Patents

Literature

311results about How to "Alleviate volume effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

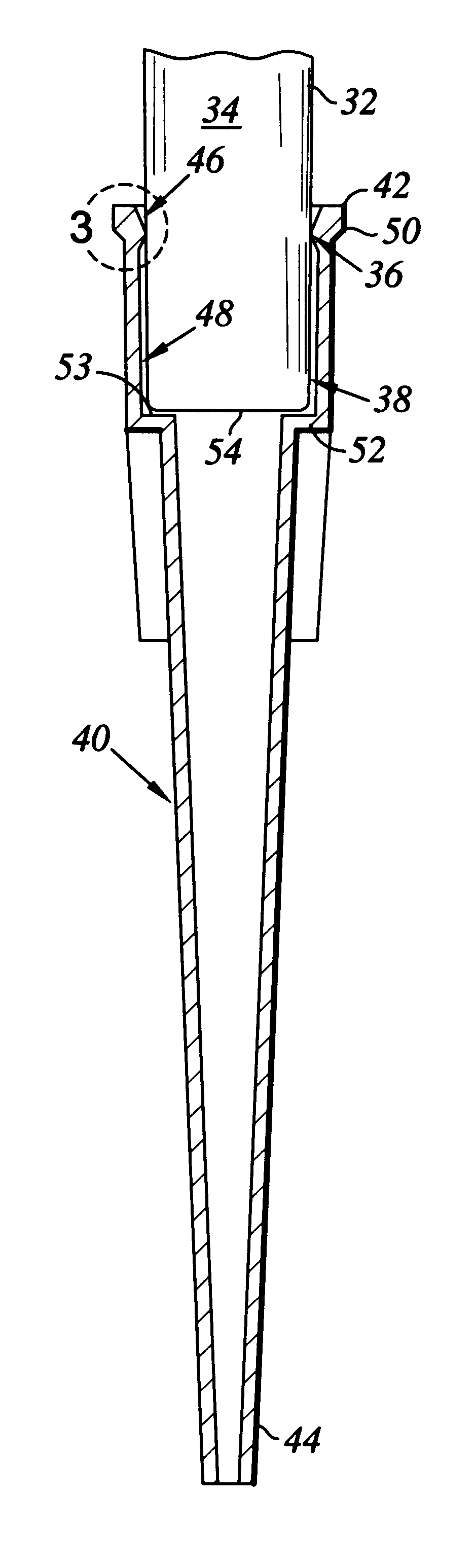

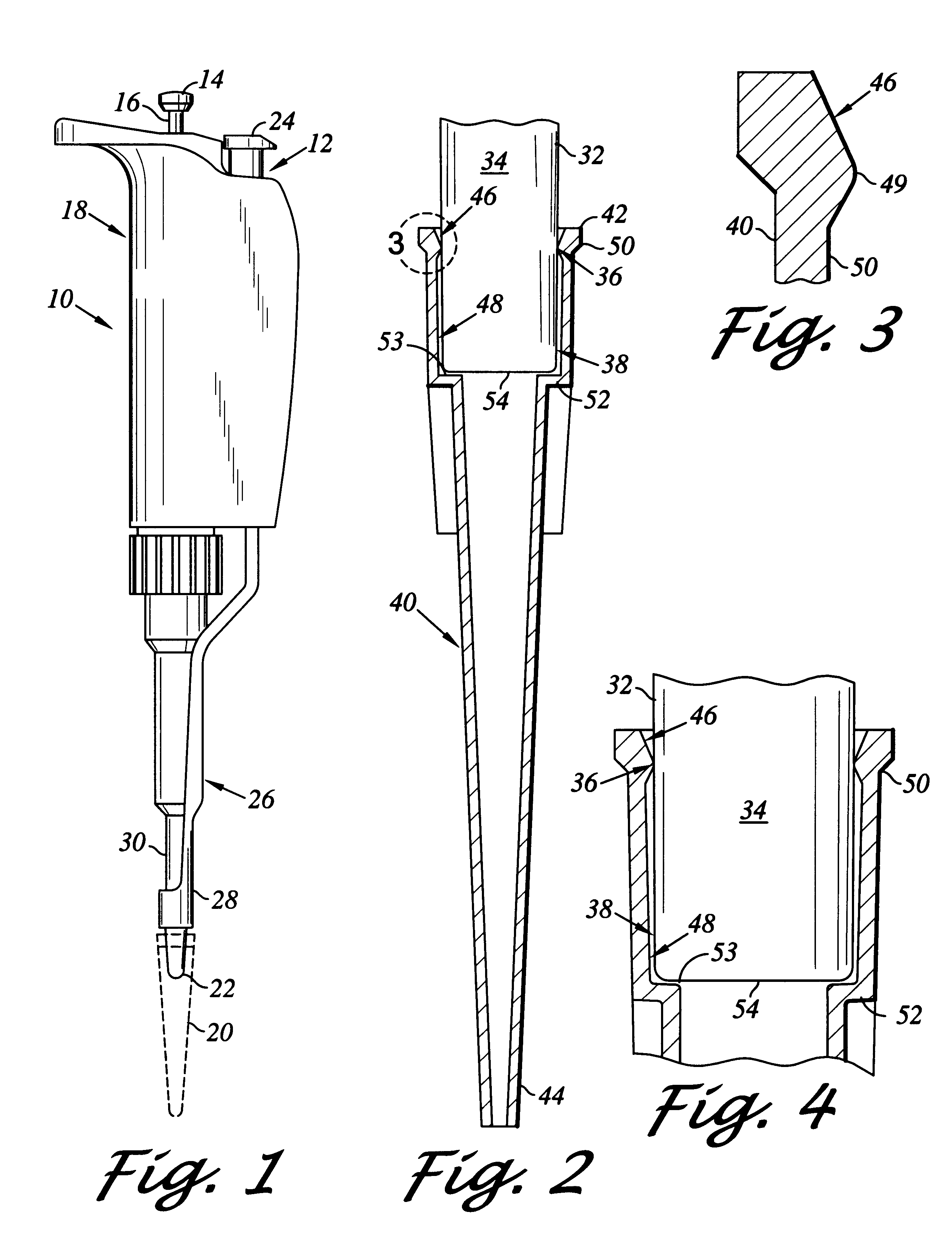

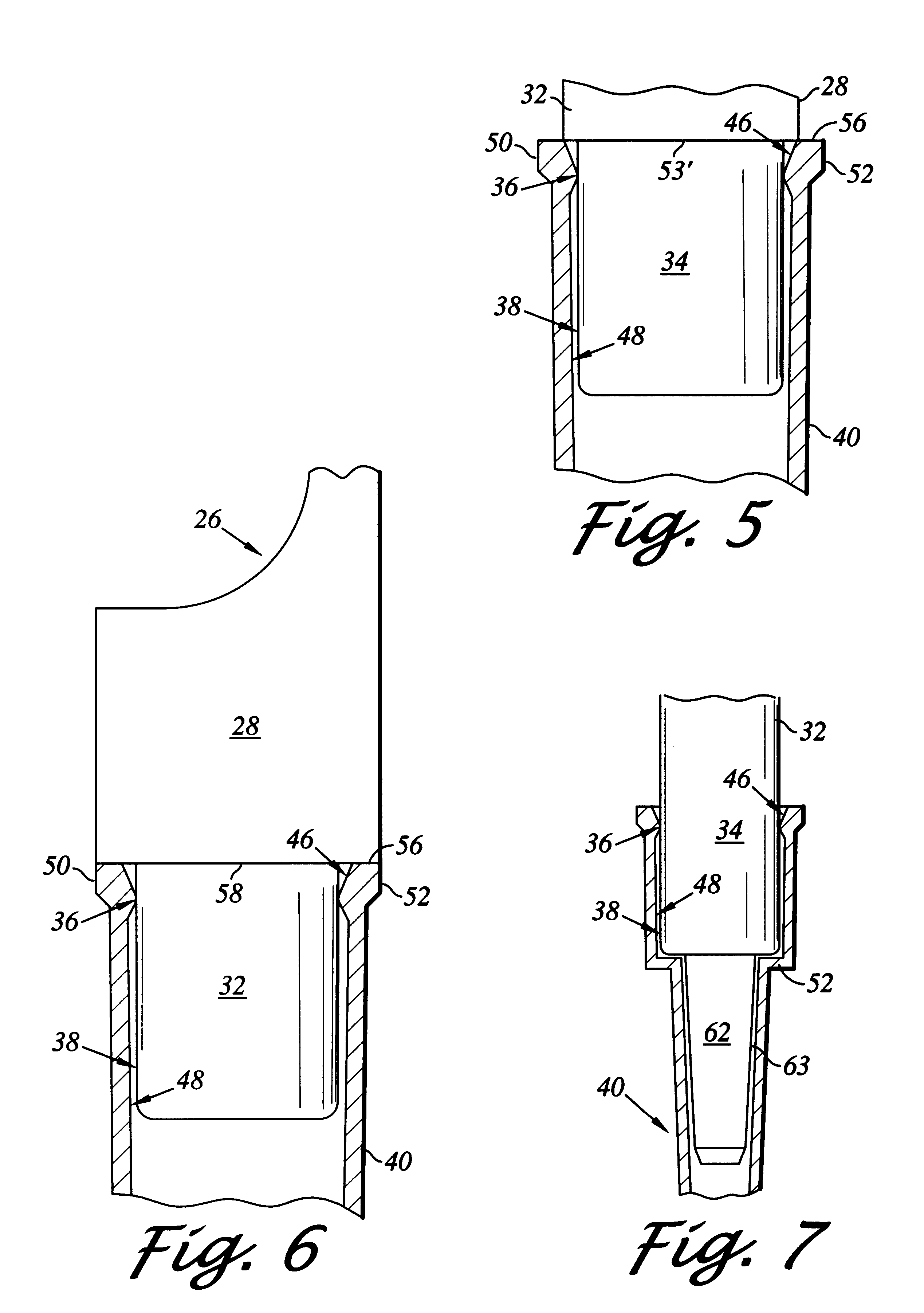

Pipette with improved pipette tip and mounting shaft

InactiveUS6168761B1Easy to installEasily ejectableWithdrawing sample devicesBurettes/pipettesPipetteEngineering

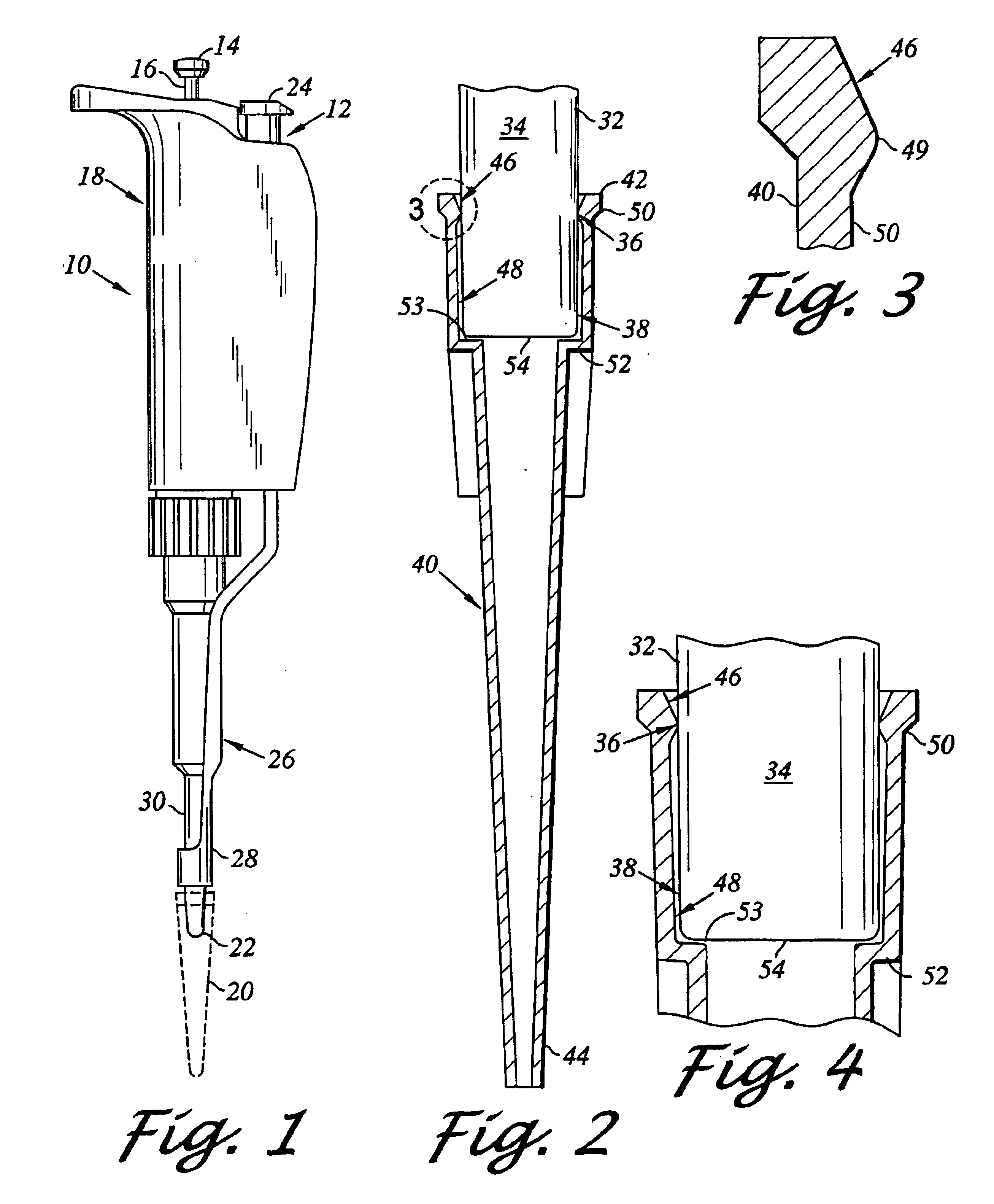

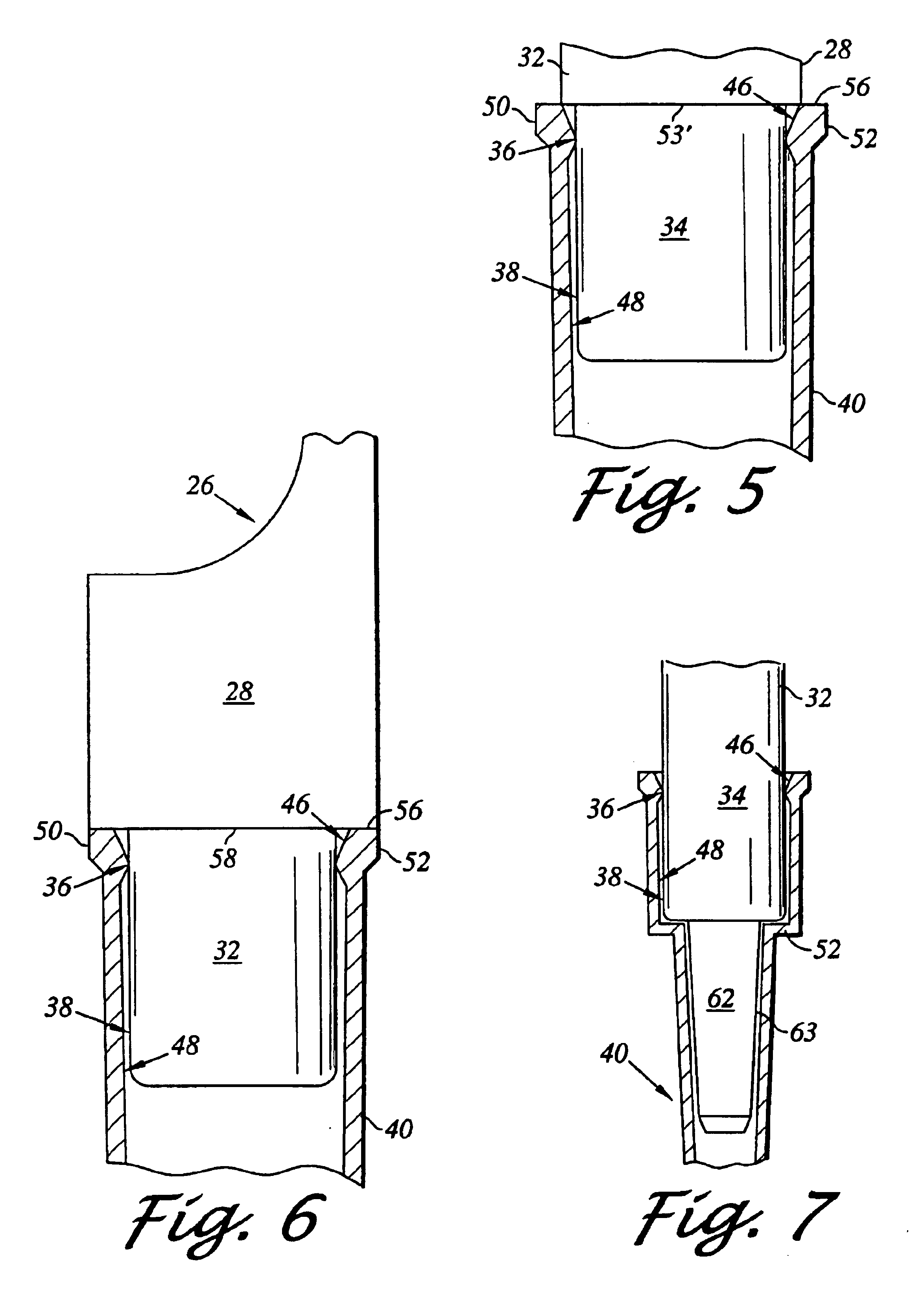

An air displacement pipette having axially spaced annular sealing and substantially cylindrical lateral support zones and regions on the pipette's mounting shaft and tip, respectively, in combination with structure for insuring uniform depth of mounting shaft penetration into the pipette tip to maintain uniform tip interference with the mounting shaft as successive tips are mounted on and ejected from the mounting shaft whereby the pipette tip is easily and firmly mountable on and easily ejectable from the pipette tip mounting shaft by the application of axial mounting and ejection forces of about two pounds and one pound, respectively.

Owner:RAININ INSTR

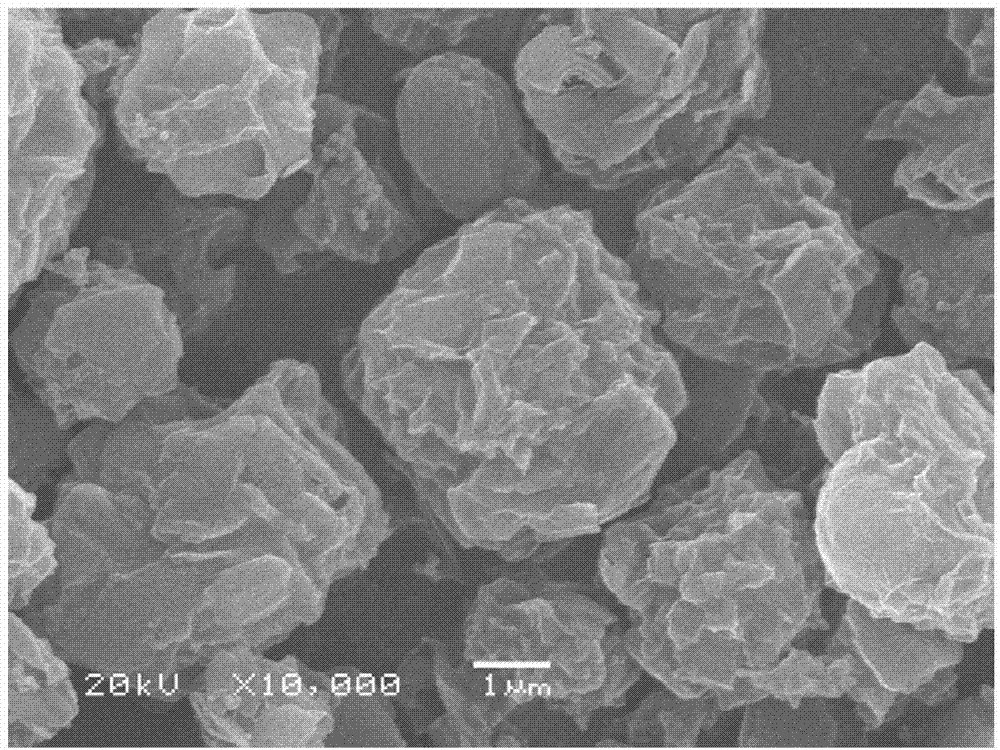

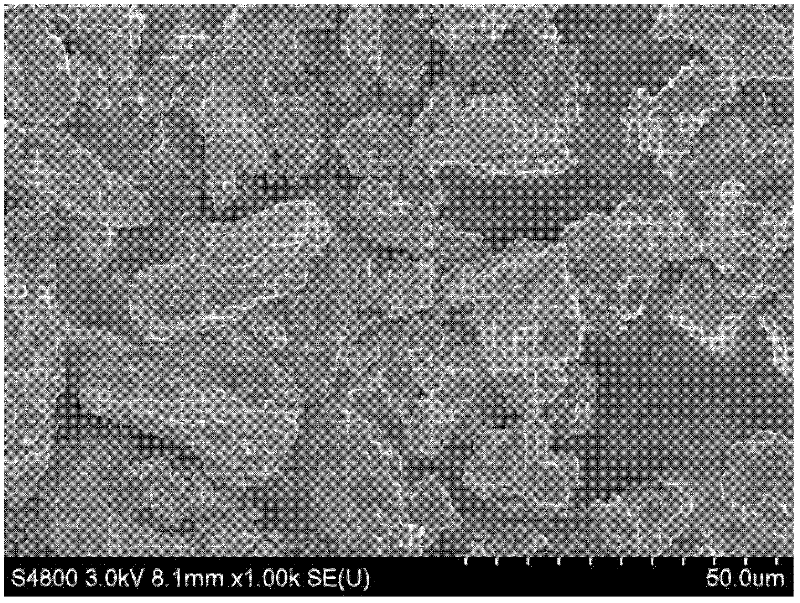

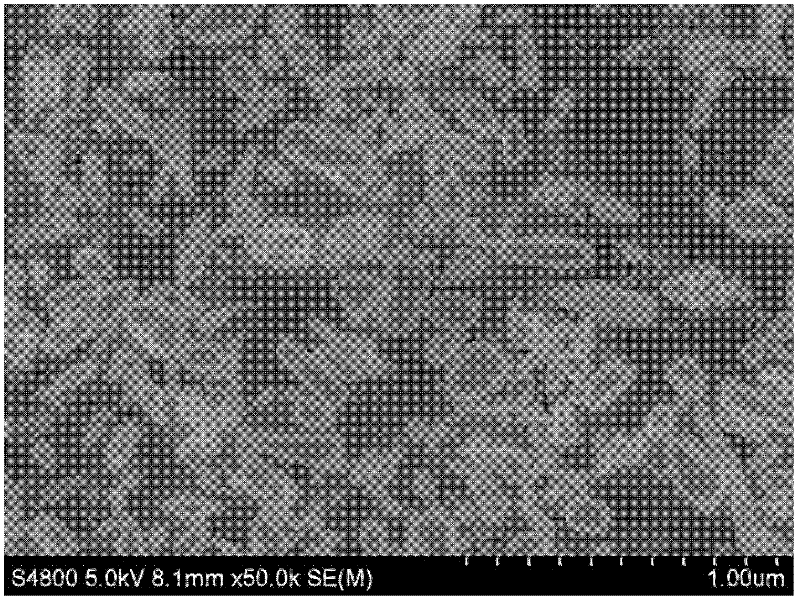

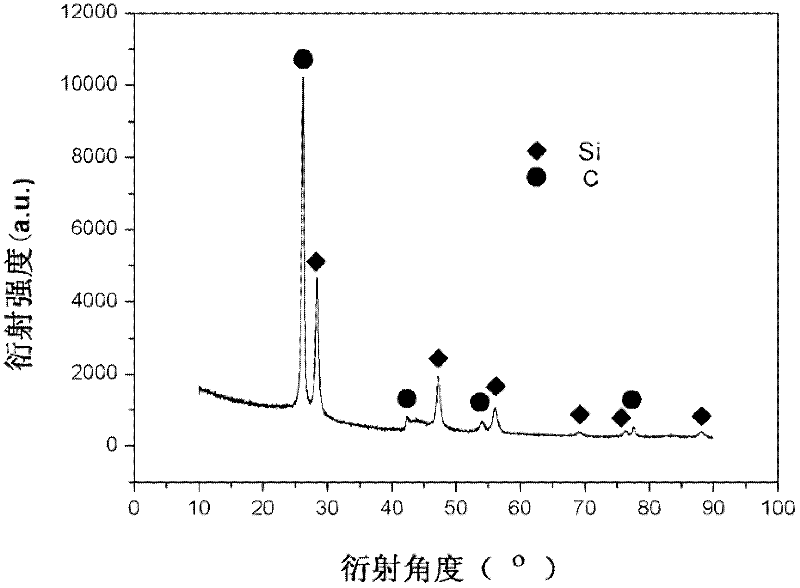

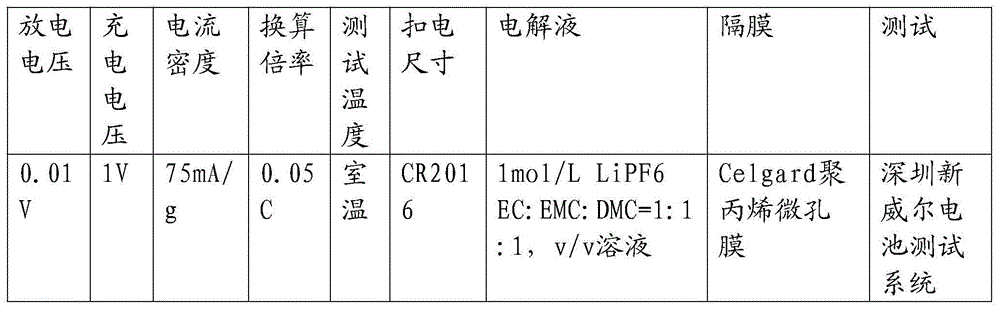

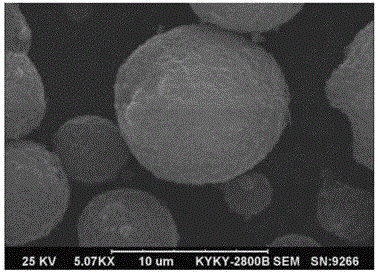

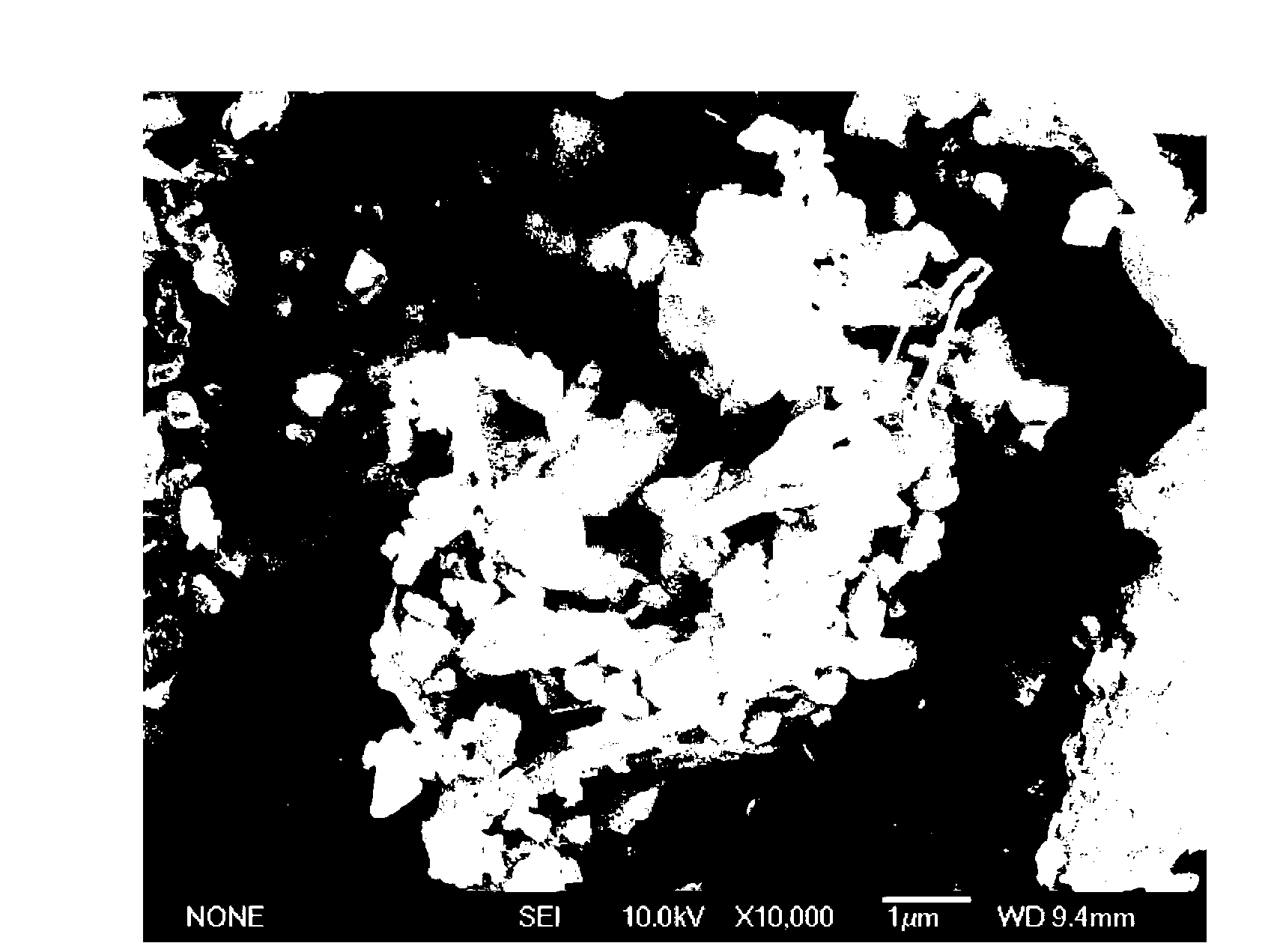

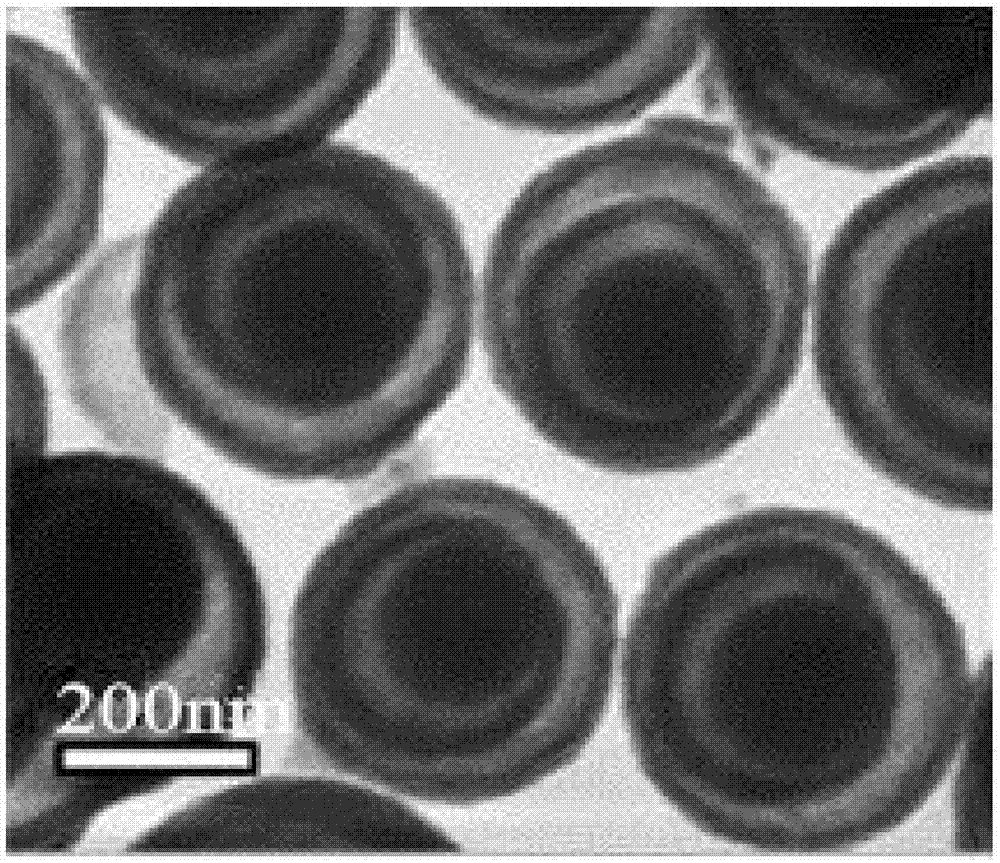

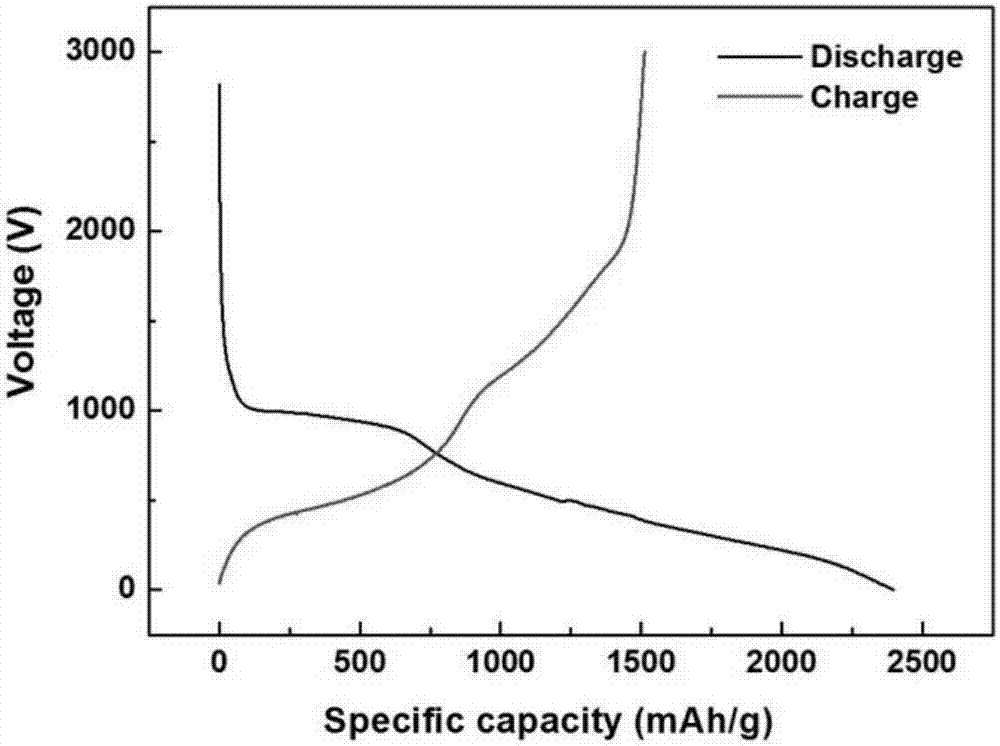

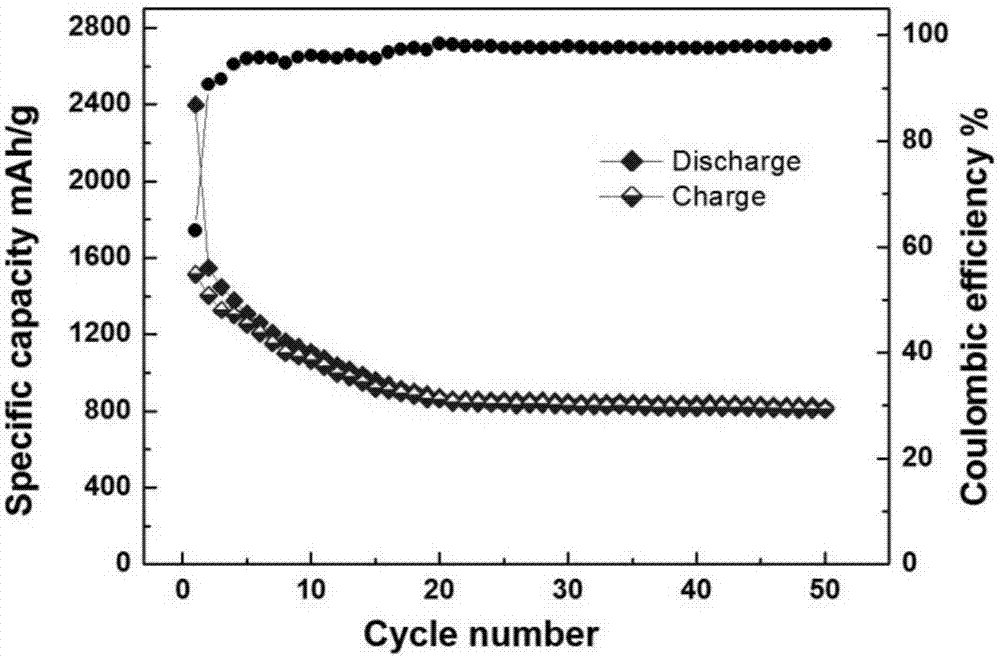

Silicon-carbon Composite Anode Material for Lithium Ion Batteries and A Preparation Method Thereof

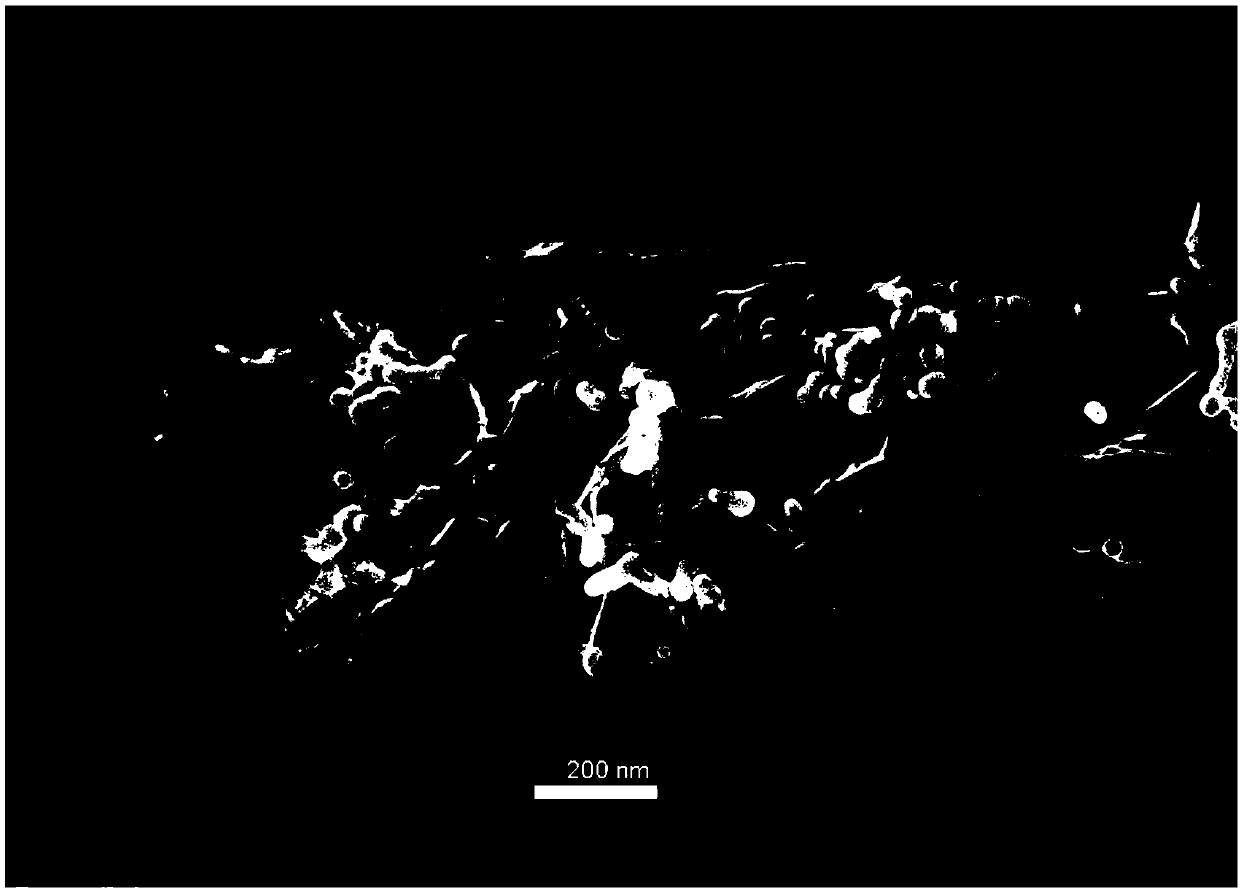

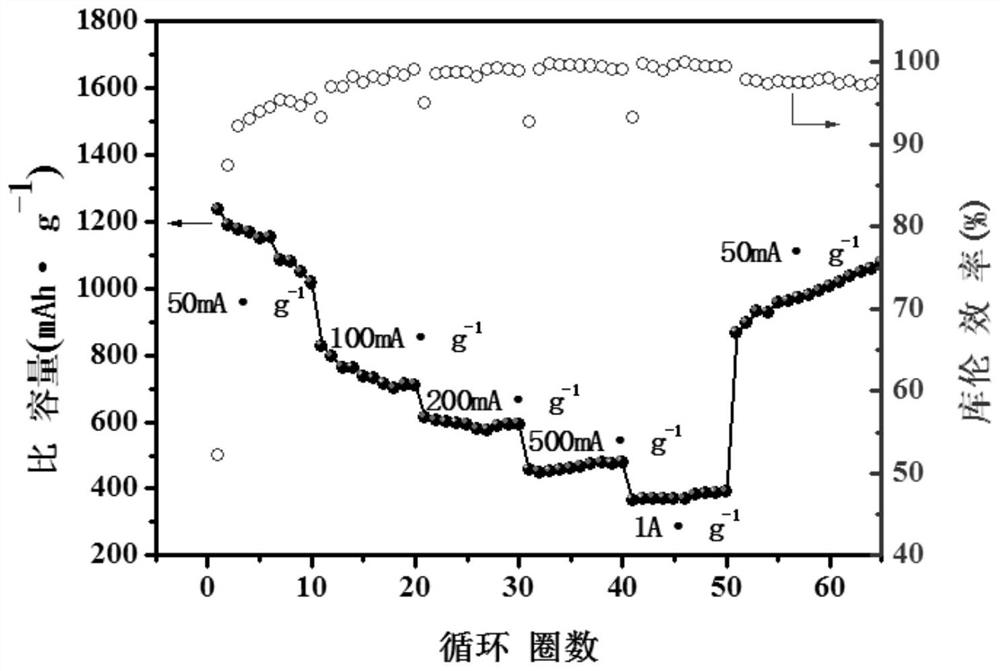

ActiveUS20140147751A1Large capacityImprove cycle stability performanceMechanical vibrations separationLiquid/solution decomposition chemical coatingCarbon compositesCarbon coating

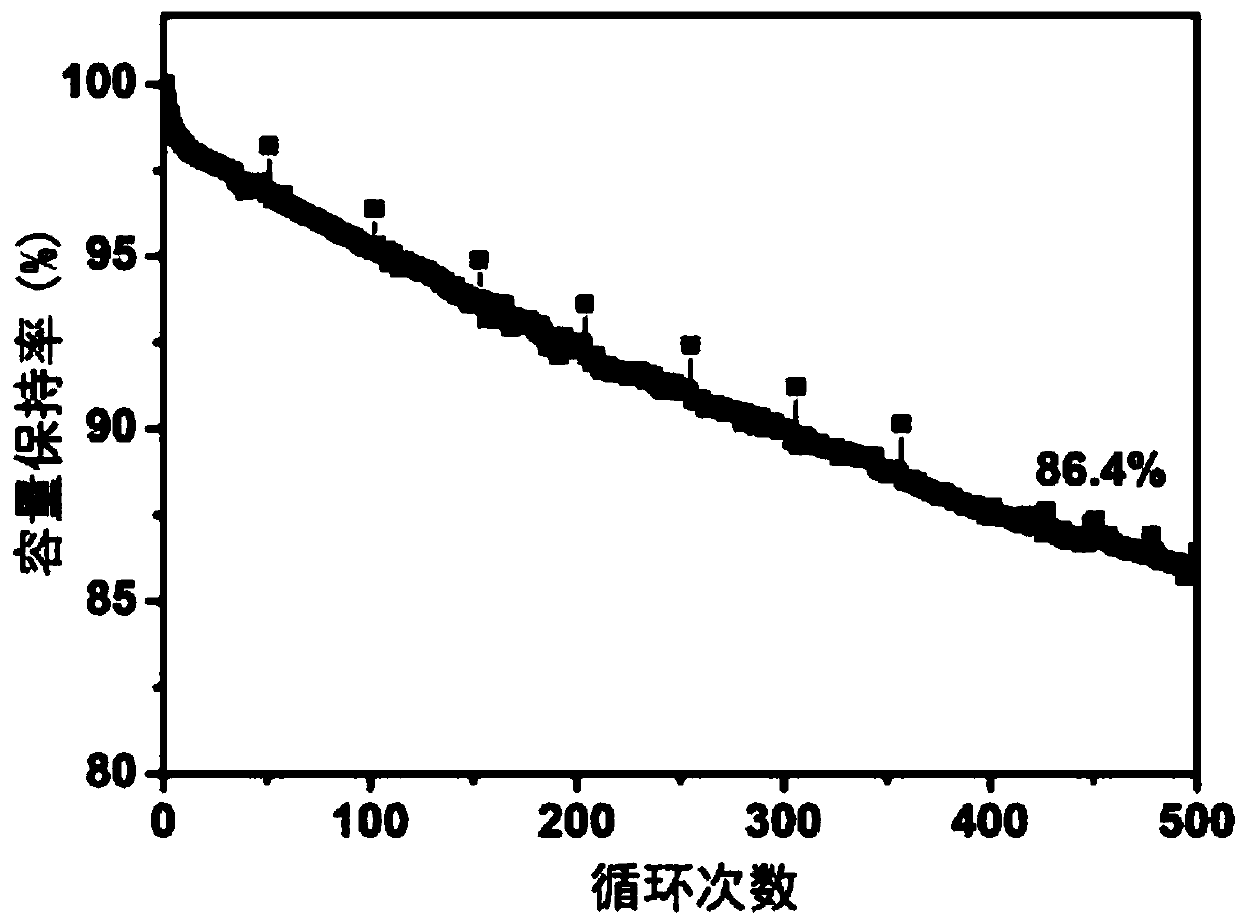

Disclosed in the invention are a silicon-carbon composite anode material for lithium ion batteries and a preparation method thereof The material consists of a porous silicon substrate and a carbon coating layer. The preparation method of the material comprises preparing a porous silicon substrate and a carbon coating layer. The silicon-carbon composite anode material for lithium ion batteries has the advantages of high reversible capacity, good cycle performance and good rate performance. The material respectively shows reversible capacities of 1,556 mAh, 1,290 mAh, 877 mAh and 474 mAh / g at 0.2 C, 1 C, 4 C and 15 C rates; the specific capacity remains above 1,500 mAh after 40 cycles at the rate of 0.2 C and the reversible capacity retention rate is up to 90 percent.

Owner:BOSCH CHINA INVESTMENT

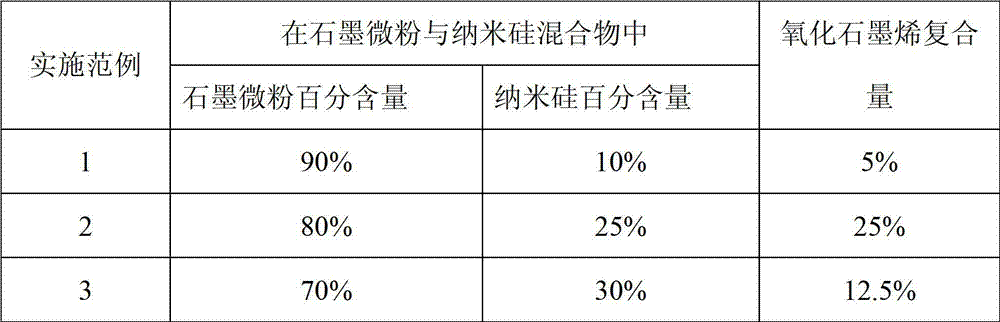

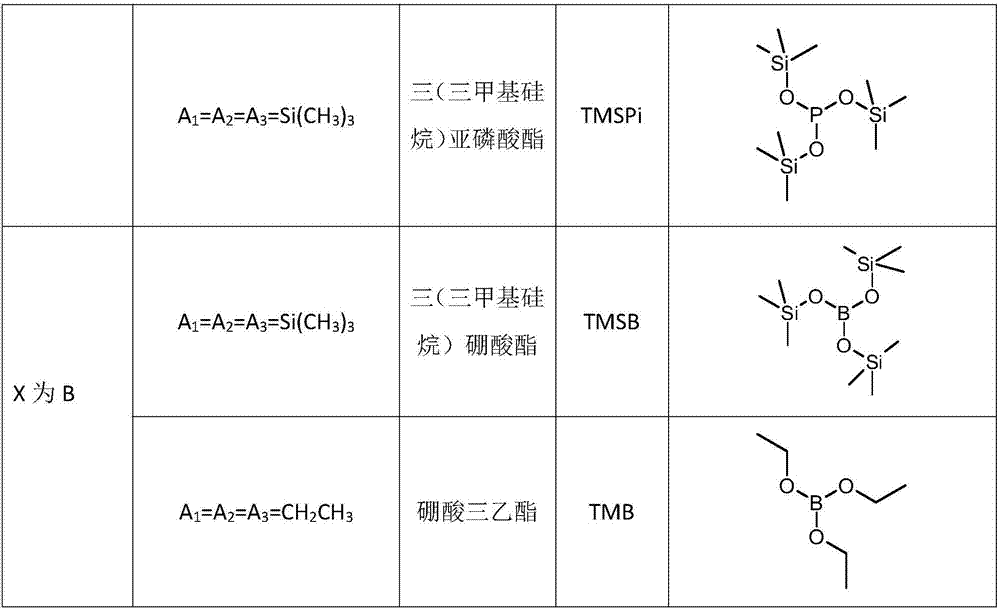

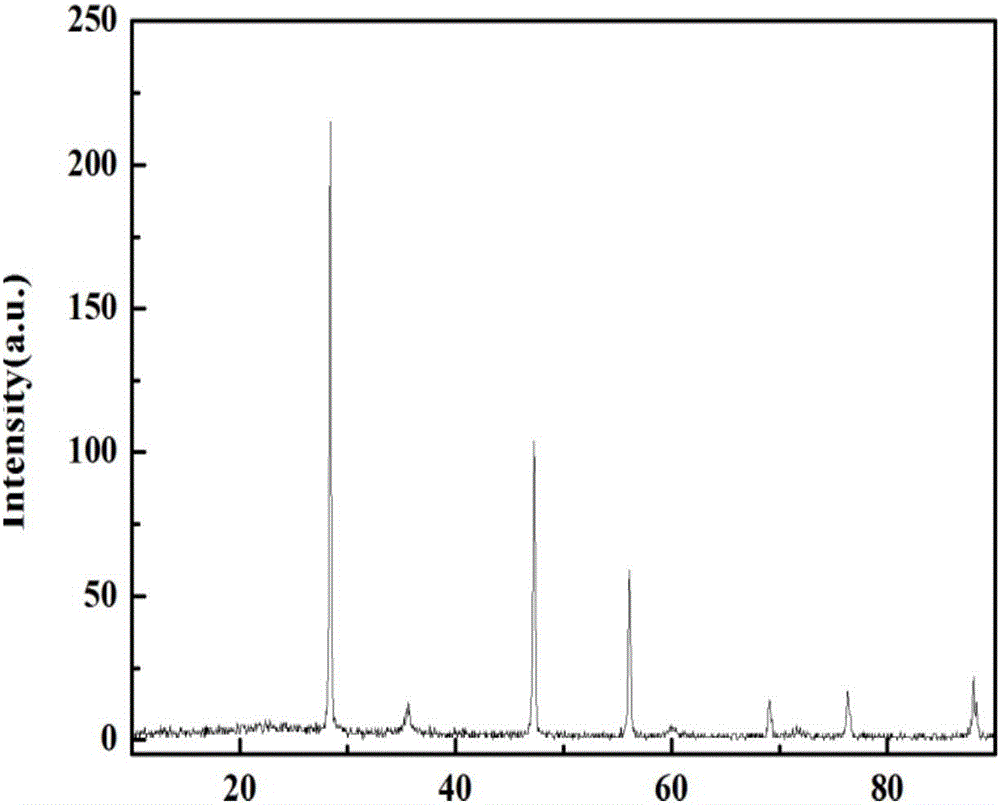

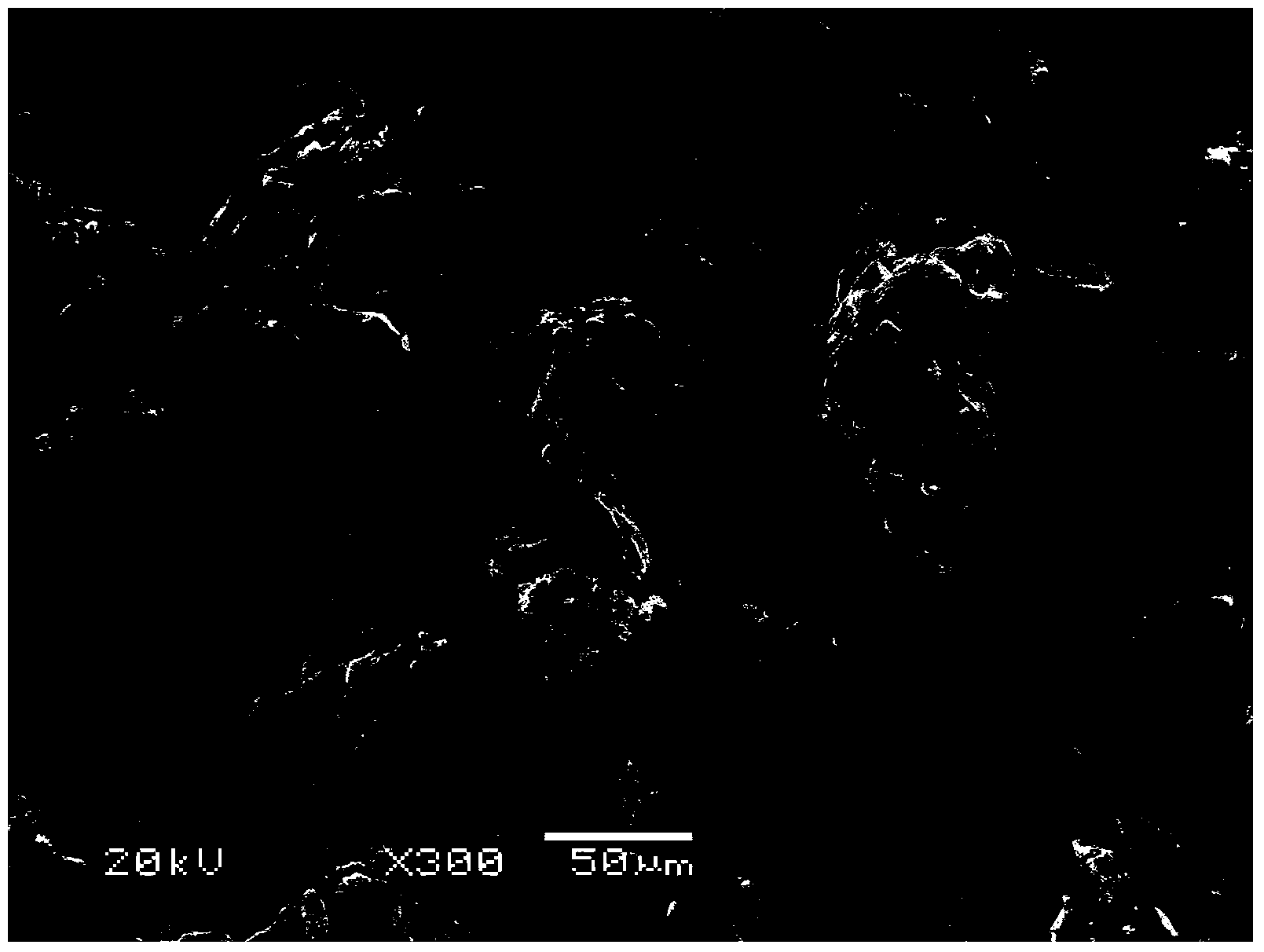

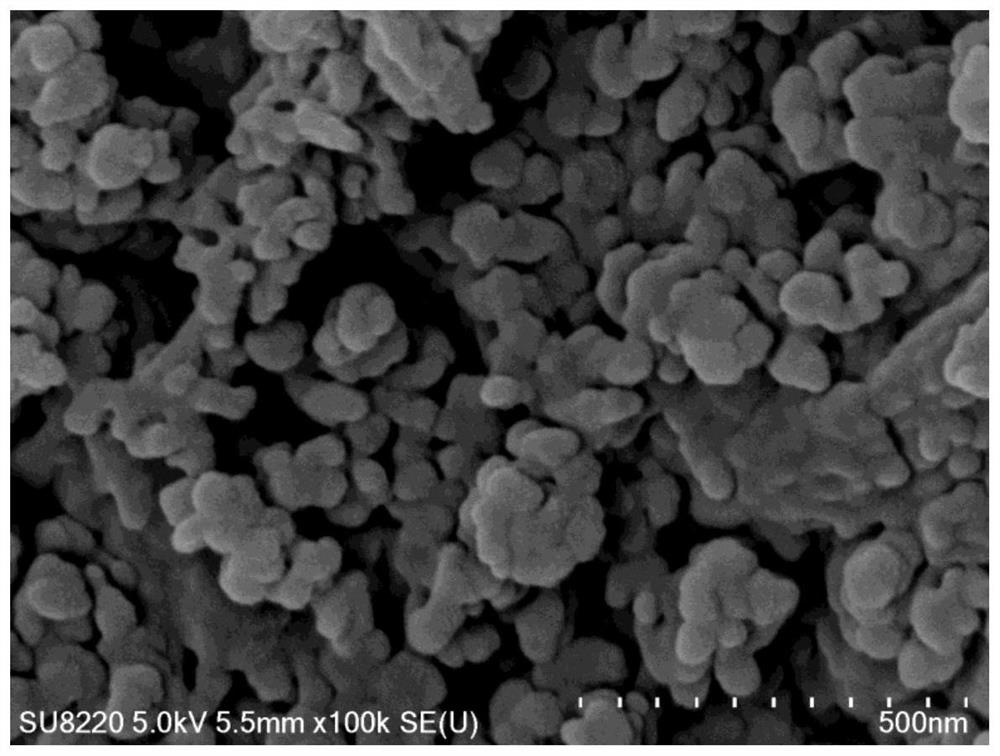

Preparation method of silicon and carbon-coated graphene composite cathode material

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

Method for preparing silicon carbide alloy negative electrode material for lithium ion battery

ActiveCN102376944AImprove dispersionInhibition of agglomerationCell electrodesSilica fumeCarbon coating

The invention discloses a method for preparing a silicon carbide alloy negative electrode material for a lithium ion battery; and a technical problem to be solved is to increase the circulation performance and the specific capacity of a silicon carbide composite negative electrode material. The method comprises the following steps of: dispersing nanometer silica powder in an organic solution to form a uniform nanometer silicon suspending liquid, then adding a silane coupling agent to the nanometer silicon suspending liquid, and finally carrying out carbon coating and thermal treatment. Compared with the prior art, the method has the advantages of increasing the dispersiveness of nanometer silicon particles in a silicon carbide composite material and inhibiting the volume effect caused by the conglobation of silicon in a lithium intercalation and deintercalation process by adding the silane coupling agent, thereby increasing the circulation performance and the specific capacity of the silicon carbide composite negative electrode material, wherein the capacity of the silicon carbide composite negative electrode material is larger than 500mAh / g, and the capacity retention rate is above 97% when the silicon carbide composite negative electrode material is circulated for 50 times; and according to the preparing method, the preparation cost is low, the technology is simple and controllable, and the silicon carbide alloy negative electrode materials with different capacities can be easily prepared by adjusting a weight proportion of Si powder, graphite and an organic matter.

Owner:BTR NEW MATERIAL GRP CO LTD

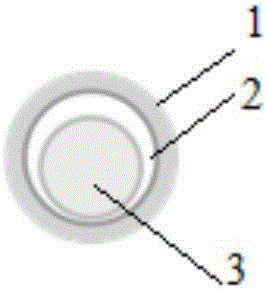

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

Pipette with improved pipette tip mounting shaft

InactiveUS6737023B1Easy to installEasily ejectableWithdrawing sample devicesBurettes/pipettesPipetteAir displacement pipette

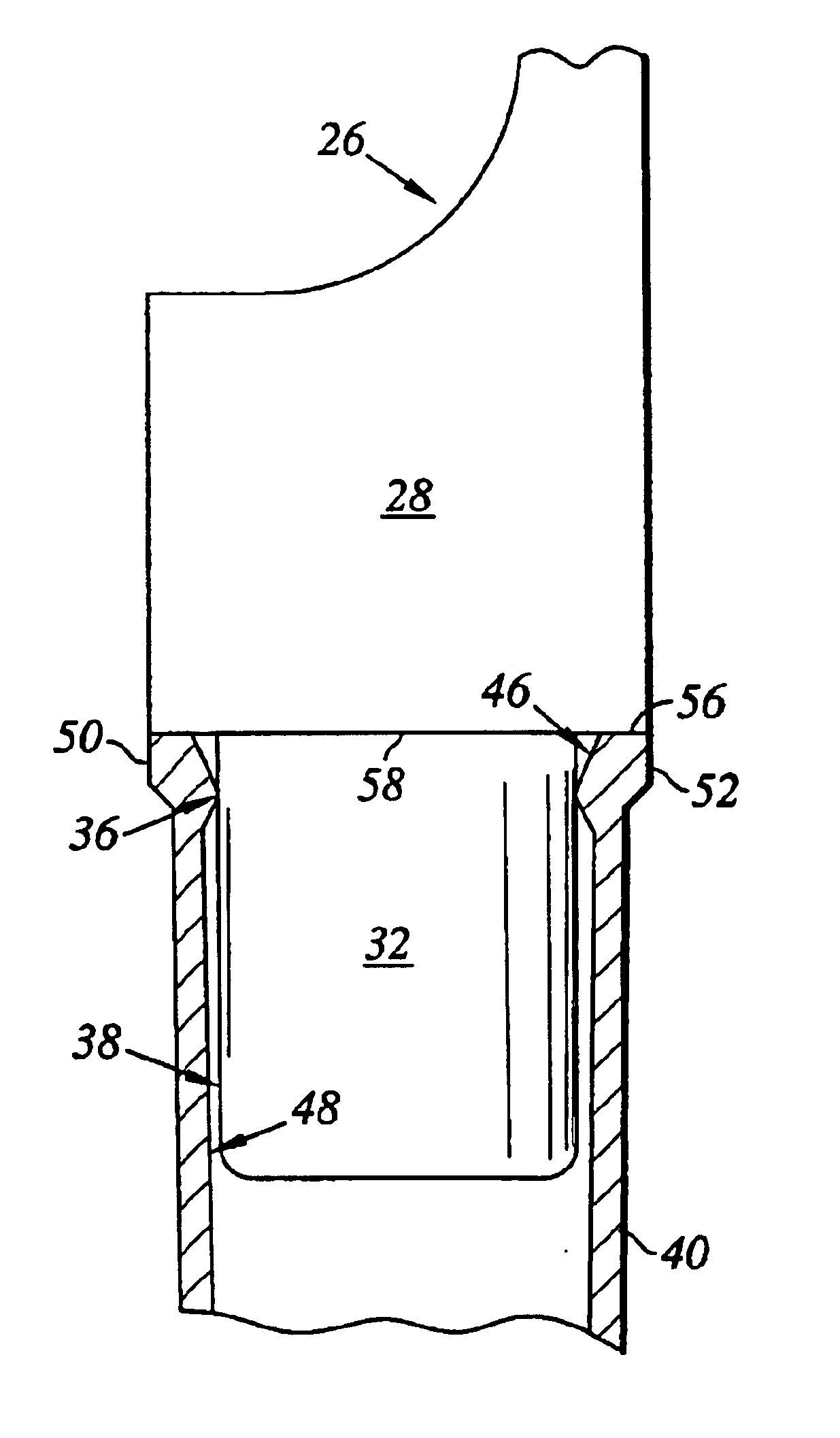

An air displacement pipette having axially spaced annular sealing and substantially cylindrical lateral support zones on the outer surface of the pipette's mounting shaft for mating with axially spaced annular sealing and substantially cylindrical lateral support regions on the inner surface of a pipette tip, whereby the pipette tip is easily and firmly mountable on and easily ejectable from the pipette tip mounting shaft by the application of minimal axial mounting and ejection forces.

Owner:RAININ INSTR

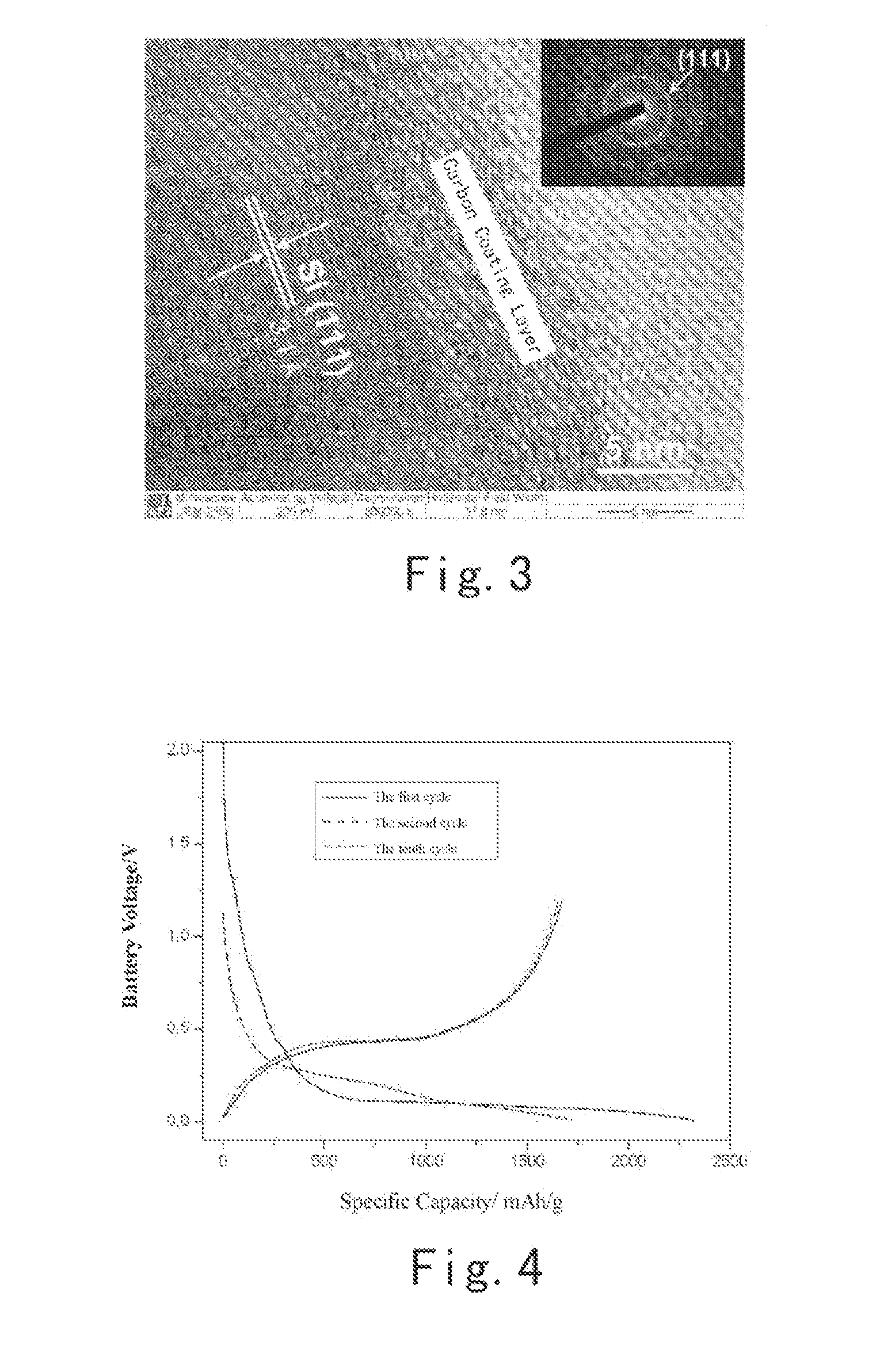

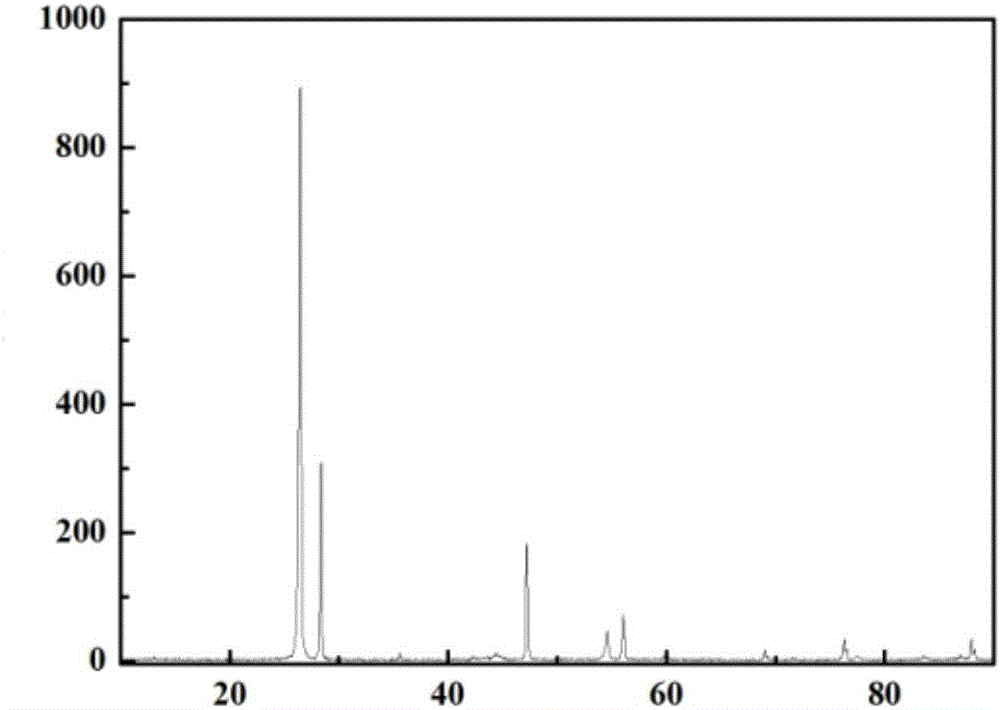

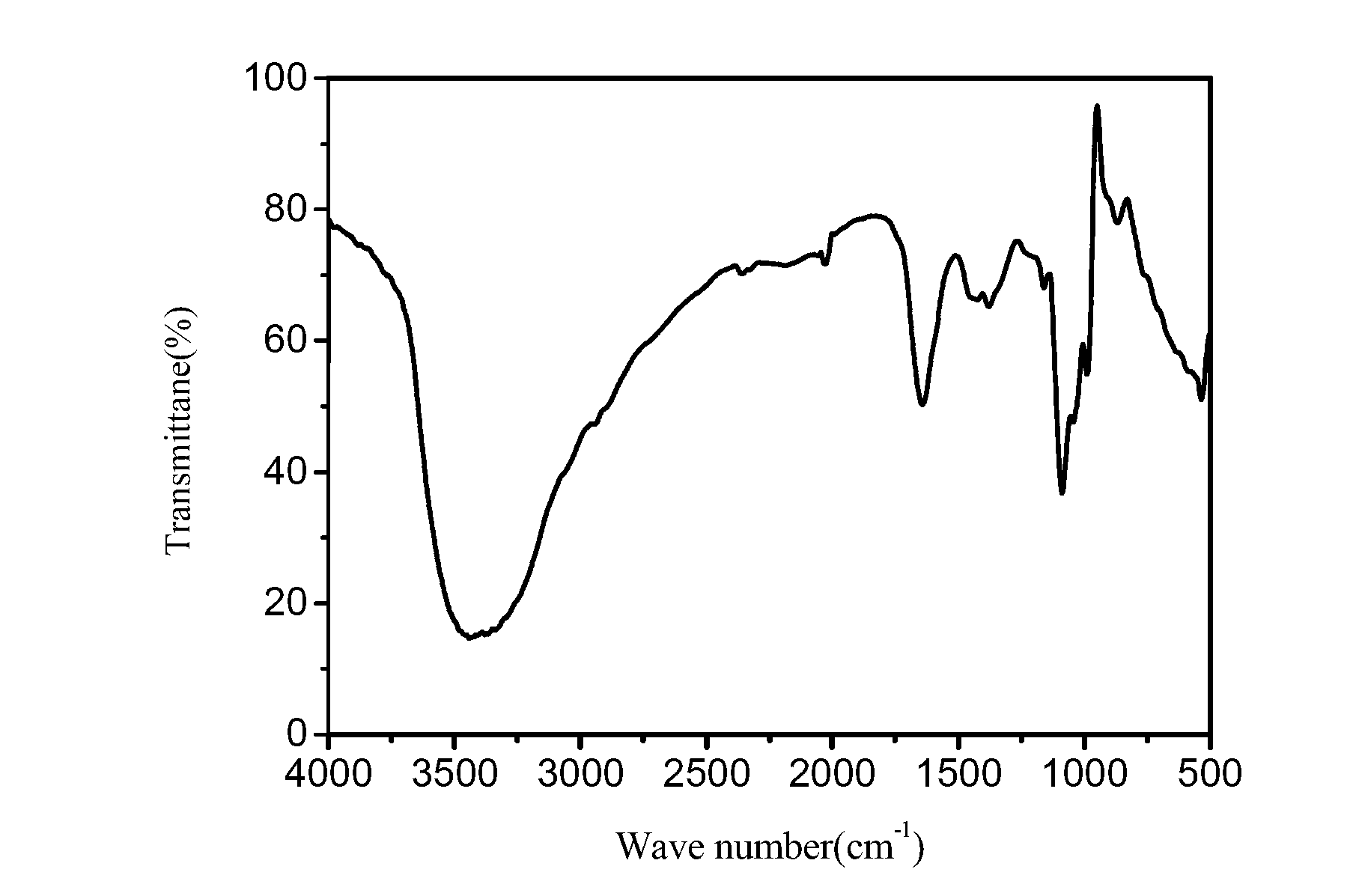

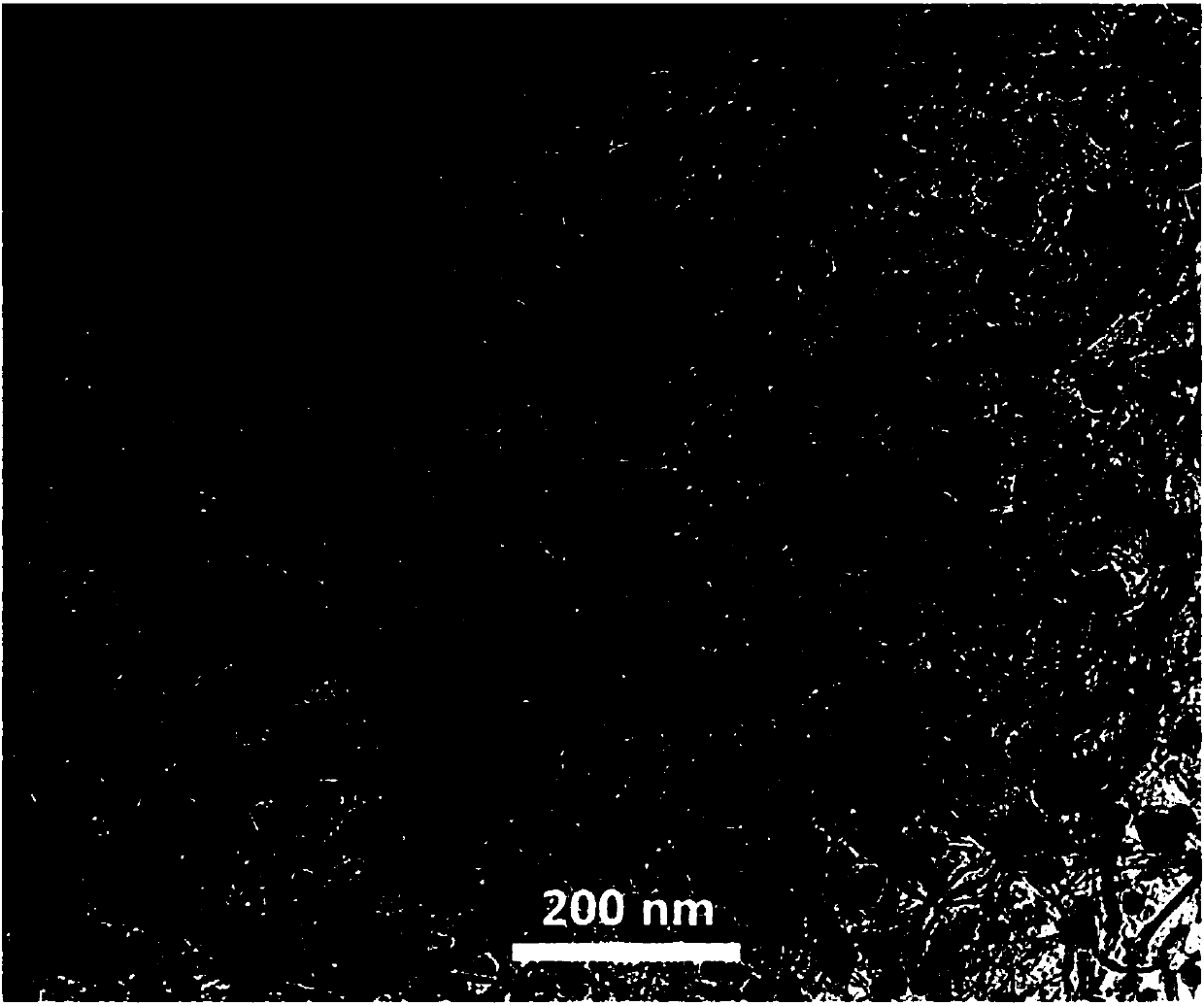

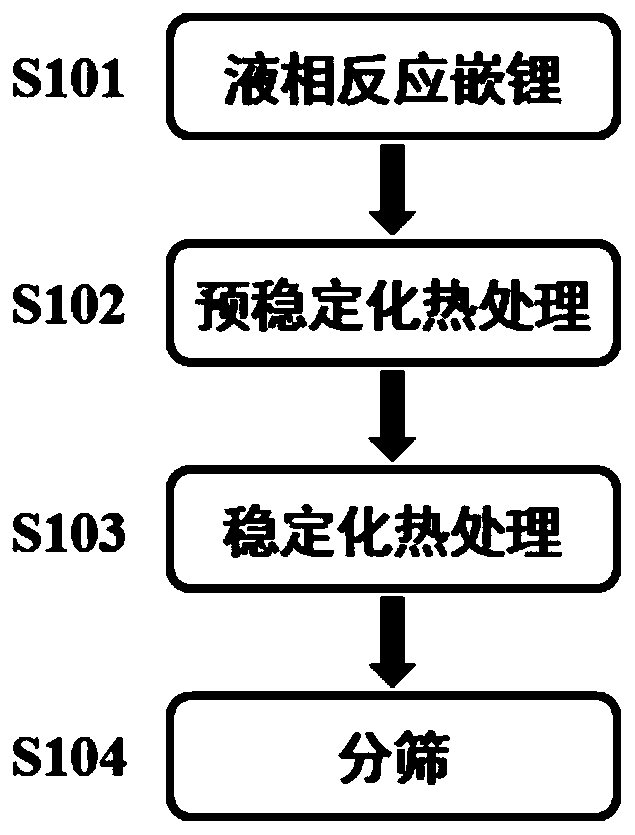

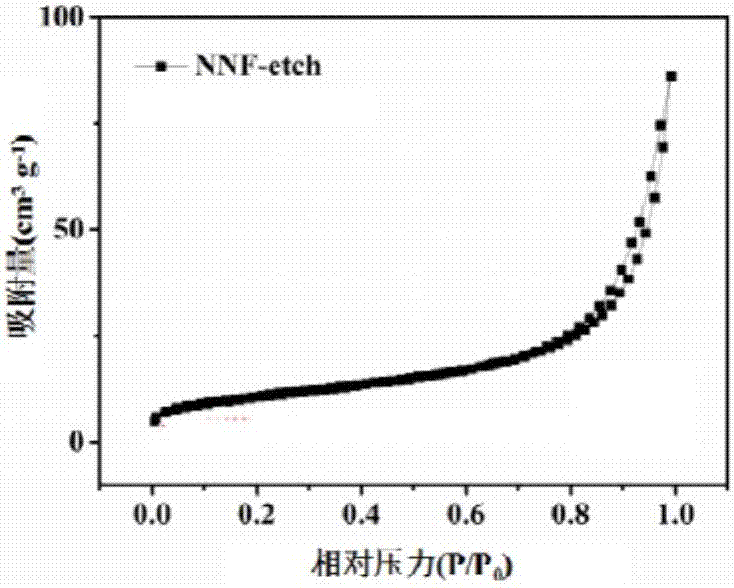

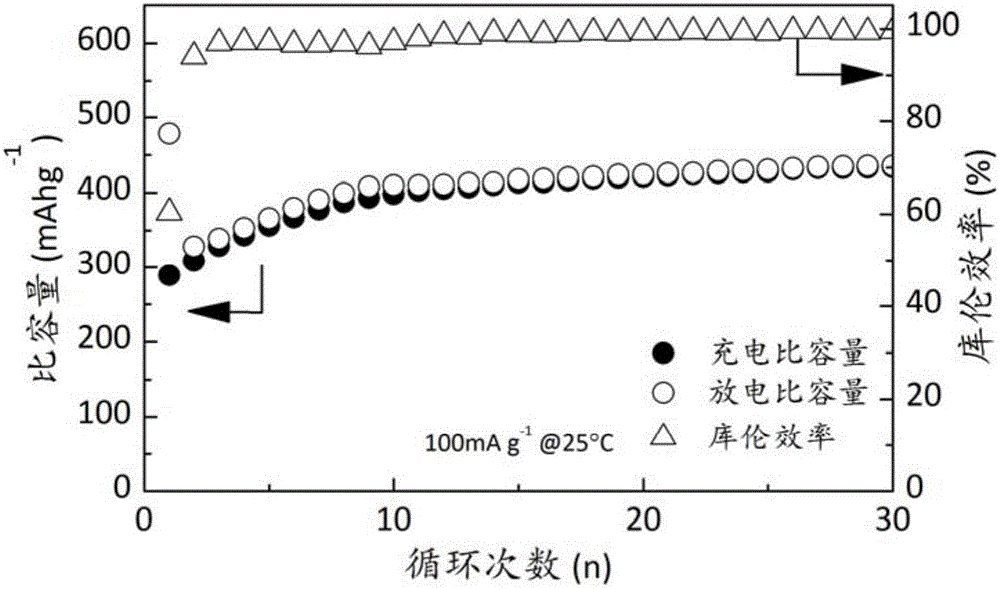

Pre-lithiated and graphene-coated mesoporous SiO negative electrode material and preparation method thereof

The invention discloses a pre-lithiated and graphene-coated mesoporous SiO negative electrode material and a preparation method thereof. The method comprises the following steps: firstly, adding metal lithium to a non-aqueous solvent to form a lithium solution; secondly, adding graphene oxide to a dispersing solvent and carrying out ultrasonic treatment to obtain 0.5-60g / L of graphene oxide dispersion; adding nano mesoporous SiO microspheres with the specific surface area of 500-700m<2> / g to the dispersion, and carrying out ultrasonic treatment; adding the lithium solution under a stirring condition; adding a lithium complexing agent, stirring, filtering and washing to obtain a precursor; and finally drying the precursor in vacuum, grinding evenly, packing into a corundum boat, sintering in an inert atmosphere furnace, and cooling along with the furnace, so as to obtain the pre-lithiated and graphene-coated mesoporous SiO negative electrode material. The composite material is prelithiated in the process of preparing the graphene-coated mesoporous SiO negative electrode material; and the initial Coulomb efficiency, the cycle performance and the charge and discharge specific capacity of a silicon oxide negative electrode material are improved.

Owner:李震祺 +1

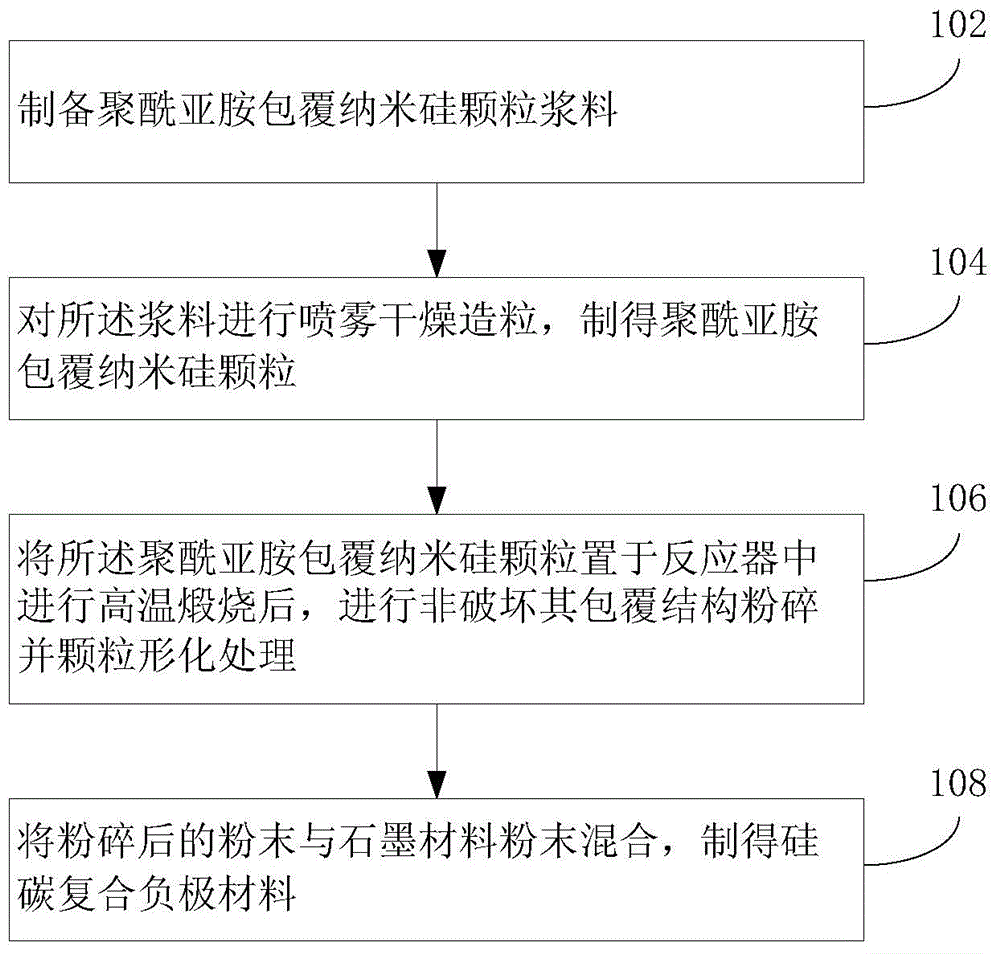

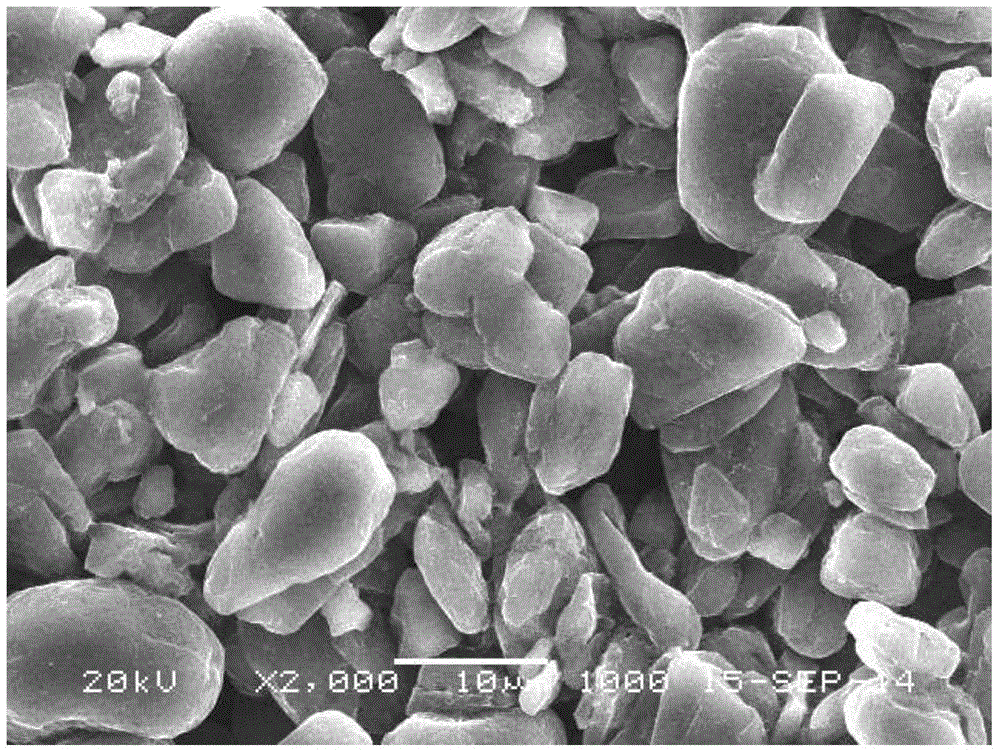

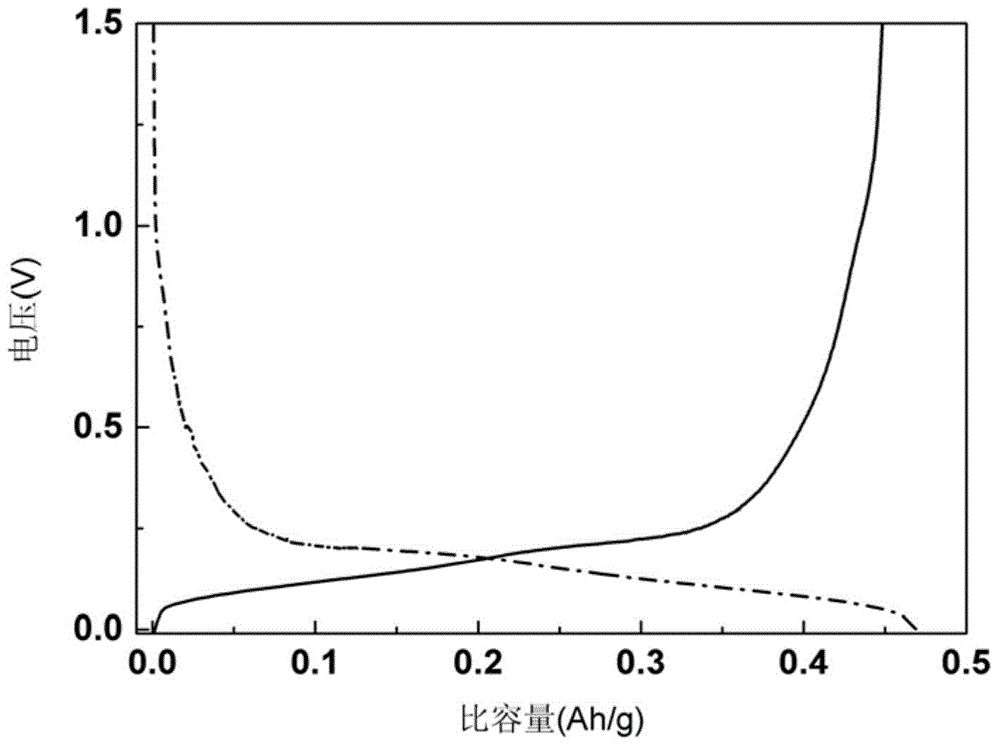

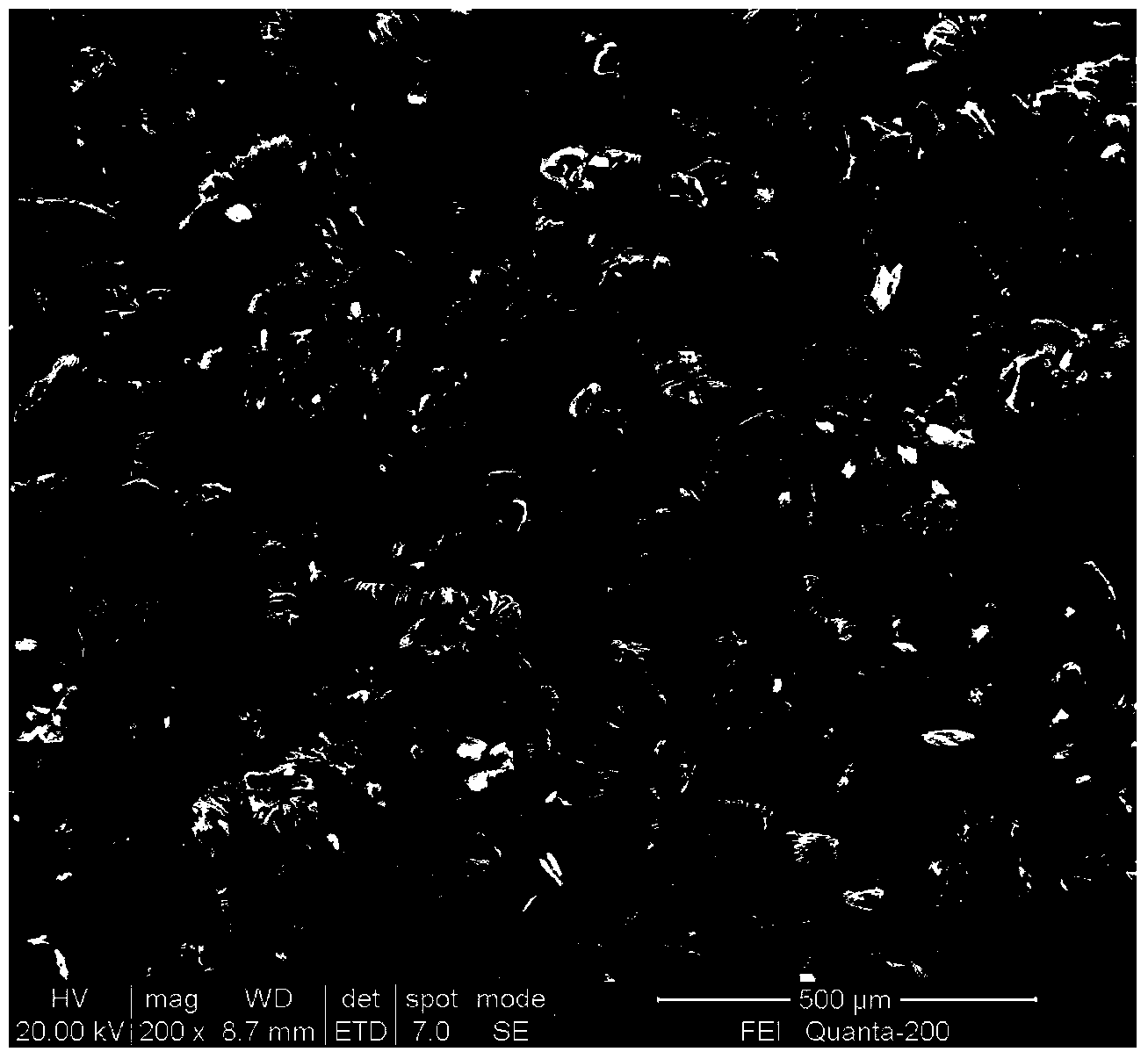

Power lithium ion battery silicon-carbon composite negative electrode material preparation method

PendingCN106207142AAlleviate volume effectInhibition of agglomerationCell electrodesCarbon layerCarbon composites

The invention discloses a power lithium ion battery silicon-carbon composite negative electrode material preparation method. The method comprises the following steps: preparing a polyimide coated nano-silicon particle slurry; carrying out spray drying granulation on the slurry to prepare polyimide coated nano-silicon particle powder; placing the polyimide coated nano-silicon particle powder in a reactor, carrying out high temperature calcining, carrying out non-destructive coating structure crushing, and granulating the crushed powder; and mixing the crushed powder with graphite material powder to prepare a silicon-carbon composite negative electrode material. The surface of silicon nano-particles is uniformly covered with a conductive carbon layer generated by pyrolysis of polyimide polymer, so the volume effect of the silicon particles, appearing in the battery charge and discharge process, is effectively inhibited, and unnecessary side reactions between silicon and an electrolyte are avoided, and a nano-silicon particle dispersion containing the polyimide polymer effectively inhibits the agglomeration phenomenon of the silicon nano-particles in the dispersion and can be used as the adhesive in a next spray drying process.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

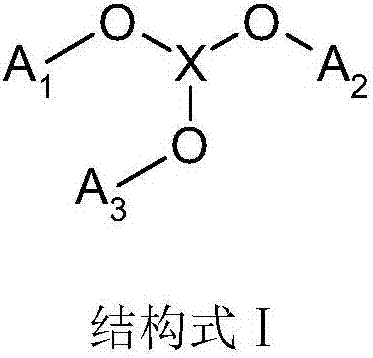

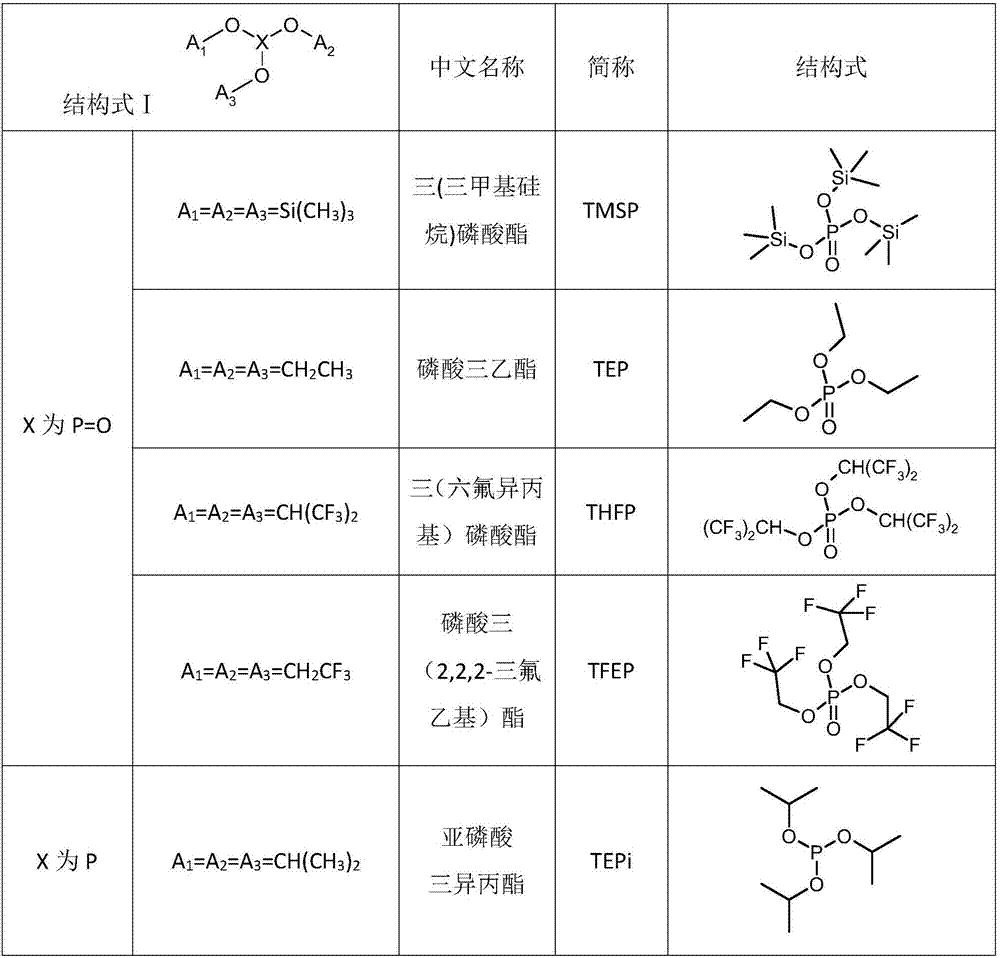

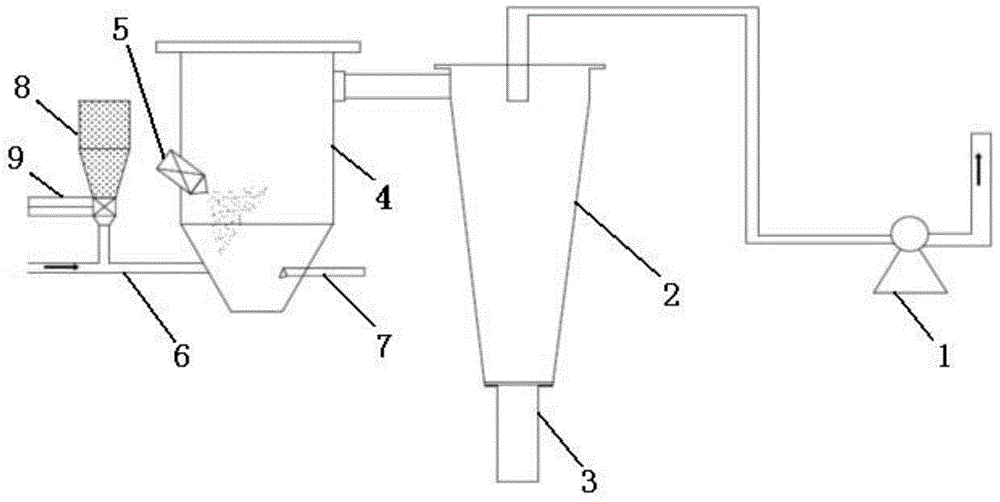

Electrolyte solution for silicon based lithium secondary battery and silicon based lithium secondary battery

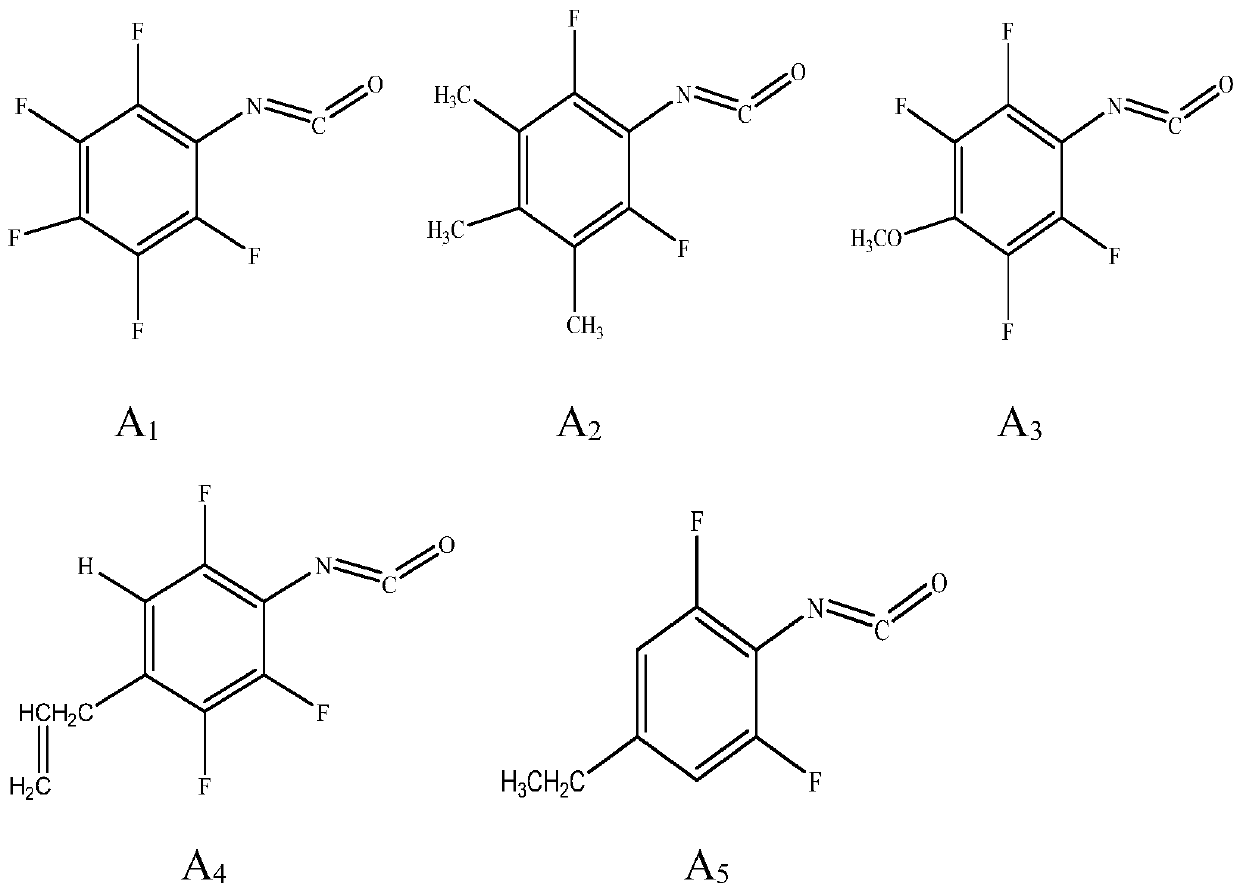

InactiveCN107275676AImprove cycle performanceAlleviate volume effectLi-accumulatorsOrganic electrolytesHigh temperature storageOrganic solvent

The invention discloses an electrolyte solution for a silicon based lithium secondary battery. The electrolyte solution comprises: a non-aqueous organic solvent, a lithium salt and an additive, wherein the additive comprises fluoroethylene carbonate, lithium difluoro(oxalato) borate and a compound with a structure shown as formula I in the specification, specifically in the formula I, X represents P=O group, P atom and B atom; A1, A2 and A3 are independently selected from one of alkyl, silicyl, and fluoroalkyl. At the same time, the invention also discloses a silicon based lithium secondary battery. The electrolyte solution can effectively improve the room temperature cycling performance, high temperature storage performance and low temperature discharge performance of the battery.

Owner:GUANGZHOU TINCI MATERIALS TECH

Anode material for lithium-ion battery and preparation method and application of anode material

The invention discloses an anode material for a lithium-ion battery. The anode material comprises a carbon core layer and a silicon wrapping layer. The silicon wrapping layer wraps the carbon core layer to form a silicon / carbon composite material. The anode material further comprises a metallic oxide wrapping layer serving as the outer wrapping layer of the silicon / carbon composite material. The anode material solves the problem that due to the fact that a silicon-contained anode material is prone to expansion, the battery capacity is rapidly reduced. The invention further discloses a preparation and application of the anode material for the lithium-ion battery. The preparation method includes the step of conducting high-temperature annealing to form the anode material after the silicon / carbon composite material is fluidified and wrapped by a metal salt solution. The lithium-ion battery more excellent in performance can be obtained when the anode material is applied.

Owner:INST OF NEW ENERGY SHENZHEN

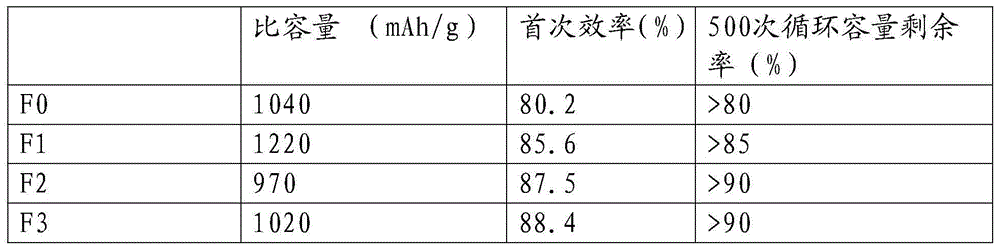

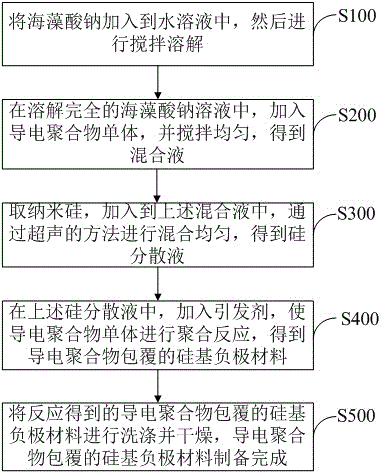

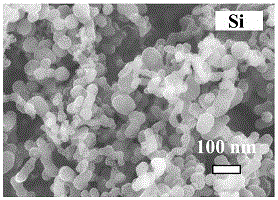

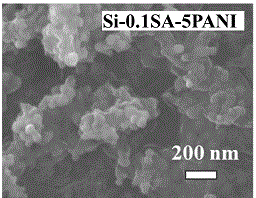

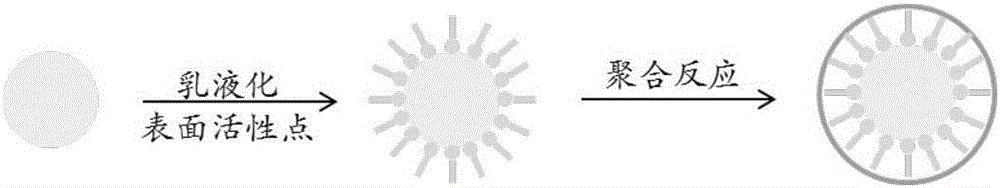

Conductive polymer-coated silicon-based negative electrode material and preparation method thereof

ActiveCN106229495AImprove electrochemical performanceAlleviate volume effectCell electrodesSecondary cellsConductive polymerUltrasound method

The invention discloses a conductive polymer-coated silicon-based negative electrode material and a preparation method thereof. The method comprises the following steps of adding sodium alginate to a water solution, and then stirring and dissolving the sodium alginate; adding a conductive polymer monomer to the completely dissolved sodium alginate solution and stirring evenly; adding taken nanometer silicon to a mixed solution and mixing evenly through an ultrasound method to obtain a silicon dispersion liquid; adding an initiator to the silicon dispersion liquid and carrying out polymerization reaction on the conductive polymer monomer to obtain the conductive polymer-coated silicon-based negative electrode material; and carrying out washing and drying and finishing preparation of a final product. A three-dimensional mesh structure is built by the conductive polymer, so that the conductive polymer-coated silicon-based negative electrode material has conductivity and also provides a certain accommodation space for volume expansion of the silicon; and the silicon is embedded into the mesh structure, so that the volume effect of the silicon is effectively relieved. Furthermore, the hydroxyl-containing sodium alginate is introduced, so that the structure stability of the overall silicon-based negative electrode material is strengthened.

Owner:SHENZHEN UNIV

Preparing method of nanometer silicon-carbon composite lithium-ion battery negative electrode material

ActiveCN106784707APromote absorptionAlleviate volume effectMaterial nanotechnologyCell electrodesCarbon compositesBall mill

The invention provides a preparing method of a nanometer silicon-carbon composite lithium-ion battery negative electrode material. A composite of porous silicon and graphite and a microwave drying method are adopted. The preparing method comprises the following steps of 1, proportionally mixing and ball-milling micrometer silicon, low-melting-point organic matter, carbon sources and a ball milling auxiliary into a ball-milled mixture, and drying the ball-milled mixture for drying pelletizing to obtain a precursor in which micrometer silicon, the low-melting-point organic matter and the carbon sources are evenly distributed; 2, conducting heating treatment on the precursor to make the low-melting-point organic matter molten out to obtain a precursor material in which silicone with a porous structure and the carbon sources are evenly distributed; 3, conducting high temperature sintering on the precursor material under the protection of inert atmosphere to obtain a carbon-covering porous silicon material; 4, proportionally mixing the carbon-covering porous silicon material with a graphite material to obtain the nanometer silicon-carbon composite lithium-ion battery negative electrode material. According to the nanometer silicon-carbon composite lithium-ion battery negative electrode material, the raw materials are rich in sources, low in cost and simple in process, and expansion of a silicon material in the charging and discharging processes is overcome, so that the material has an excellent rate capability and cycle performance.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

Method for preparing lithium ion battery carbon silicon anode material

The invention relates to a method for preparing a lithium ion battery carbon silicon anode material. The method includes that a sol formed by resorcinol and formaldehyde is used for mixing and coating nano silicon powders and superfine graphite powders to obtain a mixture, and the mixture is subjected to a carbonization. Compared with methods in prior art, by means of the method, the circularity of the carbon silicon anode material can be remarkably improved, and the specific capacitance of the carbon silicon anode material is improved.

Owner:TONGJI UNIV

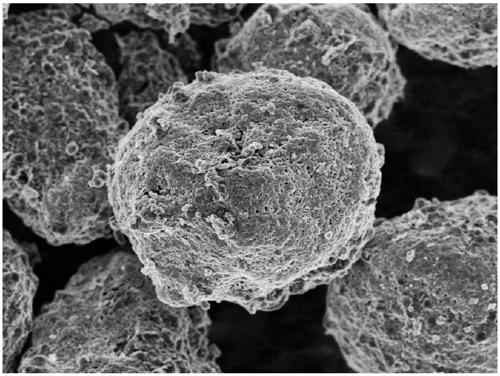

Hollow/porous structure silicon-based composite material and preparation method thereof

InactiveCN109449423AAlleviate volume effectAvoid chalkingMaterial nanotechnologySiliconCarbon compositesCarbon coating

The invention discloses a hollow / porous structure silicon-based composite material. The composite material comprises a hollow / porous structure, a silicon-carbon composite layer and a coating layer, the silicon-carbon composite layer is formed by evenly dispersing nano silicon or silica in a conductive carbon network, the conductive carbon network in the silicon-carbon composite layer is formed with binder through pyrolysis, the coating layer is a carbon coating layer, and at least one carbon coating layer is provided. The composite material provided by the invention is prepared through a method of evenly mixing the nano silicon / silica, the binder and salt, then, performing spray granulation, high temperature sintering, water desalination and coating treatment. The composite material provided by the invention is a lithium ion battery silicon-carbon cathode material with the advantages, such as high first effect, low expansion and long cycle; grain growth of the silicon material in a thermal treatment process is slowed, powdering of the material in a cycle process is avoided effectively, volume expansion effect of the silicon-based material is remitted, cycle performance is promoted,and conductivity and rate capability of the material are improved.

Owner:DONGGUAN KAIJIN NEW ENERGY TECH

Method for preparing lithium battery silicon carbon anode material

InactiveCN103022448AImprove volume effectAlleviate volume effectCell electrodesCarbon compositesCopper foil

The invention discloses a sodium alginate bonding agent used in a lithium battery silicon carbon anode, particularly discloses a method for preparing a silicon carbon anode material by the bonding agent. The method comprises the steps that: step one, micron-grade silica powder is added into a ball milling tank, and a solvent is added to perform ball milling; step two, natural graphite is added into the industrial silicon powder subjected to the ball milling in the step one to continuously perform the ball milling; step three, substances subjected to the ball milling in the step two are dried, and the dried substances are finely ground; step four, 70-80 parts by weight of the silicon carbon composite material, 5-20 parts by weight of sodium alginate and 5-20 parts by weight of acetylene black are weighed, defined amount of deionized water is added, and the materials are uniformly stirred, then coated on a copper foil and dried to obtain the silicon carbon anode material. The novel bonding agent adopted by the invention can effectively improve the cycling performance of the silicon carbon anode material and prolong the cycling service life of the anode material.

Owner:TIANJIN B&M SCI & TECH

Preparation method for silicon negative electrode material for lithium ion battery and silicon negative electrode material

InactiveCN105789577AEffective dispersionAlleviate volume effectCell electrodesSecondary cellsSilicon monoxideElectrical battery

The invention relates to a preparation method for a silicon negative electrode material for a lithium ion battery and the silicon negative electrode material. The preparation method comprises the following steps of step 1, surface hydroxylation: putting silicon monoxide into a mixed solution of ammonium hydroxide, hydrogen peroxide and water, and then heating, boiling and stirring for 10-60min, next, carrying out water washing, filtering and vacuum drying at a temperature of 80-120 DEG C for 2-12h; step 2, stirring: putting the dried product obtained in the step 1 into an absolute ethyl alcohol solution containing a titanium source, and stirring for 2-10h, then adding water and stirring for 15-75min, next, adding graphite, and then adding an absolute ethyl alcohol solution containing a lithium source, finally adding glacial acetic acid and stirring, and stopping stirring when black sol is changed into gel; step 3, aging and drying: aging the gel generated in the step 2 for 12h or more than 12h, then carrying out vacuum drying on the gel at a temperature of 70-90 DEG C for 8-16h; and step 4, calcining: smashing the gel which is aged and dried in the step 3, and calcining the processed gel under protection of an inert gas atmosphere; and finally, cooling to the room temperature to obtain the silicon negative electrode material.

Owner:CHERY AUTOMOBILE CO LTD

Carbon-carbon multi-component negative electrode material and preparation method thereof

ActiveCN104037396AIncrease the attachment areaIncrease energy densityCell electrodesSecondary cellsCarbon compositesGraphite

The invention relates to a carbon-carbon multi-component negative electrode material. The carbon-carbon multi-component negative electrode material is mainly composed of flexible graphite, nanometer silicon and amorphous carbon which respectively account for 30-60%, 30-50% and 10-30% based on mass percent, the amorphous carbon is obtained through high-temperature pyrolyzation of an organic carbon source, and the flexible graphite is obtained by applying pressure to expanded graphite. A preparation method of the product comprises the steps of: firstly, preparing an expanded graphite / silicon-silicon dioxide / carbon composite negative electrode material through high-temperature pyrolyzation; secondly, pouring the expanded graphite / silicon-silicon dioxide / carbon composite negative electrode material into a mould and applying pressure to obtain a flexible graphite / silicon-silicon dioxide / carbon composite negative electrode material; thirdly, processing silicon dioxide to obtain a flexible graphite / silicon / carbon composite negative electrode material through etching by a corrosive liquid; and finally, using asphalt to permeate a gap inside the flexible graphite / silicon / carbon composite negative electrode material in a protective atmosphere, and obtaining the product after high-temperature heat treatment and repetition. The carbon-carbon multi-component negative electrode material has the advantages of high capacity, high coulombic efficiency, good cycle performance, structure stability, high reversible capacity and the like.

Owner:CENT SOUTH UNIV

Electrolyte applicable to silicon carbon negative and lithium ion battery comprising electrolyte

ActiveCN109873205AImproved reversible capacity performanceImprove cycle performanceSecondary cells servicing/maintenanceHigh temperature storageSodium-ion battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to an electrolyte applicable to a silicon carbon negative and a lithium ion battery comprising the electrolyte. The electrolyte comprises an electrolyte lithium salt, a non-aqueous organic solvent and an additive. Wherein the additive comprises a negative film formation additive, a fluorine-substitutedphenyl isocyanate compound additive with a formula I structure and a dosilane nitrogen-based compound additive. Compared with the prior art, the actual discharging capability, the cycle stability andthe high-temperature storage performance of a silicon carbon negative electrode lithium ion battery are effectively improved by means of a synergic effect generated by combined application of variousadditives, gas generation is prevented, the problems of volume expansion and pole plate pulverization of the battery during the charge-discharge process are solved very well, and meanwhile, the electrolyte is compatible with relatively good high- and low-temperature performance.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

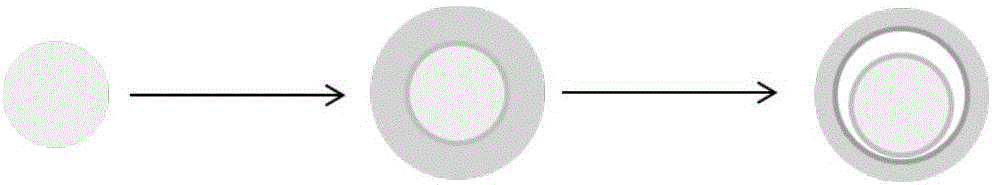

Egg-shaped dual-carbon shell layer tin-based negative electrode material of lithium ion battery and preparation method for negative electrode material

InactiveCN107369819AHigh specific capacityImprove conductivityMaterial nanotechnologyCell electrodesTin dioxideCarbonization

The invention provides an egg-shaped dual-carbon shell layer tin-based negative electrode material of a lithium ion battery and a preparation method for the negative electrode material. The egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite comprises a porous stannic oxide sphere kernel and a dual-layer carbon shell for coating the surface of the porous stannic oxide sphere kernel, and a hollow layer exists between the two parts; the preparation method comprises the steps of preparing the egg-shell-shaped silicon dioxide-coated porous stannic oxide sphere nanocomposite by adopting a surfactant soft template method, and then attaching an organic pyrolytic carbon raw material on the surface of the nanocomposite, and performing a hydrothermal reaction and then carrying out condensation polymerization and carbonization to obtain the egg-shell-shaped carbon-silicon dioxide-carbon-coated stannic oxide sphere nanocomposite, and finally, performing etching by adopting a sodium hydroxide alkali solution to obtain the egg-shell-shaped dual-layer carbon-coated stannic oxide nanocomposite. Finally, the invention provides the tin-based negative electrode material of the lithium ion battery with nanometer scale, high conductivity and capability of effectively suppressing the volume effect of stannic oxide, and a preparation method for the negative electrode material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

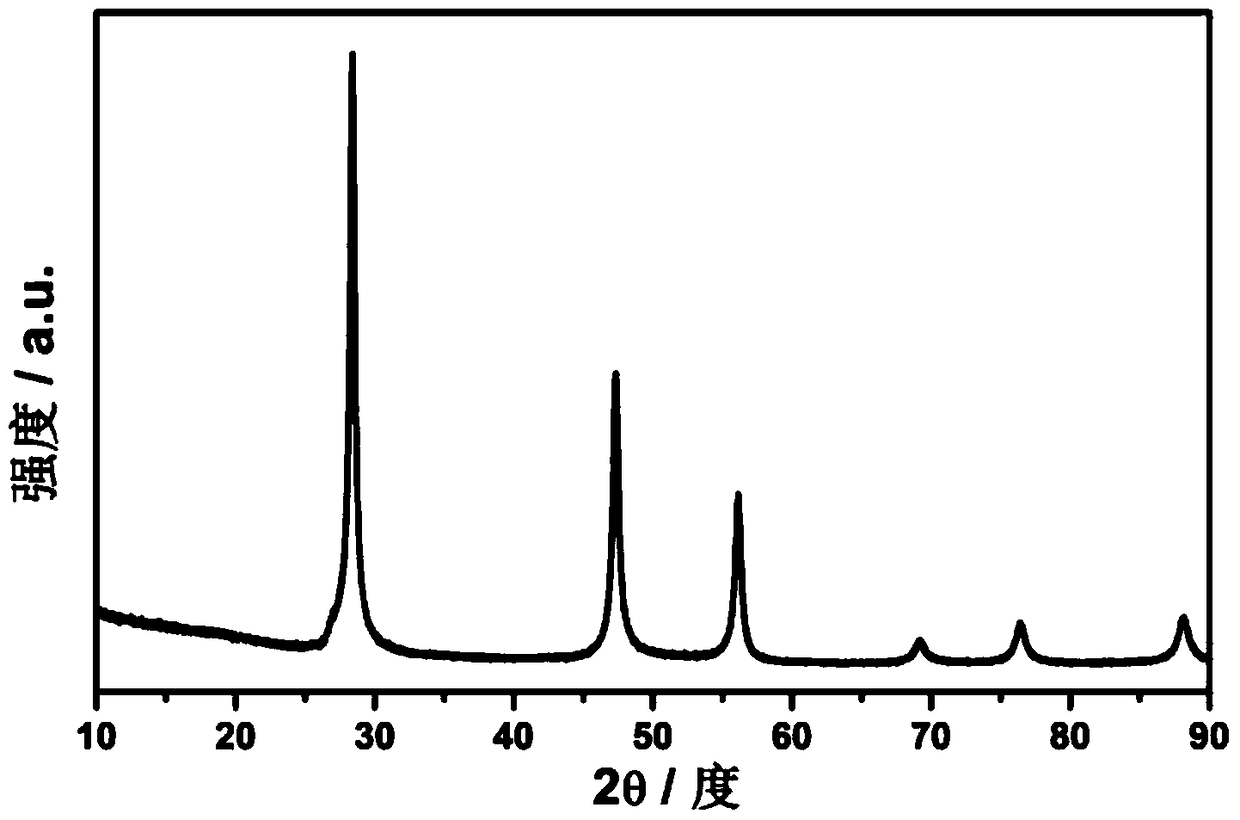

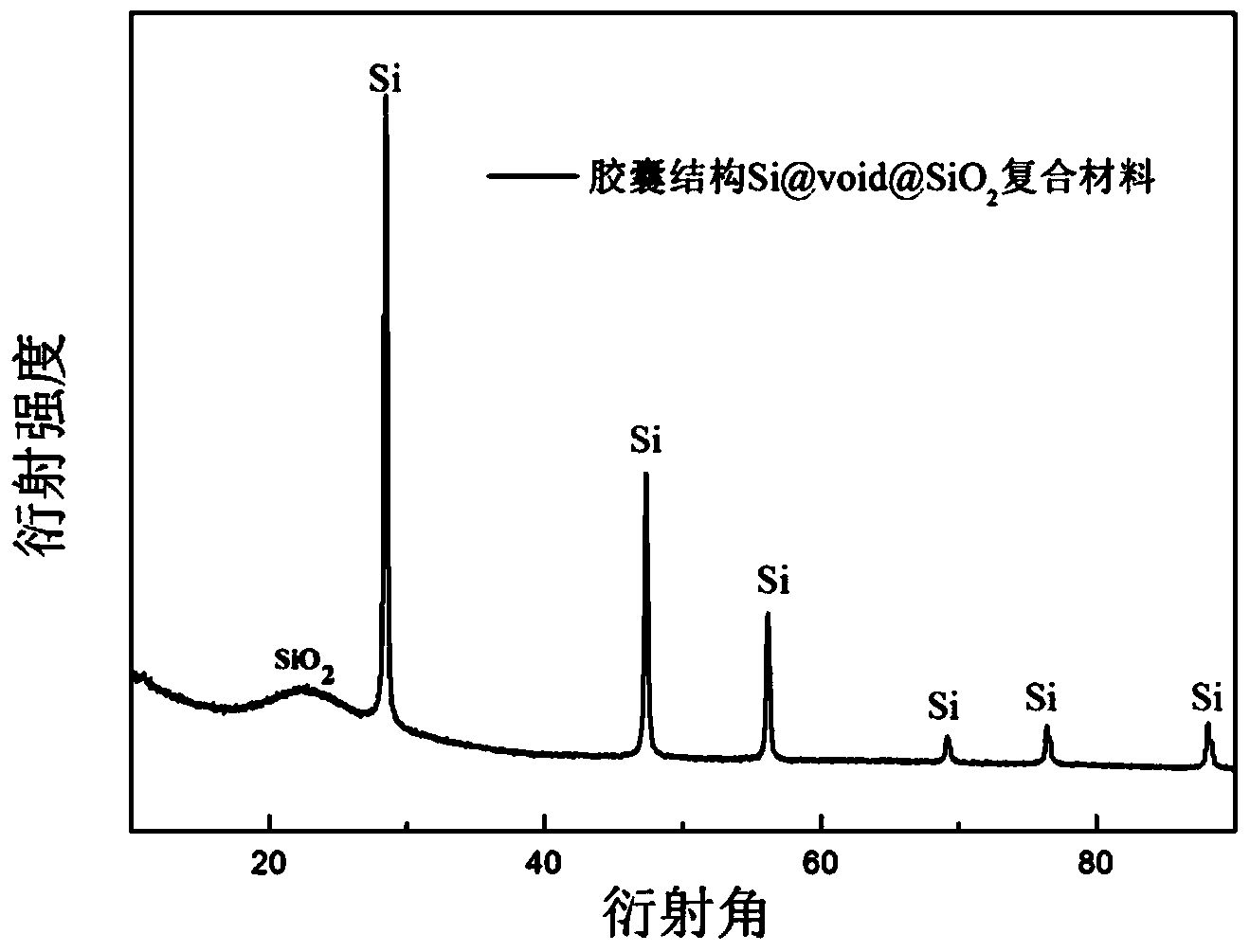

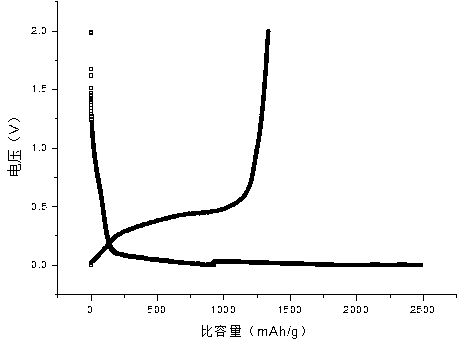

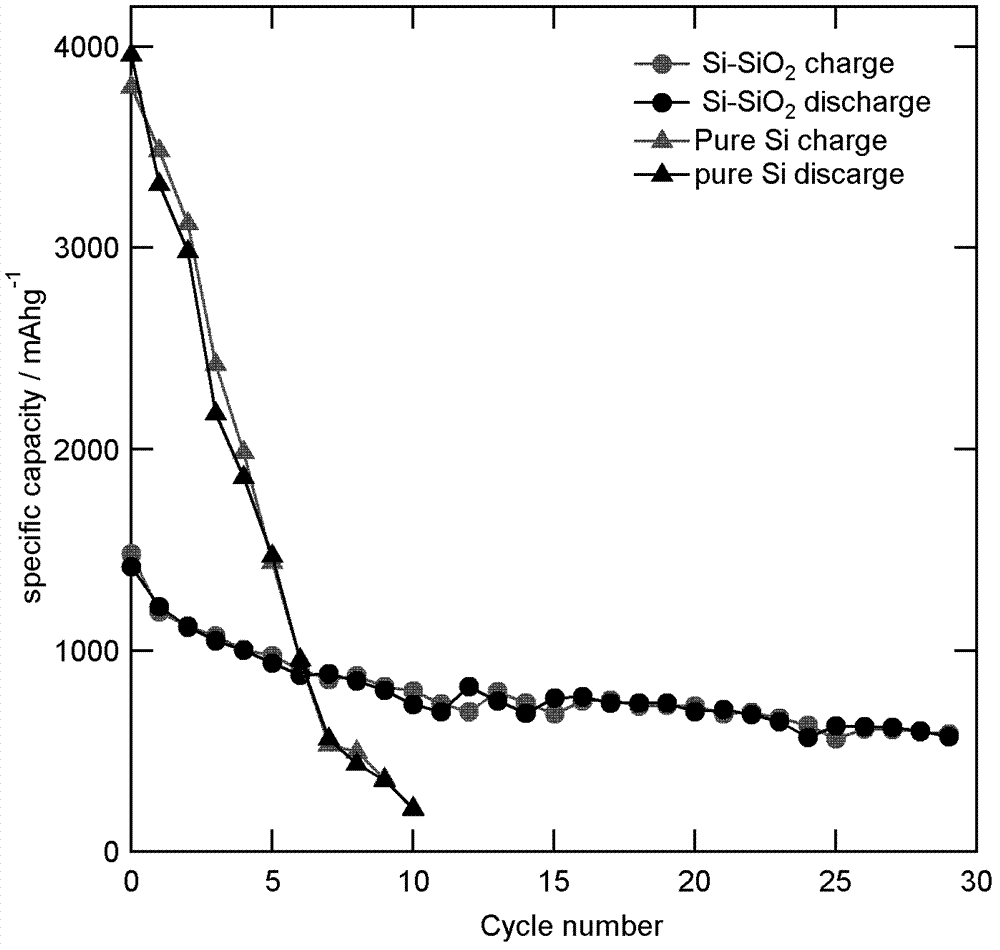

Silicon-based lithium ion battery negative electrode material and preparation method thereof

ActiveCN103474636AAlleviate volume effectMaterial nanotechnologyCell electrodesSilanesLithium-ion battery

The invention discloses a silicon-based lithium ion battery negative electrode material and a preparation method thereof. In the material, a silicon core is coated by a silicon dioxide shell, and a certain space exists between the silicon core and the silicon dioxide shell. The preparation method comprises the steps that at room temperature, a surfactant is added into deionized water and stirred; then a silicon powder suspension liquid is added and stirred; the mixed solution is heated to 40-50 DEG C, 3-aminopropyl triethoxy silane and tetraethyl orthosilicate are respectively dripped into the mixed solution and stirred; then the mixture is heated to 70-90 DEG C, and heat insulation is carried out for 15-48 hours; reaction products are collected in a centrifugal manner, are washed with ethyl alcohol and deionized water respectively, and then are dried; the obtained product is added to an acetonitrile and hydrochloric acid mixed solution and stirred for 4-8 hours, is washed again with deionized water and then is dried, thus obtaining the negative electrode material disclosed by the invention. The lithium embedding capacity of the negative electrode material is higher than 2000mAh / g for the first time, and the specific capacity of the negative electrode material can be still kept to be 520-750 mAh / g after 20 times of repeated charging and discharging circulation.

Owner:SHANGHAI JIAO TONG UNIV

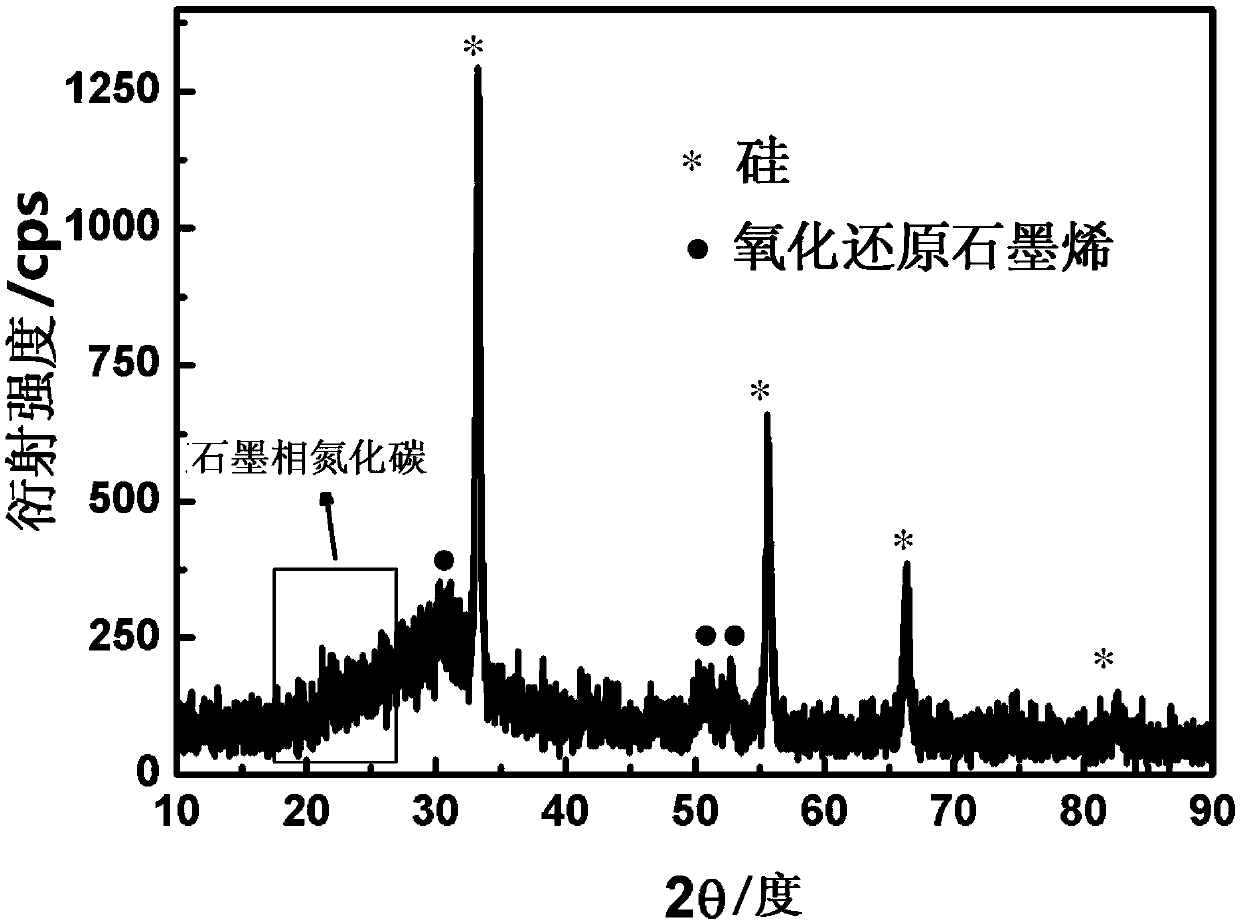

Silicon embedded redox graphene/graphite phase carbon nitride composite material, preparation and application thereof

ActiveCN107634207AReduced responseStable structureMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention discloses a silicon embedded redox graphene / graphite phase carbon nitride composite material, preparation and application thereof. The silicon embedded redox graphene / graphite phase carbon nitride composite material comprises a redox graphene / graphite phase carbon nitride composite matrix serving as the base material, nano-silicon spheres that act as the active centre and are evenlydispersed and embedded in the lamellar gap of the redox graphene / graphite phase carbon nitride composite matrix, and a carbon layer that is located on the surfaces of the nano-silicon spheres and canstrengthen the chemical bonding force between the active centre and the base material. The silicon embedded redox graphene / graphite phase carbon nitride composite material provided by the invention has good electrochemical cycle performance, excellent compatibility and structural stability, can give play to good synergistic effect between the components, also has high batch stability, and is easyfor large-scale production.

Owner:DALIAN MARITIME UNIVERSITY

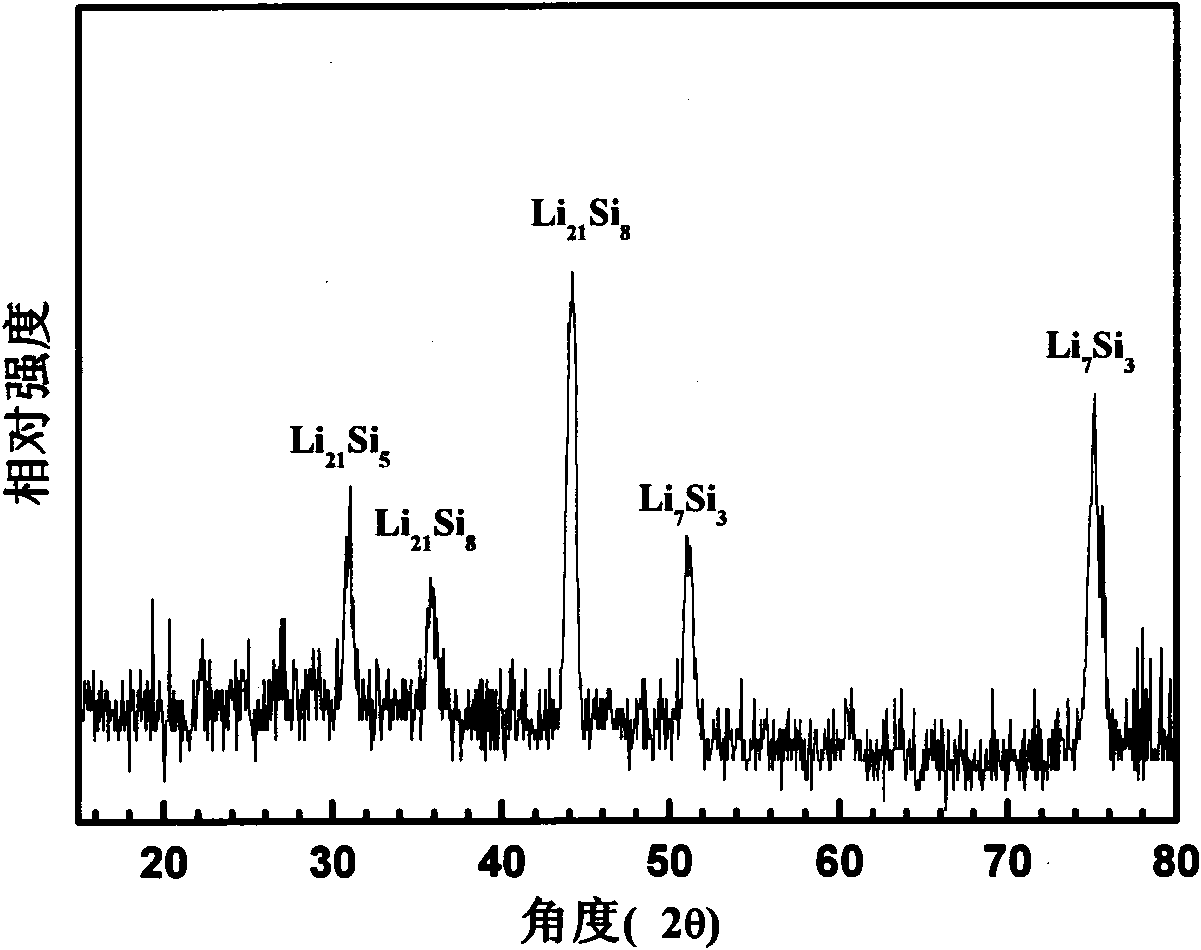

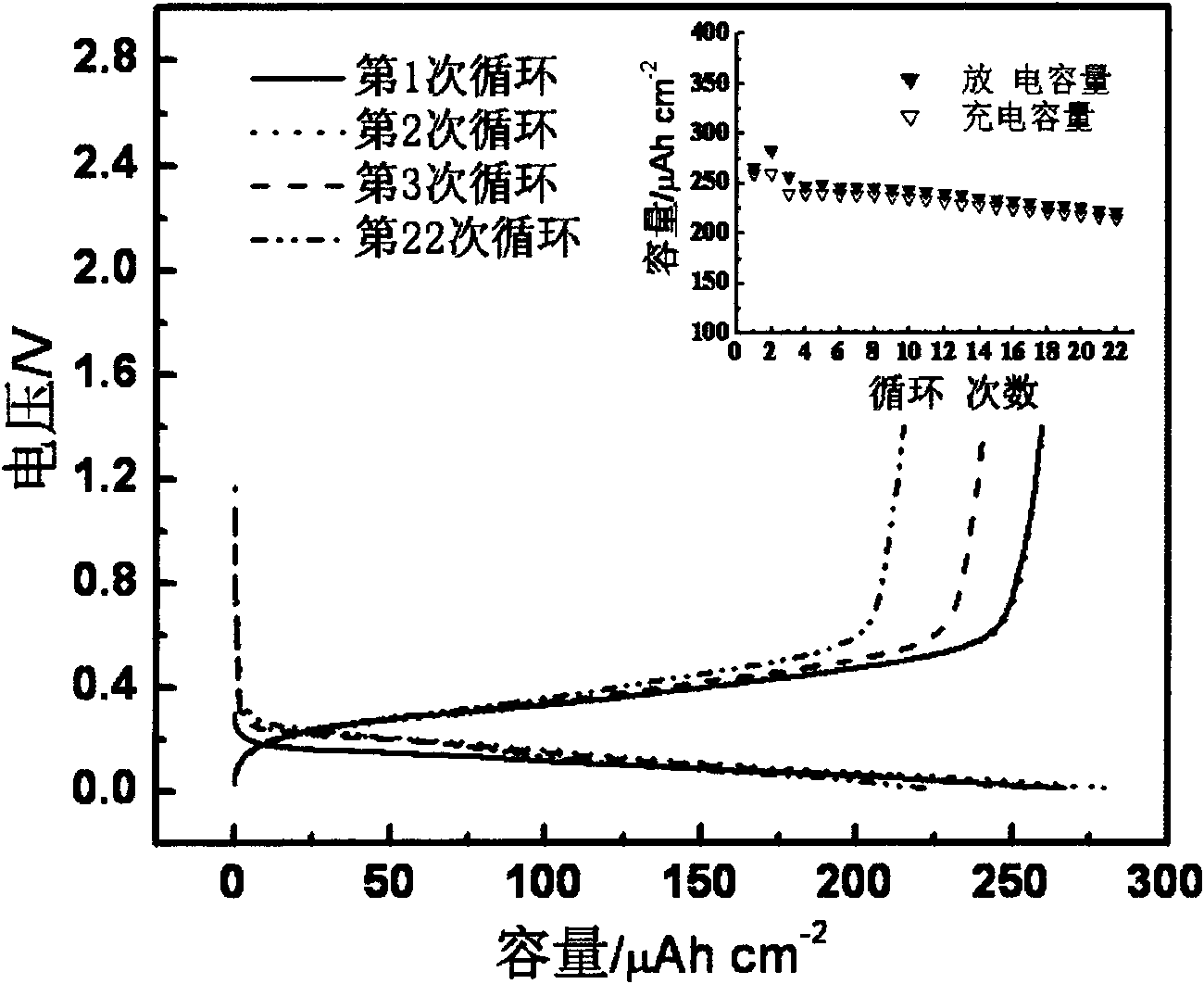

Preparation method of lithium silicon alloy membrane electrode used for lithium ion battery

InactiveCN101667638AEffective regulation of circulation capacityEffective control efficiencyElectrode manufacturing processesSilicon alloyElectrochemistry

The invention discloses a preparation method of lithium silicon alloy membrane electrode used for lithium ion battery. The lithium silicon alloy membrane electrode used for lithium ion battery is obtained by the steps of adopting electrolytic deposition method and multiple current step technology under argon protection, taking anhydrous organic solvent or ionic liquid containing silicon compound and lithium salt as electrolyte and realizing the co-deposition of silicon and lithium through electrochemical reduction on a metal current collector. By changing the composition of the electrolyte andthe parameters of the multiple current step technology, the cycle capacity and primary cycle efficiency of the lithium silicon alloy membrane electrode can be effectively regulated and controlled. The obtained lithium silicon alloy membrane electrode is used as the negative electrode of a lithium ion battery, the primary cycle efficiency is 45.0 percent -150.0 percent, the charge and discharge capacity is 50.0-1000.0MumAh cm<-2> and the cycle stability is good.

Owner:SHANGHAI JIAO TONG UNIV

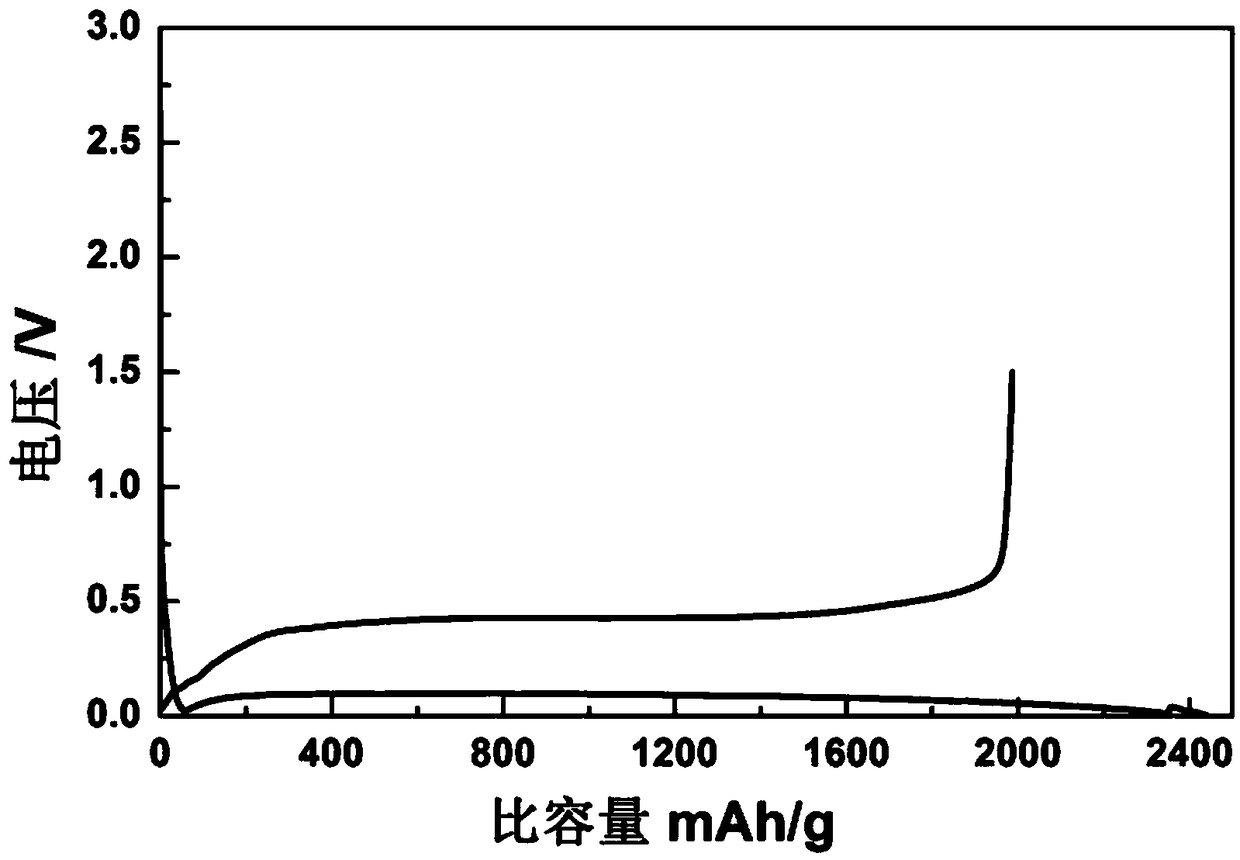

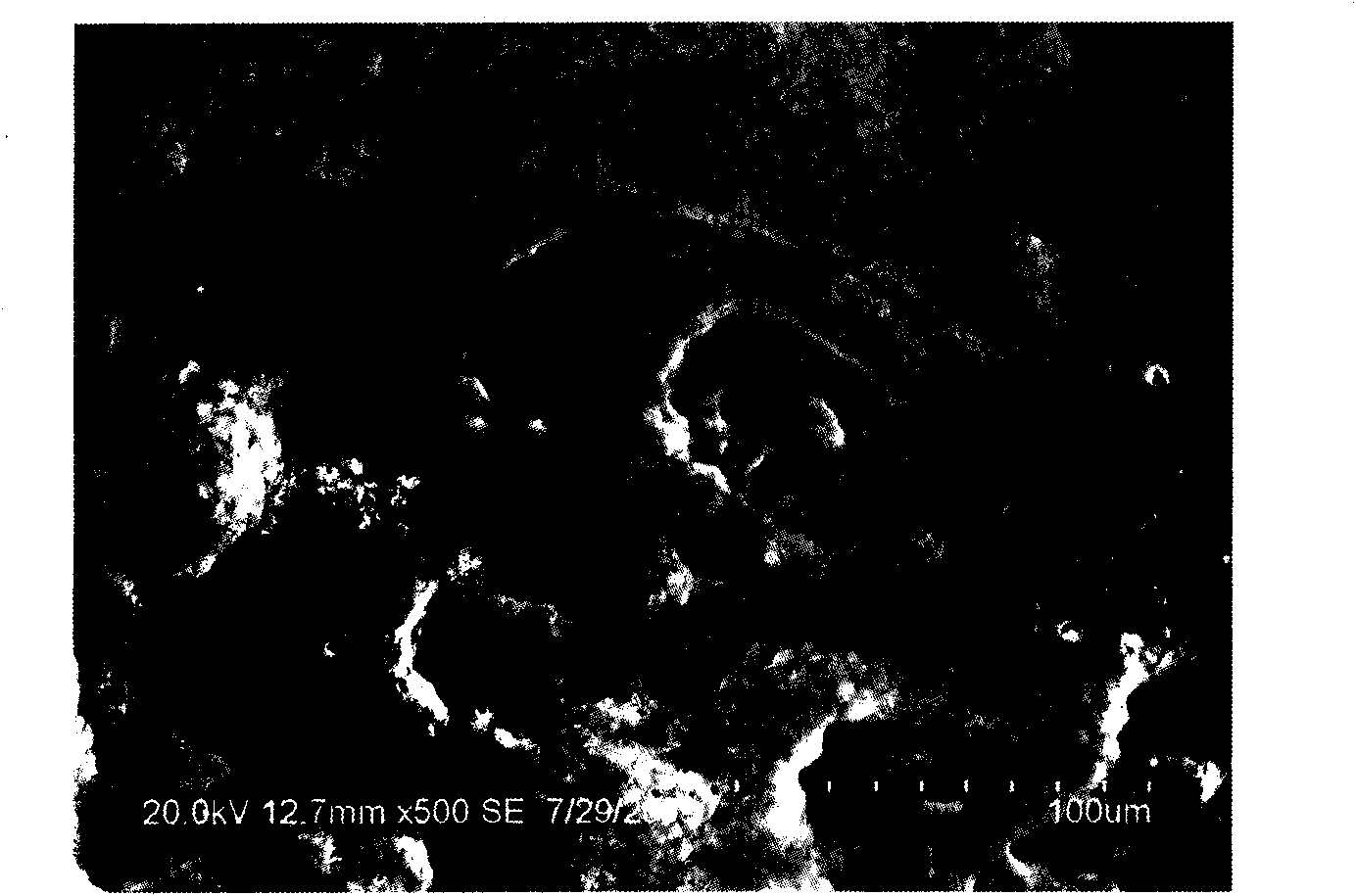

Lithium ion battery silicon-based negative material and preparation method thereof

InactiveCN103236517ASmall particle sizeAlleviate volume effectCell electrodesSilicon monoxideSilicon oxide

The invention relates to a lithium ion battery silicon-based negative material and a preparation method thereof, which belong to the technical field of lithium ion battery negative materials. The lithium ion battery silicon-based negative material is prepared from silicon monoxide; the macroscopic particle diameter of the negative material is 10-25 micrometers; according to a microstructure, the negative material is composed of nanometer silicon particles covered with silica; the internal silicon particle diameter of the negative material is 20-30 nanometers; and at 0.1C discharge rate, the first discharge capacity of the negative material reaches 2010-2640 mAh / g, and is 420-790 mAh / g after 50 cycles. The negative materials with the structure characteristic combines the dispersion and the reduction of silicon particles; and on one hand, the silicon particles can be dispersed by a pore channel structure of silica so as to provide a space for the expansion of silicon in charge and discharge processes, on the other hand, the particle diameter of silicon can be reduced, and therefore, a volume effect of silicon in the charge and discharge processes can be weakened.

Owner:中国东方电气集团有限公司

Anode active material and preparation method and application thereof

ActiveCN111180693AIncrease capacityImprove Coulombic efficiencyCell electrodesSecondary cellsPhysical chemistrySilicon oxide

The invention relates to an anode active material and a preparation method and application thereof. The anode active material includes: silicon oxide particles; and elemental silicon nanoparticles dispersed in the silicon oxide particles, wherein the median particle size of the monatomic silicon nanoparticles is 0.2-20 nm; the silicon oxide particles comprise lithium, the lithium in the silicon oxide particles comprises a lithium silicate compound, and the lithium silicate compound comprises one or more of Li2Si2O5, Li6Si2O7, Li2SiO3, Li8SiO6 and Li4SiO4. The anode active material disclosed bythe invention has the advantages of high capacity and coulombic efficiency, good multiplying power and cycle performance, the low expansion rate and the like when being used in a secondary battery. The preparation method is good in repeatability and high in safety. The secondary battery provided by the invention has the characteristics of high volume energy density, good rate capability, good cycling stability, low expansion rate and the like.

Owner:BERZELIUS (NANJING) CO LTD +1

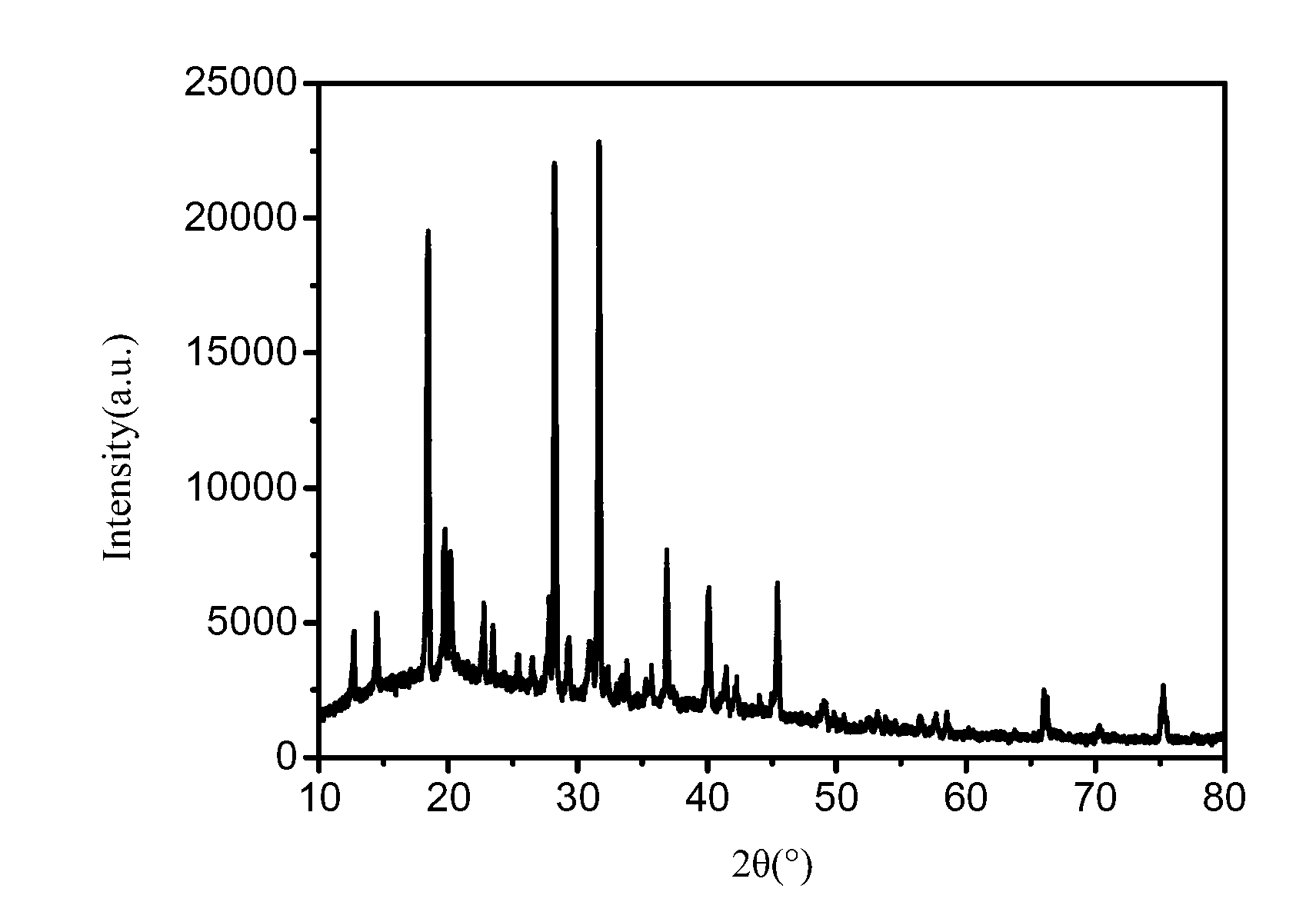

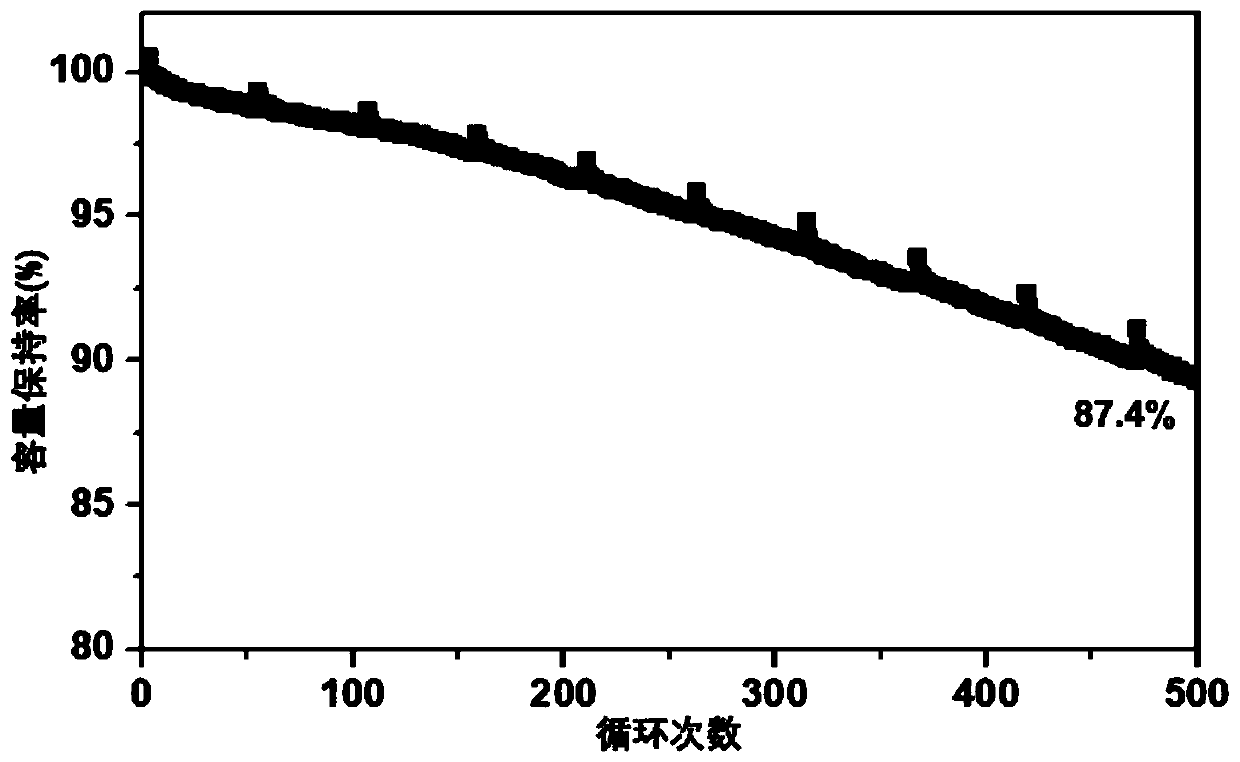

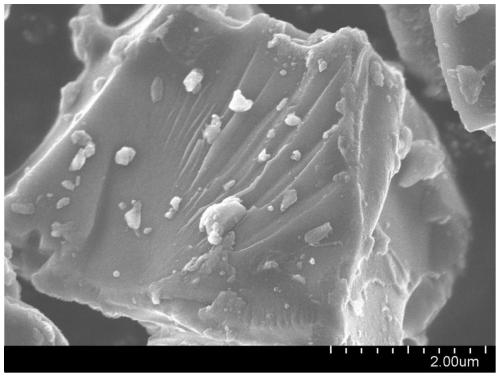

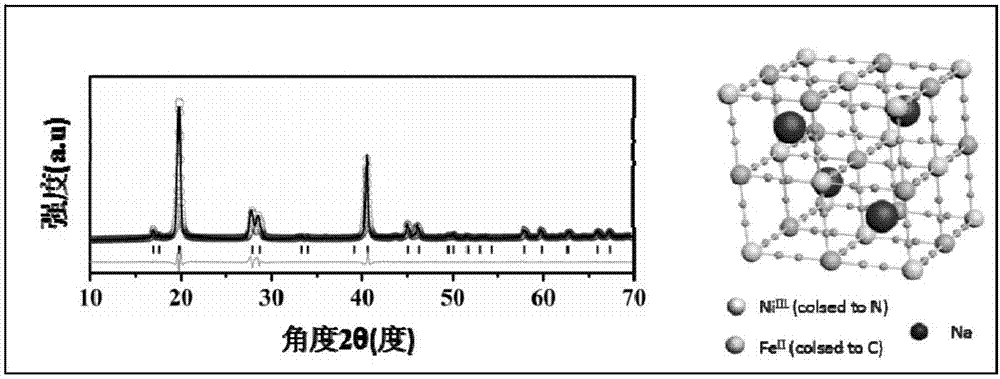

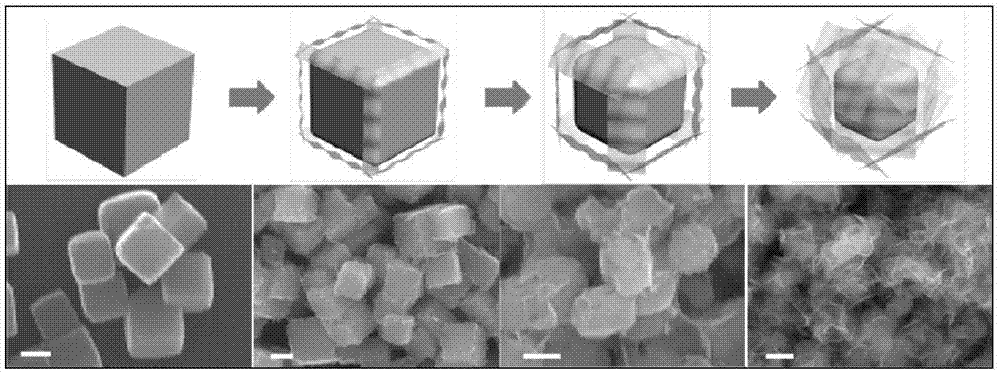

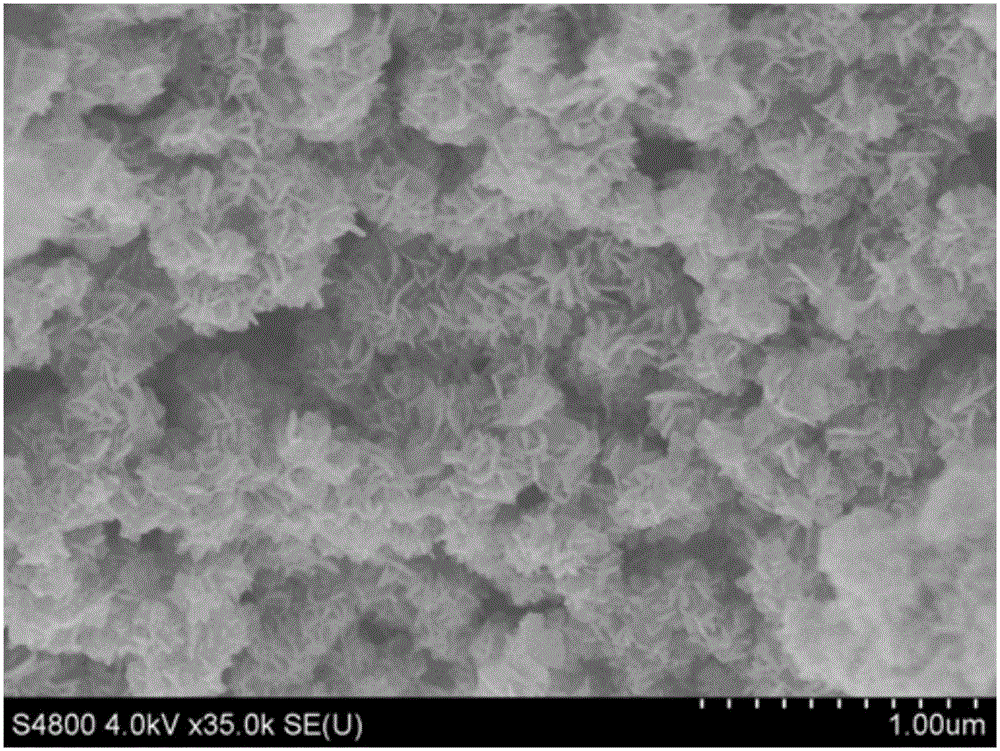

Prussian blue flower-like nano-structure material as well as preparation and application thereof

ActiveCN107082438AAlleviate volume effectImproved magnification performanceIron cyanidesSecondary cellsNano structuringSodium-ion battery

The invention relates to a preparation method of a Prussian blue flower-like nano-structure electrode material. The preparation method comprises the following steps: 1) firstly, dissolving nickel chloride hexahydrate and anhydrous sodium citrate into de-ionized water; 2) dissolving sodium ferrocyanide decahydrate into de-ionized water; 3) pouring a solution of step 2) into a mixed solution obtained by step 1) and uniformly stirring to obtain a mixed solution; 4) standing the mixed solution obtained by step 3); 5) centrifuging and collecting sediment; washing the sediment for several times; drying in vacuum to obtain Prussian blue precursor powder; 6) adding the precursor powder into a sodium hydroxide solution and carrying out ultrasonic treatment; 7) centrifuging and collecting a product and washing; drying in vacuum to obtain light green powder, namely the Prussian blue flower-like nano-structure electrode material. The preparation method provided by the invention has the beneficial effects that the specific surface area is remarkably enlarged so that reaction sites of electrolyte and the electrode material are effectively increased and an ion diffusion distance is reduced; when the Prussian blue flower-like nano-structure electrode material is used as a positive electrode active material of a sodium ion battery, the material has the characteristics of high power and good cycling stability.

Owner:WUHAN UNIV OF TECH

Polymer and nanometer sulfur composite material with shell and egg yolk structure and preparation method

ActiveCN106602019AShorten the transmission distanceAvoid reunionMaterial nanotechnologyCell electrodesLithium–sulfur batterySulfur

The invention relates to a polymer and nanometer sulfur composite material with a shell and egg yolk structure and a preparation method of the composite material. The composite material is provided with the shell and egg yolk double-layer structure, a central nucleus is formed by sulfur particles, an outer shell is formed by a polymer, a gap is preserved between the central nucleus and the shell, so that the double-layer structure like an egg shell and an egg yolk is formed; elemental sulfur is shrunk in the process that the temperature is quickly changed by using the change of crystal form and the change of density in different temperatures, and the elemental sulfur is partially dissolved and separated out by using a solvent, so that the composite material of the shell and egg yolk structure is formed. The composite material of the structure is applicable to cathodes of lithium sulfur batteries, structure collapse caused by volume expansion in the discharge process of the elemental sulfur is relieved, the dissolution and loss of discharge products are inhibited, and the electrical conductivity and circularity of the material are improved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Iron-based sulfide electrode material, preparation method and application in solid state battery

ActiveCN106784815AImprove electrochemical performanceIncrease energy densityMaterial nanotechnologyCell electrodesIron(II,III) sulfideSolid-state battery

The invention provides an iron-based sulfide electrode material, a preparation method and application in a solid state battery, and belongs to the technical field of secondary lithium batteries. The iron-based sulfide electrode material which is based on conversion reaction is selected from one or more of ferrous sulfide, ferriferous sulfide and hepta-ferous octa-sulfide. The preparation method of the iron-based sulfide electrode material has the advantages of being simple and short in time.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Lithium ion battery silicon cathode material and preparation method thereof

ActiveCN102709563AAlleviate volume effectFacilitates nanodispersionCell electrodesCopper foilSODIUM SILICATE SOLN

The invention discloses a lithium ion battery silicon cathode material and a preparation method thereof. The cathode material comprises nanometer silicon powder and a coating layer coated on the surface of the nanometer silicon powder. Grain diameter of the nanometer silicon powder ranges from 0.1 nanometer to 10 micrometers and the coating layer is a layer of silicon dioxide with thickness ranging from 1 nanometer to 1 micrometer. The preparation method for the lithium ion battery silicon cathode material includes: (1) fully dispersing the nanometer silicon powder in sodium silicate solution; (2) adding graphite conducting material and mineral acid into the mixed solution obtained in the step (1) for fully stirring and precipitating; (3) applying the precipitate obtained in the step (2) after being washed on a copper foil surface, and drying the copper foil surface applied with the precipitate at the temperature of 150 DEG C. Active silica in the lithium ion battery silicon cathode material is enabled to exert a larger capacity, and the lithium ion battery silicon cathode material is good in cycle performance simultaneously.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

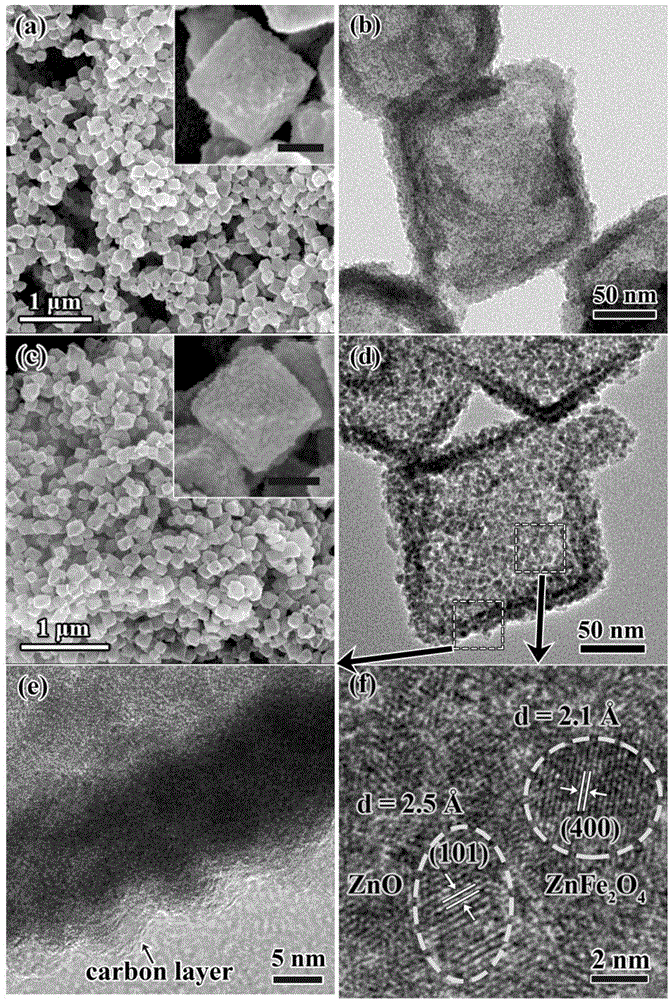

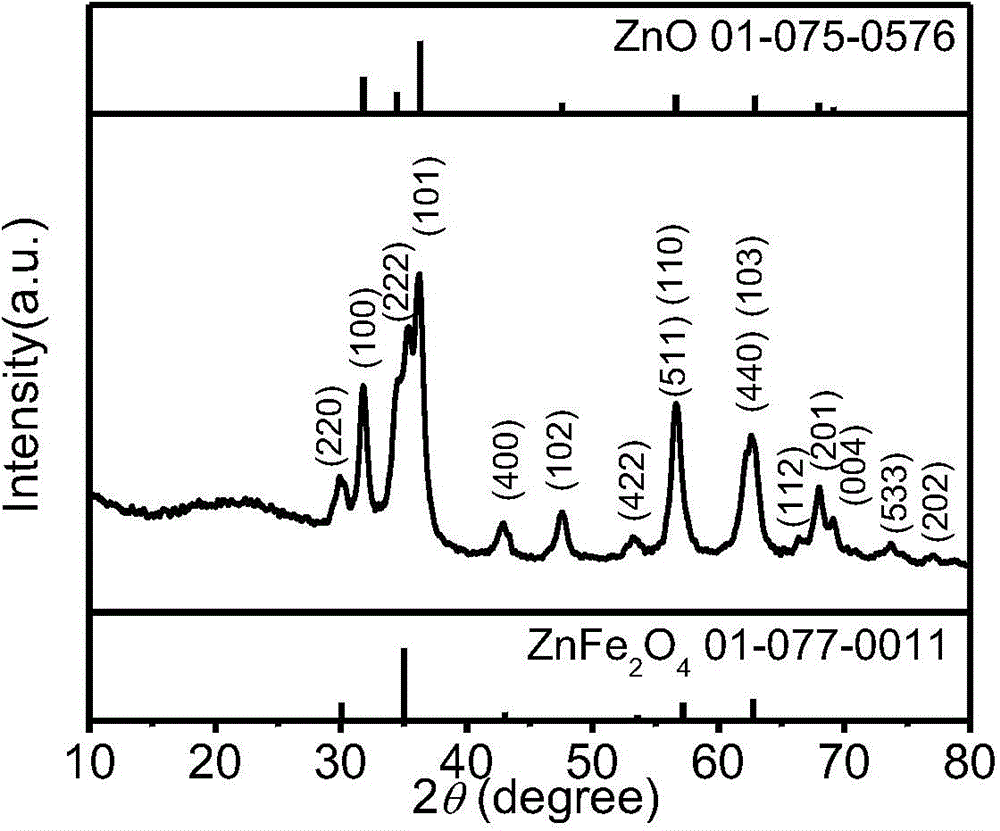

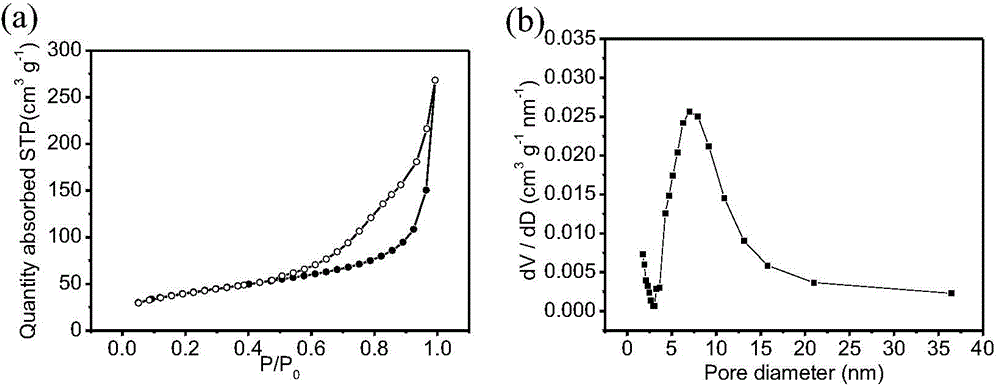

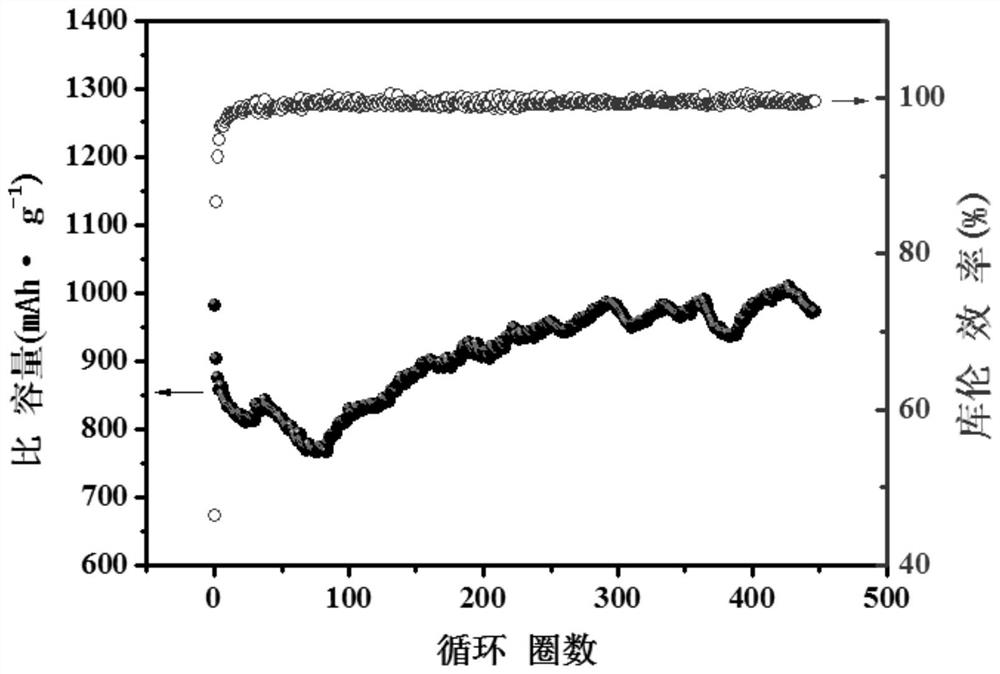

Negative electrode material and preparation method and application of negative electrode material

ActiveCN104157853AHigh specific capacityGood magnification performanceMaterial nanotechnologyCell electrodesComposite oxideZinc ferrite

Owner:HUAZHONG UNIV OF SCI & TECH

Nanometer lignin carbon-zinc oxidecomposite material as well as preparation method and application thereof

ActiveCN112072085AInhibition of volume expansionImprove conductivityMaterial nanotechnologyHybrid capacitor electrodesCarbon layerLithium-ion battery

The invention discloses a nanometer lignin carbon-zinc oxidecomposite material as well as a preparation method and application thereof. The method comprises the following steps: (1) dissolving ligninin an alkaline solution, carrying out hydrothermal pretreatment, conducting cooling, and adjusting a pH value to 3-5 to obtain an acid-soluble lignin solution; (2) adding a mixed solution of soluble zinc salt and soluble carbonate into the acid-soluble lignin solution, conducting a hydrothermal reaction, then adding aldehydes, and continuing the hydrothermal reaction to obtain a ploycondensed lignin / zinc oxide compound; and (3) carbonizing the polycondensed lignin / zinc oxide compound to obtain the nanometer lignin carbon-zinc oxidecomposite material. In the obtained nanometer lignin carbon-zinc oxidecomposite material, lignin carbon uniformly coats the surfaces of zinc oxide particles to form a uniform carbon layer with a continuous structure, so the problems of serious volume expansion and poor conductivity of zinc oxide serving as a lithium ion negative electrode material are solved, and the specific capacity, the initial coulombic efficiency and the rate capability of a lithium ionbattery are improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com