Patents

Literature

857 results about "Hummers' method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hummers' method is a chemical process that can be used to generate graphite oxide through the addition of potassium permanganate to a solution of graphite, sodium nitrate, and sulfuric acid. It is commonly used by engineering and lab technicians as a reliable method of producing quantities of graphite oxide. It is also able to be revised in the creation of a one-molecule-thick version of the substance known as graphene oxide.

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

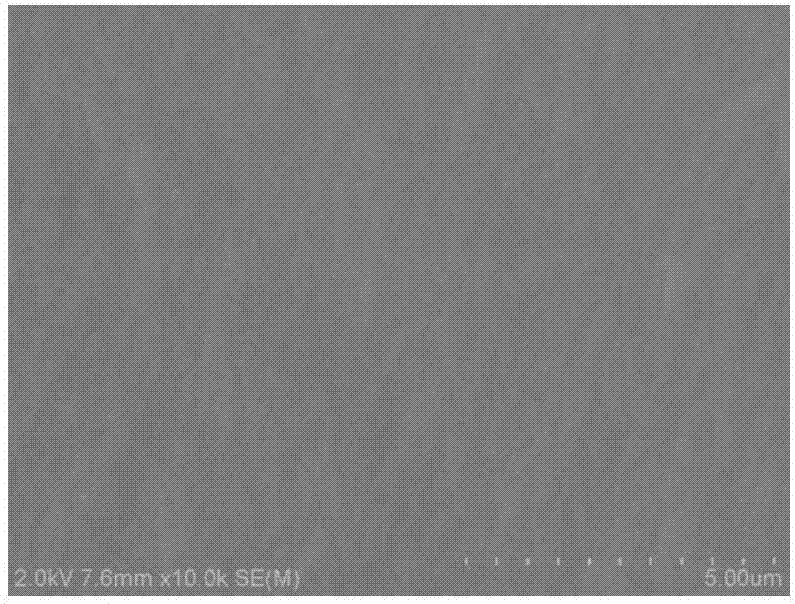

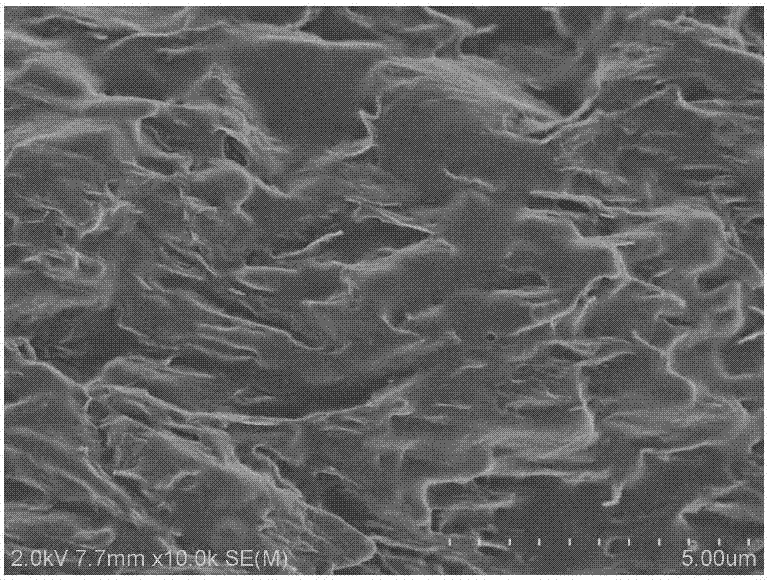

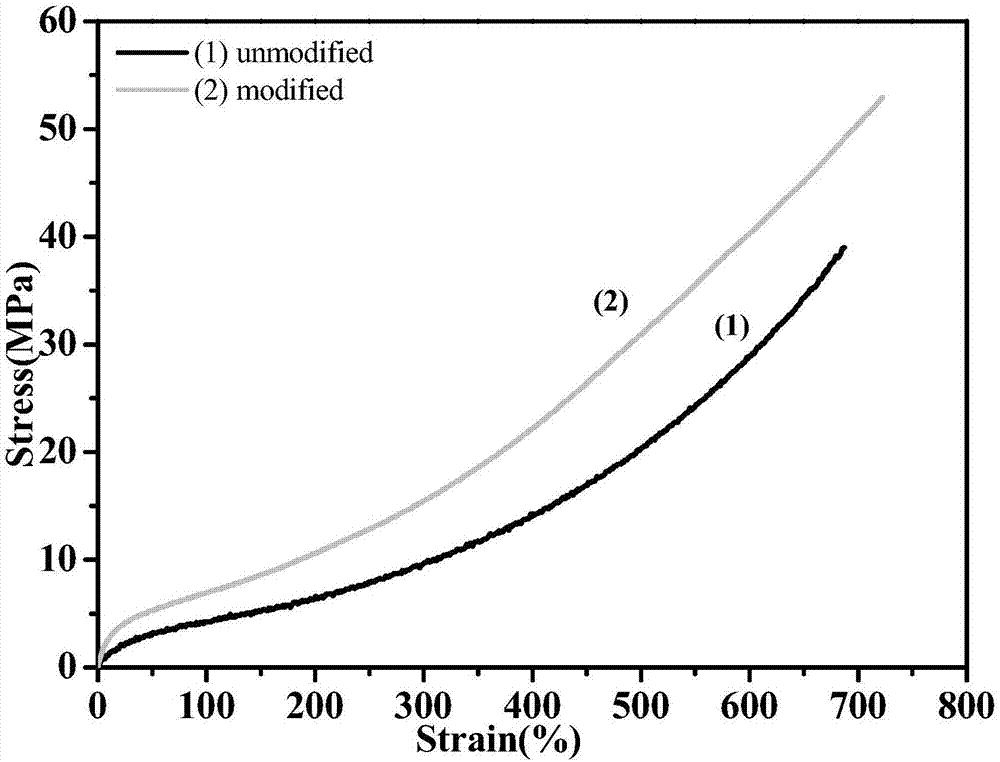

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

Method for preparing grapheme through oxidation reduction

The invention relates to a method for preparing grapheme through oxidation reduction and belongs to grapheme preparation technique. The method specifically comprises the following steps: a modified Hummer method is used for preparing graphite oxide, and an oscillator is adopted for shaking and peeling off single layer graphite oxide softly. During the step of preparing grapheme through reduction, compared with kinds of conventional major reducing agents, the method has the advantages that the reduction procedures and conditions are optimized, and further the grapheme with excellent performance is obtained. In the invention, by optimizing the preparation technique and conditions, the grapheme, which is large in size, is single-layered, is excellent in electrical conductivity and has high quality is obtained, and the method has the characteristics of low cost, high product yield and easiness in industrialization.

Owner:NANJING UNIV OF TECH

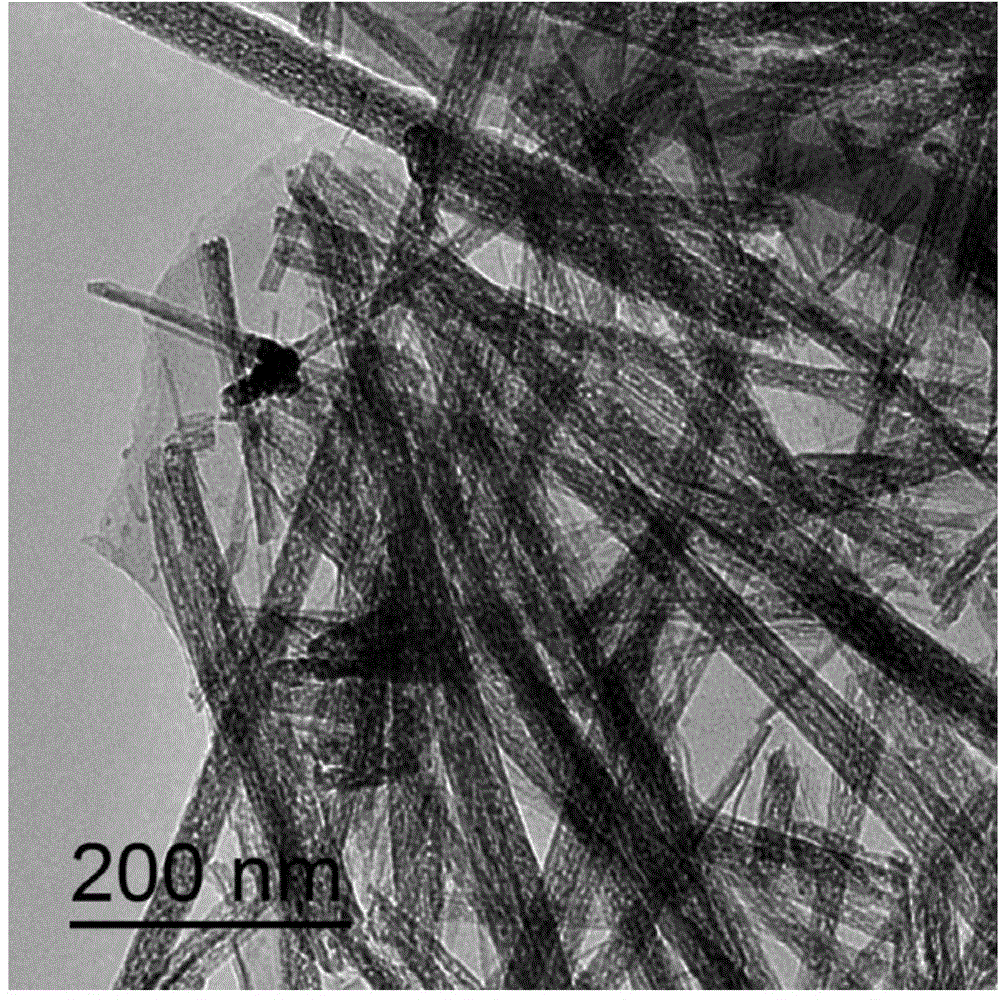

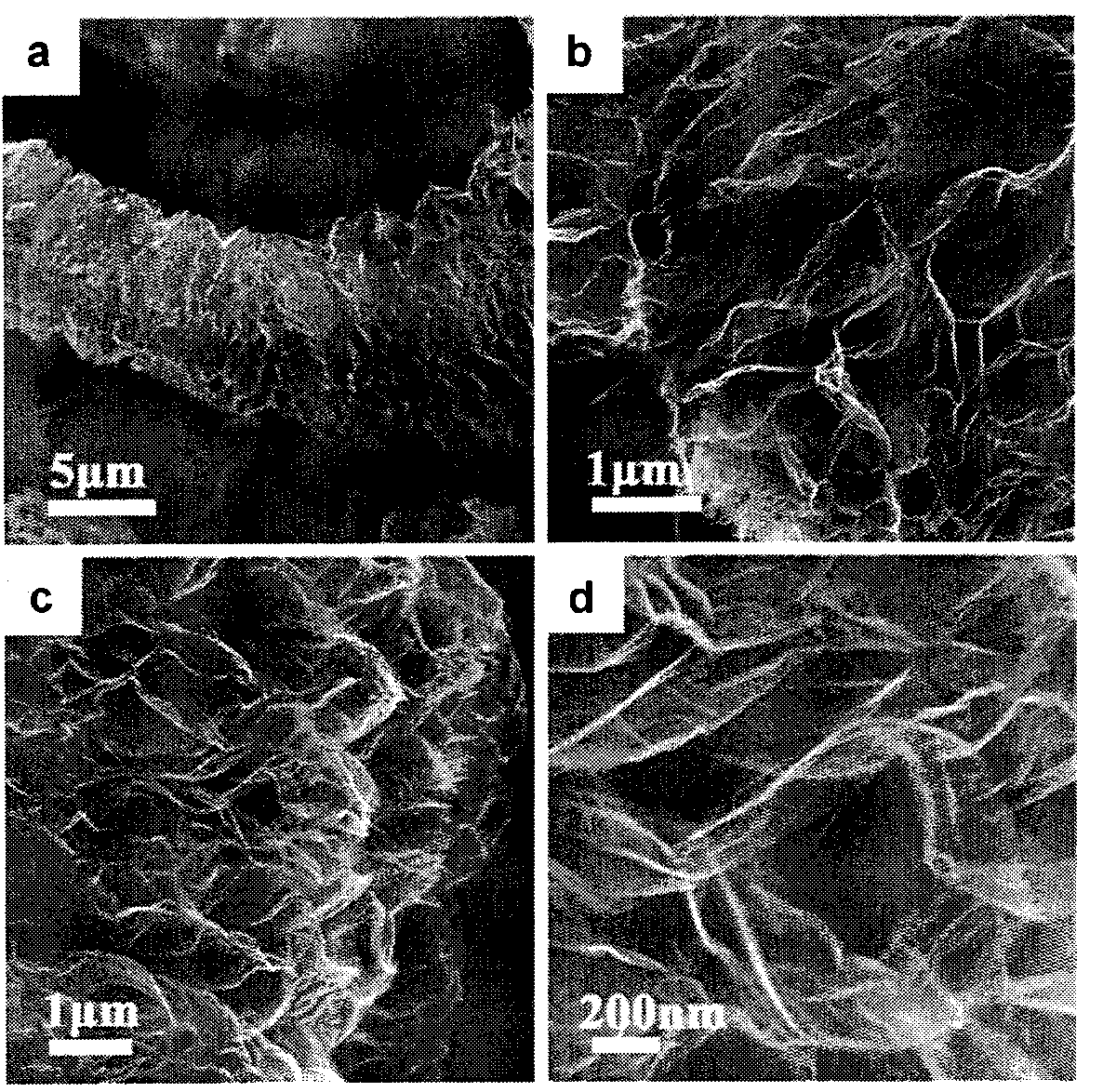

Preparation method of graphene-carbon nanotube compound film based on three-dimensional network appearance

InactiveCN102417176AImprove uniformityReduce surface resistanceNanotechnologyPolyethylene terephthalate glycolMeth-

The invention discloses a preparation method of a graphene-carbon nanotube compound film based on a three-dimensional network appearance. The method comprises the step of: transferring and stamping graphene and a carbon nanotube onto glass, a tantalum sheet, a silicon chip, a stainless steel plate or a polyethylene glycol terephthalate substrate in the mass ratio (1-10):1 through spraying deposition or vacuum suction filtration, wherein the grapheme is graphene oxide prepared by using an improved Hummers method; and a preparation method of a carbon nanotube solution comprises the following steps of: mixing acids; dispersing surfactants such as sodium lauryl sulfate, sodium dodecyl benzene sulfonate and hexadecyl trimethyl ammonium bromide in an auxiliary way, and the like. The graphene-carbon nanotube compound film prepared by adopting the method has the advantages of adjustable transmission and surface resistance, high uniformity, high stability, simple preparation method process and the like, and can be loaded on a rigid substrate as well as a flexible substrate.

Owner:TIANJIN UNIV

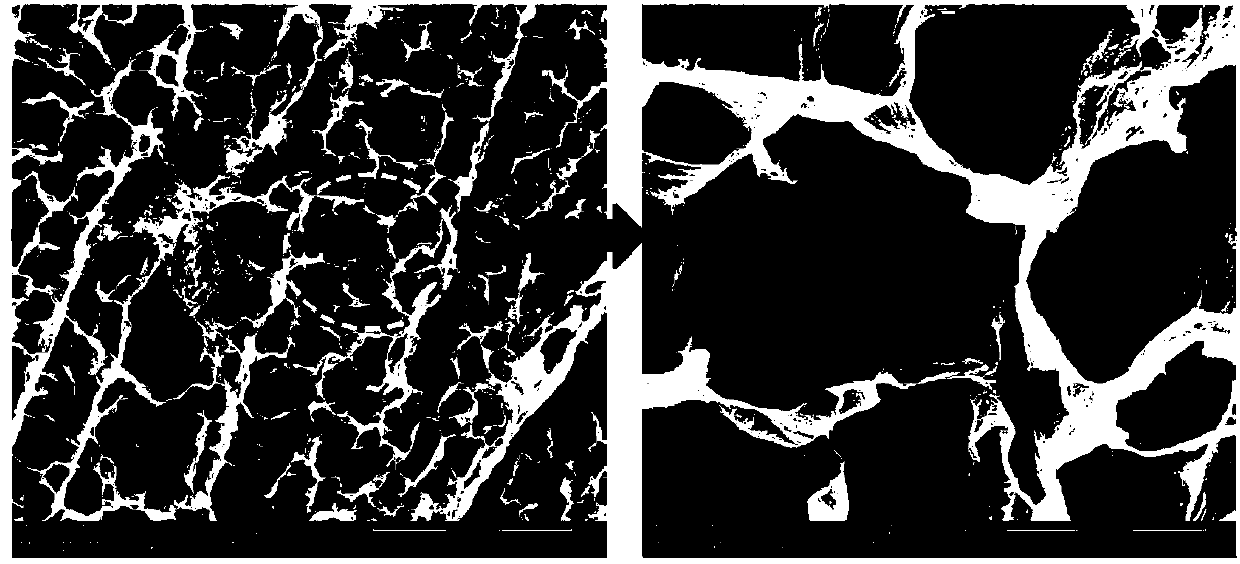

Layer-by-layer self-assembling oxidized graphene nano-filtration membrane and preparation method thereof

ActiveCN103706264AImprove permeabilityImprove interception effectSemi-permeable membranesFiltration membraneGraphene nanoribbons

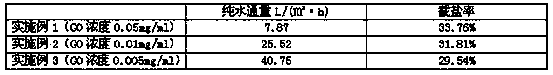

The invention relates to a layer-by-layer self-assembling oxidized graphene nano-filtration membrane and a preparation method of the layer-by-layer self-assembling oxidized graphene nano-filtration membrane, which belongs to the technical field of the preparation of a nano-filtration membrane. The layer-by-layer self-assembling oxidized graphene nano-filtration membrane comprises a supporting layer and a functional layer, wherein the functional layer is in a layered structure which is different from the compact structure of the traditional nano-filtration membrane functional layer. The preparation method comprises the following steps of (I) preparing an oxidized graphene solution through a hummers method; and (II) preparing an oxidized graphne nano-filtration membrane through a layer-by-layer self-assembling method. The oxidized graphene nano-filtration membrane is prepared through the layer-by-layer self-assembling method, a water passage is formed between the oxidized graphene lamellas, the distance of the oxidized graphene layer has a good interception effect for ions, the hydrophilia can be improved through the oxygen-containing functional groups on the surface of the oxidized graphene layer, so that the membrane is good in permeability and interception property. By utilizing the layer-by-layer self-assembling method, the high requirement of the traditional nano-filtration membrane preparation process on the condition can be avoided, the process is simple, the condition is easily controlled, and the application prospect is wide.

Owner:OCEAN UNIV OF CHINA

Preparation method and application of graphene oxide-polyurethane foam material

InactiveCN103408718AImprove adsorption capacityGood removal effectOther chemical processesWater contaminantsMalachite greenPolymer science

The invention belongs to the field of high polymer material synthesis, and relates to preparation of a graphene oxide-polyurethane foam material, in particular to a preparation method and application of the graphene oxide-polyurethane foam material. The preparation method of the graphene oxide-polyurethane foam material comprises the following steps: firstly, preparing graphene oxide by adopting an improved Hummers method, then mixing and stirring graphene oxide, polyether glycol NJ-330, foaming agent, foam stabilizer and catalyst at room temperature, adding isophorone diisocyanate, and finally, foaming further to obtain the graphene oxide-polyurethane foam material. The graphene oxide-polyurethane foam material prepared through the method can be applied to absorption of coloring matters or heavy metal ions in waste water, and has better absorption and removal effects as shown in a test by taking a solution containing malachite green and Cd (II) as the absorption object. The application of the foam material to treatment of the coloring matters and the heavy metal ions in sewage has the characteristics of simplicity in operation and high absorption rate, and has a certain practical value.

Owner:JIANGSU UNIV

Method for synthesizing graphene oxide by ultrasonic assistance Hummers method

InactiveCN102153075AImprove efficiencyHigh degree of oxidationUltrasonic oscillationMechanical property

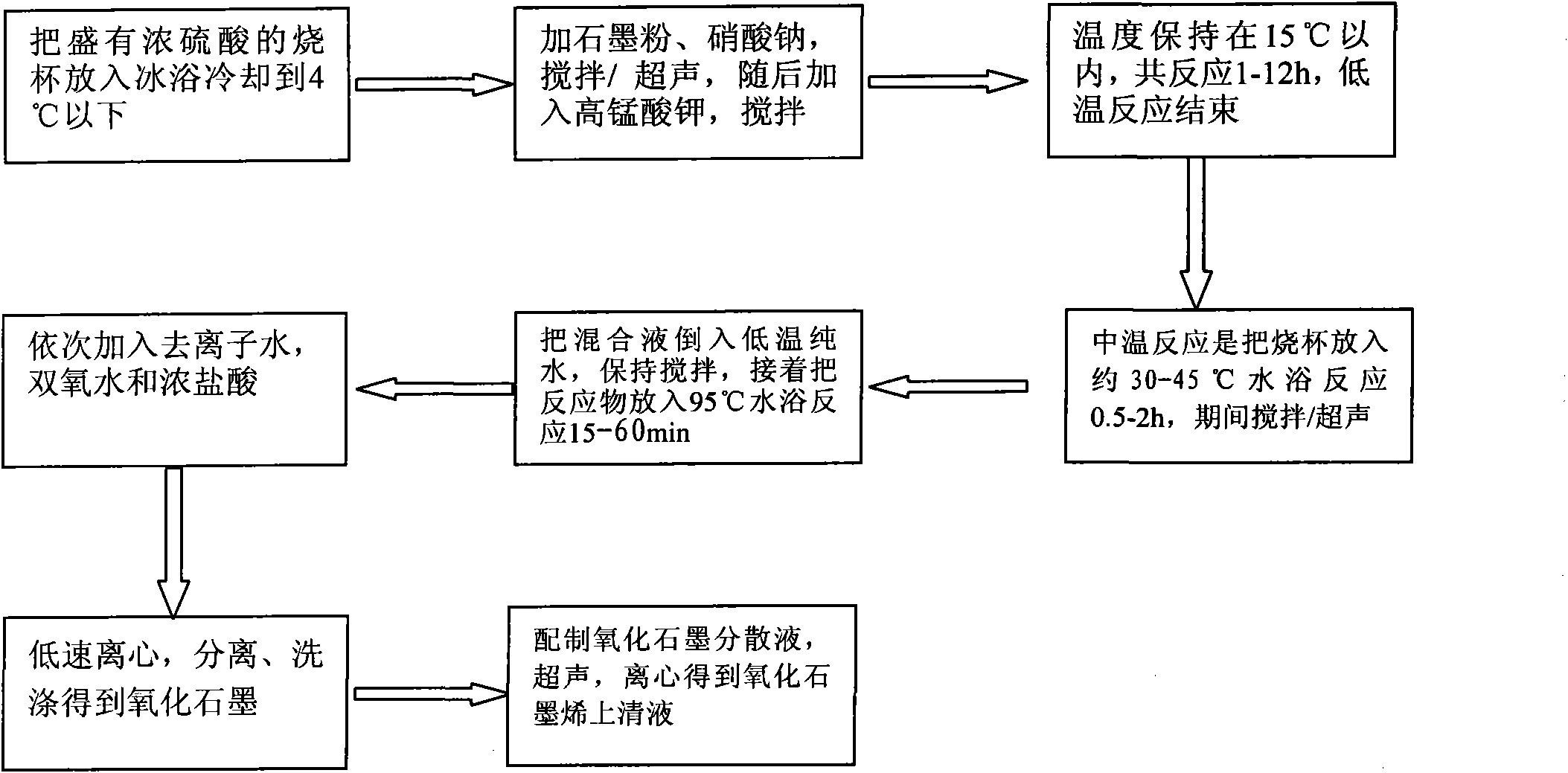

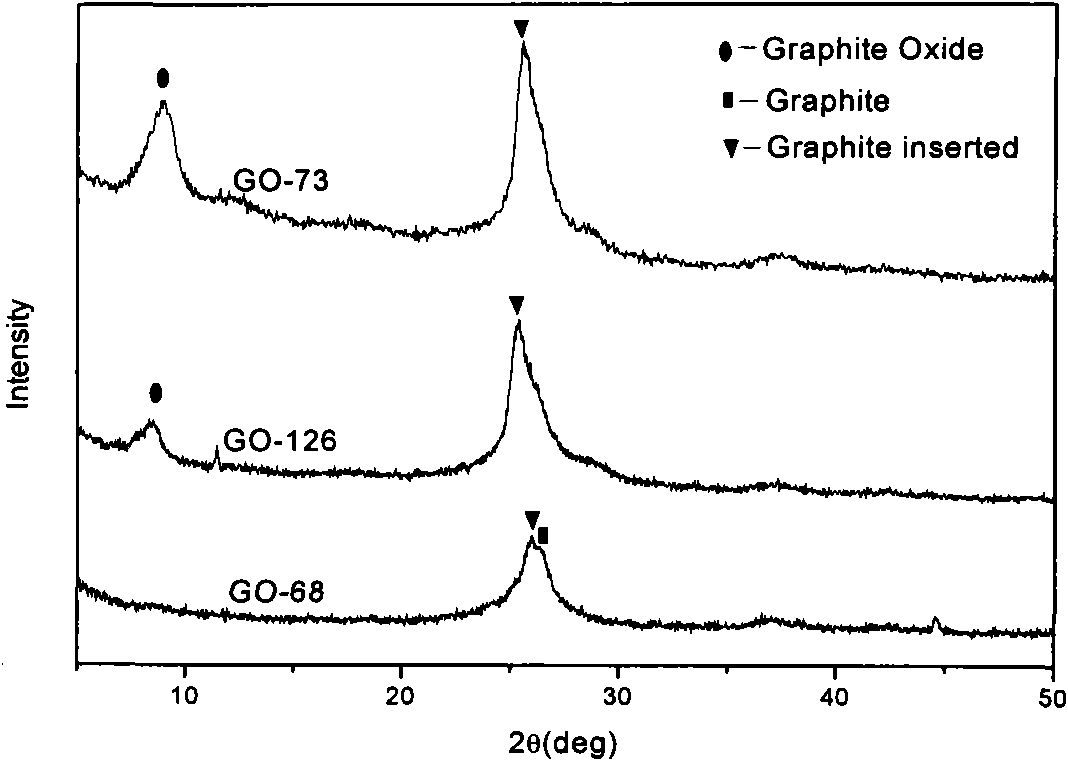

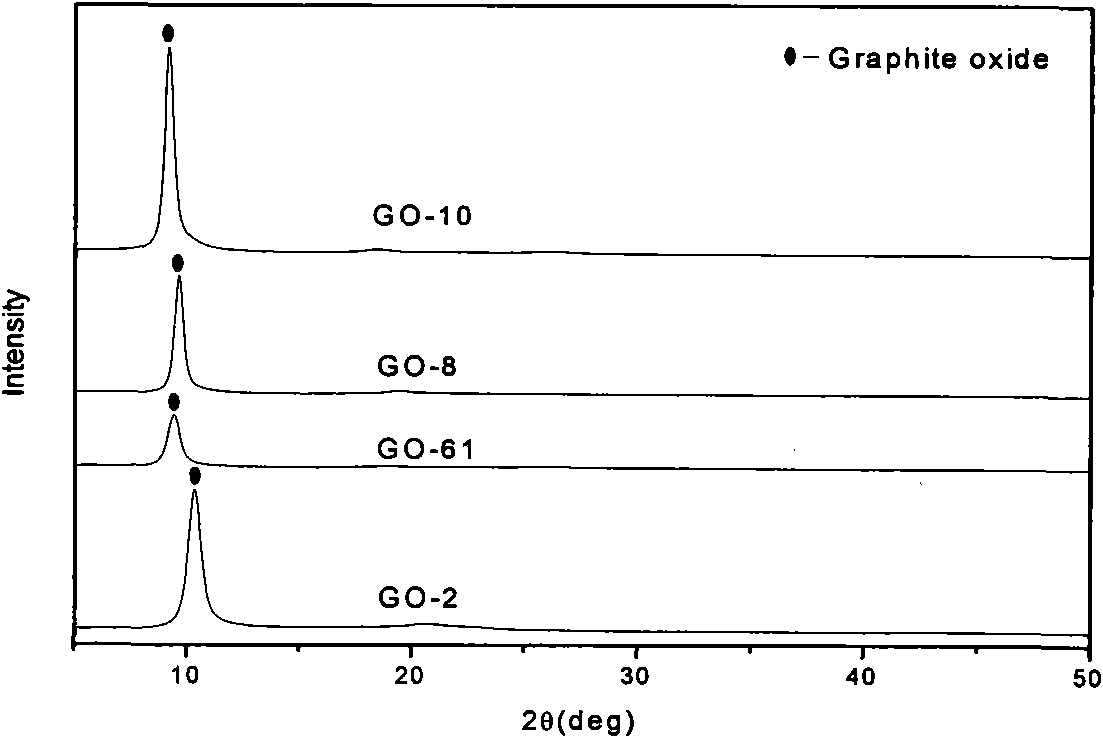

The invention relates to a method for synthesizing graphene oxide by an ultrasonic assistance Hummers method. The method for synthesizing the graphene oxide includes the steps as follows: firstly adding ultrasonic oscillation in low-temperature and middle-temperature reaction stages of the Hummers method to improve the intercalation efficiency and the oxidation degree of graphite oxide; secondly slowly dropping mixed liquor containing concentrated sulphuric acid into low-temperature deionized water to increase temperature when high-temperature reaction begins, thus effectively preventing intercalated materials such as sulphuric acid molecules and the like from rapidly escaping from graphite layers due to overhigh local temperature; and finally obtaining the graphite oxide through low-speed centrifugation. The method for synthesizing the graphene oxide by using the ultrasonic assistance Hummers method is convenient and fast, saves resources, and can effectively increase spacings of graphite oxide layers. The prepared graphene oxide can serve as a wild phase of a composite material and papyraceous laminated graphite oxide based composite material with high mechanical property and the like can be prepared. The reduction product graphene can be used for preparing graphene-based composite materials such as transparent electrodes, super capacitors, hydrogen storage materials, chemical / biological sensors, thin film transistors and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

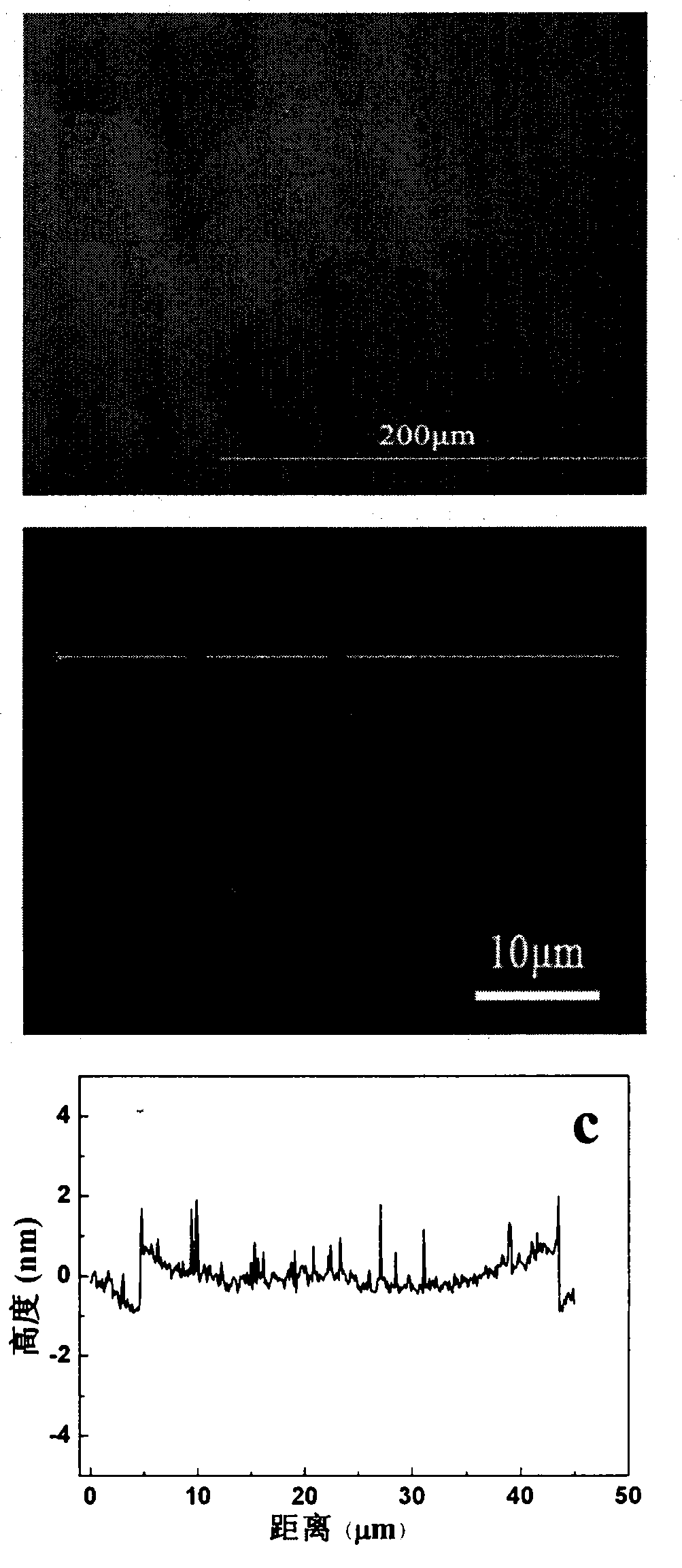

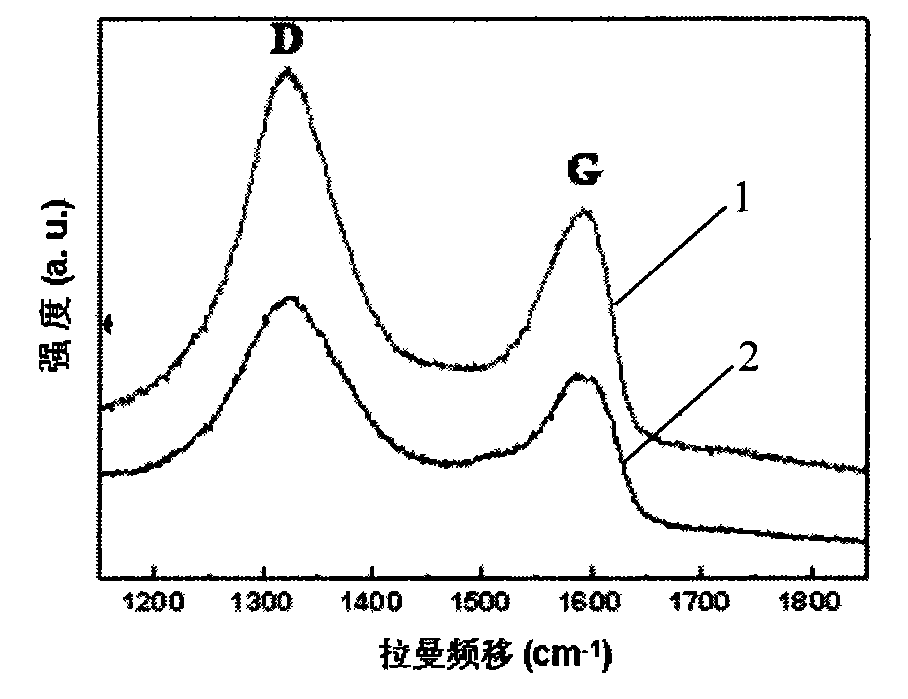

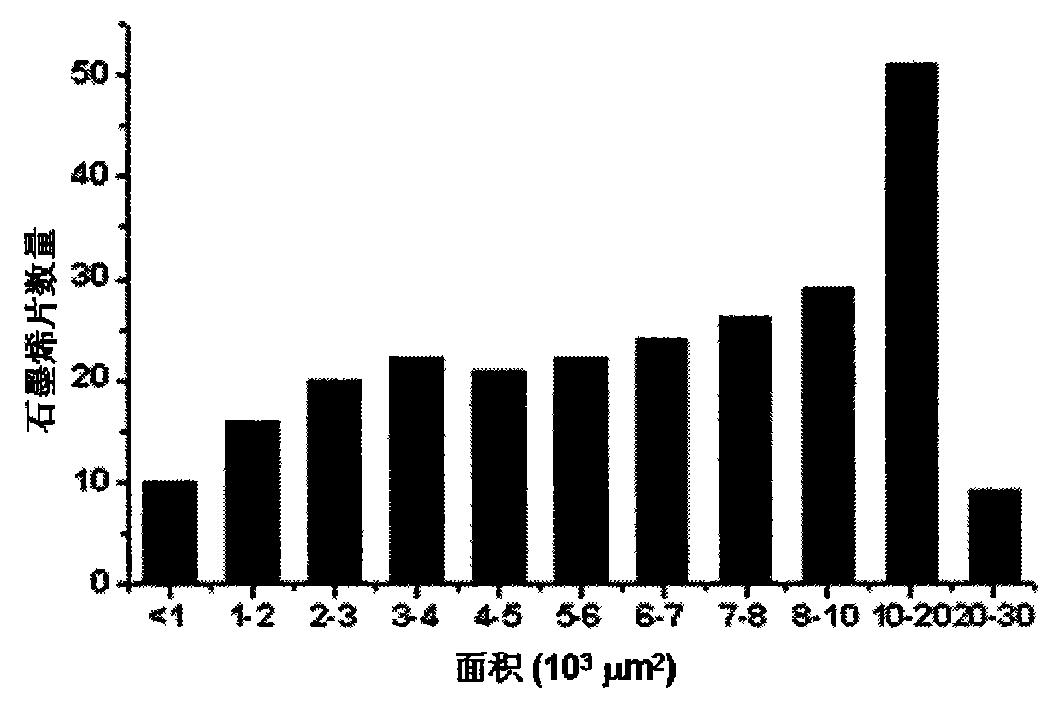

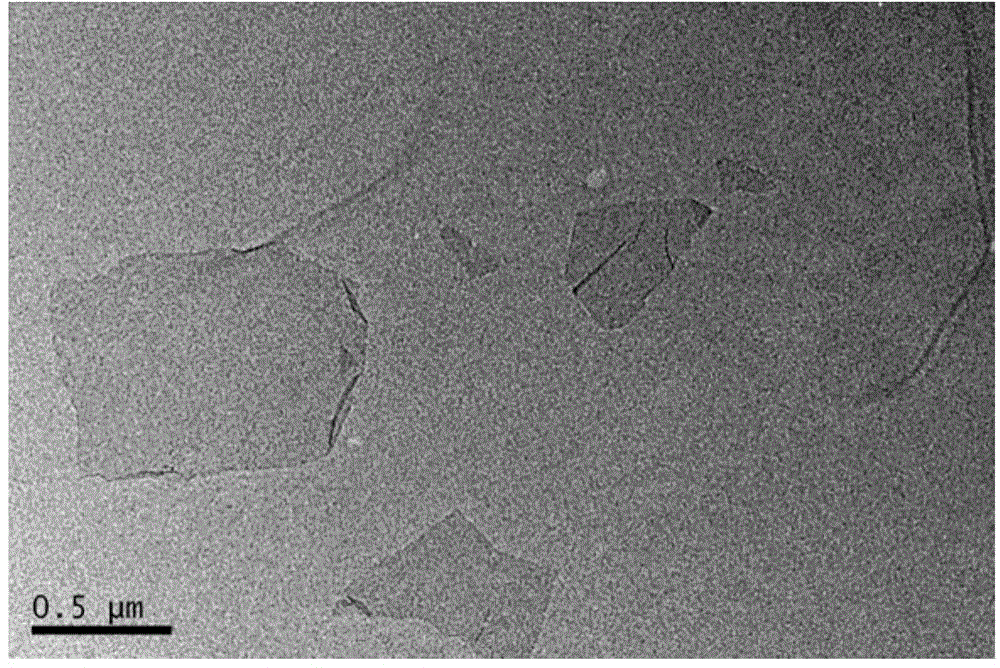

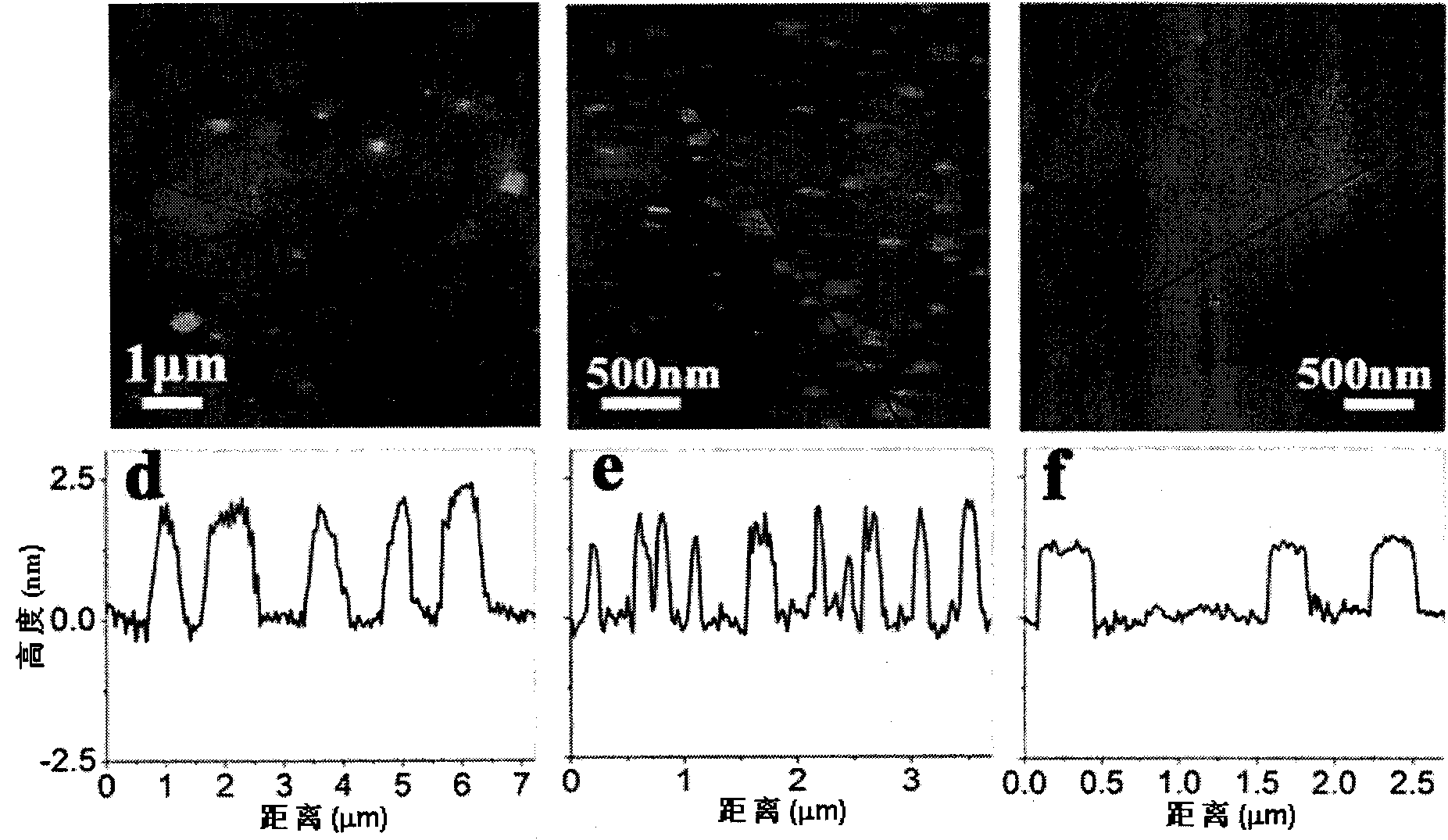

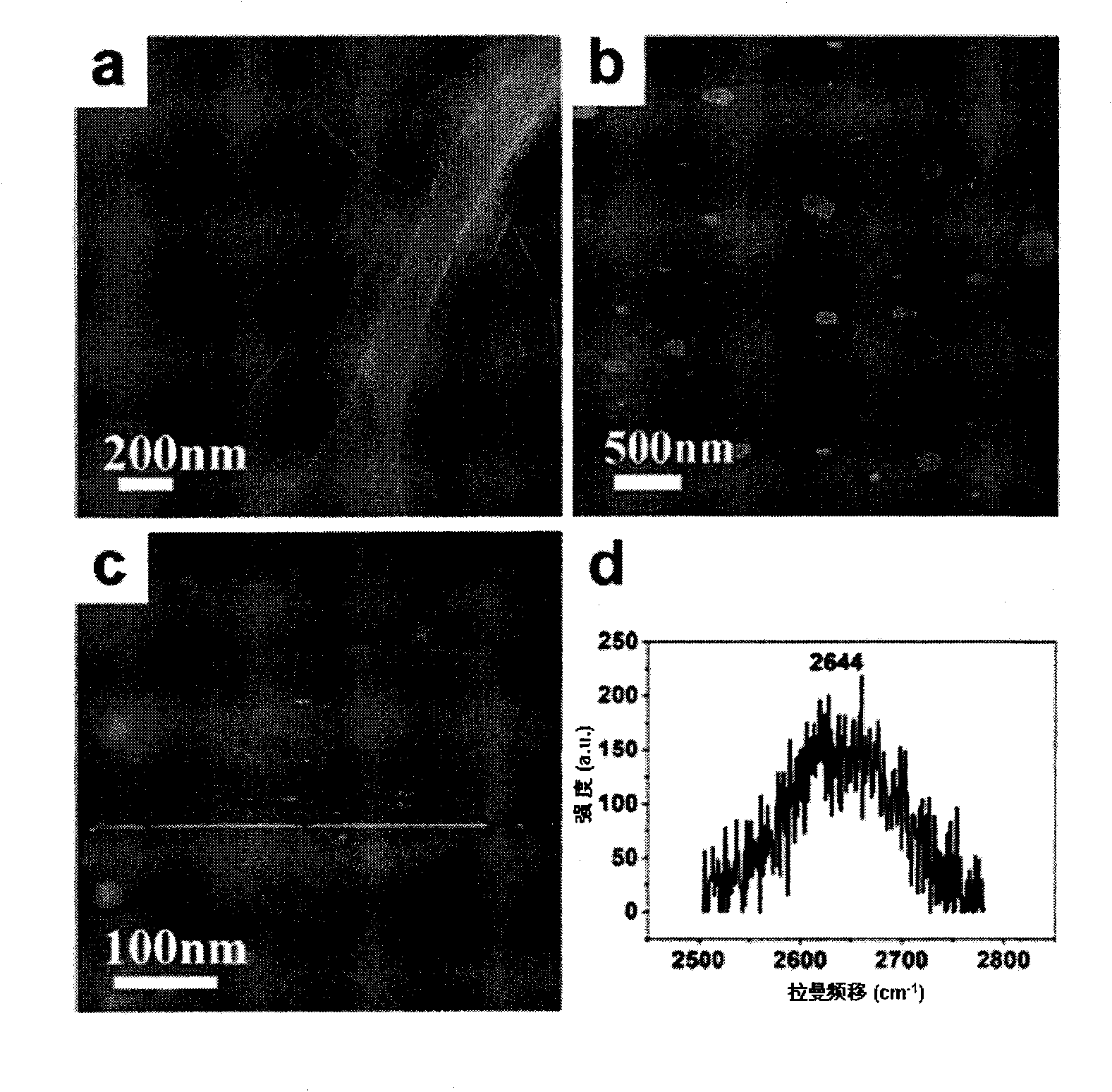

Macro-preparation for big size graphene

The invention relates to the preparation technology of graphene, in particular to a preparation method of big size graphene, which is suitable for macro-preparation of the big size graphene. The method comprises the following steps of: (1) with a big size graphite as a raw material, carrying out weak oxidation on a graphite raw material by utilizing a modified Hummers method; (2) carrying out mild peeling on a graphite oxide dispersed in water by utilizing a weak ultrasonic or oscillating method to obtain the graphene oxide; (3) separating the graphene oxide through controlling a centrifugal rotation speed and a centrifugal time by utilizing a multi-centrifuging method to obtain the uniform big size graphene oxide; and (4) depositing the graphene oxide on a substrate, and reducing by utilizing hydrazine or hydrazine hydrate to obtain the high quality big size graphene. The big size graphene can be obtained in a macro amount by utilizing the method, the maximum area can reach 3*104 microns<2>, and the method lays the foundation for application of the graphene in the field of flexible photoelectric functional films, such as transparent conducting films, display and solar battery electrodes, gas sensors, optical-electrical converters, film electronic devices, and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

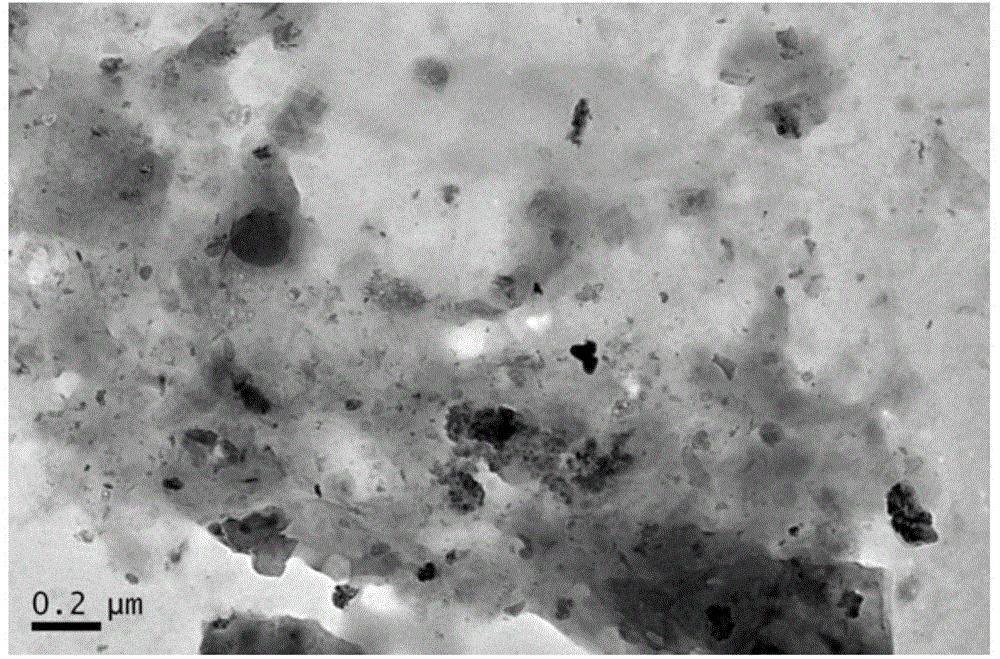

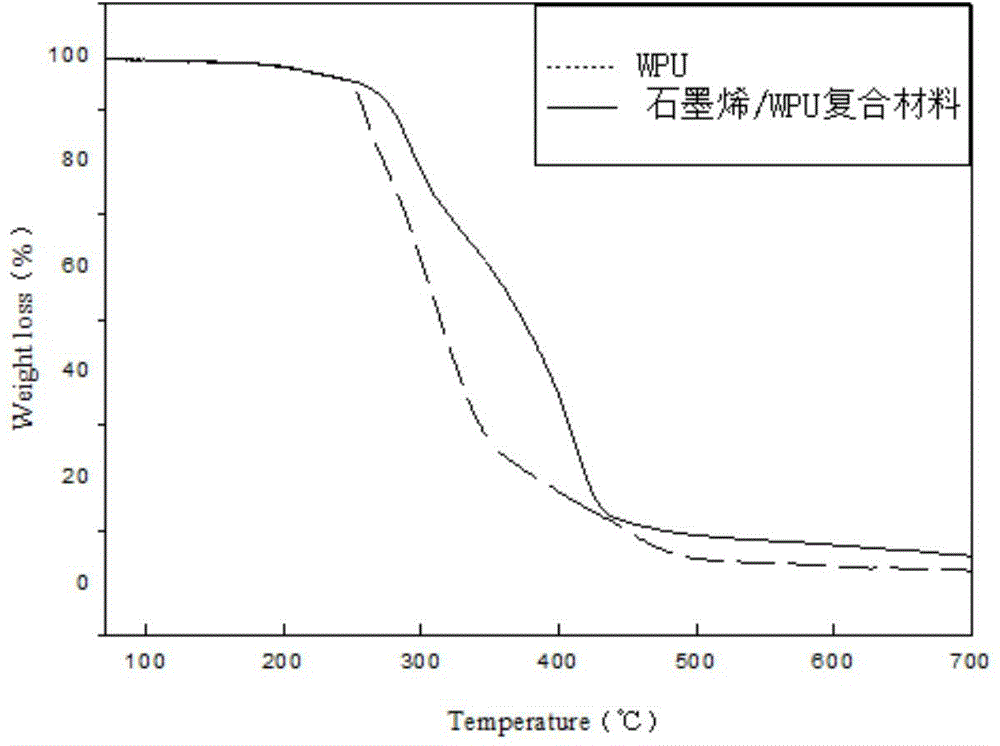

Preparing method of graphene/waterborne polyurethane composite material

The invention discloses a preparing method of a graphene / waterborne polyurethane composite material. The preparing method is characterized in that firstly, a graphene oxide aqueous dispersion is prepared by an improved Hummers method; then, modified graphene oxide is reduced through ethylenediamine so as to obtain a modified graphene aqueous dispersion; a linear polyurethane prepolymer is synthesized by diisocyanate, a dihydric alcohol oligomer and a chain extender; finally, a neutralizer is added into the linear polyurethane prepolymer for neutralization, and the product is mixed with the modified graphene aqueous dispersion so as to obtain the graphene / waterborne polyurethane composite material. The compatibility of two components in the prepared graphene / waterborne polyurethane composite material is good, and the thermostability and the mechanical strength of waterborne polyurethane are improved through graphene modification. The graphene / waterborne polyurethane composite material can be used as an environment-friendly waterborne paint and has a wide application prospect.

Owner:安徽嘉明新材料科技有限公司

Oxidized graphene insulating heat-radiating coating and preparation method thereof

ActiveCN105086688ABoth insulation propertiesBoth heat dissipation characteristicsRosin coatingsPolyurea/polyurethane coatingsPhosphide compoundThermal conductivity

The invention discloses an oxidized graphene insulating heat-radiating coating. The oxidized graphene insulating heat-radiating coating is characterized by being composed of, by weight, 300-30 parts of resin, 1 part of oxidized graphene and 100-10 parts of resin curing agent, and the oxidized graphene is synthesized by adopting an improved Hummers method or phosphorylated oxidized graphene modified by phosphide. The oxidized graphene insulating heat-radiating coating is prepared by mixing oxidized graphene dispersion liquid or phosphorylated oxidized graphene dispersion liquid prepared after dispersing oxidized graphene in a dispersion liquid solvent with resin and resin curing agent. By the oxidized graphene insulating heat-radiating coating, the problem that insulativity and thermal conductivity of existing materials are difficult to realize at the same time is solved.

Owner:山东利特纳米新材料有限公司

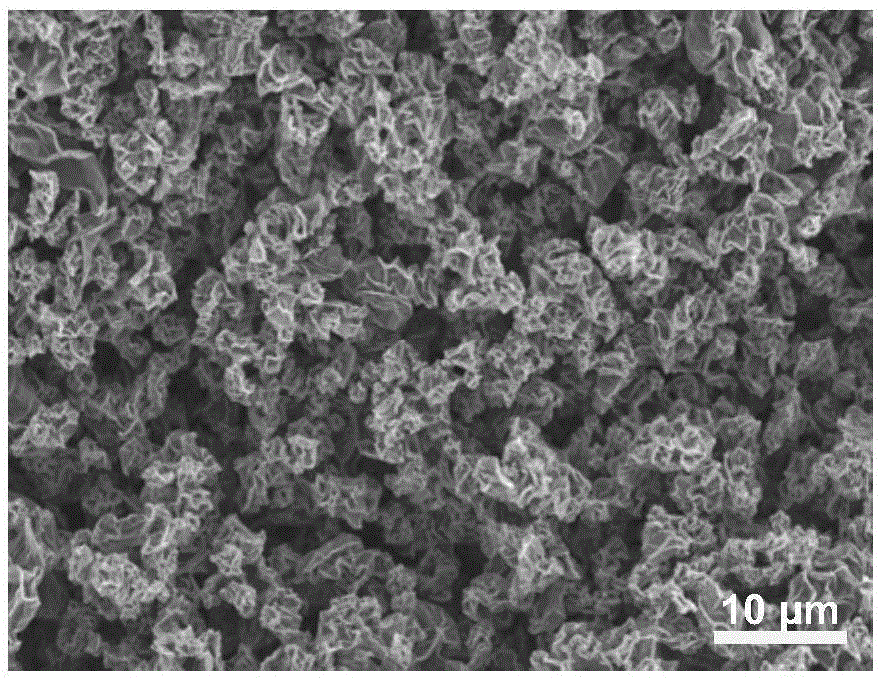

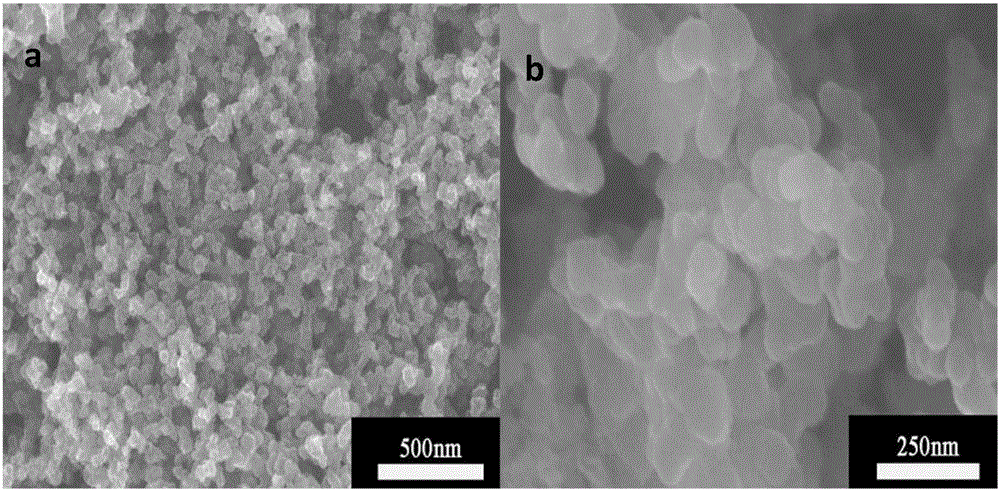

High-solubility multi-fold dry-state graphene oxide microsphere and preparation method thereof

The invention discloses a high-solubility multi-fold dry-state graphene oxide microsphere and a preparation method thereof. According to the dry-state graphene oxide microsphere, firstly graphene oxide dispersion liquid is prepared through an organic solvent dilution Hummers method, and then atomized drying is performed so that the dry-state graphene oxide microsphere can be obtained. The dry-state graphene oxide microsphere obtained through the preparation method is good in solubility, the solubility in water and common organic solvents is 20-30 mg / g, and the dry-state graphene oxide microsphere can be stably dispersed for a long time in the mode of a single-layer graphene oxide sheet; good solubility can still be kept after the dry-state graphene oxide microsphere is compressed into high-density blocks; the preparation method is simple, convenient and fast, low in energy consumption and suitable for large-scale industrial production. The problem that the solubility of graphene oxide obtained through an existing drying method is poor is solved, transportation, storage and use of the dry-state graphene oxide microsphere are facilitated because of high density, the dry-state graphene oxide microsphere can be used in the fields of graphene macroscopic assembly materials, functional graphene materials, graphene composite materials and the like.

Owner:ZHEJIANG TANGUSHANGXI MATERIAL SCI & TECH

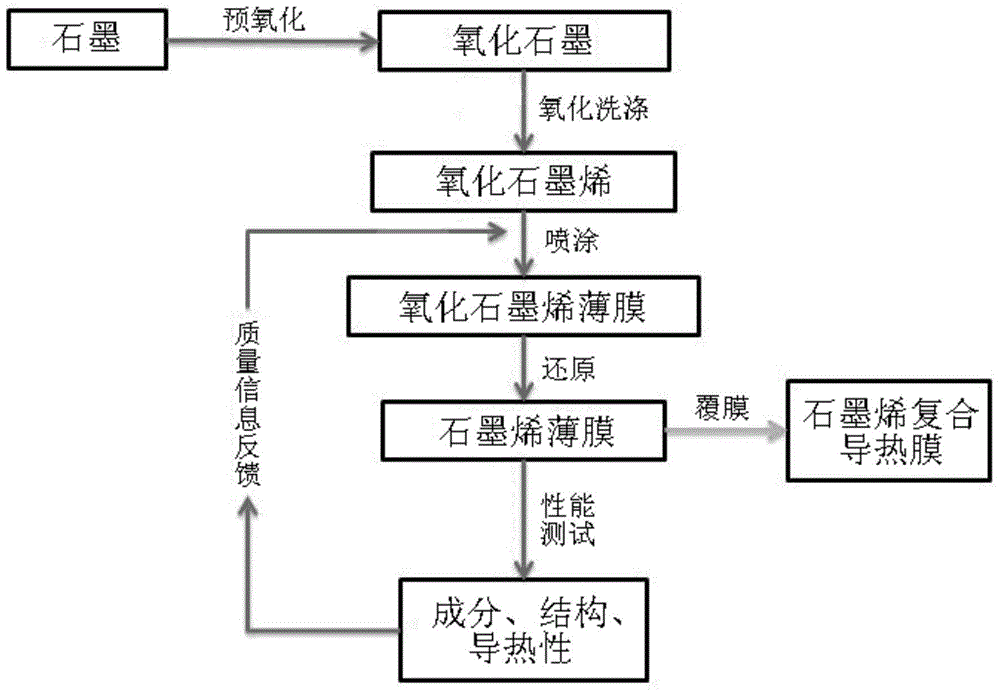

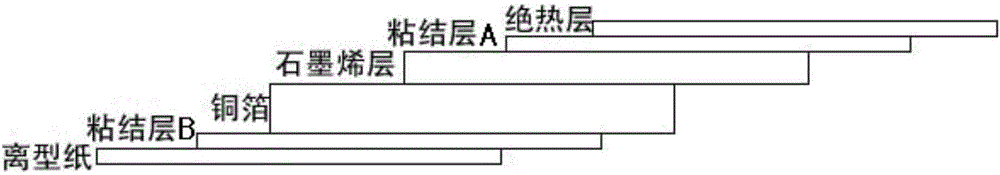

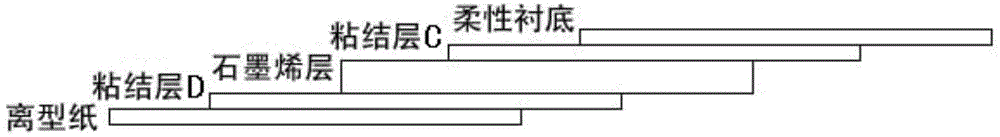

Preparation method of composite heat conduction graphene film and composite heat conduction graphene film

ActiveCN104085143AIncrease layer spacingThoroughly oxidizedMetal layered productsPotassium persulfateFiltration

The invention discloses a preparation method of a composite heat conduction graphene membrane and the composite heat conduction graphene film. The preparation method comprises the following steps: S1, putting crystalline flake graphite or graphite powder into a mixed solution of concentrated sulfuric acid, potassium persulfate and phosphorus pentoxide, soaking for a day and a night, then carrying out suction filtration, drying, and carrying out pre-oxidizing; S2, oxidizing pre-oxidized graphite further by adopting a Hummers method, that is, oxidizing fully in concentrated sulfuric acid and potassium permanganate, then adding deionized water for diluting, and carrying out repeated washing and suction filtration, so as to obtain an oxidized graphene aqueous solution; S3, spraying the oxidized graphene aqueous solution on a substrate by adopting a thermal spray method, and depositing, so as to obtain an oxidized graphene film; S4, reducing the oxidized graphene film, so as to obtain the graphene film; and S5, laminating the graphene film, so as to obtain the composite heat conduction graphene film. Compared with the prior art, the preparation method is simple, the cost is low, and the prepared composite heat conduction graphene film has a favorable heat conduction performance.

Owner:成都科愿慧希科技有限公司

Preparation method of graphene based nano composite hydrogel

The invention relates to a preparation method of a graphene based nano composite hydrogel, and belongs to the field of nano composite hydrogel preparation. An insitu polymerization method is adopted in the invention, which comprises the steps of: (1) preparing graphite into high water-soluble graphite oxide through an improved Hummers method and obtaining graphene emulsions of different varietiesand with different concentrations after peeling and processing; (2) uniformly mixing 1-10g of the graphene emulsions from step (1), 5-10g of water, 0.1-10g of water-soluble monomer, 0.005-0.5g of water-soluble initiator and 1-50[mu]l of catalyst, feeding in nitrogen for 1h to obtain a graphene pre-polymerized solution, and polymerizing under a certain temperature to obtain the graphene based nanocomposite hydrogel. The method of the present invention has a simple technology and is easy for operation; and the obtained nano composite hydrogel has excellent mechanical properties, restorability and environmental responsiveness. Therefore, the graphene based nano composite hydrogel has wide application prospects in biomedicine and machinery industry, etc.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

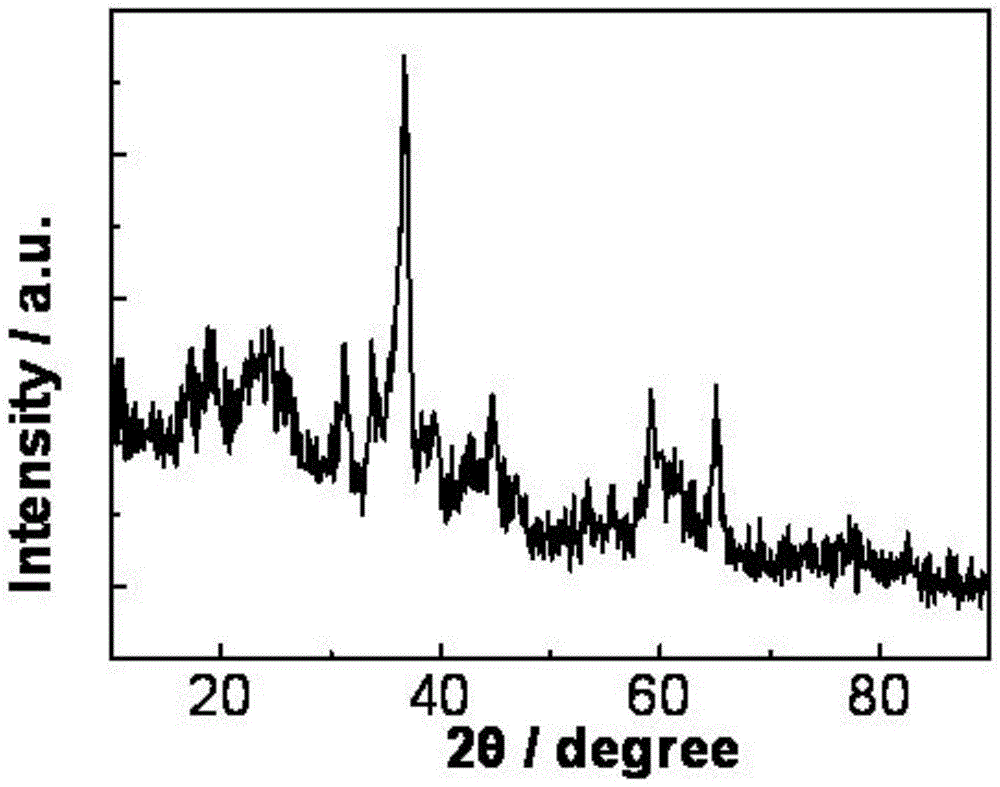

Preparation method of graphene/g-C3N4 compound photocatalyst

InactiveCN103769187AHigh degree of oxidationIncrease the areaPhysical/chemical process catalystsDecompositionHigh energy

The invention relates to a preparation method of a graphene / g-C3N4 compound photocatalyst, and adopts a high temperature decomposition method to prepare the graphene / g-C3N4 compound photocatalyst. The method comprises the following steps of (1) preparing g-C3N4 powder by adopting concentrated hydrochloric acid melamine through high temperature decomposition; (2) synthesizing high specific surface area graphite oxide by adopting an improved Hummers method, stripping the graphite oxide in an ultrasound manner, removing the graphene with the low oxidation degree through centrifugation, finally extracting a supernatant liquid, drying, and preparing polarity graphene oxide powder; and (3) uniformly mixing the prepared graphene oxide powder and the g-C3N4 through a high energy ball grinder to dissolve in hydrazine hydrate, and preparing the graphene / g-C3N4 compound photocatalyst with a high photocatalytic activity. The preparation method provided by the invention has the advantages that a raw material is cheap, the technology is simple and convenient and the like, and the prepared compound photocatalyst has the wide application prospect on the fields such as wastewater treatment and gas purification.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

Preparation method of high-performance nitrogen-doped three-dimensional graphene

ActiveCN105645403AHigh nitrogen contentPlay a skeleton roleHybrid capacitor electrodesGrapheneNitrogen gasNitrogen doped graphene

The invention relates to the technical field of synthesizing of graphene materials and provides a preparation method of nitrogen-doped graphene. The preparation method includes: using an improved Hummers method to prepare continuous large-piece graphene oxide; using a hydrothermal method to prepare the graphene oxide into graphene of a porous three-dimensional structure; ultrasonically dispersing the graphene of the porous three-dimensional structure into an acid solution with the pH being 1-5, adding aniline, well mixing, adding ammonium persulfate, well mixing, and transferring the obtained mixed liquid into a teflon container for hydrothermal reaction so as to obtain a porous three-dimensional graphene-polyaniline compound; performing high-temperature treatment under nitrogen protection to allow polyaniline to decompose out nitrogen sources so as to obtain the nitrogen-doped porous three-dimensional graphene. The method has the advantages that the nitrogen-doped graphene with high nitrogen content can be prepared, the structure of the three-dimensional graphene can be kept, the obtained nitrogen-doped porous three-dimensional graphene is good in electrochemical performance and quite suitable for being used for producing a super capacitor, and the method is convenient to operate and beneficial to industrial popularization.

Owner:NANJING UNIV OF POSTS & TELECOMM

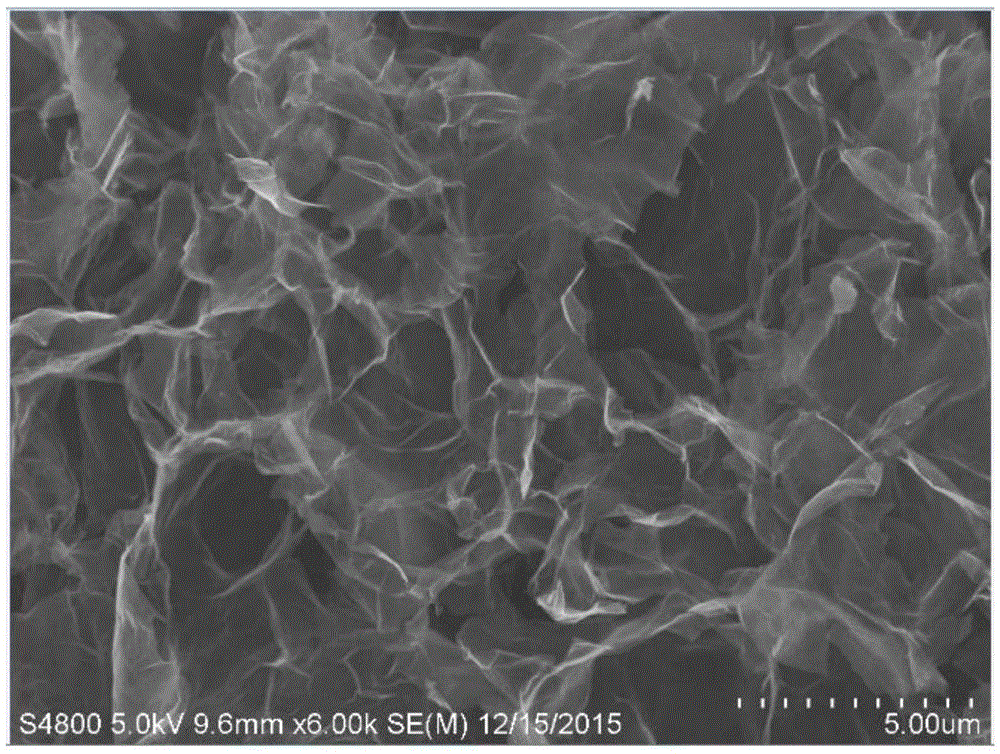

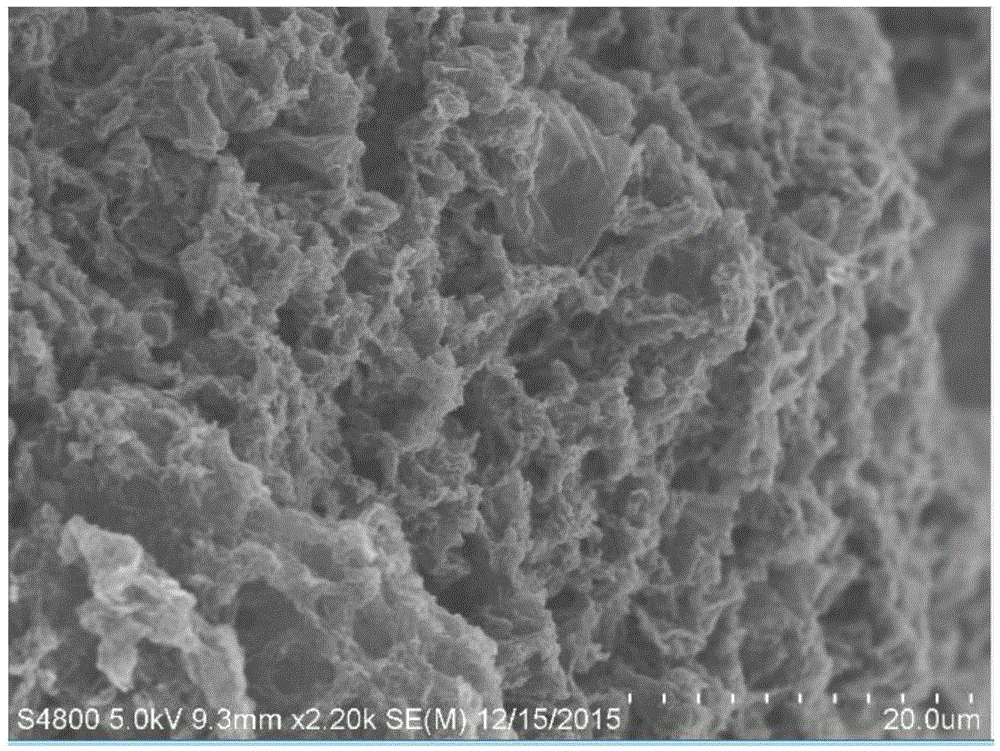

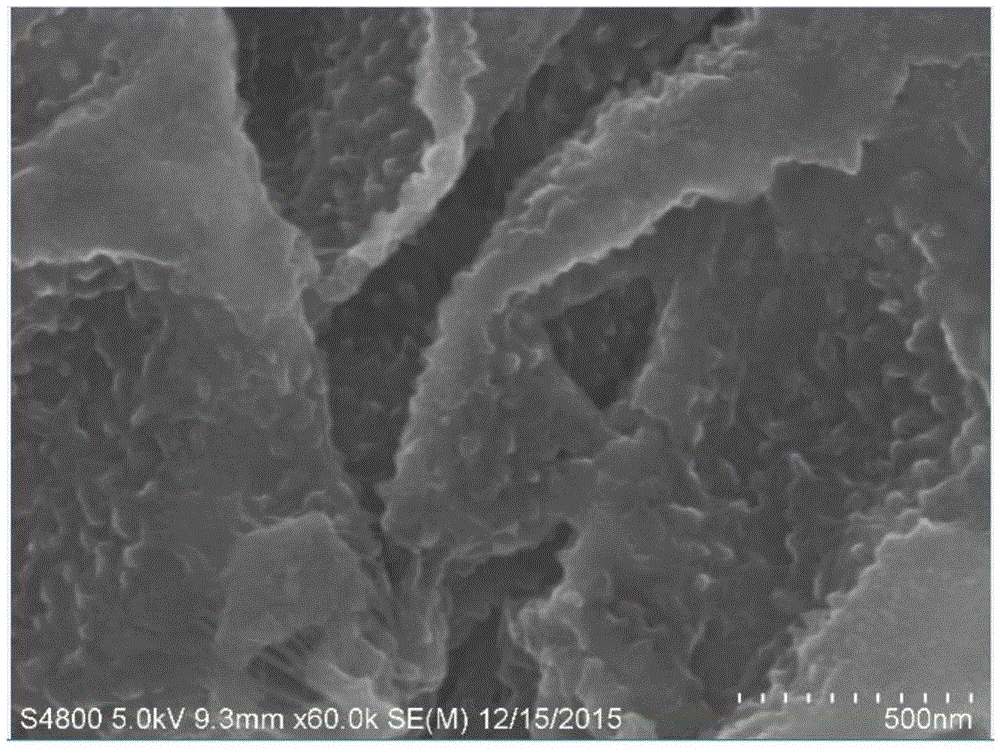

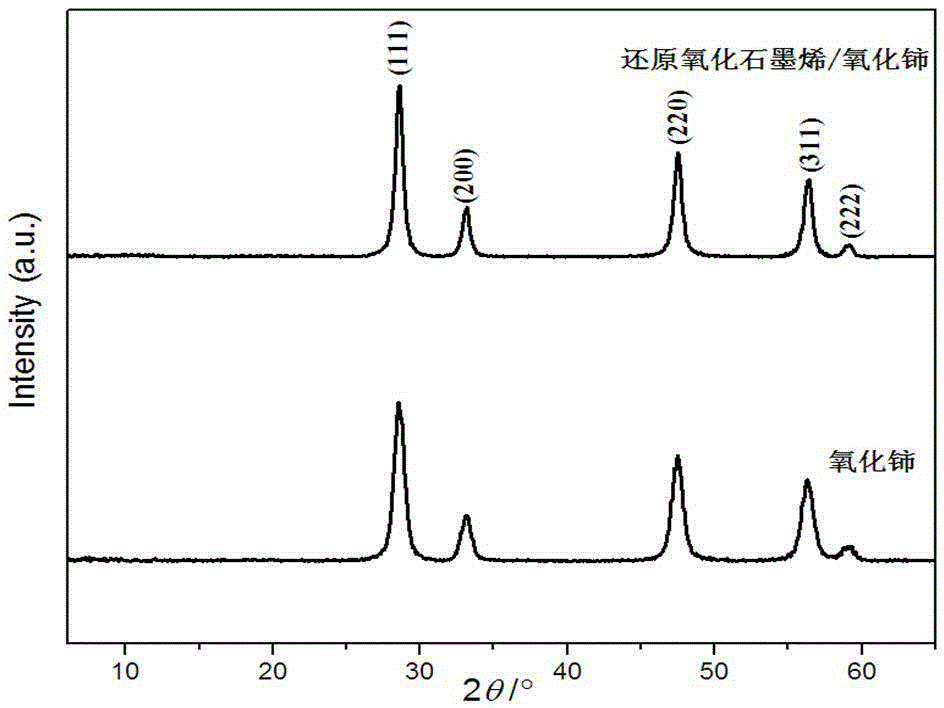

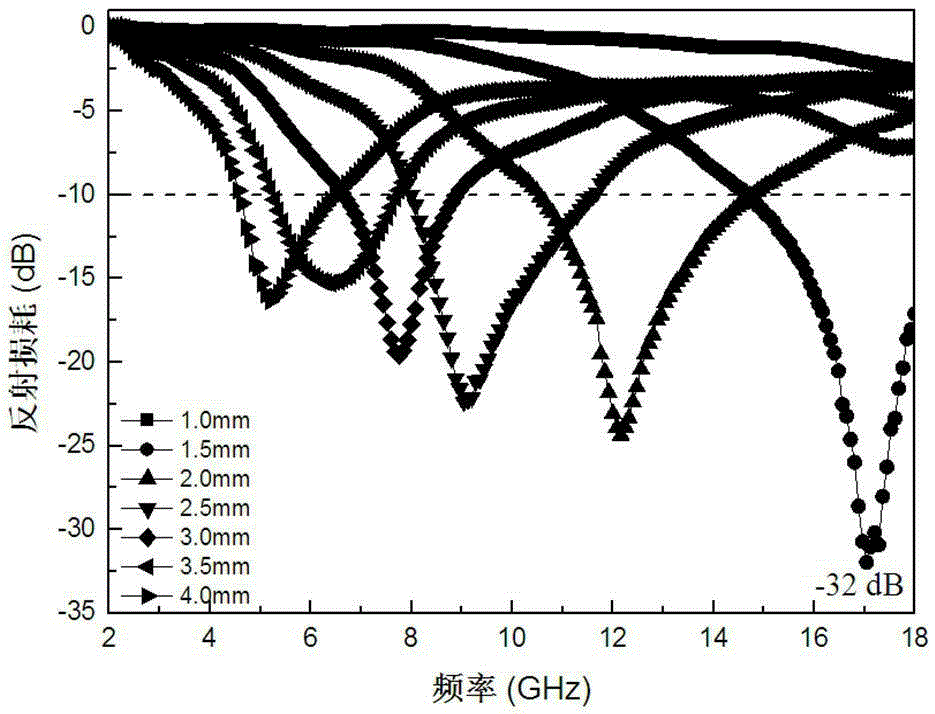

Reduced graphene oxide and nano cerium oxide composite microwave absorbing material and preparation method thereof

ActiveCN105255446AAbsorption BandwidthImprove absorbing performanceOther chemical processesCerium nitrateCoaxial line

The invention specifically relates to a reduced graphene oxide and nano cerium oxide composite microwave absorbing material and a preparation method thereof. The method comprises the following steps: preparing graphene oxide by using an improved Hummers method; mixing a graphene oxide aqueous solution with cerium nitrate in a mass ratio of 1:25, and adjusting the pH value to 10; and by using a one-step hydrothermal method, simultaneously generating nano cerium oxide and reducing the graphene oxide, so that a reduced graphene oxide and nano cerium oxide composite microwave absorbing material is obtained. The microwave absorption parameters of the composite material are tested by using a vector network analyzer, and the microwave reflection loss of the composite material is calculated by using a classical coaxial line theory. Results show that the reduced graphene oxide and nano cerium oxide composite microwave absorbing material has excellent microwave absorbing properties, high absorption strength and wide absorption band, and compared with nano cerium oxide, the microwave absorbing properties are greatly improved. Thus, the reduced graphene oxide and nano cerium oxide composite microwave absorbing material disclosed by the invention has broad application prospects, and is of great significance to the expansion of industrial application of rare earth oxides and the national defense construction.

Owner:ANHUI UNIV OF SCI & TECH

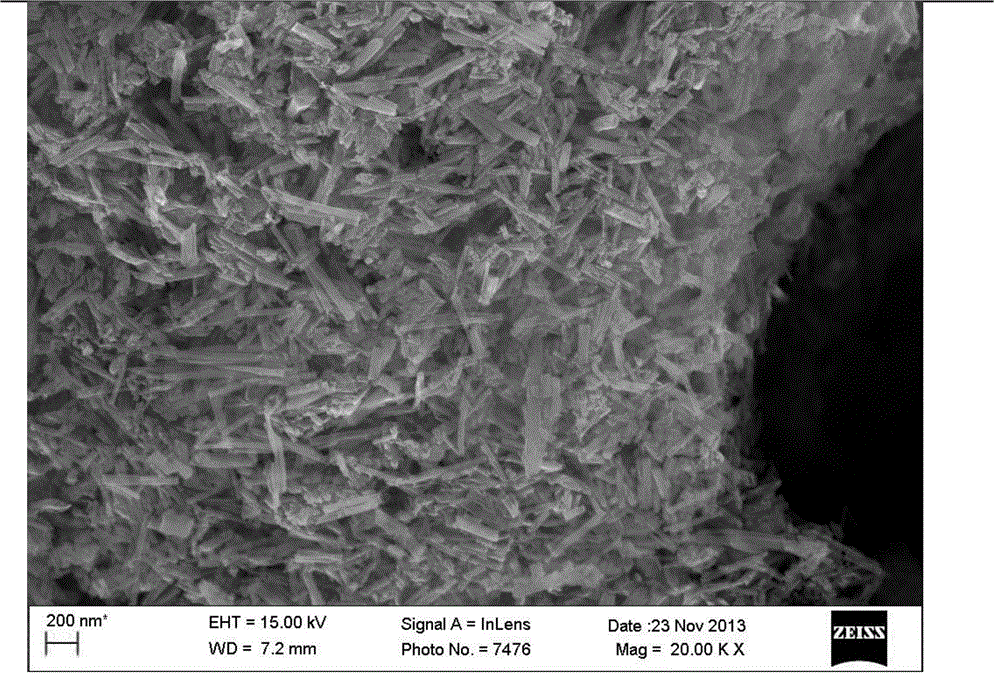

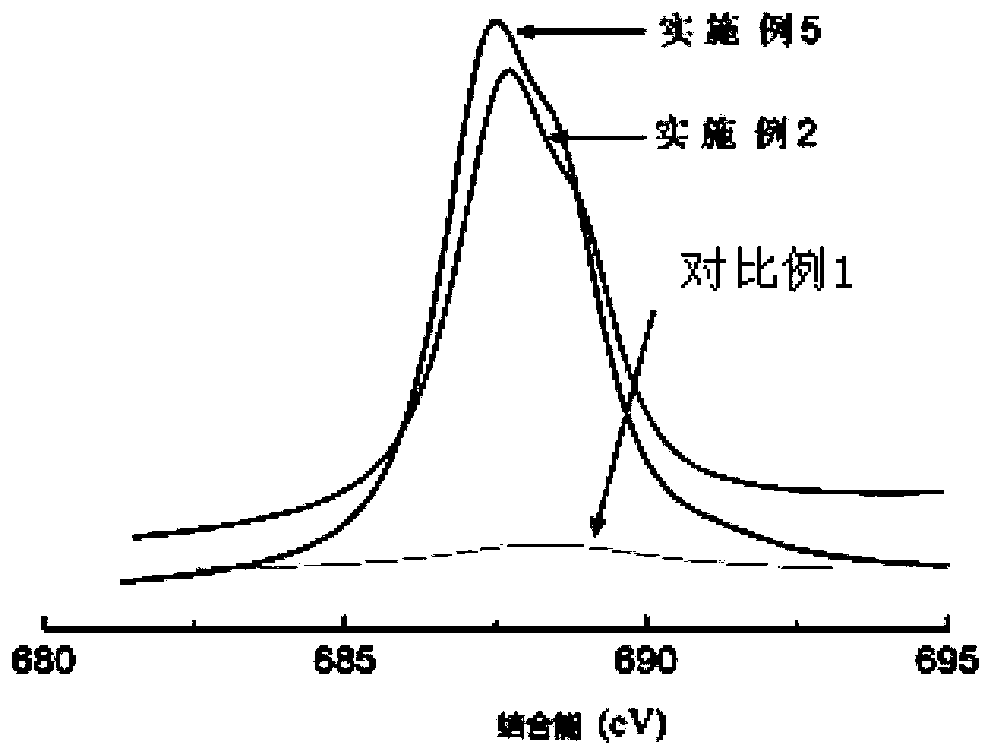

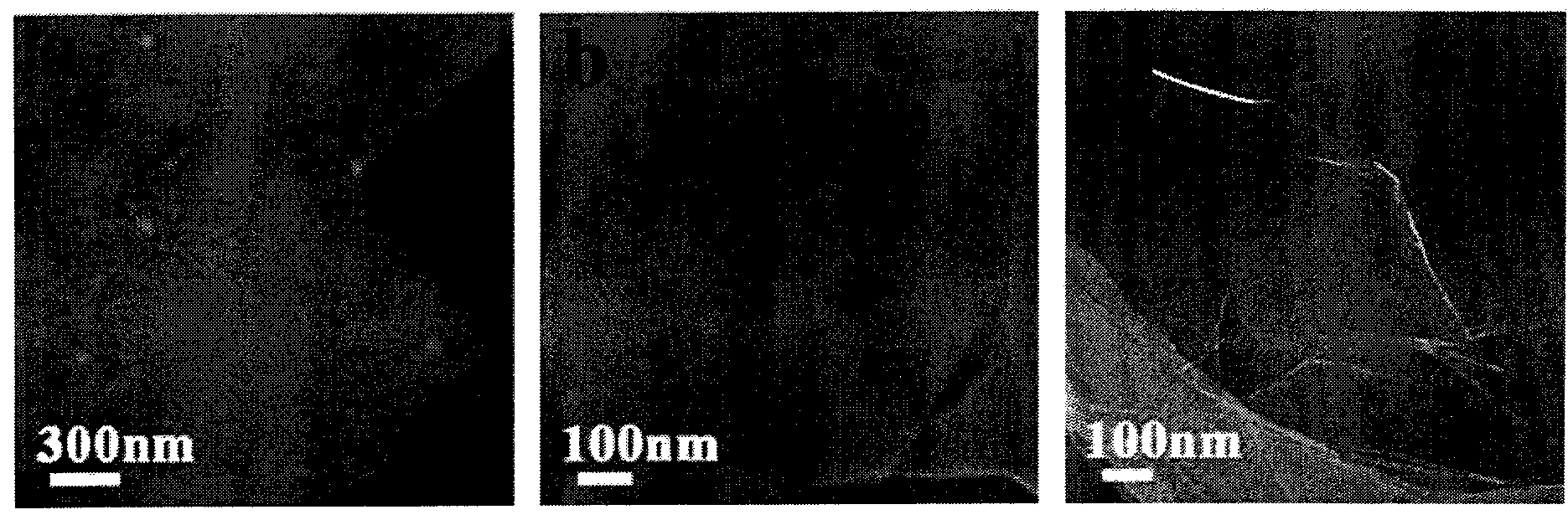

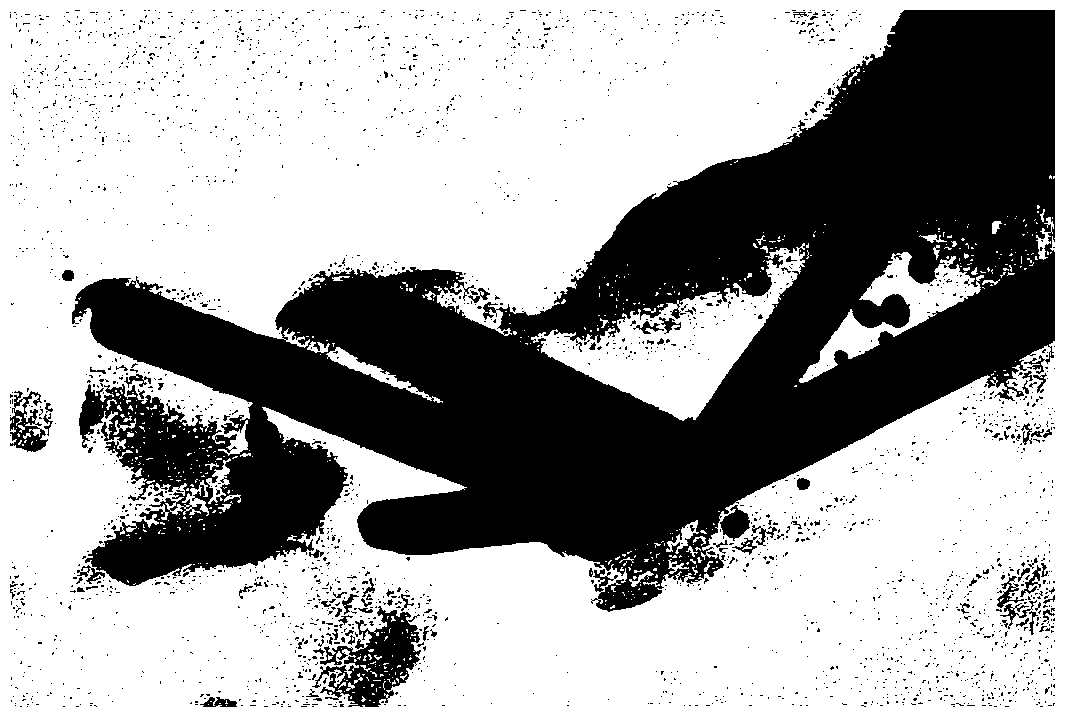

Graphene in-situ load needle-shaped Co3O4 composite electrode material and manufacturing method thereof

InactiveCN103985561AImprove conductivityOptimized areaHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNano structuring

The invention discloses a graphene in-situ load needle-shaped Co3O4 composite electrode material and a manufacturing method of the graphene in-situ load needle-shaped Co3O4 composite electrode material. Single-layer graphene with needle-shaped Co3O4 growing on the edge or two faces is adopted as a load frame of the composite electrode material, the plane size of a nanosheet layer is one micron to 50 microns, and the manufacturing method comprises the steps that graphite oxide is manufactured through a modified Hummers method, then ultrasonic treatment is carried out to obtain graphene oxide, a precursor of the composite electrode material is manufactured through the graphene oxide, and the precursor is annealed in inert atmosphere to obtain the composite electrode material. The manufacturing method of the composite electrode material is simple and environmentally friendly, according to the typical structure of the composite electrode material, the needle-shaped Co3O4 is combined with the surface or the side face of the graphene, a quasi two-dimensional nano structure is formed, the graphene sheet layer can be loaded with the needle-shaped Co3O4 in situ, the cycle life of the Co3O4 is prolonged, and the specific capacitance and other good electrochemical performance are improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS +1

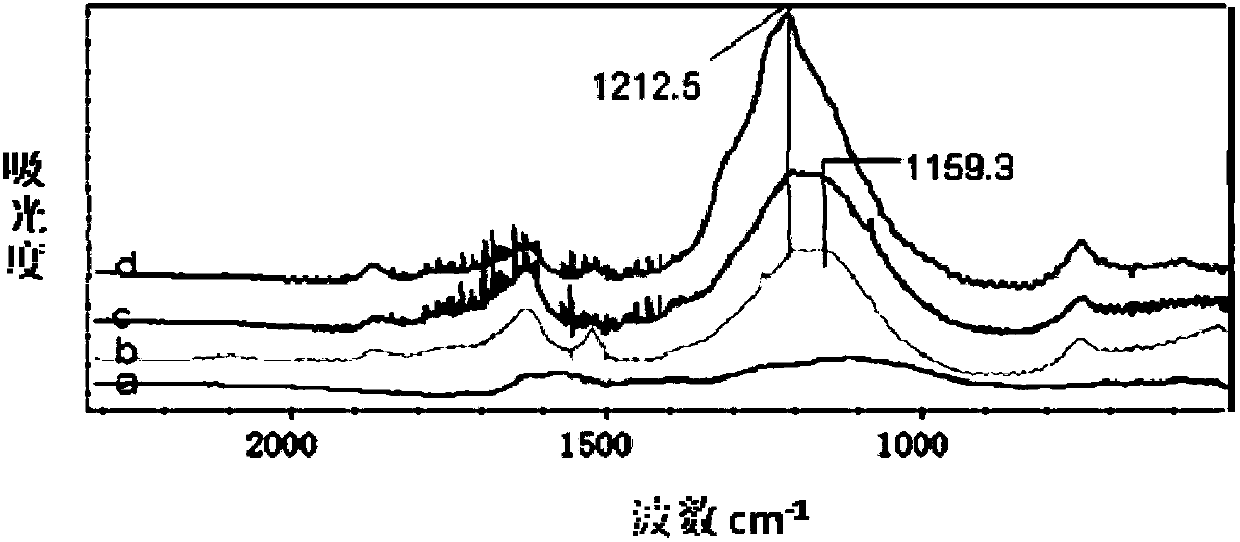

High-fluoride-content graphite fluoride and preparation method thereof

ActiveCN103420352AEasy to spreadFully contactedGrapheneCarbon fluoridesHigh fluorideReaction temperature

The invention discloses high-fluoride-content graphite fluoride and a preparation method thereof. The method comprises the following steps: preparing aqueous dispersion liquid of graphite oxide with a conventional improved Hummers method, then freezing the aqueous dispersion liquid of graphite oxide in liquid nitrogen to be completely frozen into solid, and freezing and drying to obtain cellular graphite oxide; under a mixed atmosphere of inert gas and fluoride, warming the cellular graphite oxide for fluoridation, and cooling to room temperature. The fluoride content of the prepared high-fluoride-content graphite fluoride is 55-70 percent, fluorine atoms are bonded with carbon atoms in a covalent bond mode, weightlessness peak temperature is larger than 470 DEG C, the heat stability is good, and the resistance is larger than 1012 omega. The prepared graphite fluoride has the advantages of high fluoride content, good heat resistance of fluorine-containing groups, low cost, simple process, lower reaction temperature, high safety and energy saving, is suitable for mass production, and has a better application prospect.

Owner:SICHUAN UNIV

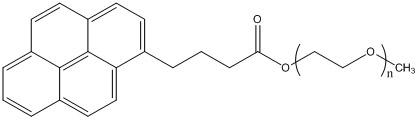

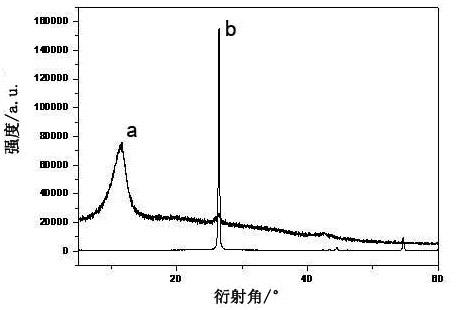

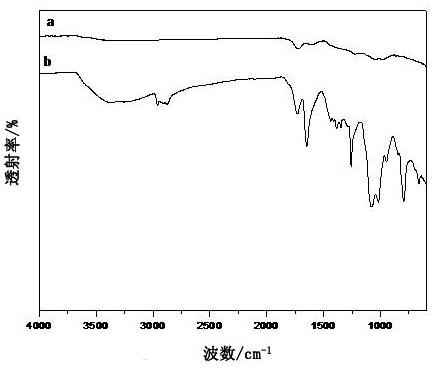

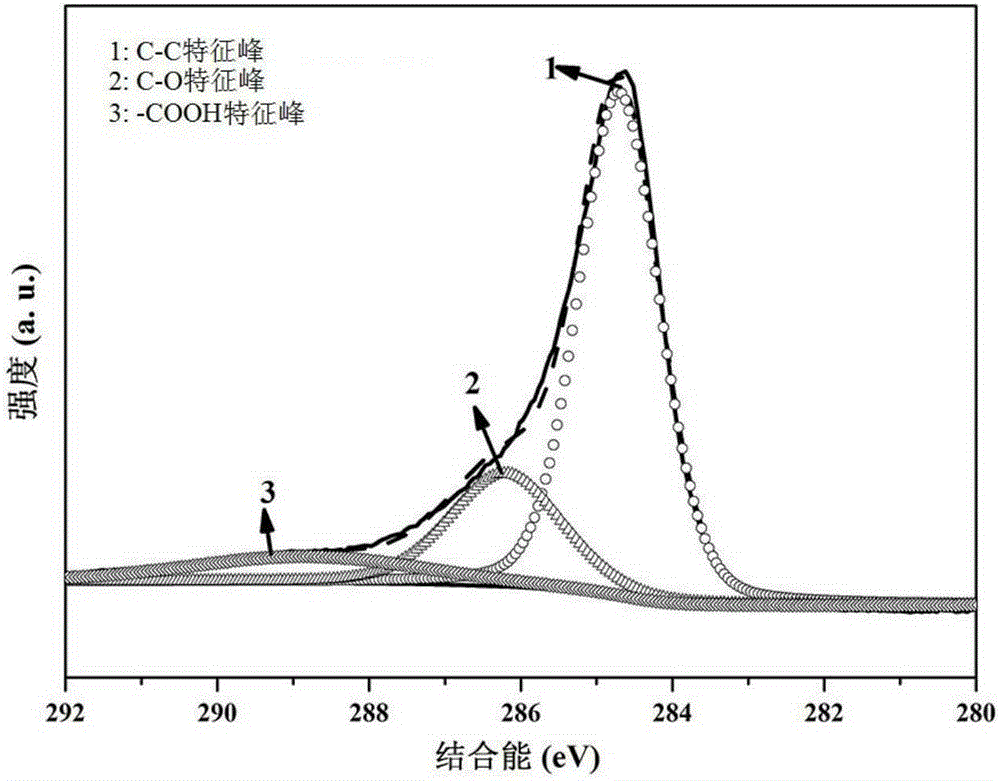

Method for functionalizing polymer on surface of nano graphene oxide

InactiveCN102320599AWide variety of sourcesImprove developmentMaterial nanotechnologySolubilityEnd-group

The invention relates to a method for functionalizing a polymer on the surface of nano graphene oxide. The method comprises the following specific steps: preparing graphene oxide from natural graphite powder by an improved Hummers method, utilizing methoxy polyethylene glycol and pyrene acids to carry out esterification to generate polyethylene glycol with pyrenyl as the terminal group, and finally grafting the polyethylene glycol with pyrenyl as the terminal group on the surface of graphene oxide through pi-pi interaction between pyrenyl and the surface of graphene oxide, thus obtaining the graphene oxide with the functionalized polymer on the surface. The solubility of the prepared graphene oxide with the functionalized polymer on the surface is greatly improved. The method has the following advantages: a main process adopted in the experiment is as follows: a polymer with a complex structure is designed and prepared in advance and then is grafted on the graphene oxide, and the grafting reaction can be carried out at normal temperature and pressure, so the whole experiment process is very simple and convenient. Therefore, the study provides a direct method for modifying the graphene oxide and preparing the functionalized graphene oxide-polymer complex to form a new inorganic-organic hybrid material, thereby promoting the development and application of graphene oxide-based materials.

Owner:TONGJI UNIV

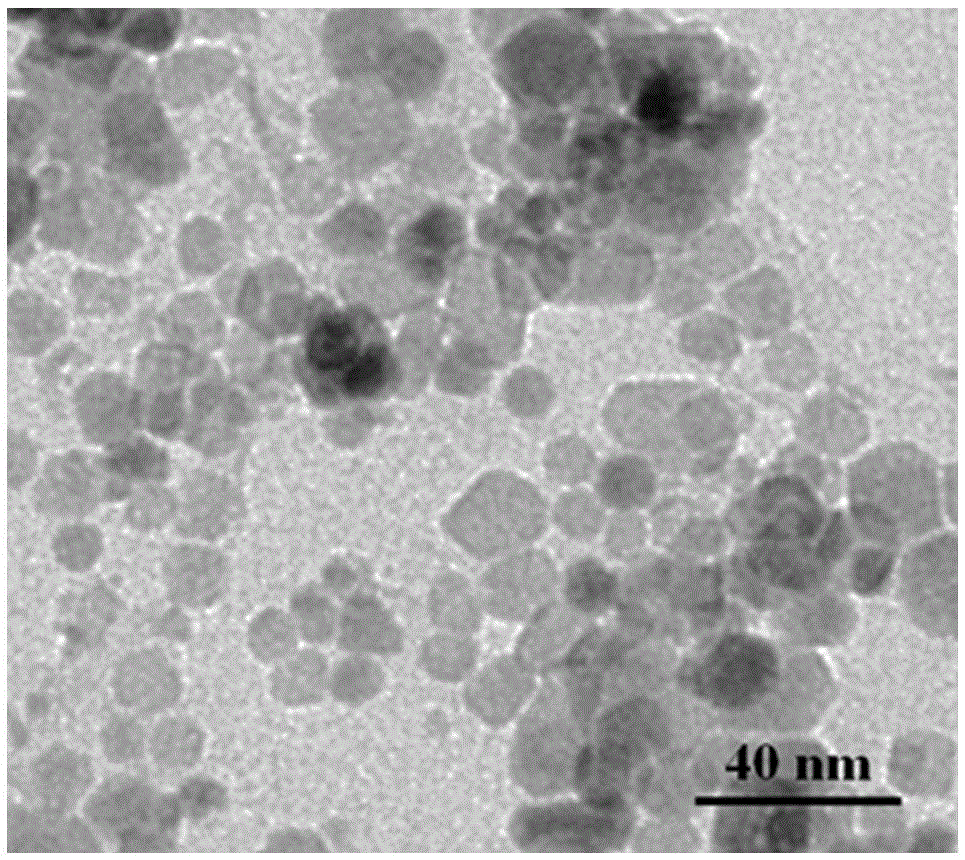

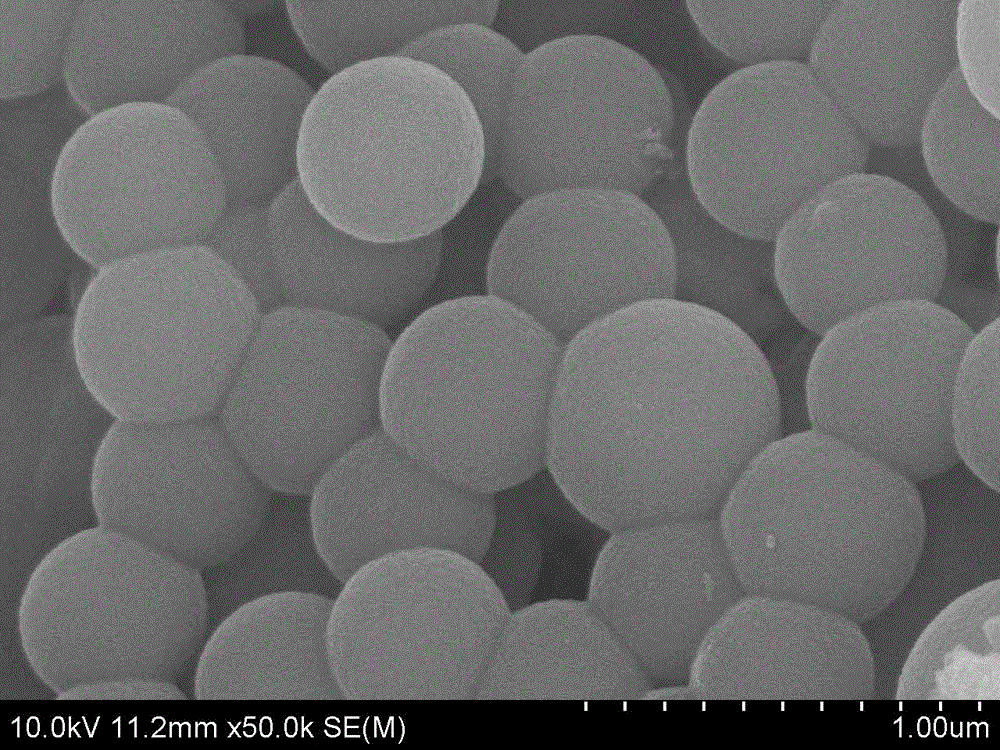

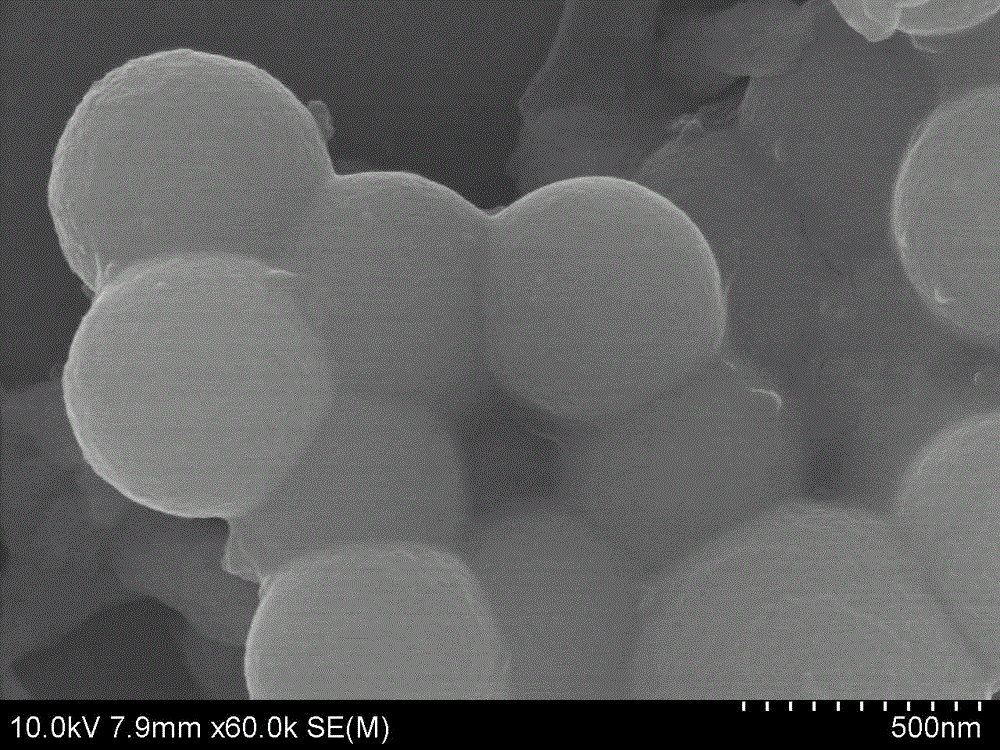

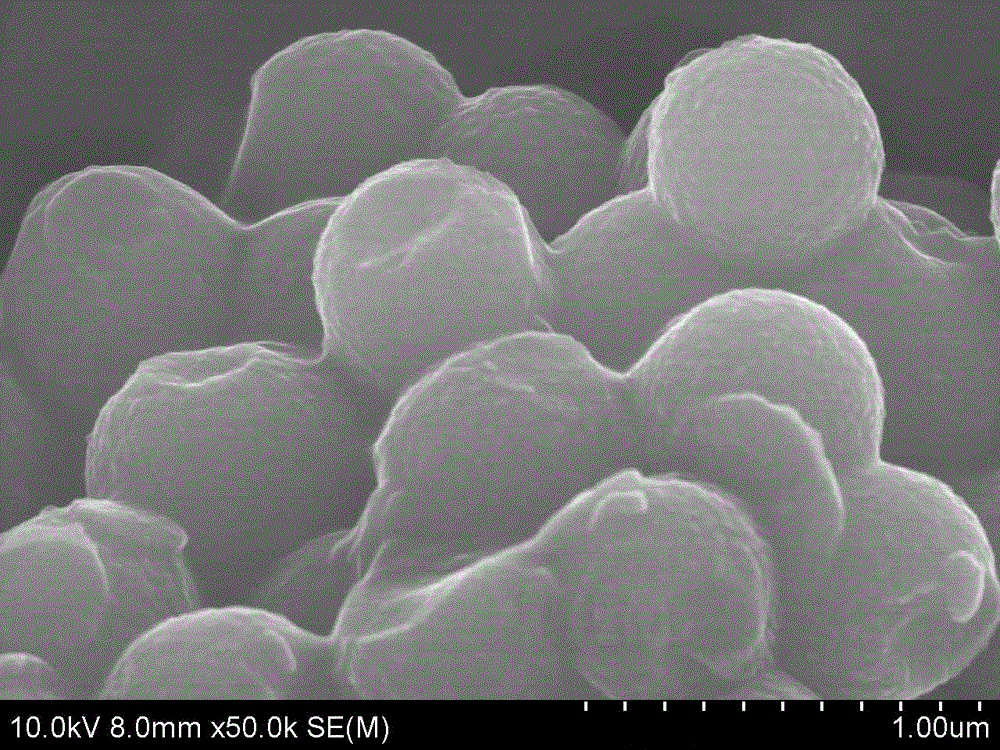

Preparation method of graphene-coated silicon dioxide nanoparticles

The invention discloses a preparation method of graphene-coated silicon dioxide nanoparticles. Graphite powder is taken as a raw material, graphene oxide with oxygen-containing functional groups is prepared with an improved Hummers method, the silicon dioxide nanoparticles are prepared with a hydrothermal method, a proper quantity of silane coupling agents are added to a solution containing silicon dioxide and uniformly stirred, the silane coupling agents are attached to the surfaces of silicon dioxide particles, and surface-modified silicon dioxide particles are obtained; graphene oxide is added to the modified silicon dioxide solution, and surfaces of the silicon dioxide particles are completely coated with graphene oxide under the interaction of functional groups. Finally, a reducing agent is added to the solution, graphene is formed by further removing the oxygen-containing functional groups of graphene oxide, and a composite with graphene completely coating silicon dioxide is prepared. The method has the advantages that a process is simple, the reaction time is short, regulation is easy and the like. The prepared composite has the characteristics of regular structure, high porosity, low density, good hydrophobicity and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

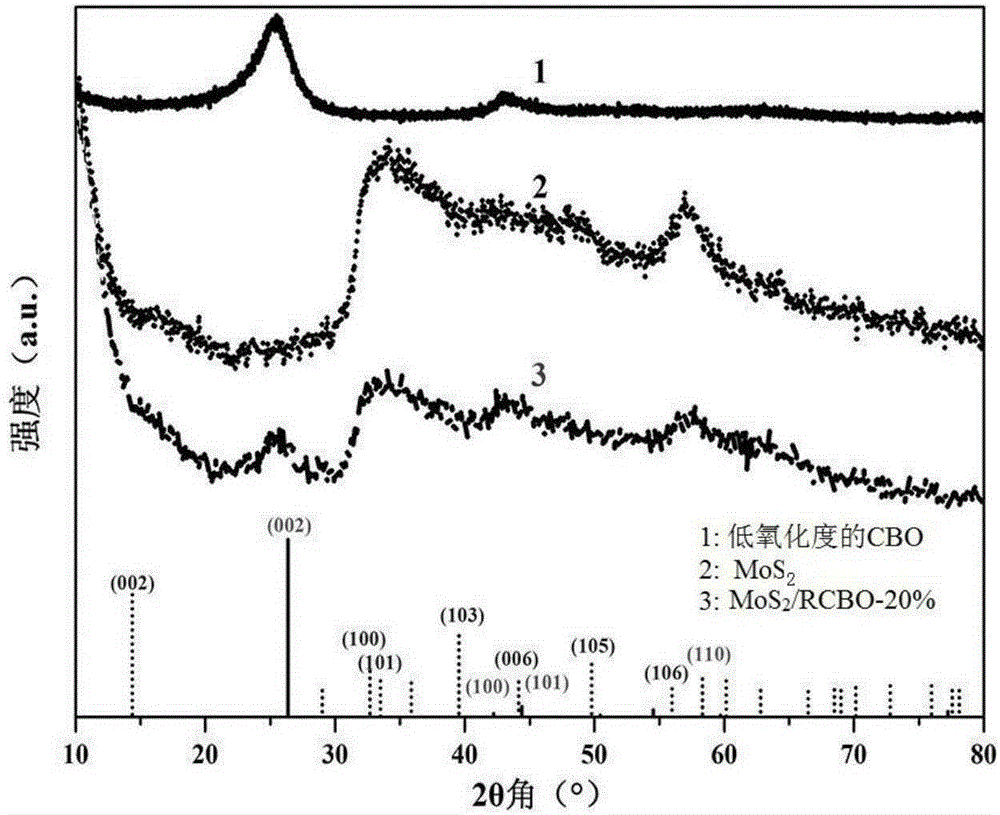

Molybdenum disulfide/carbon black composite hydrogen-evolution electrocatalytic material and preparation method therefor

InactiveCN105200450AHigh yieldLow pricePhysical/chemical process catalystsElectrodesSolvothermal reactionMaterials science

The invention relates to a molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material and a preparation method therefor and belongs to the field of electrocatalytic hydrogen evolution. According to the preparation method, firstly, a carbon black oxide with low degree of oxidation is prepared by adopting an improved Hummer method; and then, the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material is prepared through one-step solvothermal reaction at the temperature of 220 DEG C in a manner of taking sodium molybdate crystals as a molybdenum source, taking sulfourea as a sulfur source and taking dimethylformamide as a solvent. According to the method provided by the invention, the carbon black oxide with low degree of oxidation is simple in preparation process and high in yield; the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material is prepared by adopting a simple, convenient and mild one-step solvothermal method, the cost is low, the repeatability is high, and large-scale synthesis is facilitated. When the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material is applied to electrocatalytic hydrogen evolution reaction, excellent catalysis performance is shown, the reduced current density reaches 25.0mA / cm<2> when tested overpotential is 200mV, and the reduced current density reaches 36.2mA / cm<2> when tested overpotential is 226mV; the molybdenum disulfide / carbon black composite hydrogen-evolution electrocatalytic material has good electrocatalytic stability.

Owner:BEIHANG UNIV

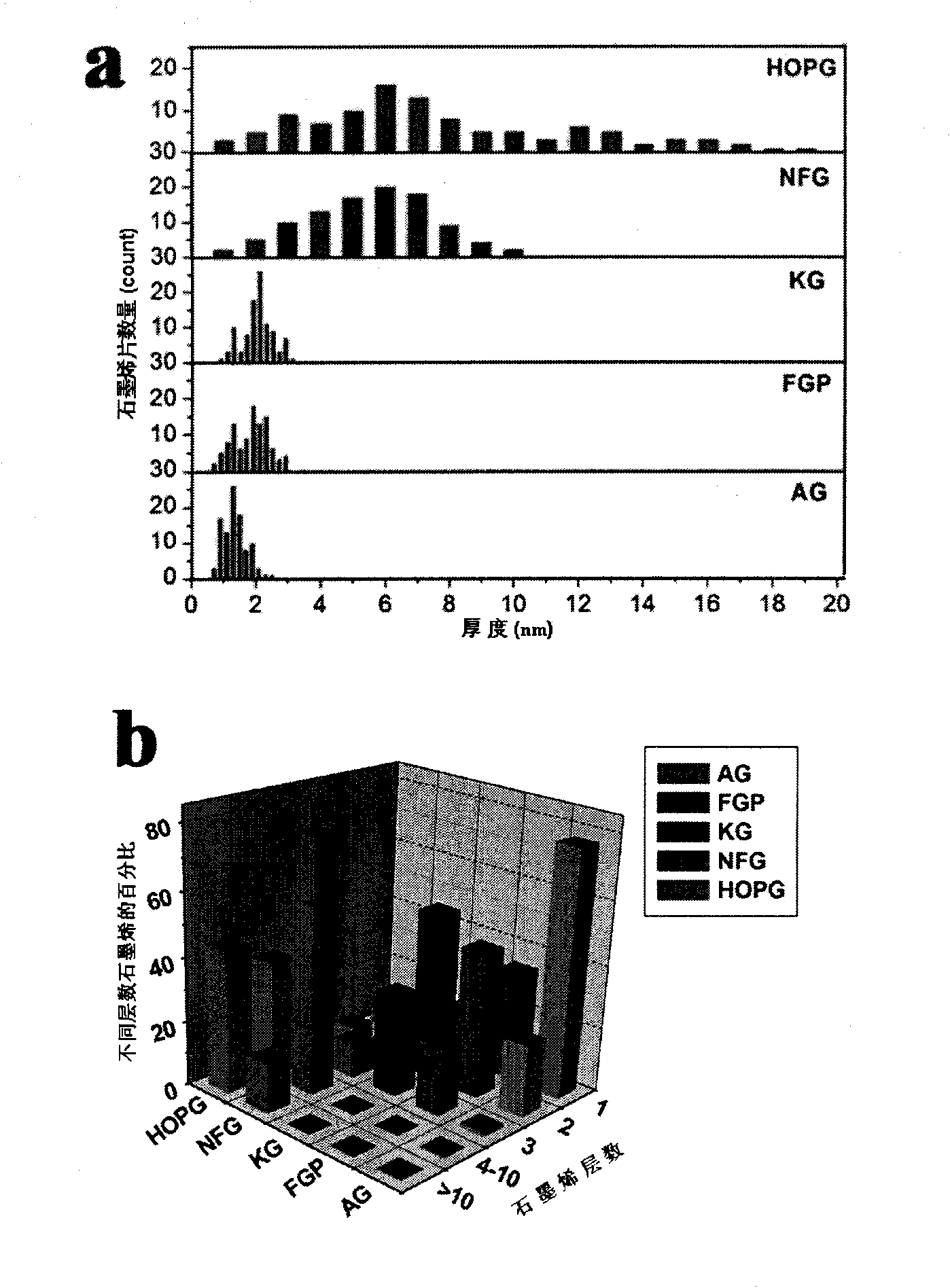

Method for preparing high-quality graphene with controllable layer number

The invention relates to technology for preparing graphene, in particular to a method for massively preparing high-quality graphene with a controllable layer number, which is suitable for massively preparing the high-quality graphene with the controllable layer number. In the method, graphite with different sizes and crystallinities is used as the raw material. The method comprises the following steps of: oxidizing the graphite by an Hummer method; swelling and splitting the oxidized graphite by a rapid heating method to obtain stripped graphite; reducing the stripped graphite at a high temperature; uniformly dispersing the reduced graphite in solution of a surfactant by an ultrasonic method; and removing the graphite which is not totally stripped and thick graphite sheets with large sizes by a high-speed centrifugation method so as to obtain the high-quality graphene with the controllable layer number. In the method, the layer number of the graphene is controlled according to different oxidization and splitting degrees of the graphite with different sizes and crystallinities, mixed gas of hydrogen and argon is used for reducing and stripping the graphite to further remove oxygenic functional groups in the graphene and improve the electrical conductivity of the graphene so as to prepare the high-quality graphene with the controllable layer number.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

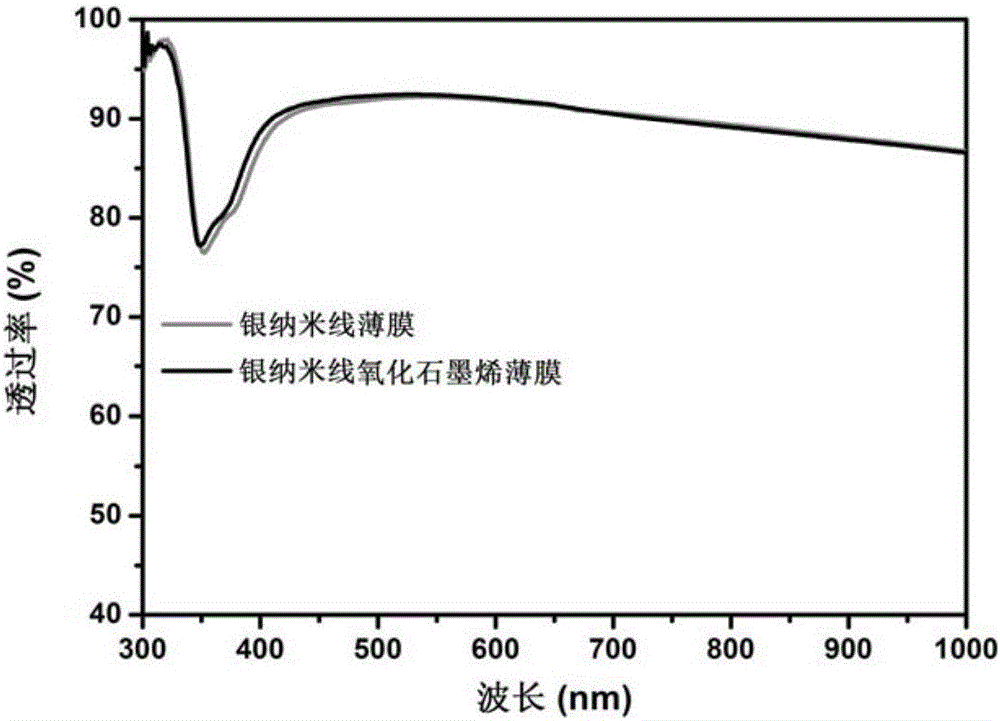

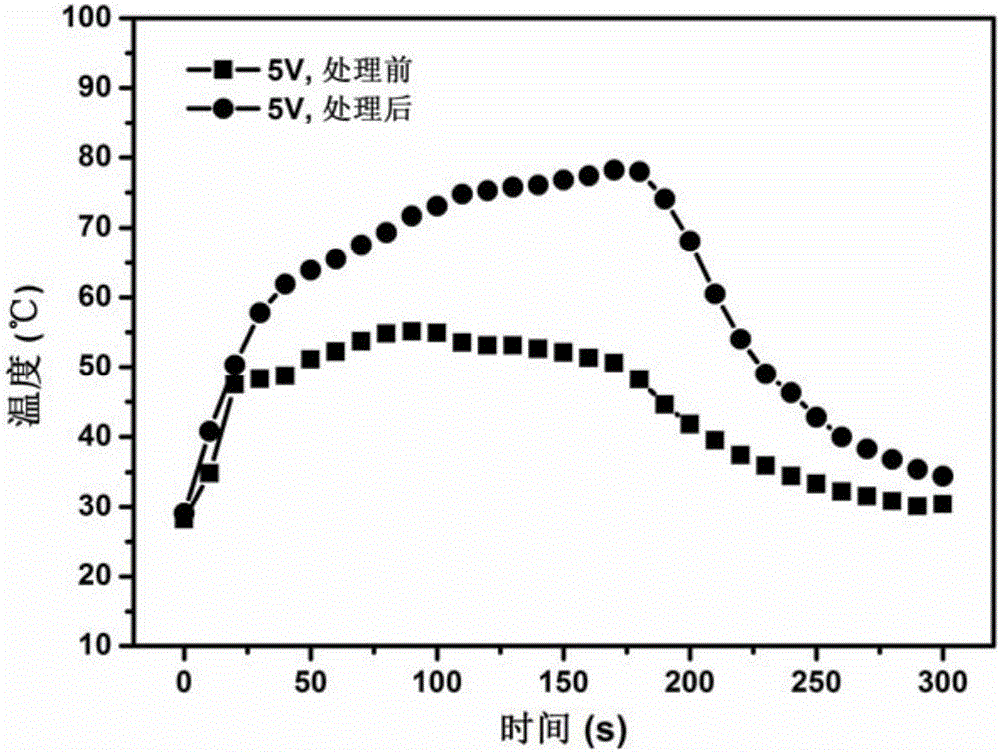

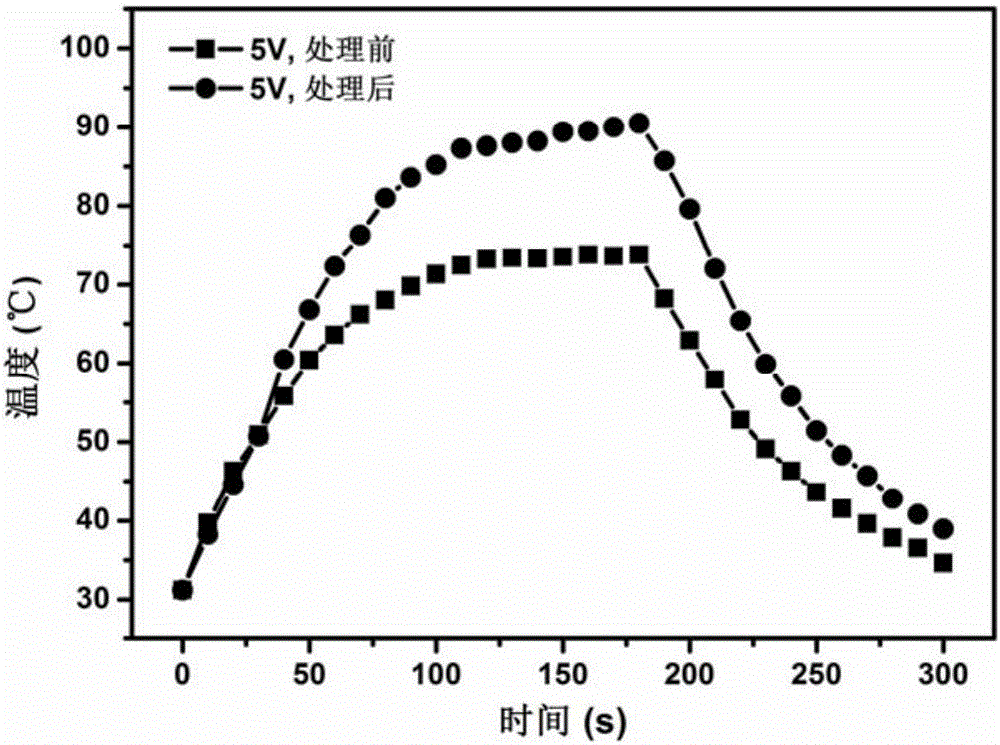

Preparation method of silver nanowire graphene oxide composite conductive thin film heater

ActiveCN106131984AReduce square resistanceImprove conductivityHeating element materialsComposite filmOxide composite

The invention discloses a preparation method of a silver nanowire graphene oxide composite conductive thin film heater, and belongs to the technical field of flexible electronic materials and thin films. The preparation method manly comprises the steps of cleaning a substrate, preparing a composite thin film, carrying out treatment after strong light illumination and the like. A silver nanowire synthesized by an improved polyol process and graphene oxide prepared by an improved Hummers method are taken as raw materials, a transparent composite conductive thin film is coated through a simple spin-coating method filming technology at normal pressure and temperature, and the thin film is irradiated through strong light, so that the heating temperature of the thin film is improved and the heating uniformity of the thin film is strengthened. The heater is simple in structure, the raw materials are cheap, the preparation process is easy to operate and industrial production is facilitated.

Owner:NANJING UNIV OF TECH

Preparation method and application of graphene/cellulose/titanium dioxide composite material

InactiveCN105251453AGood adsorption and removal effectEasy to operateOther chemical processesWater/sewage treatment by sorptionMalachite greenCellulose

The invention belongs to the field of synthesis of nano materials, relates to the preparation of graphene / mesoporous oxide series of nano composite material, and particularly relates to a preparation method and application of graphene / cellulose / titanium dioxide composite material. The graphene / cellulose / titanium dioxide composite material is prepared by preparing graphite oxide by utilizing an improved Hummers method, carrying out ultrasound to obtain graphene oxide, reducing graphene oxide into graphene by using sodium borohydride; and finally uniformly mixing cellulose, titanium dioxide, a surface active agent (hexadecyl trimethyl ammonium bromide) and grephene. According to the invention, the synthesis method is simple, the prepared graphene / cellulose / titanium dioxide composite material is taken as an adsorbent, and a malachite green dye solution is taken as an adsorption object, the experiment shows that the composite material has an excellent adsorption removal effect. The composite material is applied to the treatment of dyes in sewage water, has the advantages of simplicity in operation, convenience, easiness in availability, high adsorption rate and the like, and has good industrially practical value.

Owner:JIANGSU UNIV

Preparation method of carbon fiber/graphene/epoxy resin prepreg and carbon fiber composite material

A method for preparing carbon fiber / graphene / epoxy resin prepreg and carbon fiber composite materials, belonging to the field of carbon fiber composite material preparation. In this invention, graphene prepared by the modified Hummers method is surface modified, and -NH is grafted on the surface or edge of the graphene. 2 , improve its dispersion in the resin matrix, and at the same time, it can effectively increase the interfacial adhesion between micron-sized carbon fiber and epoxy resin matrix, reduce the existence of void defects, and thereby improve the mechanical properties of epoxy resin-based composite materials. The carbon fiber / graphene / epoxy resin composite material provided by the invention has optimal mechanical properties when the addition amount of graphene is 0.5wt%, with a bending strength of 1525.4MPa and an interlayer shear strength of 91.14MPa. Compared with carbon fiber reinforced rings, Oxygen resin composites improved by 15.41% and 14.14% respectively. The invention has the characteristics of simple process, low solvent toxicity, and is suitable for industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Aqueous graphene oxide modified poly(urethane-acrylate) composite material preparation method

The invention belongs to the technical field of polymer synthesis, and relates to aqueous poly(urethane-acrylate) emulsion modification, particularly to an aqueous graphene oxide modified poly(urethane-acrylate) composite material preparation method. According to the preparation method, an improved Hummers method is adopted to prepare graphene oxide, the graphene oxide is dissolved in N,N'-dimethylformamide, ultrasonic peeling is performed to prepare a graphene oxide dispersion solution, and the graphene oxide dispersion solution and n-butylacrylate are adopted to co-modify polyurethane. With the preparation method, the prepared composite material emulsion is uniform and stable, and the curing film has good mechanical property, and can be used in the fields of printing, packaging, furniture, electrical equipment, small metal parts, instrument panels, flooring, wood, paper coating, leathers, plastics, home appliances, electronics, telecommunications, aerospace, aviation and the like.

Owner:JIANGSU UNIV

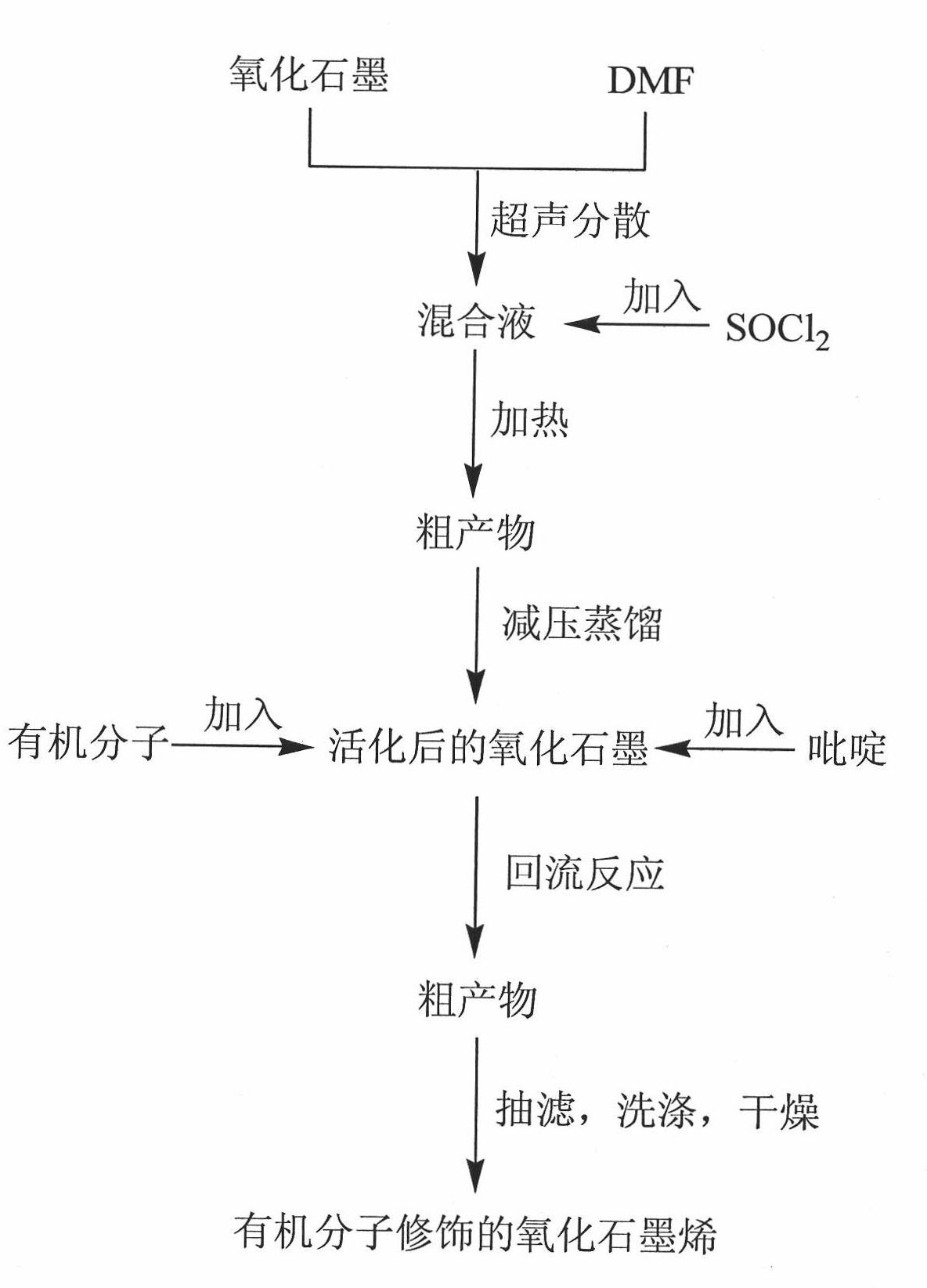

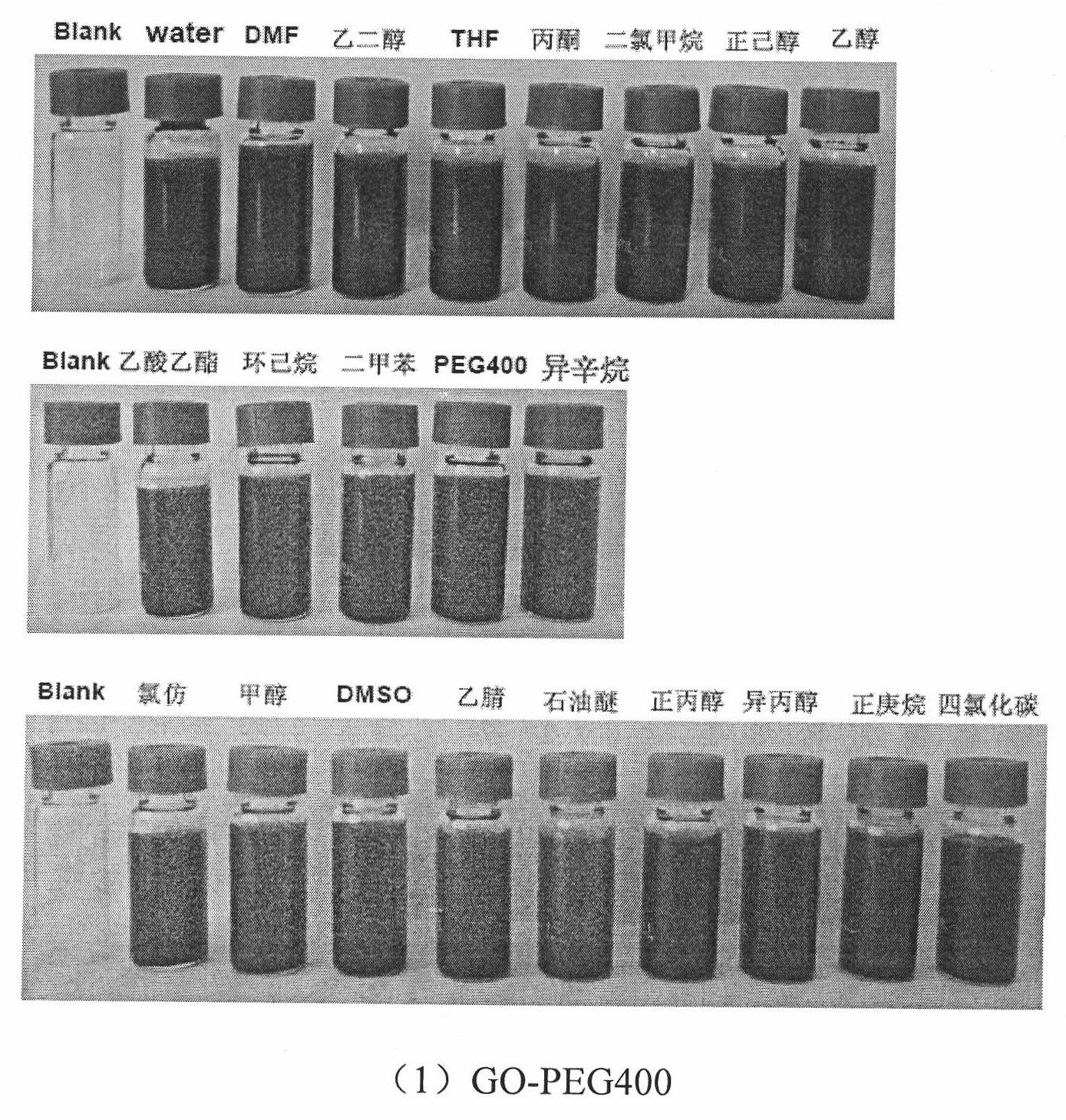

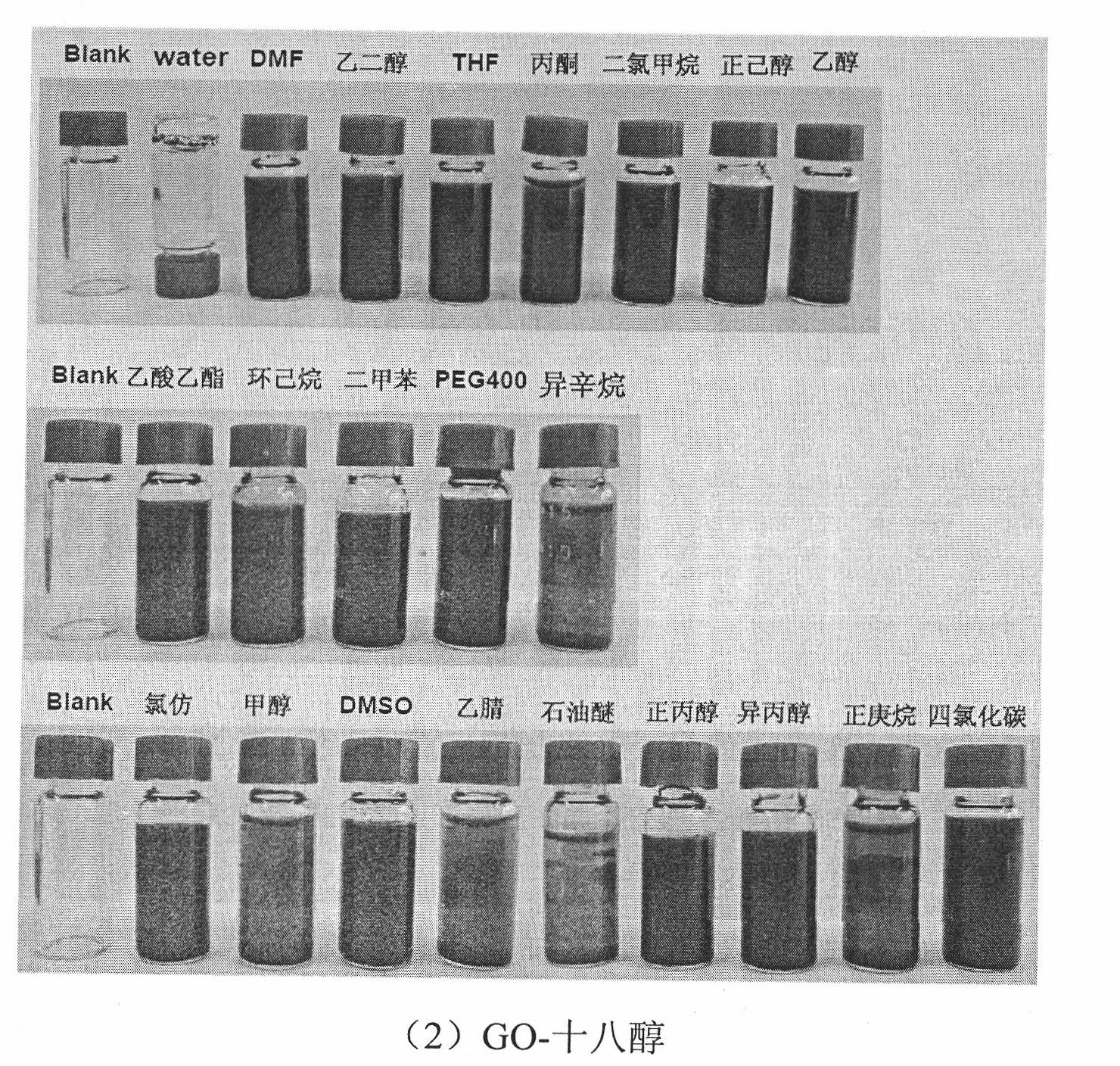

Functional graphene oxide for adjusting and controlling dispersibility of solvent by using organic chain segment as well as preparation method thereof

The invention discloses a functional graphene oxide for adjusting and controlling the dispersibility of a solvent by using an organic chain segment as well as a preparation method thereof. The structural formula of the functional graphene oxide is shown in specification, wherein R is equal to R1, R2 and R3. The preparation method comprises the following steps: 1, dispersing graphite oxide prepared by a Hummers method in N, N-dimethylformamide to form uniform dispersion liquid; 2, adding a thionyl chloride agent into the product obtained in step 1 to perform reflux reaction to synthesize an intermediate product of graphite oxide activated by acyl chloride; 3, distilling the mixed liquor obtained in step 2 under reduced pressure to remove excessive thionyl chloride; 4, adding pyridine and graft organic molecules into the product obtained in step 3, and heating and stirring the mixture; and 5, filtering, washing and then drying the mixed liquor obtained in step 4. The functional grapheneoxide can disperse well in different solvents, particularly solvents with low polarity and low boiling point, can be preferably compatible with multiple polymer molecules, leads the preparation of nano particles / polymer nano composite materials to be possible, and has good application prospects and economic benefits.

Owner:NANJING UNIV OF SCI & TECH

Method for massively preparing graphene with excellent electrical conductivity and thermal stability

The invention relates to technology for preparing graphene, in particular to a method for massively preparing high-quality graphene with excellent electrical conductivity and good thermal stability. The method comprises the following steps of: rapidly heating in an arc discharge mode under pressure atmosphere by adopting a cathode and an anode, expanding and splitting oxidized graphite to prepare exfoliated graphite, wherein the anode is the oxidized graphite prepared by a Hummer method, the total pressure of buffer gas is 50 to 1,000 torr and the discharging current is 50 to 300 amperes; uniformly dispersing the exfoliated graphite in solution of surfactant by adopting an ultrasonic method; and removing graphite which is not exfoliated completely and large-dimension thick graphite sheets by adopting a high-speed centrifugal method so as to prepare the high-quality graphene with excellent electrical conductivity and good thermal stability. The high-quality graphene with excellent electrical conductivity and good thermal stability can be prepared by simply controlling technological parameters, and the method has the characteristics of low cost, high product yield and mass production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of flexible transparent conducting polymer thin film with antibacterial properties

The invention discloses a preparation method of a flexible transparent conducting polymer thin film with antibacterial properties, and belongs to the technical field of nanocomposite materials. The preparation method comprises the steps: preparing stably dispersed graphene oxide (GO) colloid by a Hummers method at first; next, performing surface modification on the graphene oxide under the electrostatic adsorption action of poly(diallyldimethylammonium chloride) (PDDA) and preparing a nanowire / graphene nano hybrid material by a method of inducing the growth of silver nanowires in situ, and then further preparing a silver nanowire / graphene / polyvinyl alcohol thin film by a solution casting method. The thin film has the characteristics of antibiosis, high electricconductivity, high lighttransmittance, flexibility and the like, and is expected to be applied to a plurality of fields such as biosensing and nano-devices; and therefore, the flexible transparent conducting polymer thin film with antibacterial properties has a wide application prospect.

Owner:CHANGZHOU UNIV

Preparation method and application of graphene oxide composite membrane

InactiveCN105727758AAdjustable spacingImprove performanceSemi-permeable membranesDispersed particle separationGas separationHummers' method

The invention discloses a preparation method and application of a graphene oxide composite membrane, and belongs to the technical field of gas separation membranes.The preparation method of the graphene oxide composite membrane comprises the steps that an aqueous dispersion liquid of graphene oxide is prepared through a Hummer method, and ultrasonic dispersion is conducted; metal salt or oxysalt is added, and heating and mixing are conducted; the surface of a micro-filtration membrane is covered with the prepared dispersion liquid through a vacuum filtration method; the membrane is put into a drying oven to be dried.The preparation method of the graphene oxide composite membrane has the advantages that the preparation method is simple, the thickness of the obtained membrane is smaller than 10 nm, the space between graphene sheet layers is adjustable, the obtained composite membrane is used for gas separation and has excellent comprehensive performance.Particularly, the graphene oxide composite membrane prepared from sodium tetraborate has high CO2 permeation flux and CO2 / CH4 and CO2 / N2 selectivity, and it is obtained through mixed gas tests under the humidifying condition that the CO2 permeation flux can reach 650 GPU, CO2 / CH4 selectivity is 75, and CO2 / N2 selectivity is 58.

Owner:TIANJIN UNIV

Preparation method of waterborne polyurethane/graphene nano-composite emulsion

The invention relates to a preparation method of waterborne polyurethane / graphene nano-composite emulsion, and belongs to the field of organic-inorganic nano-composite materials. According to the preparation method, graphene oxide dispersion liquid is prepared by adopting an improved Hummers method, and is compounded with waterborne polyurethane to obtain the waterborne polyurethane / graphene nano-composite emulsion. By use of the preparation method disclosed by the invention, the waterborne polyurethane / graphene nano-composite emulsion is prepared by taking oligomer polyol as a soft segment, taking an isocyanate compound as a hard segment and carrying out in-situ introduction of the graphene oxide dispersion liquid in the preparation process of the waterborne polyurethane. The mechanical property, antistatic property, conductive property, electromagnetic shielding property, thermal conductivity, chemical resistance, corrosion resistance and the like of a waterborne polyurethane film and a coating are effectively improved by introducing grapheme. The waterborne polyurethane / graphene nano-composite emulsion has a better application prospect in the fields of coating materials, adhesives, ink, surface treatment agents, elastomers, foaming materials, functional films and the like.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com