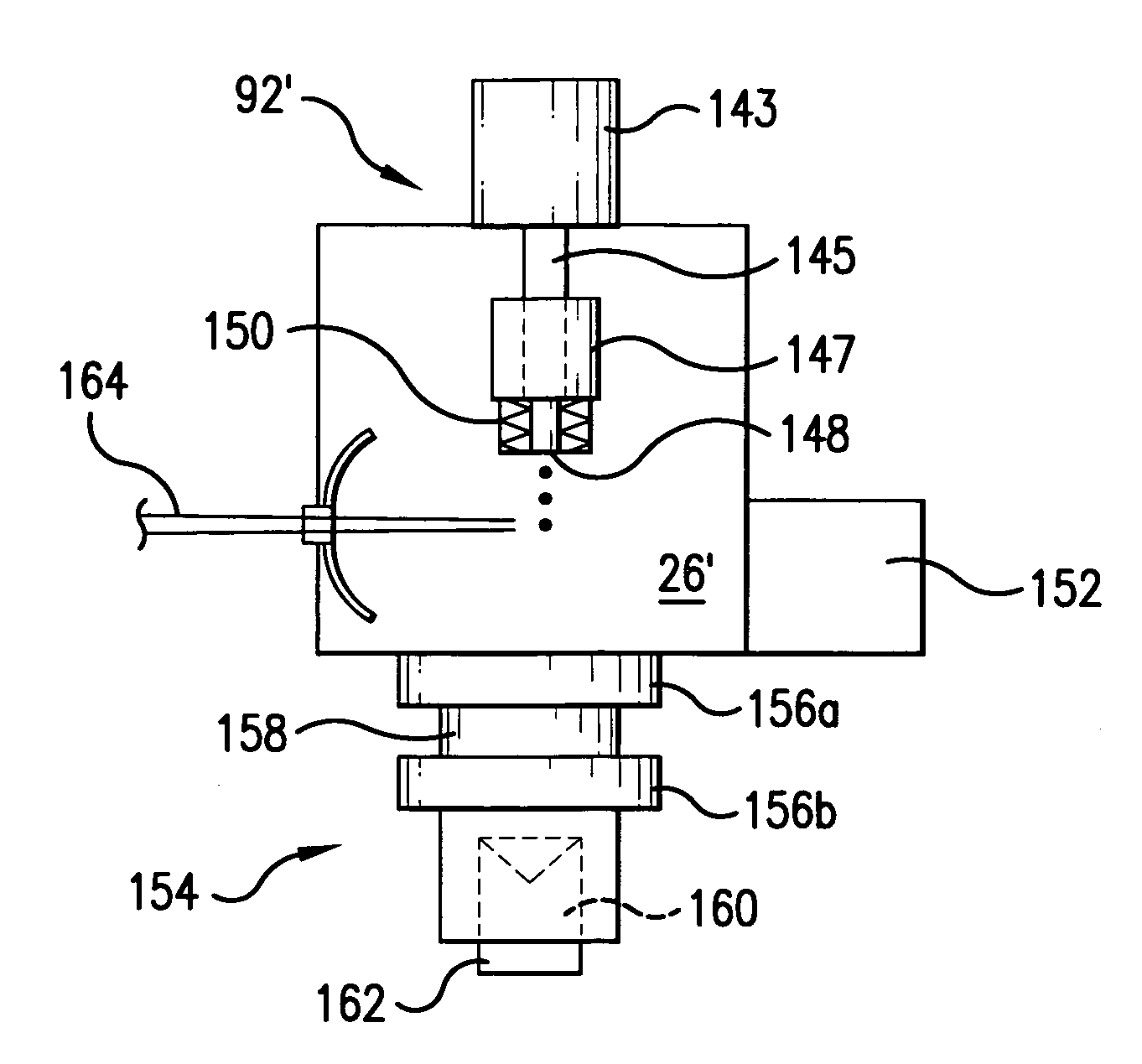

Method and apparatus for EUV plasma source target delivery

An EUV plasma formation target delivery system and method is disclosed which may comprise: a target droplet formation mechanism comprising a magneto-restrictive or electro-restrictive material, a liquid plasma source material passageway terminating in an output orifice; a charging mechanism applying charge to a droplet forming jet stream or to individual droplets exiting the passageway along a selected path; a droplet deflector intermediate the output orifice and a plasma initiation site periodically deflecting droplets from the selected path, a liquid target material delivery mechanism comprising a liquid target material delivery passage having an input opening and an output orifice; an electromotive disturbing force generating mechanism generating a disturbing force within the liquid target material, a liquid target delivery droplet formation mechanism having an output orifice; and / or a wetting barrier around the periphery of the output orifice.

Owner:ASML NETHERLANDS BV

Alternative fuels for EUV light source

An EUV light source is disclosed which may comprise at least one optical element having a surface, such as a multi-layer collector mirror; a laser source generating a laser beam; and a source material irradiated by the laser beam to form a plasma and emit EUV light. In one aspect, the source material may consist essentially of a tin compound and may generate tin debris by plasma formation which deposits on the optical element and, in addition, the tin compound may include an element that is effective in etching deposited tin from the optical element surface. Tin compounds may include SnBr4, SnBr2 and SnH4. In another aspect, an EUV light source may comprise a molten source material irradiated by a laser beam to form a plasma and emit EUV light, the source material comprising tin and at least one other metal, for example tin with Gallium and / or Indium.

Owner:ASML NETHERLANDS BV

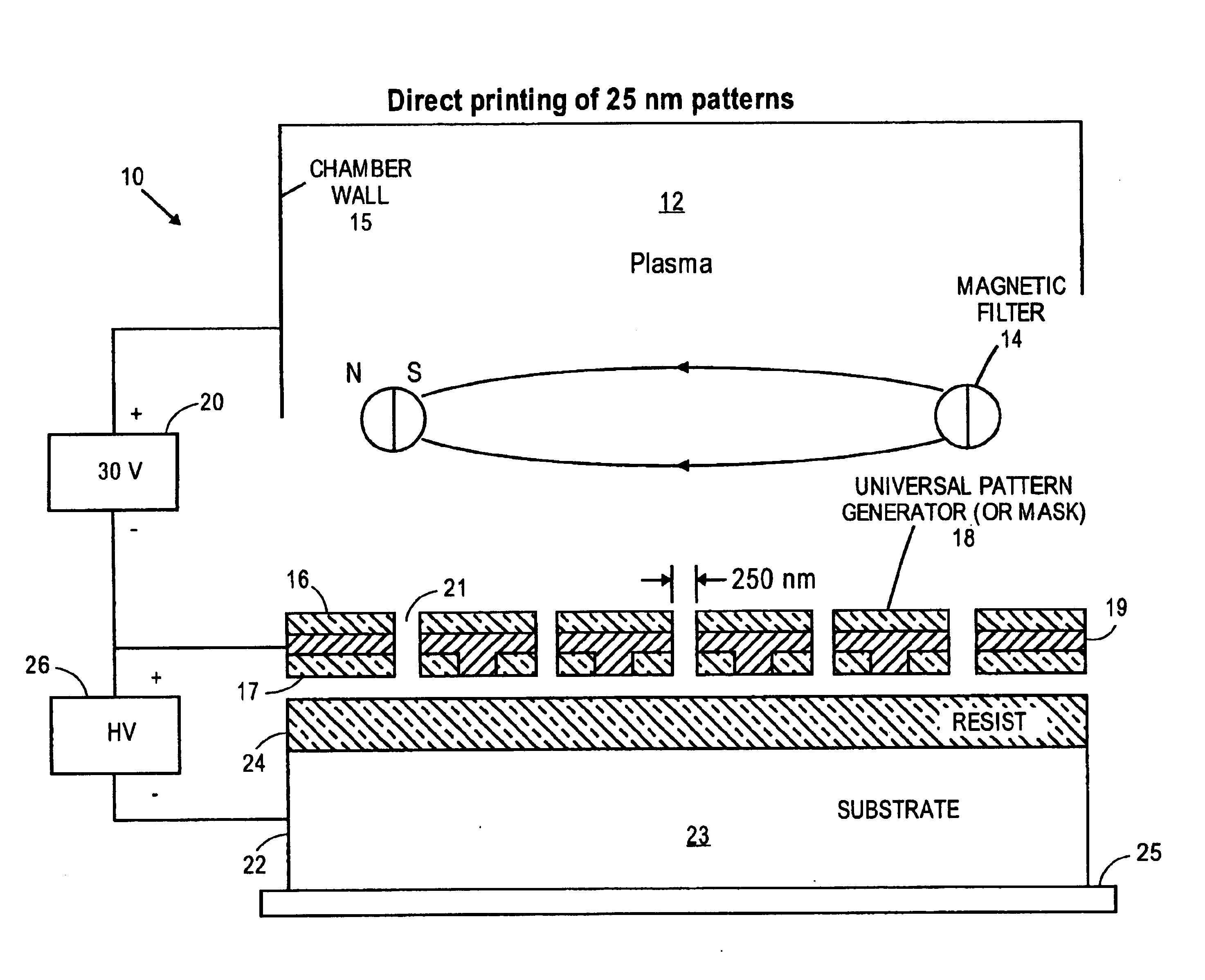

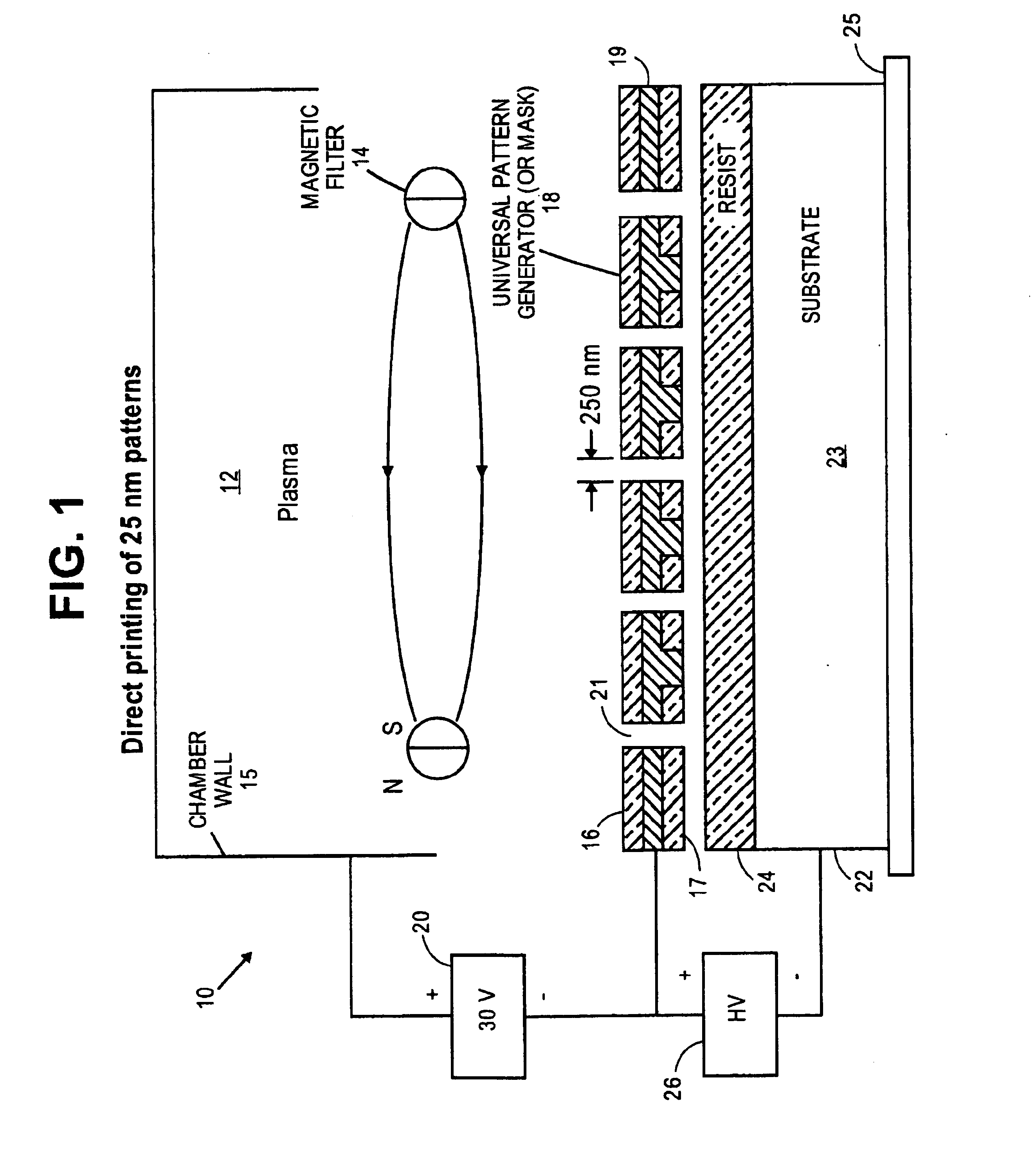

Ion beam lithography system

InactiveUS6924493B1Improve throughputElectric discharge tubesNanoinformaticsLithographic artistBeam scanning

A maskless plasma-formed ion beam lithography tool provides for patterning of sub-50 nm features on large area flat or curved substrate surfaces. The system is very compact and does not require an accelerator column and electrostatic beam scanning components. The patterns are formed by switching beamlets on or off from a two electrode blanking system with the substrate being scanned mechanically in one dimension. This arrangement can provide a maskless nano-beam lithography tool for economic and high throughput processing.

Owner:RGT UNIV OF CALIFORNIA

Alternative fuels for EUV light source

Owner:ASML NETHERLANDS BV

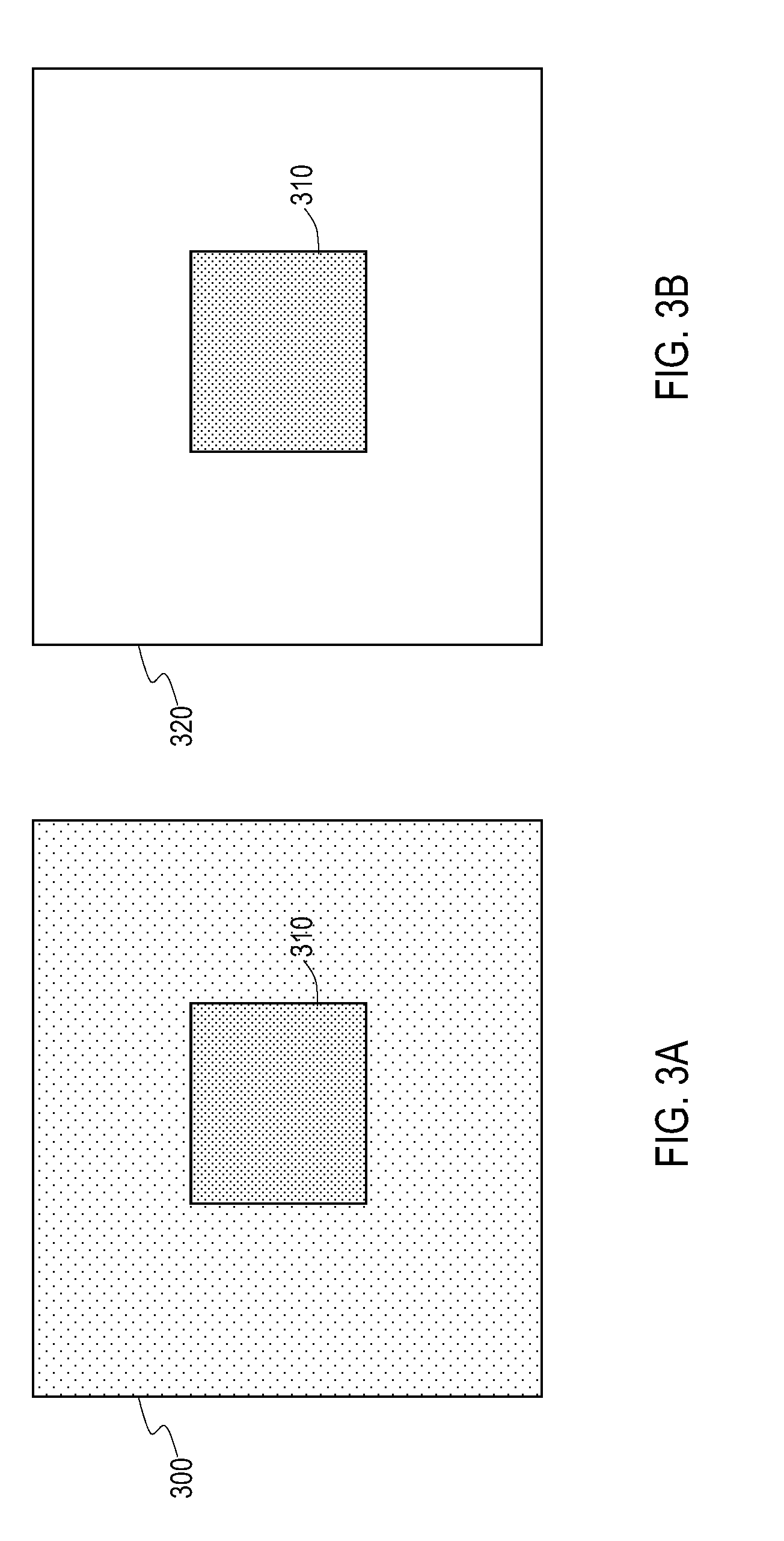

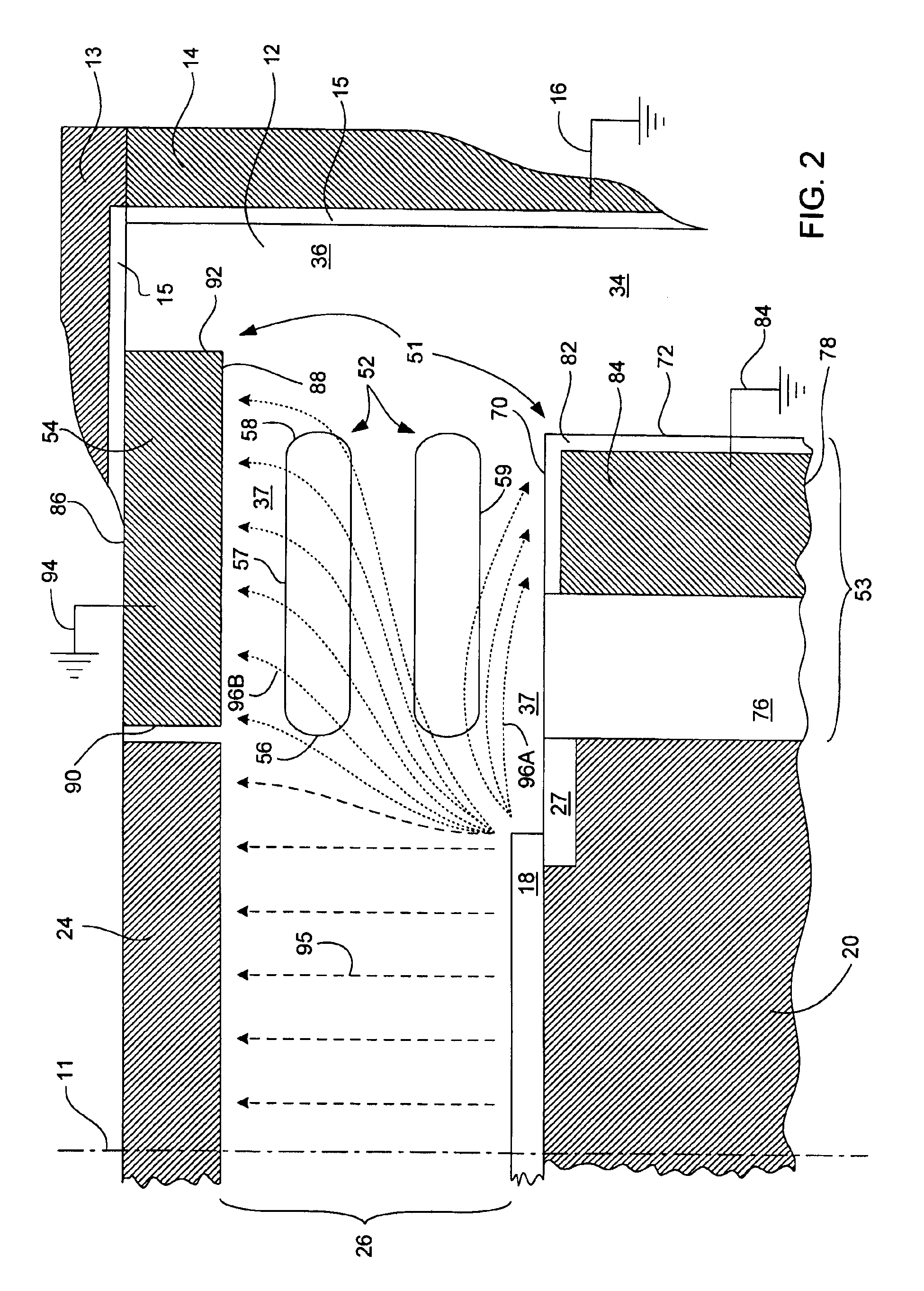

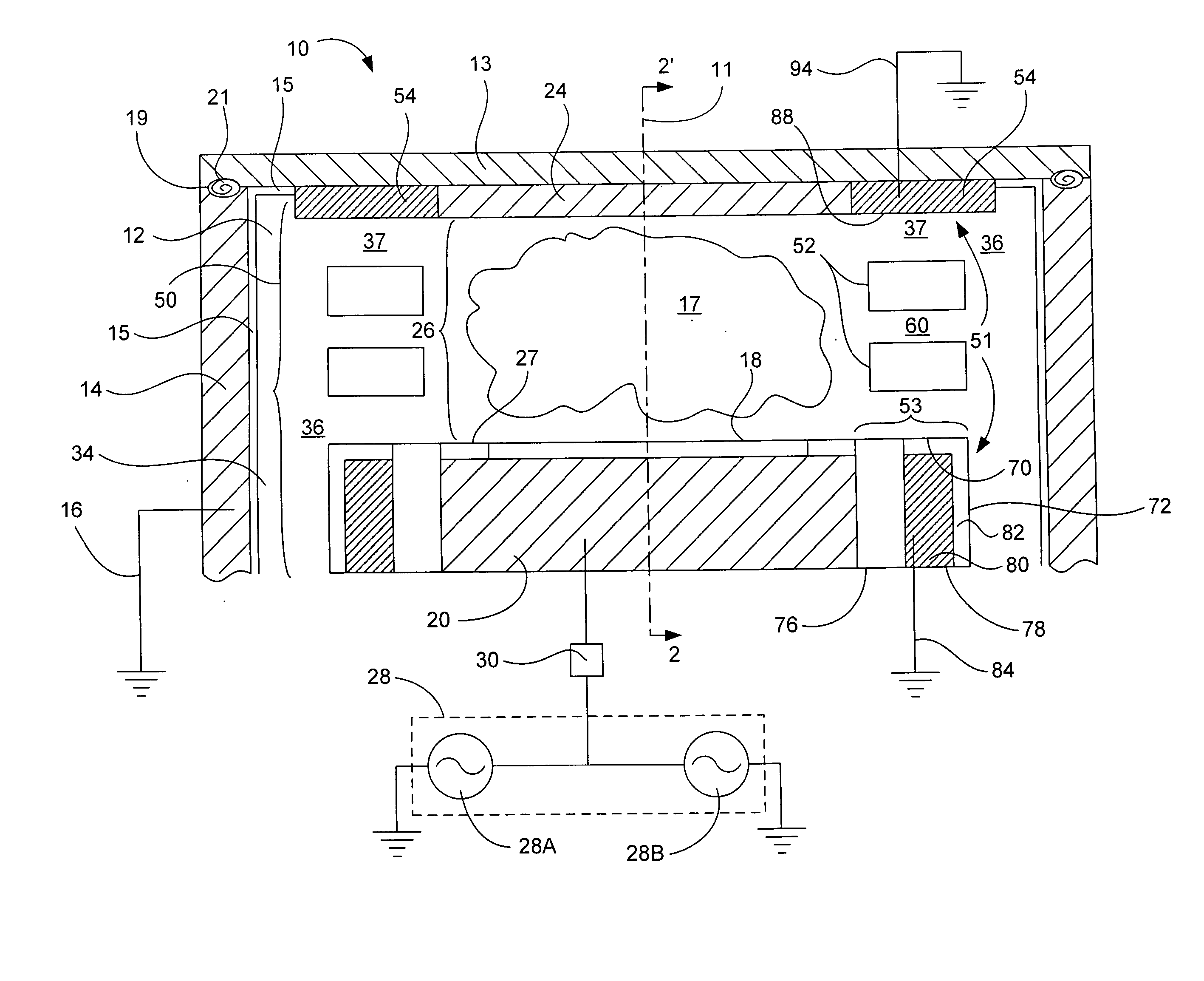

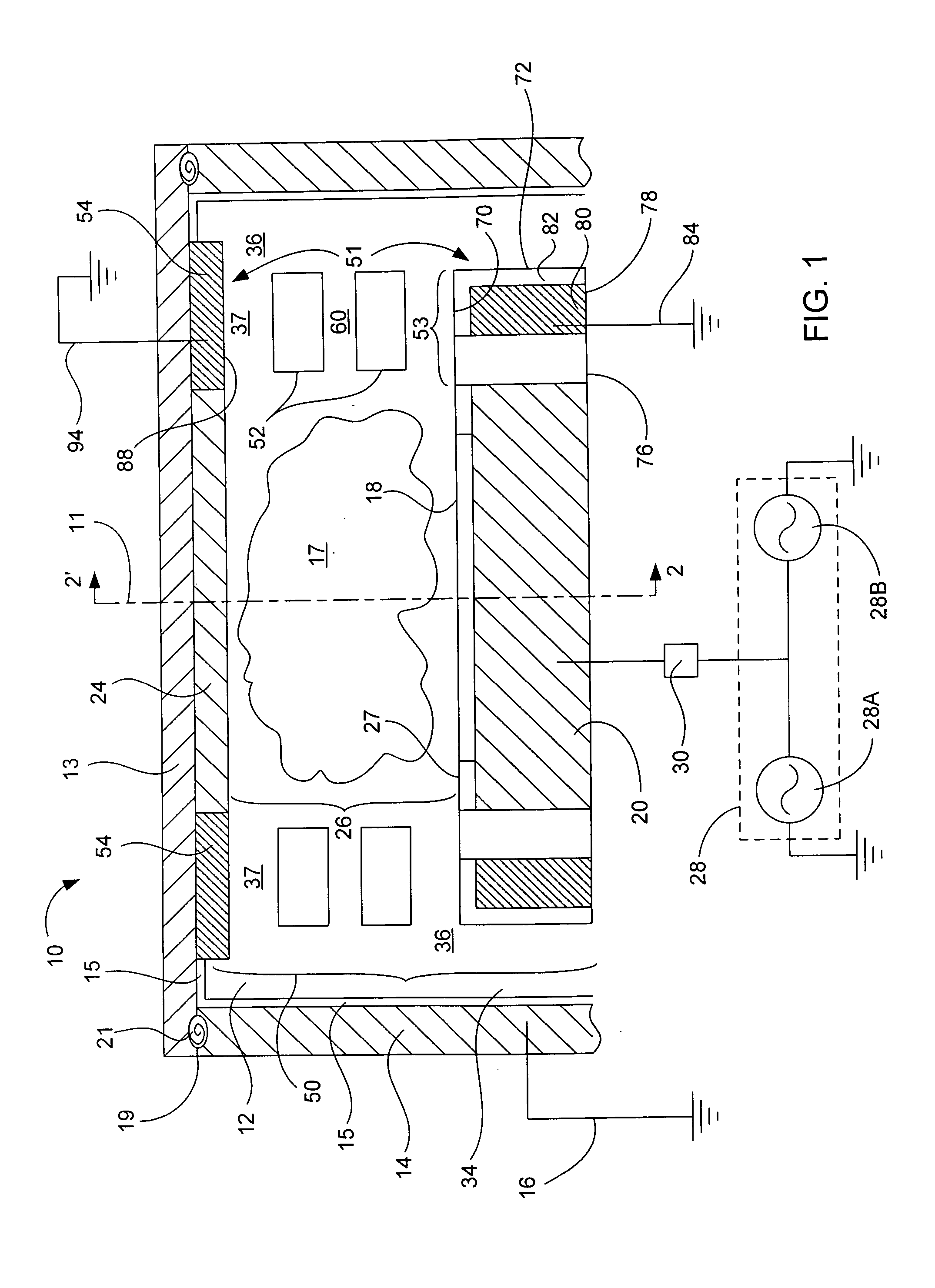

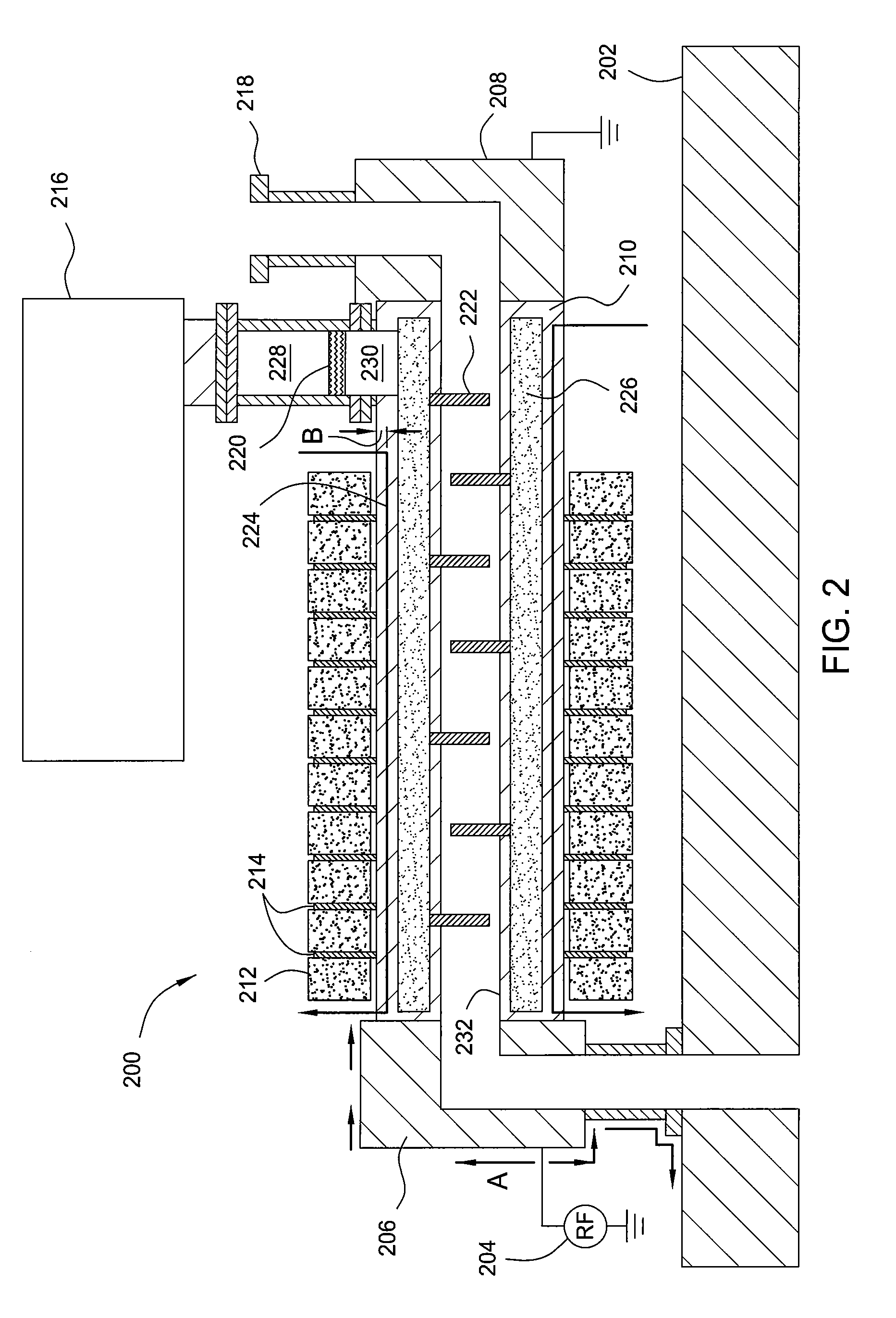

Chamber configuration for confining a plasma

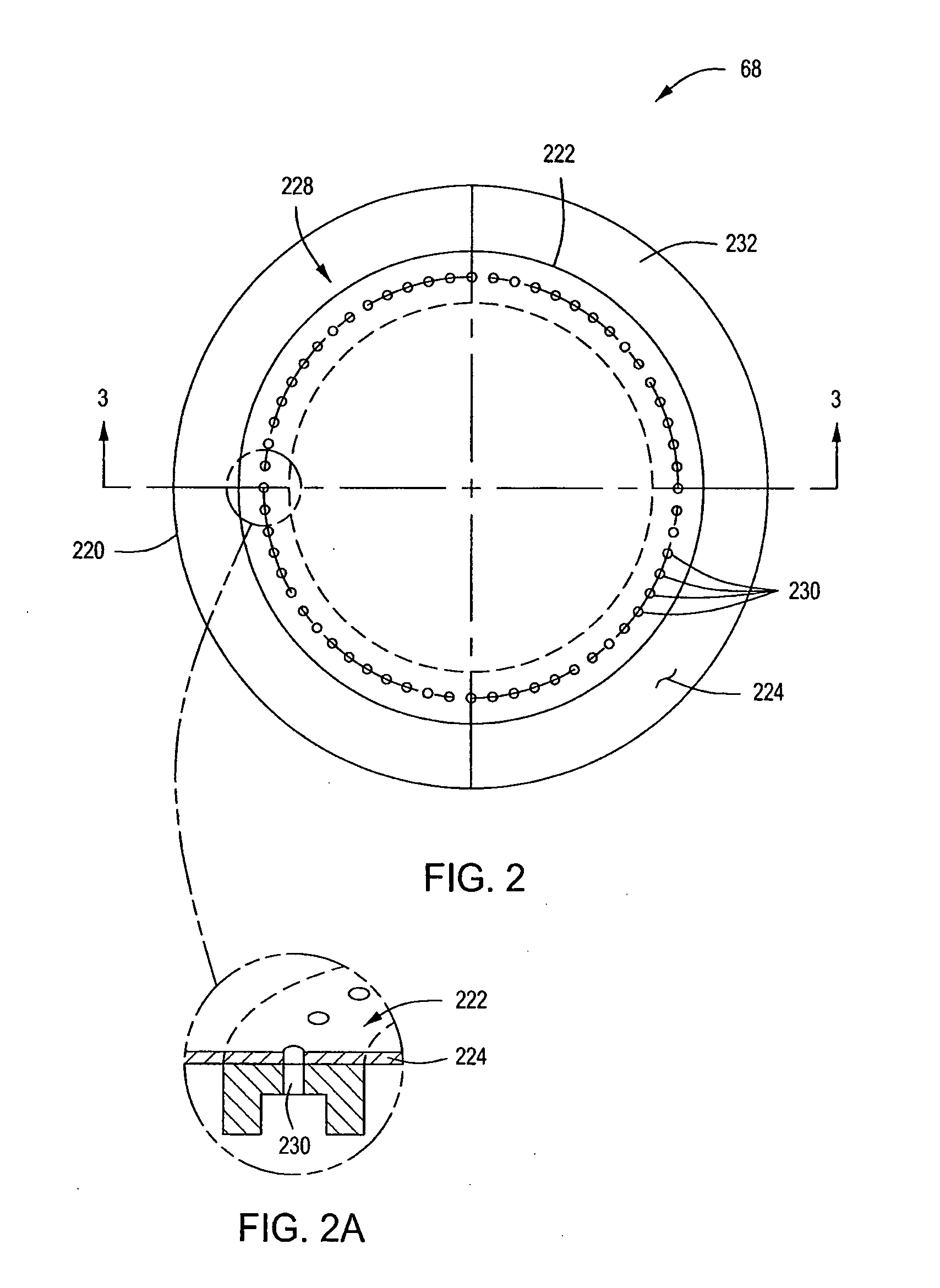

InactiveUS6872281B1Reduce impactAvoid formingElectric discharge tubesSemiconductor/solid-state device manufacturingProcess regionEngineering

A plasma confining assembly for minimizing unwanted plasma formations in regions outside of a process region in a process chamber is disclosed. The plasma confining assembly includes a first confining element and second confining element positioned proximate the periphery of the process region. The second confining element is spaced apart from the first confining element. The first confining element includes an exposed conductive surface that is electrically grounded and the second confining element includes an exposed insulating surface, which is configured for covering a conductive portion that is electrically grounded. The first confining element and the second confining element substantially reduce the effects of plasma forming components that pass therebetween. Additionally, the plasma confining assembly may include a third confining element, which is formed from an insulating material and disposed between the first confining element and the second confining element, and proximate the periphery of the process region. The third confining element further reduces the effects of plasma forming components that pass between the first confining element and the second confining element.

Owner:LAM RES CORP

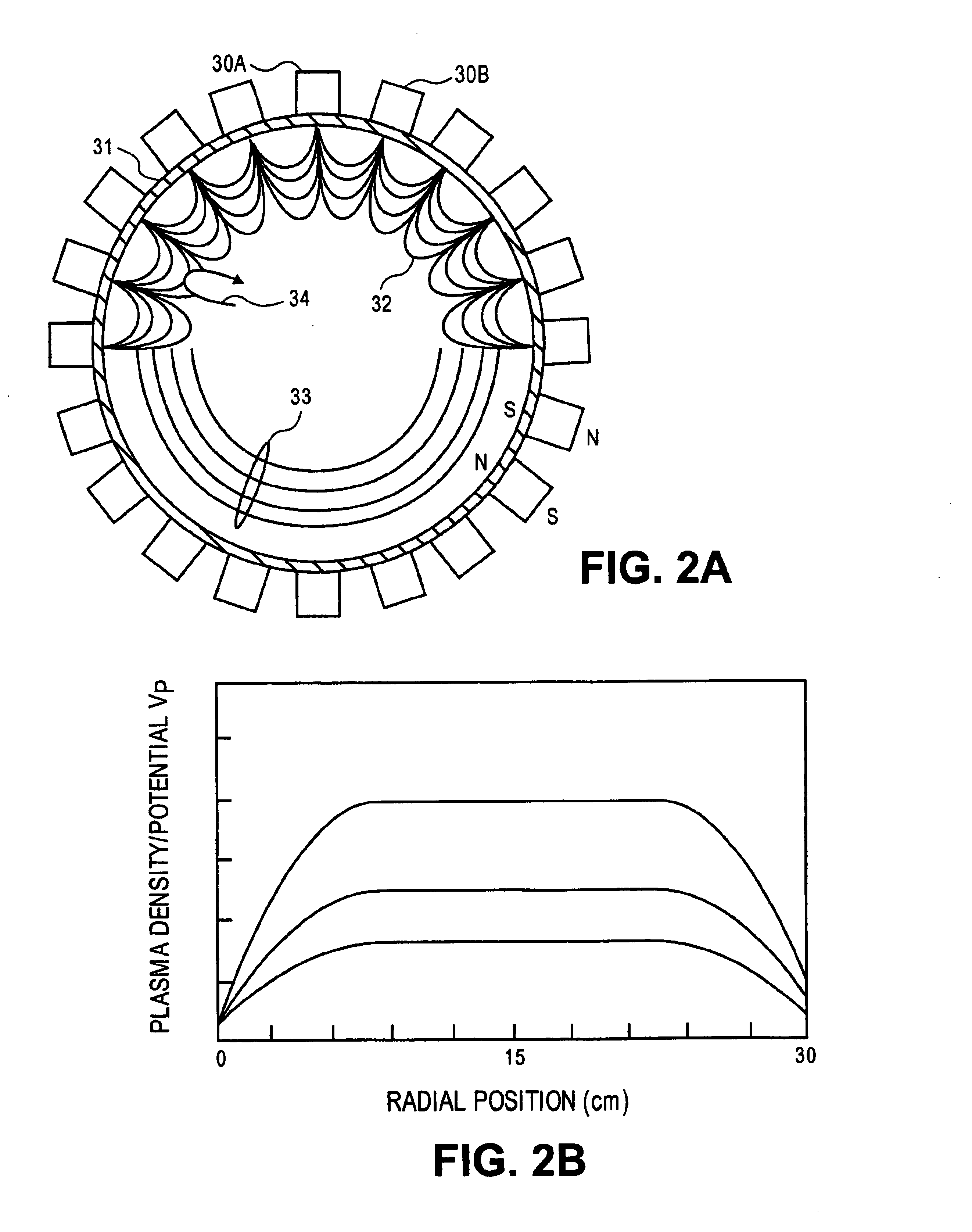

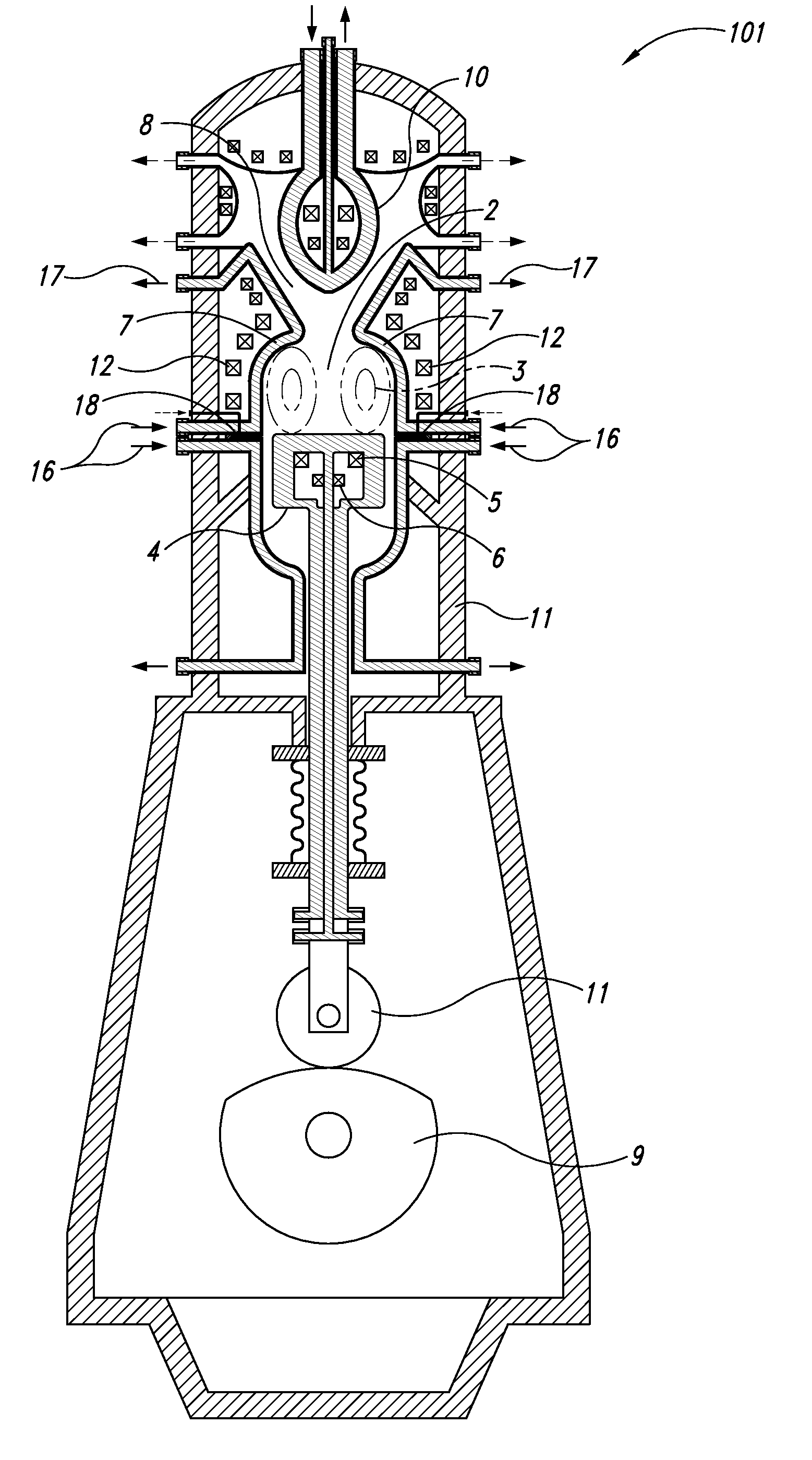

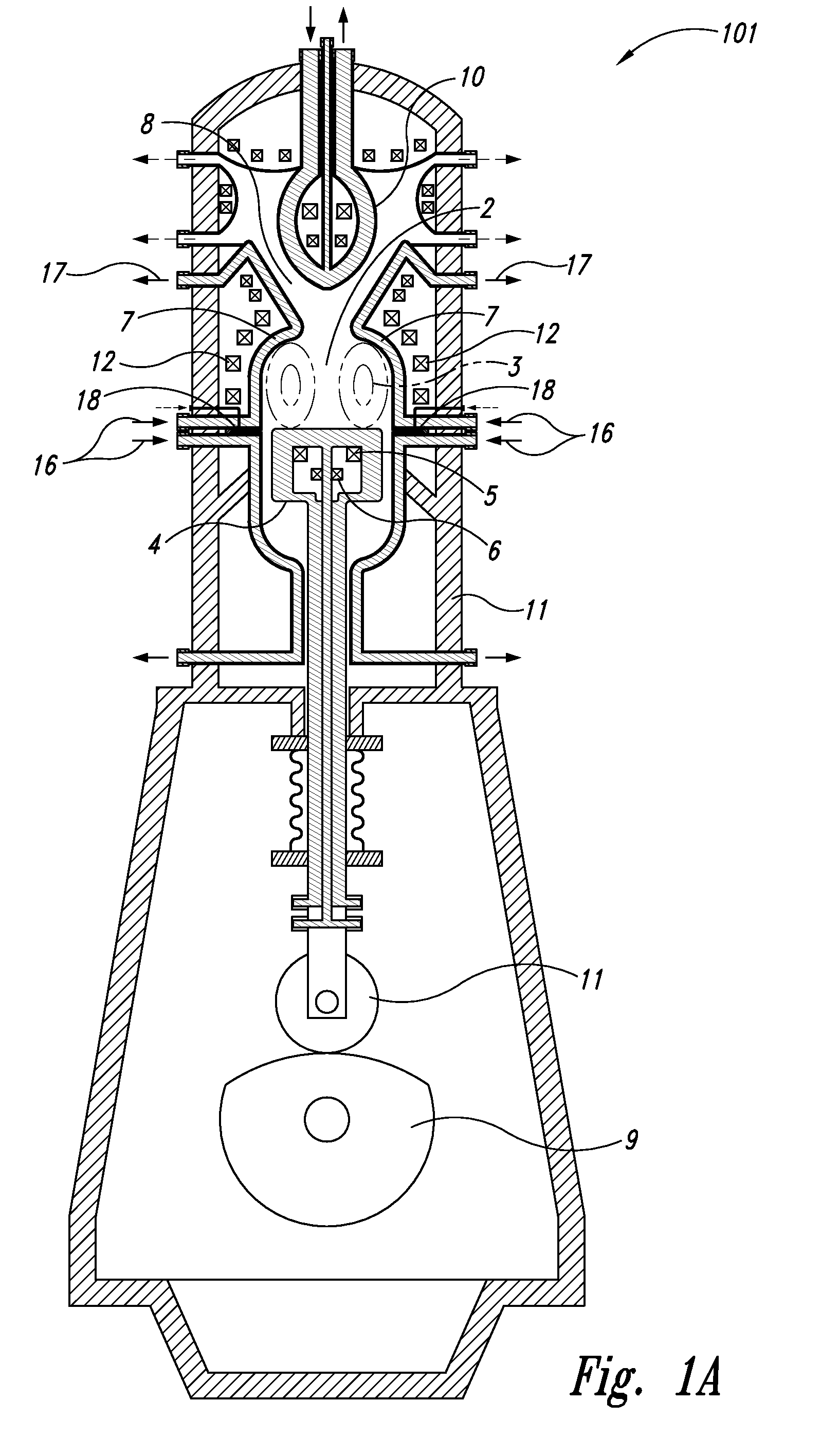

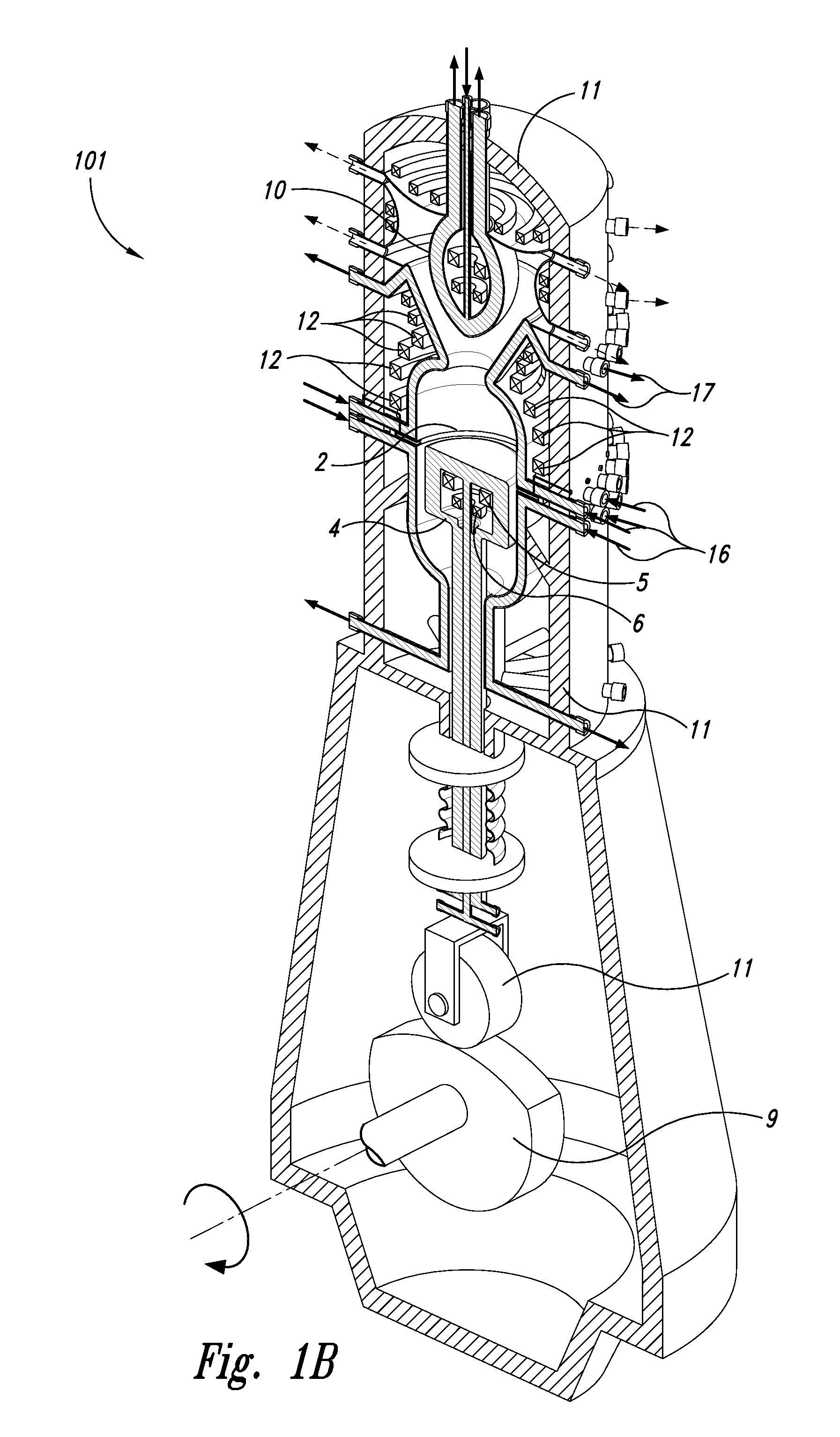

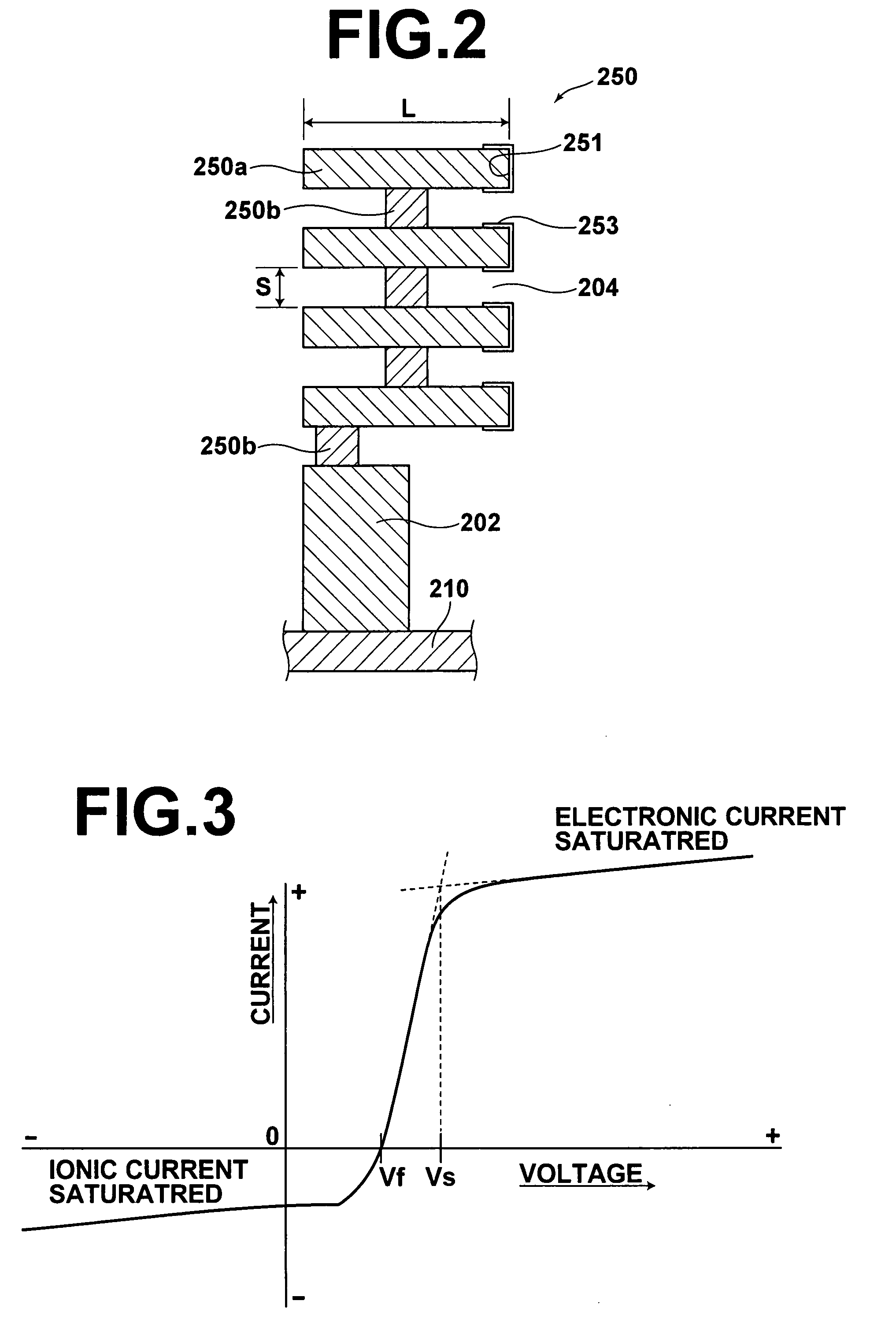

Device for compressing a compact toroidal plasma for use as a neutron source and fusion reactor

InactiveUS20110142185A1Improve isolationHigh densityNuclear energy generationAcceleratorsCombustion chamberPlasma density

Provided are methods and devices for compression of a spheromak plasma (e.g., deuterium-trirtium (D-T)-derived) in a magnetic well configured within a plasma combustion chamber using an induction coil axially adjacent to the plasma, wherein a moveable member (e.g., piston, cam and follower) drives the induction coil toward the plasma, pushing the plasma via magnetic pressure into the magnetic well and compressing the plasma substantially adiabatically (e.g., coil motion is well below the plasma sound speed). The compression quickly increases both plasma density and temperature past the point of ignition, and after plasma burn, the coil is backed-off to allow the plasma to re-expand, providing for refueling and repetition of the compression cycle. Additionally provided are spaced annular plasma formation electrodes, suitably configured for generating and injecting magnetized plasma into a plasma combustion chamber. Preferably, spaced annular plasma formation electrodes are used in combination with moveable compression members as disclosed herein.

Owner:WOODRUFF SCI

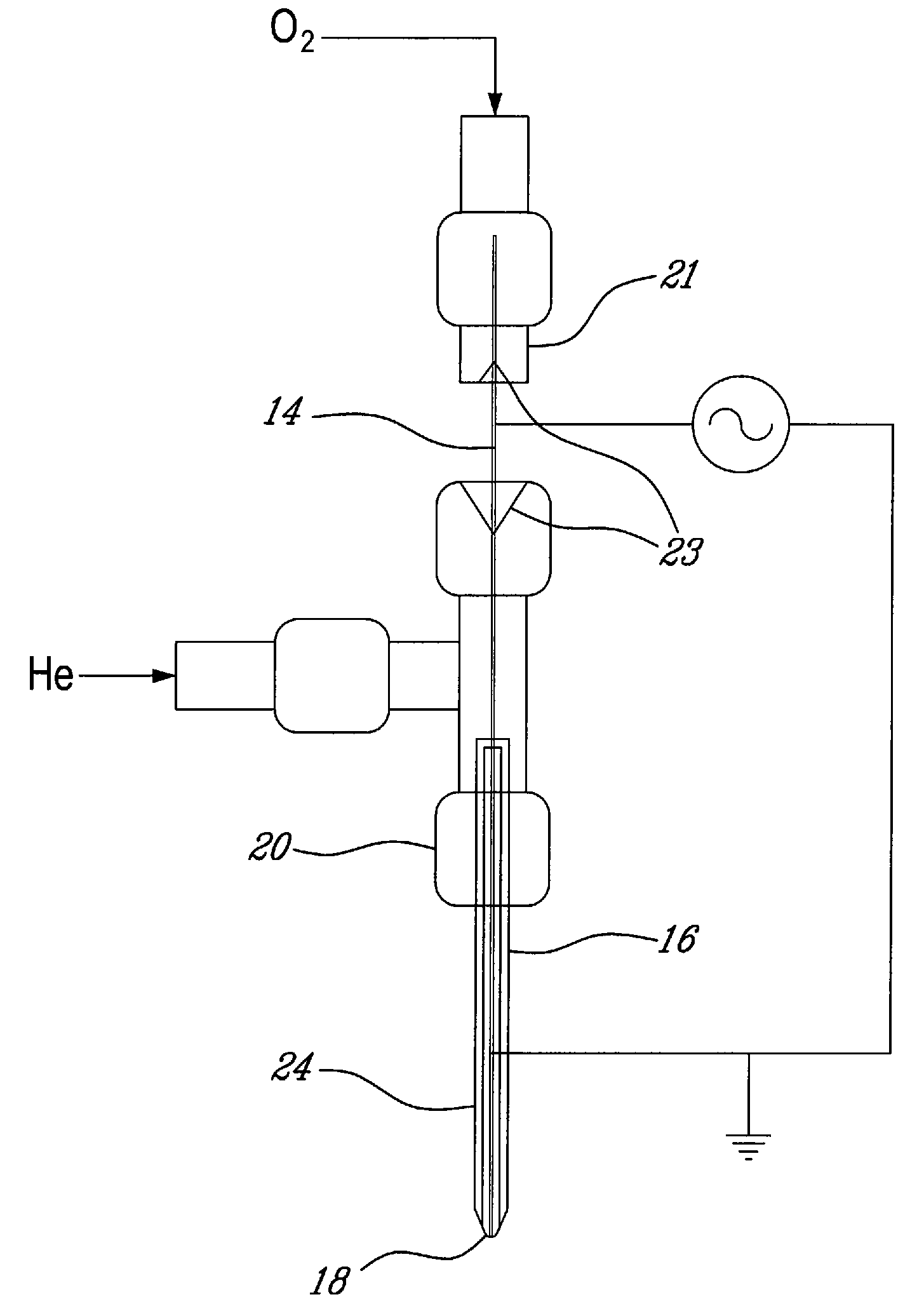

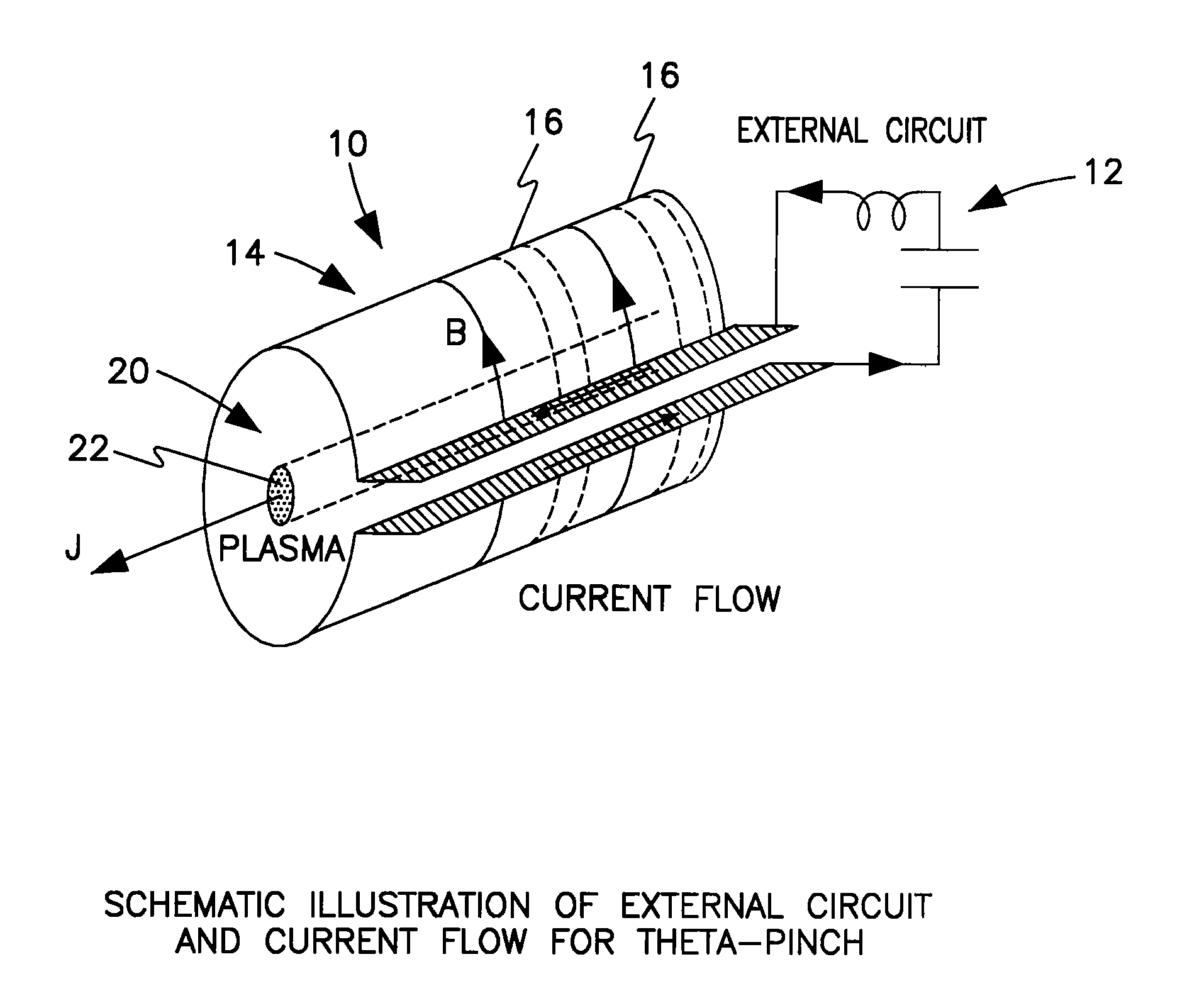

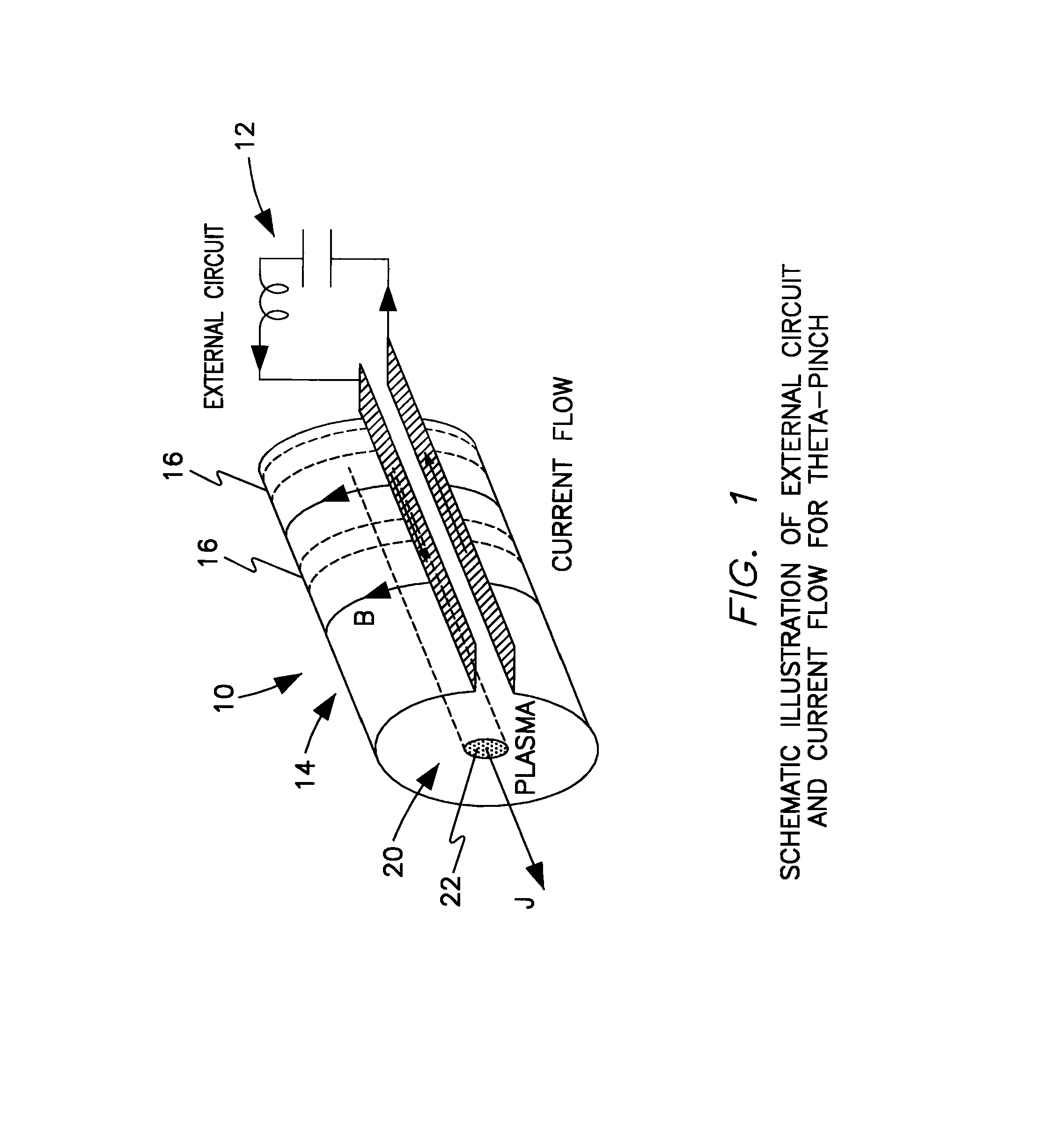

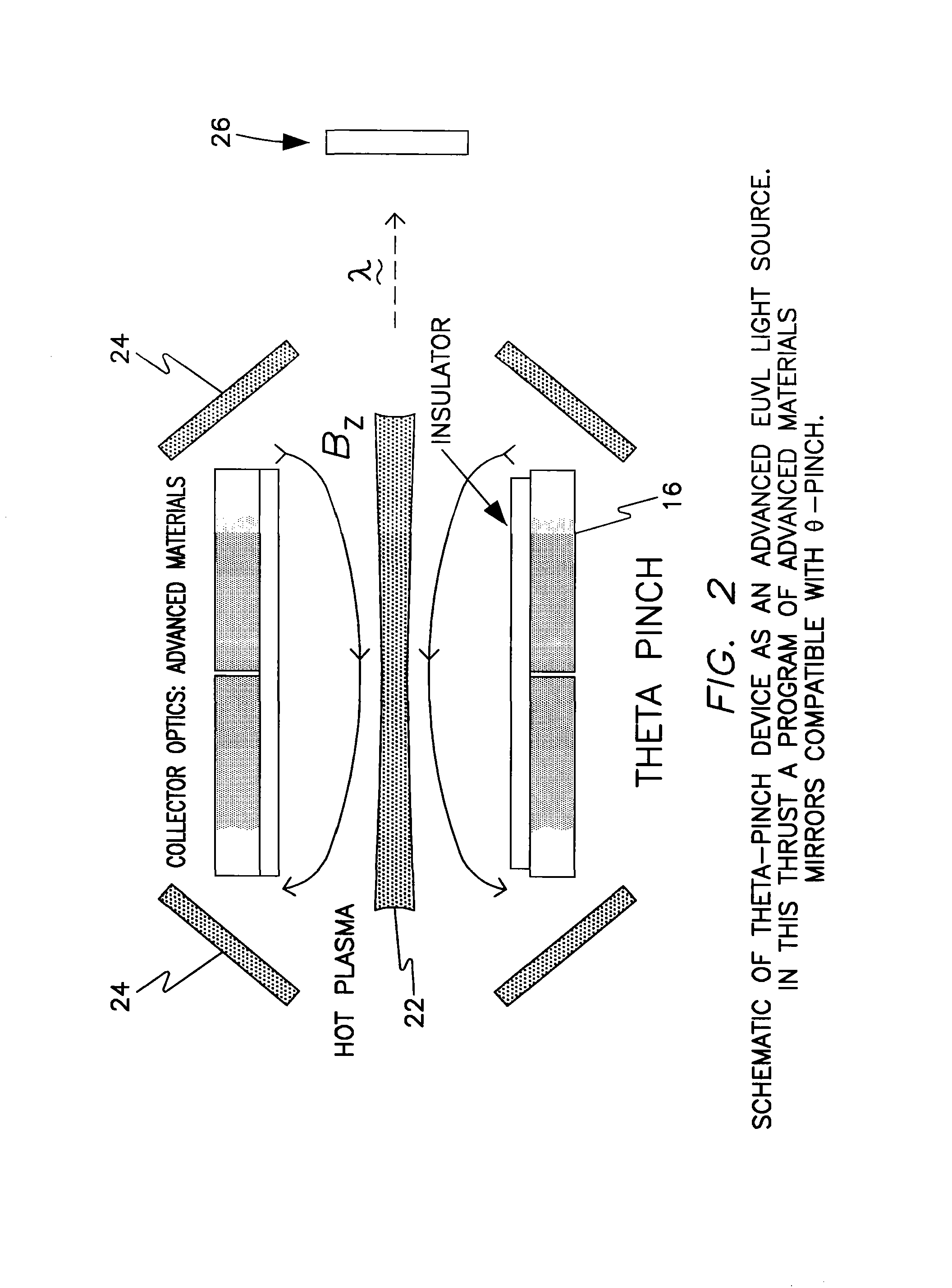

Method for plasma formation for extreme ultraviolet lithography-theta pinch

A device and method for generating extremely short-wave ultraviolet electromagnetic wave, utilizing a theta pinch plasma generator to produce electromagnetic radiation in the range of 10 to 20 nm. The device comprises an axially aligned open-ended pinch chamber defining a plasma zone adapted to contain a plasma generating gas within the plasma zone; a means for generating a magnetic field radially outward of the open-ended pinch chamber to produce a discharge plasma from the plasma generating gas, thereby producing a electromagnetic wave in the extreme ultraviolet range; a collecting means in optical communication with the pinch chamber to collect the electromagnetic radiation; and focusing means in optical communication with the collecting means to concentrate the electromagnetic radiation.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Microwave energized plasma lamp with dielectric waveguide

InactiveUS20050099130A1Minimize powerElectric light circuit arrangementDischarge tube/lamp detailsDielectricStable state

A plasma lamp including a waveguide body consisting essentially of at least one solid dielectric material. The body is coupled to a microwave power source which causes the body to resonate in at least one resonant mode. A lamp chamber integrated into the body contains a fill mixture which forms a light-emitting plasma when the chamber receives microwave power from the resonating waveguide body. The chamber has an aperture sealed to the external environment by a window or lens allowing light to be transmitted. Alternatively, the fill is in a self-enclosed bulb positioned in the chamber. Embodiments disclosed include lamps having a drive probe and a feedback probe, and lamps having a drive probe, feedback probe and start probe, which minimize power reflected from the body back to the source both before the plasma is formed and after it reaches steady state.

Owner:LUXIM CORP

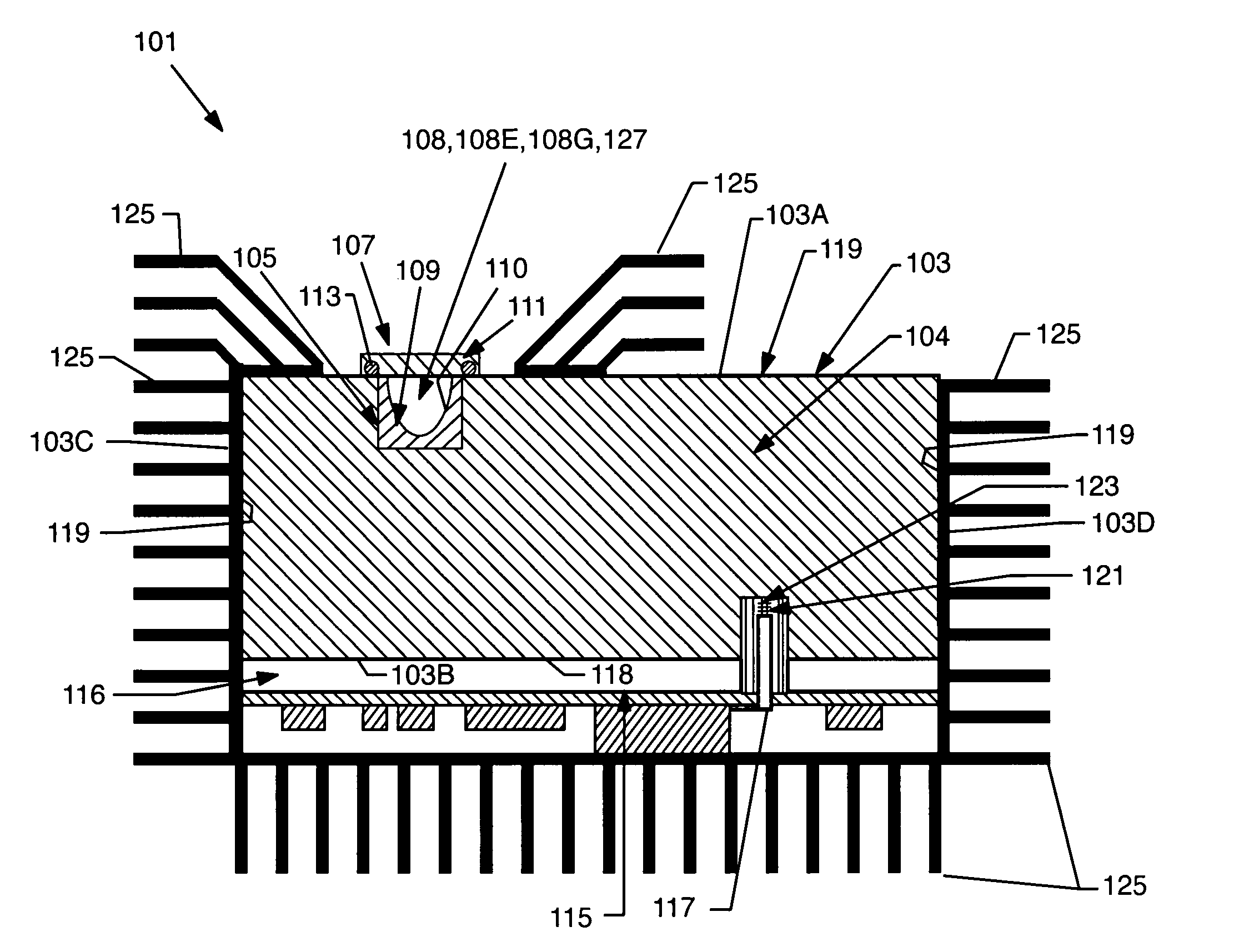

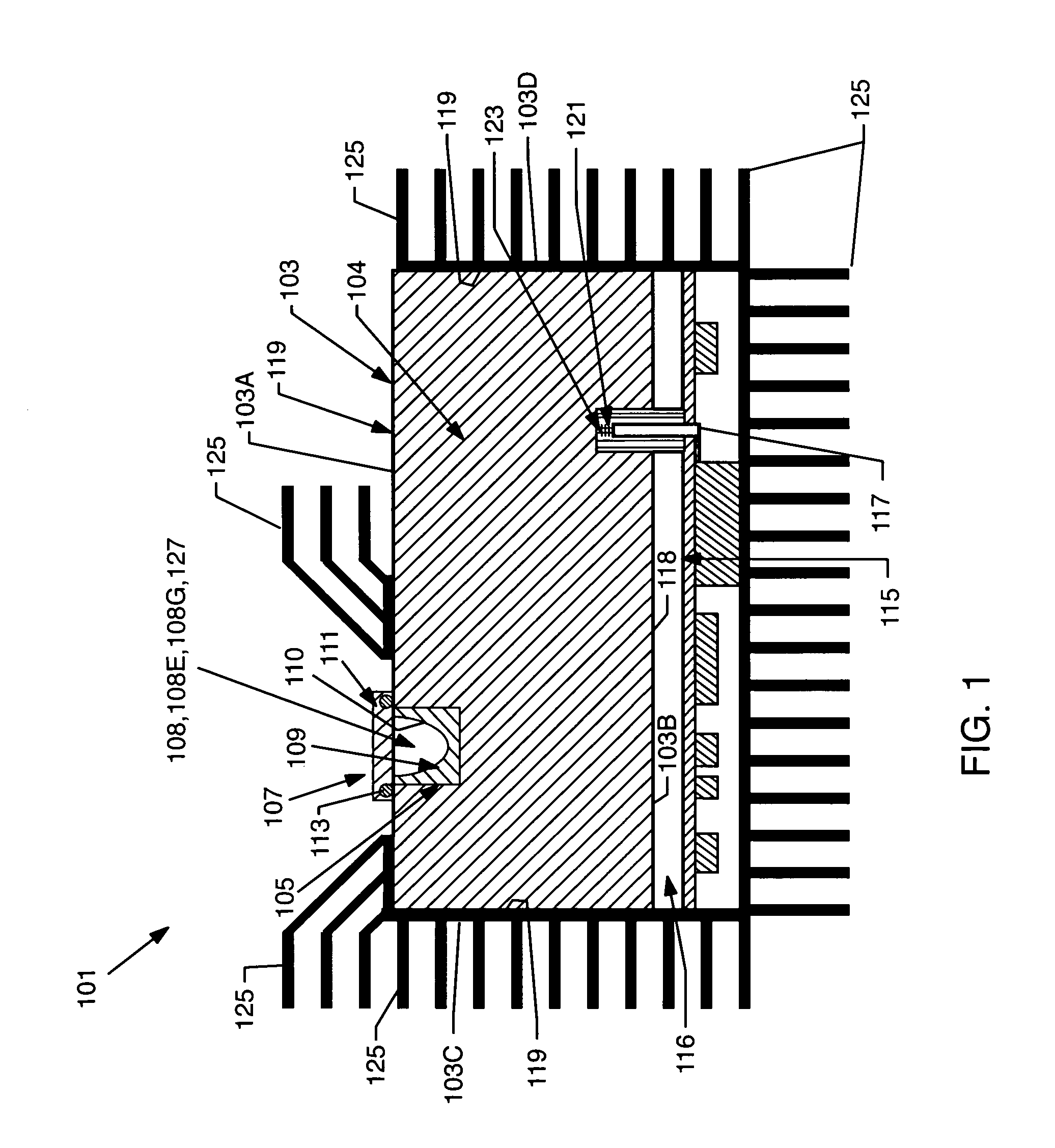

Method and apparatus for providing an electrostatic chuck with reduced plasma penetration and arcing

ActiveUS20090034147A1Reducing plasma formationSleeve/socket jointsSemiconductor/solid-state device manufacturingEngineeringHeat transfer fluid

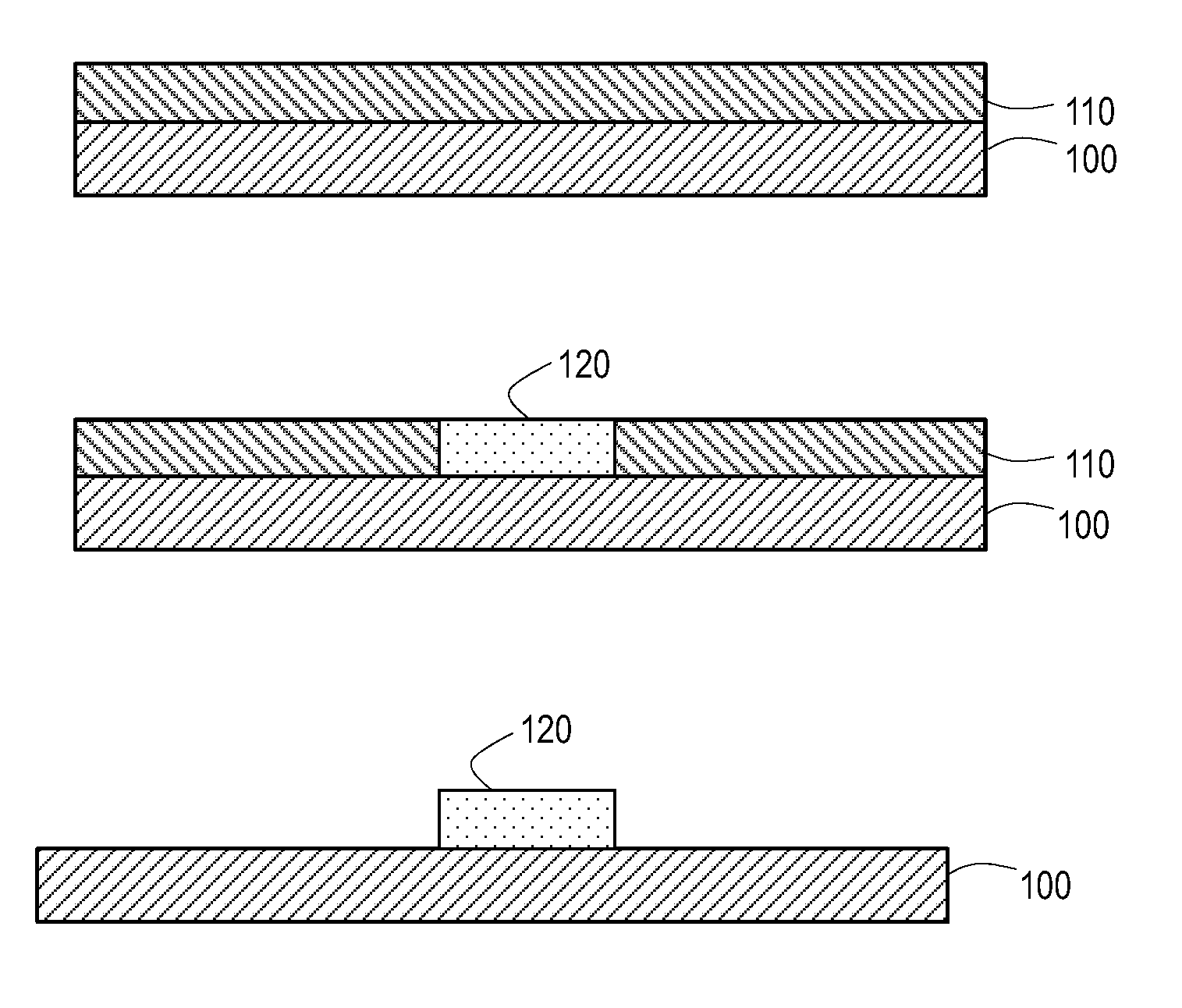

A method and apparatus for providing a fluid distribution element for an electrostatic chuck that reduces plasma formation and arcing within heat transfer fluid passages. One embodiment comprises a plate and a dielectric component, where the dielectric component is inserted into the plate. The plate is adapted to be positioned within a channel to define a plenum, wherein the dielectric component provides at least a portion of a fluid passage coupled to the plenum. A porous dielectric layer, formed upon the dielectric component, provides at least another portion of a fluid passage coupled to the plenum. In other embodiments, the fluid distribution element comprises various arrangements of components to define a fluid passage that does not provide a line-of-sight path from the support surface for a substrate to a plenum.

Owner:APPLIED MATERIALS INC

Systems and methods for deflecting plasma-generated ions to prevent the ions from reaching an internal component of an EUV light source

InactiveUS20050279946A1Reduce ion energyWeaken energyNanoinformaticsElectrode and associated part arrangementsPower gridTime difference

A system is disclosed for protecting an internal EUV light source component from ions generated at a plasma formation site. In one aspect, the system may comprise a plurality of foil plates and an arrangement for generating a magnetic field to deflect ions into one of the foil plate surfaces. In another aspect, an electrostatic grid may be positioned for interaction with ions to reduce ion energy, and a magnetic field may be used to deflect the reduced energy ions onto paths wherein the ions do not strike the internal component. In yet another aspect, a grid may be connected to a circuit tuned to a resonant frequency to reduce ion energy. For example, the resonant frequency may be substantially equal to an inverse of a time difference between the time when electrons reach the grid and a subsequent time when ions reach the grid.

Owner:ASML NETHERLANDS BV

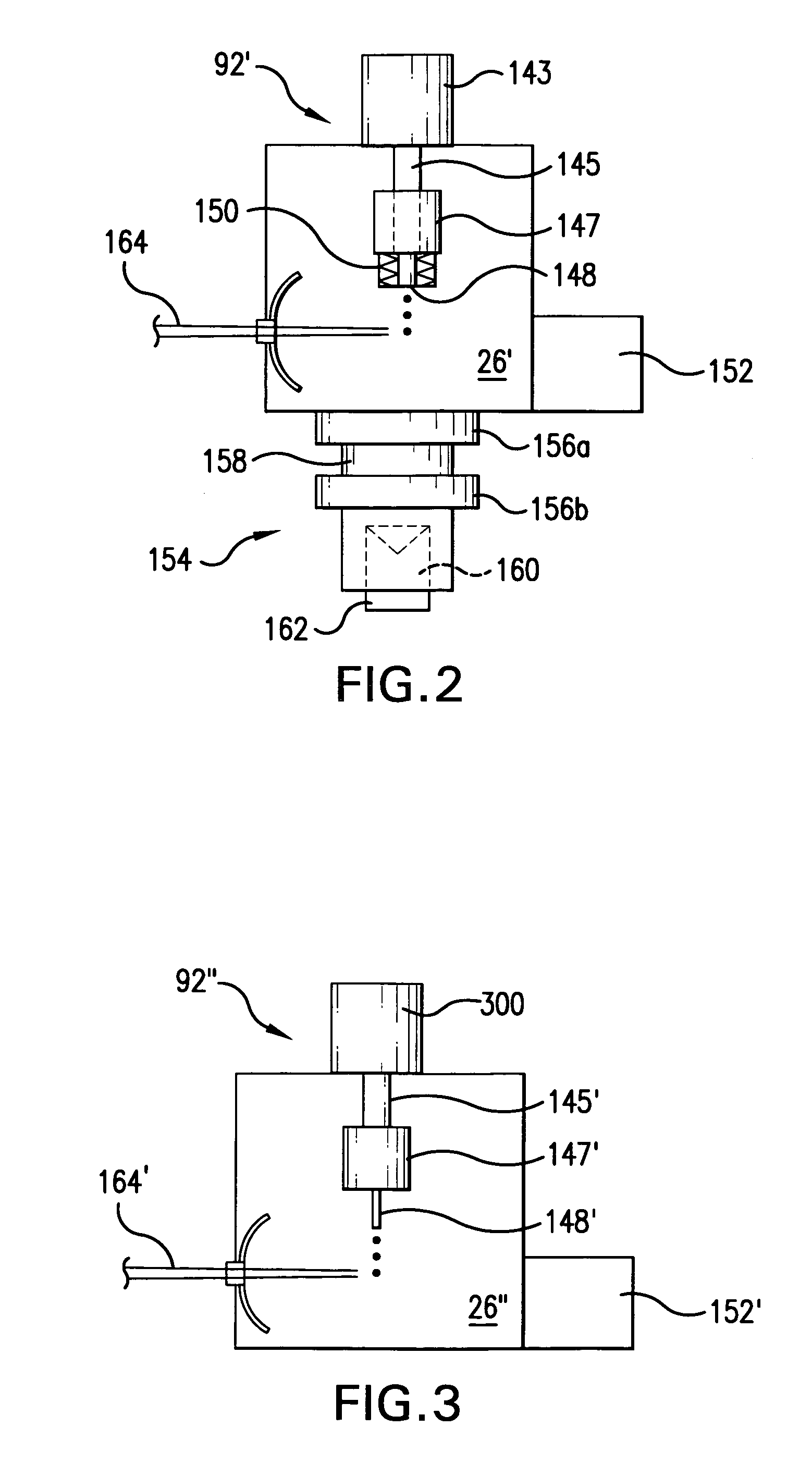

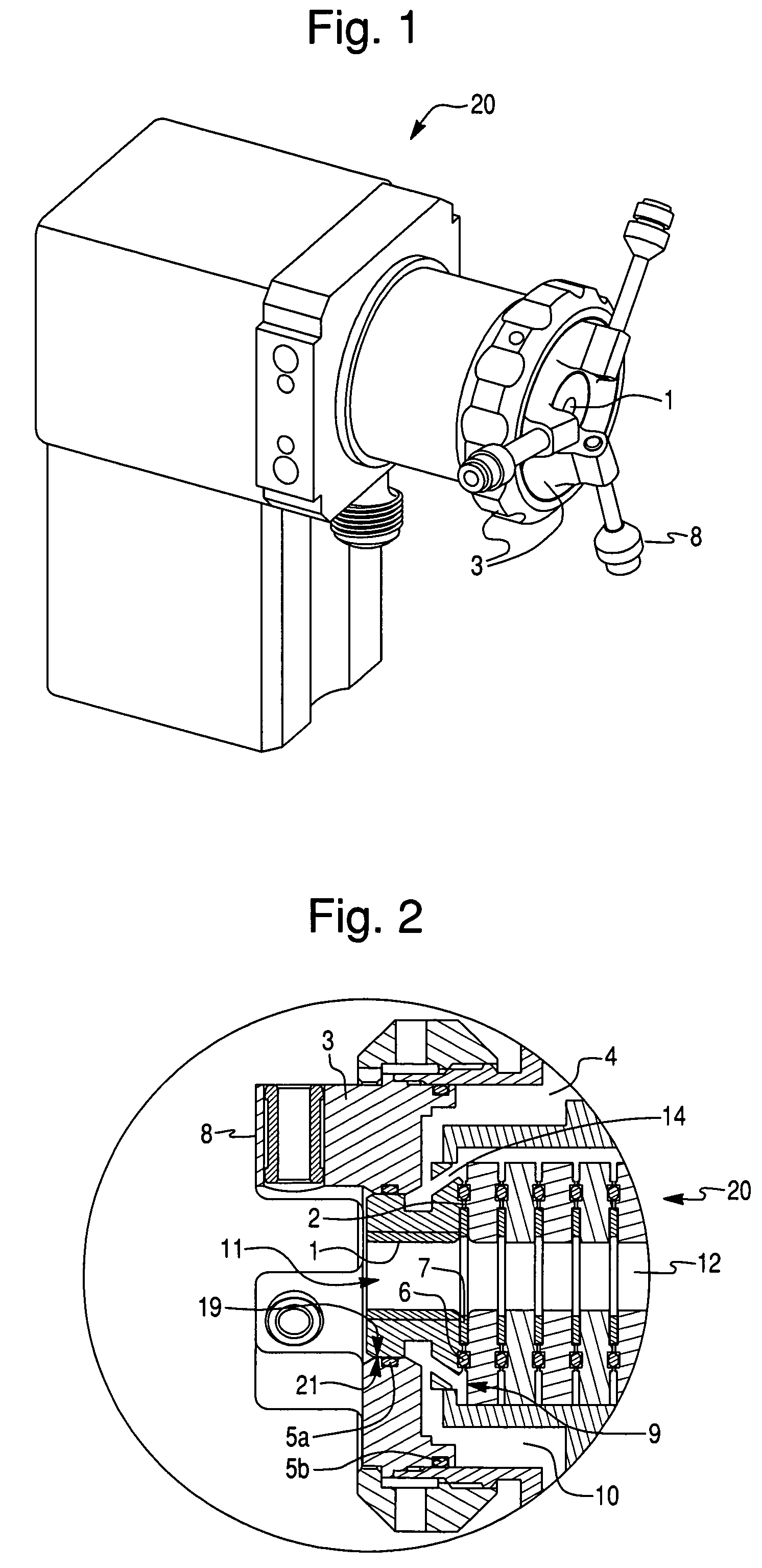

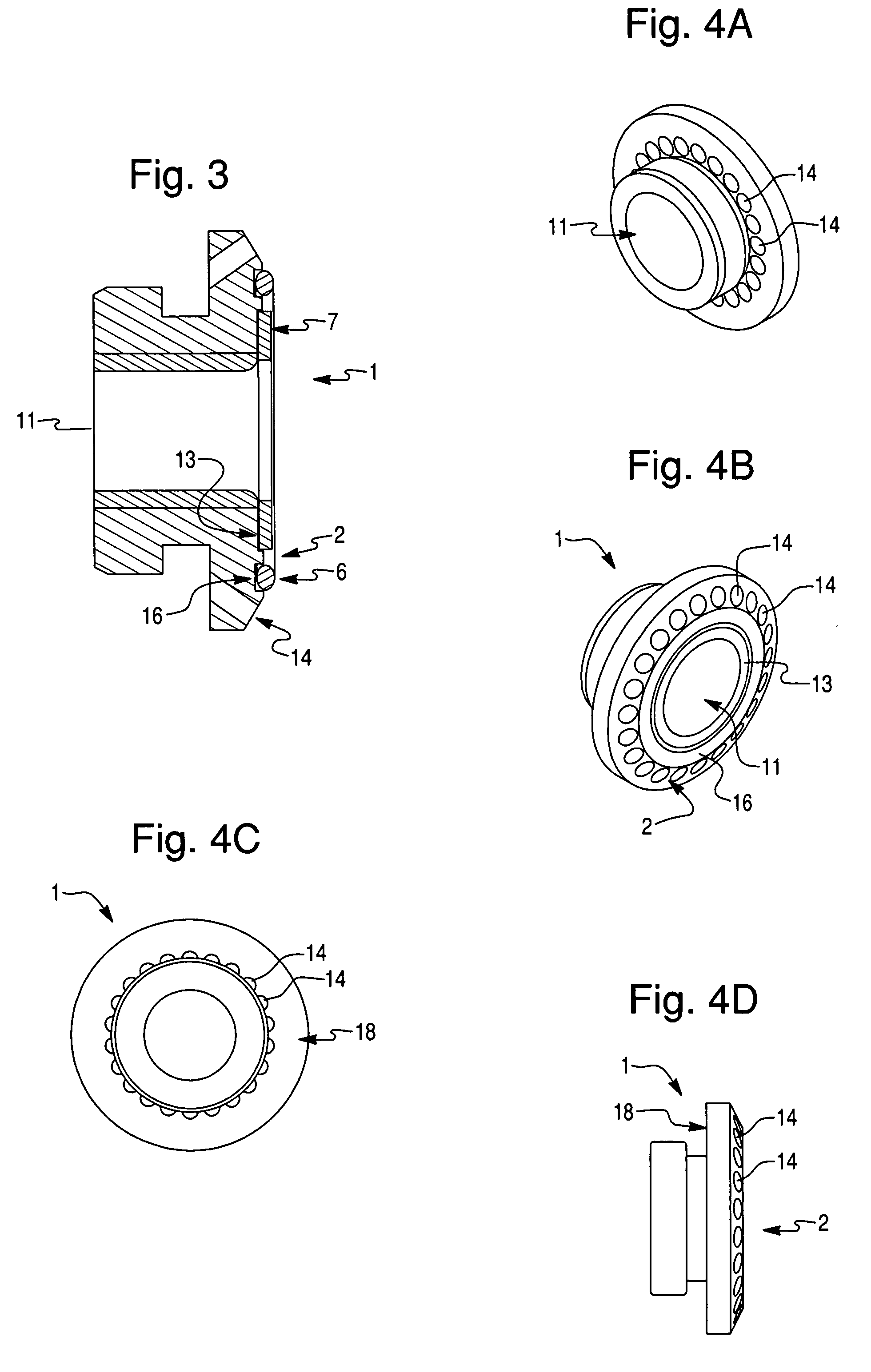

Interchangeable plasma nozzle interface

ActiveUS7759599B2Increase flexibilityEasy to usePlasma welding apparatusWelding/cutting media/materialsSpray nozzleElectrical connection

The present invention provides a standard interface for providing mechanical location, mechanical orientation, electrical connections, and water chamber seals for the exchange of a variety of plasma forming nozzles each associated with a specific plasma plume characteristic. The flexibility of the nozzle attachment is improved over prior designs by providing a standard exterior nozzle configuration and nozzle clamping assembly on the plasma gun so that multiple nozzles configurations (giving different plasma flow properties) can easily be used with the same devices. The joining of the nozzle to the receptacle forms a channel for cooling liquid to flow from the plasma gun through the nozzle to a return path in the plasma gun and creates an electrical contact between the plasma gun and the nozzle.

Owner:SULZER METCO (US) INC

Chamber configuration for confining a plasma

InactiveUS20050103442A1Minimizing unwanted plasma formationReduce impactElectric discharge tubesSemiconductor/solid-state device manufacturingProcess regionEngineering

A plasma confining assembly for minimizing unwanted plasma formations in regions outside of a process region in a process chamber is disclosed. The plasma confining assembly includes a first confining element and second confining element positioned proximate the periphery of the process region. The second confining element is spaced apart from the first confining element. The first confining element includes an exposed conductive surface that is electrically grounded and the second confining element includes an exposed insulating surface, which is configured for covering a conductive portion that is electrically grounded. The first confining element and the second confining element substantially reduce the effects of plasma forming components that pass therebetween. Additionally, the plasma confining assembly may include a third confining element, which is formed from an insulating material and disposed between the first confining element and the second confining element, and proximate the periphery of the process region. The third confining element further reduces the effects of plasma forming components that pass between the first confining element and the second confining element.

Owner:LAM RES CORP

Systems and methods for deflecting plasma-generated ions to prevent the ions from reaching an internal component of an EUV light source

InactiveUS7217941B2Weaken energyOptical radiation measurementCathode ray tubes/electron beam tubesTime differenceElectron

A system is disclosed for protecting an internal EUV light source component from ions generated at a plasma formation site. In one aspect, the system may comprise a plurality of foil plates and an arrangement for generating a magnetic field to deflect ions into one of the foil plate surfaces. In another aspect, an electrostatic grid may be positioned for interaction with ions to reduce ion energy, and a magnetic field may be used to deflect the reduced energy ions onto paths wherein the ions do not strike the internal component. In yet another aspect, a grid may be connected to a circuit tuned to a resonant frequency to reduce ion energy. For example, the resonant frequency may be substantially equal to an inverse of a time difference between the time when electrons reach the grid and a subsequent time when ions reach the grid.

Owner:ASML NETHERLANDS BV

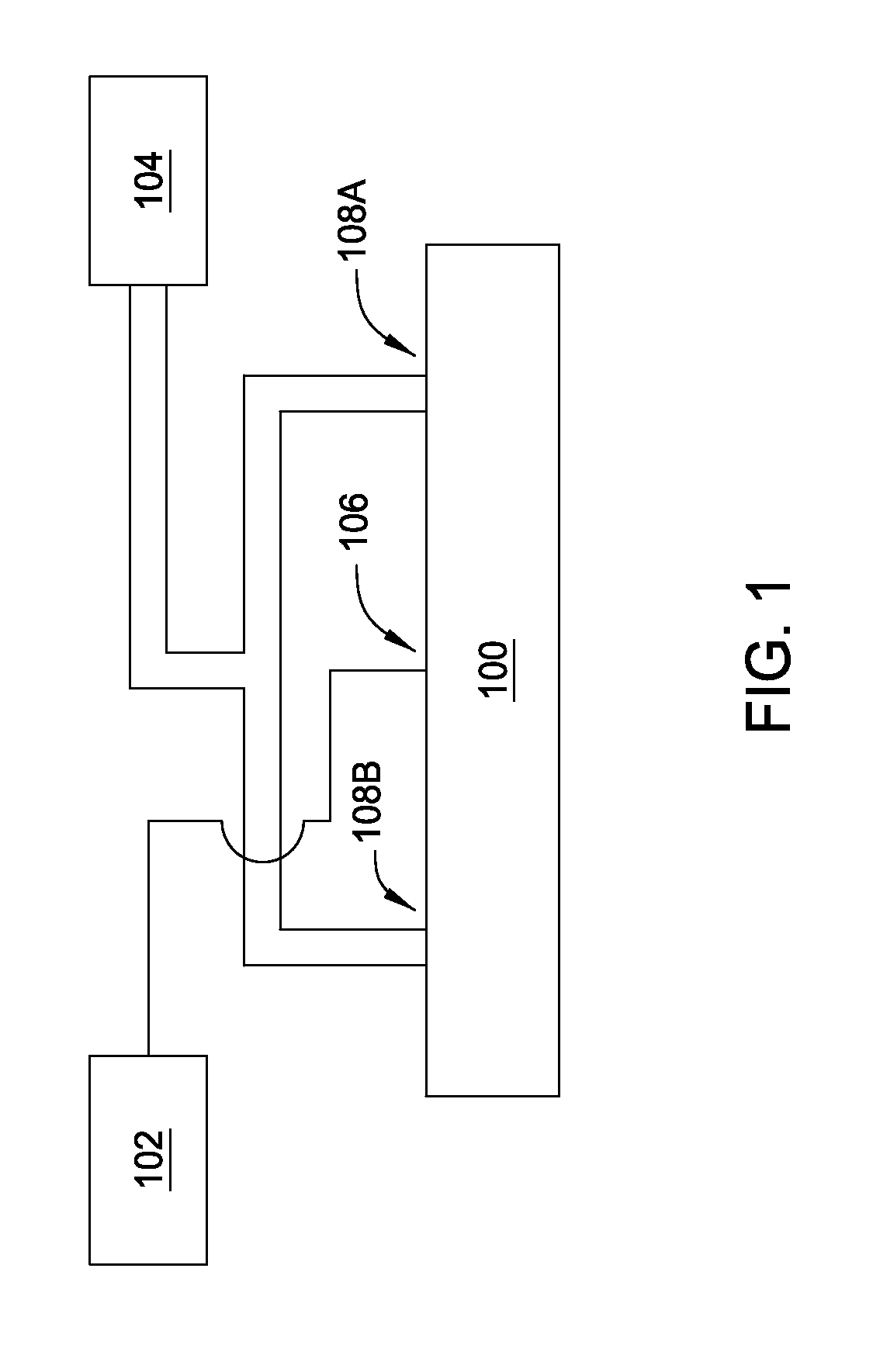

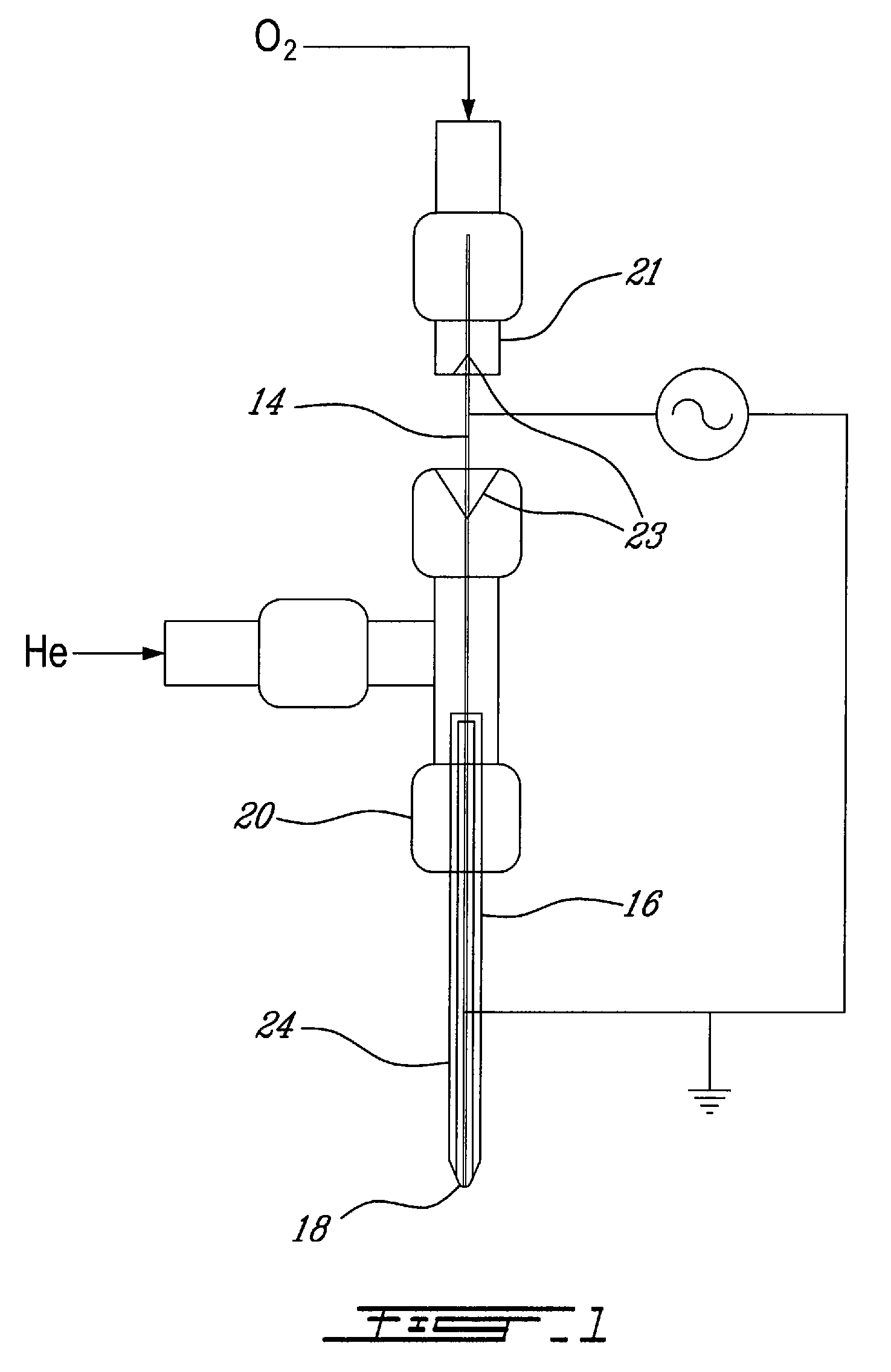

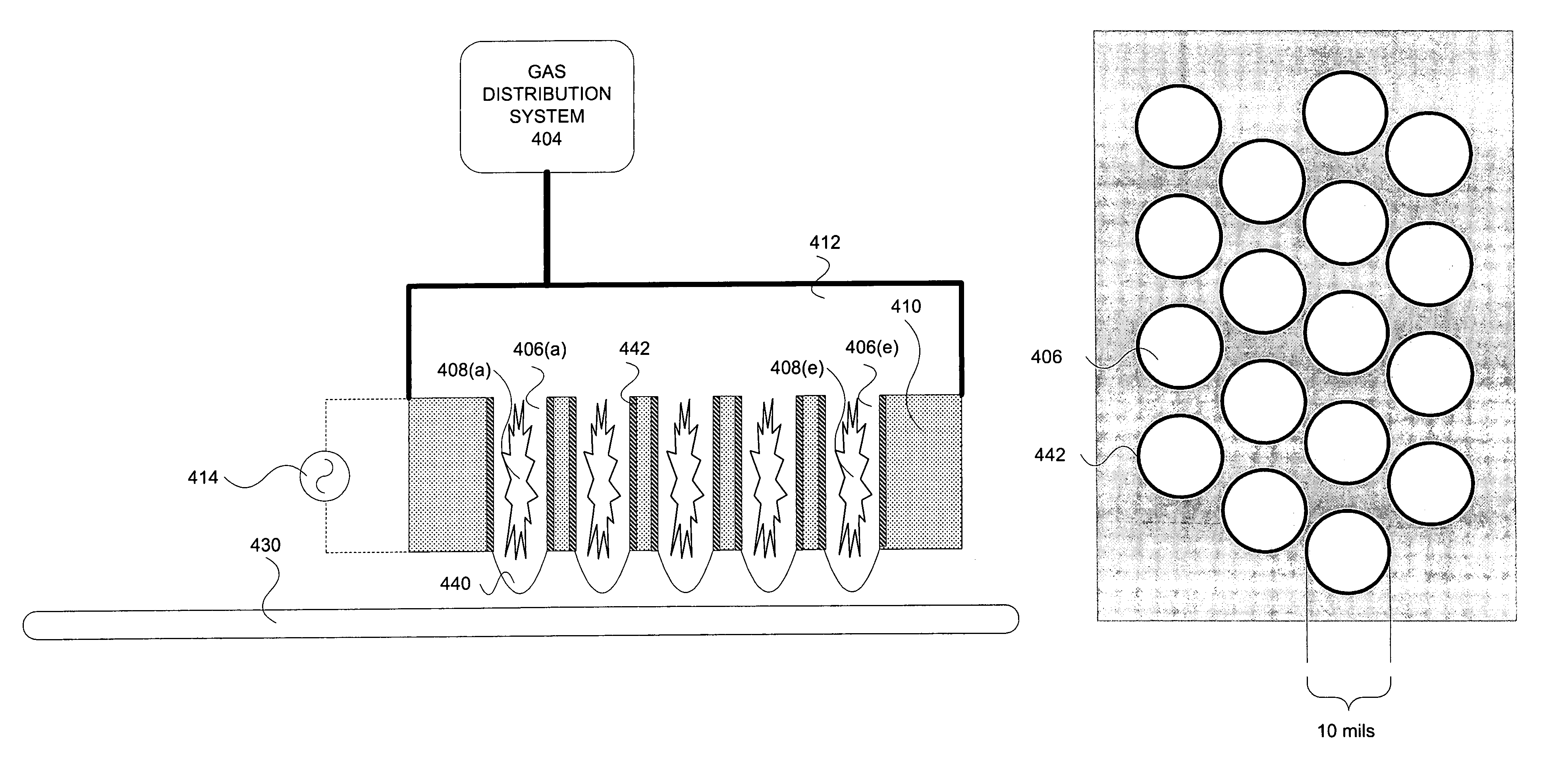

Apparatus for the optimization of atmospheric plasma in a processing system

InactiveUS20060054279A1Easy to cleanEasy to integrateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric sciencesPlasma formation

An apparatus for cleaning a substrate in a reactive ion etch process is disclosed. The apparatus is configured to produce an atmospheric plasma using a RF generation device. The apparatus includes a plasma forming chamber including a cavity defined by a set of interior chamber walls comprised of a dielectric material. The apparatus also includes an atmospheric plasma generated by the RF generation device, the atmospheric plasma protruding from a first end of the cavity to clean the substrate.

Owner:LAM RES CORP

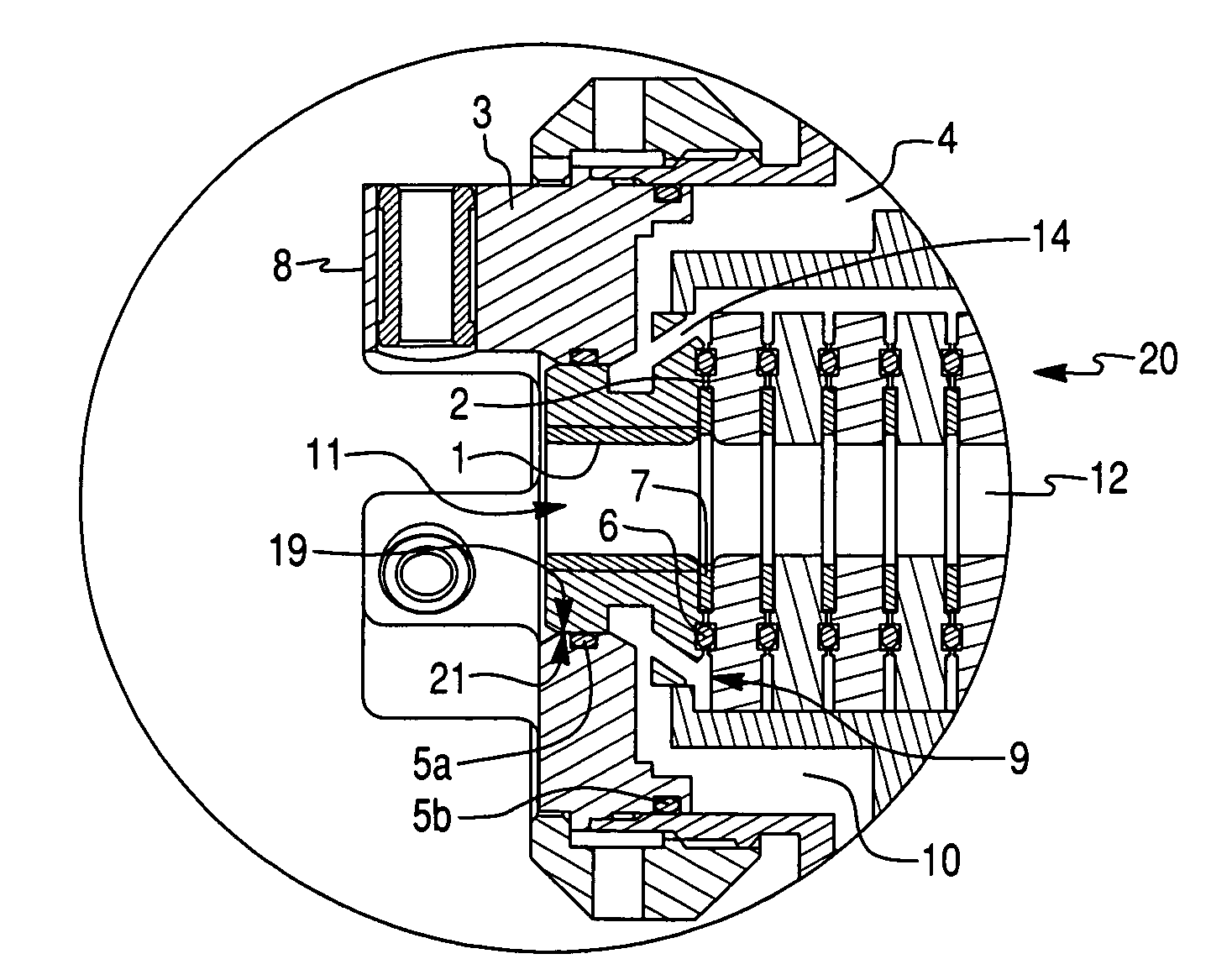

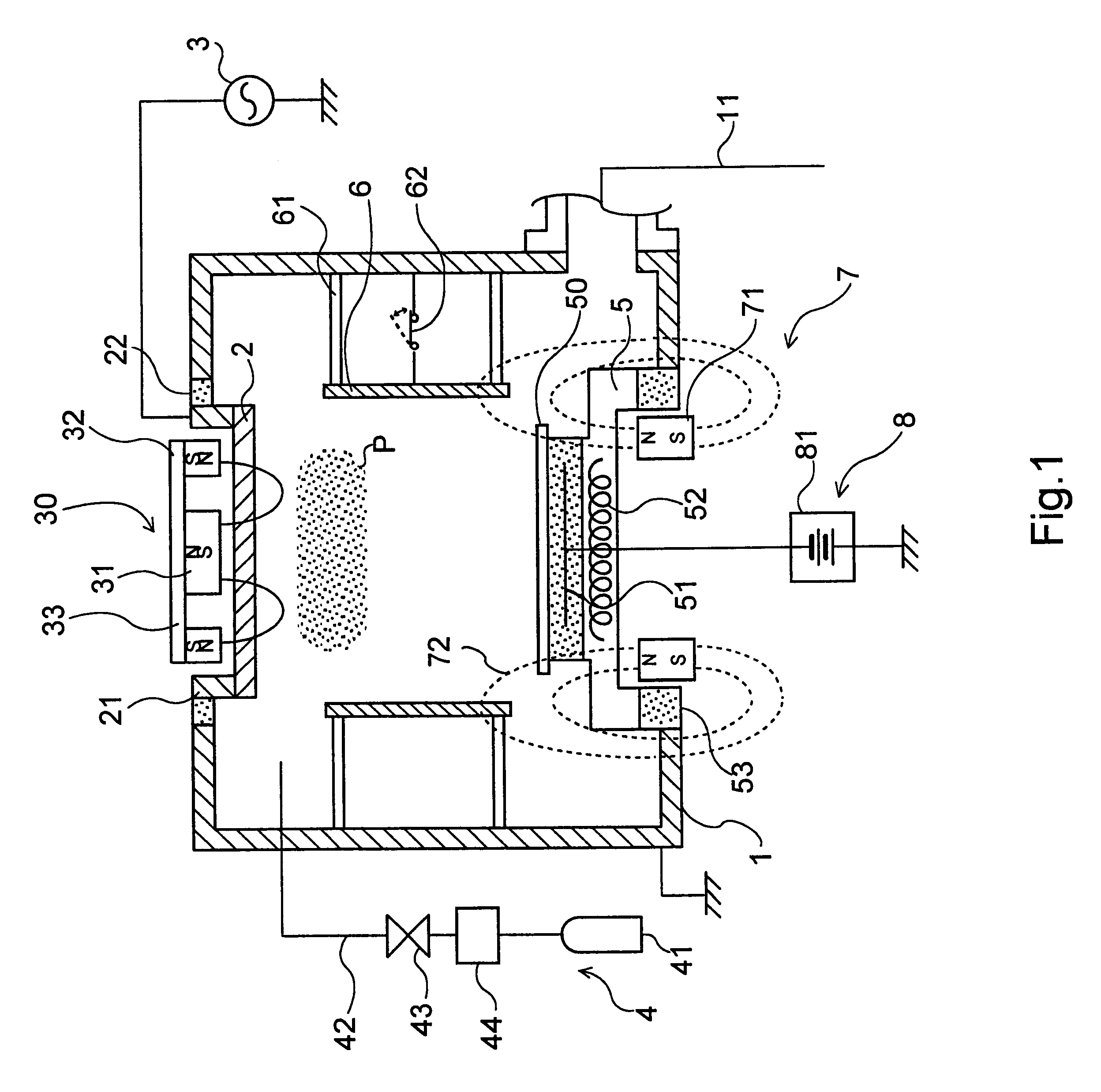

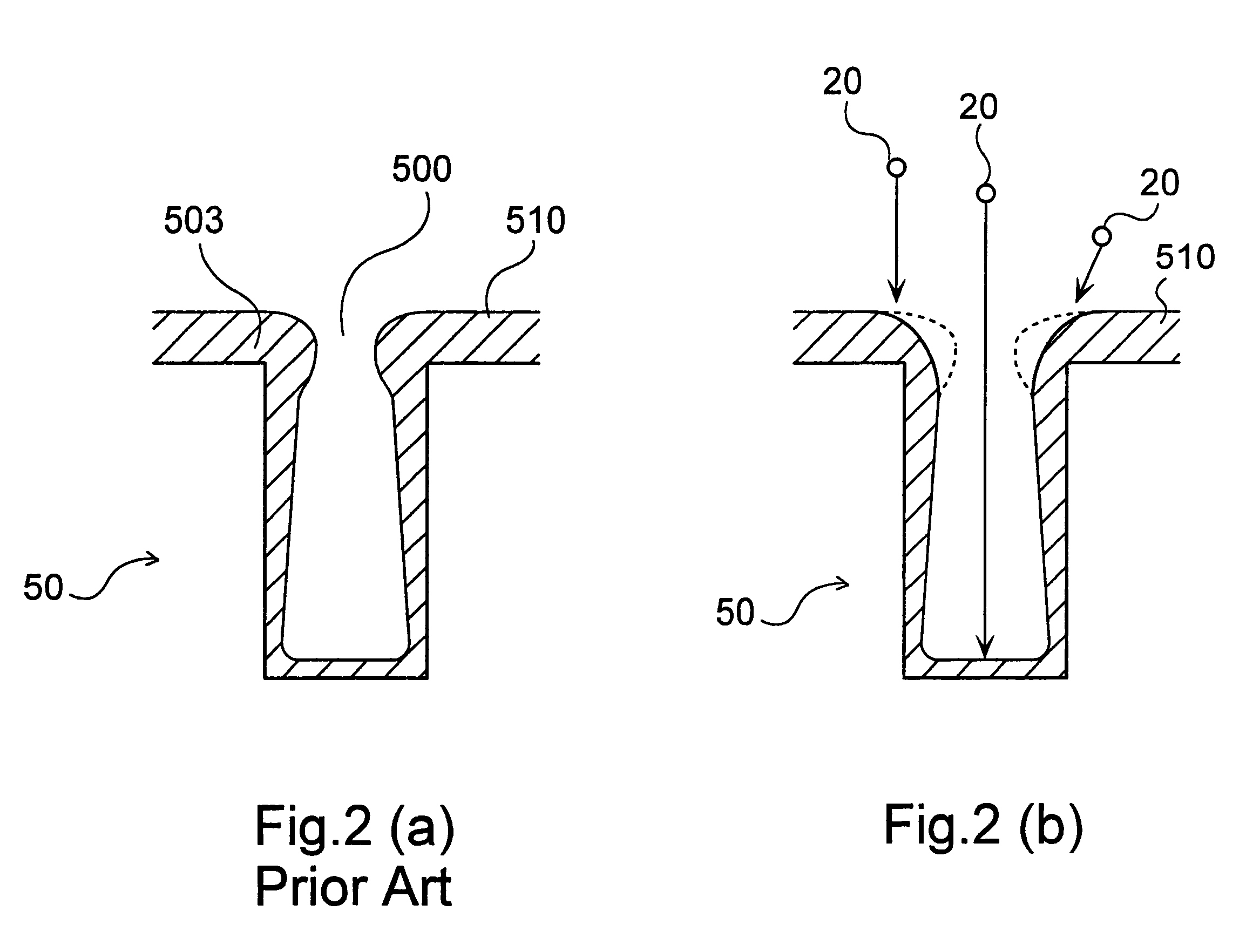

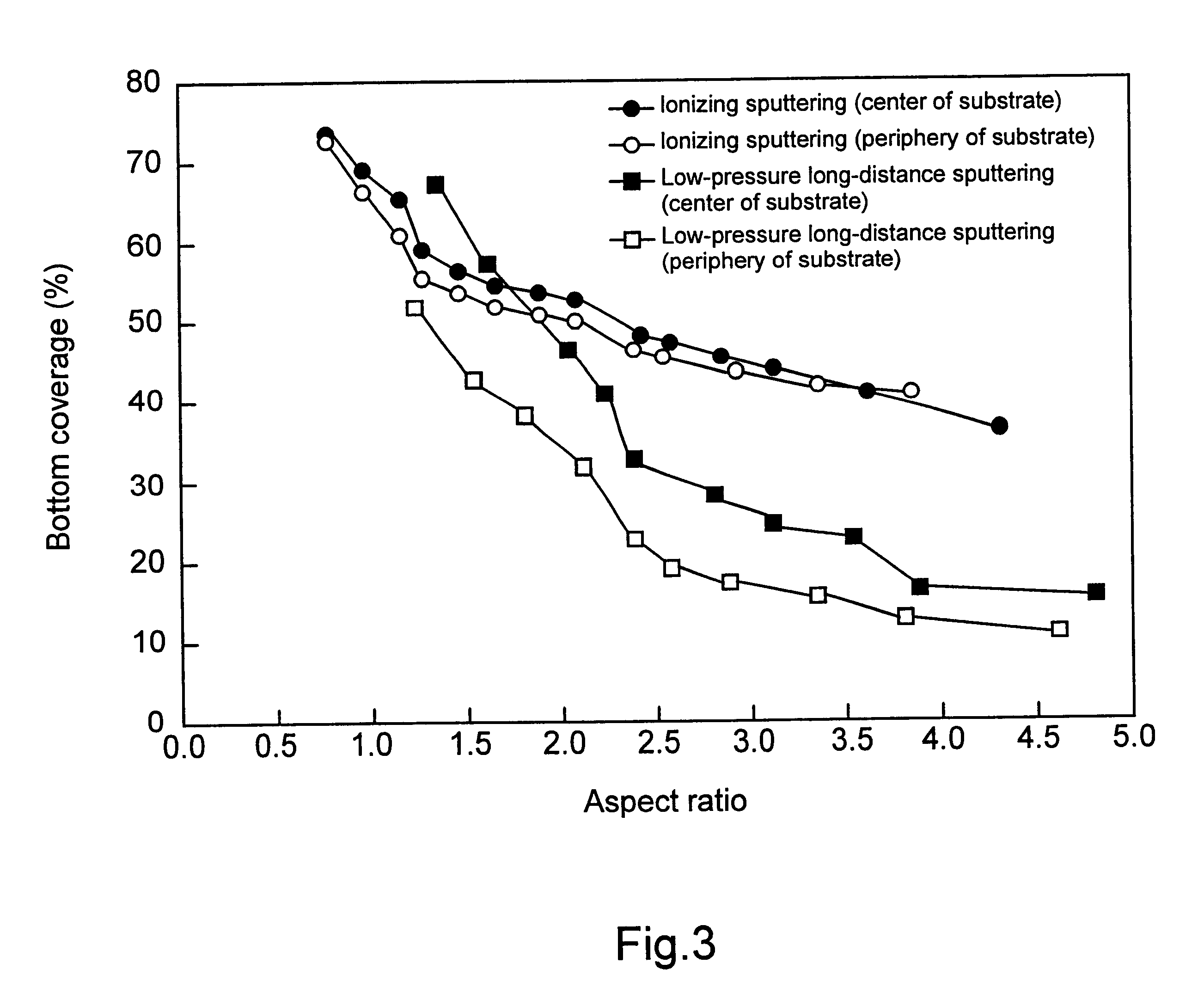

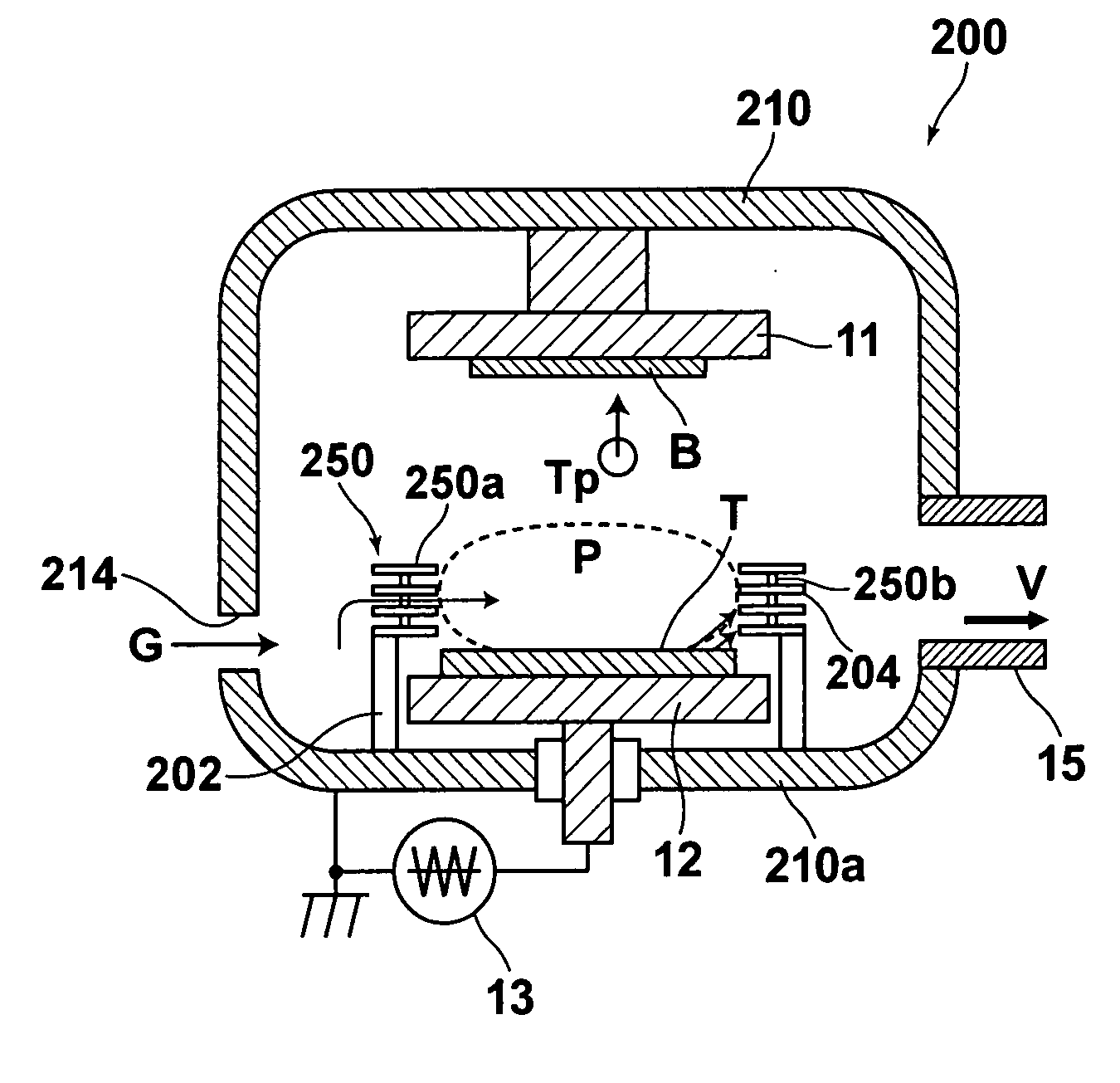

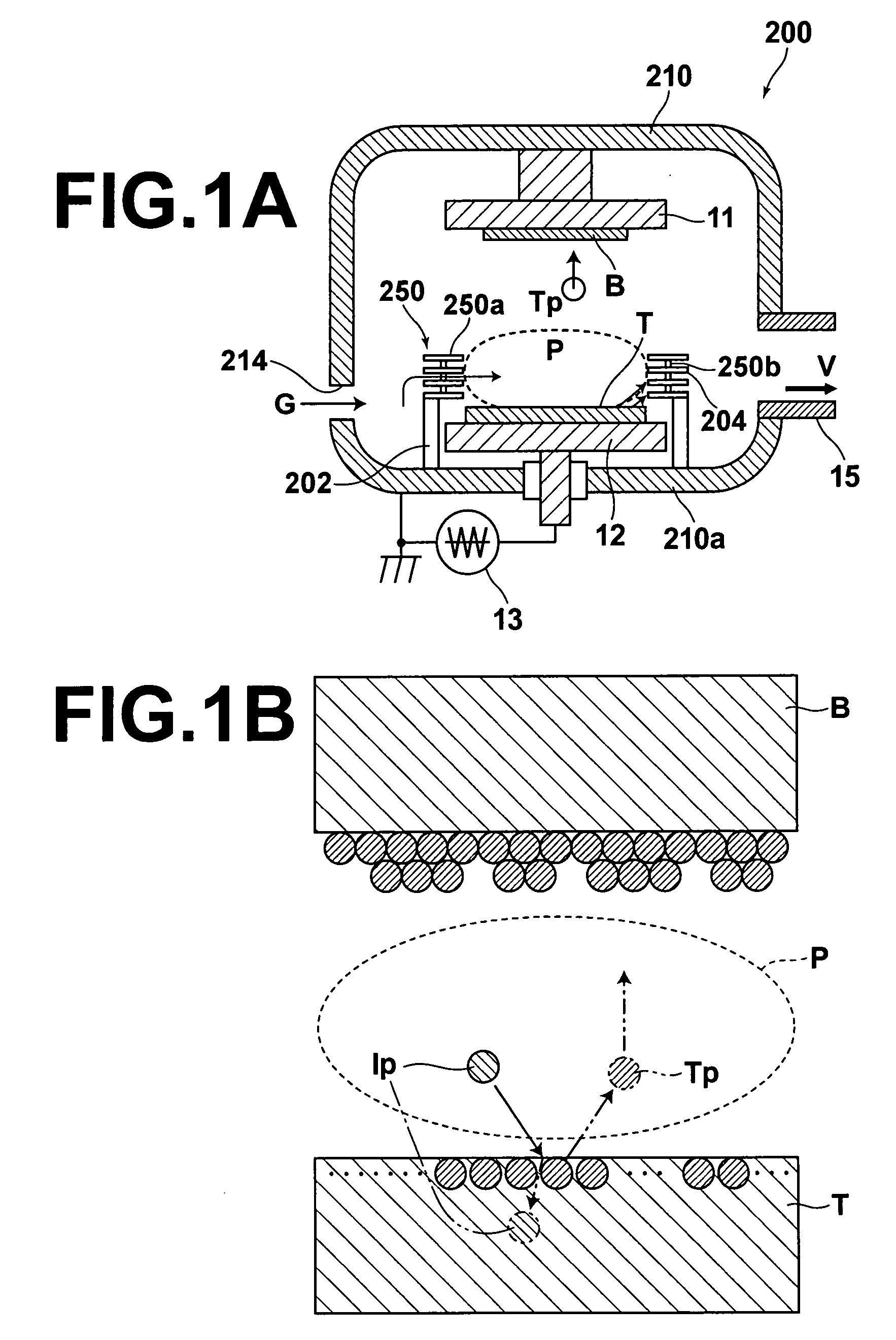

Ionizing sputtering method

InactiveUS6444099B1Less generation of particulateBottom coverage is improvedElectric discharge tubesVacuum evaporation coatingSputteringEngineering

To form a film by ionized sputtering with good bottom coverage for holes with a high aspect ratio, and to simplify the structure inside and out of the sputter chamber, a target 2 is provided inside a sputter chamber 1 equipped with an exhaust system 11 and is sputtered by a sputtering power source 3. The released sputter particles are made to arrive at a substrate 50 to form a film. The sputtering power source 3 sends electric power of at least 5 W / cm2 to a target 2, and the sputter particles are ionized in a plasma formed by this electric power alone. A cylindrical shield 6 may be provided between the target 2 and the substrate holder 5 to restrict the plasma formation space, and an electric field establishment means 8 may set up an electric field for extracting the ionized sputter particles from the plasma P and directing them at the substrate 50.

Owner:ANELVA CORP

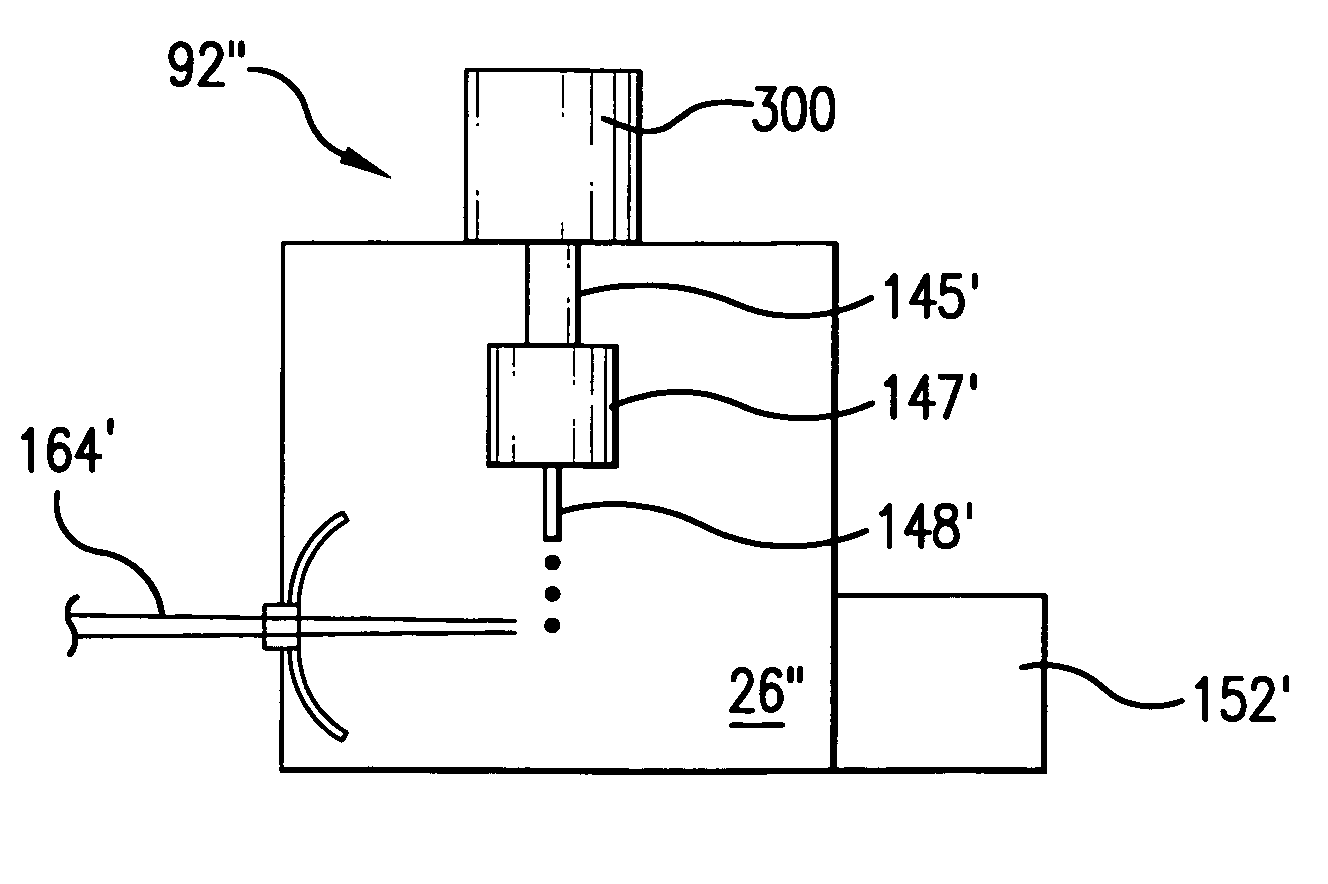

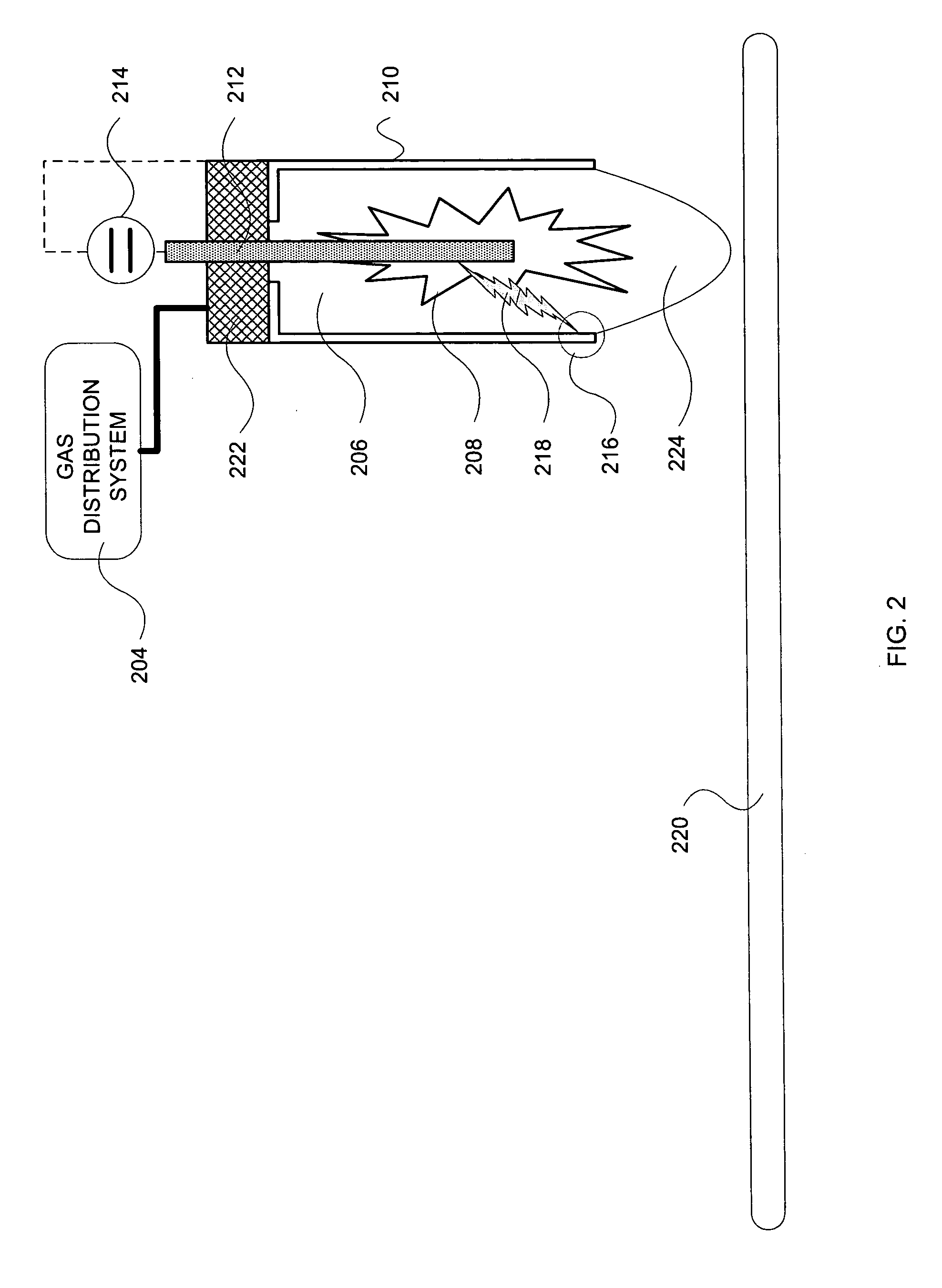

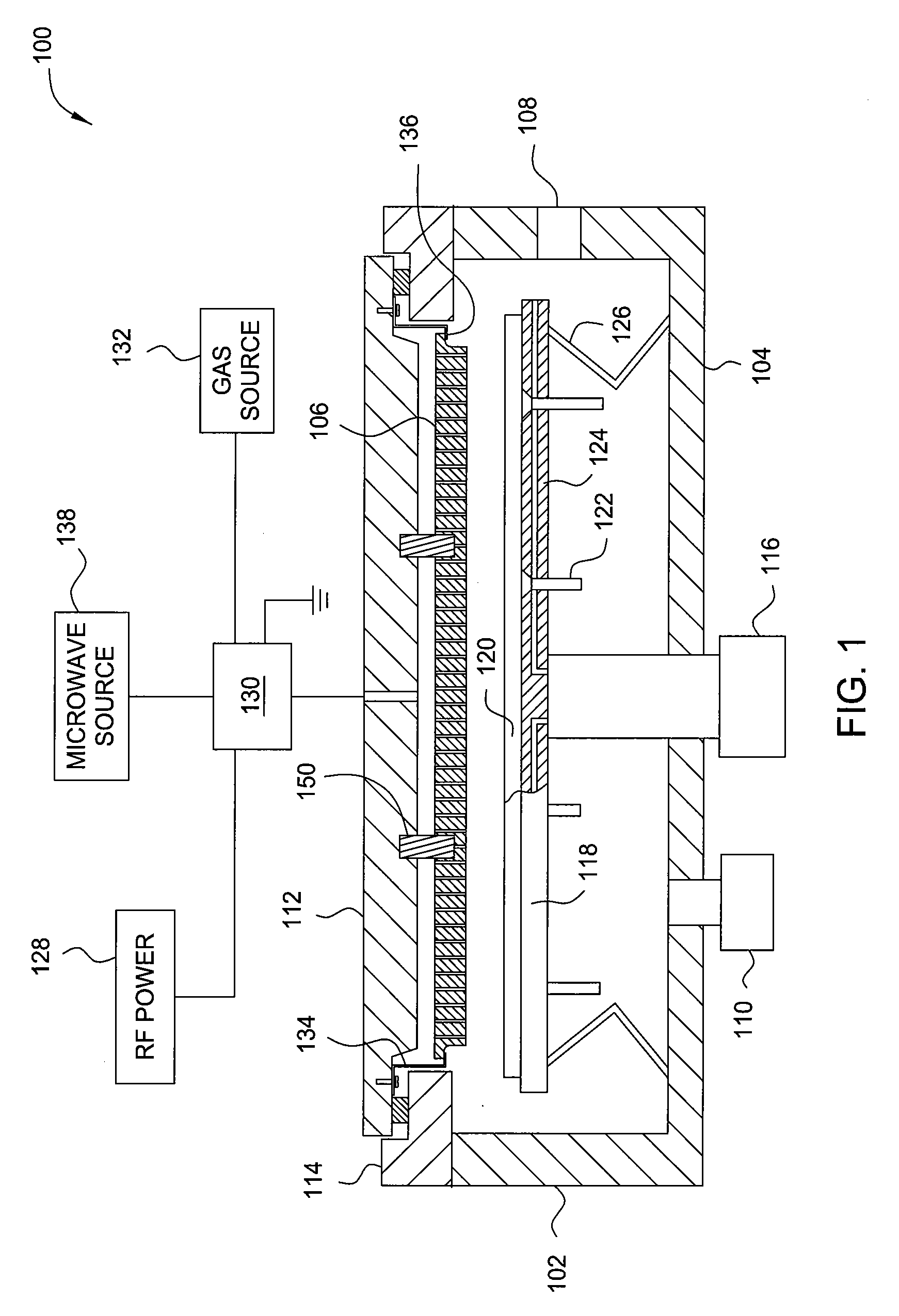

RF choke for gas delivery to an RF driven electrode in a plasma processing apparatus

ActiveUS20090022905A1Simplify chamber designSimple designTransformers/inductances coolingElectric discharge tubesRemote plasmaProduct gas

In large area plasma processing systems, process gases may be introduced to the chamber via the showerhead assembly which may be driven as an RF electrode. The gas feed tube, which is grounded, is electrically isolated from the showerhead. The gas feed tube may provide not only process gases, but also cleaning gases from a remote plasma source to the process chamber. The inside of the gas feed tube may remain at either a low RF field or a zero RF field to avoid premature gas breakdown within the gas feed tube that may lead to parasitic plasma formation between the gas source and the showerhead. By feeding the gas through an RF choke, the RF field and the processing gas may be introduced to the processing chamber through a common location and thus simplify the chamber design.

Owner:APPLIED MATERIALS INC

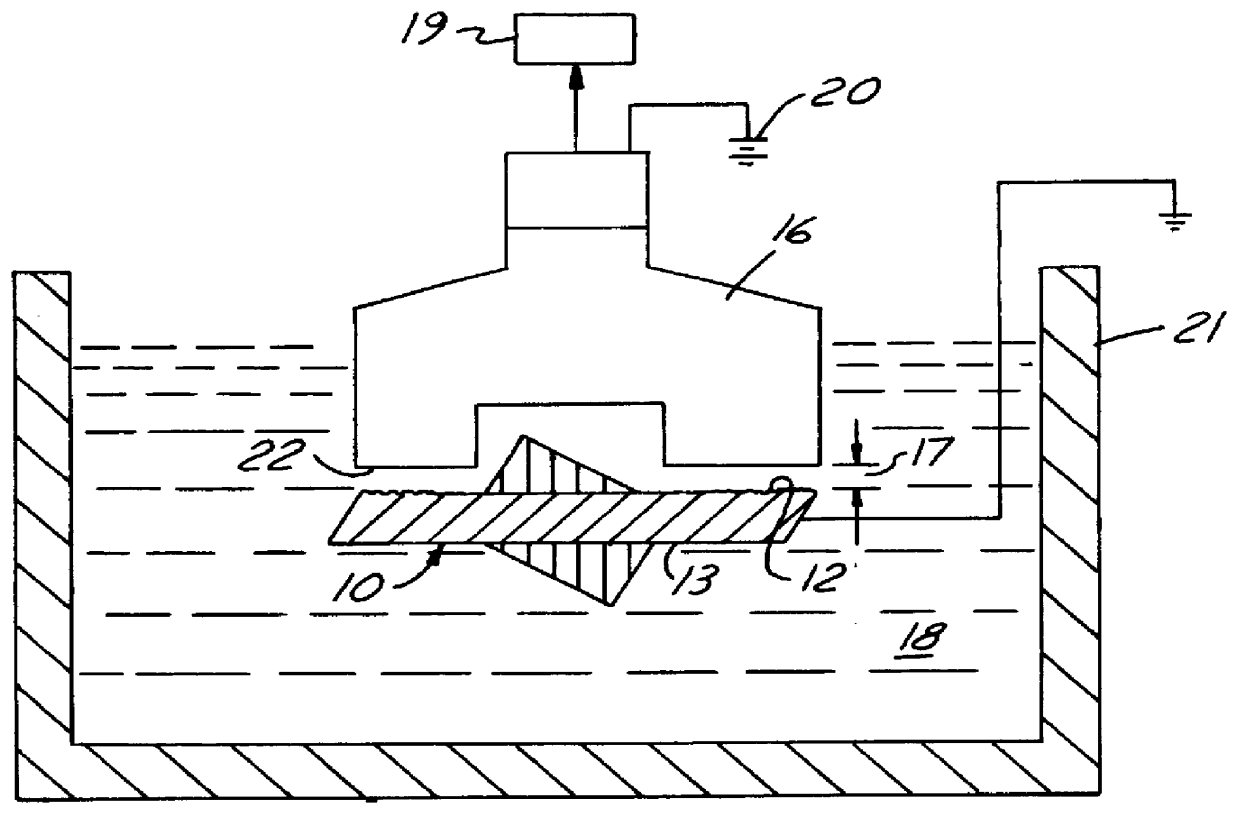

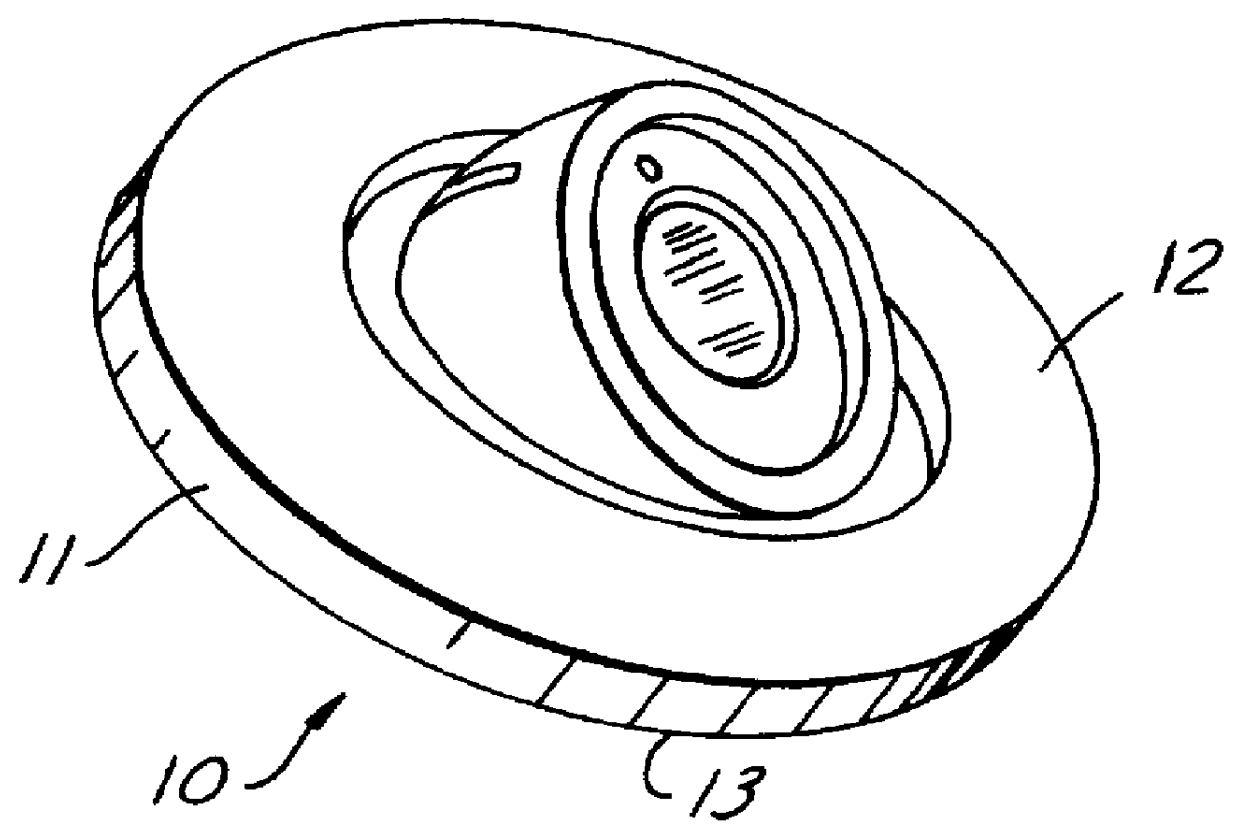

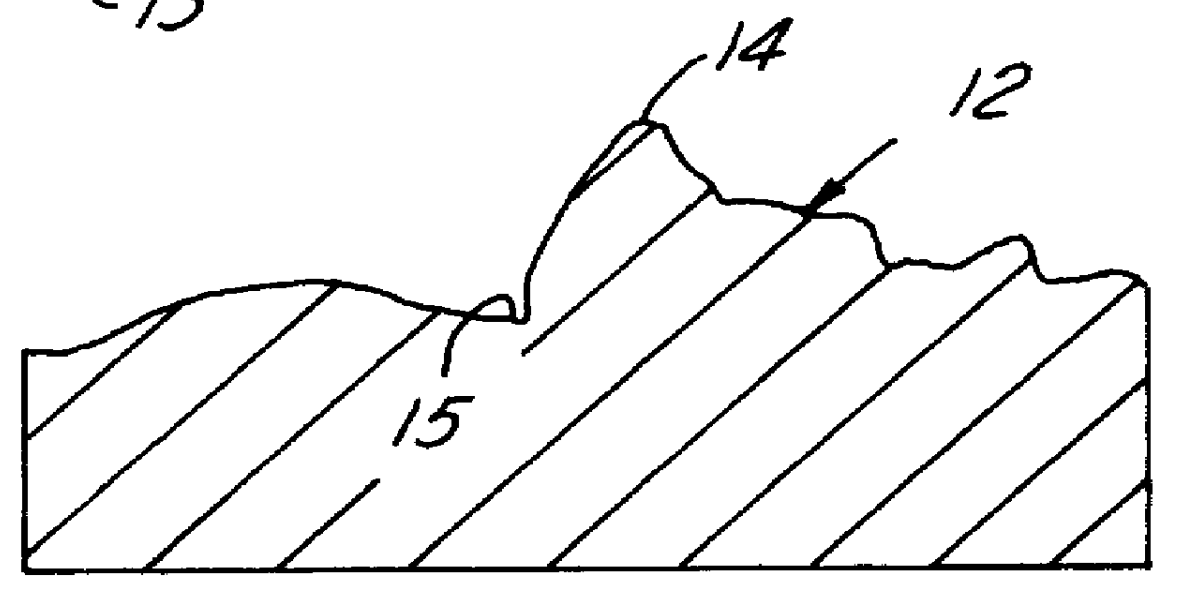

Electrochemical hardness modification of non-allotropic metal surfaces

An electrochemical method of modifying the surface hardness of a non-allotropic metal member 10, comprising: (a) forming the member to near net-shape with at least one surface 12 to be hardened; (b) subjecting the surface 12 to rapid melting and resolidification by incidence of an electrical discharge between an electrode 16 and the surface 12 closely spaced thereto, the spacing containing an electrolyte with plasma forming capability, the surface 12 being hardened by crystallographic change of the globules resulting from substitutional alloying; and (c) cropping the surface grains 29 of the surface to increase load bearing capacity while retaining liquid retention capacity.

Owner:THE RGT OF THE UNIV OF MICHIGAN

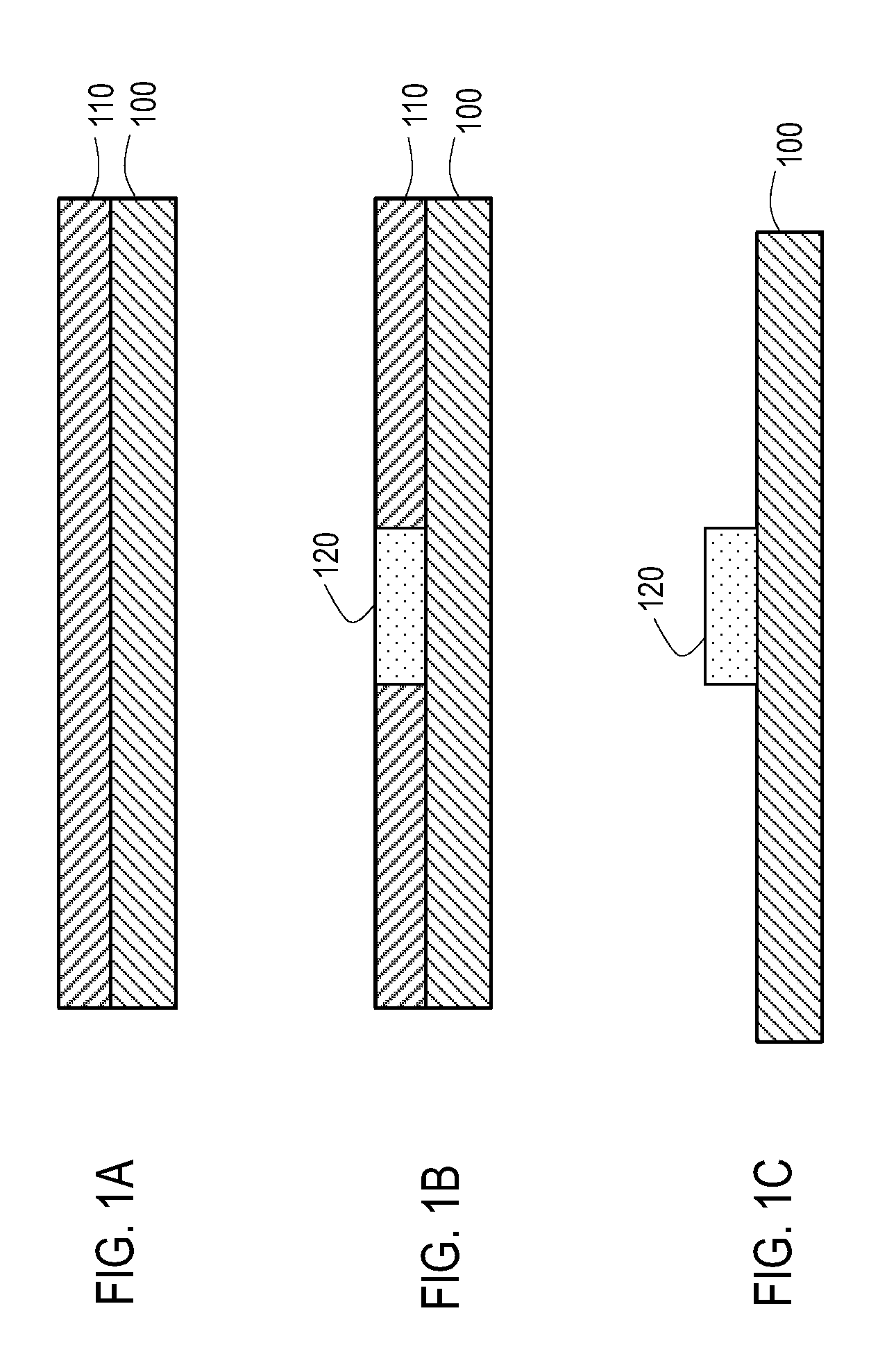

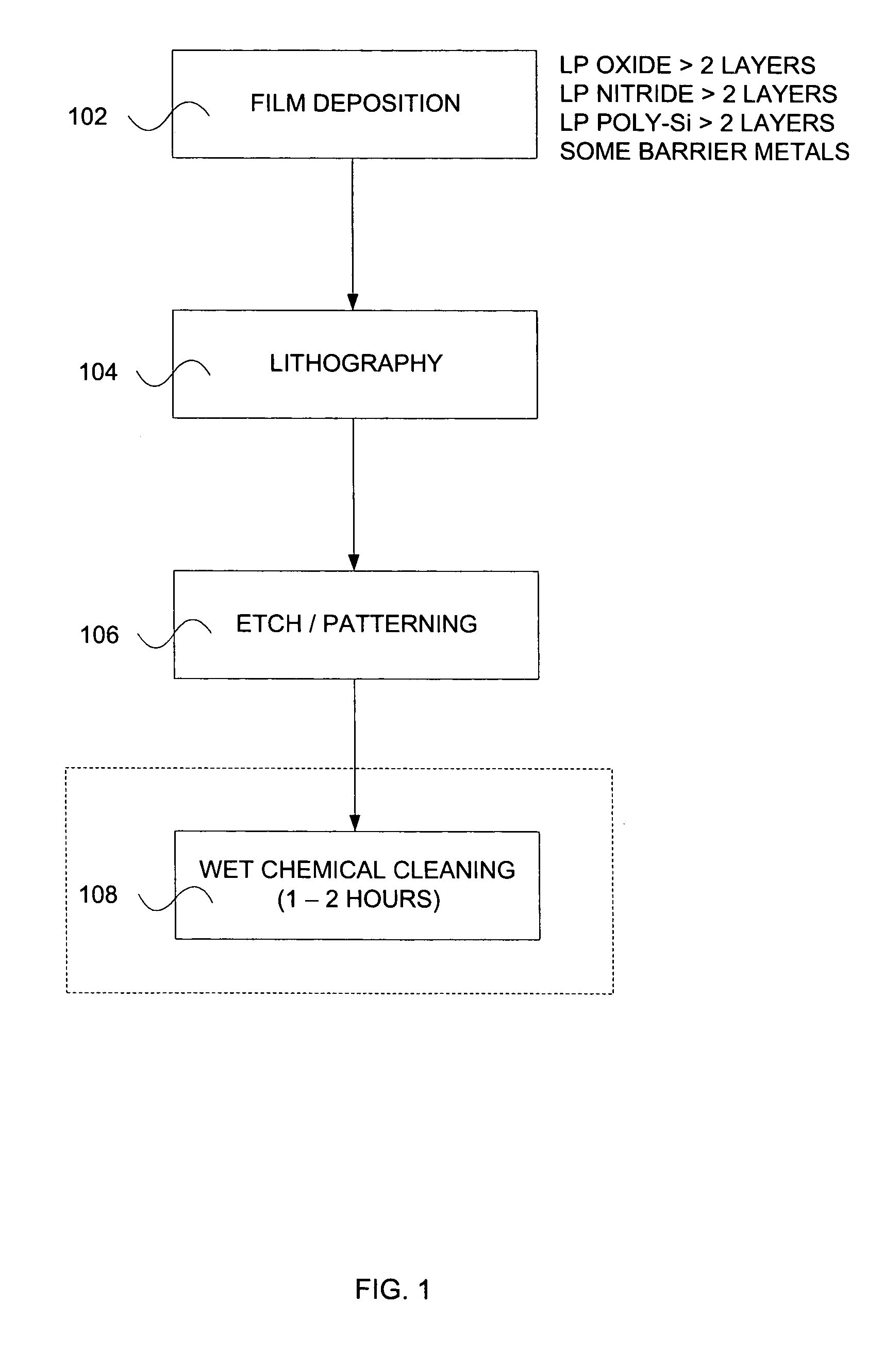

Radiation Patternable CVD Film

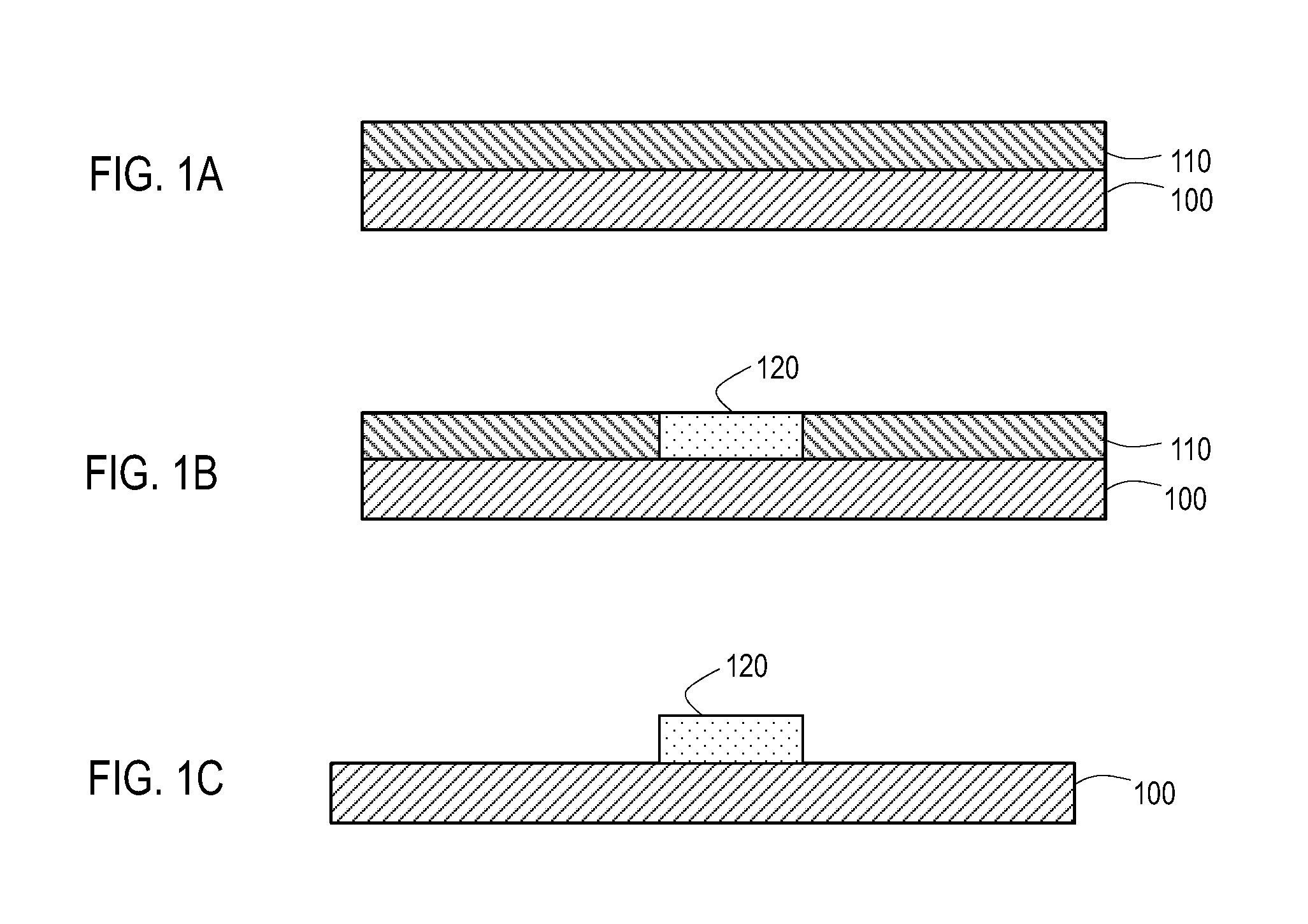

InactiveUS20120088193A1Electric discharge tubesSemiconductor/solid-state device manufacturingCross-linkGas phase

Methods for forming photoresists sensitive to radiation on a substrate are provided. Described are chemical vapor deposition methods of forming films (e.g., silicon-containing films) as photoresists using a plasma which may be exposed to radiation to form a pattern. The deposition methods utilize precursors with cross-linkable moieties that will cross-link upon exposure to radiation. Radiation may be carried out in the with or without the presence of oxygen. Exposed or unexposed areas may then be developed in an aqueous base developer.

Owner:APPLIED MATERIALS INC

Systems for protecting internal components of an EUV light source from plasma-generated debris

InactiveUS7109503B1Fully removedRadiation pyrometryRadiation/particle handlingPlasma chamberPlasma formation

Systems and methods are disclosed for protecting an EUV light source plasma production chamber optical element surface from debris generated by plasma formation. In one aspect of an embodiment of the present invention, a shield is disclosed which comprises at least one hollow tube positioned between the optical element and a plasma formation site. The tube is oriented to capture debris while allowing light to pass through the tube's lumen via reflection at relatively small angles of grazing incidence. In another aspect of an embodiment of the present invention, a shield is disclosed which is heated to a temperature sufficient to remove one or more species of debris material that has deposited on the shield. In yet another aspect of an embodiment of the present invention, a system is disclosed which a shield is moved from a light source plasma chamber to a cleaning chamber where the shield is cleaned.

Owner:ASML NETHERLANDS BV

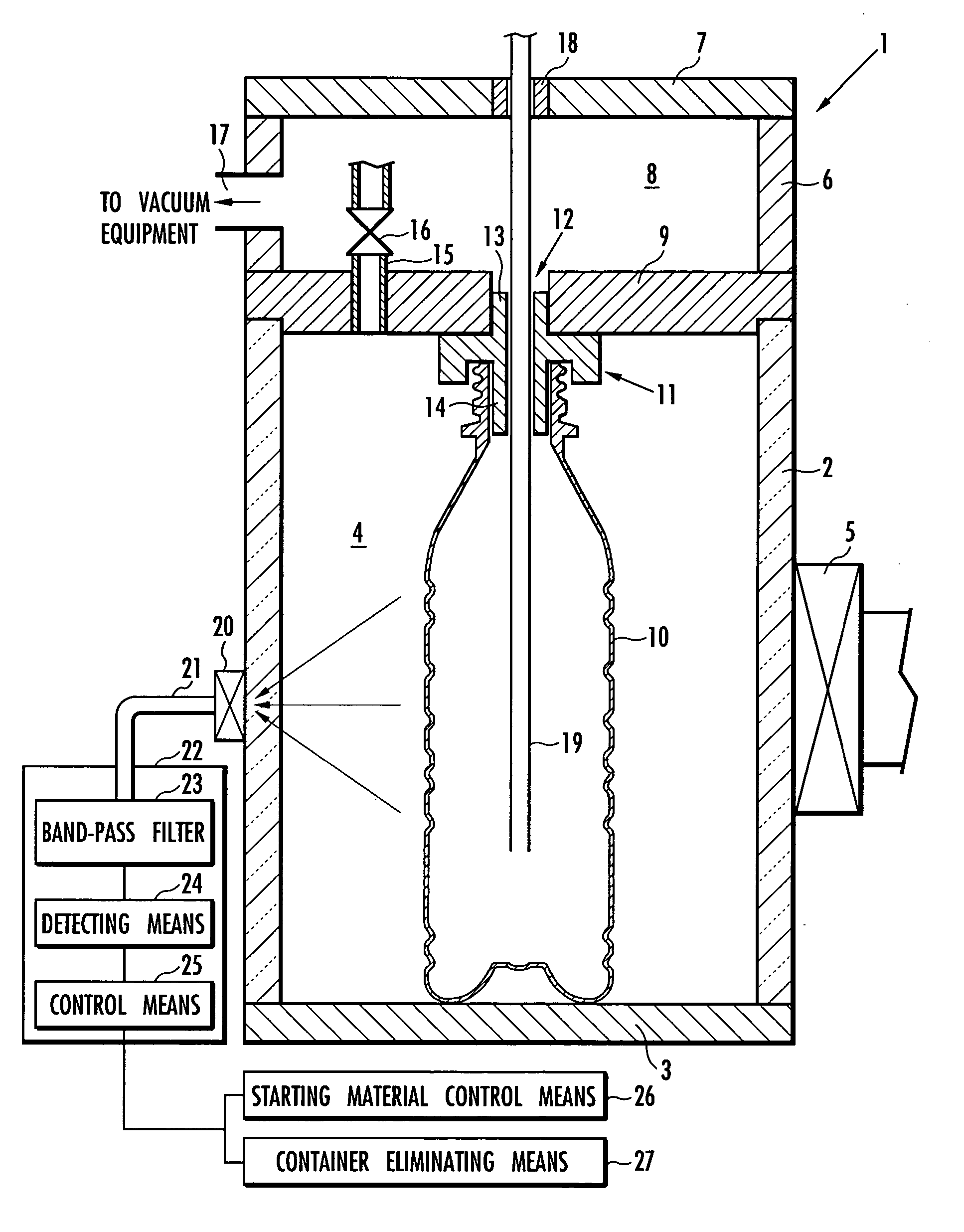

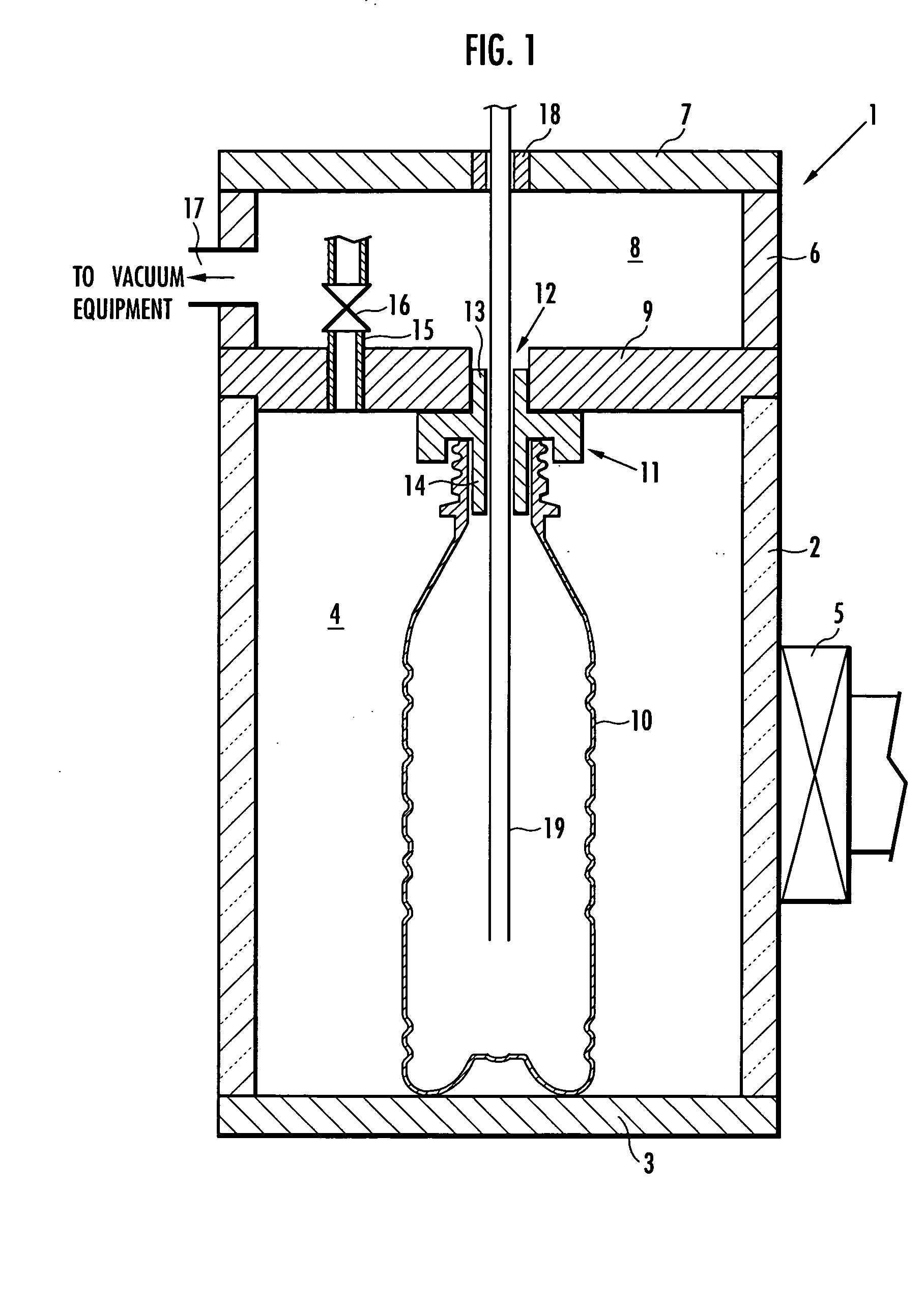

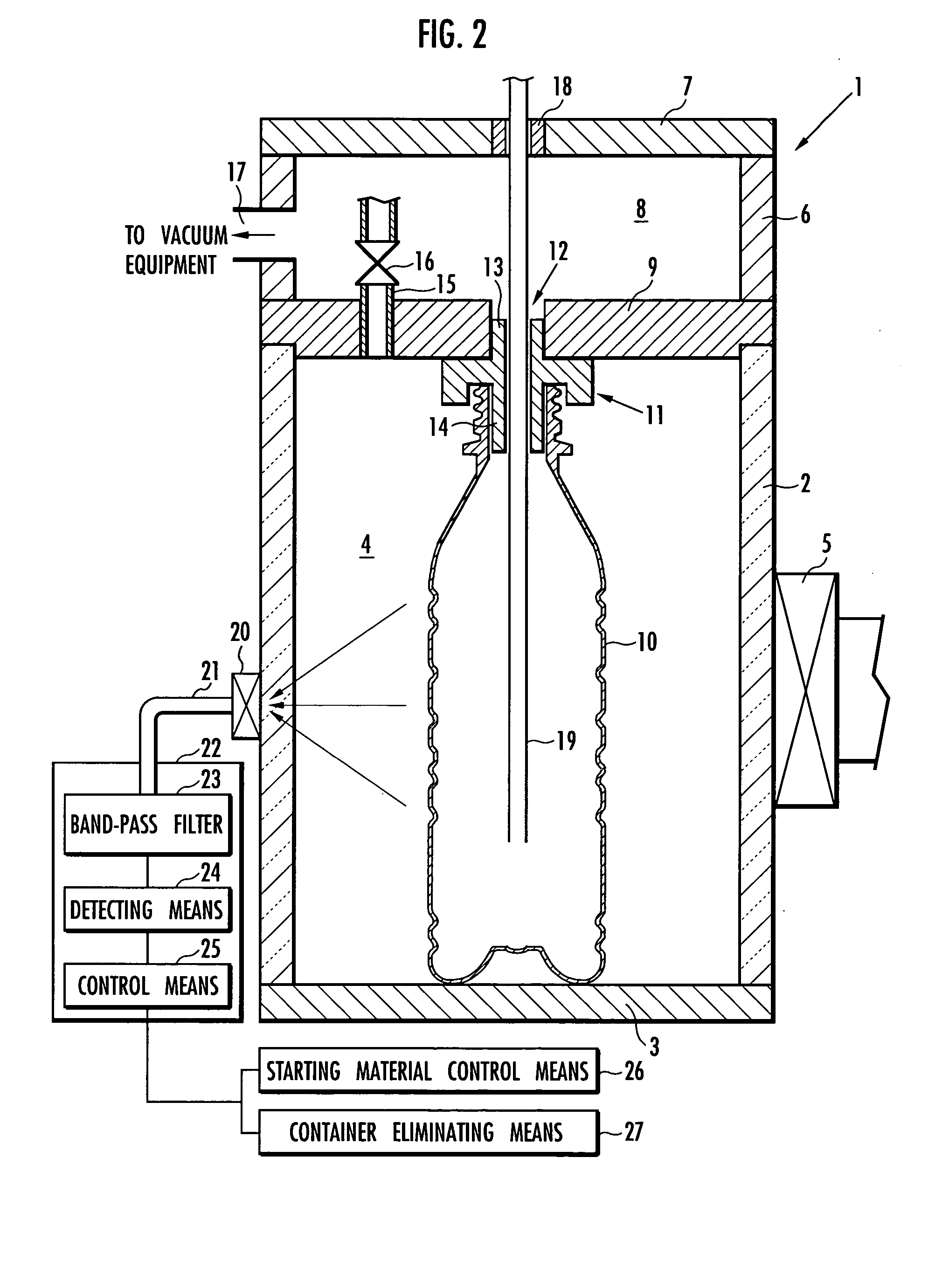

Plastic containers coated on the inner surface and process for production thereof

InactiveUS20050118365A1Excellent gas barrier performanceReduces gas barrier propertyEnvelopes/bags making machineryLiquid surface applicatorsCarbon filmNitrogen

The invention provides a plastic container with a coated inner surface having superior gas barrier properties. It further provides a plastic container with a coated inner surface capable of suppressing elution of minor components from the resin, in addition to having the superior gas barrier properties. The container has on its inner surface an amorphous carbon film formed by plasma CVD from a starting material containing carbon atoms and whose main component is carbon. In the carbon film, when the number of carbon atoms contained in the film is 100, the ratio of the number of nitrogen atoms is 15 or less, or the ratio of the number of oxygen atoms is 20 or less, or the ratio of the total number of nitrogen atoms and oxygen atoms is 27 or less. Alternatively, when the number of carbon atoms contained in the film is 100, the ratio of the number of nitrogen atoms is 15 or less, the ratio of the number of oxygen atoms is 20 or less, and the ratio of the total number of nitrogen atoms and oxygen atoms is 27 or less. The amorphous carbon film exhibits an oxygen permeability of 20×10−5 ml / day / cm2 or less.

Owner:HOKKAN HLDG

Rpsc and RF feedthrough

InactiveUS20090151636A1Electric discharge tubesChemical vapor deposition coatingRemote plasmaPower flow

The present invention generally comprises an apparatus having an RF choke and a remote plasma source combined into a single unit. Process gases may be introduced to the chamber via the showerhead assembly which may be driven as an RF electrode. The gas feed tube may provide process gases and the cleaning gases to the process chamber. The inside of the gas feed tube may remain at a zero RF field to avoid premature gas breakdown within the gas feed tube that may lead to parasitic plasma formation between the gas source and the showerhead during processing. Igniting the cleaning gas plasma within the gas feed tube permits the plasma to be ignited closer to the processing chamber. Thus, RF current travels along the outside of the apparatus during deposition and microwave current ignites a plasma within the apparatus before feeding the plasma to the processing chamber.

Owner:APPLIED MATERIALS INC

Method and apparatus for generating X-ray or EUV radiation

InactiveCN1466860AIncrease brightnessX-ray tube electrodesSemiconductor/solid-state device manufacturingSoft x rayRadiation

In a method and an apparatus for generating X-ray or EUV radiation, an electron beam is brought to interact with a propagating target jet, typically in a vacuum chamber. The target jet is formed by urging a liquid substance under pressure through an outlet opening. Hard X-ray radiation may be generated by converting the electron-beam energy to Bremsstrahlung and characteristic line emission, essentially without heating the jet to a plasma-forming temperature. Soft X-ray or EUV radiation may be generated by the electron beam heating the jet to a plasma-forming temperature.

Owner:伊克斯勒姆股份公司

Film-forming system, film-forming method, insulating film, dielectric film, piezoelectric film, ferroelectric film, piezoelectric element and liquid discharge system

InactiveUS20080081128A1Quality improvementPiezoelectric/electrostrictive device manufacture/assemblyElectric discharge tubesDielectricForming gas

A film forming system includes a vacuum chamber introduction and discharge of film-forming gas into and from which are capable. A target holder is disposed in the vacuum chamber to hold a target, a substrate holder is opposed to the target holder and holds a film-forming substrate on which film is formed and a plasma forming portion generates plasma between the target holder and the film-forming substrate. The film-forming system is characterized by having a shield which surrounds the outer peripheral surface of the target holder facing the substrate.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com