Patents

Literature

273 results about "Lithium ion intercalation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

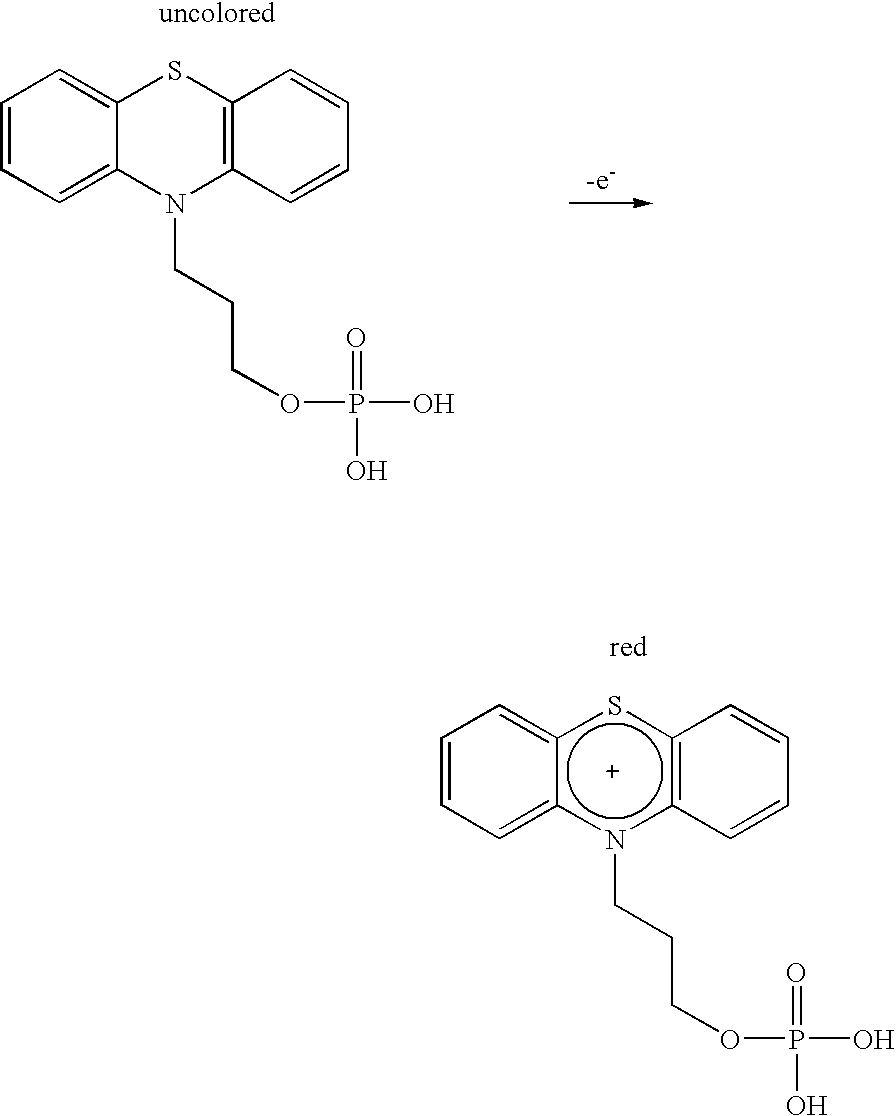

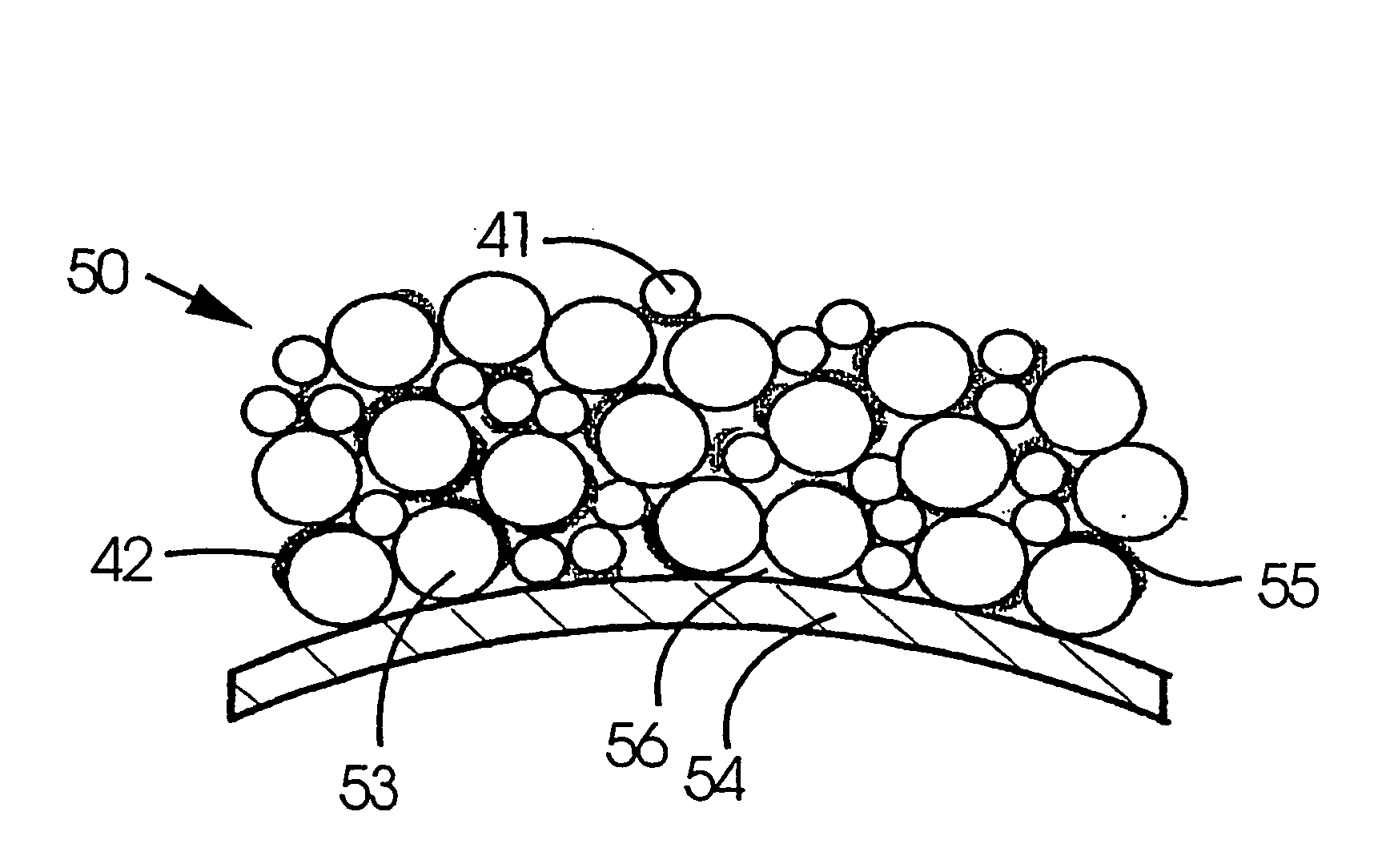

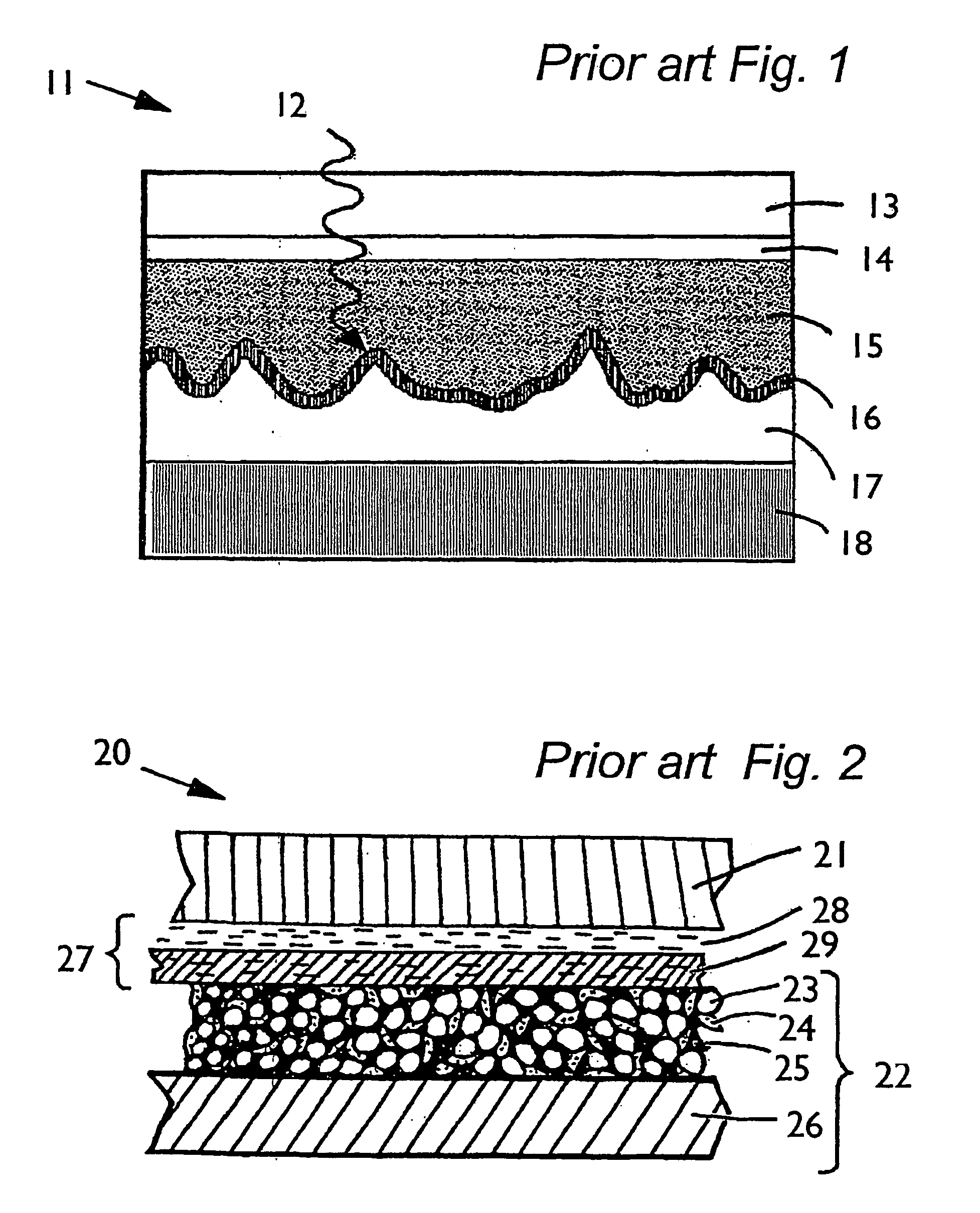

Mesoporous network electrode for electrochemical cell

InactiveUS20040131934A1Simplifies production of cellFull penetrationMaterial nanotechnologyElectrode manufacturing processesLithiumNanoparticle

A high kinetics rate electrochemical cell in which at least one of the electrodes is composed of a mesostructural electroactive material comprising nanoparticles forming a three-dimensional framework structure of mesoporous texture having a bicontinuous junction of large specific surface area with the electrolyte. A low temperature method of preparation of the electrodes employs a high-speed deposition of the electrically active material in the form of a thin film. The application of said electrodes in high power lithium ion insertion batteries, photovoltaic cells, supercapacitors and fast electrochromic devices is disclosed.

Owner:FRANCOIS SUGNAUX

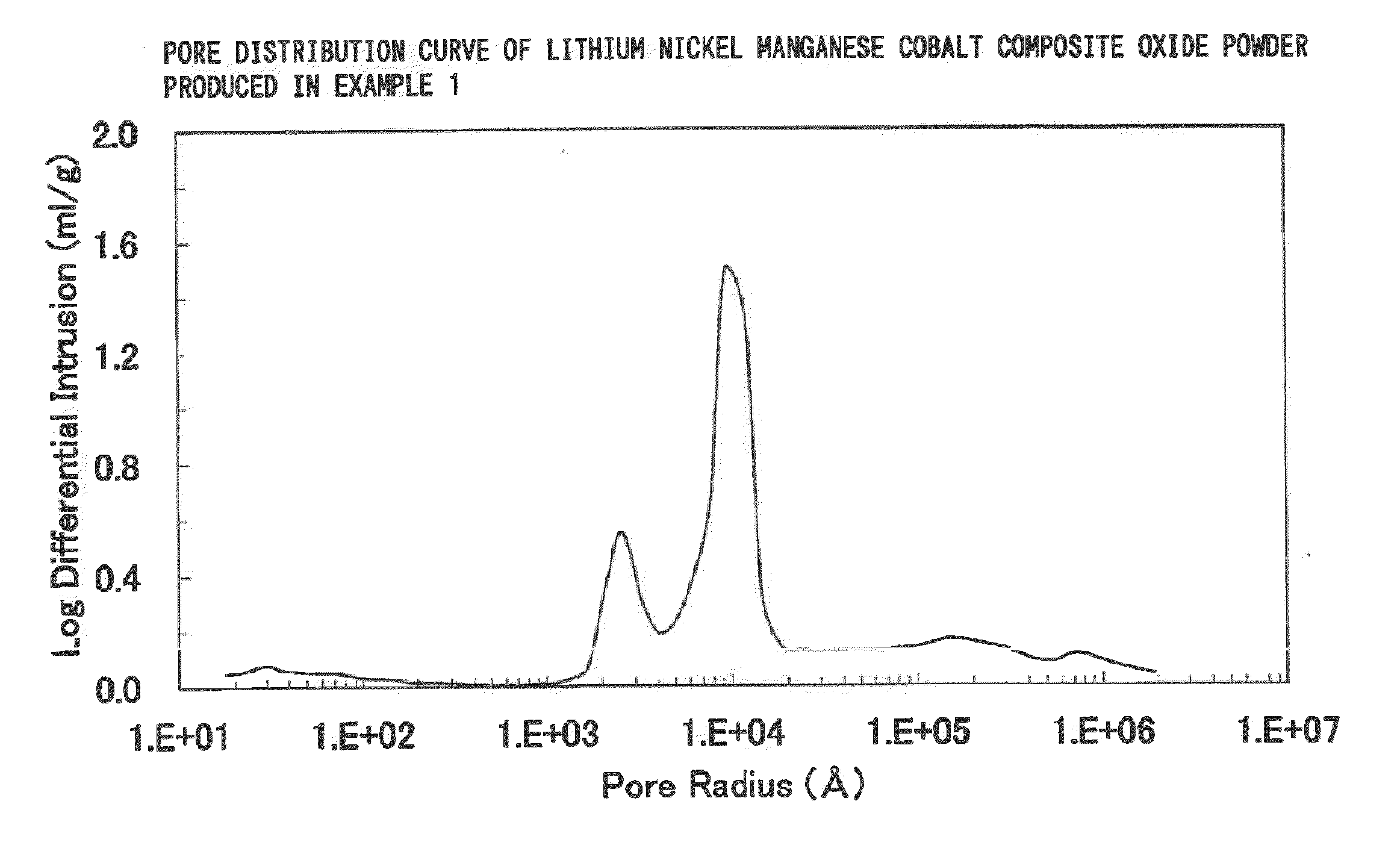

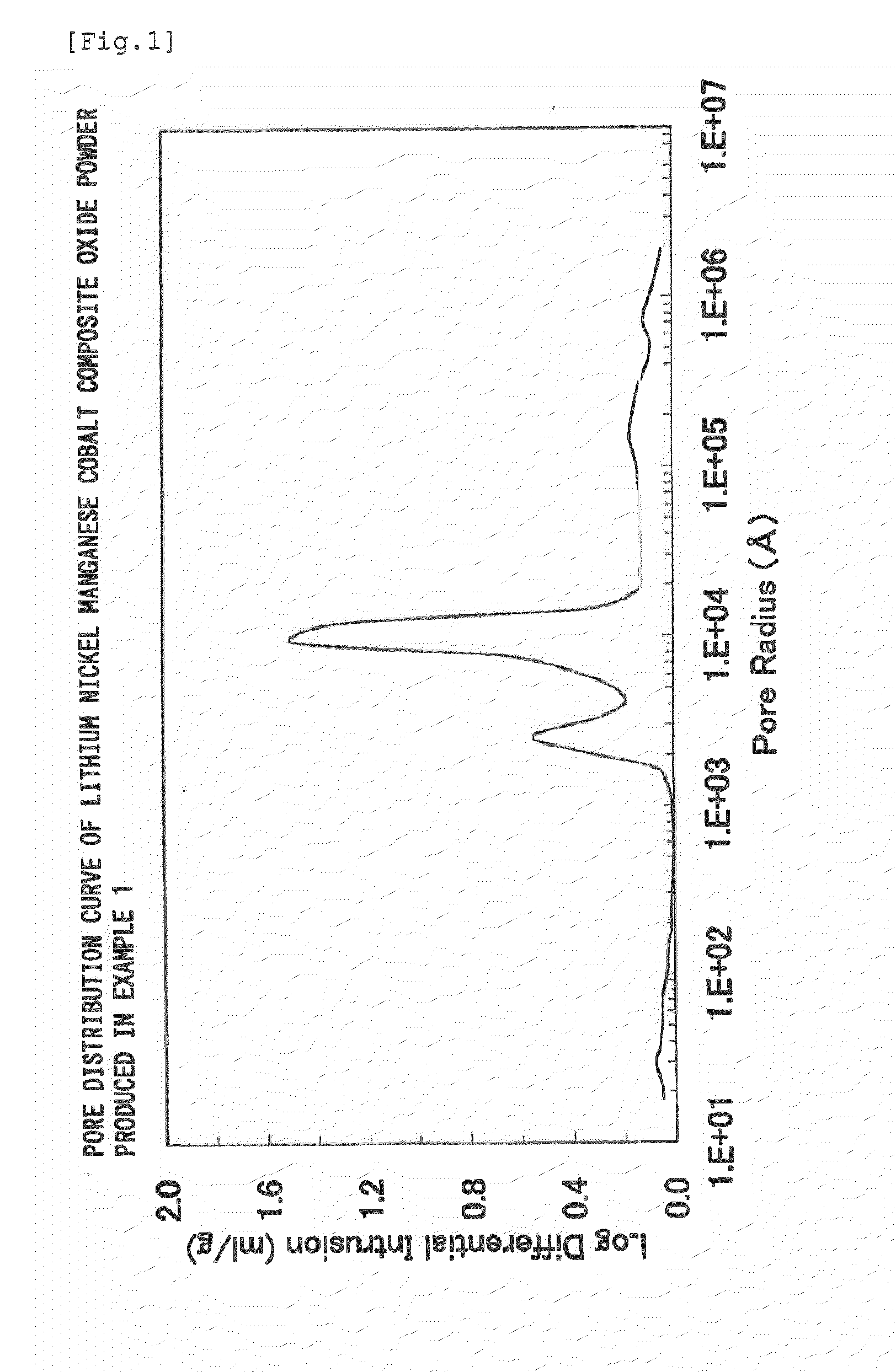

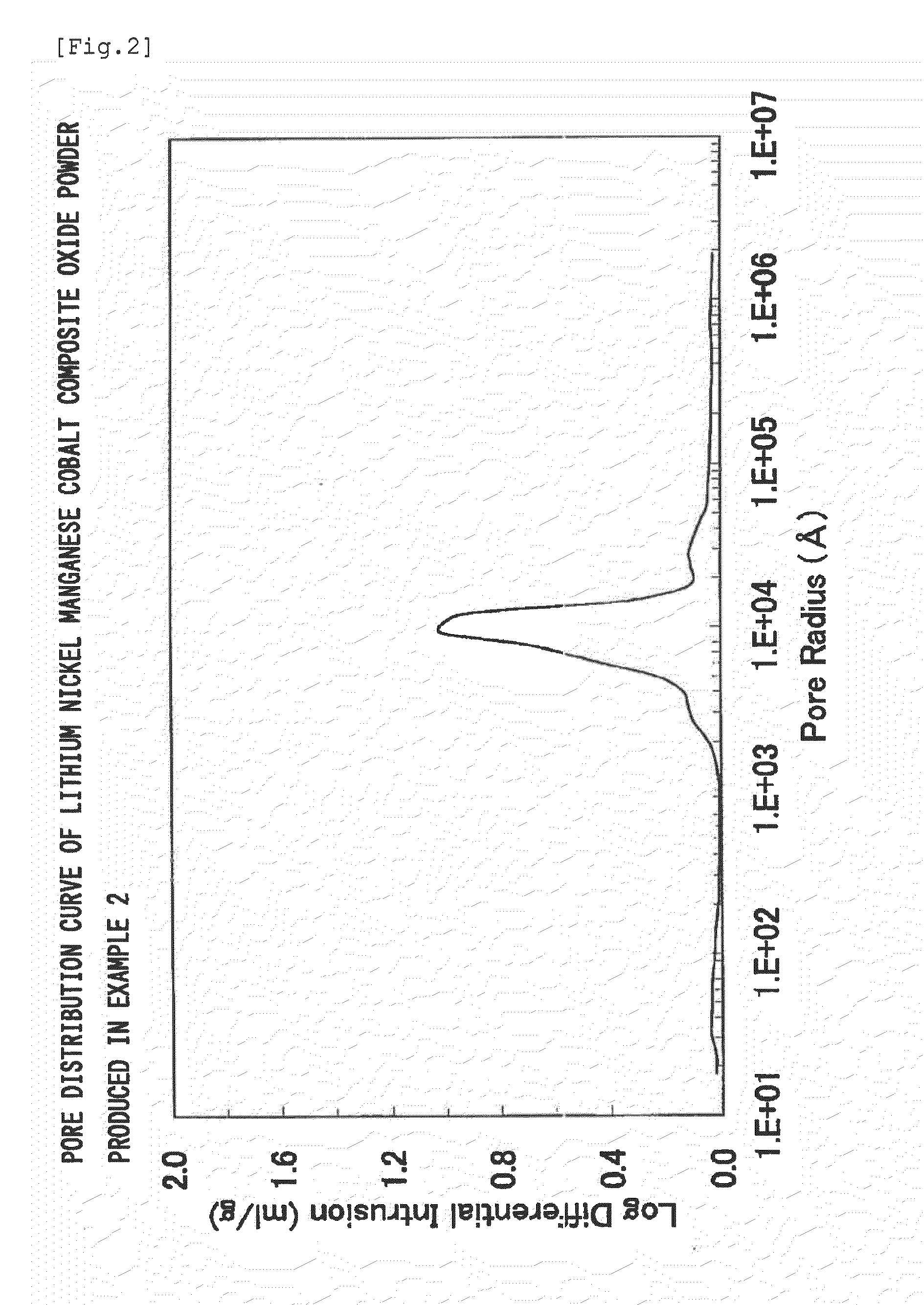

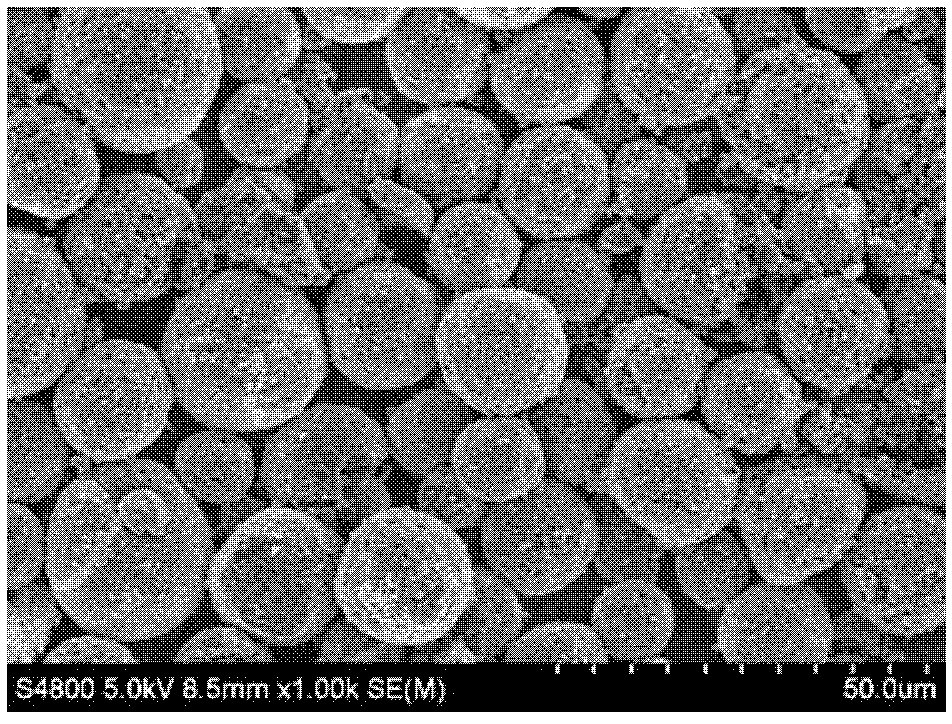

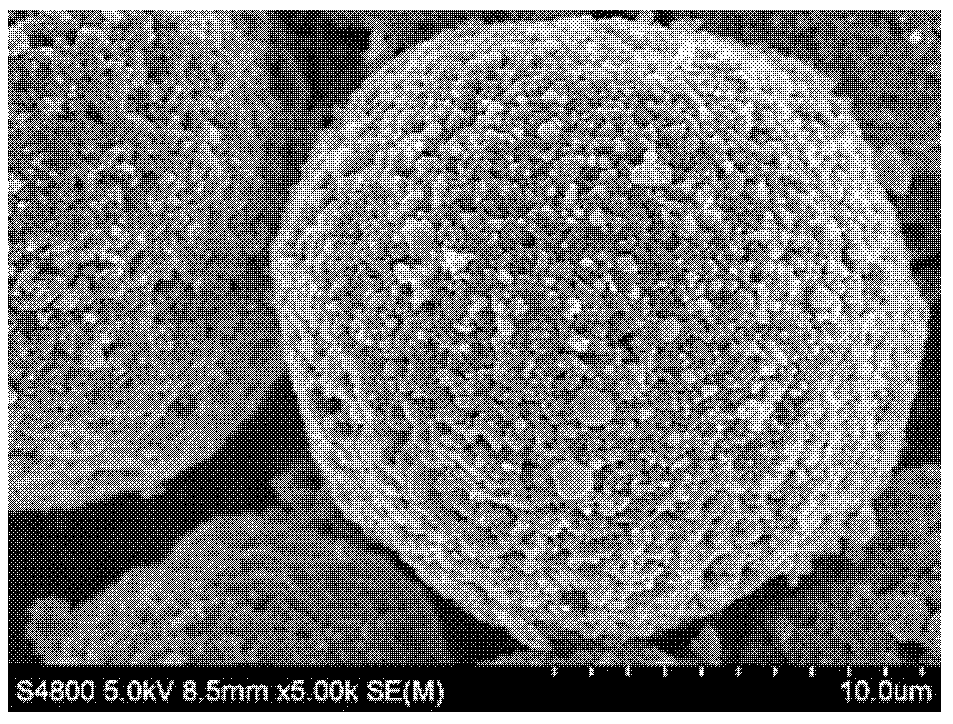

Lithium transition metal based compound powder, method for manufacturing the same, spray-dried substance serving as firing precursor thereof, lithium secondary battery positive electrode by using the same, and lithium secondary battery

InactiveUS20110003200A1Improve securityImprovement in powder handleabilityFinal product manufactureElectrode carriers/collectorsPhysical chemistryLithium-ion battery

A lithium transition metal based compound powder for a lithium secondary battery positive electrode material, characterized by including a lithium transition metal based compound, which has a function of enabling insertion and elimination of lithium ions, as a primary component and being produced by conducting firing after at least one type of compound (hereafter referred to as “Additive 1”) containing at least one type of element (hereafter referred to as “Additive element 1”) selected from B and Bi and at least one type of compound (hereafter referred to as “Additive 2”) containing at least one type of element (hereafter referred to as “Additive element 2”) selected from Mo and W are added in combination to a raw material of the primary component at a ratio of a total of Additive 1 and Additive 2 to a total amount of moles of transition metal elements in the raw material of the primary component of 0.01 percent by mole or more, and less than 2 percent by mole.

Owner:MITSUBISHI CHEM CORP

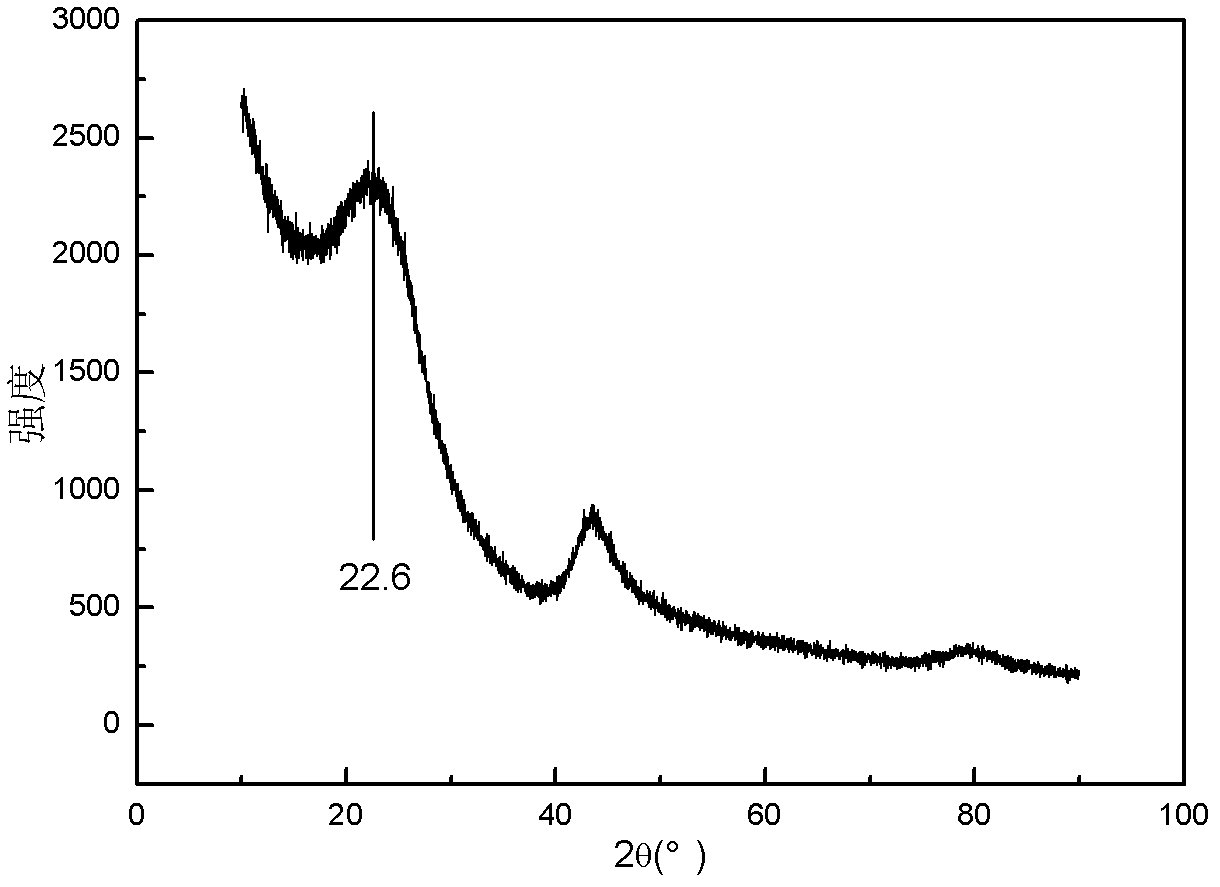

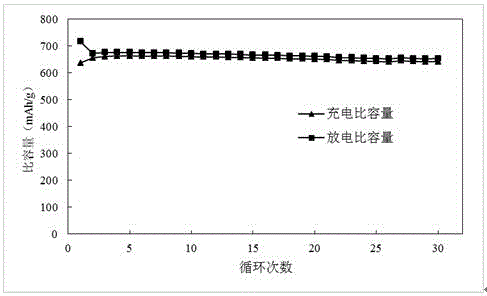

Spherical hard carbon lithium ion battery cathode material and preparation method thereof

The invention discloses a spherical hard carbon lithium ion battery cathode material and a preparation method thereof, aiming to solve the technical problem of improving the capacity retention ratio and rapid charging / discharging capacity of the material. The spherical hard carbon lithium ion battery cathode material adopts hard carbon as a basal body, carbon material is coated outside the basal body, and the 002 peak is at 22.6-23.8 degrees. The preparation method comprises ball milling a hard carbon precursor to granules, placing the granules into a water solution containing surfactant, ball milling to obtain a dispersion of the hard carbon precursor, drying, coating, and carrying out pyrolytic decomposition treatment. Compared with the prior art, the prepared spherical hard carbon material has a compacted density greater than 1.1 g / cm<3>, an initial coulombic efficiency greater than 80%, capacity retention ratio after 500 cycles greater than 85%, and 30C / 1C capacity retention ratiogreater than 98%, and has excellent rapid lithium ion intercalation and deintercalation capacity, and simple preparation method.

Owner:JIXI BTR GRAPHITE IND PARK CO LTD +3

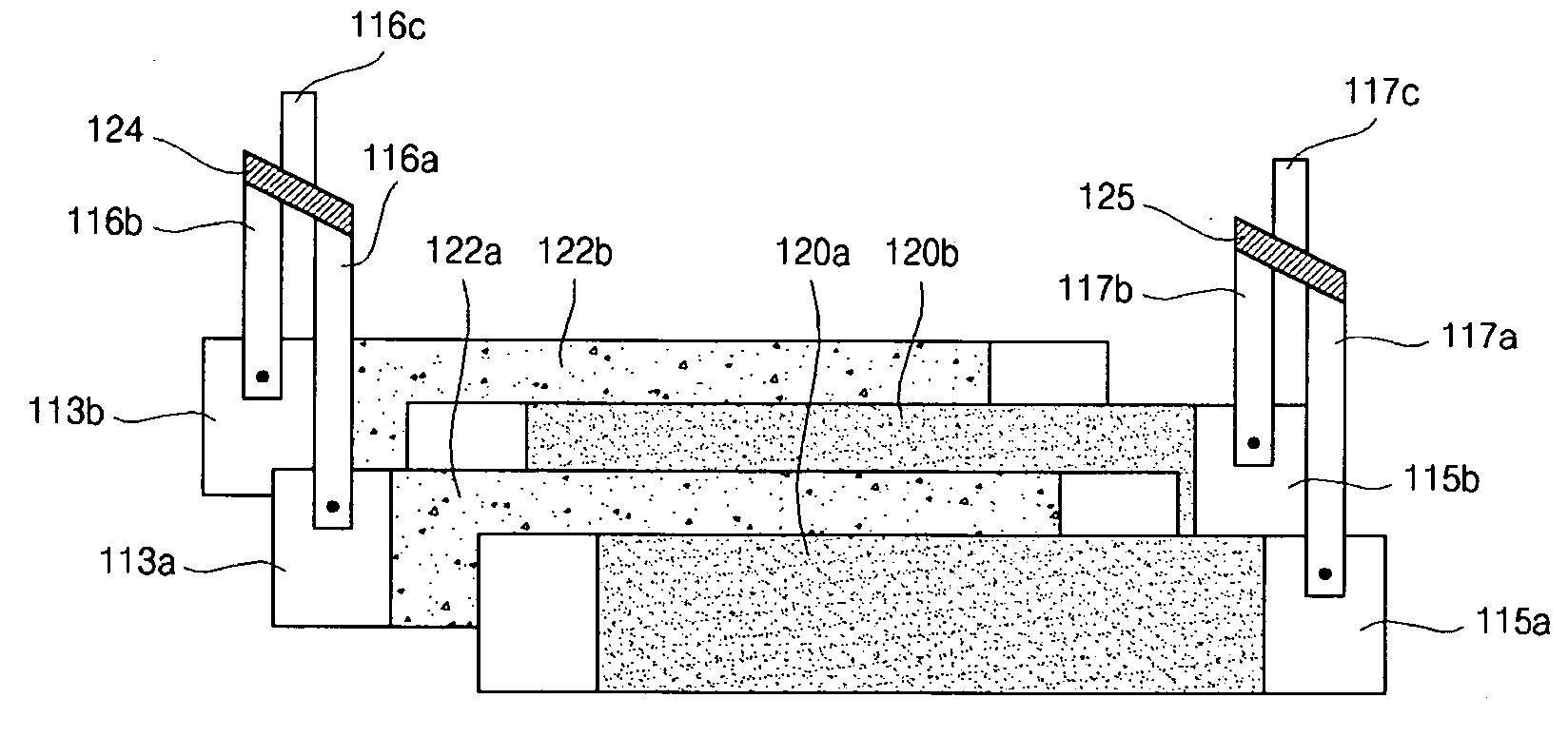

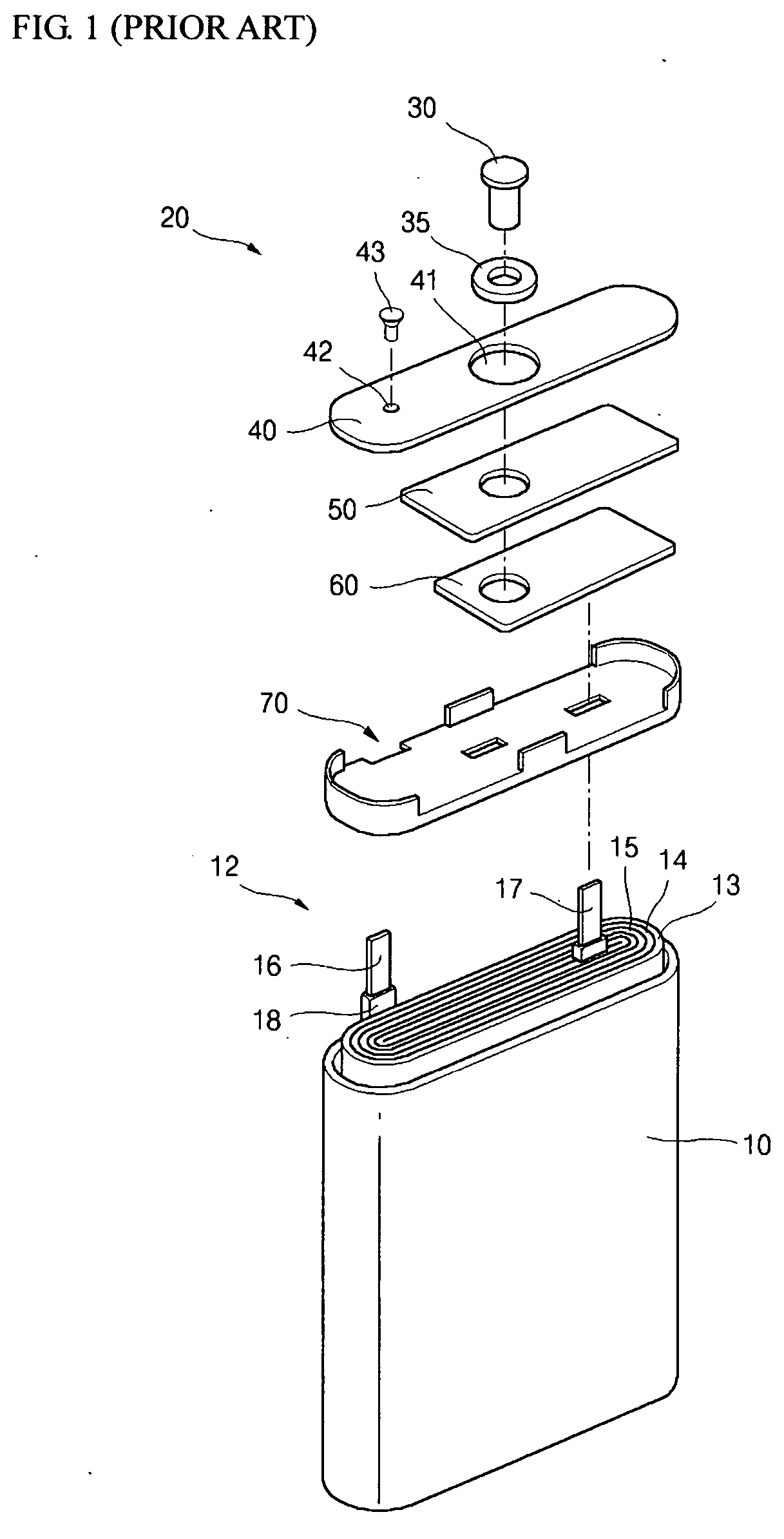

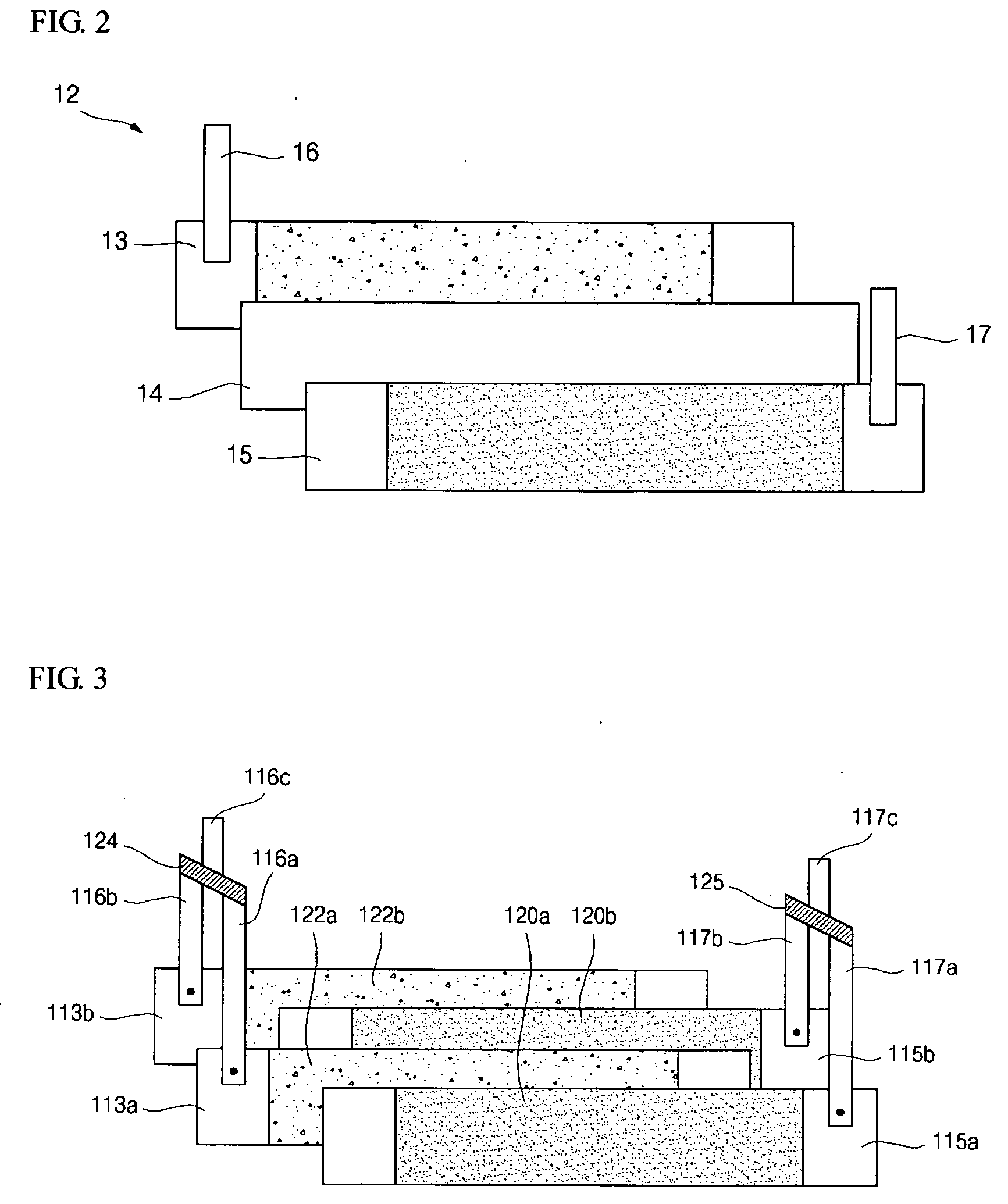

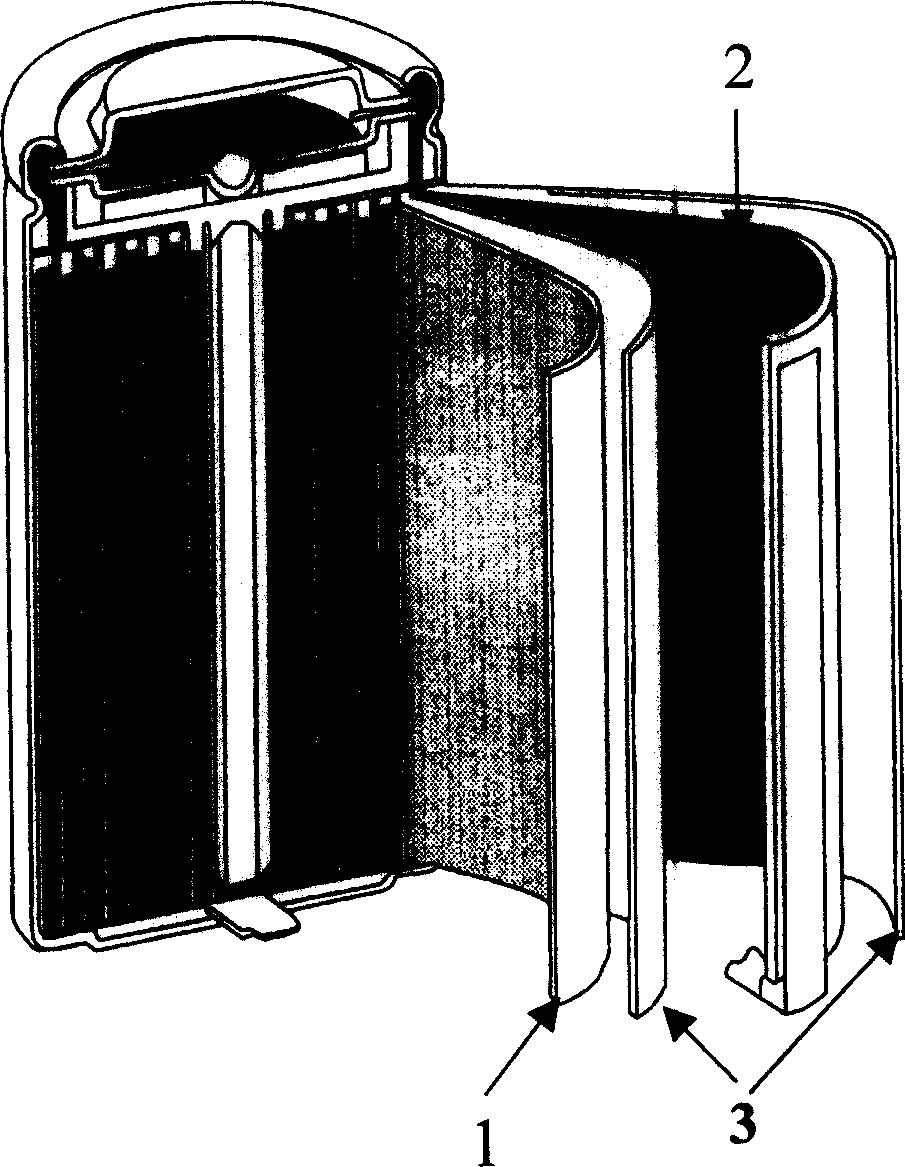

Lithium rechargeable battery

InactiveUS20060127751A1Charge-discharge efficiency can be improvedLower internal resistanceFinal product manufactureElectrode carriers/collectorsEngineeringElectrode pair

A lithium rechargeable battery with an electrode assembly comprising at least two positive electrode plates with electrode tabs coupled to each positive electrode plate, at least two negative electrode plates with electrode tabs coupled to each negative electrode plate, separators interposed between each positive and negative electrode pair, and the electrode assembly being formed by winding a layered structure of the electrode plates and separators into a jelly roll shape. The electrode plates are partially coated with electrode active material capable of reversible lithium ion intercalation and de-intercalation. The tabs coupled to the positive electrode plates are coupled with a first terminal of the battery, and the tabs coupled to the negative electrode plates are coupled with a second terminal of the battery.

Owner:SAMSUNG SDI CO LTD

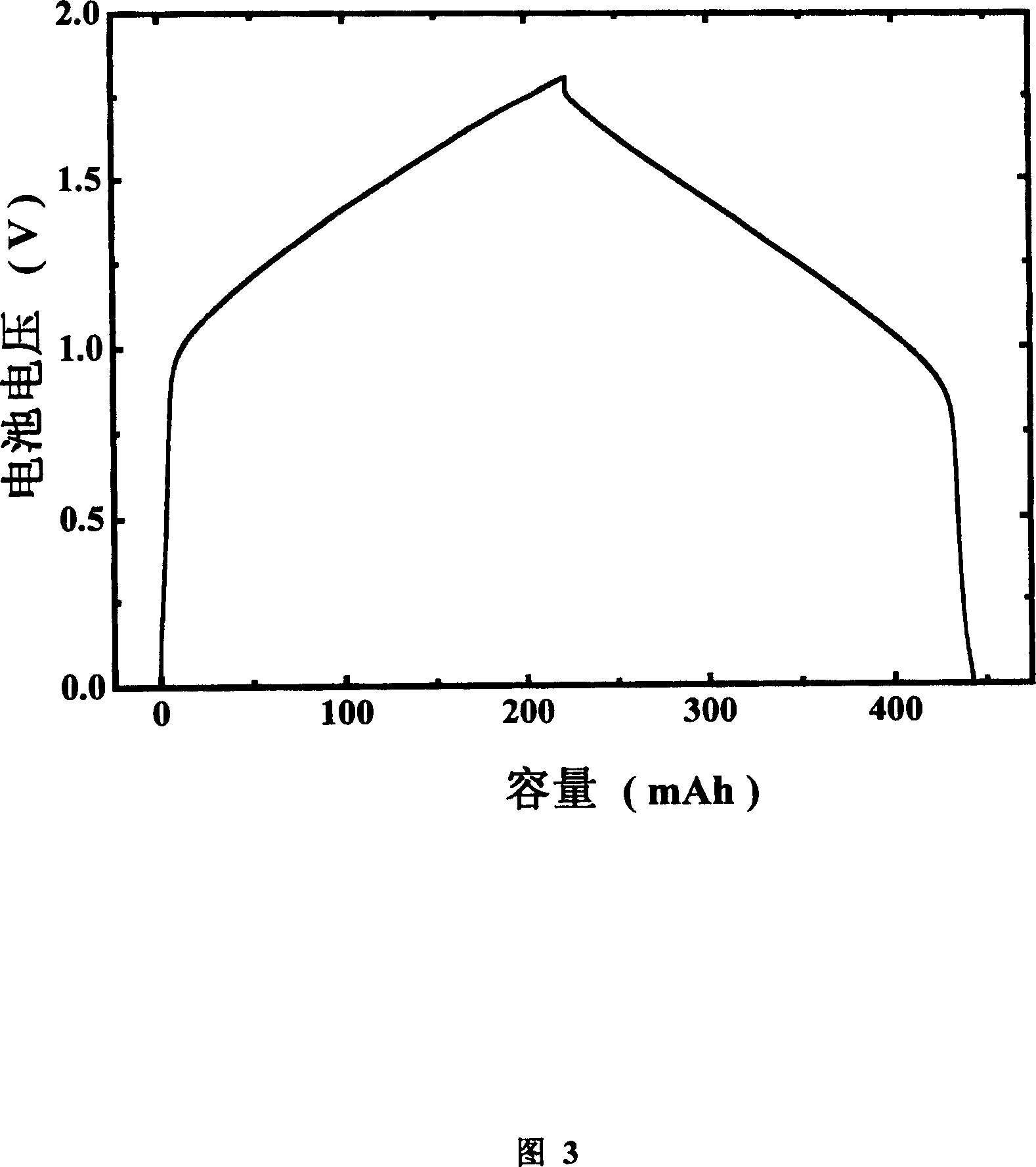

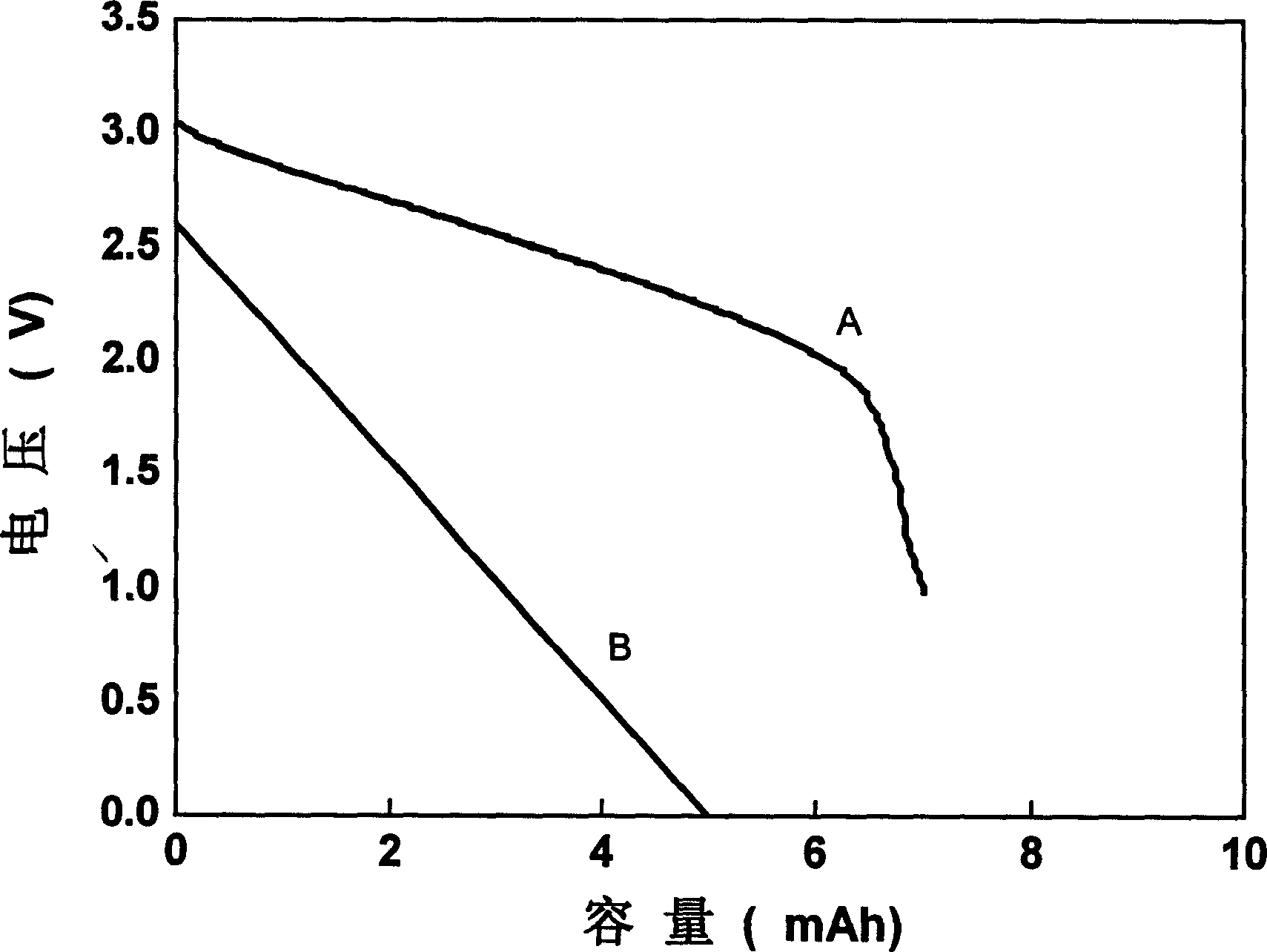

Mixed aquo-lithium ion battery

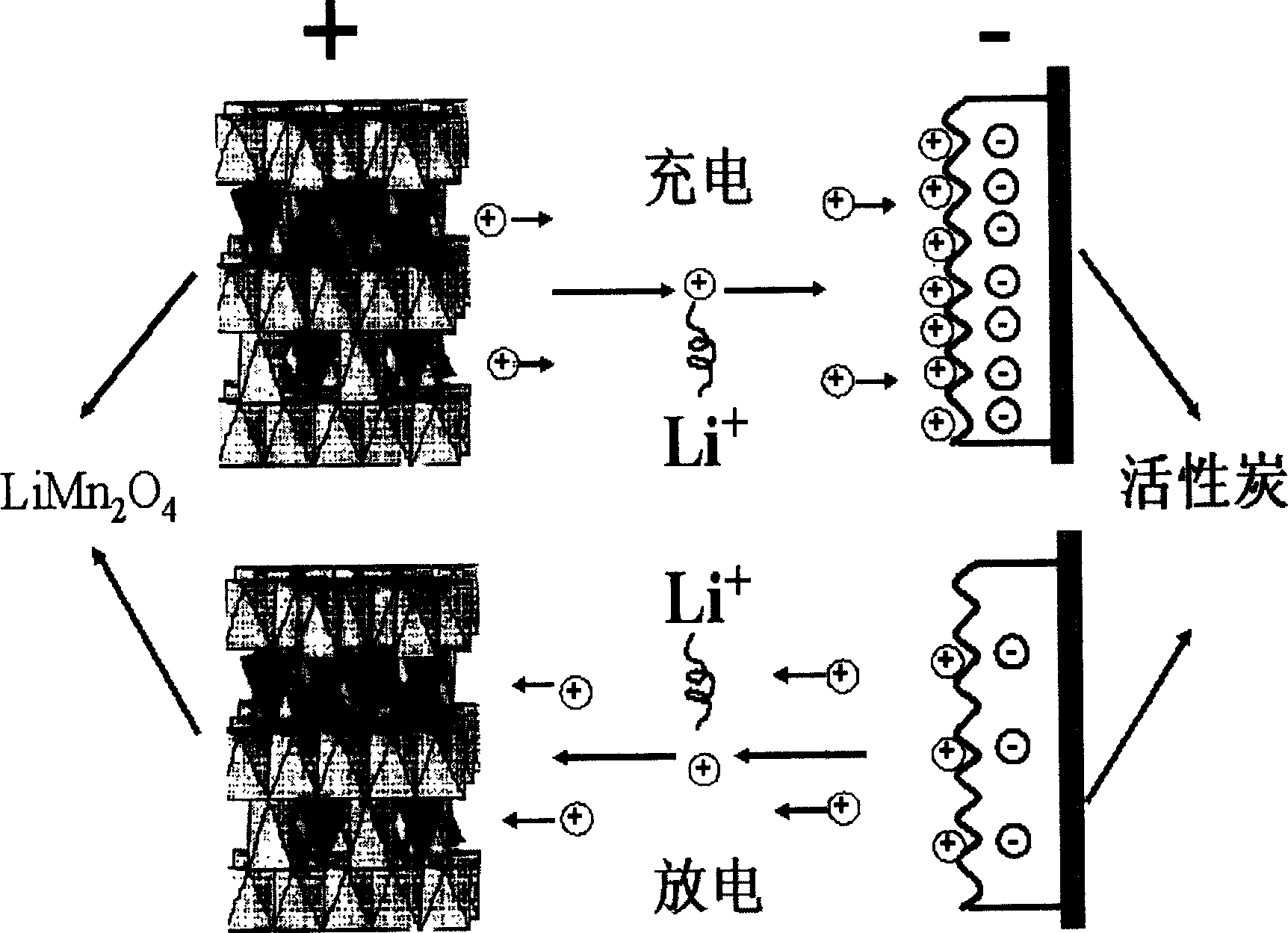

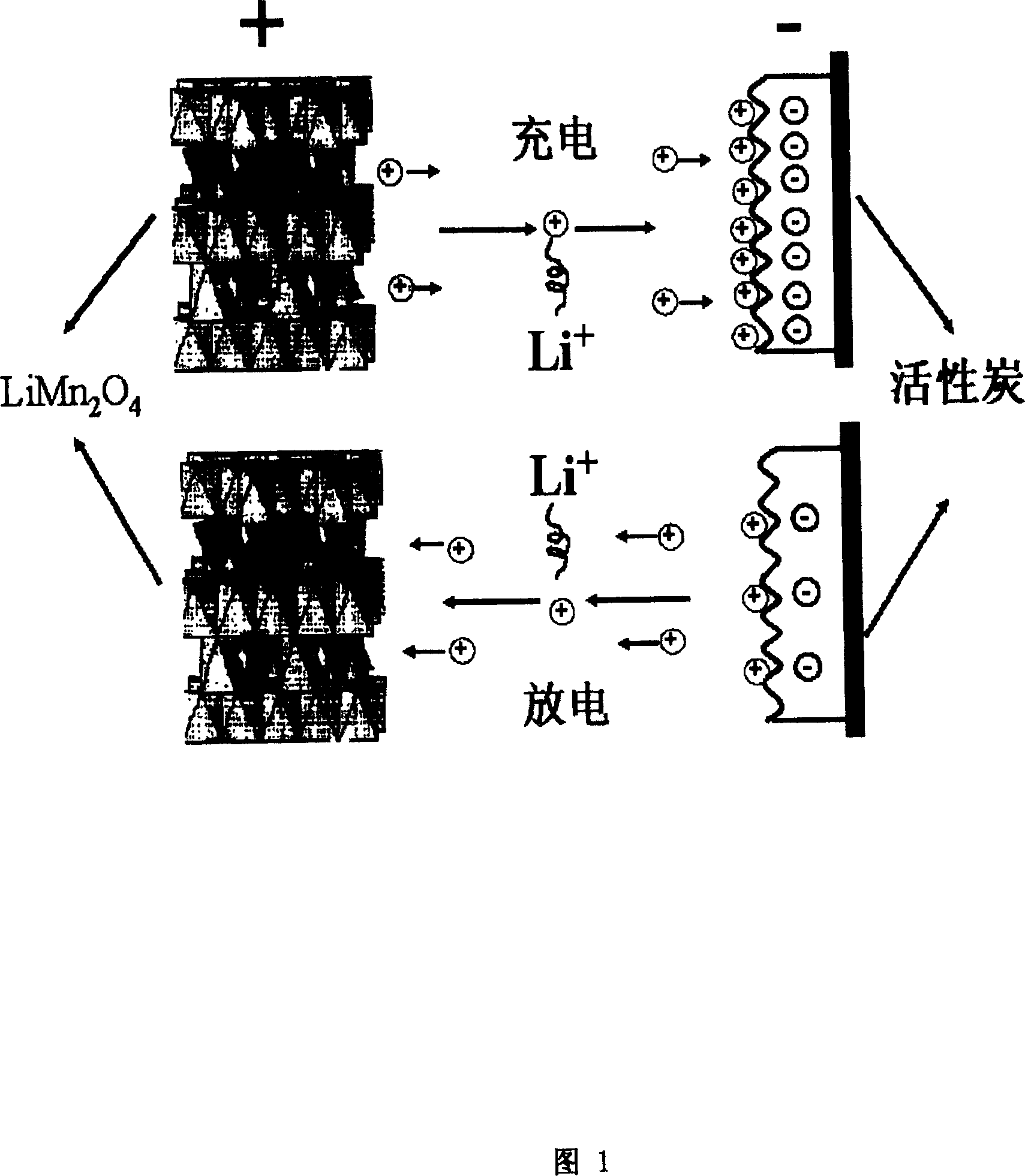

ActiveCN1674347AImprove adsorption capacityGood desorption reversibilityMaterial nanotechnologyAlkaline accumulatorsCarbon nanotubeSodium-ion battery

The present invention relates to a new-type high-performance mixed aquo system lithium ion cell. Said invention is characterized by that its positive electrode is made of intercalation compound electrode material containing lithium ion, and its negative electrode is made of the electrode materials of active carbon, mesopore carbon or carbon nano tube, etc, with high specific surface, and its electrolyte adopts aquo system electrolyte containing lithium ion. Said invention has longer circulation life, it is more than ten times that of general secondary cell, and has the features of high power, safety, low cost and free from environmental pollution.

Owner:ENPOWER ENERGY TECH CO LTD +1

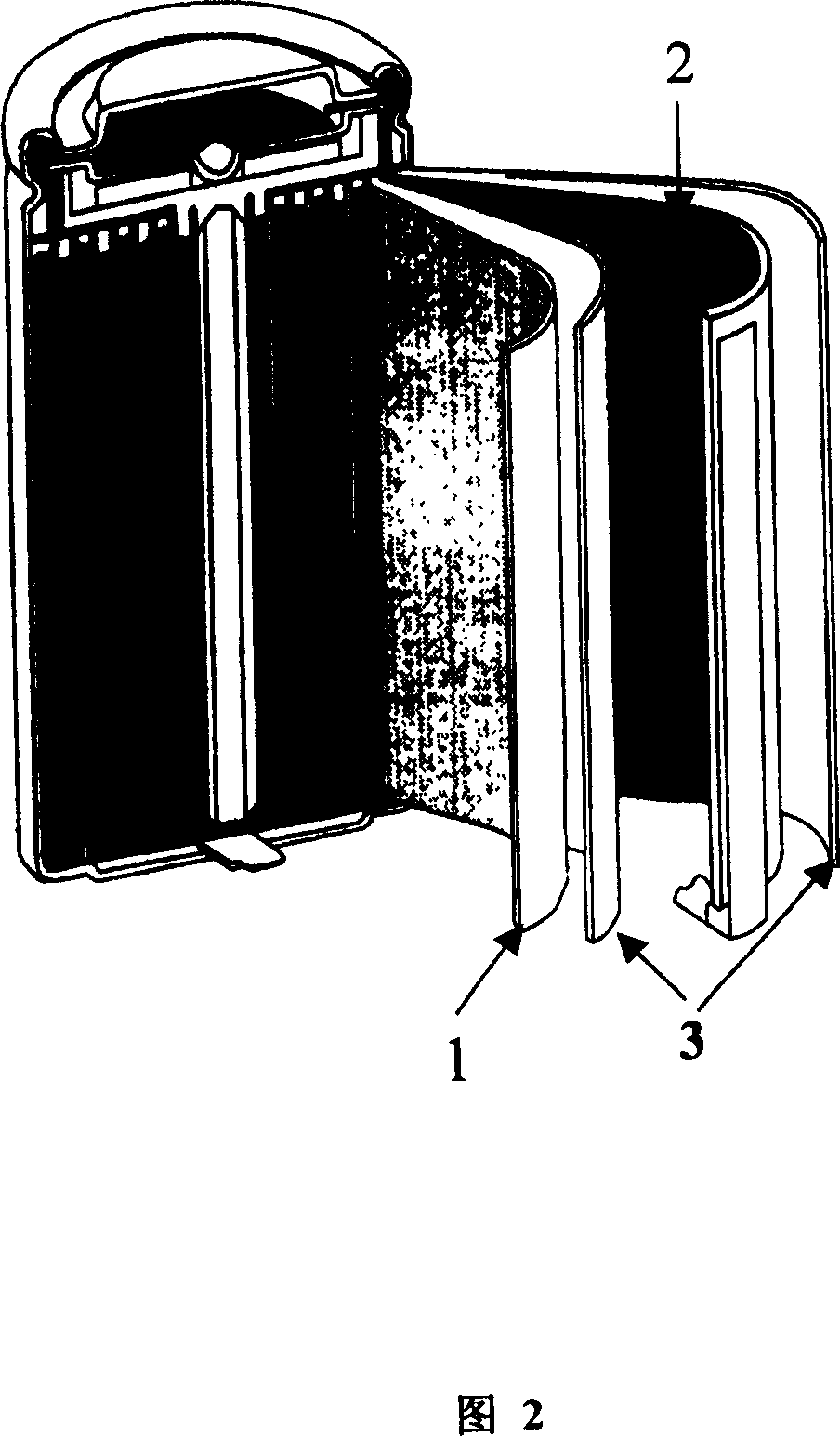

Non-water body electrochemical mixed capacitor with lithium ion battery material as positive pole

InactiveCN1773639AAvoid separationIncrease specific energyElectrochemical generatorsElectrolytic capacitorsEngineeringLithium-ion battery

A nonaqueous system electrochemical mixed capacitor using lithium cell material as positive electrode is prepared as combining ion embedding ¿C deembedding mechanism of lithium cell with double electric layer mechanism in a power accumulator, using LiMn2 ¿C x MxO4 material as positive electrode and using active carbon with high specific surface area as negative electrode to form asymmetric electrochemical capacitor.

Owner:FUDAN UNIV

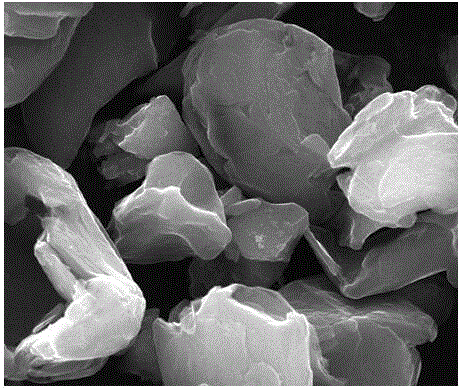

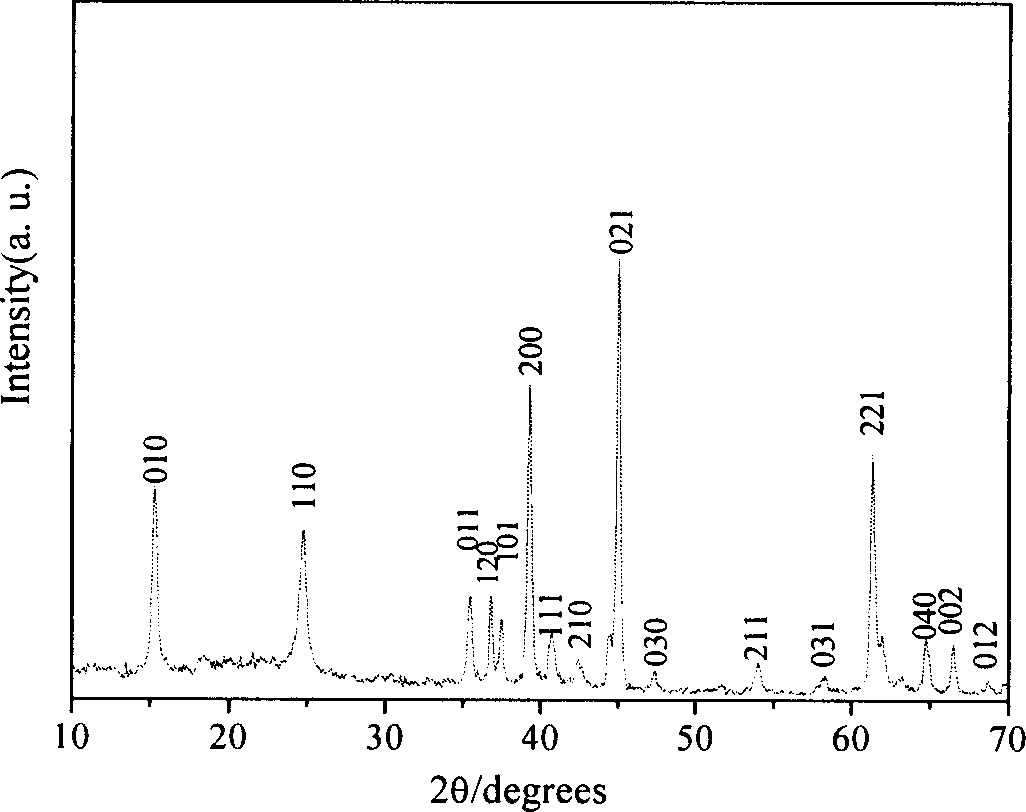

High-density spherical iron phosphate and manufacture method thereof

InactiveCN101269807AHigh crystallinityImprove crystal structurePhosphorus compoundsPhosphatePhosphoric acid

The invention relates to a high-density spherical ferric phosphate and a preparation method thereof, and preparation materials are mainly used for preparing ferrous phosphate lithium which is the anode material of a lithium ion battery. The preparation method takes an iron source and an additive as raw materials, and the raw materials are dissolved by vaal water to be made into a mixed solution A; the preparation method takes phosphate and a neutralizing agent as raw materials, and the raw materials are dissolved by the vaal water to be made into a mixed solution B. The solution A and the solution B are mixed and reacted, preparation materials are washed and parched, and the high-density spherical ferric phosphate the average grain diameter of which is 1.5-5micron, the tap density is not less than 0.95g / cm<3>, the grains are dispersed and the sizes are symmetrical is obtained. The ferrous phosphate lithium prepared by the high-density spherical ferric phosphate has perfect crystal structure, lithium ion intercalation / de-intercalation channel is normal, and the discharge capacity can reach 140mAh / g under the condition of 1C. The preparation method has simple process and is easy to technologize, and the ferrous phosphate lithium synthetized by the ferric phosphate has good crystallinity and crystal structure and can increase the electrochemical properties of the ferrous phosphate lithium.

Owner:GUANGZHOU RONGJIE MATERIAL TECH

Cathode active material comprising additive for improving overdischarge-performance and lithium secondary battery using the same

InactiveUS20070015055A1Increase cell capacityAvoid dischargeElectrode manufacturing processesOrganic electrolyte cellsCapacity lossManganese

Disclosed is a cathode active material providing a cell performance that is not adversely affected by overdischarge, and a lithium secondary cell using the same. More particularly, the cathode active material for a lithium secondary cell comprises a lithium-transition metal oxide capable of lithium ion intercalation / deintercalation, wherein the cathode active material further comprises a lithium manganese oxide having a layered structure represented by the following formula 1 as an additive:[formula 1] LiMxMn1-x02 wherein, x is a number satisfying 0.05 x<0.5, and M is at least one metal selected from the group consisting of Cr, Al, Ni, Mn and Co. The lithium manganese oxide of formula 1 used as an additive for a cathode active material of a lithium secondary cell provides lithium ions in such an amount as to compensate for an irreversible lithium ion-consuming reaction at an anode, or more, thereby providing a lithium secondary cell which is low in capacity loss by over-discharge.

Owner:LG CHEM LTD

High-specific-capacity silicon-based negative electrode composite binder and preparation method for negative plate containing same

ActiveCN106058259ASolve the technical problem of short cycle lifeCell electrodesSecondary cellsButadiene-styrene rubberPolymerization

The invention discloses a high-specific-capacity silicon-based negative electrode composite binder and a preparation method for a negative plate containing the same, belonging to the field of binders for batteries. The high-specific-capacity silicon-based negative electrode composite binder comprises 5 to 50 wt% of carboxymethylcellulose sodium, 5 to 30 wt% of polyacrylic acid and 20 to 90 wt% of styrene-butadiene rubber. The preparation method for the negative plate comprises the following steps: binder preparation; addition of a conductive agent; addition of a main material; sieving; coating; high temperature polymerization; rolling; and punching. The composite binder provided by the invention can overcome the technical problem of short cycle life of a battery caused by immense volume changes of a conventional silicon-based negative electrode material during intercalation and deintercalation of lithium ions.

Owner:WANXIANG 123 CO LTD

High-specific-energy/high-specific-power type super battery

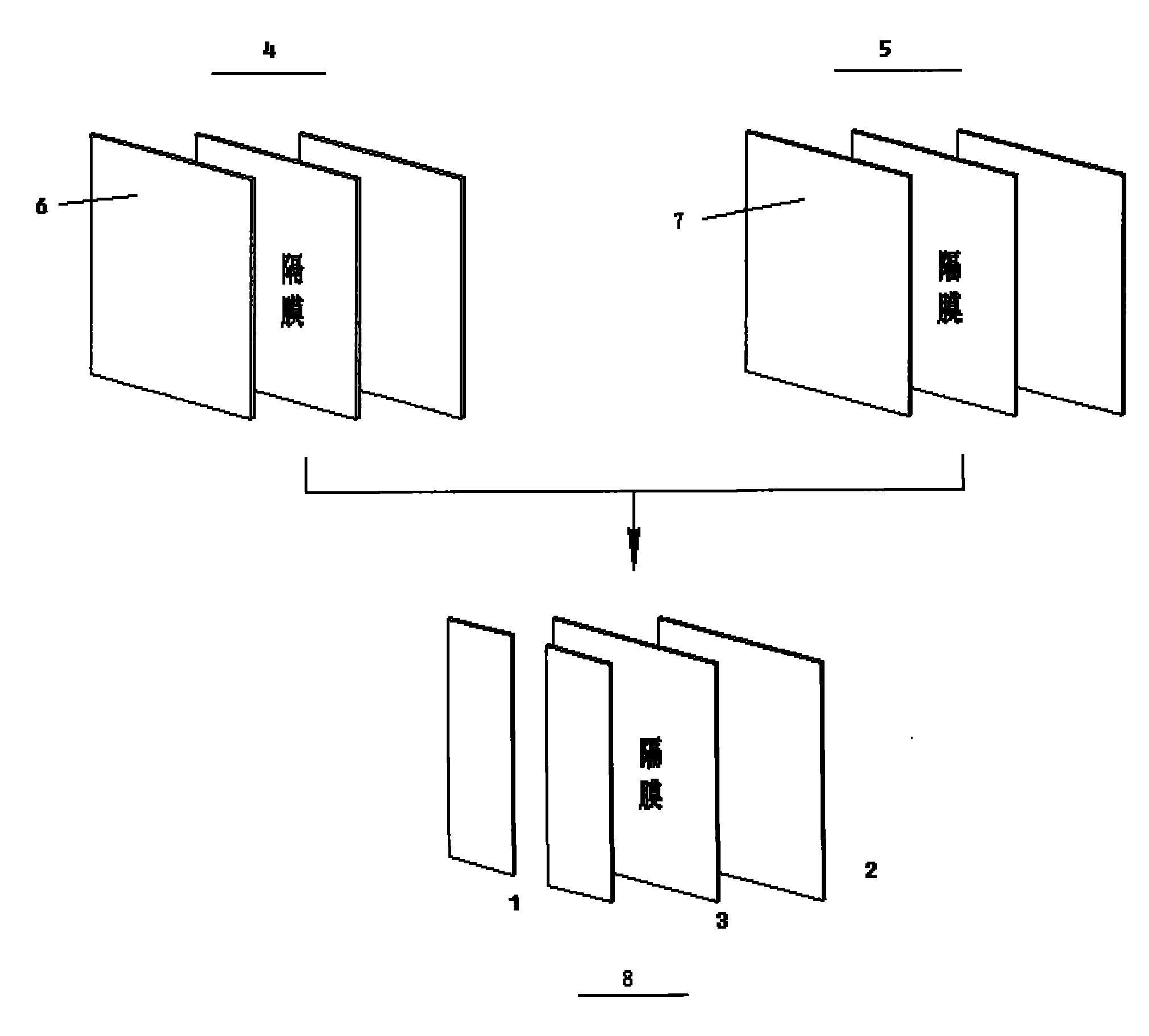

InactiveCN101847764AEasy to produceIncrease specific energyElectrode carriers/collectorsSecondary cellsPorous carbonHigh energy

The invention relates to a high-specific-energy / high-specific-power type super battery, consisting of a positive electrode, a negative electrode, a diaphragm between the positive electrode and the negative electrode, and organic electrolyte, wherein the positive electrode is formed by parallel connection of two types of electrode pieces, i.e. an electrode piece which adopts a lithium-ion-embedded compound in a lithium ion battery as an active material and an electrode piece of a porous carbon material in a double electric layer super capacitor, the negative electrode adopts a negative electrode carbon material of the lithium ion battery, and the electrolyte is of an organic solvent containing lithium ion salt electrolyte. The high-specific-energy / high-specific-power type super battery has high energy density and power density simultaneously, wherein the specific energy can be up to 50-110wh / kg, and the power density can be up to 450-8000w / kg; and the high-specific-energy / high-specific-power type super battery can be widely applied in the fields such as electric automobiles, electric tools, solar energy storage, wind energy storage, portable household appliances and the like.

Owner:SHANGHAI AOWEI TECH DEV

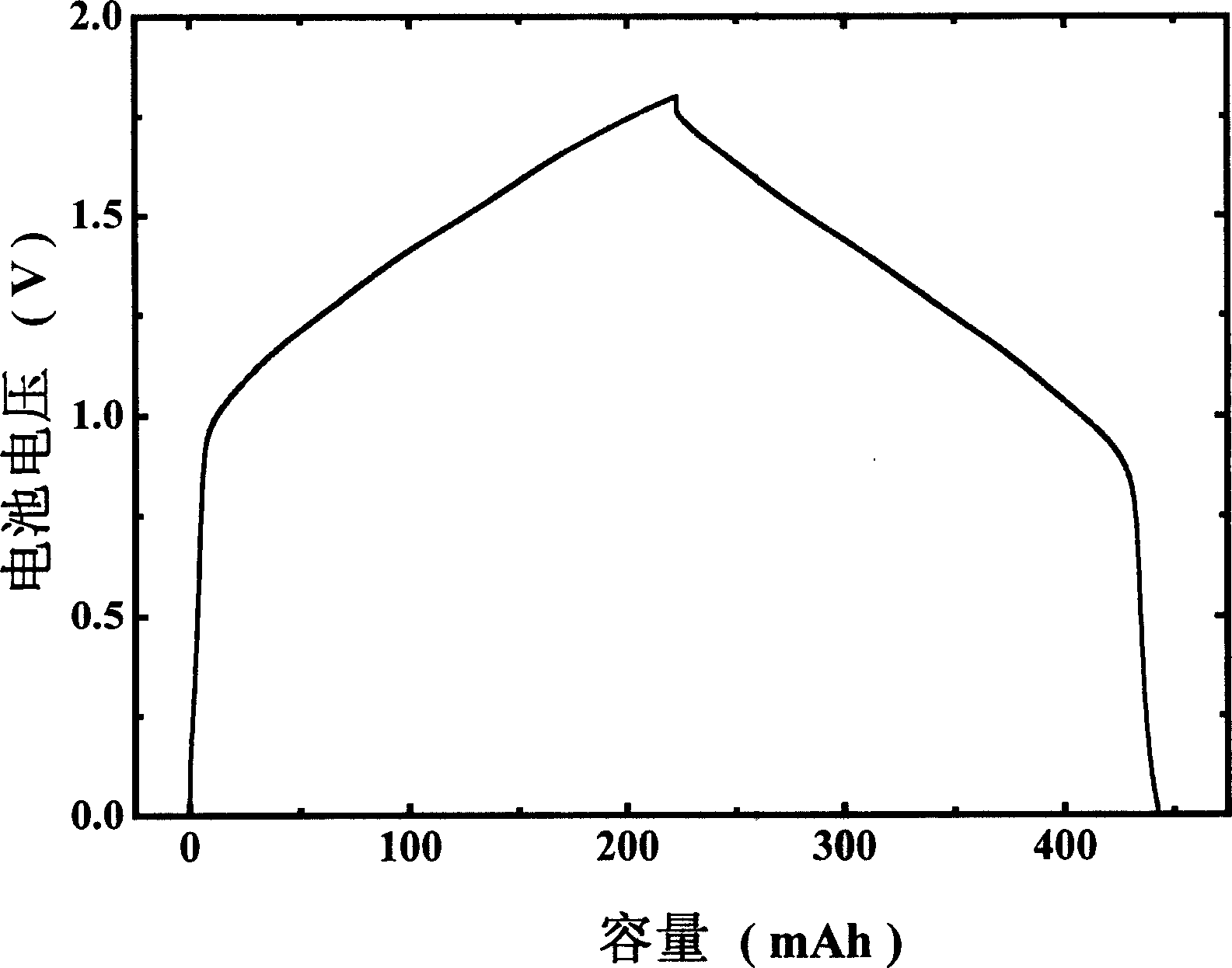

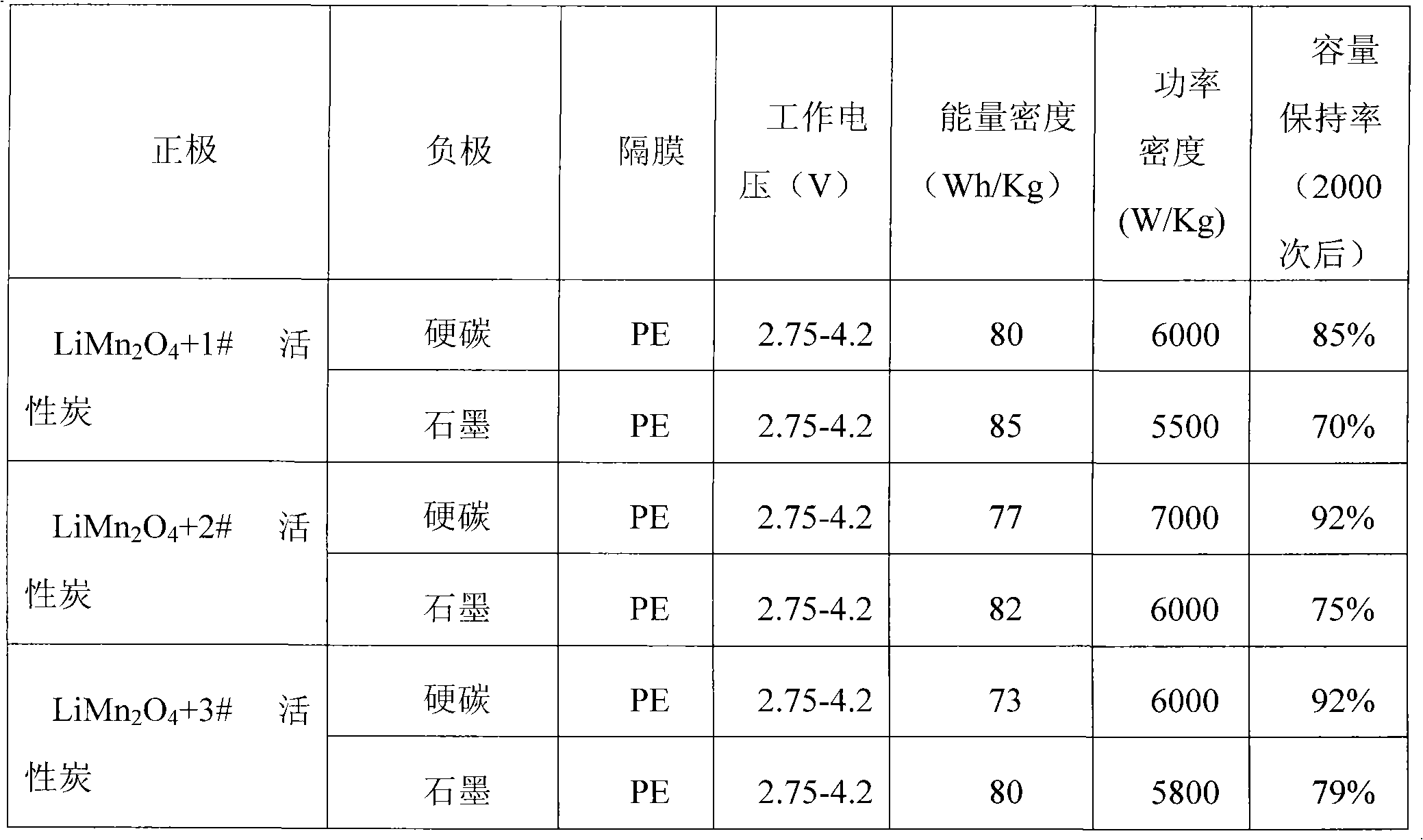

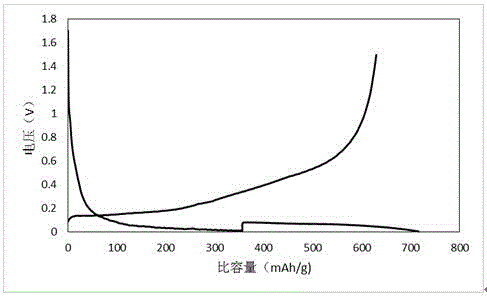

Capacitor battery of high-specific-energy organic system

InactiveCN101847516AIncrease energy densityImprove power performanceHybrid capacitor electrodesLiquid electrolytic capacitorsCapacitanceOrganic solvent

The invention relates to a capacitor battery of a high-specific-energy organic system, consisting of a positive electrode, a negative electrode, a diaphragm between the positive electrode and the negative electrode, and organic electrolyte, wherein the positive electrode adopts the mixture of a lithium-ion-embedded compound and a porous carbon material, the negative electrode is hard carbon, and the electrolyte adopts electrolyte of an organic solvent containing lithium ions. The super capacitor battery prepared by the invention has the characteristics of high energy density (up to 20-90Wh / Kg) and high power density (larger than 4500W / Kg), can be widely applied in the fields such as electric automobiles, electric tools, solar energy storage, wind energy storage, portable household appliances and the like.

Owner:SHANGHAI AOWEI TECH DEV

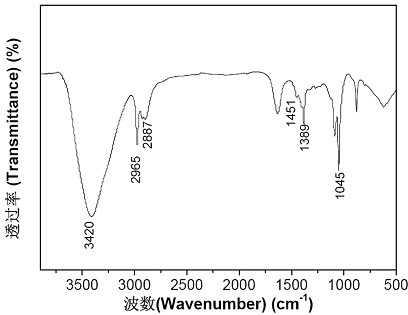

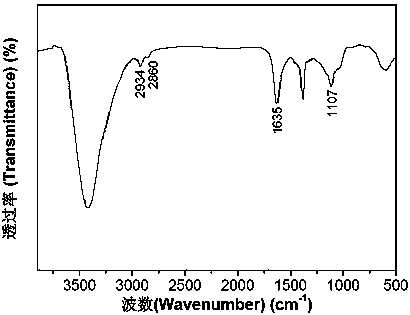

A polyimide capacitor battery and its manufacturing method

ActiveCN102290245AIncrease powerImprove cycle lifeCapacitor and primary/secondary cellsHybrid capacitor electrodesPorous carbonElectric capacity

The present invention specifically relates to a polyimide capacitance battery and a manufacturing method thereof. The polyimide capacitance battery of the present invention is obtained by manufacturing a positive electrode and a negative electrode, and then combining the positive and negative electrodes into the capacitance battery, which consists of the positive electrode, the negative electrode, a polymer membrane therebetween, and an electrolyte, wherein the positive electrode material is a mixture of a lithium-ion insertion compound and a porous carbon material, the negative electrode material is a mixture of modified graphite and a porous activated carbon material, the polymer membrane is a polyimide membrane, and the electrolyte is an electrolyte containing a lithium ion compound and an organic solvent. The polyimide capacitance battery of the present invention can be widely applied in the fields of electric automobile, electric tools, solar energy storage, wind energy storage, portable appliances and the like.

Owner:SHENZHEN HIFUTURE ELECTRIC

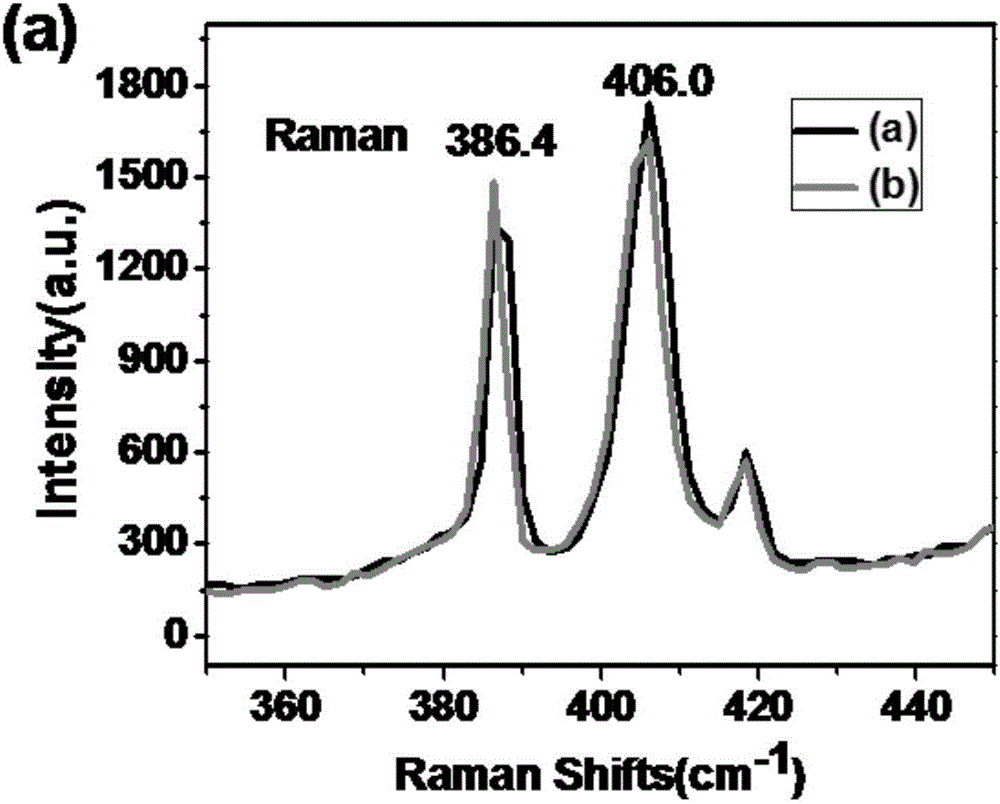

Preparation method for molybdenum disulfide nanosheet with reactive group-containing surface

ActiveCN103833081AGood dispersionReduce pollutionMaterial nanotechnologyMolybdenum sulfidesN-ButyllithiumHexane

The invention discloses a preparation method for a molybdenum disulfide nanosheet with a reactive group-containing surface. The preparation method comprises the following steps: adding one part by weight of molybdenum disulfide, 2-5 parts by weight of n-butyllithium and 10-20 parts by weight of n-hexane into a hydrothermal reaction kettle, heating at 50-150DEG C for 0.5-12 hours, cooling to room temperature, performing centrifugal separation and n-hexane washing for five times, drying at 50DEG C for 12 hours so as to obtain molybdenum disulfide powder with lithium ion intercalation, adding 1 part by weight of molybdenum disulfide powder with lithium ion intercalation, 0.05-10 parts by weight of sulihydryl reagents with reactive groups, and 100-1000 parts by weight of water into a flask for performing ultrasonic treatment for one minute to five hours under 50-100 watt, to obtain molybdenum disulfide nanosheet with the reactive group-containing surface. The method is easily available, mild to react, simple to operate, and small in environmental pollution; the prepared nanosheet can be further functionalized, thus having good application prospects.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparing method of porous monocrystal IT MoS2 nanosheet and application thereof

ActiveCN106311282AQuick peelSimple methodMaterial nanotechnologyPhysical/chemical process catalystsElectricityActive site

The invention discloses a preparing method of porous monocrystal IT MoS2 nanosheet. The method comprises the steps of 1, preparing 2H crystal form MoS2 nanosheet using hydrothermal method; 2, conducting stripping of multi-layered 2H crystal form MoS2 nanosheet with ultrasonic wave and assisting with a lithium-ion intercalation method. The 1T MoS2 nanosheet can be directly used for electro-catalysis hydrogen production, and compared with MoS2 with other structures, electro-catalysis hydrogen production property can get fast improvement, porous structure provides more edges for the catalysis, therefore can expose more active sites, which is beneficial to electro-catalysis hydrogen production; single-layered structure enables larger specific surface area of the catalyst, can provide more reaction active sites. Compared with a multi-layered structure, a single-layered structure reduces electric transmission resistance between layer and layer, is beneficial to transmission and transfer of electricity, thus accelerating velocity of electro-catalysis hydrogen production.

Owner:HENAN INST OF ENG

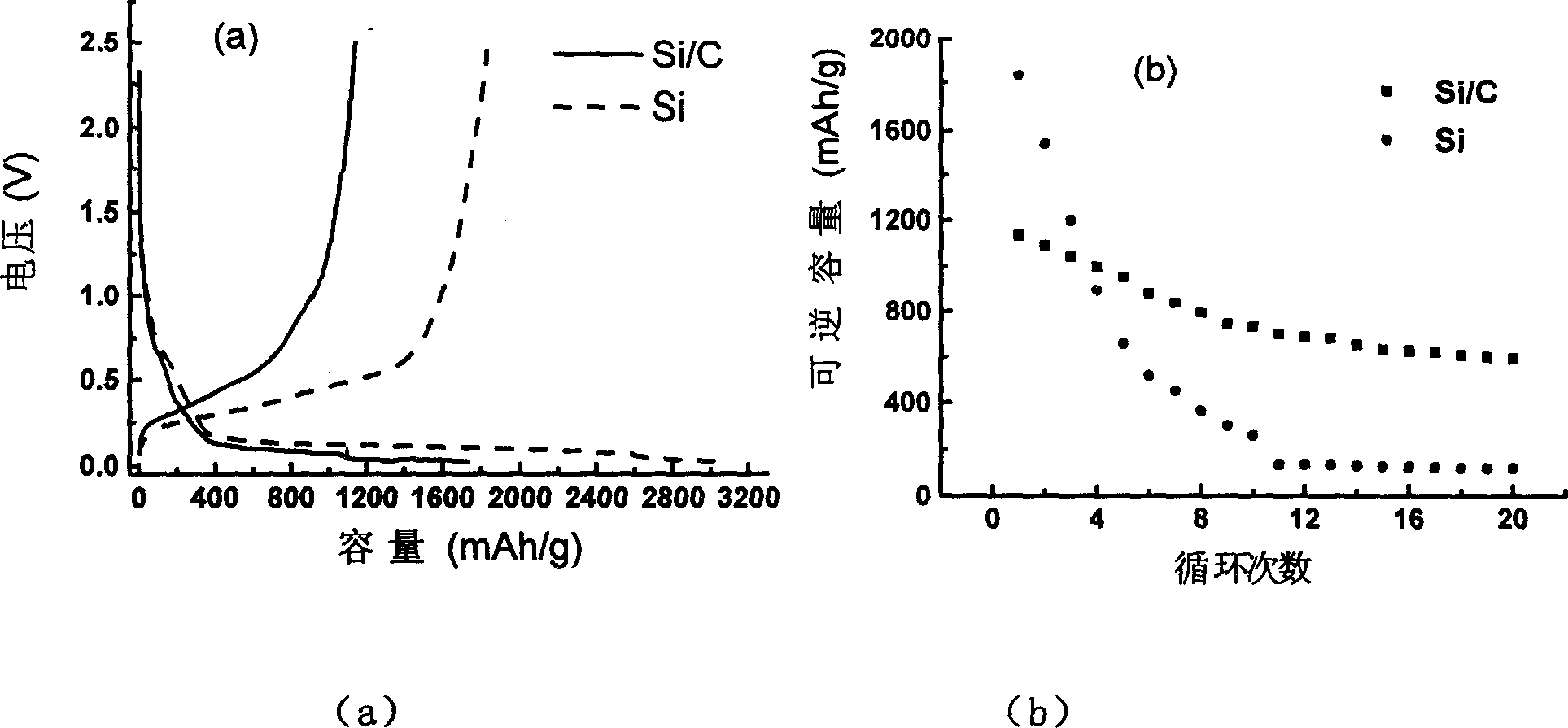

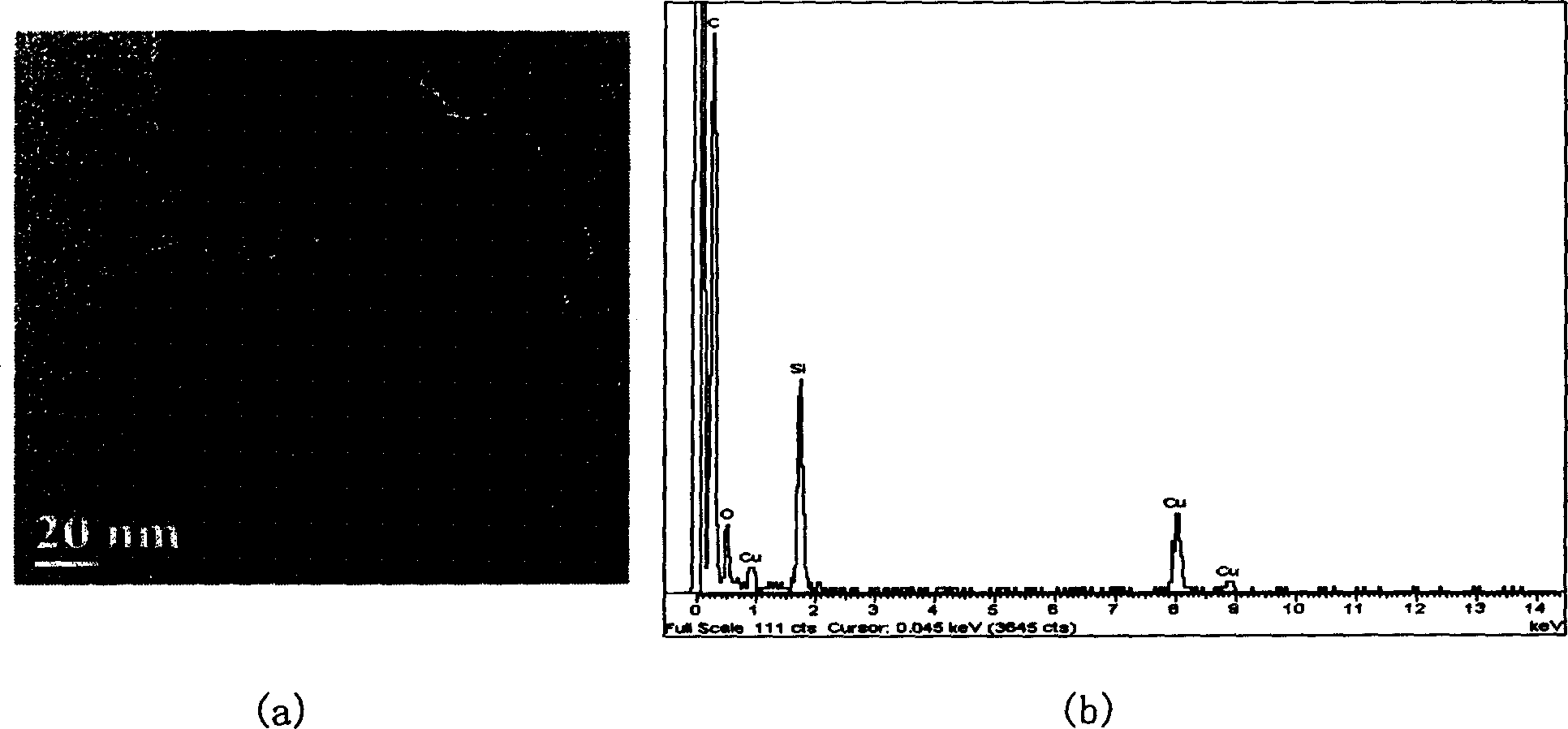

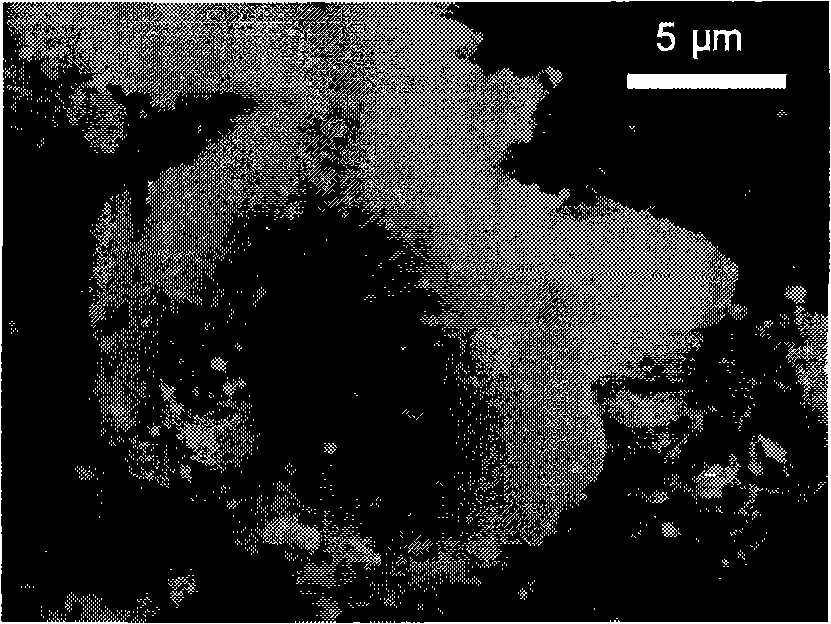

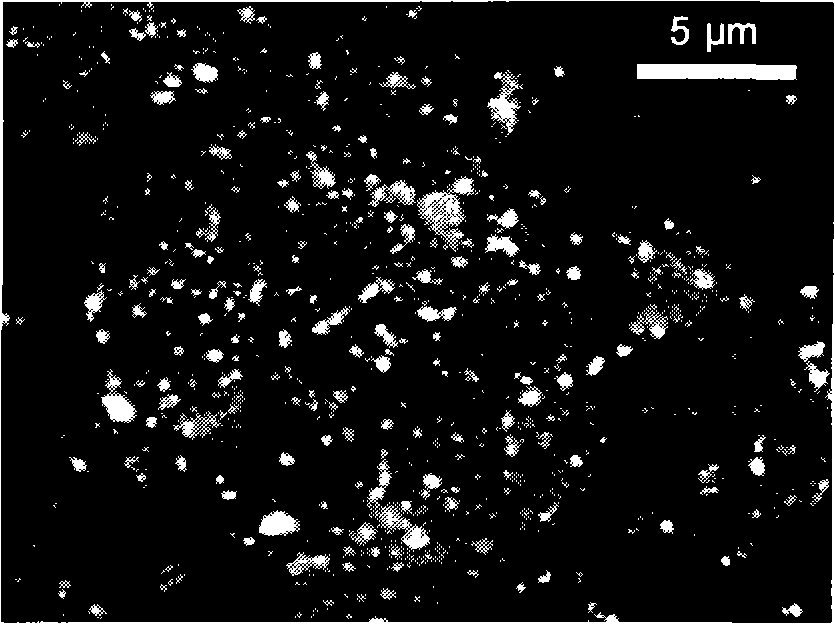

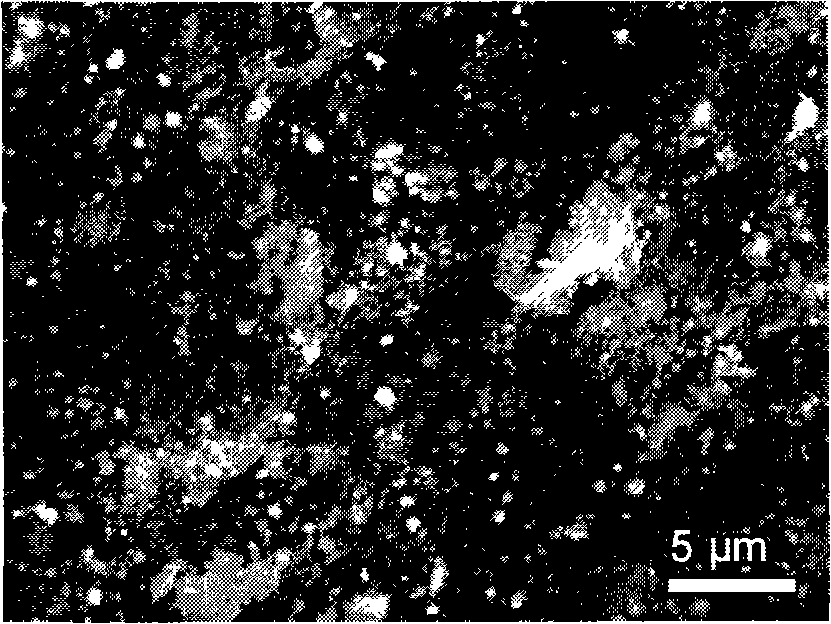

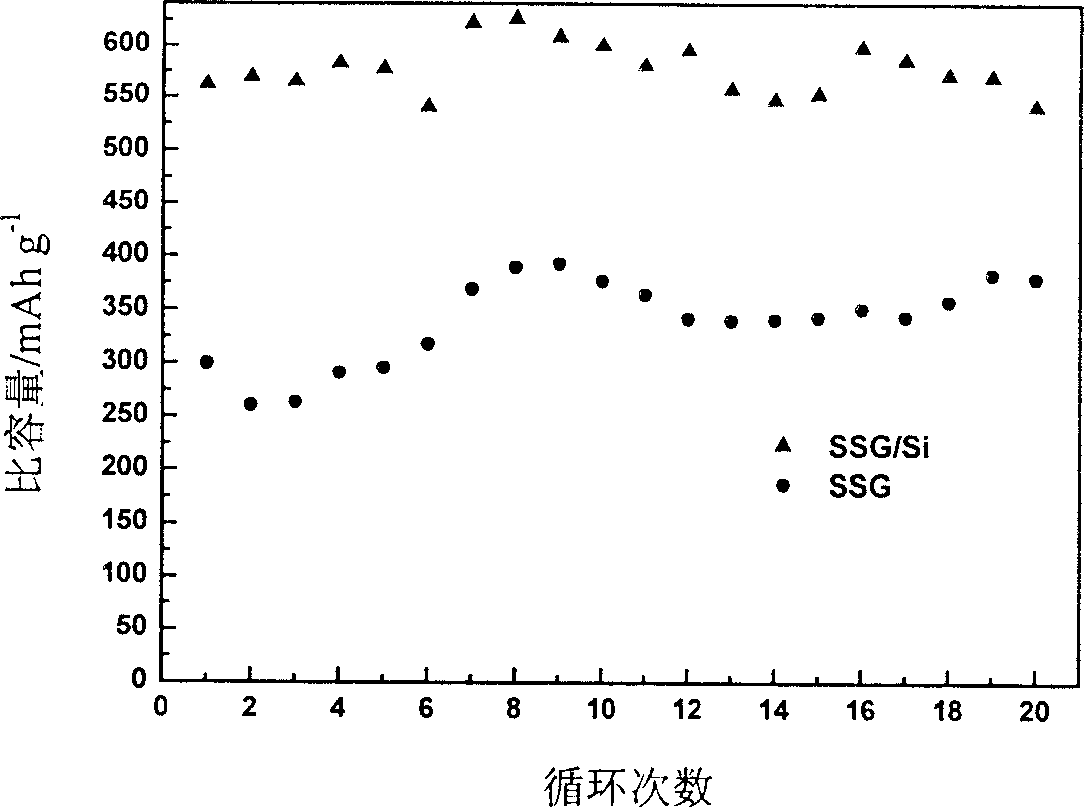

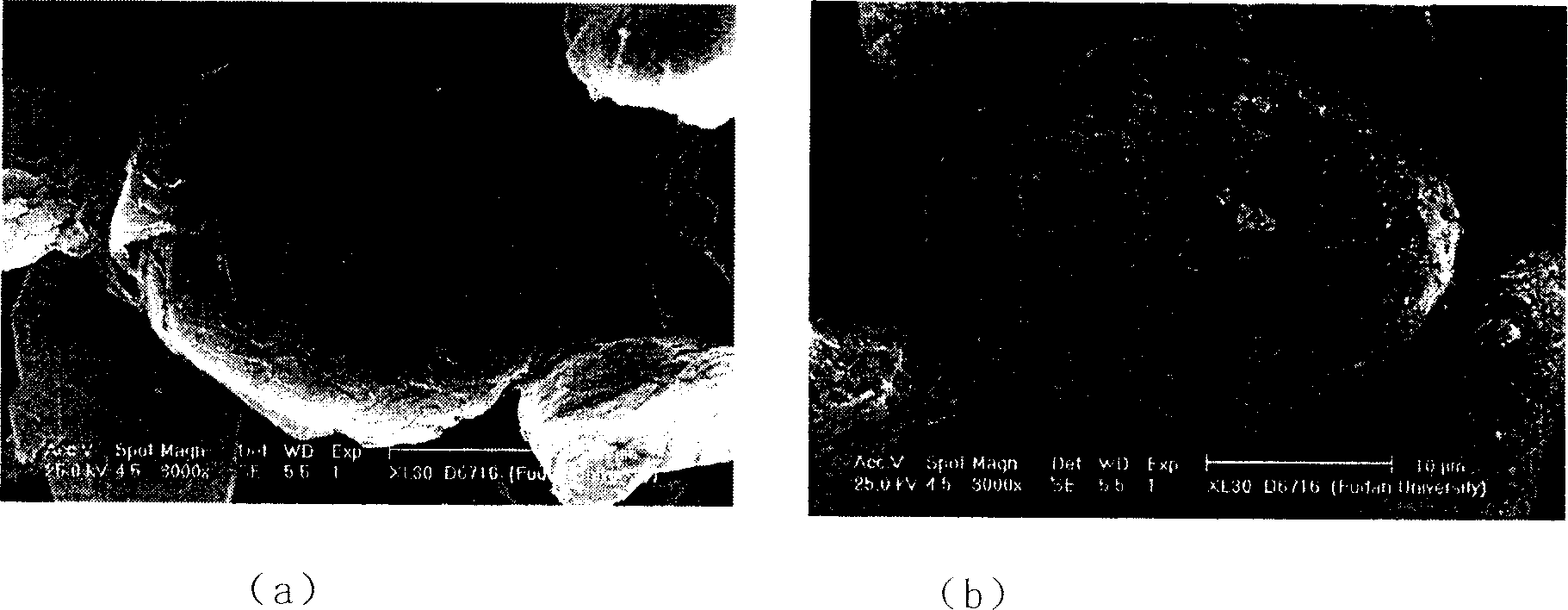

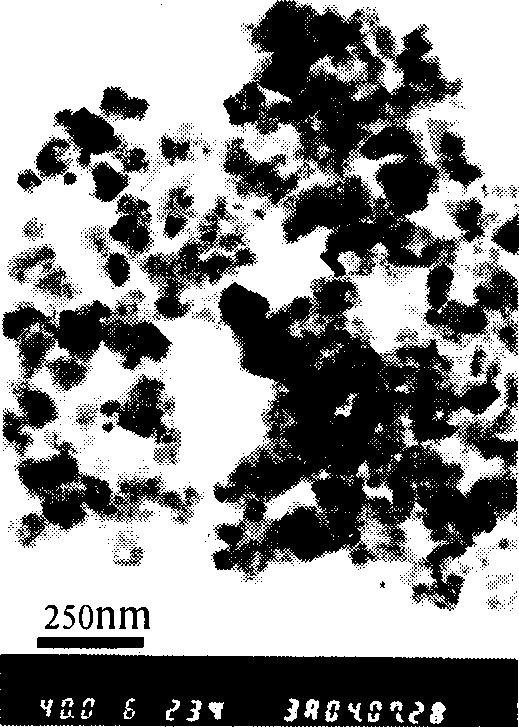

Silicon/charcoal core-shell structure nanometer composite material and its preparation method and uses

InactiveCN1800094AThe core-shell structure is stableAvoid reunionCell electrodesCapacitanceEmulsion polymerization

The invention relates to a method of preparing si / c nuclear shell structure nano composite material by emulsion polymerization and the material thereof. The construction of si / c nuclear shell structure nano composite material produced in said invention is stable with diameter of particles several hundred nanometers or less. During the process of lithium ion in-built and out-built, the shell material of hard construction could avoid the agglomeration of nano-crystals, making lithium ion battery have good reversible capacitance and circulatory function. Besides, the invention is characterized by: good operability, repeatability, stable quality of production thereof.

Owner:FUDAN UNIV

Method for preparing cathode material for high capacity lithium ion battery

InactiveCN101325253AImprove electrochemical performanceImprove wettabilityElectrode manufacturing processesCarbon compositesChemical reaction

The invention relates to the preparation technology of cathode materials for rechargeable secondary lithium-ion batteries and provides a method of preparing the cathode materials for high-capacity lithium-ion batteries. The lithium-ion battery utilizes the techniques of the in-situ carbothermic reduction reaction and the in-situ chemical reaction ball milling to prepare the uniformly-dispersed metal oxide / carbon composite cathode materials. The prepared composite cathode materials can remarkably increase the capacity of the lithium-ion batteries and have excellent cycle performance. The composite cathode materials prepared by the method make full use of high-capacity metal oxides, additionally, the metal oxides, in the form of small granules, are uniformly dispersed on the surface of the carbon-based matrix with high interface bonding strength, so that the volume change caused by the insertion and the extraction of lithium ions during the recharging process is well attenuated by the carbon-based matrix and the cycle performance is also kept excellent.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of silicon carbon negative pole composite material

InactiveCN106784768AReduce manufacturing costThe process is simple and easy to controlCell electrodesSiliconCarbon source

The invention discloses a preparation method of a silicon carbon negative pole composite material. The method comprises the following steps: dispersing silicon powder and a carbon source in a certain proportion in deionized water, stirring for some time, transferring into a teflon reaction kettle, coating the carbon precursor on the silicon powder surface by a hydrothermal process, and calcining in an inert atmosphere; dispersing the calcined material in a mixed solution a, dispersing at high speed, and drying; and carrying out etching treatment on the dried material by using an etching solution, drying the etched material to obtain the final silicon carbon negative pole composite material. The method effectively increases the lithium ion intercalation positions, improves the bulk effect of silicon, and enhances the electrochemical stability. The material has the advantages of low preparation cost and simple and controllable technique, and is suitable for large-scale industrial production.

Owner:ZHONGTIAN ENERGY STORAGE TECH

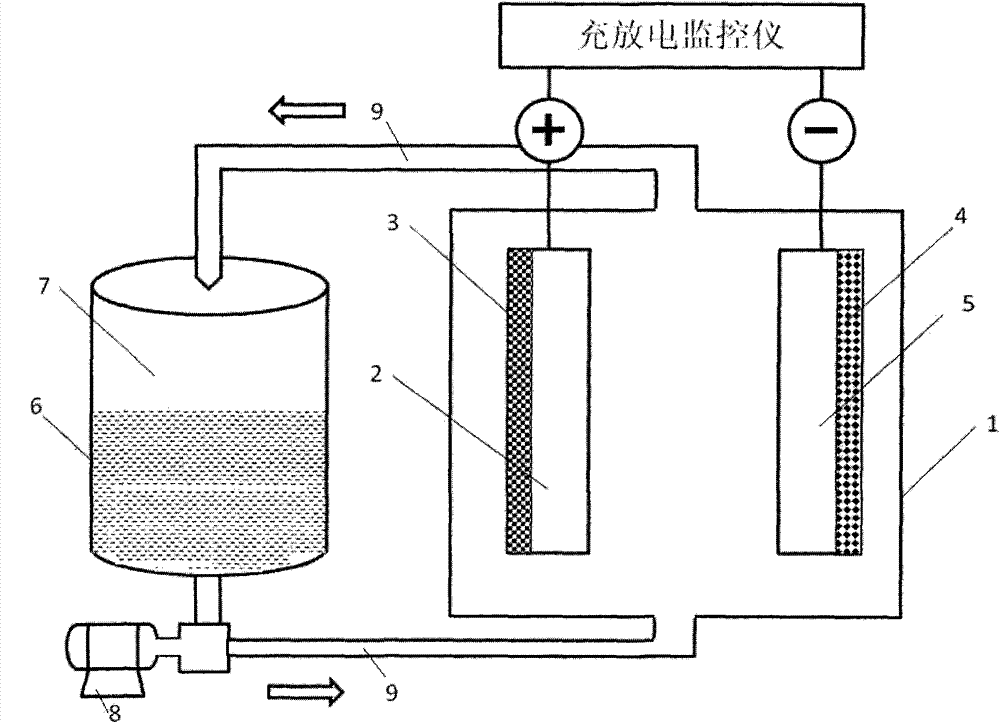

Aqueous lithium ion flow battery

InactiveCN104716372AImprove cycle lifeHigh specific capacityCell electrodesRegenerative fuel cellsEnvironmental resistanceHigh energy

The invention relates to a novel aqueous lithium ion flow battery with high performances and low cost. A lithium ion intercalation-deintercalation mechanism and a flow battery metal ion deposition-dissolution mechanism are optically combined in an energy storage device. A positive electrode adopts a lithium ion intercalatable-deintercalatable solid oxide material, a negative electrode adopts a deposition type metal electrode material deposited-dissolved on an inert electrode, an electrolyte is an aqueous electrolyte containing lithium ions and capable of depositing and dissolving metal ions, and the separation of positive electrode and the negative electrode by a diaphragm is not needed. In the charge and discharge process, the electrolyte is promoted by a liquid pump to go through a pipeline and continuously circularly flow between a storage tank and a battery main body. The aqueous lithium ion flow battery has the characteristics of long cycle life, high energy efficiency, safety, low cost, less maintenance, environmental protection, high utilization rate and energy density of active substances, and large specific capacity, and is especially suitable for large scale power storage of off-grid renewable energy power generation and distributed power supply.

Owner:NO 63971 TROOPS PLA

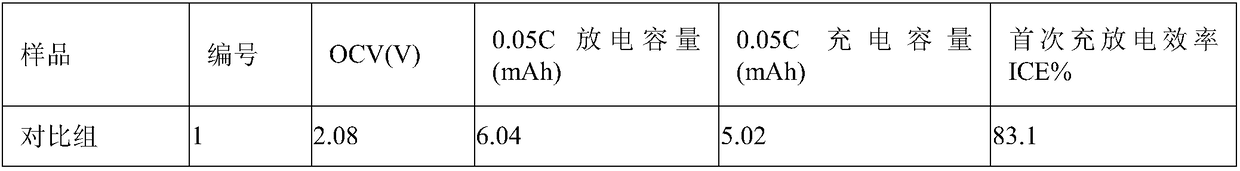

Lithium ion supplementing technology of lithium ion batteries

ActiveCN108520978AReduced volumetric deformationImprove cycle stabilityFinal product manufactureCell electrodesAluminium-ion batteryLithium-ion battery

The invention relates to a lithium ion supplementing technology of lithium ion batteries. The technology includes firstly, preparing a silicon carbon negative pole piece; then preparing a Li-naphthalene solution; soaking the prepared silicon carbon negative pole piece in the Li-naphthalene solution for 2 hours; and performing leaching. The silicon carbon negative pole piece is embedded with a certain amount of lithium ion before a battery is prepared, and irreversible capacity losses due to an SEI film which is formed by embedding lithium ions into a negative pole for the first time can be eliminated. Under the same charging and discharging depth, volume deformation amplitude reduction of silicon based negative materials during a lithium ion embedding and extracting process after the lithium ion supplementing can help improve the cyclic stability of silicon carbon negative pole based lithium ion batteries. Through experimental confirmation, charging and discharging efficiency of the silicon carbon negative pole for the first time can be significantly enhanced, and the cyclic stability can be improved as well.

Owner:WANXIANG 123 CO LTD

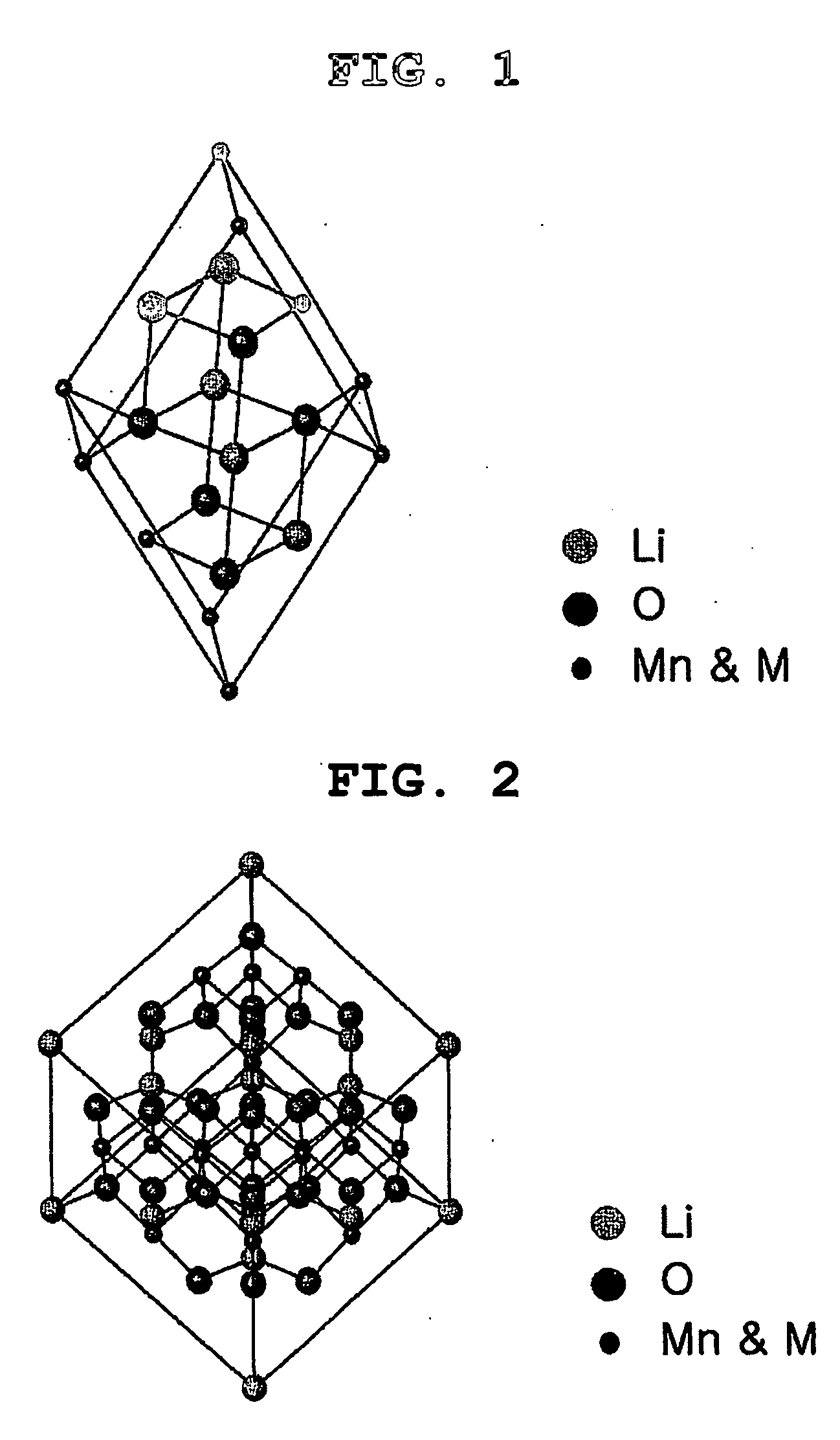

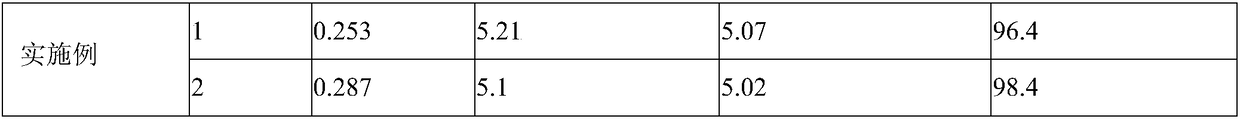

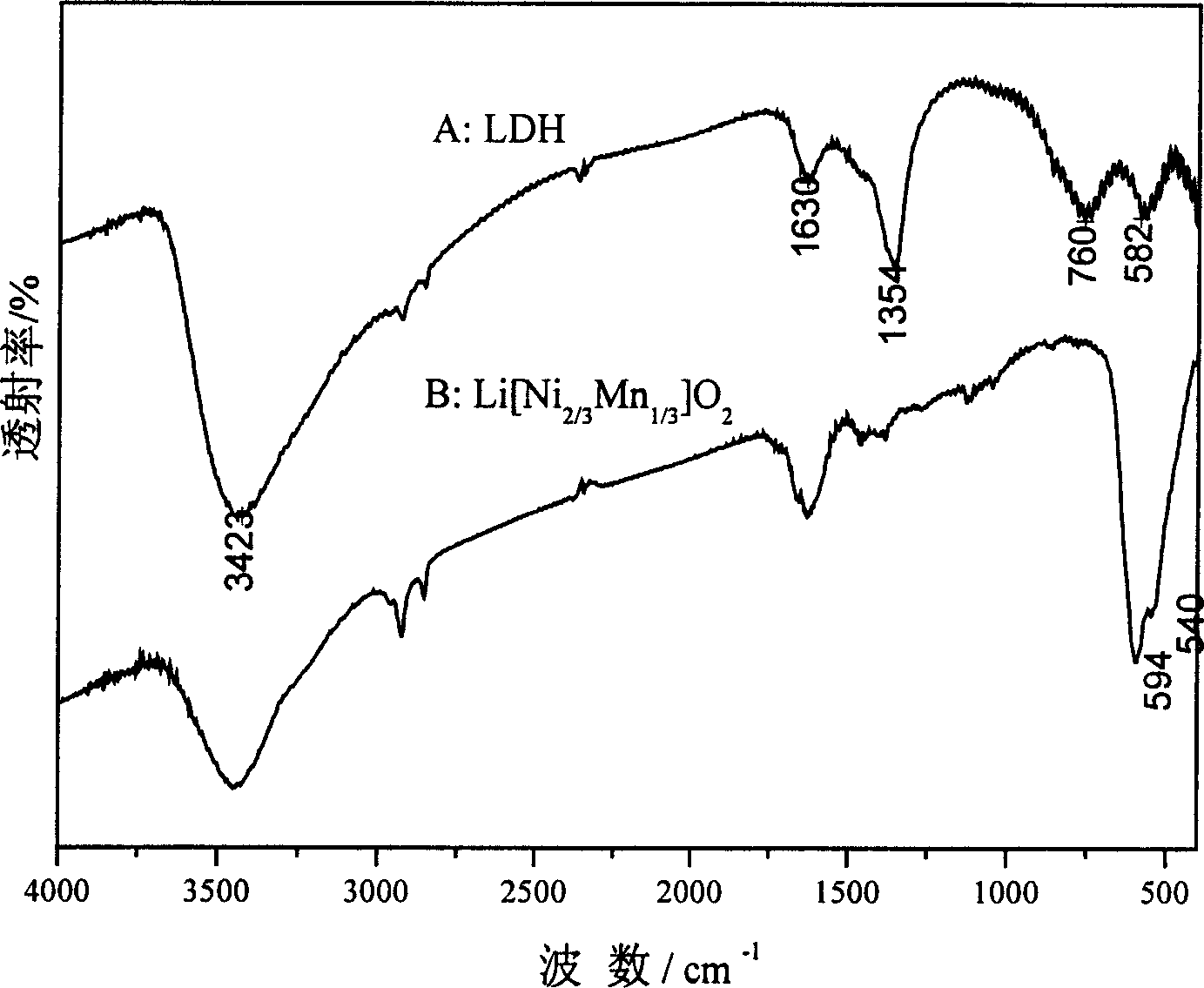

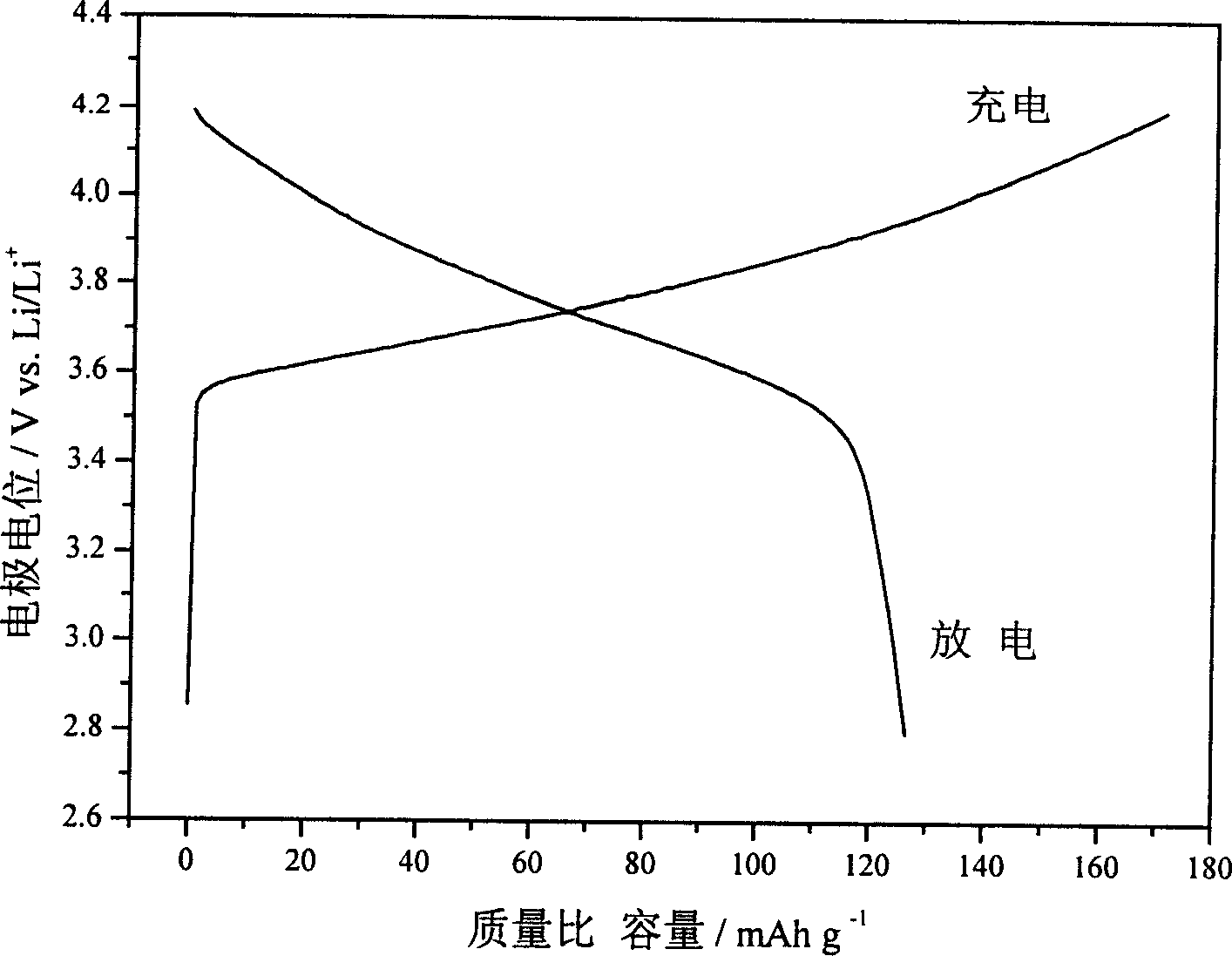

Lithium ion battery positive pole material layered transition metal composite oxide and method of preparation

InactiveCN1606185ASimple processEasy to operateElectrode manufacturing processesLithium compoundsManganeseLithium-ion battery

This invention provides a laminated transition metal composite oxide of Li ionic cell positive material by distributing binary or triple transition metals on a board uniformly. The positive material is prepared by applying laminated cathode ion material water talc fore-body method, first of all, applying the common deposition method to prepare the M-N water talc then to carryout the dehydroxy step by lamination boards to turn those with positive charges to those with negative, at the same time, the interlamination cathode ions get out and Li ions are inserted into them to get a laminated positive material with the advantage of getting composite oxide electrode material in lamination structure and uniform distribution of CoNi and Mn transition metal on the board.

Owner:BEIJING UNIV OF CHEM TECH

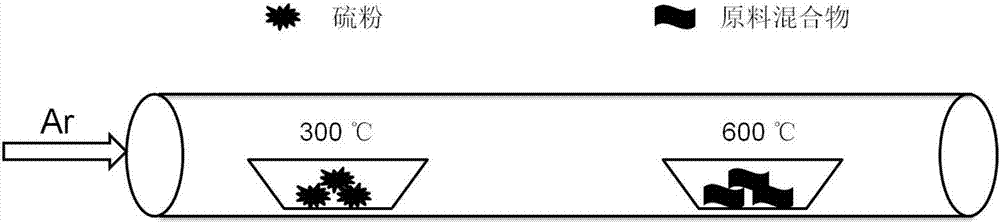

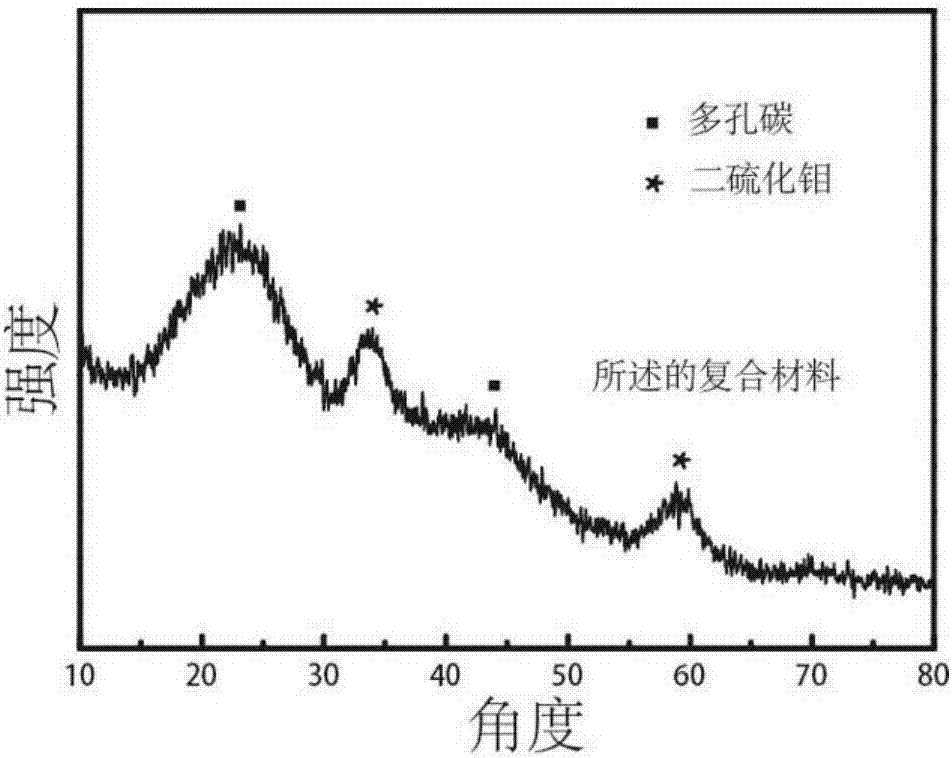

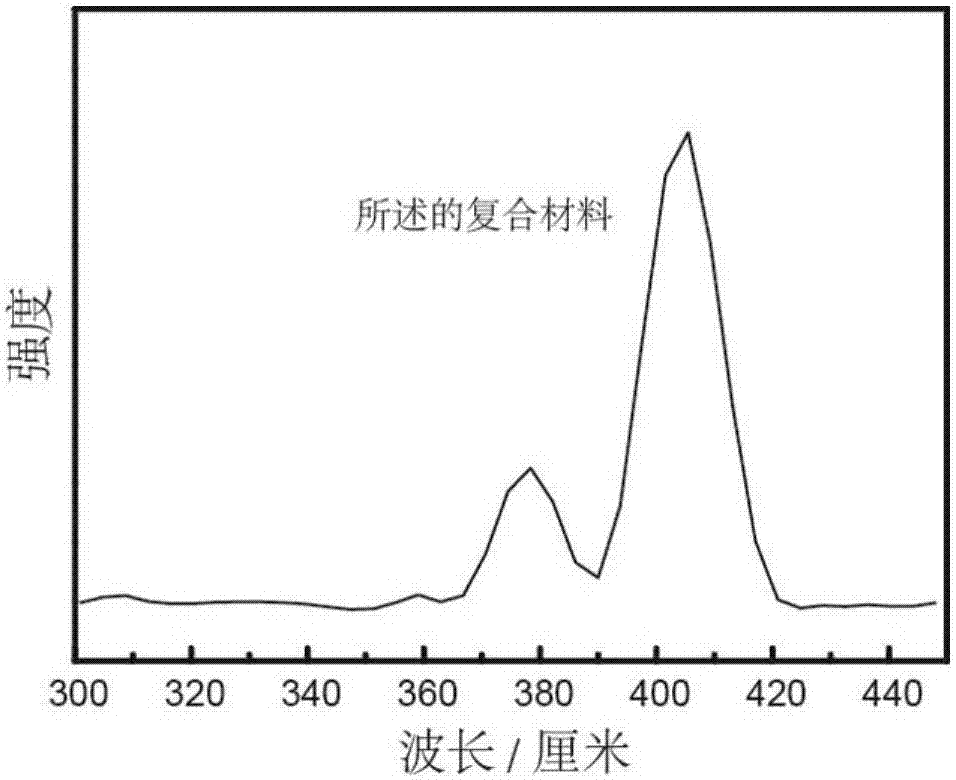

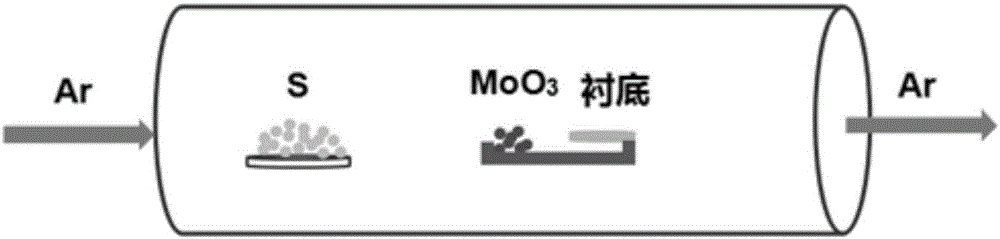

Porous carbon-loaded molybdenum disulfide nanosheet composition material and preparation method and application thereof

InactiveCN106964371AExcellent catalytic performance for hydrogen productionEasy to prepareMaterial nanotechnologyPhysical/chemical process catalystsPtru catalystPorous carbon

The invention discloses a porous carbon-loaded molybdenum disulfide nanosheet composition material and a preparation method and application thereof. The preparation method includes following steps: (1), utilizing porous carbon to adsorb molybdate to obtain a precursor; (2), in an inert atmosphere, thermally treating the precursor, and enabling sulfur steam to be in vulcanization reaction with the thermally-treated precursor to obtain the porous carbon-loaded molybdenum disulfide nanosheet composition material. Porous carbon adsorption is adopted to confine a molybdenum disulfide precursor, and a raw material precursor is directly converted into a highly-dispersed small-size ultrathin molybdenum sulfide nanosheet through vulcanization operation, so that compared with other methods like a lithium ion intercalation method, a vapor deposition method, a hydrothermal method and a solvothermal method, the preparation method is low in cost, simple in process, clear in product and suitable for large-scale production; the obtained composite material is excellent in water electrolysis hydrogen production catalytic performance and better than other reported similar catalysts.

Owner:INST OF CHEM CHINESE ACAD OF SCI

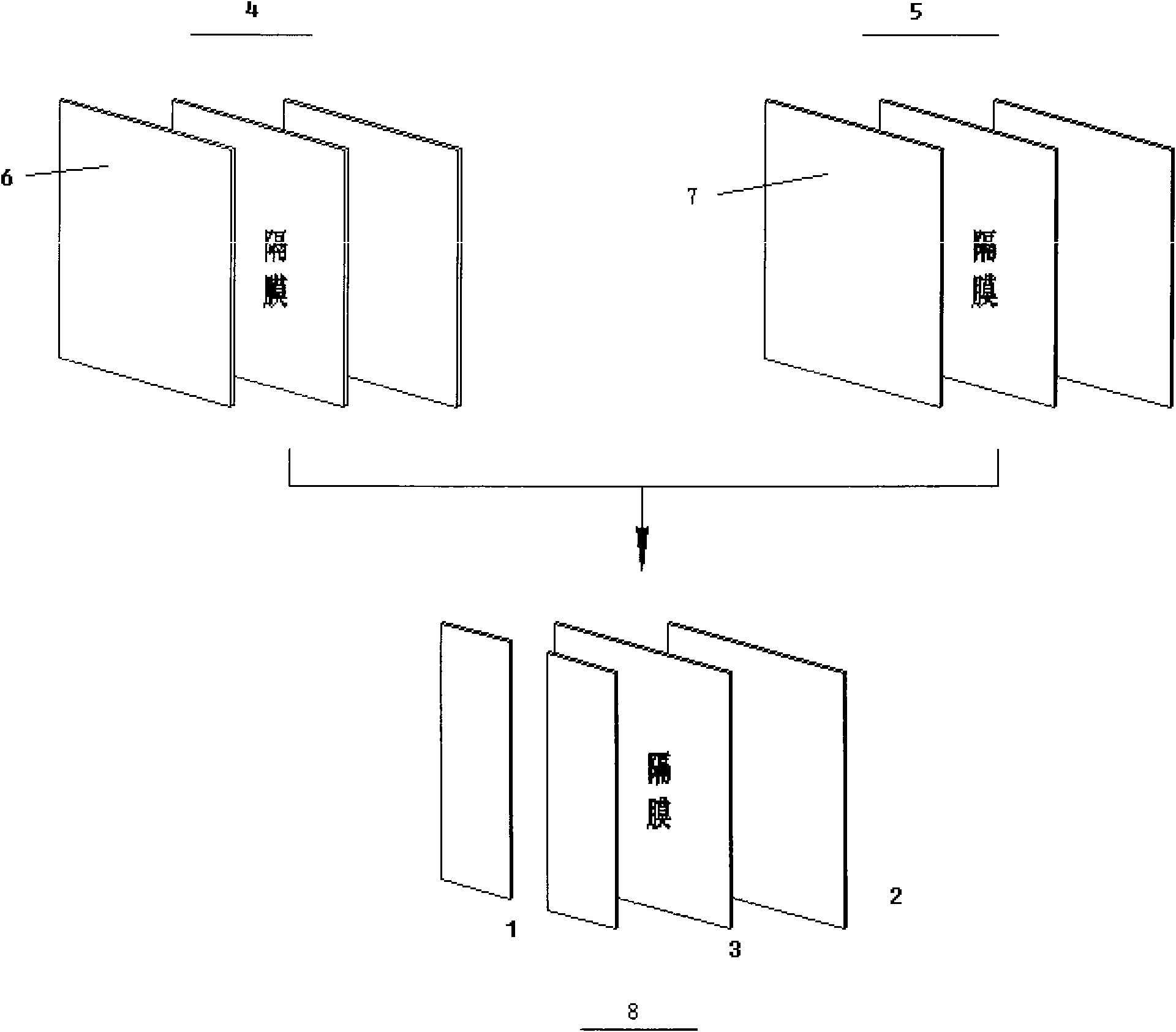

Negative plate of lithium ion battery, diaphragm and manufacturing method of negative plate and diaphragm

ActiveCN103606644AIncrease capacitySimple processCell seperators/membranes/diaphragms/spacersSecondary cellsElectrical batteryLithium metal

The invention specifically relates to a negative plate of a lithium ion battery, a diaphragm and manufacturing methods thereof. The negative plate of the lithium ion battery comprises a negative substrate. At least a surface of the negative substrate is uniformly coated with an active material layer which is characterized in that the surface of at least an active material layer is coated with lithium metal. When the negative plate is applied to a lithium ion battery, lithium metal is subjected to a dissolution reaction due to local battery theory. Simultaneously, a SEI film is generated on the surface of the active material layer of the negative plate, and a few lithium ions are embedded into the active material. Thus, capacity of the lithium ion battery is raised so as to overcome the problem that mismatching between capacity of the manufactured negative pole and capacity of a positive pole is caused and performance of the positive pole cannot be fully performed due to high irreversible capacity of materials such as Sn, Si and the like. Capacity of the lithium ion battery is raised greatly. Therefore, the negative plate can be adopted to raise capacity of the lithium ion battery.

Owner:ZHUHAI COSMX BATTERY CO LTD

Mixed aquo-lithium ion battery

ActiveCN1328818CImprove cycle performanceIncrease powerMaterial nanotechnologyHybrid capacitor electrolytesCarbon nanotubeLithium-ion battery

A hybrid aqueous battery / supercapacitor electrical storage device, wherein a double layer capacitance is integrated with an intercalated mechanism to form a hybrid system. The lithium-ion intercalated compounds are used as positive electrode material. Activated carbon, mesoporous carbon and carbon and carbon nanotubes, etc. are used as negative electrode material. A lithium-ion containing aqueous solution is used as electrolyte.

Owner:北京恩力动力技术有限公司

Method for preparing monolayer molybdenum disulfide

InactiveCN106835073AReduce stepsAvoid potential dangerChemical vapor deposition coatingHigh probabilityPiranha solution

The current methods for preparing single-layer molybdenum disulfide include micromechanical exfoliation, liquid-phase ultrasonic exfoliation, lithium ion intercalation, laser method, annealing layer-by-layer thinning method, and chemical vapor deposition method. Molybdenum disulfide prepared by chemical vapor deposition method has large size, uniform surface and controllable layer number. When molybdenum disulfide is prepared by chemical vapor deposition, molybdenum disulfide is easy to nucleate and grow on defects such as impurities or scratches on the substrate. If the substrate is not cleaned cleanly, molybdenum disulfide will easily grow into multi-layer or solid materials. To clean the substrate thoroughly, toxic and dangerous drugs such as acetone and piranha solution will be used. These drugs are toxic to the human body, so the operation process is potentially dangerous. Based on the above problems, the object of the present invention is to provide a simplified chemical vapor deposition method for the preparation of single-layer molybdenum disulfide, which can produce high-quality single-layer molybdenum disulfide without using toxic hazards such as acetone and piranha solution. Drugs are used to clean the substrate, avoiding potential danger.

Owner:BEIJING JIAOTONG UNIV

Electrochemical ultra-capacitor taking lithium ion battery electrode material as cathode

InactiveCN1632893AIncrease specific energyHigh specific powerHybrid capacitor electrodesElectrolytic capacitorsEngineeringLithium-ion battery

This invention belongs to capacitor technique field, which in detail is a new electrochemistry super capacitor. The capacitor combines the ion imbed to off imbed mechanism of the lithium ion battery and the double electric layers mechanism into one energy storage device, wherein its negative electrode adopts lithium ion imbed compound material with low imbed level and the positive electrode adopts active carbon or hole carbon to form an anisomerous super capacitor. Its negative electrode materials adopts nanometer sharp crystal rock Li#-[8x / (x+4)]Ti#-[8 / (x+4)]O#-[4] or one or multiple other metal elements mixed compound.

Owner:FUDAN UNIV

Method for preparing composite carbon cathode material for super-capacitor battery

InactiveCN101763944ALithium-ion energy storageFulfil requirementsElectrolytic capacitorsCapacitanceChemical plating

The invention relates to a high-rate lithium-ion battery and a method for preparing a composite carbon cathode material for a super-capacitor battery. The method comprises the following steps: coating a surface-nano-crystallized core with a porous carbon coat provided with macro-pore / meso-pore / micro-pore three-dimensional layer pores; doping metal particles on the surface of the coat; and carrying out low-potential treatment, wherein the three steps are sequentially achieved by a template-based method, a combined method comprising dipping, chemical plating and physical mixing, and an electrochemical method of lithium pre-doping respectively. The process of the invention has the advantages of simple method and convenient operation; the prepared material has a core-coat structure and doped metallic elements, and meanwhile, the material has good performance in double-layer electric energy storage and lithium-ion intercalation and de-intercalation energy storage and effectively improves the high-rate performance and power density of the lithium-ion battery; the material meets the requirements of super-capacitor batteries in both the lithium-ion energy storage and double-layer electric energy storage of the cathode material; accordingly, the material can be used as the cathode of a high-performance lithium-ion battery; and the material has good performance in high-rate charging / discharging, so the material has a good prospect for industrialization.

Owner:CENT SOUTH UNIV +1

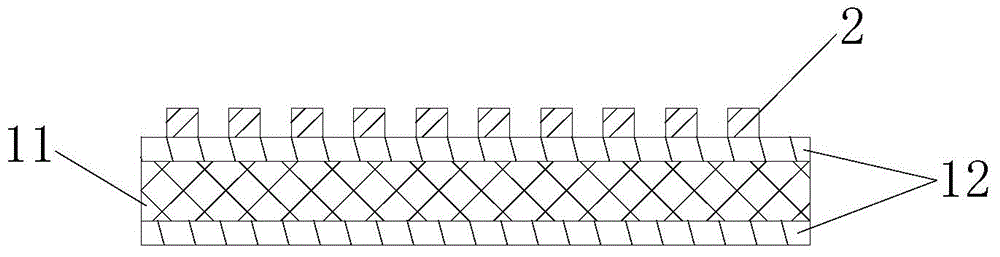

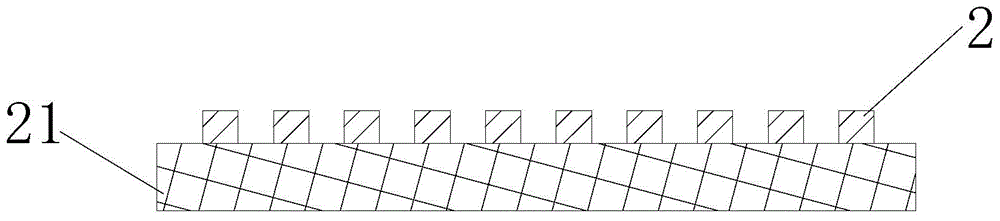

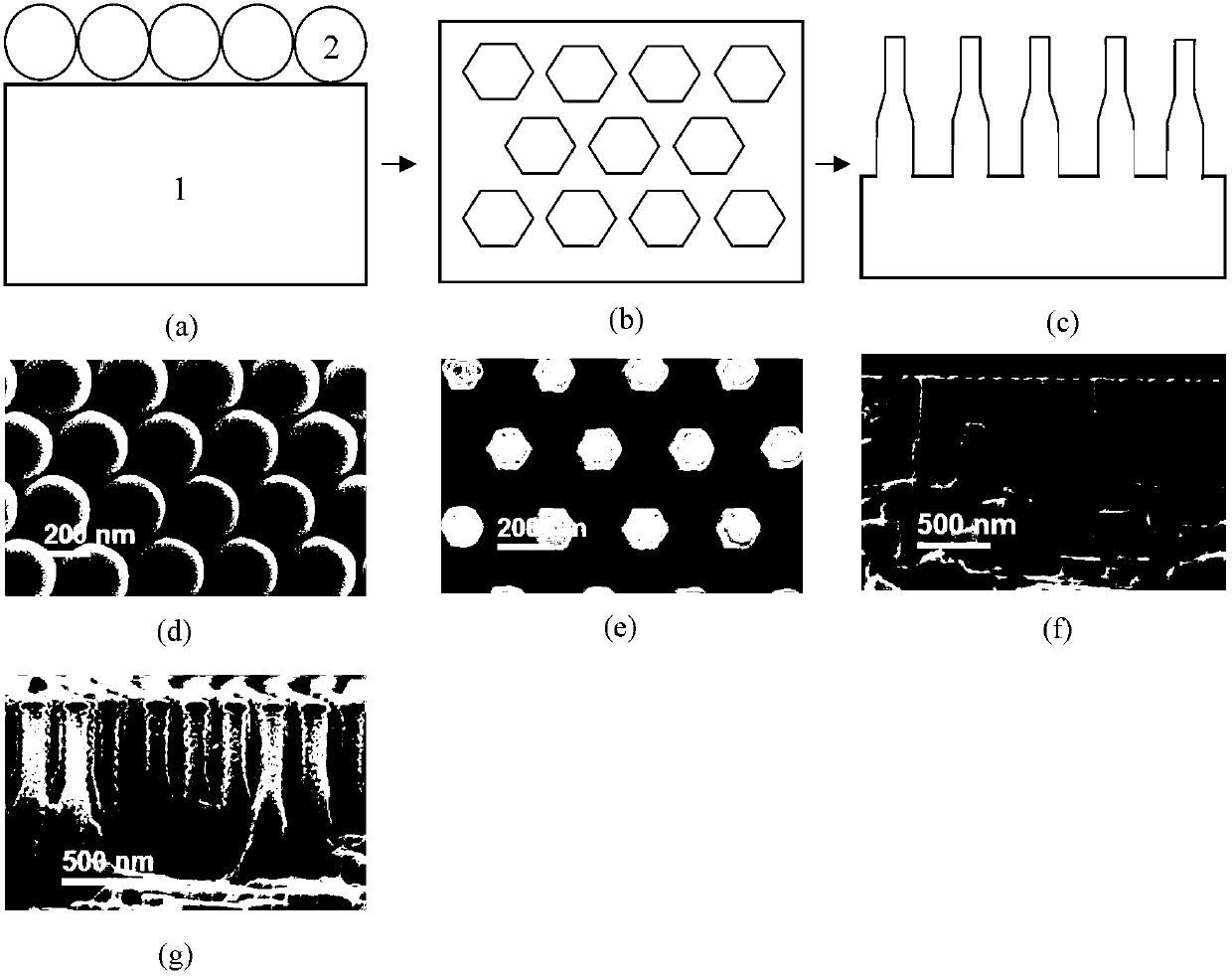

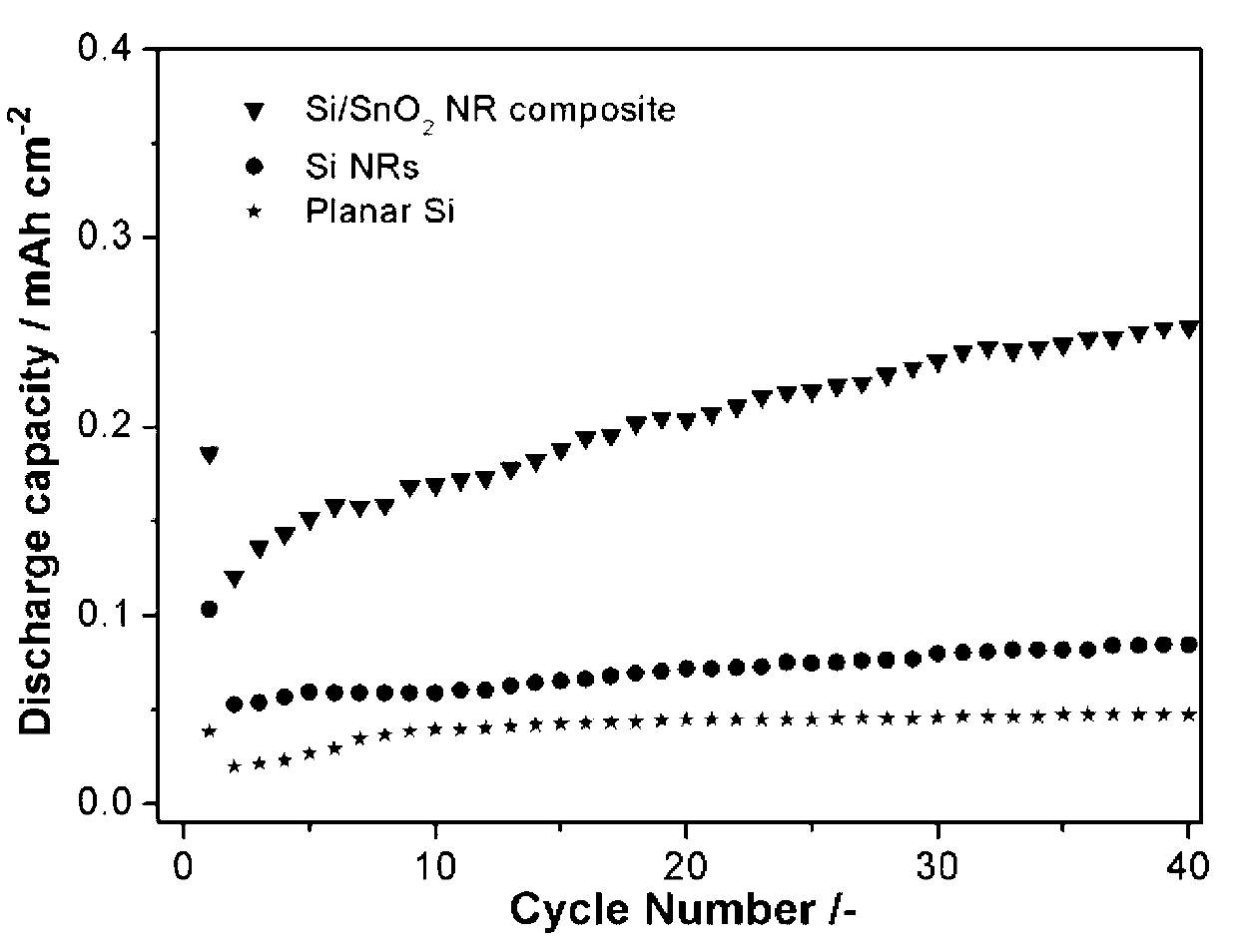

Nano electrode structure for silicon-based three-dimensional micro-battery

ActiveCN103213933AImprove stabilityImprove conductivitySemi-permeable membranesVolume/mass flow by thermal effectsLithium ion intercalationLithium electrode

The invention discloses a nano electrode structure for a silicon-based three-dimensional micro-battery. The nano electrode structure comprises a silicon nano-pillar array and a material layer compounded on the outer layers of silicon nano-pillars. The production method comprises the following steps of self-assembling hexagonal close-packed monolayer polystyrene nanospheres on the cleaned and activated silicon substrate by using a spin coating method; taking the monolayer polystyrene nanospheres as a mask, and utilizing the mask and an inductive coupled plasma etching technology to etch; sequentially using an organic solvent and a standard silicon chip cleaning process to remove the mask and byproducts generated in the etching process; and finally, utilizing the thin film deposition and material growth technology to obtain the bottle-shaped silicon-based composite nano-pillar array three-dimensional electrode structure. According to the structure, on the one hand, a lithium ion barrier layer can be deposited on the outer layers of silicon nano-pillars, and thus a structure support of the three-dimensional micro-battery that a silicon substrate does not participate in intercalation / deintercalation of lithium ions is formed, and on the other hand, the formed silicon or silicon composite material can be used as an anode material of a lithium ion battery to participate in electrode reaction.

Owner:XIAMEN UNIV

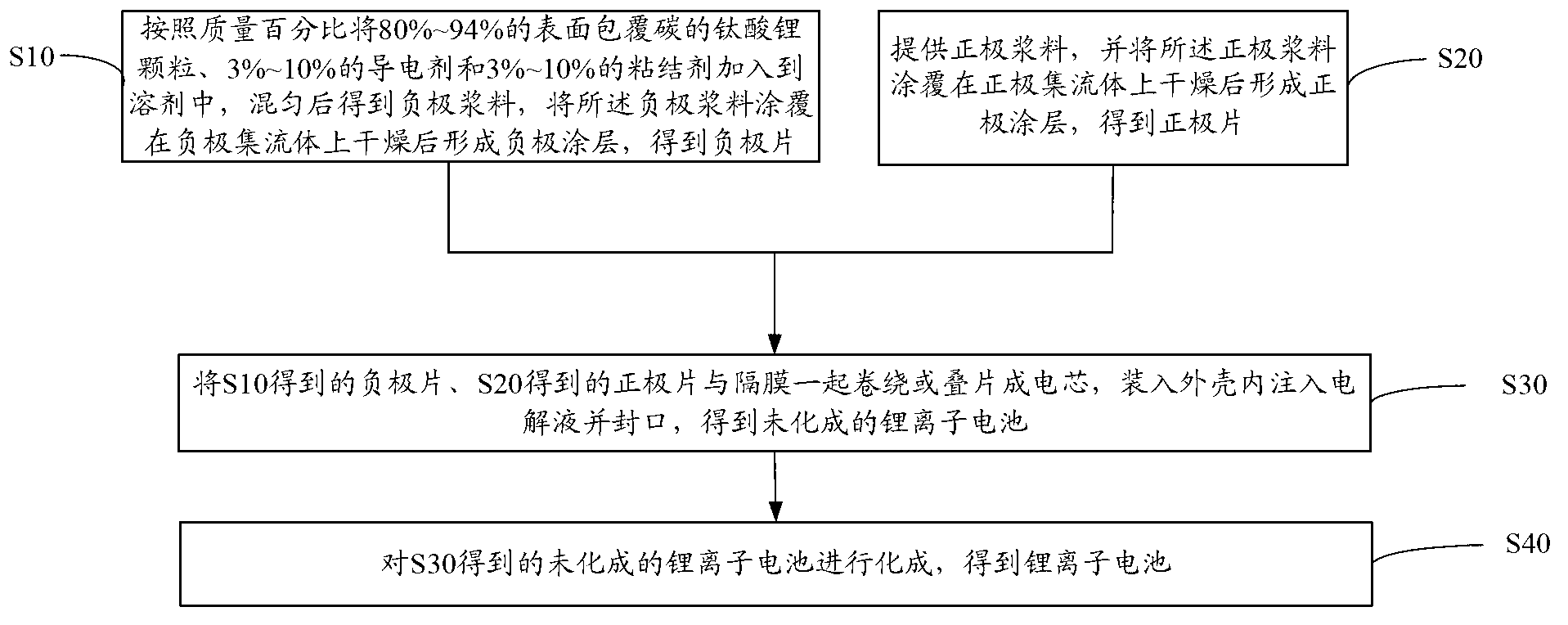

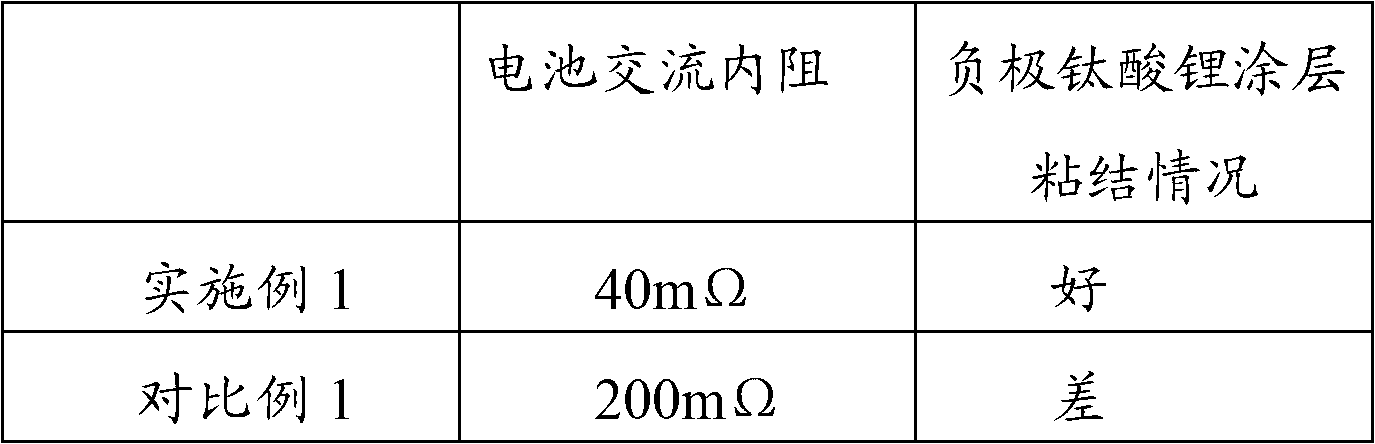

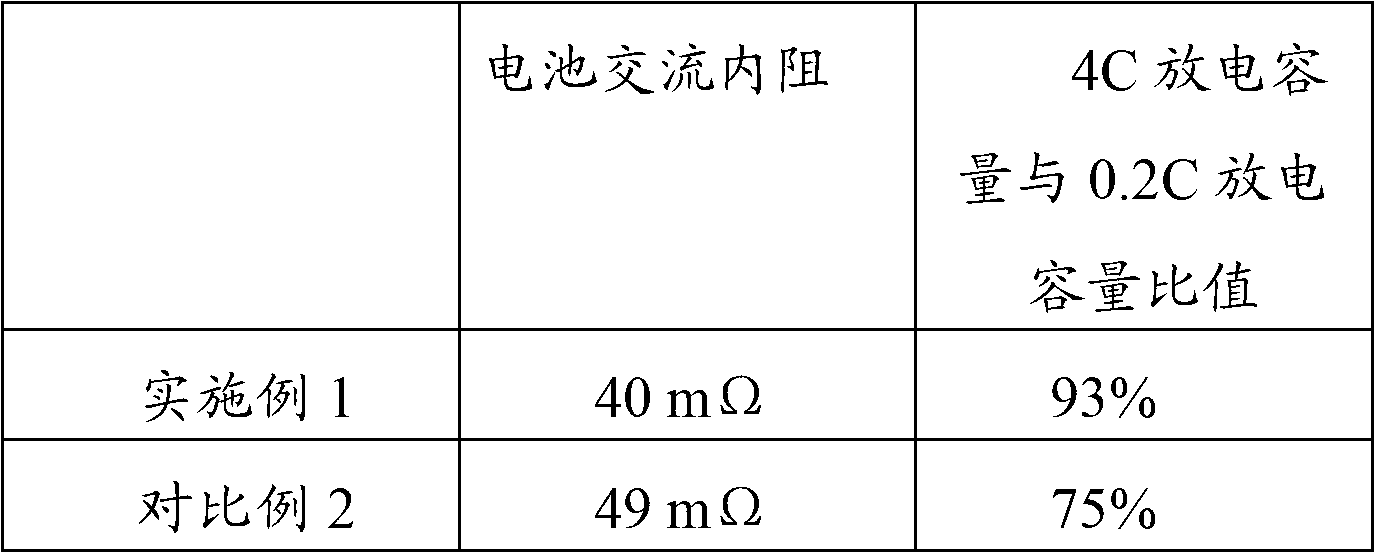

Negative plate, lithium ion battery and preparation method thereof

ActiveCN102800841AImprove cycle performanceLittle change in lattice constantFinal product manufactureElectrode carriers/collectorsLattice constantCarbon coated

The invention discloses a negative plate, comprising a negative current collector and a negative electrode coating coated on the negative current collector, wherein the negative electrode coating comprises a negative active material, a conductive agent and a bonding agent, and the negative active material comprises carbon coated lithium titanate particles which have a spinel structure. According to the invention, the negative active material of the negative plate comprises carbon coated lithium titanate, there is no change of the crystal form of the spinel lithium titanate in the process of intercalation / deintercalation of lithium ions, the crystal lattice constant has small change, and the volume change is less than 1%; when the negative plate is applied in a lithium ion battery, compared with a traditional lithium ion battery which comprises a graphite material as a negative active material, the battery cycle performance is better. The invention further provides a lithium ion battery which utilizes the negative plate and a preparation method thereof.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

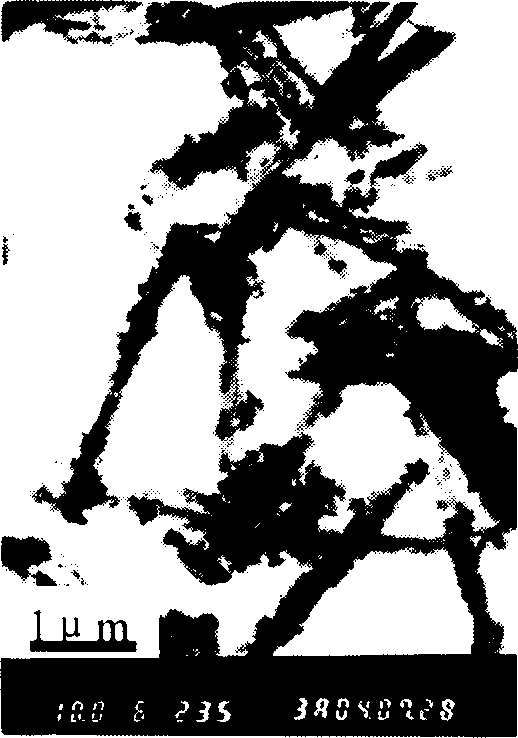

Carbon material and nano silicon composite materials and method for preparing same and use thereof

InactiveCN1884056AHigh reversible capacityPromote circulationSiliconInorganic pigment treatmentNano siliconLithium ion intercalation

The invention discloses a preparing method of carbon material or nanometer silicon composite material and material through composite sintering method in the electrochemical technological domain, which is characterized the following: possessing stable structure with even particle diameter less than 1 mm; avoiding agglomeration among large amount of nanometer particles due to stronger action of surface to surface; displaying high reversible capacity and excellent circulating property.

Owner:FUDAN UNIV

Synthesis of series nanometer lithium and manganese oxide for lithium ion battery

InactiveCN1817800AThe synthesis method is simpleEasy to operate and controlCell electrodesManganese oxides/hydroxidesLithium hydroxideSodium-ion battery

Synthesis of series nanometer lithium manganese oxide for lithium ion battery is carried out by taking mangano-manganic oxide or basic manganese oxide as precursor, hydrothermal reacting with excessive lithium hydrate in water or alcohol solution of autoclave, inserting lithium ion into lattice of manganese oxide, separating, washing and drying to obtain final product. It is simple and safe, has lower energy consumption, uniform granularity, better electrical performance and no environmental pollution.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com