Patents

Literature

623results about How to "Increase contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for selective deposition using a sacrificial capping layer

ActiveUS20210066079A1Reduce contact resistanceIncrease contact resistanceSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSelective depositionMaterials science

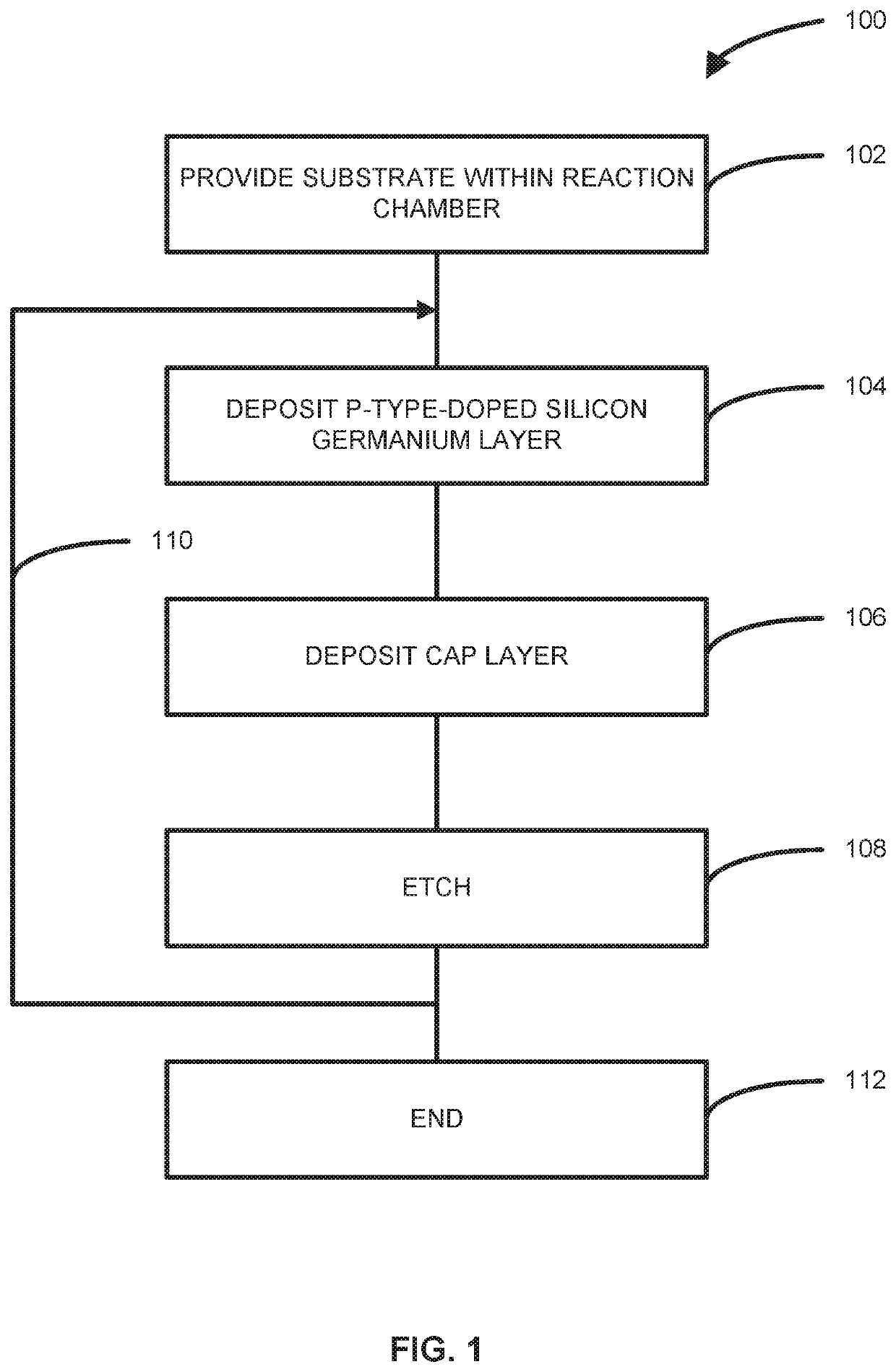

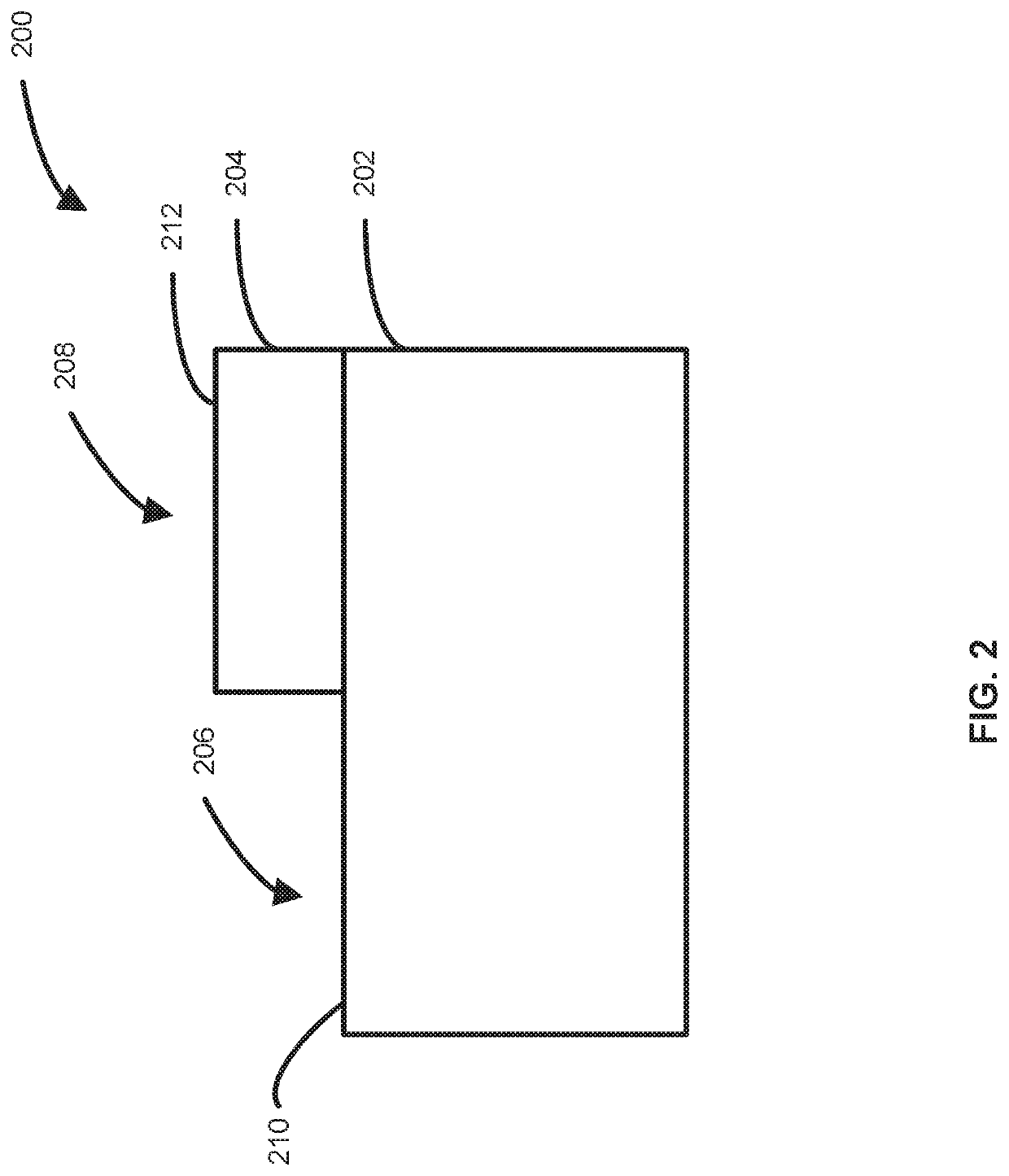

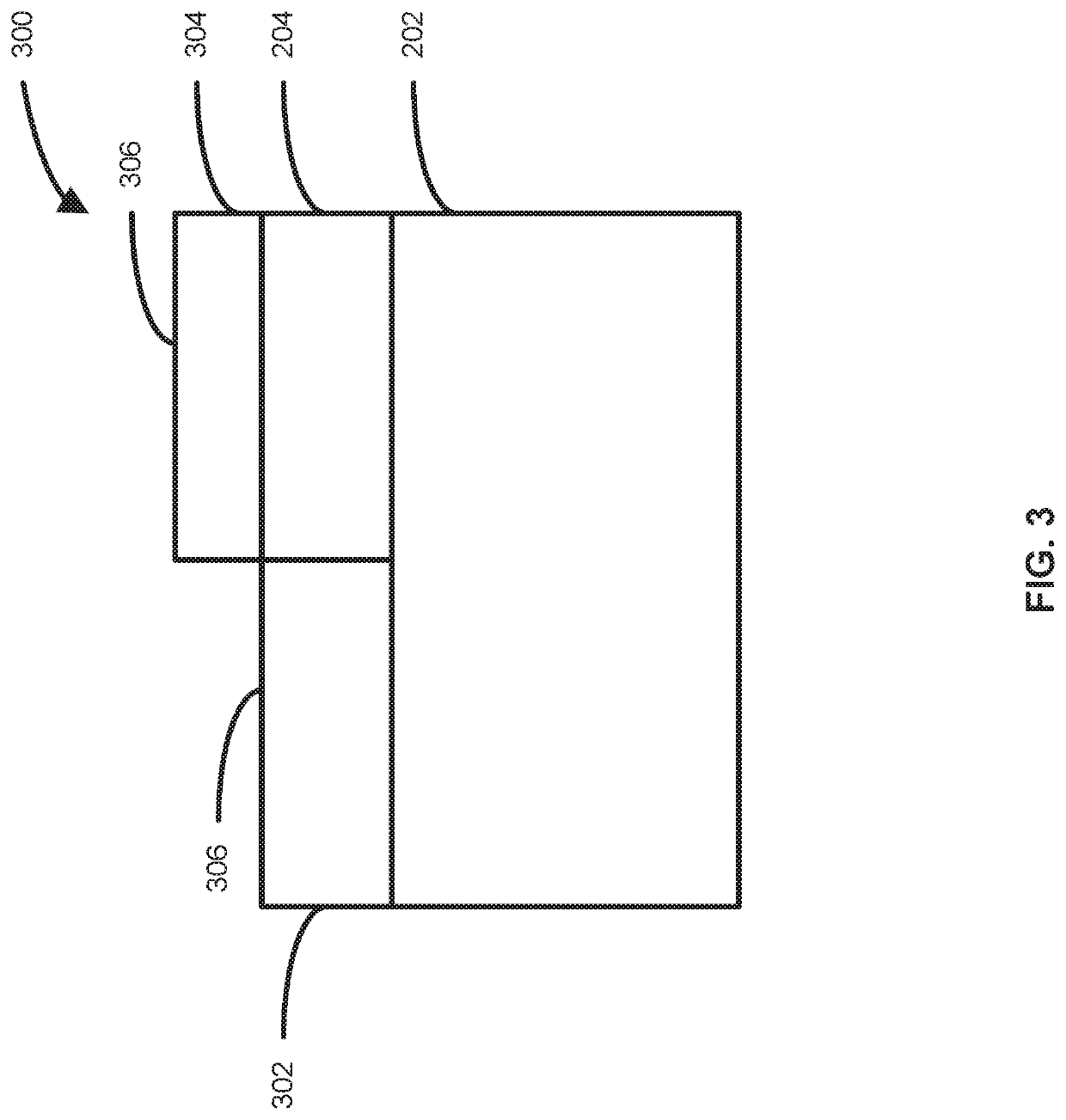

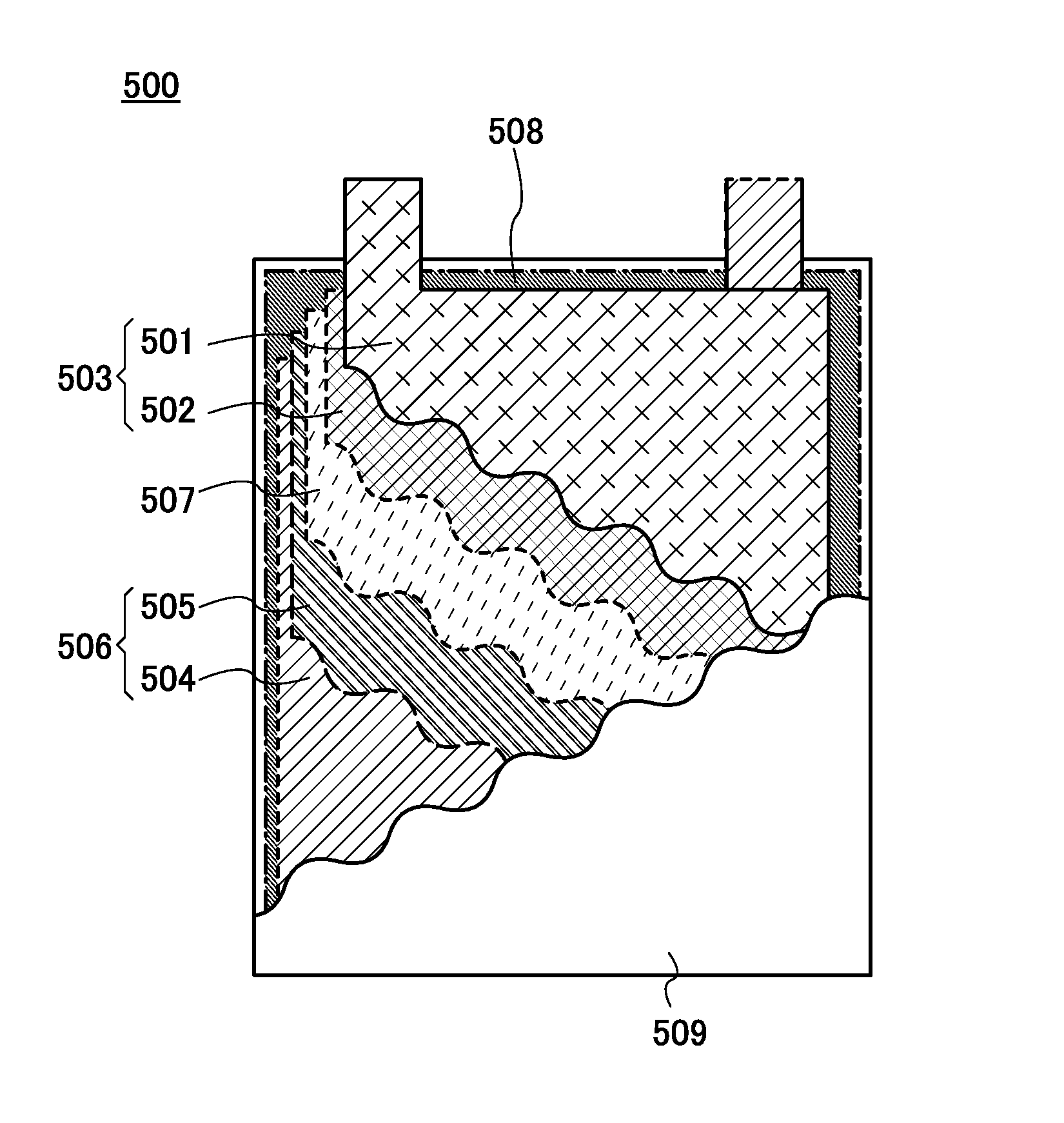

Methods and systems for selectively depositing a p-type doped silicon germanium layer and structures and devices including a p-type doped silicon germanium layer are disclosed. An exemplary method includes providing a substrate, comprising a surface comprising a first area comprising a first material and a second area comprising a second material, within a reaction chamber; depositing a p-type doped silicon germanium layer overlying the surface, the p-type doped silicon germanium layer comprising gallium; and depositing a cap layer overlying the p-type doped silicon germanium layer. The method can further include an etch step to remove the cap layer and the p-type doped silicon germanium layer overlying the second material.

Owner:ASM IP HLDG BV

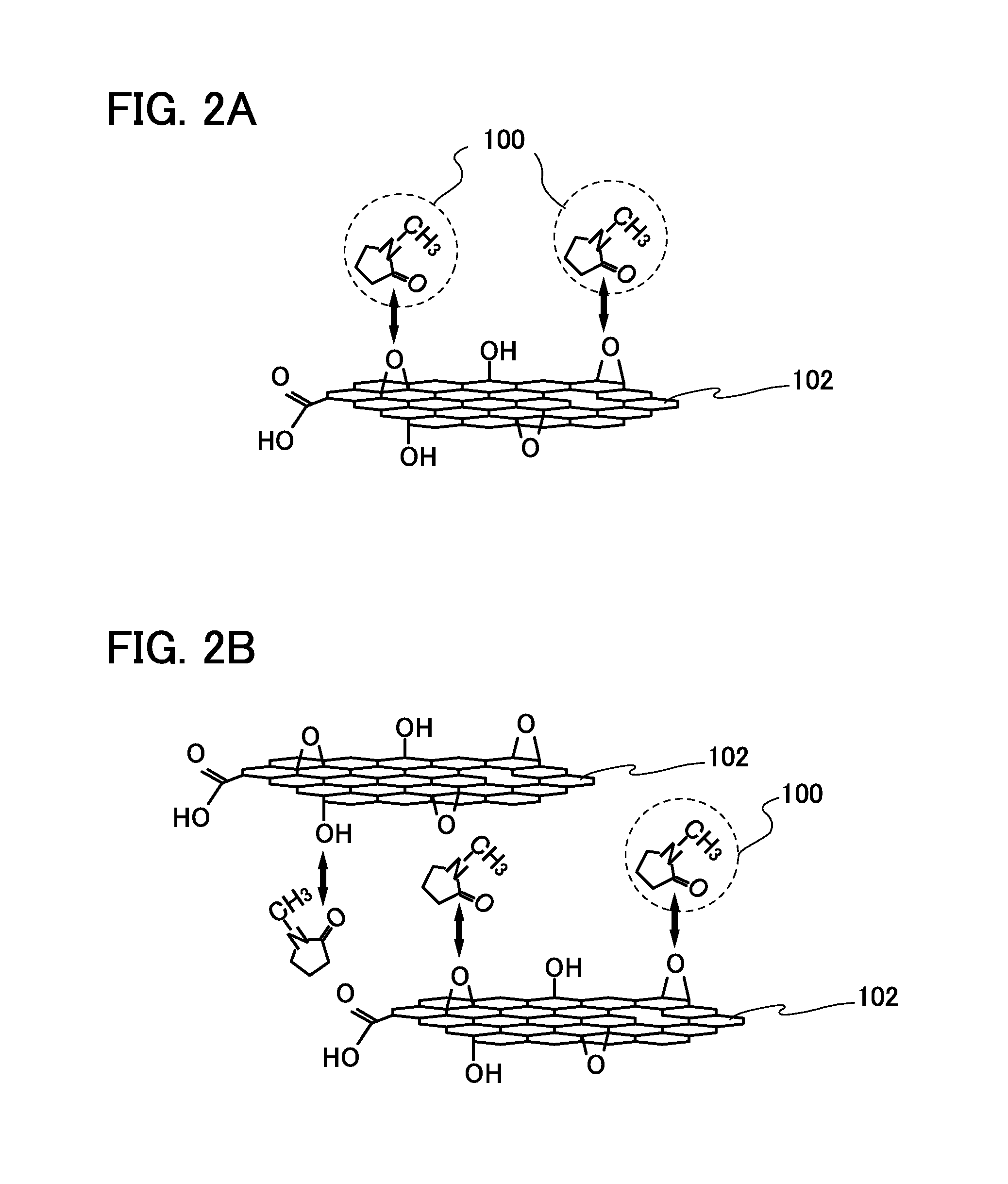

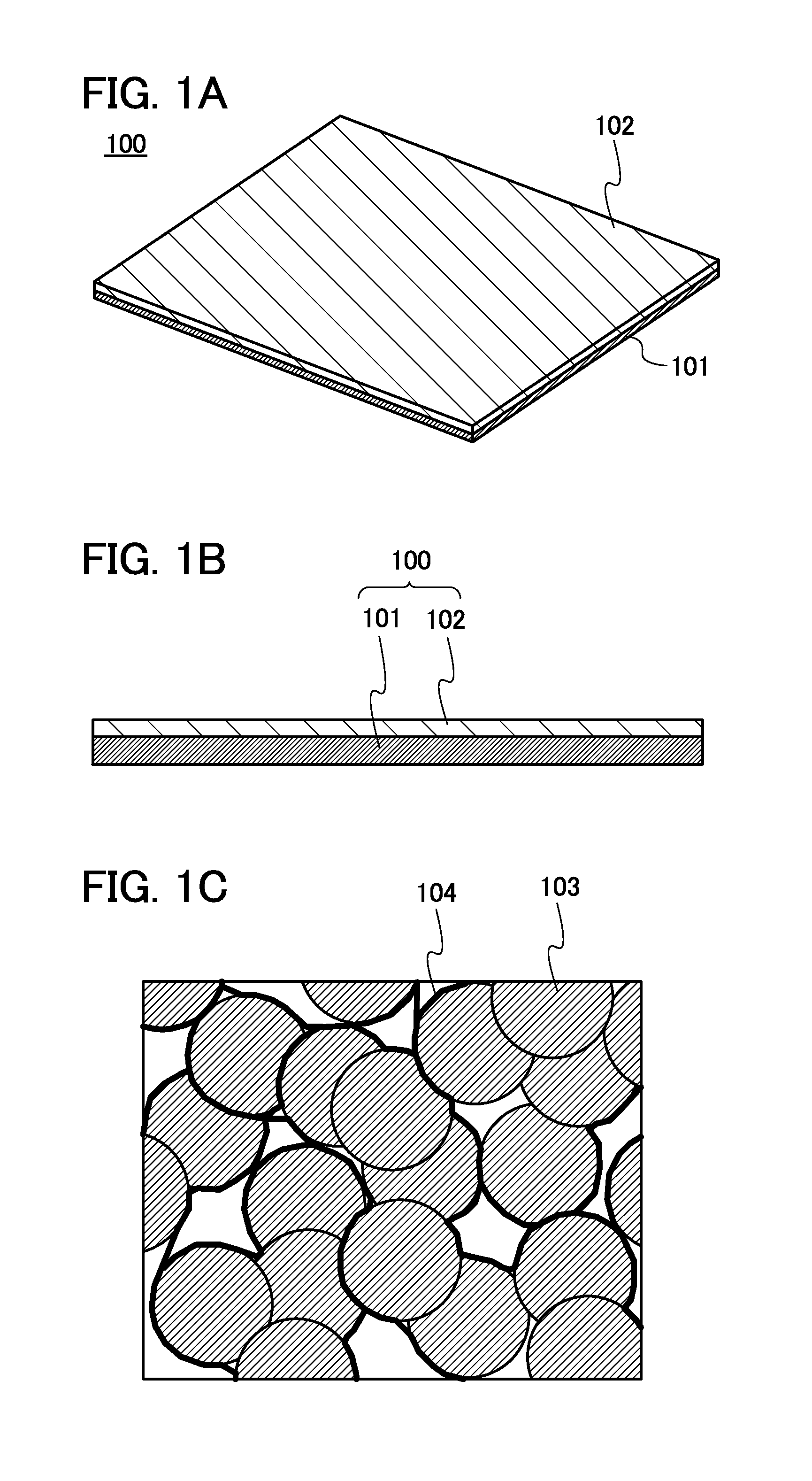

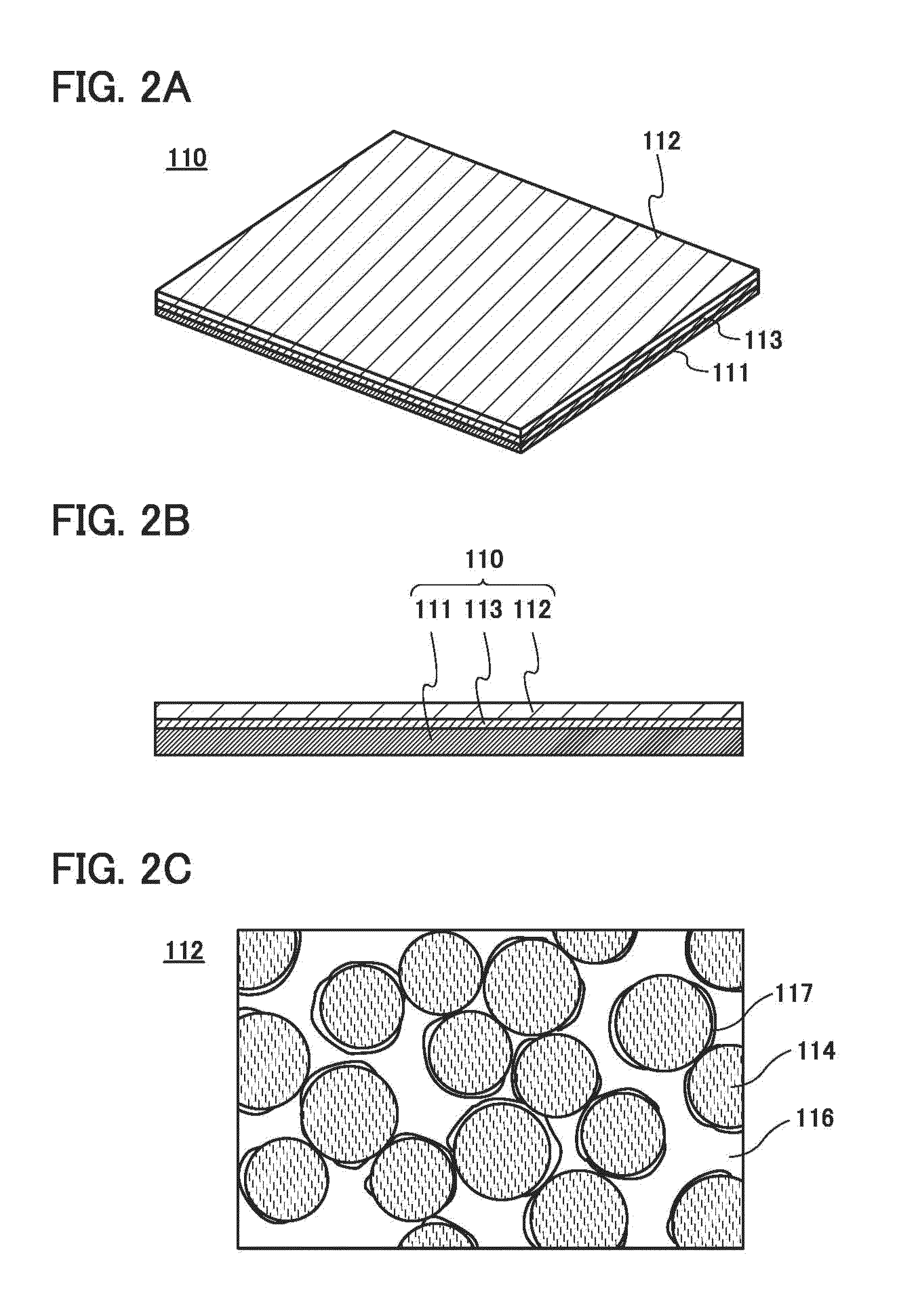

Graphene oxide, positive electrode for nonaqueous secondary battery using graphene oxide, method of manufacturing positive electrode for nonaqueous secondary battery, nonaqueous secondary battery, and electronic device

ActiveUS20130266859A1High capacityReduce capacityOrganic chemistryGraphiteGraphite oxideGraphene oxide paper

A graphene oxide used as a raw material of a conductive additive for forming an active material layer with high electron conductivity with a small amount of a conductive additive is provided. A positive electrode for a nonaqueous secondary battery using the graphene oxide as a conductive additive is provided. The graphene oxide is used as a raw material of a conductive additive in a positive electrode for a nonaqueous secondary battery and, in the graphene oxide, the weight ratio of oxygen to carbon is greater than or equal to 0.405.

Owner:SEMICON ENERGY LAB CO LTD

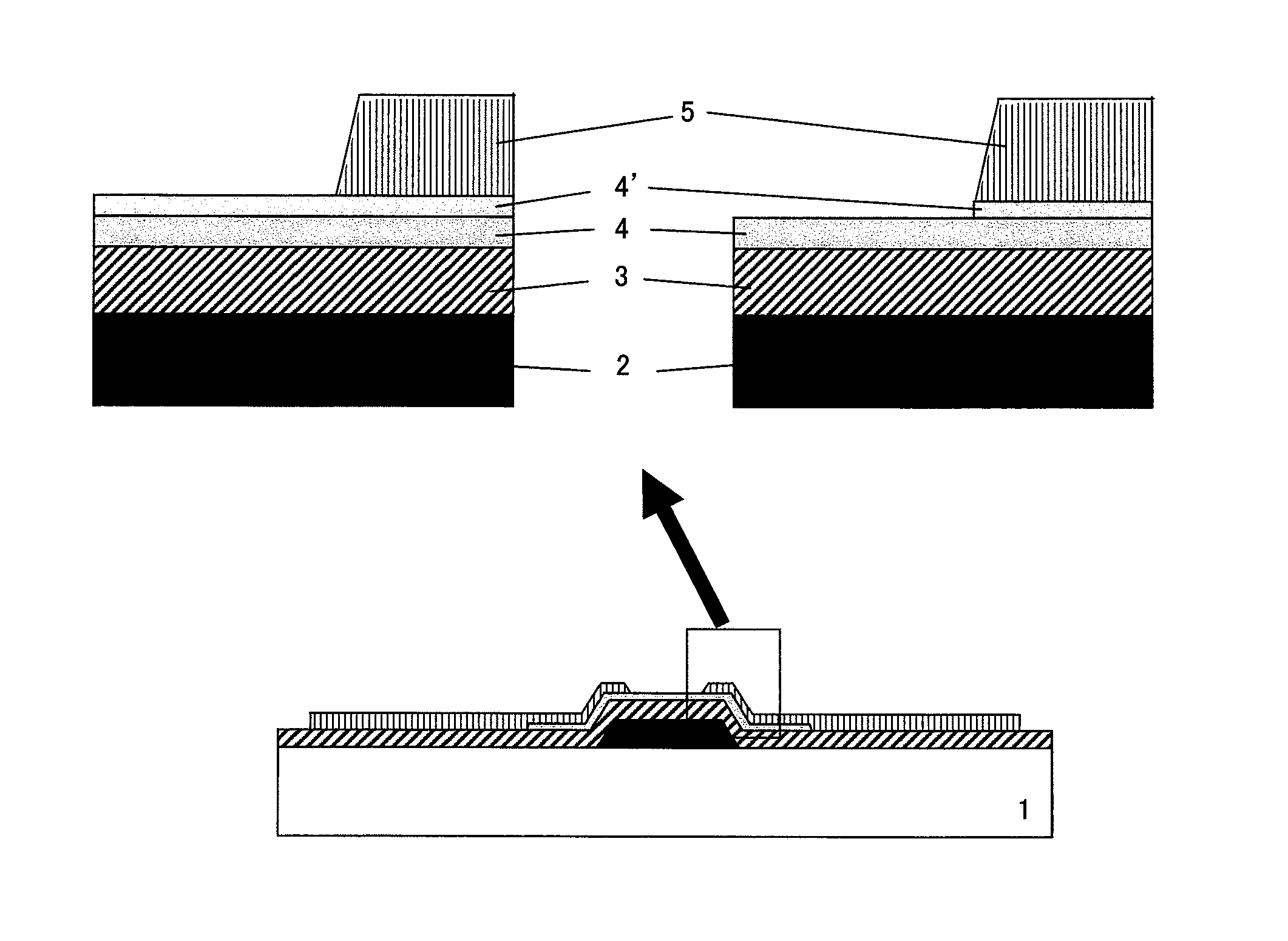

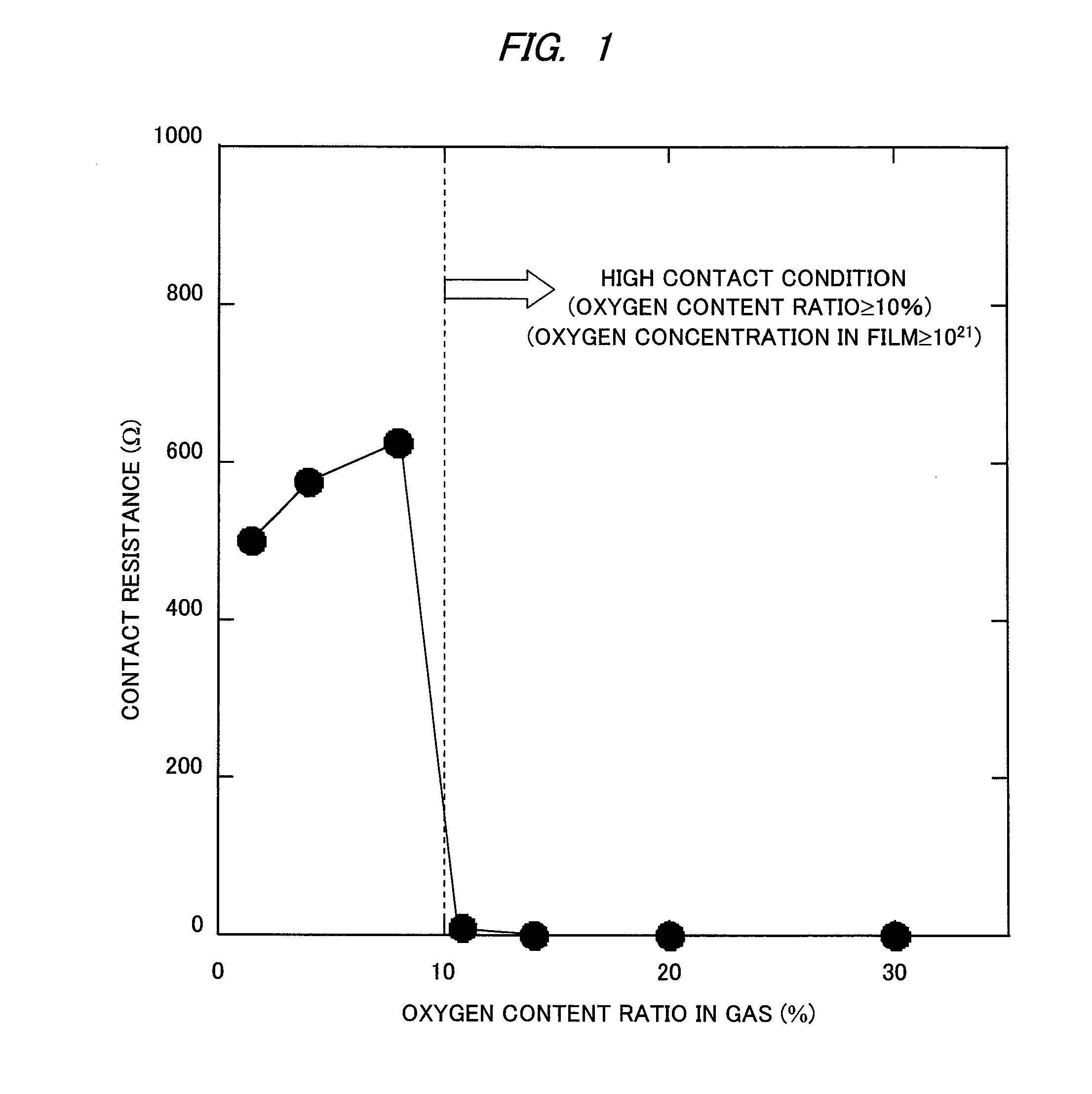

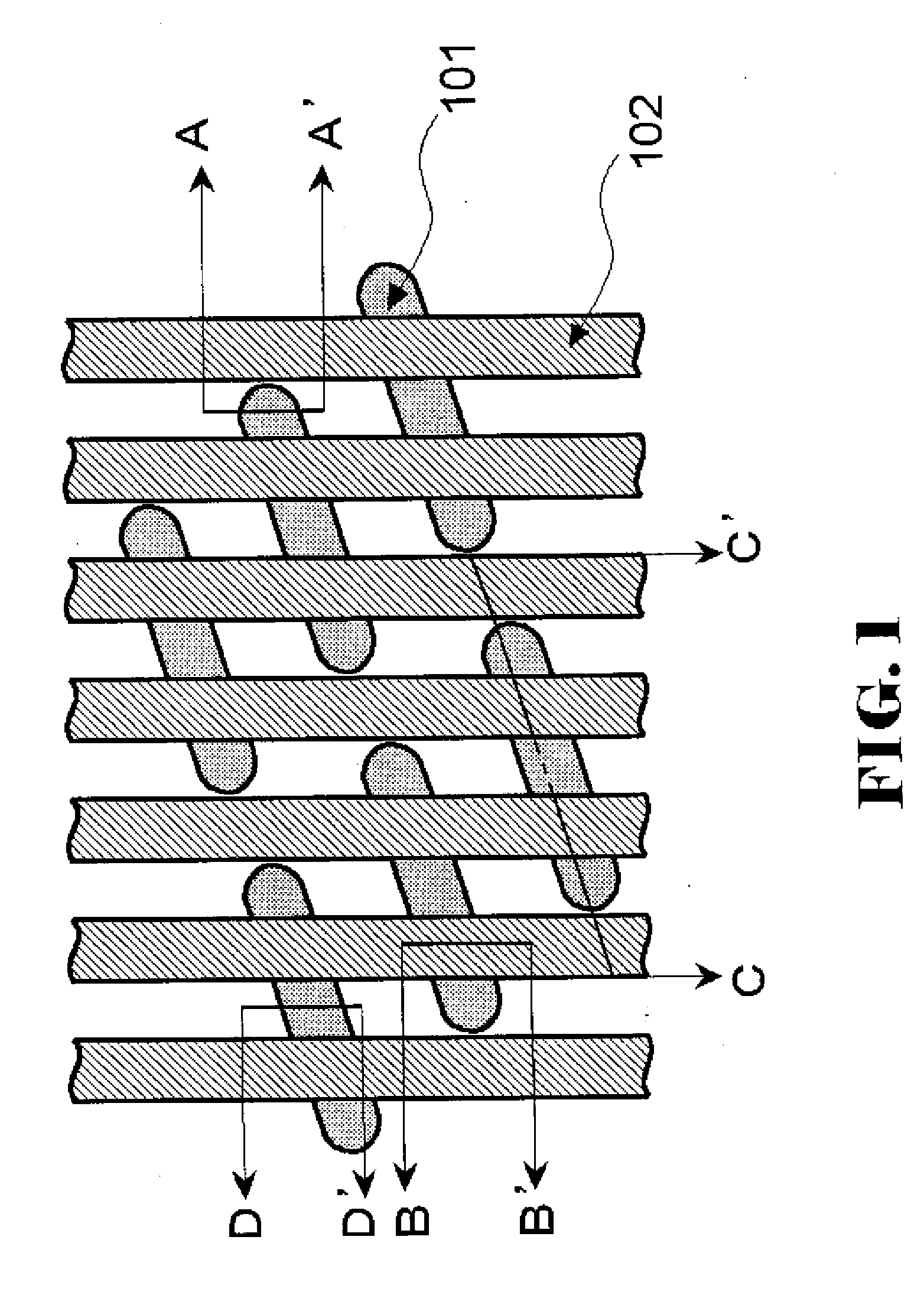

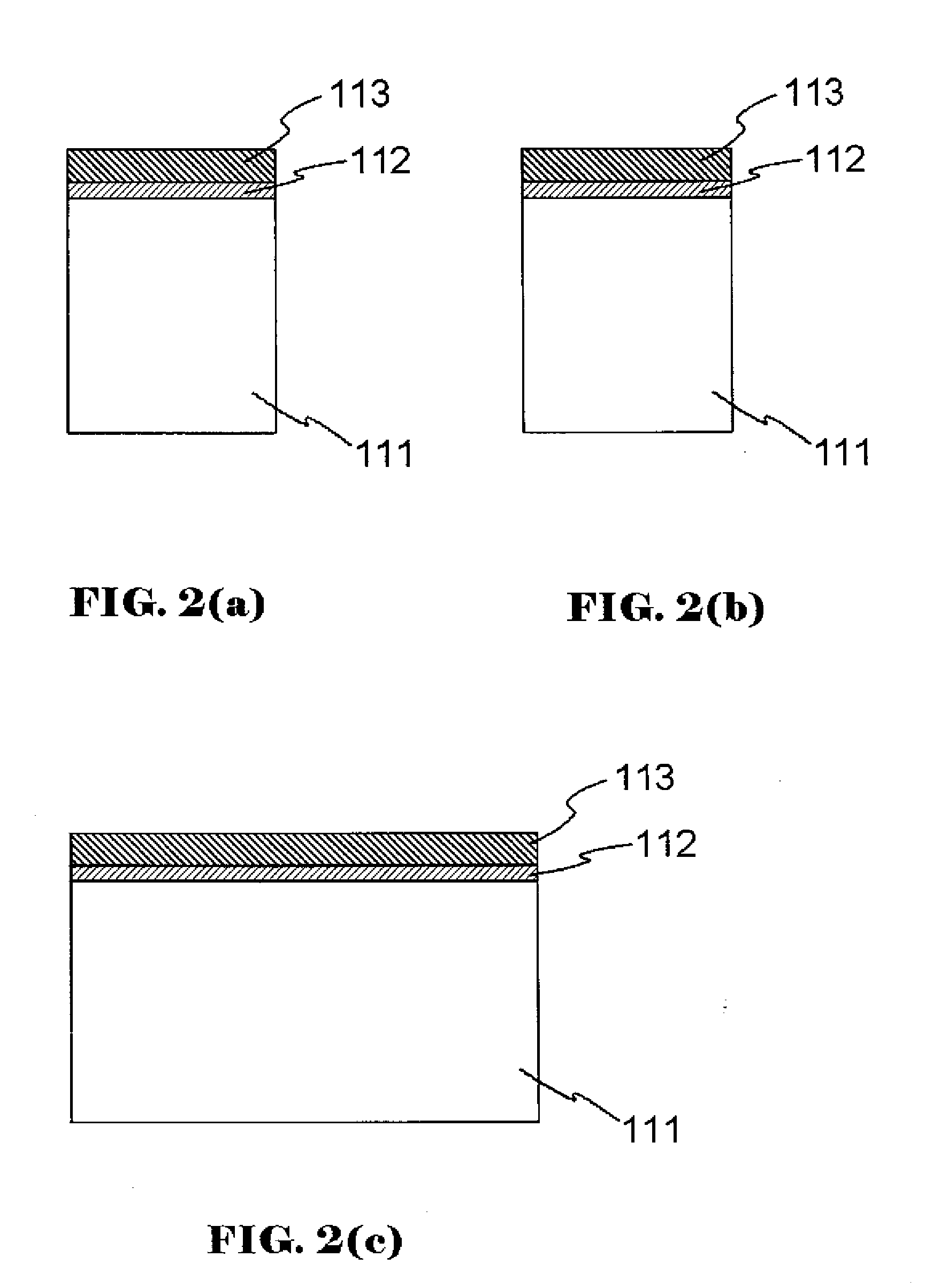

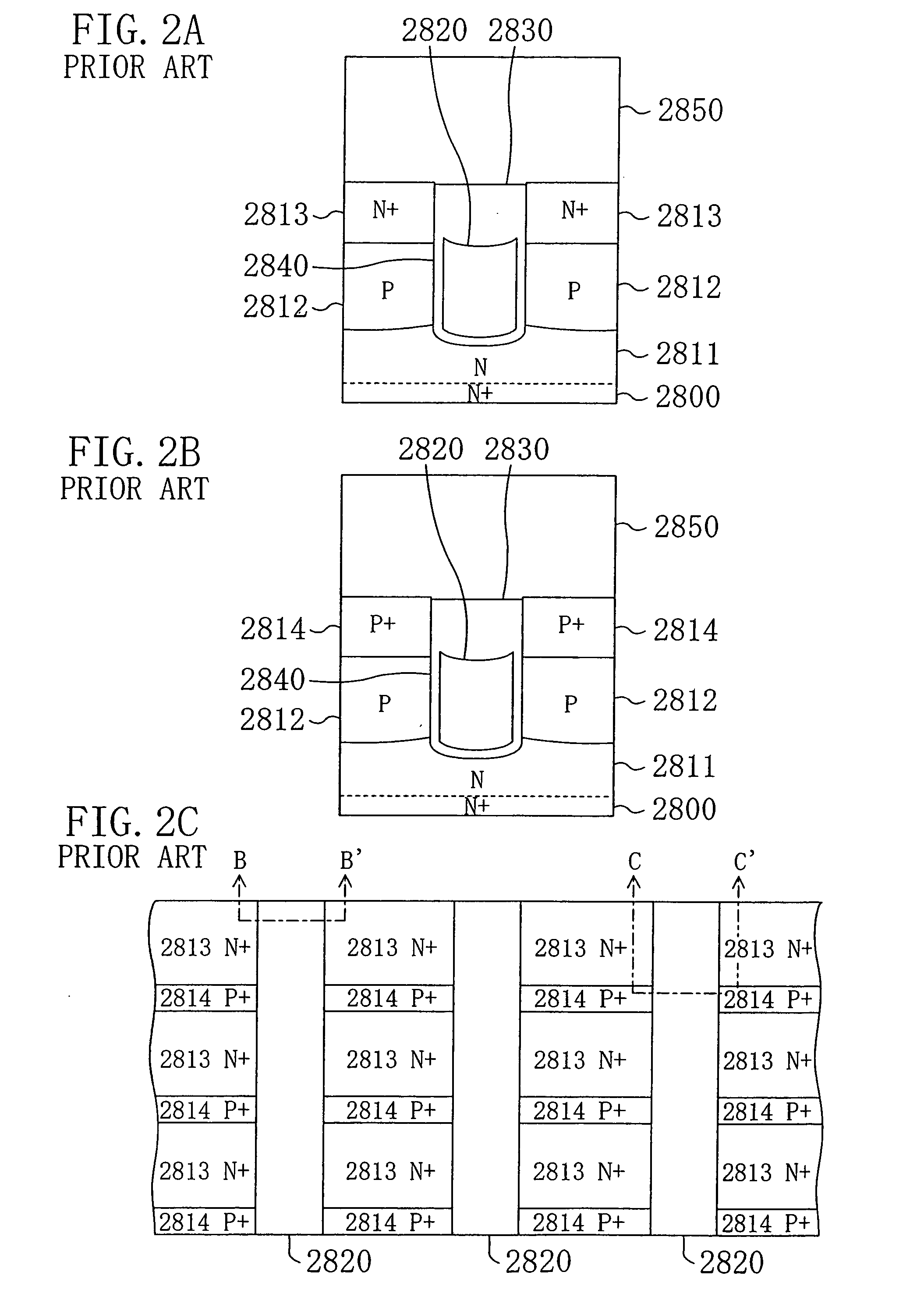

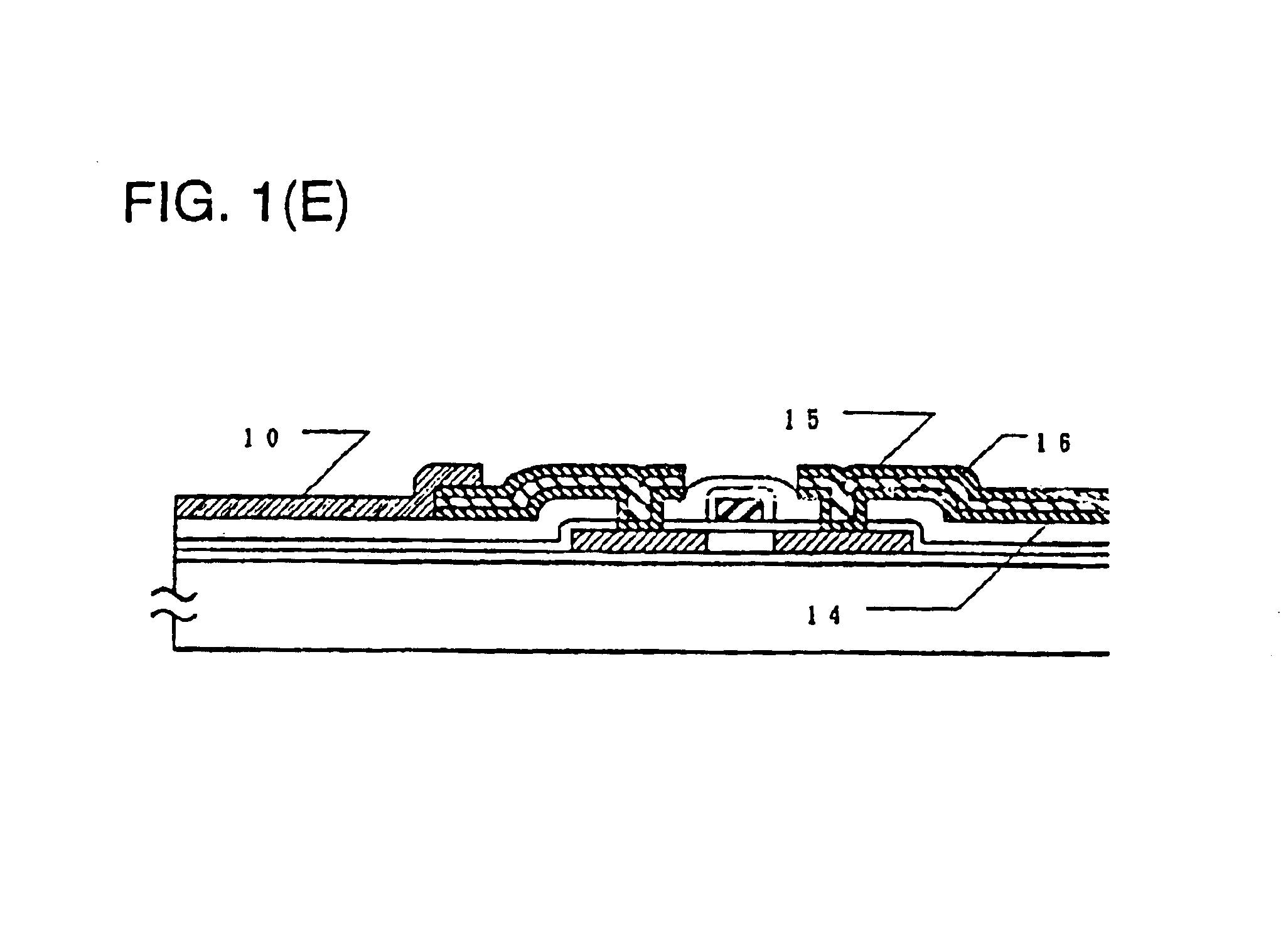

Oxide semiconductor device and method of manufacturing the same and active matrix substrate

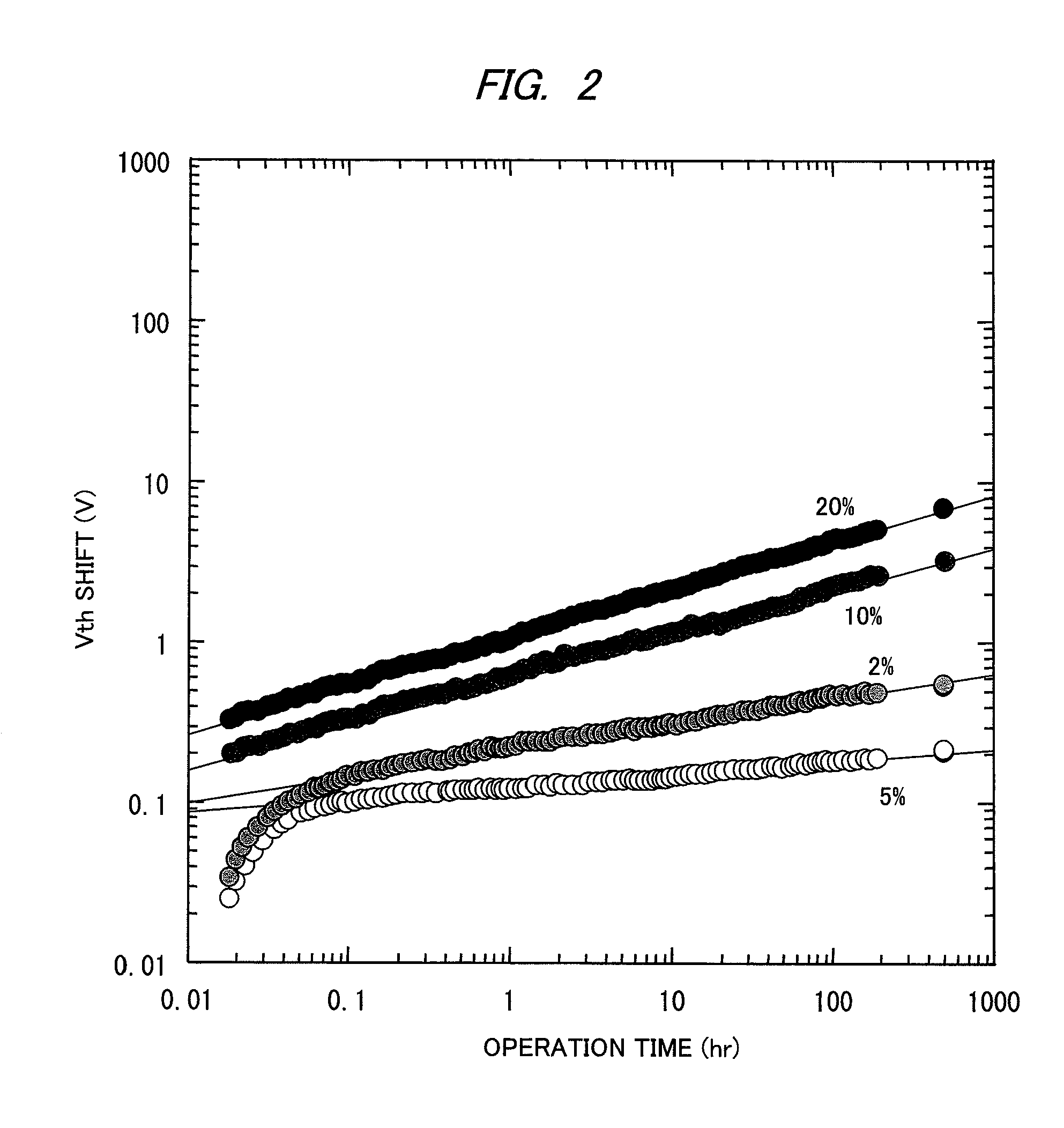

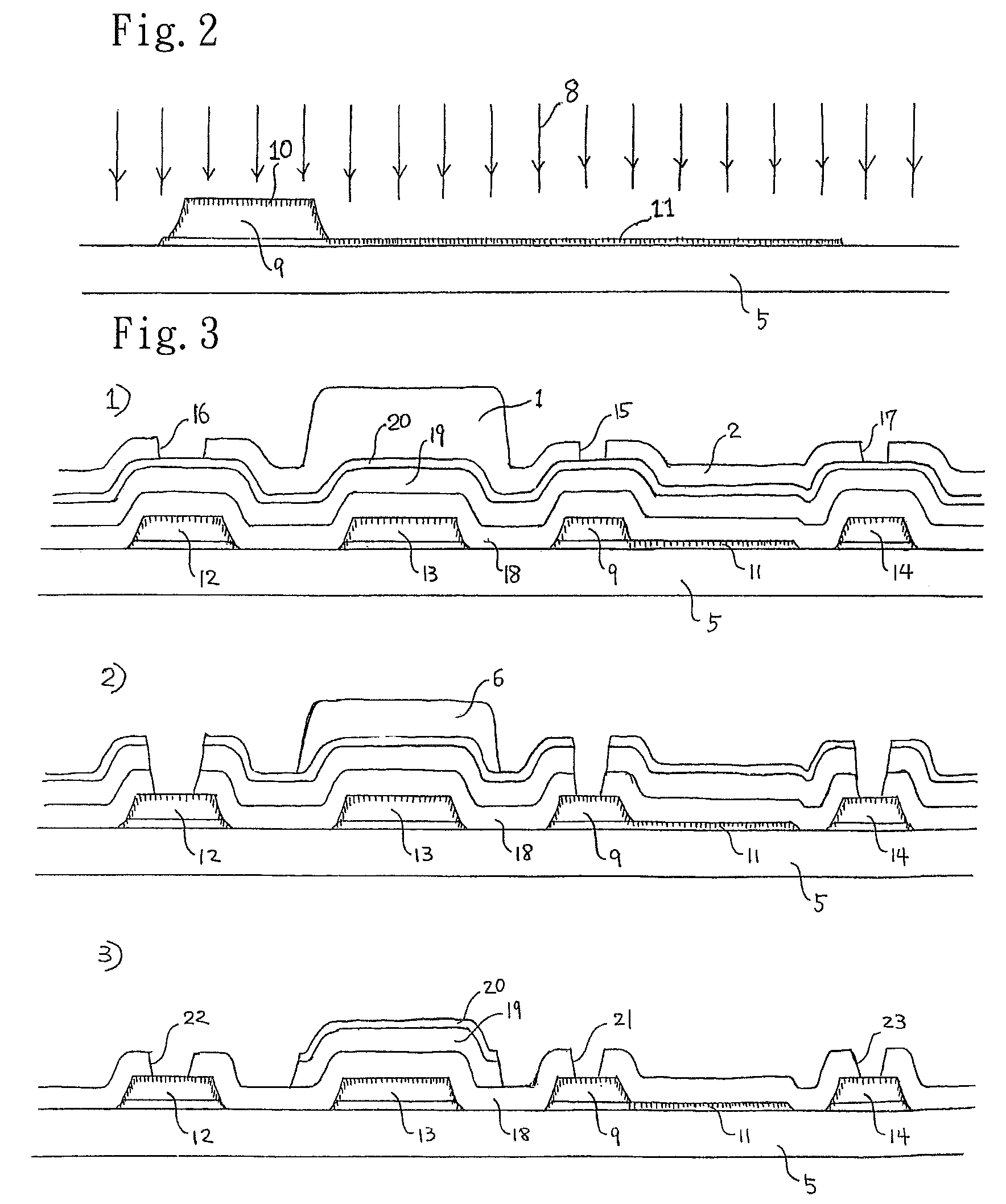

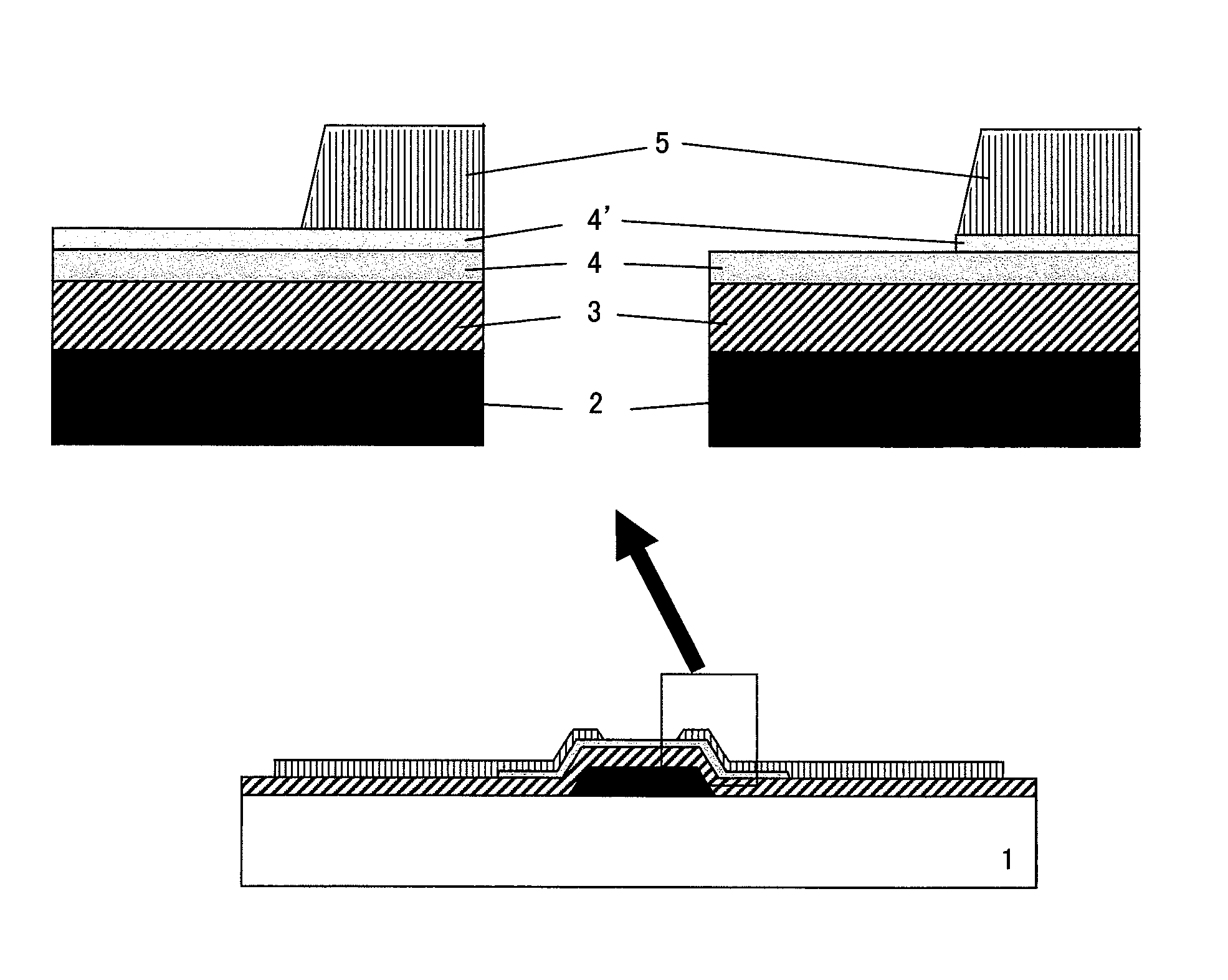

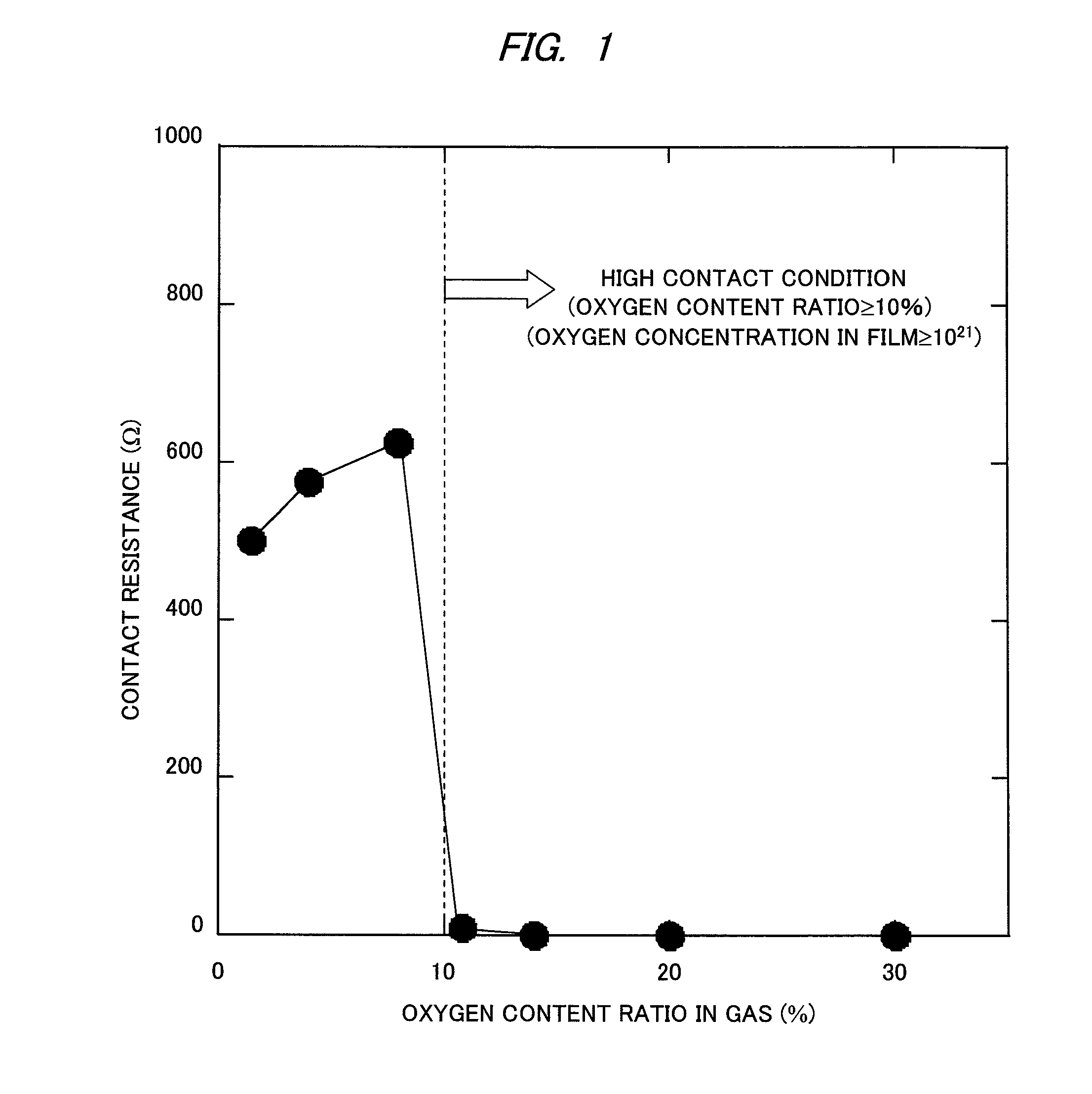

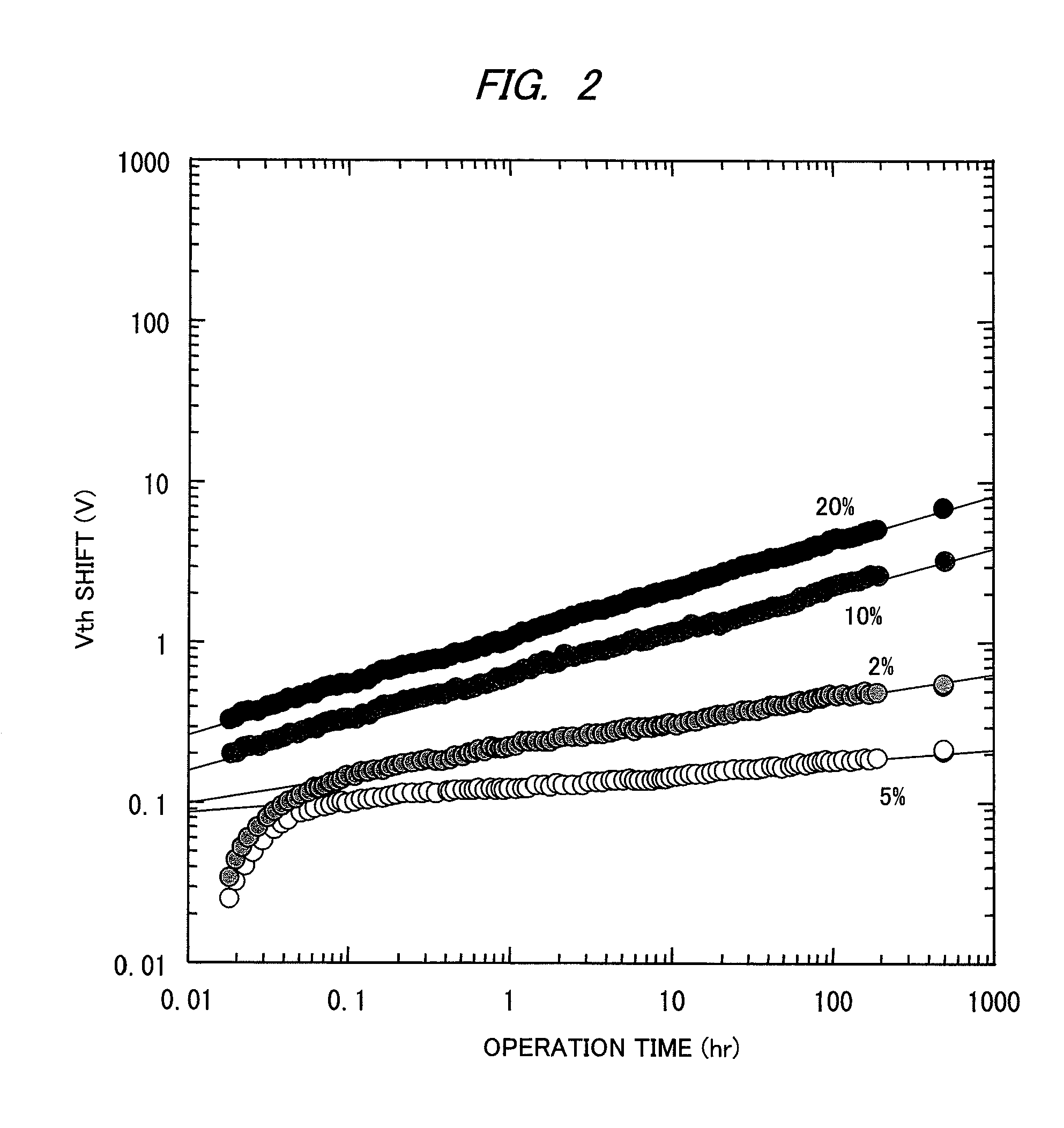

InactiveUS20100140614A1High content ratioImprove contact effectTransistorSolid-state devicesActive matrixThreshold potential

A phenomenon of change of a contact resistance between an oxide semiconductor and a metal depending on an oxygen content ratio in introduced gas upon depositing an oxide semiconductor film made of indium gallium zinc oxide, zinc tin oxide, or others in an oxide semiconductor thin-film transistor. A contact layer is formed with an oxygen content ratio of 10% or higher in a region from a surface, where the metal and the oxide semiconductor are contacted, down to at least 3 nm deep in depth direction, and a region to be a main channel layer is further formed with an oxygen content ratio of 10% or lower, so that a multilayered structure is formed, and both of ohmic characteristics to the electrode metal and reliability such as the suppression of threshold potential shift are achieved.

Owner:HITACHI LTD

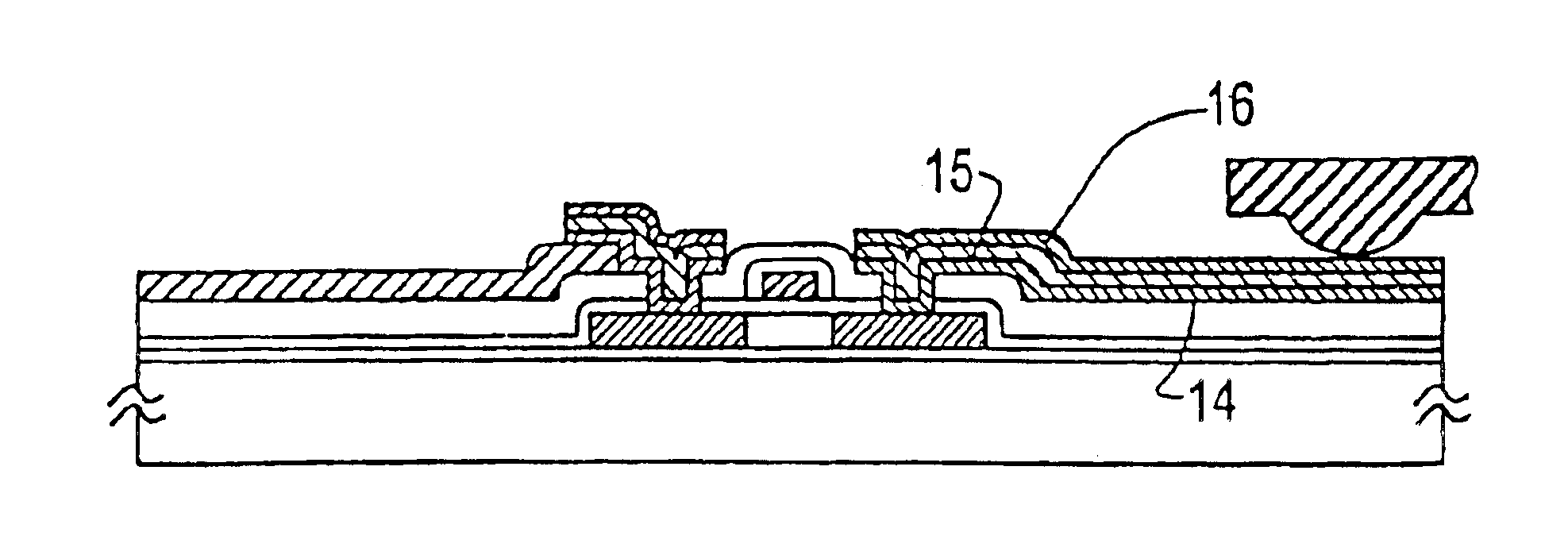

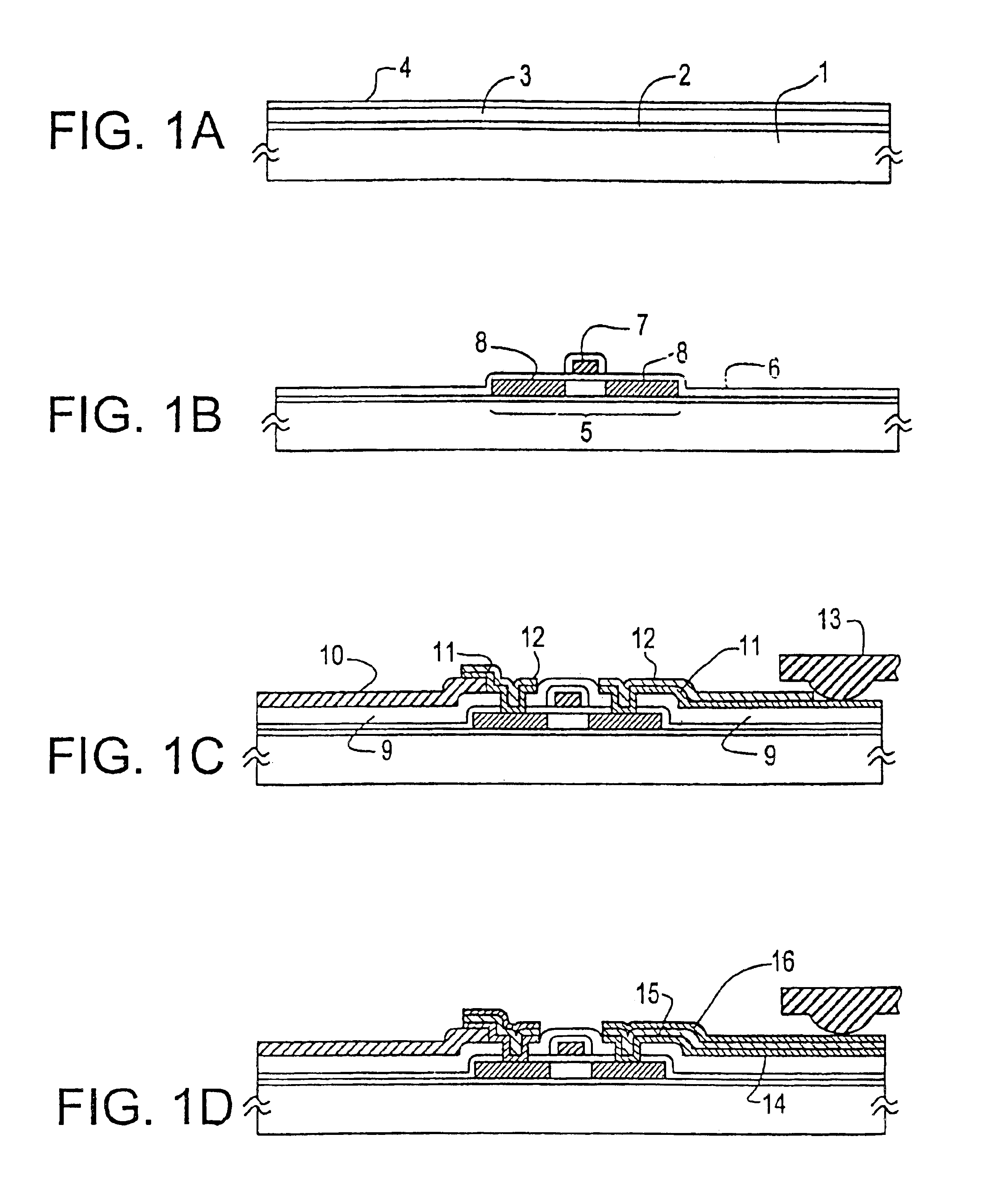

Method of manufacturing LCD apparatus by using halftone exposure method

InactiveUS20070269936A1Reduce production processIncrease contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingContact padNitrogen

The present invention discloses a method of manufacturing a super large wide-angle super high-speed response LCD apparatus by using a photolithographic process for three times. The invention adopts a halftone exposure technology and a nitrogen ion doped technology to form a gate electrode, a common electrode, a pixel electrode and a contact pad, and then uses the halftone exposure technology to form a silicon (Si) island and a contact hole, and a general exposure technology to form a source electrode, a drain electrode and an alignment control electrode. A P-CVD apparatus is provided for forming a passivation layer into a film by using a masking deposition method, or an ink-jet coating method is used to coat a protective layer at a partial area, and a photolithographic process is performed for three times to manufacture a TFT matrix substrate of the super large wide-angle super high-speed response LCD.

Owner:MIKUNI ELECTORON

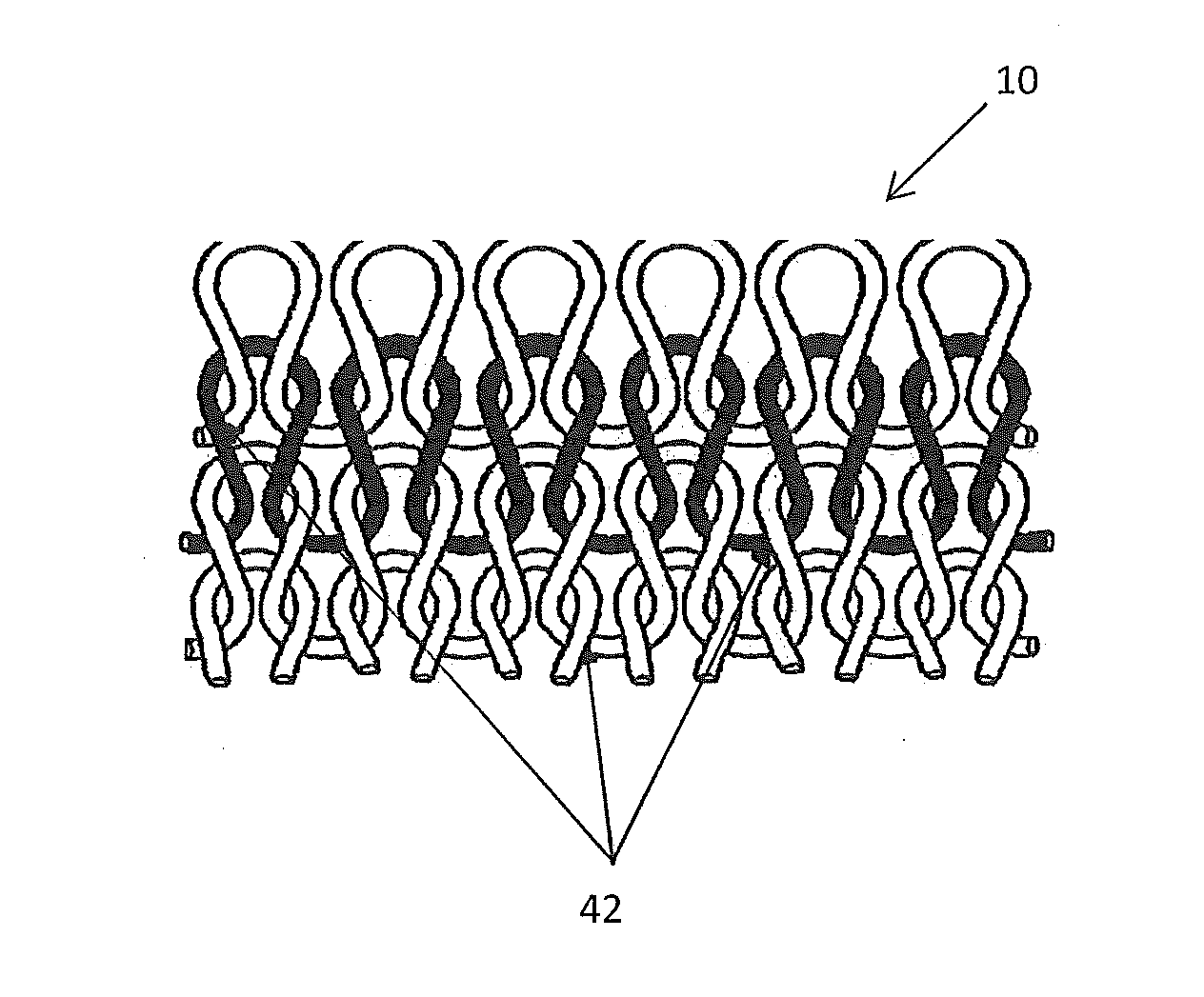

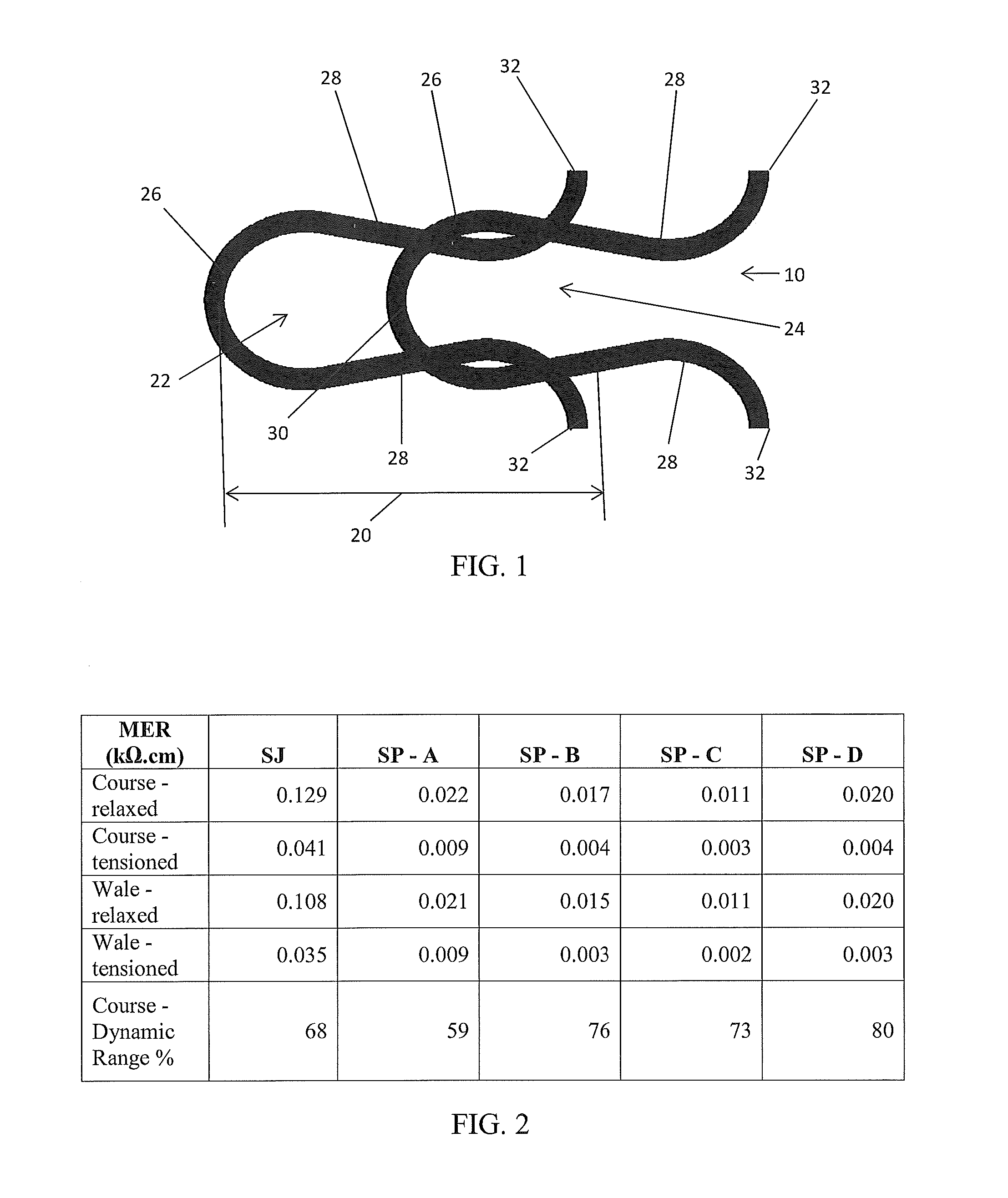

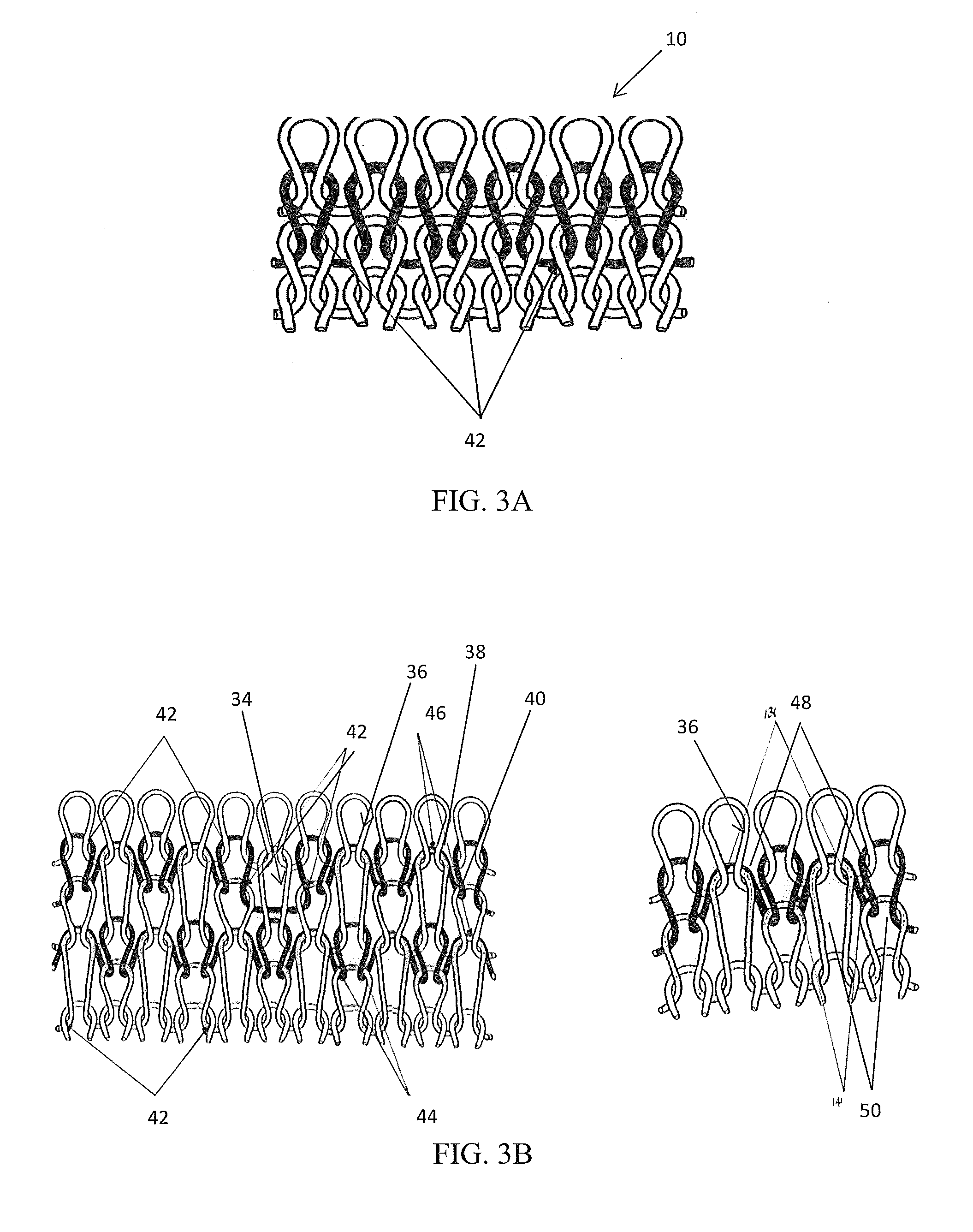

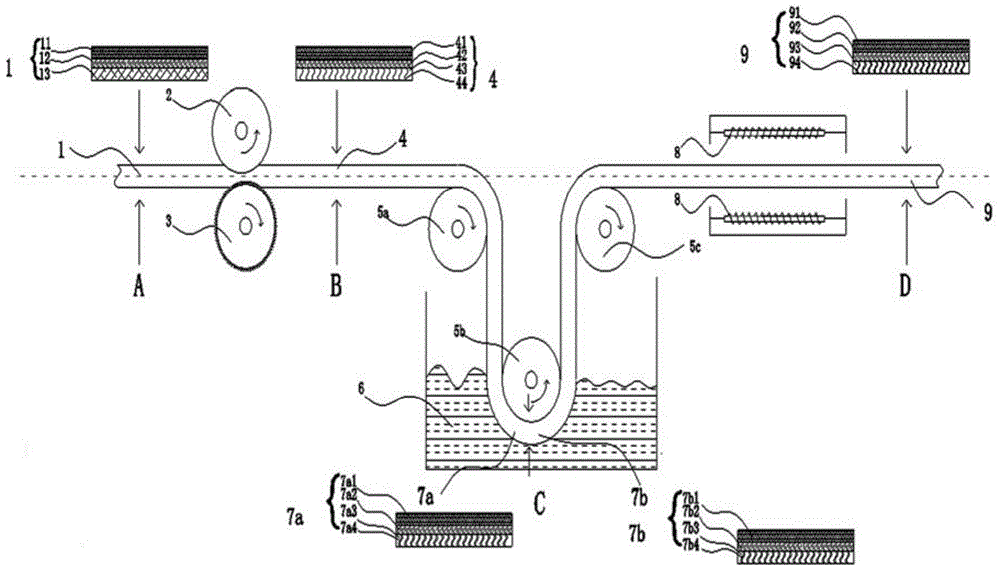

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

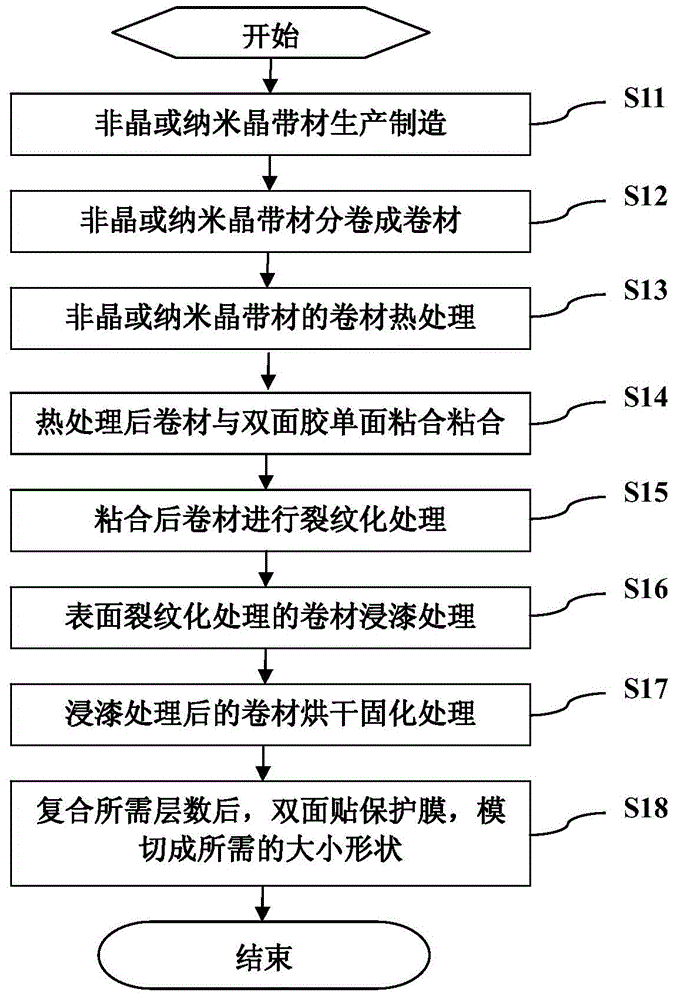

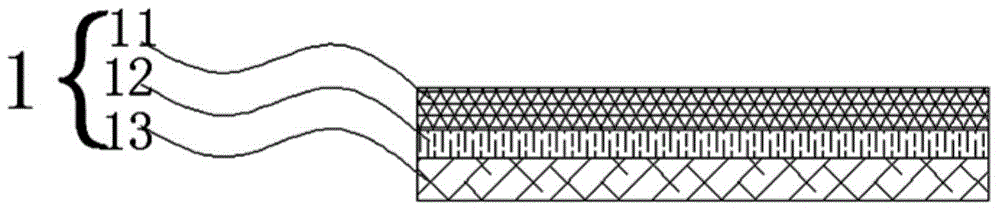

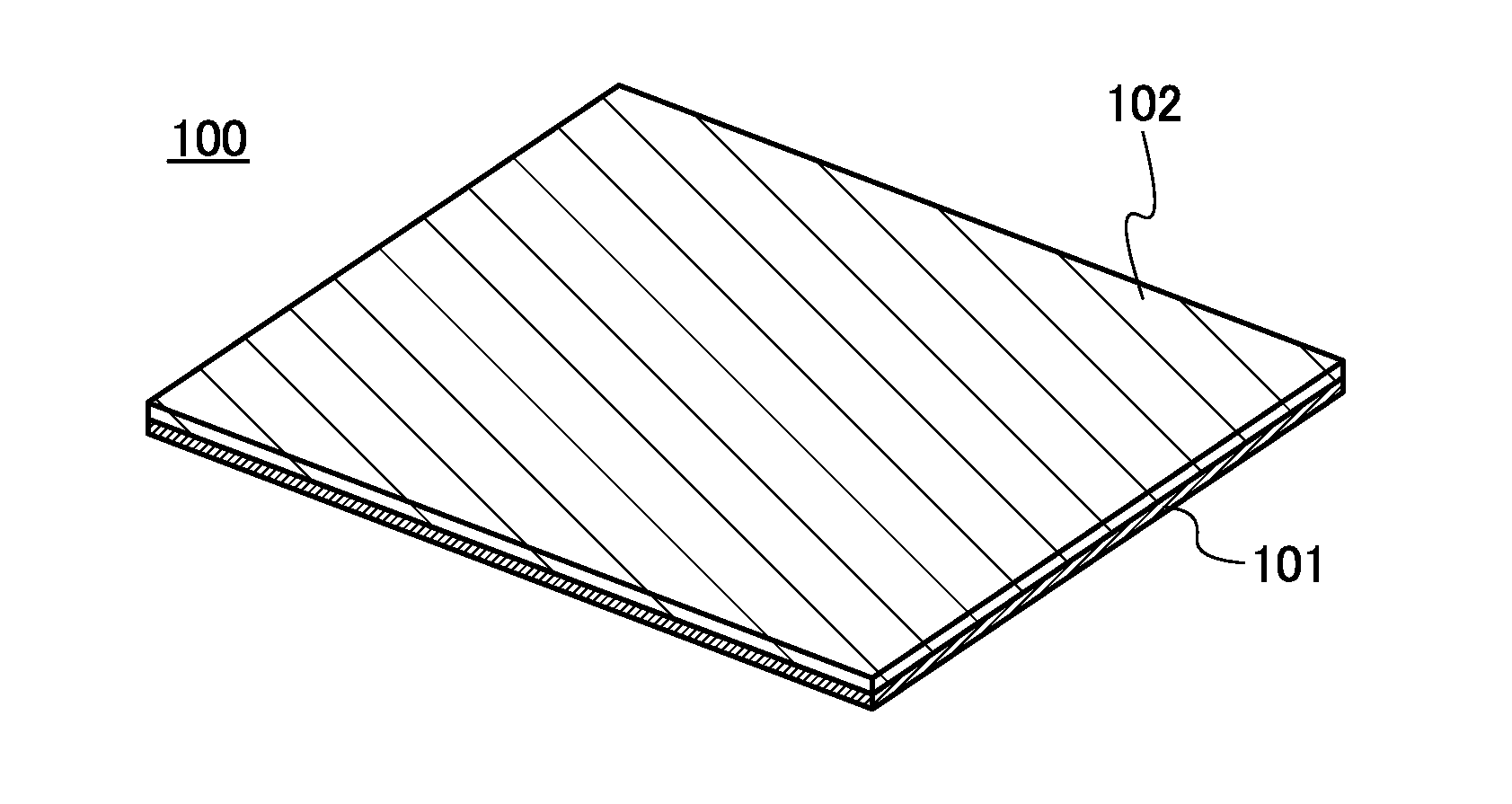

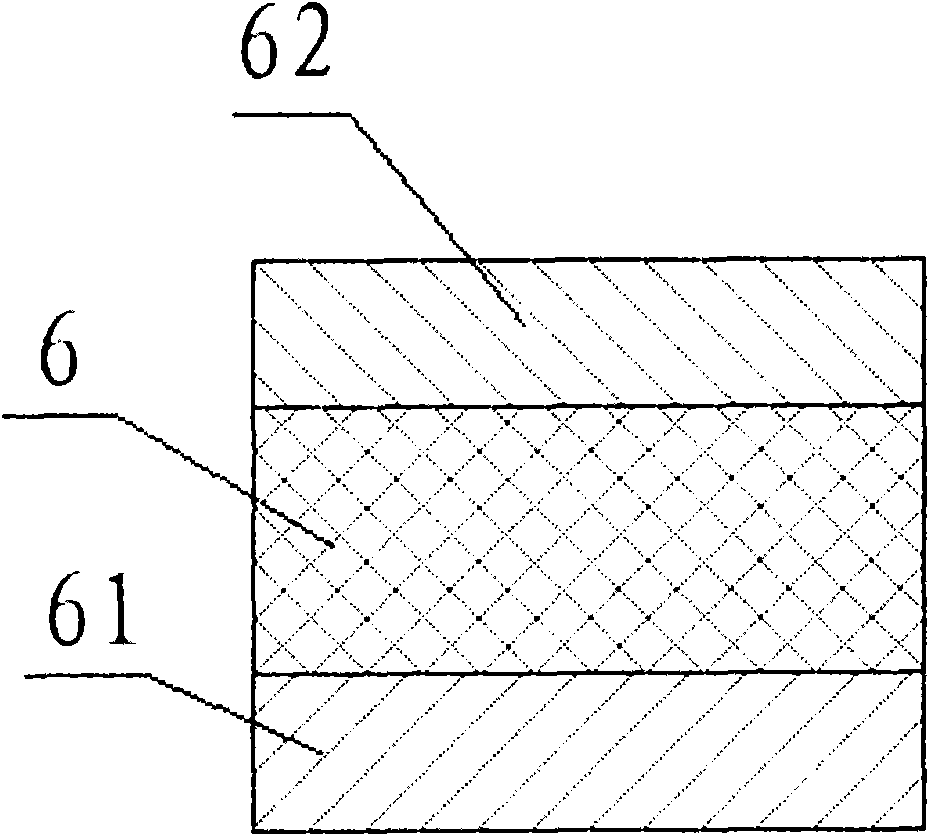

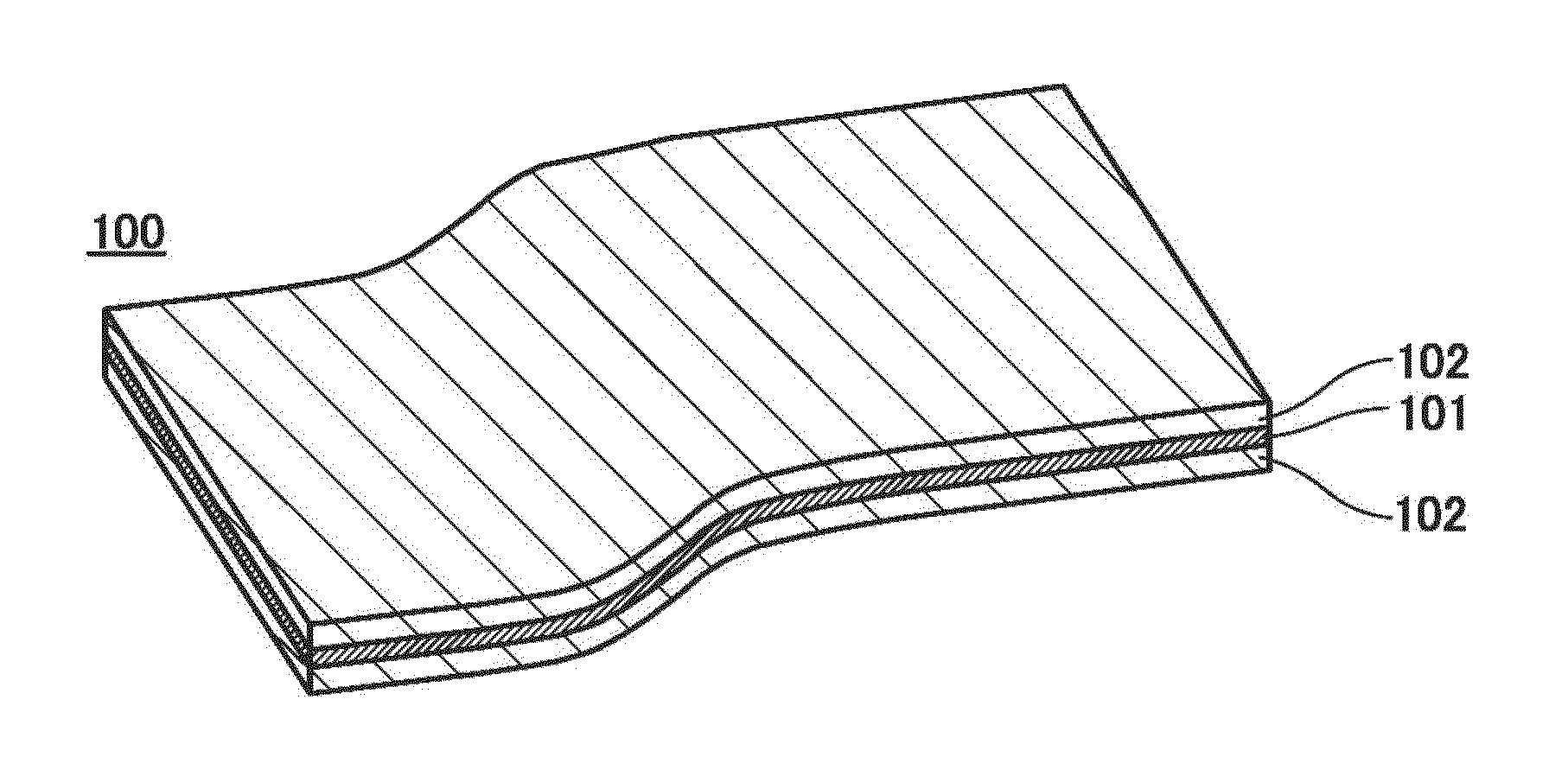

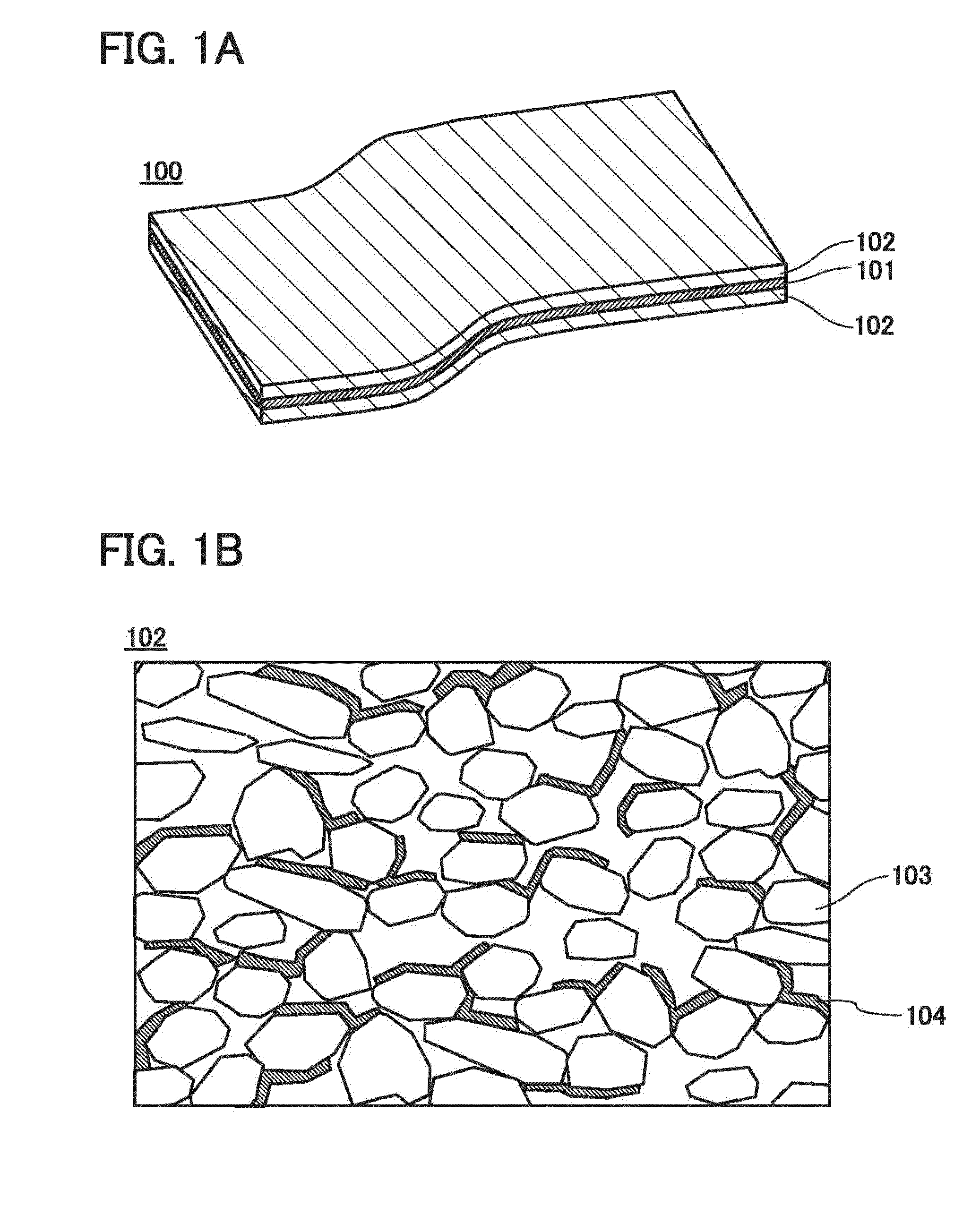

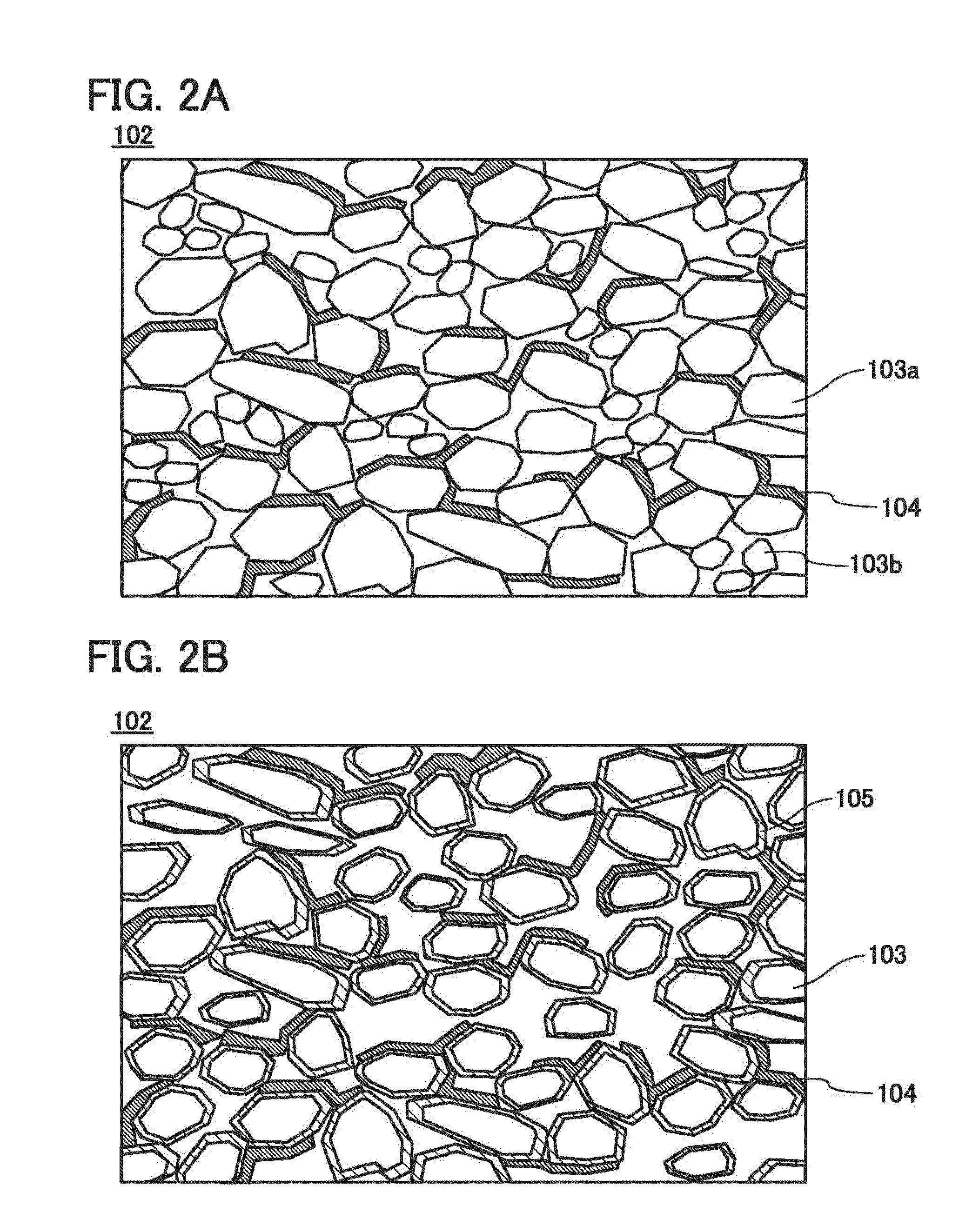

Single/multi-layer magnetic conductive sheet for wireless charging and preparation method thereof

ActiveCN104900383AImprove permeabilityIncrease contact resistanceBatteries circuit arrangementsElectromagnetic wave systemCrazingEngineering

The invention discloses a single / multi-layer magnetic conductive sheet for wireless charging and a preparation method thereof. The single-layer magnetic conductive sheet comprises a layer of magnetic slice. Multiple strips of cracks are uniformly distributed on the slice and divide the slice into multiple fragment units. Gaps of the cracks are filled with insulation medium, so fragment units on two sides of the cracks are mutually insulated. The single-layer magnetic conductive sheet also comprises a double-faced adhesive tape which is adhered to one face of the magnetic slice. A protection film formed by the insulation medium is formed on the other face of the magnetic slice. The preparation method comprises steps of heat treatment, adhesion of the double-faced adhesive tape, crack processing, gum dipping processing and drying and curing processing. According to the invention, inductance value and quality factor of a charging coil are increased, charging efficiency is increased and loss is reduced. The continuously prepared magnetic conductive sheet is characterized by controllable magnetic conductivity, continuous production, convenient operation and simple insulation processing.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

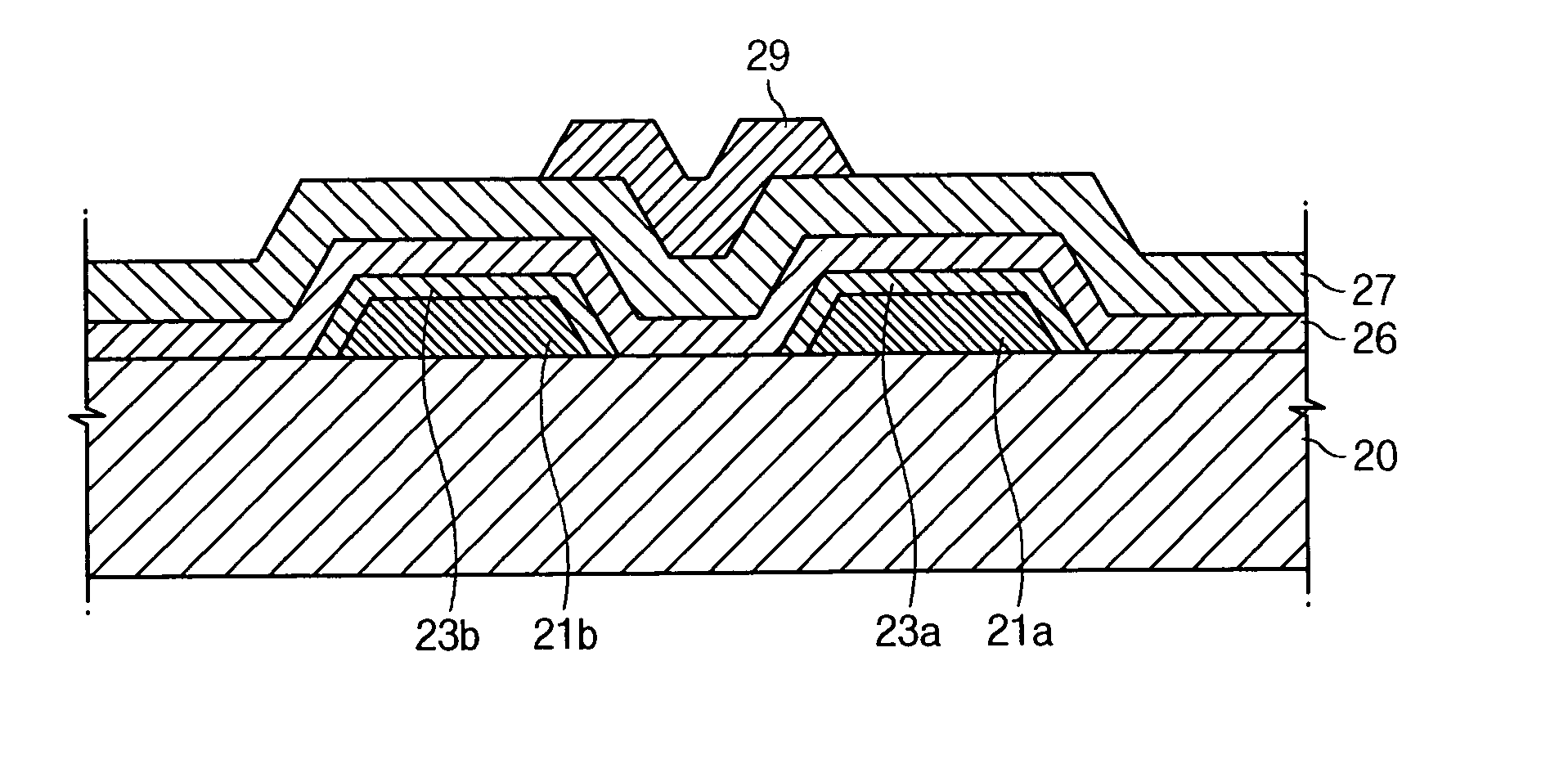

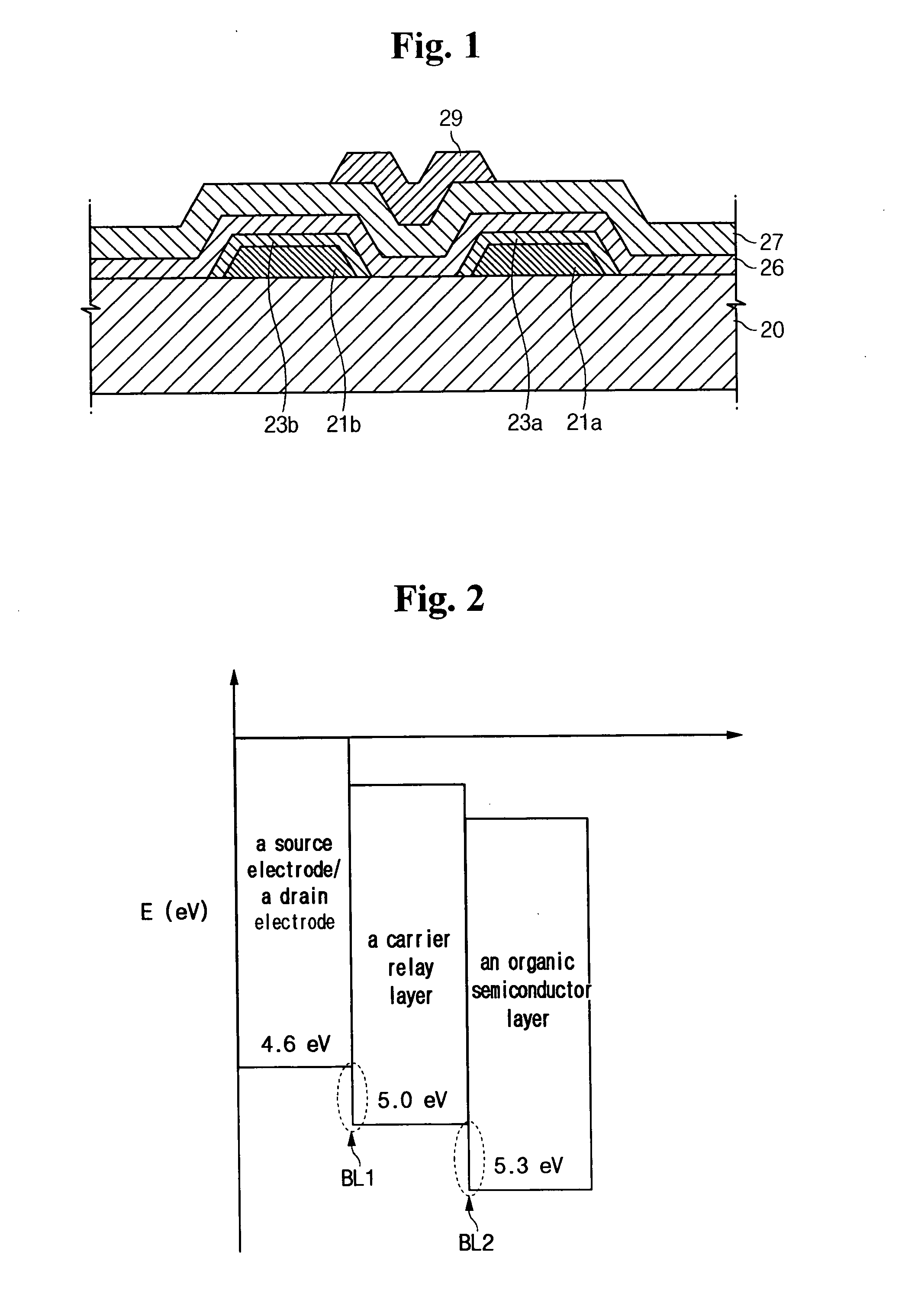

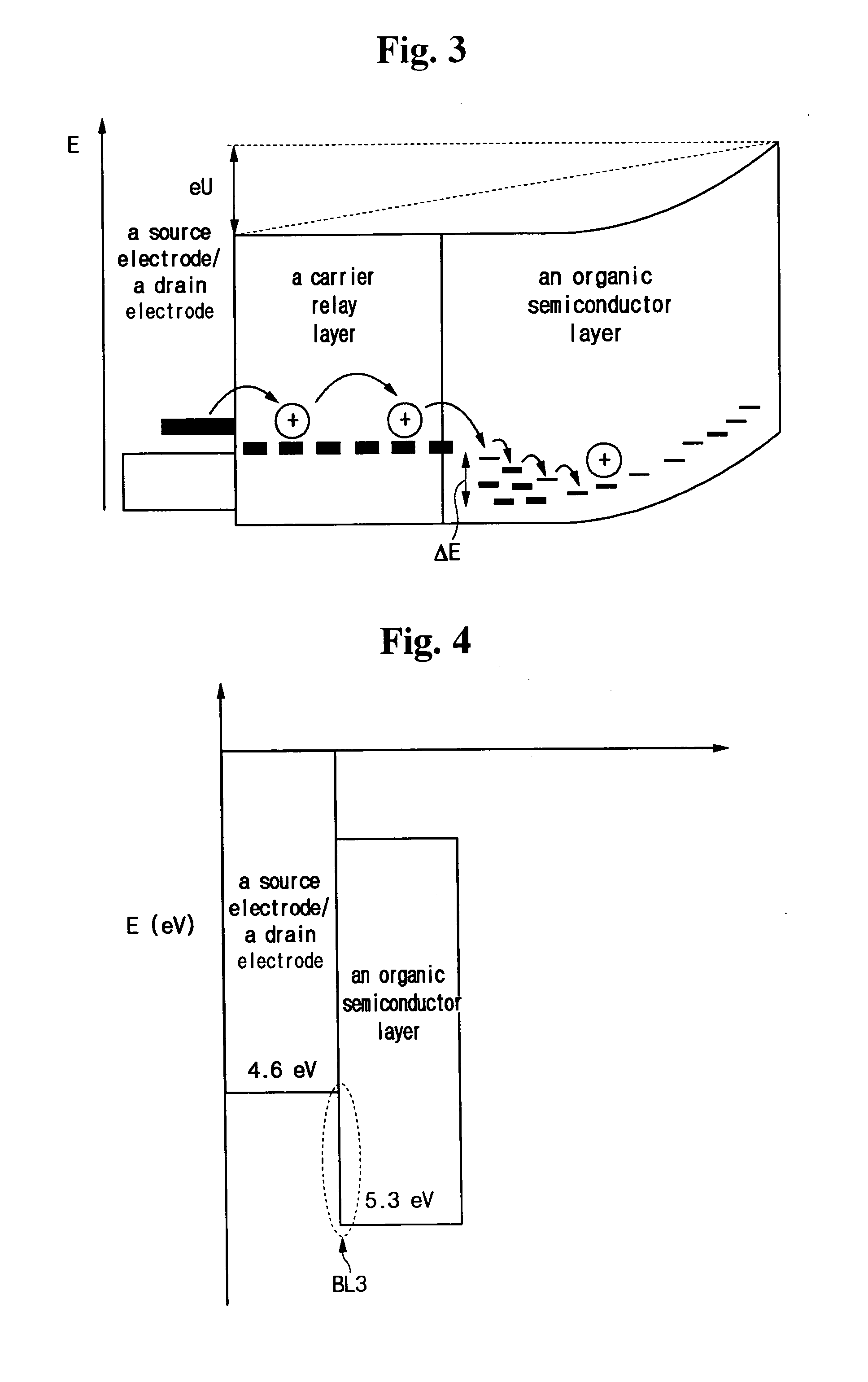

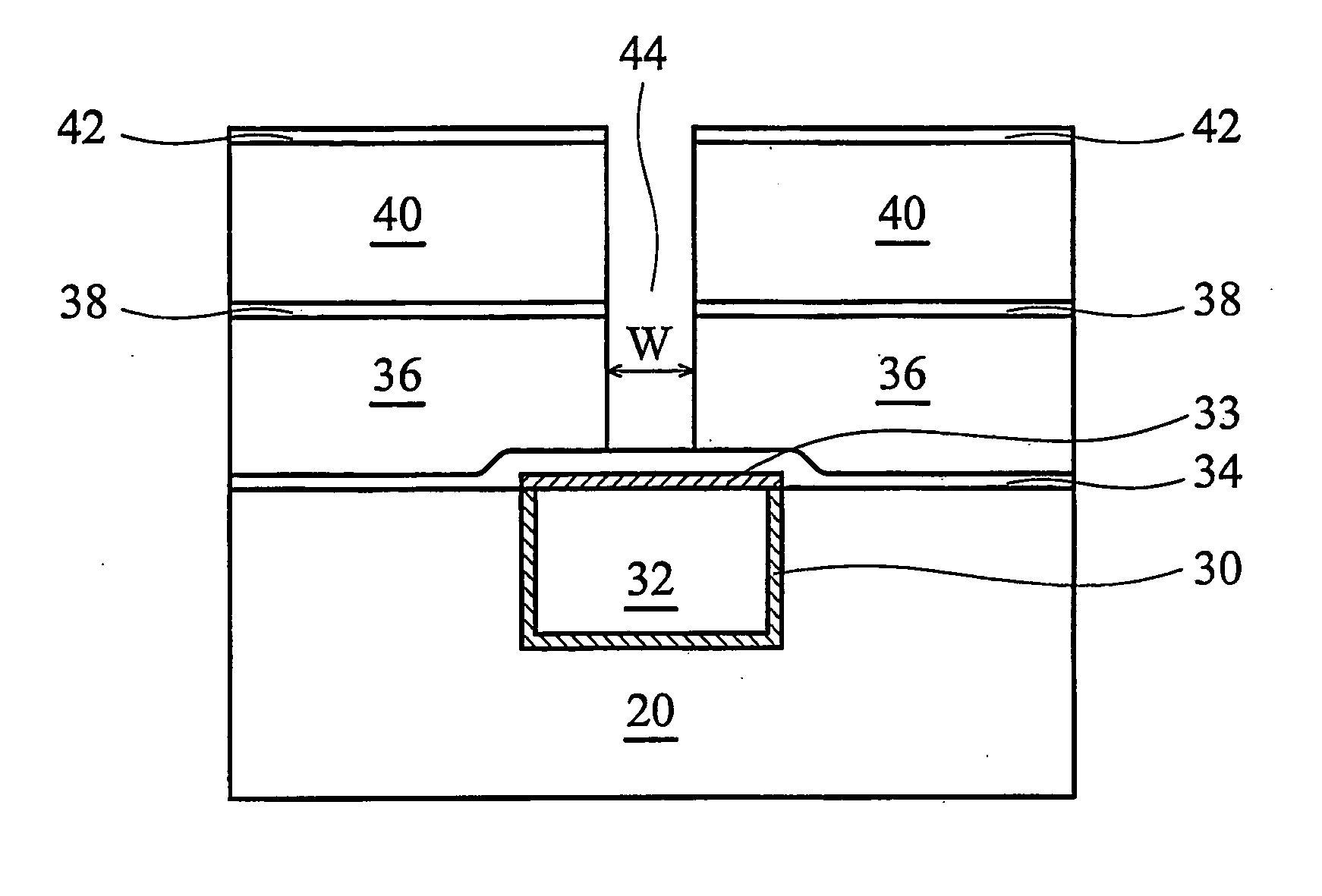

Organic thin film transistor, method of manufacturing the same, and flat panel display device with the organic thin film transistor

InactiveUS20060108581A1Improve adhesionIncrease contact resistanceMaterial nanotechnologySolid-state devicesOrganic filmConductive polymer

An organic thin film transistor that has good adhesiveness and good contact resistance as well as allows ohmic contact between an organic semiconductor layer and a source electrode and a drain electrode, and its manufacturing method. There is also provided a flat panel display device using the organic thin film transistor. The organic thin film transistor includes a source electrode, a drain electrode, an organic semiconductor layer, a gate insulating layer, and a gate electrode formed on a substrate, and a carrier relay layer including conductive polymer material formed at least between the organic semiconductor layer and the source electrode or the organic semiconductor layer and the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

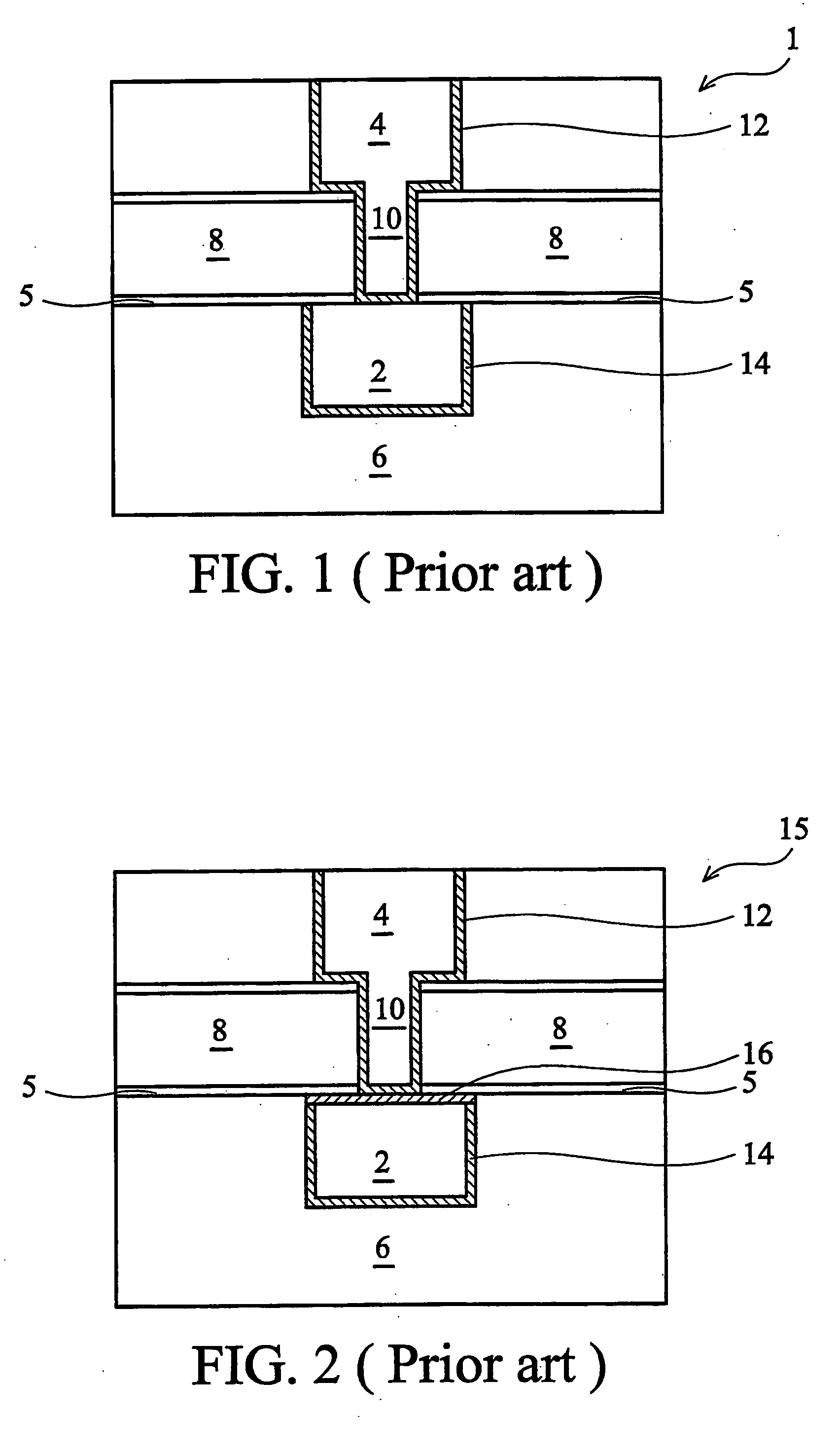

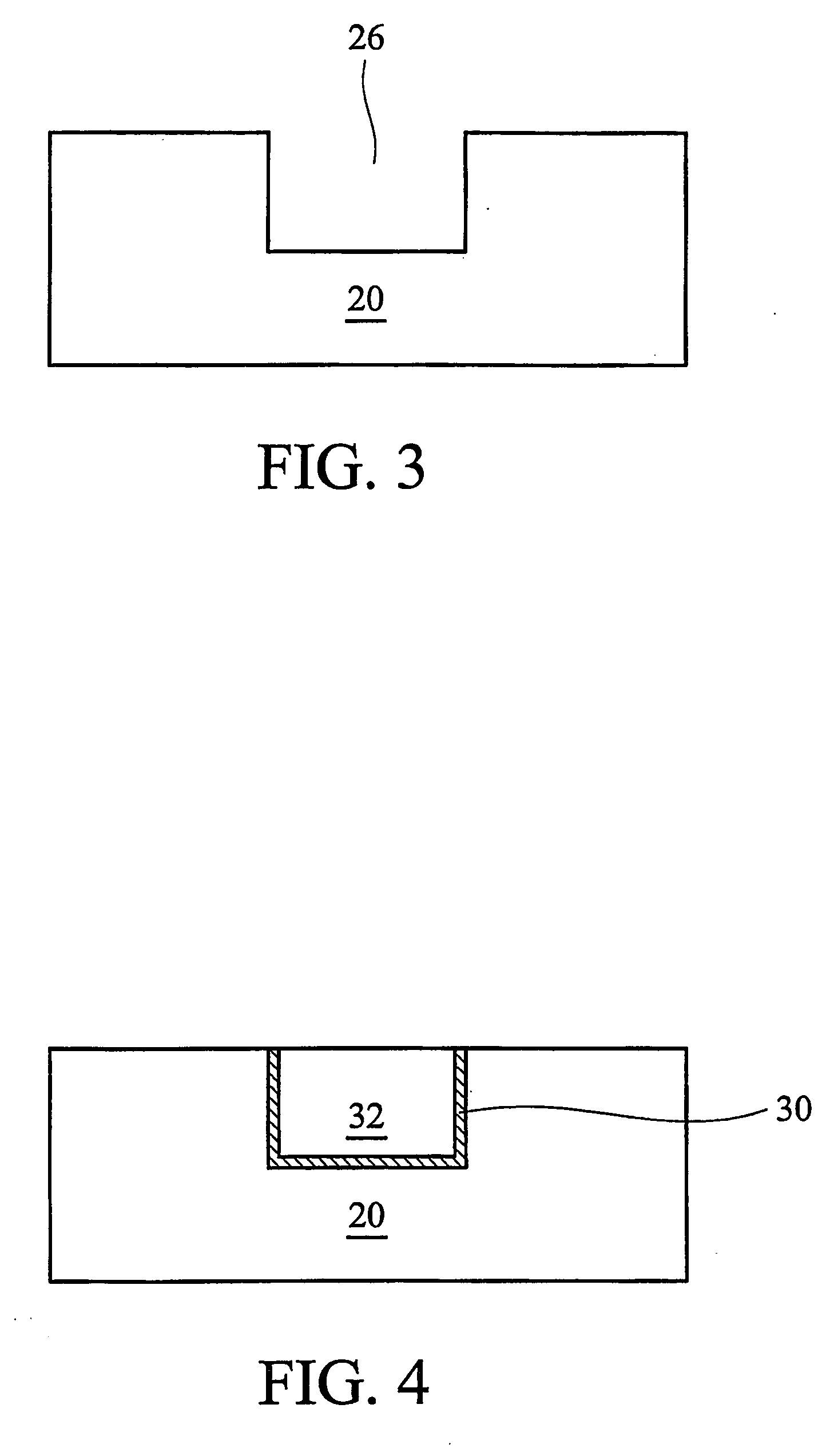

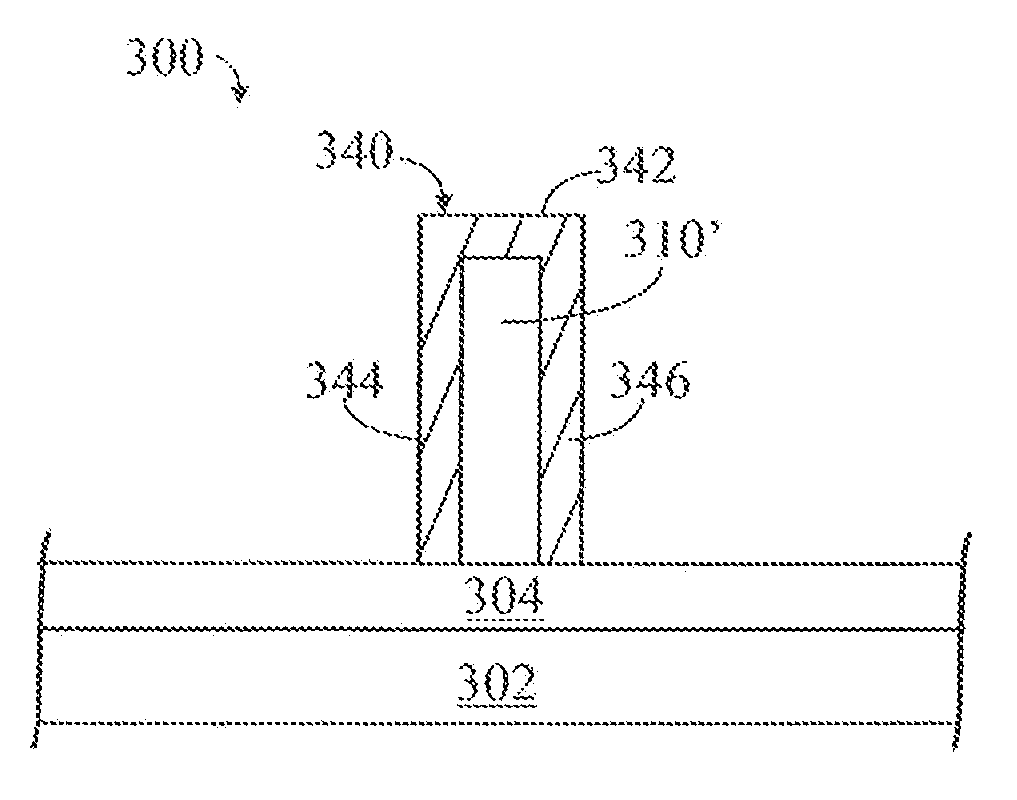

Damascene interconnect structure with cap layer

ActiveUS20060118962A1Improve reliability and performanceHigh contact resistanceSemiconductor/solid-state device detailsSolid-state devicesIntegrated circuit interconnectDielectric

A method of forming an integrated circuit interconnect structure is presented. A first conductive line is formed over a semiconductor substrate. A conductive cap layer is formed on the first conductive line to improve device reliability. An etch stop layer (ESL) is formed on the conductive cap layer. An inter-level dielectric (IMD) is formed on the ESL. A via opening and a trench are formed in the ESL, IMD, and conductive cap layer. A recess is formed in the first conductive line. The recess can be formed by over etching when the first dielectric is etched, or by a separate process such as argon sputtering. A second conductive line is formed filling the trench, opening and recess.

Owner:TAIWAN SEMICON MFG CO LTD

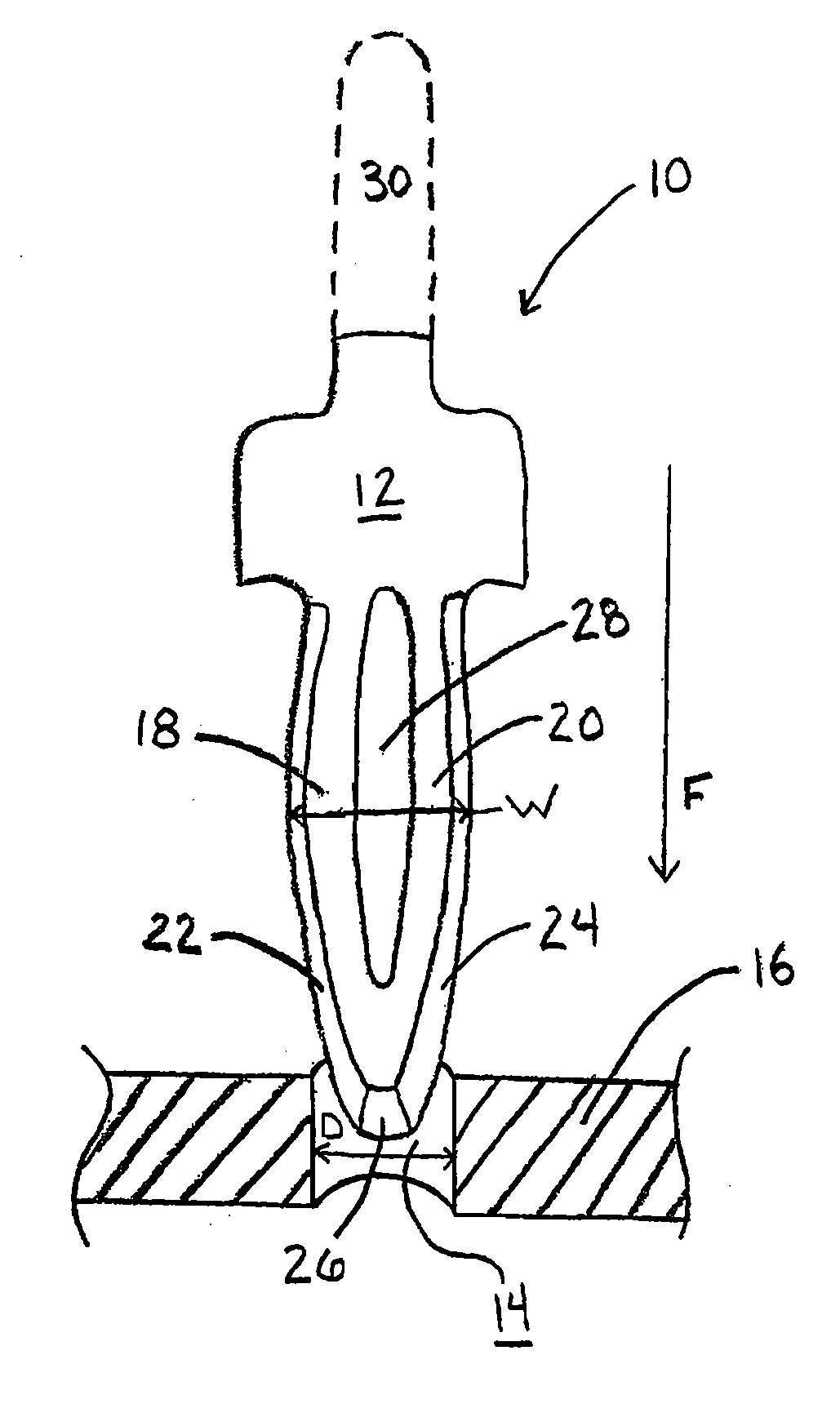

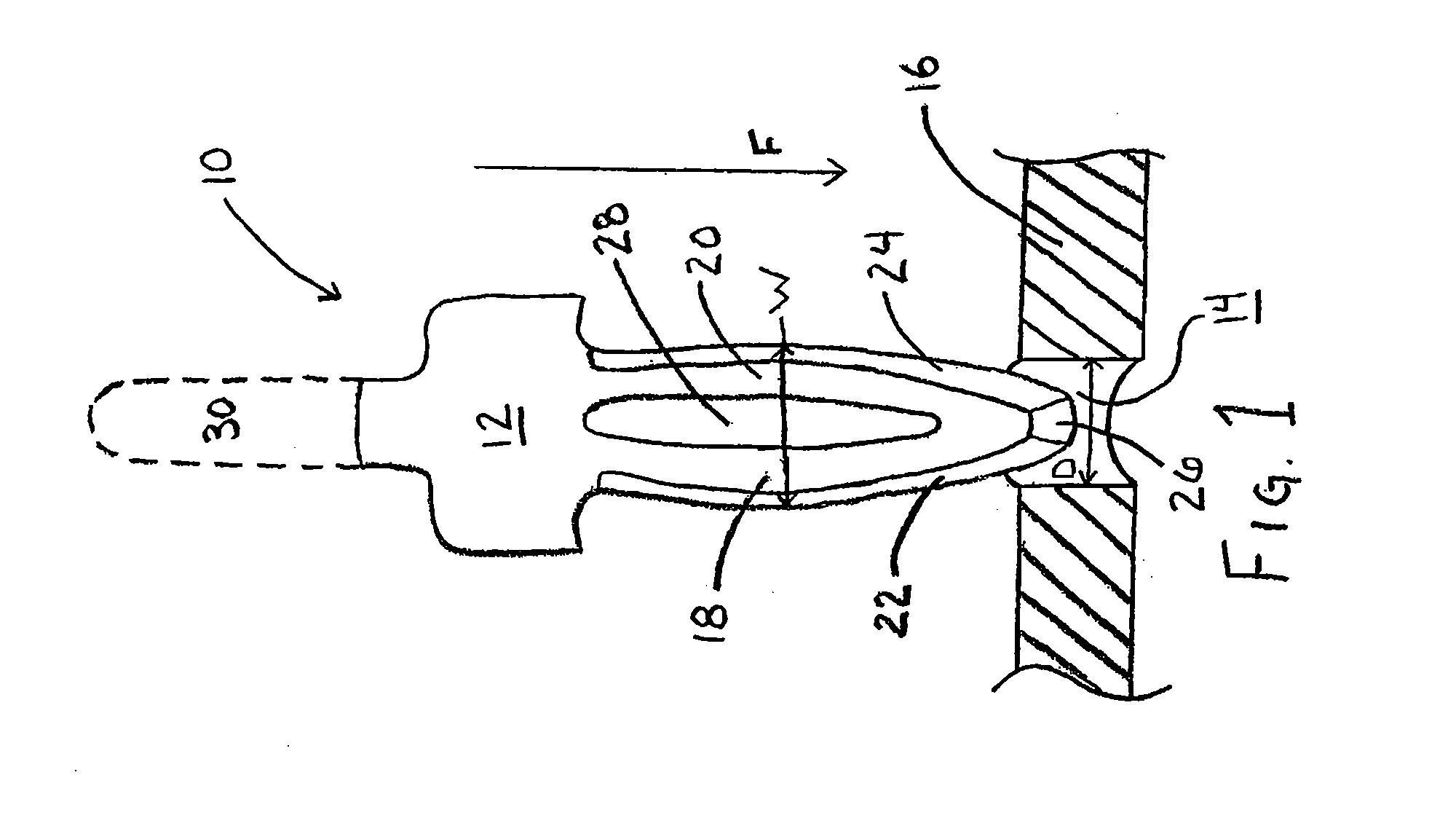

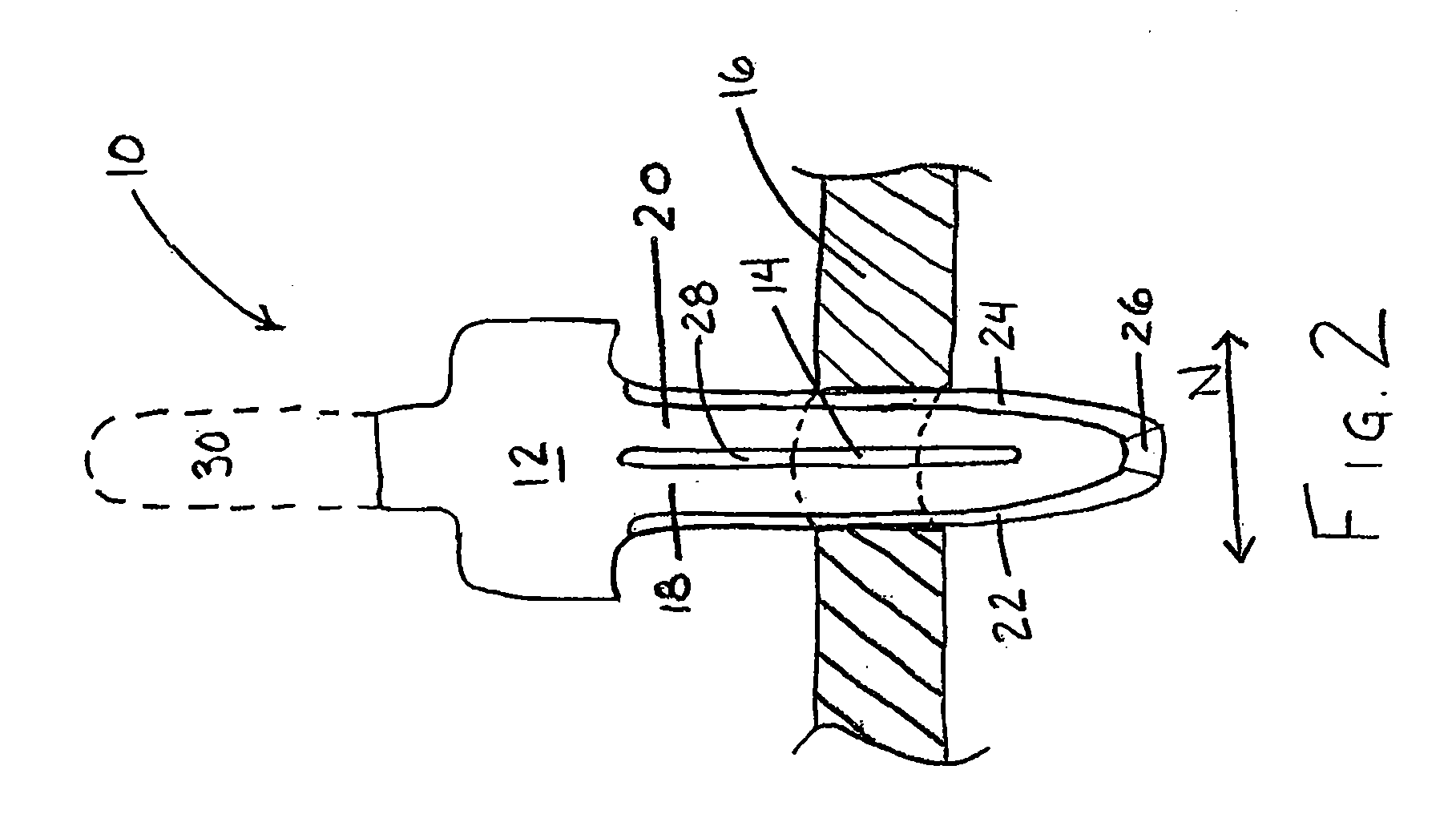

Press fit (compliant) terminal and other connectors with tin-silver compound

InactiveUS20090239398A1Increased riskInhibition formationLine/current collector detailsCoupling contact membersCompound aWhiskers

A tin-silver press-fit interconnect which includes a press-fit terminal having a coating or finish of a tin-silver compound for use with a terminal receiving device. The tin-silver compound serves to prevent the formation of tin whiskers which appear most frequently in pure tin coated electrical components under mechanical stress and which make the electronic device susceptible to short circuits. The tin-silver compound may include between 85 and 99.5% weight of tin and between 0.5 and 15% weight of silver and is applied at a thickness range between 0.4 and 5 microns using a technique such as electroplating, hot dip or immersion.

Owner:INTERPLEX IND

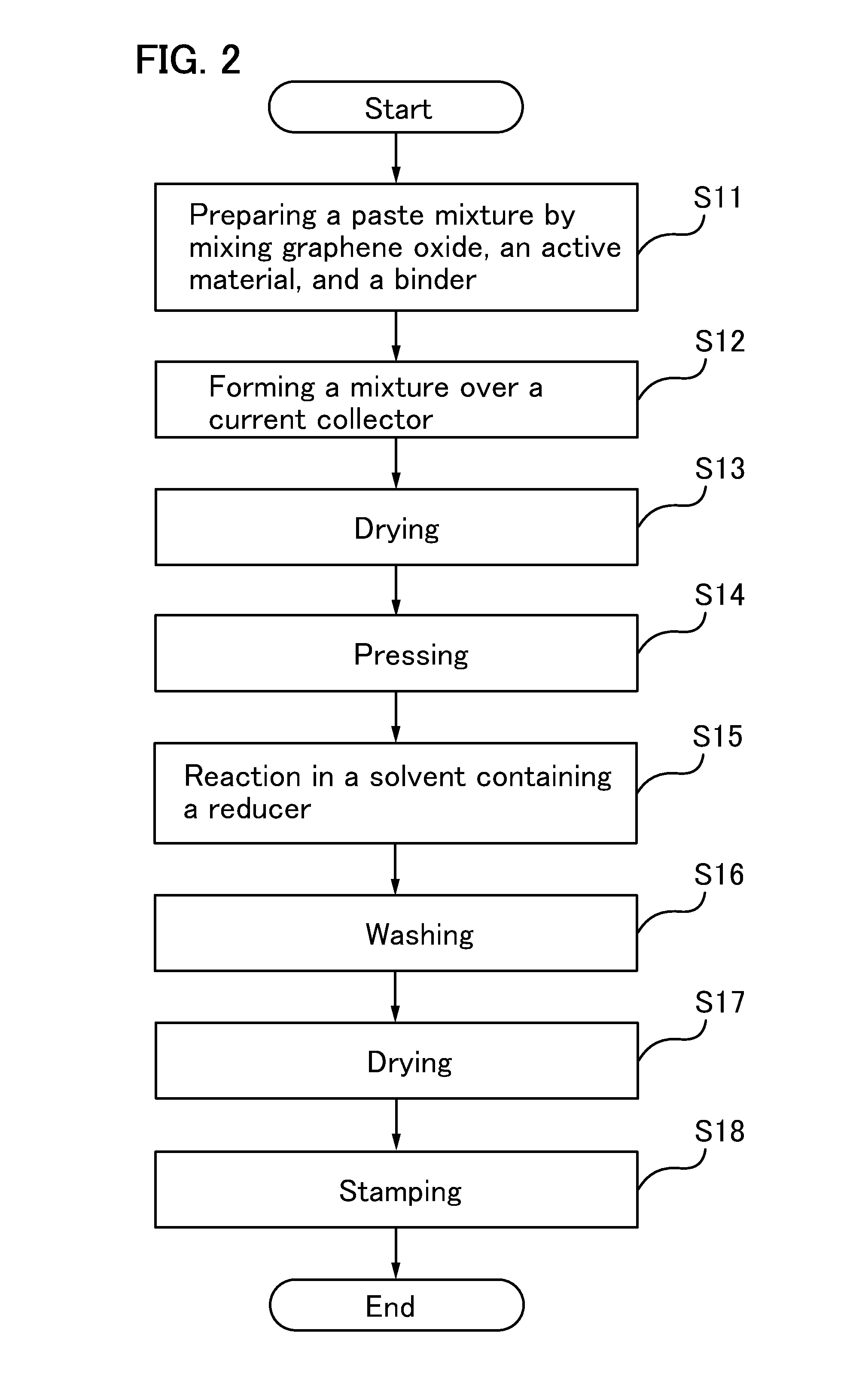

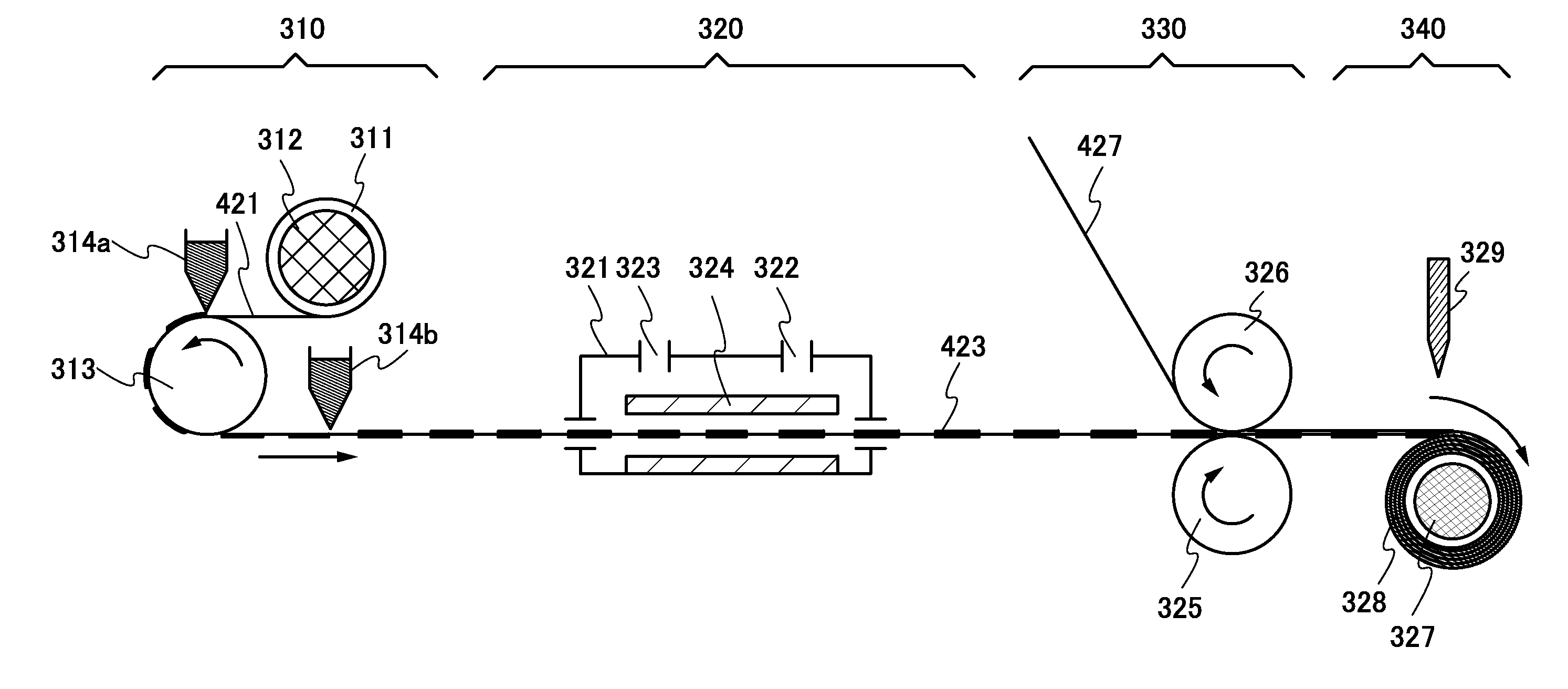

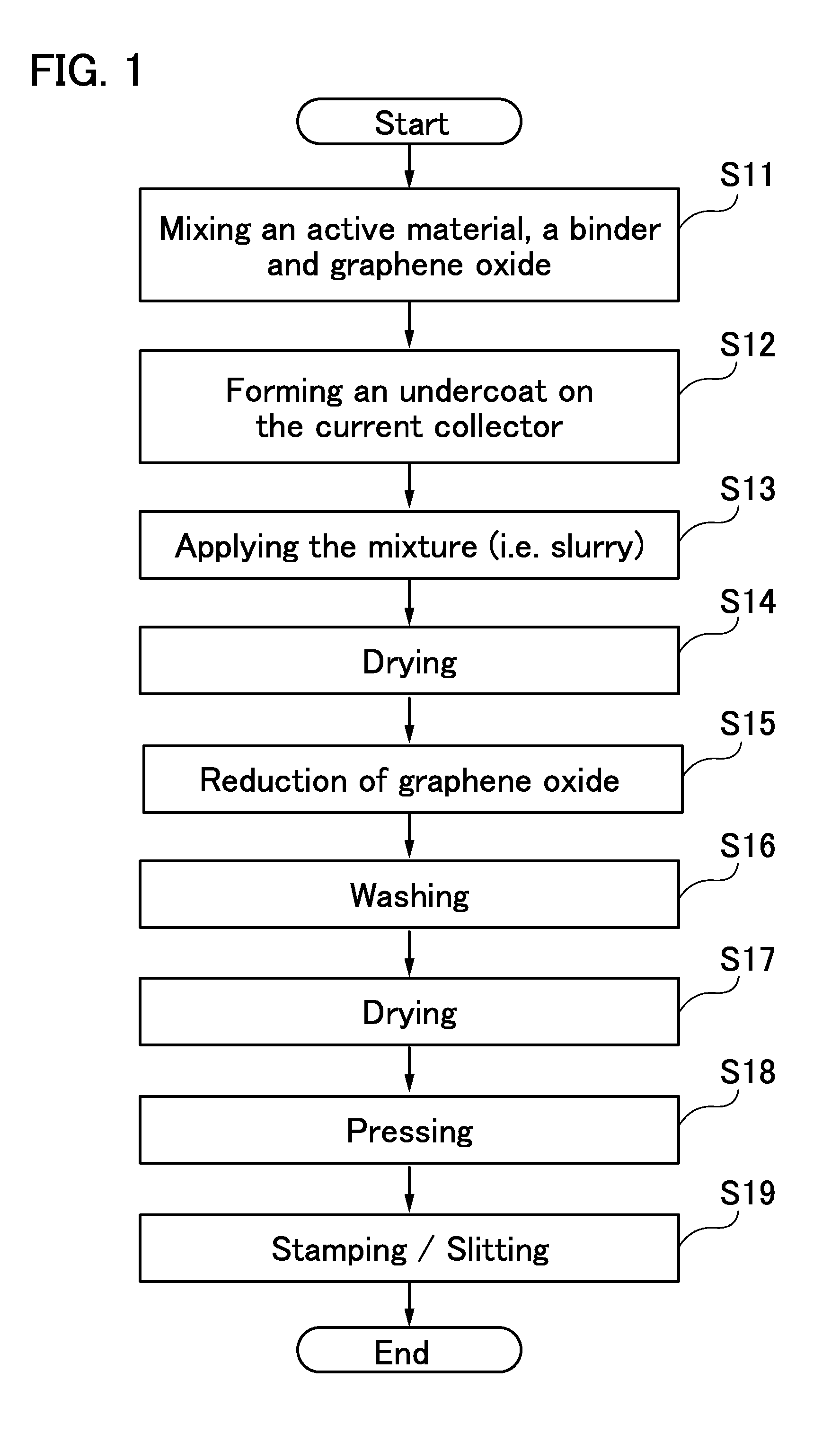

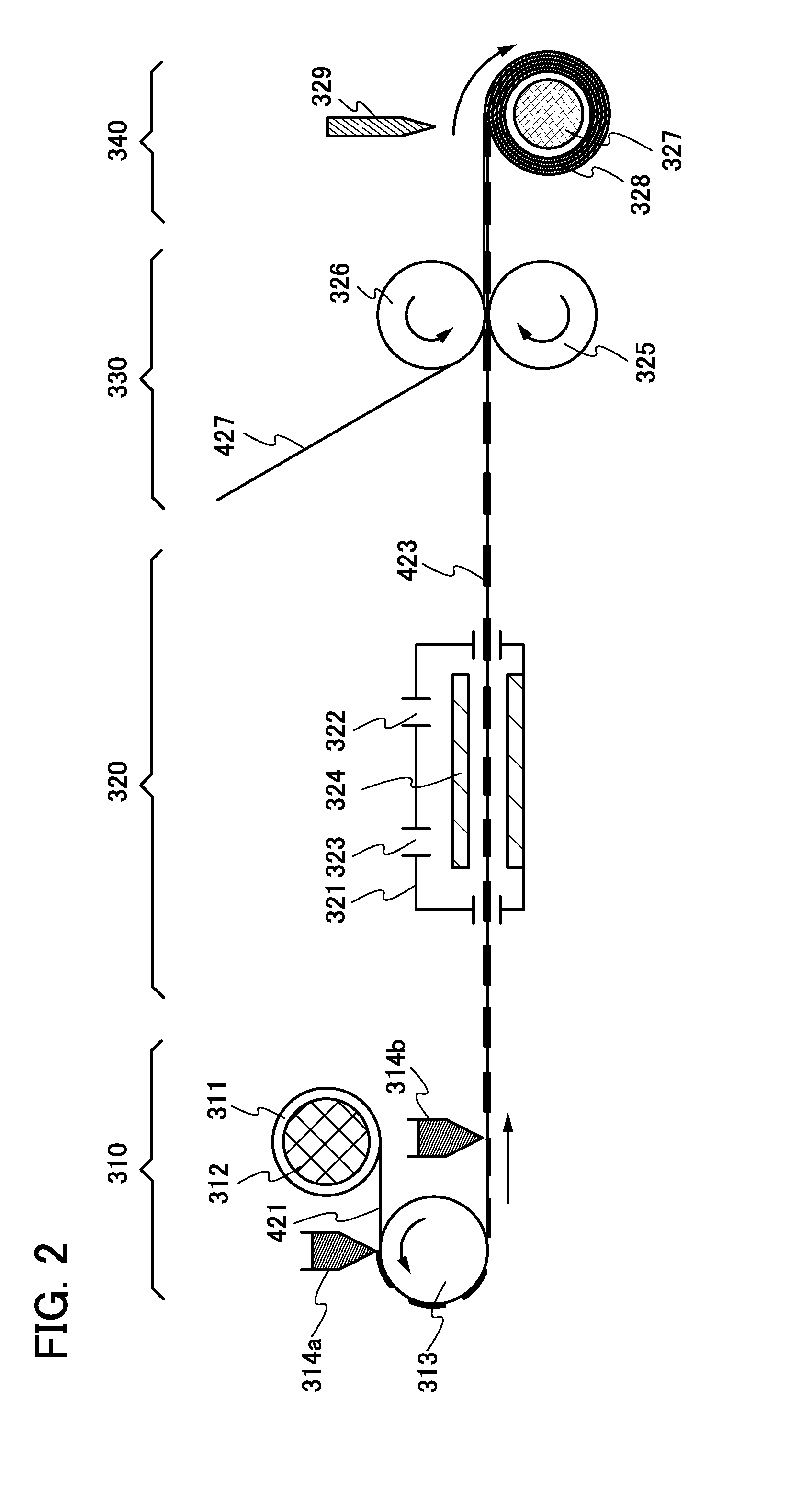

Method for manufacturing storage battery electrode, storage battery electrode, storage battery, and electronic device

ActiveUS20130337320A1High densityReduce electrical conductivityElectrode rolling/calenderingElectrode thermal treatmentSolventElectron

To provide a method for forming a storage battery electrode including an active material layer with high density in which the proportion of conductive additive is low and the proportion of the active material is high. To provide a storage battery having a higher capacity per unit volume of an electrode with the use of a storage battery electrode formed by the formation method. A method for forming a storage battery electrode includes the steps of forming a mixture including an active material, graphene oxide, and a binder; providing a mixture over a current collector; and immersing the mixture provided over the current collector in a polar solvent containing a reducer, so that the graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

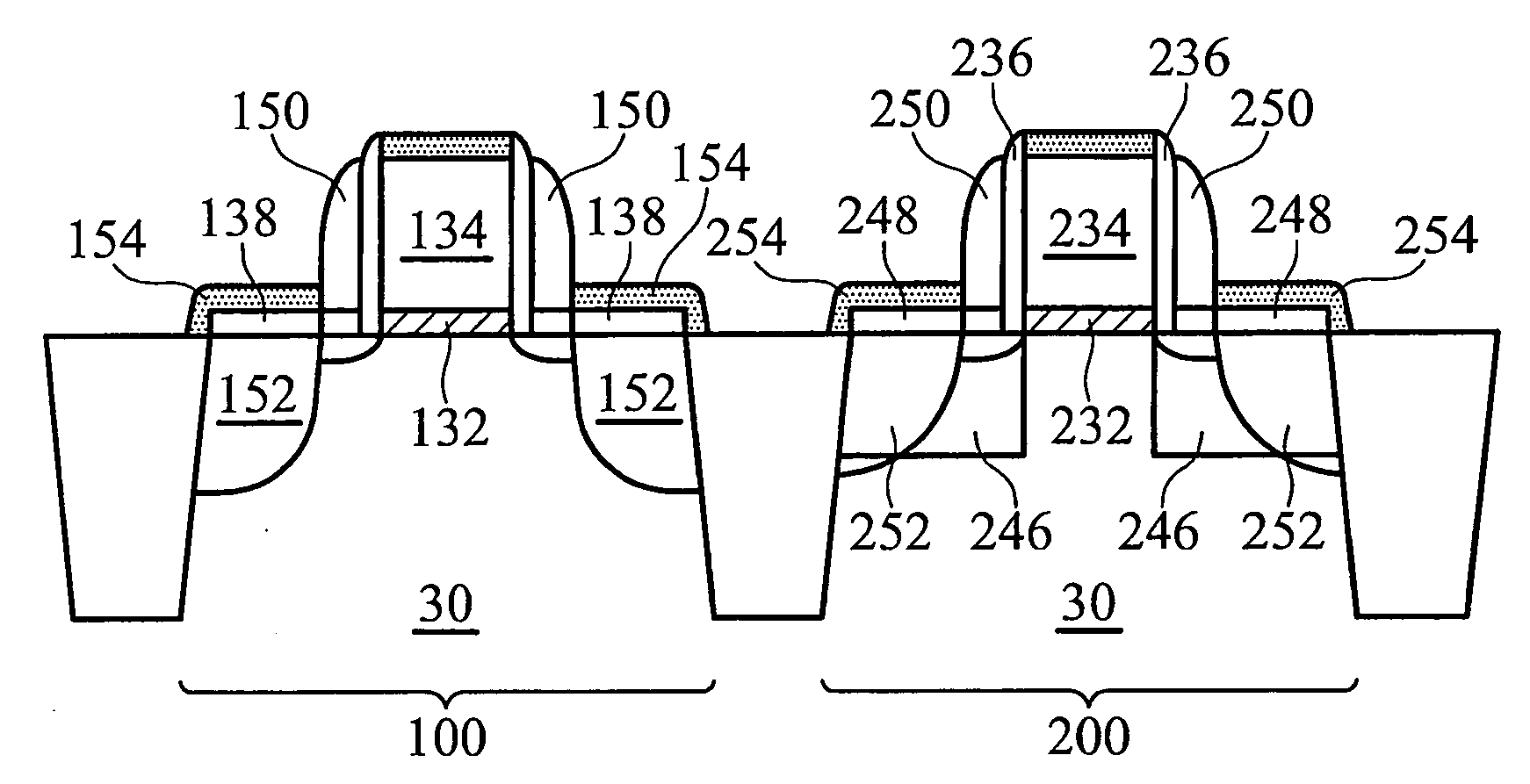

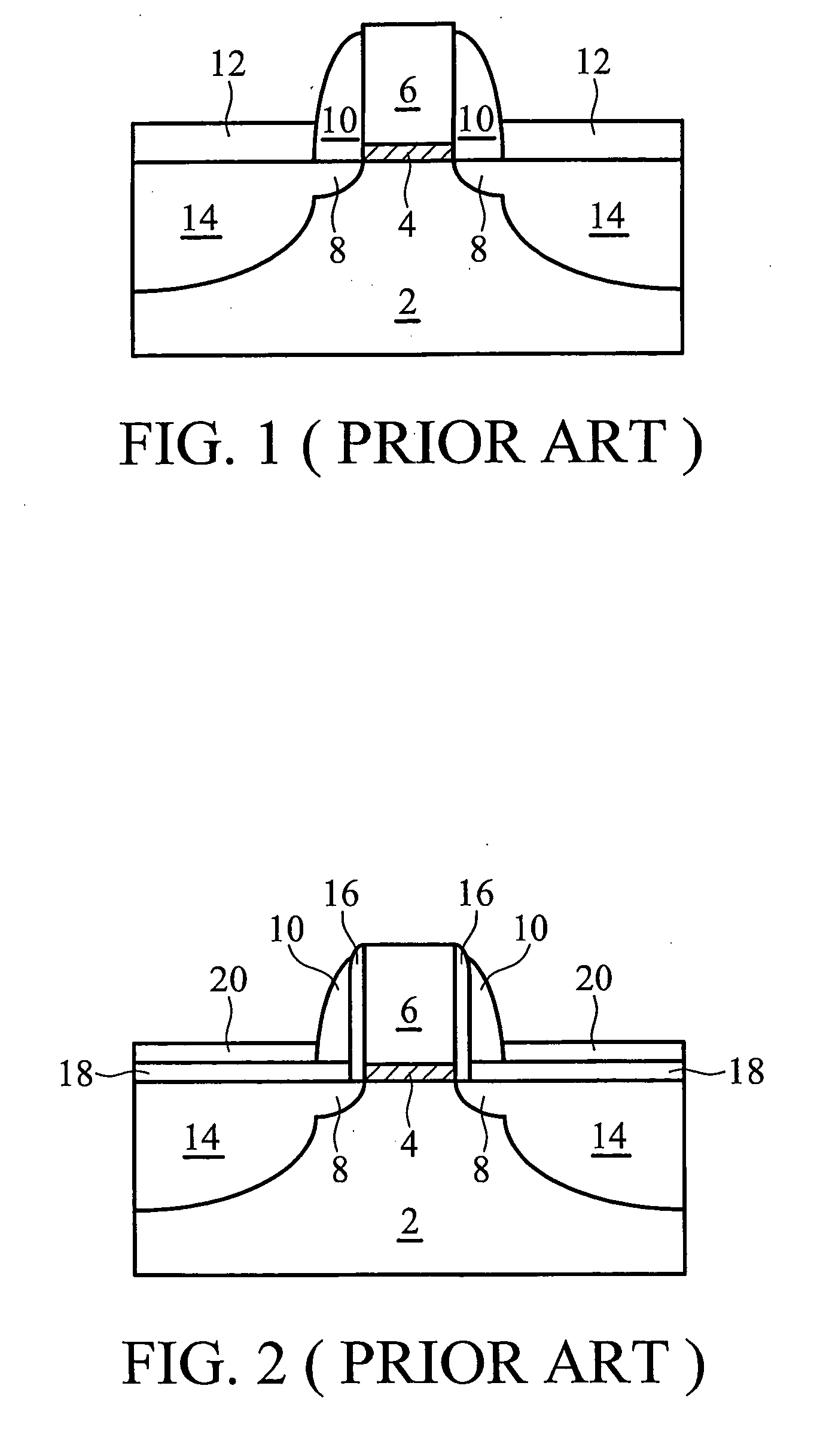

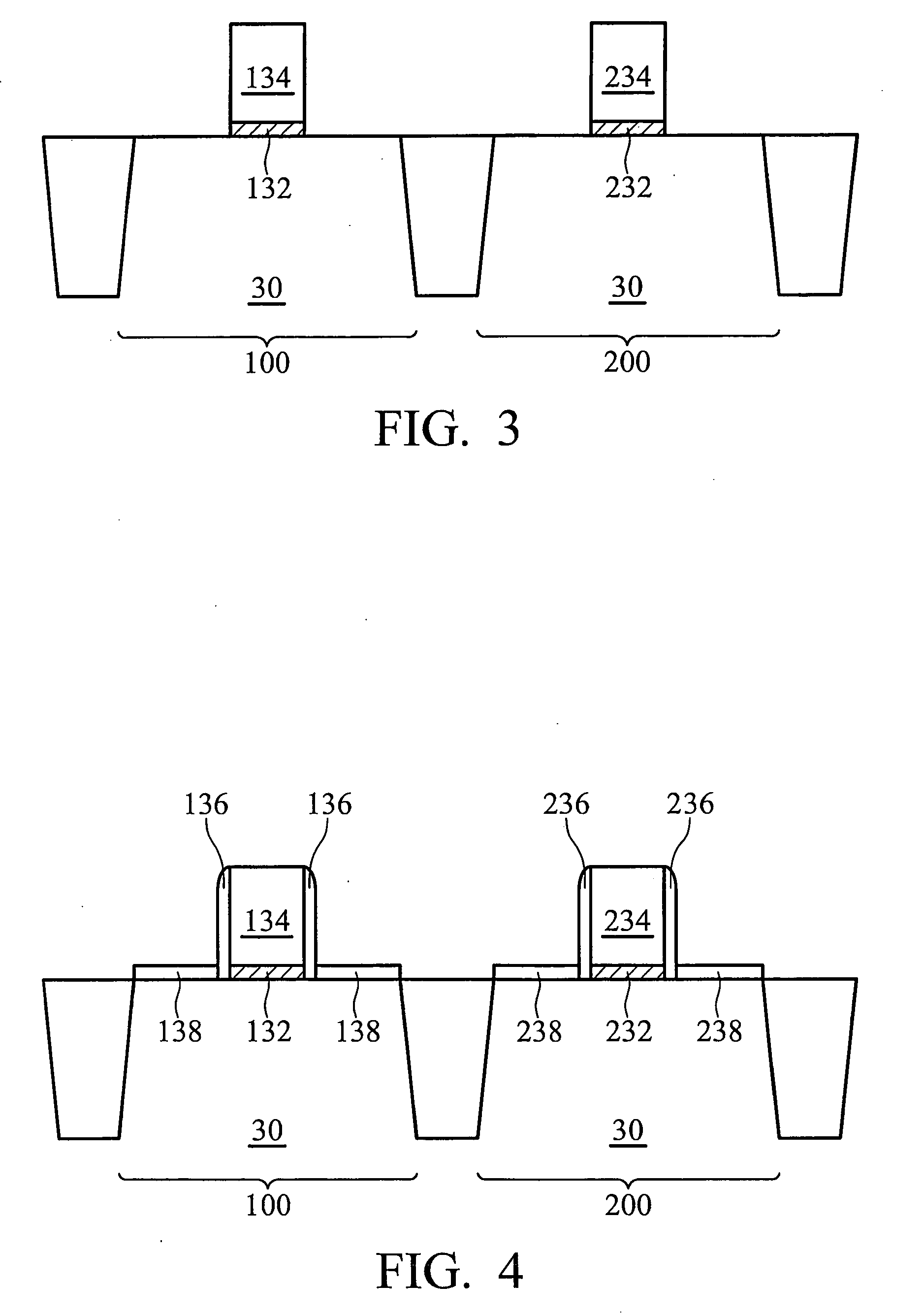

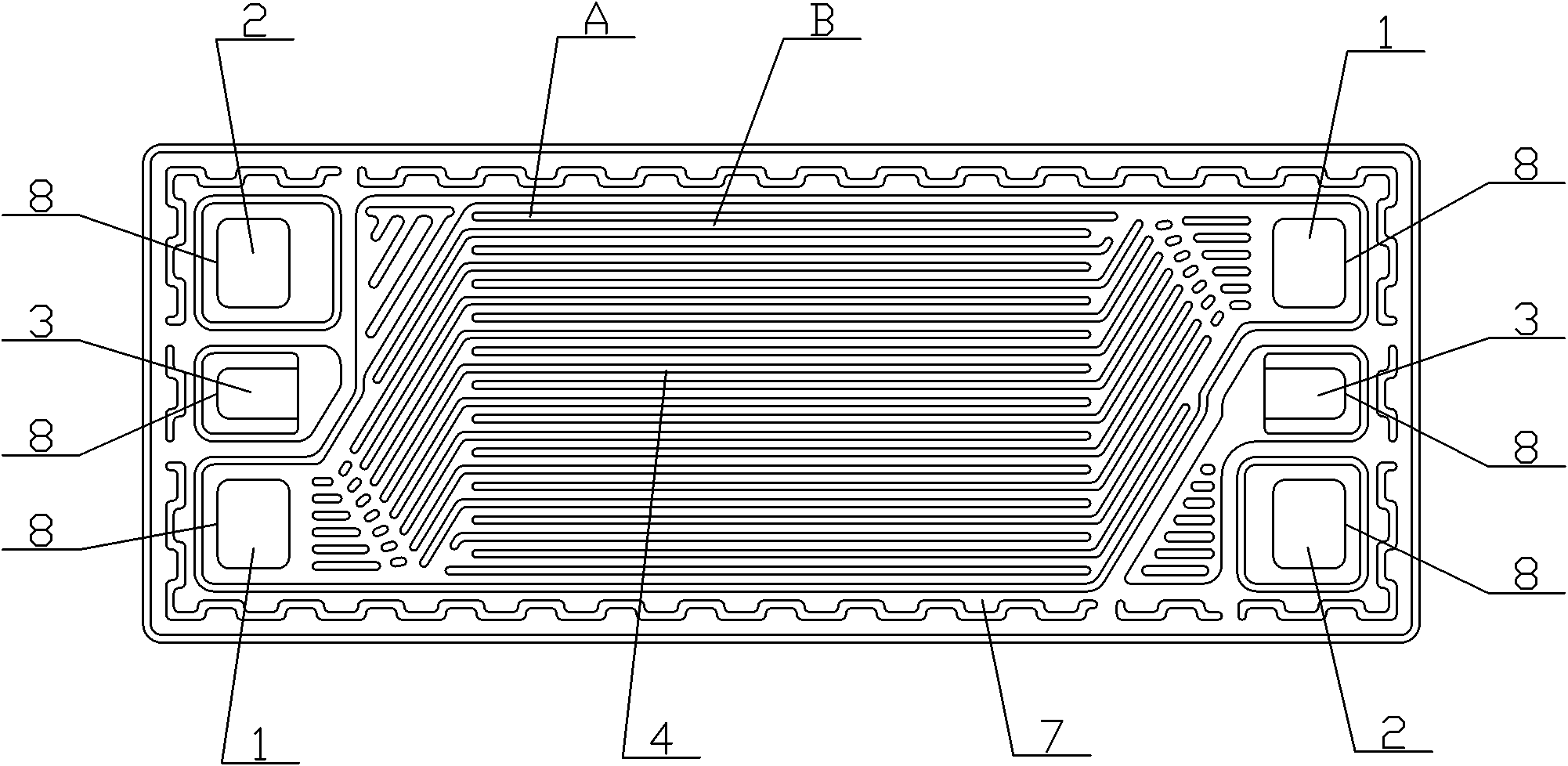

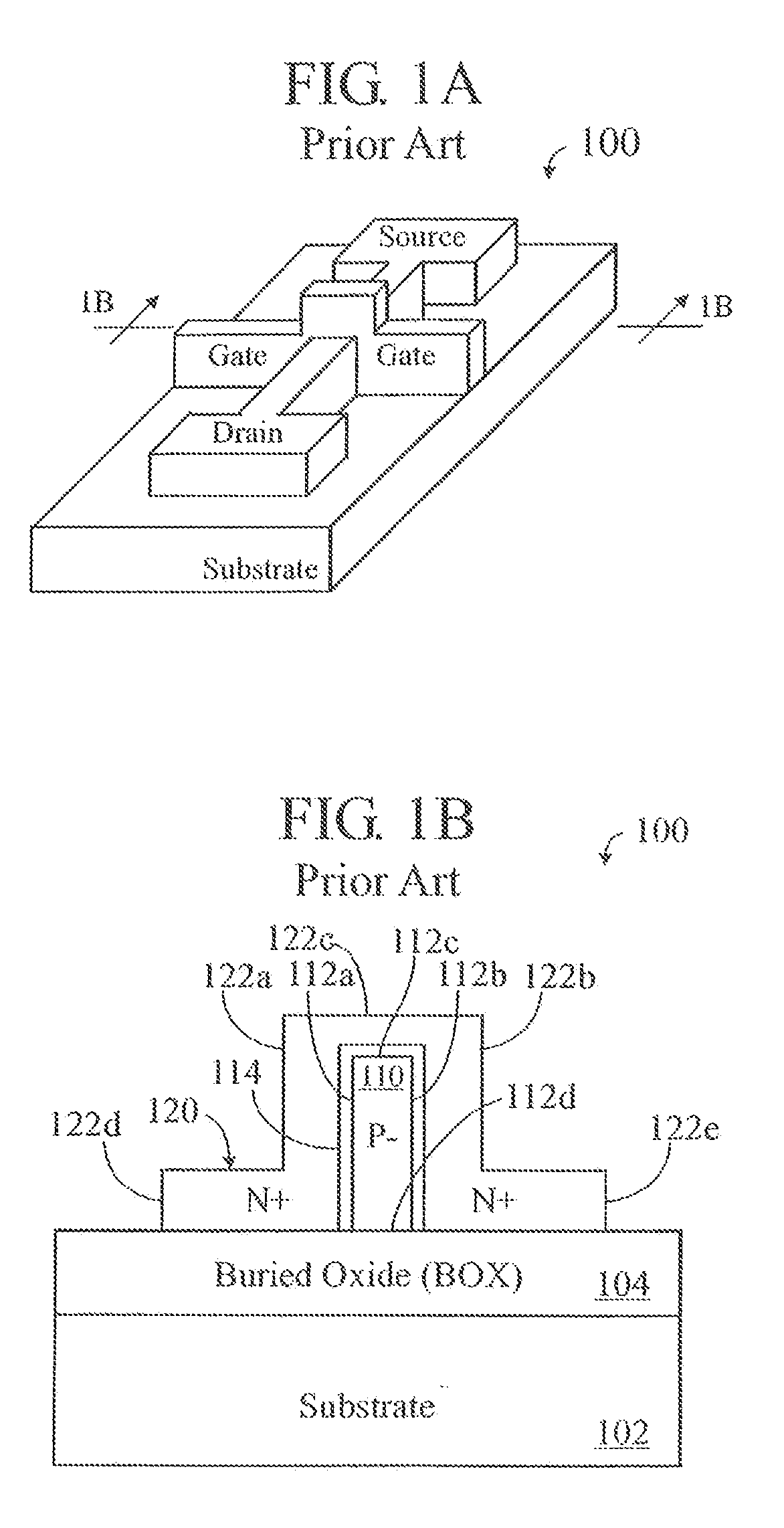

CMOS device with raised source and drain regions

ActiveUS20080102573A1Short channel performanceReduce the probability of activationTransistorSemiconductor/solid-state device manufacturingCMOSSemiconductor structure

A method of forming a semiconductor structure includes forming a PMOS device and an NMOS device. The step of forming the PMOS device includes forming a first gate stack on a semiconductor substrate; forming a first offset spacer on a sidewall of the first gate stack; forming a stressor in the semiconductor substrate using the first offset spacer as a mask; and epitaxially growing a first raised source / drain extension (LDD) region on the stressor. The step of forming the NMOS device includes forming a second gate stack on the semiconductor substrate; forming a second offset spacer on a sidewall of the second gate stack; epitaxially growing a second raised LDD region on the semiconductor substrate using the second offset spacer as a mask; and forming a deep source / drain region adjoining the second raised LDD region.

Owner:TAIWAN SEMICON MFG CO LTD

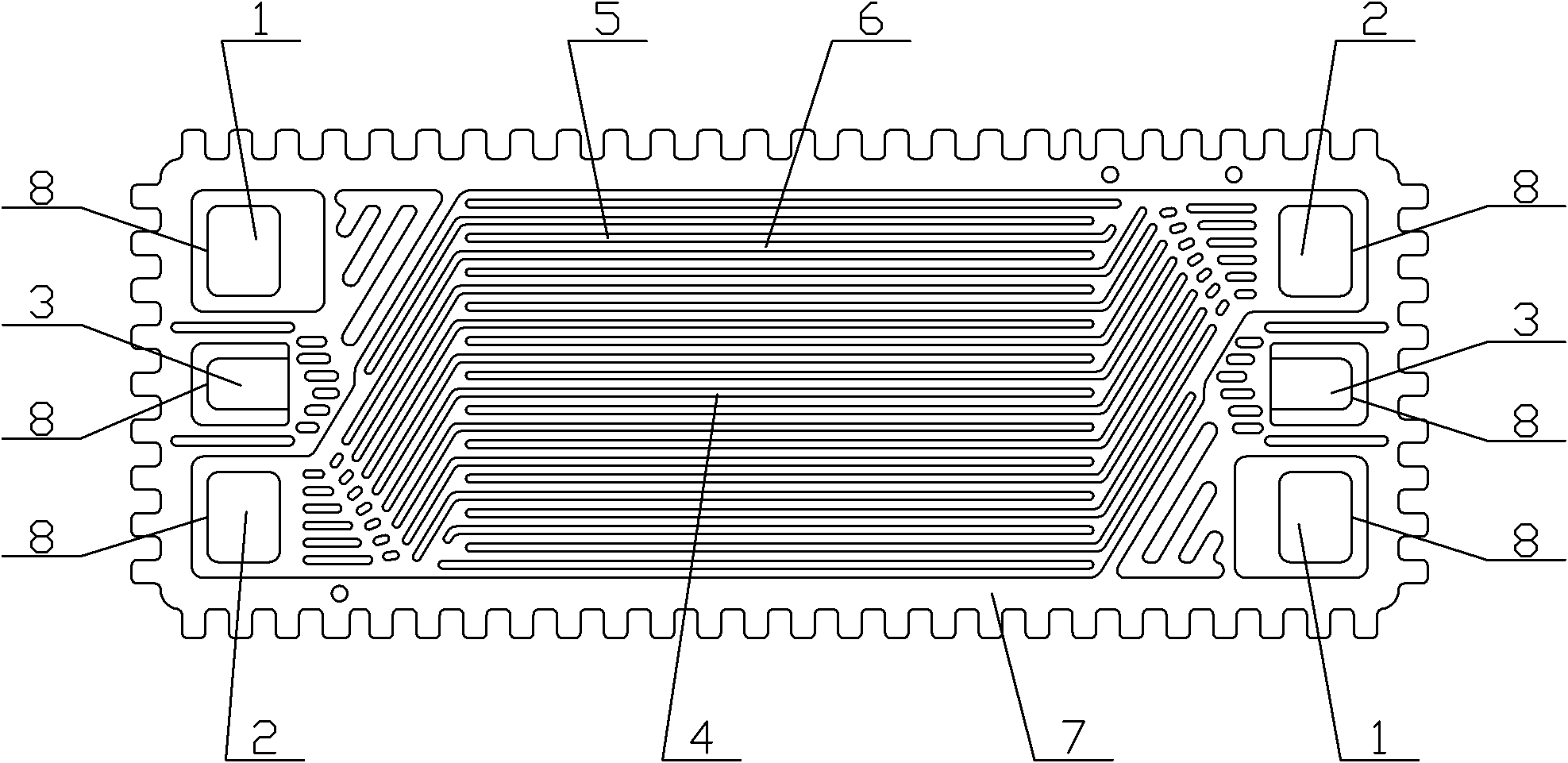

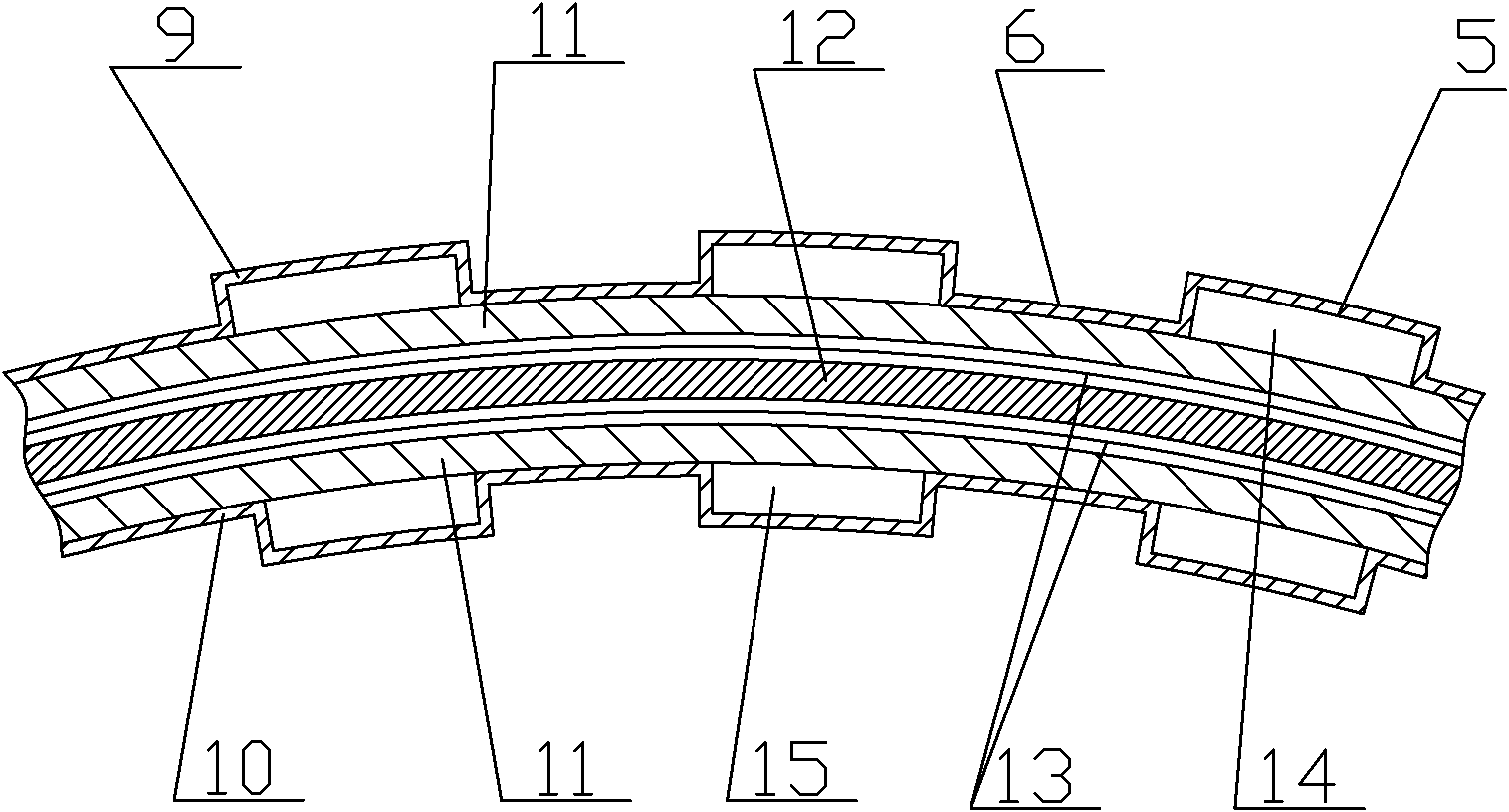

Metallic bipolar plate of proton exchange membrane fuel cell and single cell and electric stack formed by same

ActiveCN101937997AIncrease contactReduce reaction efficiencyFuel cells groupingCell electrodesInternal resistanceEngineering

The invention discloses a metallic bipolar plate of a proton exchange membrane fuel cell and a single cell and an electric stack formed by the same. The metallic bipolar plate is a non-planar arc plate with certain curvature, and is formed by relatively combining a cathode monopolar plate and an anode monopolar plate which are made of metal sheets; cathode and anode cavities, cooling medium cavities, flow field area grooves and lug bosses of the two plates have mutual corresponding convex-concave shapes and form a fuel gas passage, an oxidant gas passage and a cooling medium passage respectively; and a membrane electrode and single bipolar plate can be combined into single fuel cell, and a plurality of single cells can be superposed and connected to form the electric stack. Compared with a common metallic bipolar plate, the bipolar plate has better mechanical property, is not easy to deform or dislocated after assembly, and has high stability; and because the contact between the bipolar plate and a diffusion layer of the membrane electrode is good, the internal resistance is low, the energy consumption is low, and the formed electric stack can provide higher output voltage and higher output power.

Owner:WUHAN UNIV OF TECH

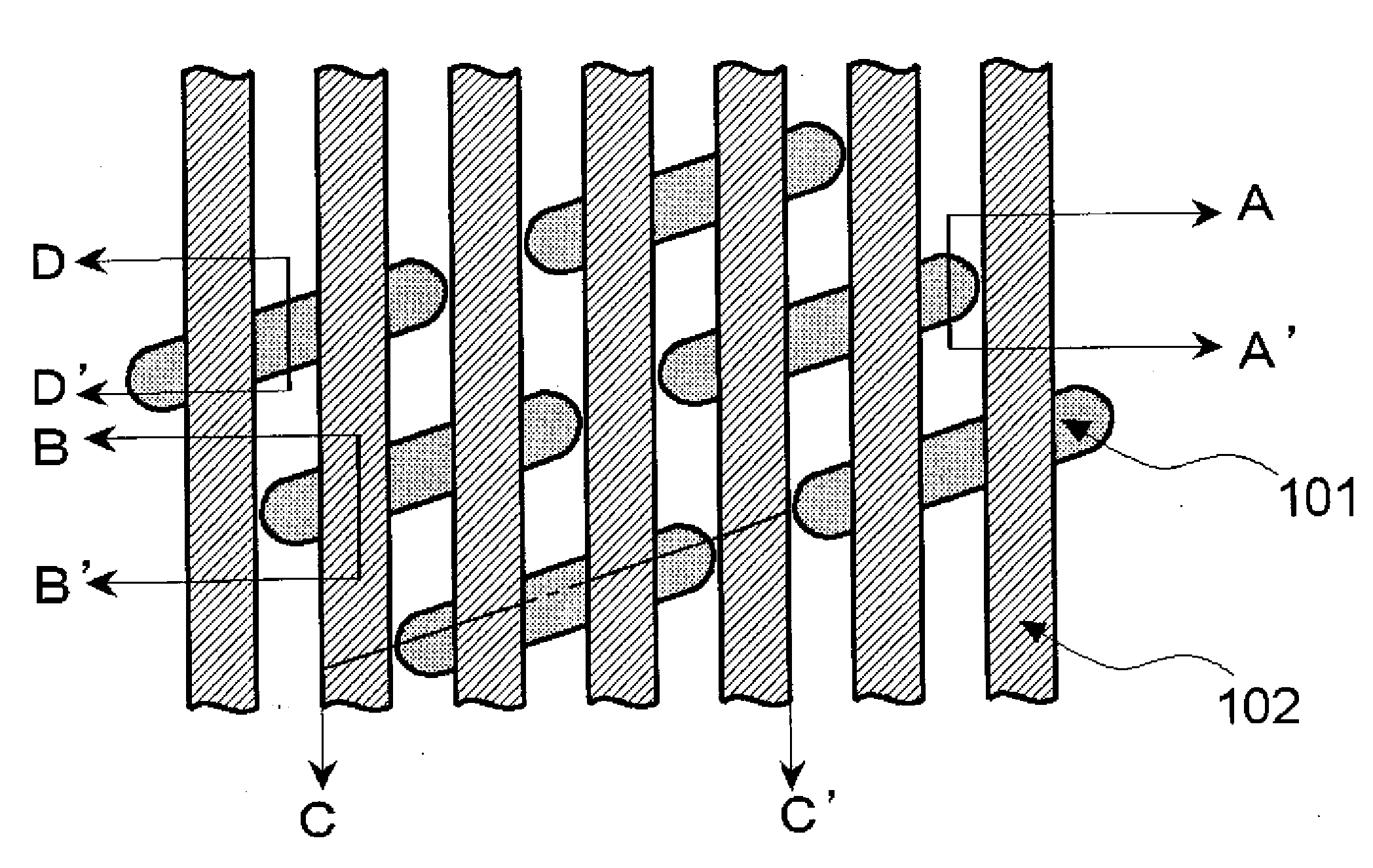

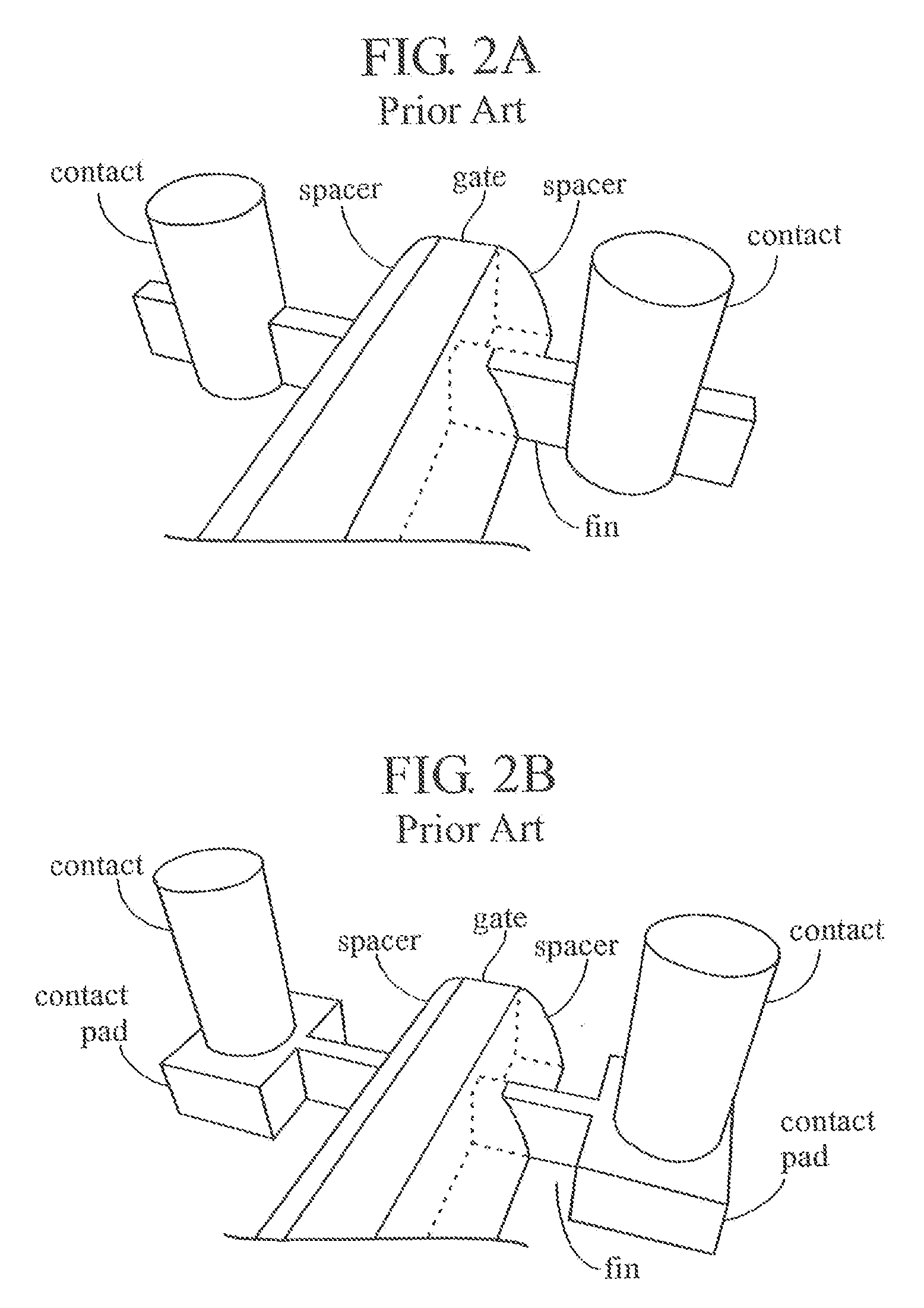

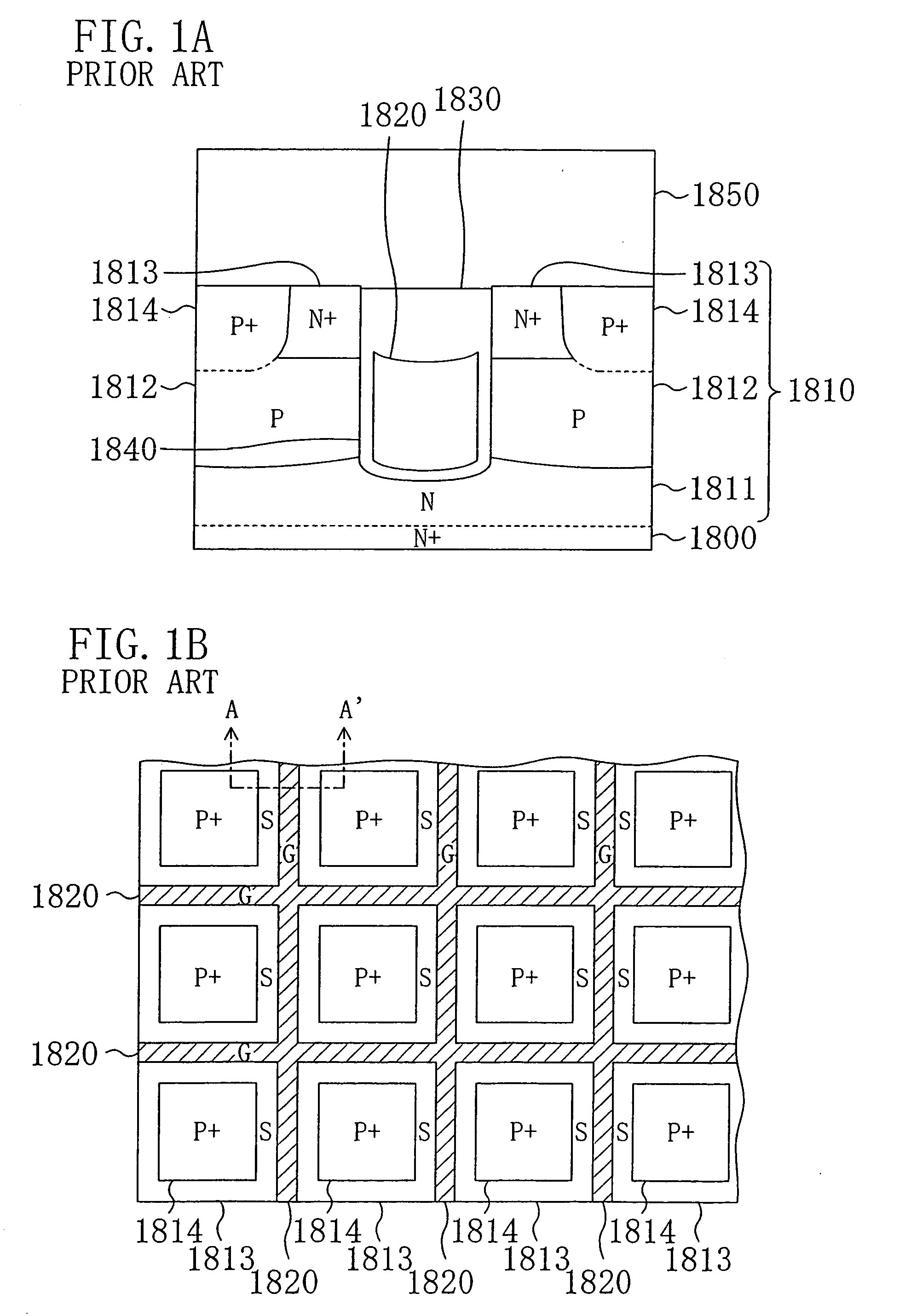

Semiconductor device

InactiveUS20110049599A1Decreasing of on-currentLarge widthTransistorSolid-state devicesPower semiconductor deviceEngineering

In Trench-Gate Fin-FET, in order that the advantage which is exerted in Fin-FET can be sufficiently taken even if a transistor becomes finer and, at the same time, decreasing of on-current can be suppressed by saving a sufficiently large contact area in the active region, a fin width 162 of a channel region becomes smaller than a width 161 of an active region.

Owner:PS4 LUXCO SARL

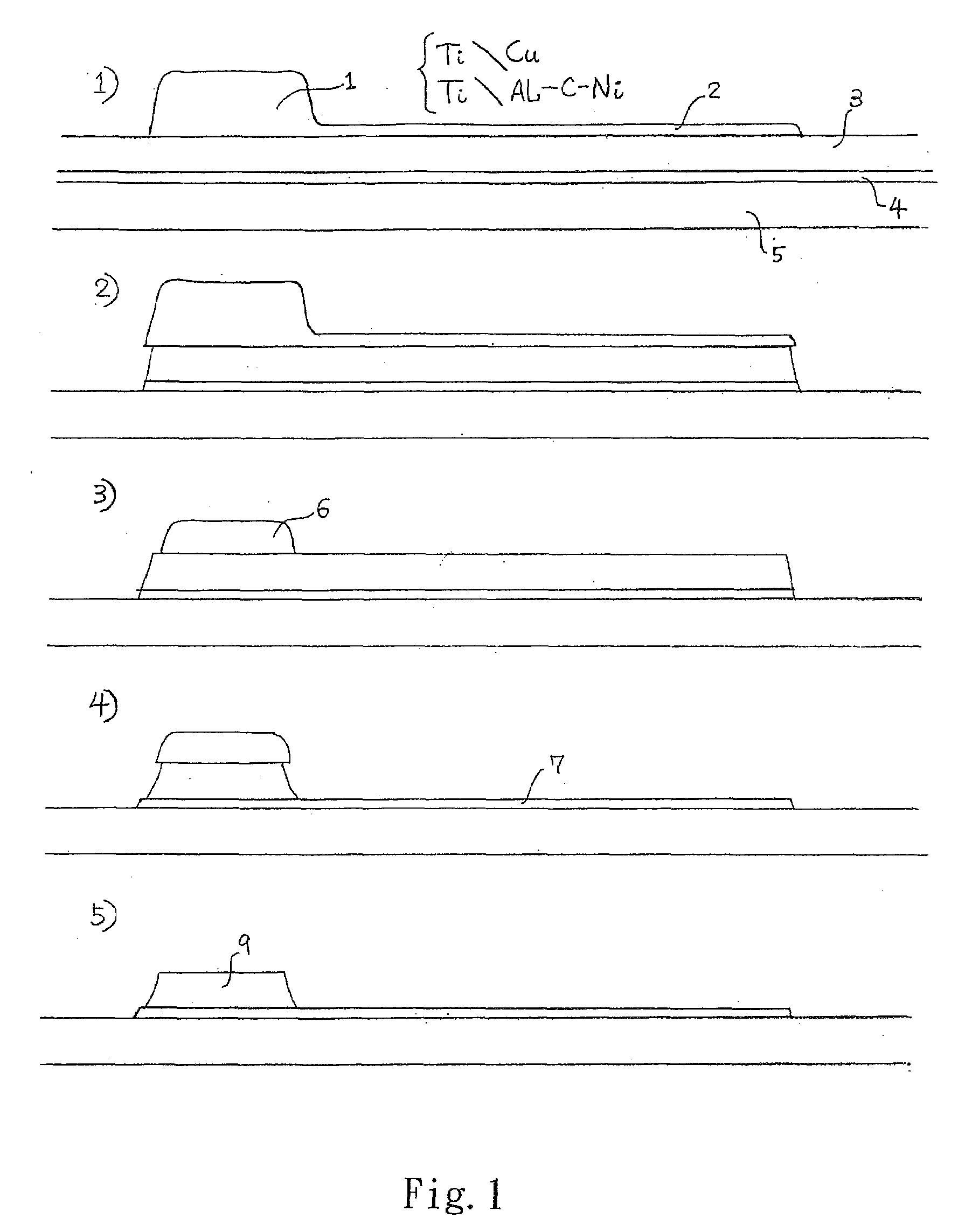

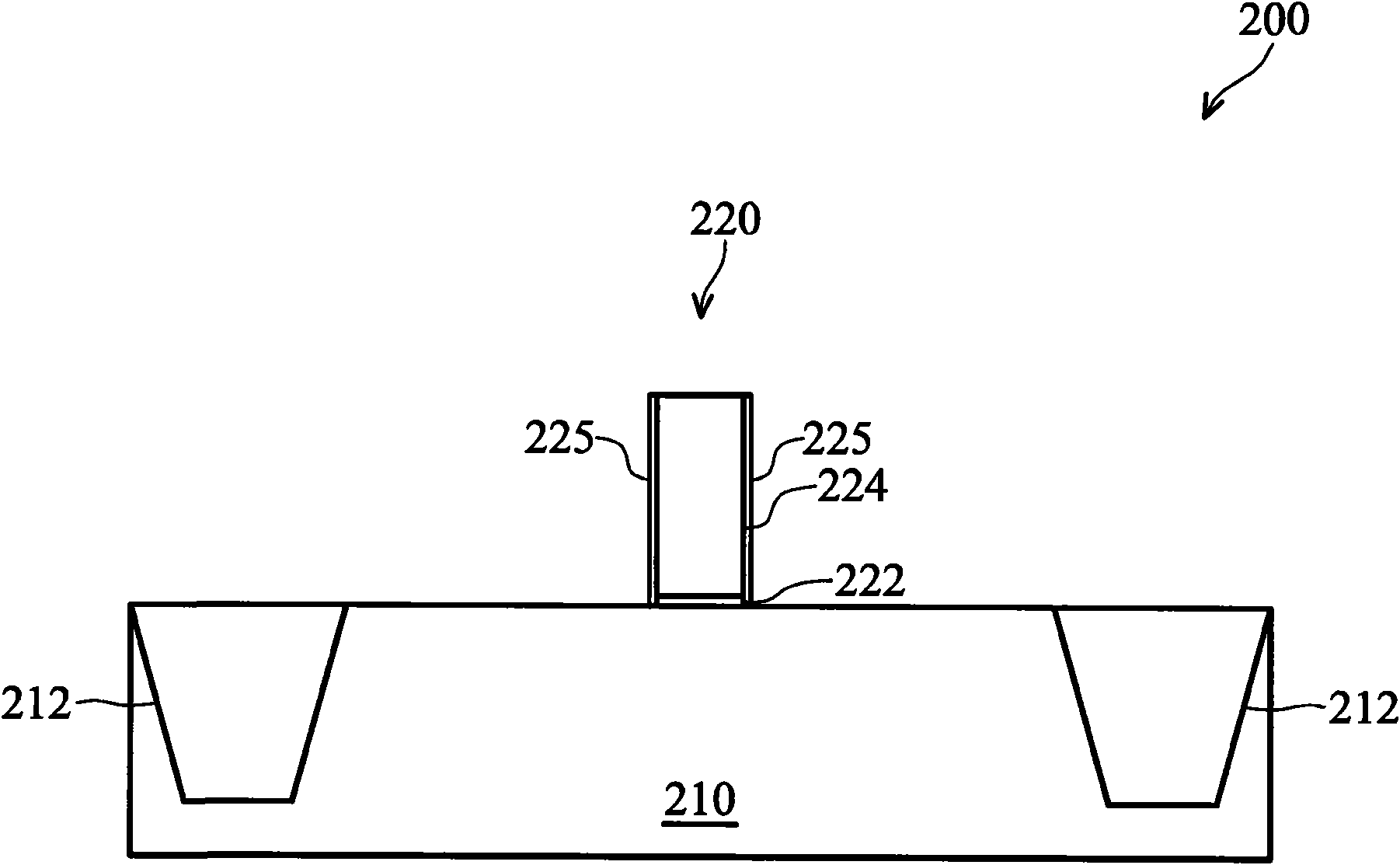

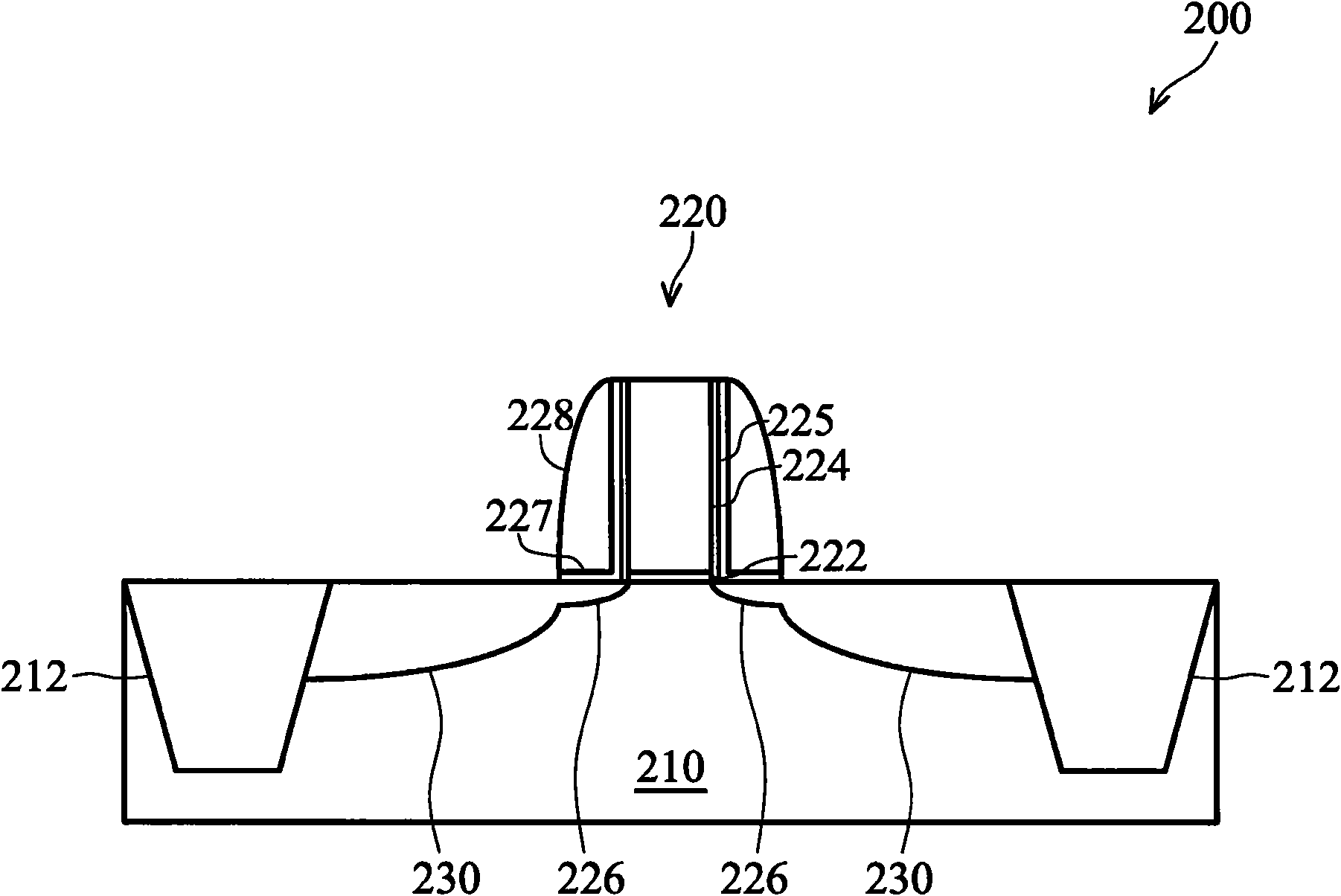

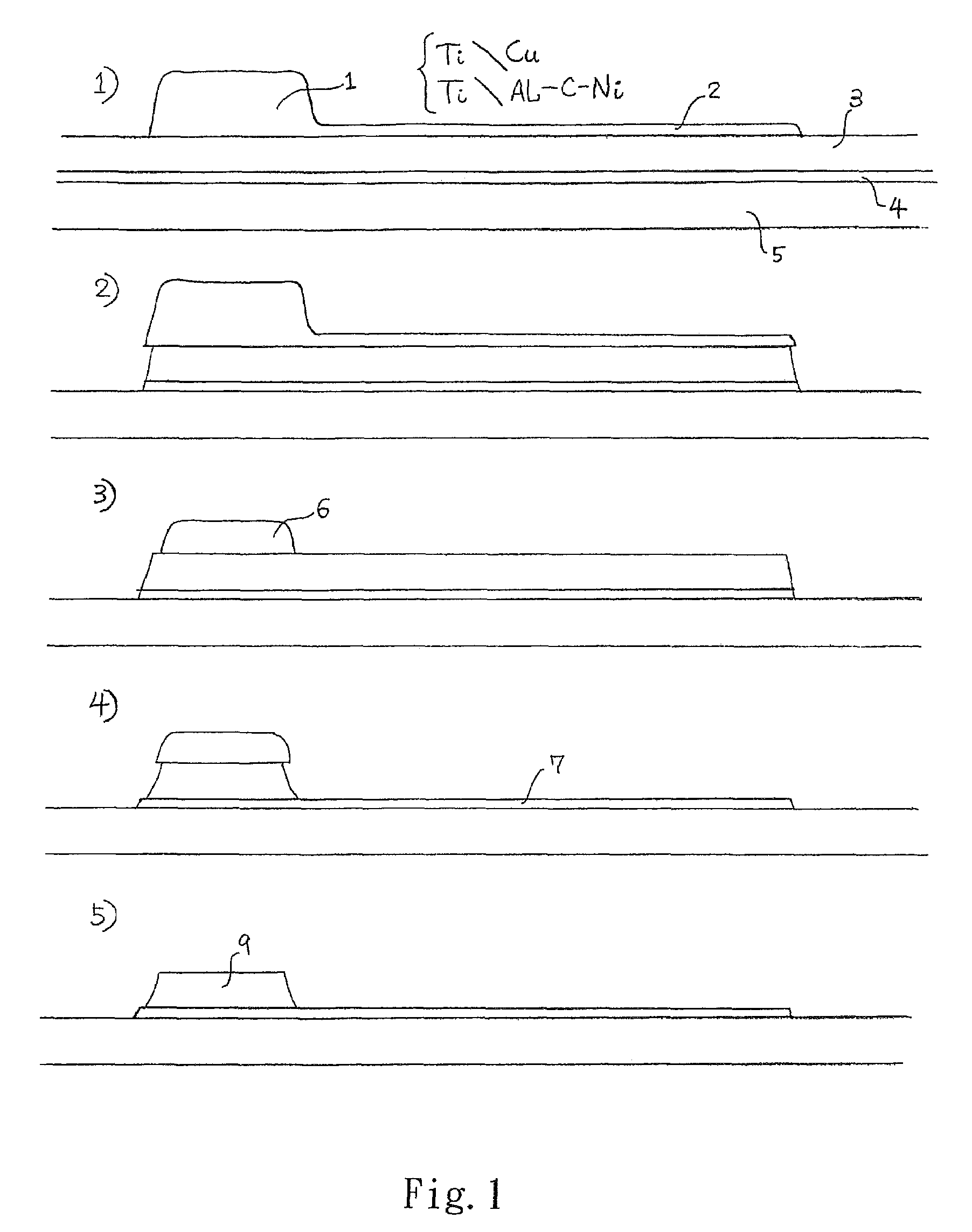

Forming uniform silicide on 3D structures

InactiveUS20110001169A1Increase contact resistanceDiffusion slowSemiconductor/solid-state device manufacturingSemiconductor devicesTitanium nitrideDiffusion barrier

By using a non-conformal diffusion barrier in conjunction with a similarly deposited non-conformal initial deposition of siliciding material, a substantially uniform and conformal silicide can be formed in a 3D structure such as the fin of a FinFET. The siliciding material may be nickel (Ni), the diffusion barrier may be titanium (Ti) or titanium nitride (TiN). Generally, the diffusion barrier may be any material which will inhibit, but not block, diffusion of the siliciding material into the silicon. In this manner, a non-conformal barrier deposition, in conjunction with a non-conformal silicide material deposition, after anneal, results in substantially conformal silicide formation.

Owner:GLOBALFOUNDRIES INC

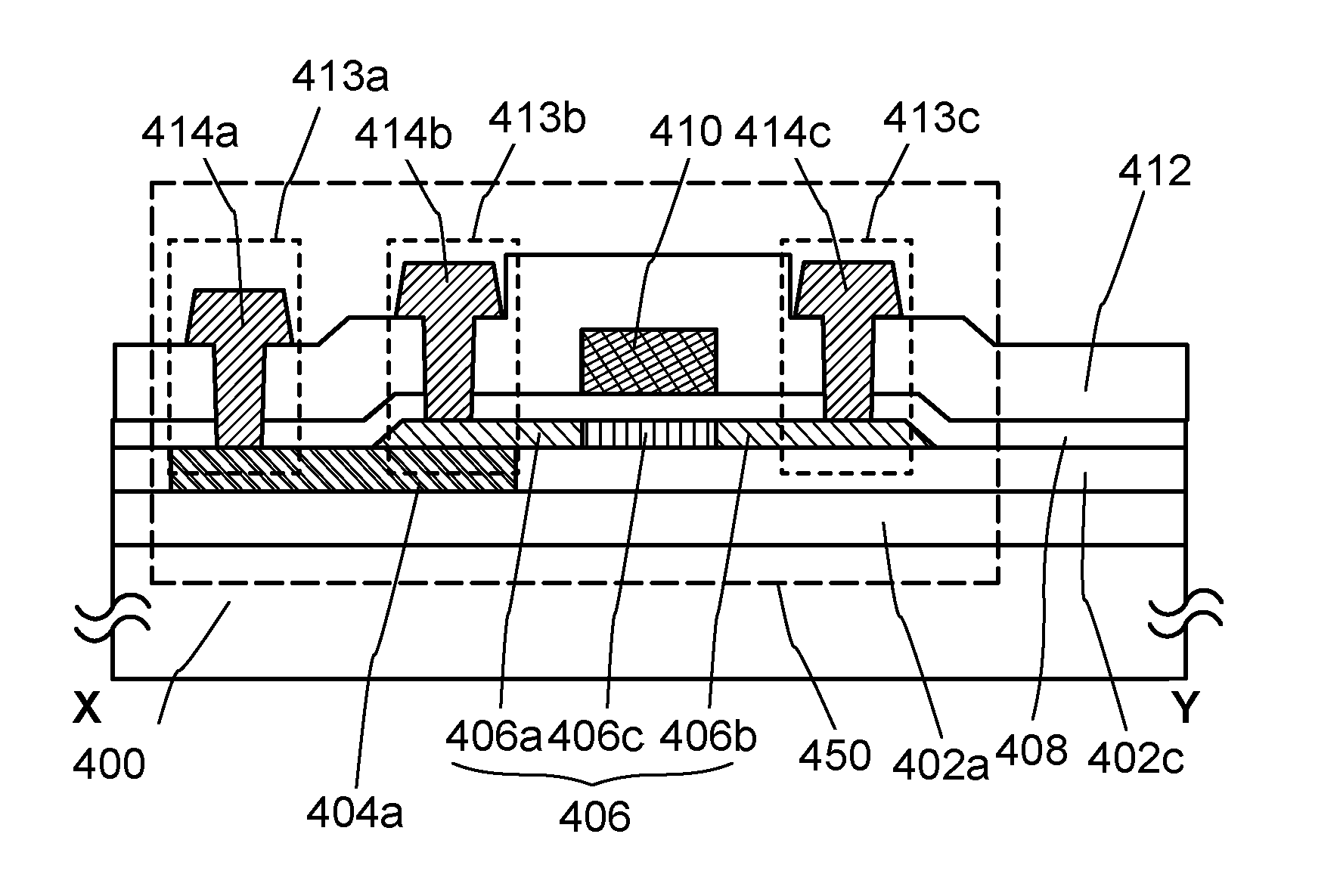

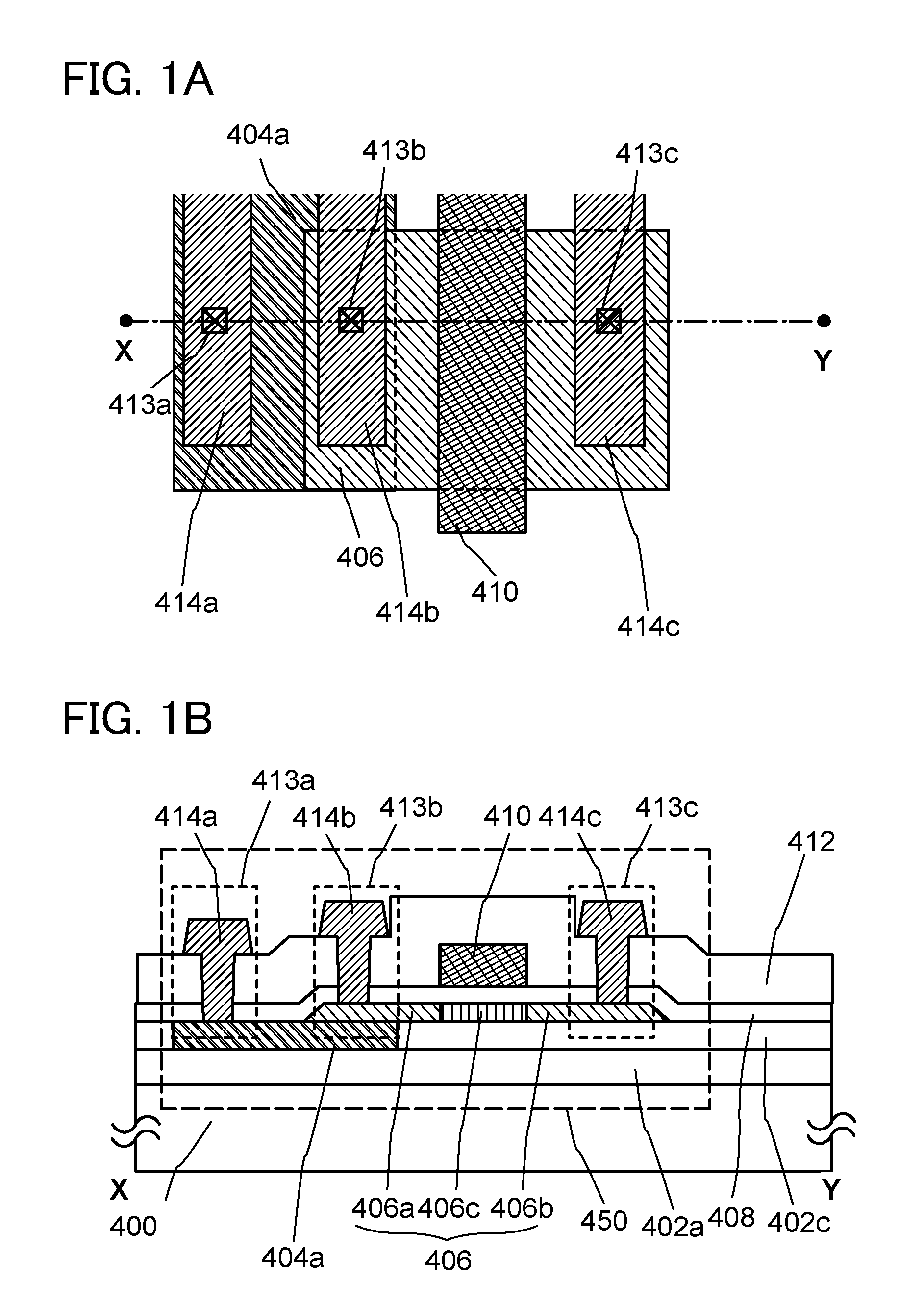

Semiconductor device and manufacturing method thereof

ActiveUS20130069054A1Excellent electrical propertiesResistanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceEngineering

In a semiconductor device including an oxide semiconductor layer, a conductive layer is formed in contact with a lower portion of the oxide semiconductor layer and treatment for adding an impurity is performed, so that a channel formation region and a pair of low-resistance regions between which the channel formation region is sandwiched are formed in the oxide semiconductor layer in a self-aligned manner. Wiring layers electrically connected to the conductive layer and the low-resistance regions are provided in openings of an insulating layer.

Owner:SEMICON ENERGY LAB CO LTD

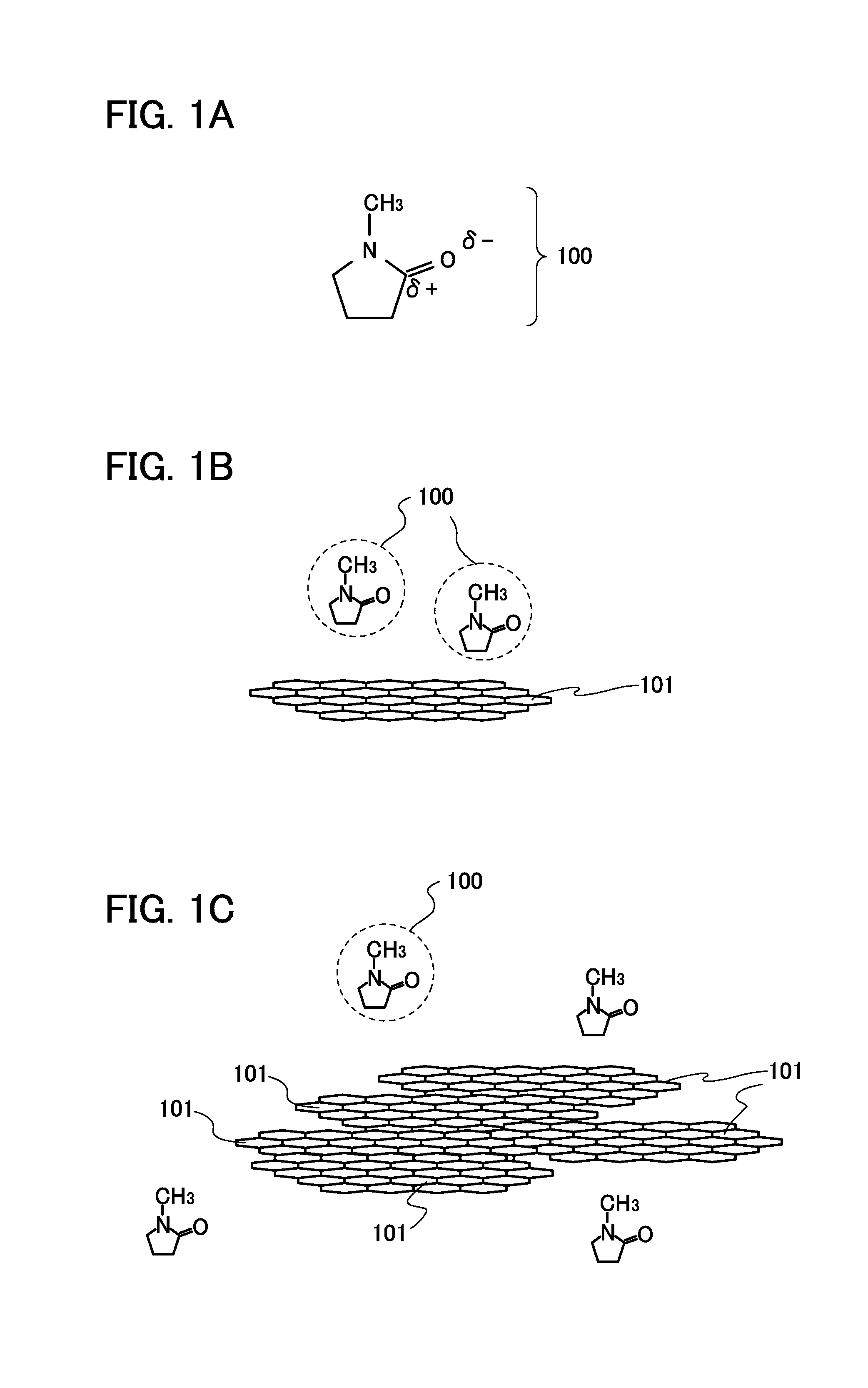

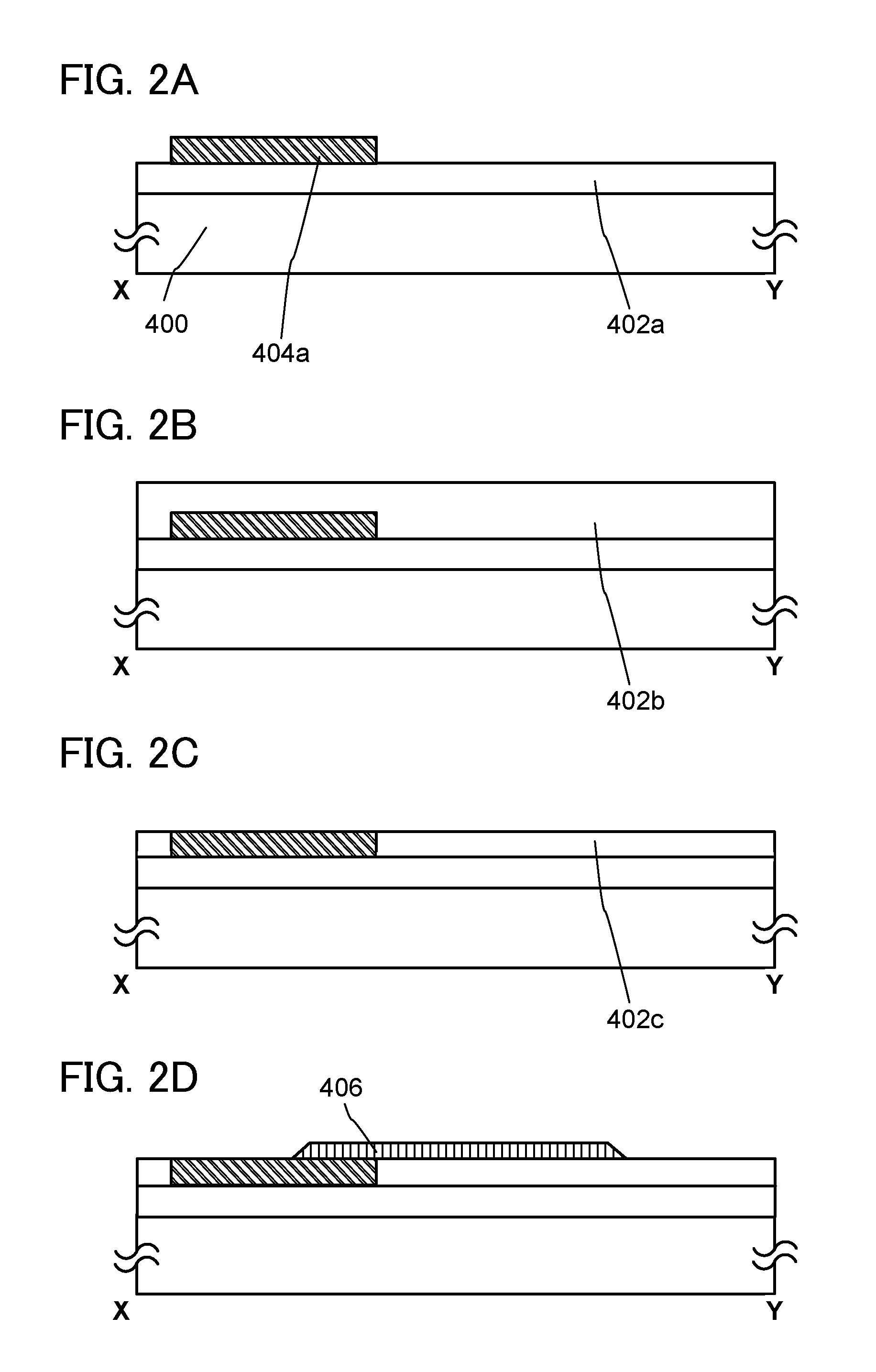

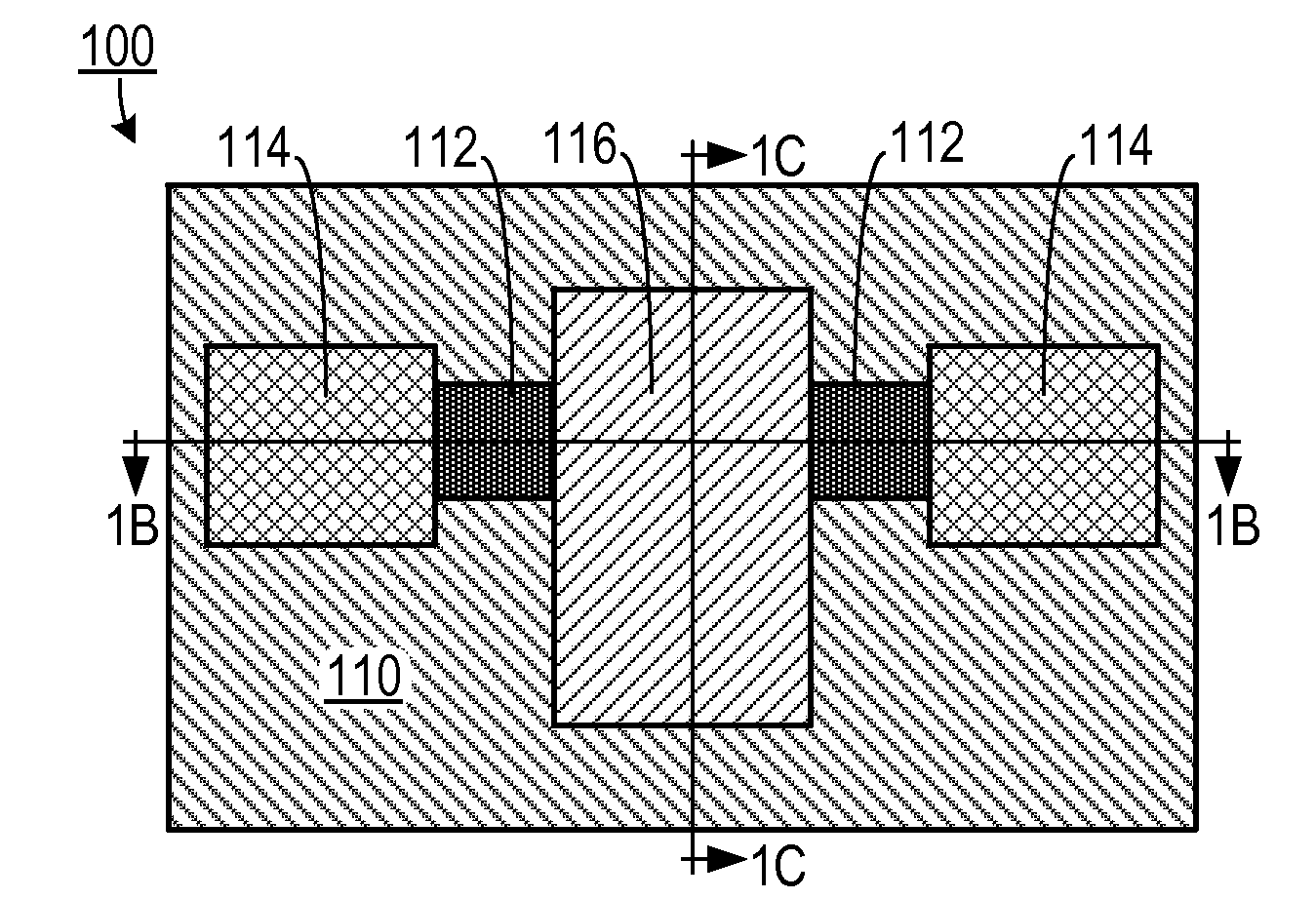

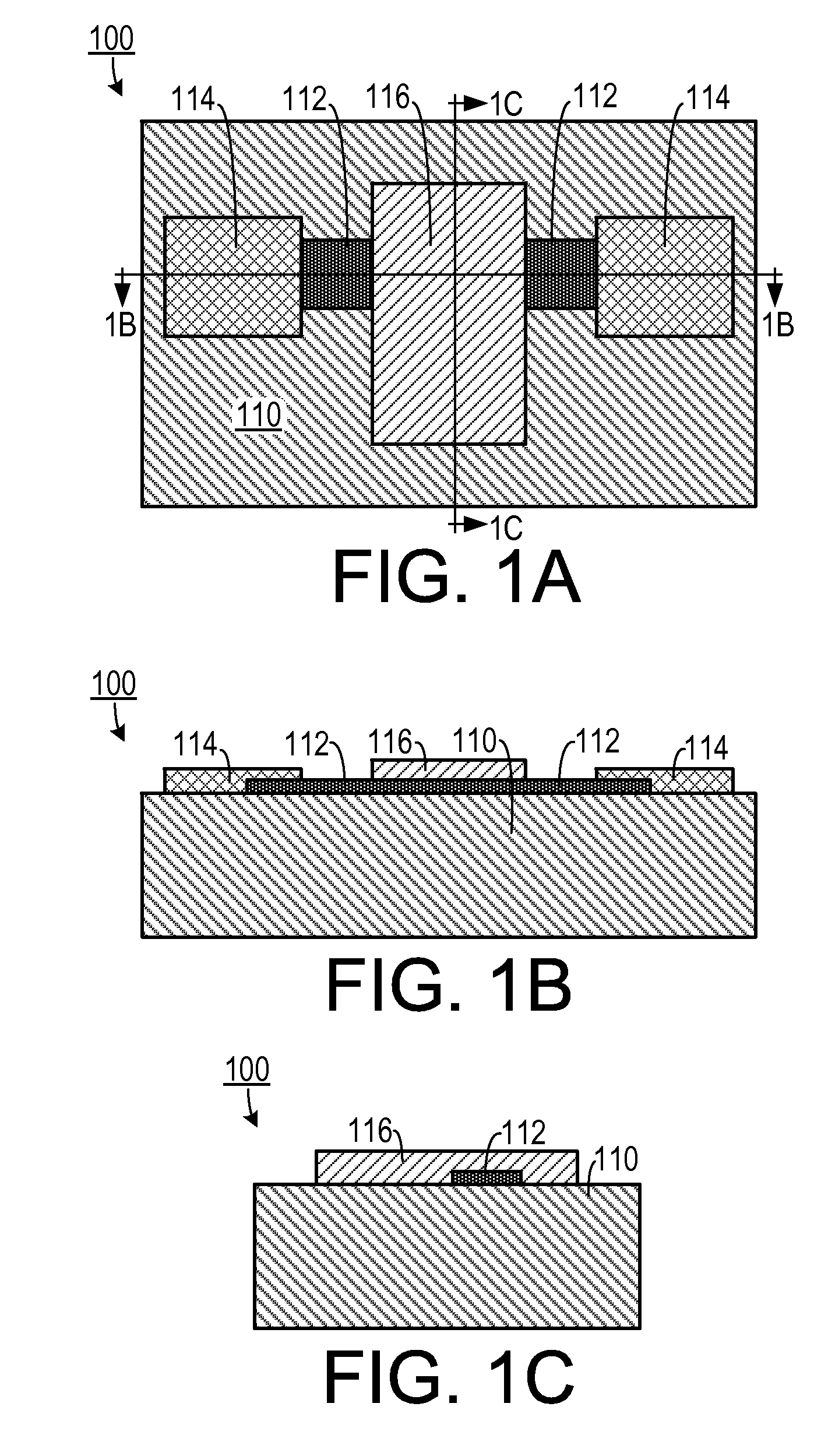

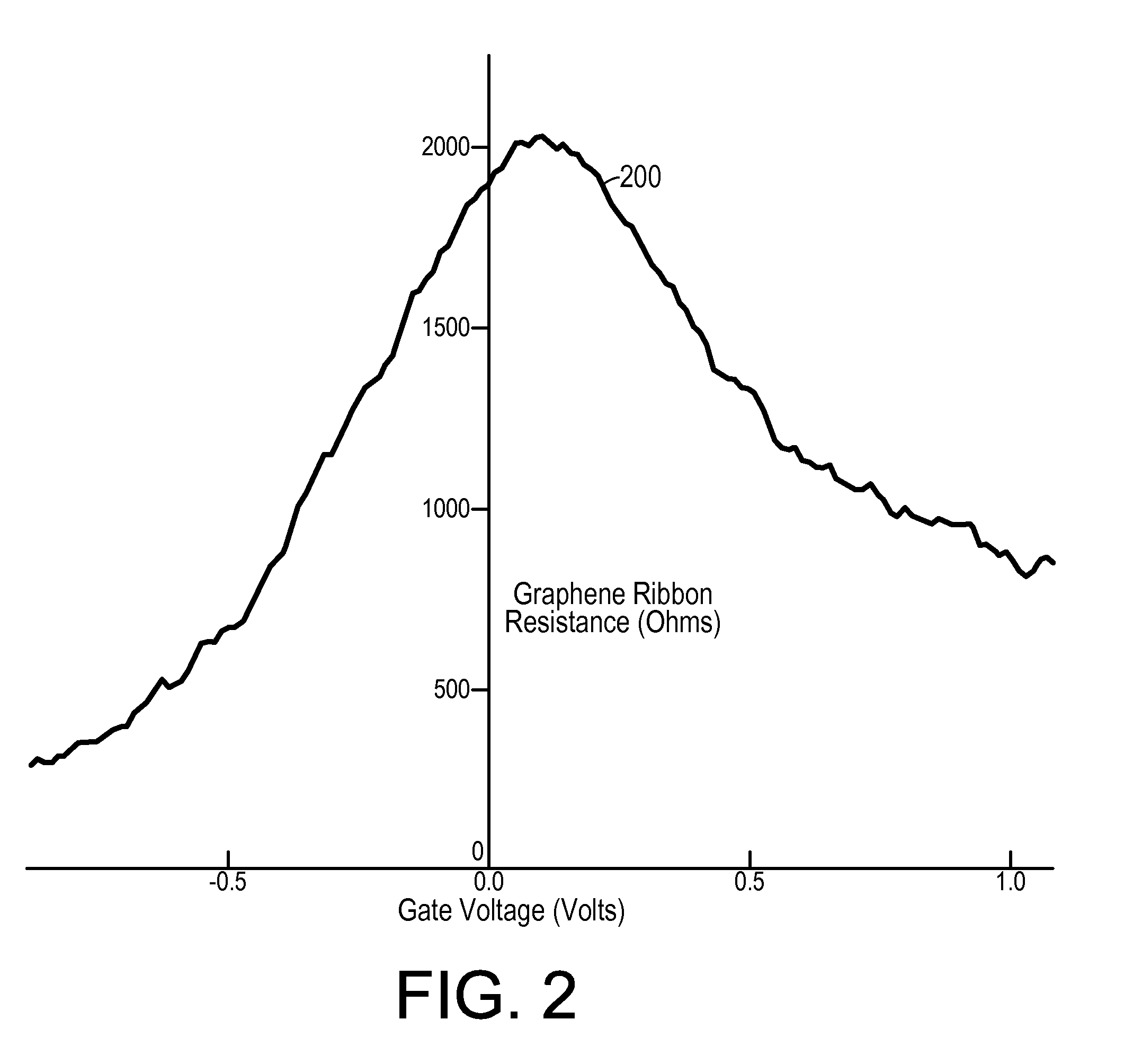

Method to Modify the Conductivity of Graphene

ActiveUS20110108806A1Increase contact resistanceNanoinformaticsSolid-state devicesGrapheneContact resistance

A gated electrical device includes a non-conductive substrate and a graphene structure disposed on the non-conductive substrate. A metal gate is disposed directly on a portion of the graphene structure. The metal gate includes a first metal that has a high contact resistance with graphene. Two electrical contacts are each placed on the graphene structure so that the metal gate is disposed between the two electrical contacts. In a method of making a gated electrical device, a graphene structure is placed onto a non-conductive substrate. A metal gate is deposited directly on a portion of the graphene structure. Two electrical contacts are deposited on the graphene structure so that the metal gate is disposed between the two electrical contacts.

Owner:GEORGIA TECH RES CORP

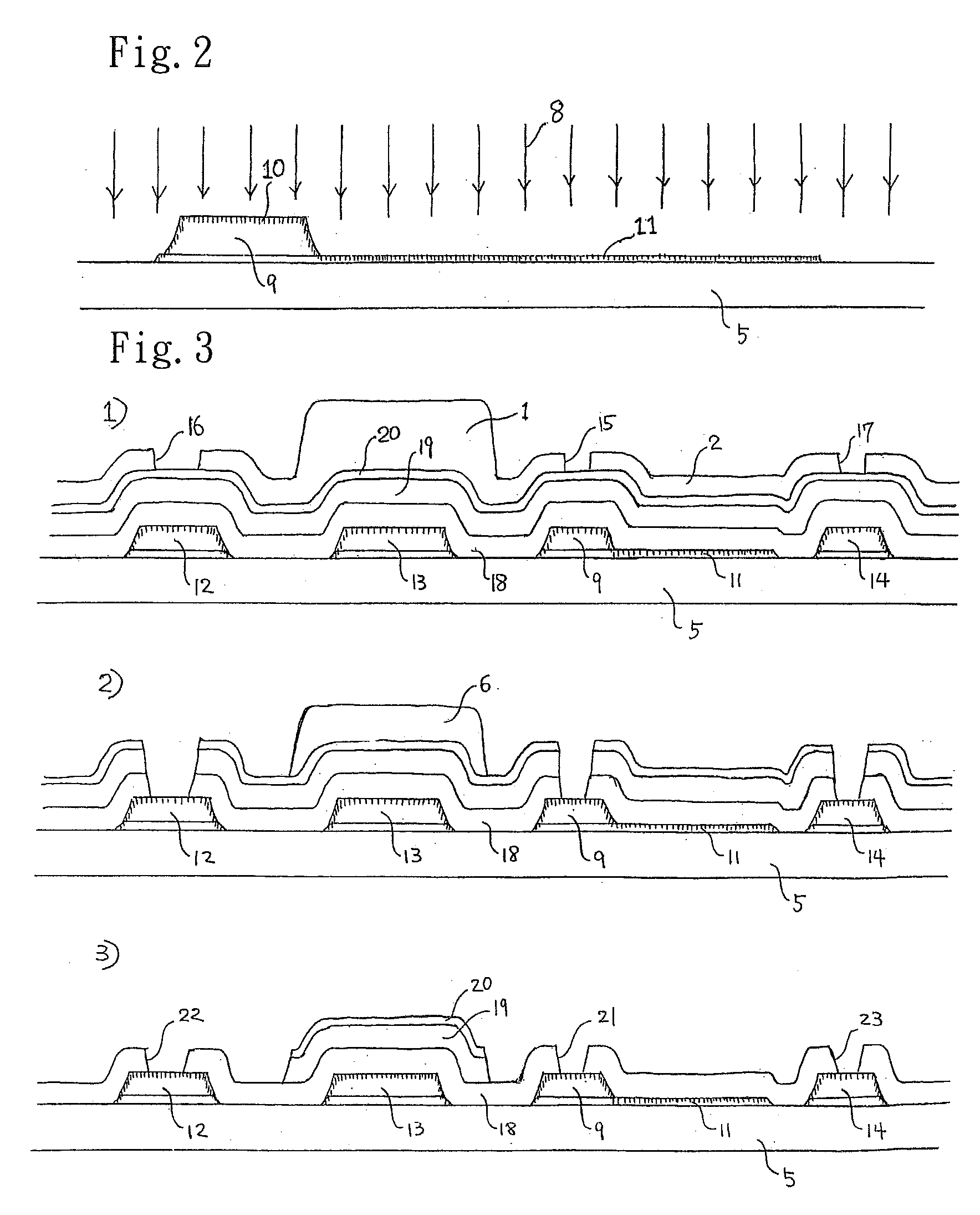

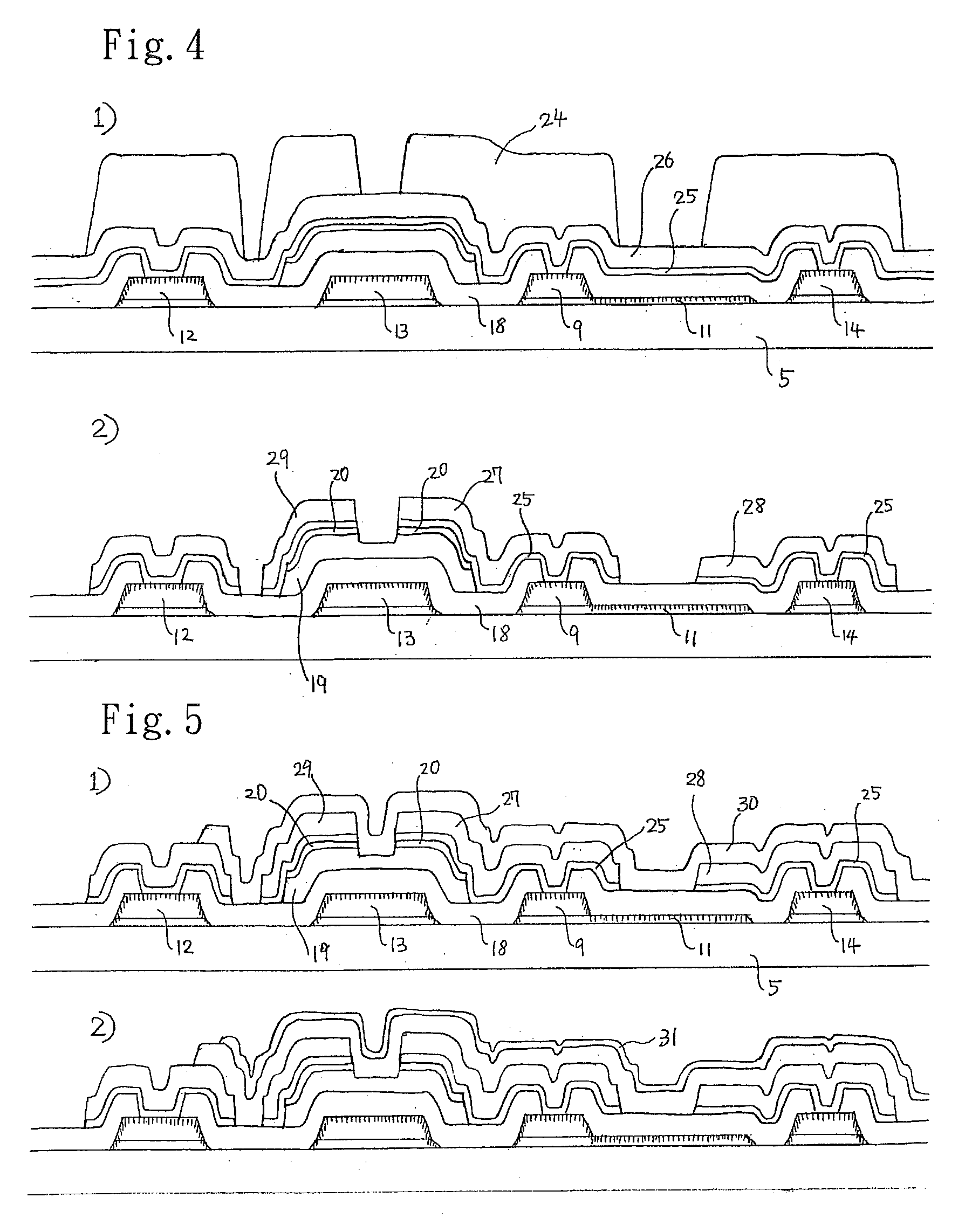

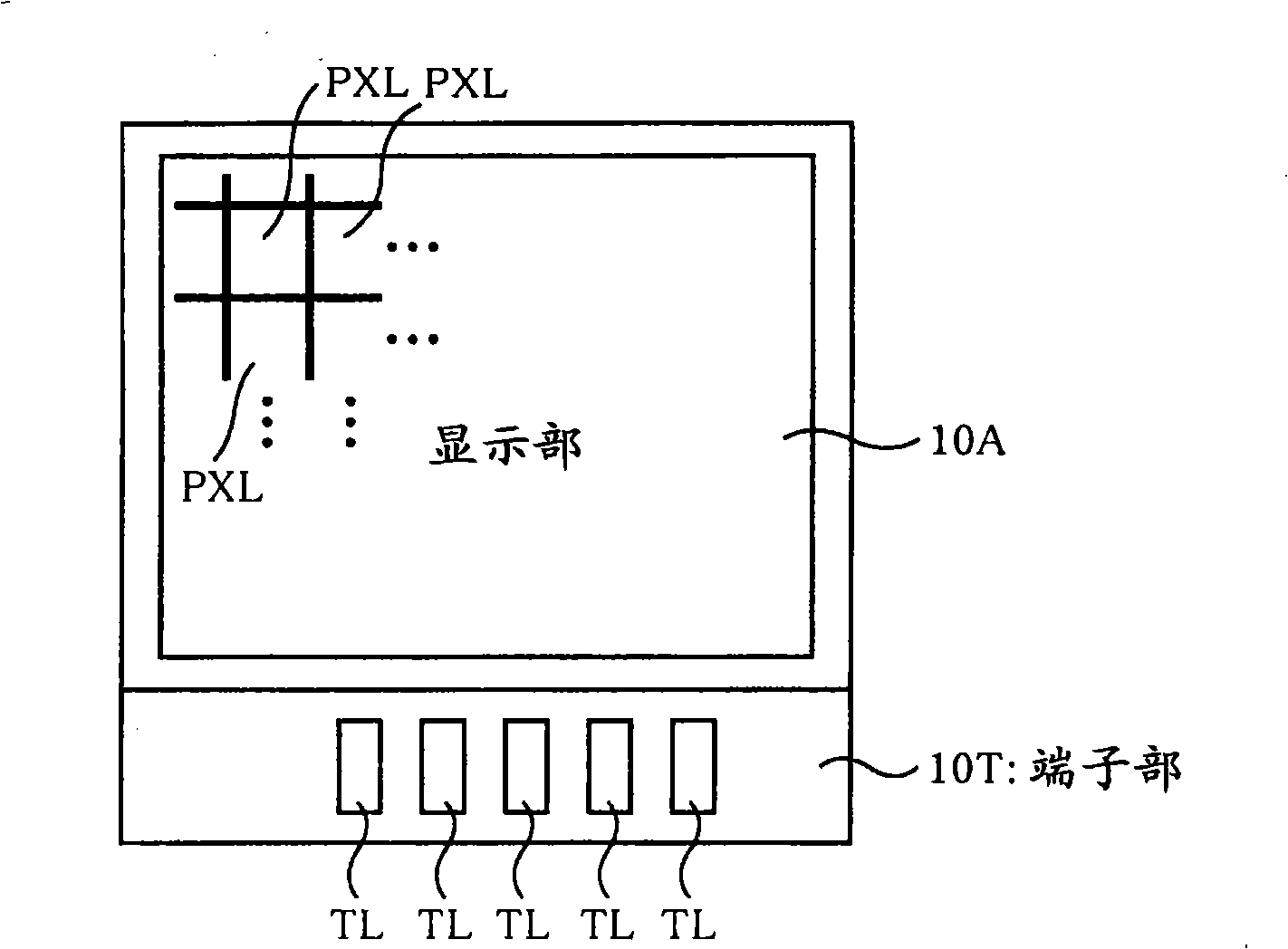

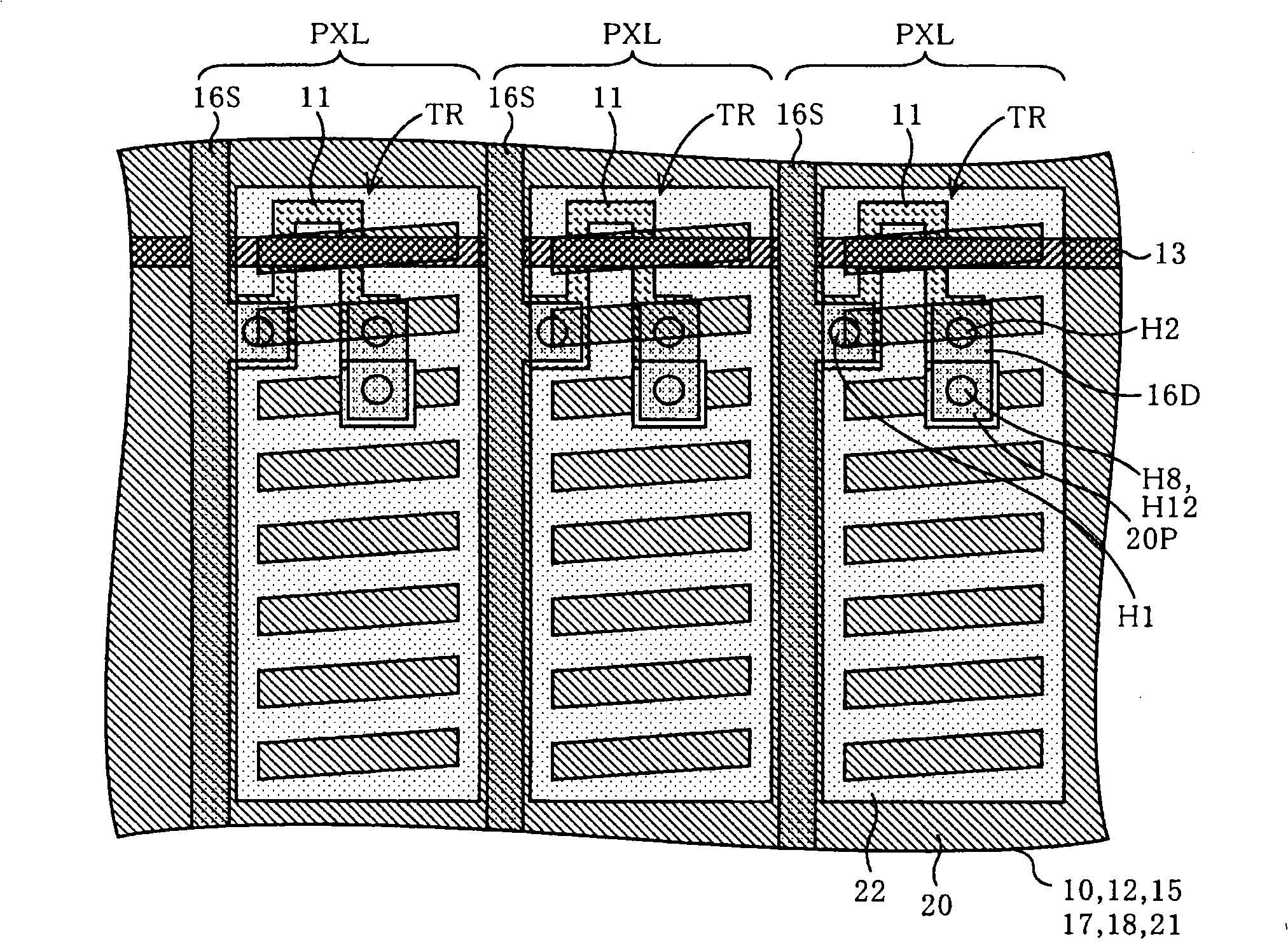

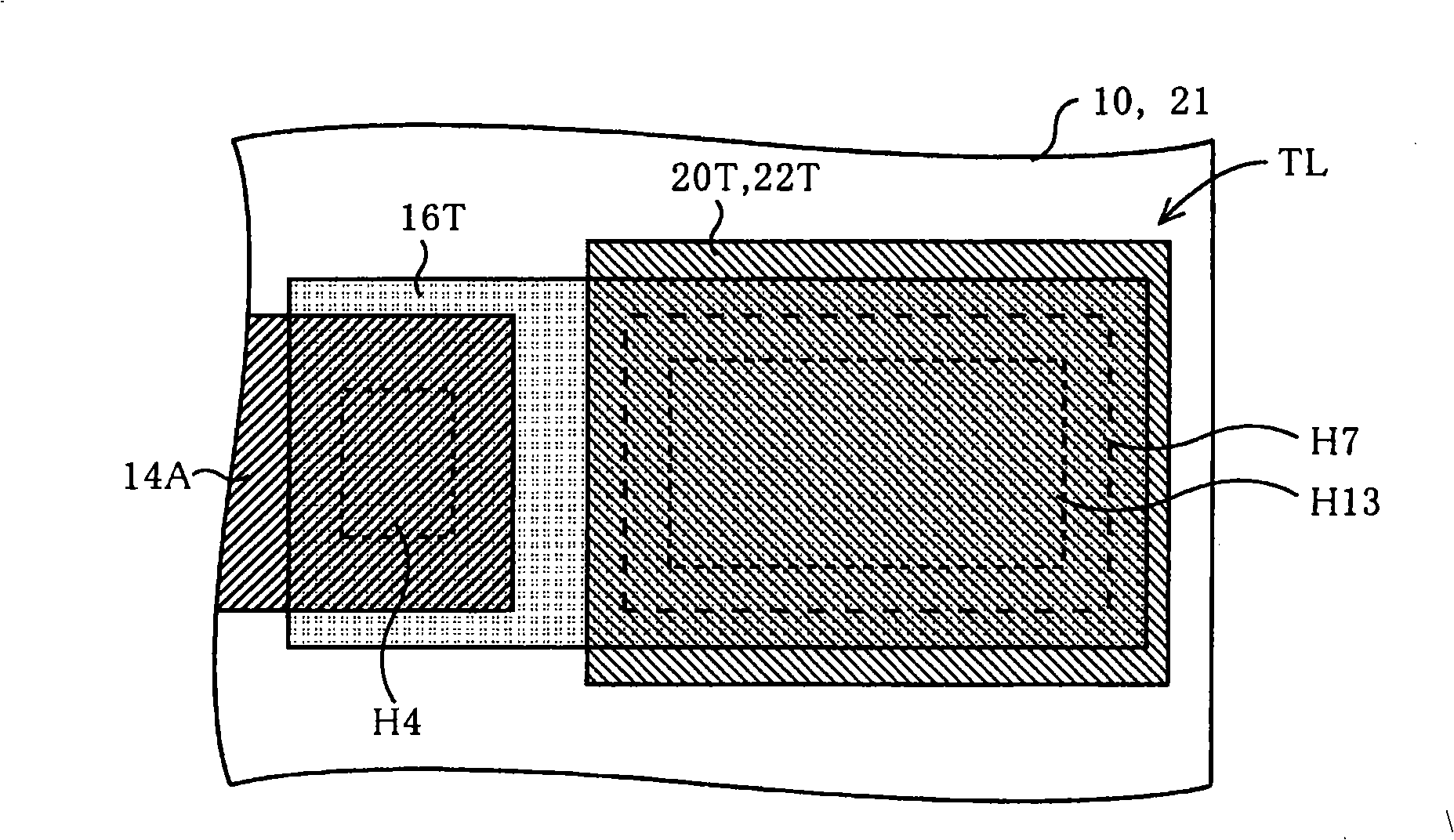

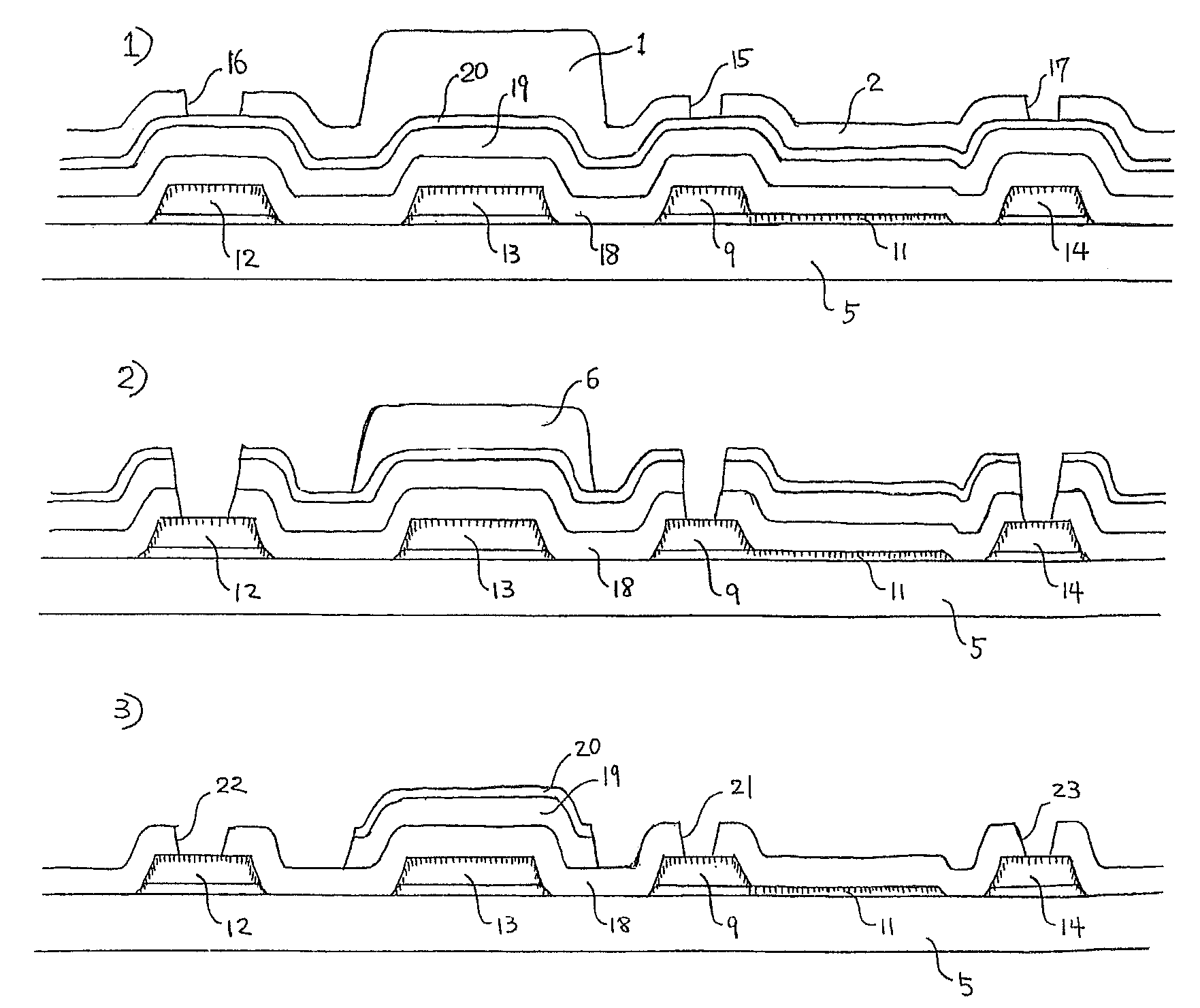

Liquid crystal display device and method of manufacturing the liquid crystal display device

ActiveCN101354513AIncrease contact resistanceSuppression of pass rate dropSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEngineering

The object of the invention is to suppress the increase of contact resistance between electrodes and restrain the reducing of pass percent in a liquid crystal display device that controls a liquid crystal using an electric field that is substantially horizontal with respect to a transparent substrate. A method of manufacturing the liquid crystal display device includes: forming a first etching stopper electrode (20P) connected to the drain electrode(16D) and a common electrode (20) connected to a leading-out line, which pass through openings (H8, H9) formed on a passivating film (17) and a plainness film (18) covering a switching element (TR); forming a insulating film (21) by covering the first etching stopper electrode and the common electrode; selectively etching the insulating film in a dry-type way; removing a residue on the first etching stopper electrode by etching in a wet-type way; forming a pixel electrode (22) that is connected to the first etching stopper electrode and that extends onto the second insulating film.

Owner:JAPAN DISPLAY INC

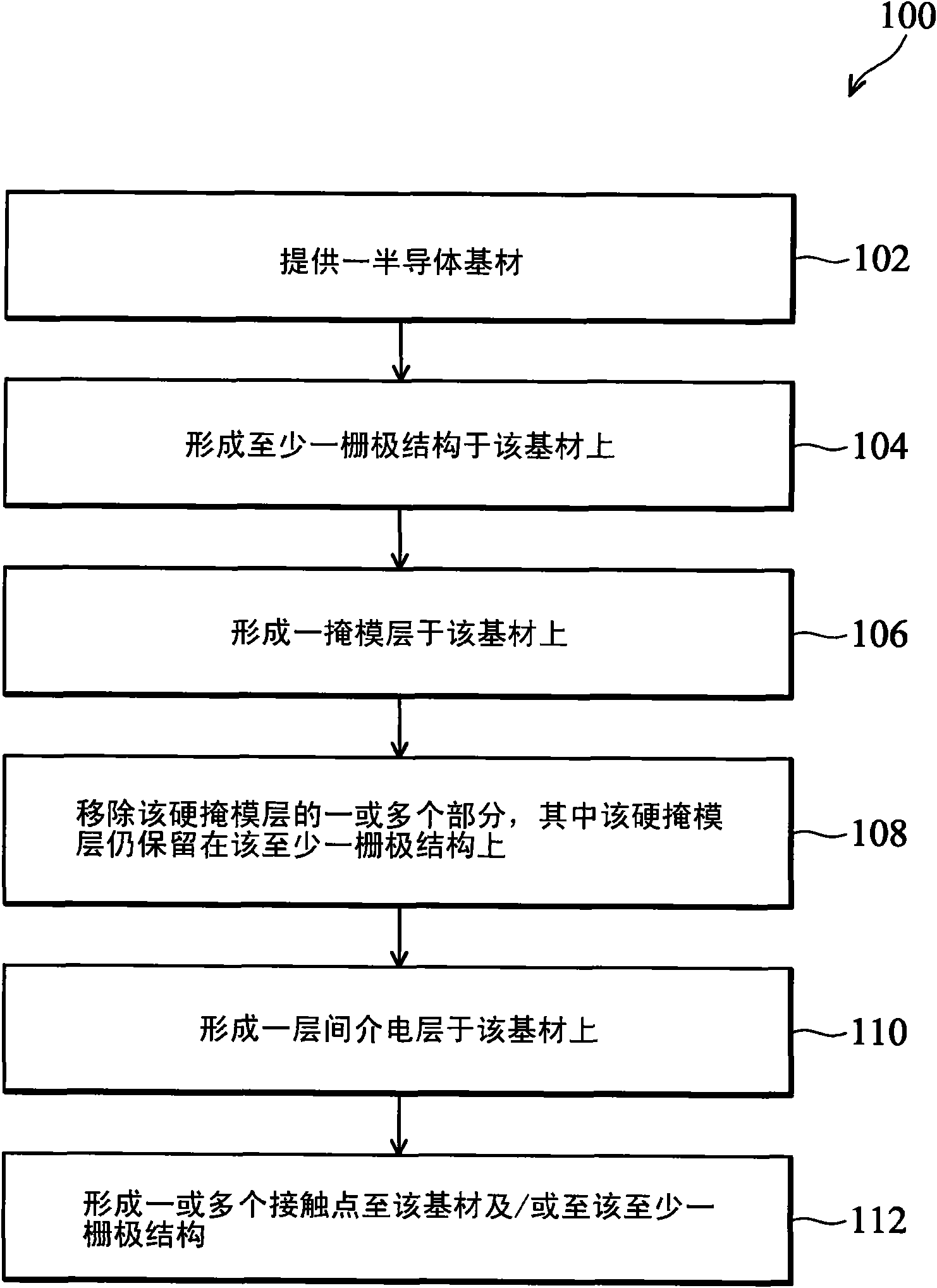

Semiconductor device and manufacturing method

ActiveCN101872742AAvoid etchingIncrease contact resistanceTransistorSemiconductor/solid-state device detailsEngineeringSemiconductor

A method for fabricating a semiconductor device is disclosed. The method includes providing a substrate; forming at least one gate structure over the substrate; forming a plurality of doped regions in the substrate; forming an etch stop layer over the substrate; removing a first portion of the etch stop layer, wherein a second portion of the etch stop layer remains over the plurality of doped regions; forming a hard mask layer over the substrate; removing a first portion of the hard mask layer, wherein a second portion of the hard mask layer remains over the at least one gate structure; and forming a first contact through the second portion of the hard mask layer to the at least one gate structure, and a second contact through the second portion of the etch stop layer to the plurality of doped regions.

Owner:TAIWAN SEMICON MFG CO LTD

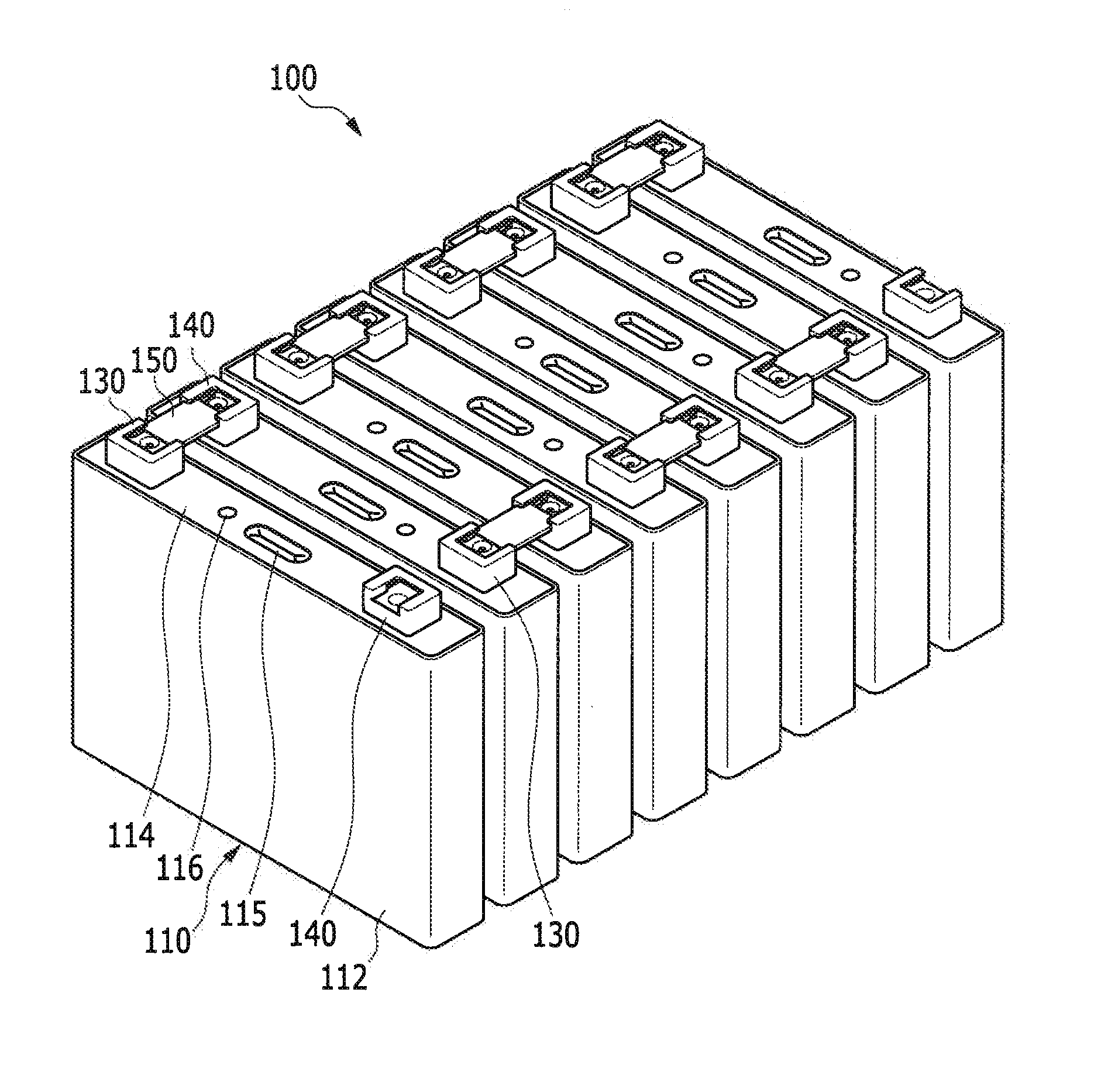

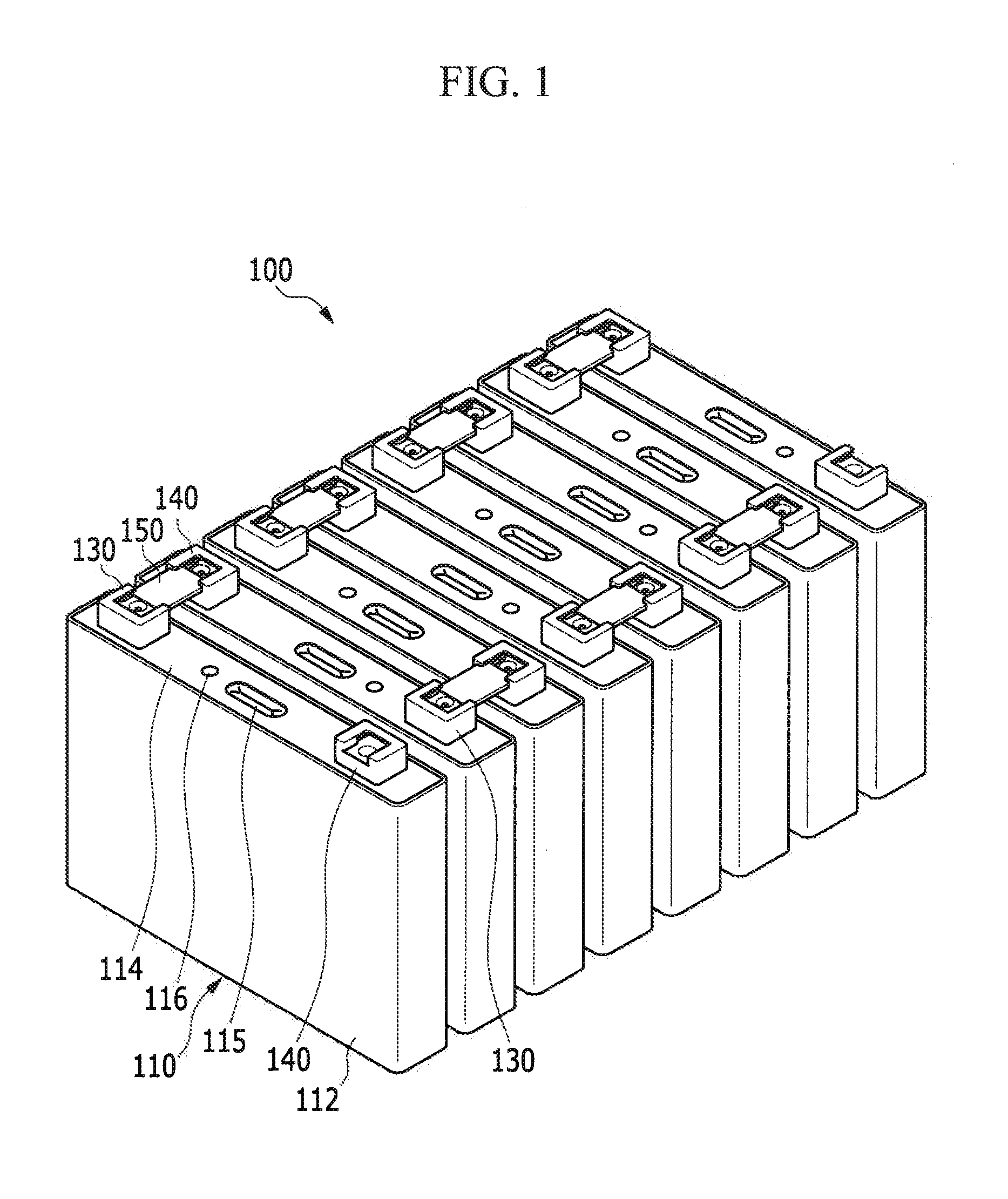

Battery module

ActiveUS20120288744A1Increase contact resistanceEasy to fixPrimary cell to battery groupingCurrent conducting connectionsElectricityElectrical battery

A battery module including: a plurality of rechargeable batteries including a first terminal and a second terminal; and a connecting member electrically connecting rechargeable batteries of the plurality of rechargeable batteries through the first and second terminals, the connecting member including an access protrusion protruded toward the first terminal, and the first terminal includes a pressurizer configured to press the access protrusion toward a part of the first terminal.

Owner:ROBERT BOSCH GMBH +1

High-aspect ratio screen printable thick film paste compositions containing wax thixotropes

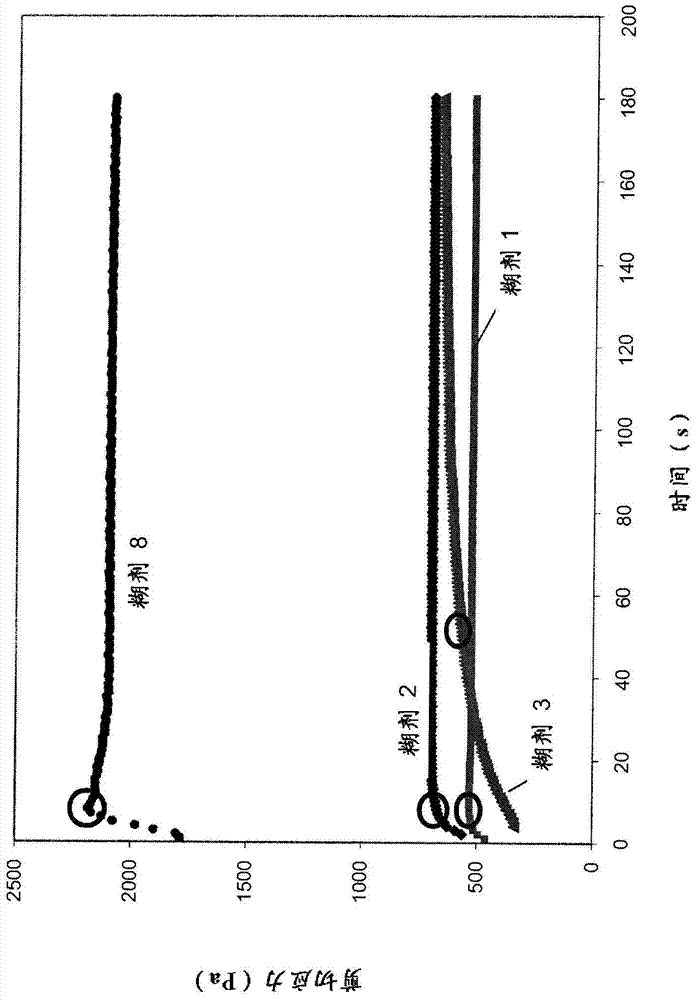

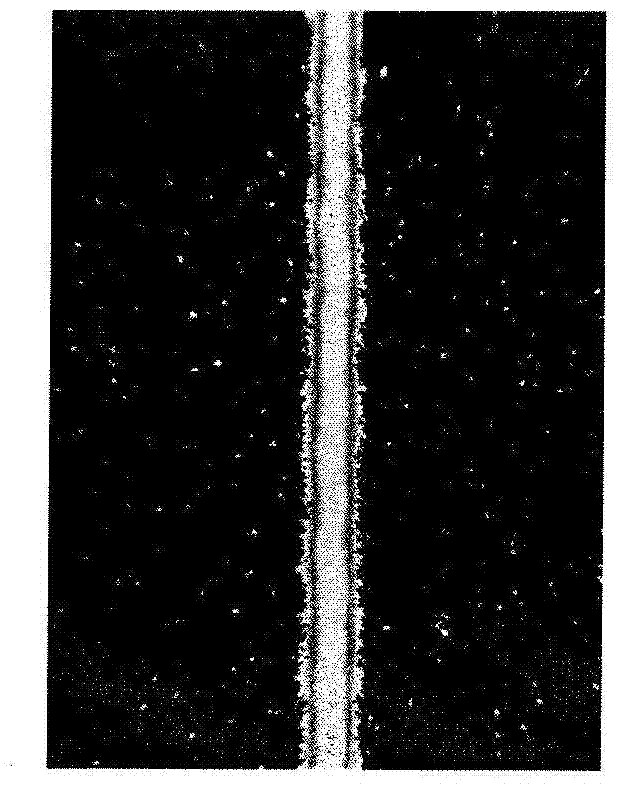

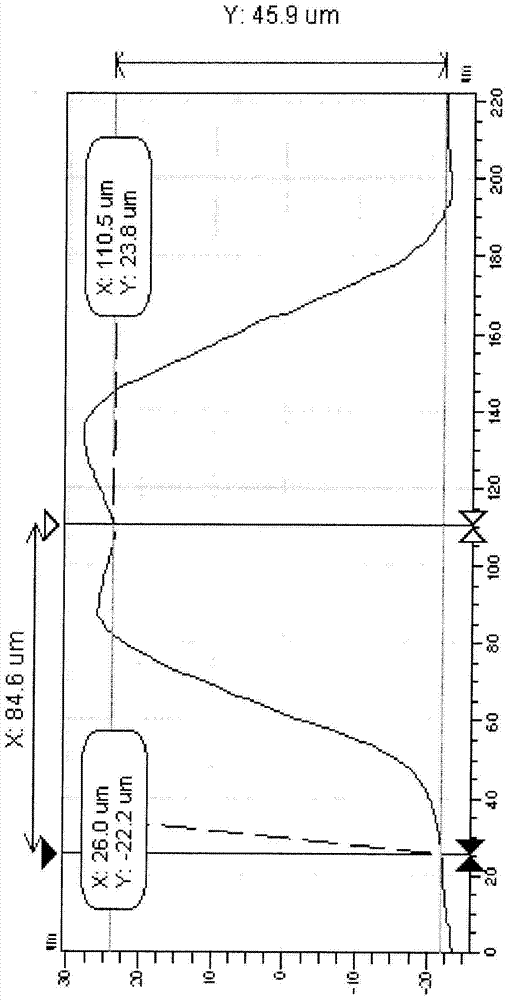

ActiveCN103597547AHigh aspect ratioGood printabilityOxide conductorsNon-conductive material with dispersed conductive materialScreen printingElectrical battery

Provided are high-aspect ratio printable thick film metal paste compositions that can be deposited onto a substrate using, for example, screening printing techniques; and methods of preparing and using thick film printable metal pastes; and methods of screen printing of the thick film metal paste compositions onto a substrate to produce printed circuits, conductive lines or features on the substrate and / or a conductive surface on a solar cell device. Also provided are printed substrates containing an electronic feature produced by the high-aspect ratio printable thick film metal paste compositions.

Owner:SUN CHEM CORP

Method for manufacturing electrode for storage battery

ActiveUS20140295068A1High densityLarge capacityElectrode rolling/calenderingElectrode thermal treatmentHigh densitySlurry

To provide a storage battery electrode including an active material layer with high density that contains a smaller percentage of conductive additive. To provide a storage battery having a higher capacity per unit volume of an electrode with the use of the electrode for a storage battery. A slurry that contains an active material and graphene oxide is applied to a current collector and dried to form an active material layer over the current collector, the active material layer over the current collector is rolled up together with a spacer, and a rolled electrode which includes the spacer are immersed in a reducing solution so that graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

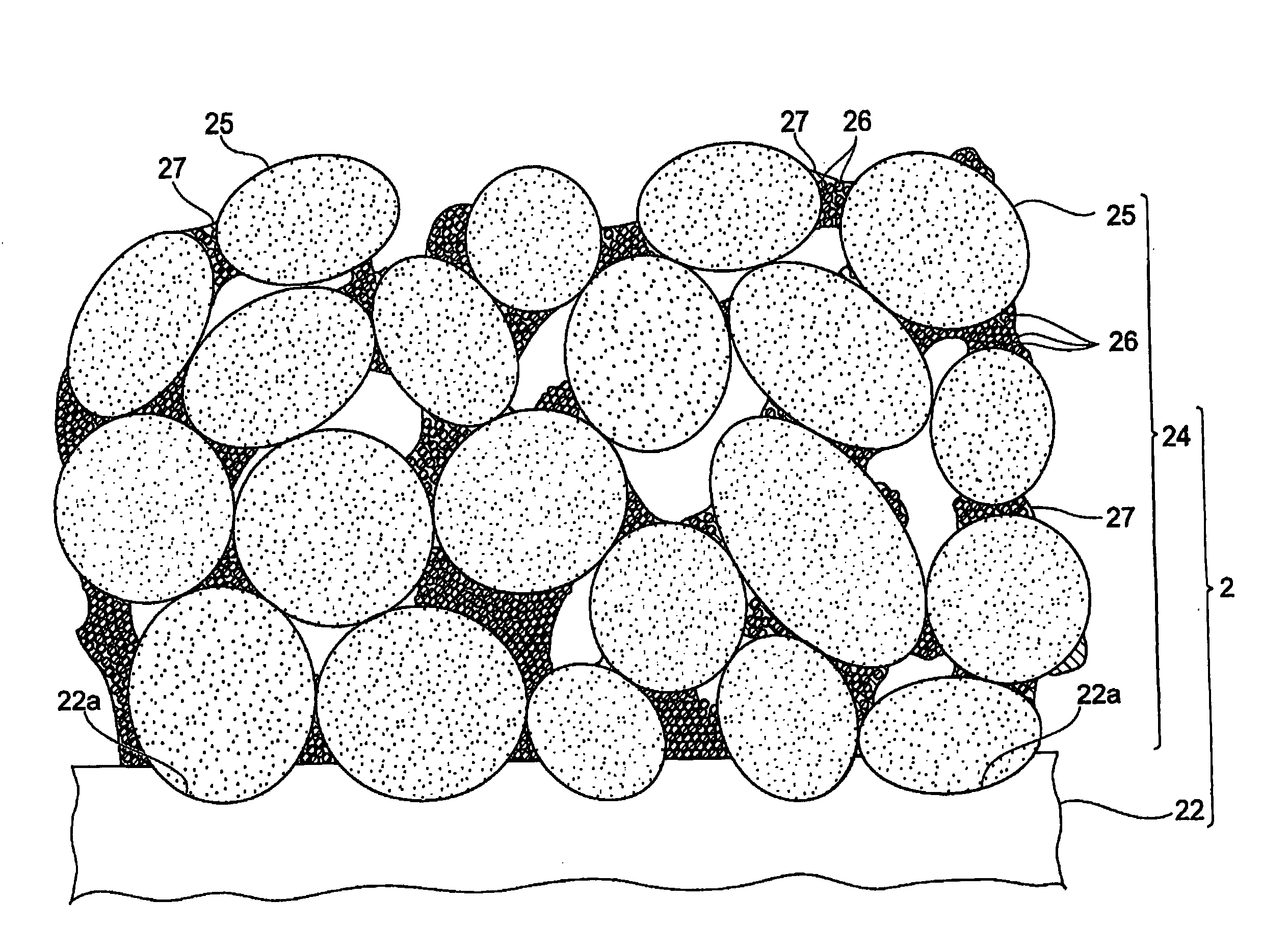

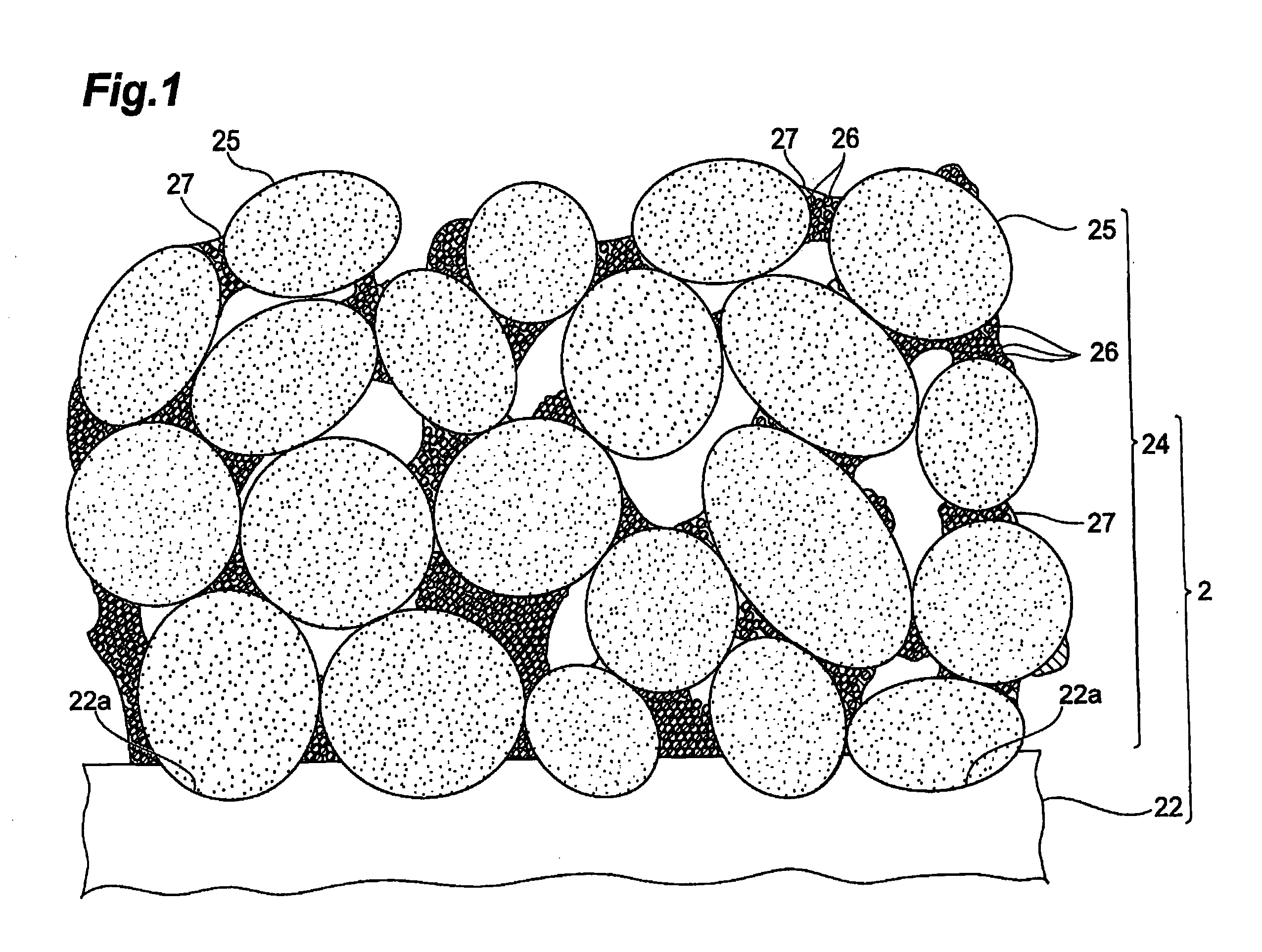

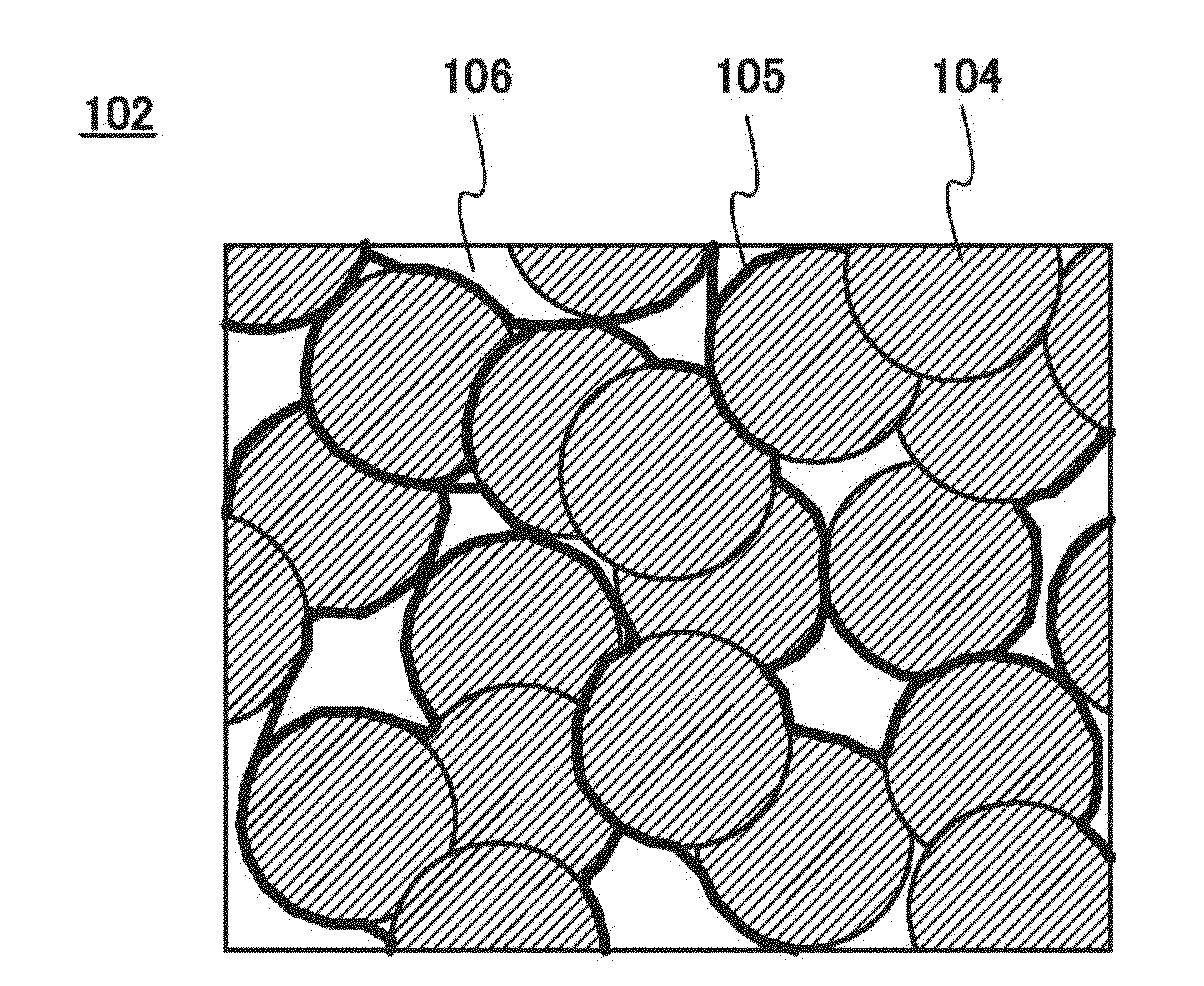

Electrode, electrochemical device, and method of making electrode

InactiveUS20050241137A1Reduce contact resistanceIncrease contact resistanceMachining electrodesElectrode rolling/calenderingPolymer chemistryElectrode

An electrode comprises a planar collector, and an active material containing layer disposed on the collector. The active material containing layer comprises a plurality of particles containing an active material, and a binder for binding the particles containing the active material to each other and the particles containing the active material to the collector. The collector has a surface depressed in conformity to a form of the particles containing the active material.

Owner:TDK CORPARATION

Method of manufacturing LCD apparatus by using halftone exposure method

InactiveUS7602456B2Reduce production processIncrease contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingContact padNitrogen

The present invention discloses a method of manufacturing a super large wide-angle super high-speed response LCD apparatus by using a photolithographic process for three times. The invention adopts a halftone exposure technology and a nitrogen ion doped technology to form a gate electrode, a common electrode, a pixel electrode and a contact pad, and then uses the halftone exposure technology to form a silicon (Si) island and a contact hole, and a general exposure technology to form a source electrode, a drain electrode and an alignment control electrode. A P-CVD apparatus is provided for forming a passivation layer into a film by using a masking deposition method, or an ink-jet coating method is used to coat a protective layer at a partial area, and a photolithographic process is performed for three times to manufacture a TFT matrix substrate of the super large wide-angle super high-speed response LCD.

Owner:MIKUNI ELECTORON CO LTD

Oxide semiconductor device with oxide semiconductor layers of different oxygen concentrations and method of manufacturing the same

InactiveUS8368067B2Easiness of flexibilityImprove the level ofTransistorSolid-state devicesThreshold potentialMain channel

A phenomenon of change of a contact resistance between an oxide semiconductor and a metal depending on an oxygen content ratio in introduced gas upon depositing an oxide semiconductor film made of indium gallium zinc oxide, zinc tin oxide, or others in an oxide semiconductor thin-film transistor. A contact layer is formed with an oxygen content ratio of 10% or higher in a region from a surface, where the metal and the oxide semiconductor are contacted, down to at least 3 nm deep in depth direction, and a region to be a main channel layer is further formed with an oxygen content ratio of 10% or lower, so that a multilayered structure is formed, and both of ohmic characteristics to the electrode metal and reliability such as the suppression of threshold potential shift are achieved.

Owner:HITACHI LTD

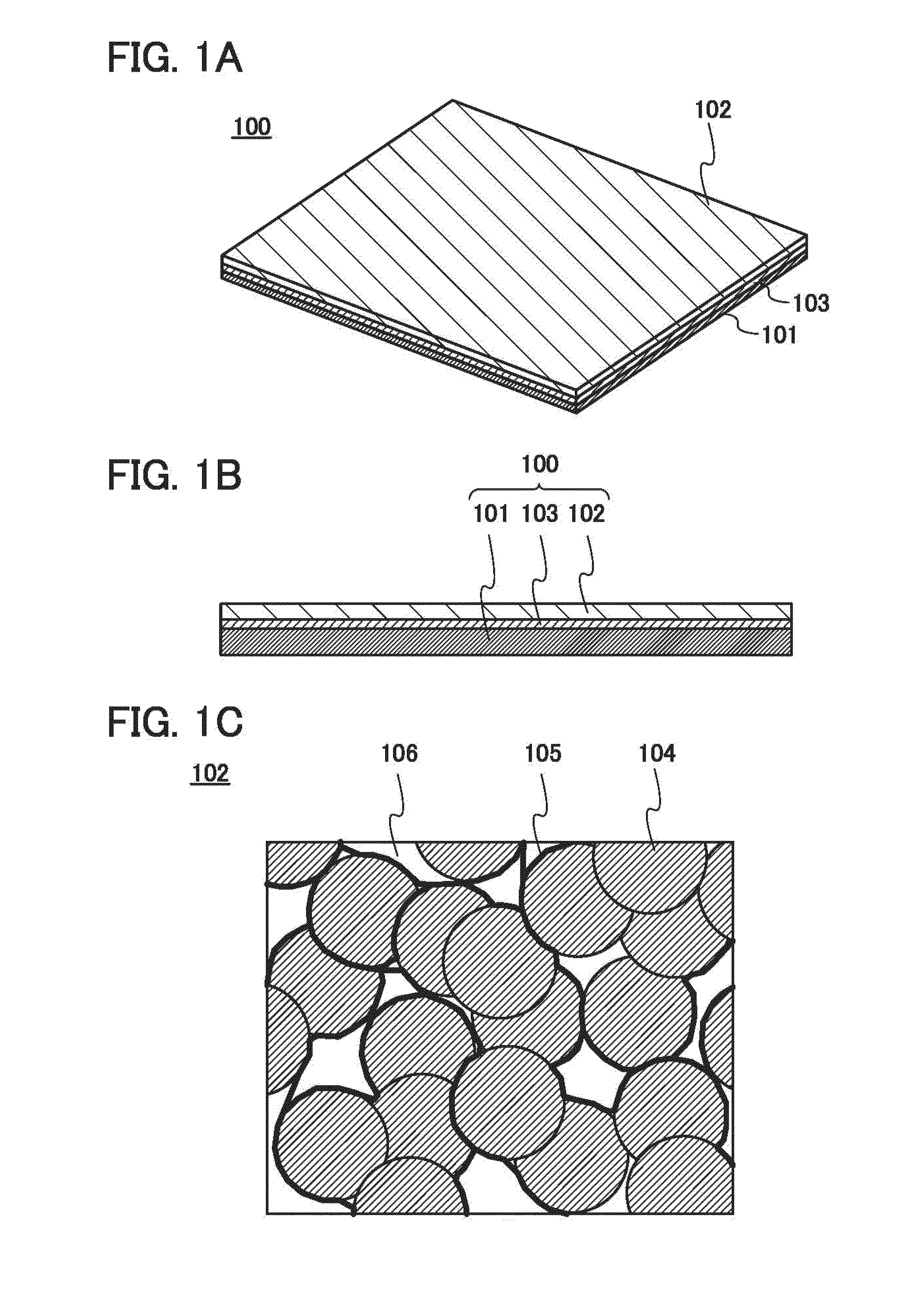

Electrode for storage battery

ActiveUS20140234700A1Large capacityImprove conductivityNon-metal conductorsElectric discharge heatingEngineeringGraphene

With a small amount of a conductive additive, an electrode for a storage battery including an active material layer which is highly filled with an active material is provided. The use of the electrode enables fabrication of a storage battery having high capacity per unit volume of the electrode. By using graphene as a conductive additive in an electrode for a storage battery including a positive electrode active material, a network for electron conduction through graphene is formed. Consequently, the electrode can include an active material layer in which particles of an active material are electrically connected to each other by graphene. Therefore, graphene is used as a conductive additive in an electrode for a sodium-ion secondary battery including an active material with low electric conductivity, for example, an active material with a band gap of 3.0 eV or more.

Owner:SEMICON ENERGY LAB CO LTD

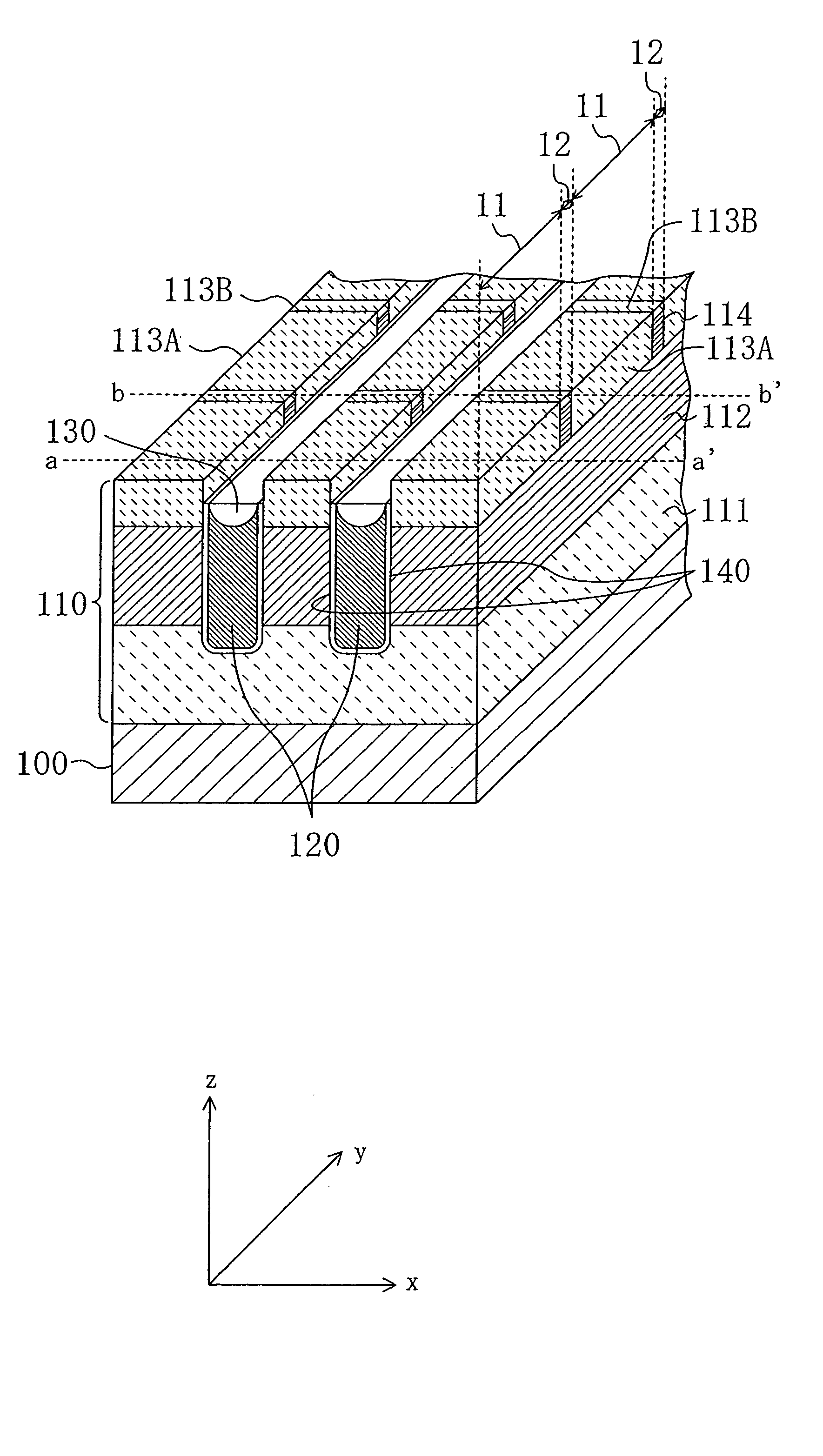

Vertical gate semiconductor device and method for fabricating the same

ActiveUS20050133861A1Increase contact resistanceTransistorSolid-state devicesBody regionSemiconductor

A first region 11 functioning as a transistor includes a drain region 111, a body region 112 formed over the drain region 111, a source region 113A formed over the body region 112 and a trench formed through the body region 112 and having a gate electrode 120 buried therein. A source region 113B is formed over the body region 112 extending in a second region 12.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Electronic circuit

InactiveUS7045399B2Increase contactExcellent barrier propertiesTransistorStatic indicating devicesOptoelectronicsTitanium

An electronic circuit formed on an insulating substrate and having thin-film transistors (TFTs) comprising semiconductor layers. The thickness of the semiconductor layers is less than 1500 Å, e.g., between 100 and 750 Å. A first layer consisting mainly of titanium and nitrogen is formed on the semiconductor layer. A second layer consisting aluminum is formed on top of the first layer. The first and second layers are patterned into conductive interconnects. The bottom surface of the second layer is substantially totally in intimate contact with the first layer. The interconnects have good contacts with the semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

AgWC (wolfram carbide) electrical contact material and manufacturing method thereof

InactiveCN101834070AReduce manufacturing costImprove pass rateContact materialsCarbideHeating furnace

The invention relates to an AgWC (wolfram carbide) electrical contact material and a manufacturing method thereof, in particular to a silver-based electric contact material and a manufacturing method thereof, belonging to the technical field of electrical contact materials. A substrate of the AgWC electrical contact material is infiltrated with silver from upper surface to lower surface. The manufacturing method comprises the following steps of: obtaining Ag and WC mixed powder by applying a powder mixing process; pressing the mixed powder into a powder billet by applying a powder pressing process; then putting a prepared thin silver sheet on the powder billet by applying an infiltration sintering process, conveying into a heating furnace and heating, melting the silver sheet and infiltrating into the powder billet to further obtain an AgWC electric contact; and beautifying the surface of the AgWC electric contact by applying a polishing process. The AgWC electric contact manufactured by adopting the manufacturing process has favorable electric conduction performance and heat conduction performance, high corrosion resistance, strong fusion welding resistance, and the like.

Owner:SHANGHAI DIANKE ELECTRICAL MATERIAL CO LTD

A kind of electronic silver paste and its preparation process

ActiveCN102290118ALow melting pointLow softening pointNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteElectricity

The invention relates to electronic silver paste and a preparation process thereof, belonging to the technical field of production of such base materials as electronic ceramic components, thick film hybrid circuits, touch components and the like. The electronic silver paste is prepared by mixing and stirring 4-9% of glass powder, 63-80% of silver powder, 12-28% of organic carrier and 0.2-2% of additive, rolling, dispersing and grinding the mixture, then adding 1-2wt% of bismuth stearate, stirring the mixture uniformly and filtering the mixture with a screen. The electronic silver paste and the preparation process have the following beneficial effects: the glass powder system does not contain lead; the minimum grain size and shape of the silver powder are not strictly required; and the silver paste is especially suitable for the positive electrodes of the solar cells on the crystalline silicon solar cell silicon substrates produced in large batch and has excellent electrical property and mechanical property..

Owner:郴州雄风环保科技有限公司

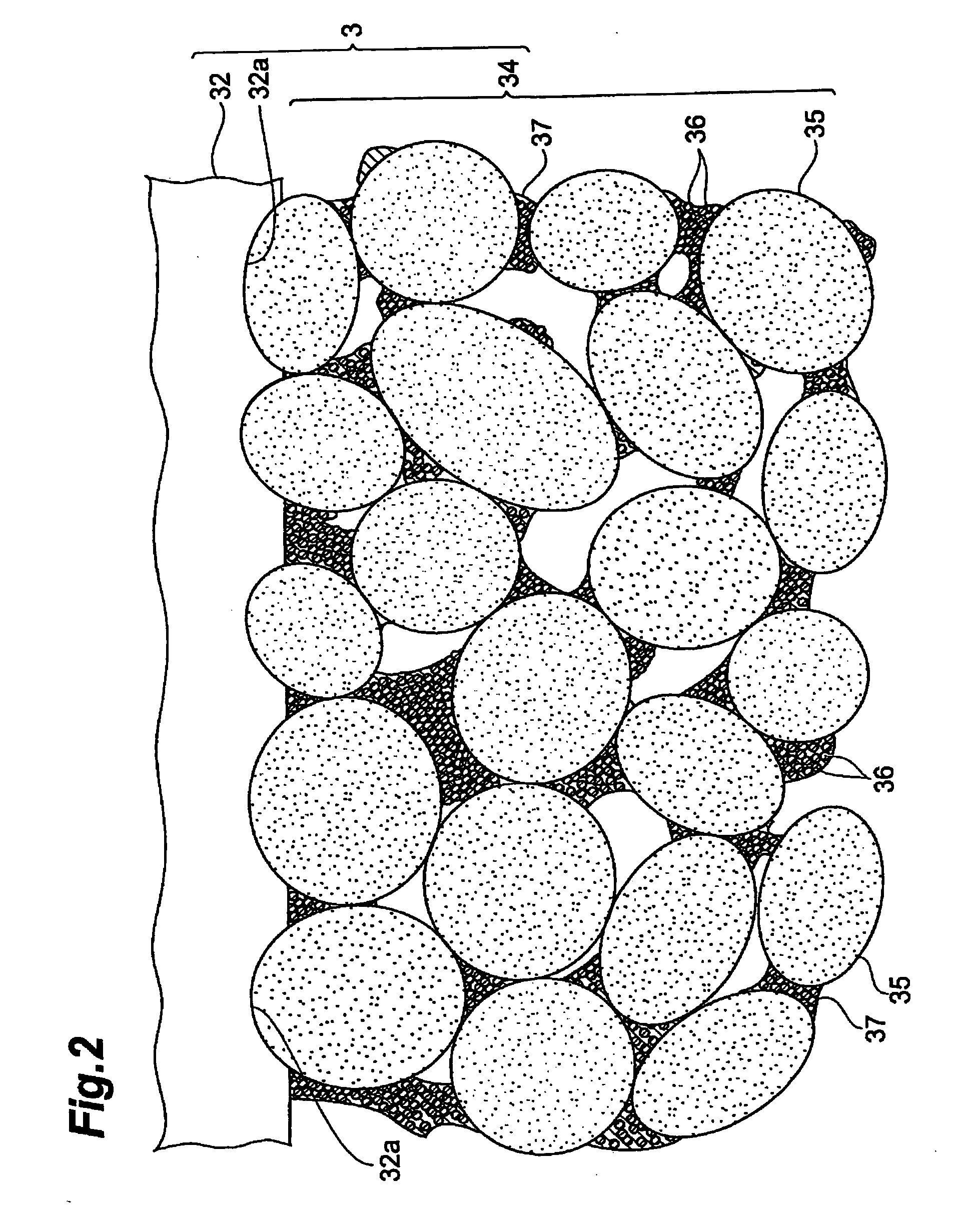

Positive electrode for nonaqueous secondary battery, method for forming the same, nonaqueous secondary battery, and electrical device

ActiveUS20140127568A1Lower discharge capacityHigh volumeConductive materialActive material electrodesEngineeringGraphene

A positive electrode for a nonaqueous secondary battery including an active material layer which has sufficient electron conductivity with a low ratio of a conductive additive is provided. A positive electrode for a nonaqueous secondary battery including an active material layer which is highly filled with an active material, id est, including the active material and a low ratio of a conductive additive. The active material layer includes a plurality of particles of an active material with a layered rock salt structure, graphene that is in surface contact with the plurality of particles of the active material, and a binder.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com