Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

A lithium-ion battery and positive electrode material technology, applied in the field of energy storage and conversion, can solve the problems of electrode structure damage, cycle stability deterioration, complex preparation process, etc., and achieve the effects of optimized conductivity, stable structure, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

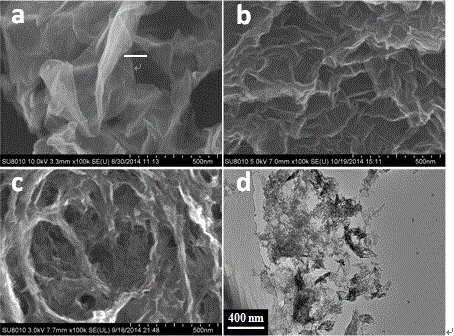

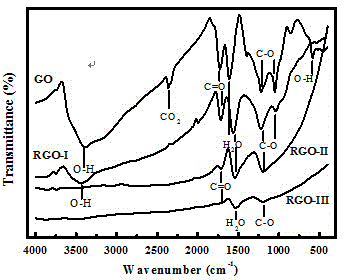

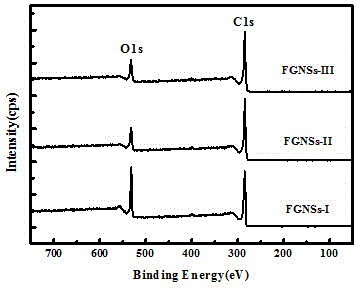

Image

Examples

Embodiment 1

[0057] The first example: (1) The first step is to improve the Hummers method to prepare graphite oxide: 1. Weigh 1g of graphite powder and 0.5g of NaNO 3 Mix evenly; 2. Under the condition of ice-water bath, add 5mL concentrated H 2 SO 4 Stir well, and slowly add 1.5g KMnO 4 Stir for 1 hour; 3. After stirring for 5 days at room temperature, add 50 mL of 5% H 2 SO 4 Stir for 1 hour; 4. Add an appropriate amount (about 3mL) of hydrogen peroxide (H 2 o 2 ) Stir until there are no bubbles in the solution; 5. Clean, use 10% HNO in a 4000mL beaker 3 Wash 2 times, then use 5% HNO 3 Wash twice; 6. Add deionized water and centrifugally wash to pH = 7, and dry the resulting solution at room temperature 25° C. to obtain graphite oxide.

[0058] The second example: (2) The first step is to improve the Hummers method to prepare graphite oxide: 1. Weigh 5g of graphite powder and 5g of NaNO respectively 3 Mix evenly; 2. Under the condition of ice-water bath, add 100mL concentrated H...

Embodiment 2

[0061] The first step is the same as the first example of embodiment 1: (1)

[0062] The second step, sodium citrate oil bath reflux method to reduce graphene oxide: 1. The prepared graphite oxide is fully ground to obtain a brownish-yellow powder (graphite oxide); 2. Weigh 200mg of graphite oxide powder and disperse it in 100mL of deionized water , after 30 minutes of ultrasonic peeling by an ultrasonic cell pulverizer to obtain a graphene oxide dispersion with a concentration of 2 mg / mL; 3. Centrifuge the above dispersion in a centrifuge at a speed of 10,000 rpm for 40 minutes to remove the centrifuged impurities; 4. Weigh 2g of sodium citrate and add it to the above-mentioned graphene oxide dispersion, and reflux the reaction in an oil bath at 80°C for 12 hours under vigorous stirring; 5. Extract and wash the above-mentioned reaction product with deionized water, and freeze the product After 12 hours, dry in a vacuum freeze dryer for 24 hours to obtain the reduced graphene ...

Embodiment 3

[0064] The first step is the same as the first example of embodiment 1: (2)

[0065]The second step is sodium borohydride reduction of graphene oxide: 1. The prepared graphite oxide is fully ground to obtain a brownish-yellow powder (graphite oxide); 2. Weigh 50 mg of graphite oxide powder and disperse it in 100 mL of deionized water. Ultrasonic peeling with a pulverizer for 15 minutes to obtain a graphene oxide dispersion with a concentration of 0.5 mg / mL; 3. Centrifuge the above dispersion in a centrifuge at a speed of 10,000 rpm for 20 minutes to remove the centrifuged impurities; 4. Weigh 0.1 Add 1 g of sodium borohydride to the above graphene oxide dispersion, and react at room temperature for 6 hours under vigorous stirring; 5. Extract and wash the above reaction product with deionized water, freeze the product for 12 hours and dry it in a vacuum freeze dryer for 24 hours The reduced graphene oxide (RGO) product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com