Patents

Literature

163results about How to "Corrosion protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

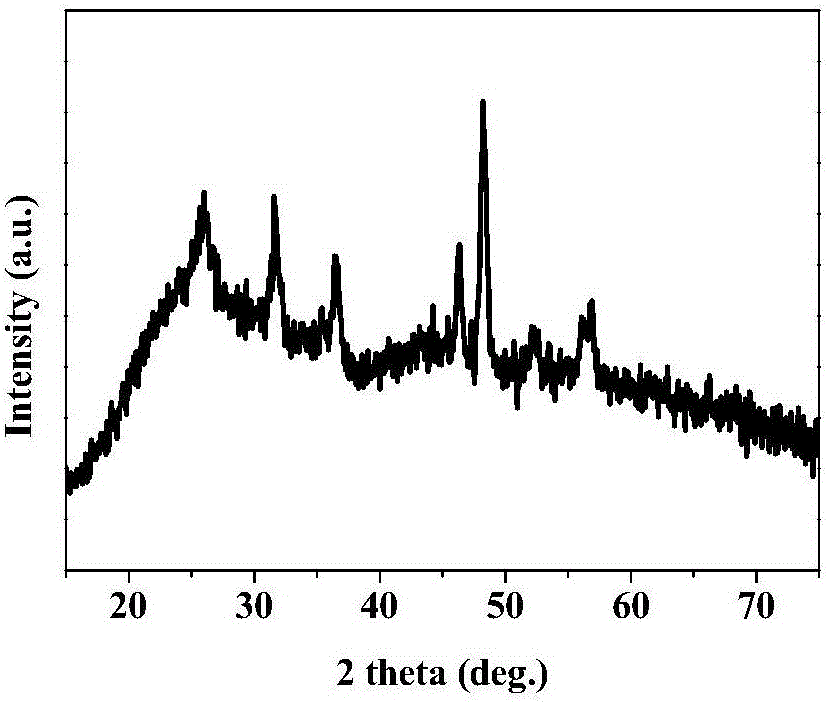

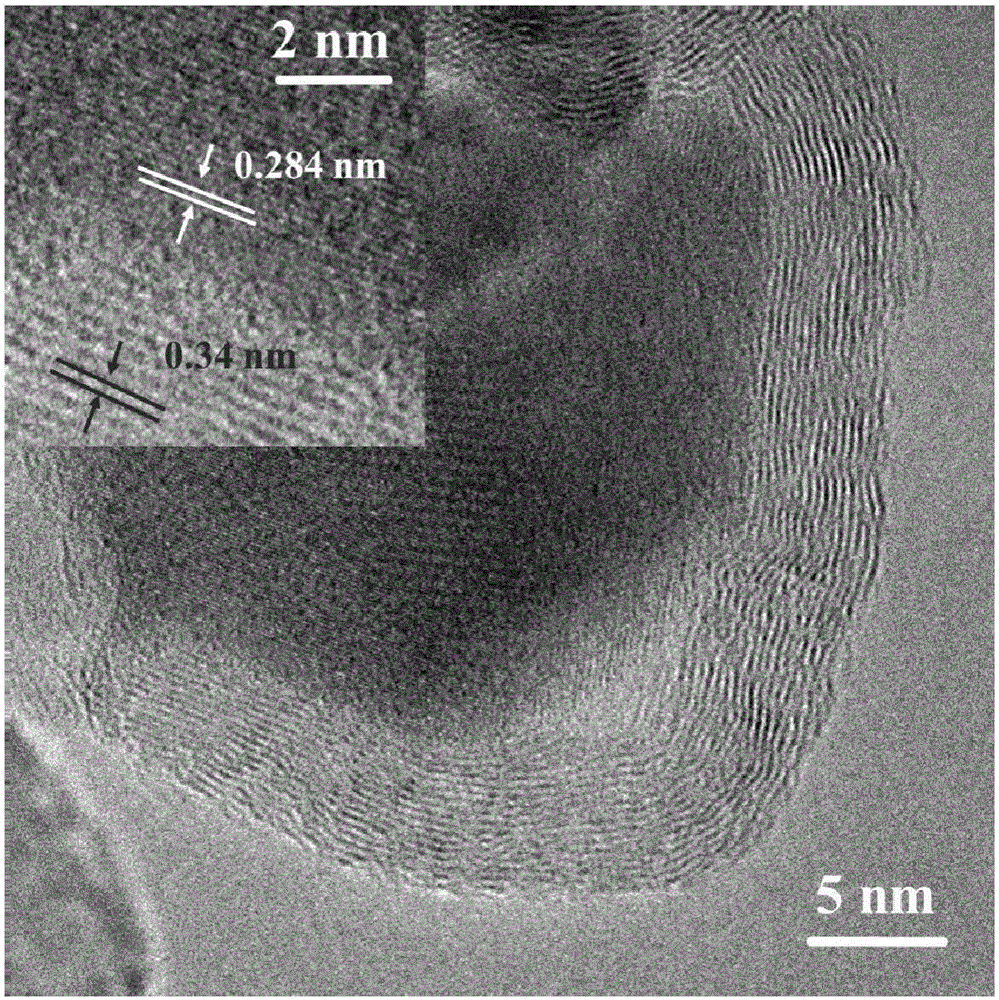

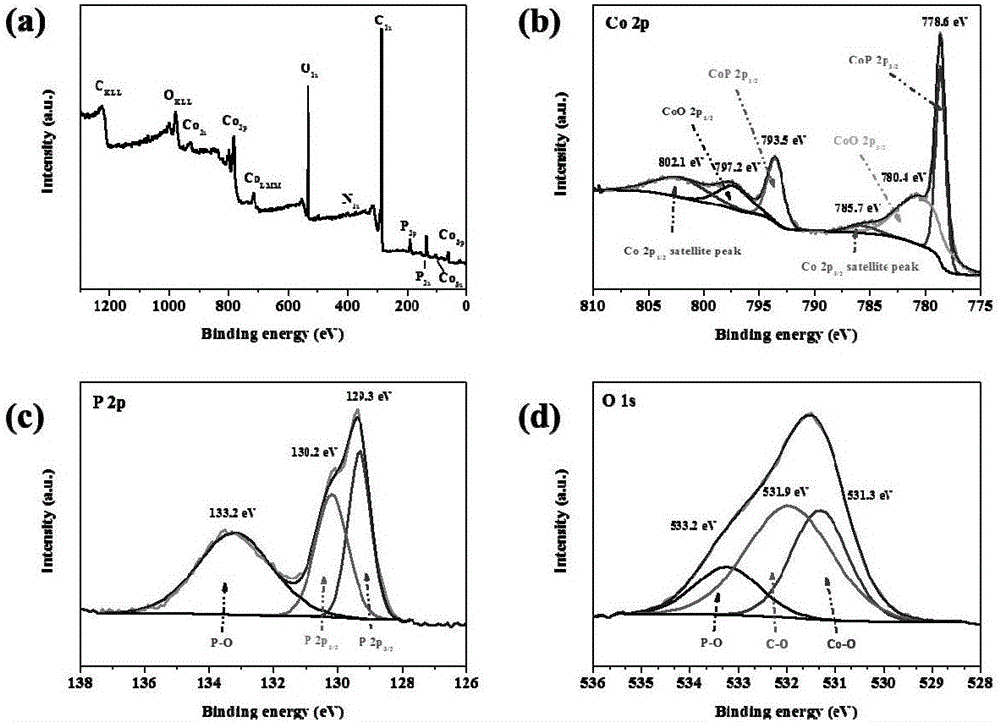

Preparation method of cobalt phosphide coated with carbon layers

InactiveCN106111171ACorrosion protectionHigh yieldPhysical/chemical process catalystsElectrodesCarbon layerHydrogen

The invention relates to a preparation method of cobalt phosphide coated with carbon layers. According to the method, cobalt salt and organic ligands are used as raw materials, a cobalt-containing metal-organic framework material is synthesized firstly and then subjected to high-temperature pyrolysis, air oxidation and low-temperature phosphating sequentially, and cobalt phosphide coated with the carbon layers is synthesized. Prepared cobalt phosphide is used as a hydrogen evolution catalyst under acidic and alkaline conditions and has high activity and high stability. The method is low in cost, mild in condition and suitable for industrial large-scale production, and products with relatively high purity can be obtained.

Owner:SUZHOU INSTITUE OF WUHAN UNIV

Corrosion inhibiting formulations

InactiveUS6984340B1Give protectionAvoid corrosionOther chemical processesWater softeningWater basedN acylaminoacid

The present invention relates to formulations for corrosion-inhibiting, emulsifying, lubricating or as a surfactant in organic hydrocarbon and / or water based system containing an acyl amino acid derivative and a triazole derivative.

Owner:BRAD CHEM

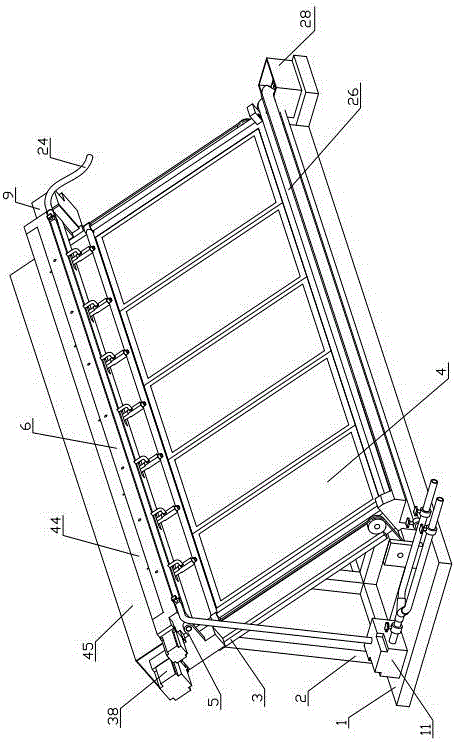

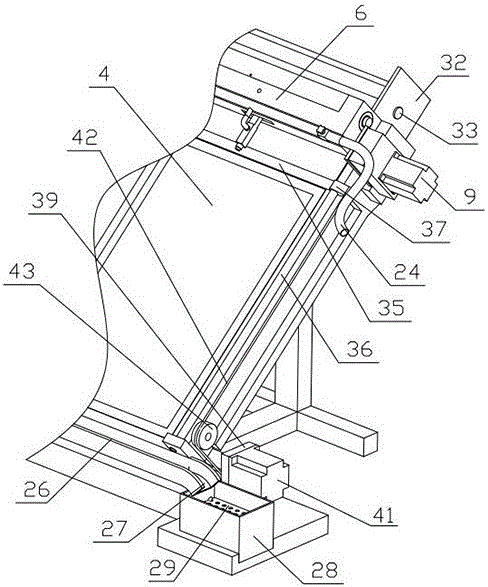

Photovoltaic panel frame with cleaning and protecting functions

InactiveCN106788207AEnable selective useEasy to usePhotovoltaic supportsPhotovoltaic energy generationImpuritySnow

The invention discloses a photovoltaic panel frame with cleaning and protecting functions. The photovoltaic panel frame comprises a base plate, a bracket, a mounting panel and a photovoltaic panel. The photovoltaic panel frame is characterized in that a cleaning assembly is rotatably mounted on the mounting panel and comprises a mounting block, a first pipeline is fixedly connected to the end surface of the mounting block, a water pump is mounted on the base plate, a water outlet of the water pump is connected with one end of the first pipeline, and a first valve is arranged at the joint of the water outlet and the first pipeline; a plurality mounting grooves are formed in the mounting block, worm wheels are mounted in the mounting groove, and nozzles are radially and fixedly connected to the side walls of the worm wheels; worm rods matched with the worm wheels are rotatably mounted on the mounting block and coaxially connected with a second electric motor mounted on the mounting block; and the photovoltaic panel frame further comprises a hose, one end of the hose is communicated with inner cavities of the nozzles, and the other end of the hose is communicated with an inner cavity of the first pipeline. According to the photovoltaic panel frame with the cleaning protecting function, the photovoltaic panel can be cleaned completely with no dead angle, accumulated dust, impurities, accumulated snow and ice on the photovoltaic panel can be effectively cleaned, and the photovoltaic panel can be protected under bad weather environments.

Owner:国网山东省电力公司潍坊市寒亭区供电公司 +1

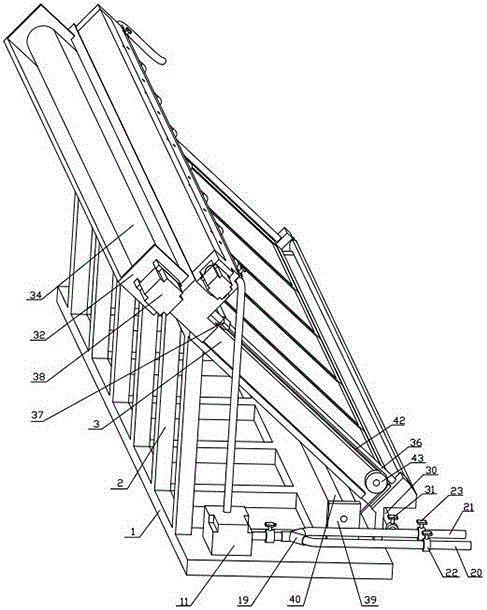

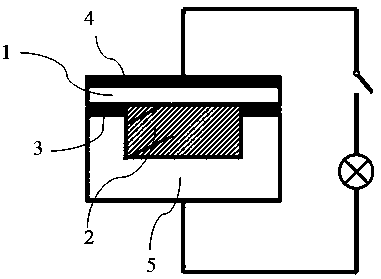

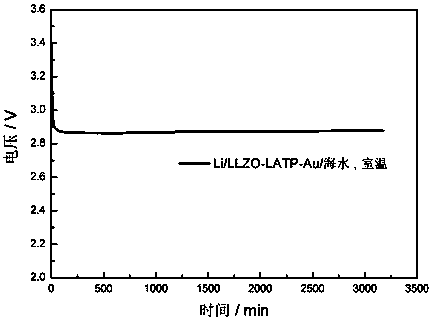

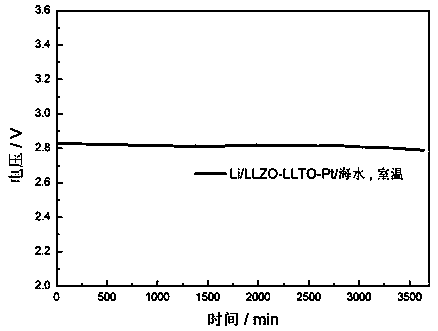

Preparation method and application of double-layer oxide solid electrolyte

InactiveCN110165236ACorrosion protectionExcellent duty cycle stabilityFuel and primary cellsSolid electrolyte cellsSolid state electrolyteElectron

The invention discloses a preparation method and application of a double-layer oxide solid electrolyte. A double-layer LLZO / LATP multifunctional oxide solid electrolyte comprises a dense LLZO ceramicelectrolyte layer and a porous LATP solid electrolyte layer. The dense LLZO electrolyte layer is stable to a metal lithium negative electrode and prevents corrosion of the metal lithium negative electrode by seawater. The porous LATP solid electrolyte layer is stable to seawater and air and provides an ionic conductive framework for the air positive electrode reaction. The double-layer oxide solidelectrolyte can be used for preparing a lithium seawater battery pack. The lithium seawater battery comprises the LLZO / LATP multifunctional oxide solid electrolyte, a lithium negative electrode packaged in a dense garnet electrolyte layer and an air positive electrode material having an ion / electron conductive network. Compared with the present lithium seawater battery, the structure design of the lithium seawater battery is more suitable for complicated seawater condition and has better working stability.

Owner:QINGDAO UNIV

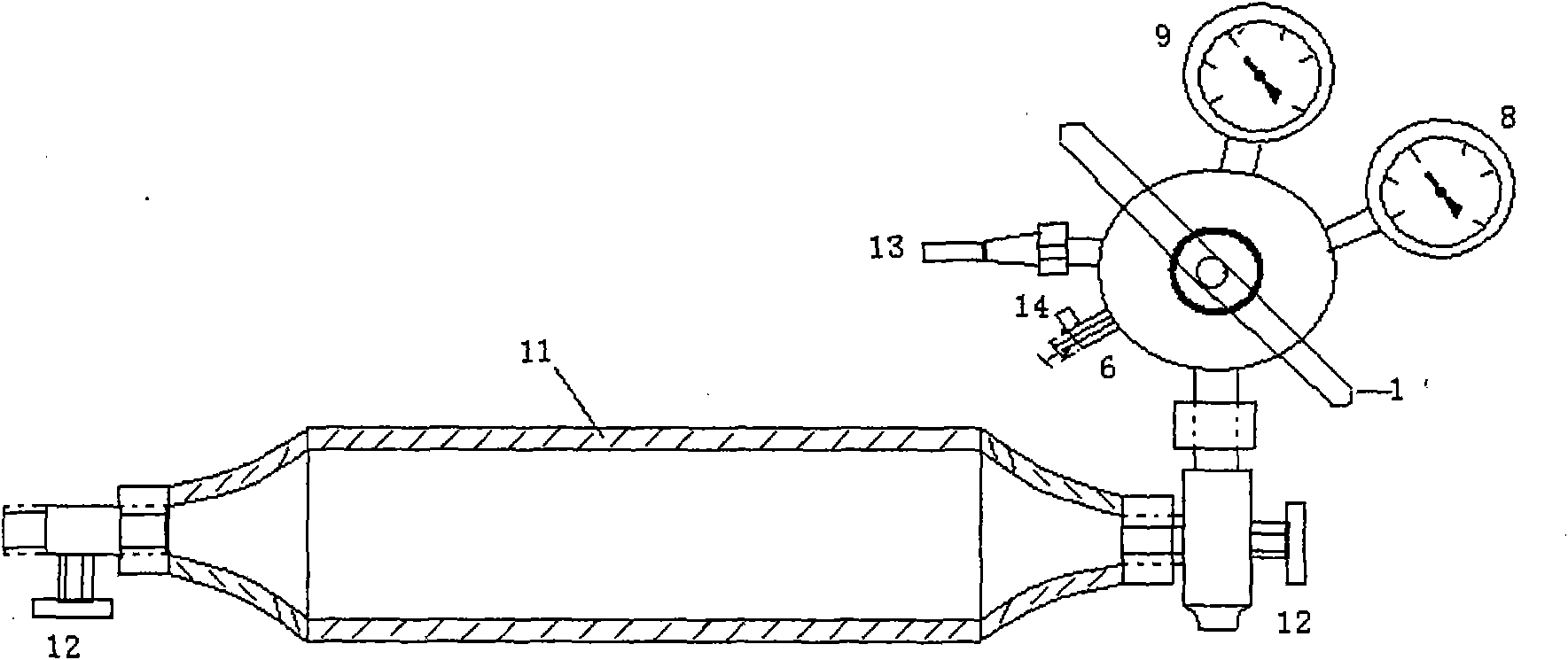

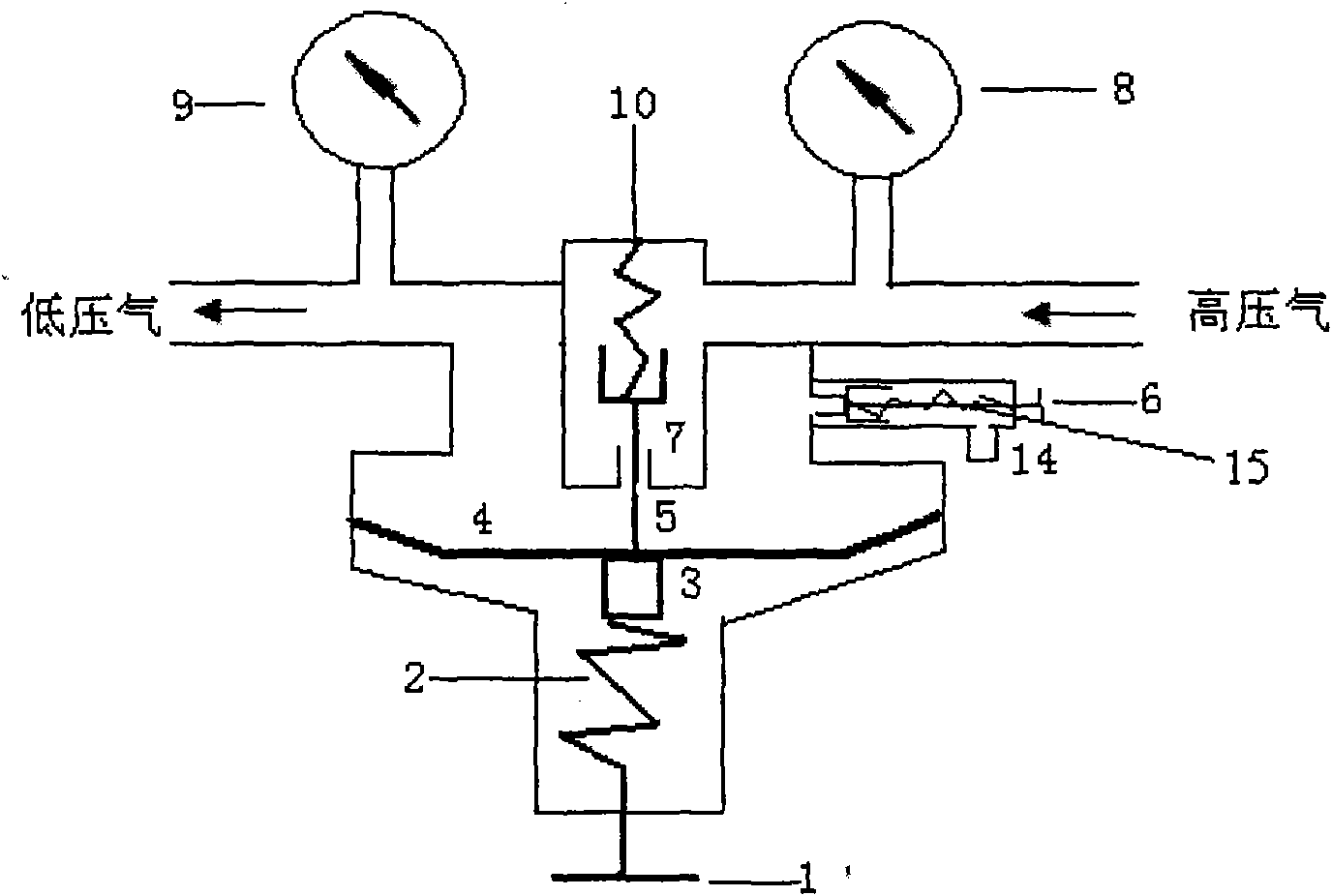

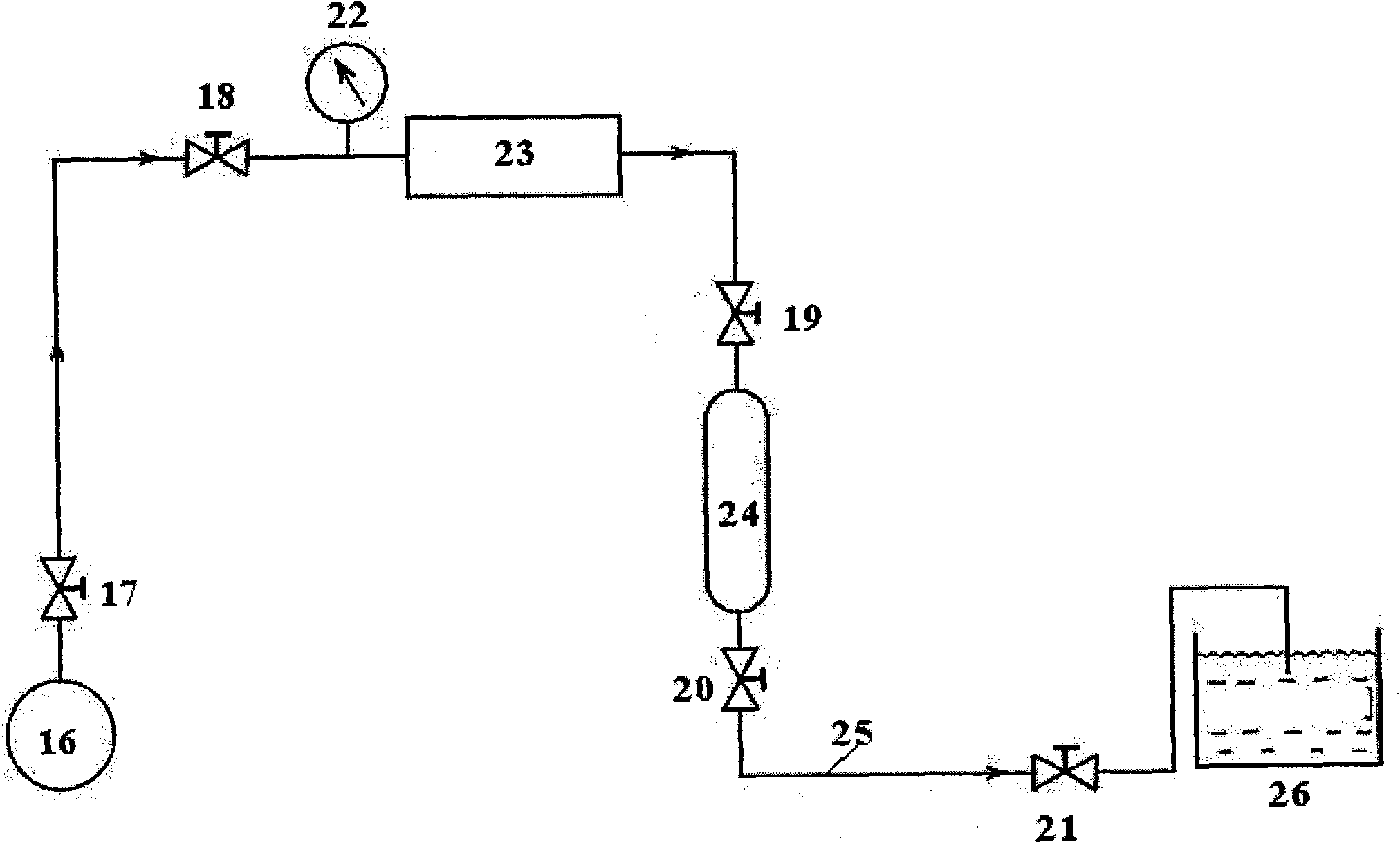

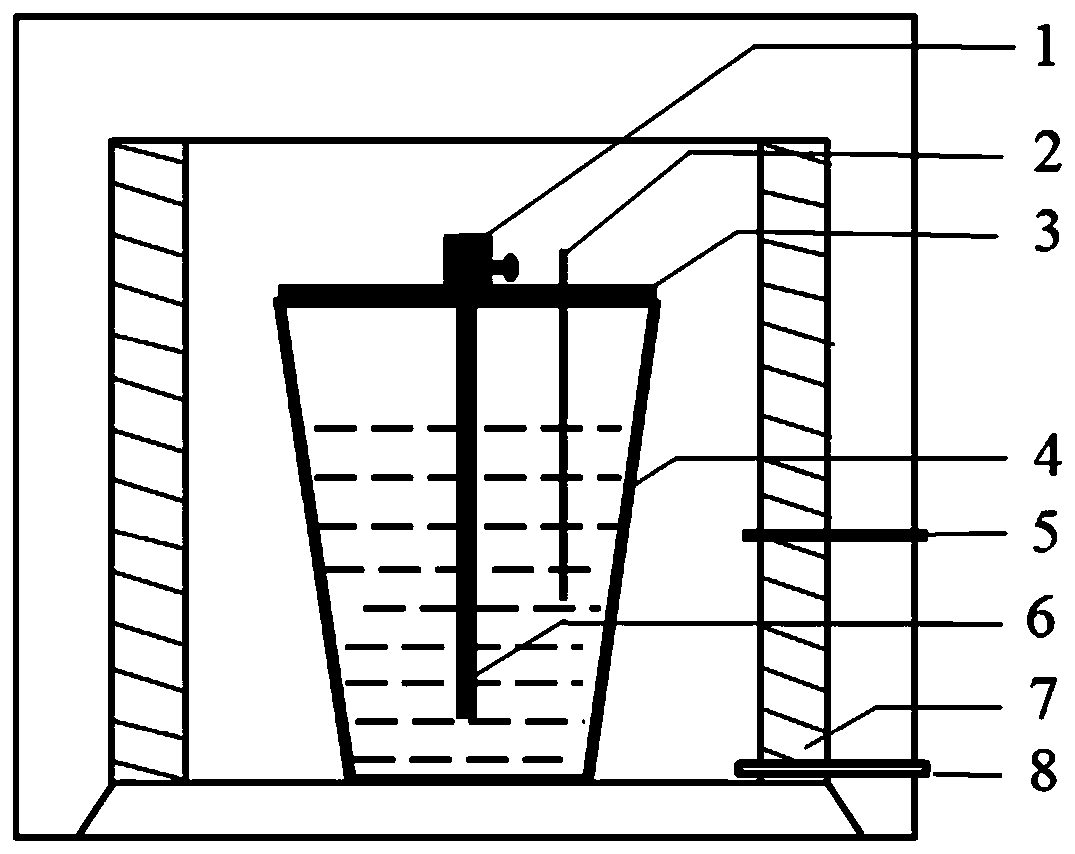

Sampling device, system for carrying out field sampling in oil field, method and application thereof

ActiveCN102052075ALarge diameterSmall dead volumeWithdrawing sample devicesBorehole/well accessoriesEngineeringBottle

The invention belongs to the field of development of oil and gas wells, and relates to a wellhead sampling device, in particular to a wellhead sampler designed for the characteristic of gas field environment containing high content of H2S / CO2, and a sampling system thereof. The sampling device comprises a sampling valve, a sampling bottle and a pressure reducing valve, wherein two ends of the sampling bottle are in threaded connection with the sampling valve; the external connection of the sampling valve is external-thread clamping sleeve type connection; the pressure reducing valve is used for carrying out pressure reduction and sample injection on high-pressure gas in the sampling bottle; the pressure reducing valve comprises an outer conveying sample injection port which is connected with an outer detector; and the outer conveying sample injection port is a clamping sleeve type connection port so as to eliminate dead angles of pipelines. In the invention, the field sampling for analysis is achieved, the result of experimental analysis has good consistency, the device is safe and reliable, and the corrosion resistance to H2S / CO2 is strong. In the gas field sampler disclosed by the invention, the sampling process is safer, the experimental process is more precise and faster, the applicable pressure range is wider, and more safety is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

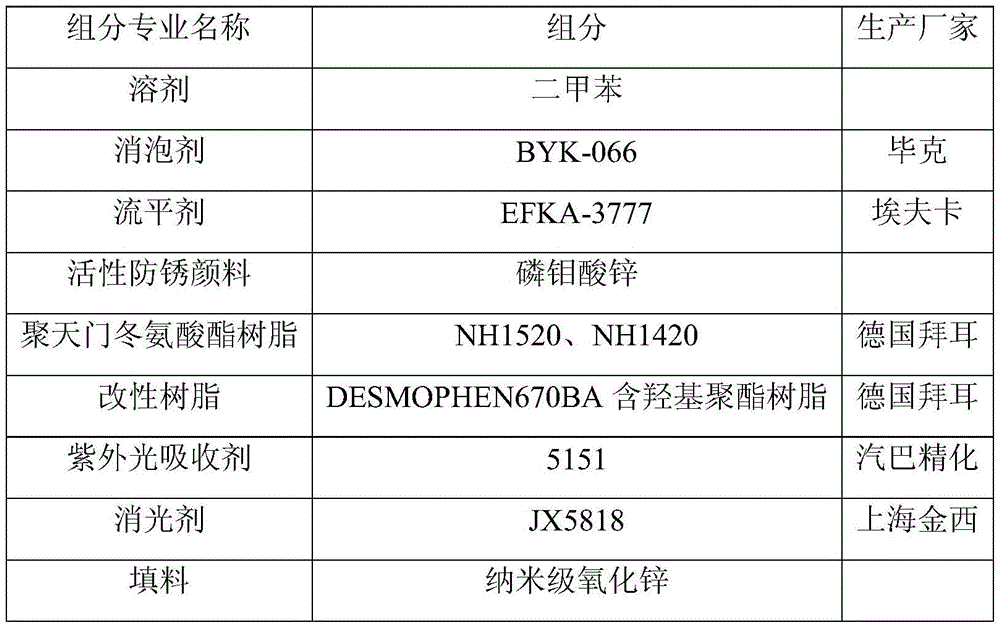

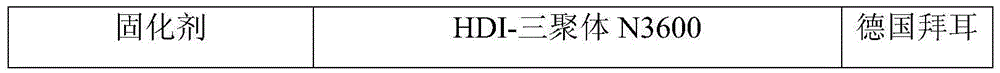

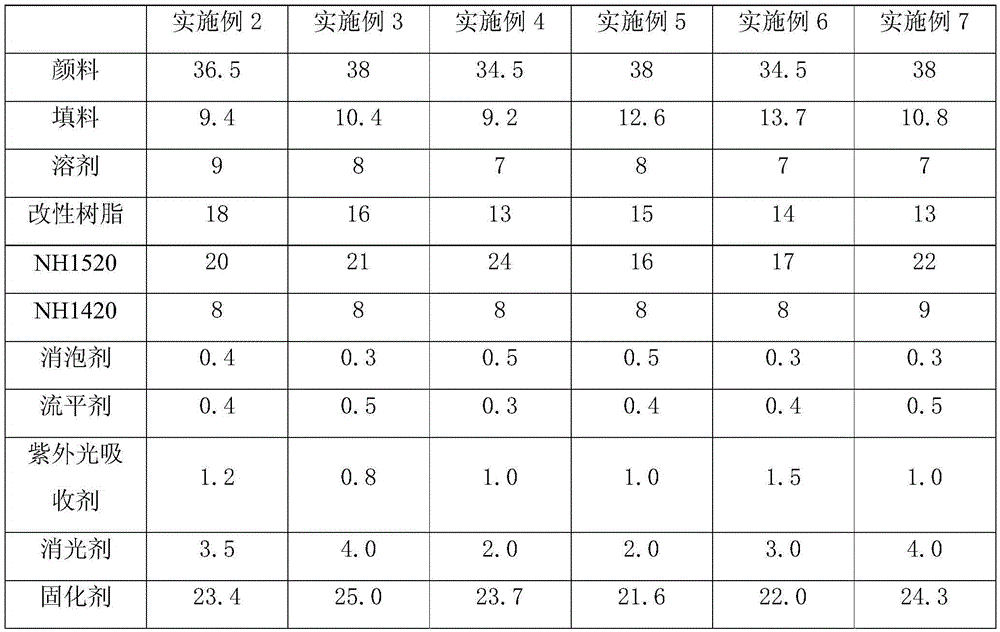

High-solid-content weather-proof bottom-face integrated anticorrosive paint containing polyaspartic acid ester

ActiveCN105462484AGood weather resistanceThe average molecular weight is largeAnti-corrosive paintsPolyamide coatingsChemical compositionPolyaspartic acid

The invention belongs to the field of painting preparation and particularly relates to a bottom-face integrated anticorrosive paint obtained through modification by using the polyaspartic acid ester as the base. The anticorrosive paint is prepared from, by mass, 20-35% of polyaspartic acid ester, 10-18% of modified resin, 0.2-0.8% of a defoaming agent, 0.3-0.5% of a leveling agent, 0.5-1.5% of ultraviolet absorber, 32-42% of pigment, 10-25% of pigment, 5-10% of a solvent, 20-29% of a curing agent and 1-5% of a flatting agent. The paint has the excellent weather resistance, gloss retention, color retention and weather resistance and high solid content, meets the requirement for environmental protection, does not need a primer or intermediate coat, can achieve bottom-face integration, the thickness of the film formed at a time can reach 150-375 micrometers, and the construction cost is lowered.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

Decoking agent

The invention relates to a decoking agent capable of reducing or removing coked blocks and deposited dust in coal-fired boilers and industrial boilers. The components and weight percentage of each component of the decoking agent are as follows: 10-20 of borax, 10-25 of active metal powder, 10-25 of a combustion-supporting material and 10-30 of a high-melting point material. The basic material-borax can lower bonding strength of slag, is easy to produce volatile gas, and makes coked slag loosen; the combustion-supporting material can generate a lot of oxygen atoms under a high temperature, and directly promotes the combustion of coal powder. Besides, metal ions such as manganese ions and copper ions in reaction products can catalyze the combustion of oxydic coal powder and increases combustion efficiency, thereby reducing coke and the deposited dust; the active metal powder can form a dense high-melting point material oxide film under high temperature, protects the heating surface from washing of corrosion and smoke, and prolongs service life.

Owner:SNTO TECH GRP

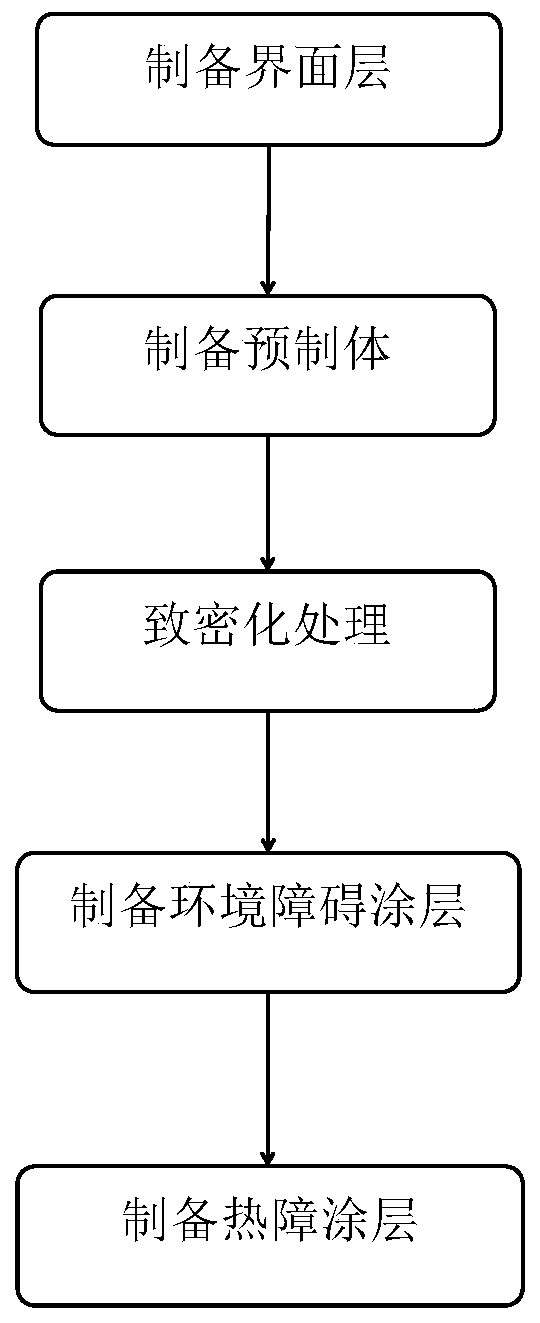

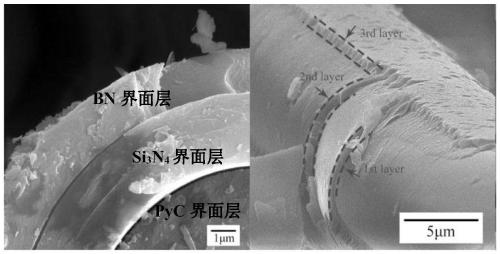

SiCf/SiC composite material flame tube and automatic preparation method thereof

ActiveCN110330353AHigh mechanical strengthCorrosion protectionContinuous combustion chamberCeramic layered productsPolymer scienceGas phase

The invention discloses an automatic preparation method of a SiCf / SiC composite material flame tube. The preparation method comprises the following steps: preparing an interface layer from SiC fibersby adopting chemical vapor deposition, so as to obtain SiC fibers with a continuous interface layer; performing unidirectional tape laying and filament winding on the SiC fibers with the continuous interface layer according to the fiber volume and fiber orientation obtained by simulation calculation, so as to obtain net size forming preform; performing densifying treatment on the obtained preformby adopting a reactive melt infiltration process and the chemical vapor deposition process; preparing an environmental barrier coating on the surface of the obtained preform; finally, continuously preparing a thermal barrier coating on the surface, thereby fully intelligently obtaining the high-density SiCf / SiC composite material flame tube. The SiCf / SiC composite material flame tube prepared withthe method disclosed by the invention has the characteristics of high temperature resistance and long service life and also has the advantages such as low thermal expansion coefficient, high thermalconductivity, high thermal shock resistance and excellent mechanical property. Meanwhile, the preparation method is high in degree of automation, short in production cycle, low in cost and controllable in quality.

Owner:CENT SOUTH UNIV

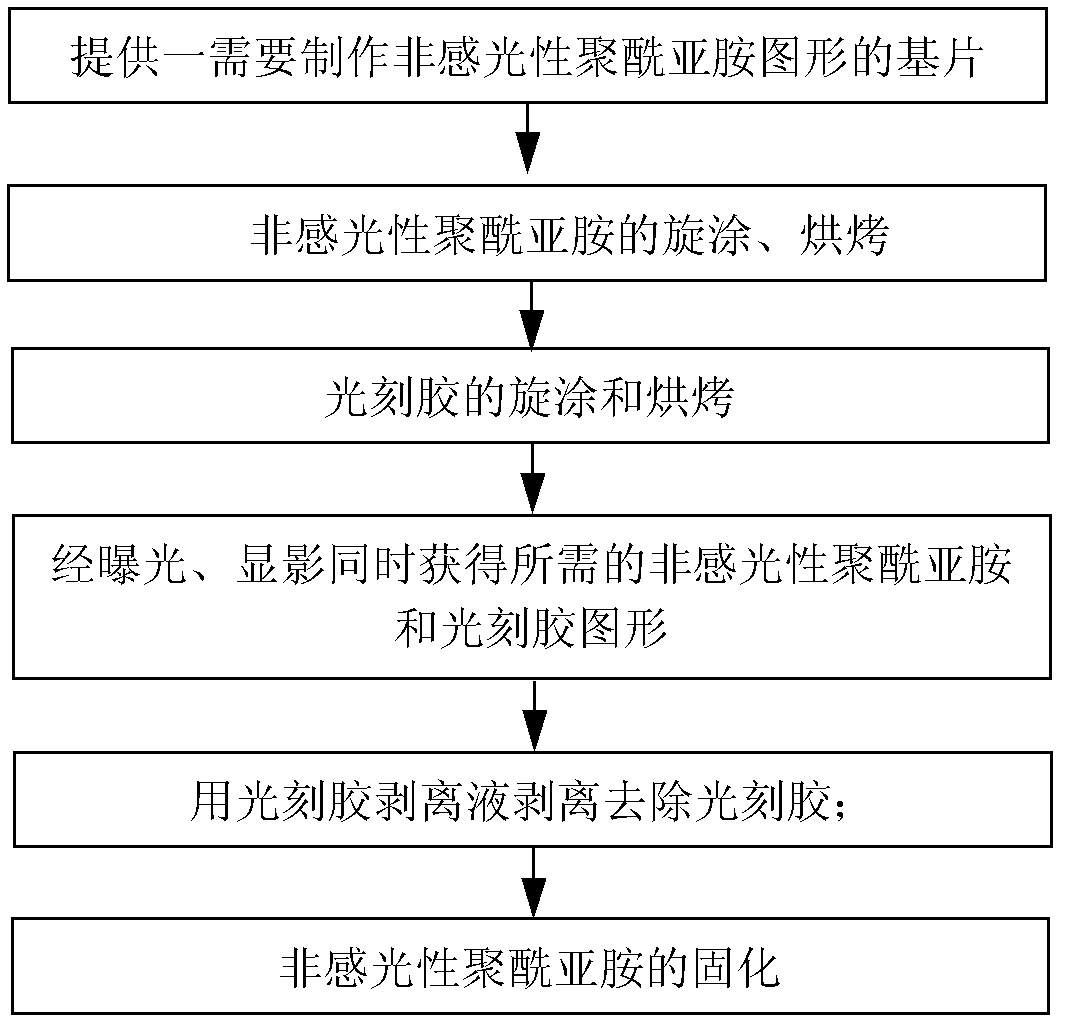

Method for manufacturing non-photosensitive polyimide passivation layer

ActiveCN103137469ATroubleshoot topographyCorrosion protectionSemiconductor/solid-state device detailsSolid-state devicesMetallic aluminumSilicon dioxide

The invention discloses a method for manufacturing a non-photosensitive polyimide passivation layer. Non-photosensitive polyimide is spin-coated and baked on a substrate on which a passivation layer is required to be manufactured, a layer of silica is grown by a low temperature method, photoresist is spin-coated and baked on the silica, exposure and developing are performed to obtain a photoresist pattern, the photoresist pattern is used as a mask layer, the silica is etched to form a pattern, the photoresist is stripped, pattern silica is used as a mask layer, the non-photosensitive polyimide is subjected to dry etching to form a pattern, the silica is removed by a drying back etching method, and finally, the curing is performed to obtain the non-photosensitive polyimide passivation layer. By means of the method for manufacturing the non-photosensitive polyimide passivation layer, problems that metallic aluminum is developed and corroded, morphology of the non-photosensitive polyimide is poor, photoresist residues exist and the like in terms of traditional non-photosensitive polyimide processes are solved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

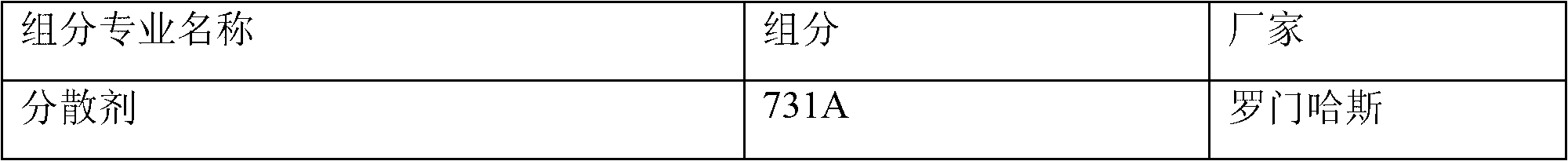

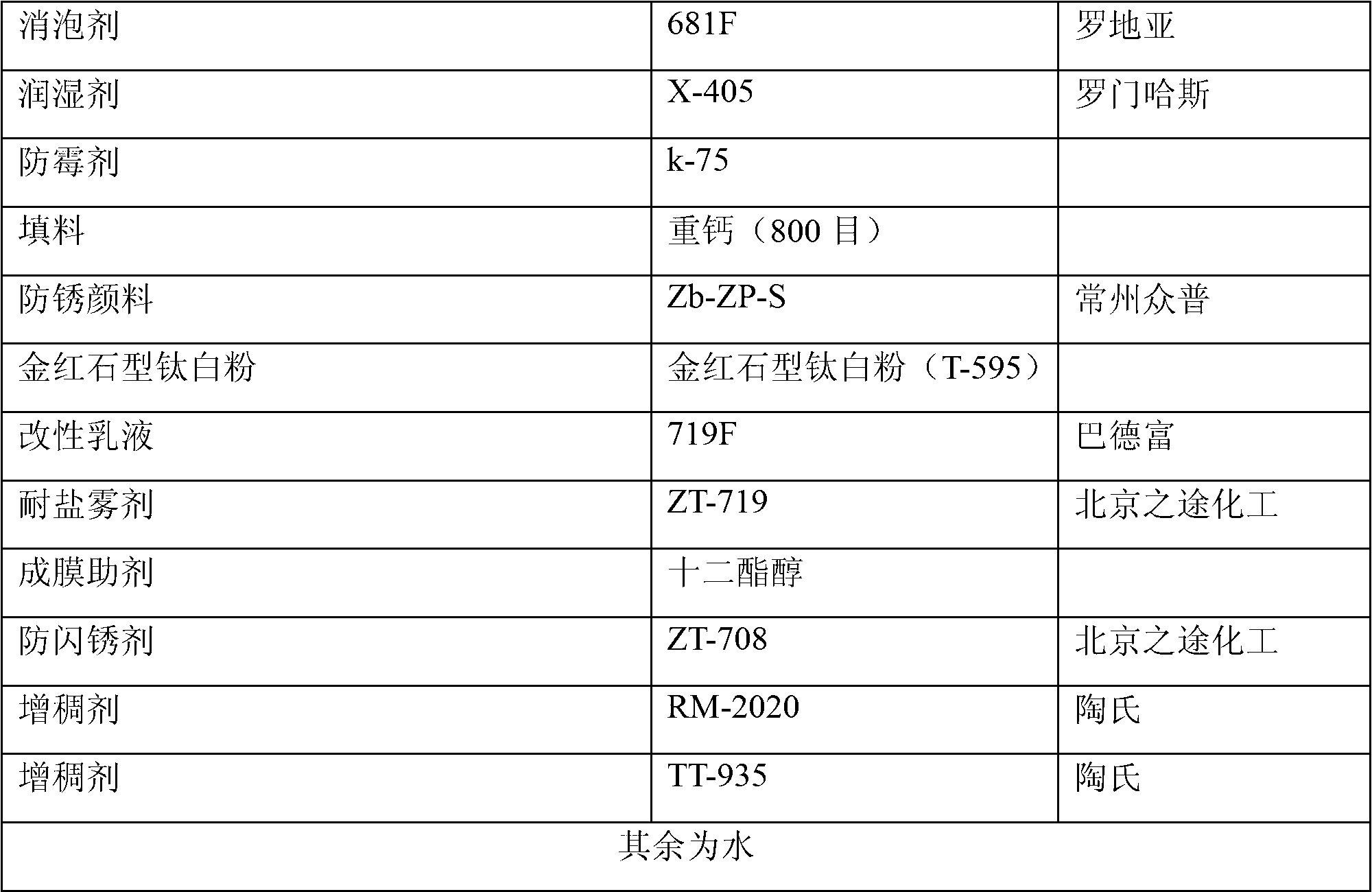

Water-based modified pure acrylic acid anticorrosive paint

ActiveCN102702899ACorrosion protectionImprove anti-corrosion performanceAnti-corrosive paintsWater basedEmulsion

The invention relates to a water-based modified pure acrylic acid anticorrosive paint which is prepared from the following components in percentage by mass: 30-45% of modified acrylic acid emulsion, 3-5% of film-forming assistant, 0.6-1.2% of dispersant, 0.1-1.0% of defoaming agent, 0.1-0.2% of wetting agent, 0.05-0.10% of mold preventive, 1-2% of flash-rust inhibitor, 2-5% of pigment, 15-30% of antirust pigment and filler, 2-5% of filler, 2-5% of thickening agent, 1-2.5% of salt-fog inhibitor and the balance of water. The pH value is regulated to 8-9. The anticorrosive paint provided by the invention has the advantages of combined primer and precoat functions, single component and self drying, is water-based, and satisfies the requirement for environmental protection. The invention has the advantages of simple production technique, accessible raw materials, low cost, low VOC (volatile organic compound), environmental protection and high safety, can easily implement industrialization, and is simple and convenient for construction.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

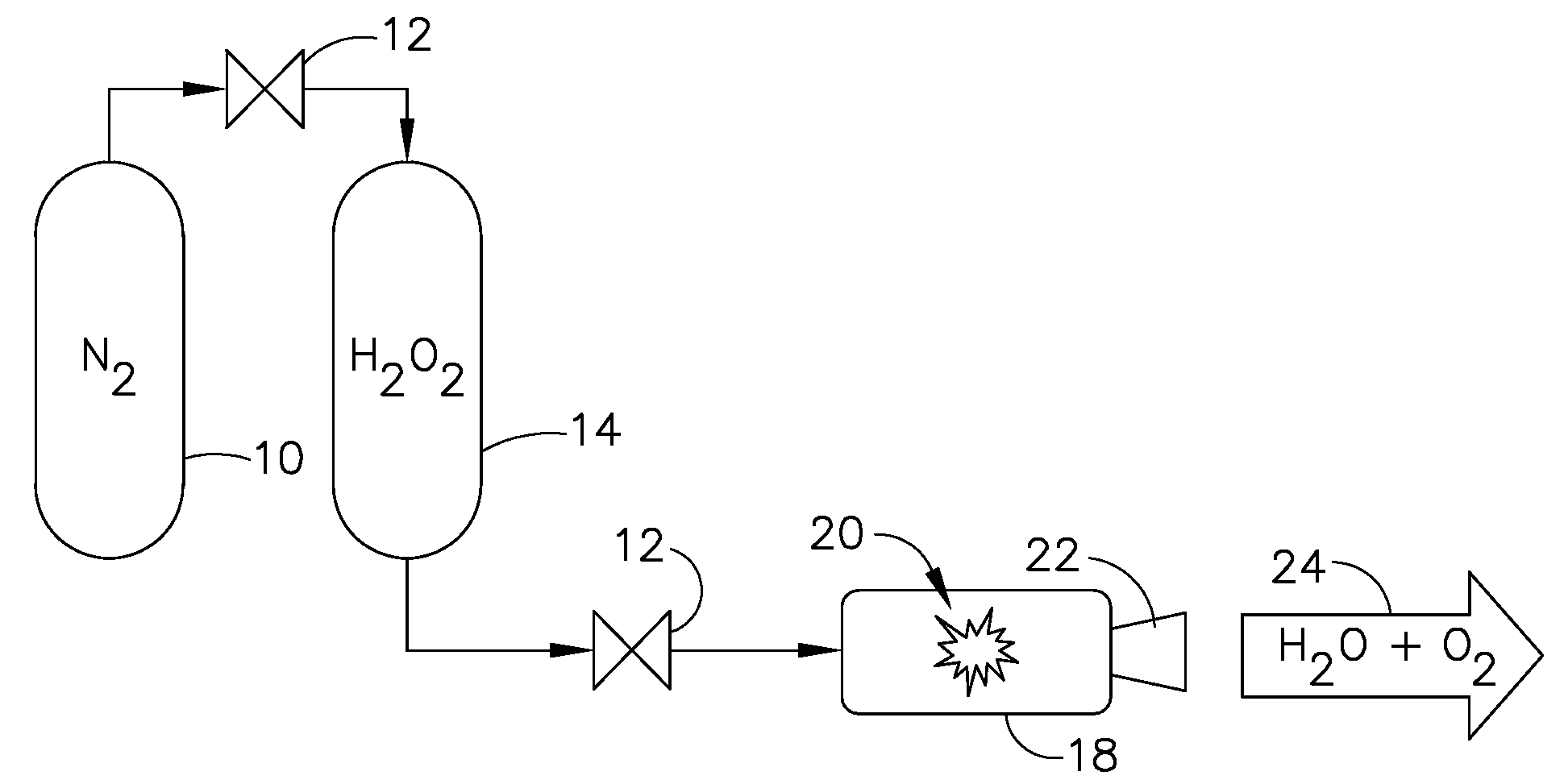

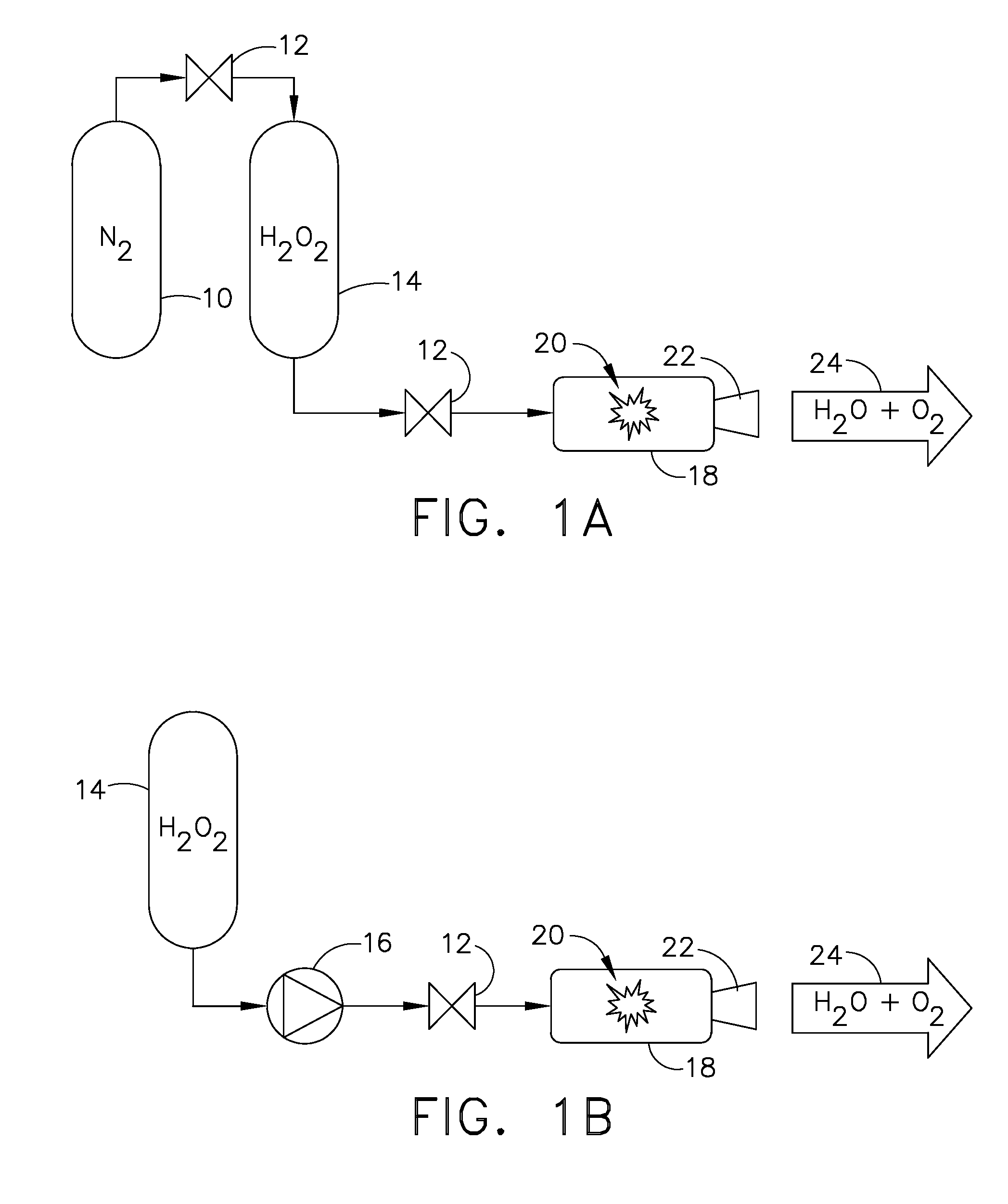

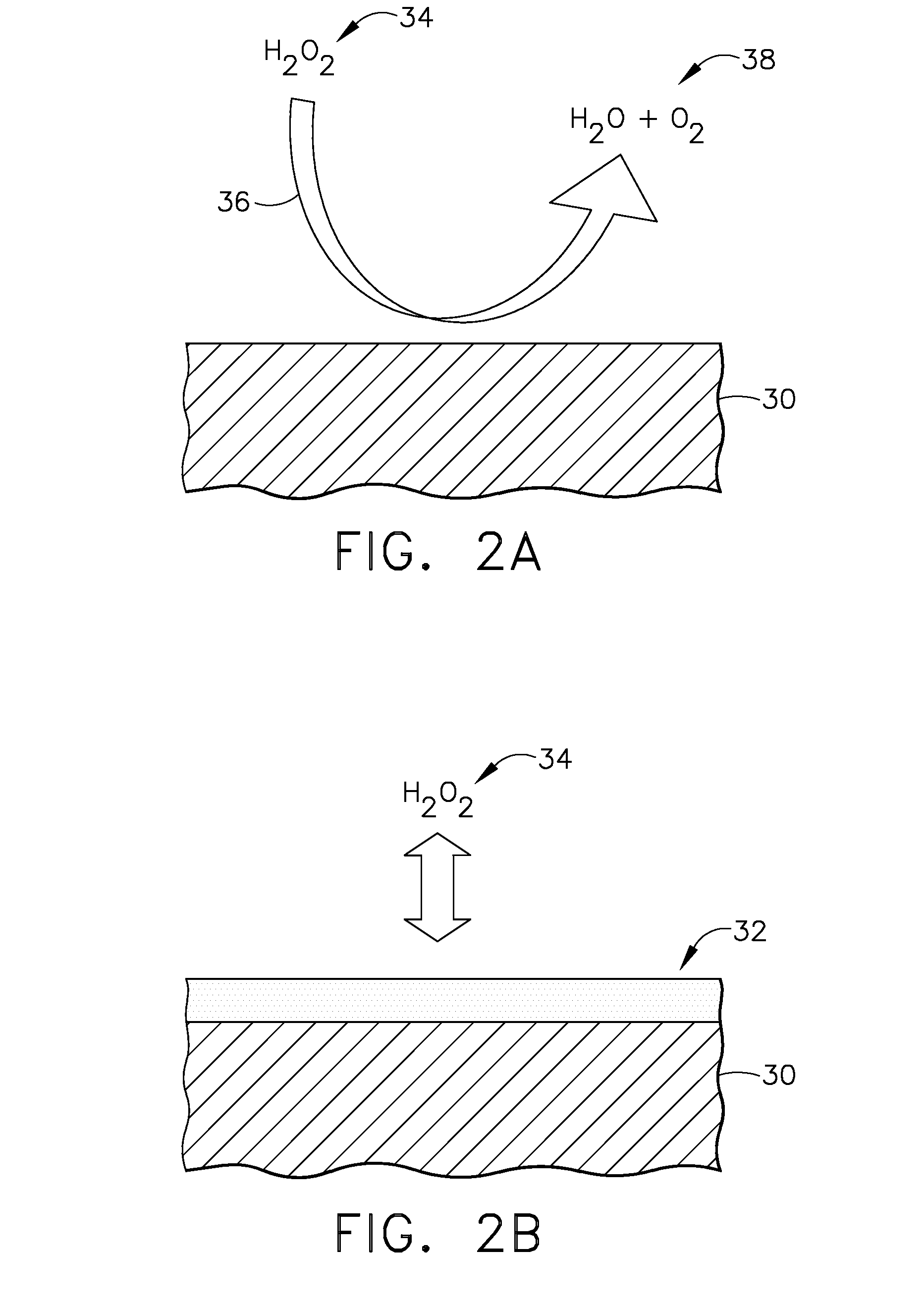

Coating for components requiring hydrogen peroxide compatibility

ActiveUS20080121548A1Prevention of hydrogen peroxide decompositionCorrosion protectionCosmonautic vehiclesEngine fuctionsHydrogen peroxide breakdownDecomposition

The present invention provides a heretofore-unknown use for zirconium nitride as a hydrogen peroxide compatible protective coating that was discovered to be useful to protect components that catalyze the decomposition of hydrogen peroxide or corrode when exposed to hydrogen peroxide. A zirconium nitride coating of the invention may be applied to a variety of substrates (e.g., metals) using art-recognized techniques, such as plasma vapor deposition. The present invention further provides components and articles of manufacture having hydrogen peroxide compatibility, particularly components for use in aerospace and industrial manufacturing applications. The zirconium nitride barrier coating of the invention provides protection from corrosion by reaction with hydrogen peroxide, as well as prevention of hydrogen peroxide decomposition.

Owner:THE BOEING CO

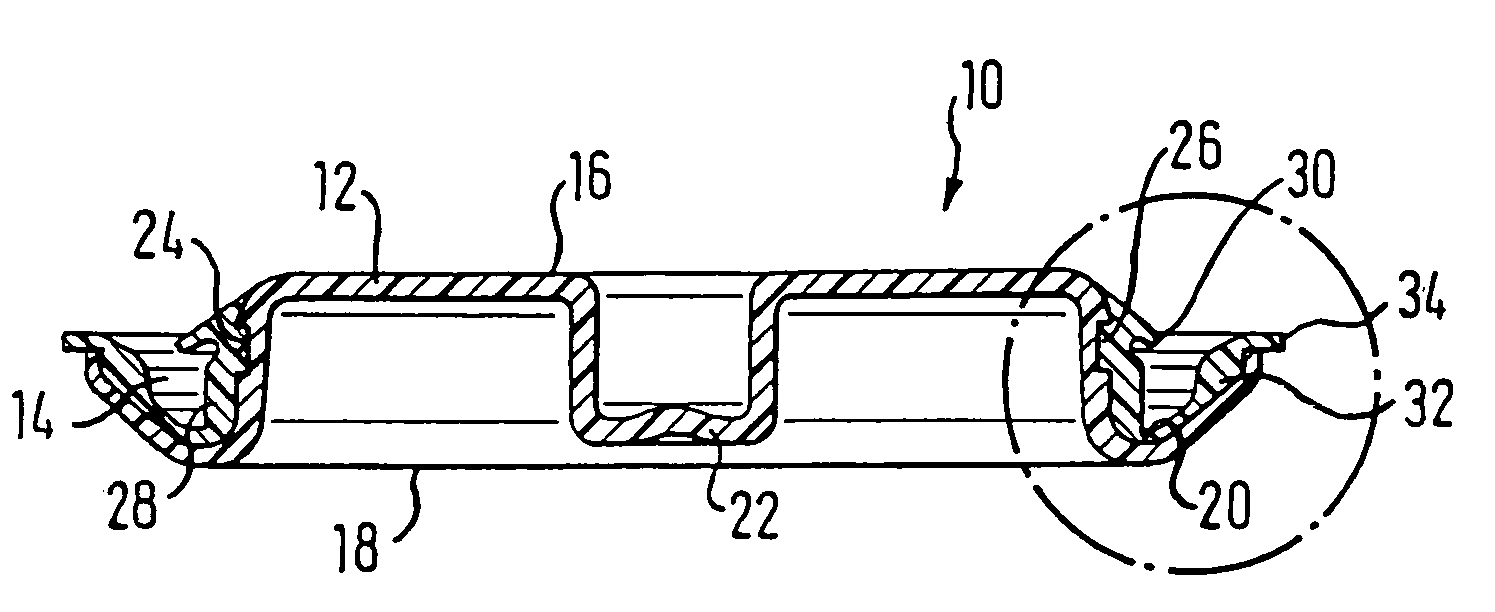

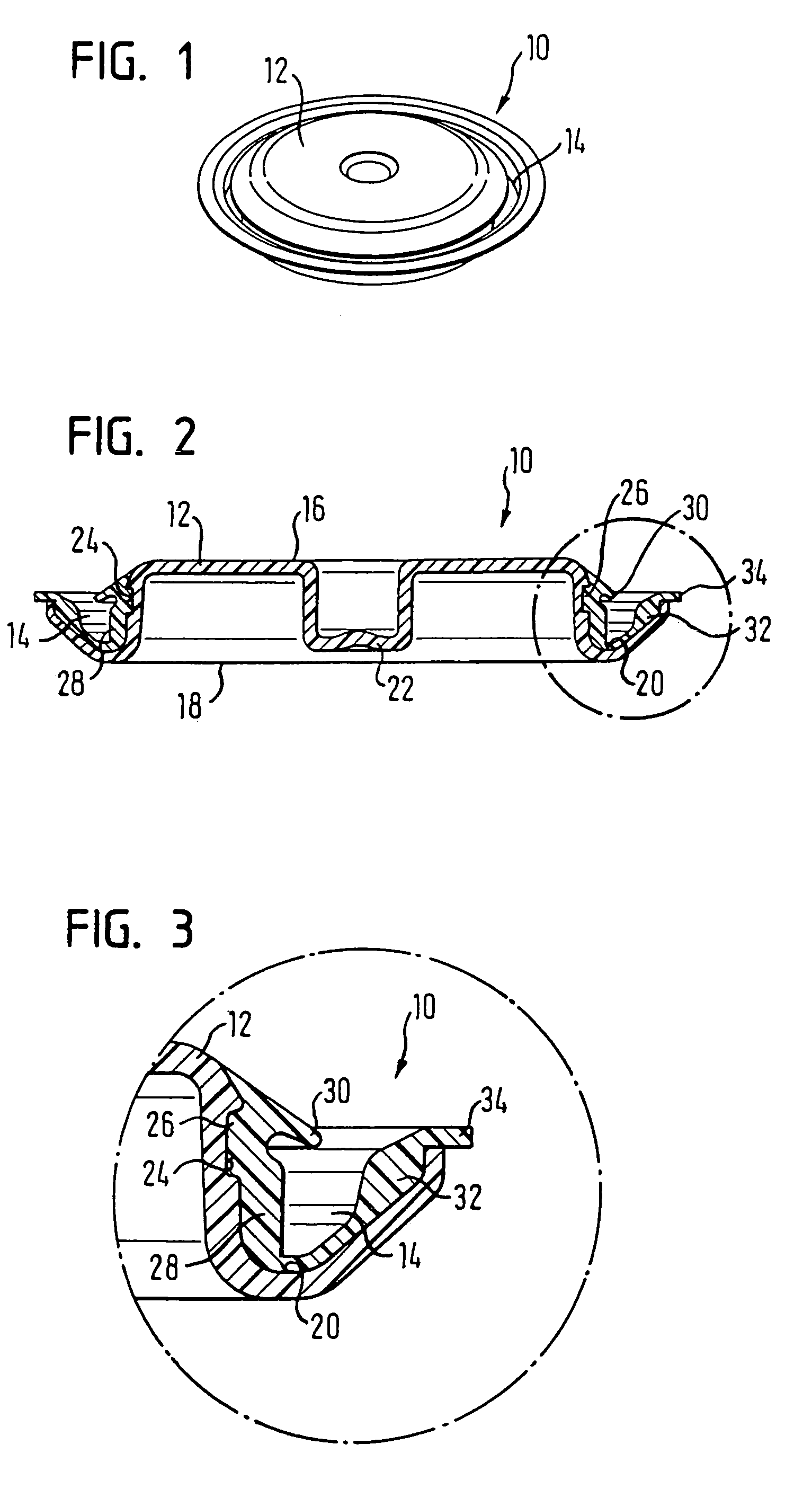

Body filler plug

ActiveUS7997437B2Improve sealingCorrosion protectionCapsClosure using stoppersPlastic materialsEngineering

Owner:ILLINOIS TOOL WORKS INC

Self-adhesive waterproofing membrane for metal roof and manufacturing method thereof

InactiveCN108084917ASuperior super aging resistanceGood chemical resistanceNon-macromolecular adhesive additivesRoof covering using flexible materialsThermal expansionSelf adhesive

The invention provides a self-adhesive waterproofing membrane for a metal roof. The self-adhesive waterproofing membrane for the metal roof comprises a base layer, a butyl rubber pressure-sensitive adhesive self-adhesive layer and a release film which are sequentially arranged, wherein the butyl rubber pressure-sensitive adhesive self-adhesive layer comprises the following components in parts by weight: 3 to 5 parts of PIB of which the molecular weight is 10,000 to 100,000, 2 to 4 parts of EPDM, 16 to 20 parts of butyl rubber, 18 to 23 parts of light calcium carbonate, 4 to 6 parts of white carbon black, 24 to 28 parts of PIB of which the molecular weight is 1000 to 3500, 18 to 22 parts of petroleum resin C5, 1 to 3 parts of polyethylene wax, 1 to 3 parts of white cement, 0.5 to 1 part ofan antioxidant, 1 to 2 parts of a coupling agent, and 1 to 2 parts of other additives. Butyl rubber pressure-sensitive adhesive of the invention is a permanent non-drying solid type stable material, has creep and self-healing properties, does not have the phenomenon of edge warping on seams, and can resist the thermal expansion and contraction of a color steel plate and displacement caused by theexternal vibration and the problems of steam leakage and water seepage because fasteners of metal roof nails and the like penetrate through a waterproof layer.

Owner:DANDONG SANGUAN WATERPROOF MATERIAL CO LTD

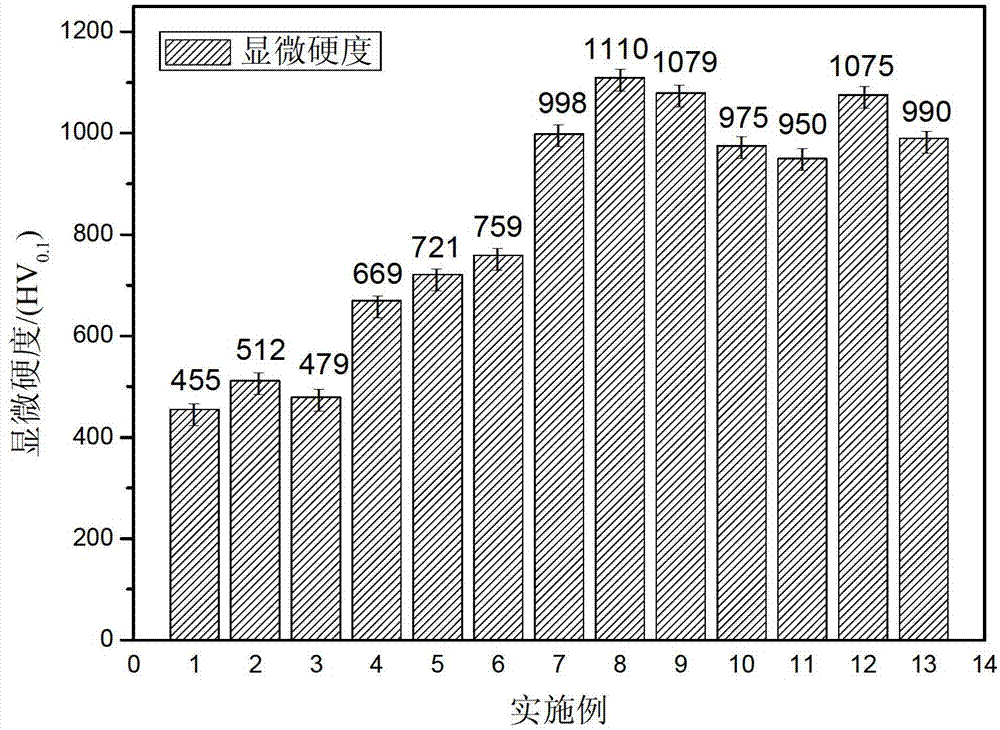

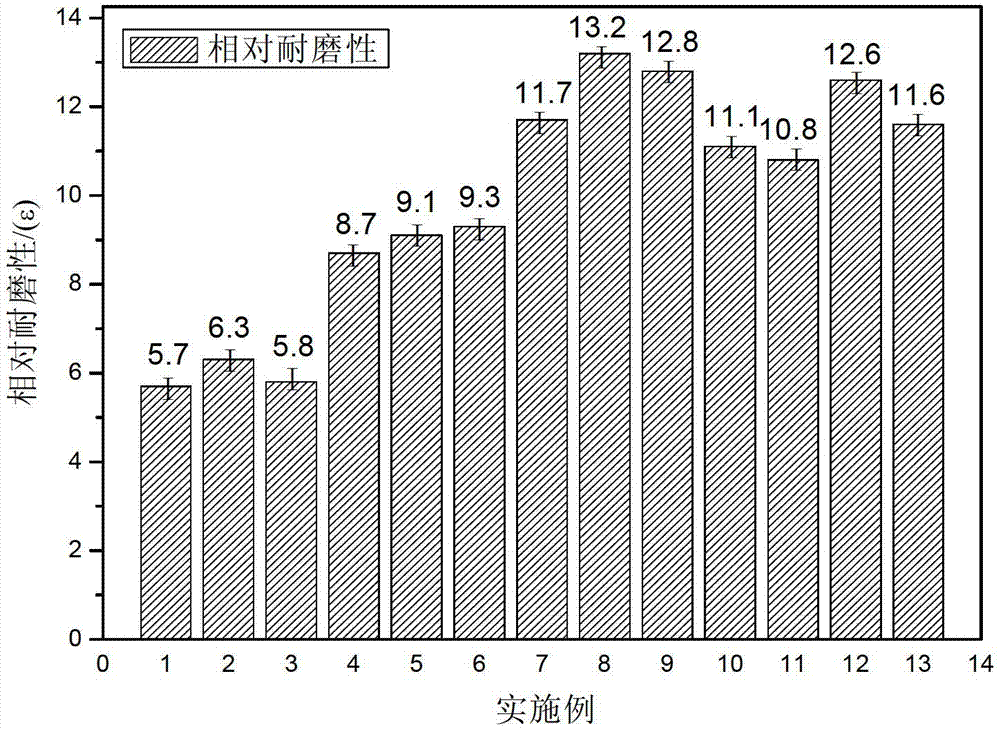

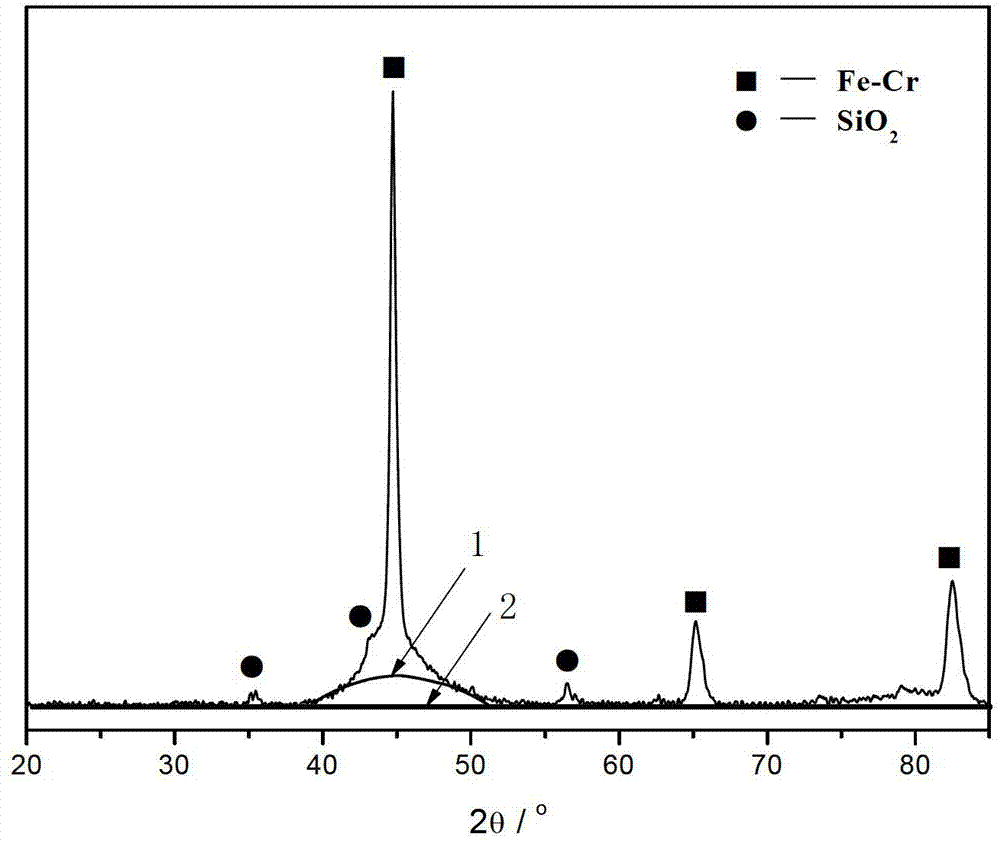

Cored wire for preparing iron-based coating as well as preparation method and application thereof

InactiveCN103088280AImprove corrosion resistanceCorrosion resistant barrierMolten spray coatingThermal sprayingFilling rate

The invention provides a cored wire for preparing an iron-based coating as well as a preparation method and application thereof and belongs to the field of thermal spraying in material processing engineering. The flux composition comprises 15-35 at.% of Cr, 5-25 at.% of B, 5-25 at.% of Si, 2.5 to 5.5 at.% of C and the balance of Fe; a strip material for a sheath of the cored wire is a stainless steel band; and the filling rate of the cored wire is 33%. When electric-arc spraying is used for preparing an iron-based amorphous / nanocrystal coating containing ceramic phase SiO2, firstly a matrix is pretreated, and according to a spraying technology, the voltage is 28-34V, the electric current is 160-220A, the spraying distance is 190-210mm, and the compressed air pressure is 0.4-0.6Mpa. The coating can be widely applied to repair and protection of equipment parts in industries such as metallurgy, electricity and petroleum. The coating with the advantages of corrosion resistance, high hardness and high wearing resistance is obtained according to the preparation method.

Owner:BEIJING UNIV OF TECH

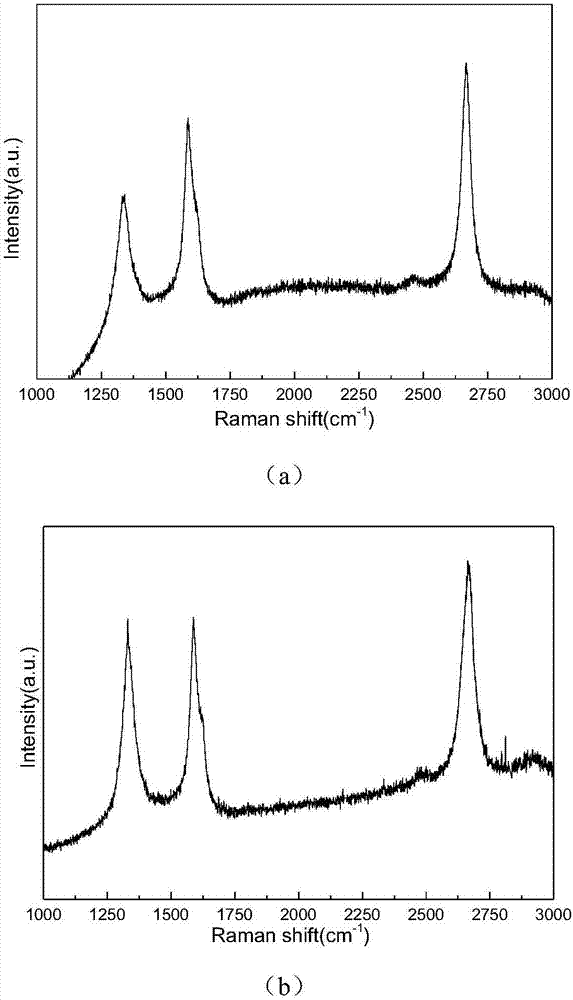

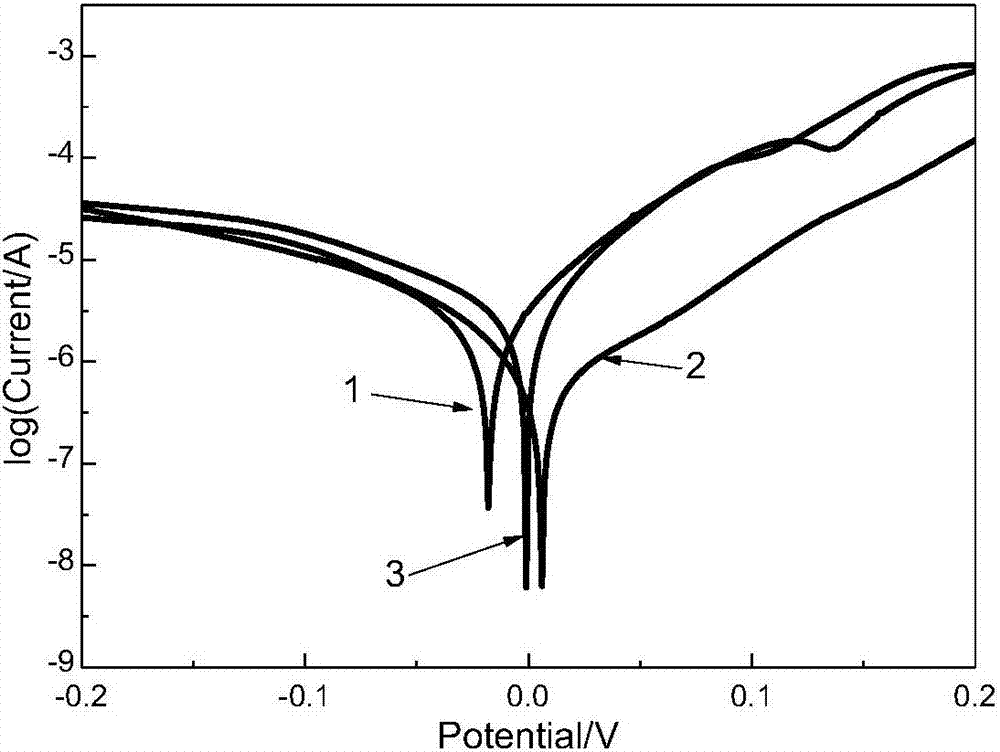

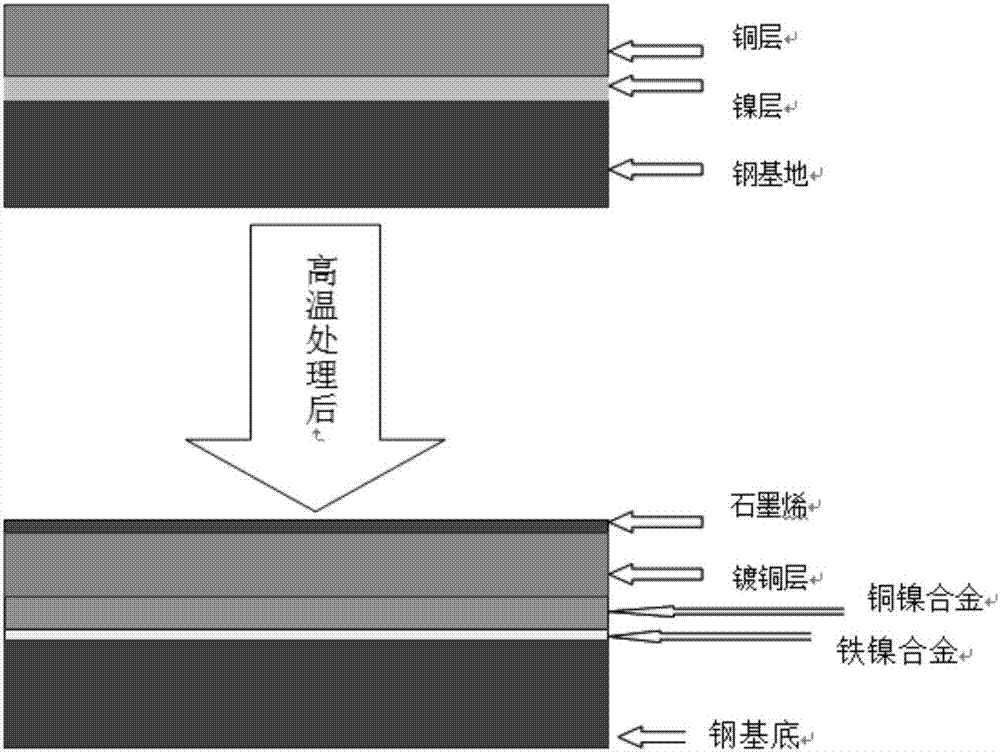

Preparation method of graphene steel-based alloy

ActiveCN107034498AControl layersQuality improvementChemical vapor deposition coatingSuperimposed coating processCopper platingHeat conducting

The invention discloses a preparation method of graphene steel-based alloy. The method comprises the following steps that a steel metal substrate is selected, and the steel metal substrate is subjected to cleaning and surface activating processing; (2), a sample pretreated through the above step is subjected to nickel plating processing; (3), the nickel-plated sample is subjected to copper plating processing, and a product is washed and dried; (4), the dried sample is subjected to high-temperature chemical vapor deposition to generate graphene, while the graphene is generated, the alloy at the interface between the nickel-plated layer / steel substrate and the nickel-plated layer / copper-plated layer is controlled, then cooling is performed, and the alloy is prepared. After the steel metal substrate is subjected to nickel plating and copper plating, the surface of the steel metal substrate generates the graphene in the high-temperature condition; and meanwhile, the steel substrate / the nickel-plated layer forms ferronickel or iron nickel chromium alloy, the nickel-plated layer and the copper-plated layer form copper nickel alloy, the substrate double-layer alloy is matched with the graphene, and the effects that the overall corrosion-resistant performance of a composite material is enhanced, and conductivity and the heat-conducting property of the metal substrate are not influenced are achieved.

Owner:WUHAN UNIV OF TECH

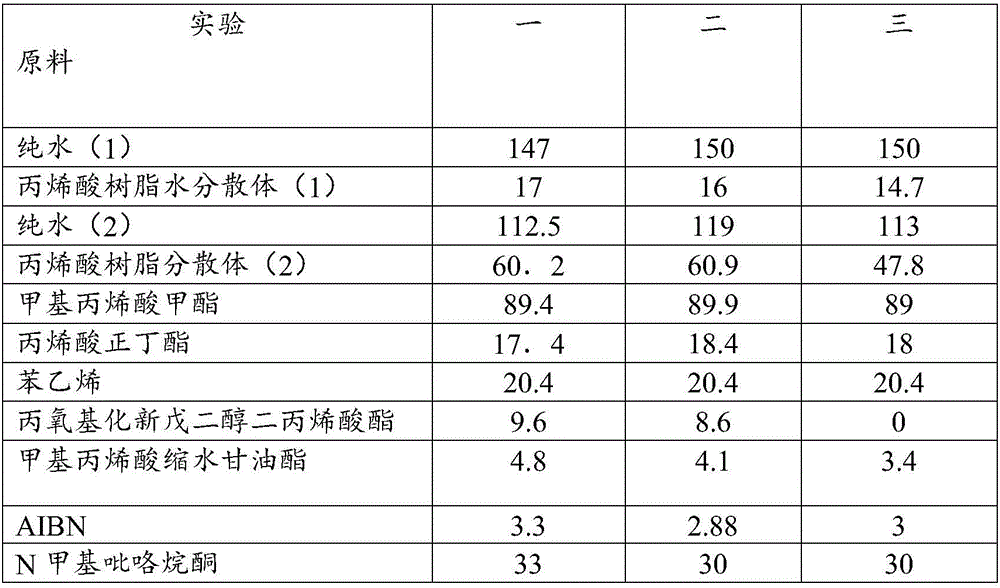

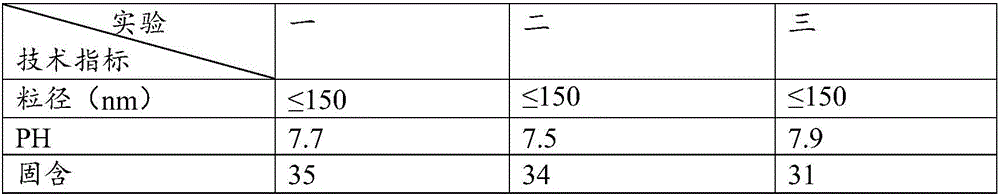

Microgel aqueous acrylic acid shell-core resin emulsion and preparation method thereof

The invention belongs to the field of aqueous coatings, and relates to a microgel aqueous acrylic acid shell-core resin emulsion. The resin emulsion is prepared through a reaction of 13-16 parts of an acrylic acid resin water dispersion (with the solid content of 28-34%), 18-21 parts of a vinyl monomer, 20.5-27.6 parts of an acrylic acid and acrylate monomer, 0.3-0.6 parts of an initiator, 5-6 parts of an organic solvent and 49-53 parts of water. The microgel resin emulsion is added to an aqueous coating, so the sagging property of a paint film is obviously improved, a good anti-sagging effect is reached, the thickness of the paint film in closed angles or edges and other difficult coating positions of a coated member is obviously increased, and the corrosion resistance of the surface of the coated member is improved. The nanometer-level aqueous acrylic acid emulsion with the particle size being smaller than 150nm is produced through the method, can be added to the aqueous coating without thickening the coating, and facilitates maintenance of high construction solid content.

Owner:LANGFANG JINHUILI INDAL PAINT

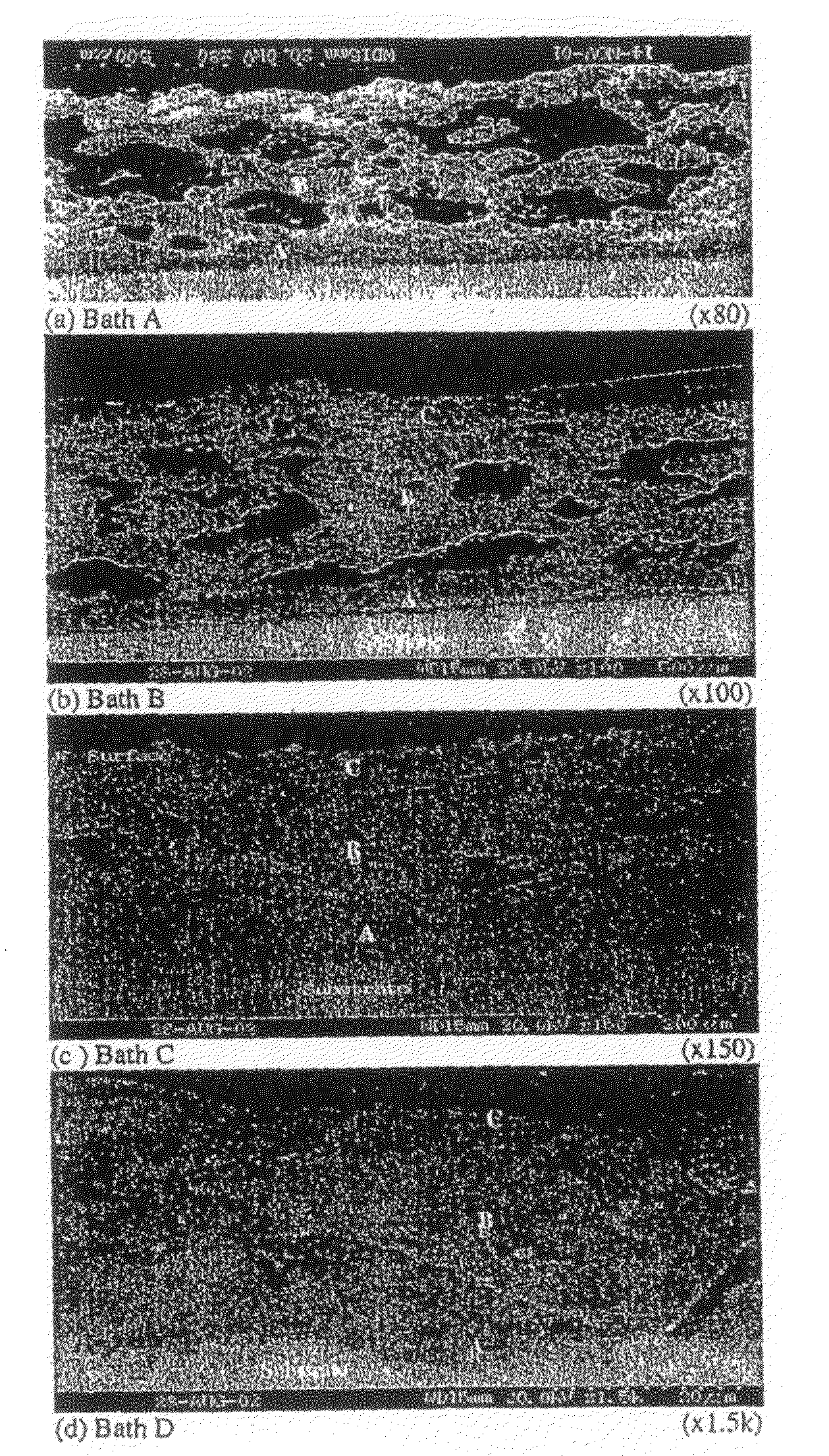

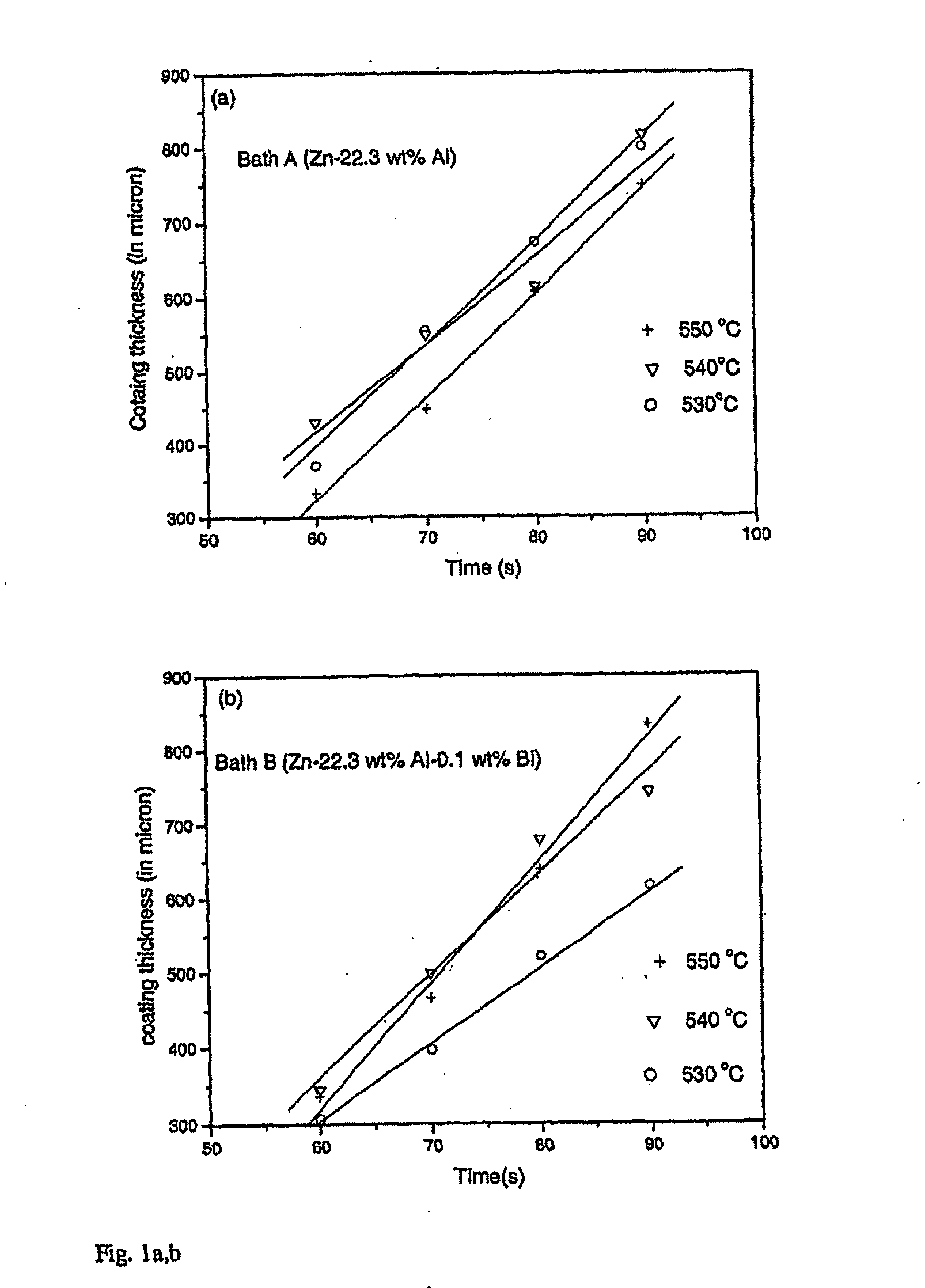

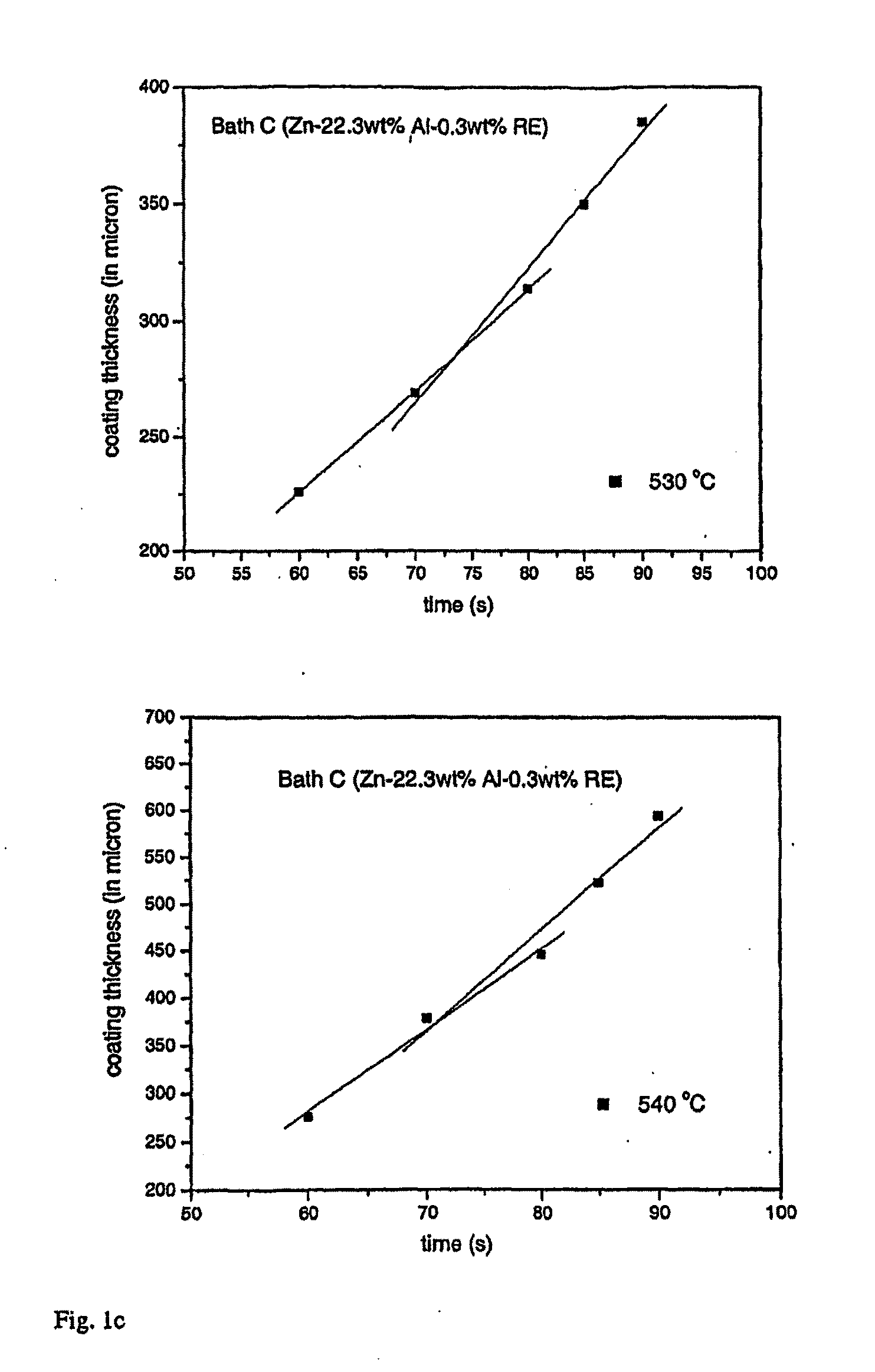

Effect of Ternary Additions on the Structure and Properties of Coatings Produced by a High Aluminum Galvanizing Bath

InactiveUS20090004400A1Thin coatingEliminate stomataHot-dipping/immersion processesLiquid surface applicatorsRare earthZinc

Owner:TECK METALS

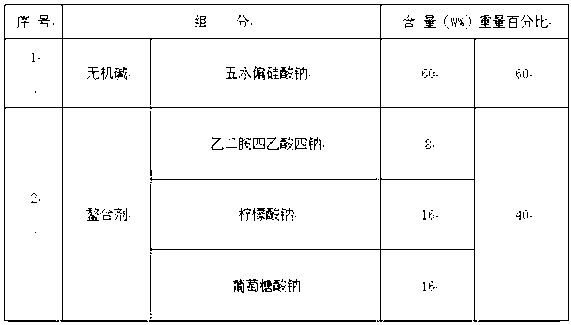

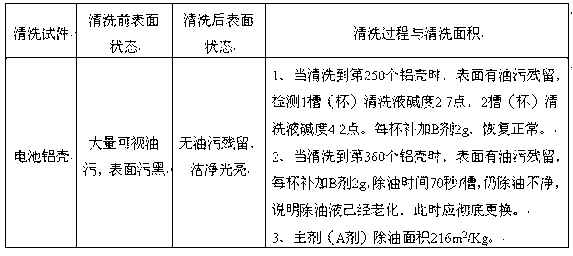

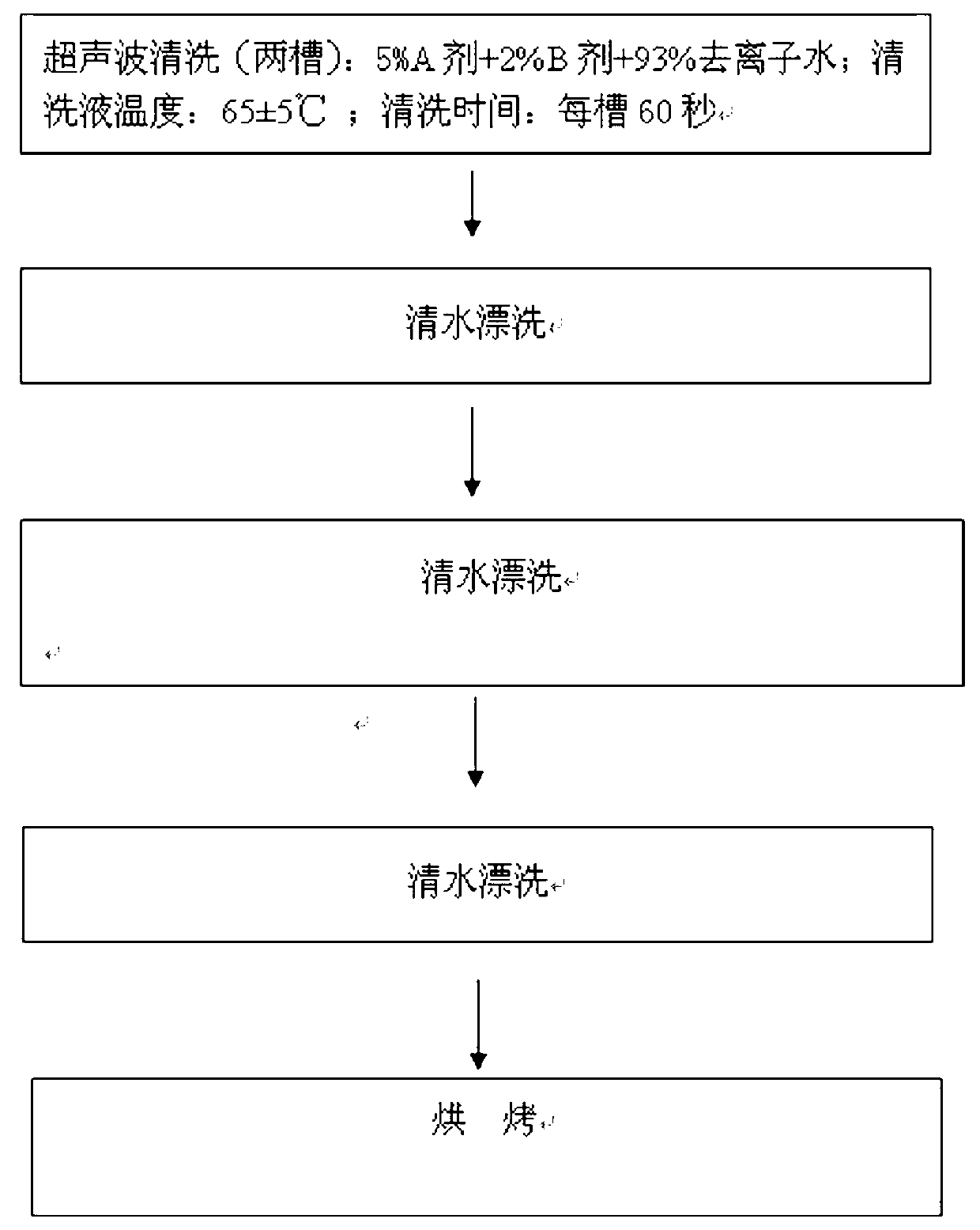

Dual-ingredient degreasing agent for battery aluminum shell and preparation and use methods of dual-ingredient degreasing agent

ActiveCN103343063AEasy to cleanAvoid corrosionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEthylenediamineSodium metasilicate

The invention discloses a dual-ingredient degreasing agent for a battery aluminum shell. The dual-ingredient degreasing agent consists of an agent A (a main agent) and an agent B (an assistant), wherein the agent A is prepared from the following ingredients in percentage by weight: 15-20% of anionic surfactant, 30-45% of nonionic surfactant, 10-15% of solvent and the balance of water, and the agent B is prepared from the following ingredients in percentage by weight: 50-70% of inorganic base and 30-50% of chelating agent; the anionic surfactant is one or a mixture of more of the following substances: secondary alkyl sulphonate sodium and sodium dodecylbenzensulfonate; the nonionic surfactant is one or a mixture of more of the following substances: isomeric fatty alcohol-polyoxyethylene ether and fatty alcohol-polyoxyethylene ether, wherein the number of carbon atoms of the isomeric fatty alcohol-polyoxyethylene ether is 13, and the number of EO is 7; the solvent is 2-methyl-2,4-pentanediol; the inorganic base is sodium metasilicate; and the chelating agent is a mixture of tetrasodium ethylenediamine tetraacetate, sodium citrate and sodium gluconate. The dual-ingredient degreasing agent disclosed by the invention has the advantages of high degreasing speed, little corrosiveness, large unit degreasing area and good washing power.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

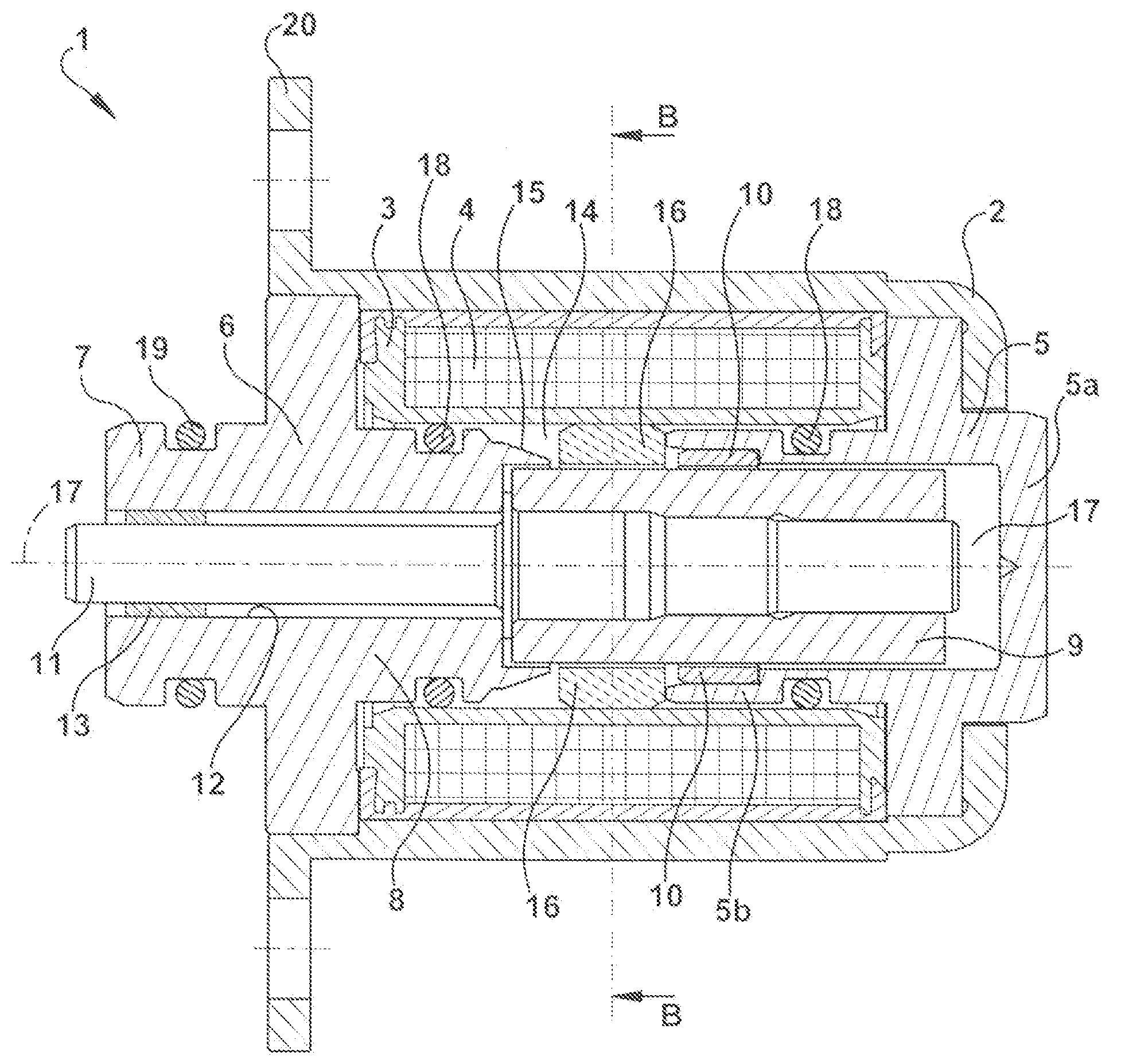

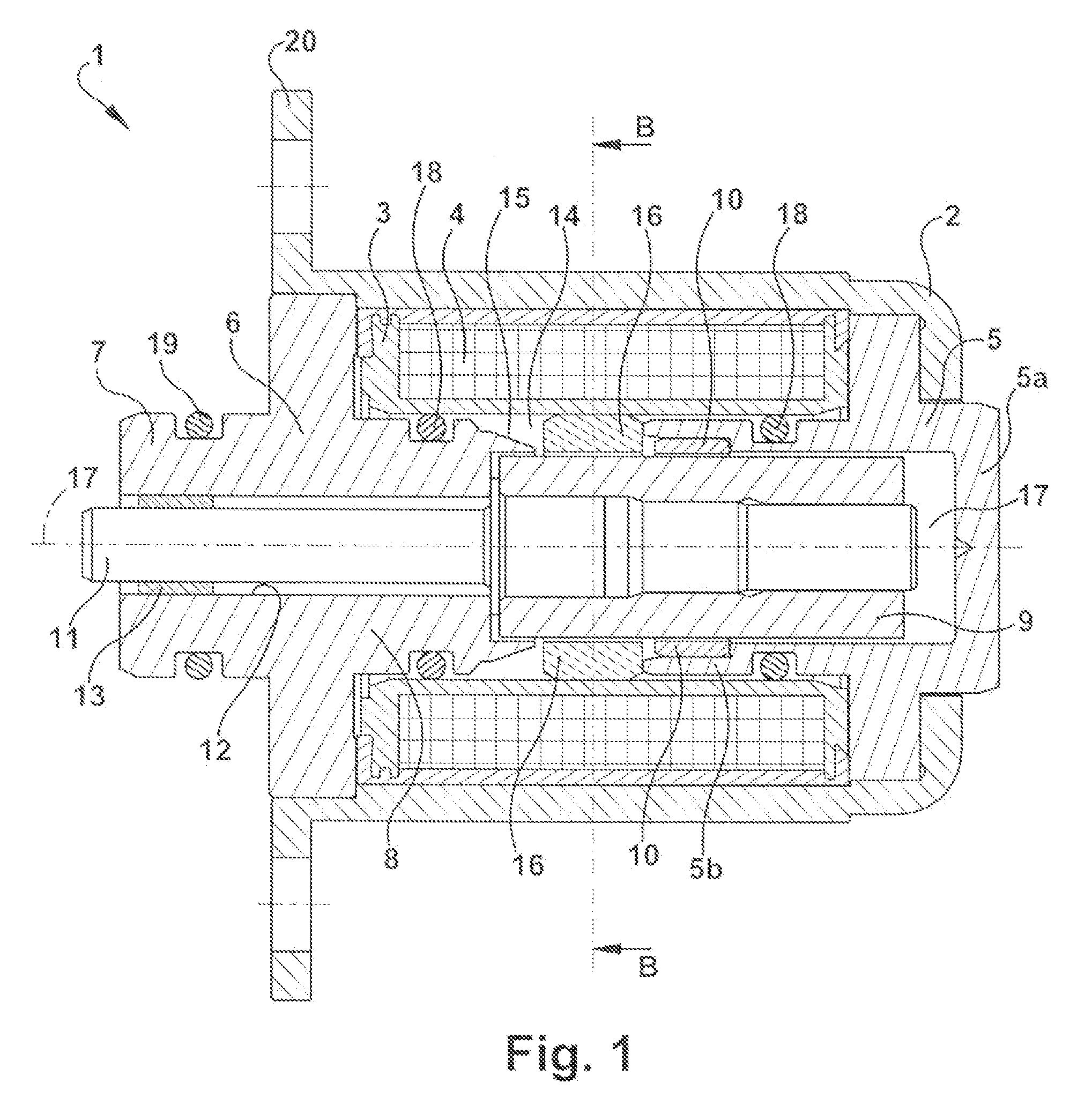

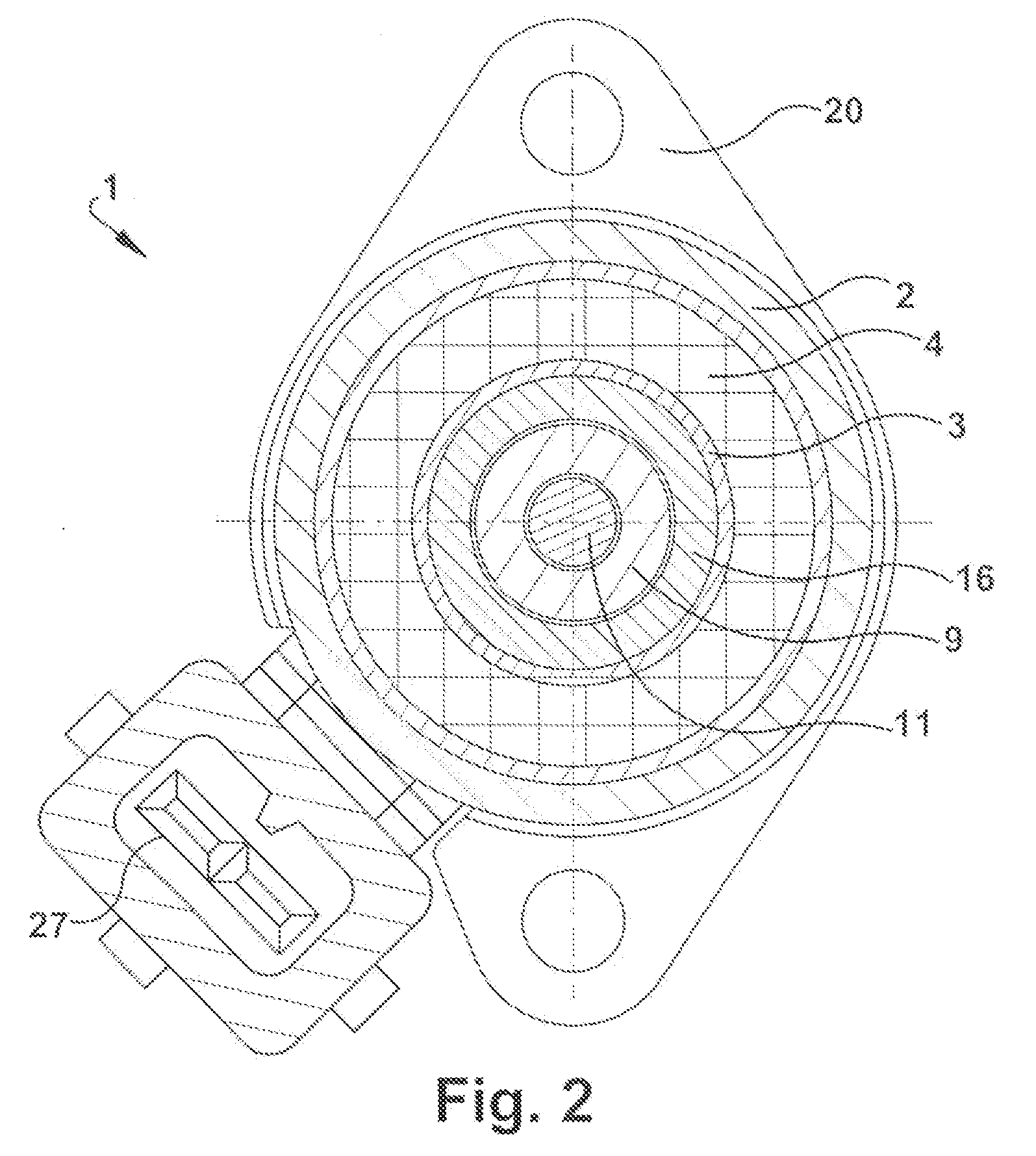

Proportional magnet

InactiveUS20080224805A1Low production costAvoid less flexibilityOperating means/releasing devices for valvesMagnetic materialsEngineeringPole piece

The invention relates to a proportional magnet, including a winding carried by a coil body, two pole shoes which project into the coil body from opposite sides and which are spaced apart axially from one another, and a gap provided between the pole shoes. The invention further includes a magnet armature, which is arranged within the winding in an axially displaceable manner substantially parallel to the longitudinal axis thereof. The axial movement of the magnet armature can be transmitted to a valve member. The invention still further includes an electrically conductive element, wherein the magnet armature can be moved through the element, wherein the element is formed from a basic body having an electrically conductive layer, and wherein the electrically conductive layer is applied separately to the basic body.

Owner:THOMAS MAGNETE GMBH

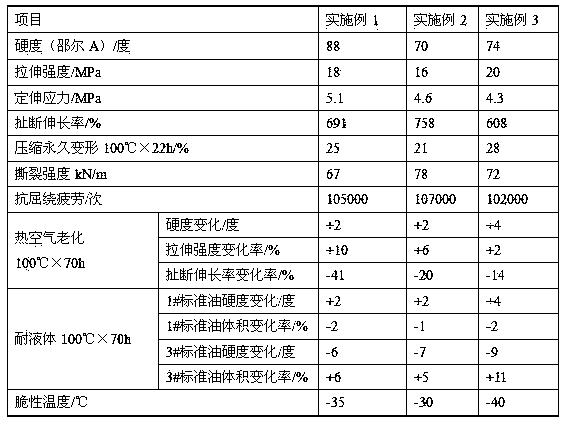

Oil-resistant air tank capsule and preparation method thereof

ActiveCN104177674AImproved flex fatigue resistanceImprove mechanical propertiesAgricultural engineeringHigh pressure

The invention discloses an oil-resistant air tank capsule and a preparation method thereof and relates to an air tank capsule for a slurry pump. The oil-resistant air tank capsule is prepared by plastifying, mixing, vulcanizing and shaping the following components in parts by weight: 15-25 parts of butyronitrile rubber, 0.5-1.5 parts of zinc oxide, 0.1-0.5 part of stearic acid, 0.1-0.5 part of accelerator DM, 0.1-0.3 part of accelerator CZ, 1-3 parts of dioctyl phthalate, 0.5-1.5 parts of coumarone resin, 0.1-0.2 part of anti-aging agent DMBPPD, 0.1-0.2 part of anti-aging agent MB, 0.1-0.3 part of anti-aging agent HB-5, 3-6 parts of spraying carbon black, 1-3 parts of white carbon black, 0.2-0.4 part of sulfur and 0.1-0.2 part of dicumyl peroxide. The air tank capsule disclosed by the invention has the advantages of prominent corrosion resistance in oil-based slurry as well as excellent tear resistance, flexural resistance, fatigue resistance and ageing resistance under a high-pressure environment. The service life of the air tank capsule is prolonged in multiples and the service cycle of an air tank is increased.

Owner:PUYANG HENGXIN RUBBER & PLASTIC

Ternary cathode material having high electric conductivity and preparation method thereof

ActiveCN109301185ACorrosion protectionAvoid decompositionCell electrodesSecondary cellsConductive polymerElectrical battery

A ternary cathode material having high electric conductivity is characterized by including a core and a shell coating the core and having the chemical formula of LicNiaCobMn<1-a-b>O2; 0 <= a <= 1, 0 <= b <= 1, 0.4 <= c <= 1.5. The core is a lithium-coated Ni-Co-Mn ternary material. The shell is a conductive polymer film. In the invention, the thin film of the shell has high electric conductivity,so that surface resistance of the ternary material can be reduced, thus improving rate capability of a battery. Meanwhile, the ternary cathode material can be combined with a binder better, so that increase of resistance during charge / discharge processes can be inhibited to certain degree, thereby improving cycle performance of the material.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

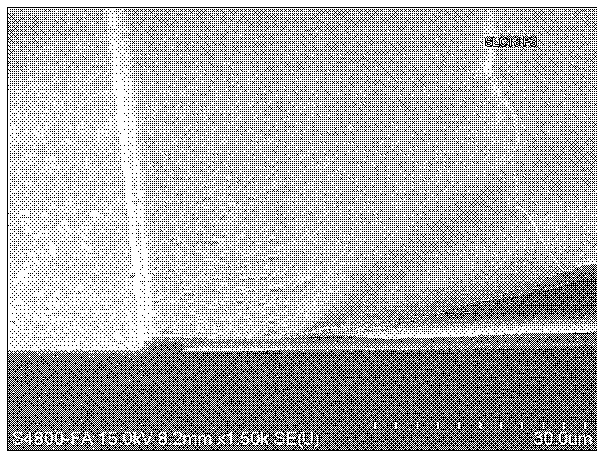

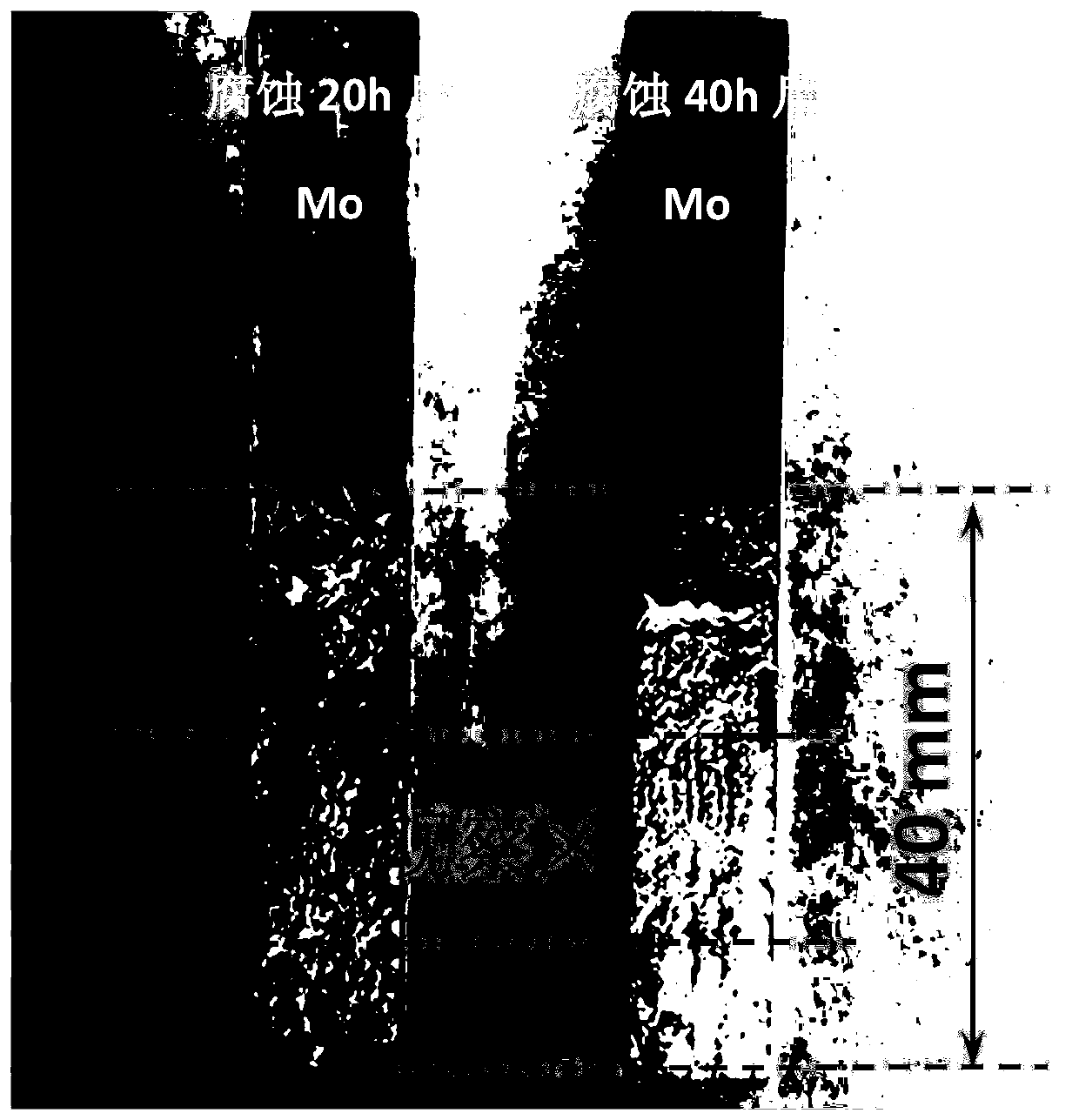

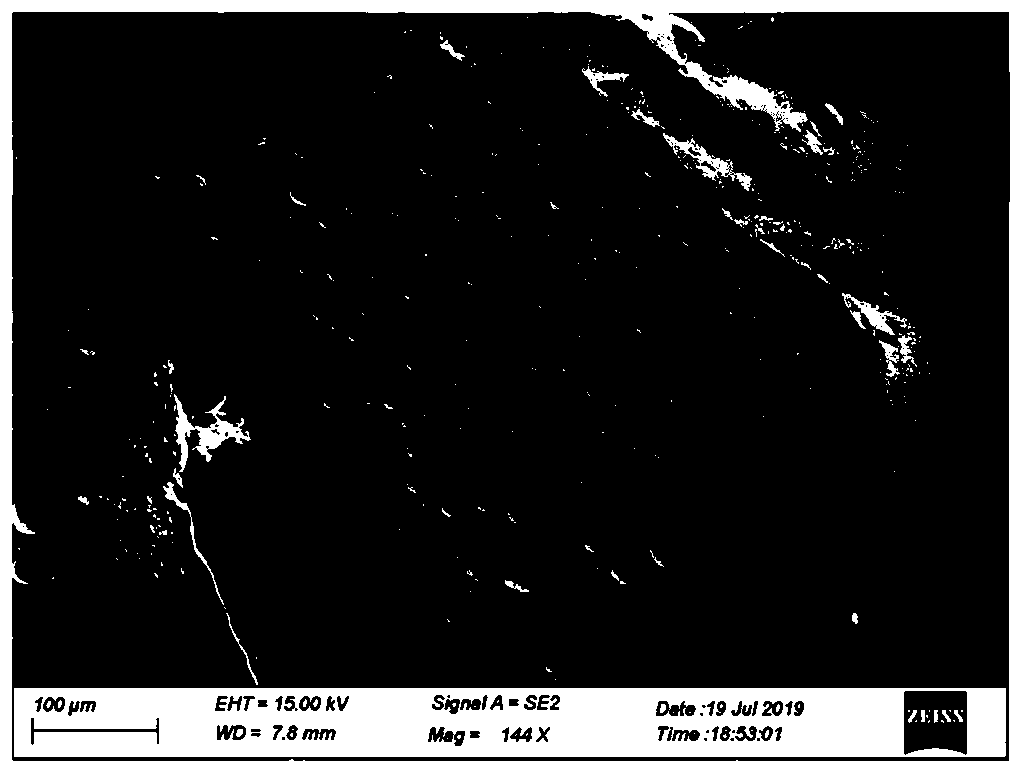

Preparation method of refractory metal molybdenum protective film resisting liquid lead-bismuth corrosion

ActiveCN111020552AGood stabilityGood combinationMetallic material coating processesMuffle furnacePowder metallurgy

The invention discloses a preparation method of a refractory metal molybdenum protective film resisting liquid lead-bismuth corrosion. The preparation method comprises the steps of preparing molybdenum by a powder metallurgy method, forging, extruding and processing the molybdenum into a rod, cutting the rod into an experimental sample, and performing annealing; placing a lead-bismuth alloy in a muffle furnace to be melted into liquid lead-bismuth alloy; inserting the molybdenum rod experimental sample into a crucible containing a liquid lead-bismuth alloy, keeping the temperature and the oxygen concentration in the crucible in a saturated state, and performing corroding; cooling the liquid lead-bismuth alloy, rapidly taking out the molybdenum rod experimental sample, and placing the molybdenum rod experimental sample on a stainless steel sheet for rapid cooling; and obtaining a compact PbMoO4 / Pb2MoO5 double-layer structure metal protective film. Through detection and characterization,specific components, morphology, thickness, compactness and other comprehensive information of the protective film are obtained. The PbMoO4 / Pb2MoO5 double-layer protective film prepared by the methodgreatly prolongs the service life of the refractory metal molybdenum in the liquid lead and bismuth, and accelerates the application of the refractory metal molybdenum in the liquid lead and bismuth.

Owner:XI AN JIAOTONG UNIV

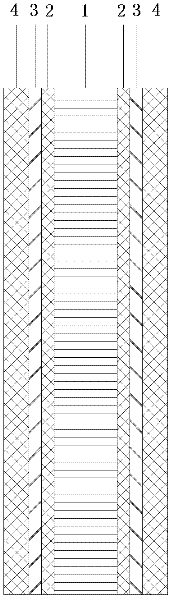

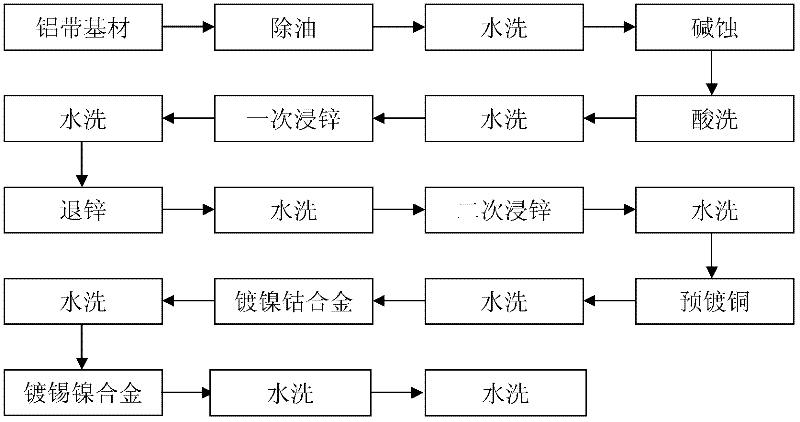

Aluminium strip with tin soldering performance and high corrosion resistance and preparation technology thereof

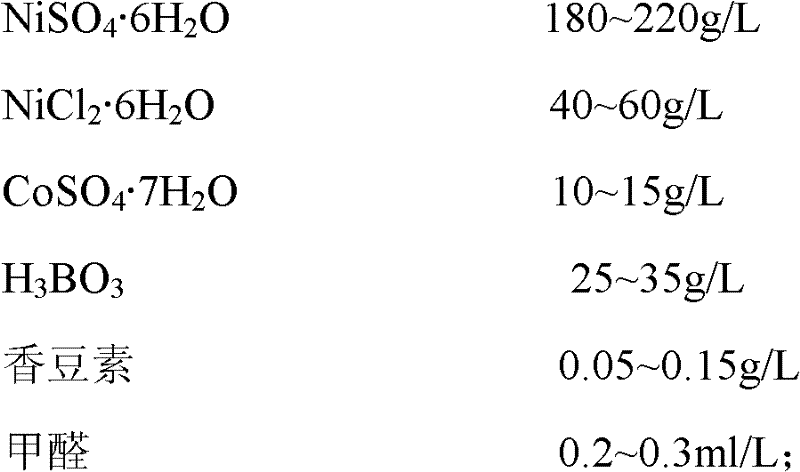

ActiveCN102212855AImprove corrosion resistanceImprove acid and alkali corrosion resistanceLiquid/solution decomposition chemical coatingCopper coatingNickel alloy

The invention discloses an aluminium strip with tin soldering performance and high corrosion resistance and a preparation technology thereof. The aluminium strip can be widely applied to various fields of electrons, energy, precise instruments, automobiles and the like, and the problem that the aluminium strip is difficult to weld is solved. According to the aluminium strip and the preparation technology thereof, aluminium and aluminium alloy strips (aluminium strips for short) serve as a substrate; two surfaces of the substrate are successively electroplated with a copper coating, a nickel and cobalt alloy coating and a tin and nickel alloy coating; and multiple electroplated membranes and the substrate have the advantages of good bonding force, strong anticorrosion performance and better tin soldering performance. The aluminium strip prepared by the preparation technology can be produced by a continuous electroplating method so as to satisfy the requirement on aluminium strip surface treatment.

Owner:HUNAN YONGSHENG NEW MATERIALS

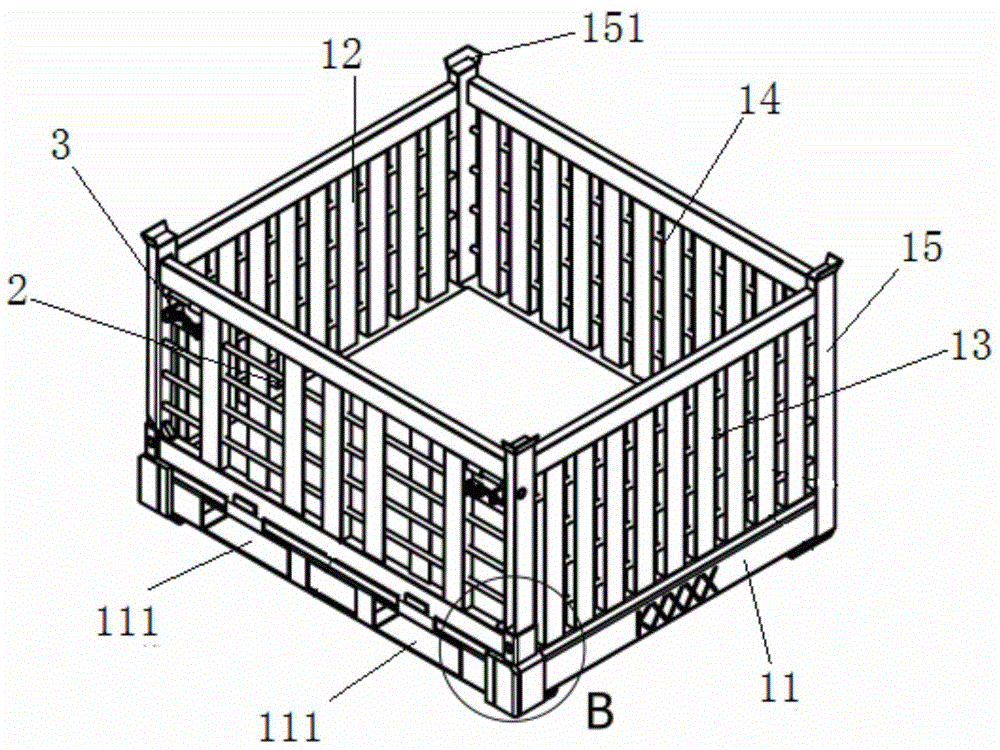

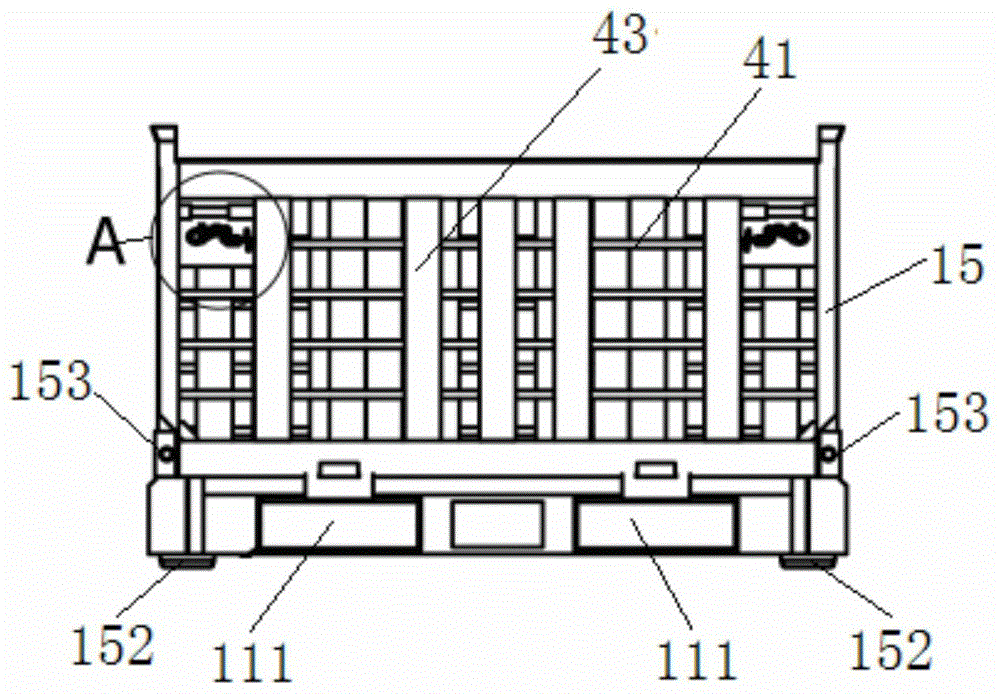

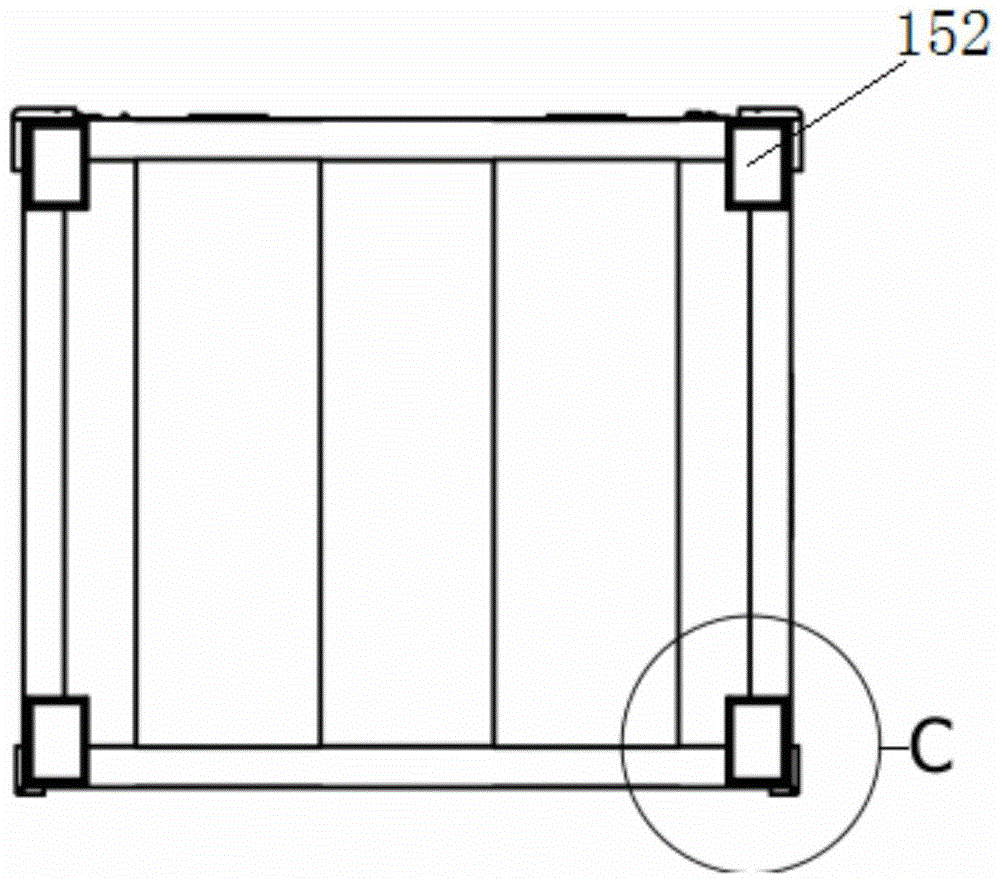

Aluminum box pallet and matched container

InactiveCN103552733ACorrosion protectionPromote sheddingLarge containersRigid containersEngineeringUltimate tensile strength

The invention relates to an aluminum box pallet and a matched container. The aluminum box pallet comprises a box body and a door plate, wherein the box body comprises a square base, a left side plate, a right side plate and a rear end plate, a forklift groove is formed in the bottom of the square base from the front part to the rear part, the left side plate, the right side plate and the rear end plate are respectively connected with the left side, the right side and the rear side of the base and are perpendicular to the base, and the door plate is arranged on the front side of the base of the box body; corner columns which are perpendicular to the base are respectively arranged at the four corners of the base, a limit groove is formed in the top of each corner column, a limit block is arranged at the bottom of each corner column, and the shape of each limit block is matched with that of each limit groove. The invention further provides the container which is matched with the aluminum box pallet. The aluminum box pallet and the container have the advantages of high strength, strong corrosion resistance and stability in a transport process.

Owner:太仓莫迪思能源工程有限公司

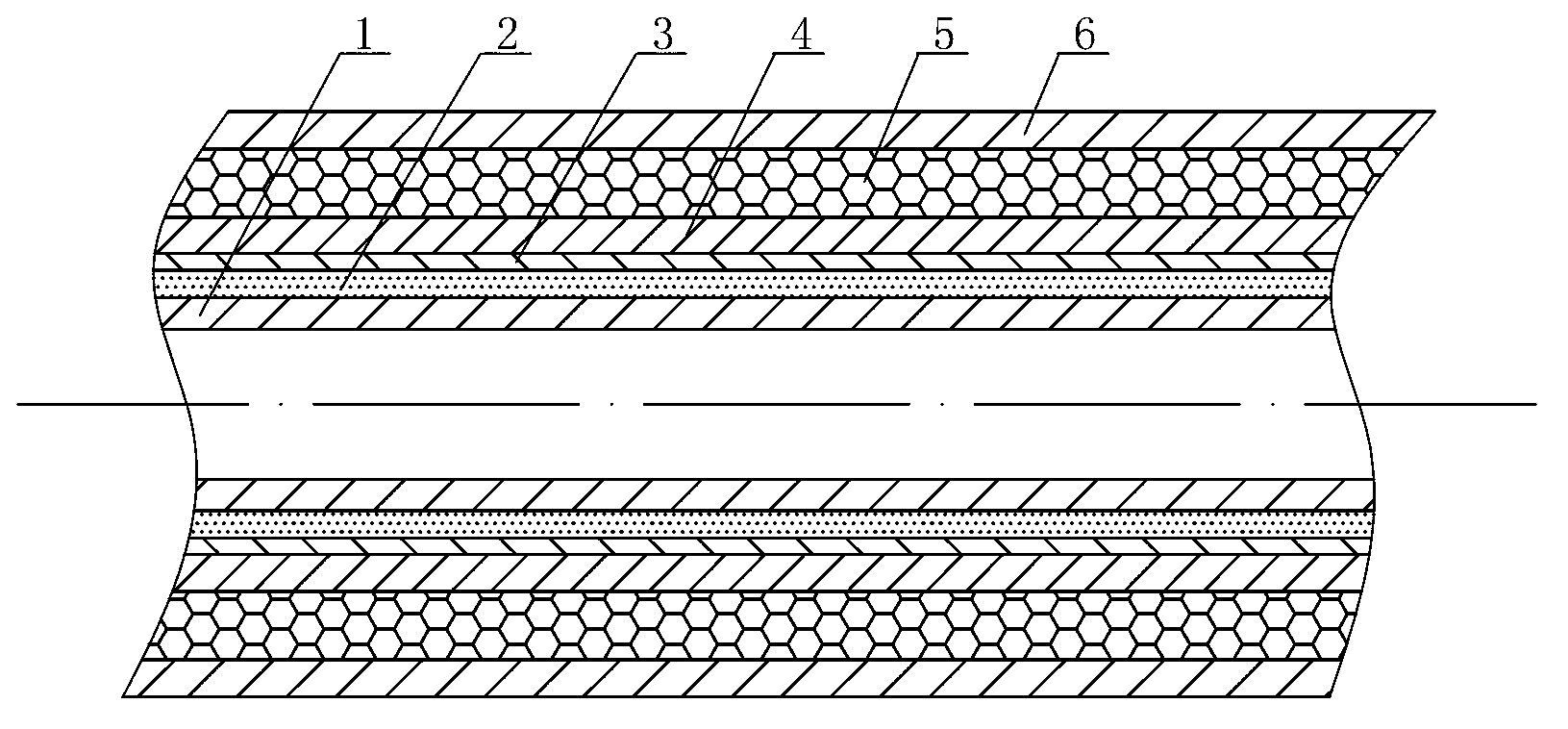

High shearing force three-layered polyolefin anti-corrosive thermal insulation steel pipe and manufacturing process thereof

InactiveCN102705633ASolve the difficult problem of making large shear force insulation pipeCorrosion protectionThermal insulationCorrosion preventionPolyolefinThermal insulation

The invention belongs to the field of anti-corrosive thermal insulation steel pipes, and particularly relates to a high shearing force three-layered polyolefin anti-corrosive thermal insulation steel pipe and a manufacturing process thereof. The steel pipe includes a three-layered polyolefin anti-corrosive pipe, which sequentially includes a steel pipe body, an epoxy resin layer, a glue adhesive layer and a polyolefin layer from inside to outside, wherein a polyethylene jacket pipe is jacketed outside the anti-corrosive pipe, and a polyurethane foaming material layer is arranged between the anti-corrosive pipe and the polyethylene jacket pipe. The manufacturing process is mainly used for the compound treatment of shot blasting and flame heating polarization on the polyolefin layer. The process not only enhances the adhesive properties of the polyurethane foaming material layer and the polyolefin layer on the 3PE anti-corrosive pipe surface, so as to improve the shearing strength of the 3PE anti-corrosive foaming jacket pipe, but also doesn't damage the anti-corrosive performance of the epoxy powder layer in the 3PE anti-corrosive pipe, so as to break through the limit of manufacturing big-shearing force thermal insulation pipe through utilizing the 3PE anti-corrosive pipe, so as to solve the difficulties of the industry, and provide a reliable anti-corrosive thermal insulation steel pipe product for crossing special areas as marsh and mire.

Owner:SHANDONG SHENGLI STEEL PIPE

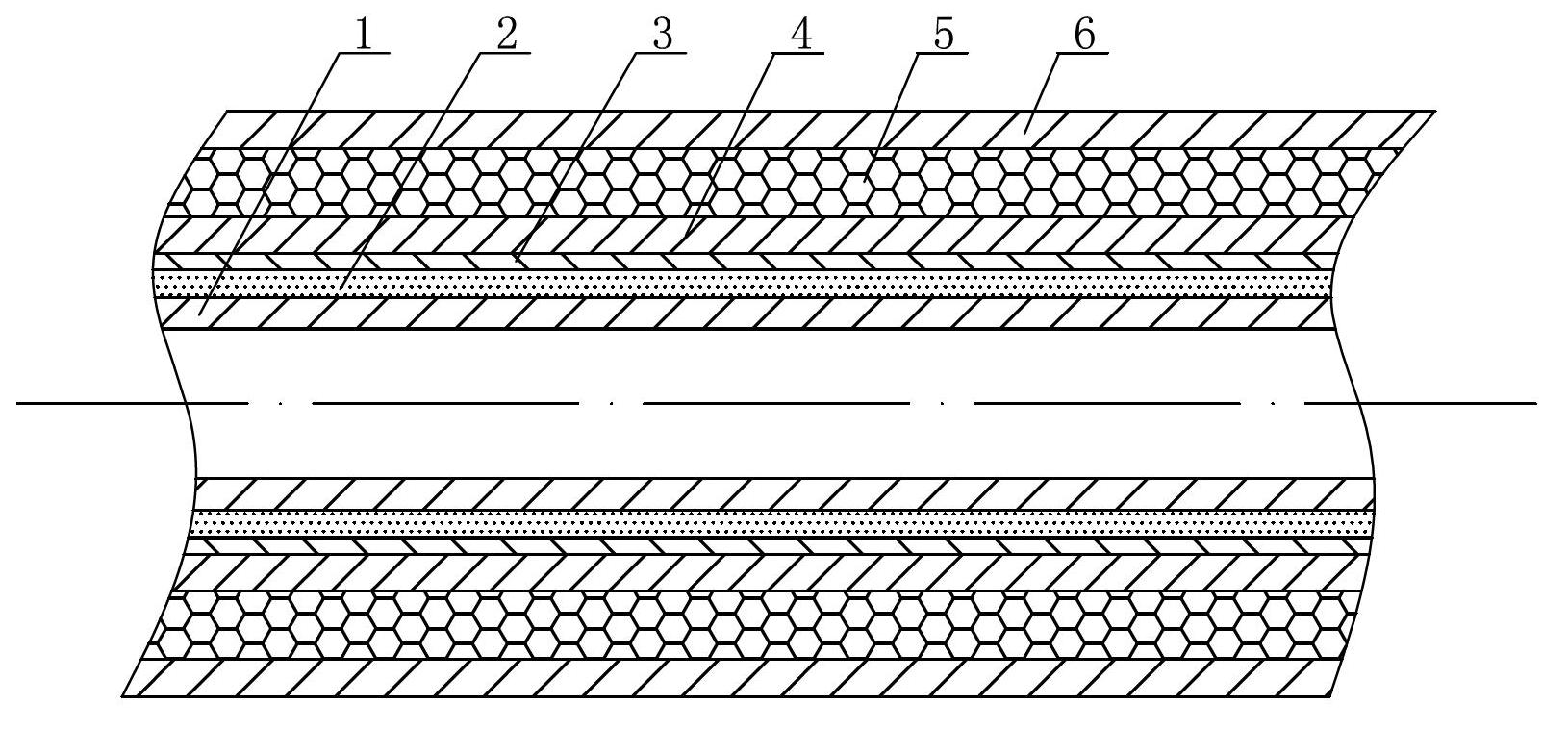

Anticorrosion device and anticorrosion method of ground wire

InactiveCN105506645ACorrosion protectionProlong lifeConnection contact member materialStructural engineeringAuxiliary electrode

Belonging to the field of power transmission and transformation, the invention relates to an anticorrosion device and anticorrosion method of a ground wire. The anticorrosion device comprises a ground lead, the periphery of the ground lead's vertical lead is covered with an insulating layer, the periphery of a horizontal lead and the peripheries of branch leads are covered with a conductive cement layer, the ground lead is provided with the negative pole of an additional direct current power supply, the additional direct current power supply is photovoltaic power generation component, the positive pole of the additional direct current power supply is connected to an auxiliary electrode, the ground lead is connected to a sensor, the sensor is in connection with a ground monitor, and the monitor is also connected to a reference electrode. According to the invention, the corrosion degree of the ground wire is alleviated, the corrosion resistance of the ground wire is improved, and the service life of the ground wire is prolonged.

Owner:DATANG LINZHOU THERMAL POWER CO LTD

MOS transistor and MOS transistor manufacturing method

InactiveCN105529265ACorrosion protectionTo prevent conductionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

The invention discloses an MOS transistor and an MOS transistor manufacturing method. The MOS transistor manufacturing method comprises the steps of: providing a semiconductor substrate which comprises an active region and an isolation region adjacent to the active region; forming gate structures on the semiconductor substrate, wherein the gate structures stretch across the active region and the isolation region; forming a first groove in the active region on two sides of the gate structures; forming protective layers on surfaces of the active region and the isolation region on two sides of the gate structures; and cleaning the first groove, and removing an oxide on the surface of the first groove. The MOS transistor manufactured by adopting the manufacturing method provided by the invention has high performance.

Owner:SEMICON MFG INT (SHANGHAI) CORP

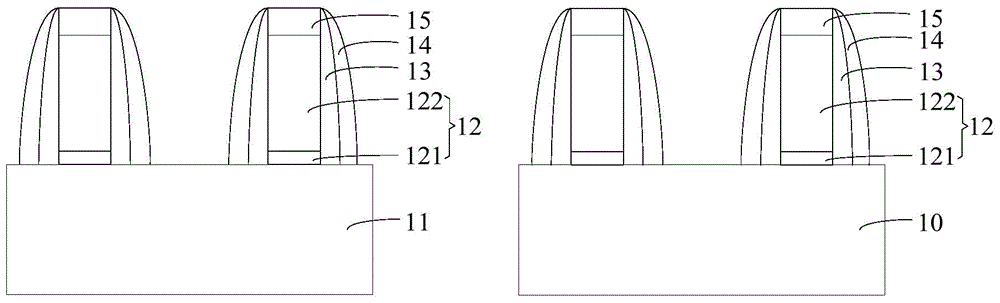

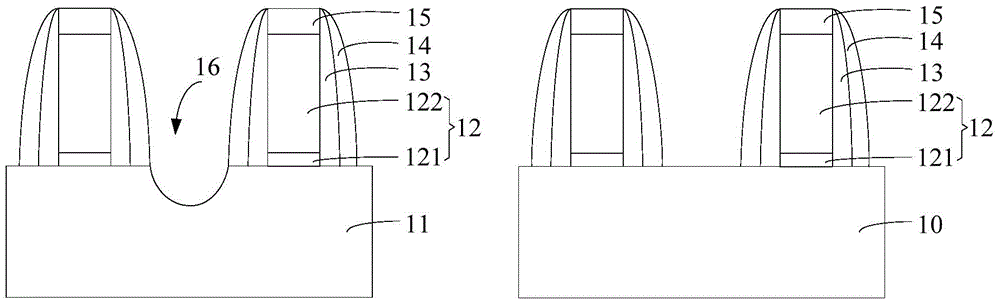

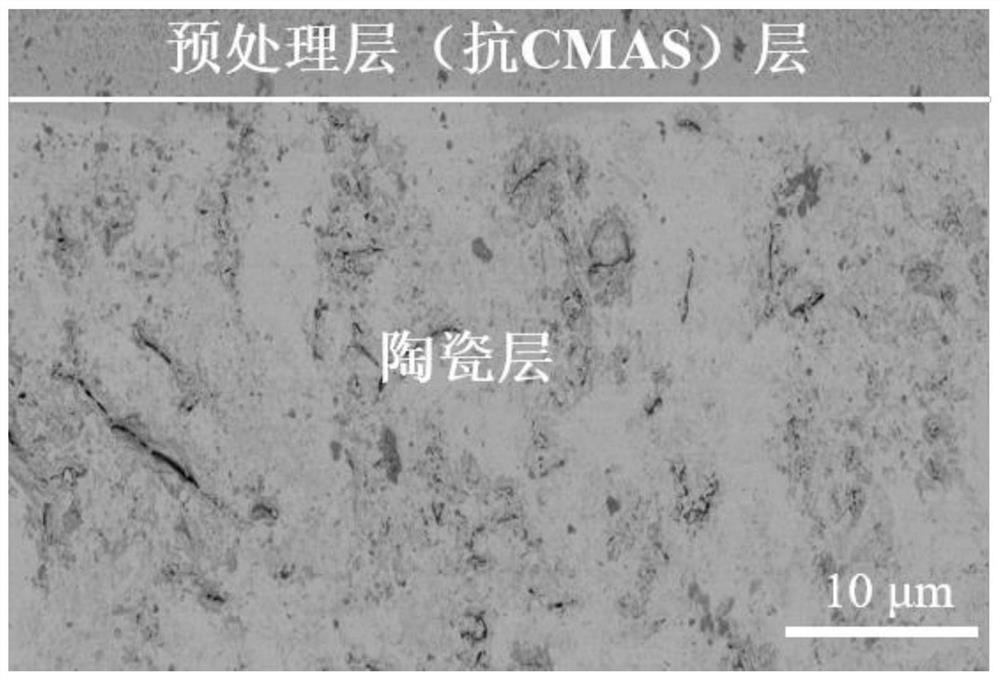

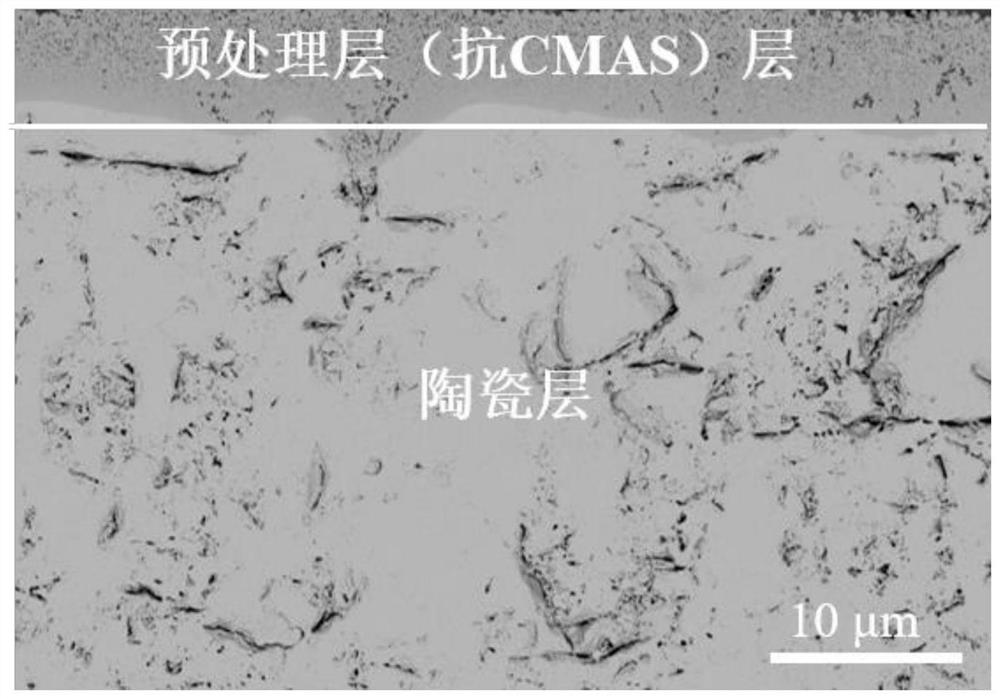

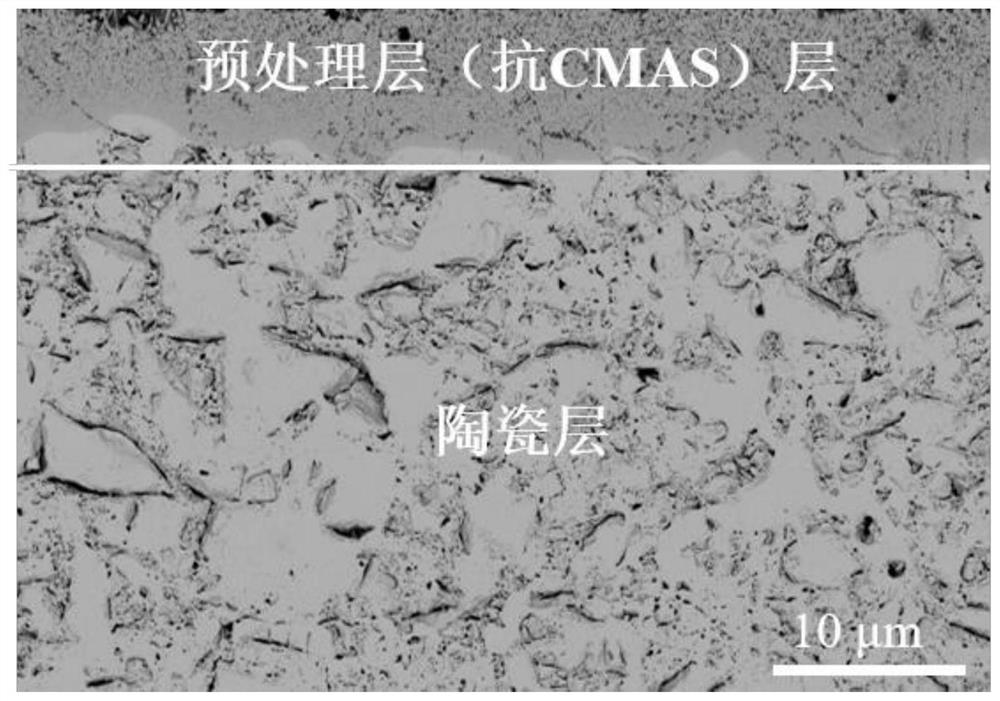

Thermal barrier coating layer resisting CMAS erosion and preparation method

ActiveCN111850454AImprove the ability to resist CMAS erosionHigh melting pointMolten spray coatingEfficient propulsion technologiesCrazingThermal barrier coating

The invention relates to the technical field of surface corrosion and protection of thermal barrier coating layers, specifically to a thermal barrier coating layer resisting CMAS erosion and a preparation method. In the technical solution of the invention, prefabricated CMAS suspension is uniformly coated on the surface of a thermal barrier coating layer; and then, the coating layer is sintered for a period of time in a high-temperature furnace to form a compact apatite phase barrier layer on the surface. The layer has the features of high melting point, high compactness, excellent phase stability and high bonding force, not only can fill inevitable holes and cracks in the surface spraying process of ceramic layers, but also can block CMAS diffusion channels in the ceramic layers, effectively improves the CMAS erosion resistance of the thermal barrier coating layer.

Owner:JIANGSU UNIV

Method for tungsten inert gas welding or plasma welding

InactiveUS20150165541A1Reduce appearance problemsAvoid corrosionArc welding apparatusPlasma welding apparatusShielding gasNitrogen

A method and gas mixture of argon, nitrogen and carbon dioxide for tungsten inert gas welding or plasma welding is described wherein the gas mixture is a protective gas for tungsten inert gas welding or an outer gas for plasma welding. The method is particularly useful for welding stainless steels and / or duplex steels.

Owner:LINDE AG

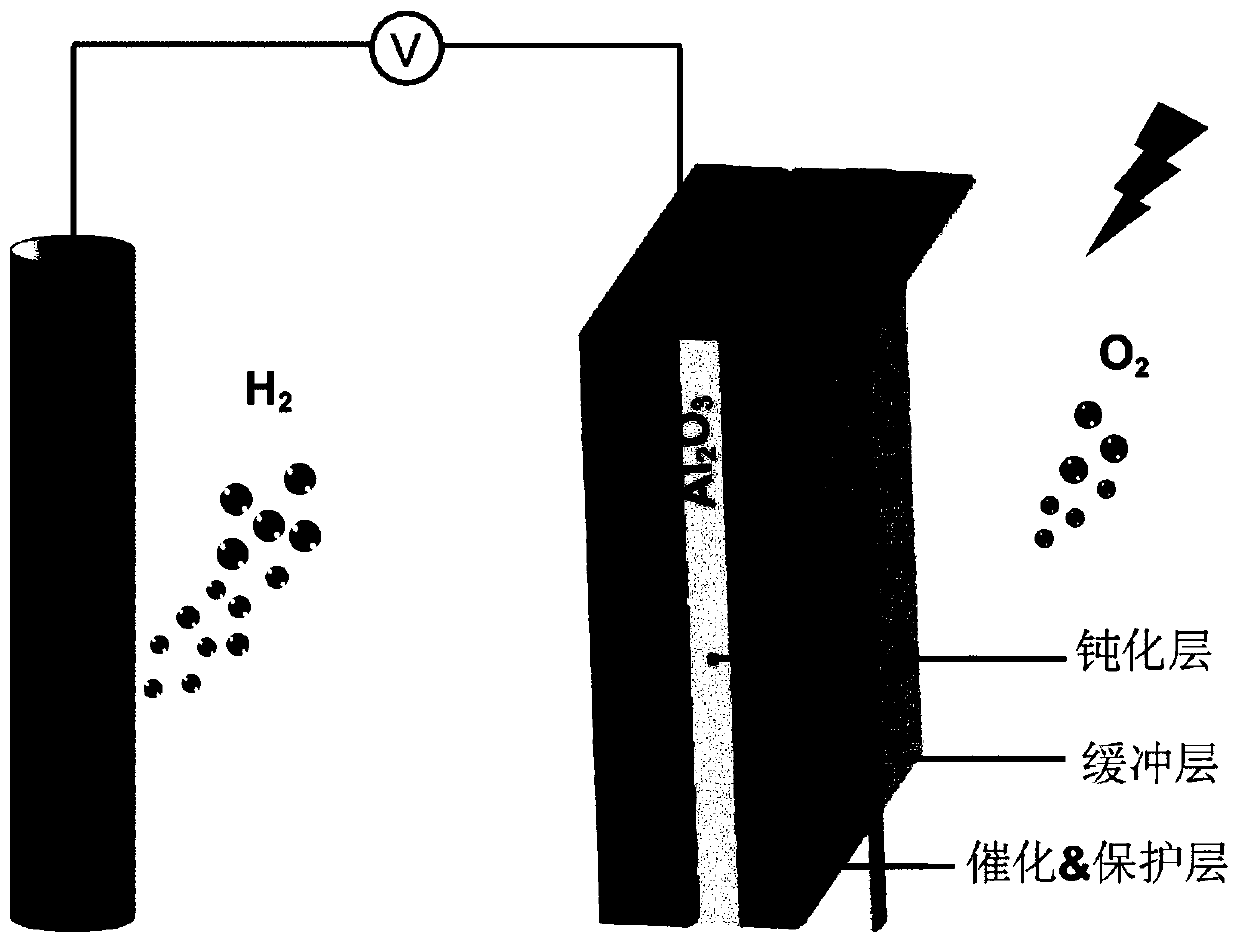

Silicon-based photoelectrode and preparation method and application thereof

ActiveCN109943857AImprove photoelectric performanceImprove electrocatalytic activityVacuum evaporation coatingSputtering coatingProtection layerFilm material

The invention relates to a silicon-based photoelectrode and a preparation method and application thereof. The silicon-based photoelectrode includes a Si layer, a passivation layer, a buffer layer anda catalytic protection layer, wherein the passivation layer, the buffer layer and the catalytic protection layer are sequentially disposed on the surface of the Si layer. The passivation layer, the buffer layer and the catalytic protection layer in the silicon-based photoelectrode are all made of dense film materials, wherein the catalytic protection layer has high electrocatalytic activity and can effectively reduce the reaction overpotential and maintain high stability in a solution; the passivation layer on the surface of the Si layer can reduce the surface state of Si, reduce Fermi level pinning and inhibit the recombination of electrons and holes on the silicon surface; the buffer layer can protect the passivation layer from damage in the process of preparing the catalytic protectionlayer, and the photoelectric property of the photoelectrode is improved from two aspects including thermodynamics and kinetics.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com