Patents

Literature

122results about How to "Simple electrode structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

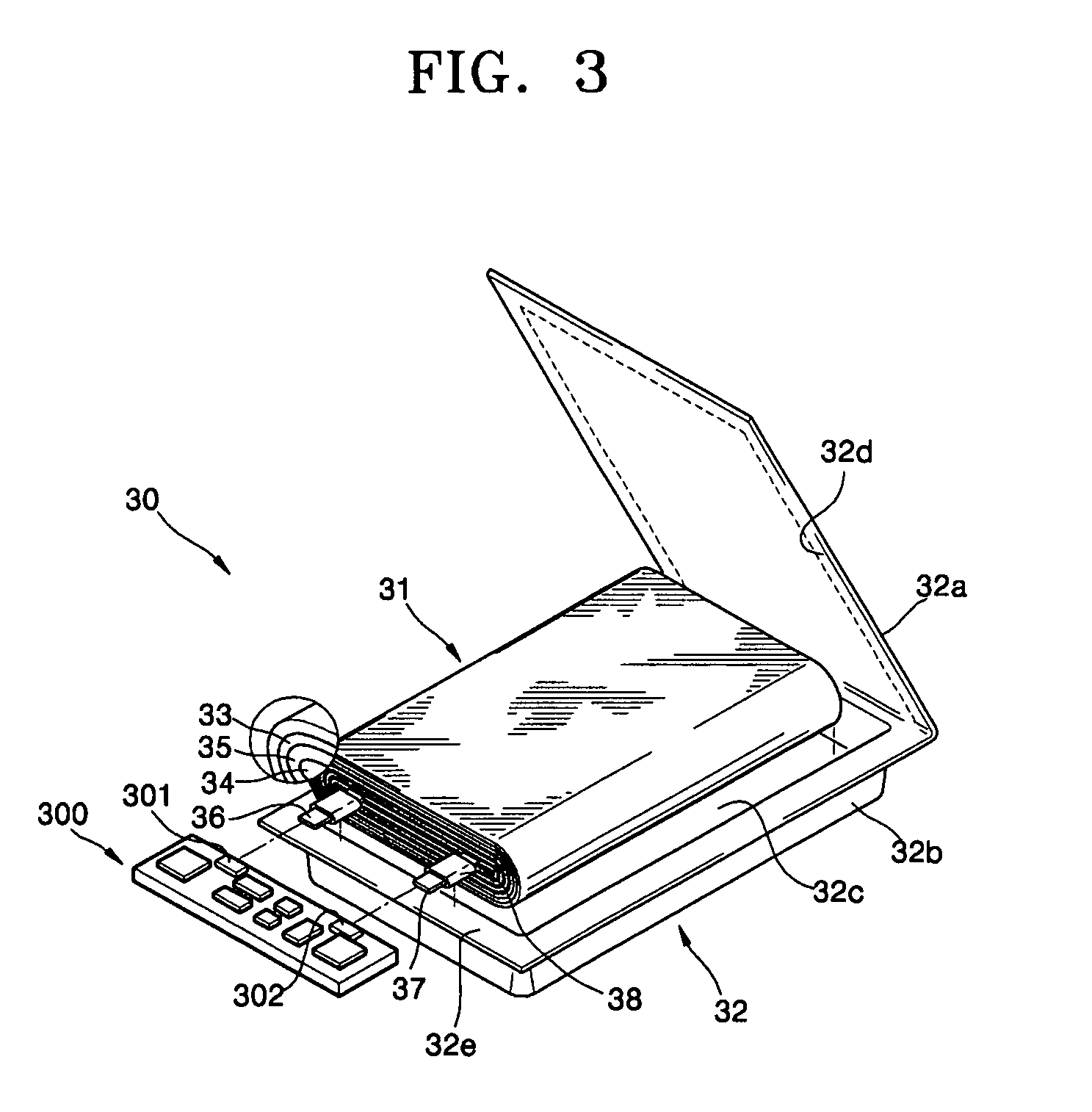

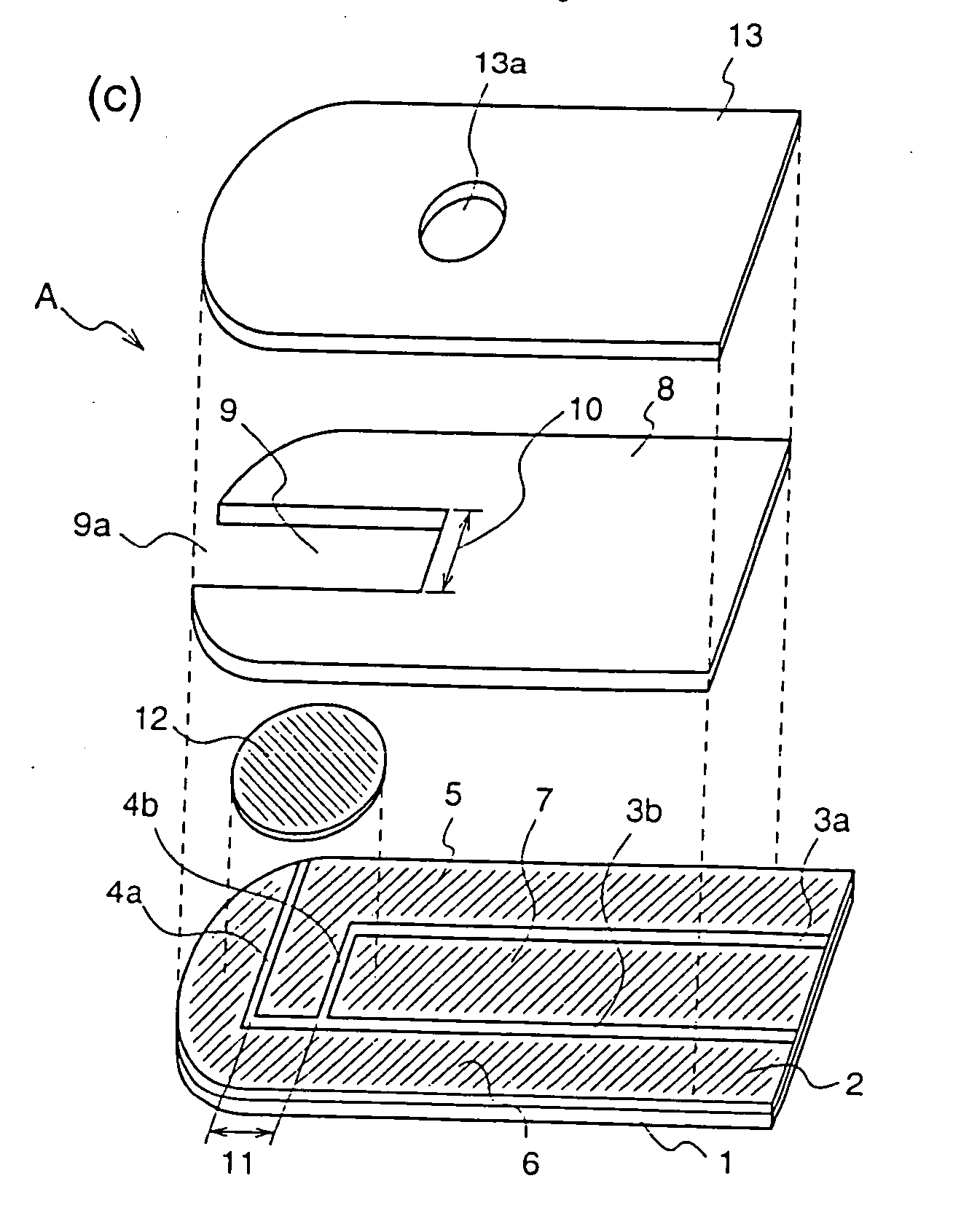

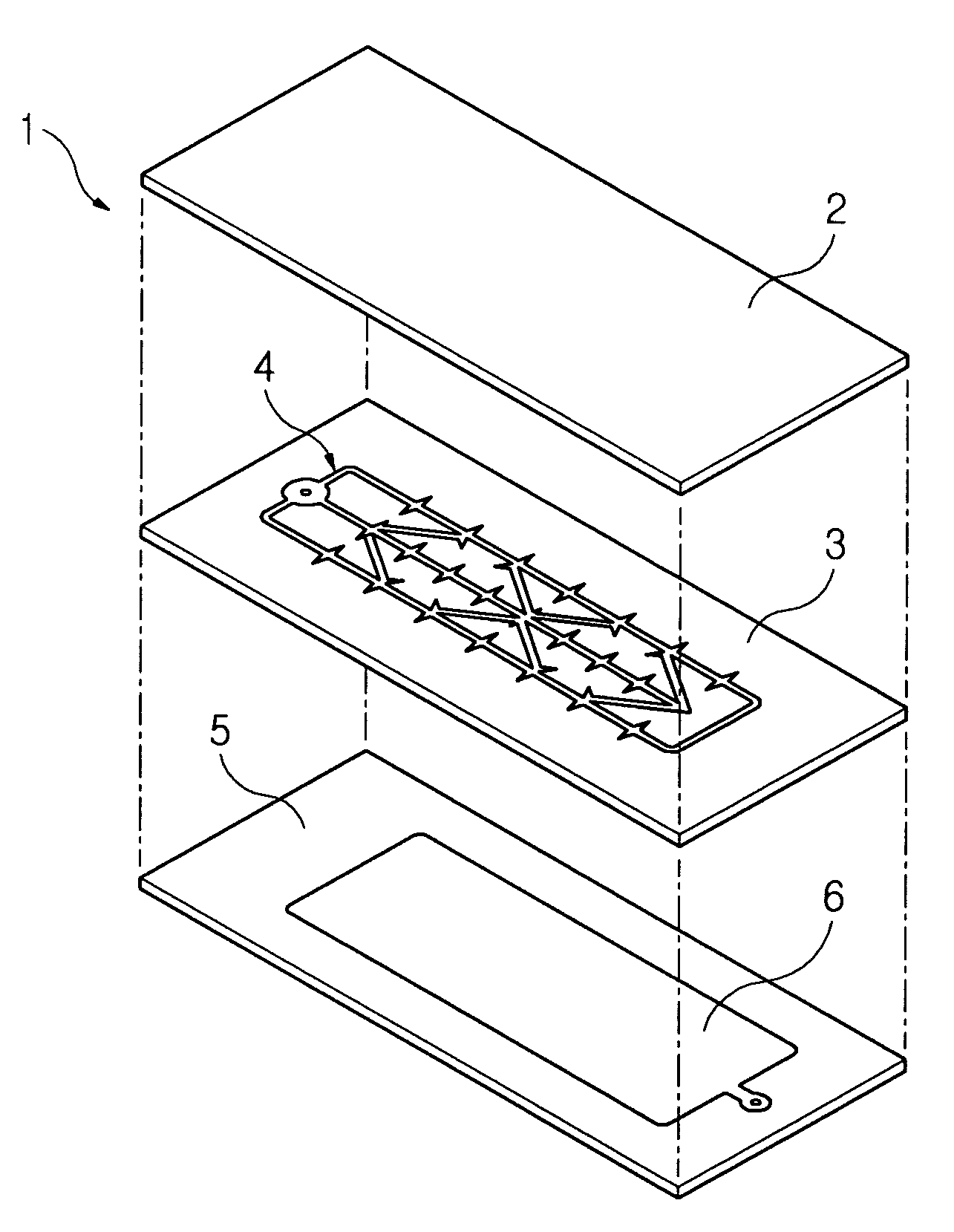

Biosensor, method of forming thin-film electrode, and method and apparatus for quantitative determination

InactiveUS6875327B1Improve convenienceImprove securityImmobilised enzymesBioreactor/fermenter combinationsThin film electrodeQuantitative determination

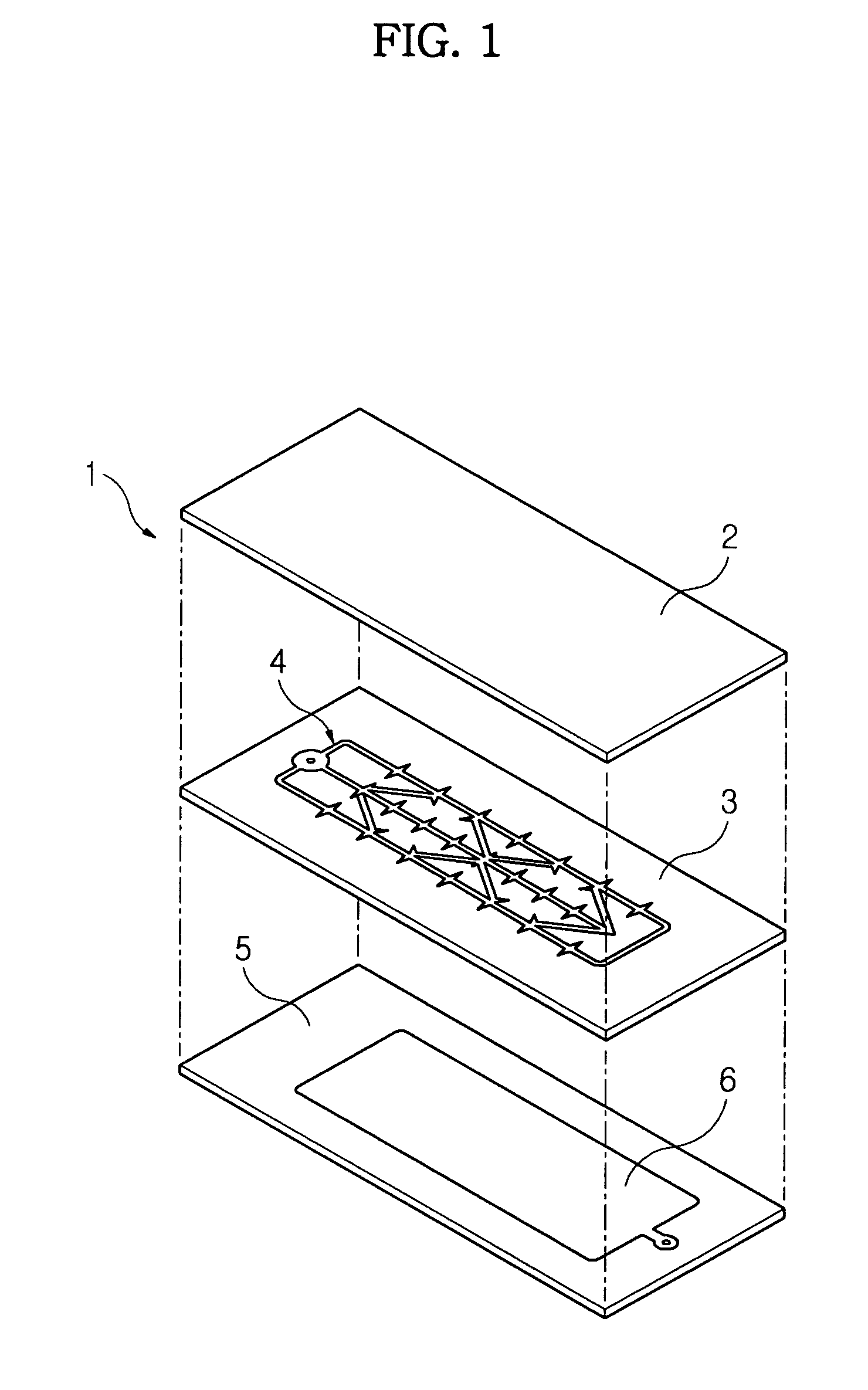

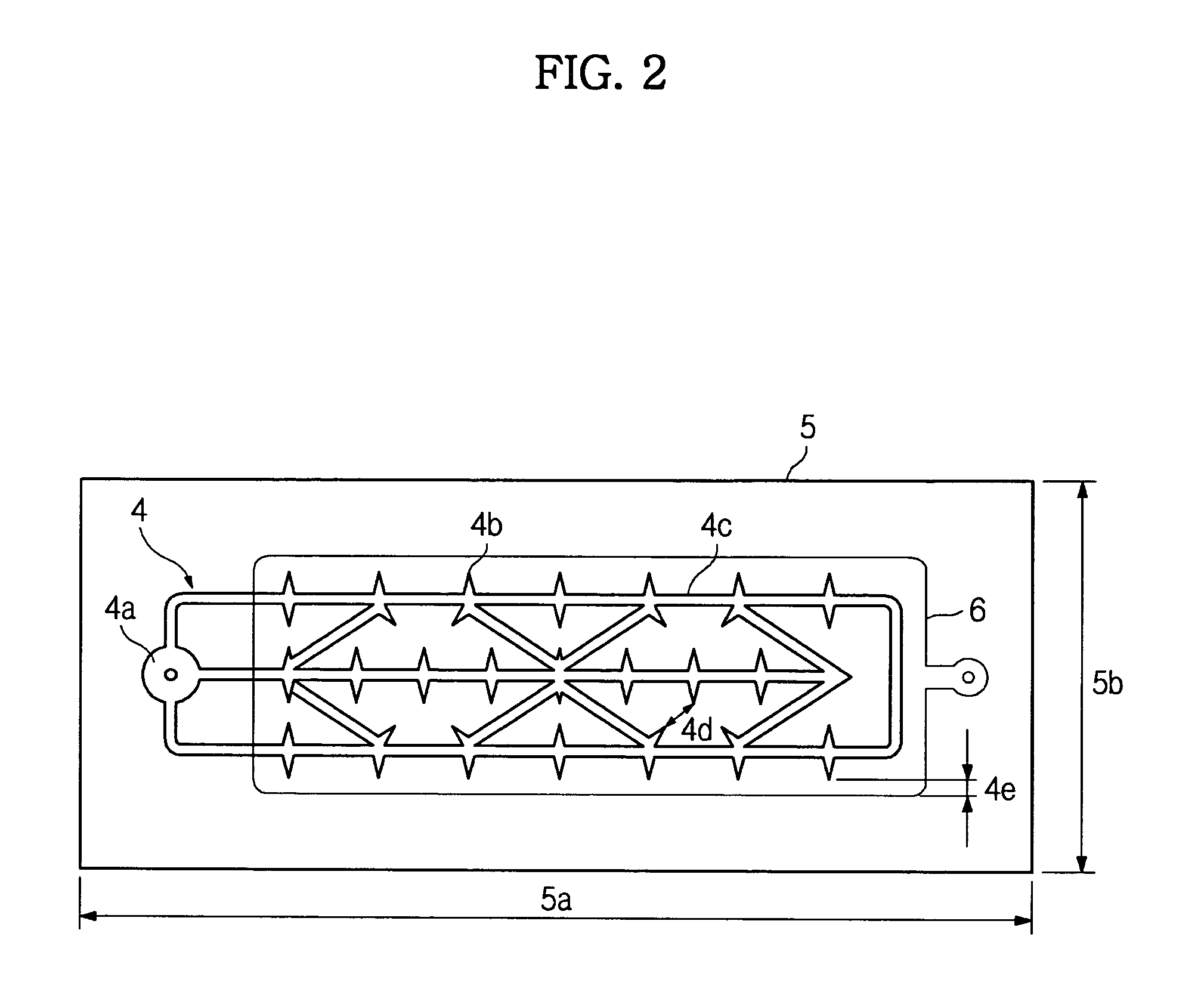

The invention provides a biosensor comprising a support; a conductive layer composed of a electrical conductive material such as a noble metal, for example gold or palladium, and carbon; slits parallel to and perpendicular to the side of the support; working, counter, and detecting electrodes; a spacer which covers the working, counter, and detecting electrodes on the support; a rectangular cutout in the spacer forming a specimen supply path; an inlet to the specimen supply path; a reagent layer formed by applying a reagent containing an enzyme to the working, counter, and detecting electrodes, which are exposed through the cutout in the spacer; and a cover over the spacer. The biosensor can be formed by a simple method, and provides a uniform reagent layer on the electrodes regardless of the reagent composition.

Owner:PHC HLDG CORP

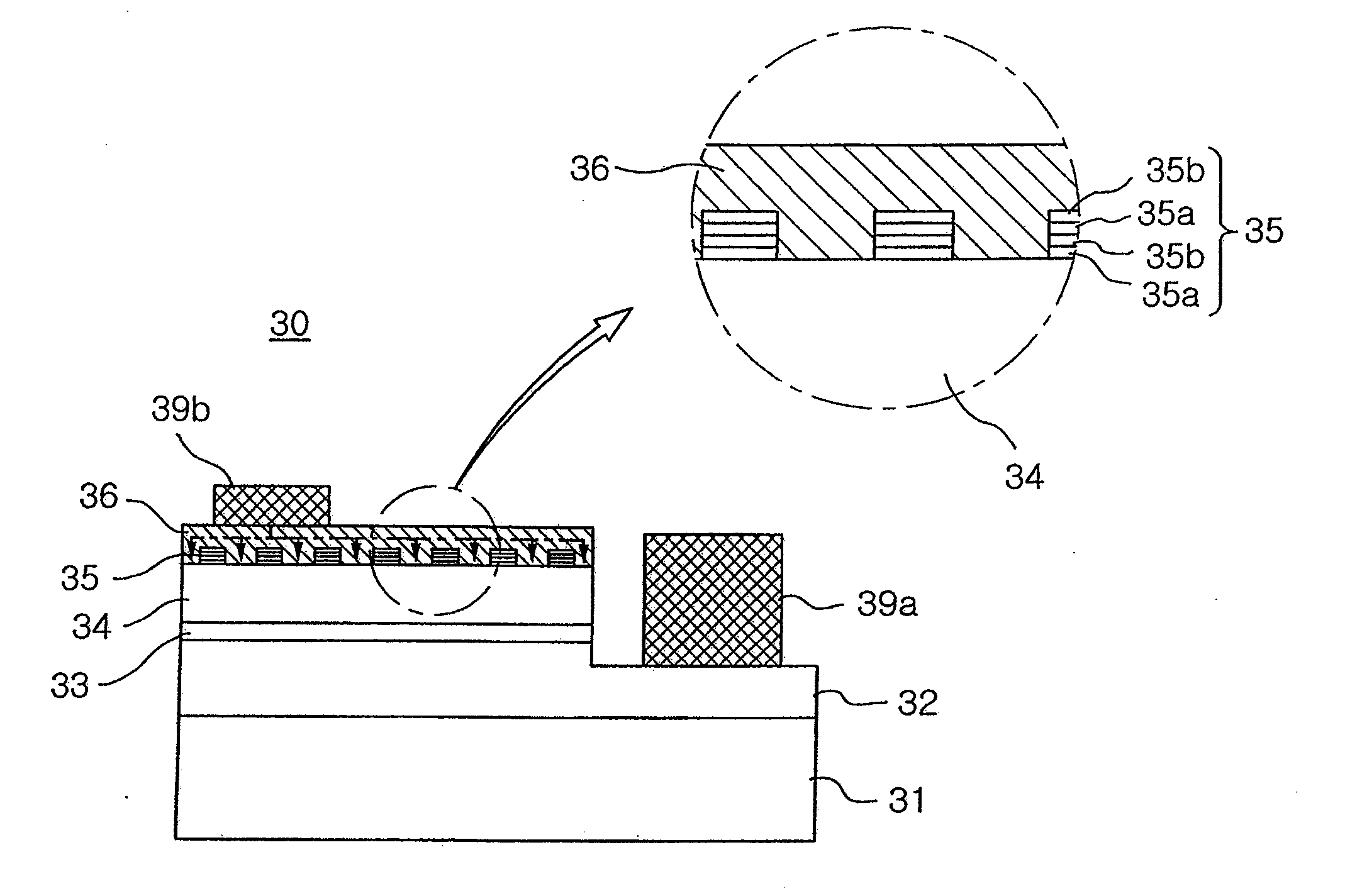

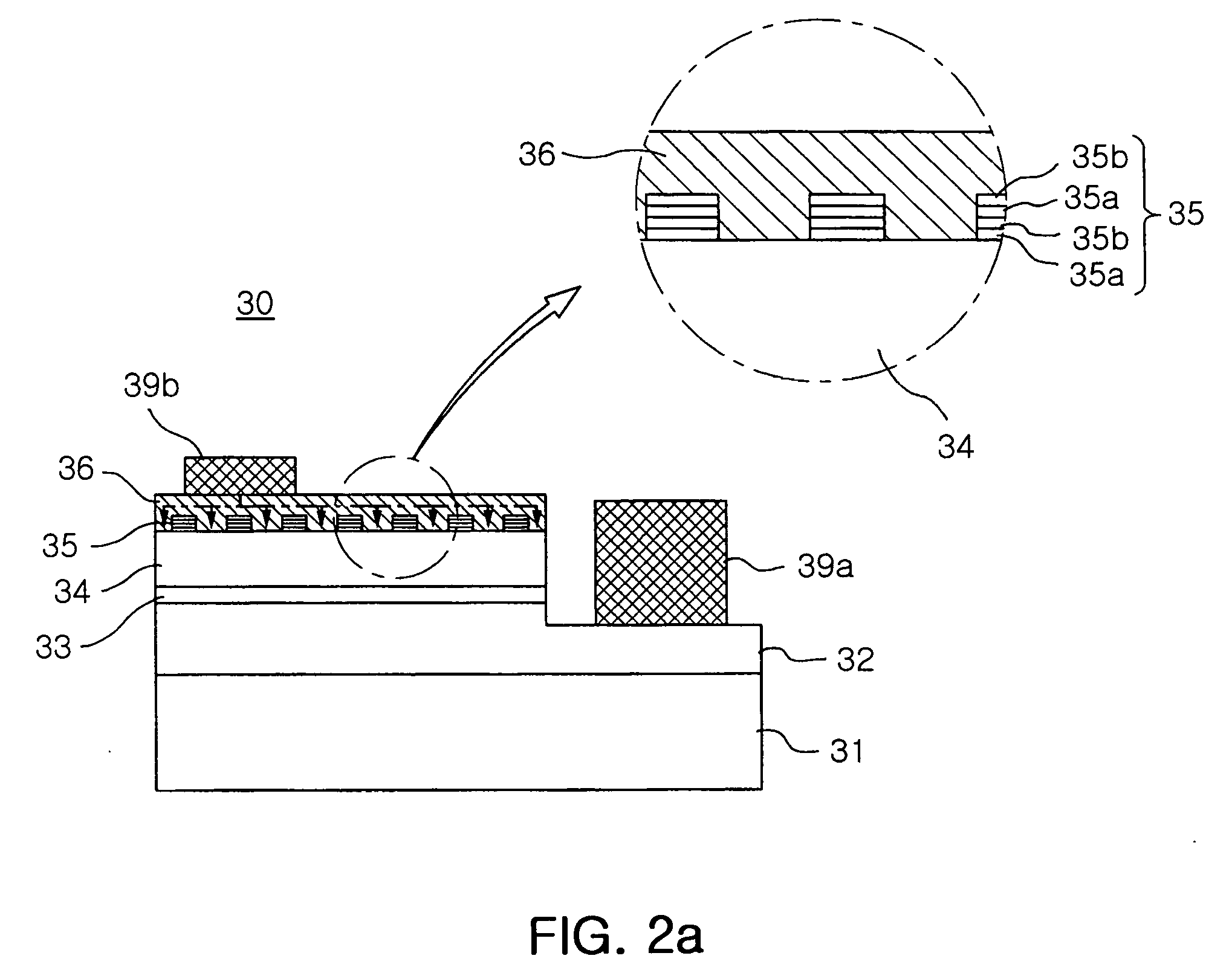

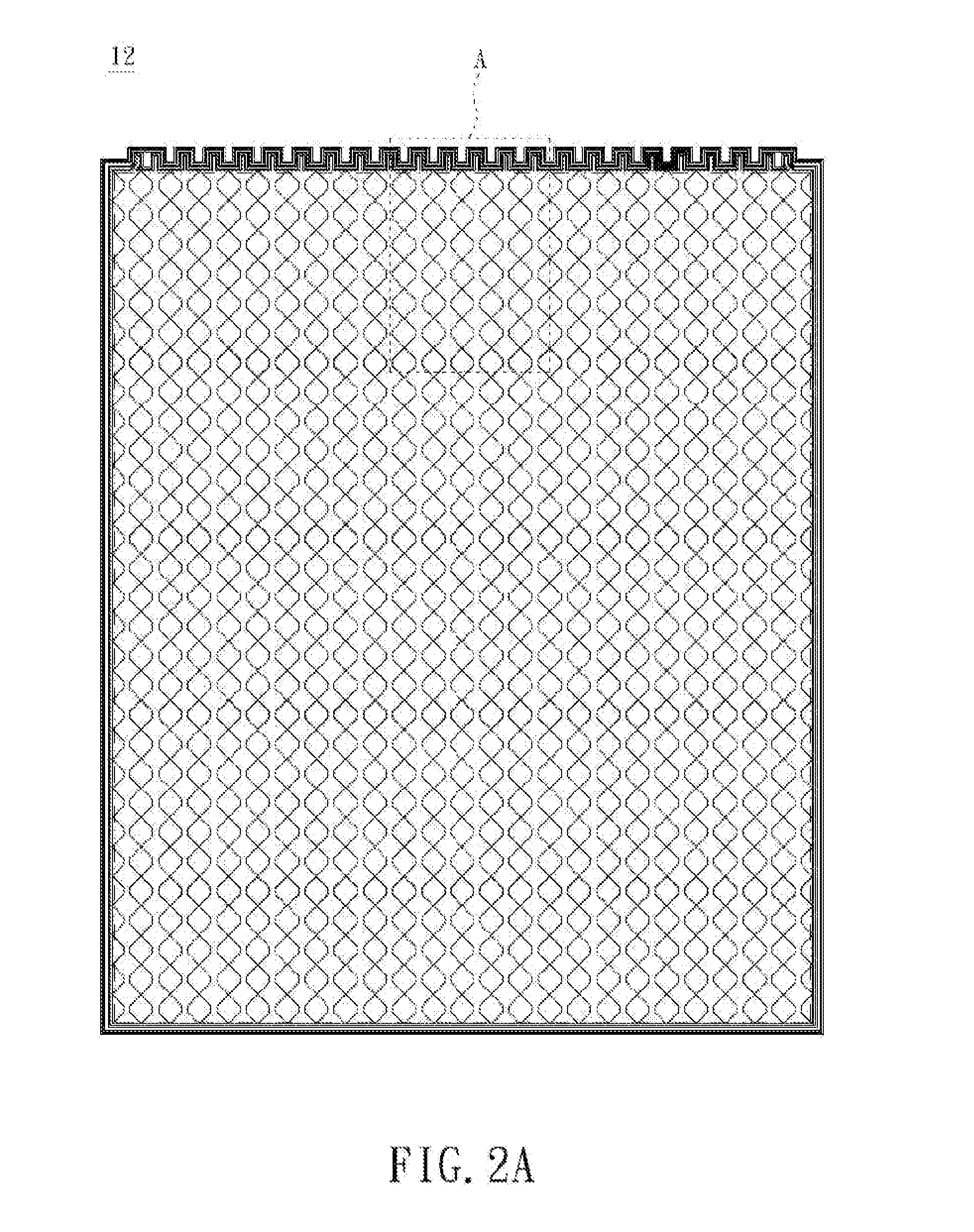

Nitride semiconductor light emitting diode and method of manufacturing the same

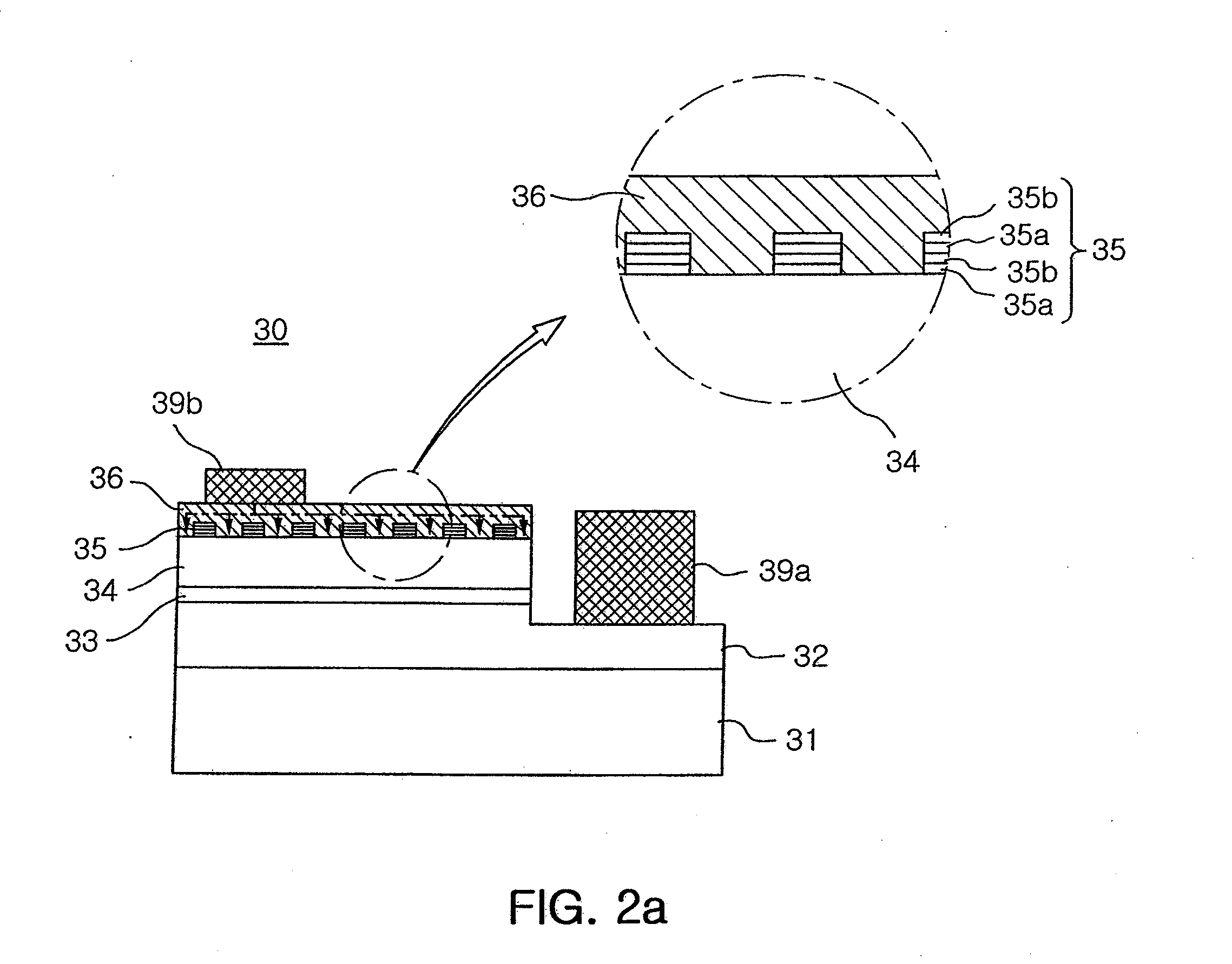

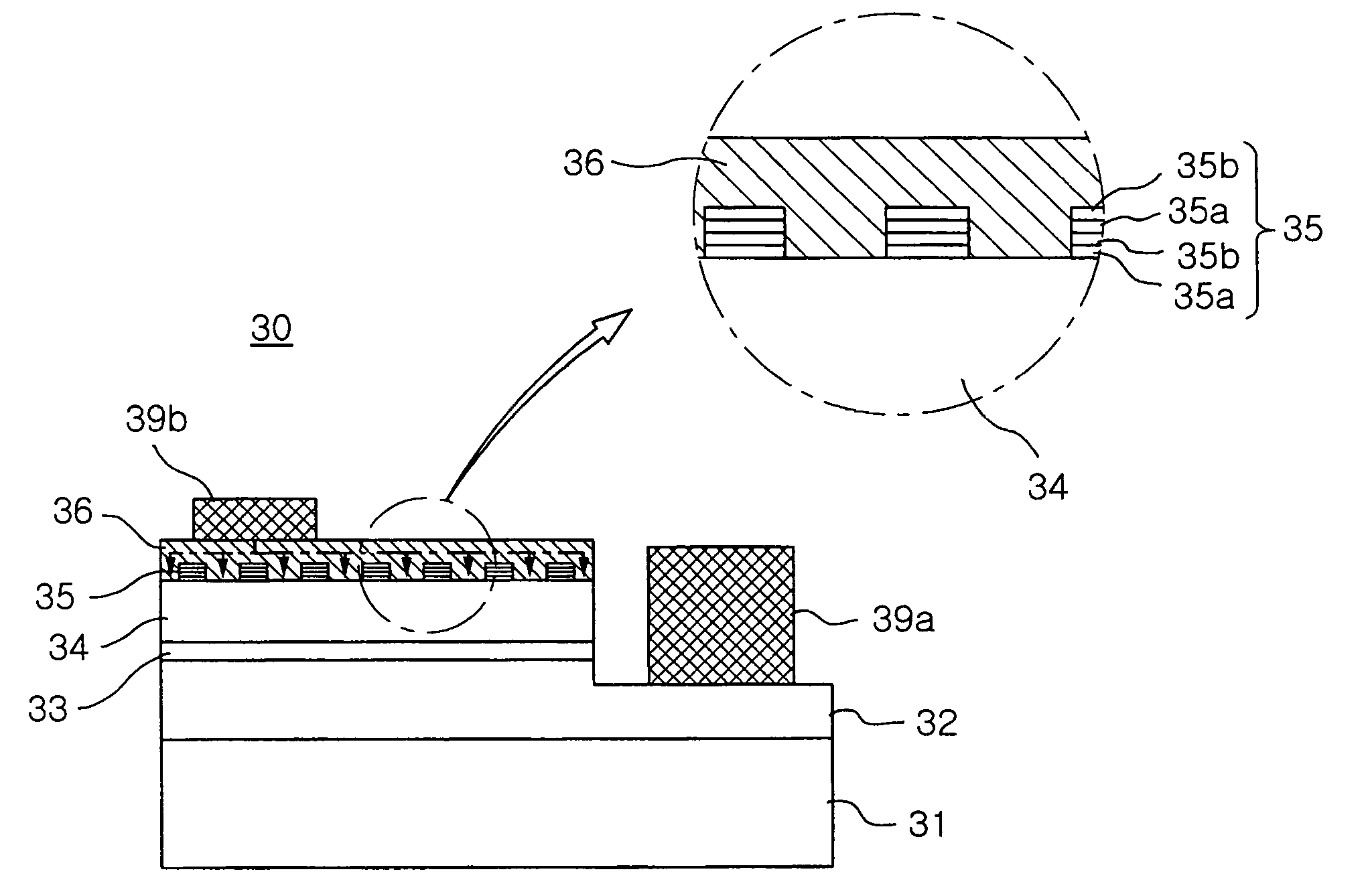

ActiveUS20080064133A1Simple electrode structureGood effectSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactTransmittance

A flip chip-type nitride semiconductor light emitting diode includes a light transmittance substrate, an n-type nitride semiconductor layer, an active layer, a p-type nitride semiconductor layer and a mesh-type DBR reflecting layer. The mesh-type DBR reflecting layer has a plurality of open regions. The mesh-type DBR reflecting layer is composed of first and second nitride layers having different Al content. The first and second nitride layers are alternately stacked several times to form the mesh-type DBR reflecting layer. An ohmic contact layer is formed on the mesh-type DBR reflecting layer and on the p-type nitride semiconductor layer.

Owner:SAMSUNG ELECTRONICS CO LTD

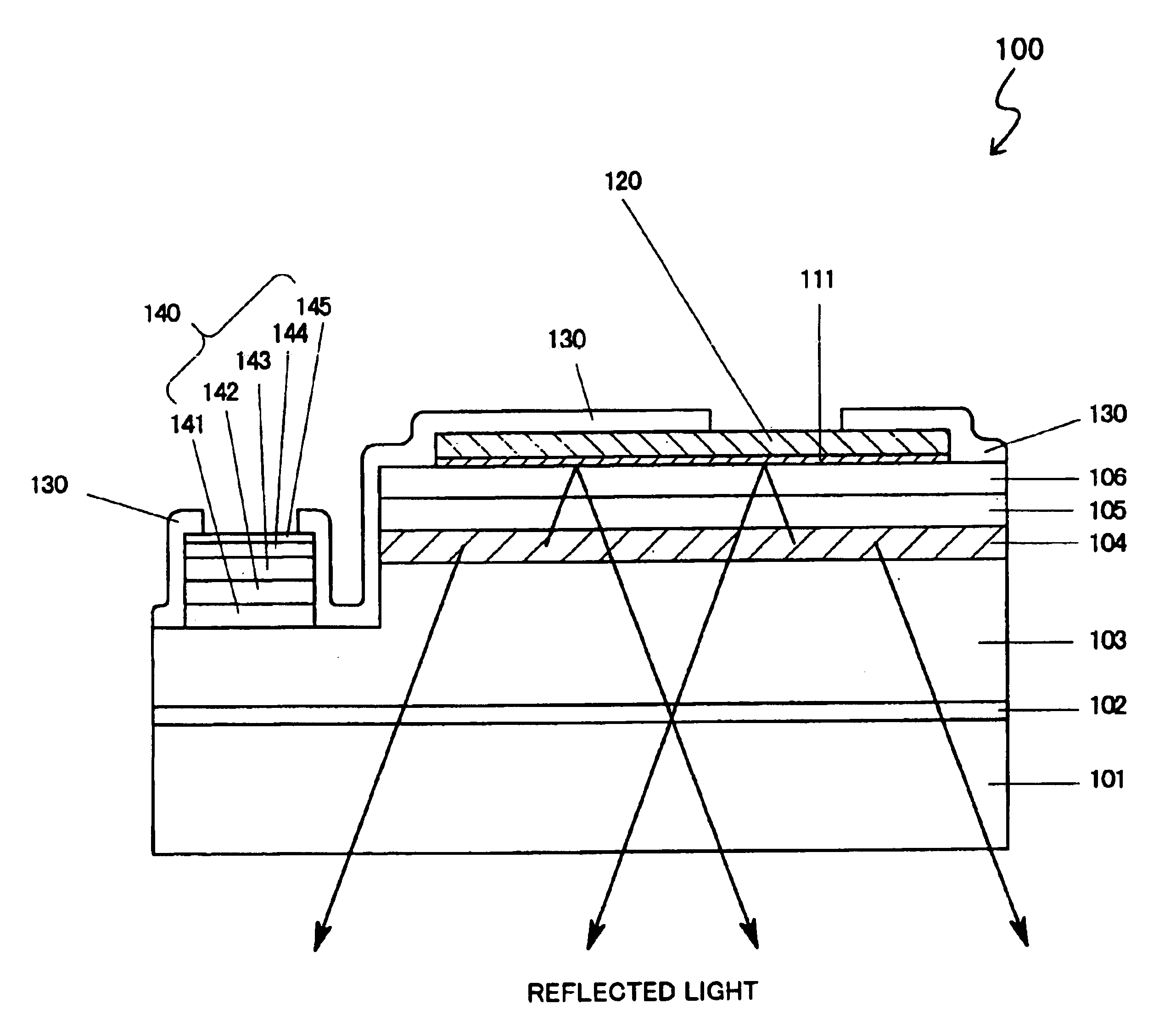

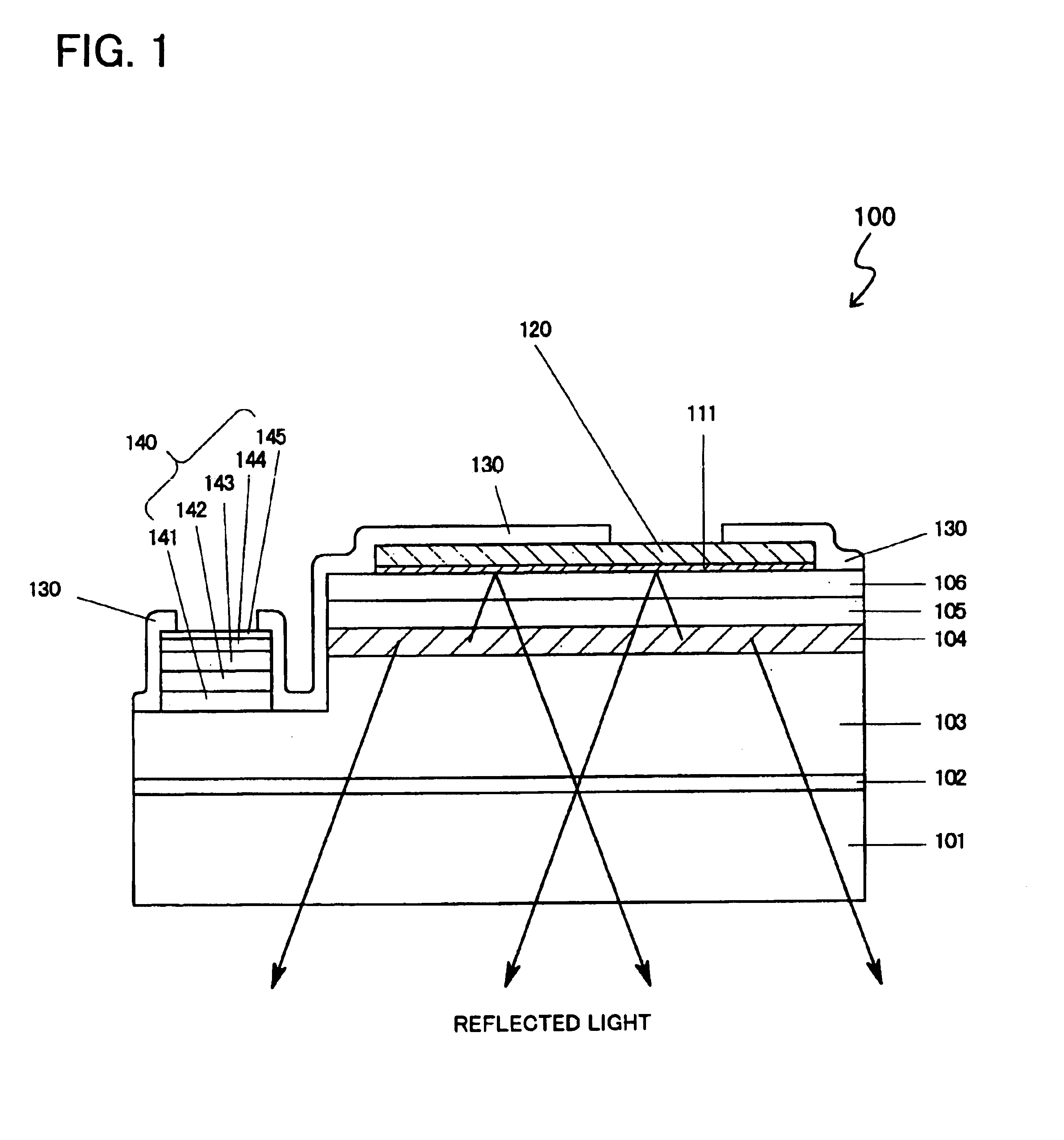

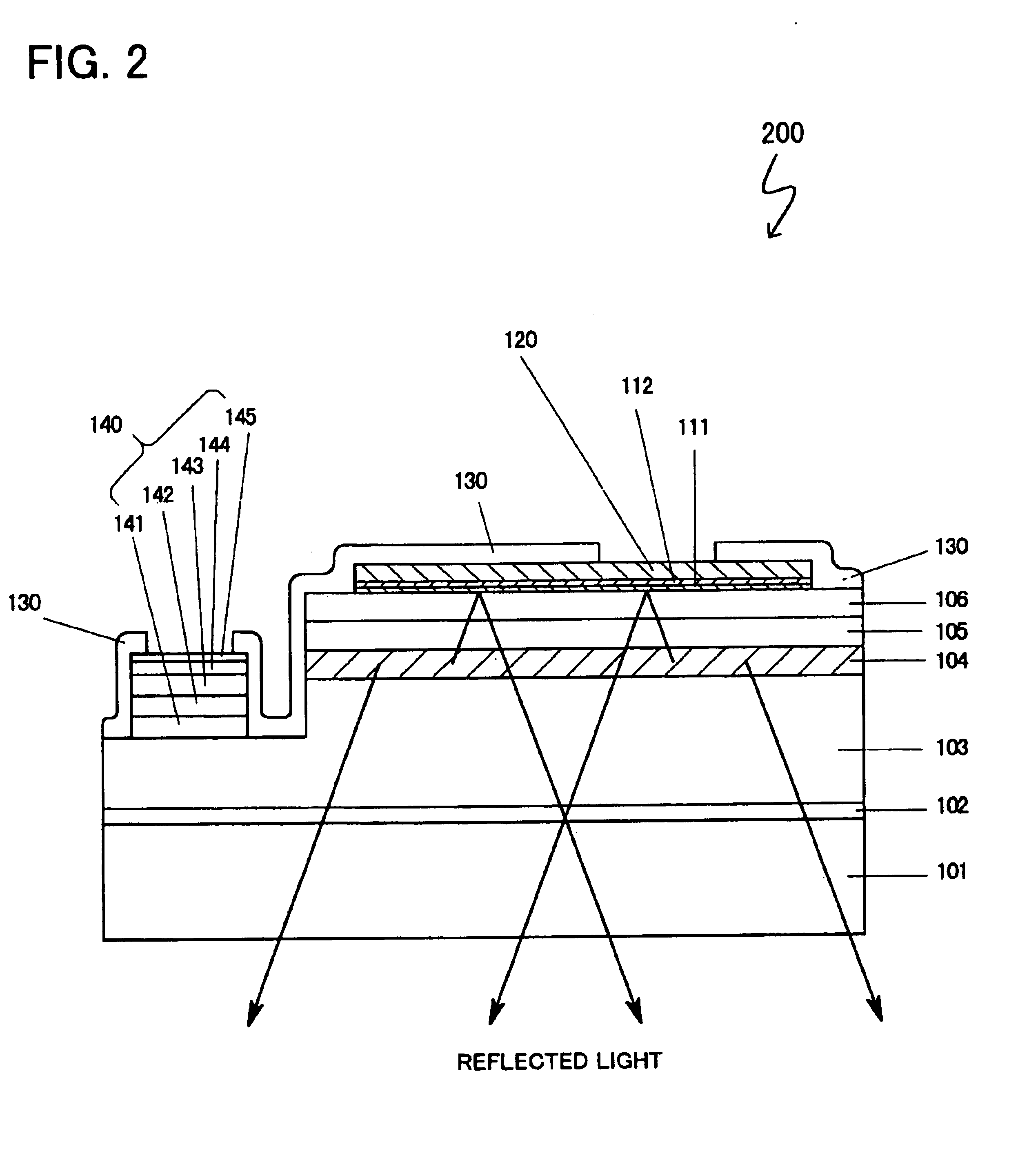

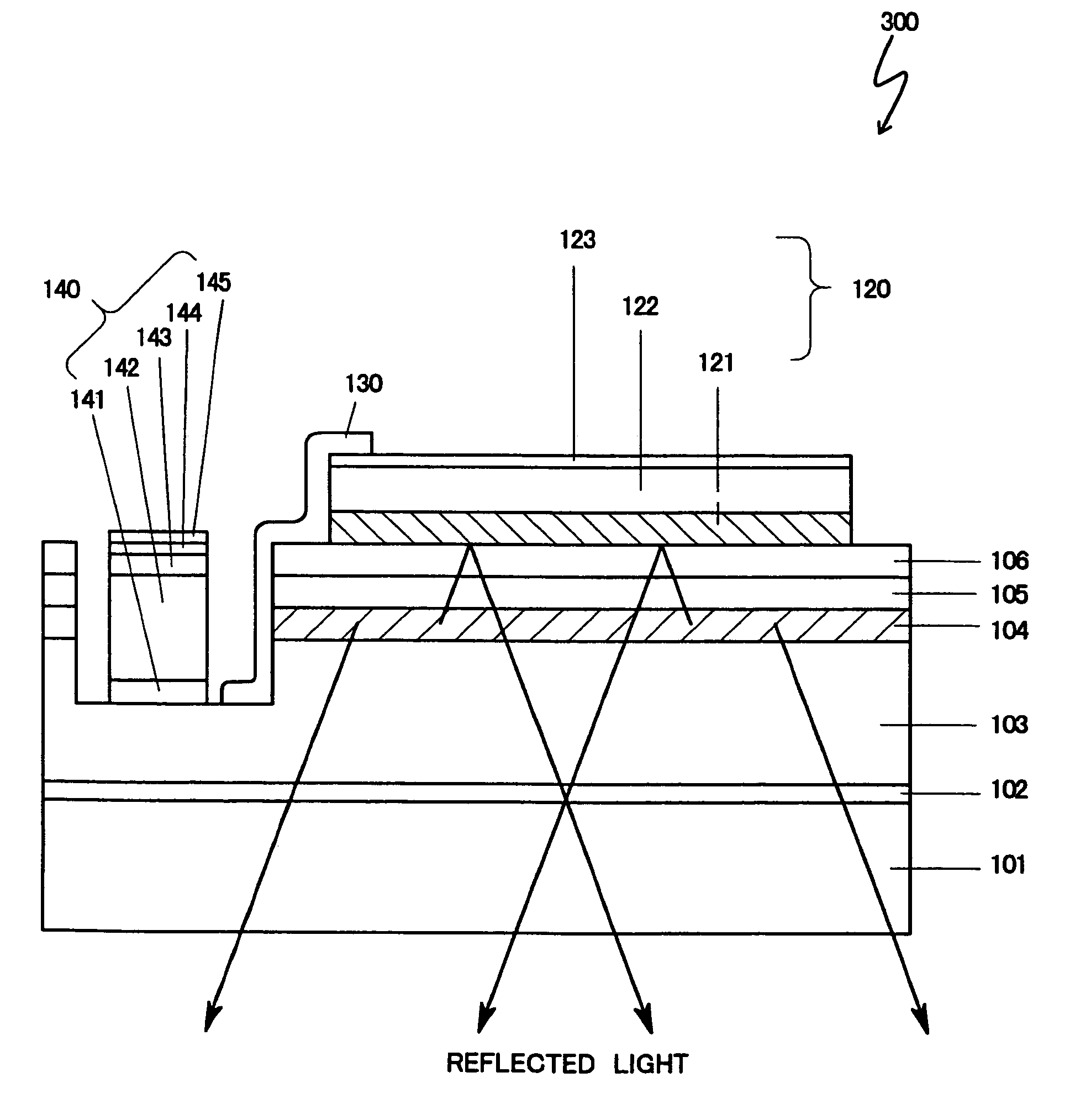

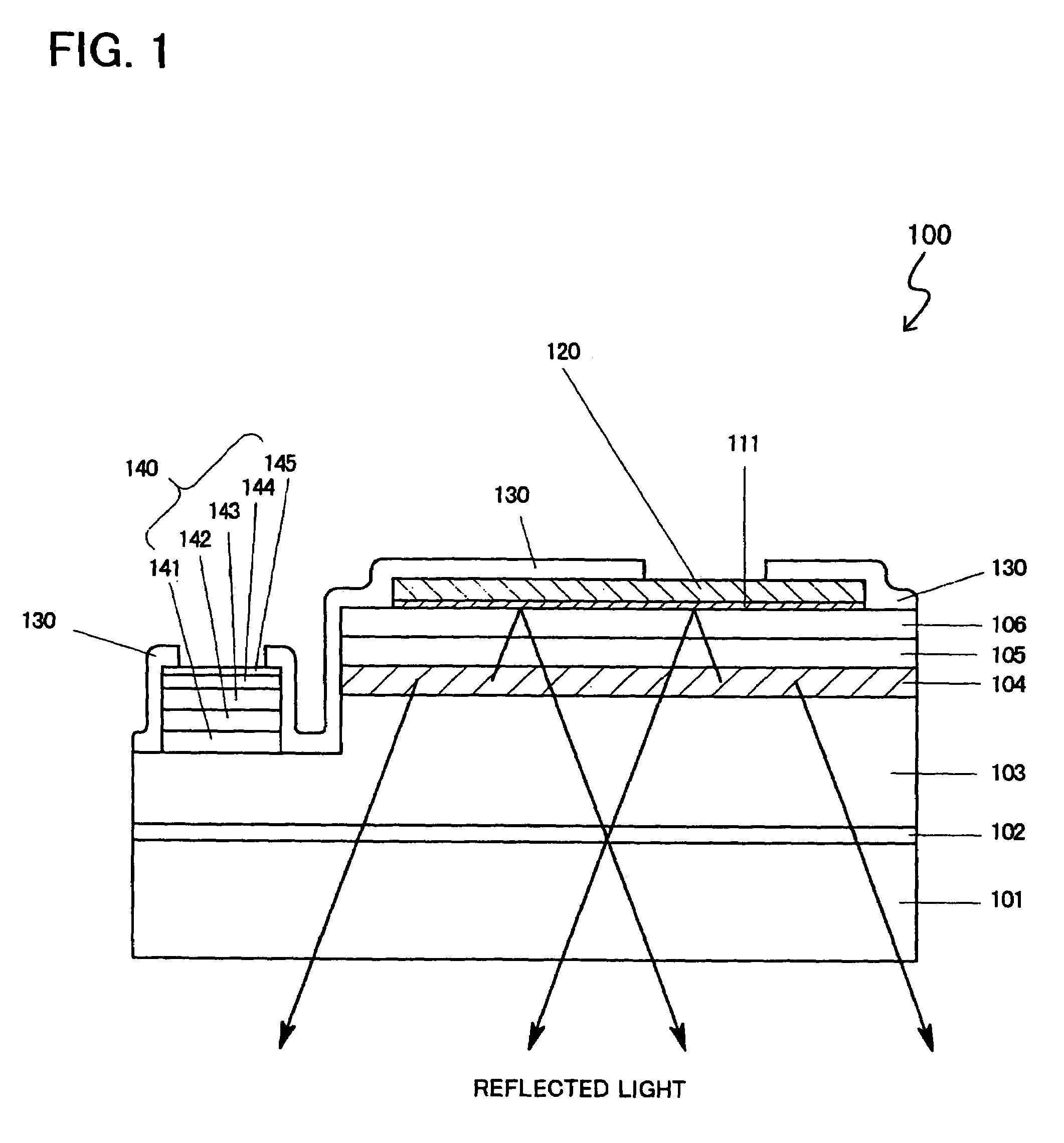

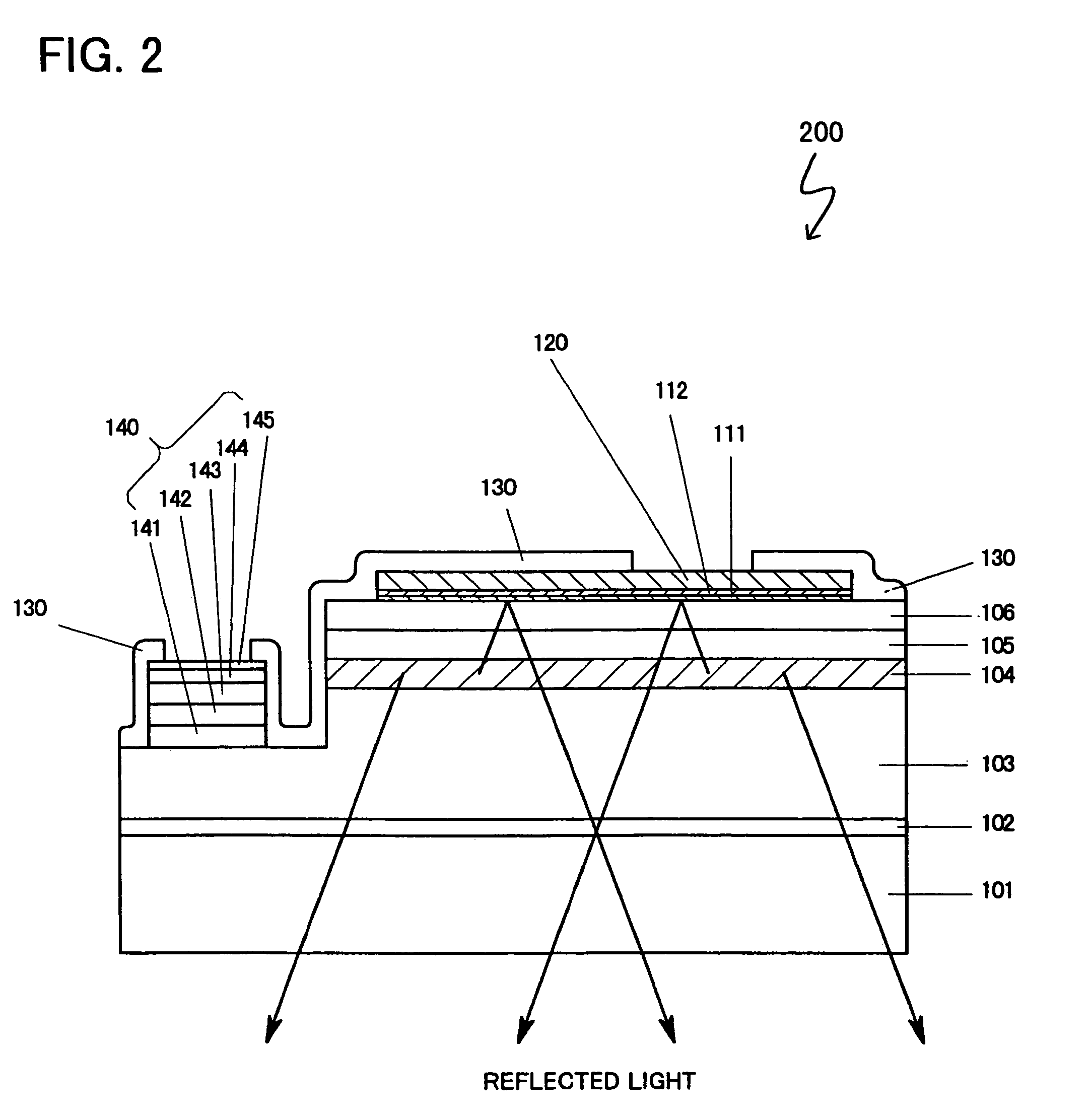

Nitride semiconductor light emitting diode and method of manufacturing the same

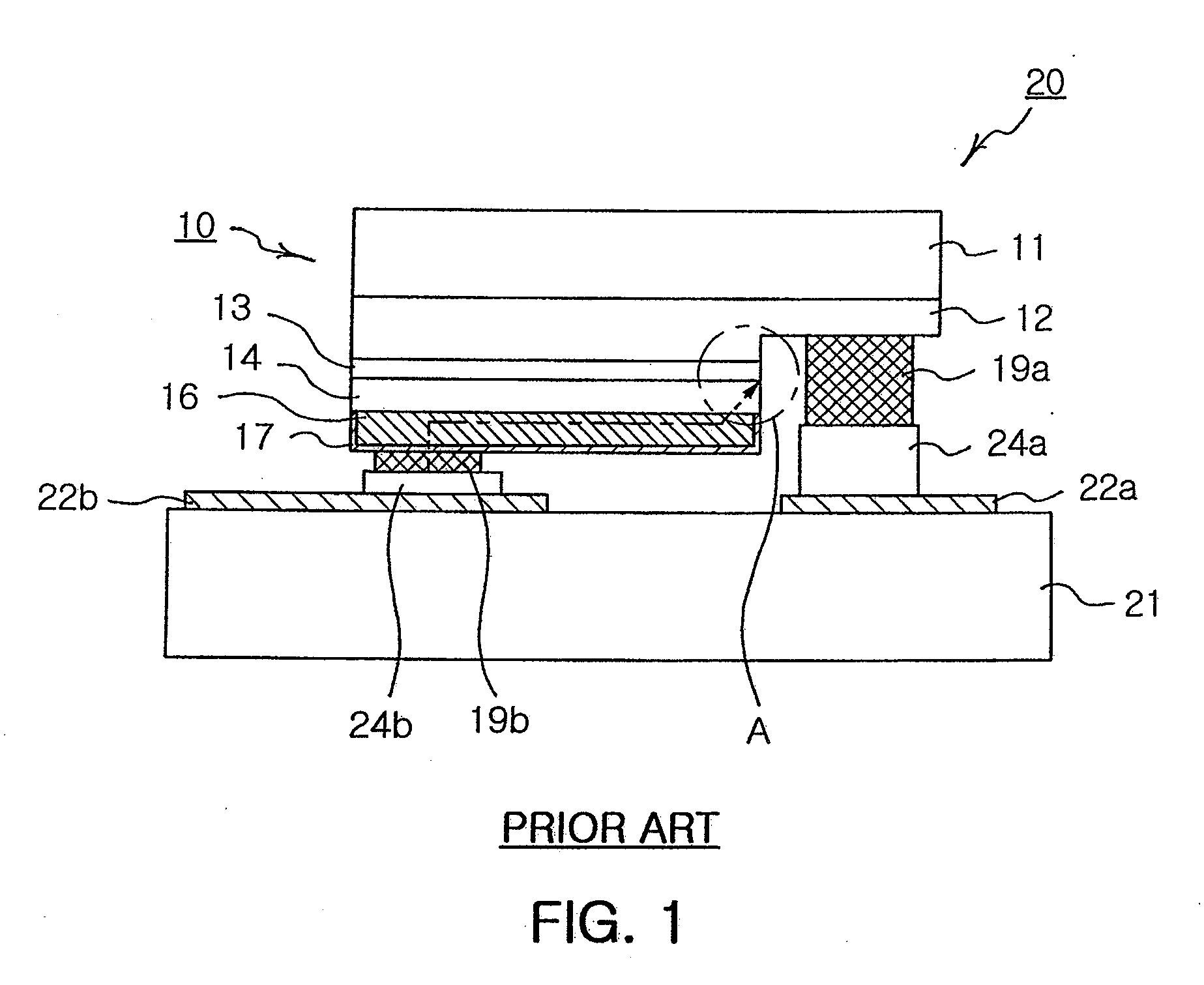

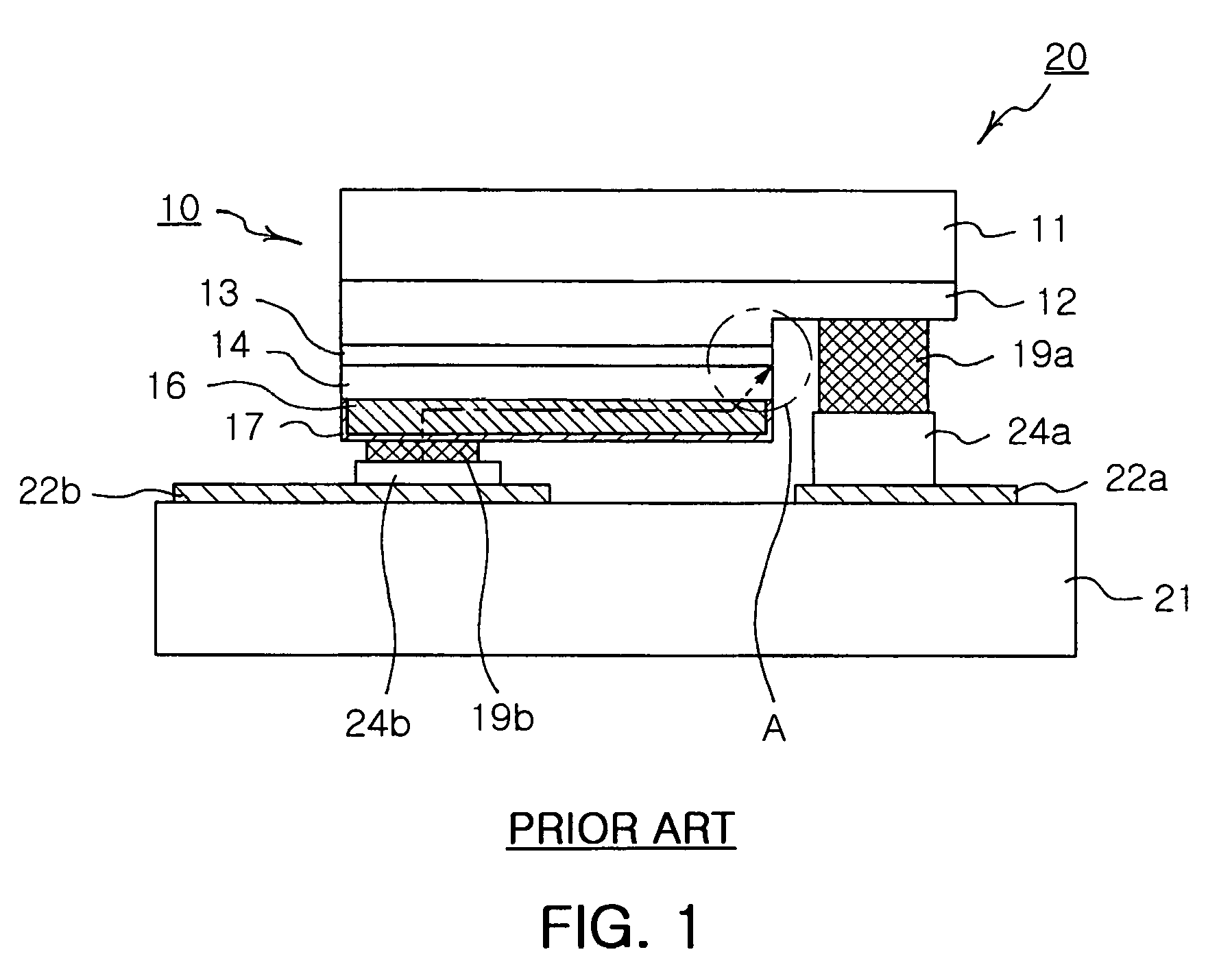

InactiveUS20060033113A1Simple electrode structureGood effectSolid-state devicesSemiconductor devicesOhmic contactTransmittance

The present invention provides a flip chip-type nitride semiconductor light emitting diode. The nitride semiconductor light emitting diode comprises a light transmittance substrate, an n-type nitride semiconductor layer, an active layer, a p-type nitride semiconductor layer and a mesh-type DBR reflecting layer. The mesh-type DBR reflecting layer has a plurality of open regions. The mesh-type DBR reflecting layer is composed of first and second nitride layers having different Al content. The first and second nitride layers are alternately stacked several times to form the mesh-type DBR reflecting layer. An ohmic contact layer is formed on the mesh-type DBR reflecting layer and on the p-type nitride semiconductor layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

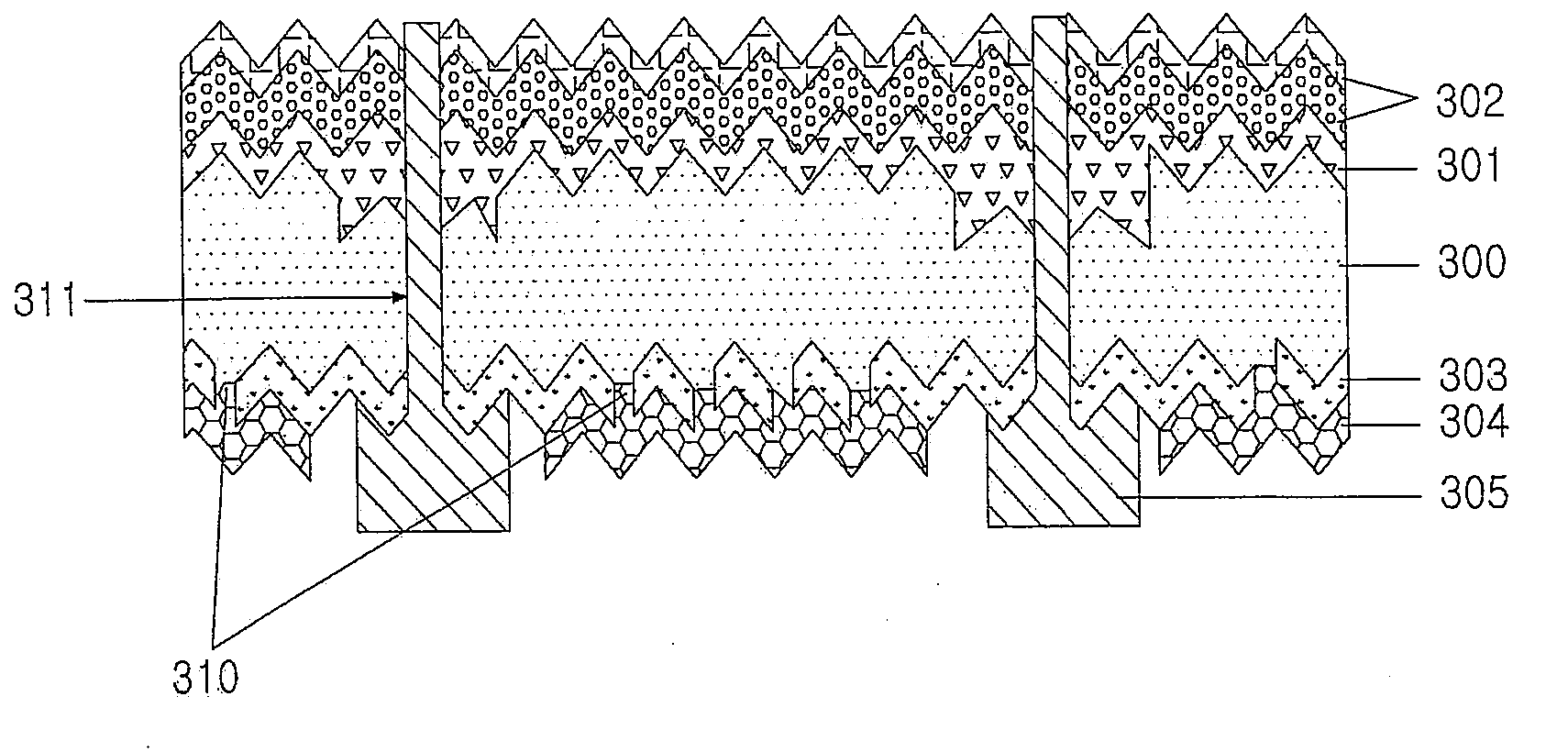

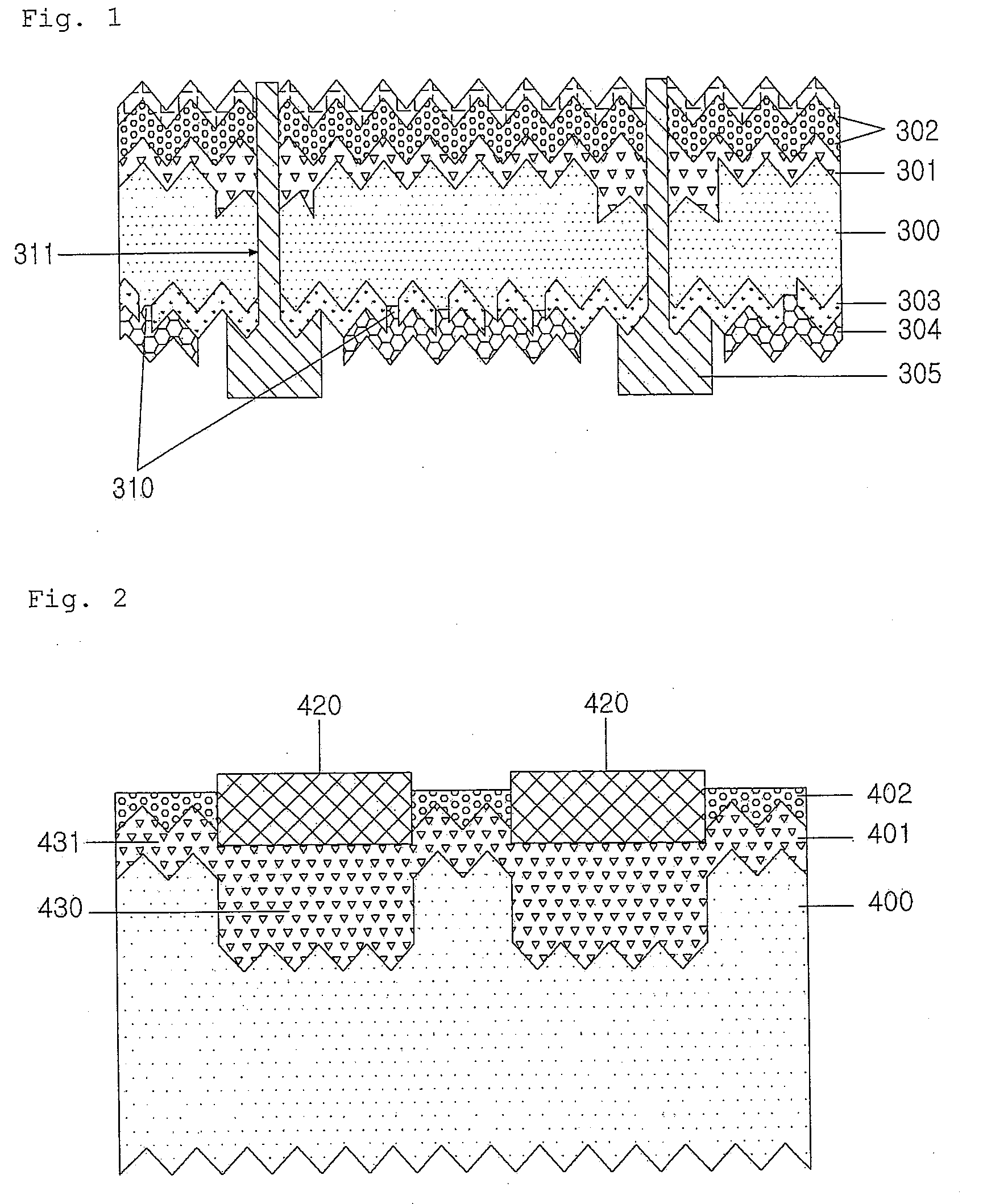

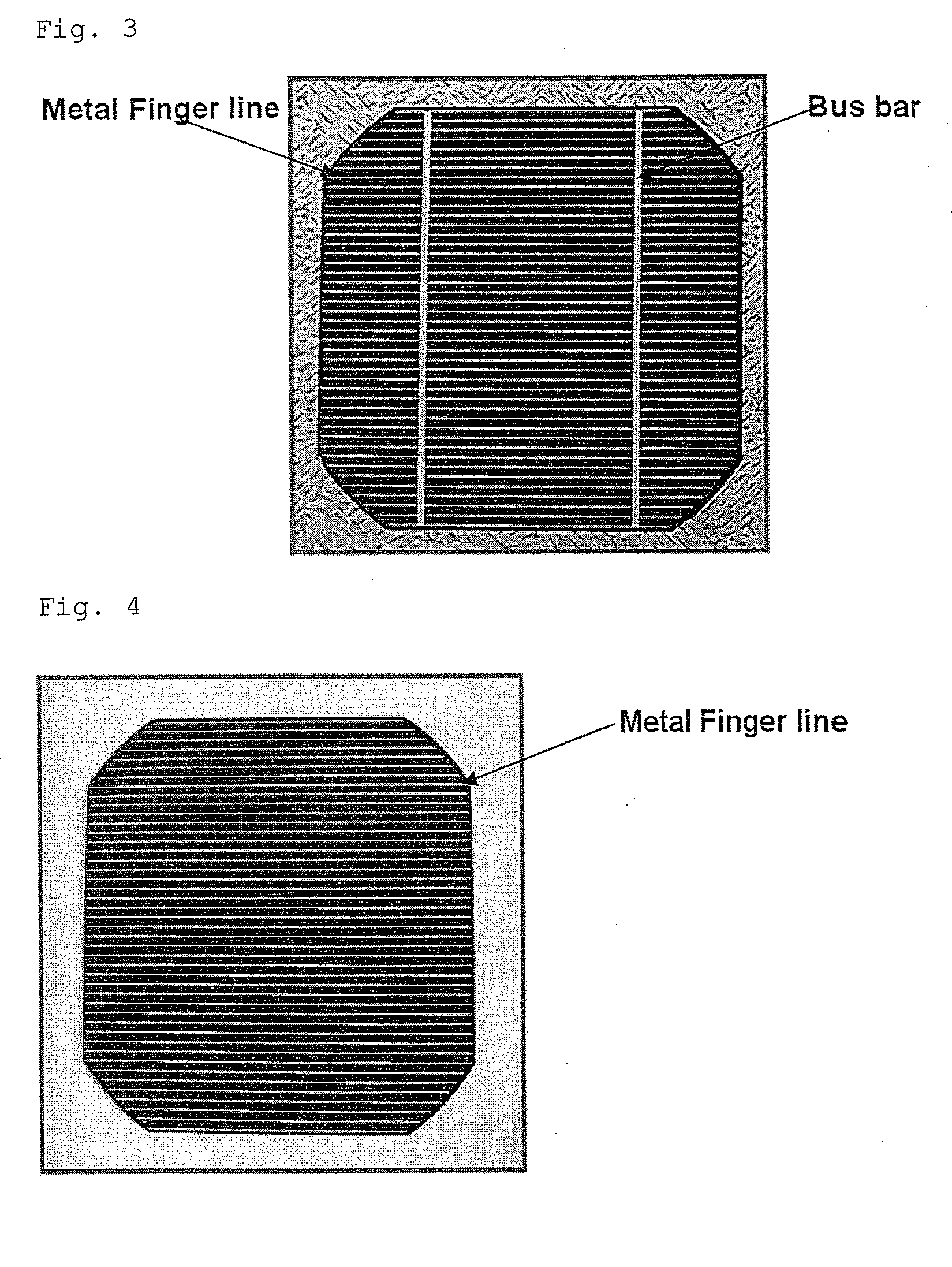

Solar cell and fabrication method thereof

InactiveUS20100243040A1Light trapping capabilityIncrease contact resistanceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon solar cell

Disclosed are a metal wrap through solar cell including a metal wrap through (MWT) structure as a back contact silicon solar cell and a fabrication method thereof.

Owner:LG ELECTRONICS INC

Light-emitting semiconductor device using group III nitride compound

InactiveUS6936859B1Improve reflectivityIncreased durabilitySemiconductor/solid-state device detailsSolid-state devicesAlloyContact layer

A flip chip type of light-emitting semiconductor device using group III nitride compound comprising a thick positive electrode. The positive electrode, which is made of at least one of silver (Ag), rhodium (Rh), ruthenium (Ru), platinum (Pt) and palladium (Pd), and an alloy including at least one of these metals, is adjacent to a p-type semiconductor layer, and reflect light toward a sapphire substrate. Accordingly, a positive electrode having a high reflectivity and a low contact resistance can be obtained. A first thin-film metal layer, which is made of cobalt (Co) and nickel (Ni), or any combinations of including at least one of these metals, formed between the p-type semiconductor layer and the thick electrode, can improve an adhesion between a contact layer and the thick positive electrode. A thickness of the first thin-film metal electrode should be preferably in the range of 2 Å to 200 Å, more preferably 5 Å to 50 Å. A second thin-film metal layer made of gold (Au) can further improve the adhesion.

Owner:TOYODA GOSEI CO LTD

Light-emitting semiconductor device using group III nitride compound

InactiveUS7109529B2Improve reflectivityIncreased durabilitySemiconductor/solid-state device detailsSolid-state devicesAlloyContact layer

A flip chip type of light-emitting semiconductor device using group III nitride compound includes a thick positive electrode. The positive electrode, which is made of at least one of silver (Ag), rhodium (Rh), ruthenium (Ru), platinum (Pt) and palladium (Pd), and an alloy including at least one of these metals, is adjacent to a p-type semiconductor layer, and reflect light toward a sapphire substrate. Accordingly, a positive electrode having a high reflectivity and a low contact resistance can be obtained. A first thin-film metal layer, which is made of cobalt (Co) and nickel (Ni), or any combinations of including at least one of these metals, formed between the p-type semiconductor layer and the thick electrode, can improve an adhesion between an contact layer and the thick positive electrode. A thickness of the first thin-film metal electrode should be preferably in the range of 2 Å to 200 Å, more preferably 5 Å to 50 Å. A second thin-film metal layer made of gold (Au) can further improve the adhesion.

Owner:TOYODA GOSEI CO LTD

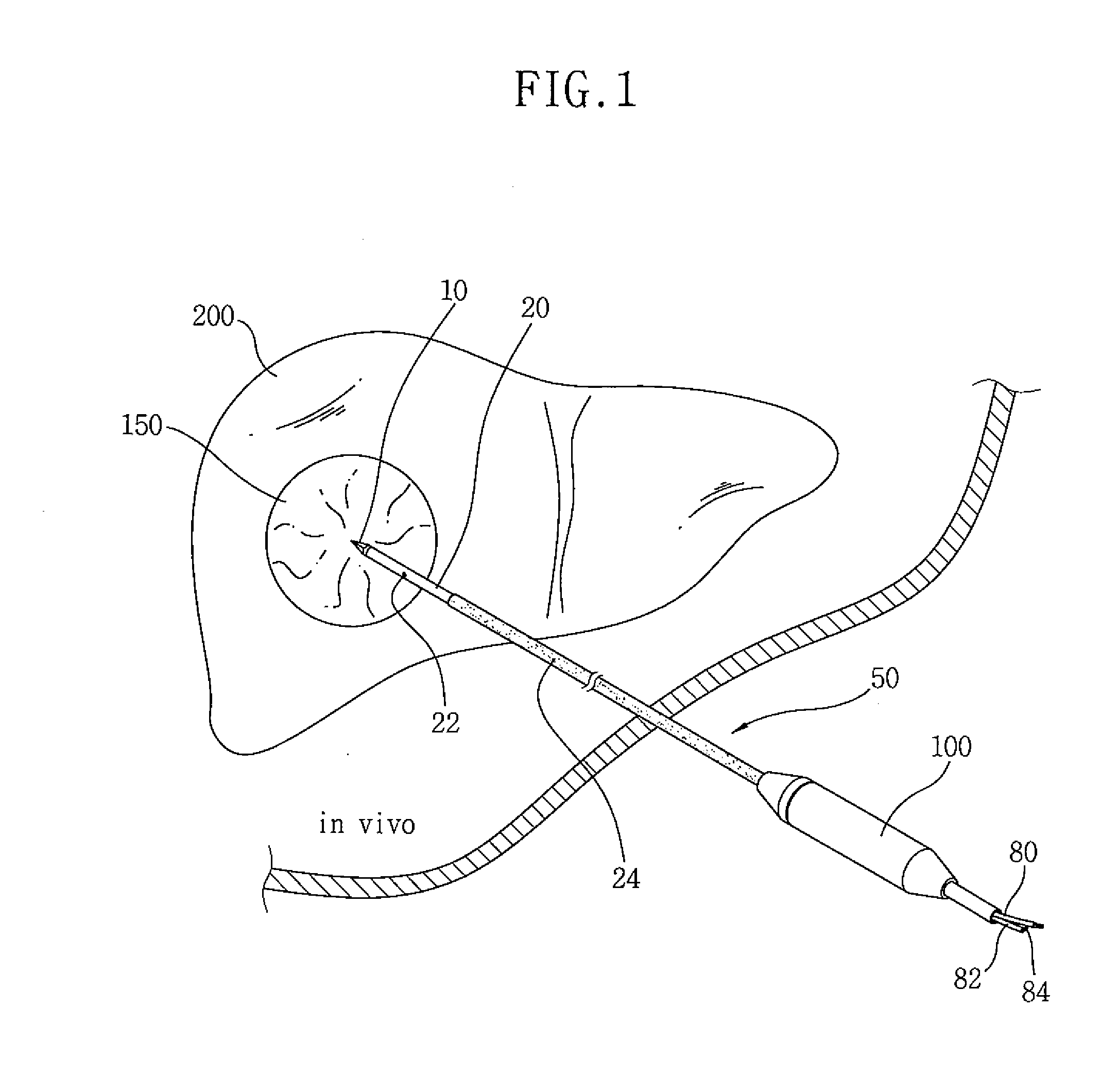

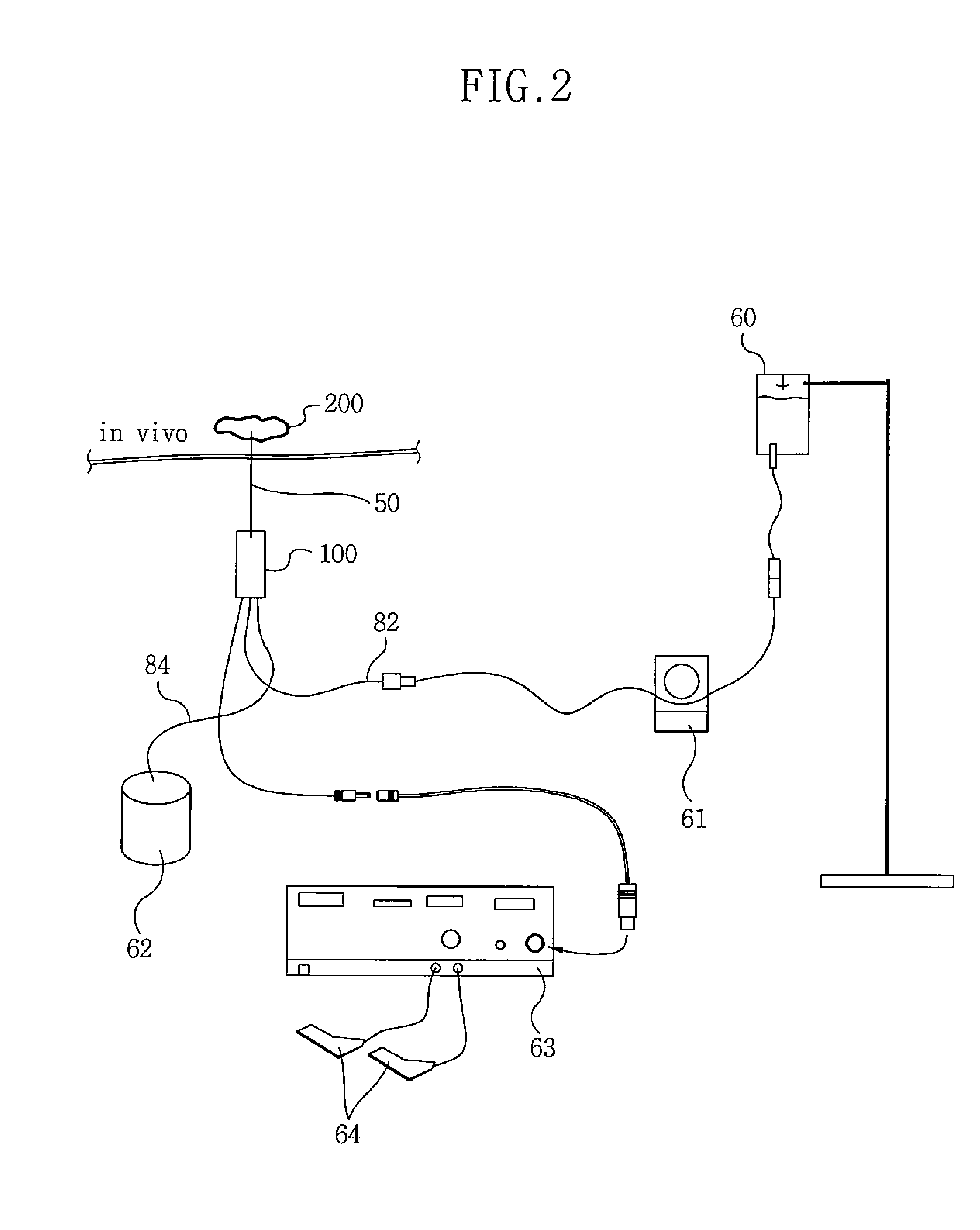

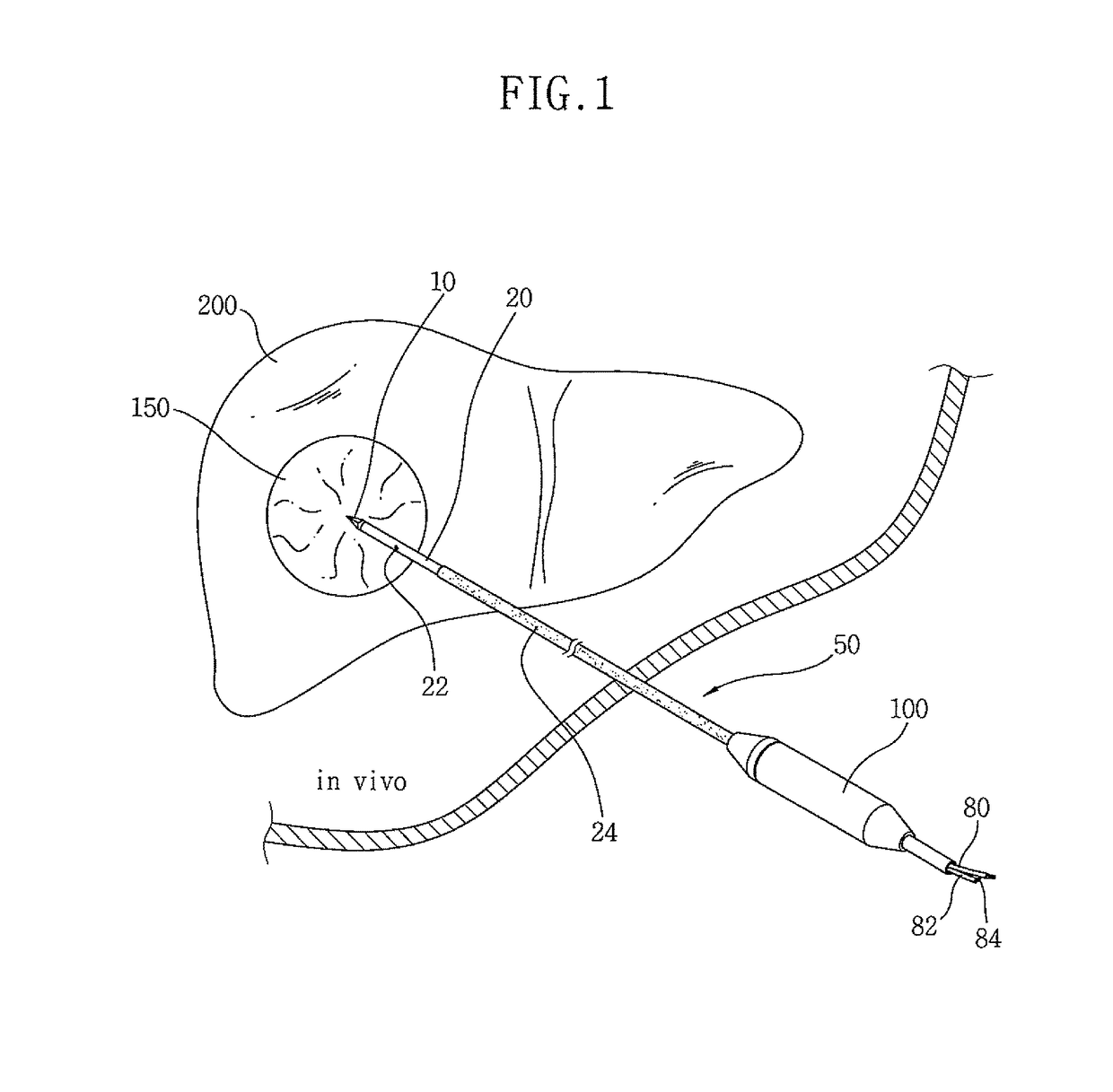

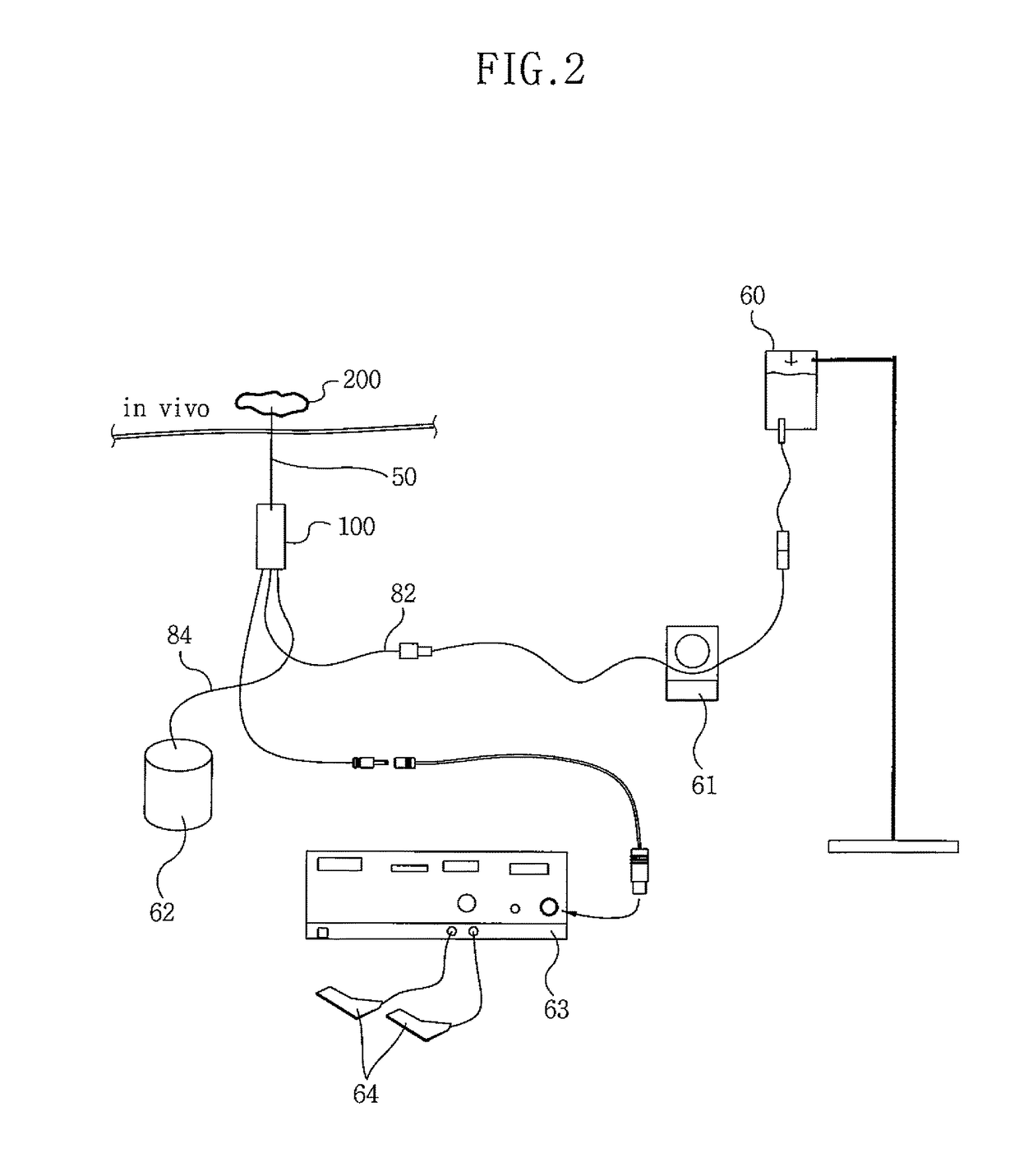

Electrode for radiofrequency tissue ablation

ActiveUS20090287206A1Easy to liftMaximized economicallySurgical needlesSurgical instruments for heatingRadiofrequency ablationElectrosurgery

The present invention relates to an electrode for an electrosurgical unit for the use in ablating and necrosing a living tissue by RF electric energy. The present invention provides an electrode for an electrosurgical unit, including: a hollow electrode formed in an elongated hollow tube shape, a non-insulating region of a predetermined length being formed on one side of which, an insulating region being formed on an outer surface of which other than the non-insulating region; a saline solution circulation structure that supplies pressurized saline solution for cooling a living tissue which is in contact with the hollow electrode from the outside of the living tissue to the inside of the hollow electrode, and discharges the pressurized saline solution from the inside of the hollow electrode to the outside of the living tissue; and one or more saline solution discharge holes formed in the non-insulating region of the hollow electrode to discharge some of the circulating pressurized saline solution to the living tissue which is in contact with the hollow electrode.

Owner:RF MEDICAL

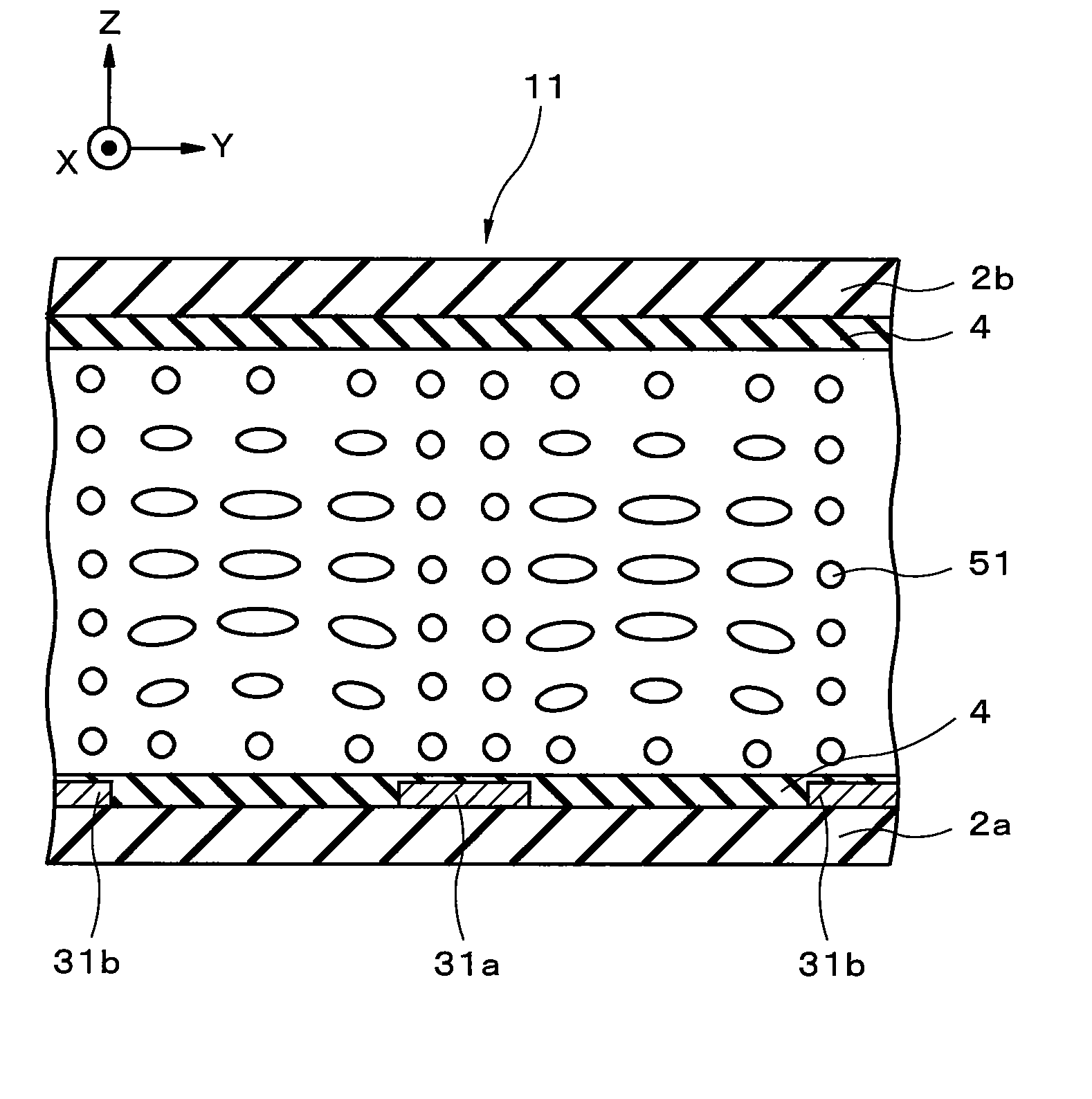

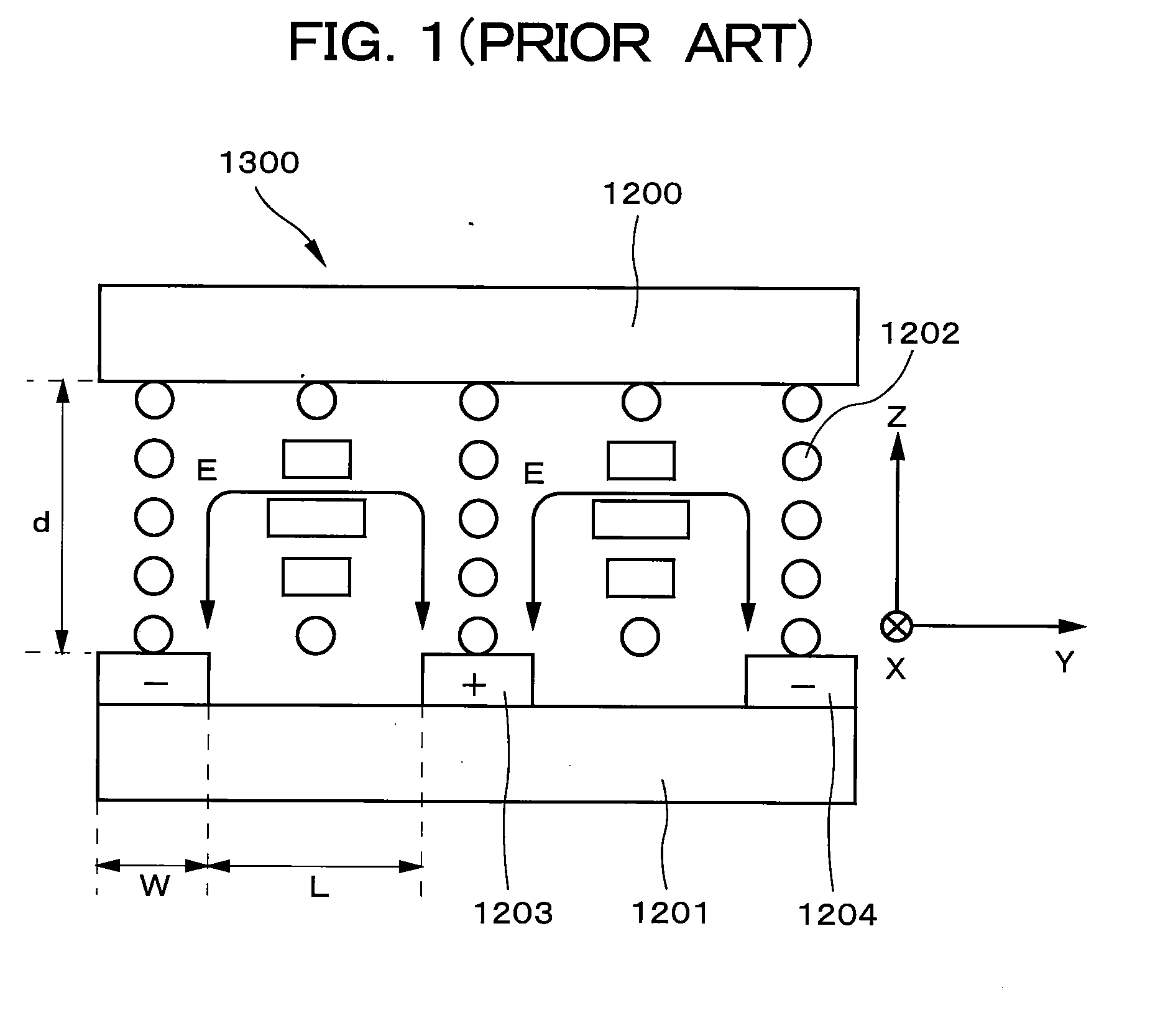

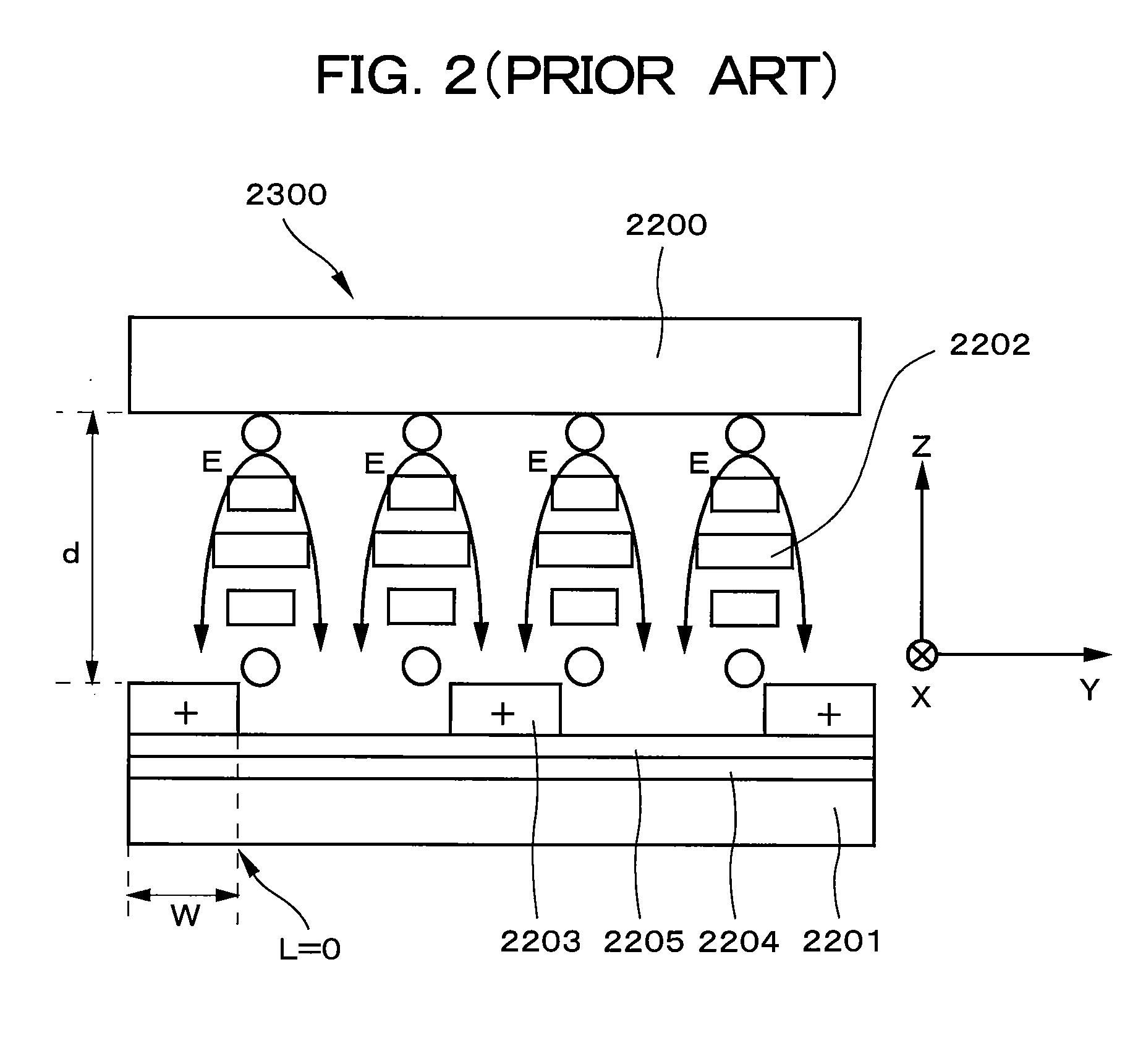

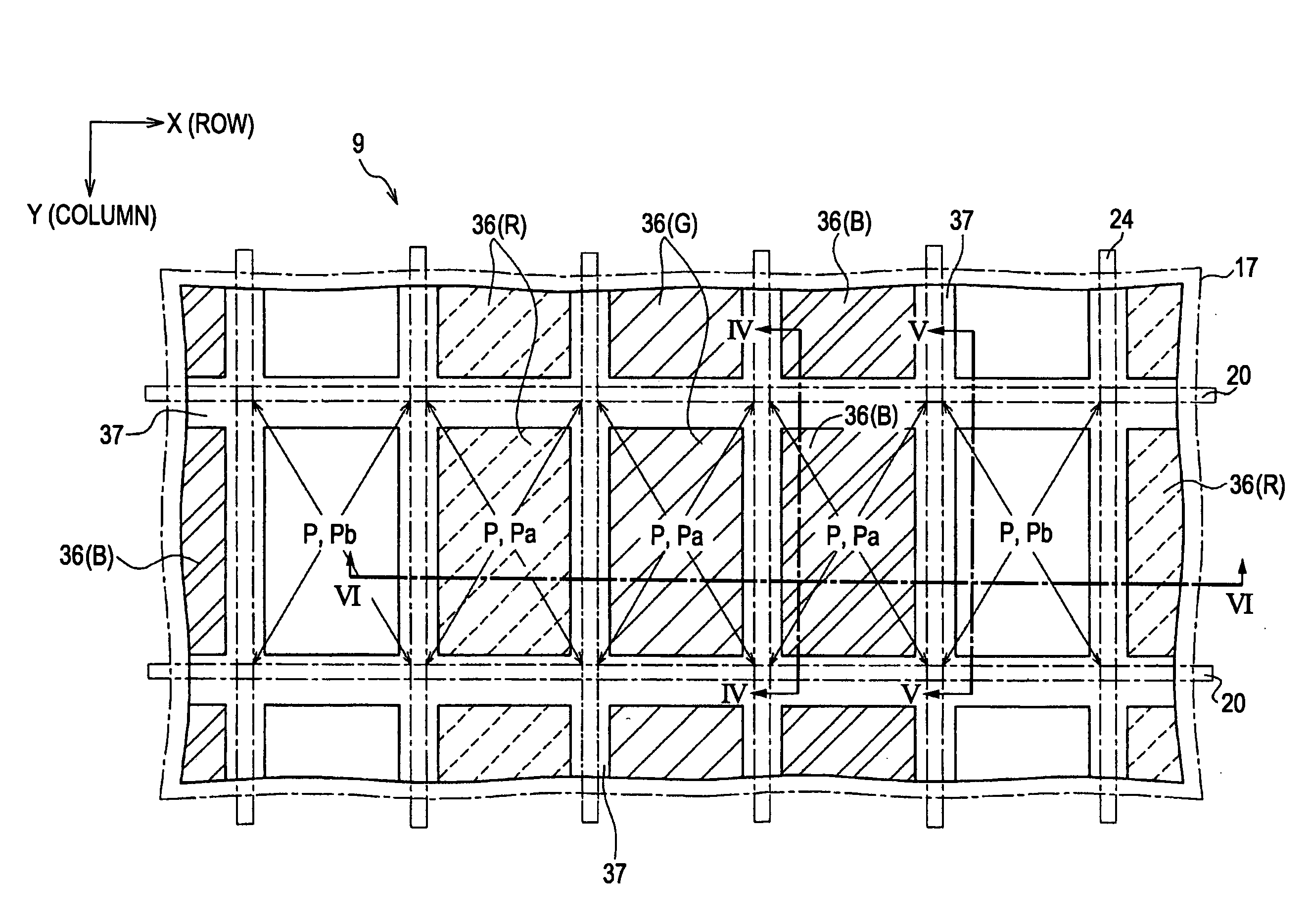

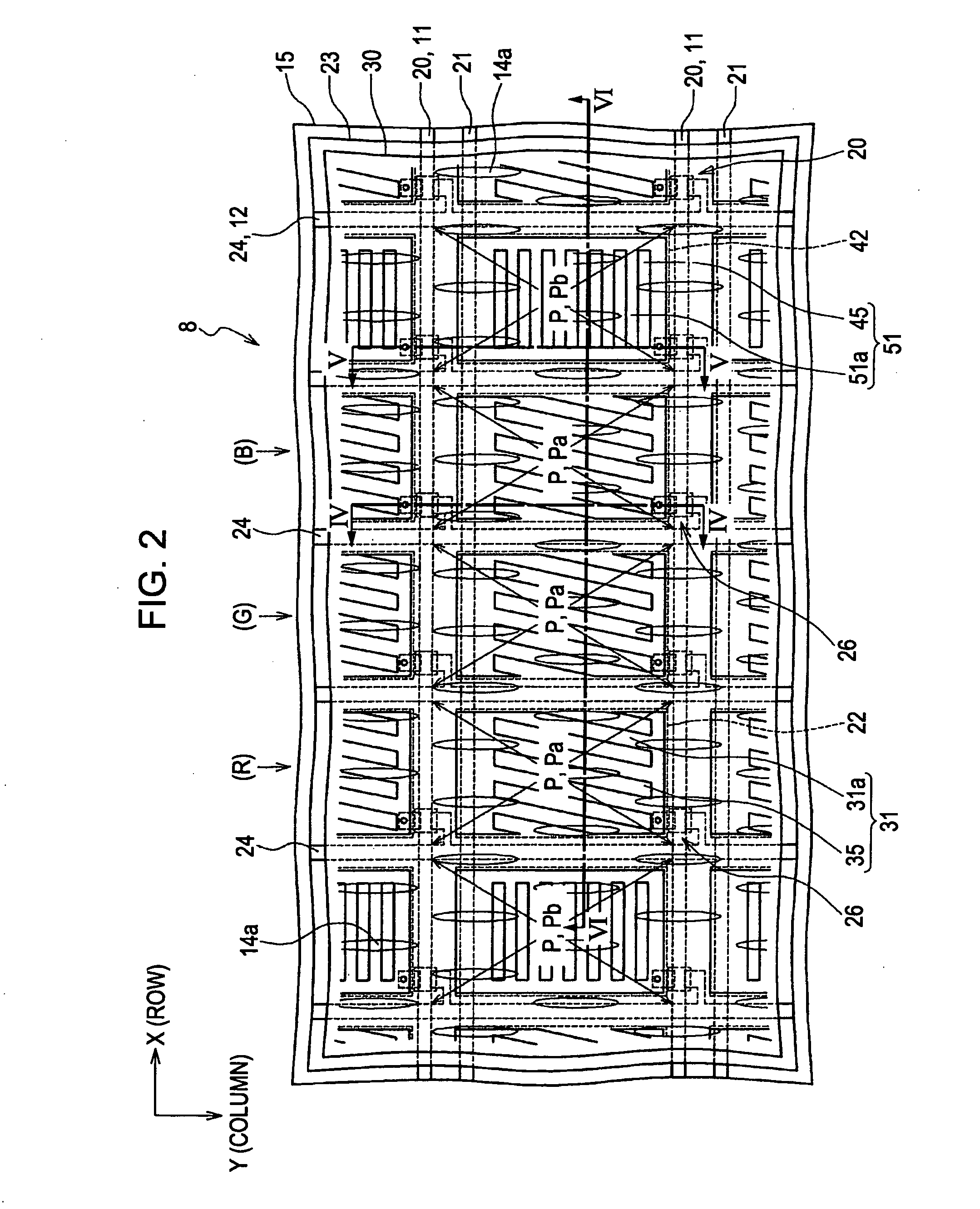

In-plane switching liquid crystal display apparatus

A pixel region between a common electrode and a pixel electrode is composed of a principal portion in which the direction of extension of the common electrode and the pixel electrode is parallel with the initial alignment direction of the liquid crystal molecules, and a specific portion not parallel with the initial alignment direction of the liquid crystal molecules. In the specific portion, the distal portion of the pixel electrode and the basal portion of the common electrode are mutually parallel and inclined by a prescribed angle with respect to the initial alignment direction of the liquid crystal molecules. When voltage is applied across the common electrode and the pixel electrode to generate a horizontal electric field, the horizontal electric field will be perpendicular to the initial alignment direction of the liquid crystal molecules within the principal portion that occupies a major part of a column, whereas the field will not be perpendicular within the specific portion. The principal portion occupies the major part of the column.

Owner:NEC LCD TECH CORP

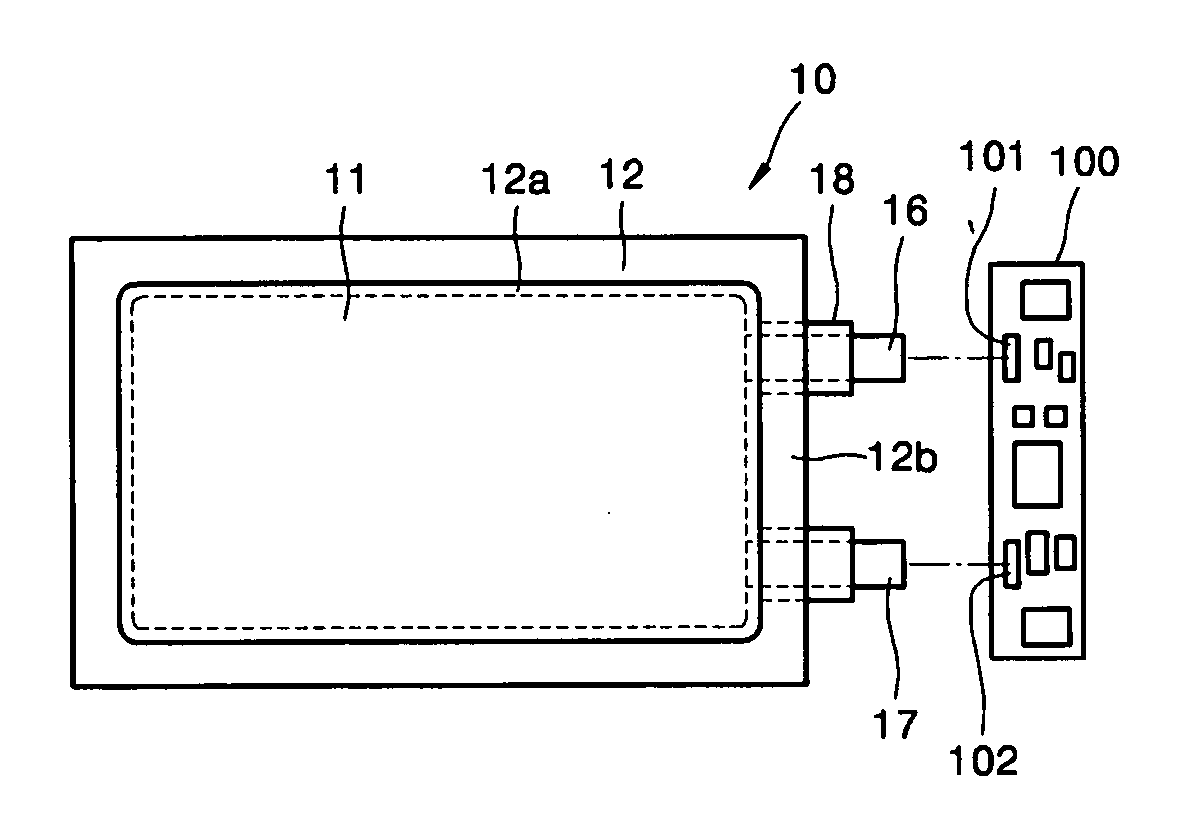

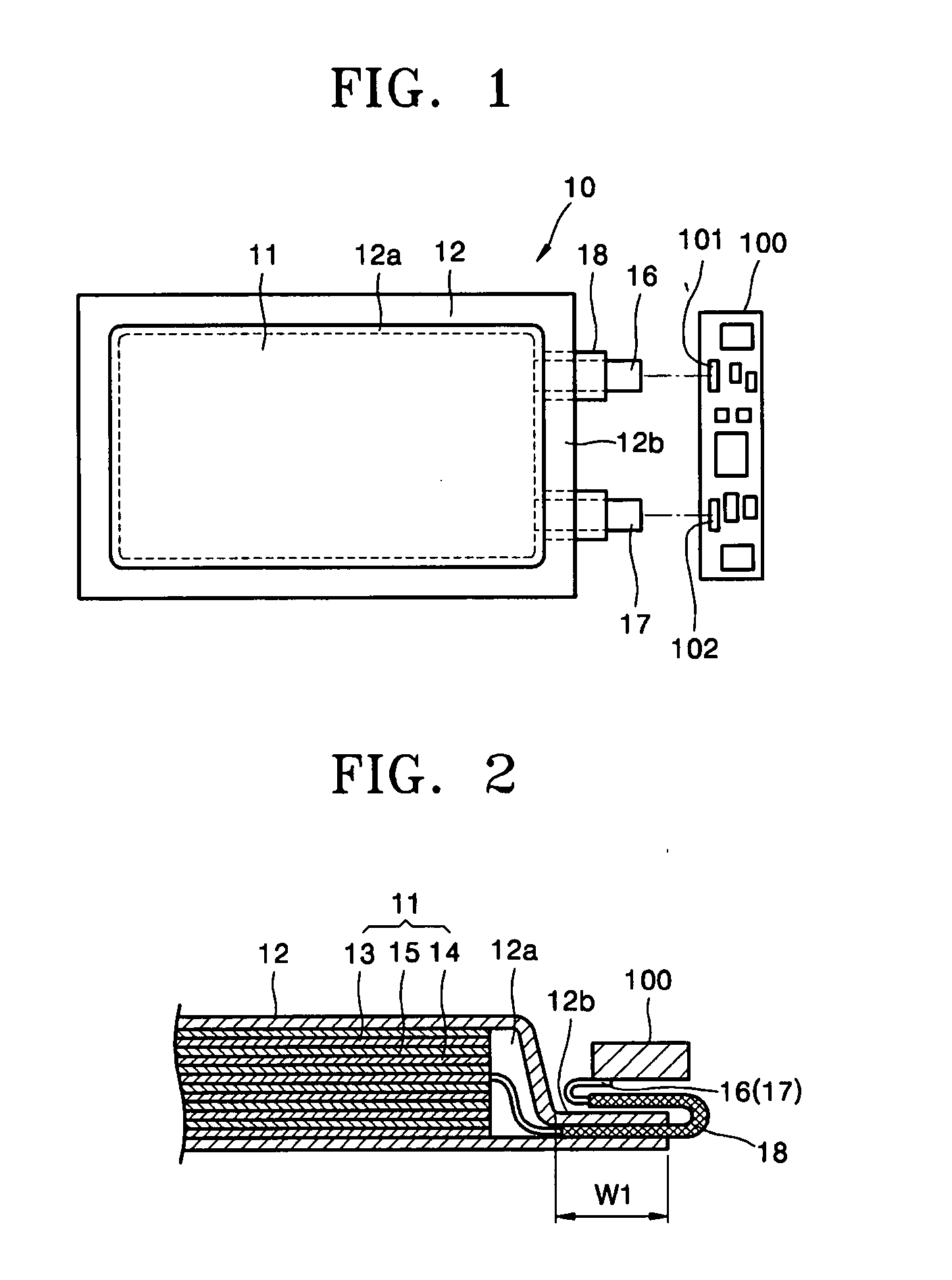

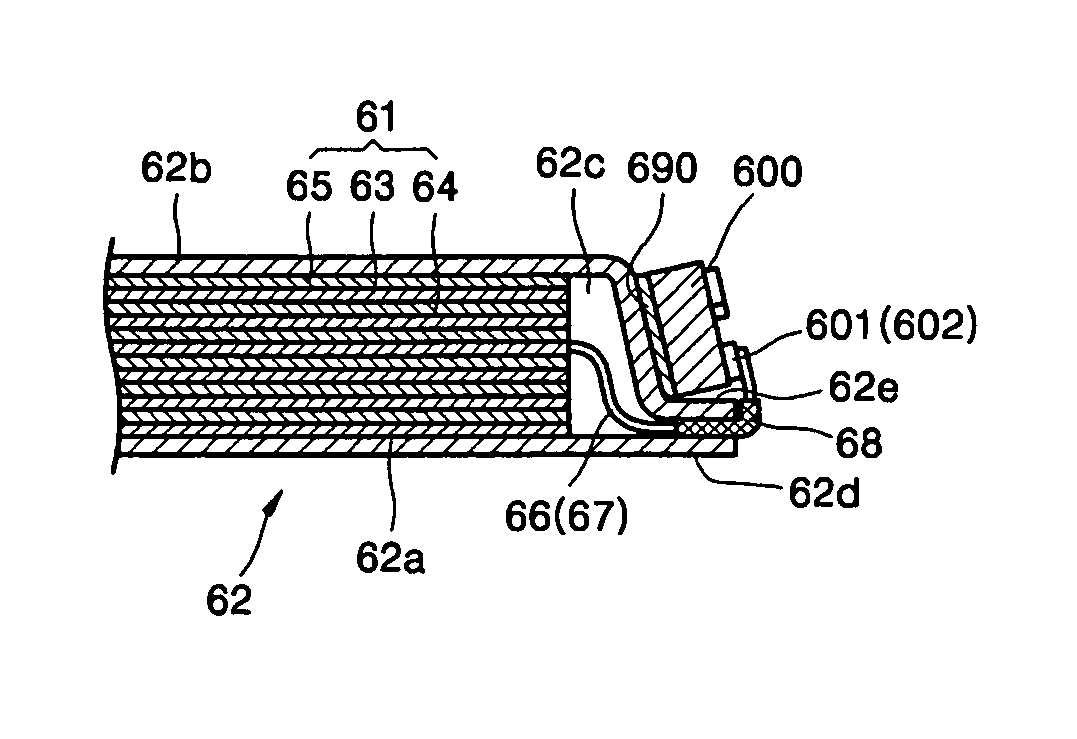

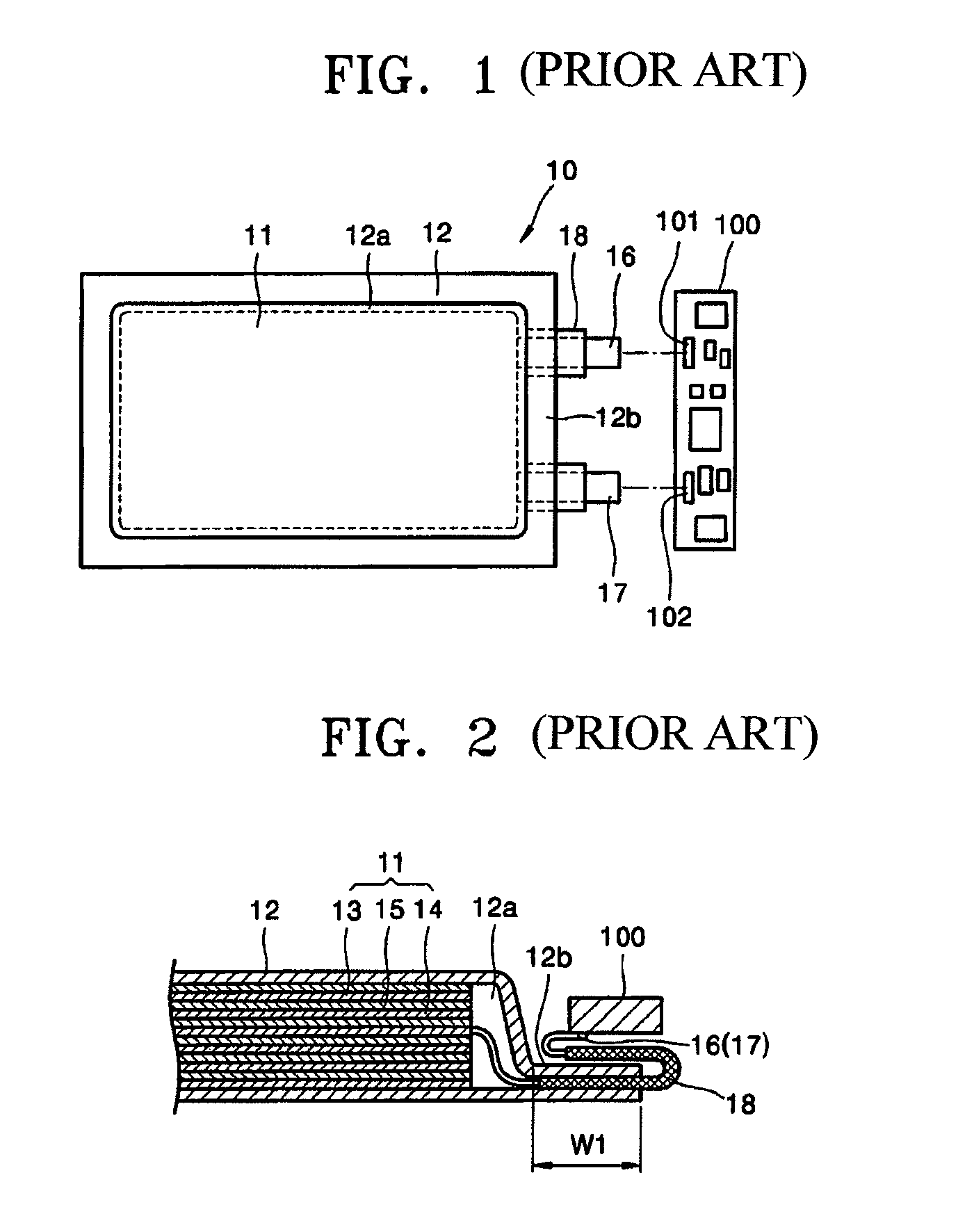

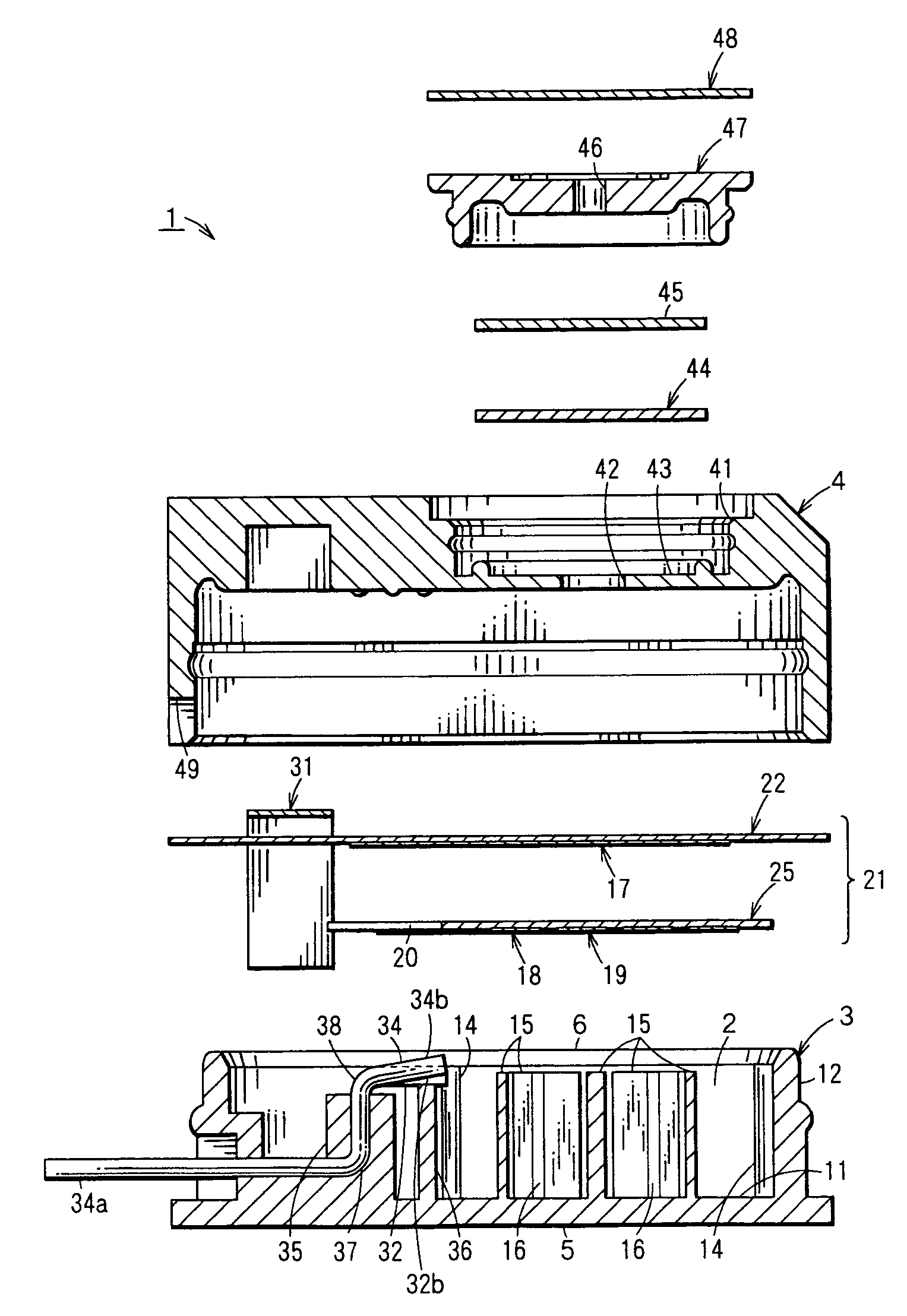

Pouch-type lithium secondary battery and fabrication method thereof

ActiveUS20060068275A1Minimizes seal surfaceStrengthen the connection structureFinal product manufactureCells structural combinationLithiumEngineering

A pouch-type lithium secondary battery including: a battery unit comprising a positive electrode plate, a separator, and a negative electrode plate, wherein the separator is disposed between the positive and negative electrode plates; electrode tabs extending from each of the positive and negative electrode plates of the battery unit, respectively; a case having a space to accommodate the battery unit and sealing surfaces formed along the periphery of the space, wherein the case is sealed at the sealing surfaces by thermal fusion; and a protection circuit board 600 electrically connected to the electrode tabs. The protection circuit board is disposed parallel to an outer wall of the case. Since the electrode tabs are bent in an upright position with respect to the sealing surfaces, and the protection circuit board electrically connected to the bent electrode tabs is disposed between the outer wall of the case and the electrode tabs, the size of the sealing surfaces of the case can be minimized.

Owner:SAMSUNG SDI CO LTD

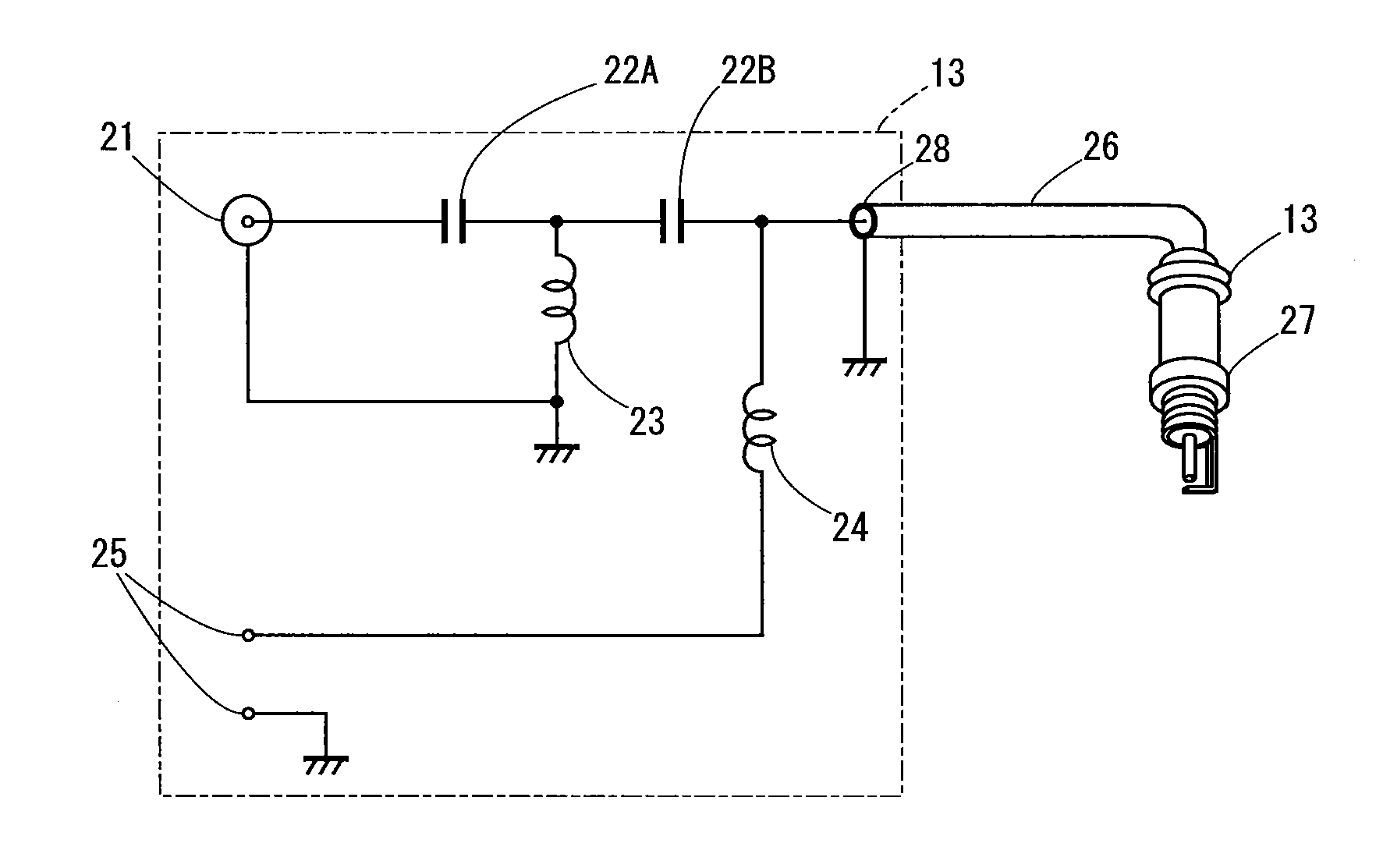

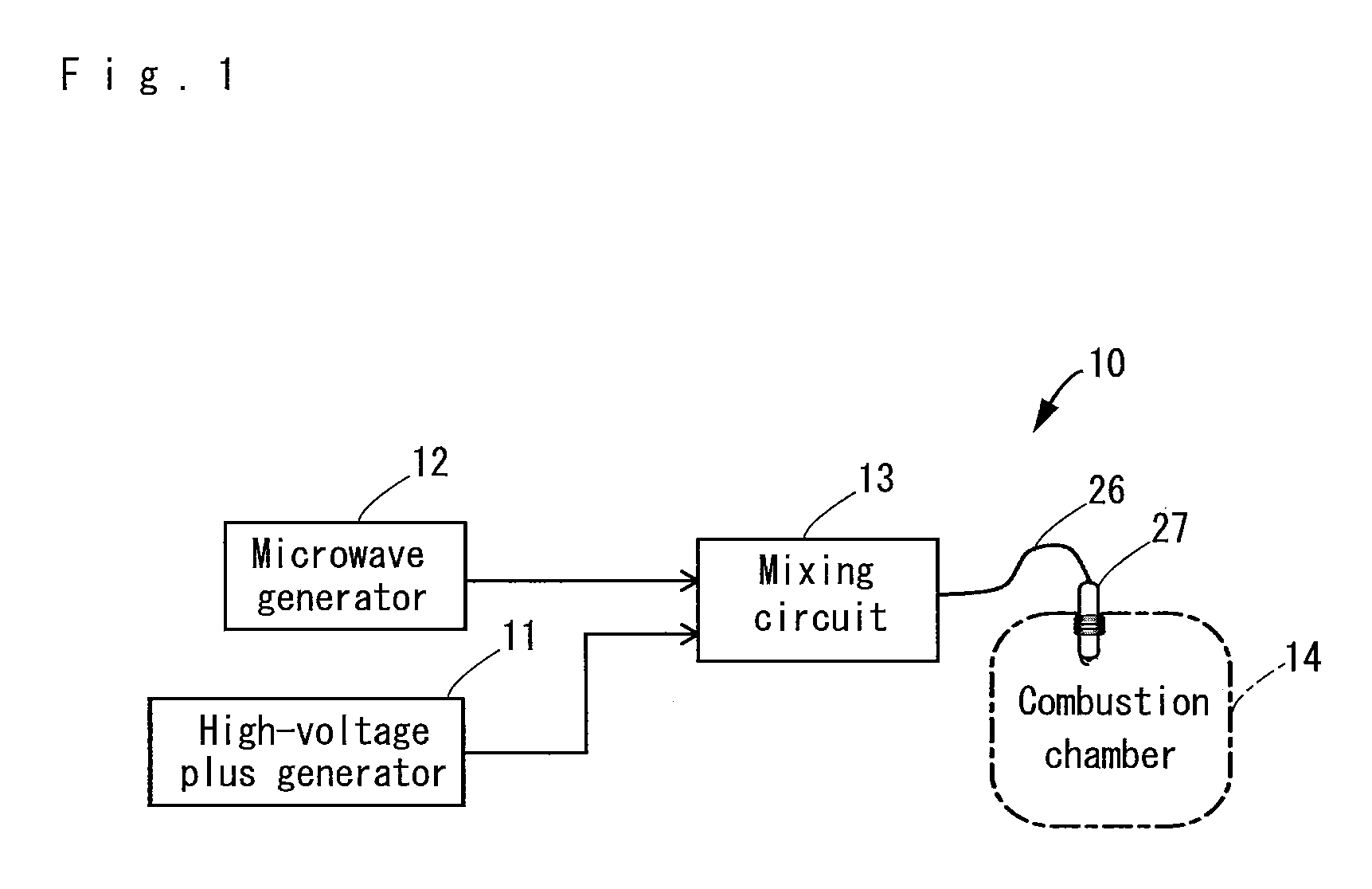

Ignition or plasma generation apparatus

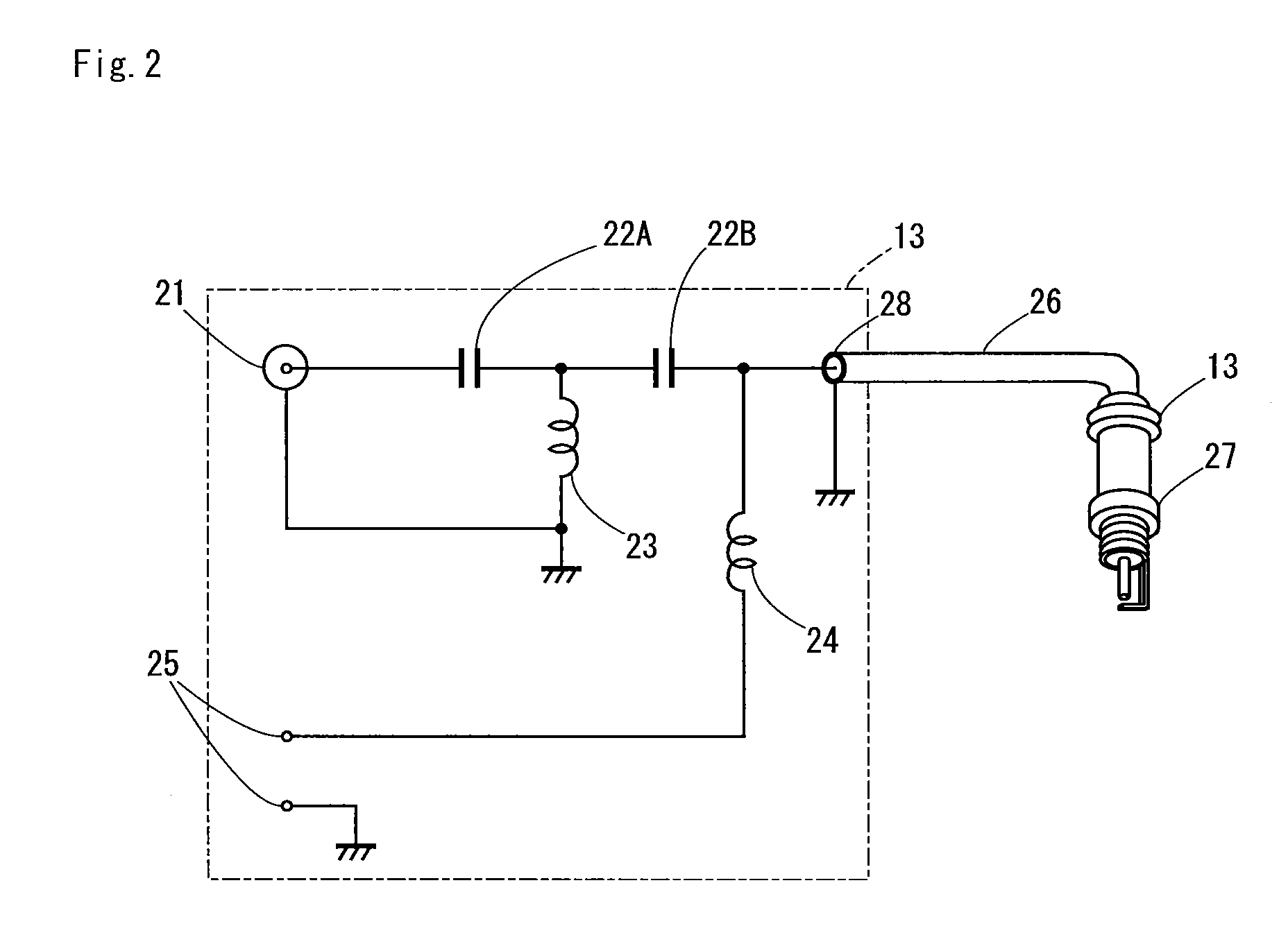

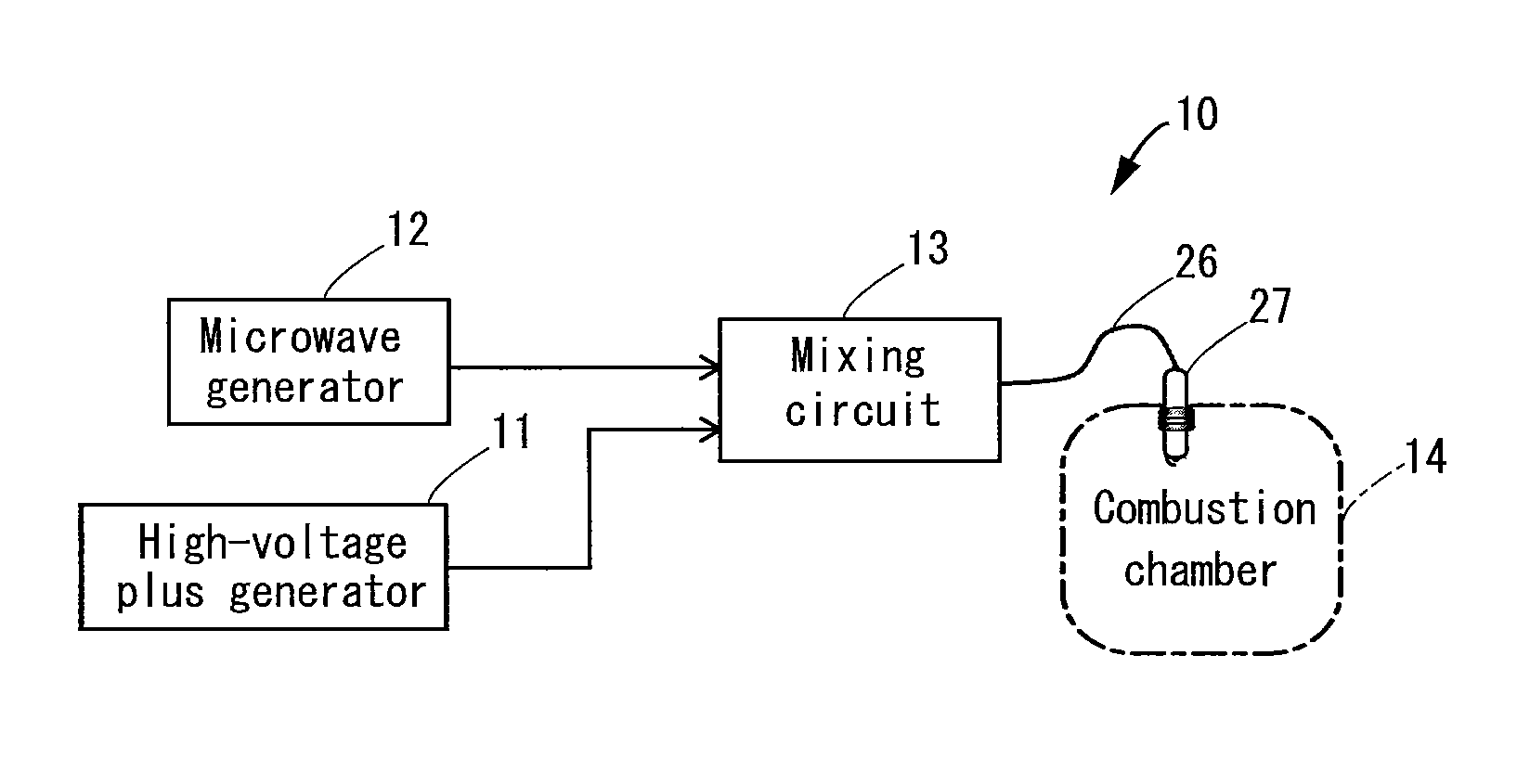

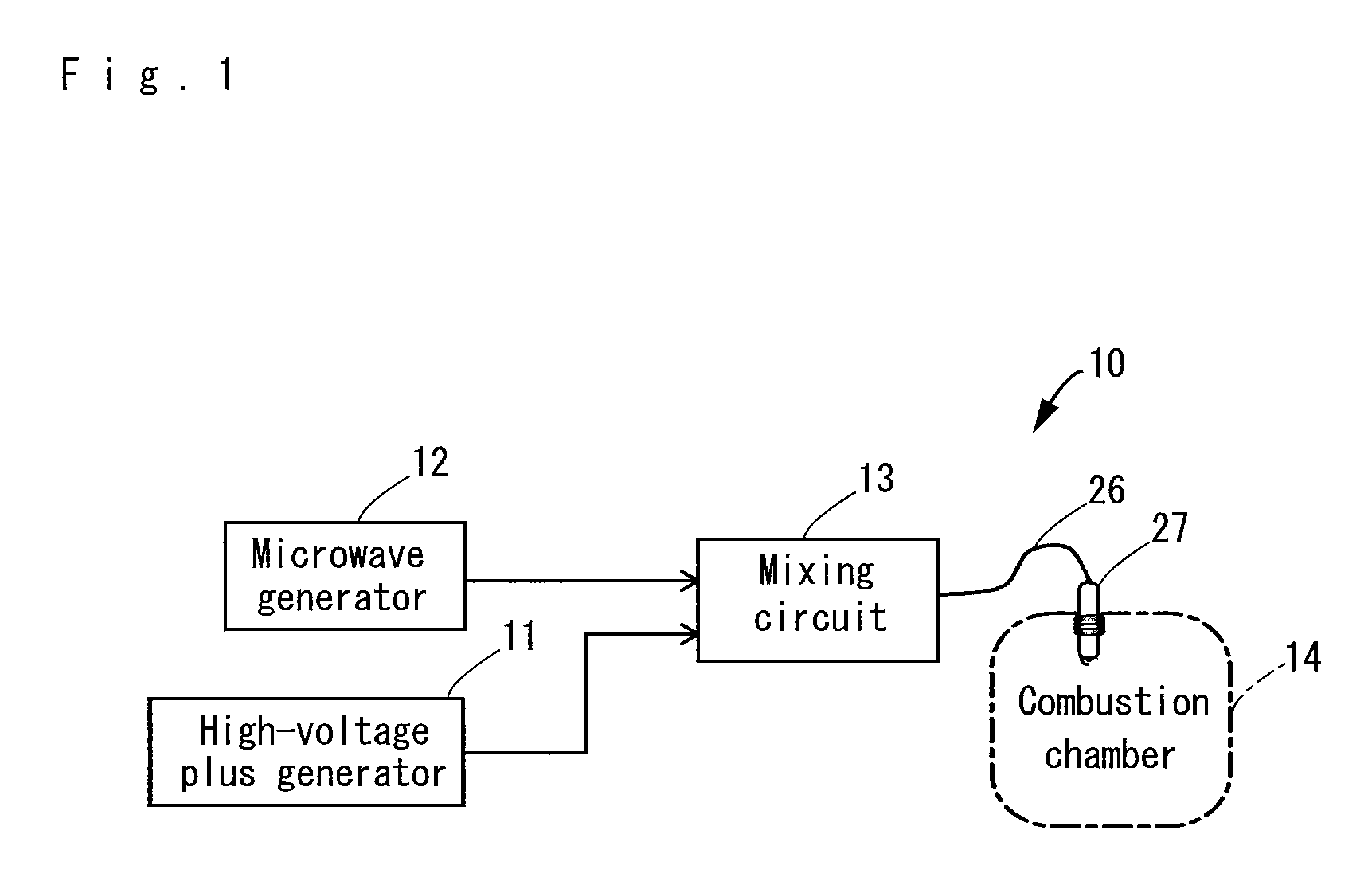

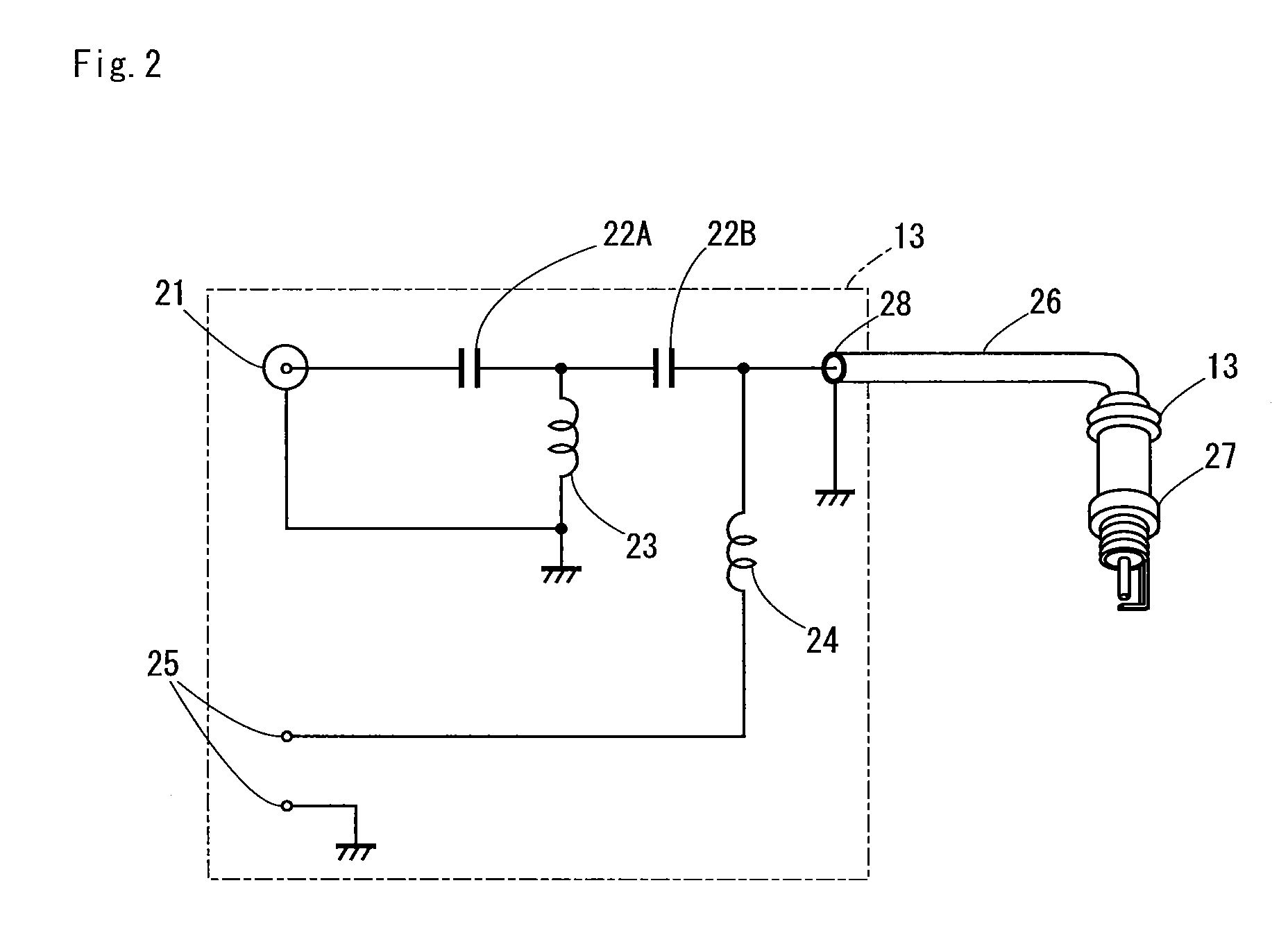

InactiveUS20100196208A1Easy to mass produceEasy wiringSparking plugsMaterial analysis by electric/magnetic meansCombustion chamberMicrowave

There is provided an ignition or plasma generation apparatus that eliminates the need for resonance means in a combustion chamber and simplifies the electrode structure within the combustion chamber in an instance where energy from each of a spark discharge and microwaves is used to ignite an air-fuel mixture gas in an internal combustion engine. The ignition or plasma generation apparatus includes a mixing circuit for mixing a high-voltage pulse from a high-voltage pulse generator and microwave energy from a microwave generator; and an ignition plug into which an output from the mixing circuit is supplied, the plug used for introducing the output into a combustion chamber of an internal combustion engine. The output supplied from the mixing circuit to the ignition plug is supplied in a manner in which the microwave energy and the high-voltage pulse are superimposed on each other on a same transmission line.

Owner:MAGINEERING INC

Ignition or plasma generation apparatus

InactiveUS8226901B2Simple electrode structureEliminate needSparking plugsMaterial analysis by electric/magnetic meansCombustion chamberMicrowave

There is provided an ignition or plasma generation apparatus that eliminates the need for resonance means in a combustion chamber and simplifies the electrode structure within the combustion chamber in an instance where energy from each of a spark discharge and microwaves is used to ignite an air-fuel mixture gas in an internal combustion engine. The ignition or plasma generation apparatus includes a mixing circuit for mixing a high-voltage pulse from a high-voltage pulse generator and microwave energy from a microwave generator; and an ignition plug into which an output from the mixing circuit is supplied, the plug used for introducing the output into a combustion chamber of an internal combustion engine. The output supplied from the mixing circuit to the ignition plug is supplied in a manner in which the microwave energy and the high-voltage pulse are superimposed on each other on a same transmission line.

Owner:MAGINEERING INC

Liquid crystal display device and terminal device that uses same

ActiveUS20070146603A1High light transmittanceSimple electrode structureLiquid crystal compositionsNon-linear opticsIn planeTransmittance

In a liquid crystal display device, a liquid crystal layer is provided between a principal substrate and an opposing substrate that are disposed so as to face each other, and a shared electrode and a pixel electrode, which is a parallel electrode pair formed in the shape of a comb, are formed on the surface of the principal substrate that faces the opposing substrate. Orientation films are also formed on the opposing surfaces of the principal substrate and the opposing substrate. The electrodes of the parallel electrode pair are formed so that the width thereof is smaller than the thickness of the liquid crystal layer. The orientation of the liquid crystal molecules between the electrodes is thereby changed by an electric field generated by the parallel electrode pair, and the orientation of liquid crystal molecules disposed above the electrodes is changed in the same direction as in the liquid crystal molecules between the electrodes in accordance with the change in orientation of the liquid crystal molecules between the electrodes. A high degree of transmittance can thereby be achieved by a simple electrode structure in an in-plane switching liquid crystal display device.

Owner:NEC LCD TECH CORP

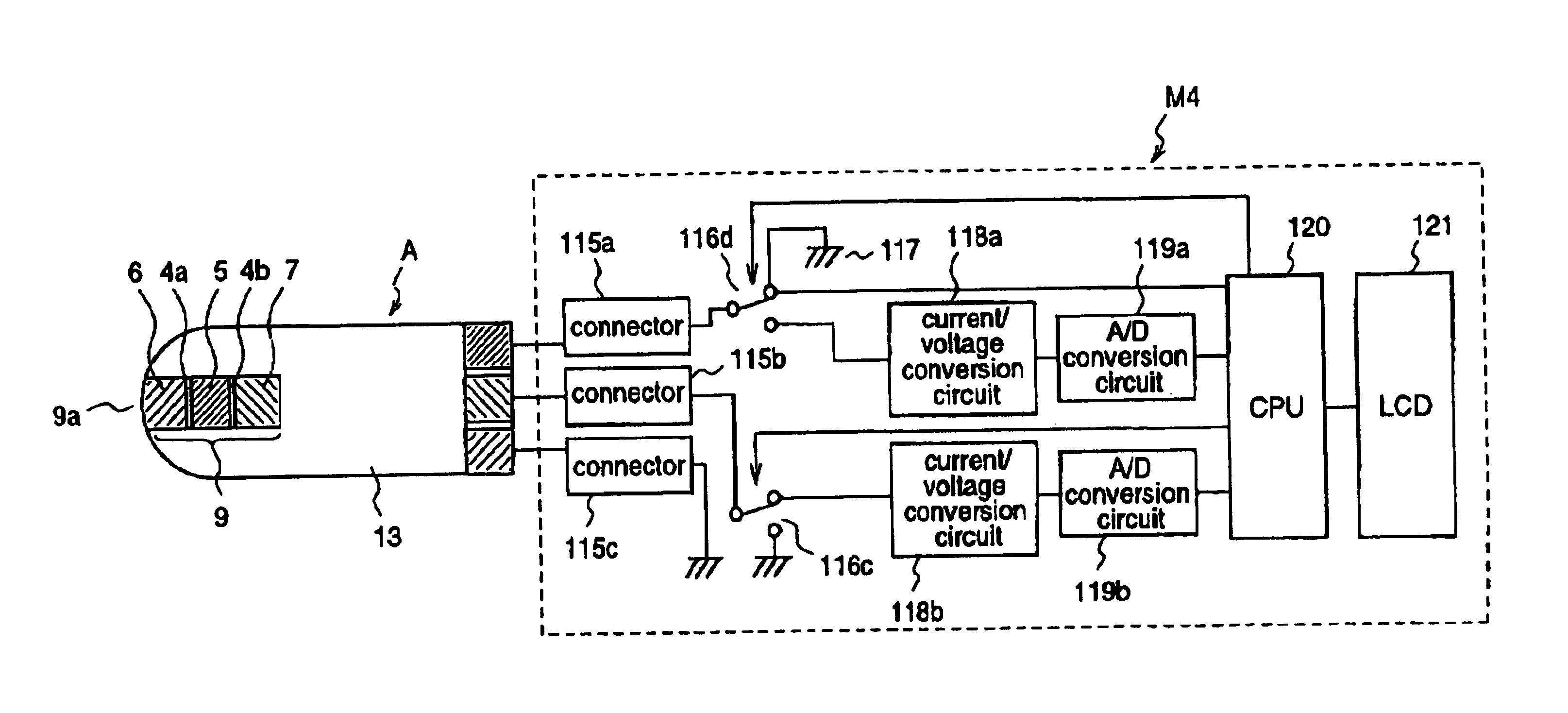

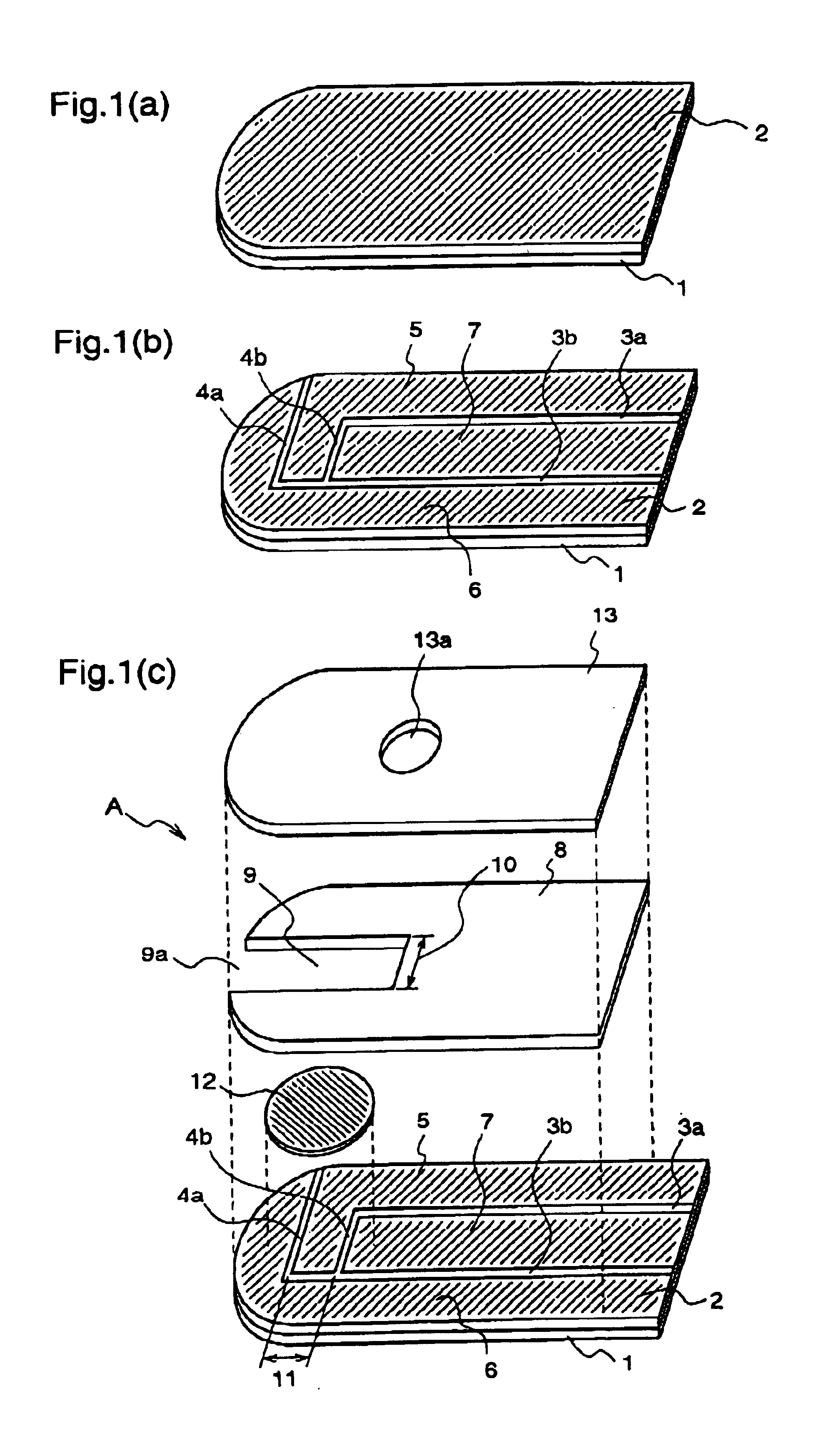

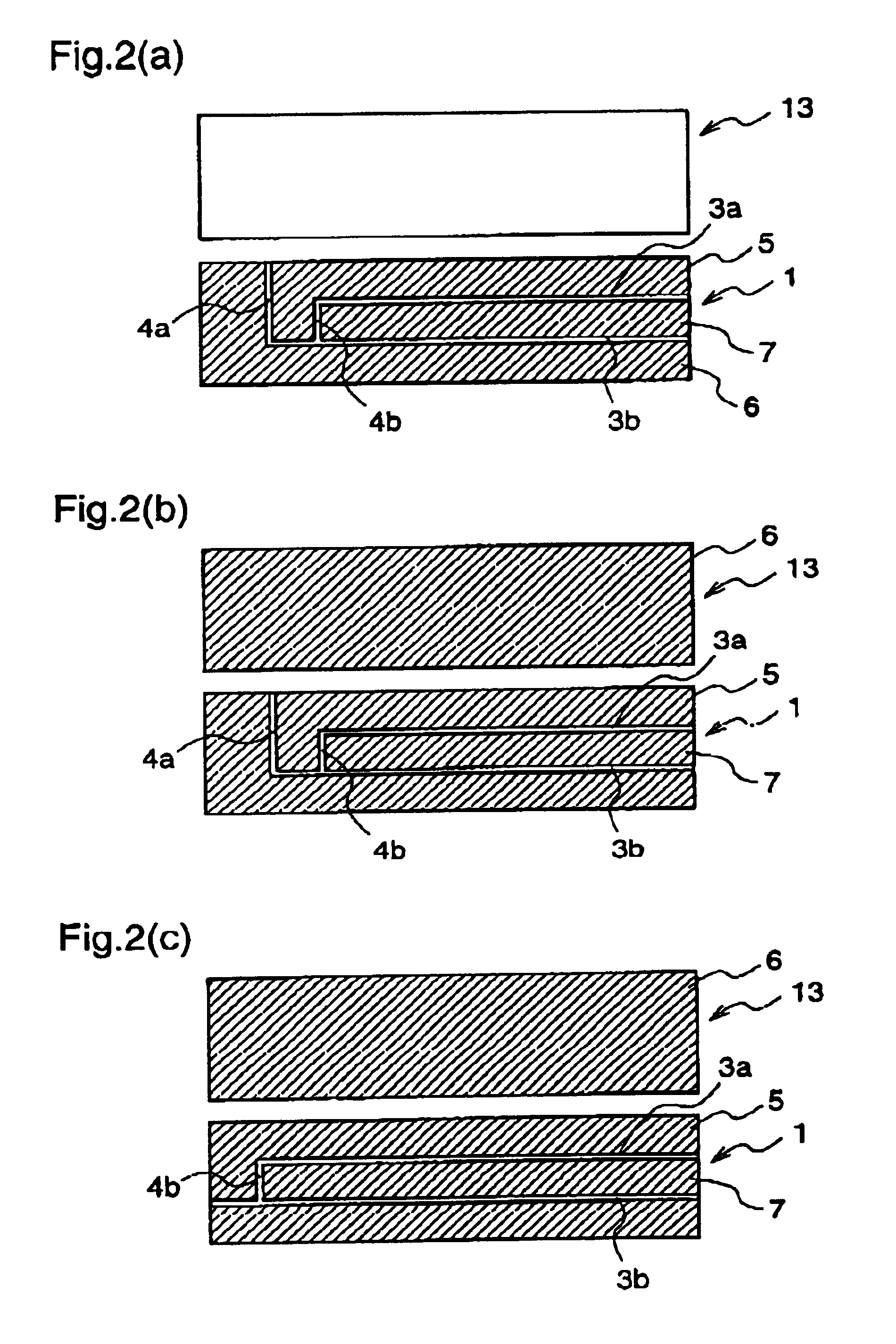

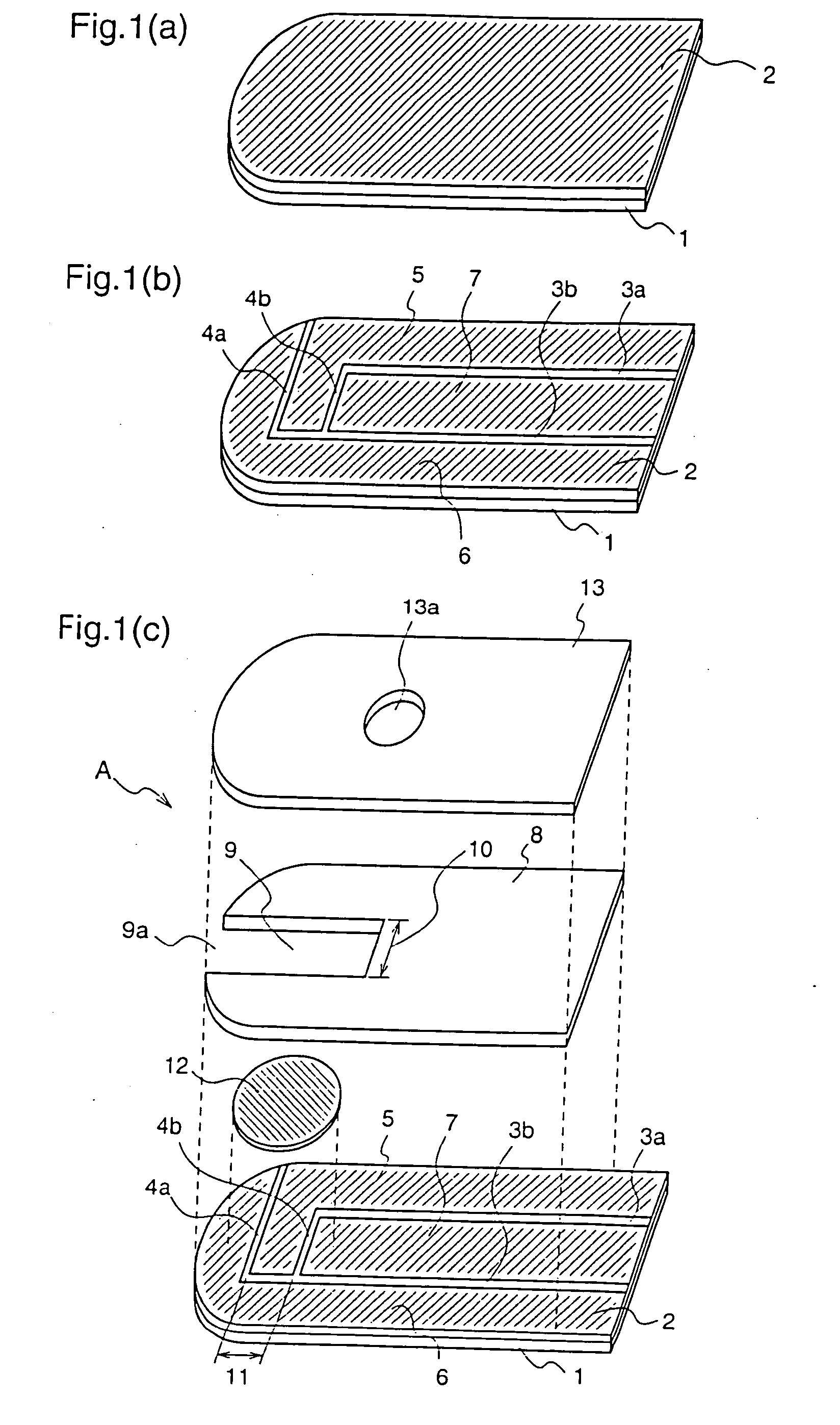

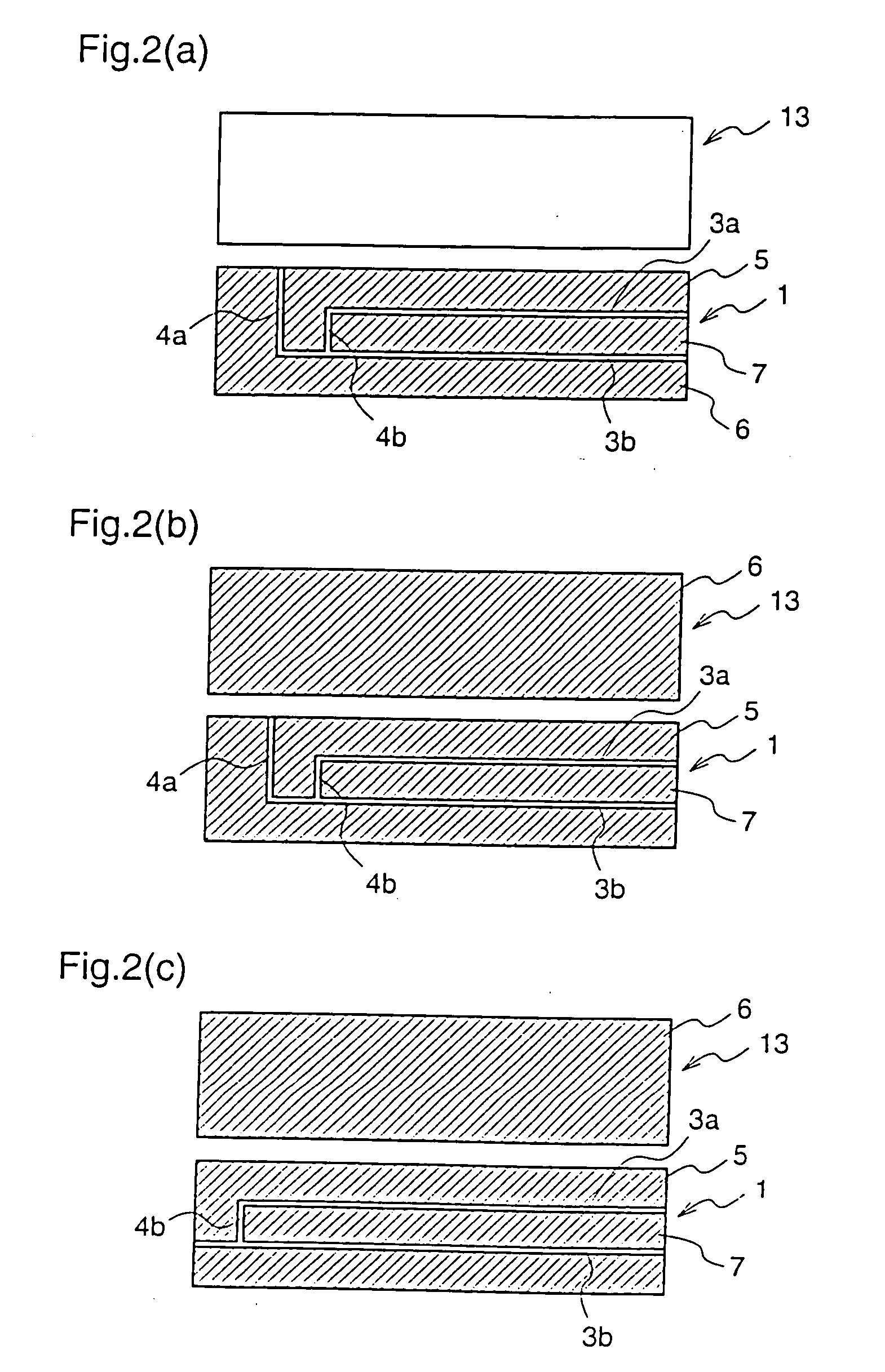

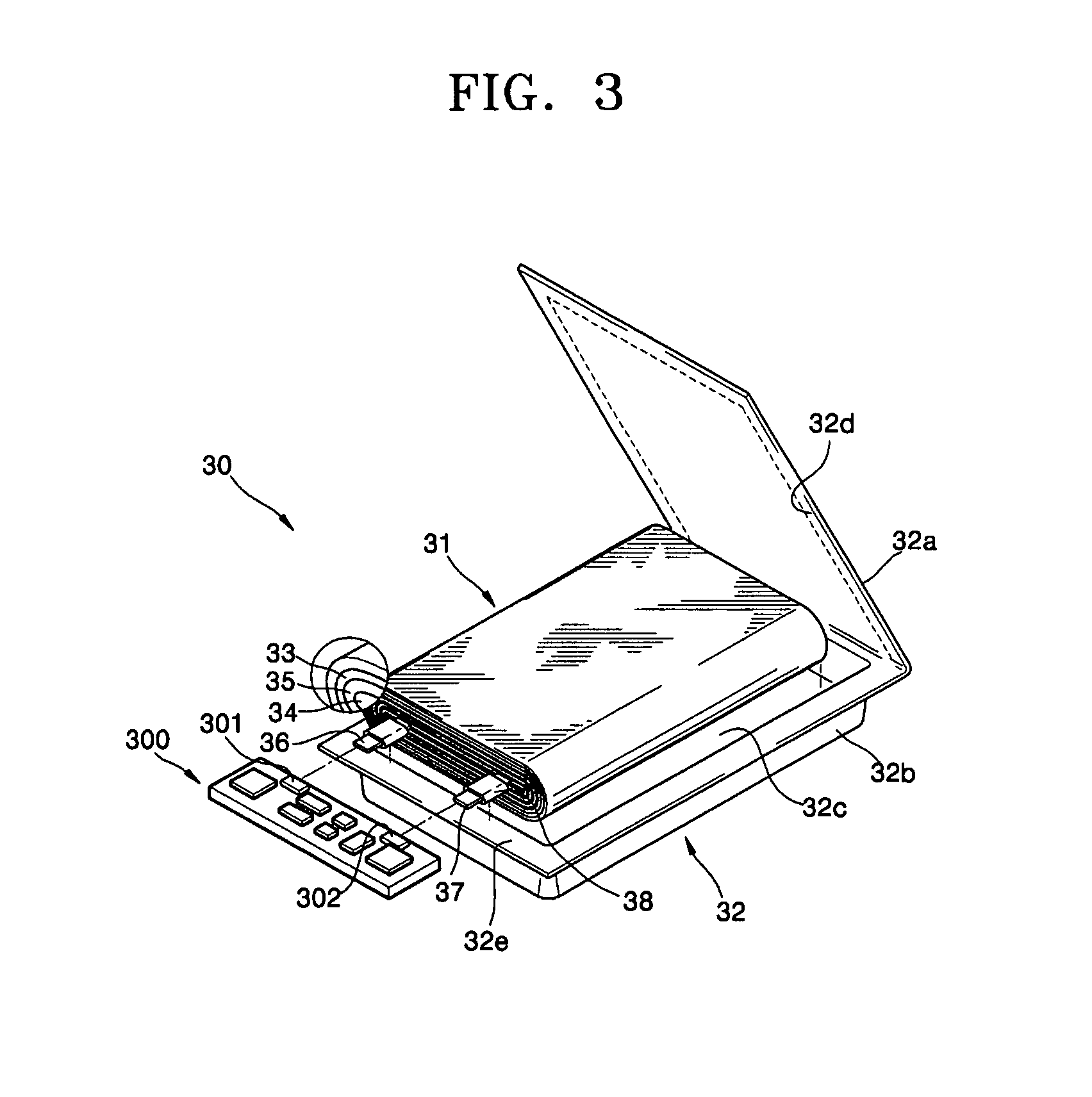

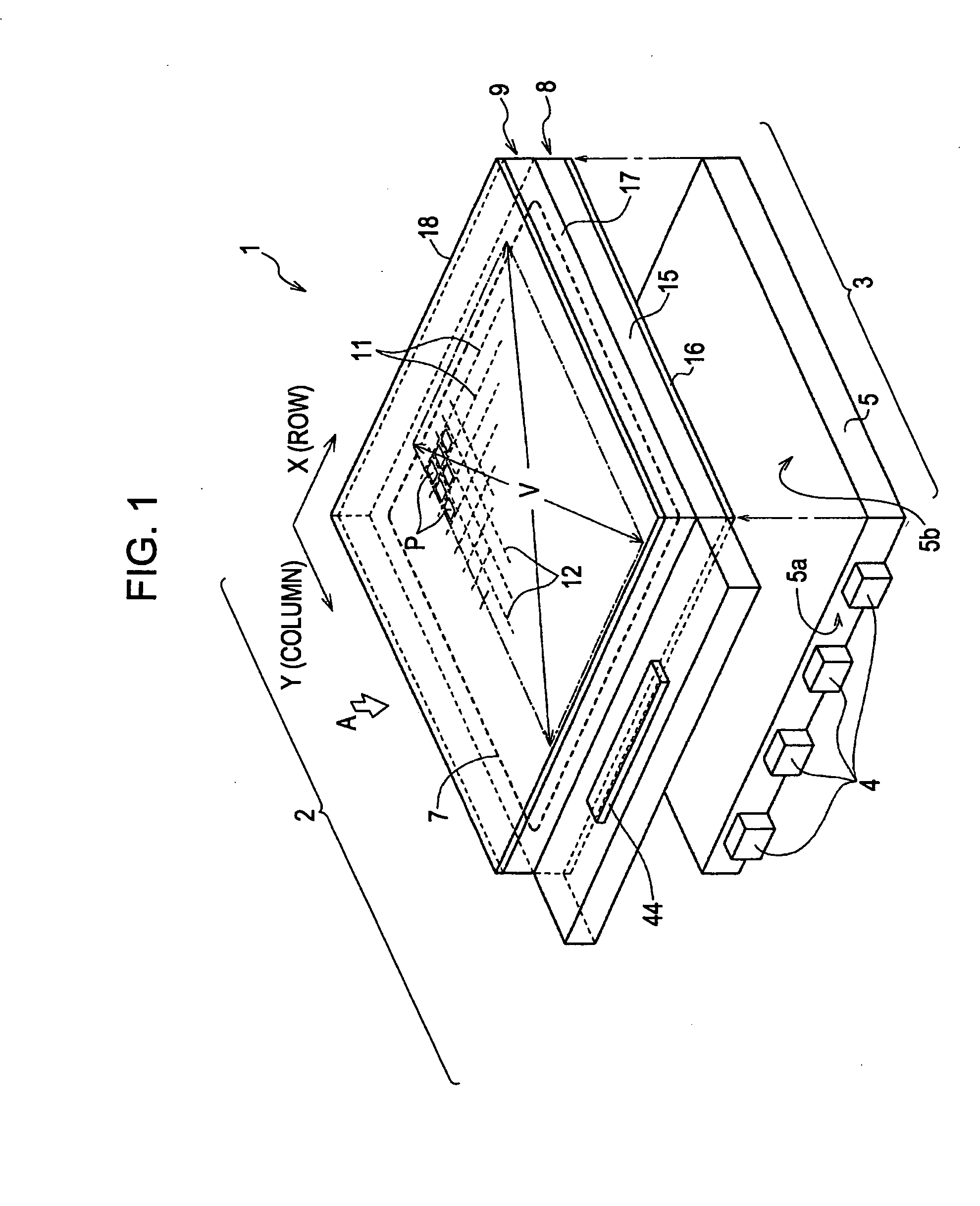

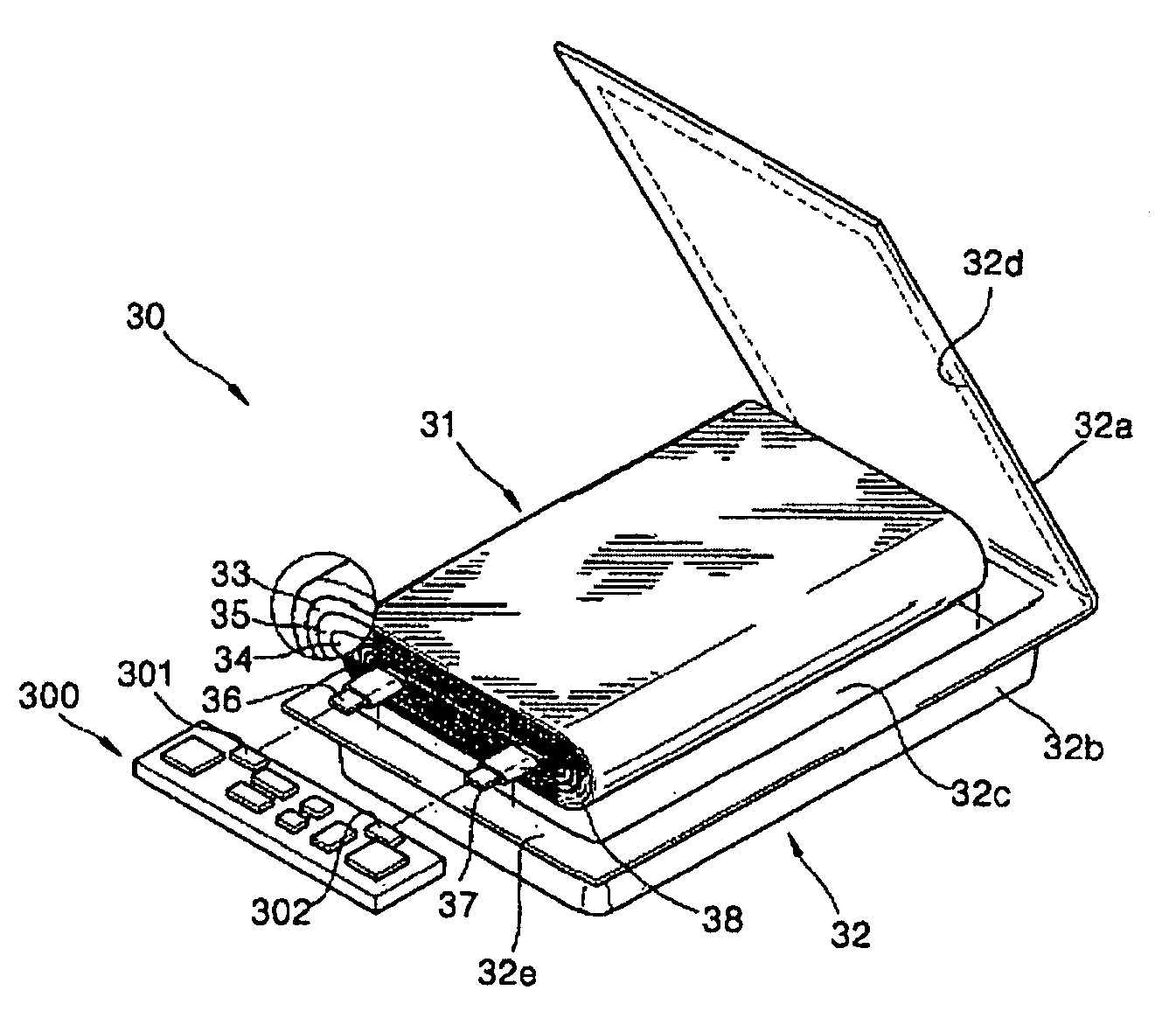

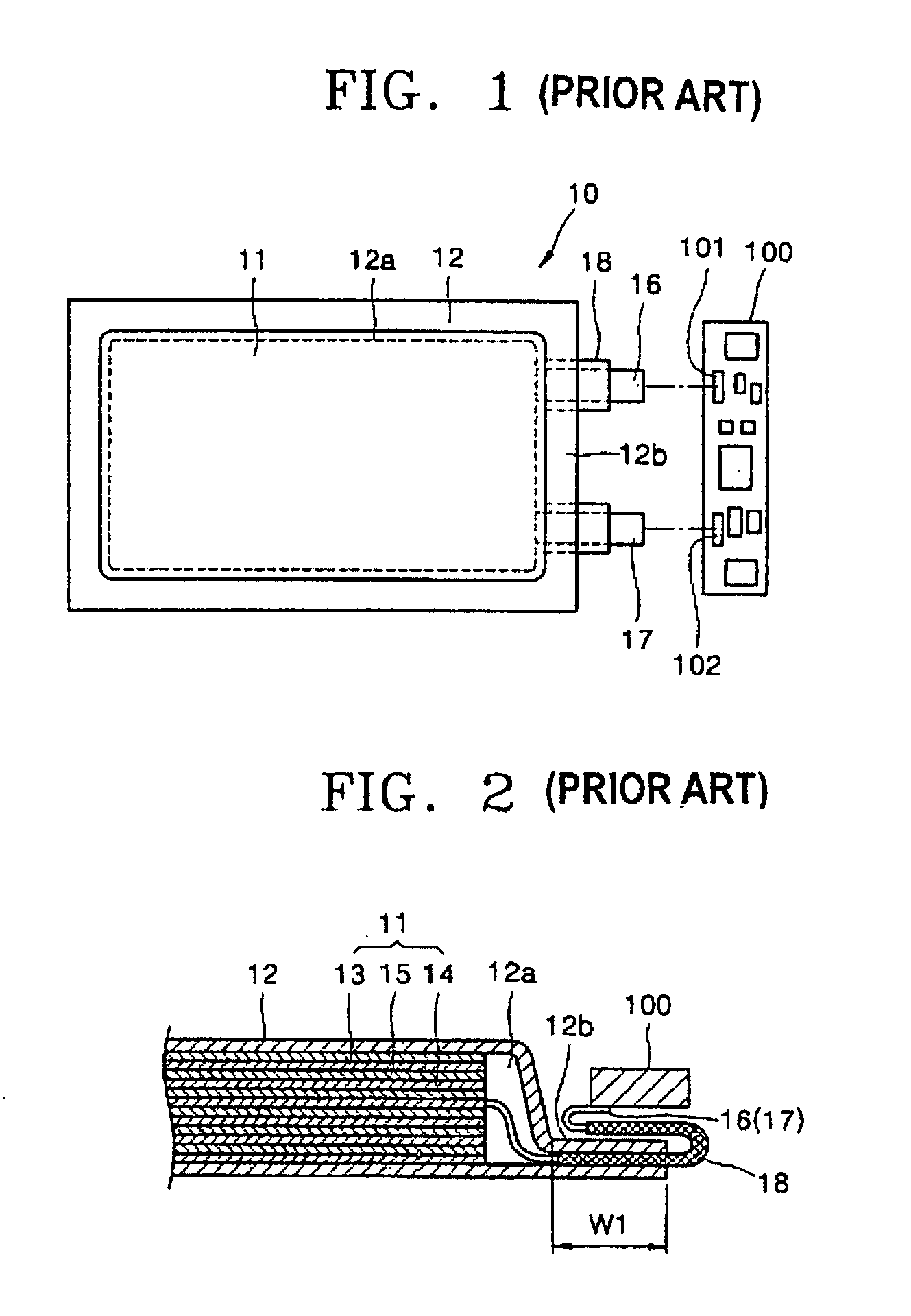

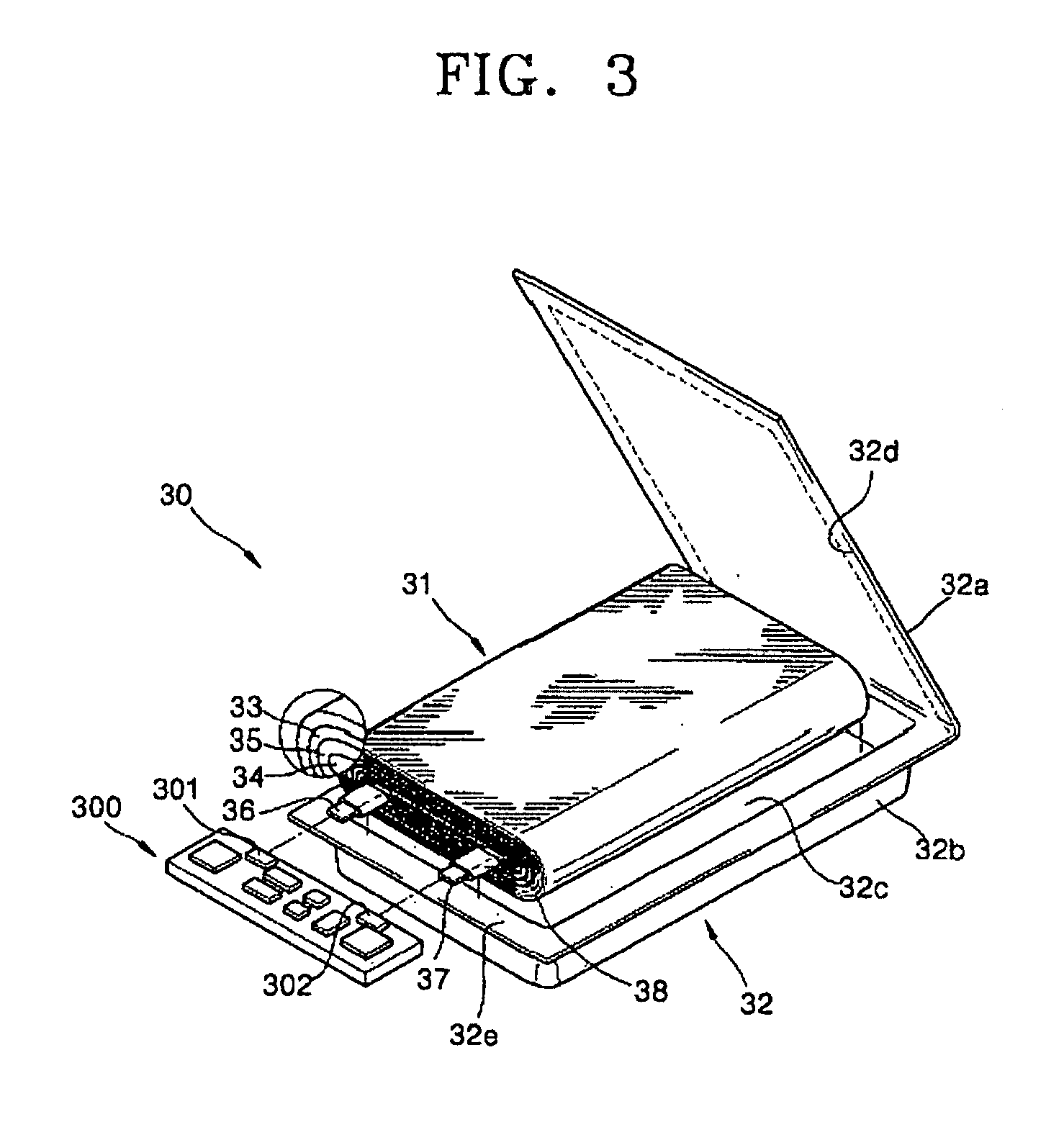

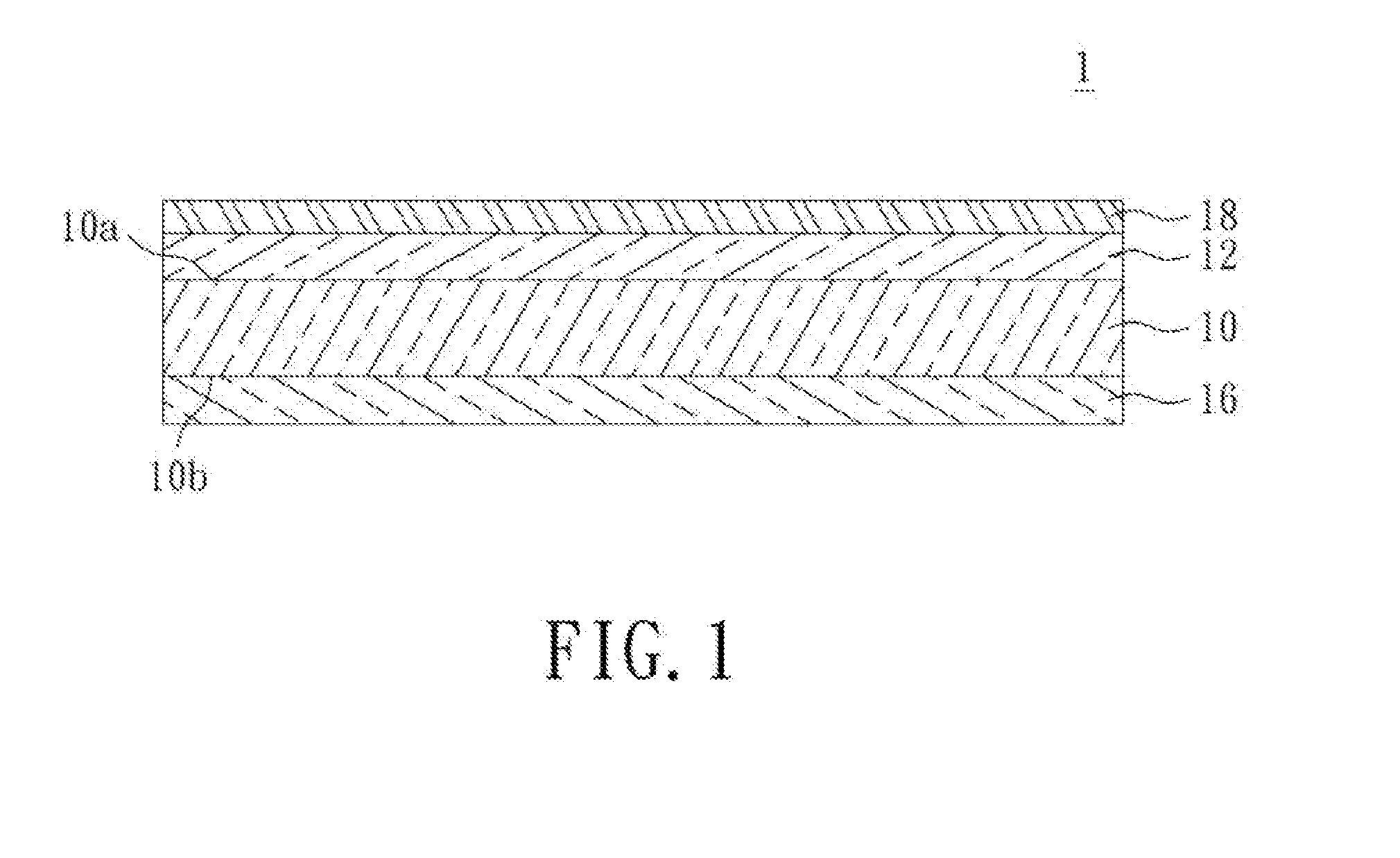

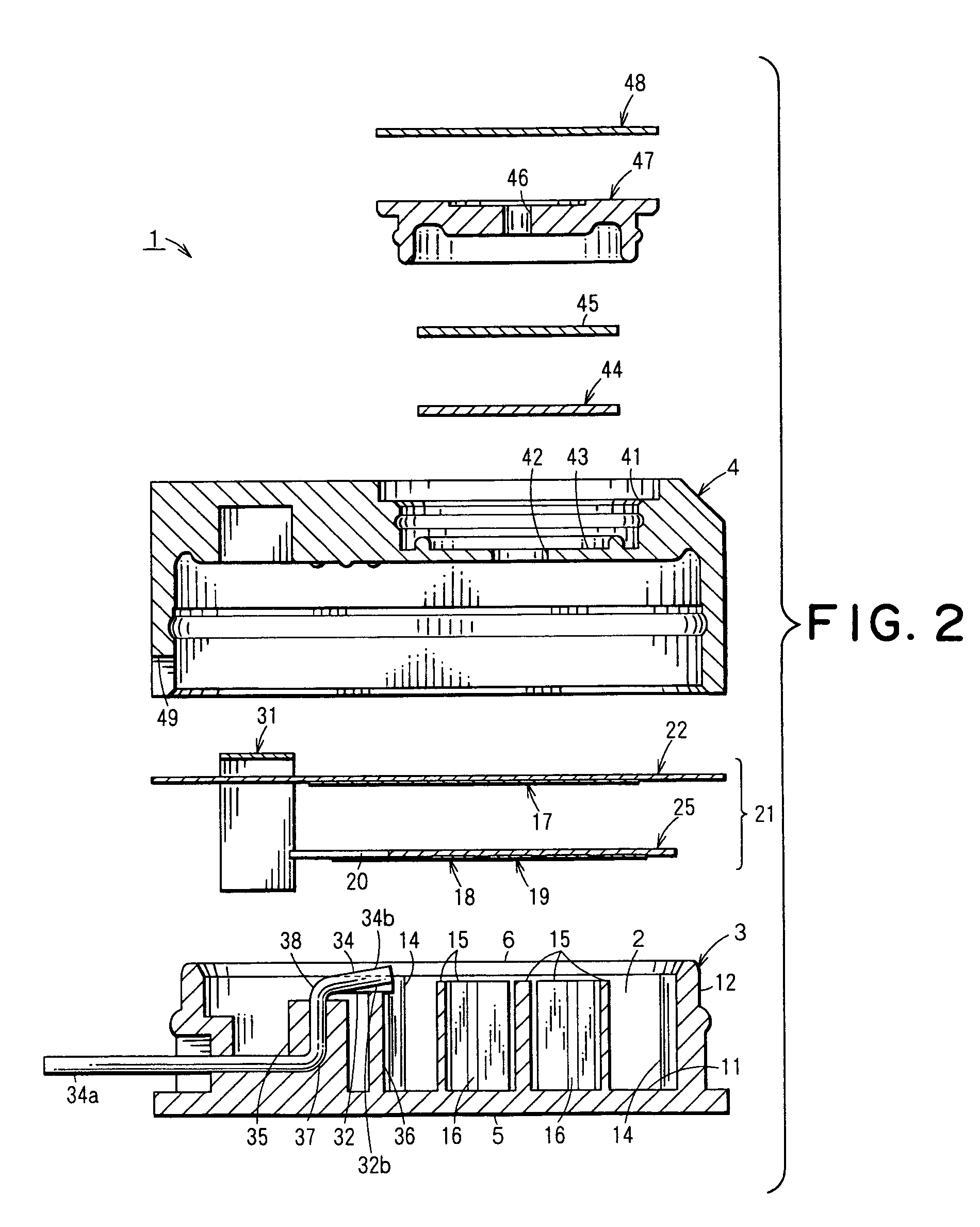

Biosensor, thin film electrode forming method, quantification apparatus, and quantificaion method

InactiveUS20090152111A1Well formedSimple definitionImmobilised enzymesBioreactor/fermenter combinationsThin film electrodeConductive materials

A biosensor according to the present invention comprises a support 1, a conductive layer 2 composed of an electrical conductive material such as noble metal, for example gold, palladium or the like, and carbon, slits 3a and 3b parallel to the side of the support 1, slits 4a and 4b vertical to the side of the support 1, a working electrode 5, a counter electrode 6, a detecting electrode 7, a spacer 8 which covers the working electrode 5, the counter electrode 6 and the detecting electrode 7 on the support 1, a rectangular cutout part 9 forming a specimen supply path, an inlet 9a of the specimen supply path, a reagent layer 12 formed by applying a reagent including an enzyme or the like to the working electrode 5, the counter electrode 6 and the detecting electrode 7, which is exposed from the cutout part 9 of the spacer 8, and a cover 13 which covers the spacer 8, as shown in FIG. 1. The so-constructed biosensor can be formed by a simple method, and a biosensor which is excellent in a measuring accuracy as well as a biosensor in which a reagent layer is placed uniformly on the electrodes regardless of a reagent liquid composition, and which has a uniform performance can be realized.

Owner:PHC HLDG CORP

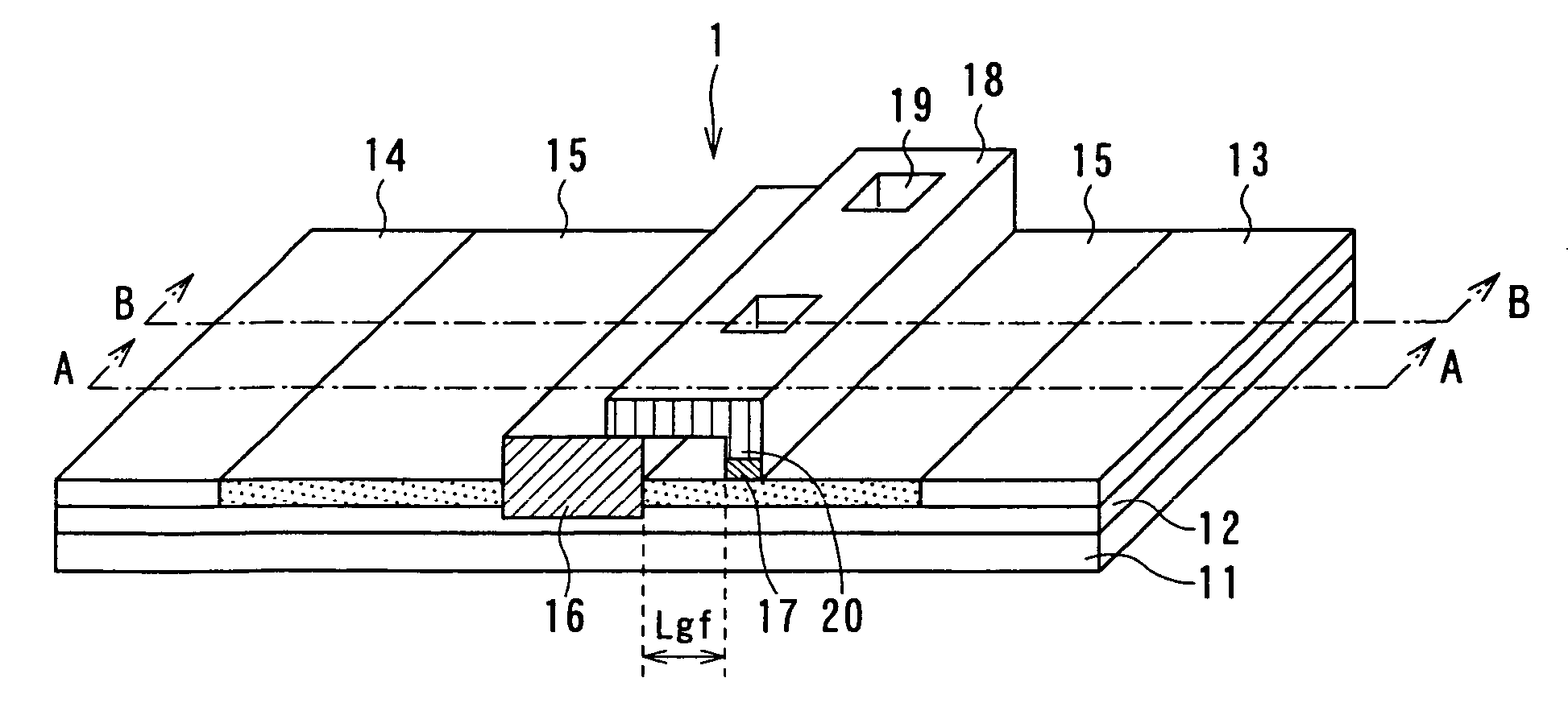

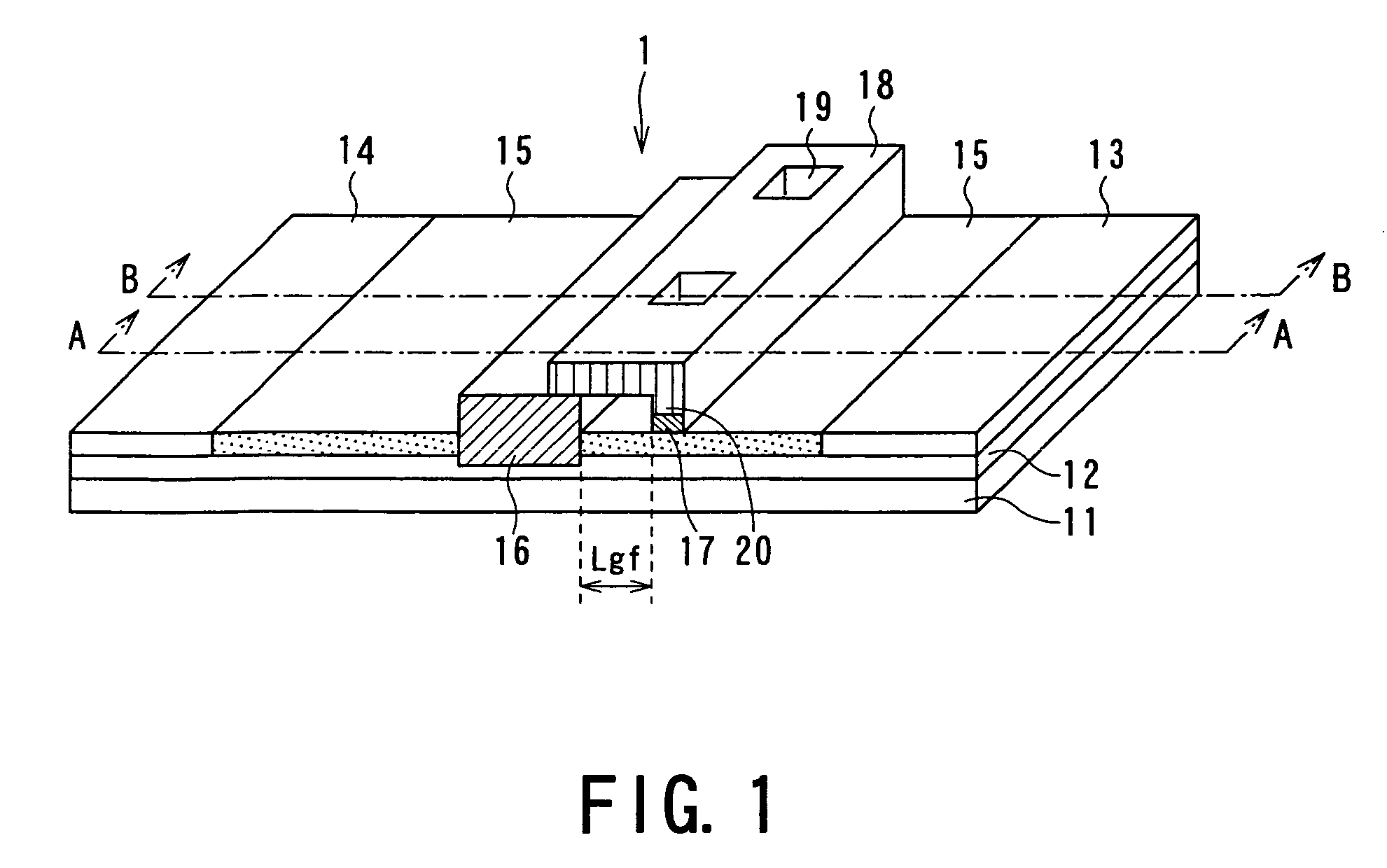

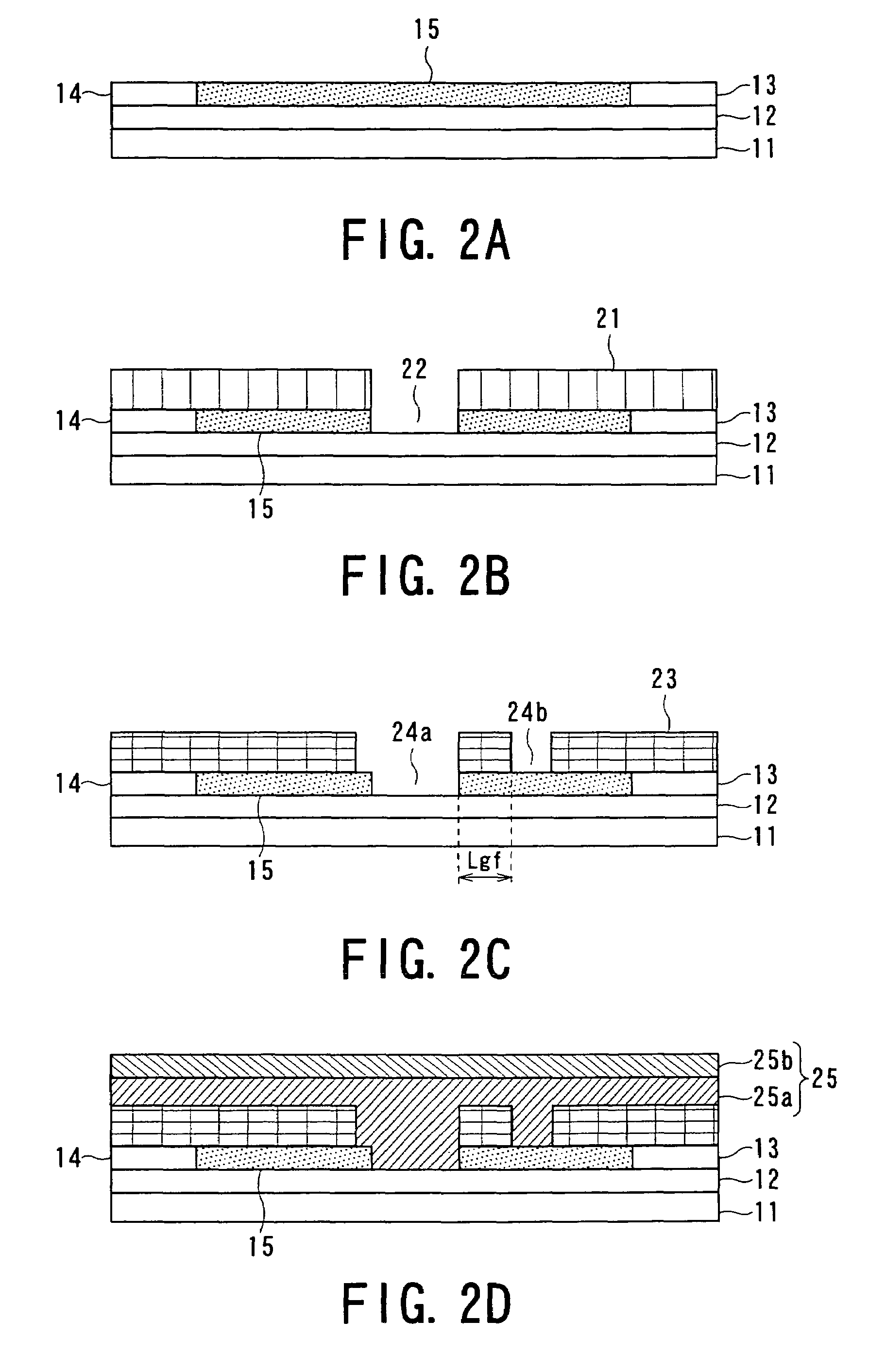

Semiconductor device and manufacturing method thereof

InactiveUS7696531B2Simple electrode structureSuperior high-frequency characteristic and performanceThyristorSemiconductor/solid-state device manufacturingSemiconductorSemiconductor device

Owner:KK TOSHIBA

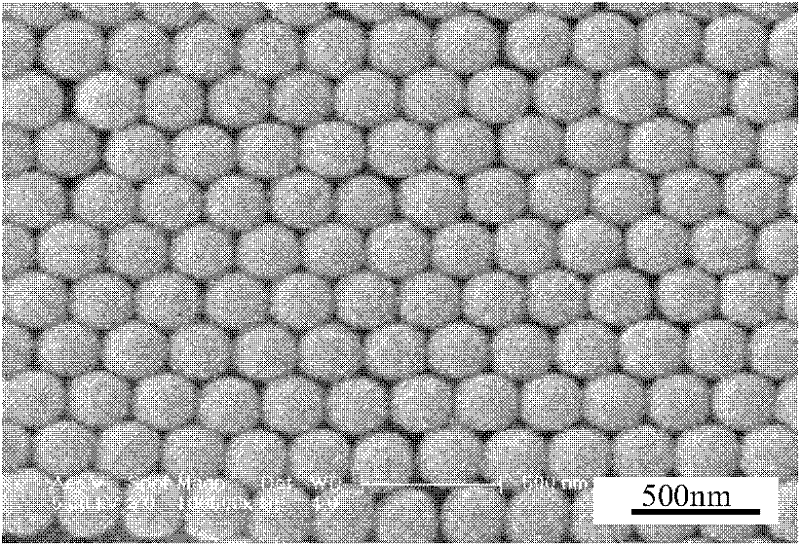

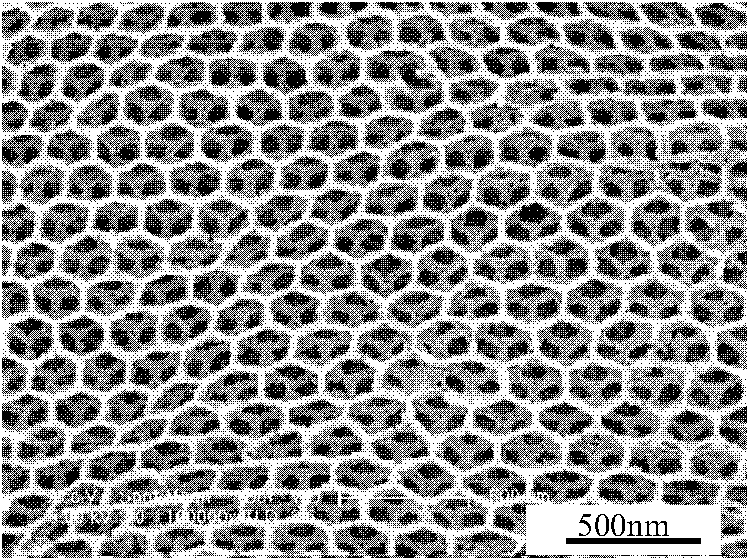

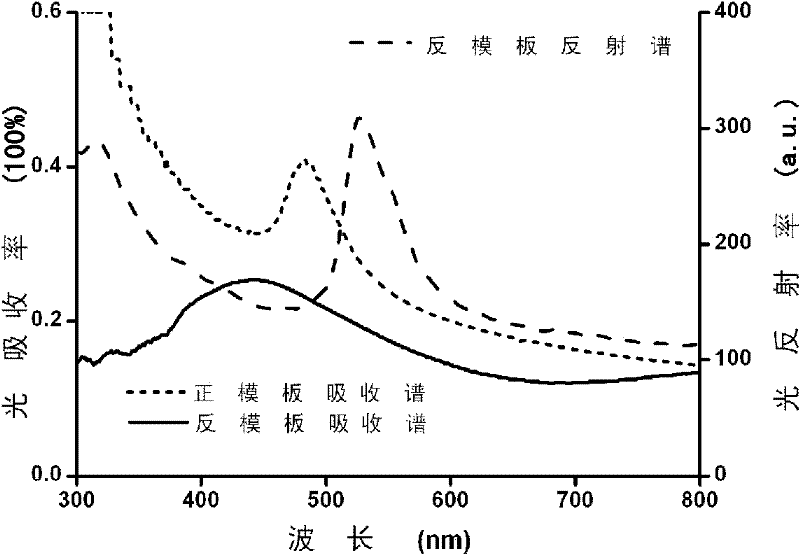

Preparation method for photonic crystal structure film electrode of dye solar cell

InactiveCN101752093AHigh application potentialImprove the decorative effectLight-sensitive devicesFinal product manufacturePhotonic crystal structureSolar cell

The invention discloses a preparation method for a photonic crystal structure film electrode of a dye solar cell in the technical field of solar cells. A photonic crystal structure positive template structure is introduced into the solar cell and is packaged combined with a pyridine complex dye of ruthenium so as to form the photonic crystal dye solar cell with improved efficiency. A photonic crystal structure positive template is prepared through emulsifier-free emulsion polymerization and a vertical deposition method, and a titanium dioxide photonic crystal reverse template is prepared through a sandwich treatment topology, thereby improving an electrode structure of the traditional dye cell, exceeding the limitation of laboratory photo-etching processing and enhancing the application potential thereof. The prepared photonic crystal structure film electrode takes a three-dimension ordered anatase type titanium dioxide hole arranged by an inverse opal structure as the electrode of the dye solar cell, the hole diameter of film materials thereof ranges from 50nm to 500nm, and the thickness ranges from 0.5 micron to 40 microns, thereby enlarging the specific surface area combined with the dye and having higher short circuit current and filling factors.

Owner:SHANGHAI JIAO TONG UNIV

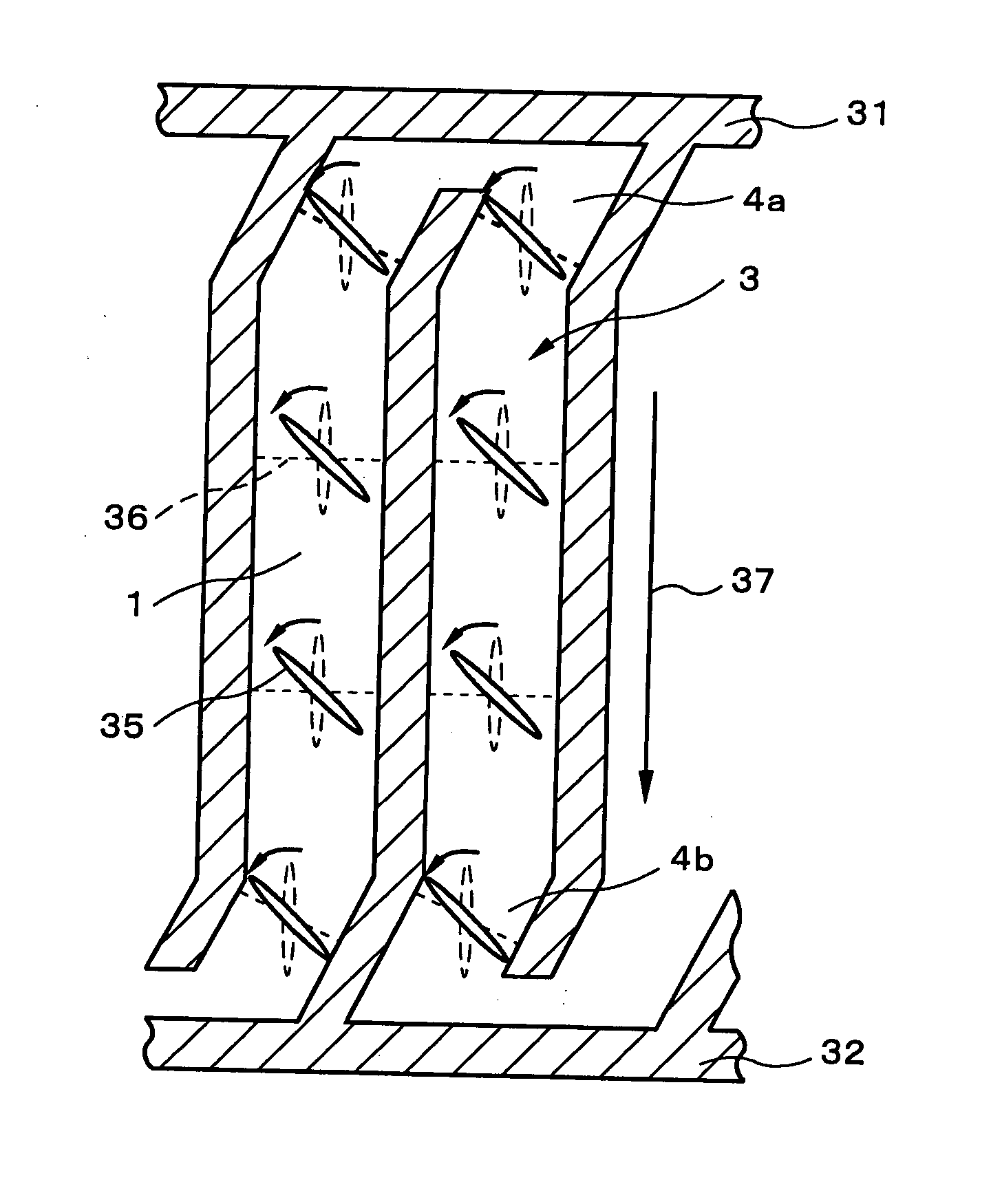

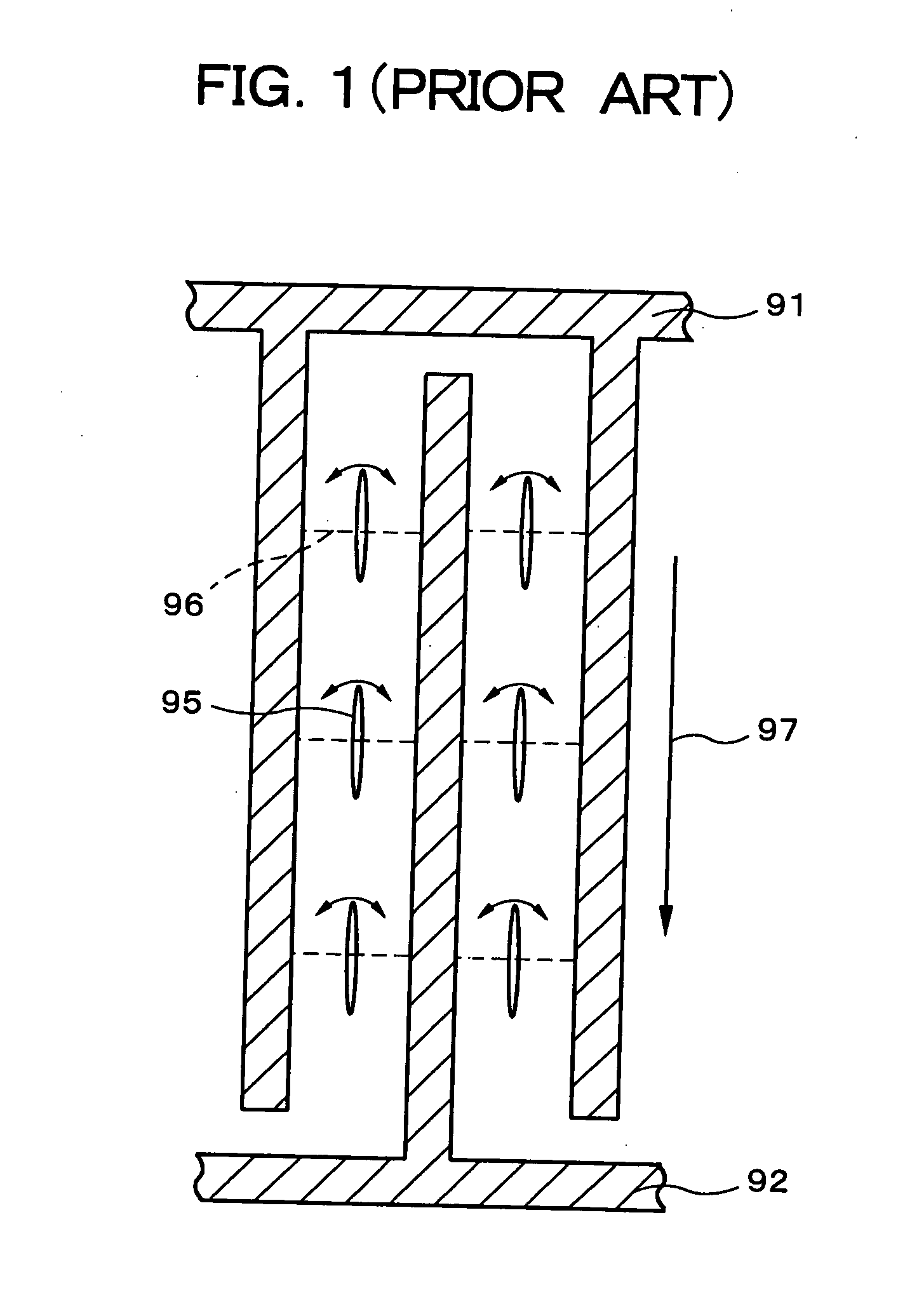

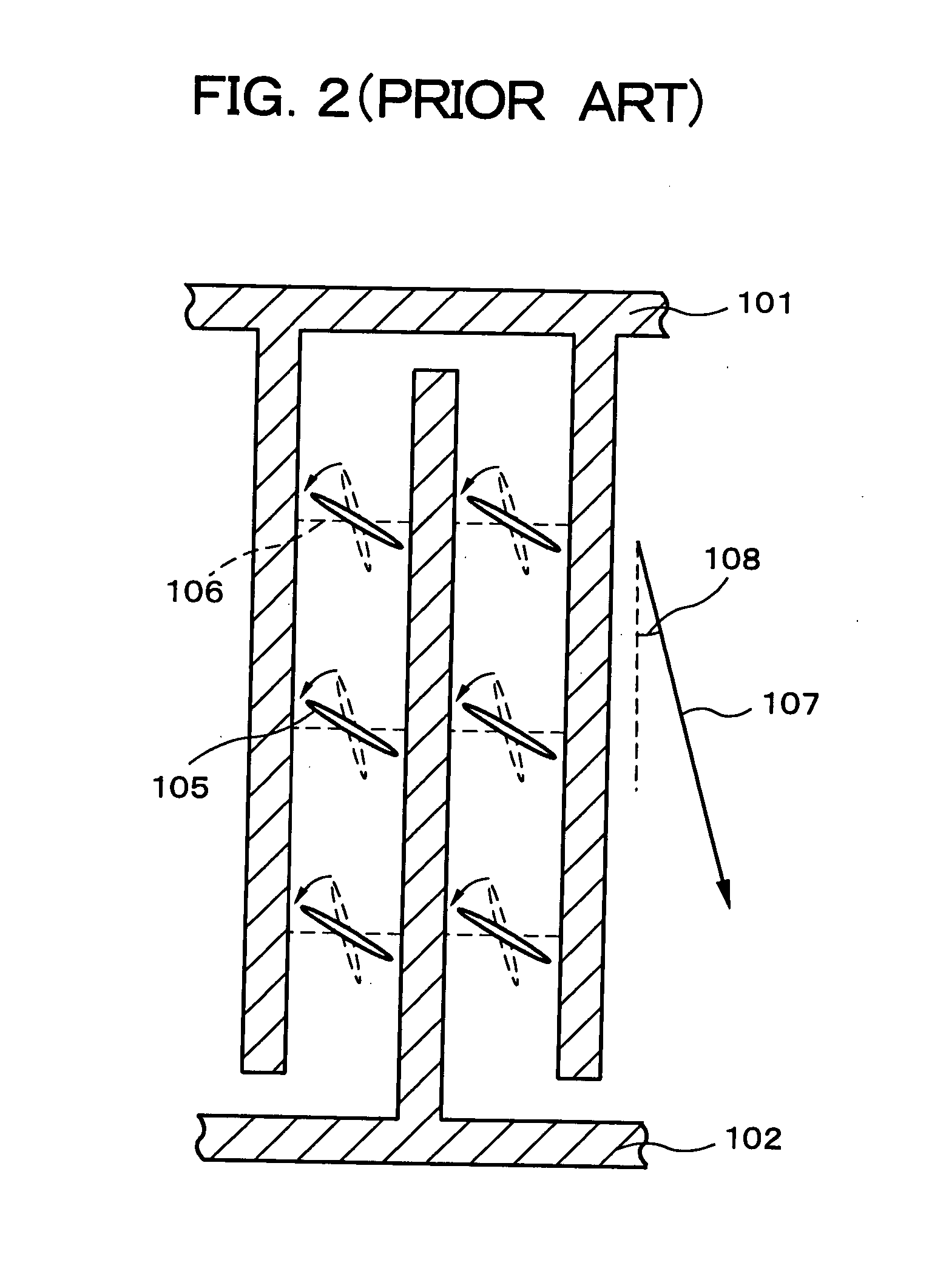

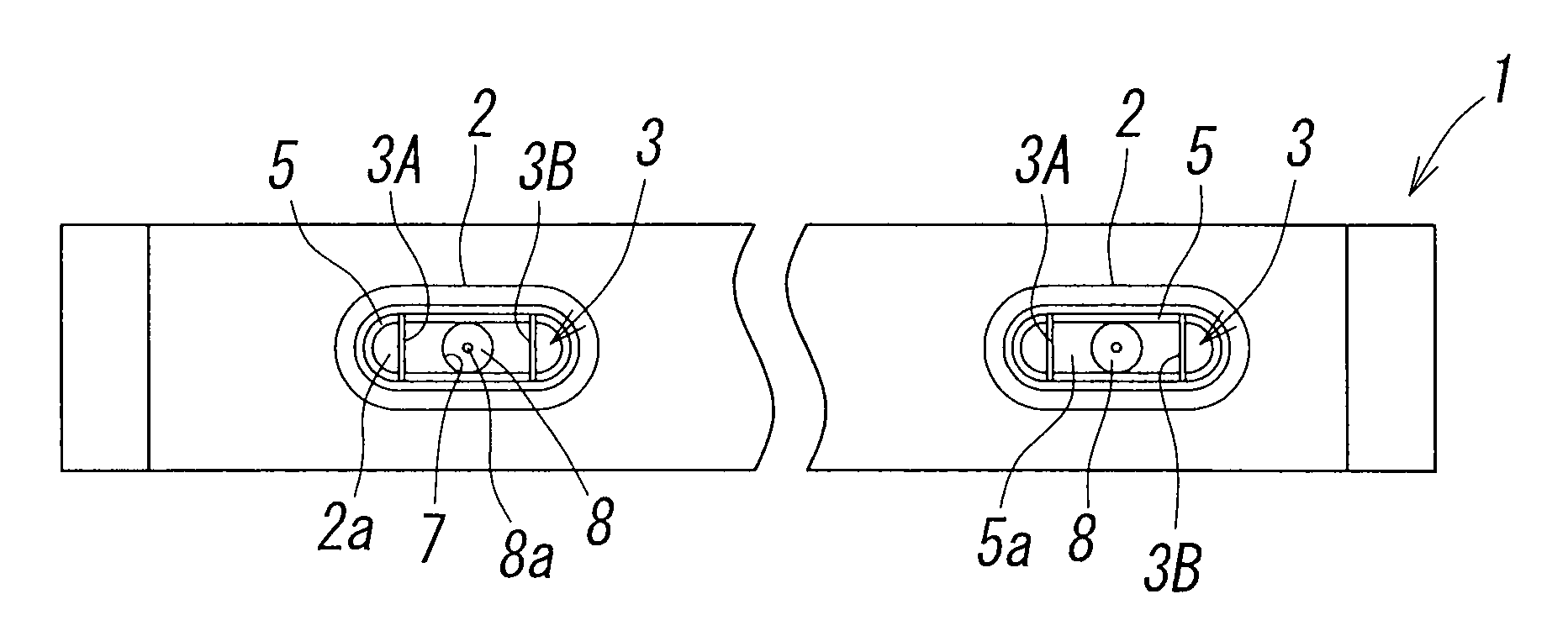

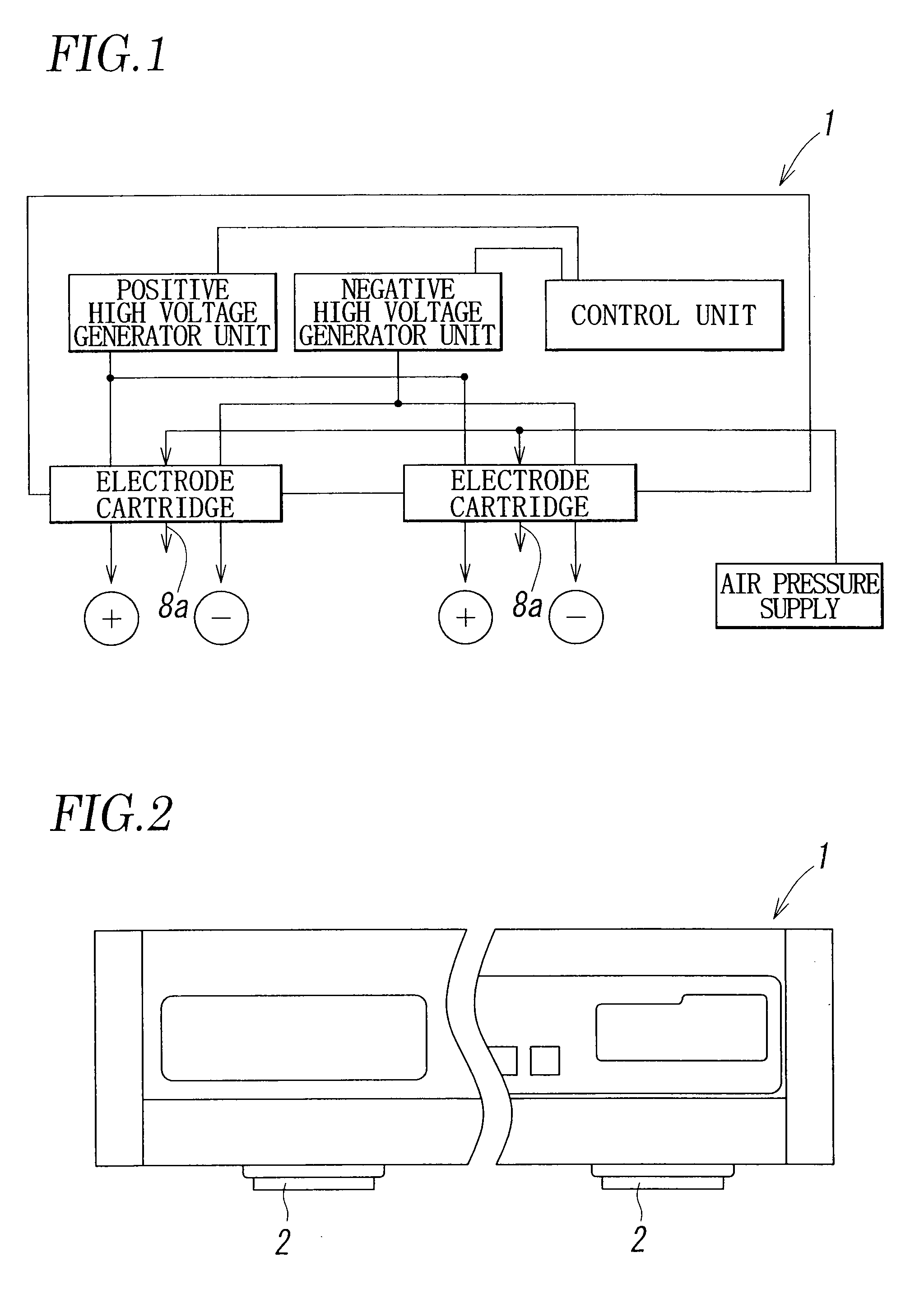

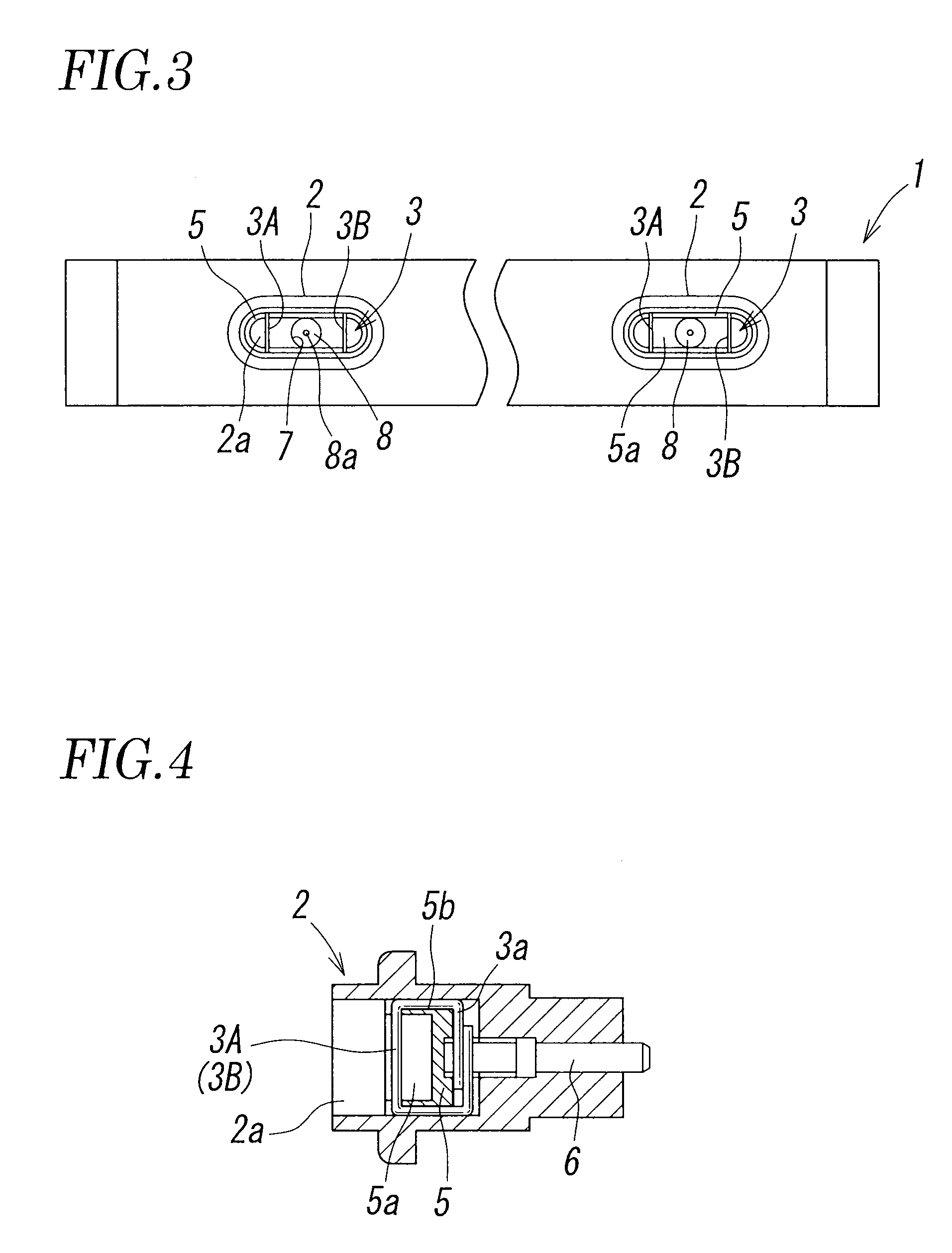

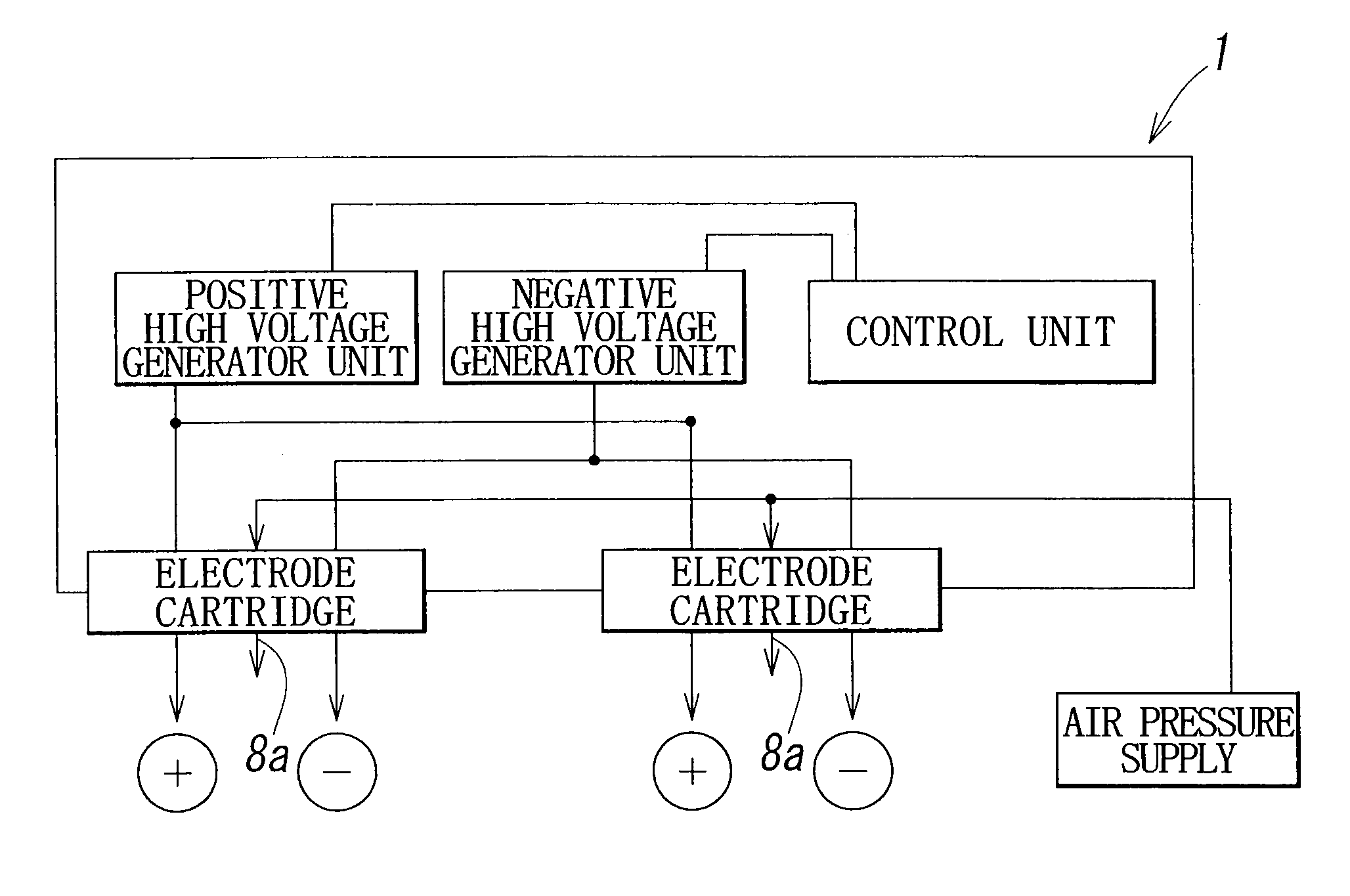

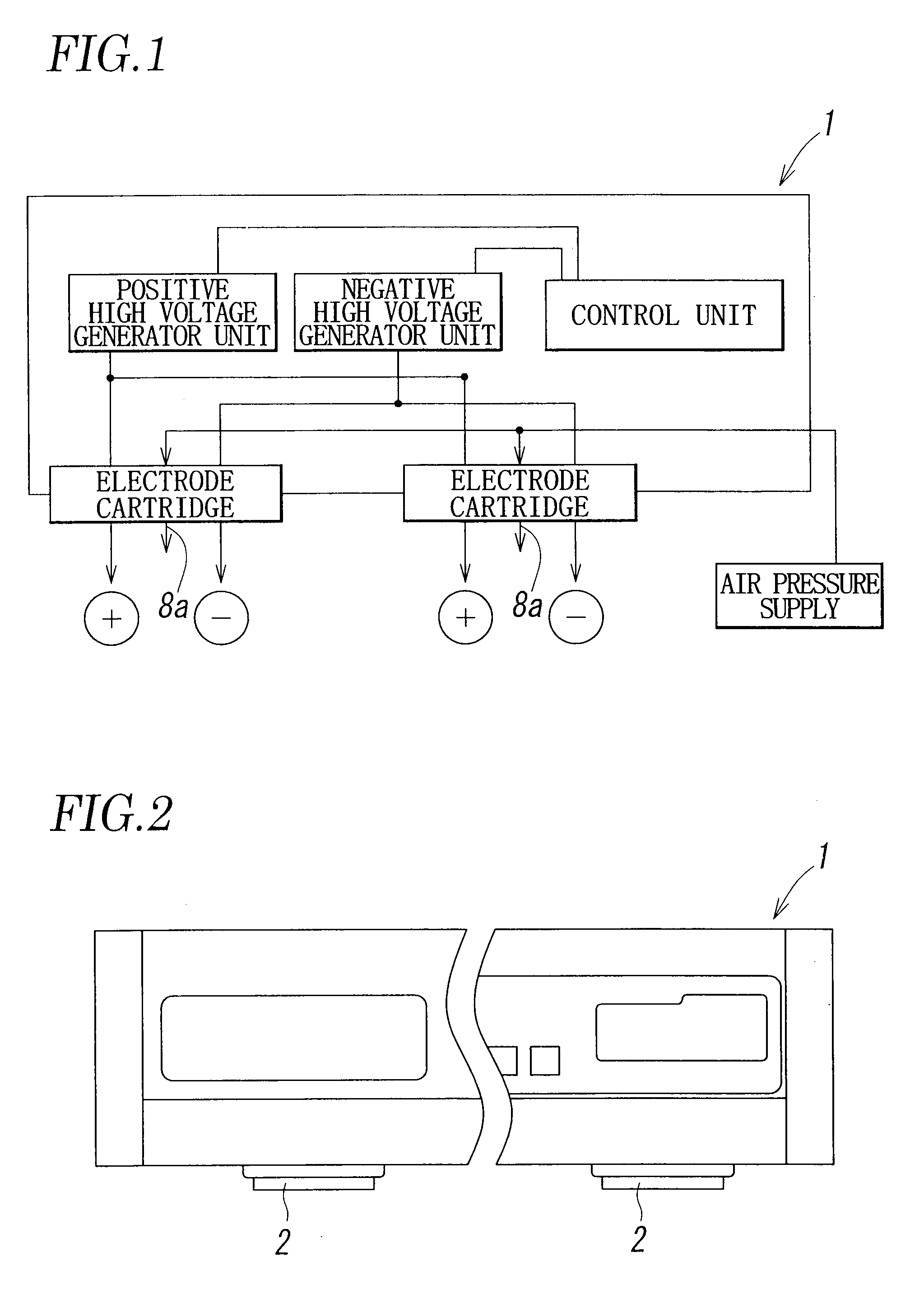

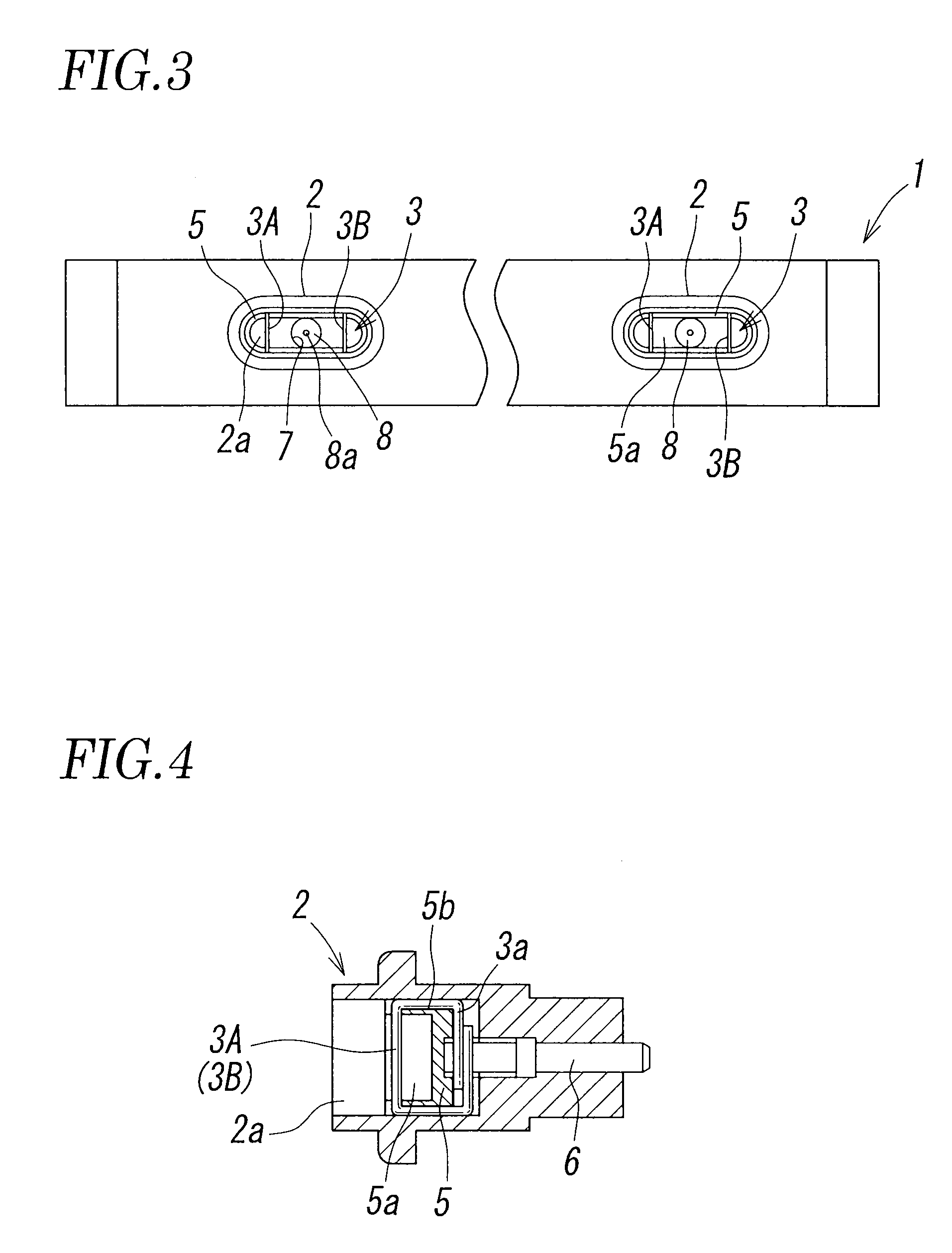

Wire electrode type ionizer

ActiveUS8174814B2Simple electrode structureReduce the amount of solutionElectrostatic chargesCorona dischargeEngineering

Owner:SMC CORP

Wire electrode type ionizer

ActiveUS20090135537A1Simple electrode structureReduce the amount of solutionElectrostatic chargesCorona dischargeEngineering

An ionizer includes positive and negative wire electrodes each formed of a conductive wire with a circular cross section. The wire electrodes are arranged in parallel with each other, each having circumferential surfaces serving as a discharge surface on which a corona discharge occurs upon application of positive and negative high voltages for discharging positive and negative ions.

Owner:SMC CORP

Pouch-type lithium secondary battery and fabrication method thereof

ActiveUS8999566B2Minimizes seal surfaceStrengthen the connection structureFinal product manufactureCells structural combinationLithiumEngineering

A pouch-type lithium secondary battery including: a battery unit comprising a positive electrode plate, a separator, and a negative electrode plate, wherein the separator is disposed between the positive and negative electrode plates; electrode tabs extending from each of the positive and negative electrode plates of the battery unit, respectively; a case having a space to accommodate the battery unit and sealing surfaces formed along the periphery of the space, wherein the case is sealed at the sealing surfaces by thermal fusion; and a protection circuit board 600 electrically connected to the electrode tabs. The protection circuit board is disposed parallel to an outer wall of the case. Since the electrode tabs are bent in an upright position with respect to the sealing surfaces, and the protection circuit board electrically connected to the bent electrode tabs is disposed between the outer wall of the case and the electrode tabs, the size of the sealing surfaces of the case can be minimized.

Owner:SAMSUNG SDI CO LTD

Liquid crystal device and electronic apparatus

InactiveUS20080165297A1Thin thicknessIncreasing the thicknessStatic indicating devicesNon-linear opticsElectronElectric field

A liquid crystal device includes a first substrate, a second substrate, a liquid crystal layer, a display pixel, and a viewing angle control pixel. The liquid crystal layer is provided between the first substrate and the second substrate. The display pixels and the viewing angle control pixels are arranged in a planar region of the first substrate and second substrate to form a display area. Each of the display pixels and each of the viewing angle control pixels each drive the liquid crystal layer by electric field generated between a first electrode and a second electrode. In each of the viewing angle control pixels, a direction of a plane along which electric field is generated between the first electrode and the second electrode is substantially parallel to an initial alignment direction of liquid crystal molecules of the liquid crystal layer.

Owner:JAPAN DISPLAY WEST

Pouch-type lithium secondary battery and fabrication method thereof

InactiveUS20060051668A1Minimizes seal surfaceStrengthen the connection structureFinal product manufactureSmall-sized cells cases/jacketsLithiumEngineering

A pouch-type lithium secondary battery including a battery unit having a positive electrode plate, a negative electrode plate, and a separator between the positive and negative electrode plates; electrode tabs extending from each of the positive and negative electrode plates of the battery unit, respectively; a case having a space to accommodate the battery unit; a sealing surface along the periphery of the space; and a protection circuit board electrically connected to the electrode tabs, wherein portions of each of the electrode tabs extend outside the case, and are bent in an upright position with respect to a plane of the sealing surface.

Owner:SAMSUNG SDI CO LTD

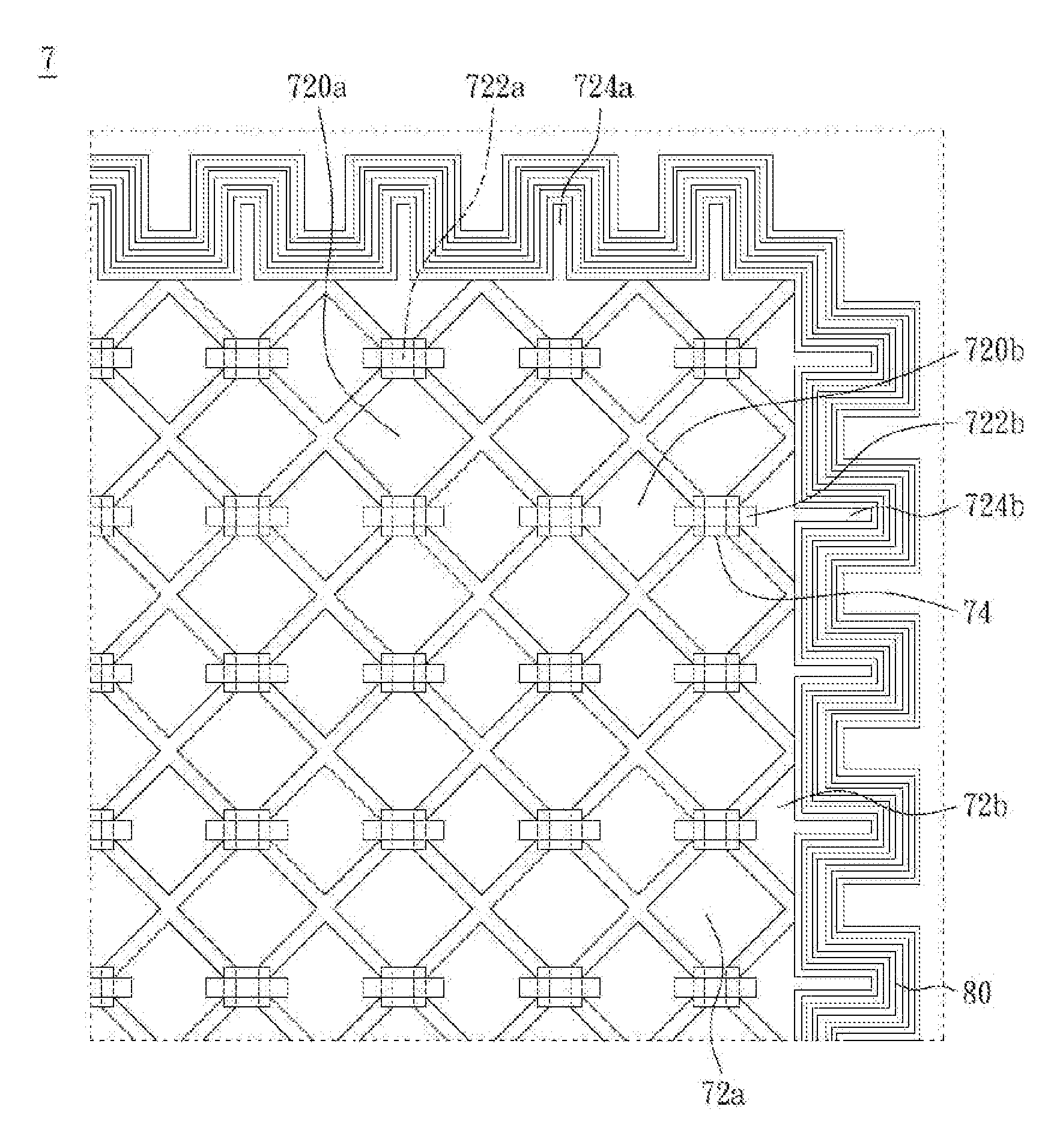

Touch electrode structure and a method for manufacturing the same

ActiveUS20140124347A1Increase productivityLow production costConductive layers on insulating-supportsElectronic switchingLaser etchingOptoelectronics

The present disclosure discloses a touch panel, a touch electrode structure, and a manufacturing method thereof. The touch electrode structure comprises a plurality of first-axis sensing lines and at least one first laser etching line. The plurality of first-axis sensing lines are formed by laser etching a first conducting layer, wherein each first-axis sensing line at least has a first output pin. The first laser etching line is formed around the corresponding first output pin by laser etching the first conducting layer. Thus, the present disclosure can reduce overall production time by using a simplified manufacturing process in a laser etching process to form an improved touch electrode structure.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

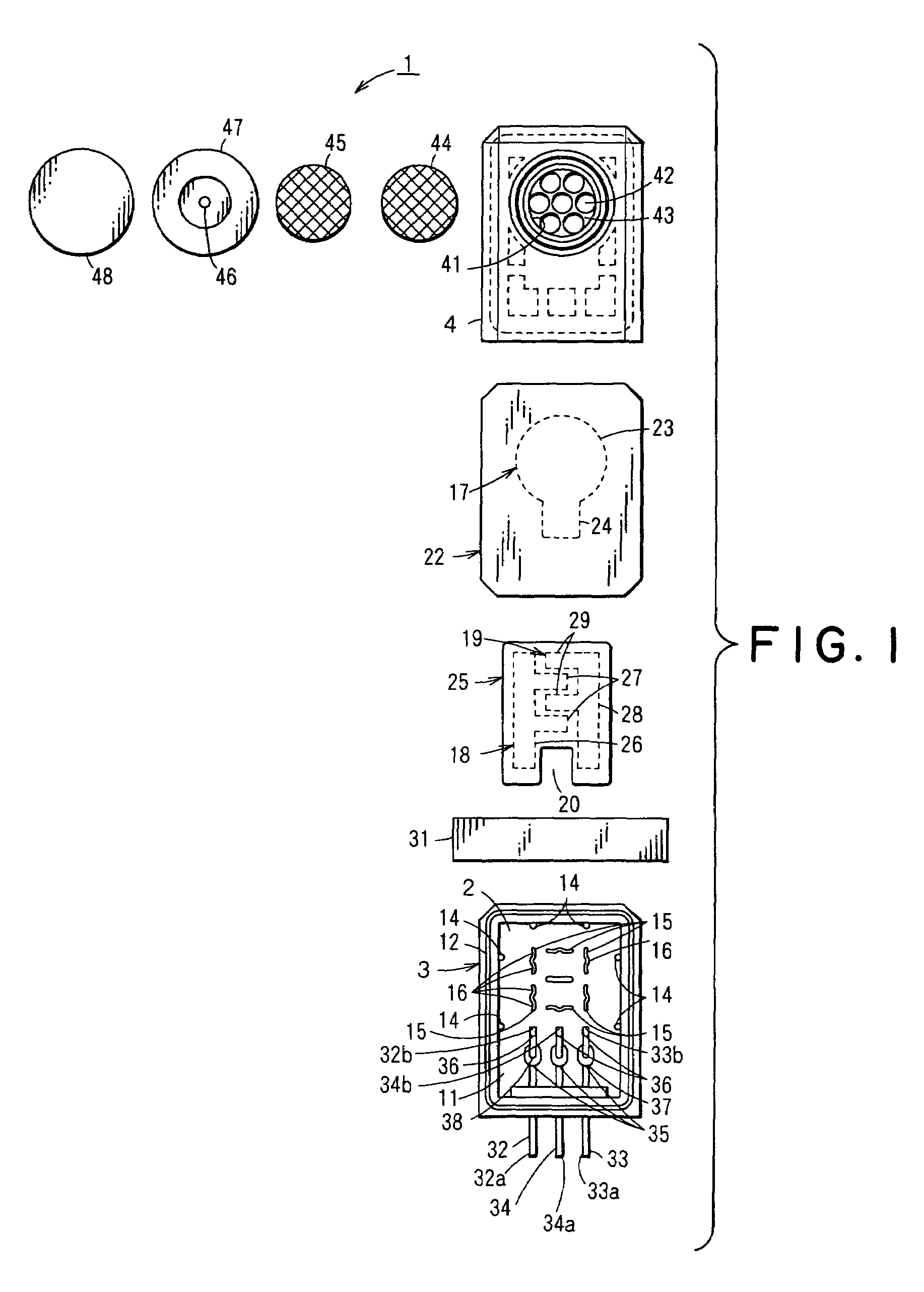

Electrochemical sensor

ActiveUS7279081B2Improve manufacturabilitySimplify electrode structureMaterial analysis by electric/magnetic meansTa elementSingle component

Electrolytic solution which contains sulfuric acid and is stored in an electrolytic solution storage 2 of a case 3 is caused to be retained in an electrolytic solution retainer 25. A reference electrode 18 and a counter electrode 19 are printed on the underside of the electrolytic solution retainer 25. The reference electrode 18, the counter electrode 19, and the electrolytic solution retainer 25 are thus formed into a single component, with the reference electrode 18 and the counter electrode 19 being formed simultaneously. Electrode pins 32,33,34 are brought into contact with the reference electrode 18, the counter electrode 19, and a detection electrode 17. The electrode pins 32,33,34 are made of tantalum. A contact portion 32b,33b,34b and a lead portion 32a,33a,34a of each electrode pin 32,33,34 are formed as a seamless, integral body.

Owner:NEMOTO TOKUSHIYU KAGAKU KK

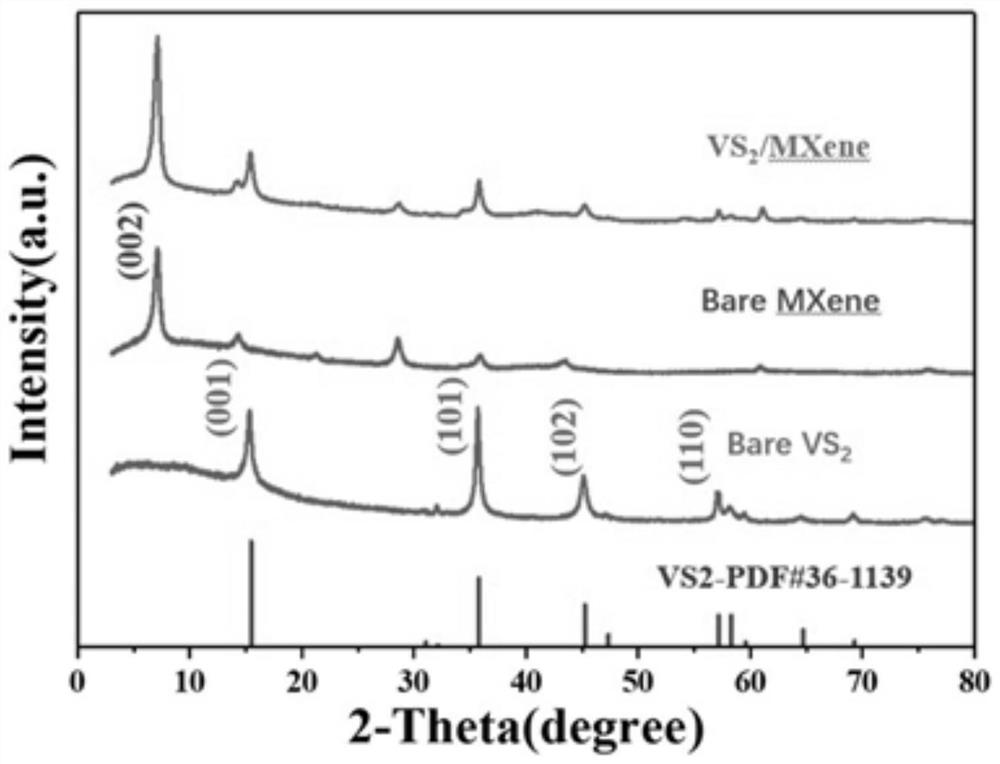

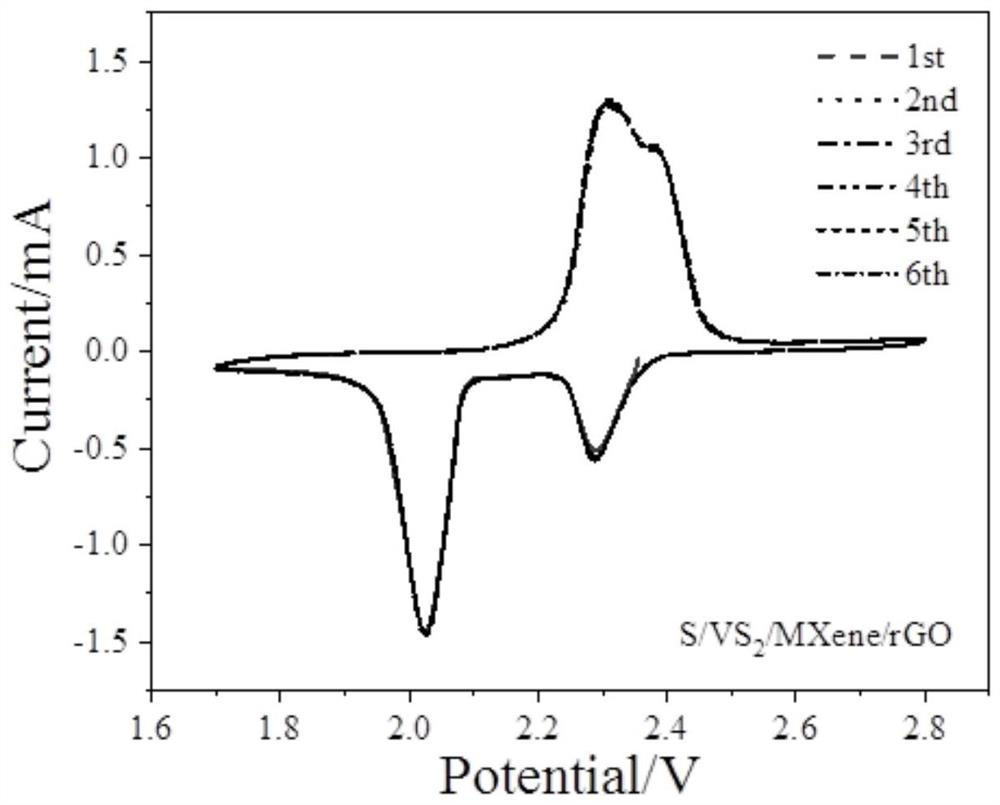

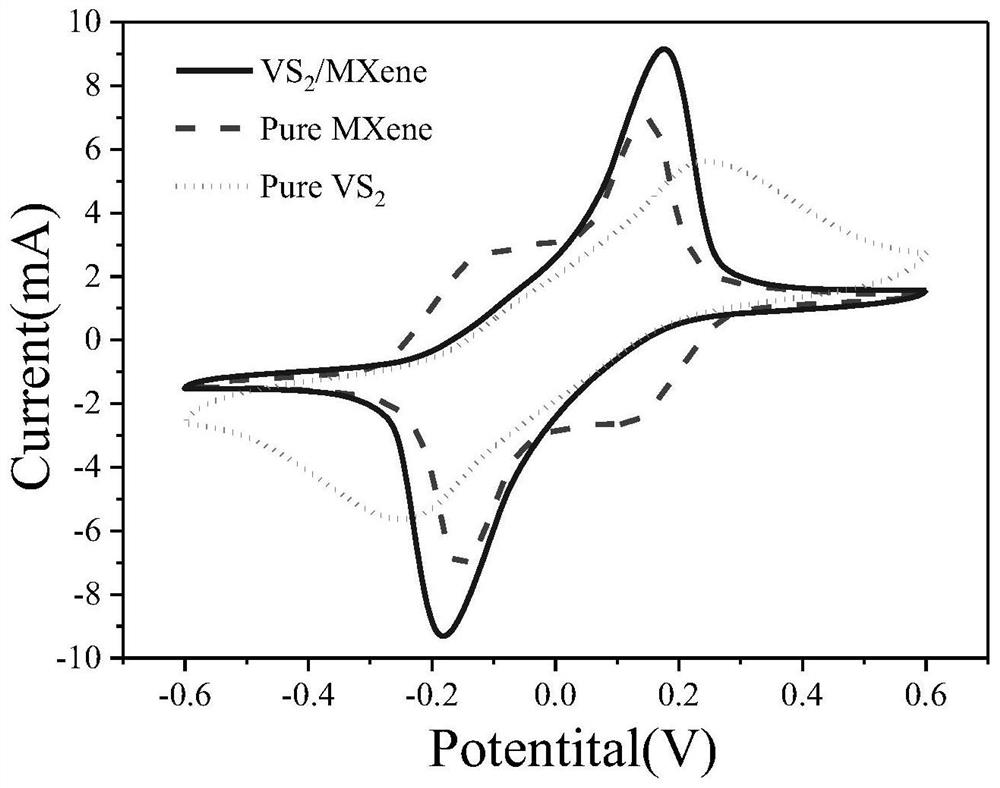

Sulfur/vanadium disulfide/MXene composite material as well as preparation method and application thereof

ActiveCN111816858AUniform particlesUniform particle sizeMaterial nanotechnologyCell electrodesElectrolytic agentVanadium disulfide

The invention relates to the technical field of battery materials, in particular to a sulfur / vanadium disulfide / MXene composite material as well as a preparation method and application thereof. According to the preparation method disclosed by the invention, the sulfur loading capacity can be improved due to the high specific surface area and a large number of active sites of the sulfur loading material MXene; MXene has unique flexibility and conductivity, so that the volume change of the positive electrode material can be buffered, and the conductivity of the composite material can be improved; the surface of the MXene is provided with a large number of functional groups and static electricity, so that vanadate ions can be attracted to generate a coordination effect; the vanadate ions areuniformly adsorbed on the surface of the MXene, so that the vanadate ions and a sulfur source generate uniform vanadium disulfide nanosheets on the surface of the MXene in situ at a proper temperature; by introducing the vanadium disulfide nanosheet with catalytic activity and high conductivity into MXene, lithium polysulfide can be chemically adsorbed, and the vanadium disulfide nanosheet can bequickly catalyzed and converted into insoluble Li2S2 / Li2S in an electrolyte, so that a serious shuttle effect is inhibited, the stability of the lithium-sulfur battery is improved, and the cycle lifeof the lithium-sulfur battery is prolonged.

Owner:GUANGDONG UNIV OF TECH

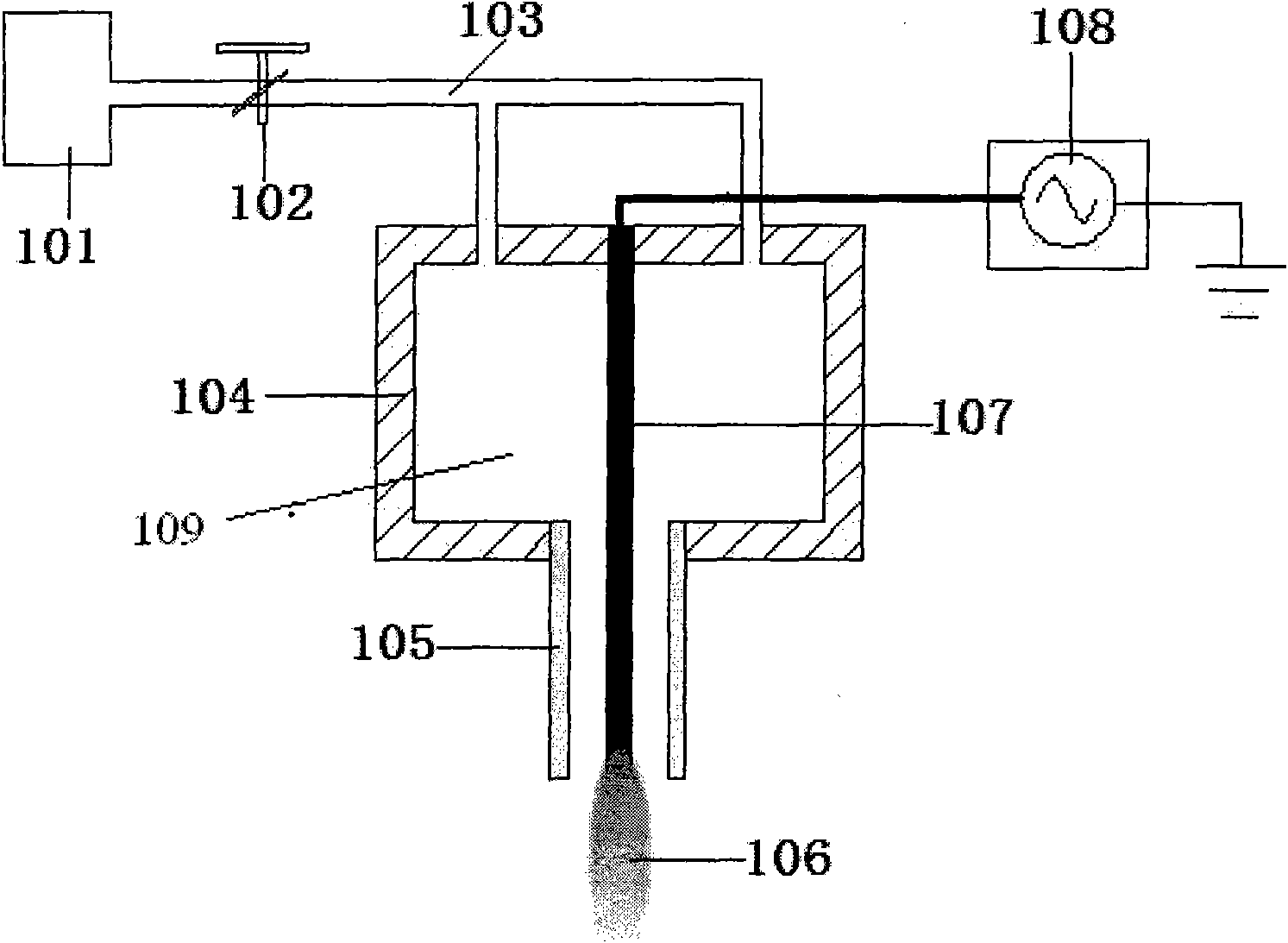

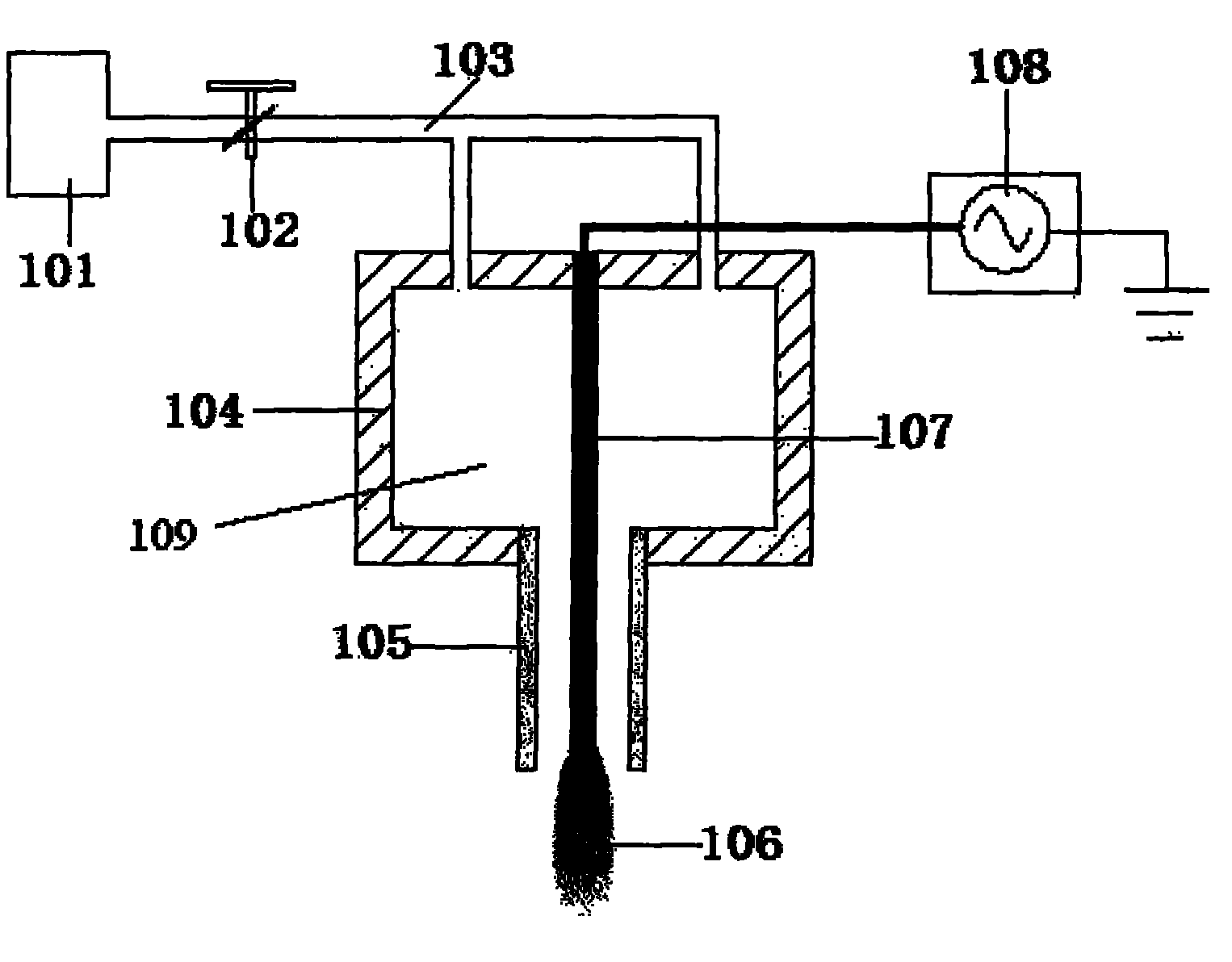

High-frequency and high-voltage single electrode plasma thruster

InactiveCN102146902AAvoid heat lossImprove driving efficiencyMachines/enginesUsing plasmaSpace vehicleIonization

The invention discloses a high-frequency and high-voltage single electrode plasma thruster. The high-frequency and high-voltage single electrode plasma thruster comprises a point electrode, a gas ejection pipe, a high-frequency and high-voltage power supply and the like, and is characterized in that: the high-frequency and high-voltage point electrode is arranged on the central line of the gas ejection pipe; the gas ejection pipe is fixed on an insulation material with a gas inlet channel; a source gas enters the gas ejection pipe through a gas channel in the insulation material and is ejected outward through a gas ejection pipe opening; the high-voltage point electrode is also fixed on the insulation material and connected with the high-frequency and high-voltage power supply; the other end of the high-frequency and high-voltage power supply is grounded; after a line is conducted, a high-frequency and high-voltage electric field is formed at the end of the point electrode and the gas around ionization is punctured so as to form a plasma ejected outward through a spout; and the plasma produces a reverse thrust at the same time. The system is arranged on a space vehicle so as to thrust the space vehicle in the space.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

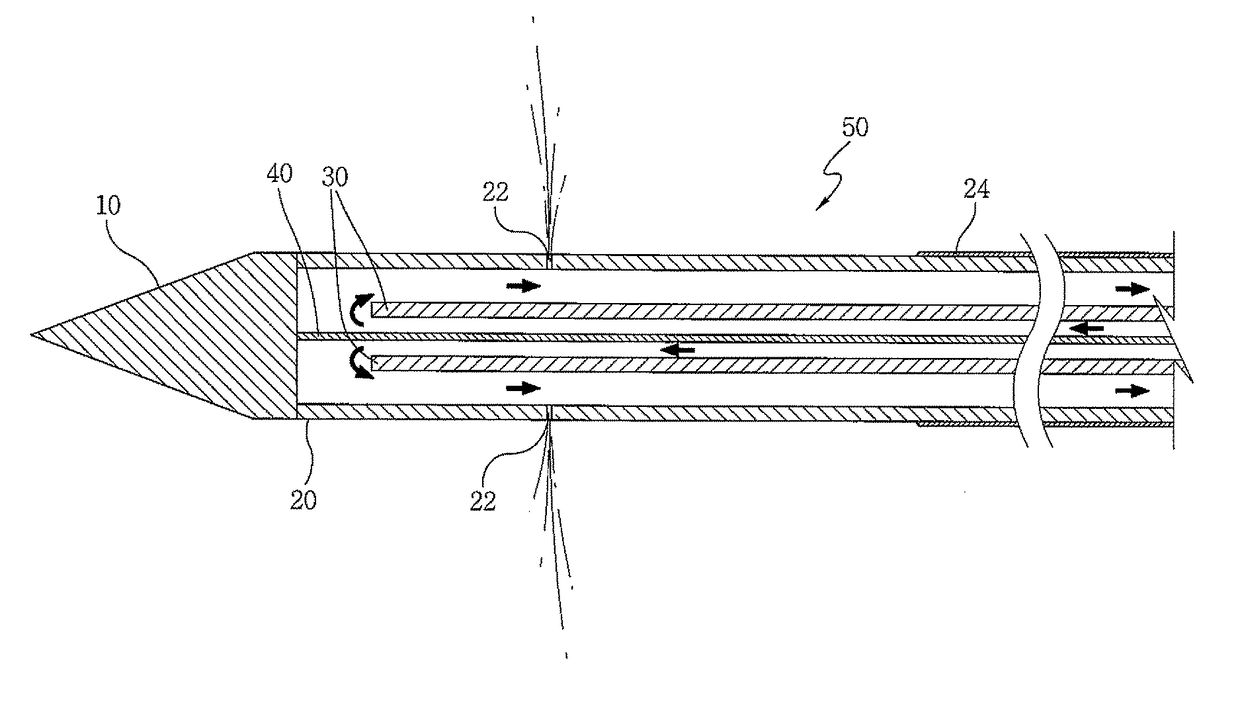

Electrode for radiofrequency tissue ablation

ActiveUS9833282B2Simple electrode structureEasy to liftSurgical needlesSurgical instruments for heatingMedicineSaline solutions

Owner:RF MEDICAL

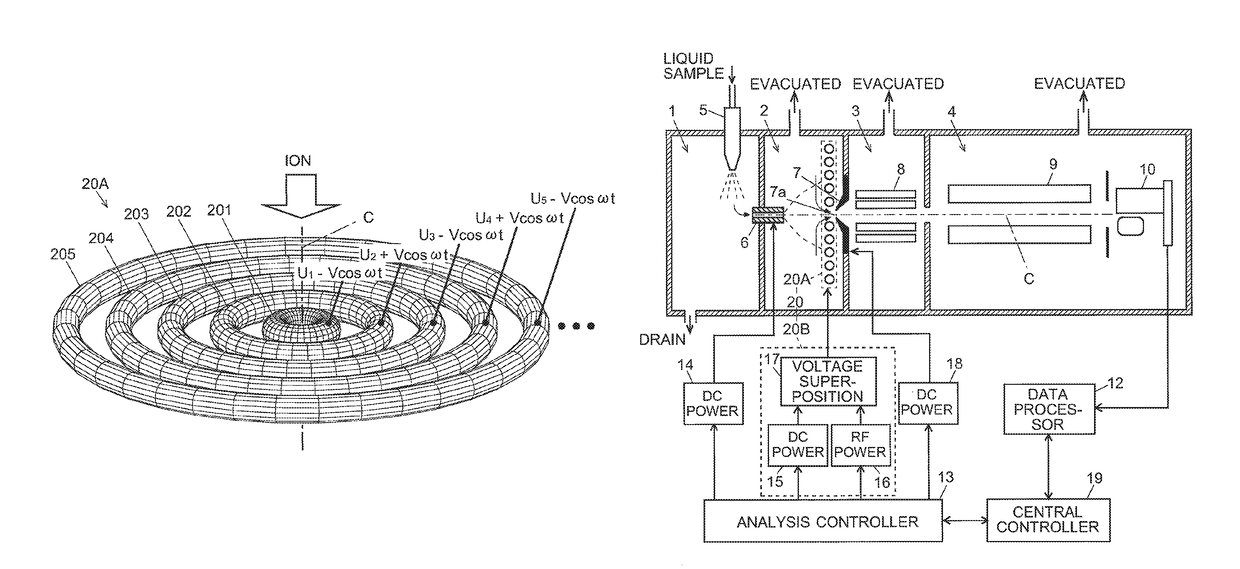

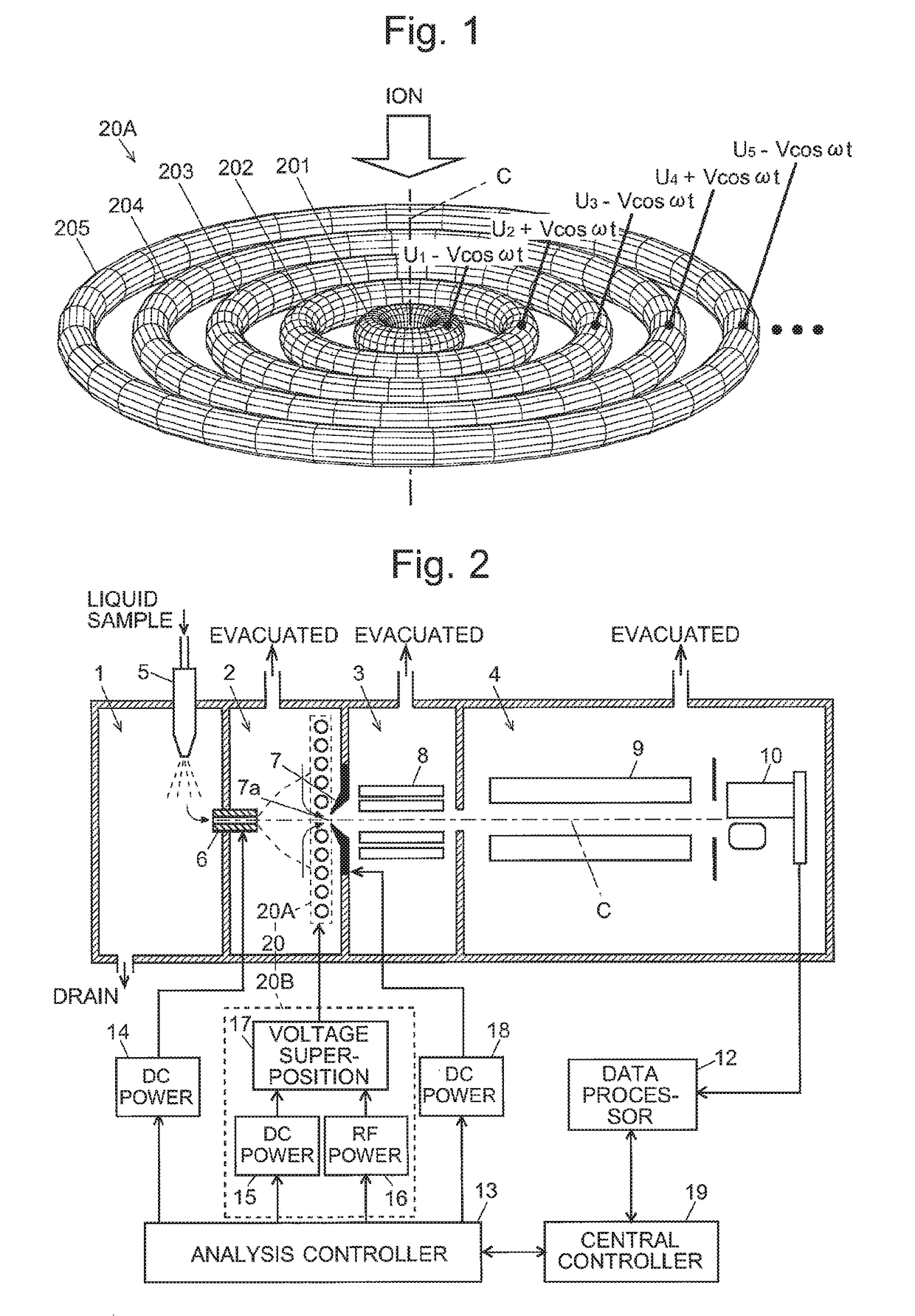

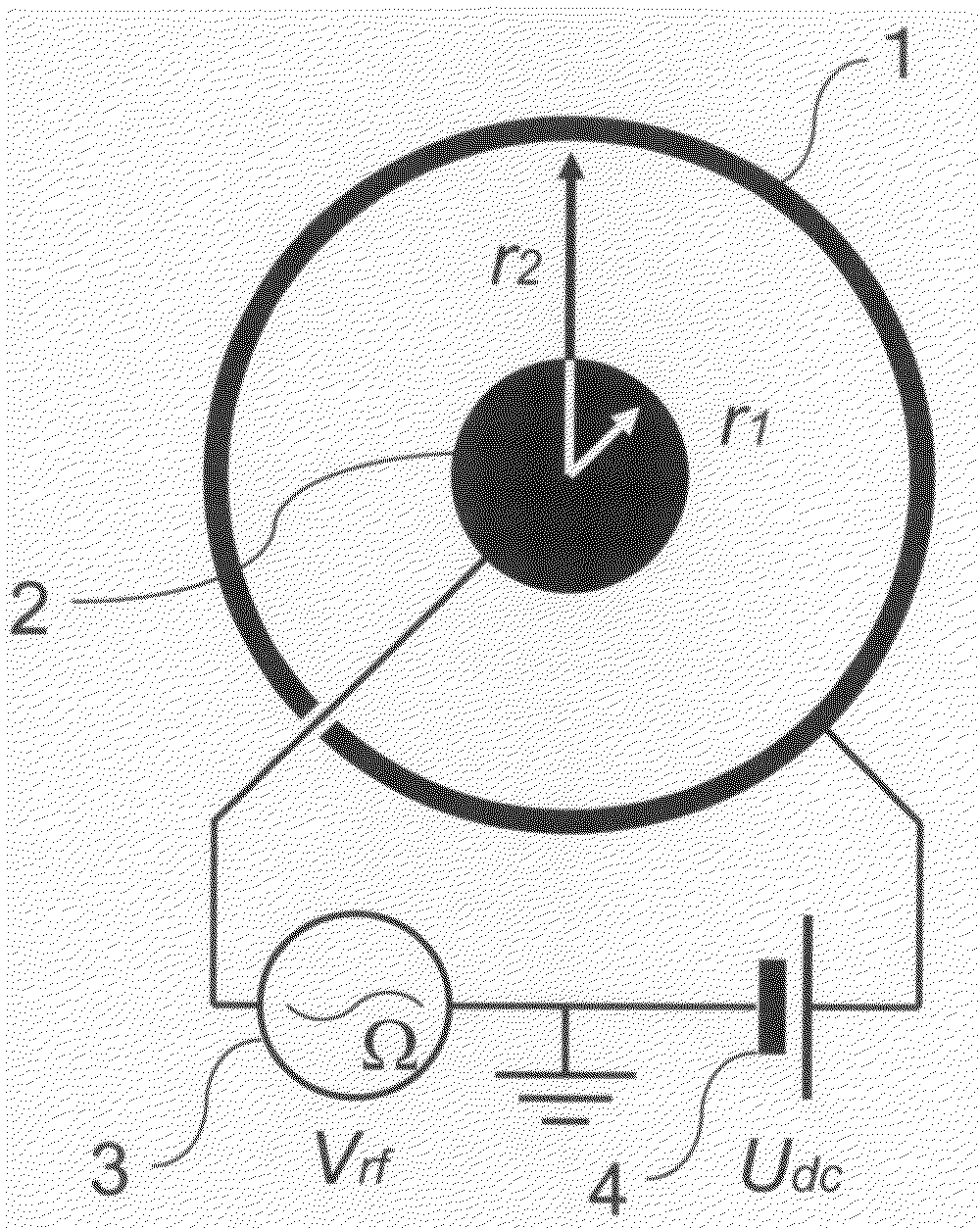

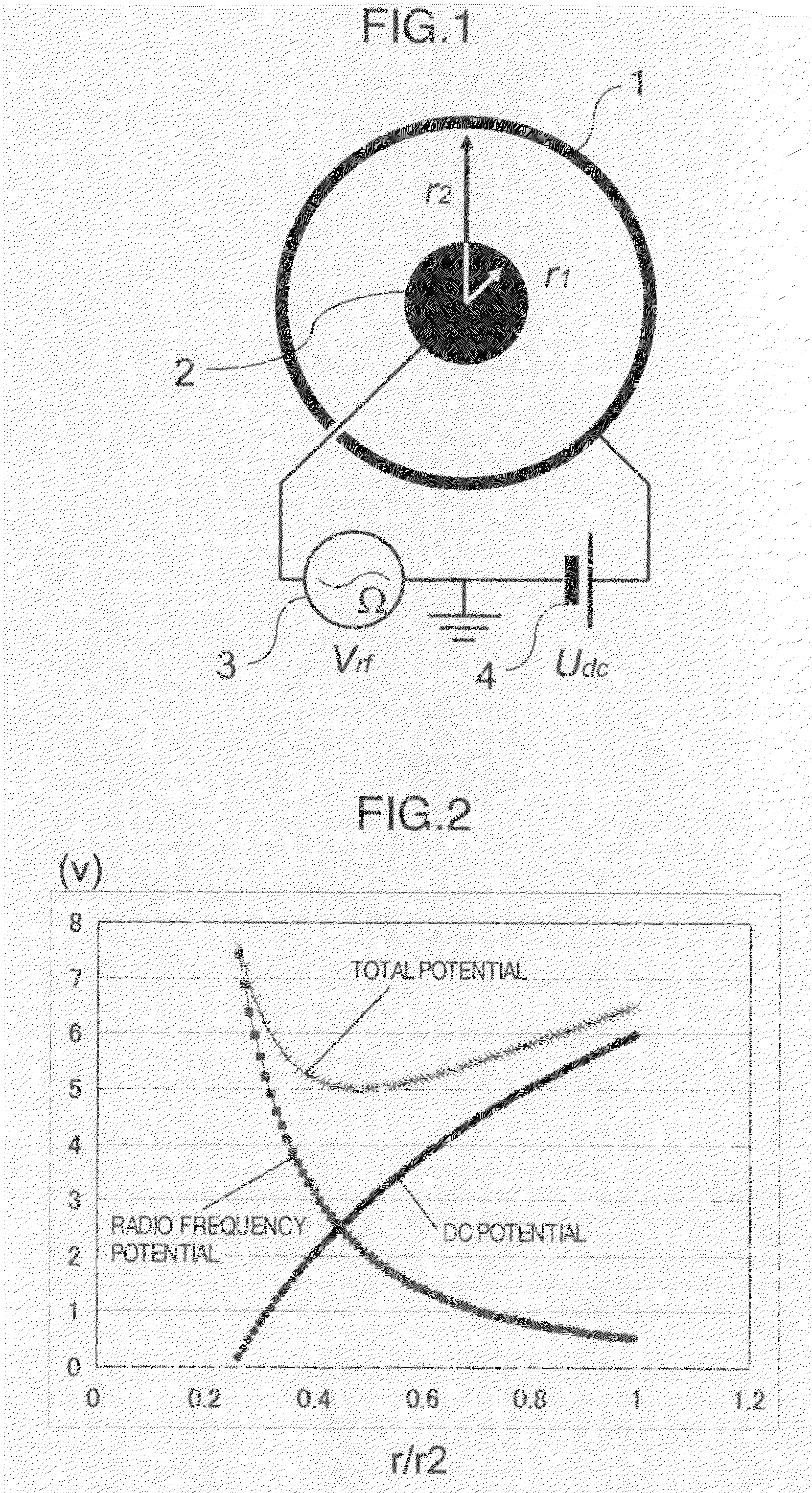

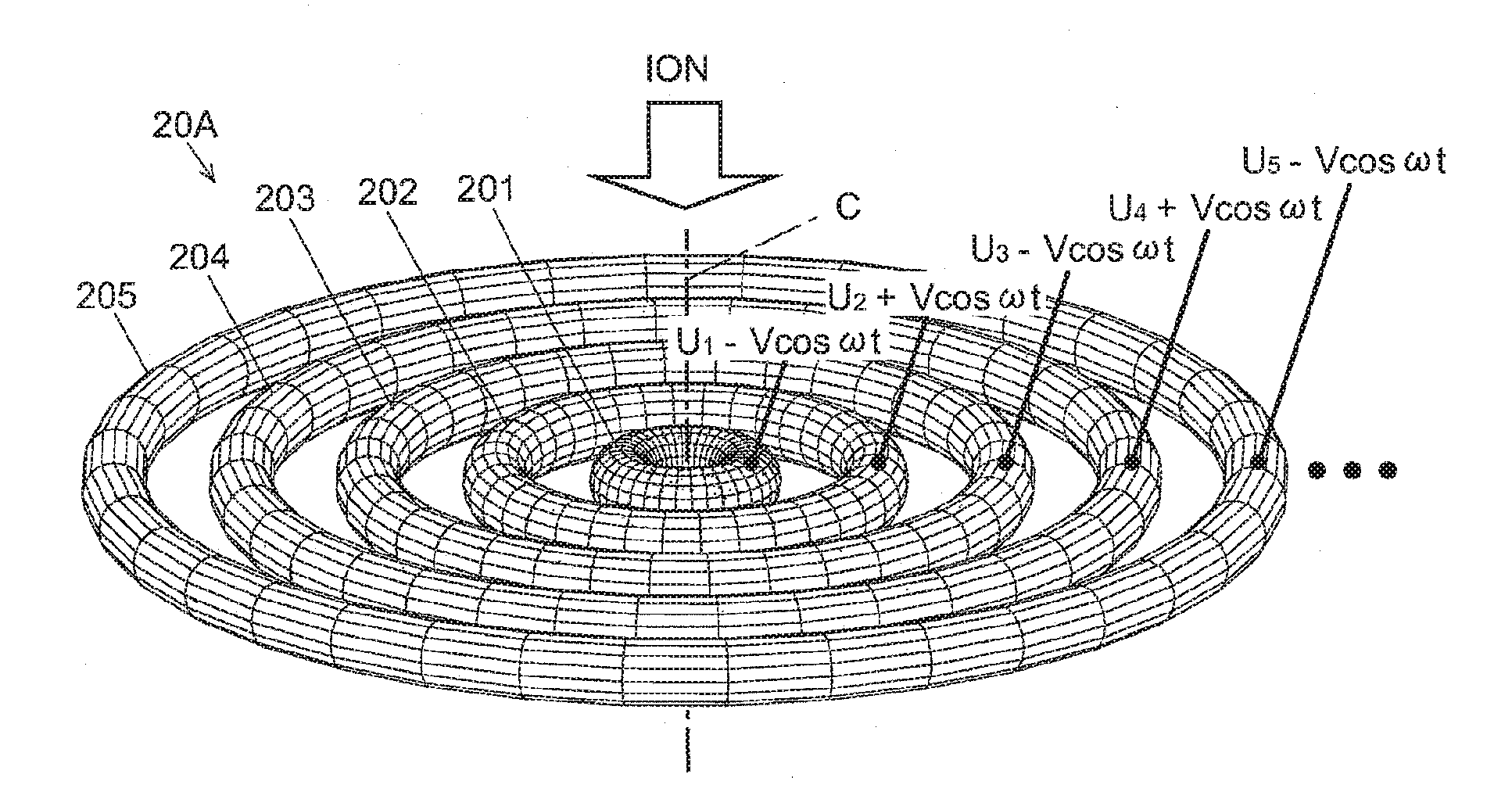

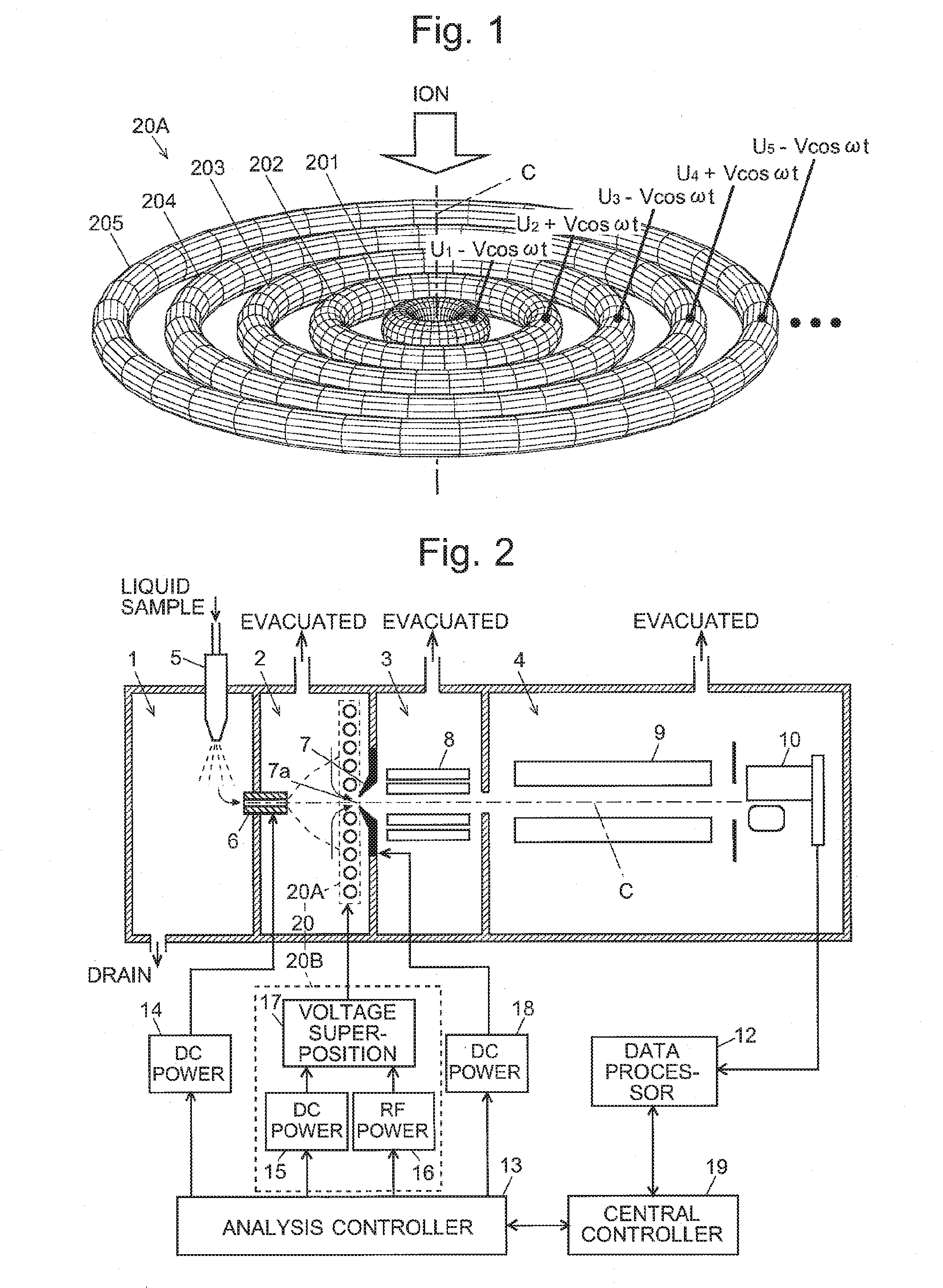

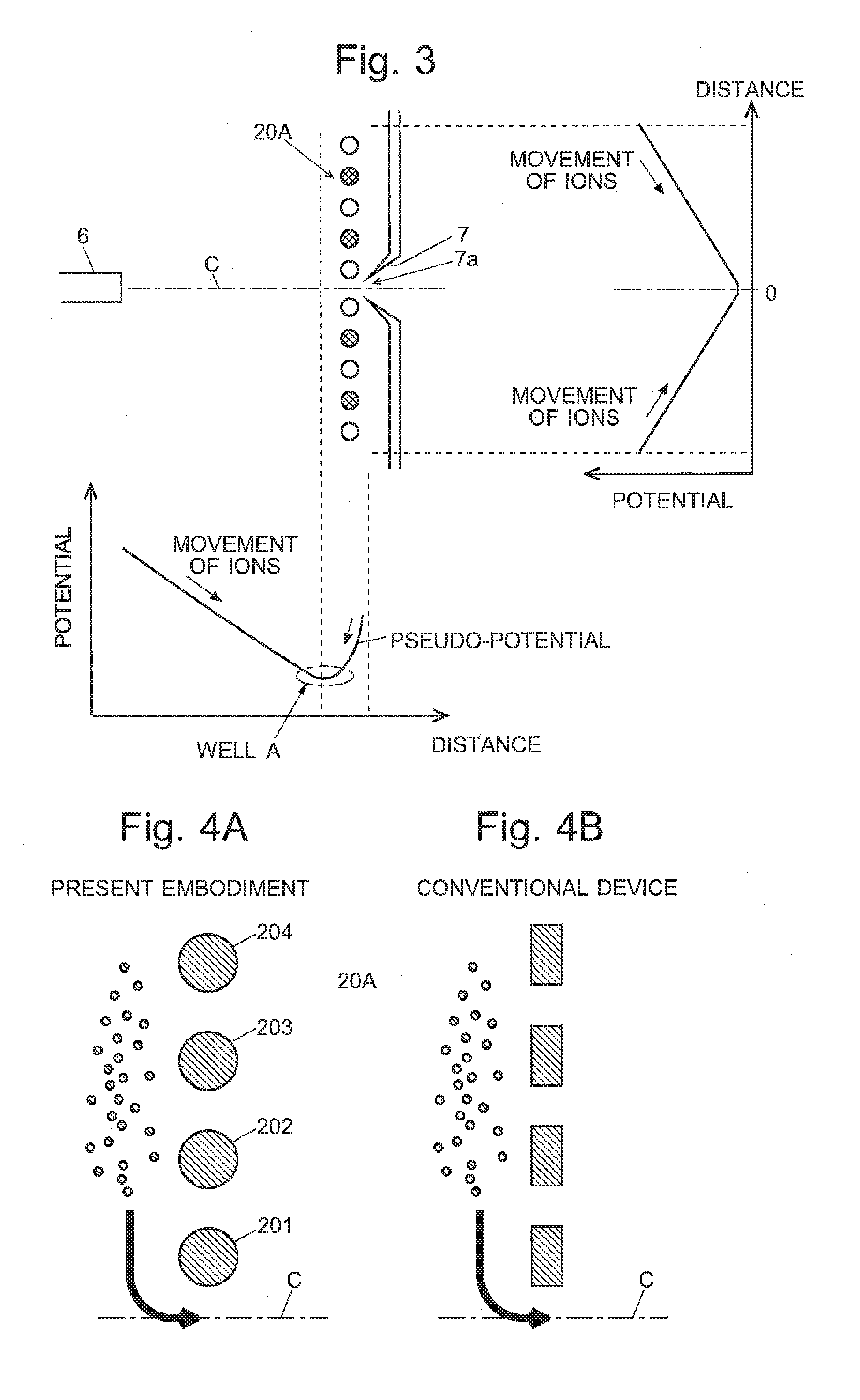

Ion transport apparatus and mass spectrometer using the same

InactiveUS9601323B2Simple structureSame of efficiencyTime-of-flight spectrometersElectron/ion optical arrangementsElectricityIonization chamber

Within an intermediate vacuum chamber next to an ionization chamber maintained at atmospheric pressure, an electrode group of a radio-frequency carpet composed of a plurality of concentrically arranged ring electrodes is placed before a skimmer, with its central axis coinciding with that of an ion-passing hole. Each ring electrode has a circular radial sectional shape. Radio-frequency voltages with mutually inverted phases are applied to the ring electrodes neighboring each other in the radial direction. Additionally, a different level of direct-current voltage is applied to each ring electrode to create a potential which is sloped downward from the outer ring electrode to the inner ring electrode. The circular cross section of the electrode produces a steep pseudo-potential near the electrode and thereby increases the repulsive force which acts on the ions to repel them from the electrode.

Owner:SHIMADZU CORP

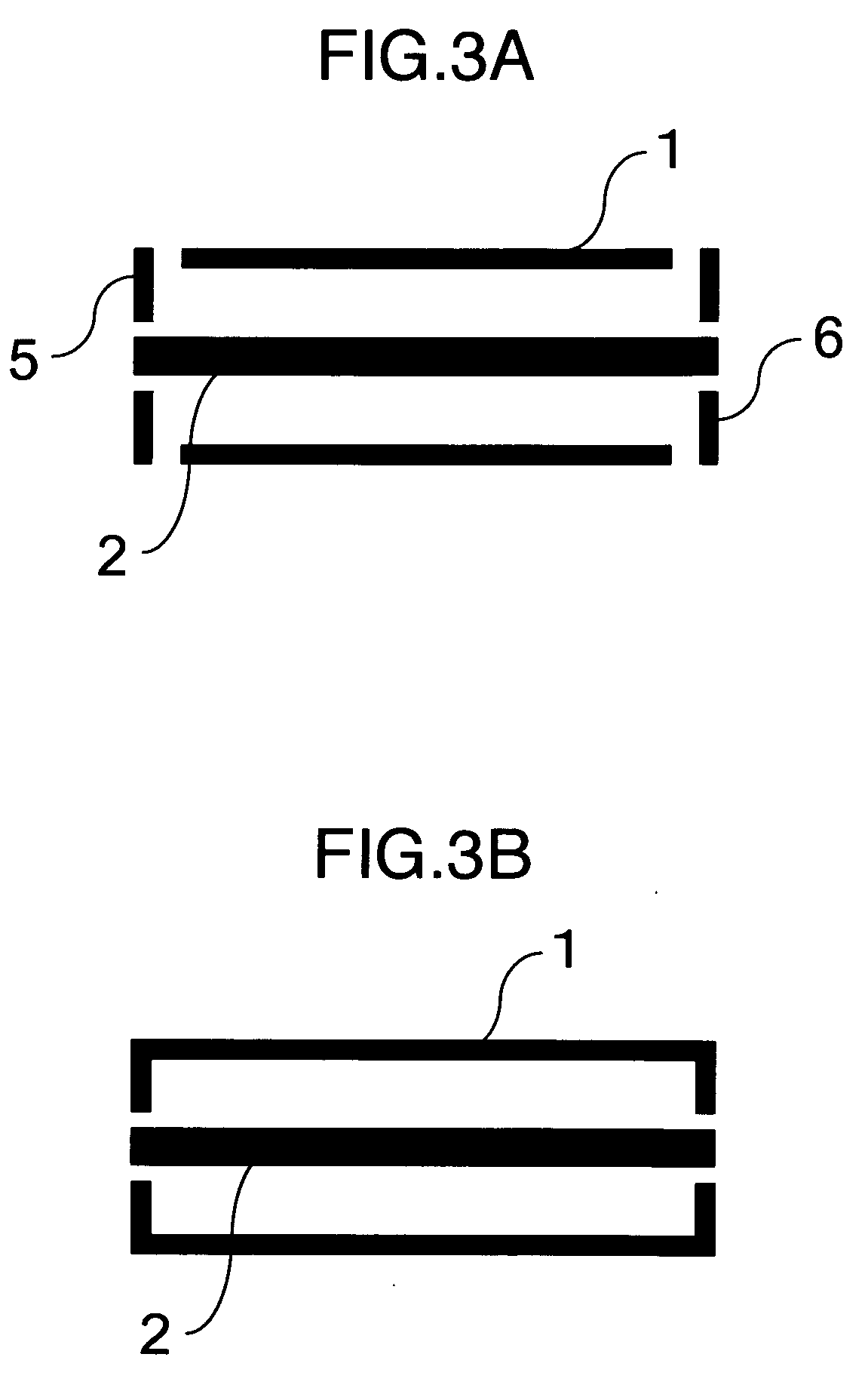

Ion trap, mass spectrometer and ion mobility analyzer using the ion trap

InactiveUS20090001265A1Increase usageAccurate ion trajectoryMaterial analysis by electric/magnetic meansIsotope separationIon trap mass spectrometryMass analyzer

A mass spectrometer using a one-dimensional ion trap is disclosed. The mass spectrometer having the one-dimensional ion trap can trap a great amount of ions, and the provision of a mass spectrometric analyzer capable of operation in a low vacuum eliminates the need of a high vacuum.

Owner:HITACHI LTD

Ceramic electrode structure for generating ions, and ion generating apparatus using the same

ActiveUS7485265B2Simple electrode structureSuppresses the production of ozoneBiocidePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesPulse voltageMaterials science

A ceramic electrode structure designed to have an enhanced construction, wherein an induction electrode has an area larger than that of a discharge electrode. A high square pulse voltage is applied to the enhanced ceramic electrode structure, thereby increasing an efficiency of ion generation and effectively restricting generation of ozone.

Owner:SAMSUNG ELECTRONICS CO LTD

Preparation method of lithium-sulfur battery positive electrode

InactiveCN110752349AHigh specific capacityAvoid local agglomeration of materialsElectrode manufacturing processesLi-accumulatorsElectrical batteryElectrically conductive

The invention provides a preparation method of a lithium-sulfur battery positive electrode. The preparation method comprises the following steps: uniformly mixing an active substance sulfur, a conductive agent and a binder to obtain a mixture, then adding a dispersing solvent into the mixture, and uniformly mixing to obtain electrode slurry; uniformly coating a positive electrode current collectorwith the electrode slurry to obtain a wet electrode coated with the slurry; freezing the wet electrode coated with the slurry in a low-temperature environment of -80 to -5 DEG C for 1-5 hours until the wet electrode is frozen and formed, so that the dispersing solvent in the wet electrode is solidified and crystallized to obtain a solidified electrode; placing the solidified electrode in a vacuumenvironment with the vacuum degree of 0.1-100Pa for 1-5 hours, so that solid-phase sublimation of ice crystals in the solidified electrode is carried out to obtain a solid-phase sublimated electrode;and carrying out rolling treatment on the solid-phase sublimated electrode, and controlling the porosity of the electrode to be 50-70% to obtain the lithium-sulfur battery positive electrode. The preparation method is simple, and the problem of electrode cracking in the preparation of a high-sulfur-carrying positive electrode by adopting a traditional hot drying method is effectively solved.

Owner:TONGJI UNIV

Ion transport apparatus and mass spectrometer using the same

InactiveUS20160189946A1Same level of ion-trappingSame level of ion-transporting efficiencyTime-of-flight spectrometersElectron/ion optical arrangementsElectricityIonization chamber

Within an intermediate vacuum chamber next to an ionization chamber maintained at atmospheric pressure, an electrode group of a radio-frequency carpet composed of a plurality of concentrically arranged ring electrodes is placed before a skimmer, with its central axis coinciding with that of an ion-passing hole. Each ring electrode has a circular radial sectional shape. Radio-frequency voltages with mutually inverted phases are applied to the ring electrodes neighboring each other in the radial direction. Additionally, a different level of direct-current voltage is applied to each ring electrode to create a potential which is sloped downward from the outer ring electrode to the inner ring electrode. The circular cross section of the electrode produces a steep pseudo-potential near the electrode and thereby increases the repulsive force which acts on the ions to repel them from the electrode.

Owner:SHIMADZU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com