Vertical-type tubular furnace infrared carbon sulfur analyzer

An infrared carbon and sulfur analysis, tube furnace technology, which is applied in the analysis of materials, chemical analysis by combustion, and material analysis by optical means, etc., can solve the problems of broken combustion tubes, shortened service life of combustion tubes, and limited use space. , to achieve the effect of accurate pick and place position, long service life and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

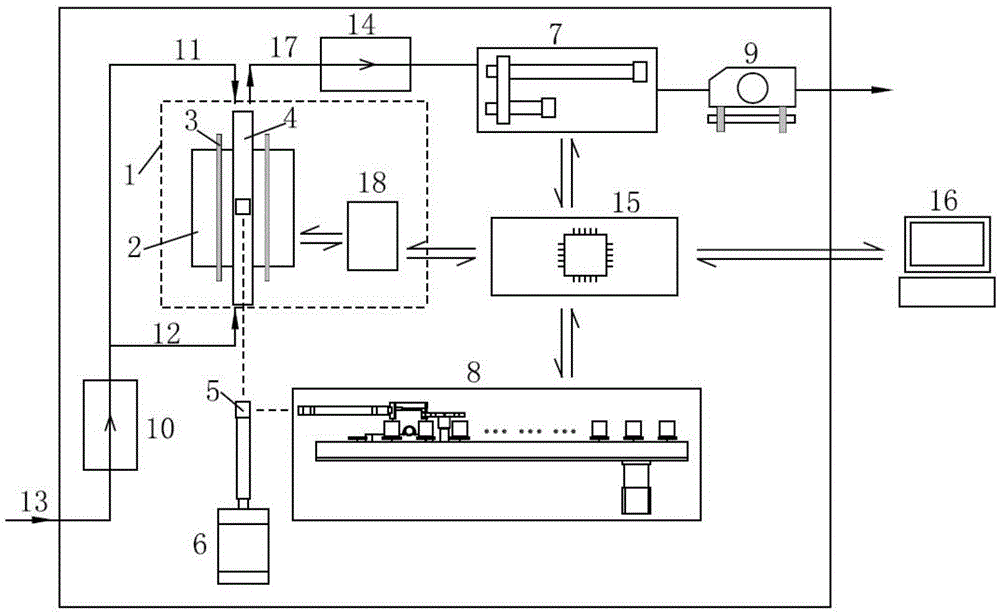

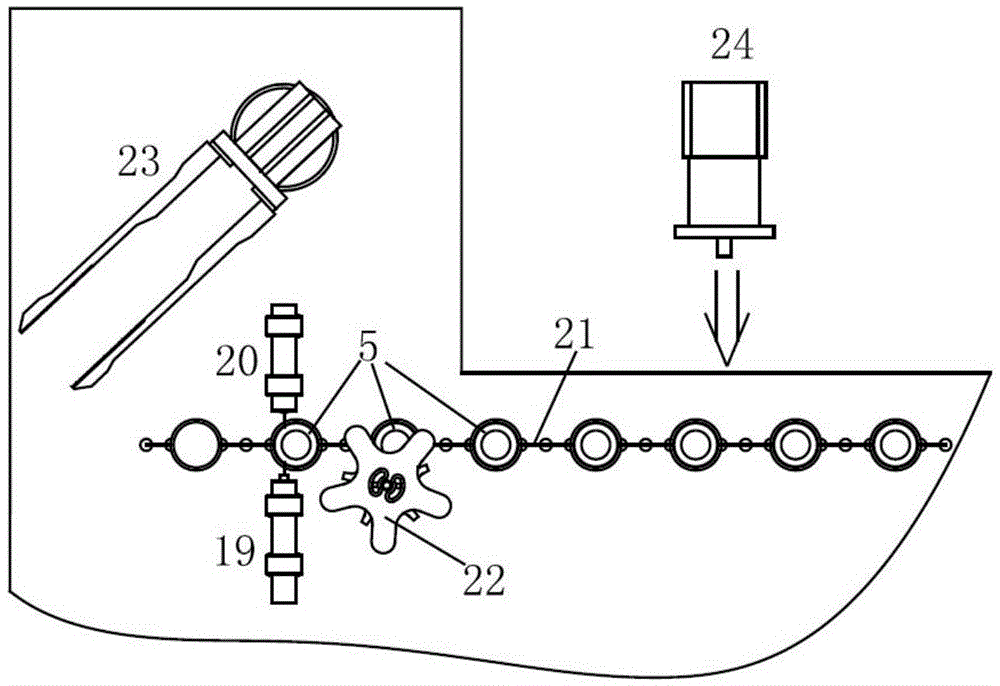

[0034] figure 1 , figure 2 It is a specific embodiment of the present invention.

[0035] The invention consists of a tubular furnace heating system 1, a fully automatic sample adding system, a gas circuit system with a vacuum pump, an infrared detection system 7, and a data acquisition and control system. The automatic sampling system is installed under the heating system 1 of the tube furnace, and pushes the crucible containing the sample into the combustion tube; Between the furnace heating system 1 and the vacuum pump, the carbon dioxide and sulfur dioxide in the combusted analysis gas are detected; the data acquisition and control system are respectively connected to the temperature control device 18, the infrared detection system 7, and the automatic sampling device through the data connection line 8 connections to control and collect signals.

[0036] Among them, the tube furnace heating system 1 is composed of a furnace 2, a silicon carbide rod 3, a combustion tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com