Patents

Literature

6822 results about "Ultrasonic dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic dispersing is usually a small vibration, acceleration, it has been in the food, fuel, new materials, chemical products, coatings and other fields are widely used. Ultrasonic dispersing can also be used for the preparation of nanomaterials; for food sample detection analysis.(ultrasonic liquid processor)

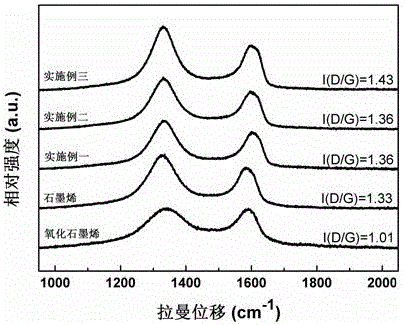

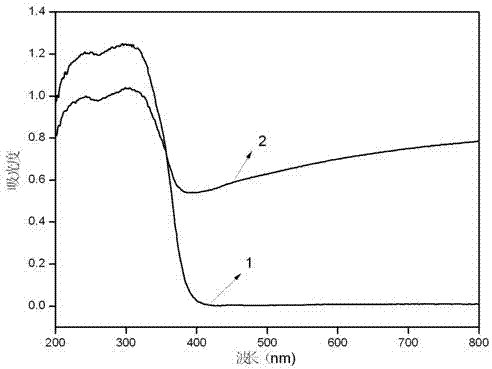

Preparation method of high purity and high concentration graphene suspension

InactiveCN101830458AFacilitate the reduction reactionInhibition of agglomerationHigh concentrationUltrasonic radiation

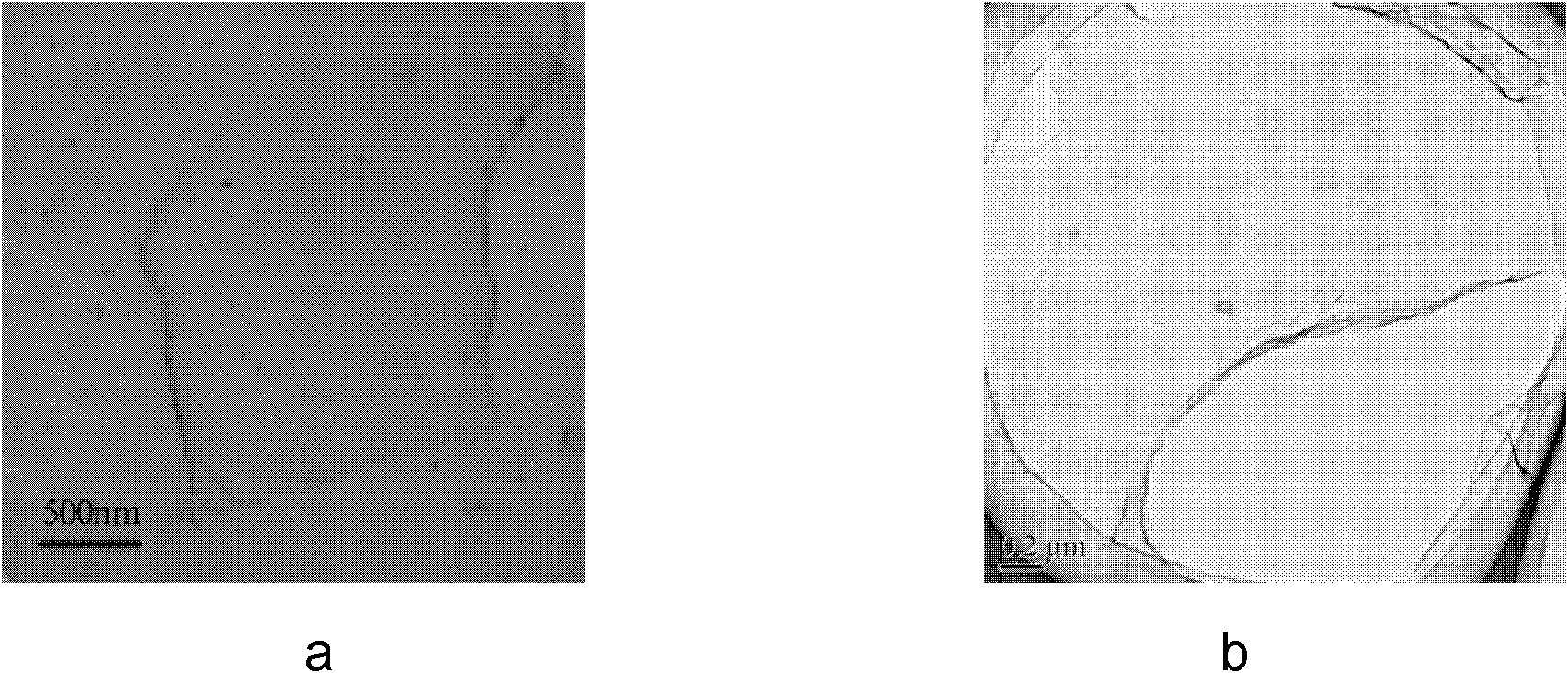

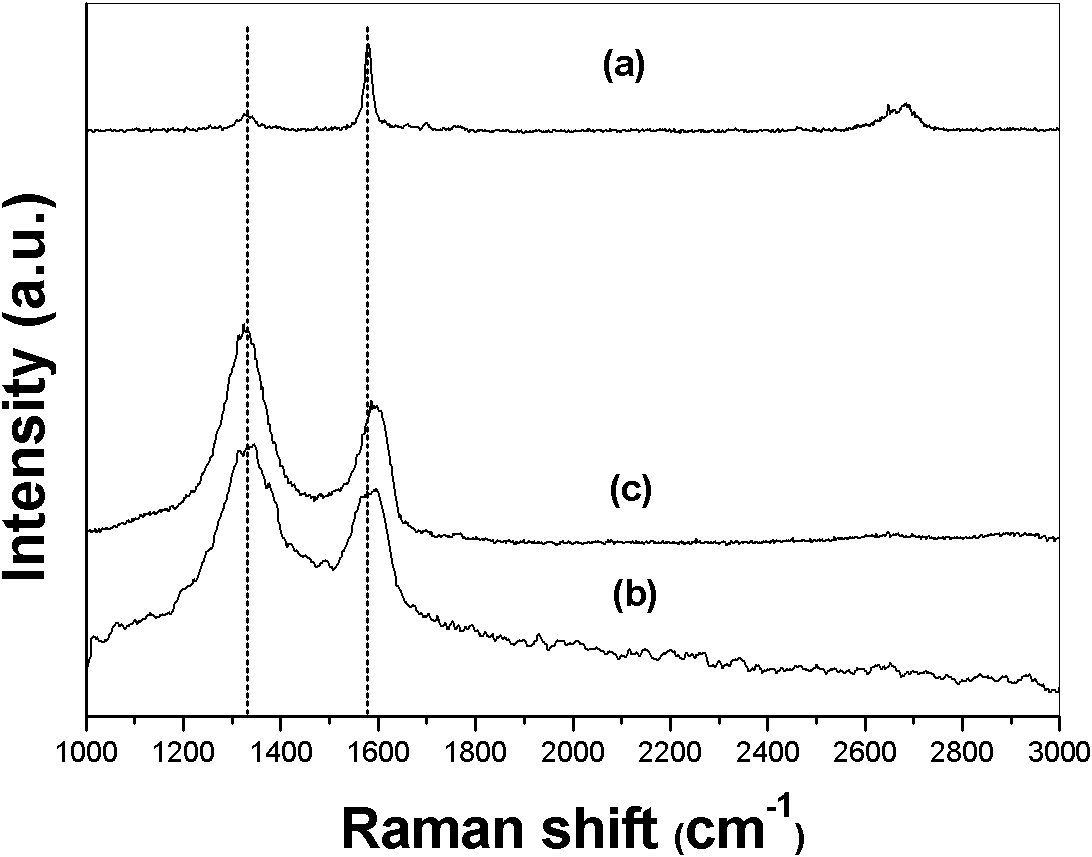

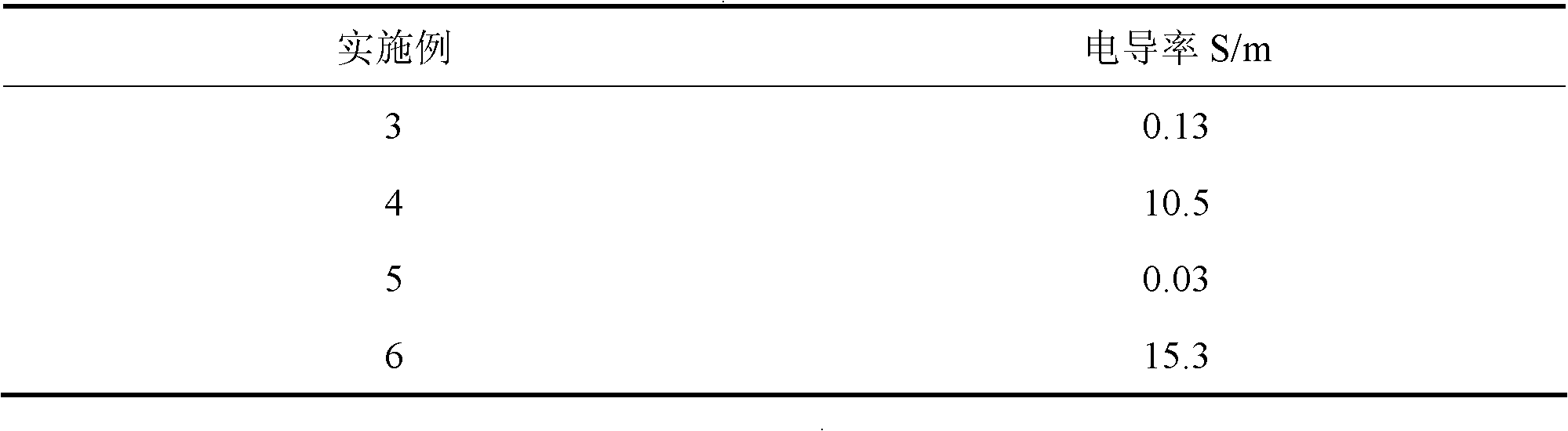

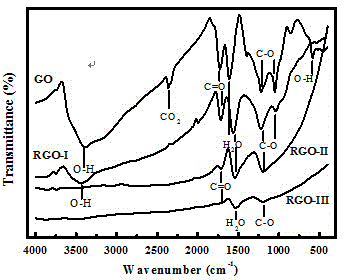

The invention relates to a preparation method of a high purity and high concentration graphene suspension, which comprises the following steps of: reacting natural crystalline flake graphite with a strong oxidizer to obtain graphite oxide; spreading the graphite oxide into a dispersing agent, and obtaining a graphene oxide suspension by ultrasonic dispersion; mixing the graphene oxide suspension with hydrazine hydrate under the protection of nitrogen and reacting at constant temperature under ultrasonic radiation to prepare stable graphene suspension. Compared with the traditional method for preparing the graphene suspension, the method introduces ultrasonic in the reduction process of the graphite oxide. The invention has the following advantages that the prepared graphene suspension has high concentration (higher than 1 mg.mL<-1>), high purity (without influence of surface active agents and other impurities), high dispersionstability (time for stable dispersion is more than 60 days) and the like; the graphene prepared by the method has high electrical conductivity (high than 700 S.m<-1>), less number of layers, is simple and easy to implement, and is very suitable for large scale production in industy.

Owner:XI AN JIAOTONG UNIV

Preparation method of graphene/polymer nano composite material

ActiveCN102161785AEvenly dispersedGood mechanical propertiesOther chemical processesMagnetic/electric field screeningUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a graphene / polymer nano composite material, which is characterized by comprising the following steps: adding 0.1-30 parts by weight of graphite oxide into 10-3000 parts by weight of water, and dispersing and exfoliating by carrying out ultrasonic dispersion (the power is 50-500W, and the frequency is 10-100000Hz) at 10-100 DEG C for 15 minutes-5 hours or mechanical lapping for 15 minutes-5 hours or mechanical stirring for 1-48 hours to obtain a graphene oxide water solution; adding the graphene oxide water solution into 100 parts by weight of polymer emulsion of which the solid content is 10-70%; continuing the ultrasonic or mechanical stirring to carry out uniform mixing; demulsifying by adding 1-100 parts by weight of 5-100% demulsifier toobtain a graphene oxide / polymer granular suspension; adding 0.1-100 parts by weight of reducer into the graphene oxide / polymer granular suspension, reducing at 20-100 DEG C for 1-72 hours, filtering,and drying in a drying oven at 20-100 DEG C for 2-72 hours or drying in a vacuum drying oven at 20-120 DEG C under a vacuum degree of 0.1-0.01 MPa for 2-48 hours, thereby obtaining the graphene / polymer nano composite material.

Owner:SICHUAN UNIV

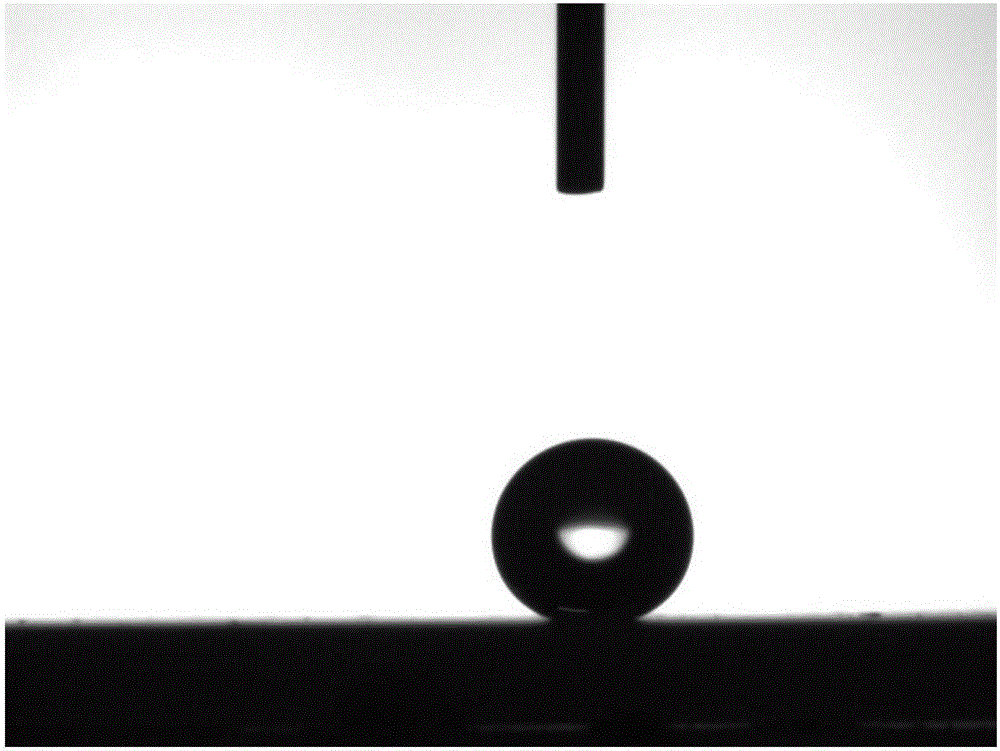

Super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and preparation method and application thereof

InactiveCN103316507AHas super oleophobic propertiesLow costFatty/oily/floating substances removal devicesLiquid separationHydrophilic polymersSewage

The invention discloses a super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane, and a preparation method and an application thereof. According to the method, fabric mesh with a specification of 100-300 meshes is subjected to ultrasonic cleaning, and is air-dried under normal temperature; a hydrophilic polymer water-sensitive agent and a cross-linking agent are dissolved in water according to a ratio of 1:9-9:1; the mixture is well mixed by magnetic stirring, such that a solution with a concentration of 1-99% is prepared; nano-sol is prepared with a sol-gel method; the solution and the nano-sol are prepared into a mixed solution with a concentration of 1-99%, and the solution is well dispersed through ultrasonic dispersion; the mesh is soaked in the mixed solution and is vertically lifted, or the mesh is directly sprayed by using a high-pressure spraying gun; and the mesh is bake-dried, such that the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane is obtained. Contact angles of the super-hydrophilic and underwater-super-oleophobic oil-water separation mesh membrane with water and oil in air are both 0 DEG, and the membrane is super-hydrophilic. Under water, the contact angle of the membrane with oil drops is larger than 150 DEG, and the membrane has an oil drop low adhesion characteristic. The mesh membrane provided by the invention can be used in oil-water mixture separation and oil-containing sewage processing.

Owner:SOUTH CHINA UNIV OF TECH

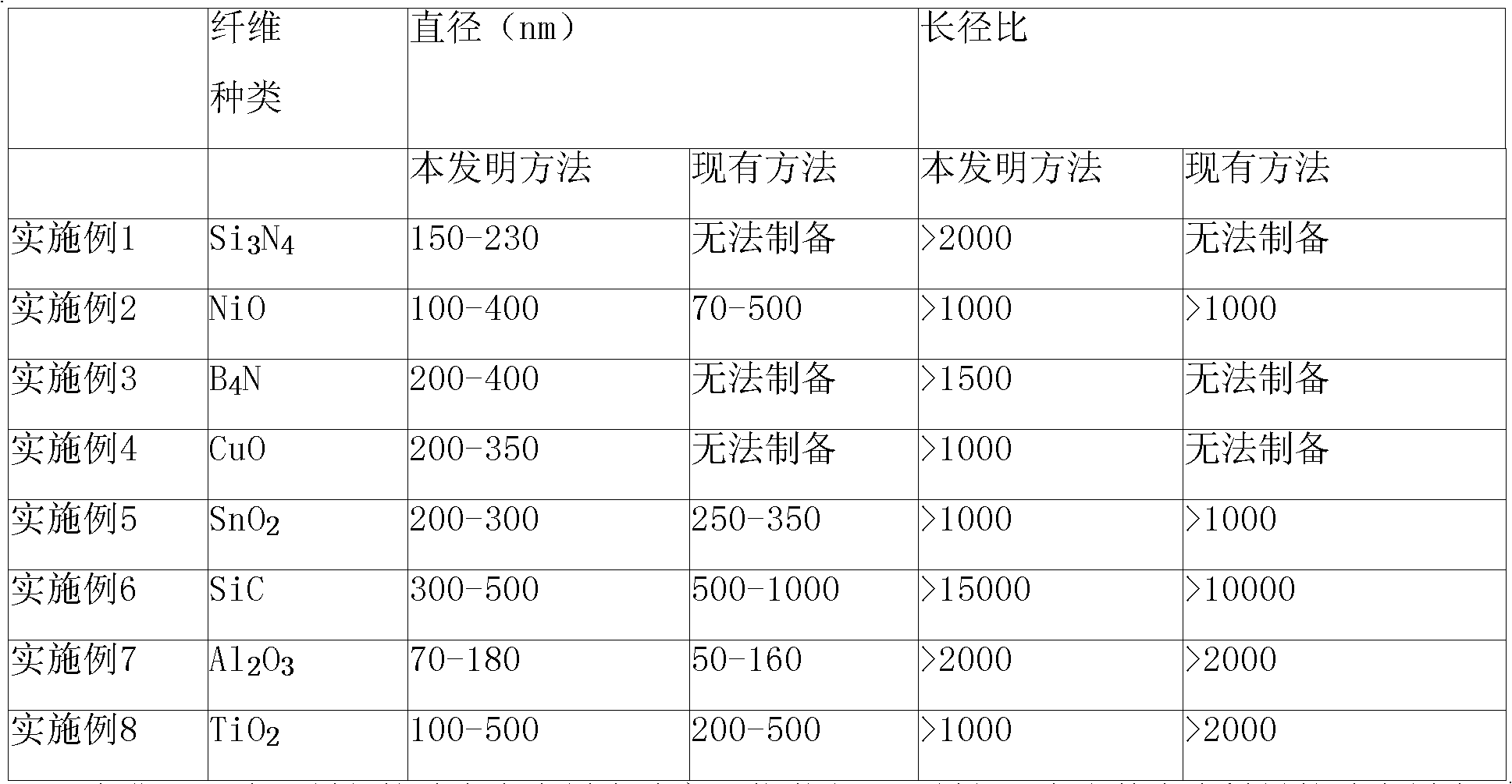

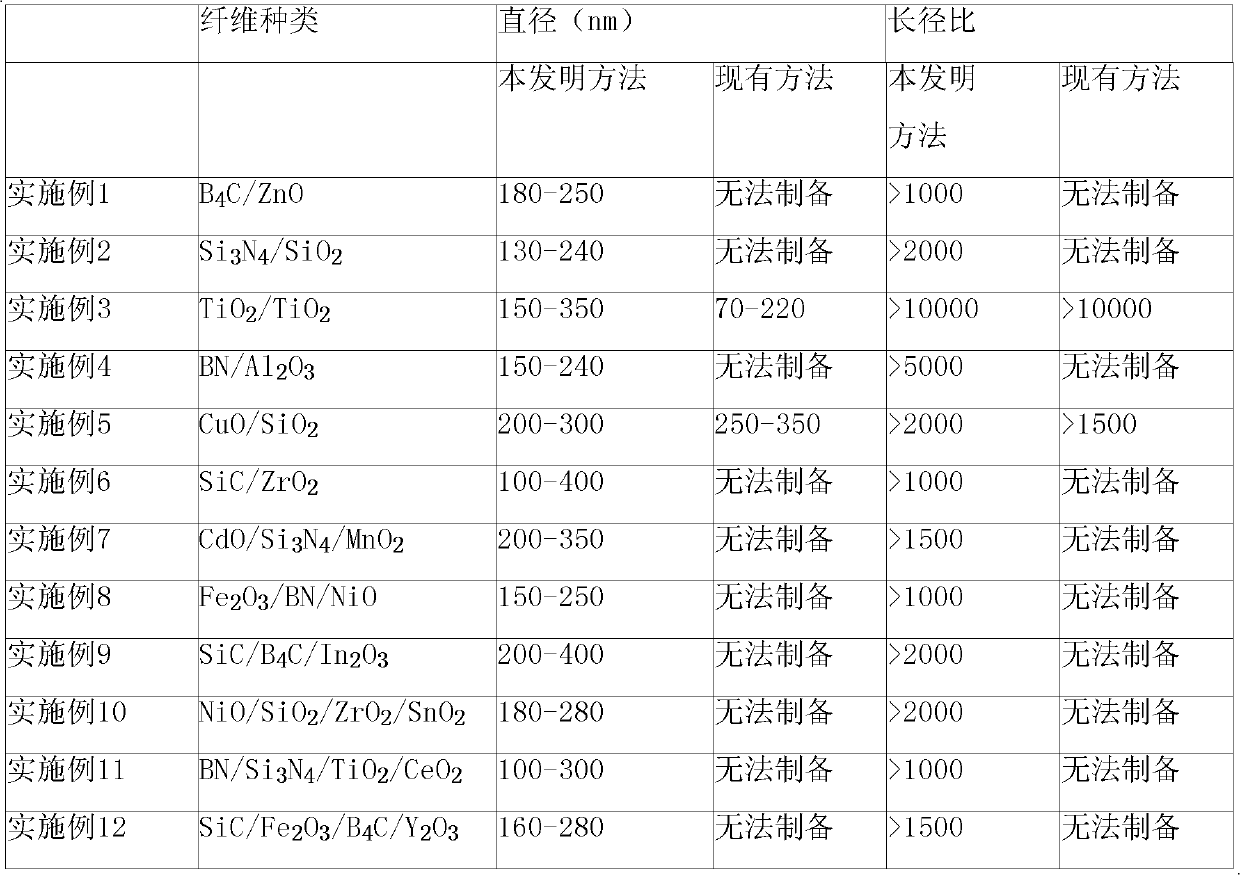

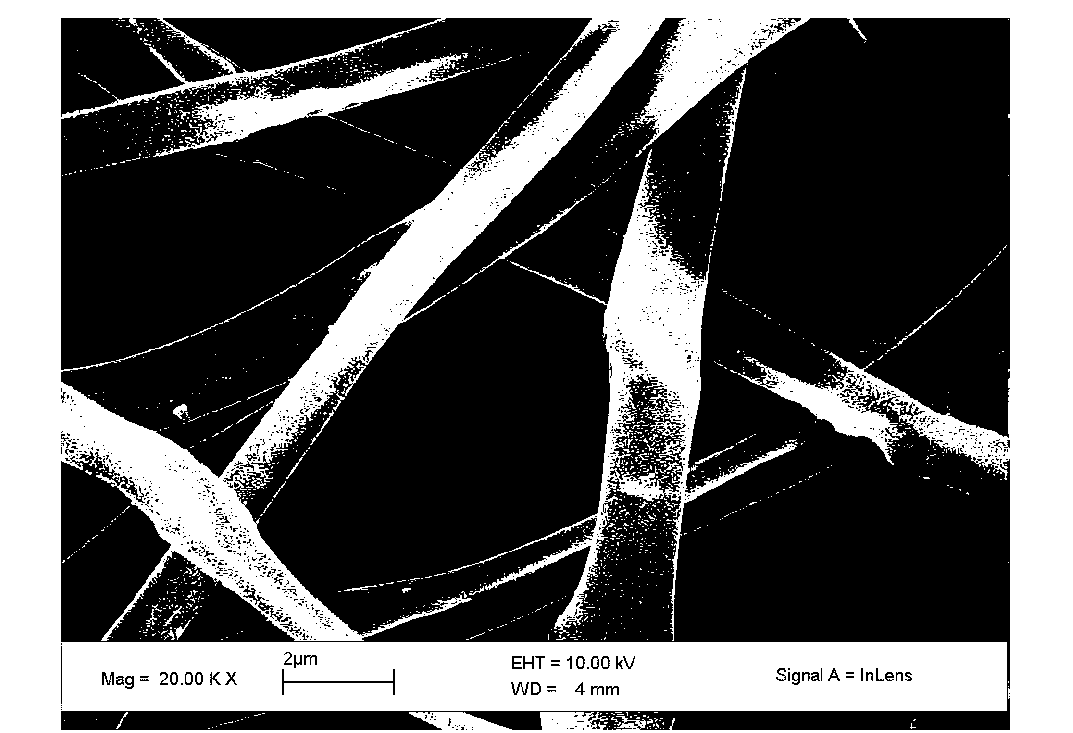

Method for preparing nano ceramic fibers

InactiveCN101880917AAverage diameter distributionHigh aspect ratioInorganic material artificial filamentsFilament/thread formingFiberWater baths

The invention discloses a method for preparing nano ceramic fibers, which is implemented by the following steps: 1, preparing 3 to 15 volume percent of 10 to 30 nanometer ceramic nanoparticles, 5 to 30 volume percent of spinnable high polymer, 0.5 to 5 volume percent of dispersant and the balance of solvent, wherein the total volume of the raw materials is 100 volume percent; 2, adding the spinnable high polymer into the solvent, heating the mixture in a water bath with magnetic stirring to obtain solution of spinnable high polymer; 3, adding the ceramic nanoparticles and the dispersant into the solution of spinnable high polymer obtained by the step 2, keeping the temperature of the mixture constant in a water bath, performing dispersion and ultrasonic dispersion, and performing swelling at a constant temperature to obtain ceramic nanoparticle / spinnable high polymer / solvent spinning solution; 4, controlling the electrostatic spinning process parameters of the spinning solution obtained by the step 3 to obtain nano fibers; and 5, sintering the nano fibers at 400 to 1,200 DEG C to obtain nano ceramic fibers.

Owner:XIAN UNIV OF TECH

Electrostatic spinning preparation method of ceramic nanometer composite fibers

The invention discloses an electrostatic spinning preparation method of ceramic nanometer composite fibers, comprising the following concrete steps of: firstly, according to volume percentage, weighing 3-10 percent of ceramic nanometer particles with the partilce size of 10-300 nm, 3-20 percent of ceramic precursor, 5-30 percent of spinnable polymer and 40-89 percent of solvent with the total volume of 100 percent; secondly, adding the spinnable polymer into the solvent, heating in water bath and magnetically stirring; thirdly, adding the ceramic precursor into the spinnable polymer solution obtained in the second step, heating in water bath, magnetically stirring and ageing; fourthly, adding the ceramic nanometer particles into the ceramic precursor spinnable solution obtained in the third step, heating at constant temperature in the water bath and forming a spinning solution by carrying out ultrasonic dispersion and constant temperature swelling; fifthly, preparing composite nanometer fibers by the spinning solution according to an electrostatic spinning technology; and sixthly, obtaining the ceramic nanometer composite fibers by sintering the composite nanometer fibers. In the method, raw materials have wide selection conditions and wide optional range.

Owner:XIAN UNIV OF TECH

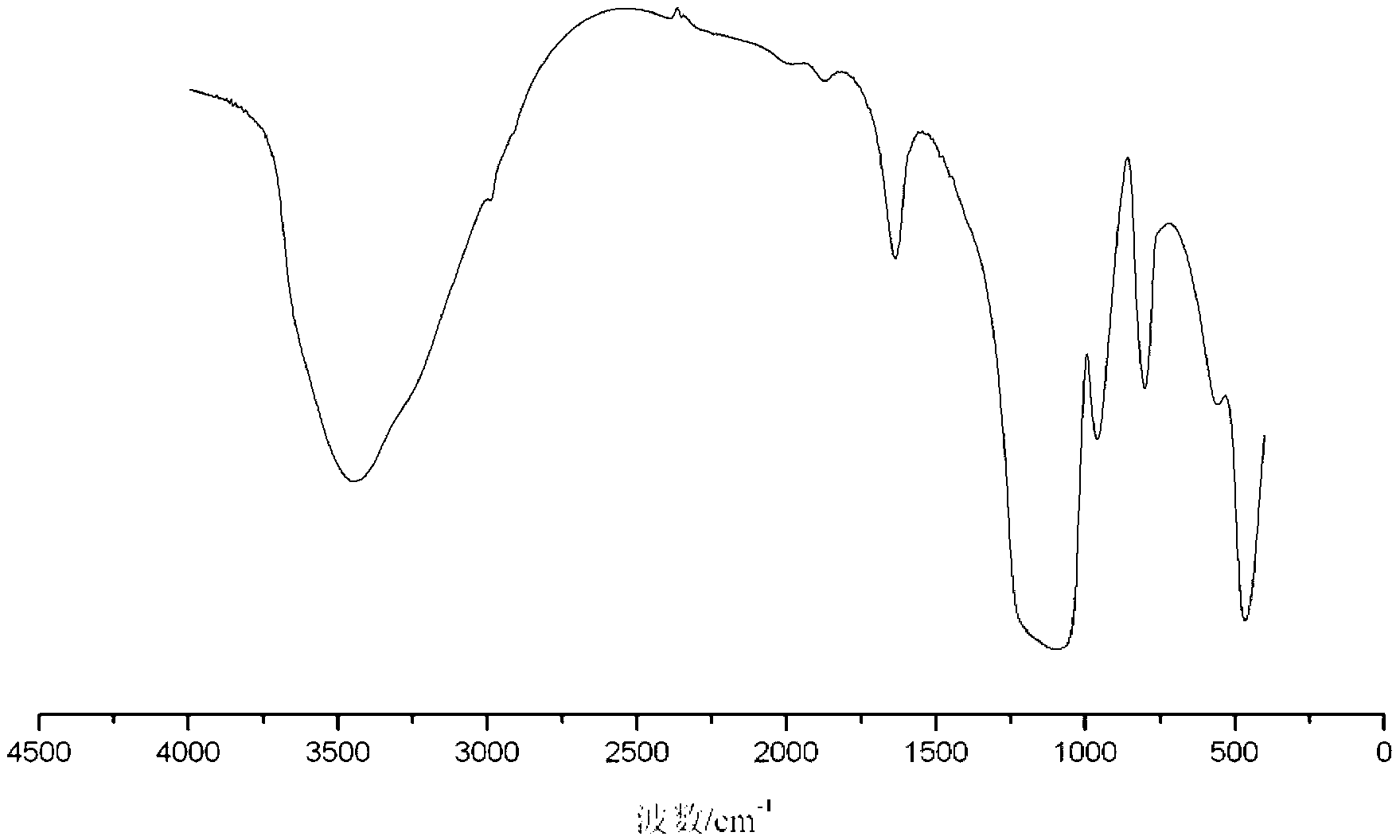

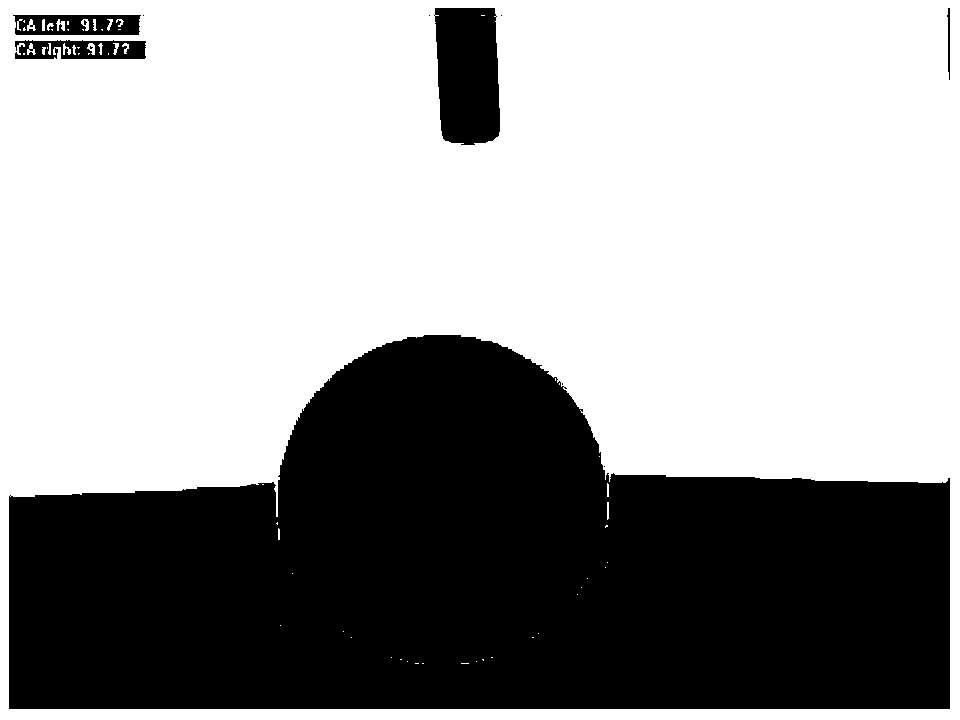

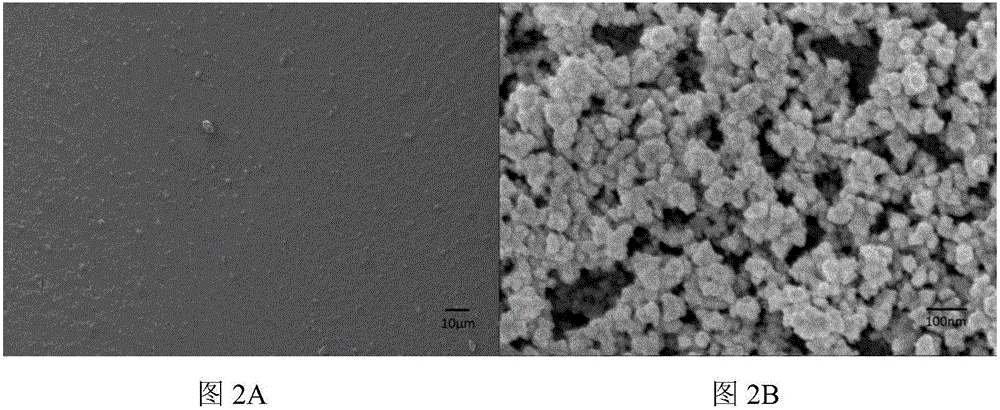

Super-hydrophobic nanometer transparent coating and preparation method thereof

ActiveCN104987520AExcellent superhydrophobic propertiesHigh transparencyCoatings with pigmentsFibre treatmentOrganic solventUltrasonic dispersion

The invention provides a super-hydrophobic nanometer transparent coating and a preparation method thereof and belongs to the technical field of super-hydrophobic paint. The method includes the steps that firstly, a first category of inorganic nanometer particles are added into an organic solution, and ultrasonic dispersion is performed; secondly, dispersing agents and a second category of inorganic nanometer particles are added, and ultrasonic dispersion is performed so that a dispersion solution can be obtained; crosslinking agents and additives are added in the dispersion solution, ultrasonic dispersion is performed, finally, low-surface energy polymers are added, mixtures are evenly mixed, and transparent and clear super-hydrophobic paint is obtained; the surface of a solid base materials is coated with the transparent and clear super-hydrophobic paint, and the super-hydrophobic nanometer transparent coating is obtained through low-temperature thermal drying and curing. The super-hydrophobic performance of the super-hydrophobic nanometer transparent coating prepared through the method is excellent, the contact angle can be 160 degrees, the rolling angle is 1-7 degrees, the super-hydrophobic nanometer transparent coating can be sprayed to the surfaces of most of common materials, the morphology of the surfaces of the materials are not changed, and the application prospects and the application potency are very wide.

Owner:BEIHANG UNIV

Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

The invention discloses a method for preparing a lithium ion battery anode / cathode material from reduced graphene oxide. The method comprises the following steps: performing ultrasonic dispersion on graphite oxide in an organic solvent, thereby obtaining a graphene oxide dispersion liquid; reducing by using an appropriate reducing agent or directly using a solvent, oxidizing graphene through oil bath backflow, a hydrothermal method or other reduction methods, thereby obtaining a reduced graphene oxide material containing part of oxygen-containing groups. When the prepared reduced graphene oxide material is used in a lithium ion battery anode material, a relatively high specific discharge capacity can be achieved, that is, is up to 280mAh / g, and good circulation stability and excellent rate performance are achieved. The prepared reduced graphene oxide material can be also used in a lithium ion battery cathode material, the specific discharge capacity can be kept being 900mAh / g and more than 900mAh / g after 100 rounds of charge / discharge circulation, and the circulation stability is relatively good. The method can be a significant study point of high-performance low-cost electrode materials of lithium ion batteries.

Owner:TIANJIN NORMAL UNIVERSITY

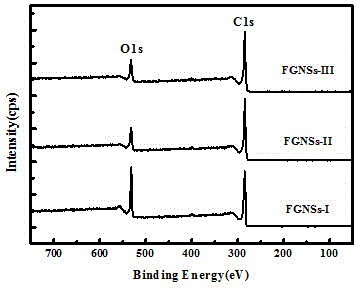

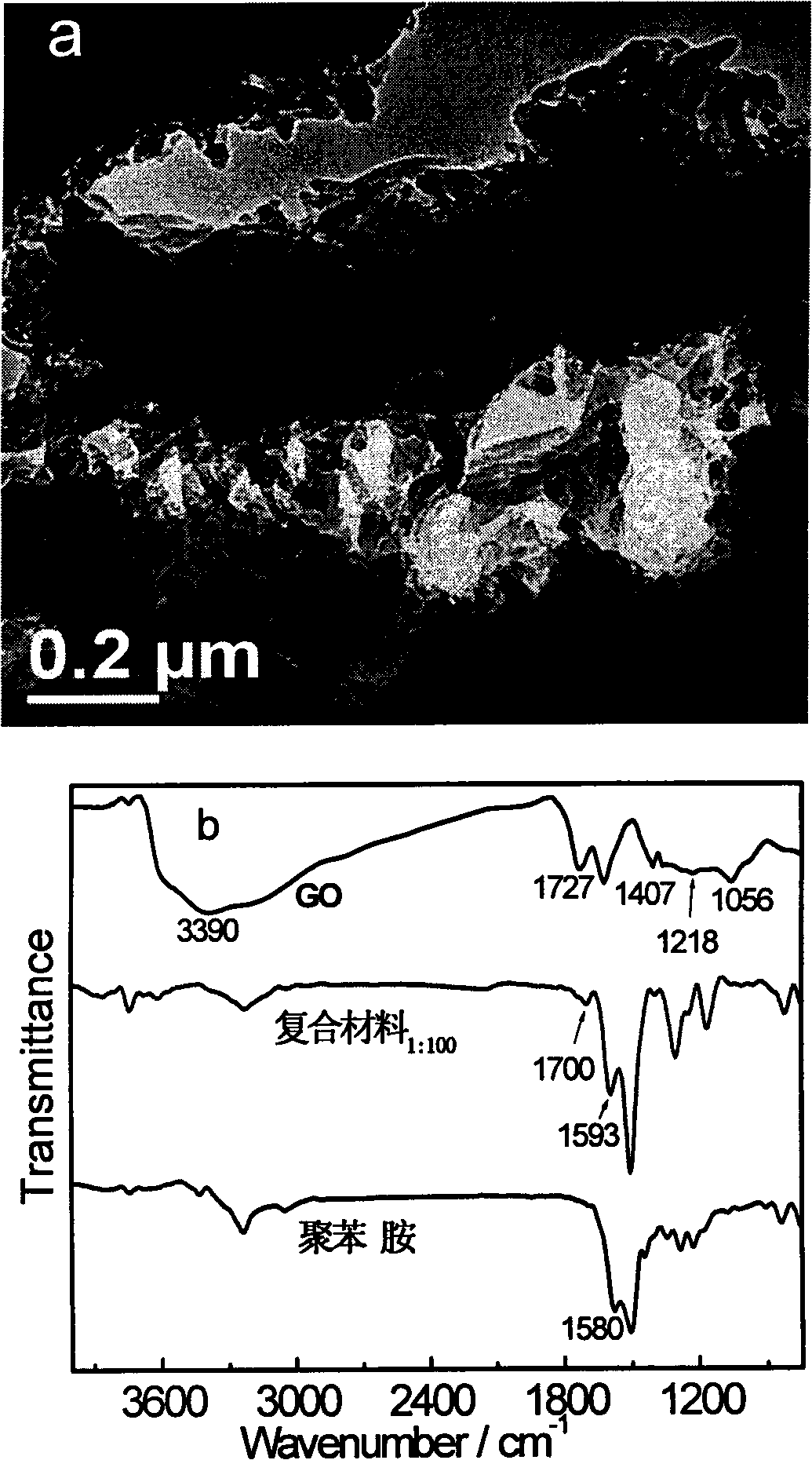

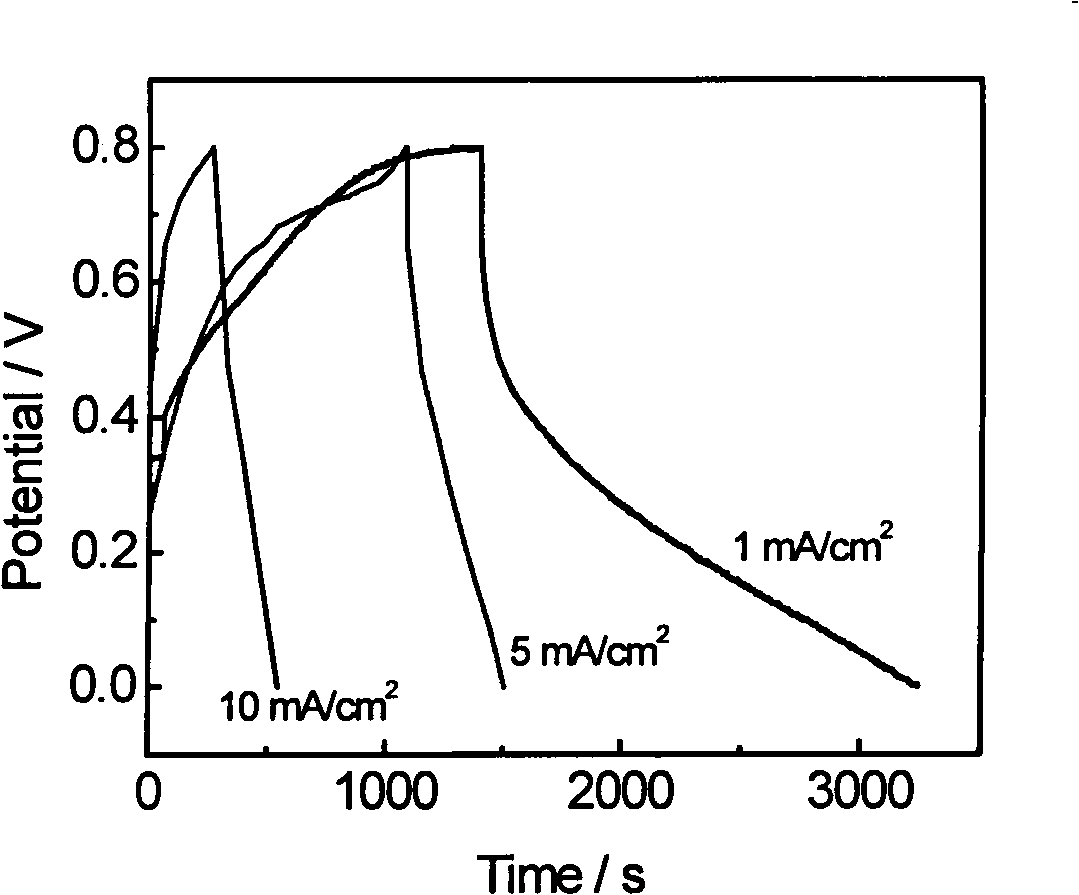

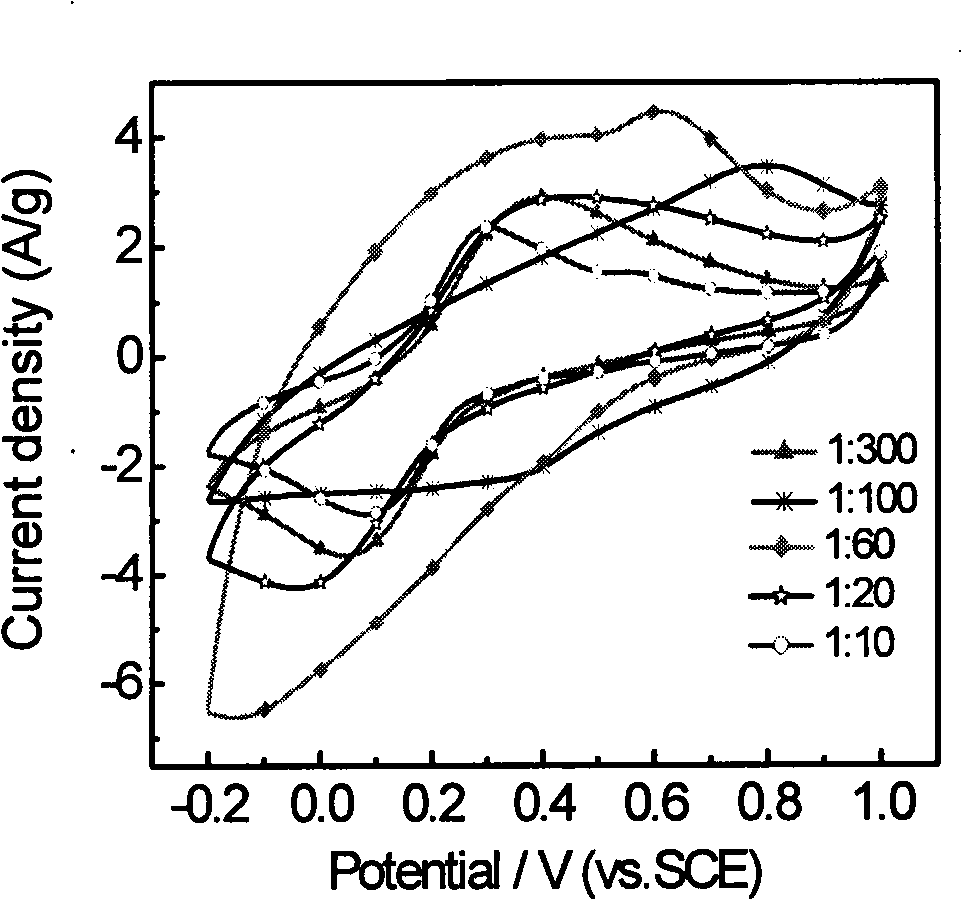

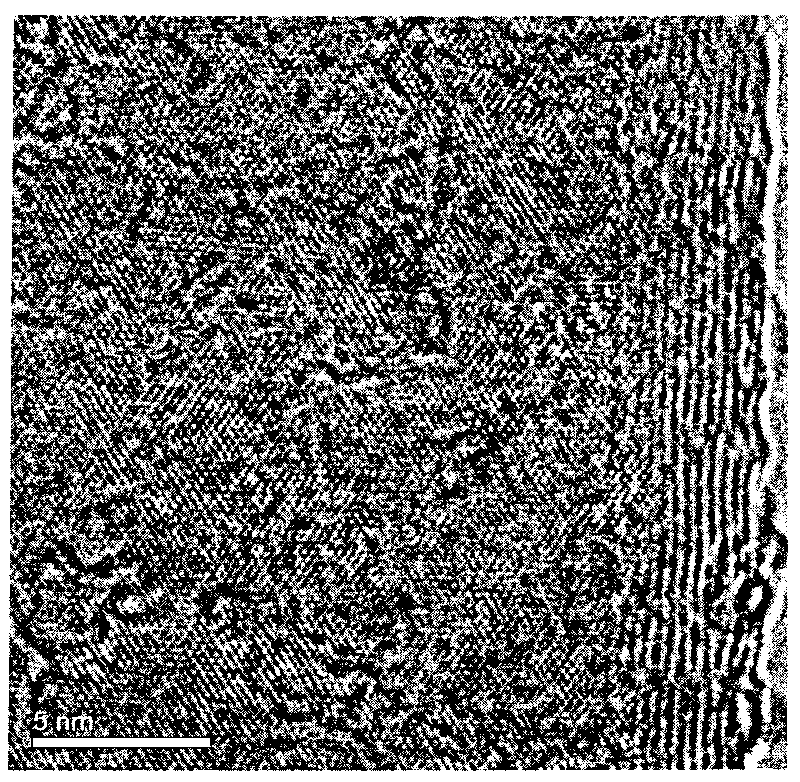

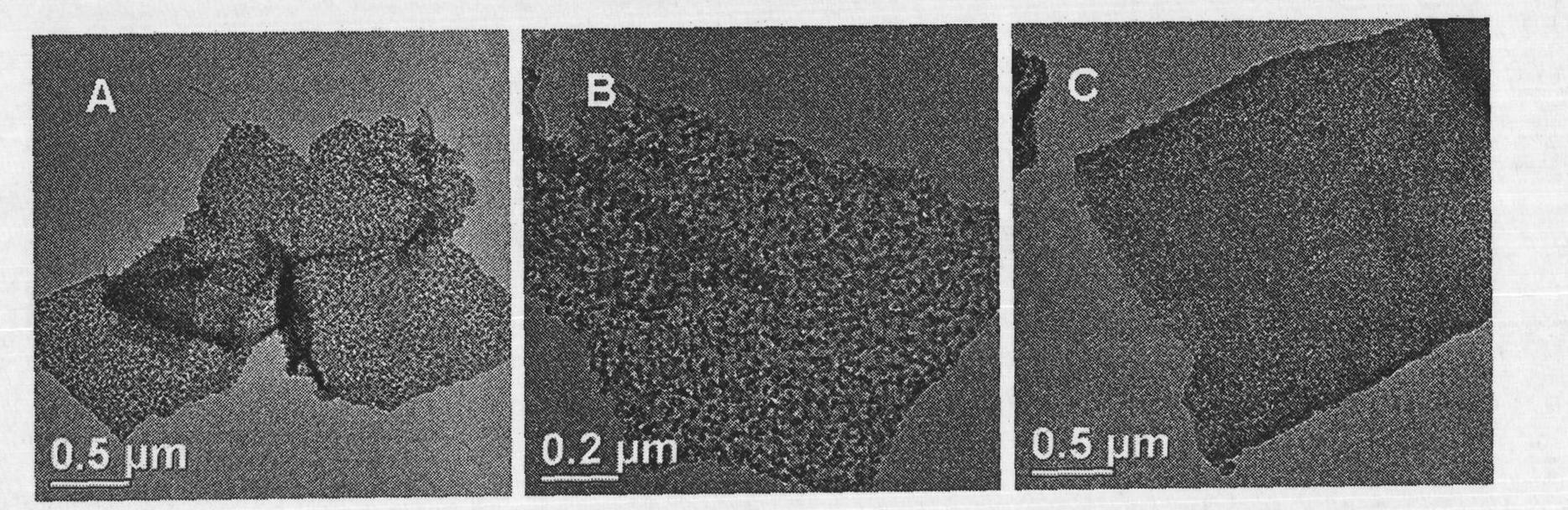

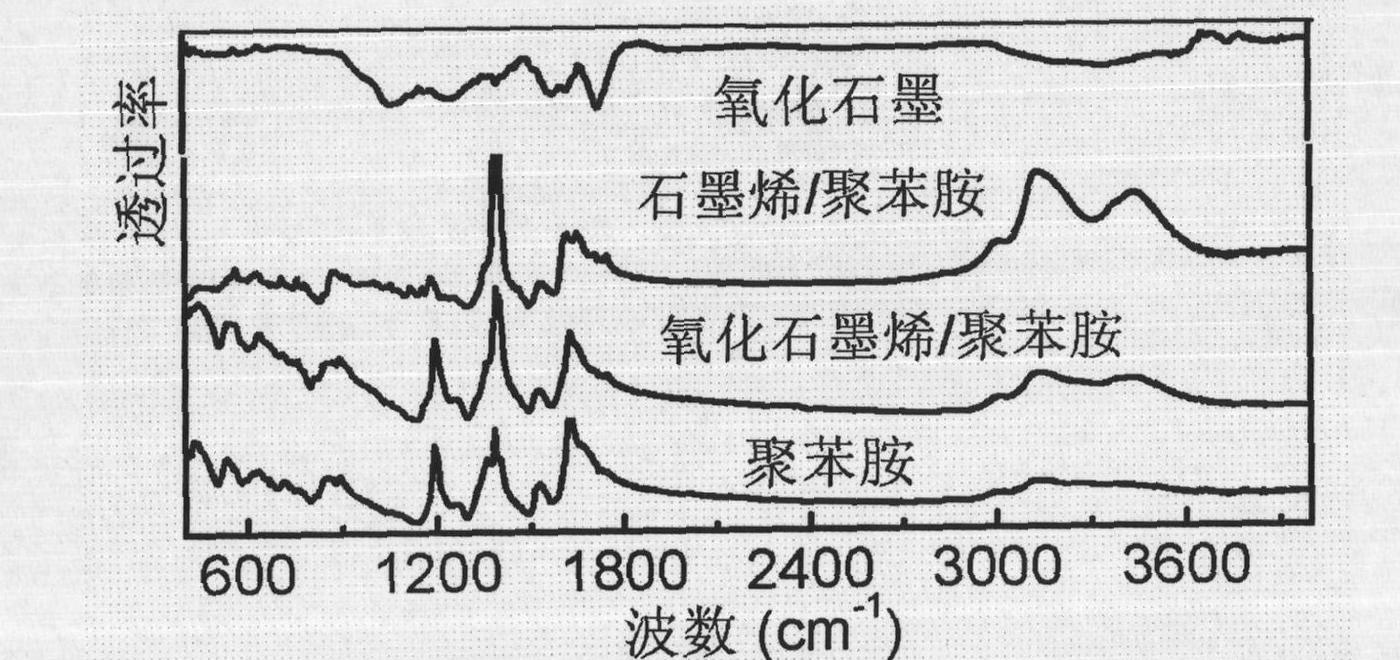

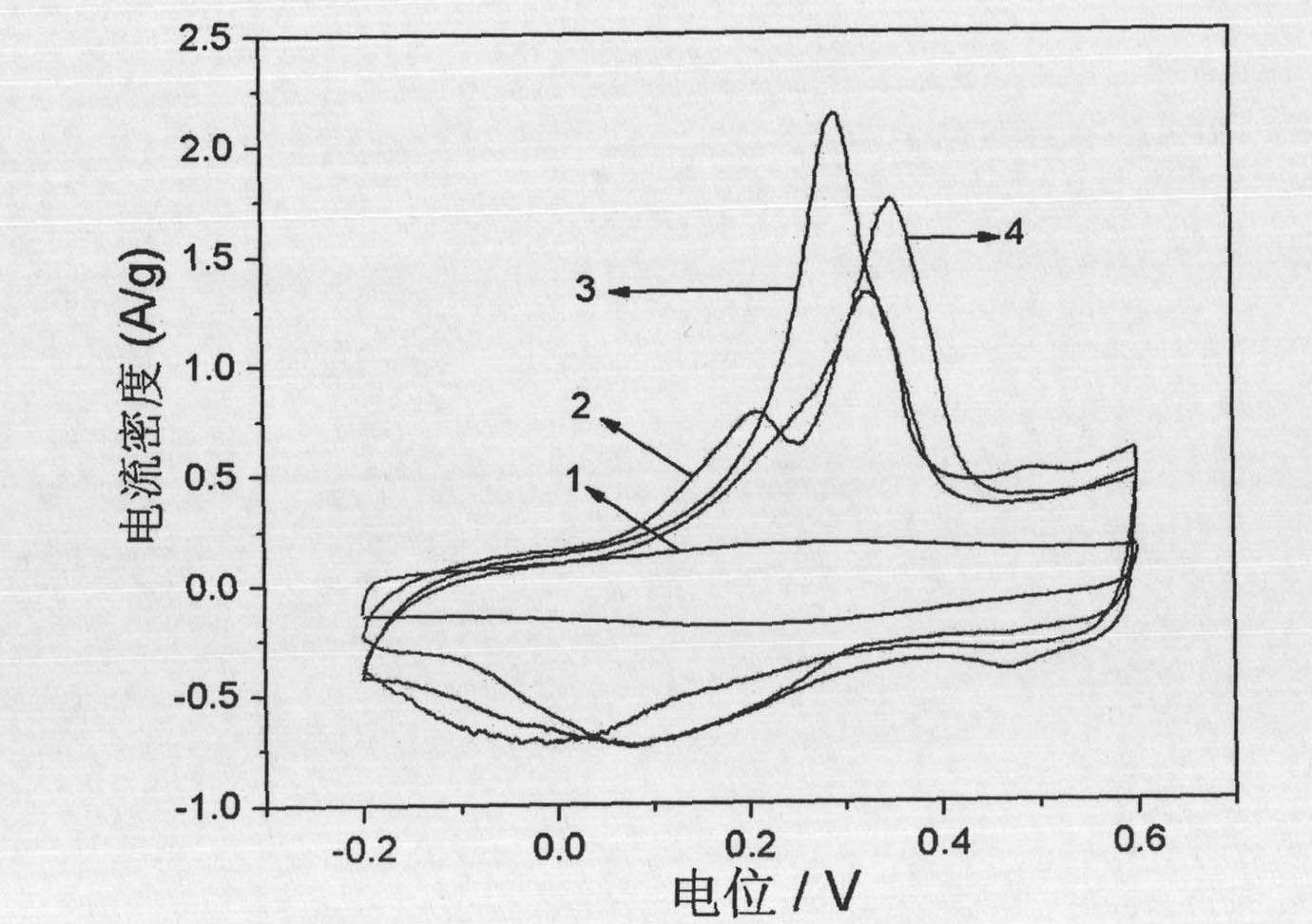

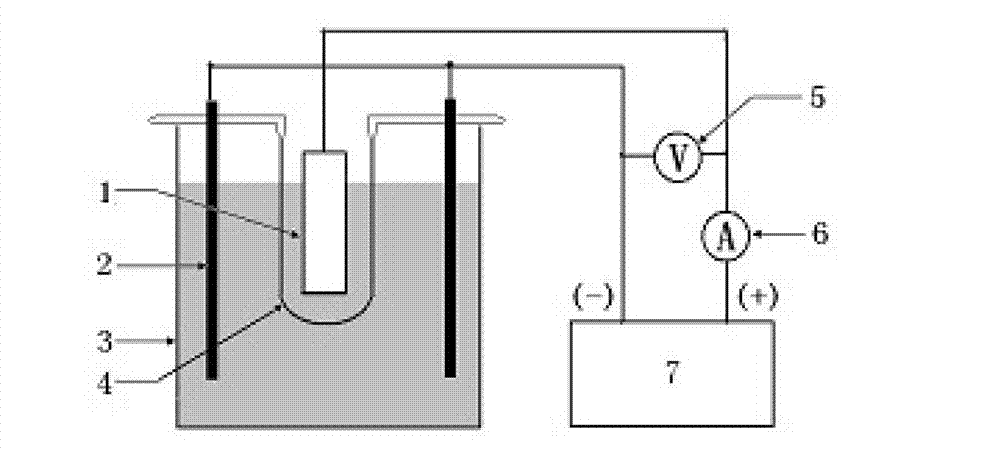

Oxidized grapheme/polyaniline super capacitor composite electrode material and preparation method and application thereof

ActiveCN101527202AImprove double layer capacitanceExcellent supercapacitor performanceElectrolytic capacitorsHybrid capacitor electrodesPolyaniline compositeAniline

The invention discloses an oxidized grapheme / polyaniline super capacitor composite electrode material and the preparation method and the application thereof. The preparation method comprise the following steps: firstly, adding oxidized graphite to water for ultrasonic dispersion so as to form an oxidized grapheme solution with uniformly dispersed single pieces; at room temperature, dropping aniline to the obtained oxidized grapheme solution for continuous ultrasonic dispersion to from a mixed solution; at a low temperature condition, adding hydrogen peroxide, ferric trichloride and a hydrochloric acid solution dropwise to the mixed solution, and stirring the solution for polymerization; and after the reaction is finished, centrifugating, washing and roasting the obtained mixed solution in vacuum to obtain the oxidized grapheme / polyaniline super capacitor composite electrode material which is used as the electrode material of an electricity storage system of a super capacitor and a battery. The oxidized grapheme / polyaniline super capacitor composite electrode material with good electrochemistry performance is obtained by the method, and the specific capacity of the oxidized grapheme and the polyaniline is greatly improved. In addition, the addition of the oxidized grapheme improves the charge and discharge service life of the polyaniline.

Owner:NANJING UNIV OF SCI & TECH

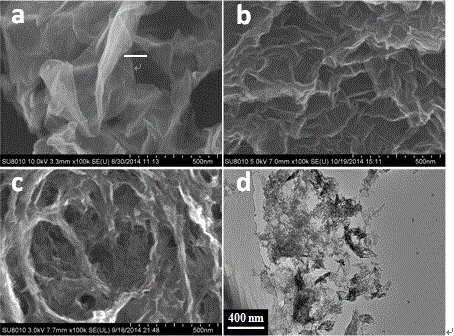

Graphene three-dimensional material as well as preparation method and application thereof

The invention discloses a graphene three-dimensional material as well as a preparation method and an application thereof. The material consists of 10 to 99% of graphene and 1 to 90% of the oxide of manganese, nickel, iron or cobalt. The preparation method comprises the following steps: performing ultrasonic dispersion on graphite oxide to prepare a graphite oxide solution; adding a metal salt solution while stirring or under ultrasonic conditions, and adding a hydrazine hydrate solution; conducting reaction in a drying oven or a hydro-thermal reaction kettle; and then drying to obtain the graphene three-dimensional material. The graphene three-dimensional material is applied to a super capacitor with the capacity of 200 to 800 F / g, or used for making the cathode of a lithium ion battery with the capacity of 300 to 1,400 mAh / g. According to the invention, the preparation process is simple; the prepared graphene three-dimensional macroscopic material has high conductivity and strength; and when being used for the cathode of the lithium ion battery and the super capacitor, the material has high performance.

Owner:TIANJIN UNIV

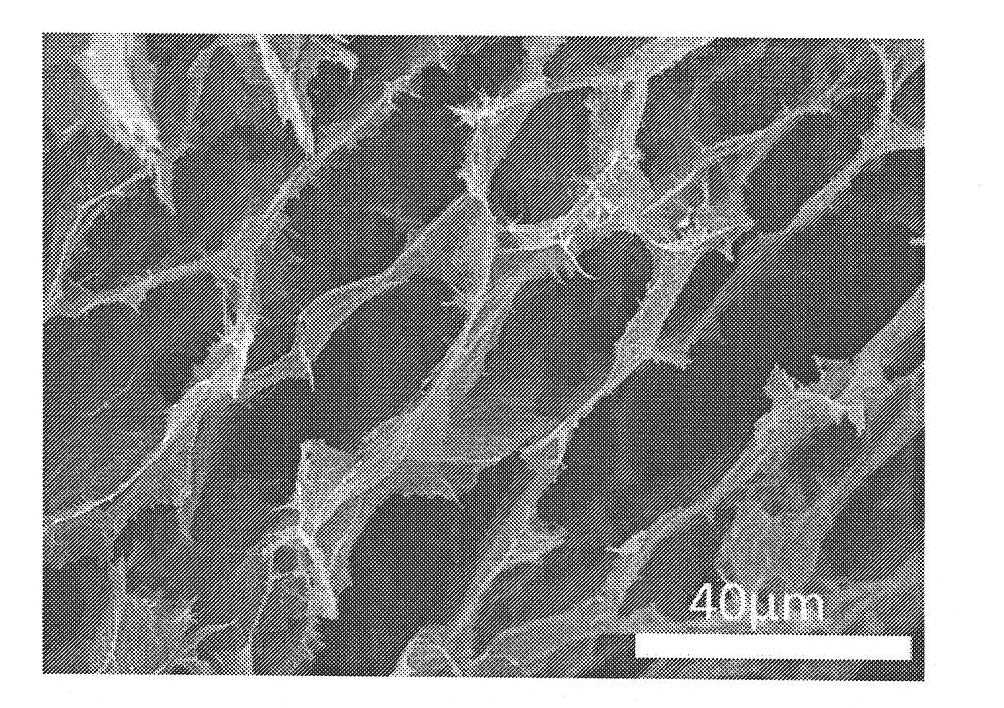

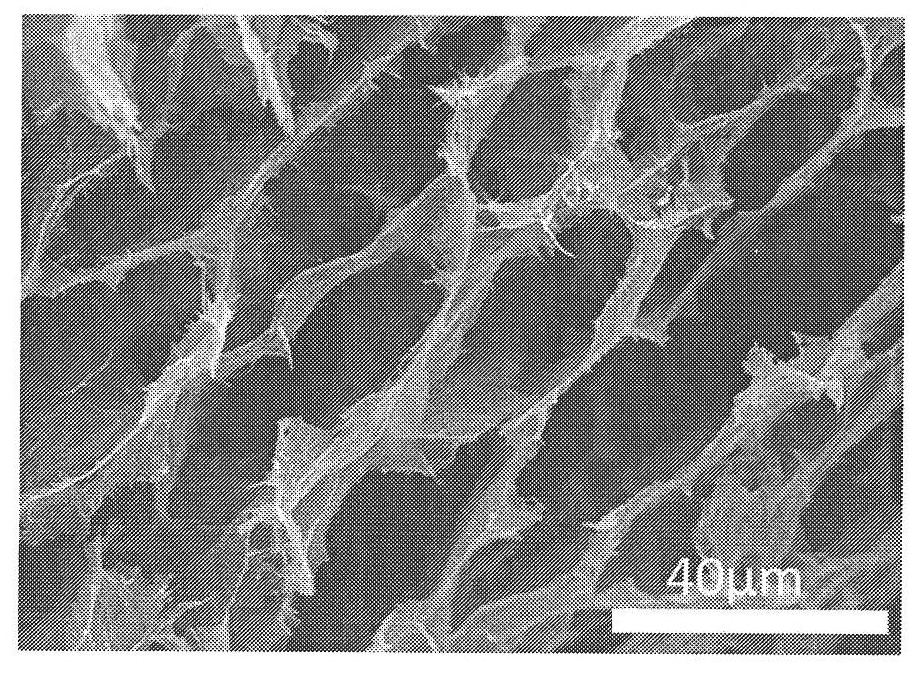

Film made from graphene-carbon nanotube composite material and preparation method of film

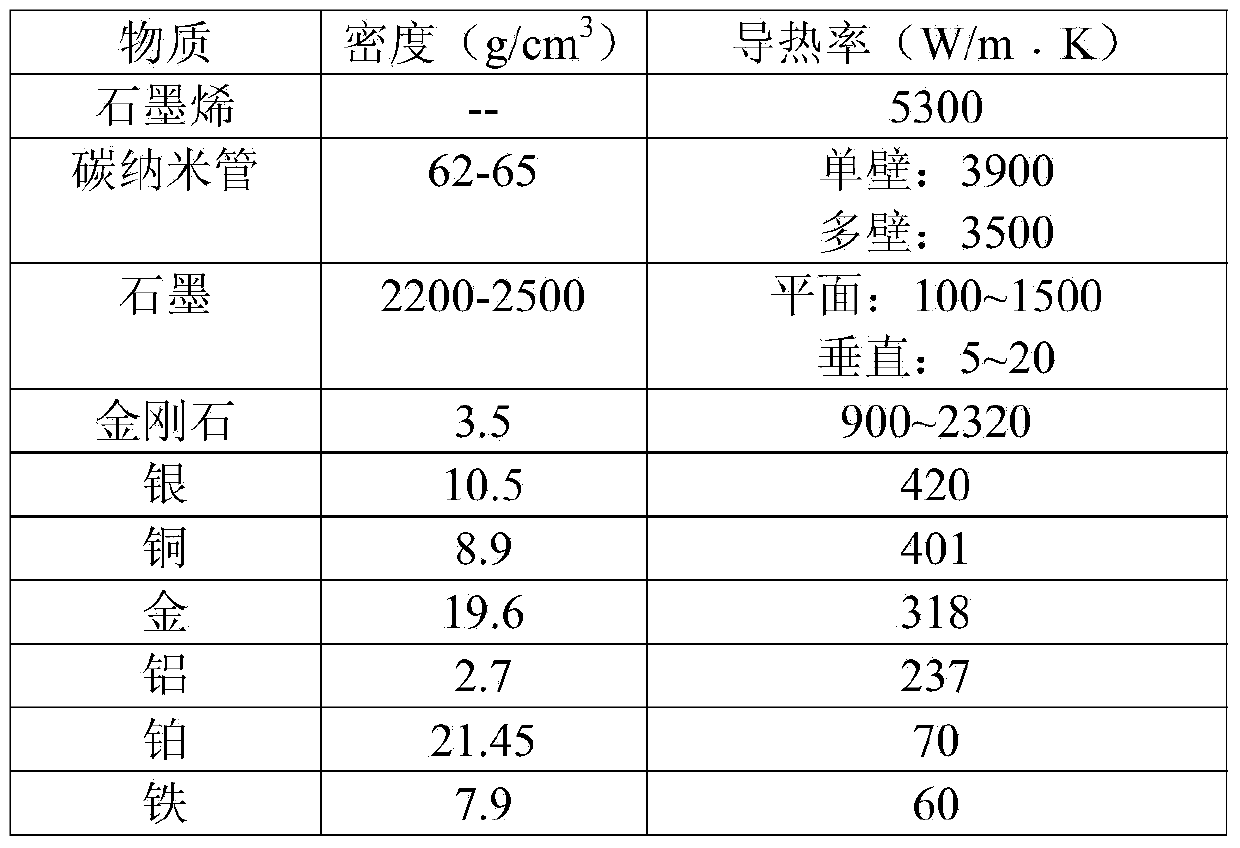

InactiveCN103725263AHave flexibilityGood flexibilityHeat-exchange elementsCooling/ventilation/heating modificationsComposite filmLiquid-crystal display

The invention discloses a film made from a graphene-carbon nanotube composite material and a preparation method of film. The preparation method comprises the following steps: mixing graphene and carbon nanotubes sufficiently and evenly via stirring and ultrasonic dispersion, reacting the graphene with the carbon nanotubes sufficiently via hydrothermal or solvothermal conditions, removing solvents after finishing the reaction to obtain the graphene-carbon nanotube composite materials which are preformed and tangled in a network structure, forming the film on the surfaces of various base materials via coating, spraying, spin-coating and filtering the obtained graphene-carbon nanotube composite materials to obtain the composite film made from the graphene-carbon nanotube composite materials and the base materials, and removing the base materials to obtain the film made from the graphene-carbon nanotube composite materials. According to the method, graphene-carbon nanotube composition is realized simply and effectively and dispersed in the solvents stably, and the two obtained films can be applied in the aspects of heat conduction and heat radiation systems of high calorific value electronic devices, LED (light-emitting diode) lamps and liquid crystal display products.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

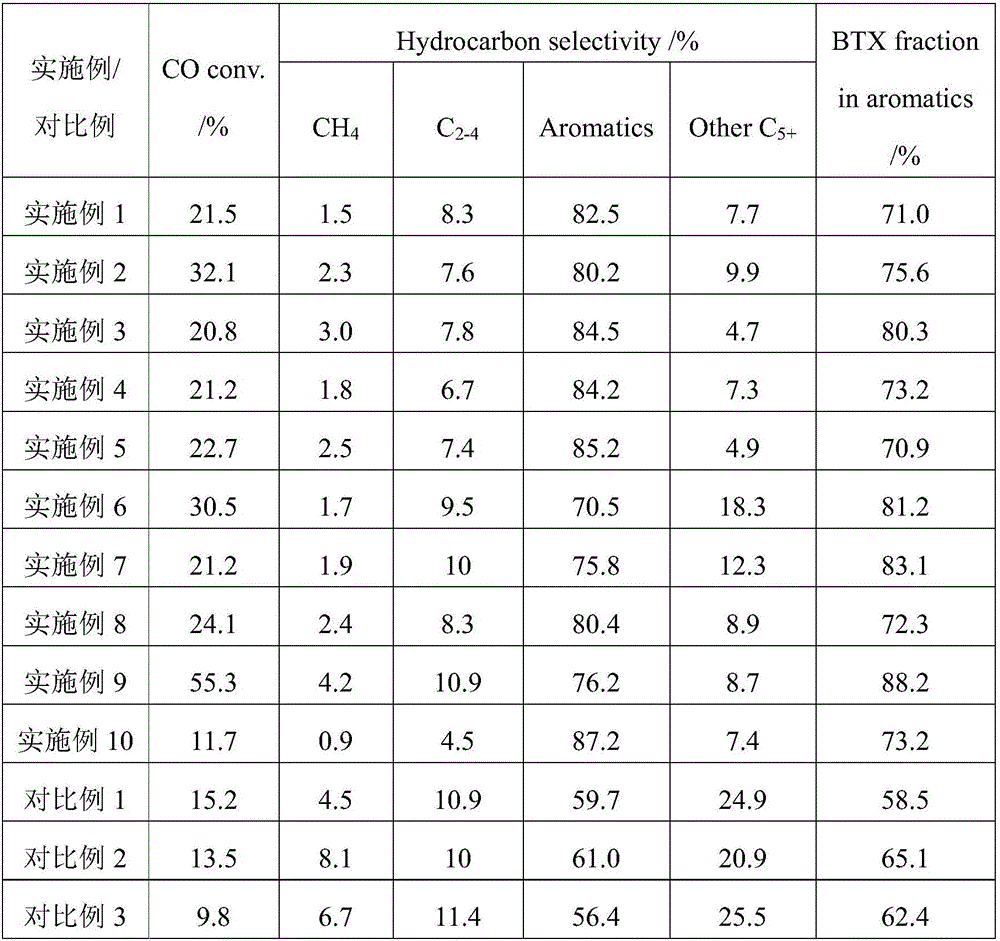

Catalyst for high-selectivity preparation of light aromatic hydrocarbon by using synthesis gas and preparation method thereof

ActiveCN106540740AImprove catalytic performanceHigh conversion rate of COHydrocarbon from carbon oxidesMolecular sieve catalystsPolycyclic aromatic hydrocarbonMolecular sieve

The invention provides a catalyst for high-selectivity preparation of light aromatic hydrocarbon by using synthesis gas and a preparation method thereof and belongs to the field of catalysts. The catalyst is prepared from, by mass, 20%-60% of modified zeolite molecular sieve and 40%-80% of zirconium-containing composite oxide. The preparation method comprises the steps that the zirconium-containing composite oxide is added to a solvent, and ultrasonic dispersion is performed to obtain a solution A; the modified zeolite molecular sieve is added into the solution A; the mixture obtained after ultrasonic dispersion is subjected to suction filtration, and the obtained filter cake after washing is dried; the sample obtained after drying is grinded into powder; the powdery sample is calcinated, and the obtained sample is the catalyst for high-selectivity preparation of the light aromatic hydrocarbon by using synthesis gas. The light aromatic hydrocarbon can be prepared in a high-selectivity mode, and the stability is good. The preparation method of the catalyst for high-selectivity preparation of the light aromatic hydrocarbon by using the synthesis gas is simple and low in cost and has good industrial application prospect.

Owner:XIAMEN UNIV

Flexible nanocellulose-graphene composite membrane and preparation method thereof

InactiveCN105860143ANo pollution in the processSimple processHeat-exchange elementsNanofiberCvd graphene

The invention discloses a flexible nano-cellulose-graphene composite film and a preparation method thereof. The mass fraction of the composite film is composed of: graphene 0.1%-90%, nano-cellulose 10%-99.9%, and the preparation steps are as follows: : (1) Prepare a graphene oxide dispersion with a concentration of 0.05-5 mg / ml and a nano-cellulose dispersion with a concentration of 0.05-5 mg / ml, ultrasonically disperse for 1-2 hours, and mix to obtain a concentration of 0.05-5 mg / ml The first dispersion liquid of nanocellulose-graphene oxide; (2) add reducing agent in the first dispersion liquid, heat up, stir, stir evenly, obtain the second dispersion liquid of nanocellulose-graphene; (3) The above-mentioned second dispersion liquid is subjected to centrifugal degassing, and then vacuum-filtered to form a composite film, and the composite film is transferred to an oven, and vacuum-dried to obtain a flexible nanocellulose-graphene composite film. There will be no agglomeration between the graphene sheets in the composite film, and its thermal conductivity in the parallel direction is ≥2W·m ‑1 ·K ‑1 , vertical thermal conductivity ≤0.3W·m ‑1 ·K ‑1 , Thermal conductivity anisotropy ratio ≥ 5.

Owner:SHANGHAI UNIV

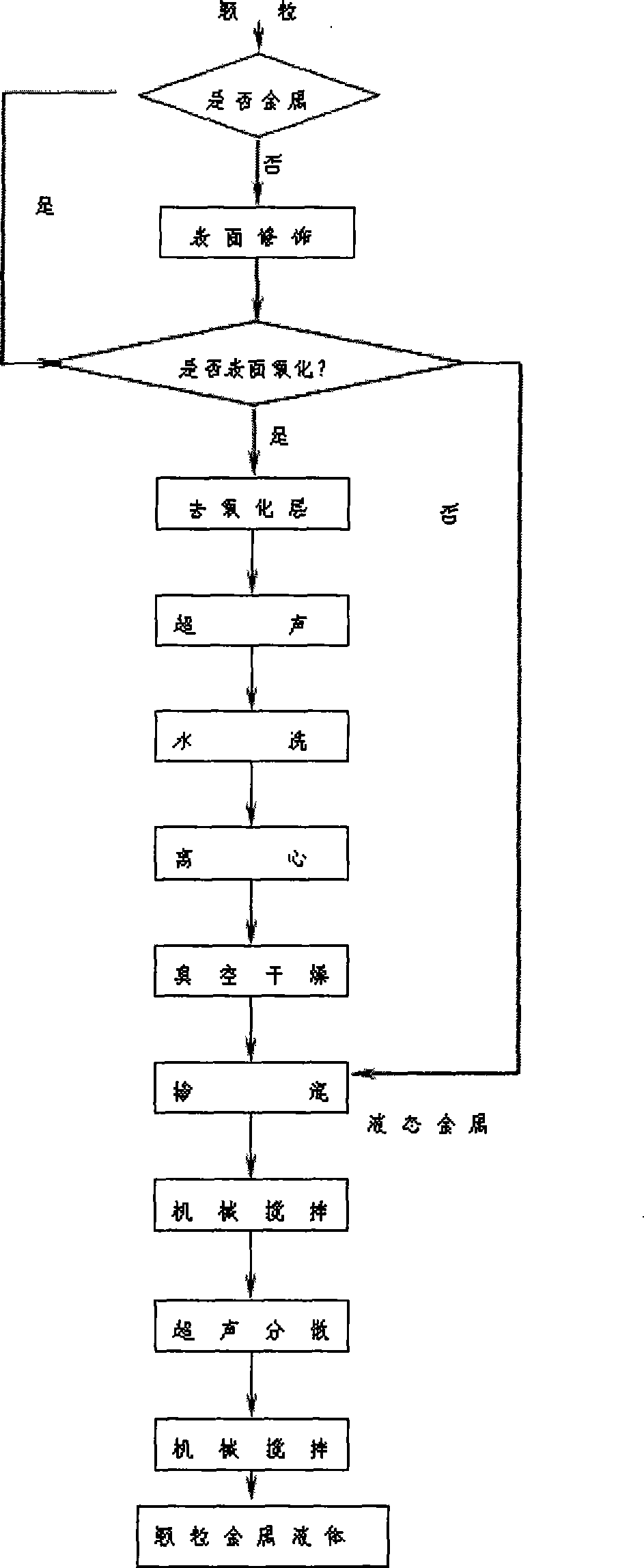

Method for preparing metal liquid mixed with granule having high heat-transfer performance

ActiveCN101418210AReduce thermal resistanceImprove thermal conductivityHeat-exchange elementsLiquid metalSolvent

The invention relates to a method for preparing a metal liquid mixed with particles which has high heat transferring performance. The method comprises the following steps: a. particles as a solute and liquid metal as a solvent are mixed to form the liquid metal mixed with the particles; the ratio of mass portions of the particles to the liquid metal is between 1 to 0.1 and 1 to 99; and b. the liquid metal mixed with the particles is subjected to mechanical stirring and ultrasonic dispersion in order that the particles in the liquid metal are evenly dispersed, thereby obtaining the metal liquid mixed with the particles. Through the method, the prepared metal liquid mixed with the particles has high thermal conductivity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing multi-layer graphene

ActiveCN101746755AImprove conductivityImprove thermal conductivityUltrasonic dispersionMaterials science

The invention relates to a method for preparing multi-layer graphene, and belongs to the technical field of carbon materials. The multi-layer graphene is prepared from expanded graphite serving as a raw material through ultrasonic dispersion, solid-liquid separation and drying. The thickness of the multi-layer graphene prepared by the method is between 1 and 10nm; the number of layers is between 2 and 20 layers; and the aperture is mainly between 6 and 50nm. The multi-layer graphene has the characteristics of high electrical conductivity, high heat conductivity, high electromagnetic wave absorptivity, wear resistance and the like. The method has the advantages of simpleness, convenient operation and low production cost, capability of reducing production energy consumption, no three wastes emission, environmental friendliness and convenient popularization and application. The multi-layer graphene prepared by the method can be used as the electrode materials of batteries and super capacitors, can also be used as the conductive agents of high molecular materials, ceramic materials, silicate materials and the like, and can also be used as the conductive agents of lithium batteries, alkaline batteries and nickel-metal hydride batteries.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Graphene -organic acid doped polyaniline composite material and preparation method thereof

The invention discloses graphene-organic acid doped polyaniline composite material and a preparation method thereof. The preparation method includes the following steps: adding graphite oxide to dispersing agent for ultrasonic dispersion to form evenly dispersed graphene oxide liquid mixture; adding aniline monomer to the liquid mixture obtained in the first step for further dispersion under room temperature to form liquid mixture, and then blending for certain time; gradually dripping oxidizer and organic doping acid to the liquid mixture obtained in the second step, and blending for polymerization; centrifuging the liquid mixture obtained in the third step, and washing to get graphene oxide-polyaniline composite material; adding concentrated alkaline to the water suspension of the graphene oxide-polyaniline composite material, heating and blending for reaction; and centrifuging the mixture obtained in the fifth step and washing to get graphene-polyaniline composite material. The invention takes the advantage of the big specific surface area of graphene oxide and the capability of the graphene oxide for absorbing aniline on the surface thereof in on organic system to form sandwiched polyaniline / graphene oxide- polyaniline compound through polymerization.

Owner:NANJING UNIV OF SCI & TECH

Nano-silver conductive slurry

ActiveCN101710497AHigh resolutionLower maximum sintering temperatureNanostructure manufactureConductive materialDirect writingSlurry

The invention provides nano-silver conductive slurry, which comprises the following components in percentage by weight: 10 to 70 percent of nano-silver granules serving as a functional phase, and the balance of carrier phase. The nano-silver granules are uniformly dispersed in the carrier phase by methods of mechanical stirring, ultrasonic dispersion and the like to form the nano-silver conductive slurry; the slurry is molded by methods of spin coating, screen printing, micro thinning and micro-spray direct writing and the like, and then the molded slurry is thermally treated at the temperature of below 250 DEG C by a programmed heating method to form conductive patterns with good conductivity (the electrical resistivity is at a magnitude order of 0 to 50 ohm.cm) and high resolution (the maximum resolution is 30 mu m).

Owner:HUAZHONG UNIV OF SCI & TECH

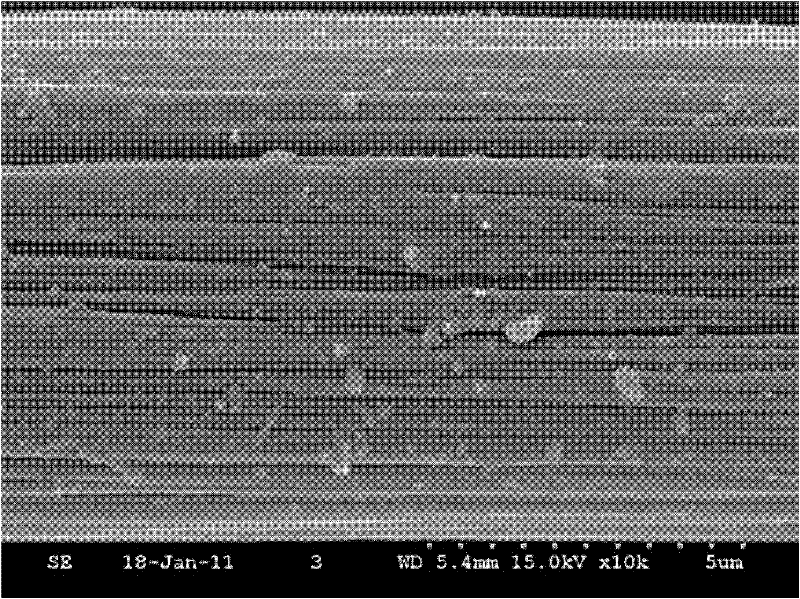

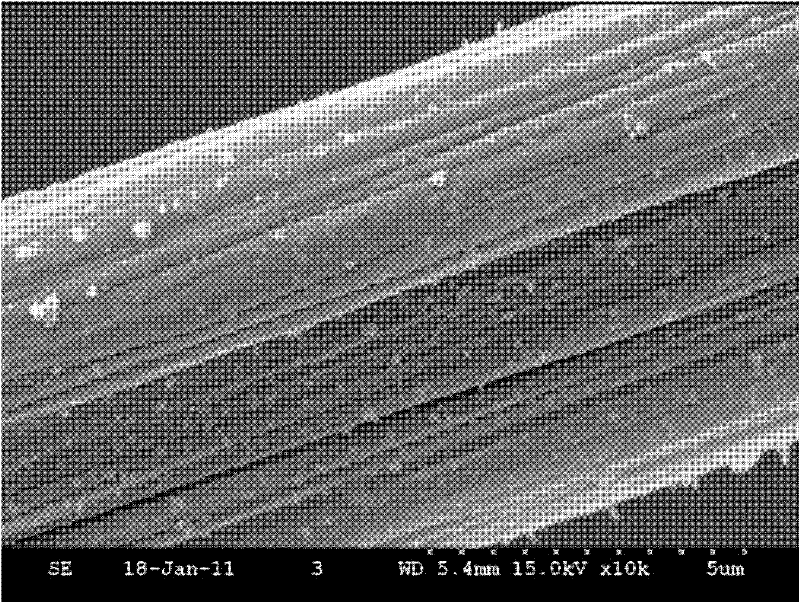

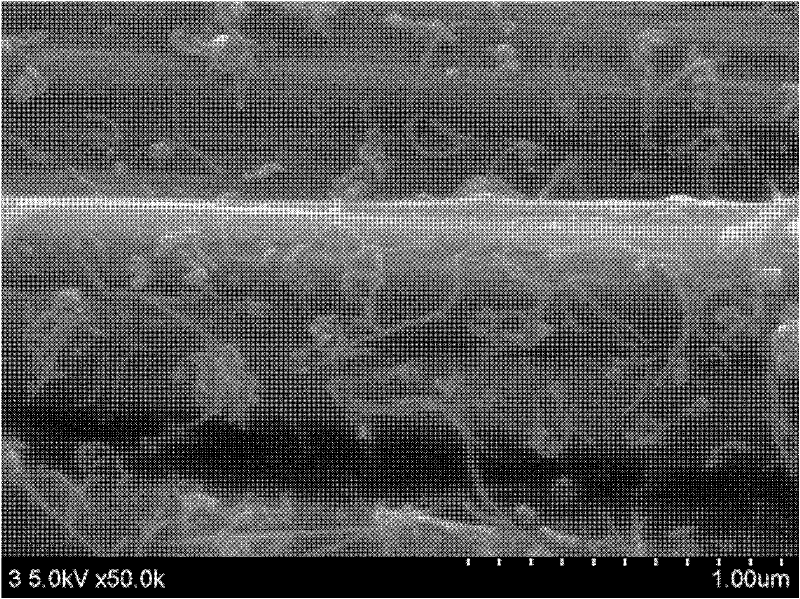

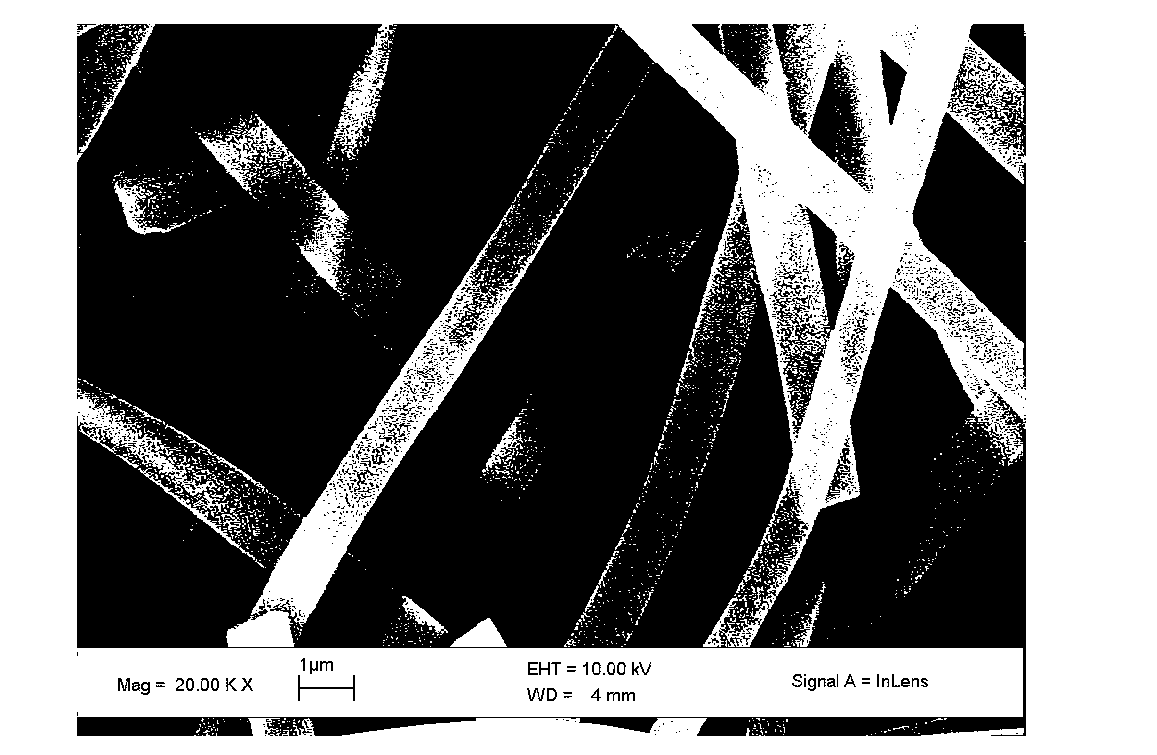

Carbon fiber emulsion sizing agent improved by carbon nano tube and preparation method of carbon fiber emulsion sizing agent

InactiveCN102212967APlay the role of stress transmissionIncreased interlaminar shear strengthCarbon fibresEmulsionCarbon fibers

The invention relates to a carbon fiber emulsion sizing agent improved by a carbon nano tube and a preparation method of the carbon fiber emulsion sizing agent. The carbon fiber emulsion sizing agent comprises a carbon fiber sizing agent, the carbon nano tube, a dispersing agent and a solvent. The preparation method comprises the following steps of: 1, preparing the carbon fiber sizing agent; and 2, adding the carbon fiber sizing agent into the solvent to prepare a sizing working solution, mixing the carbon nano tube and the sizing working solution, performing ultrasonic treatment for 1 to 4 hours at the power of 300 to 600w, adding the dispersing agent, and performing ultrasonic dispersion for 2 to 4 hours to obtain the carbon fiber emulsion sizing agent improved by the carbon nano tube. The carbon fiber emulsion sizing agent has favorable stability, the post processability of carbon fiber can be improved after being processed by the emulsion sizing agent, the interfacial bond strength between the carbon fiber and substrate resin can be enhanced, the shear strength among layers is enhanced, and the performance of a composite material is improved to a certain extent. Moreover, the preparation method is simple, low in cost and environment-friendly.

Owner:DONGHUA UNIV

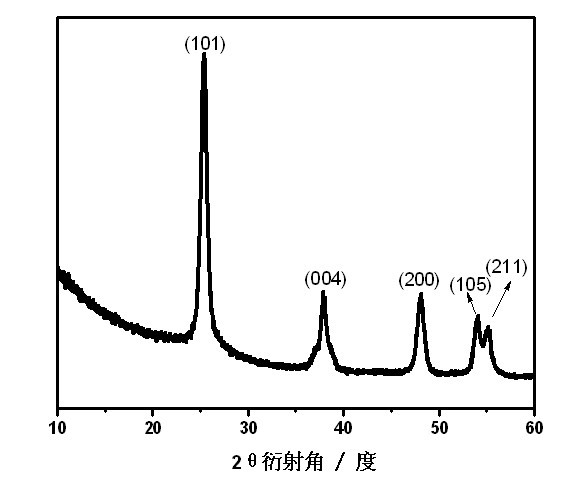

Graphene/mesoporous titanium dioxide visible light catalyst and preparation method

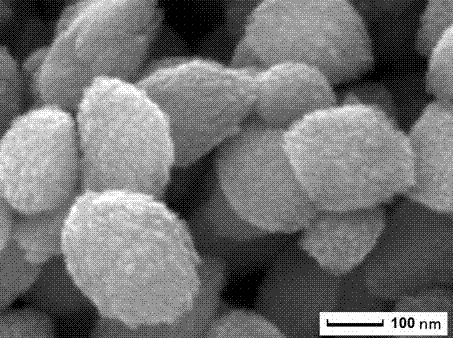

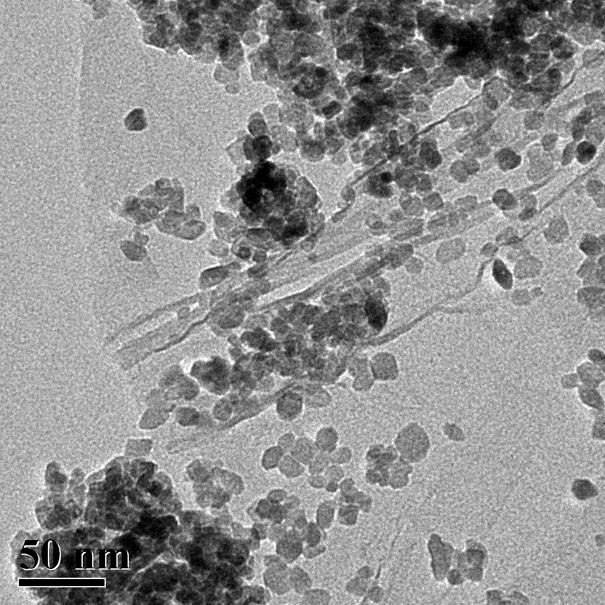

InactiveCN102350334AUniform particle sizeUniform sizePhysical/chemical process catalystsWater/sewage treatment by irradiationDispersityAcetic acid

The invention relates to a graphene / mesoporous titanium dioxide visible light catalyst and a preparation method, and belongs to the technical fields of nanometer composite materials and photocatalysis. The method comprises the following steps of: adding a graphene oxide into glacial acetic acid, and performing ultrasonic dispersion to obtain dispersion liquid of the graphene oxide; and adding a titanium source into the dispersion liquid of the graphene oxide, and preparing the graphene / mesoporous titanium dioxide nanometer composite visible light catalyst in a one-step in-situ form by a hydrothermal method. The graphene / mesoporous titanium dioxide visible light catalyst has the advantages of readily available raw materials and low cost, the preparation process is simple and convenient, and titanium dioxide in the obtained nanometer composite material has a nanometer poroid structure, a regular size and a special appearance; and titanium dioxide nanometer granules can be distributed onthe surface of graphene and are high in dispersity. Photocatalytic degradation experiments indicate that the graphene / mesoporous titanium dioxide nanometer composite light catalyst has a good photocatalytic degradation effect on rhodamine B under the irradiation of visible light, and is an ideal nanometer composite visible light catalyst.

Owner:JIANGSU UNIV

Graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and preparation method thereof

ActiveCN103215693AEvenly dispersedGood flexibilityFibre chemical featuresOrganic solventPorous carbon

The invention relates to graphene-oxide-modified phenolic-resin-based ultrafine porous carbon fiber and a preparation method thereof. The diameter of the fiber is in a range of 0.3-1.7mum, and the specific surface area of the fiber is 500-900m<2> / g. The fiber has a porous structure which is formed by microporous mainly. Micro-pore volume is 0.20-0.50cm<3> / g, and surface oxygen atomic ratio is lower than 10%. The preparation method comprises the steps that: graphene oxide is added into an organic solvent and is subjected to ultrasonic dispersion, such that a graphene oxide solution is formed; termosetting phenolic resin and a high-molecular-weight linear polymer are added into the graphene oxide organic solution, and are completely dissolved by stirring; the mixed solution is spun into composite fiber, and solidification and carbonization are carried out, such that porous phenolic-resin-based carbon / graphite oxide composite ultrafine fiber is obtained. The sources of adopted raw materials are rich. The prepared composite fiber has the advantages of high structural stability, good flexibility, developed pore structure, controllable surface oxygen content, and suitability for practical application.

Owner:TSINGHUA UNIV

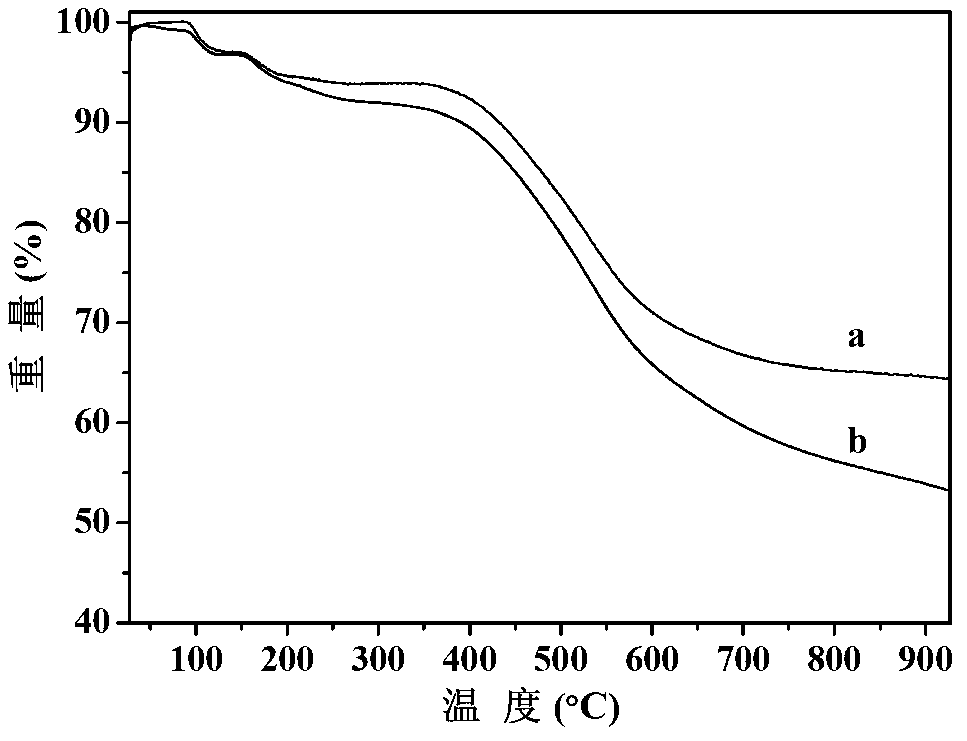

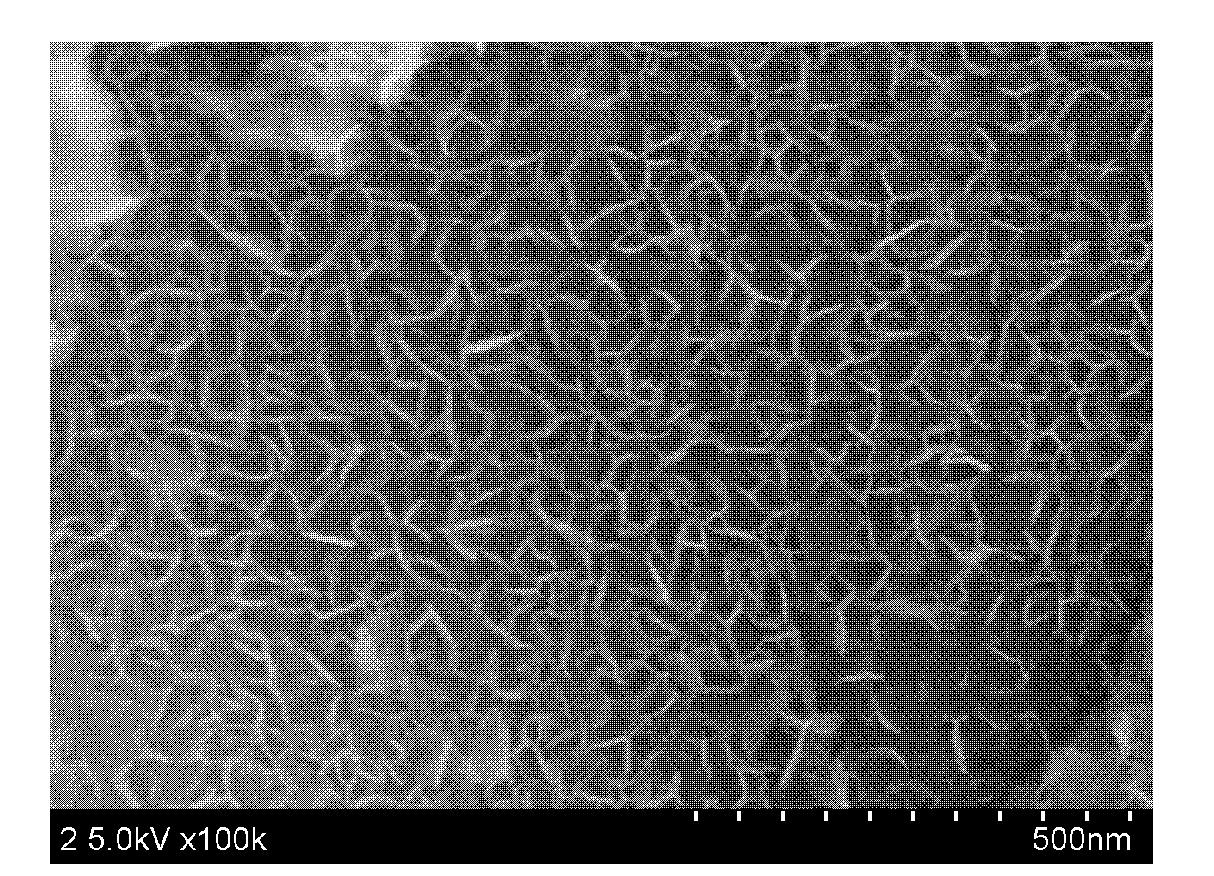

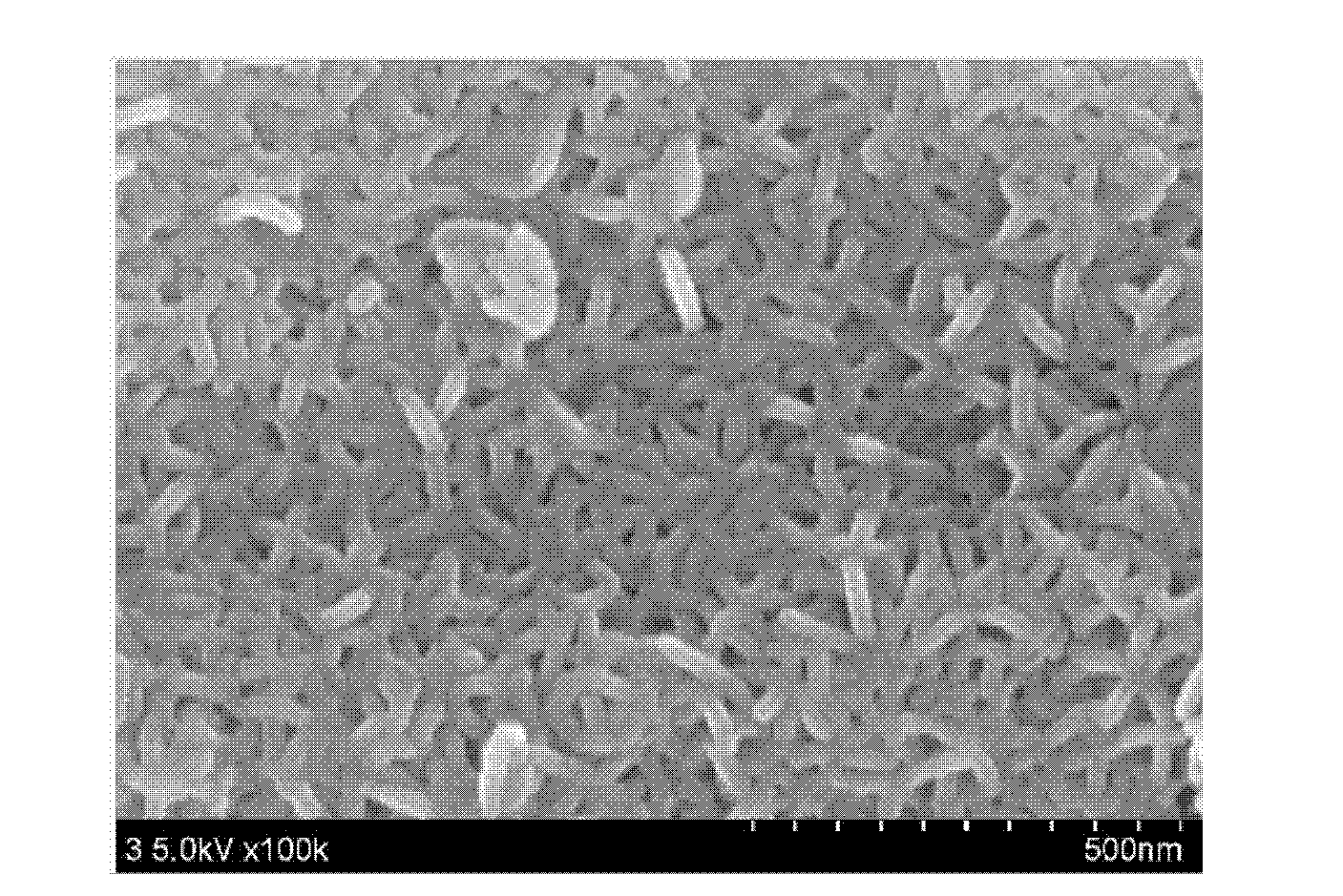

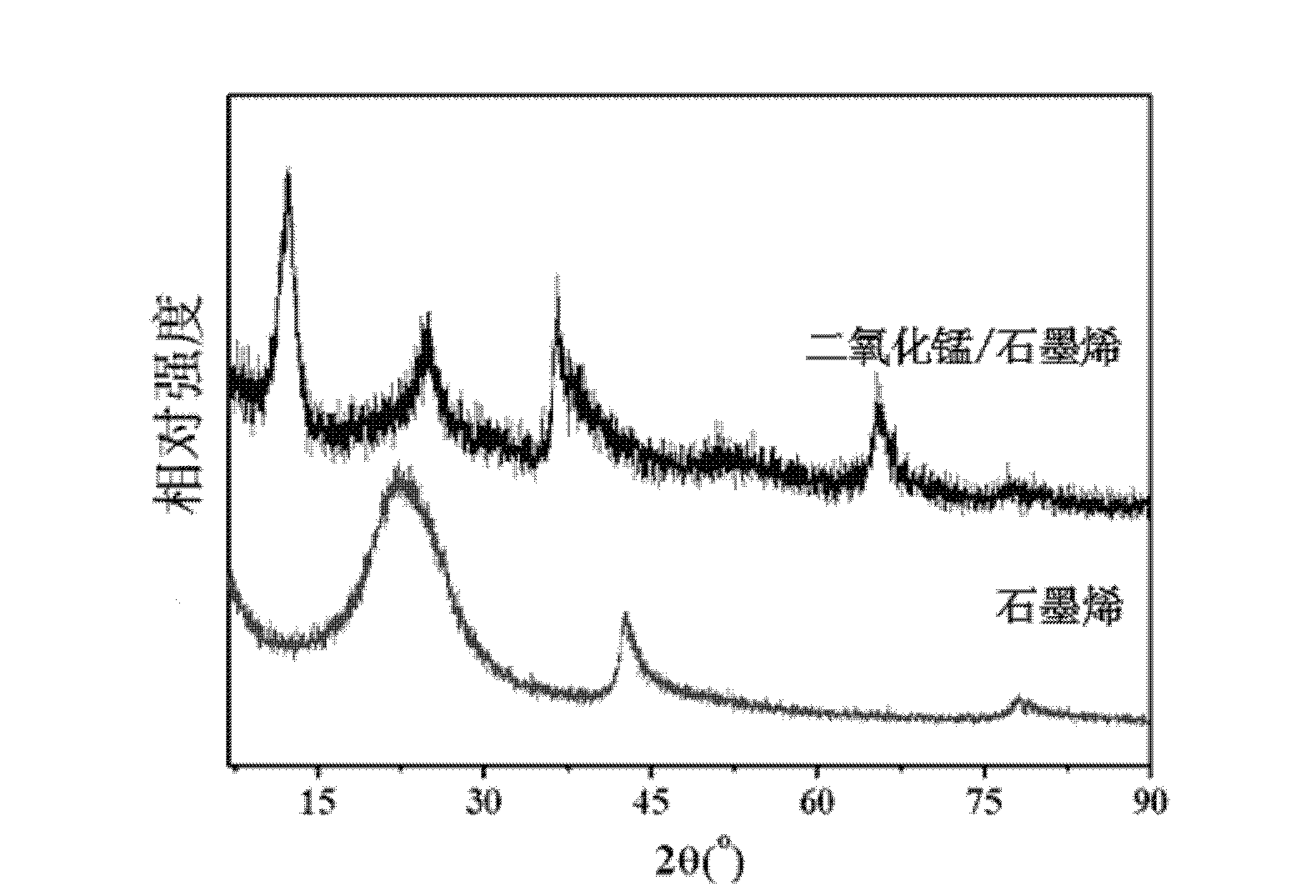

A kind of preparation method of graphene and manganese dioxide nanocomposite material

InactiveCN102275903AReduce typesLow costMaterial nanotechnologyManganese oxides/hydroxidesHydrazine compoundManganese

The invention relates to a preparation method of a graphene and manganese dioxide nanocomposite material, comprising: (1) stirring and mixing graphite, potassium nitrate and concentrated sulfur evenly, adding potassium permanganate, and reacting at 30-40° C. for 20-40 minutes , add deionized water at room temperature, add hydrogen peroxide after reacting for 15 to 30 minutes to obtain graphite oxide; (2) disperse the above graphite oxide in water, add hydrazine hydrate, and react at 95°C for 1 to 24 hours to obtain graphene (3) ultrasonically disperse the graphene in a saturated potassium permanganate solution, add acid, and react at 60-80° C. for 1-5 hours to obtain graphene and manganese dioxide nanocomposite material. The invention has the advantages of simple reaction, easy control, convenient operation and simple process; the obtained composite material has broad application prospects and can be used for catalysts, biosensing materials, electrode materials of lithium ion batteries and supercapacitor electrode materials, and the like.

Owner:DONGHUA UNIV

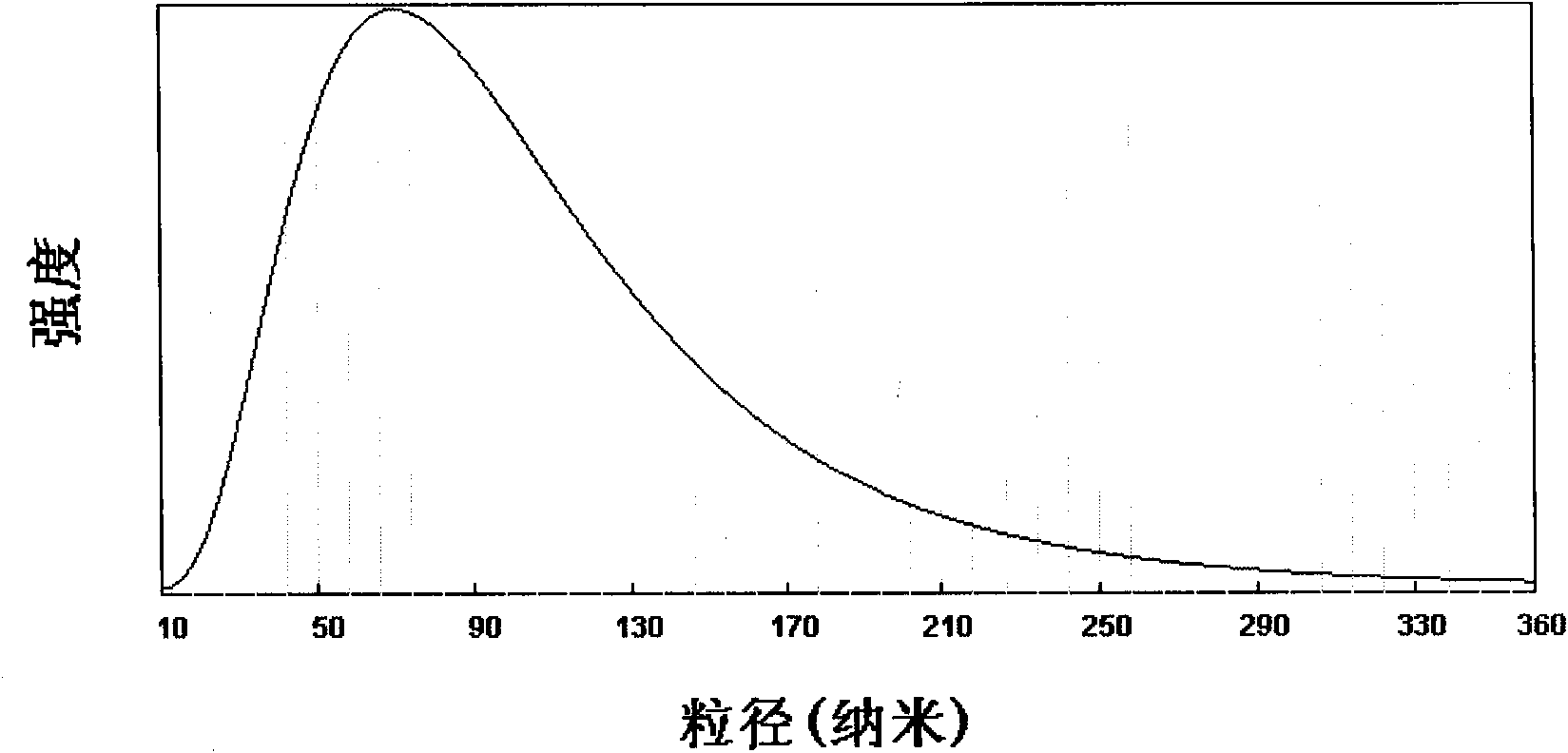

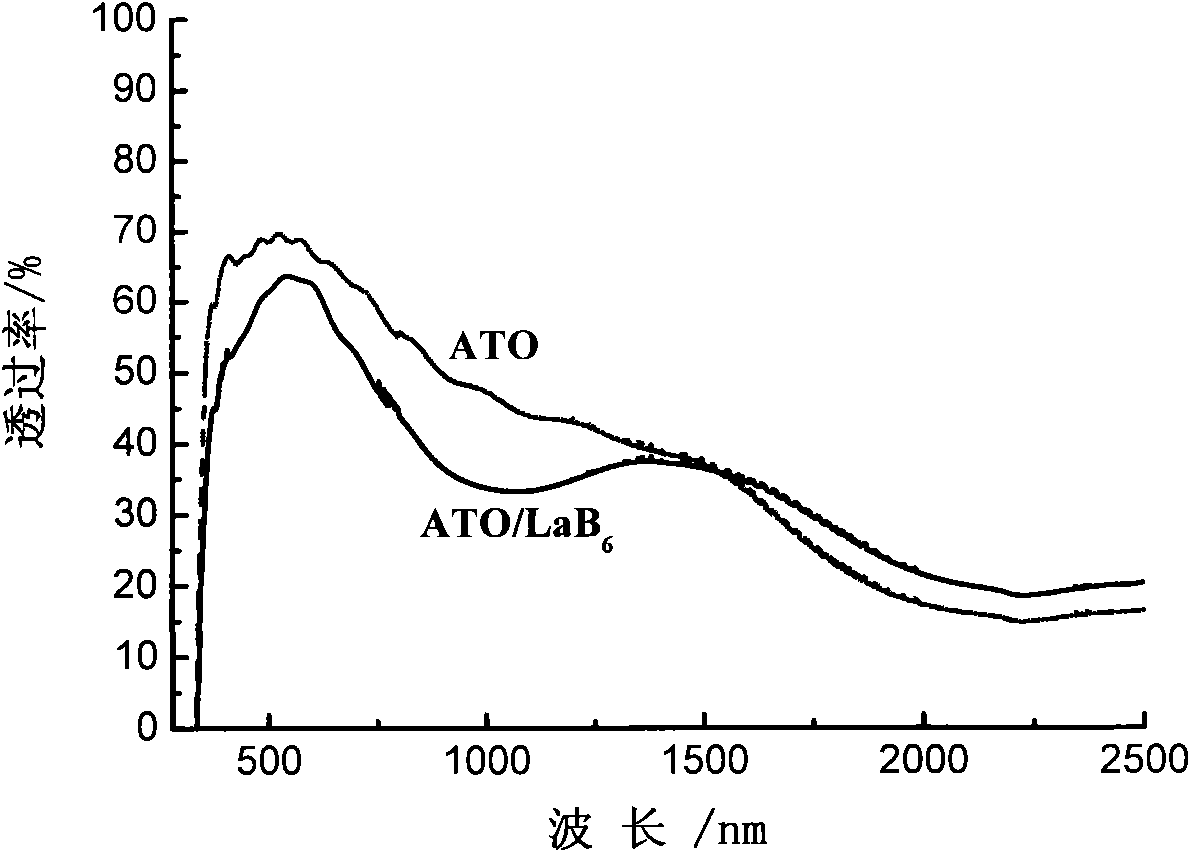

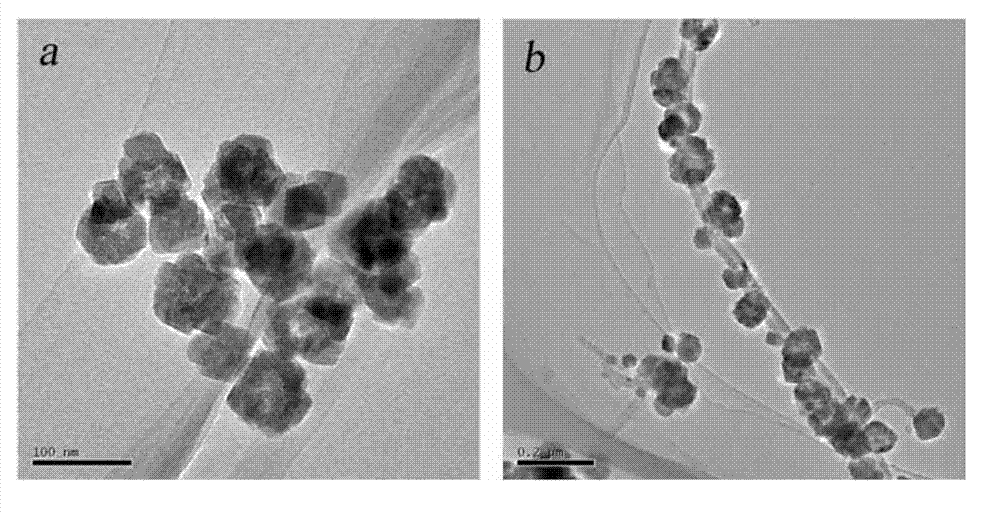

Transparent heat insulation coating material, preparation method and application thereof

InactiveCN101550307AImprove adhesionGood infrared blocking performancePolyurea/polyurethane coatingsPolyester coatingsDispersion stabilityPolyester

The invention relates to a transparent heat insulation coating material, the preparation method and the application thereof. The material is made from the raw material of lanthanum hexaboride / tin indium oxide or lanthanum hexaboride / tin antimony oxide, by the steps of pretreating by ultrasonic dispersion, and grinding to prepare nanometer slurry with heat insulation function, wherein the nanometer slurry has particle sizes mainly between 10nm and 200nm, the average particle size between 50nm and 120nm, and superior dispersion stability; mixing the nanometer slurry with film forming substance, auxiliary agent and solvent, to obtain the transparent heat insulation coating material. The coating material can obstruct more than 80% of infrared light, has a visible light transmittance above 60%, achieves excellent transparency and sunshine energy shielding effect; can be directly coated on transparent glass, polycarbonate, synthetic glass and polyester; and achieves the aims of energy conservation and heat insulation.

Owner:FUDAN UNIV +1

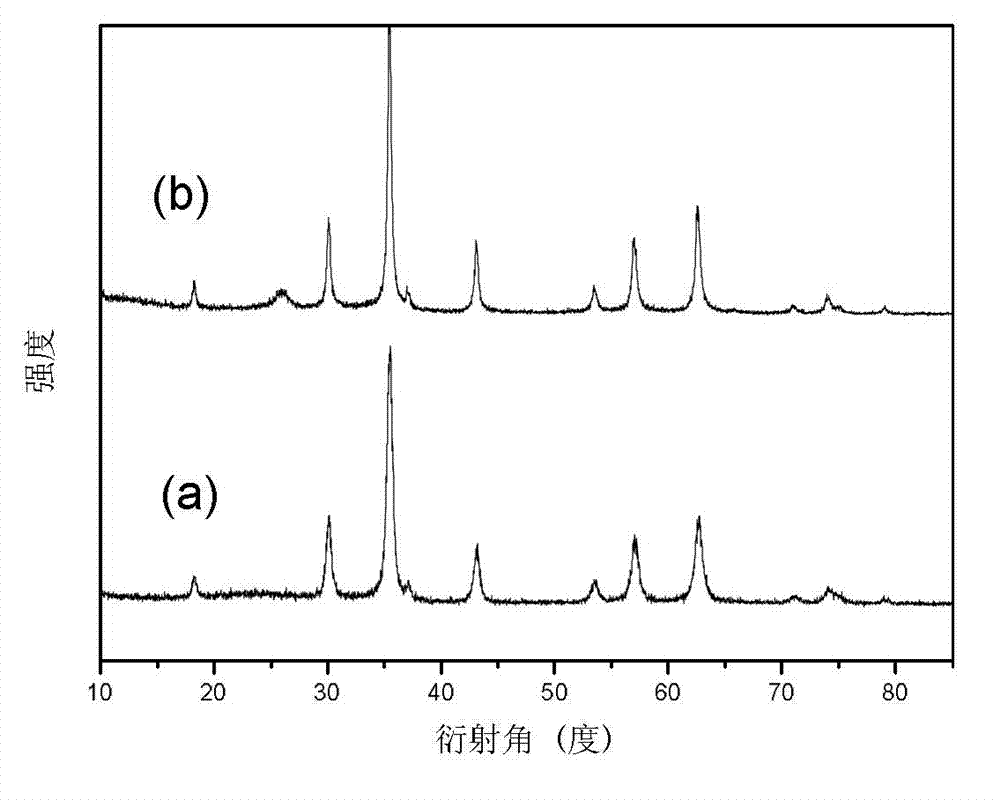

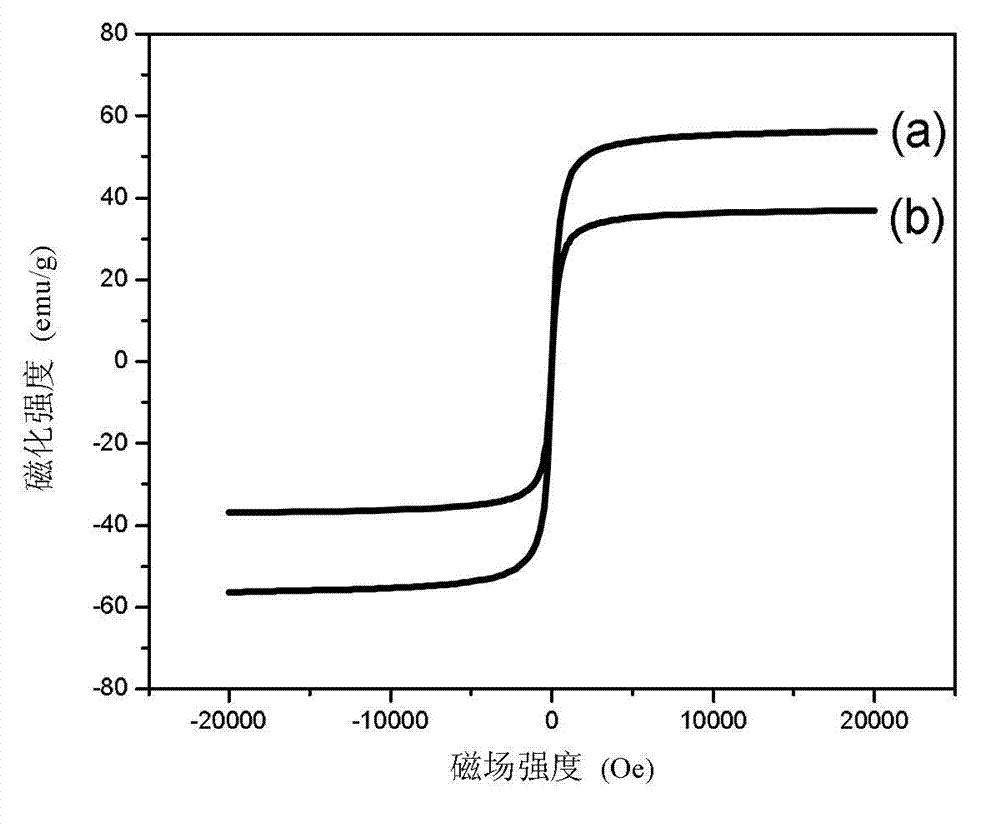

Magnetic carbon nanotube composite material and preparation method and application thereof

InactiveCN103041773AImprove bindingEasy to separateIon-exchange process apparatusComponent separationSorbentHexamethylenediamine

The invention discloses a magnetic carbon nanotube composite material and a preparation method and an application thereof. The preparation method comprises the following steps: adding FeCl3.6H2O to an ethylene glycol solution; then adding anhydrous sodium acetate and polyethylene glycol; adding a carboxylated multiwalled carbon nanotube; performing ultrasonic dispersion; adding hexamethylenediamine or ethanediamine; heating to 200-300 DEG C for reaction for 8-24h; and washing and performing vacuum drying to prepare the amino-modified magnetic Fe3O4-carbon nanotube composite material. The amino-modified magnetic Fe3O4-carbon nanotube composite material prepared by the invention is of nanoscale and superparamagnetism, can be stably dispersed in solutions, and can be quickly separated and enriched through a simple action of a magnetic field. As an adsorbent, the material is large in superficial area and has various active groups on the surface. The material can adsorb pigments from complex substrates through pi-pi electron interaction and hydrophobic effect of the carbon nanotube and can adsorb compounds such as organic acids and phenols through weak anion exchange effect of amino groups on the surfaces of magnetic nanoparticles.

Owner:TIANJIN UNIV

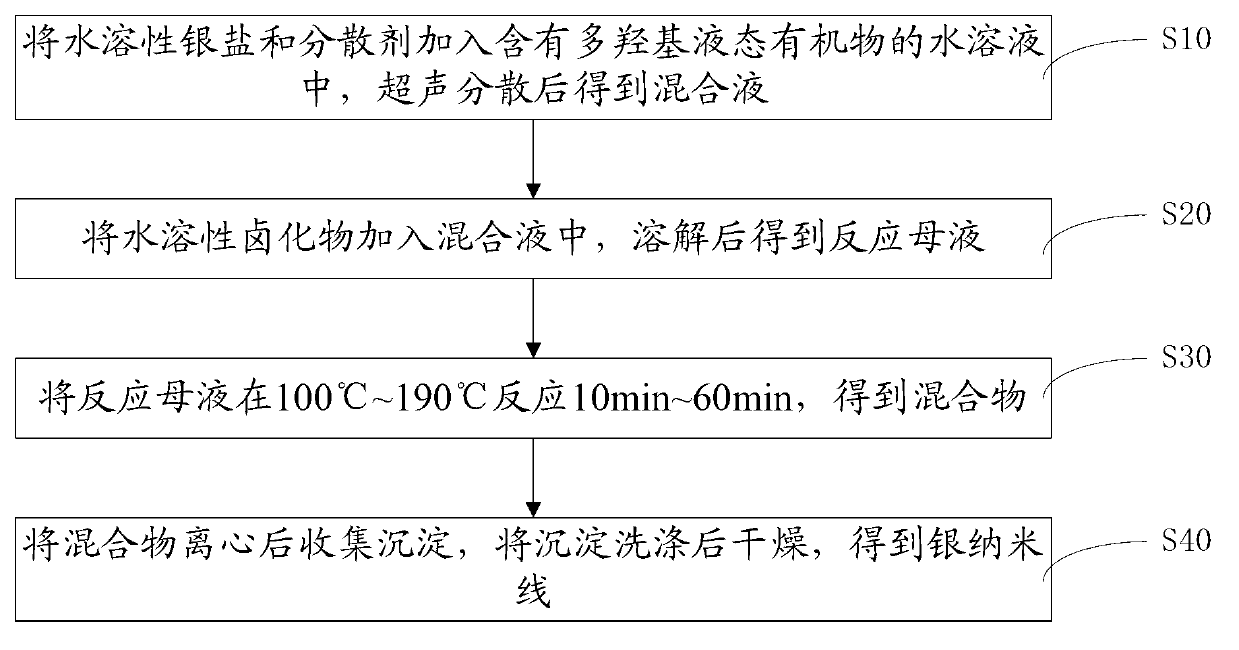

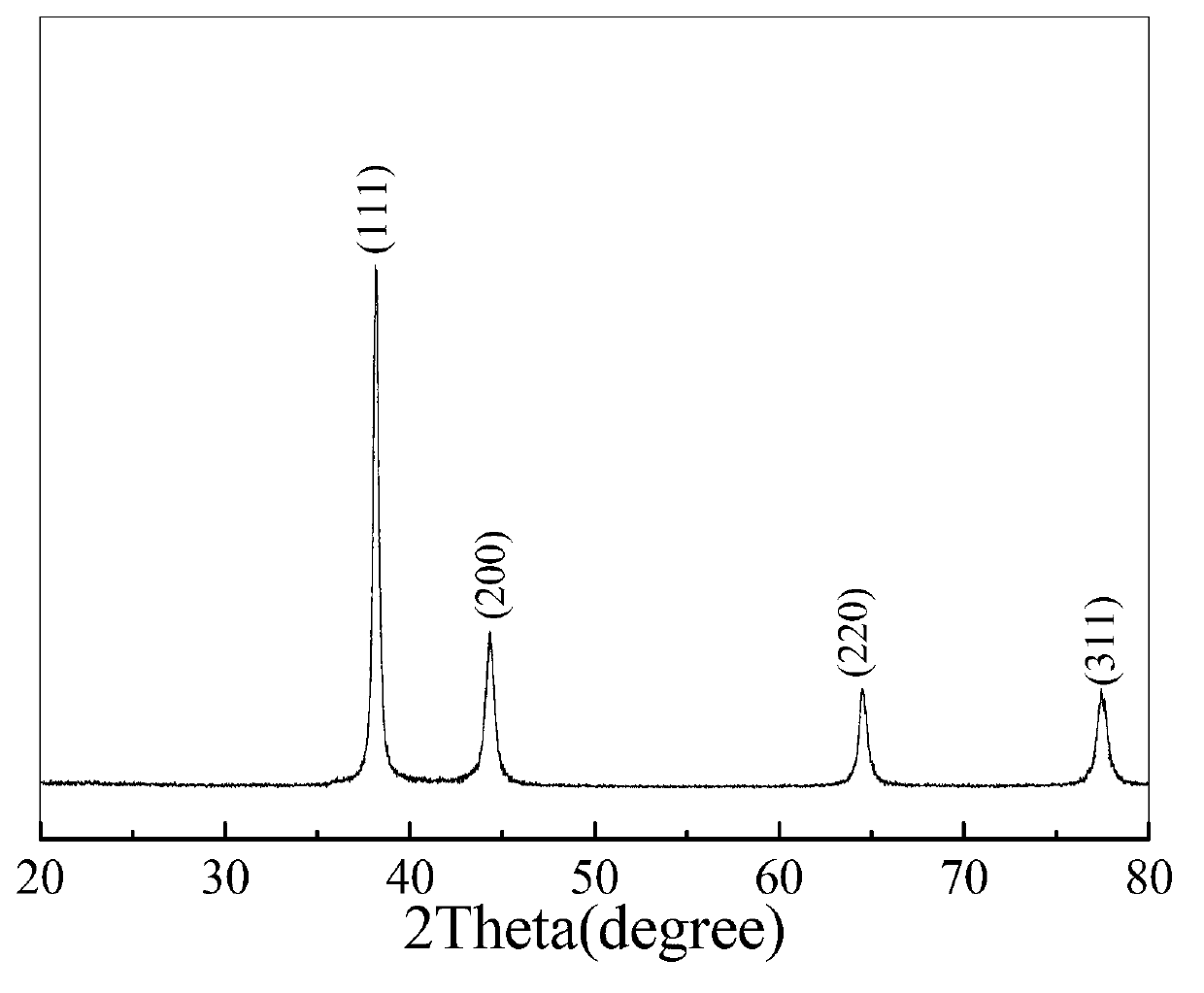

Preparation method of silver nanowires

Provided is a preparation method of silver nanowires. The preparation method of the silver nanowires includes the following steps: adding water-solubility silver salt and dispersing agents into aqueous solution comprising polyhydroxy liquid organic matters, and obtaining mixed liquor after ultrasonic dispersion; adding water-solubility halide into the mixed liquor, and obtaining reaction mother liquor after dissolving; reacting the mother liquor under 100-190 DEG C for 10-60 minutes, and obtaining mixtures; and collecting sediment after centrifugation of the mixtures, drying the sediment after washing of the sediment and obtaining the silver nanowires. The preparation method of the silver nanowires is short in preparation time.

Owner:SHENZHEN INST OF ADVANCED TECH

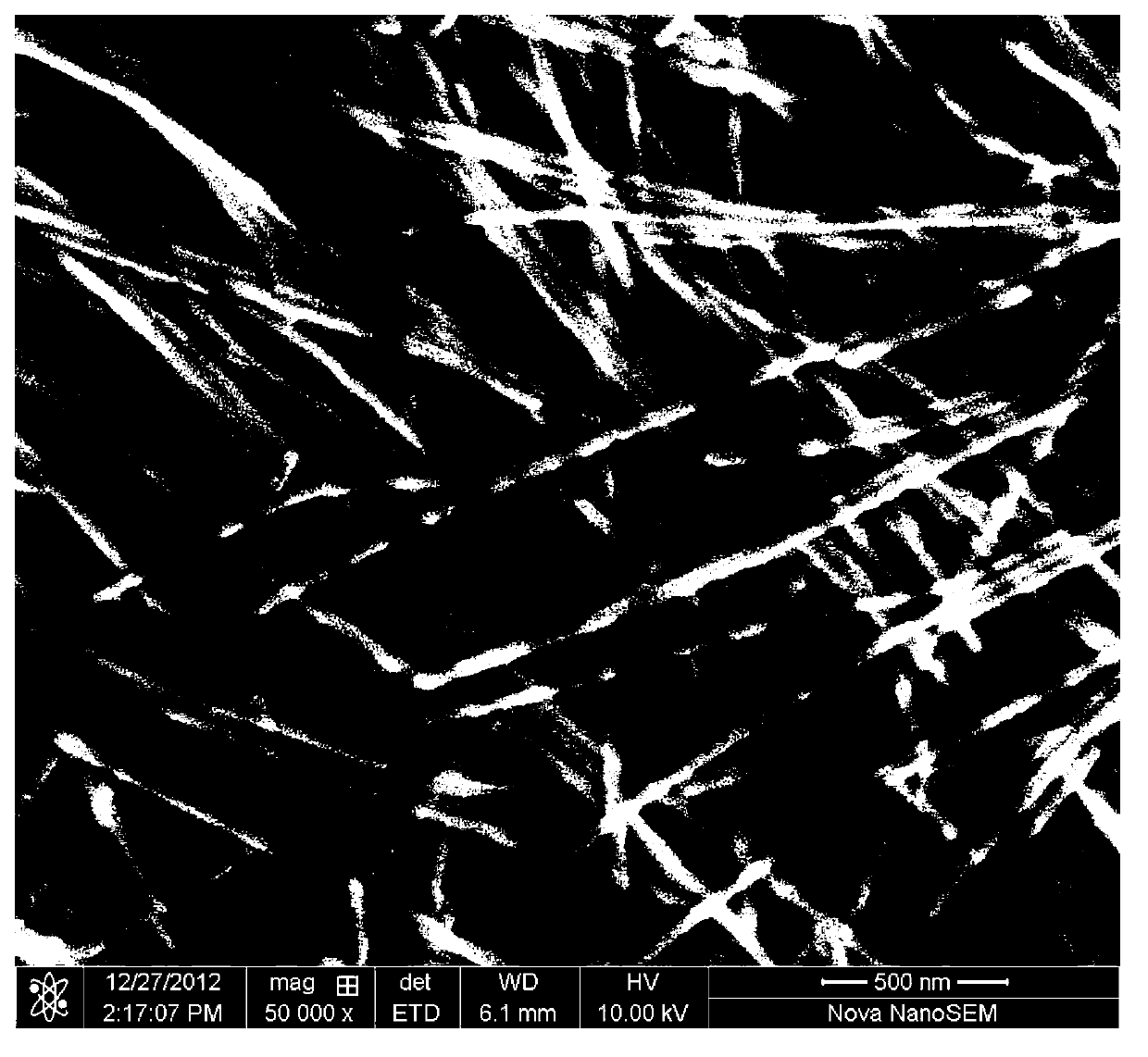

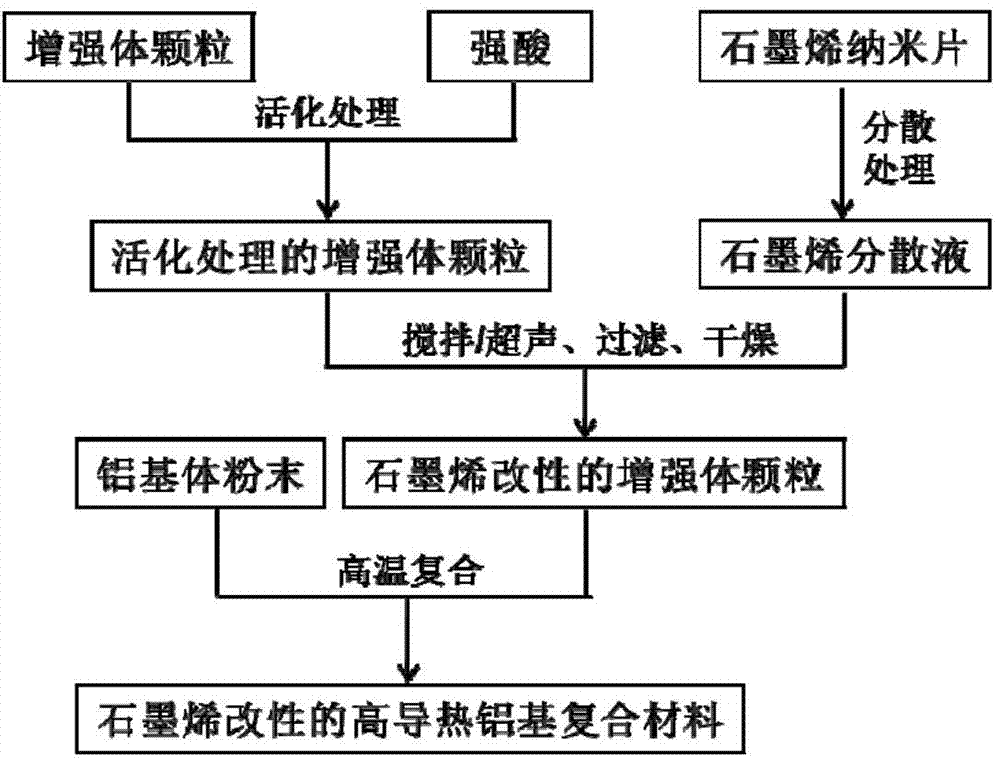

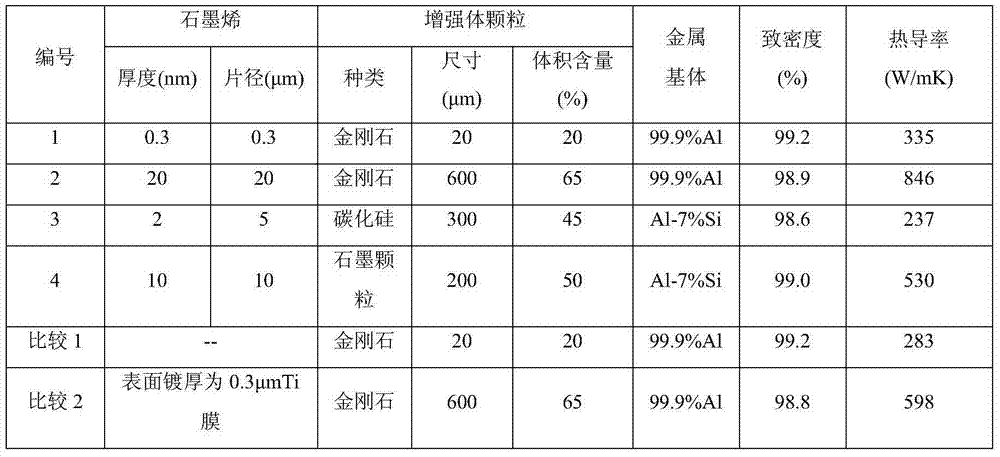

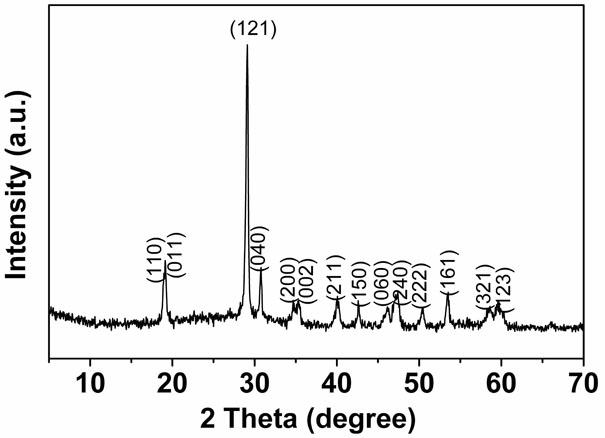

Graphene modified high-heat-conductivity aluminum-based composite material and powder metallurgy preparation method

ActiveCN104264000AReduce thermal resistanceHigh thermal conductivityMaterial nanotechnologyStrong acidsAluminum substrate

The invention provides a graphene modified high-heat-conductivity aluminum-based composite material and a powder metallurgy preparation method thereof. The material comprises reinforced grains and an aluminum substrate, wherein the composite boundary of the reinforced grains and the aluminum substrate contains high-heat-conductivity graphene nanosheets. The method comprises the following steps: (1) soaking the reinforced grains with a strong acid solution, subsequently washing with deionized water till being neutral, drying, and removing the surface impurities, thereby obtaining activated reinforced grains; (2) adding the activated reinforced grains into a graphene dispersion liquid, mechanically stirring or performing ultrasonic dispersion, and wrapping the graphene nanosheets on the surface, thereby preparing the graphene modified reinforced grains; and (3) mixing the graphene modified reinforced grains with the aluminum substrate powder, pressing into blanks, and sintering, thereby preparing the graphene modified high-heat-conductivity aluminum-based composite material. The composite material provided by the invention is good in chemical stability, high in thermal conductivity and can be used as a heat management material of a large-power semiconductor device.

Owner:SHANGHAI JIAO TONG UNIV

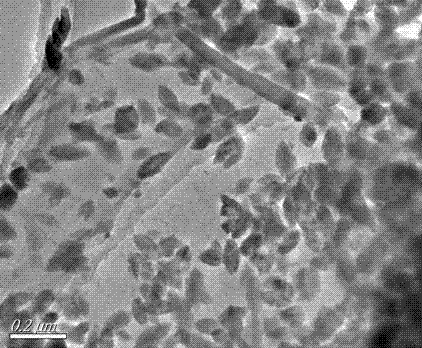

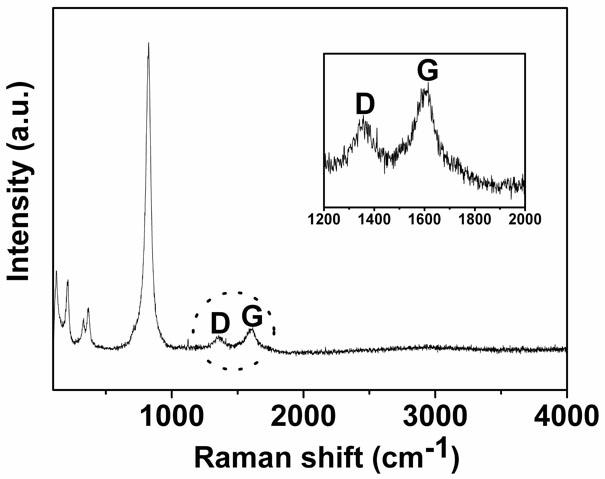

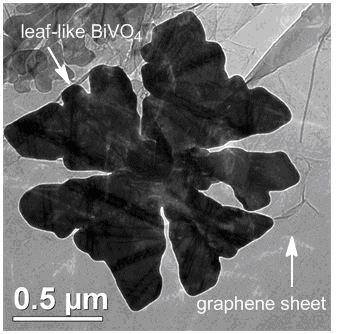

Visible light responsive pucherite-graphene composite photocatalyst and preparation method thereof

ActiveCN102125832AImprove adsorption capacityIncrease surface areaMetal/metal-oxides/metal-hydroxide catalystsAmmonium metavanadateUltrasonic dispersion

The invention discloses a visible light responsive pucherite-graphene composite photocatalyst and a preparation method thereof. The composite photocatalyst is prepared by compositing pucherite and graphene according to the mass ratio of (1:2)-(1:5). The preparation method comprises the following steps of: putting graphite oxide into a mixed solution of water and ethanol for ultrasonic dispersion,respectively adding bismuth nitrate and ammonium metavanadate into ethanol for stirring, and finally mixing the three systems and regulating the pH to be greater than 7; then, transferring the mixed system into a hydrothermal kettle for reacting; and after the reaction is finished, centrifugally separating, washing and drying the product to obtain a leaf-shaped pucherite-graphene composite photocatalyst. In the invention, by using graphene as a template, the leaf-shaped pucherite-graphene composite photocatalyst is prepared by a hydrothermal synthesis method. The pucherite-graphene composite photocatalyst prepared by the method disclosed by the invention has better application prospect and economic benefit in the aspect of sewage treatment.

Owner:NANJING UNIV OF SCI & TECH

Grapheme-containing reinforced wear-resistant material composition, reinforced wear-resistant material and preparation method thereof

The invention relates to a grapheme reinforcing agent-containing reinforced wear-resistant material and a preparation method thereof. A composition of the wear-resistant material comprises grapheme, polyolefin and a coupling agent, wherein the weight ratio of the grapheme to the polyolefin is 0.5:99.5-10:90; and the using amount of the coupling agent is 0.5-5 percent of the mass of the grapheme. The preparation method of the wear-resistant material comprises the following steps of: putting grapheme and the coupling agent which is dissolved into acetone or absolute ethyl alcohol serving as a solvent into a container; dispersing with ultrasonic waves; removing the solvent to constant weight; uniformly mixing with the polyolefin; and fusing in an internal mixer at the temperature 190-230 DEGC, and blending for 7-20 minutes. By adopting the method disclosed by the invention, the wear performance and mechanical property of a polyolefin material are enhanced remarkably, and the applicationfield of the polyolefin material is expanded.

Owner:RIFENG ENTERPRISE GRP CO LTD

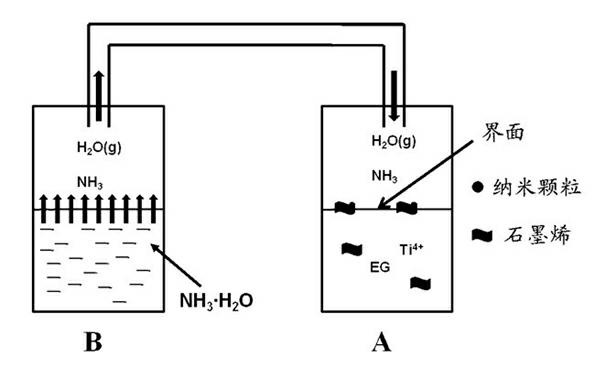

Preparation method of nitrogen doped graphene/ metal oxide nanometer composite material

ActiveCN102602917ASimple processLess investmentMaterial nanotechnologyCarbon compoundsNitrogenNitrogen doped graphene

The invention discloses a preparation method of a nitrogen doped graphene / metal oxide nanometer composite material. The preparation method comprises the following steps of: weighing graphene and metal salt the cation of which is trivalent or quadrivalent to be added in a dispersant, and then carrying out ultrasonic dispersion to obtain mixed liquor; (2), reacting the mixed liquor obtained in the step (1) with alkaline air on a gas-liquid interface for 3-12hours at the temperature of 60-200 DEG C, cooling, centrifuging, washing a precipitate and drying to obtain powder; and (3) introducing the alkaline air or a mixed gas of the alkaline air and inert gas, maintaining the powder to be at the constant temperature of 600-900 DEG C for 2-6 hours, and cooling to room temperature to obtain the nitrogen doped graphene / metal oxide nanometer composite material. According to the invention, the conductibility and interface action of the composite material obtained by the method provided by the invention are improved due to the doping of nitrogen; and the method provided by the invention has the advantages of simple process, cheap cost, high productive rate, short cycle and the like, and is environment-friendly, and can be suitable for industrialization large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

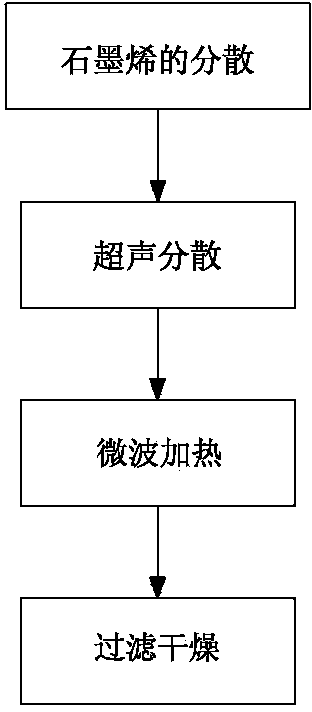

Method for preparing nitrogen-doped graphene with high nitrogen doping amount

The invention discloses a method for preparing nitrogen-doped graphene with high nitrogen doping amount. The method comprises the following steps: (1) dispersing of graphene; (2) ultrasonic dispersion; (3) microwave heating; and (4) filtering and drying. The nitrogen doping amount of the nitrogen-doped graphene prepared by the method disclosed by the invention is 10%-15.0%, the density of free carriers in graphene is greatly increased by the high nitrogen doping amount, the interaction of graphene and metal is enhanced, no oxidation pretreatment is carried out, no toxic solvent is used in the reaction process, reactants are simple in component, reaction conditions are mild, and the prepared nitrogen-doped graphene has excellent electrochemical property and can be used for preparation of new energy materials such as lithium ion battery, lithium-air battery, super capacitor electrode material and fuel cell oxygen reduction catalysts. According to the method disclosed by the invention, a high-pressure kettle is heated by using microwaves without high temperature; the method is low in energy consumption, is carried out in an airtight environment and therefore hardly causes environment pollution; in addition, the method is simple in process and convenient to operate and needs less production equipment, thus, the cost is further reduced.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

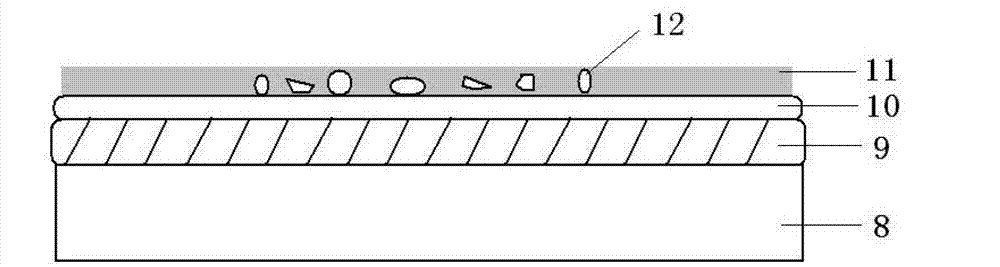

Method of electrolytically extracting and detecting fine inclusions in steel

ActiveCN102818723ACollect fast and losslessAvoid lostPreparing sample for investigationTesting metalsElectrolysisScanning electron microscope

The invention discloses a method of electrolytically extracting and detecting fine inclusions in steel, belonging to the technical field of metal physical research methods. The method comprises the following technical steps of: using an organic electrolyte to carry out electrolysis on a steel sample; after electrolysis, washing the electrolyte mixed with the inclusions by absolute ethyl alcohol, and carrying out magnetic separation on the electrolyte by a magnet; separating the electrolyte after magnetic separation and collecting the inclusions by adopting a method of centrifugation by a centrifugal machine; putting the collected inclusions into a solvent easy to volatilize, carrying out ultrasonic dispersion on the inclusions by an ultrasonic cleaner, and then dripping a solution after ultrasonic dispersion on a carrier drop by drop by a trace pipette; and after the solvent volatilizes, putting the carrier which is distributed with the inclusions into a scanning electron microscope to analyze. The method has the advantages that the fine inclusions can be extracted in an undamaged way, the obtained inclusions are good in dispersion under a field of view of the scanning electron microscope, the shapes of the inclusions are perfect, and a good space statistic analysis result can be obtained so as to supply accurate data for a product.

Owner:SHOUGANG CORPORATION

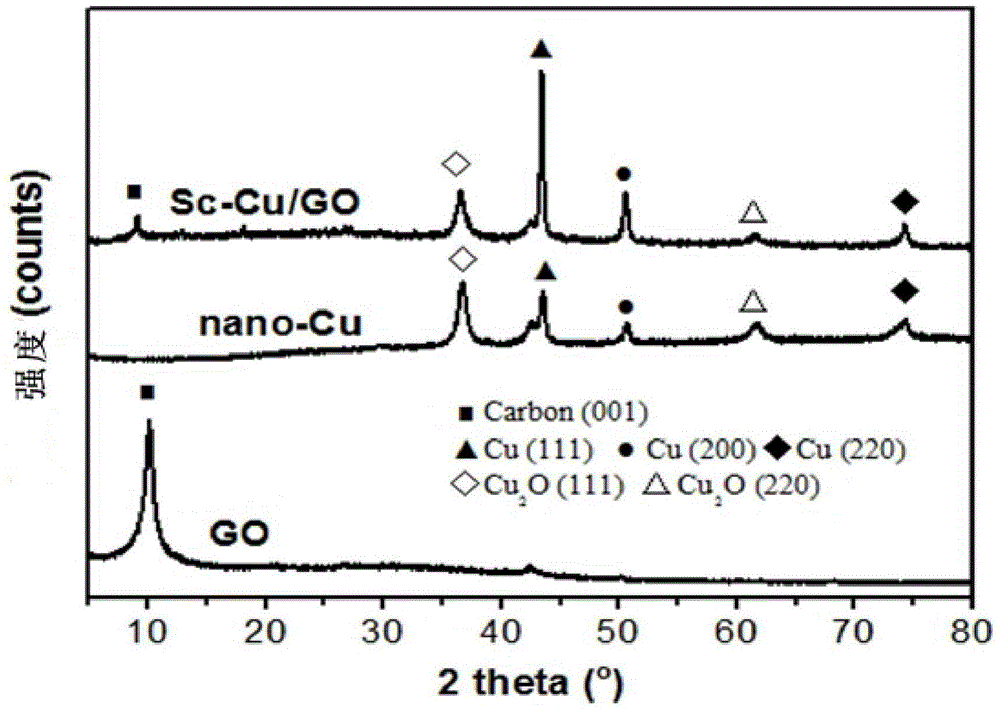

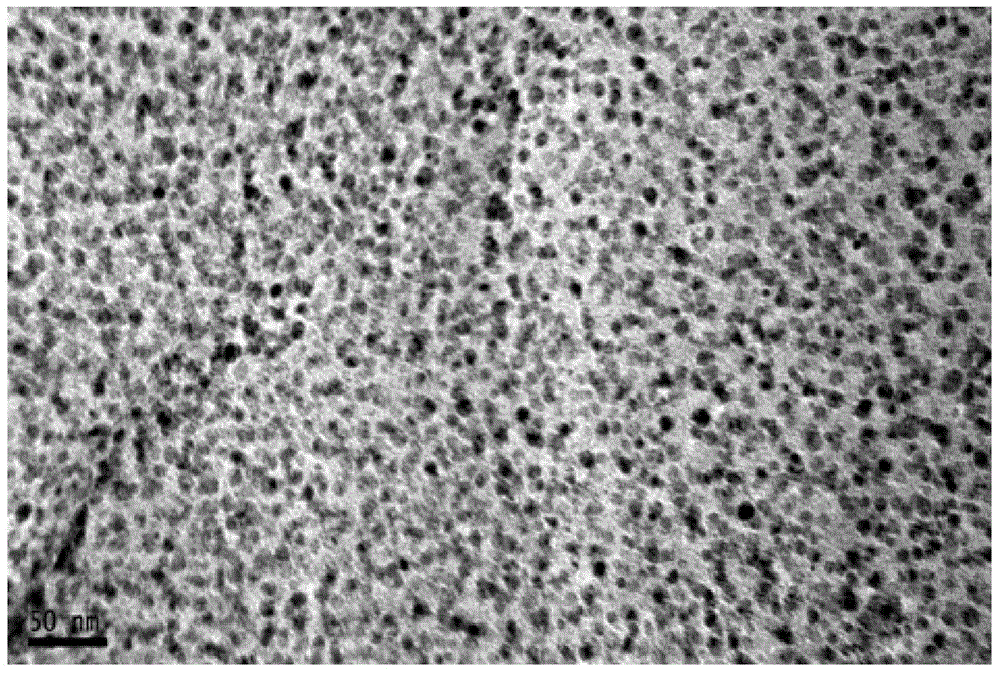

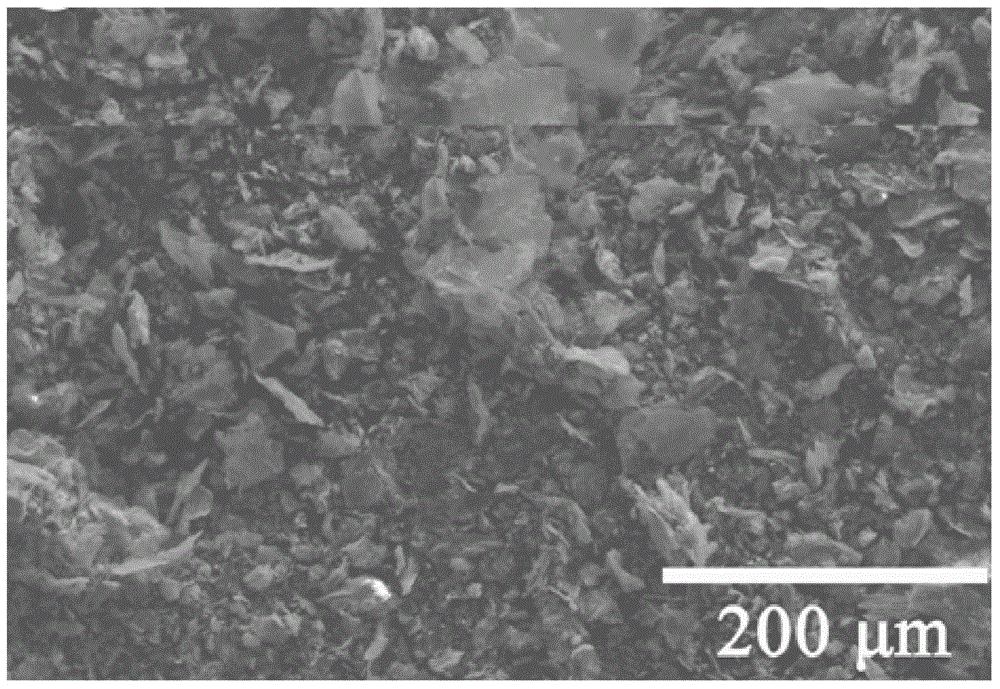

Nanometer copper/graphene composite material and preparation method and application thereof

InactiveCN104479804AThe preparation method is simple and quickShort processing timeAdditivesOil additiveSurface-active agents

The invention belongs to the technical field of new material preparation and lubricating oil additives, and discloses a nanometer copper / graphene composite material and a preparation method and application thereof. The preparation method comprises the following steps of: firstly dissolving a copper precursor compound, a surface active agent and a complexing agent into reducing alcohol, then adding graphene oxide, and carrying out ultrasonic dispersion to obtain a mixed solution; then adding a reducing agent to the mixed solution, transferring into a reaction kettle, introducing CO2 gas, and controlling gas pressure and temperature so that CO2 achieves a supercritical state; stirring the mixed solution inside the reaction kettle for reacting, cooling, decompressing, washing by centrifuging, and carrying out vacuum drying to obtain the nanometer copper / graphene composite material. The preparation method disclosed by the invention is simple, saved in time and fast. The prepared nanometer copper / graphene composite material has the characteristics of single phase, controllability in loading capacity, small nanometer copper particle size, uniformity in nanometer copper distribution on the surface of a graphene nanometer layer, and the like, has a synergetic lubricating effect, and can be used for outstandingly improving the antifriction and abrasion-resistant property of basic lubricating oil.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com