Electrode, electrochemical device, and method of making electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0136] In the following, the present invention will be explained in more detail with reference to examples and a comparative example, which do not restrict the present invention at all.

example a1

[0137] First, electrodes for an electric double layer capacitor were made.

[0138] (1) Making of Composite Particles

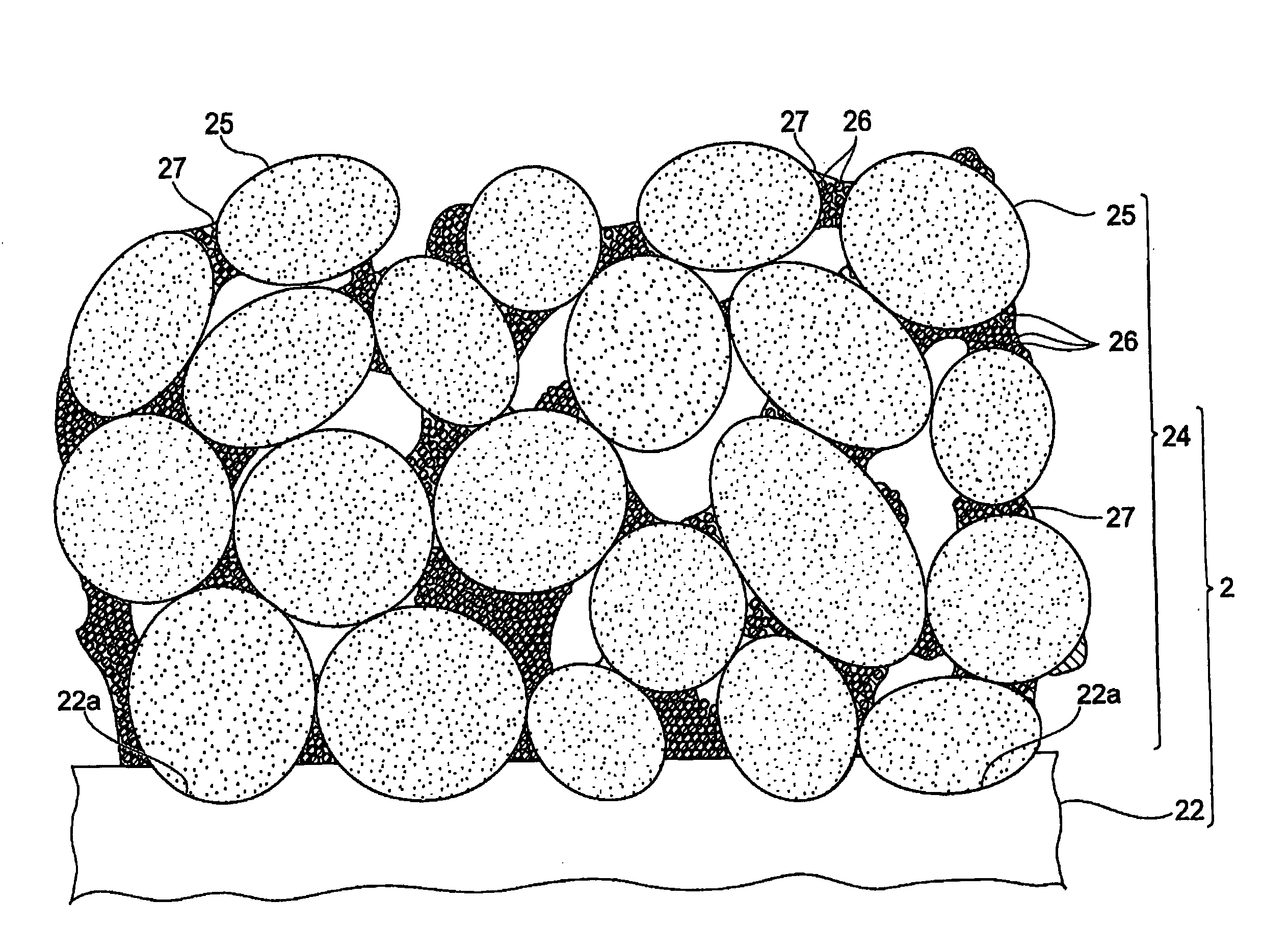

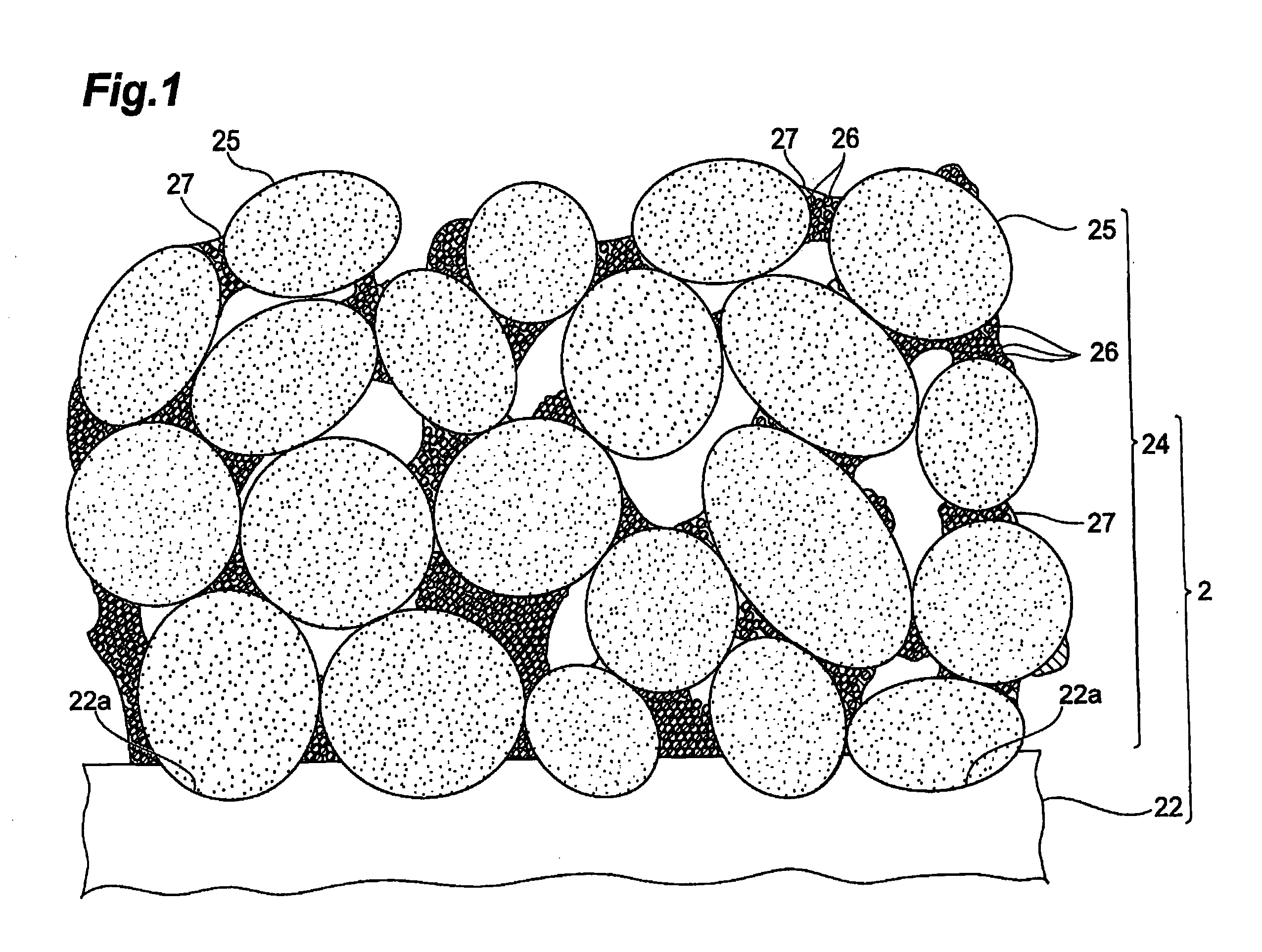

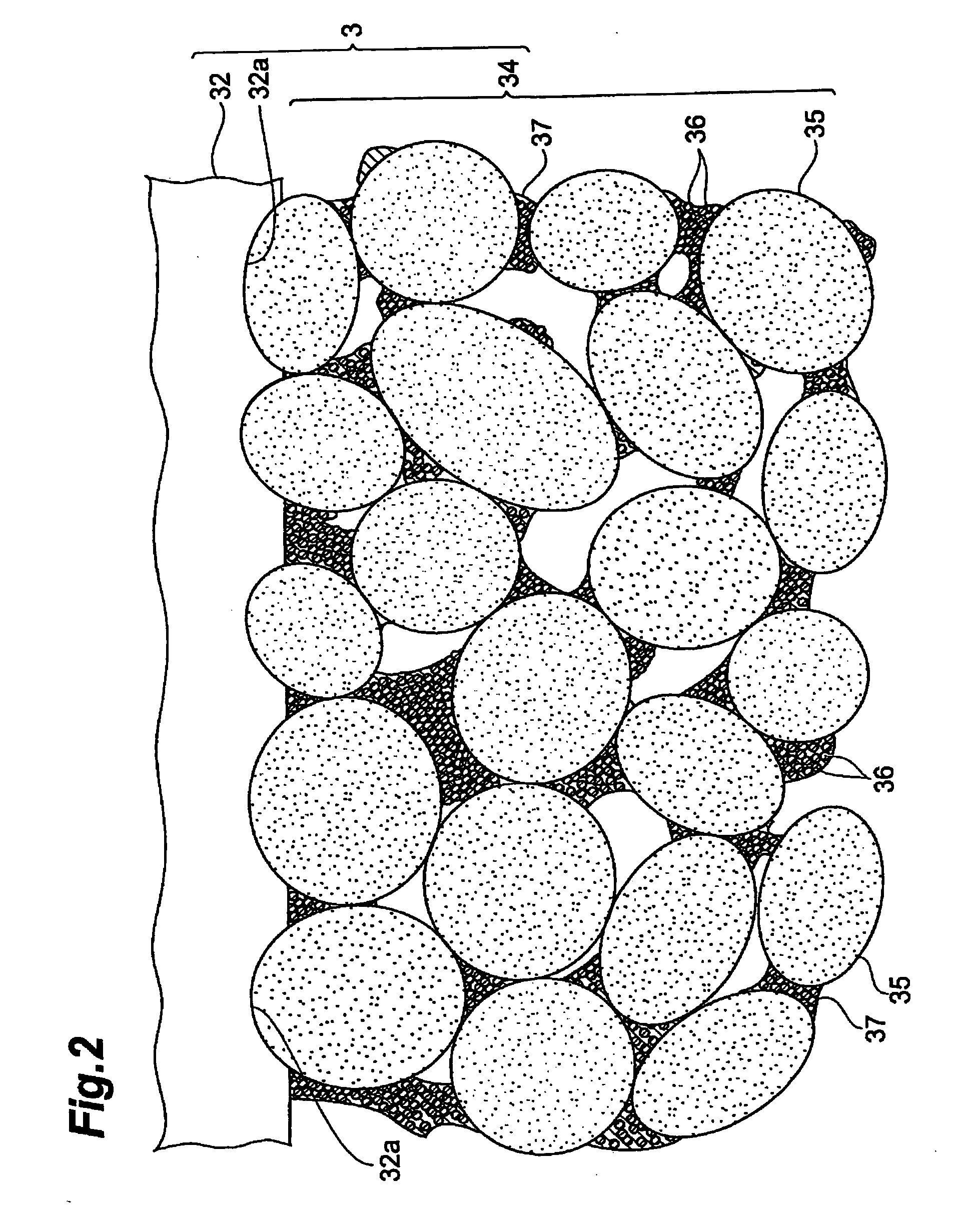

[0139] To begin with, composite particles 250 for use in the manufacturing of active material containing layers in electrodes for the electric double layer capacitor were made by the following procedure. Here, the composite particles 250 were constituted by a cathode / anode active material (90 mass %), conductive auxiliary agent particles (5 mass %), and a binder (5 mass %).

[0140] As the cathode and the anode active material particles containing the active material), activated carbon (having an average particle size of 15 μm) was used. As the conductive auxiliary agent particles, carbon black (acetylene black) was used As the binder, polyvinylidene fluoride PVDF) was used

[0141] First, a “material liquid” (containing 3 mass % of carbon black and 2 mass % of polyvinylidene fluoride) in which carbon black was dispersed in a solution in which polyvinylidene fluoride had b...

examples a2

and A3

[0149] Examples A2 and A3 were the same as Example A1 except that the roller line pressure was 200×102 N / m and 2000×102 N / m, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Force constant | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com