Carbon-carbon multi-component negative electrode material and preparation method thereof

A negative electrode material and multi-component composite technology, which is applied in the field of negative electrode materials for lithium ion batteries and their preparation, can solve the problems of low capacity, mechanical pulverization, poor cycle performance, etc. poor rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] The preferred embodiment of the present invention is as follows:

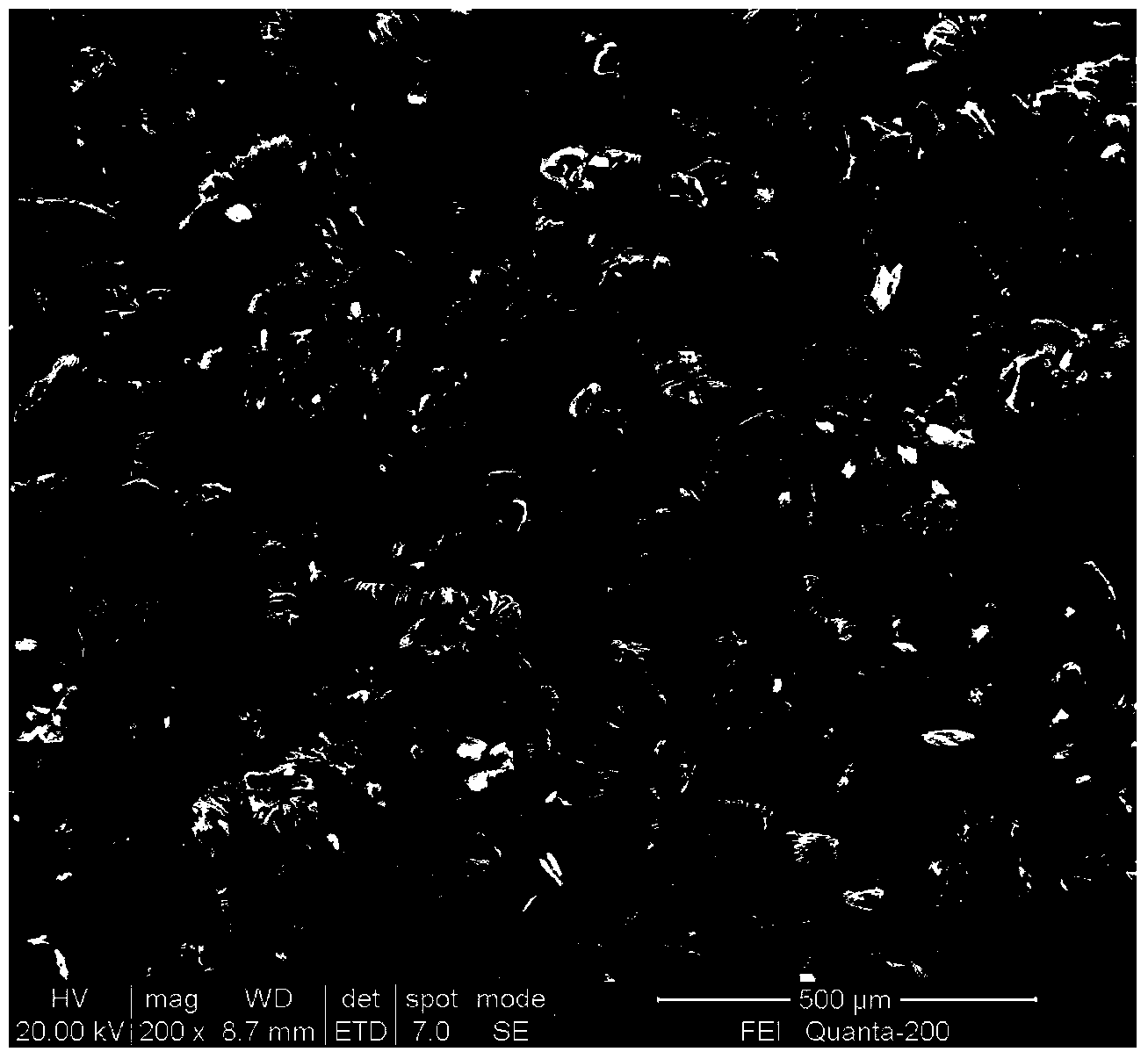

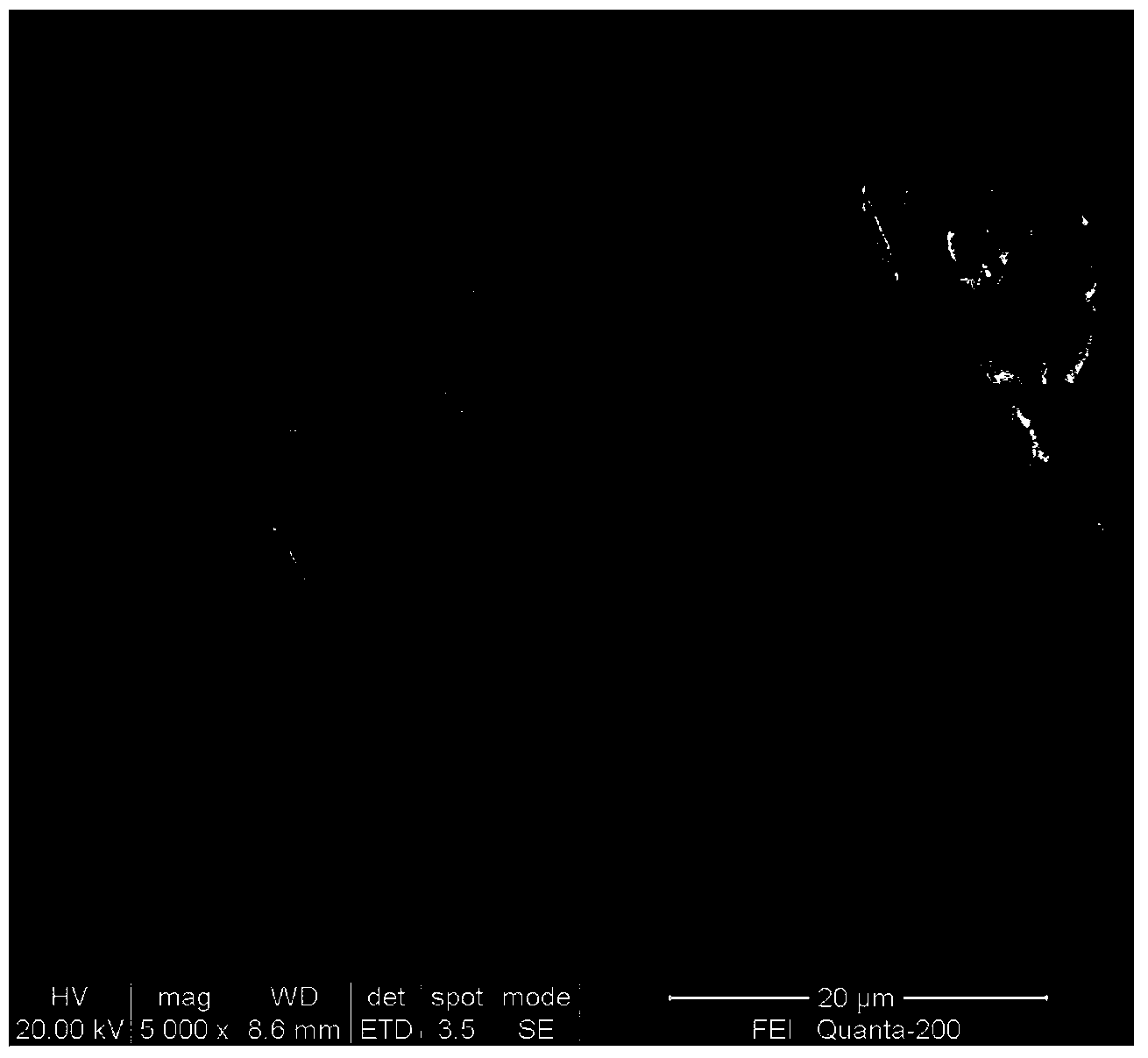

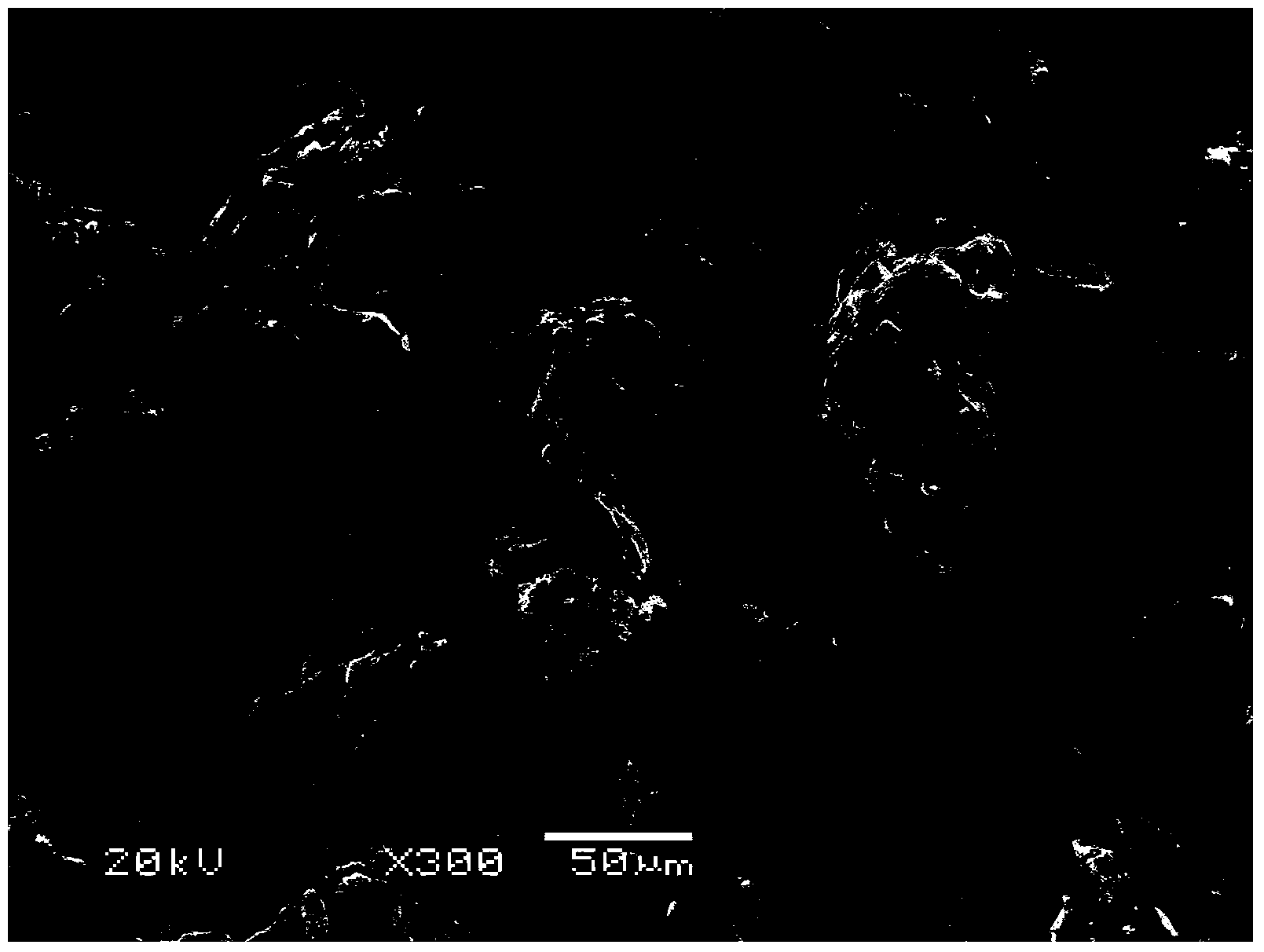

[0031] A silicon-carbon multi-component composite negative electrode material, which is mainly composed of flexible graphite, nano-silicon and amorphous carbon, wherein the mass fractions of flexible graphite, nano-silicon and amorphous carbon in the silicon-carbon multiple-component composite negative electrode material are respectively It is: 30%-60%, 30%-50% and 10%-30%; and the amorphous carbon is mainly obtained after high-temperature pyrolysis of the organic carbon source, and the flexible graphite is mainly obtained by applying pressure to the expanded graphite; its preparation The method includes the following steps:

[0032] (1) Preparation of expanded graphite: first, potassium dichromate is dissolved in concentrated sulfuric acid with a mass fraction ≥ 98%, the mass ratio of potassium dichromate to concentrated sulfuric acid is controlled to be 1:5 to 1:27, and in a beaker Stir continuously; ...

Embodiment 1

[0038] A silicon-carbon multi-component composite negative electrode material, which is mainly composed of flexible graphite, nano-silicon and amorphous carbon, wherein the mass fractions of flexible graphite, nano-silicon and amorphous carbon in the silicon-carbon multiple-component composite negative electrode material are respectively They are: 40%, 30% and 30%; and the amorphous carbon is mainly obtained after high-temperature pyrolysis of an organic carbon source, and the flexible graphite is mainly obtained by applying pressure to expanded graphite.

[0039] The preparation method of the silicon-carbon multi-component composite negative electrode material in this embodiment specifically includes the following steps:

[0040] (1) The preparation of expanded graphite: at first potassium dichromate is dissolved in the concentrated sulfuric acid of 98% by mass fraction, the mass ratio of potassium dichromate and the concentrated sulfuric acid is controlled as 1: 5, and consta...

Embodiment 2

[0047] A silicon-carbon multi-component composite negative electrode material, which is mainly composed of flexible graphite, nano-silicon and amorphous carbon, wherein the mass fractions of flexible graphite, nano-silicon and amorphous carbon in the silicon-carbon multiple-component composite negative electrode material are respectively They are: 30%, 50% and 20%; and the amorphous carbon is mainly obtained after high-temperature pyrolysis of the organic carbon source, and the flexible graphite is mainly obtained by applying pressure to expanded graphite.

[0048] The preparation method of the silicon-carbon multi-component composite negative electrode material in this embodiment specifically includes the following steps:

[0049] (1) The preparation of expanded graphite: at first potassium dichromate is dissolved in the concentrated sulfuric acid that mass fraction is 98%, the mass ratio control of potassium dichromate and the concentrated sulfuric acid is 1: 27, and constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com