Patents

Literature

82 results about "Gas element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The 13 elements that are room temperature gases are radon (Rn), xenon (Xe), krypton (Kr), argon (Ar), chlorine (Cl), neon (Ne), fluorine (F), oxygen (O), nitrogen (N), helium (He) and hydrogen (H). Most non-metals in the periodic table have a gaseous elemental form.

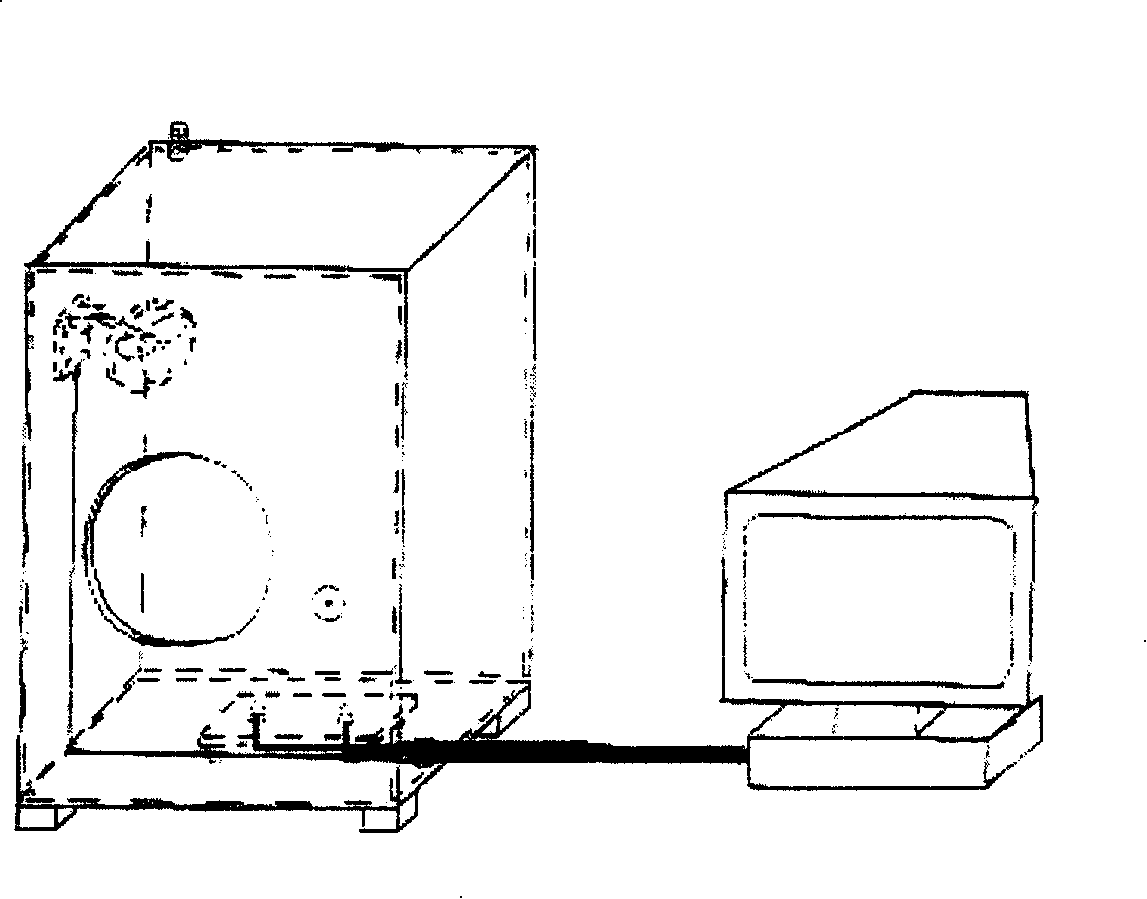

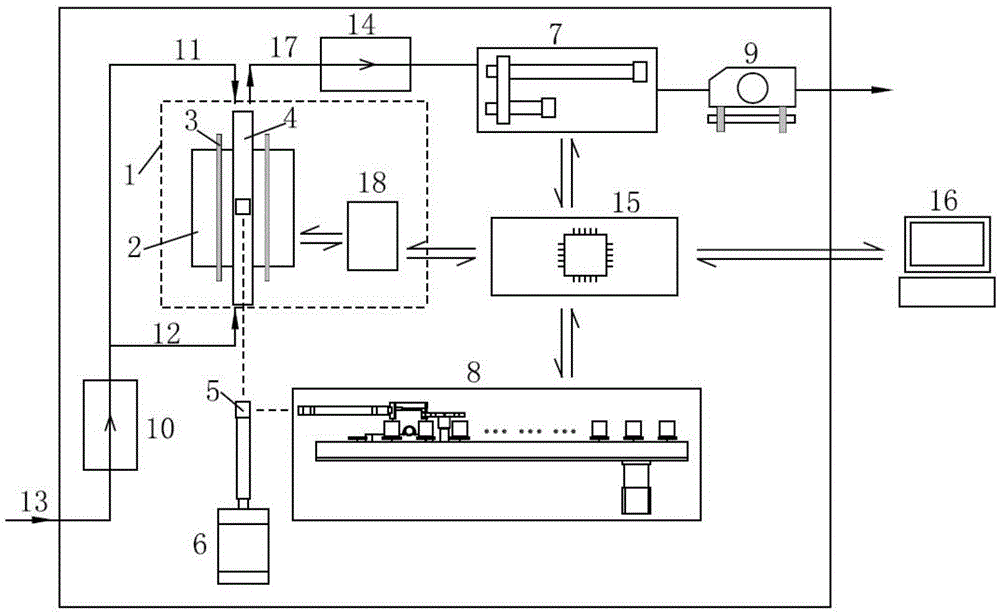

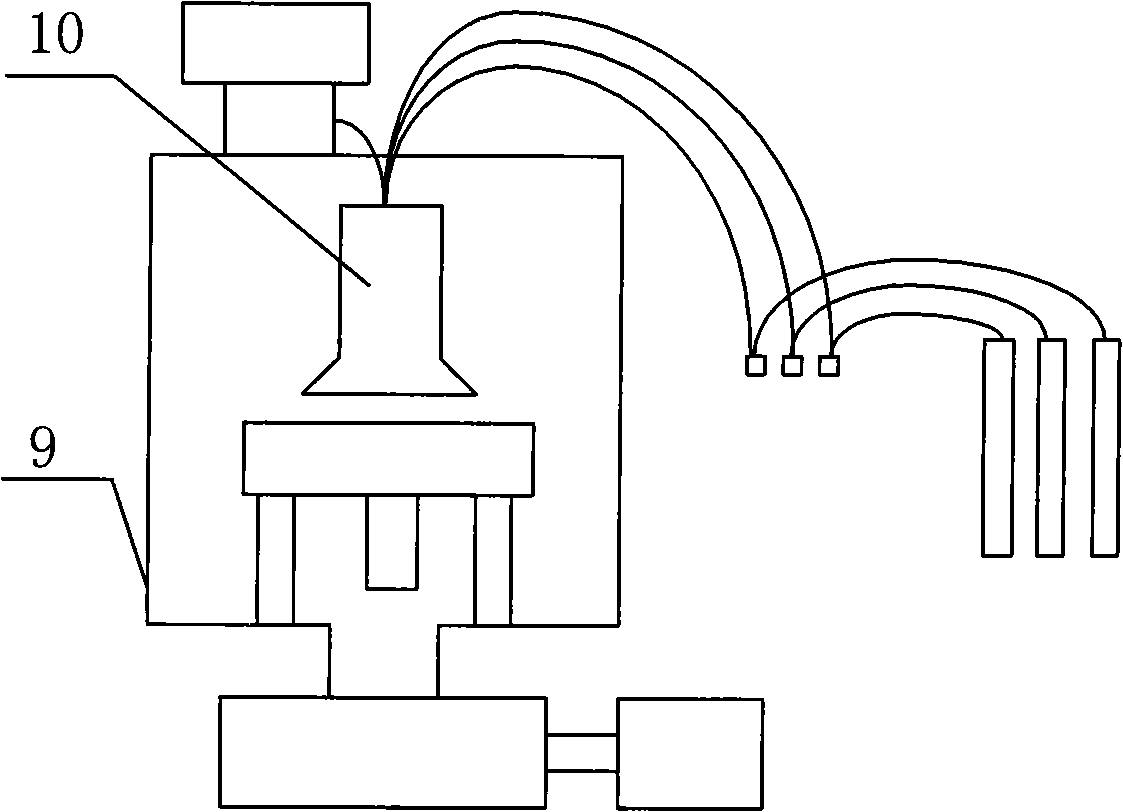

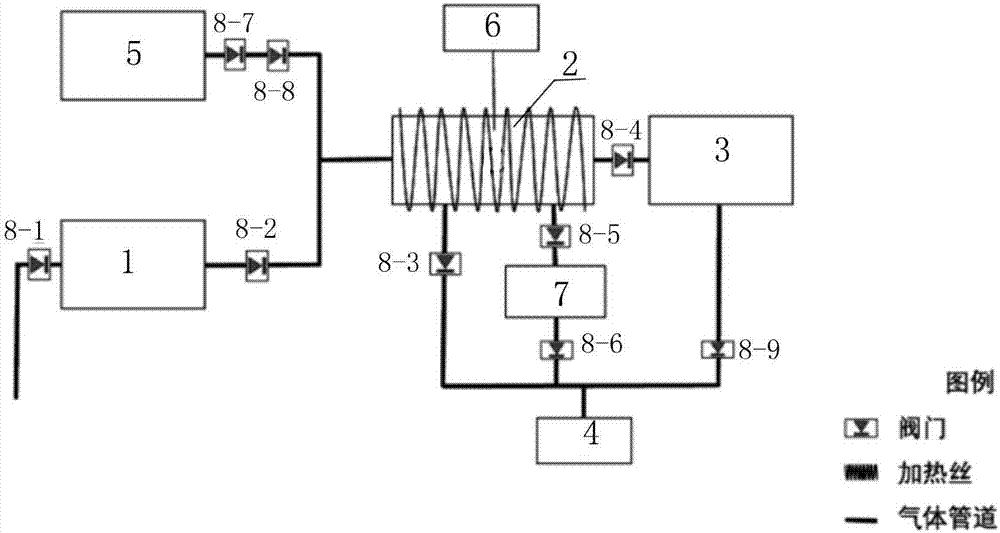

Gas-sensitive sensor calibration and reliability testing system

InactiveCN101241093ASelect precise controlPrecise control of gas concentrationMaterial analysis by electric/magnetic meansElectricityMeasurement device

The invention relates to the field of testing technique of gas sensor and discloses a system for testing calibration and reliability of gas sensor. The system comprises of inlet unit, gas flow monitor, components control unit, gas mixed cavity, vacuum testing cavity and sensor electric parameter measuring device. Gas in said inlet unit is entered in gas mixed cavity to premix under the control of gas flow monitor and components control unit, and then to vacuum testing cavity which has gas sensor to be determined, the said sensor electric parameter measuring device is connected with vacuum testing cavity to detect capacity of gas sensor to be determined in vacuum testing cavity. The present invention avoids the disadvantages of dynamic gas elements capacity testing device in existence, realizes controlling exactly consistence of gas to be measured, testing different gas and controlling exactly temperature of elements.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

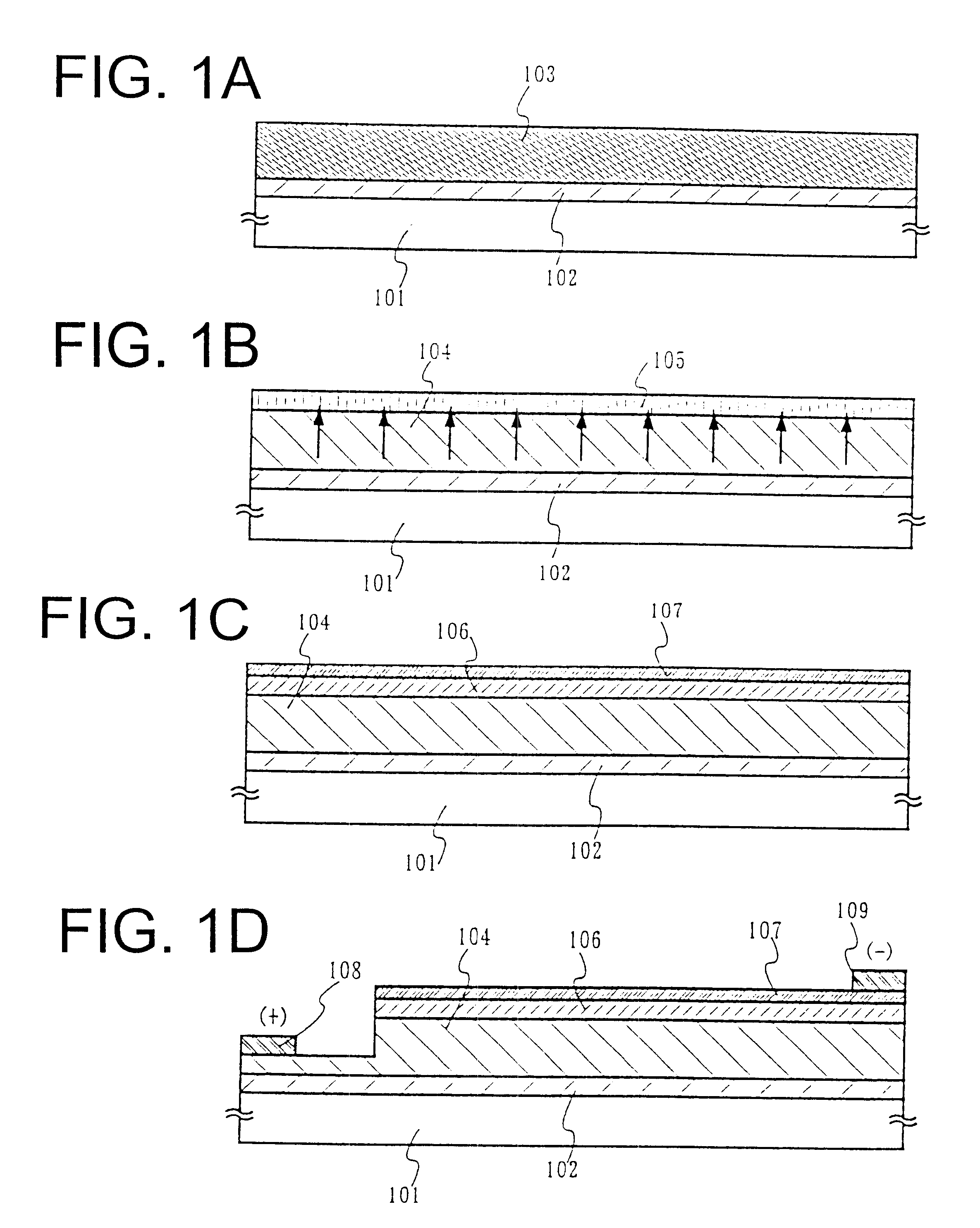

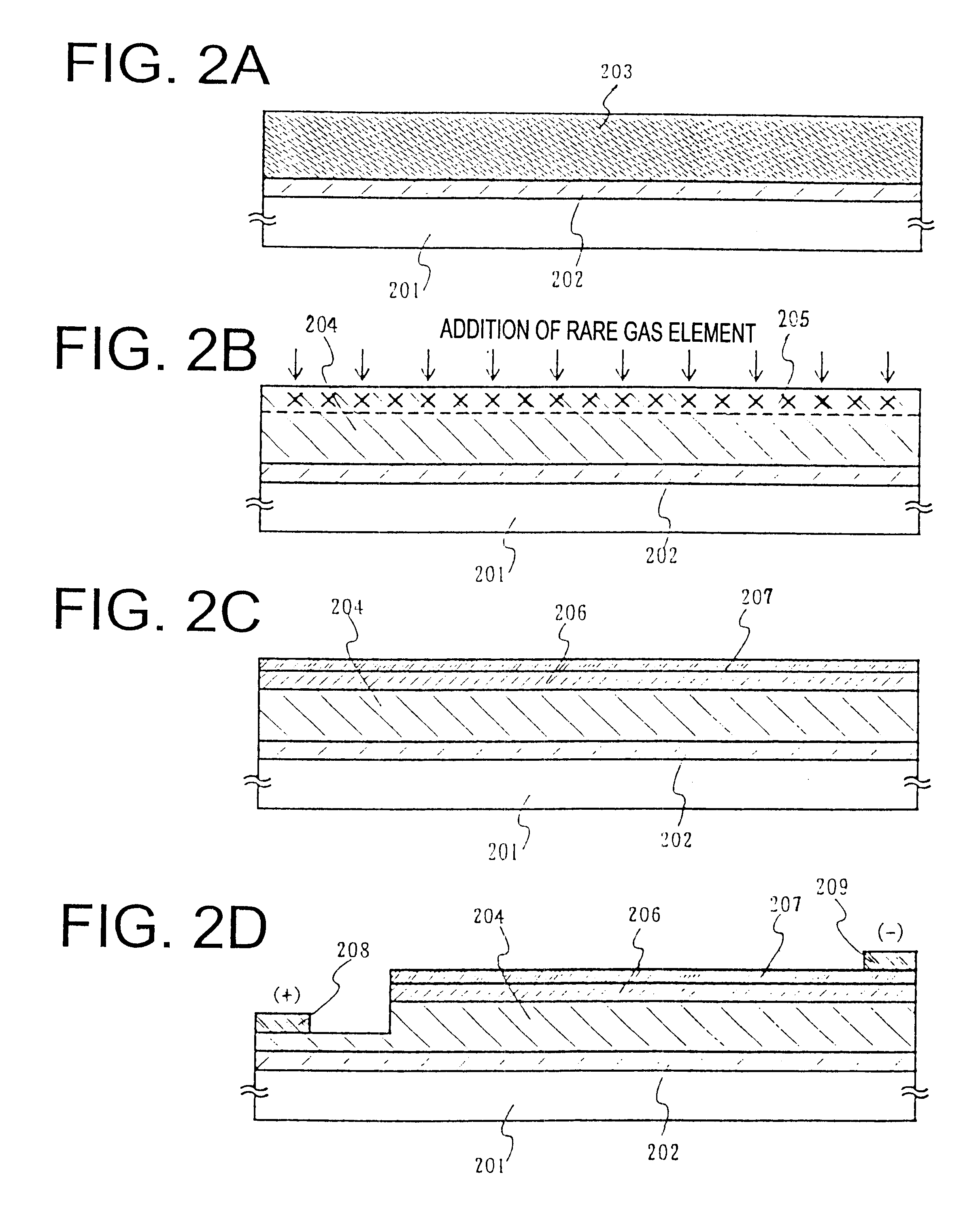

Process for producing a photoelectric conversion device

InactiveUS6686262B2Rapid thermal annealing (RTA)Polycrystalline material growthFrom solid stateNoble gasElectrical conductor

Owner:SEMICON ENERGY LAB CO LTD

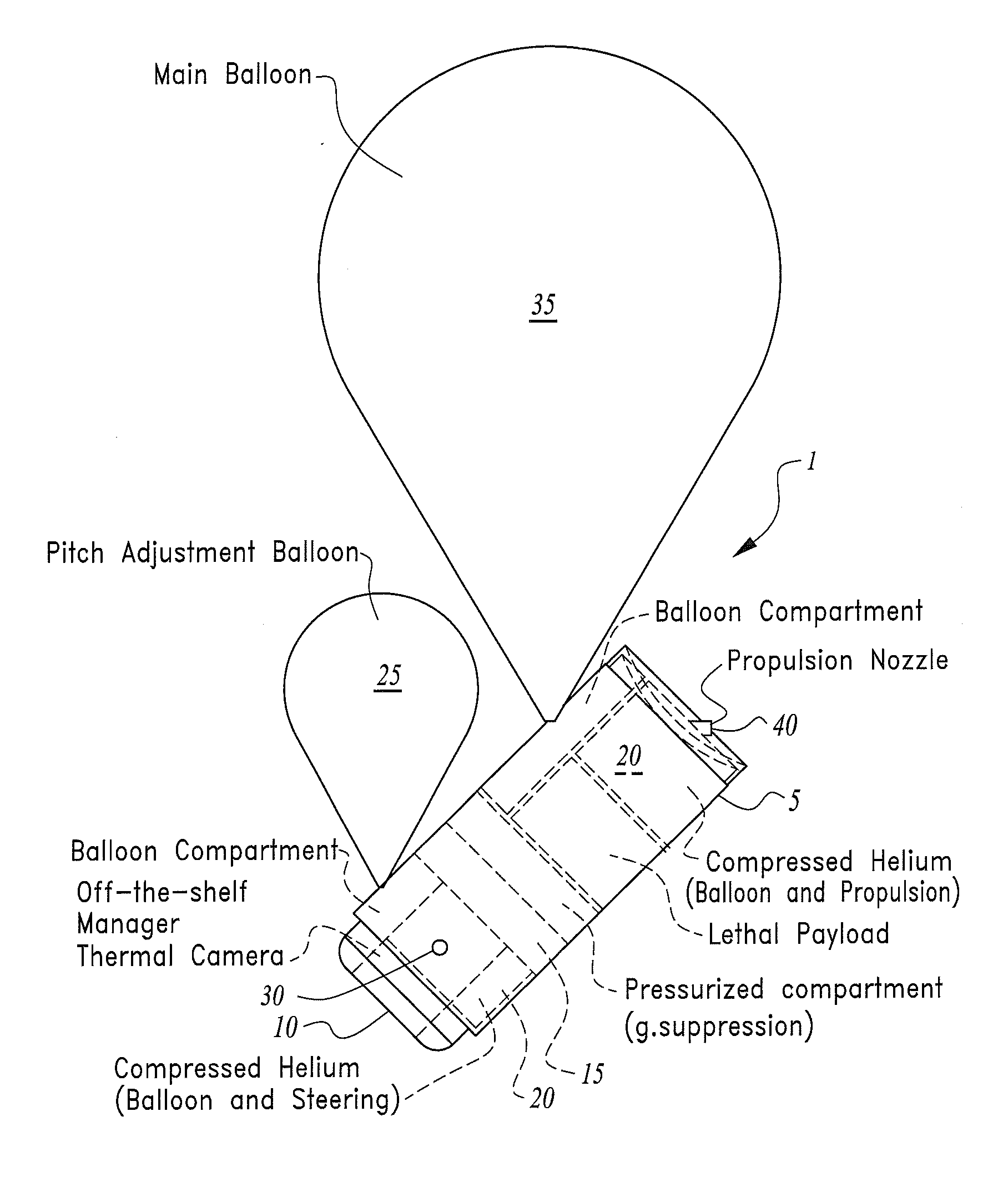

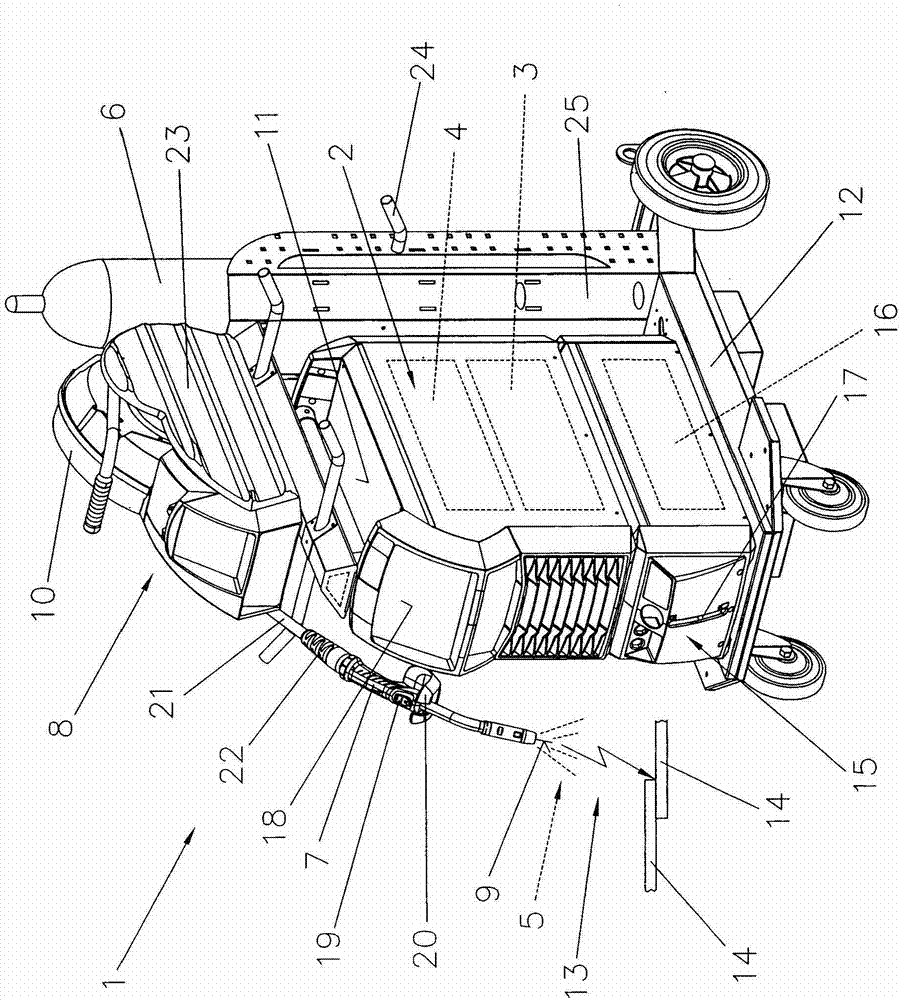

Hovering Surveillance Air Vehicle

A hovering surveillance device. An electronic imaging device is disposed on a housing having a primary lift element, at least one compressed lighter-than-air gas element, a pitch adjustment element, and, a steering element. The compressed lighter-than-air gas is channeled to the primary lift element and the pitch adjustment element to selectively vary the altitude and angle for the housing such that scene of interest may be imaged. The lighter-than-air gas may be selected from the group of helium, hydrogen, heated air, neon, ammonia, and methane.

Owner:PFG IP

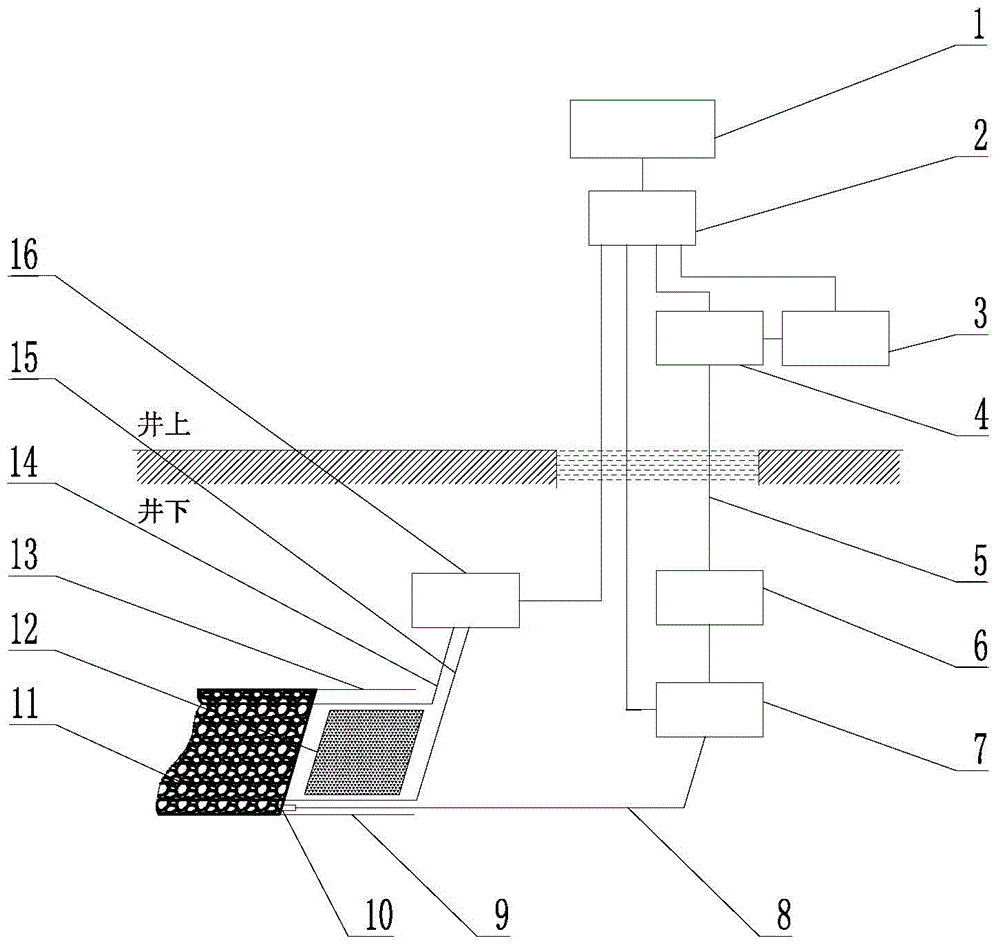

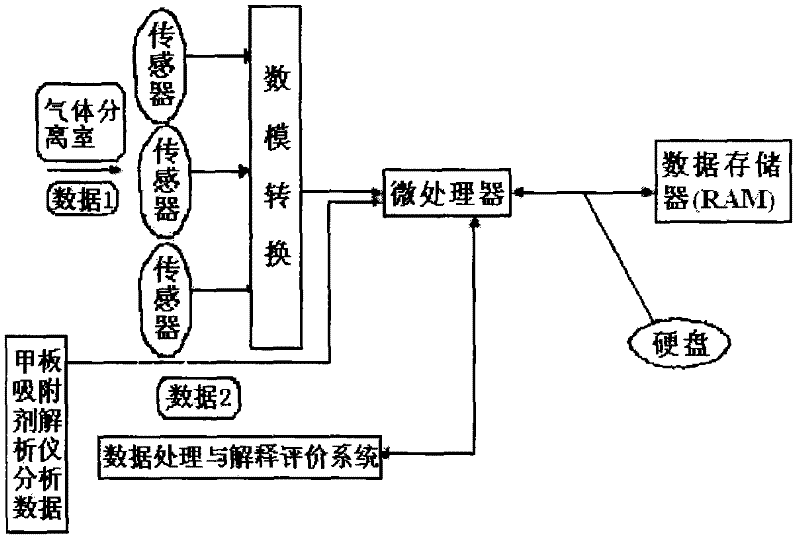

Coal mine spontaneous fire fiber temperature detection beam tube monitoring system and method

The invention relates to a coal mine spontaneous fire fiber temperature detection beam tube monitoring system and a method, and belongs to the field of coal mine spontaneous fire tendency monitoring and predicting. The coal mine spontaneous fire fiber temperature detection beam tube monitoring system comprises a beam tube monitoring system, distributed fiber temperature detection monitoring systems and a monitoring and analyzing system, wherein the beam tube monitoring system and the distributed fiber temperature detection monitoring systems are respectively connected with the monitoring and analyzing system. The method comprises the following steps: A, the beam tube monitoring system collects underground gas, detects and analyzes gas elements, and transmits data to a monitoring mainframe; B, the monitoring mainframe computes collected gas elements and contents of the collected gas elements according to the data obtained in the step A, and judges fire tendency according to gas element change; C, the distributed fiber temperature detection systems utilize a Raman scattering effect to obtain a temperature change curve of a whole fiber at different positions, and transmit the associated data to the monitoring mainframe; D, the monitoring mainframe receives the data obtained in the step C in real time; E, the monitoring mainframe performs correlation statistic analysis on the data obtained in the step D, determines the fire tendency and determines the position of a fire source point. According to the coal mine spontaneous fire fiber temperature detection beam tube monitoring system and the method, the firing tendency can be judged, and meanwhile, the position of the fire source point can be determined.

Owner:淄博祥龙测控技术有限公司

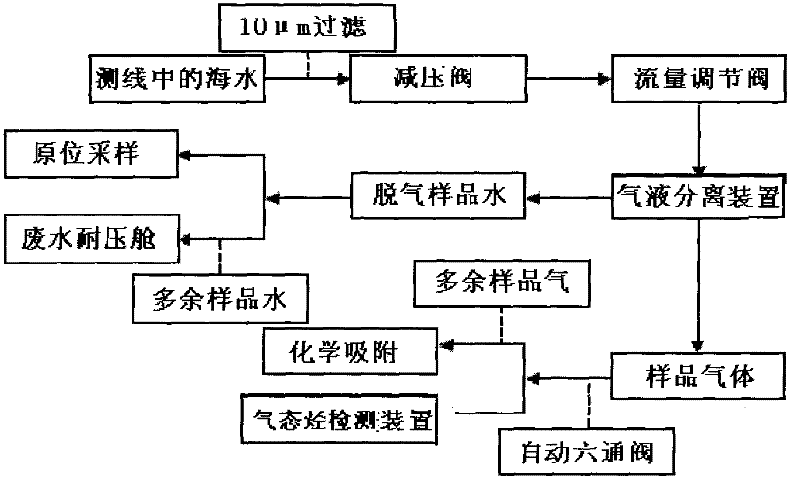

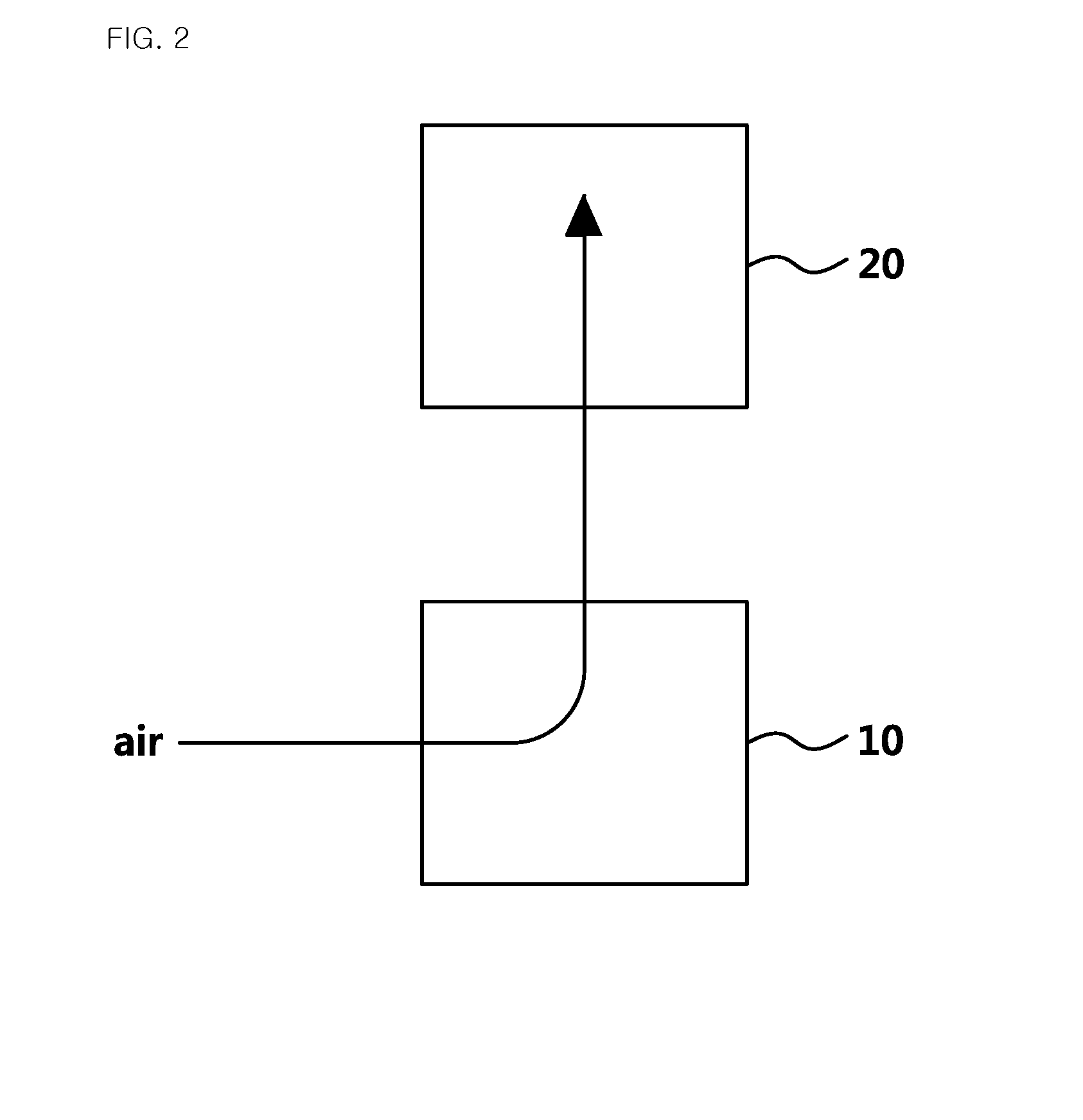

An in-situ detection system for methane concentration in seawater

InactiveCN102288719AImprove detection accuracyLess distracting factorsComponent separationData displayChemical adsorption

The invention relates to a system for detecting the methane concentration of seawater in situ. In the system, bottom seawater in a measuring line enters a reducing valve through a filter, so that the pressure of the seawater is lowered to normal pressure; normal-pressure sample water flows into a gas-liquid separating device after being adjusted by a flow valve; a seawater sample is separated into sample water and sample gas by the gas-liquid separating device; the sample water is collected by a sample water collector; excessive sample water flows into a waste water compressive cabin; the sample gas is collected by an automatic sample valve, and is conveyed into a gaseous hydrocarbon detection device for testing; the excessive sample gas is emptied, and is adsorbed by chemical adsorption equipment; the sample gas enters the gaseous hydrocarbon detection device; target gas undergoes a reduction oxidation reaction through a high-sensitivity gas element to generate an electric signal; and the electric signal is acquired by corresponding chromatogram software, is converted into a digital signal by using analog-digital conversion equipment, and is transmitted to a PC (Personal Computer) on a boat through an optical cable to realize data display. The system has the advantages of capability of detecting the methane concentration of a seabed in situ, high accuracy, small interference and accurate data.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

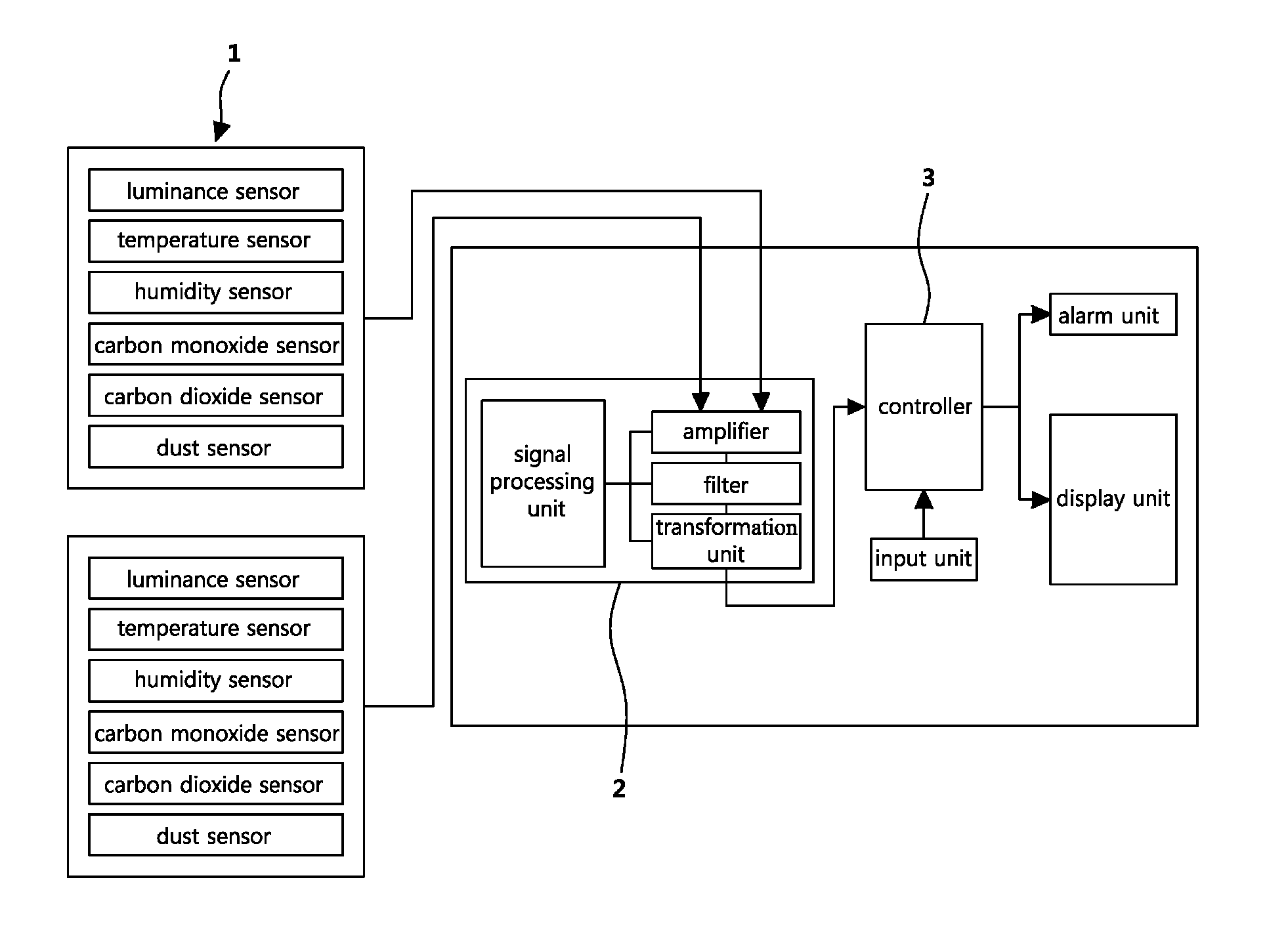

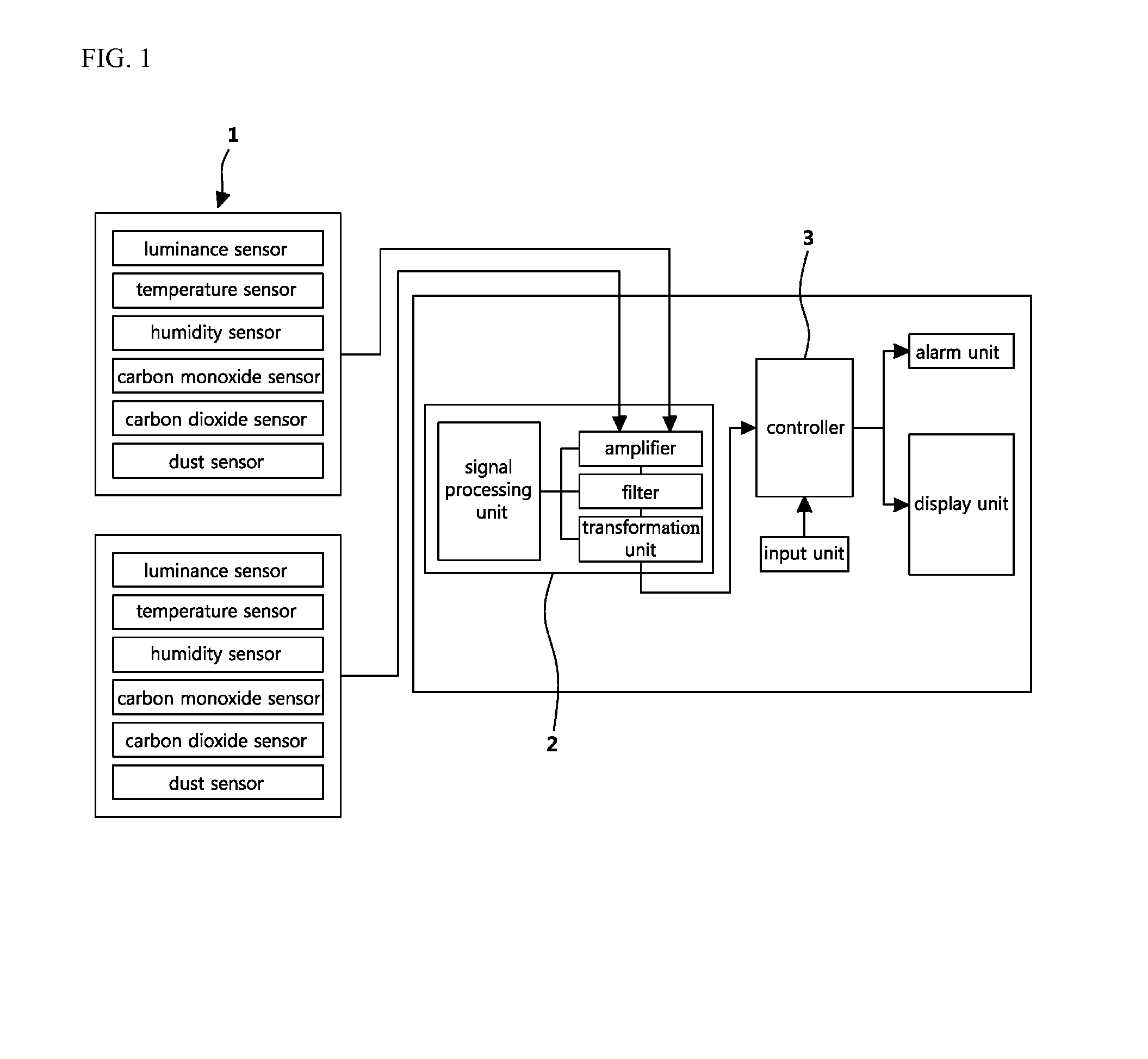

Hybrid environment sensor

InactiveUS20160334320A1Reduce manufacturing costSmall sizeTelevision system detailsGas dispersion analysisParticulatesEngineering

The present description relates to a hybrid environment sensor configured to measure a concentration of a particulate matter and gas element and concentration. More particularly, a hybrid environment sensor that can reduce the size of the entire environment sensor and substantially reduce the total power consumption through arranging a gas sensor configured to measure gas element and concentration included in the air in a housing unit that measures concentration of the particulate matter.

Owner:CENT FOR INTEGRATED SMART SENSORS FOUND

Method for preparing molybdenum target

ActiveCN103132033ALow melting pointGood removal effectVacuum evaporation coatingSputtering coatingGas elementMuffle furnace

The invention discloses a method for preparing a molybdenum target. The method comprises the following steps of: (1) compacting molybdenum powder into a molybdenum blank material, and pre-sintering the molybdenum blank material in a high-temperature furnace so as to obtain a pre-sintered blank; (2) sintering the pre-sintered blank in a high-temperature furnace so as to obtain a high-purity molybdenum metal blank; (3) heating the high-purity molybdenum metal blank in a muffle furnace, and carrying out pressure processing on the heated high-purity molybdenum metal blank so as to obtain a molybdenum plate; (4) heating the molybdenum plate, cooling and then machining; and (5) cleaning the machined molybdenum plate, and then binding the molybdenum plate to a metallic back plate, thereby obtaining the molybdenum target. According to the method, the pre-sintering is carried out under low pressure, so that the melting point of impurities can be lowered, the conditions for impurity volatilization are created, and the removal of gas elements and low-melting-point impurities from the material is favored; and particularly, the content of impurity elements, such as C, O, Si, Cr, Ca, K, Mg, Ti and Ni, in the material is reduced, so that the purity of the finished products is remarkably improved, and the purity and product quality of molybdenum-sputtered target materials are guaranteed.

Owner:JINDUICHENG MOLYBDENUM CO LTD

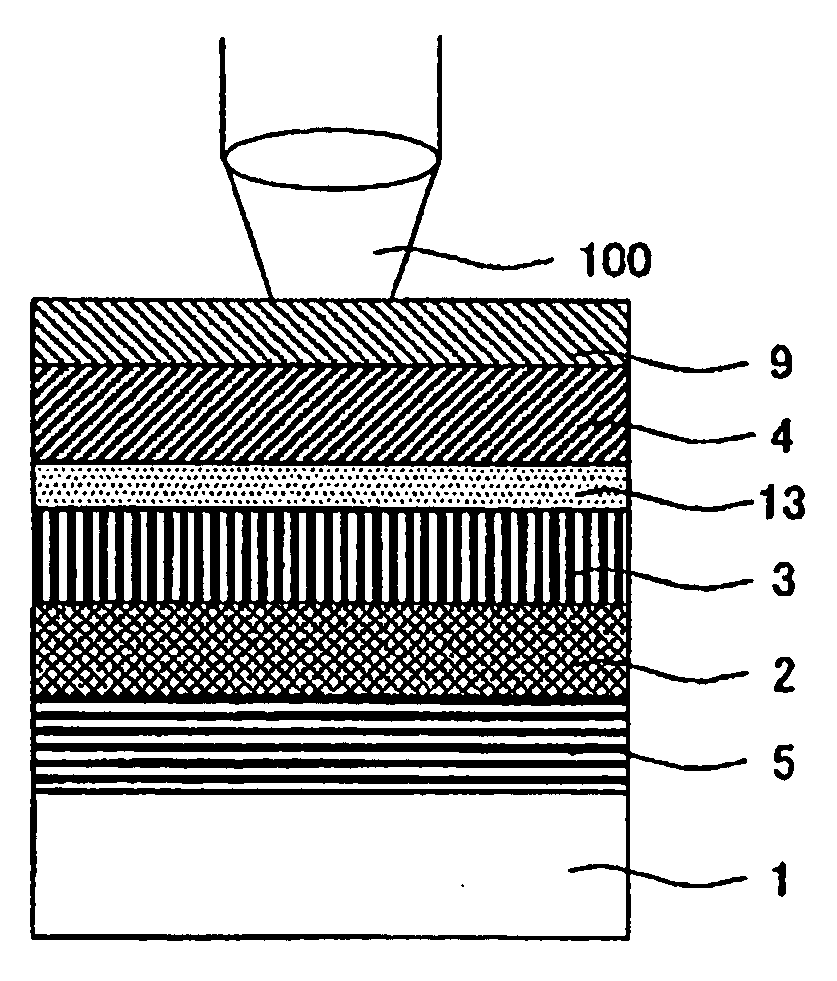

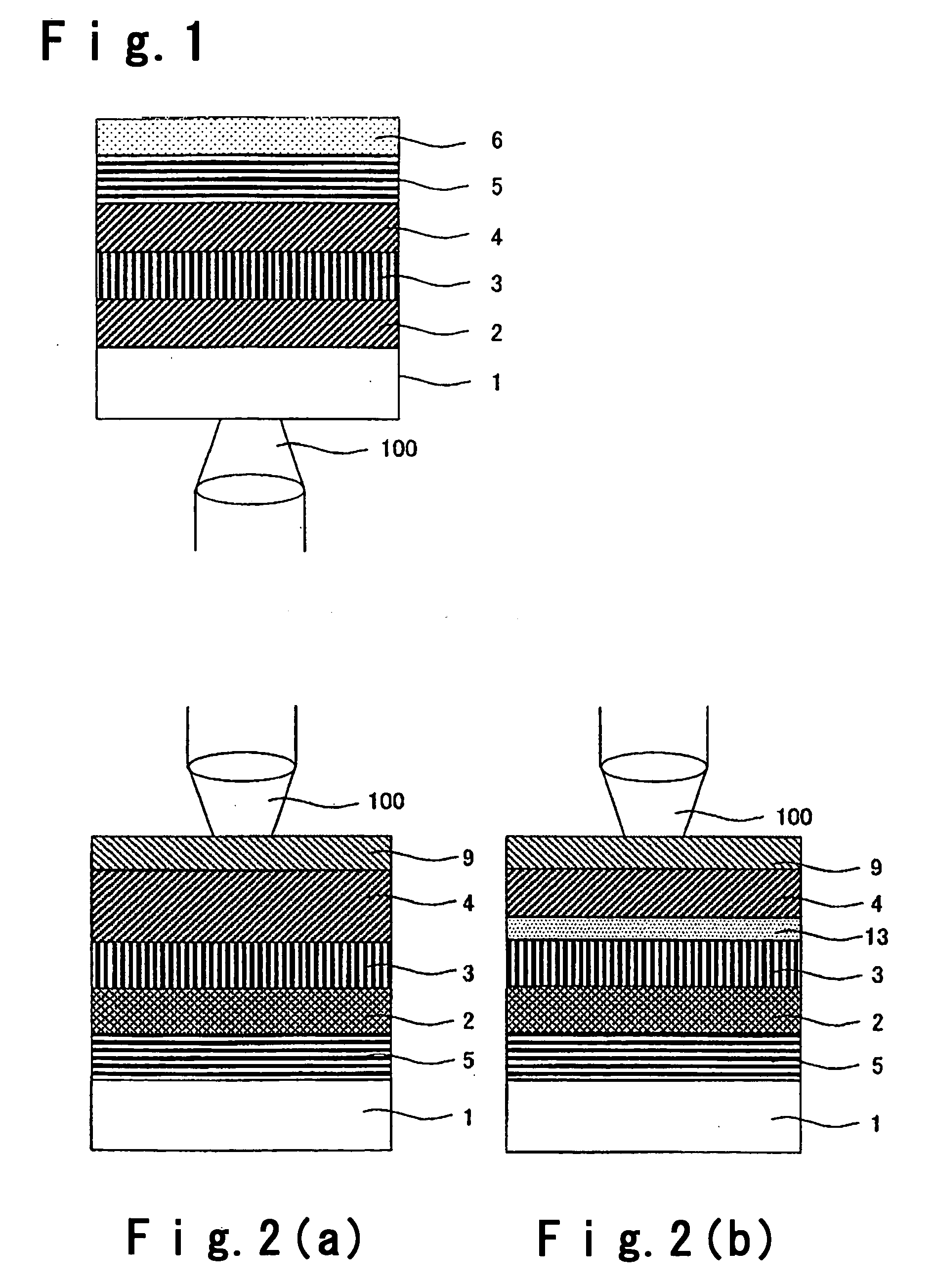

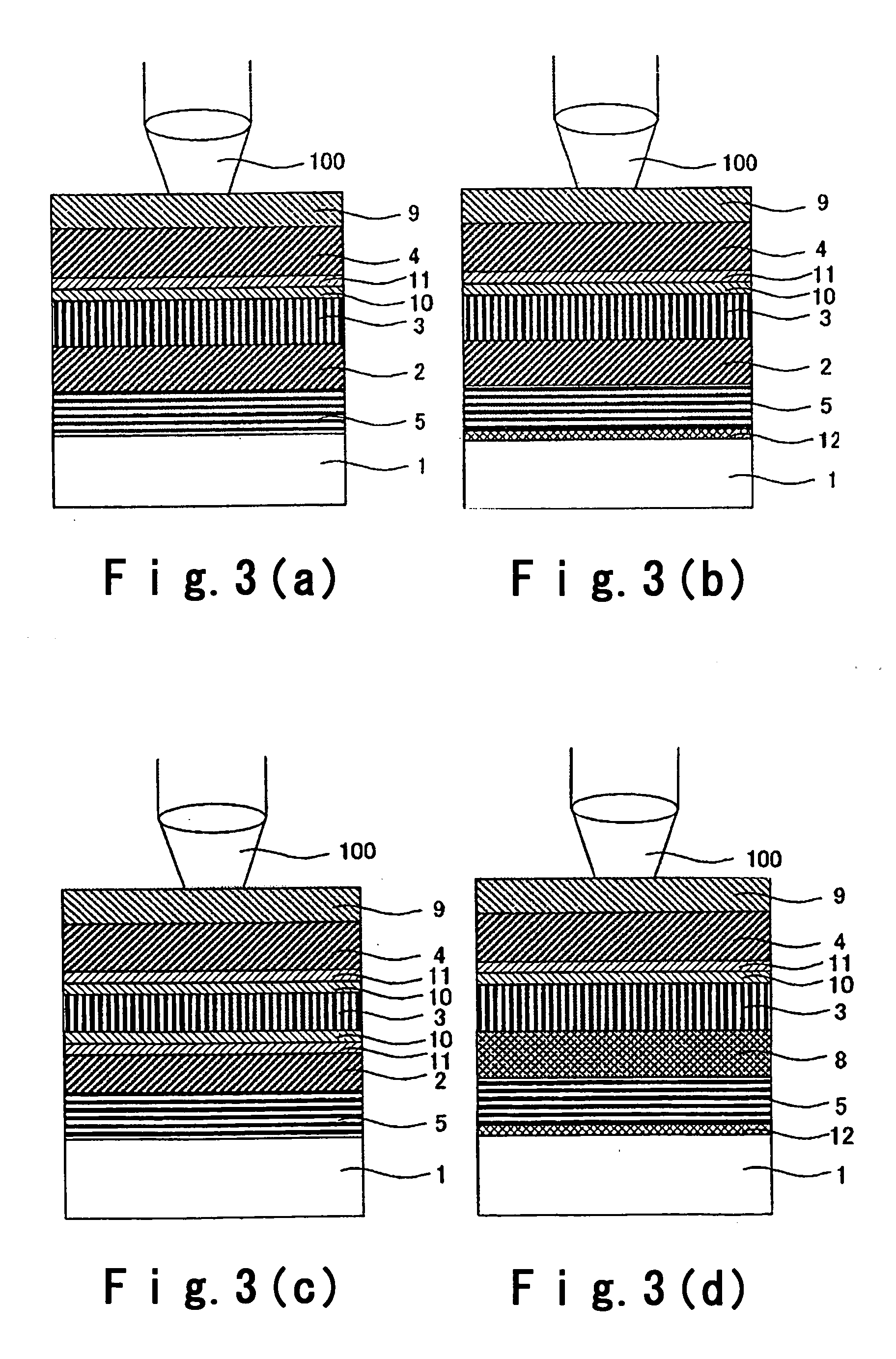

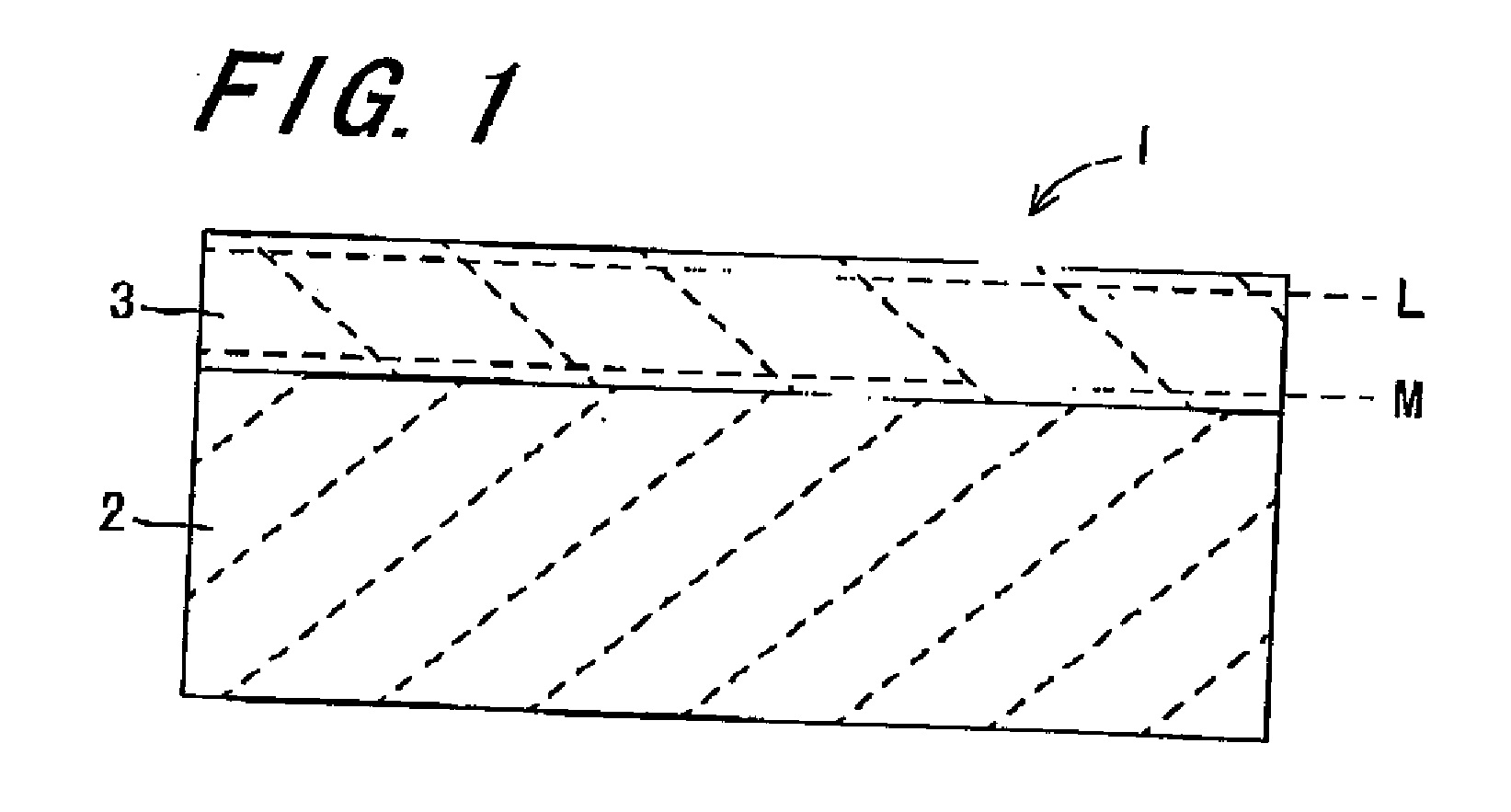

Optical recording medium

InactiveUS20050079444A1Efficient solutionStorage stability of the optical recording mediumLayered productsPhotomechanical apparatusDiffusionNitrogen

An optical recording medium simultaneously having higher recording characteristics and storage stability than ever, is obtained. An optical recording medium comprising at least a phase change recording layer, a first diffusion preventing layer, a second diffusion preventing layer and a protective layer formed in this order on a substrate, characterized in that the first diffusion preventing layer and the second diffusion preventing layer comprise a non-gas element and nitrogen and / or oxygen as the main components, the non-gas element in each of the first diffusion preventing layer and the second diffusion preventing layer, is the same, and the content (atomic %) of nitrogen and / or oxygen contained in the second diffusion preventing layer, is larger than the content (atomic %) of nitrogen and / or oxygen contained in the first diffusion preventing layer.

Owner:CMC MAGNETICS CORPORATION

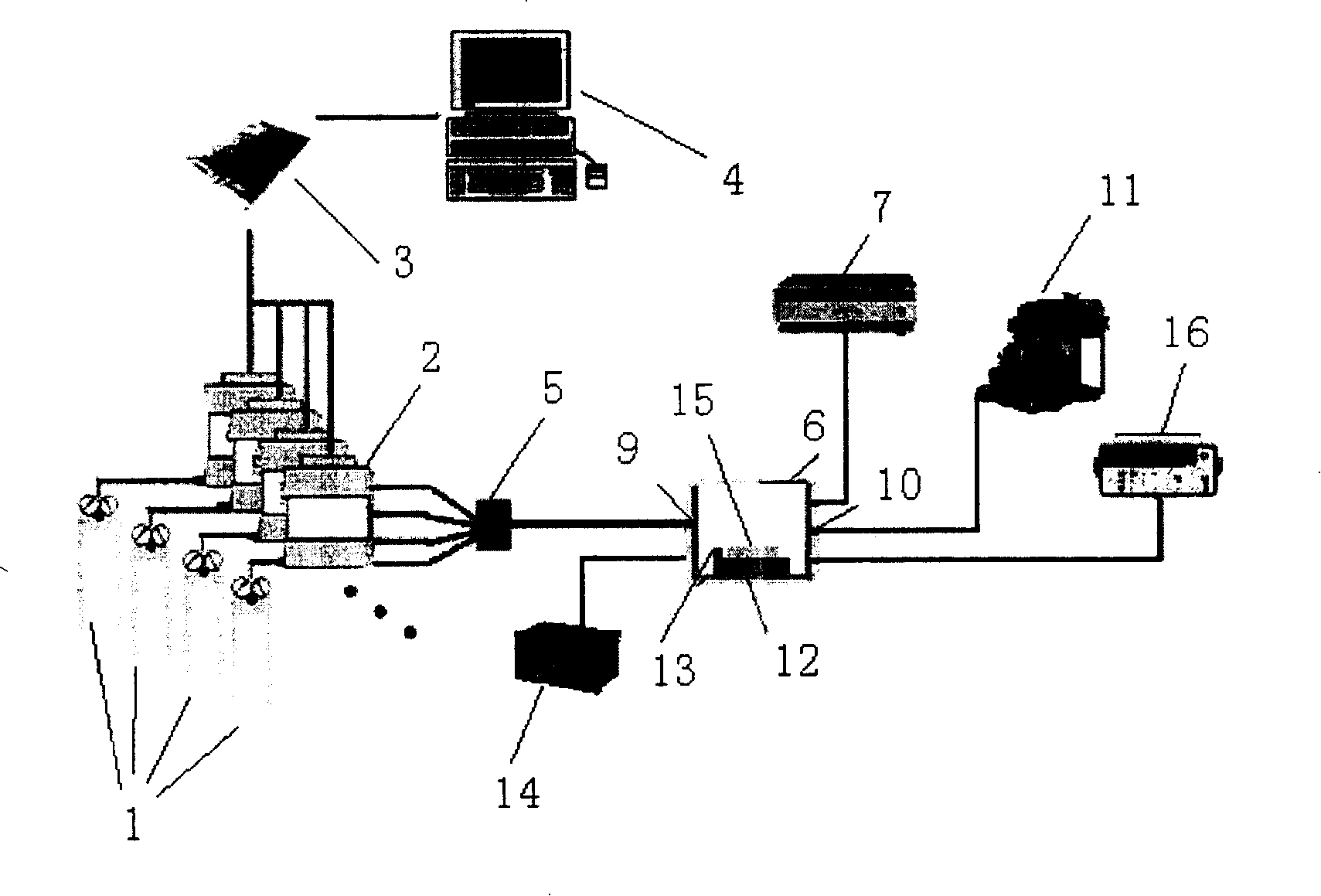

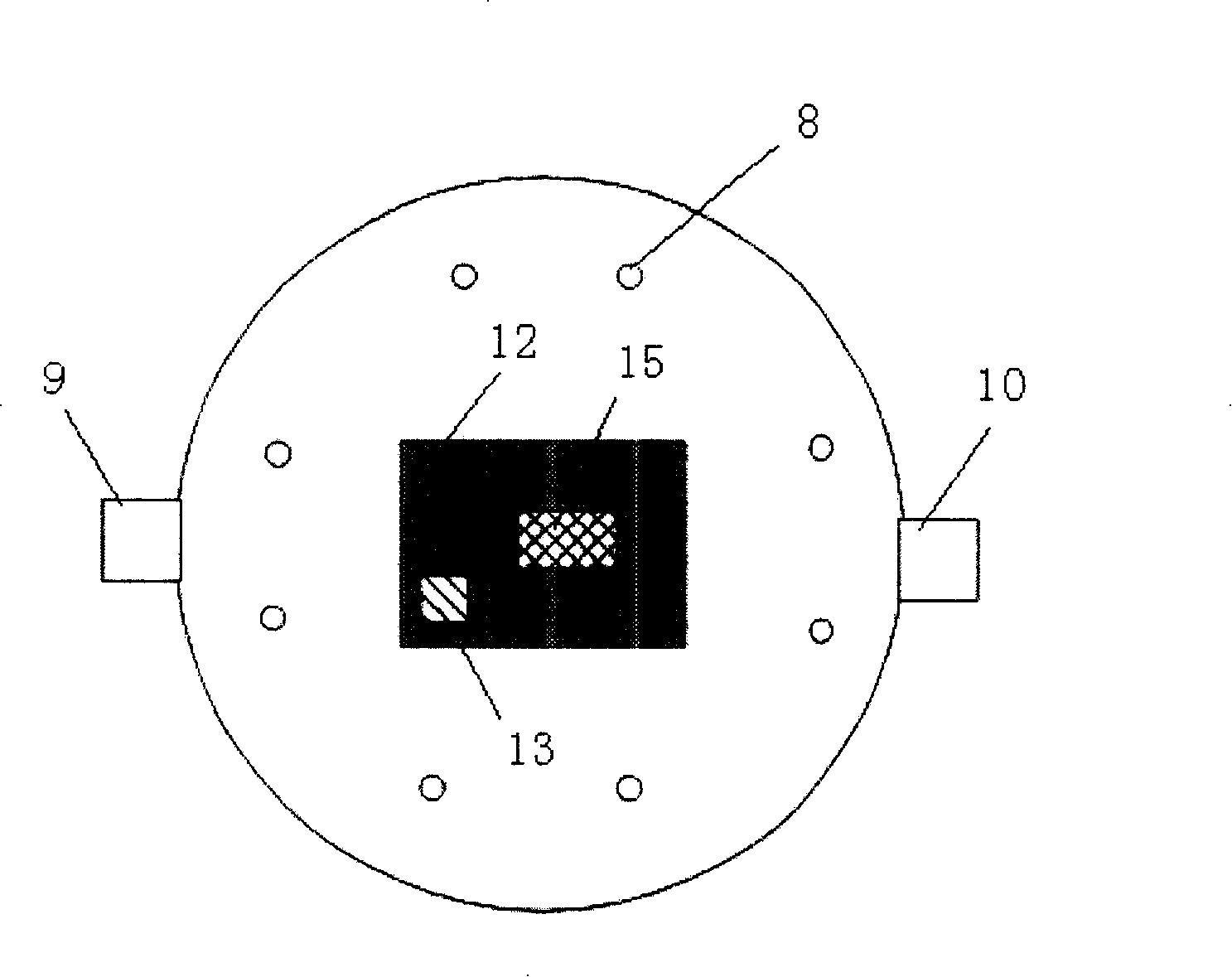

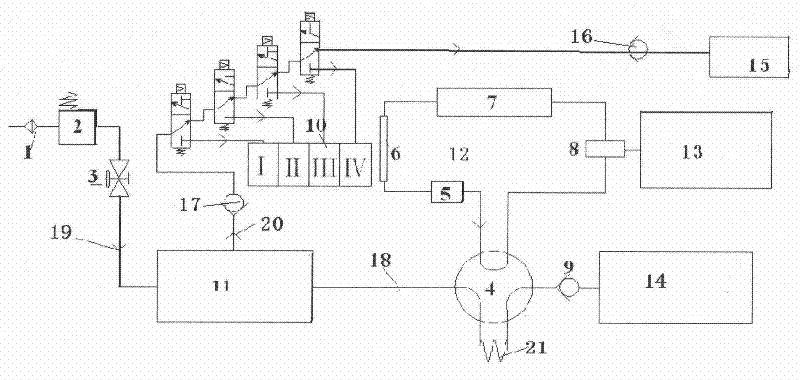

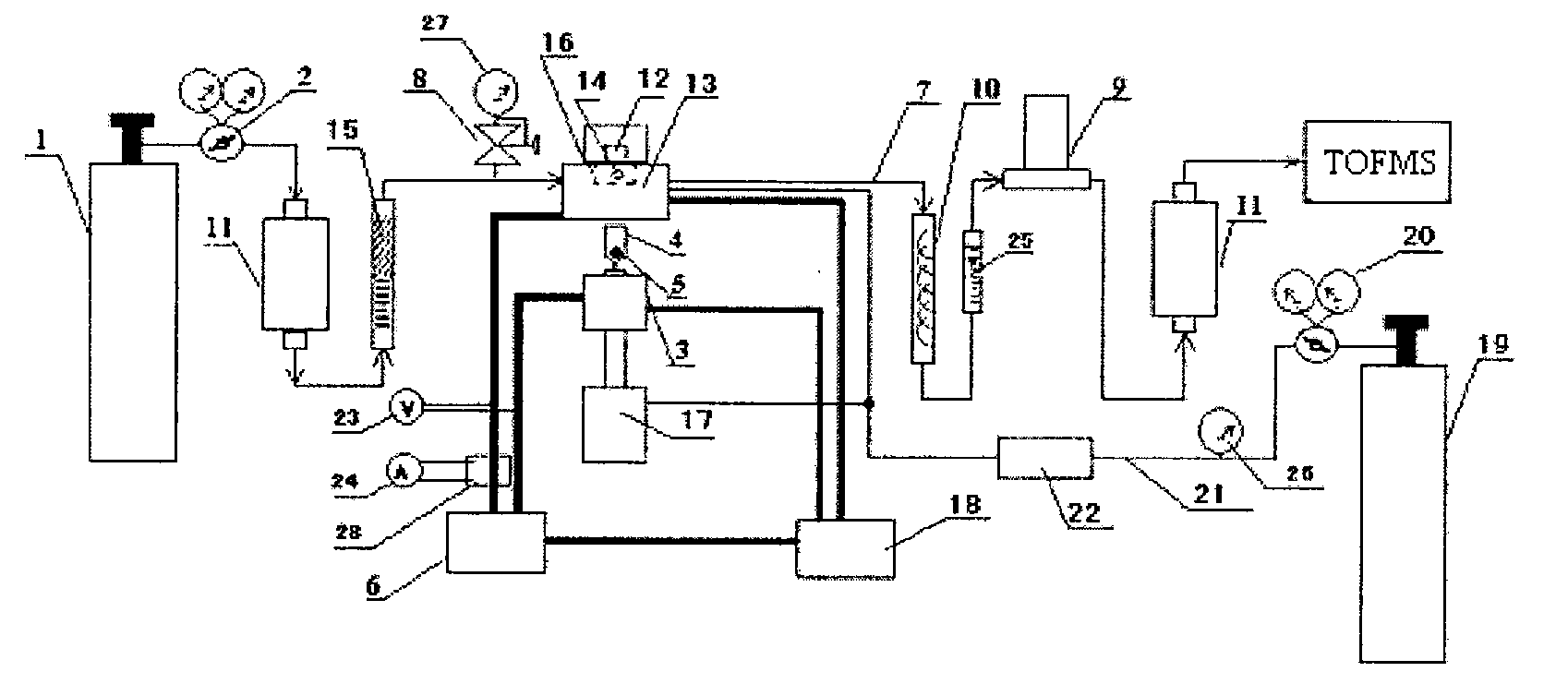

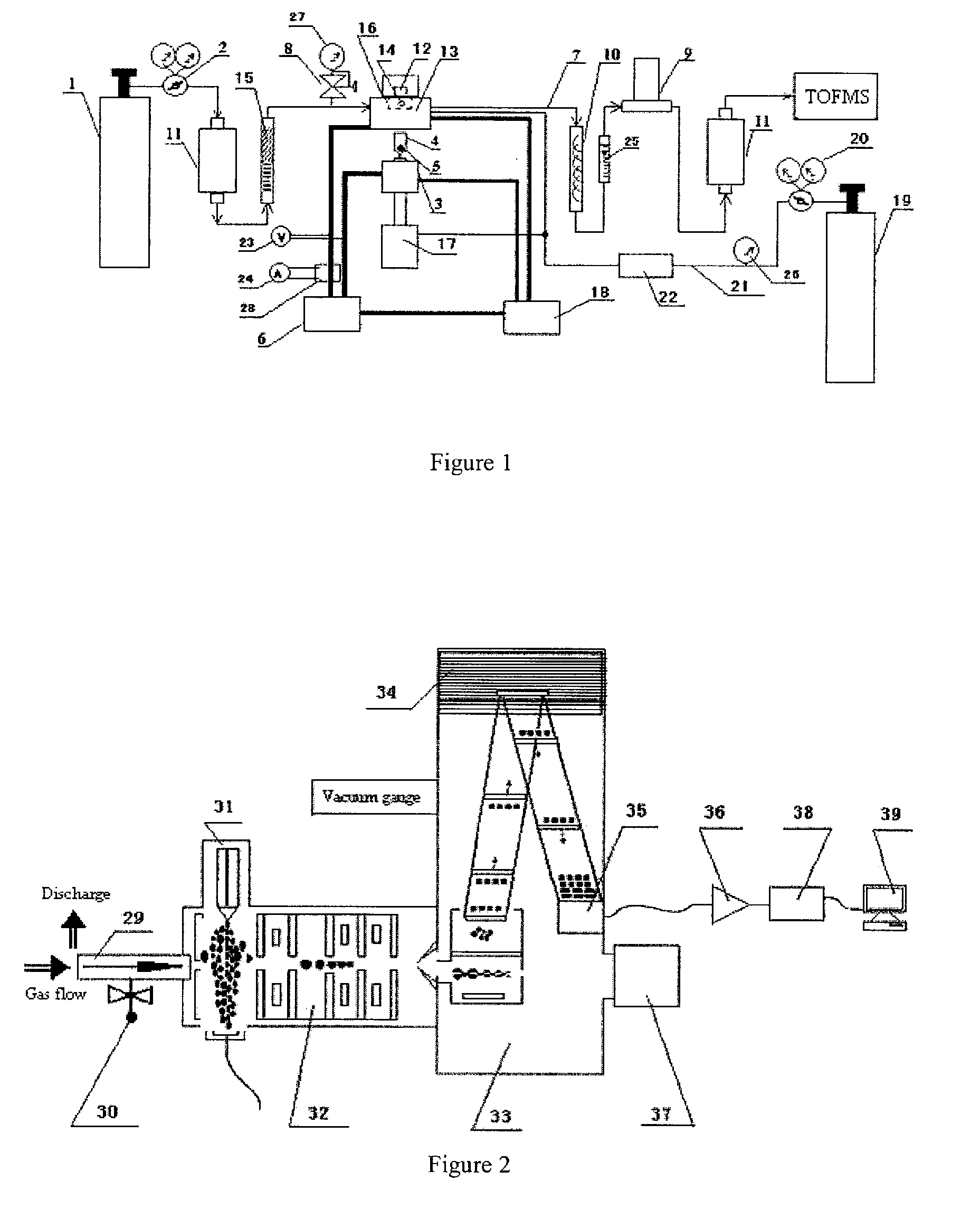

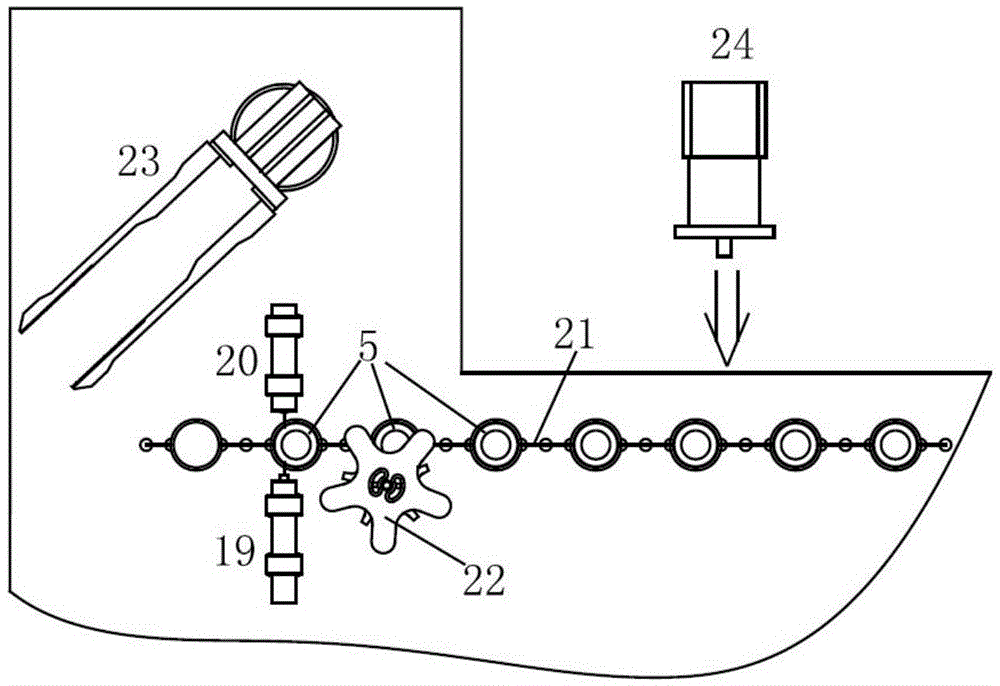

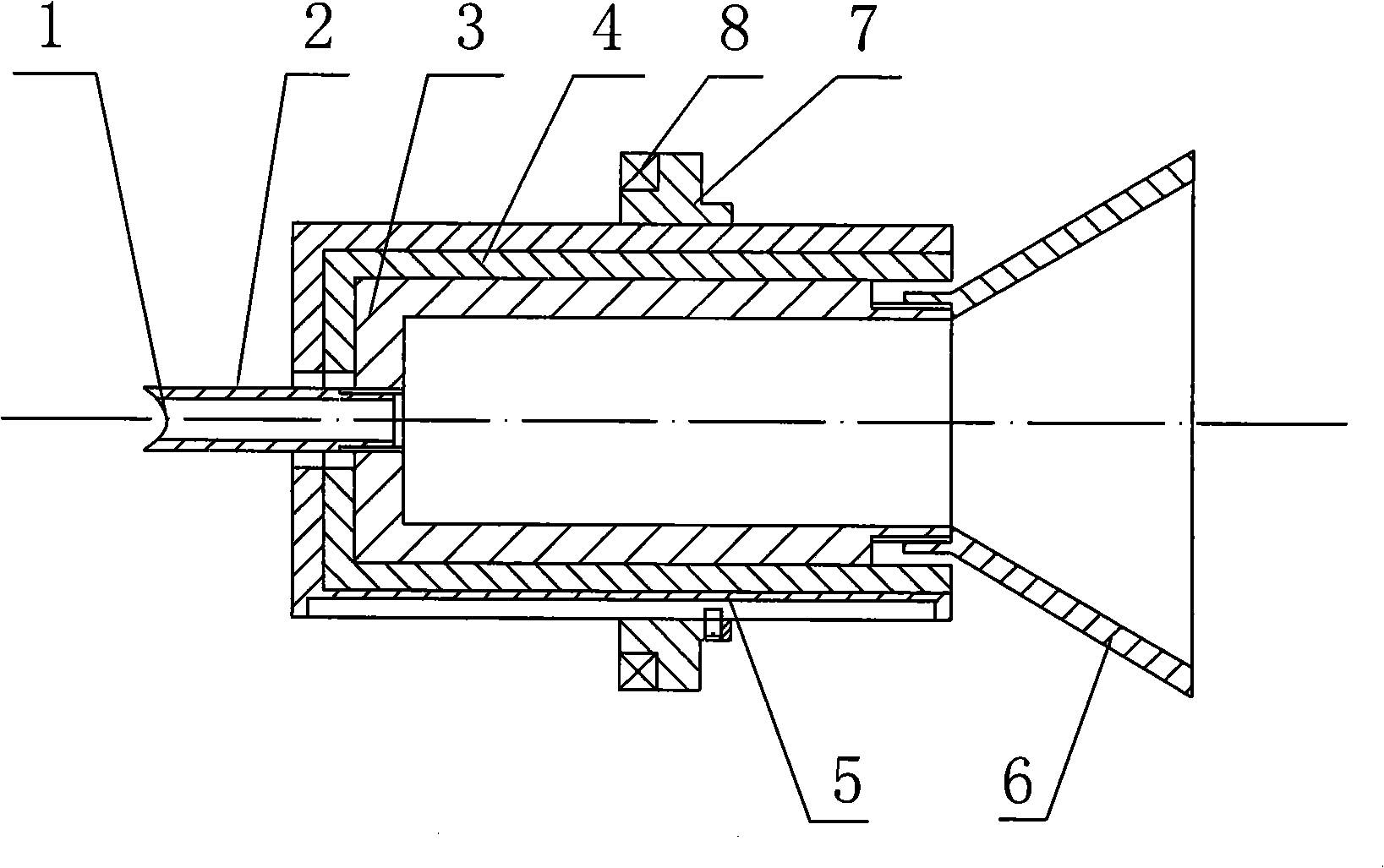

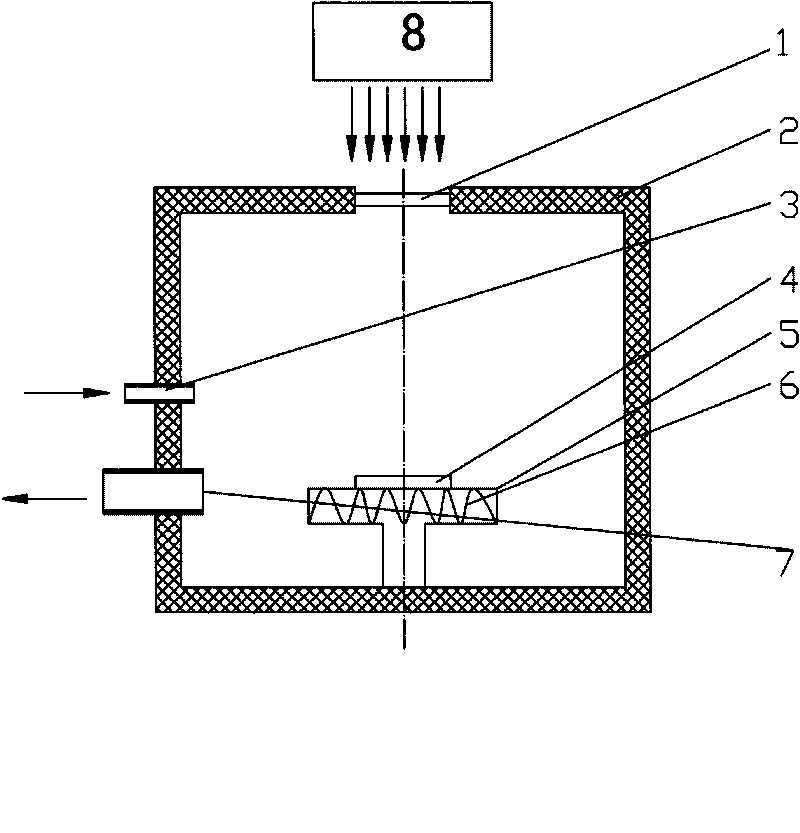

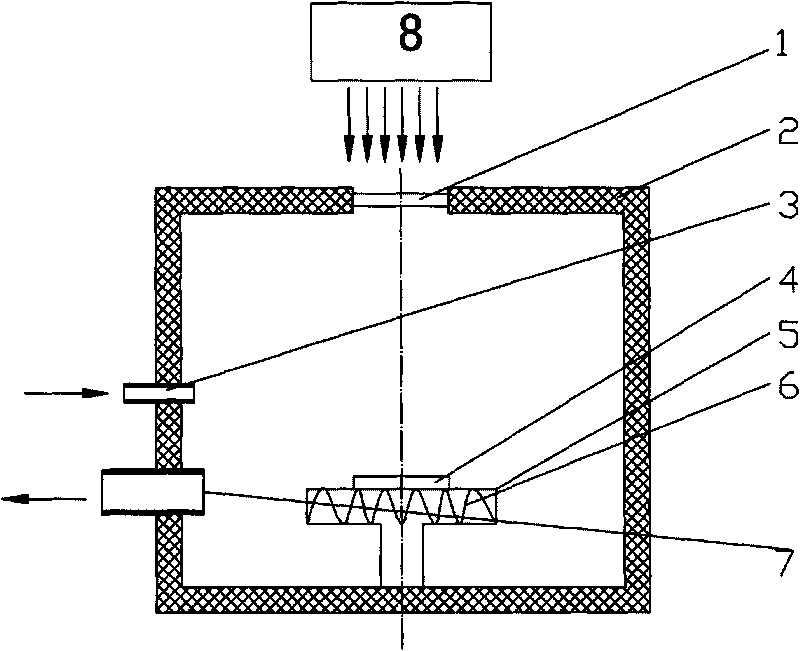

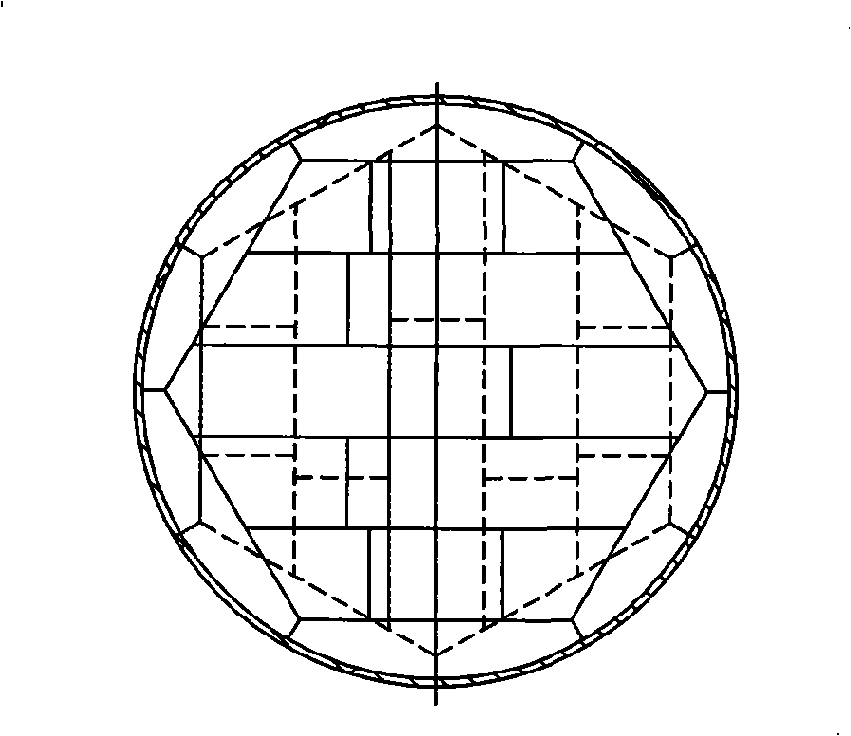

Pulse heating-time of flight mass spectrometric gas elements analyzer

InactiveUS20090121129A1High sensitivityTime-of-flight spectrometersSamplingAutomatic controlGas composition

A pulse heating—time of flight mass spectrometric gas elements analyzer, which involves the chemical analysis field of inorganic materials, and comprises of a pulse heating electrode furnace, a sample charging system, a purification device, a time-of-flight mass spectrometer, a signal acquisition and data processing system, and an automatic control system. Said electrode furnace and sample charging system are united as one via upper / lower electrodes and pneumatic cylinders, to form a closed hearth. Said electrode furnace, purification device and time-of-flight mass spectrometer are interconnected through the gas pipelines: the purified inert carrier gas comes into the hearth from its top, carrying out the gas components released from sample fusion, and upon re-purification, comes into the time-of-flight mass spectrometer; said signal acquisition and data processing system is connected to the detector of the said mass spectrometer via signal cables, and on the basis of computation by the data processing module of the relevant computer software, outputs the mass percentages of O, N, H and Ar in the sample. The lower limit of detection can be below 0.01 ppm to 0.1 ppm, and no less than three elements can be measured simultaneously in one analysis cycle.

Owner:NCS TESTING TECH

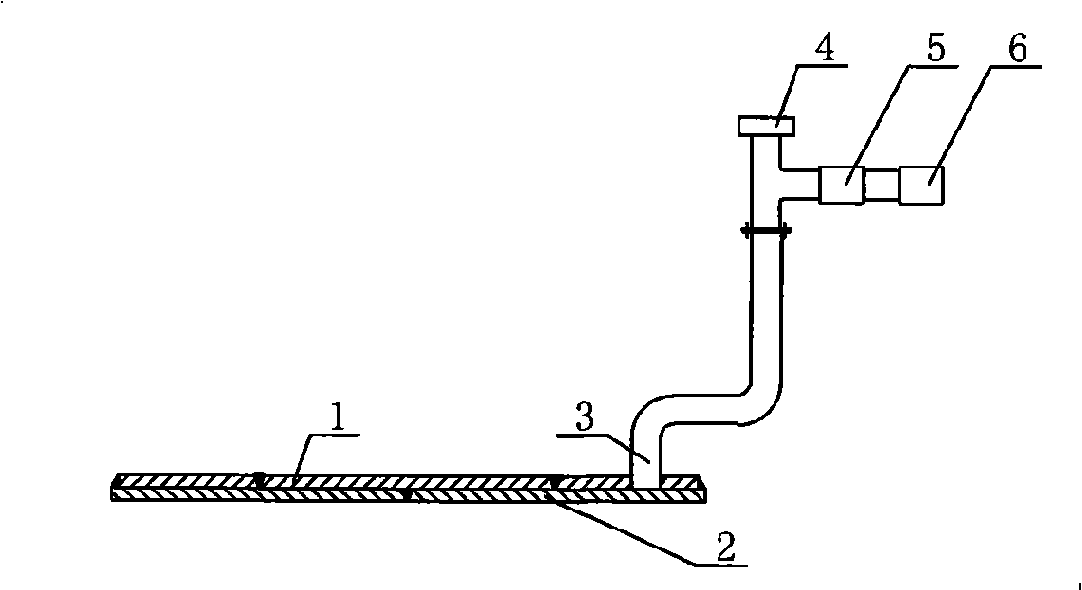

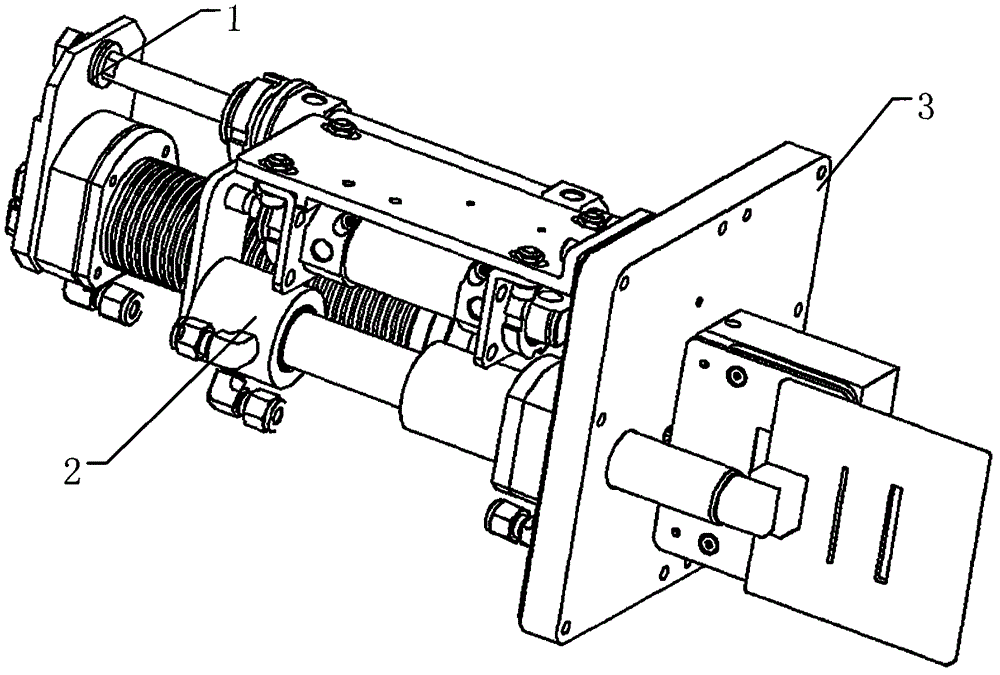

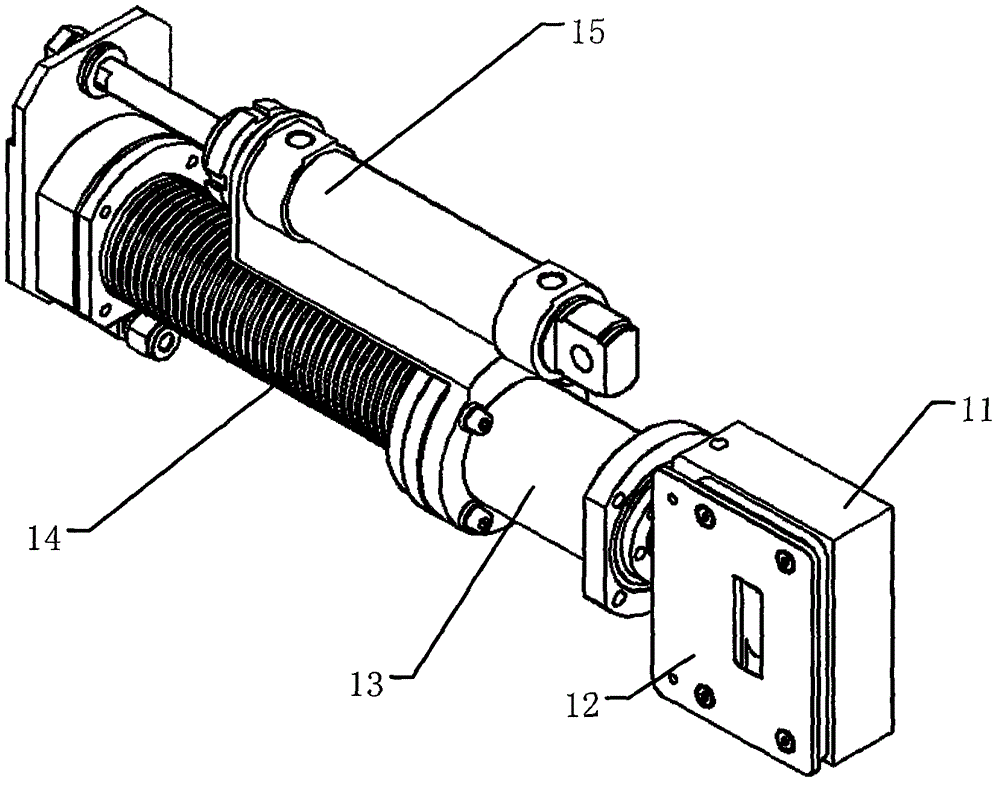

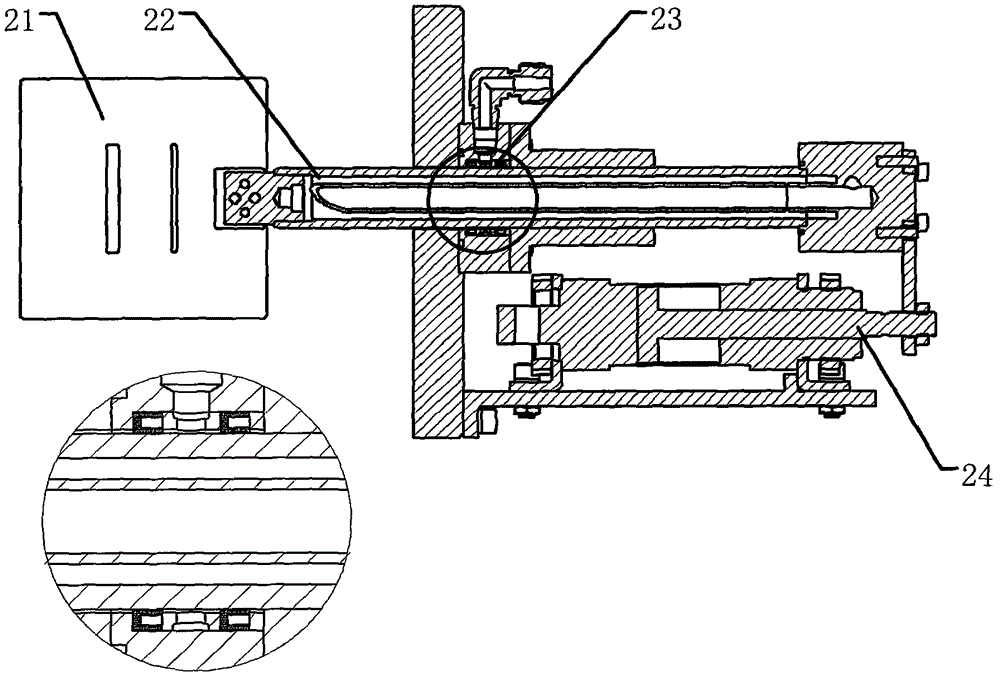

Vertical-type tubular furnace infrared carbon sulfur analyzer

ActiveCN105486879AAvoid crackingAccurate pick and placeChemical analysis using combustionMaterial analysis by optical meansData connectionElemental analysis

A vertical-type tubular furnace infrared carbon sulfur analyzer belongs to the technical field of gas elemental analysis in a material, comprises a tubular furnace heating system (1), a fully-automatic sampling system, a gas path system with a vacuum pump, an infrared detection system, a signal acquisition system and a signal processing system, the fully-automatic sampling system is installed below the tubular furnace heating system (1), and is used for pushing a crucible, in which a sample is contained, into a combustion tube; the vacuum pump is installed at the terminal end of a gas path to achieve gas flow stability in the whole gas path system; the infrared detection system (7) is mounted between the tubular furnace heating system (1) and the vacuum pump and is used for detection of carbon dioxide and sulfur dioxide in an analysis gas after combustion; a data acquisition and control system is connected via a data connection line, respectively with a temperature control device (18), the infrared detection system (7) and a fully-automatic sampling device (8), and is used for signal control and acquisition. Advantages are that the analysis is fast and results are stable.

Owner:NCS TESTING TECH

Metal ion source

InactiveCN1594649ASo as not to damageIncrease sputtering throughputVacuum evaporation coatingSputtering coatingHigh densityGas element

The invention relates to a metal ion source capable of promoting high-density metallic element ion. In the invention auxiliary cathode is added to the cathode, and protrudes in the anode region, and constitutes a discharge chamber with anode. Circular magnet and ferromagnet is mounted under the auxiliary cathode, ferromagnet placing in circular magnet, and connected to cathode. Auxiliary cathode is made of needed metal element, when a certain metal element is needed, auxiliary cathode and magnet prepared from the material are mounted to constitute magnetron sputtering source, so the auxiliary cathode enlarge the metal element sputtering yield, protect the original cathode, prolong the ion source life time. When gas ion is needed, it is OK that circular magnet and ferromagnet under the auxiliary cathode be removed. The ion sputtering source can satisfy the needs of gas ion or metal ion.

Owner:XI AN JIAOTONG UNIV

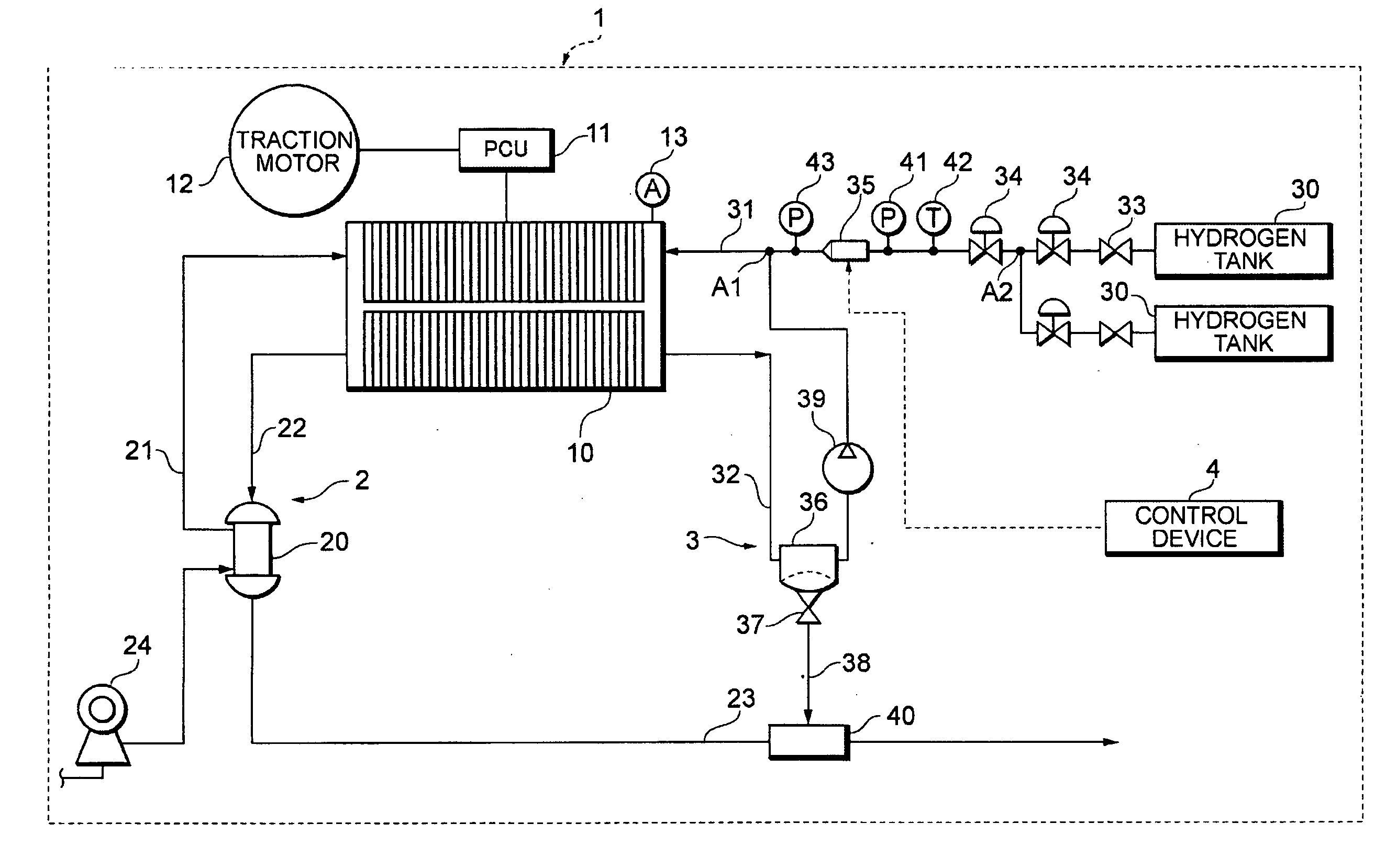

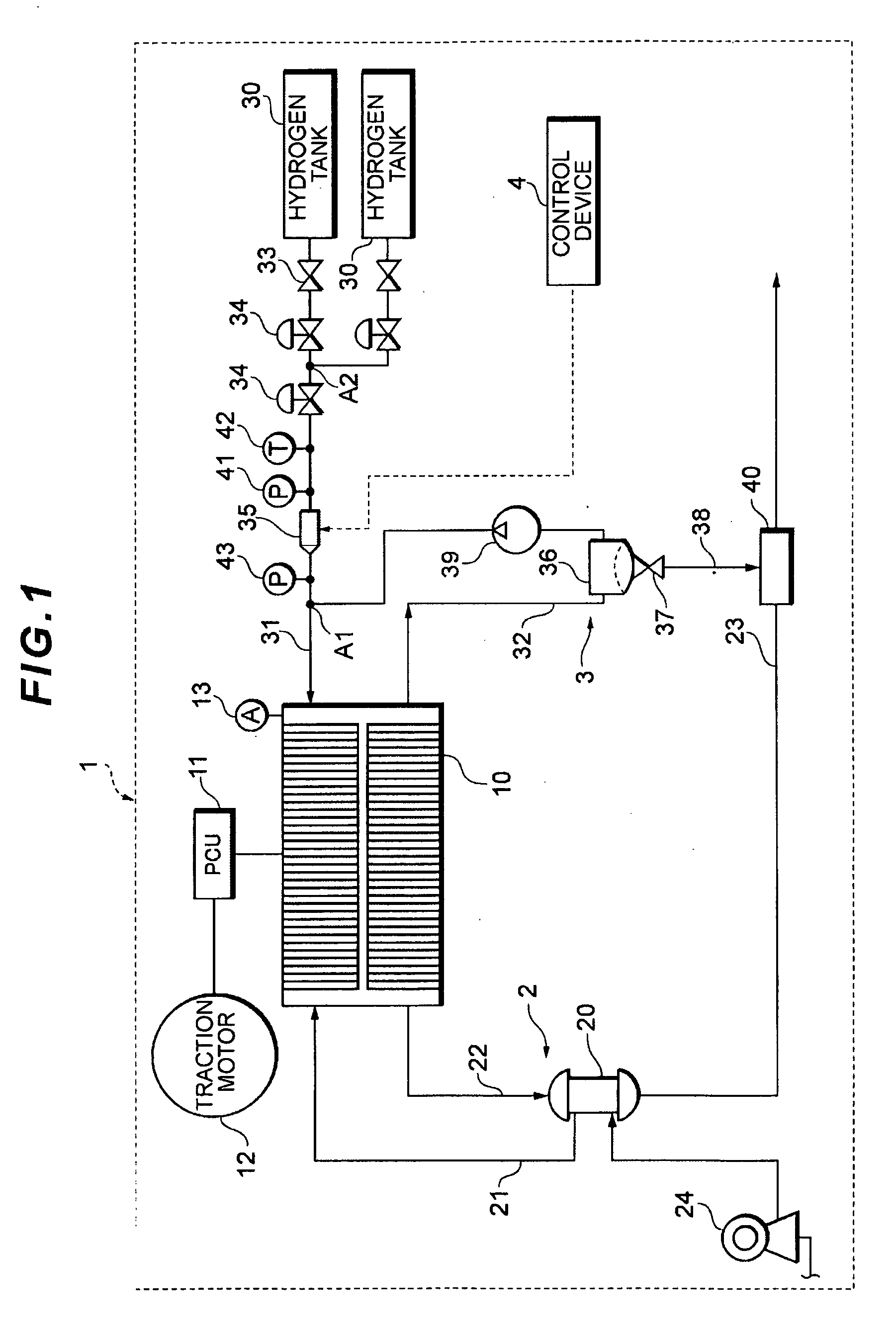

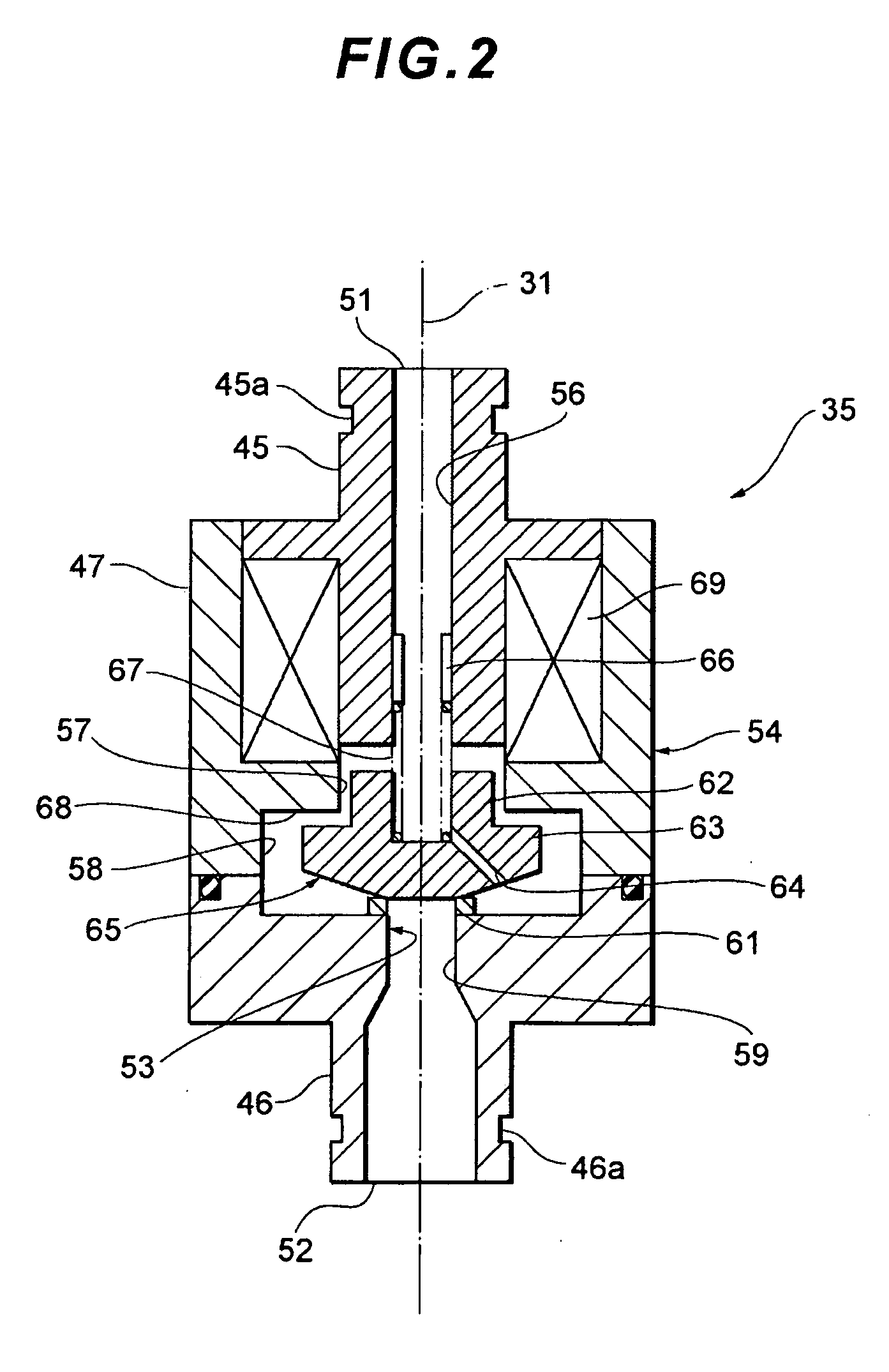

Fuel cell system

ActiveUS20100040922A1Controlling time delayImprove responseOperating means/releasing devices for valvesReactant parameters controlFuel cellsGas element

A fuel cell system having a fuel cell, a reactant gas pipe for supplying a reactant gas to the fuel cell, and an injector for driving a valve body at a predetermined drive cycle by an electromagnetic driving force to separate the valve body from a valve seat, regulating conditions of the gas on the upstream side in the reactant gas pipe and supplying the gas to the downstream side. A gas element component responding to the physical quantity of the reactant gas circulating through the reactant gas pipe is integrally provided in the injector so as to come close to the injector.

Owner:TOYOTA JIDOSHA KK

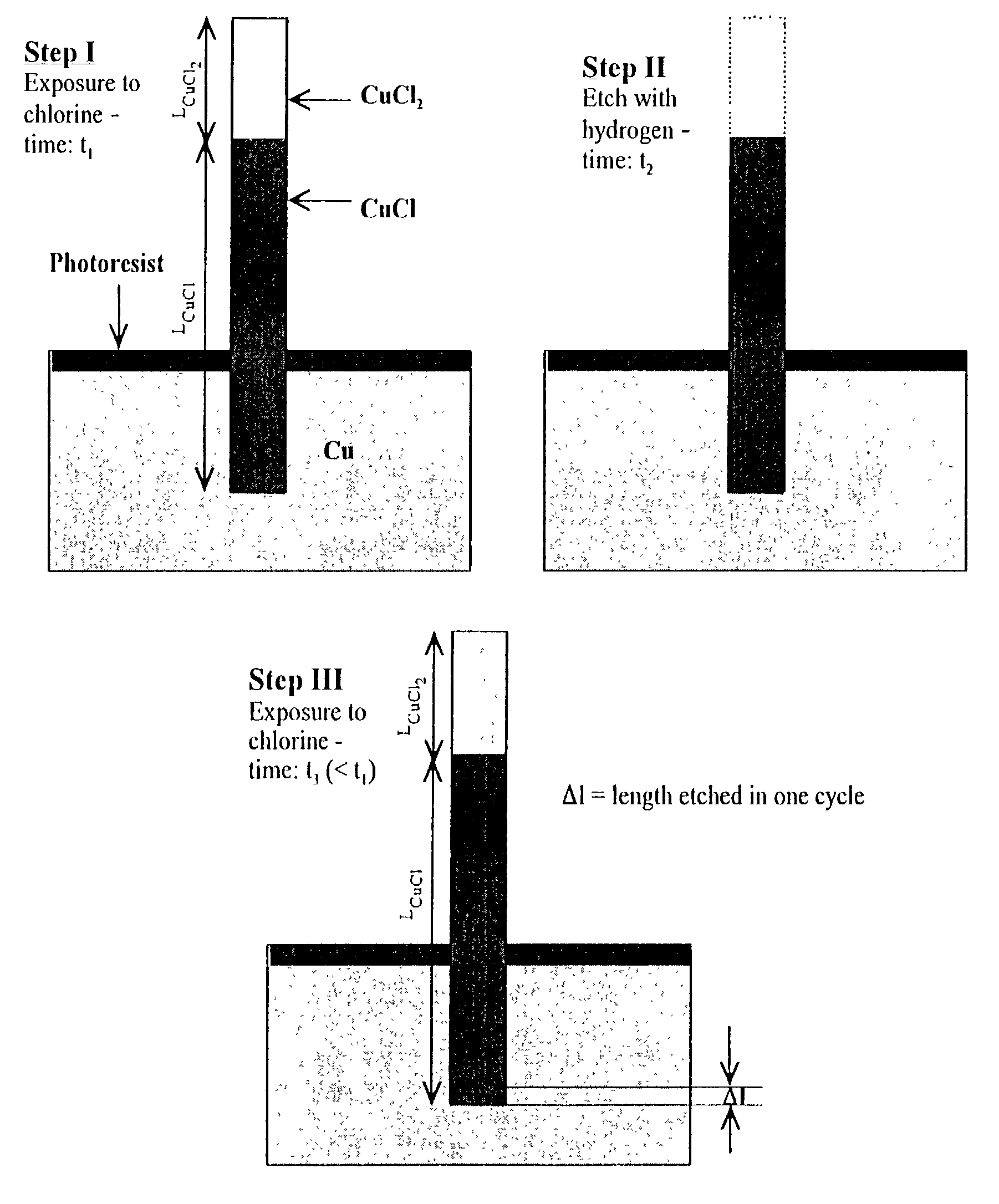

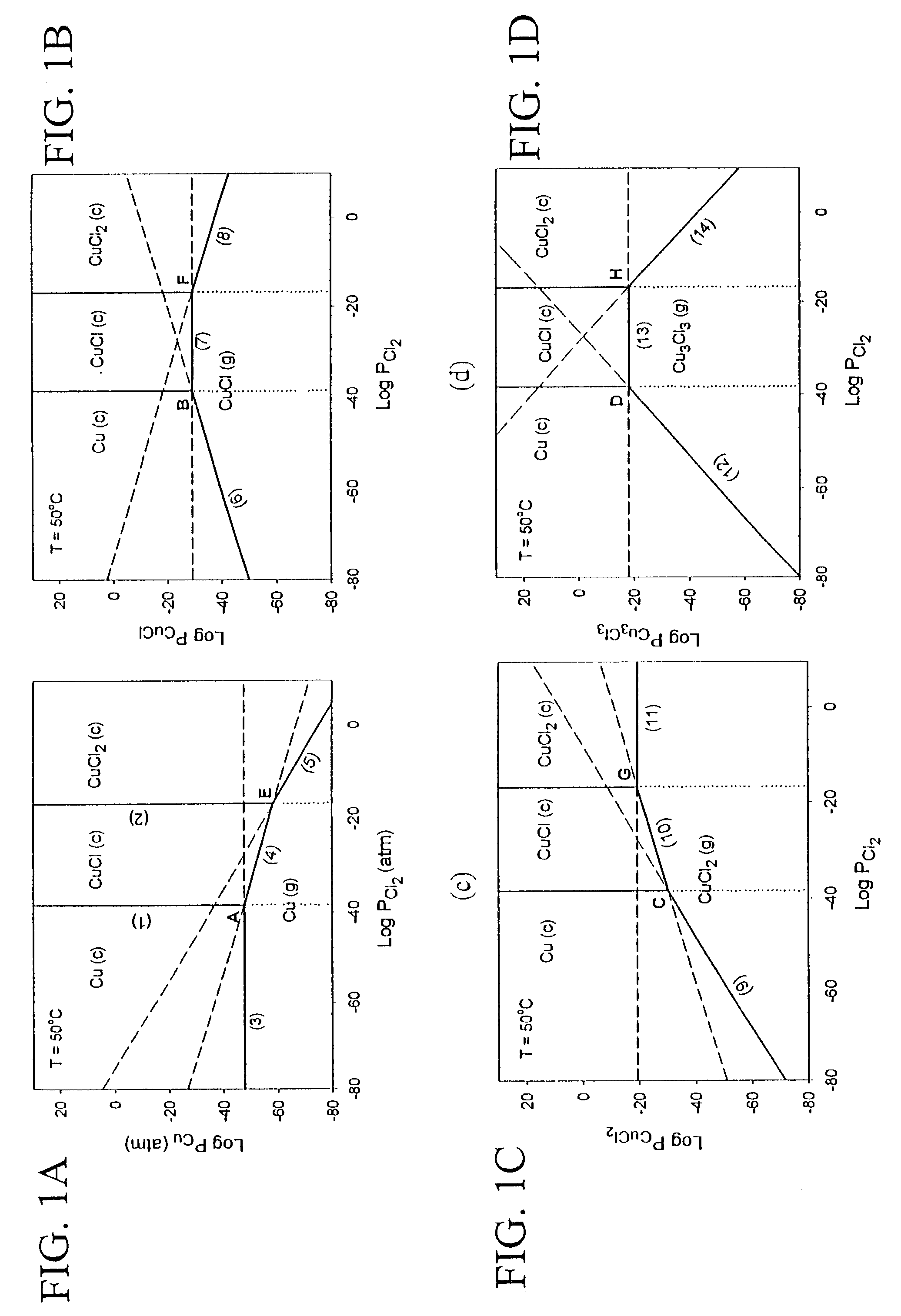

Process for low temperature, dry etching, and dry planarization of copper

InactiveUS7064076B2Decorative surface effectsSemiconductor/solid-state device manufacturingHydrogenSufficient time

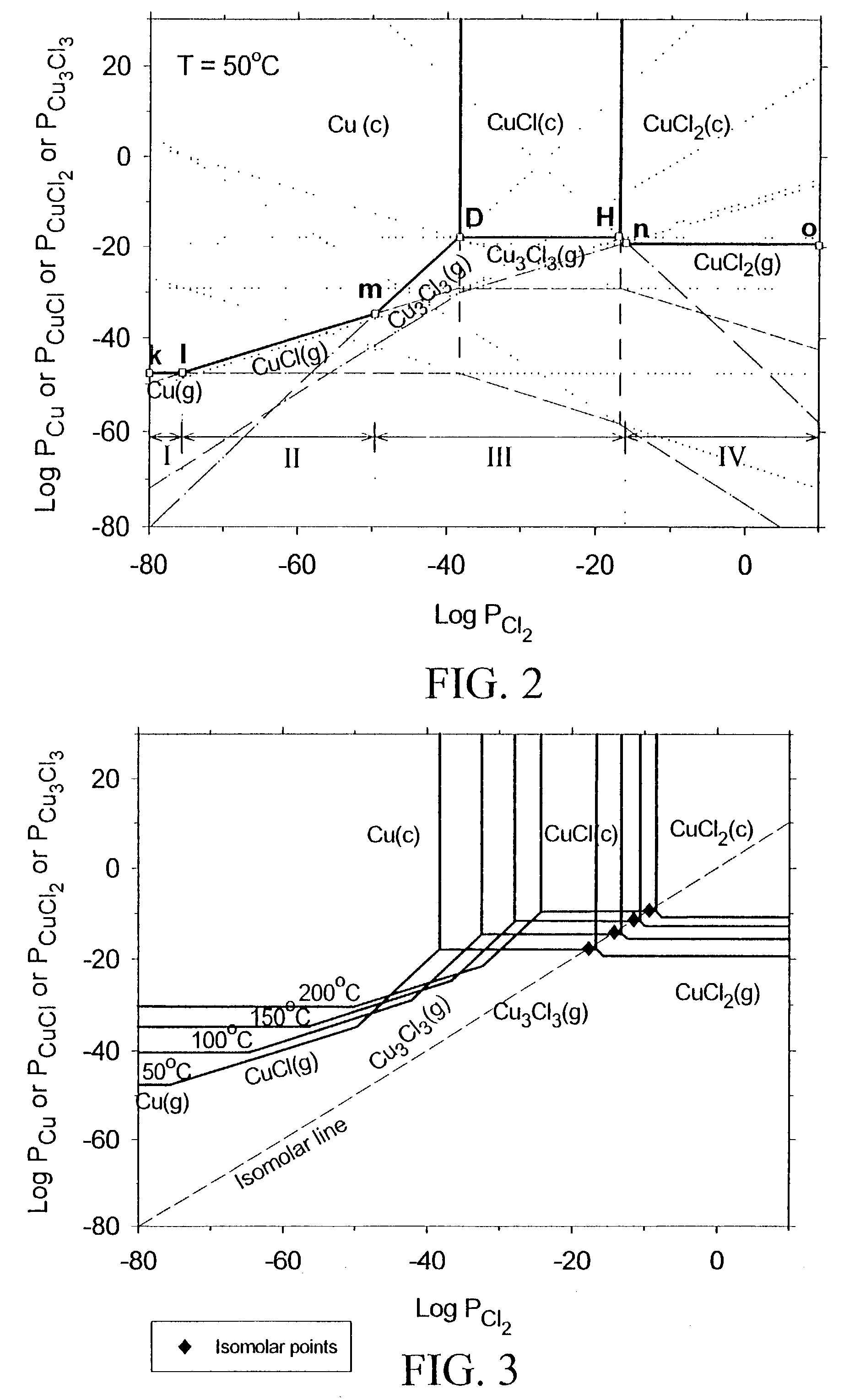

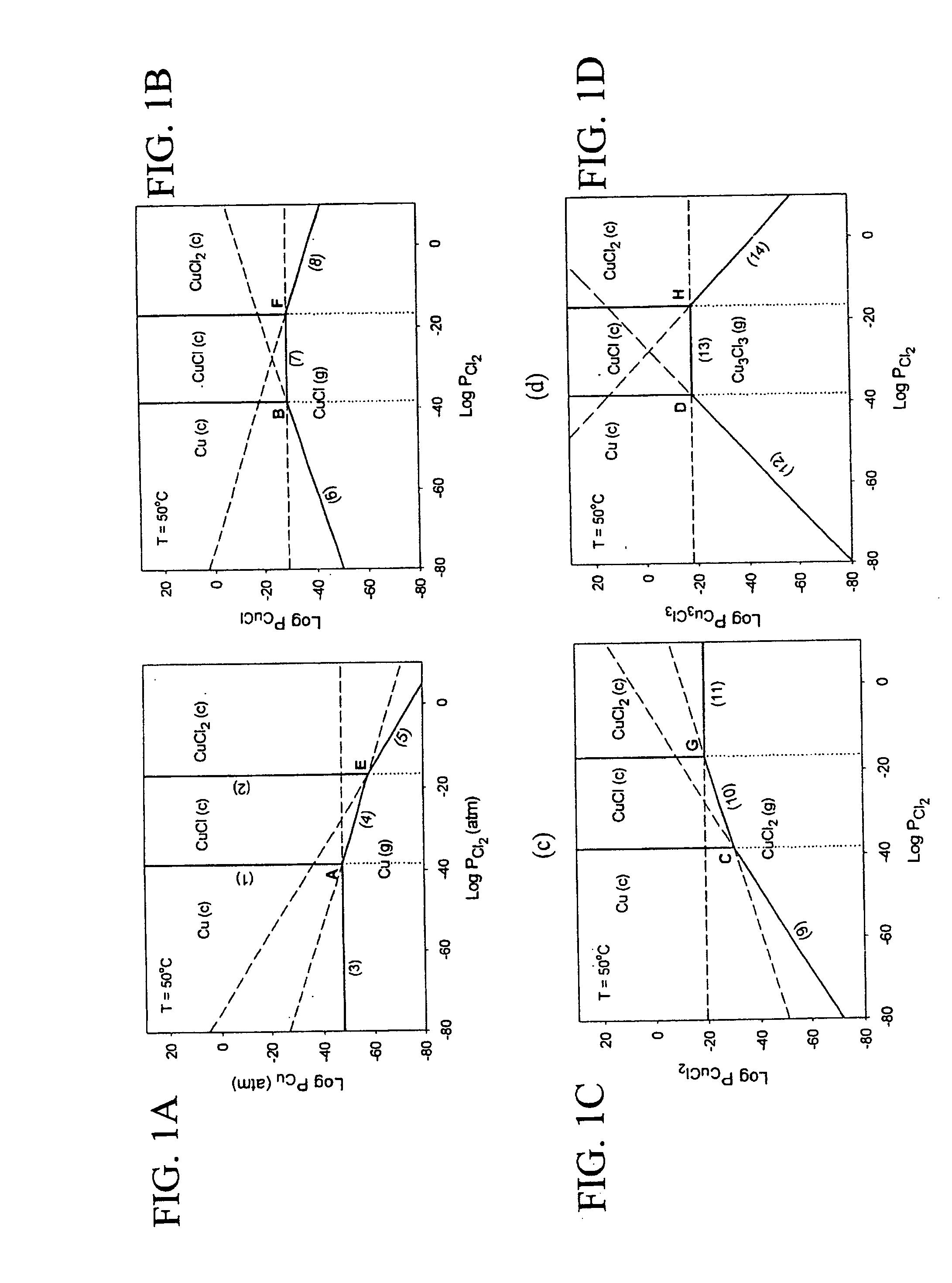

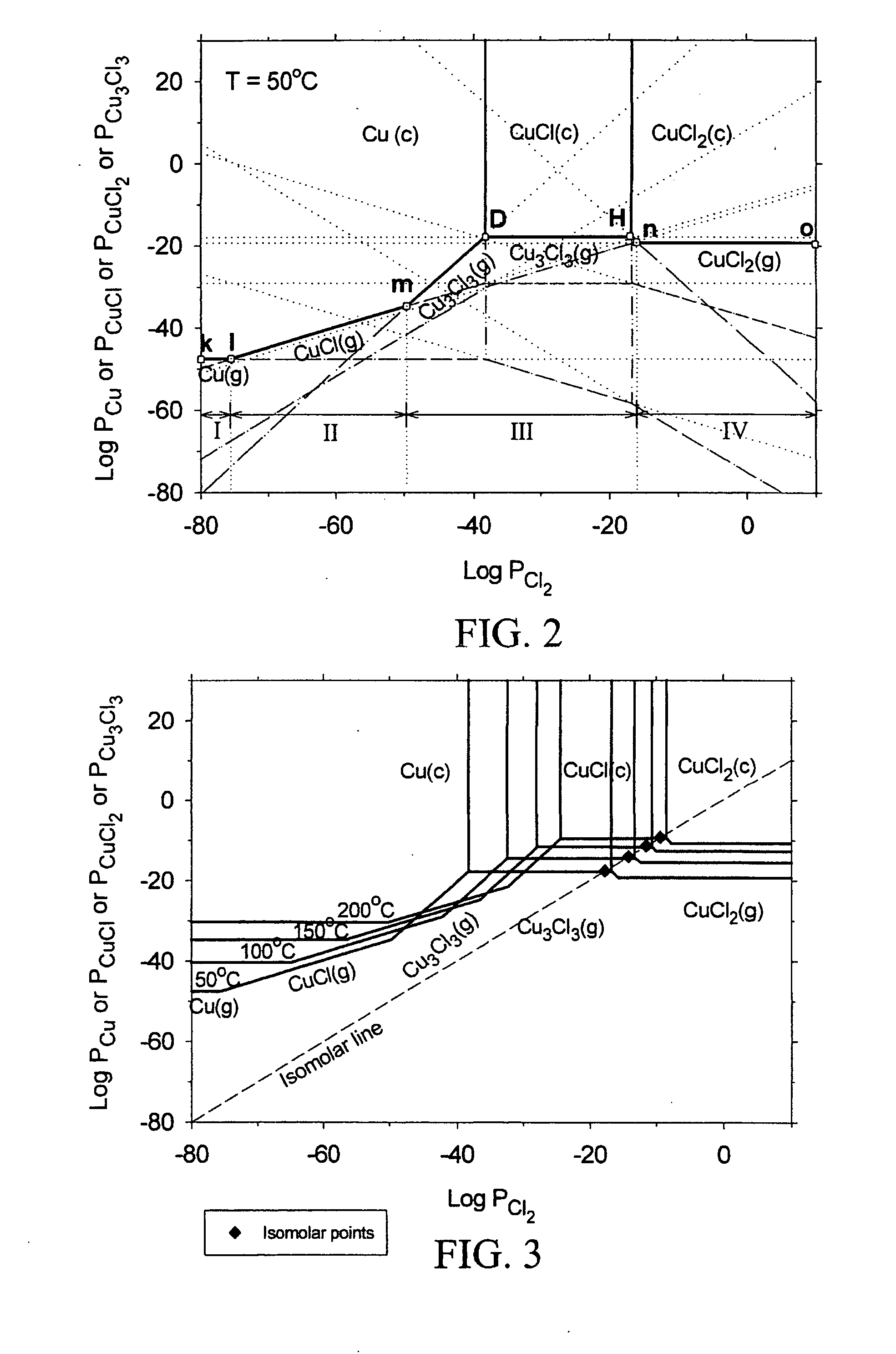

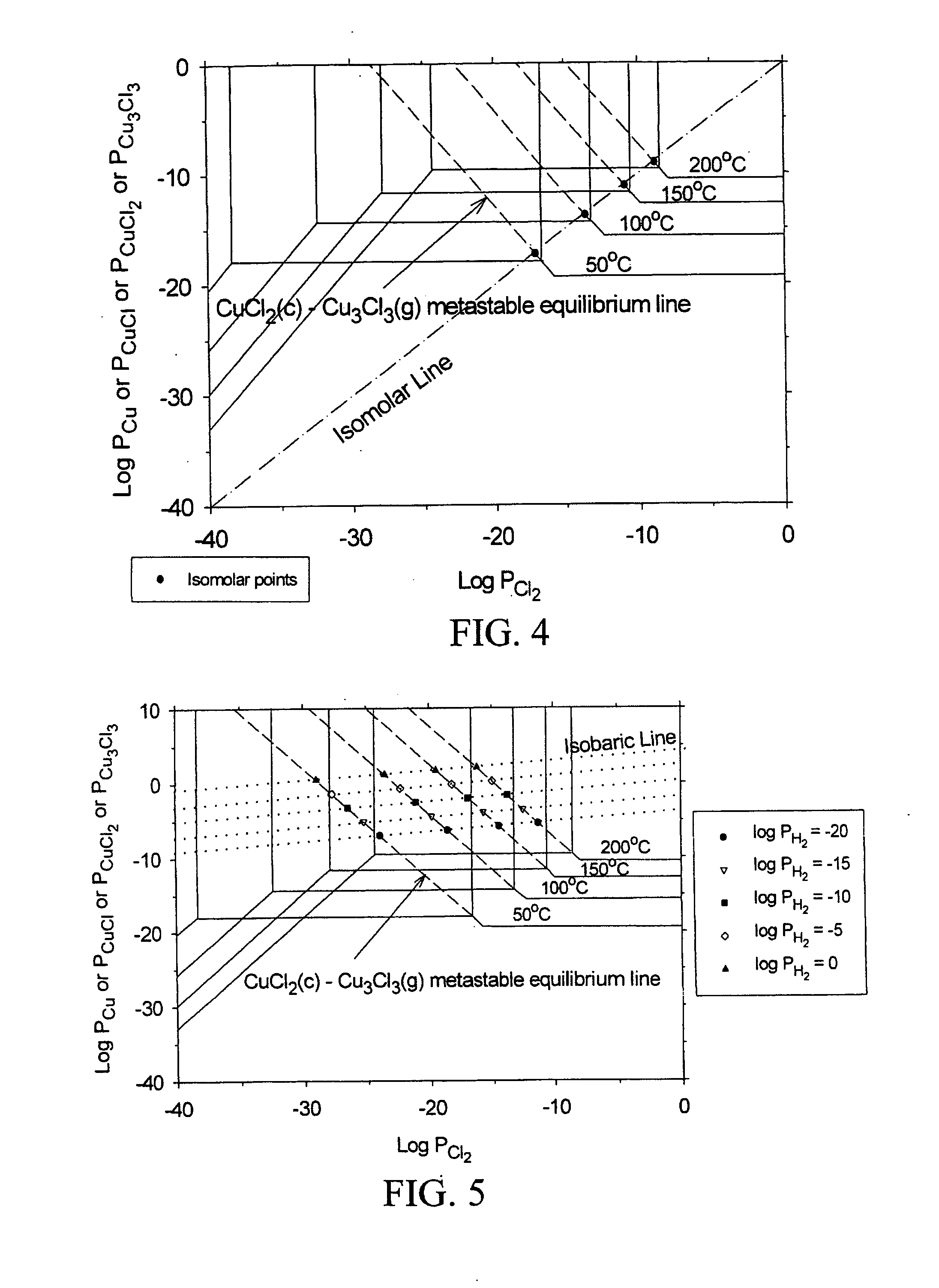

The subject invention pertains to a method and apparatus for etching copper (Cu). The subject invention can involve passing a halide gas over an area of Cu such that CuX, or CuX and CuX2, are formed, where X is the halide. Examples of halides which can be utilized with the subject matter include, but are not necessarily limited to, Cl, Br, F, and I. Once the CuX, or CuX and CuX2, are formed the subject invention can then involve passing a reducing gas over the area of Cu for a sufficient time to etch away at least a portion of the CuX, or CuX2, respectively. With respect to a specific embodiment in which CuX and CuX2 are produced when the halide gas is passed over the area of Cu, the reducing gas can be passed until essentially all of the CuX2 is etched and at least a portion of the CuX is etched. Examples of reducing gases which can be utilized with the subject invention include, but are not necessarily limited to, hydrogen gas and hydrogen gas plasma. The subject invention can accomplish the etching of Cu by passing the reducing gas over the Cu so as to be on a CuX2—Cu3X2 metastable line when etching CuX2 and to be a CuY—CuX metastable line, where Y is the reducing gas element, when etching CuX. FIGS. 5, 6, and 8, show such metastable lines for Cu, with X being Cl, from temperatures ranging from 50° C. to 200° C. These can be extrapolated to other temperatures, for other halides, and / or other reducing gases. The subject invention can be used to, for example, etch partial into a layer of Cu, through a layer of Cu, or to smooth a Cu surface.

Owner:KULKARNI NAGRAJ

Method for measuring content of hydrogen element in nuclear-grade zirconium material

ActiveCN103713106AGuaranteed releaseEnsure full releasePreparing sample for investigationTesting metalsNuclear gradeHydrogen

The invention discloses a method for measuring the content of a hydrogen element in a nuclear-grade zirconium material. The method comprises the following steps: 1, cutting the nuclear-grade zirconium material into 0.1-0.3g of a solid test sample; 2, firstly, pickling the solid test sample for 5-30s so as to remove an oxygen enrichment layer on the surface of the solid test sample and hydrogen and other gas elements adsorbed in the machining process, subsequently washing the pickled test sample for 10-50 seconds by using acetone, subsequently putting the test sample into an oven to be dried at 50-60 DEG C, and removing a contaminated layer on the surface of the test sample so as to ensure the cleanness of the test sample; 3, putting the test sample pretreated in the step 2 into a hydrogen measuring instrument so as to measure the content of the hydrogen in the solid test sample by using the hydrogen measuring instrument. By adopting the method, the defects of the conventional measuring method are overcome, and requirements of practical detection on the nuclear-grade zirconium material are met.

Owner:国核锆铪理化检测有限公司 +1

Process for low temperature, dry etching, and dry planarization of copper

InactiveUS20060014394A1Rapid and cost-effectiveDecorative surface effectsSemiconductor/solid-state device manufacturingHydrogenSufficient time

The subject invention pertains to a method and apparatus for etching copper (Cu). The subject invention can involve passing a halide gas over an area of Cu such that CuX, or CuX and CuX2, are formed, where X is the halide. Examples of halides which can be utilized with the subject matter include, but are not necessarily limited to, Cl, Br, F, and I. Once the CuX, or CuX and CuX2, are formed the subject invention can then involve passing a reducing gas over the area of Cu for a sufficient time to etch away at least a portion of the CuX, or CuX2, respectively. With respect to a specific embodiment in which CuX and CuX2 are produced when the halide gas is passed over the area of Cu, the reducing gas can be passed until essentially all of the CUX2 is etched and at least a portion of the CuX is etched. Examples of reducing gases which can be utilized with the subject invention include, but are not necessarily limited to, hydrogen gas and hydrogen gas plasma. The subject invention can accomplish the etching of Cu by passing the reducing gas over the Cu so as to be on a CuX2—Cu3X2 metastable line when etching CuX2 and to be a CuY—CuX metastable line, where Y is the reducing gas element, when etching CuX. FIGS. 5, 6, and 8, show such metastable lines for Cu, with X being Cl, from temperatures ranging from 50° C. to 200° C. These can be extrapolated to other temperatures, for other halides, and / or other reducing gases. The subject invention can be used to, for example, etch partial into a layer of Cu, through a layer of Cu, or to smooth a Cu surface.

Owner:KULKARNI NAGRAJ S

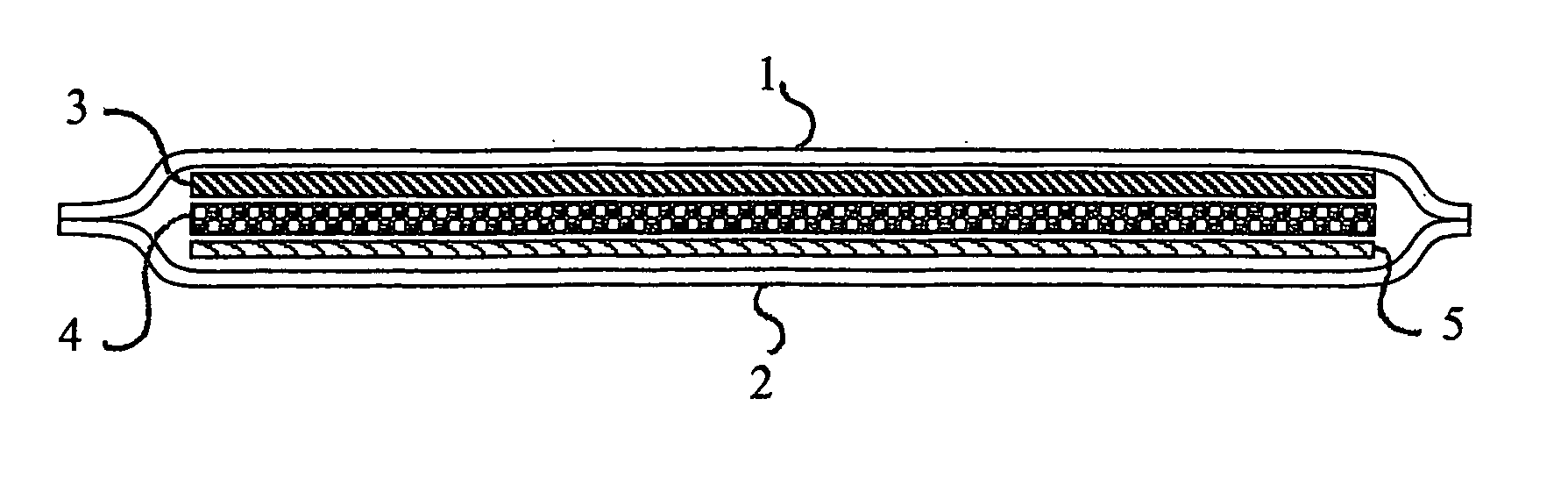

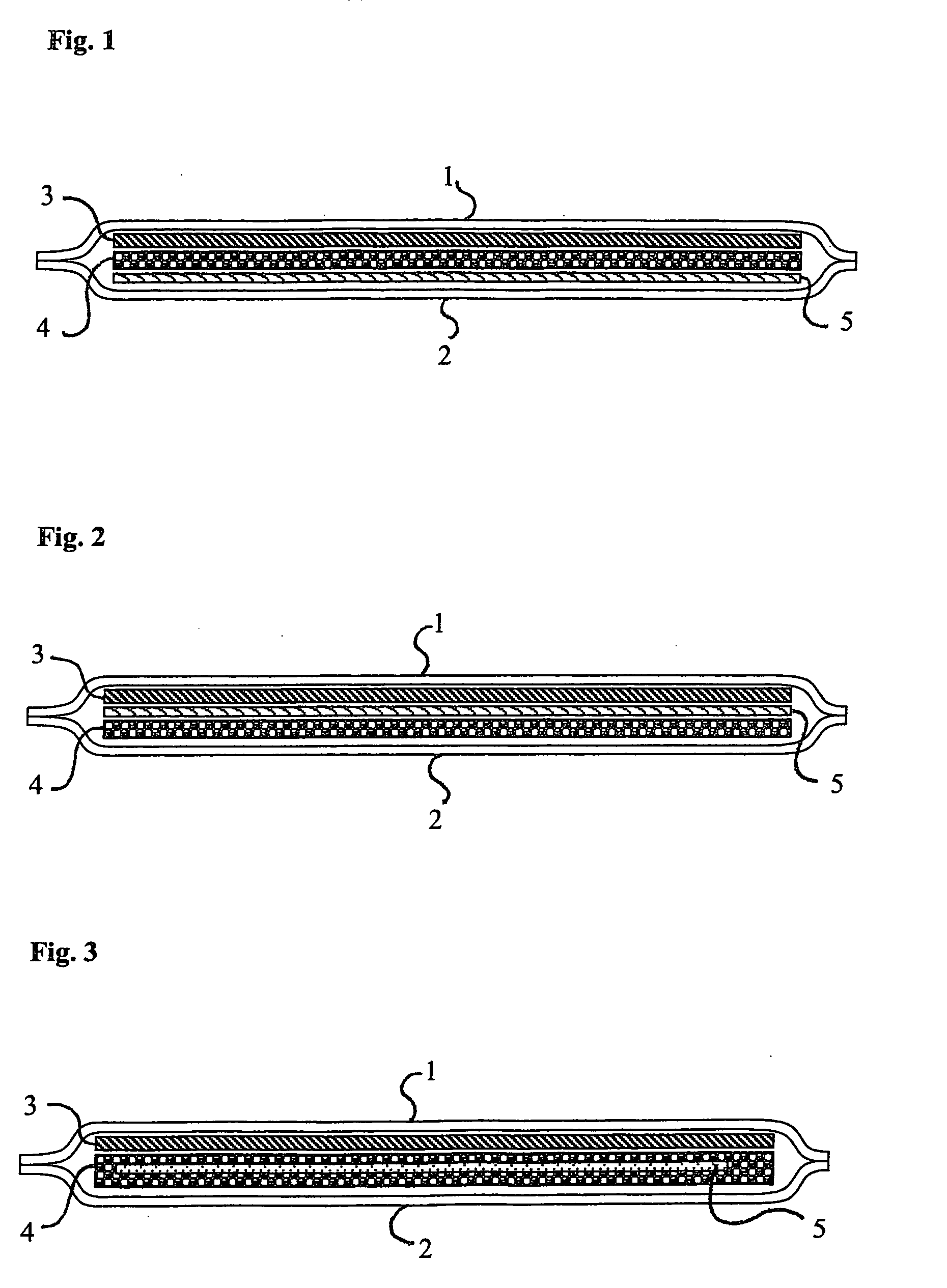

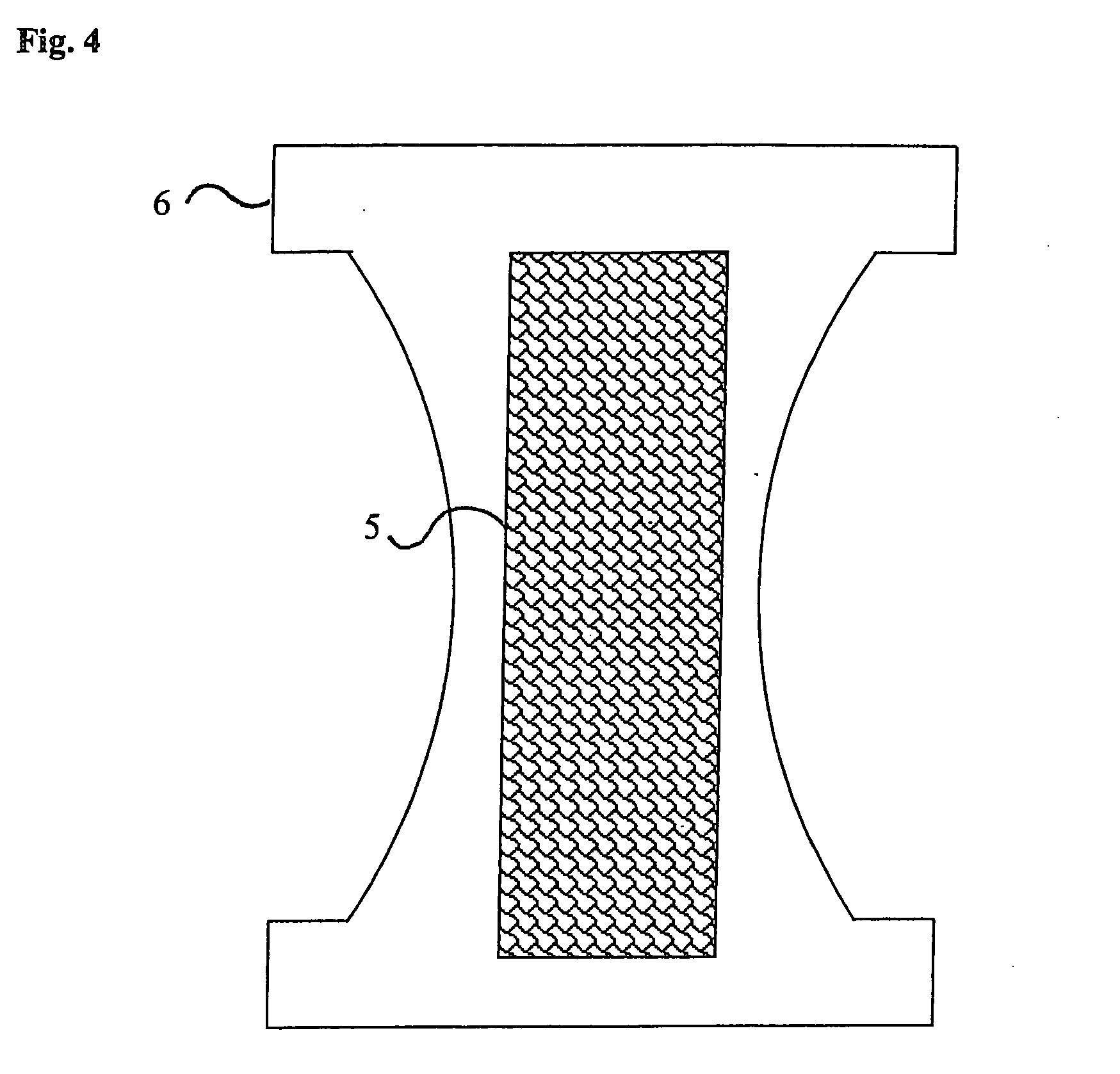

Absorbent hygiene article provided with a wet indicator

InactiveUS20050165370A1Reduced wearing comfortReduced flexibilityBaby linensTamponsBody fluidGas element

The present invention relates to an absorbent hygiene article, comprising (a) a stiff element which stiffens on contact with body fluids, or (b) a gas element which forms a gas on contact with body fluids, or both as an indicator and (c) At least one hygiene article component, wherein the stiff element or the gas element which forms a gas or both are in contact with the hygiene article component.

Owner:STOCKHAUSEN GMBH & CO KG DEGUSSA-HUELS AKTIENGESE

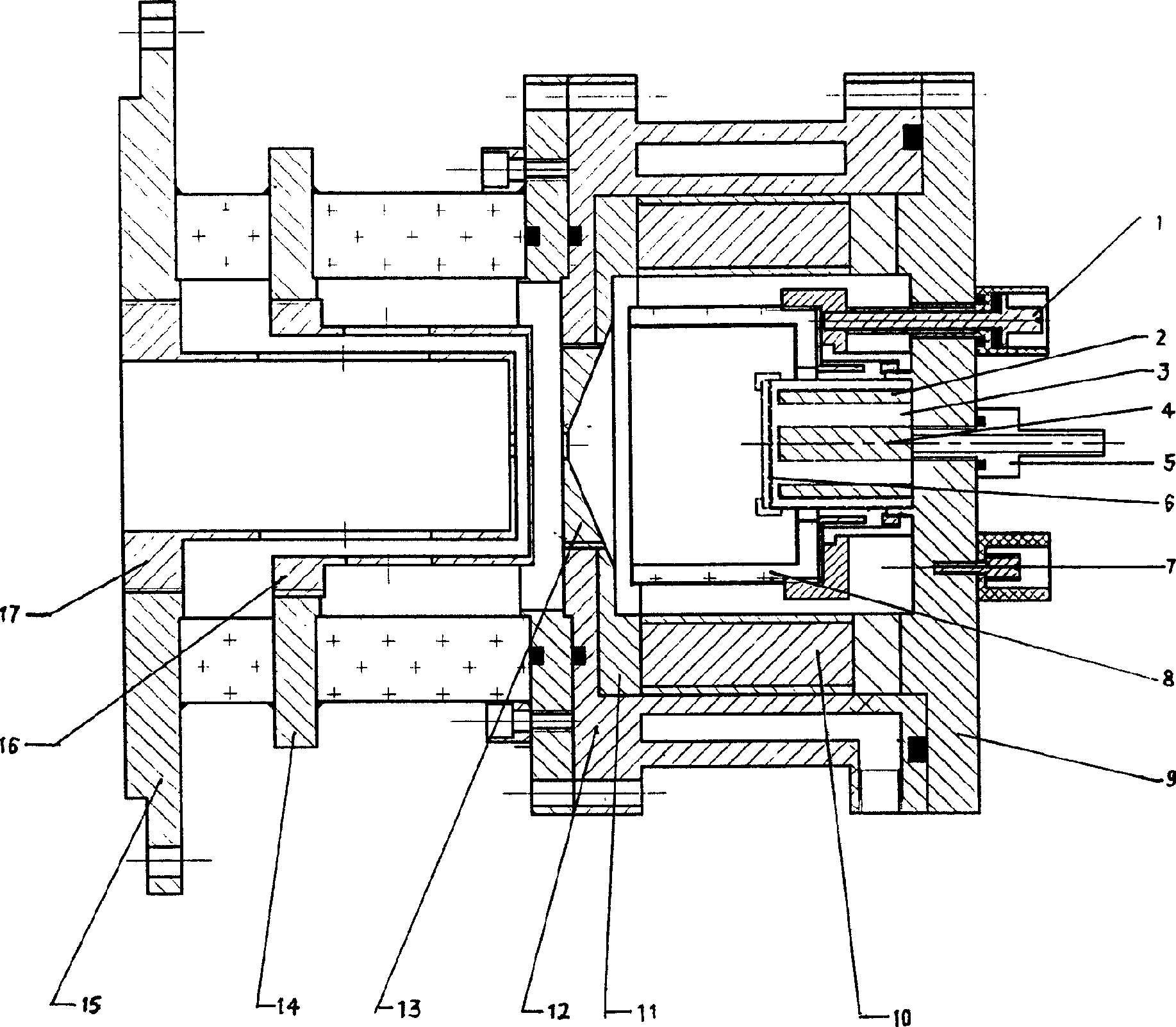

Plasma processing device

InactiveCN101289285AExtend the motion pathIncrease the number of collisionsCapacitanceInterference fit

The invention relates to the technical field of non-contact polishing and particularly relates to a plasma processing device, which aims at solving the problems that in the prior art, a polished surface is polluted by extraneous elements introduced to the polished surface and reaction gas elements absorbed on the polished surface results in damage to the completeness of crystal lattice on the polished surface and easy damage to a subsurface. In order to solve the problems in the prior art, the technical proposal which is provided is: the plasma processing device comprises a workroom and a capacity coupling plasma generator which is internally arranged in the workroom. The capacity coupling plasma generator comprises an air intake, a radio frequency connector and an inner bushing. The workroom is a vacuum chamber and the outside of the inner bushing of the capacity coupling plasma generator is provided with an insulating layer and a shielding layer in sequence. The inner bushing, the insulating layer and the shielding layer are connected in an interference fit way. The outer side of the shielding layer is surrounded with an annular magnet and the annular magnet is linked on the shielding layer by a linear moving mechanism.

Owner:XIAN TECHNOLOGICAL UNIV

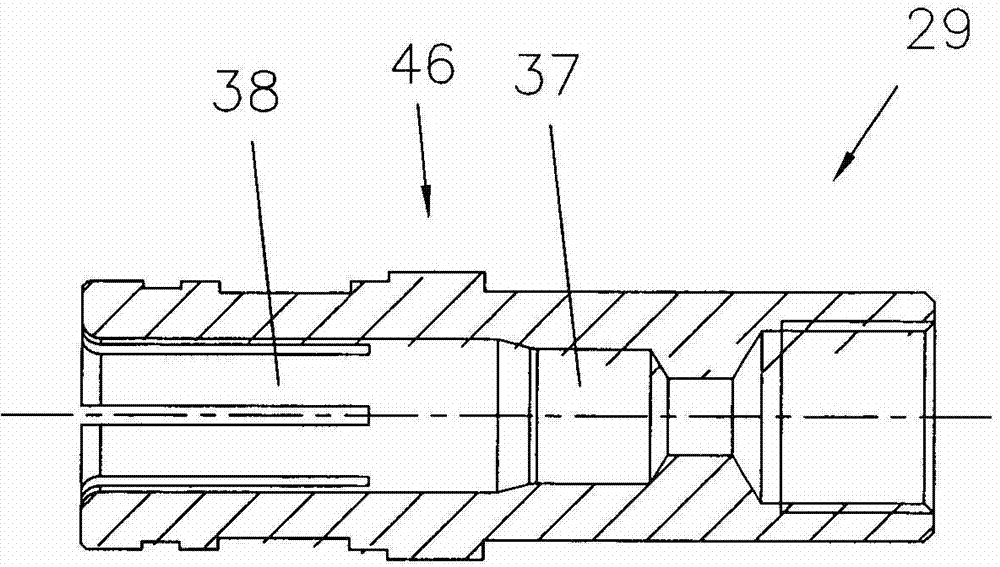

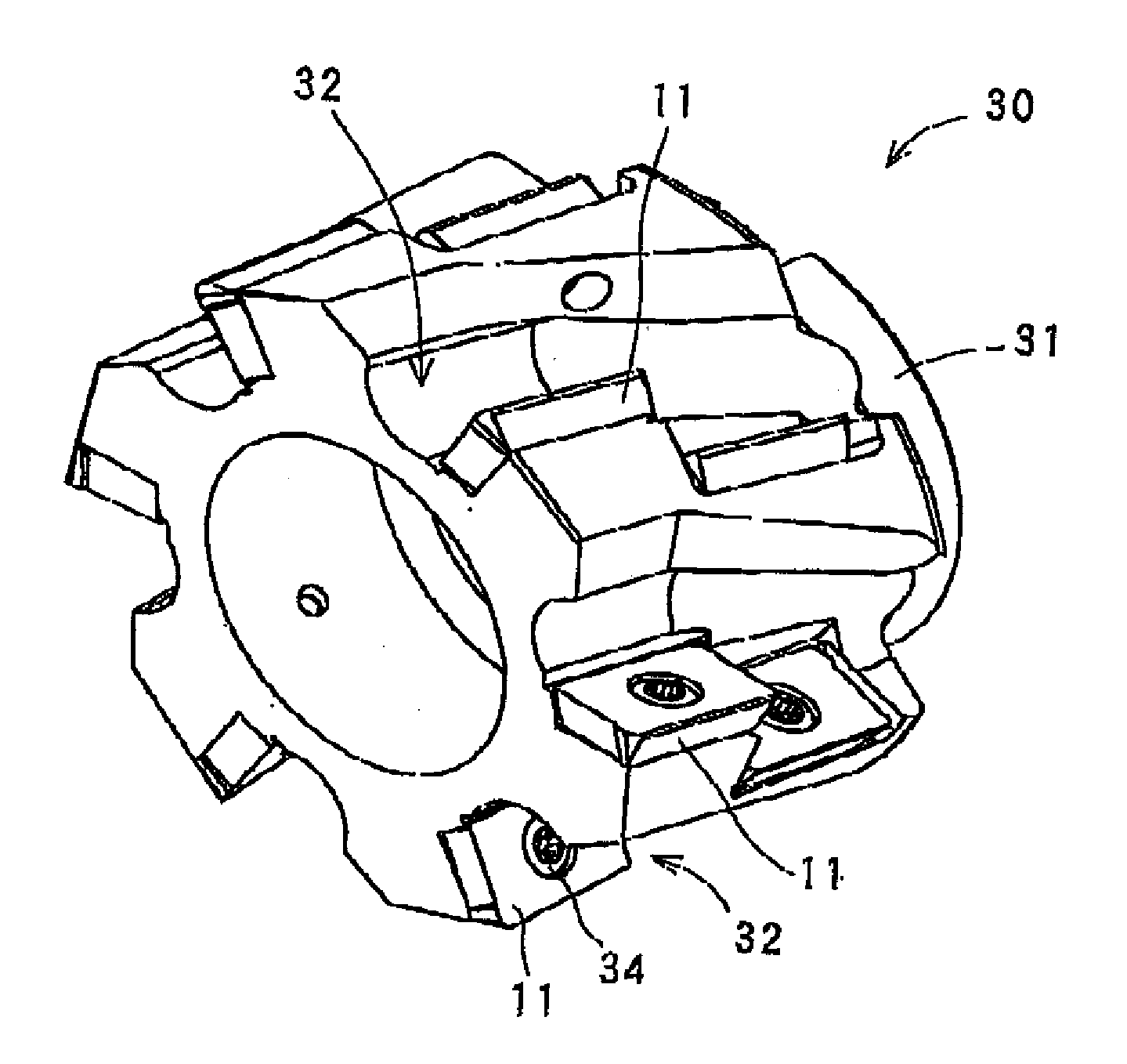

Burner body comprising a securing system and TIG welding torch comprising the burner body

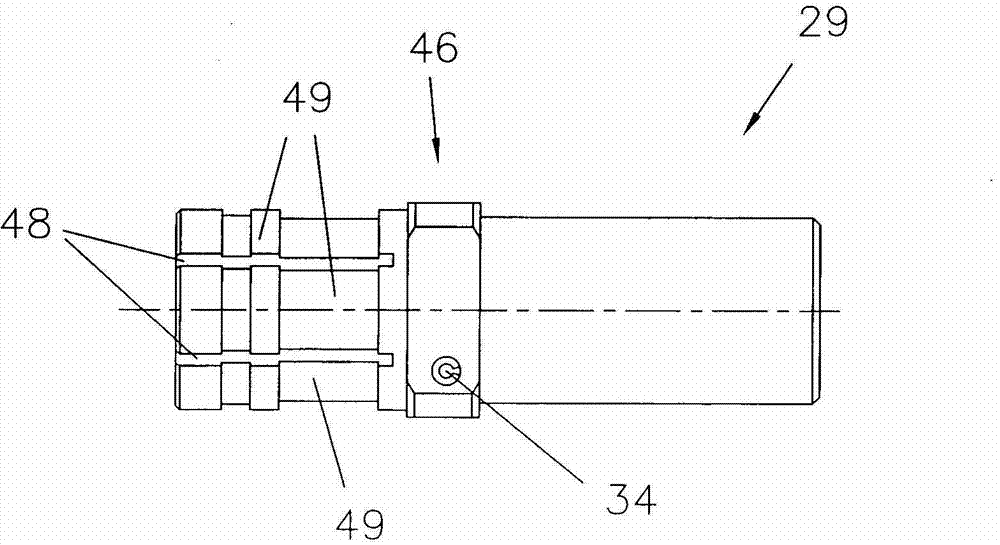

ActiveCN103025468AImprove accessibilitySave spaceShielding gas supply/evacuation devicesSupport devices with shieldingCurrent elementCoupling

The invention relates to a securing element (30) arranged between a gas element (32) and a current element (33) of the plug-in element (28). A fixing element (34) is arranged in the coupling (29) of the torch handle and meshes with said securing element (30), and, for guiding over said fixing element (34) arranged in the coupling (29), the gas element (32) has a diameter smaller than those of the securing element (30) and of the current element (33). Said securing element (30) can be guided over the fixing element (34) using a flat area (35), while the gas element (32) is arranged in a gas bore hole (37) in the coupling (29) in a sealing manner. The position of the burner body (27) can be freely adjusted by means of a manual rotational movement, said fixing element (34) being guided in a circumferential groove (36) in said securing element (30).

Owner:FRONIUS INTERNATIONAL GMBH

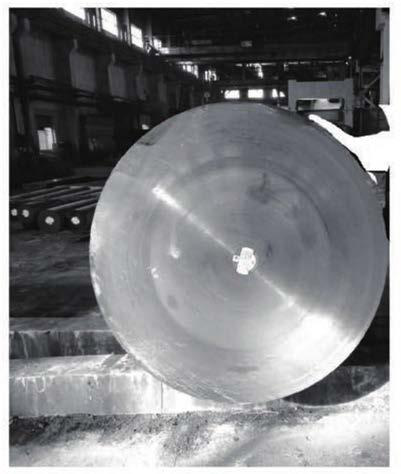

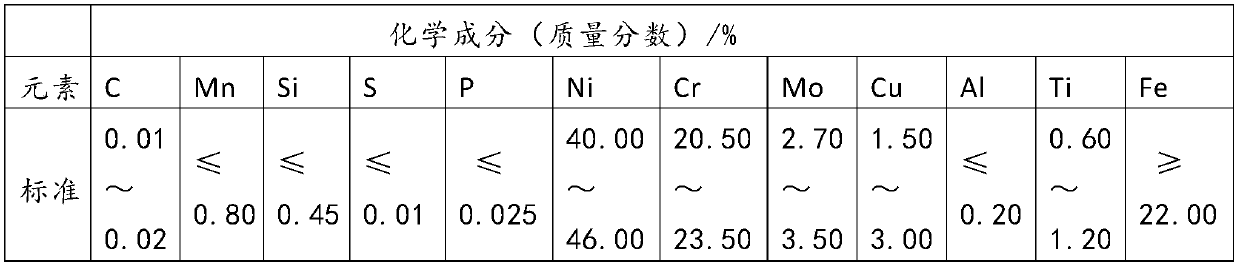

Manufacturing method of 825 anti-corrosion alloy bar material with super-large diameter

The invention discloses a manufacturing method of 825 anti-corrosion alloy bar material with a diameter phi of 1300 mm. The purpose is to solve the technical problem that the risks that chemical compositions and homogeneity do not meet a standard stipulation can be caused, and segregation and porosity existing in a macroscopic examination structure can be caused when the diameter of a steel ingotis increased. According to an electric furnace and electroslag smelting novel technology and forging technology, 1, the technical route comprises the steps of smelting through a non-vacuum induction furnace, processing through an LF furnace, processing through a VOD furnace, conducting electroslag remelting, processing through an 8000 t high-speed forging machine, smoothing on a lathe and conducting packaging; 2, according to the specific solving measures and beneficial effects, (1) a superior raw material is selected to avoid drag-in of a harmful element; (2) the slag whitening time of the LFfurnace is prolonged to effectively reduce the content of D-type inclusion; (3) the vacuum degree of VOD is reduced, the degassing time is shortened, and the content of gas elements is reduced; (4) in the pouring process, ultra-low carbon protecting slag is used for optimizing the surfaces of electrodes, and the deficiency of double skin of the surfaces of the electrodes is overcome; and (5) increasing of the ingot case of steel ingot electroslag meets the requirement for the size of the finished products of phi 1300 mm, and meanwhile, the annealing requirements are increased to avoid the risk of cracking of the steel ingot.

Owner:FUSHUN SPECIAL STEEL SHARES

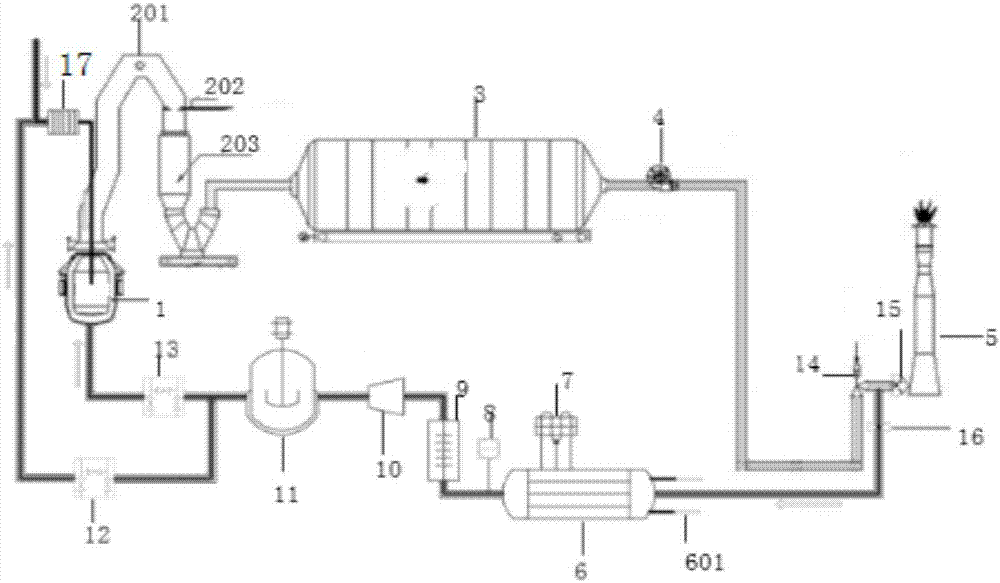

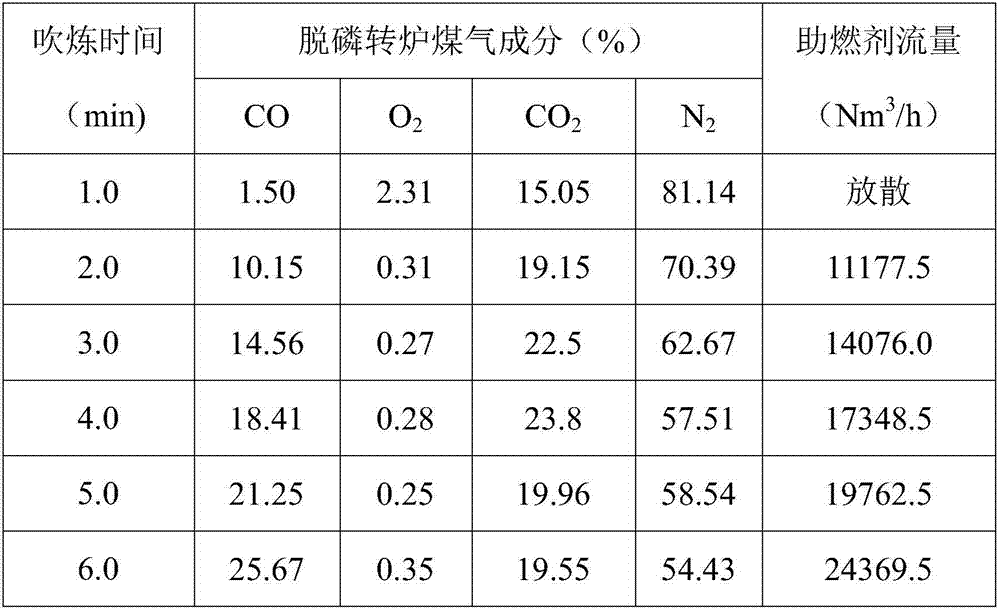

Multi-element-injection efficient dephosphorization method and device for dephosphorization converter gas mass energy conversion cycle

ActiveCN107151724AImprove mechanical propertiesImprove dynamic conditionsManufacturing convertersExhaust gas handlingSteelmakingTemperature control

The invention belongs to the technical field of ferrous metallurgy and relates to a multi-element-injection efficient dephosphorization method and device for the conversion cycle of dephosphorization converter gas mass energy of duplex steelmaking. According to the multi-element-injection efficient dephosphorization method and device, dephosphorization converter gas enters a combustion chamber after being subjected to cooling and dedusting, the gas CO component is converted into CO2 in the combustion chamber, meanwhile heat generated during combustion is recycled, dephosphorization converter gas mass energy conversion is achieved, the injection and dephosphorization of multiple gas elements of O2, N2 and CO2 of the converted gas are achieved through a dephosphorization converter top-blowing system, bottom blowing stir of the mass energy conversion gas is achieved through a bottom blowing system, and the multi-element-injection process is controlled in a sectioned manner. The method and device are suitable for 30-350-ton dephosphorization converter, the strong stir and temperature control functions of N2 and CO2 in the mass energy conversion gas are used, the good thermodynamics and kinetics conditions are provided for dephosphorization, the dephosphorization rate is increased over 5%, the resource utilization of steel with dephosphorization gas of 10-50 Nm<3> / t is achieved, and steel with the quantity of steam of 5-20 kg / t of is recovered.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing ultra-shallow junction on surface of semiconductor chip through laser

InactiveCN101719464ASettle the lossSolving Diffusion ProblemsSemiconductor/solid-state device manufacturingSemiconductor chipGas element

The invention discloses a method for preparing an ultra-shallow junction on the surface of a semiconductor chip through laser, which comprises the following steps of: leading the mixture of H2 and another gas at the speed with the lead-in gas flow capacity of 50-1000sccm under a vacuum condition, and doping the mixed gas onto the surface of the semiconductor chip when chip lattices are activated; using laser to irradiate the semiconductor chip to instantly increase the temperature of the semiconductor chip by 1000-1400DEG C, and finally forming the ultra-shallow junction on the surface of the semiconductor chip, further preferably, the instant increased temperature of the chip is 1200DEG C. The depth of the prepared ultra-shallow junction can be smaller than 30 nanometers, and the doping concentration can be adjusted according to specific requirements. The invention simplifies working procedures and shortens process time. Gas elements can be adjusted, being beneficial to adjusting the doping concentration according to the different purposes of the ultra-shallow junction. The lead-in gas flow capacity is controlled, being beneficial to forming a uniform atmosphere in a vacuum chamber and ensuring the uniformity of the prepared ultra-shallow junction.

Owner:GD SOLAR +2

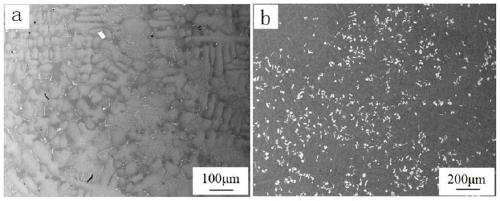

Preparation process of nickel-based high temperature alloy with high-content refractory elements

ActiveCN109913702AImprove melting efficiencyImproves ingredient uniformityIncreasing energy efficiencyRefractoryLow density

The invention discloses a preparation process of a nickel-based high temperature alloy with high-content refractory elements, and belongs to the technical field of alloy preparation. According to theprocess, a vacuum induction melting (VIM) and electroslag remelting (ESR) process is adopted for preparing the alloy containing the high-content refractory elements. During the vacuum induction melting stage, by controlling the feeding mode, increasing the refining temperature, prolonging the refining time, accelerating the solidification rate and the like, the segregation phenomena of refractorymetal and low-density alloy elements are effectively suppressed, and the composition uniformity of upper and lower parts of a parent alloy ingot is improved. Through electroslag remelting, secondary shrinkage in the alloy ingot is eliminated, the impurity content is reduced, and the metallurgical quality is improved. The preparation process can significantly reduce the microsegregation and macrosegregation phenomena of the high-content refractory elements and can effectively reduce the content of harmful gas elements such as O and N in the high-temperature alloy, the purity of the alloy is improved, the degree of segregation of the high-specific gravity elements is reduced, the heredity of alloy anomalous tissues is improved, and the overall mechanical properties of the alloy are improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Measuring instrument and measuring method for extraterrestrial celestial body atmosphere compositions and isotopes

ActiveCN107045016ASimple structureLight in massMaterial analysis by electric/magnetic meansMeasuring instrumentMass spectrometry

The invention mainly belongs to the technical field of atmosphere composition measurement and in particular relates to a measuring instrument and a measuring method for extraterrestrial celestial body atmosphere compositions and isotopes. The measuring instrument disclosed by the invention comprises a gas collection chamber, a gas treatment chamber, a quadrupole mass spectrometer and a high vacuum pump, wherein the gas collection chamber is used for collecting and storing to-be-measured extraterrestrial celestial body atmosphere; a heating device is arranged at the periphery of the gas treatment chamber, and a temperature and pressure sensing device is arranged inside the gas treatment chamber; the gas treatment chamber is used for treating the to-be-measured extraterrestrial celestial body atmosphere and making a preparation for gas elements and isotopes; the quadrupole mass spectrometer is used for testing the to-be-measured extraterrestrial celestial body atmosphere treated by the gas treatment chamber and measuring the composition and isotope content of the to-be-measured extraterrestrial celestial body atmosphere; and the high vacuum pump is connected with the gas treatment chamber and the quadrupole mass spectrometer and is used for maintaining a high vacuum environment. The measuring instrument has low weight in a range capable of being borne by the conventional space load, and high-precision accurate and reliable experimental data can be tested by the measuring instrument.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

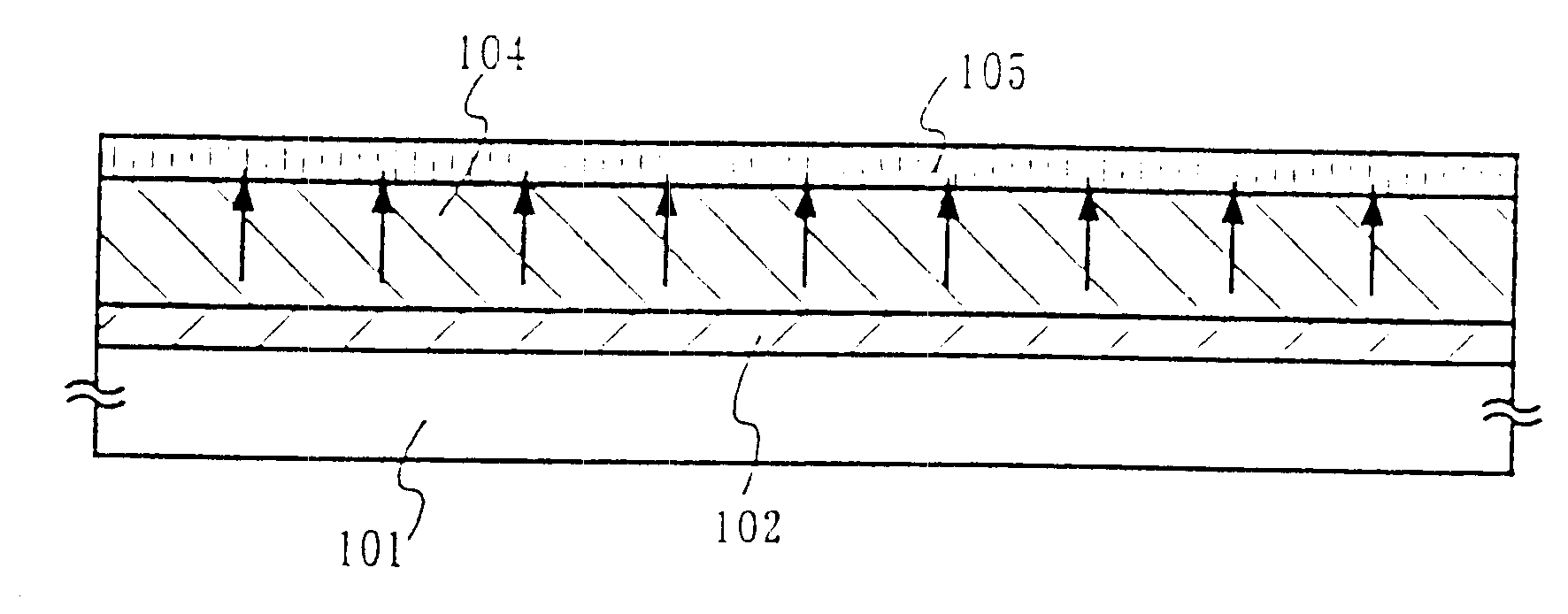

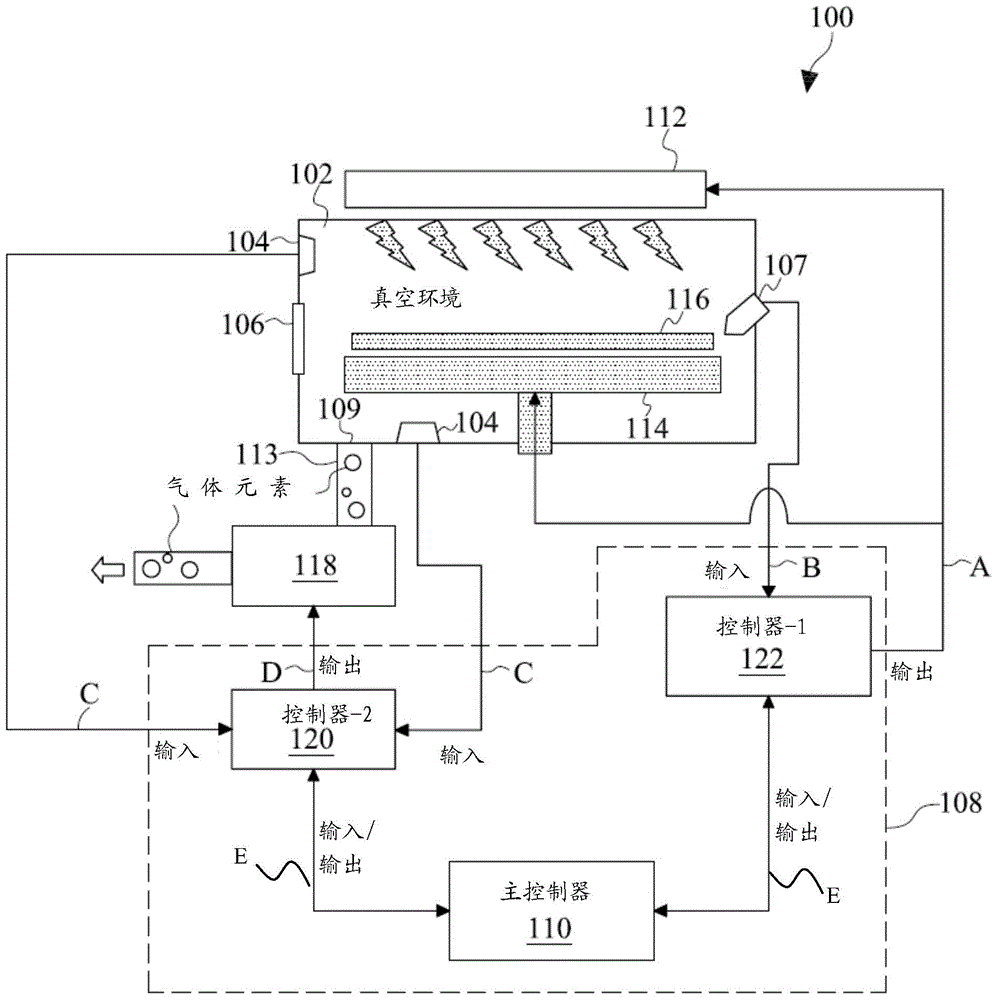

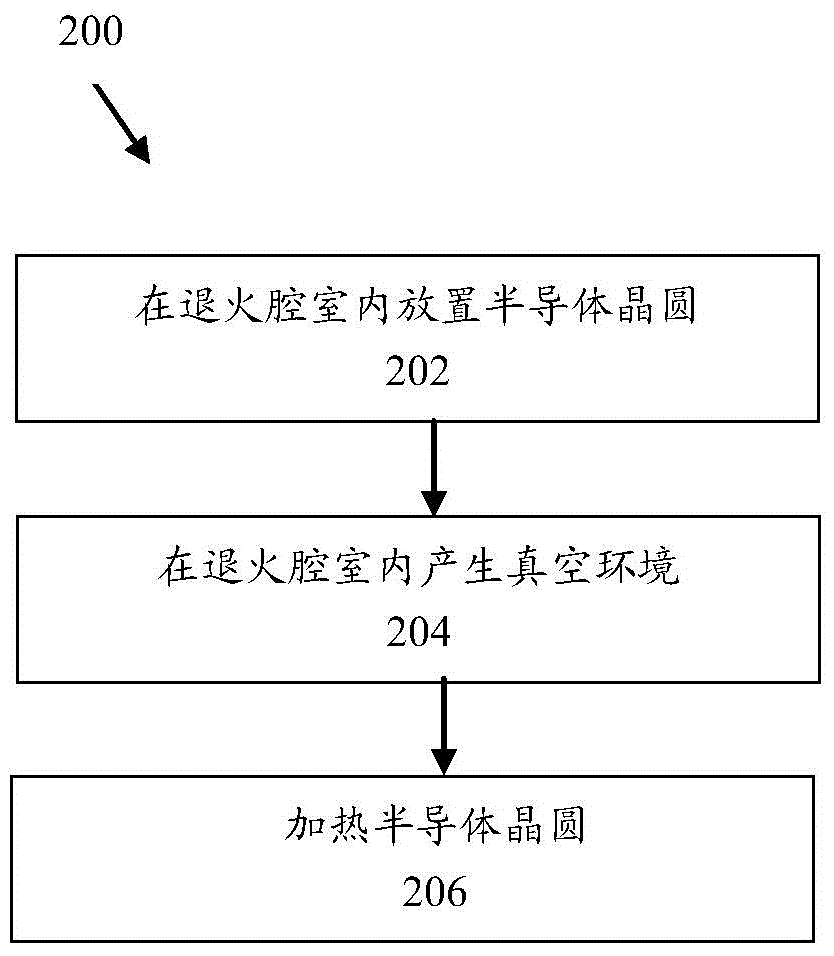

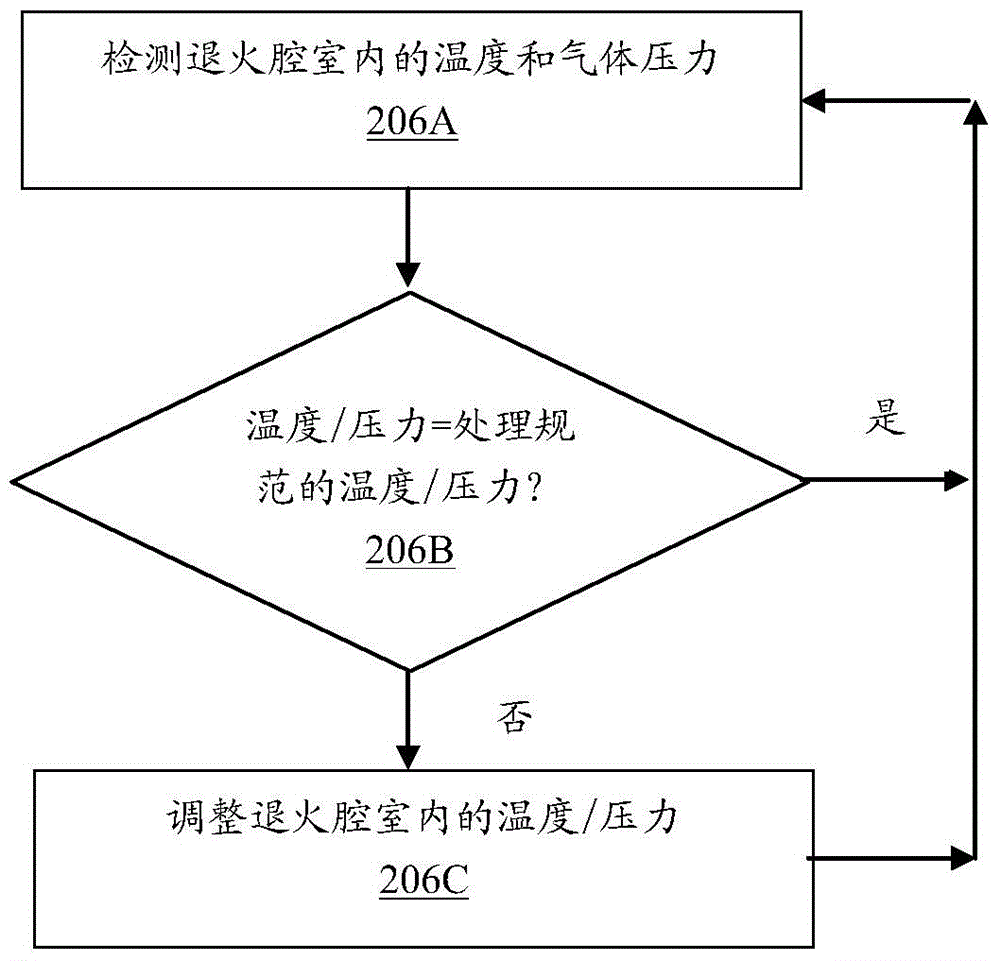

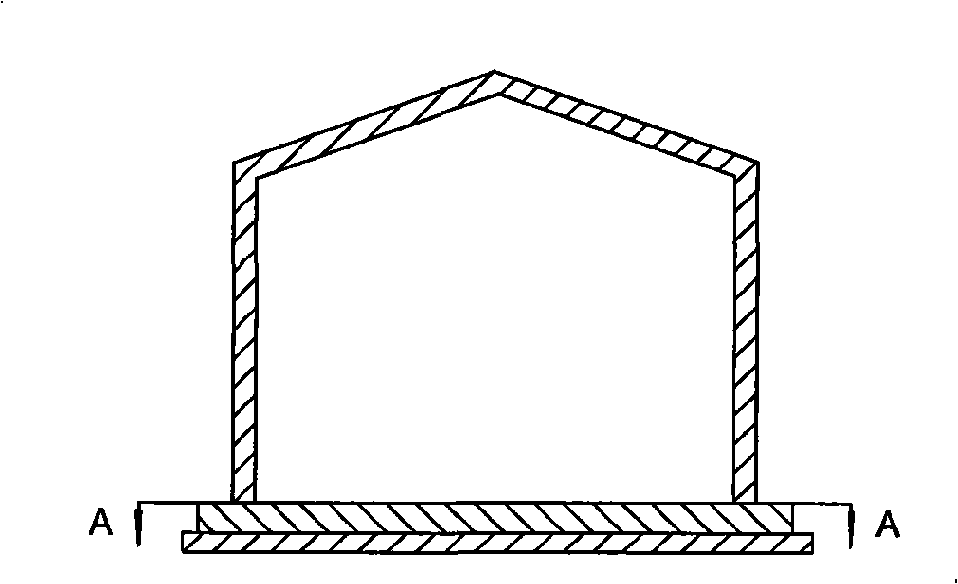

Semiconductor annealing method utilizing a vacuum environment

ActiveCN104916525AChange air pressureSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingControl systemGas element

A semiconductor annealing method and system uses a vacuum pump to produce a vacuum environment in the annealing chamber to thereby remove undesired gas element influences. A control system obtains pressure and temperature measurements from the annealing chamber to control operation of the heating elements and vacuum pump to thereby maintain process integrity.

Owner:TAIWAN SEMICON MFG CO LTD

Vertical tank capable of real-time monitoring leakage of tank bottom

InactiveCN101254848ALong cycleReasonable structureLarge containersBiochemical engineeringMonitoring system

The invention relates to a vertical storage tank capable of monitoring tank bottom leakage in real-time. The invention aims at providing a storage tank having pressure bearing and real-time monitoring functions with simple and convenient operation and lower cost. The vertical storage tank comprises a tank body and a tank bottom, wherein the tank bottom is laminated by an upper layer plate and a lower layer plate, the surroundings of the two layer plates are all sealed and fixedly connected to form a hollow cavity between the surfaces of the two layer plates; the tank bottom is also provided thereon with a connecting pipe communicated with the hollow cavity; a gas element analyzer is arranged inside the connecting pipe, and the data line of the gas element analyzer is communicated with a monitoring system. The connecting pipe is also provided thereon with a suction pump. The diameter of the lower layer plate is slightly larger than that of the upper layer plate, thereby facilitating welding the surroundings of the upper and the lower layer plates.

Owner:ZHEJIANG PROVINCIAL SPECIAL EQUIP INSPECTION & RES INST

Copper alloy conductor for railway electric power transmission line and preparation method thereof

InactiveCN108265194AGas element content is smallImprove corrosion resistanceConductive materialMetal/alloy conductorsElectric power transmissionMicro structure

The invention relates to a copper alloy conductor for a railway electric power transmission line and a preparation method thereof and belongs to the technical field of non-ferrous metal conductor processing, copper alloy preparation and cable manufacture. The copper alloy is a copper-silver two-component alloy having silver content of 0.05% to 0.12%. Through a vacuum self-consuming melting-vacuumelectron beam melting combined technology, a molten copper-silver rod is cleaned and purified and harmful gas such as oxygen, hydrogen and nitrogen and harmful impurities are eliminated so that the high purity and high clarity of the copper-silver alloy are realized. Through large extrusion ratio deformation, casting defects are eliminated, the micro-structure is refined and the plasticity of thealloy is improved. The later drawing process is free of annealing and the total deformation of drawing is 50% to 75%. The preparation method can produce the high purity and high clarity copper-silverconductor, has gas element content of less than 10ppm, oxygen content of less than 3ppm and conductivity of 100.5% to 102.5% IACS and can be used for preparation of wear-resistant and corrosion-resistant railway power transmission line.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +2

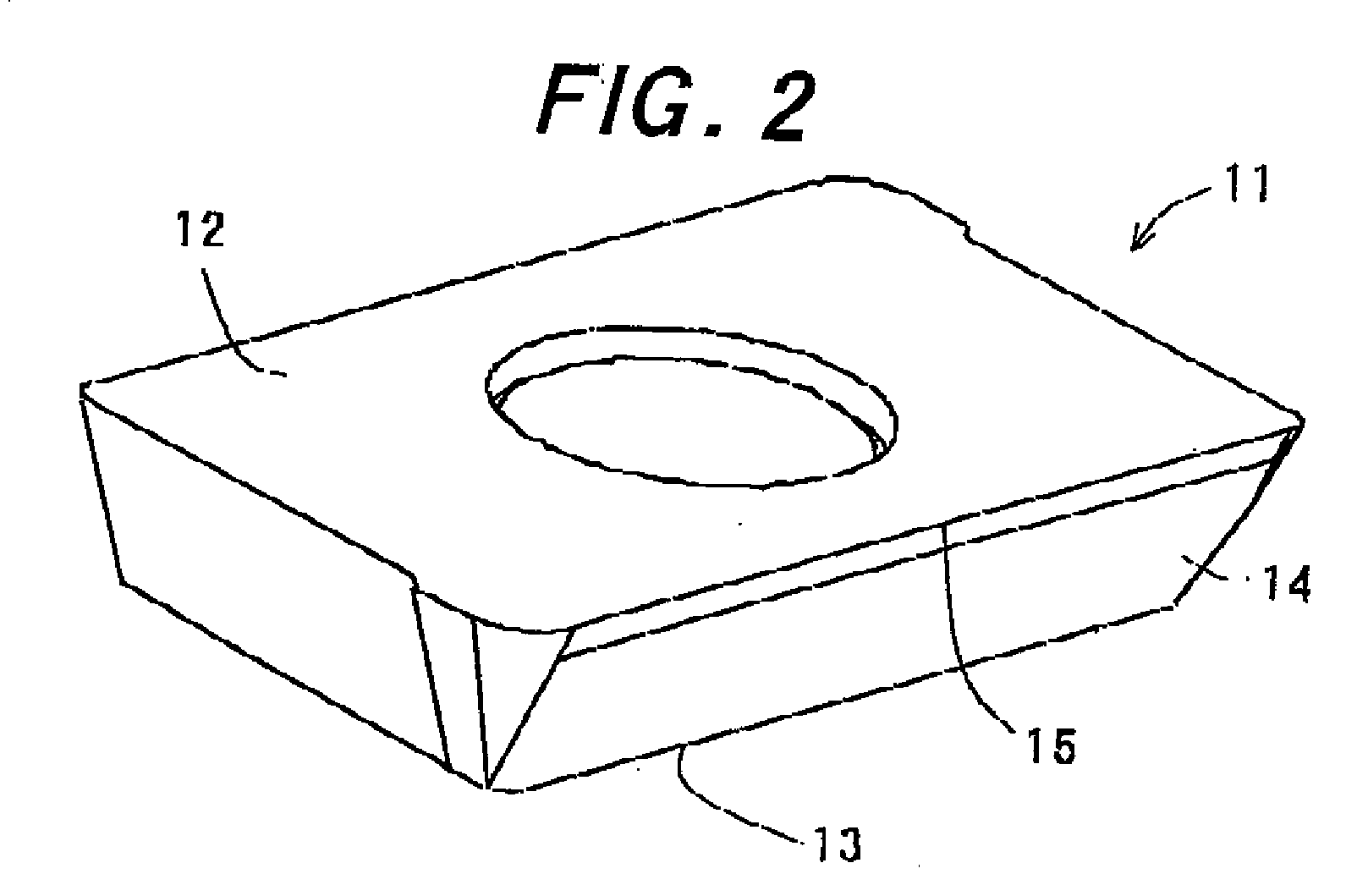

Wear-resistant structure

Owner:KYOCERA CORP

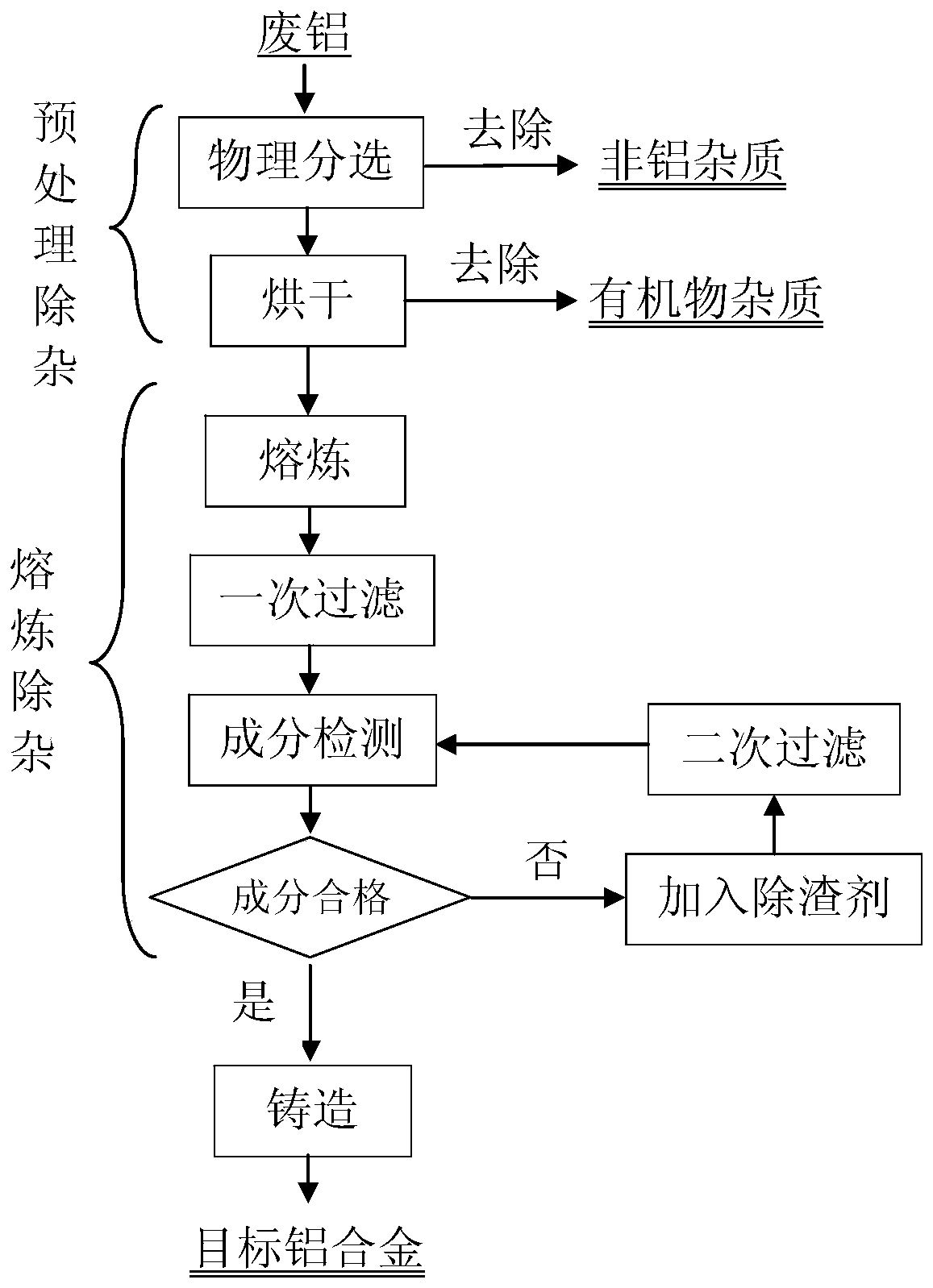

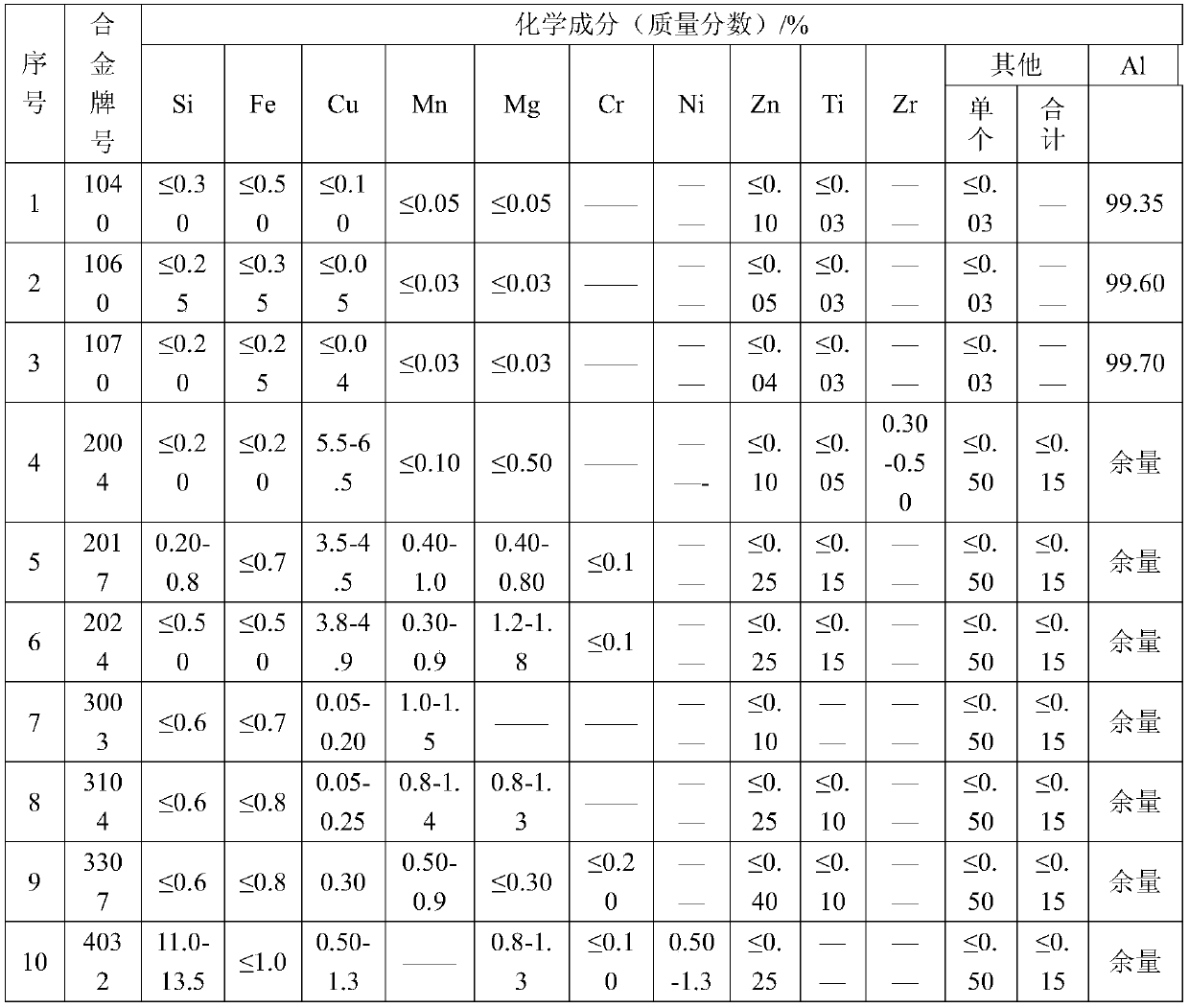

Recycled aluminium alloy non-gaseous impurity removing method

The invention belongs to the technical field of recycled metal, and particularly relates to a recycled aluminium alloy non-gaseous impurity removing method. The method comprises the steps of pretreatment impurity removal and smelting impurity removal; scrap aluminum pretreatment comprises physical sorting, and drying, the physical sorting is adopted for removing non-aluminum impurities, and organic matter impurities are removed through drying; according to smelting impurity removal, the impurities are removed in the smelting process through using of the differences of the impurity element andthe aluminum element in the aspect of density, the melting point and the chemical property; the recycled aluminum alloy is subjected to melting, stirring and standing, and the high-melting-point high-density non-aluminum impurities are subjected to primary filter impurity removal; the recycled aluminum alloy melt subjected to primary filter impurity removal is subjected to component benchmarking,if the melt is not qualified, an impurity removal agent is added for slagging impurity removal, and through secondary filtering, exceeding non-gas element impurities are removed until the target aluminum alloy required by GBT3190-2008 deforming aluminum and aluminum alloy chemical components is achieved. Recycled aluminium alloy non-gaseous impurity removing is achieved, the process is simple, andthe industrial application is easily achieved.

Owner:UNIV OF SCI & TECH BEIJING

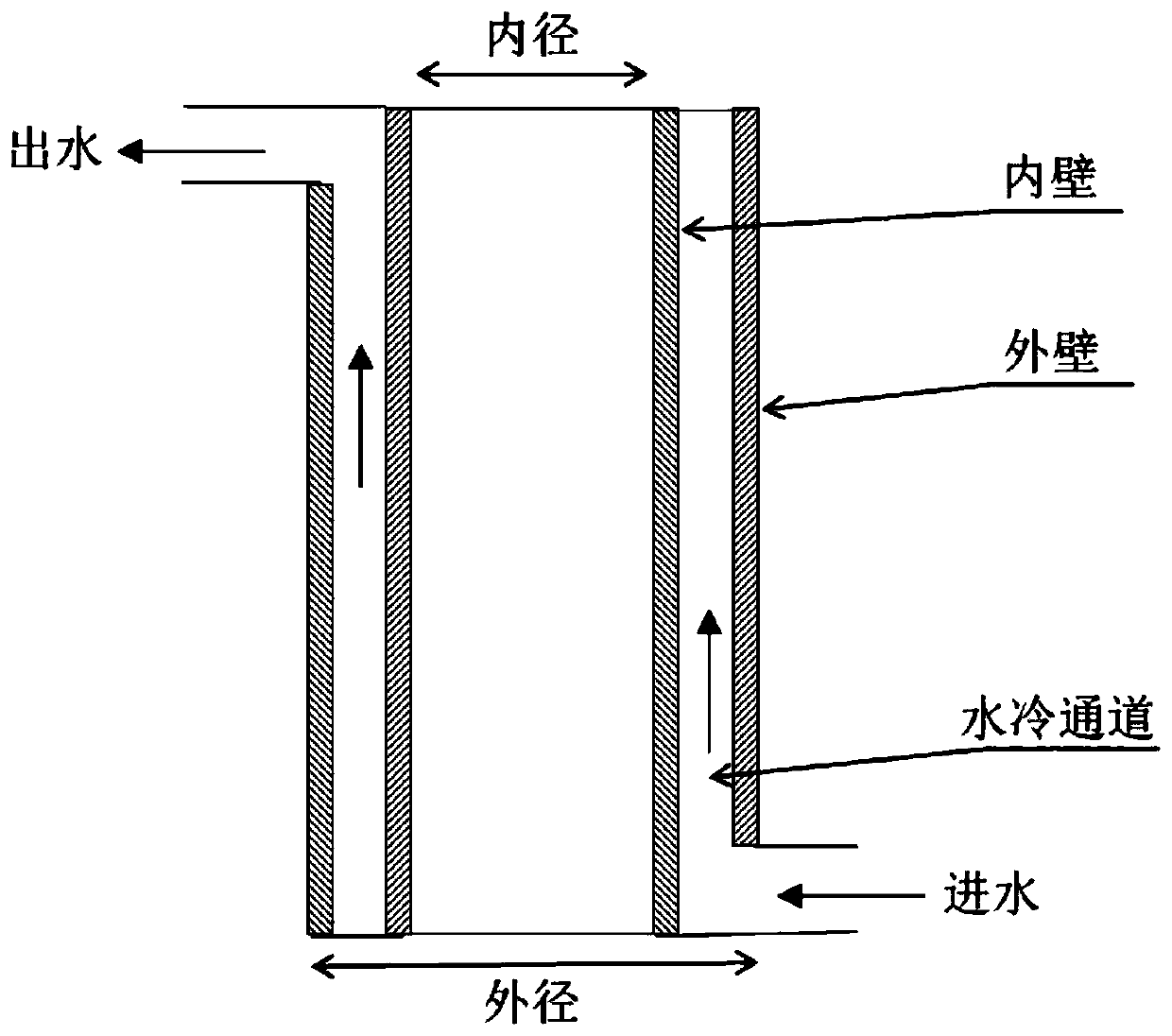

Ion beam detection device

ActiveCN105895479AConvenient injection process debuggingImprove water cooling effectElectric discharge tubesGraphite electrodeDrive shaft

The invention discloses an ion beam detection device. The ion beam detection device comprises an ion beam detection module, a pre-filtering diaphragm module, a supporting plate, and the like. The ion beam detection module is composed of a Faraday cup, a driving shaft, vacuum bellows and a driving air cylinder; the ion beam detection module is designed to detect gas element ions and detect special metal ions; the entrance of the Faraday cup is provided with an inhibition graphite electrode which can effectively prevent external electrons from entering the Faraday cup and inhibit electrons from overflowing from the Faraday cup; the beam detection module can accurately detect ion beams; the pre-filtering diaphragm module is composed of a filtering graphite diaphragm plate, a moving main shaft, a differential air extraction module and a driving air cylinder; the pre-filtering diaphragm module can pre-filter ions entering the Faraday cup; and two kinds of filtering slits are designed on the filtering graphite diaphragm plate. With the ion beam detection device adopted, the quality of the ions entering the Faraday cup can be effectively improved, the measurement accuracy of the Faraday cup can be effectively improved, and ion implantation process debugging can be facilitated. The invention relates to an ion implantation device and belongs to the semiconductor manufacturing field.

Owner:BEIJING ZHONGKEXIN ELECTRONICS EQUIP

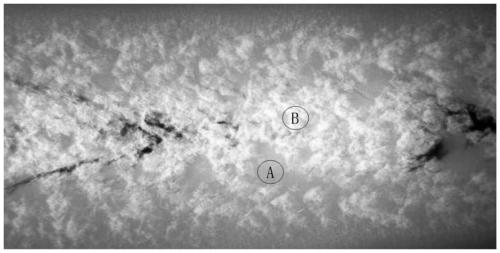

Process for eliminating impurity and gas element defects in nickel plate targets

InactiveCN107893214AConcentrated shrinkage cavity noLoose withoutVacuum evaporation coatingSputtering coatingMaterials preparationNonferrous metal

The invention belongs to the field of nonferrous metal machining, and provides a purifying process for eliminating impurity and gas element defects in nickel plate targets. The process mainly comprises the steps of material preparation, furnace cleaning, vacuumizing, smelting, purification and smelting, forging, hot rolling, cold rolling and annealing, and inspection. The process can fully removeimpurities and gas elements, such as Co, Fe, Cu and C, N, O and the like; and through further machining, the purity of the nickel plate targets can be not less than 99.996%, the internals of the nickel plate targets are continuous and consistent, and the nickel plate targets have no defects such as centralized shrinkage holes, looseness, air holes, segregation, grain increment and the like.

Owner:宝鸡一众有色金属材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com