Patents

Literature

645 results about "Silicon monoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

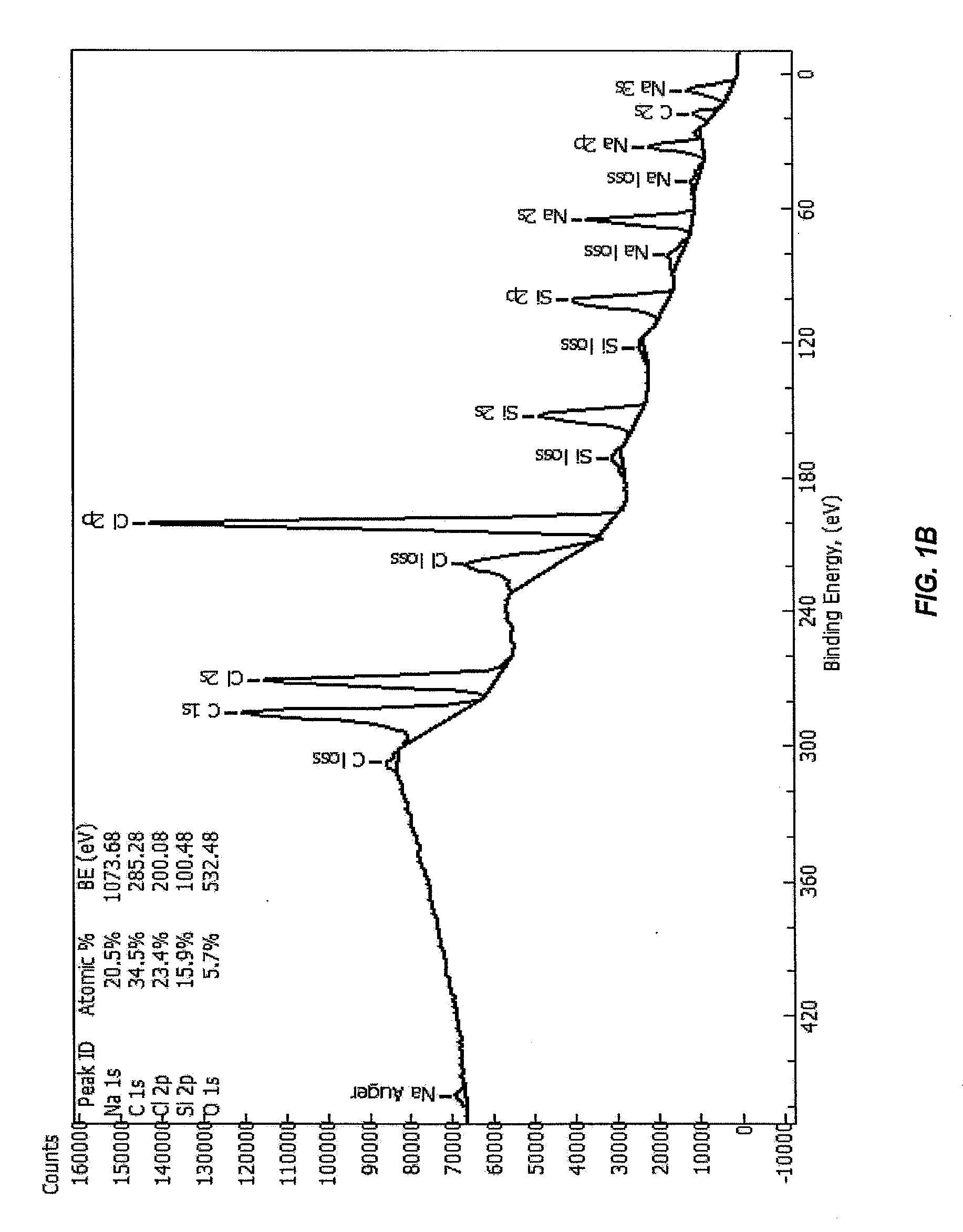

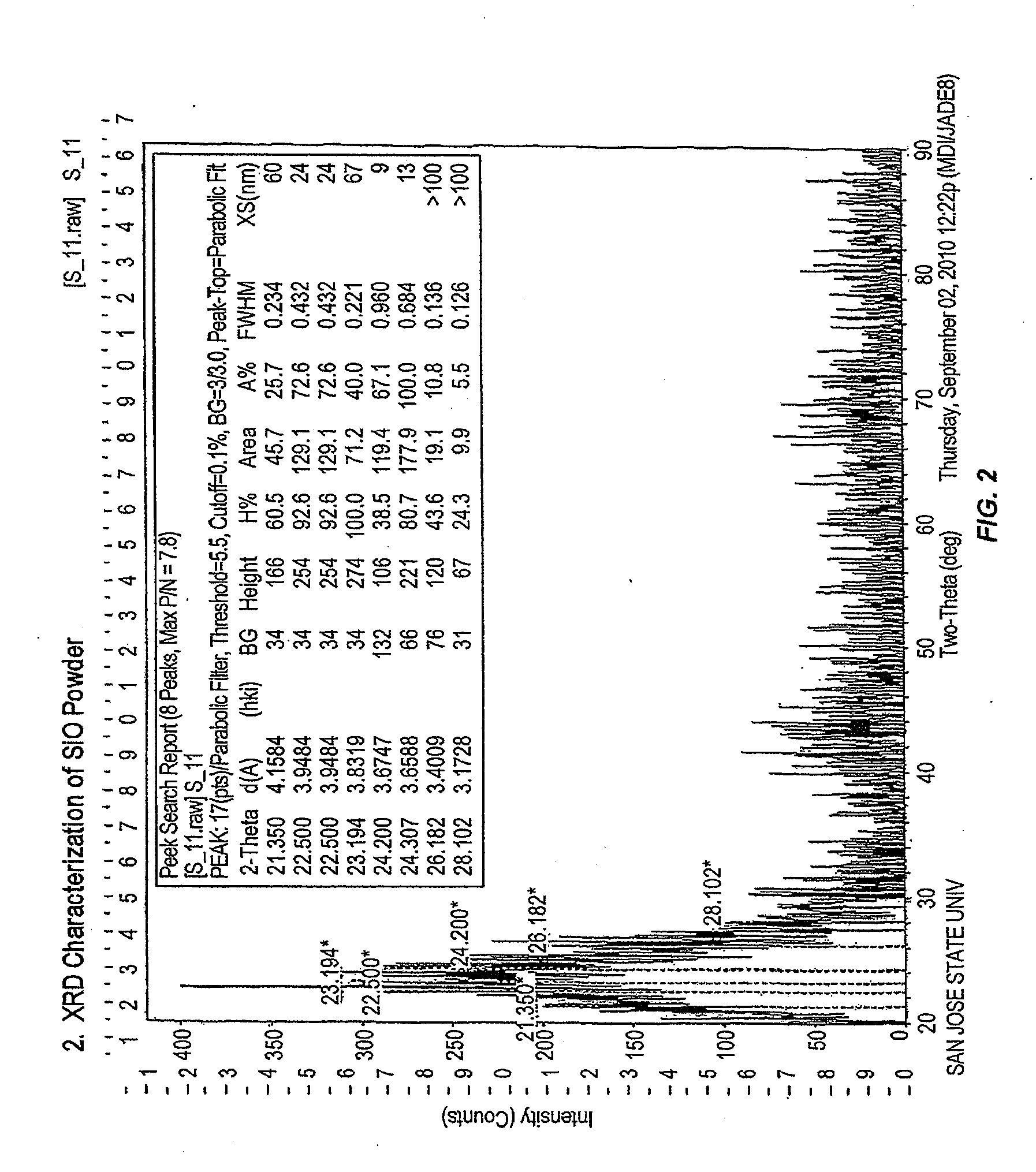

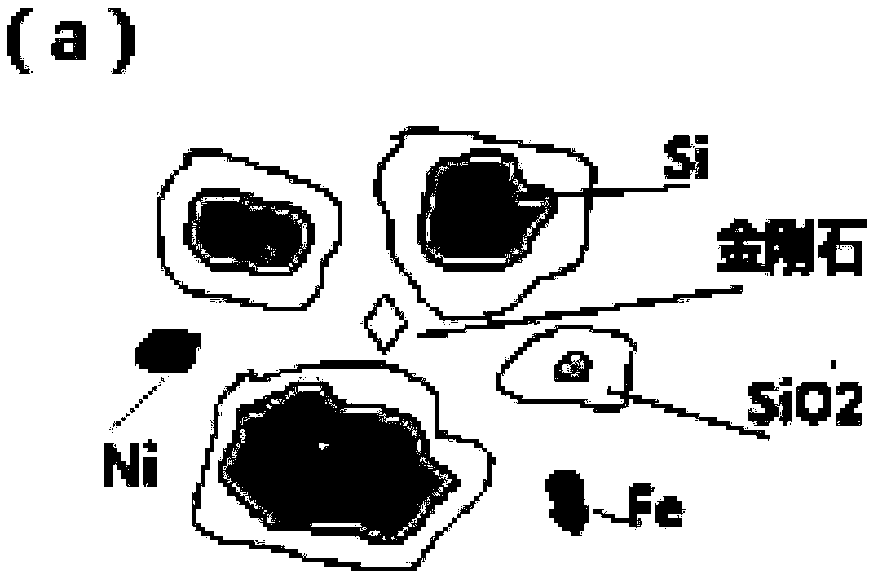

Silicon monoxide is the chemical compound with the formula SiO where silicon is present in the oxidation state +2. In the vapour phase it is a diatomic molecule. It has been detected in stellar objects and it has been described as the most common oxide of silicon in the universe. When SiO gas is cooled rapidly, it condenses to form a brown/black polymeric glassy material, (SiO)ₙ, which is available commercially and used to deposit films of SiO. Glassy (SiO)ₙ is air- and moisture-sensitive. Its surface readily oxidizes in air at room temperature, giving an SiO₂ surface layer that protects the material from further oxidation. However, (SiO)ₙ irreversibly disproportionates into SiO₂ and Si in a few hours between 400 and 800°C, and very rapidly between 1,000 and 1,440°C, although the reaction does not go to completion.

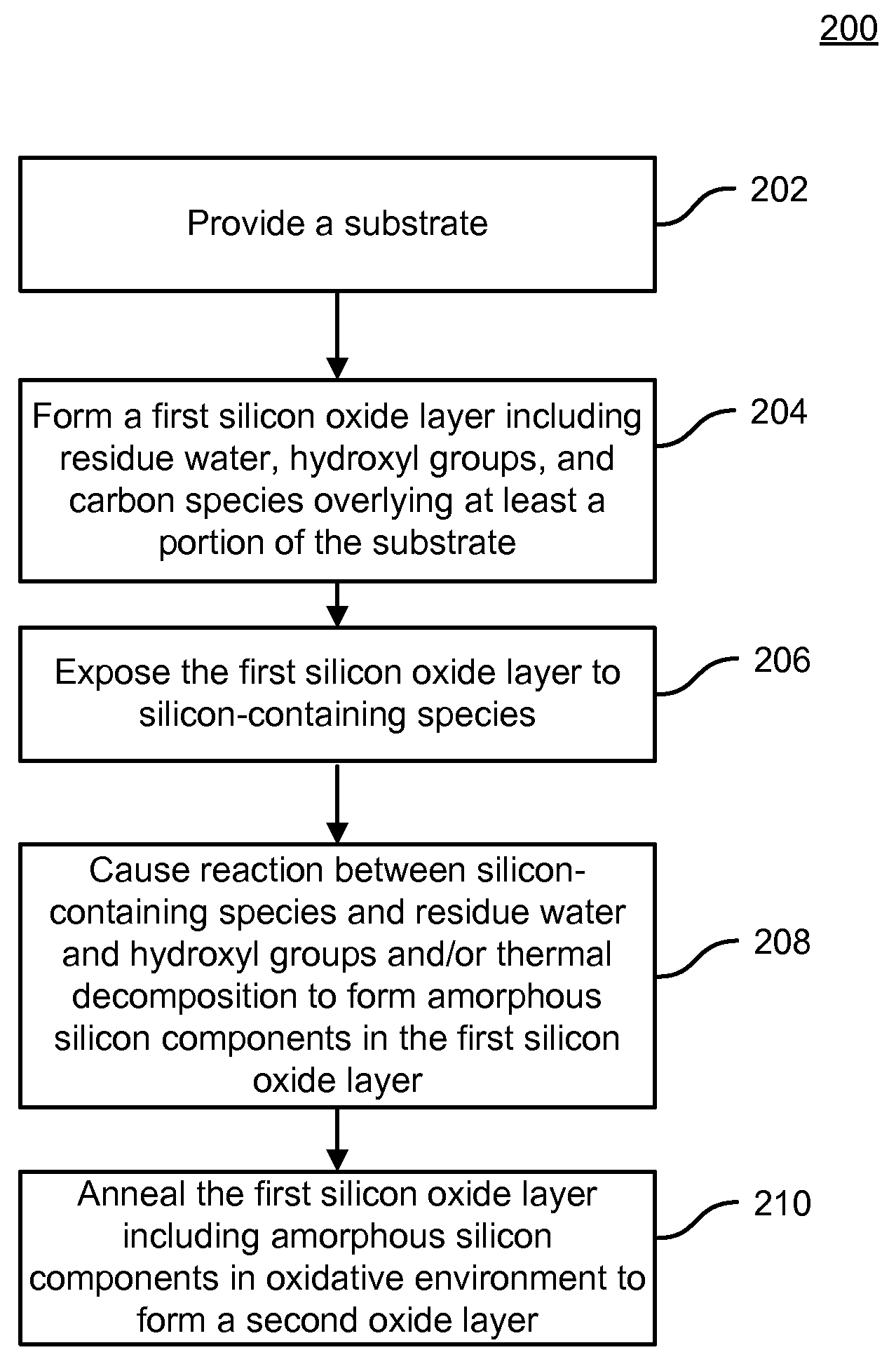

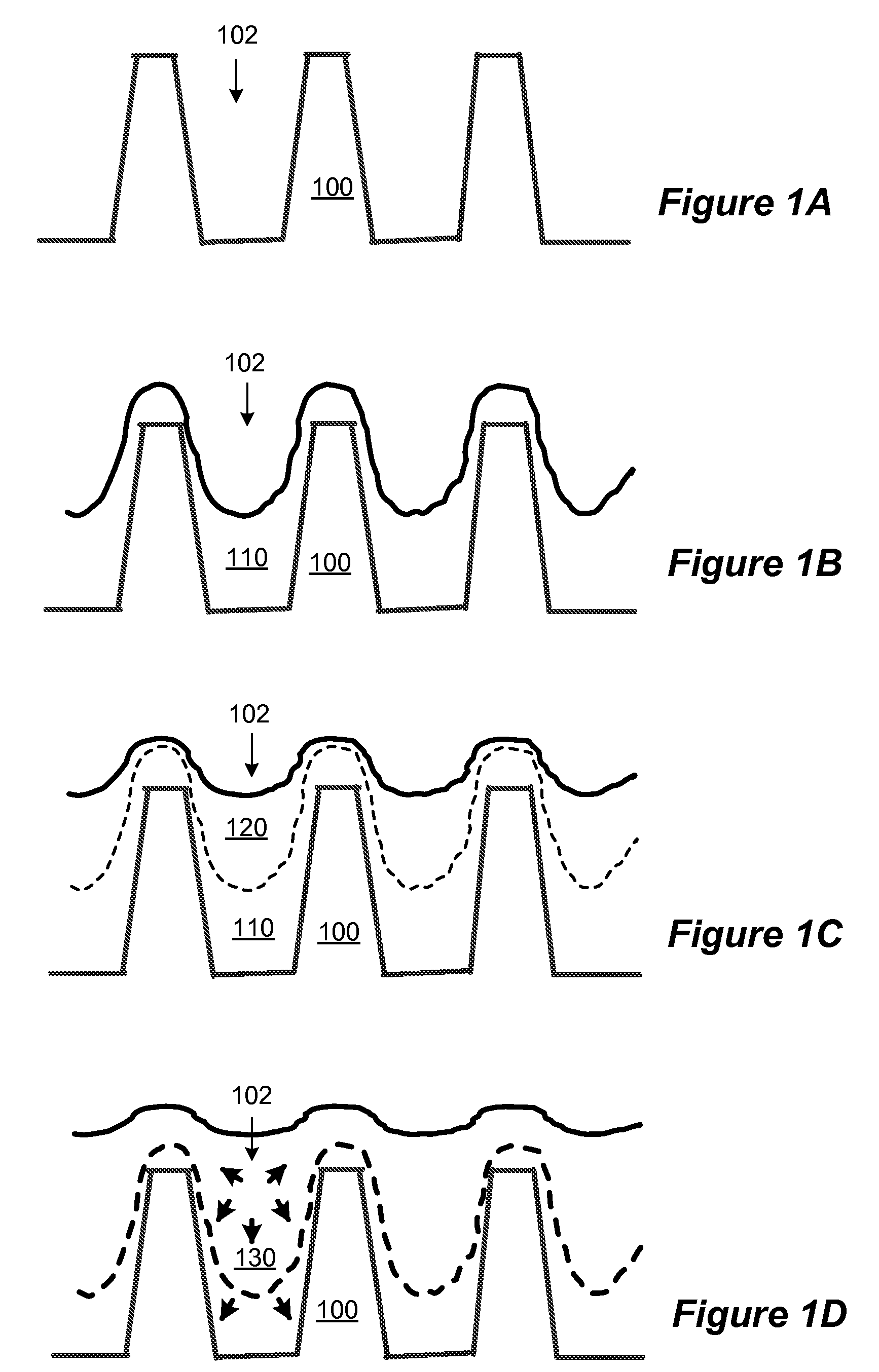

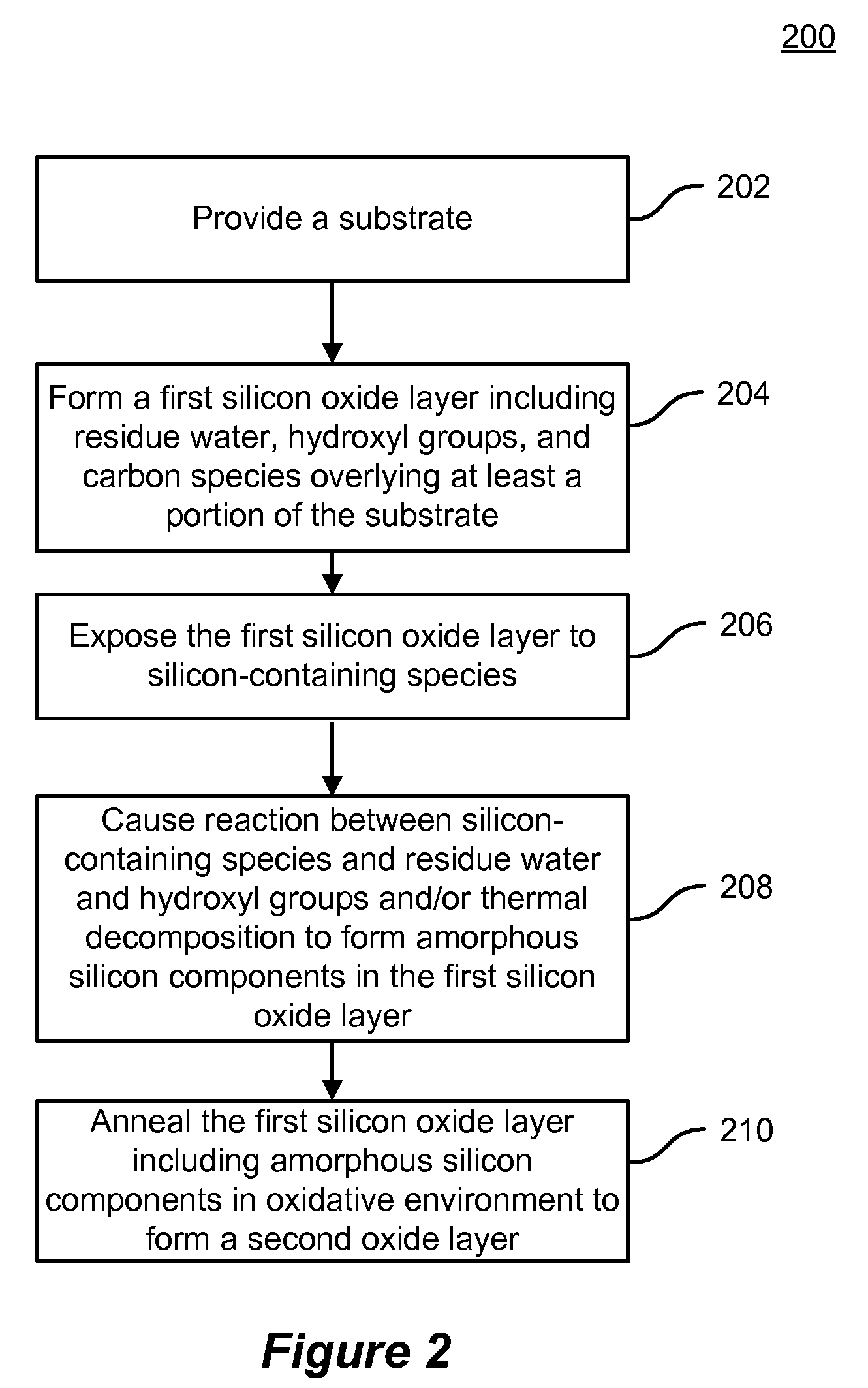

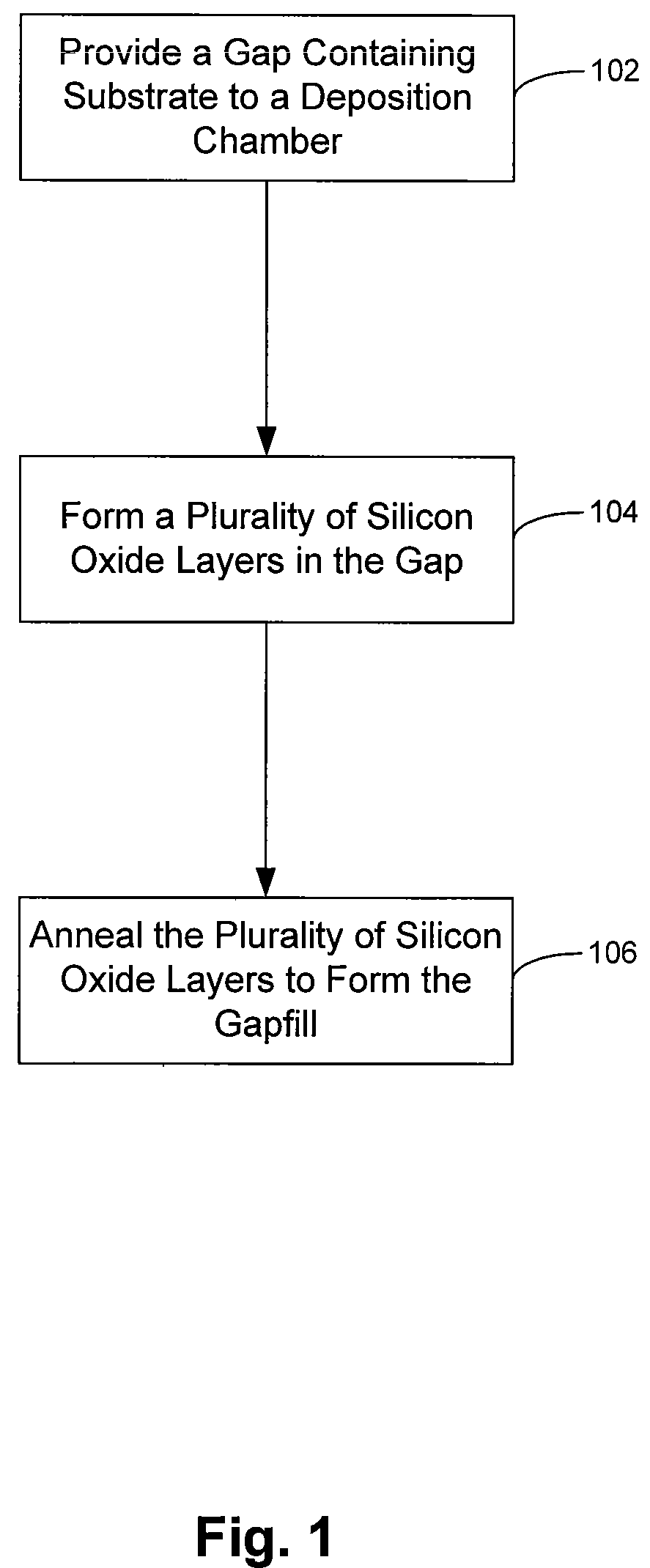

Method and system for improving dielectric film quality for void free gap fill

ActiveUS20090104789A1Quality improvementHigh densitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon monoxideAmorphous silicon

A method of forming a silicon oxide layer on a substrate. The method includes providing a substrate and forming a first silicon oxide layer overlying at least a portion of the substrate, the first silicon oxide layer including residual water, hydroxyl groups, and carbon species. The method further includes exposing the first silicon oxide layer to a plurality of silicon-containing species to form a plurality of amorphous silicon components being partially intermixed with the first silicon oxide layer. Additionally, the method includes annealing the first silicon oxide layer partially intermixed with the plurality of amorphous silicon components in an oxidative environment to form a second silicon oxide layer on the substrate. At least a portion of amorphous silicon components are oxidized to become part of the second silicon oxide layer and unreacted residual hydroxyl groups and carbon species in the second silicon oxide layer are substantially removed.

Owner:APPLIED MATERIALS INC

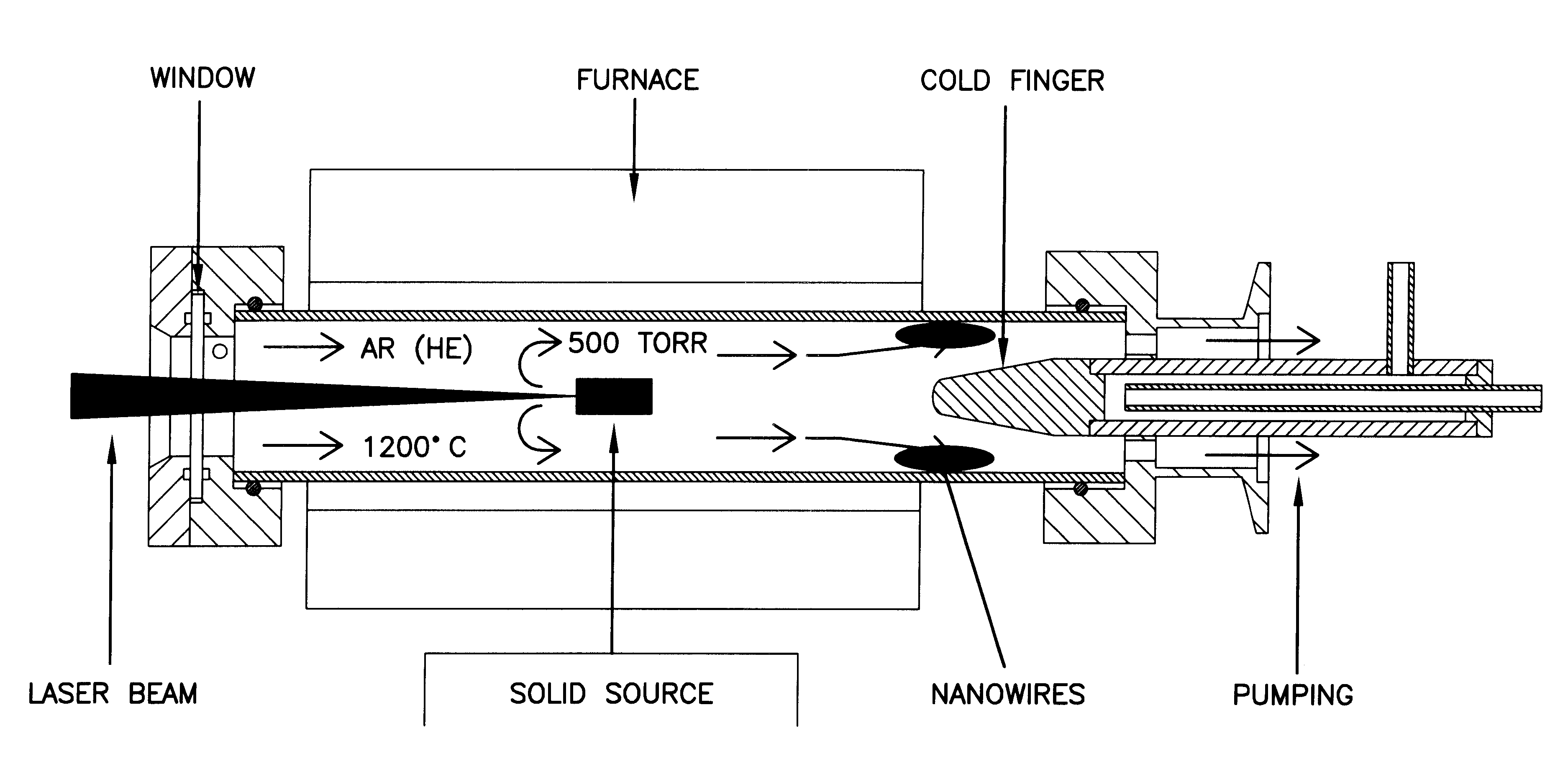

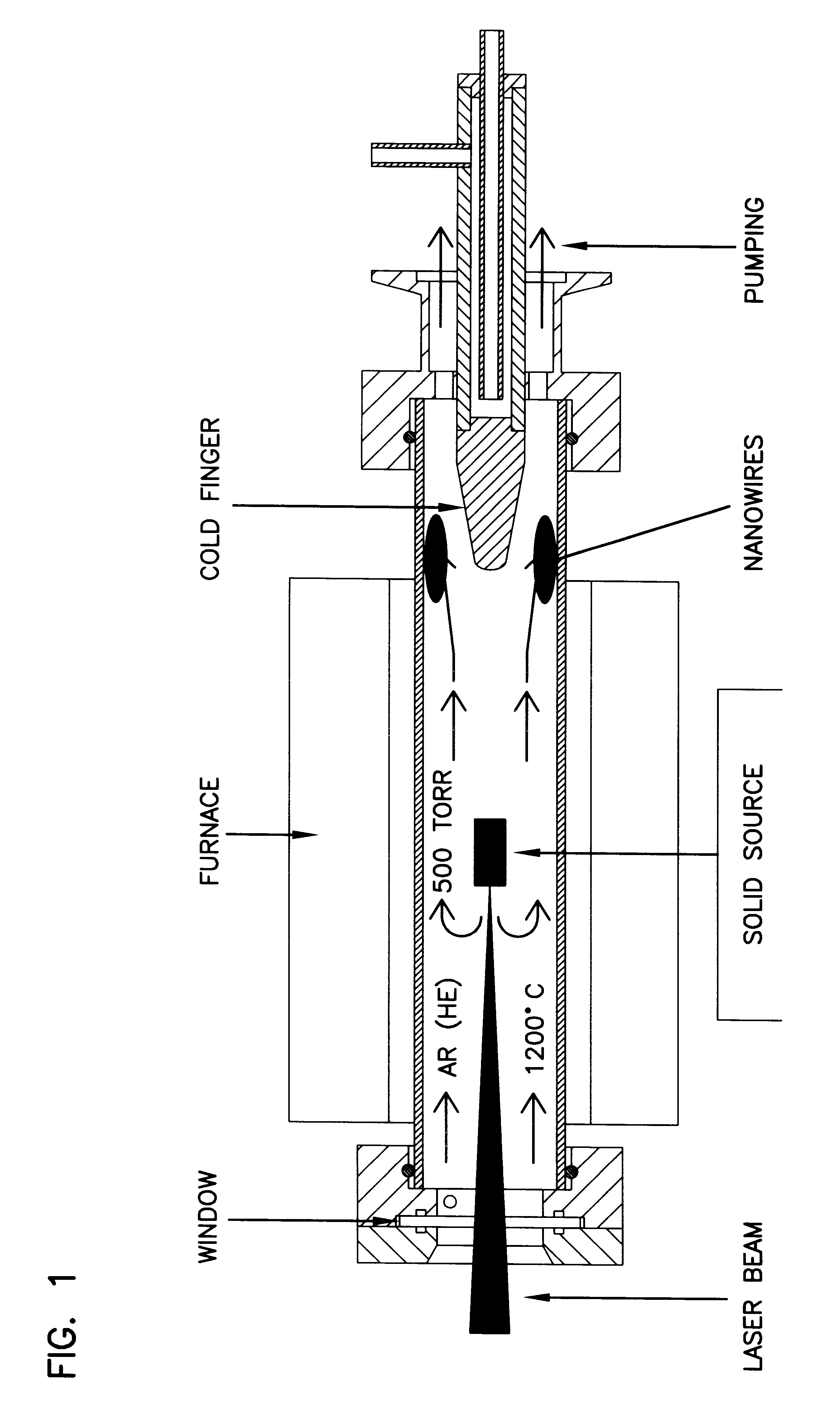

Growth method for silicon nanowires and nanoparticle chains from silicon monoxide

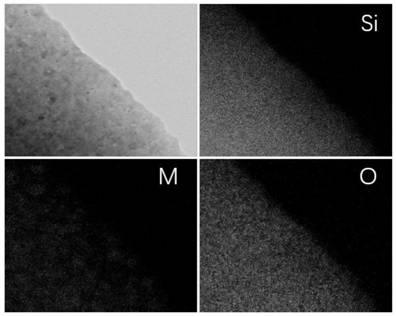

InactiveUS6313015B1Enhance one-dimensional growthLowering of total energy of systemPolycrystalline material growthNanotechSputteringSilicon monoxide

Silicon nanowires and silicon nanoparticle chains are formed by the activation of silicon monoxide in the vapor phase. The silicon monoxide source may be solid or gaseous, and the activation may be by thermal excitation, laser ablation, plasma or magnetron sputtering. The present invention produces large amounts of silicon nanowires without requiring the use of any catalysts that may cause contamination.

Owner:HONG KONG CITY UNIV OF

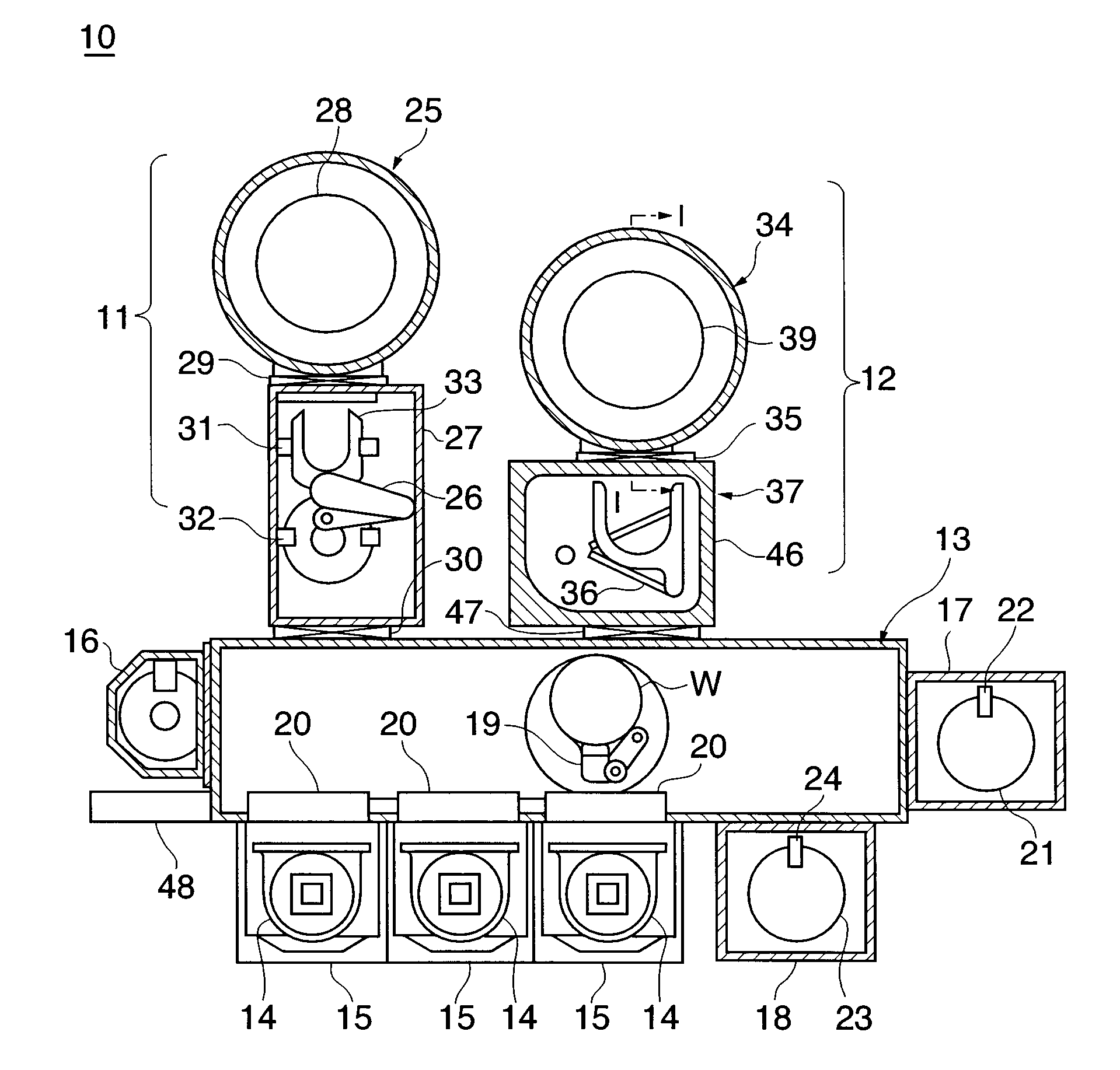

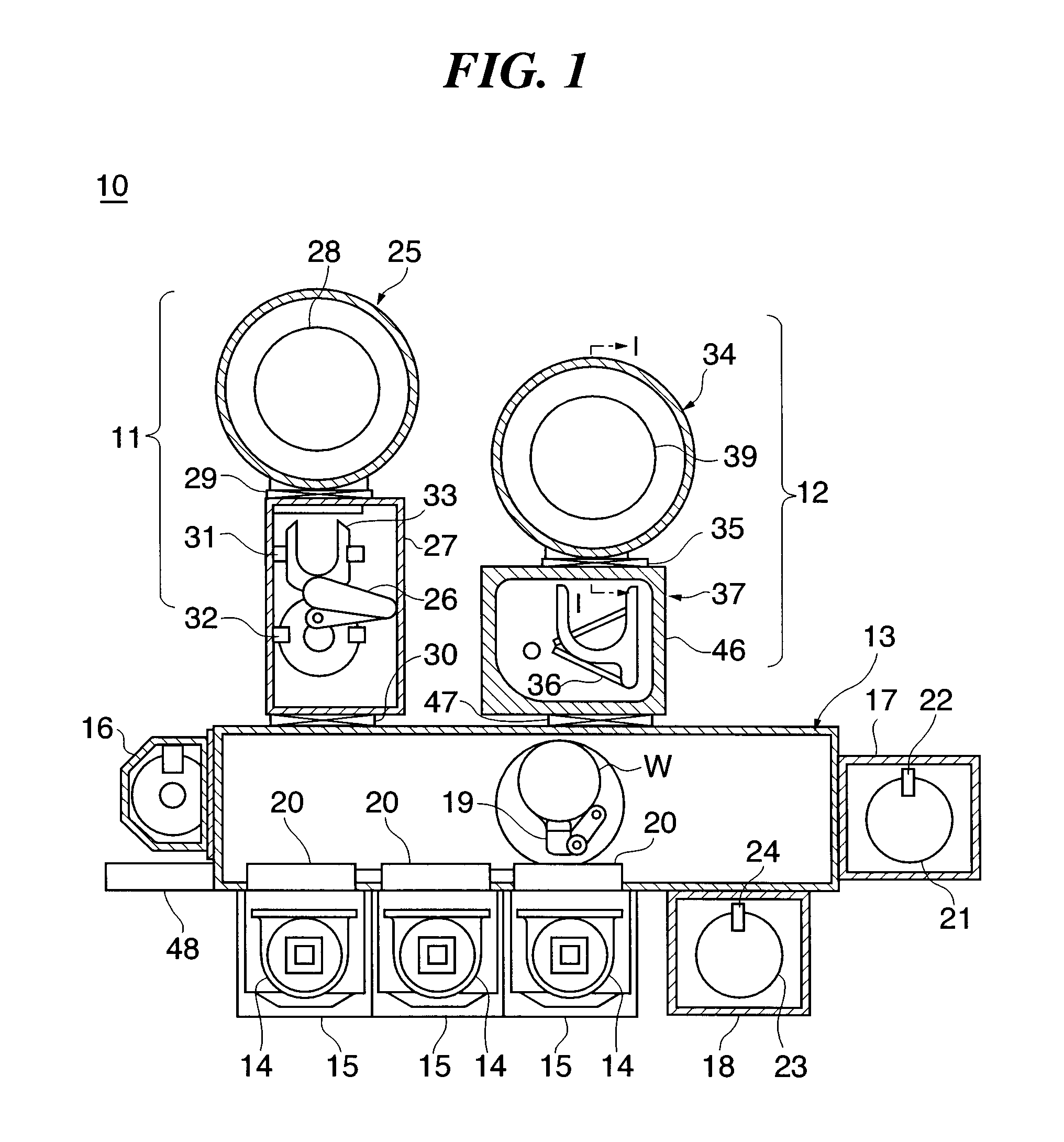

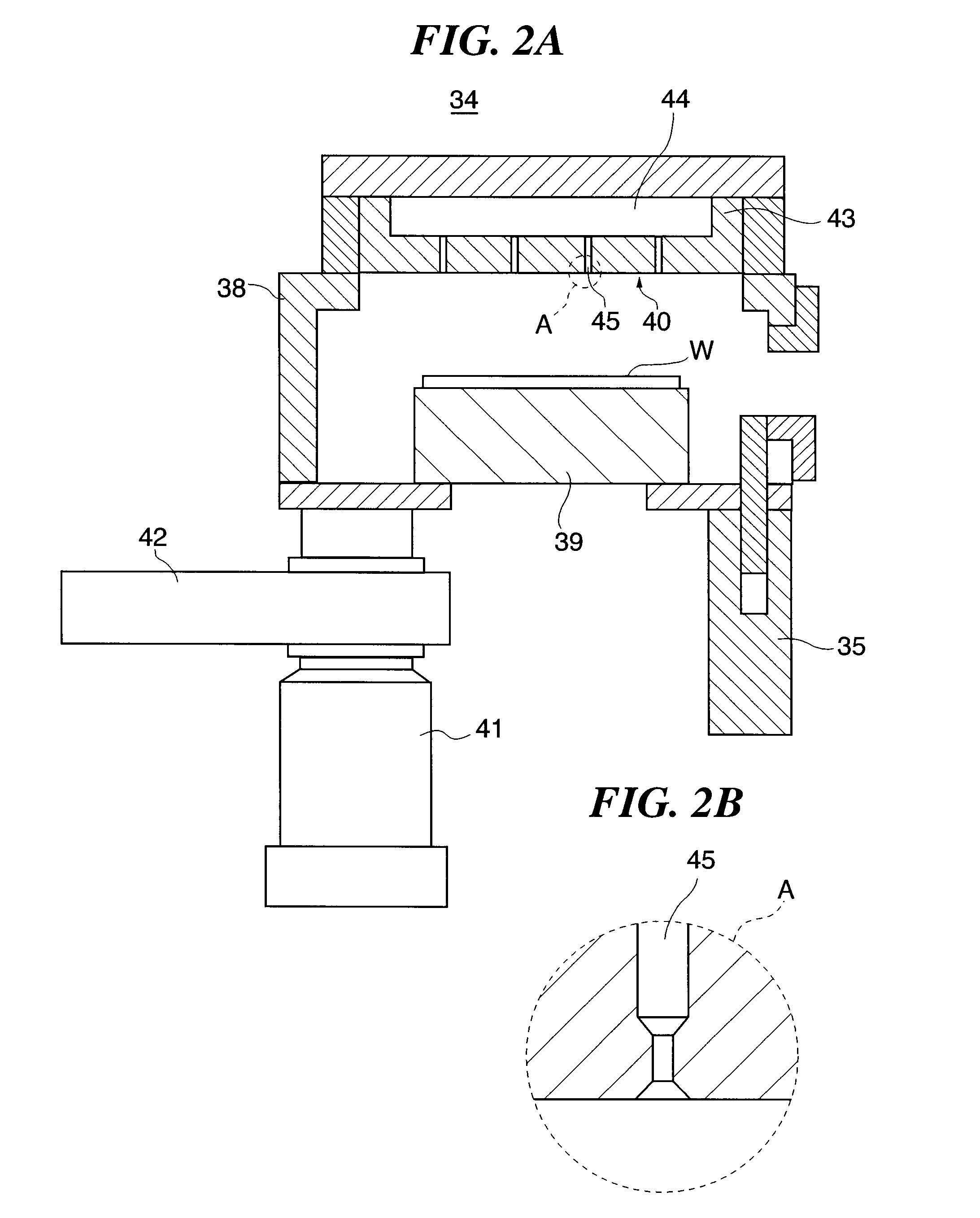

Substrate processing method and substrate processing apparatus

ActiveUS20080003836A1Achieve effectSelectively remove the flat portion of the nitride filmSemiconductor/solid-state device manufacturingHydrofluoric acidSilicon monoxide

A substrate processing method capable of selectively removing a nitride film. Oxygen plasma containing plasmarized oxygen gas is made to be in contact with a silicon nitride film, which is made of SiN, of a wafer to thereby cause the silicon nitride film to be changed to a silicon monoxide film. The silicon monoxide film is selectively etched by hydrofluoric acid generated from HF gas supplied toward the silicon monoxide film.

Owner:TOKYO ELECTRON LTD

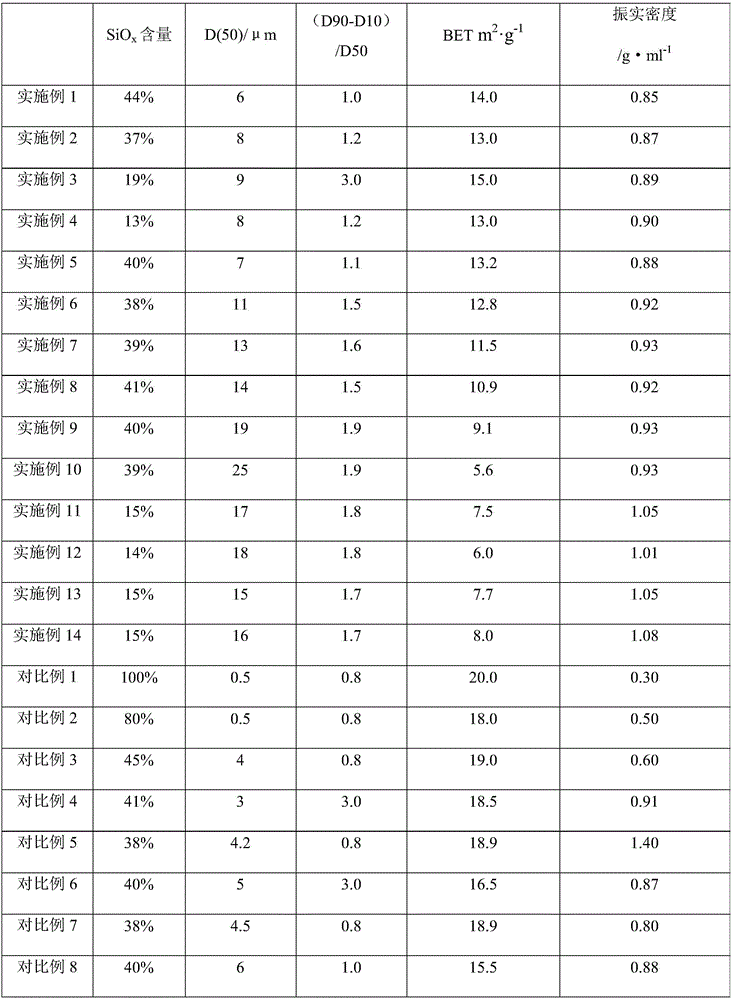

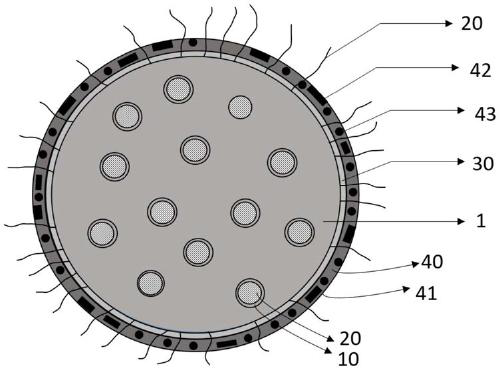

Silicon-carbon composite material, lithium ion battery, and preparation method and application of silicon-carbon composite material

ActiveCN103633295AAlleviate volume expansionAvoid direct contactCell electrodesSecondary cellsCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a lithium ion battery, and a preparation method and application of the silicon-carbon composite material. The preparation method of the silicon-carbon composite material comprises the steps: uniformly mixing silicon powder and silicon monoxide powder, then mixing with a solution containing an organic carbon source dispersant, and performing wet-process ball milling to obtain a slurry; uniformly mixing the slurry, graphite and a conductive agent, and performing spray drying to obtain spherical-like particles, wherein graphite is synthetic graphite and / or intermediate-phase graphite; mixing the spherical-like particles and asphalt, performing cladding processing under the inert atmosphere to obtain a cladded material; and then performing carbonizing processing to obtain the silicon-carbon composite material, wherein silicon powder, silicon monoxide powder, graphite and asphalt respectively accounts for 5-15%, 3-10%, 45-75% and 5-40% by weight of the sum of the above materials, and the organic carbon source dispersant and the conductive agent both accounts for 0.1-2% by weight of the sum of silicon powder, silicon monoxide powder and graphite. The silicon-carbon composite material has relatively good cycle performance, and can be directly used as a cathode material of the lithium ion battery. The preparation method is simple in technology, low in cost and applicable to industrial production.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Method for manufacturing polycrystalline silicon used for solar battery

InactiveCN101122047ASolve environmental problemsPolycrystalline material growthFinal product manufactureSilicon monoxideElectrical battery

A method of preparing a polycrystalline silicon for solar batteries adopts combined means of silicon monoxide disproportionation, acid dipping separation and vacuum melting and processes by the following procedures: (1) the silicon monoxide is made from chemical pure industrial silicon and high purity sand quartz. (2) the high purity silicon is obtained by disproportionation of the silicon monoxide. (3)impurities boron and phosphorus in the silicon are removed by soaking with aquafortis. (4) the high purity silicon is further purified by melting of a vacuum electro beam furnace, and parts with impurities heavily gathered in a cast ingot are cut. (5) nitrogen or nitrogen plus hydrogen is fed into a plasma furnace for melting, so as to further remove the rest boron, phosphorus and other impurities, and conduct directional solidification. (6)the outer skin and parts with impurities heavily gathered of the cast ingot are cut, and finally the high purity silicon which is above 6N pure and applicable to solar batteries is obtained. The invention rejects the technical route of the Siemens method, prevents environment pollution, improves safety of production, and is good for promotion and application in China.

Owner:李绍光

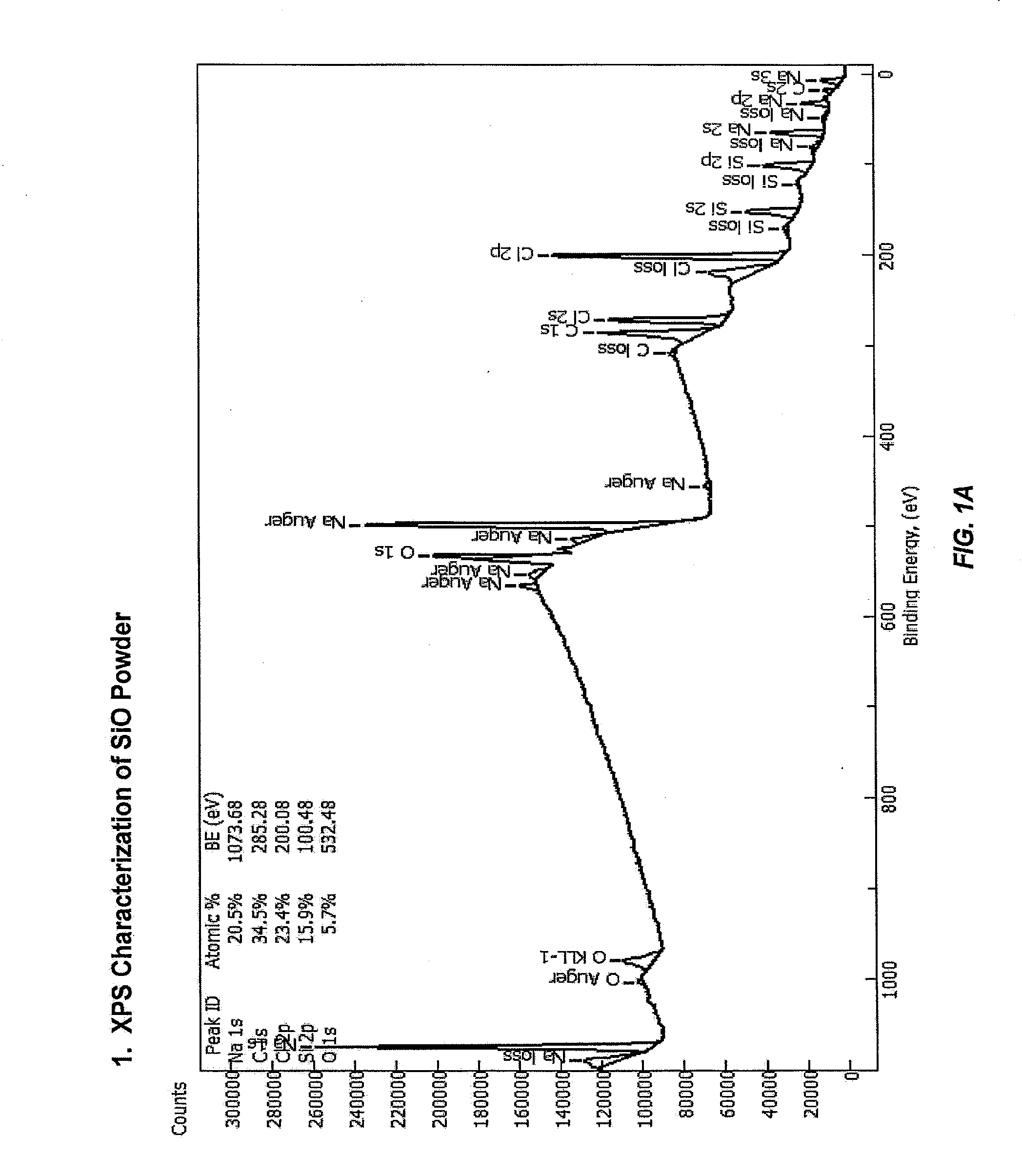

Fabrication and use of carbon-coated silicon monoxide for lithium-ion batteries

ActiveUS20140004426A1Smooth connectionNanotechPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSilicon monoxideMetallurgy

The present invention provides anode materials, methods of producing them, anodes, methods of producing them, electrochemical cells, and lithium-ion batteries, where the anode material comprises a silicon monoxide nanoparticle. In certain embodiments, the silicon monoxide is porous or mesoporous. In certain embodiments, the porous or mesoporous silicon additionally comprises other materials within its pores, such as lithium.

Owner:NEXEON LTD

Optical flame detection system and method

ActiveUS7541938B1Improve reflectivityShort response timeRadiation pyrometryMaterial analysis by optical meansSilicon monoxideOptoelectronics

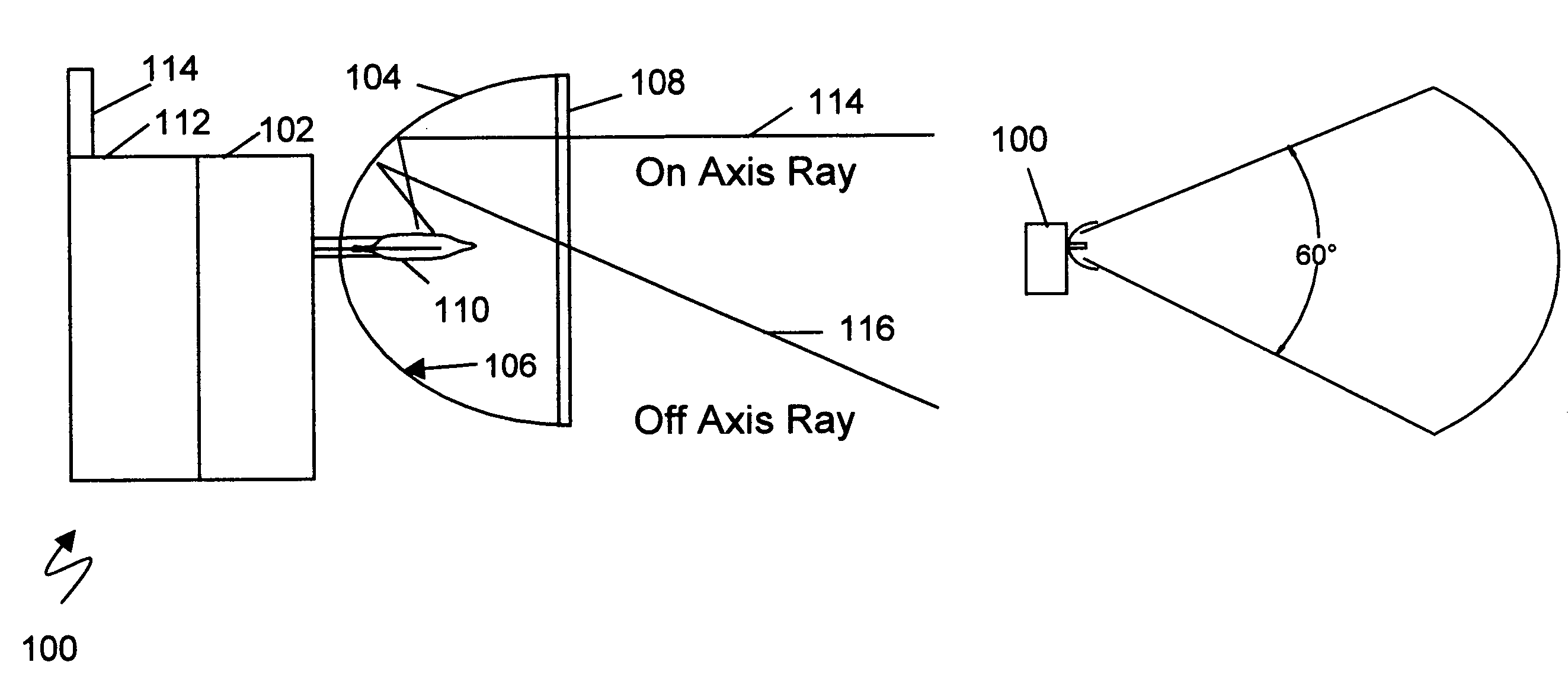

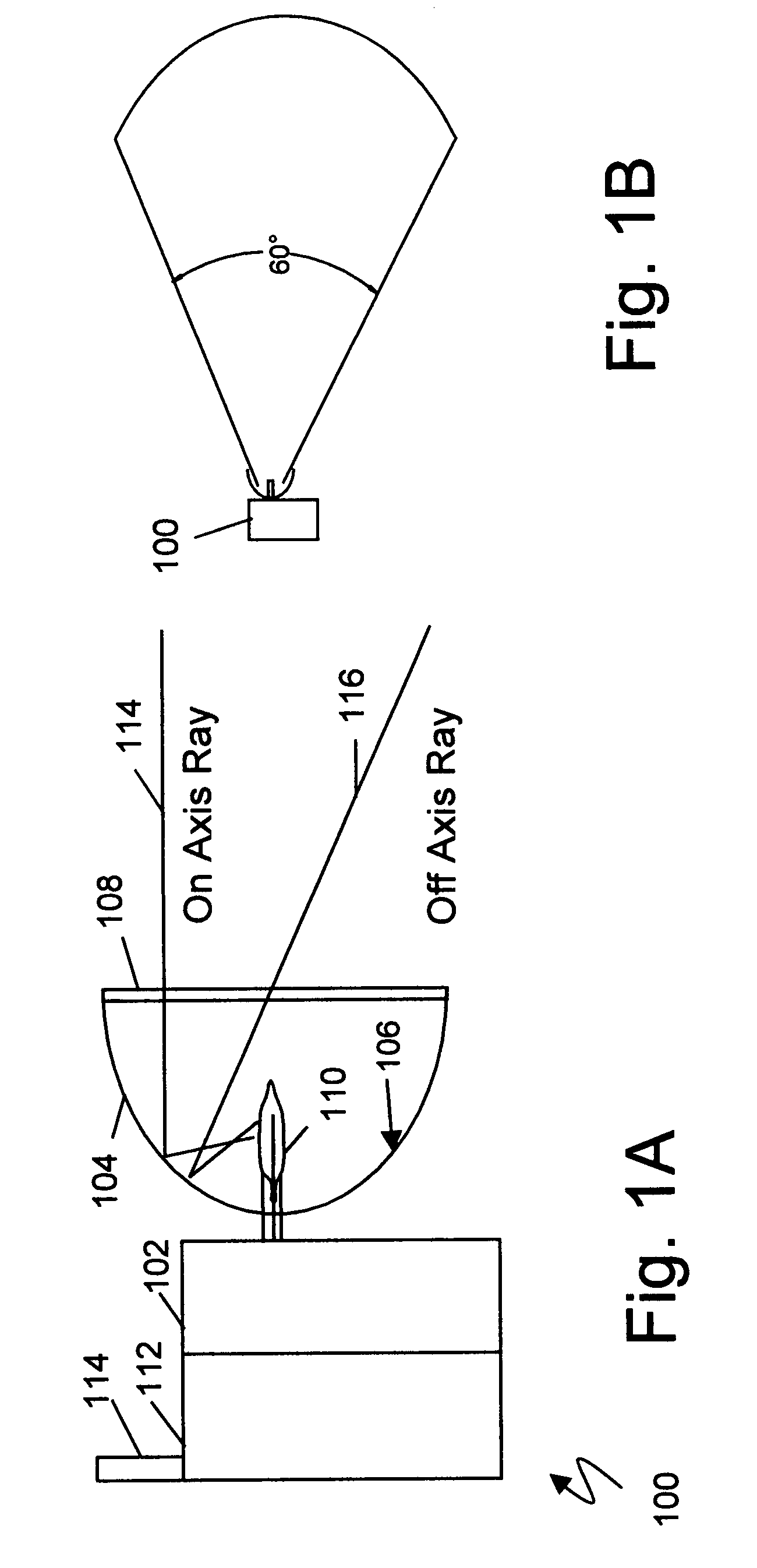

A long range optical sensor and system for detecting the flame of forest fires or other fires while rejecting false alarms due to solar radiation is described. The sensor utilizes a collector optic that collects energy from a wide field of view and concentrates the energy onto a detector. The collector may be a non-imaging collector and may match to a non-planar sensor. In one embodiment the sensor may be arrayed to achieve larger area coverage. In another, the sensor system may be scanned to increase the encompassed viewing area. Larger areas may be covered by RF radio links or networks interconnecting multiple arrayed sensor modules. UVC reflective coatings may include enhanced aluminum with silicon dioxide, silicon monoxide, or magnesium fluoride, or high phosphorous nickel phosphorous. In one embodiment a UVC sensitive Geiger Mueller tube may be coupled to a non-imaging spherical reflective collector. A catadioptric UVC / infra-red flame sensor is disclosed. Refractive or reflective designs are considered.

Owner:UNIVERSITY OF ALABAMA

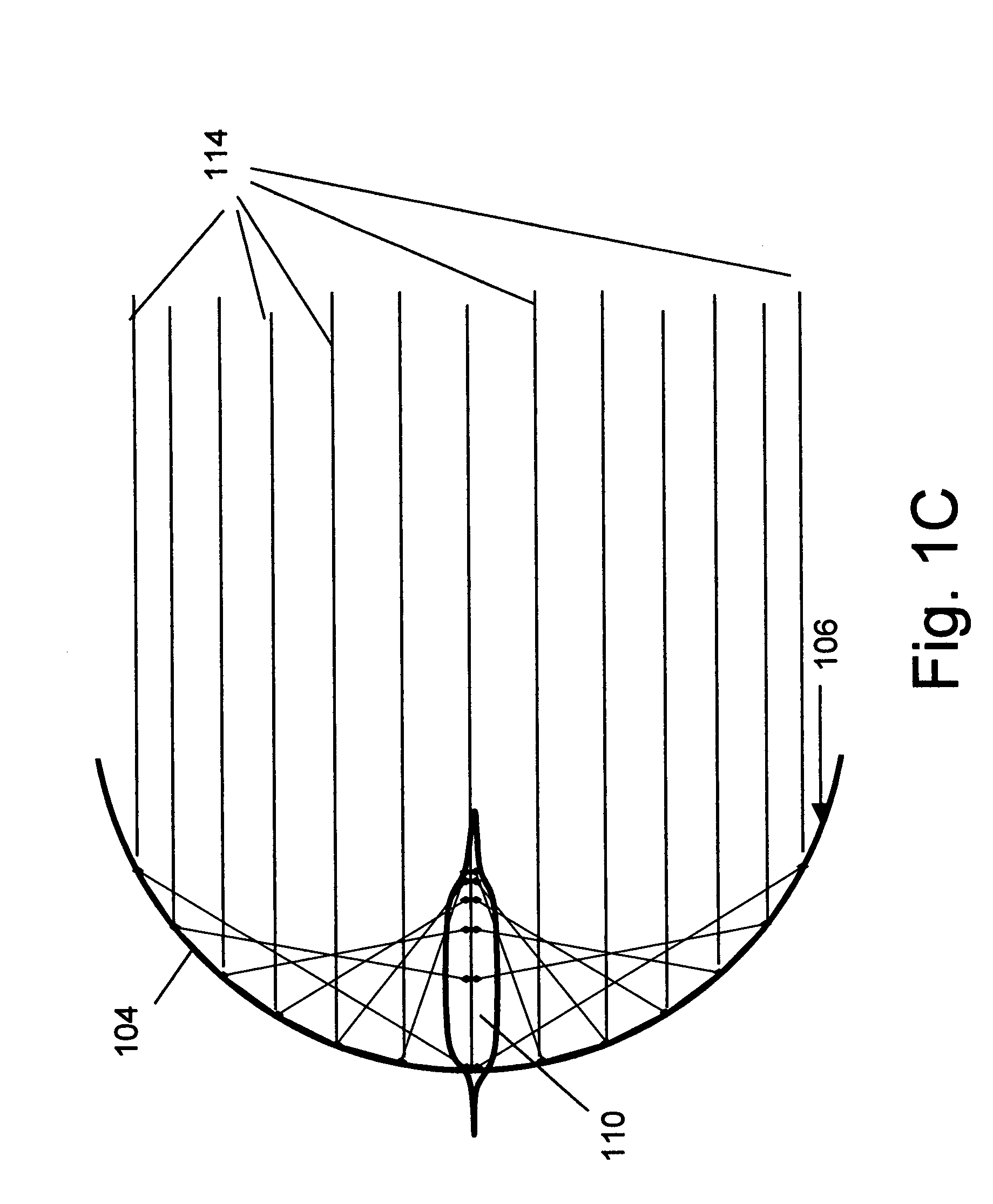

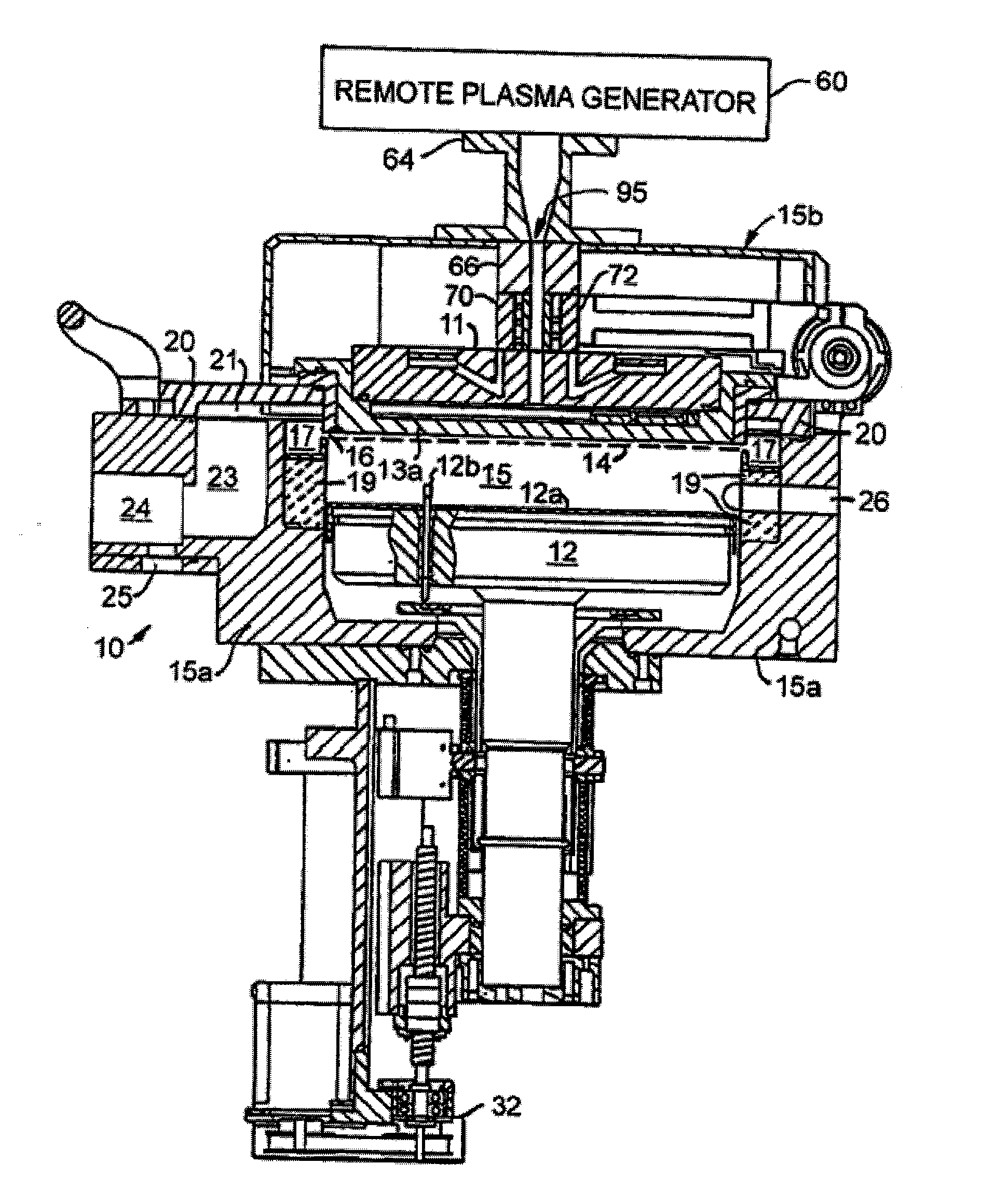

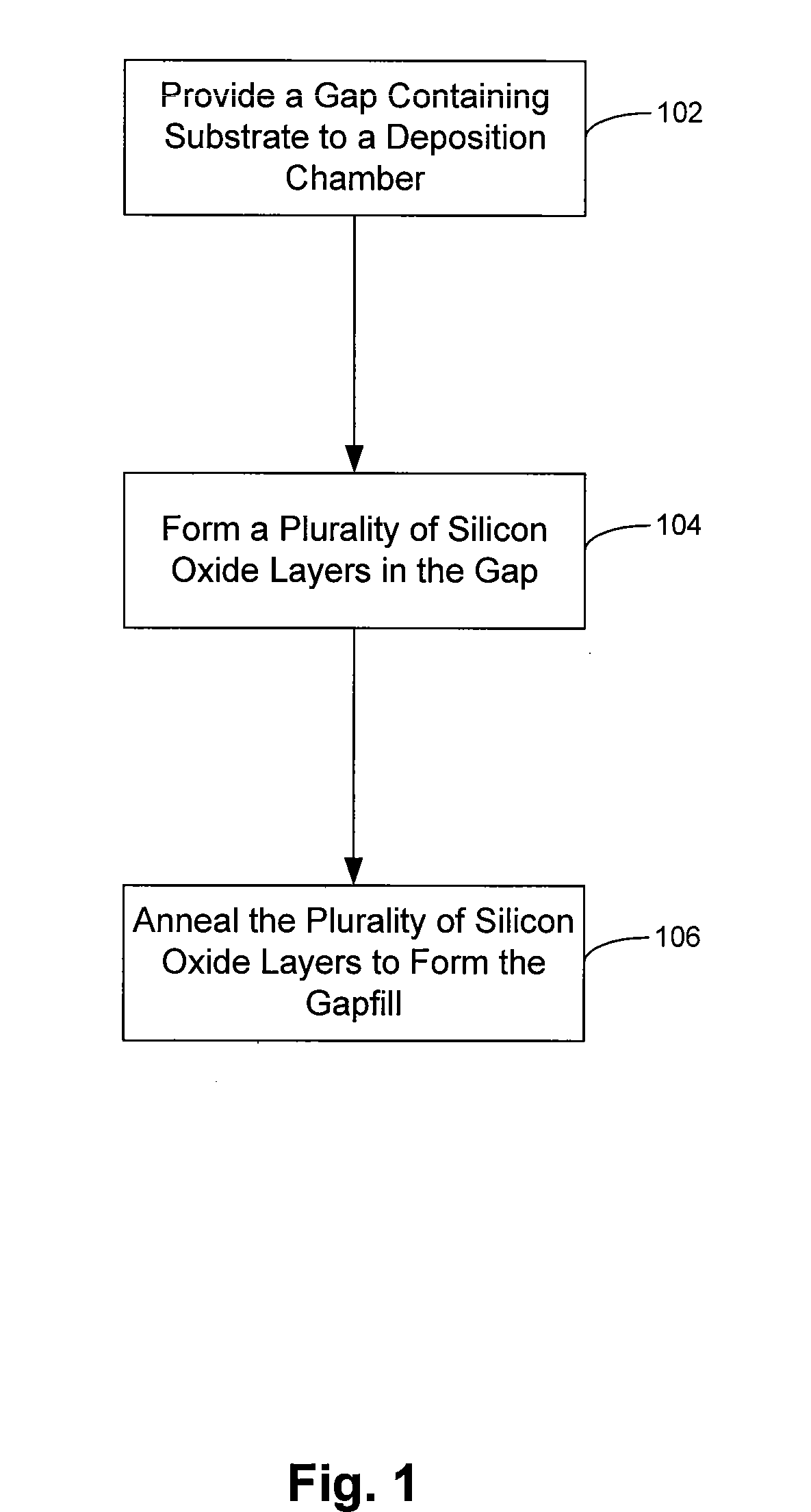

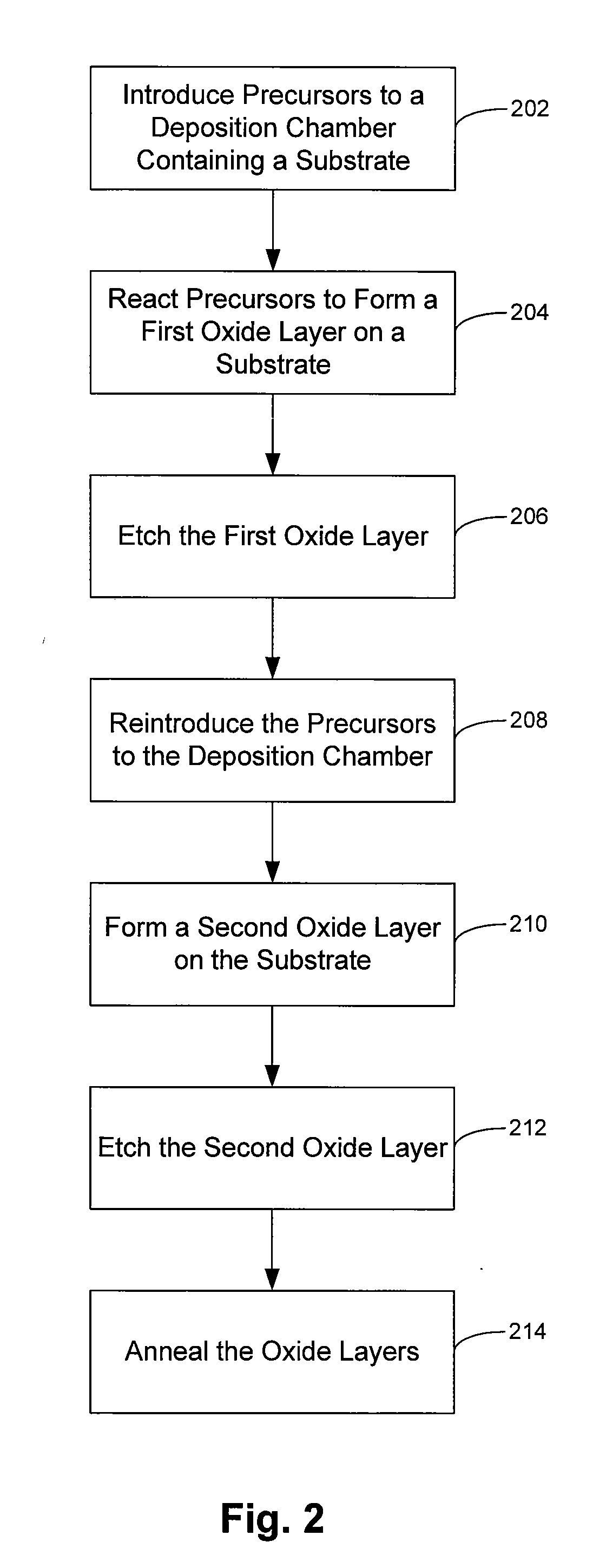

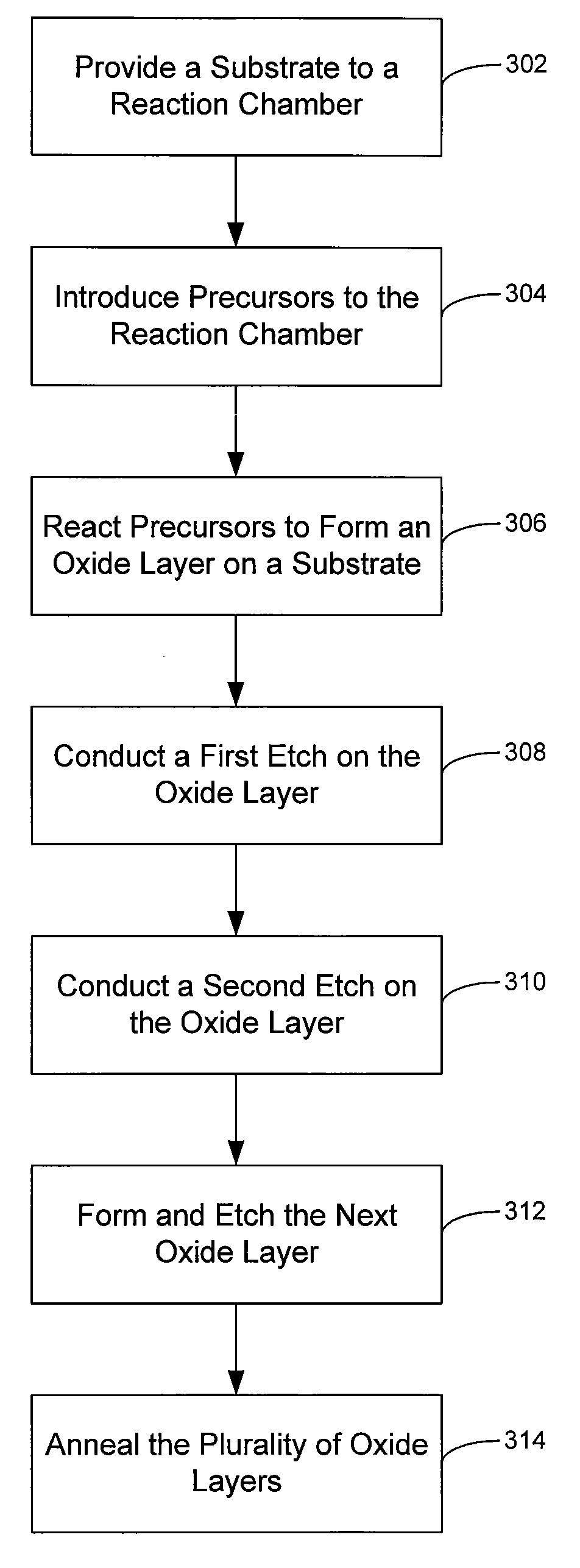

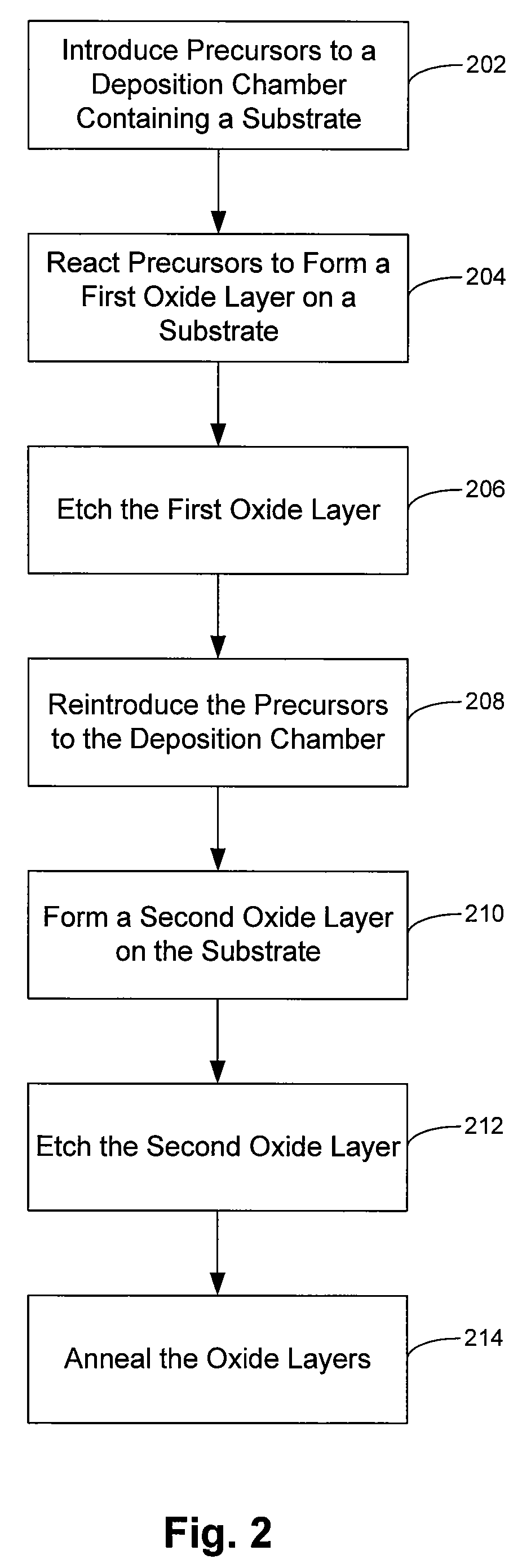

Novel deposition-plasma cure cycle process to enhance film quality of silicon dioxide

ActiveUS20070281448A1Reduce carbon contentDecorative surface effectsSemiconductor/solid-state device manufacturingSilicon oxideOxygen

Methods of filling a gap on a substrate with silicon oxide are described. The methods may include the steps of introducing an organo-silicon precursor and an oxygen precursor to a deposition chamber, reacting the precursors to form a first silicon oxide layer in the gap on the substrate, and etching the first silicon oxide layer to reduce the carbon content in the layer. The methods may also include forming a second silicon oxide layer on the first layer, and etching the second layer to reduce the carbon content in the second layer. The silicon oxide layers are annealed after the gap is filled.

Owner:APPLIED MATERIALS INC

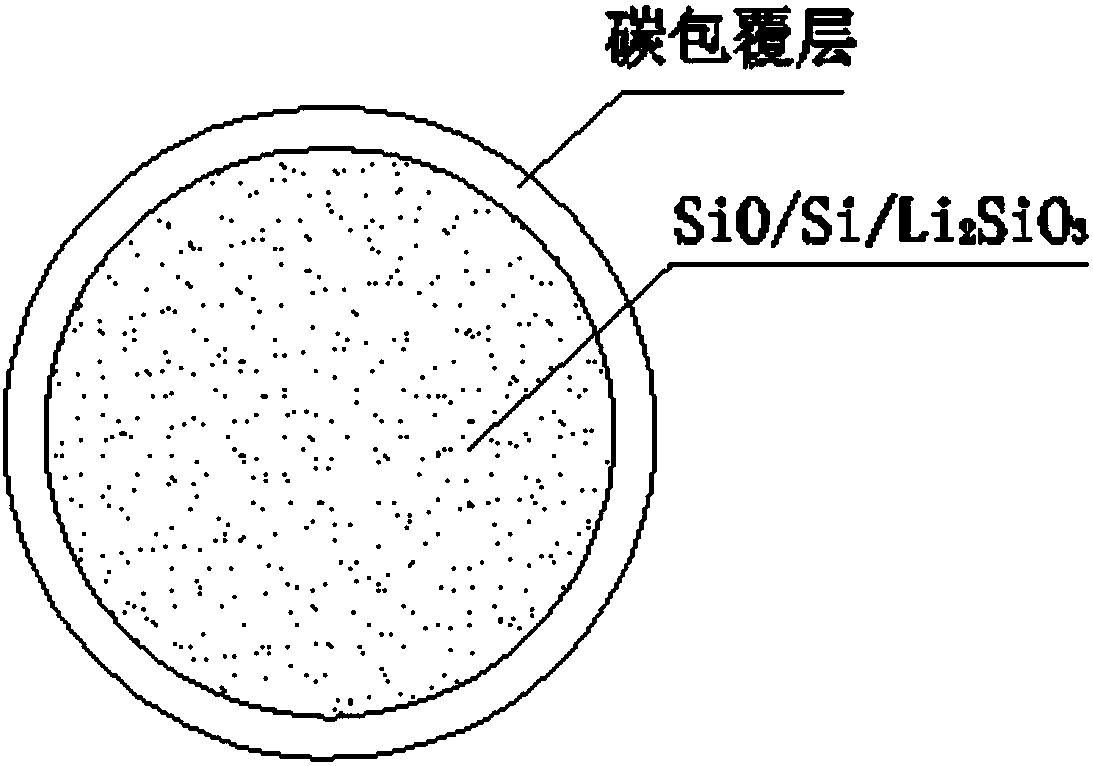

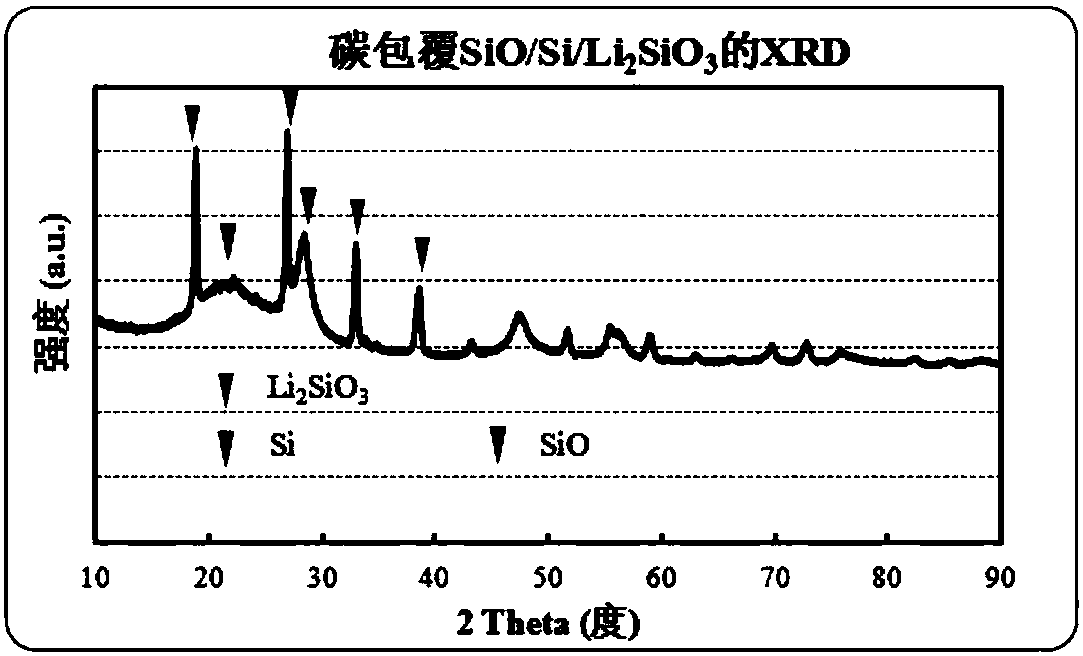

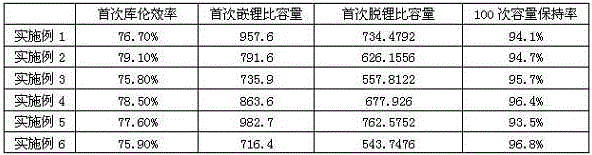

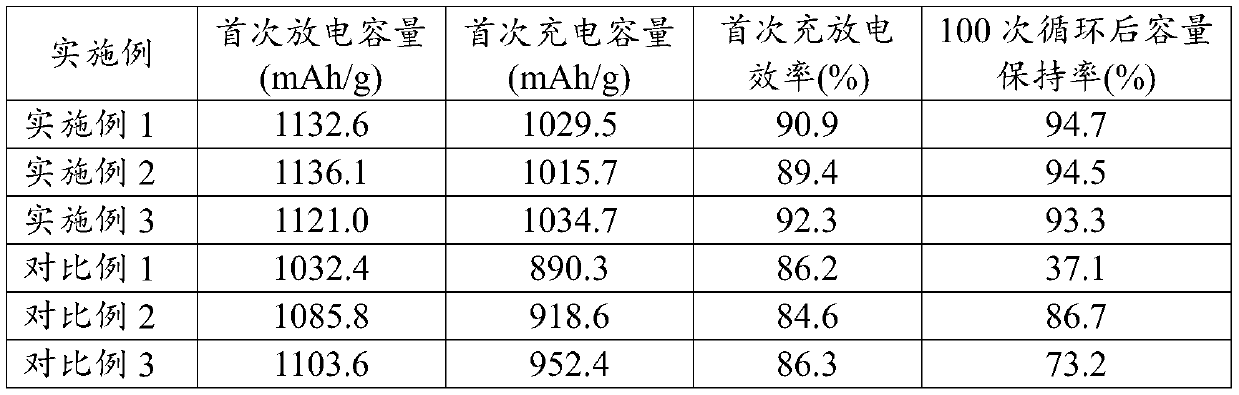

Silicon monoxide/silicon/lithium metasilicate composite negative electrode material and preparation method thereof

InactiveCN108269979AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSilicon monoxideShielding gas

The invention discloses a silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The silicon monoxide / silicon / lithium metasilicate composite negative electrode material comprises a silicon monoxide / silicon / lithium metasilicate composite material and an inorganic matter coating layer. The invention also provides a preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The preparation method comprises the following steps: taking silicon monoxide and an inorganic compound of lithium element, mixing and ball-milling the silicon monoxide and the inorganic compound of the lithium element, sintering the obtained mixture in a protection gas environment, and naturally cooling the sintered mixture to obtain the silicon monoxide / silicon / lithium metasilicate composite material; and mixing and ball-milling the silicon monoxide / silicon / lithium metasilicate composite material and sintering the obtained mixture undera protection gas condition. The preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material has the advantages of simplicity, safety, low cost, and easiness in operation and industrial production, and the obtained composite negative electrode material has the advantages of high reversible capacity, excellent cycle performances and high initial Coulomb efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Deposition-plasma cure cycle process to enhance film quality of silicon dioxide

ActiveUS7902080B2Decorative surface effectsSemiconductor/solid-state device manufacturingSilicon monoxideSilicon oxide

Owner:APPLIED MATERIALS INC

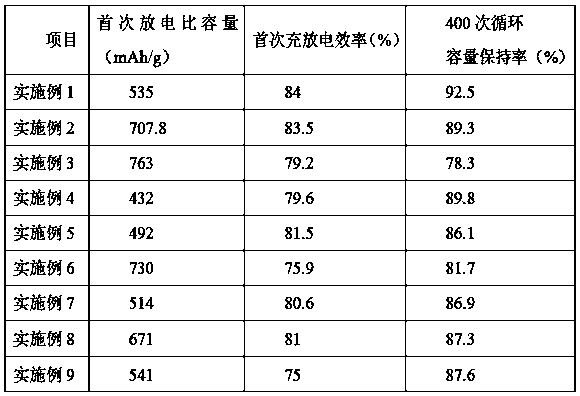

Silicon-carbon composite material, preparation method thereof and lithium ion battery employing same

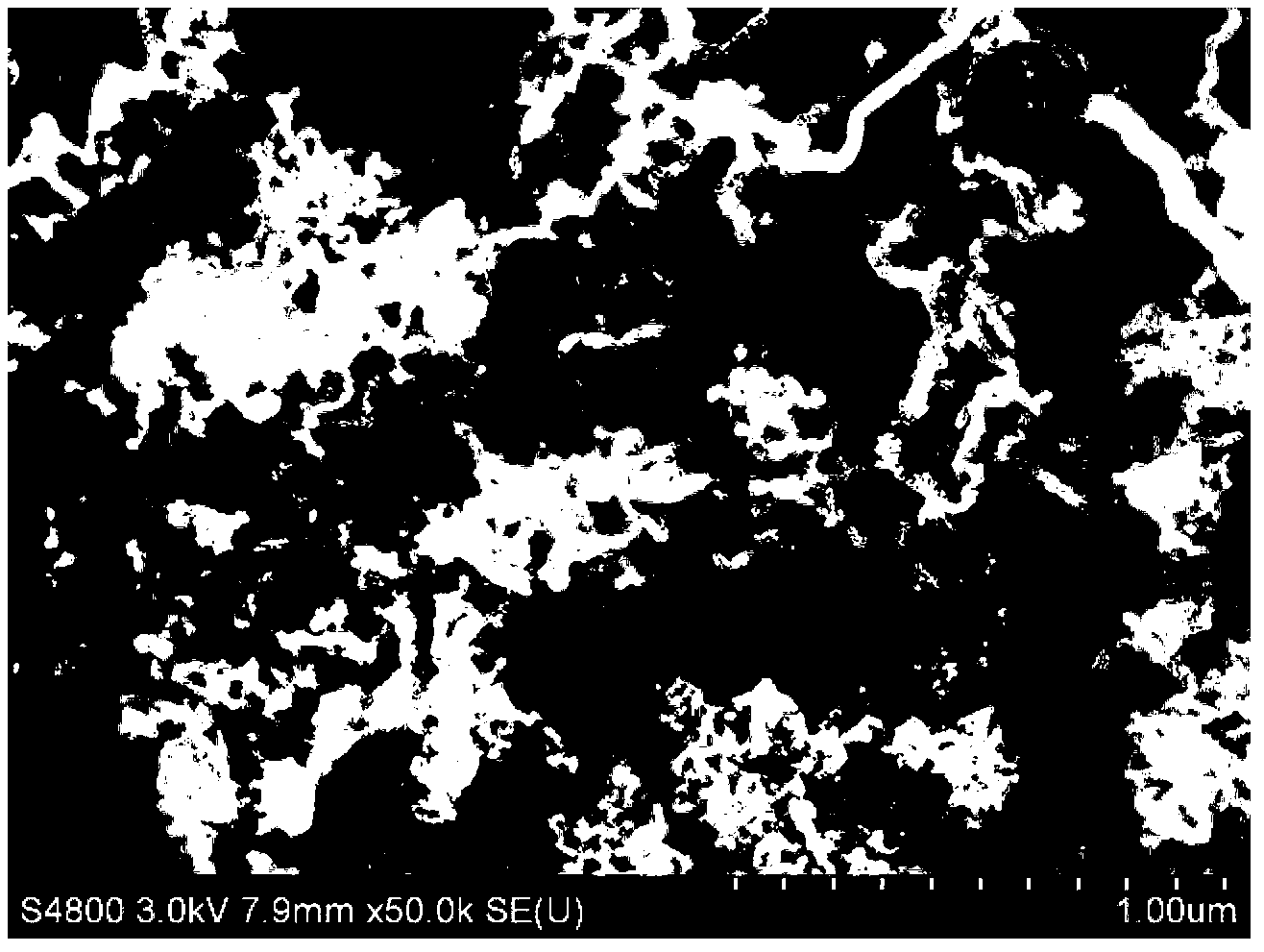

ActiveCN102694155APossesses electrochemical reversible intercalation and delithiation performanceAlleviate chalking and sheddingMaterial nanotechnologyCell electrodesCarbon compositesSilicon monoxide

The invention discloses a silicon-carbon composite material, a preparation method thereof and a lithium ion battery prepared by adopting the material. The preparation method of the silicon-carbon composite material comprises the following steps: (1) mixing a composite material (silica-coated nano-silicon) manufactured by silicon monoxide, a porous carbon-based material and excessive hydrofluoric acid solution to obtain another composite material in which nano-silicon particles are compounded in pores of the porous carbon-based material; and (2) heating a composite material in which nano-silicon particles are compounded in pores of a high polymer-coated porous carbon-based material under an inert atmosphere to obtain the silicon-carbon composite material coated by porous carbon spheres. The process raw materials are accessible and simple to prepare. The silicon-carbon composite material has electrochemical reversible embedded lithium removal performance, greatly relieves efflorescence and falling-off phenomena of active particles in the charge-discharge process and has the high lithium storage capacity characteristic of silicon materials and the high cycling stability of carbon materials, and a battery prepared by the silicon-carbon composite material has better cyclicity.

Owner:CHERY AUTOMOBILE CO LTD

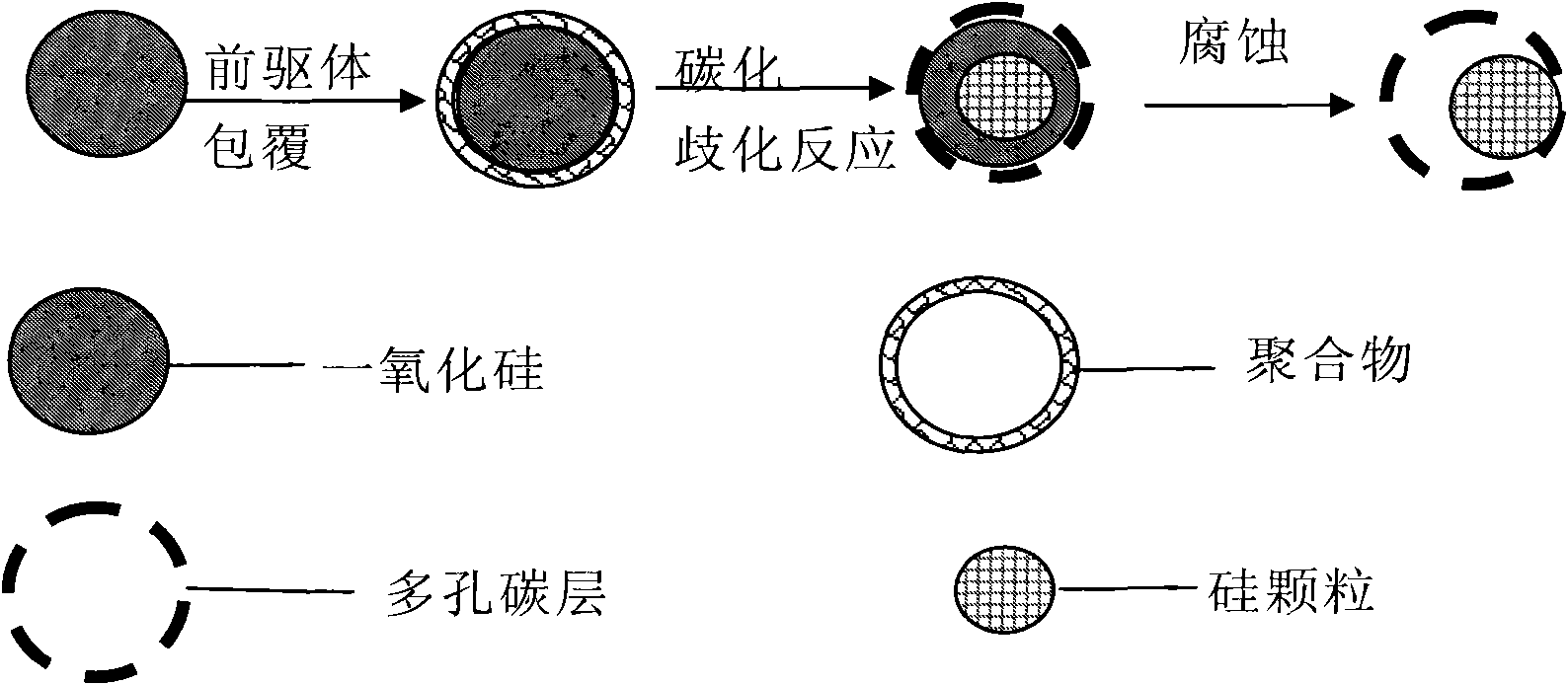

Preparation method for silicon-carbon composite material, prepared silicon-carbon composite material, lithium ion battery anode containing silicon-carbon composite material and battery

ActiveCN102437318AIncrease the embedding positionImproved silicon volume effectSecondary cellsNon-aqueous electrolyte accumulator electrodesCarbon compositesSilicon monoxide

The invention provides a preparation method for a silicon-carbon composite material, the prepared silicon-carbon composite material, a battery anode prepared from the material and a lithium ion battery. The preparation method comprises the following steps of: directly mixing free phenol, free aldehyde and silicon monoxide, performing polymerization reaction under certain conditions to obtain a mixture of a phenolic resin and the silicon monoxide which is coated by the phenolic resin, and performing thermal treatment and corrosion to obtain the silicon-carbon composite material with a core shell structure. The preparation method is simple. The prepared silicon-carbon composite material has the advantages of high specific capacity and high cycle performance.

Owner:CHERY AUTOMOBILE CO LTD

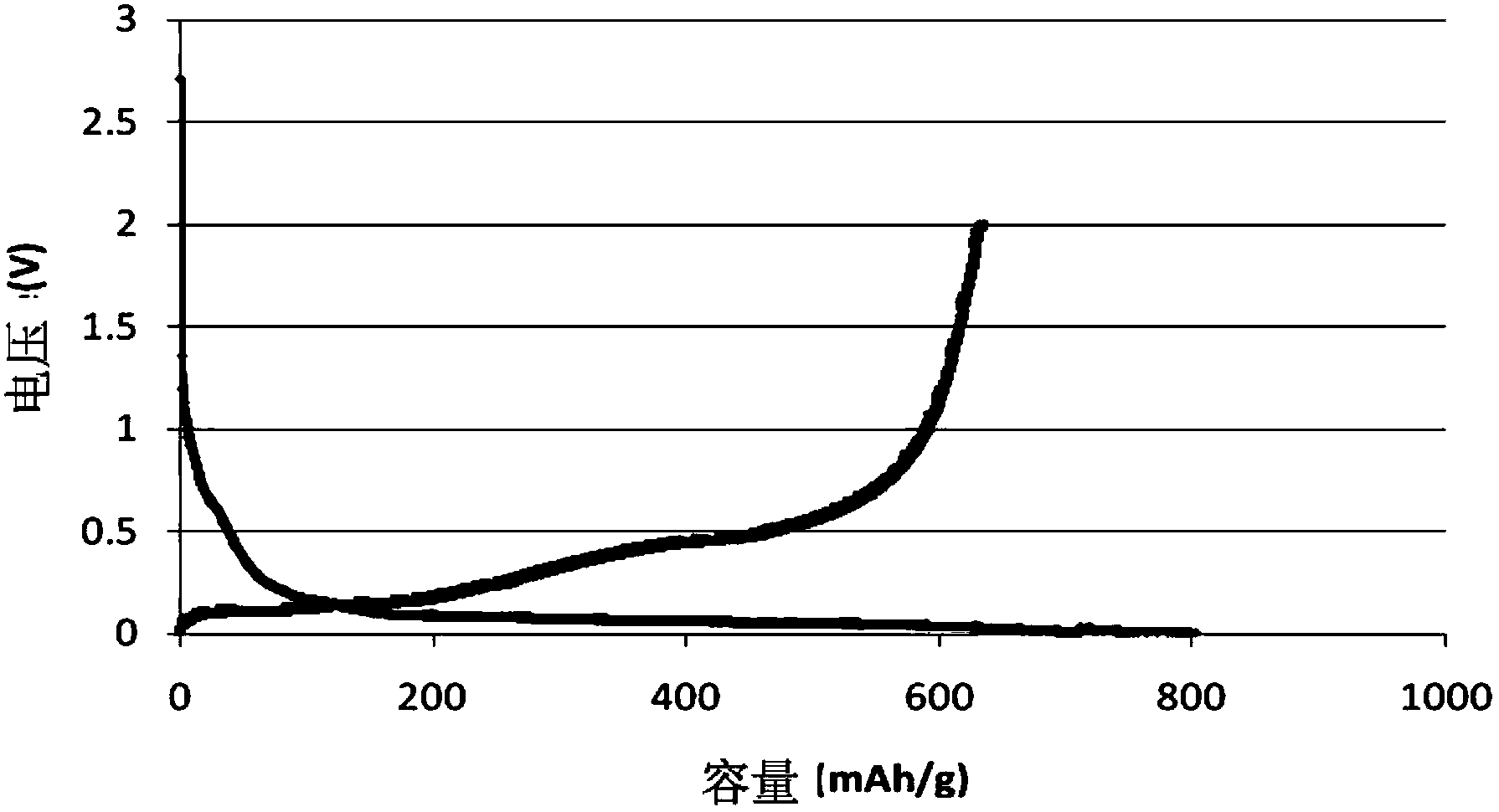

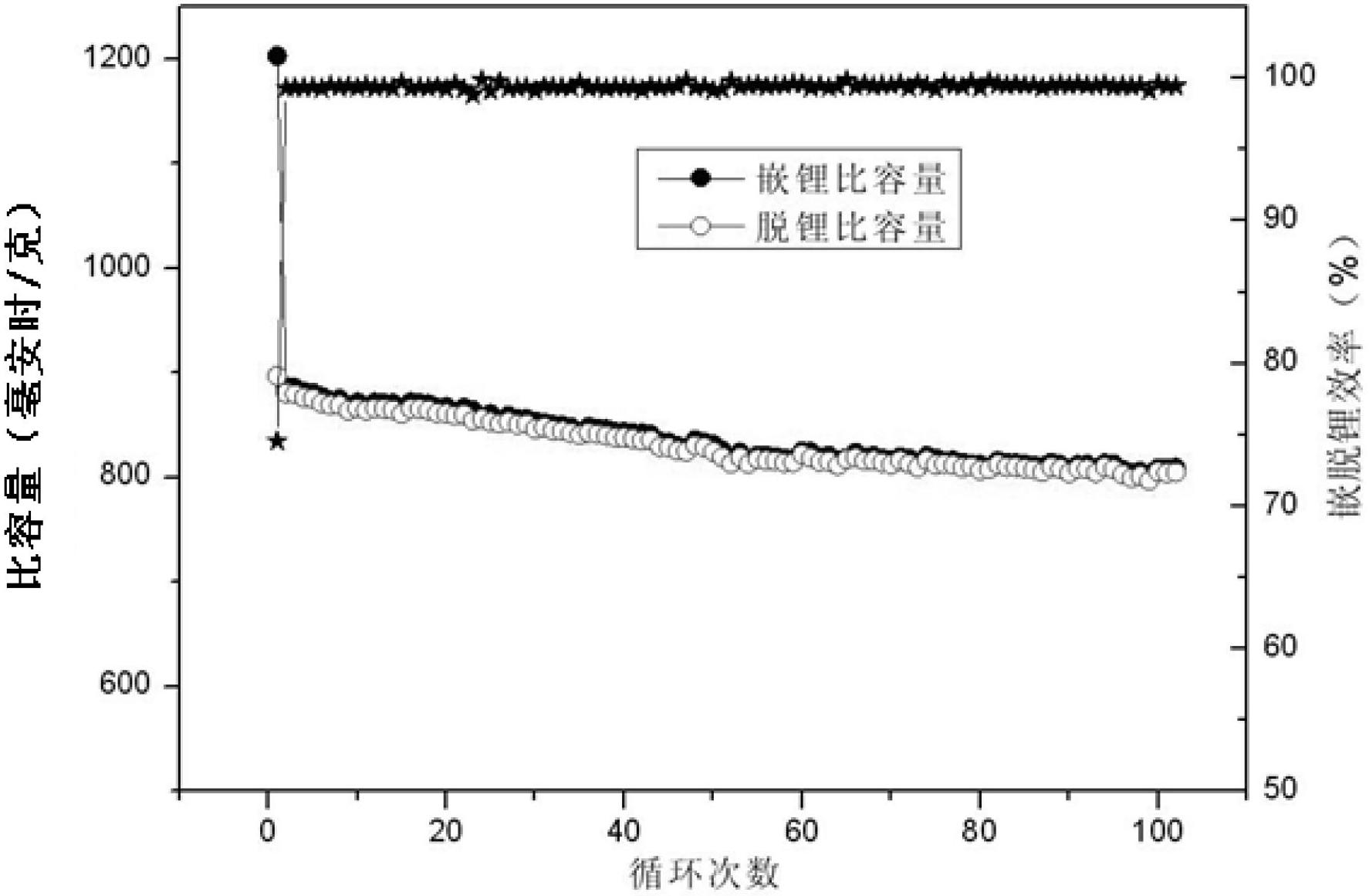

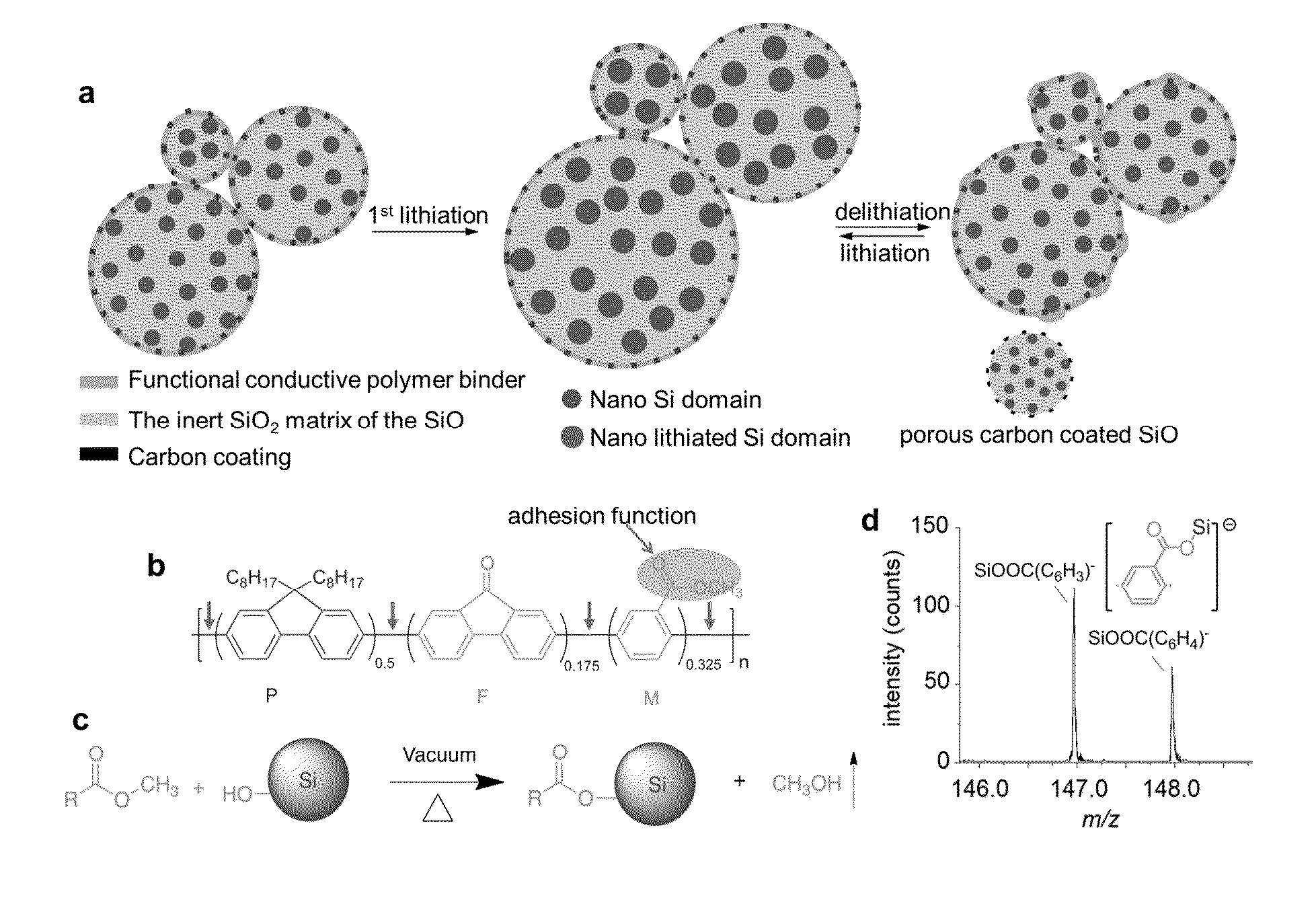

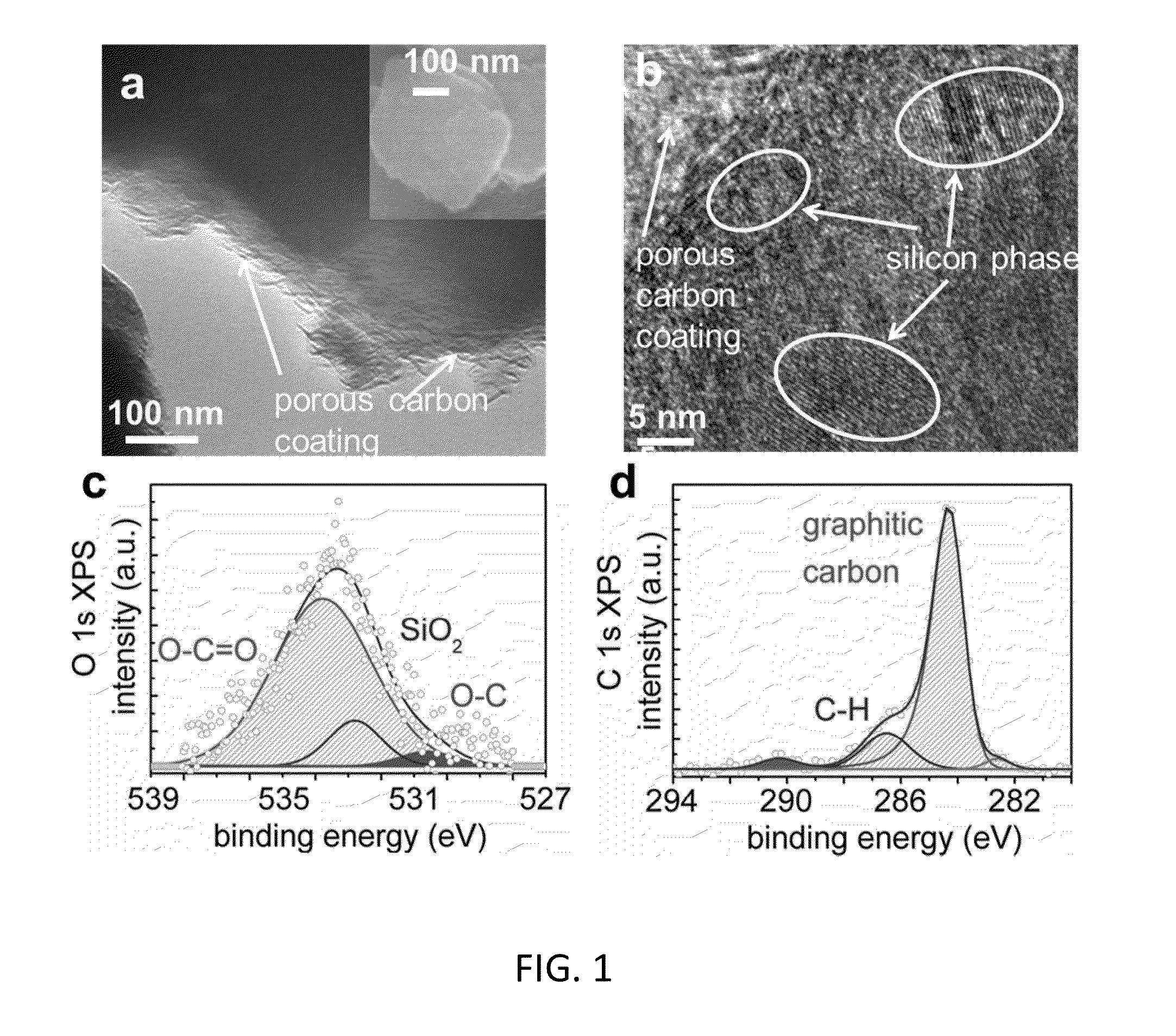

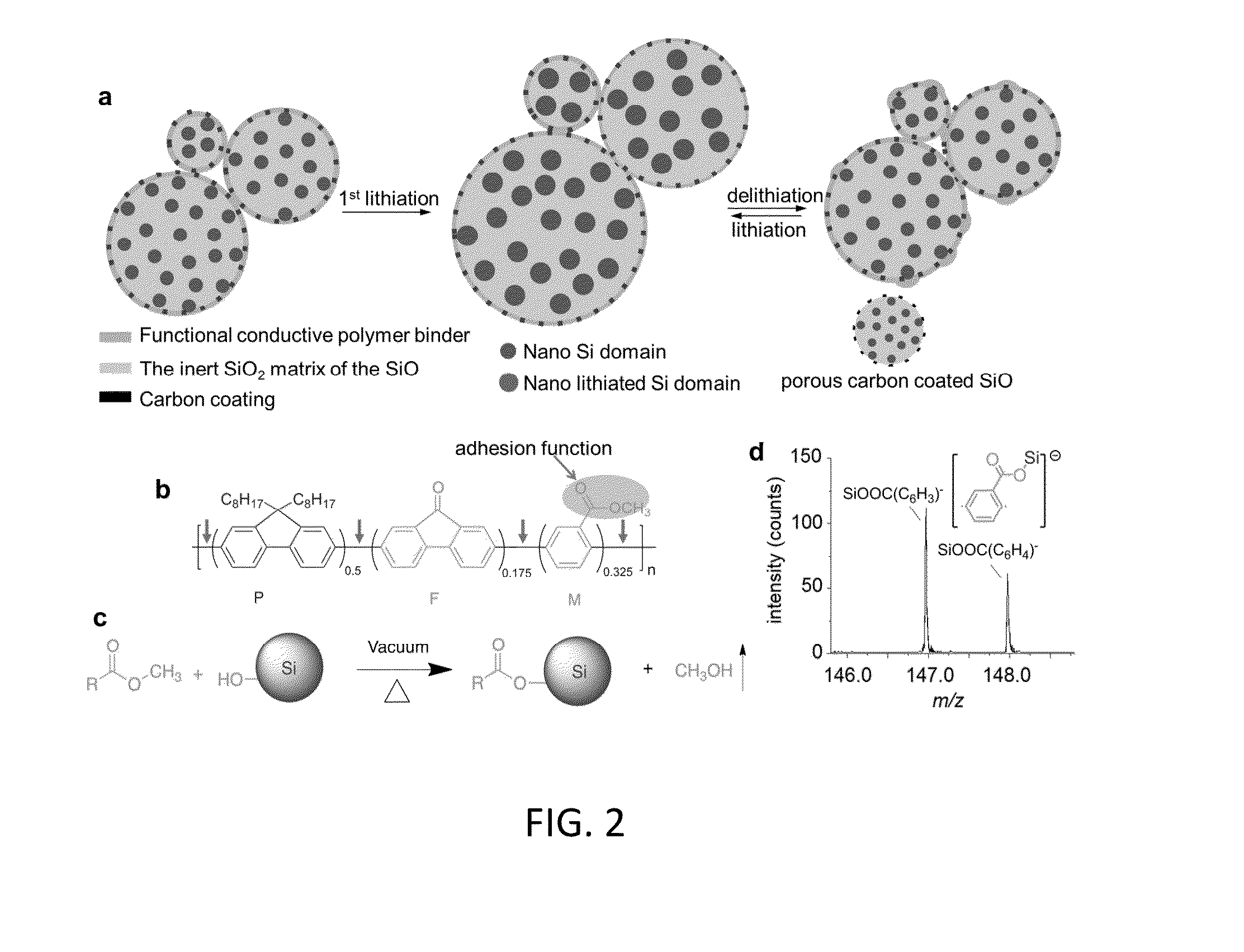

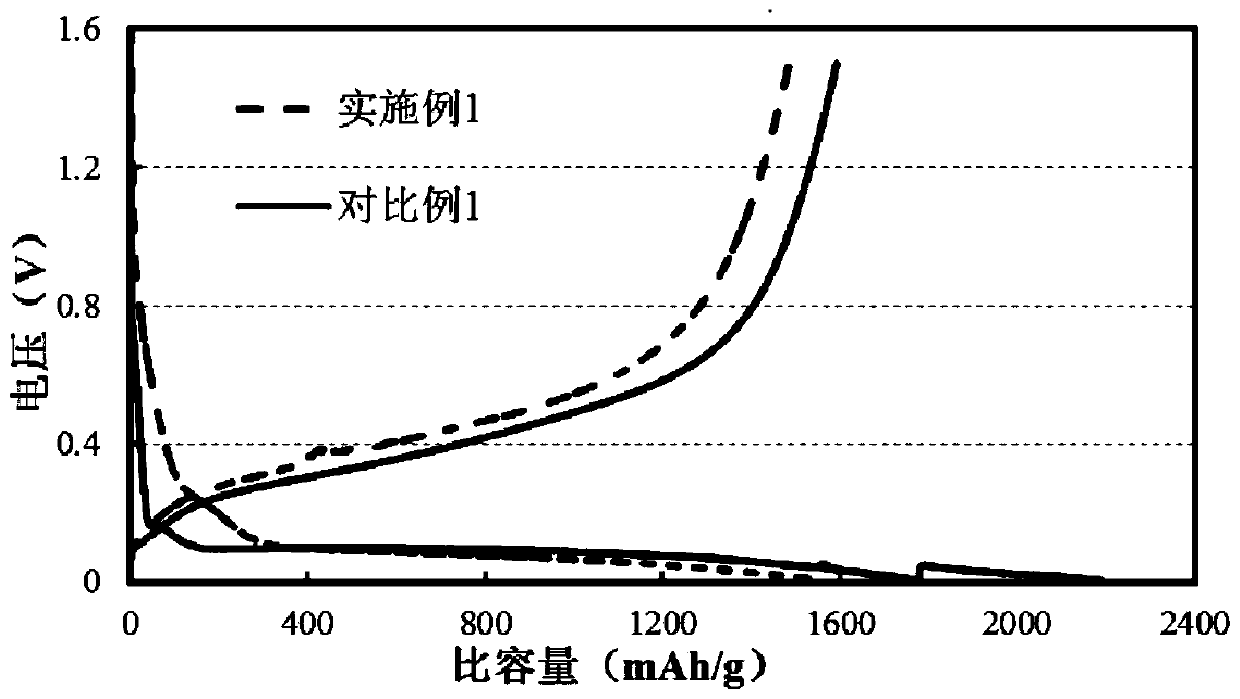

Silicon Oxide (SiO) Anode Enabled by a Conductive Polymer Binder and Performance Enhancement by Stabilized Lithium Metal Power (SLMP)

InactiveUS20150364755A1Electrode carriers/collectorsConductive materialPerformance enhancementSilicon monoxide

Silicon alloys have the highest specific capacity when used as anode material for lithium-ion batteries, however, the drastic volume change inherent in their use causes formidable challenges toward achieving stable cycling performance. Large quantities of binders and conductive additives are typically necessary to maintain good cell performance. In one embodiment of the invention, only 2% (by weight) functional conductive polymer binder without any conductive additives was successfully used with a micron-size silicon monoxide (SiO) anode material, demonstrating stable and high gravimetric capacity (>1000 mAh / g) for ˜500 cycles and more than 90% capacity retention. Prelithiation of this anode using stabilized lithium metal powder (SLMP®) improves the first cycle Coulombic efficiency of a SiO / NMC full cell from ˜48% to ˜90%. This combination enables good capacity retention of more than 80% after 100 cycles at C / 3 in a lithium-ion full cell.

Owner:RGT UNIV OF CALIFORNIA

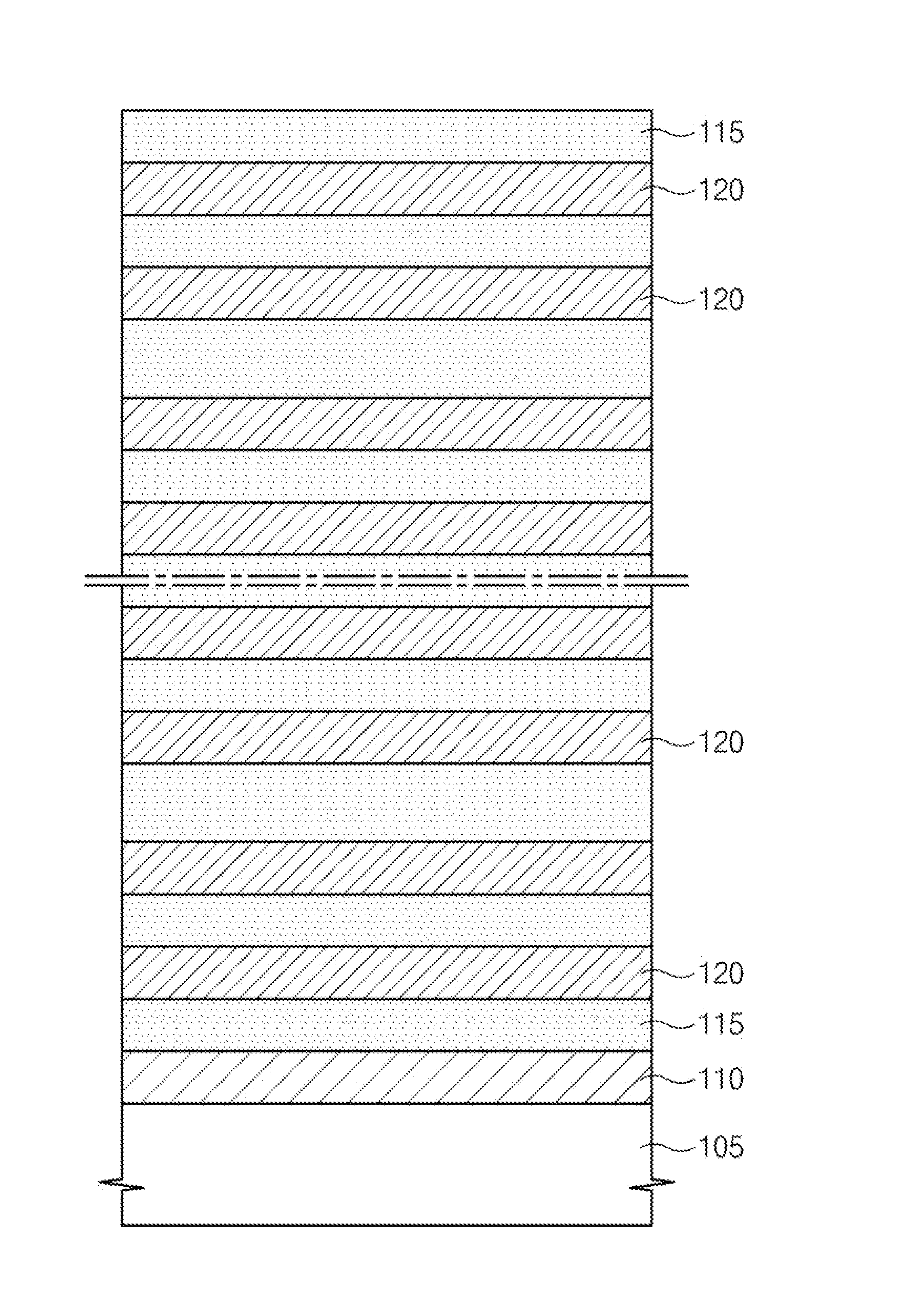

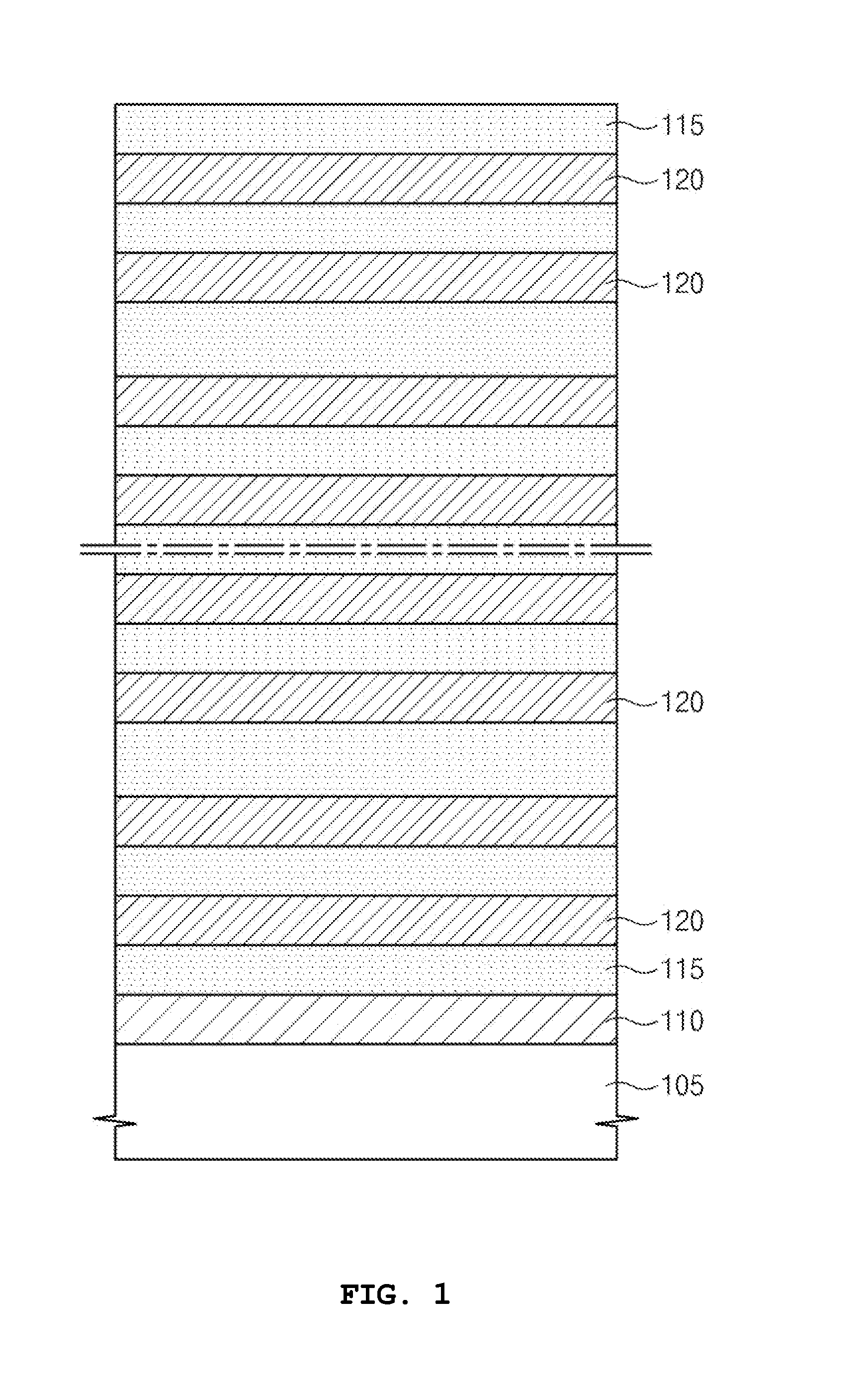

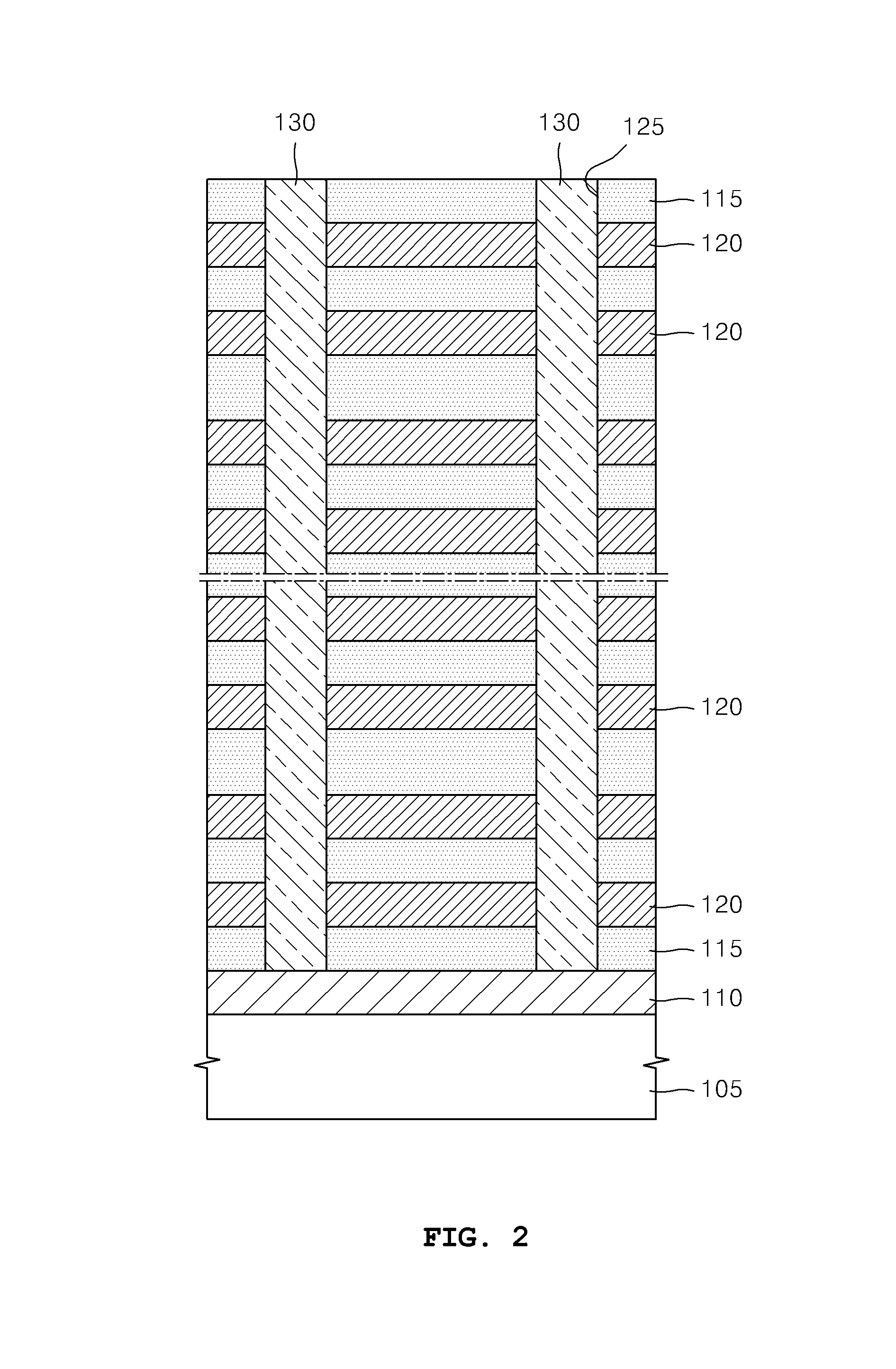

Method and apparatus for manufacturing three-dimensional-structure memory device

ActiveUS20130171827A1Lower the volumeAvoid deformationSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSilicon monoxide

A method for manufacturing a memory device having a vertical structure according to one embodiment of the present invention comprises: a step for alternatingly laminating one or more insulation layers and one or more sacrificial layers on a substrate; a step for forming a penetration hole for penetrating the insulation layer and the sacrificial layer; a step for forming a pattern for filling up the penetration hole; a step for forming an opening for penetrating the insulation layer and the sacrificial layer; and a step for removing the sacrificial layer by supplying an etchant through the opening, wherein the step for laminating the insulation layer includes a step for depositing a first silicon oxide film by supplying to the substrate at least one gas selected from the group consisting of SiH4, Si2H6, Si3H8, Si4H10, and the step for laminating the sacrificial layer includes a step for depositing a second silicon oxide film by supplying dichlorosilane (SiCl2H2) to the substrate.

Owner:EUGENE TECH CO LTD

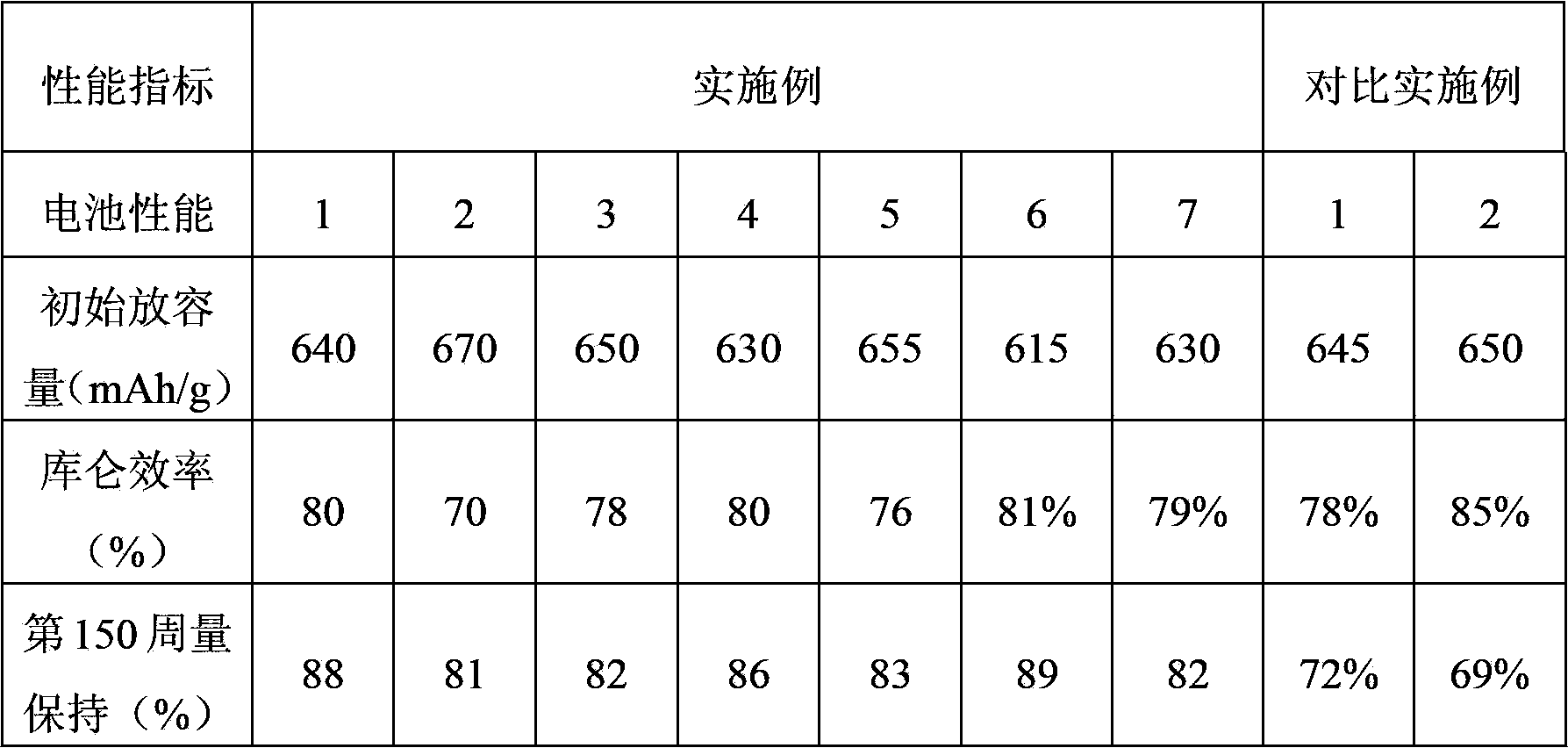

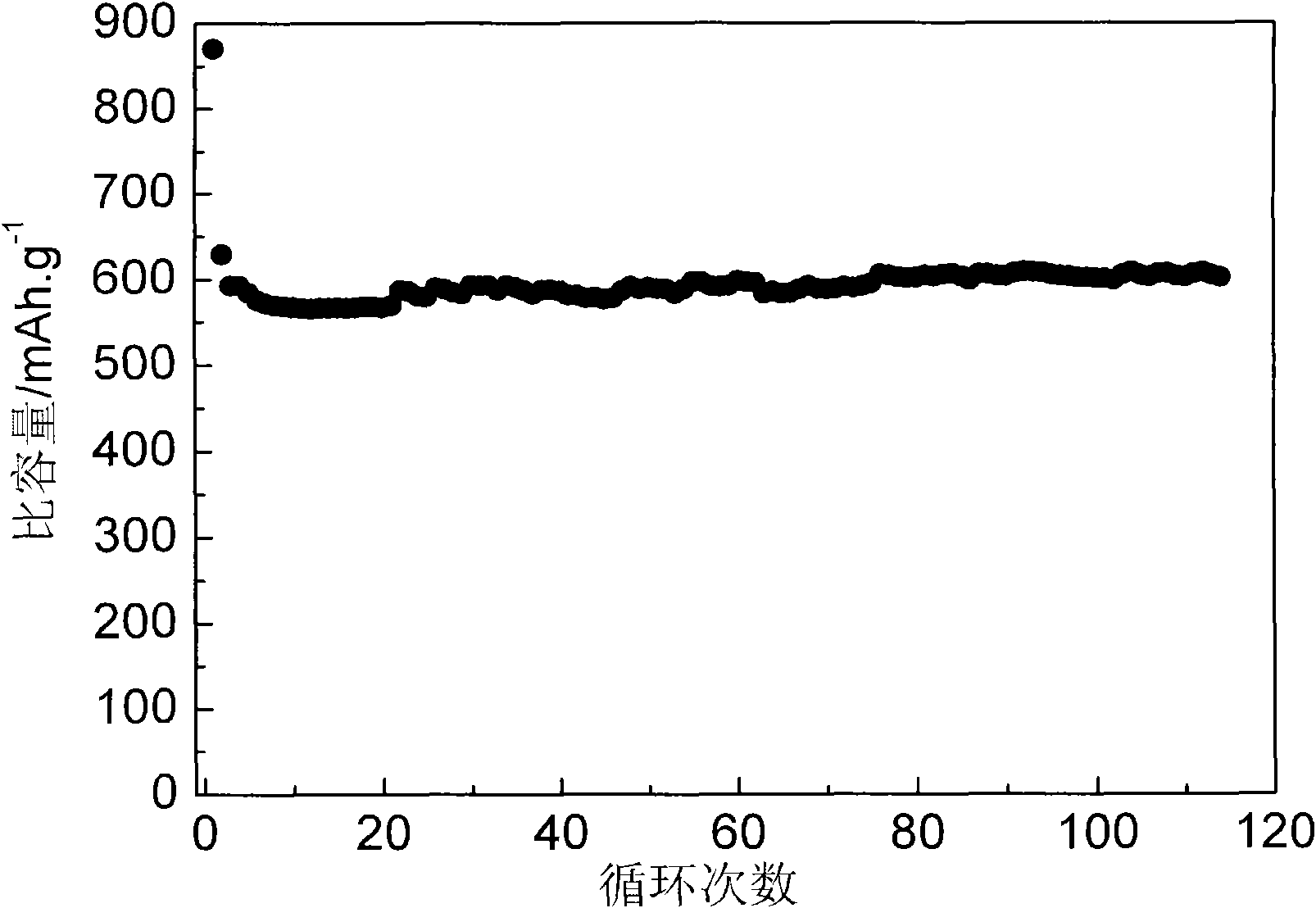

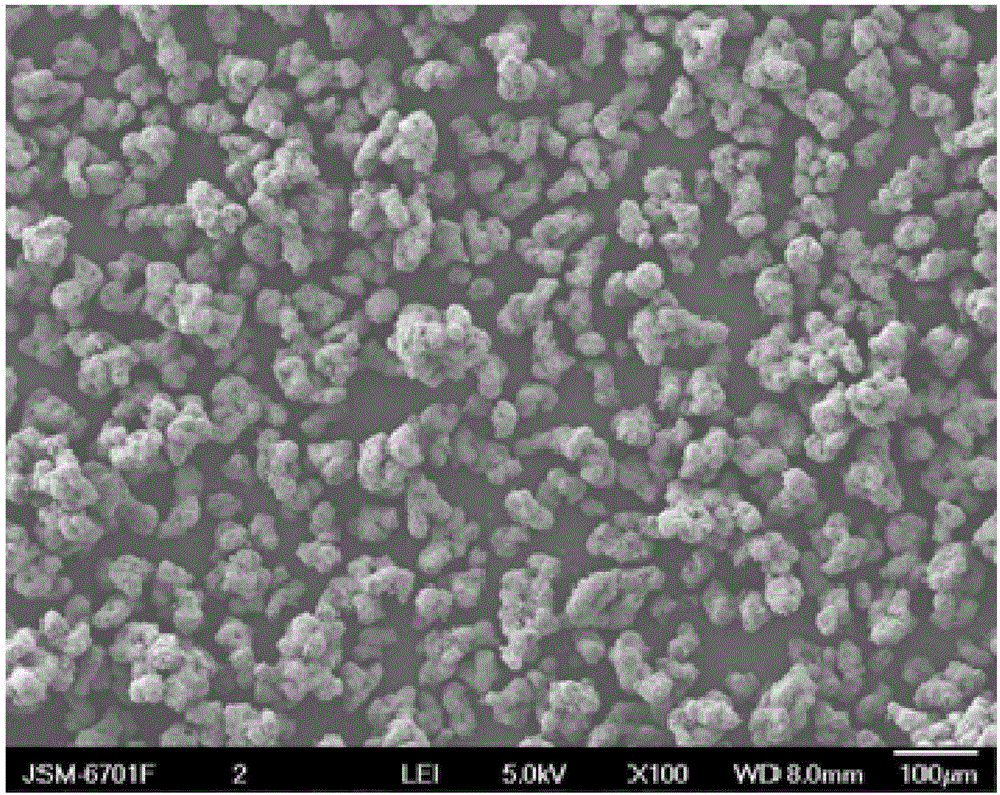

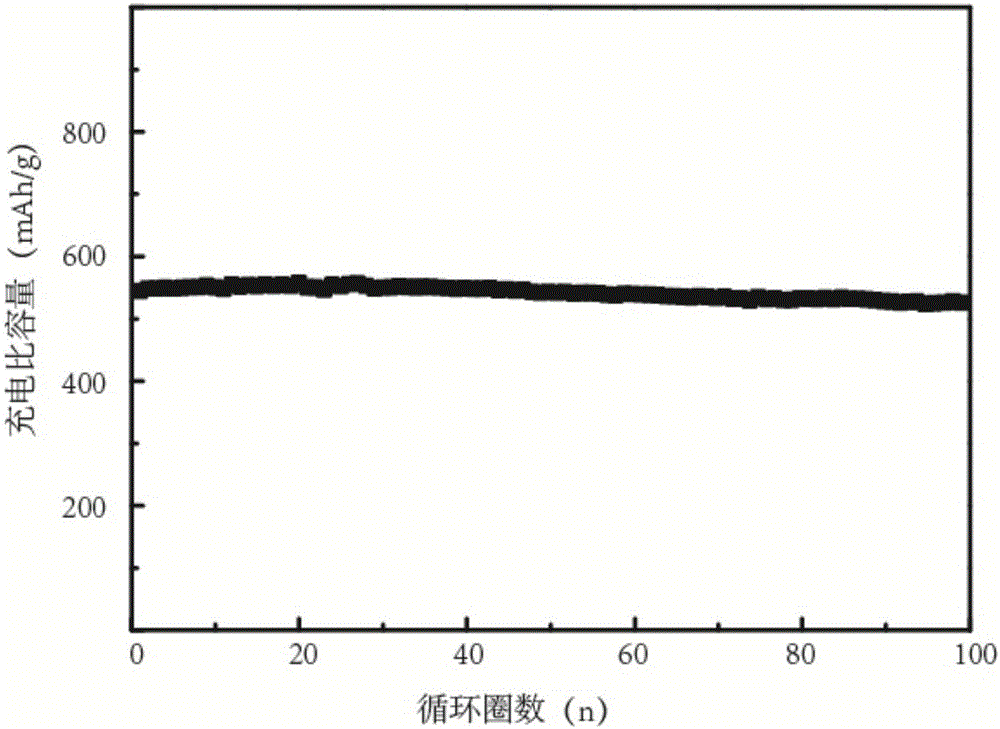

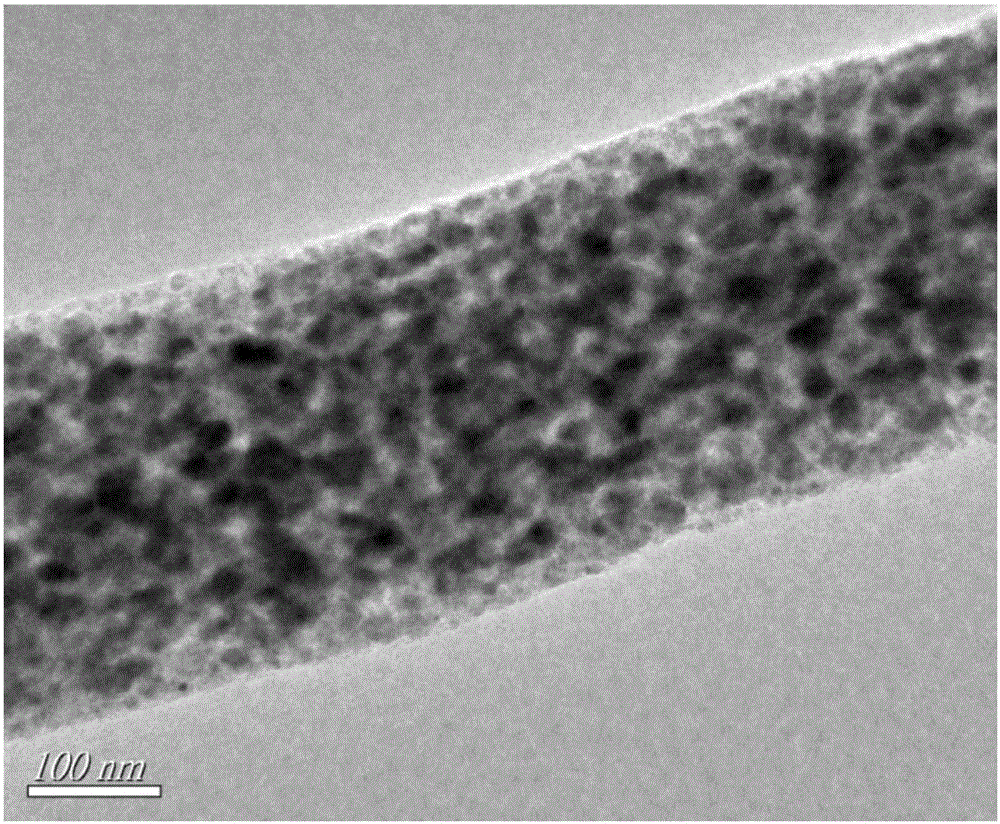

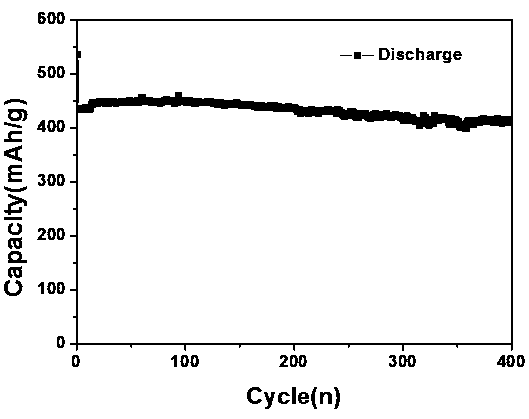

Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

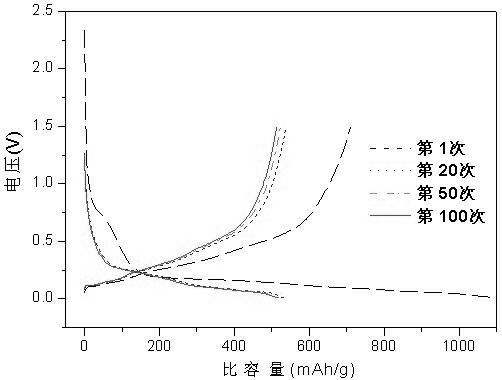

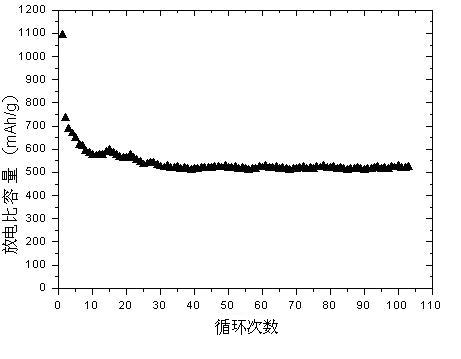

The invention discloses a silicon monoxide composite cathode material for a lithium ion battery, and a preparation method of the silicon monoxide composite cathode material, aiming at improving the cycle performance. The composite cathode material comprises the components by mass percent: 10-30% of composite particle material and 70-90% of natural graphite or artificial graphite, wherein the composite particle material is silicon monoxide covered by a carbon nano tube and an amorphous carbon coating layer. The method comprises the following steps of: forming the carbon nano tube and the amorphous carbon coating layer on the surface of silicon monoxide to obtain composite particles, and mixing the composite particles with the graphite. Compared with the prior art, the preparation method enables cracking carbon to be covered on the surfaces of silicon monoxide particles, so that the volume effect of the silicon monoxide particles can be effectively inhibited in the charge-discharge process of a battery, the cycle performance is good, the specific capacity is more than 500mAh / g, and the capacity retention ratio is more than 85% after the circulation is carried out for 100 times; and the preparation method is simple in preparation technology, low in raw material cost and suitable for the cathode material for the high-capacity lithium ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

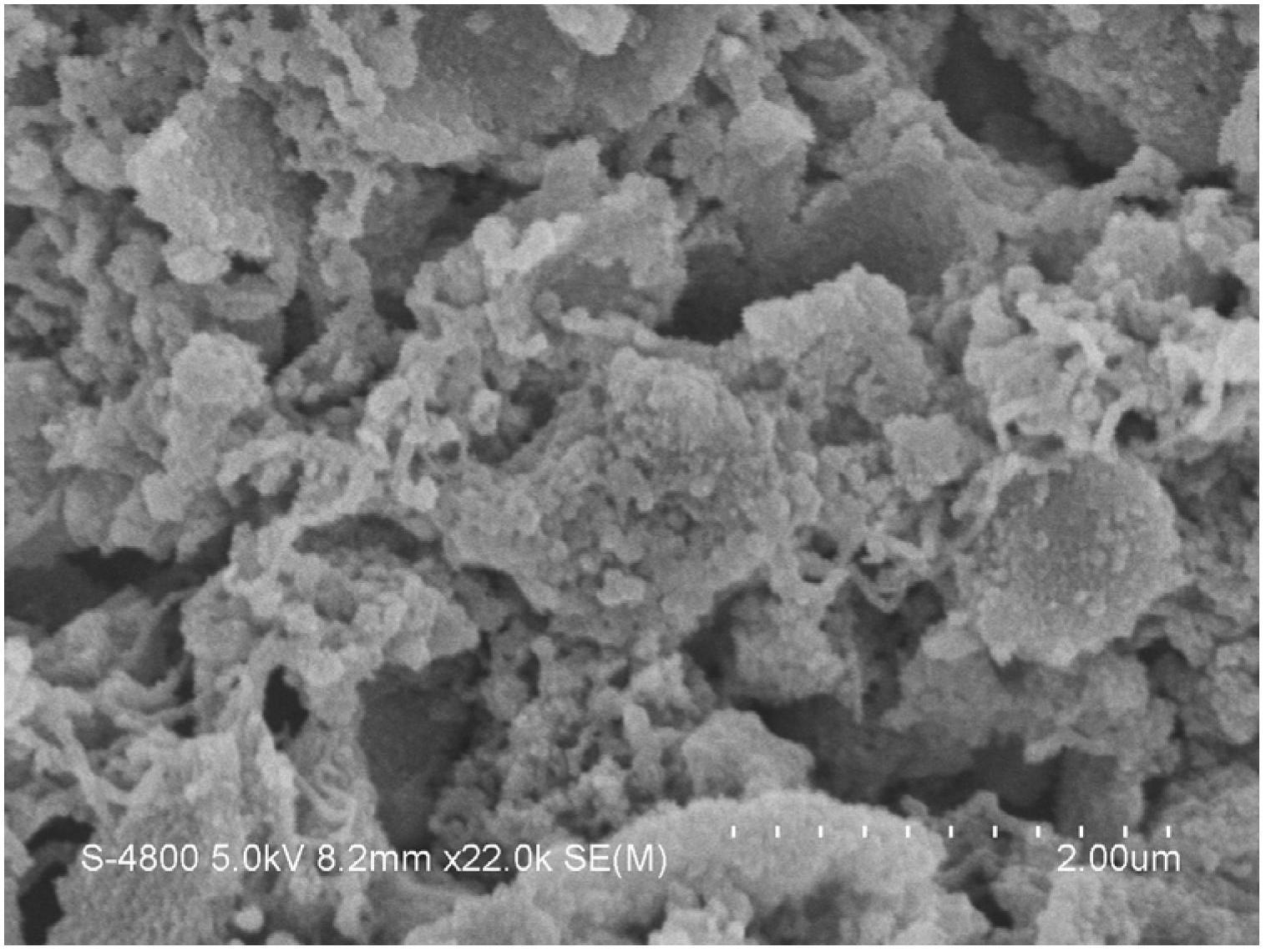

Graphene modified silicon monoxide and carbon composite microsphere, and preparation method and application thereof

ActiveCN106410158AAlleviate volume expansionActive connectionCell electrodesBatteriesCarbon compositesSilicon monoxide

The invention provides a graphene modified silicon monoxide and carbon composite microsphere prepared from graphene, asphalt and silicon monoxide, and a preparation method and an application thereof. Asphalt and silicon monoxide bulk are adopted as raw materials, so the cost is low; a high temperature and high pressure reaction is adopted to obtain a silicon monoxide and carbon composite material in a liquid phase, so the technology is simple; and a dispersant can be recycled, so no waste liquid is generated, and no toxic substances are discharged. The above obtained material has a small specific surface area, and is in favor of forming a stable SEI film; a graphene two-dimensional material has an obvious modification effect, effectively connects active substances, and alleviates volume expansion of an electrode, and good dispersion and reasonable cavity of silicon monoxide make the material have excellent cycle performances.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

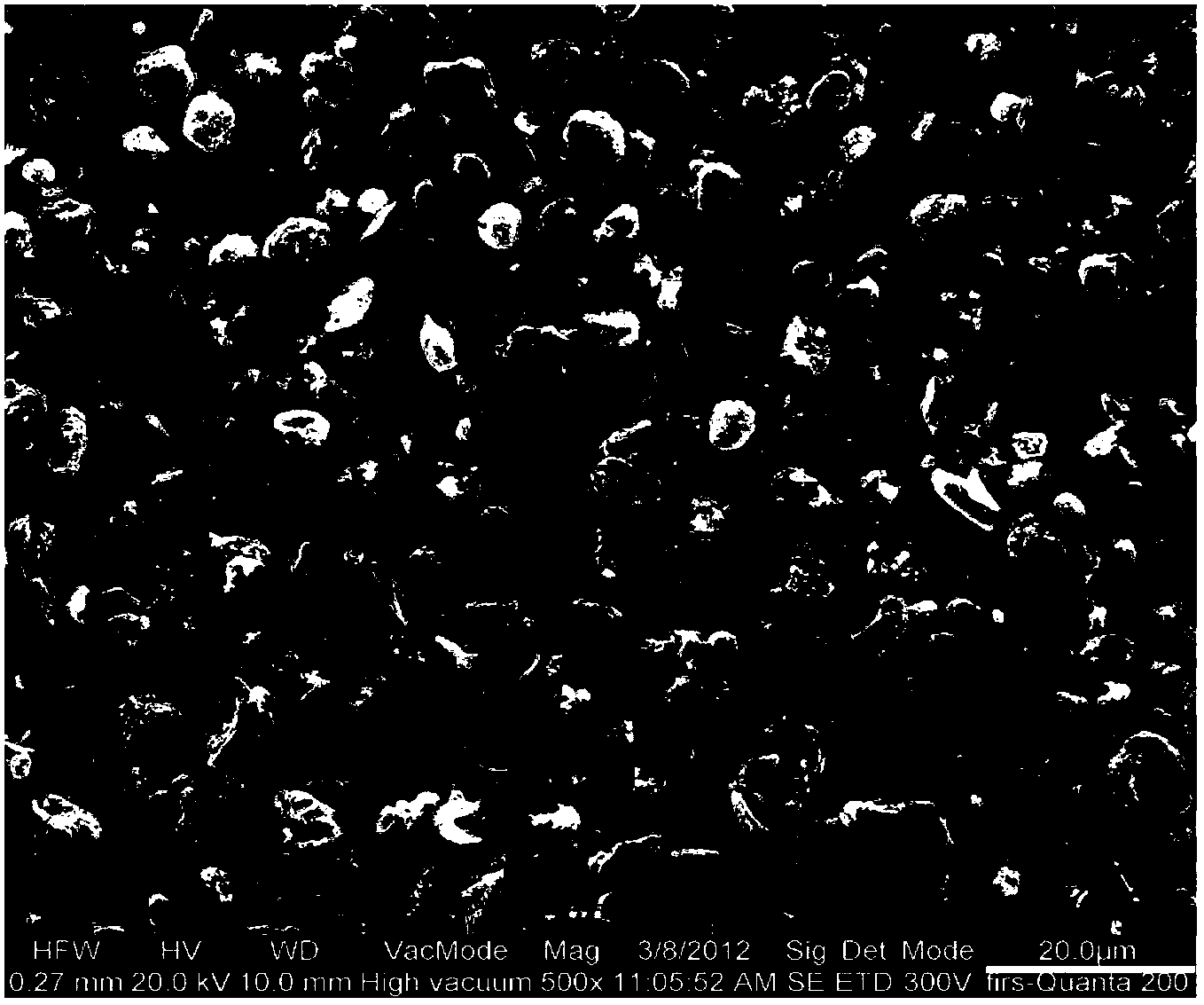

Silicon monoxide composite cathode material for lithium ion battery, and preparation method thereof

ActiveCN102306759AIncrease capacityImprove cycle performanceCell electrodesSilicon monoxideLithium-ion battery

The invention discloses a silicon monoxide composite cathode material for a lithium ion battery, and a preparation method thereof. The method comprises steps that: (1) silicon monoxide is sintered under a high temperature in an inert atmosphere, such that nano-sized silicon particles and amorphous silicon dioxide are produced; (2) a certain amount of sintered silicon monoxide and a certain amount of a conductive agent are accurately weighed, the materials are added into a planetary ball mill, and composite ball-milling is carried out upon the materials, such that the silicon monoxide composite cathode material is obtained, wherein silicon monoxide takes 30% to 90% of a total mass of the silicon monoxide composite cathode material. The silicon monoxide composite cathode material provided by the invention has advantages of high capacity, good cycling performance, and good conductivity. The preparation method has advantages of low raw material cost, simple preparation technology, and suitability for industrialized productions.

Owner:CHERY AUTOMOBILE CO LTD

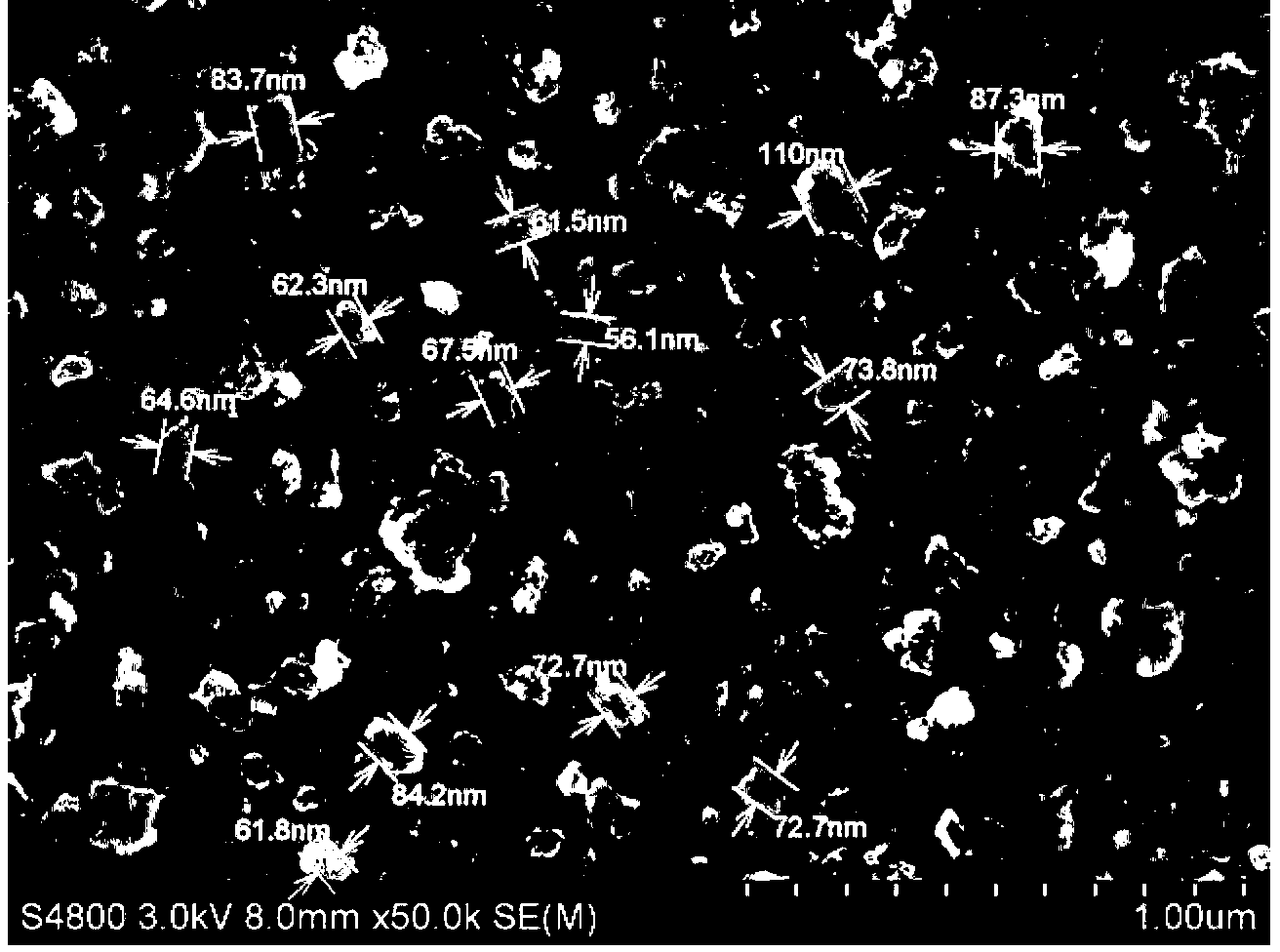

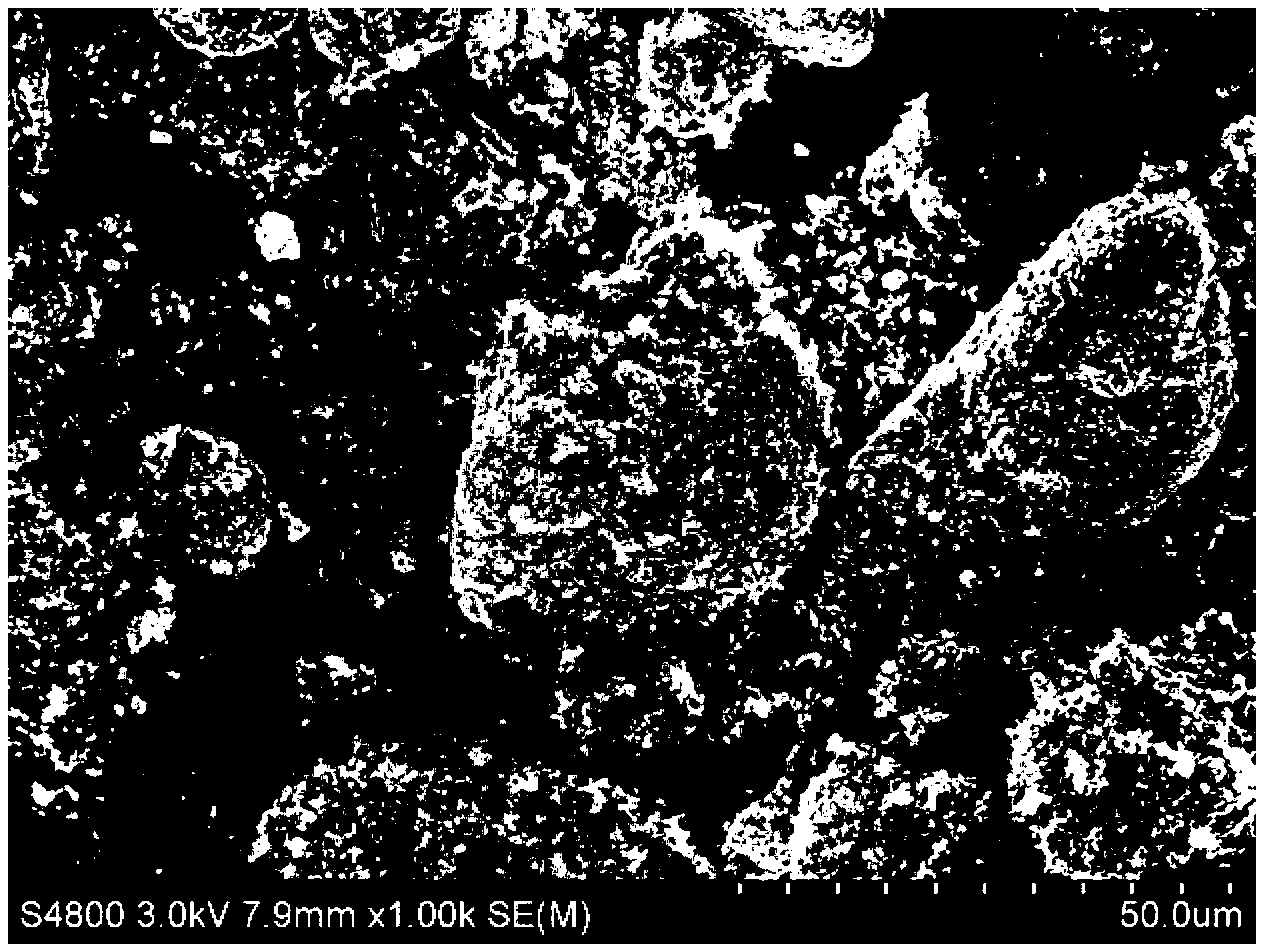

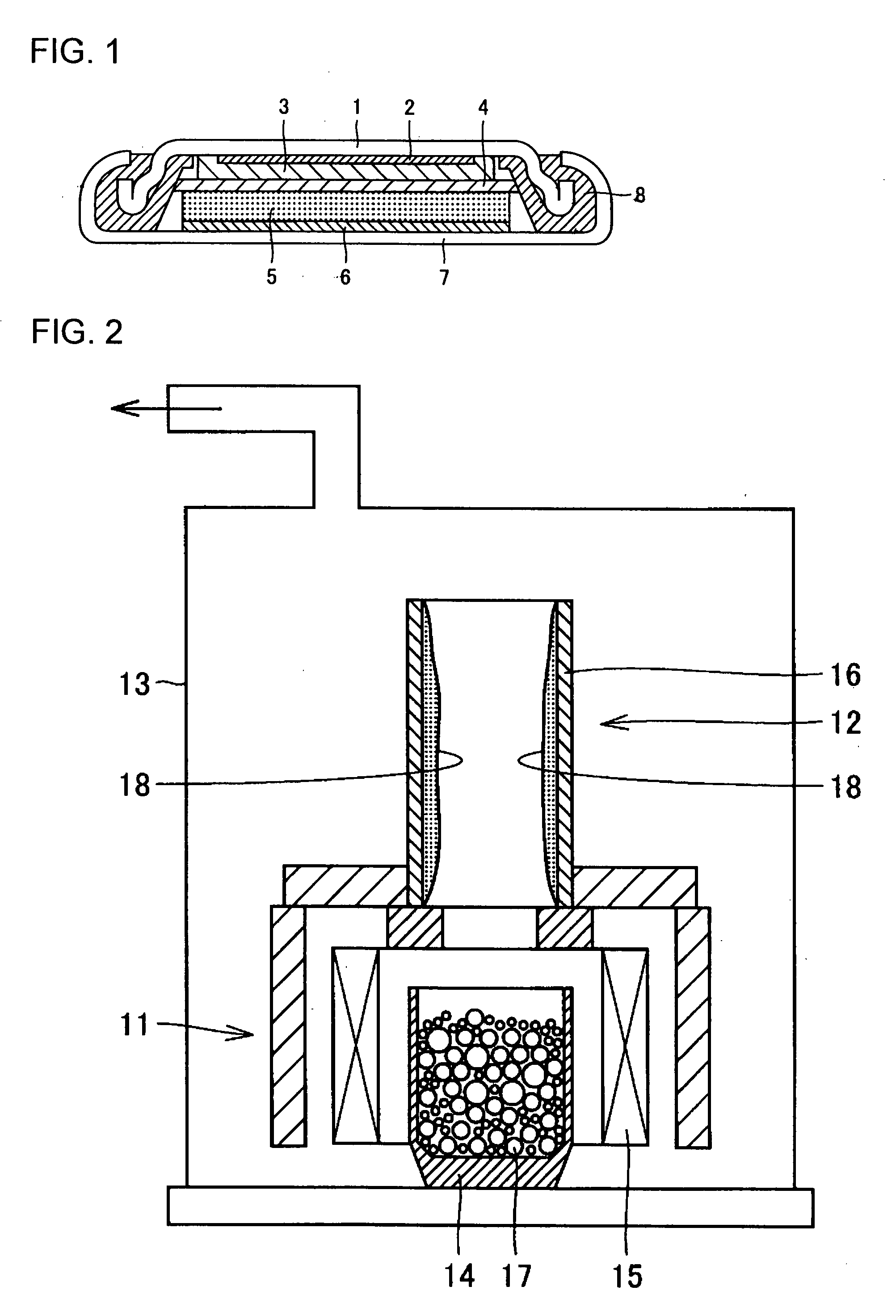

Silicon Monoxide Powder For Secondary Battery and Method For Producing the Same

InactiveUS20080135801A1Miniaturization and cost reductionEfficient productionElectrode thermal treatmentPositive electrodesLithiumHydrogen

A silicon monoxide powder for secondary battery of the present invention is characterized in that the silicon monoxide powder for secondary battery is used in a negative-electrode material of a lithium secondary battery and a hydrogen gas content is not less than 80 ppm. In the silicon monoxide powder for secondary battery, a discharge capacity and a cycle capacity durability rate can dramatically be improved, and miniaturization and cost reduction of the lithium secondary battery can be achieved. In a method for producing the silicon monoxide powder for secondary battery of the present invention, a silicon dioxide powder and a silicon powder with a hydrogen gas content of not less than 30 ppm are mixed together, heated to temperatures of 1250° C. to 1350° C. to vaporize a silicon monoxide, wherein the silicon monoxide thus vaporized is deposited on a deposition substrate to be subsequently crushed. Therefore, the silicon monoxide powder can efficiently be produced to largely reduce production costs such as electric power cost, thus enabling the present invention to be widely applied to the silicon monoxide powder for secondary battery.

Owner:OSAKA TITANIUM TECHNOLOGIES

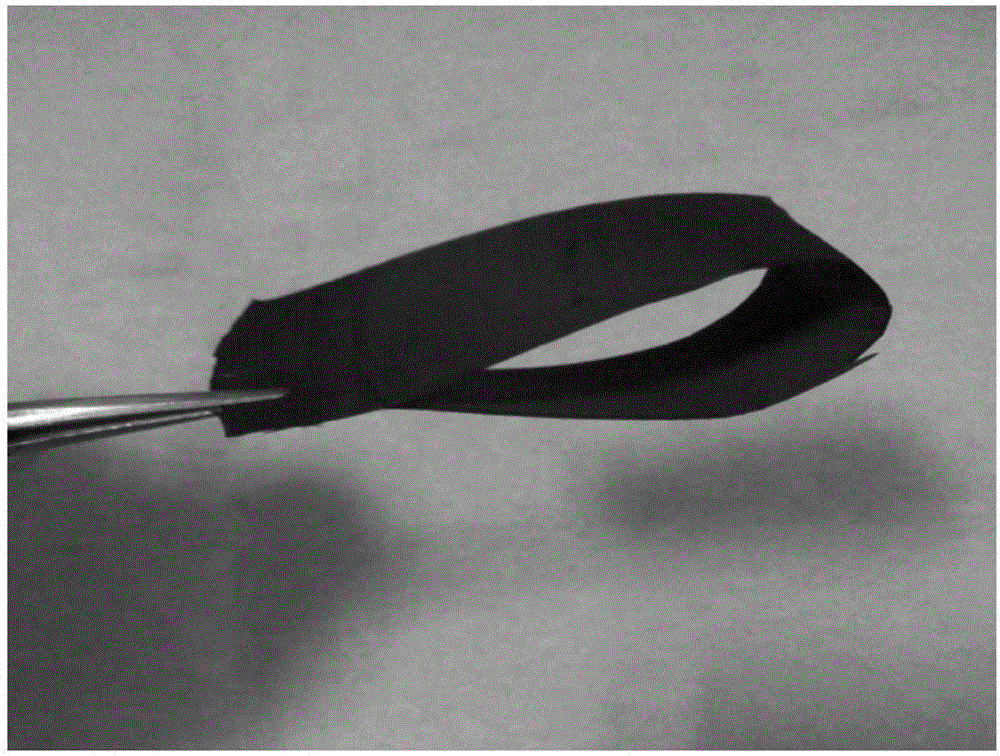

Lithium ion battery anode material, and preparation method thereof

InactiveCN106571451AVolume change controlThe process is easy to controlMaterial nanotechnologyNegative electrodesFiberSilicon monoxide

The invention discloses a lithium ion battery anode material, and a preparation method thereof. The preparation method comprises following steps: 1, a carbon source is mixed with an organic solvent so as to obtain a sol A; 2, nano silicon monoxide, a surfactant, the carbon source, and the organic solvent are mixed so as to obtain a sol B; 3, the sol A and the sol B are taken as raw materials for electrostatic spinning so as to obtain a composite fiber with a double-layer structure, wherein a shell layer is formed by the sol A, and a core layer is formed by the sol B; and 4, the composite fiber is dried, is subjected to pre-oxidation, and then is subjected to calcination at an insert atmosphere. The process of the preparation method is simple and controllable; large-scale production is easy to realize; an obtained composite material is a carbon-coated flexible self-supported silicon monoxide / amorphous carbon composite fiber anode material; in charging-discharging process of lithium ion batteries prepared from the composite material, the volume change of silicon-based oxide anode materials is controlled effectively, electrode structures are maintained to be complete, first time coulombic efficiency is increased obviously, cycling life is prolonged, and electrochemical performance is excellent.

Owner:TIANNENG SAFT ENERGY JOINT CO

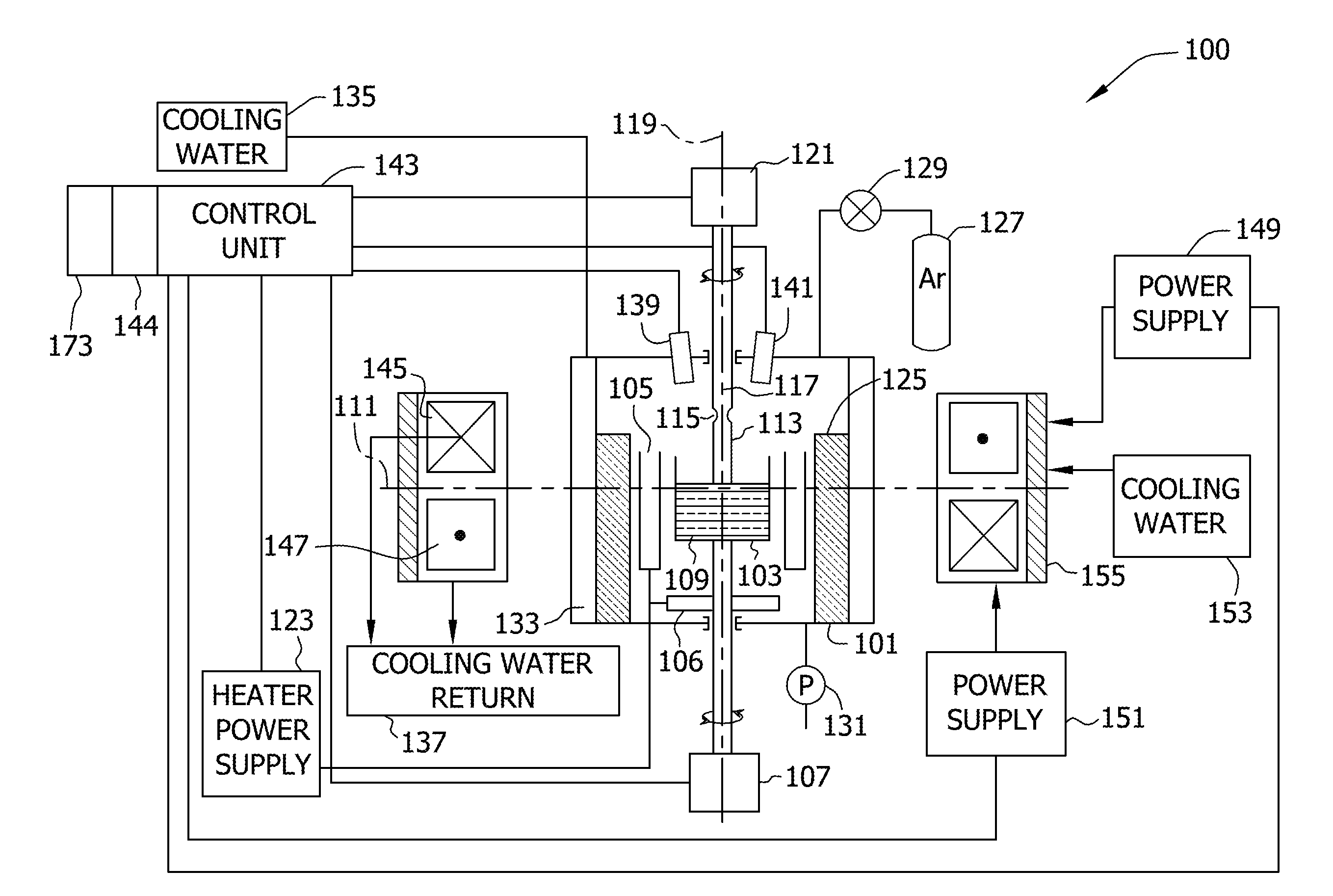

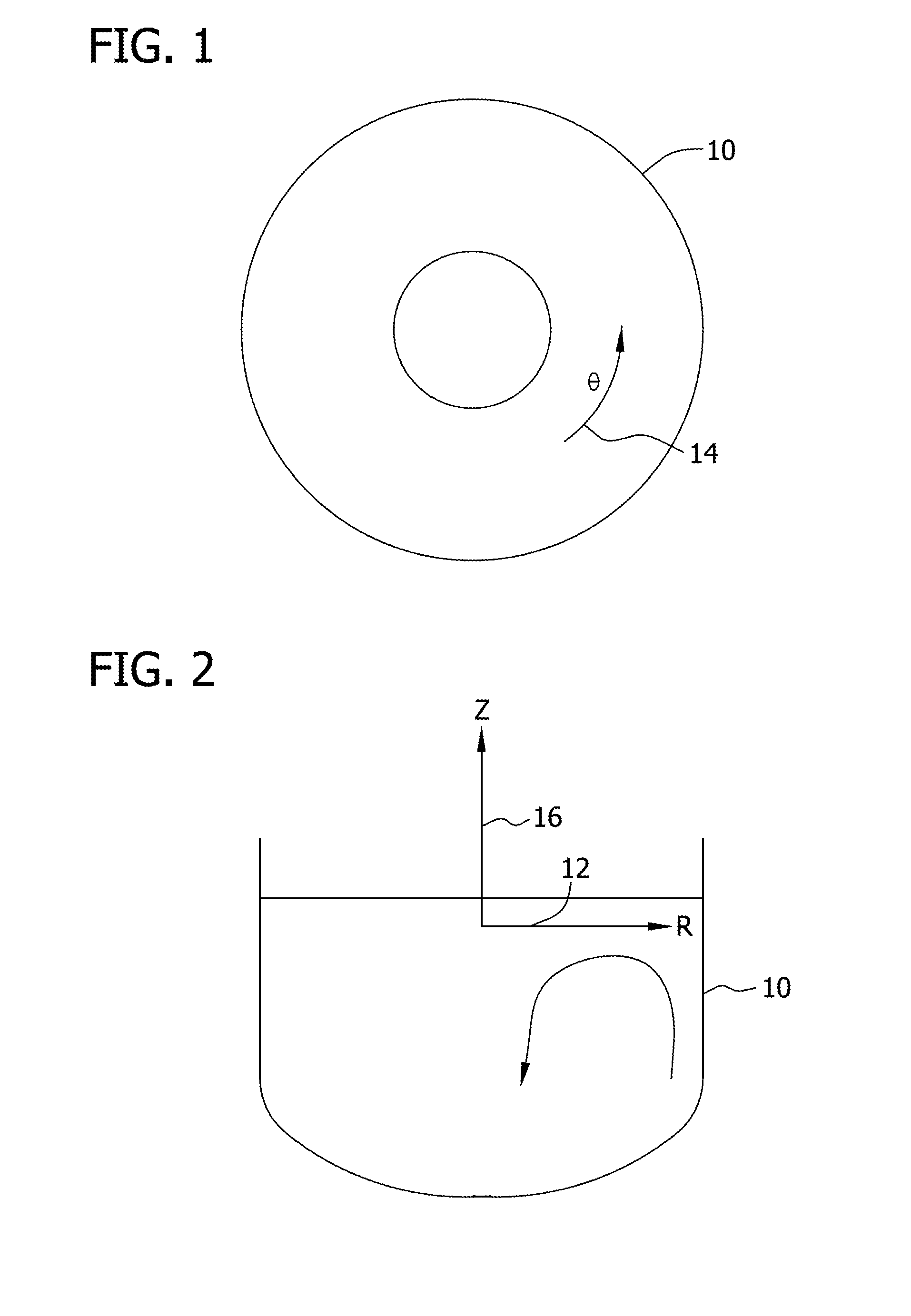

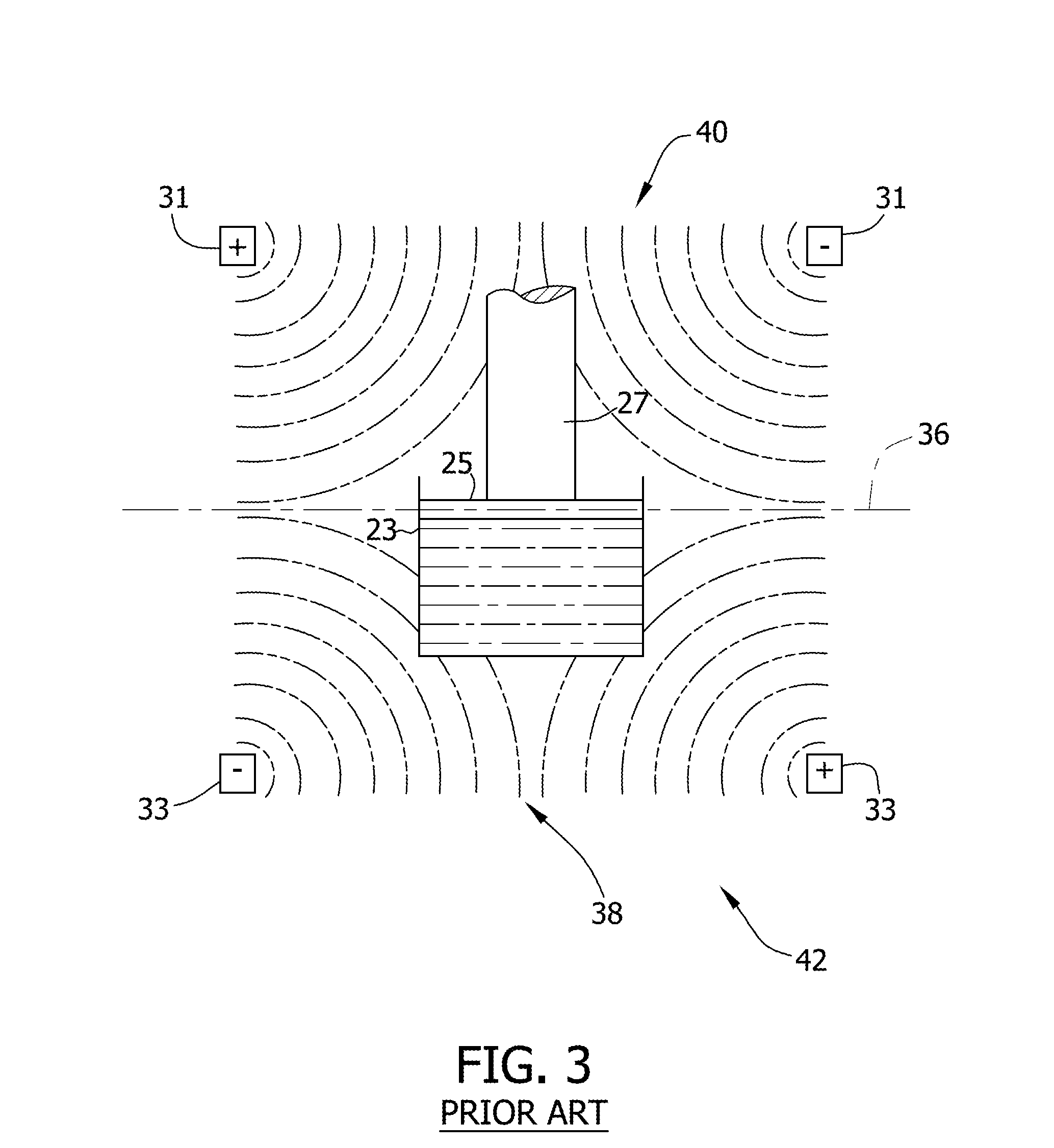

Methods for producing low oxygen silicon ingots

An method for producing a silicon ingot includes melting polycrystalline silicon in a crucible enclosed in a vacuum chamber to form a melt, generating a cusped magnetic field within the vacuum chamber, dipping a seed crystal into the melt, withdrawing the seed crystal from the melt to pull a single crystal that forms the silicon ingot, wherein the silicon ingot has a diameter greater than about 150 millimeters (mm), and simultaneously regulating a plurality of process parameters such that the silicon ingot has an oxygen concentration less than about 5 parts per million atoms (ppma). The plurality of process parameters include a wall temperature of the crucible, a transport of silicon monoxide (SiO) from the crucible to the single crystal, and an evaporation rate of SiO from the melt.

Owner:GLOBALWAFERS CO LTD

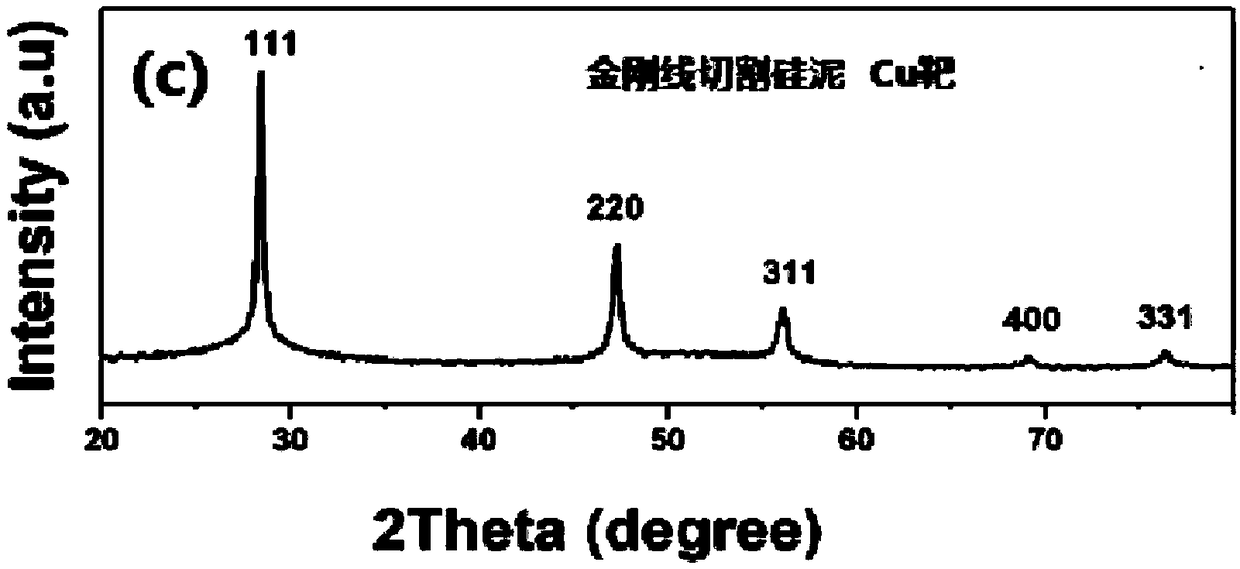

Method and device for producing silicon monoxide

ActiveCN108821292ASimple processShort processSilicon oxidesPressure vessel componentsSilicon monoxideSilicon oxygen

The invention provides a method and device for producing silicon monoxide. The method disclosed by the invention is mainly characterized in that a silicon-containing substance such as silicon oxide, monatomic silicon, silicon-containing gas (liquid) , and non-completely oxidized silicon, particularly dried solid silicon powder separated from diamond wire silicon cutting waste slurry is subjected to further oxidation (including incomplete oxidation), reduction or addition of silicon dioxide to approach to an ideal ratio of generation of silicon monoxide, and then a silicon monoxide gas is formed under a condition facilitating overflow of silicon monoxide, and then the gas is condensed into rod-shaped, plate-shaped, granular or powdery silicon monoxide. In one embodiment, an oxide layer (SiO2) on the surface of silicon particles (Si) is controlled, so that a silicon monoxide precursor can be prepared, and the preparation process can be oxidization of the silicon or reduction of overly-oxidized silicon-oxygen compounds, and optionally, in another embodiment of the present application, a silicon monoxide powder can be directly produced by utilizing incomplete oxidation of a silicon-containing gas.

Owner:储晞

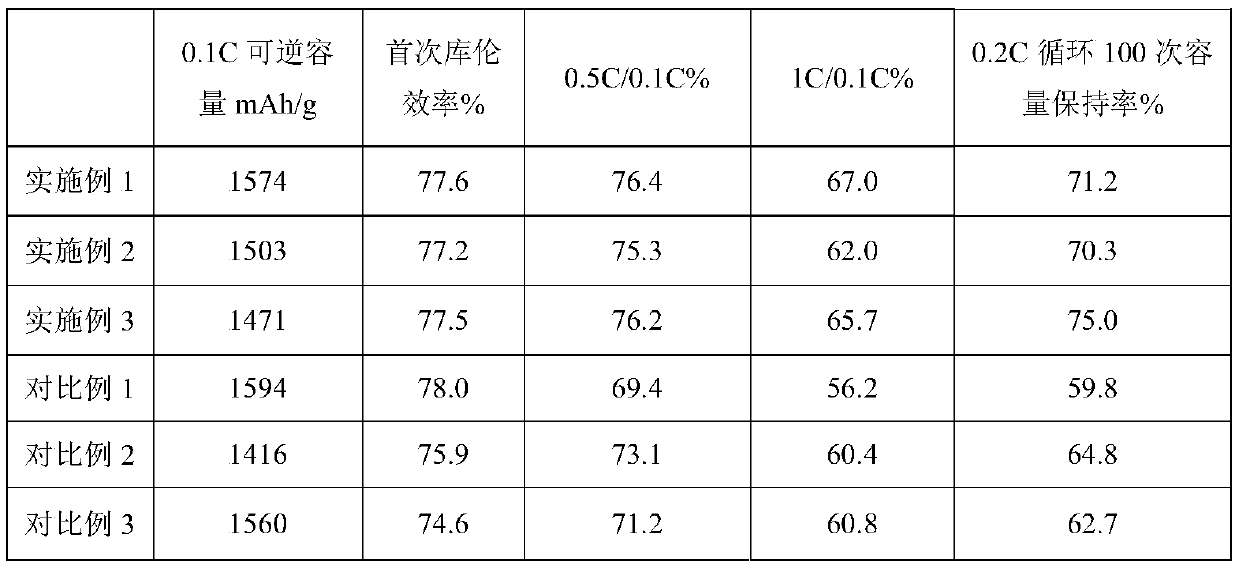

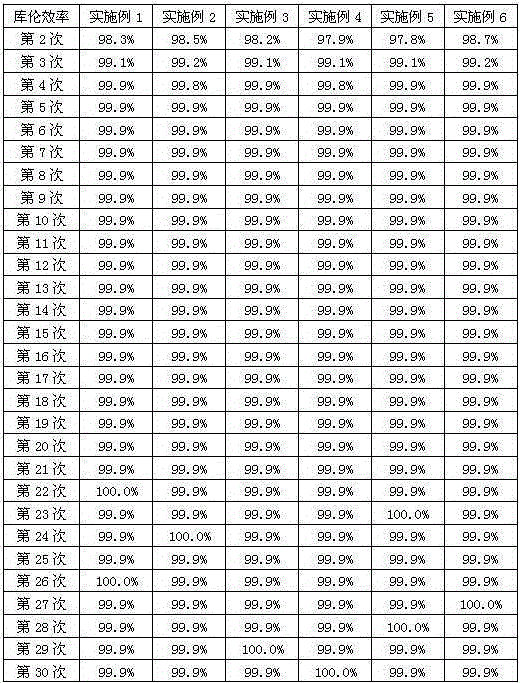

Lithium-ion battery silicon monoxide negative electrode material, preparation method and application thereof

ActiveCN110767877AShorten migration distanceImprove poor conductivitySecondary cellsNegative electrodesSilicon monoxideChemical physics

The invention relates to a lithium-ion battery silicon monoxide negative electrode material, and a preparation method and application thereof. A method for improving rate performance and cycle performance of the lithium-ion battery silicon monoxide negative electrode material includes the following steps: S1: crushing silicon monoxide to silicon monoxide particles having a particle size of 100 to800 nm; S2: after mixing the silicon monoxide particles, a conductive agent, an organic carbon source, and a solvent to obtain a slurry, performing granulation to obtain spherical silicon monoxide secondary particles having a particle size of 4 to 8 [mu]m; S3: pyrolyzing the silicon monoxide secondary particles; and S4: performing secondary coating on pyrolyzed silicon monoxide secondary particlesto obtain the silicon monoxide negative electrode material. In the invention, pulverization, secondary granulation, pyrolysis, and secondary coating processing are performed on the silicon monoxide,on the basis of retaining original first-time coulombic efficiency to a large extent, thereby shortening a lithium-ion diffusion path, improving lithium-ion conductivity, limiting lithium-ion volume expansion, and having better rate performance and cycle performance.

Owner:乳源东阳光新能源材料有限公司

Preparation method for silicon negative electrode material for lithium ion battery and silicon negative electrode material

InactiveCN105789577AEffective dispersionAlleviate volume effectCell electrodesSecondary cellsSilicon monoxideElectrical battery

The invention relates to a preparation method for a silicon negative electrode material for a lithium ion battery and the silicon negative electrode material. The preparation method comprises the following steps of step 1, surface hydroxylation: putting silicon monoxide into a mixed solution of ammonium hydroxide, hydrogen peroxide and water, and then heating, boiling and stirring for 10-60min, next, carrying out water washing, filtering and vacuum drying at a temperature of 80-120 DEG C for 2-12h; step 2, stirring: putting the dried product obtained in the step 1 into an absolute ethyl alcohol solution containing a titanium source, and stirring for 2-10h, then adding water and stirring for 15-75min, next, adding graphite, and then adding an absolute ethyl alcohol solution containing a lithium source, finally adding glacial acetic acid and stirring, and stopping stirring when black sol is changed into gel; step 3, aging and drying: aging the gel generated in the step 2 for 12h or more than 12h, then carrying out vacuum drying on the gel at a temperature of 70-90 DEG C for 8-16h; and step 4, calcining: smashing the gel which is aged and dried in the step 3, and calcining the processed gel under protection of an inert gas atmosphere; and finally, cooling to the room temperature to obtain the silicon negative electrode material.

Owner:CHERY AUTOMOBILE CO LTD

Silicon monoxide-based carbon negative electrode material, negative electrode plate, preparation method thereof and lithium ion battery

InactiveCN110085853AImprove the first effectImprove conductivityNegative electrodesSecondary cellsSilicon monoxideSlurry

The invention discloses a silicon monoxide-based carbon negative electrode material, a negative electrode plate, a preparation method thereof and a lithium ion battery. Through special treatment of asilicon monoxide raw material (calcination, heat preservation, cooling to room temperature, and ball milling, dispersion of the silicon monoxide after ball milling to a sodium hydroxide solution witha concentration of 0.2M to 2M to prepare slurry, etching for 1h to 5h in a magnetic stirrer, and washing and vacuum drying treatment of the slurry to obtain silicon monoxide after pre-treatment), thecontent of oxygen in the silicon monoxide is changed, first effects of silicon monoxide can be effectively improved, the conductivity is increased, expansion is alleviated, and the purposes of improving the first effects of the material or improving the cycle performance of the material are thus achieved. Through improvement of the preparation process, the negative electrode material capacity execution ability is greatly improved, more graphite can be blended to relieve the strain and suppress the rebound, and at the same time, in combination of measures such as surface coating carbon, the material is higher compatible with the current commercial battery system.

Owner:郑州中科新兴产业技术研究院 +1

Phosphorus-contained negative electrode composite material and preparation method therefor, and lithium ion battery

ActiveCN105845906AActivate reversible charge capacityImproving the reversibility of electrochemical lithium storageCell electrodesSecondary cellsSilicon monoxideSodium-ion battery

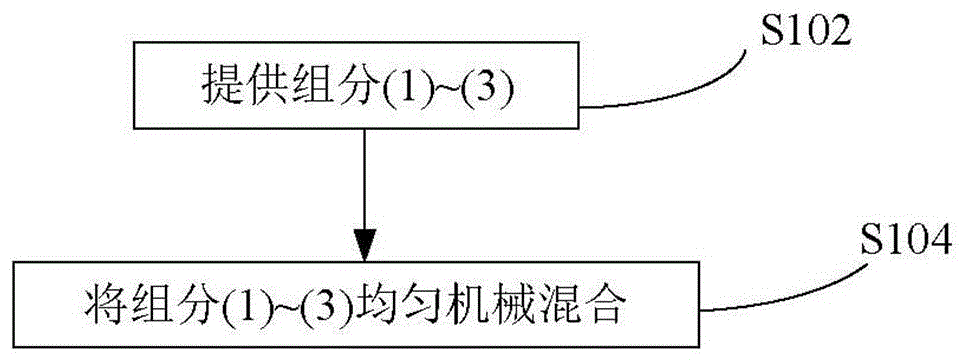

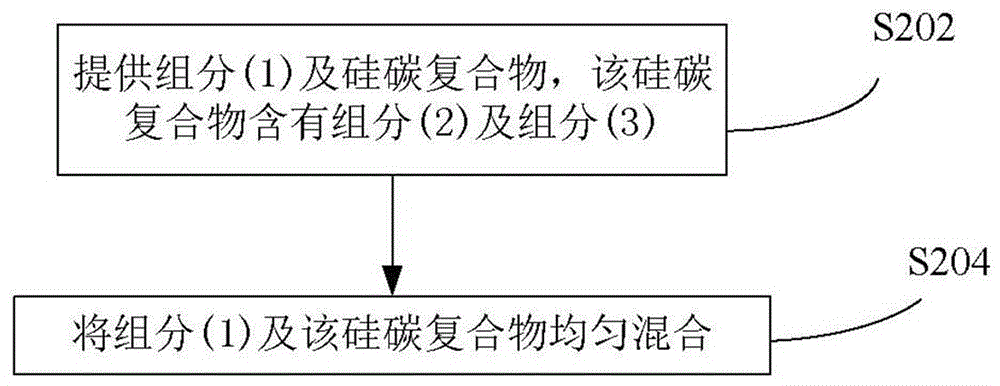

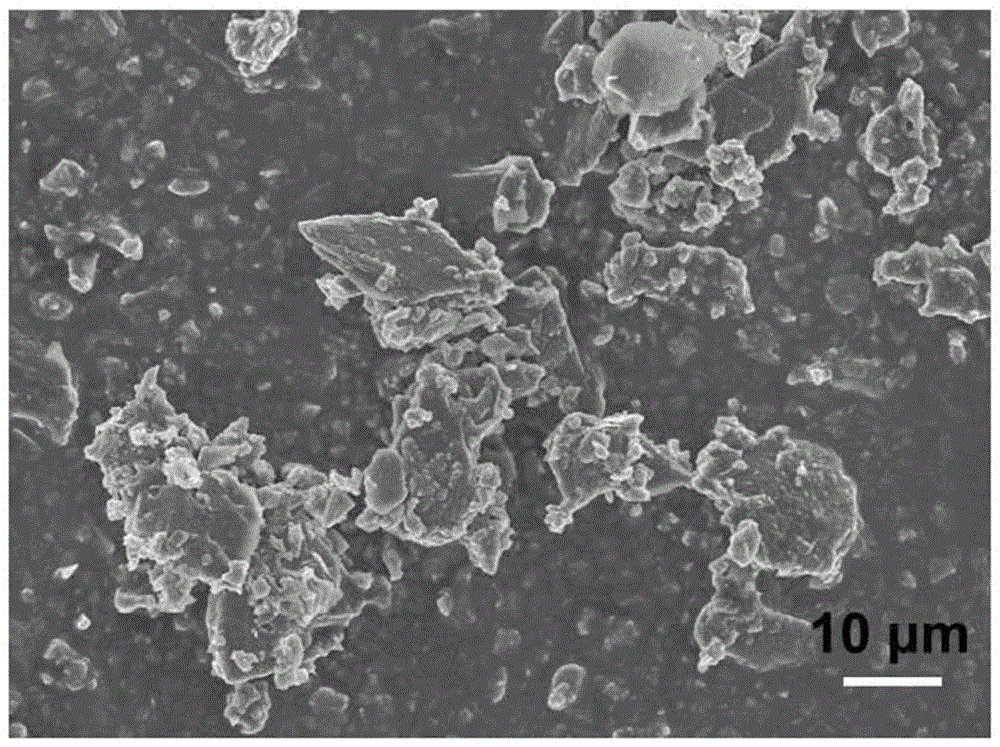

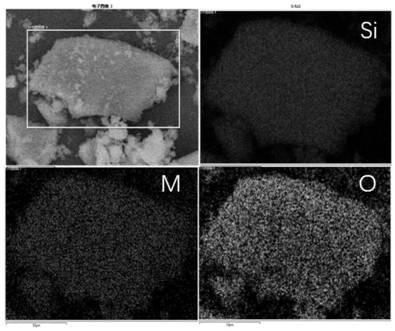

The invention relates to a phosphorus-contained negative electrode composite material. The composite material comprises red phosphorus, a conductive carbon elementary substance, and at least one kind of elemental silicon and silicon monoxide. The invention also relates to a preparation method for the phosphorus-contained negative electrode composite material, wherein the preparation method comprises the steps of providing the red phosphorus and a silicon-carbon compound, and enabling the red phosphorus and the silicon-carbon compound to be uniformly mixed. The invention also relates to a lithium ion battery.

Owner:TSINGHUA UNIV

Modified silicon monoxide material for lithium ion battery negative electrode and preparation method thereof

ActiveCN111072038ASmall volume expansionReduce consumptionSilicaSecondary cellsSilicon monoxideSilicon oxide

The invention discloses a modified silicon monoxide material and a preparation method thereof. The modified silicon monoxide material is the modified silicon monoxide material used for a lithium battery negative electrode. The modified silicon monoxide material is prepared by the following steps: reacting raw materials silicon, silicon dioxide and metal silicate under high-temperature and vacuum conditions to prepare silicon monoxide, and reacting metal steam with silicon monoxide in the preparation process to form metal silicate in situ; wherein the metal silicate is uniformly dispersed around the silicon and the silicon monoxide to form silicon-containing particles, and the carbon material is coated on the surfaces of the silicon-containing particles. The silicate in the modified siliconmonoxide material is uniformly dispersed, the carbon material is uniformly coated, and the modified silicon monoxide material shows high specific capacity, high initial coulombic efficiency, excellent cycle performance and rate capability when used as the lithium ion battery negative electrode material. Moreover, the preparation method disclosed by the invention is low in raw material price and beneficial to industrial implementation, so that the modified silicon monoxide has a very wide application prospect.

Owner:JIANGXI IAMETAL NEW ENERGY TECH CO LTD

Powder pre-lithiated silicon-based negative electrode material, preparation method and application thereof

ActiveCN110212183AMake up for loose and porous defectsImprove cycle stabilityNegative electrodesSecondary cellsCarbon layerLithium oxide

The invention discloses a powder pre-lithiated silicon-based negative electrode material, a preparation method and application thereof. A lithium-containing carborane cluster compound coated silicon monoxide material is firstly prepared and obtained, then through segmented heating sintering, boron element in a lithium-containing carborane cluster compound is diffused into a silicon-based materialcontinuously, a part of silicon atoms are replaced to form displaced doping, and the vacancy current-carrying concentration is improved, so that the intrinsic electronic conductivity of the silicon material is improved. Moreover, in the high temperature sintering process, incompletely reacted lithium ions inside the lithium-containing carborane cluster compound react with silicon monoxide, and thebyproducts such as lithium metasilicate, lithium silicate and lithium oxide are further formed to realize pre-lithiation, so that the initial coulomb efficiency of the battery prepared from the material is improved. And then, a uniformly compact carbon layer is formed on the surface of the material through chemical vapor deposition, and the defect that the carbon layer formed by the carbonizationof the carborane cluster compound is relatively loosened and porous can be solved, so that the cycling stability of the material is further improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

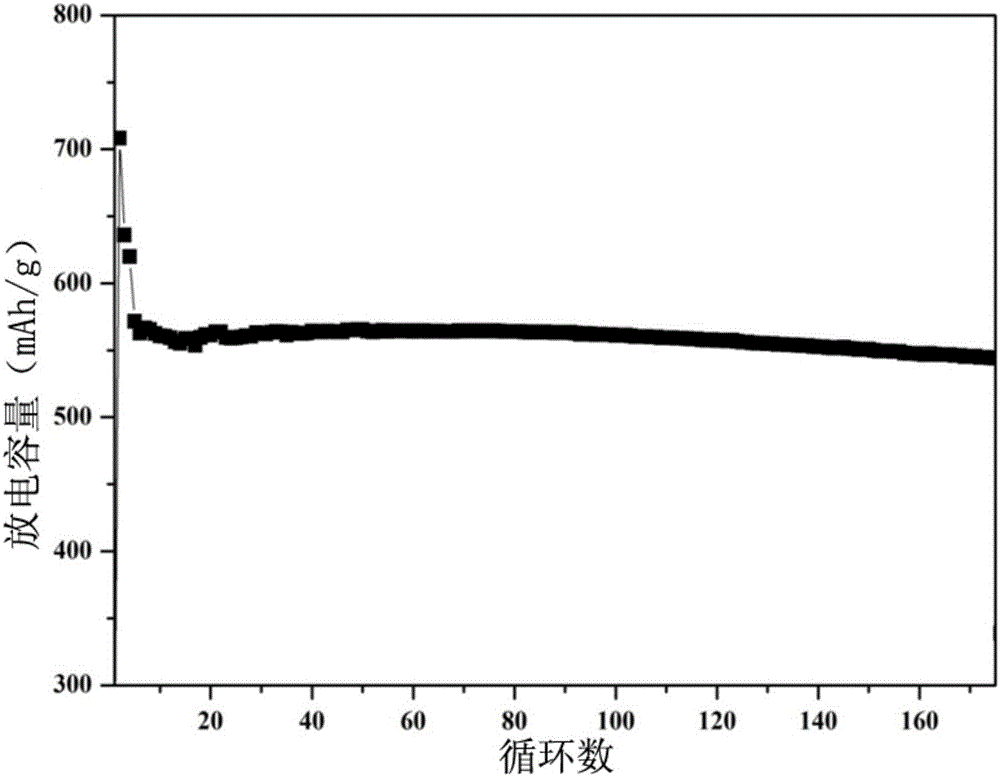

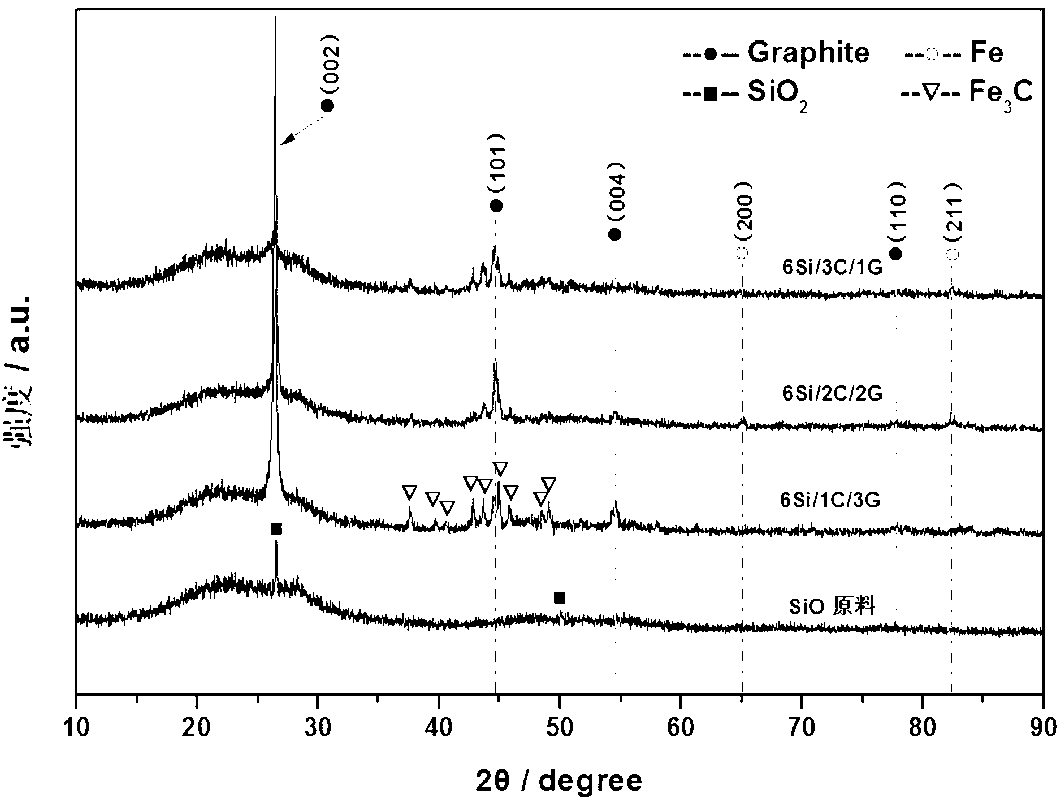

High-performance silicon monoxide/amorphous carbon/graphite composite negative electrode material and preparation method thereof

ActiveCN103258988AIncrease capacityImprove cycle stabilityCell electrodesSilicon monoxideHigh energy

The invention discloses a high-performance silicon monoxide / amorphous carbon / graphite composite negative electrode material. The high-performance silicon monoxide / amorphous carbon / graphite composite negative electrode material comprises the following components in parts by weight: 5-7 parts of silicon monoxide, 1-2 parts of carbohydrate and 1-4 parts of natural flake graphite. The preparation method of the composite negative electrode material comprises the following steps of: mixing the materials; carrying out high-energy ball milling and high-temperature pyrolysis; and grinding and sieving to obtain the composite material. The composite negative electrode material is excellent in cycle performance and capacity performance, so that a certain feasibility choice is provided for practicability of the SiO negative electrode material. Moreover, the preparation method is simple to operate, environment-friendly, pollution-free and easy to popularize.

Owner:CHINA THREE GORGES UNIV +1

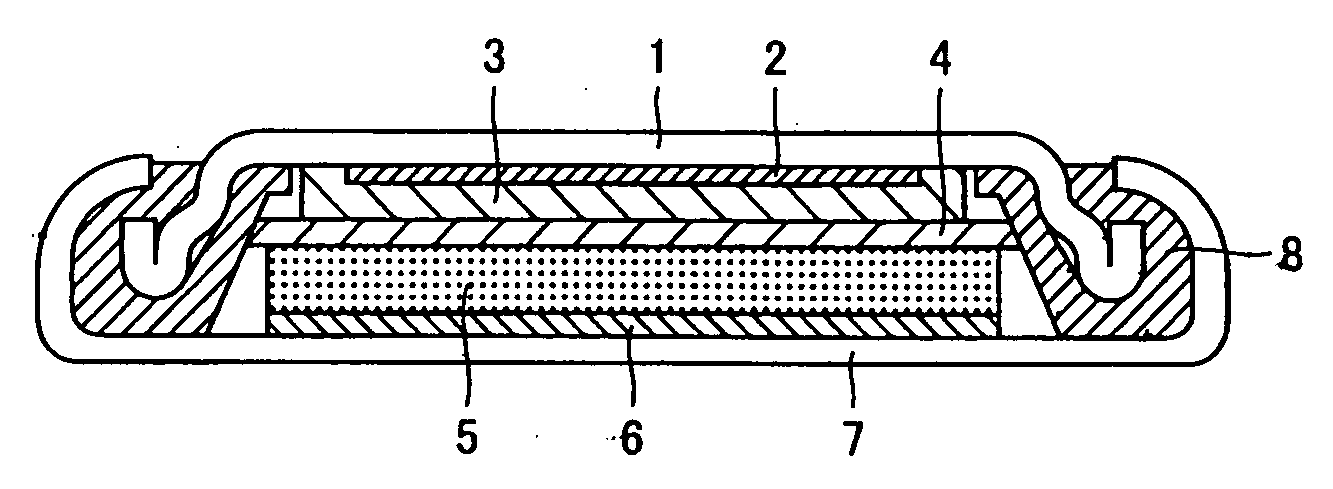

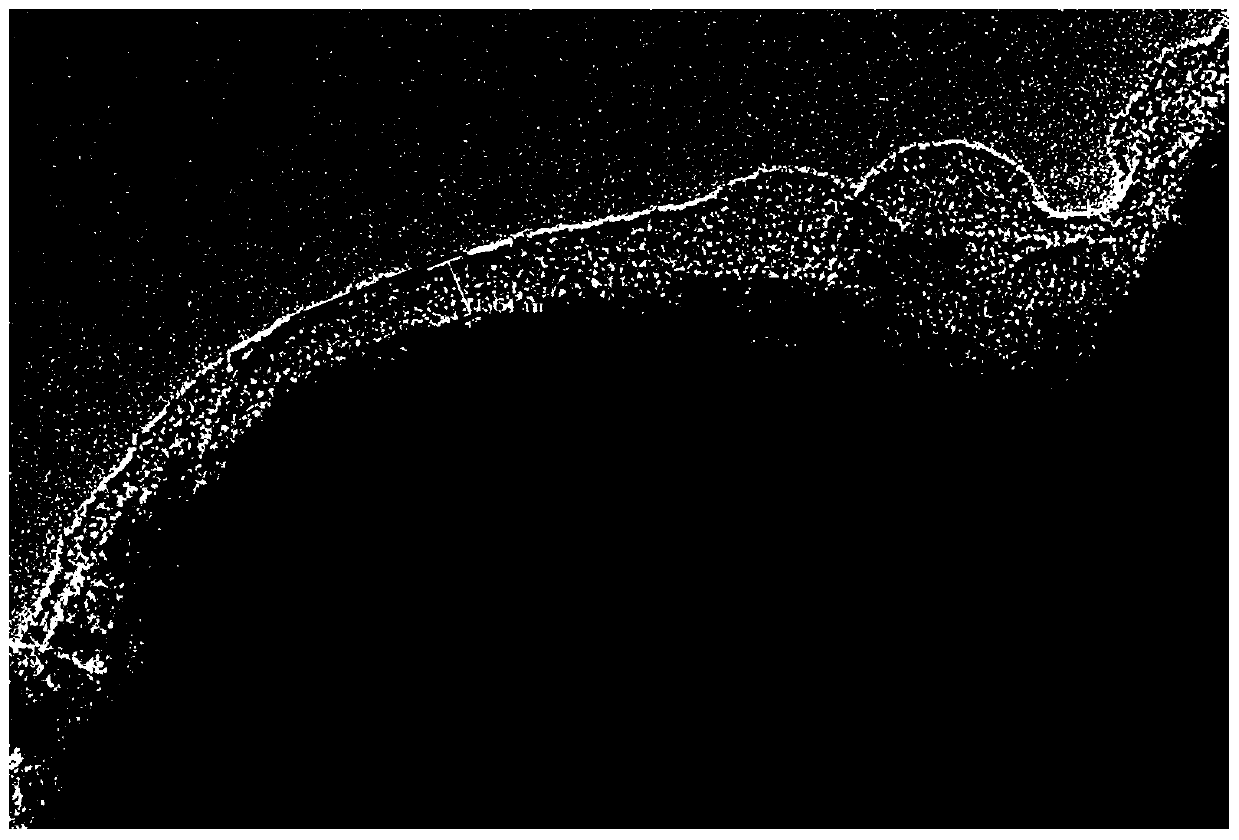

Metallized polyimide film

InactiveUS6767644B2High bonding strengthGood dimensional stabilityMolten spray coatingVacuum evaporation coatingSilicon monoxideMetal

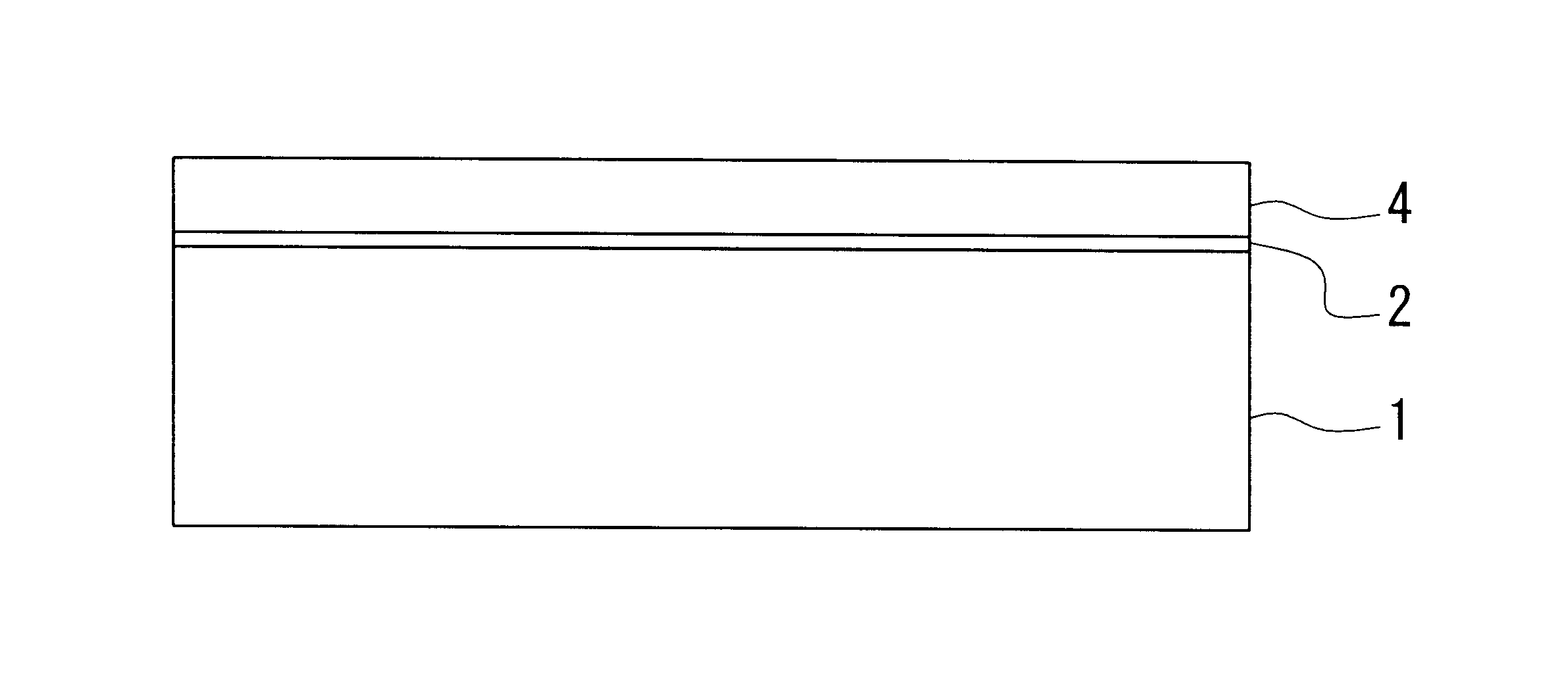

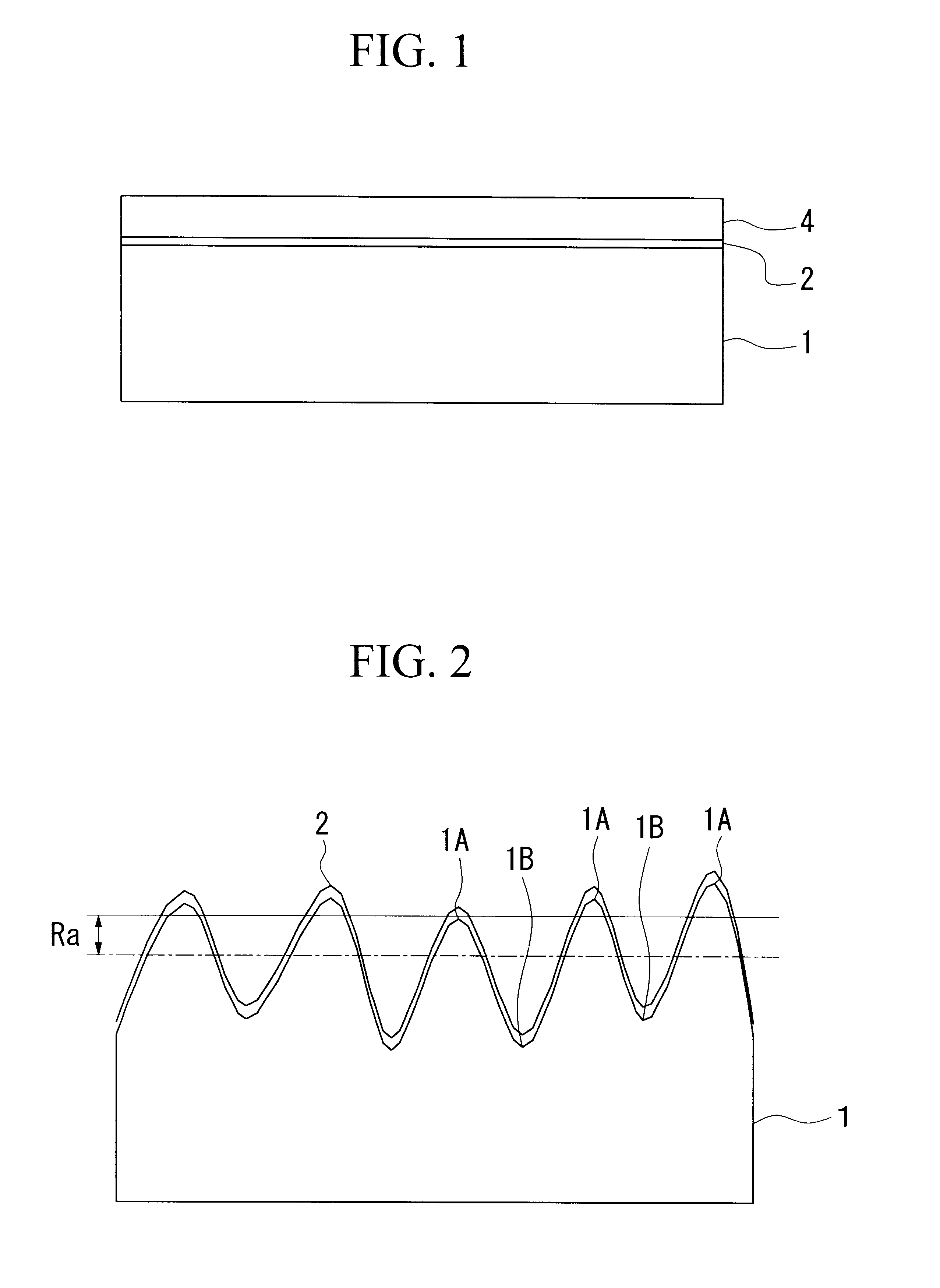

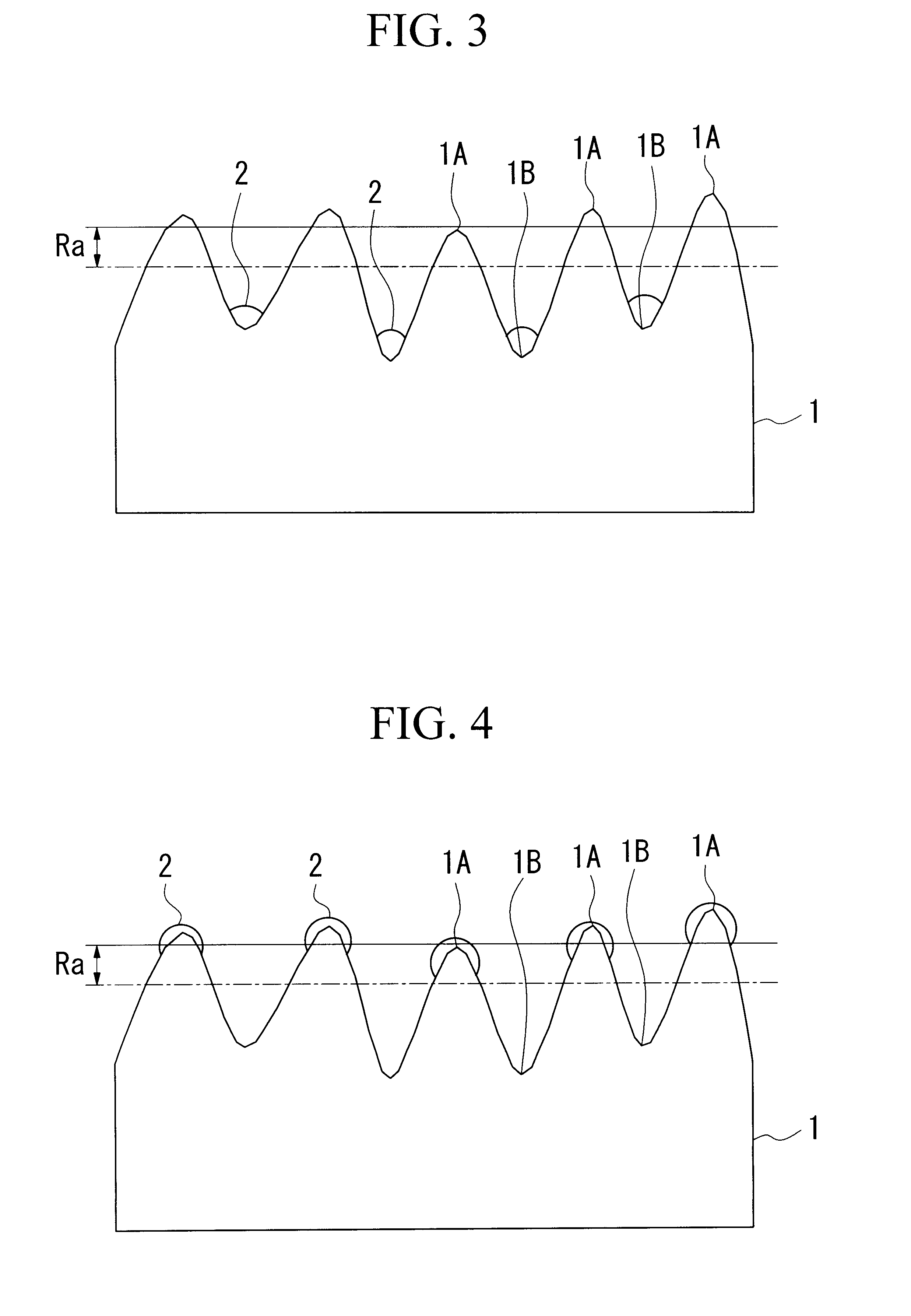

A metallized polyimide film of the present invention comprises a polyimide film 1 which has undergone surface roughening treatment to produce a surface Ra value of 2 to 10 nm, an intermediate layer 2 formed from one, or two or more elements selected from a group consisting of molybdenum, silicon and silicon monoxide, which is formed on top of the surface which has undergone surface roughening treatment with an average thickness of 5 to 50% of the aforementioned Ra value, and a conductive metal layer 4 which is formed on top of the intermediate layer 2. This construction improves the bonding strength between the polyimide film and the metal layer.

Owner:MITSUBISHI SHINDOH CO LTD

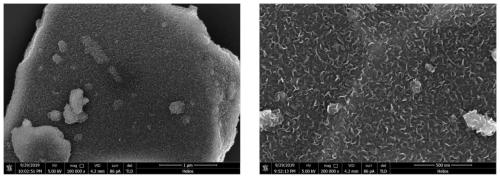

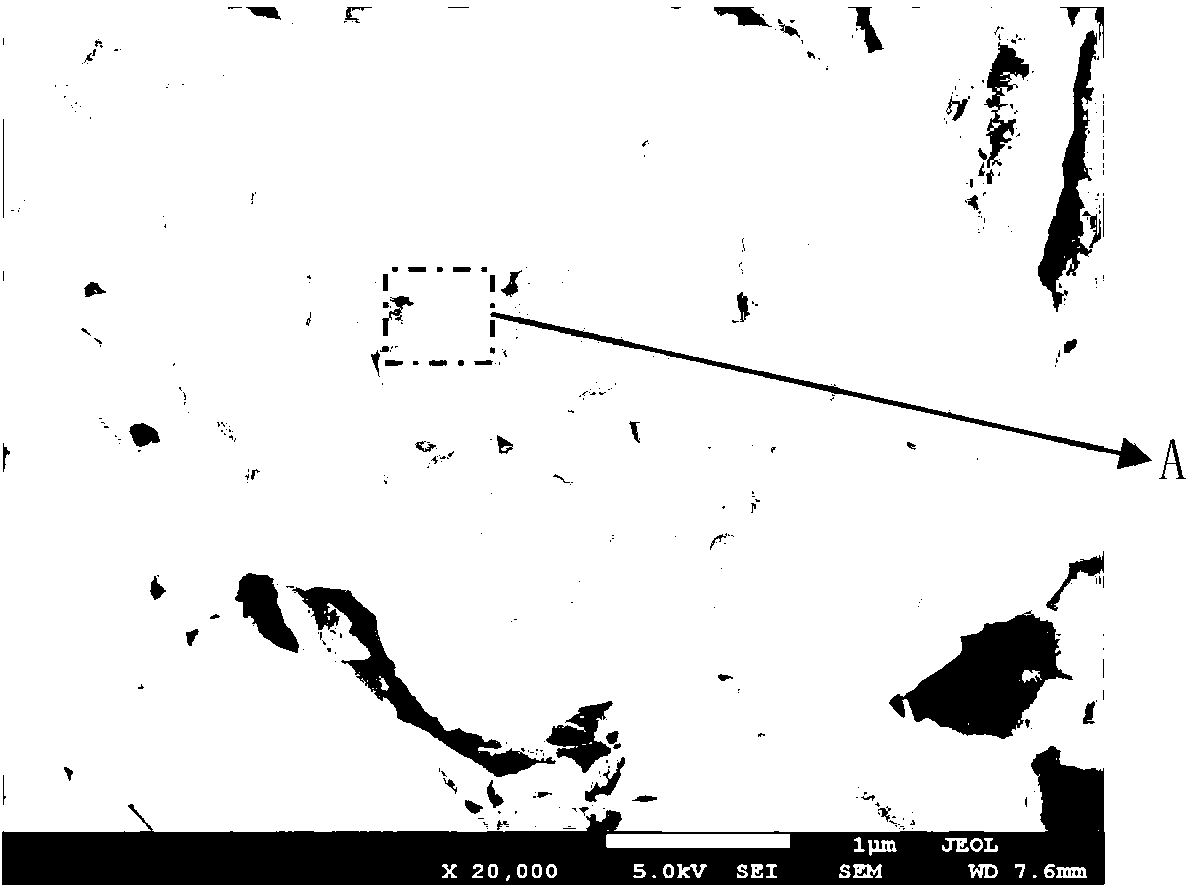

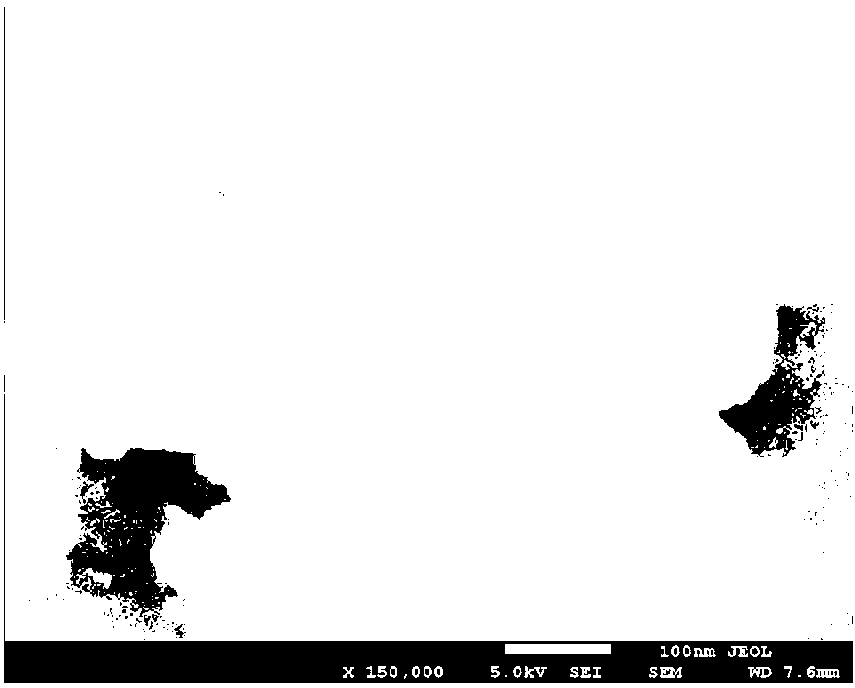

Silicon-based composite negative electrode material and preparation method and application thereof

ActiveCN111525110AVolume expansion effect is not obviousImprove cycle stabilityNegative electrodesSecondary cellsCarbon coatingSilicon monoxide

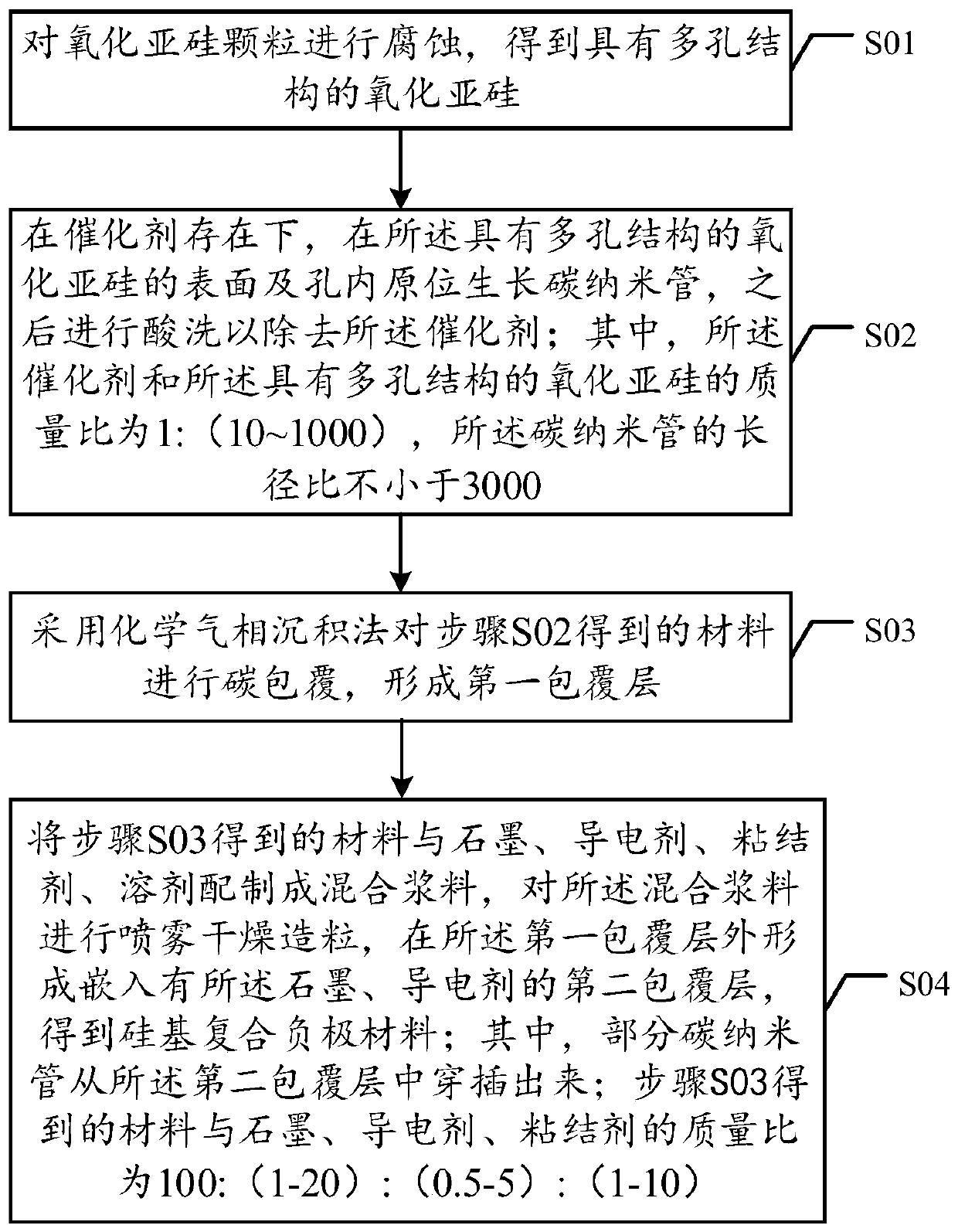

The invention provides a preparation method of a silicon-based composite negative electrode material, which comprises the following steps: (1) corroding silicon monoxide particles to obtain silicon monoxide with a porous structure; (2) in the presence of a catalyst, growing carbon nanotubes in situ on the surface and in pores of the silicon monoxide with the porous structure; (3) carrying out carbon coating on the material obtained in the step (2) by adopting a chemical vapor deposition method to form a first coating layer; and (4) preparing mixed slurry from the material obtained in the step(3), graphite, a conductive agent, a binder and a solvent, and carrying out spray drying granulation on the mixed slurry to form a second coating layer outside the first coating layer. The preparationmethod is simple in process and low in cost, and can be used for industrial production; meanwhile, the obtained silicon-based composite negative electrode material has good conductivity and cycling stability. The invention also provides a silicon-based composite negative electrode material and application thereof.

Owner:SHENZHEN DYNANONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com