Patents

Literature

1882results about "Electrode rolling/calendering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

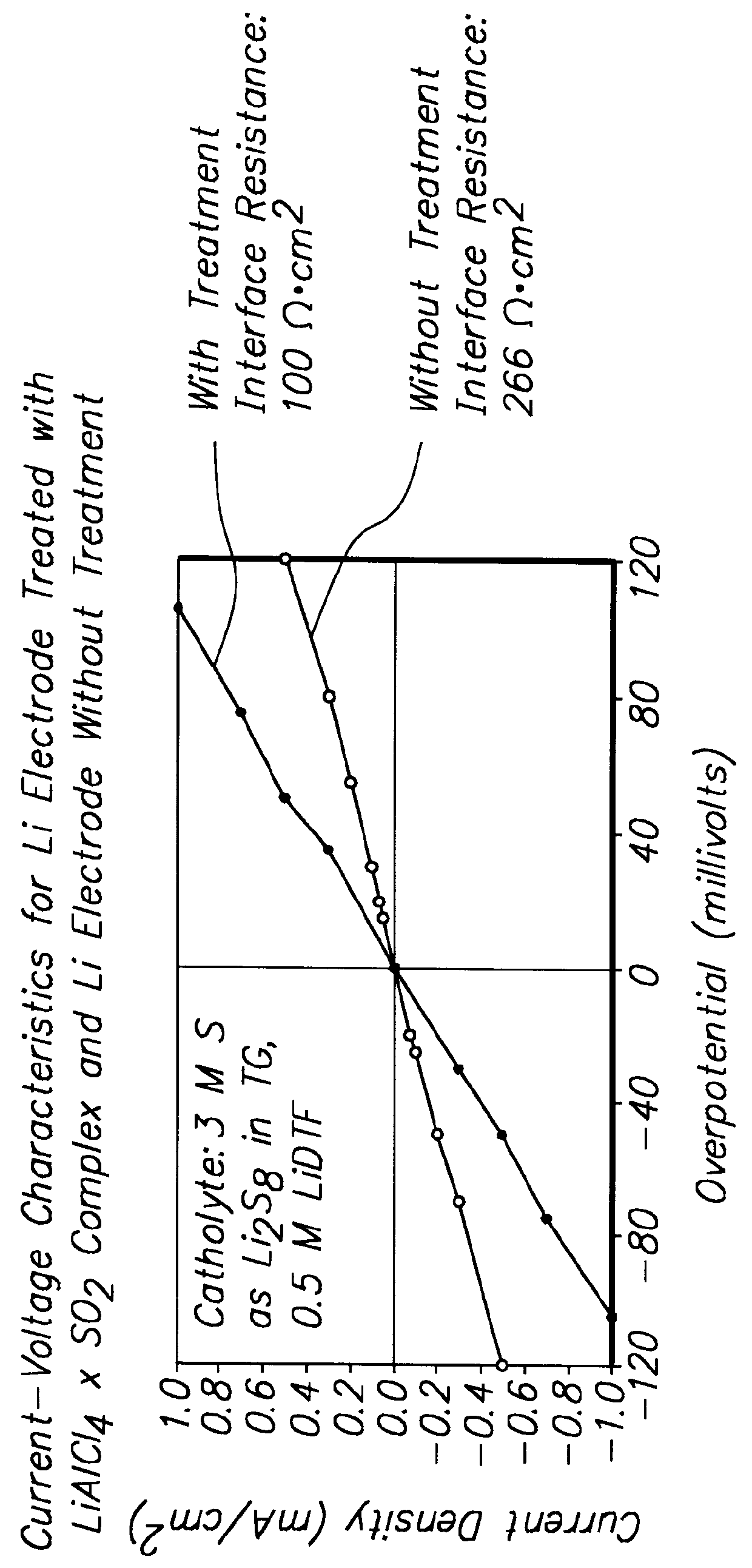

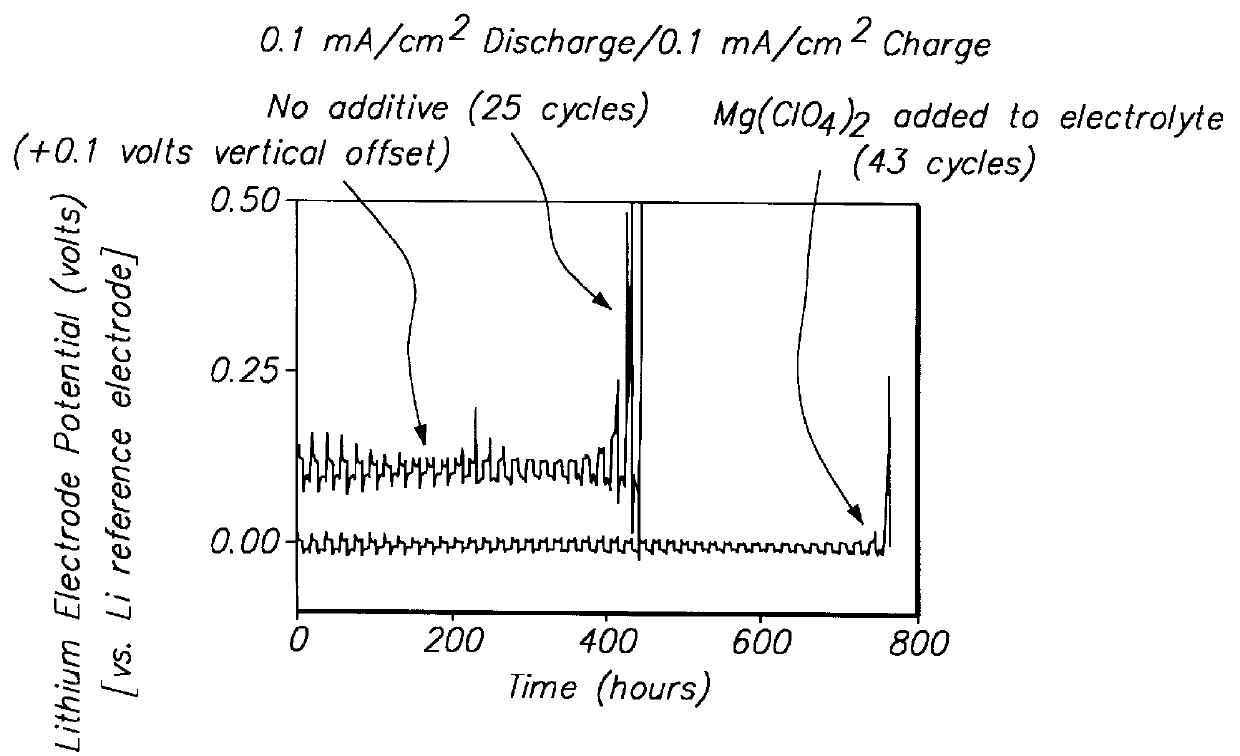

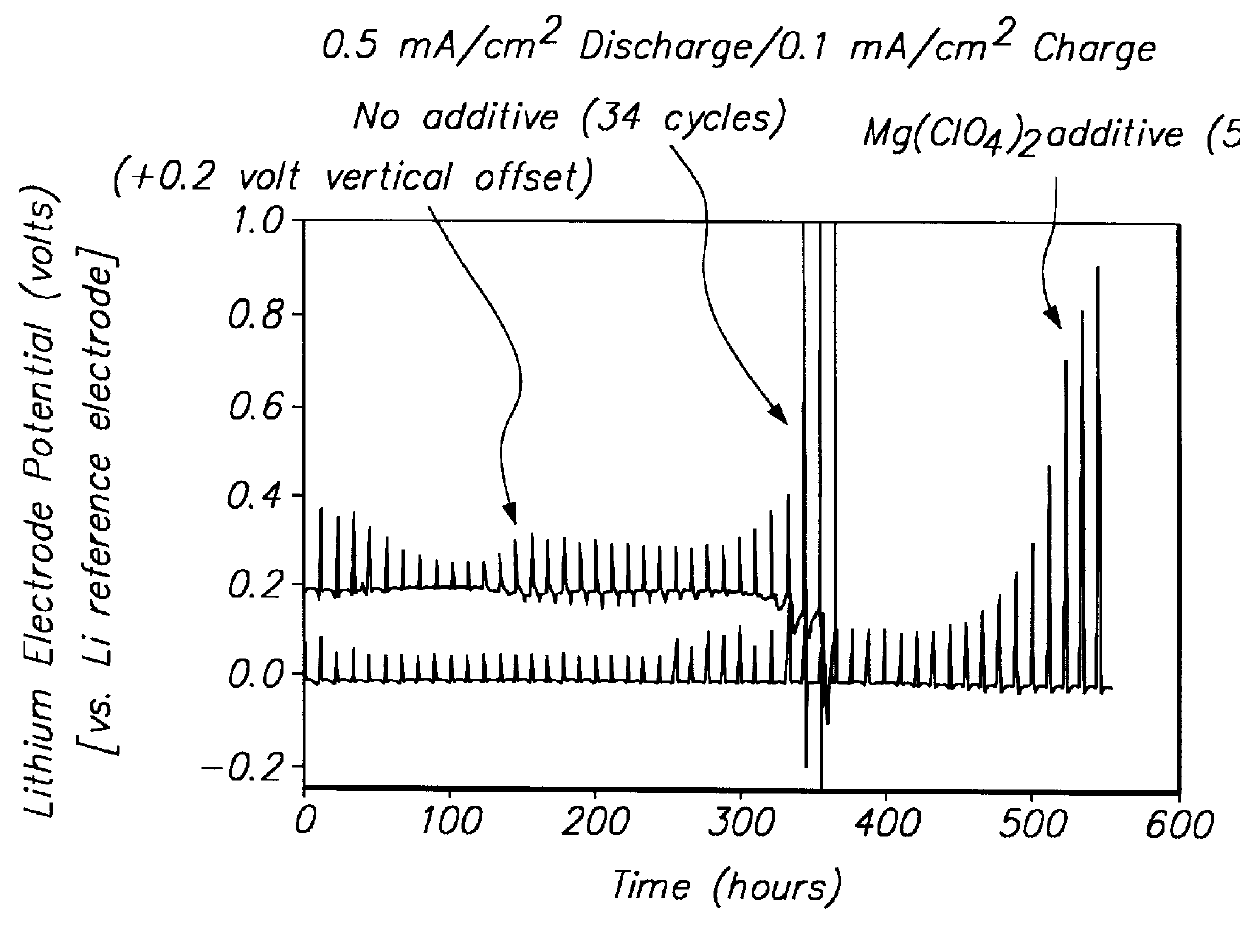

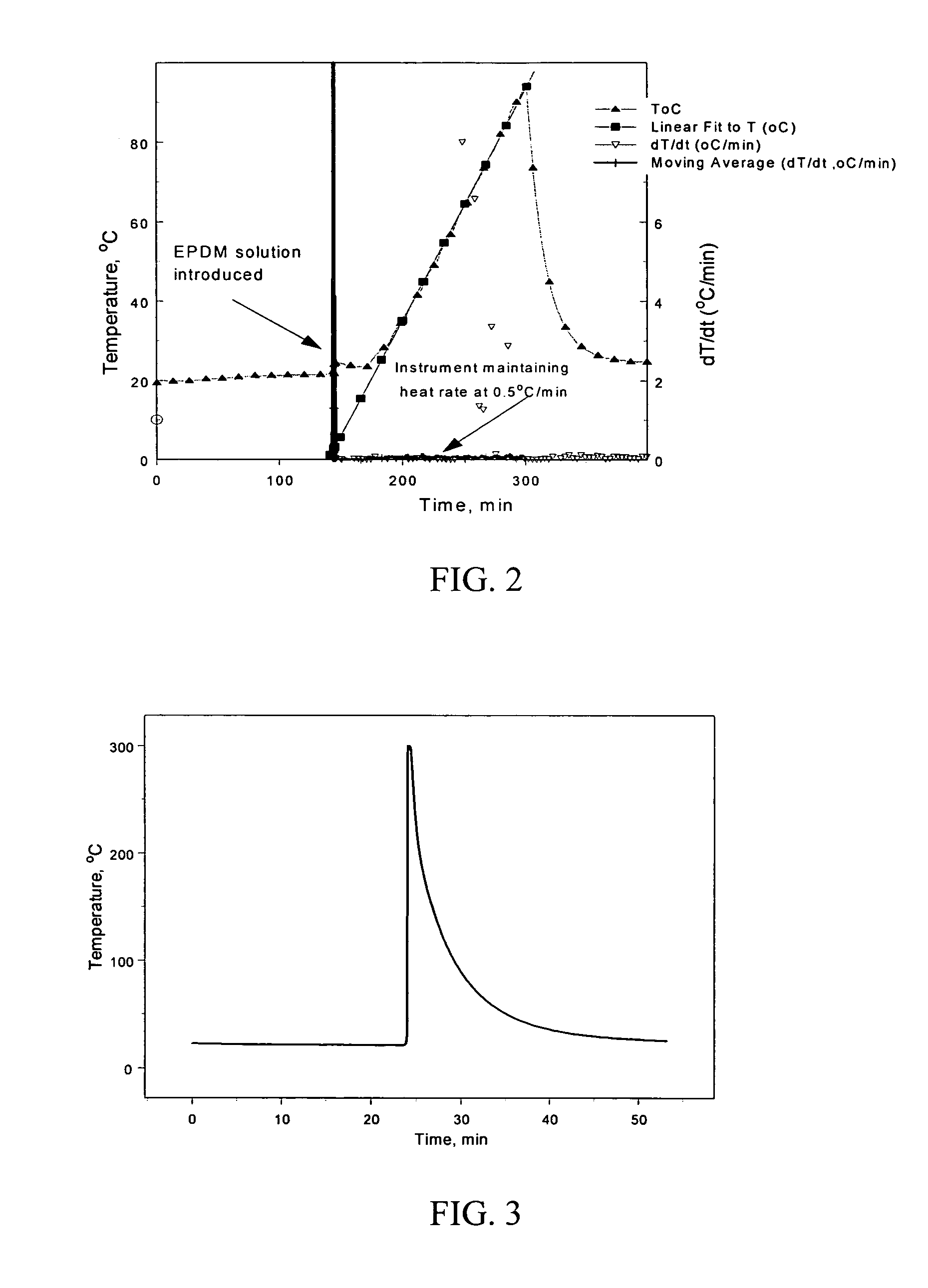

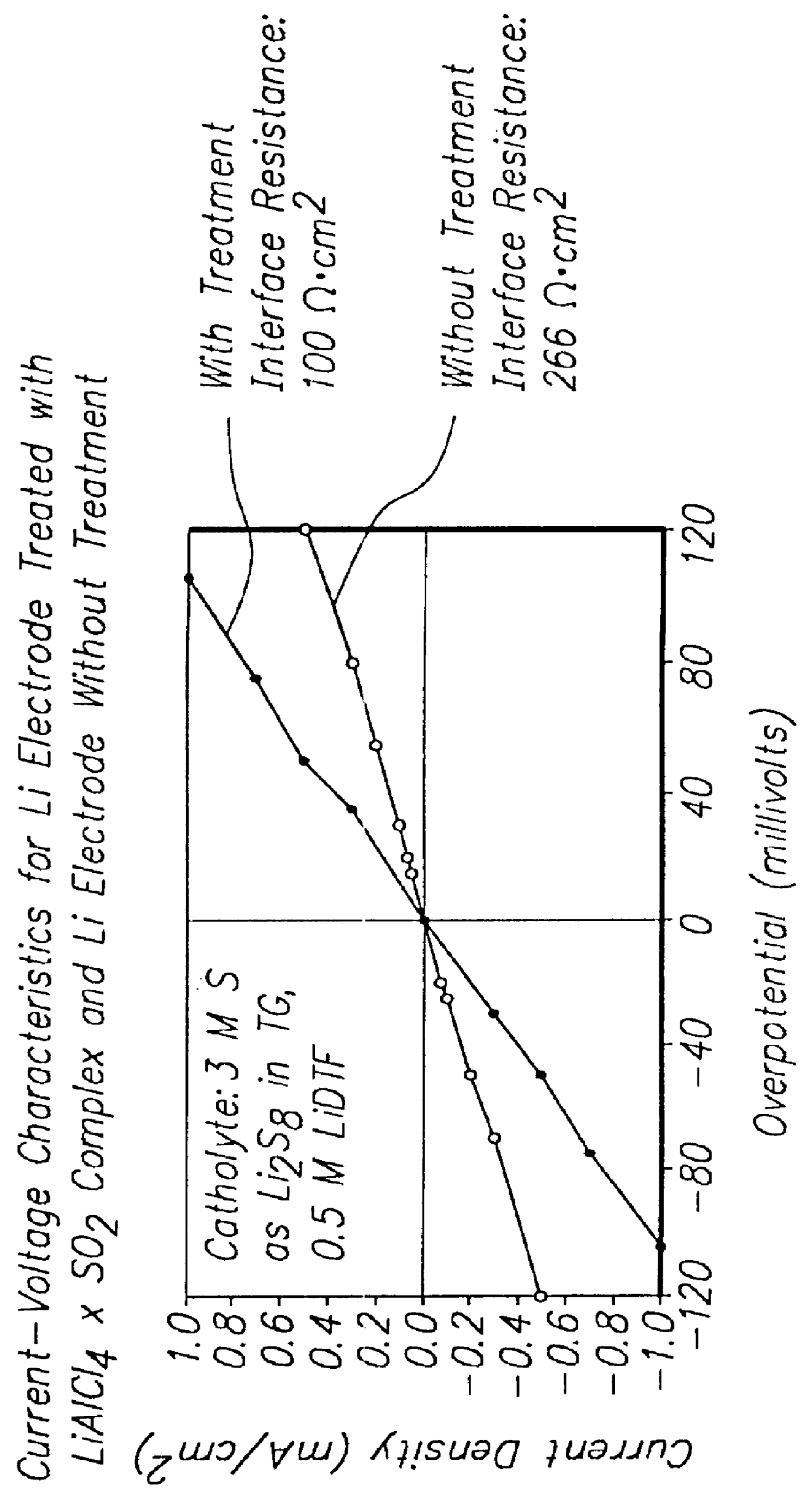

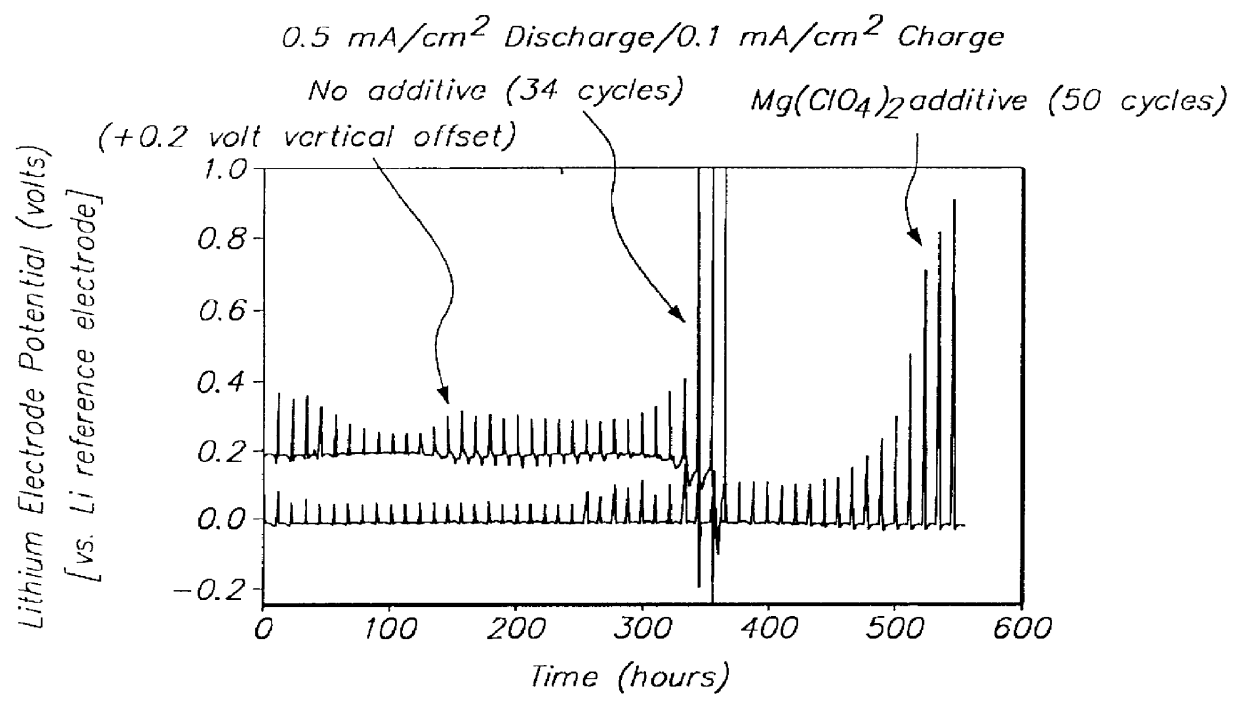

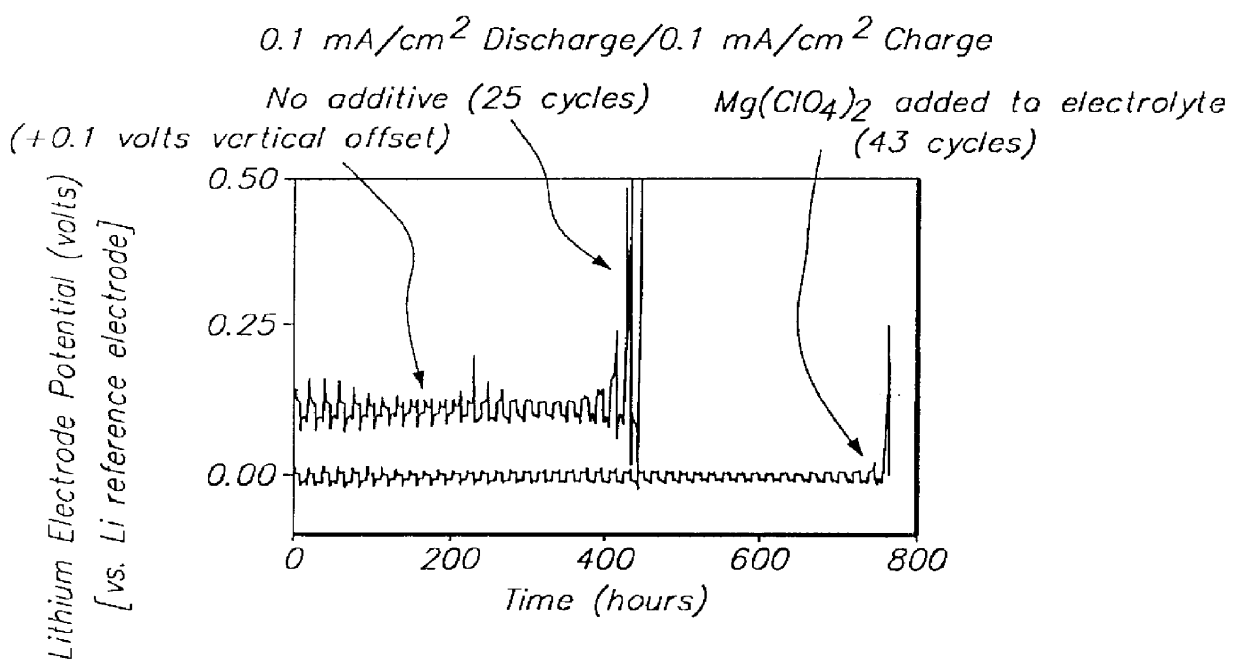

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6017651AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

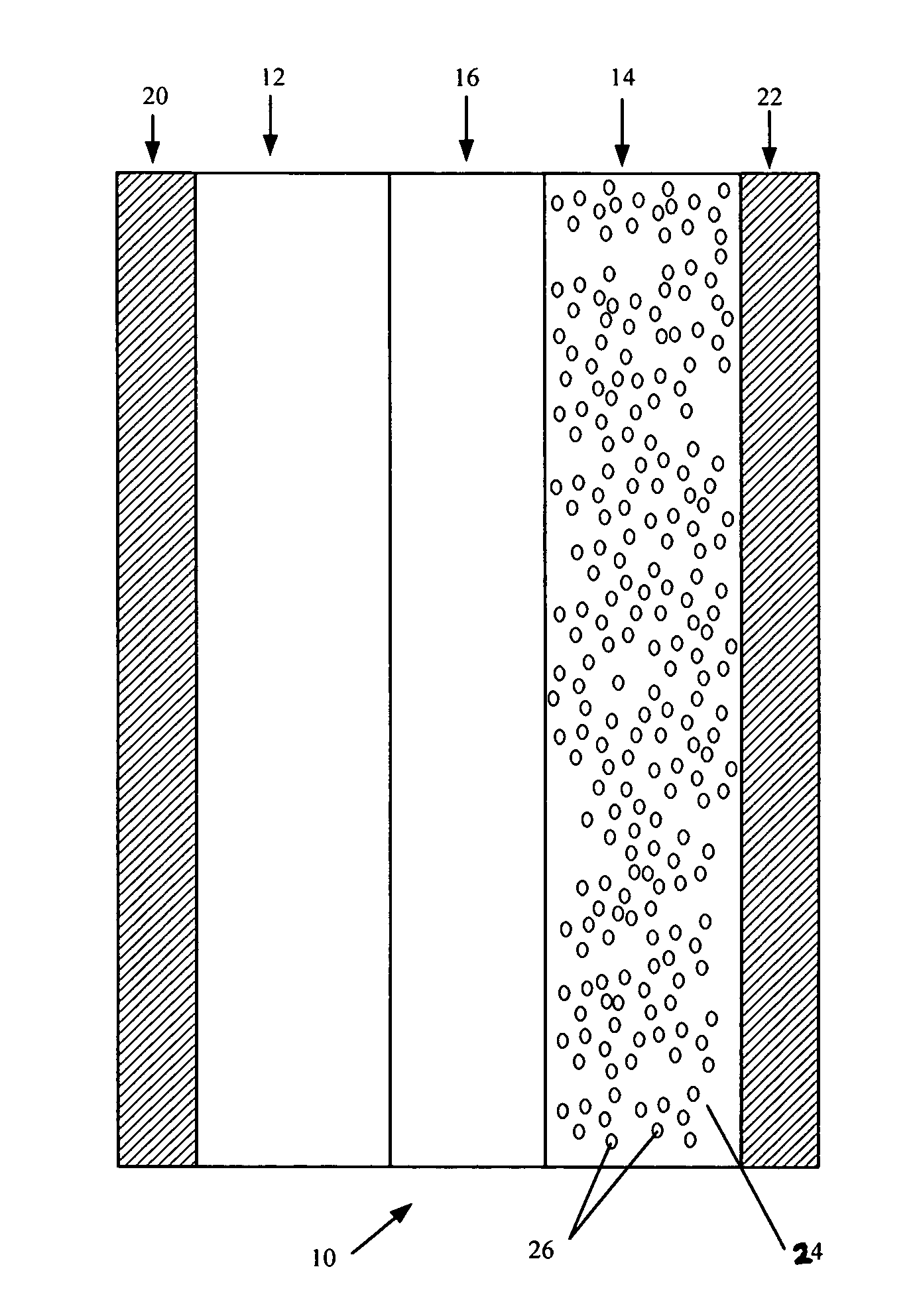

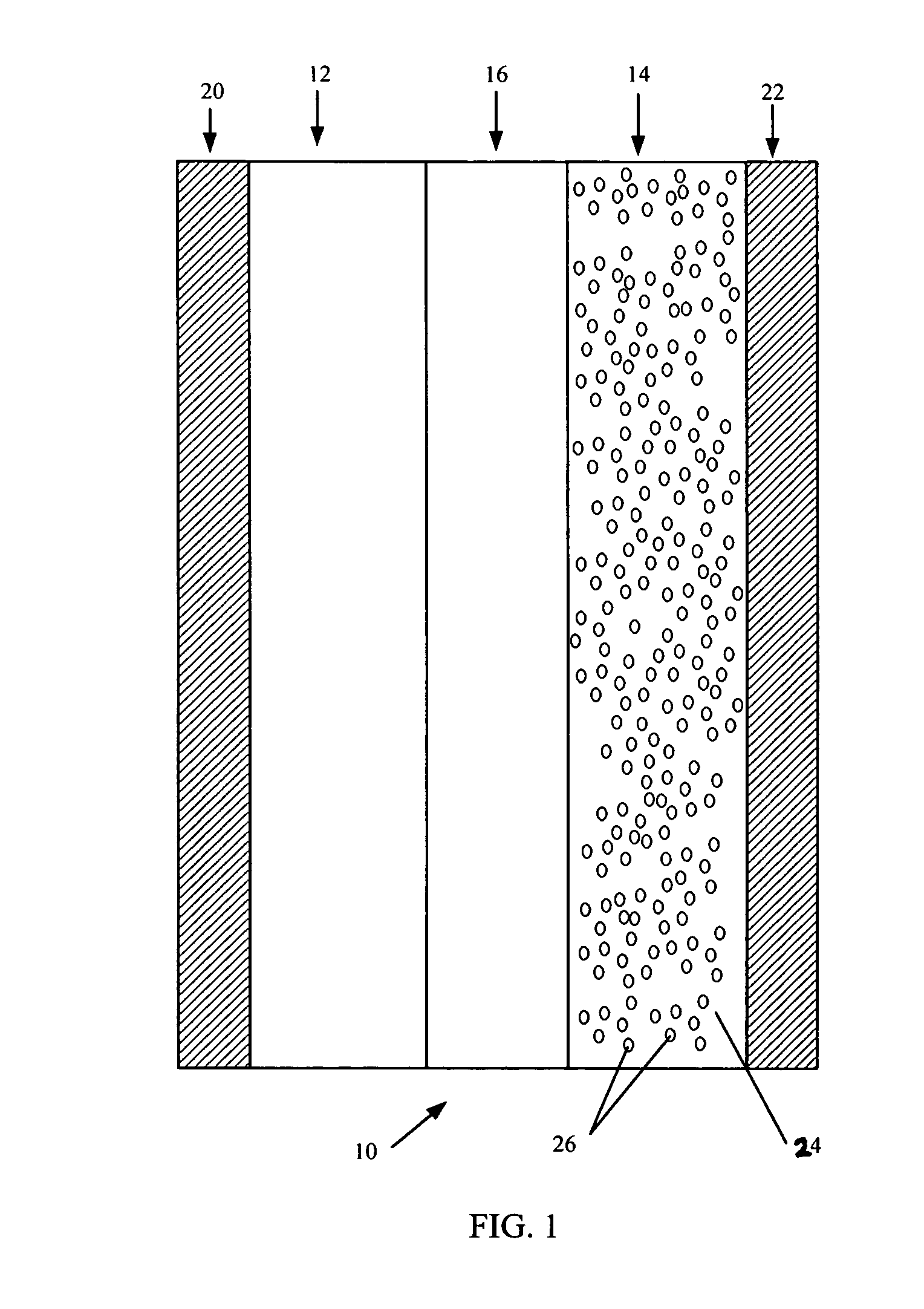

Lithium metal dispersion in electrodes

InactiveUS20050130043A1High specific capacityPromote circulationElectrode rolling/calenderingElectrode thermal treatmentLithium metalHost material

Electrodes, such as anodes and cathodes, can include a host material that is prelithiated or undergoes lithiation upon electrolyte introduction into a battery. Lithiation of the host material can occur by the agitation of lithium metal and a host material, the agitation of a lithium metal powder and a host material at a temperature greater than room temperature, the application of pressure to a lithium metal and host material mixture, contact of the host material with molten lithium metal, the lamination of lithium foil or lithium mesh onto an electrode containing the host material, or by lamination of lithium metal or mesh onto an electrode at elevated temperatures.

Owner:AEA TECH BATTERY SYST +1

Methods and reagents for enhancing the cycling efficiency of lithium polymer batteries

InactiveUS6165644AImprove efficiencyElectrode rolling/calenderingElectrochemical processing of electrodesLithium metalSulfur electrode

Batteries including a lithium electrode and a sulfur counter electrode that demonstrate improved cycling efficiencies are described. In one embodiment, an electrochemical cell having a lithium electrode and a sulfur electrode including at least one of elemental sulfur, lithium sulfide, and a lithium polysulfide is provided. The lithium electrode includes a surface coating that is effective to increase the cycling efficiency of said electrochemical cell. In a more particular embodiment, the lithium electrode is in an electrolyte solution, and, more particularly, an electrolyte solution including either elemental sulfur, a sulfide, or a polysulfide. In another embodiment, the coating is formed after the lithium electrode is contacted with the electrolyte. In a more particular embodiment, the coating is formed by a reaction between the lithium metal of the lithium electrode and a chemical species present in the electrolyte.

Owner:POLYPLUS BATTERY CO INC

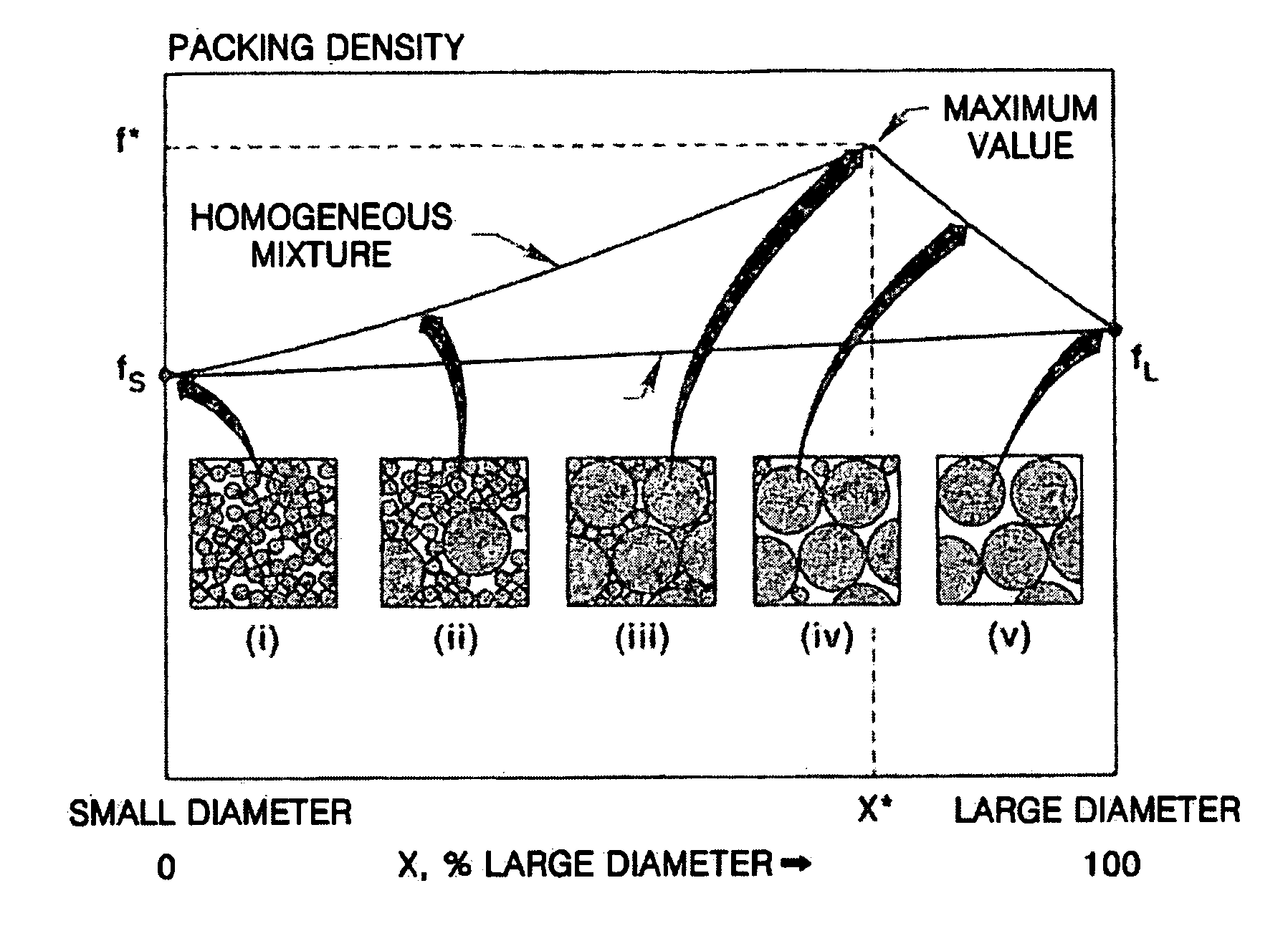

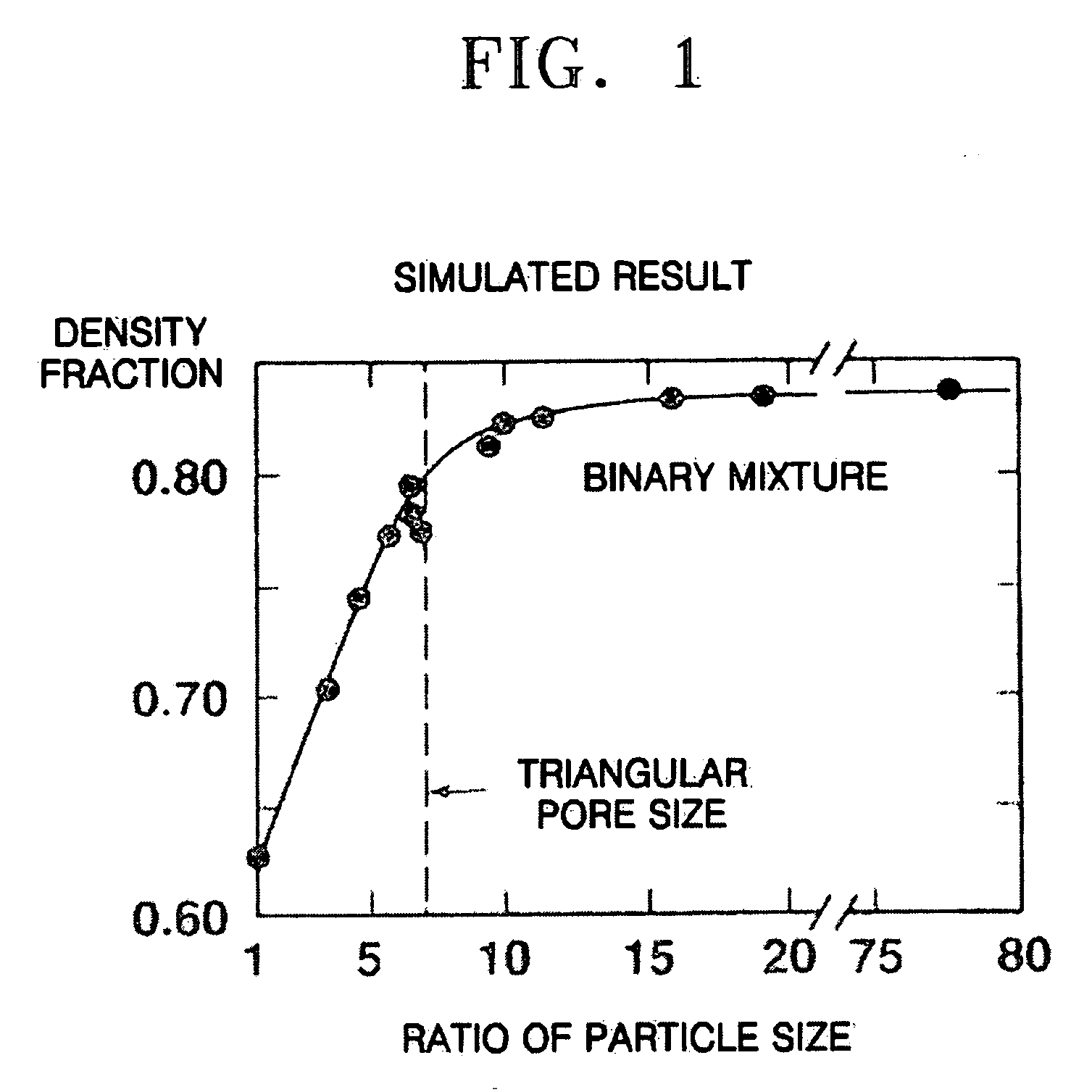

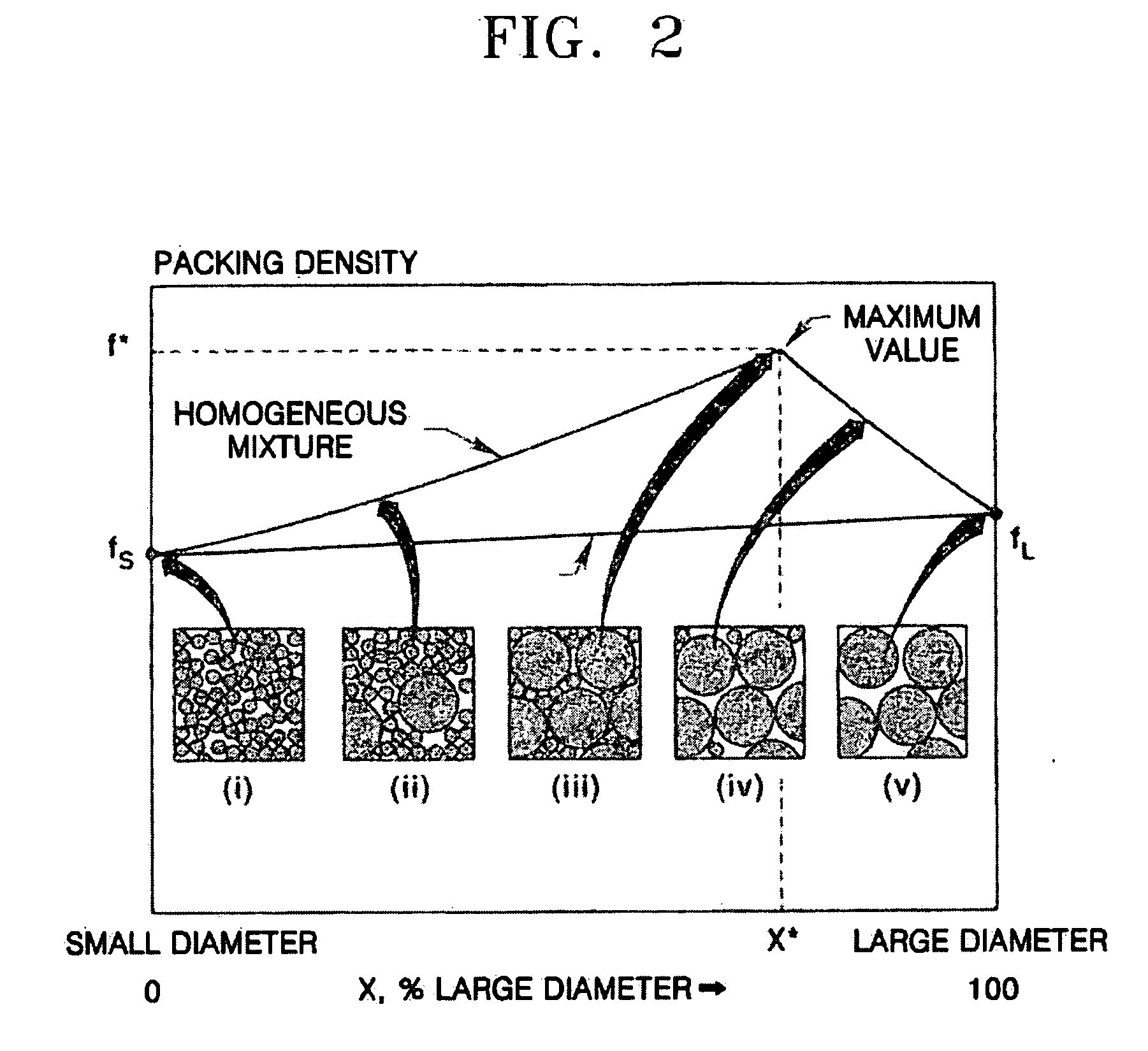

Cathode active material, method of preparing the same, and cathode and lithium battery containing the material

ActiveUS20060257745A1Improve high voltage stabilityImprove thermal stabilityWalking sticksElectrode rolling/calenderingComposite cathodeHigh rate

Composite cathode active materials having a large diameter active material and a small diameter active material are provided. The ratio of the average particle diameter of the large diameter active material to the average particle diameter of the small diameter active material ranges from about 6:1 to about 100:1. Mixing the large and small diameter active materials in a proper weight ratio improves packing density Additionally, including highly stable materials and highly conductive materials in the composite cathode active materials improves volume density, discharge capacity and high rate discharge capacity.

Owner:SAMSUNG SDI CO LTD

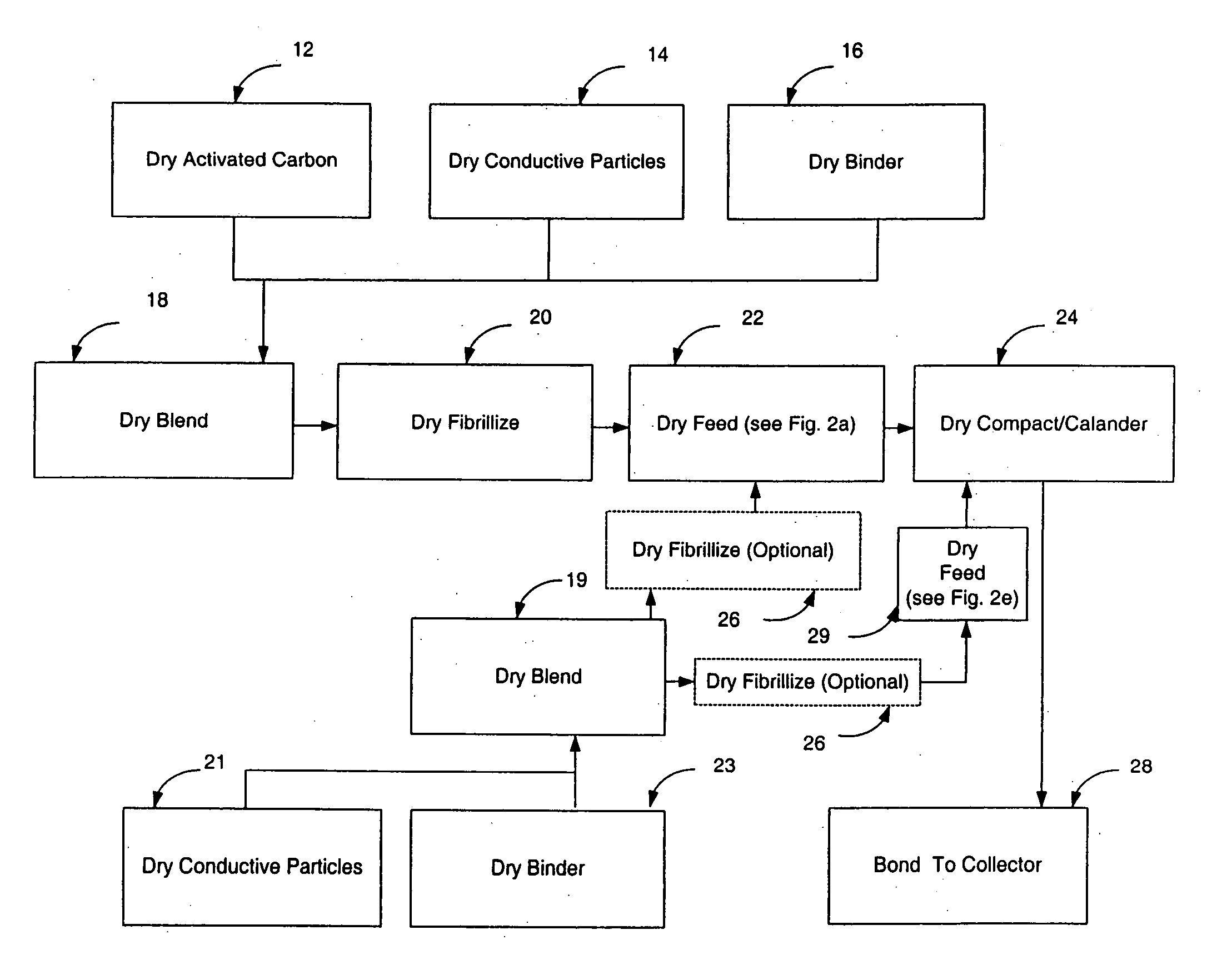

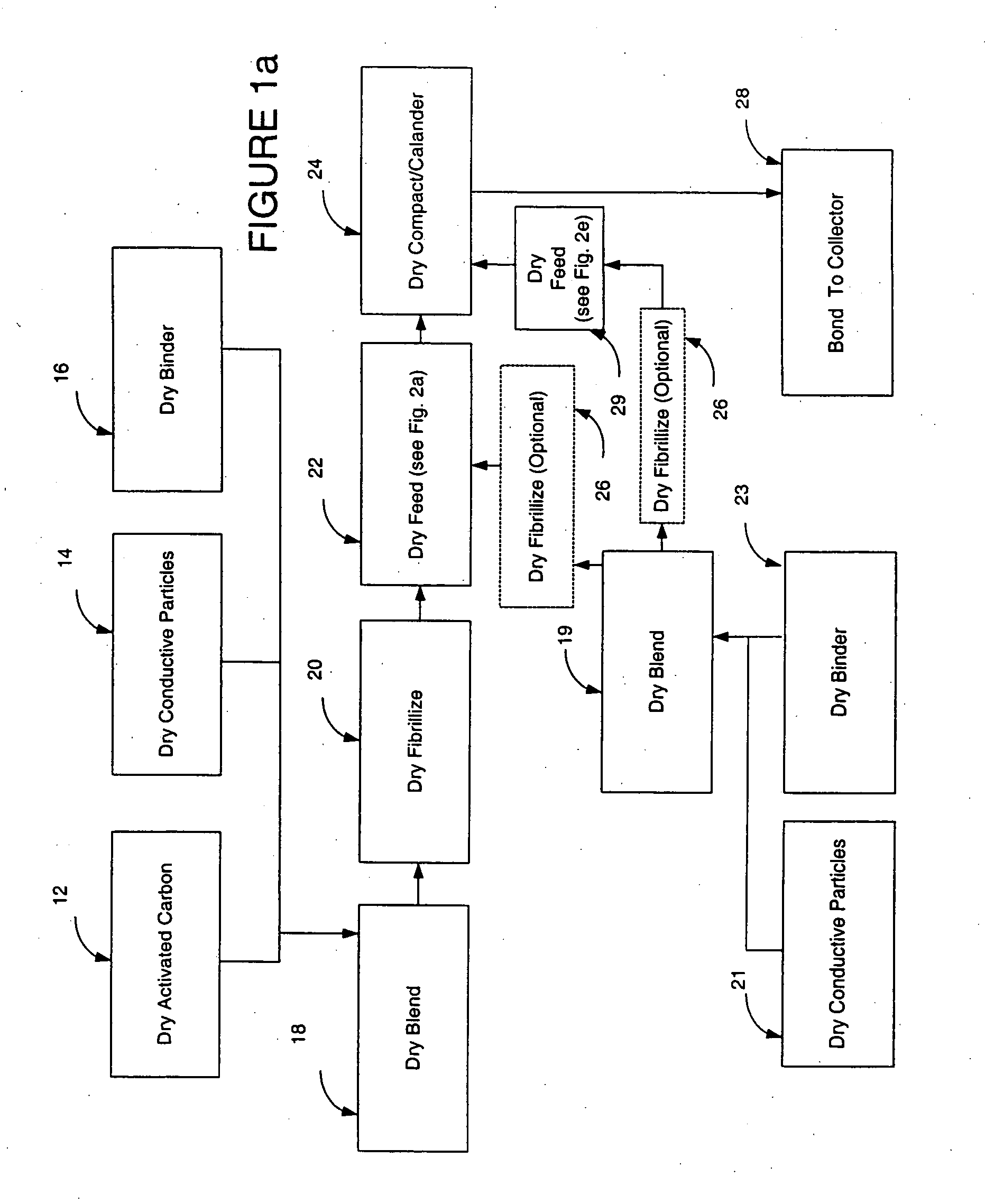

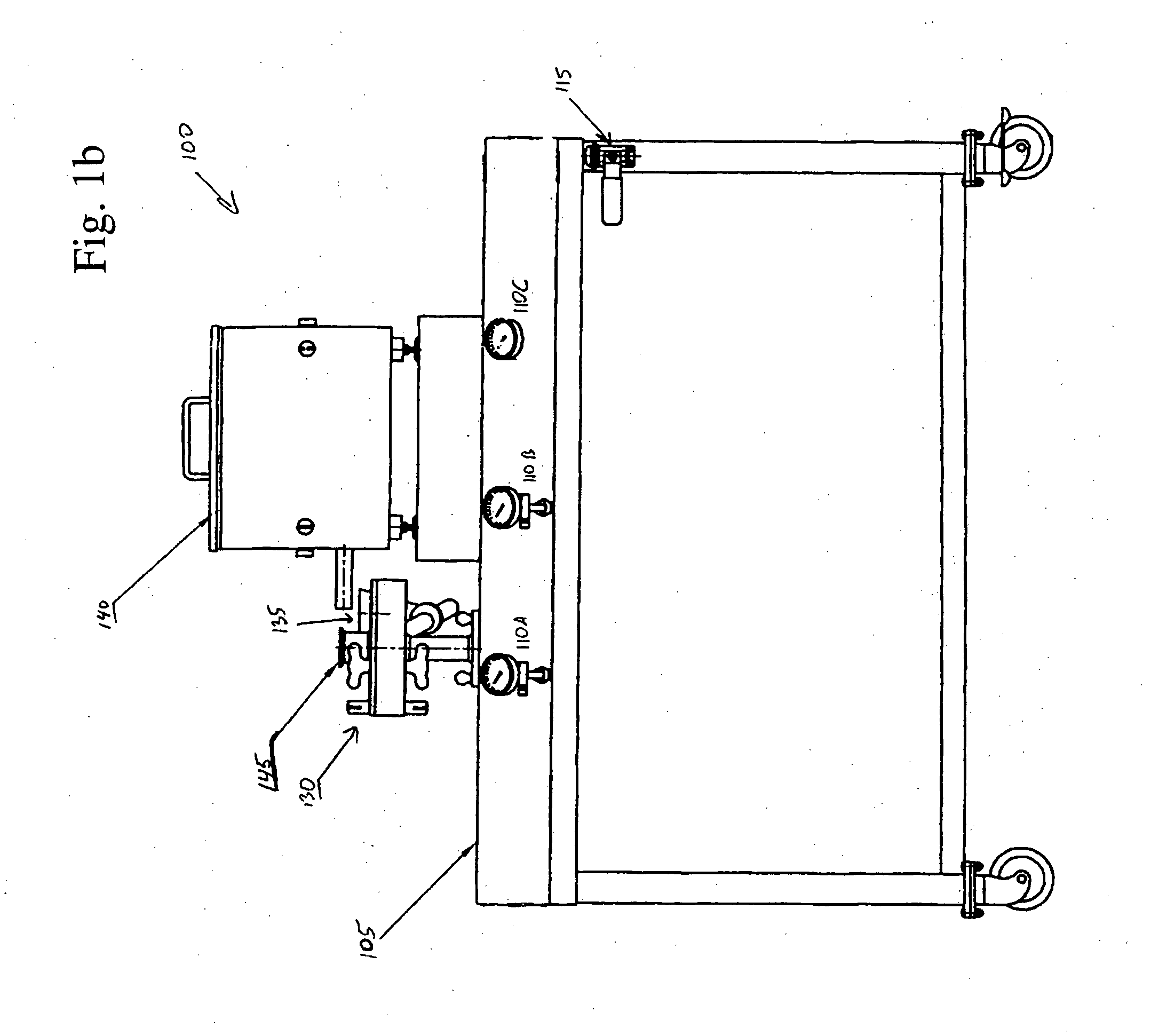

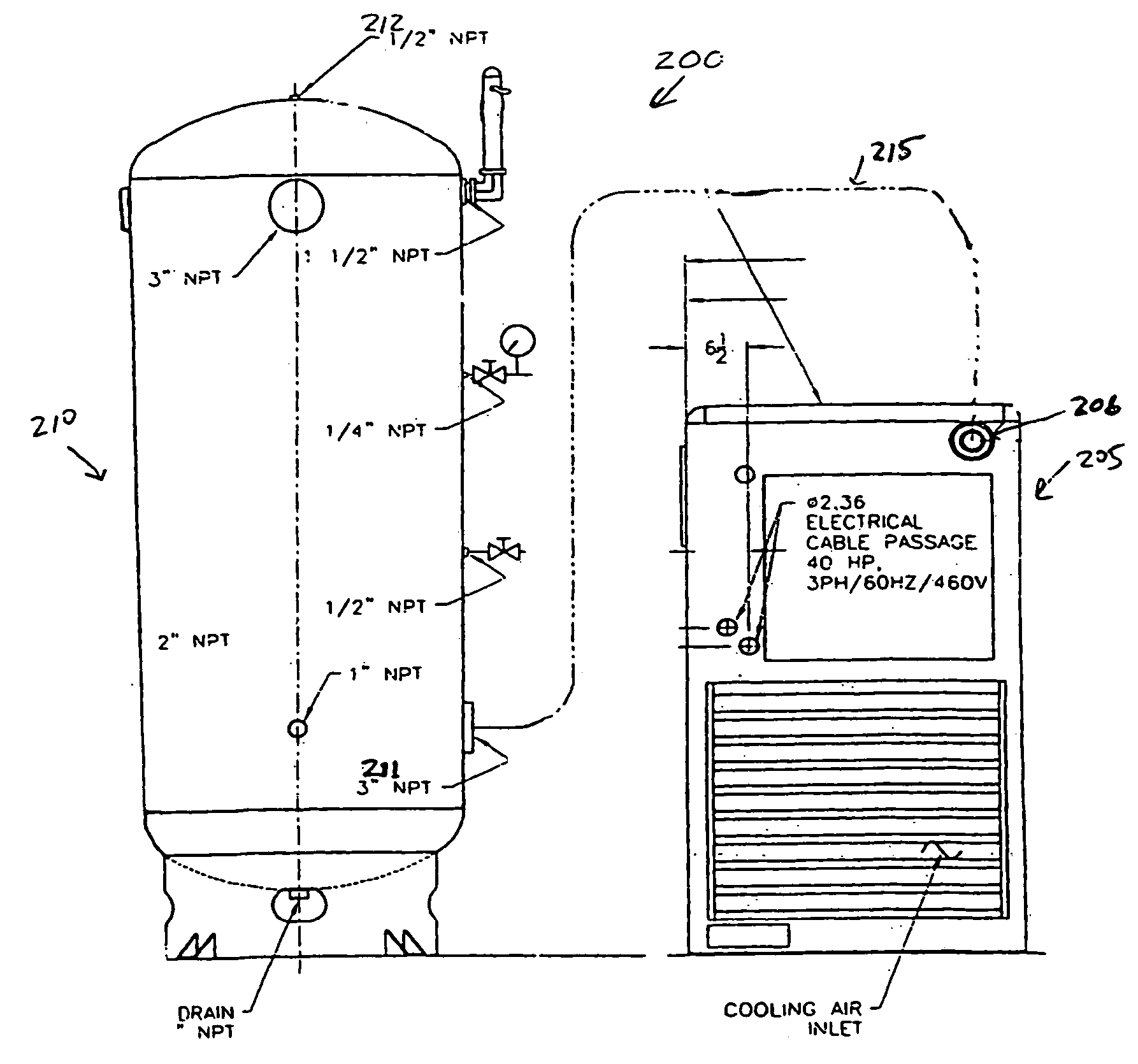

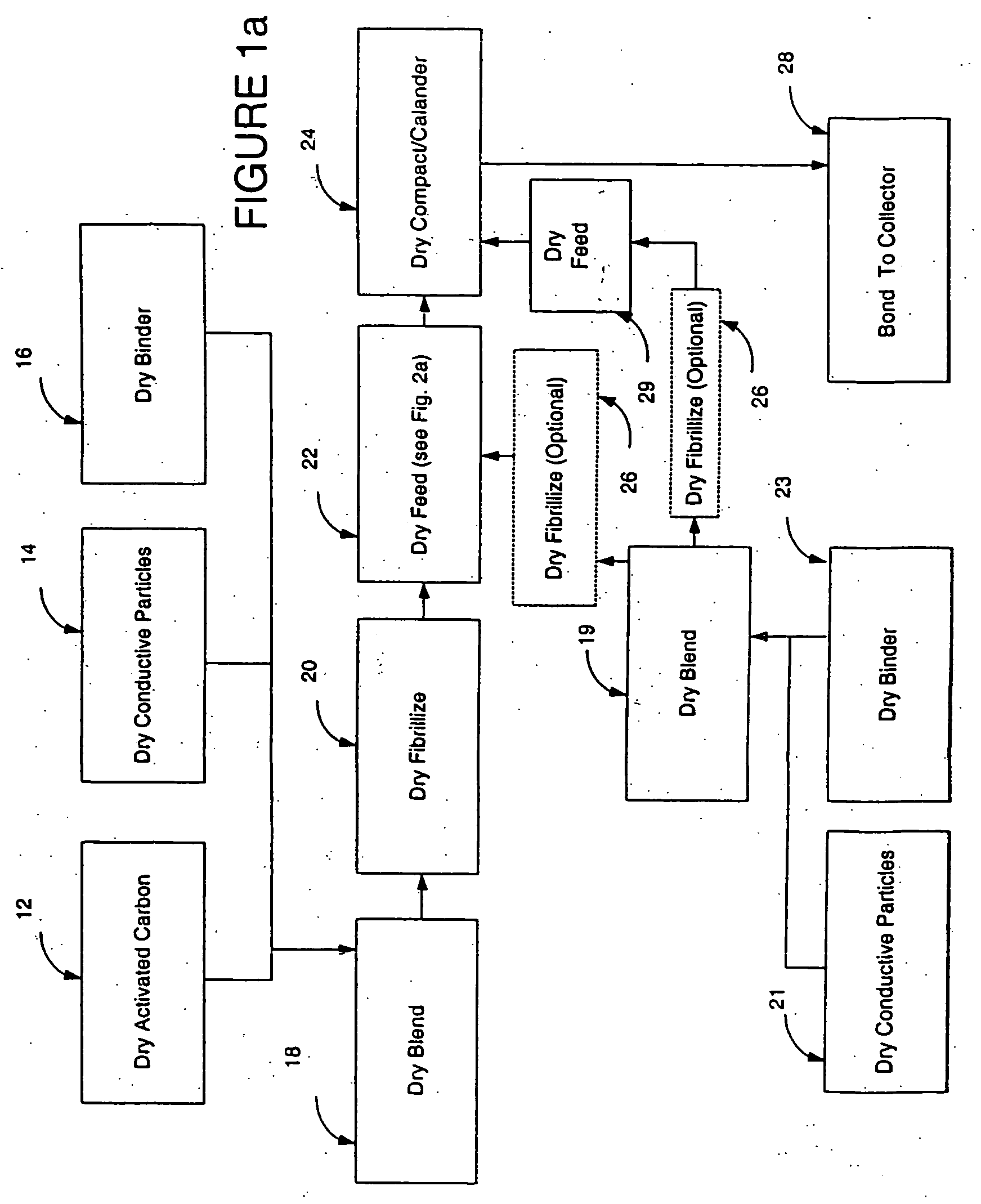

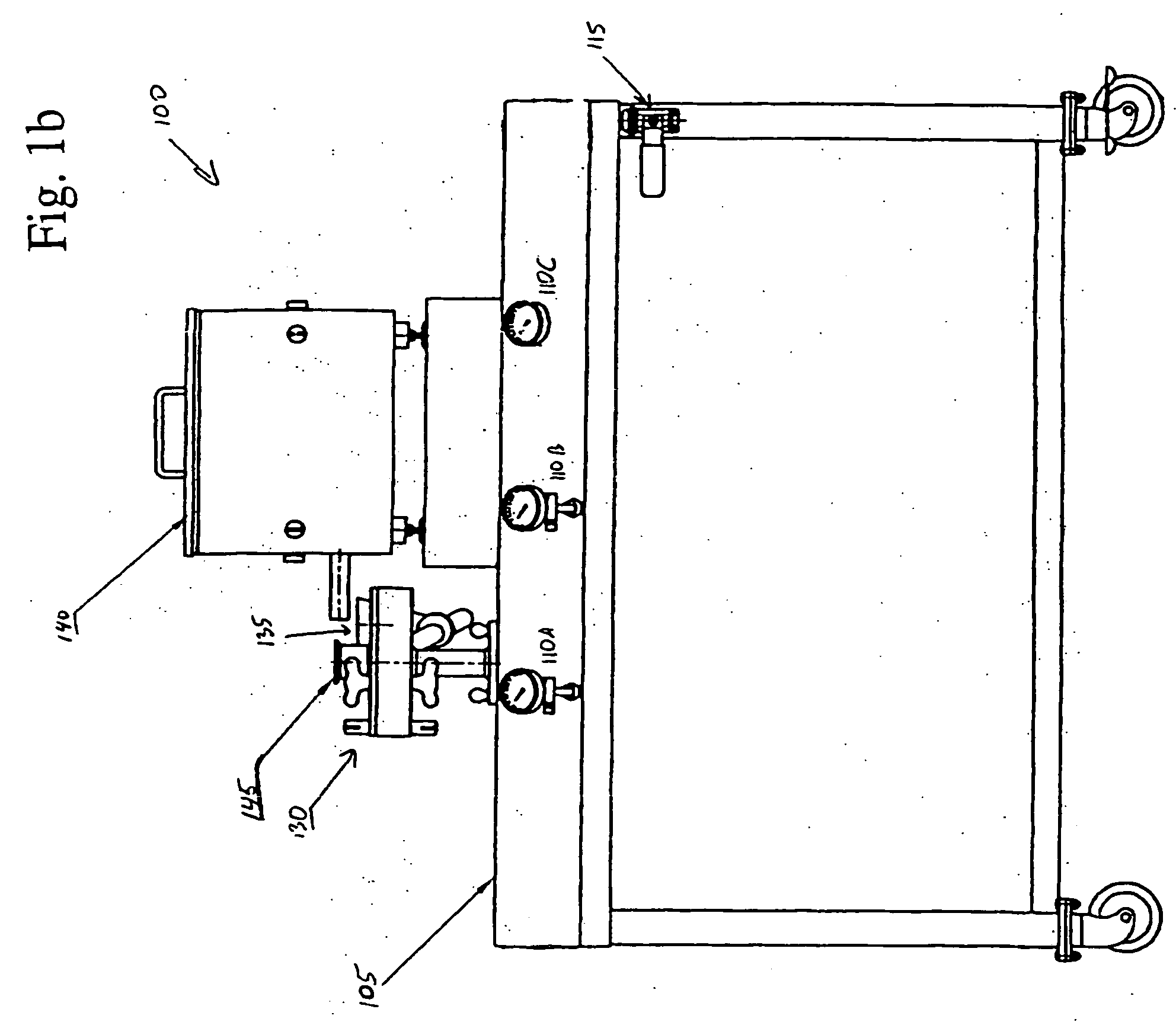

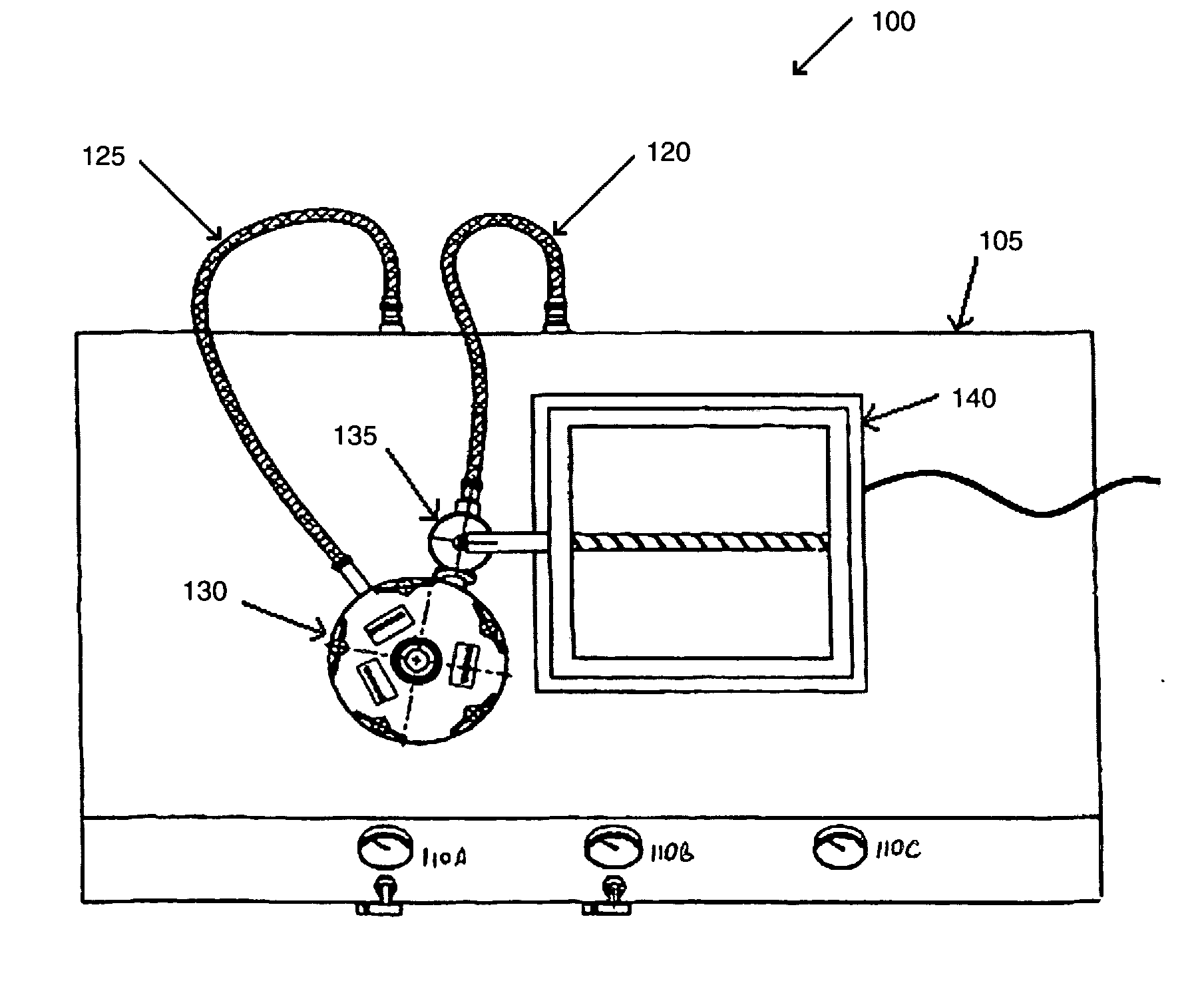

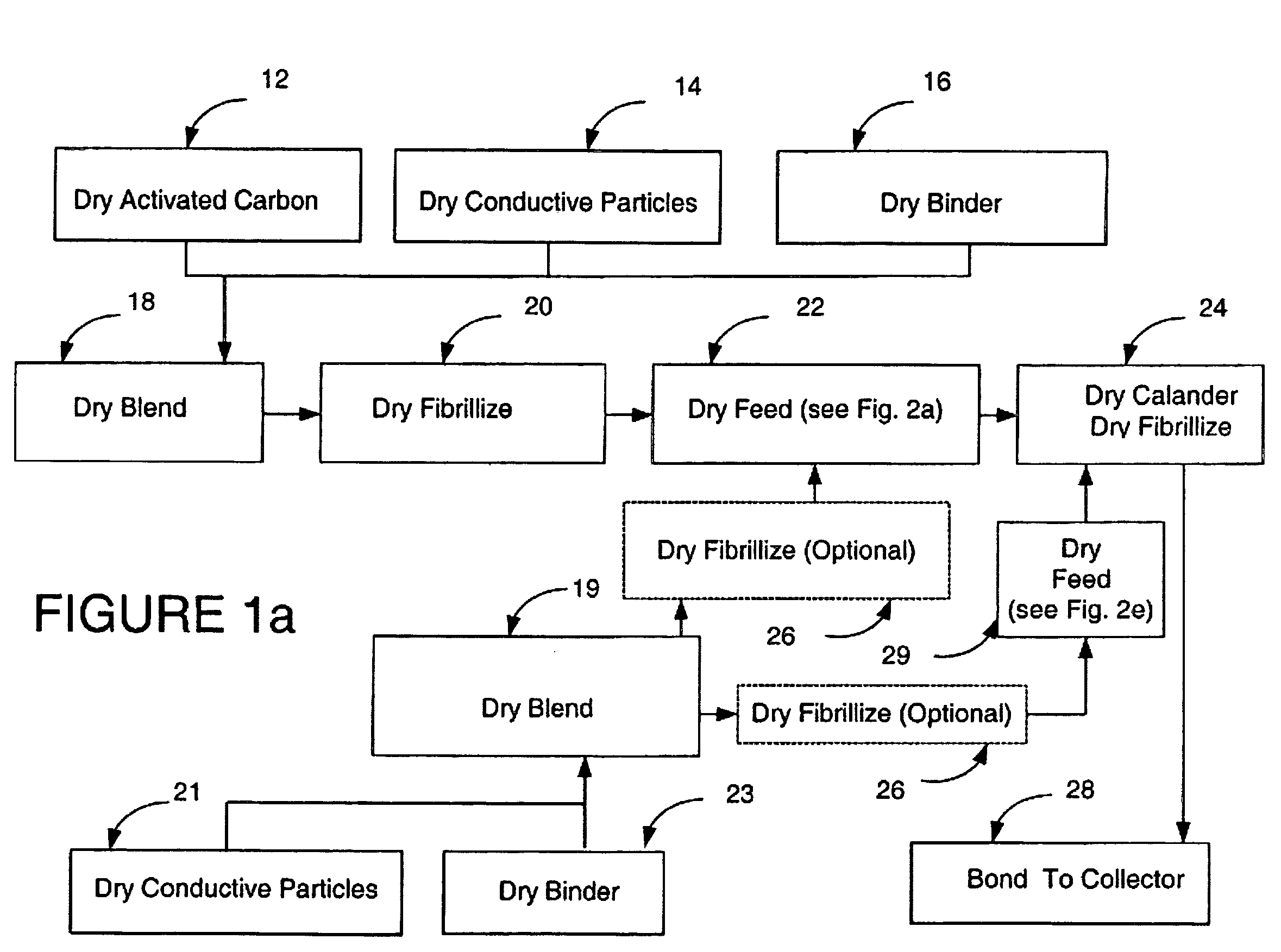

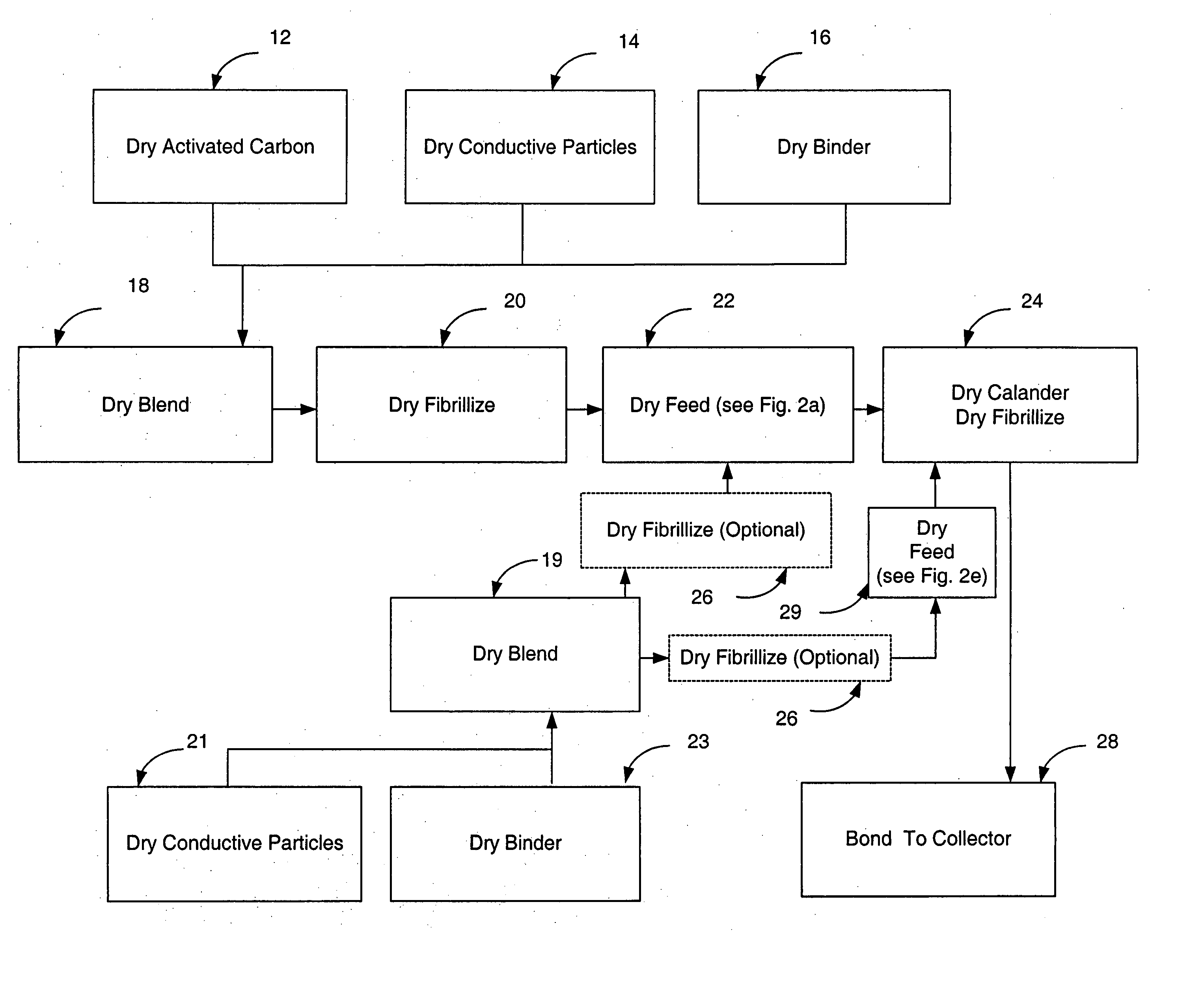

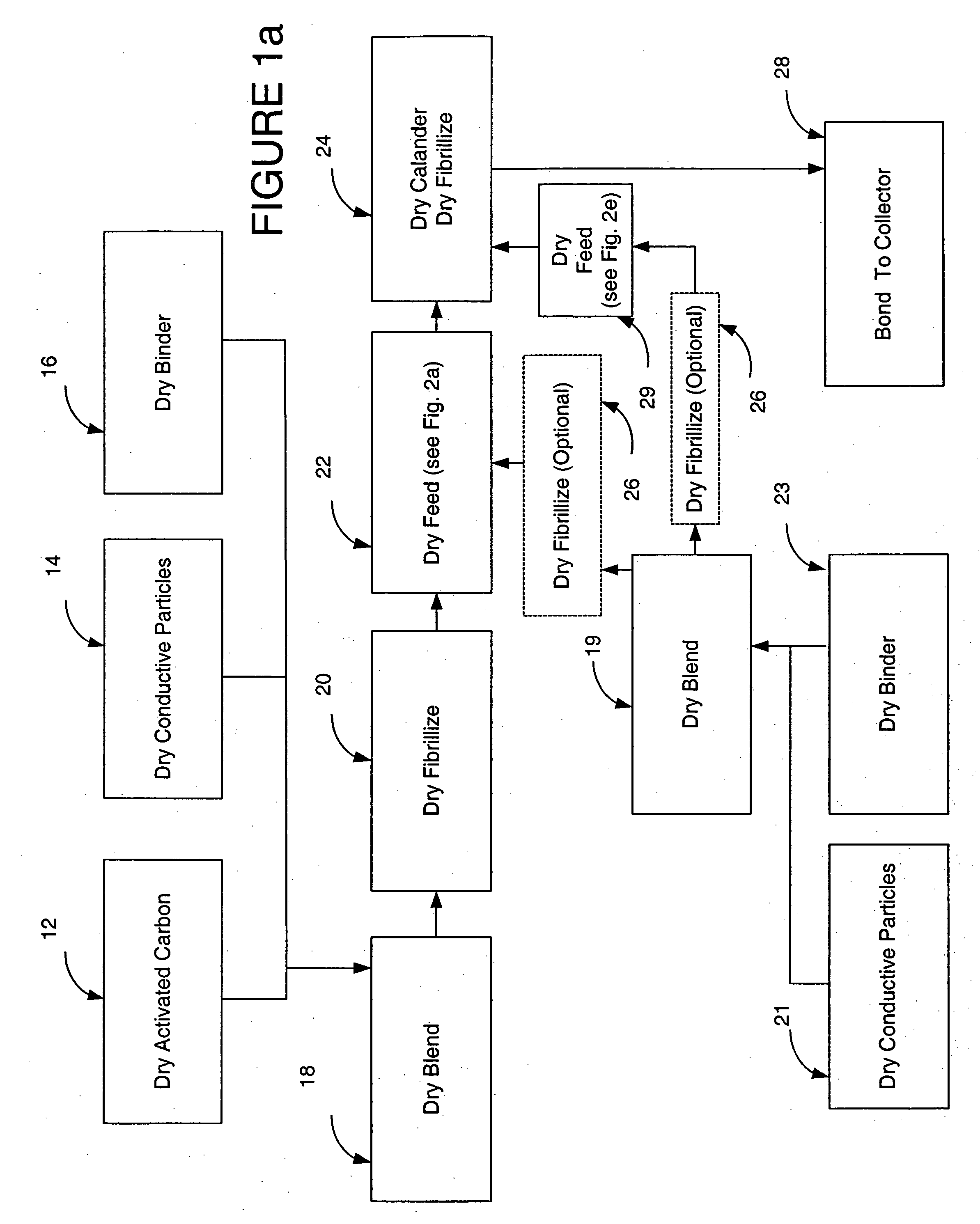

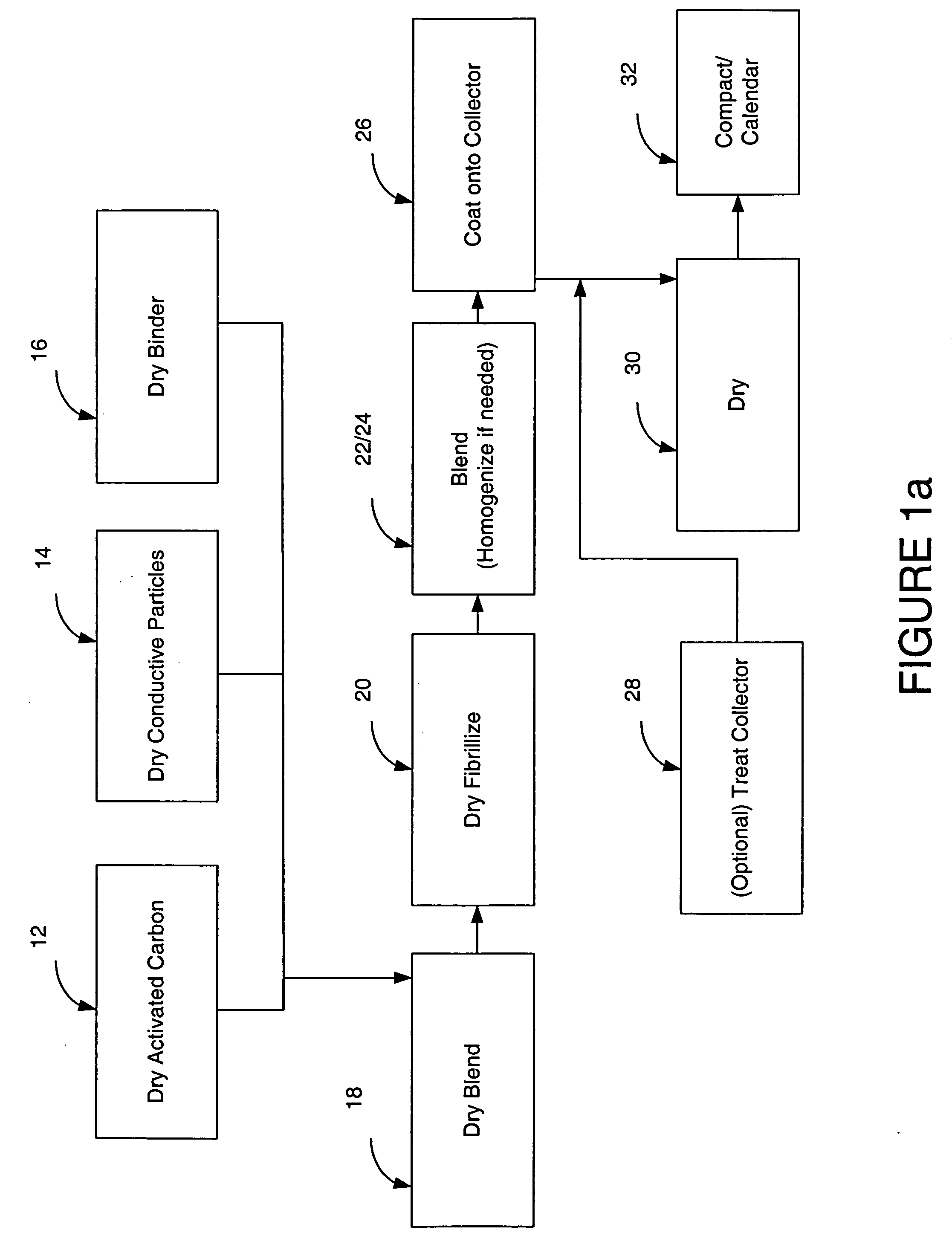

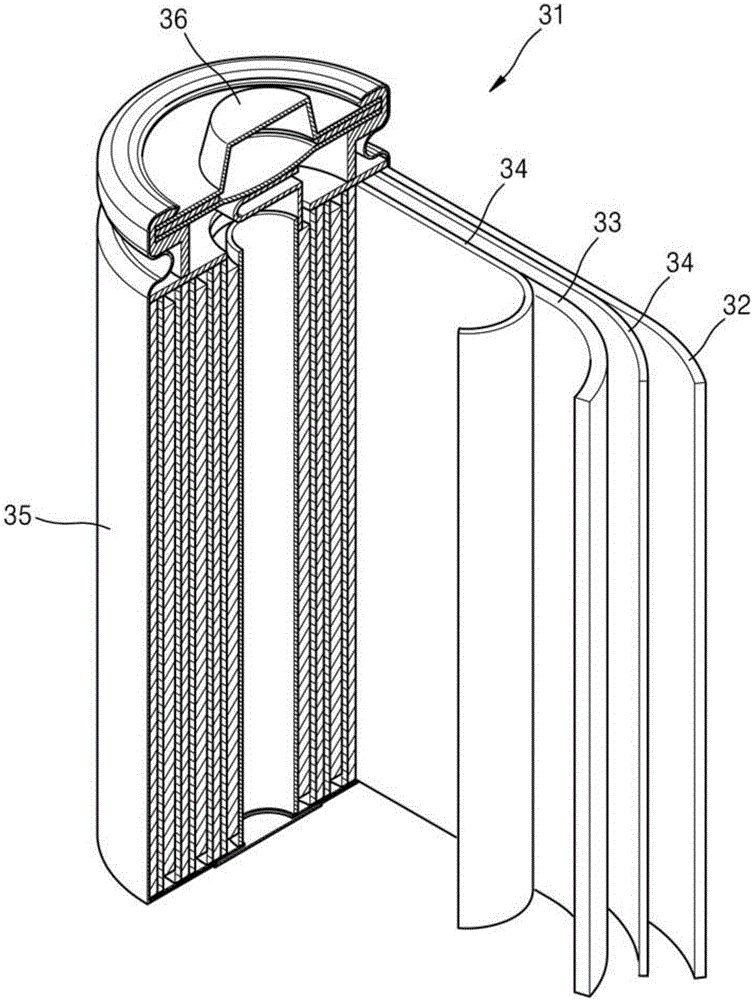

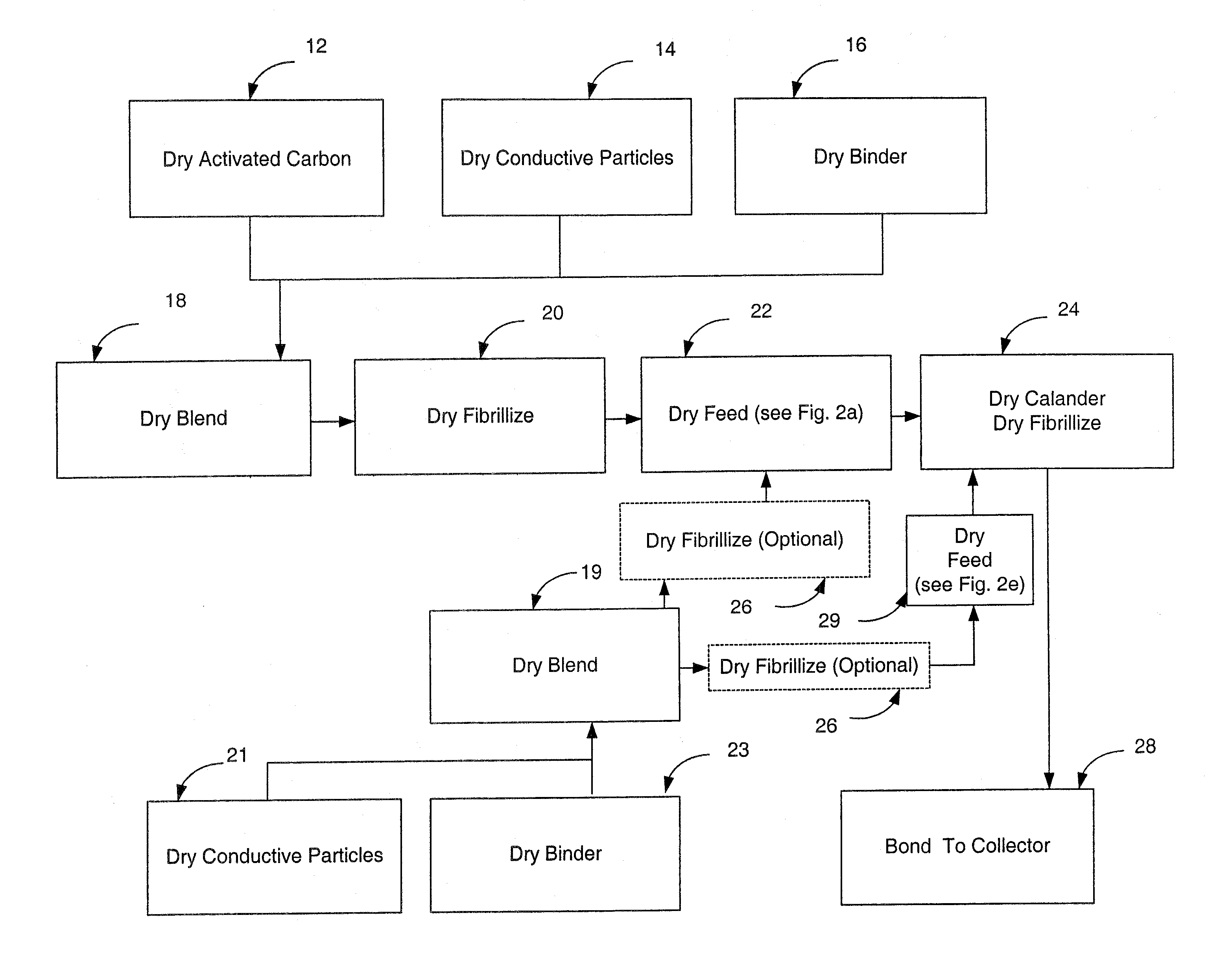

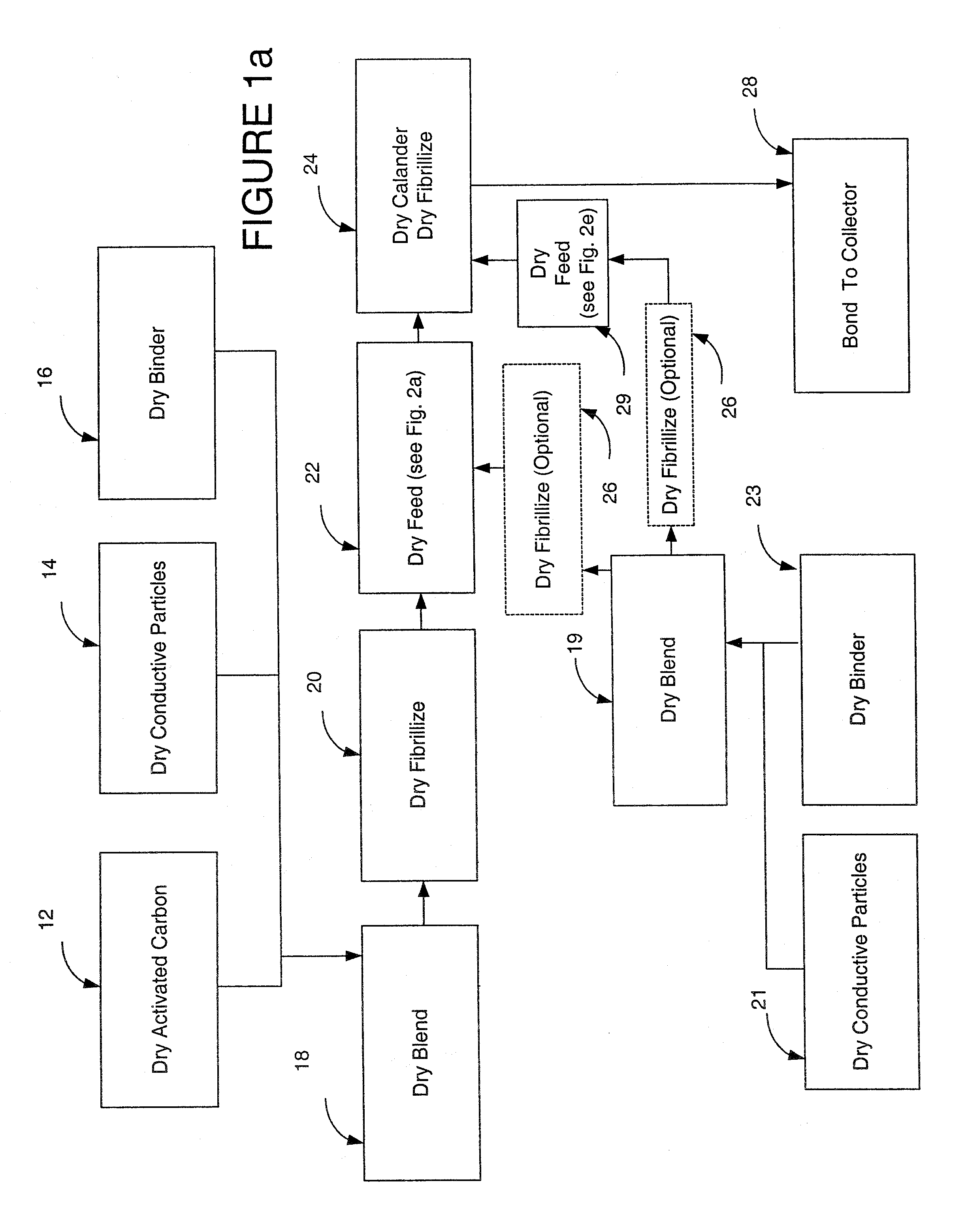

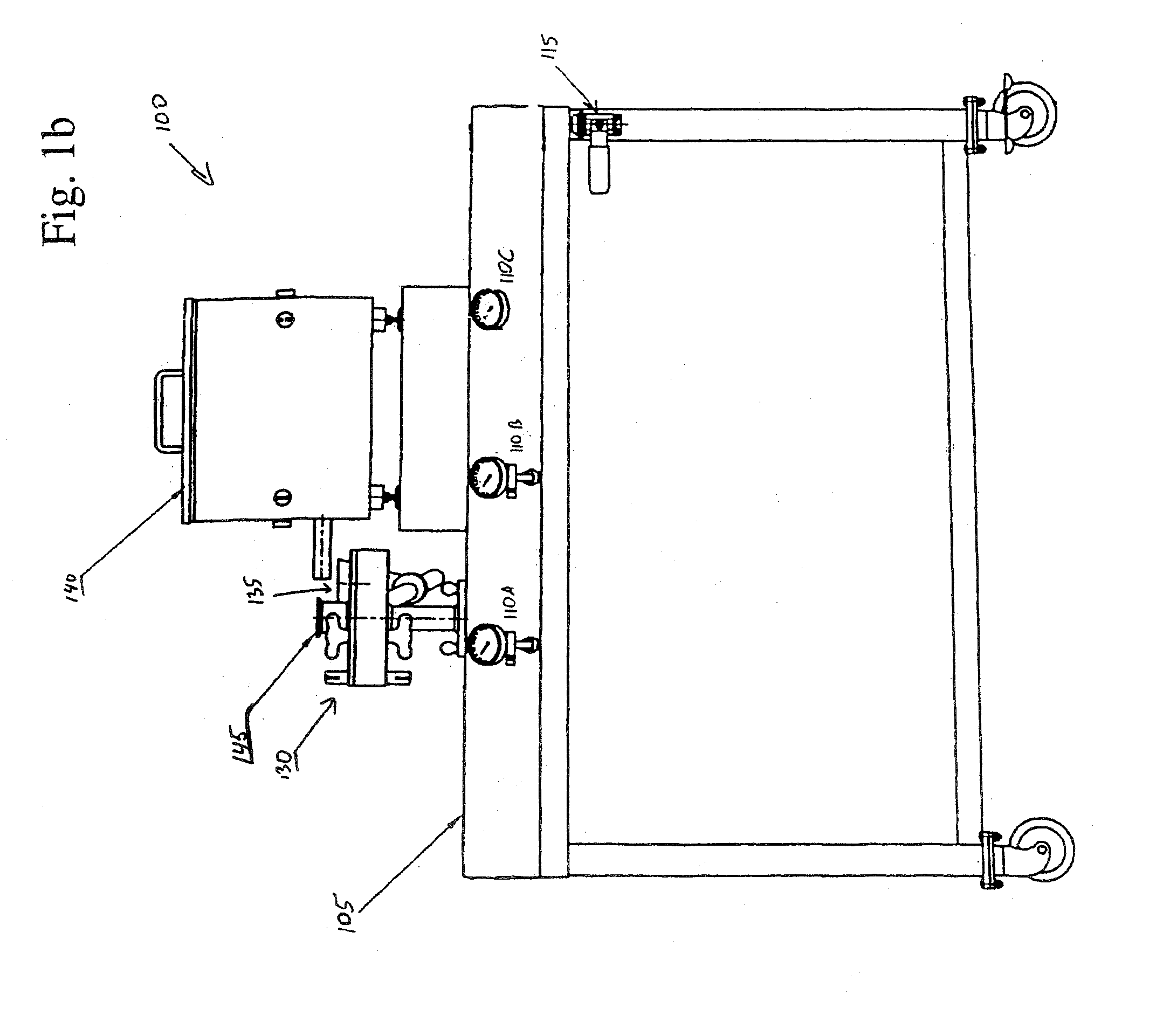

Dry particle based electro-chemical device and methods of making same

InactiveUS20050266298A1Reduce usageHigh yieldElectrode rolling/calenderingFinal product manufactureFuel cellsBiochemical engineering

A dry process-based electro-chemical device and method for making a self-supporting dry electrode film for use therein is disclosed. Cost effective manufacture of electrochemical devices such as batteries, capacitors, and fuel cells is enabled.

Owner:TESLA INC

Particle packaging systems and methods

InactiveUS20050250011A1Reduce water consumptionHigh yieldElectrode rolling/calenderingHybrid capacitor electrodesFuel cellsMedical device

A dry process-based particle packaging method and system is disclosed where a matrix of dry fibrillized binder is formed so as to support one or more type of particle. Reliable and inexpensive products, including films, sheets, electrodes, batteries, capacitors, fuel cells, and / or medical devices can be thus manufactured.

Owner:TESLA INC

Dry-particle based adhesive and dry film and methods of making same

InactiveUS20070122698A1Reduce water consumptionHigh yieldElectrode rolling/calenderingFinal product manufactureAdhesiveEngineering

Dry process based energy storage device structures and methods for using a dry adhesive therein are disclosed.

Owner:TESLA INC

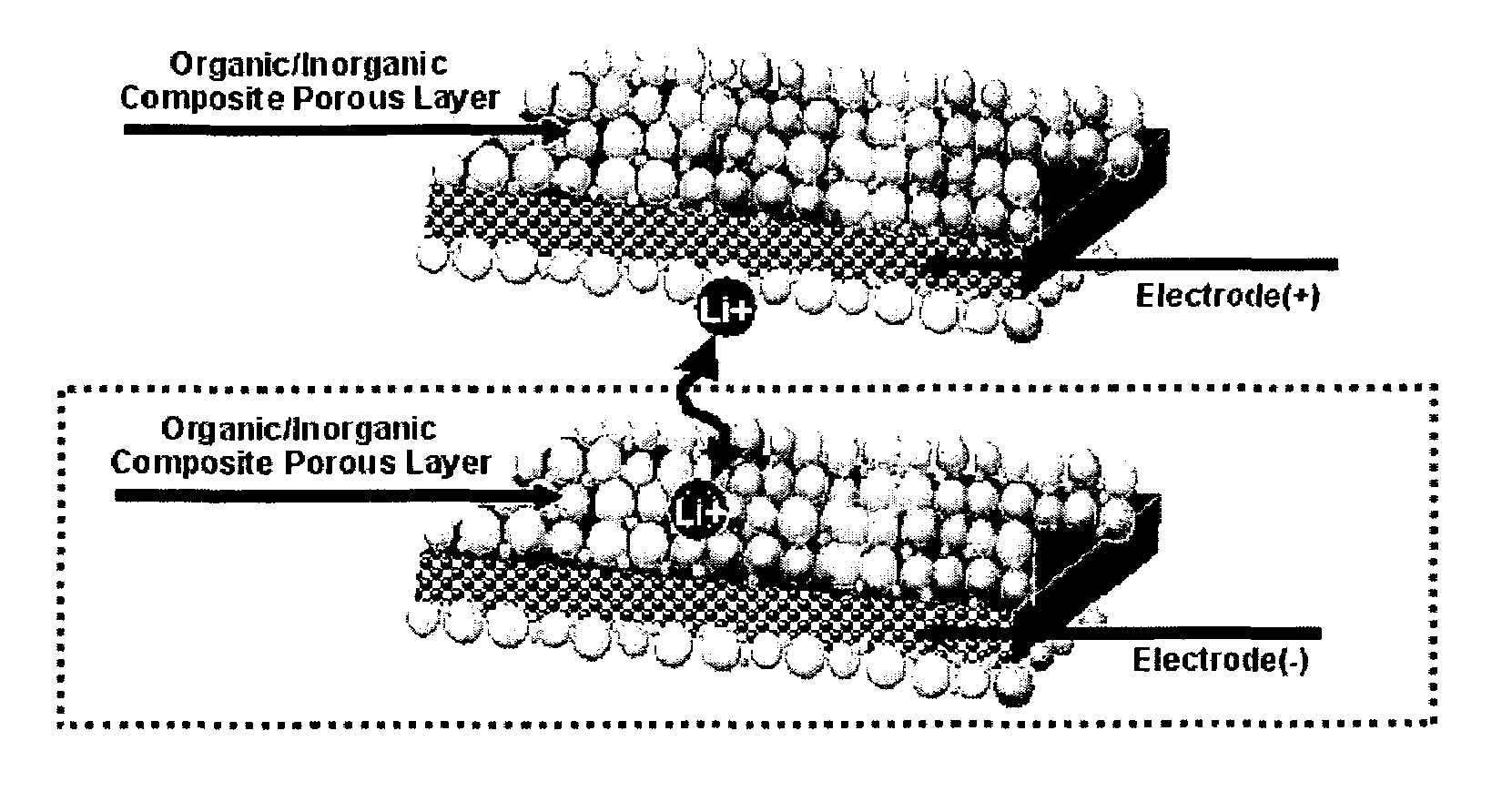

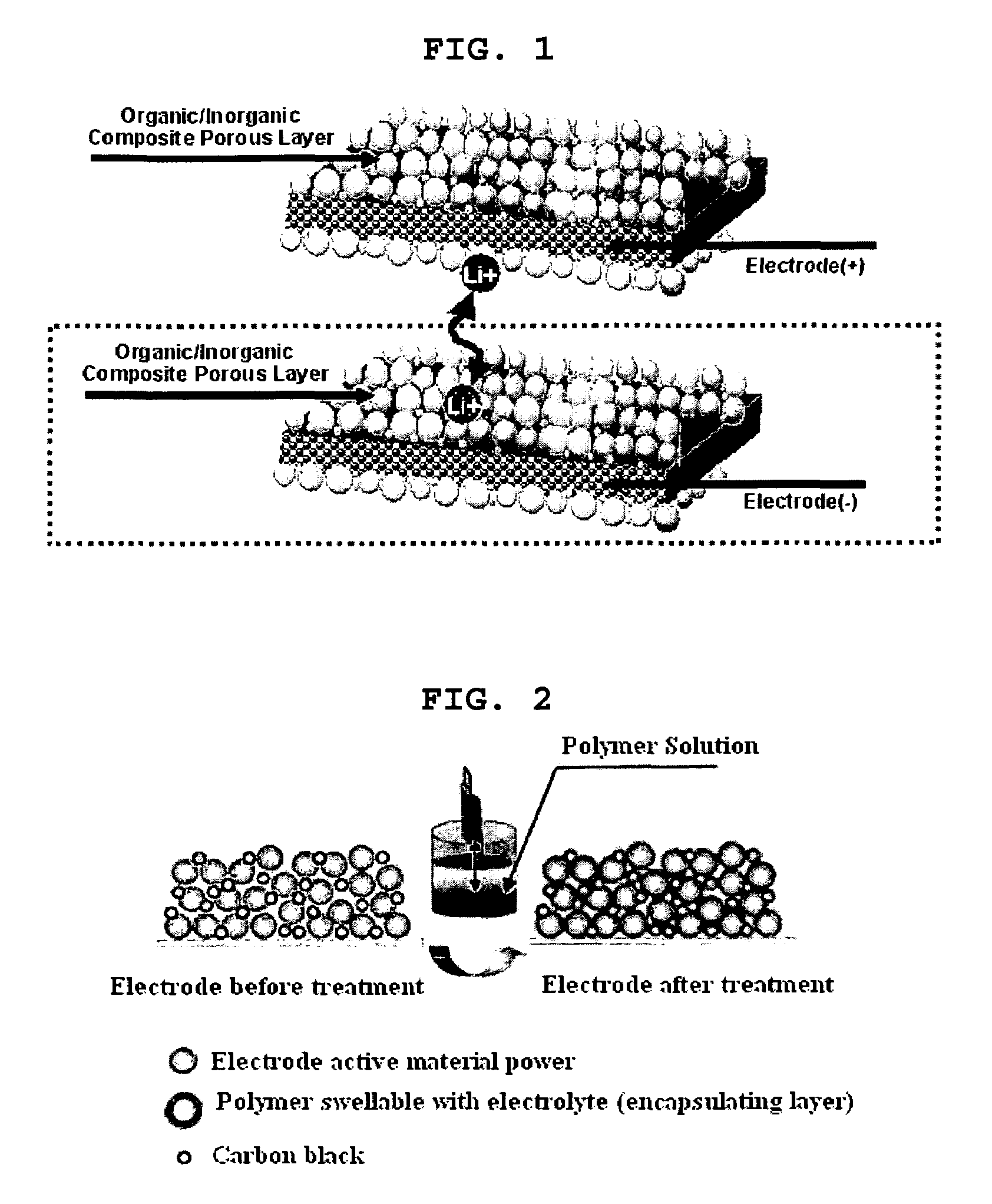

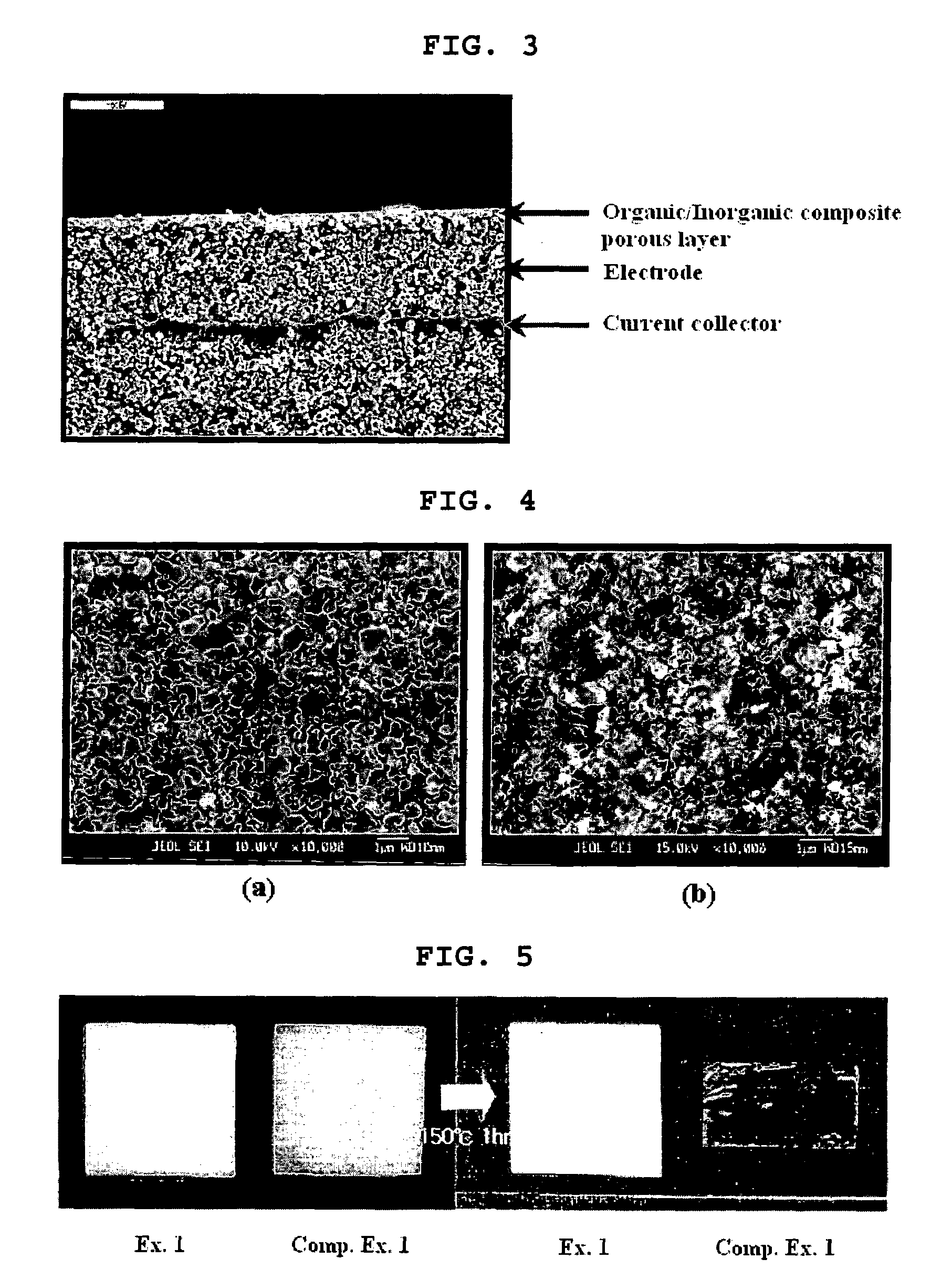

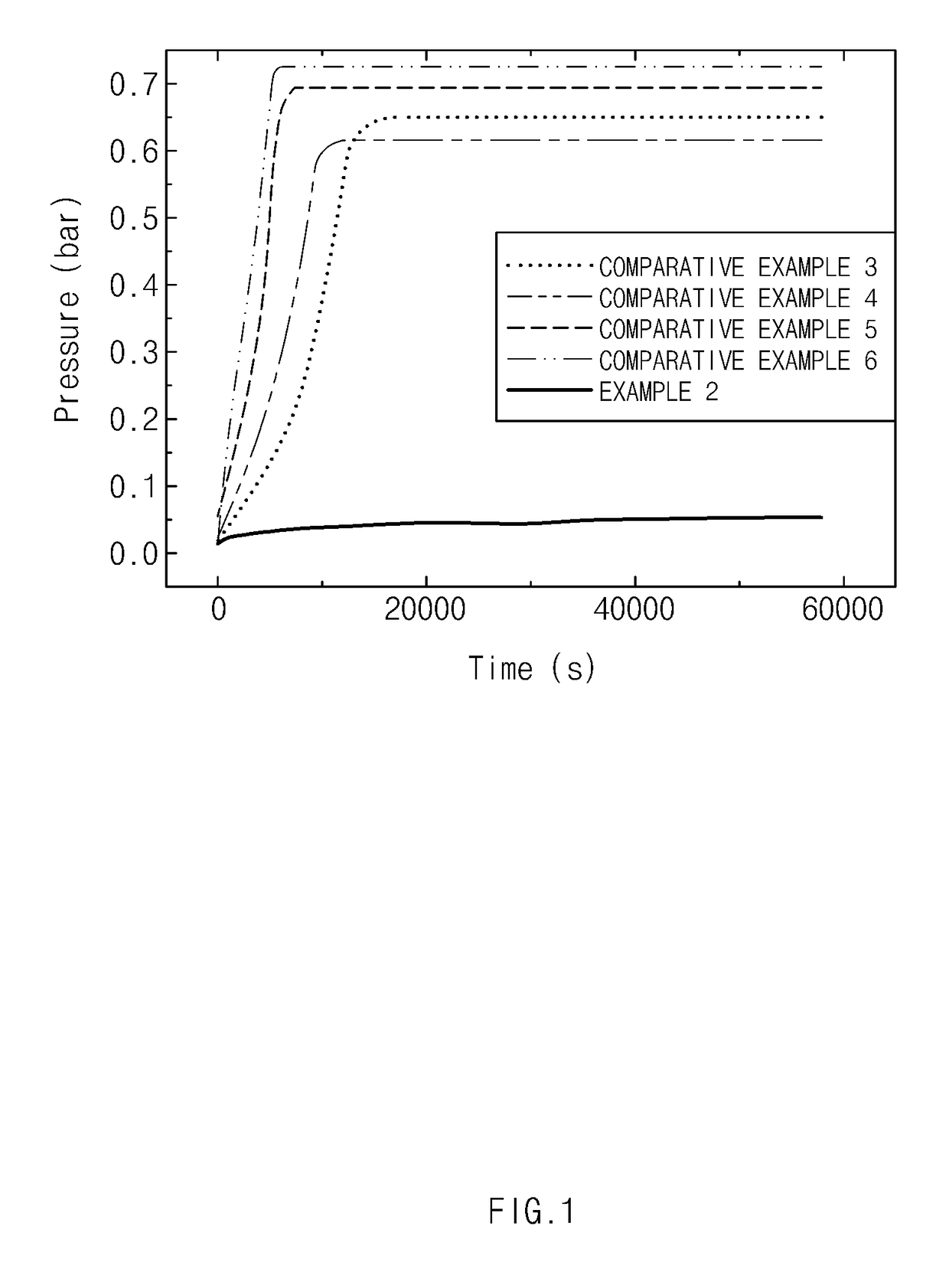

Organic/inorganic composite porous layer-coated electrode and electrochemical device comprising the same

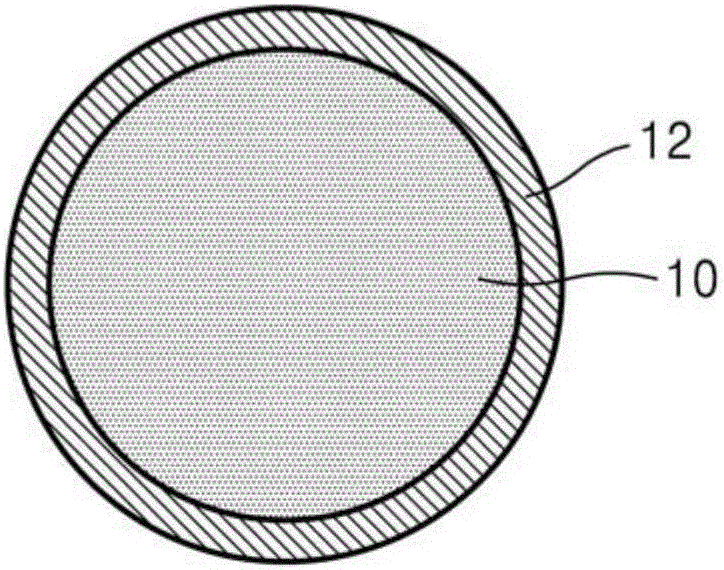

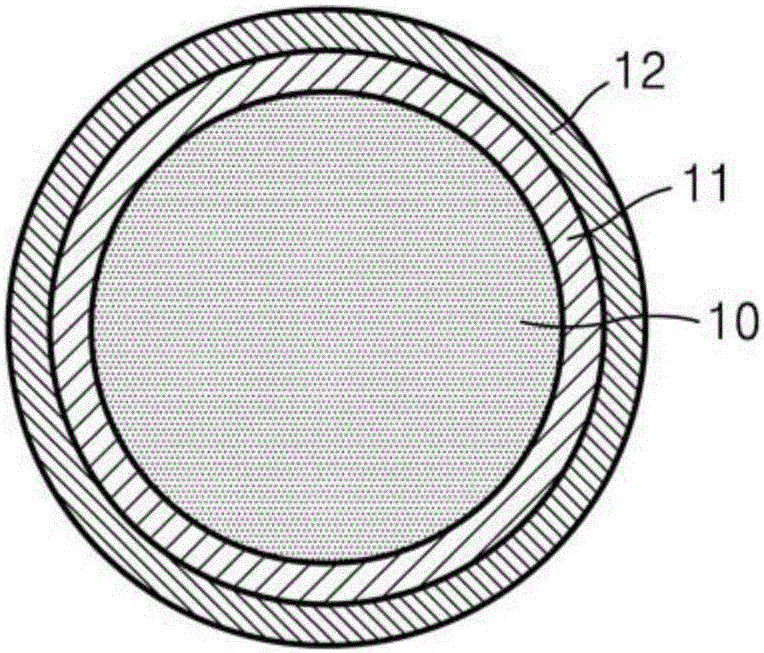

ActiveUS7682740B2Improve performanceImprove securityElectrode rolling/calenderingNon-aqueous electrolyte accumulator electrodesPorous coatingInorganic particle

Disclosed is an electrode comprising a first organic / inorganic composite porous coating layer formed on its surface, wherein the first coating layer includes inorganic particles and a binder polymer for interconnecting and fixing the inorganic particles, and has micropores formed by interstitial volumes among the inorganic particles. An electrochemical device including the same electrode is also disclosed. Further, disclosed is a method for manufacturing an electrode having an organic / inorganic composite porous coating layer on the surface thereof, comprising the steps of: (a) coating a current collector with slurry containing an electrode active material and drying it to provide an electrode; and (b) coating the surface of electrode obtained from step (a) with a mixture of inorganic particles with a binder polymer. A lithium secondary battery including the electrode shows improved safety and minimized degradation in battery performance.

Owner:LG ENERGY SOLUTION LTD

Lithium metal dispersion in electrodes

InactiveCN1830110AElectrode rolling/calenderingElectrode thermal treatmentLithium metalHost material

Electrodes, such as anodes and cathodes, can include a host material that is prelithiated or undergoes lithiation upon electrolyte introduction into a battery. Lithiation of the host material can occur by the agitation of lithium metal and a host material, the agitation of a lithium metal powder and a host material at a temperature greater than room temperature, the application of pressure to a lithium metal and host material mixture, contact of the host material with molten lithium metal, the lamination of lithium foil or lithium mesh onto an electrode containing the host material, or by lamination of lithium metal or mesh onto an electrode at elevated temperatures.

Owner:ФМК ЛИТИУМ ЮЭСЭЙ КОРП.

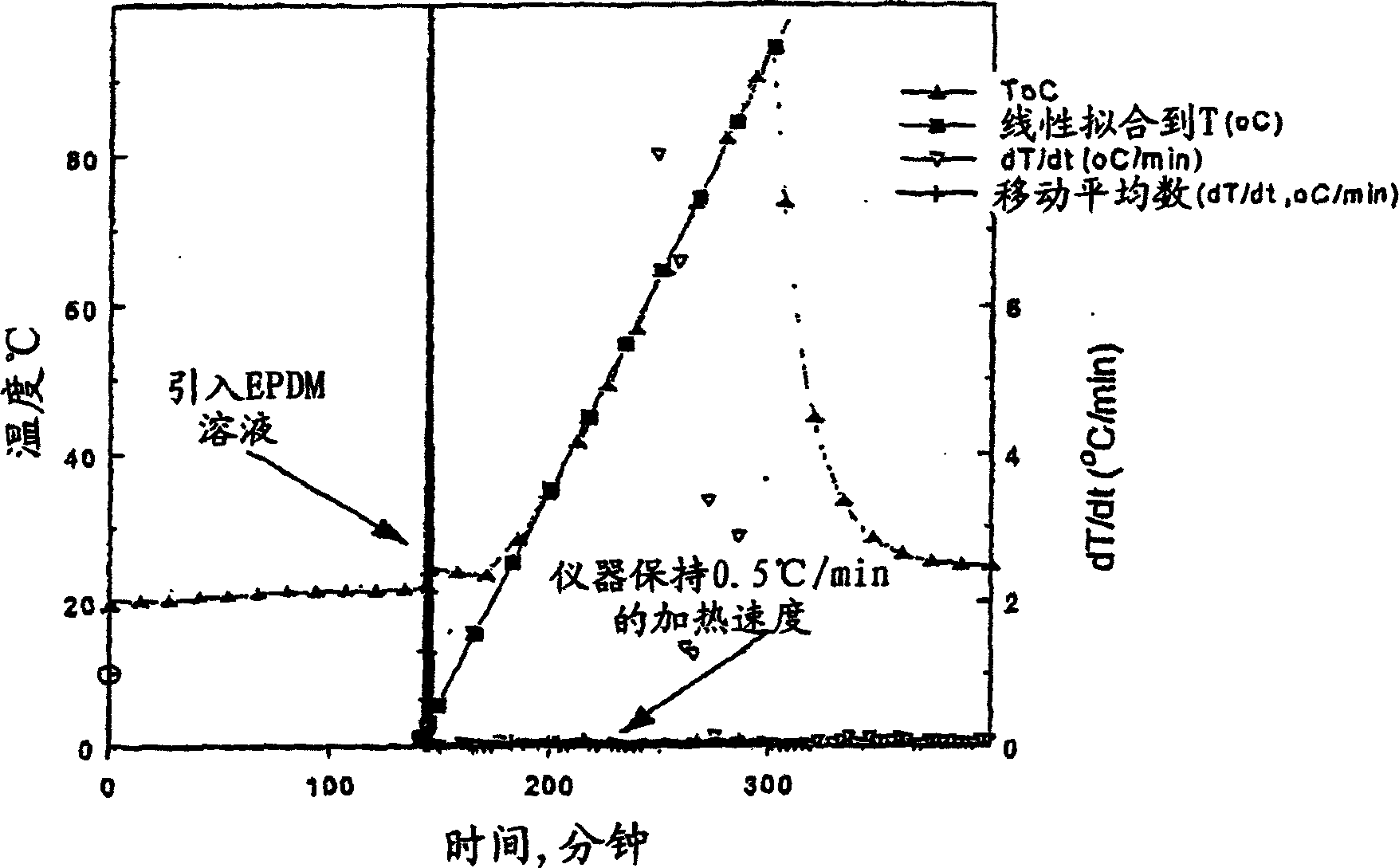

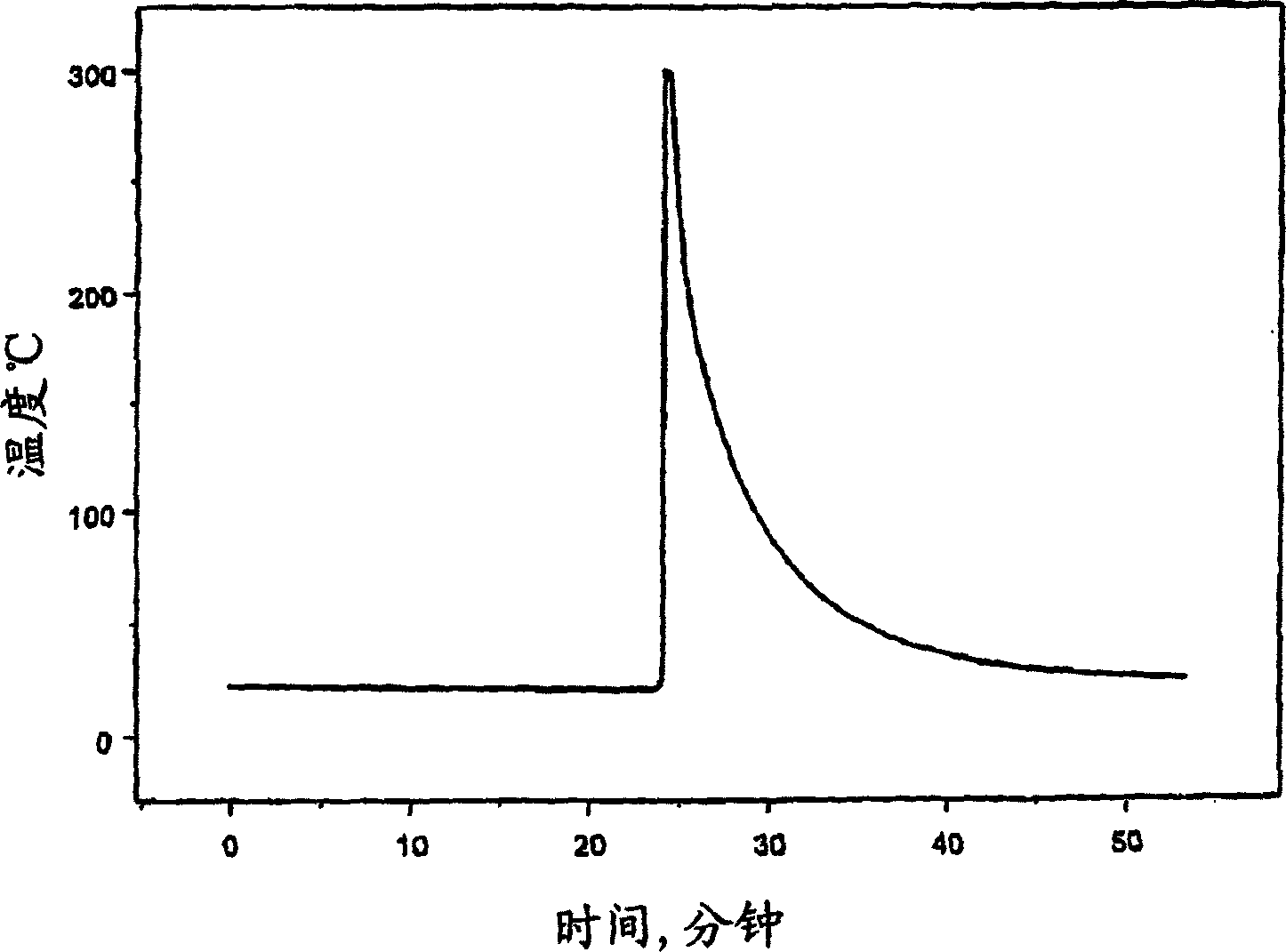

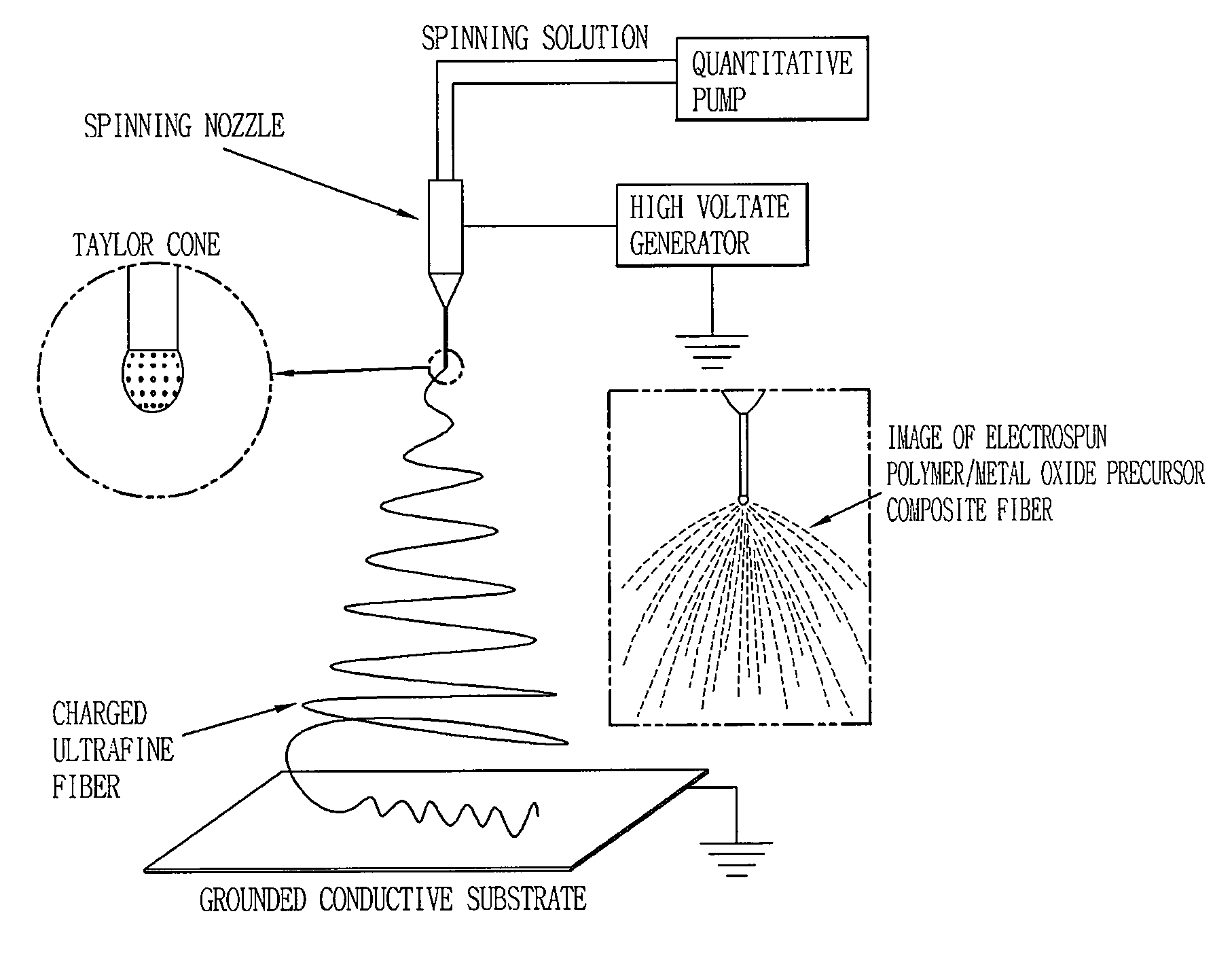

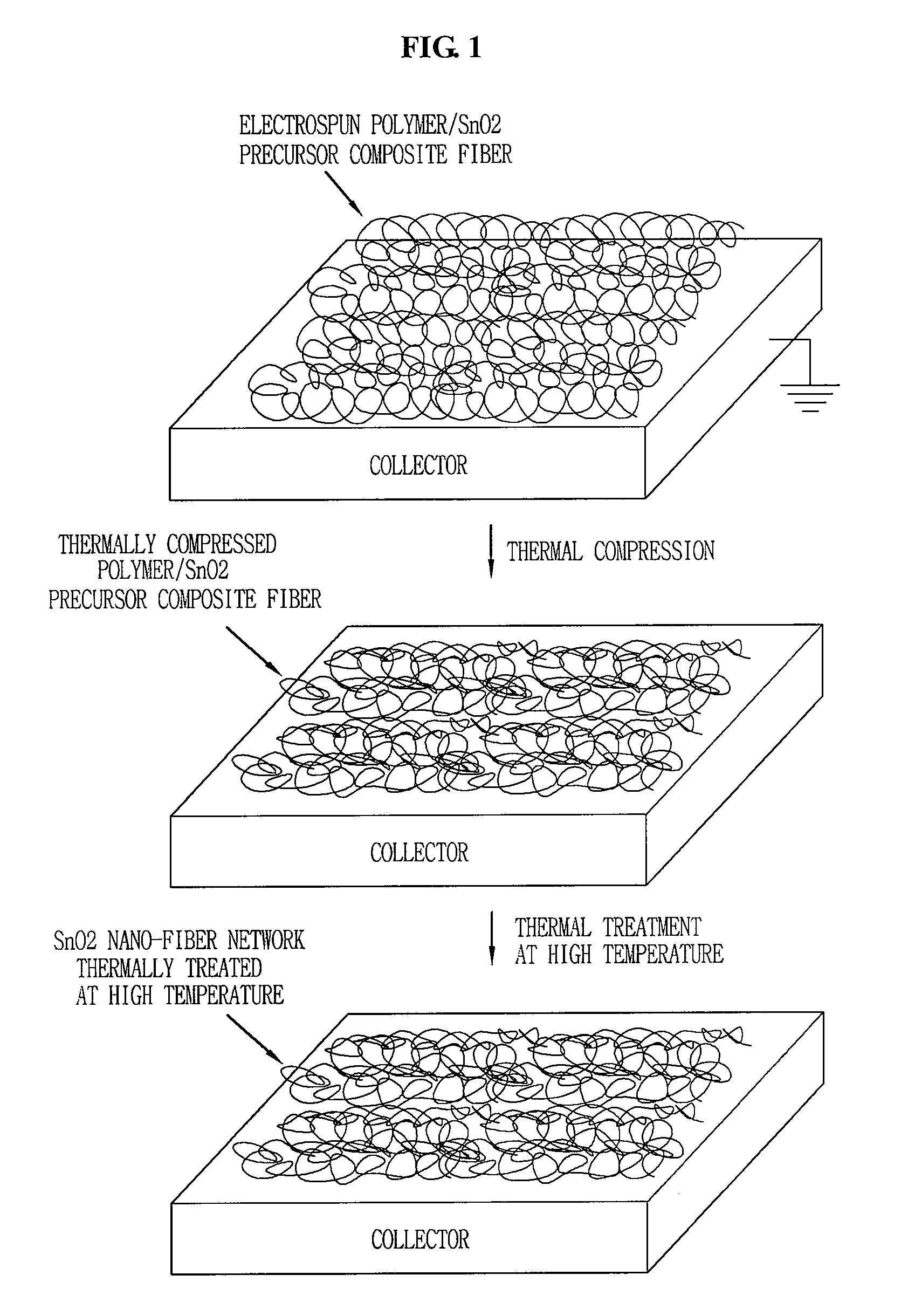

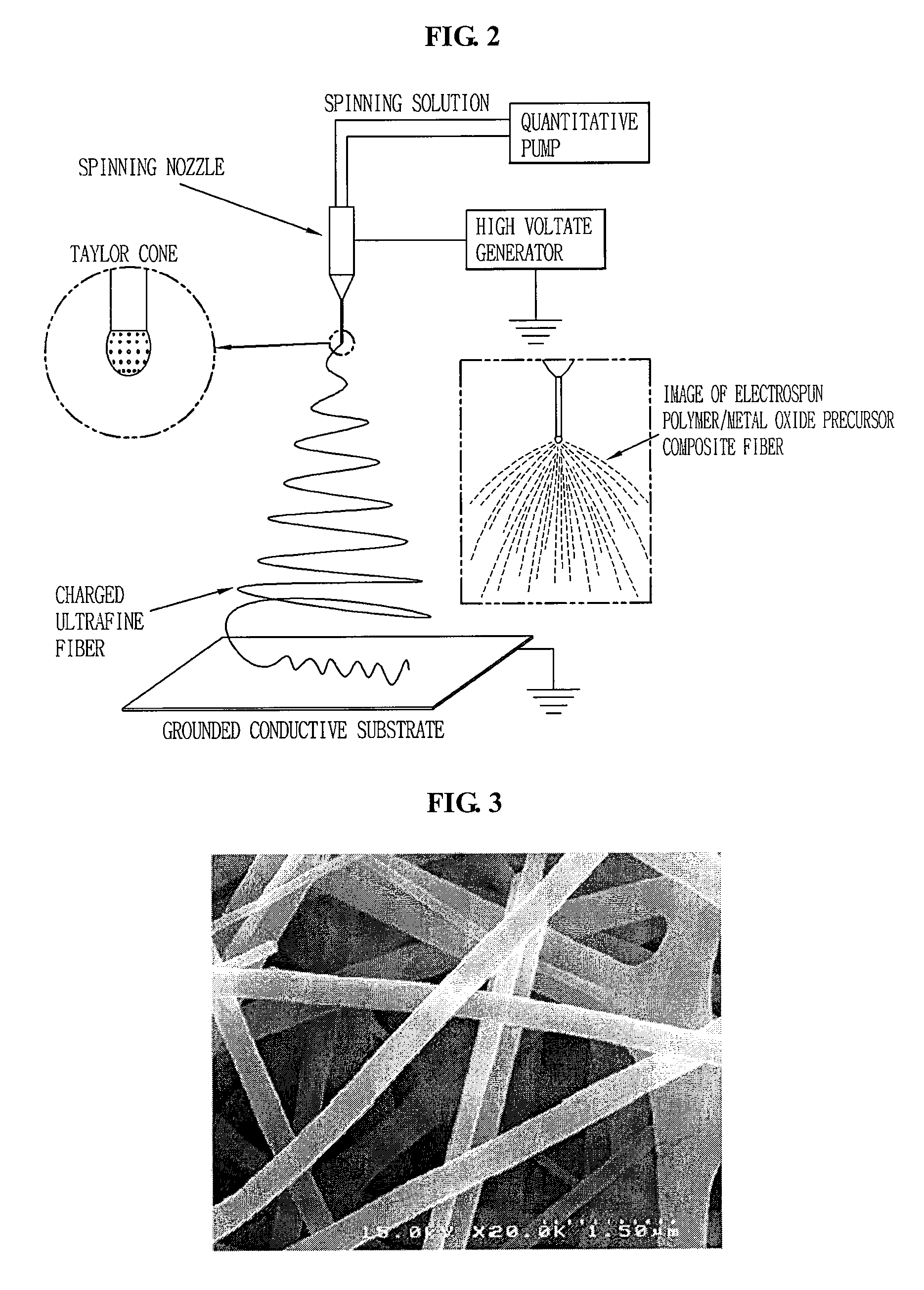

Anode for secondary battery having negative active material with nano-fiber network structure and secondary battery using the same, and fabrication method of negative active material for secondary battery

InactiveUS20080274403A1Maximize cycling characteristicIncrease speedElectrode rolling/calenderingMaterial nanotechnologyCurrent collectorFiber network

Owner:KOREA INST OF SCI & TECH

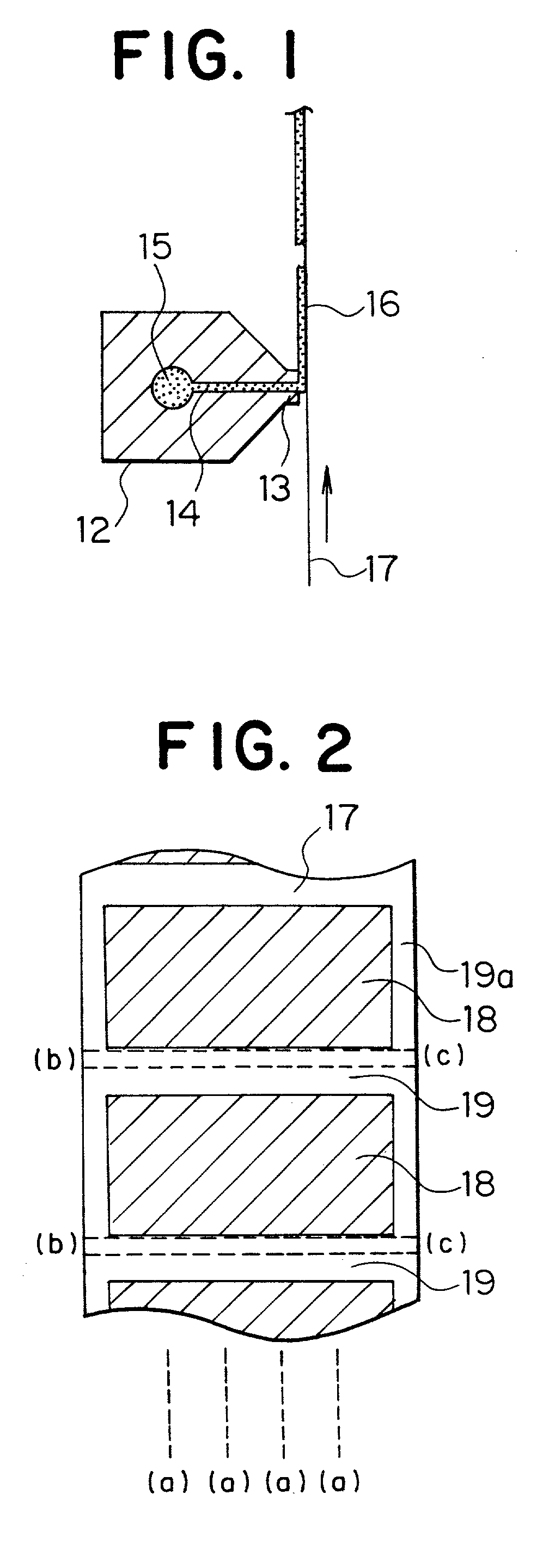

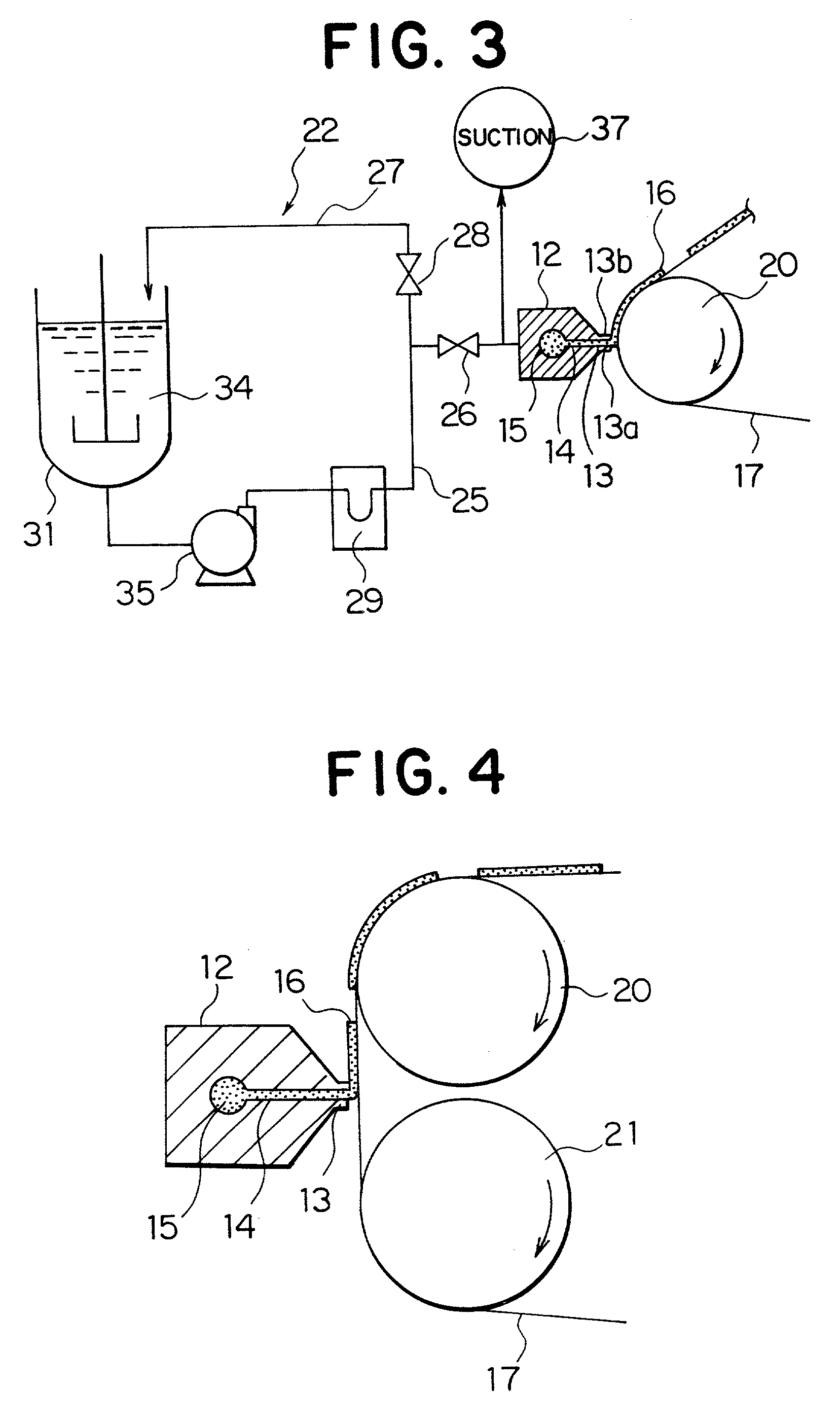

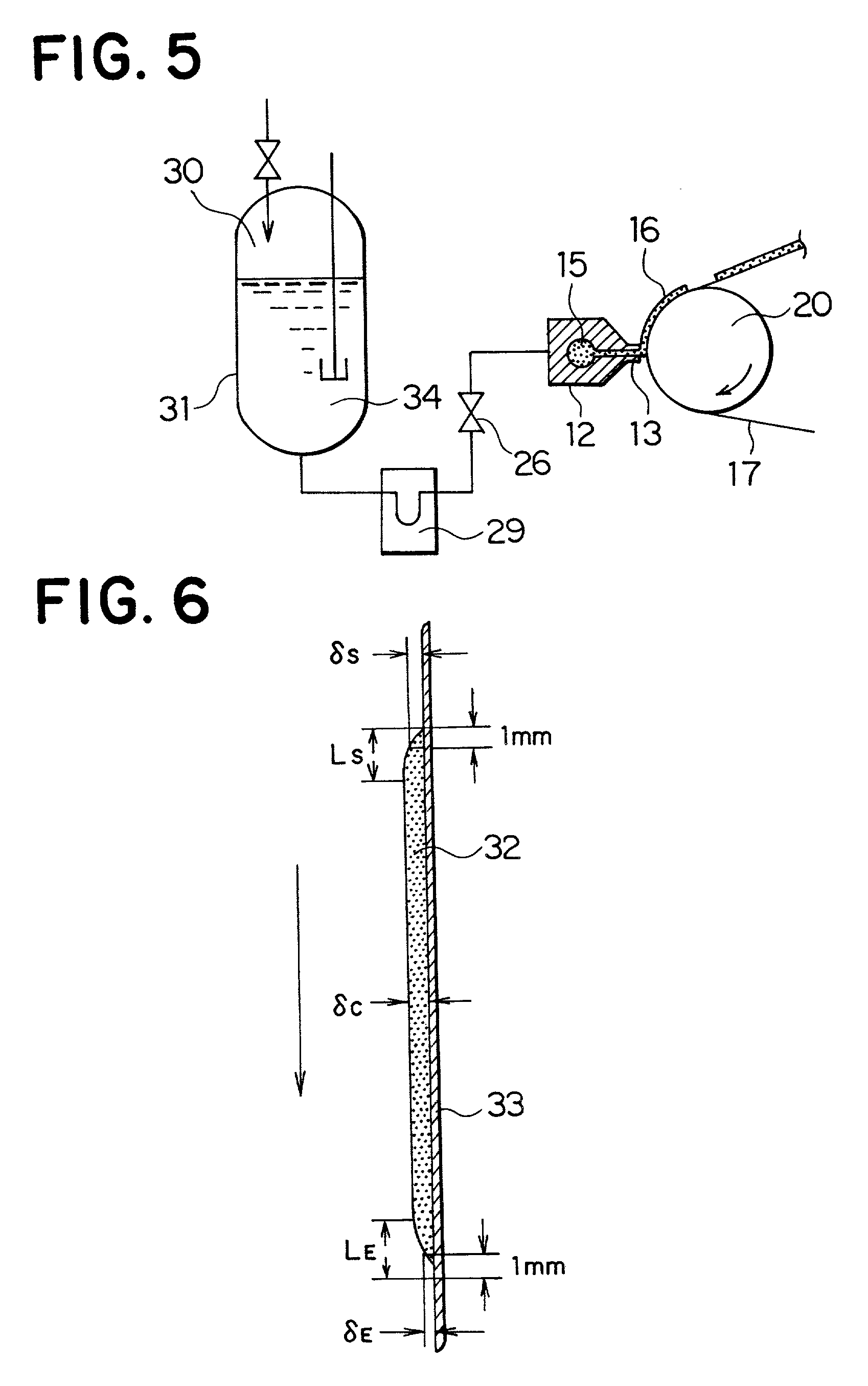

Nonaqueous electrolyte battery, electrode plate for nonaqueous electrolyte battery, and method for manufacturing electrode plate for nonaqueous electrolyte battery,

InactiveUS20010012588A1Electrode rolling/calenderingFinal product manufactureElectrolyteMaterials science

A method for manufacturing an electrode plate of a nonaqueous electrolyte battery comprises the steps of: running a sheet conductive base material in a first direction; and injecting an electrode material composition containing an electrolyte from a die nozzle onto a first surface of the running sheet conductive base material to form uncoated areas at predetermined intervals on the first surface along the first direction.

Owner:KK TOSHIBA

Dry energy storage device electrode and methods of making the same

ActiveUS20150303481A1Electrode rolling/calenderingSolid electrolytic capacitorsEthylene oxidePolyvinylidene difluoride

An energy storage device can include a cathode and an anode, where at least one of the cathode and the anode are made of a polytetrafluoroethylene (PTFE) composite binder material including PTFE and at least one of polyvinylidene fluoride (PVDF), a PVDF co-polymer, and poly(ethylene oxide) (PEO). The energy storage device can be a lithium ion battery, a lithium ion capacitor, and / or any other lithium based energy storage device. The PTFE composite binder material can have a ratio of about 1:1 of PTFE to a non-PTFE component, such a PVDF, PVDF co-polymer and / or PEO.

Owner:TESLA INC

Lithium-nickel-cobalt-maganese containing composite oxide, material for positive electrode active material for lithium secondary battery, and methods for producing these

ActiveUS20060083989A1Large capacityExcels in charge-discharge cycle durabilityElectrode rolling/calenderingFluoride preparationManganeseOxygen

Coagulated particles of nickel-cobalt-manganese hydroxide wherein primary particles are coagulated to form secondary particles are synthesized by allowing an aqueous solution of a nickel-cobalt-manganese salt, an aqueous solution of an alkali-metal hydroxide, and an ammonium-ion donor to react under specific conditions; and a lithium-nickel-cobalt-manganese-containing composite oxide represented by a general formula, LipNixMn1-x-yCoyO2-qFq (where 0.98≦p≦1.07, 0.3≦x≦0.5, 0.1≦y≦0.38, and 0≦q≦0.05), which is a positive electrode active material for a lithium secondary cell having a wide usable voltage range, a charge-discharge cycle durability, a high capacity and high safety, is obtained by dry-blending coagulated particles of nickel-cobalt-manganese composite oxyhydroxide formed by making an oxidant to act on the coagulated particles with a lithium salt, and firing the mixture in an oxygen-containing atmosphere.

Owner:SUMITOMO CHEM CO LTD

High capacity solid state composite cathode, solid state composite separator, solid-state rechargeable lithium battery and methods of making same

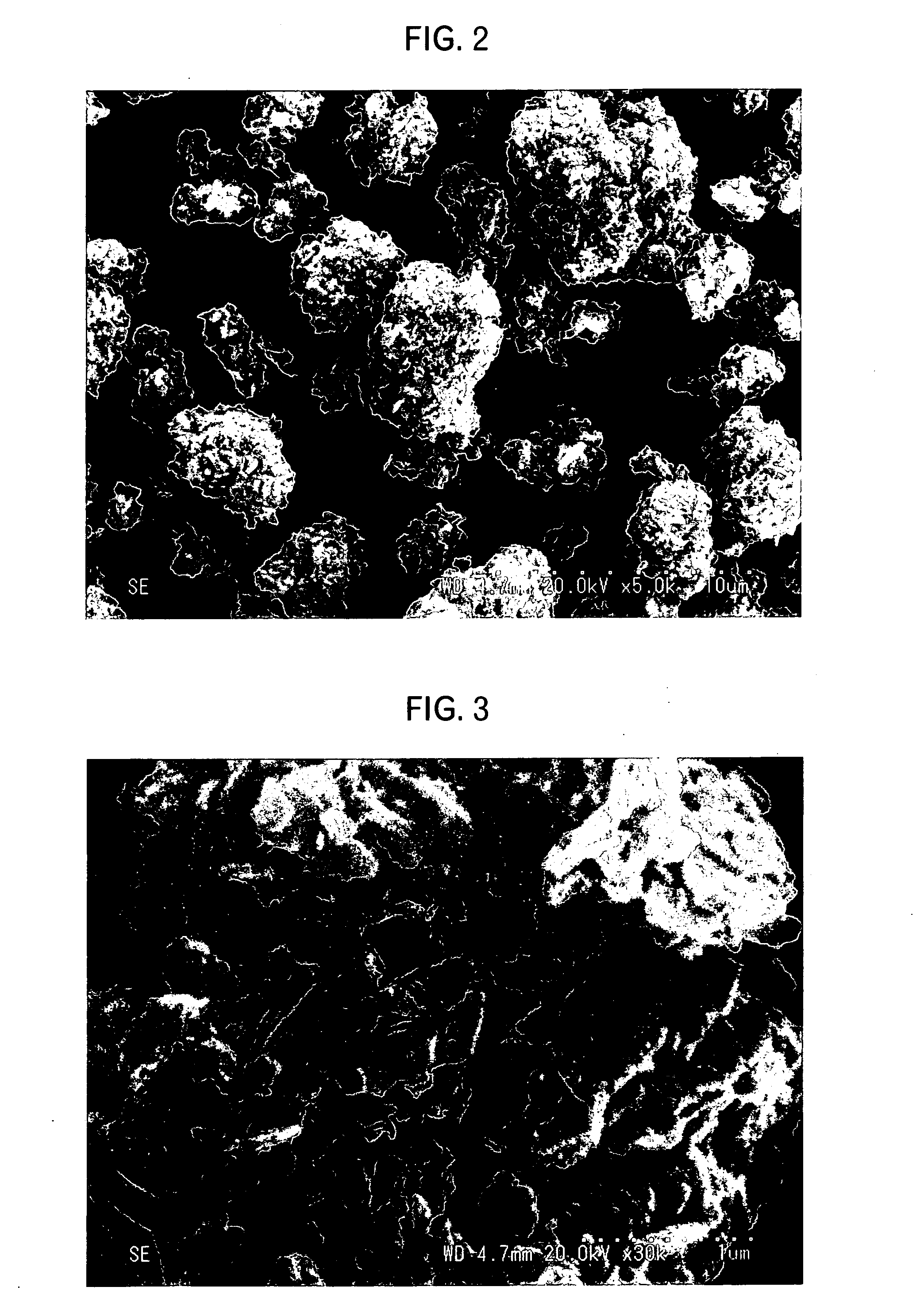

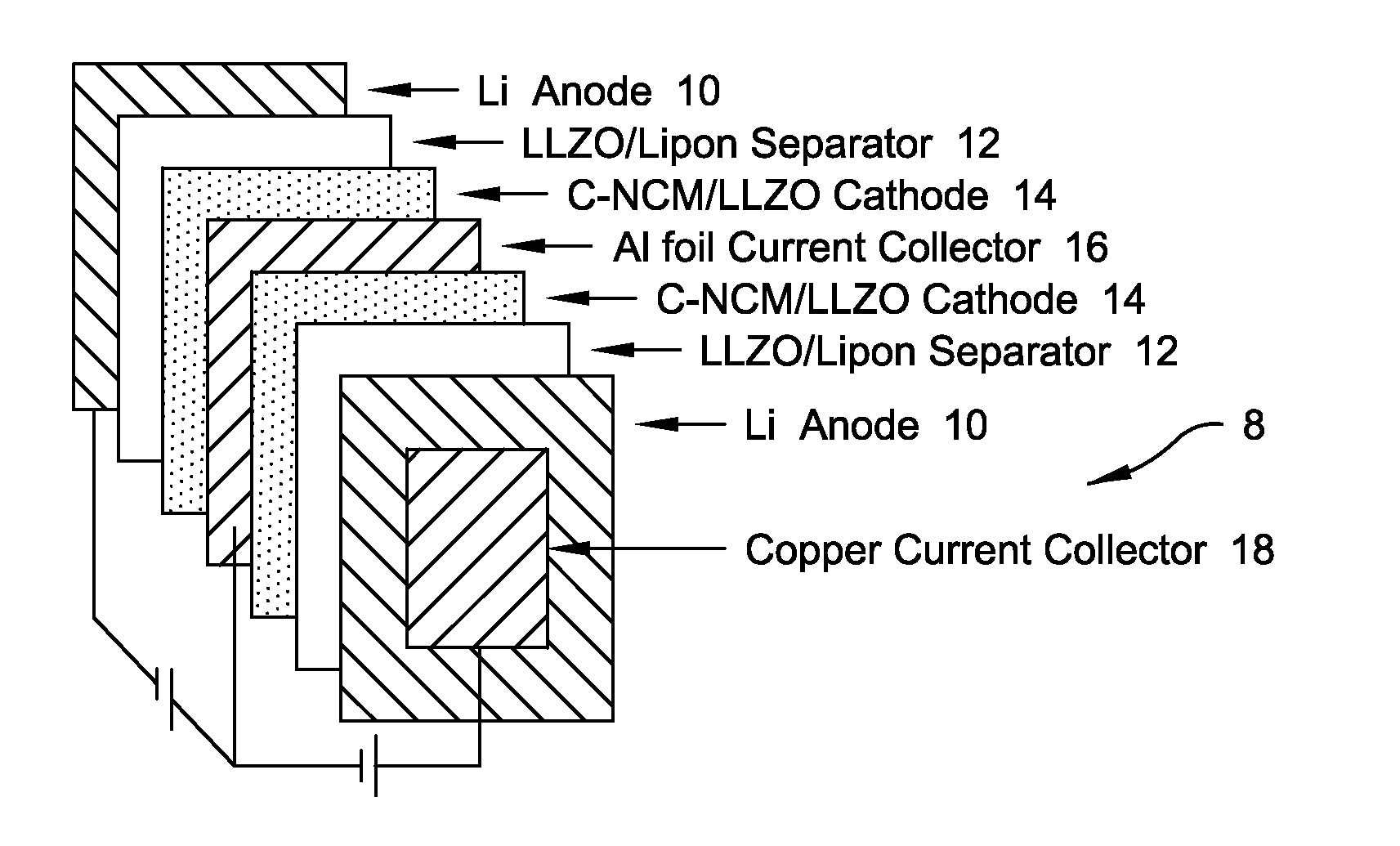

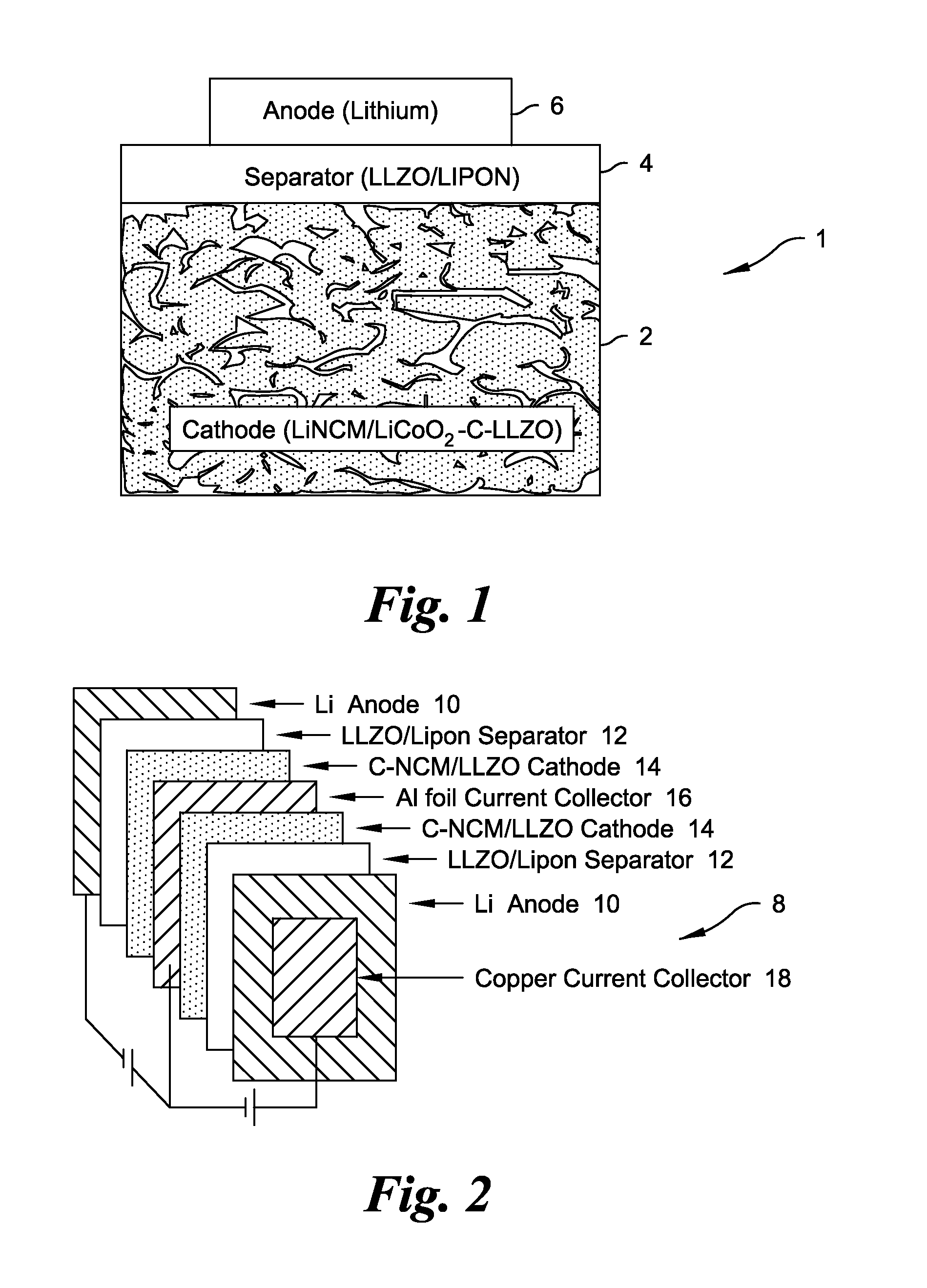

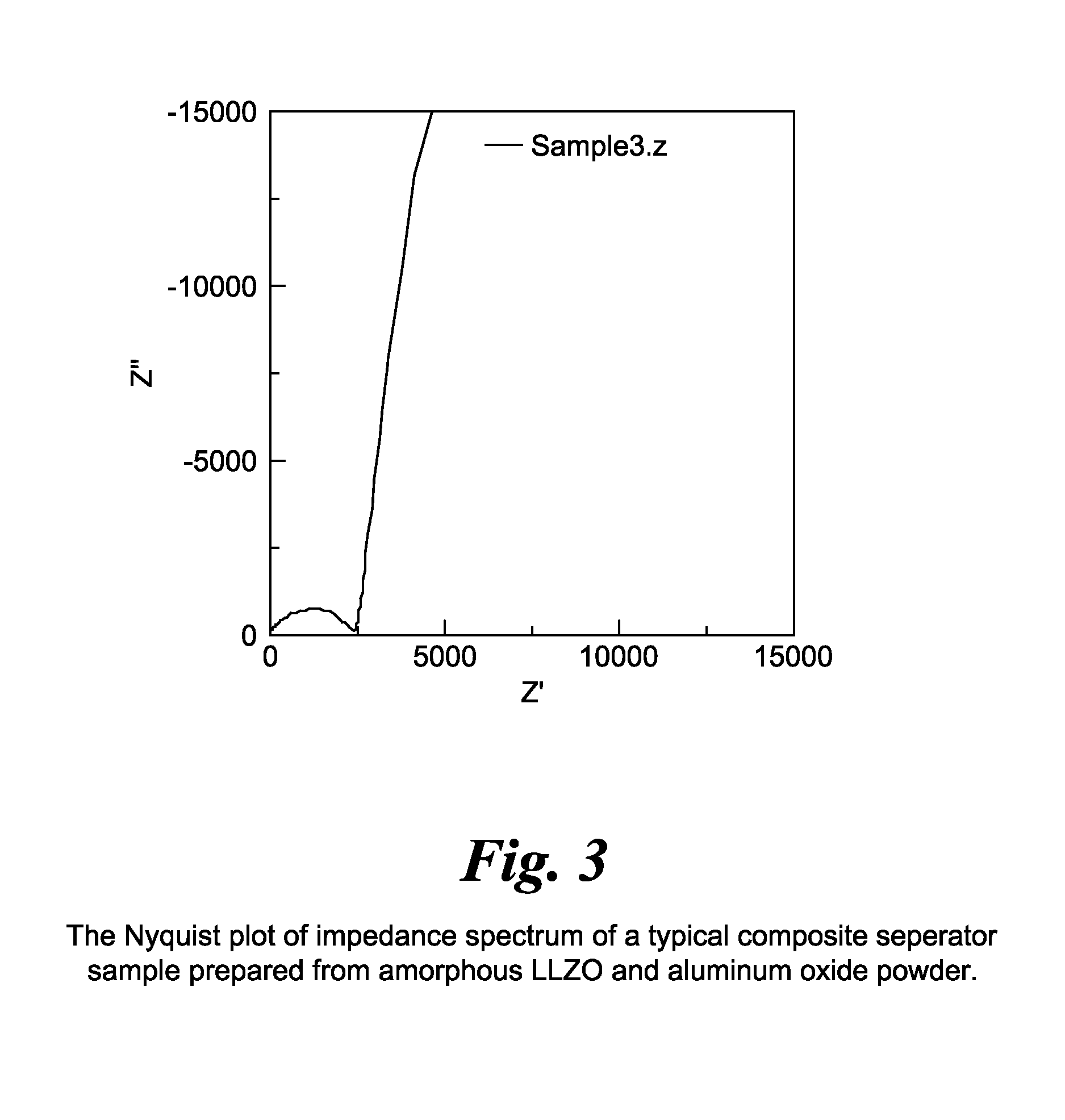

ActiveUS20150333307A1Large capacityLow costElectrode rolling/calenderingElectrode thermal treatmentComposite cathodeLanthanum

A high capacity solid state composite cathode contains an active cathode material dispersed in an amorphous inorganic ionically conductive metal oxide, such as lithium lanthanum zirconium oxide and / or lithium carbon lanthanum zirconium oxide. A solid state composite separator contains an electronically insulating inorganic powder dispersed in an amorphous, inorganic, ionically conductive metal oxide. Methods for preparing the composite cathode and composite separator are provided.

Owner:JOHNSON IP HLDG LLC

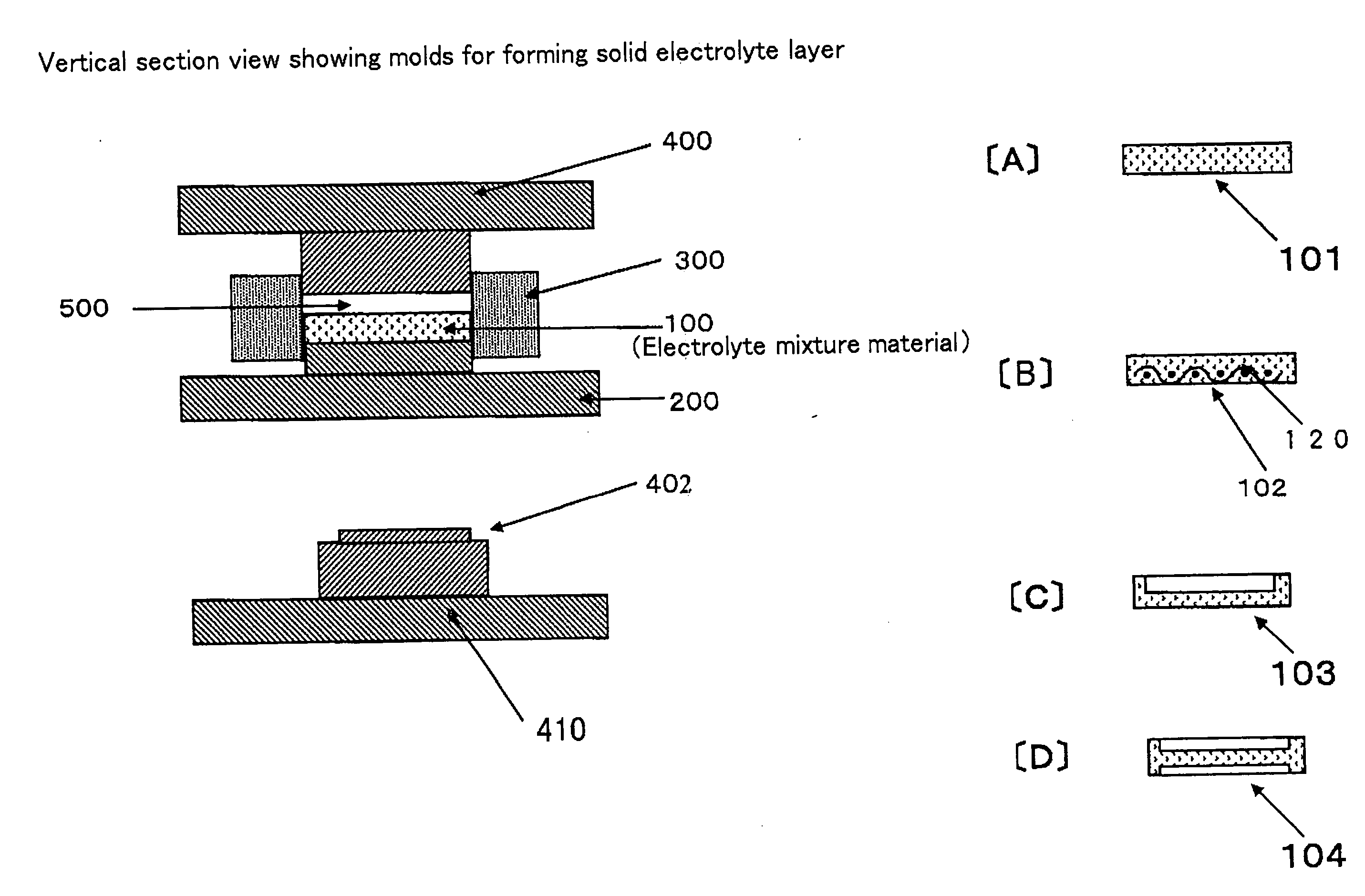

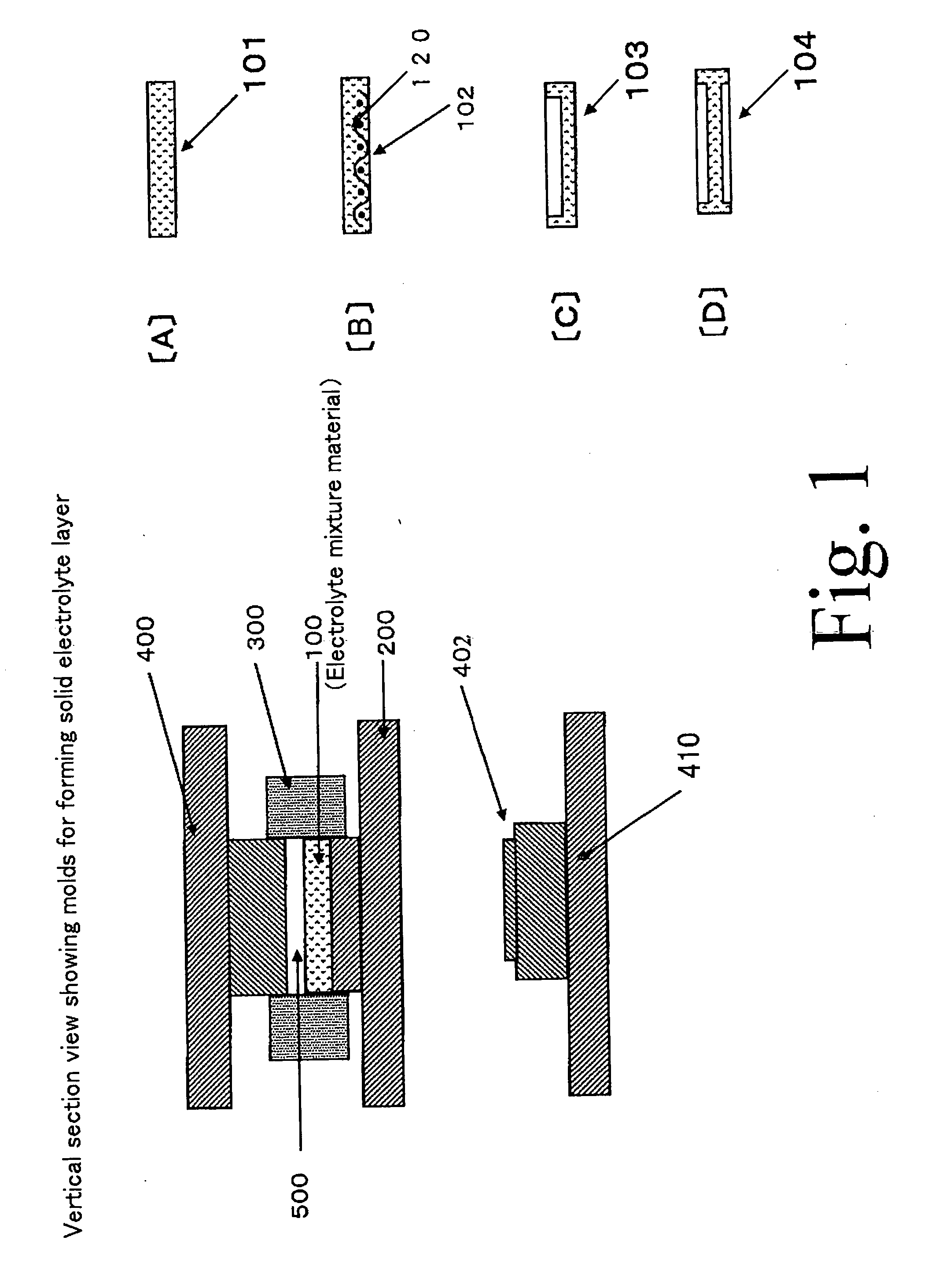

Electrochemical device

ActiveUS20090081553A1Maintain good propertiesIncrease resistanceSilver accumulatorsElectrode rolling/calenderingElectrochemistryOragene

An electrochemical device manufactured using an electrode layer in which severe increase of electrode resistance is prevented and / or a solid electrolyte layer in which severe decrease of ion conductivity of a solid electrolyte is prevented is provided. The electrochemical device includes a pair of electrode layers, and a solid electrolyte layer provided between the pair of electrode layers, wherein at least one layer of the electrode layers and the solid electrolyte layer is composed of first particles each providing a function of the at least one layer, second particles and a binder which is composed of an organic polymer and binds the first and second particles, and wherein the at least one layer is formed from a mixture material containing the first particles and binder particles, each of the binder particles including the second particle and the binder carried on at least a part of a surface thereof.

Owner:SEIKO EPSON CORP

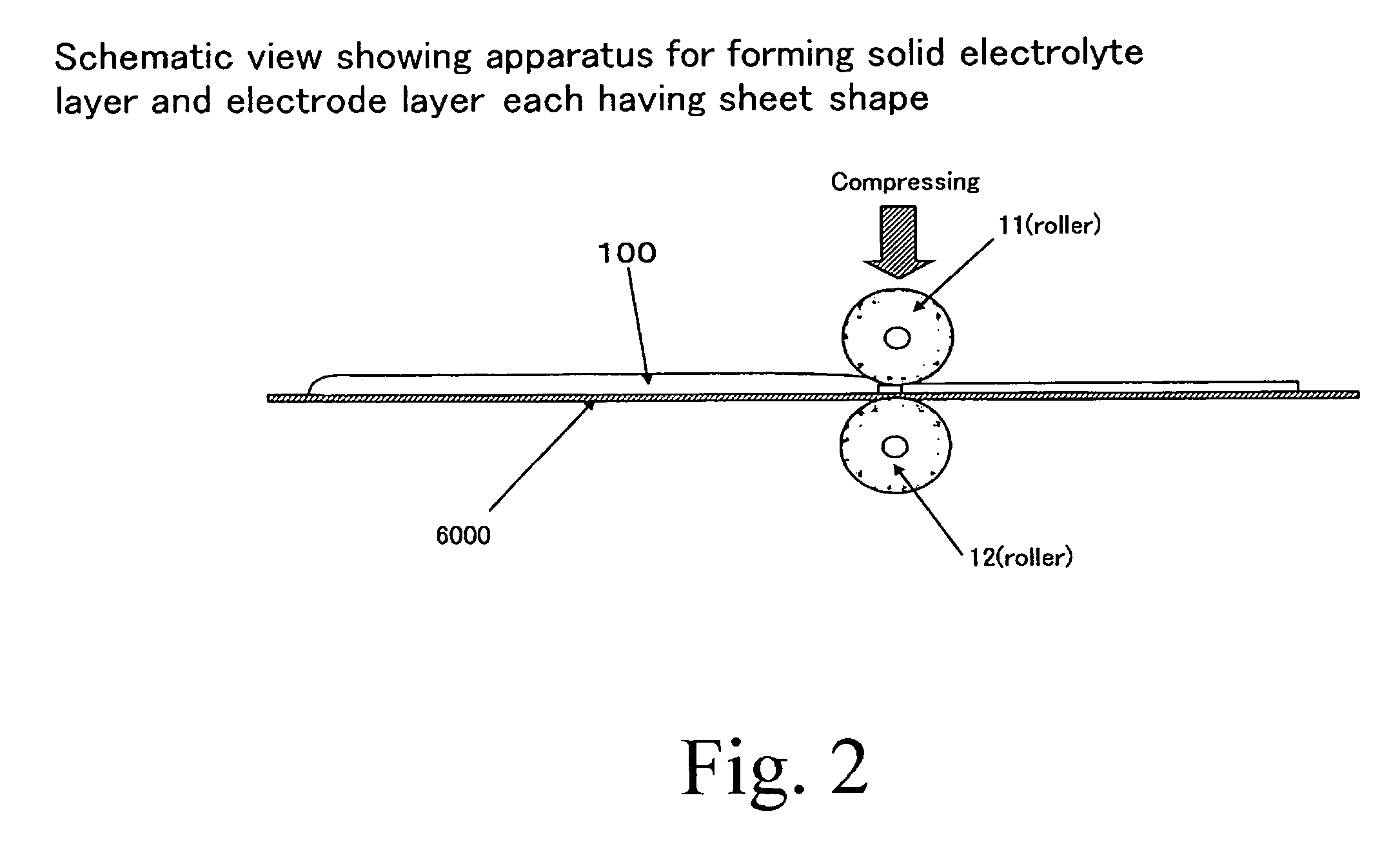

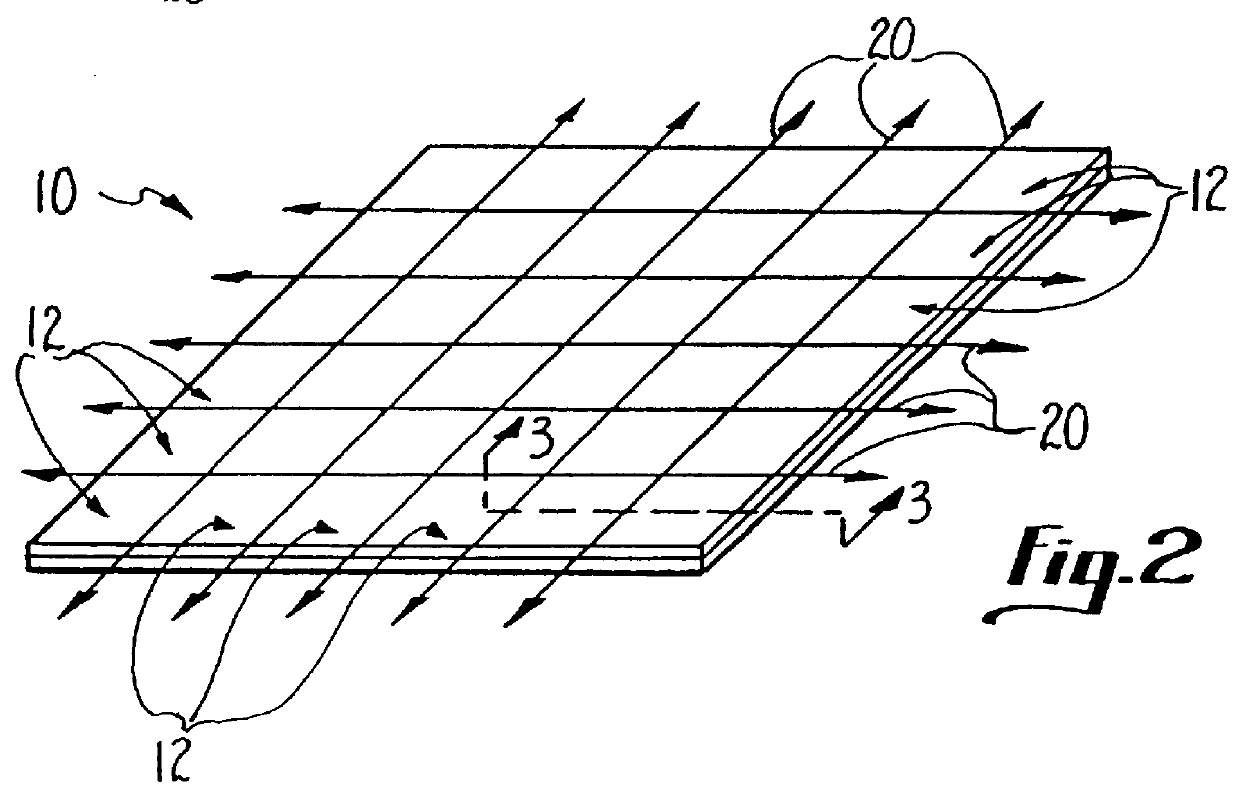

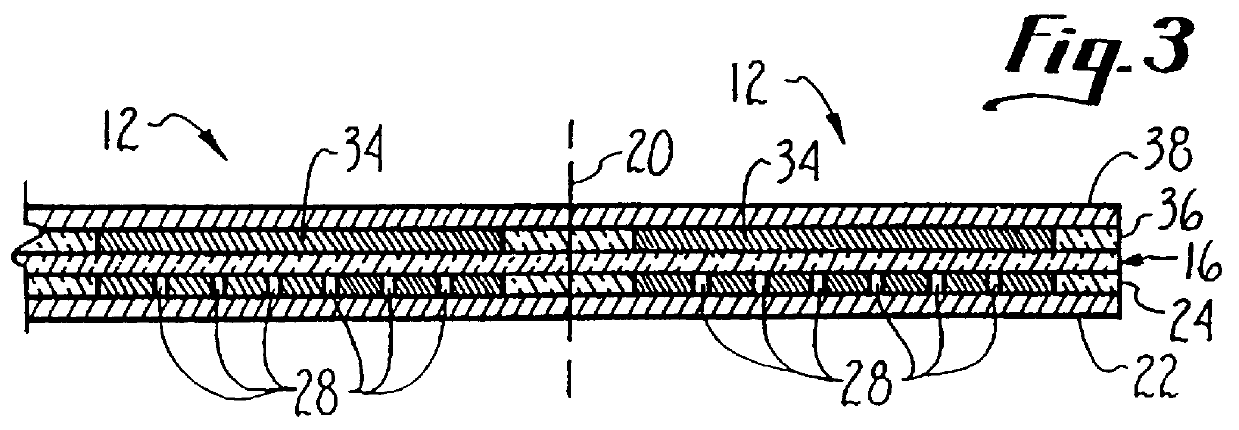

Polymer-lithium batteries and improved methods for manufacturing batteries

InactiveUSRE36843E1Prevent and minimize electrical shortingHigh voltageElectrode rolling/calenderingFinal product manufactureEngineeringDeposition process

Improved polymer batteries and improved methods of manufacturing such polymer batteries are provided. One improved method of manufacture involves the formation of a laminated array structure that includes a number of individual battery cells. After formation of the laminated array the individual batteries are singulated from the array by cutting, shearing or stamping. Other manufacturing improvements include the use of a printing process (e.g. stenciling) to form the cathodes, the use of permanent mask layers to contain and insulate the cathodes and anodes, and the use of a molten lithium deposition process for forming the anodes.

Owner:ROUND ROCK RES LLC

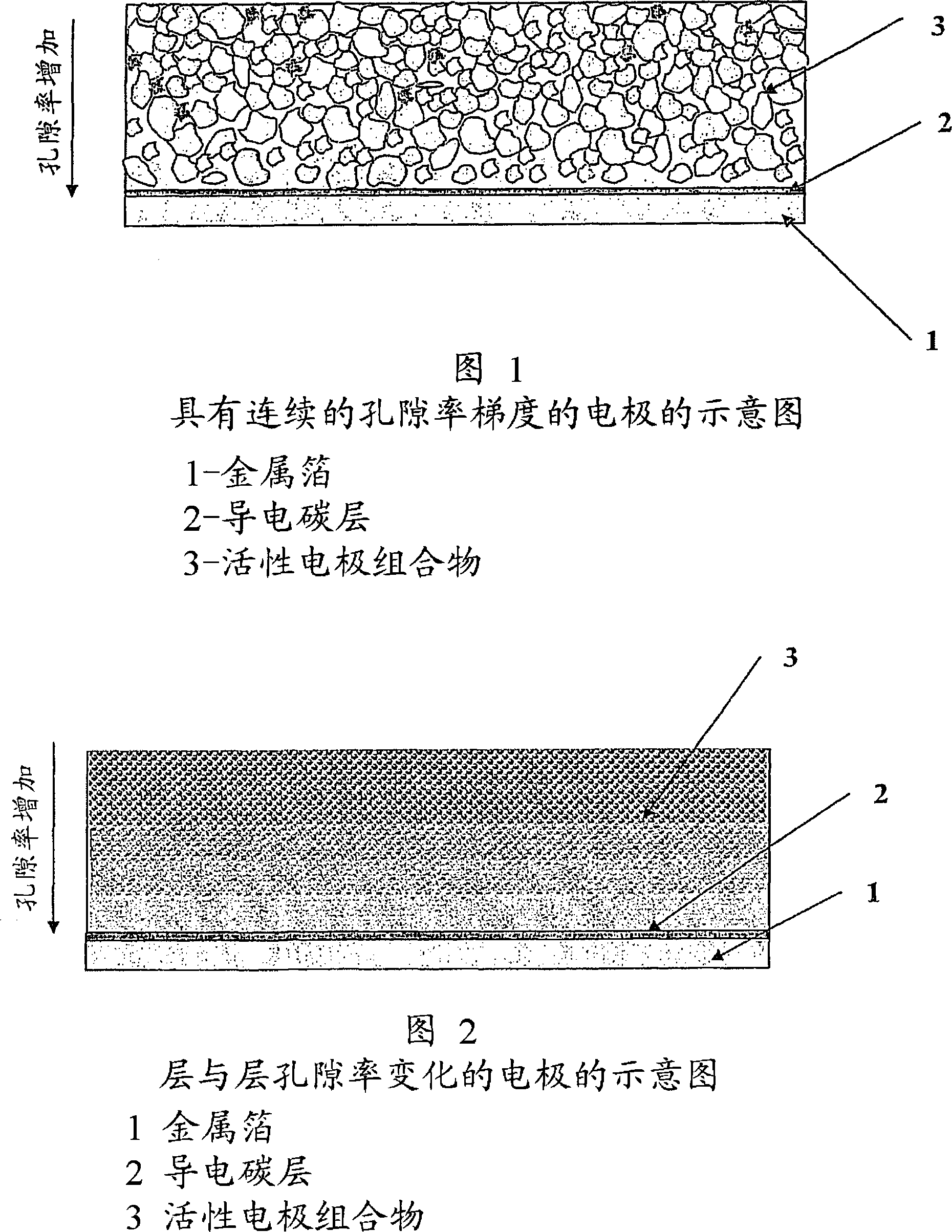

Improvements relating to electrode structures in batteries

ActiveCN101002351ASolve the real problemImprove electrochemical utilizationElectrode rolling/calenderingFinal product manufacturePorosityComposite electrode

There are disclosed solid composite electrodes with electrode active layers that include an electrode active material, an optional electron conductive material, an optional binder and other optional additives. The solid composite electrodes are formed by the deposition of an electrode composition (slurry) onto a current collector in one or many layers. The electrode structure is characterised by a porosity of the electrode composition layer that decreases in a direction from the back side of the layer (close to the current collector) towards the outer side of the layer. The gradient of the decrease in the porosity is controlled by the content of solid substance in the slurry, by the composition of the solvent in the slurry, by the temperature of the layer drying after deposition, as well as by the pressing or calendering conditions for each layer. The electrode structures can be used in chemical sources of electric energy such as primary (non-rechargeable) as well as secondary (rechargeable) batteries.

Owner:JOHNSON MATTHEY PLC

Dry particle packaging systems and methods of making same

InactiveUS20060246343A1Reduce water consumptionHigh yieldElectrode rolling/calenderingElectrolytic capacitorsBiomedical engineering

Owner:TESLA INC

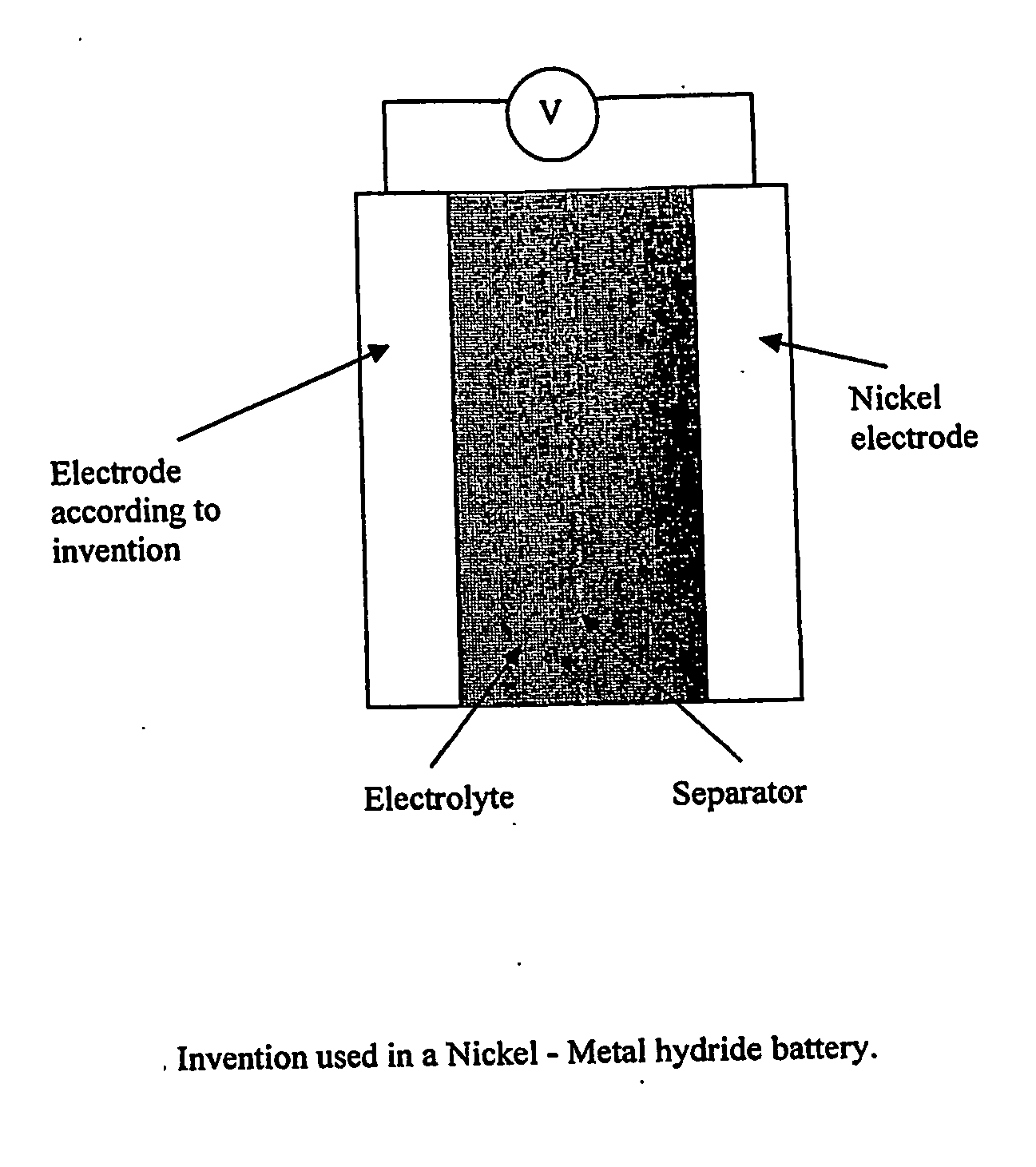

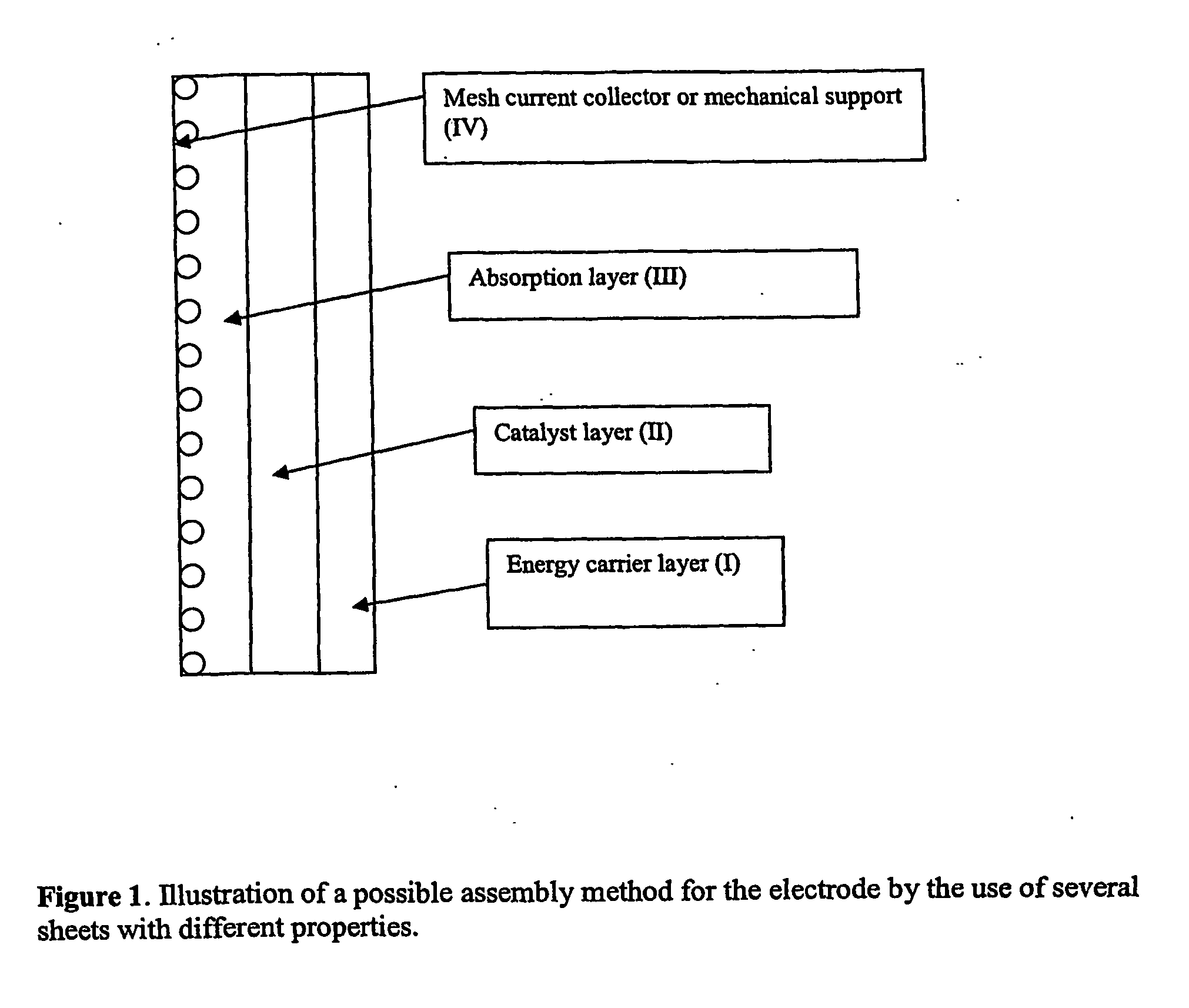

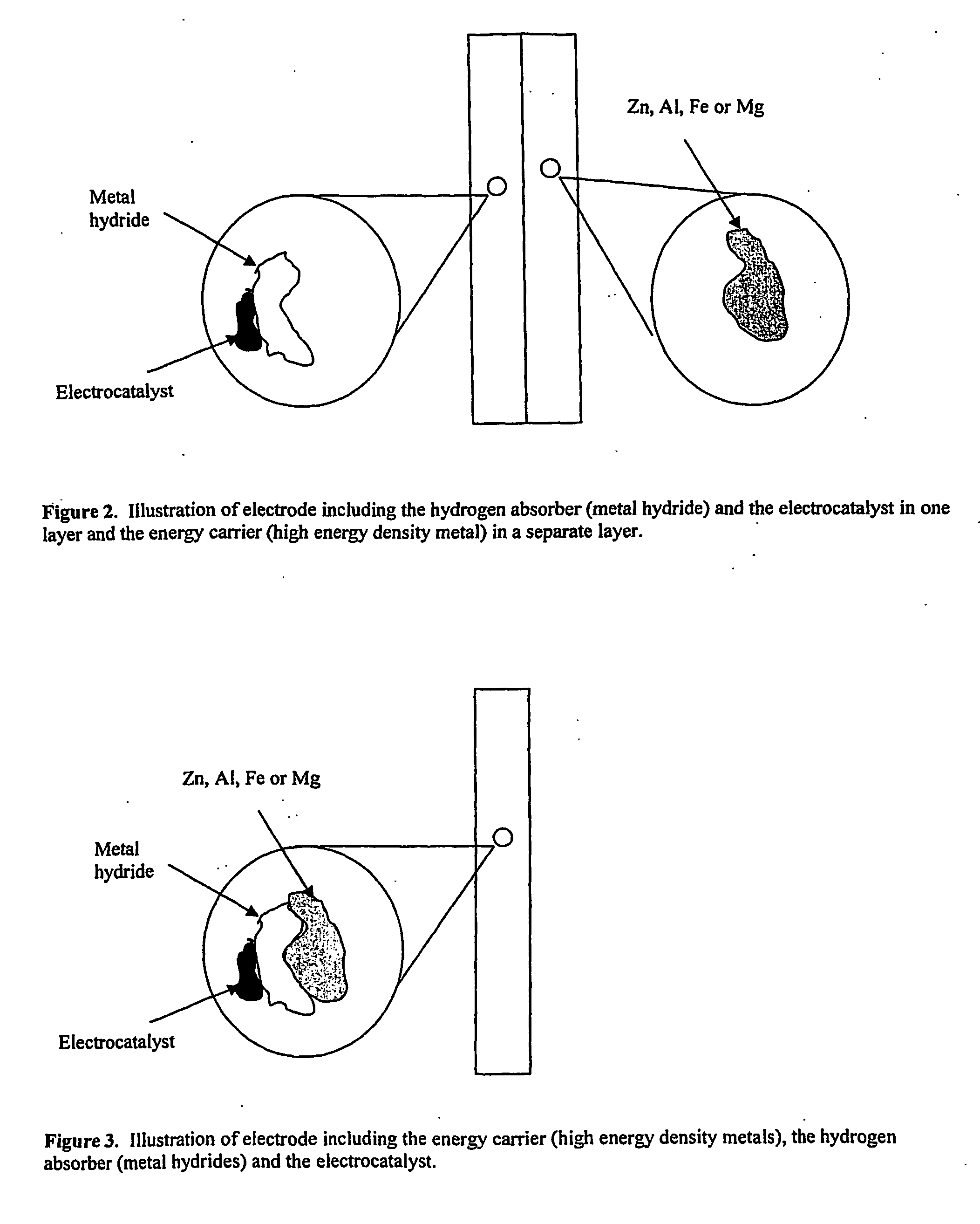

Electrode, method of its production, metal-air fuel cell and metal hydride cell

InactiveUS20070077491A1Improve energy efficiencyHigh energy capacityElectrode rolling/calenderingHydrogenFuel cellsReaction rate

The invention described concerns an anode electrode comprising a hydrogen storage material / alloy and a high energy density metal. In addition a hydrogen electrocatalyst may be added to increase the hydrogen reaction rate. The high energy density metal is selected from a group consisting of Al, Zn, Mg and Fe, or from a combination of these metals. A method of production of an electrode comprising a hydrogen storage alloy and a high energy density metal is also described. The method comprises sintering or binding a high energy density metal powder and / or hydrogen storage alloy into at least one thin street, and calendaring or pressing said sheet forming the electrode. The anode electrode may be used in metal hydride batteries and metal air fuel cells.

Owner:REVOLT TECH LTD

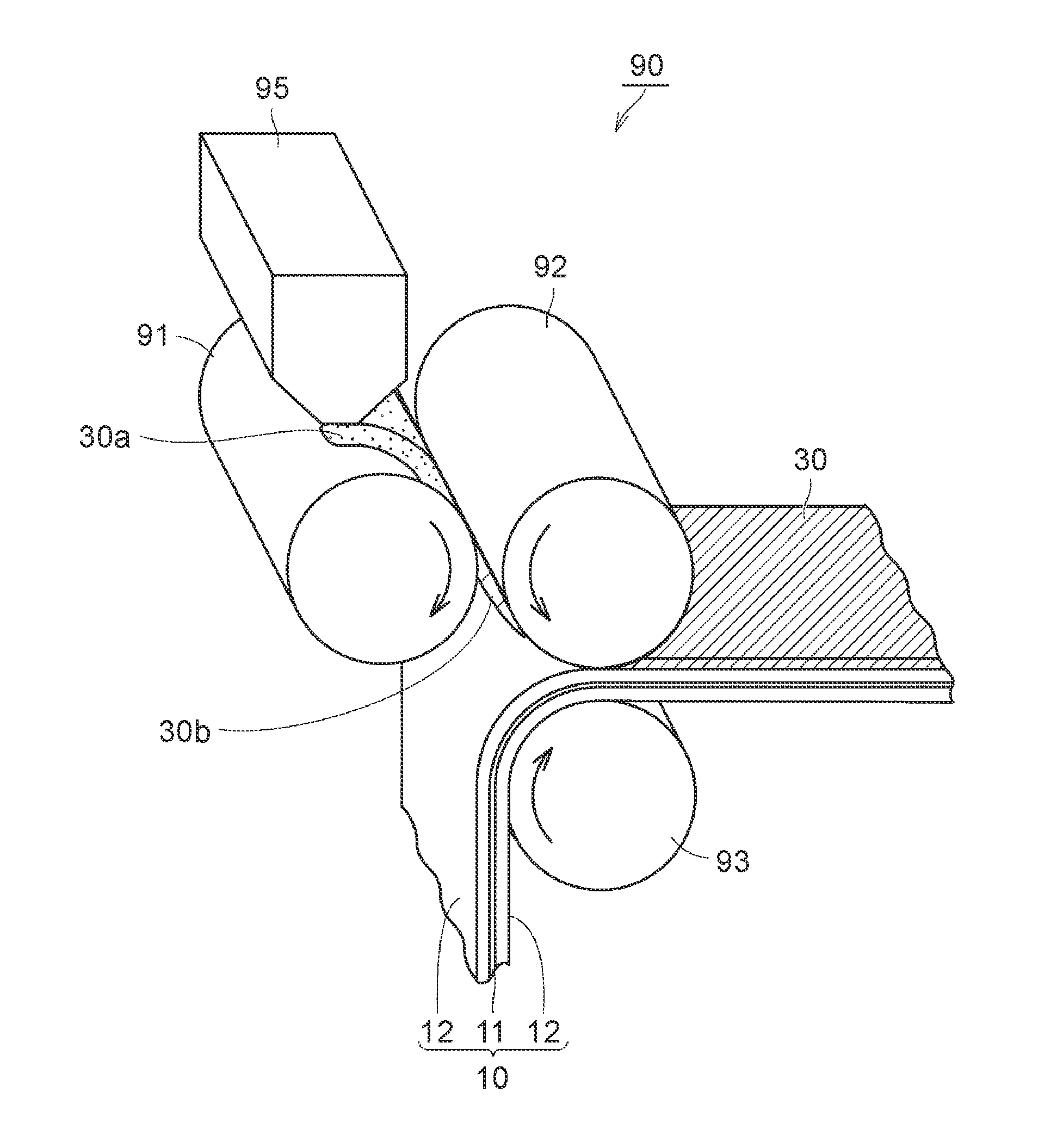

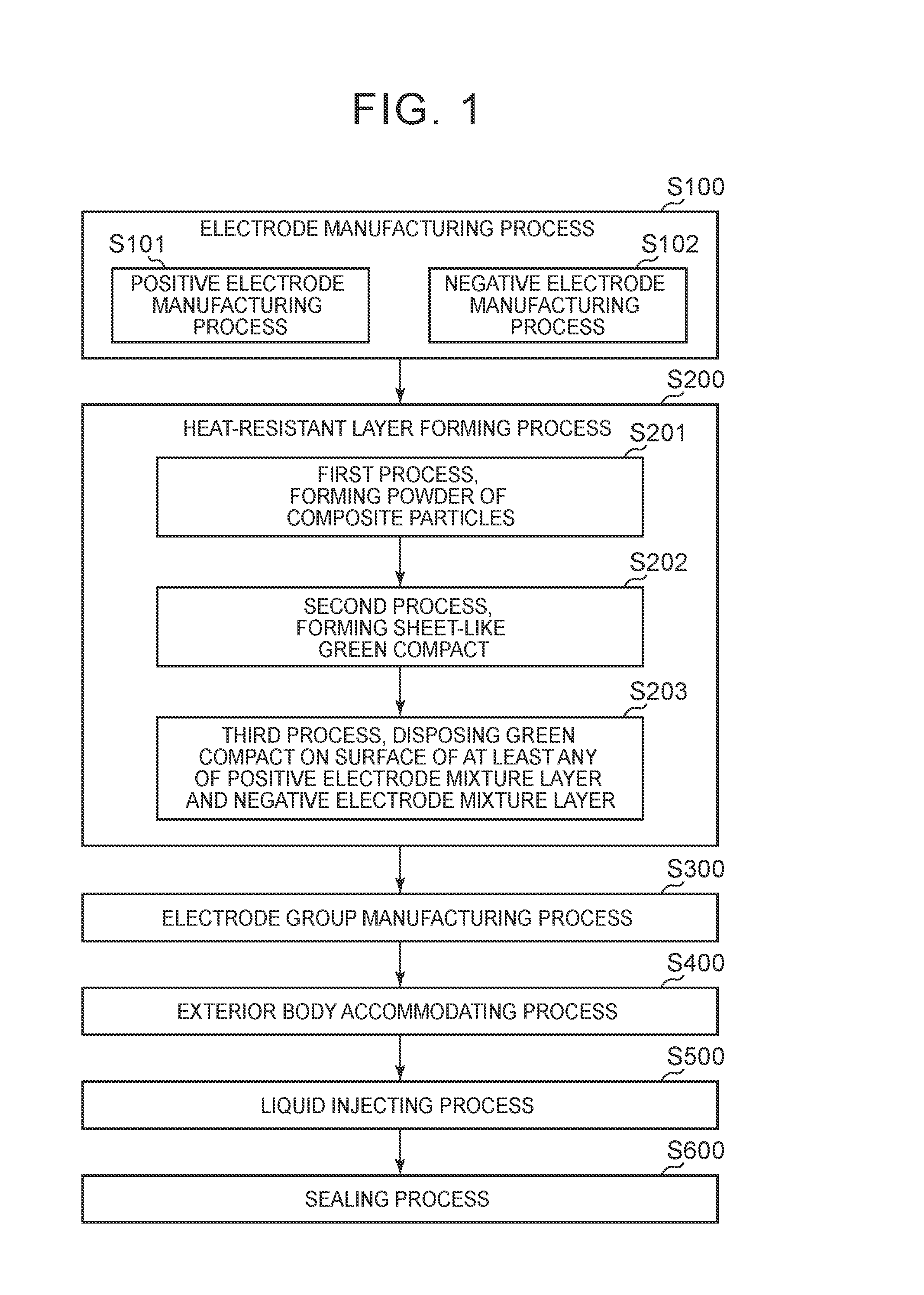

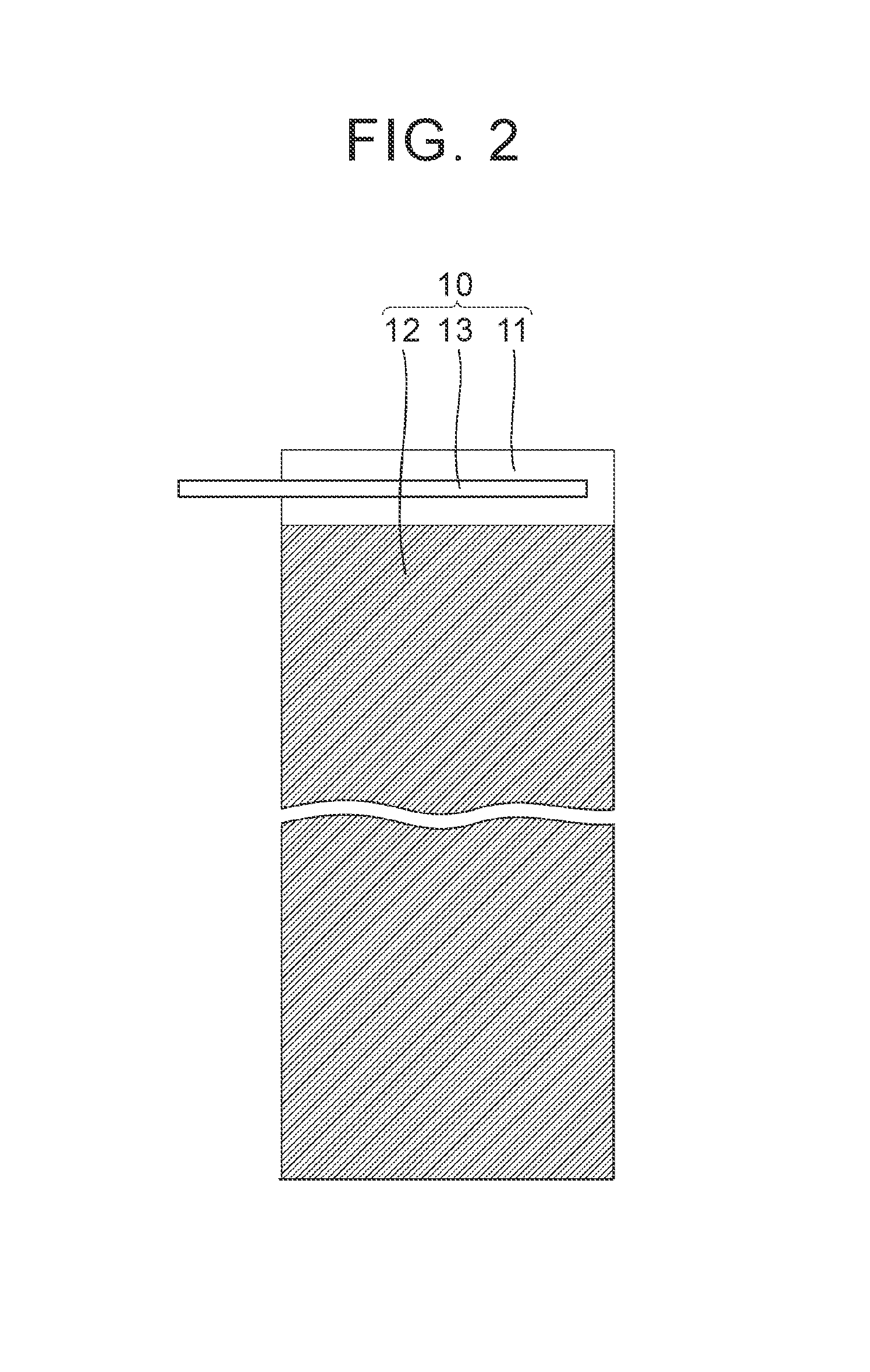

Manufacturing method for non-aqueous electrolyte secondary battery

ActiveUS20160240839A1Reduce the amount requiredHigh strengthElectrode rolling/calenderingNon-aqueous electrolyte accumulatorsSolventInorganic filler

A manufacturing method for a non-aqueous electrolyte secondary battery includes: forming a powder; forming a sheet-like green compact; and forming a heat-resistant layer. The powder contains composite particles and a solvent. The composite particles contain inorganic filler particles and a binder. The green compact is formed by pressing the powder in a state in which the solvent remains. The heat-resistant layer is formed by disposing the green compact on a surface of at least any of a positive electrode mixture layer and a negative electrode mixture layer after the green compact is formed.

Owner:TOYOTA JIDOSHA KK

Particles based electrodes and methods of making same

ActiveUS20060114643A1Long lasting and durable and inexpensiveImprove throughputElectrode rolling/calenderingLiquid electrolytic capacitorsCoated electrodesEnergy storage

A coated electrode is provided for use in energy storage devices. The coated electrode comprises a dry particles that are fibrillized.

Owner:TESLA INC

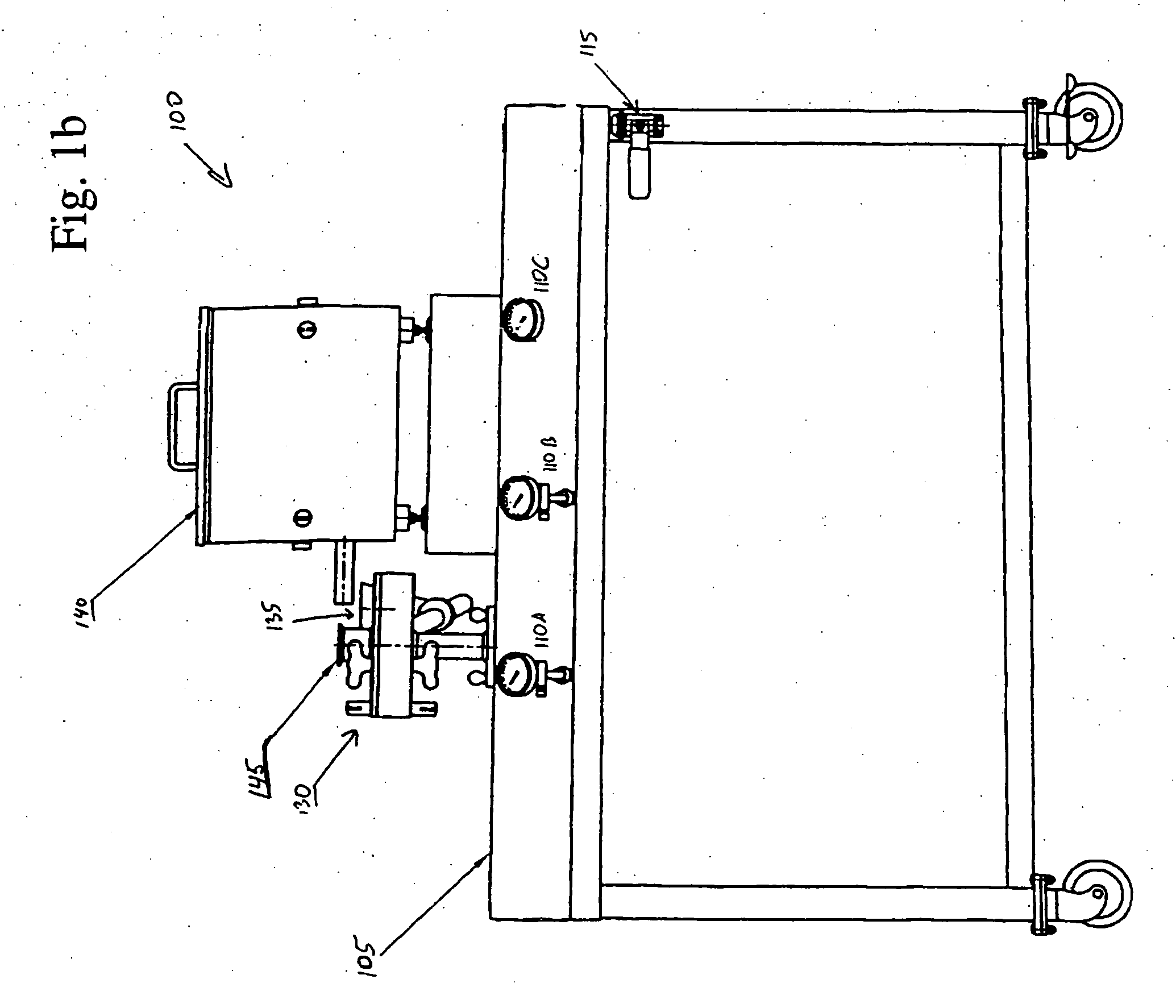

Lithium supplement method and system of pole plate

ActiveCN105489846AHigh strengthAvoid tearingElectrode rolling/calenderingFinal product manufactureUltimate tensile strengthLithium-ion battery

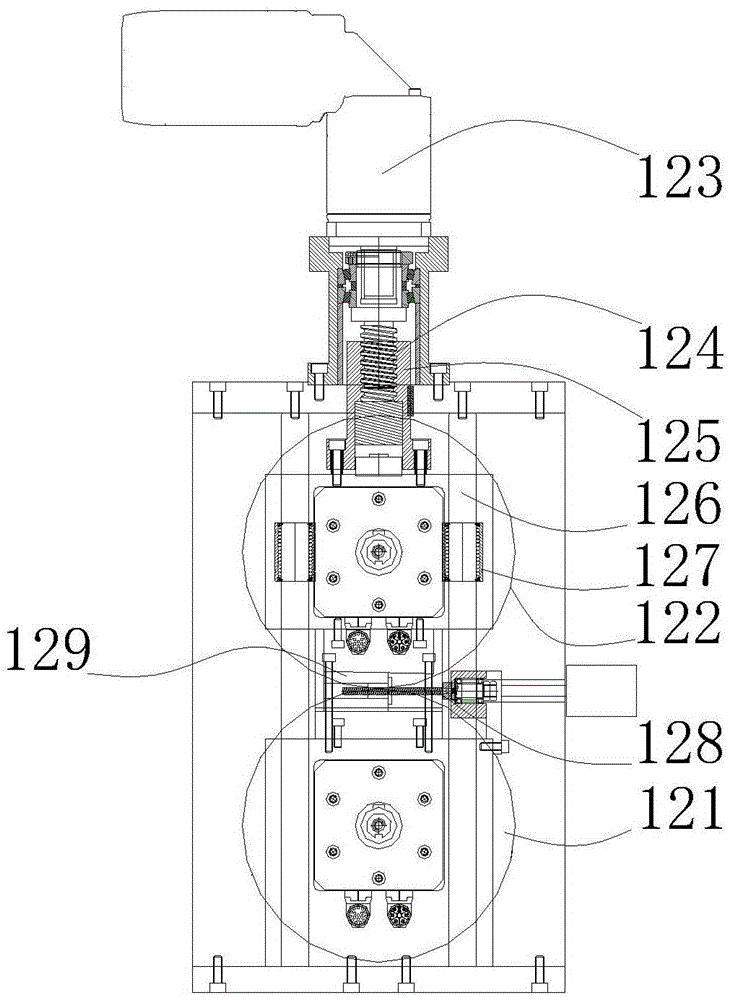

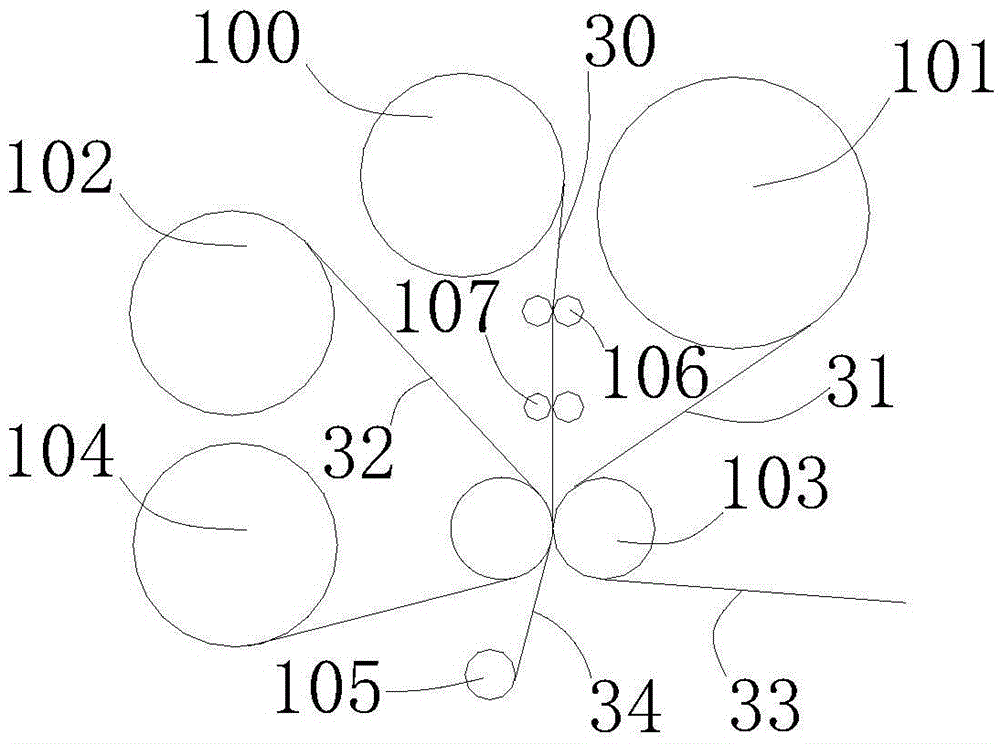

The application relates to the technical field of production of a lithium ion battery, in particular to a lithium supplement method and system of a pole plate. The method comprises the following steps of combining a first substrate and a first lithium strip to form a first composite lithium strip, forming separation between the first lithium strip and a composite device by using a second substrate; combining the first composite lithium strip and a pole plate to be lithium-supplemented to form a lithium-supplement composite pole plate, wherein the first substrate is arranged at one side far away from the pole plate to be lithium-supplemented; and stripping and winding the first substrate to form the lithium-supplemented pole plate. The device comprises a pole plate unwinding device, a first composite lithium strip transmission device, a pole plate lithium supplement rolling device, a first pole plate stripping device and a first substrate winding device, wherein the pole plate lithium supplement rolling device comprises two press rollers arranged in opposite. The lithium supplement method and system of the pole plate, provided by the application, adopt the substrates, on one hand, the strength of the lithium strip is enhanced, on the other end, separation is formed between the lithium strip and the composite device, and thus, the lithium strip is prevented from being broken by pulling or clamping.

Owner:CONTEMPORARY AMPEREX TECH CO

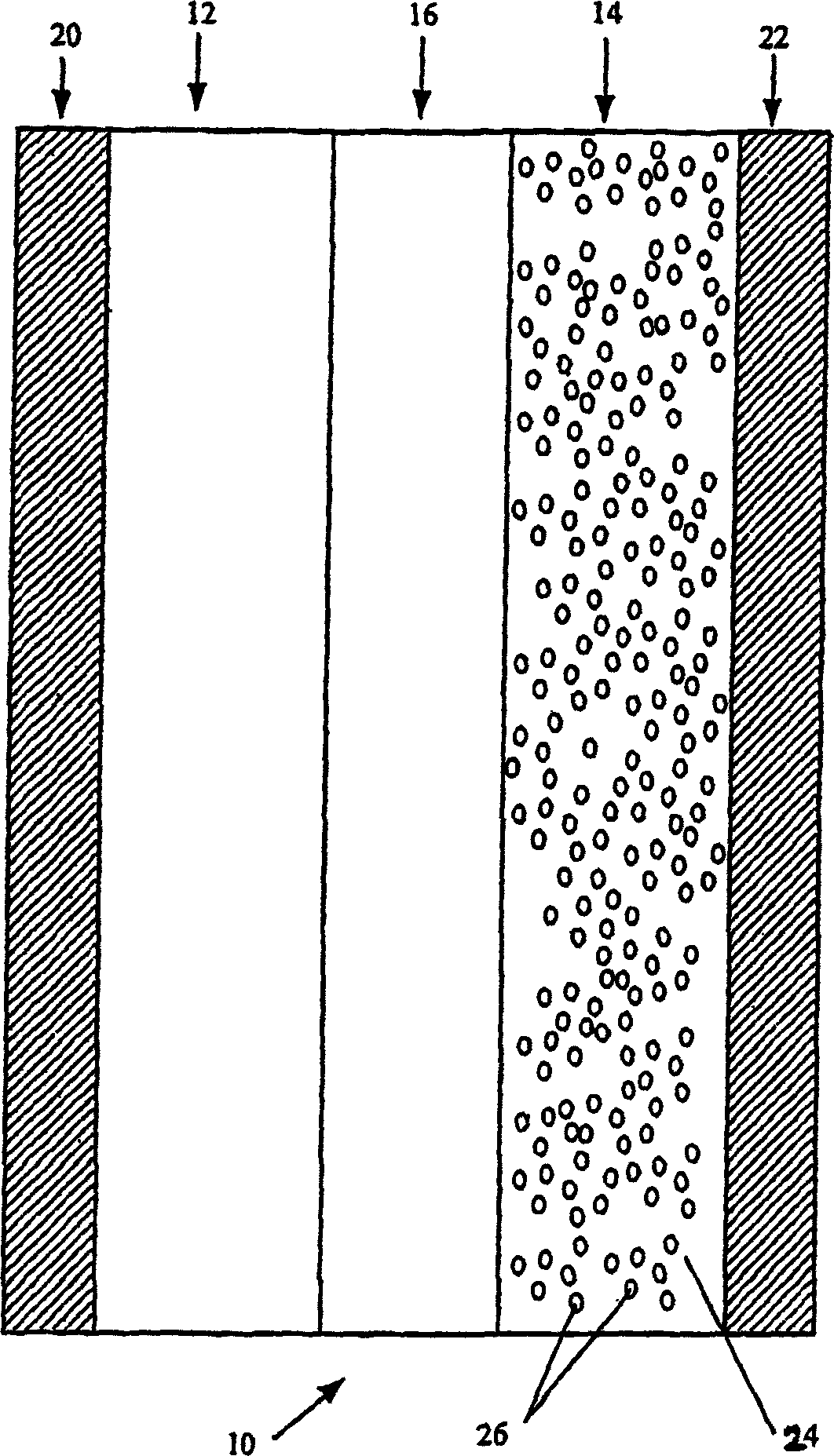

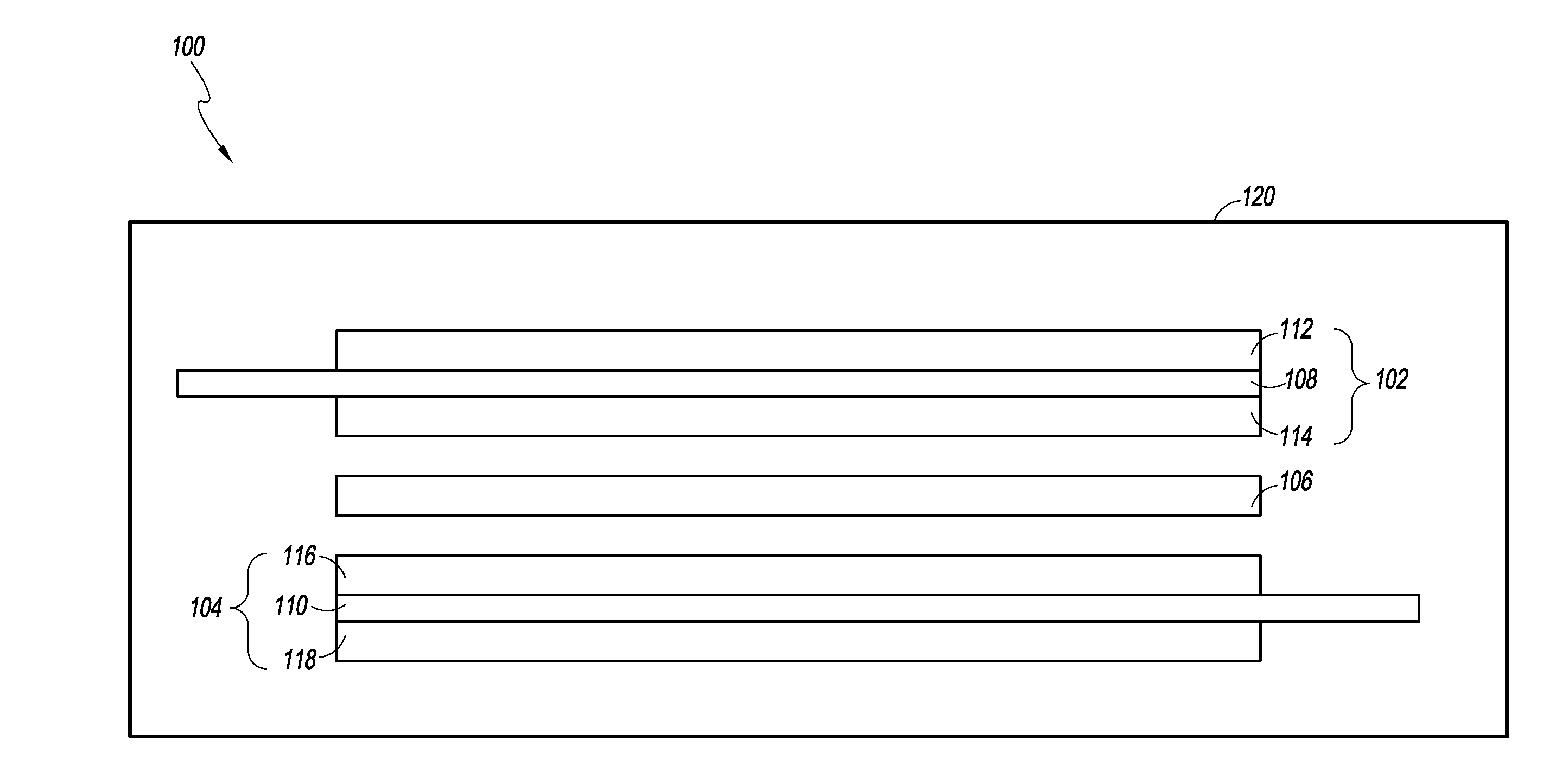

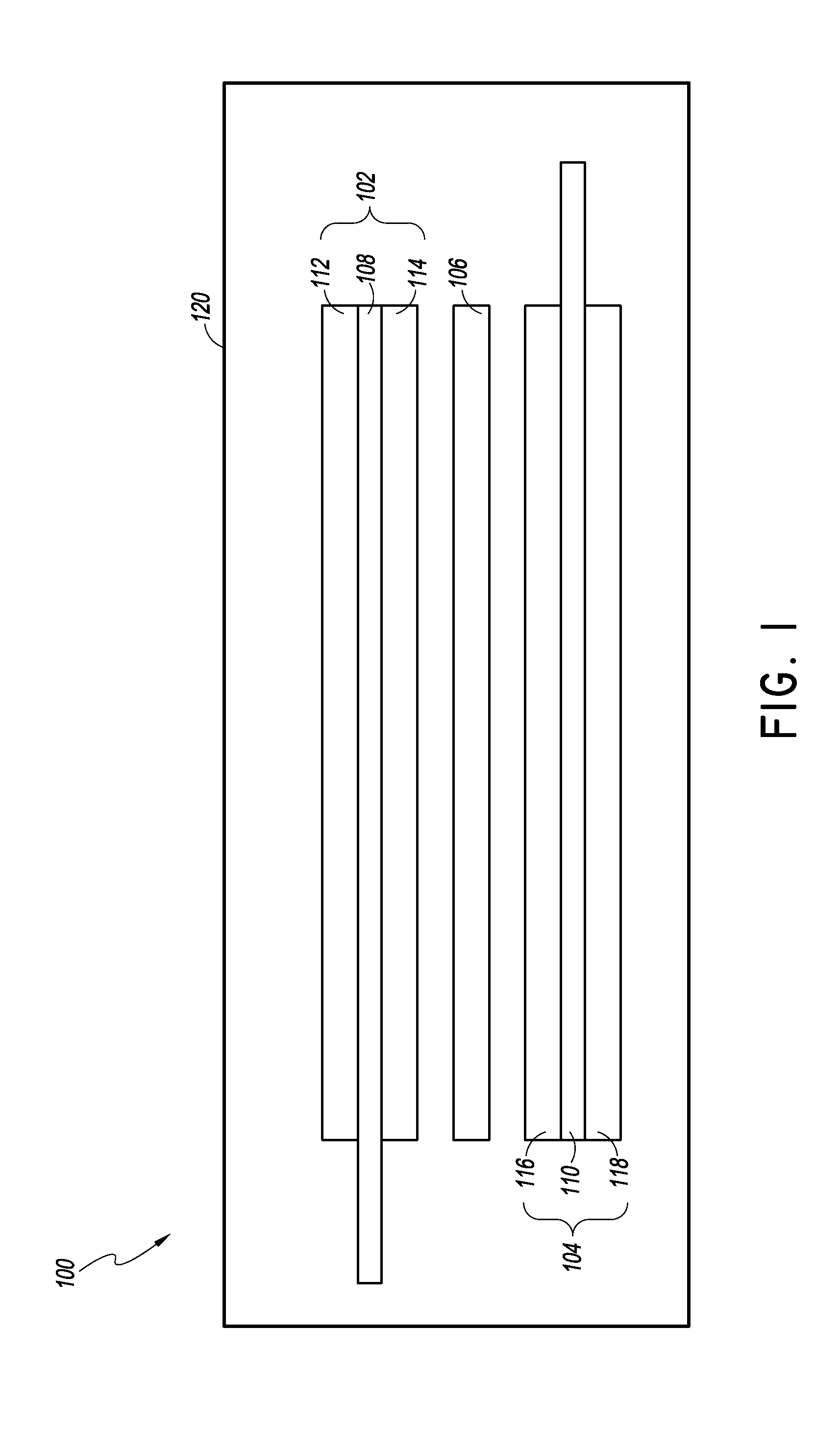

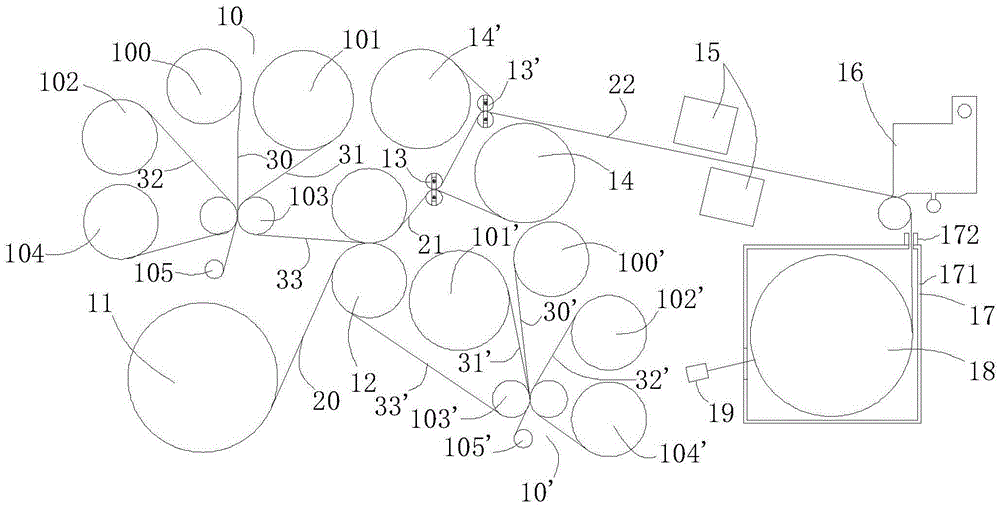

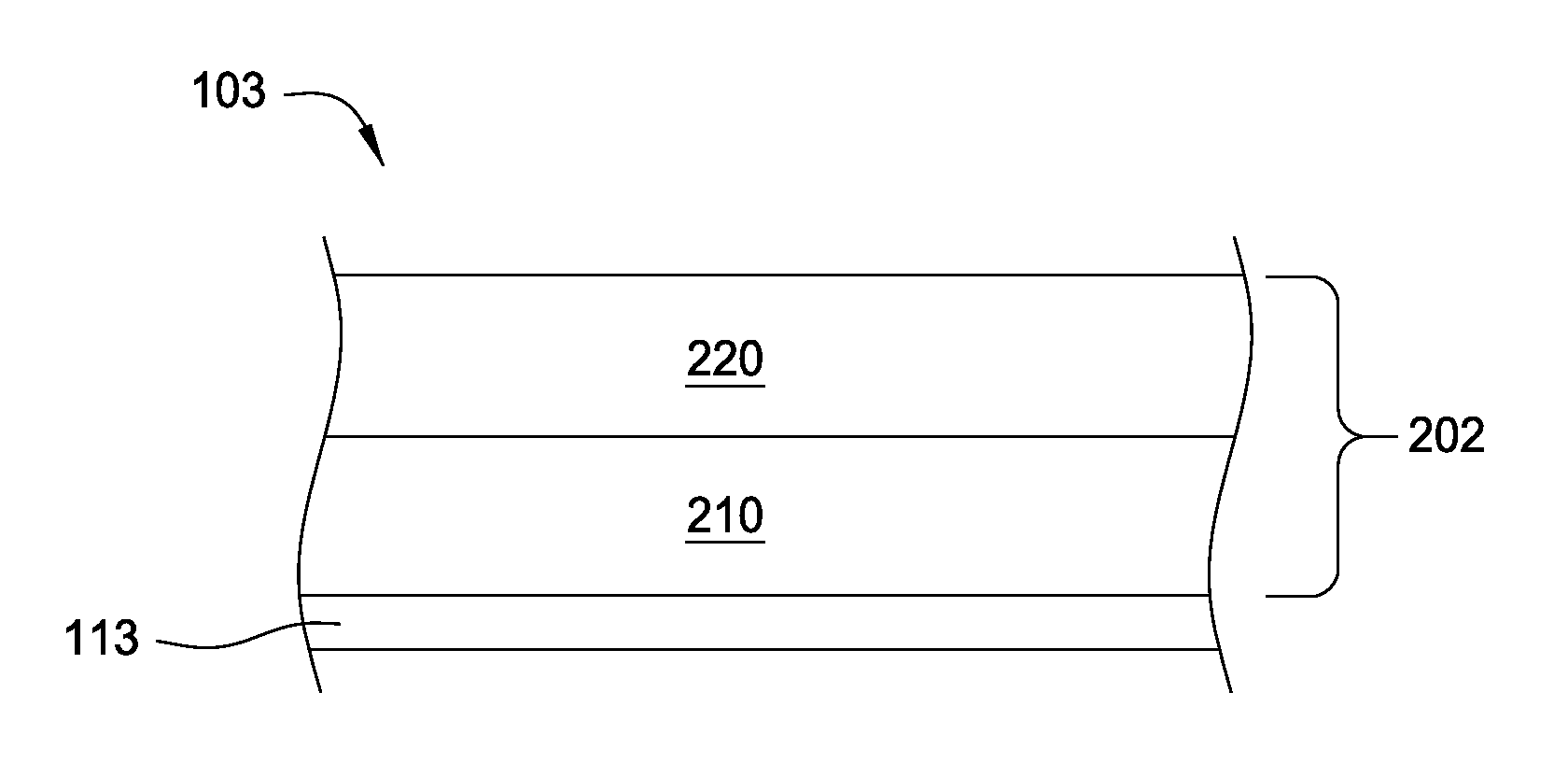

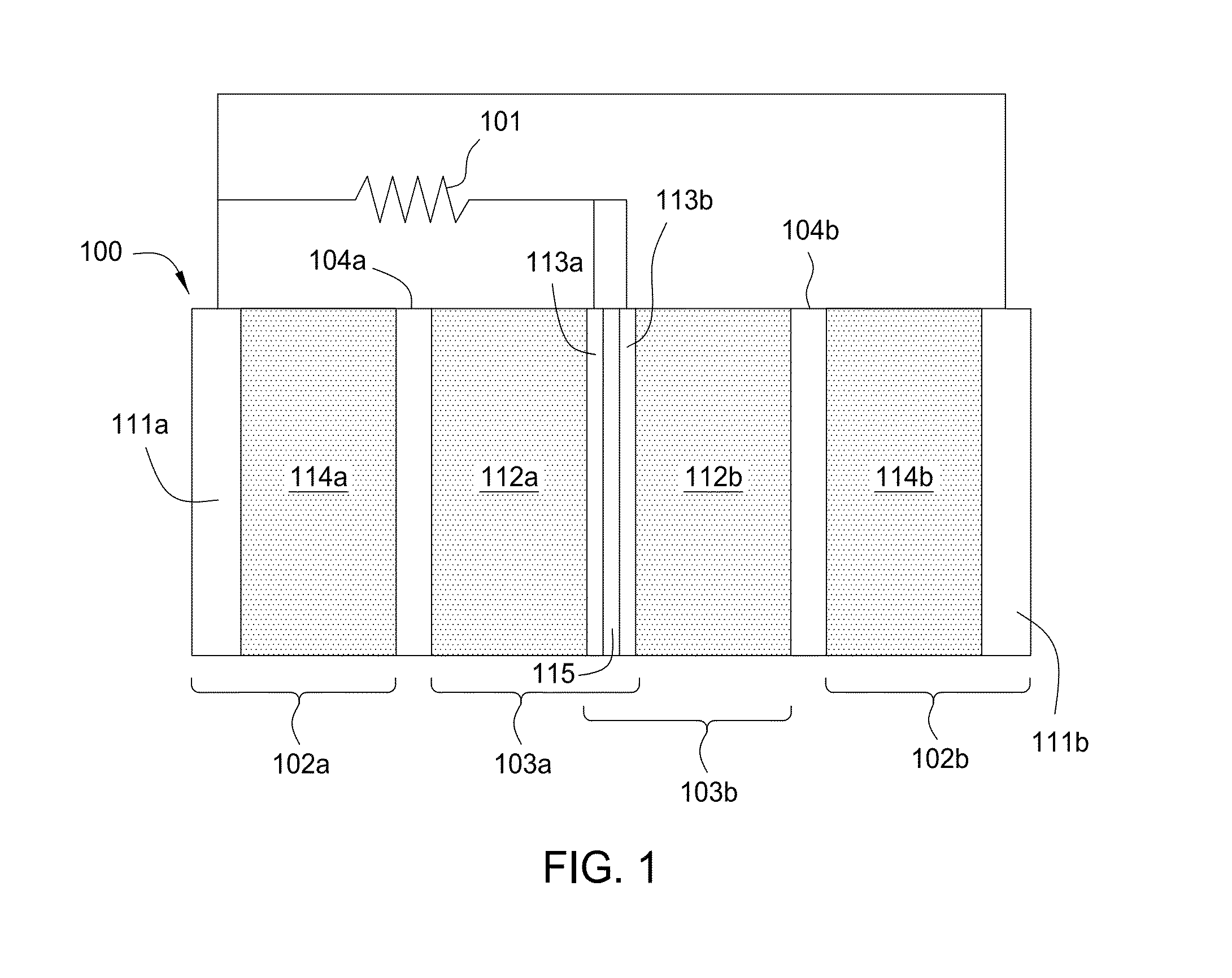

Multi-layer battery electrode design for enabling thicker electrode fabrication

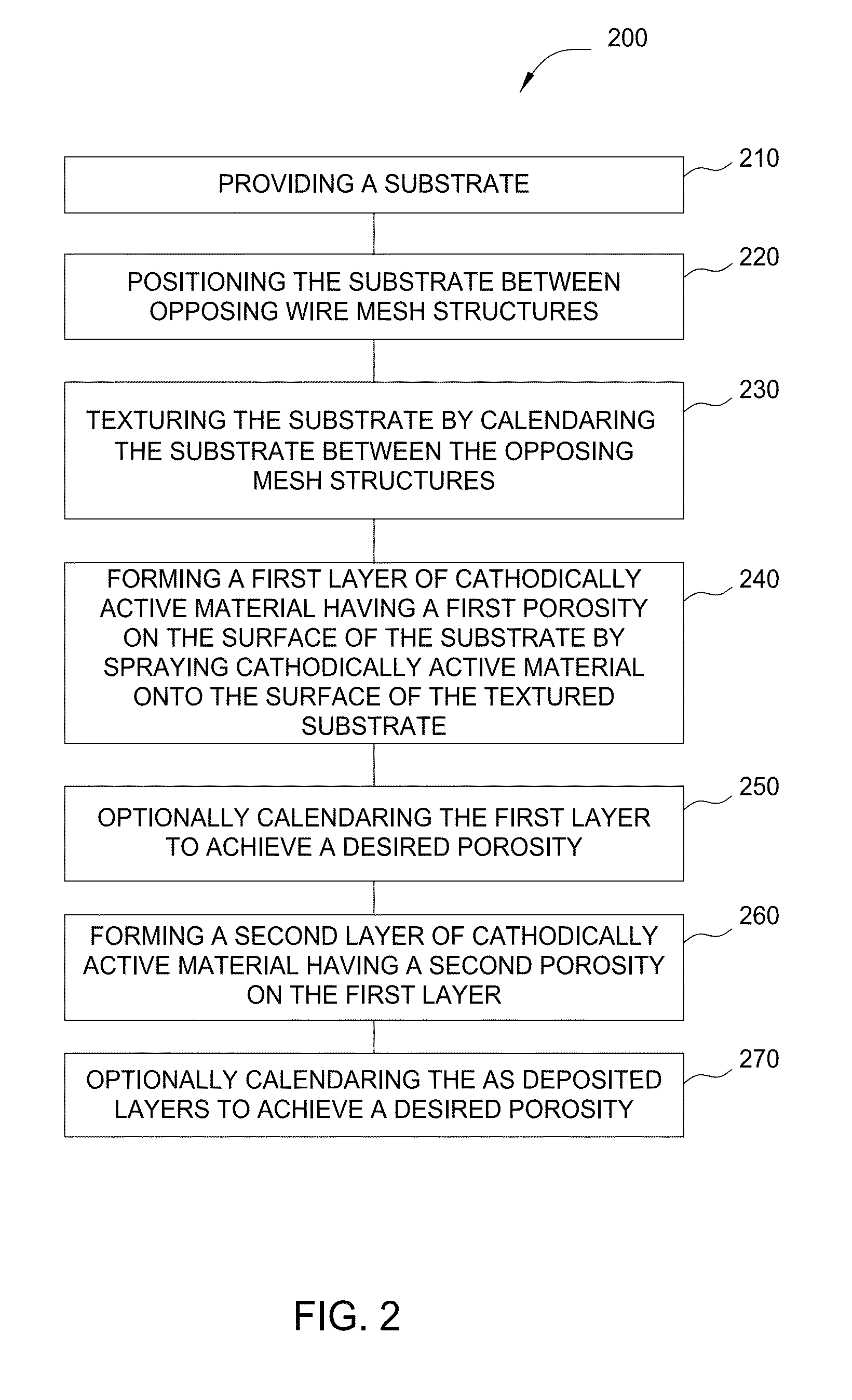

Implementations of the present invention relate generally to high-capacity energy storage devices and methods and apparatus for fabricating high-capacity energy storage devices. In one implementation, a method for forming a multi-layer cathode structure is provided. The method comprises providing a conductive substrate, depositing a first slurry mixture comprising a cathodically active material to form a first cathode material layer over the conductive substrate, depositing a second slurry mixture comprising a cathodically active material to form a second cathode material layer over the first cathode material layer, and compressing the as-deposited first cathode material layer and the second cathode material layer to achieve a desired porosity.

Owner:APPLIED MATERIALS INC

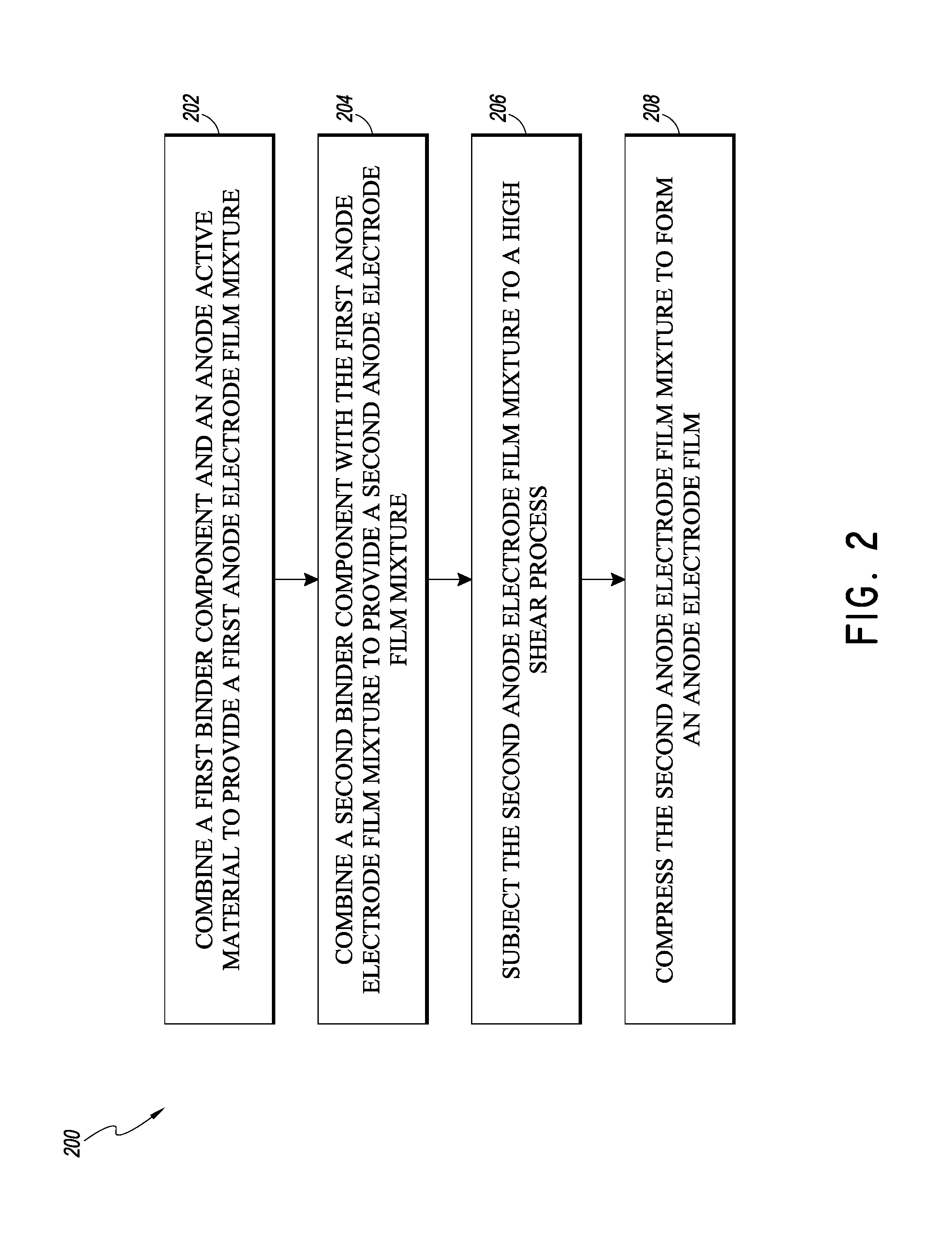

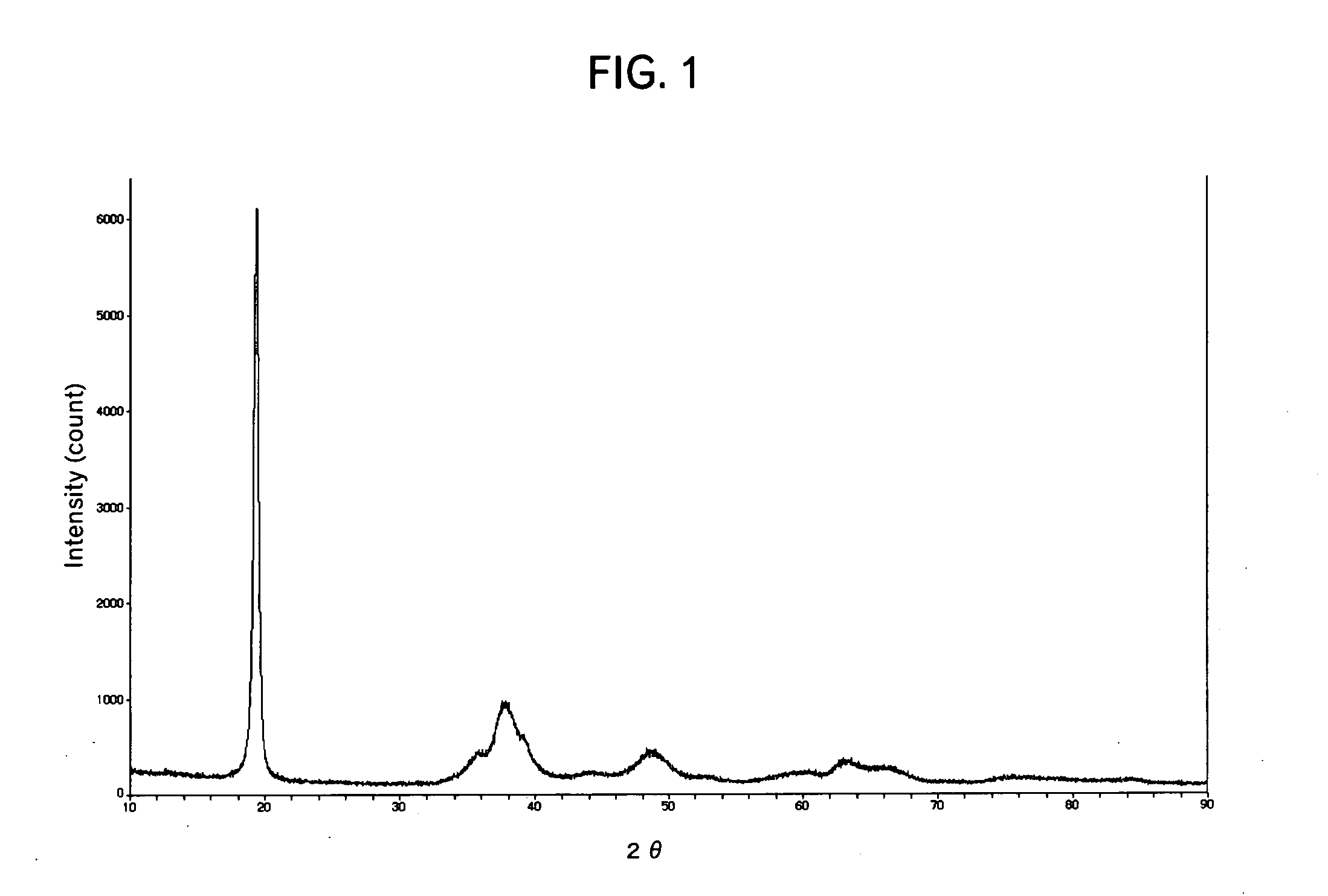

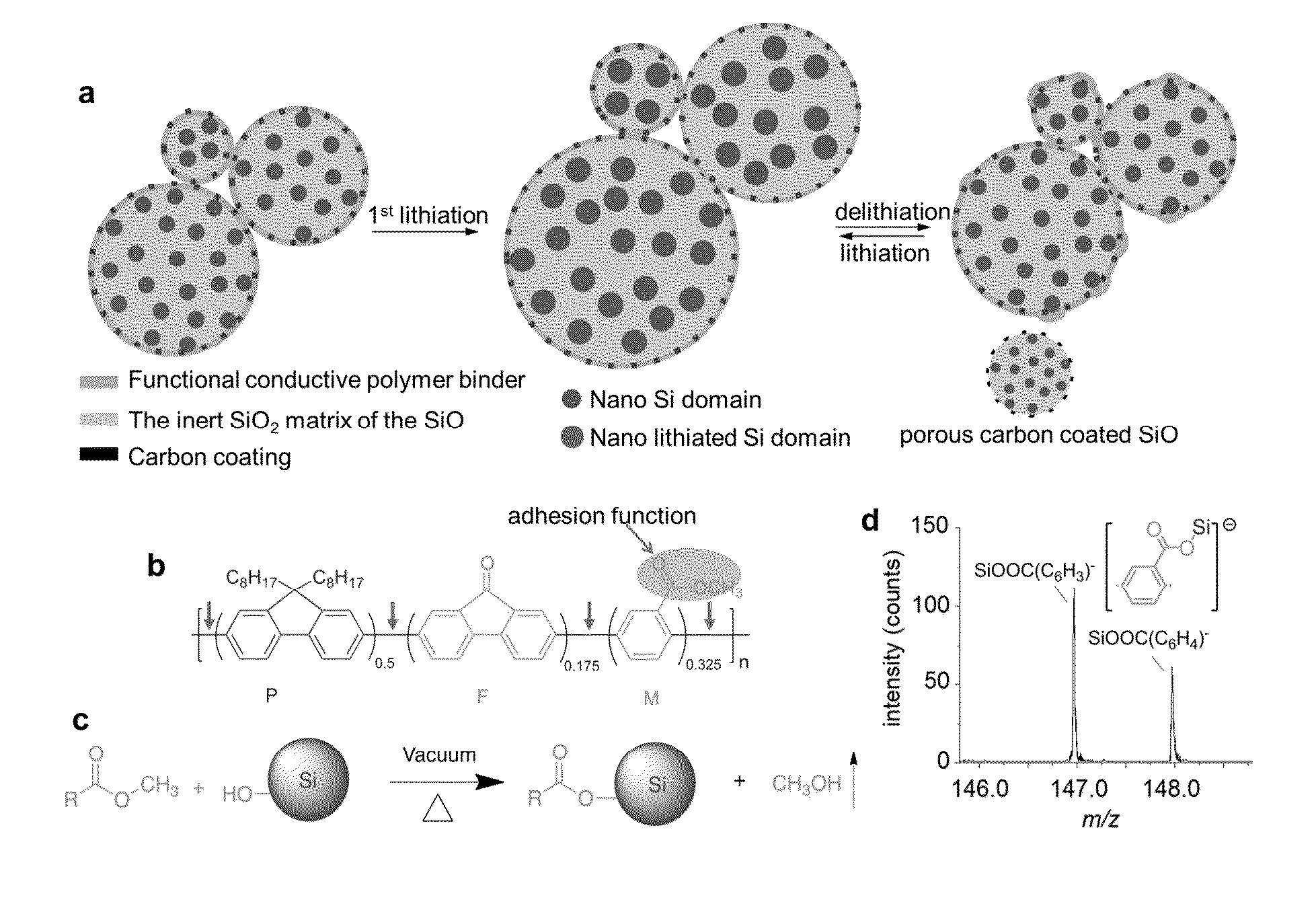

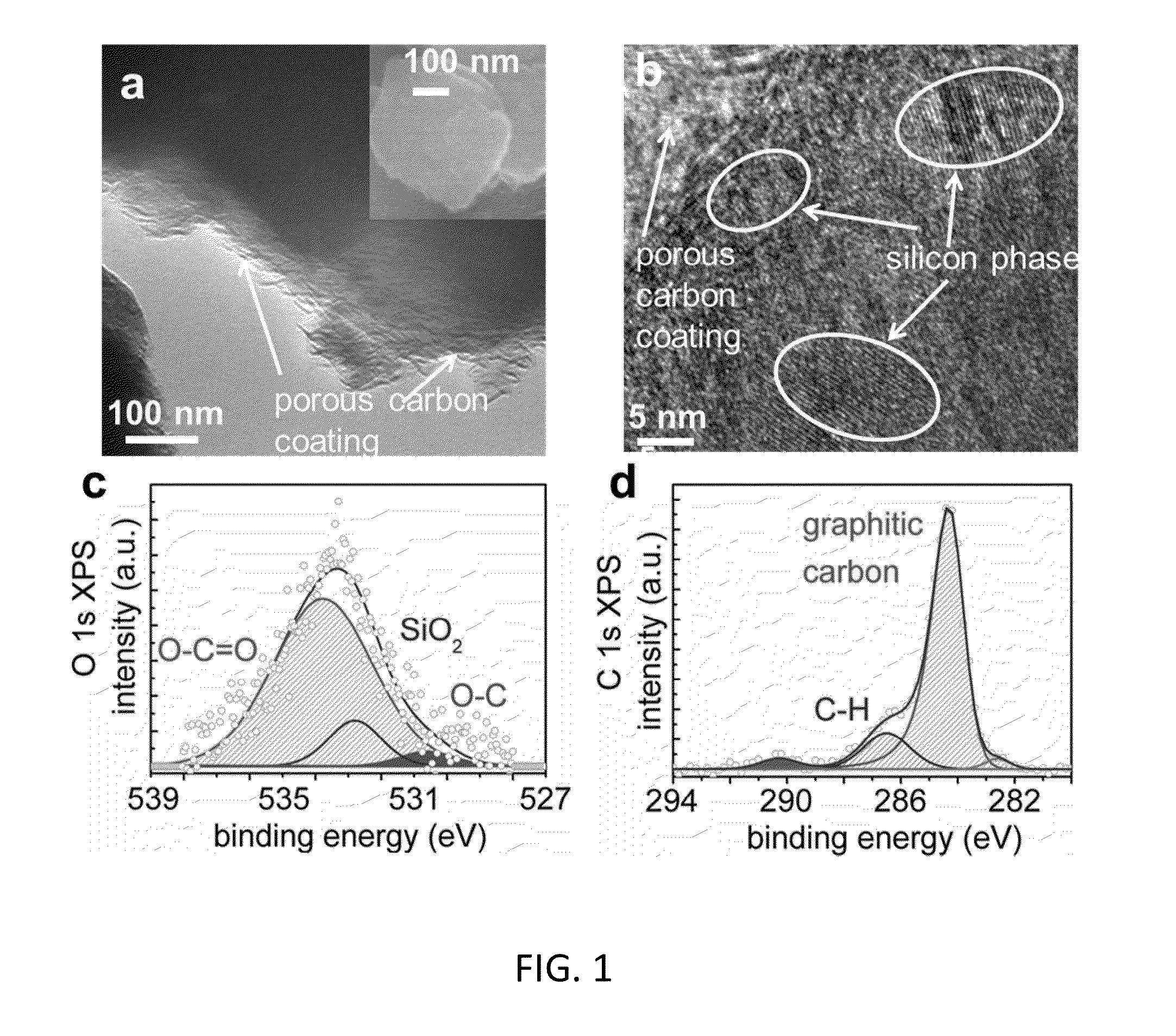

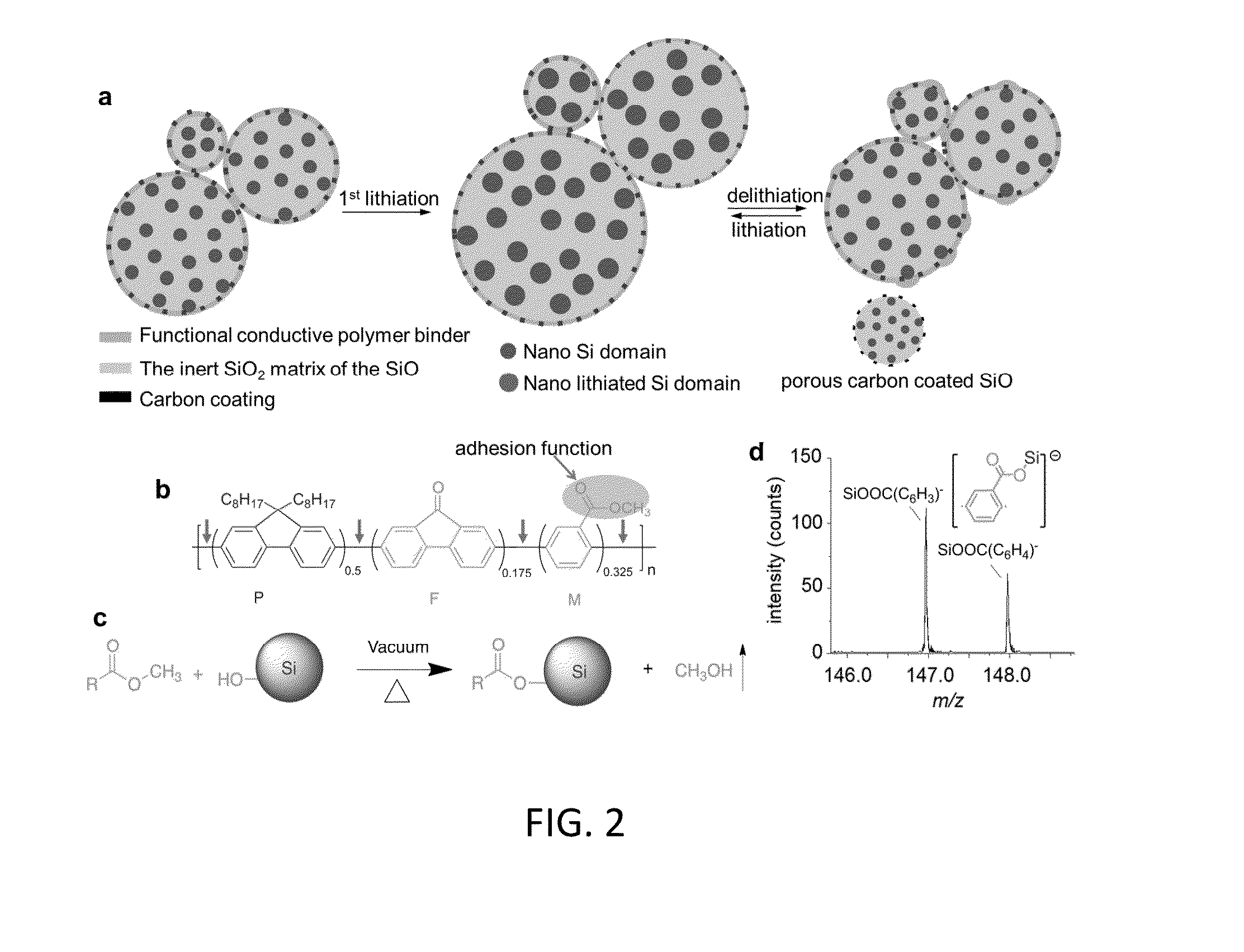

Silicon Oxide (SiO) Anode Enabled by a Conductive Polymer Binder and Performance Enhancement by Stabilized Lithium Metal Power (SLMP)

InactiveUS20150364755A1Electrode carriers/collectorsConductive materialPerformance enhancementSilicon monoxide

Silicon alloys have the highest specific capacity when used as anode material for lithium-ion batteries, however, the drastic volume change inherent in their use causes formidable challenges toward achieving stable cycling performance. Large quantities of binders and conductive additives are typically necessary to maintain good cell performance. In one embodiment of the invention, only 2% (by weight) functional conductive polymer binder without any conductive additives was successfully used with a micron-size silicon monoxide (SiO) anode material, demonstrating stable and high gravimetric capacity (>1000 mAh / g) for ˜500 cycles and more than 90% capacity retention. Prelithiation of this anode using stabilized lithium metal powder (SLMP®) improves the first cycle Coulombic efficiency of a SiO / NMC full cell from ˜48% to ˜90%. This combination enables good capacity retention of more than 80% after 100 cycles at C / 3 in a lithium-ion full cell.

Owner:RGT UNIV OF CALIFORNIA

Composite cathode active material for lithium battery, cathode for lithium battery including the same, and lithium battery including the cathode

A composite cathode active material for a lithium battery including: a lithium composite oxide; and a coating layer including a metal oxide and a lithium fluoride, (LiF) wherein the coating layer is disposed on at least a portion of a surface of the lithium composite oxide.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Battery with a recyclable dry particle based electrode

InactiveUS20130157141A1High yieldInexpensive and durable and highly reliableElectrode rolling/calenderingHybrid capacitor electrodesEngineeringElectrode

A dry process based battery that includes an electrode with one or more recycled structure is disclosed.

Owner:TESLA INC

Negative electrode active particle and method for manufacturing the same

ActiveUS20170117543A1Suppress gas productionImprove stabilityElectrode rolling/calenderingElectrode thermal treatmentActive particlesMaterials science

Owner:LG ENERGY SOLUTION LTD

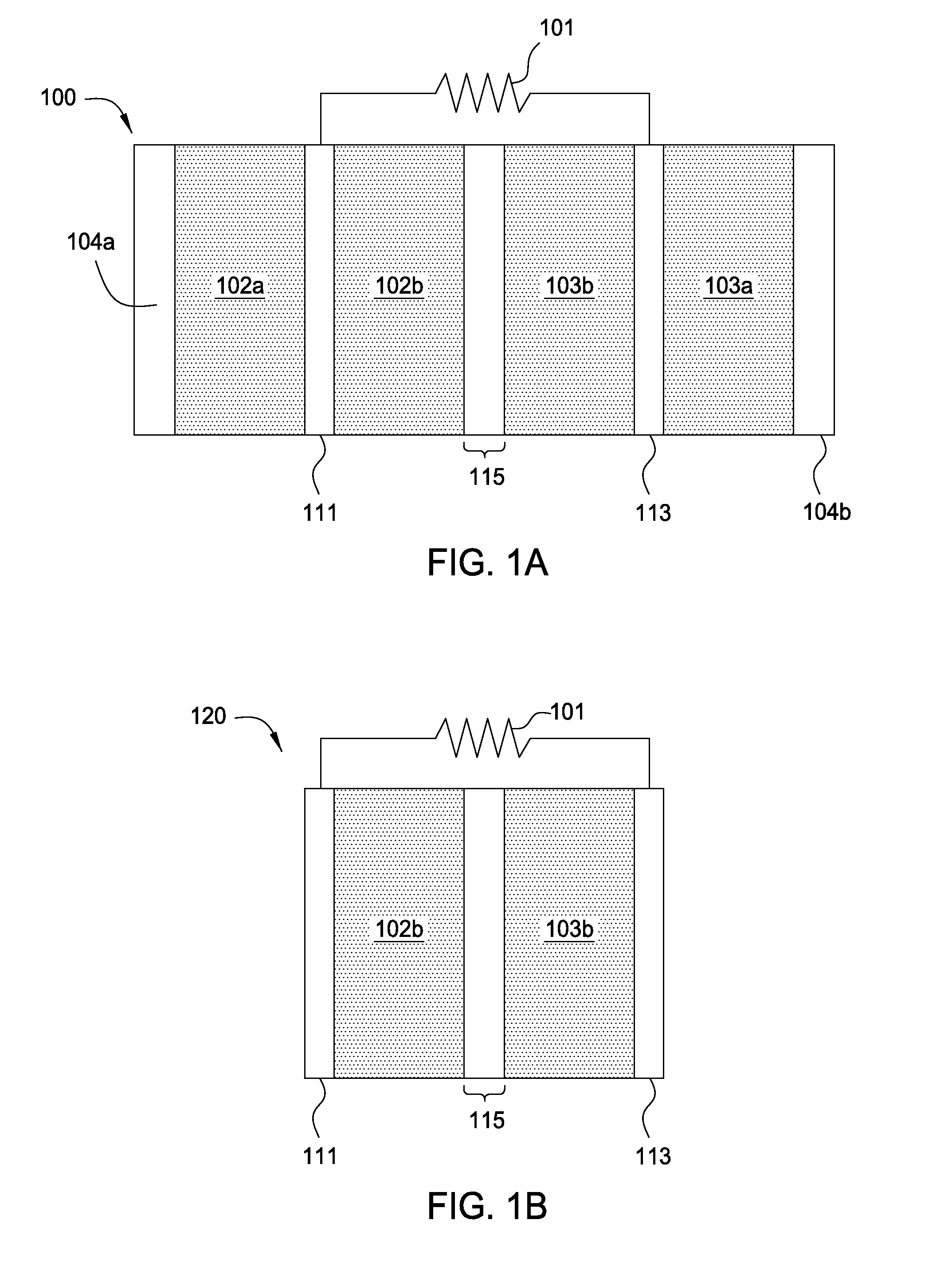

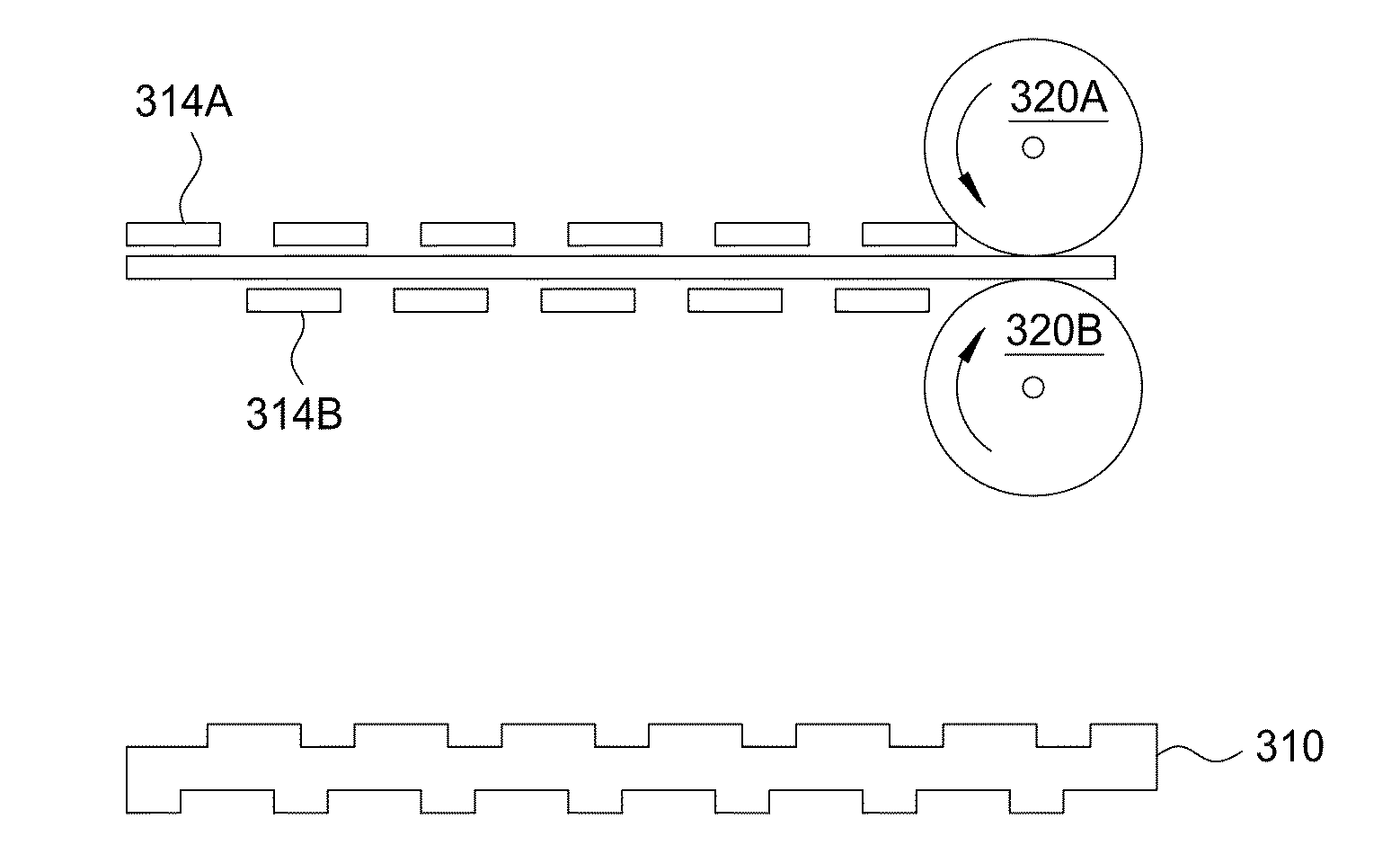

Methods to fabricate variations in porosity of lithium ion battery electrode films

A method and apparatus for forming lithium-ion batteries and battery cell components, and more specifically, to a system and method for fabricating such batteries and battery cell components using deposition processes that form three-dimensional porous structures are provided. One method comprises texturing a conductive substrate by calendering the conductive substrate between opposing wire mesh structures, forming a first layer of cathodically active material having a first porosity on the surface of the textured conductive substrate, and forming a second layer of cathodically active material having a second porosity on the first layer, wherein the second porosity is greater than the first porosity.

Owner:APPLIED MATERIALS INC

Electrode for electrochemical cell, method of manufacturing the same, and electrochemical cell includng the electrode

An electrode for an electrochemical cell is provided. The electrode comprises an electrode active material coated on a current collector. The surface of the electrode active material has a greater porosity than the portion nearest the current collector. The electrode includes an active material with controlled porosity, where the porosity of the inner portion is equal to or less than the porosity of the surface of the electrode after the electrode is roll-pressed. As a result, the impregnating characteristics of the electrolytic solution are improved and decreases in capacity upon charging and discharging at high rates are prevented. Therefore, excellent charge and discharge characteristics are obtained. In addition, cells including the inventive electrodes exhibit excellent charge and discharge characteristics.

Owner:SAMSUNG SDI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com