Patents

Literature

274results about How to "Reduce square resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

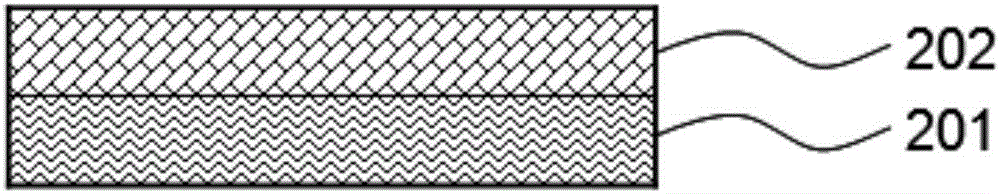

Transparent conducting thin film and preparation method thereof

InactiveCN102938262AHigh visible light transmittanceReduce square resistanceConductive layers on insulating-supportsMetal/alloy conductorsCvd grapheneTransmittance

The invention discloses a transparent conducting thin film and a preparation method thereof. The transparent conducting thin film is located on a transparent substrate and comprises a graphene sheet and a silver nanowire, the transparent conducting thin film is a combined layer formed by a graphene sheet layer and a silver nanowire layer, or the transparent conducting thin film is formed by blending the graphene sheet and the silver nanowire. The transparent conducting thin film and the preparation method thereof have the advantages that the visible light transmittance is high, the square resistance is low, the complexity of the preparation process is reduced, and the production cost is lowered.

Owner:SHANGHAI JIAO TONG UNIV

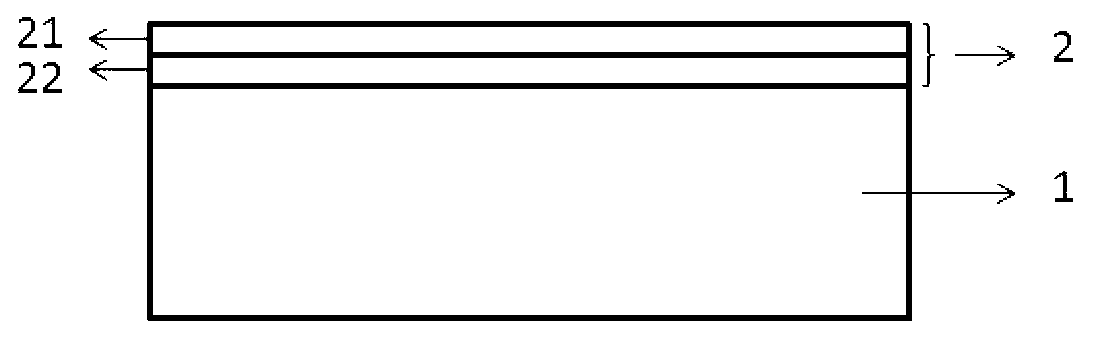

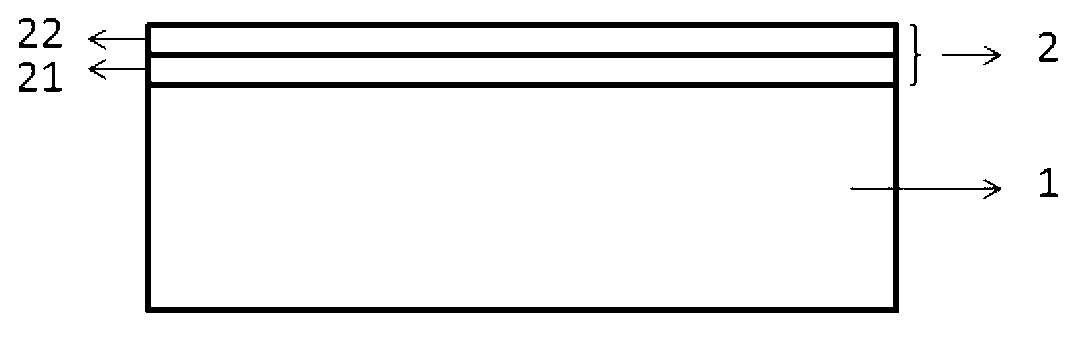

Composite of graphene and conducting polymer and preparation method of composite

InactiveCN103963403AEasy to makeReduce square resistanceSynthetic resin layered productsGlass/slag layered productsConductive polymerAttenuation ratio

The invention discloses a composite of graphene and a conducting polymer. The composite comprises a base body; a graphene layer and a conducting polymer layer are arranged in sequence on the surface of the base body, or the conducting polymer layer and the graphene layer are arranged in sequence on the surface of he base body. A preparation method of the composite comprises the following steps: transferring the graphene onto the surface of the base body first, then coating the graphene with the conducting polymer; or coating the surface of the base body with the conducting polymer first, then transferring the graphene onto the conducting polymer; baking to obtain the composite of the graphene and the conducting polymer. According to the invention, the composite is simple in preparation process and can lower sheet resistance obviously after the graphene is transferred; the stability is excellent, that is, even though the composite is placed for a long time, attenuation of the sheet resistance of the graphene is extremely small, and the sheet resistance attenuation ratio of the composite placed for 30 days is less than 10%.

Owner:WUXI GRAPHENE FILM

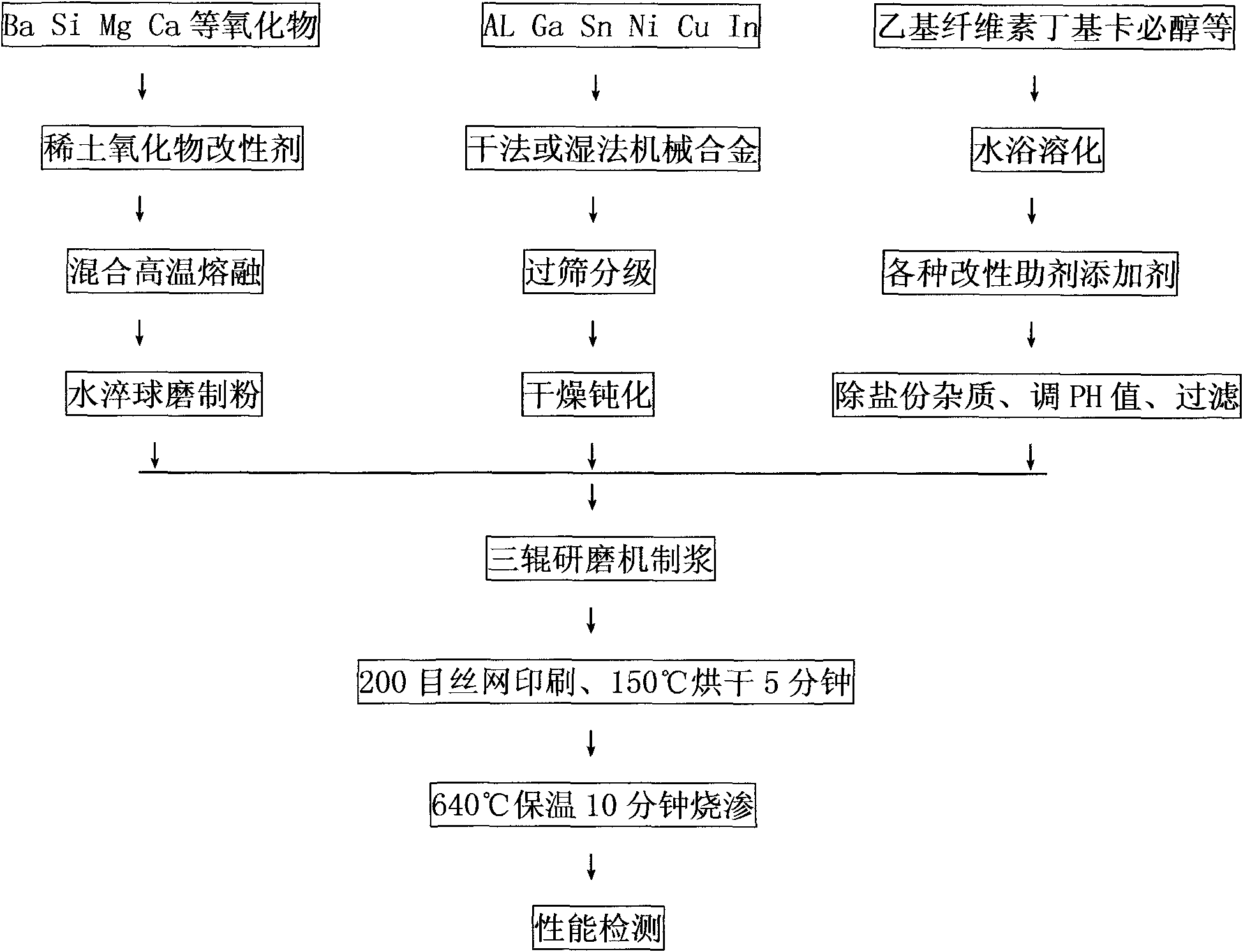

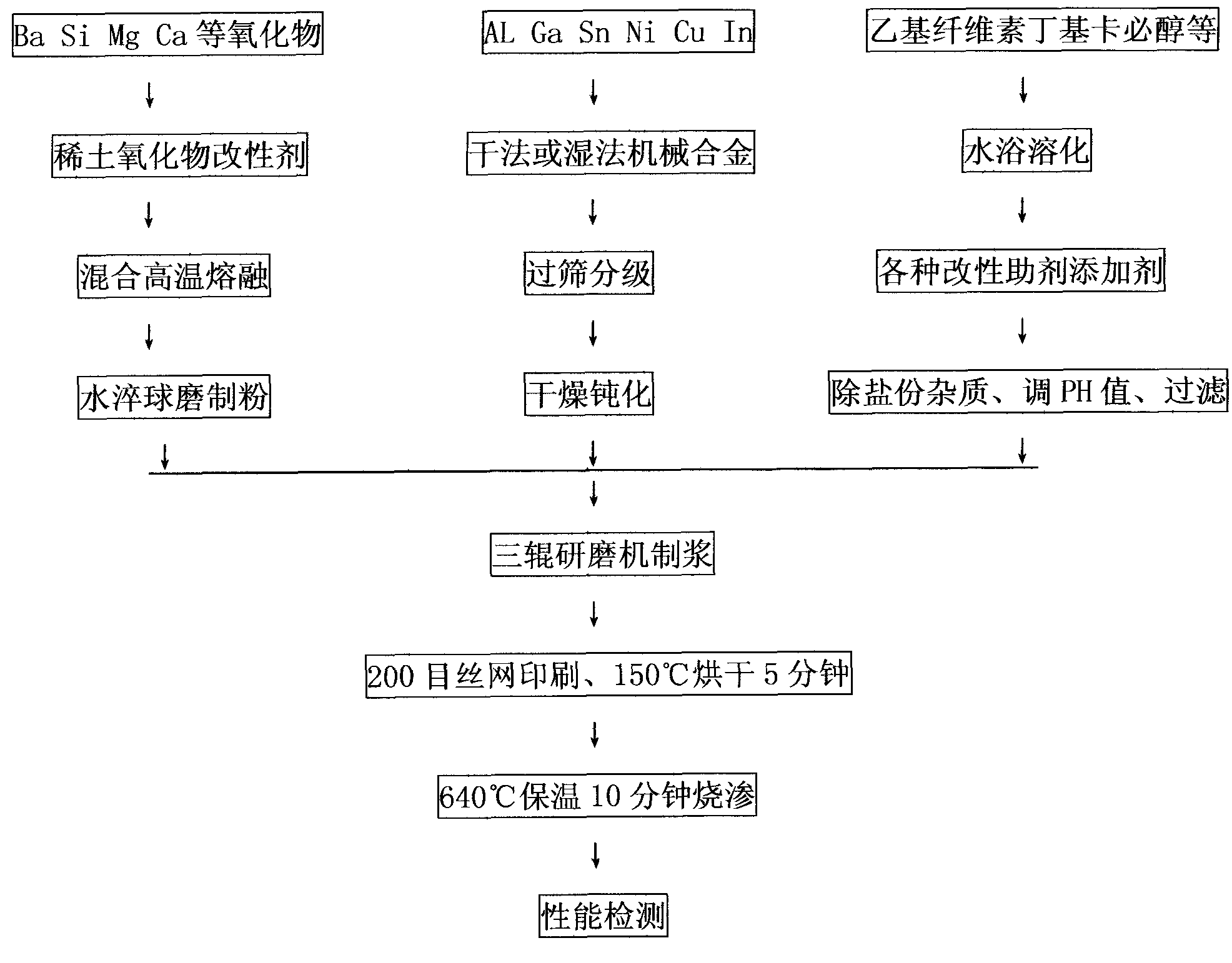

Medium temperature sintering type electro-conduction slurry with lead-free glass powder and preparation method of medium temperature sintering type electro-conduction slurry

InactiveCN103903677ALow softening temperatureMeet the requirements of energy saving and environmental protectionNon-conductive material with dispersed conductive materialCable/conductor manufactureMicron scaleAlkali metal oxide

The invention discloses a medium temperature sintering type electro-conduction slurry with lead-free glass powder and a preparation method of the medium temperature sintering type electrocondution slurry. The preparation method is characterized by comprising the steps of preparing an organic carrier, preparing the lead-free glass powder, preparing silver powder and preparing the electro-conduction slurry. The electro-conduction slurry comprises, by mass, 0 to 80% of micron-scale spherical silver powder, 5% to 70% of micron-scale flake silver powder, 2% to 25% of the lead-free glass powder and 0 to 25% of the organic carrier. The lead-free glass powder comprises, by mass, 25% to 75% of Bi2O3, 20% to 60% of B2O3, 0 to 20% of ZnO, 0 to 20% of Sb2O3, 0 to 10% of Al2O3 and 0 to 8% of alkali metal oxide. The organic carrier comprises, by mass, 50% to 80% of terpilenol, 10% to 40% ofbutyl carbitol acetic ester, 0 to 10% of tributyl citrate, 3% to 10% of ethocel, 0 to 2% of hydrogenated castor oil and 0 to 3% of addition agent.

Owner:SHANGHAI INTELLIGENT SENSOR ELECTRONICS TECHCO

Touch screen and production method thereof

ActiveCN103207702AReduce square resistanceHigh light transmittanceInput/output processes for data processingMetallic materialsEngineering

A touch screen comprises a glass substrate, a first conducting layer, an insulating layer and a second conducting layer. The first conducting layer is directly formed on the glass substrate and comprises a plurality of first conducting pattern areas. The insulating layer is adhered to the glass substrate, and first grooves are formed on the insulating layer close to one side of the glass substrate. The first conducting pattern areas are accommodated in the first grooves, and accordingly the first grooves are insulated from one another. Second grooves are arranged on the insulating layer away from one side of the glass substrate. The second conducting layer is accommodated in the second grooves, and a plurality of mutually-insulated second conducting pattern areas are formed. Since the first conducting layer is directly formed on the glass substrate and is made of metal materials, an adhesive layer is omitted to reduce cost; in a production method, different forming processes of the first conducting layer and the second conducting layer are adopted, the first conducting layer is directly plated on the glass substrate due to good coating property of the glass substrate, and the second conducting layer is formed by filling conducting materials in stamped grooves, so that the production method is easy to operate.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

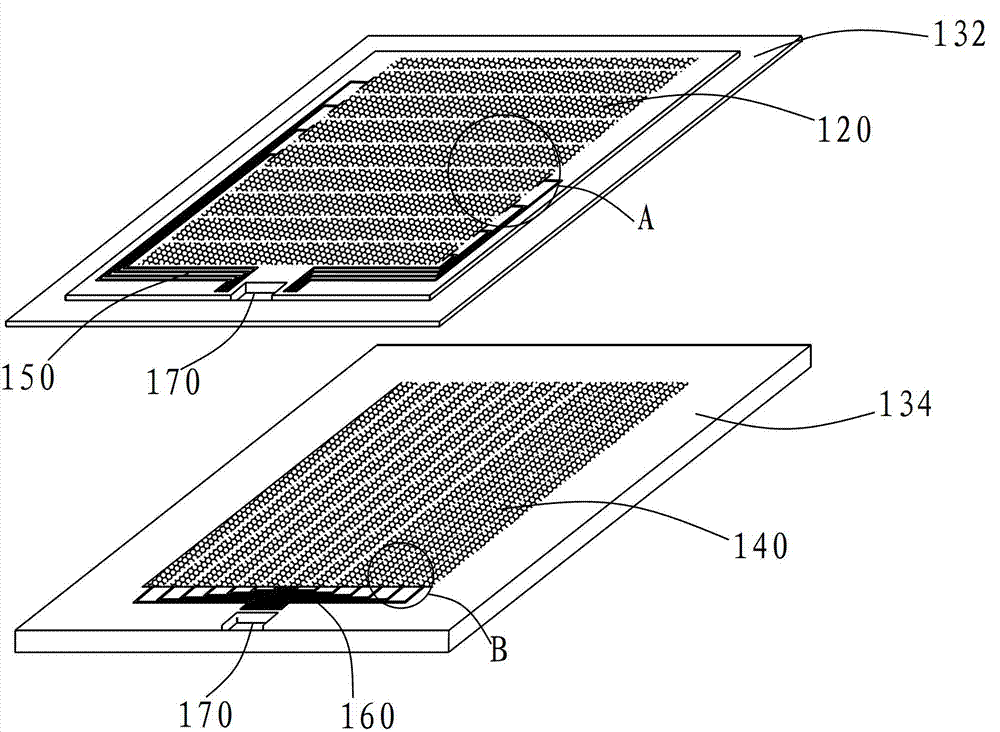

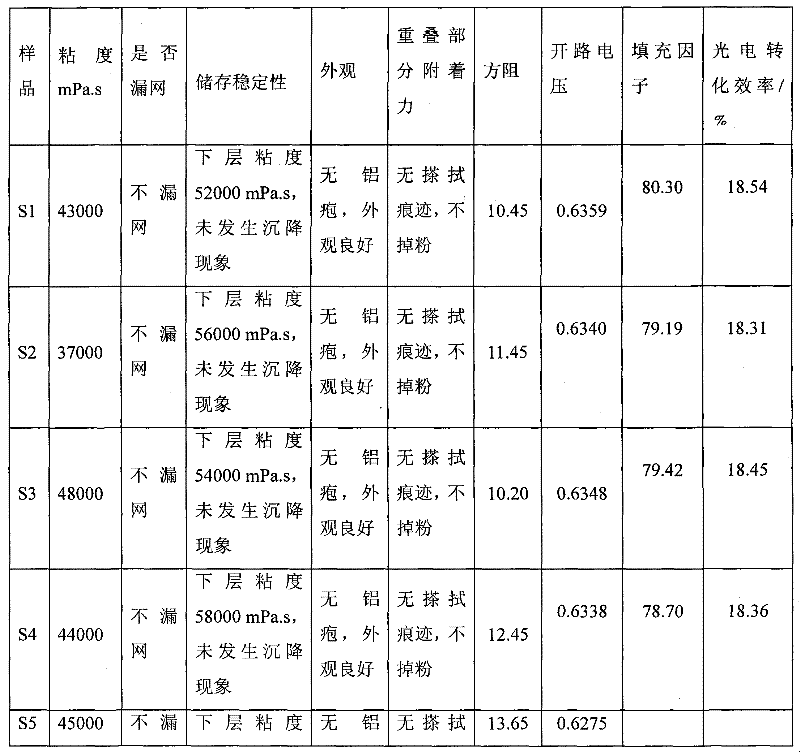

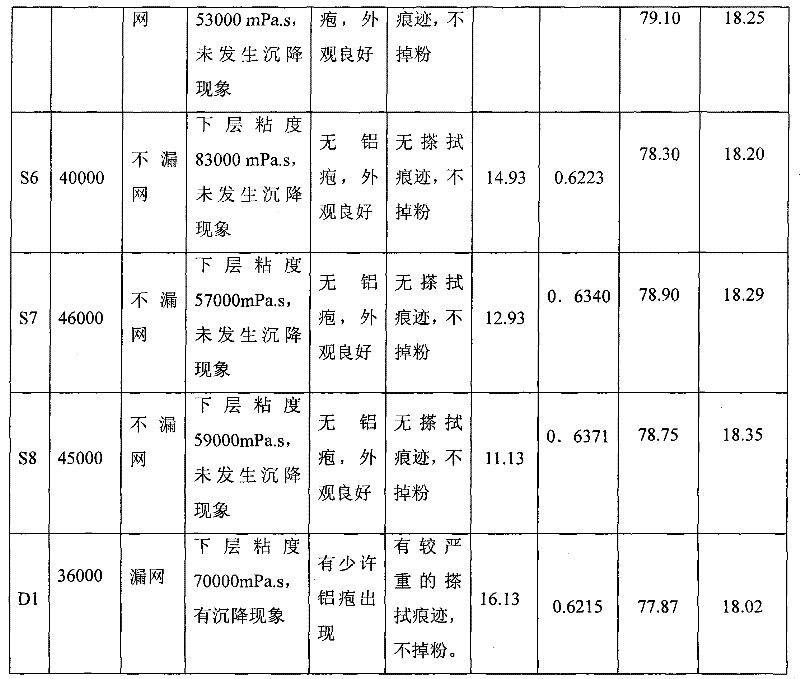

Conductive paste for solar cell and preparation method thereof

ActiveCN102479568AImprove rheologyEasy constructionNon-conductive material with dispersed conductive materialCable/conductor manufactureOpen-circuit voltageSedimentation

The invention provides a conductive paste and a preparation method thereof. The conductive paste comprises aluminum powder, an inorganic binding agent, an organic carrier and metal-glass composite powder, wherein the metal-glass composite powder is of nano-particles and a core-shell structure, glass is used as a core material, and metal is used as a shell material. The conductive paste disclosed by the invention is good in storage stability and less prone to sedimentation and agglomeration, and the conductive paste is less prone to leakage from a screen during screen printing; after sintering, an aluminum film is smooth in surface and grey white, and has no aluminum vesicles or aluminum beads; and furthermore, the part in contact and superimposition with a back silver electrode, of the aluminum film is wiped by a non-dust cloth, and wiping traces and powder dropping can be avoided. The series resistance of the produced solar cell is reduced obviously, a filling factor is increased obviously, and the average photoelectric conversion efficiency of a monocrystalline silicon cell piece can be above 18.20%. Simultaneously, the conductive paste disclosed by the invention is good in construction performance, a film layer formed after sintering is compact, the sintering thickness is uniform, the bending of a silicon chip is small, the sheet resistance is small and the open circuit voltage (Voc) of the formed cell is high.

Owner:BYD CO LTD

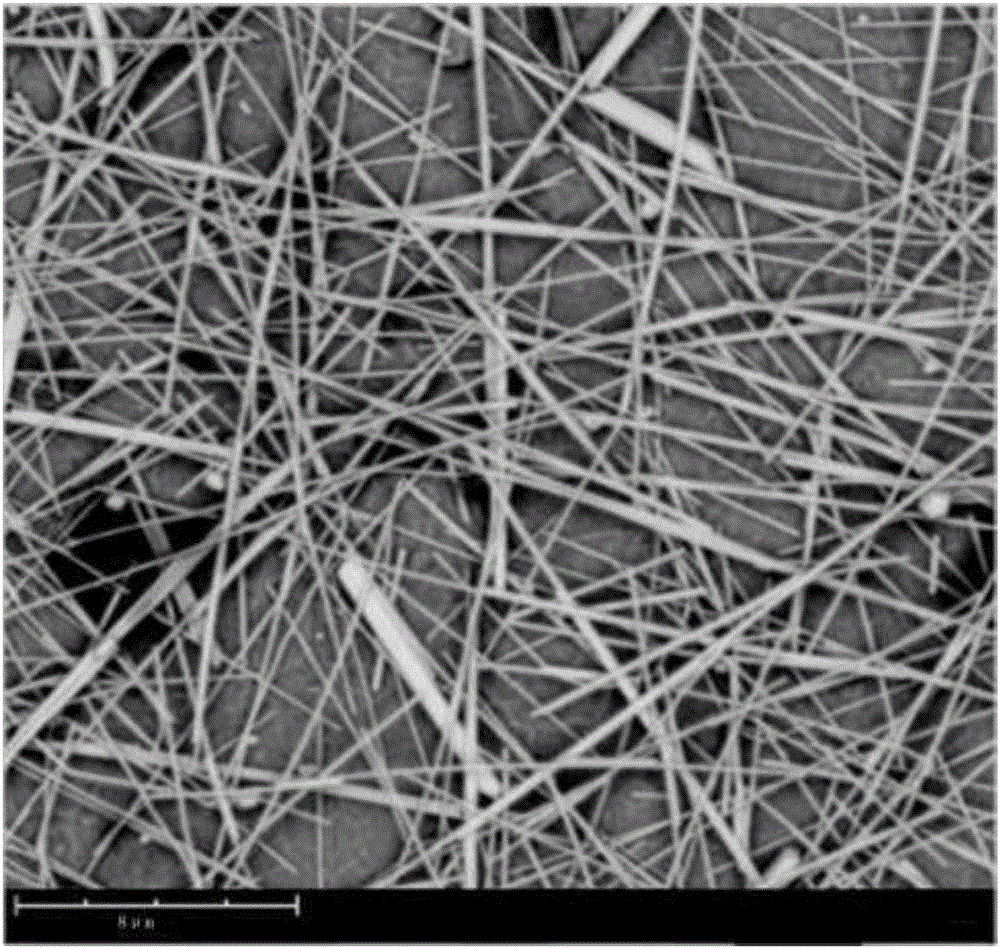

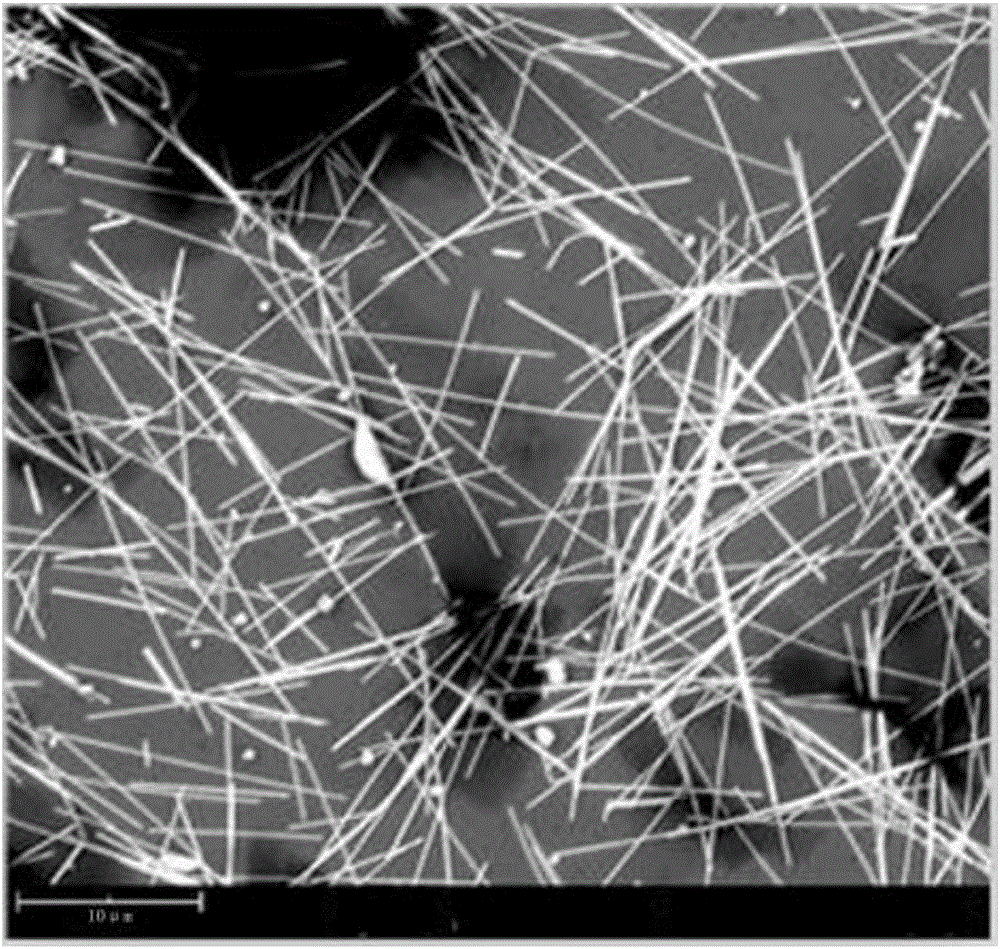

Method for directly preparing metal oxide/silver nanowire composite conductive network

InactiveCN104575864AHigh mechanical strengthHigh visible light transmittanceCable/conductor manufactureOxygen plasmaElectrostatic coating

The invention relates to a method for directly preparing a metal oxide / silver nanowire composite conductive network, belongs to the technical field of transparent conductive thin films and anti-static coating layers, and aims to solve the technical problem that the technology for preparing a silver nanowire / inorganic metal oxide composite conductive thin film by two steps in the prior art is complicated. The method comprises the following steps: preparing a soluble metal oxide precursor solution; mixing the prepared metal oxide precursor solution with dispersion liquid of a silver nanowire to obtain soluble metal oxide / silver nanowire mixing dispersion liquid, and forming a film on the upper surface of a substrate by a wet processing technology; finally performing high-temperature annealing, ultraviolet ozone irradiation or oxygen plasma treatment to obtain the metal oxide / silver nanowire composite conductive network. According to the method, the metal oxide / silver nanowire composite conductive network is prepared in one step, so that the preparation technology is greatly simplified, and the production cost is reduced; the prepared composite conductive network is high in mechanical strength, higher in visible light transmittance and lower in square resistivity.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

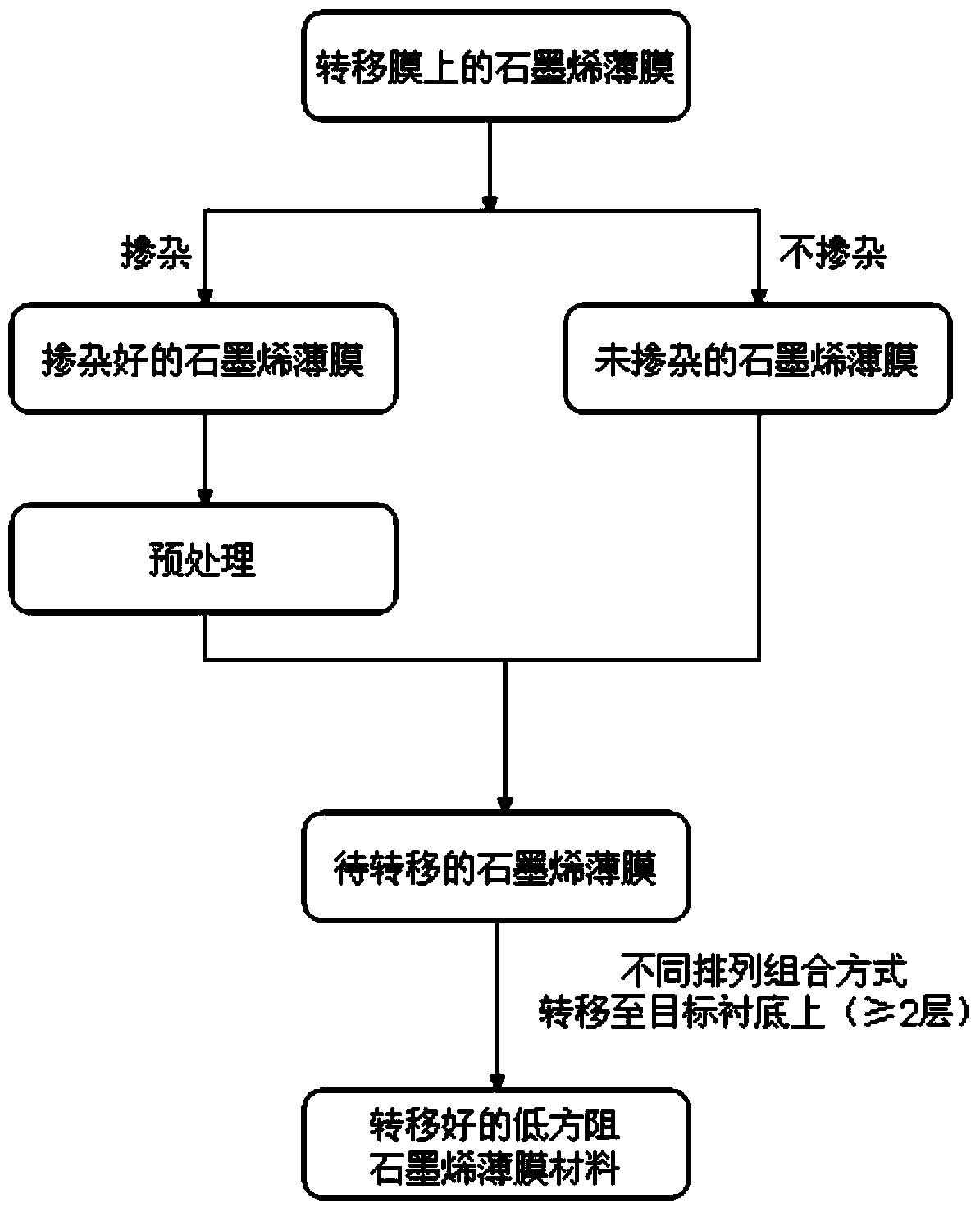

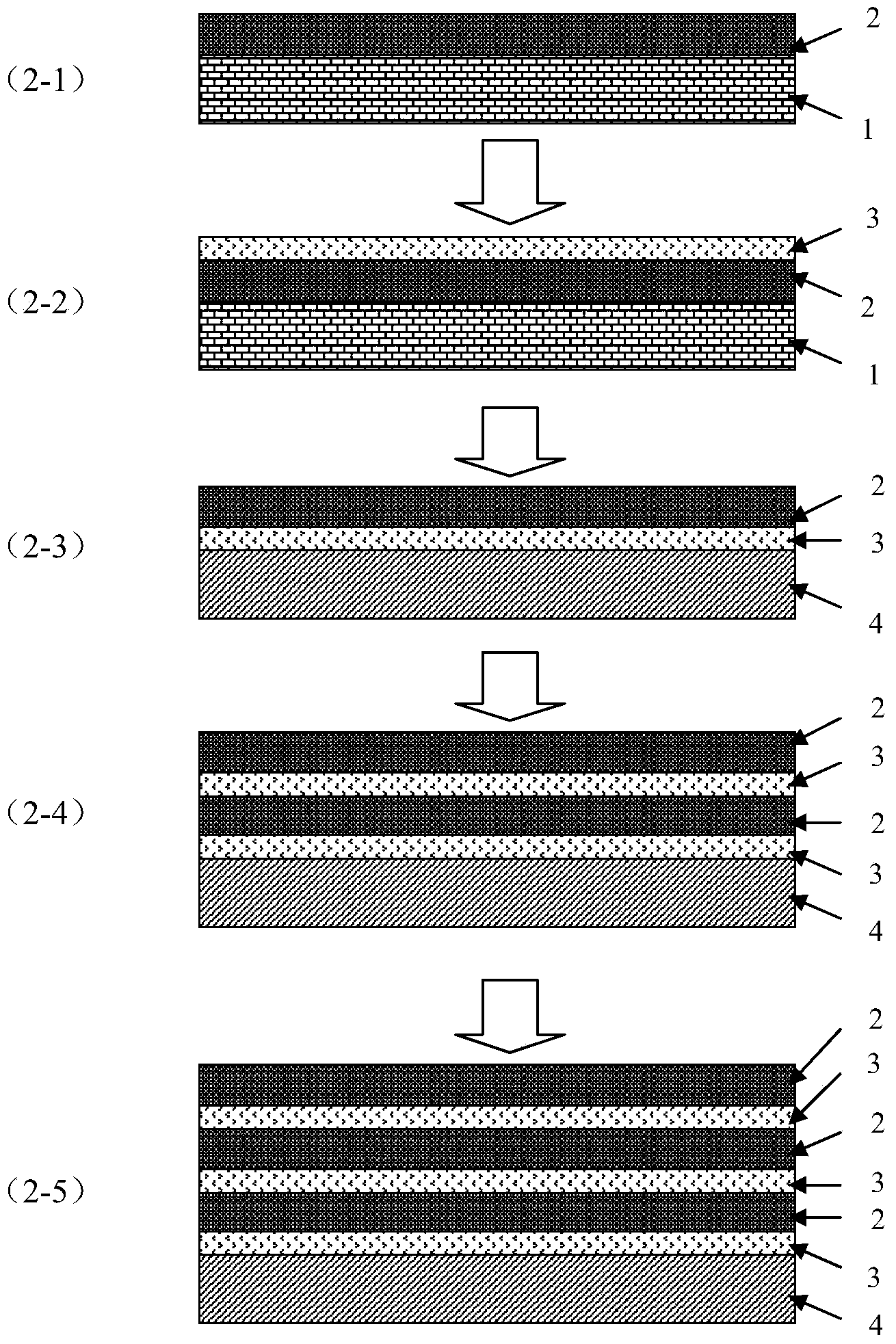

Dope-transferring method for reducing sheet resistance of graphene

ActiveCN104021881AReduce square resistanceReduce exposureCarbon compoundsCable/conductor manufactureCvd grapheneSheet resistance

The invention discloses a dope-transferring method for reducing the sheet resistance of graphene. According to the method, a graphene film on a transfer film is doped with a doping reagent, the doped graphene film is transferred to a target substrate, and at least two graphene films are transferred by repeating the steps. Graphene on the transfer film can also be undoped, or different doping reagents can be used for multiple times of transferring in different permutation and combination sequences. By means of the method, a large-area low-sheet-resistance graphene material can be obtained conveniently and quickly, the obtained material is high in conductivity and stability, and meanwhile, sheet resistance reduction caused after dope-transferring of graphene can be effectively reduced or even avoided.

Owner:WUXI GRAPHENE FILM +1

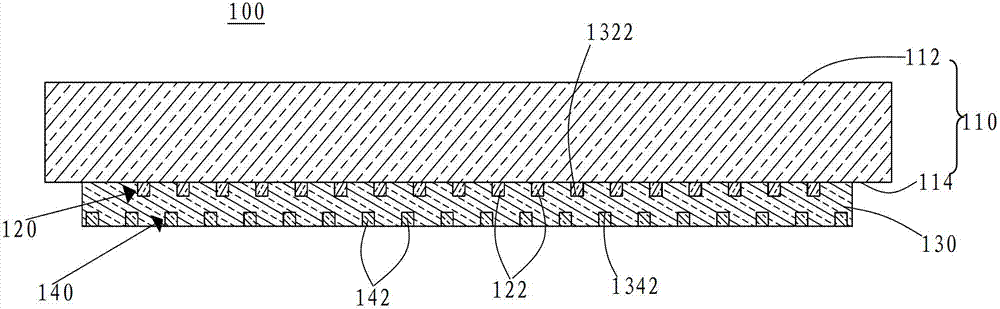

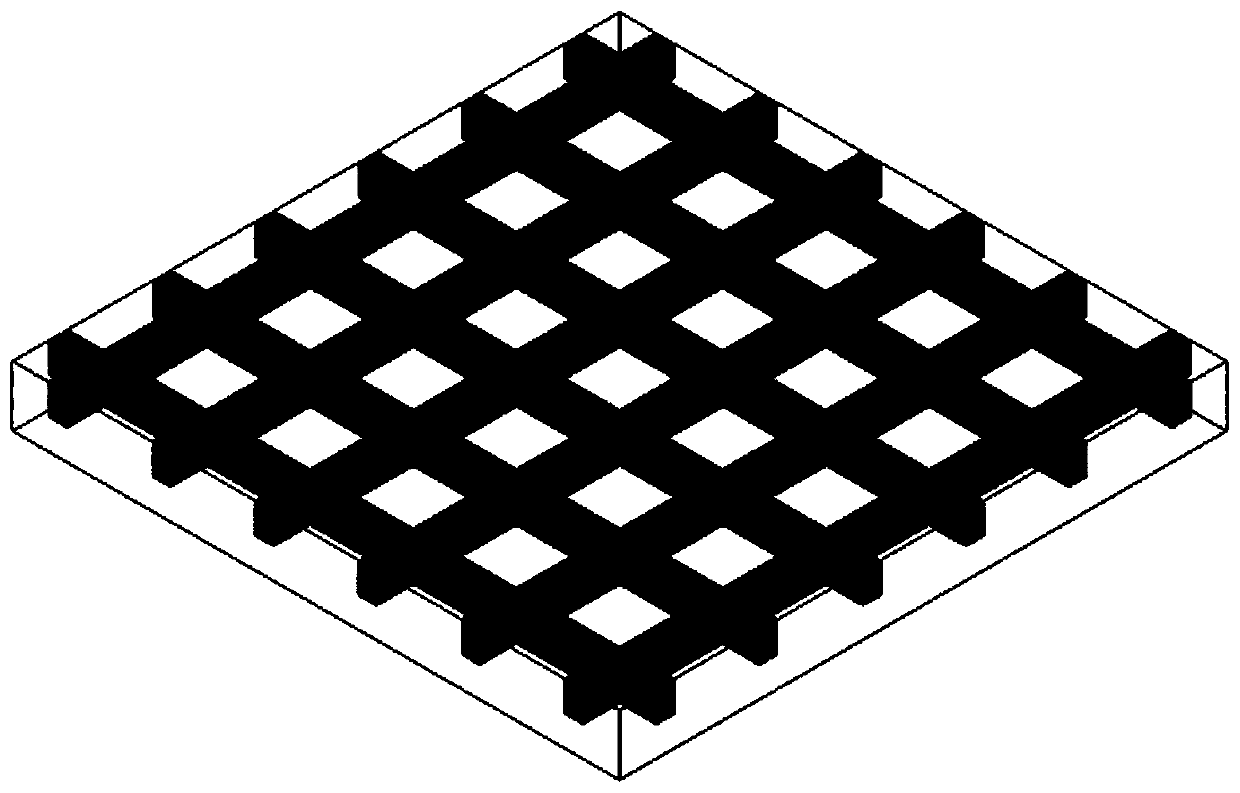

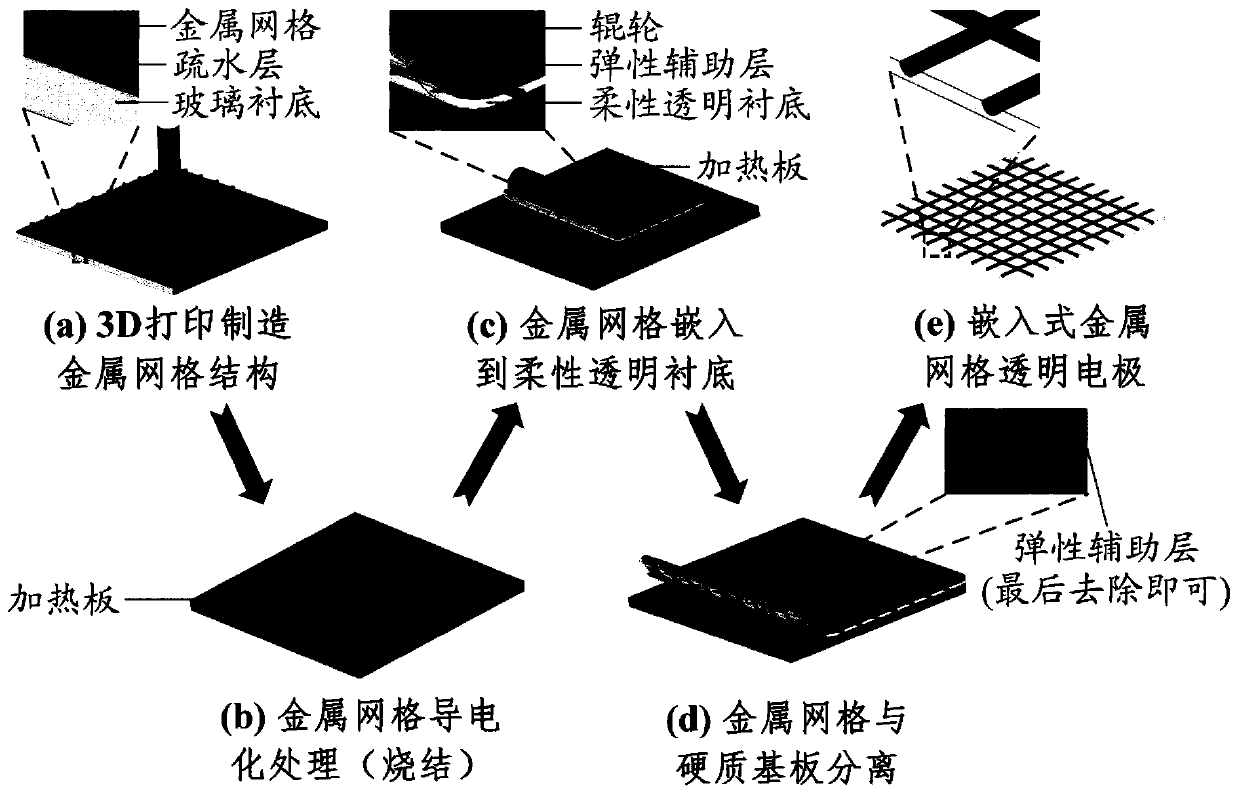

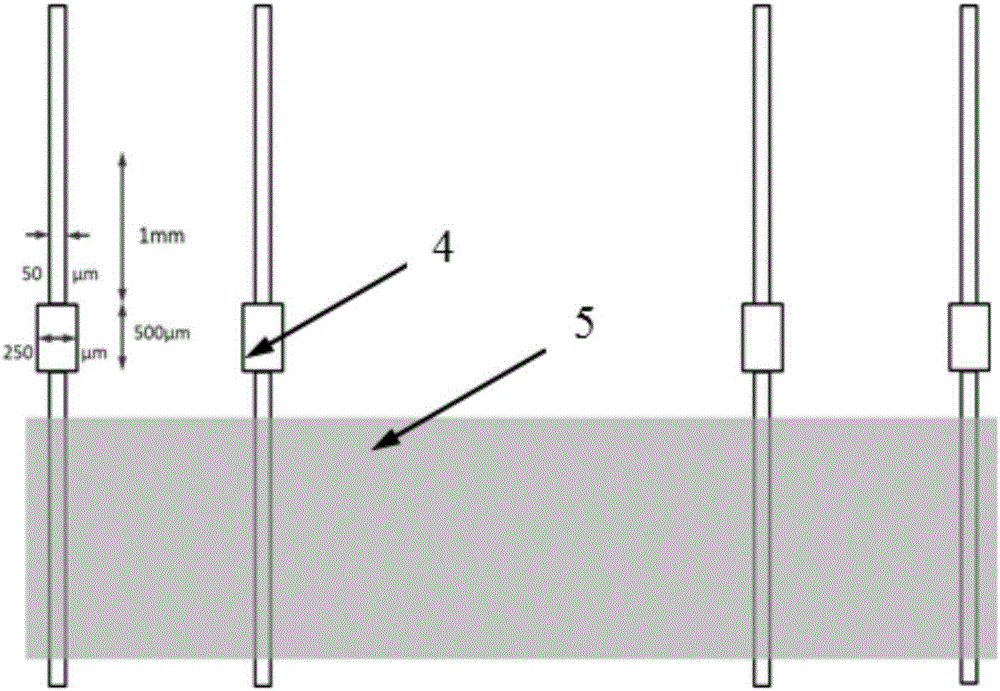

Manufacturing method and application of embedded metal grid flexible transparent electrode

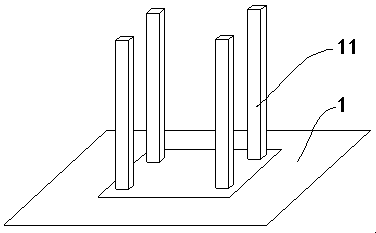

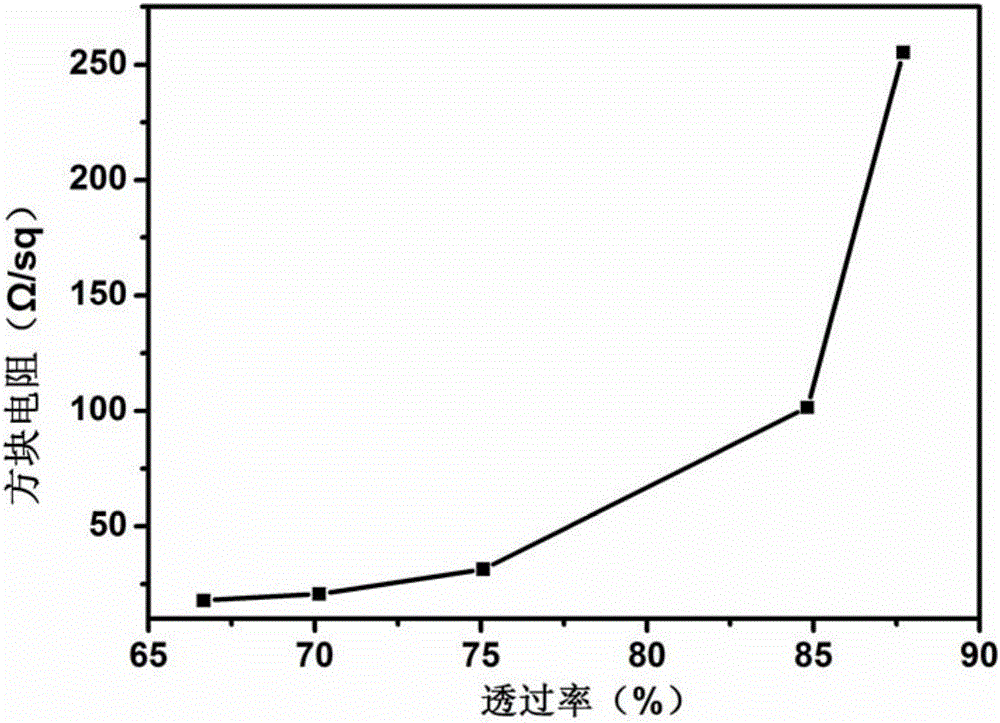

ActiveCN110021462AIncrease profitNo wasteAdditive manufacturing apparatusConductive layers on insulating-supportsHot stampingMicro nano

The invention belongs to the field of flexible transparent electrodes, and particularly relates to a manufacturing method and an application of an embedded metal grid flexible transparent electrode. The method comprises the following steps: 1) by use of an electric field driven spray deposition micro-nano 3D printing technology, a metal grid transparent electrode is directly printed on a hard substrate; 2) conductive treatment is carried out on a printed metal grid structure by adopting a sintering process so as to realize conductive treatment of a metal grid; 3) a flexible transparent substrate and the hard substrate are heated to a set temperature, and a hot stamping process is adopted for completely embedding the metal grid structure on the hard substrate into the flexible transparent substrate; and 4) the metal grid which is completely embedded into the flexible transparent substrate is separated from the hard substrate to obtain the embedded metal grid flexible transparent electrode. According to the method, the electric field driven spray deposition micro-nano 3D printing technology is combined with the roller pair plane hot stamping technology to realize efficient and low-cost batch manufacturing of the large-sized embedded metal grid flexible transparent electrode; and the prepared transparent electrode also has excellent square resistance and light transmittance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Conductive ink and preparation method thereof

The invention discloses conductive ink and a preparation method thereof. The conductive ink consists of the following components in percentage by mass: 1 to 2 percent of carbon powder, 3 to 5 percent of organic carrier A, 50 to 65 percent of sheet silver, 0.5 to 1 percent of nickel powder, 30 to 45 percent of organic carrier B, and 0.1 to 0.2 percent of dispersant, wherein the organic carrier A is formed by completely dissolving diethyl adipate or 2-butoxyethyl acetate with mass percentage of between 65 and 75 percent with polyester resins or acrylic resins with mass percentage of between 25 and 35 percent; and the organic carrier B is formed by completely dissolving 1,4-butyrolactone or terpineol with mass percentage of between 62 and 77 percent with a chloride-vinyl acetate resin with mass percentage of between 22 and 38 percent, and then adding a coupling agent with mass percentage of between 0.05 and 1 percent into the mixture. Compared with the prior carbon-silver paste, the carbon powder of the conductive ink is combined with paste better, carbon-silver paste is more compact, and the conductance is better when the compactness is better.

Owner:IRICO

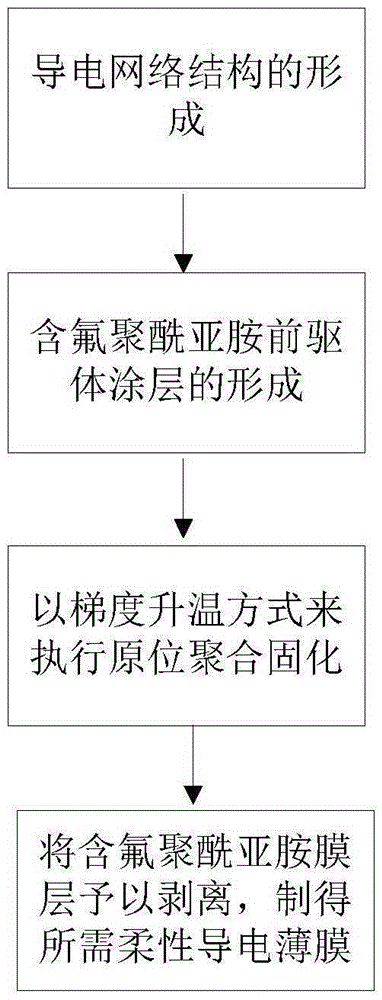

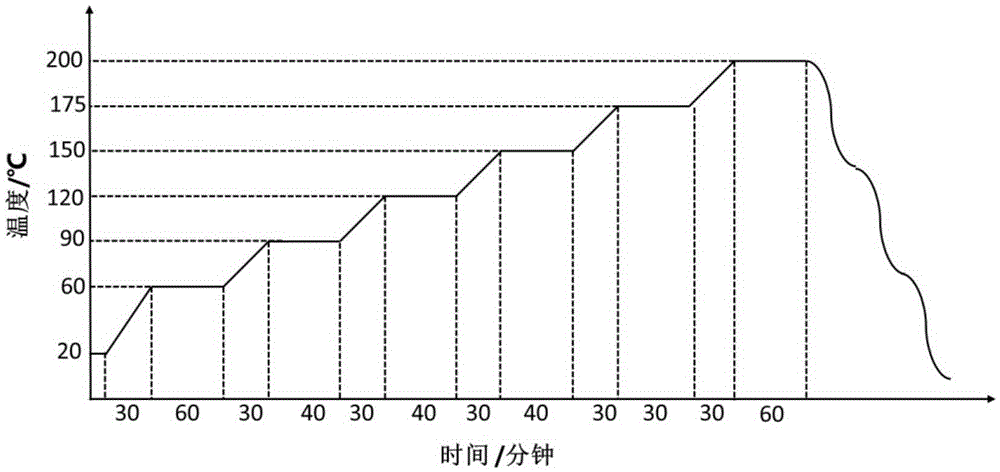

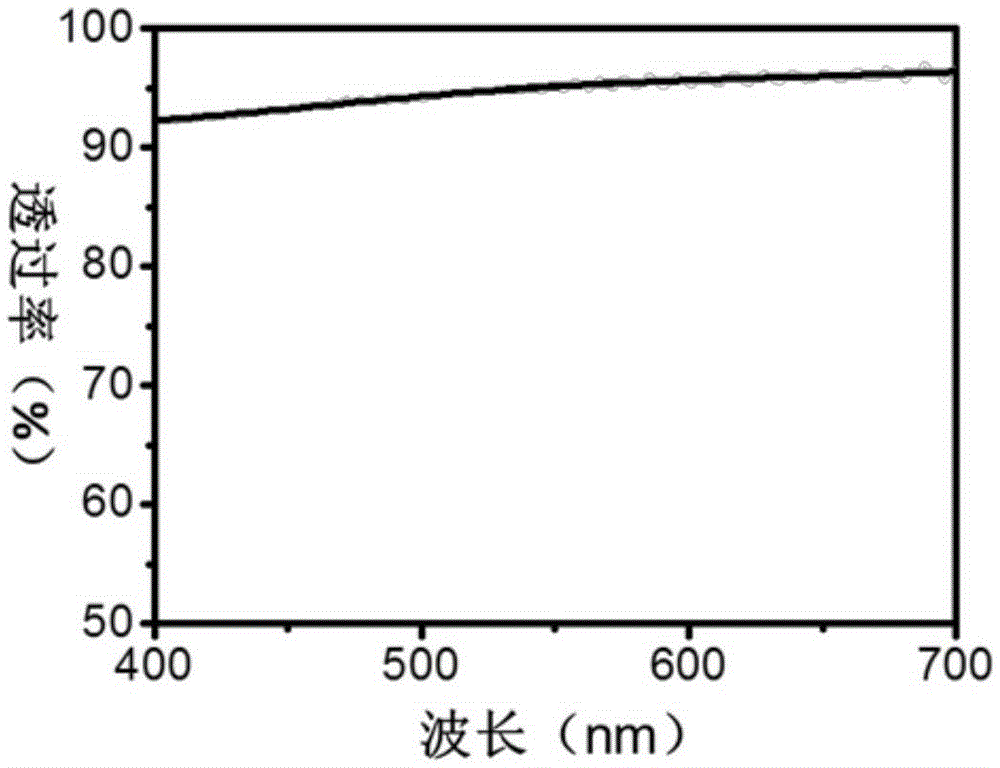

Preparation method for flexible transparent conductive thin film with high thermal stability and product thereof

ActiveCN105405492AFracture failure temperature increasedImprove thermal stabilityConductive layers on insulating-supportsCable/conductor manufactureUltravioletTransmittance

The invention discloses a preparation method for a flexible transparent conductive thin film with high thermal stability. The preparation method comprises the steps of step 1, uniformly coating the surface of a tidy and smooth target substrate with a one-dimension-structured conductive metal nanomaterial, and forming a conductive network structure; step 2, performing blade coating on the surface of the target substrate with the conductive network structure to form a precursor coating layer containing fluorinated polyimide; step 3, performing a curing process on the precursor coating layer containing fluorinated polyimide through a gradient temperature rise manner; and step 4, peeling off the cured fluorinated polyimide contained film layer from the target substrate to obtain the required finished product. The invention also discloses a corresponding flexible transparent conductive thin film product and characteristics of the product. Through the preparation method, the flexible transparent conductive thin film can be prepared in an efficient manner, and the quality control can be performed conveniently; and the prepared flexible transparent conductive thin film has the characteristics of low sheet resistance, high visible light transmittance, anti-ultraviolet property, high flexibility, low surface roughness, excellent high-temperature endurance and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

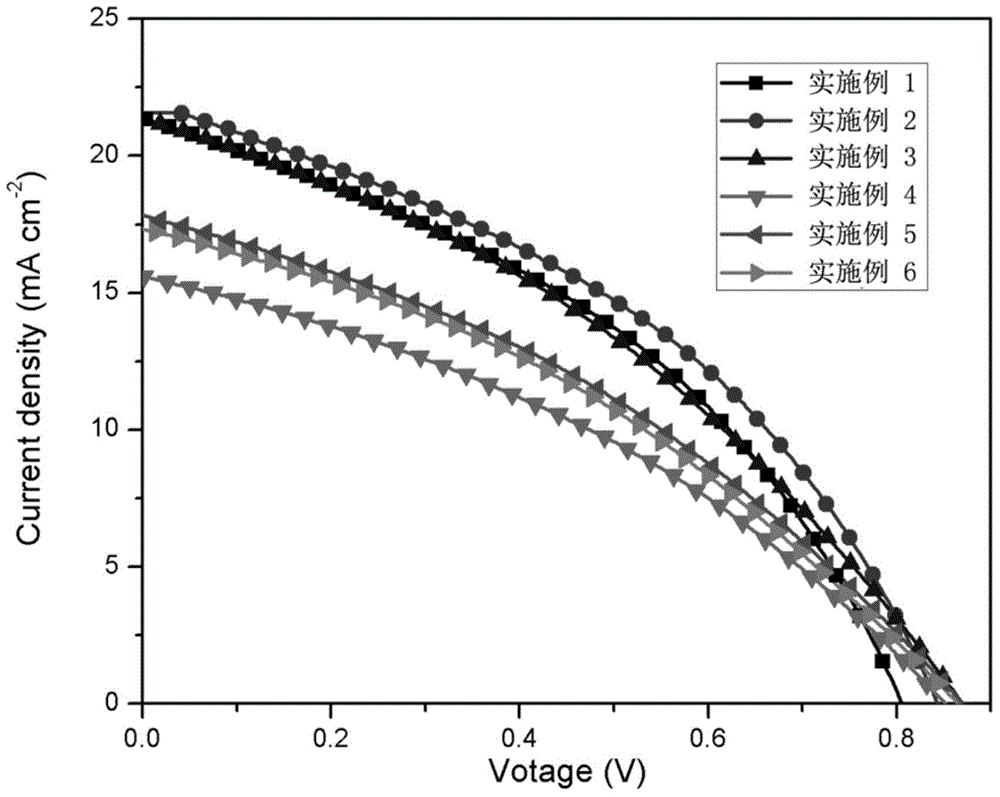

Perovskite solar cell conductive carbon paste, carbon counter electrode, cell and method of manufacturing the conductive carbon paste

InactiveCN104966548ABlocking compositeIncrease photocurrentSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingOrganic solvent

The invention discloses perovskite solar cell conductive carbon paste which comprises organic solvents, binders and conductive filling materials. The conductive carbon paste further comprises inorganic additives. The inorganic additives are ZrO2 or NiO powder. By mass percent, the conductive carbon paste comprises 6%-15% of binders, 14%-20% of conductive filling materials and 3%-5% of inorganic additives. The invention further discloses a carbon counter electrode for a perovskite solar cell. The carbon counter electrode is prepared and acquired by adopting the above-mentioned conductive carbon paste in a screen printing means. The invention further discloses the perovskite solar cell comprising the above-mentioned carbon counter electrode. A method of preparing the conductive carbon paste is further disclosed. The conductive carbon paste which does not make a perovskite film corroded further increases the photoelectric conversion efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

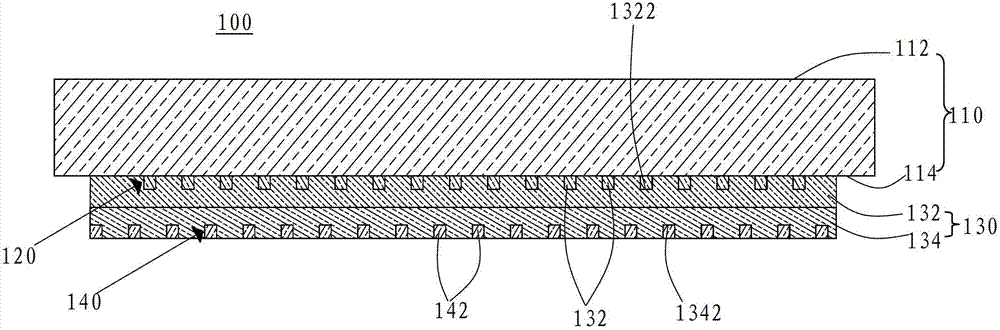

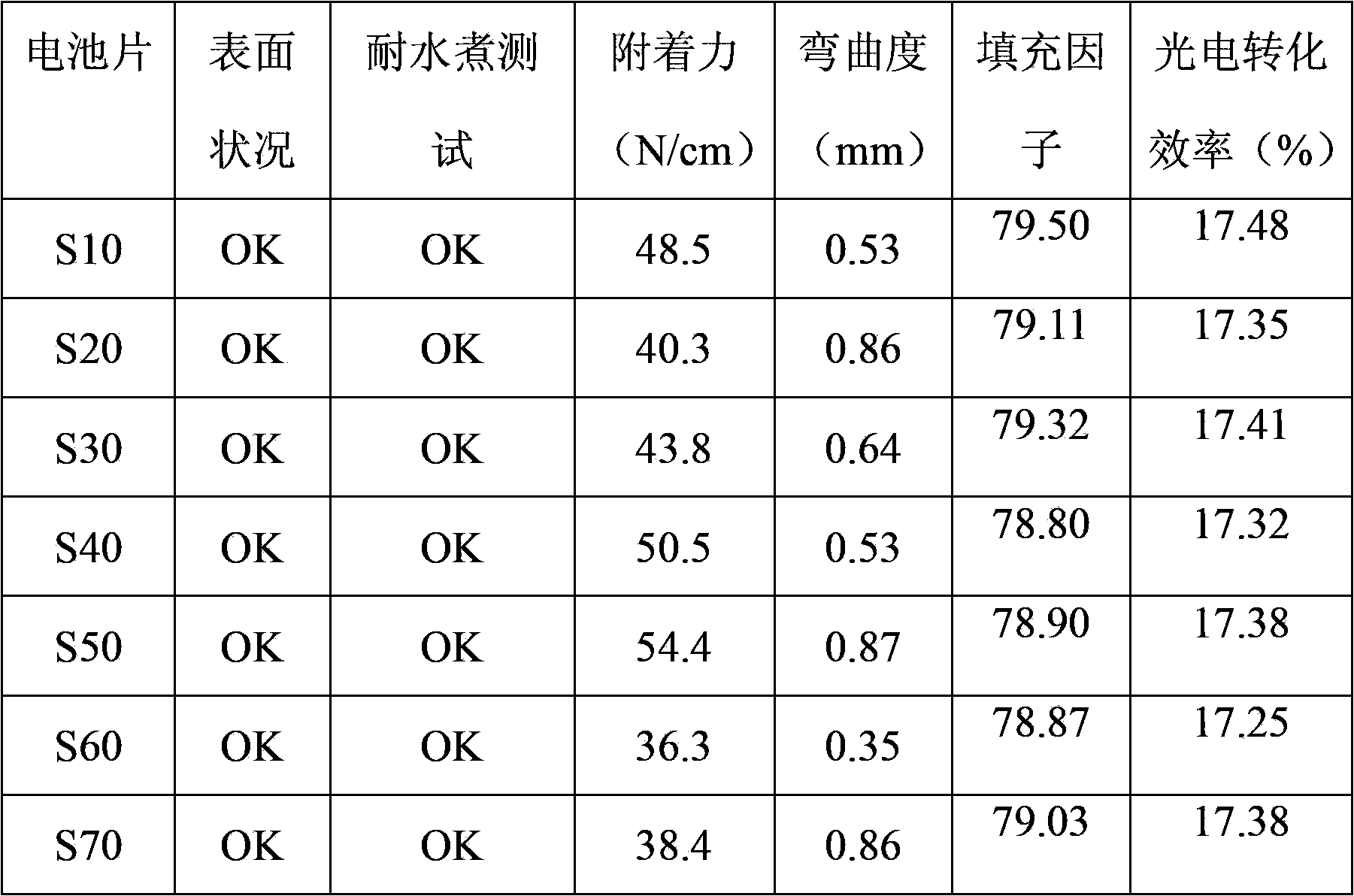

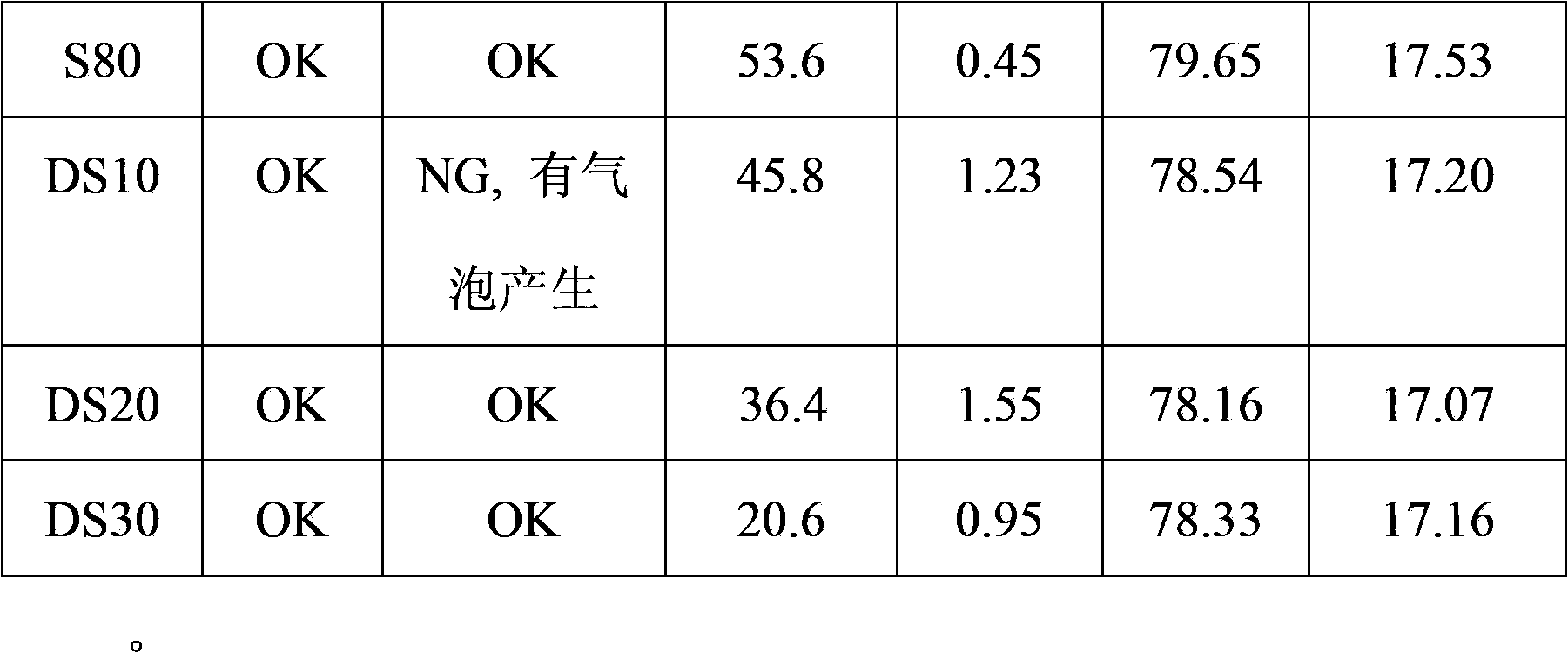

Conductive slurry used for solar cell and method of preparing the same

ActiveCN103514973ANo resistanceReduce the amount requiredNon-conductive material with dispersed conductive materialCable/conductor manufactureBack surface fieldSlurry

The invention provides conductive slurry used for solar cells and a method of preparing the same. The conductive slurry comprises metal powder, an inorganic binder and an organic carrier. The inorganic binder contains at least two kinds of inorganic glass powder. The prepared aluminium back surface field conductive slurry is silk-screened on a silicon chip to obtain a metal film layer that is smooth and compact, has a nice appearance, is free of bubbles and metal particles, and is high in cell filling factor and high in photoelectric conversion efficiency. Meanwhile, the metal film layer is tightly adhered to the silicon chip, the warping degree of cells is low, and cells can stand a water boiling test.

Owner:BYD CO LTD

Laminated metal chalcogenide/carbon nanotube flexible compound film material of highly ordered structure and preparation

ActiveCN106744820APrecise control of ingredientsPrecise control structureCarbon compoundsVacuum evaporation coatingComposite filmCarbon nanotube

The invention belongs to the field of composite materials and in particular relates to a laminated metal chalcogenide (LMC) / carbon nanotube (CTNs) flexible compound film material of a highly ordered structure and a preparation method thereof. The composite material comprises an ultrathin self-supporting (transparent) CNTs film substrate and an LMC film which uniformly wraps the surface thereof to form the flexible composite film material which has a nanoscale porous structure and a three-dimensional network structure of a high electric channel. The preparation method comprises the following steps: providing an alloy bracket for bearing a self-supporting CNTs film and cleaning the carried CNTs film under a heating condition with plasma; and preparing the LMC / CNTs composite functional film material from the pre-treated CNTs film at an air pressure of 0.2-2Pa and at a temperature of 30-800 DEG C by virtue of a magnetron sputtered deposition technology. According to the material provided by the invention, a crispy laminated metal chalcogenide functional two-dimensional (2D) material and one-dimensional (1D) CNTs are effectively connected to form a three-dimensional (3D) network structure of structural flexibility.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Glass-powder-free crystalline silicon solar battery aluminum paste and preparation method thereof

ActiveCN102324266ARealize normal temperature processReduce productionNon-conductive material with dispersed conductive materialCable/conductor manufactureAdjuvantCITRATE ESTER

The invention relates to a glass-powder-free crystalline silicon solar battery aluminum paste and a preparation method thereof. The aluminum paste consists of the following raw materials by mass portions: 70-80 portions of aluminum powder, 18-28 portions of organic bond, 0.5-1.5 portions of adhesive force additive and 0.5-1.5 portions of adjuvant, wherein the adhesive force additive is zinc decanoate, zinc naphthenate, zinc citrate or zirconium citrate. After the aluminum paste is screen-printed and dried, the aluminum paste can be sintered within a wider temperature range, a back surface field can be in good ohmic contact with a silicon wafer, the adhesive force is good, the conversion efficiency of cells is high and the warping degree of the cells is reduced.

Owner:JIANGSU HOYI TECH

Environmental friendly lead-free aluminum slurry and preparation method thereof

InactiveCN101840744AAchieve stabilityAchieving printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureHazardous substanceFerrosilicon

The invention relates to an environmental friendly lead-free aluminum slurry and a preparation method thereof. The environmental friendly lead-free aluminum slurry comprises the following components: antioxidant ultrafine aluminum alloy micropowder, barium ferrosilicon borate composite frit and a composite organic carrier. The invention has the advantages that the prepared lead-free aluminum slurry is an environmental friendly electronic slurry without harmful substances including lead, cadmium, mercury and hexavalent chromium, is used as a function material, completely replaces lead containing aluminum slurry, is stable and reliable, and has excellent performance, favorable ohmic contact quality, wide sintering temperature range, low sheet resistance, water boiling resistance, long ageing life and favorable replaceability to noble metals.

Owner:WUHAN YILAI RUIER HIGH TECH

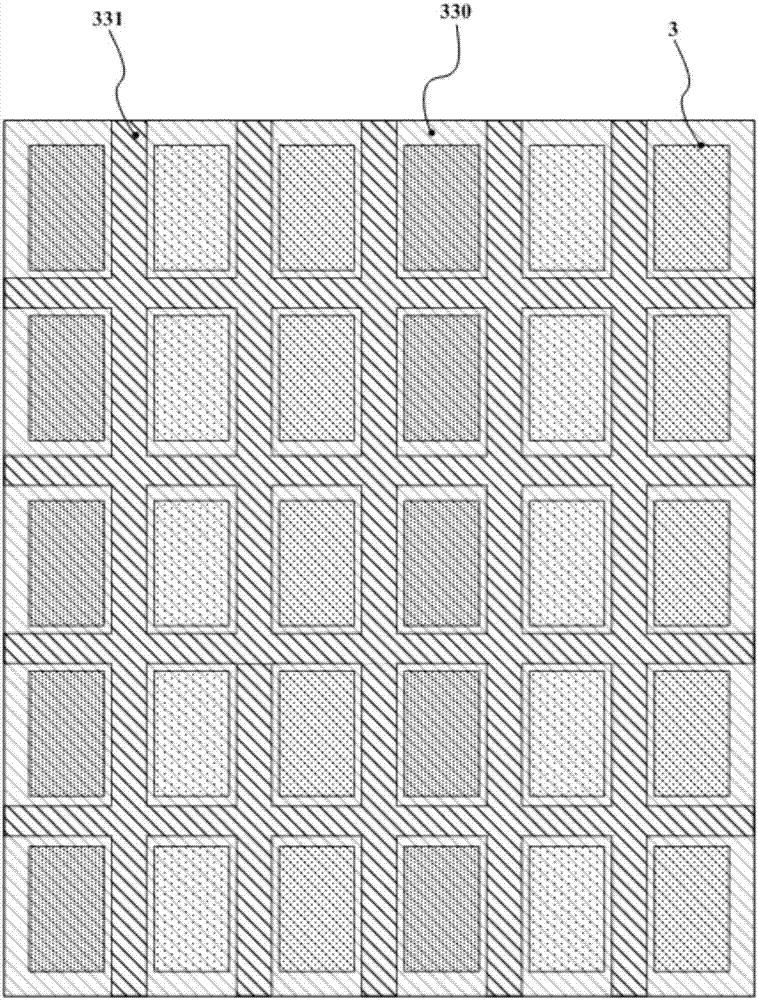

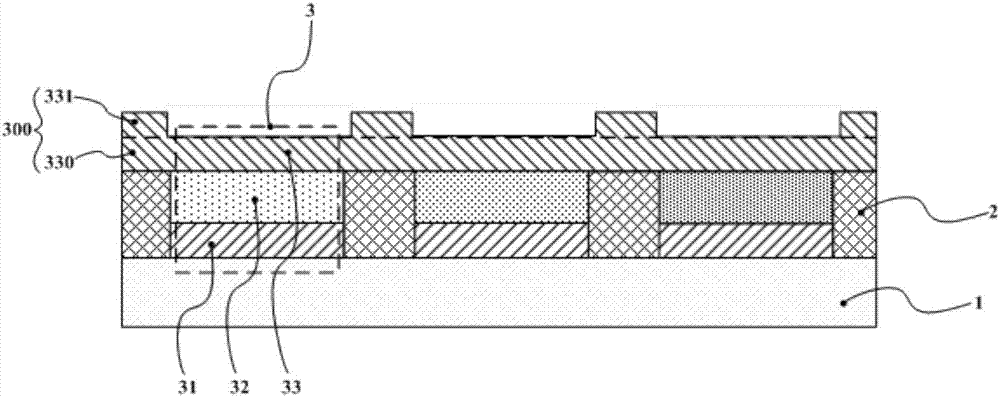

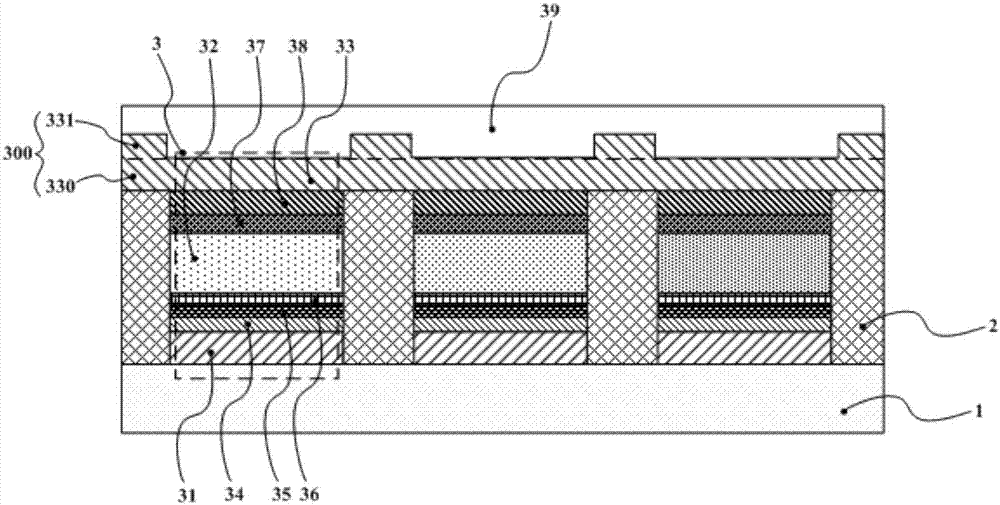

Display panel, display apparatus and manufacturing method of display panel

InactiveCN107359274AReduced in-plane pressure dropImprove transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingIn planeTransmittance

The invention discloses a display panel, a display apparatus and a manufacturing method of the display panel, aiming at reducing the in-plane voltage drop of an entire surface shared cathode layer, increasing the transmittance of the entire surface shared cathode layer, and further increasing display effects. The display panel includes a liner substrate, and a pixel defining layer and a plurality of light-emitting devices which are disposed on one side of the substrate. The pixel defining layer defines a plurality of opening units. The plurality of light-emitting devices are disposed corresponding to the plurality of opening units. Each light-emitting device includes an anode, a light-emitting layer and a cathode which are successively arranged distant from the substrate. The cathodes of the light-emitting devices are connected into the entire surface shared cathode layer which includes a body layer and a protruding mechanism which is disposed on one side of the body layer distant from the substrate and is opposite to the position of the pixel defining layer.

Owner:SHANGHAI TIANMA AM OLED

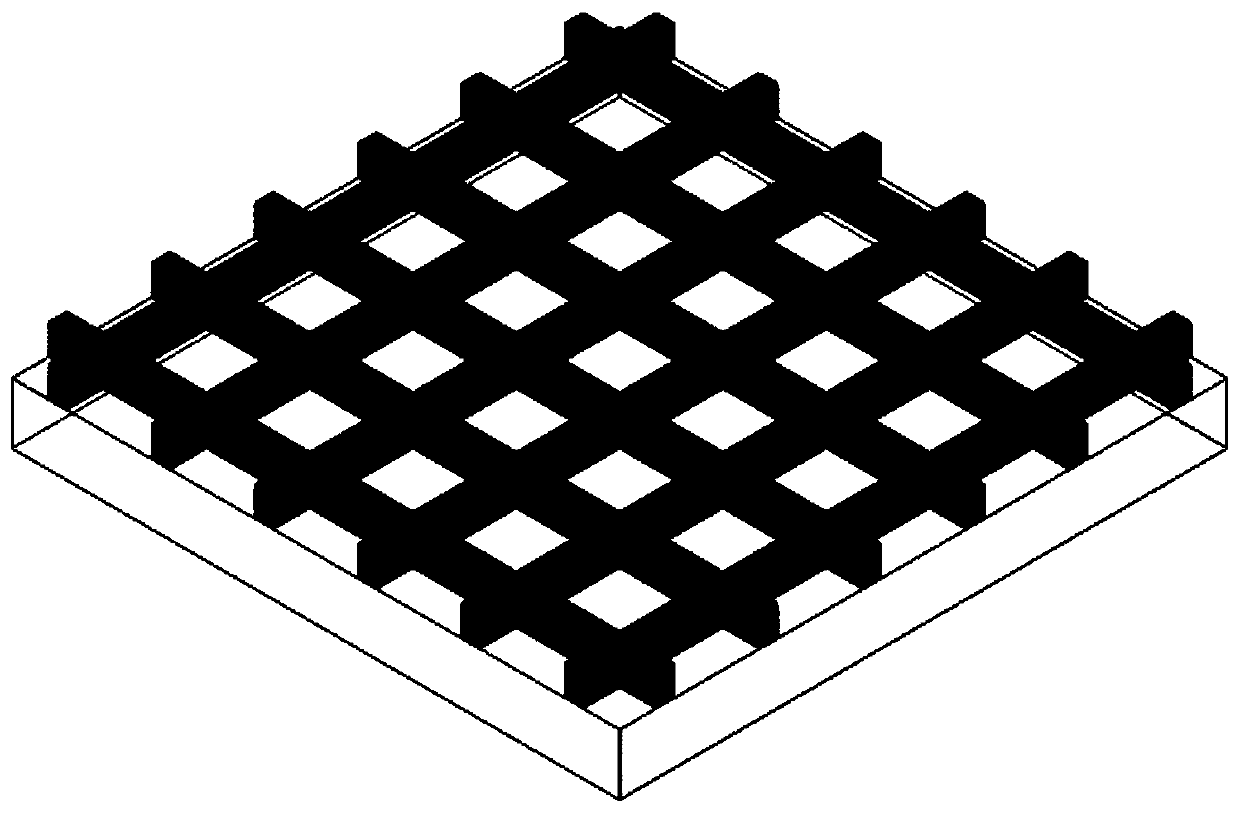

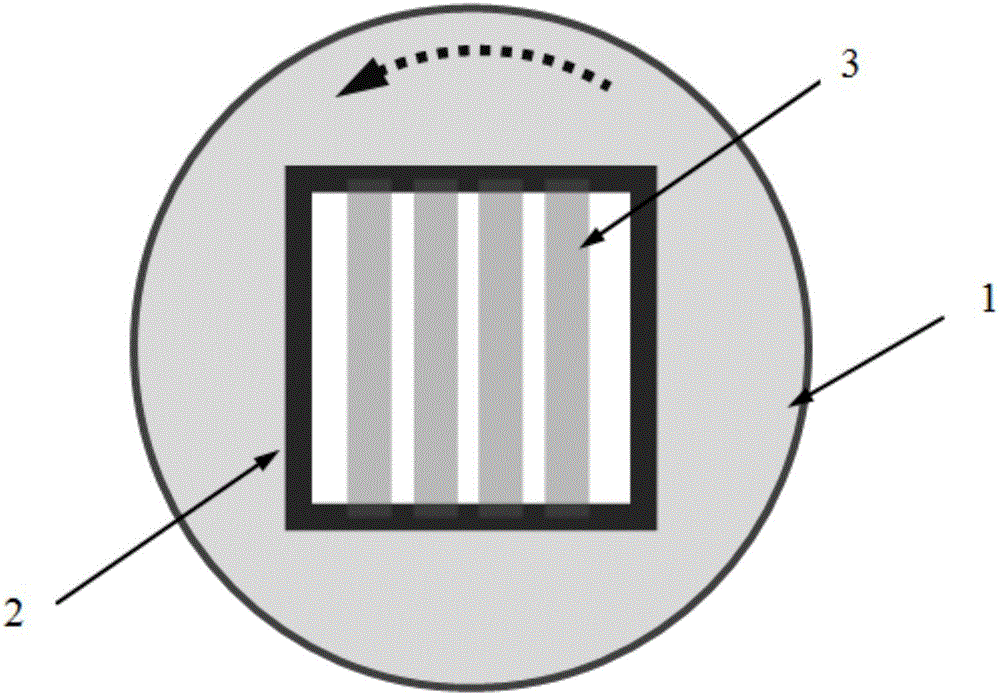

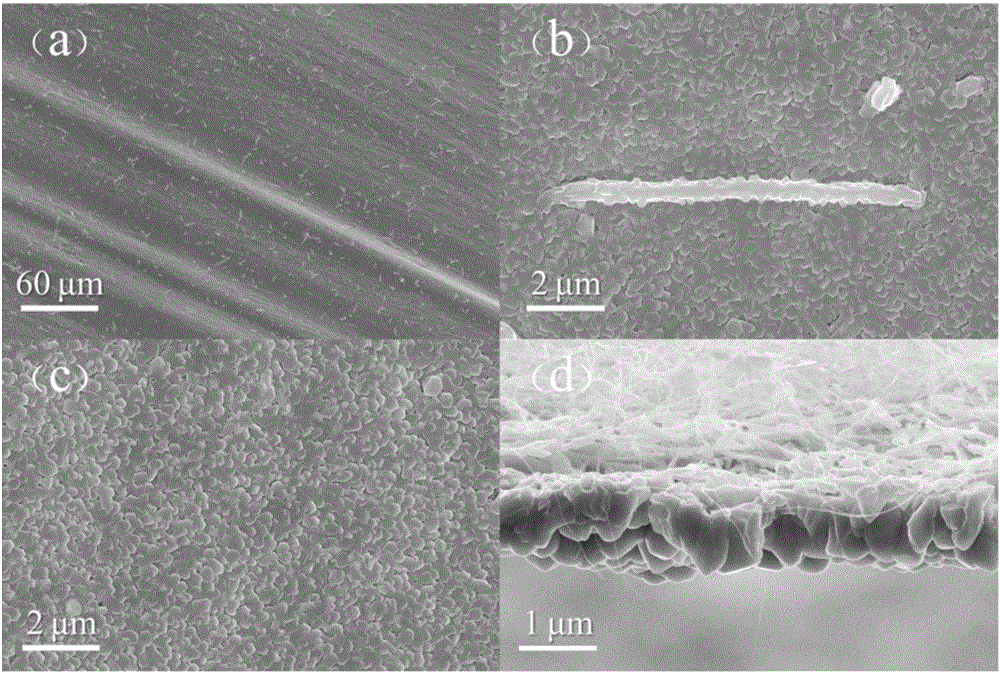

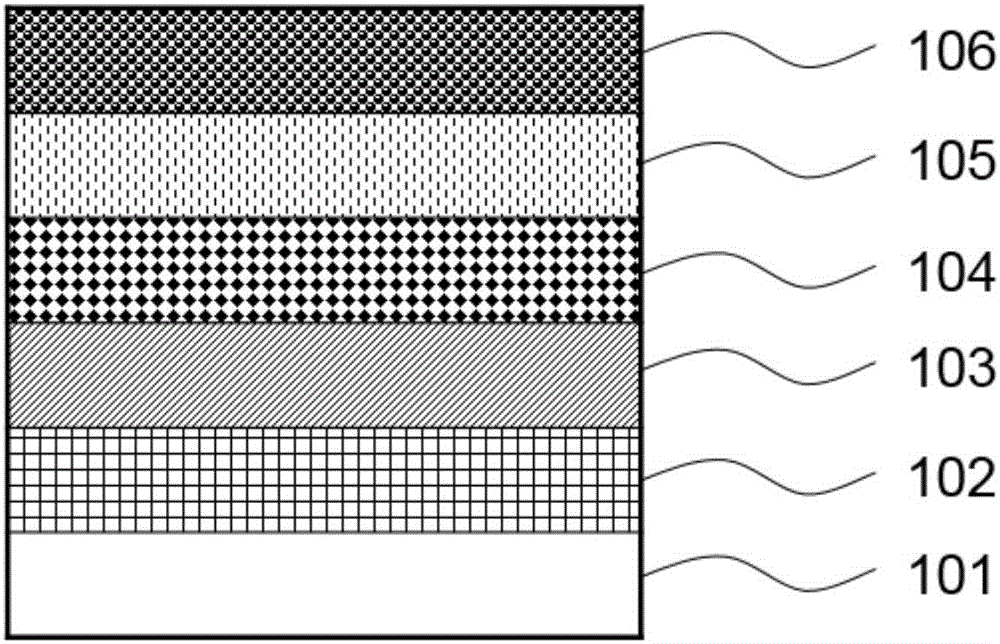

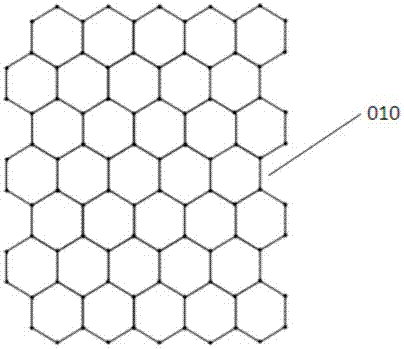

Flexible perovskite solar cell with metal grid graphene composite electrode and preparation method thereof

InactiveCN106410032AReduce square resistanceHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingElectrical batteryEngineering

The invention belongs to the field of semiconductor photo-electronic devices and particularly relates to a flexible perovskite solar cell with a metal grid graphene composite electrode and a preparation method thereof. The flexible perovskite solar cell with the metal grid graphene composite electrode sequentially comprises a flexible substrate, a metal grid graphene composite photo-electrode, a first carrier transporting layer, a perovskite light absorption layer, a second carrier transporting layer and a back electrode. The metal grid graphene composite photo-electrode is a composite electrode structure which is composed of an embedded metal grid and graphene; the grid structure is a regular triangle, a regular quadrangle or a regular hexagon. The solar cell structure has the advantages of being flexible, light, thin, low in cost, high in efficiency and etc.; various products can be developed by utilizing the flexibility of the solar cell, so that the flexible perovskite solar cell with the metal grid graphene composite electrode is more diversified in application; meanwhile, a road is opened up for adoption of a large-batch and large-area reel-to-reel technology, and a new idea is provided for final commercialization of perovskite.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

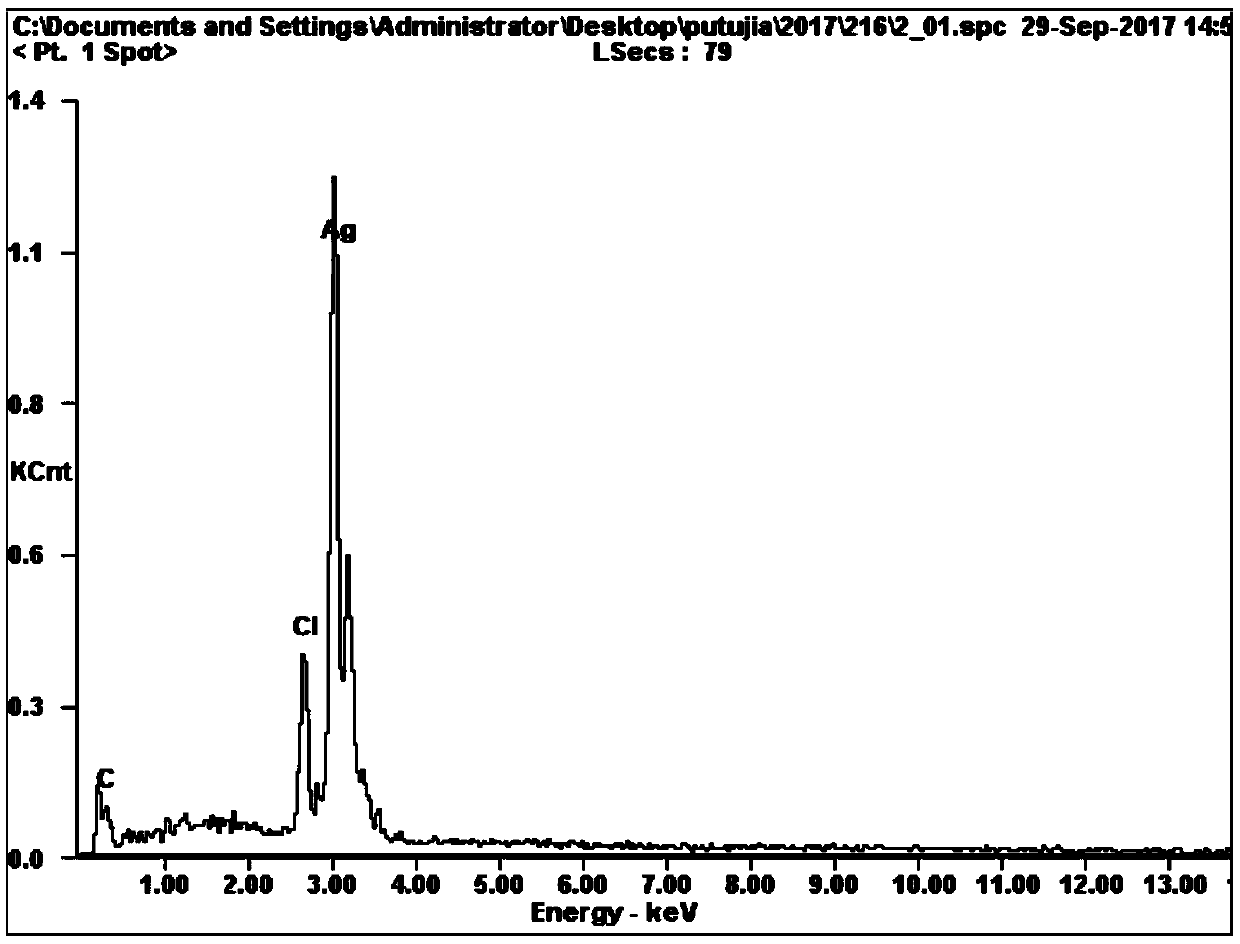

Low-temperature curing silver/silver chloride slurry for flexible bioelectrode and preparation method thereof

ActiveCN109645986AReduce square resistanceGood adhesionDiagnostic recording/measuringSensorsBiocompatibility TestingBlood glucose testing

The invention discloses a low-temperature curing silver / silver chloride slurry for a flexible bioelectrode and a preparation method thereof. The silver / silver chloride slurry comprises, by weight, 38-70wt% of silver / silver chloride powder and 30-62wt% of an organic carrier, wherein the silver / silver chloride powder is composed of 40-90wt% of silver powder and 10-60wt% of silver chloride powder. The prepared flexible bioelectrode is low in square resistance, good in adhesion, good in electrode potential stability, high in anti-interference capability and good in biocompatibility, specific shapes can be formed for different use environments, the cost is low, and mass production is easy. The obtained flexible bioelectrode can highly fit the human tissue, especially the skin, can meet the wearing requirements of different parts of the human body, can measure more accurate and reliable bioelectrical signal data, and can be applied to the fields of biosensor electrodes, ECG electrodes, electrochemical reference electrodes, blood glucose test reference electrodes, environment test electrodes and the like.

Owner:KUNMING INST OF PRECIOUS METALS

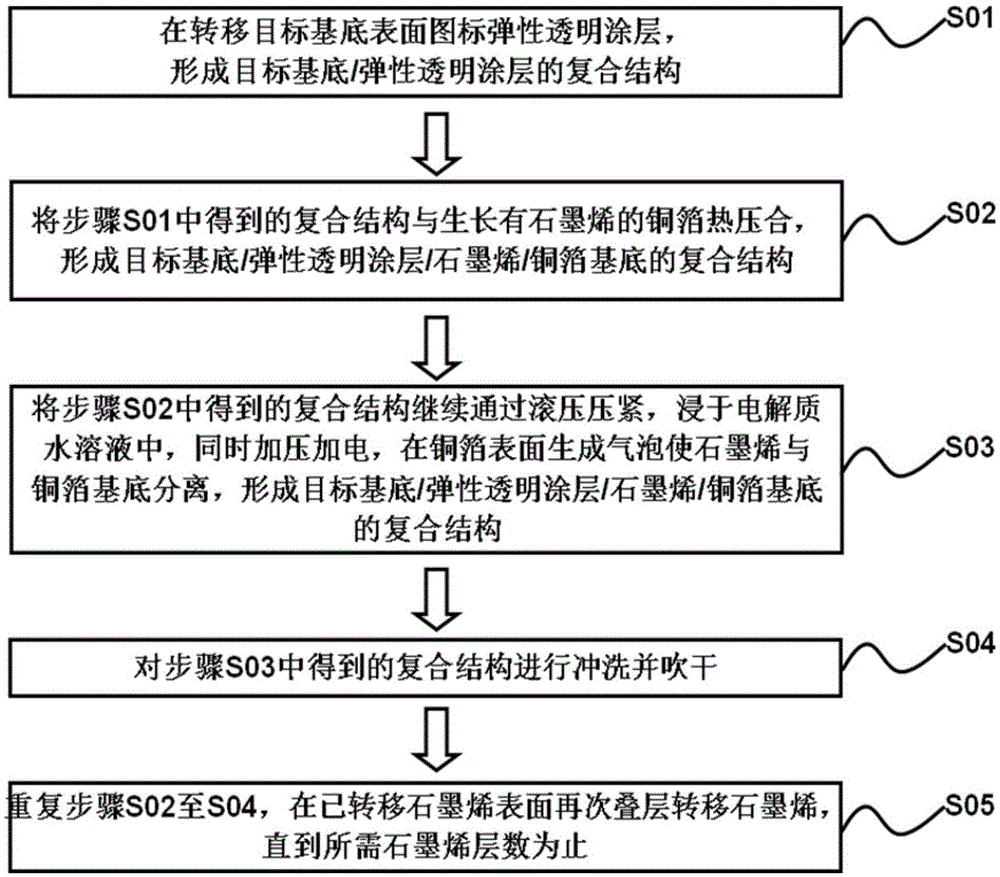

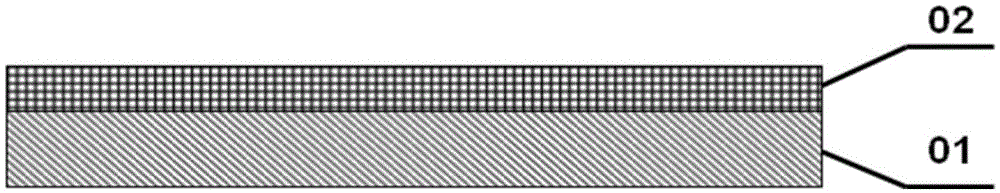

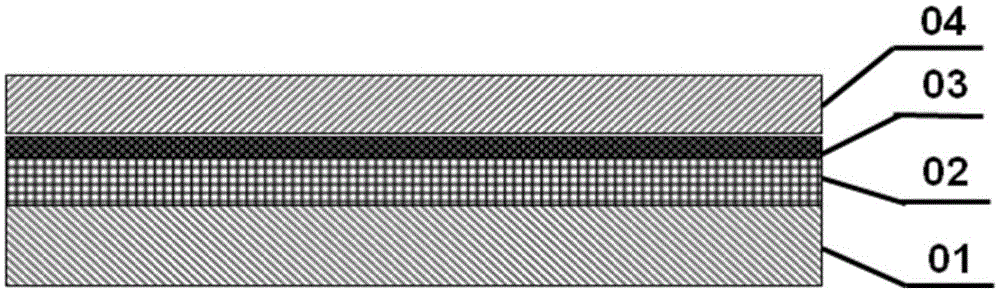

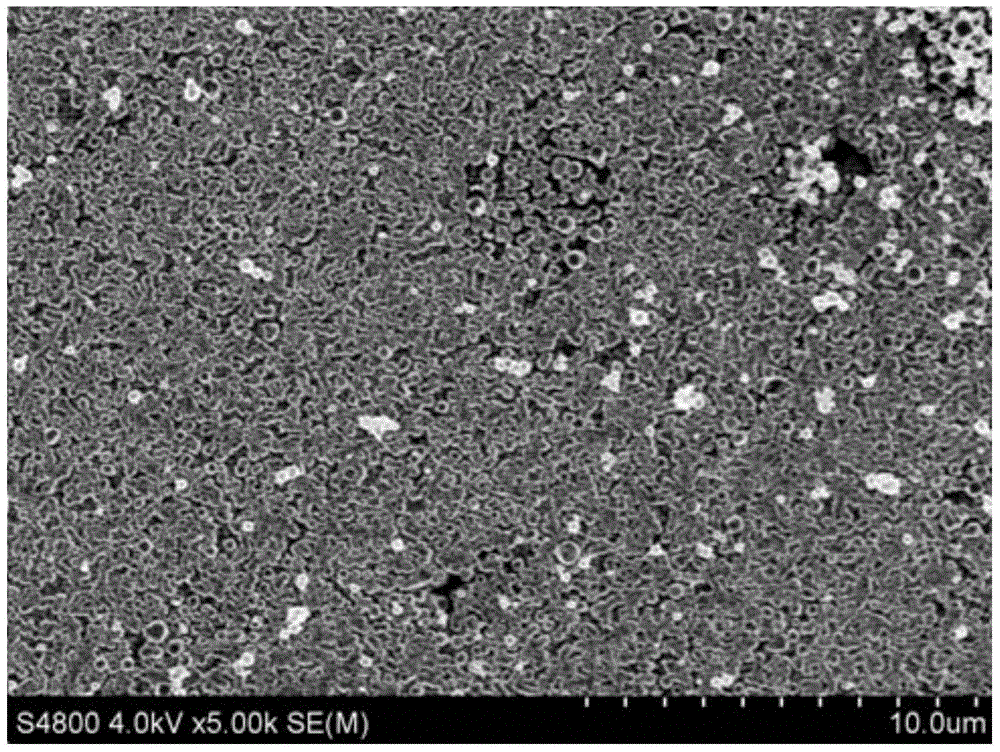

Multi-layer stacking and transferring method for graphene

The invention relates to a multi-layer stacking and transferring method for graphene. The method includes the operation steps that S01, the bottom face and the surface of a transferring target substrate are coated with an elastic transparent coating; S02, thermo-compression bonding is conducted on copper foil where graphene grows and the coated elastic transparent coating in a rolling mode; S03, the obtained compressed structure continues to be soaked in an electrolyte solution through rolling pressing, and electricity is applied for bubbling at the same time so that graphene and copper coil can be separated, attached and transferred to the target substrate; S04, washing and blow-drying are conducted on the surface of transferred graphene; S05, the step S02, the step S03 and the step S04 are repeatedly executed, graphene is stacked and transferred on the surface of transferred graphene till graphene is stacked to the required level number. Rapid and complete transferring of graphene is achieved by coating the graphene transferring target substrate with the elastic coating for modification and through the electrochemistry bubbling stripping method, multiple layers of stacked graphene are transferred according to practical requirements, and the electrical property uniformity and stability of graphene are improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

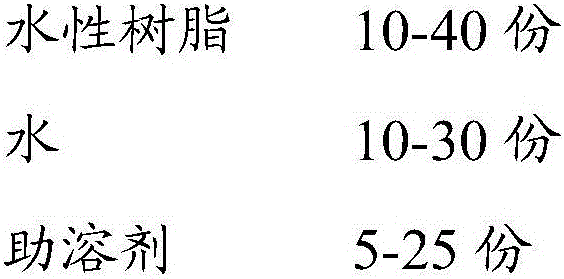

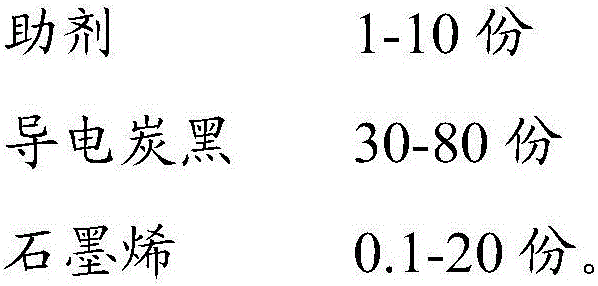

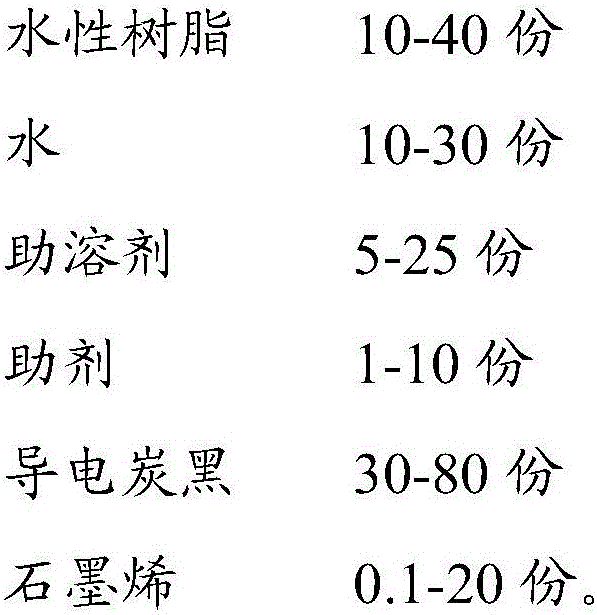

Graphene modified water-based conductive ink and preparation method thereof

The invention belongs to the technical field of ink, and in particular relates to graphene modified water-based conductive ink and a preparation method thereof. The graphene modified water-based conductive ink comprises the following materials in parts by weight: 10-40 parts of water-base resin, 0-30 parts of water, 5-25 parts of cosolvent, 10 parts of additive, 30-80 parts of conductive carbon black, and 0.1-20 parts of graphene. According to the graphene modified water-based conductive ink, the outstanding electricity conducting and heat conducting performances of the graphene are fully utilized; the prepared graphene modified water-based conductive ink is outstanding in mechanical performance, high in flexibility, resistant to bending, high in attaching force relative to a base material, and resistant to peeling; a printing product prepared through the conductive ink is hard to oxidize after being cured, stable in performance, and resistant to acid, alkaline and chemical solvent corrosion; the graphene is high in electricity conducting performance, and on that basis, the square resistance of the conductive ink is less than 10 ohms; the conductive ink can be used for replacing an oily product, so that the amount of used and discharged organic solvents can be greatly decreased, and the damage to the body of a construction worker can be greatly reduced, and as a result, the purpose of reducing VOC emission is achieved; the conductive ink is environmentally friendly, and high in market value.

Owner:QINGDAO REALEADER ADVANCED MATERIALS TECH

Method for reducing sheet resistance of graphene thin film

InactiveCN102180463AIncrease electron concentrationReduce square resistanceCarbon-silicon compound conductorsCable/conductor manufactureAlkaneAlcohol

The invention relates to a method for reducing sheet resistance of a graphene thin film, comprising the following step of soaking the graphene thin film and a substrate in a solution with an electron or hole donation capability for a certain time, wherein the solution in the step is one or mixed solution with an electron donation capability of low-valence solutions of heavy metal inorganic acid, organic alcohol and organic amine; or the solution in the step is one or mixed solution with a hole donation capability of a nonmetal inorganic acid solution and an organic alkane solution. The invention has the beneficial effects that: after the graphene thin film arranged on the substrate is soaked in a solution with the electron donation capability, the solution captures holes in the graphene thin film, thus the consistency of electrons in the graphene thin film is increased, and the sheet resistance of the graphene thin film is reduced.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Titanium quantum dot doped graphene-based electric heating plate and electric heating device

ActiveCN111432509AReduce square resistanceHigh temperature resistantOhmic-resistance heatingLuminescent compositionsDoped grapheneGraphite

The invention provides a titanium quantum dot doped graphene-based electric heating plate. The titanium quantum dot doped graphene-based electric heating plate which comprises an insulating layer anda graphene conductive film arranged on the insulating layer. The , the invention discloses a preparation method of a the graphene conductive film. The preparation method comprises the following steps: preparing graphene dispersion liquid, preparing titanium quantum dot dispersion liquid, preparing graphene-carbon black paste, preparing titanium quantum dot paste, preparing titanium quantum dot doped graphene-based mixed liquid, preparing titanium quantum dot doped graphene-based conductive ink and preparing the titanium quantum dot doped graphene-based electric heating plate. The invention further provides an electric heating device. The titanium quantum dot doped graphene-based electric heating plate has the advantages that the manufacturing process is rapid, the thickness is convenientto control, the preparation process is rapid, and the prepared titanium quantum dot doped graphene-based conductive film has the functions of flexibility and tear resistance or fracture resistance.

Owner:FOSHAN SHUNDE SANBEI ELECTRONICS CO LTD

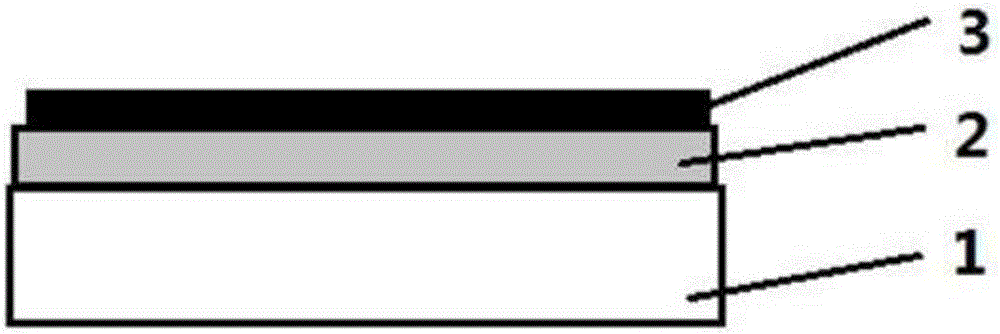

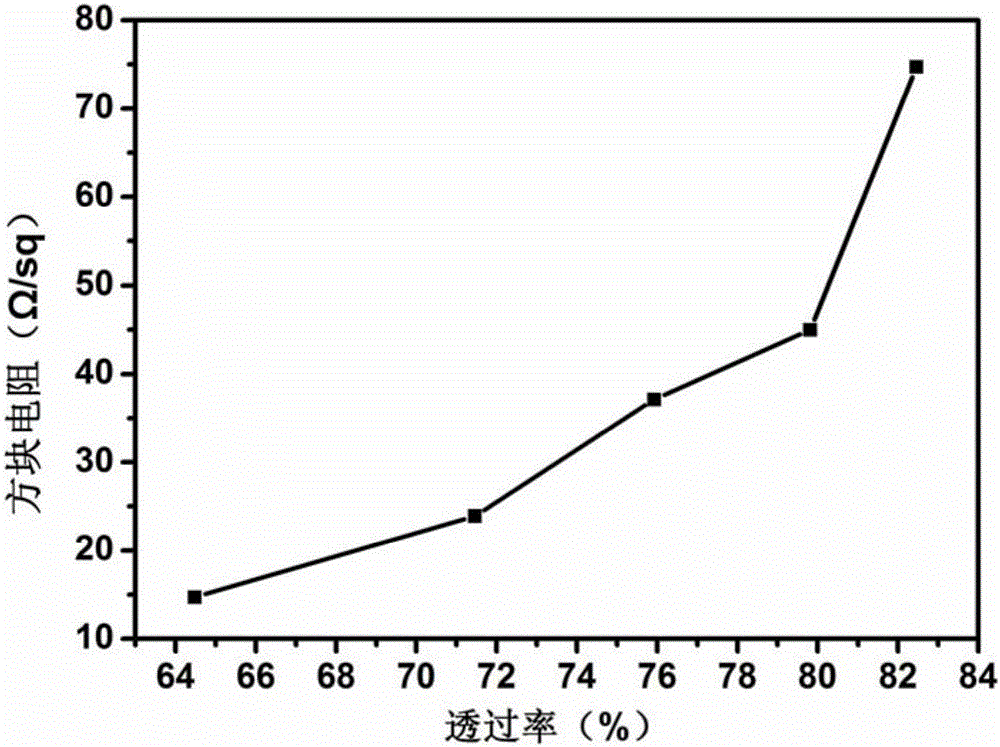

Ultra-soft low-resistance transparent conductive film and preparation method thereof

ActiveCN108630339AReduce viscosityIncrease productivityConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersTransmittanceTransparent conducting film

The invention relates to conductive material, especially to an ultra-soft low-resistance transparent conductive film and a preparation method thereof, and aims at solving the problem that the surfaceresistance and light transmittance integrated performance of a present transparent conductive film is relatively low. The transparent conductive film is provided, and comprises a transparent substrate, a conductive network layer and a hardened glue protective layer; the transparent substrate is coated with the conductive network layer, and the conductive network layer is coated with the hardened glue protective layer; and the conductive network layer includes nano silver wires and silver nanoparticles. The nano silver wires and silver nanoparticles for the conductive network layer, and the transparent conductive film is lower in sheet resistance, higher in light transmittance and higher in integrated performance.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

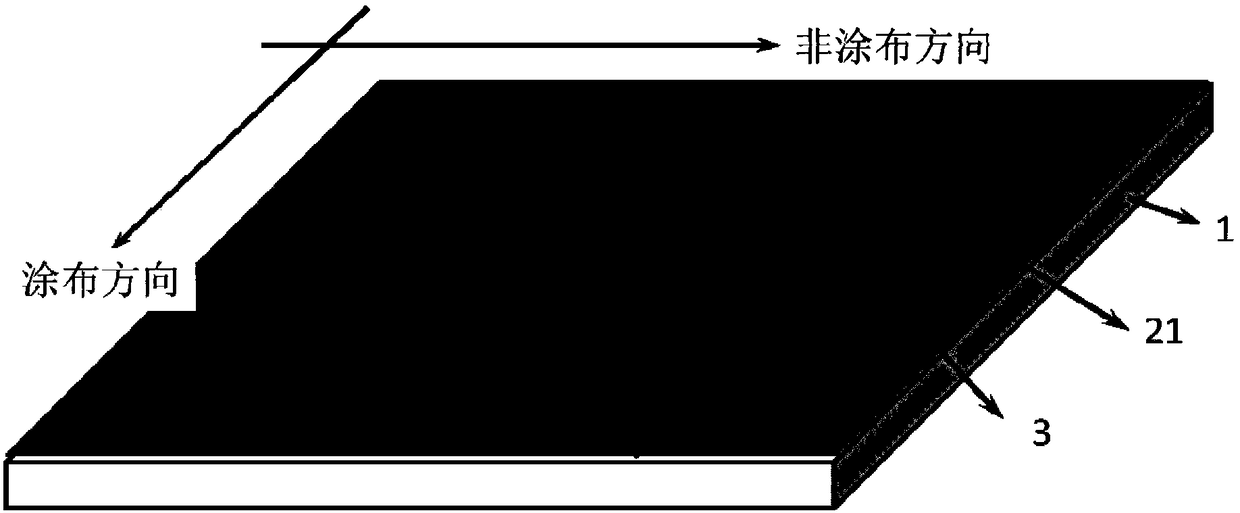

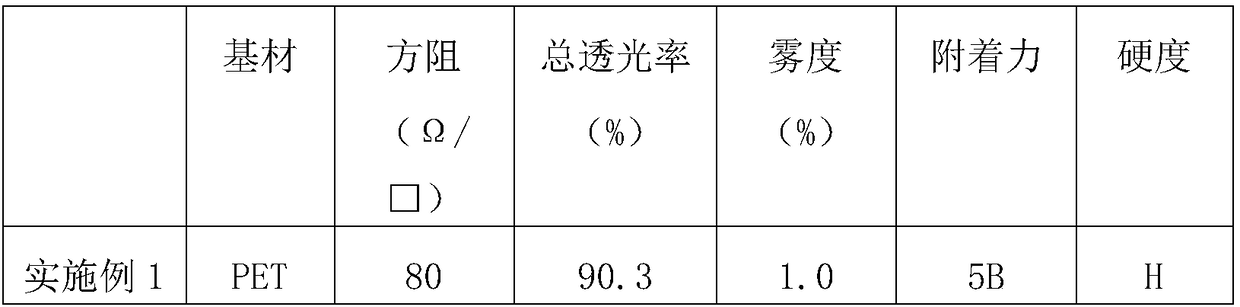

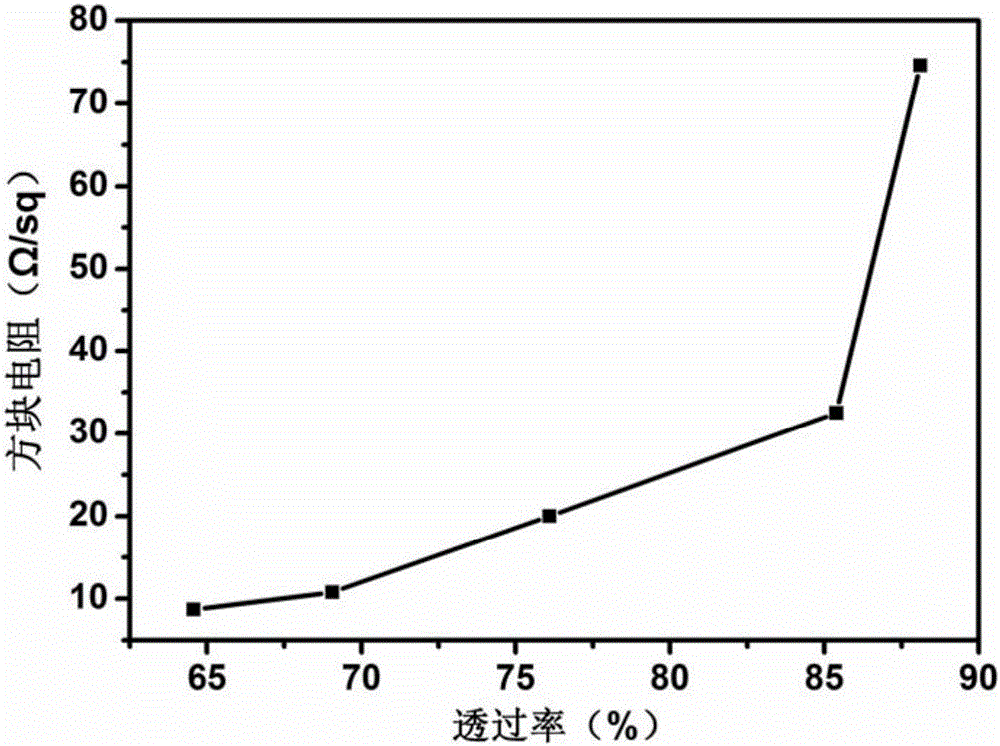

Flexible composite transparent conductive film and preparation method thereof

ActiveCN106229037AImprove conductivityLittle effect on light transmissionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersConductive materialsSilver nanowires

The invention belongs to the field of conductive materials, and discloses a flexible composite transparent conductive film. A zinc oxide film is arranged on a substrate, and a silver nano wire is arranged on the zinc oxide film. The invention also discloses a method for preparing the transparent conductive film. The method includes steps of performing preprocessing on the substrate, performing spin coating of the zinc oxide film on the substrate, dispensing silver nano wire disperse solution on the zinc oxide film, and performing drying treatment. According to the transparent conductive film, the requirements of low sheet resistance and high light transmittance are met, the light transmittance is 70-95%, and the sheet resistance reaches 15 ohms / square. By employing the preparation method, the source of raw materials is abundant, the operation is simple, the repeatability is good, the dependence on equipment is prevented, vacuum equipment is not needed, high-temperature conditions are not needed, the cost is low, and the time consumption is low.

Owner:SHENZHEN GUOHUA OPTOELECTRONICS +2

Silk-screen transparent conductive slurry, preparation method of silk-screen transparent conductive slurry and application of silk-screen transparent conductive slurry

InactiveCN108269645ASolving Printability IssuesGood printabilityMaterial nanotechnologyNon-conductive material with dispersed conductive materialOrganic solventAdhesive

The present invention discloses a silk-screen transparent conductive slurry. The silk-screen transparent conductive slurry is prepared by the following raw materials comprising, percentage by weight:0.05-0.5% of silver nanowire, 0-0.25% of PEDOT / PSS, 0.01-0.05% of surfactant, 0.01-0.05% of flatting agent, 0.01-0.5% of dispersing agent, 0.01-0.5% of coupling reagent, 0.01-0.5% of antifoaming agent, 0.01-1% of adhesive, 0.01-1% of thickening agent, 0-0.5% of emulgator, 0-30% of organic solvent, and balance water. The present invention further discloses a preparation method of silk-screen transparent conductive slurry and an application of silk-screen transparent conductive slurry. The silk-screen transparent conductive slurry can improve the condition of bluish hue of the conducting layer,can greatly improve the appearance effect, has good printability, and is stable in square resistance, high in light transmittance and low in haze.

Owner:珠海纳金科技有限公司

Preparation method of aluminum conductive paste of high-performance environment protection solar cell

InactiveCN101752459AImprove photoelectric conversion rateReduce stressFinal product manufactureNon-conductive material with dispersed conductive materialSilicon chipLinear expansion coefficient

The invention discloses a preparation method of aluminum conductive paste of a high-performance environment protection solar cell. The aluminum conductive paste produced by the method is free of lead and solves the problem of environment pollution. The linear expansion coefficient of lead-free glass powder obtained in the preparation process is close to that of a silicon chip, and the success rate after burning is improved. The preparation method of the paste comprises the following steps: (1) preparing glass powder; (2) preparing inorganic adhesive glass metal powder; (3) manufacturing organic carriers; (4) adopting carbon powder of 2-5 mu m for later use; and (5) preparing the aluminum conductive paste: taking the following components by mass percent: 75-85% of aluminum powder coated by aluminum nitride, 9-20% of organic carrier, 3-4% of inorganic adhesive glass metal powder and 1-3% of C powder, wherein the total amount is 100%, and after mixing, grinding with a three-roller mill to particle size of 15-30 mu m to obtain the product with the viscosity of 25000-35000 mpa.s.

Owner:广东鑫皇冠新材料有限公司

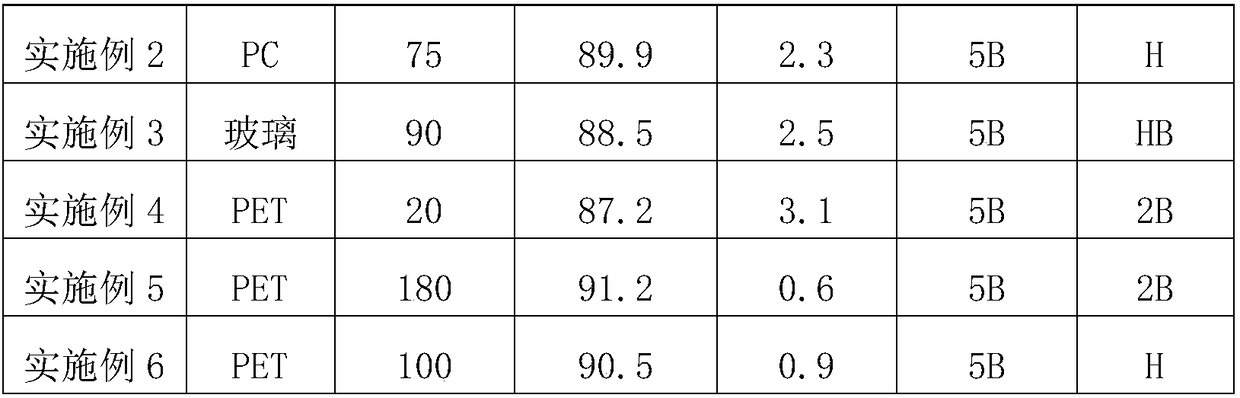

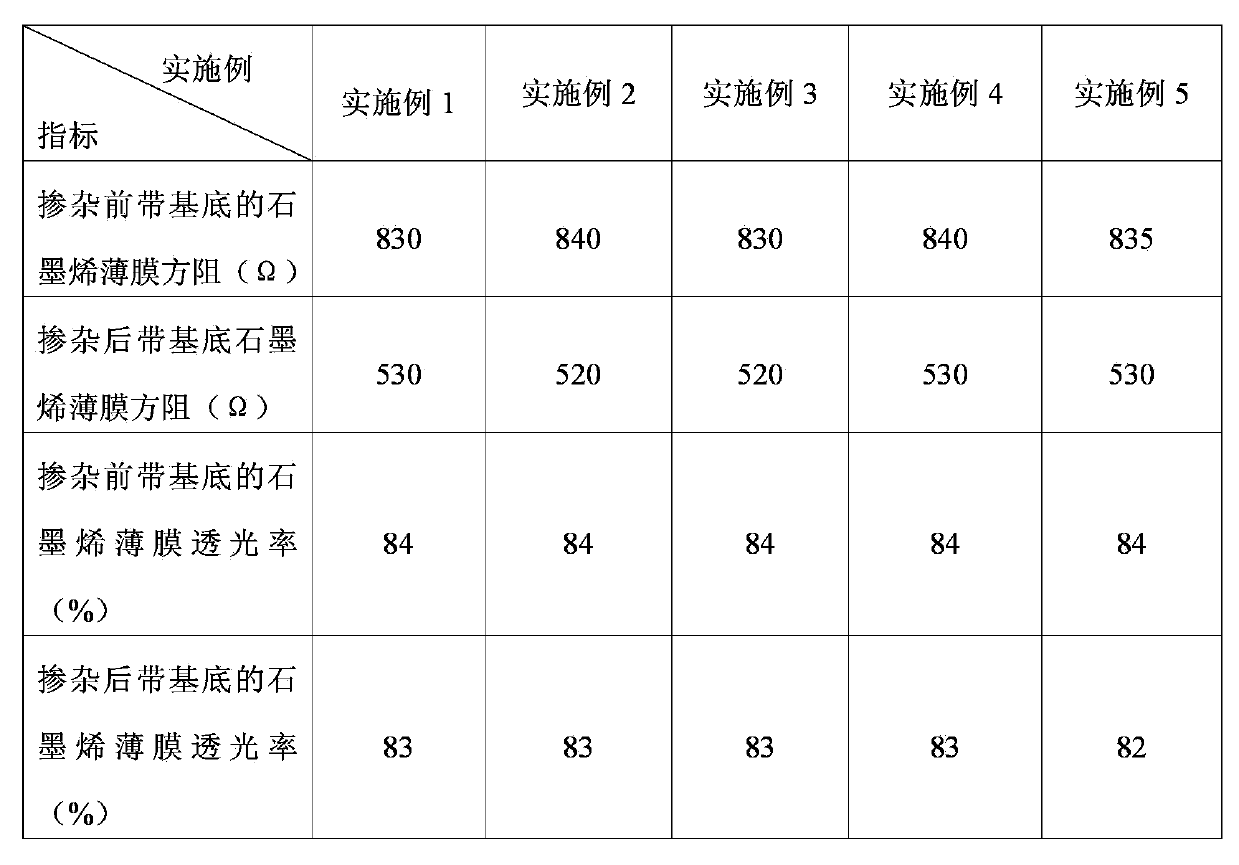

Graphene doping material, and preparation method and application of graphene doping material

ActiveCN103400632AReduce square resistanceThickness is easy to controlCarbon-silicon compound conductorsCable/conductor manufactureSputteringDopant

The invention relates to a graphene doping agent, a graphene doping process and the application of a doped graphene material. A doping process can be completed by using processes such as a dry process (including thermal evaporation and sputtering) or a wet process (including spinning, electrochemical deposition and solution soaking). By virtue of the graphene doping agent, the sheet resistance of a graphene film with a substrate is reduced from about 830 ohms to about 530 ohms on the premise that the transmittance of graphene in a visible light range is not influenced, the conductivity is improved, and the stability is high. By the adoption of the wet process or the dry process for doping, the advantages of controllability in plating thickness, controllability in doping amount, high uniformity and the like are achieved; and by the adoption of an annealing process, the doping agent is more compactly combined with the graphene, the doped graphene material is unlikely to be influenced by the environment when being subsequently used.

Owner:2D CARBON CHANGZHOU TECH INC

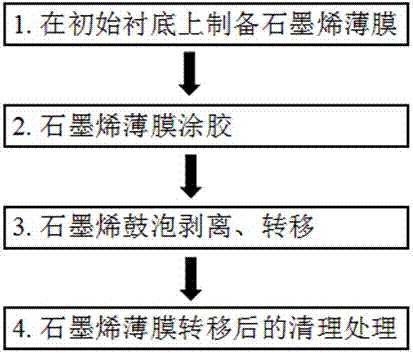

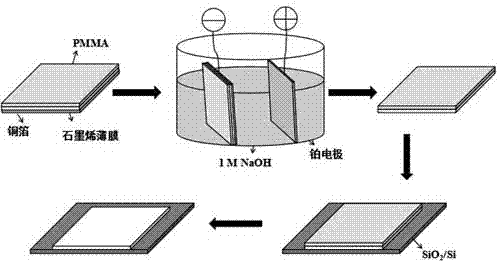

Method for transferring graphene

The invention discloses a method for transferring graphene. The method comprises four steps: preparing a graphene film on an initial substrate; coating the surface of graphene with a conductive adhesive; peeling the graphene film from the initial substrate through an electrochemical method, and attaching the peeled graphene film to a target substrate; and finally cleaning the target substrate with a graphene film attached to complete graphene transfer. Through an electrochemical bubbling transferring method, a graphene film is peeled from the initial substrate. A metal corrosion method for transferring is avoided, pollution of a corrosion product to a graphene film is prevented, the production cost and time are effectively reduced, and damage and wrinkle of the graphene film are reduced. The method is simple to operate and is convenient to be used in the graphene field.

Owner:国成仪器(常州)有限公司

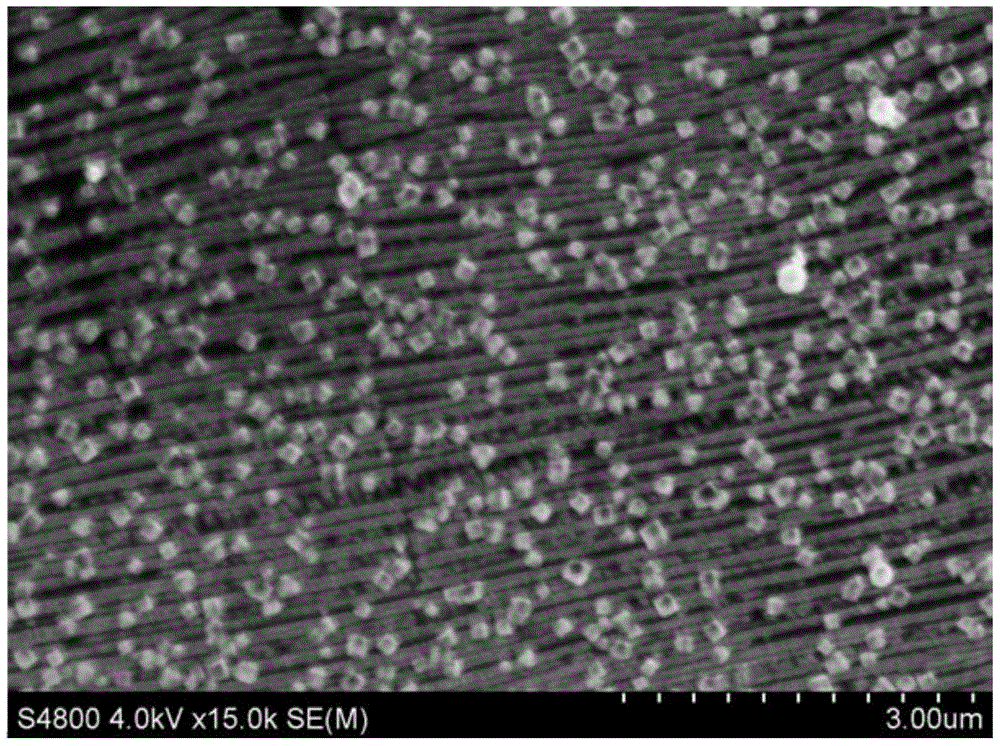

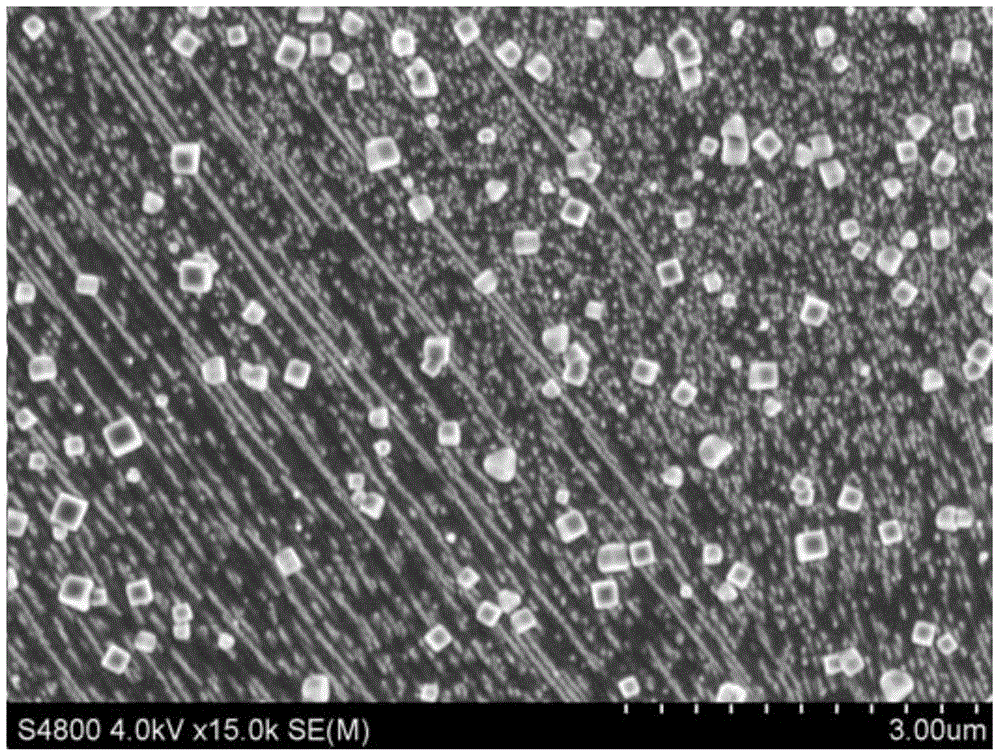

Graphene/metal composite thin film and preparation method thereof

ActiveCN105239061AReduce square resistanceStrong reductionLiquid/solution decomposition chemical coatingCvd grapheneSheet resistance

The invention provides a preparation method for a graphene / metal composite thin film. The method comprises the following steps that (A) a growth substrate with a graphene thin film is immersed in a reduction solution to be subjected to an in-situ reduction reaction, and a metal particle / graphene thin film / growth substrate composite thin film is obtained; and (B) a metal particle / graphene thin film in the metal particle / graphene thin film / growth substrate composite thin film is transferred to a target substrate, and a target substrate / metal particle / graphene thin film composite thin film is obtained. According to the preparation method, metal particles are reduced to the graphene thin film in situ, a compositing process is omitted, and the metal particles well disperse on the graphene thin film, so that the sheet resistance of the graphene / metal composite thin film is lowered. The metal particles in the prepared graphene / metal composite thin film are clamped between the graphene thin film and the target substrate so as to be well protected, and therefore the time stability of the sheet resistance of the composite thin film is greatly enhanced.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Processing method for silver nanowire conductive thin film

InactiveCN105810364AImprove conductivityReduce square resistanceMetal/alloy conductorsCable/conductor manufactureFlexible electronicsSilver nanowires

The invention discloses a processing method for a silver nanowire conductive thin film, and belongs to the technical field of a flexible electronic material and a thin film. According to the processing method, the photoelectric property of the silver nanowire conductive thin film is improved mainly by acid treatment on the silver nanowire conductive thin film. The processing method has the advantages of (1) the process is simple and is easy to operate; (2) silver oxide on the surface of the silver nanowire conductive thin film is efficiently removed; (3) the surface flatness of the silver nanowire conductive thin film is improved; and (4) the conductivity of the silver nanowire conductive thin film is improved, and the square resistance of the thin film is reduced.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com