Patents

Literature

685 results about "Copper coil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

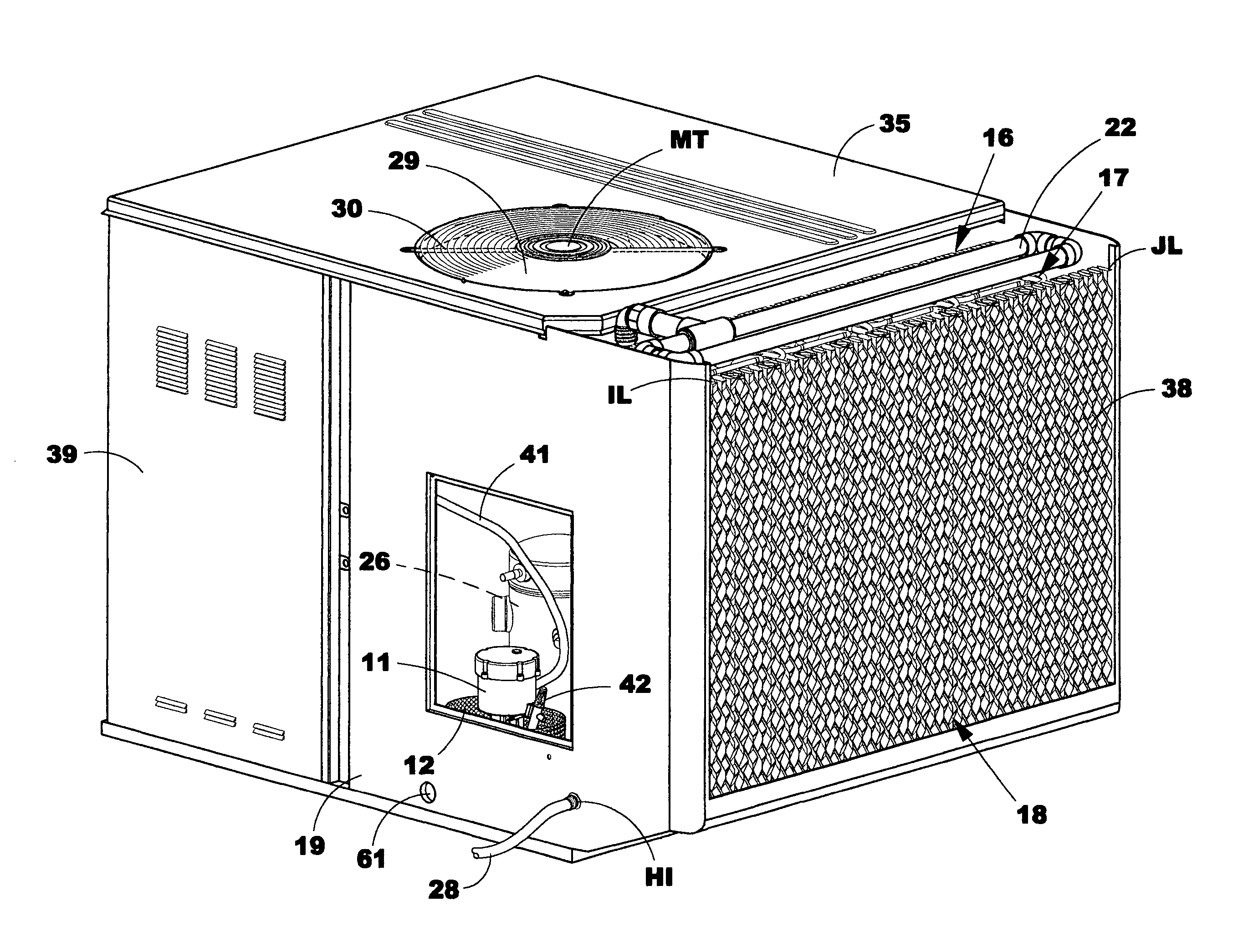

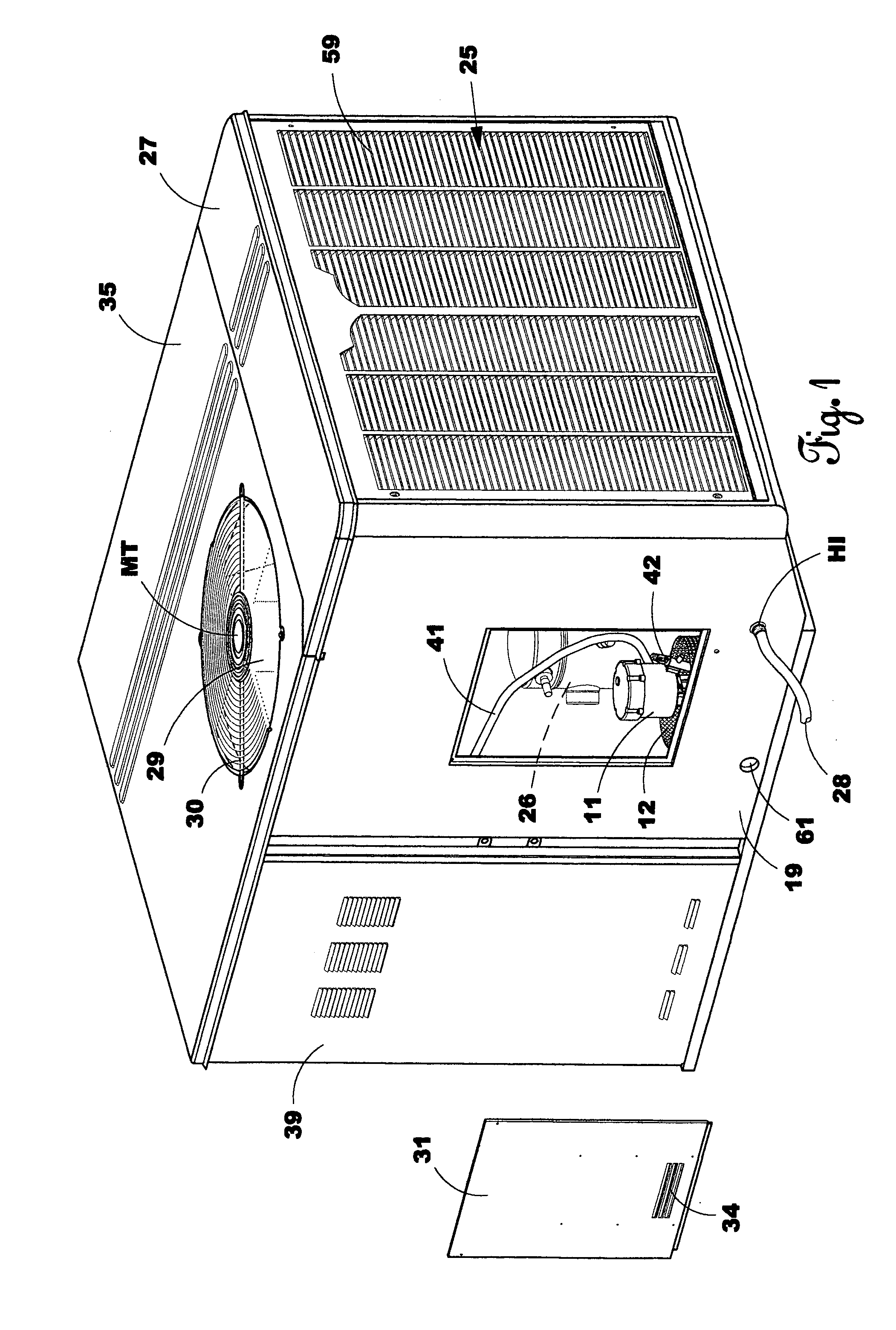

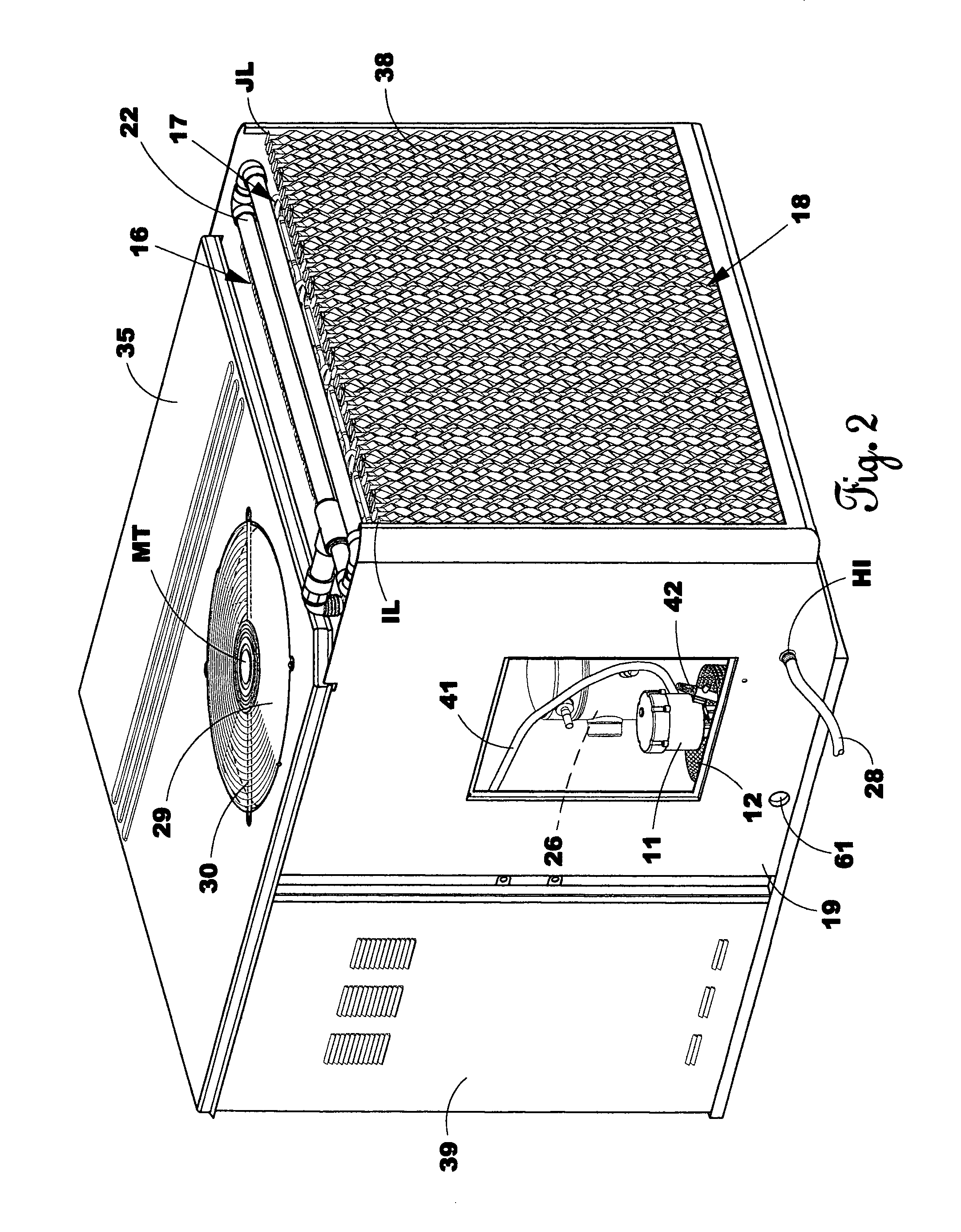

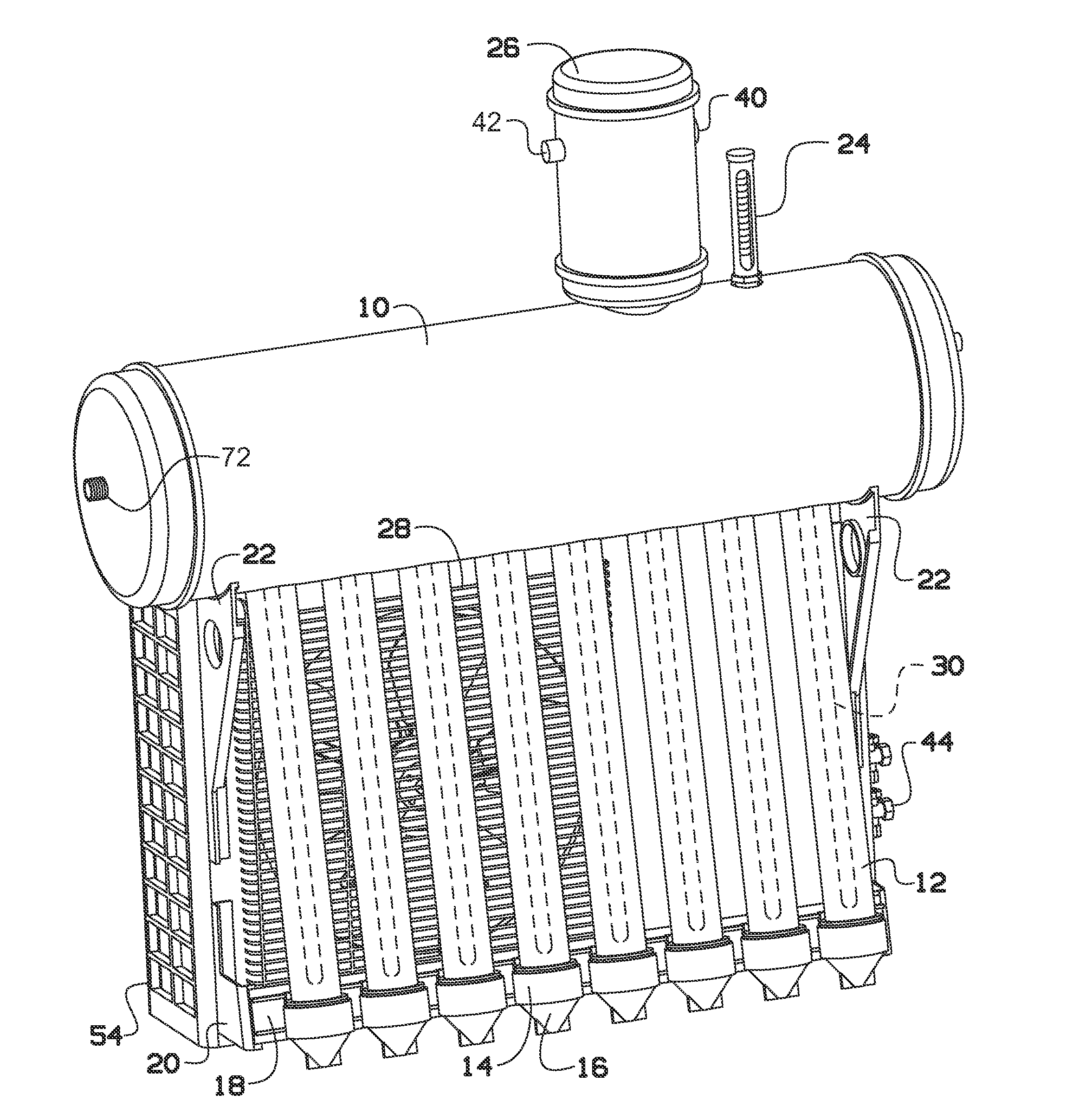

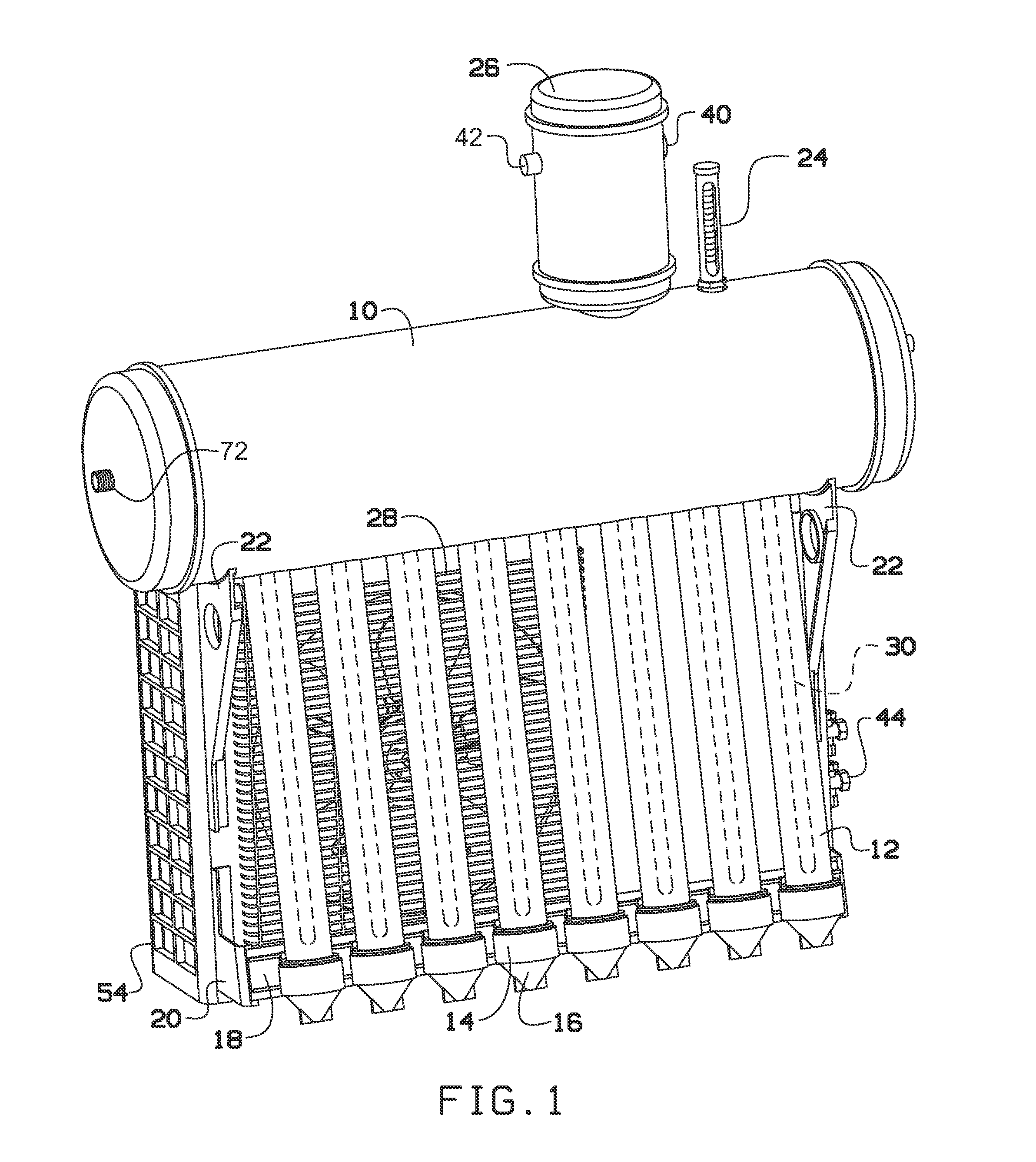

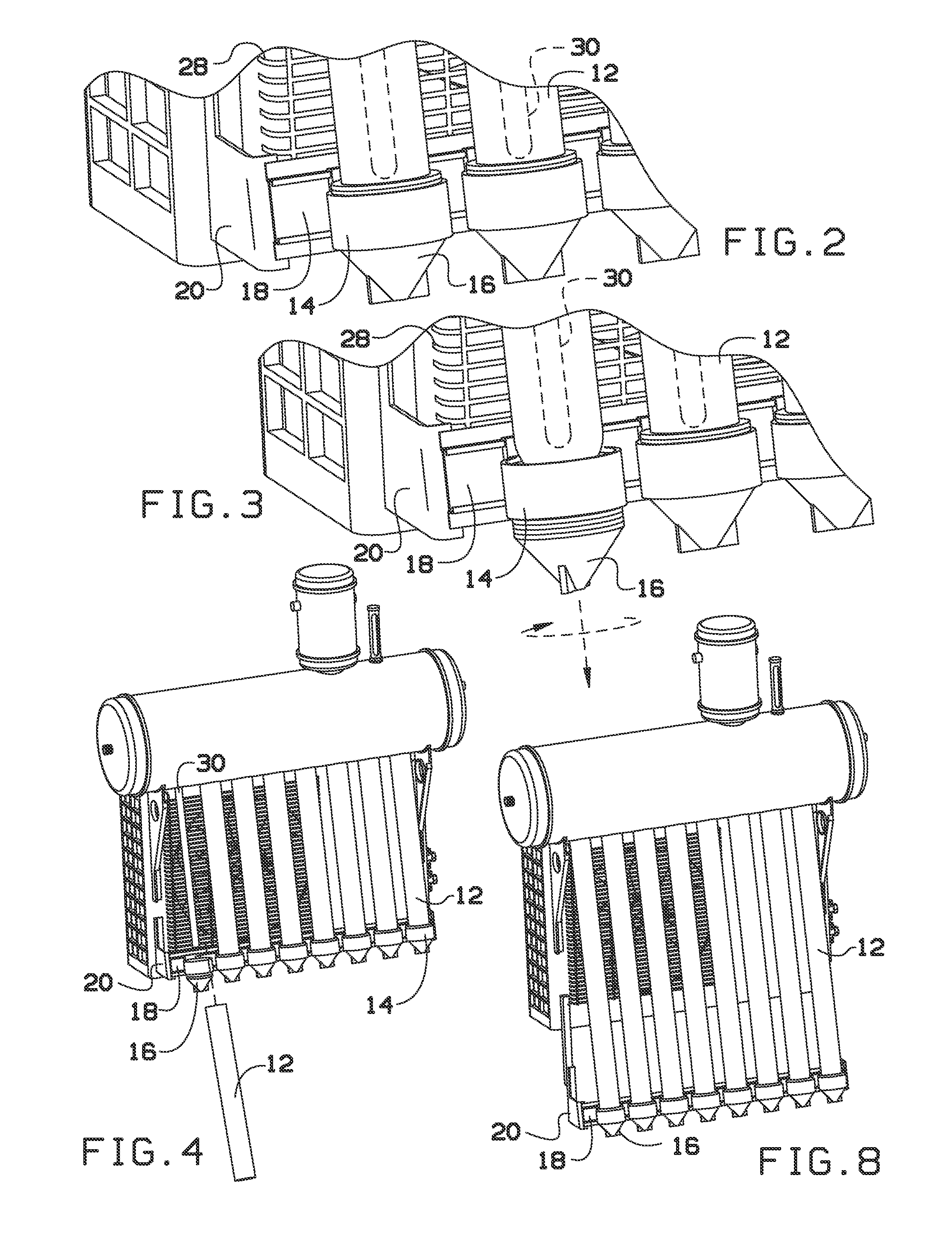

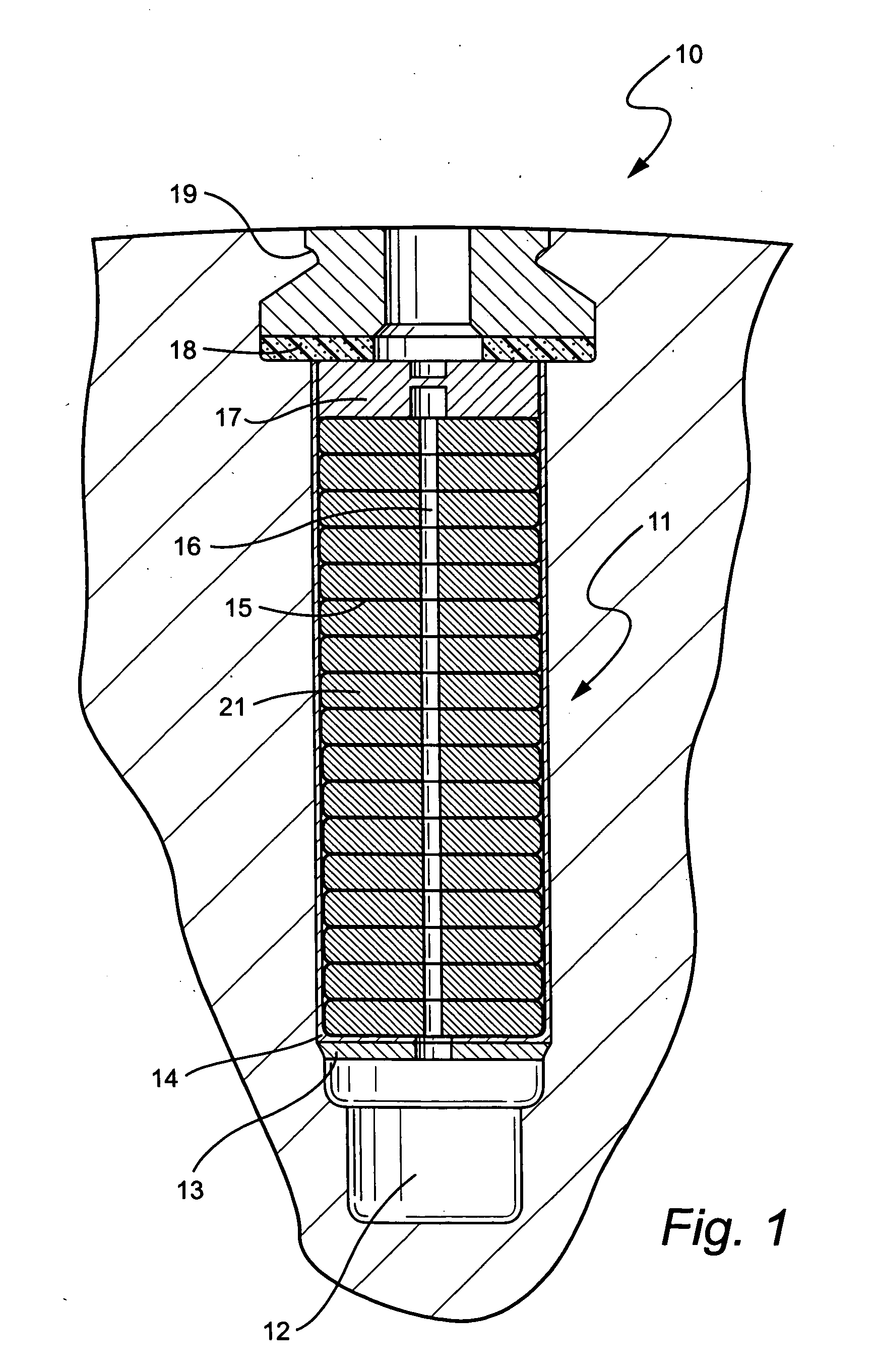

Heat exchanger apparatus and method for evaporative cooling refrigeration unit

InactiveUS7263852B2Improve heat transfer performanceCooling waterEvaporators/condensersStationary conduit assembliesEngineeringAir conditioning

This invention is for a highly efficient heat transfer unit and method for heat transfer for an air conditioning refrigeration unit. The invention has a plurality of condenser coils that stand generally vertically upright (with up to 20° tilt to optimize downward water flow with air being pulled across) between a splash louver and an evaporative fill material. The evaporative fill material and the splash louver transfer heat from the water by air cross flow to make the air conditioning unit very efficient and reduces the amount of copper coils needed. The condenser coils are cooled by water flowing down through them and into a sump. The condenser coils are also cooled by air pulled across them by a fan mounted on the top of the air conditioning unit. The sump in the bottom of the unit has a wall that directs the water in it to a water pump that then sends the water to the water distribution pipe. The water pipe covers the water distribution member with water, which then allows the water to flow down the condenser coils. The large amount of heat that is transferred from the condenser coils to the water and the air cross flow is what enables the air conditioning unit to be so efficient. A low pressure drop of refrigerant in the condensing coils, the large surface area, and horizontal air flow also helps the air conditioning unit to be efficient.

Owner:EP INVESTMENTS INC THROUGH ITS CHAPTER 7 TRUSTEE

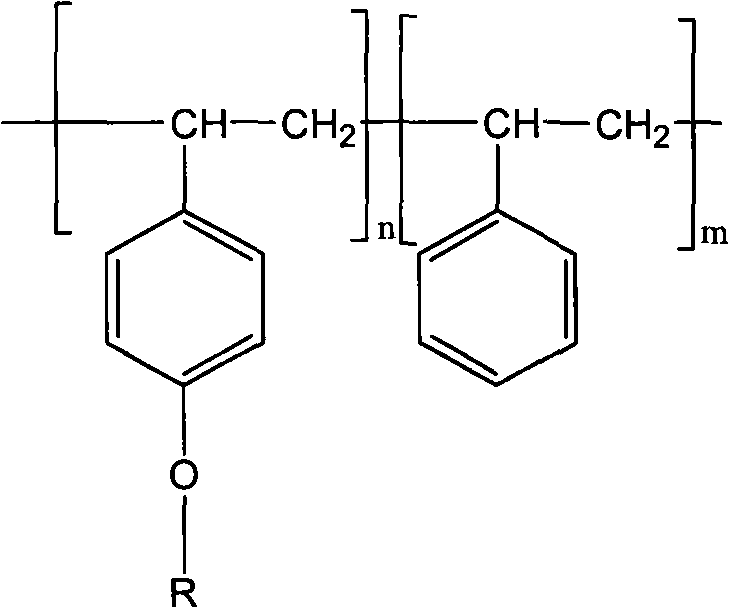

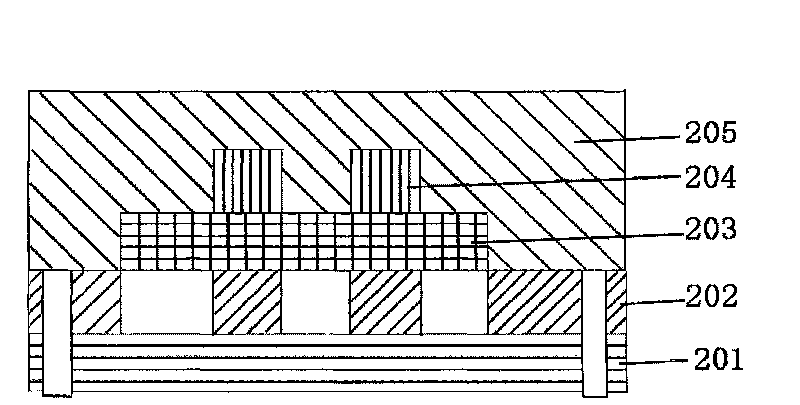

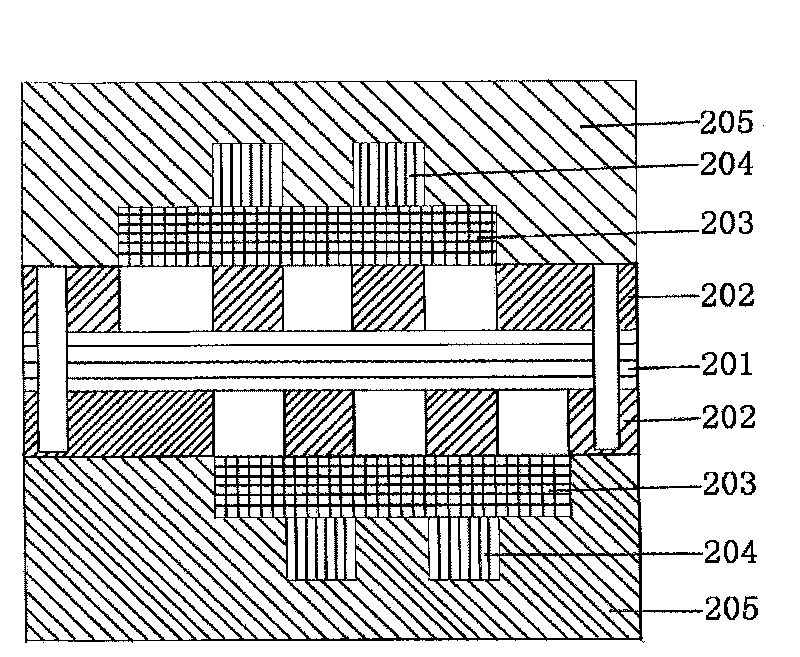

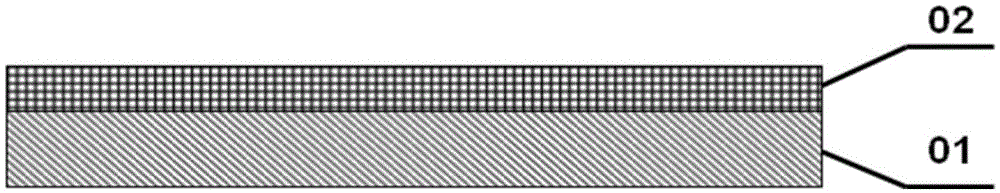

Composite material, high frequency circuit board prepared from same and preparation method thereof

ActiveCN101643565AExcellent dielectric propertiesImprove heat resistancePrinted circuit aspectsWoven fabricsHemt circuitsCopper foil

The invention relates to a composite material, a high frequency circuit board prepared from same and a preparation method thereof. The composite material comprises the following components: 20-70 parts of thermosetting mixture containing a hydrocarbon resin with the molecular weight of less than 11000 and more than 60% of ethylene group and a solid styryl resin with unsaturated double bond and medium or low molecular weight; glass fiber cloth; filler powder; and fire retardant and curing initiator. The prepared high frequency circuit board comprises a plurality of prepreg layers which are superimposed and prepared from the composite material, and copper coils which are pressed and coated on both sides of prepreg layers. The preparation of the prepregs prepared by the composite material ofthe invention is simple and the high frequency circuit board prepared from the prepregs has low dielectric constant and dielectric loss angle tangent, good heat resistance and convenient technologicaloperation so that the composite material of the invention is suitable to prepare circuit boards of high frequency electronic equipments.

Owner:GUANGDONG SHENGYI SCI TECH

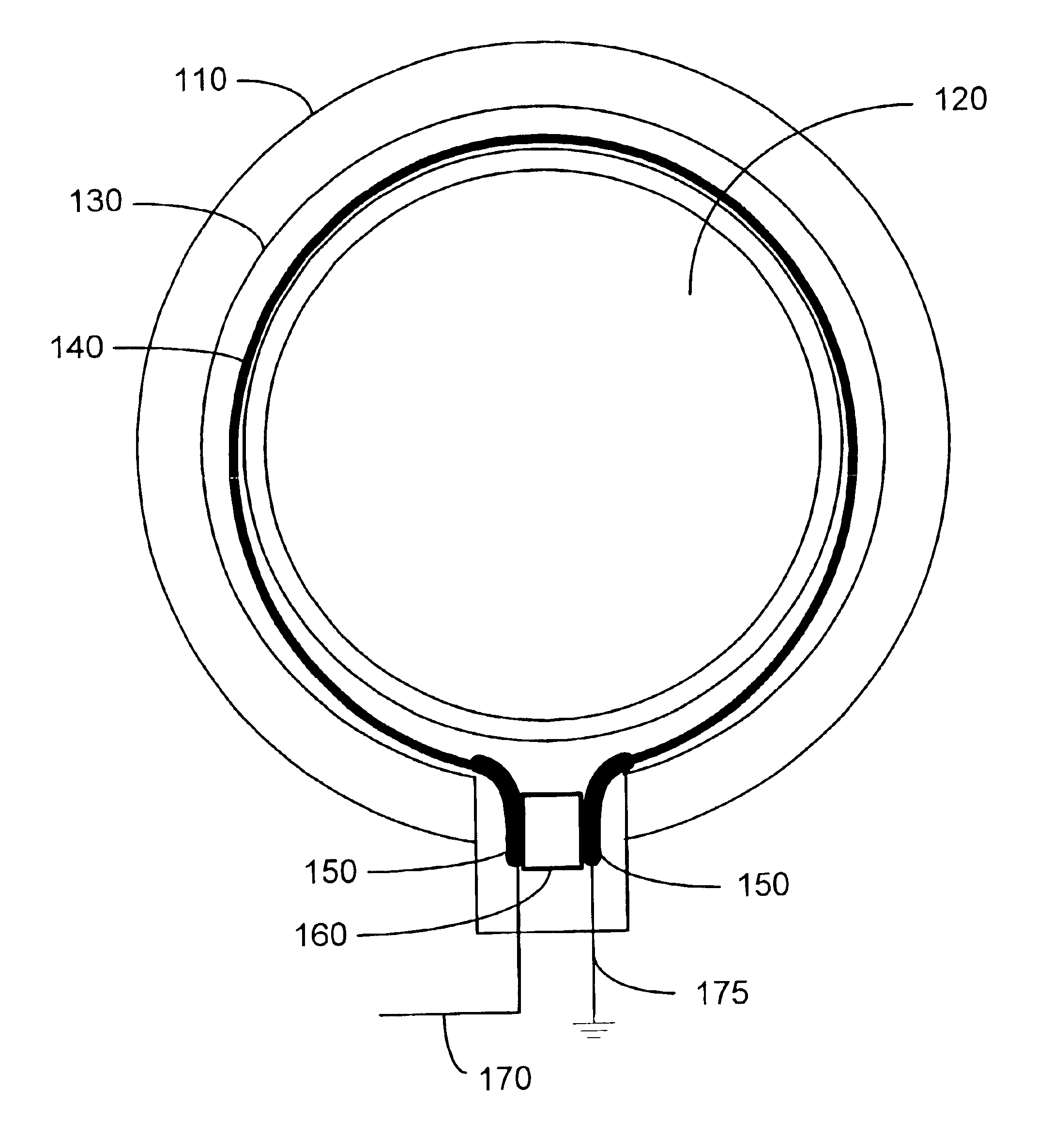

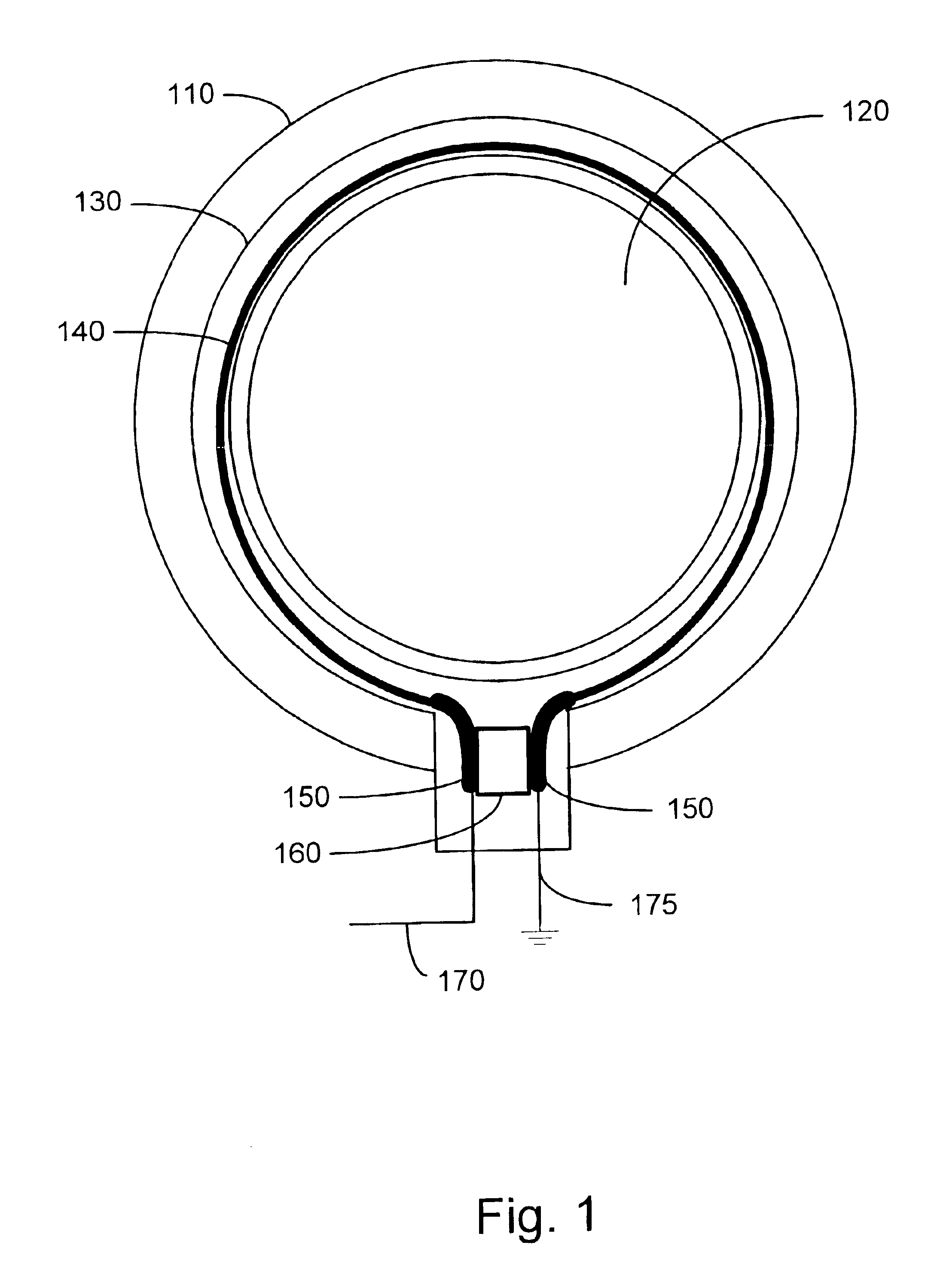

High temperature superconductor tape RF coil for magnetic resonance imaging

ActiveUS6943550B2Decorative surface effectsSuperconductor device manufacture/treatmentHigh-temperature superconductivityEtching

A HTS RF coil is disclosed having at least a factor of three improvement in the SNR over a comparable copper coil and at least a factor of six improvement in Q over a comparable copper coil. A commercially available HTS tape is formed into a loop. High-Q capacitors are soldered across the loop ends. The silver sheath covering the tape is removed through chemical etching. The coil is placed in a holder for mechanical support and protection and covered with a cover having through holes enabling the coolant to directly contact the HTS coil.

Owner:HONG KONG THE UNIV OF +1

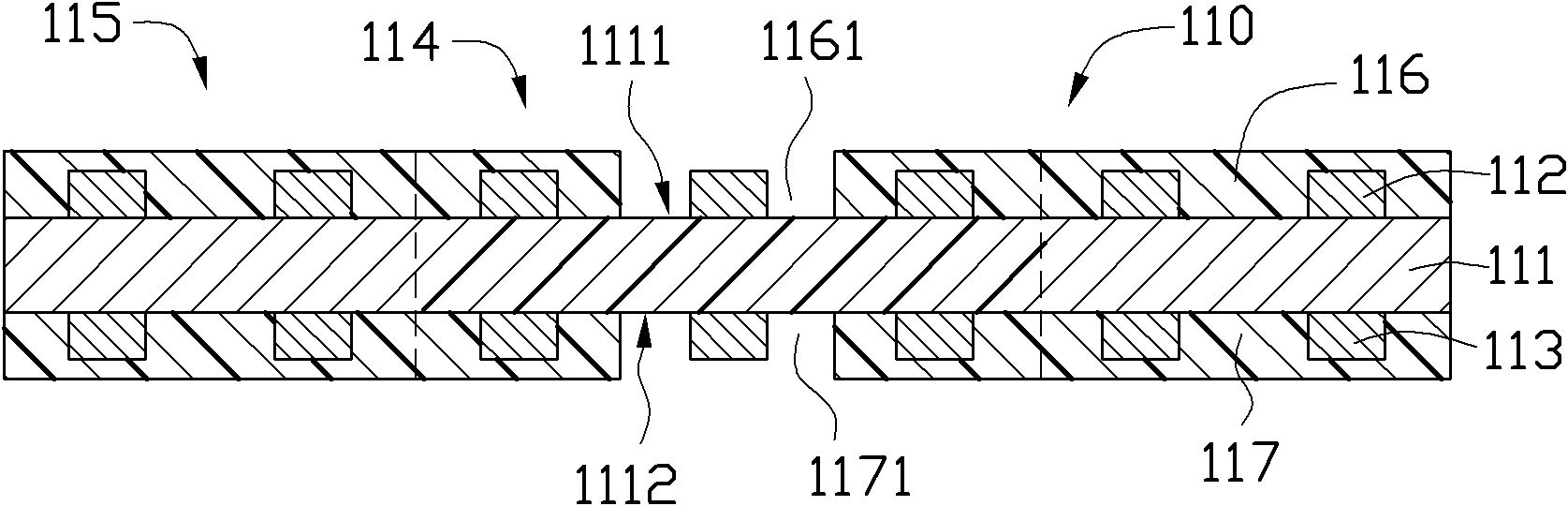

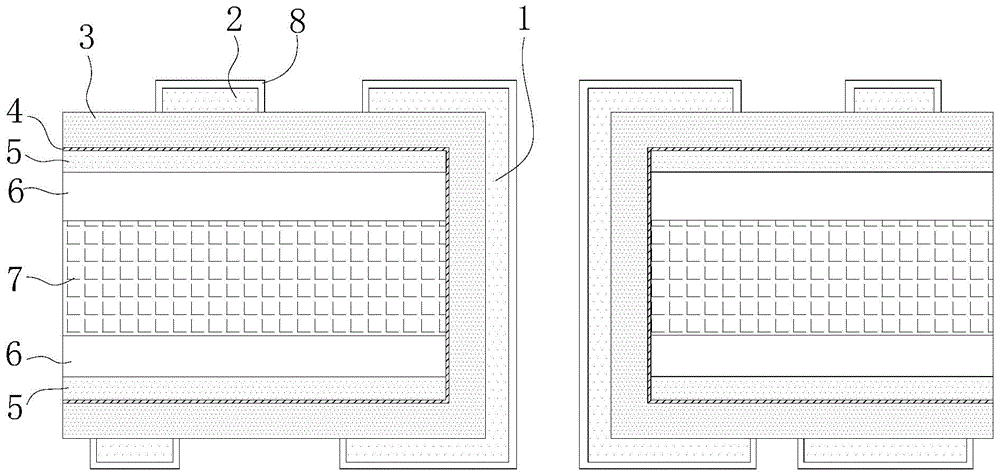

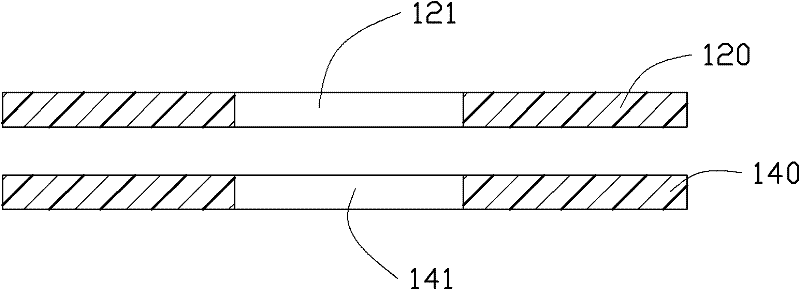

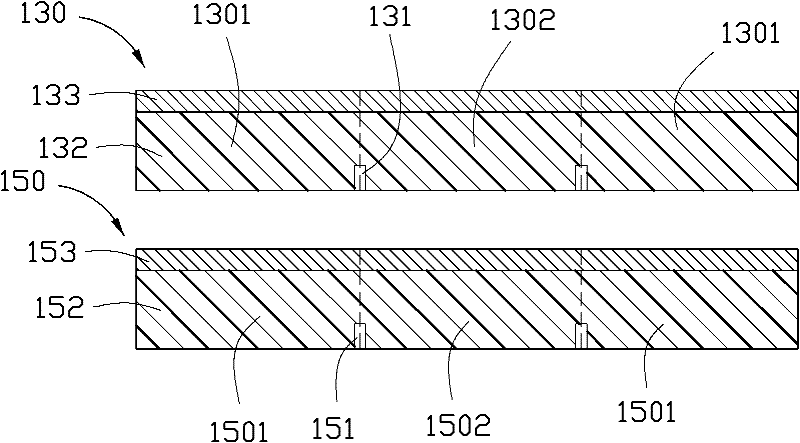

Manufacturing method of circuit board with combination of flexible circuit board and hard circuit board

ActiveCN102487577ACorrosion protectionPrevent stayingPrinted circuit assemblingSheet filmFlexible circuits

The invention relates to a manufacturing method of a circuit board with combination of a flexible circuit board and a hard circuit board. The method comprises the following steps that: a flexible circuit board including a bending area is provided, wherein the flexible circuit board has a conductive line that is covered by a covering film; besides, a through hole is arranged on the covering film and a portion of the conductive line is exposed from the through hole, wherein the portion of the conductive line is in the bending area; a strippable film is provided, wherein the shape of the strippable film is corresponded to that of the bending area, and a groove that penetrates a mucilage layer and is corresponded to the through hole is formed in the strippable film; the strippable film is attached to the bending area, the mucilage layer is contacted with the covering film in the bending area, and the through hole is correspondedly communicated with the groove; a film and a copper foil are provided, wherein an opening that is corresponded to the bending area is formed in the film; a copper coil substrate, the film and the flexible circuit board are successively stacked and stitched, wherein the opening is corresponded to the bending area; the copper coil is manufactured to form an external layer conductive line and the material of the corresponded copper coil in the bending area is removed, so that the strippable film is exposed. And the strippable film is removed.

Owner:HONGQISHENG PRECISION ELECTRONICS (QINHUANGDAO) CO LTD +1

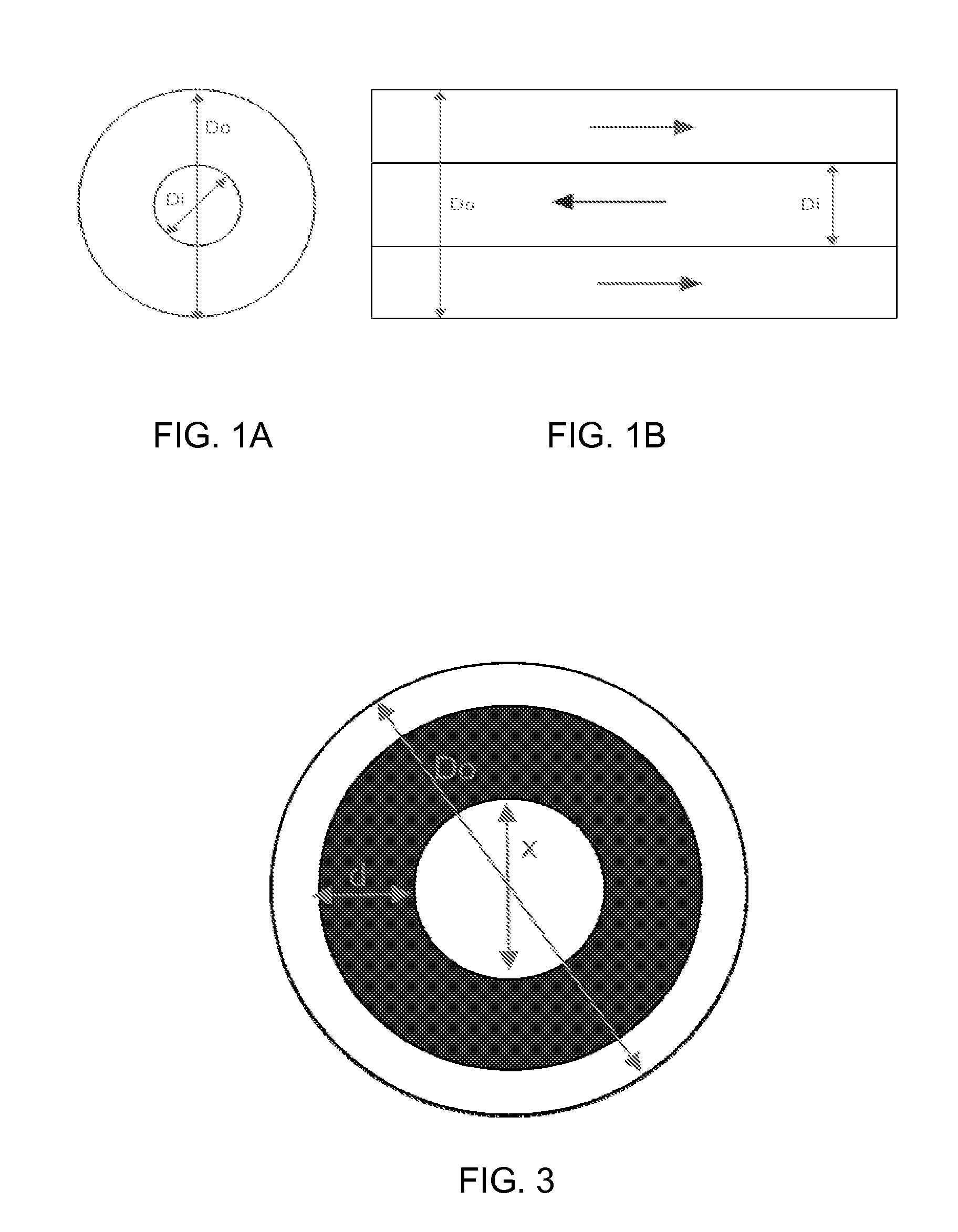

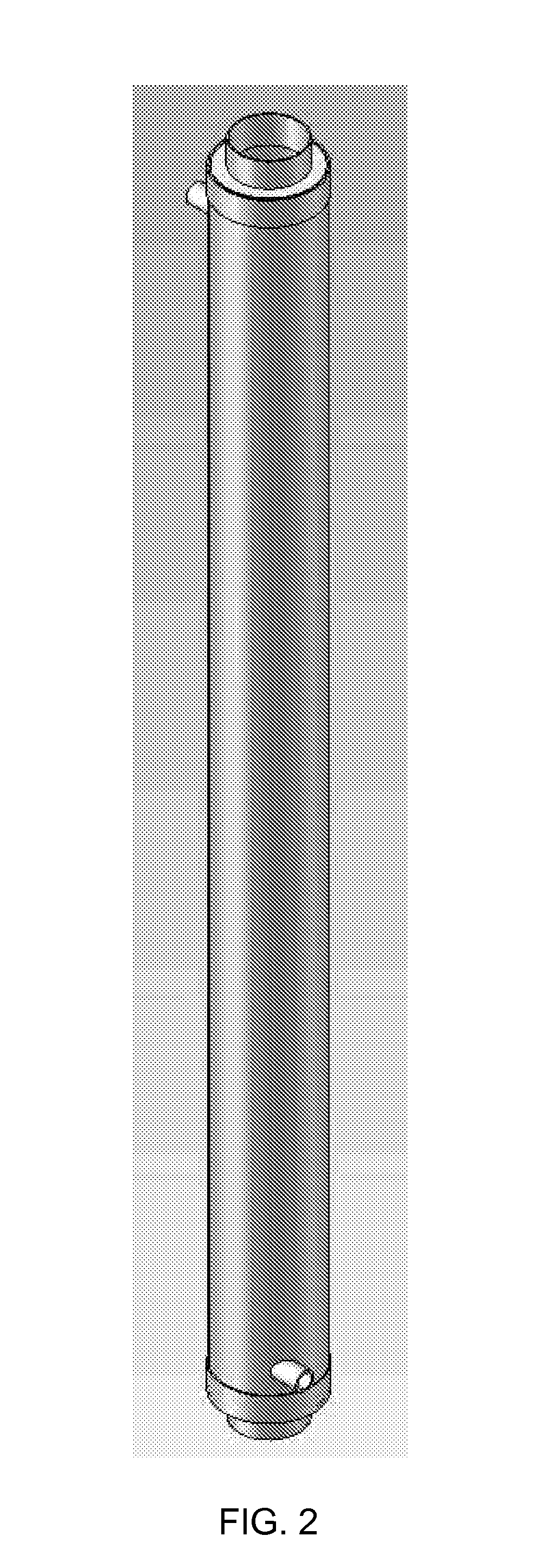

Grey water heat recovery system

InactiveUS20110155366A1Heat recovery systemsRecuperative heat exchangersThermal energyPlate heat exchanger

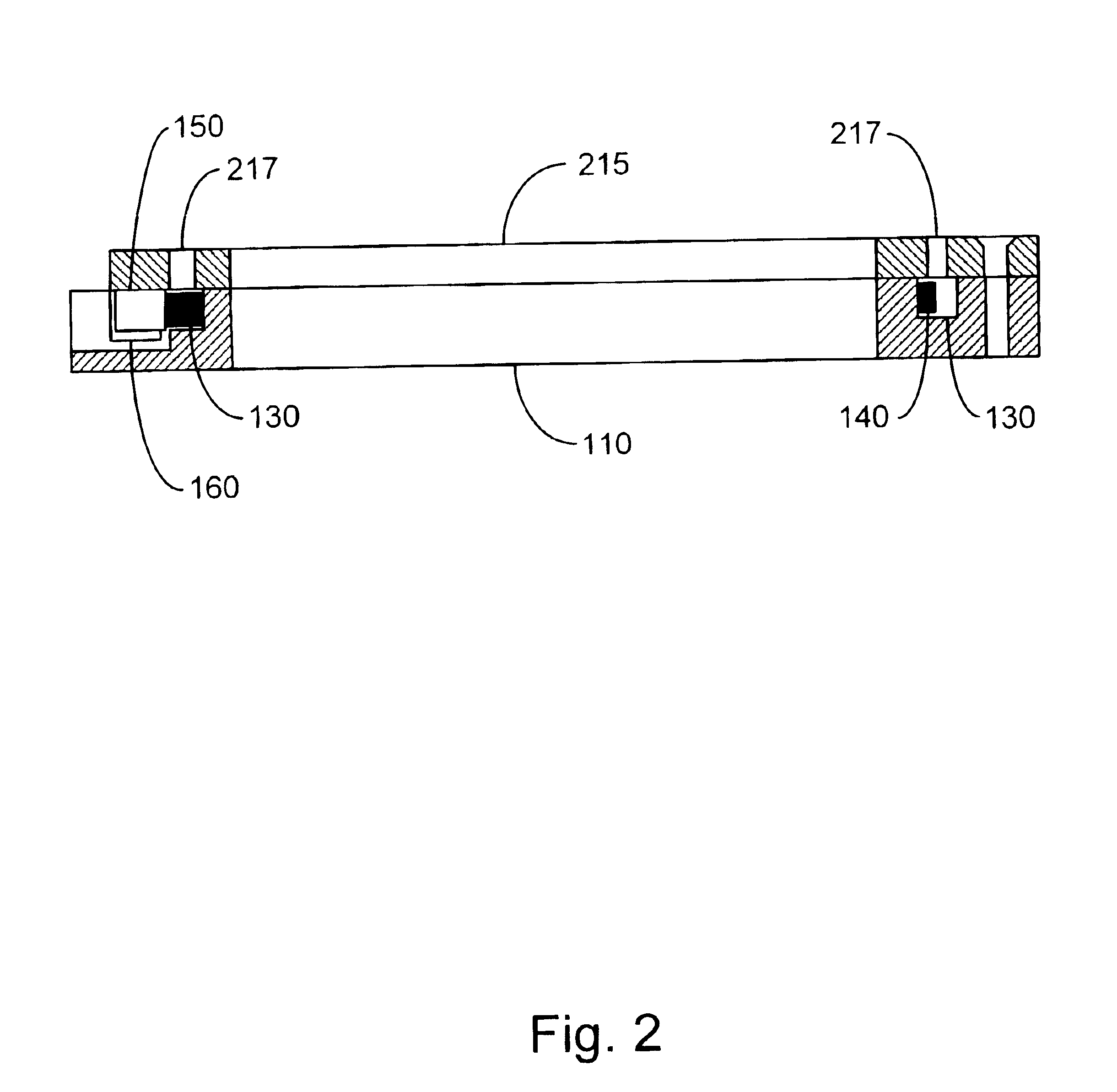

A grey water to clean water heat exchanger and methods of use. A heat exchanger having a copper coil carrying clean water inside a grey water discharge pipe is described. The heat exchanger can use counterflow geometry. The heat exchanger has a controller that directs grey water through a bypass pipe whenever the grey water has too low a temperature to provide useful thermal energy. When the grey water is hot enough, the controller directs it through the heat exchanger to heat the clean water. A filter is provided to eliminate fouling of the interior of the heat exchanger. The controller provides an indication when the filter needs to be cleaned or replaced.

Owner:BRUNN JOSHUA

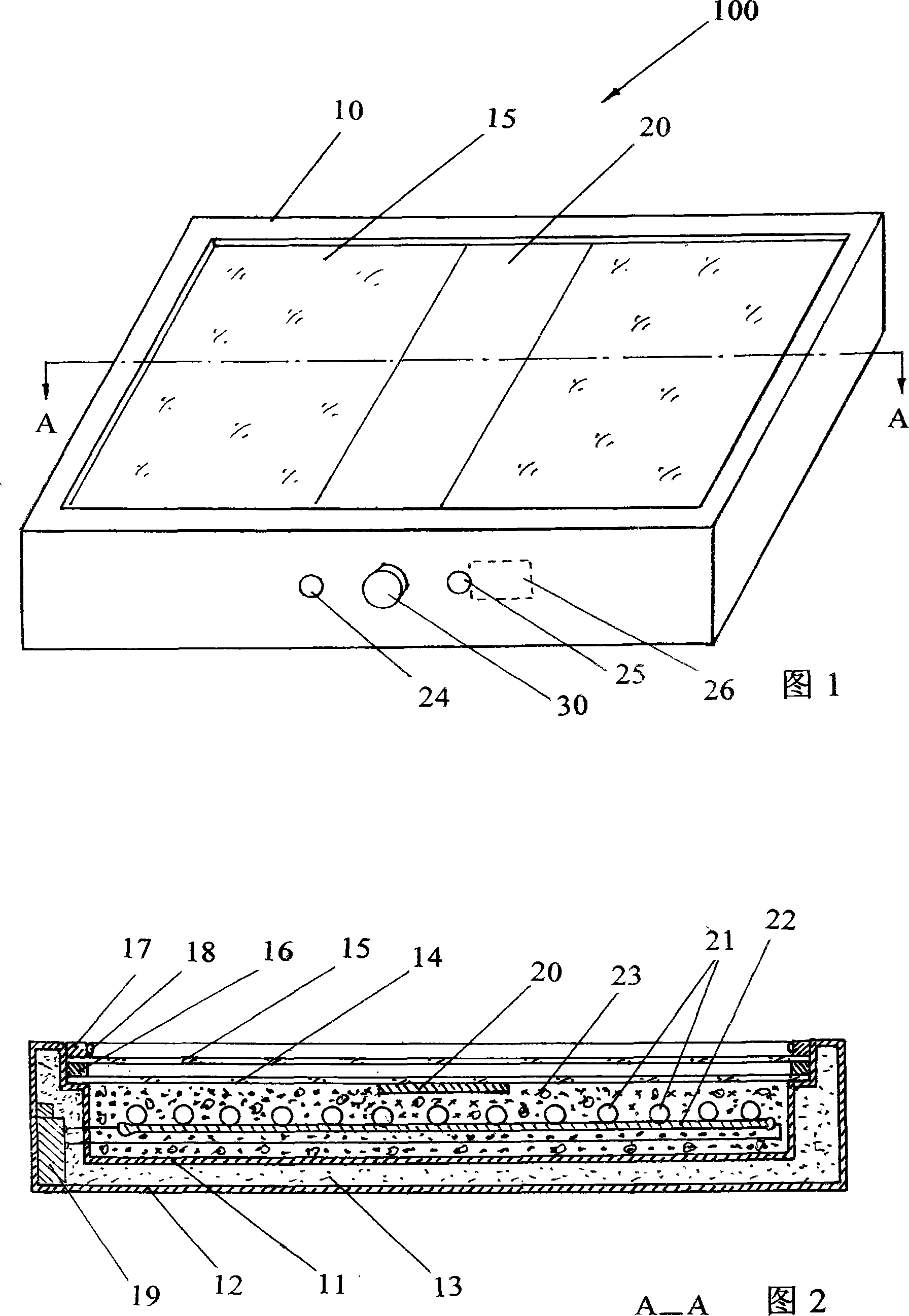

Solar thermal air conditioning unit

A solar thermal air conditioning unit is provided. The solar thermal air condition unit includes a pressurized water tank with a water entrance port for receiving water. A copper coil tube may be within the pressurized water tank. The copper coiled tube may include a liquid refrigerant inlet and a gas refrigerant outlet. A solar heat converter may be connected to the pressurized water tank and may heat the water within the pressurized water tank, thereby heating the copper coil tube. The liquid refrigerant may be injected into the copper coil tube via the liquid refrigerant inlet and travels through the copper coil and is heated, thereby turning the liquid refrigerant to a gas refrigerant.

Owner:RAHL STEVEN RICHARD

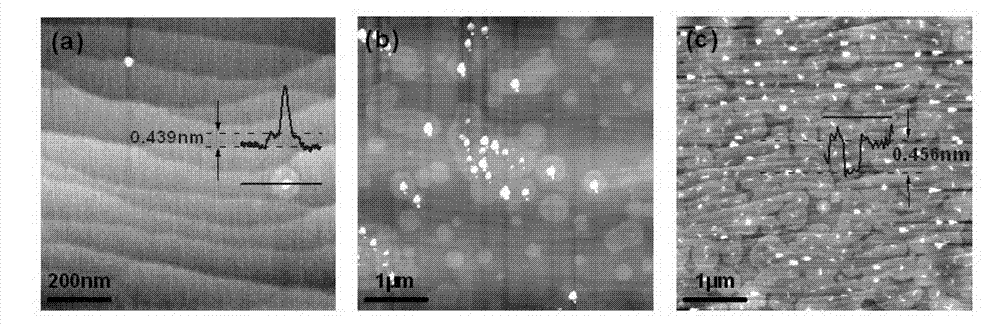

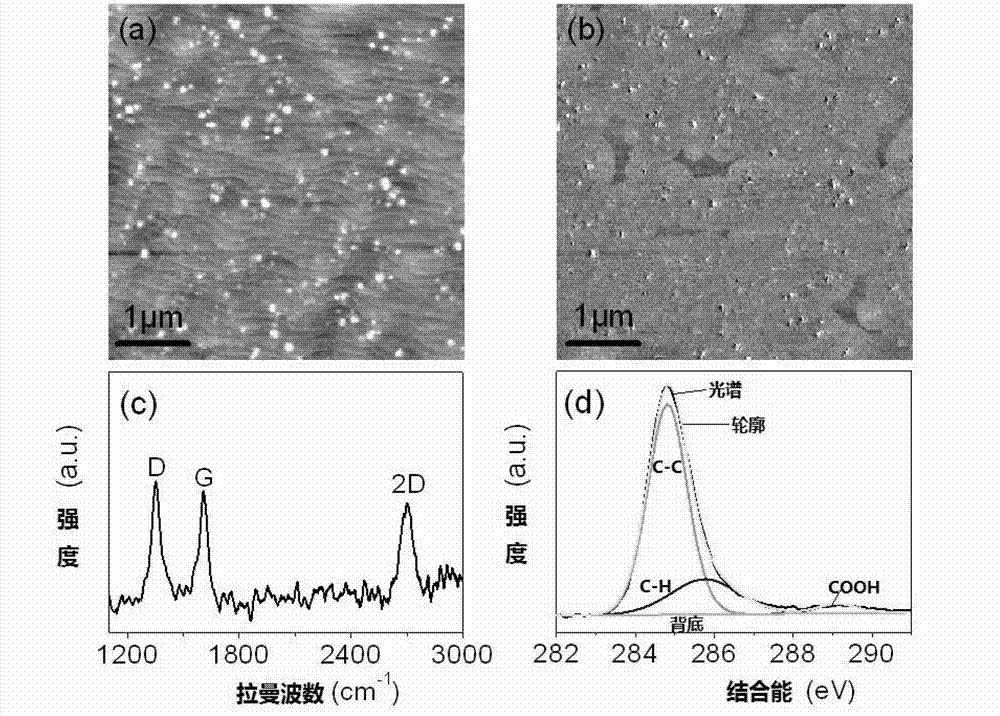

Method for growing large-area graphene on insulating substrate

The invention discloses a method for growing large-area graphene on an insulating substrate. According to the method, a growing substrate is taken as an insulating material, a copper foil is taken as a catalyst and a carbon source, nitrogen and protective gas are taken as source gases, and the large-area graphene is grown on the insulating substrate by adopting a two-step (low-pressure growth and high-pressure growth) chemical vapor deposition method and using the short-range catalytic effect of the copper coil through face-to-face contact of the insulating substrate and the copper foil. The method disclosed by the invention is simple in operation of the whole process and low in cost; and the sample preparation is very high in repeatability and is less interfered by external world. The prepared single-layer graphene can be made into a large-area circuit device by using an exposure method without needing a complex transfer technology.

Owner:PEKING UNIV

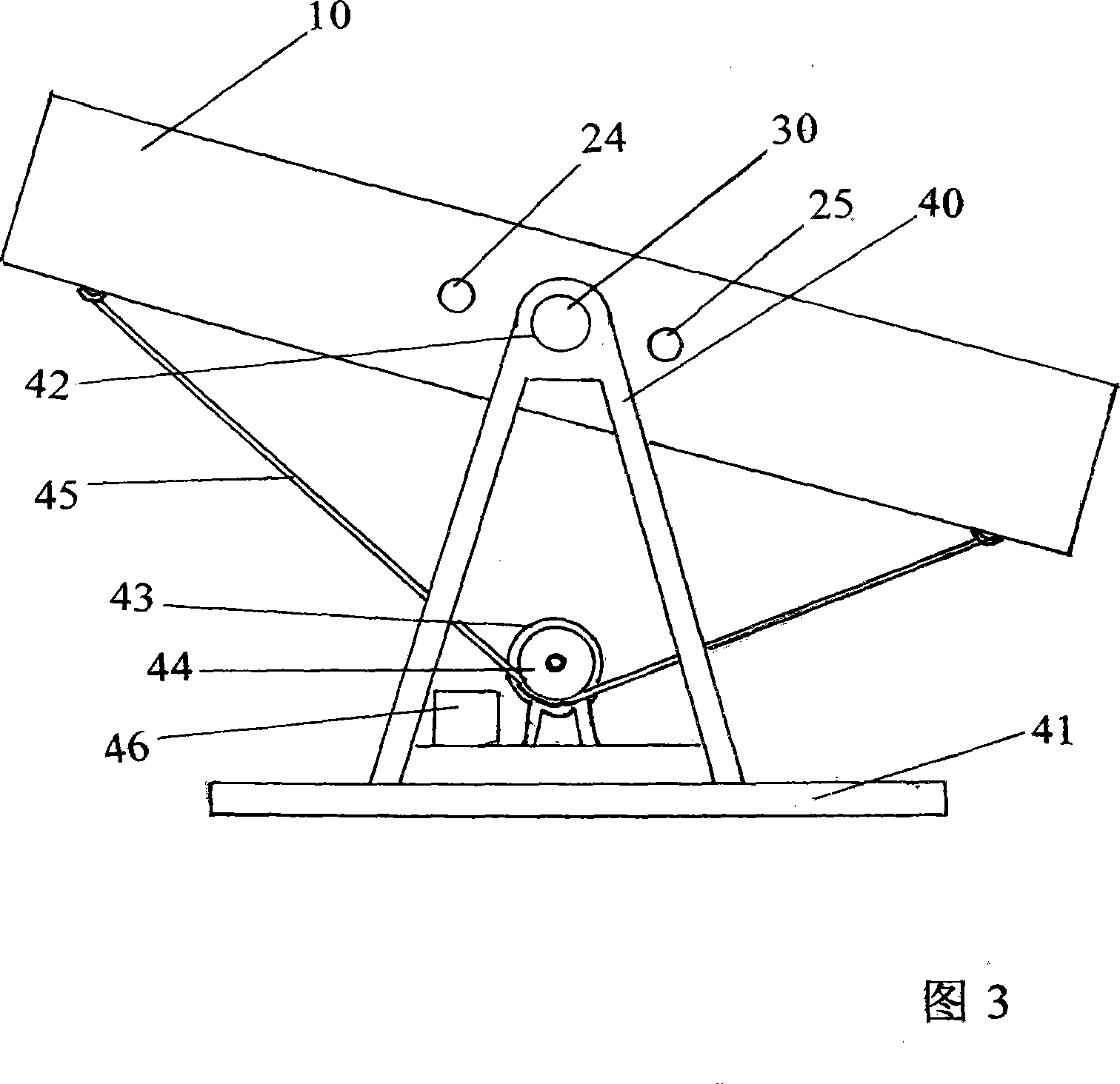

Negative pole made of silicon/graphite nanosheet composite material of lithium ion battery and preparation method thereof

InactiveCN101593827AComposite uniformAvoid the disadvantage of uneven mixingElectrode manufacturing processesActive material electrodesCopper foilElectrochemistry

The invention discloses a negative pole made of a silicon / graphite nanosheet composite material of a lithium ion battery, which comprises the following components in percentage by mass: 85 to 95 percent of nanometer silicon powder-graphite nanosheet composite material, and 5 to 15 percent of polyvinylidene fluoride, wherein the content of nanometer silicon powder is between 20 and 75 percent in the nanometer silicon powder-graphite nanosheet composite material. A preparation method thereof comprises the steps of: preparing graphite oxide, preparing a mixed dispersion system of the nanometer silicon powder and graphite oxide nanosheets; adding a reducing agent, namely hydrazine hydrate into the mixed dispersion system of the nanometer silicon powder and the graphite oxide nanosheets, and reducing the graphite oxide nanosheets into graphite nanosheets to obtain a composite material of the nanometer silicon powder and the graphite nanosheets; and fully mixing the composite material of the nanometer silicon powder and the graphite nanosheets with N-methylpyrrolidone sol of the polyvinylidene fluoride, blending the mixture into paste, evenly coating the paste onto a copper coil, and performing drying and roller compaction. The negative pole made of the silicon / graphite nanosheet composite material of the lithium ion battery has high electrochemical capacity and good cycling stability performance.

Owner:ZHEJIANG UNIV

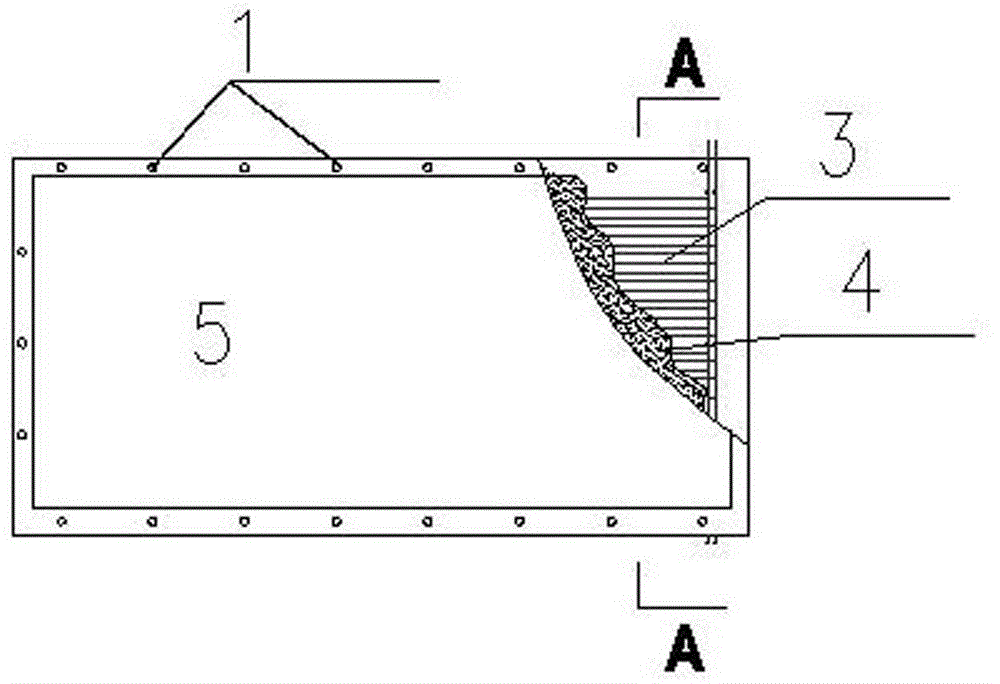

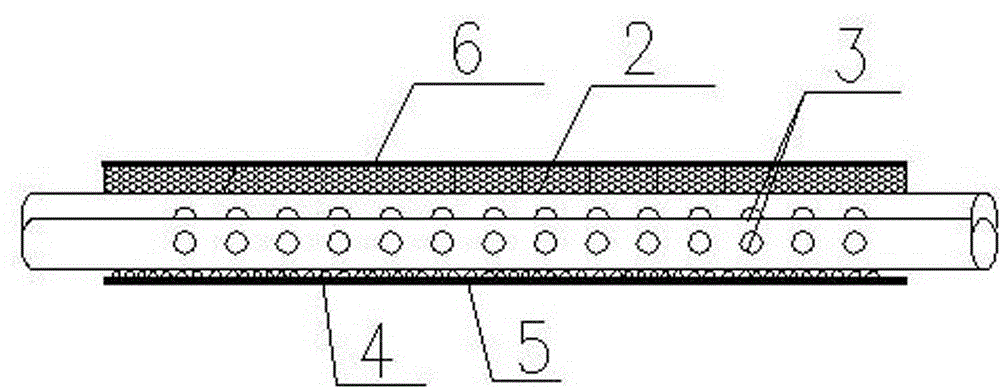

Anti-condensation metal radiant panel and manufacturing method thereof

InactiveCN103982017ASolve excessive energy consumptionIncrease heat dissipation terminalCovering/liningsLighting and heating apparatusCapillary networkManufacturing technology

The invention discloses an anti-condensation metal radiant panel device and a manufacturing method thereof. The method comprises the following steps: performing super-hydrophobic treatment on a metal panel by adopting a super-hydrophobic surface manufacturing technology, so as to enable the surface of the metal panel to be in a super-hydrophobic state; then installing a capillary network or a copper coil pipe on a super-hydrophobic metal radiant panel; paving an aluminum foil in the middle so as to ensure that the capillary network or the copper coil pipe is in close contact with the super-hydrophobic metal radiant panel; installing a thermal insulating layer on the upper surface of the capillary network or the copper coil pipe; then covering the thermal insulating layer by use of a cover plate; performing fastening combined installation by use of a fastener, thereby forming the metal radiant panel with a radiation function, a cold supply function and a heat supply function. The radiant panel is capable of preserving the super-hydrophobic characteristic of a lower radiant surface after being put in the air for a long time, so that when the metal radiant panel is used in a radiant cold-supply air-conditioning system, a condensation phenomenon can not occur to the surface in any wet air; the anti-condensation metal radiant panel can be used for thoroughly solving the problem that condensation occurs easily when the radiant panel is used for radiation and cold supply.

Owner:BEIJING HENGTONG GREEN BUILDING ENERGY EFFICIENT TECH CO LTD

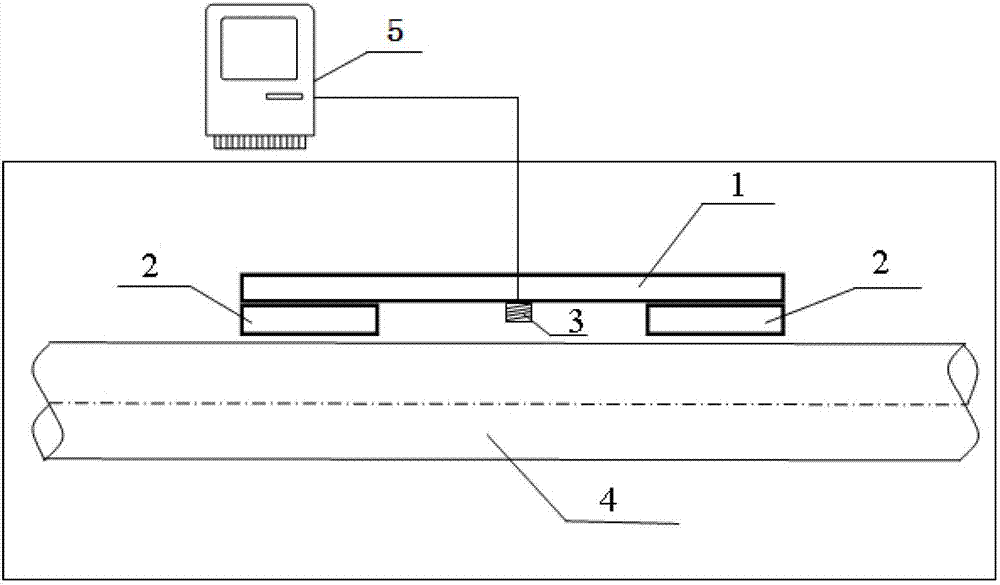

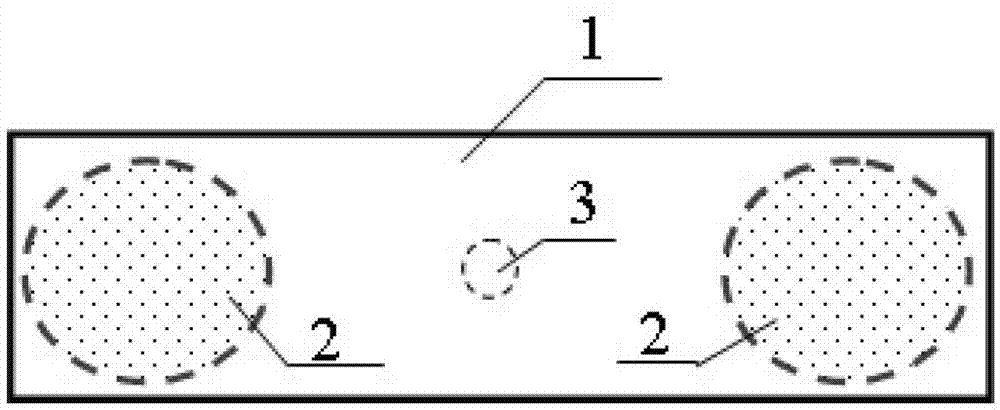

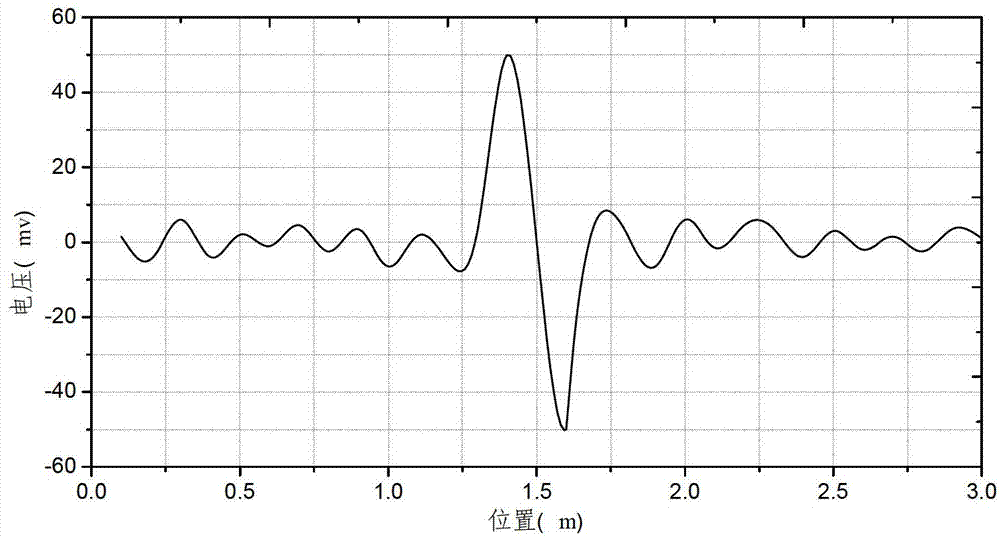

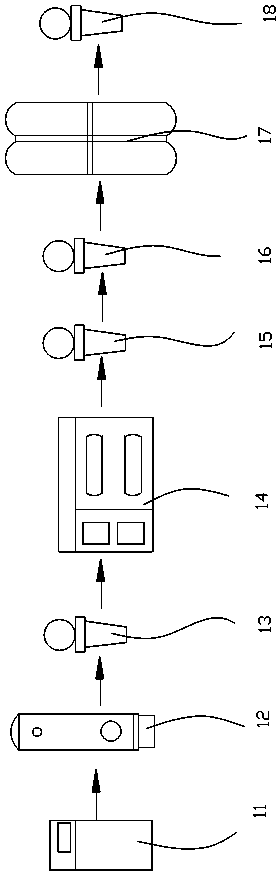

Device and method for recognizing damage to bridge stay cable

InactiveCN103048379AHigh sensitivityEasy to zoom inMaterial magnetic variablesSignal analyzerEngineering

The invention discloses a device and a method for recognizing damage to a bridge stay cable. The device comprises an iron plate, two magnets and a signal analyzer, wherein a copper coil is fixedly arranged on the bottom surface of the iron plate; the two magnets are arranged on the bottom surface of the iron plate at an interval; the copper coil is located at the center of the connection line between the two magnets; and the signal analyzer is used for real-timely collecting and displaying magnetic flux of the copper coil. The invention provides an optimized structure scheme for detecting damage to the bridge stray cable according to a magnetic flux leakage detection principle. The device provided by the invention is simple in structure, convenient and easy to operate and carry, and can improve the magnetic flux leakage detection sensitivity by replacing the conventional Hall sensor by the coil, thereby facilitating signal amplification and subsequent analysis.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

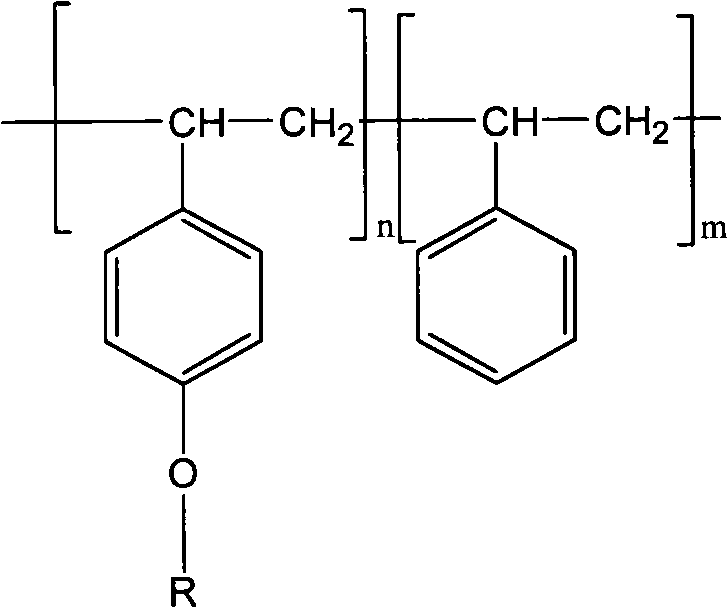

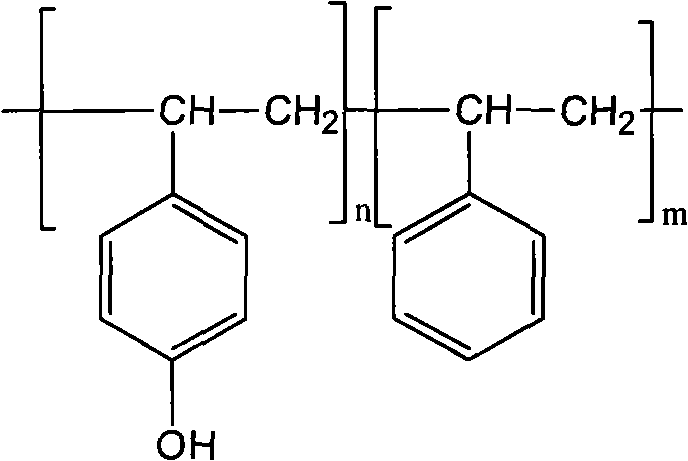

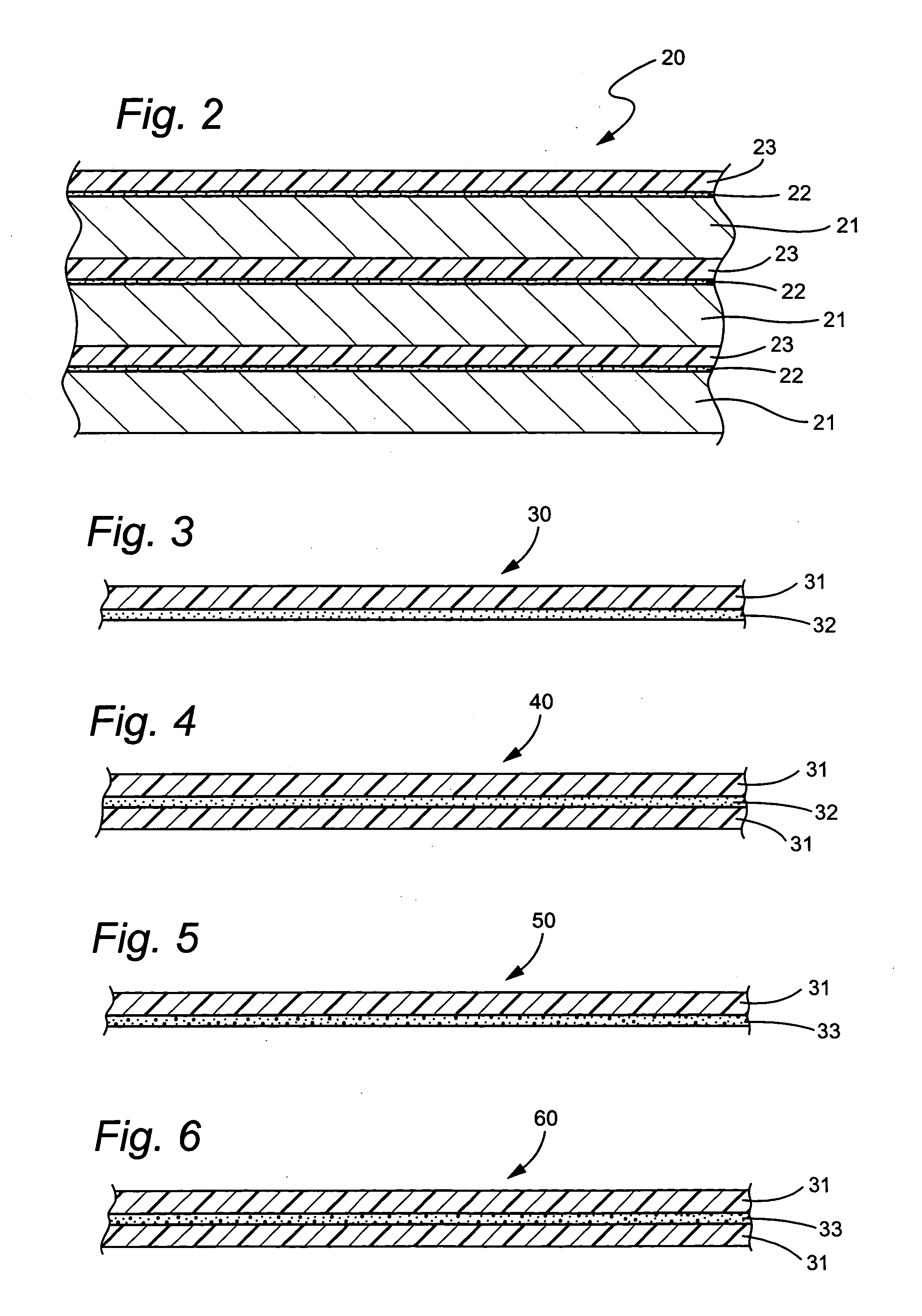

One part, heat cured pressure sensitive adhesives

Novel one part, heat cured pressure-sensitive adhesives capable of bonding metallic and non-metallic materials at ambient temperatures and curing at elevated temperatures to form a bond with very high adhesive bond strengths at temperatures up to at least 160° C. The invention is particularly well suited for use with insulated copper coils in electrical generators and includes both the adhesive compositions per se and adhesive transfer tapes capable of bonding to the copper coils at ambient temperatures upon contact due to the pressure sensitive tack of the adhesive. The transfer tapes can subsequently be cured to a hard, thermoset adhesive with high adhesive bond strength. In applications on insulated copper coils, exemplary one part, heat cured pressure-sensitive adhesives can be used either alone or in combination with a substrate to form single or double-sided adhesive tape capable of securing the generator rotor turn insulation. The pressure sensitive materials can also be applied to a mat carrier, such as aramid paper, polyester glass, or glass cloth based epoxy sheets.

Owner:GENERAL ELECTRIC CO

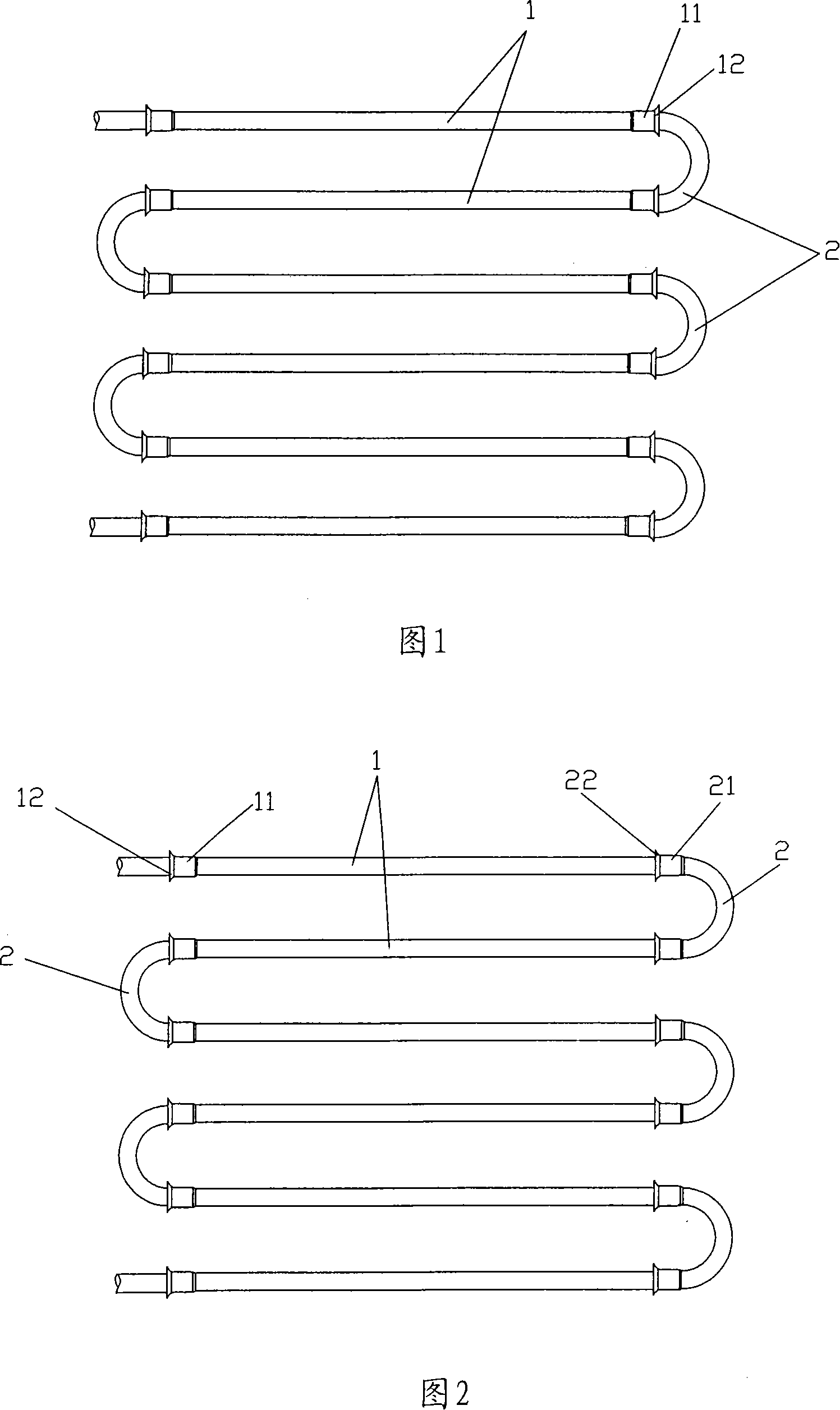

Heat-exchanging non-corrosive steel alloy foil coil and its manufacture method

InactiveCN101149236ADesign scienceReasonable structureSoldering apparatusTubular elementsAlloyCopper coil

This invention is a heat transferring stainless steel alloy foil coil and its production method. The coil is welded by stainless alloy foil straight pipe and bended pipe. The thickness of the straight pipe wall is 0.02mm-0.3mm, while the thickness of the bended pipe wall is 0.15-0.45mm. The production method includes: material prepare, bended pipe production, bended pipe or straight pipe end making and welding. This invention has reasonable structure and easy technique. The chlorine anion resistant capability of the said coil is higher than 100ppm and increases more than 50% times than that of the copper materials. The strength increases one time. The ductility is nearly the same as that of the copper materials. The heat power is higher than that of the existing heat transferring copper coil. All of its heat superconductivity is suitable for various kinds of condensers and evaporators. This invention can be used on various kinds of air conditioners and refrigerating equipments.

Owner:陈卫东

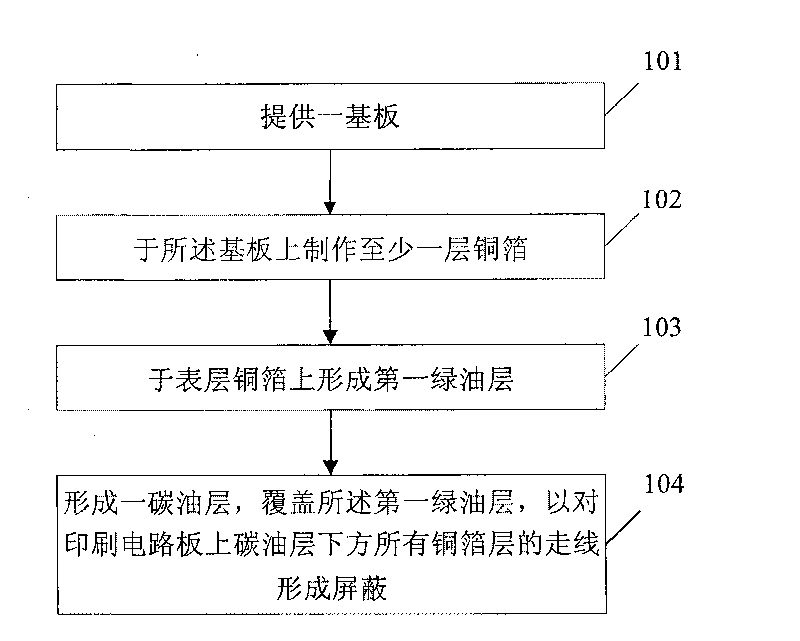

Printed circuit board shielding method and printed circuit board

ActiveCN101742814AGuaranteed shielding effectLow costMagnetic/electric field screeningCross-talk/noise/interference reductionCarbon filmSurface layer

Owner:HUAWEI DEVICE CO LTD

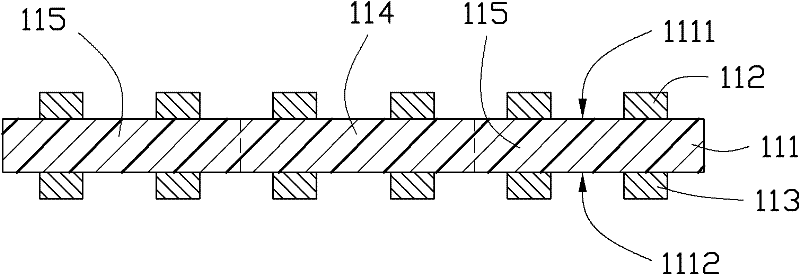

Manufacturing method of thick hole copper PCB

ActiveCN104363704AReduce thicknessThere will be no problem of unclean etchingCircuit metal processingMultilayer circuit manufactureEtchingCopper coil

The invention relates to the technical field of PCB production, in particular to a manufacturing method of a thick hole copper PCB. The method is characterized in that a board electric copper layer is formed on a hole wall through whole board electroplating, a thickened copper layer is further formed in the hole wall through pattern electroplating during outer-layer circuit manufacturing, and the thickened copper layer and the board electric copper layer jointly form a hole wall copper layer. The method has the advantages that abrasive belt board grinding in film hole plating is omitted, accurate alignment of subsequent work procedures is unaffected due to the fact stretching of a semi-finished product is avoided, and production efficiency can be increased; due to the fact that the part of the copper thickness of the hole wall copper layer is formed during pattern electroplating, the problems that film clamping is caused by the fact that the copper layer on the surface of a multilayer board is excessively thick, and unclean etching occurs are solved; outer layer copper coil thickness is reduced before drilling, surface copper thickness can be reduced relatively, and etching is benefited.

Owner:JIANGMEN SUNTAK CIRCUIT TECH

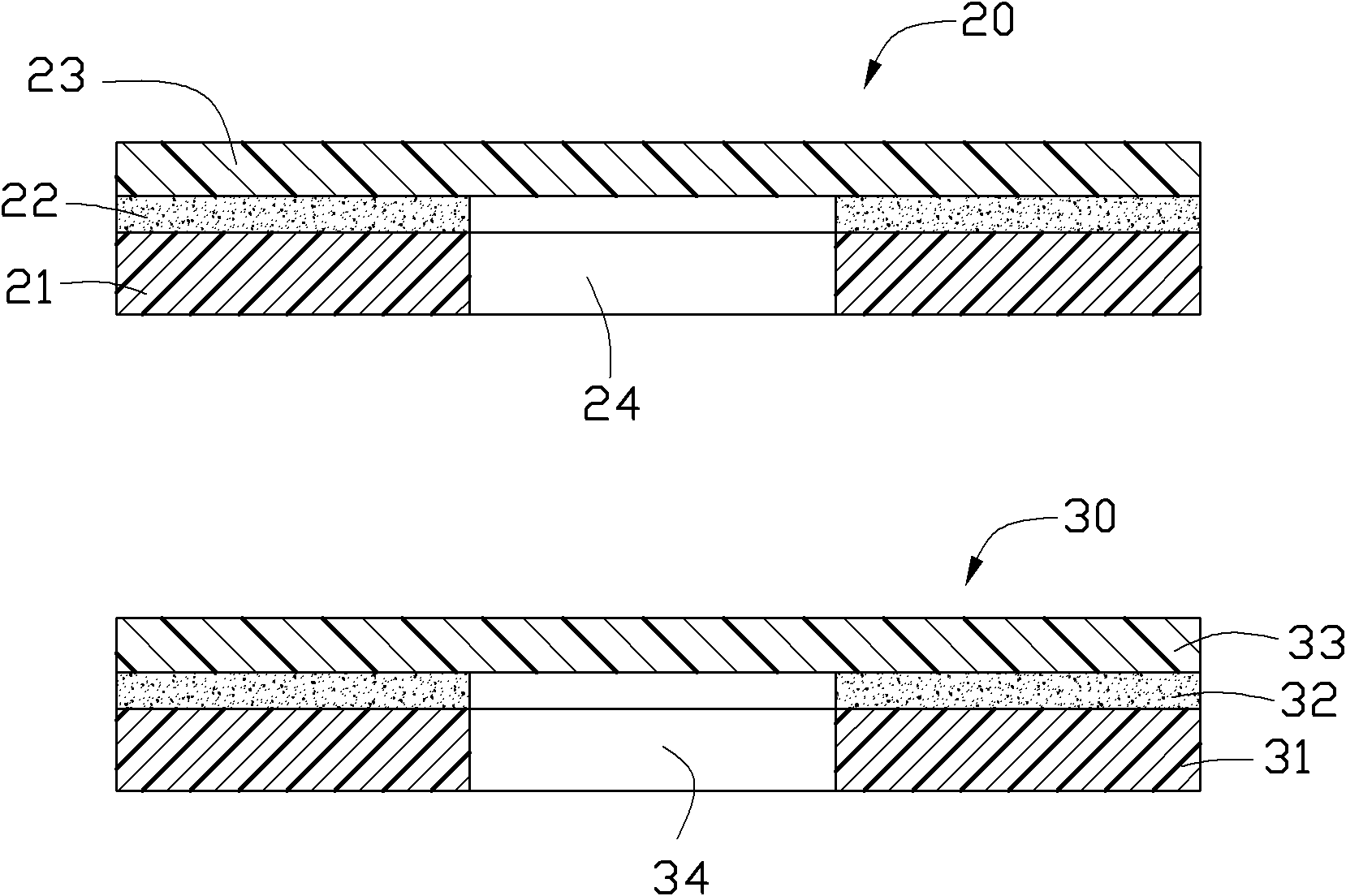

Manufacturing method for rigid-flexible circuit board

ActiveCN102458055AAvoid contactFlattened structurePrinted circuit assemblingPrinted circuit aspectsFlexible circuitsEngineering

The invention discloses a manufacturing method for a rigid-flexible circuit board. The manufacturing method comprises the following steps of: providing a flexible circuit board, wherein the flexible circuit board comprises a bending region and a fixing region which are connected to each other; providing a film and a hard copper-clad substrate, wherein an opening is formed in the film, and the copper-clad substrate comprises a substrate and a copper foil layer and is provided with a windowing region and a product region which correspond to each other; forming a first cut at one side away from the copper foil layer in the substrate along the boundary of the windowing region, wherein the first cut does not penetrate through the substrate; sequentially stacking and laminating the copper-clad substrate, the film and the flexible circuit board, wherein the substrate of the copper-clad substrate is contacted with the film, the copper coil layer is away from the film and the windowing region is overlapped with the bending region; manufacturing the copper foil layer to form an outer-layer circuit; forming a second cut in the substrate along the boundary of the windowing region, wherein the second cut is communicated with the first cut; and removing a material in the windowing region from the copper-clad substrate.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

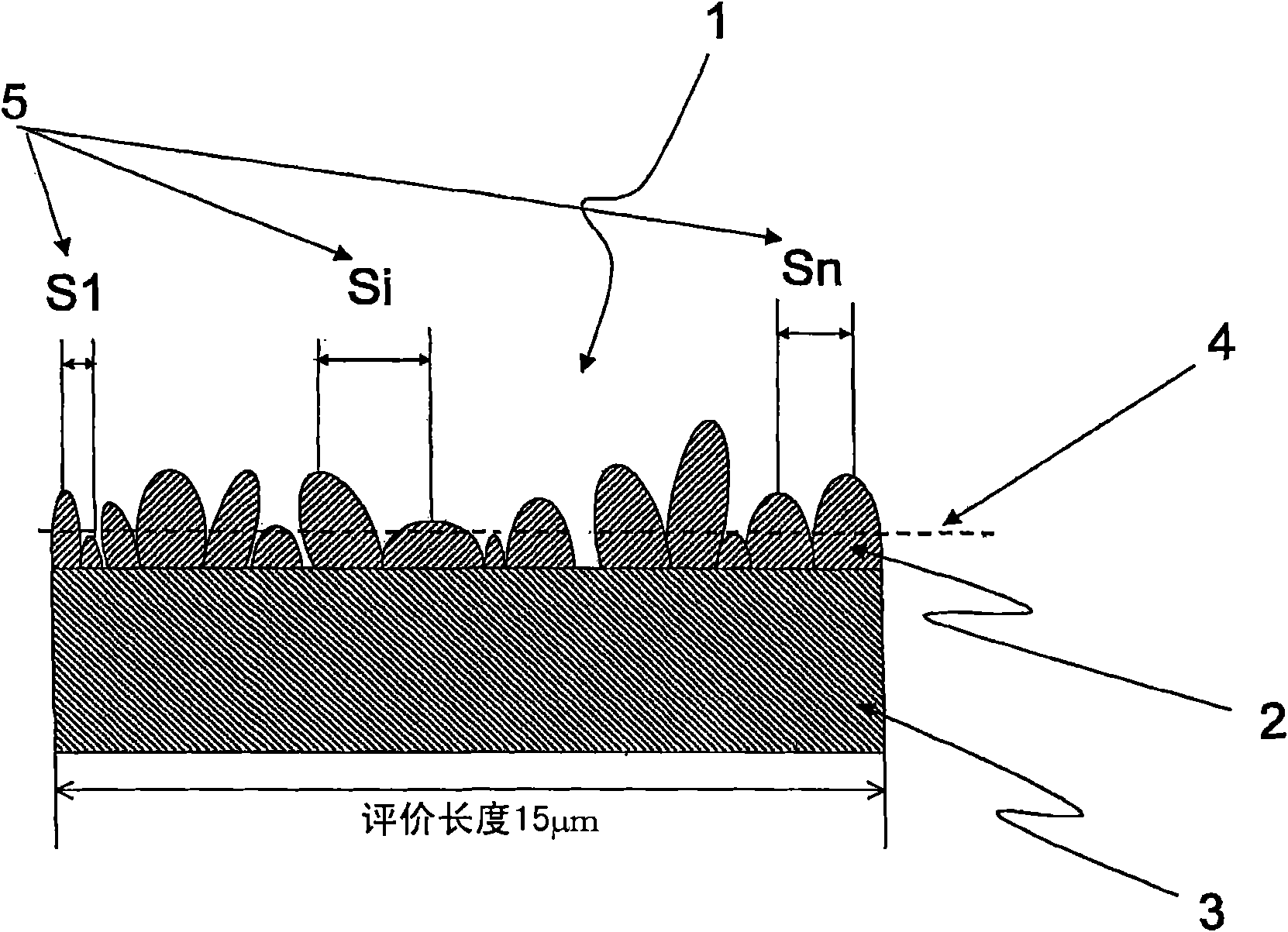

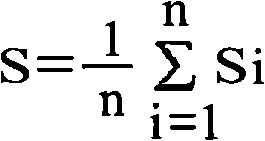

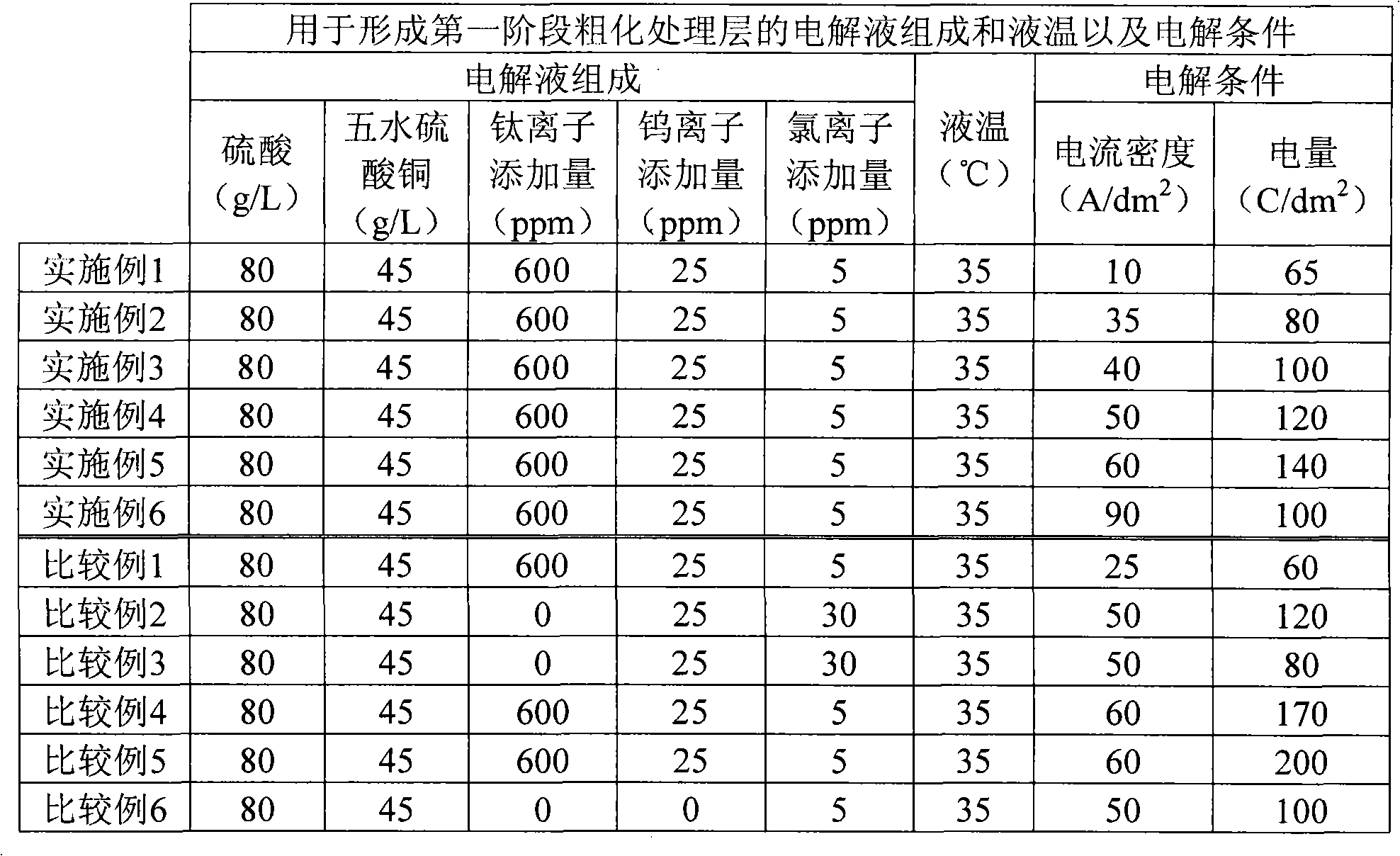

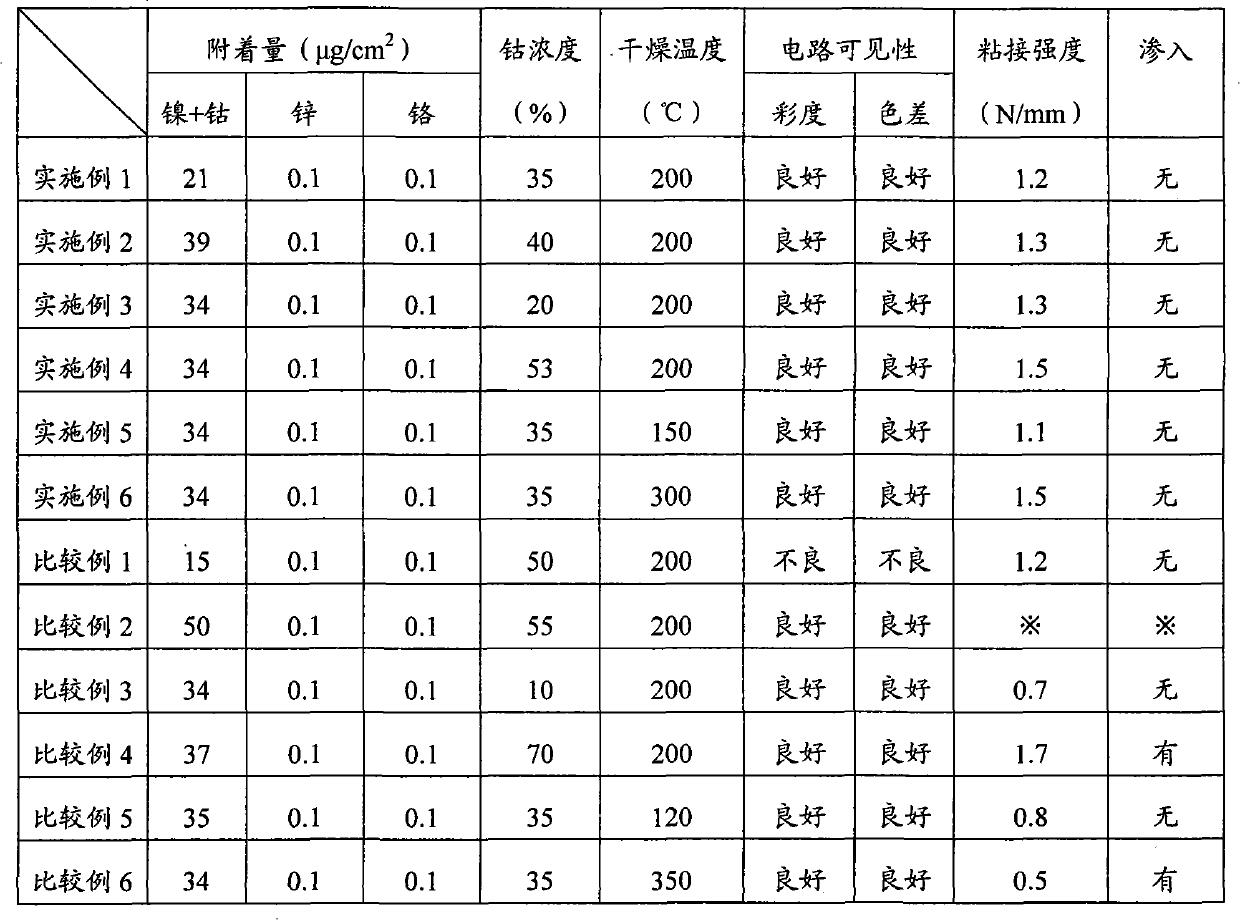

Copper foil for processing copper clad laminate, copper clad laminate and printed wiring board equipped with copper clad laminate

ActiveCN102215635AReduce deterioration rateImprove etching effectInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentDeterioration rateSilanes

The invention provides a treatment copper foil, which is low in roughness and high in peeling strength with an insulating resin substrate. After an absorption treatment, an active processing liquid after being impregnated is low in deterioration rate of the peeling strength, less in penetration amount and excellent in etching property. The copper foil is characterized in that the surface of the copper foil is sequentially equipped with a roughening treatment layer, a chromate layer and a silane coupling agent layer. The ten-point average roughness Rz of the copper foil surface is 1.0 mu m to 2.7 mu m. When the surface of the copper coil with the area thereof 177 mu M2 is measured by purple laser of visible light with the wavelength thereof 408 nm, the average interval S of local peaks is below 0.0230 mm and S does not include 0.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

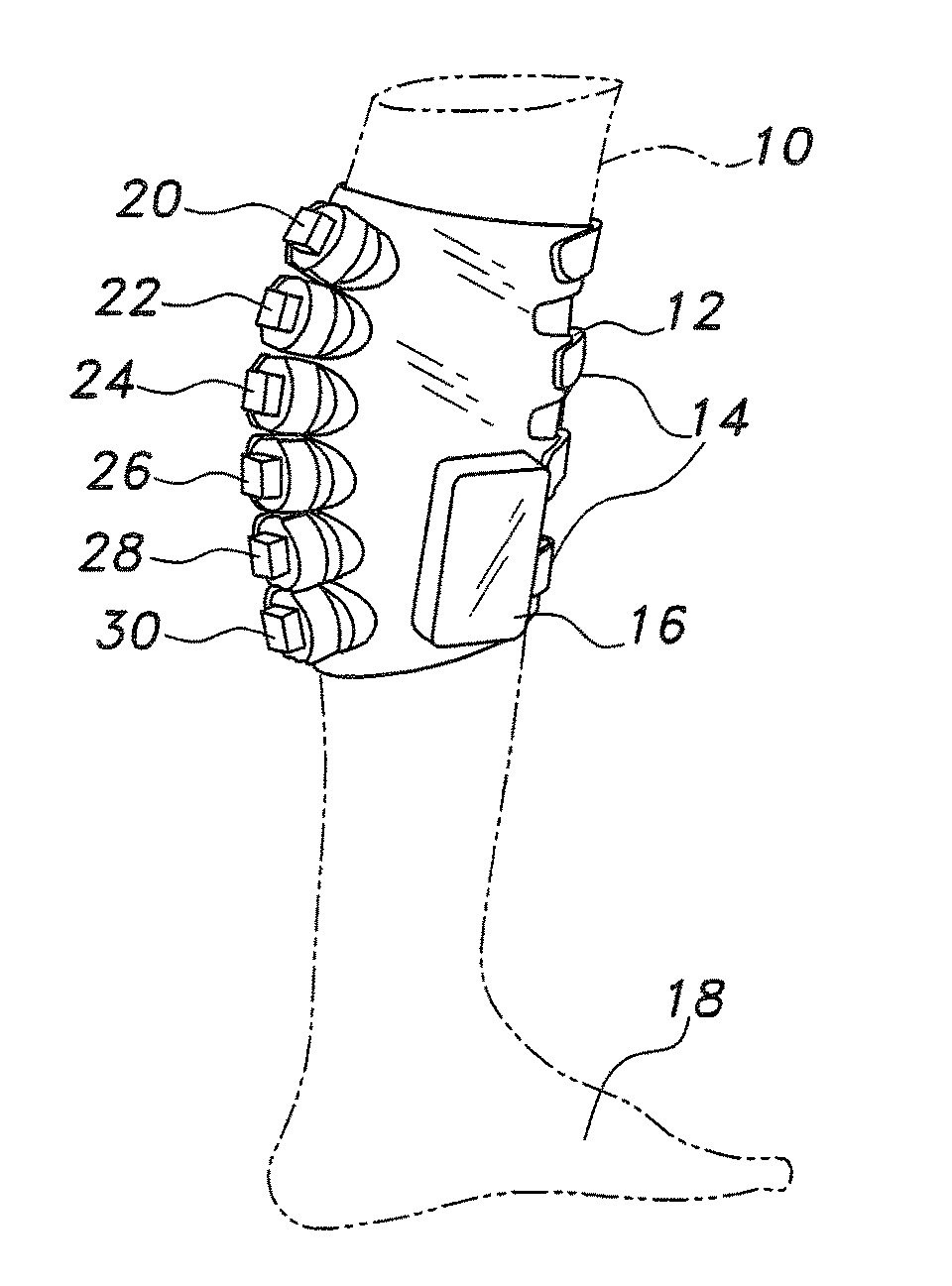

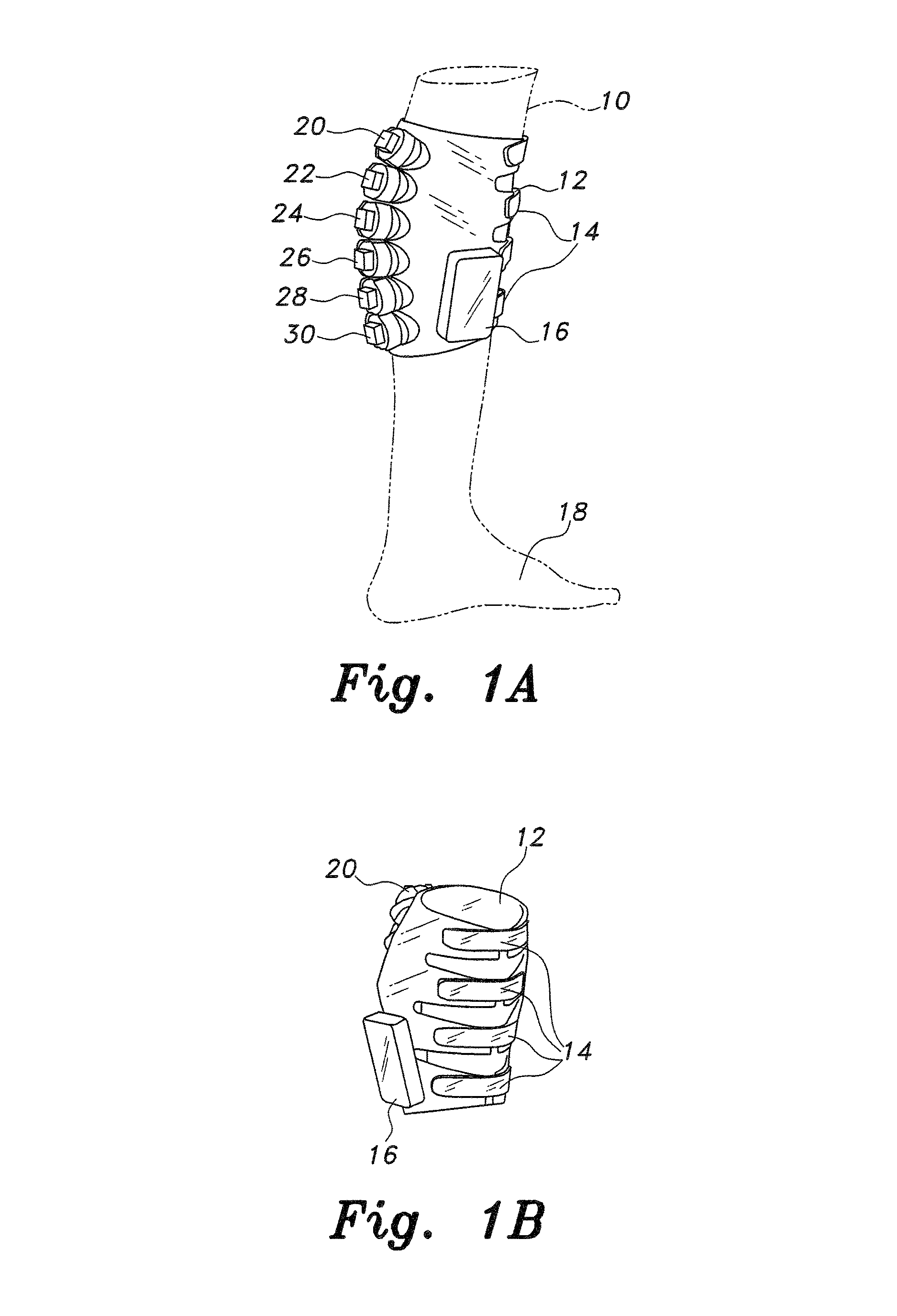

Sequential compression device for treatment and prophylaxis of deep vein thromboses

The sequential compression device for treatment and prophylaxis of deep vein thromboses includes a compression sock having a plurality of electromechanical units positioned along the calf muscle of a user's leg. Each of the electromechanical units includes a front housing component and a back housing component. The front housing component of the unit includes a compressor piston positioned in communicating relation with the user's calf muscle and the back housing component of the unit includes a magnet and a copper coil. The magnet is positioned in communicating relation with the compressor piston of the front housing component. Upon activation, the compressor piston selectively compresses the small saphenous vein to simulate the effect of the calf muscle during walking and promote the flow of blood back to the user's heart.

Owner:KING SAUD UNIVERSITY

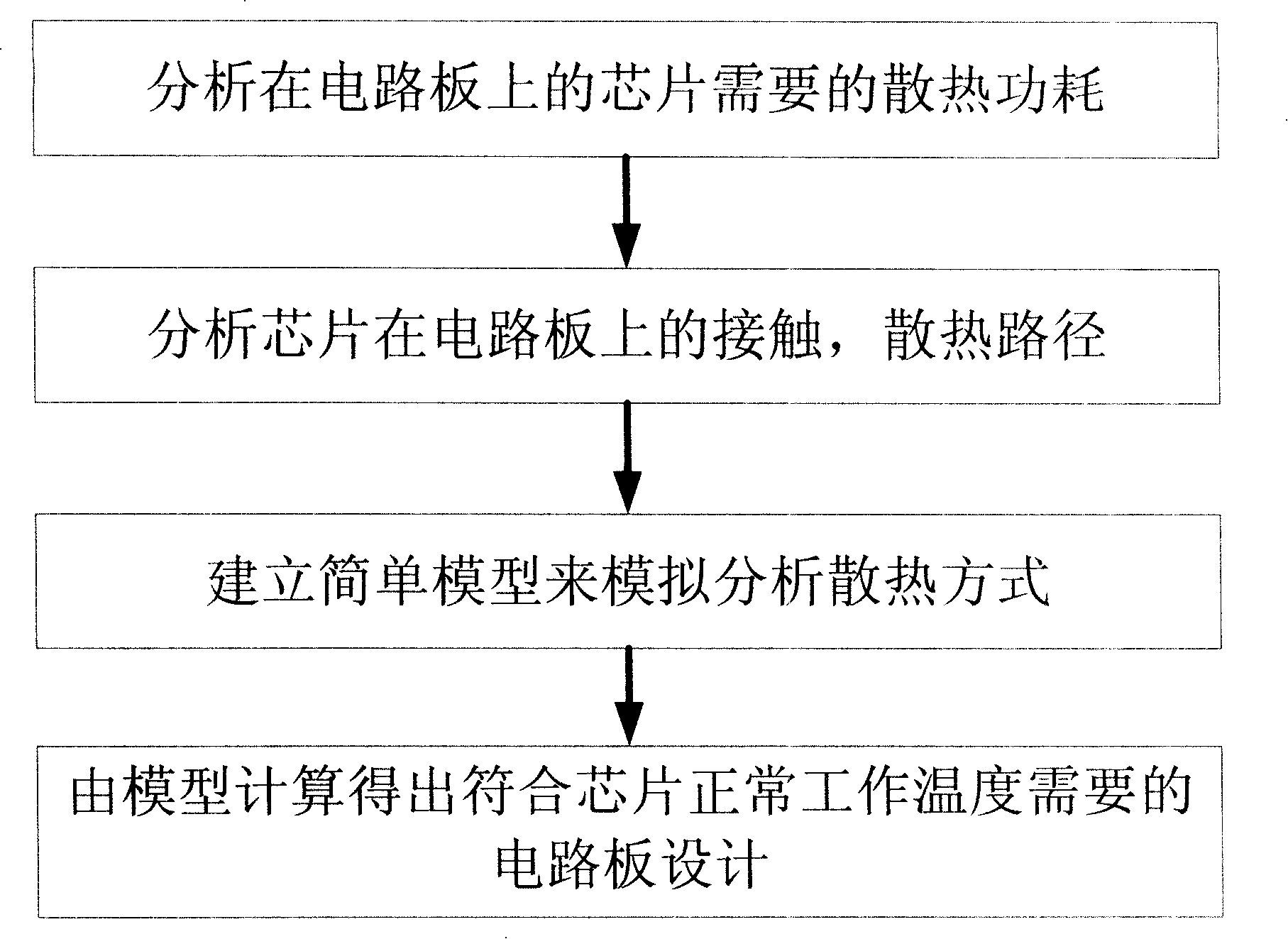

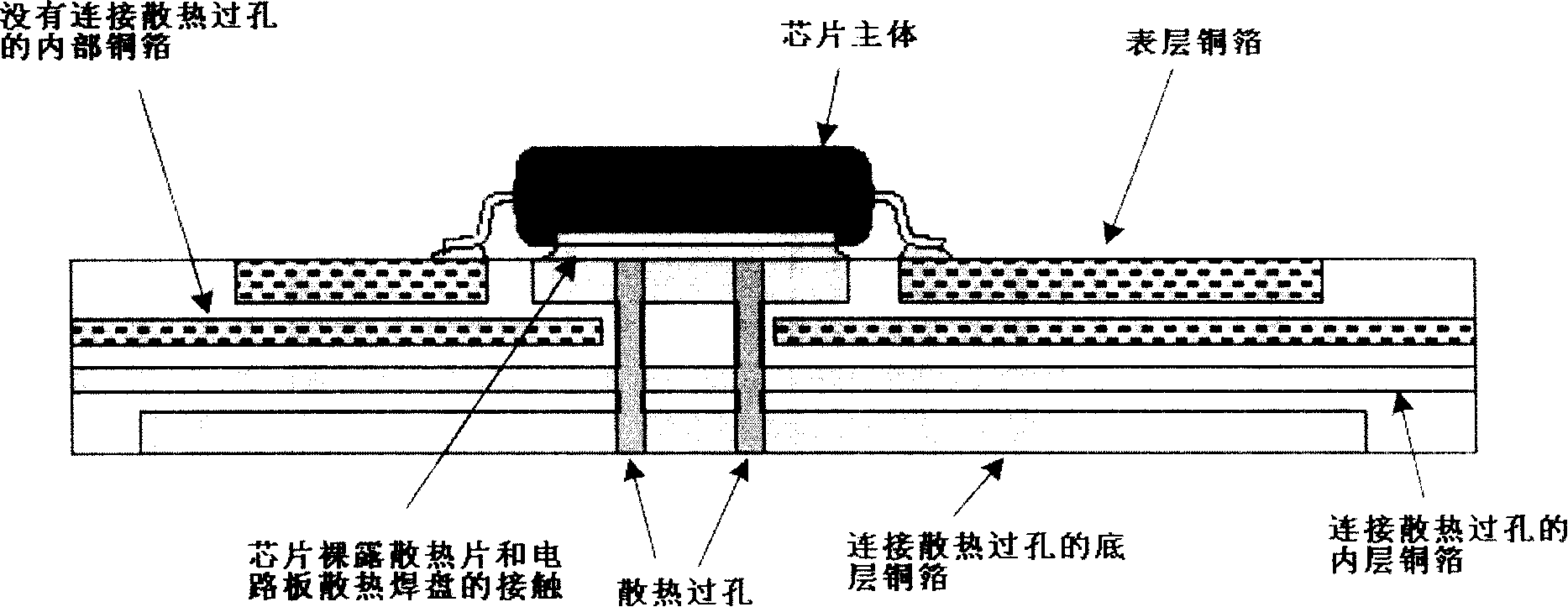

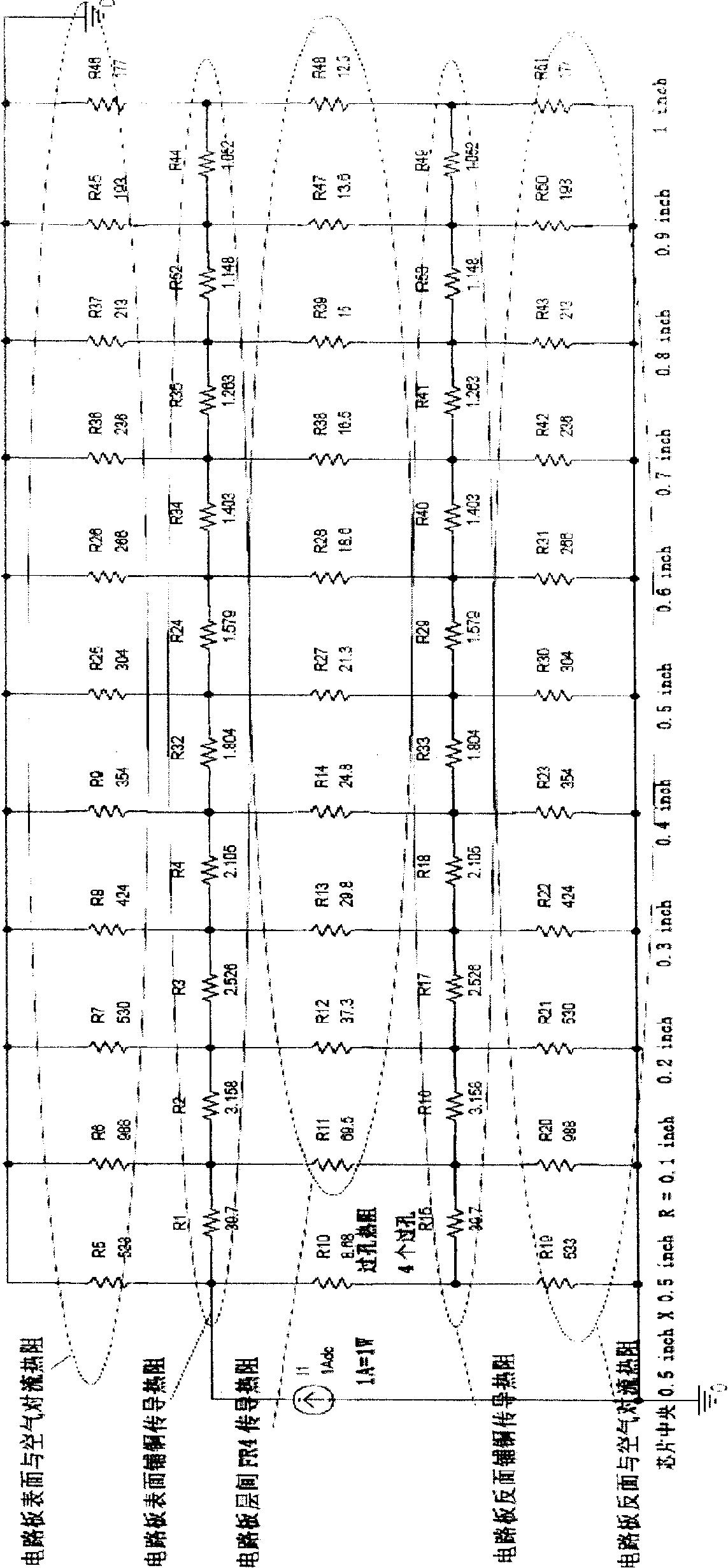

Radiation design method in PCB design

InactiveCN101221588ASimple designStable jobSpecial data processing applicationsCooling/ventilation/heating modificationsCopper coilEngineering

The invention discloses a thermal design method in the PCB design, which comprises the following steps: step 1, analyzing and determining elements generating much heat dissipation in the PCB design and the encapsulation pattern selection of the elements; determining the difference between a chip normal working temperature of the PCB and a chip maximum limiting temperature and the power consumption of the heat dissipation required by the chip on the PCB; step 2, analyzing the welding contact mode between the elements, the laminated structure and material of the PCB and corresponding heat dissipation modes; step 3, establishing a model to simulate the PCB heat dissipation and analyzing the heat dissipation modes; step4, designing the copper coil laying, the technological requirements and the laminated construction of the PCB according to model computing results, and enabling the chip to keep the normal working temperature when working on the PCB. The invention improves the design of the PCB through establishing the simple model, thereby enabling the heat dissipated by the elements to evenly reach the surface of the PCB as soon as possible, and enabling the PCB to have good heat dissipation and work stably without an external radiator.

Owner:昆山杰得微电子有限公司

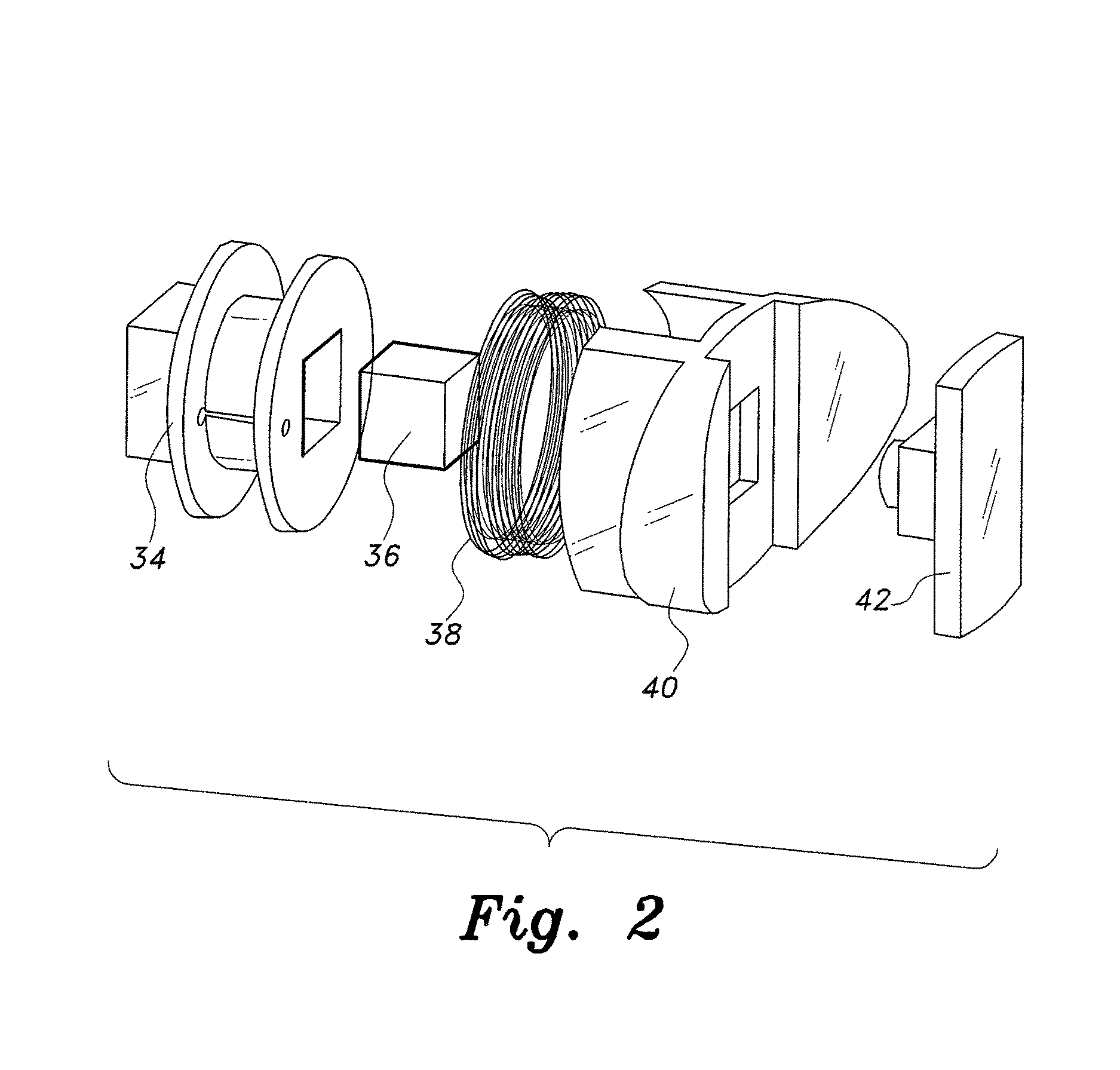

Additive for manufacturing ultrathin electrolytic copper foil

InactiveCN101481811AIncrease the volume-to-capacity ratioIncrease the number of charge and discharge cyclesElectroforming processesElectrolysisPolyethylene glycol

The invention relates to an additive for manufacturing ultrathin electrolytic copper coil, which is characterized in that the additive is prepared by 300-800 milligram of acid amide, 20-40 milligram of casein, 5-10 milligram of tetrahydro-thiazoles sulfur copper, 5-10 milligram of polyethyleneglycol, and 40-50 milligram of gelatin which are added into per 10000 liter deionized water and well blended. The electrolytic copper coil with high performance ,which is manufactured by the additive and used in lithium ion batteries with high capacity, has basically consistent double sided structure, namely, double sided light copper coil; the thickness of the copper coil is thin; the actually measured thickness & is less than equal to 12micron; the crystal structure of the rough surface is uniform, smooth and compact; the metal density is close to the theoretical density of pure copper; the profile tolerance of the rough surface Rz is less than 2 micron; and the elongation is larger than 5%; the tensile strength is larger than 400N / mm2; the thickness extreme difference of the copper coil with the same mass area ratio is less than equal to 0.5 micron.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

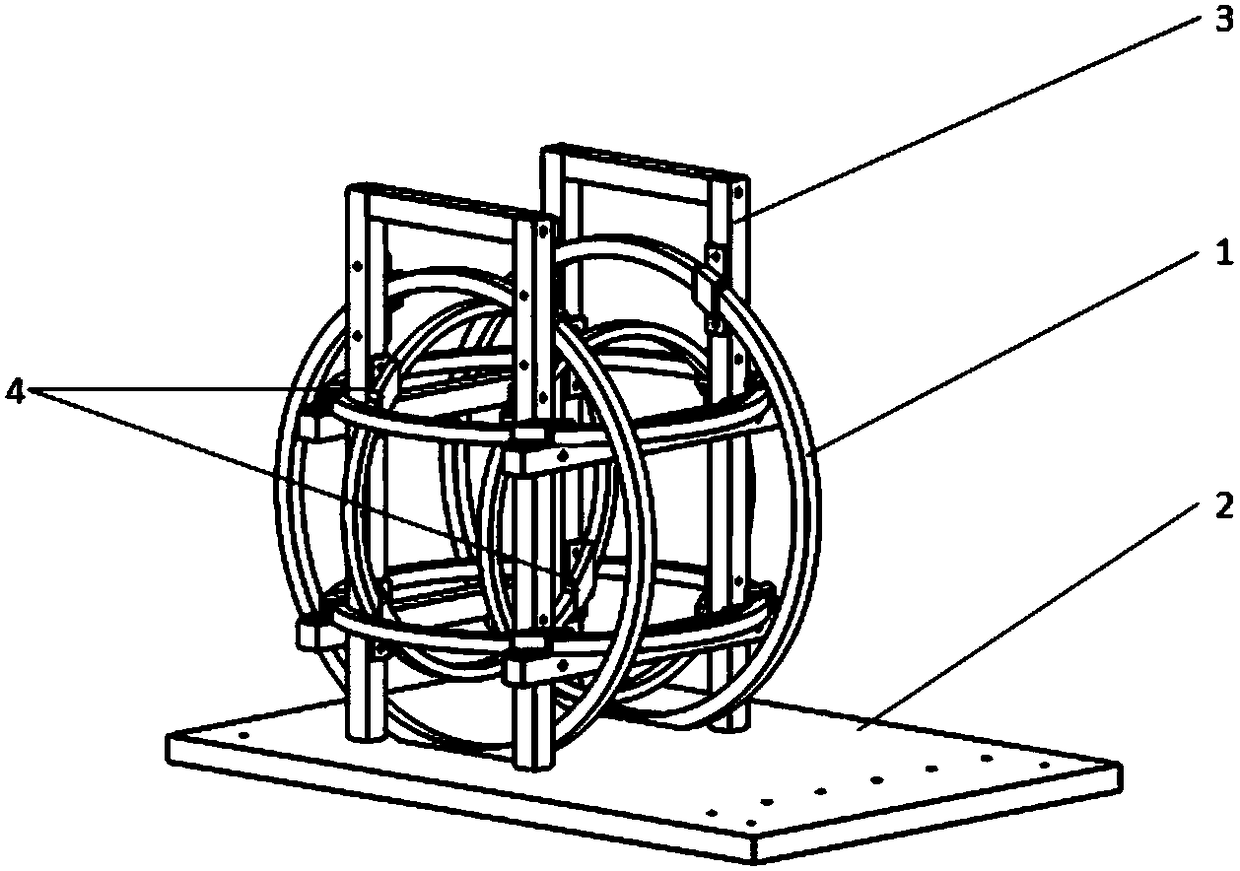

Random-direction dynamic vector uniform magnetic field generating device and control system

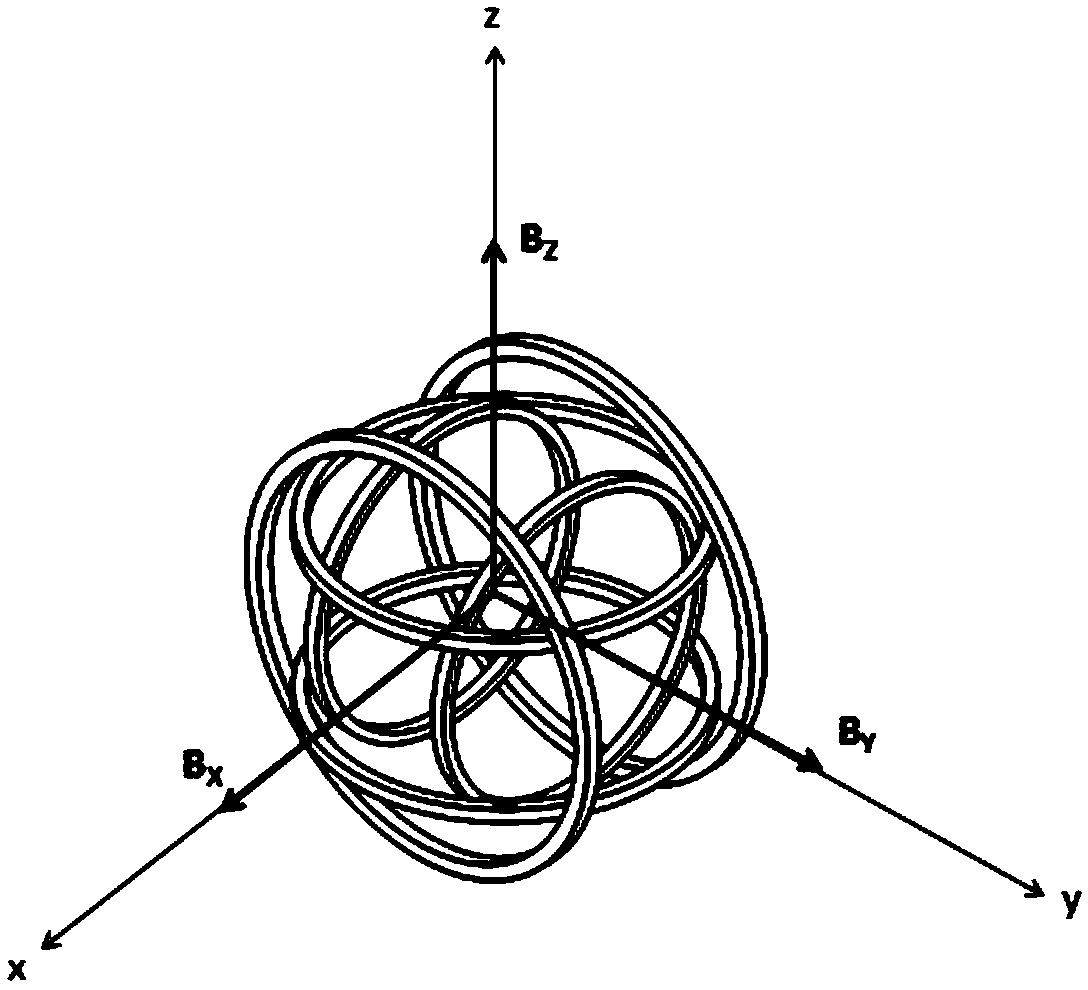

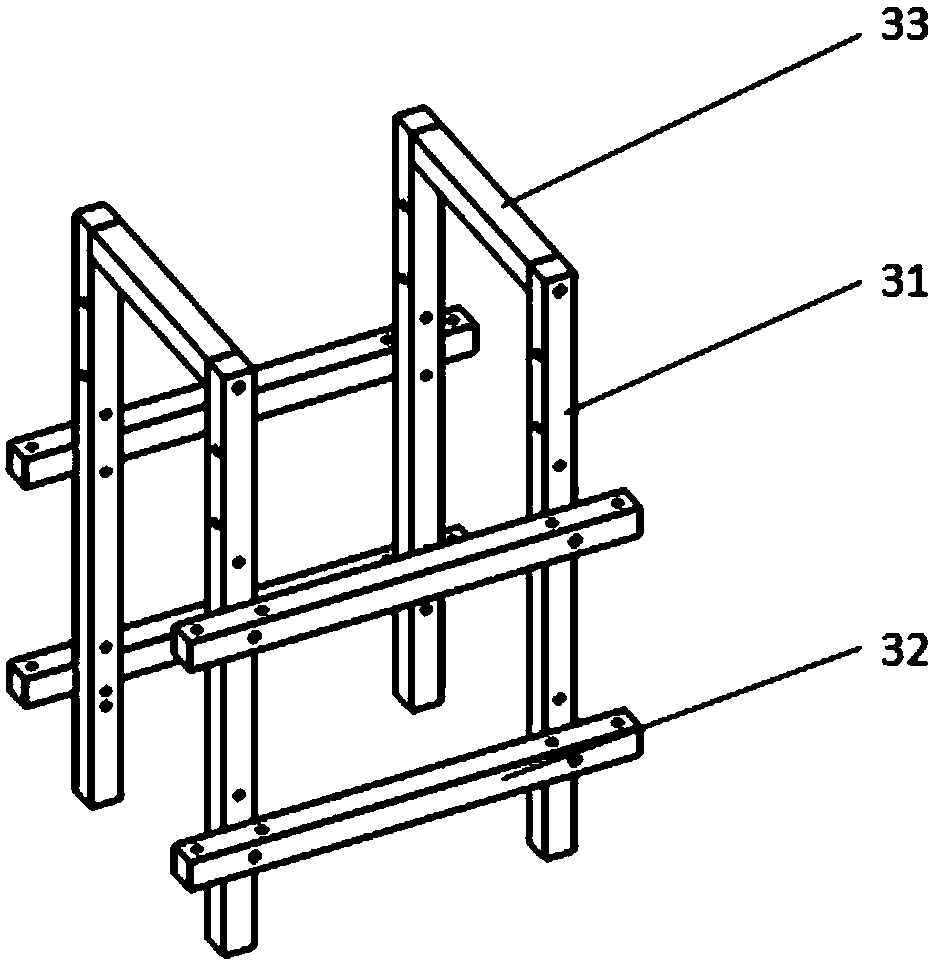

InactiveCN108535666AEasy to useUse adjustableMagnetic measurementsElectrical measurementsHelmholtz coilControl system

The invention provides a random-direction dynamic vector uniform magnetic field generating device and a control system, and relates to the technical fields of magnetic field generation and control andrelated magnetism testing engineering. The device comprises three groups of orthogonally-placed Helmholtz coils, a non-magnetic structural component and a three-channel current source. The three groups of Helmholtz coils are respectively wound around the X-axis, Y-axis and Z-axis of a space coordinate system, wherein the X-axis, the Y-axis, and the Z-axis are taken as the axes. Each Helmholtz coil comprises two enamelled copper coils which are coaxially wound clockwise in series, wherein the axial spacing of the two enamelled copper coils of the same group is the same as the radius of the enamelled copper coils. A uniform magnetic field in any direction and with adjustable size and variable timing sequence can be generated in the space near the geometric center of the device, thereby effectively solving a problem of the urgent need for uniformity, time-varying, directionality and high precision of the magnetic field.

Owner:深圳市启荣科技发展有限责任公司

Production method of 304 stainless steel and pure-copper cold compound coiled material

ActiveCN102794300AConvenient sourceImprove corrosion resistanceMetal rolling arrangementsRoom temperatureCopper coil

The invention relates to a production method of a 304 stainless steel and a pure-copper cold compound coiled material. The production method comprises the following process steps of: (1) preparing raw materials: carrying out surface oil-removing and decontaminating treatment on 304 coldly-rolling stainless steel and a pure-copper coiled material; (2) carrying out compound rolling: conveying the 304 coldly-rolling stainless steel and a copper metal material into a compound rolling machine to carry out synchronous room-temperature continuous compound rolling; (3) dispreading and annealing: carrying out the dispreading and annealing on a rolled stainless steel copper compound coiled material on an alloy layer; (4) flattening the stainless steel copper compound coiled material which is dispread and annealed; (5) carrying out bending and strengthening treatment on the flattened stainless steel copper compound coiled material; and (6) carrying out cutlengthing and splitting on the stainless steel copper compound coiled material to form a 304 stainless steel and copper cold compound material. The production method disclosed by the invention has a simple manufacturing process and low production cost; and the corrosion resistance of the steel-copper compound coiled material is strong and no rusts are formed on the end surfaced of the steel-copper compound coiled material, so that the requirements of a plurality of indoor and outdoor decorative materials are met.

Owner:无锡银荣板业有限公司

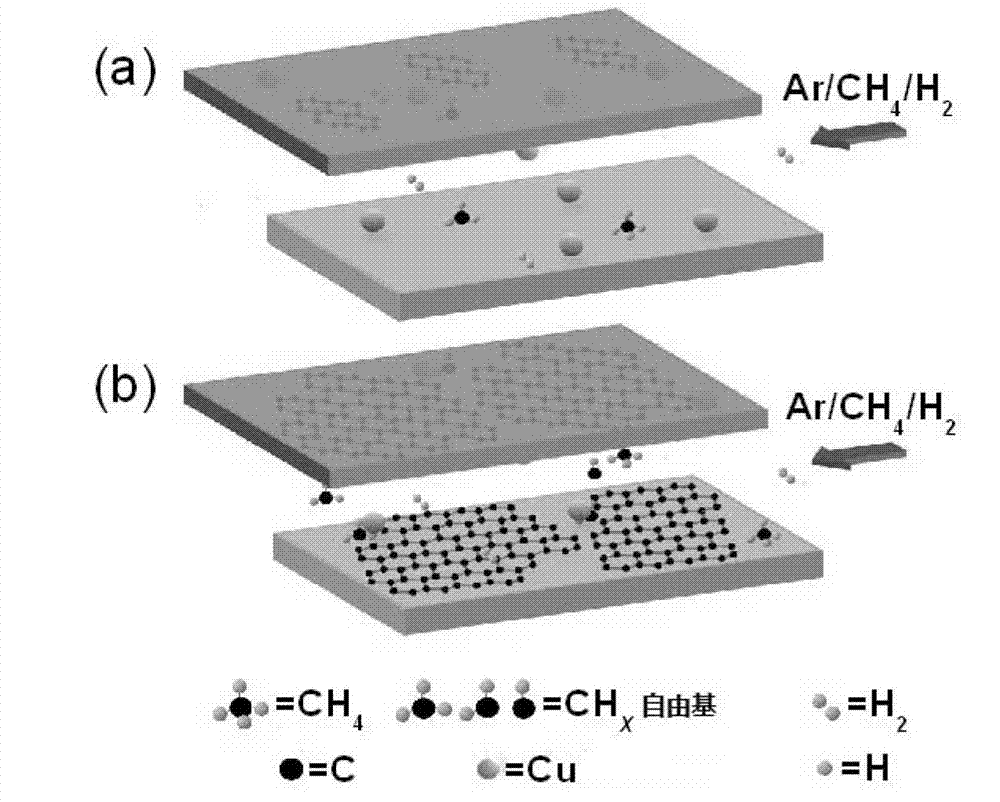

Large-scale production method for chemical vapor deposition (CVD) graphene film

ActiveCN105603384AAvoid stickingDoes not affect depositionChemical vapor deposition coatingCatalytic pyrolysisCopper foil

The invention discloses a large-scale production method for a chemical vapor deposition (CVD) graphene film. By the adoption of a CVD technology, first, heat treatment is performed on metal substrates under a vacuum state, inert gas and carbon source gas are injected, the carbon source gas is subjected to catalytic pyrolysis on the surfaces of the metal substrates at high temperature, then graphene grows, large-scale growth is achieved by the adoption of the mode that the multiple layers of metal substrates are overlaid, and every two adjacent layers of metal substrates are separated through a separation layer. Through arranging the separation layers, adhesion between the metal substrates is prevented, in addition, deposition of high-quality graphene on each layer of copper coil is not affected, the multiple layers of metal substrates used for graphene growth can be installed on one basal plate, in this way, the capacity which is a hundred times that of a traditional CVD method is achieved through the same reaction furnace, and large-scale production is achieved.

Owner:WUXI GRAPHENE FILM +1

Water heater of solar energy in type of power generation stored energy

InactiveCN101093111ASimple structureIncrease heat absorption areaSolar heating energySolar heat collector controllersFiberCarbon fibers

This invention relates to a generating energy-storage solar water heater including a shell characterizing in including groove-like inner and outer shells filled with a heat-insulation material layer and setting a storage battery, in which a heat-storage layer mixed by pitch and concave-convex stones are set in the inner shell buried with heat-sink copper coiled pipe and a carbon fiber electric felt, a solar cell board is set at the middle of the surface of the heat storage layer, a steel glass plate is covered above the cell board and the pitch layer and fixed by an interval frame covered with a steel glass plate and fixed by blank strip and screws, two ends of the heat-sink copper coiled pipe are connected with the inlet and outlet at one side of the shell, a fixed shaft is set at both sides of the shell and set in the shaft hole at the top of a bracket, the fixed frame is set at the bottom of the bracket holding a motor and a time controller, a gear is installed on the rotary shaft and meshed with a transfer chain.

Owner:中山市志兴环保科研有限公司

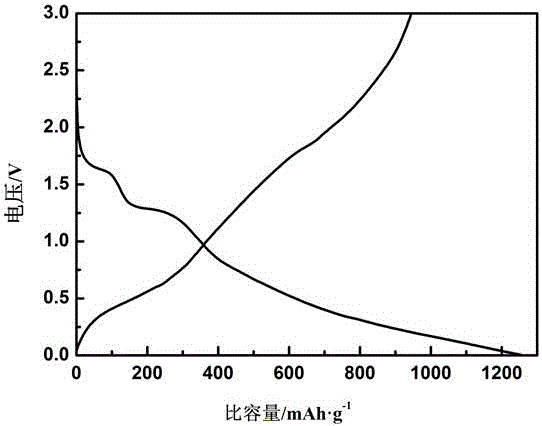

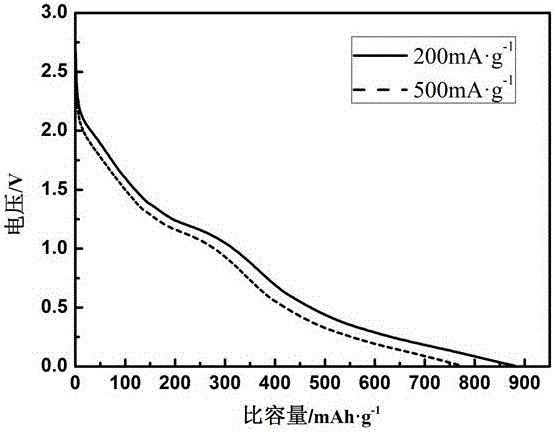

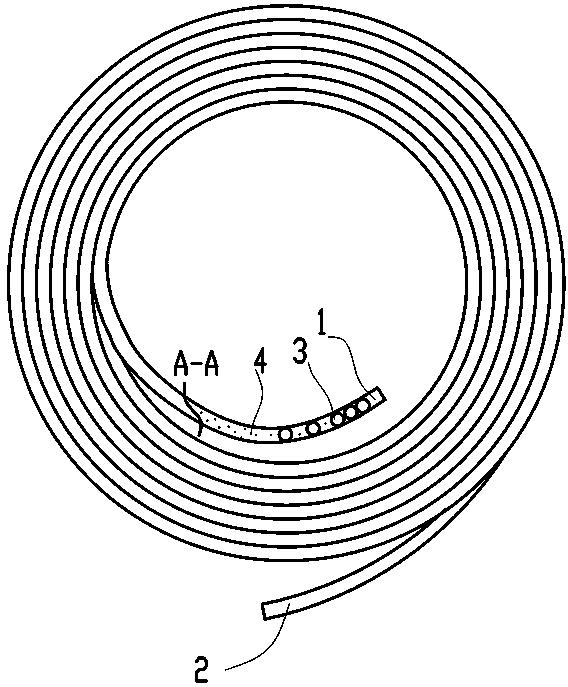

Membrane electrode based on spiral carbon nanofiber bundle and preparation method thereof

InactiveCN102306749AHigh reversible specific capacityImproved magnification performanceCell electrodesFiberGas phase

The invention discloses a membrane electrode based on a spiral carbon nanofiber bundle and a preparation method thereof, belonging to the technical field of lithium ion batteries. The membrane electrode comprises a copper coil current collector and the spiral carbon nanofiber bundle growing on the surface of the copper coil current collector, wherein the spiral carbon nanofiber bundle is formed by spirally winding a plurality of carbon nanofibers, and a graphite layer of the carbon nanofibers is vertical to the axial direction of the carbon nanofibers. The preparation method of the membrane electrode comprises the following steps: loading a nickel-based catalyst on the surface of a copper coil; and then growing the spiral carbon nanofiber bundle on the surface of the copper coil by adopting a chemical vapor deposition method. The membrane electrode and the preparation method provided by the invention have the advantages that the unique structure of the membrane electrode enables the membrane electrode to have higher reversible specific capacity, good electrochemical cycle stability and higher multiplying power performance; and the preparation technology is simple, convenient to operate, and easy to implement large-scale industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Production technology for high-precision fully resistance carbon film overlapping board

ActiveCN101106866ARealize functionMeet production needsPrinted electric component incorporationHigh resistanceCarbon film

The invention relates to a printing technology for high-resistance carbon film layer. The problem to be solved is that the provided technology can effectively realize resistance control on a high-resistance carbon film lamination, further to improve production efficiency and reduce production cost. The technical proposal is that the production technology for the high-precision whole-resistance carbon film laminated plate includes a production technology for a carbon film surface adhering plate in which a carbon film resistor is printed during printing process for the carbon film lamination. The printing process of the carbon film resistor is performed by following steps in sequence: firstly, determining proportion of the conductive carbon ink; and secondly, printing the conductive carbon ink on copper coil contact points at two ends of a resistor on the circuit board to form a carbon film resistor. The geometric shape of the carbon film resistor is determined by the following relationship: resistance of the carbon film resistor is equal to resistance of the formula of the carbon ink multiplied by length of the carbon film resistor and then divided by width of the carbon film resistor, in which the resistance of the carbon film resistor is determined by thickness of the carbon film resistor and the proportion of the conductive carbon ink, and width of the carbon film resistor is determined by thickness of the printed film.

Owner:徐立军

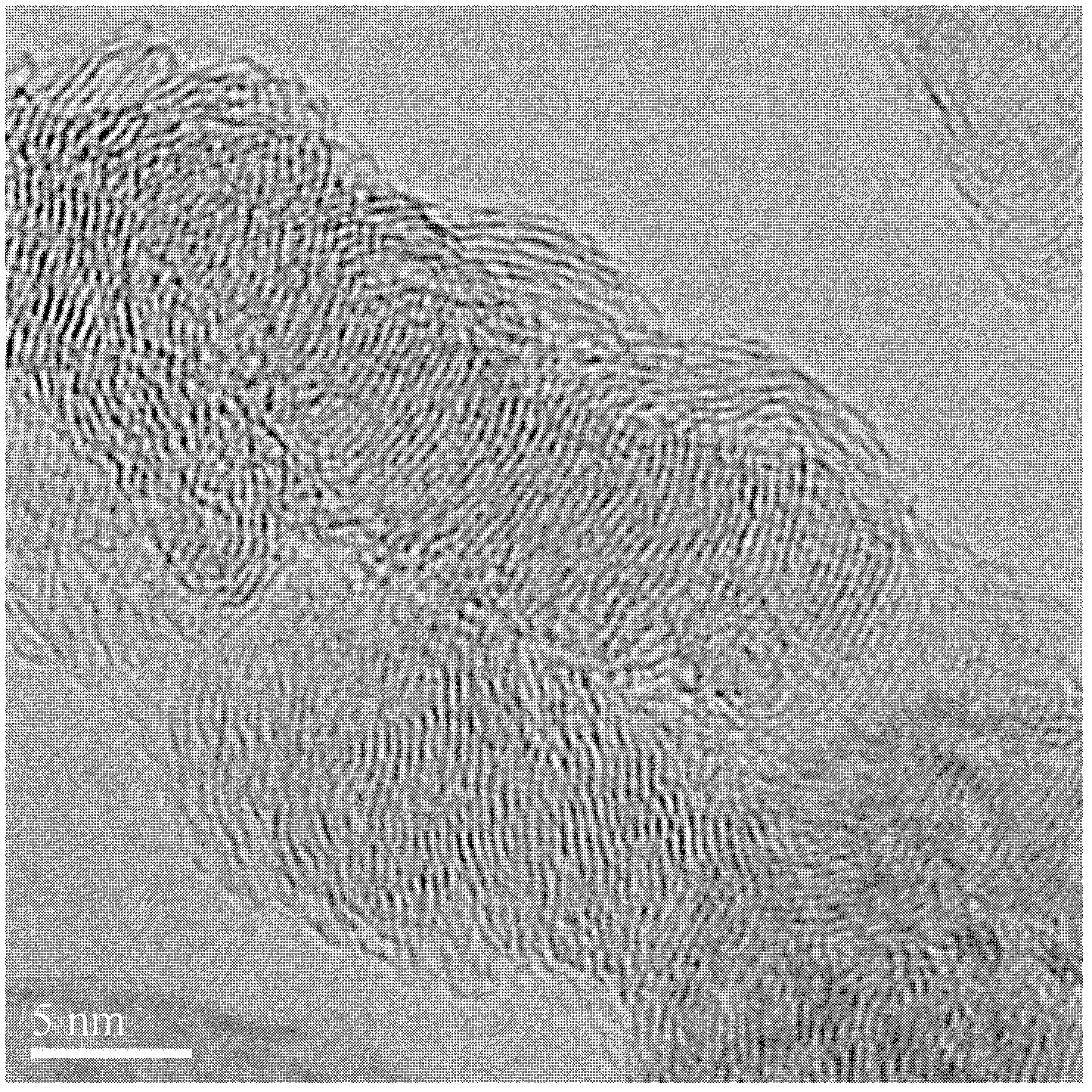

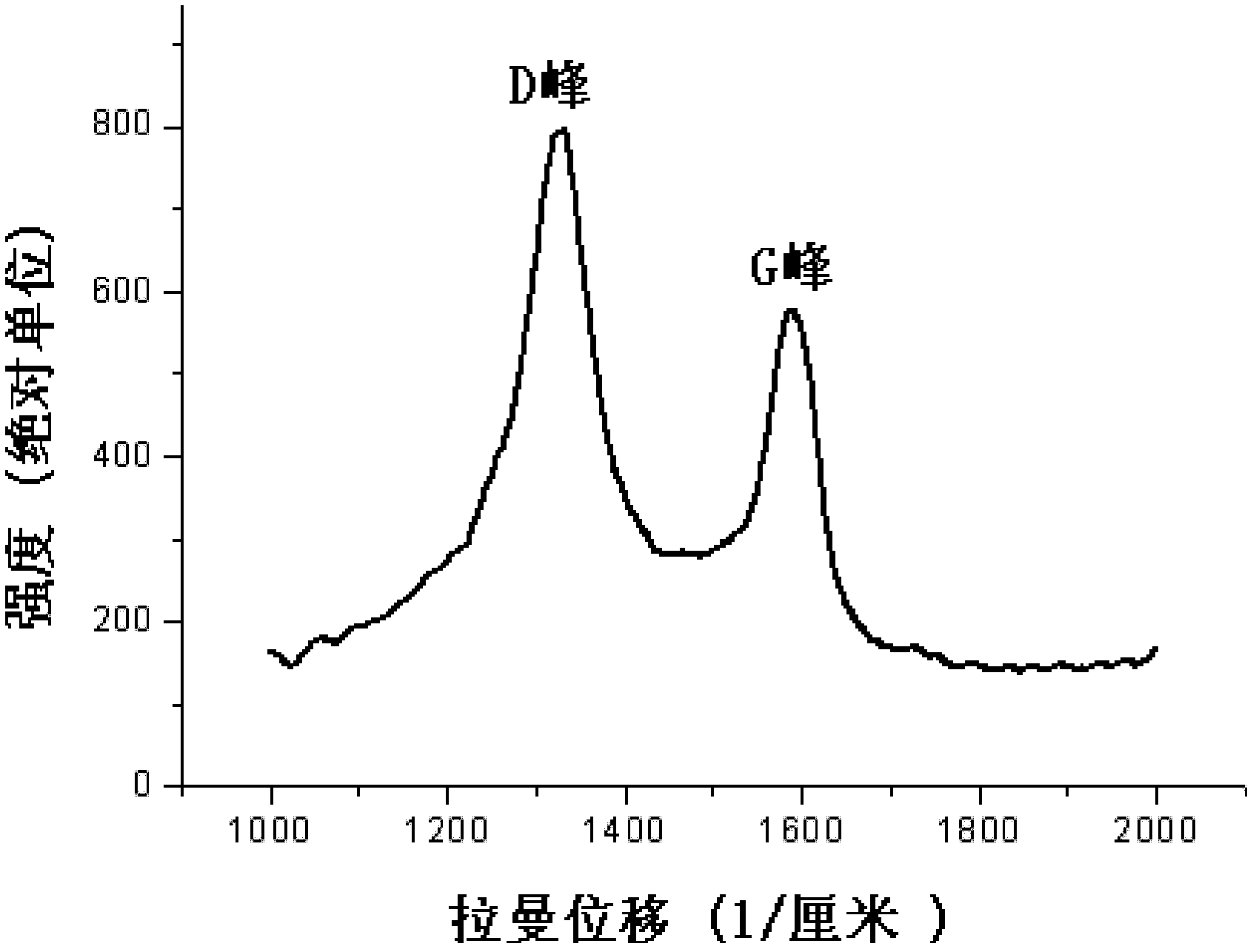

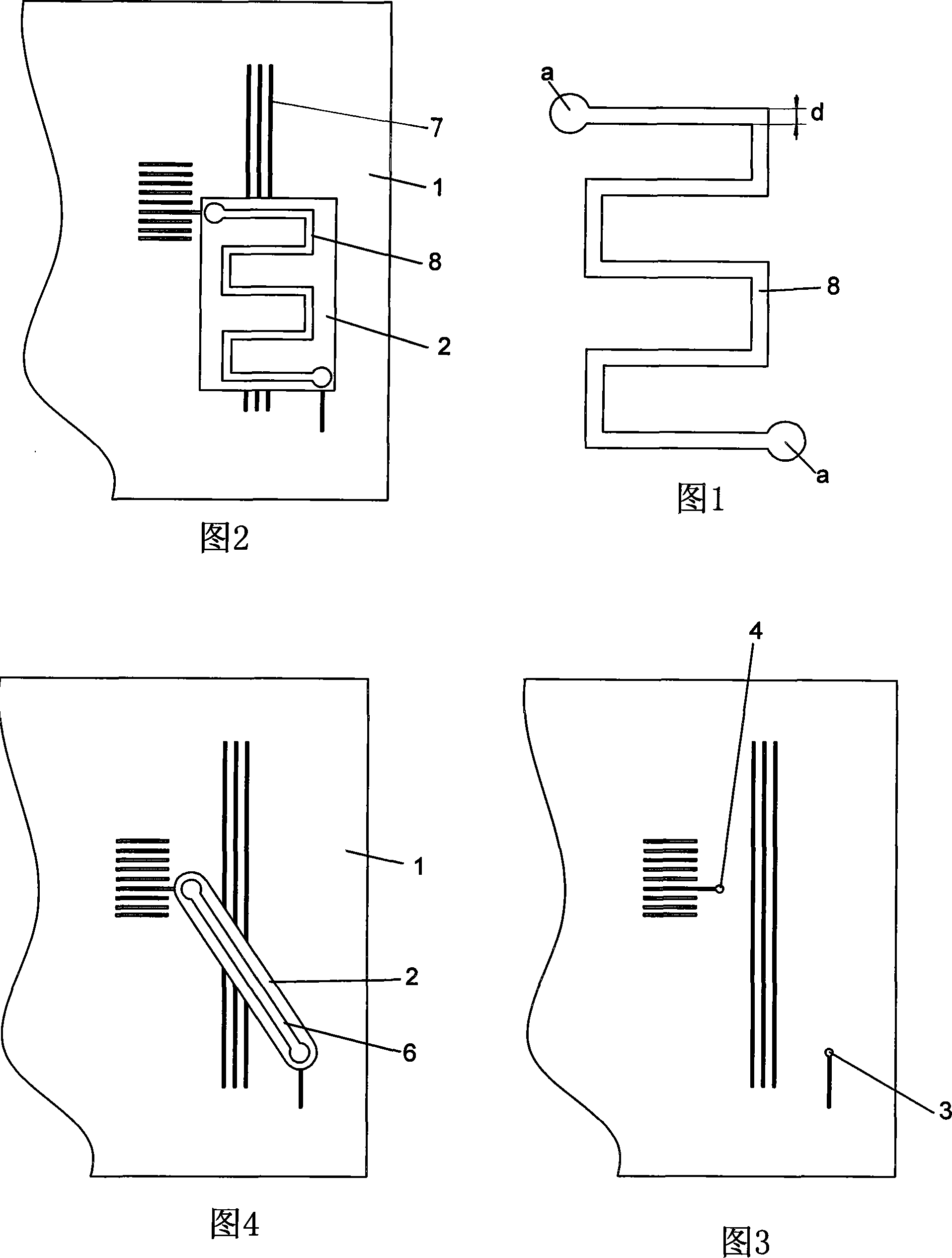

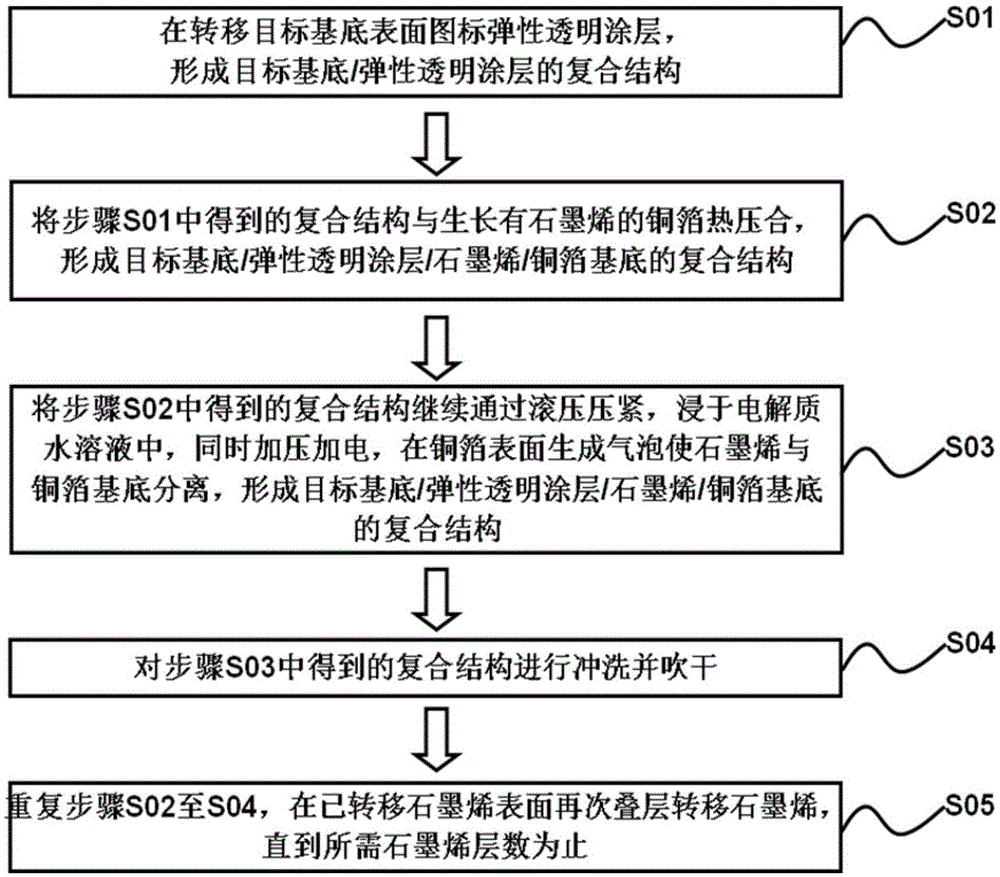

Multi-layer stacking and transferring method for graphene

The invention relates to a multi-layer stacking and transferring method for graphene. The method includes the operation steps that S01, the bottom face and the surface of a transferring target substrate are coated with an elastic transparent coating; S02, thermo-compression bonding is conducted on copper foil where graphene grows and the coated elastic transparent coating in a rolling mode; S03, the obtained compressed structure continues to be soaked in an electrolyte solution through rolling pressing, and electricity is applied for bubbling at the same time so that graphene and copper coil can be separated, attached and transferred to the target substrate; S04, washing and blow-drying are conducted on the surface of transferred graphene; S05, the step S02, the step S03 and the step S04 are repeatedly executed, graphene is stacked and transferred on the surface of transferred graphene till graphene is stacked to the required level number. Rapid and complete transferring of graphene is achieved by coating the graphene transferring target substrate with the elastic coating for modification and through the electrochemistry bubbling stripping method, multiple layers of stacked graphene are transferred according to practical requirements, and the electrical property uniformity and stability of graphene are improved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Copper foil for printed circuit boards and method for manufacturing the same

ActiveCN101998776AImprove visibilityInsulating substrate metal adhesion improvementPrinted circuit aspectsCobalt nickel alloyCopper coil

The present invention provides a copper foil for printed circuit boards and a method for manufacturing the same, the copper foil has high visibility of penetrating an insulating base material, and it is possible to avoid inleakage and peeling in a process of manufacturing the printed circuit board. The copper coil for the printed circuit board is characterized in that the copper coil is used for forming a conductor distribution picture of the printed circuit board and is pasted to the surface of the insulating base material, and has a cobalt-nickel alloy plating layer in which a chroma (based on Japanese Industrial Standard JIS Z 8729) c *= (a*2 + b*2) 1 / 2 of the surface of the copper coil is less than 6 optically detected by spacing the insulating base material.

Owner:CHANG CHUN PETROCHEMICAL CO LTD

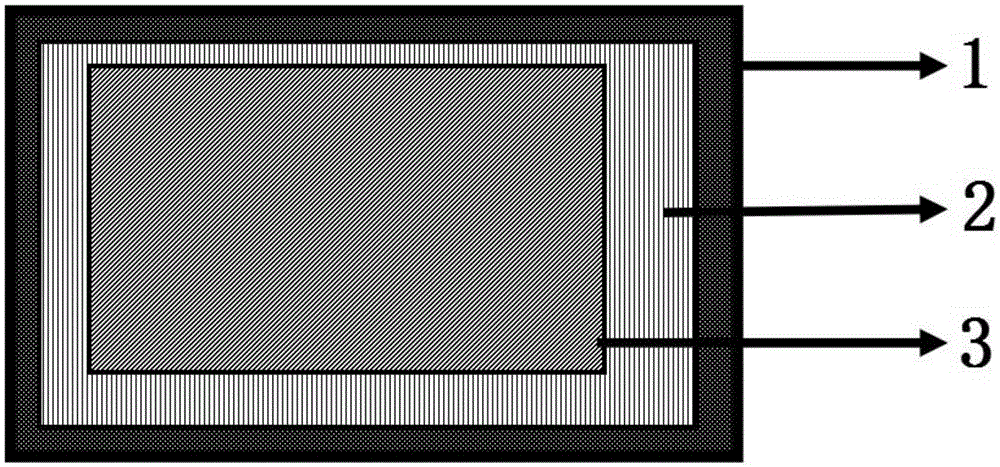

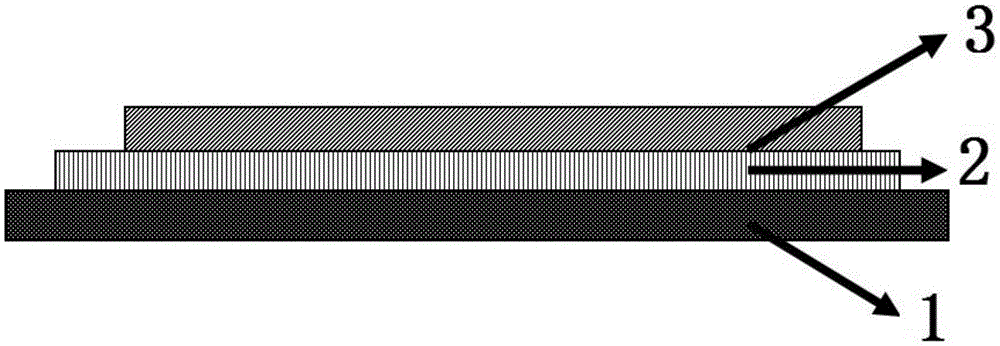

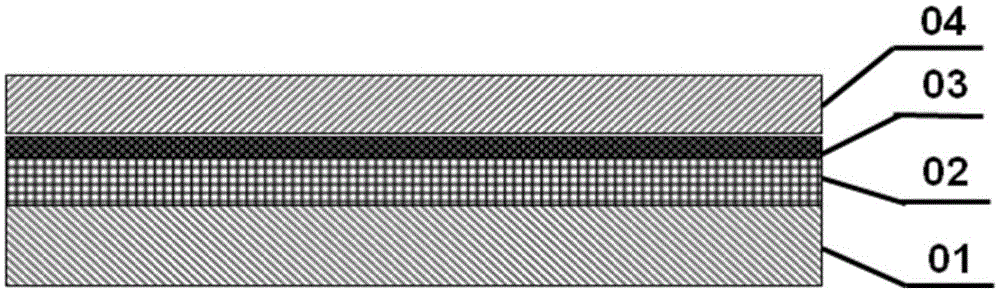

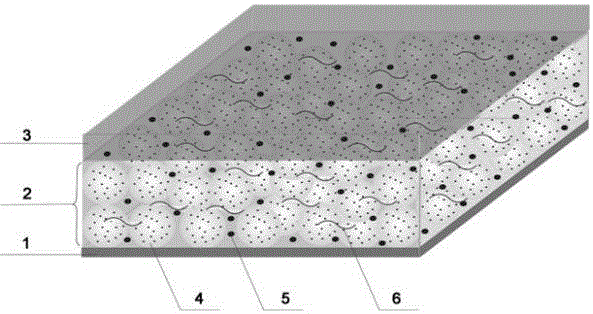

Negative electrode pole piece made of graphene hollow sphere loaded tin disulfide composite material and used for lithium-ion battery

InactiveCN106129376AInhibition of dissolutionInhibition of the shuttle effectCell electrodesSecondary cellsCopper foilPole piece

The invention discloses a negative electrode pole piece made of a graphene hollow sphere loaded tin disulfide composite material and used for a lithium-ion battery. The negative electrode pole piece comprises a current collection body layer (1), an active material layer (2) and a coating layer (3), wherein the active material layer (2) coats one face or two faces of the current collection body layer (1) and the coating layer (3) coats the surface of the active material layer (2); the current collection body layer (1) is a copper coil material; the active material layer (2) is composed of the graphene hollow sphere loaded tin disulfide composite material (4), a conducting agent (5) and a binding agent (6); and the coating layer (3) is a graphene oxide thin film. A composite negative electrode can be used for effectively buffering volume expansion of tin disulfide in a charging / discharging process; and meanwhile, the problems that lithium sulfide is irreversible in the charging / discharging process and lithium polysulfide is dissolved into electrolyte to cause a shuttle effect and the like can also be solved, and the capacity performing and circulating properties of the battery are greatly improved.

Owner:SHANGHAI UNIV

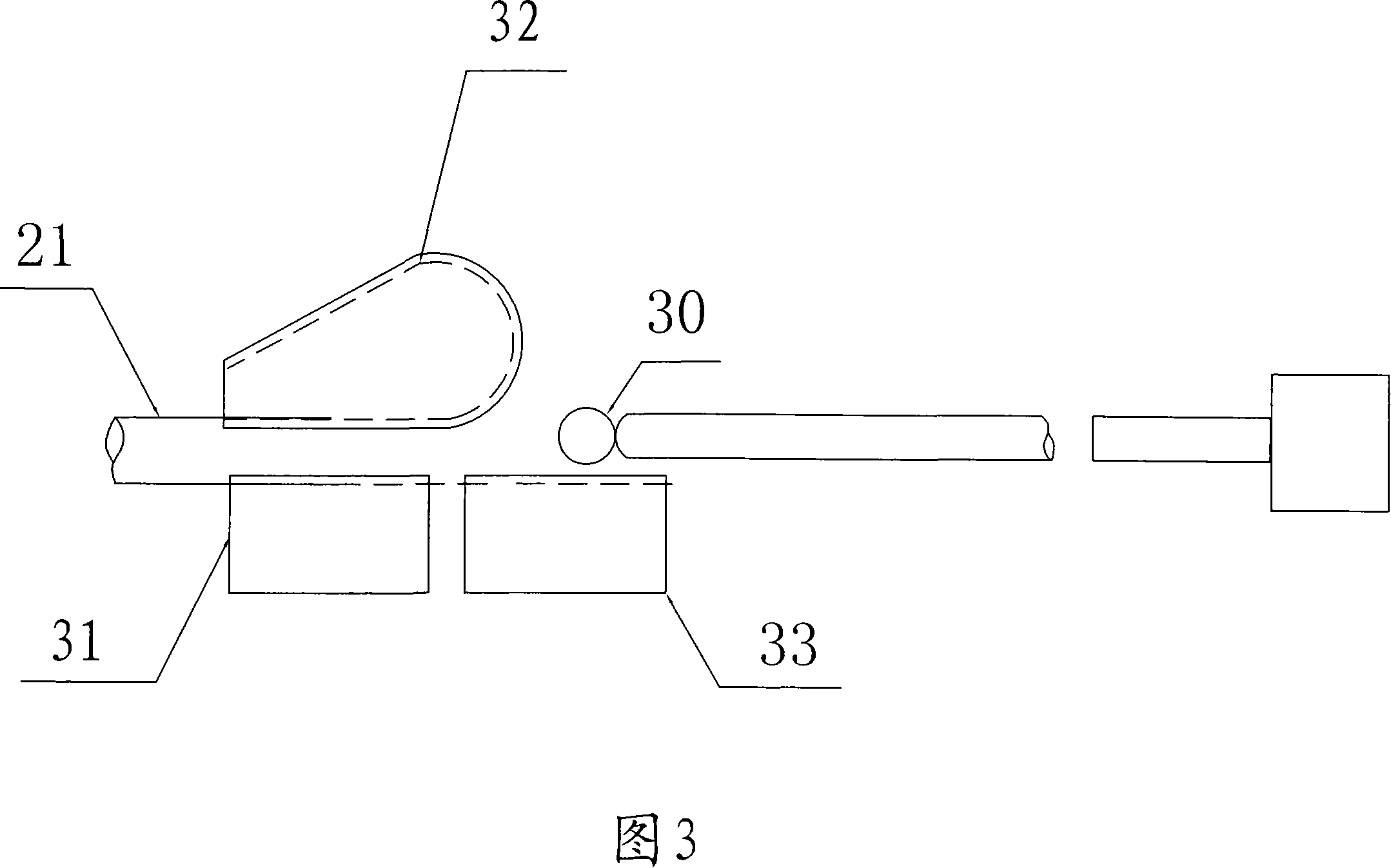

Method for cleaning internal surface of copper coil

Owner:NINGBO JINTIAN COPPER TUBE +1

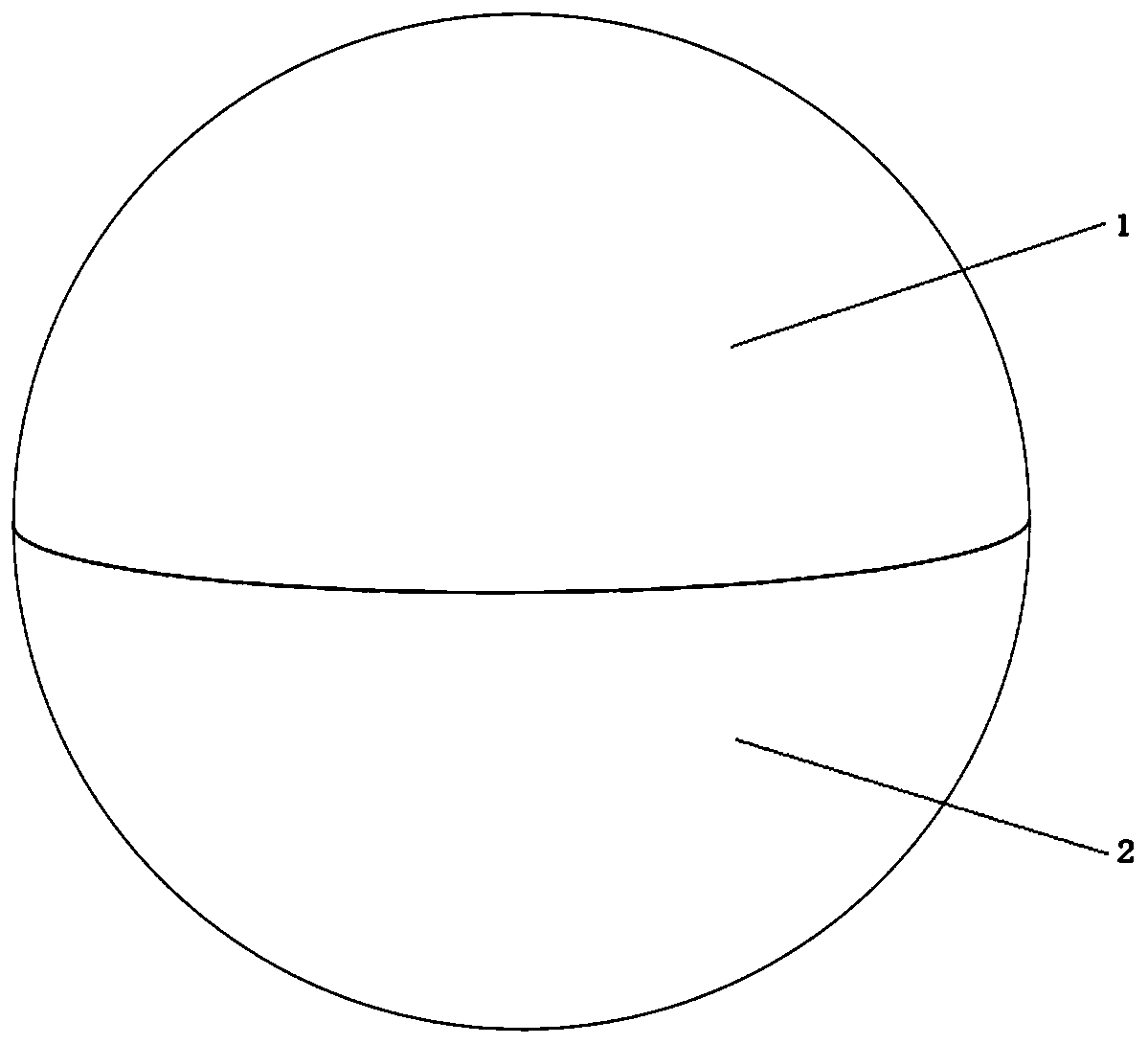

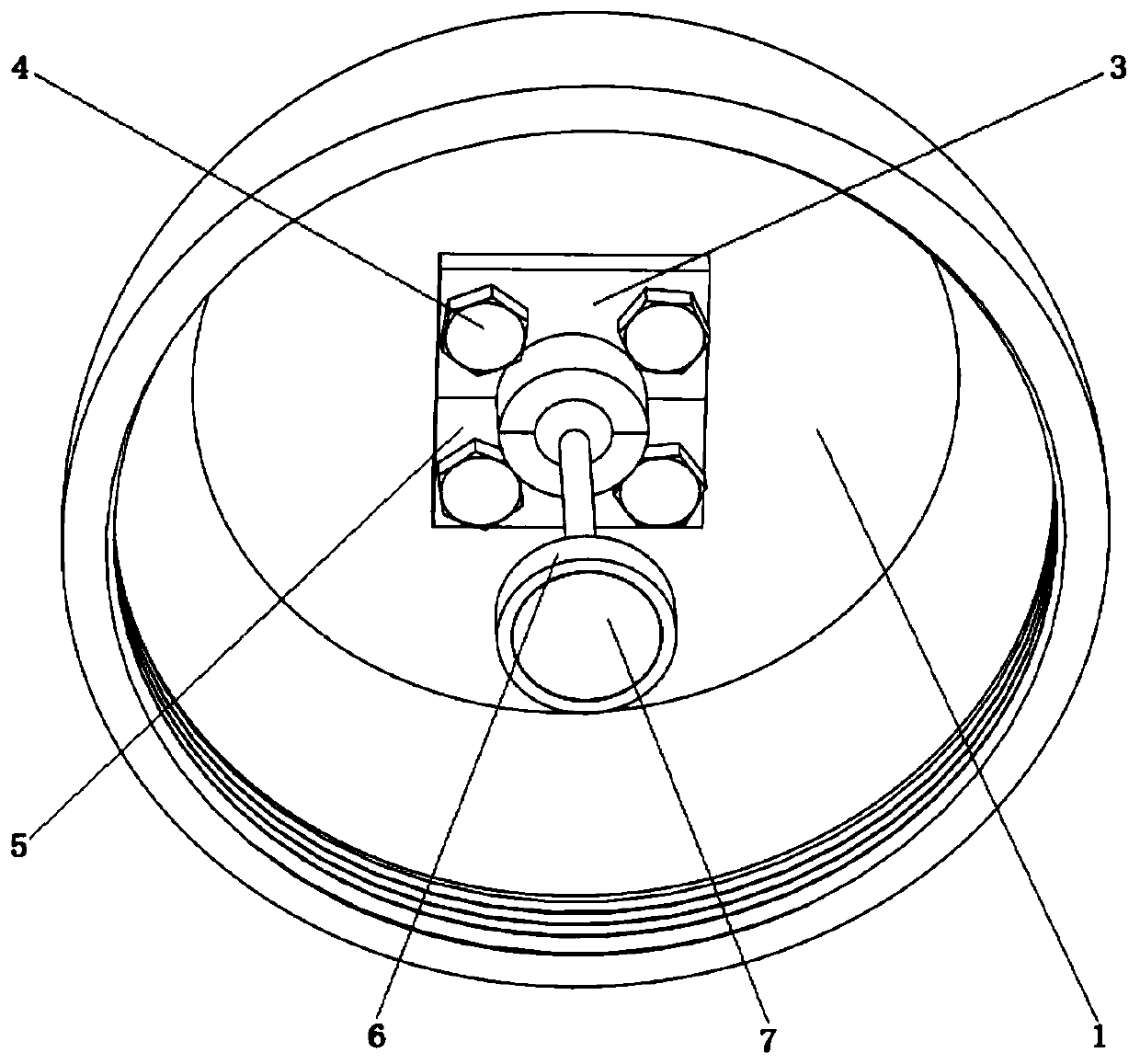

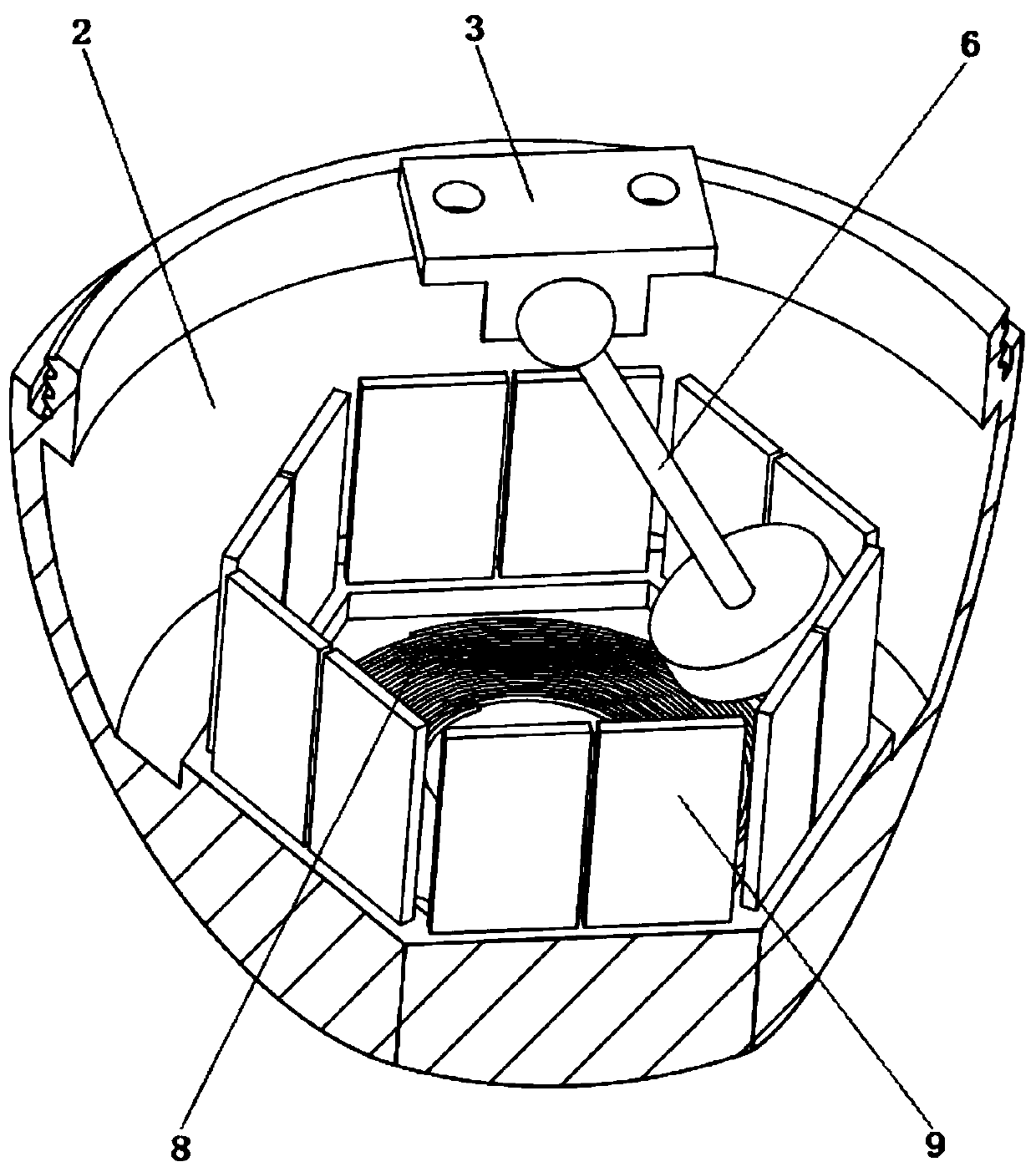

Omnidirectional piezoelectricity electromagnetic composite wave energy acquiring device

PendingCN111156128AHarvesting power advantageExtraction Efficiency AdvantageBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesEngineeringCopper coil

The invention provides an omnidirectional piezoelectricity electromagnetic composite wave energy acquiring device, and belongs to the field of energy collecting device designing and manufacturing. A spherical housing is divided into an upper shell and a lower shell, wherein threads which are in mutual cooperation are formed in the openings of the upper shell and the lower shell; the top surface ofthe inner part of the upper shell is a plane, and is provided with four threaded holes; the upper parts of a left spherical hinging seat and a right spherical hinging seat are slabs and are providedwith a pair of screw hole structure, and the lower parts of the left spherical hinging seat and the right spherical hinging seat are provided with a semispherical cavity; the upper part of a pendulumswinging rod is a spherical body, and the lower part of the pendulum swinging rod adopts a round cake shaped structure; a circular permanent magnet is embedded on the lower surface of the round cake shaped structure; the spherical body at the upper part is fixed to the top surface in the upper shell through the clearance fit of the two combined semispherical cavities in the lower parts of the leftspherical hinging seat and the right spherical hinging seat; a part of which the height is one third of that of the inner part of the lower shell, of the lower shell is a plane formed by a solid sphere; grooves which are formed in a regular hexagon shape are annularly formed; the lower parts of bimorph piezoelectricity pieces are embedded in the grooves; and a copper coil is embedded on a plane in the lower shell.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com