Carbon material and nano silicon composite materials and method for preparing same and use thereof

A technology of composite materials and carbon materials, applied in chemical instruments and methods, silicon, fibrous fillers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

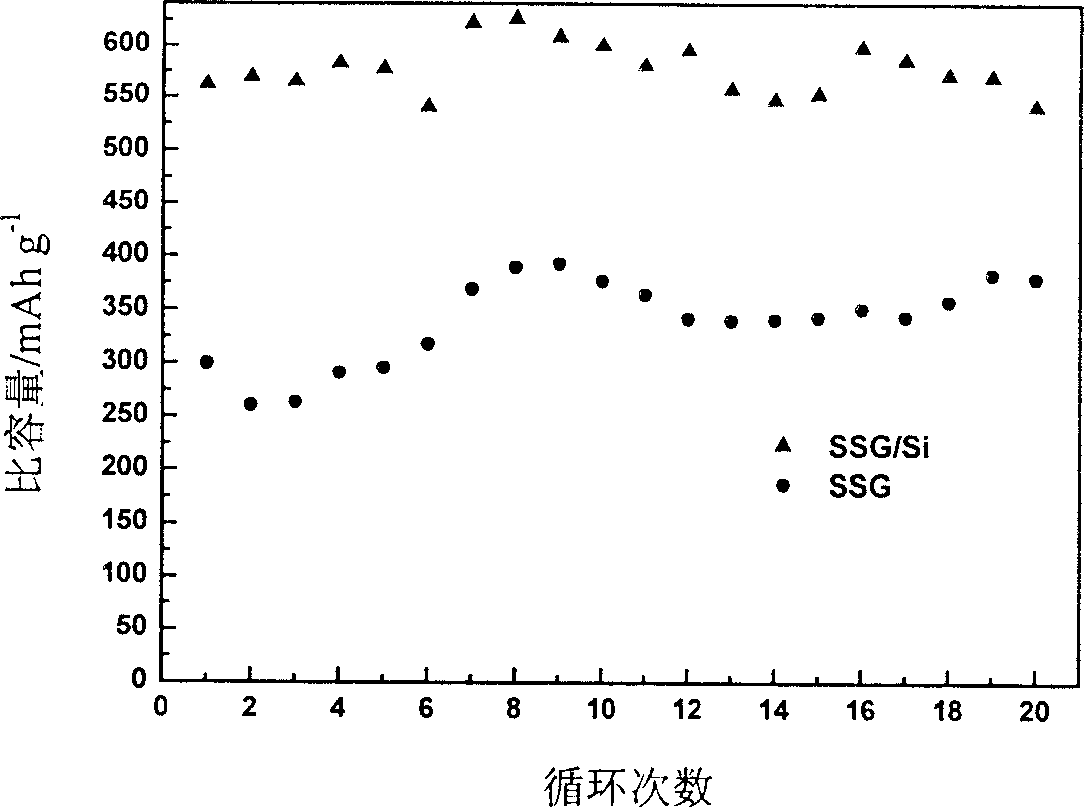

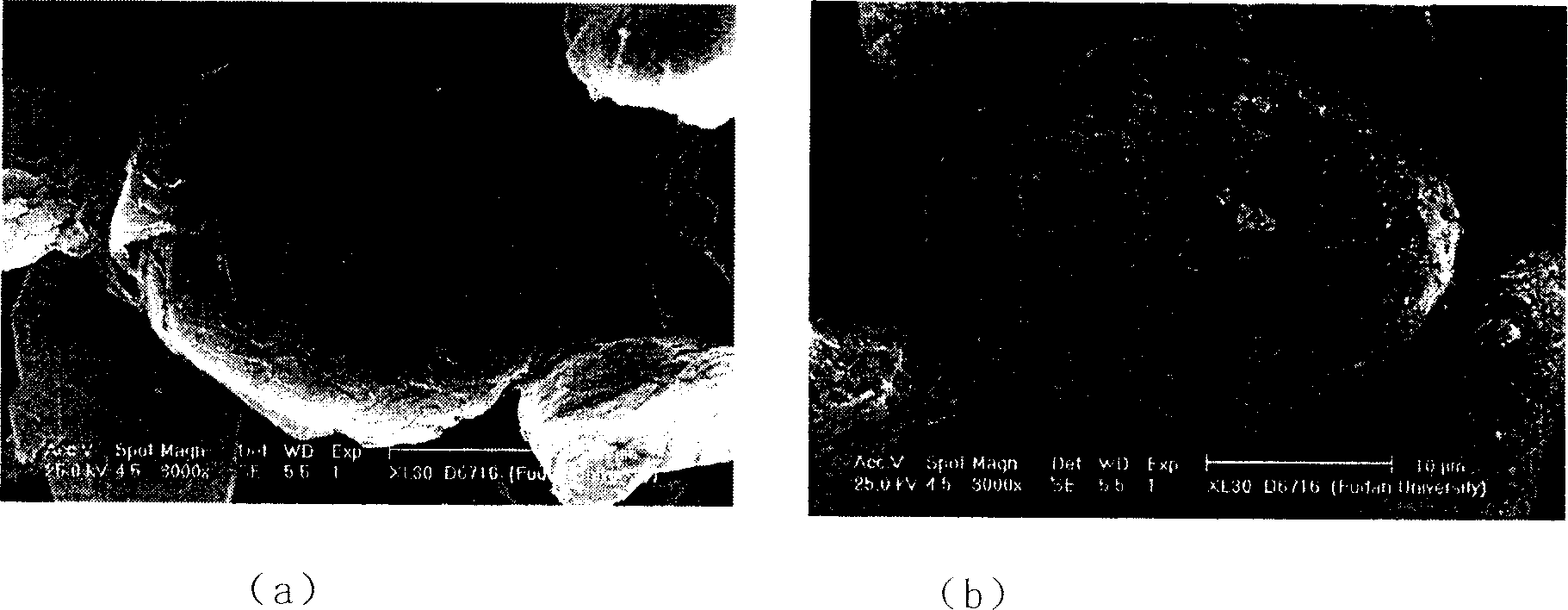

[0015] In the carbon material / nano-silicon composite material preparation method of the present invention, the carbon material in step (1) is artificial graphite, natural graphite or low-temperature amorphous carbon, and the average particle size of the carbon material is 0.01-1000 microns.

[0016] In the carbon material / nano-silicon composite material preparation method of the present invention, step (1) involves ultrasonic dispersion of nano-silicon. The nano-silicon used in this step can be industrial-grade nano-silicon or high-purity silicon. In terms of cost, industrial grade nano silicon is preferred. The particle size of nano-silicon is within the range of 1 nm-500 nm, preferably 5 nm-200 nm, more preferably 10 nm-100 nm. The shape of nano-silicon can be nanosphere, nanowire, nanorod, nanofiber, nanotube, etc., preferably nanosphere. The particle size of the carbon material used in this step is preferably 0.1 micron to 20 micron, more preferably 2 micron to 15 micron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com