Patents

Literature

2606 results about "Plasma generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

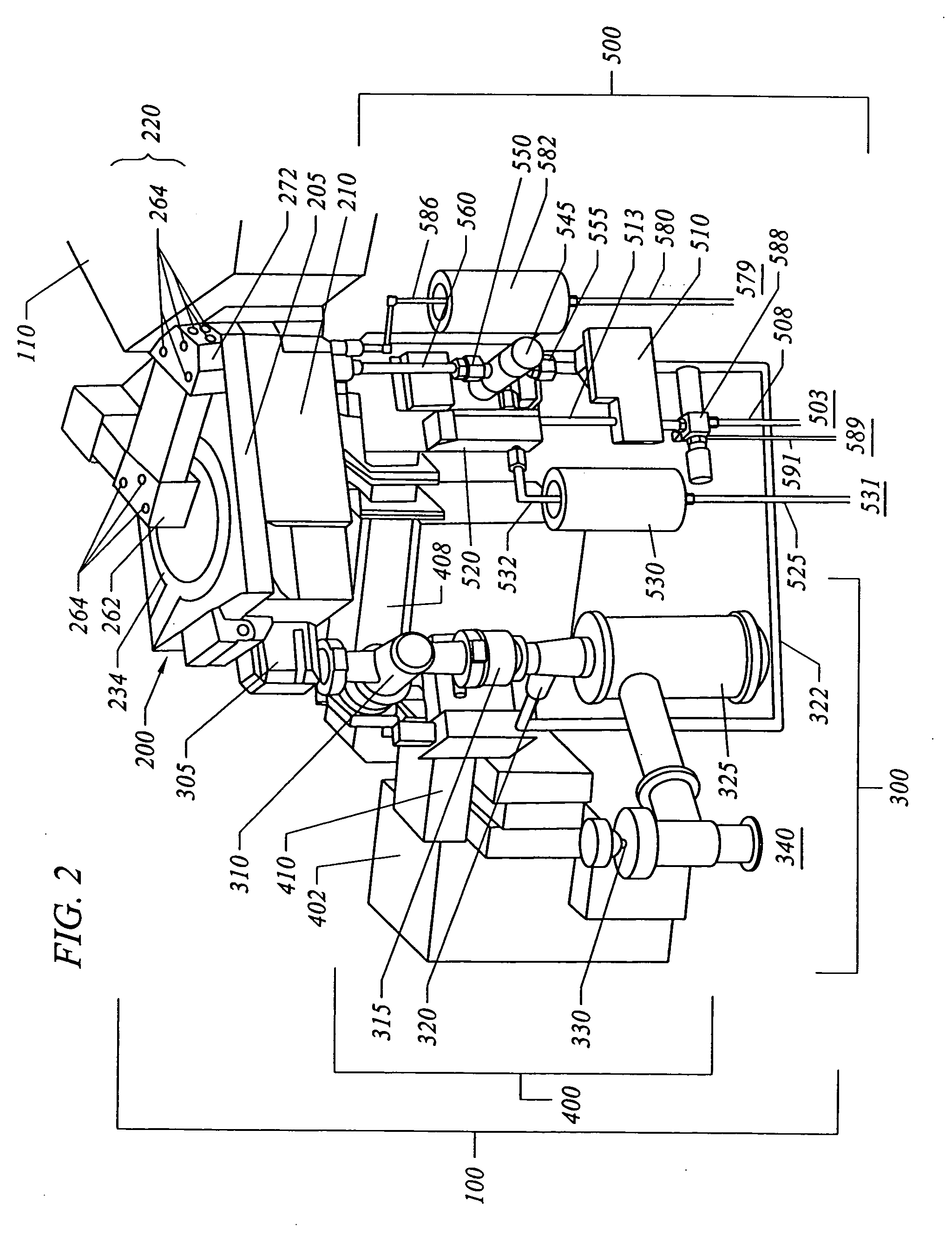

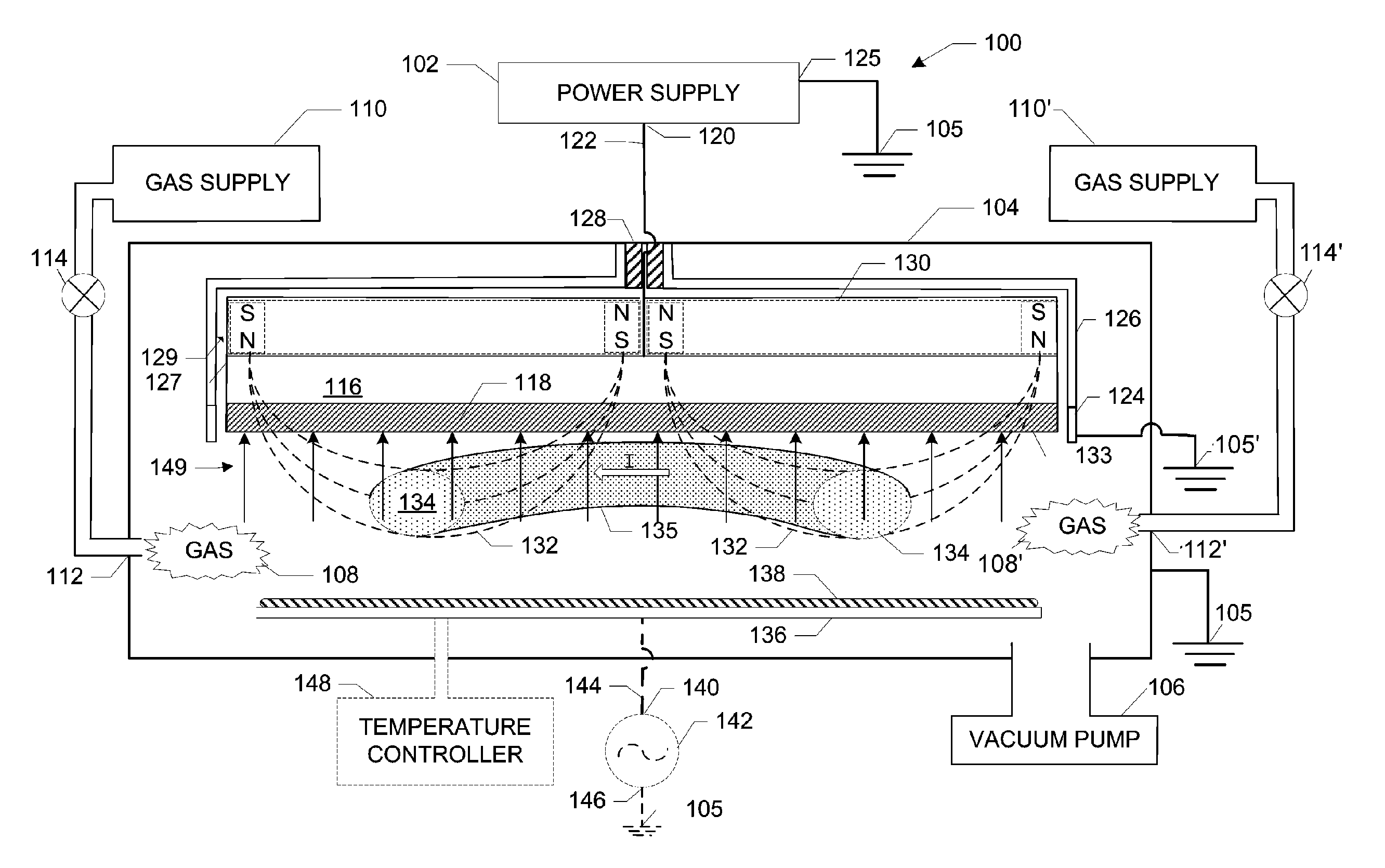

Apparatus and process for plasma-enhanced atomic layer deposition

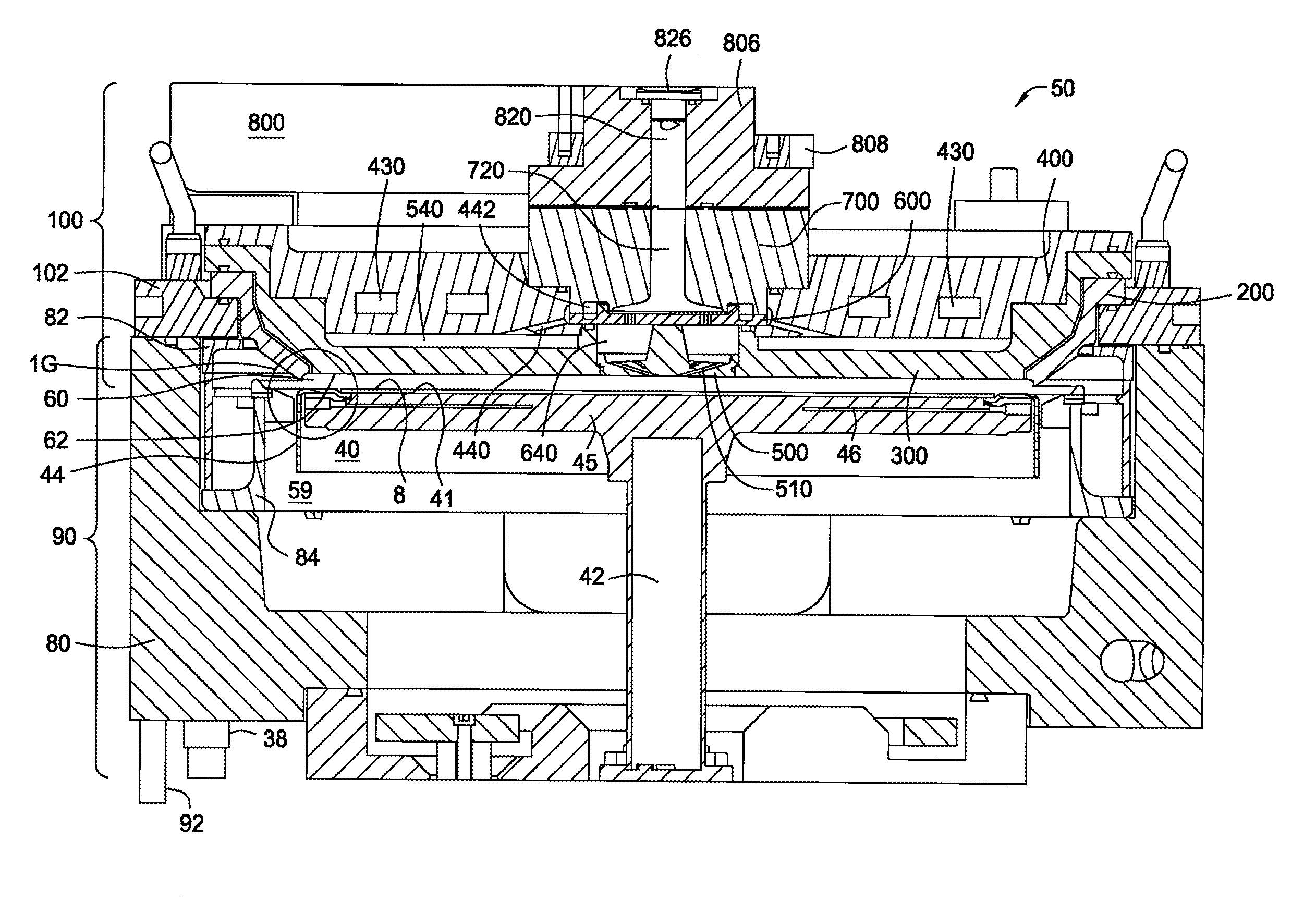

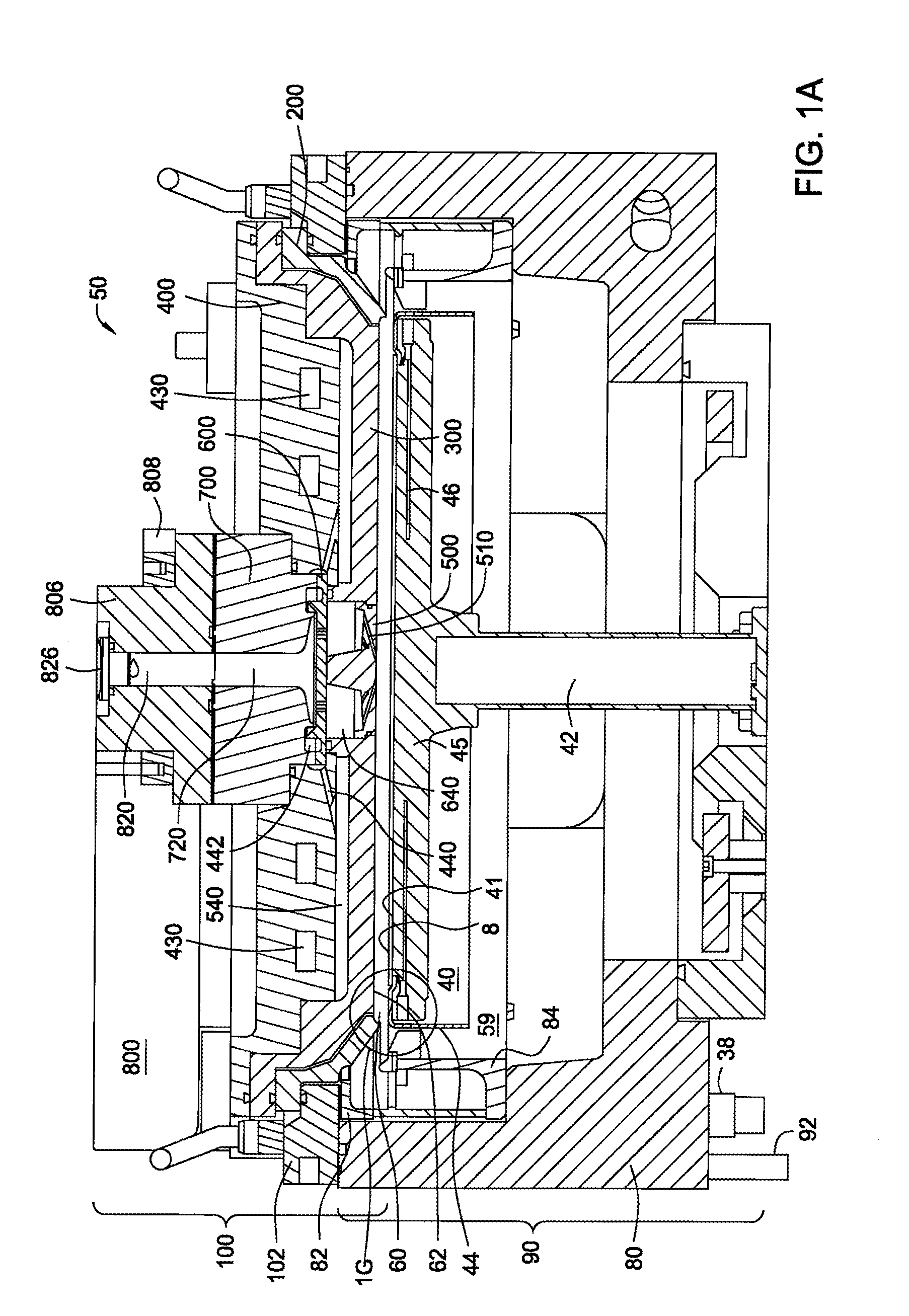

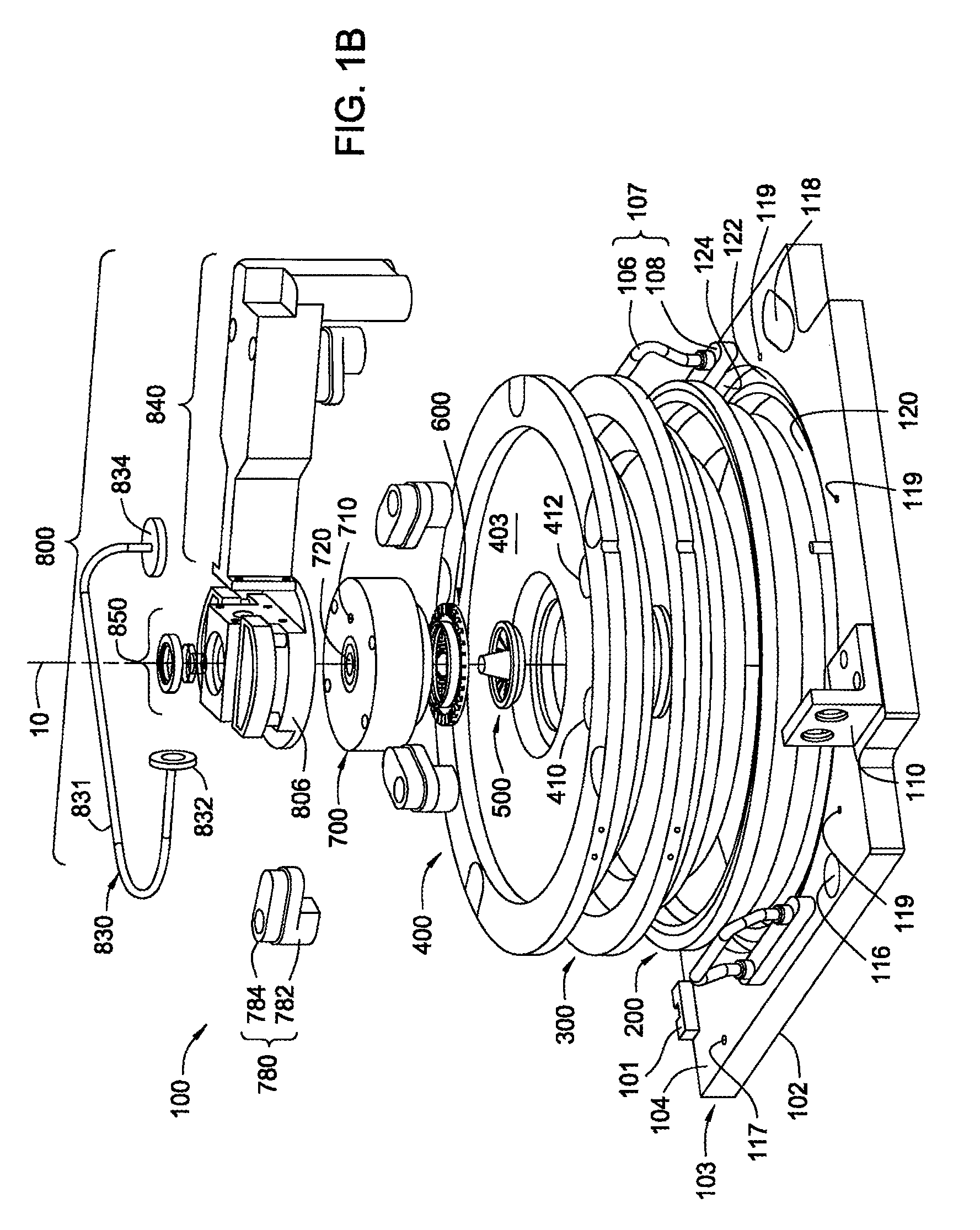

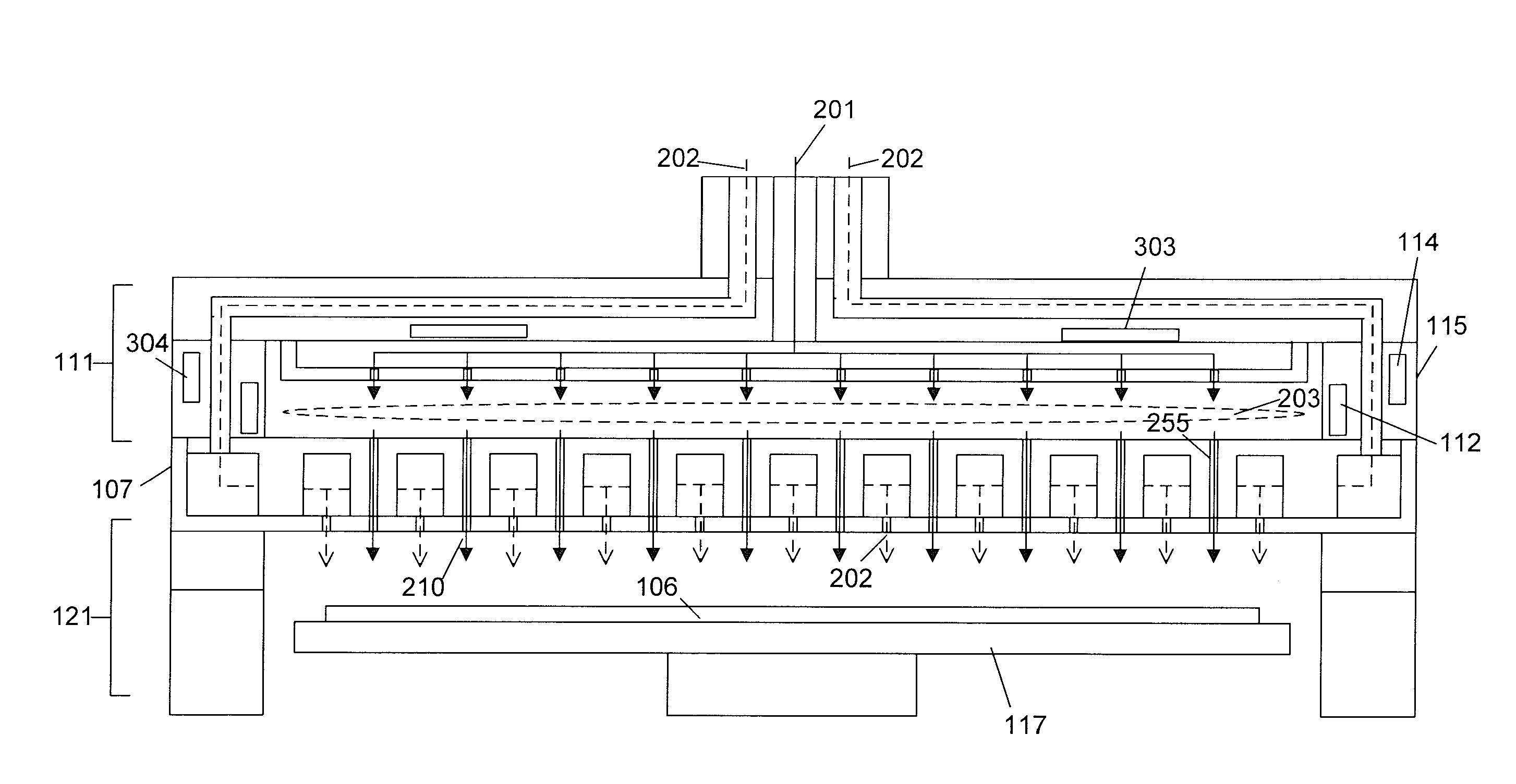

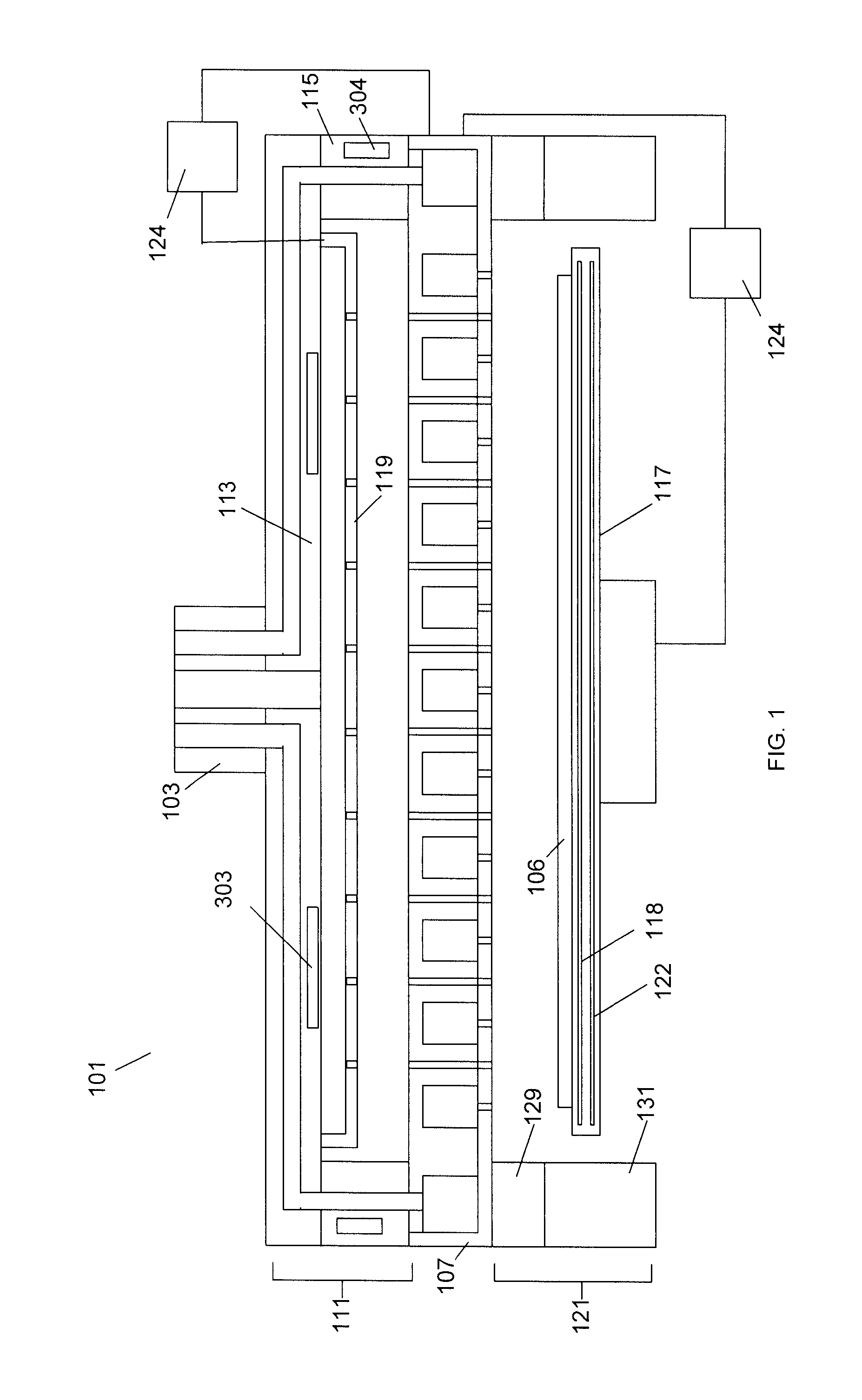

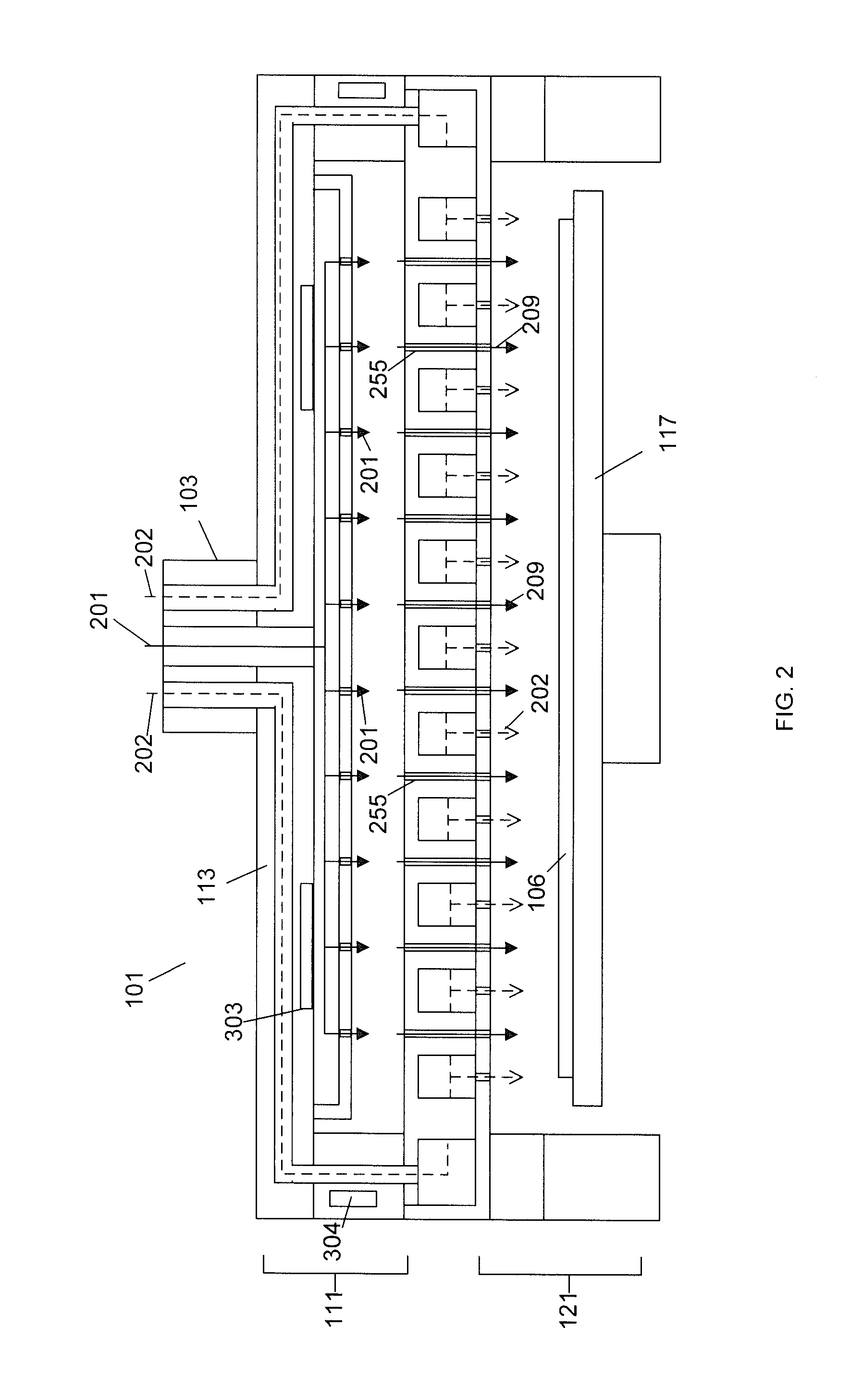

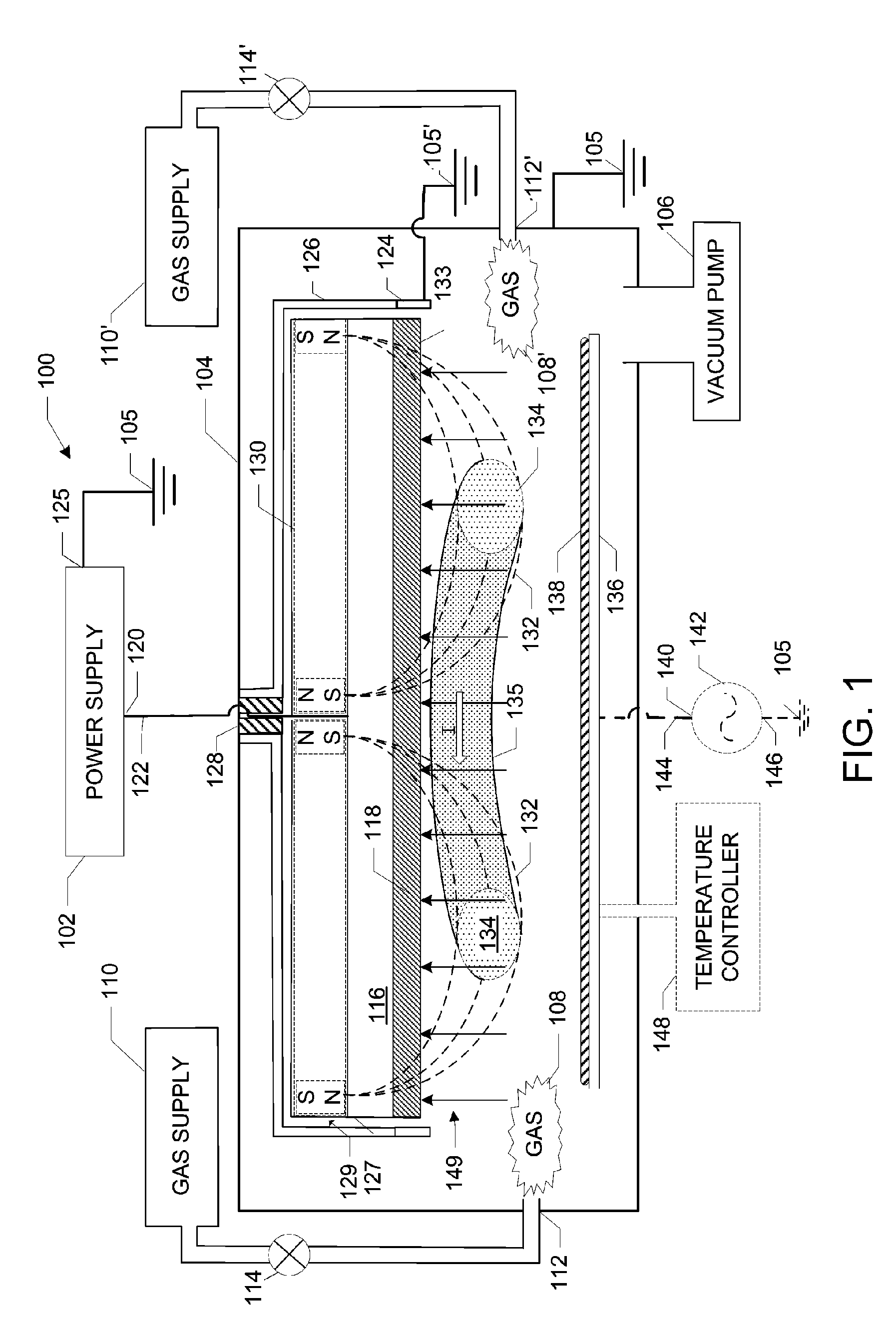

Embodiments of the invention provide an apparatus configured to form a material during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a process chamber is configured to expose a substrate to a sequence of gases and plasmas during a PE-ALD process. The process chamber comprises components that are capable of being electrically insulated, electrically grounded or RF energized. In one example, a chamber body and a gas manifold assembly are grounded and separated by electrically insulated components, such as an insulation cap, a plasma screen insert and an isolation ring. A showerhead, a plasma baffle and a water box are positioned between the insulated components and become RF hot when activated by a plasma generator. Other embodiments of the invention provide deposition processes to form layers of materials within the process chamber.

Owner:APPLIED MATERIALS INC

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20100255625A1Comparable and good performanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingPlasma generatorProduct gas

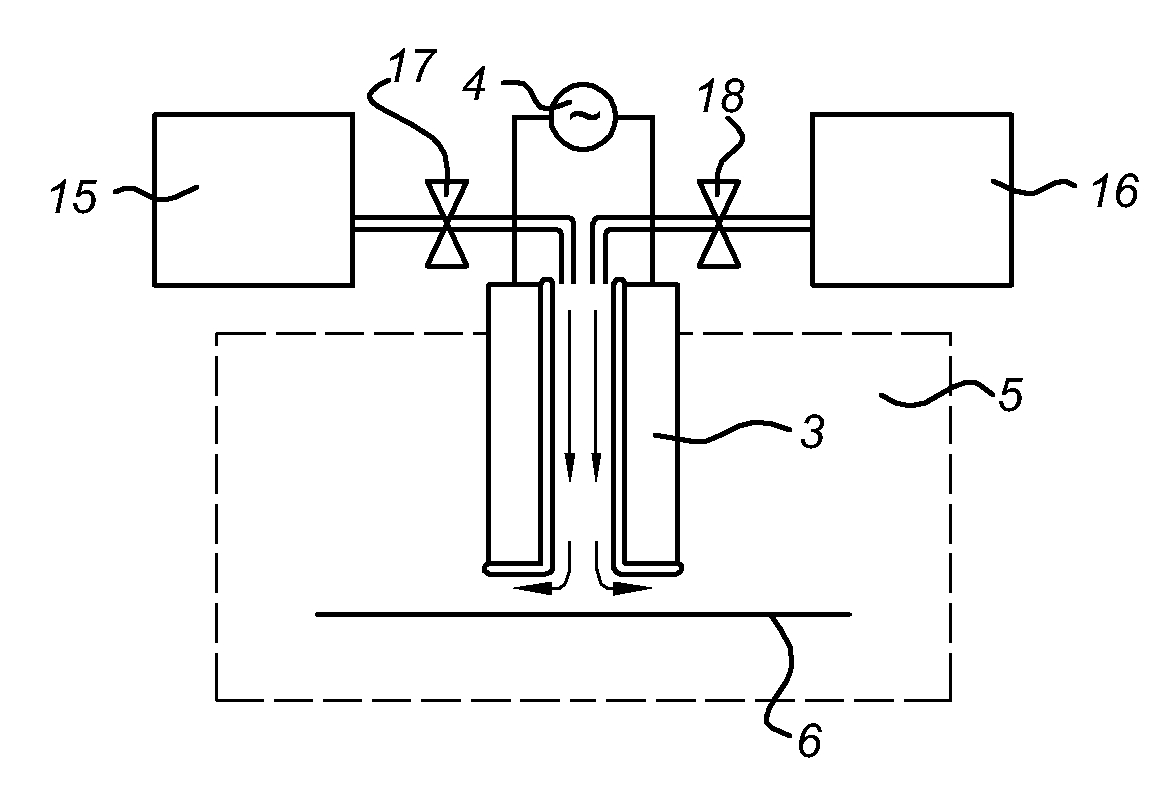

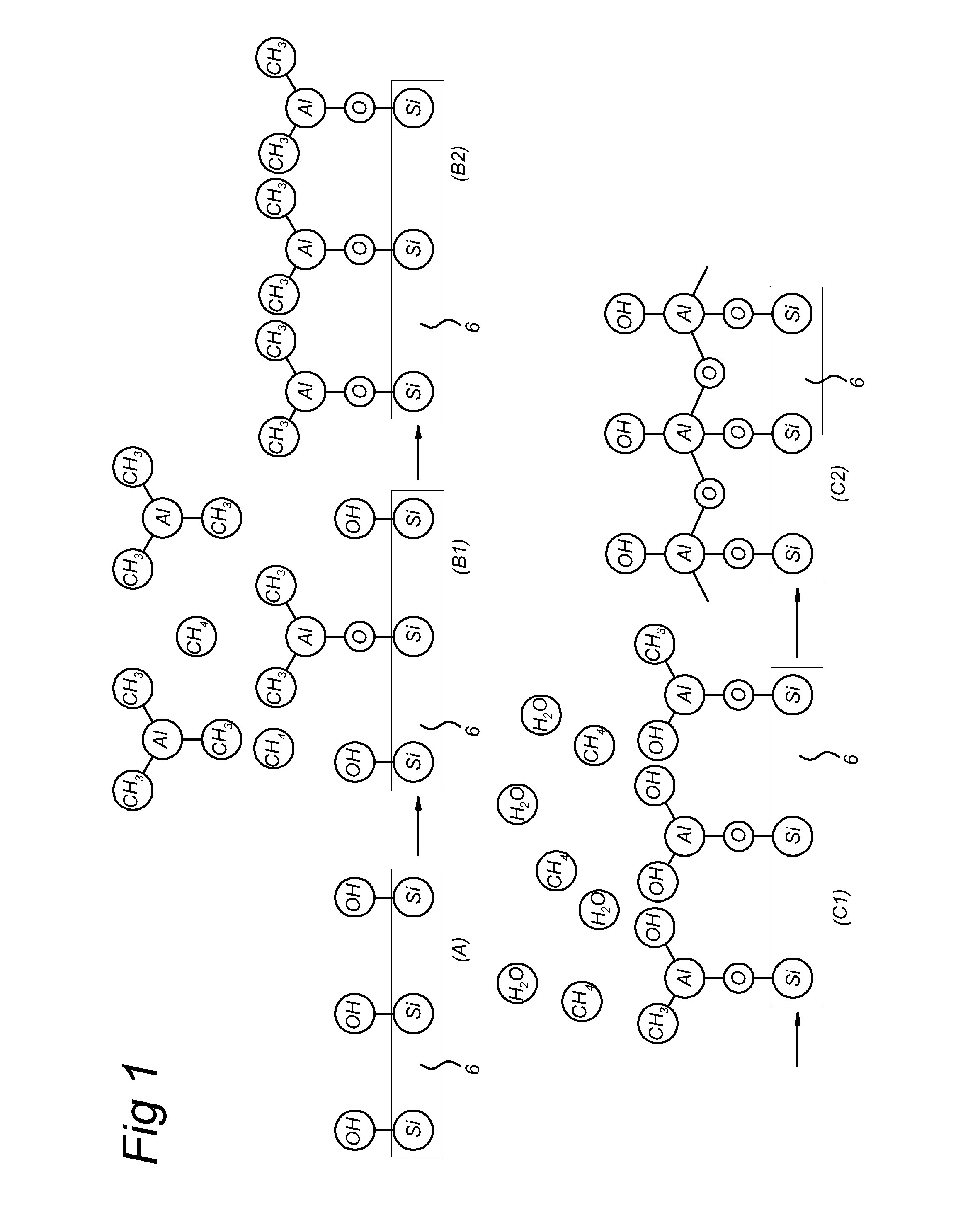

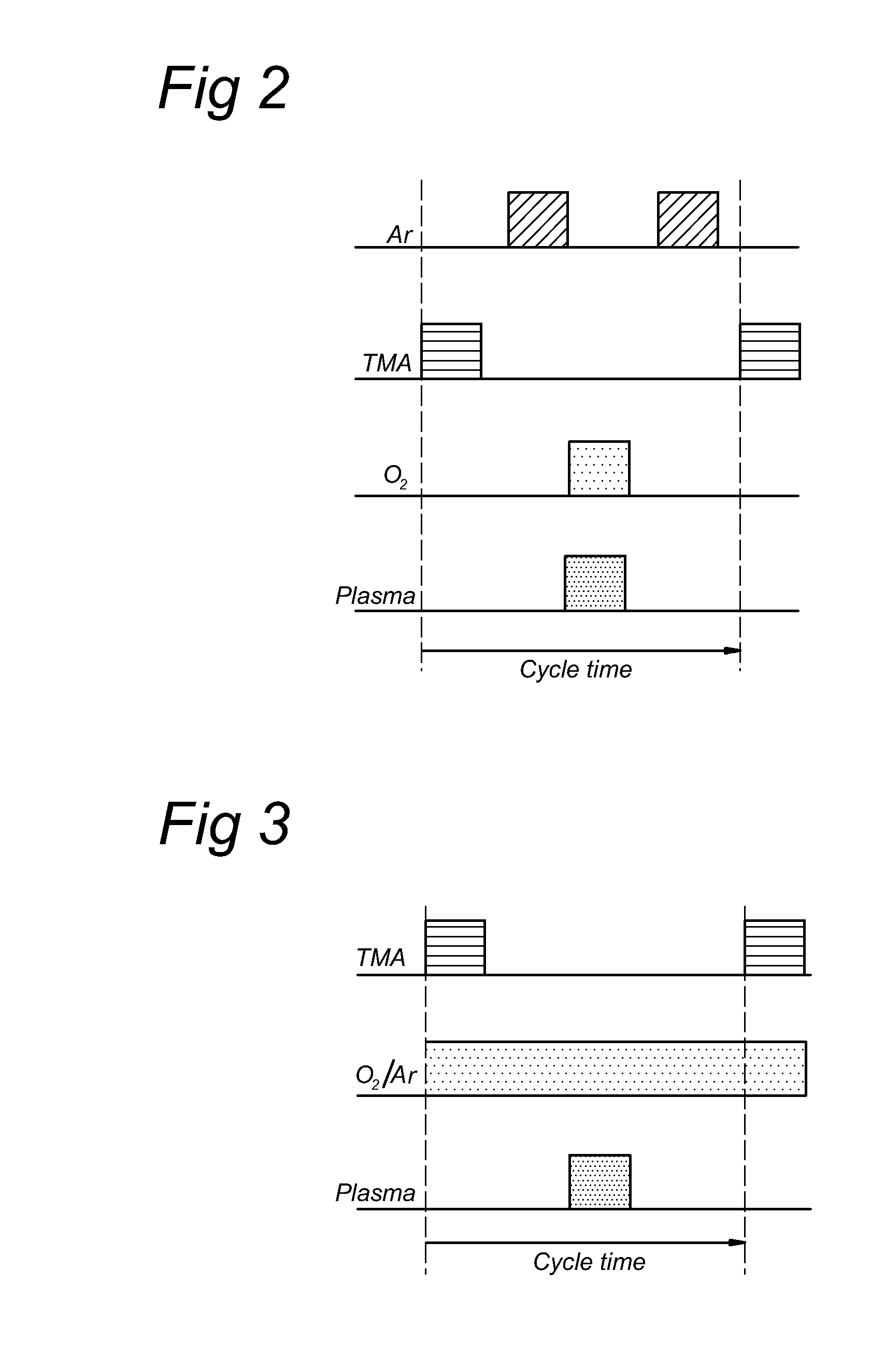

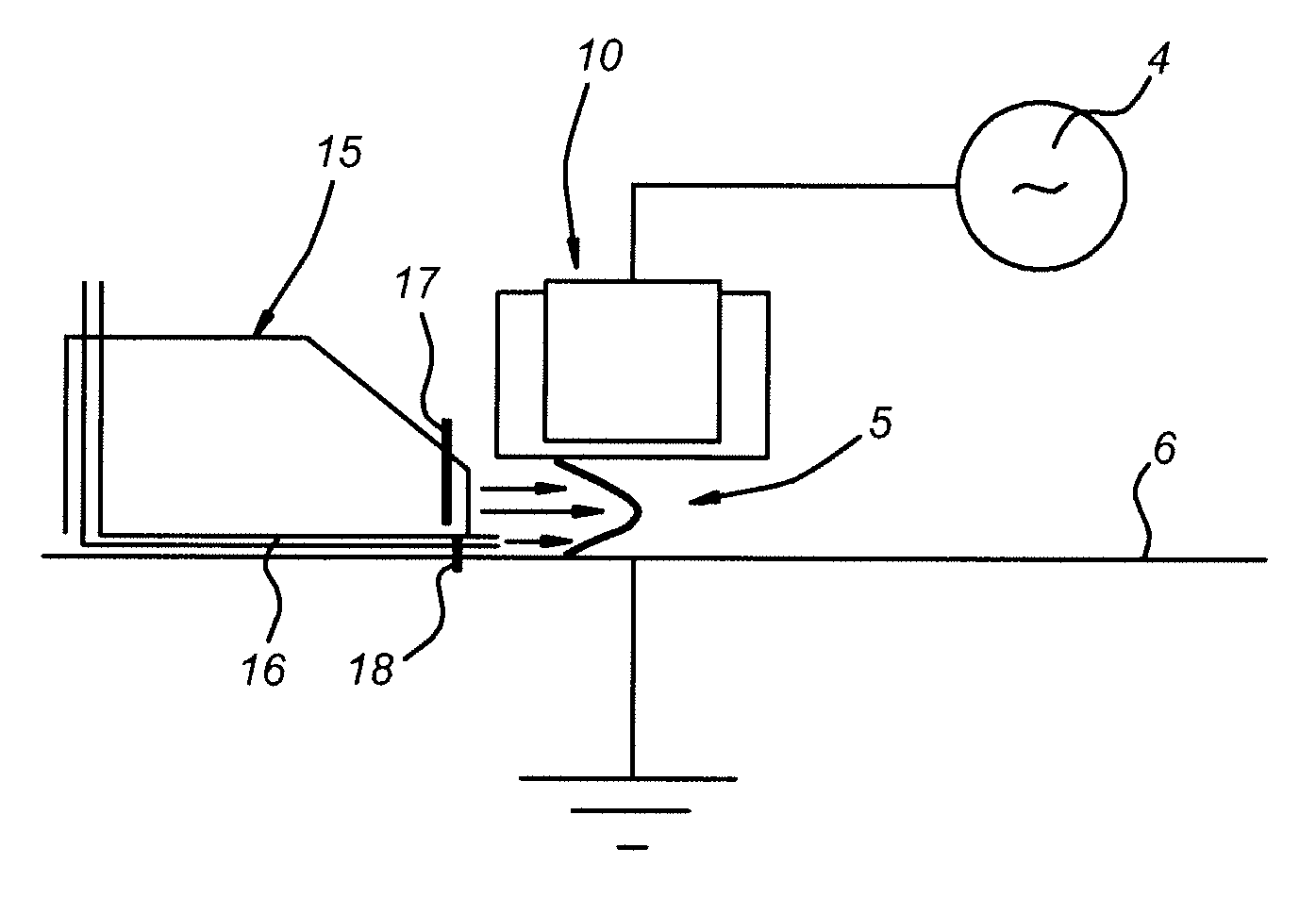

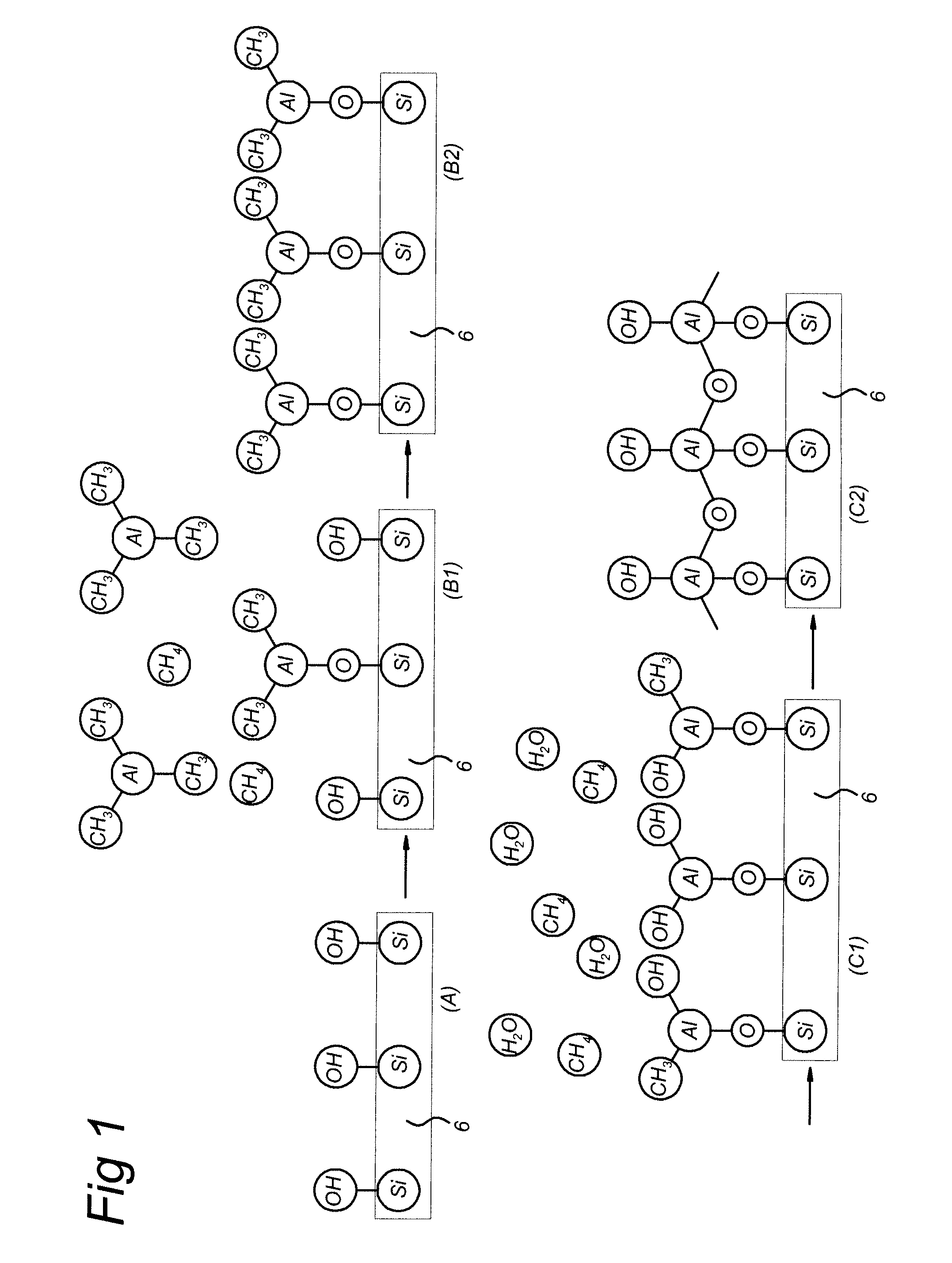

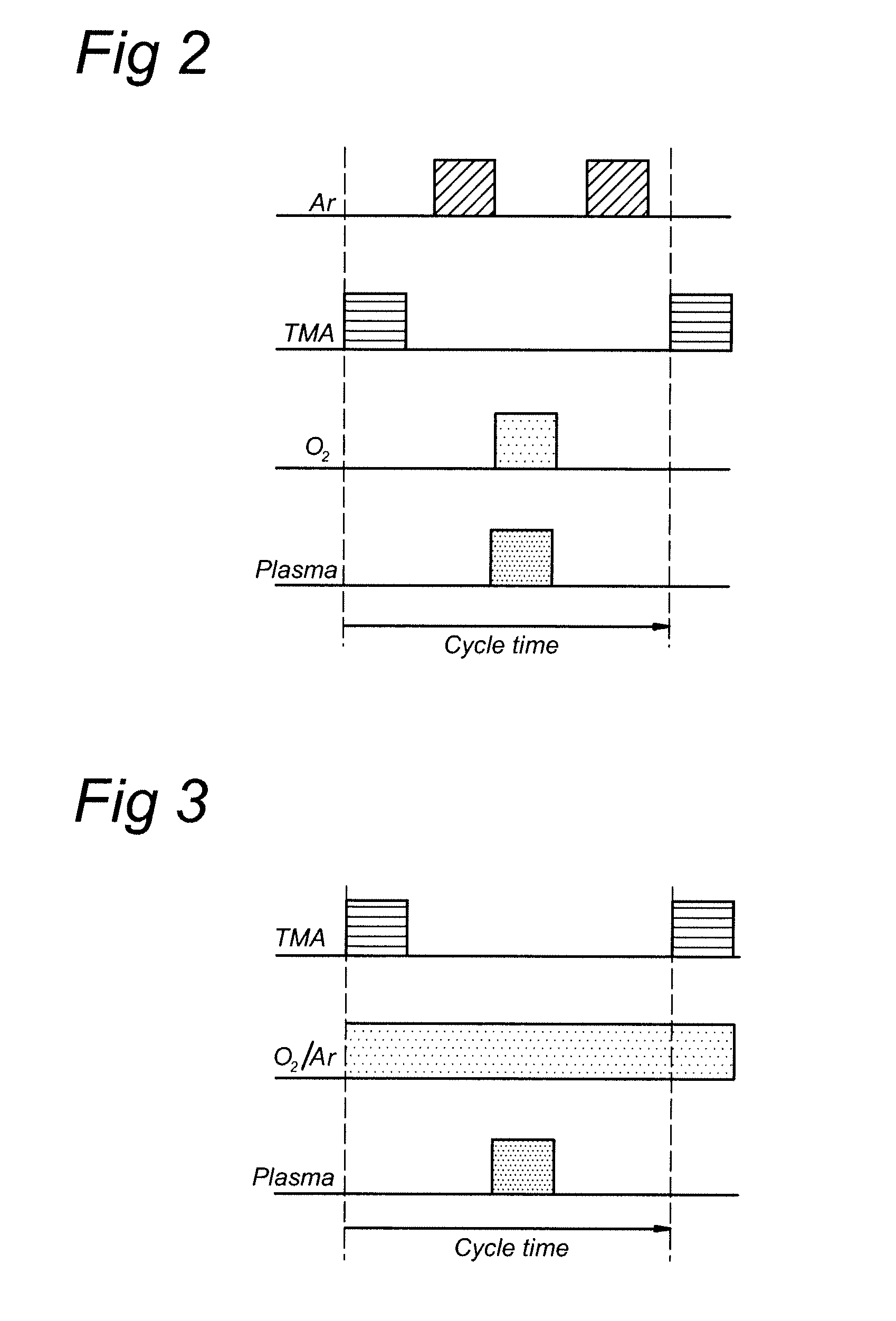

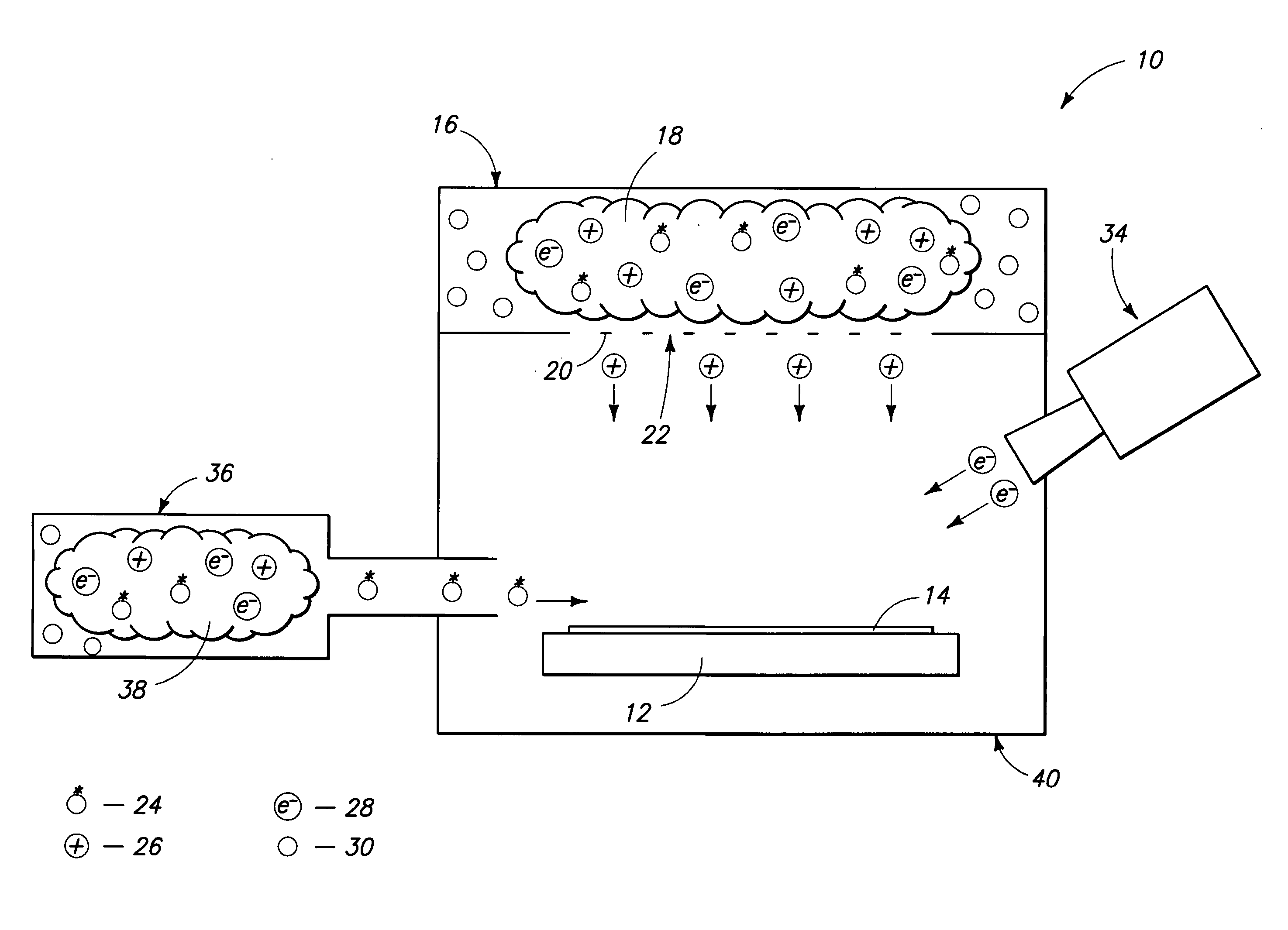

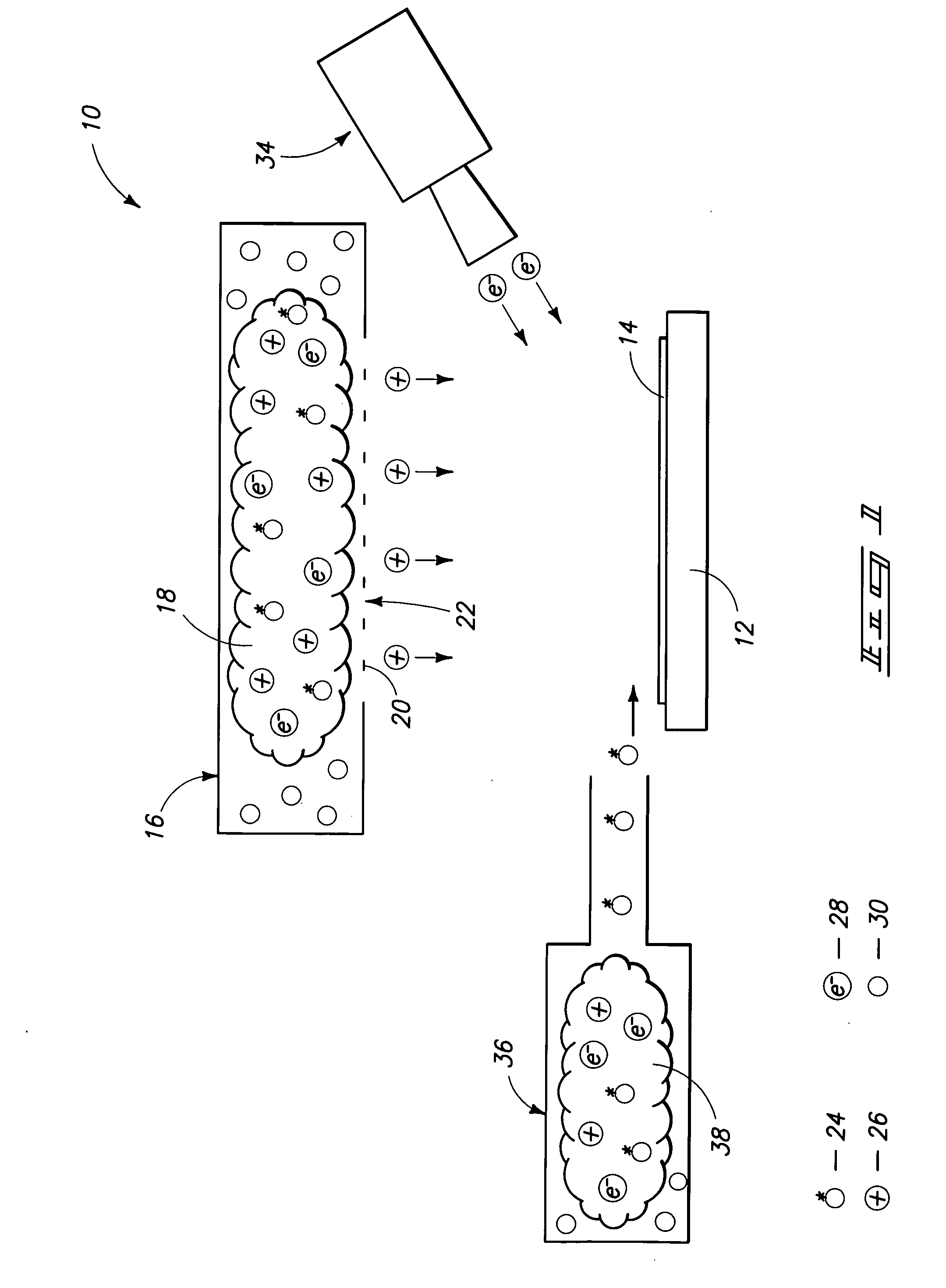

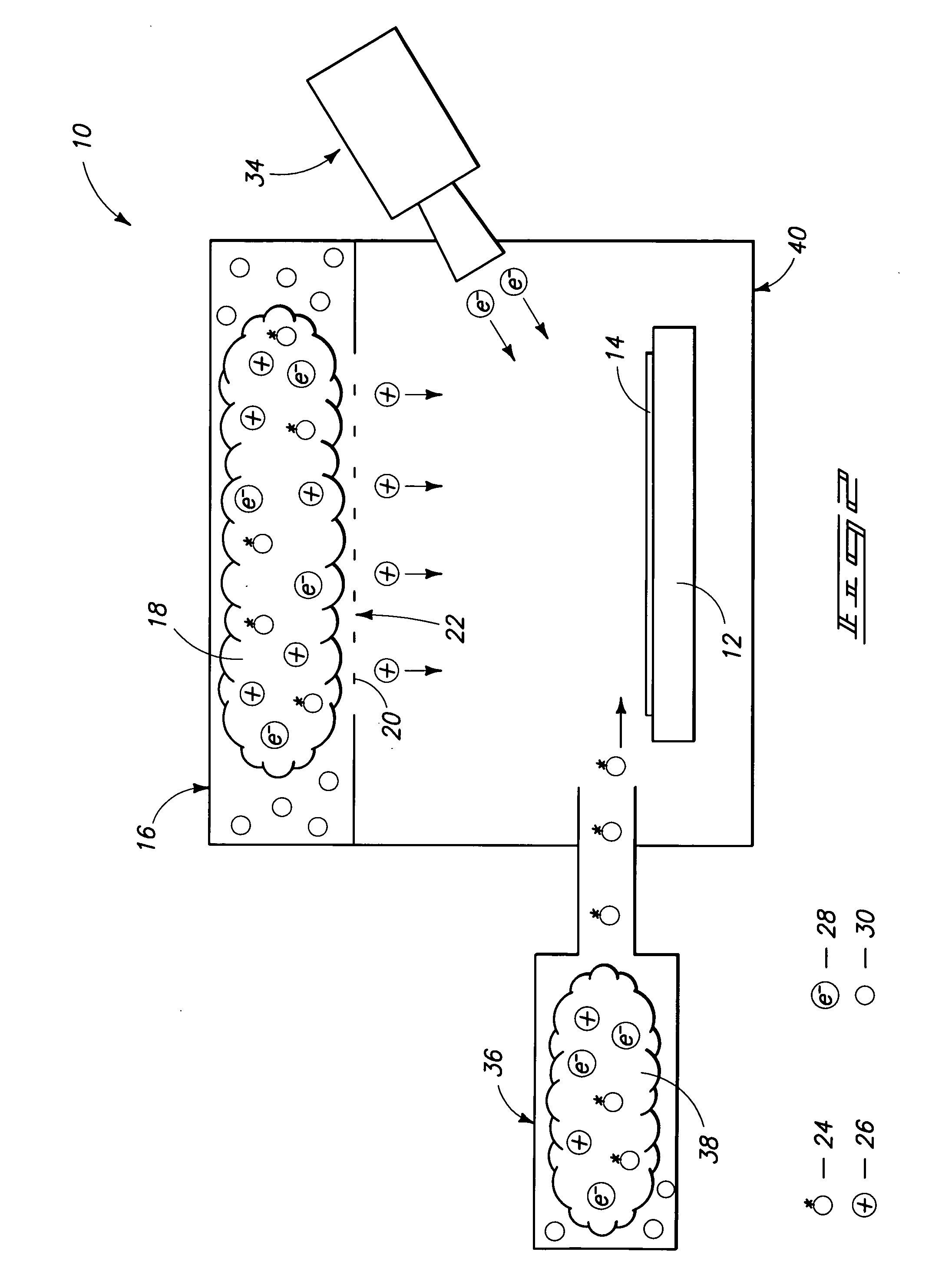

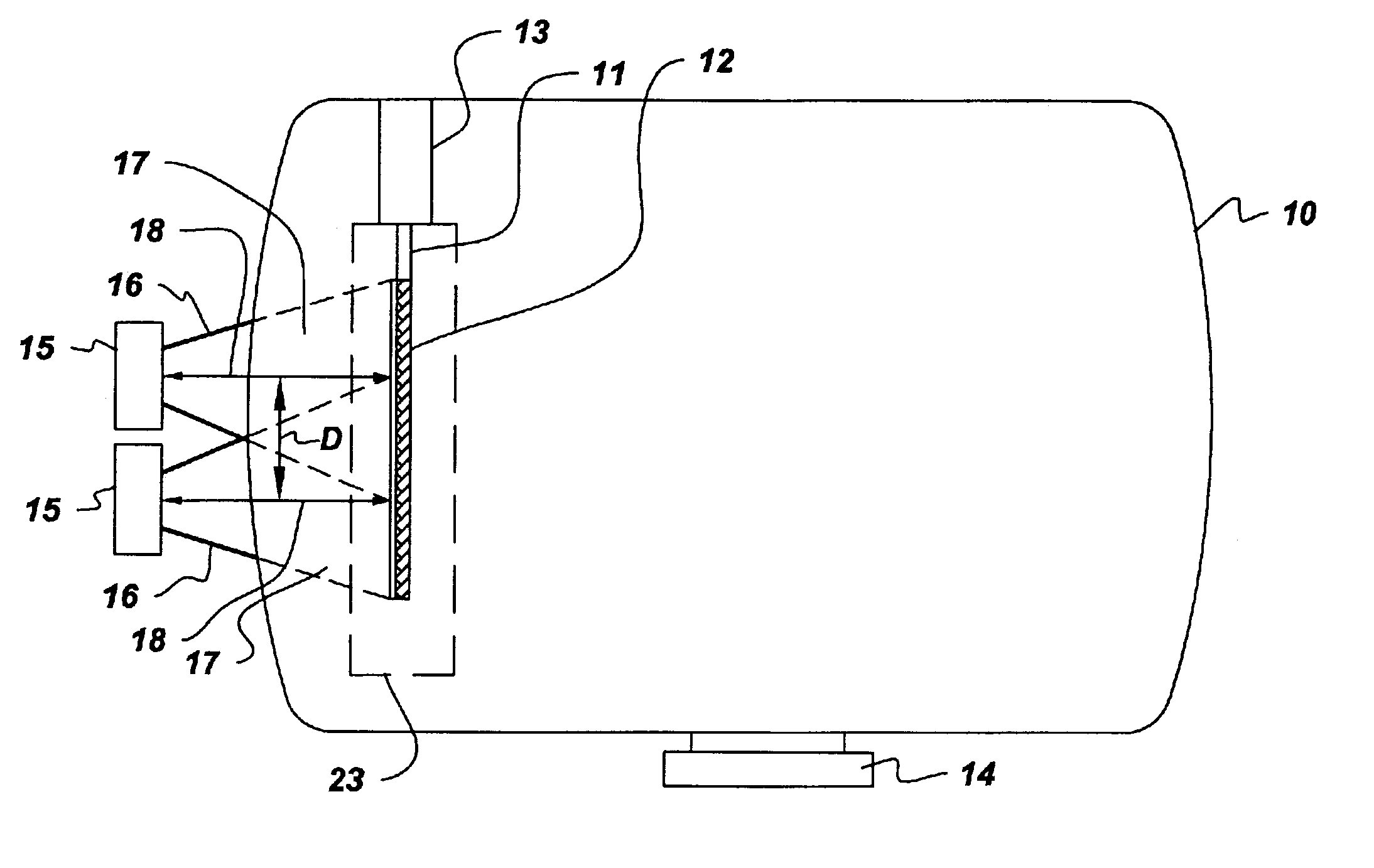

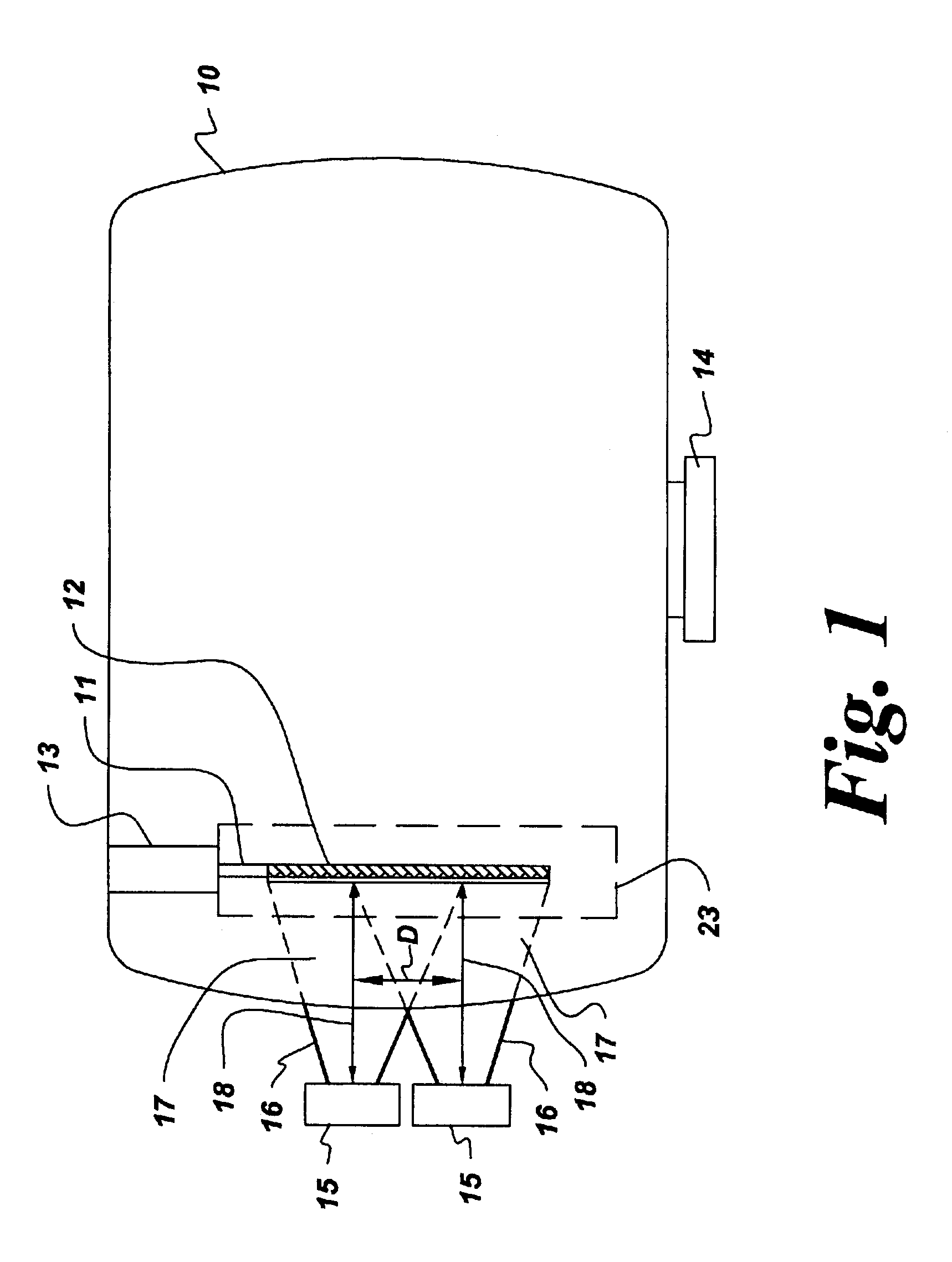

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space (1, 2). The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent, the plasma generator being arranged remote from the treatment space (1, 2).

Owner:FUJIFILM MFG EURO

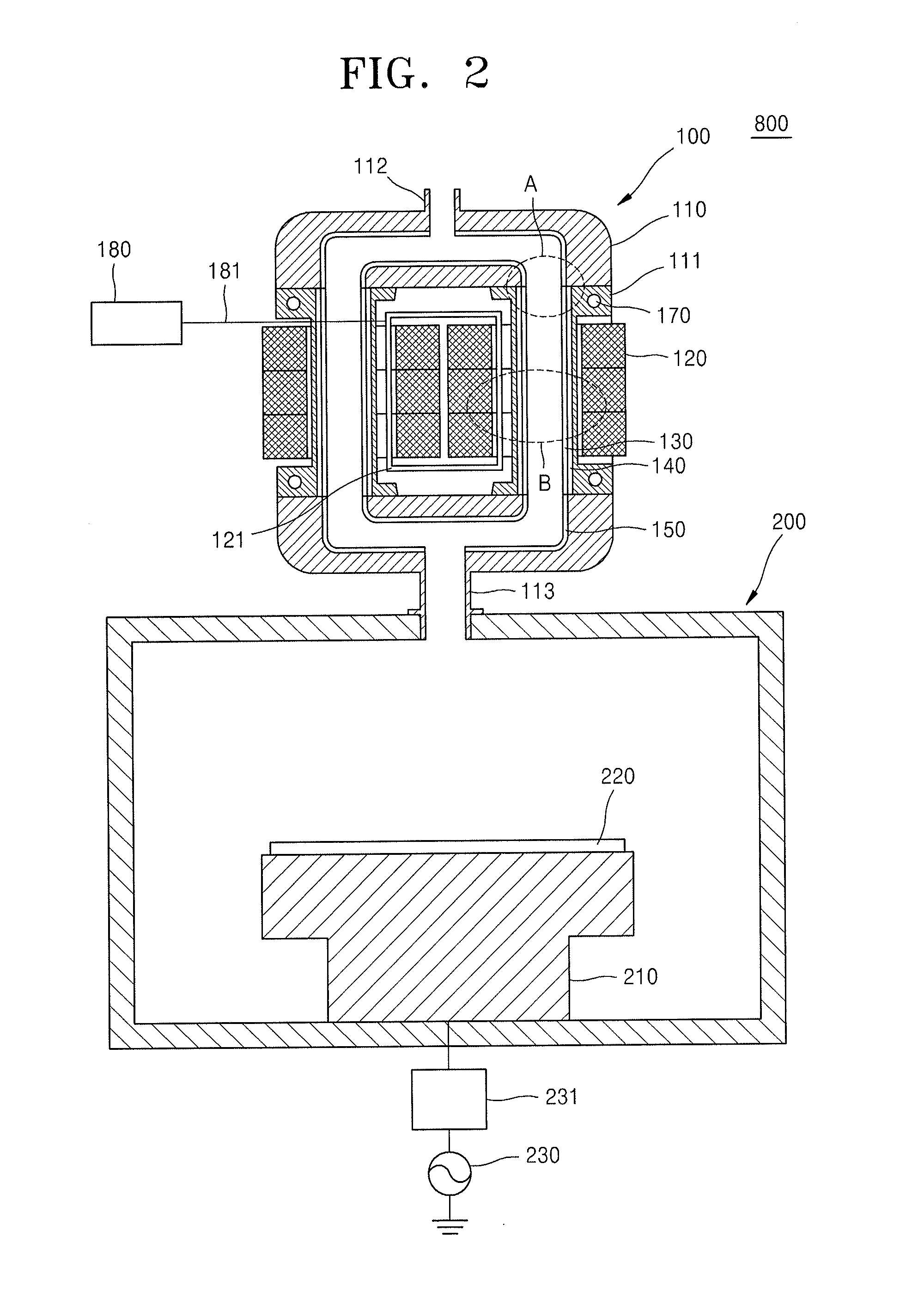

Atomic layer etching apparatus and etching method using the same

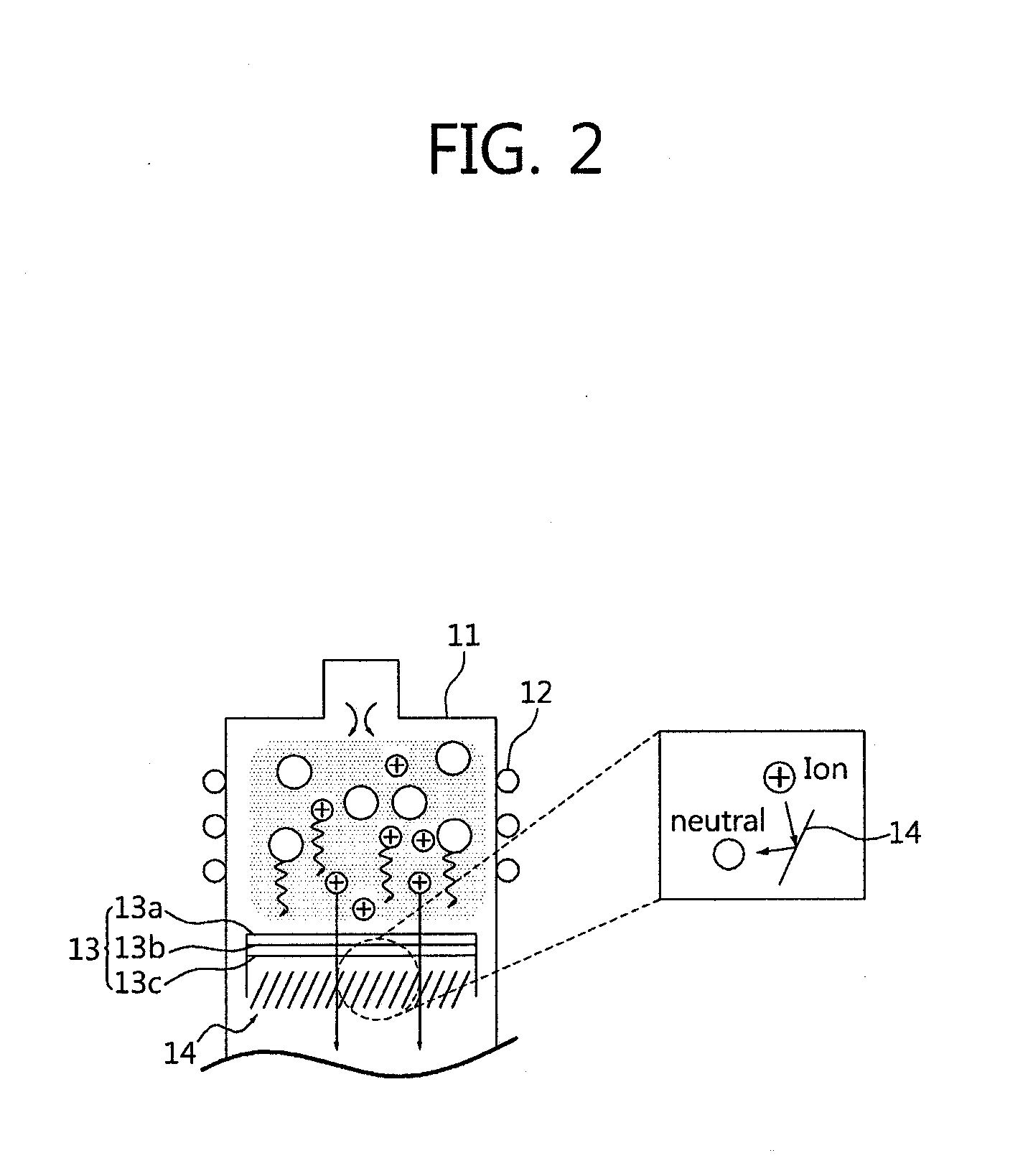

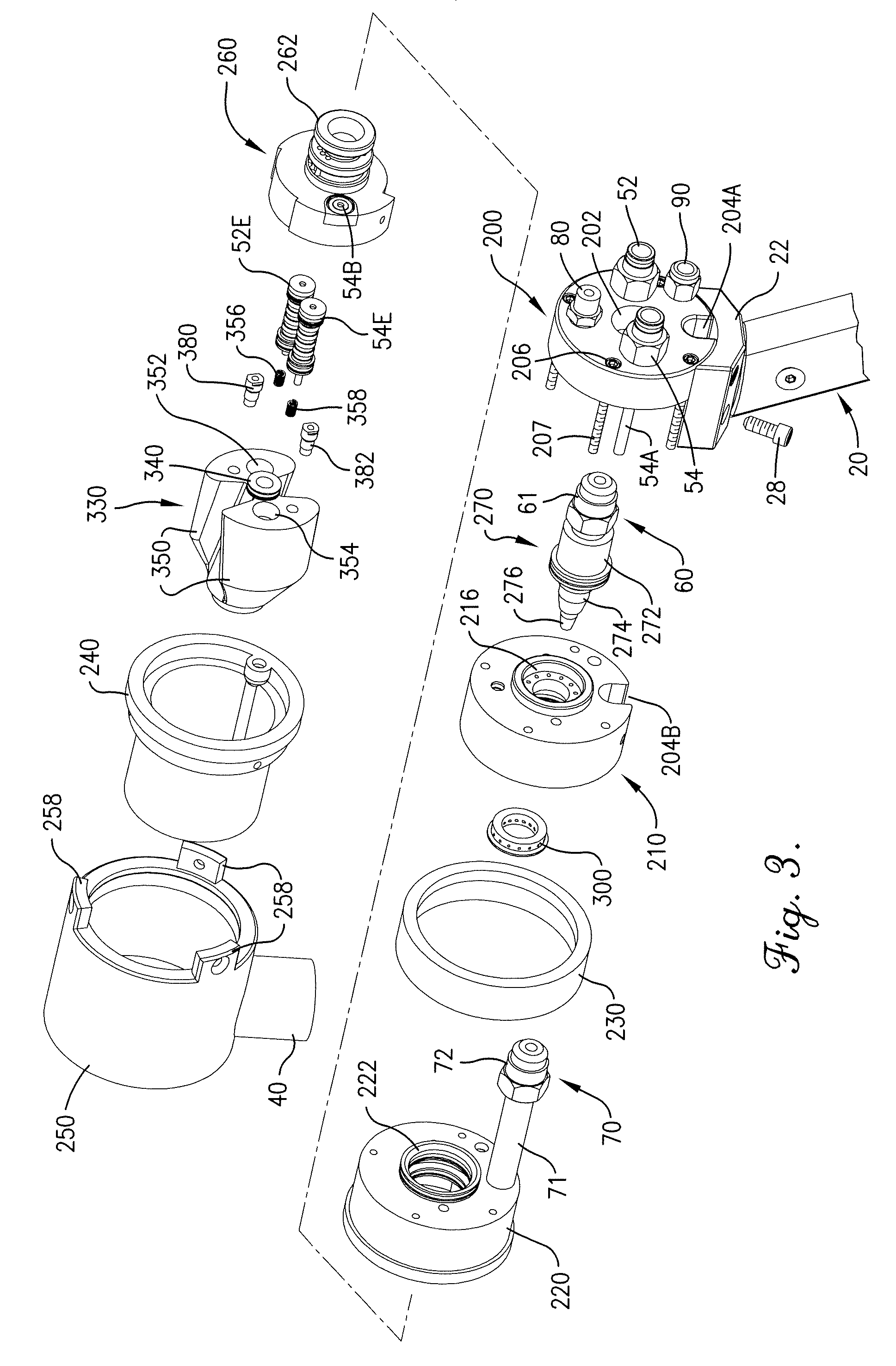

An atomic layer etching apparatus using reactive radicals and neutral beams and an etching method using the same are provided. The atomic layer etching apparatus includes a reaction chamber including a stage on which a substrate to be etched is seated, a plasma generator including a plasma chamber configured to supply reactive radicals and neutral beams into the reaction chamber and receive a source gas to generate plasma, an inductive coil configured to surround the exterior of the plasma chamber to generate an electric field, a grid assembly disposed at a lower part of the plasma chamber and including first, second and third grids for extracting ion beams, and a reflective body disposed under the grid assembly and configured to supply electrons to the ion beams to convert the ion beams into neutral beams, a shutter installed between the plasma generator and the reactive chamber and configured to adjust supply of the neutral beams into the reaction chamber, a purge gas supply part configured to supply a purge gas into the reaction chamber, and a controller configured to control supply of the source gas, an etching gas and the purge gas, and opening / closing of the shutter.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Method and apparatus for atomic layer deposition using an atmospheric pressure glow discharge plasma

InactiveUS20090324971A1Increase response rateImprove productivitySynthetic resin layered productsChemical vapor deposition coatingPlasma generatorProduct gas

Apparatus and method for atomic layer deposition on a surface of a substrate (6) in a treatment space. A gas supply device (15, 16) is present for providing various gas mixtures to the treatment space. The gas supply device (15, 16) is arranged to provide a gas mixture with a precursor material to the treatment space for allowing reactive surface sites to react with precursor material molecules to give a surface covered by a monolayer of precursor molecules attached via the reactive sites to the surface of the substrate. Subsequently, a gas mixture comprising a reactive agent capable to convert the attached precursor molecules to active precursor sites is provided. A plasma generator (10) is present for generating an atmospheric pressure plasma in the gas mixture comprising the reactive agent.

Owner:FUJIFILM MFG EURO

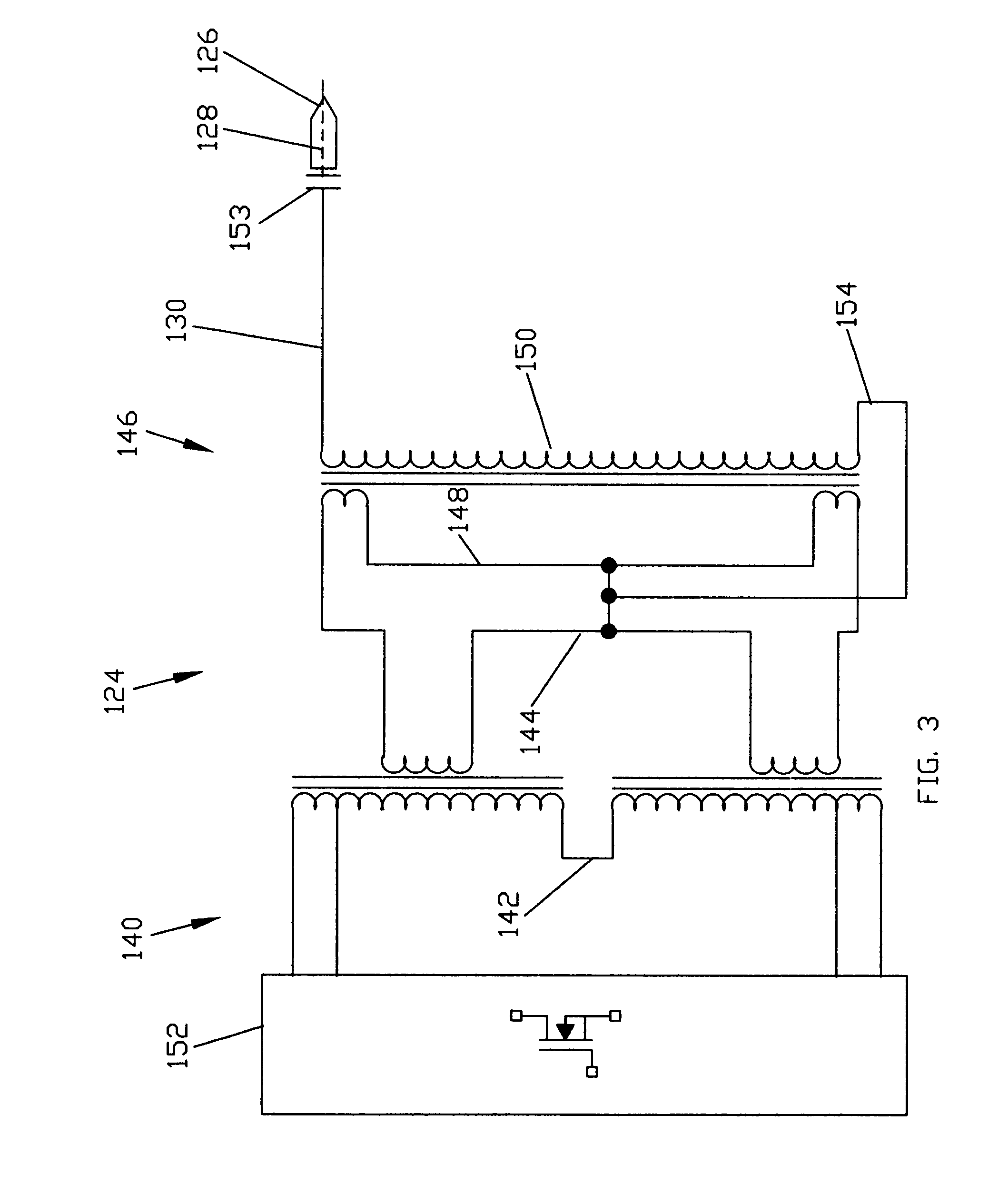

Apparatus and process for plasma-enhanced atomic layer deposition

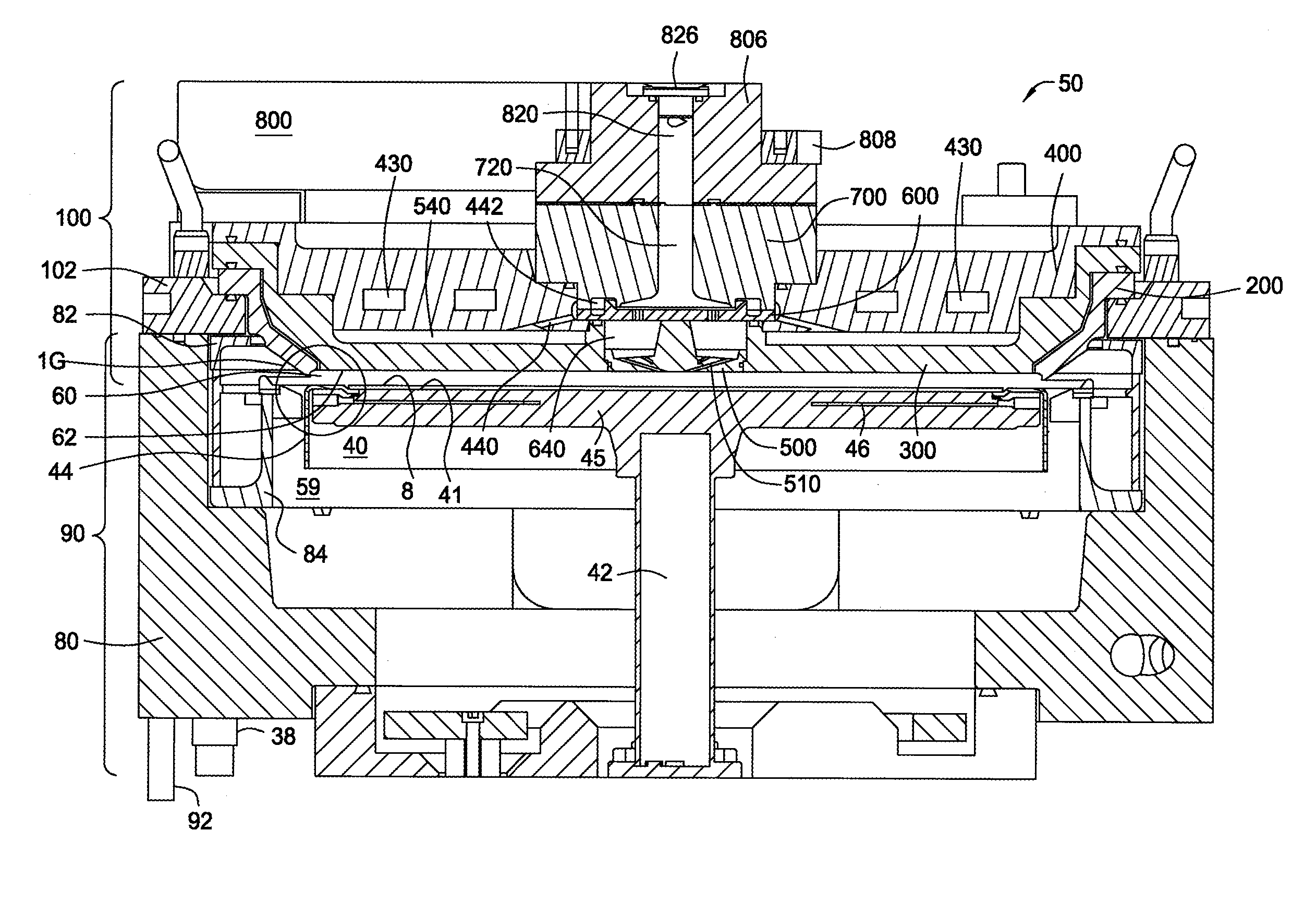

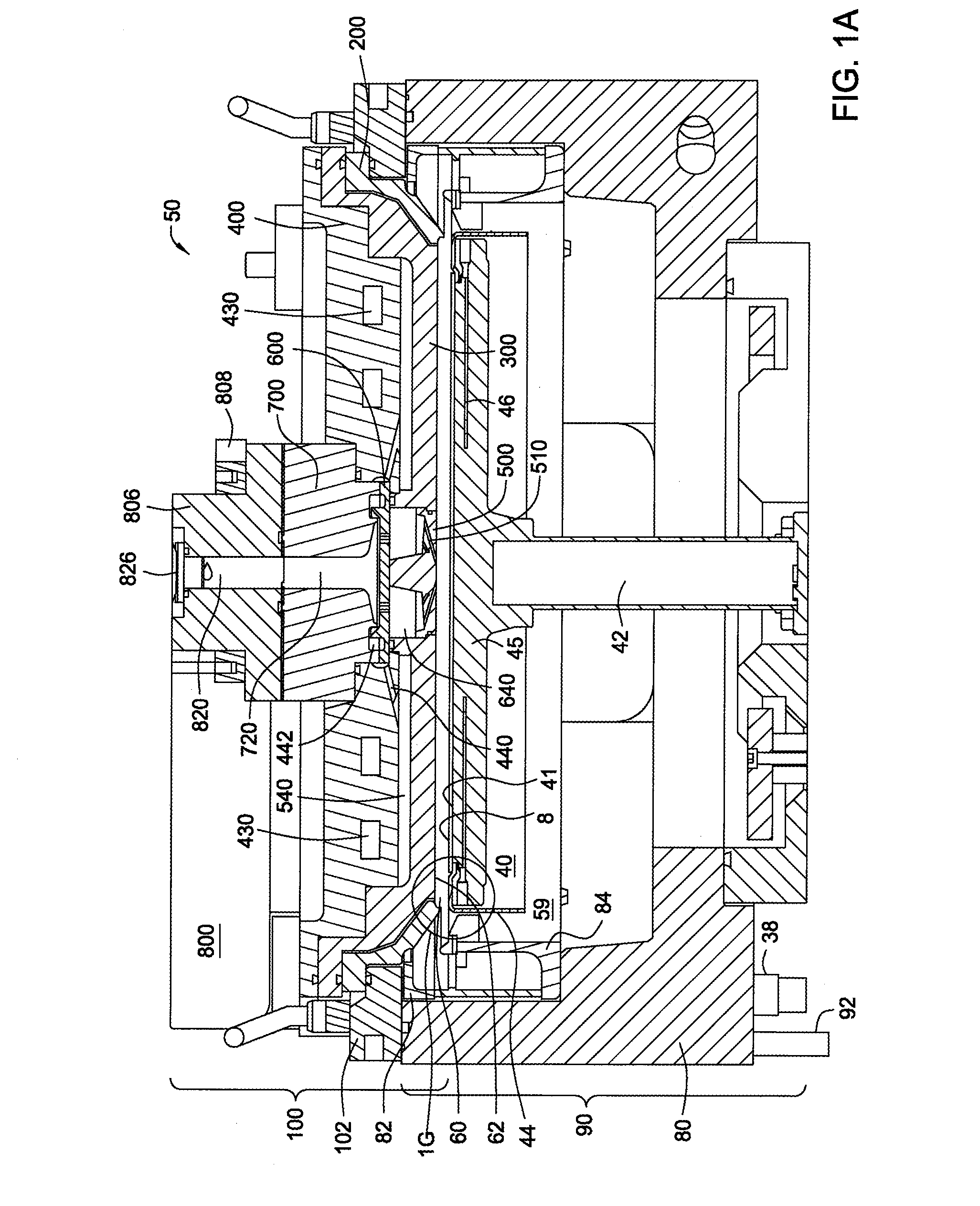

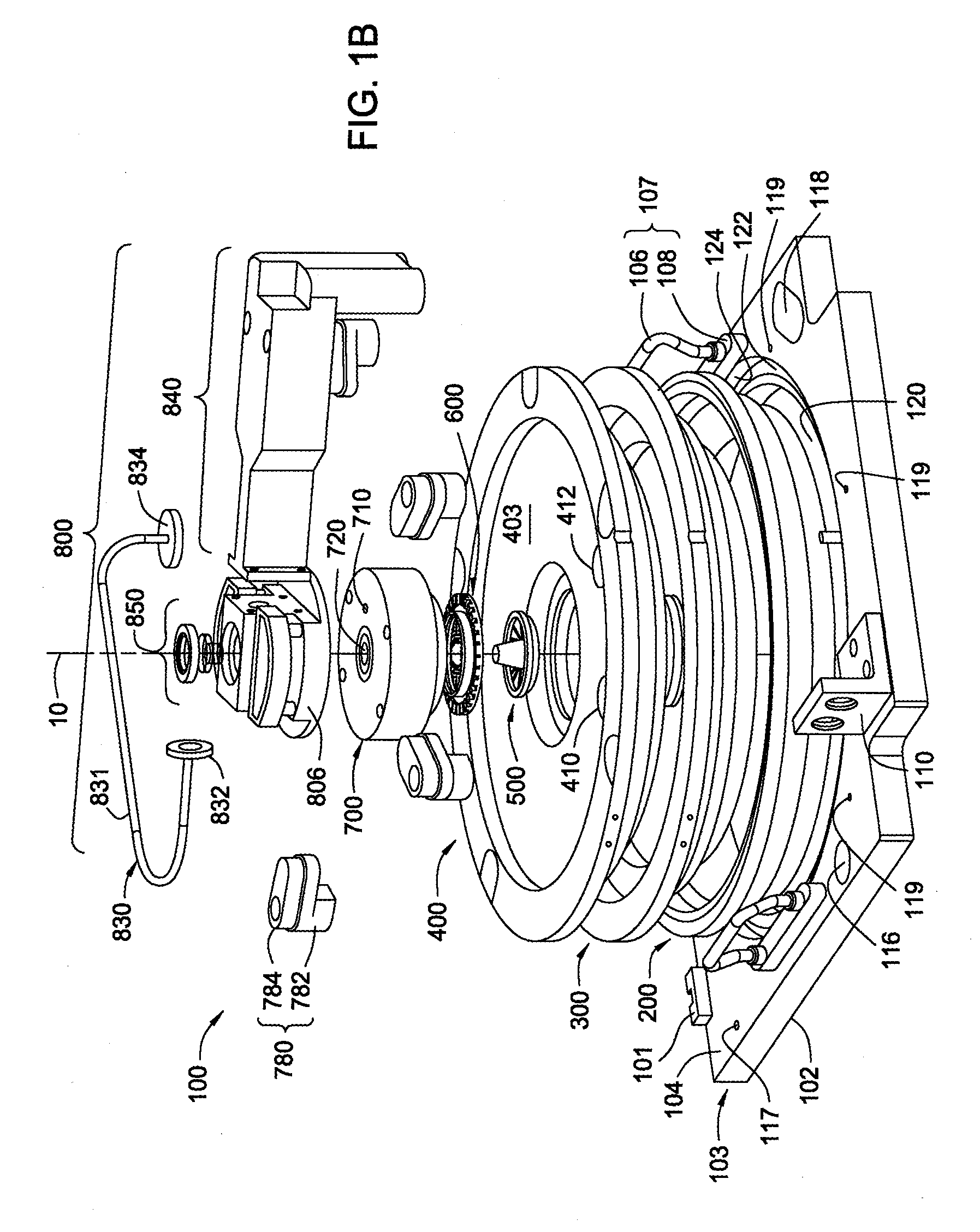

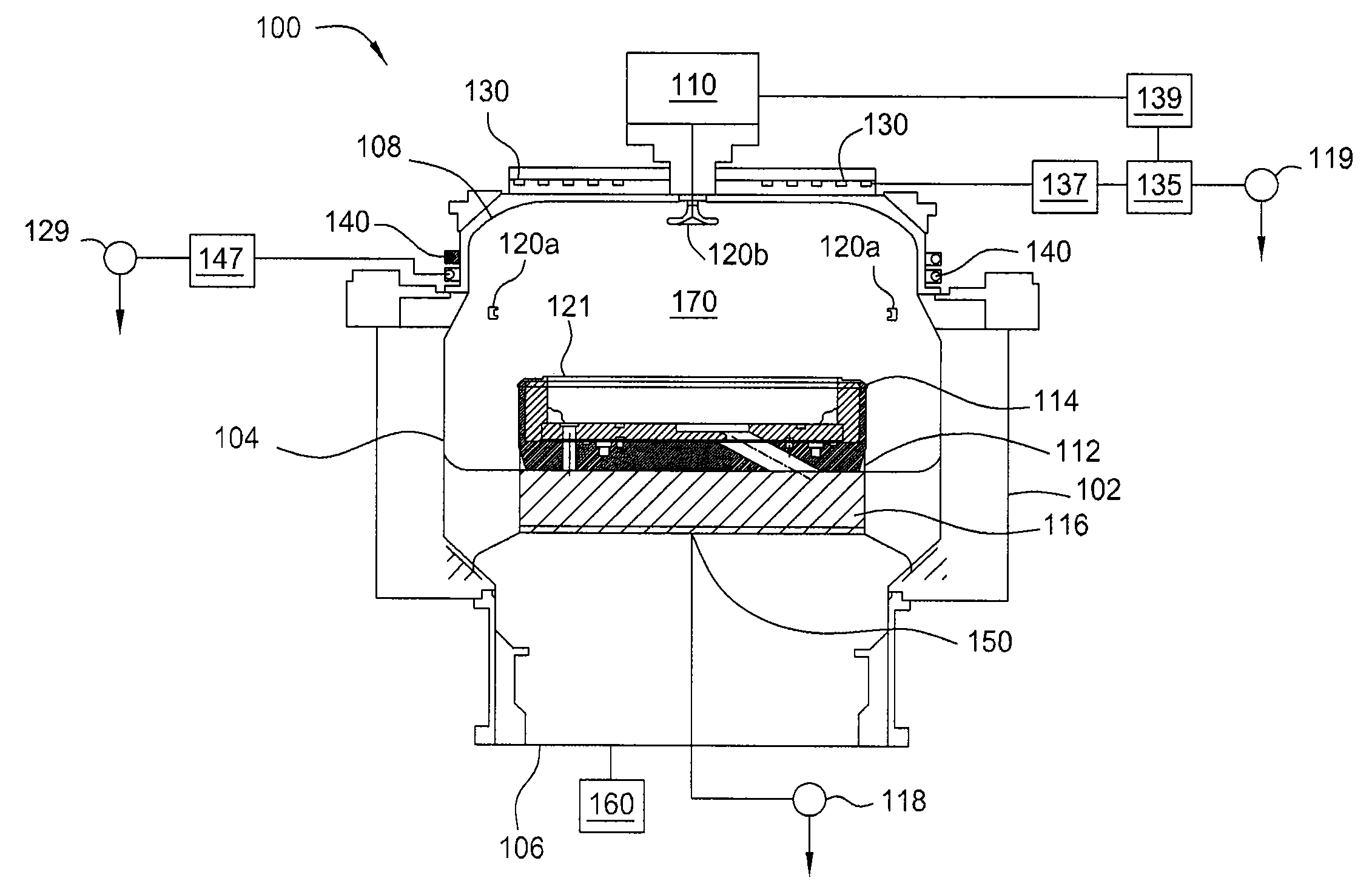

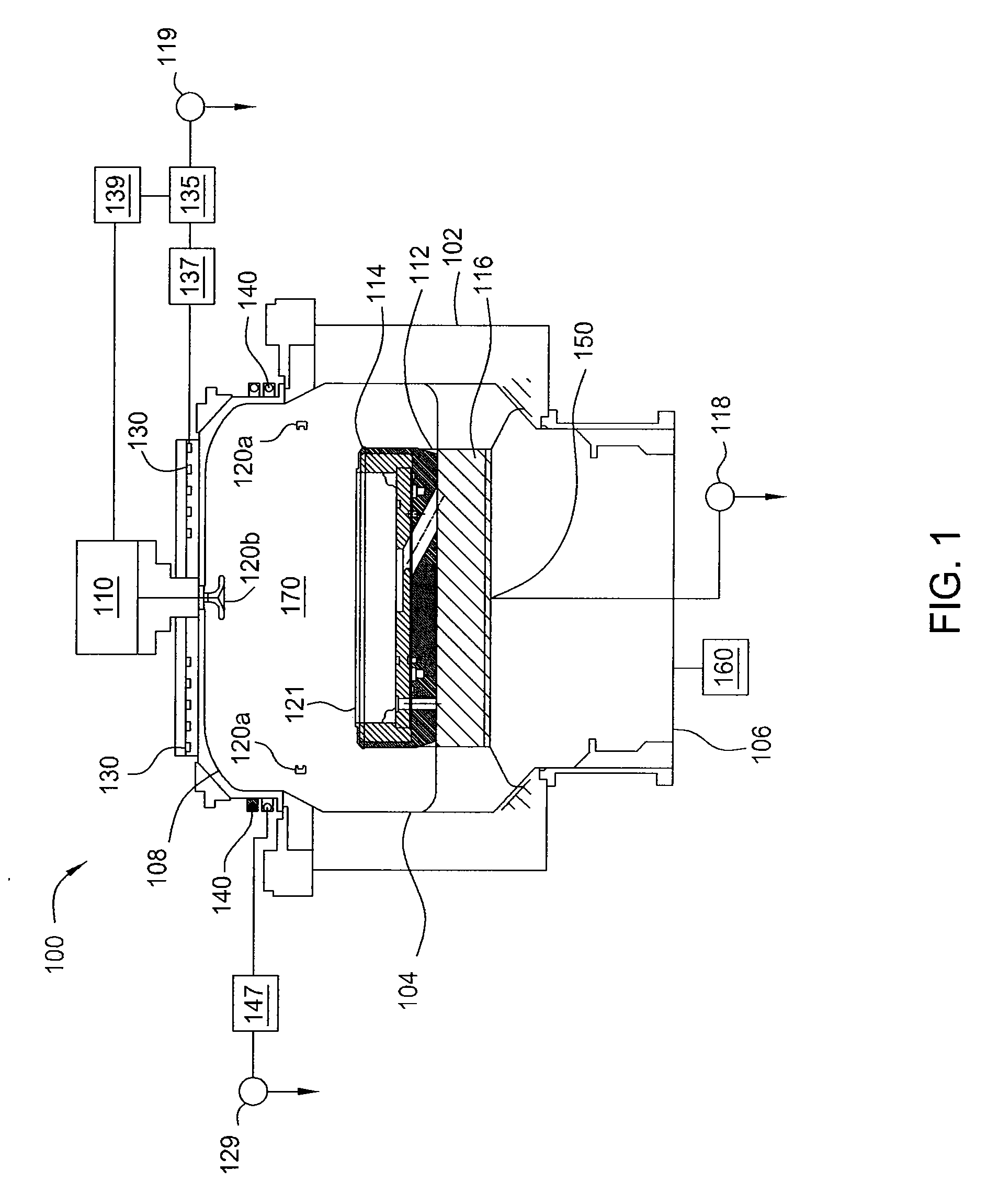

Embodiments of the invention provide an apparatus configured to form a material during an atomic layer deposition (ALD) process, such as a plasma-enhanced ALD (PE-ALD) process. In one embodiment, a lid assembly is configured to expose a substrate to a sequence of gases and plasmas during a PE-ALD process. The lid assembly comprises components that are capable of being electrically insulated, electrically grounded or RF energized. In one example, the lid assembly comprises a grounded gas manifold assembly positioned above electrically insulated components, such as an insulation cap, a plasma screen insert and an isolation ring. A showerhead, a plasma baffle and a water box are positioned between the insulated components and become RF hot when activated by a plasma generator. Other embodiments of the invention provide deposition processes to form layers of materials within the process chamber.

Owner:APPLIED MATERIALS INC

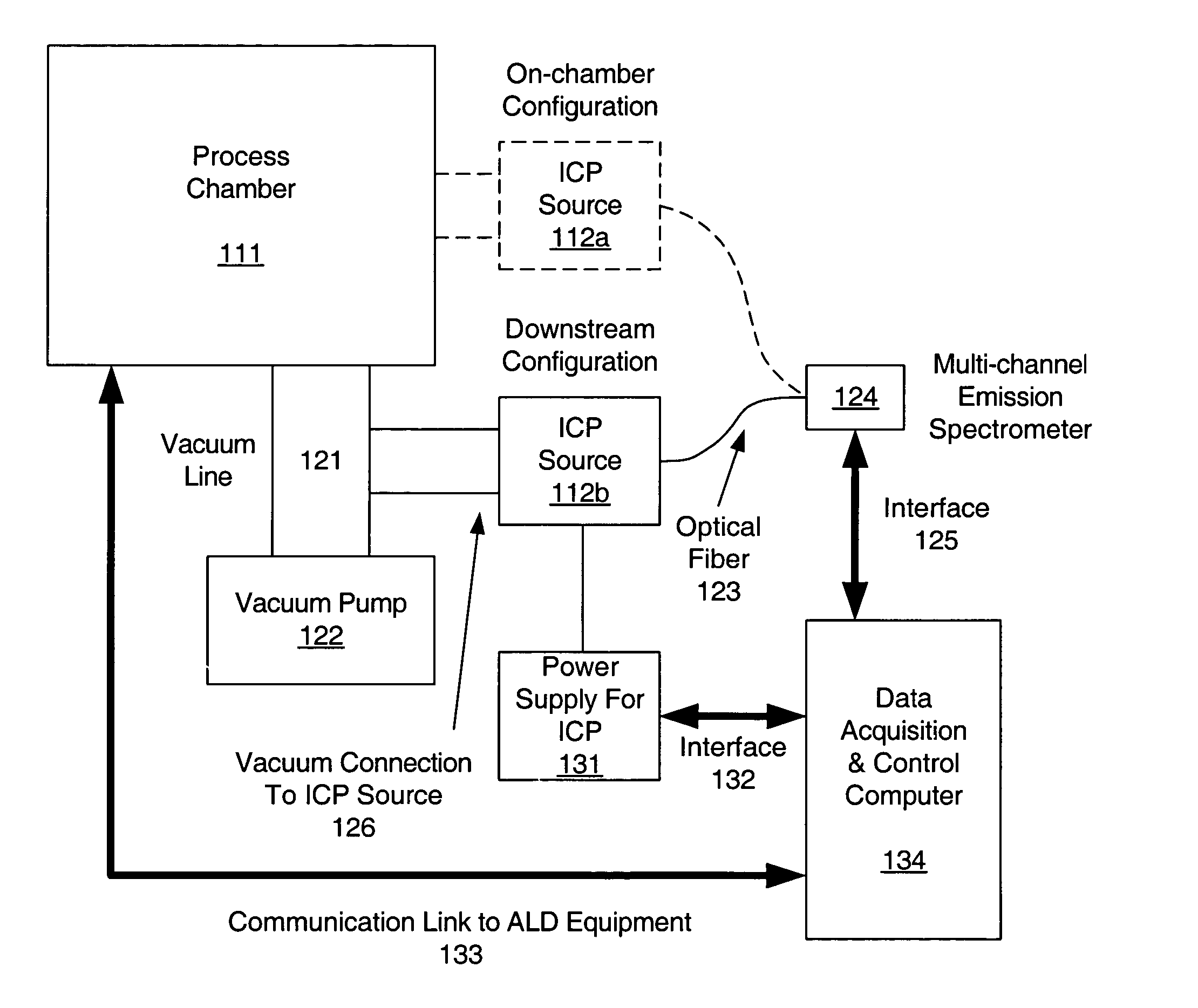

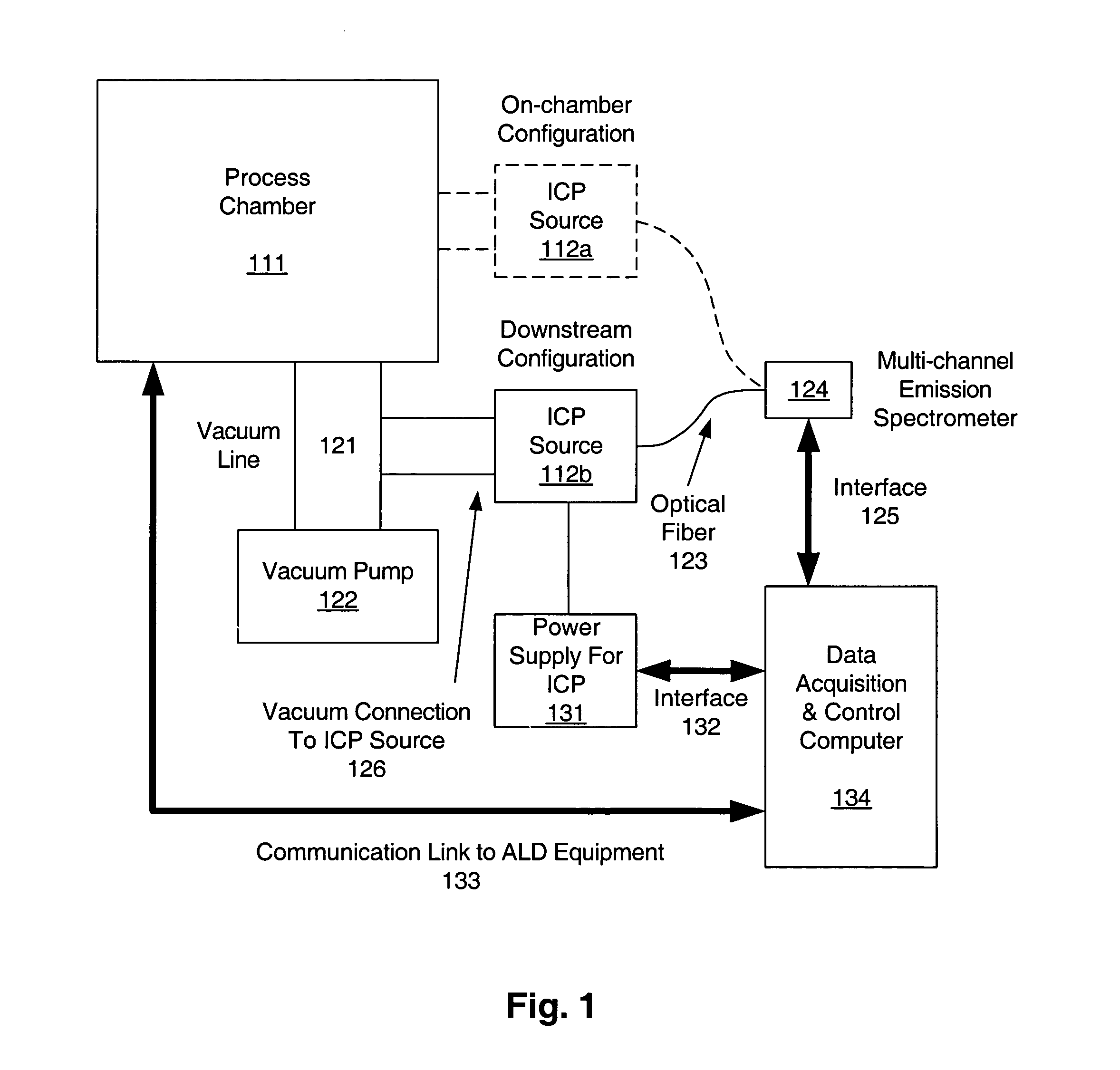

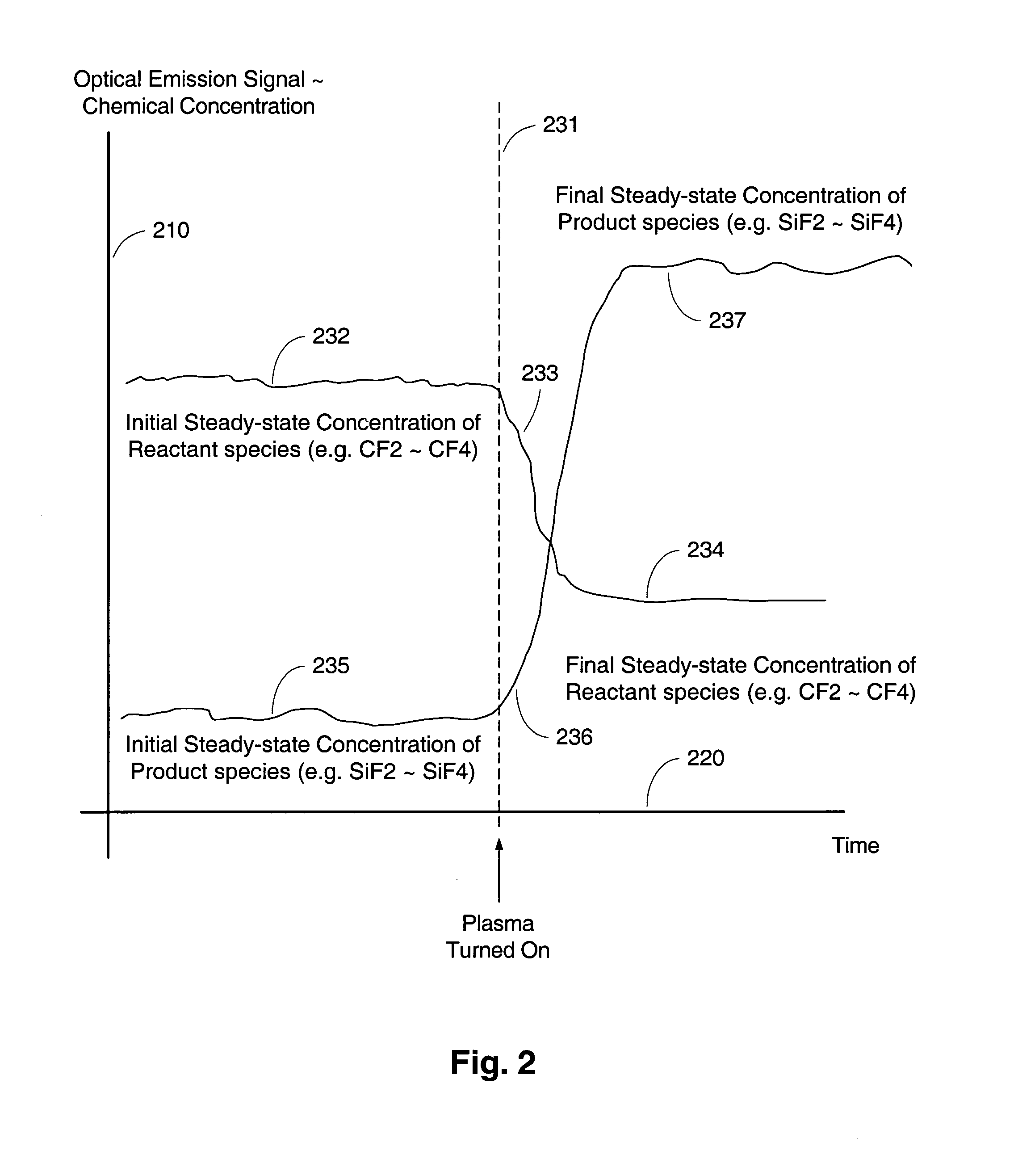

Method and apparatus for chemical monitoring

The present invention relates to monitoring chemicals in a process chamber using a spectrometer having a plasma generator, based on patterns over time of chemical consumption. The relevant patterns may include a change in consumption, reaching a consumption plateau, absence of consumption, or presence of consumption. In some embodiments, advancing to a next step in forming structures on the workpiece depends on the pattern of consumption meeting a process criteria. In other embodiments, a processing time standard is established, based on analysis of the relevant patterns. Yet other embodiments relate to controlling work on a workpiece, based on analysis of the relevant patterns. The invention may be either a process or a device including logic and resources to carry out a process.

Owner:LIGHTWIND CORP

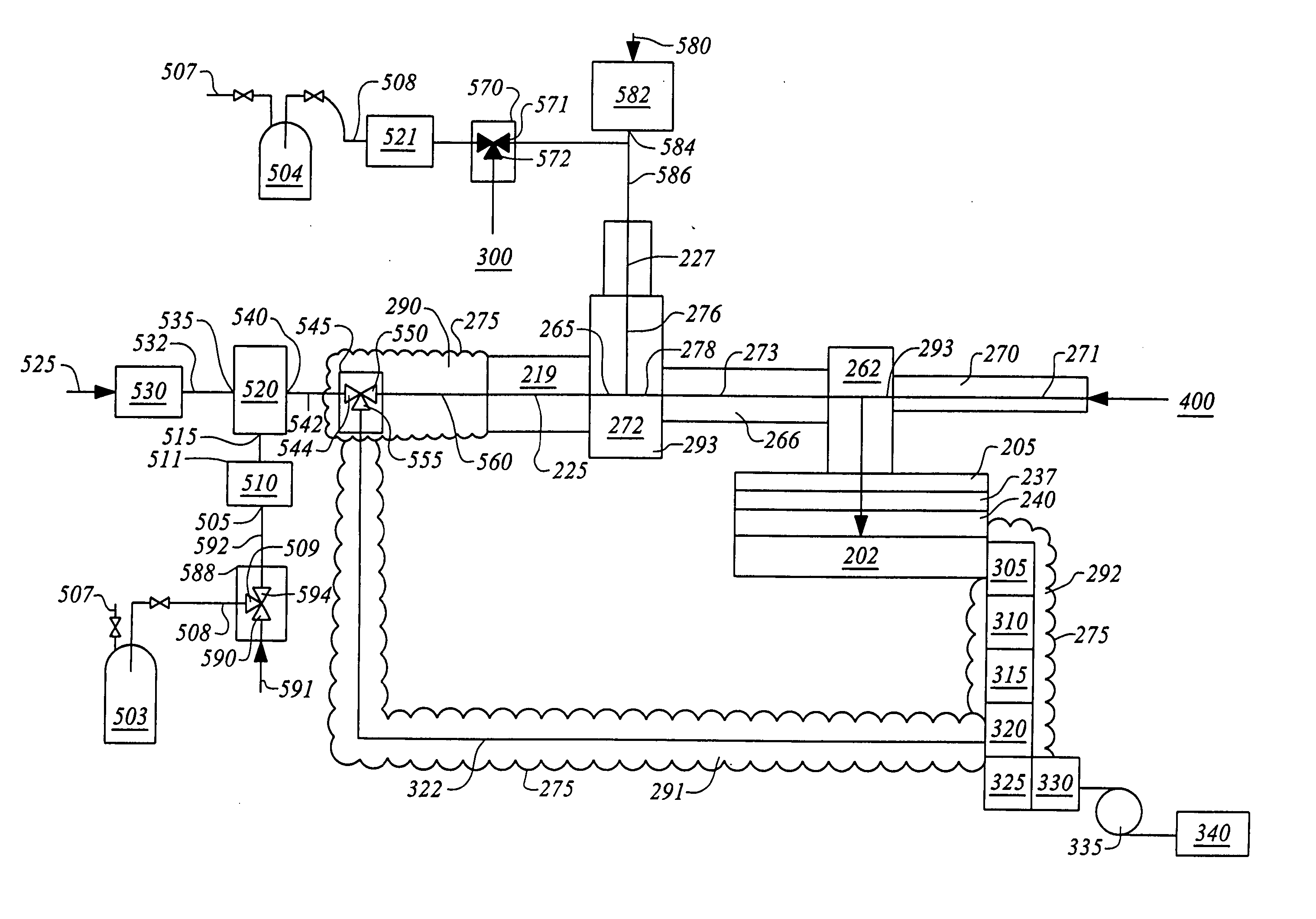

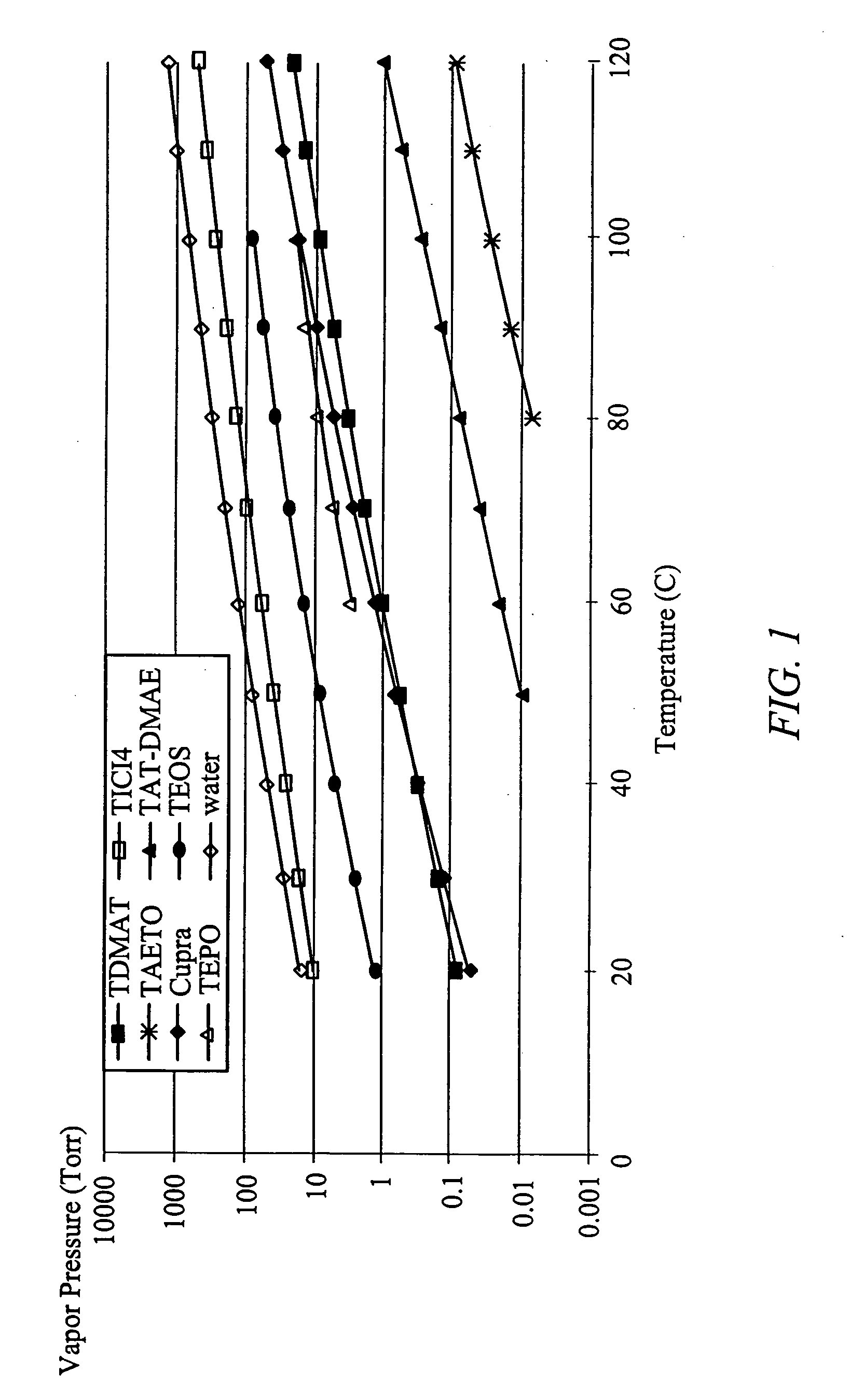

Apparatus for the deposition of high dielectric constant films

InactiveUS20060196421A1Precise temperature controlEasy temperature controlSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricElectricity

An integrated deposition system is described that is capable of vaporizing low vapor pressure liquid precursors and conveying the vapor to a processing region to fabricate advanced integrated circuits. The integrated deposition system includes a heated exhaust system, a remote plasma generator, a processing chamber, a liquid delivery system, and a computer control module that together create a commercially viable and production worthy system for depositing high capacity dielectric materials from low vapor pressure precursors.

Owner:APPLIED MATERIALS INC

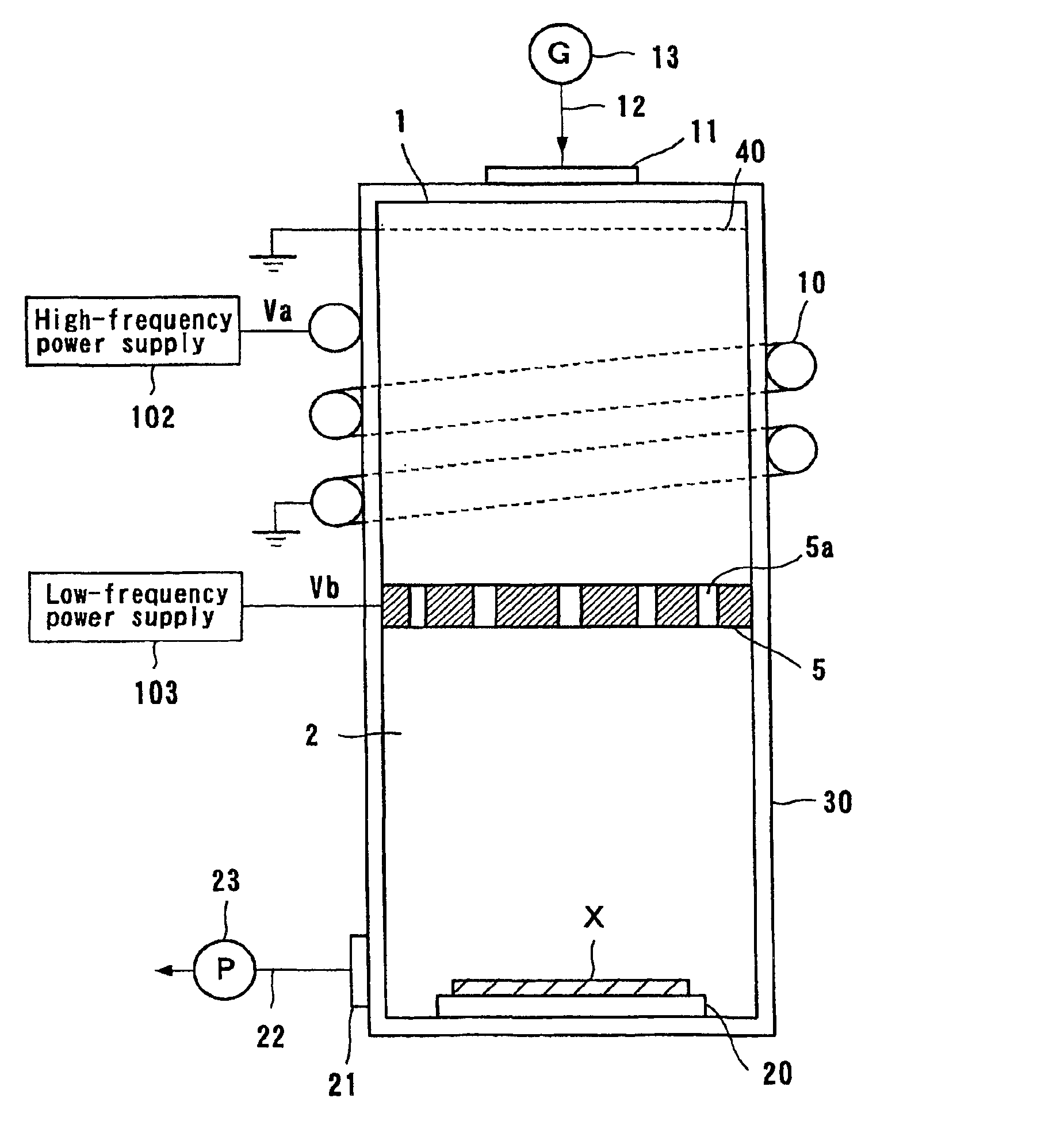

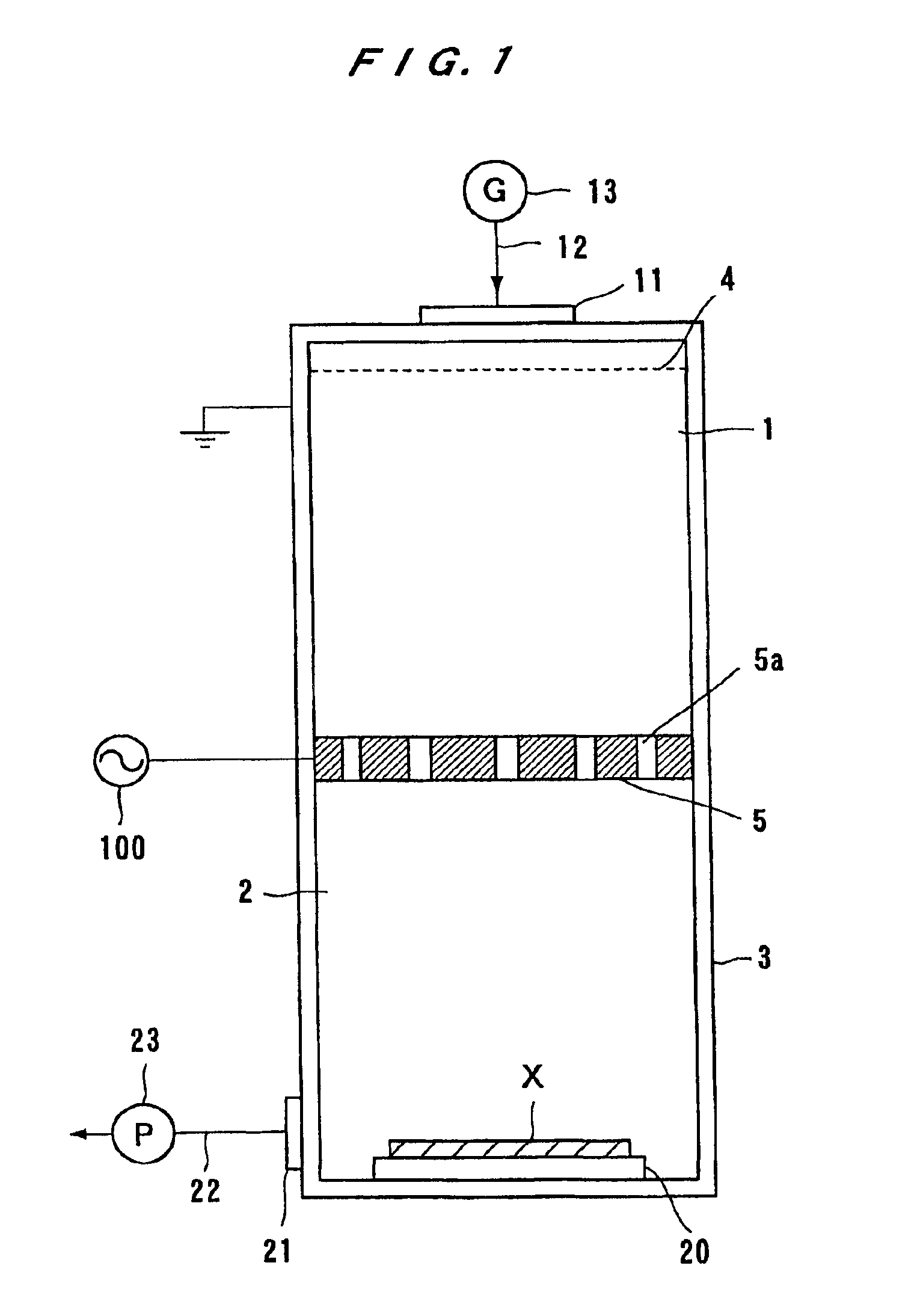

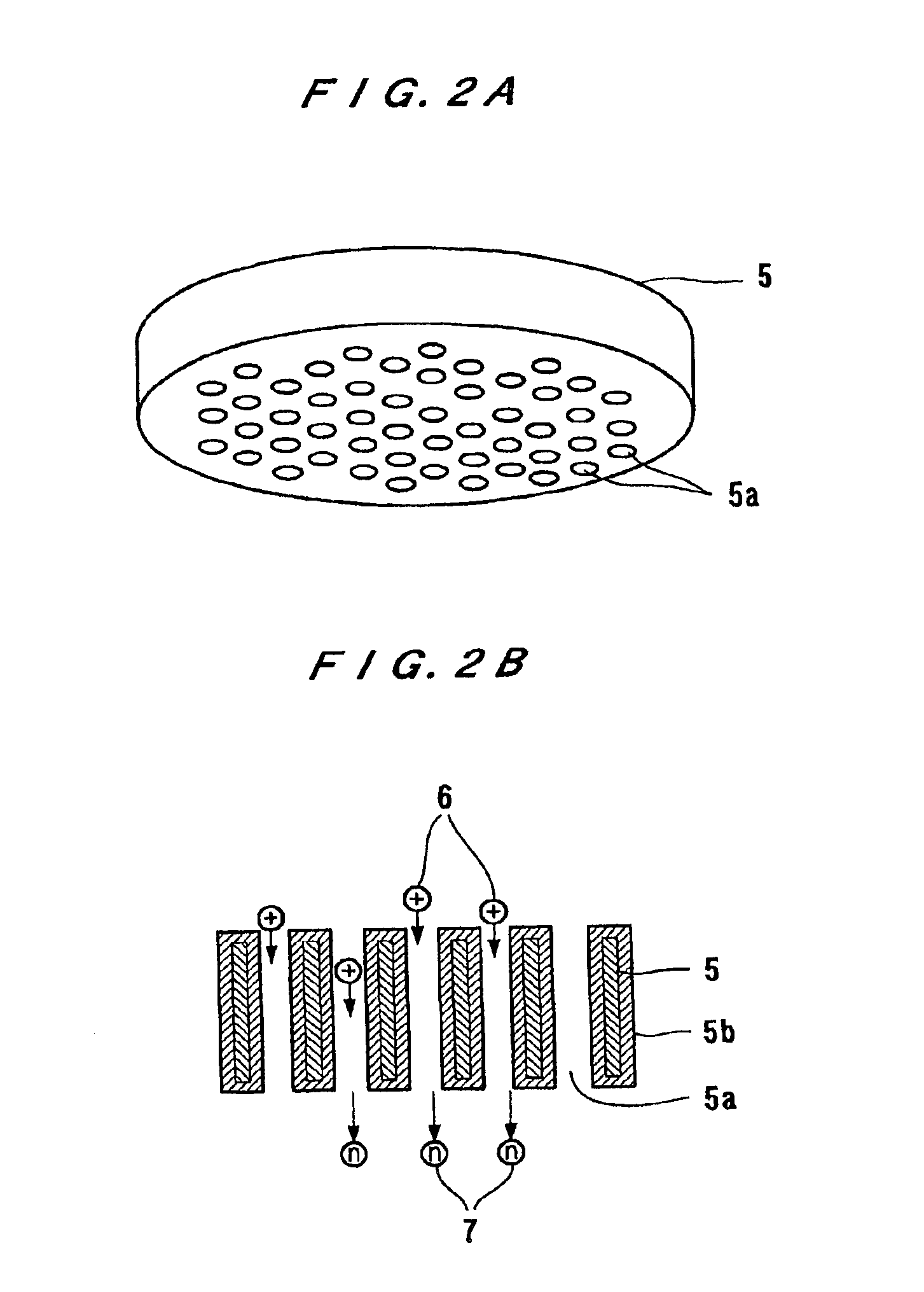

Neutral particle beam processing apparatus

InactiveUS6861642B2Inexpensive and compact structureImprove neutralization efficiencyLaser detailsVacuum evaporation coatingDielectricPlasma generator

A neutral particle beam processing apparatus comprises a workpiece holder (20) for holding a workpiece (X), a plasma generator for generating a plasma in a vacuum chamber (3), an orifice electrode (5) disposed between the workpiece holder (20) and the plasma generator, and a grid electrode (4) disposed upstream of the orifice electrode (5) in the vacuum chamber (3). The orifice electrode (5) has orifices (5a) defined therein. The neutral particle beam processing apparatus further comprises a voltage applying unit for applying a voltage between the orifice electrode (5) and the grid electrode (4) via a dielectric (5b) to extract positive ions from the plasma generated by the plasma generator and pass the extracted positive ions through the orifices (5a) in the orifice electrode (5).

Owner:ASM IP HLDG BV

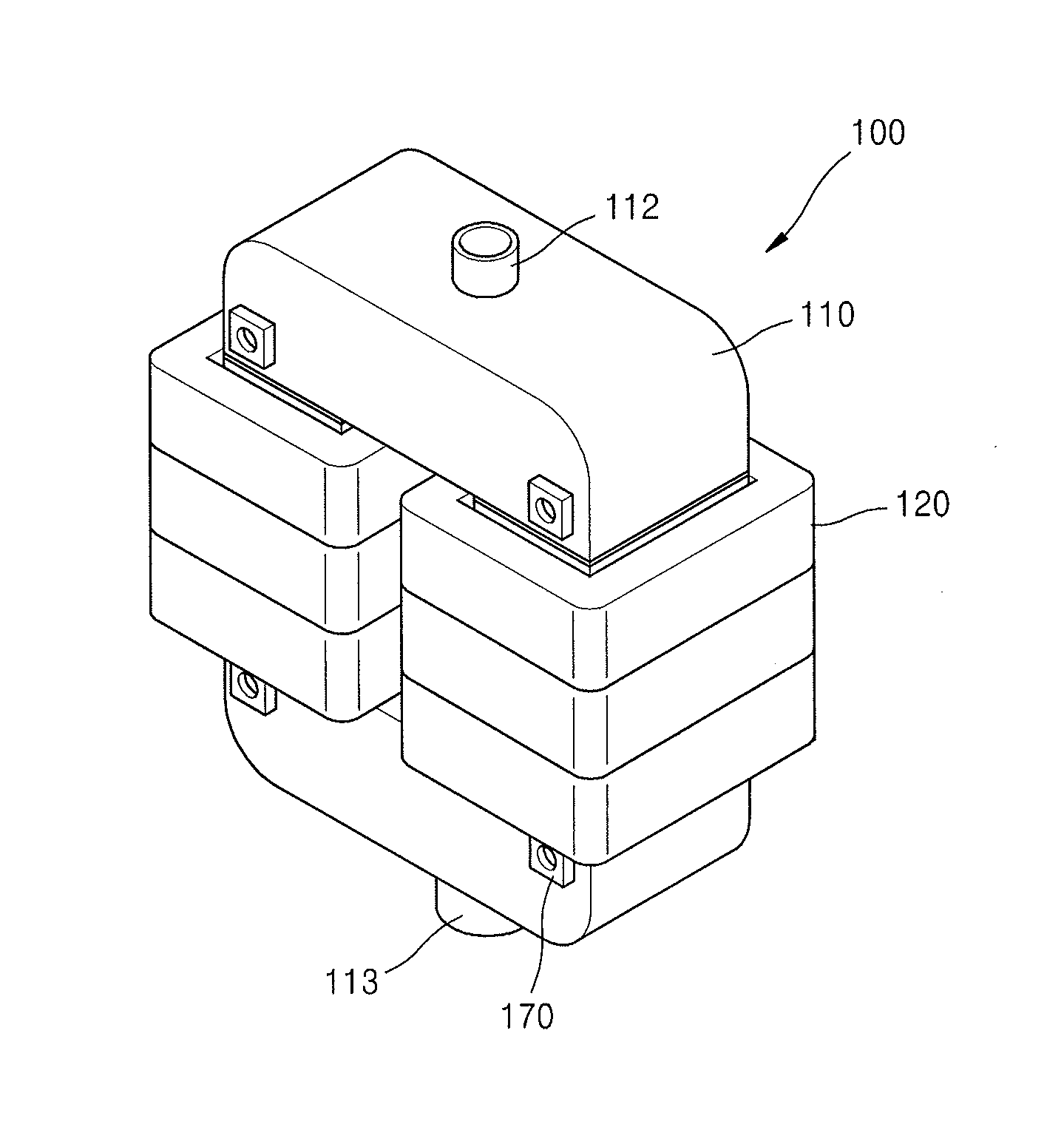

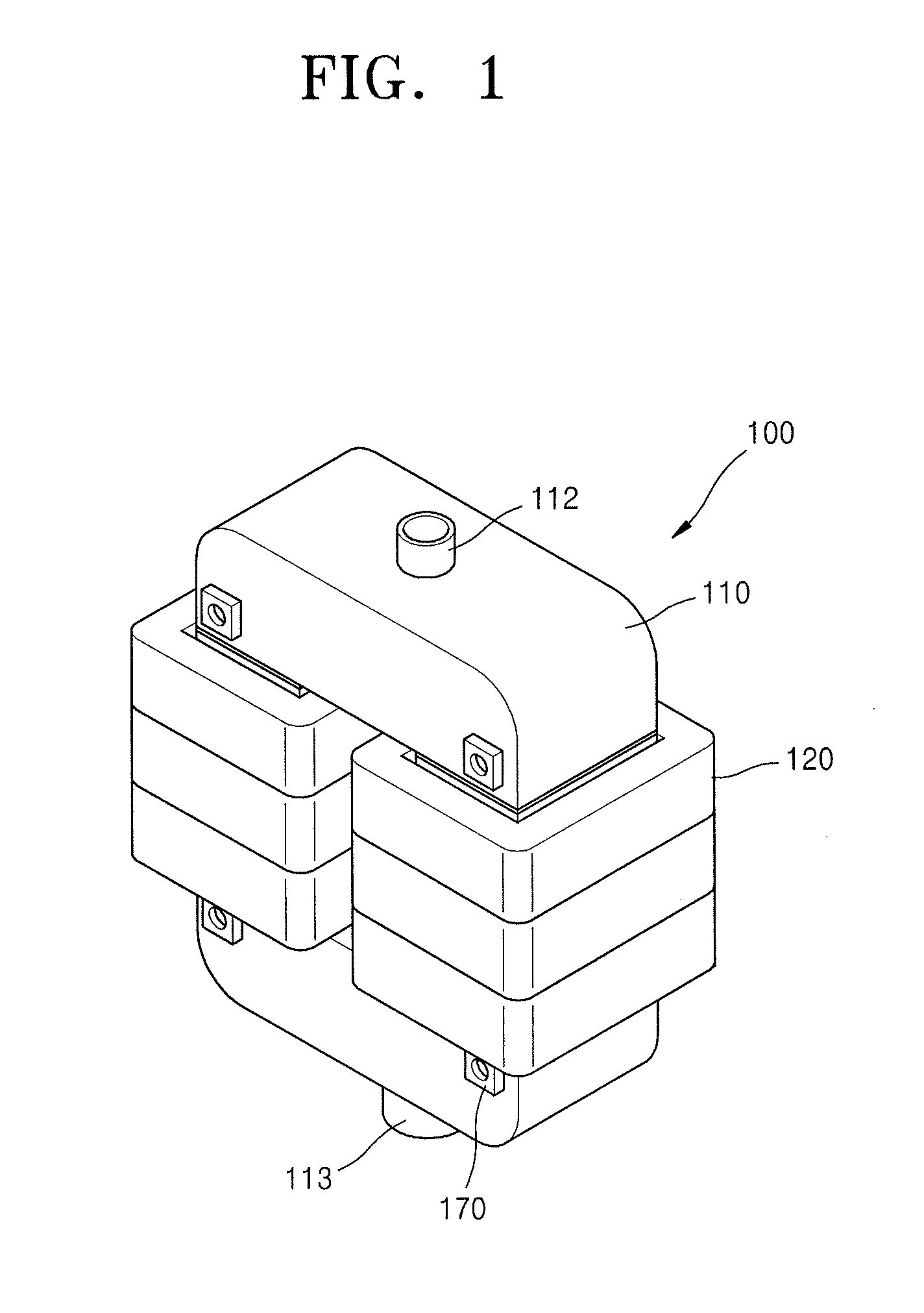

Remote plasma generator using ceramic

A remote plasma generator includes a body, a driver, and a protection tube. The body includes a gas injection port, a plasma exhaust port, and a plasma generation pipe through which discharge gas or plasma flow. The driver is coupled to the body and generates a magnetic field and plasma in the body. The protection tube is at an inner side of the plasma generation pipe to protect the plasma generation pipe from plasma.

Owner:SAMSUNG ELECTRONICS CO LTD +2

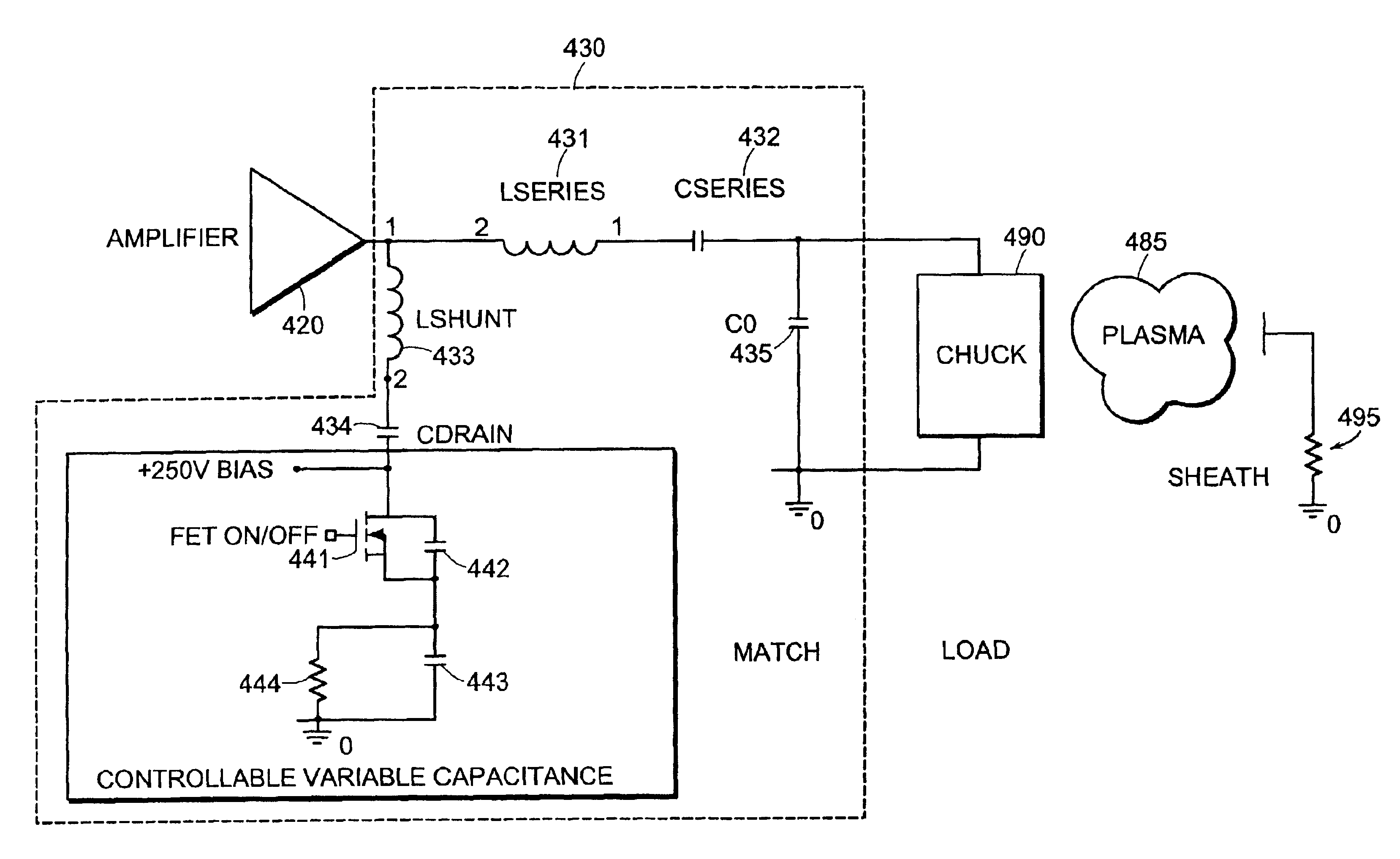

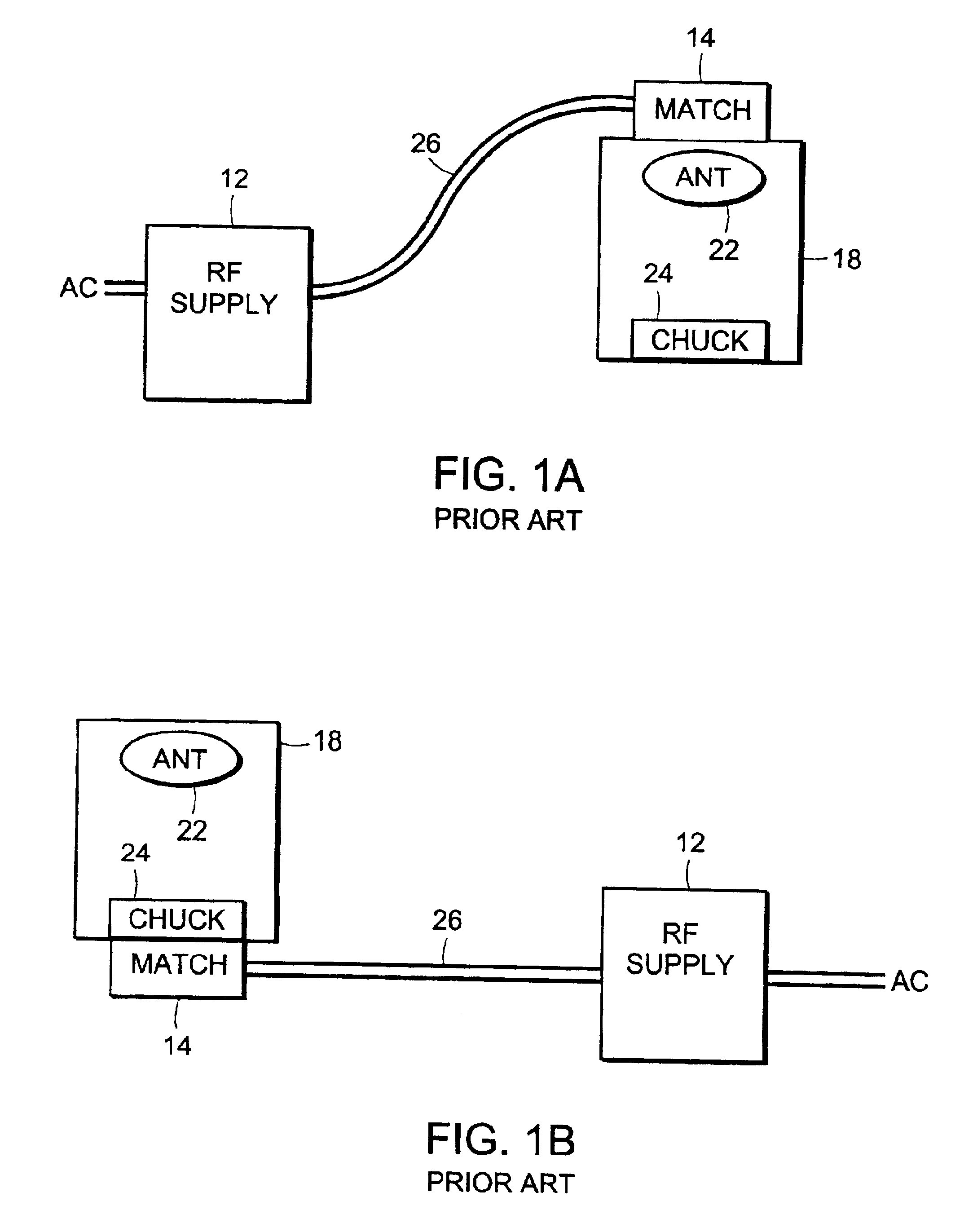

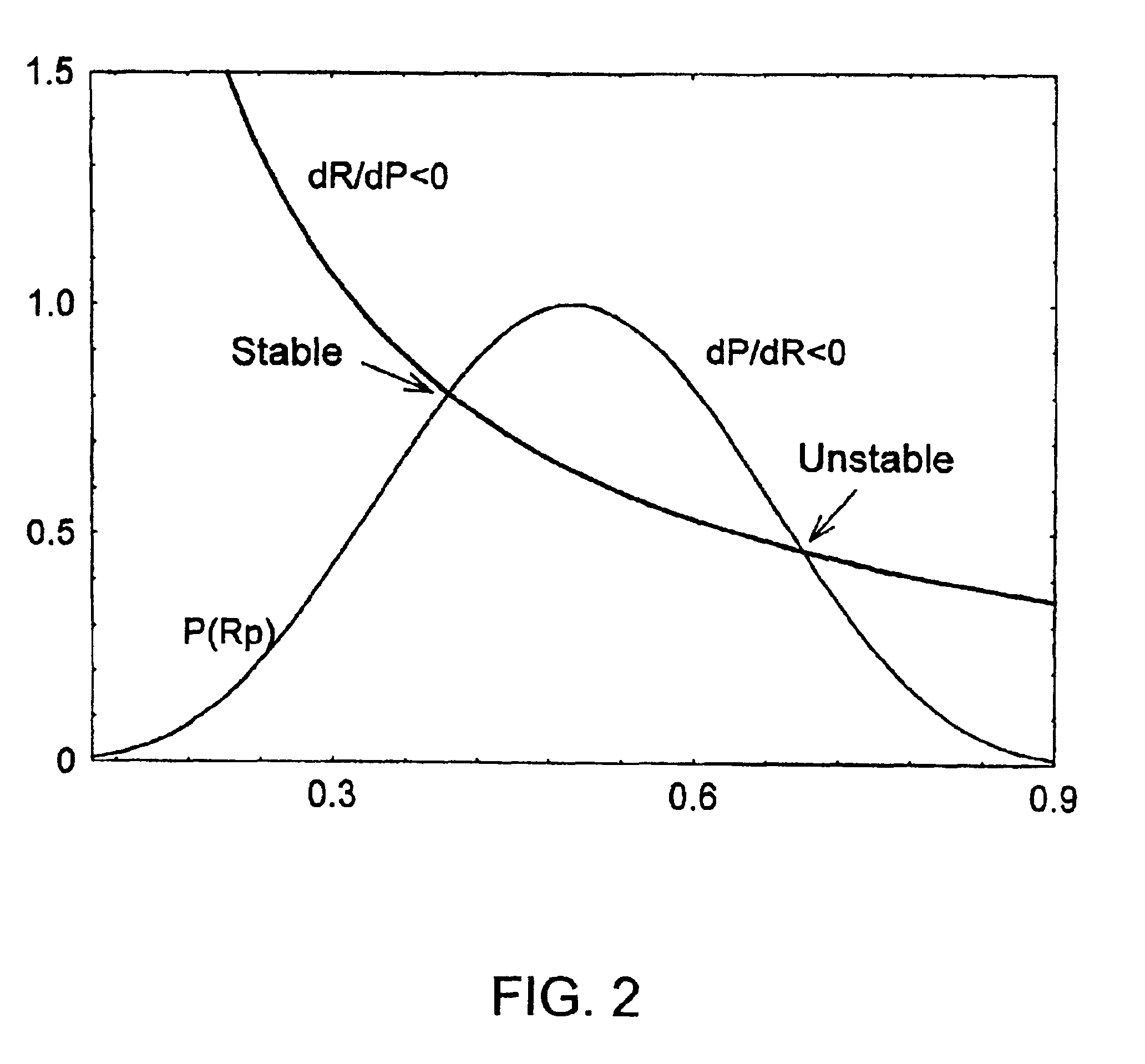

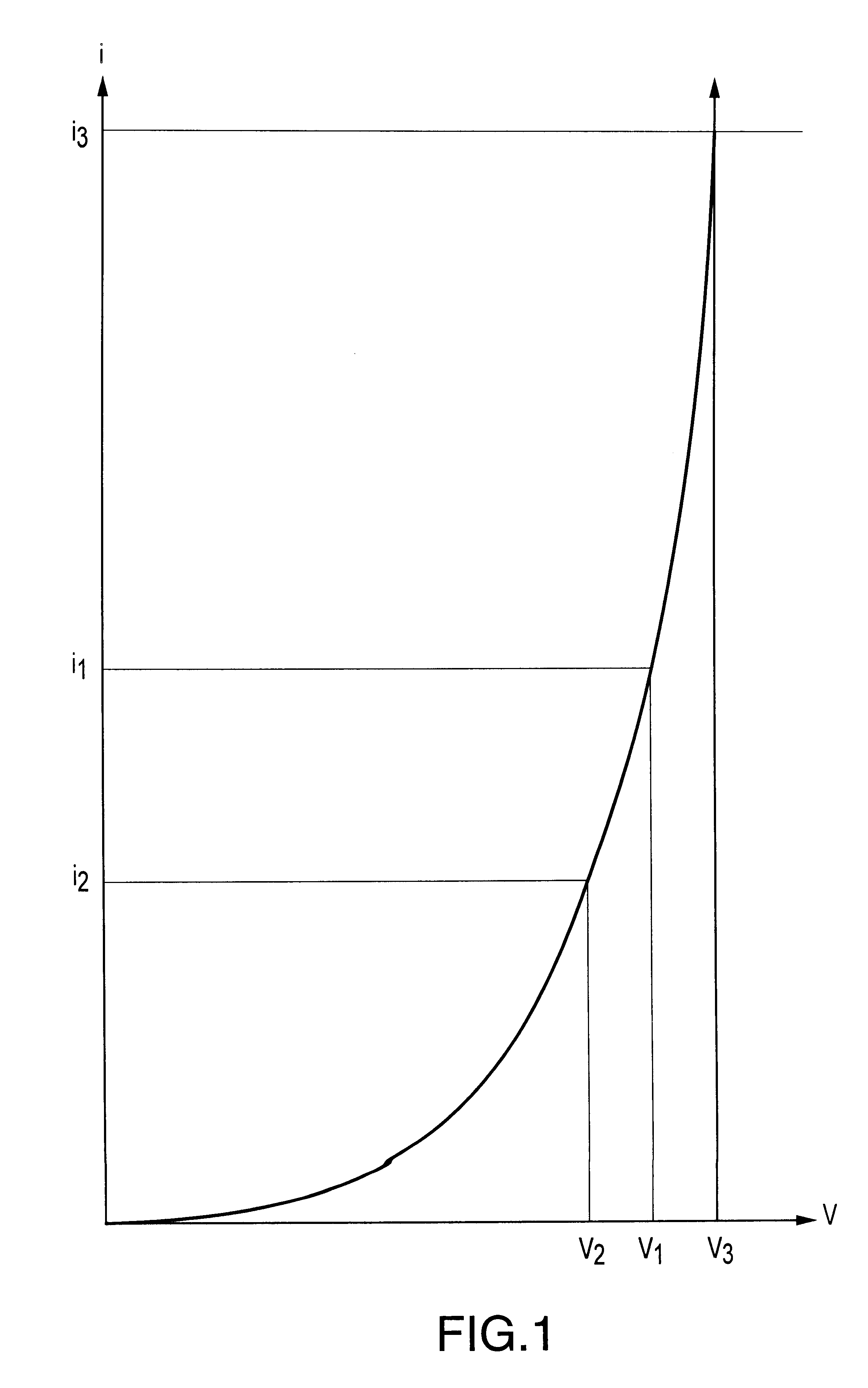

RF power supply with integrated matching network

InactiveUS6887339B1Eliminate useConstant powerMultiple-port networksElectric discharge tubesElectromagnetic couplingPlasma generator

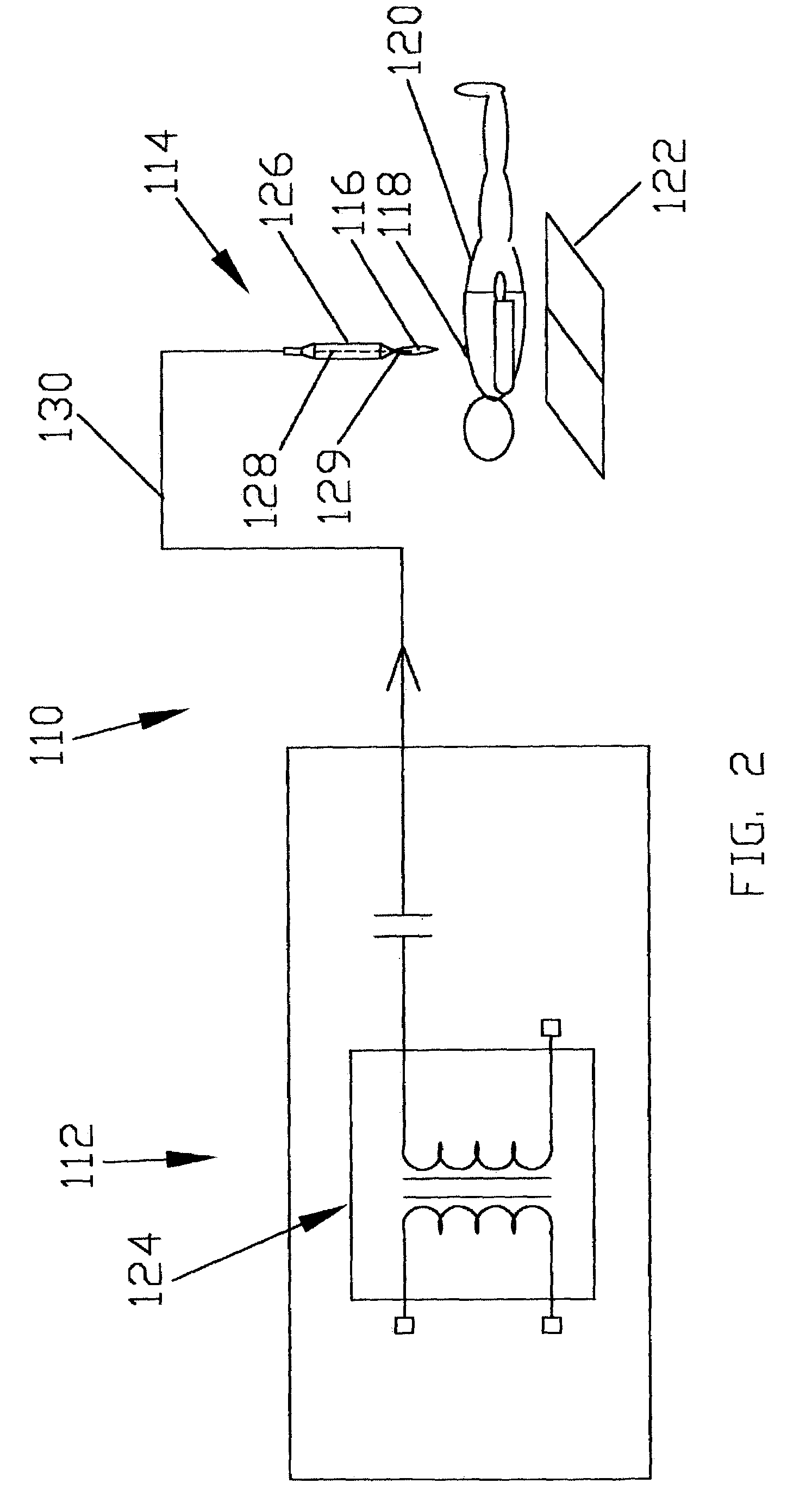

The invention features an RF plasma generator. The RF plasma generator includes a variable frequency RF generator, comprising an H-bridge and an RF output. The RF generator generates electromagnetic radiation having a power. The RF plasma generator further includes a matching network that includes at least one variable impedance component. The matching network also includes a first port that is electromagnetically coupled to the output of the RF generator and a second port. The RF plasma generator also includes a load that is electromagnetically coupled to the second port of the matching network, and a plasma chamber for containing a plasma having a power. The plasma chamber is electromagnetically coupled to the load and receives electromagnetic radiation having a power from the load. Adjusting at least one of the frequency of the RF generator and the variable impedance component in the matching network changes the power in the plasma.

Owner:MKS INSTR INC

Method to generate a plasma stream for performing electrosurgery

InactiveUS8057468B2Control areaEnhance flow-assisted removalSurgical instruments for heatingSurgical instruments for aspiration of substancesNoble gasSurgical site

Owner:BOVIE MEDICAL CORP

Plasma processing apparatuses and methods

InactiveUS20060260750A1Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaElectron source

A plasma processing apparatus and method includes a processing chamber having a substrate support and at least two separate and independently controlled devices selected from the following three devices: a first plasma generator, a second plasma generator, and an electron source. The first plasma generator directs plasma-generated cations toward the substrate support. The second plasma generator directs plasma-generated reactive neutral species toward the substrate support. The electron source directs electrons toward the substrate support. The first chamber may be separated from the substrate by an ion filter and the method may include directing predominately cations, rather than electrons, through the filter to the substrate. Along with the step of generating a remote plasma, the method may also includes directing predominately reactive neutral species, rather than ions and electrons, to the substrate. The apparatus or method may reduce structural charging on the substrate.

Owner:RUEGER NEAL R

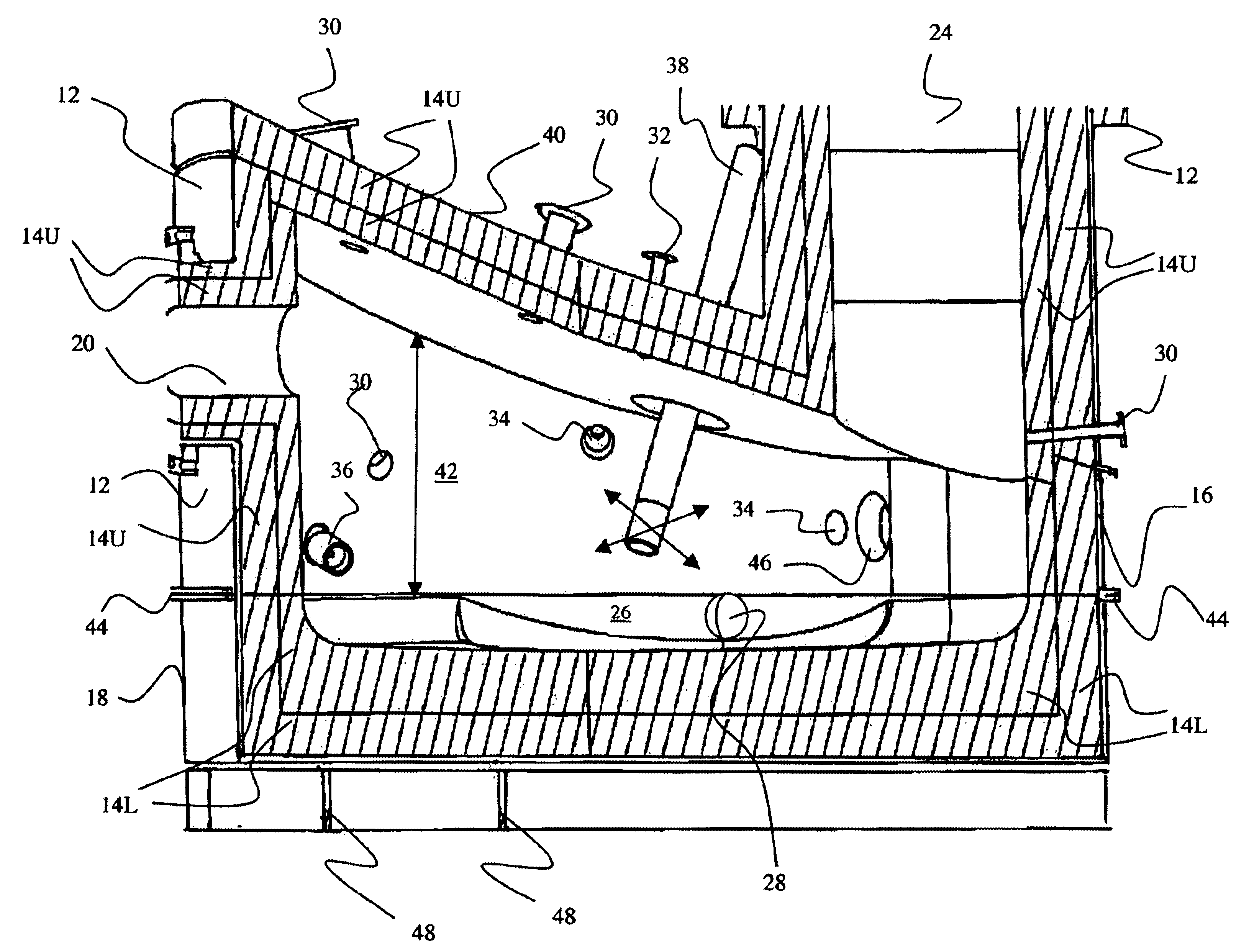

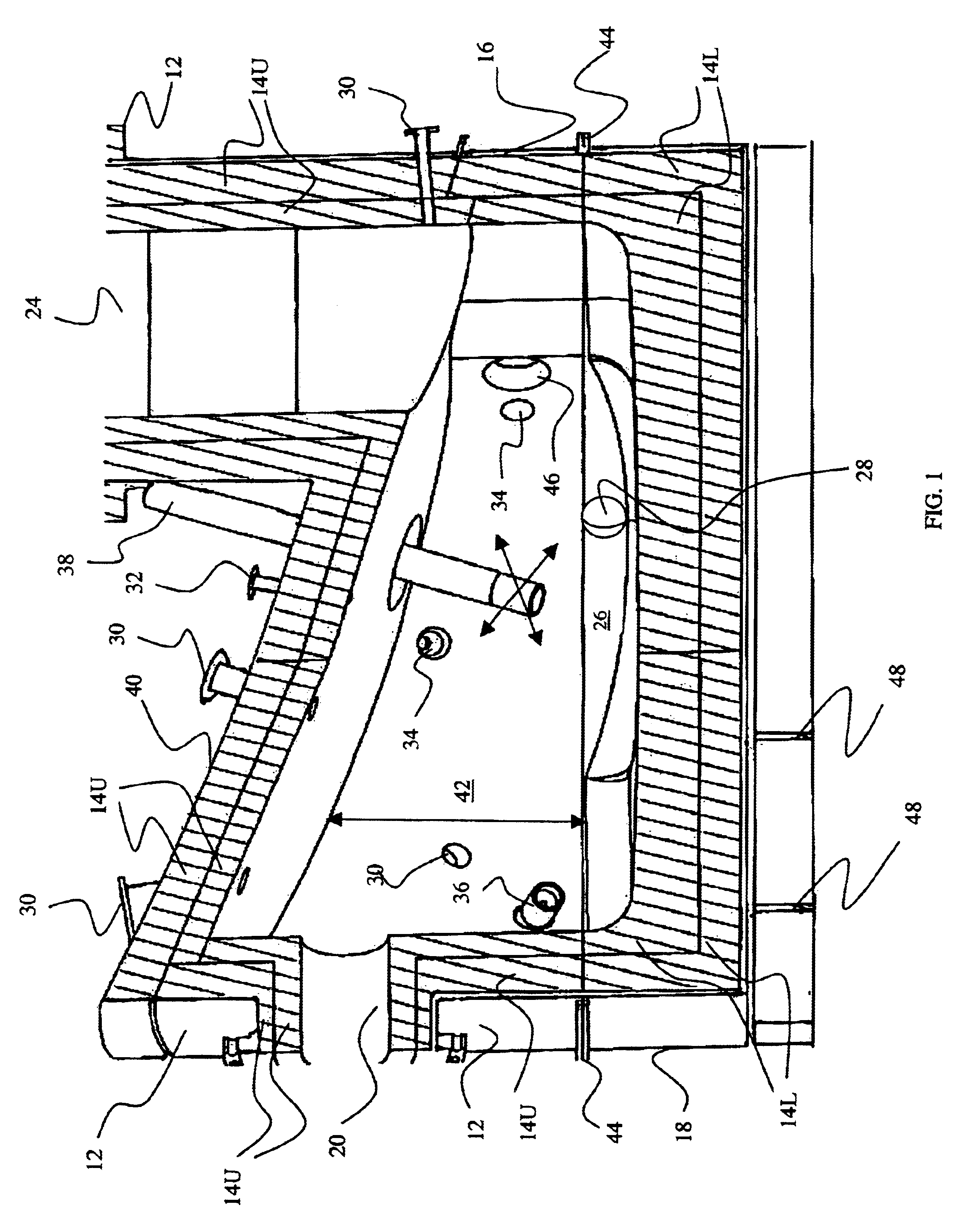

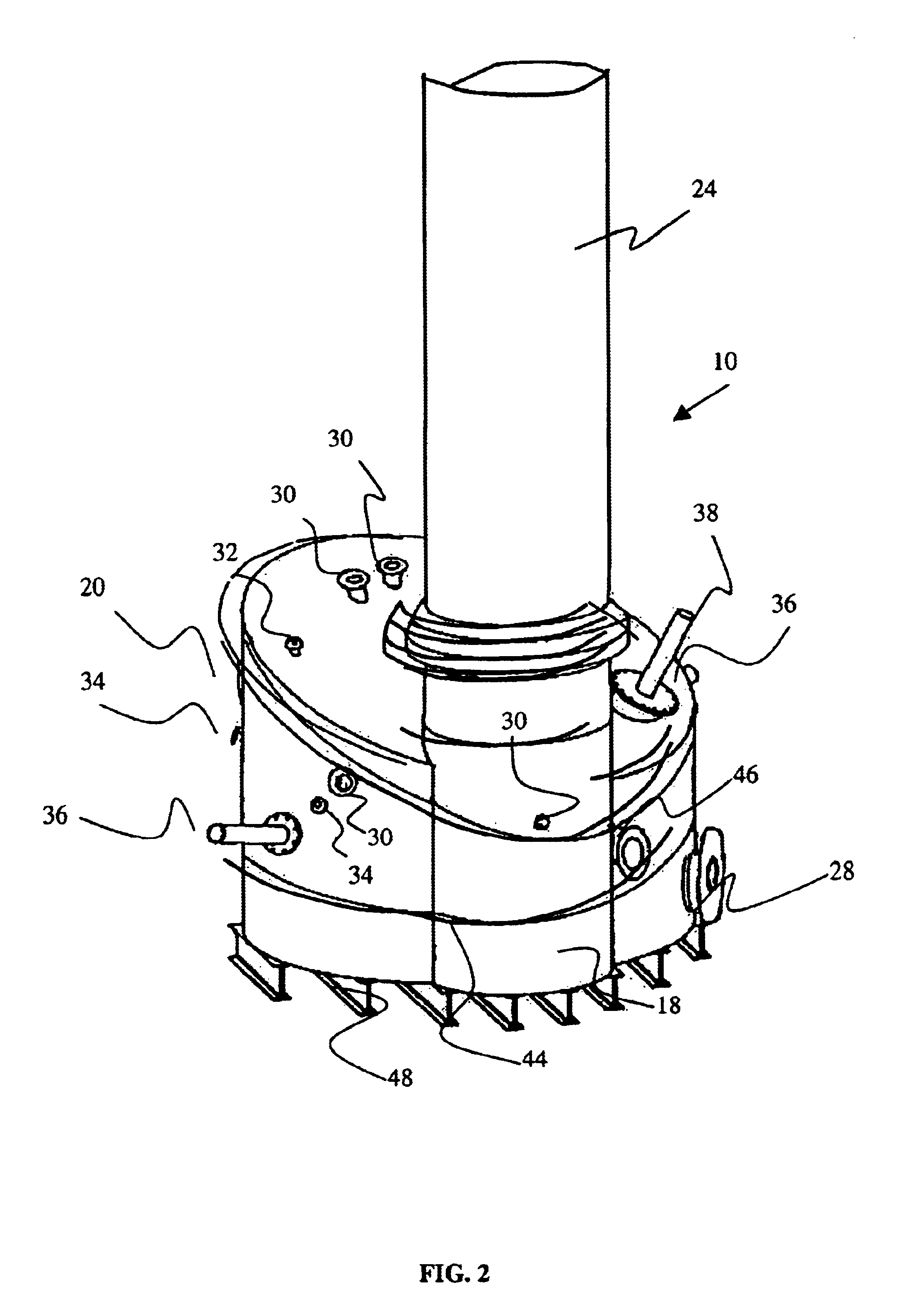

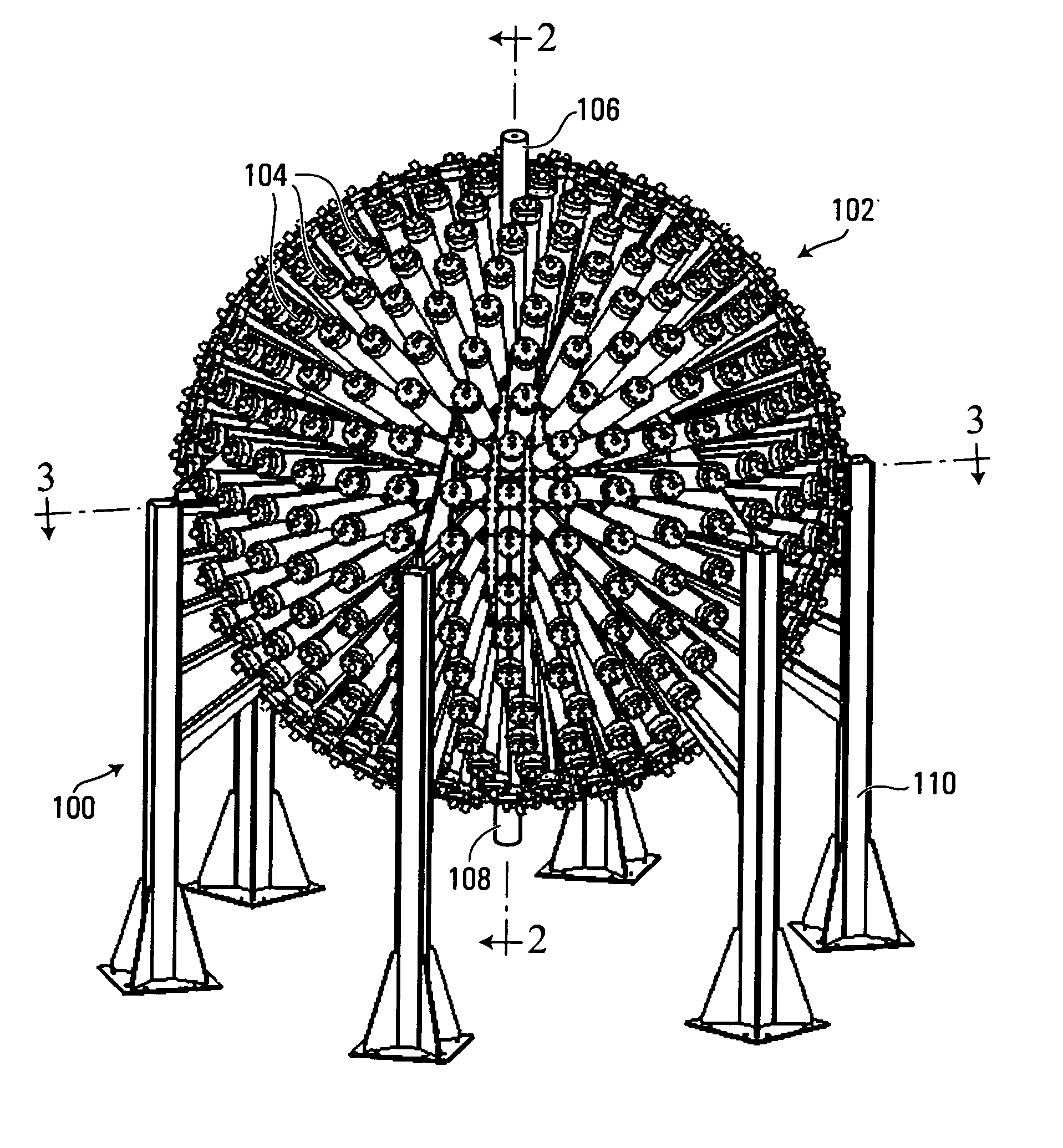

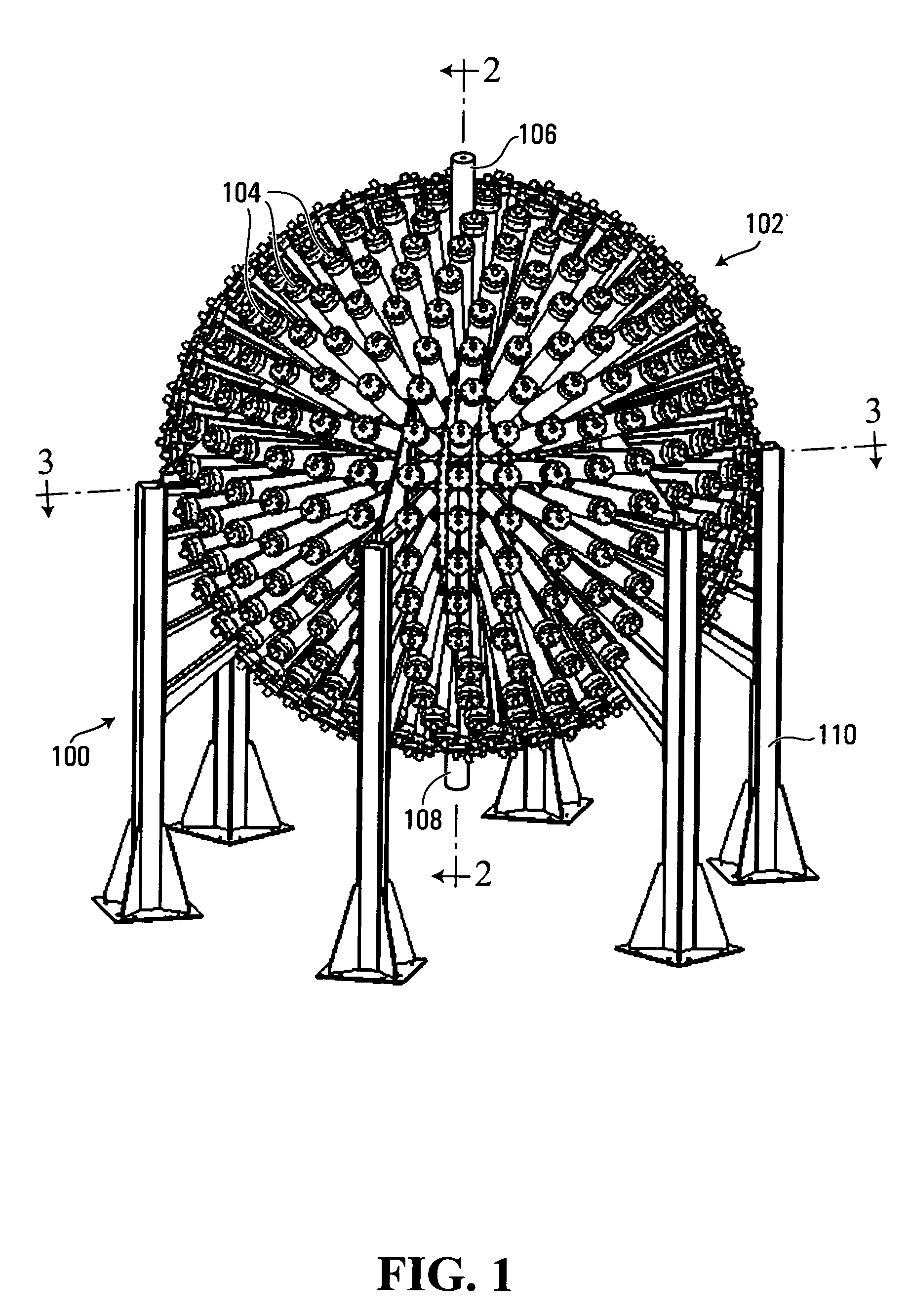

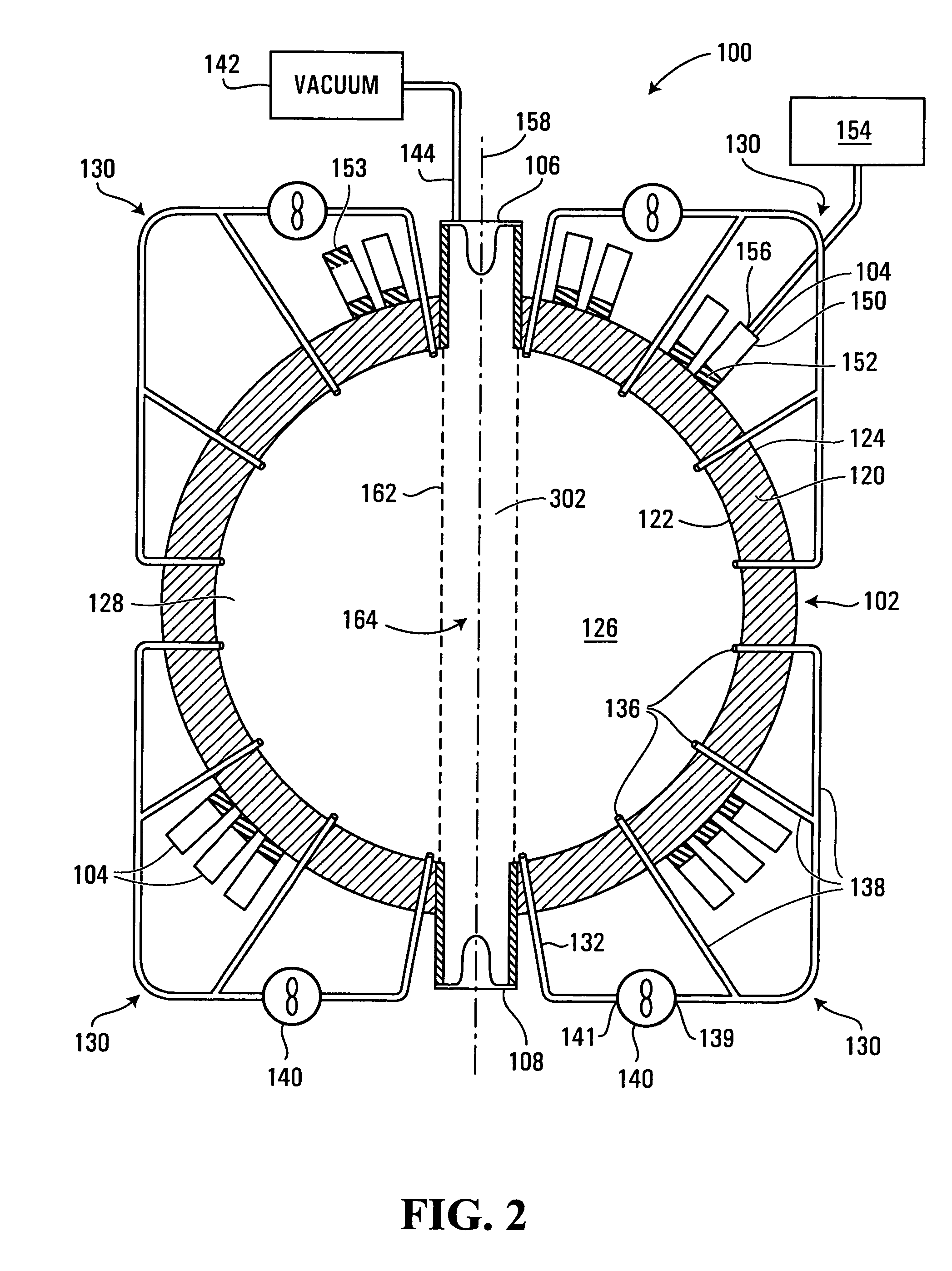

Apparatus for large area chemical vapor deposition using multiple expanding thermal plasma generators

InactiveUS6397776B1Efficient coatingDesirable propertyElectric discharge tubesChemical vapor deposition coatingThermoplasticGas phase

Chemical vapor deposition is performed using a plurality of expanding thermal plasma generating means to produce a coating on a substrate, such as a thermoplastic and especially a polycarbonate substrate. The substrate is preferably moved past the generating means. Included are methods which coat both sides of the substrate or which employ multiple sets of generating means, either in a single deposition chamber or in a plurality of chambers for deposition of successive coatings. The substrate surfaces spaced from the axes of the generating means are preferably heated to promote coating uniformity.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Dual delivery chamber design

InactiveUS20120097330A1Avoid heat damageKeep coolSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDual deliveryPlasma generator

A substrate processing system includes a thermal processor or a plasma generator adjacent to a processing chamber. A first processing gas enters the thermal processor or plasma generator. The first processing gas then flows directly through a showerhead into the processing chamber. A second processing gas flows through a second flow path through the showerhead. The first and second processing gases are mixed below the showerhead and a layer of material is deposited on a substrate under the showerhead.

Owner:APPLIED MATERIALS INC

Multiple plasma generator hazardous waste processing system

A waste processing system is provided herein which entails the use of at least one fixed-position plasma arc generator for primary processing and at least one moveable plasma arc generator for secondary processing assistance and / or final conditioning of the slag prior to exit from the reactor vessel. This optimum processing environment is provided by control of reactor vessel configuration and real time control of processing characteristics to ensure maximum processing efficiency.

Owner:PLASCO ENERGY GROUP INC

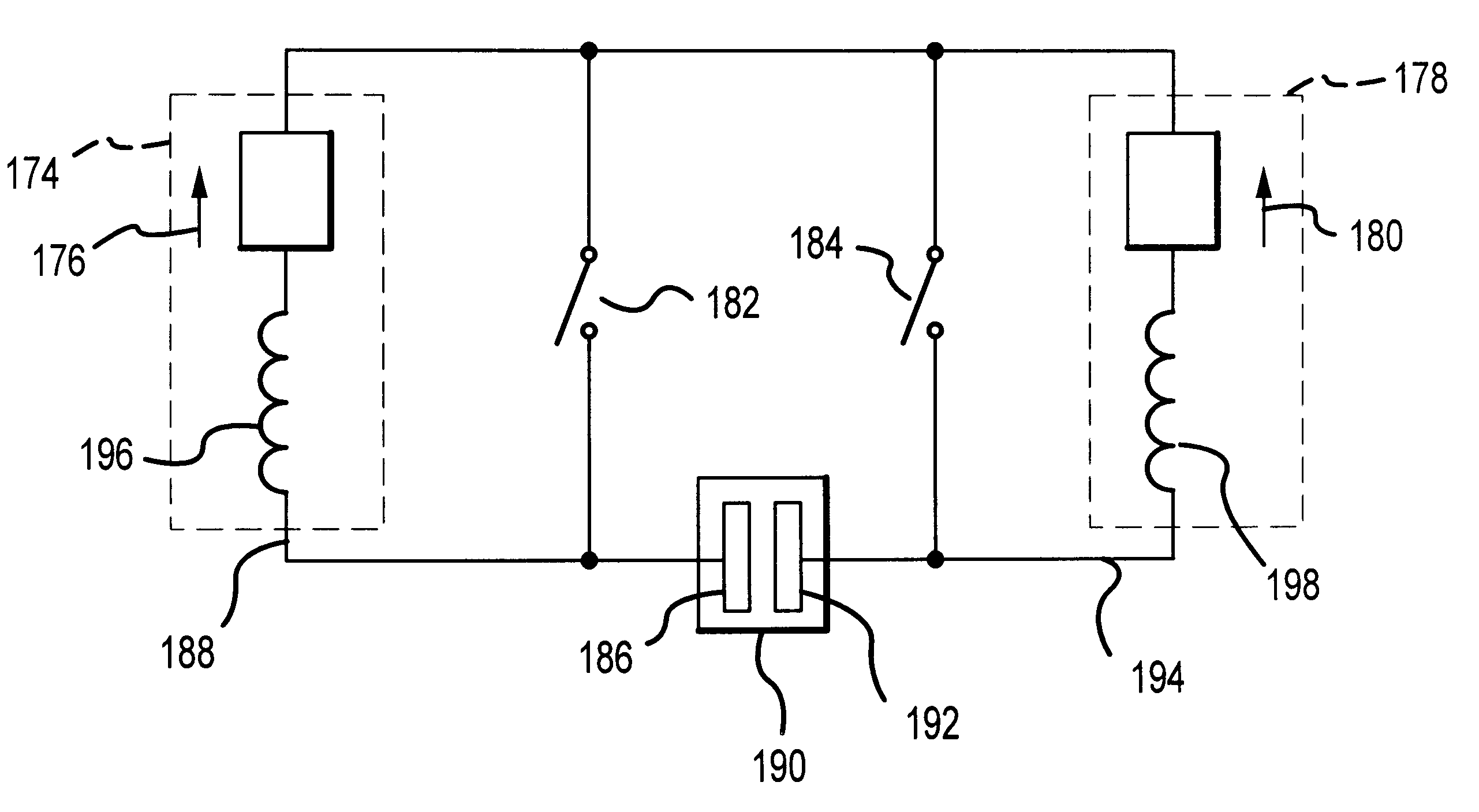

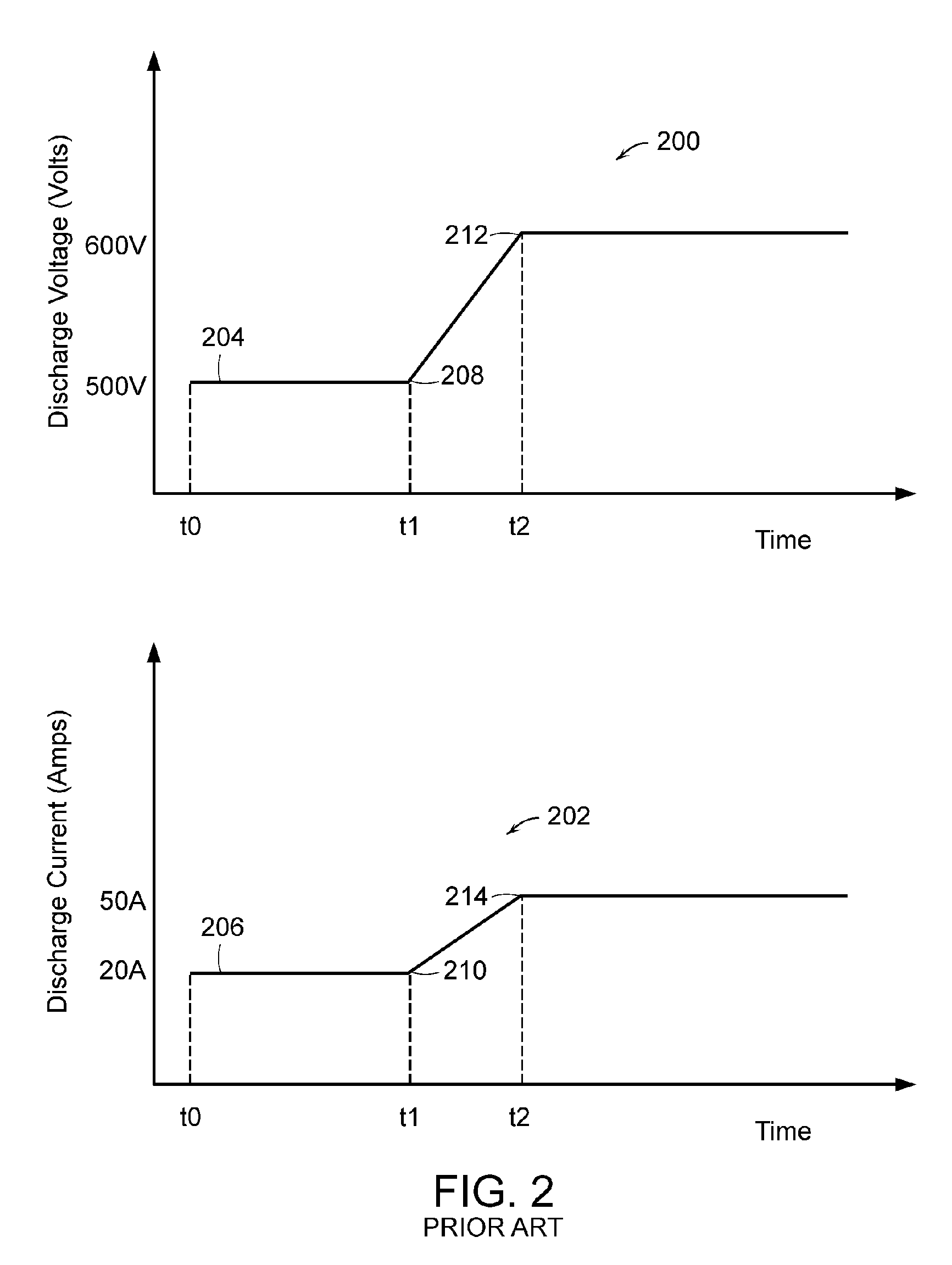

Plasma generator pulsed direct current supply in a bridge configuration

InactiveUS6222321B1Easy to controlIncrease depositionCellsElectric discharge tubesDc currentPulsed DC

Current controlled power sources are disclosed that are capable of generating currents in low resistance, high temperature plasmas that are regulated to prevent the generation of excessive currents in the plasma. Current reversing switches are provided that control the flow of a direct current in a plasma chamber between various electrodes. Multiple power sources are provided in association with shunt switches for delivering a plurality of sources of direct current in various directions between electrodes in a plasma chamber. Inductive impedance can be provided in switch paths to cause a source of direct current to flow through a plasma chamber in various directions between electrodes.

Owner:ADVANCED ENERGY IND INC

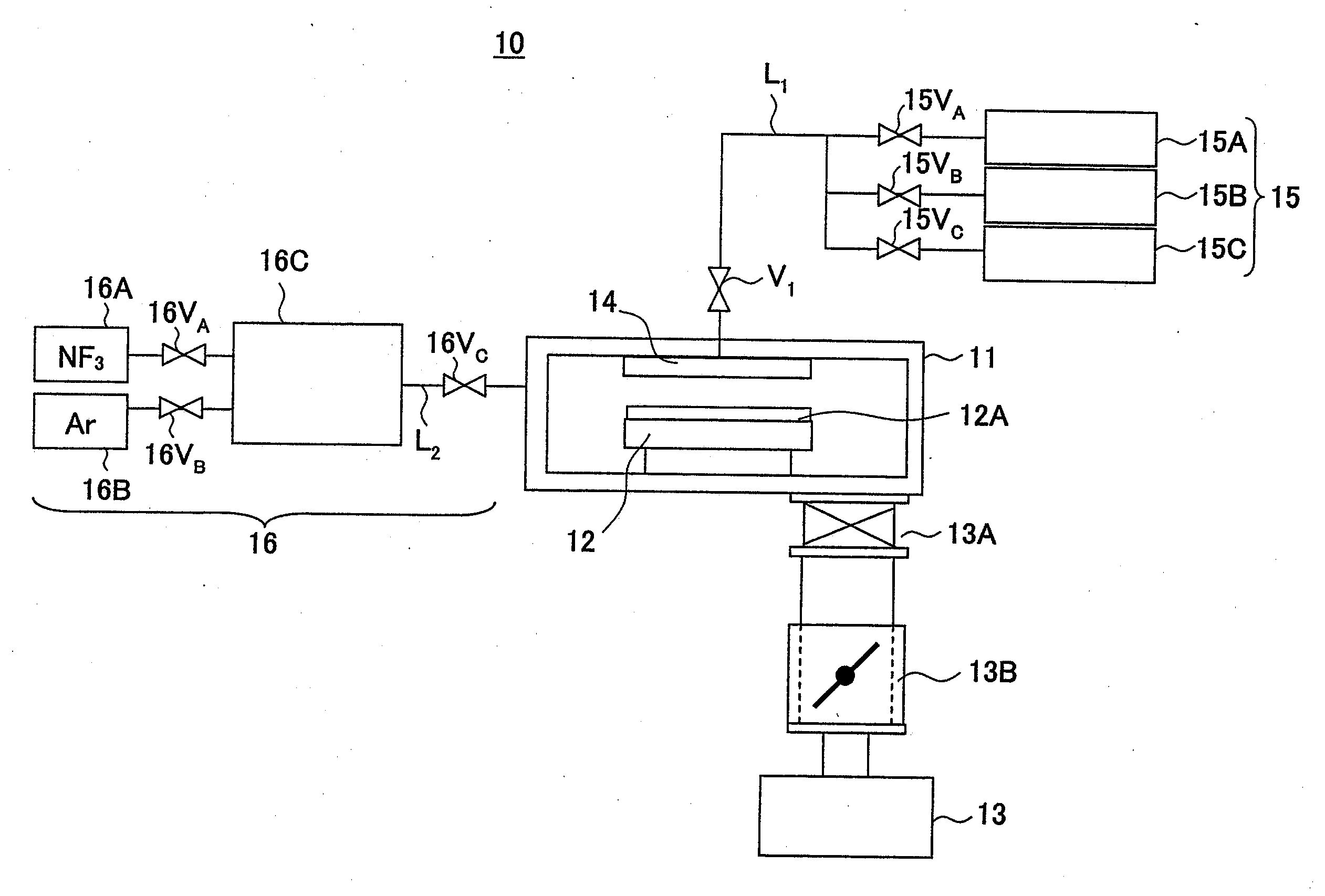

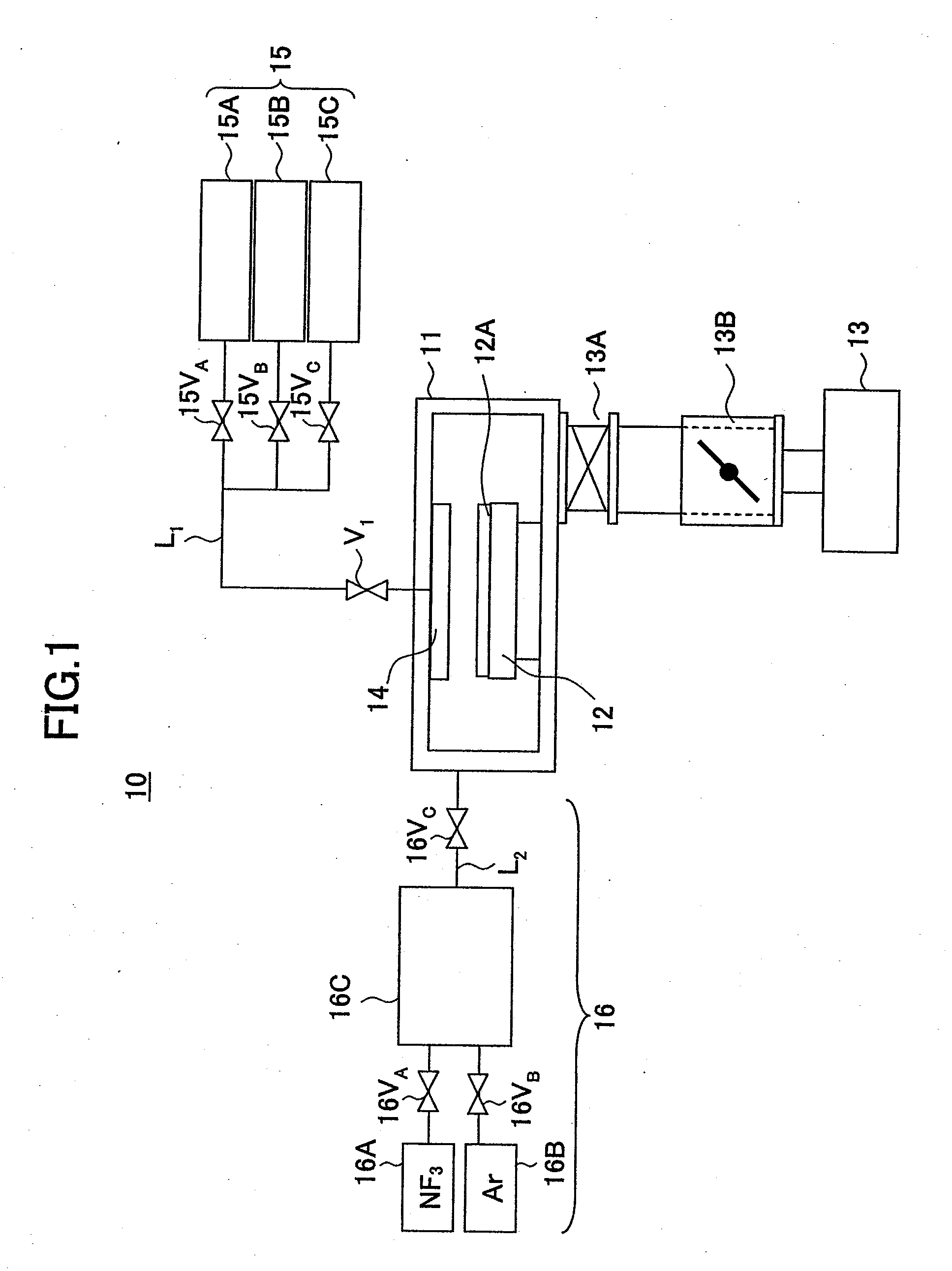

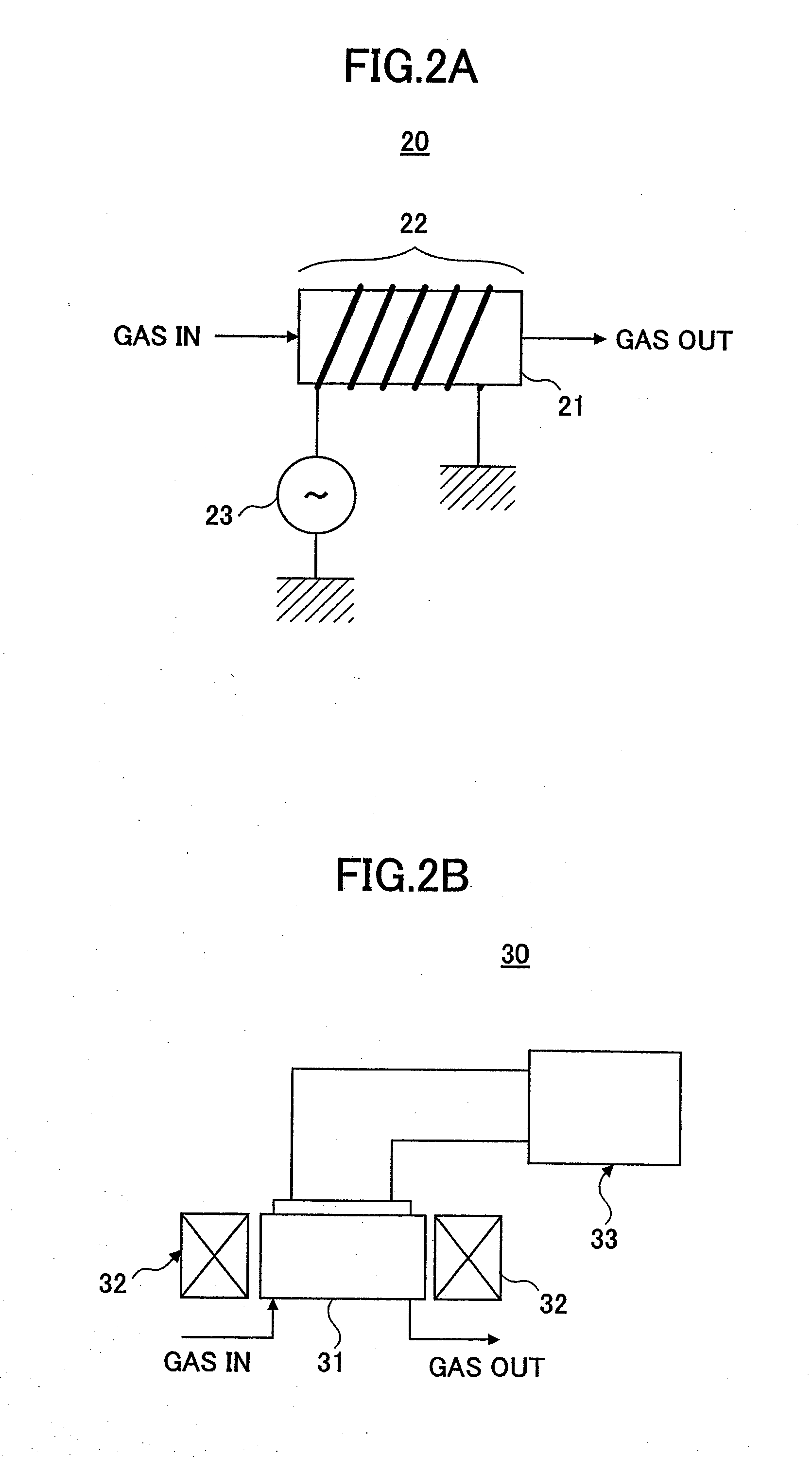

Plasma Generation Method, Cleaning Method, and Substrate Processing Method

InactiveUS20100252068A1Improve throughputAvoid it happening againElectric discharge tubesDecorative surface effectsHigh frequency powerPlasma generator

A plasma generation method in a toroidal plasma generator that includes a gas passage having a gas entrance and a gas outlet and forming a circuitous path and a coil wound around a part of the gas passage includes the steps of supplying a mixed gas of an Ar gas and an NF3 gas containing at least 5% of NF3 and igniting plasma by driving the coil with a high-frequency power, wherein the plasma ignition step is conducted under a total pressure of 6.65-66.5 Pa.

Owner:TOKYO ELECTRON LTD

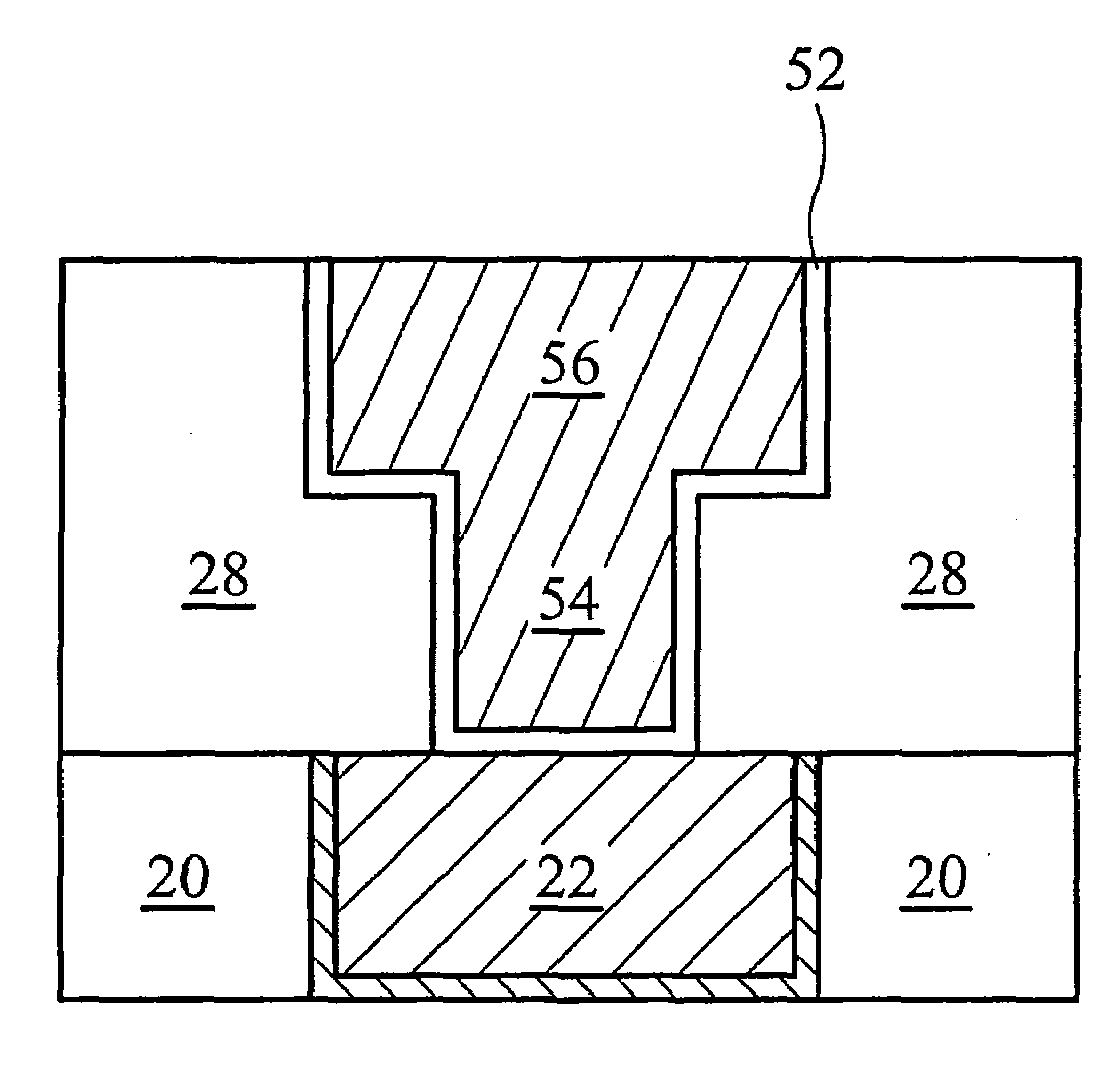

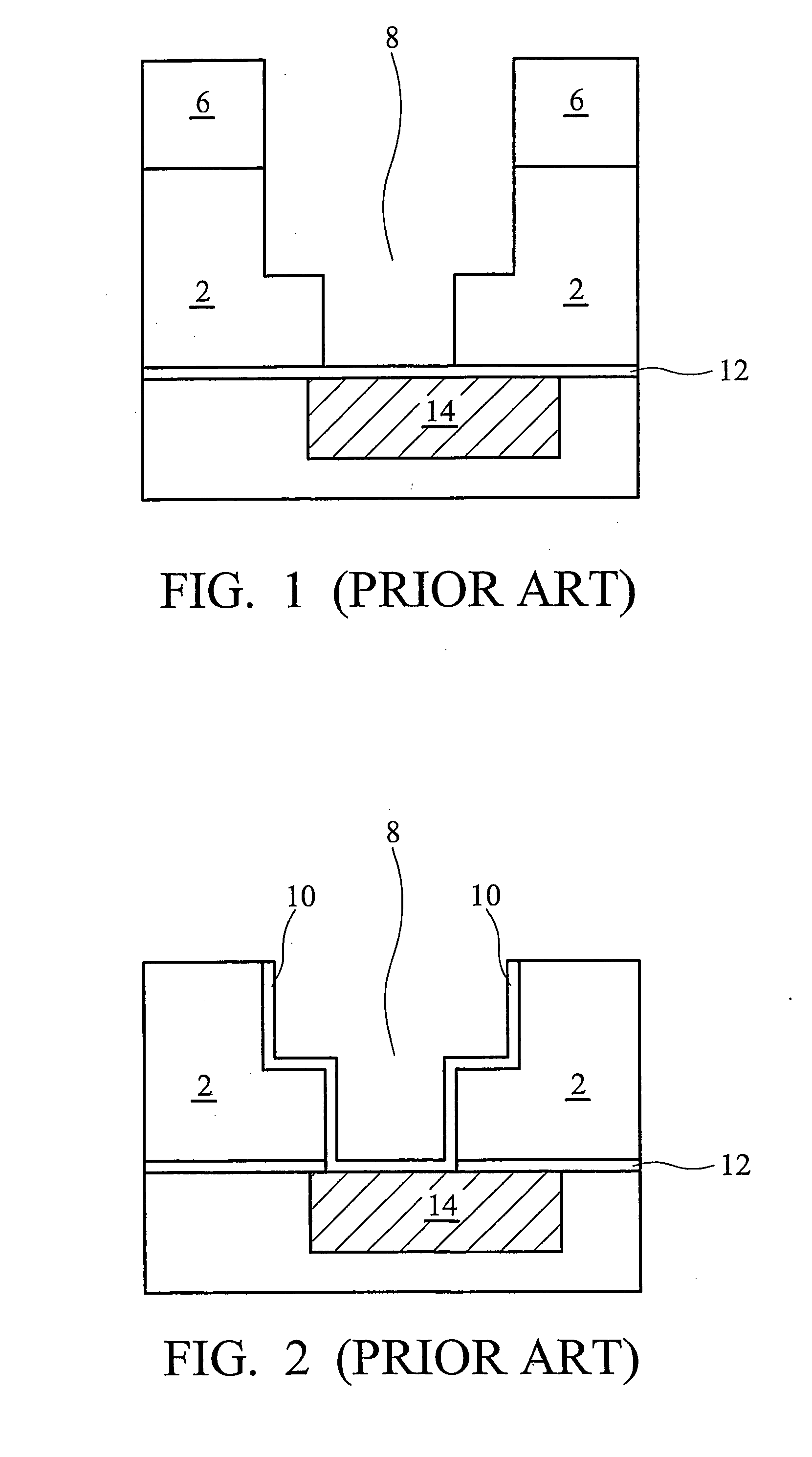

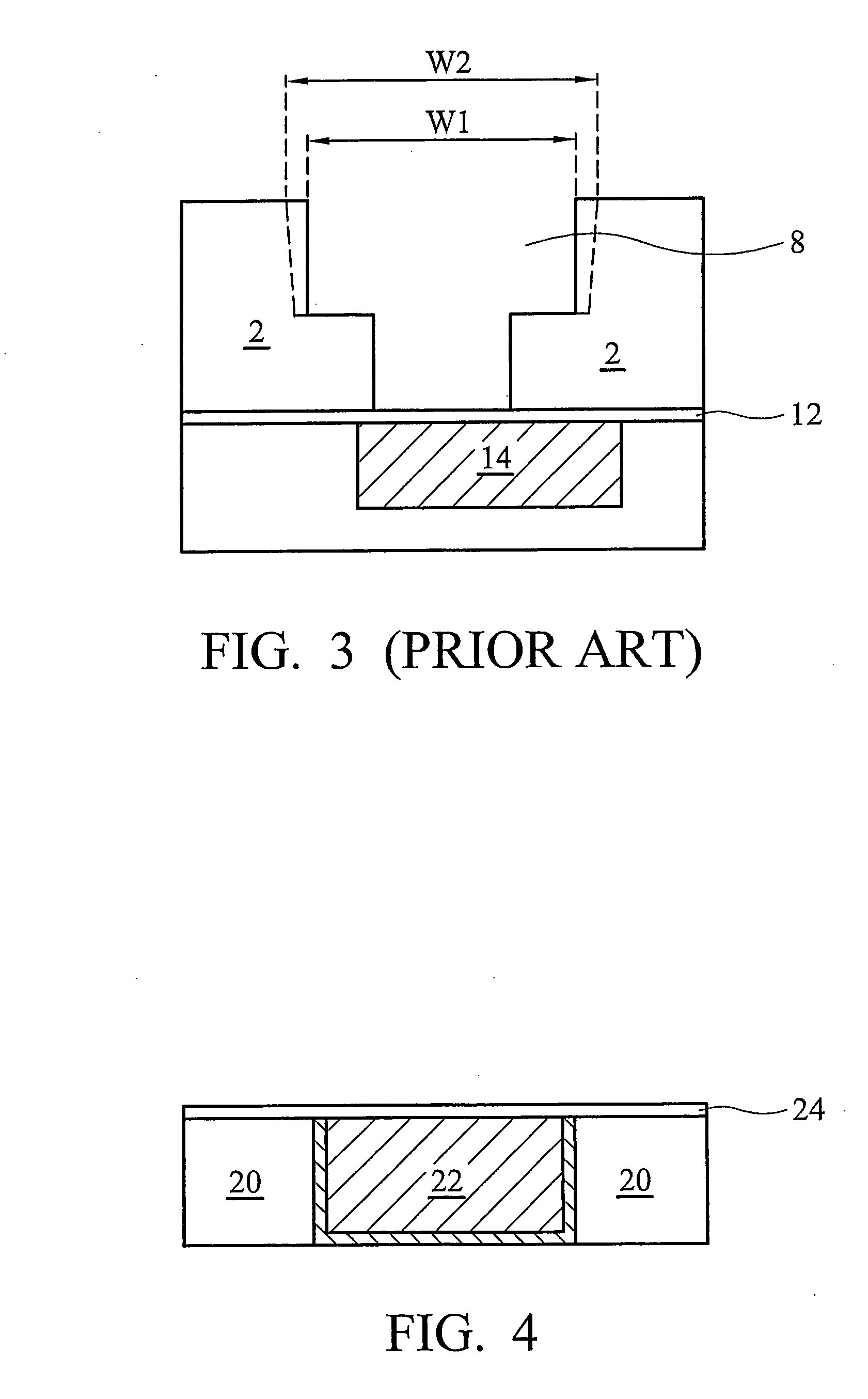

Cleaning processes in the formation of integrated circuit interconnect structures

InactiveUS20080124919A1Small shiftDecreased trench enlargementSemiconductor/solid-state device manufacturingRemote plasmaIntegrated circuit interconnect

A method for fabricating an integrated circuit includes providing a substrate, forming a low-k dielectric layer over the substrate, etching the low-k dielectric layer to form an opening in the low-k dielectric layer wherein an underlying metal is exposed through the opening, performing a remote plasma treatment to the substrate wherein a plasma used for the remote plasma treatment is generated from a plasma generator separated from a chamber in which the substrate is located, forming a diffusion barrier layer in the opening, and filling the opening with a conductive material. The method preferably includes an in-situ plasma treatment in a same chamber as the step of etching the low-k dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

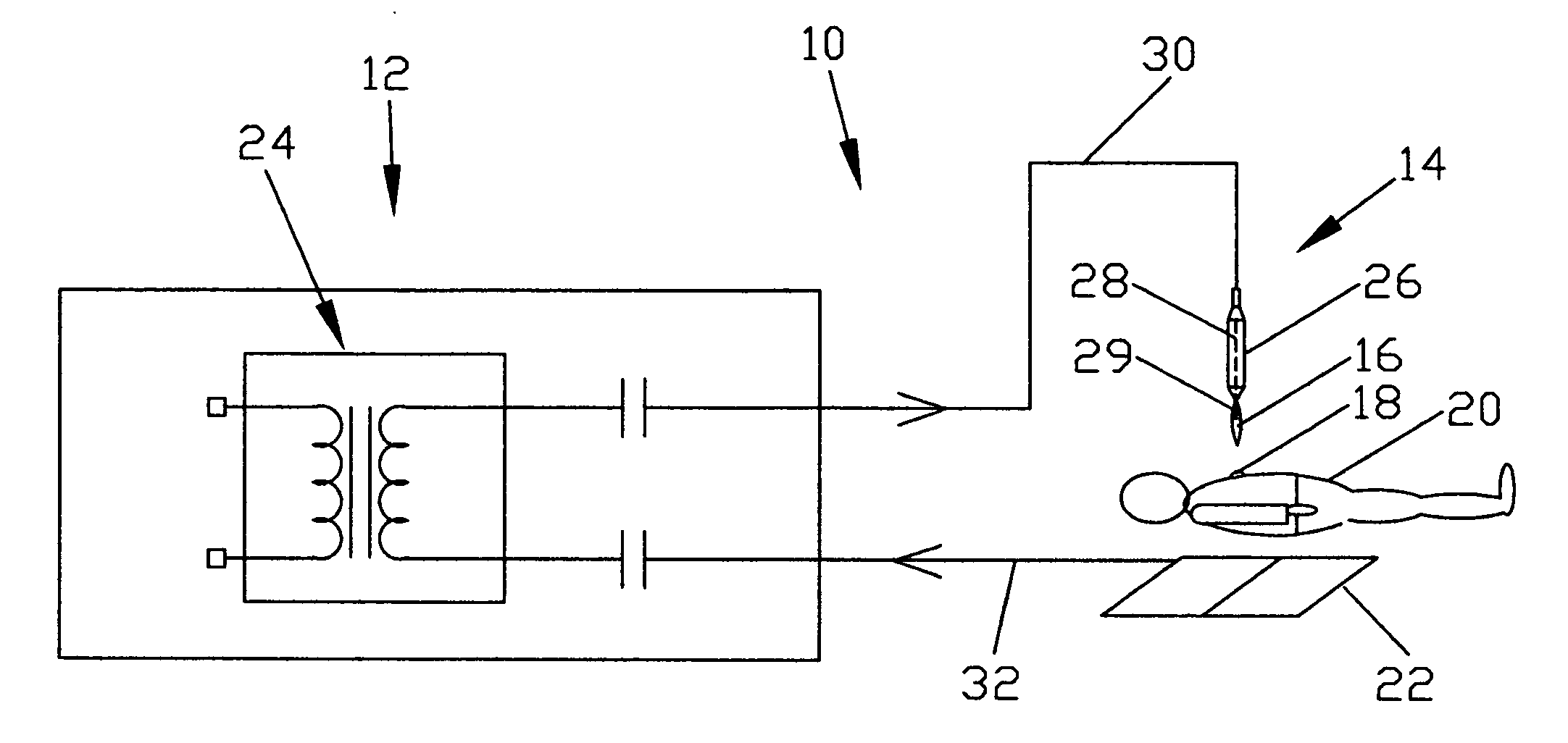

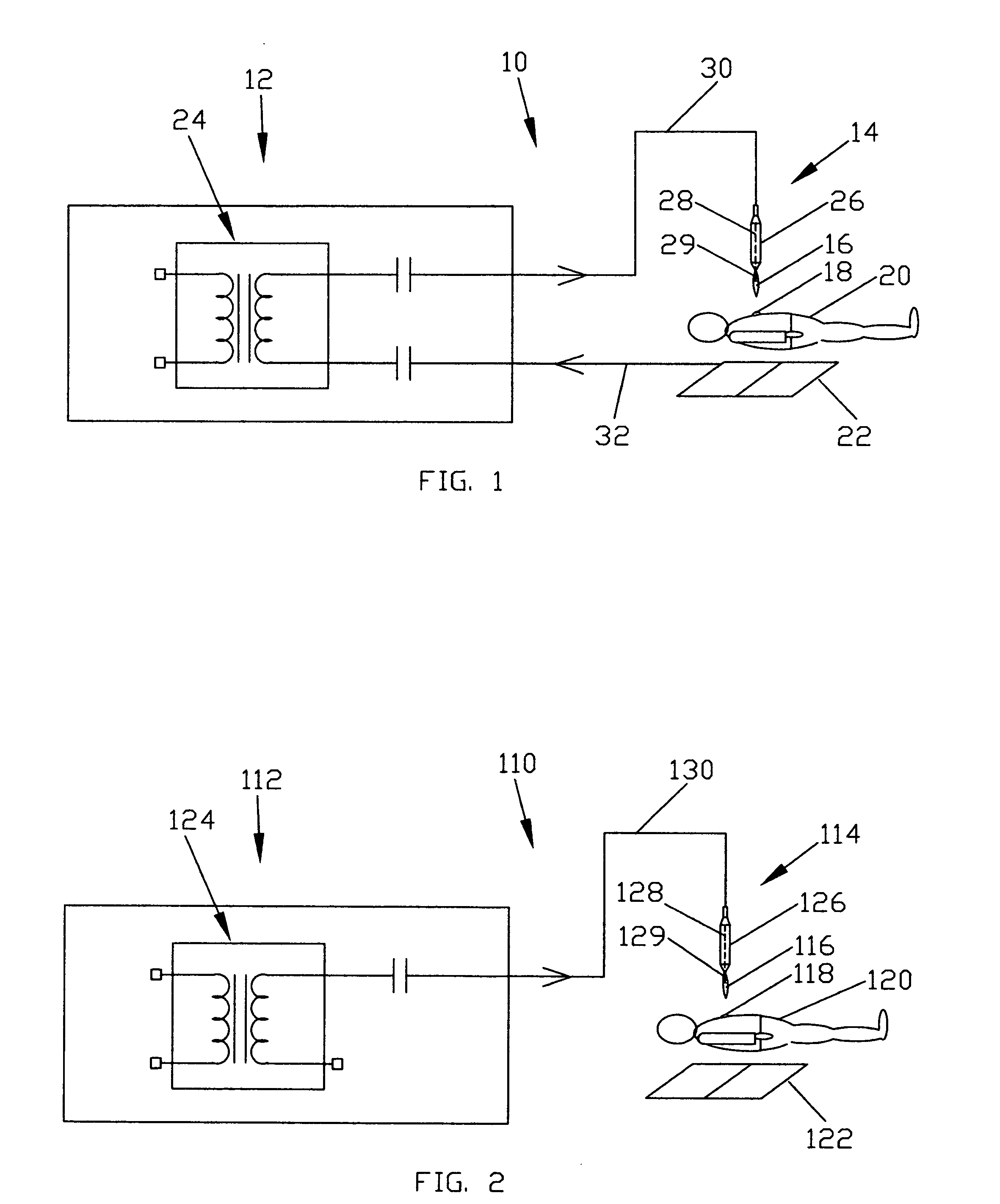

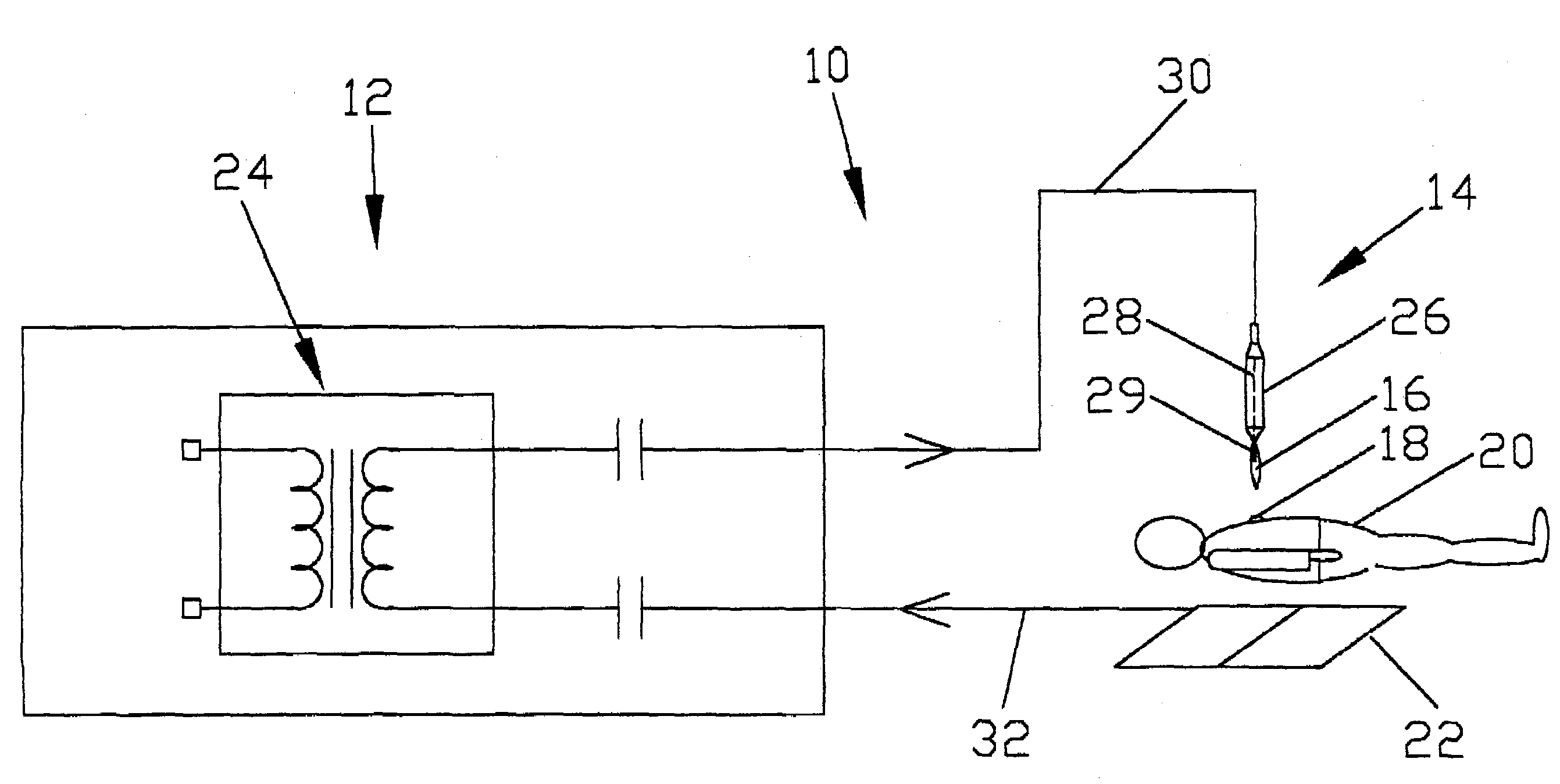

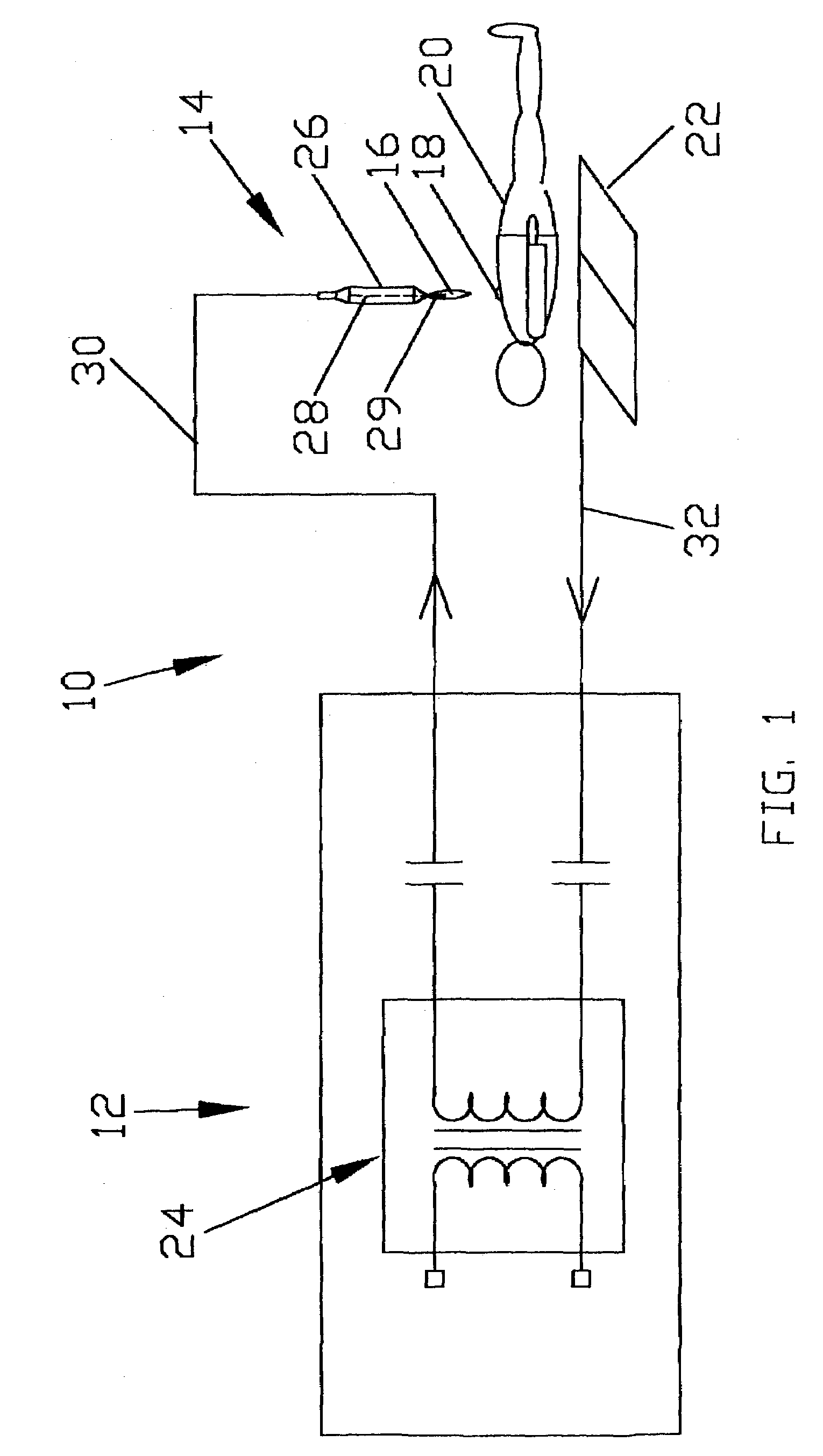

Electrosurgical device to generate a plasma stream

ActiveUS7316682B2Enhance flow-assisted removalSurgical instruments for heatingSurgical instruments for aspiration of substancesElectricityNoble gas

An electrosurgical device to generate a plasma stream for performing electrosurgery on a surgical site on a patient comprising an electrosurgical generator coupled to a electrical power source to supply power to the electrosurgical device and a plasma generator including an electrode operatively coupled to the electrosurgical generator to receive electrical energy therefrom and concentrically disposed within an inner noble gas conduit to form a plasma channel coupled to a noble gas source to feed noble gas to the inner noble gas conduct, an intermediate electronegative gas conduit disposed in surrounding coaxial relation relative to the noble gas conduit to cooperatively form an electronegative gas channel therebetween coupled to a gas source to feed electronegative gas to the electronegative gas channel and an outer aspiration conduit disposed in surrounding coaxial relation relative to the intermediate electronegative gas conduit to cooperatively form an aspiration channel therebetween coupled to a negative pressure source such that the electrode heats the noble gas to at least partially ionize the noble gas to generate the plasma stream to be directed to the surgical site to perform the surgical procedure while the electronegative gas maintains or sustains the plasma stream and the negative pressure source removes fluid and solid debris from the surgical site.

Owner:BOVIE MEDICAL CORPORATION

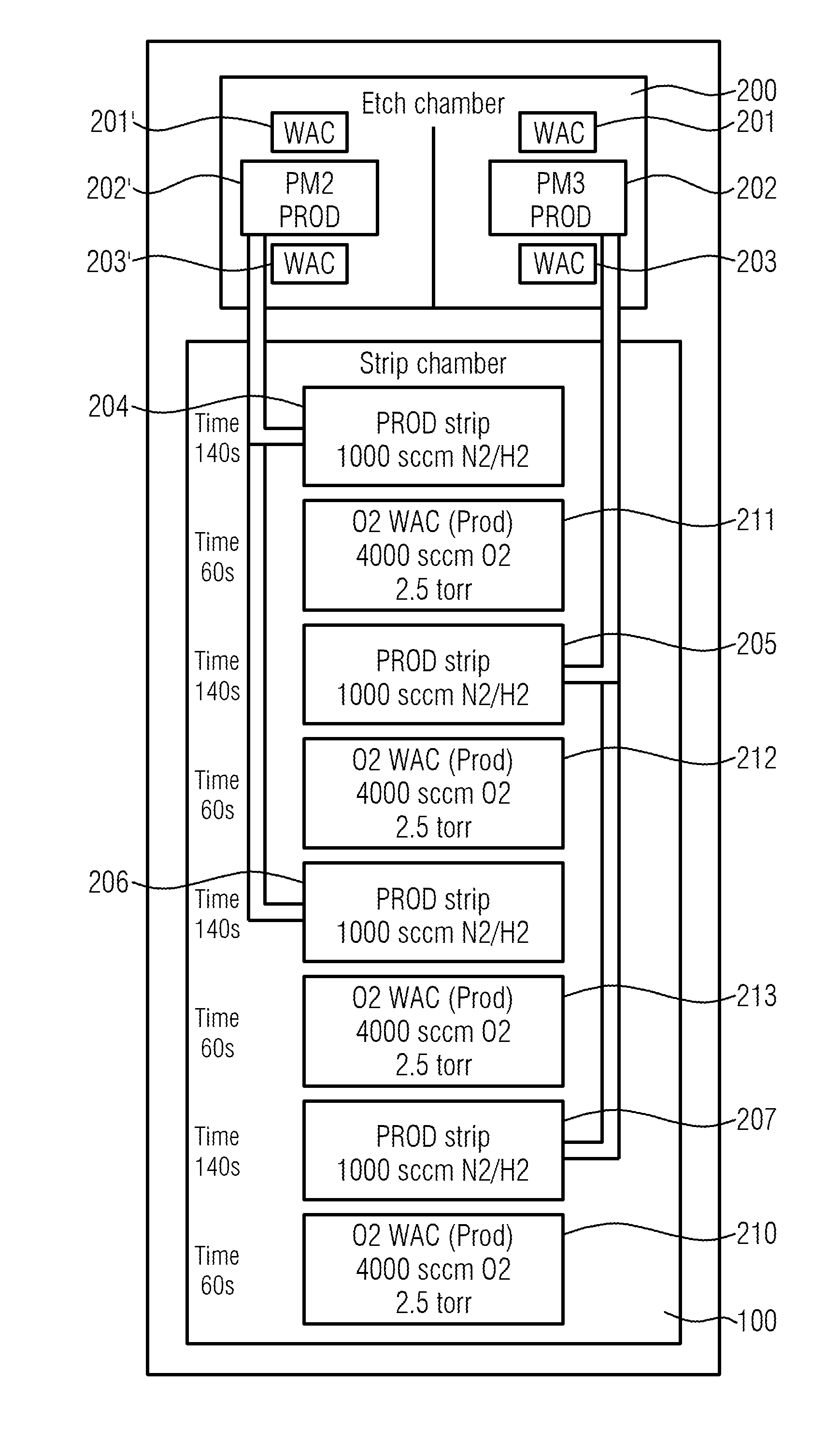

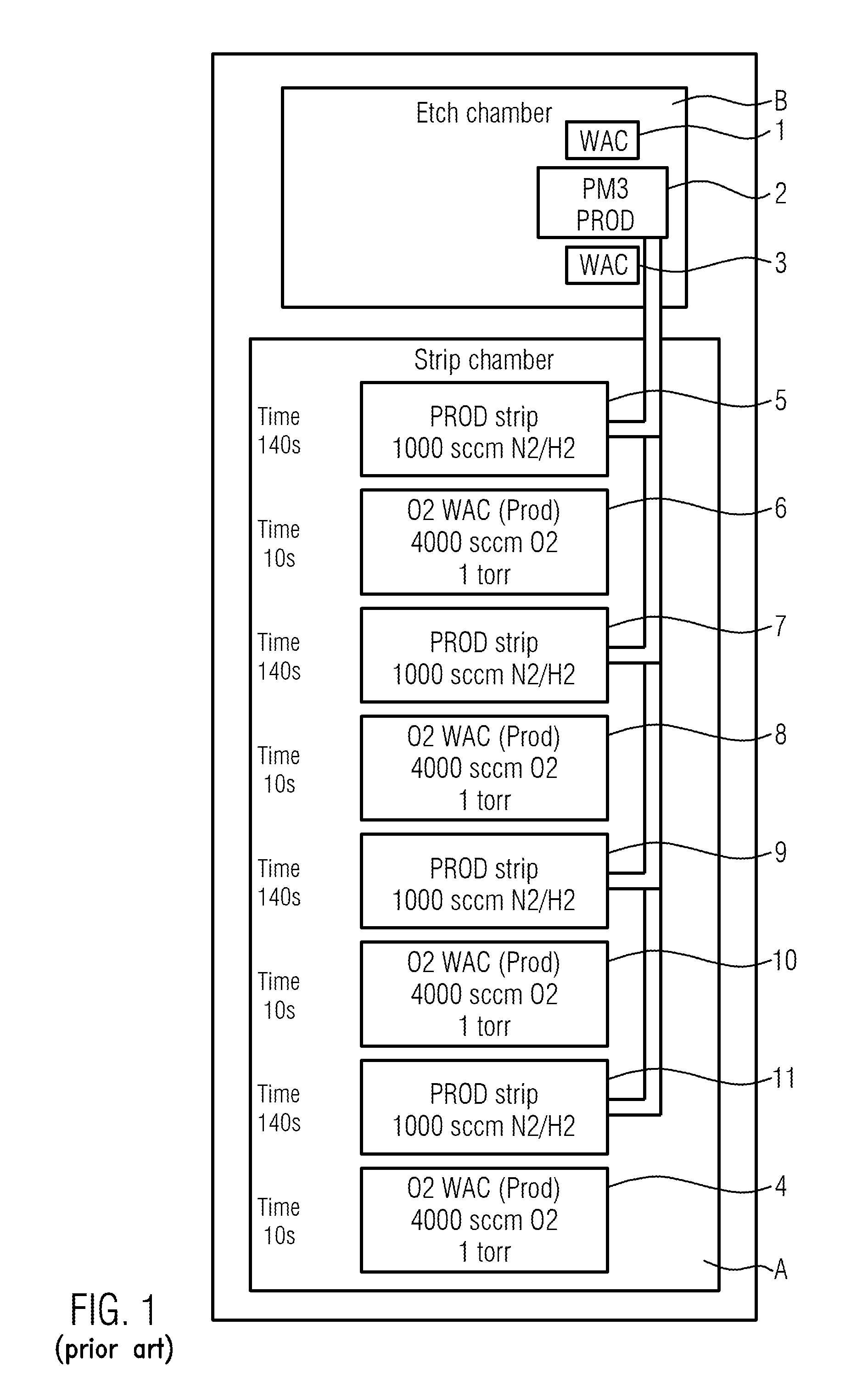

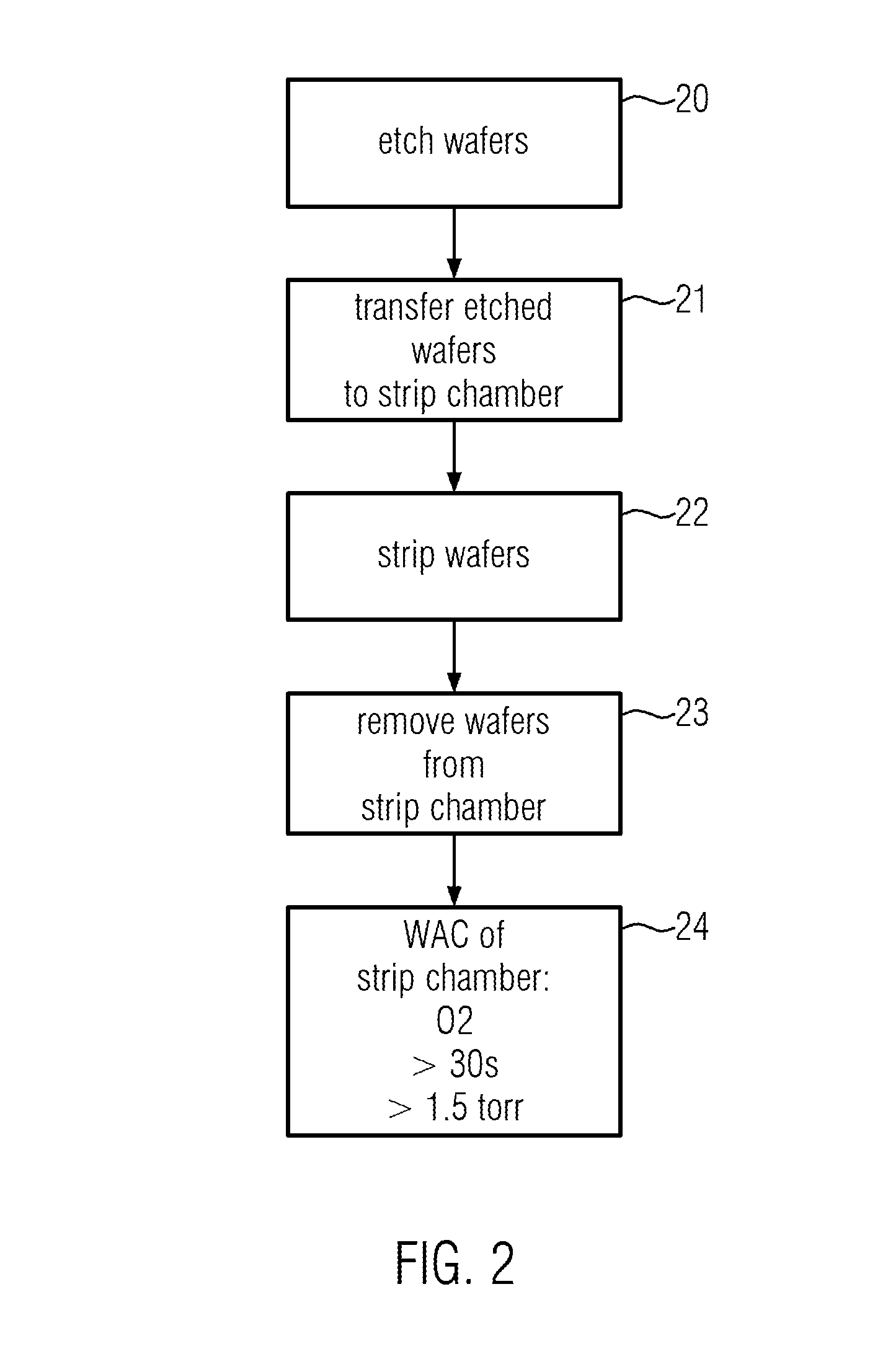

Wafer-less auto clean of processing chamber

InactiveUS20150050812A1Easy to cleanElectric discharge tubesElectrostatic cleaningWaferingOxygen plasma

A method for cleaning a processing chamber, for example, a strip chamber, configured for processing a wafer is provided which includes the steps of introducing an oxygen-containing gas into the processing chamber, generating an oxygen plasma from the oxygen-containing gas in the processing chamber, establishing a pressure of the oxygen plasma in the processing chamber of at least 1 Torr and maintaining the pressure of at least 1 Torr for at least 40 seconds. A system is also provided including a strip chamber for receiving and stripping the wafer and including a gas inlet and plasma generator means, as well as a controller configured for performing, when no wafer is present in the strip chamber, controlling inflow of an oxygen-containing gas into the processing chamber through the gas inlet and controlling the plasma generator means to generate an oxygen plasma.

Owner:GLOBALFOUNDRIES INC

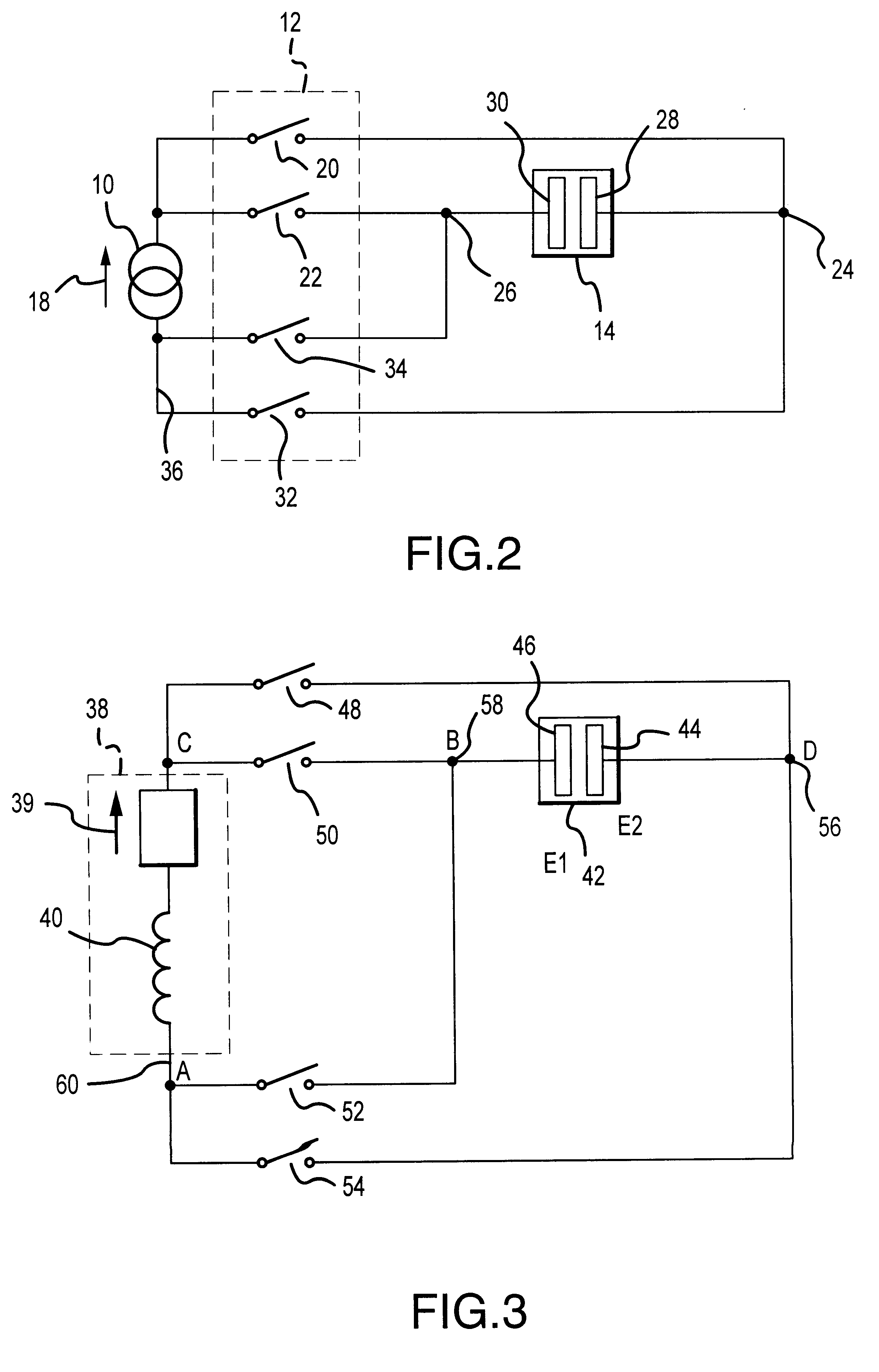

Plasma source for chamber cleaning and process

InactiveUS20100098882A1Enhanced vapor depositionElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaSwitch box

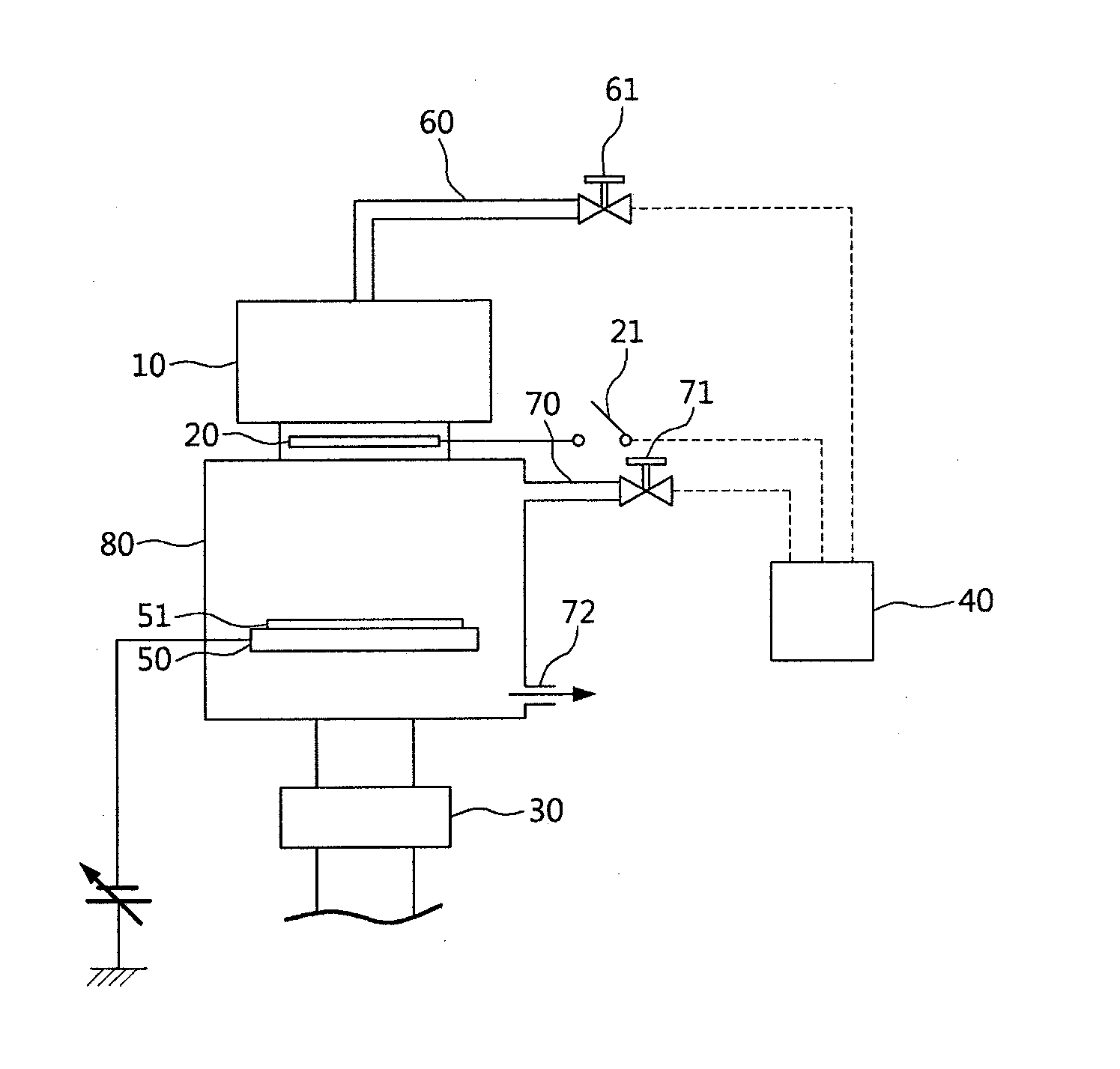

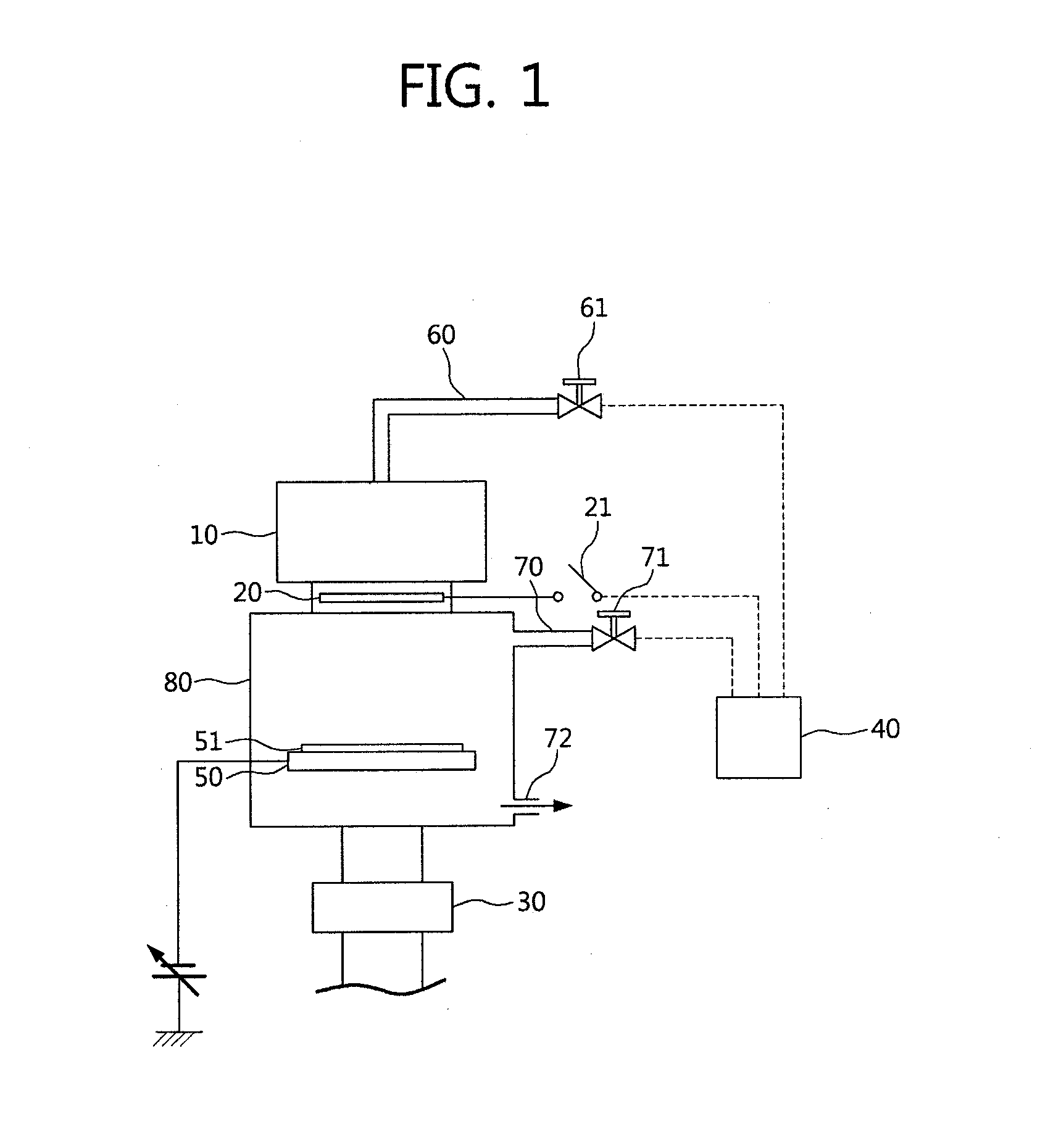

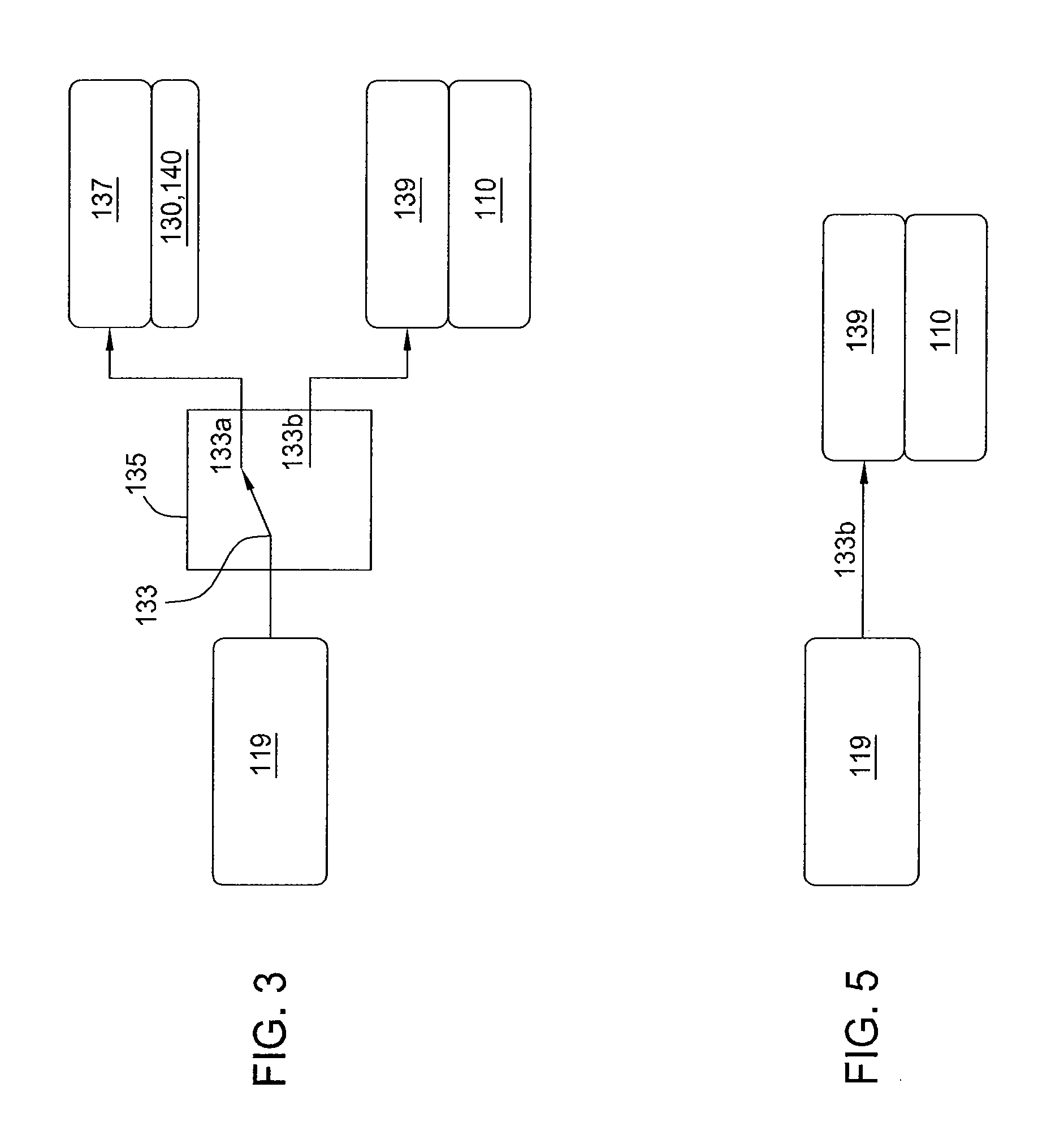

Apparatus and methods for processing a substrate and processing a process chamber are provided. In one embodiment, an apparatus is provided for processing a substrate including a power source, a switch box coupled to the power source and the switch box having a switch interchangeable between a first position and a second position, a first match box coupled to the switch box, a plasma generator coupled to the first match box, a second match box coupled to the switch box, and a remote plasma source coupled to the second match box.

Owner:APPLIED MATERIALS INC

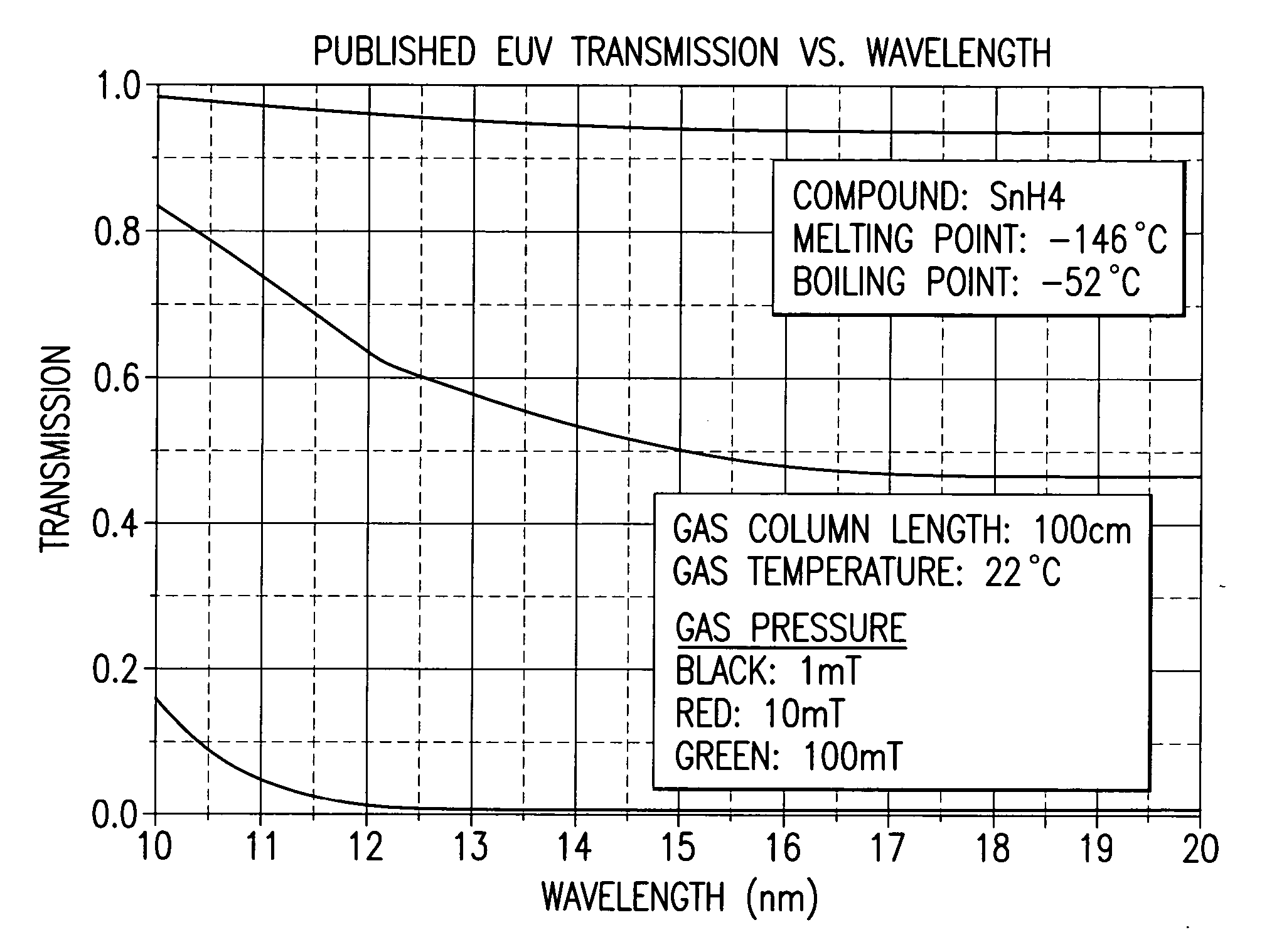

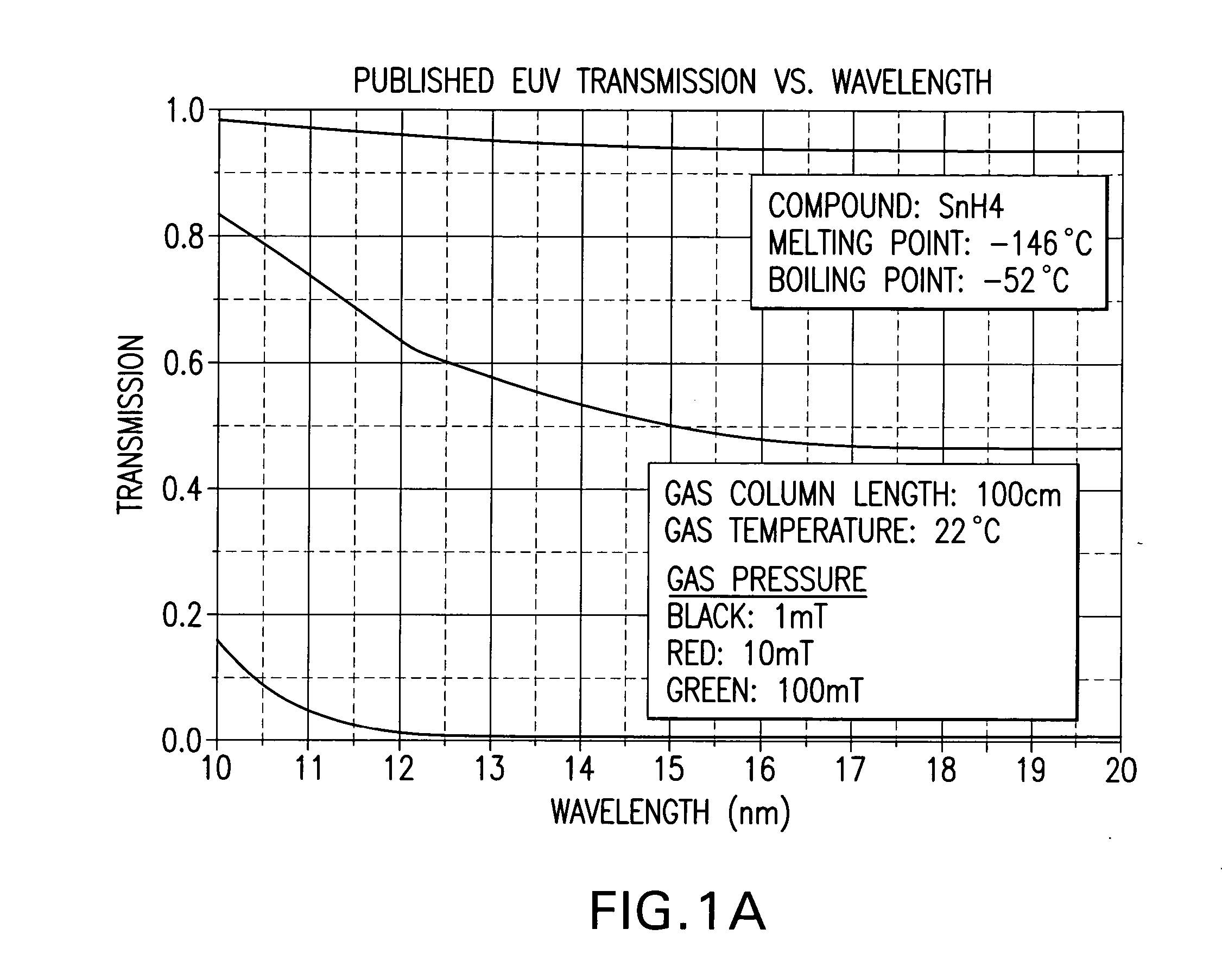

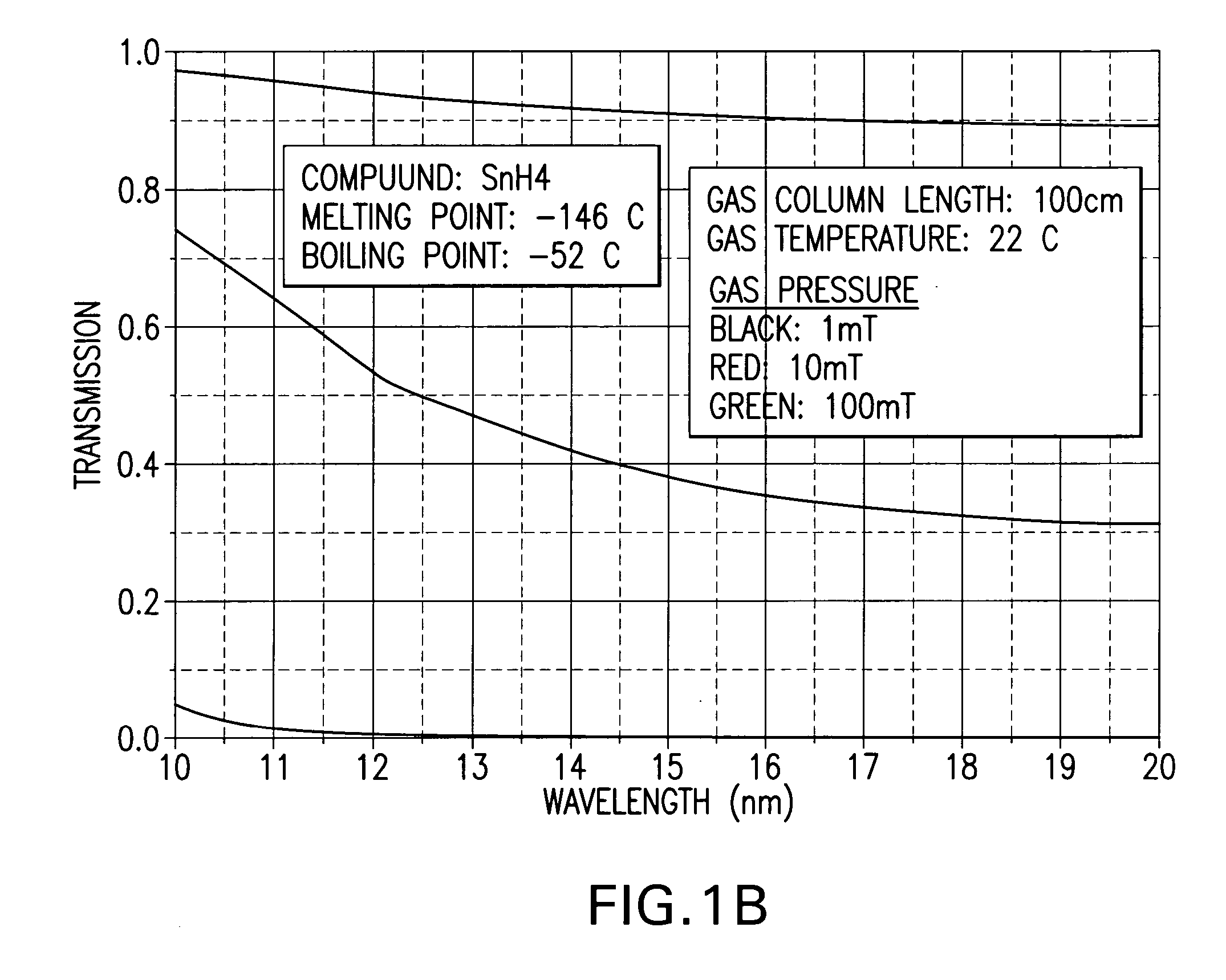

EUV collector debris management

InactiveUS20060091109A1Reduce reflectivityLow material performance requirementsDecorative surface effectsSemiconductor/solid-state device manufacturingEtchingSource material

A method and apparatus that may comprise an EUV light producing mechanism utilizing an EUV plasma source material comprising a material that will form an etching compound, which plasma source material produces EUV light in a band around a selected center wavelength comprising: an EUV plasma generation chamber; an EUV light collector contained within the chamber having a reflective surface containing at least one layer comprising a material that does not form an etching compound and / or forms a compound layer that does not significantly reduce the reflectivity of the reflective surface in the band; an etchant source gas contained within the chamber comprising an etchant source material with which the plasma source material forms an etching compound, which etching compound has a vapor pressure that will allow etching of the etching compound from the reflective surface. The etchant source material may comprises a halogen or halogen compound. The etchant source material may be selected based upon the etching being stimulated in the presence of photons of EUV light and / or DUV light and / or any excited energetic photons with sufficient energy to stimulate the etching of the plasma source material. The apparatus may further comprise an etching stimulation plasma generator providing an etching stimulation plasma in the working vicinity of the reflective surface; and the etchant source material may be selected based upon the etching being stimulated by an etching stimulation plasma. There may also be an ion accelerator accelerating ions toward the reflective surface. The ions may comprise etchant source material. The apparatus and method may comprise a part of an EUV production subsystem with an optical element to be etched of plasma source material.

Owner:ASML NETHERLANDS BV

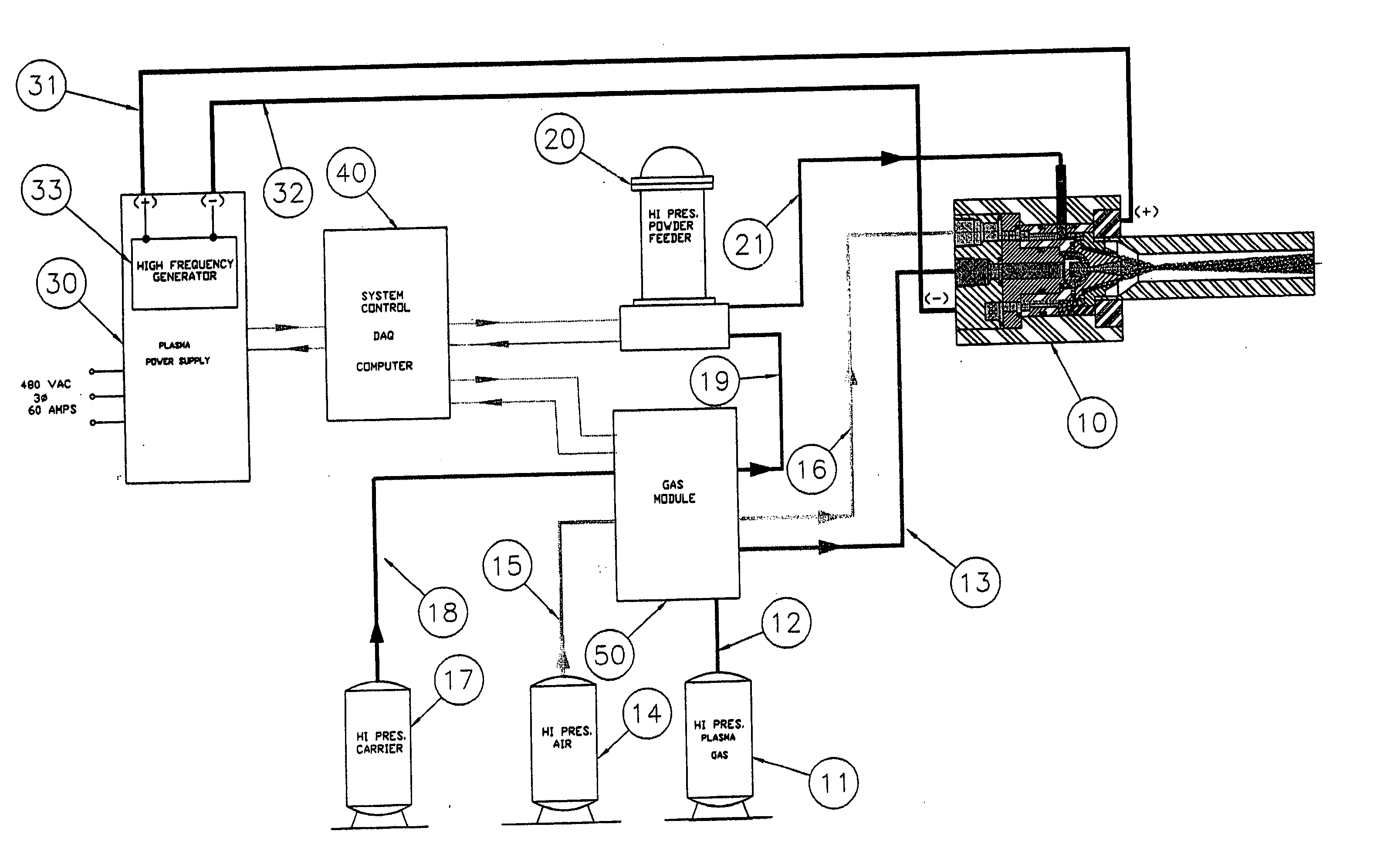

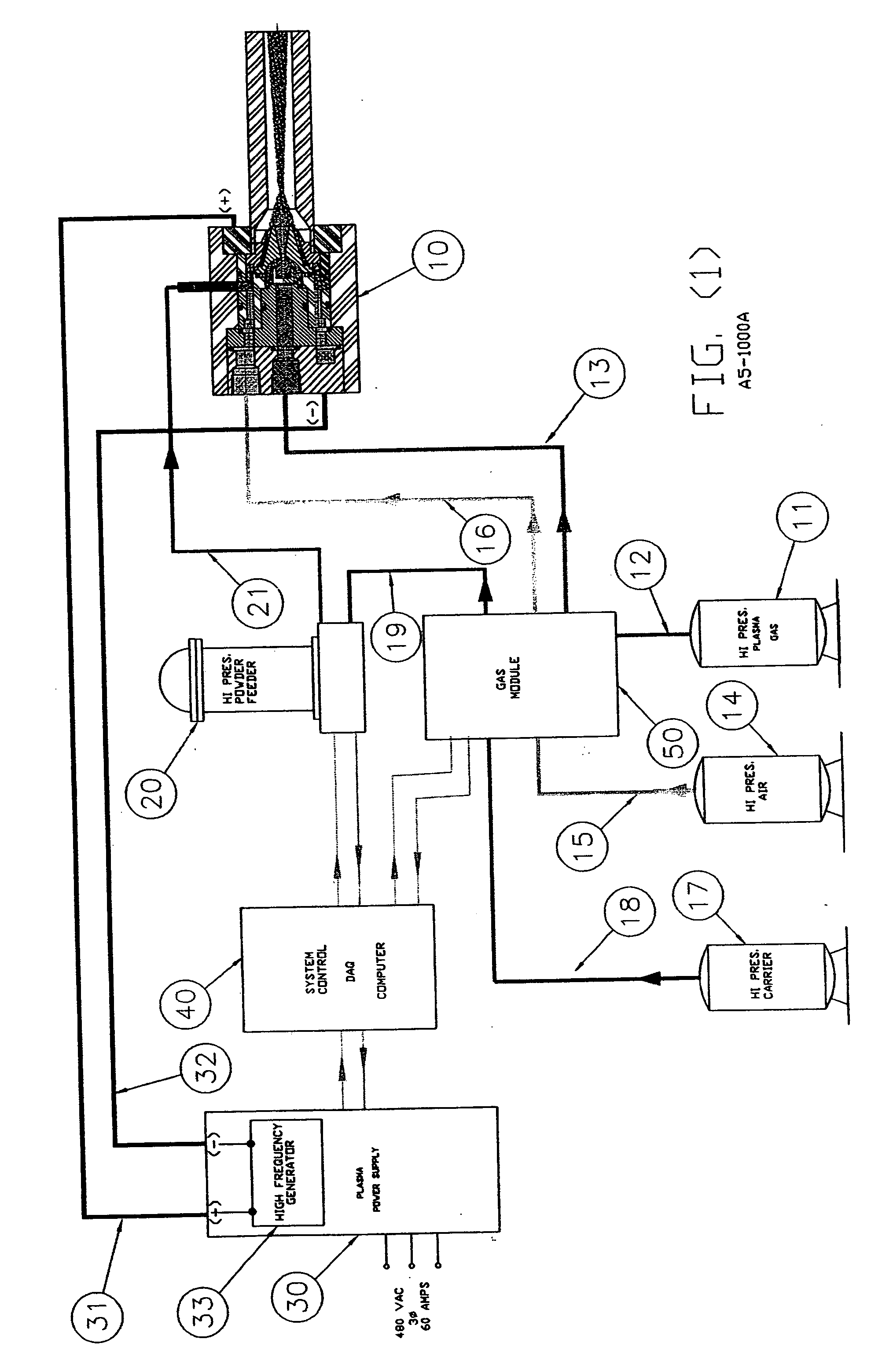

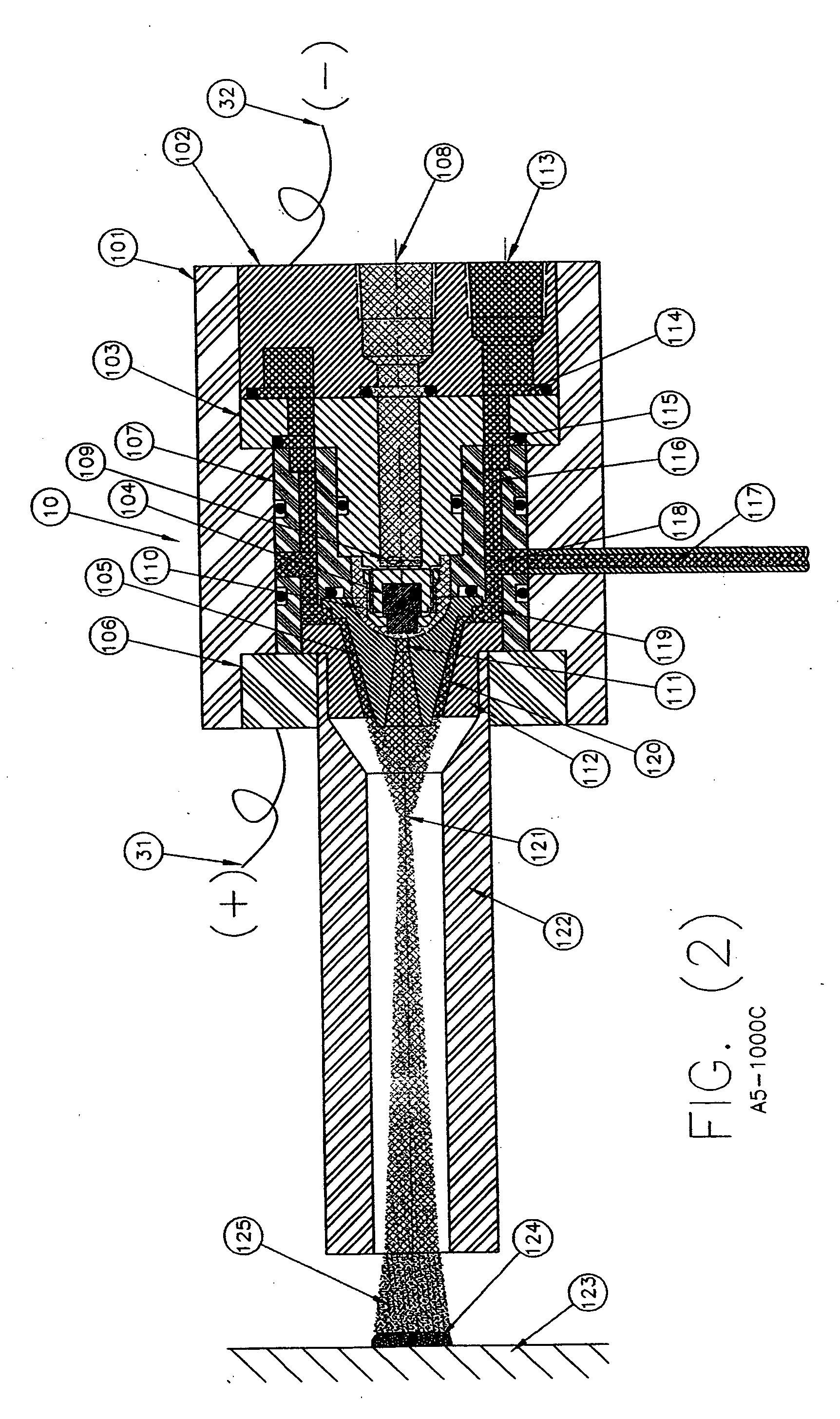

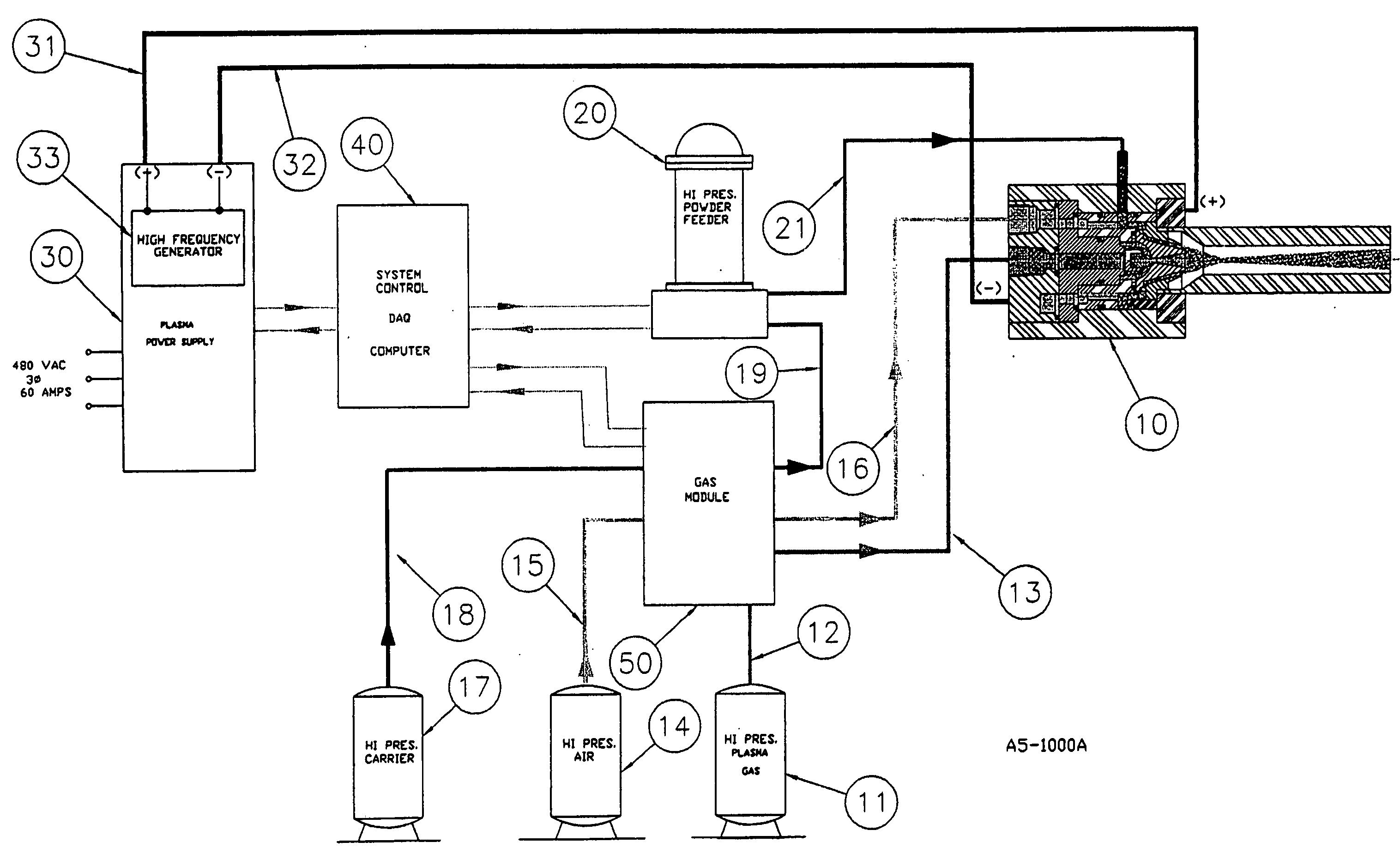

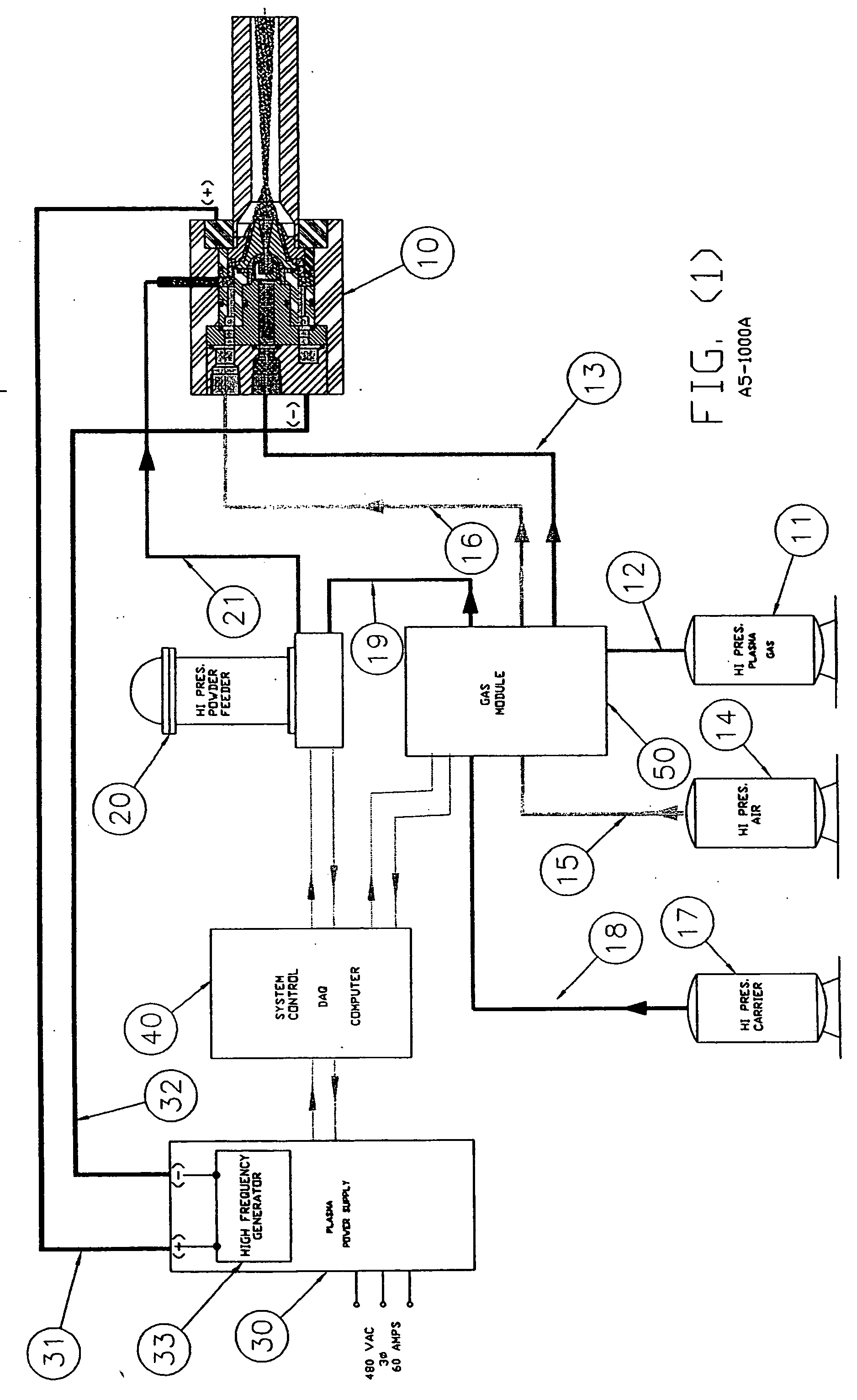

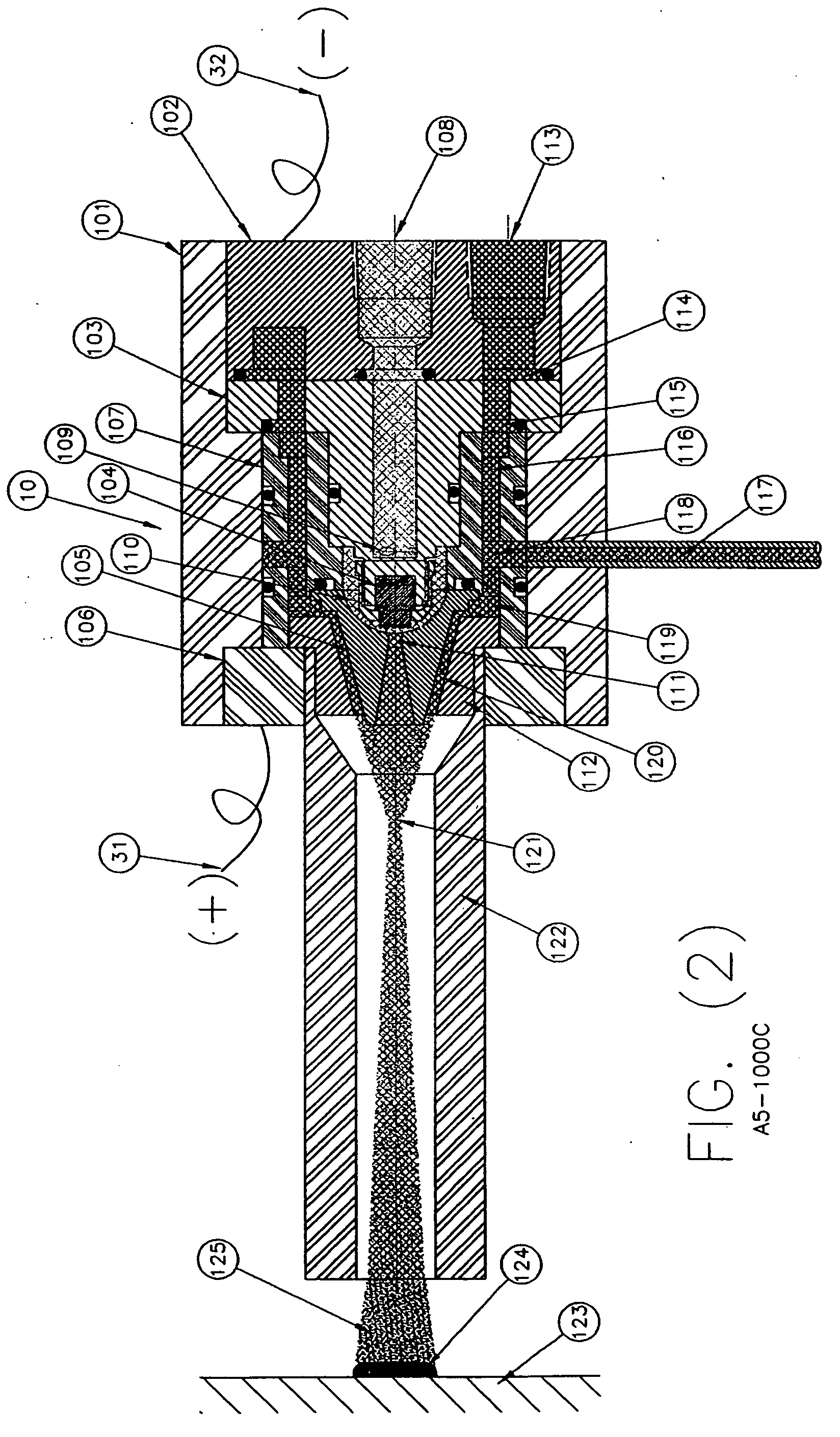

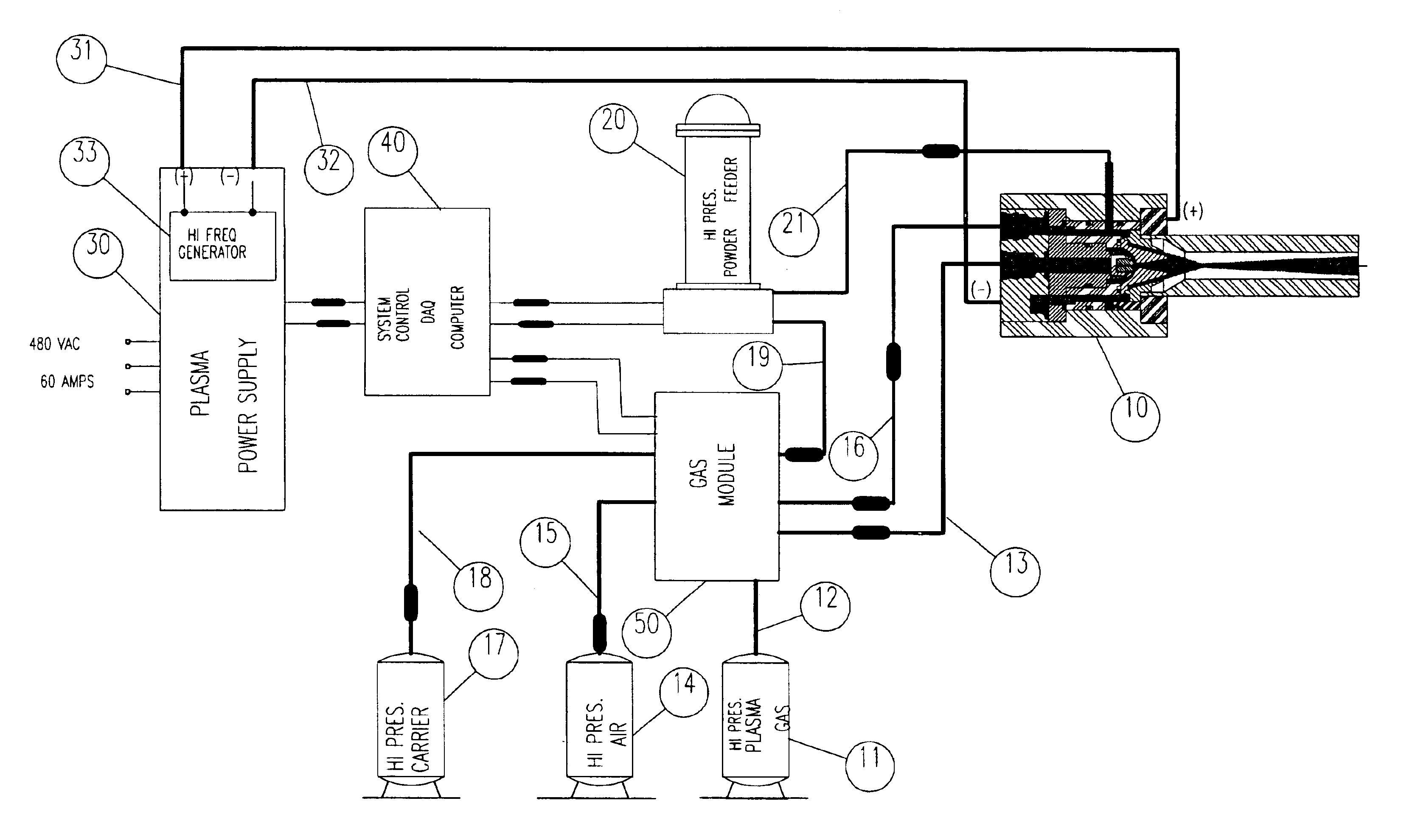

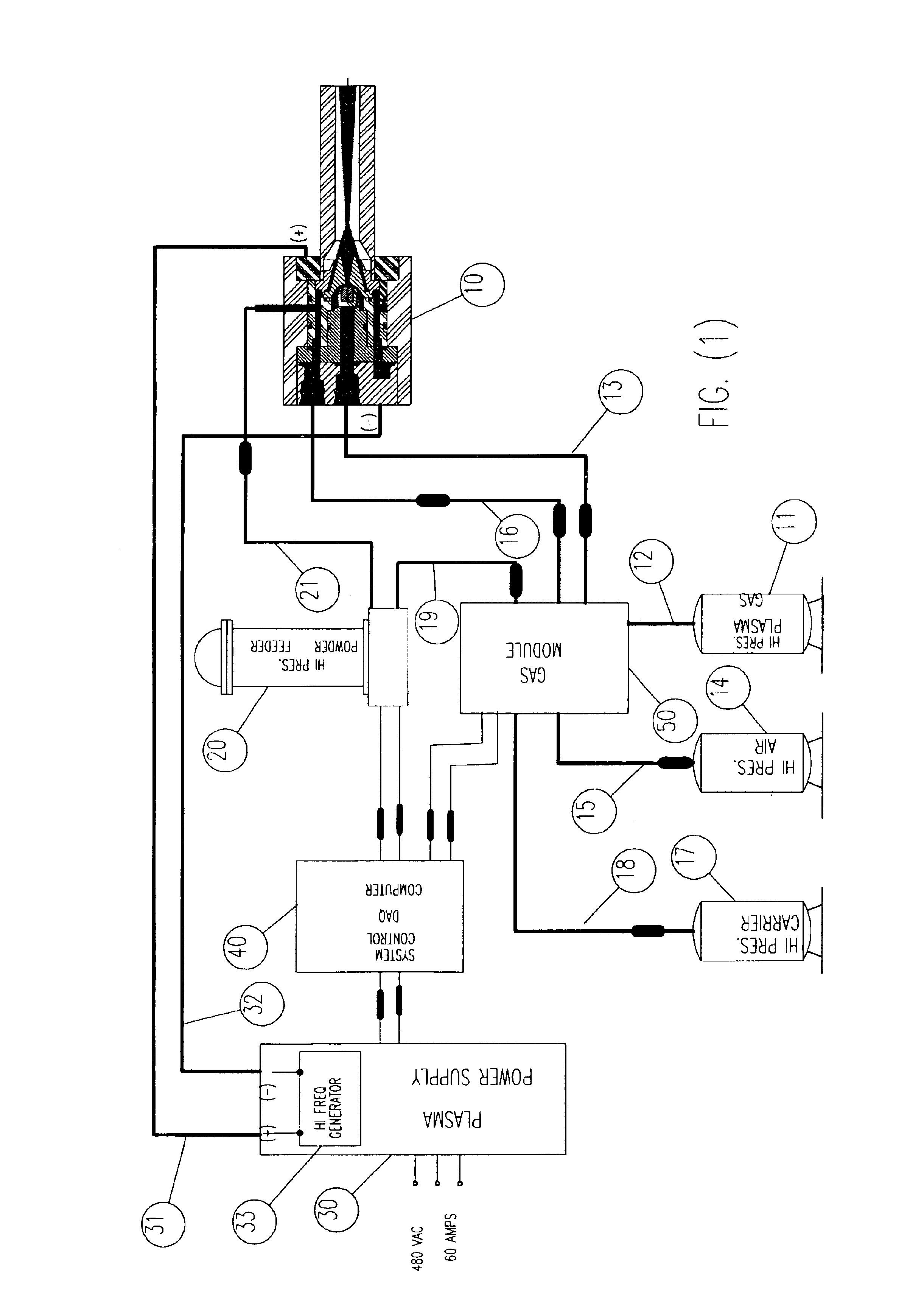

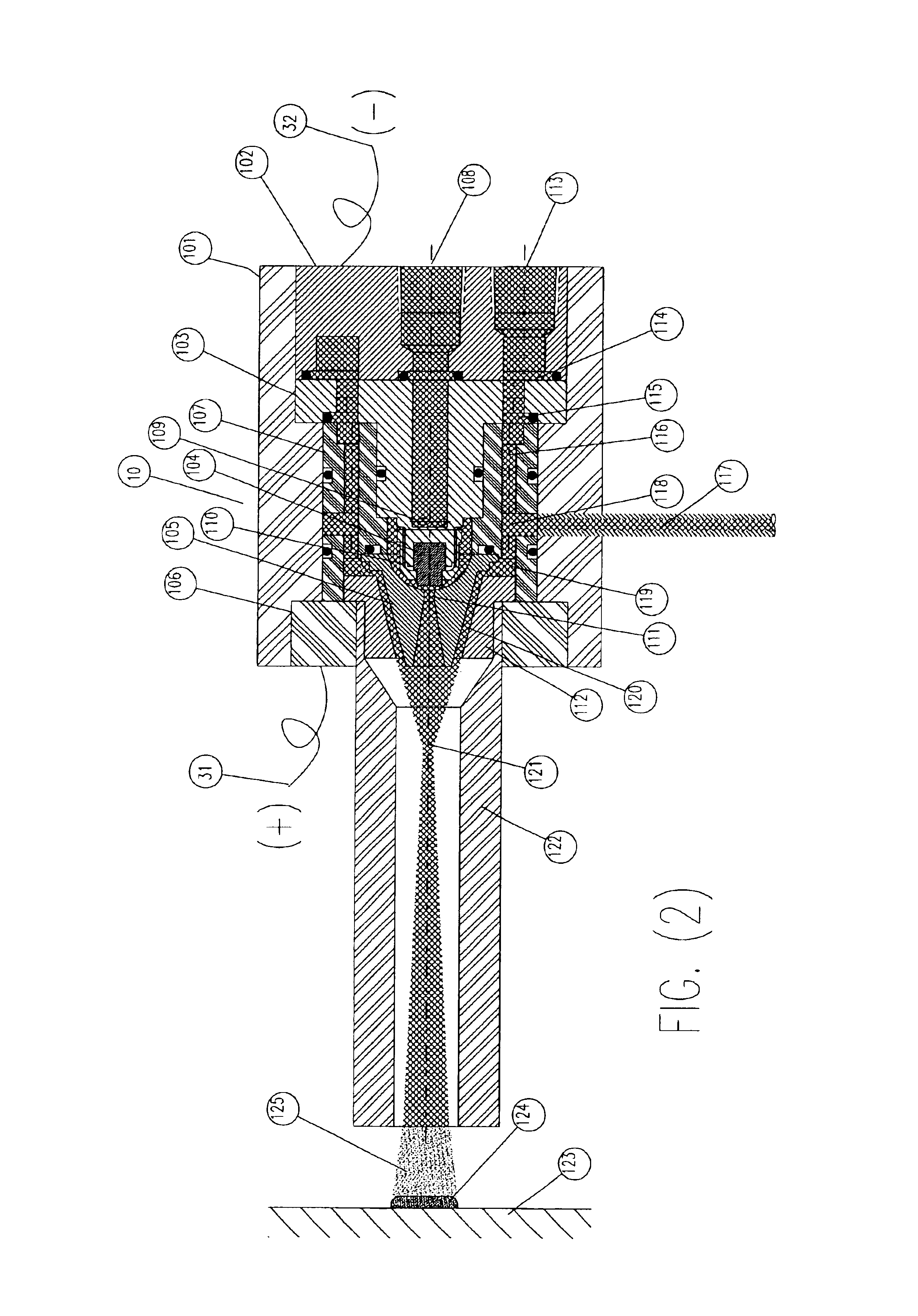

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050120957A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns.

Owner:FLAME SPRAY IND

Plasma spray method and apparatus for applying a coating utilizing particle kinetics

InactiveUS20050252450A1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorAlloy

A method of operation of a plasma torch and the plasma apparatus to produce a hot gas jet stream directed towards a workpiece to be coated by first injecting a cold high pressure carrier gas containing a powder material into a cold main high pressure gas flow and then directing this combined high pressure gas flow coaxially around a plasma exiting from an operating plasma generator and converging directly into the hot plasma effluent, thereby mixing with the hot plasma effluent to form a gas stream with a net temperature based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, establishing a net temperature of the gas stream at a temperature such that the powdered material will not melt or soften, and projecting the powder particles at high velocity onto a workpiece surface. The improvement resides in mixing a cold high pressure carrier gas with powder material entrained in it, with a cold high pressure gas flow of gas prior to mixing this combined gas flow with the plasma effluent which is utilized to heat the combined gas flow to an elevated temperature limited to not exceeding the softening point or melting point of the powder material. The resulting hot high pressure gas flow is directed through a supersonic nozzle to accelerate this heated gas flow to supersonic velocities, thereby providing sufficient velocity to the particles striking the workpiece to achieve a kinetic energy transformation into elastic deformation of the particles as they impact the onto the workpiece surface and forming a dense, tightly adhering cohesive coating. Preferably the powder material is of metals, alloys, polymers and mixtures thereof or with semiconductors or ceramics and the powder material is preferably of a particle size range exceeding 50 microns. The system also includes a rotating member for coating concave surfaces and internal bores or other such devices which can be better coated using rotation.

Owner:FLAME SPRAY IND

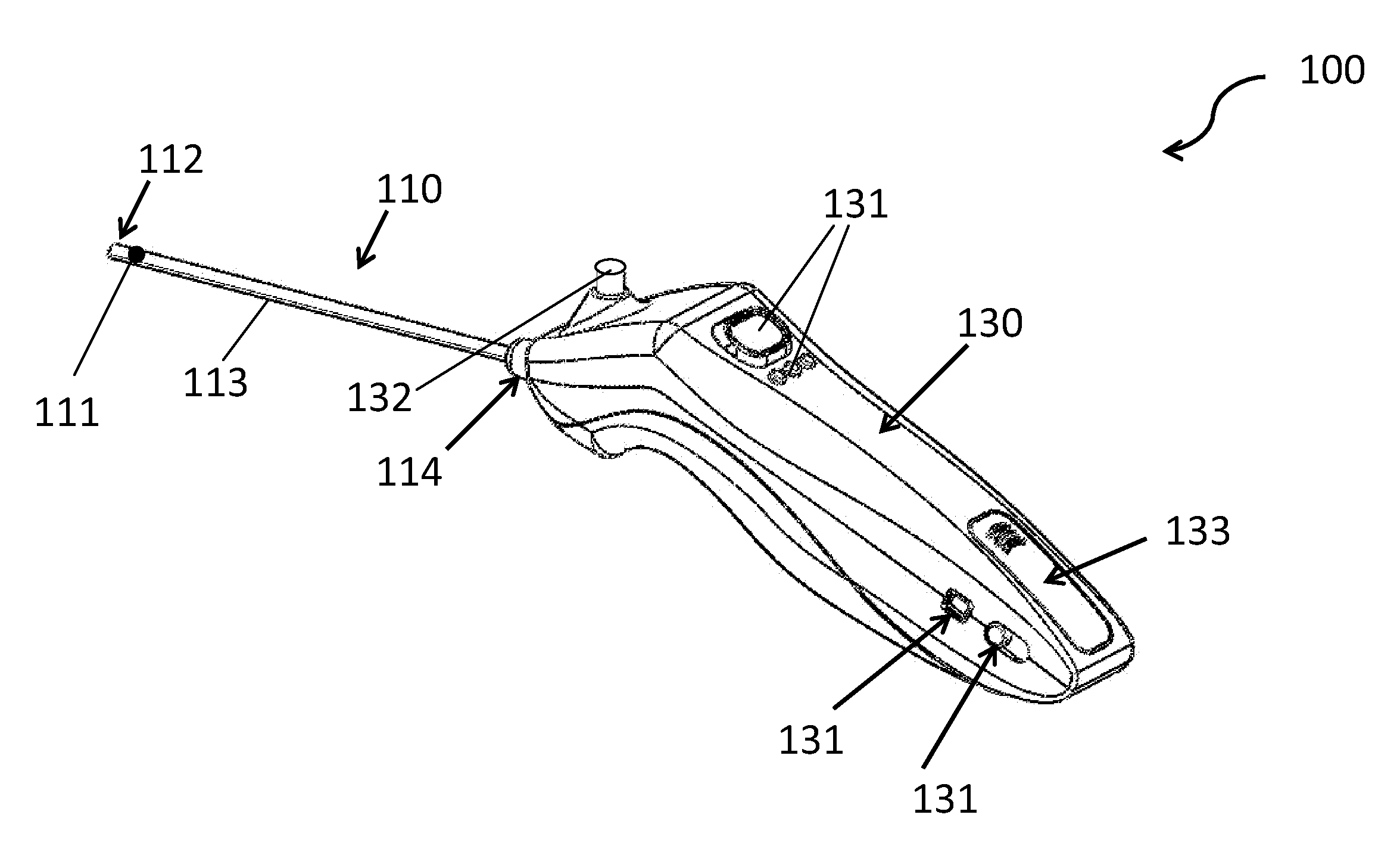

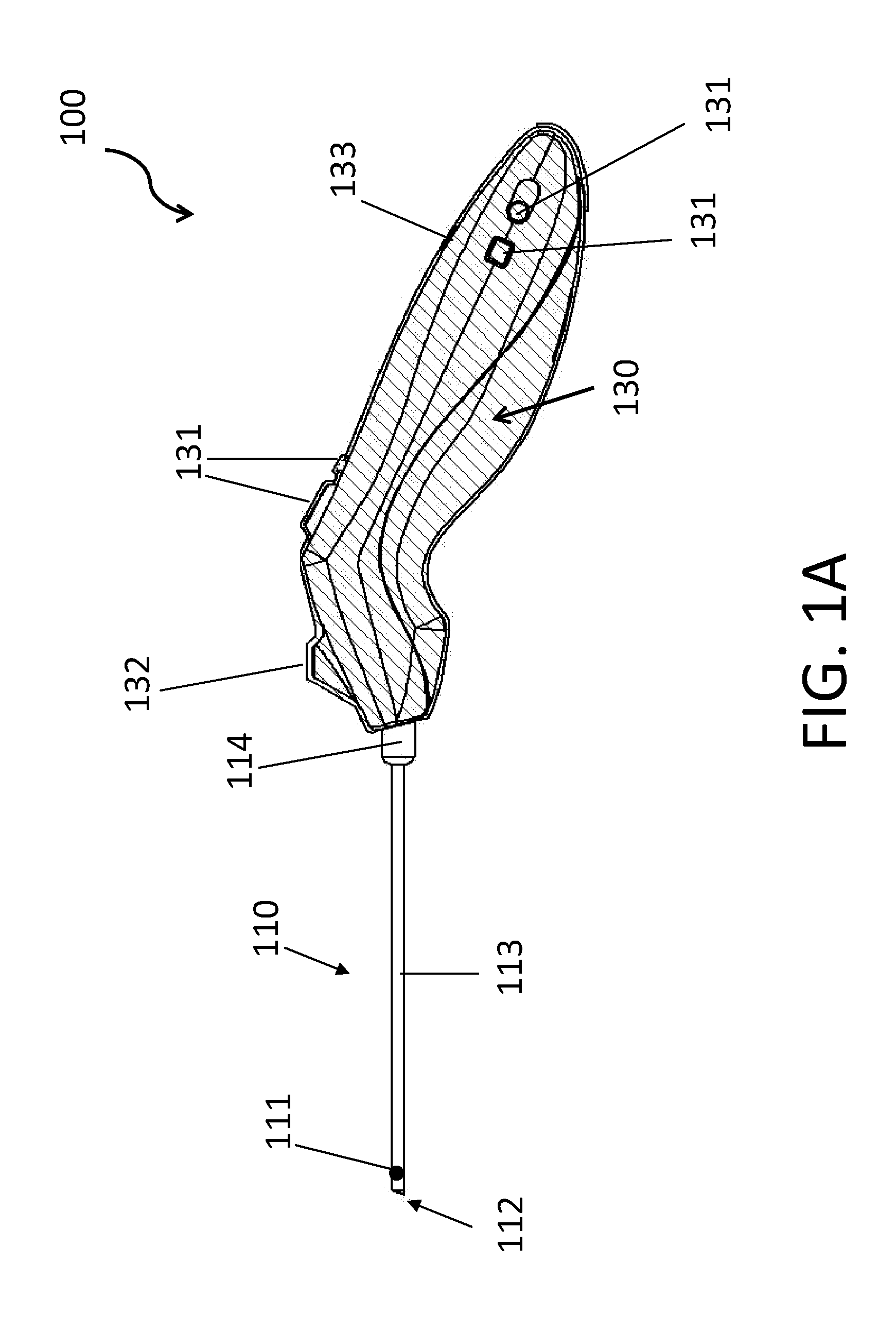

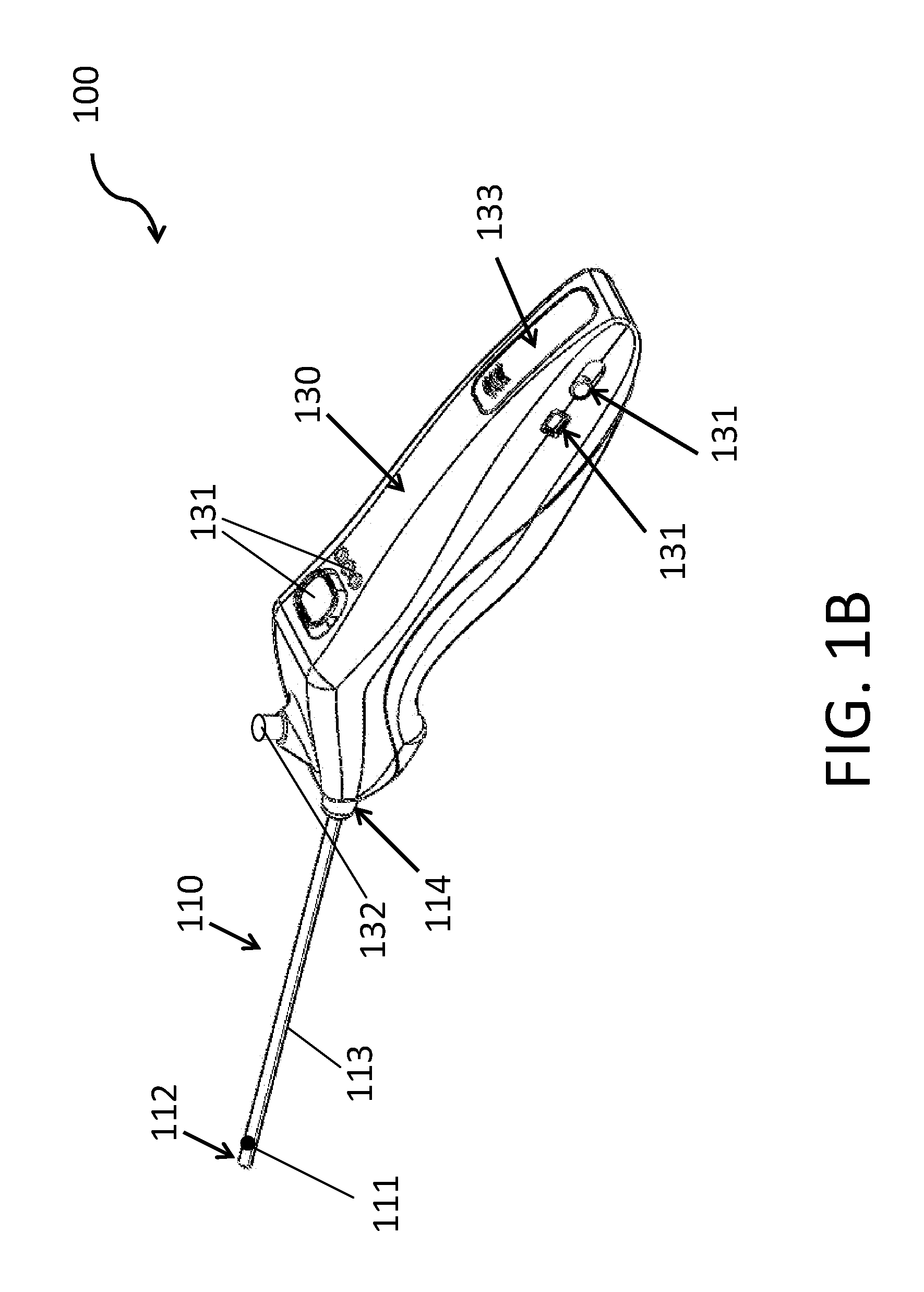

RF Tissue Modulation Devices and Methods of Using the Same

Minimally invasive RF tissue modulation devices are provided. In some aspects, the devices include a hand-held control unit and an elongated member. The hand-held control unit includes an electrical energy source and the elongated member has a proximal end operably coupling to the hand-held control unit. The RF tissue modulation device is configured to generate a plasma at a distal end plasma generator for a therapeutic duration. In some aspects, RF tissue modulation devices are provided and include an adapter that operably couples to a hand-held medical device. The adapter generates RF energy for delivery to a plasma generator on an elongated member. Methods of delivering the RF energy to the internal target tissue site are also provided.

Owner:TRICE MEDICAL

Apparatus for generating high current electrical discharges

InactiveUS20060066248A1Electric discharge tubesVacuum evaporation coatingElectricityHigh current density

A high current density plasma generator includes a chamber that contains a feed gas. An anode is positioned in the chamber. A cathode assembly is position adjacent to the anode inside the chamber. A power supply having an output is electrically connected between the anode and the cathode assembly. The power supply generates at the output an oscillating voltage that produces a plasma from the feed gas. At least one of an amplitude, frequency, rise time, and fall time of the oscillatory voltage is chosen to increase an ionization rate of the feed gas.

Owner:ZOND

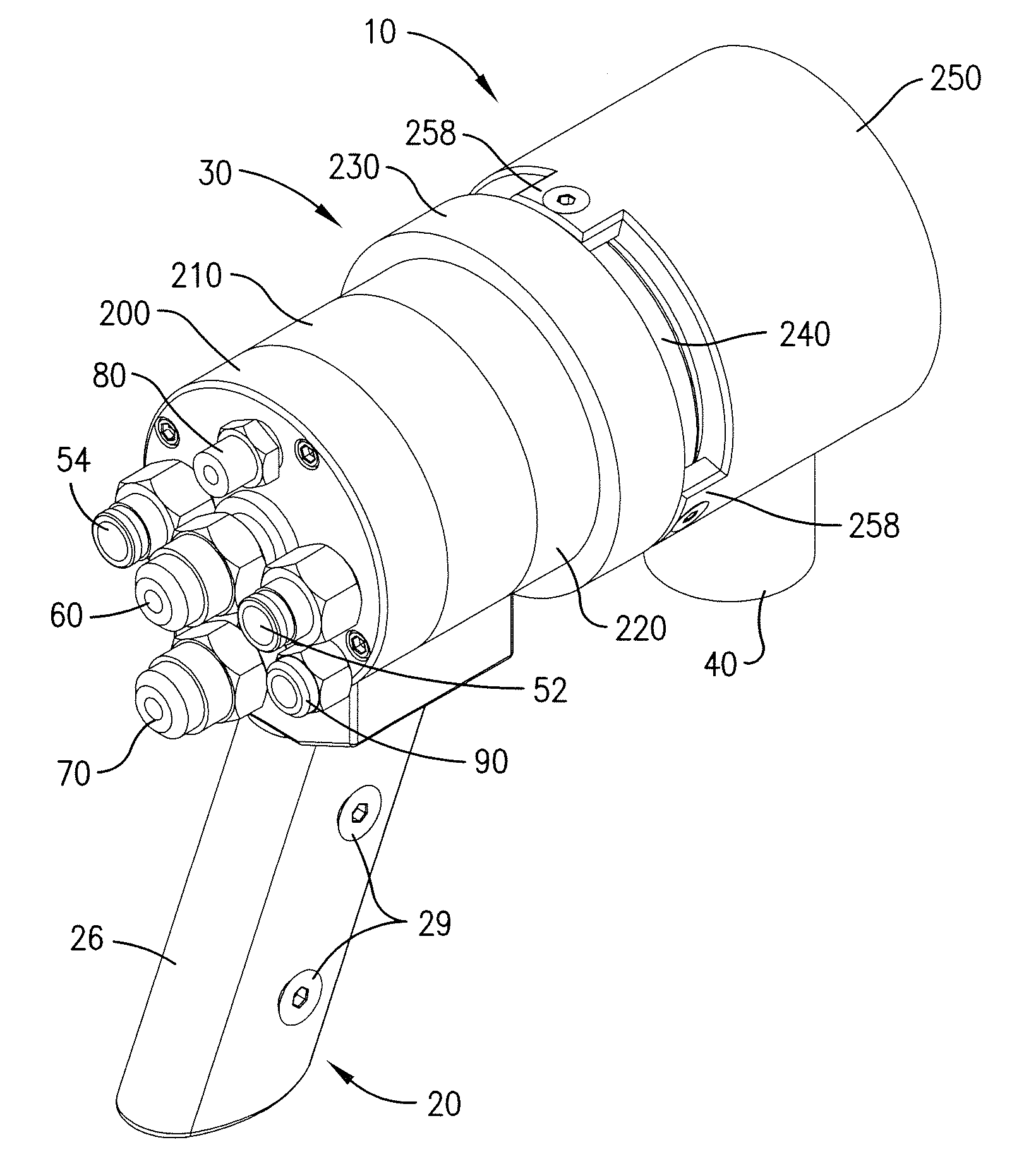

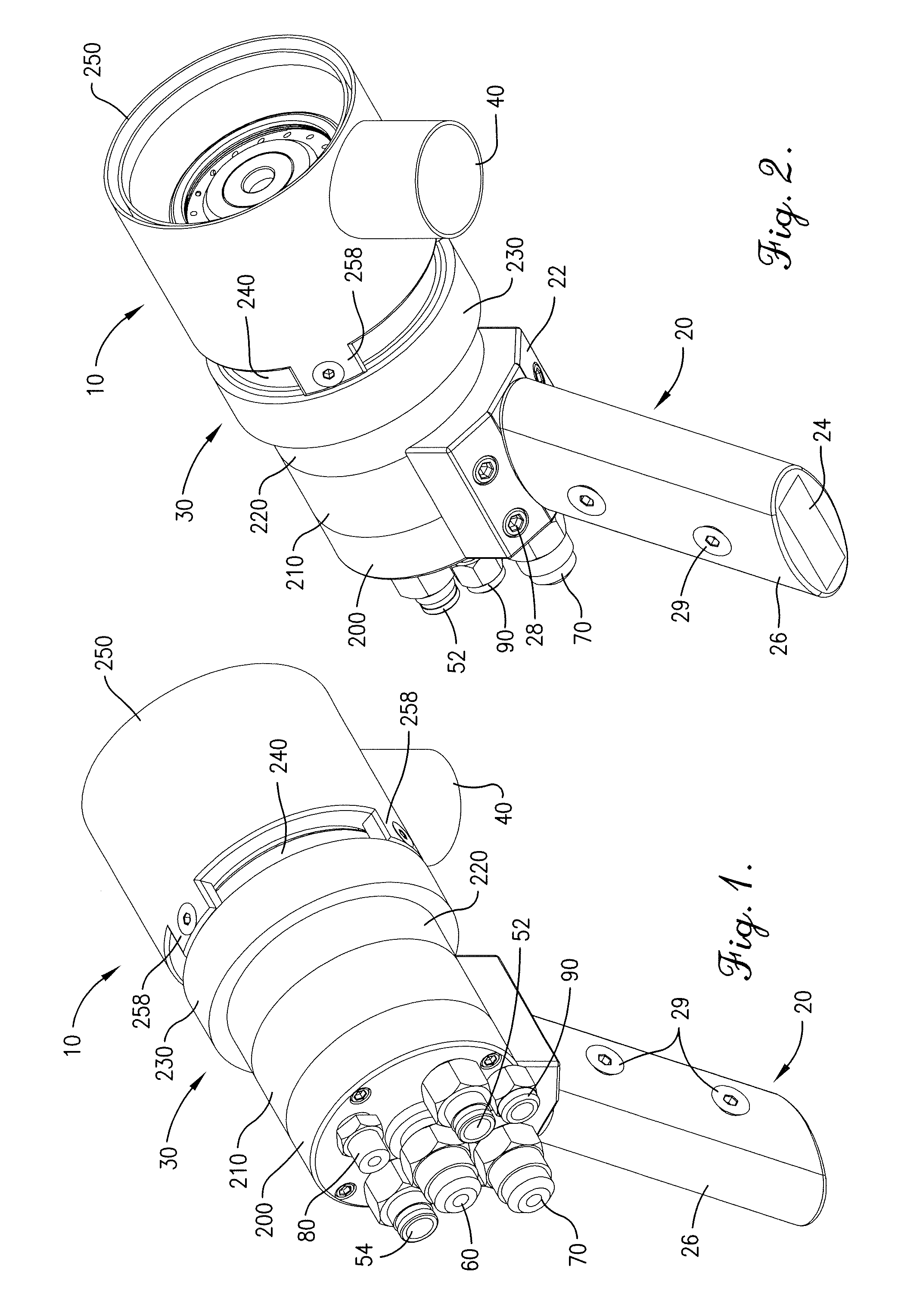

Apparatus and method for applying antifoulants to marine vessels

ActiveUS20080116178A1Avoid pollutionPrevent flame conditionLiquid surface applicatorsElectric heatingBond coatingPlasma generator

A plasma spray apparatus in the form of a gun is utilized to apply an antifoulant coating to marine vessels. The apparatus includes a plasma generator, an electrophoresis element, a heating element, a shield gas element, a liquid cooling system, a forced air system, and a vacuum system. The plasma generator ionizes gas to create a plasma stream, which is utilized in part to supply energy to the heating element that heats a powder material. The heated powder material is exposed to the electrophoresis element to create a covalently bonded coating material. The coating material is injected into the plasma stream and is applied to a target surface. The shield gas element injects a gas flow to surround and protect the plasma and coating material stream as the stream is in flight to the target surface. The liquid cooling system cools portions of the plasma generator and heating element. The forced air system cools a portion of the target surface as the coating material is being applied. The vacuum system removes fumes and stray particles during the application process.

Owner:REINTJES MARINE SURFACE TECH

Injection member for manufacturing semiconductor device and plasma processing apparatus having the same

InactiveUS20130276983A1High-frequency powerElectric discharge tubesSemiconductor/solid-state device manufacturingPower semiconductor devicePlasma generator

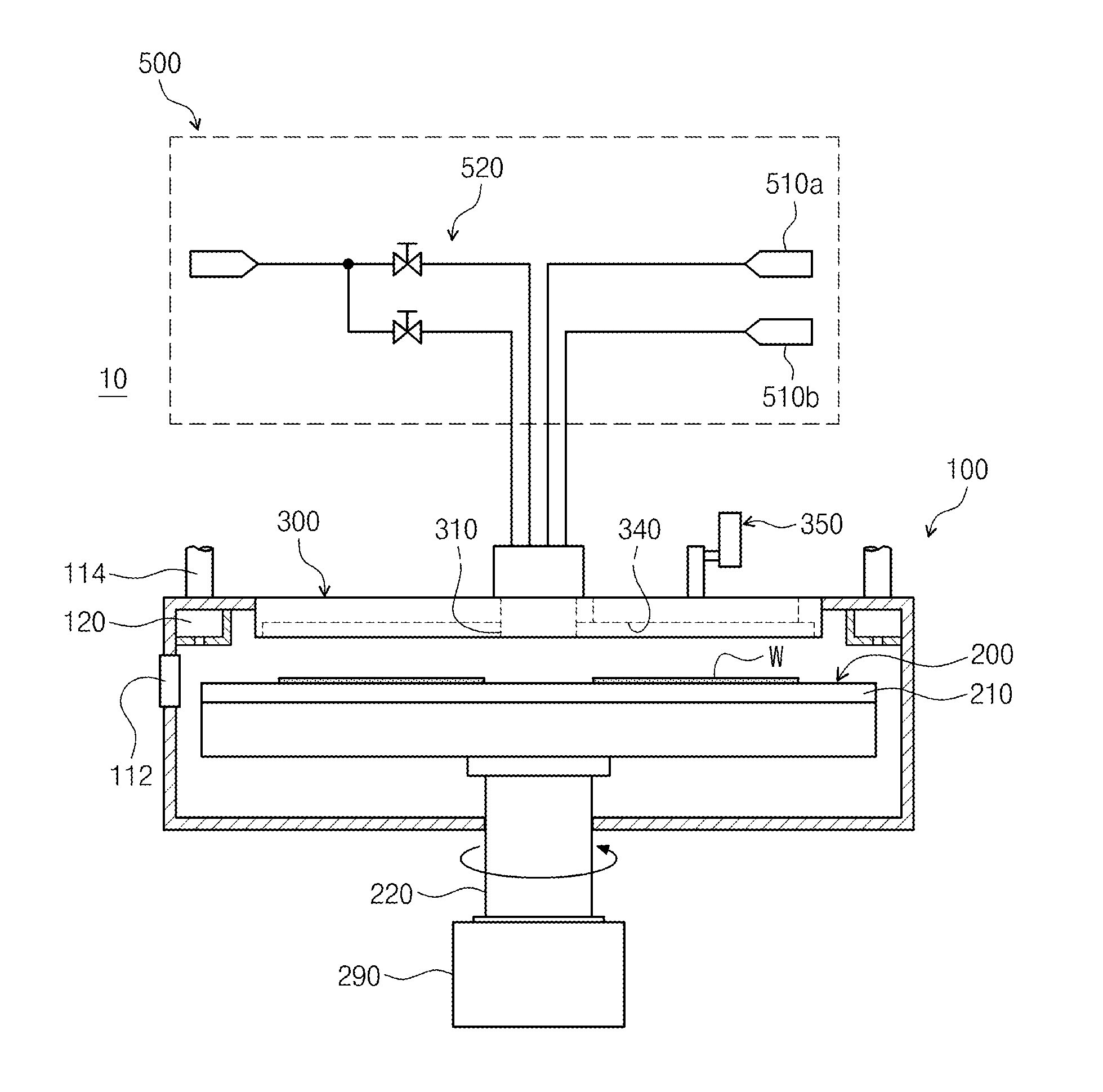

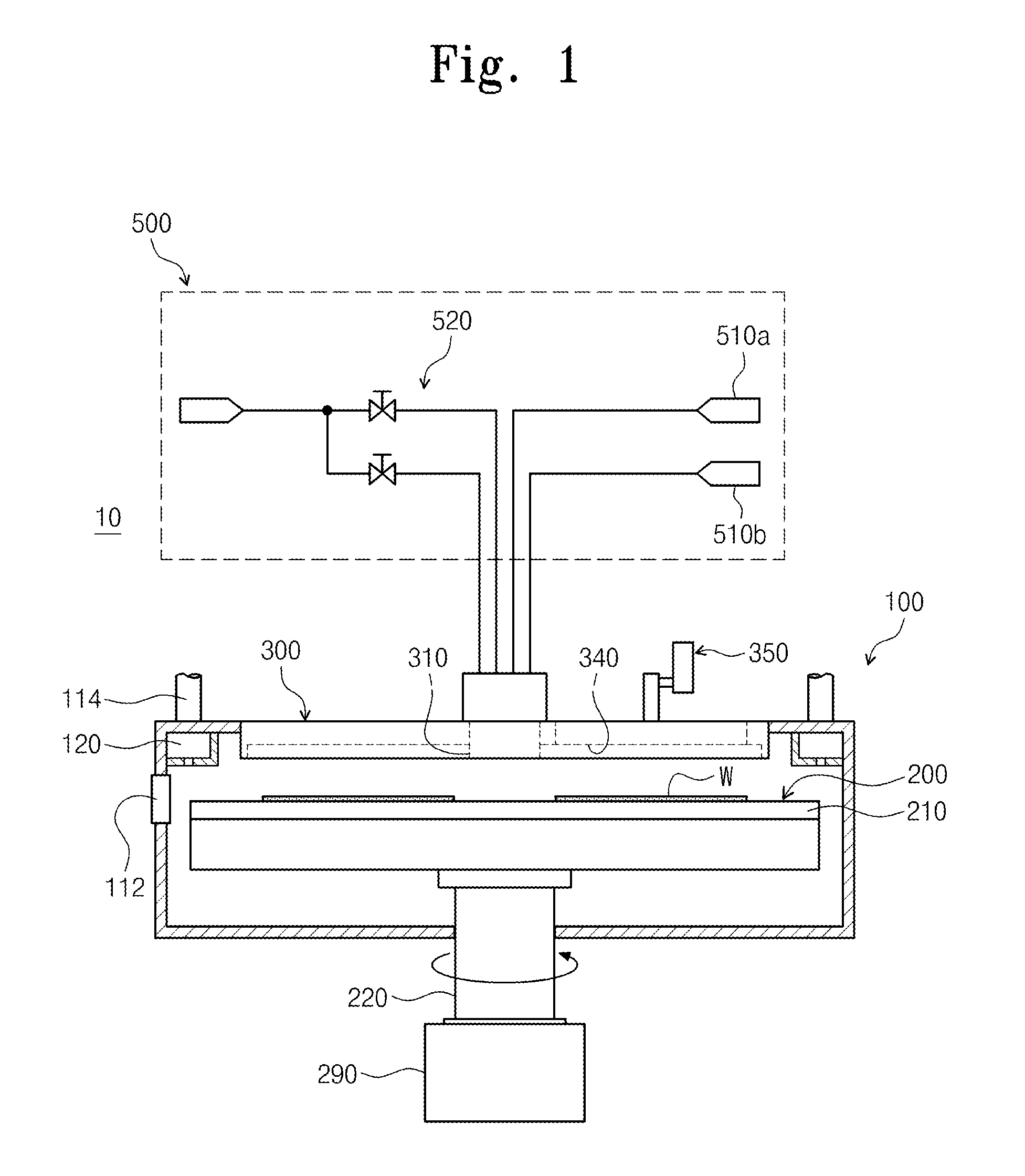

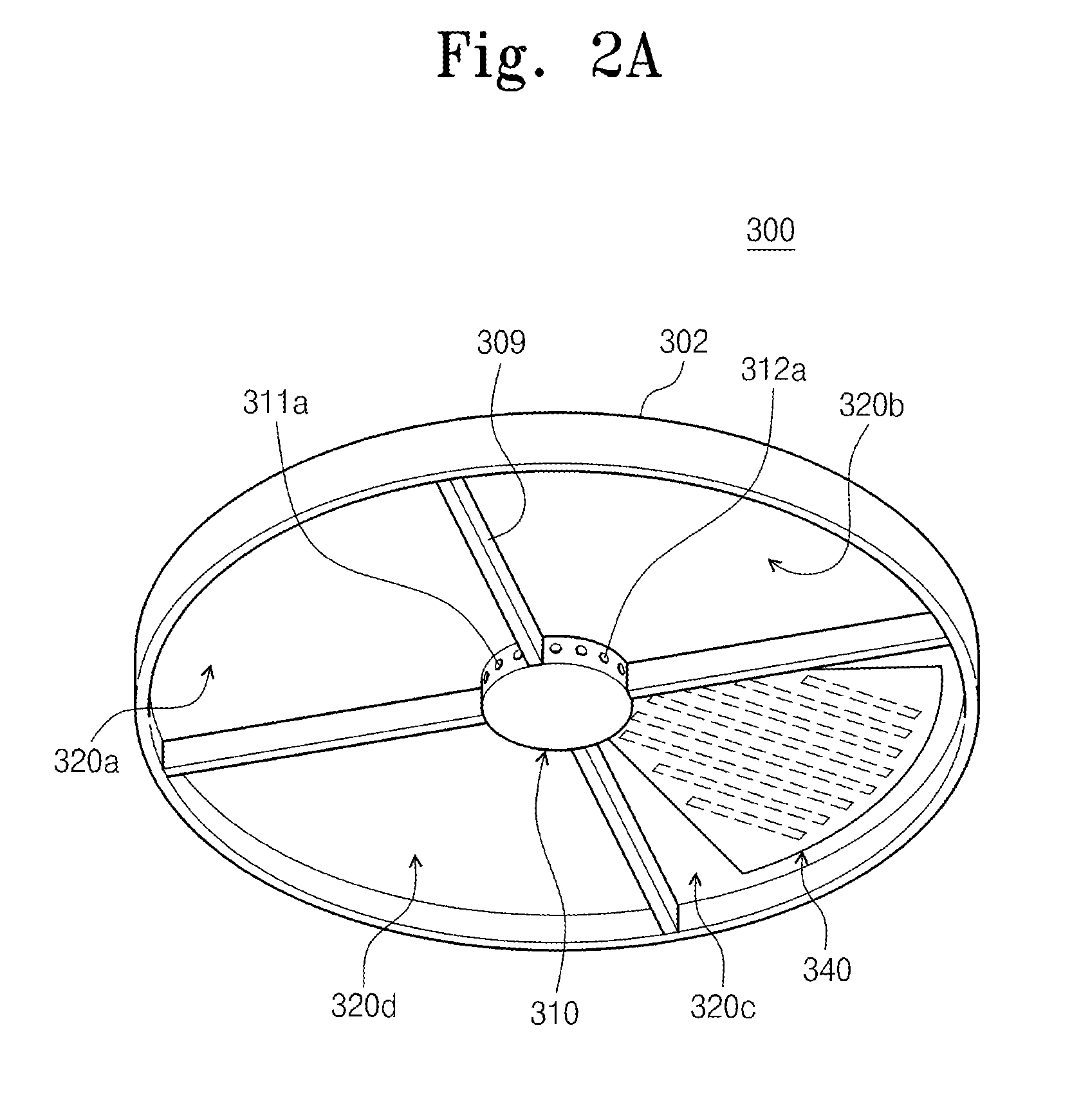

A plasma processing apparatus may include a process chamber configured to perform a plasma using process and contain a plurality of substrates, a support member provided in the process chamber, the substrates being laid on the same level of the support member, an injection member provided to face the support member and include a plurality of baffles, such that at least one reaction gas and a purge gas can be injected onto the substrates in an independent manner, and a driving part configured to rotate the support member or the injection member, such that the baffles of the injection member can orbit with respect to the plurality of the substrates laid on the support member. The injection member may include a plasma generator, which may be provided on at least one, configured to inject the reaction gas, of the baffles to turn the reaction gas into plasma.

Owner:KOOKJE ELECTRIC KOREA +1

Plasma spray method for applying a coating utilizing particle kinetics

InactiveUS6861101B1Efficient systemUniform compositionLiquid surface applicatorsMolten spray coatingPlasma generatorHigh pressure

A method of operation of a plasma torch. A cold high pressure carrier gas containing a powder material is injected into a cold main high pressure gas flow and then this combined flow is directed coaxially around a plasma exiting from an operating plasma generator and converging into the hot plasma effluent, mixing with the effluent to form a gas stream with a net temperature, based on the enthalpy of the plasma stream and the temperature and volume of the cold high pressure converging gas, such that the powdered material will not melt. The combined flow with entrained is directed through a supersonic nozzle accelerating the flow to supersonic velocites sufficient that the particles striking the workpiece achieve kinetic energy transformation into elastic deformation of the particles as they impact the workpiece forming a cohesive coating.

Owner:FLAME SPRAY IND

Magnetized plasma fusion reactor

InactiveUS20060198483A1Convenient introductionNuclear energy generationLow temperature fusion reactorLiquid mediumWavefront

A fusion reactor apparatus for initiating a fusion reaction in a fusionable material is disclosed. The apparatus includes a vessel operable to contain a liquid medium and a vortex generator operable to generate a vortex in the liquid medium. The apparatus also includes a plasma generator operable to generate a magnetized plasma of the fusionable material and to introduce the magnetized plasma into the vortex and a pressure wave generator operably configured to cause a pressure wavefront in the liquid medium to envelope the magnetized plasma and to converge on the magnetized plasma to impart sufficient energy to the fusionable material to initiate fusion in the fusionable material.

Owner:GENERAL FUSION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com